Patents

Literature

4295 results about "Pickling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from ferrous metals, copper, precious metals and aluminum alloys. A solution called pickle liquor, which usually contains acid, is used to remove the surface impurities. It is commonly used to descale or clean steel in various steelmaking processes.

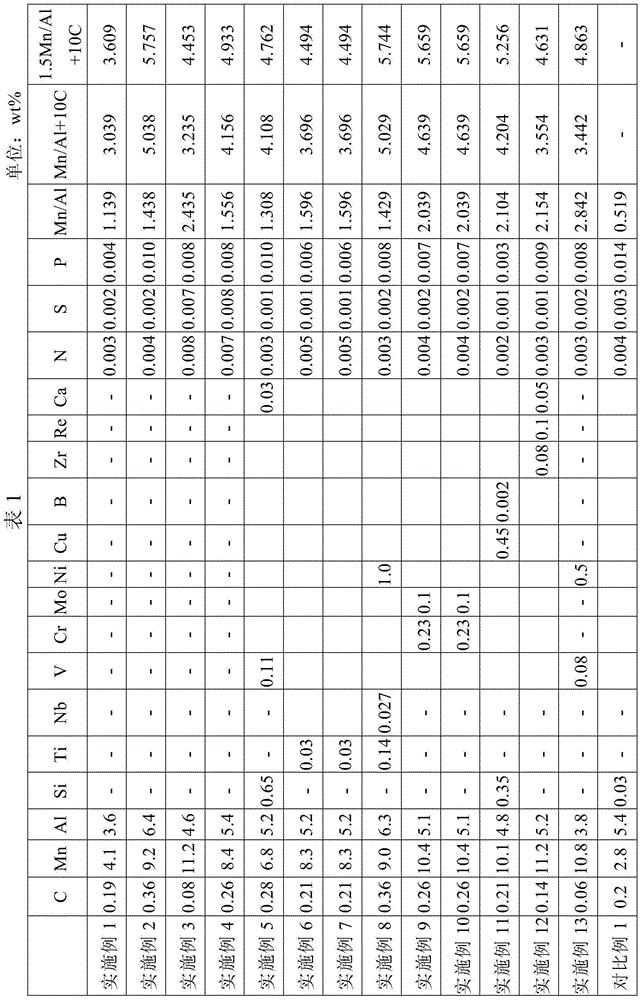

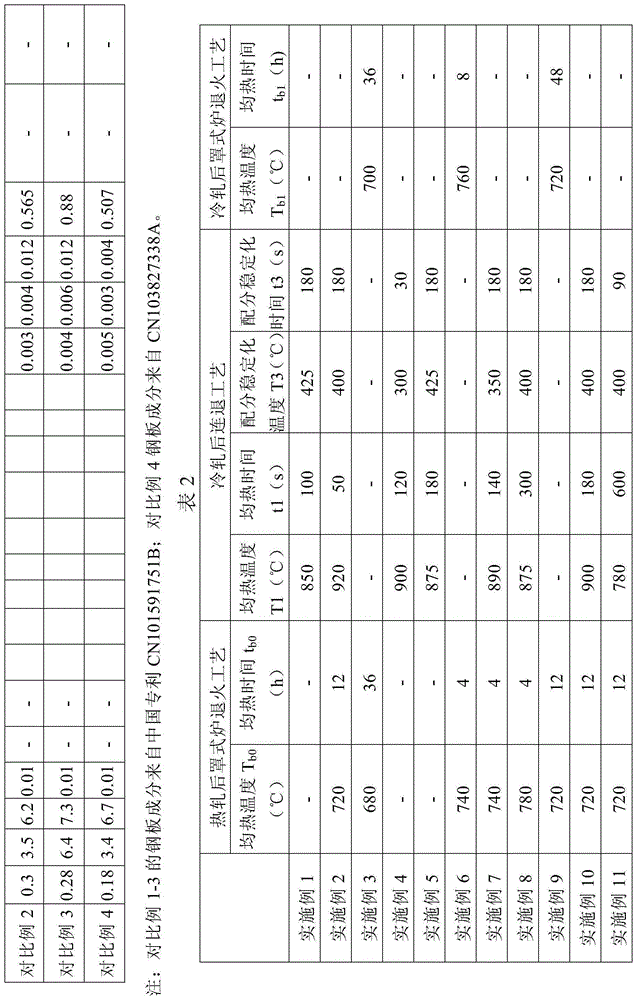

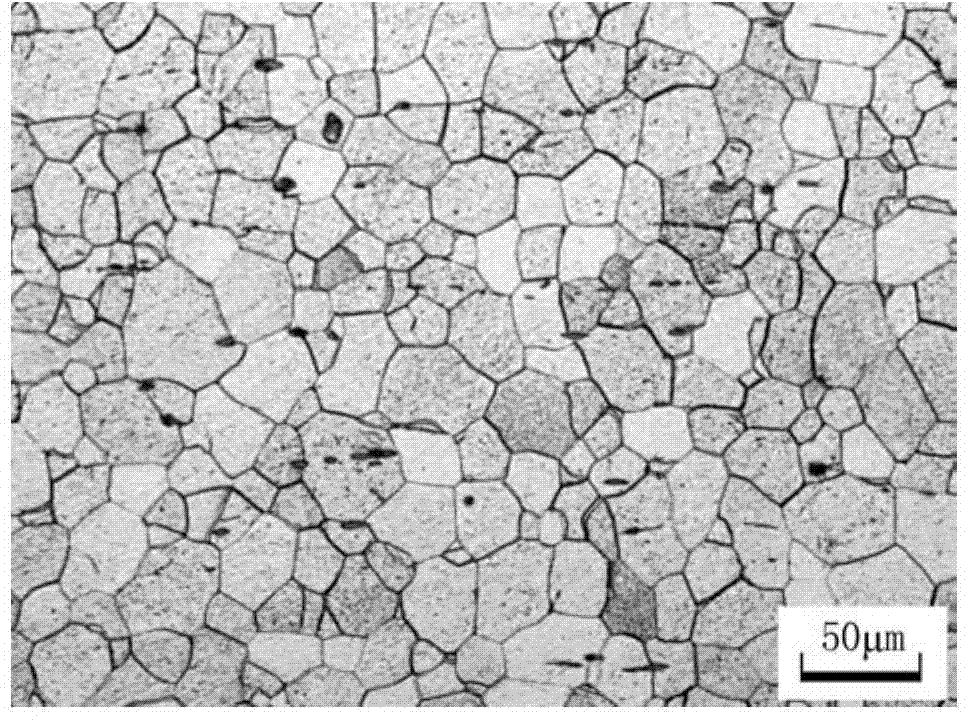

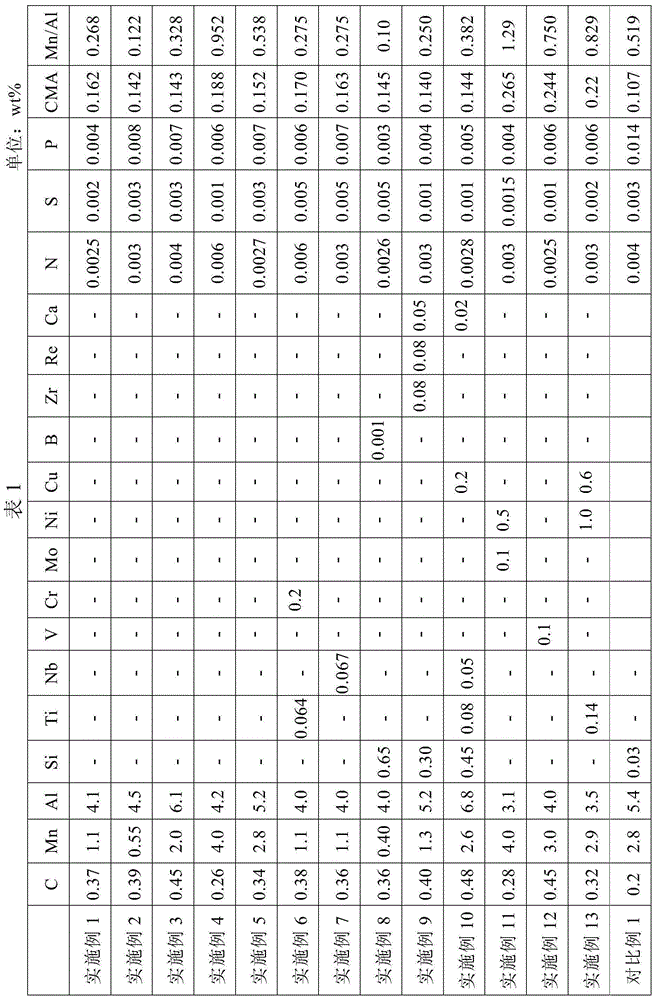

Ferrite low-density high-strength steel and manufacturing method thereof

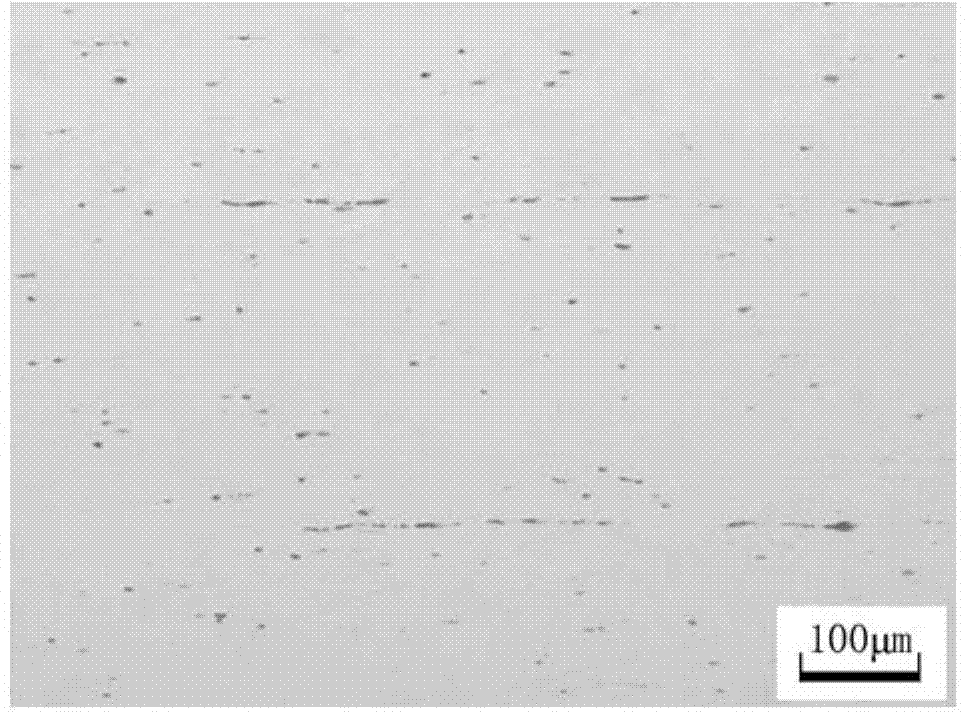

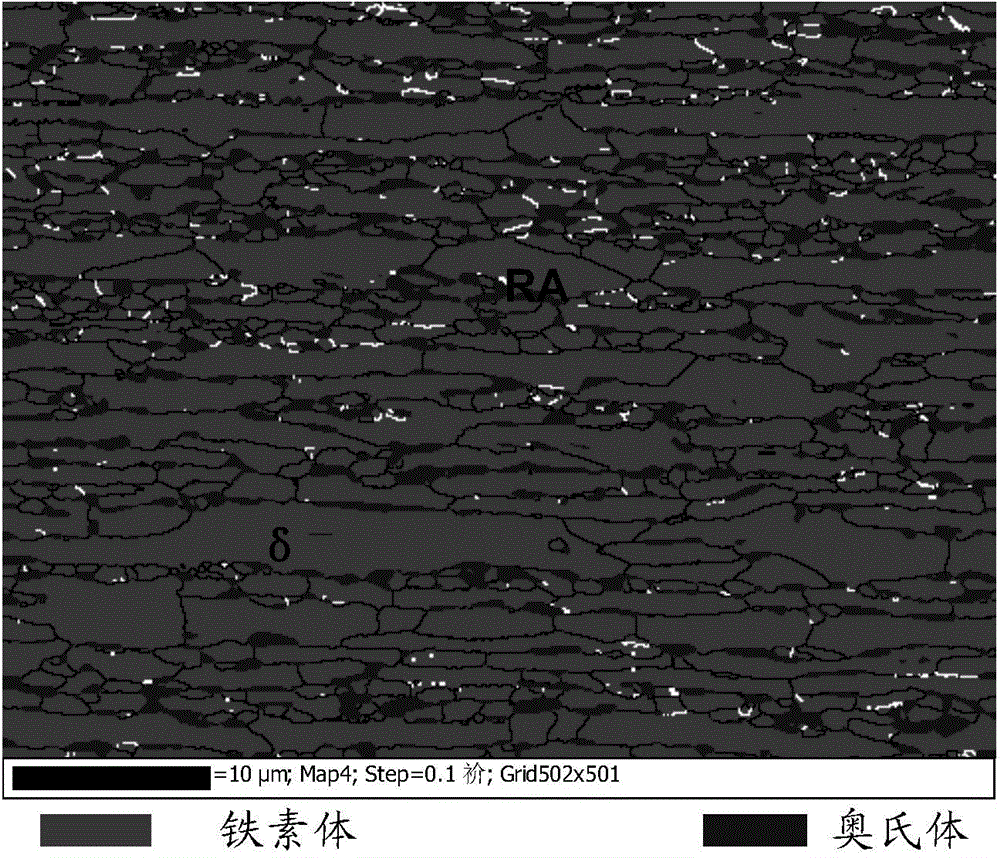

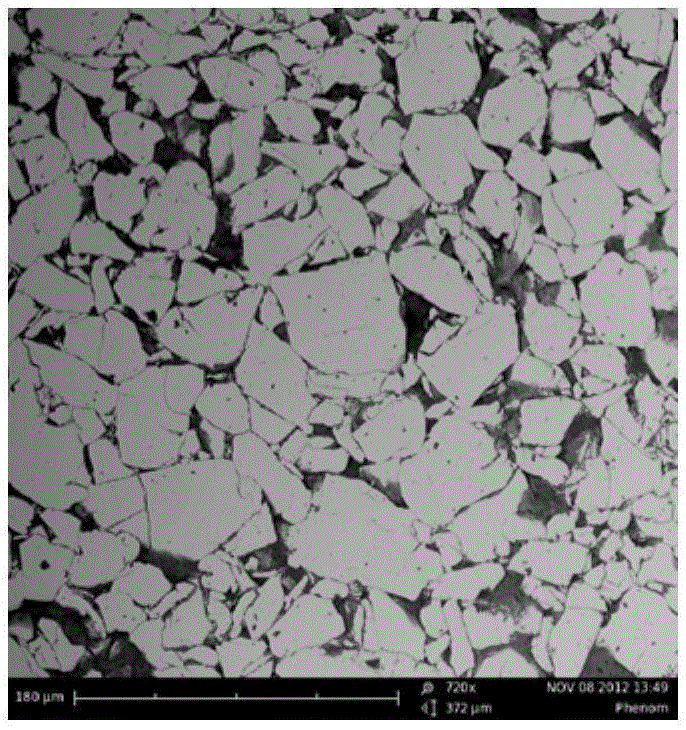

A ferrite low-density high-strength steel and manufacturing method thereof. The ferrite low-density high-strength steel chemical comprises the following chemical components composition by mass percentage: 0.05-0.40% of C, 4.0-12.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements. The above elements satisfy the following relationship: 1.0<Mn / Al, 3.5 <1.5Mn / Al+10C, and Mn / Al + 10C <5.2 The manufacturing method comprises hot rolling, annealing, pickling, cold rolling and annealing to prepare the low-density high-strength steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-40% of residual austenite. The low-density high-strength steel plate has tensile strength no less than 800MPa, elongation no less than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

