Patents

Literature

1602results about How to "Improve manufacturability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

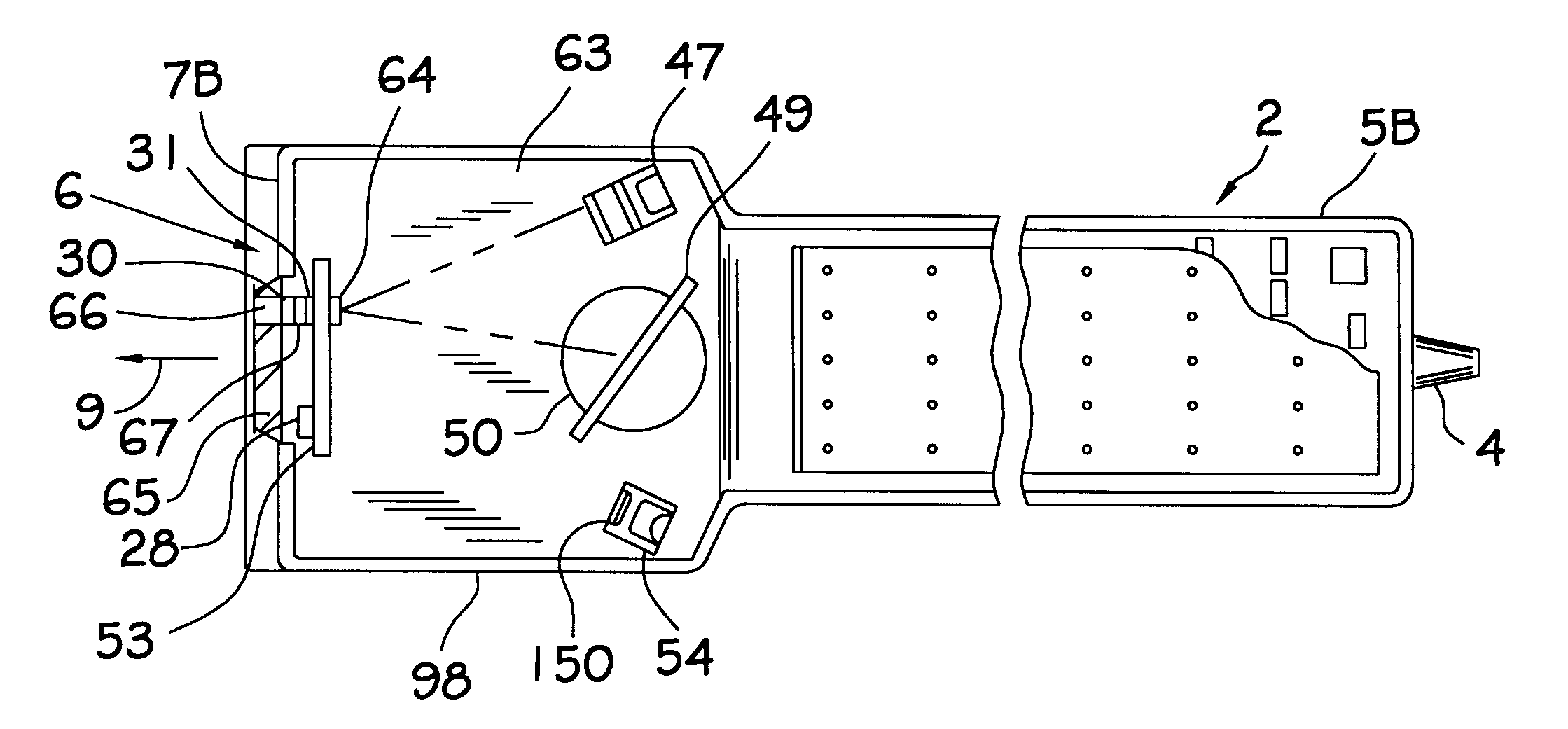

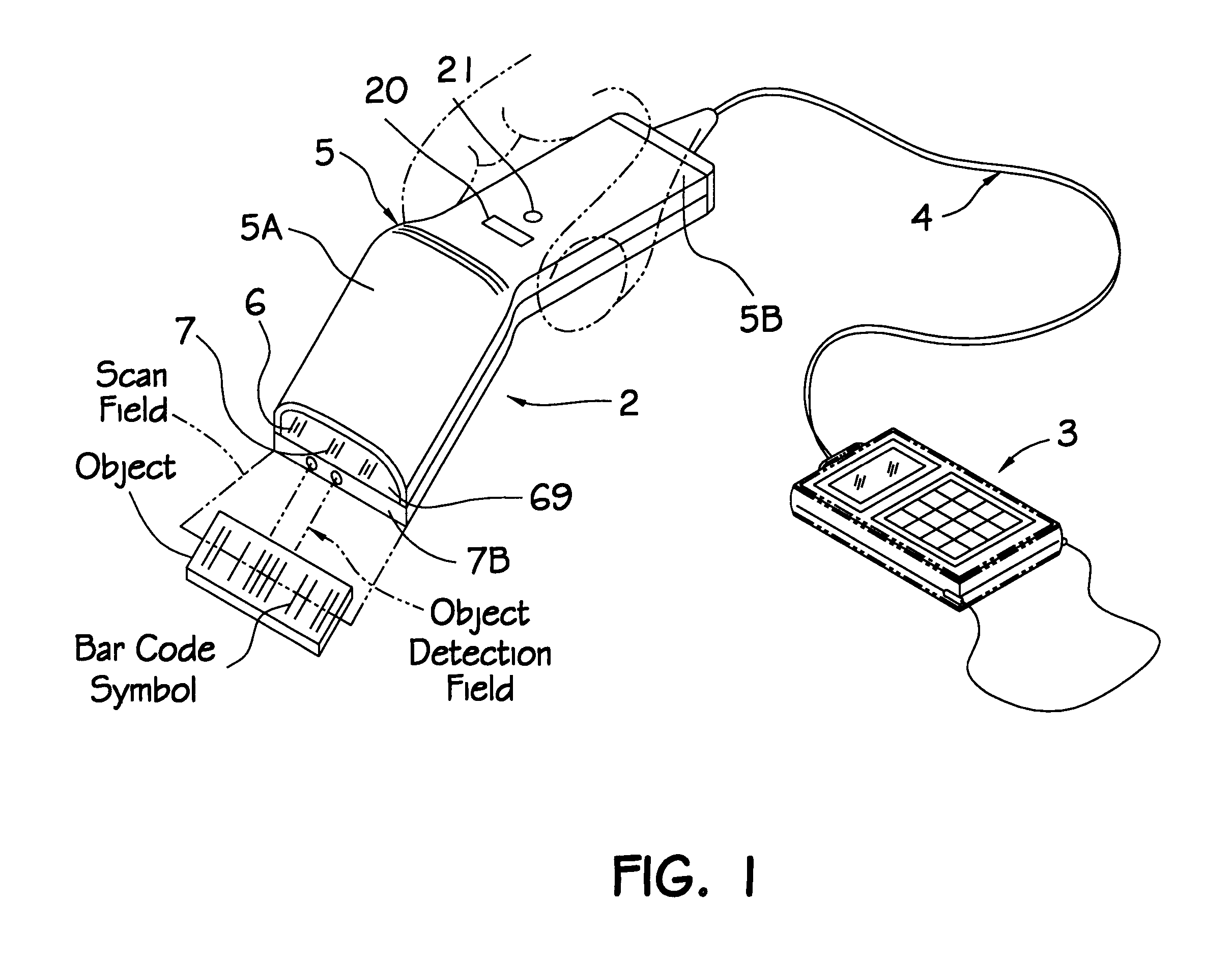

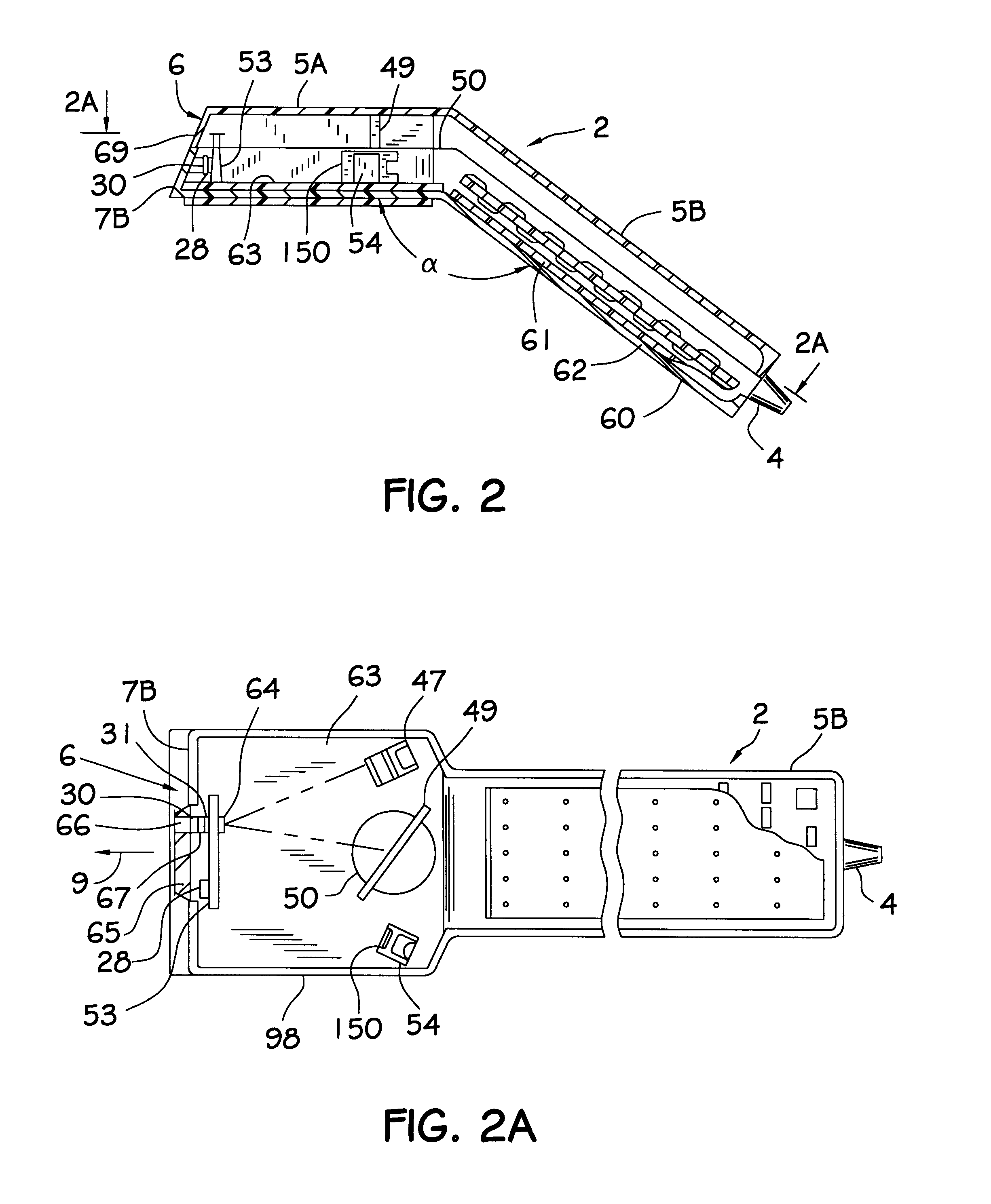

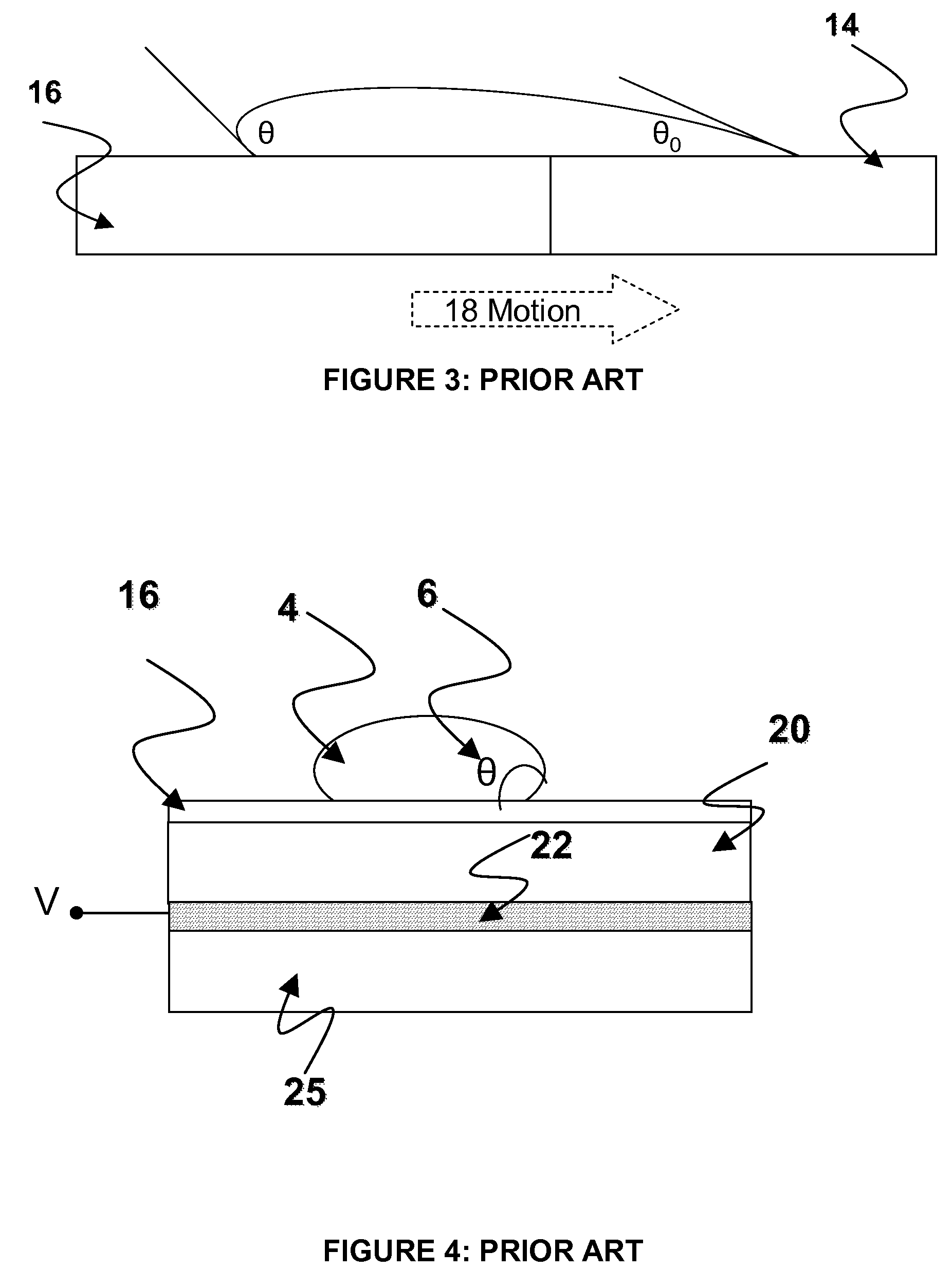

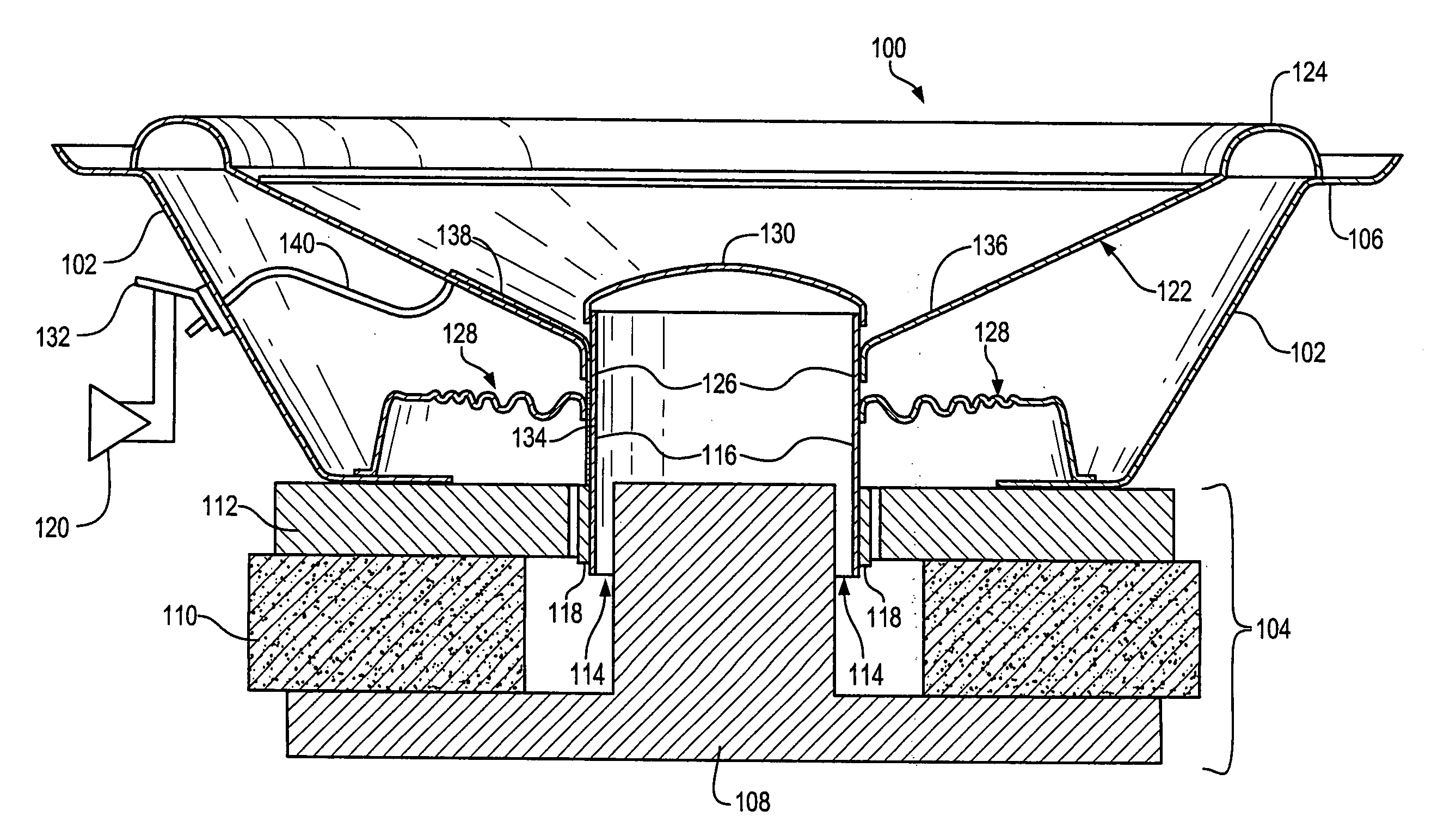

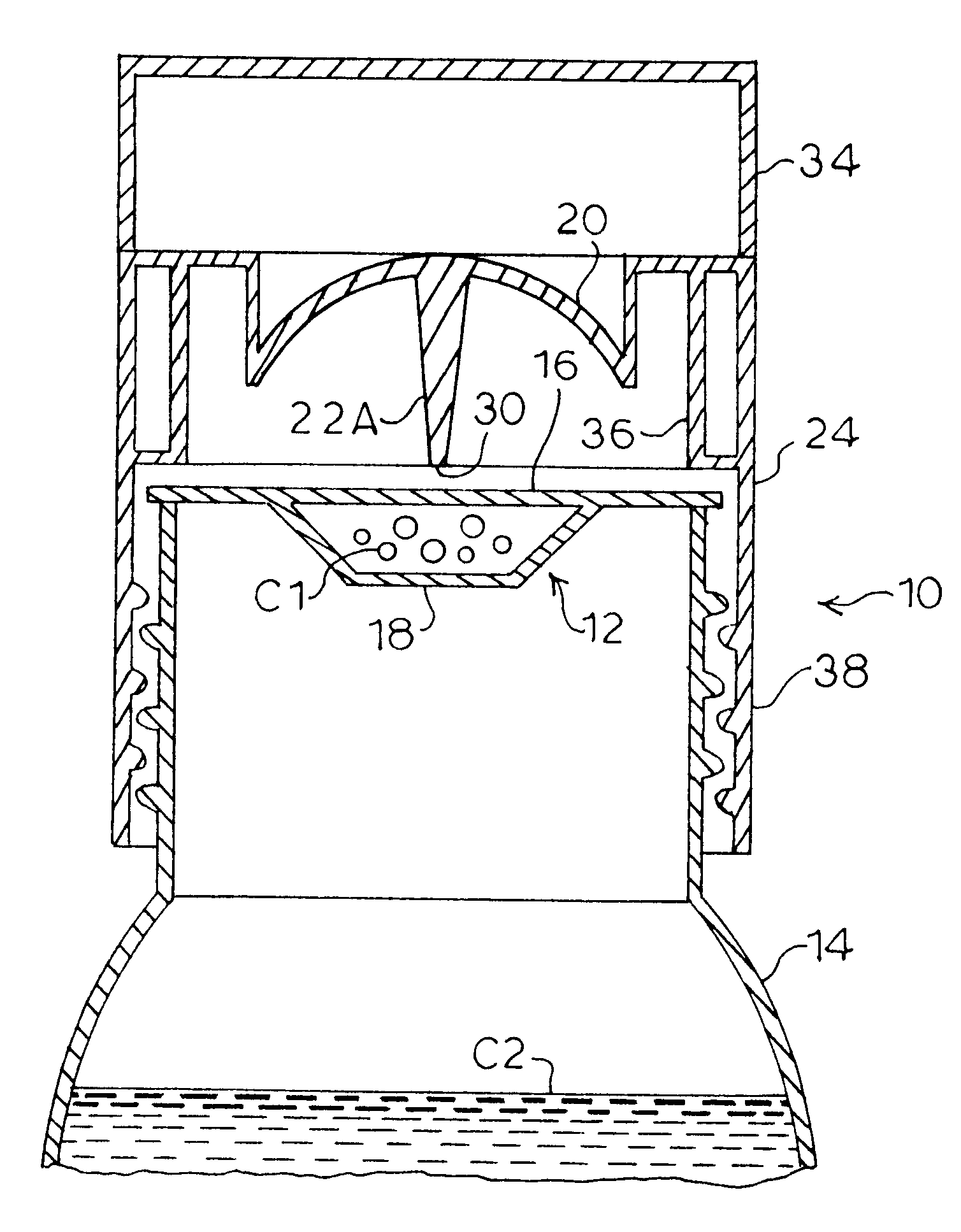

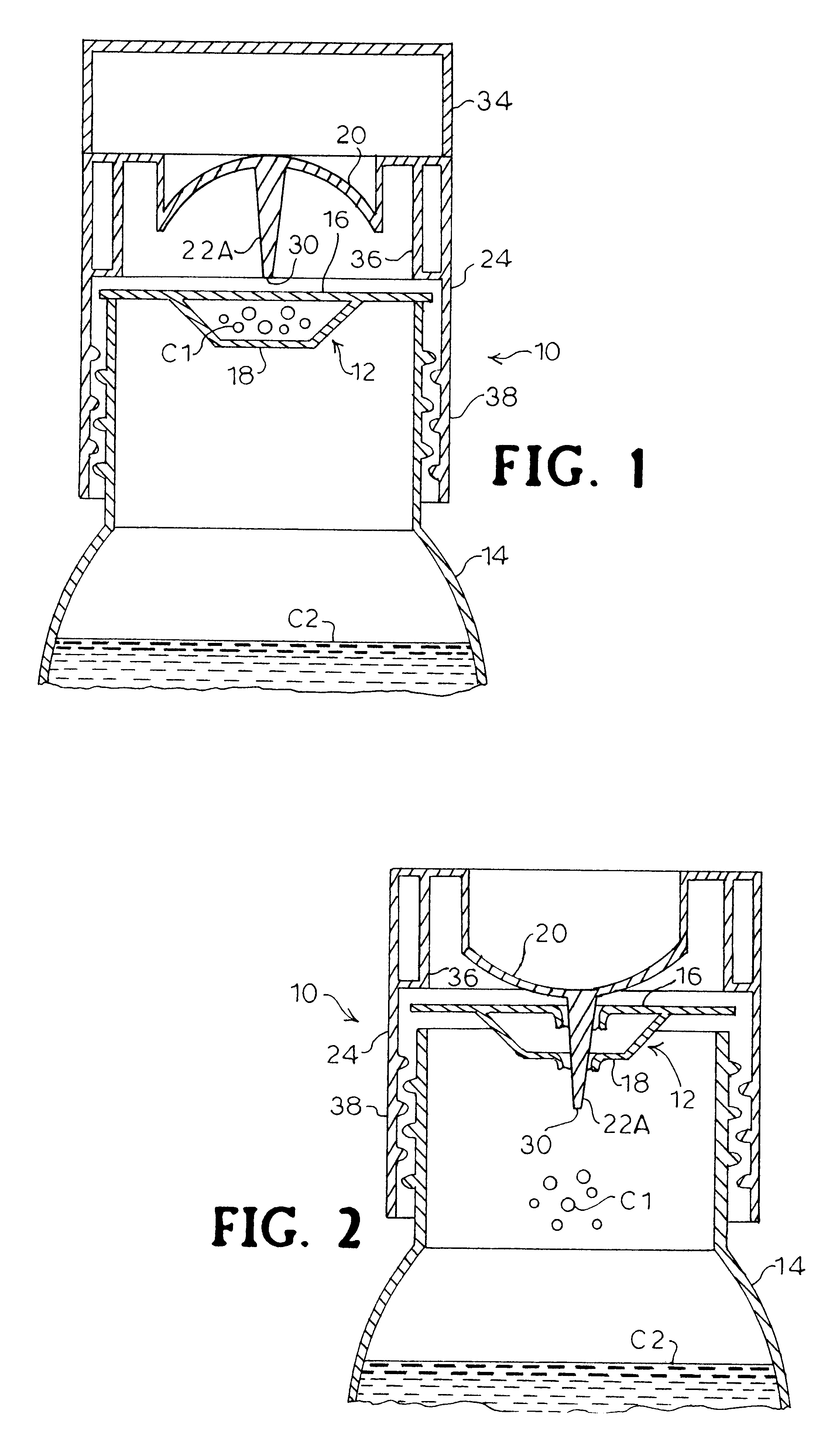

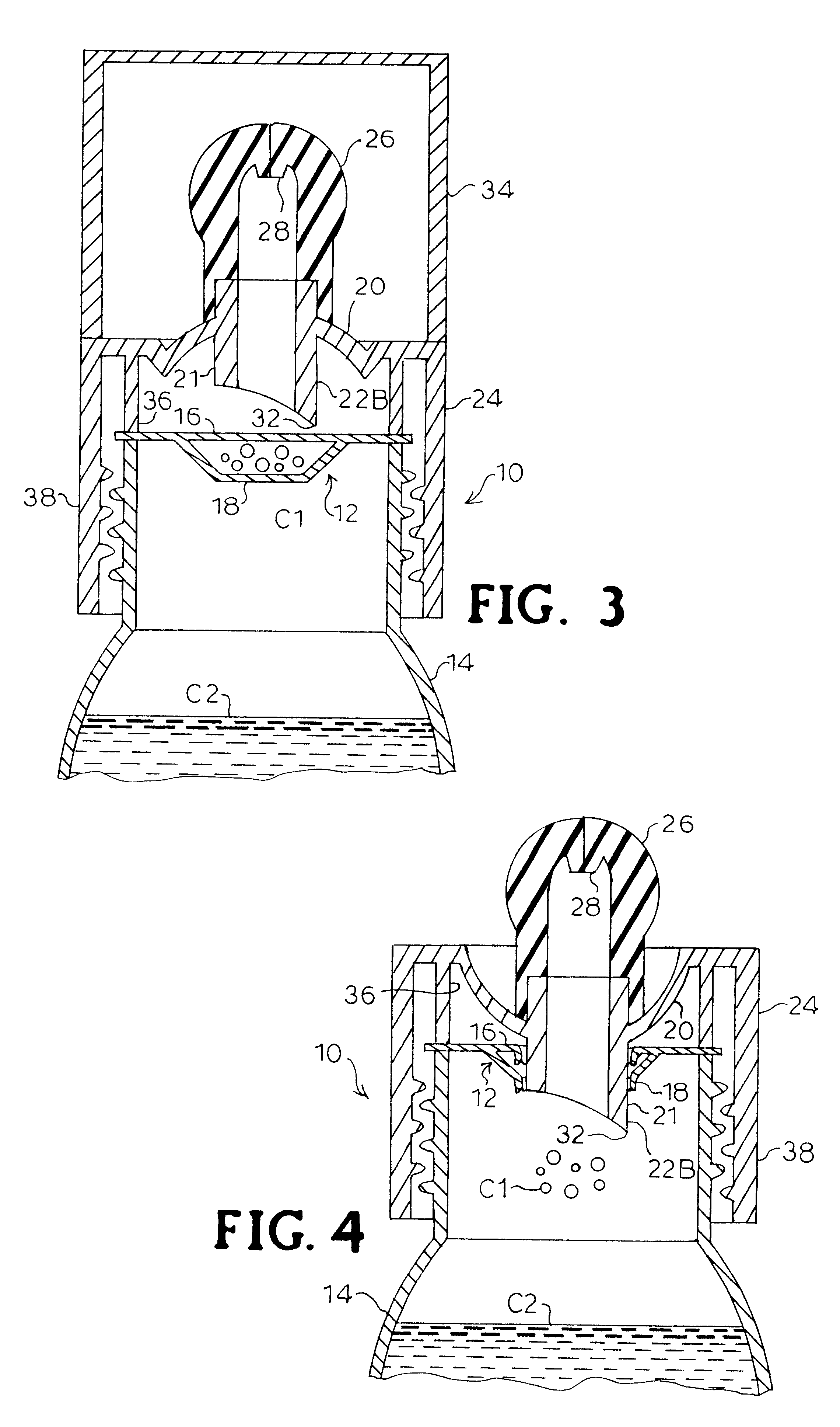

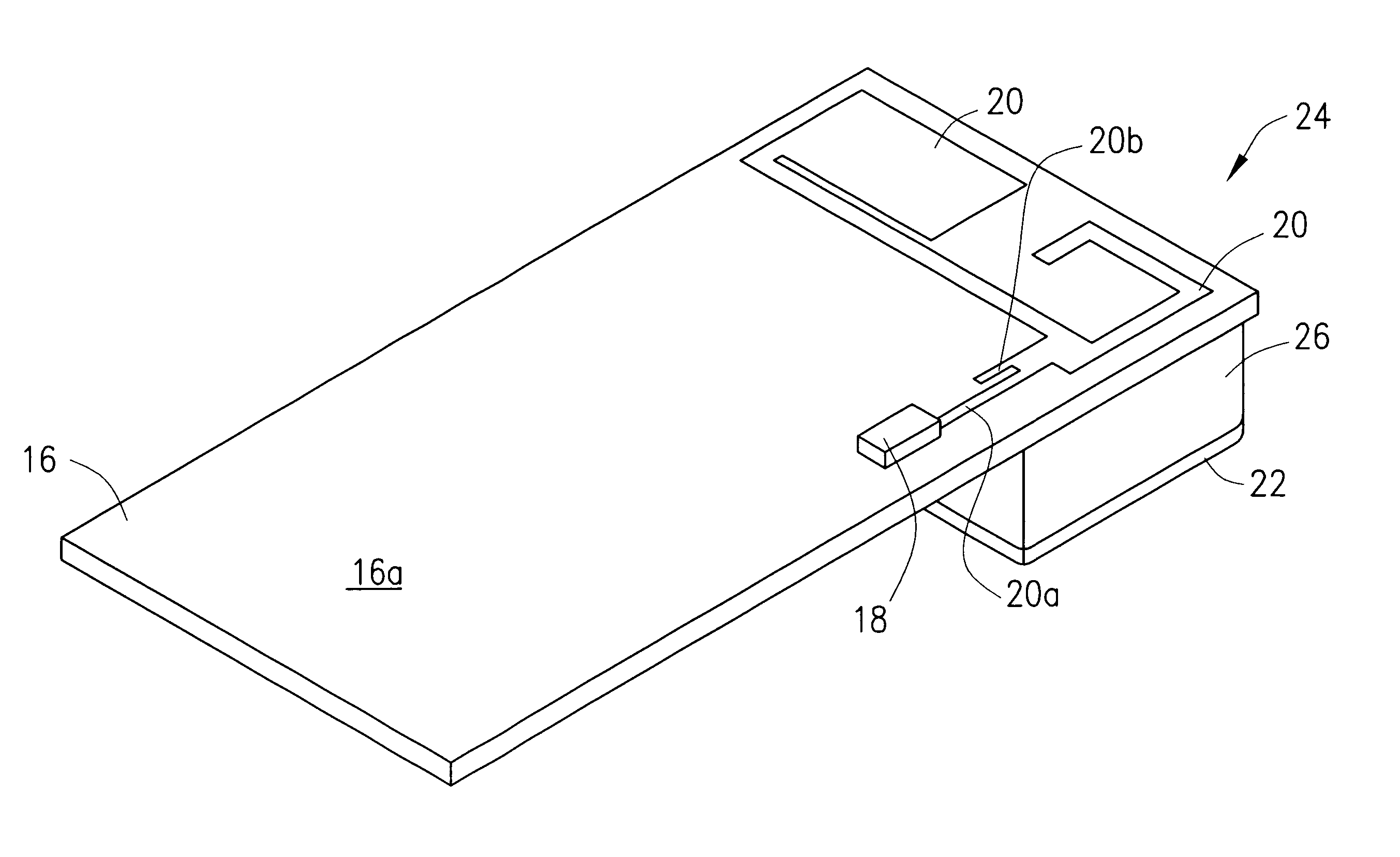

Optical filtering system for a laser bar code scanner having narrow band-pass characteristics employing spatially separated filtering elements including a scanner window

InactiveUS6209789B1Good lookingImprove manufacturabilityMirrorsCo-operative working arrangementsBand-pass filterBarcode

A novel optical filtering system for a laser bar code scanner having narrow band-pass characteristics is disclosed. The optical filtering system has two different optical filtering elements which are disposed in a scanner housing in a spatially separate relationship. One of the optical filtering elements is positioned inside of the scanner housing in front of and close to the light detection element. The other optical filtering element is positioned in the light transmission aperture of the scanner housing and forms the scanning window. The optical filtering characteristics of the scanning window obscure the internal components of the scanner from plain view making the scanner appear more aesthetically pleasing. Together the optical filtering element cooperate to form a narrow-band pass filter to provide for better light collection and scanning.

