Ferrite low-density high-strength steel and manufacturing method thereof

A manufacturing method and low-density technology, applied in the field of high-strength steel, can solve problems such as surface decarburization, lower manufacturability of steel types, lower steel plate strength and plasticity, etc., to reduce production costs, improve manufacturability, and good mechanical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

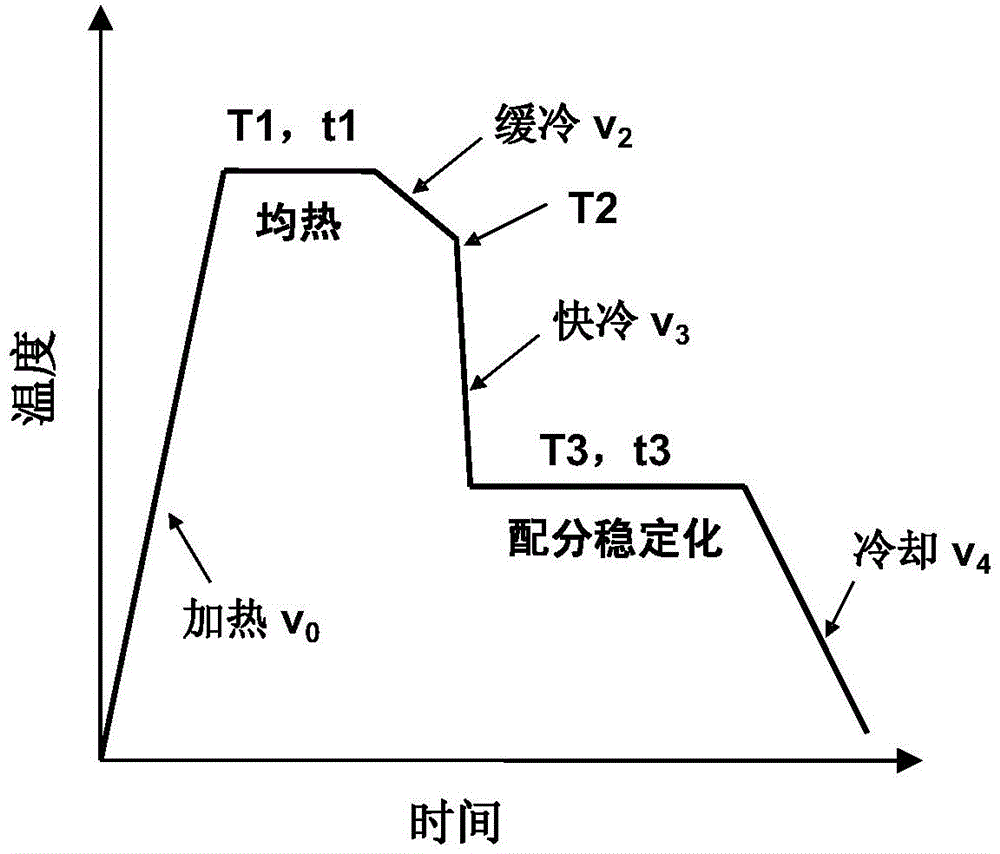

[0097] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

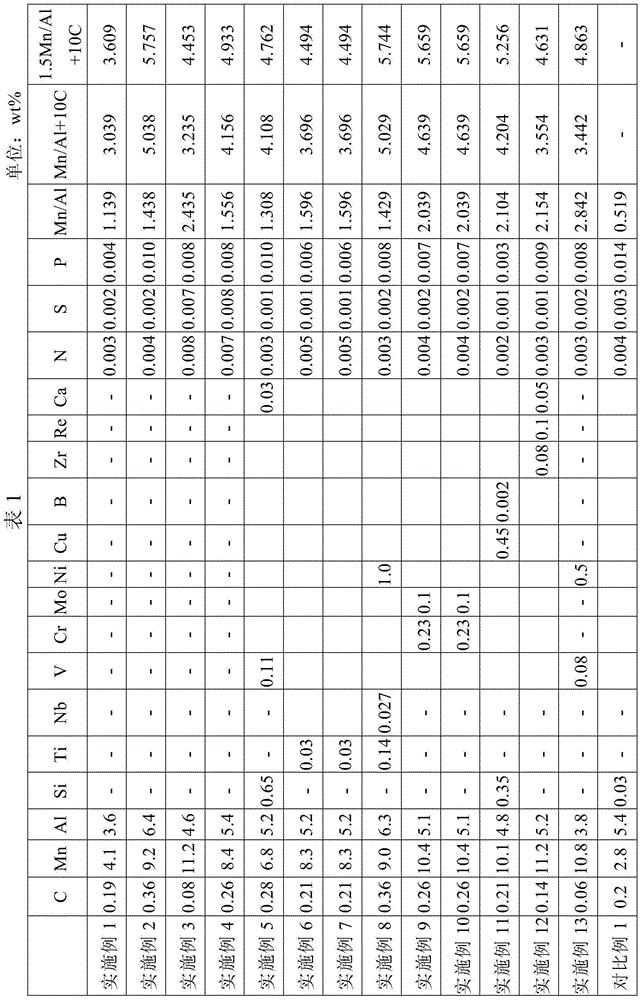

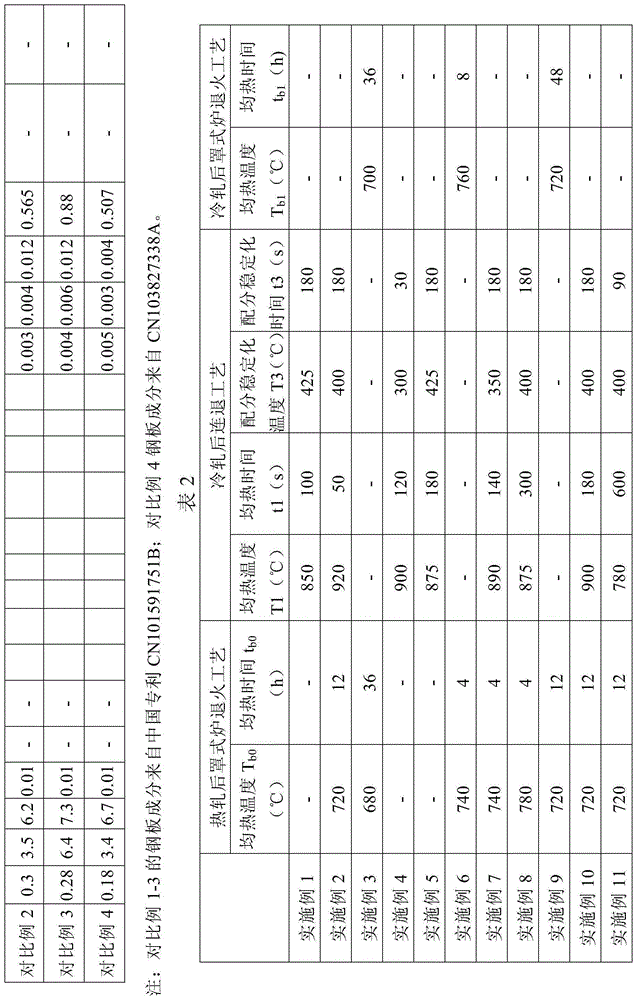

[0098] Table 1 is the composition of the steel grades of the embodiments of the present invention and comparative examples, Table 2 is the manufacturing process of the steel grades of the embodiments of the present invention and comparative examples, and Table 3 is the retained austenite in the microstructure of the steel plates of the embodiments of the present invention and comparative examples The volume fraction and the mechanical properties of the steel plate.

[0099] Steel materials having the composition shown in Table 1 were smelted and cast to produce slabs. The slab is heated at a heating temperature of 1200°C, and the slab is hot-rolled after a holding time of 1.5 hours. The hot-rolling finish rolling is completed at a final rolling temperature above 860°C. The thickness of the hot-rolled steel plate is about 3.2mm. The hot-rolled steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com