Enamel steel with scaling resistance and manufacturing method thereof

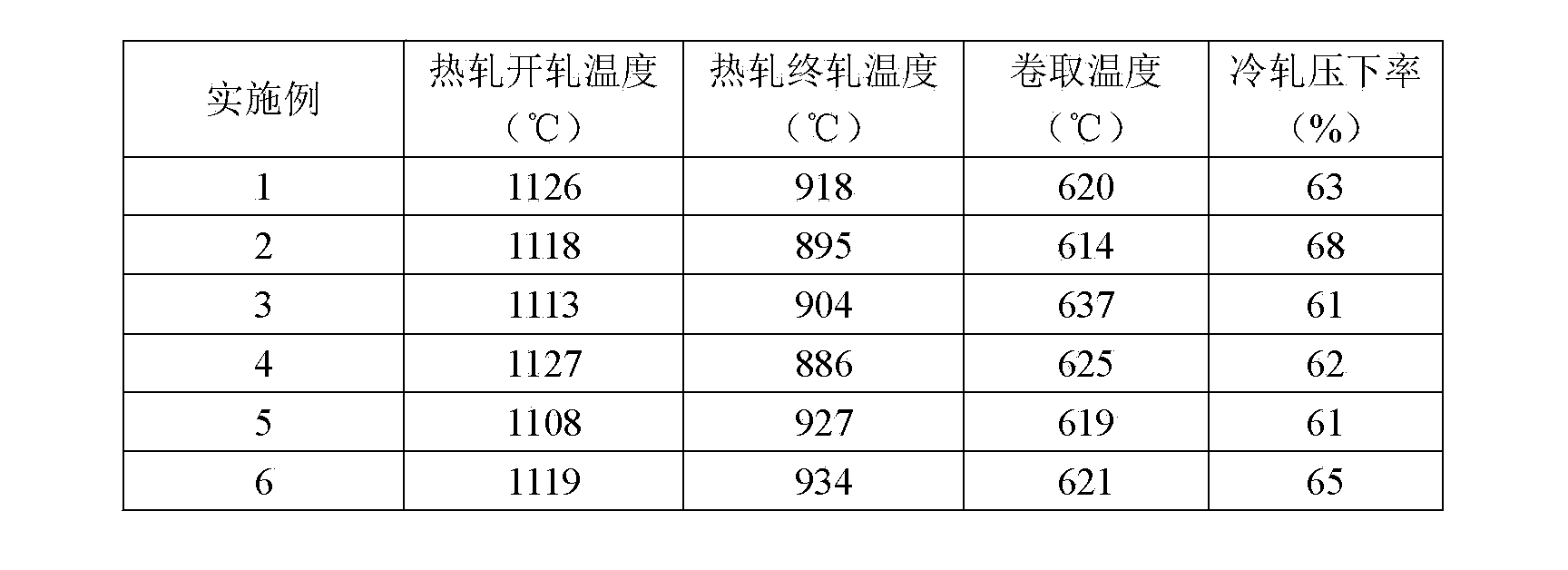

InactiveCN103484757ASimple chemical compositionReduce smelting costTemperature control deviceReduction rateAcid washing

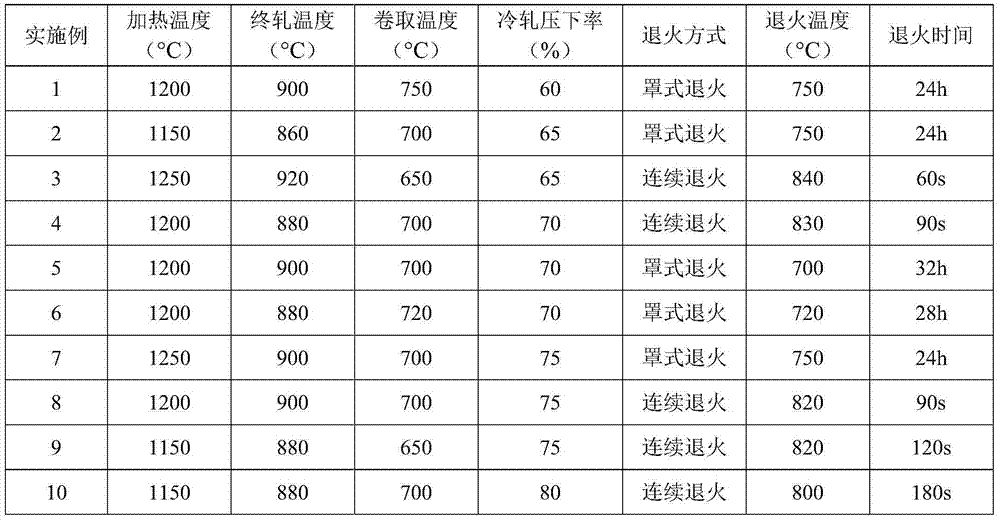

The invention discloses enamel steel with scaling resistance. The enamel steel is prepared from the following components in percentage by weight: 0.0020-0.0050% of C, 0.30-0.50% of Mn, 0.0050-0.0100% of Si, 0.010-0.015% of P, 0.011-0.020% of S, 0-0.010% of Als, 0.011-0.020% of O and the balance of Fe and other inevitable impurities. A manufacturing method sequentially comprises the following steps: pretreatment of molten iron, smelting by a converter, refining, continuous casting, hot continuous rolling, acid washing, cold continuous rolling, annealing and finishing, wherein the heating temperature for hot continuous rolling is 1150-1250 DEG C, the finish rolling temperature is 860-920 DEG C, the winding temperature is 650-750 DEG C, and the cold rolling reduction rate of cold continuous rolling is 60-80%. The enamel steel disclosed by the invention has no scaling phenomenon and low production difficulty, and is suitable for being applied to the technical field of iron and steel smelting.

Owner:WUHAN IRON & STEEL (GROUP) CORP

800MPa grade high-ductility low-density steel and manufacturing method thereof

An 800MPa grade high-ductility low-density steel and a manufacturing method thereof. The steel comprises the following chemical composition by weight percentage: 0.25-0.50% of C, 0.25-4.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements, and these elements meet the following relationship: 0.14<= (1.5C + 0.1Mn) / Al<=0.30. The manufacturing method comprises hot rolling, pickling, cold rolling and continuous annealing to prepare a low-density steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-30% of residual austenite, wherein the content of C in the residual austenite is not less than 0.8%. The steel plate has tensile strength higher than 800MPa, elongation higher than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-rolled fine-grained steel for electrostatic enamel and manufacturing method thereof

ActiveCN101063189AHigh strengthGood formabilityRoll force/gap control deviceTemperature control deviceManganeseAlloy

The invention discloses a preparing method of electrostatic enamel hot-roller fine-grained steel, which is characterized by the following: allocating mass percent as 0. 02-0. 10 carbon, not more than 0. 10 silicon, 0. 4-1. 0 manganese, not more than 0. 05 phosphor, 0. 02-0. 05 sulfur, 0. 01-0. 10 aluminum, 0. 003-0. 010 nitrogen, 0. 03-0. 10 titanium, surplus ferric and unavoidable impurity; setting the content of TiN at 0. 013-0. 044; setting ferrite tissue grain fineness number not less than 10 grade. This invention possesses good enamel adherence property and against squama knock property.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing magnetic sludge-based biochar material from sludge and application of magnetic sludge-based biochar material

ActiveCN112354516AEasy to separateLarge specific surface areaOther chemical processesSludge treatment by pyrolysisSludgeRed mud

The invention discloses a method for preparing a magnetic sludge-based biochar material from sludge and the application of the magnetic sludge-based biochar material, and belongs to the technical field of sludge resource utilization. The invention aims to fully utilize municipal and industrial wastes such as sewage sludge, hematite, rust, Bayer process red mud, high-iron-content fly ash, picklingwastewater and the like, and prepare magnetic sludge-based biochar from a solid waste iron source: dried sludge with the water content of less than 15% and a solid iron source are mechanically crushedand uniformly mixed; continuous pyrolysis is carried out, the pyrolysis temperature is 400-800 DEG C, the solid material stays in the device for 20-120 min, and fine ball milling and smashing are carried out until the particle size is 100 [mu] m or below; in the nano Fe3O4 / magnetic sludge-based biochar core-shell material prepared by the method, both the material core and the shell have magnetism, so that efficient recycling can be realized.