Owner:METROLOGIC INSTR

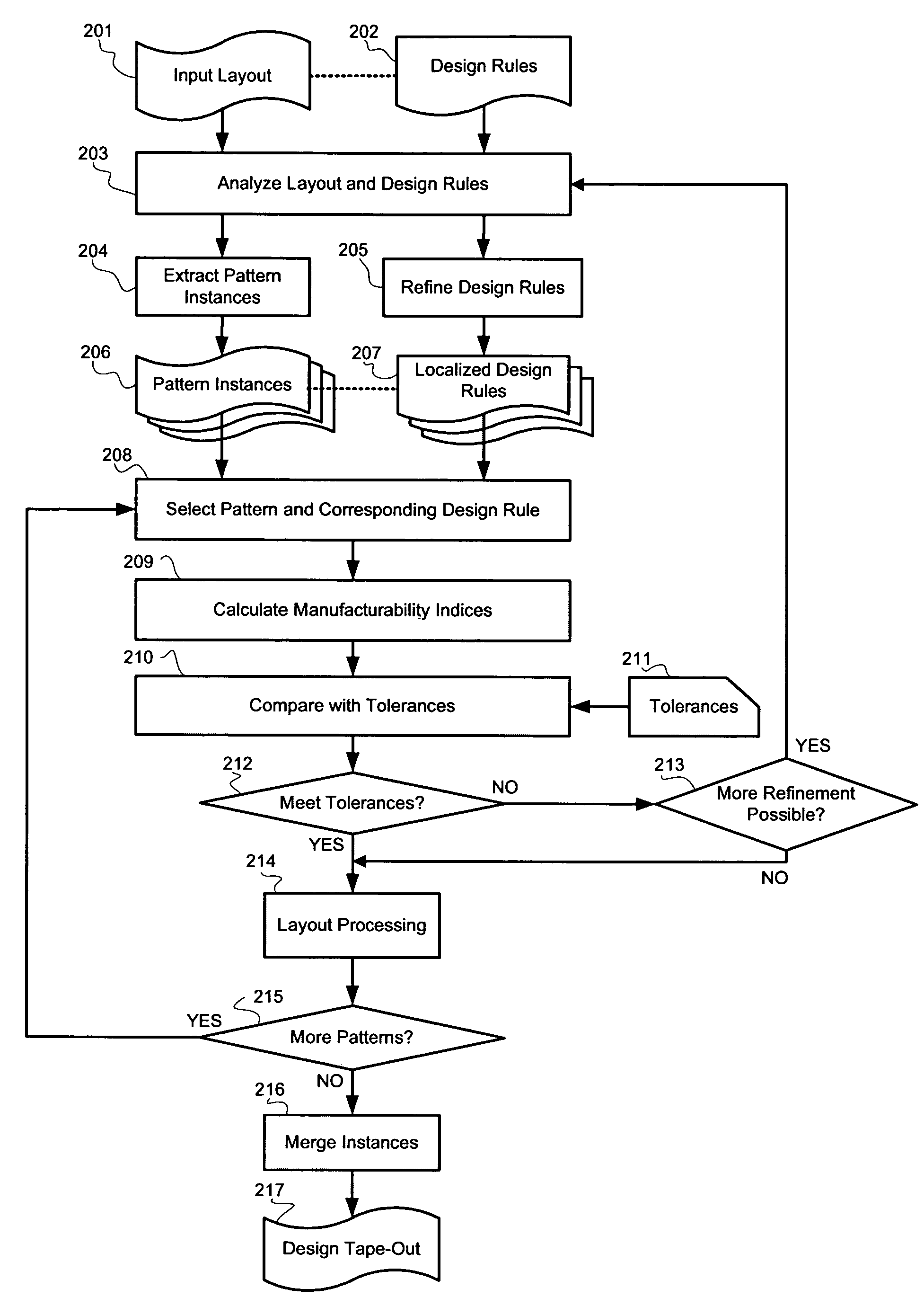

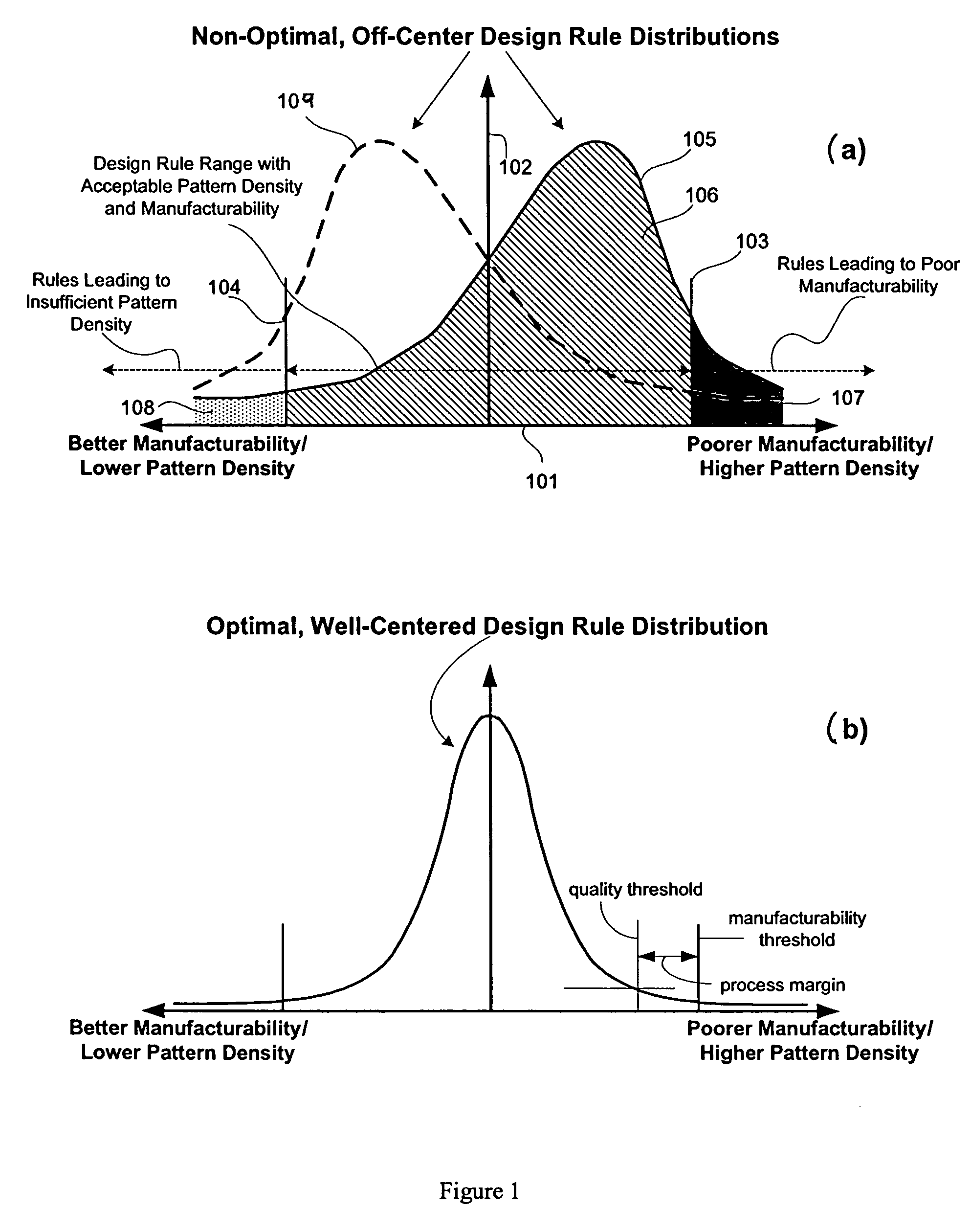

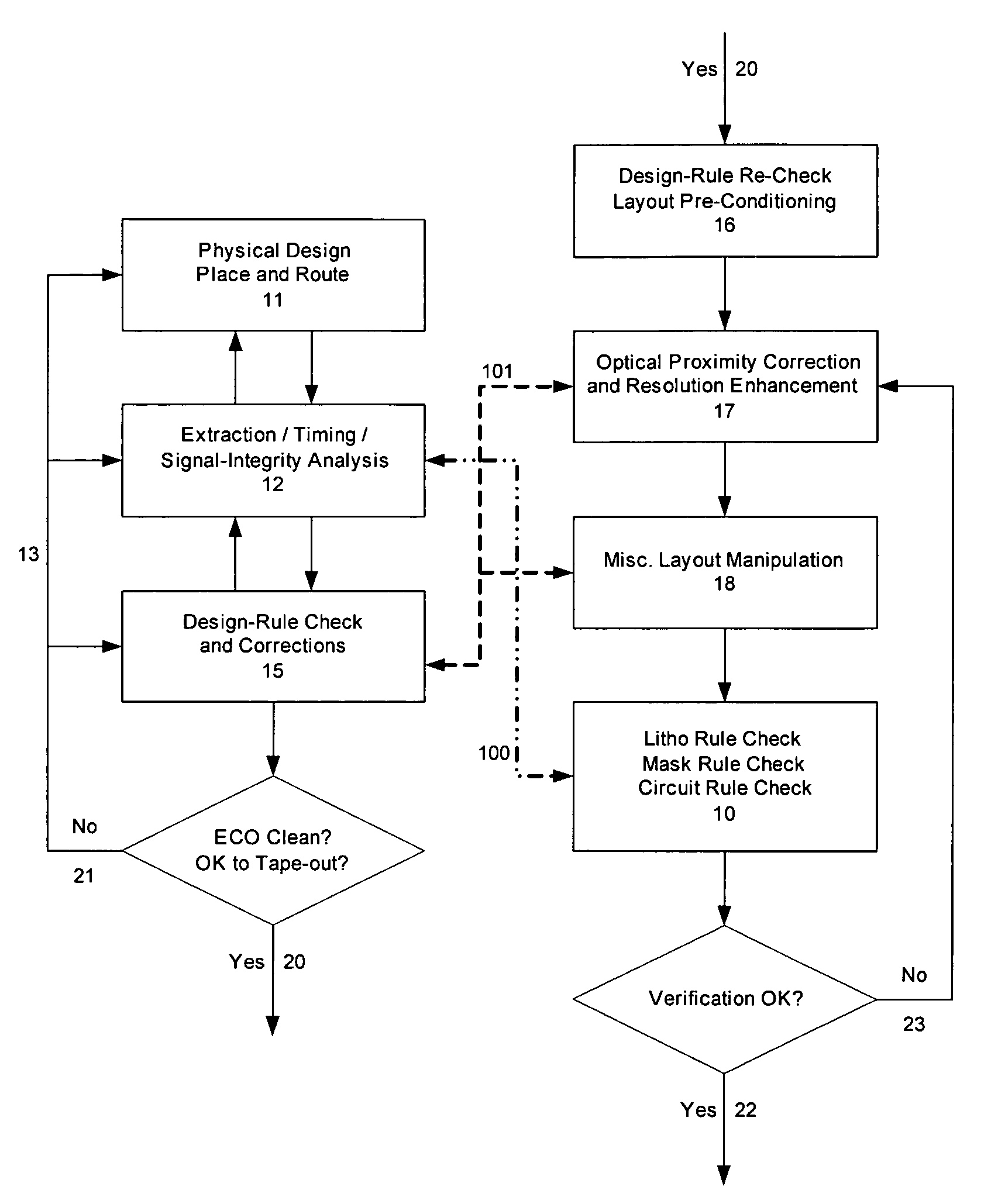

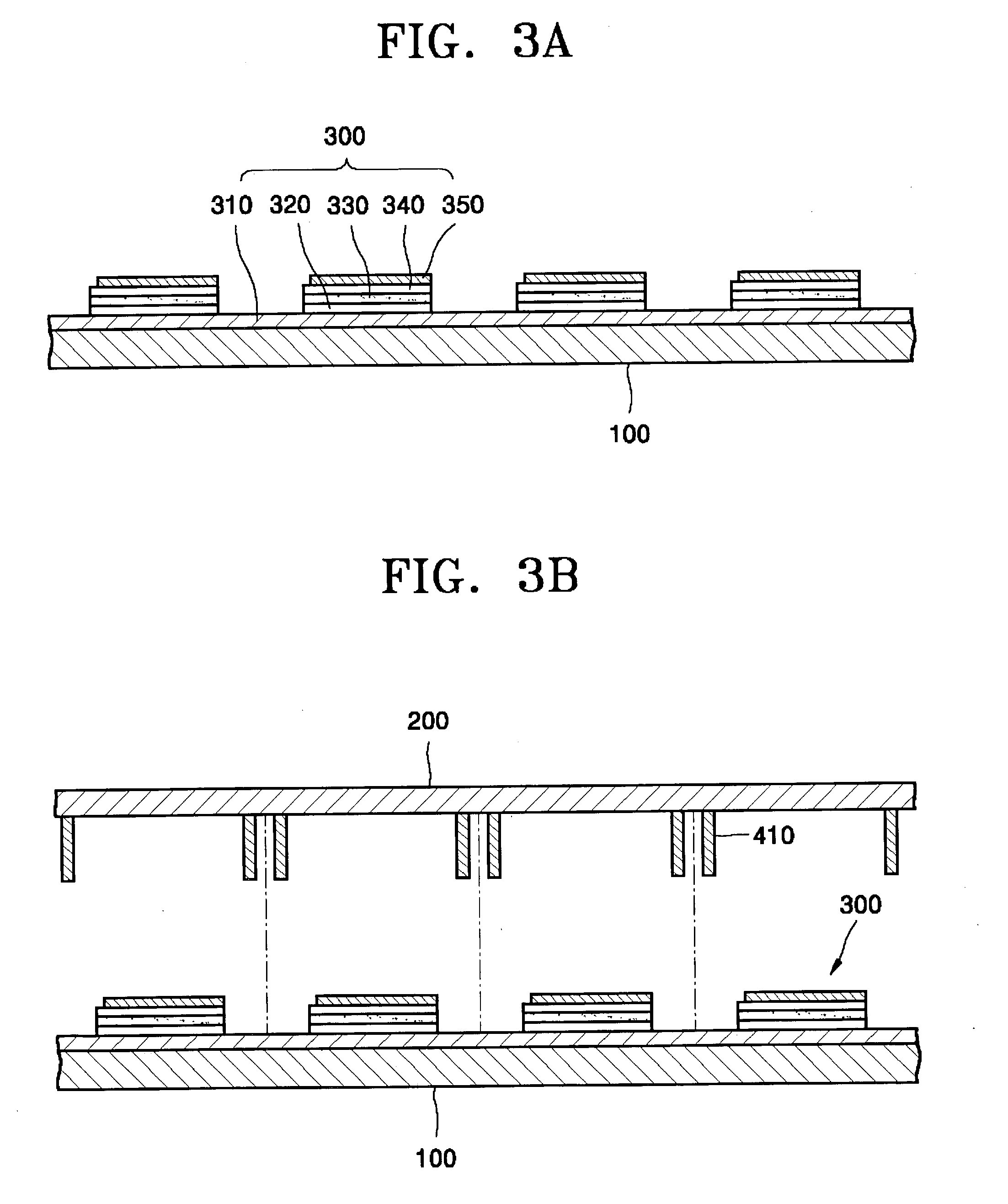

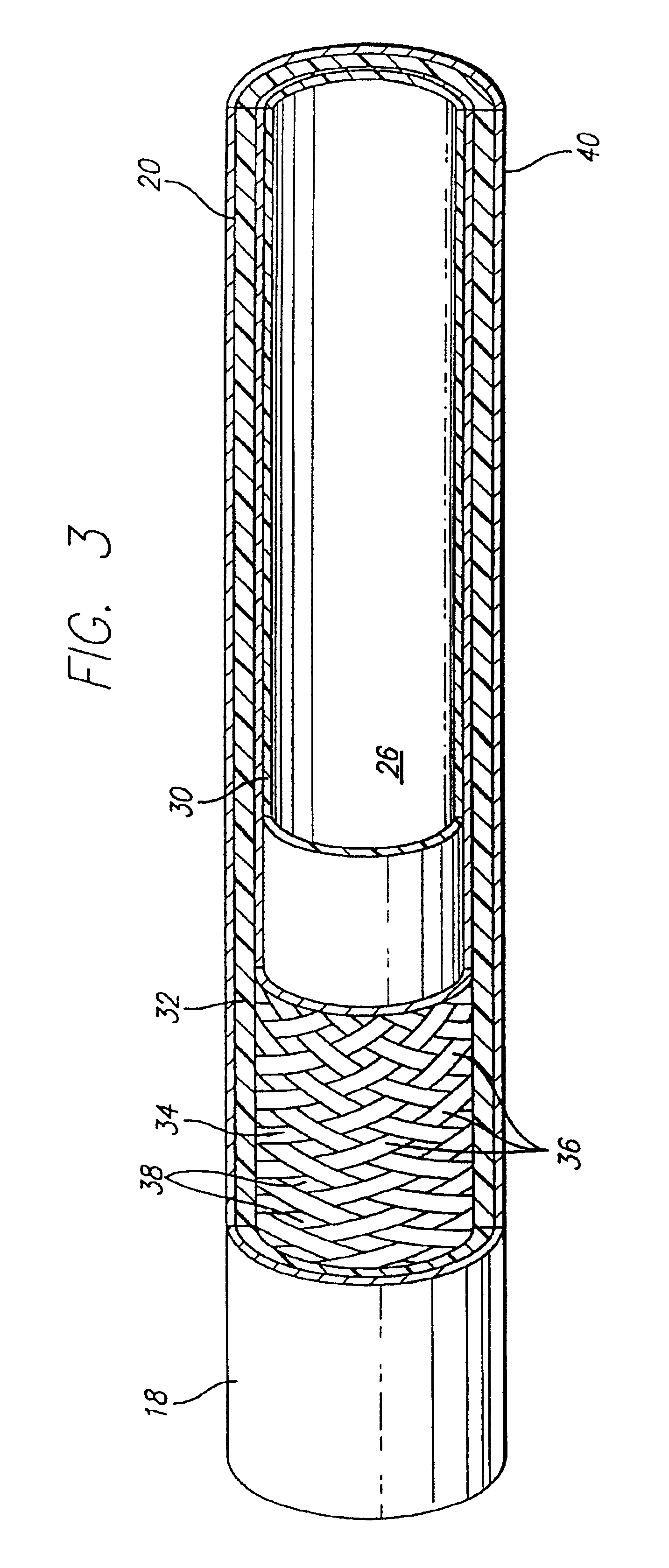

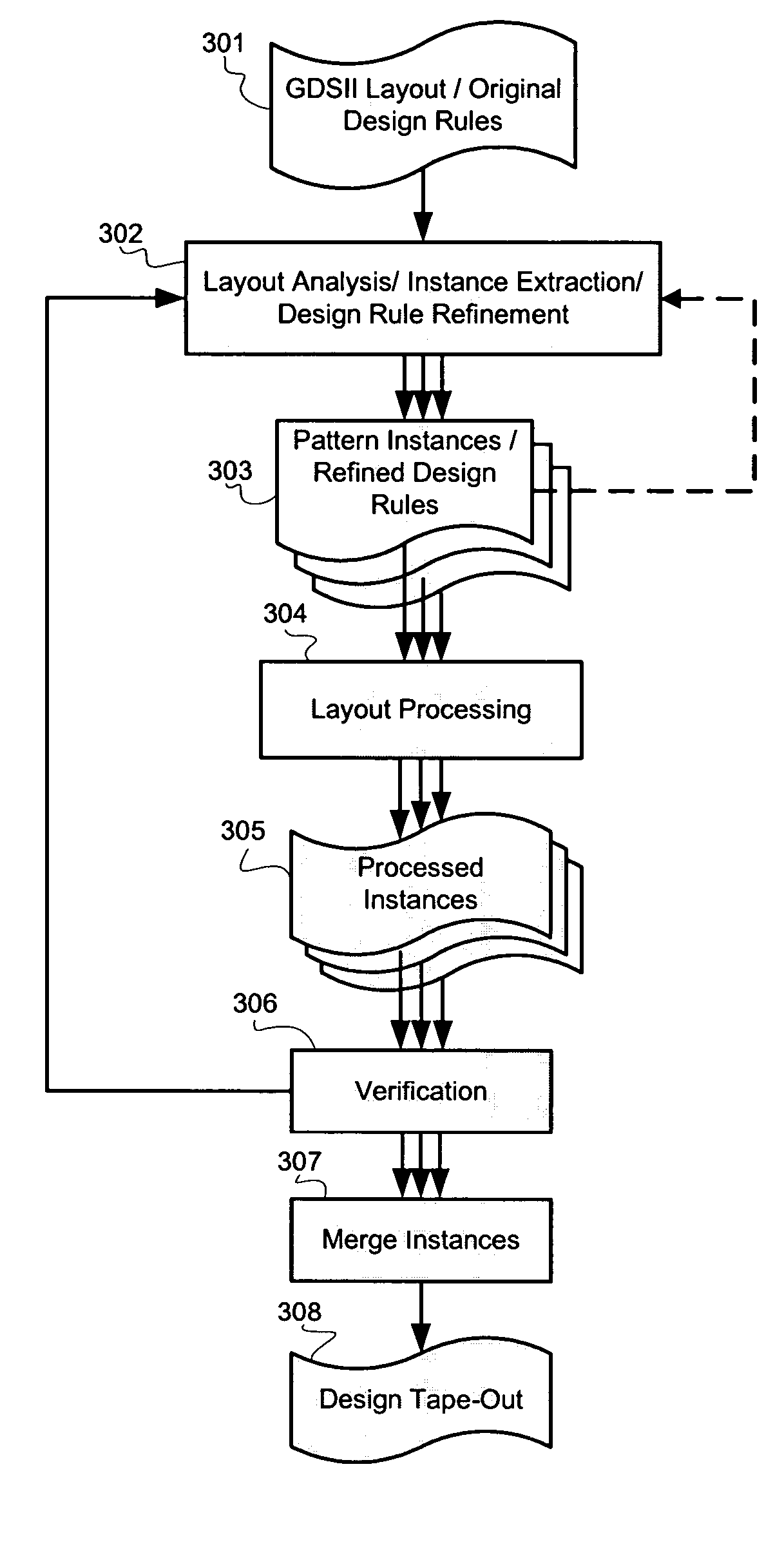

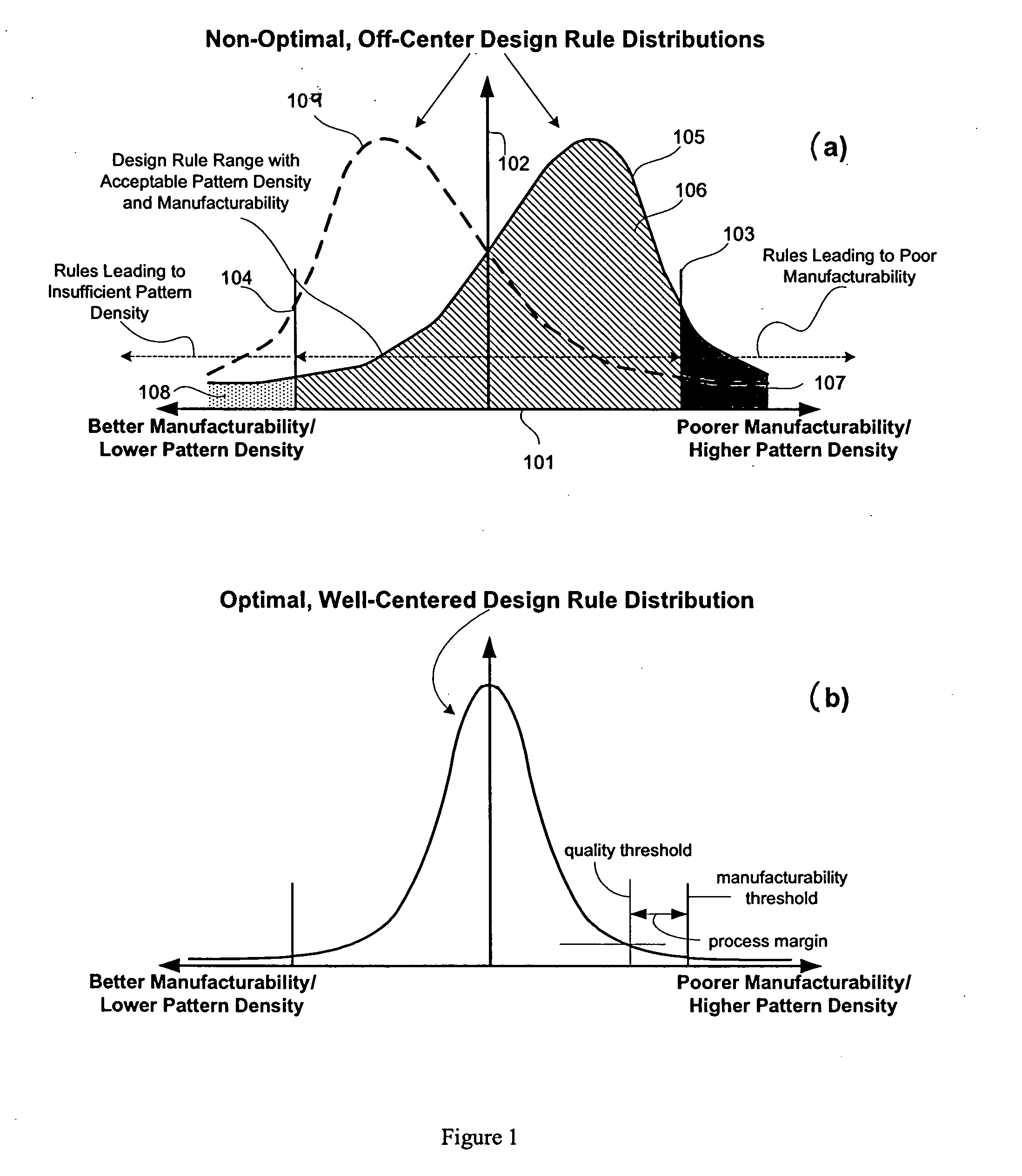

System for designing integrated circuits with enhanced manufacturability

ActiveUS7523429B2Improve manufacturabilityLittle interferencePressersMattress sewingGranularityEngineering

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

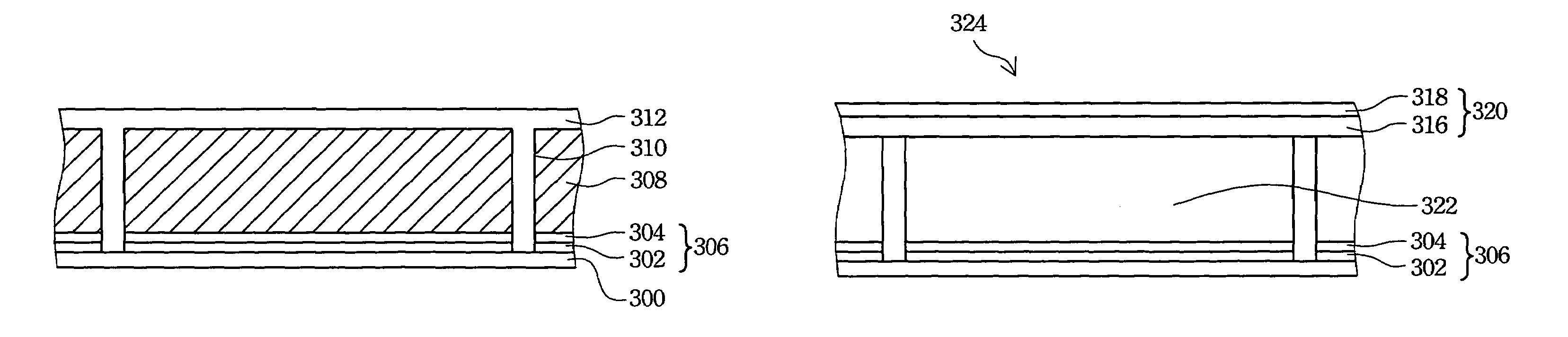

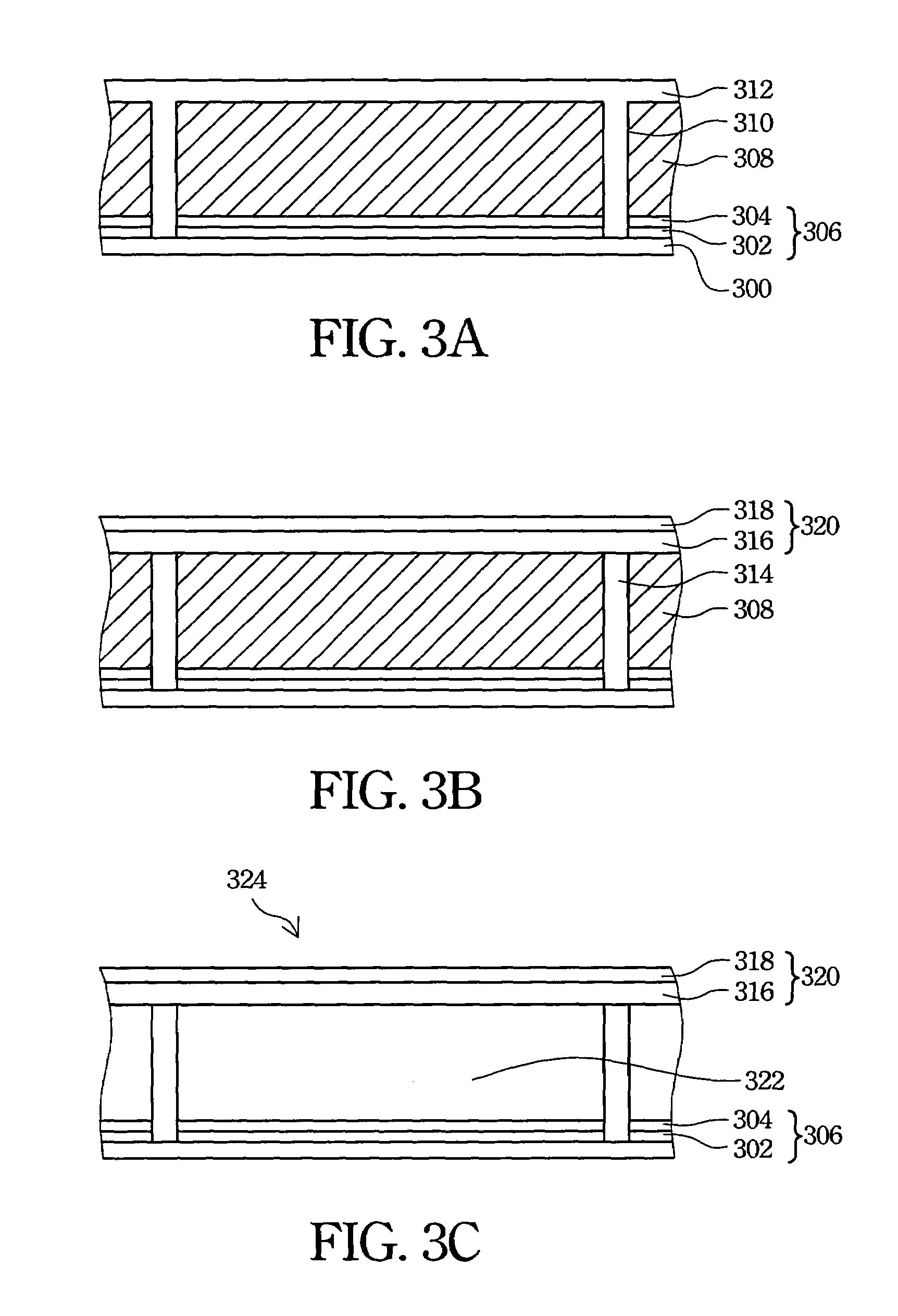

Structure of an optical interference display unit

InactiveUS6958847B2Avoid pollutionIncreased process complexityTelevision system detailsColor television detailsLight reflectionReflective layer

Owner:SNAPTRACK

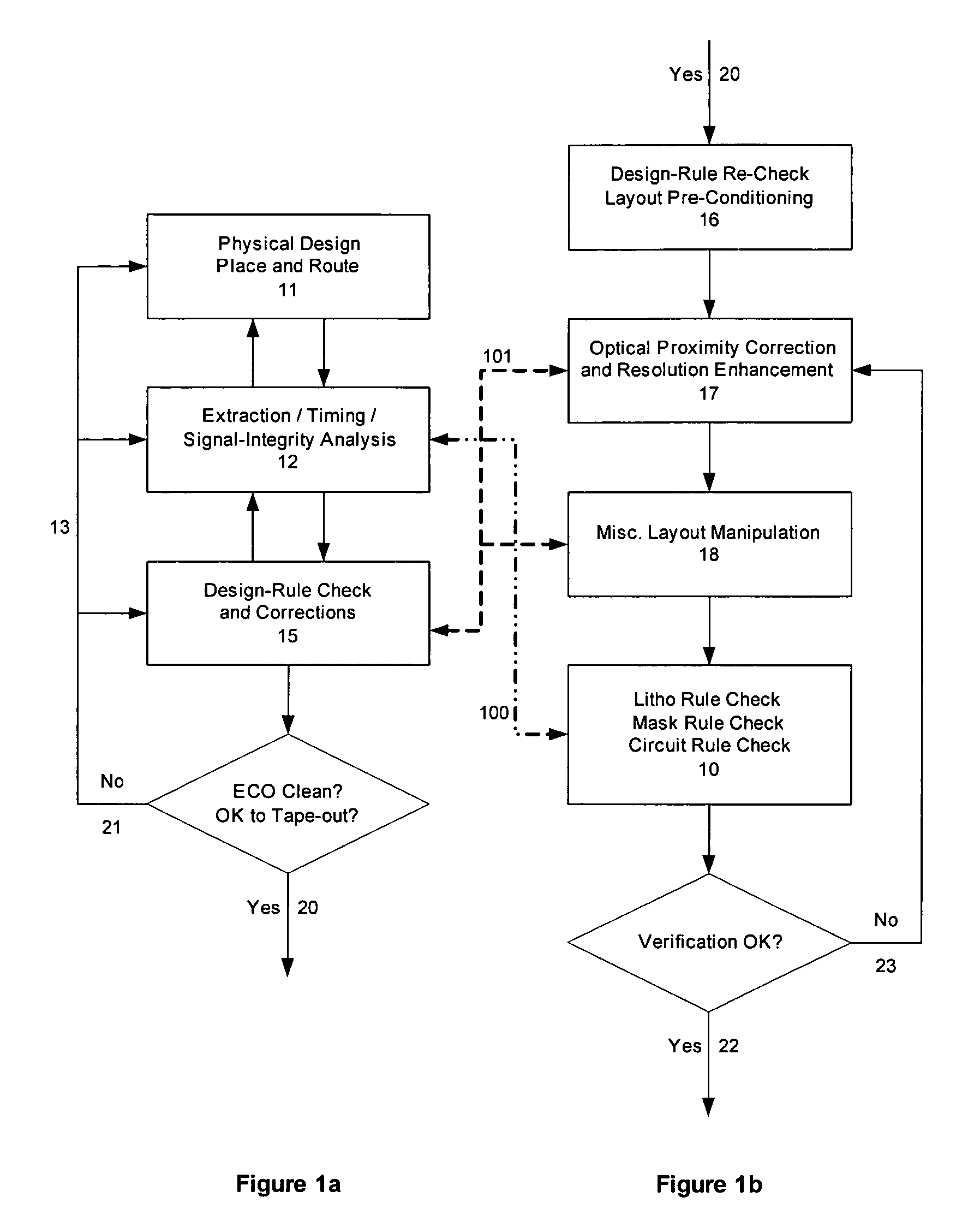

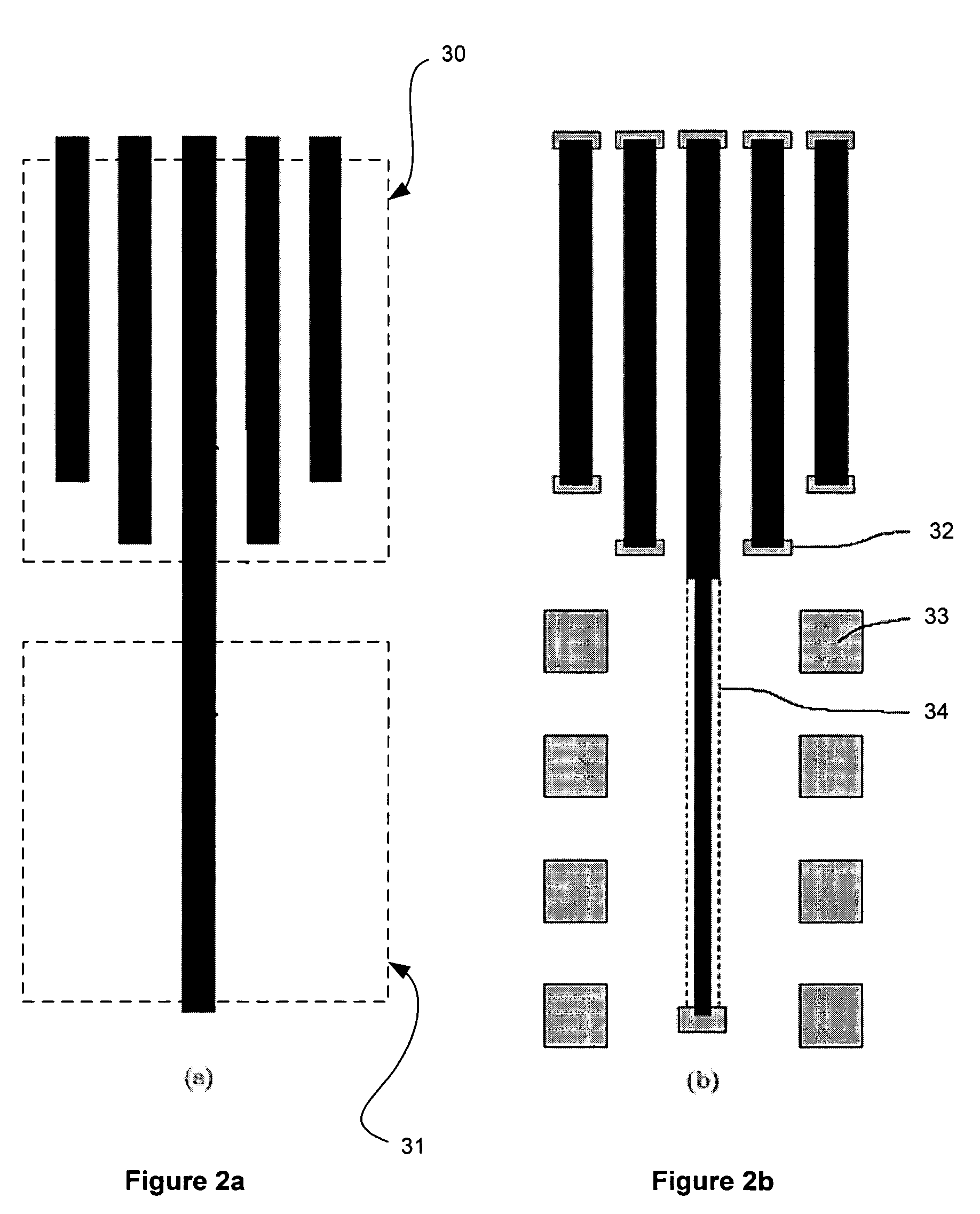

Method and apparatus for selective, incremental, reconfigurable and reusable semiconductor manufacturing resolution-enhancements

InactiveUS20050229130A1Improve manufacturabilityHigh yieldCAD circuit designSpecial data processing applicationsImage resolutionPhysical verification

An automated design for manufacturability platform for integrated physical verification and manufacturing enhancement operations. Given original layouts and one or more associated resolution-enhanced layouts, intermediate resolution-enhancement state layouts are reconstructed, and selective localized resolution-enhancement reconfigurations, modifications, and / or perturbations are introduced on any existing enhancements in order to improve manufacturability and yield.