Owner:SHANGHAI FUTING TECH CO LTD

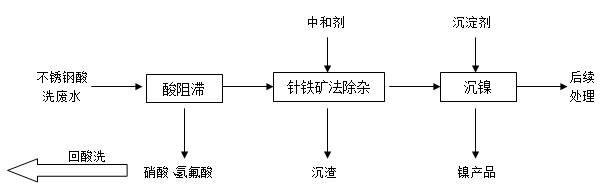

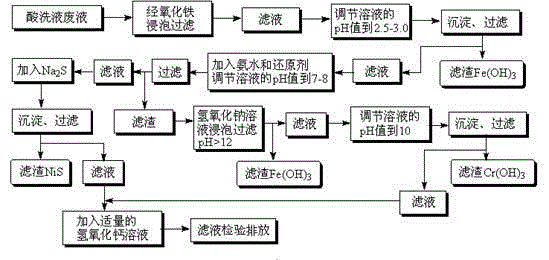

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

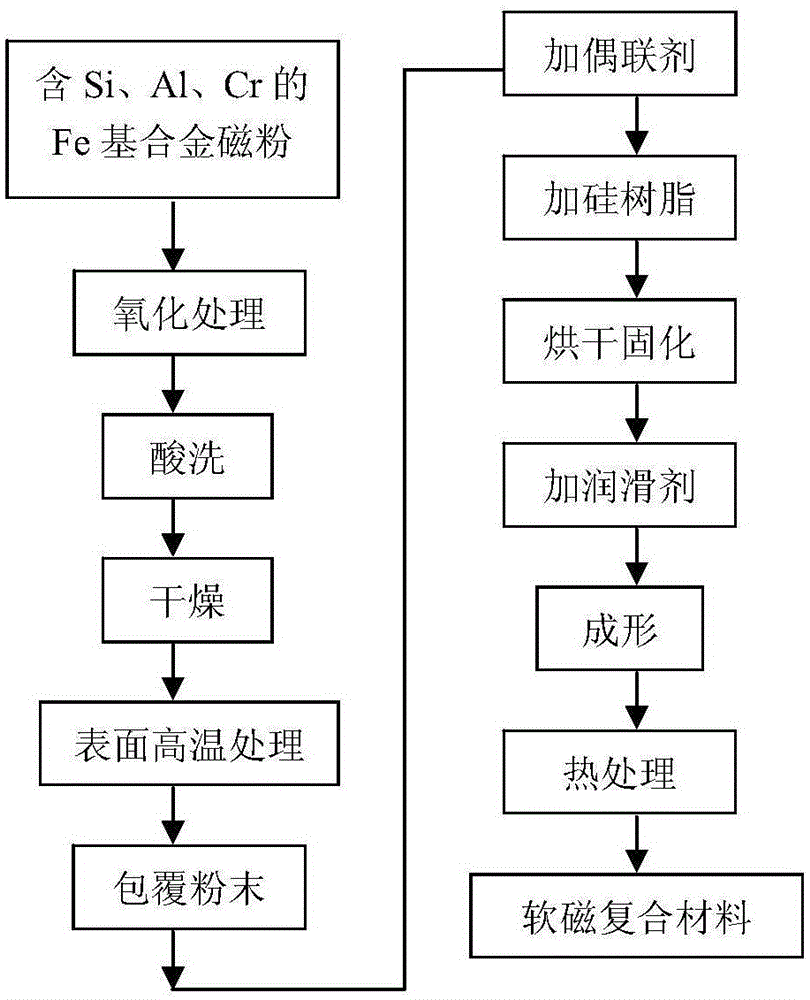

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

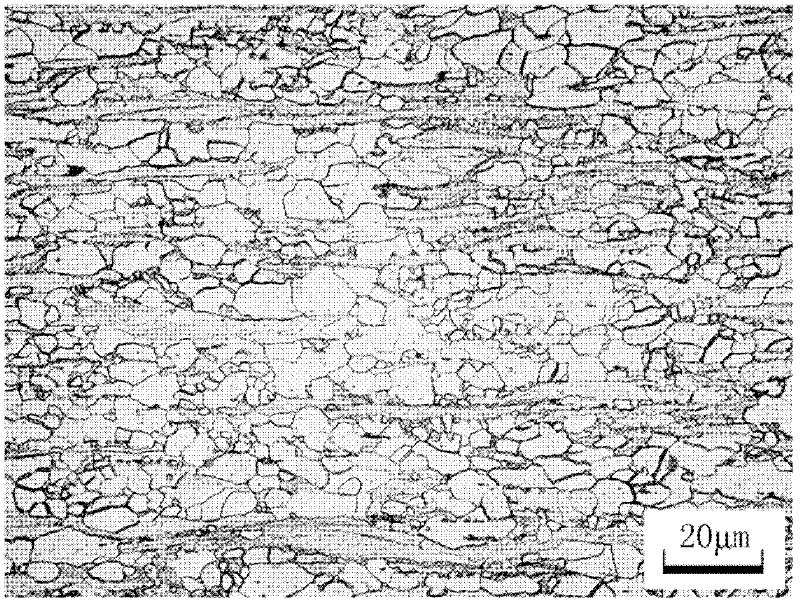

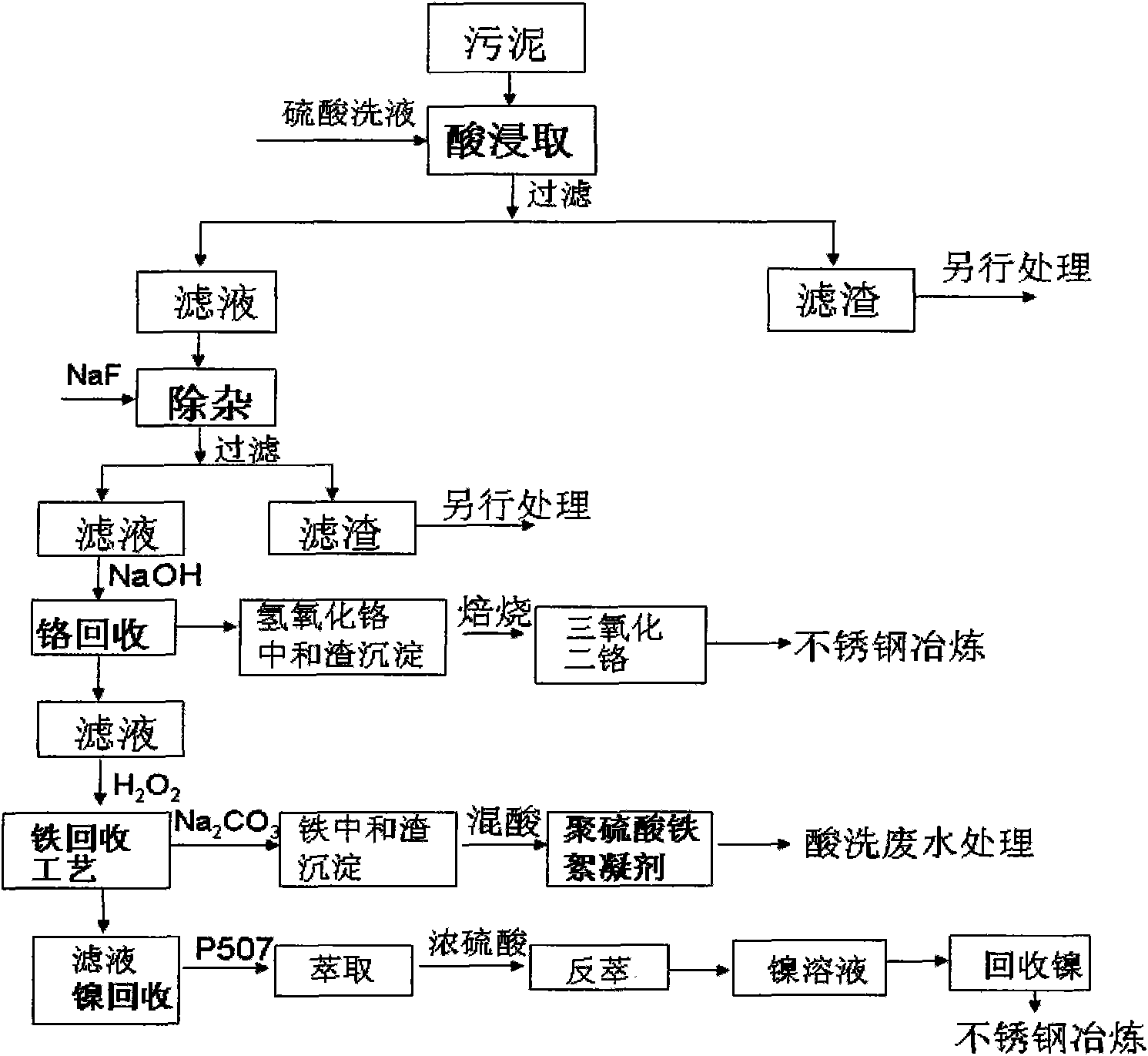

Recovery and comprehensive utilization method of heavy metals in stainless steel pickling wastewater sludge

InactiveCN101618892AImprove efficiencyAvoid secondary pollutionSludge treatmentChromium trioxideSolubilityHeavy metals

The invention relates to a recovery and comprehensive utilization method of heavy metals in stainless steel pickling wastewater sludge and discloses a method for recovering and recycling nickel and chrome in sludge generated during the treatment process of stainless wastewater. The method comprises the following steps: leading waste liquid during the pickling process to be directly used for leaching metal ions in the sludge to save the consumption of reagents; adding a certain quantity of acid or alkali in each reaction tank through arranging a plurality of reaction tanks; controlling a pH value; effectively separating various matters according to different solubility of inorganic compounds; researching and developing a recycling technology of the heavy metals in the stainless steel industrial sludge, wherein the recovery efficiency of the heavy metals like the chrome and the nickel is high; leading the recovered heavy metals to be used for smelting stainless steel; leading recovered iron to be used for preparing an efficient flocculating agent; and leading the flocculating agent to be used for sewage treatment to realize sewage reuse and save the treatment cost. The invention has the advantages of simple process and easy operation, as well as popularization and application.

Owner:SOUTHEAST UNIV

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

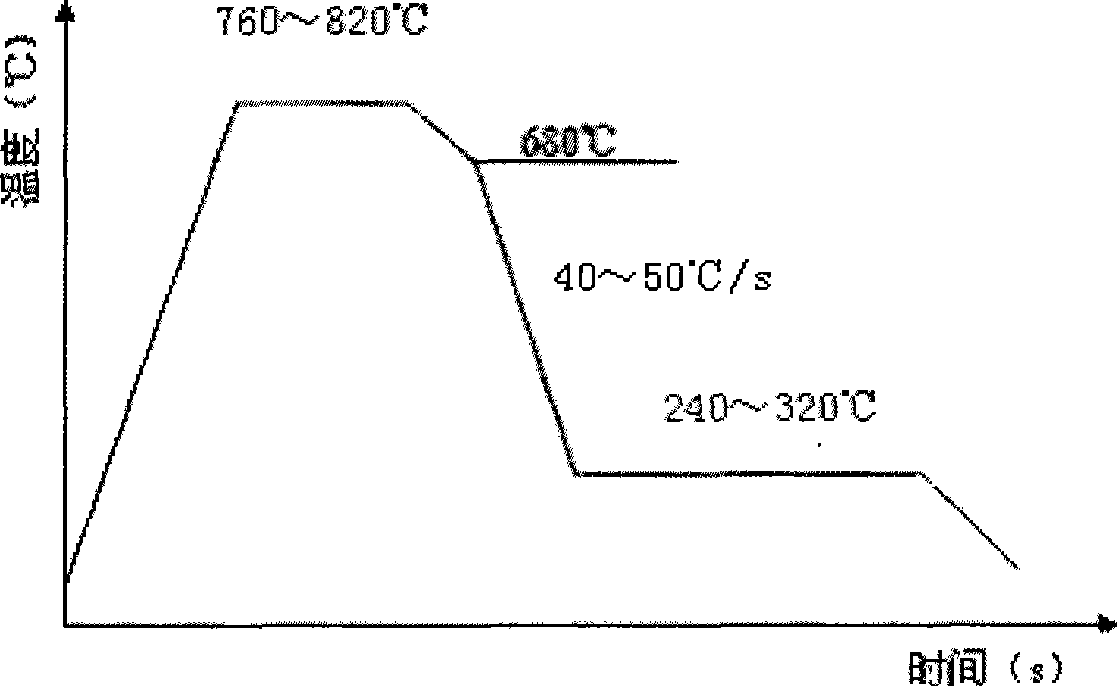

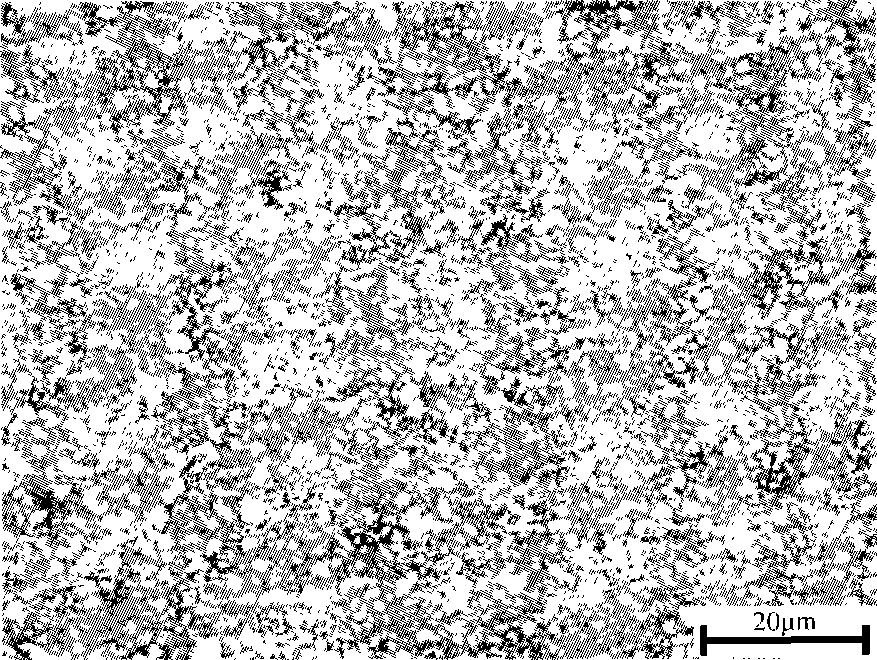

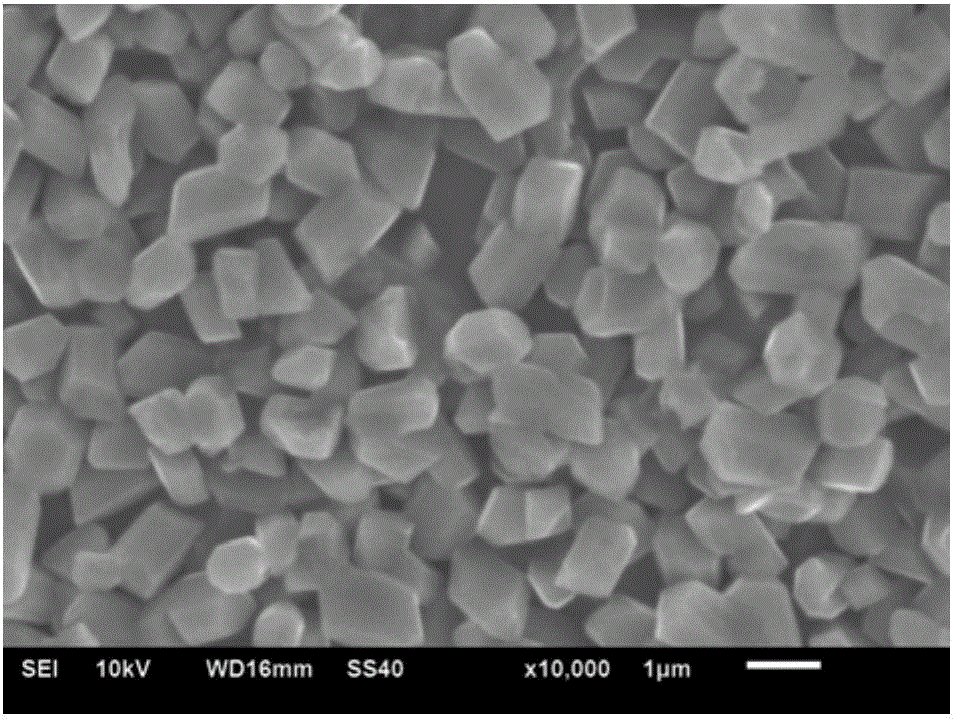

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

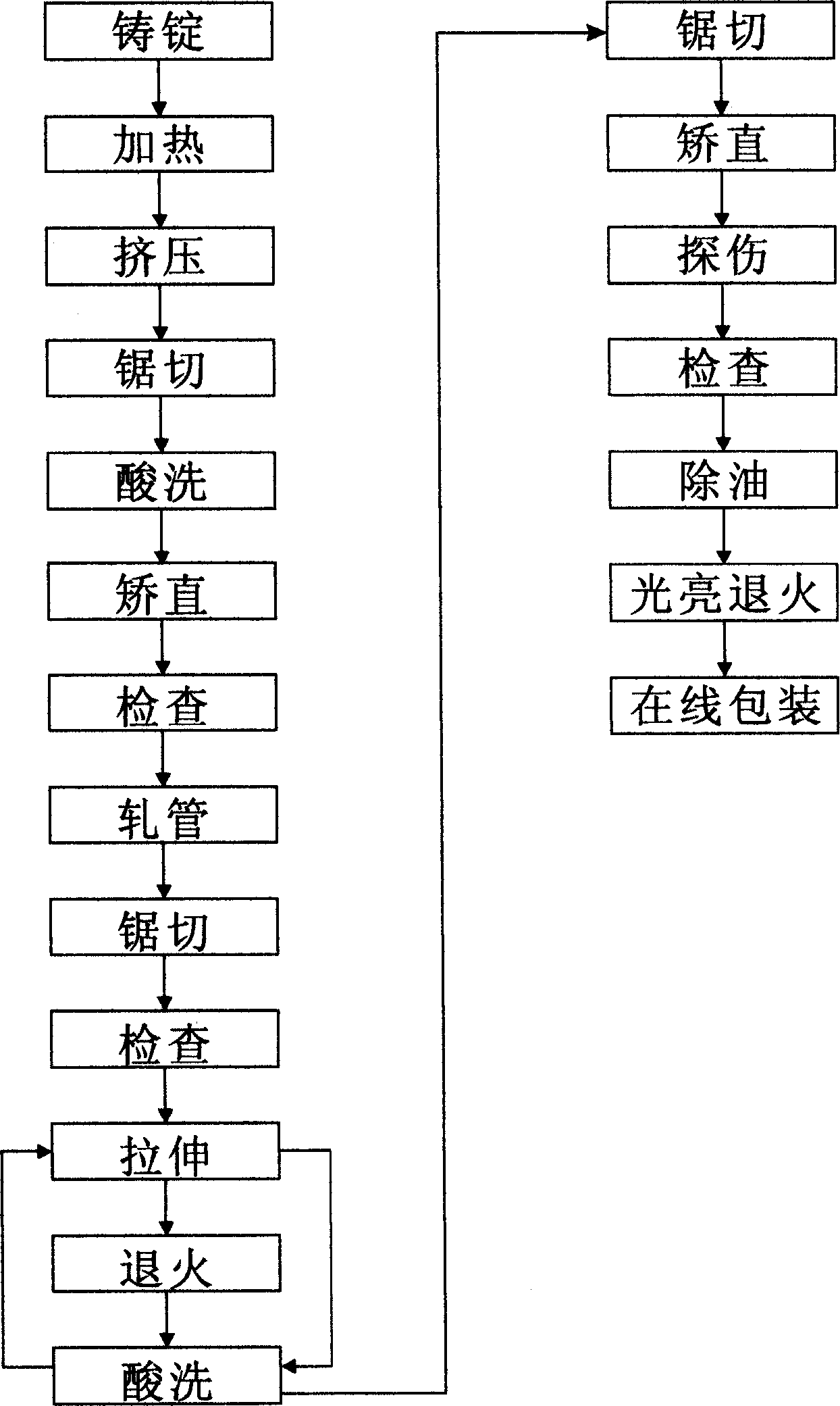

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

High strength steel sheet having excellent formability and method for manufacturing the same

ActiveUS20140230971A1High strengthImprove fuel efficiencyHot-dipping/immersion processesFurnace typesChemical compositionImpurity

A method for manufacturing the high strength steel sheet having excellent formability includes hot-rolling a steel slab having a chemical composition containing, by mass %, C: 0.03% or more and 0.35% or less, Si: 0.5% or more and 3.0% or less, Mn: 3.5% or more and 10.0% or less, P: 0.1% or less, S: 0.01% or less, N: 0.008% or less and the balance comprising Fe and inevitable impurities, coiling the hot-rolled steel sheet at a temperature range of the Ar1 transformation point to the Ar1 transformation point+(the Ar3 transformation point−the Ar1 transformation point) / 2, cooling the coiled steel sheet down to 200° C. or lower, heating and holding the cooled steel sheet at a temperature range of the Ac1 transformation point−200° C. to the Ac1 transformation point for 30 minutes or more, pickling the heated steel sheet, cold-rolling the pickled steel sheet under the condition that the rolling reduction is 20% or more, and heating and holding the cold-rolled steel sheet at a temperature range of the Ac1 transformation point to the Ac1 transformation point+(the Ac3 transformation point−the Ac1 transformation point) / 2 for 30 seconds or more.

Owner:JFE STEEL CORP

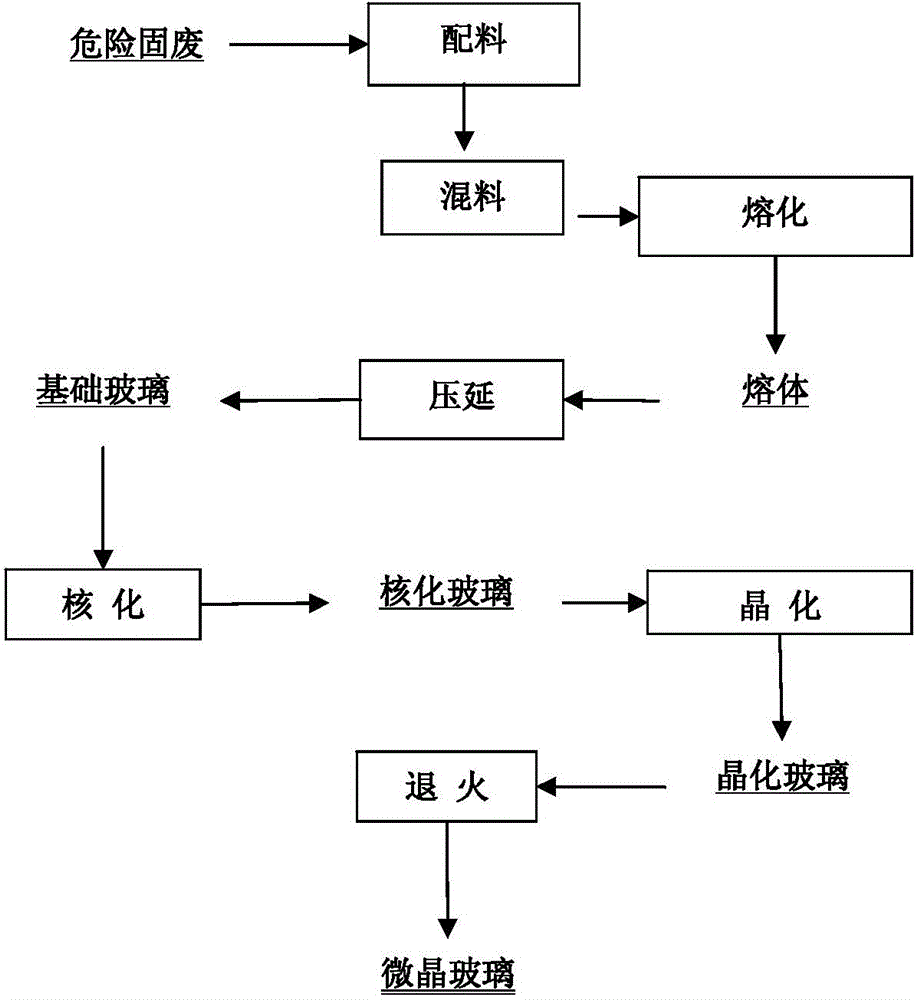

Method for preparing microcrystalline glass from hazardous solid wastes

The invention discloses a method for preparing microcrystalline glass by taking hazardous solid wastes which are hazardous solids for short. The method is characterized by taking heavy metals in the hazardous solids as nucleating agents, mixing, fusing, rolling, nucleating, crystallizing and annealing to obtain the microcrystalline glass. The method has the advantages that the heavy metal elements in waste incineration ash, stainless steel slag, stainless steel acid pickling sludge, electroplating sludge, chromium slag, lead-zinc smelting slag and coal ash can be stably solidified; the pollution is avoided; meanwhile, high-additional-value microcrystalline glass is prepared; the harmless high-value application of the hazardous solids is realized; and the method has remarkable environmental and economic benefits and wide market prospects.

Owner:UNIV OF SCI & TECH BEIJING

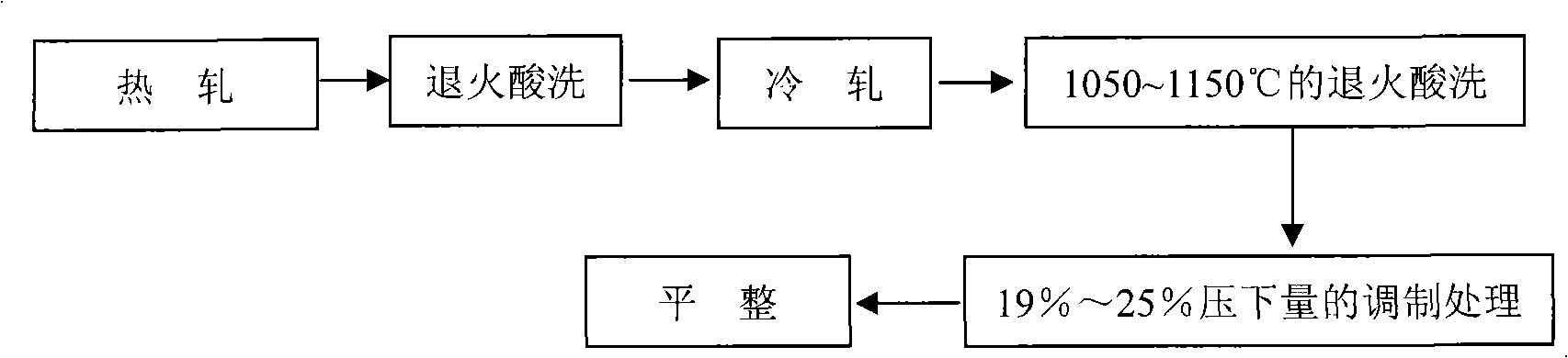

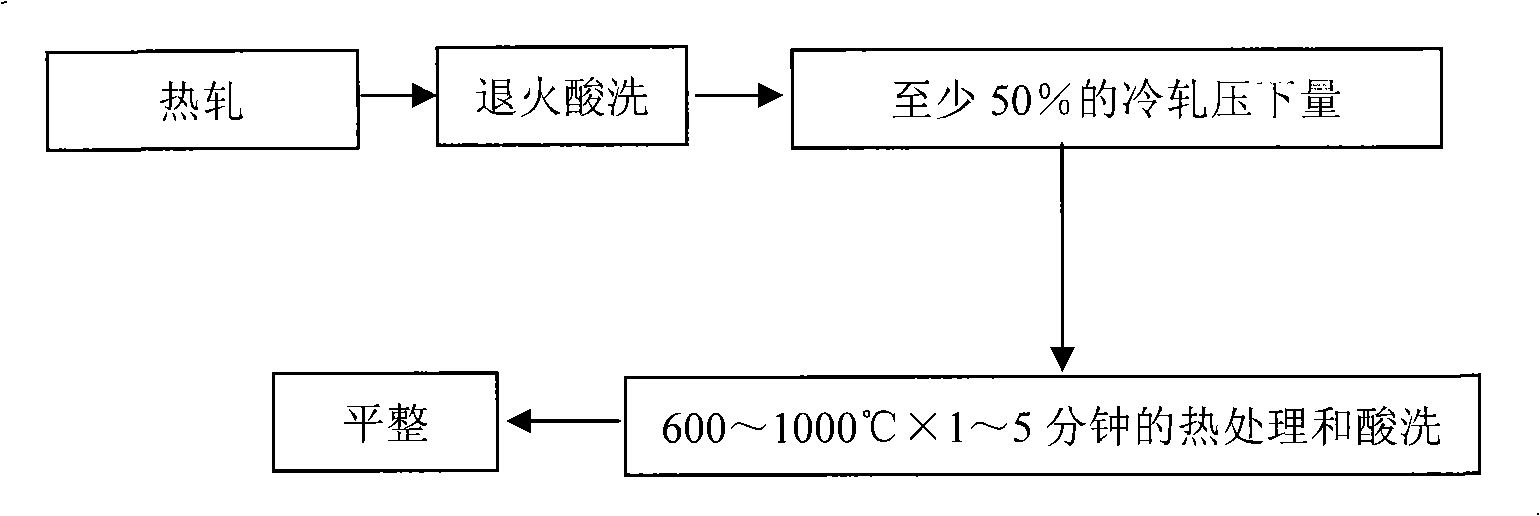

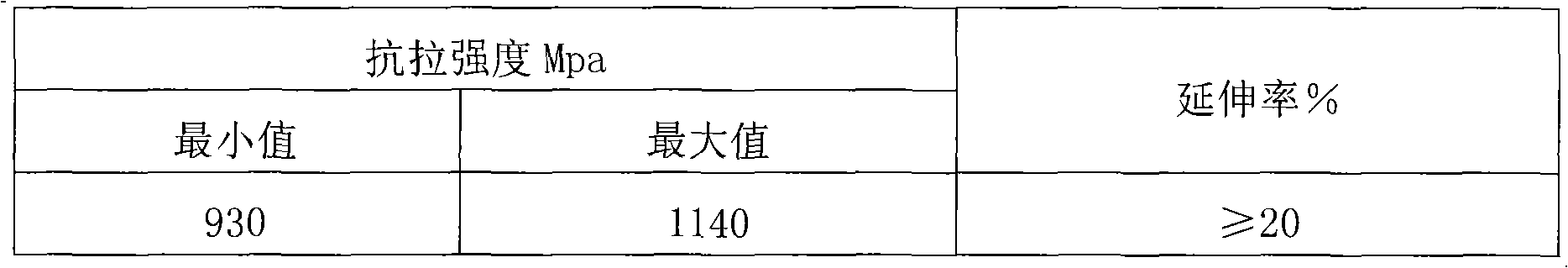

Austenic stainless steel and method for manufacturing same

ActiveCN101311291AGuaranteed StrengthReduce processing costsRoll mill control devicesHeat treatment process controlChemical compositionIngot

The invention discloses an austenitic stainless steel and a manufacturing method thereof. The weight percentages of the chemical components of the stainless steel are as follows: C, less than or equal to 0.03 percent; Si, 0.3 to 0.9 percent; Mn, 0.6 to 1.5 percent; Cr, 16.0 to 18.0 percent; Ni, 5.5 to 7.5 percent; N, 0.1 to 0.25 percent; P, less than or equal to 0.040 percent; S, less than or equal to 0.03 percent; the rest, Fe and inevitable impurity elements; wherein, the numerical value of Md30 is 20 to 60. The manufacturing method of the stainless steel is as follows: 1) preparation of ingots or slabs; 2) hot rolling; 3) annealing and acid pickling; 4) cold rolling with the reduction no less than 50 percent; 5) heat treatment and acid pickling. The method can lead the material elongation reach above 25 percent and improve the corrosion resistance of high-strength austenitic stainless steel used in vehicles and the processing and manufacture performance of steel.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

InactiveCN102162075AImprove grinding effectImprove surface polishing performanceTemperature control deviceFurnace typesElectrolysisAcid washing

The invention discloses an austenitic stainless steel with excellent polishing performance. The austenitic stainless steel comprises the following chemical components in percentage by weight: 16 to 20 percent of Cr, 7 to 15 percent of Ni, less than or equal to 2 percent of Mn, 0.2 to 2 percent of Cu, less than or equal to 0.05 percent of Al, less than or equal to 0.5 percent of Si, 0.03 to 0.1 percent of C, less than or equal to 0.05 percent of N, 0.01 to 0.06 percent of P, 0.003 to 0.05 percent of S, 0.05 to 0.5 percent of V, and the balance of iron and inevitable impurities. A manufacturing method for an austenitic stainless steel cold-rolled plate comprises the following steps of: heating a continuous cast plate blank to the temperature of between 1,100 and 1,300 DEG C; performing rough rolling at the temperature of between 1,000 and 1,250 DEG C; performing final rolling at the temperature of between 950 and 1,100 DEG C; performing quick cooling; coiling at the temperature of less than 700 DEG C; performing hot rolling to form a hot-rolled plate of the required specification; annealing the hot-rolled plate at the temperature of between 950 and 1,200 DEG C; removing oxide skin by adopting a continuous acid washing process of phosphorus breakage, shot blasting, electrolysis and mixed acid washing; performing cold rolling, wherein the overall reduction rate is more than 50 percent; and performing continuous annealing at the temperature of between 950 and 1,200 DEG C, or performing full-hydrogen bright annealing at the temperature of between 950 and 1,200 DEG C. The austenitic stainless steel cold-rolled plate has completely improved grinding performance and surface polishing performance, and is particularly suitable for the industries of building decoration, plastic dies, food sanitation, electronics and the like with strict polishing performance requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-chromium electrolytic polishing solution for stainless steel and surface polishing process for stainless steel

The invention discloses a non-chromium electrolytic polishing solution for stainless steel and a surface polishing process for stainless steel. The polishing solution mainly comprises alcohol (at least one selected from the group consisting of methanol and ethanol) and acid (at least one selected from the group consisting of sulfuric acid and acetic acid). The surface polishing process for stainless steel provided in the invention comprises the following steps: removal of oil stains, rinsing with ultrasonic vibration, pickling with ultrasonic vibration, alkali washing with ultrasonic vibration, electropolishing, rinsing with ultrasonic vibration, passivation, cleaning and drying. Compared to conventional electrolytic polishing solutions for stainless steel, the polishing solution provided in the invention contains no chromic anhydride, which enables environmental pollution to be reduced and waste liquid to be easy to treat, being an environment-friendly type polishing solution; the polishing solution further contains no expensive phosphoric acid, which enables polishing cost to be reduced and is favorable for the popularization of the electropolishing process for stainless steel. According to results of tests, the polishing solution and the process provided in the invention can effectively remove oxide films and scratches on the surface of stainless steel, enable a workpiece to have an effect of mirror brightness, and effectively enhance the quality of polishing.