Owner:RPX CORP

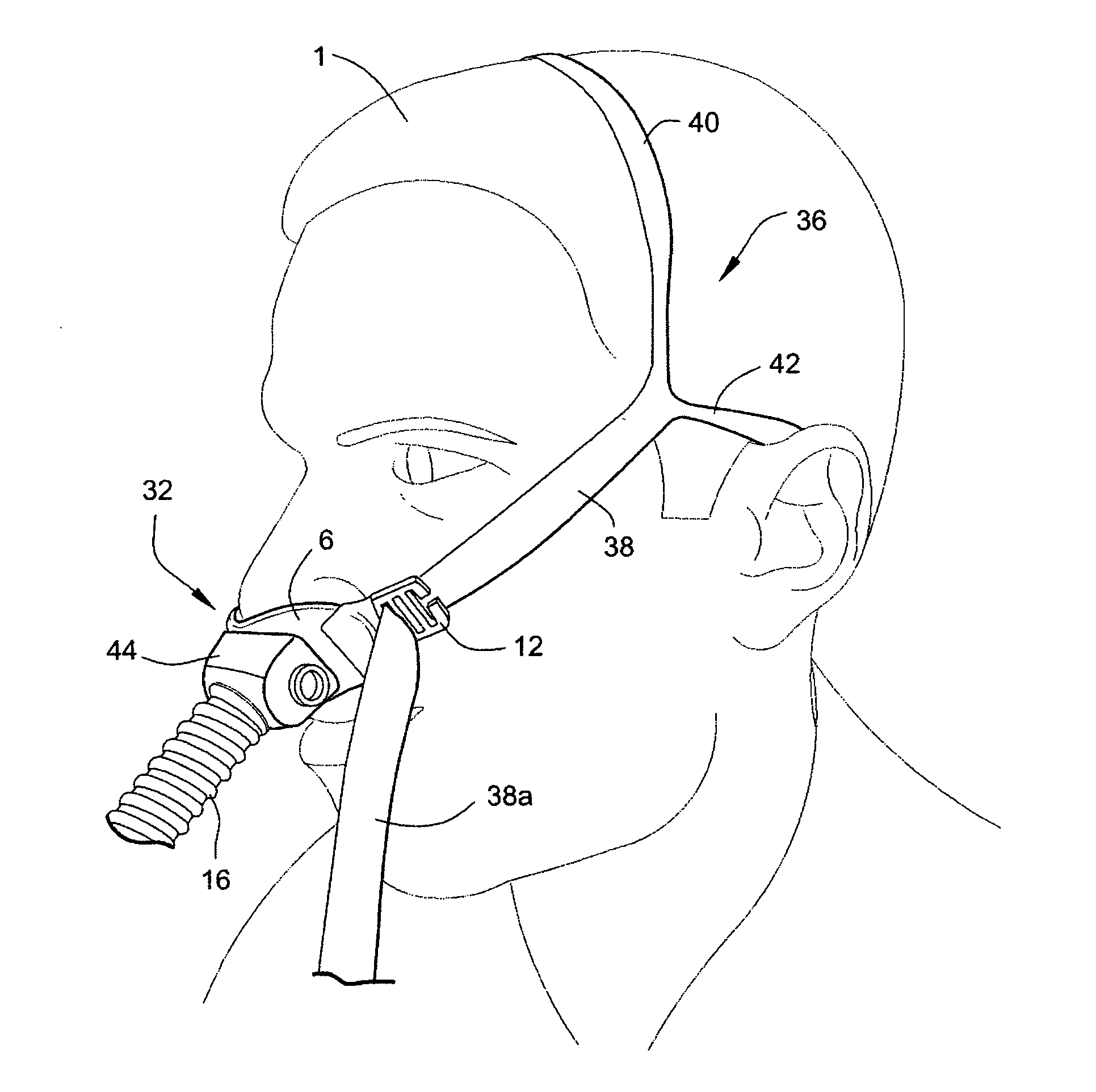

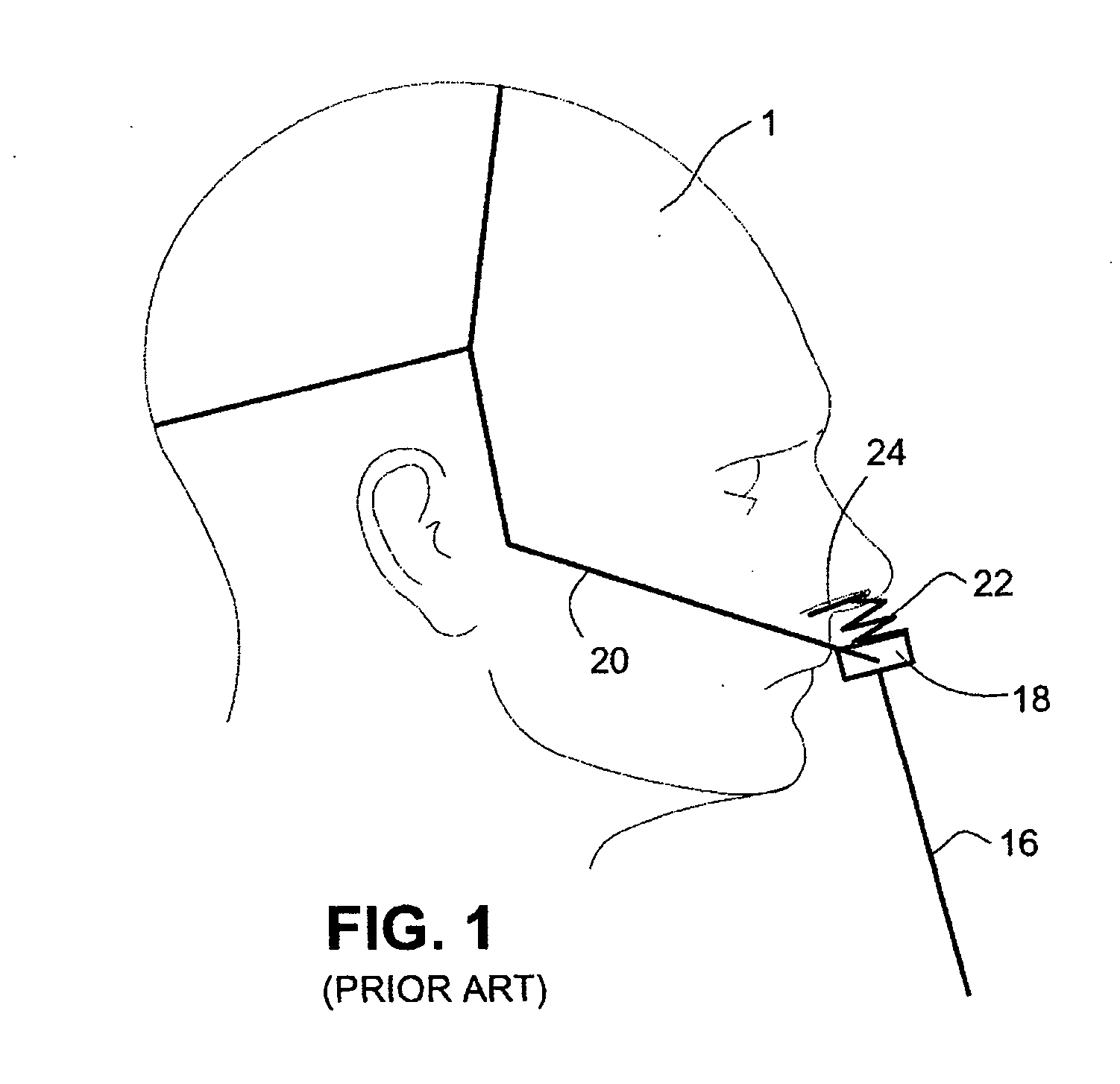

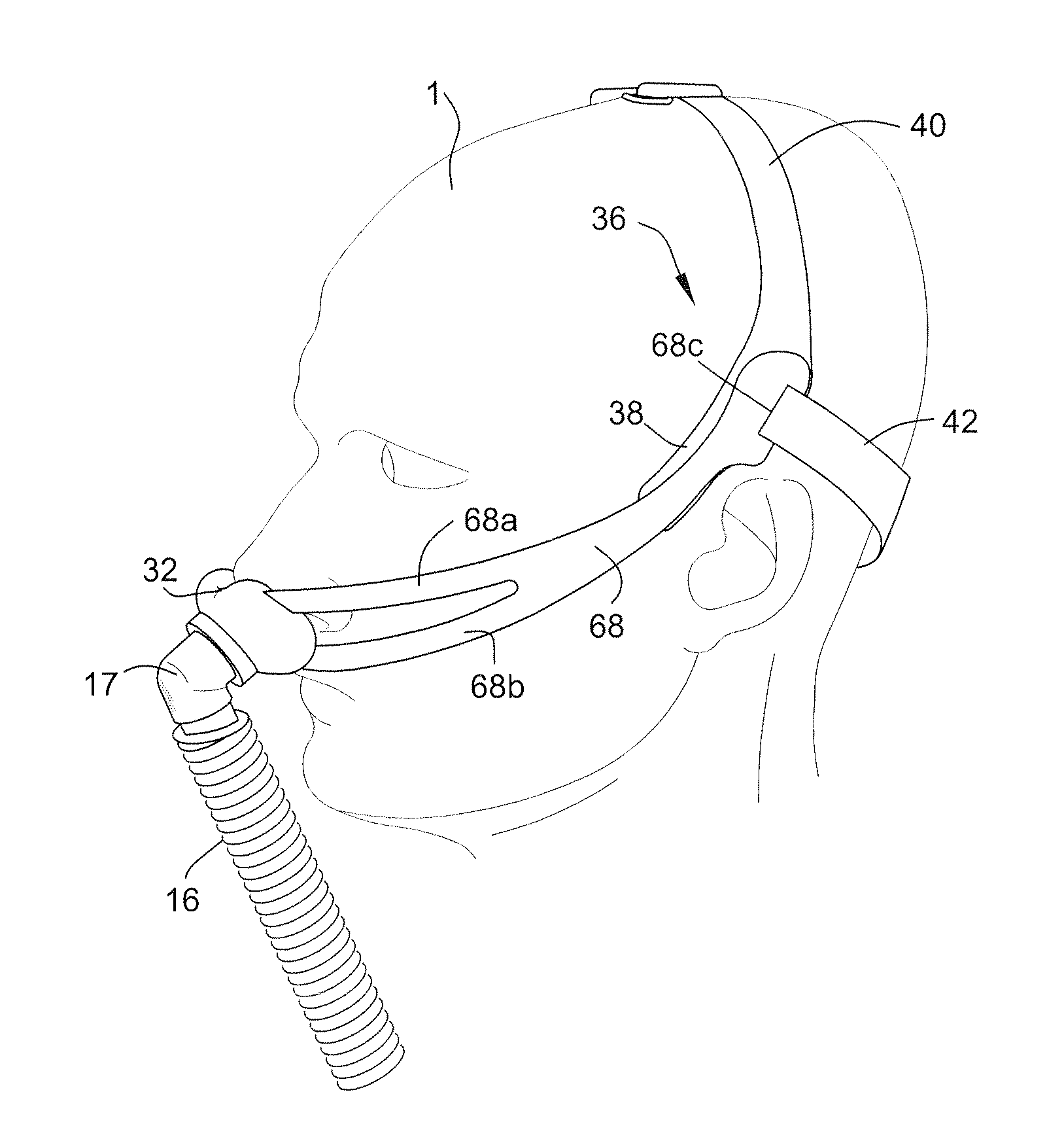

Patient interface systems

ActiveUS20100307502A1Improve manufacturabilityImprove usabilityRespiratory masksBreathing masksPositive pressureSleep disordered breathing