Owner:CENT SOUTH UNIV

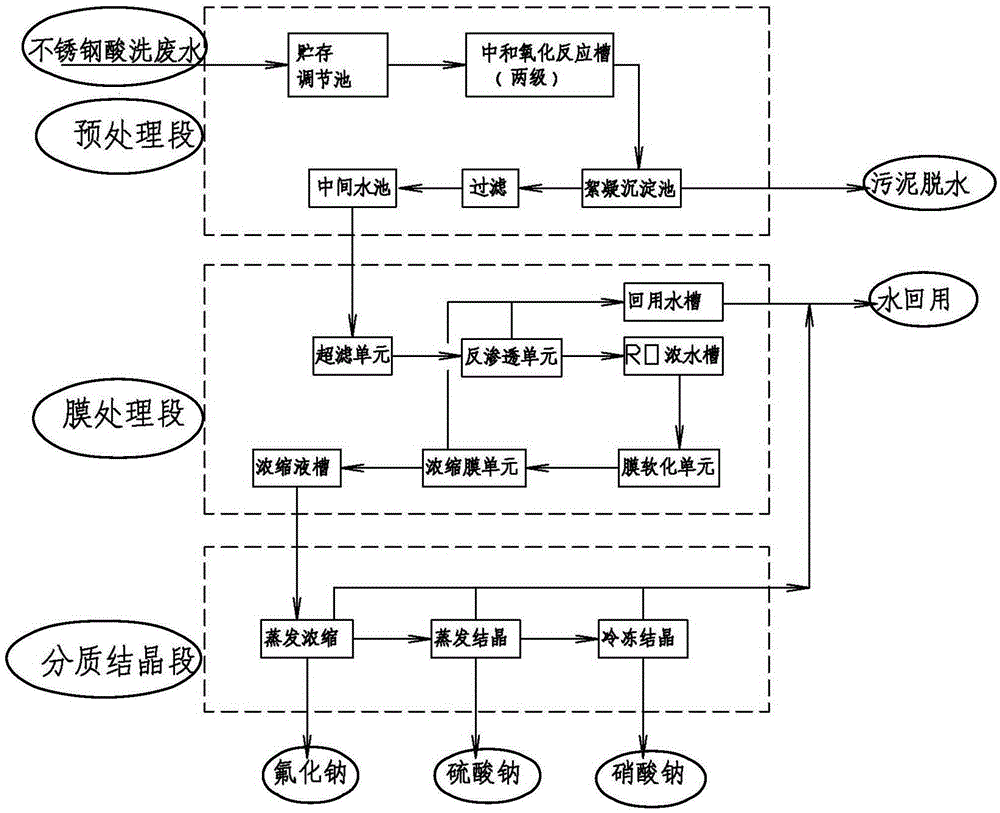

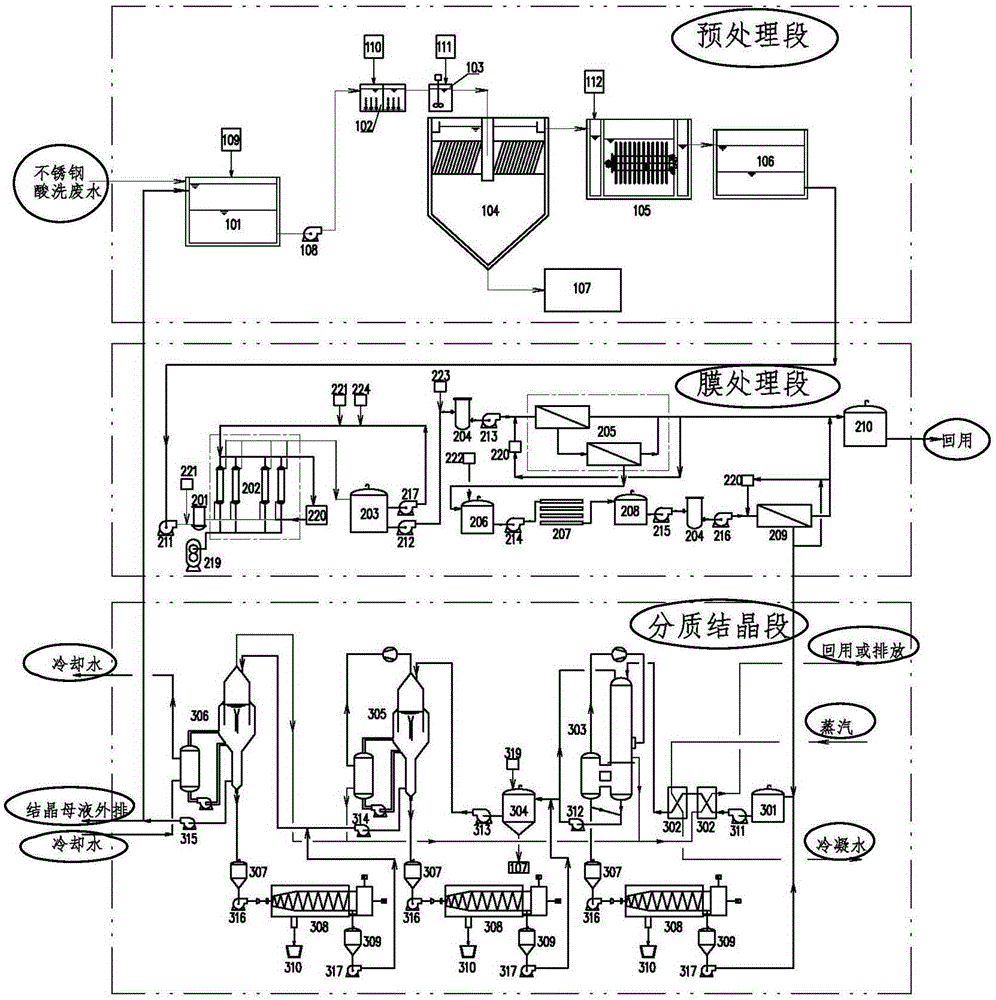

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and treatment process

PendingCN106565045AAchieve reuseRealize zero-emission resource utilizationAlkali metal nitratesWaste water treatment from metallurgical processChemical reactionUltrafiltration

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and a treatment process are disclosed. A pretreatment section, a membrane treatment section and a quality-based crystallization section are involved. The invention is characterized in that a storage regulating basin, a neutralization-oxidation reaction tank, a flocculent precipitation tank, a filter, an ultrafiltration and reverse osmosis system, a membrane concentration system and an evaporation and concentration and quality-based crystallization system are mutually connected end to end through pipelines. Each dosage device is respectively arranged on corresponding section. According to the order of the pretreatment section, the membrane treatment section and the quality-based crystallization section, thirteen steps are included for the operation. By the treatment process of chemical reactive precipitation, membrane separation concentration and evaporation and quality-based crystallization, various acid wastewaters mainly containing acid and inorganic salt can be treated to realize recycling of wastewater. After crystallization of salt, sodium sulfate (and sodium chloride), sodium nitrate, sodium fluoride and other products can be recycled, and zero-discharge resource utilization of stainless steel pickling wastewater is realized. Meanwhile, system sludge yield is greatly reduced such that the burden of sludge treatment is decreased.

Owner:MAIWANG INT BUSINESS SHANGHAI

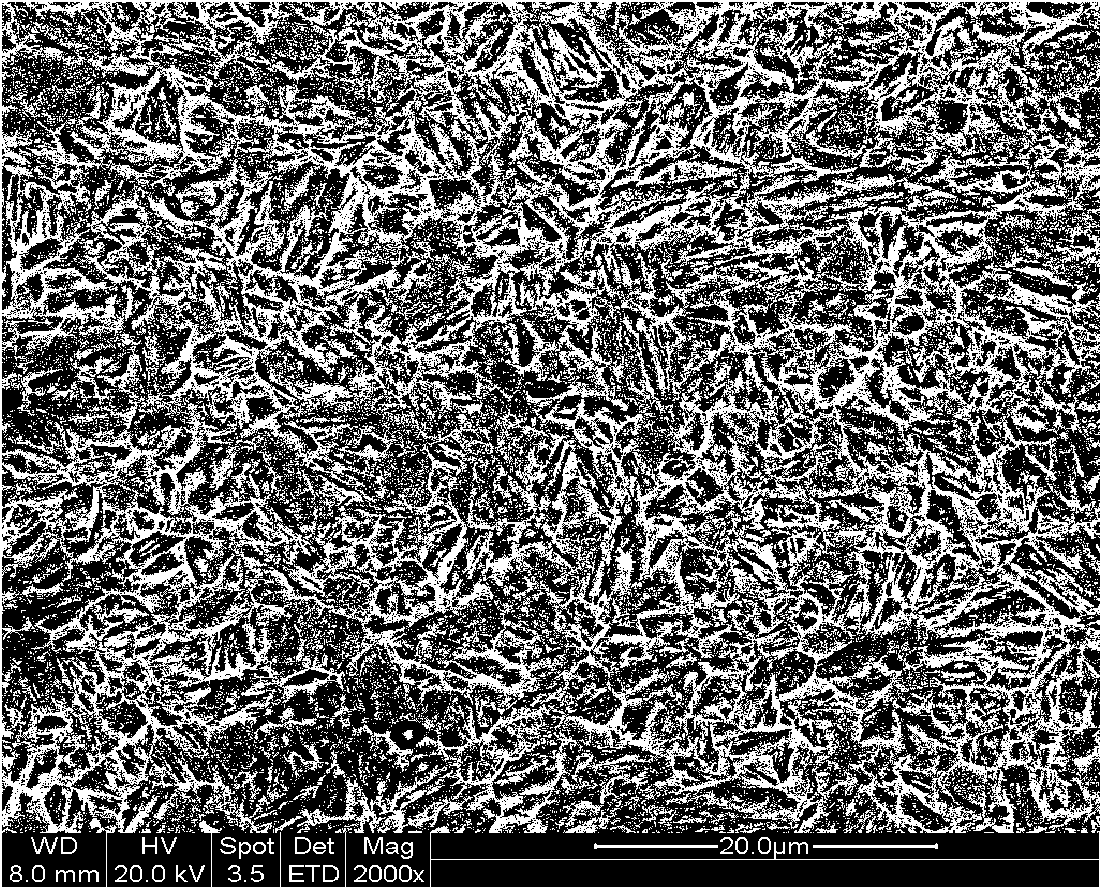

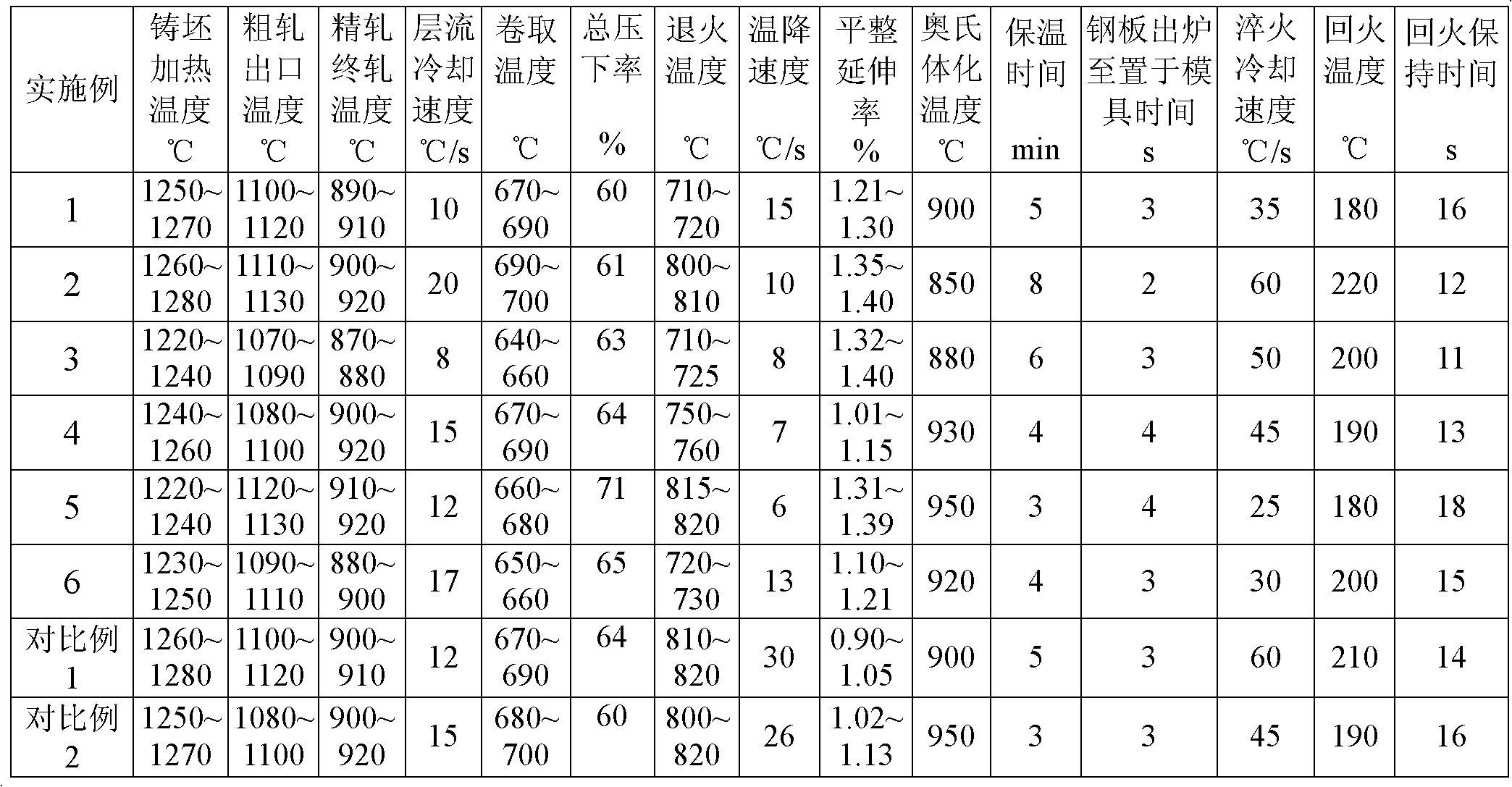

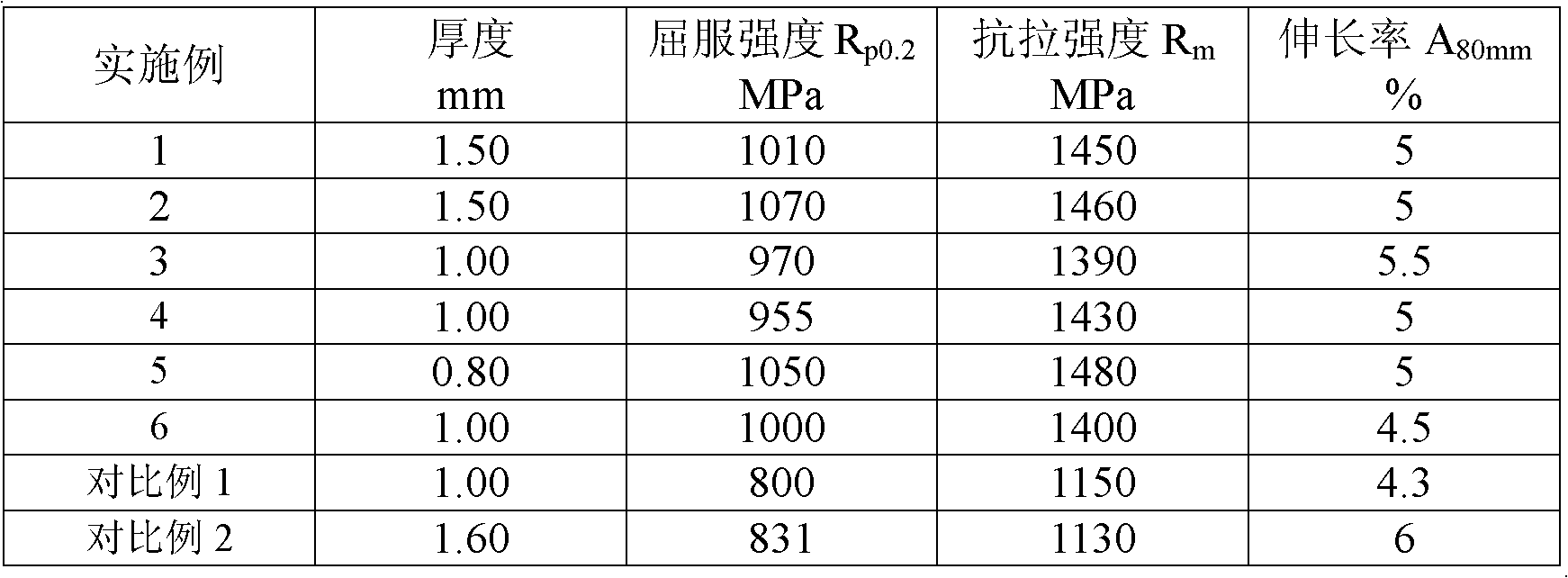

Steel with 1,300MPa-level tensile strength for automobile safety piece and production method thereof

The invention relates to steel with 1,300MPa-level tensile strength for an automobile safety piece and a production method thereof. The steel comprises the following components in percentage by weight: 0.12 to 0.22 percent of C, 0.10 to 0.40 percent of Si, 1.00 to 1.60 percent of Mn, 0.10 to 0.45 percent of Cr, 0.01 to 0.10 percent of Ti, 0.0005 to 0.005 percent of B, 0.01 to 0.06 percent of Als,less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S and less than or equal to 0.008 percent of N. The production method comprises the following steps of: smelting by using a converter; alloying; performing vacuum treatment and component fine turning; continuously casting; heating a casting blank to the temperature of between 1,220 and 1,280 DEG C; performing rough rolling; performing fine rolling; performing laminar flow cooling; reeling; performing acid-washing; performing cold rolling; annealing; smoothing; finishing; cutting; heating and austenitizing under the protective atmosphere of nitrogen; forming a mold; quenching; tempering; and taking a member out for later use. The steel has ultrahigh intensity, meets the requirements of an automobile industry on the intensity and the rigidity of the safety piece of a vehicle body, can be complicatedly deformed without resilience, has high dimensional accuracy of parts and can be industrially produced on common large production equipment.

Owner:武汉钢铁有限公司

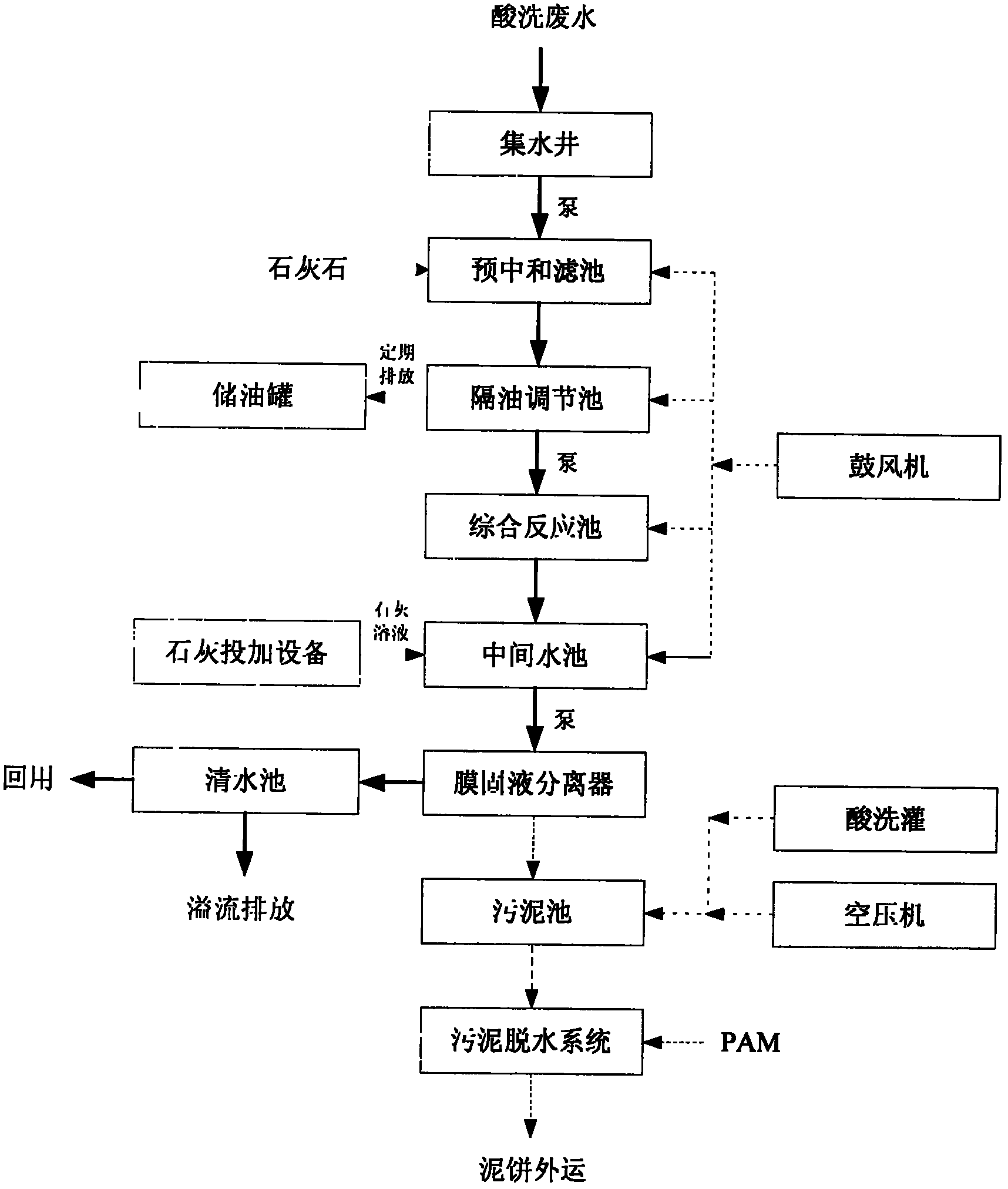

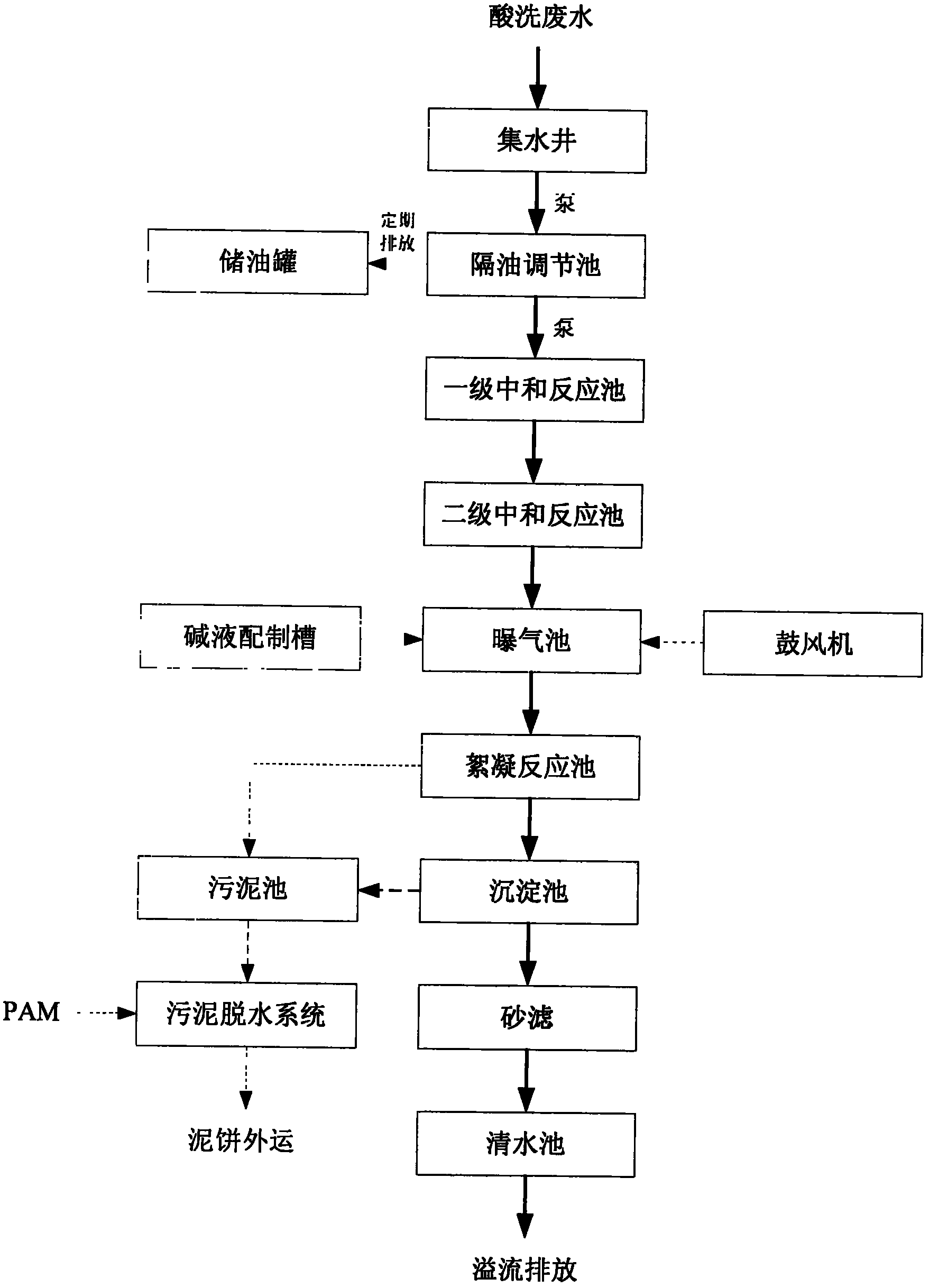

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

High-strength high-plasticity cold-rolled steel plate for automobiles and production method thereof