Owner:RESMED LTD

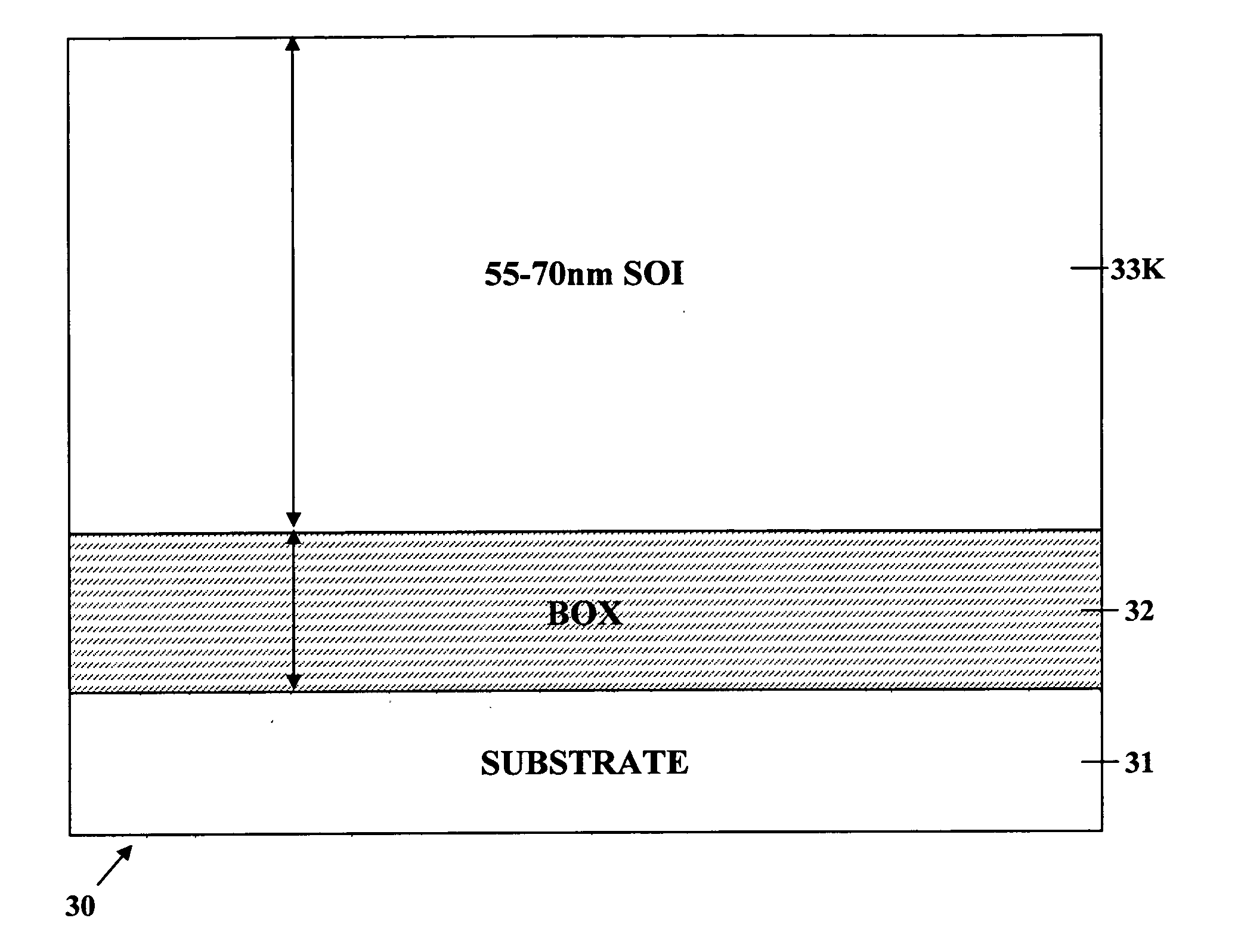

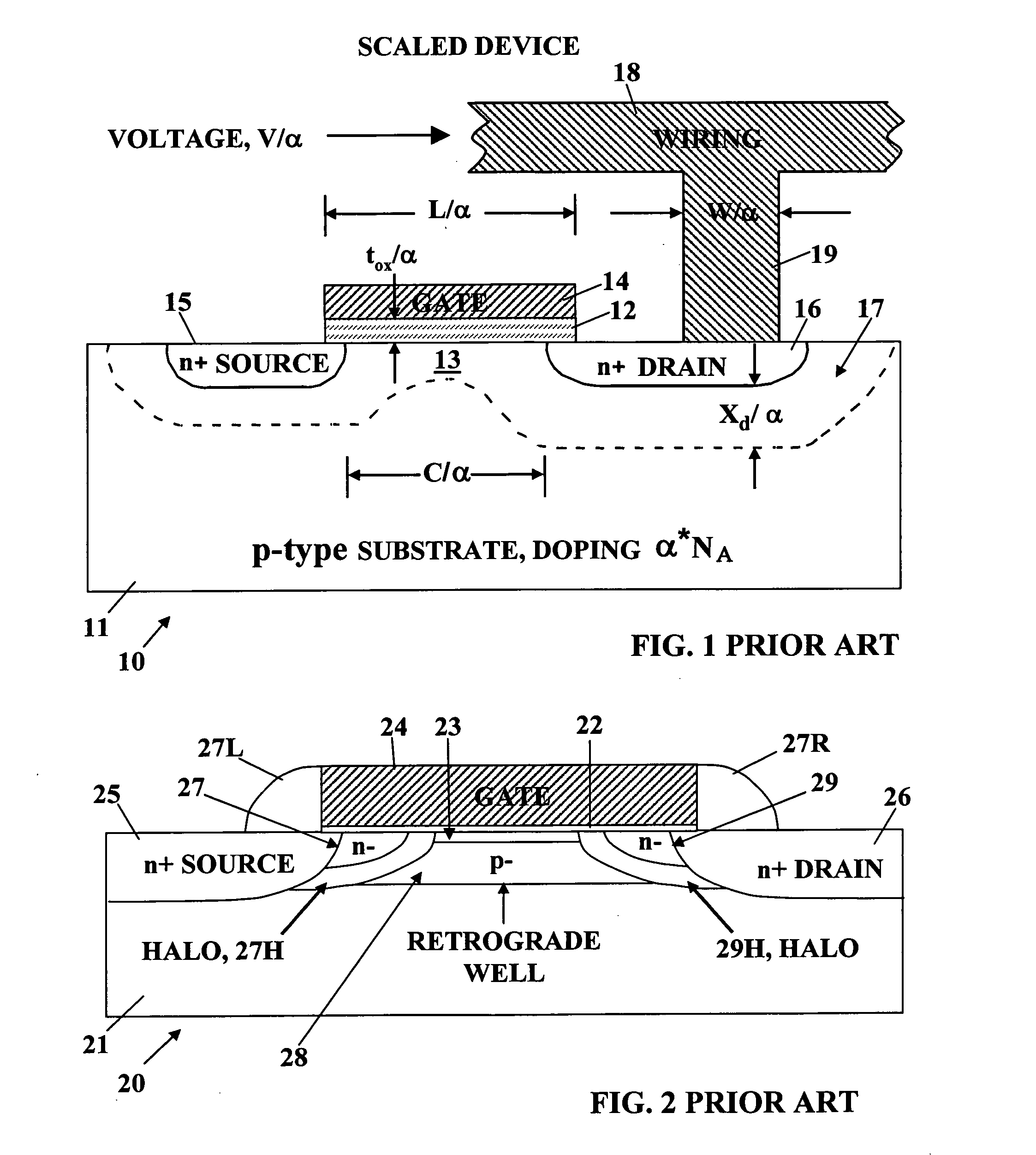

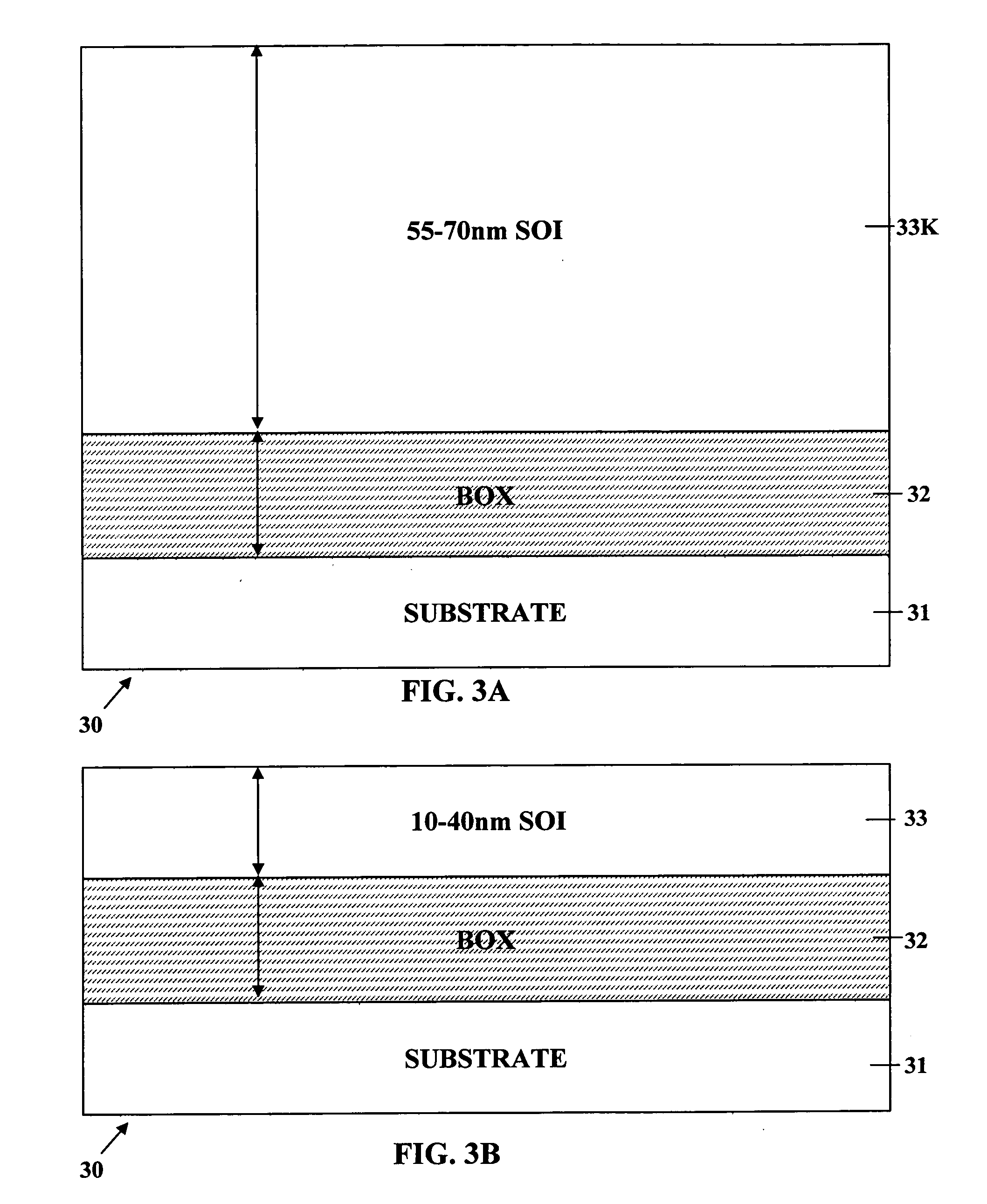

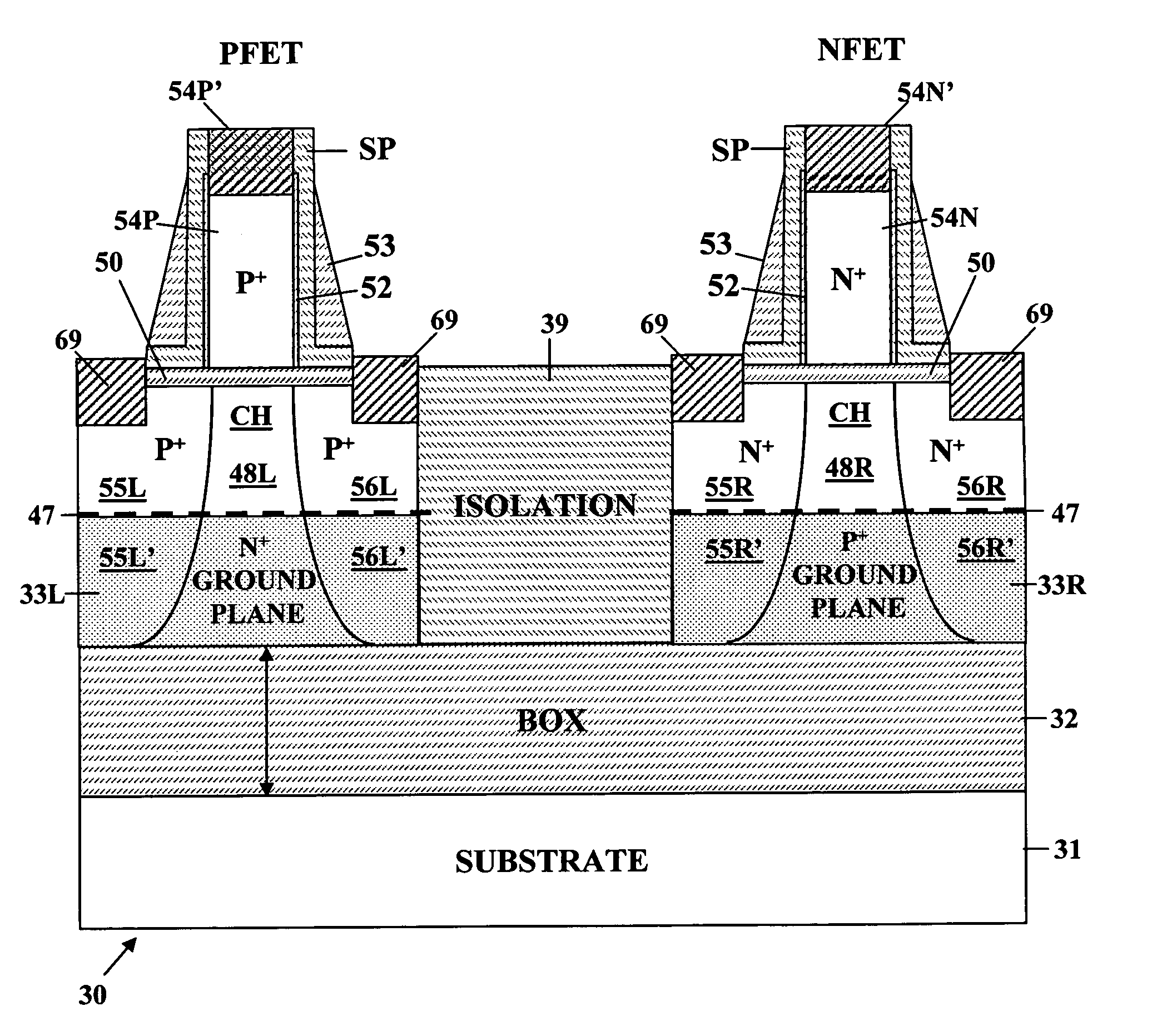

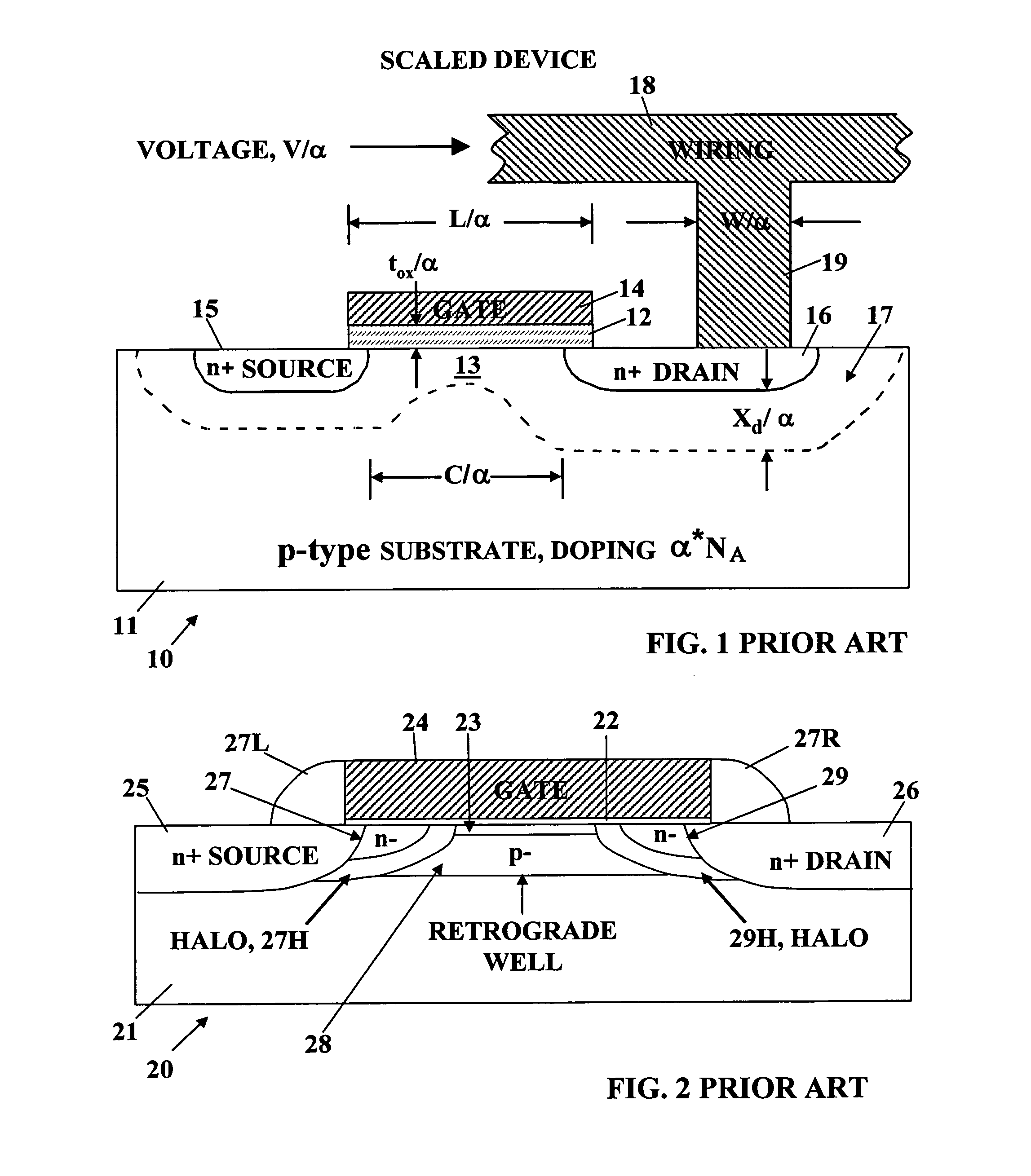

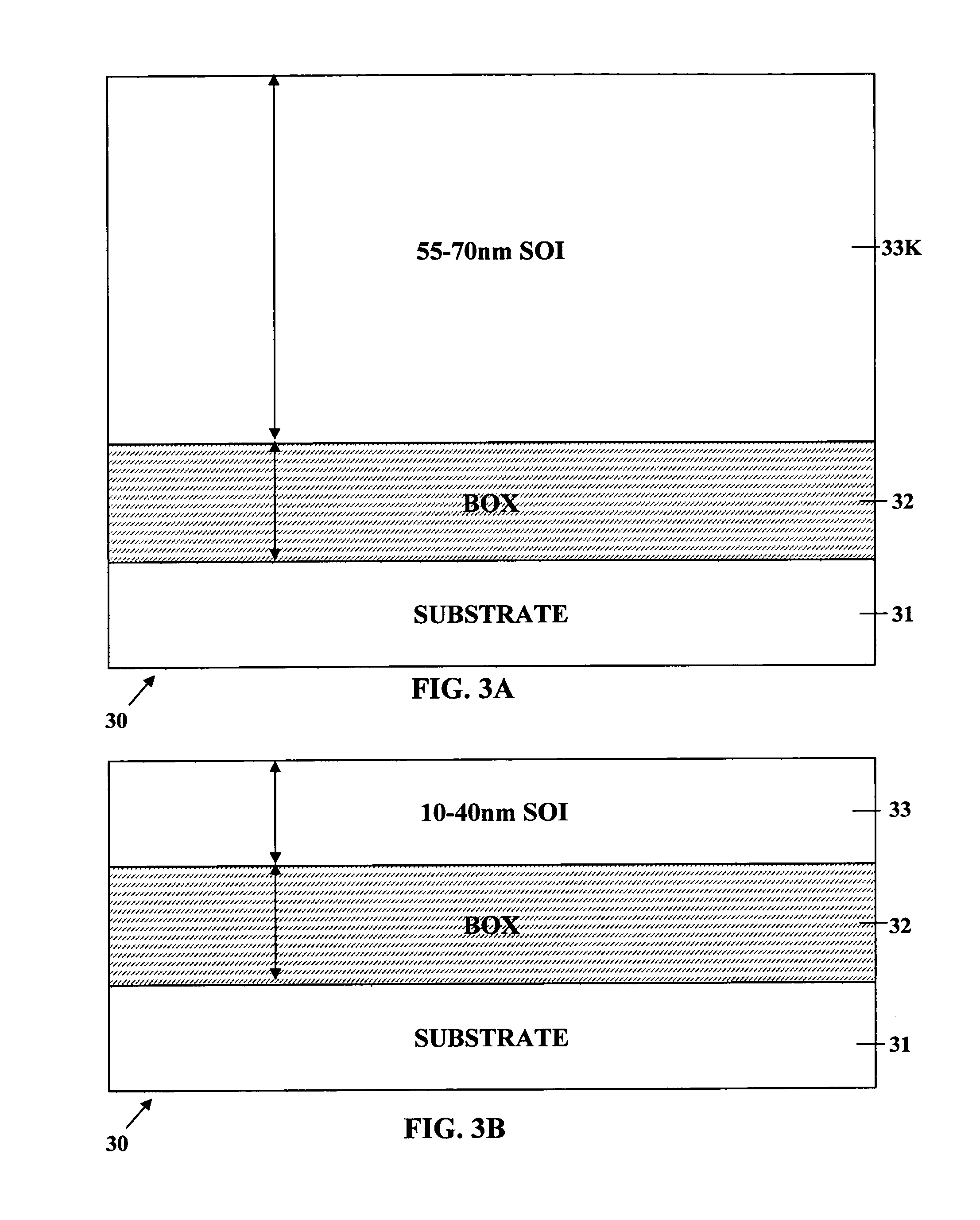

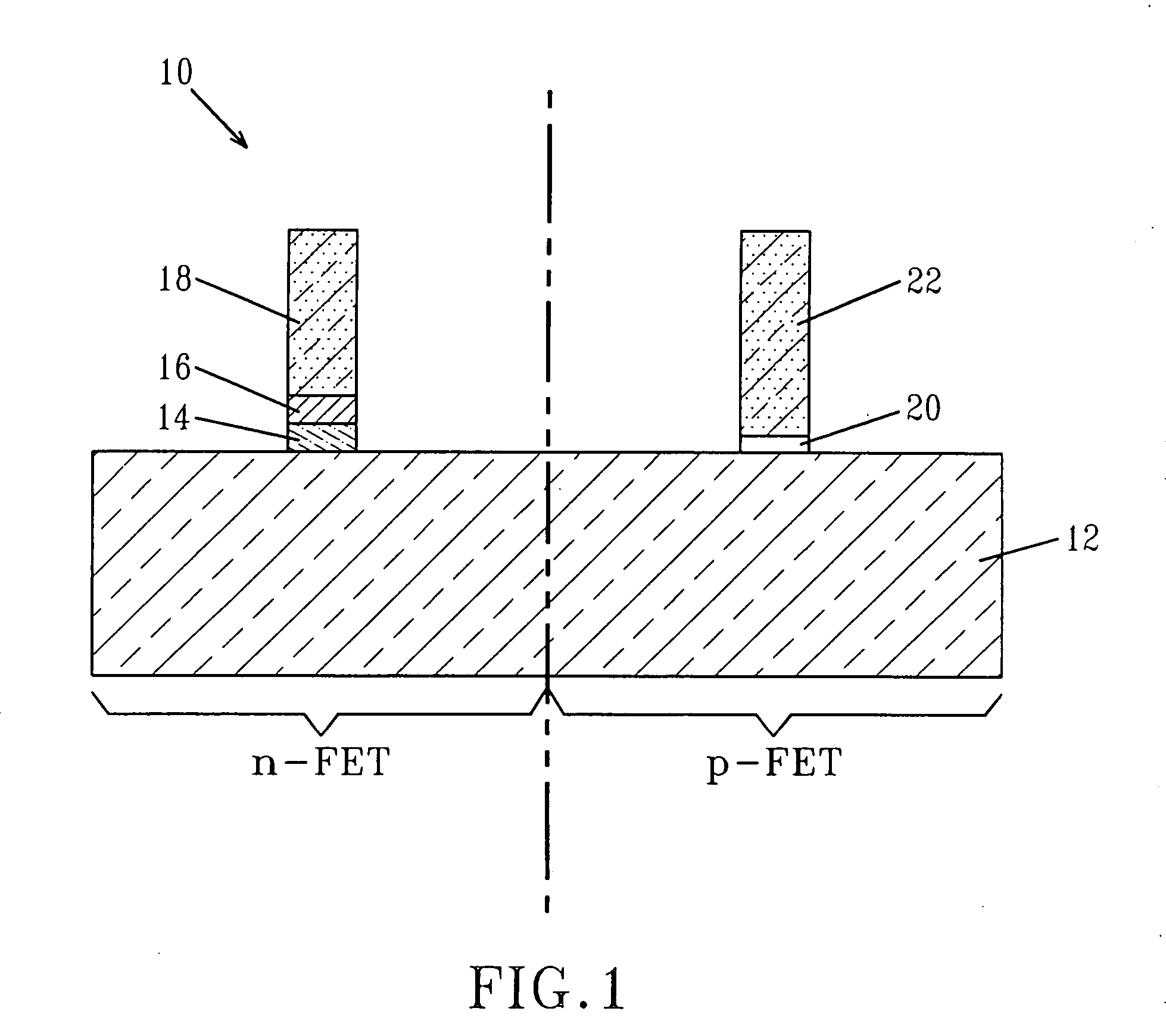

Ultra-thin body super-steep retrograde well (SSRW) FET devices

ActiveUS20060022270A1Minimize space-charge related fluctuationReduce capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingDopantGround plane

A method of manufacture of a Super Steep Retrograde Well Field Effect Transistor device starts with an SOI layer formed on a substrate, e.g. a buried oxide layer. Thin the SOI layer to form an ultra-thin SOI layer. Form an isolation trench separating the SOI layer into N and P ground plane regions. Dope the N and P ground plane regions formed from the SOI layer with high levels of N-type and P-type dopant. Form semiconductor channel regions above the N and P ground plane regions. Form FET source and drain regions and gate electrode stacks above the channel regions. Optionally form a diffusion retarding layer between the SOI ground plane regions and the channel regions.

Owner:GLOBALFOUNDRIES US INC

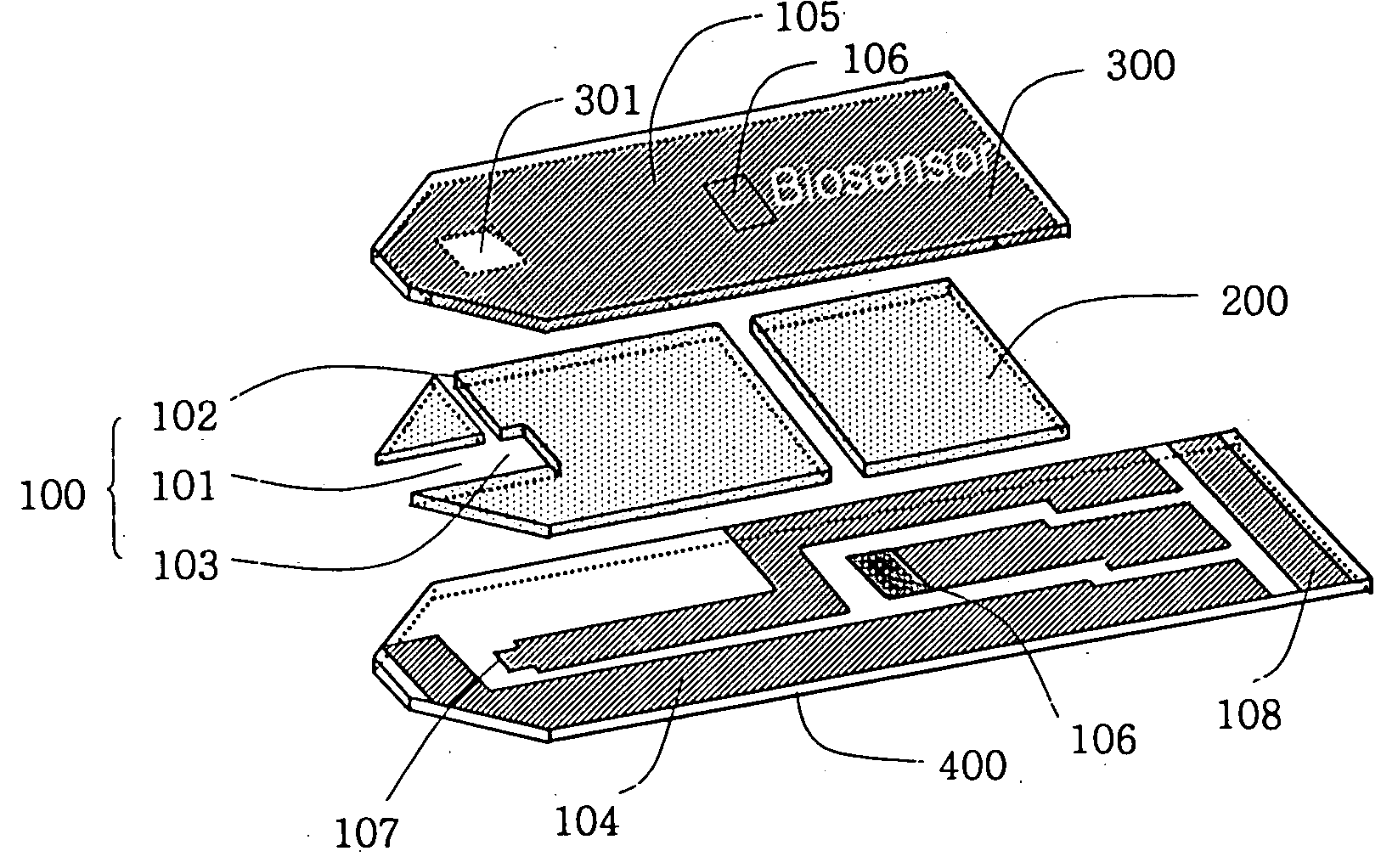

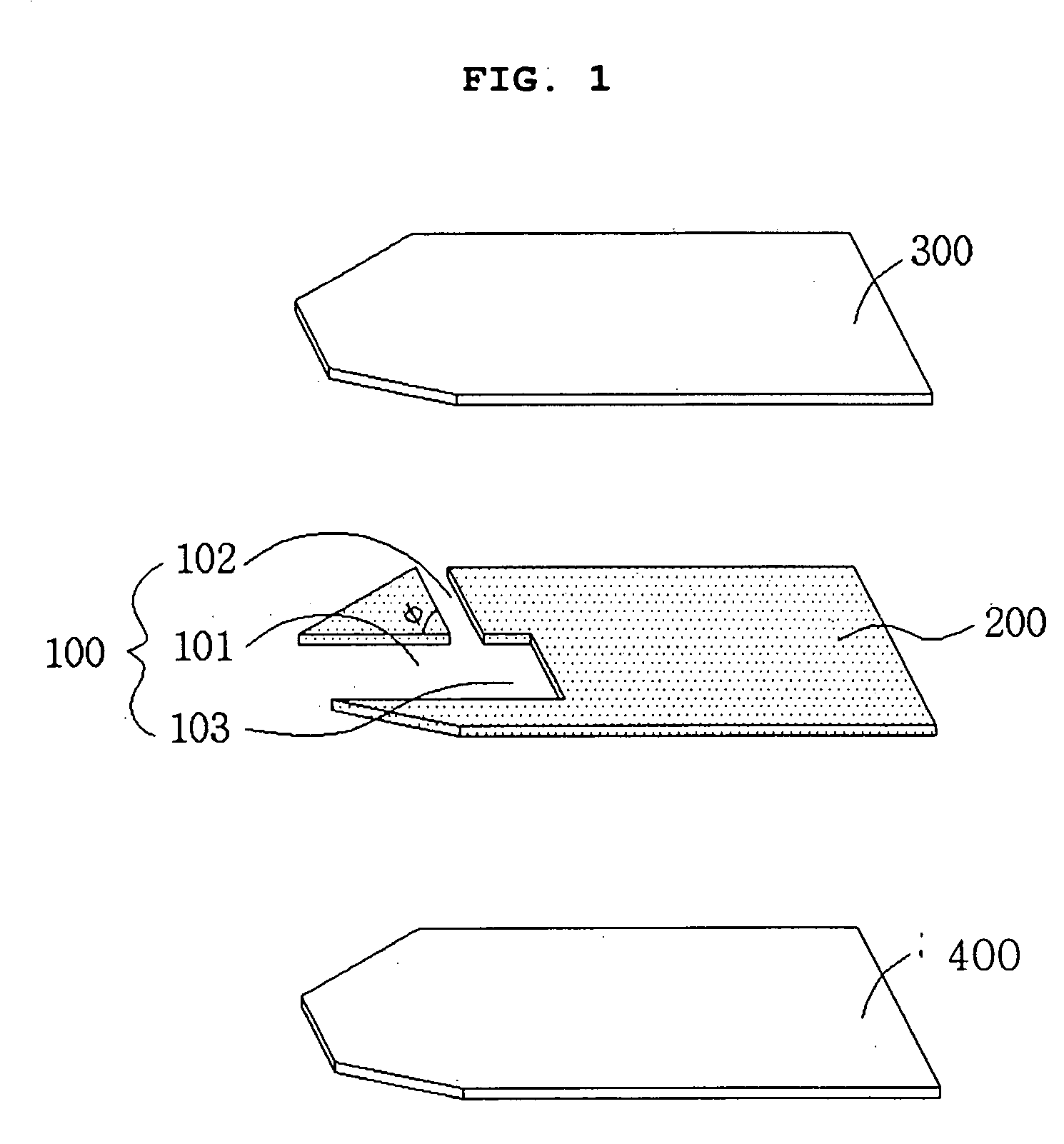

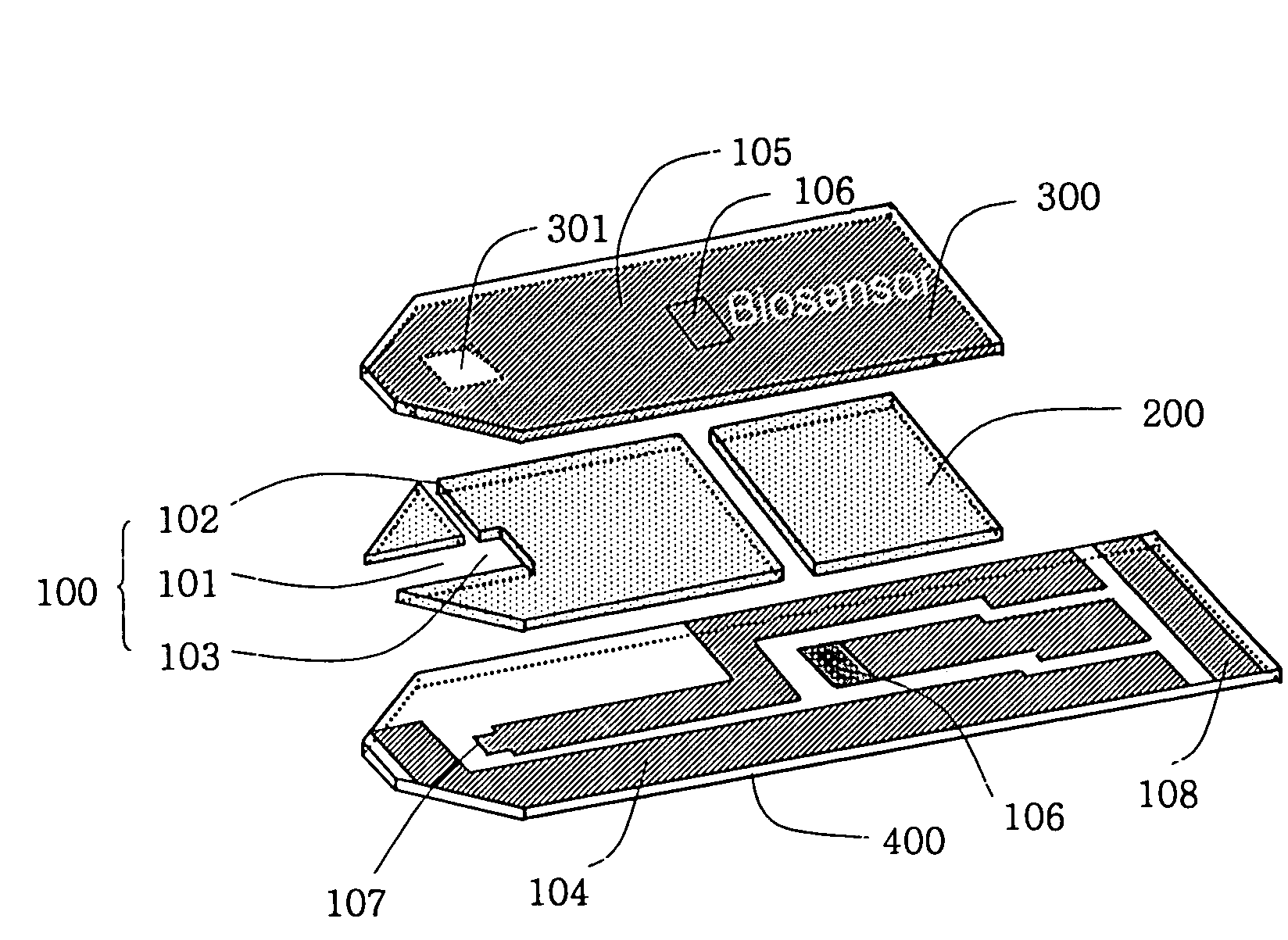

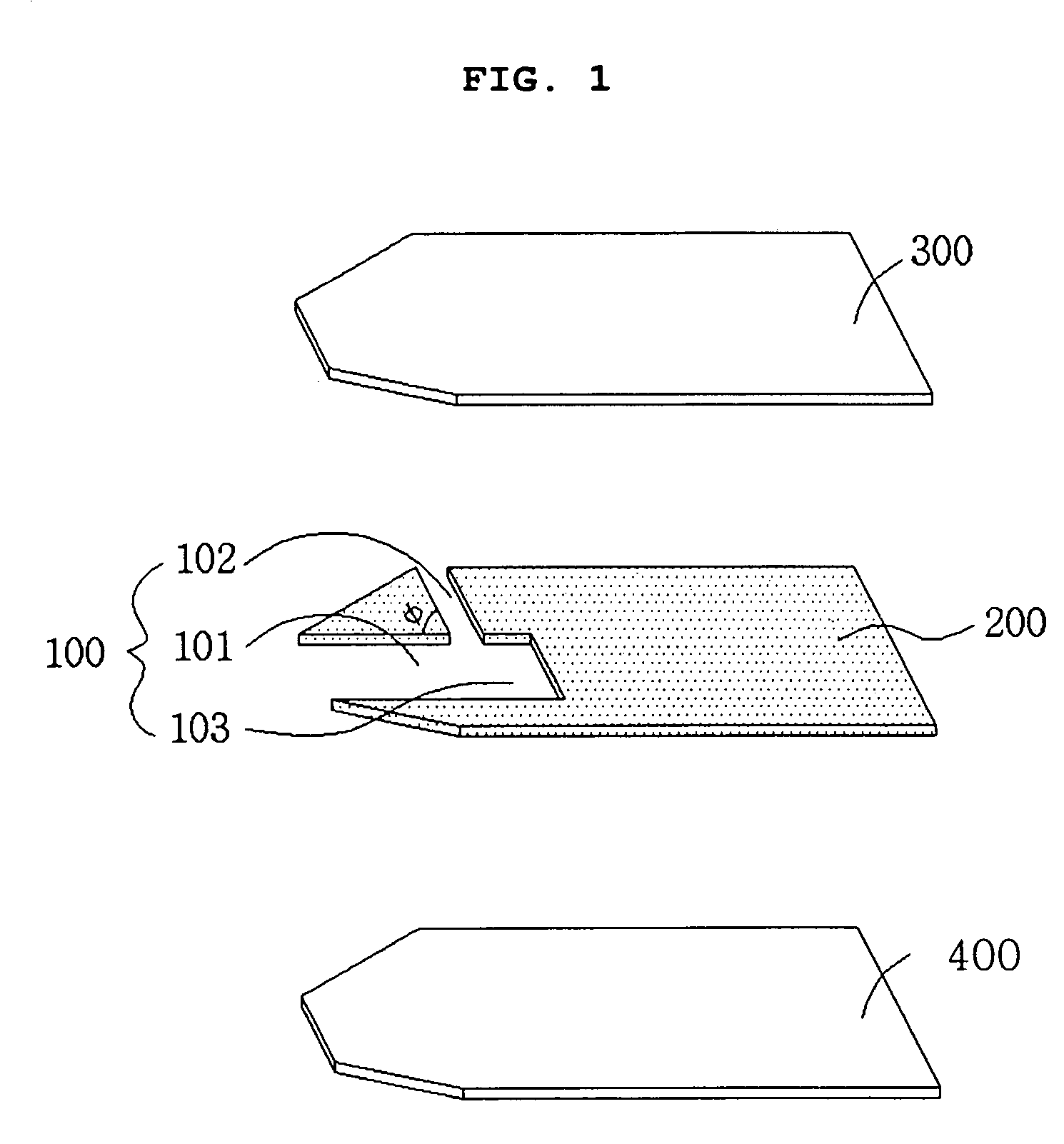

Electrochemical biosensor

ActiveUS20050000808A1Reduced hematocrit level-dependent biasImprove manufacturabilityImmobilised enzymesBioreactor/fermenter combinationsElectron transfer mediatorElectrochemical biosensor

There is provided the reagent layer composition that can substantially reduce the measurement bias arising from hematocrits. The addition of fatty acid (4-20 carbons) and quaternary ammonium salt to a commonly used reagent layer composition composed of an enzyme, an electron transfer mediator, and several water soluble polymers not only reduce the hematocrit level-dependent bias but also provide very stable performance for an extended period of time. Disclosed are also various types of sub microliter sample volume electrochemical biosensors that are suitable to use with the reagent layer composition of present invention.

Owner:I SENS INC

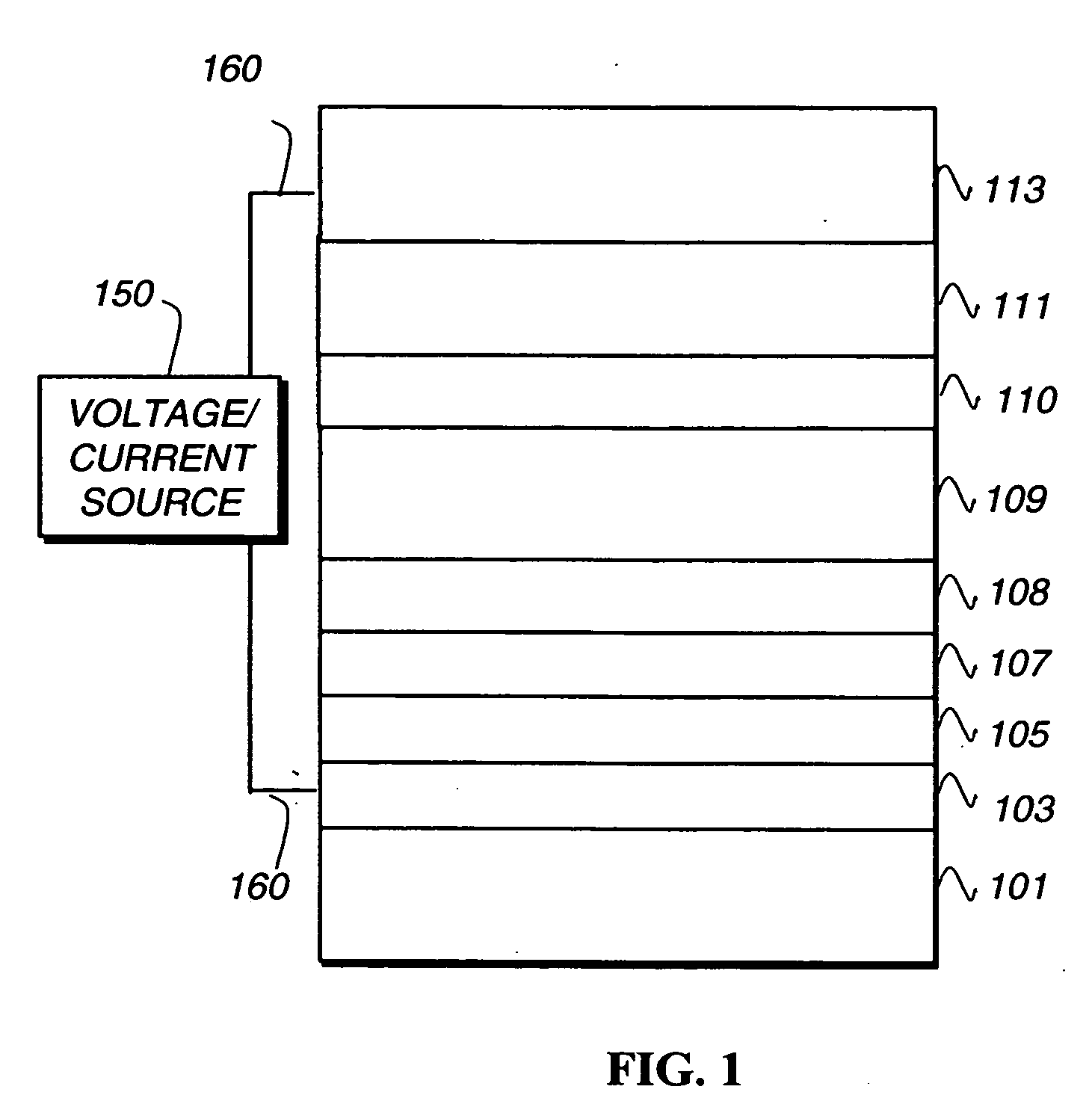

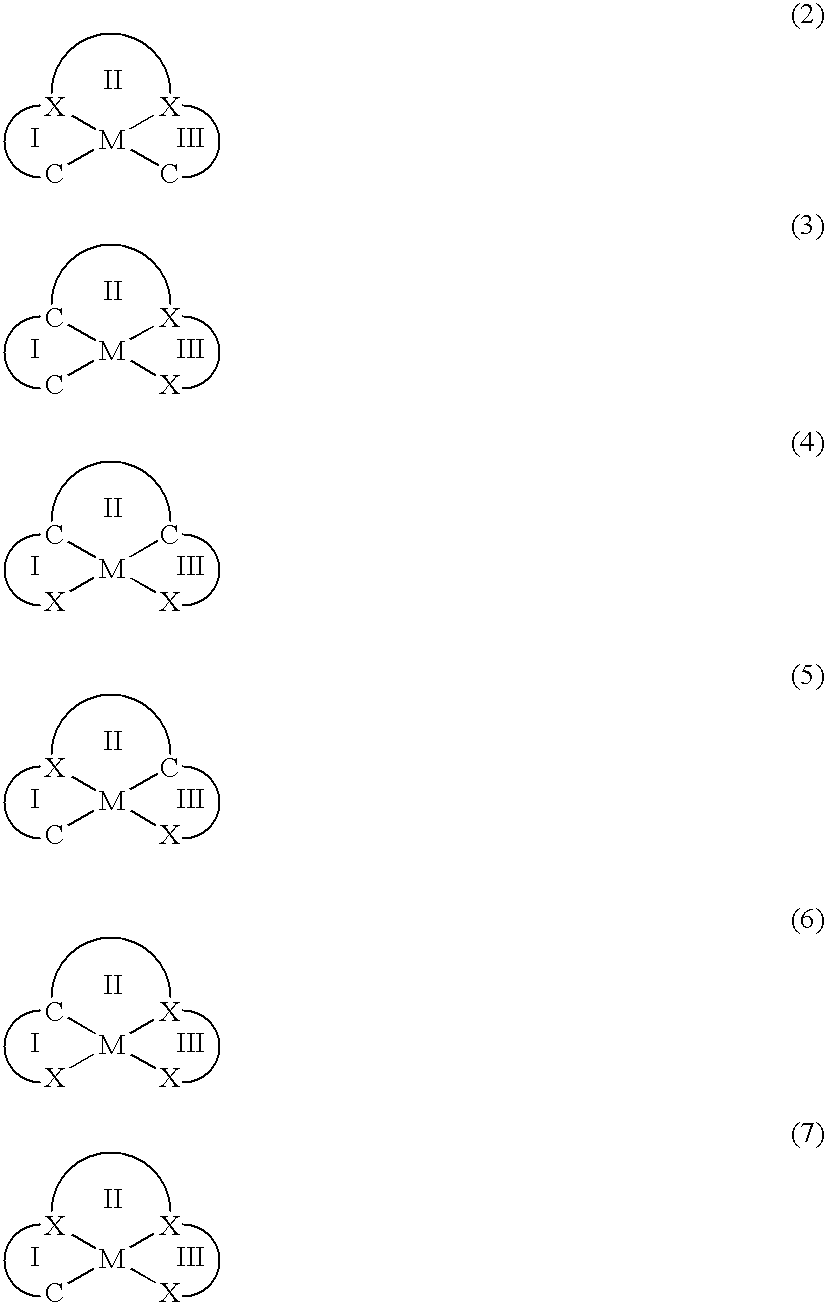

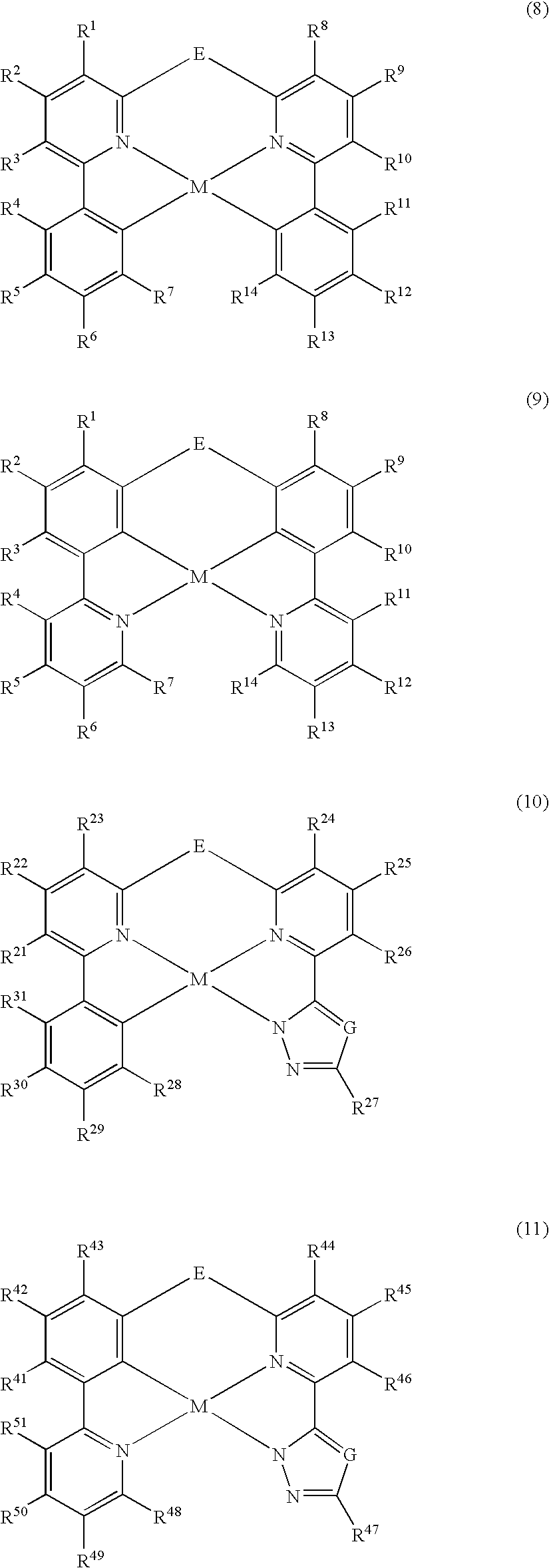

Organometallic materials and electroluminescent devices

InactiveUS20060134461A1Improve efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingCompound (substance)Metal

An electroluminescent device comprises a light-emitting layer containing an organometallic compound comprising a metal and a ligand that coordinates to the metal through at least four bonds as represented by Formula (1) wherein at least one is a carbon-metal bond: MX)n (1) wherein M represents a metal, X represents an independently selected atom, n≧4, at least one X is carbon, and all X are linked to form a multidentate ligand.

Owner:EASTMAN KODAK CO

Ultra-thin body super-steep retrograde well (SSRW) FET devices

ActiveUS7002214B1Reduce capacitanceReduce junctionSolid-state devicesSemiconductor/solid-state device manufacturingDopantGround plane

A method of manufacture of a Super Steep Retrograde Well Field Effect Transistor device starts with an SOI layer formed on a substrate, e.g. a buried oxide layer. Thin the SOI layer to form an ultra-thin SOI layer. Form an isolation trench separating the SOI layer into N and P ground plane regions. Dope the N and P ground plane regions formed from the SOI layer with high levels of N-type and P-type dopant. Form semiconductor channel regions above the N and P ground plane regions. Form FET source and drain regions and gate electrode stacks above the channel regions. Optionally form a diffusion retarding layer between the SOI ground plane regions and the channel regions.

Owner:GLOBALFOUNDRIES US INC

Electrochemical biosensor

ActiveUS7288174B2Reduced hematocrit level-dependent biasImprove manufacturabilityImmobilised enzymesBioreactor/fermenter combinationsElectron transfer mediatorElectrochemical biosensor

There is provided the reagent layer composition that can substantially reduce the measurement bias arising from hematocrits. The addition of fatty acid (4-20 carbons) and quaternary ammonium salt to a commonly used reagent layer composition composed of an enzyme, an electron transfer mediator, and several water soluble polymers not only reduce the hematocrit level-dependent bias but also provide very stable performance for an extended period of time. Disclosed are also various types of sub microliter sample volume electrochemical biosensors that are suitable to use with the reagent layer composition of present invention.