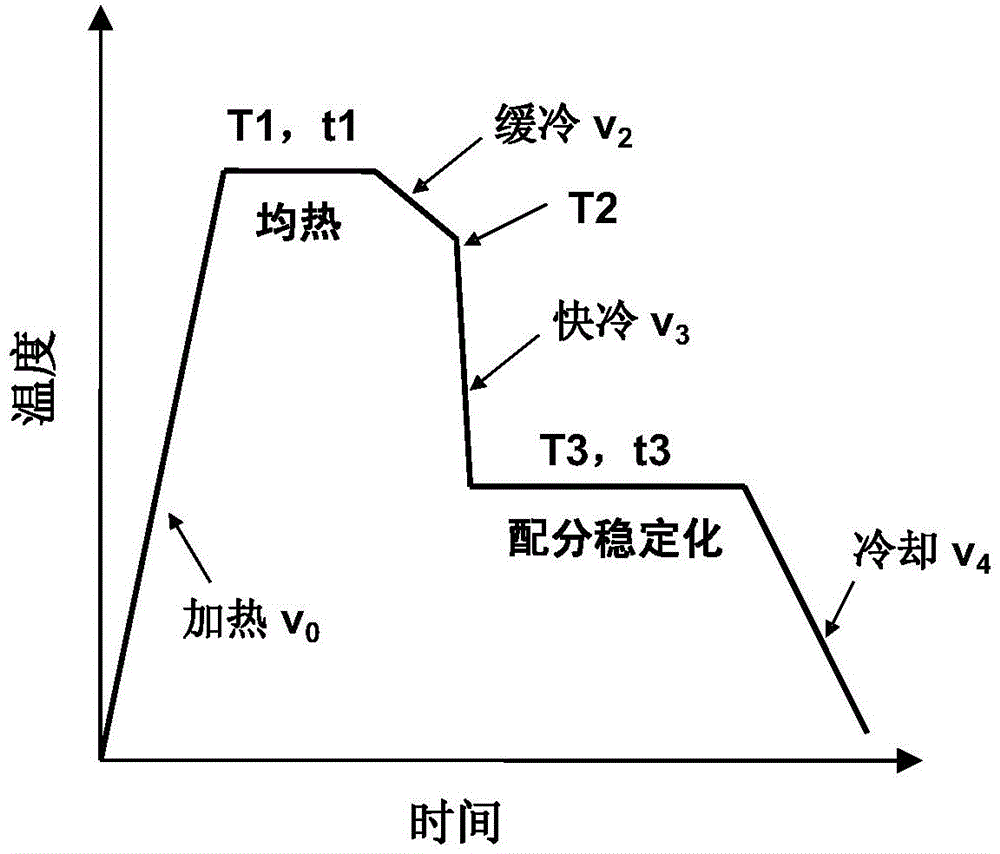

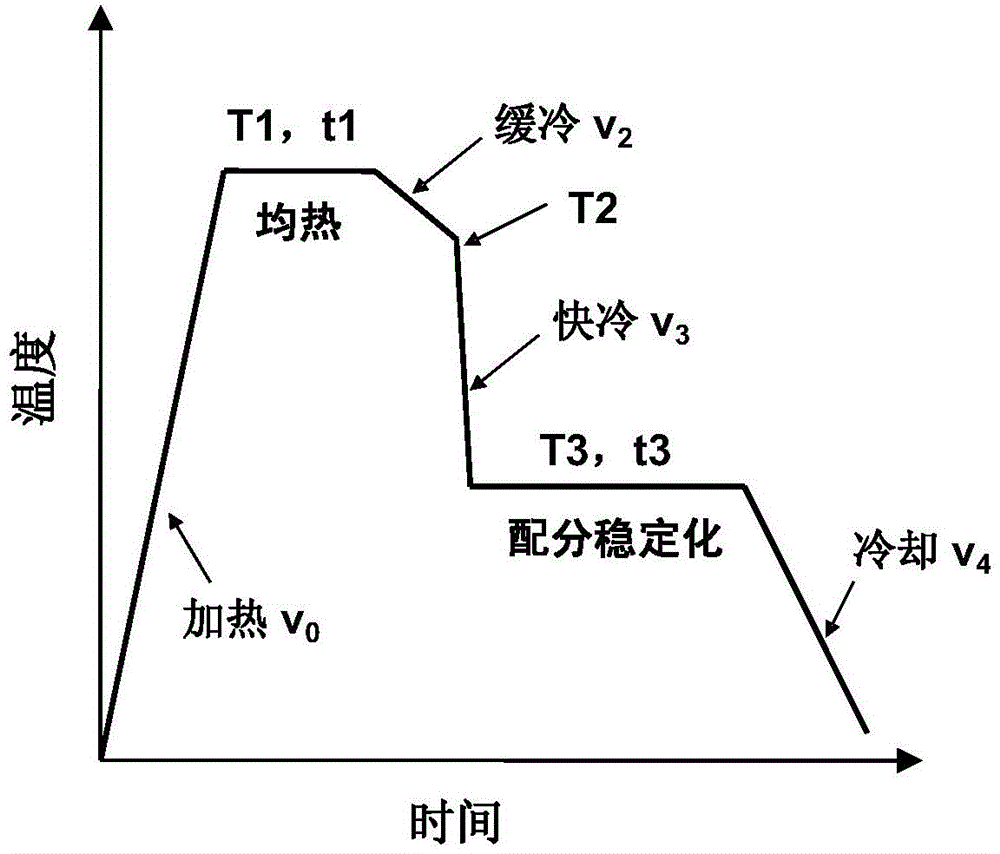

ActiveCN104278194AReduce equipment performance requirementsComply with reduction requirementsThermal insulationRoom temperature

The invention discloses a high-strength high-plasticity cold-rolled steel plate for automobiles and a production method thereof. The high-strength high-plasticity cold-rolled steel plate comprises, by weight, 0.25-0.35% of C, 0.8-1.2% of Si, 2.0-2.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, 0.5-1.0% of Al, 0.001-0.002% of B and the balance Fe and unavoidable impurities. The production method comprises smelting, continuous casting, hot rolling, pickling, cold rolling and continuous annealing. A continuous annealing heating temperature is in a range of 800-850 DEG C, thermal insulation time is in a range of 150-180s, a cooling rate is greater than or equal to 50 DEG C / s, a quenching temperature is in a range of 250-280 DEG C, a partition temperature is in a range of 350-400 DEG C, partition time is in a range of 300-600s and after partition, the product is cooled to a room temperature at a cooling rate greater than or equal to 50 DEG C / s.

Owner:ANGANG STEEL CO LTD

AlN ceramic bonded copper substrate and preparation method thereof

The invention provides an AlN ceramic bonded copper substrate which comprises an AlN ceramic substrate and copper foil bonded and connected onto the AlN ceramic substrate and is characterized in that a spinel structure compound modification layer is formed between the AlN ceramic substrate and the copper foil and comprises one or two of CuAlO2, CuAl2O4, Cu2O and CuO. The invention further provides a preparation method of the AlN ceramic bonded copper substrate. The method comprises the steps of spraying nano Cu2O on the surface of the AlN substrate, sintering in inert gas with a micro oxygen content and air sequentially, and then removing a surface oxide by a pickling manner. The prepared modification layer is tightly combined with matrix ceramic, and also has good affinity characteristic with the Cu foil. A uniform oxidation layer can be formed on the surface of the Cu foil by putting the Cu foil in a prepared solution at a certain temperature for specified time and more facilitates an AlN-DBC (direct bonded copper) technology.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

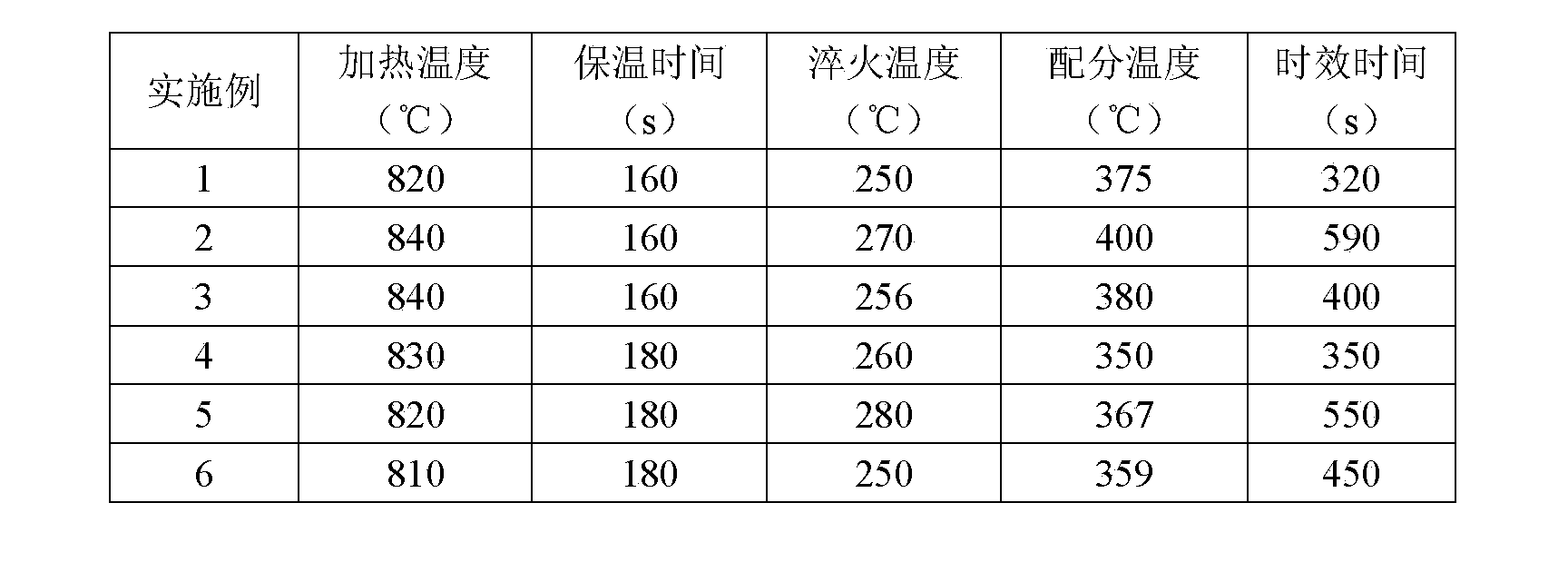

Stainless steel environment-friendly pickling solution

The invention discloses a stainless steel environment-friendly pickling solution. The stainless steel environment-friendly pickling solution is characterized by being compounded by nitric acid, environment-friendly additives and water. During an environment-friendly picking process design process, process data allowance has been reserved. The using concentration of the nitric acid has a wider range, and the using concentration of the additives has a wide enough range, so that a satisfactory pickling effect can be achieved by operating within the ranges, and therefore, simple maintenance can be carried out according to experimental parameters, and the method is simple and practical.

Owner:张文卓

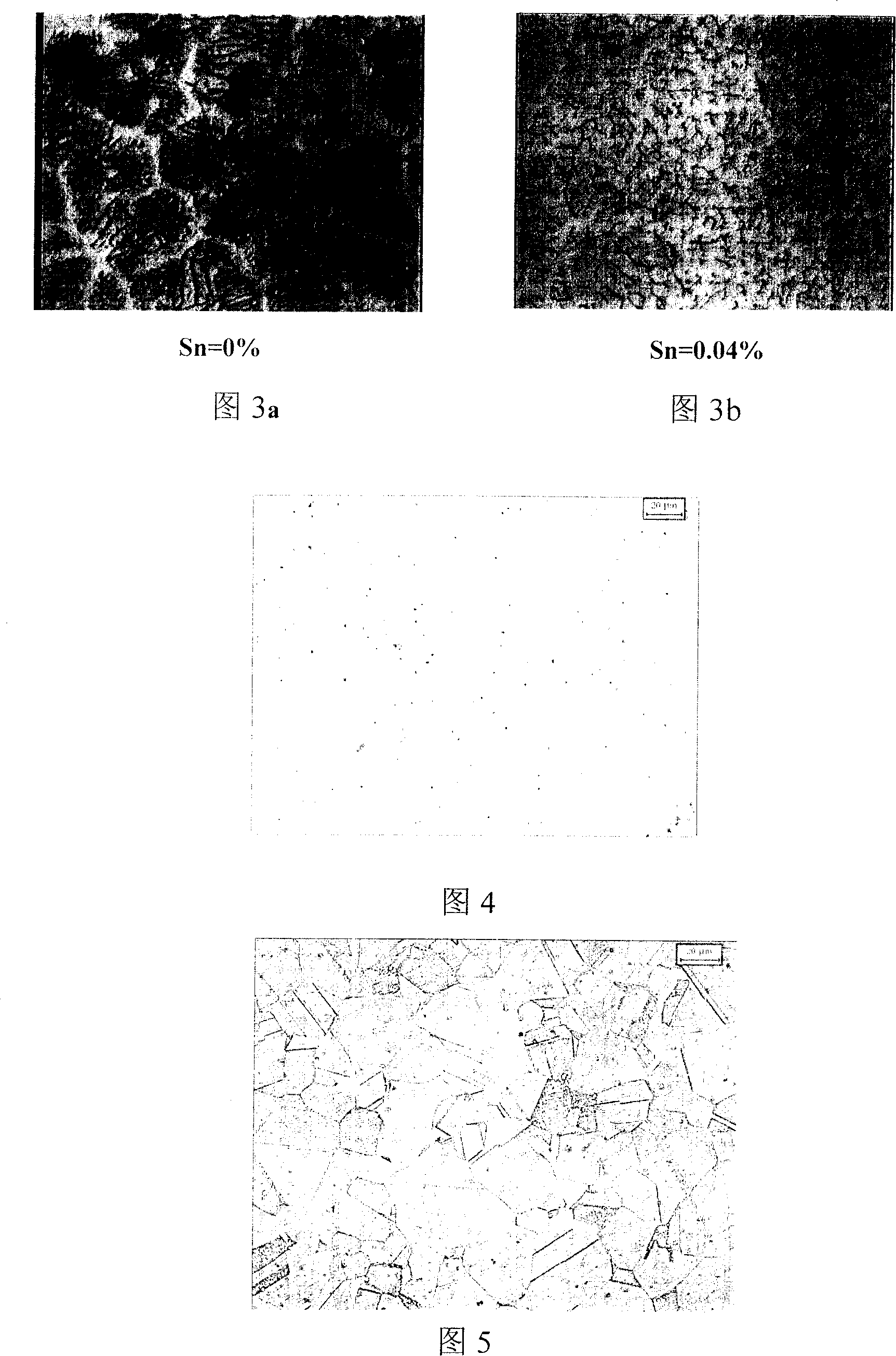

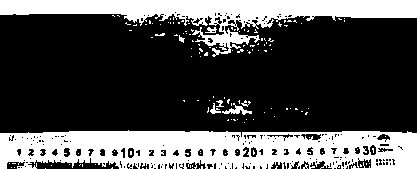

Thin belt continuous casting austenitic stainless steel belt and manufacturing method thereof

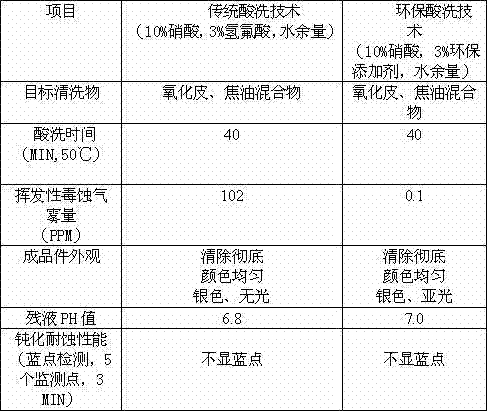

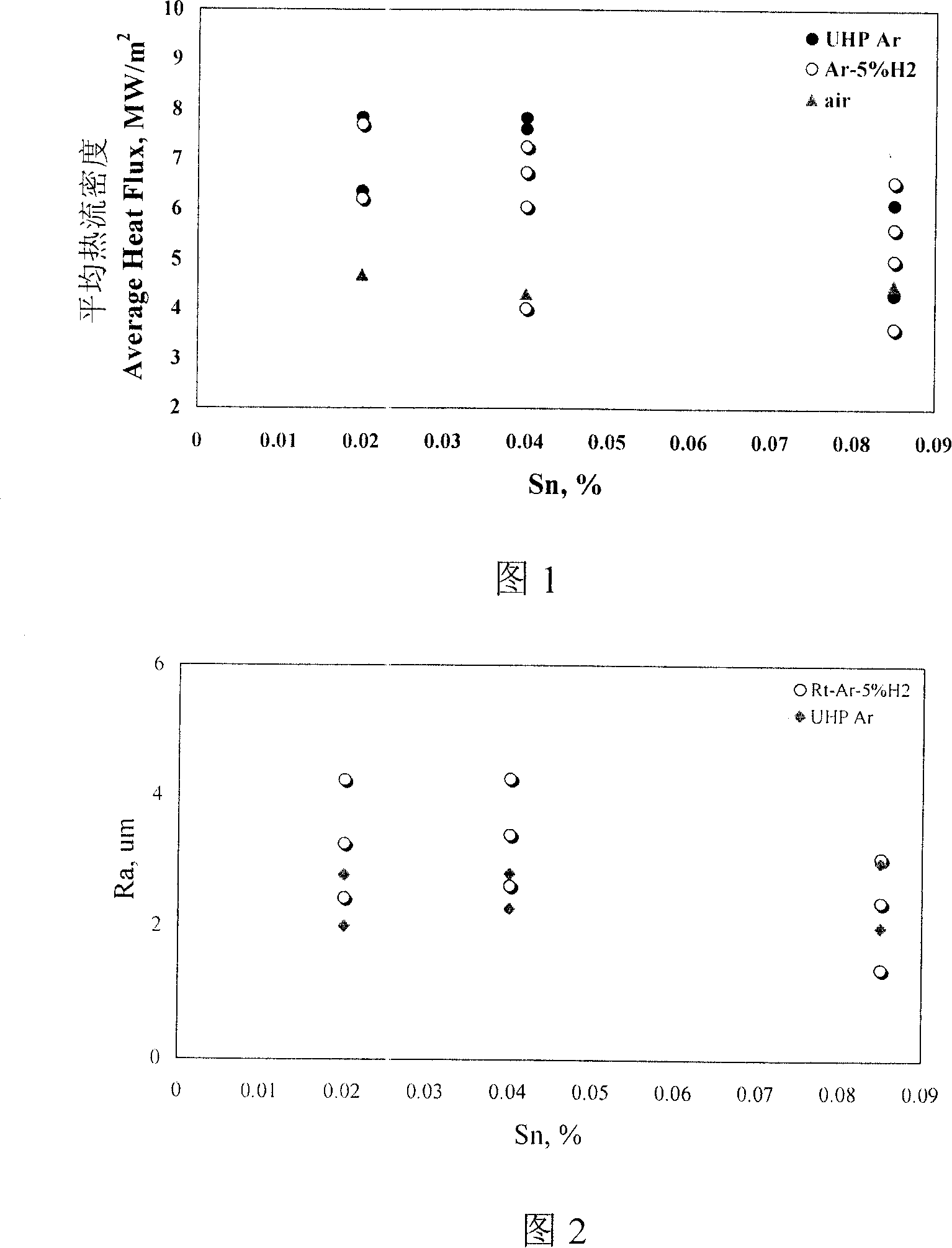

ActiveCN101148741AReduce sizeLow investment costRoll mill control devicesHeat treatment process controlAustenitic stainless steelNickel

The present invention discloses one kind of continuously cast austenite stainless steel sheet band and its production process. The austenite stainless steel sheet band has the components including C 0.04-0.12 wt%, Si0.2-1 wt%, Mn 0.8-2 wt%, P not more than 0.04 wt%, S not more than 0.03 wt%, Cr 0.017-0.019 wt%, Ni 0.08-0.011 wt%, Sn 0.005-0.04 wt%, and Fe and inevitable impurity for the rest. Its production process includes the following steps: smelting, continuously casting to form 1-5 mm thick band and winding; solid solution treatment at 1050-1150 deg.c for 5-8 min; pickling, cold rolling, annealing at 1050-1100 deg.c for 3-8 min, re-pickling and cold rolling for the second time to reach required thickness. The present invention has utilization of Sn in waste steel, reduced residual ferrite, reduced nickel consumption, lowered production cost and raised comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-oriented high-silicon electrical steel ribbon and its making method

InactiveCN103060701ASolve the characteristics of poor processing performanceImprove magnetismElectrical steelUltimate tensile strength

The invention relates to a non-oriented high-silicon electrical steel ribbon and its making method, and belongs to the fields of the metallurgical technology and the material science. The chemical components of the ribbon comprise 4.5-7.0wt% of Si, 2.0-5.0wt% of Cr, 0.06-1.0wt% of Al, 0.3-0.8wt% of Mn, 0.005wt% or less of N, 0.004wt% or less of S, 0.02wt% or less of P, 0.003wt% or less of O, 0.005wt% or less of C, and the balance Fe, and the thickness of the ribbon is 0.35-0.5mm. The making method comprises the following steps: smelting non-oriented high-silicon steel in a vacuum smelting furnace; carrying out double-roller ribbon roll-casting at a casting temperature of 1420-1460DEG C to the ribbon thickness of 1.0-1.5mm; carrying out hot rolling of the ribbon at 800-1100DEG C to the hot rolled ribbon thickness of 0.8-1.0mm; pickling, and preheating the ribbon, and carrying out warm rolling at 400-700DEG C; and annealing. The addition of the Cr element in the high-silicon electrical steel ribbon obviously improves the processing performance of the high-silicon steel ribbon, the iron loss value is same to the iron losses of present high-silicon steel products, and the magnetic induction intensity is above 0.03T higher than that of the present products. The making method has the advantages of simple technology, low energy consumption, high yield, and excellent product magnetic property.

Owner:NORTHEASTERN UNIV

Pickling passivation method of stainless steel

ActiveCN102965675AImprove corrosion resistanceEnsure surface decorationMetallic material coating processesSS - Stainless steelFluorhydric Acid

A pickling passivation method of stainless steel is characterized in that the method comprises the following steps of: (1) oil removing; (2) first rinsing; (3) pickling passivation, wherein a specially-prepared pickling passivating solution is proportioned by 20% of nitric acid, 10% of hydrofluoric acid, and 70% of purified water, and the workpiece is soaked in groove liquid completely; (4) second rinsing; (5) meutralization by alkali liquor, wherein the workpiece is soaked in an alkaline groove liquid completely; (6) first water washing; (7) third rinsing; (8) air drying; (9) stoving; (10) confining liquid spraying; (11) natural air drying; (12) packaging with air-cushion films. The invention combines two original steps of pickling and passivation into one step, which effectively increases the corrosion resistance of the stainless steel, improves the hand fingerprint contamination resistance of the stainless steel, ensures the surface decoration performance of the stainless steel products, and the method has the characteristics of simple process, low production cost, less environment pollution, easy operation, low labor intensity, low energy consumption, and high efficiency.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel

InactiveCN104805291AHigh puritySolve processingWater contaminantsWaste water treatment from metallurgical processFerric hydroxideFractional Precipitation

The invention discloses a method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel. According to the method, a sodium hydroxide solution is adopted to control the pH of the stainless steel pickling waste liquor to achieve the purpose of recovery of iron, chromium and nickel through fractional precipitation. Because pH ranges of deposition of the iron, chromium and nickel elements are overlapped, part of iron oxide-hydroxide is precipitated firstly in a separation and recovery process, residual iron and chromium elements are co-precipitated out, and then chromium is precipitated and dissolved under the strong alkaline condition to realize final separation of iron and chromium. Due to presence of ammonia water and a reducing agent, the nickel element exists in the form of ions or a nickel ammine complex, is dissolved in the waste liquor, and finally reacts with a sulfide to precipitate NiS. The method has the characteristics of low cost, easiness in control, high separation and recovery rate of the iron, chromium and nickel elements and the like. The method can treat the stainless steel pickling waste liquor effectively, and the natural environment cannot be polluted after emission; the recovered metal elements have the recycling economic benefits, and the method has high application value and important technological innovation meaning.

Owner:NANYANG NORMAL UNIV

Manufacture method of high-silicon aluminum content non-oriented silicon steel strip

ActiveCN102367547ASolving the problem of edge cracking in cold rollingSimple process routeMaterials preparationStress concentration

The invention discloses a manufacture method of a high-silicon aluminum content non-oriented silicon steel plate cold-rolled sheet, belonging to the field of material preparation and comprising the following components in parts by mass: 0.003 percent of C, 3.20 percent of Si, 0.60 percent of Mn, 0.008 percent of P, 0.001 percent of S, 1.10 percent of Al, 0.002 percent of Ti, not more than 0.03 percent of Ni, not more than 0.03 percent of Cr, not more than 0.03 percent of Cu and the balance of Fe or trace elements and unavoidable impurities. The manufacture method comprises the steps of: smelting in a converter, refining in a vacuum furnace, continuous-casting, thermal-rolling, normalizing, scouring and trimming, once-cold-rolling, intermediate-annealing, secondary-annealing, and annealing. A continuous casting blank is rolled into a strip, a hot-rolled strip enters a souring line for souring and trimmed on line after the scouring is finished; and the trimmed steel strip is subjected to normalization and annealing on a normalizing line and finally rolled and annealed. According to the invention, a stress concentrated part caused by trimming of the hot-rolled strip is released through the normalizing process, so that internal reasons causing cold rolling edge crack are eliminated and a cold rolling edge gap is completely removed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

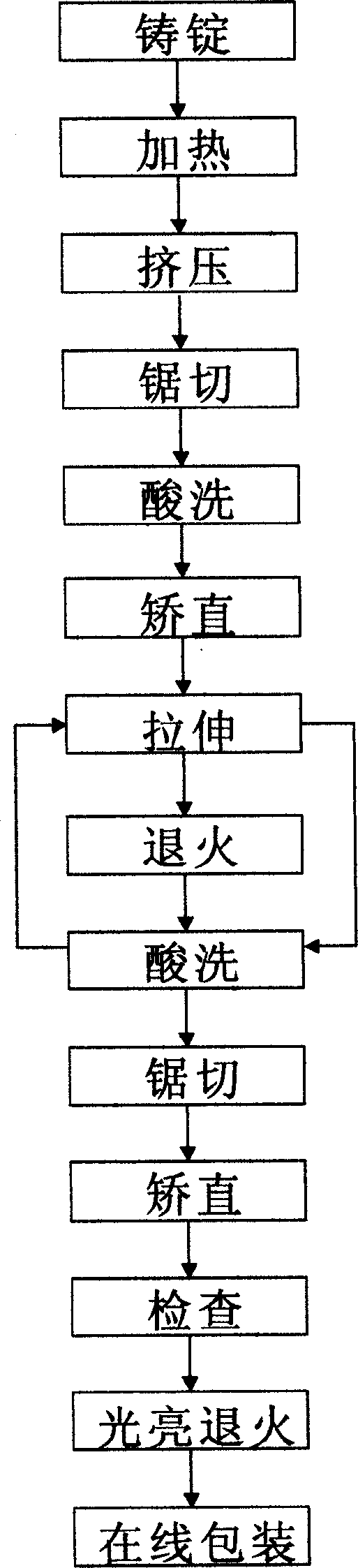

Method for producing red brass pipe

The production process of red brass pipe includes the steps of: fusion casting, heating, extruding, finishing, acid pickling, inspection, rolling, cutting to required size, inspection, annealing, acid pickling, forming head, drawing, finishing, inspection, deoiling, and product annealing. The present invention features that in common pressure processing apparatus, with common brass as material and through extrusion to generate red, acid pickling to increase color, drawing to decrease color, further acid pickling to increase color and annealing to maintain color, red brass pipe with high anticorrosion and homogeneous performance may be produced in low cost.

Owner:中铝洛阳铜业有限责任公司

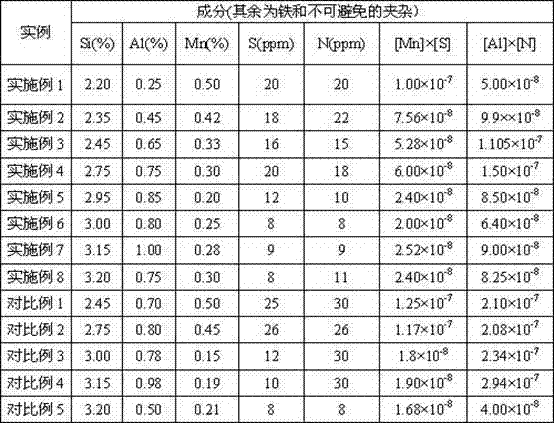

High grade non-oriented silicon steel produced by continuous casting and rolling of sheet billet and production method thereof

High grade non-oriented silicon steel produced by continuous casting and rolling of sheet billet comprises the following components, by weight: no more than 0.003% of C, 2.20-3.20% of Si, 0.25-1% of Al, no more than 0.002% of S, no more than 0.002% of N, no more than 0.02% of Cu, 0.20-0.50% of Mn, and the balance of Fe and unavoidable impurities; besides, contents of the components satisfy the following relations: Si+Al<=4.2%, [Al]*[N]: 5+10<-8>-1.5*10<-7>, and [Mn]*[S]: 2*10 <-8>-1*10<-7>. The manufacture method comprises the steps of: smelting and vacuum treatment; continuous casting with liquid core reduction; billet heating; hot continuous rolling; flattening; normalizing treatment; conventional acid pickling; cold rolling; and finished product annealing. The steel plate provided by the invention has advantages of good surface quality, low iron loss, excellent magnetic, and no corrugated defects.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com