Owner:I SENS INC

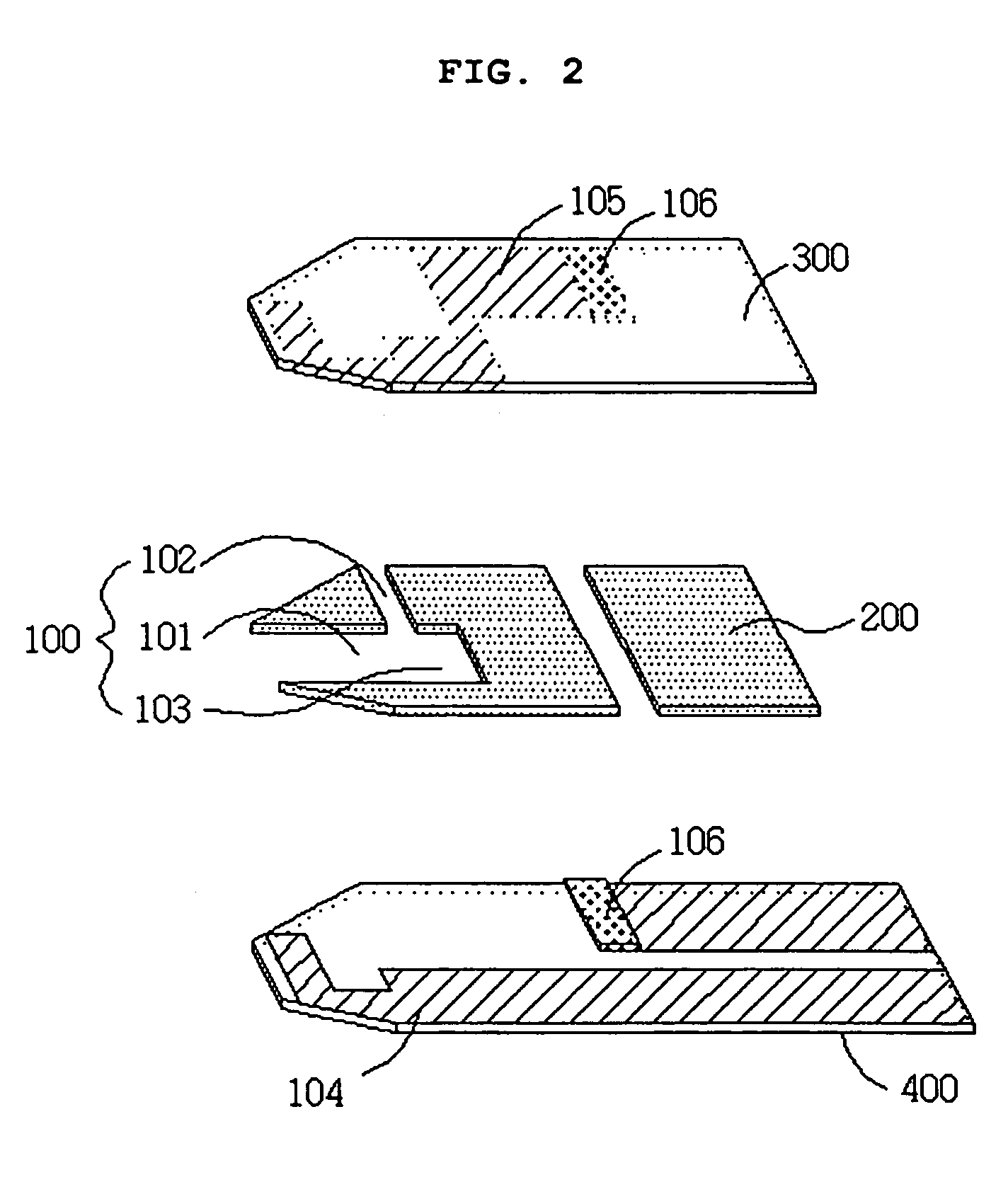

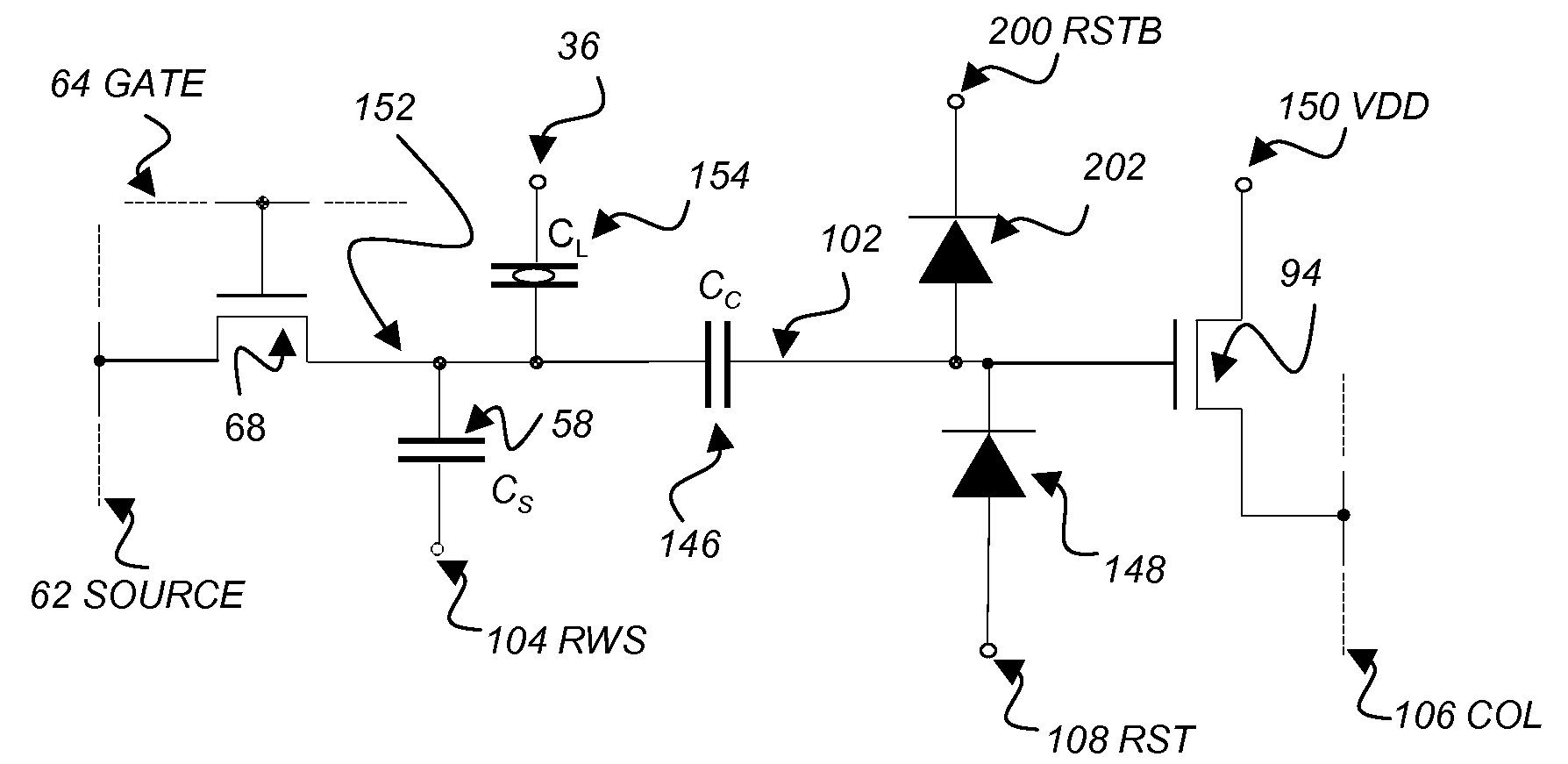

Array element circuit and active matrix device

ActiveUS8653832B2Determine sizeImprove manufacturabilitySludge treatmentStatic indicating devicesActive matrixArray element

Owner:SHARP LIFE SCI EU LTD

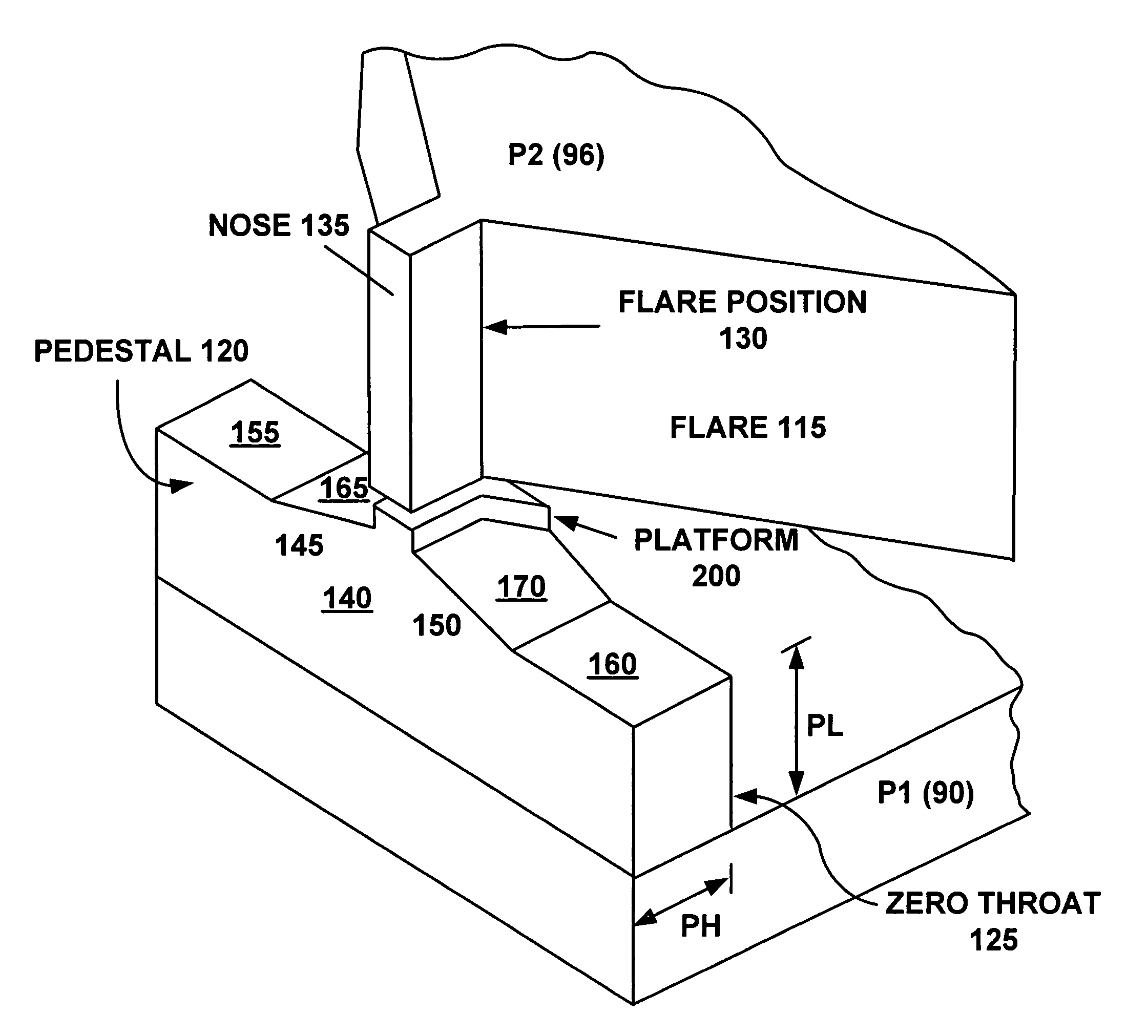

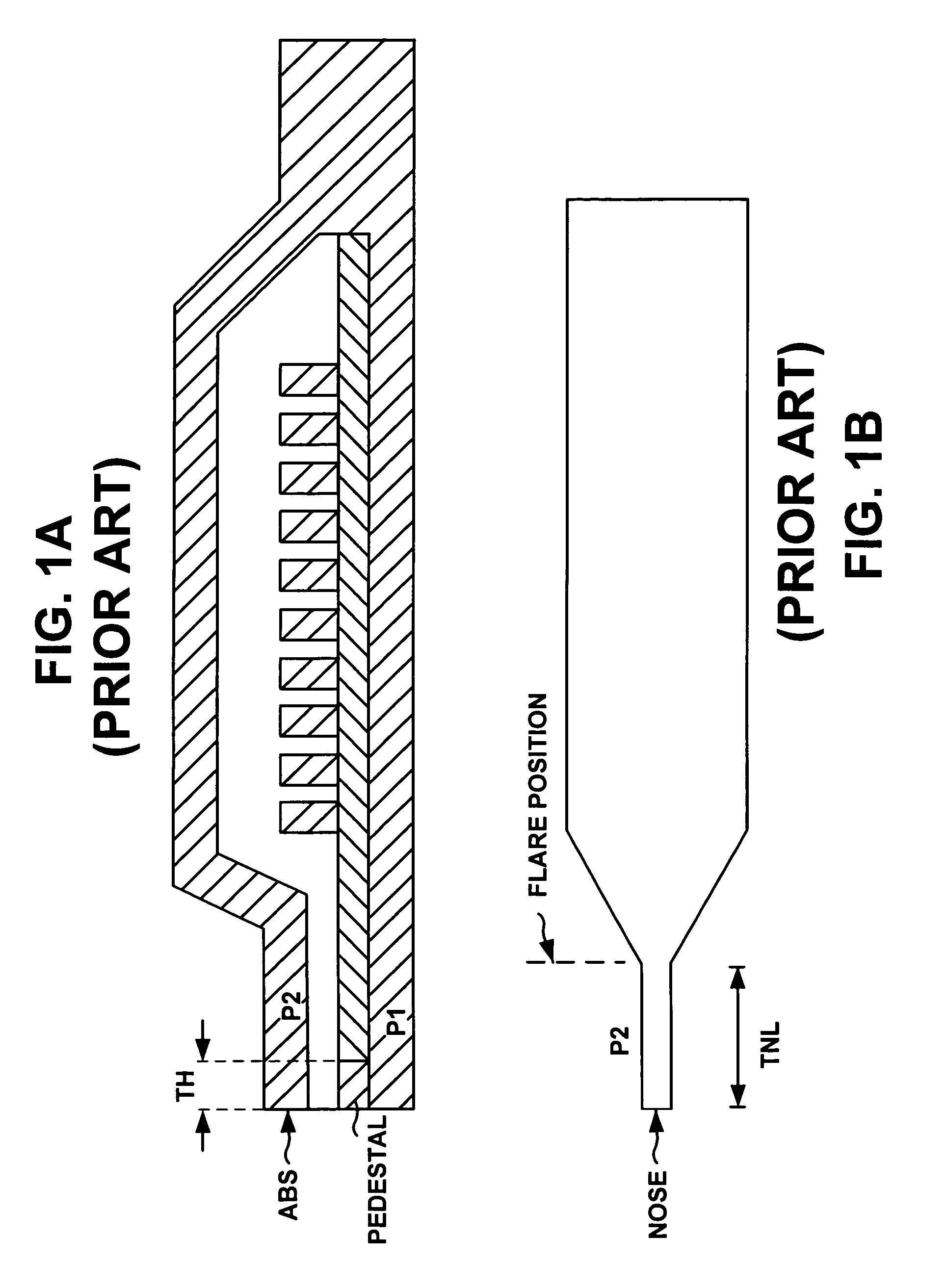

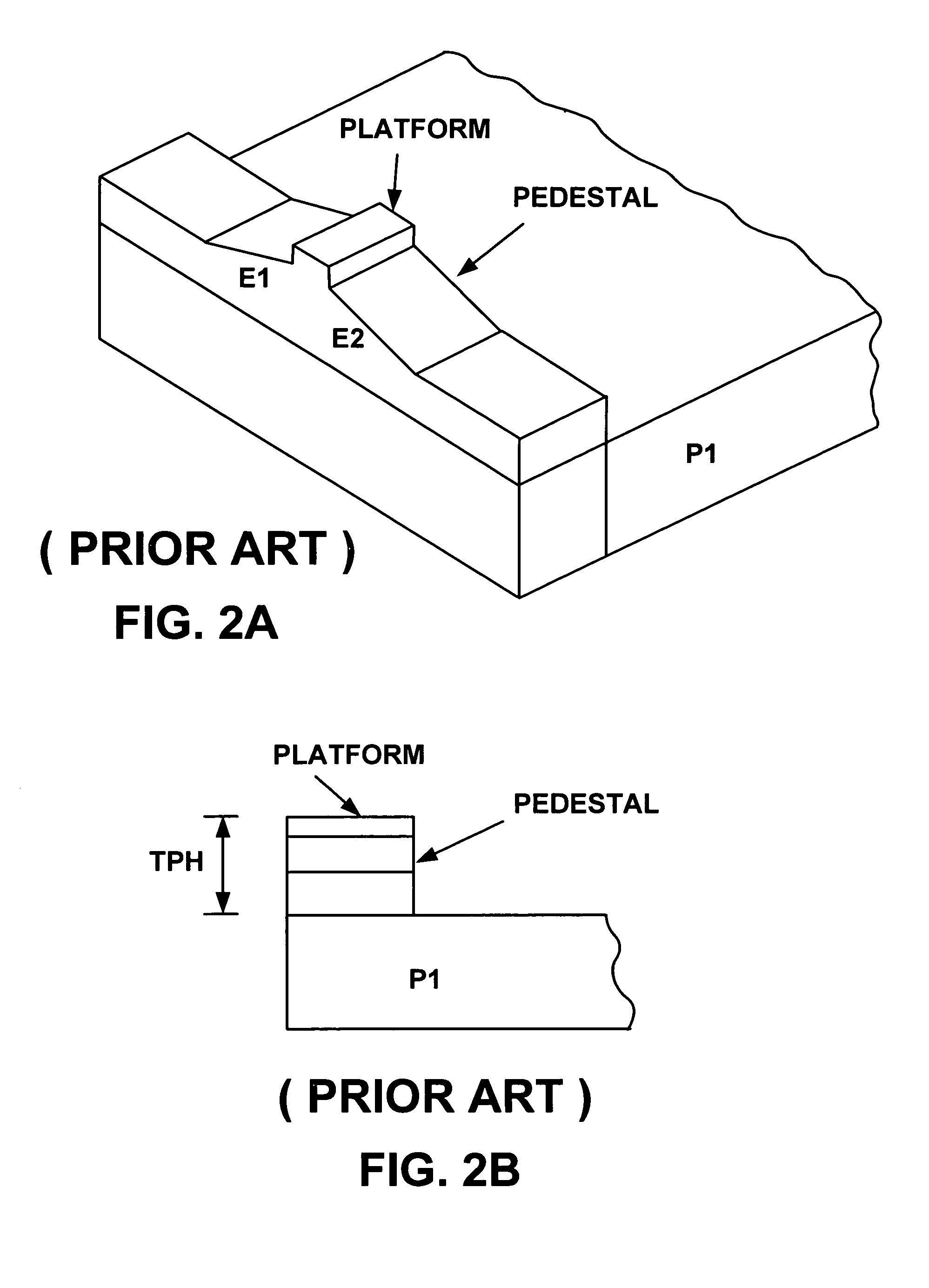

Write head for improved manufacturability larger write field and reduced adjacent track erasure

InactiveUS7349179B1Improve manufacturabilityReduce decreaseRecord information storageMagnetic recordingNoseMagnetic flux

A magnetic write head provides a significant write field and minimal adjacent track erasure, and lends itself to improved manufacturability. The write head includes a pedestal throat height that defines a bottom pole, P1, and that is substantially recessed from the air bearing surface. The write head further includes a top pole, P2, that defines a nose that is closer to the air bearing surface than the pedestal zero throat. This design achieves a relatively high ratio of the off-track to on-track field. As an example, a 1:4 ratio could be achieved to significantly mitigate the erasure problem of the adjacent tracks resulting from magnetic flux saturation.

Owner:WESTERN DIGITAL TECH INC

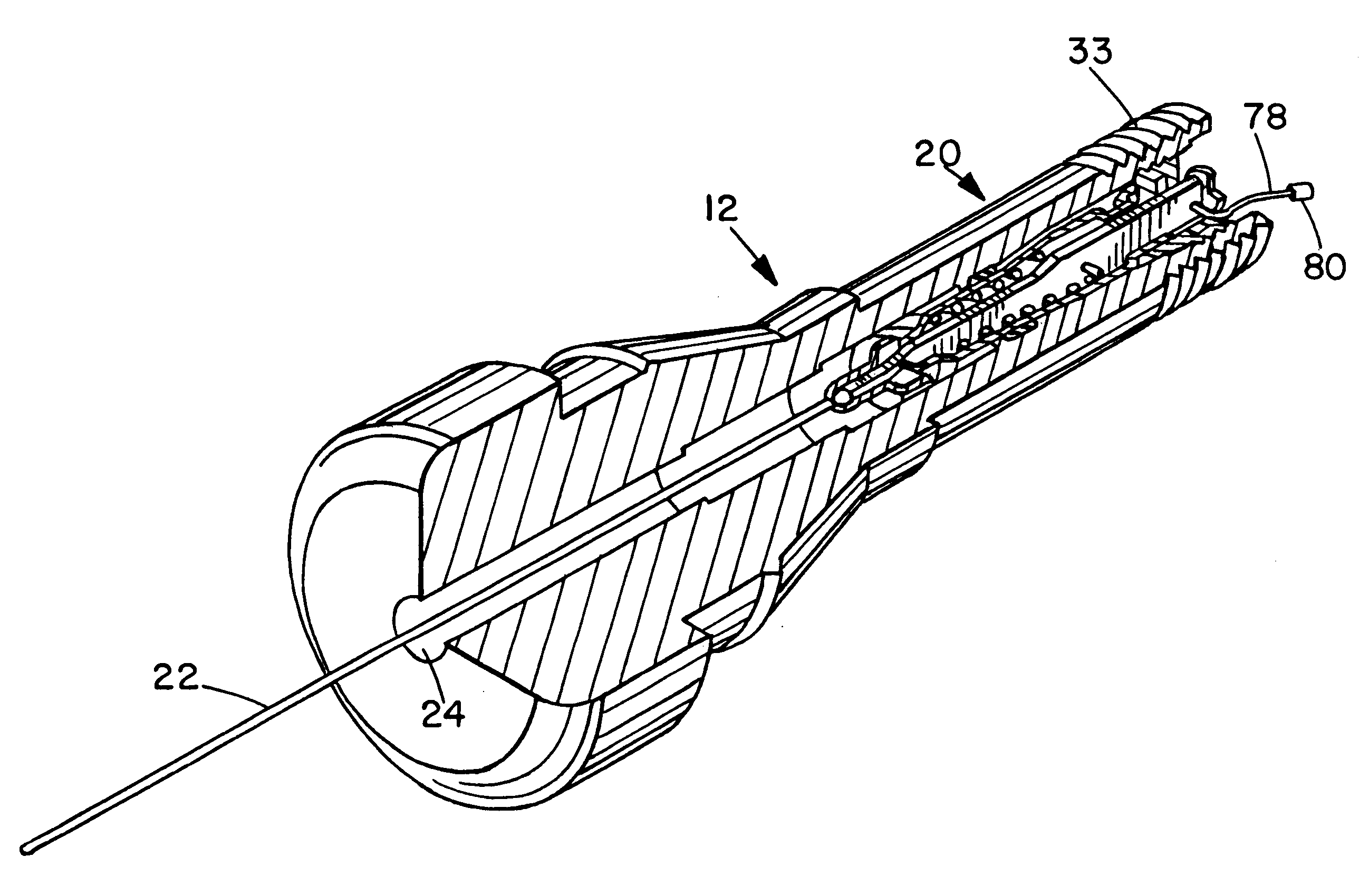

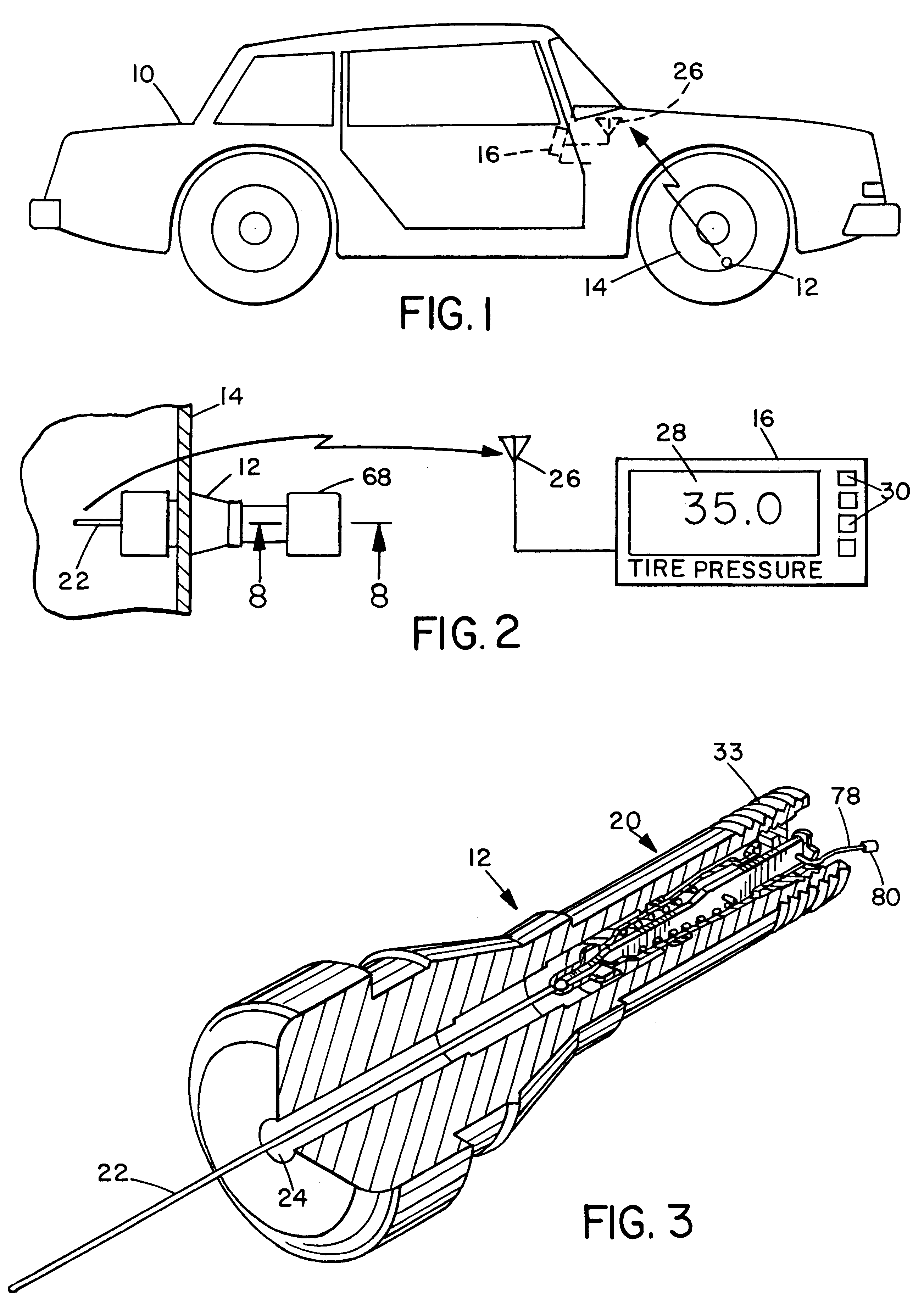

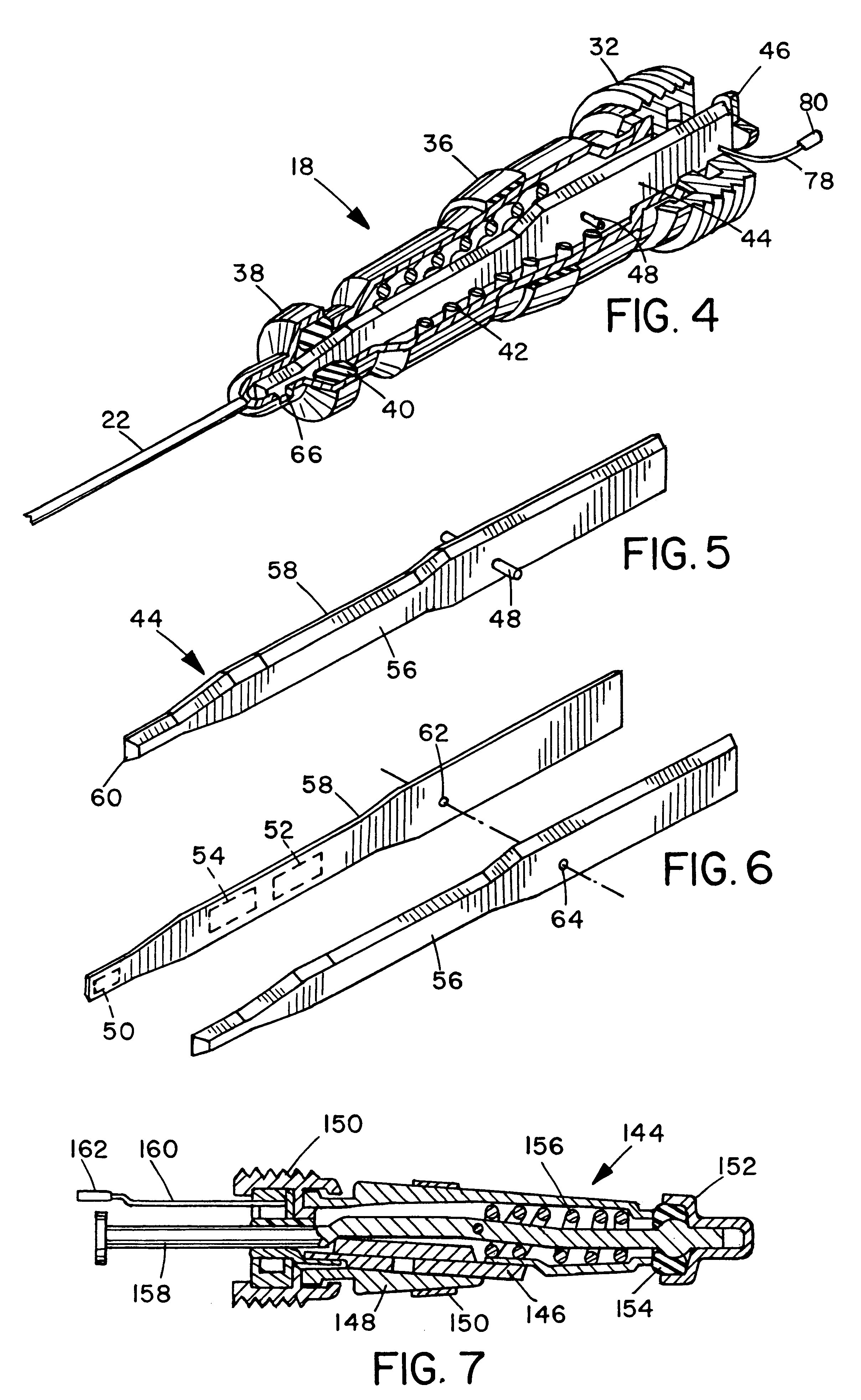

Miniature combination valve and pressure transducer system

InactiveUS6199575B1Easy to integrateImprove manufacturabilityCheck valvesPipeline systemsEngineeringForce transducer

A valve system includes a movable microelectromechanically structured (MEMS) pressure sensor that not only senses pressure but also functions as a mechanical actuator for the valve. An alternative valve system includes a MEMS pressure sensor that extends through an aperture in a curved wall, such as a curved wall of a valve body or a valve core, at an oblique angle to allow it be securely mounted in the confined space of an automotive-type tire inflation valve. The valve system includes a transmitter integrated with the valve and a receiver located at a remote location, such as the passenger compartment of an automobile.

Owner:WIDNER RONALD D

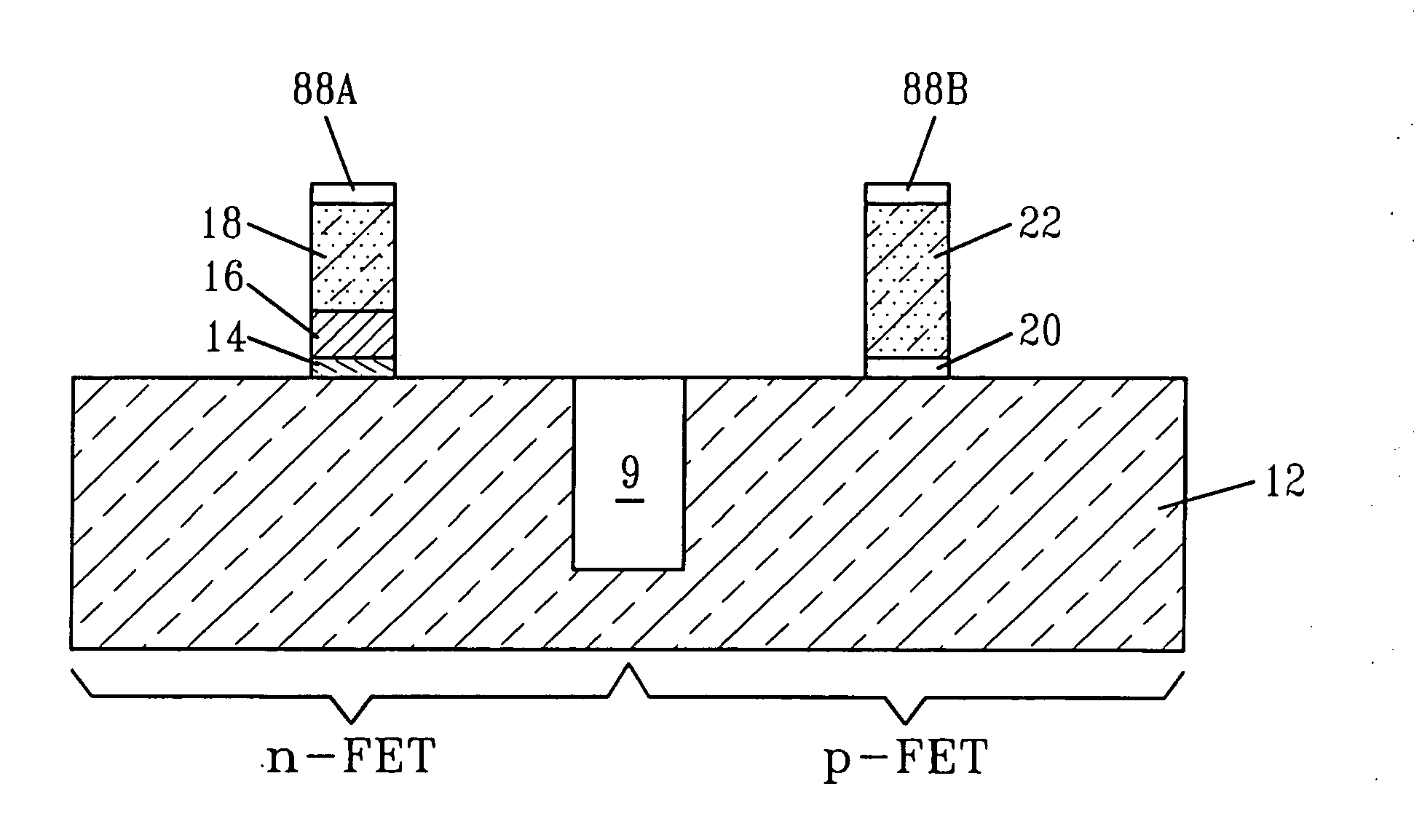

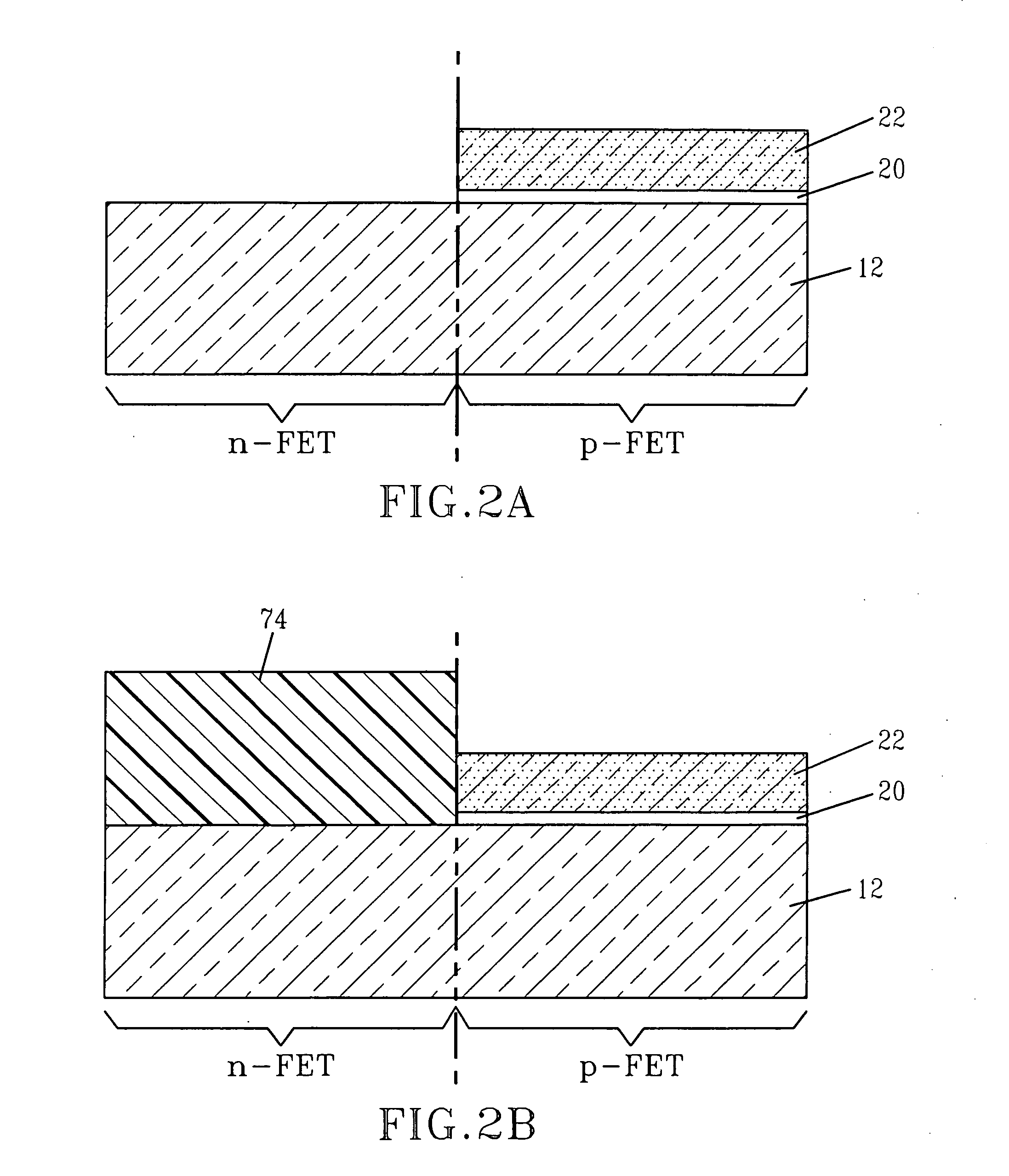

High performance CMOS circuits, and methods for fabricating the same

InactiveUS20070152276A1Improve manufacturabilityImprove performanceTransistorSemiconductor/solid-state device manufacturingCMOSGate dielectric

The present invention relates to complementary metal-oxide-semiconductor (CMOS) circuits that each contains at least a first and a second gate stacks. The first gate stack is located over a first device region (e.g., an n-FET device region) in a semiconductor substrate and comprises at least, from bottom to top, a gate dielectric layer, a metallic gate conductor, and a silicon-containing gate conductor. The second gate stack is located over a second device region (e.g., a p-FET device region) in the semiconductor substrate and comprises at least, from bottom to top, a gate dielectric layer and a silicon-containing gate conductor. The first and second gate stacks can be formed over the semiconductor substrate in an integrated manner by various methods of the present invention.

Owner:GLOBALFOUNDRIES INC

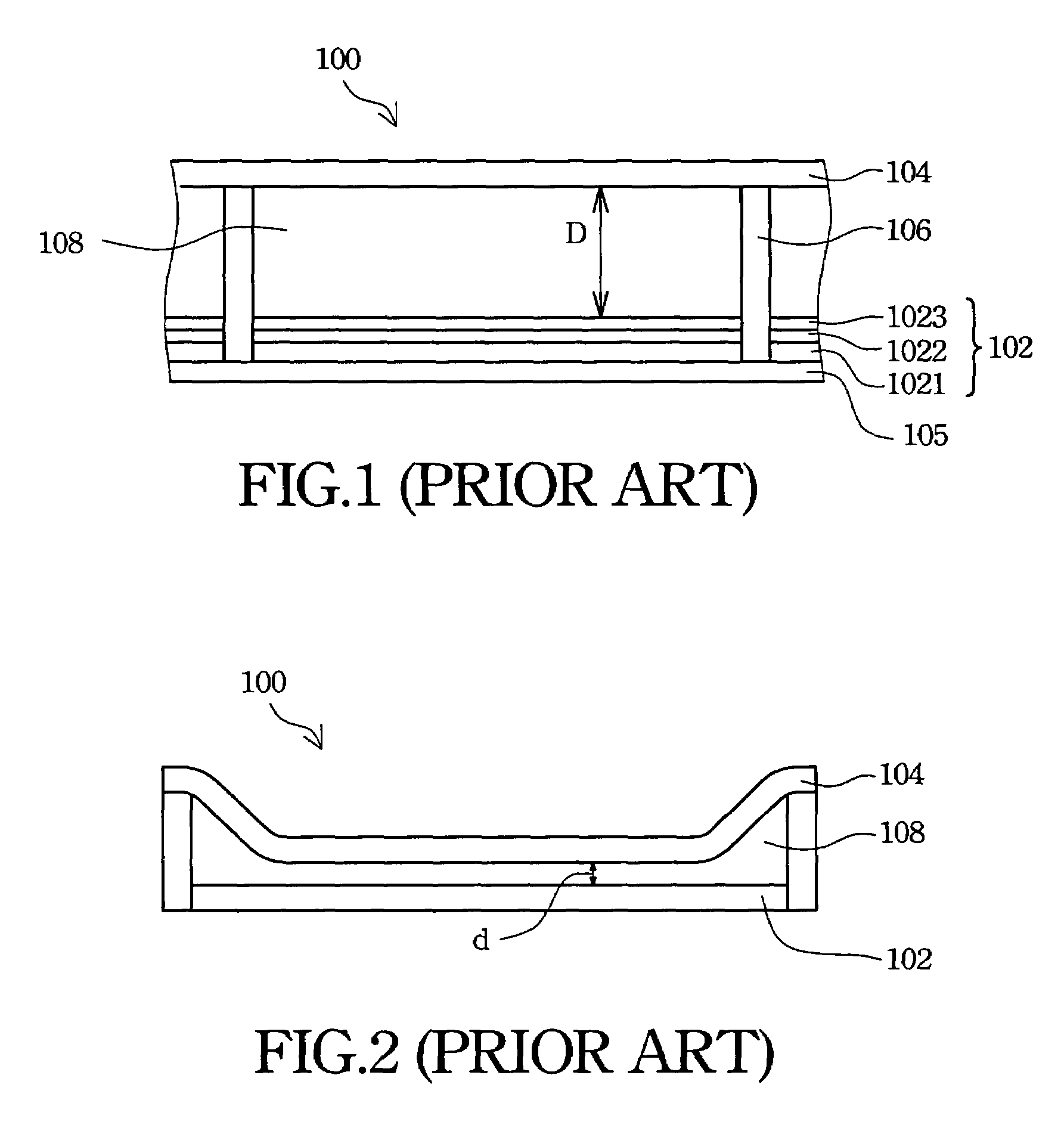

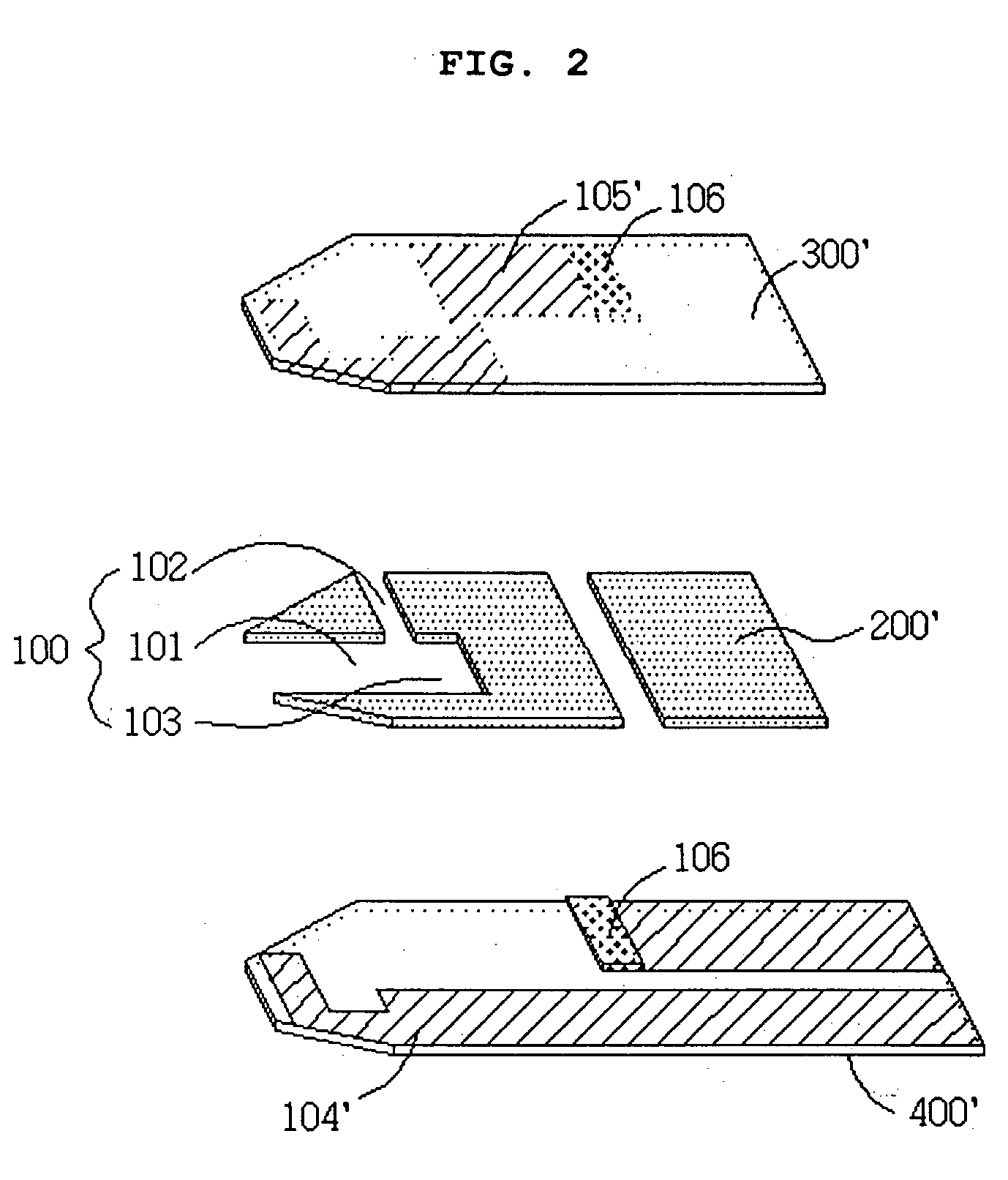

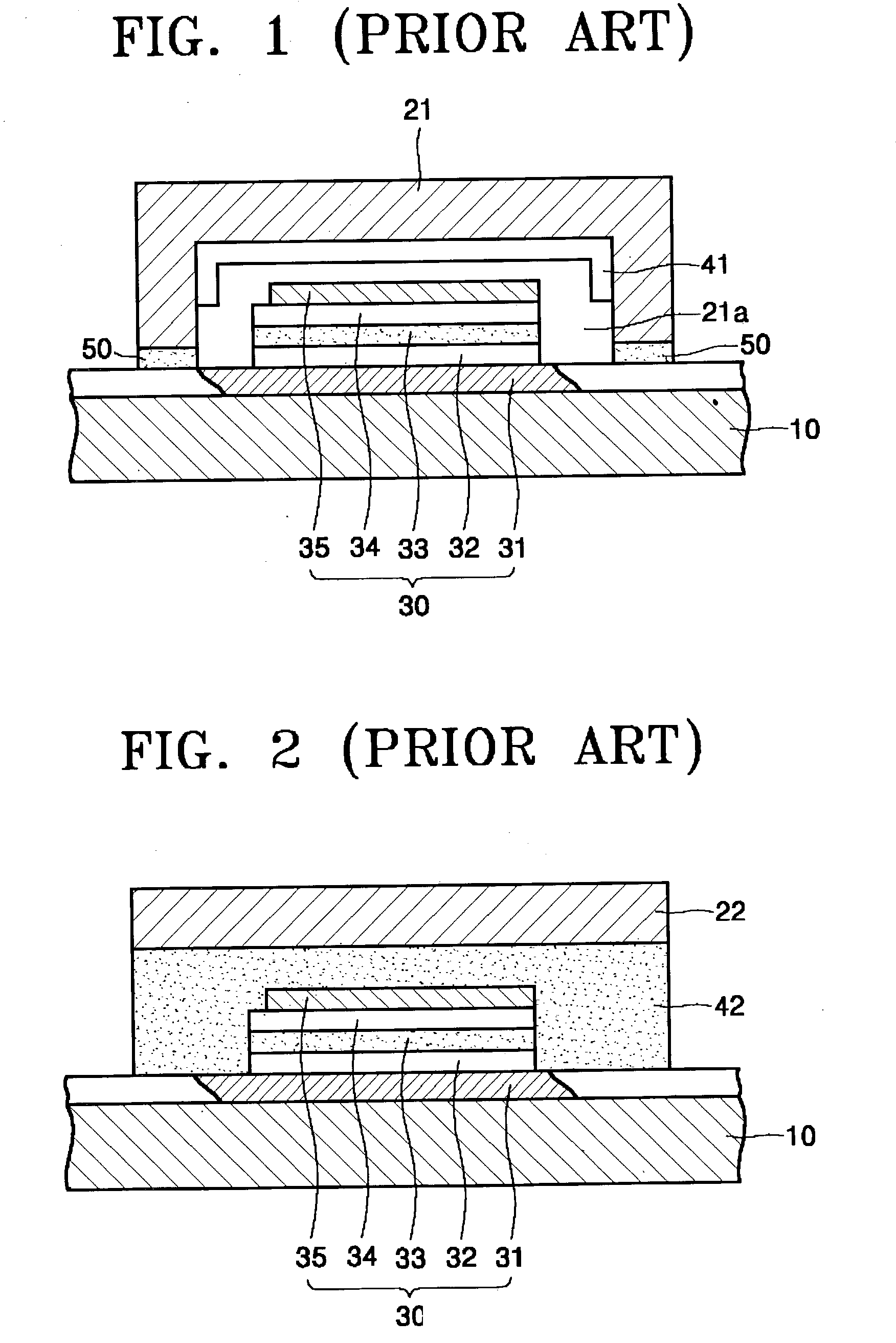

Method for encapsulating organic electroluminescent device and an organic electroluminescent panel using the same

InactiveUS20030218422A1Improve manufacturabilityReduce defective rateDischarge tube luminescnet screensElectroluminescent light sourcesDevice formOrganic layer

A method of encapsulating an organic electroluminescent (EL) device. The method includes applying a first sealant to a portion of an encapsulation plate facing a substrate to define one selected from a plurality of organic EL devices formed on the substrate, each including a first electrode layer, organic layers, and a second electrode layer. A space produced by the encapsulation plate and the first sealant and having an open face is filled with a second sealant. The substrate and the encapsulation plate are bonded together by applying pressure. The first sealant and the second sealant are then cured. The substrate and the encapsulation plate are cut into a plurality of independent organic EL panels.

Owner:SAMSUNG DISPLAY CO LTD

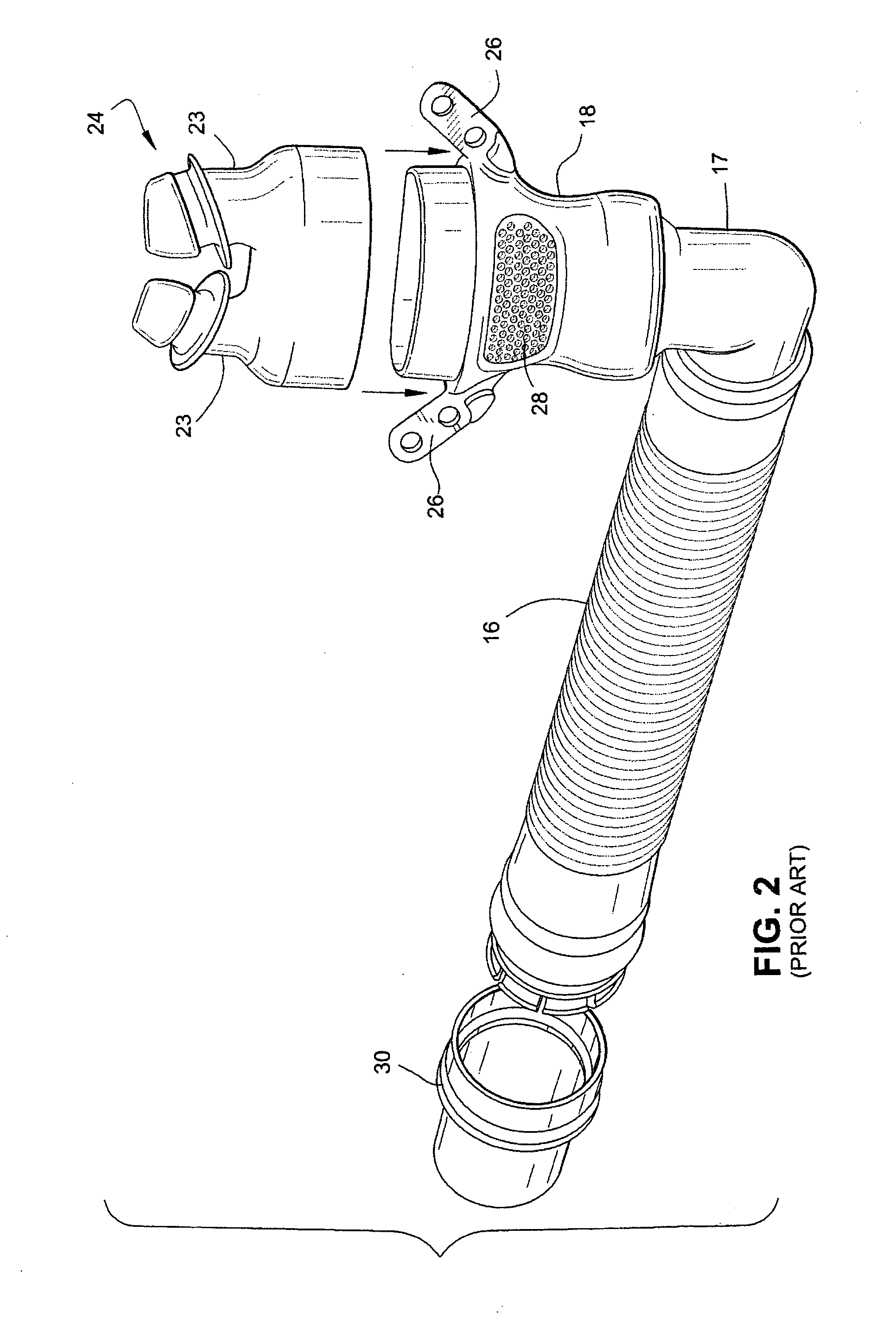

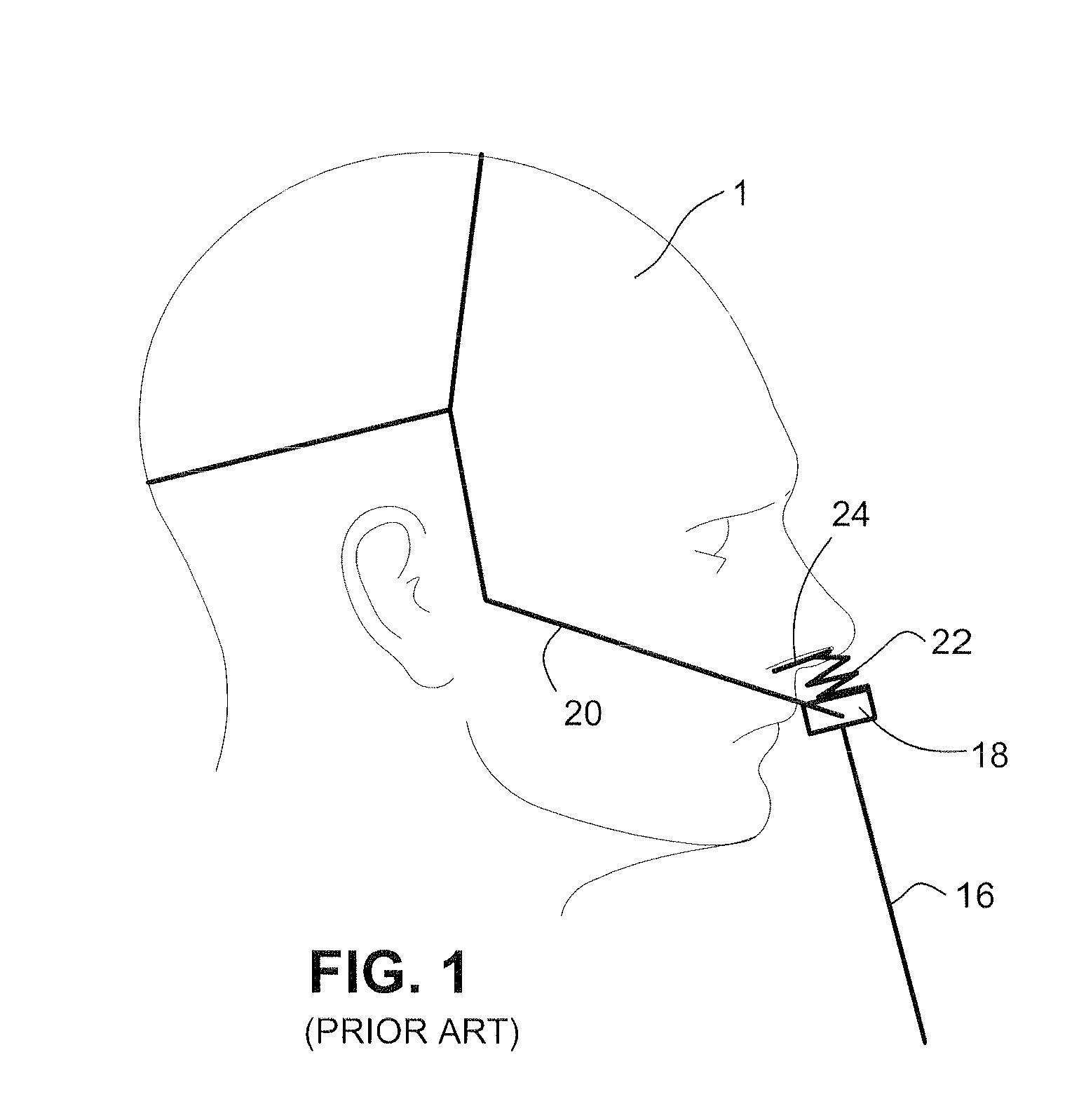

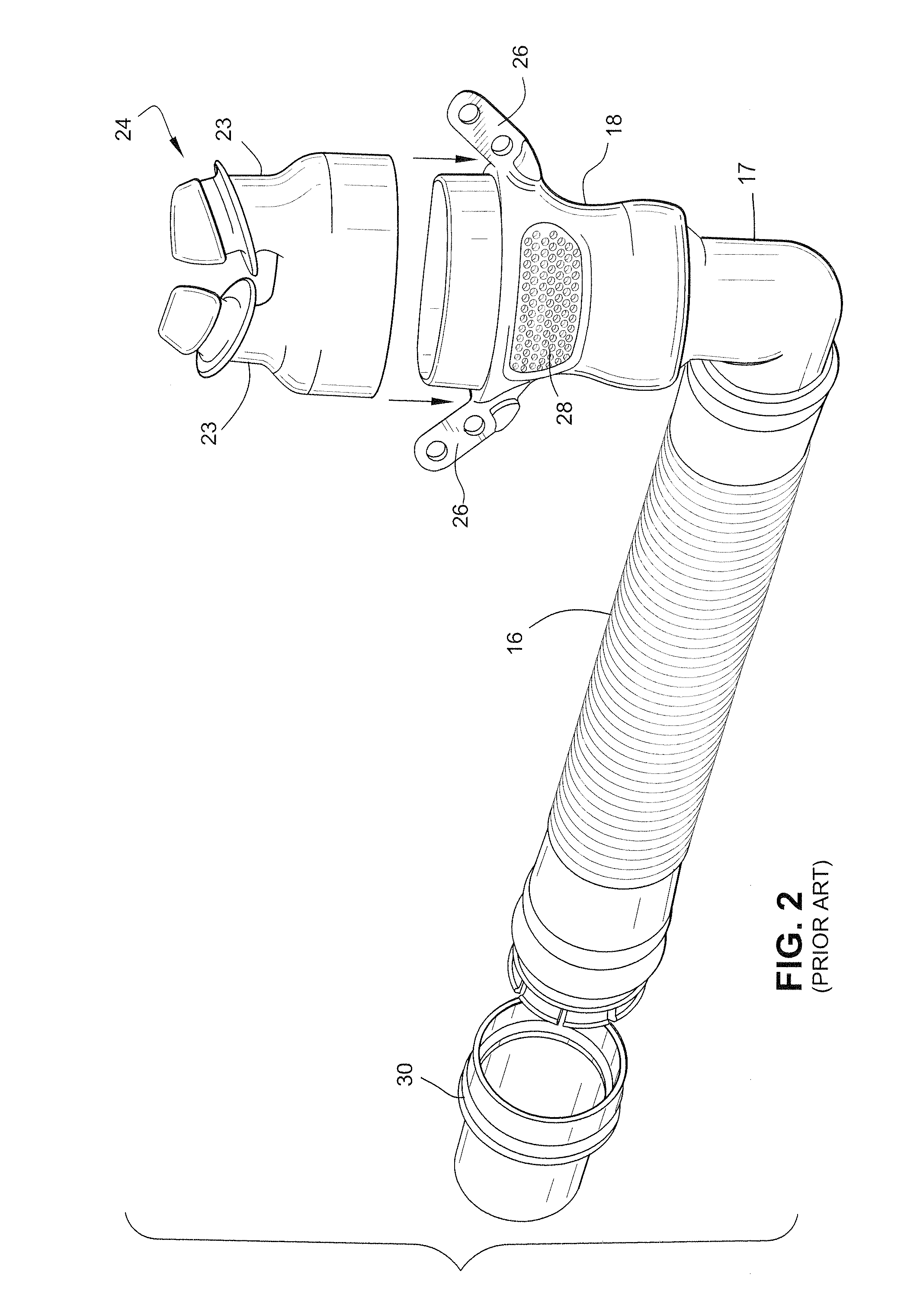

Patient interface systems

InactiveUS20100229868A1Improve manufacturabilityImprove usabilityButtonsBreathing masksEngineeringElbow joints

A headgear for positioning a patient interface structure for delivering a pressurized flow of breathable gas to the airways of a patient includes at least one flexible strap loop which is attachable to the patient interface structure by a forked region of the at least one strap loop that is mountable on the patient interface structure. The at least one strap loop positions the patient interface structure on the face of the patient. The forked region includes two forks adapted to be attached to an upper and lower portion on the patient interface structure. The two forks are connected by a bridge so that the forked region is divided into a first region and a second region, and the first region is mountable on the patient interface structure. An elbow for a patient interface system for delivering a flow of breathable gas to a patient includes a first portion having a first end configured to be connected to the patient interface system; and a second portion having a second end configured to be connected to a tube that delivers the flow of breathable gas. An outer circumferential wall includes a plurality of perpendicular steps formed therein and a plurality of vent holes are provided perpendicular to the plurality of perpendicular steps.

Owner:RESMED LTD

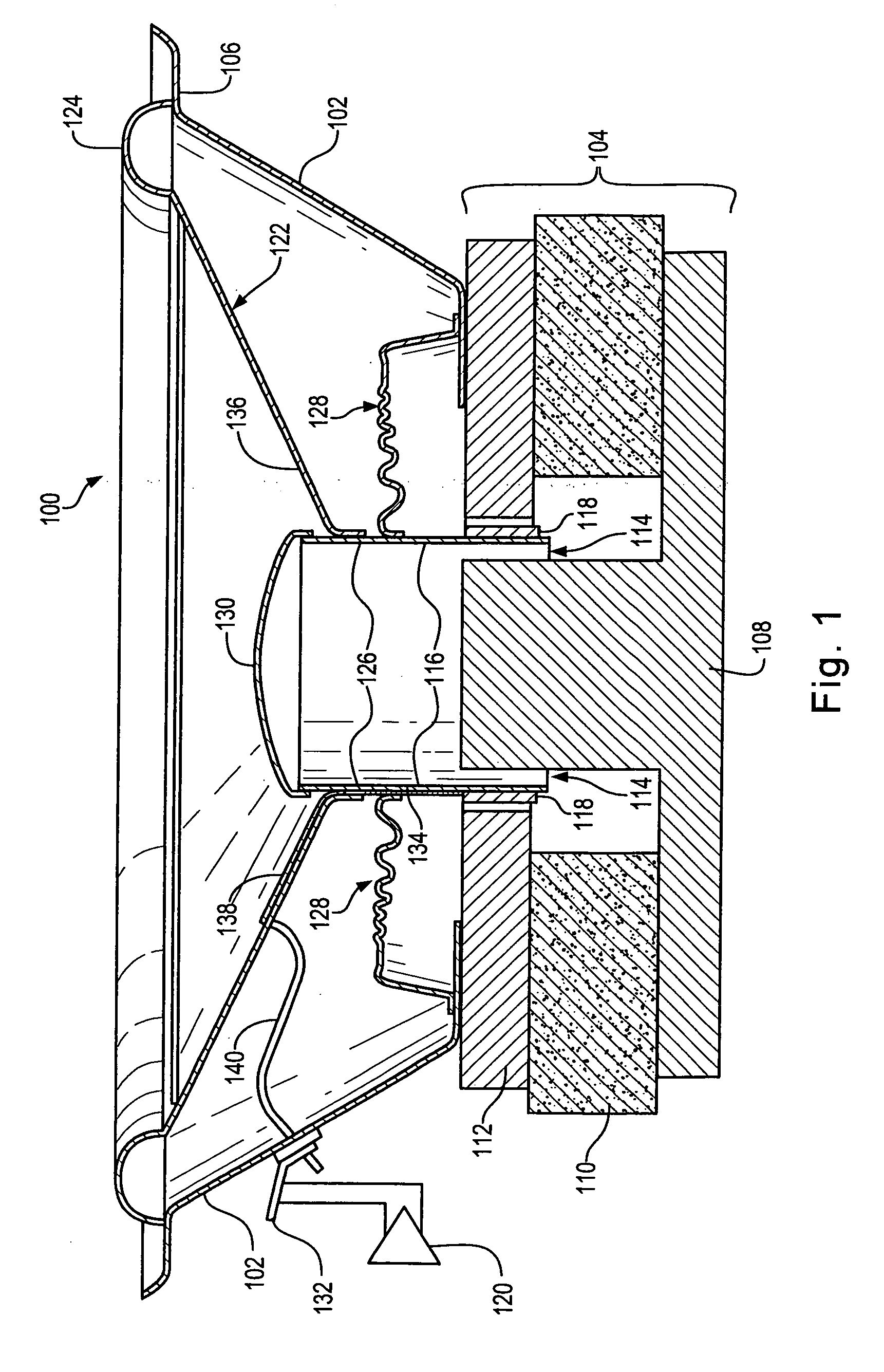

Loudspeaker plastic cone body

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

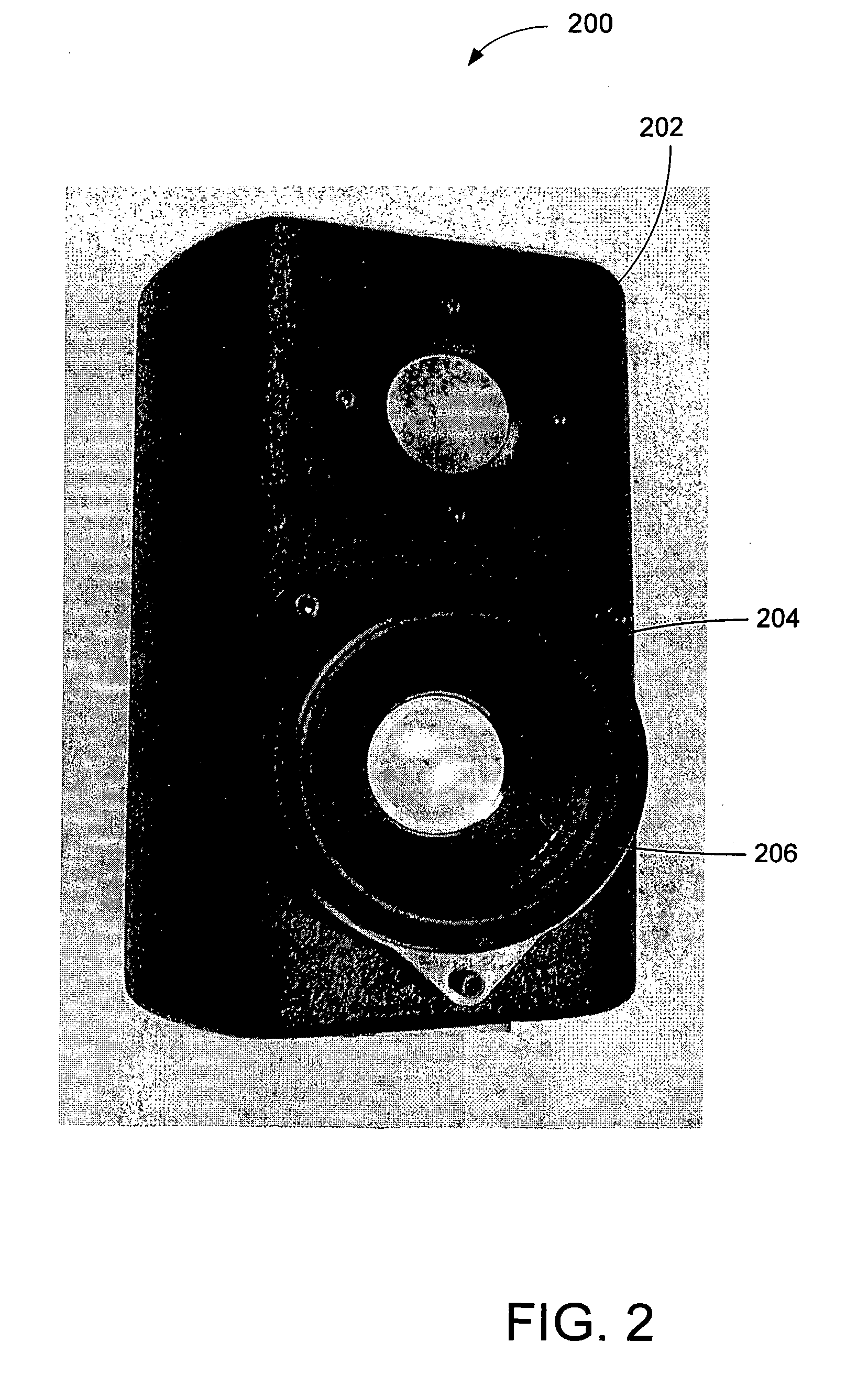

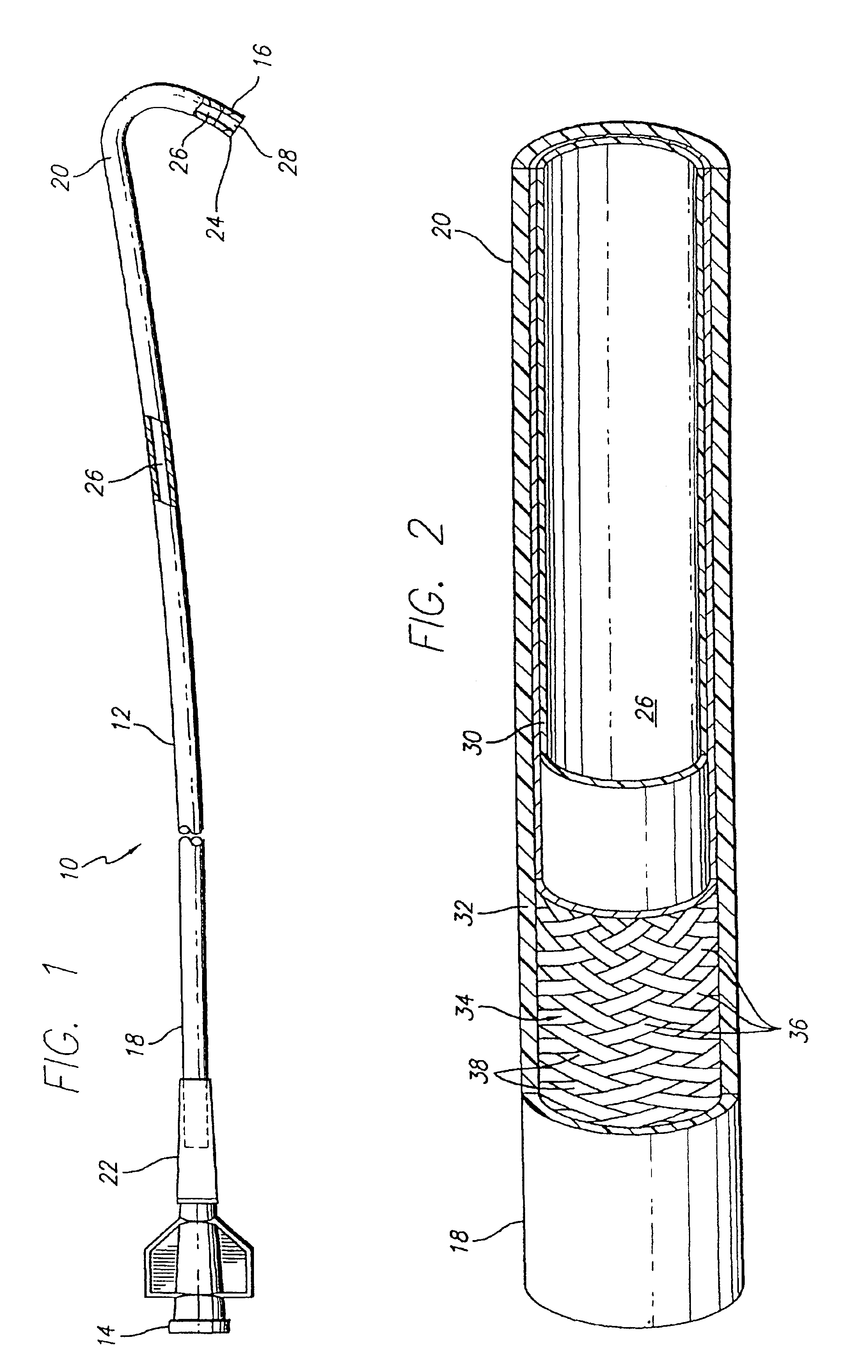

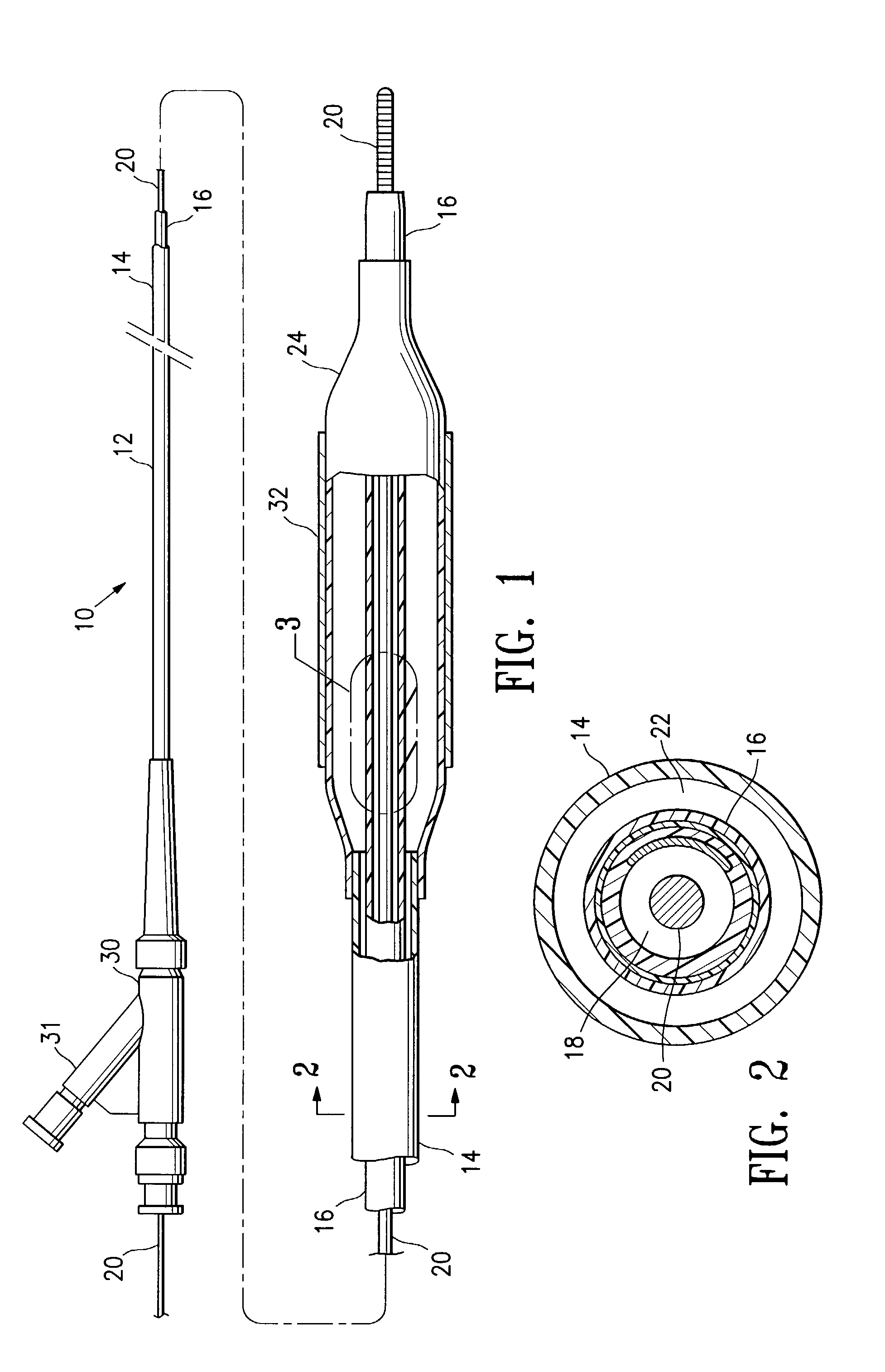

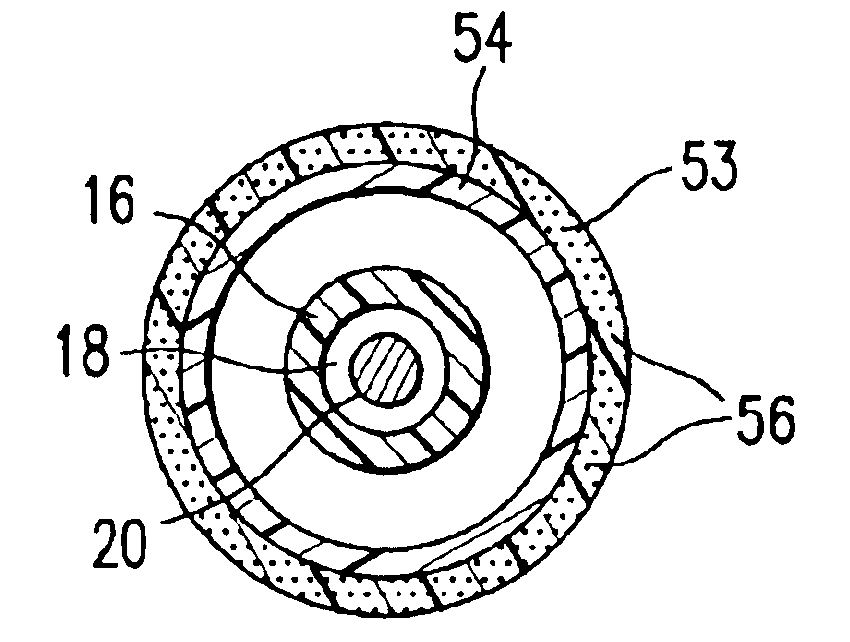

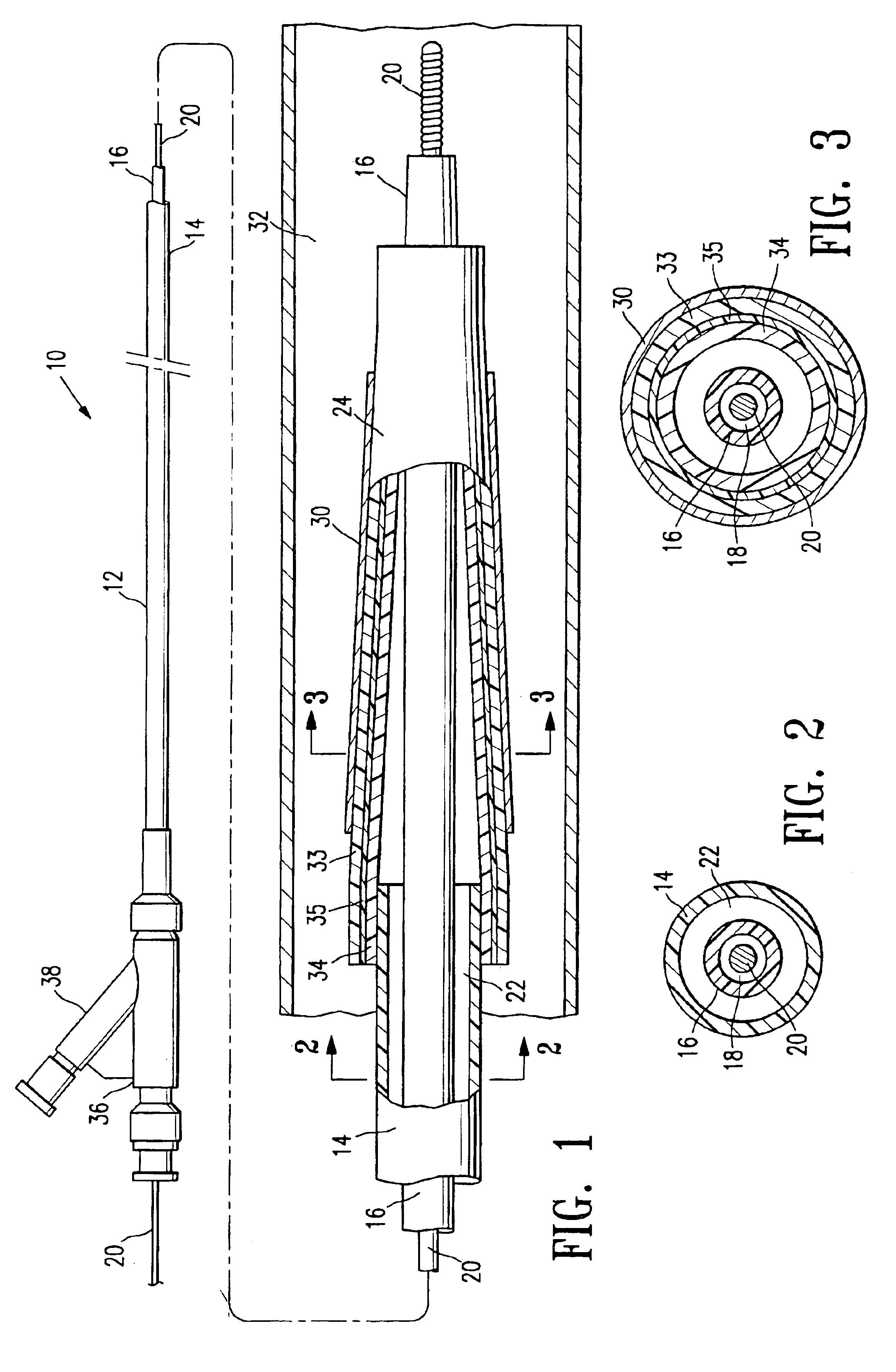

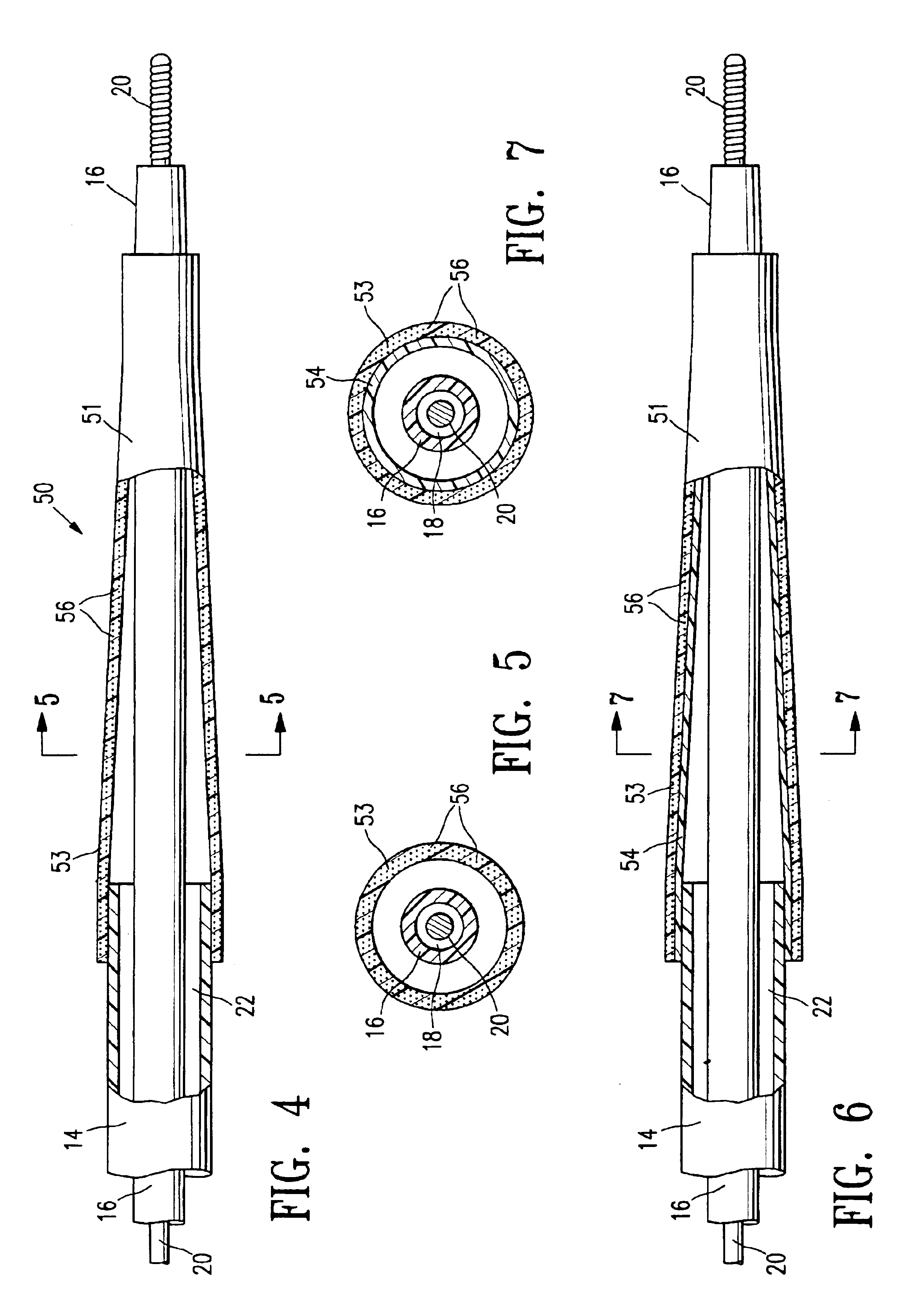

Expanded UHMWPE for guiding catheter liners and other lubricious coatings

An intraluminal catheter, such as a guiding catheter, employed for intravascular procedures and having an inner liner formed of expanded Ultra High Molecular Weight Polyethylene (UHMWPE) is disclosed. The expanded UHMWPE is microporous and has an oriented microstructure structure characterized by nodes interconnected by fibrils. The inner liner formed of expanded UHMWPE is very thin to maximize the inner lumen diameter and has excellent mechanical properties.

Owner:ABBOTT CARDIOVASCULAR

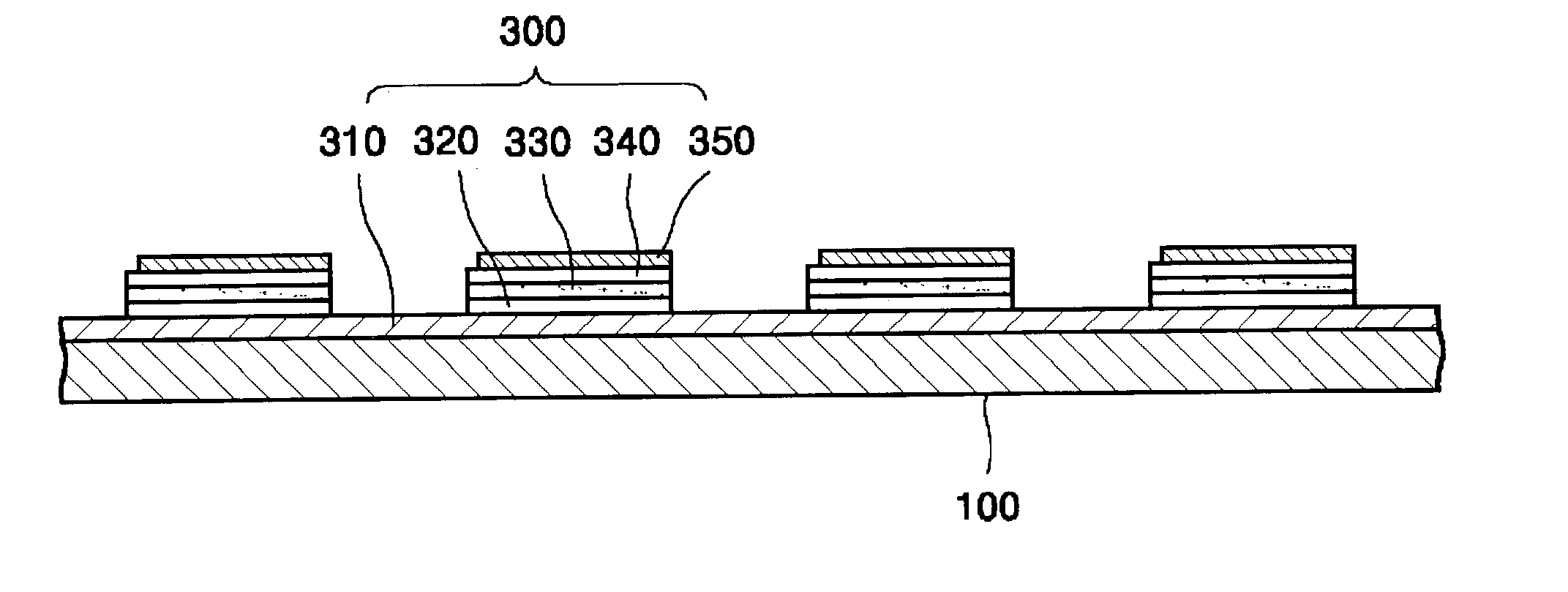

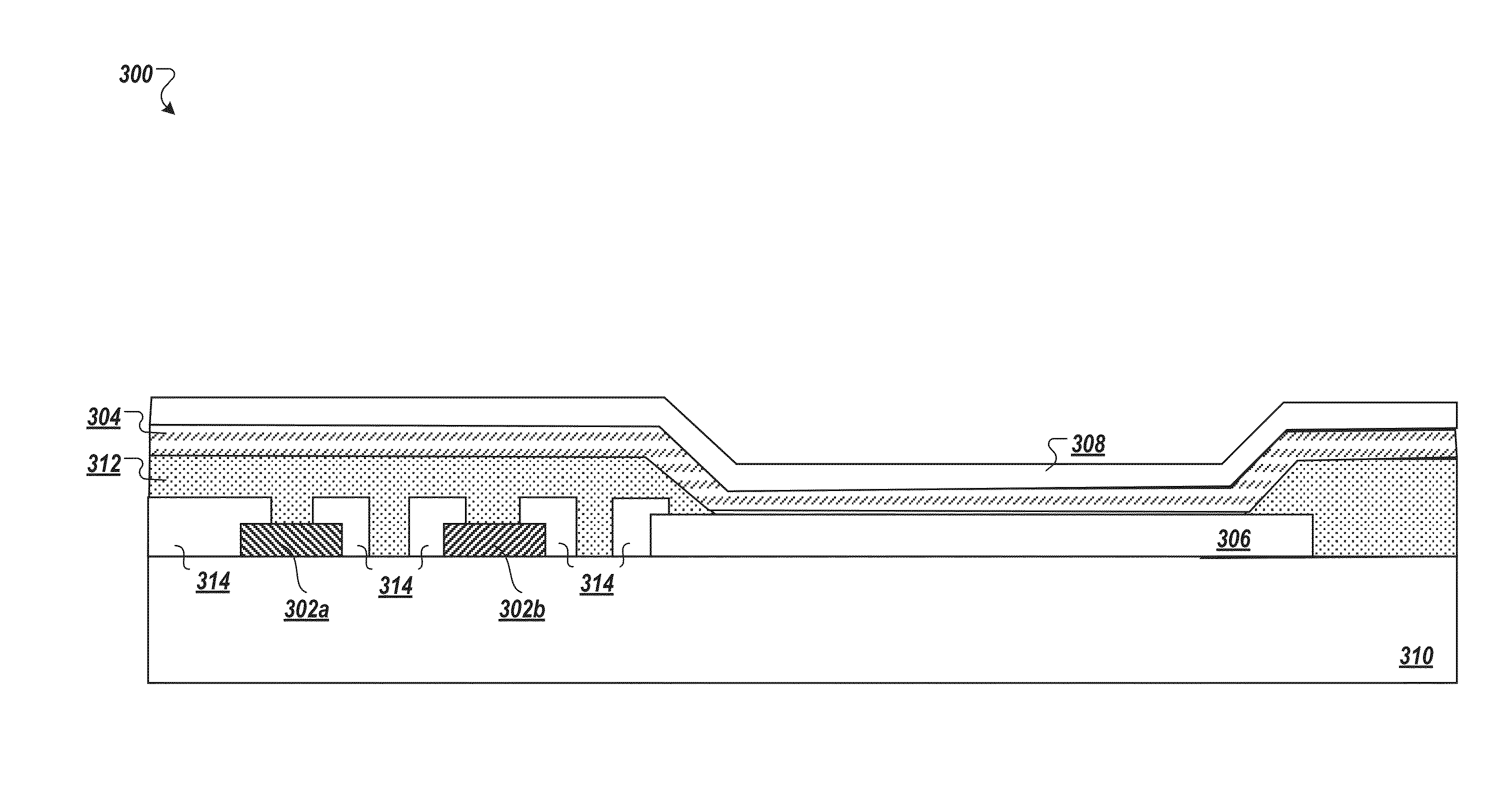

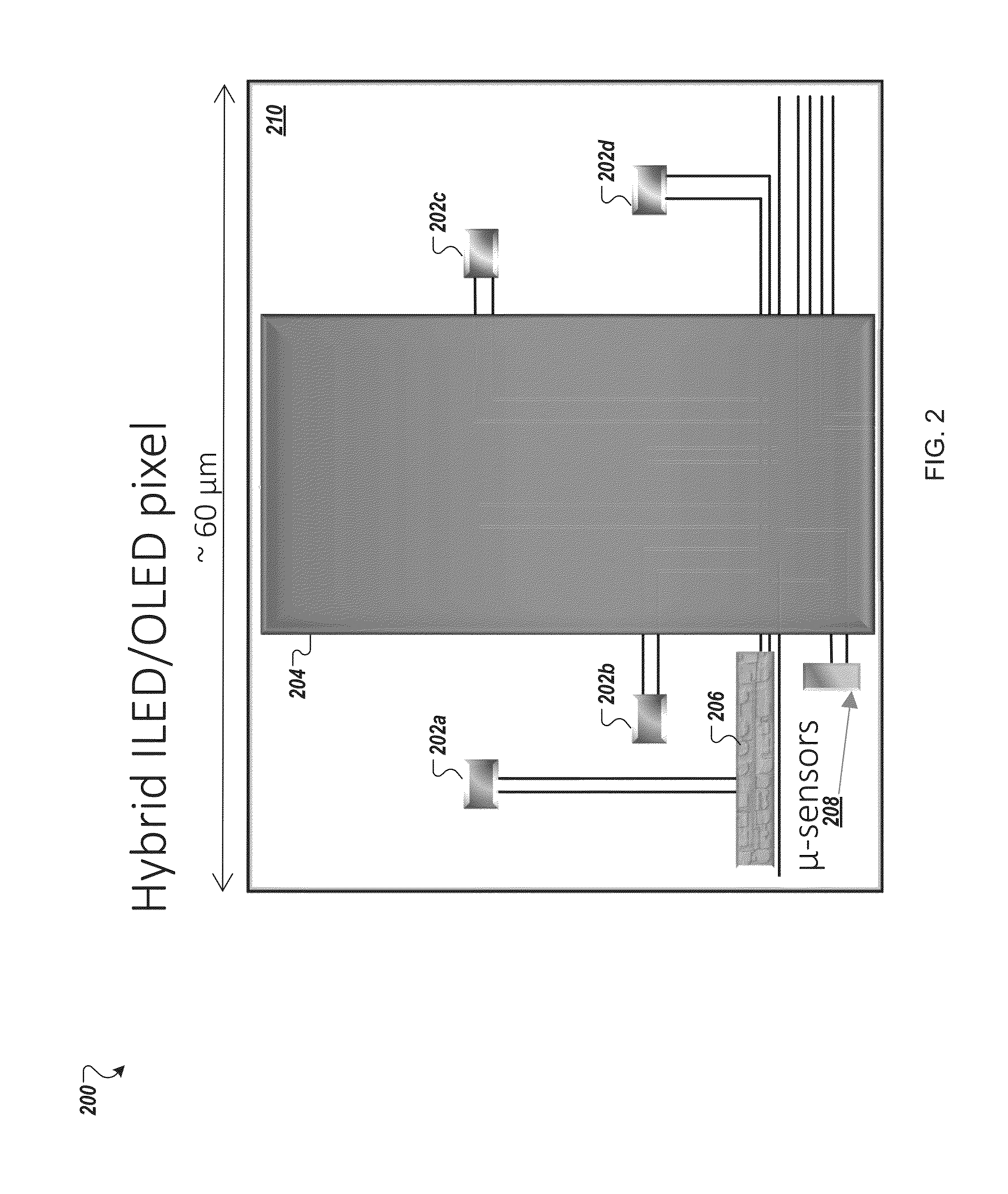

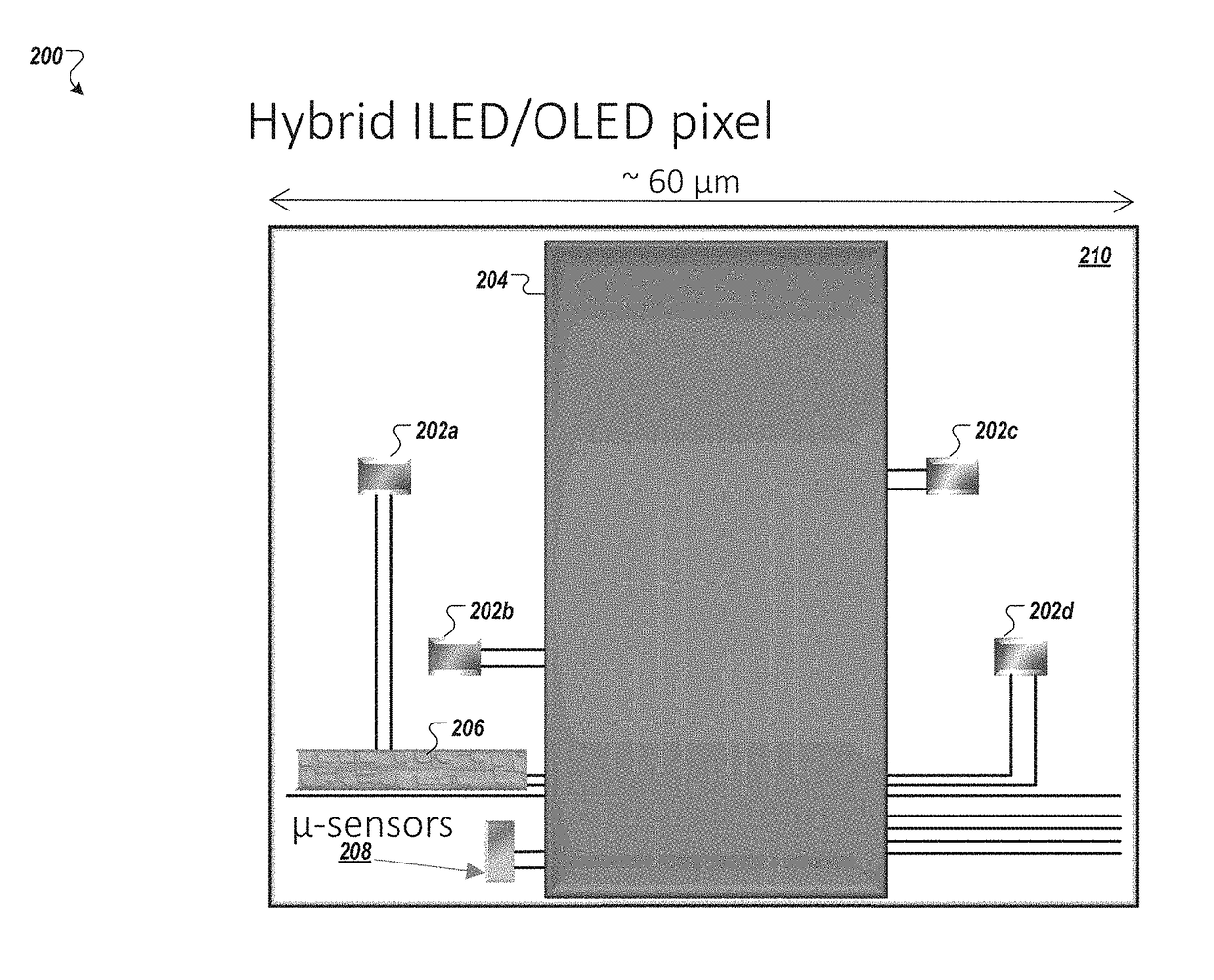

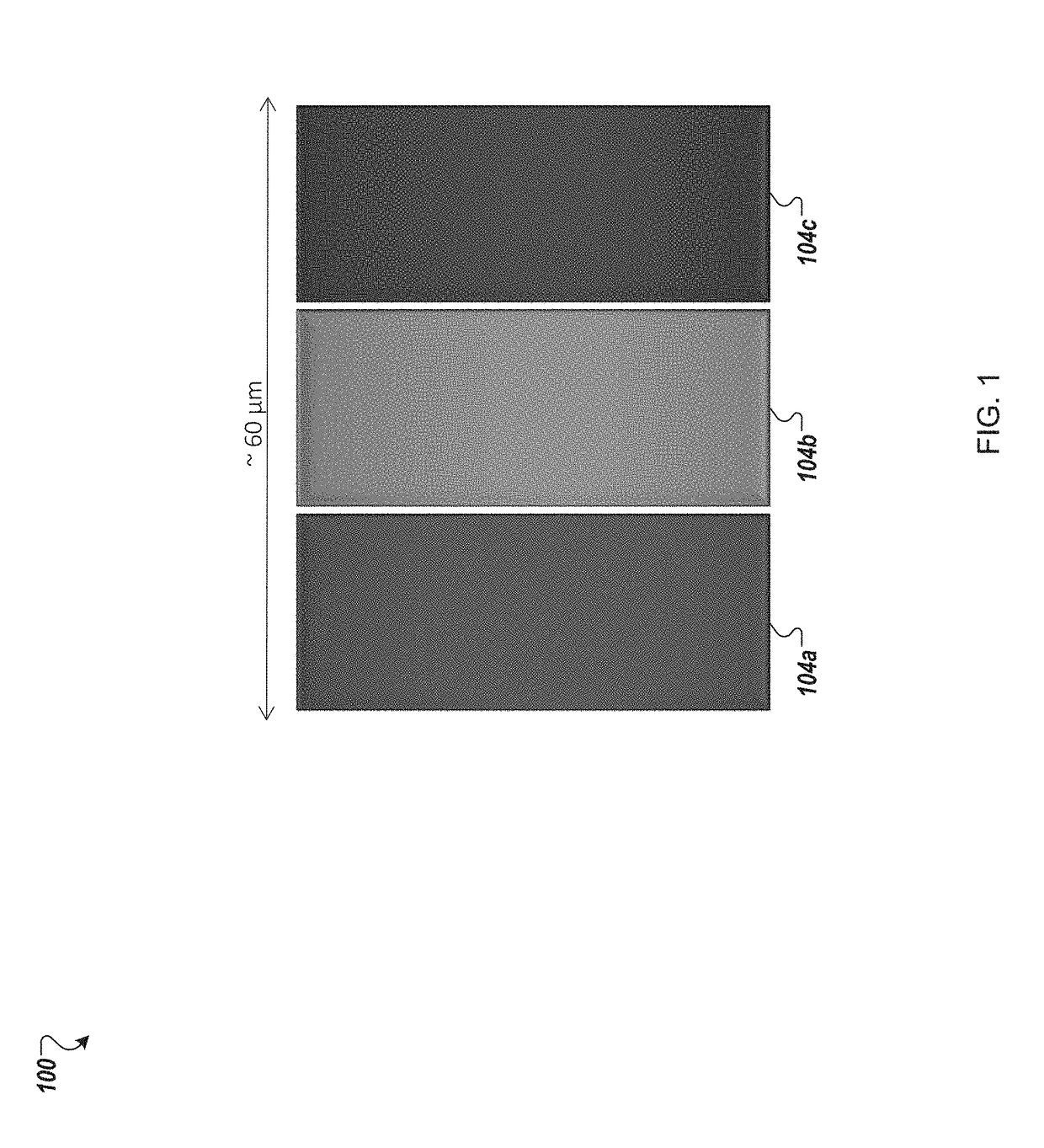

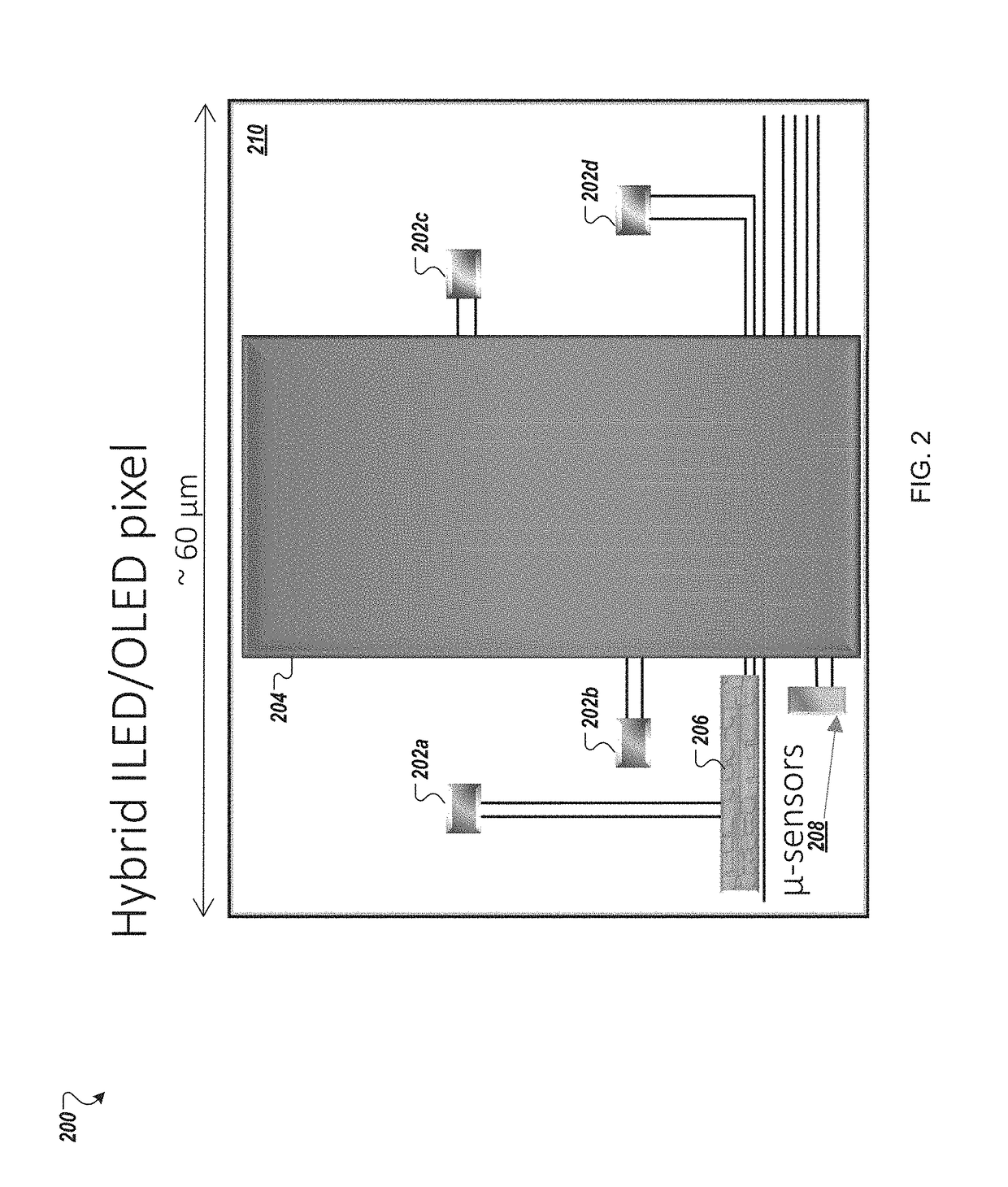

Micro assembled hybrid displays and lighting elements

ActiveUS20160064363A1Improve efficiencyImprove manufacturabilityFinal product manufactureElectroluminescent light sourcesLithographic artistDisplay device

The disclosed technology relates generally hybrid displays with pixels that include both inorganic light emitting diodes (ILEDs) and organic light emitting diodes (OLEDs). The disclosed technology provides a hybrid display that uses a mixture of ILEDs and OLEDs in each pixel. In certain embodiments, each pixel in the hybrid display includes a red ILED, a blue ILED, and a green OLED. In this instance, the OLED process would not require a high resolution shadow mask, thereby enhancing the manufacturability of OLEDs for larger format displays. Additionally, the OLED process in this example would not require any fine lithography. The OLED subpixel (e.g., green subpixel) can be larger and the ILEDs can be small (e.g., micro-red and micro-blue ILEDs). The use of small ILEDs allows for other functions to be added to the pixel, such as micro sensors and micro integrated circuits.

Owner:X DISPLAY CO TECH LTD

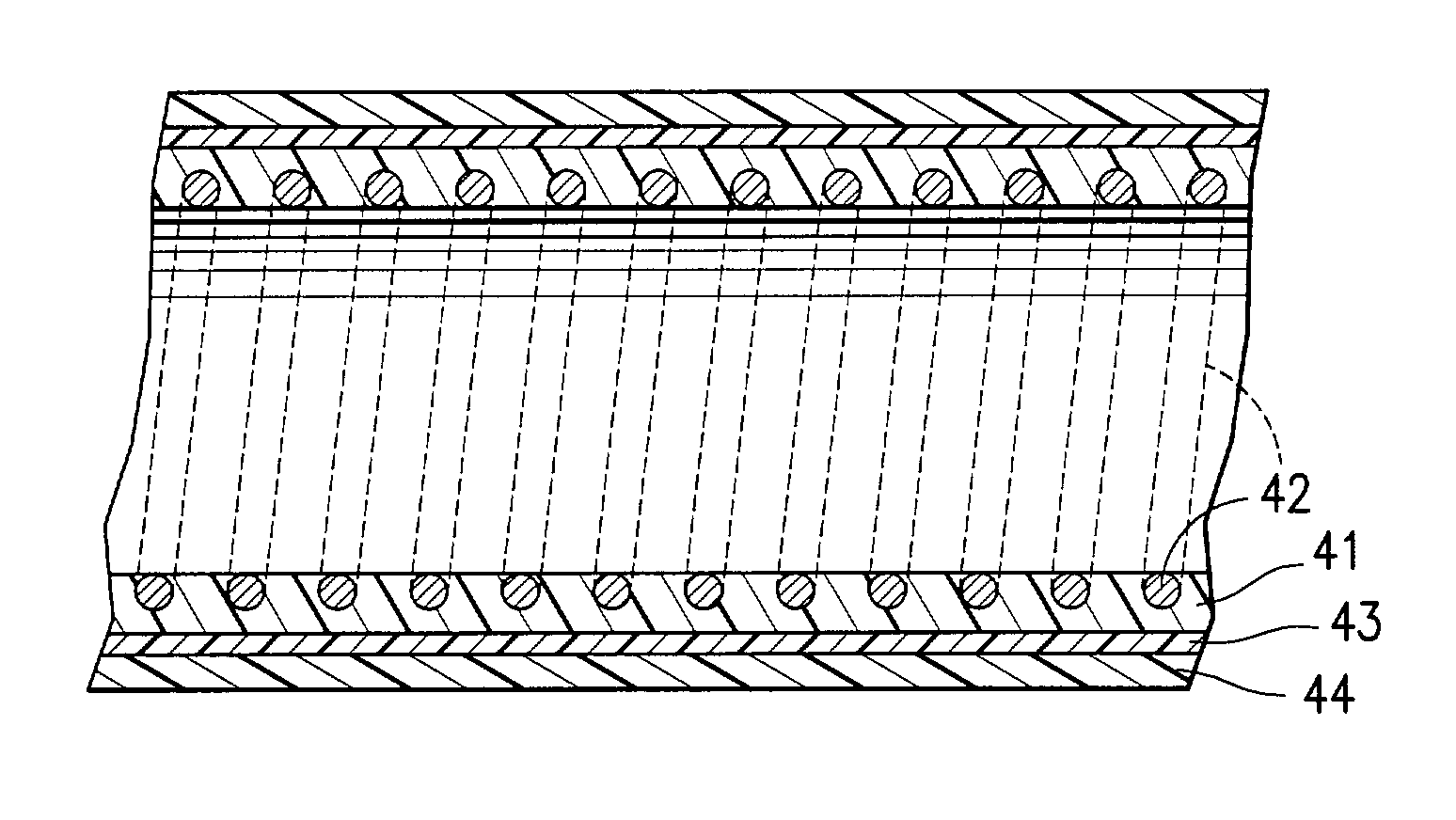

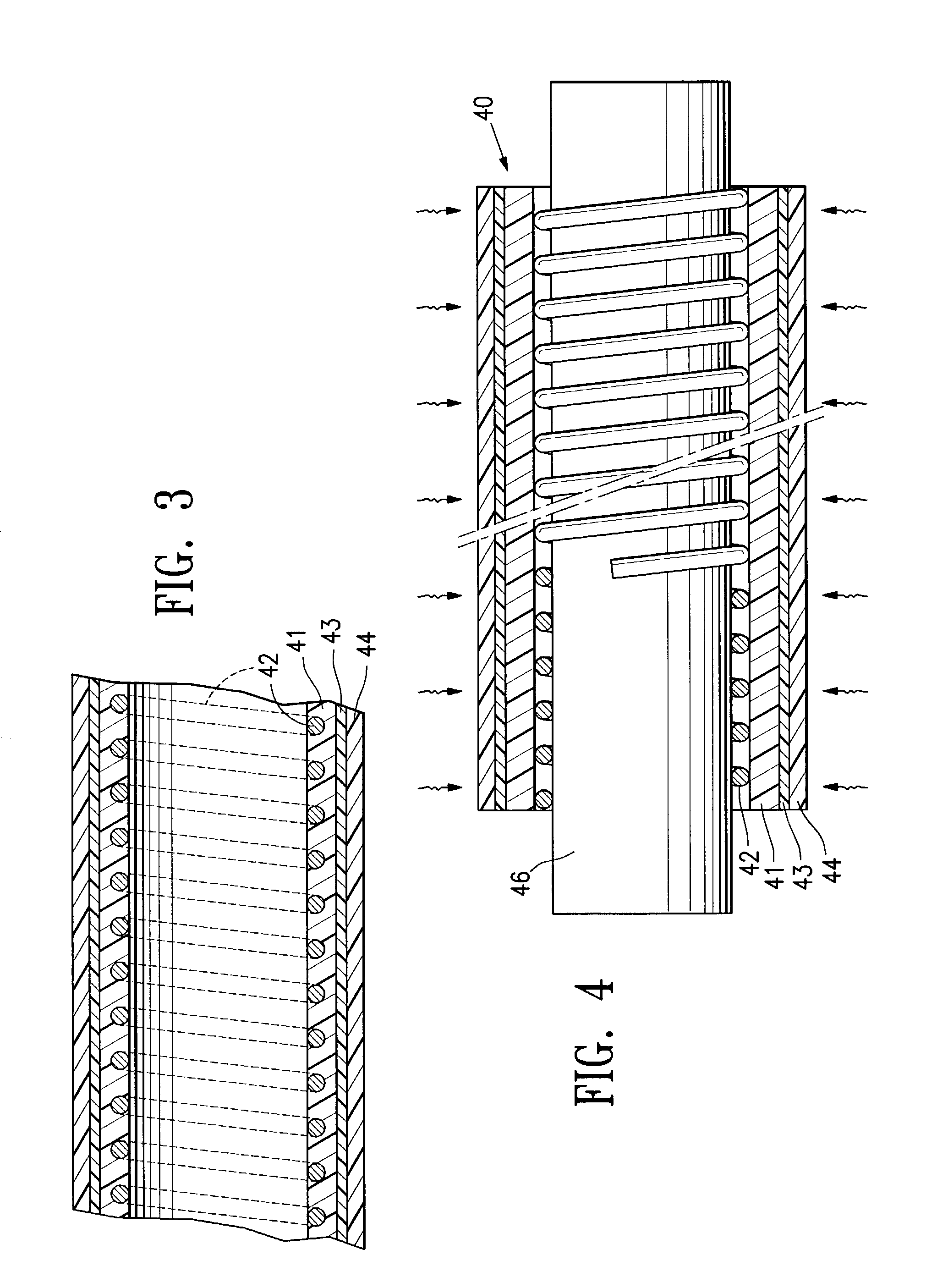

Coil reinforced multilayered inner tubular member for a balloon catheter

A catheter having an elongated shaft formed of a polymeric tubular member with at least a section having a lubricious inner layer defining the guidewire lumen, a coiled support member at least partially embedded in the lubricious inner layer, and an outer layer on an outer surface of at least a distal portion of the lubricious inner layer. In a presently preferred embodiment, the coil supported polymeric tubular member forms an inner tubular member of a balloon catheter.

Owner:ABBOTT CARDIOVASCULAR

Two-compartment container

InactiveUS6513650B2Improve manufacturabilityReduce leakageClosure with auxillary devicesPharmaceutical containersEngineeringMechanical engineering

A two-compartment container in which the first compartment has an upper layer and a lower layer and contains a first component that is to be added to the second compartment. Above the first compartment is a dome that is bowed upward and is flexible. Attached to the dome is a cutting means. Depressing the dome by pushing downward on it lowers the cutting means so that both the upper and lower layer of the first compartment are cut by the cutting means, releasing the first component into the second compartment. The cutting means may be a simple puncturer, or in the case where the second compartment comprises a beverage container or the like, the cutting means may be part of a tubular wall surrounding the opening through which someone can drink the beverage.

Owner:BIOGAIA AB NEW NAME

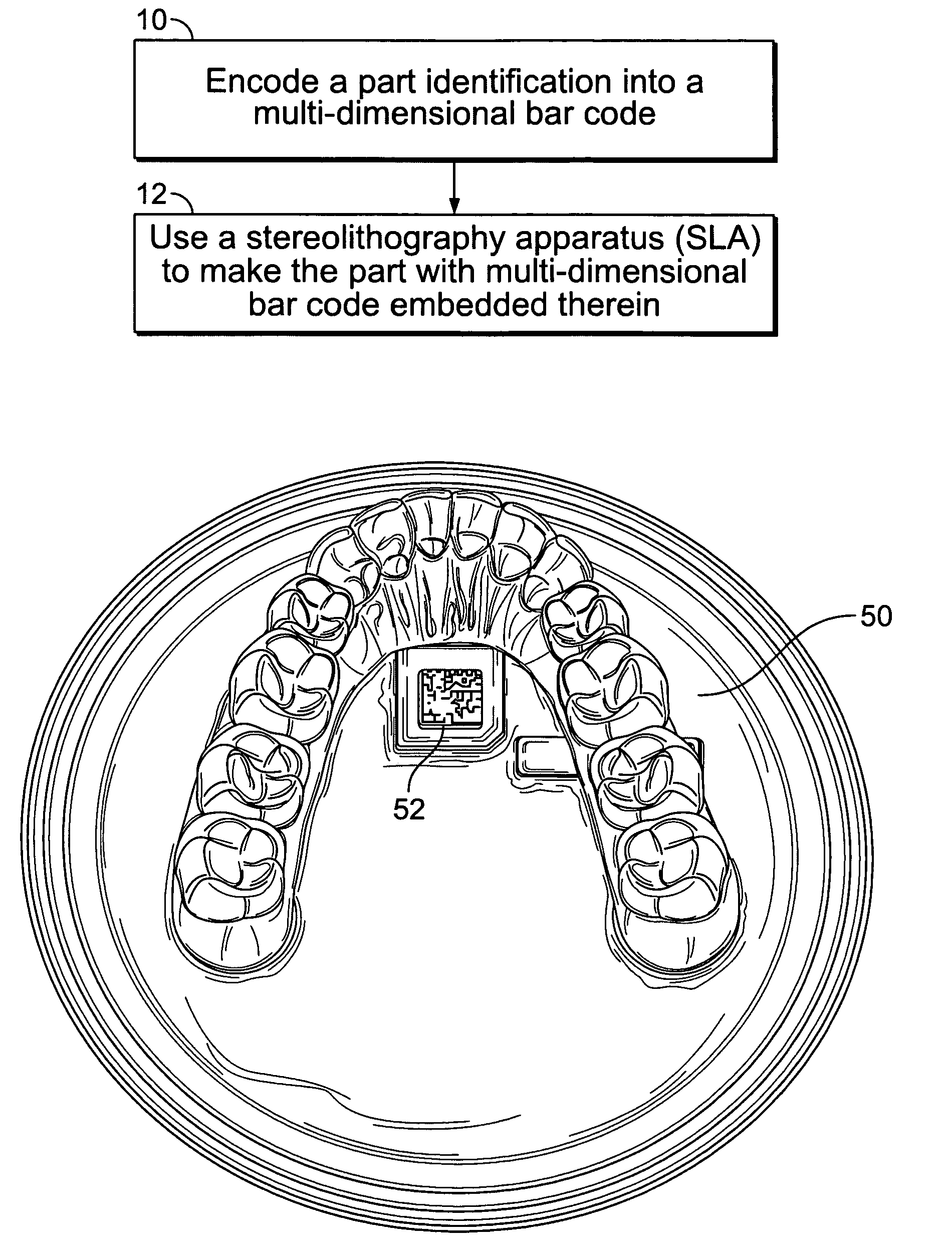

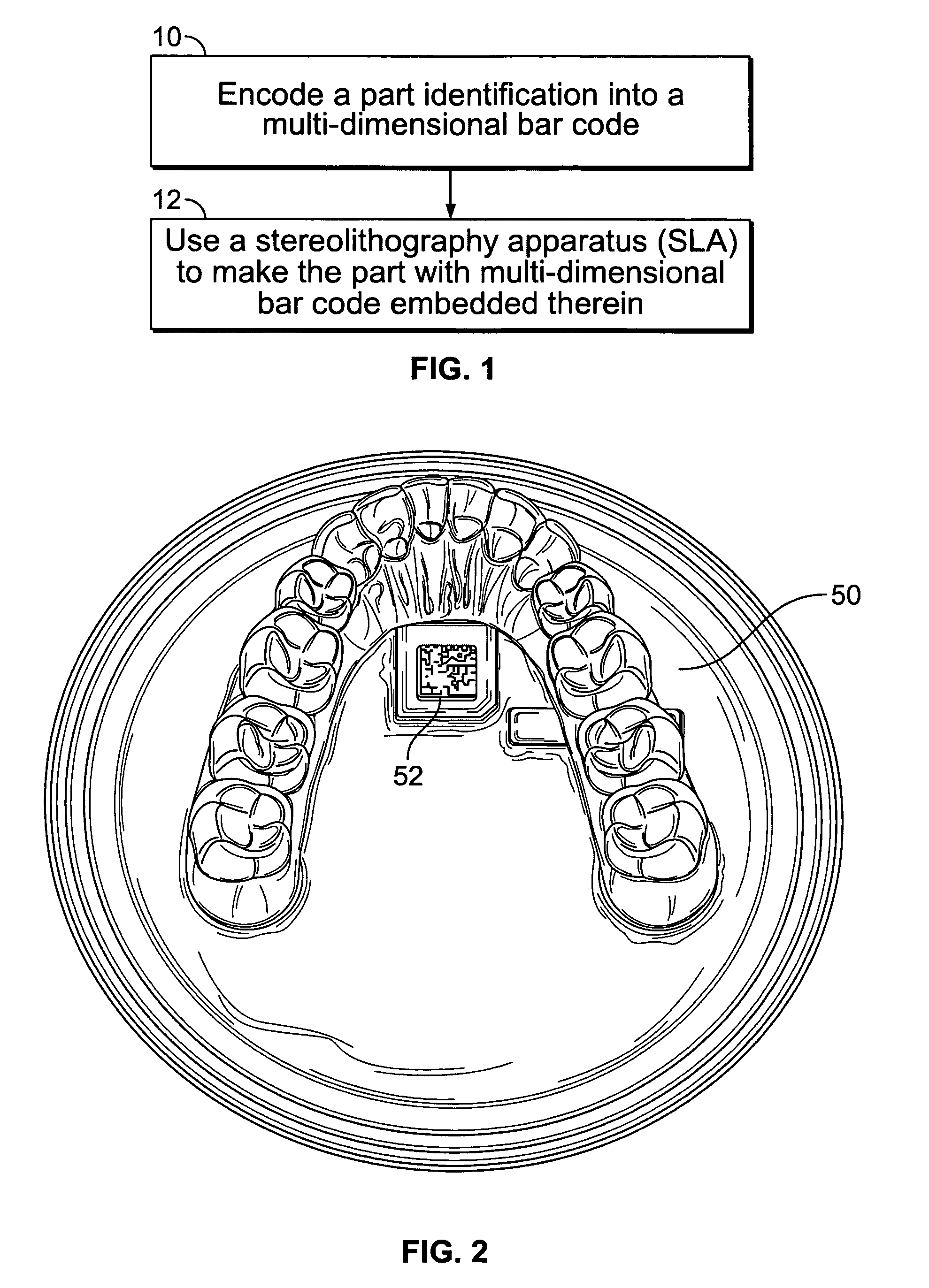

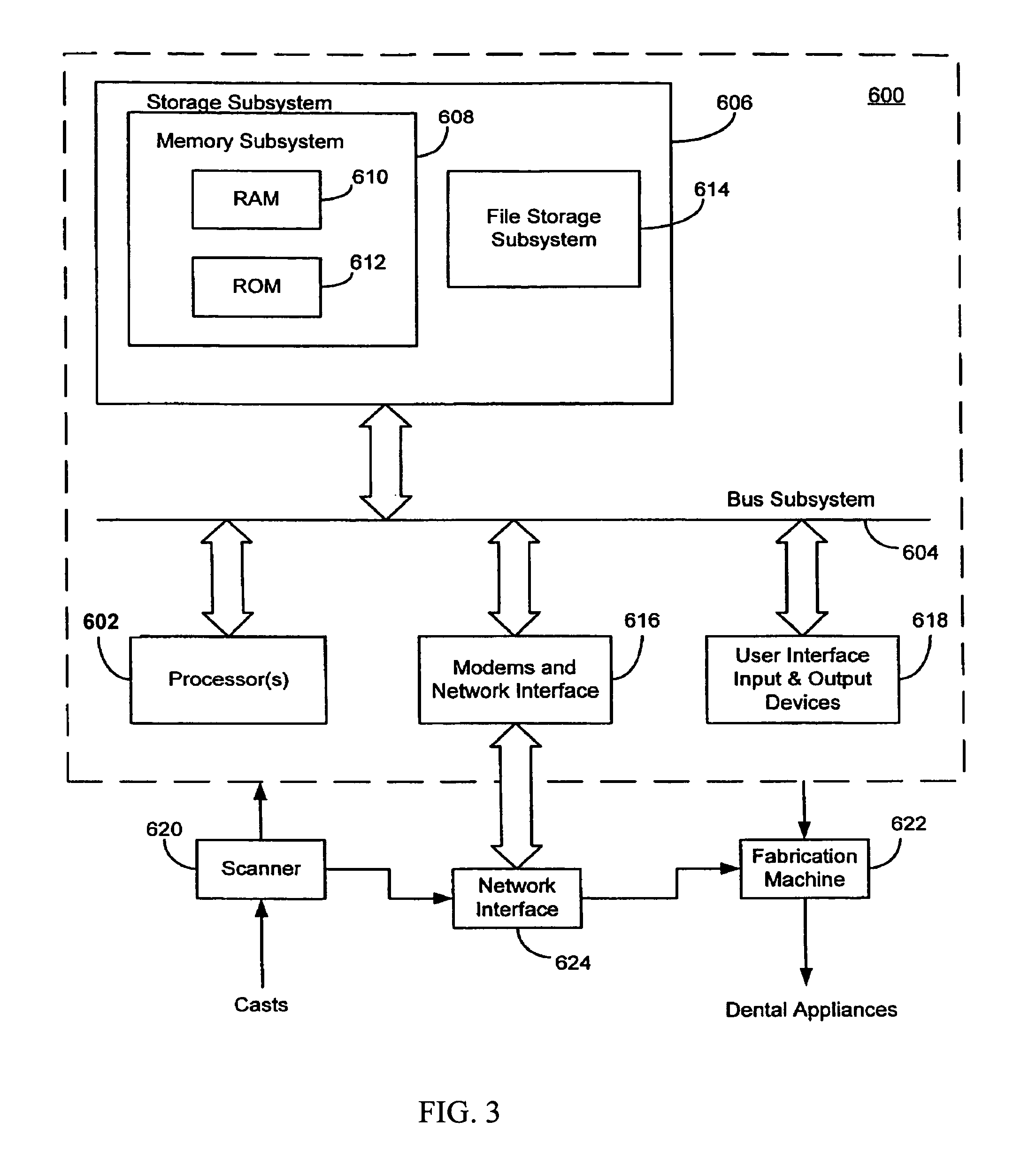

Identification of units in customized production

ActiveUS6976627B1Effective estimateImprove manufacturabilityAdditive manufacturing apparatusCo-operative working arrangementsMass customizationBarcode

Systems and methods are disclosed for identifying a mass-customized part by encoding a part identification into a multi-dimensional bar code; and using a stereolithography apparatus (SLA) to make the part with multi-dimensional bar code embedded therein.

Owner:ALIGN TECH

Micro assembled hybrid displays and lighting elements

ActiveUS9716082B2Improve efficiencyImprove manufacturabilityFinal product manufactureElectroluminescent light sourcesDisplay deviceLight-emitting diode

The disclosed technology relates generally hybrid displays with pixels that include both inorganic light emitting diodes (ILEDs) and organic light emitting diodes (OLEDs). The disclosed technology provides a hybrid display that uses a mixture of ILEDs and OLEDs in each pixel. In certain embodiments, each pixel in the hybrid display includes a red ILED, a blue ILED, and a green OLED. In this instance, the OLED process would not require a high resolution shadow mask, thereby enhancing the manufacturability of OLEDs for larger format displays. Additionally, the OLED process in this example would not require any fine lithography. The OLED subpixel (e.g., green subpixel) can be larger and the ILEDs can be small (e.g., micro-red and micro-blue ILEDs). The use of small ILEDs allows for other functions to be added to the pixel, such as micro sensors and micro integrated circuits.

Owner:X DISPLAY CO TECH LTD

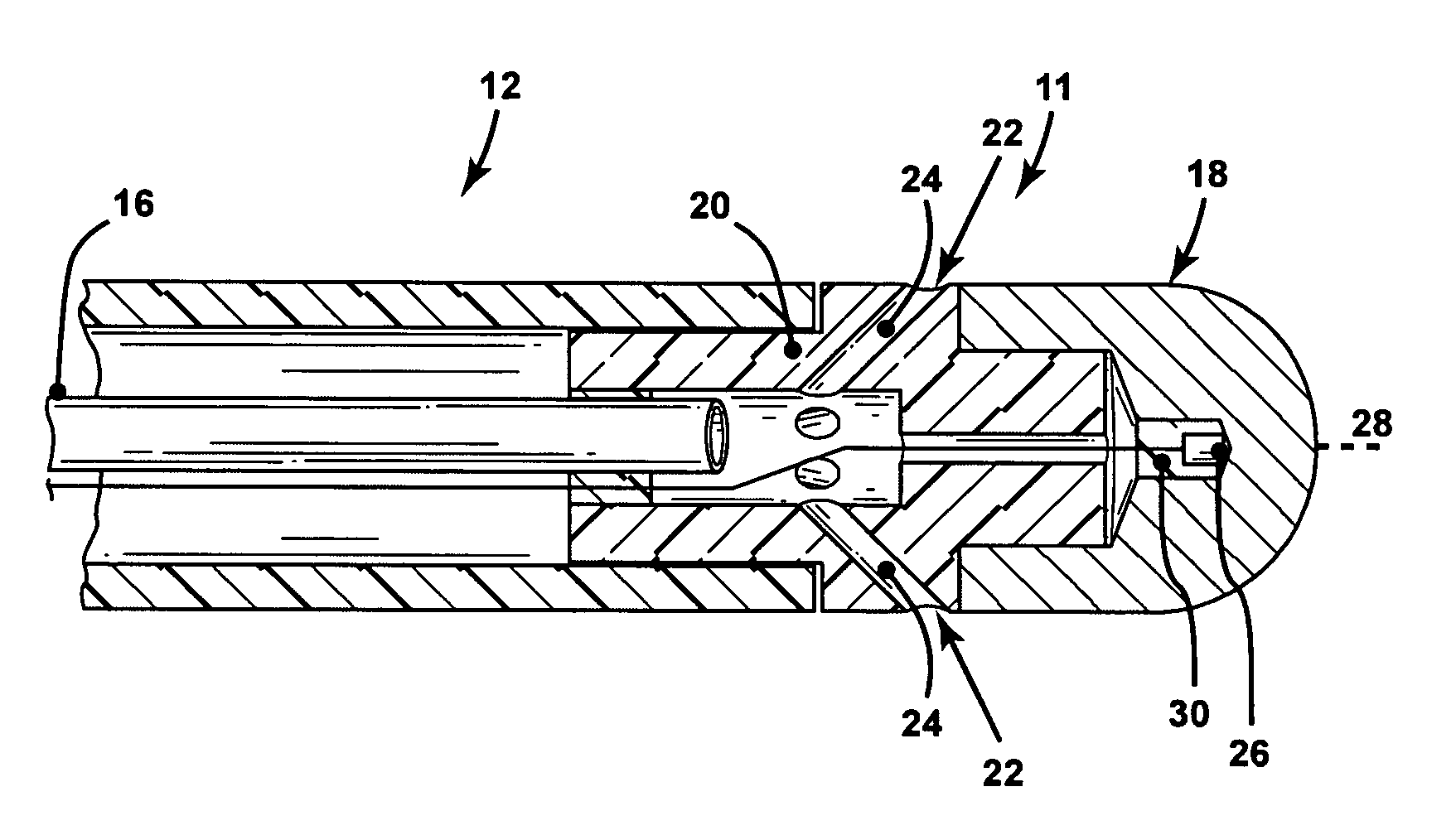

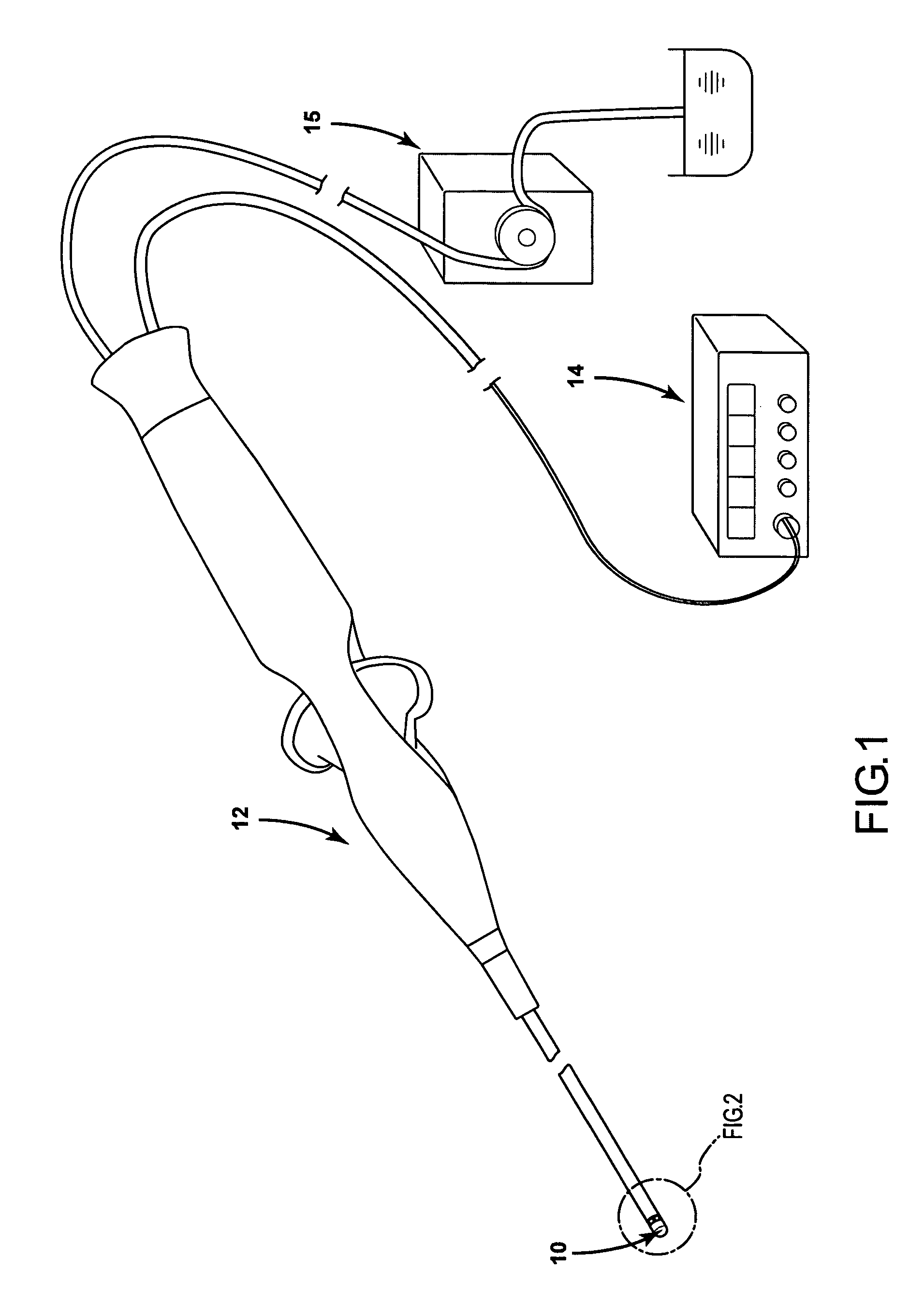

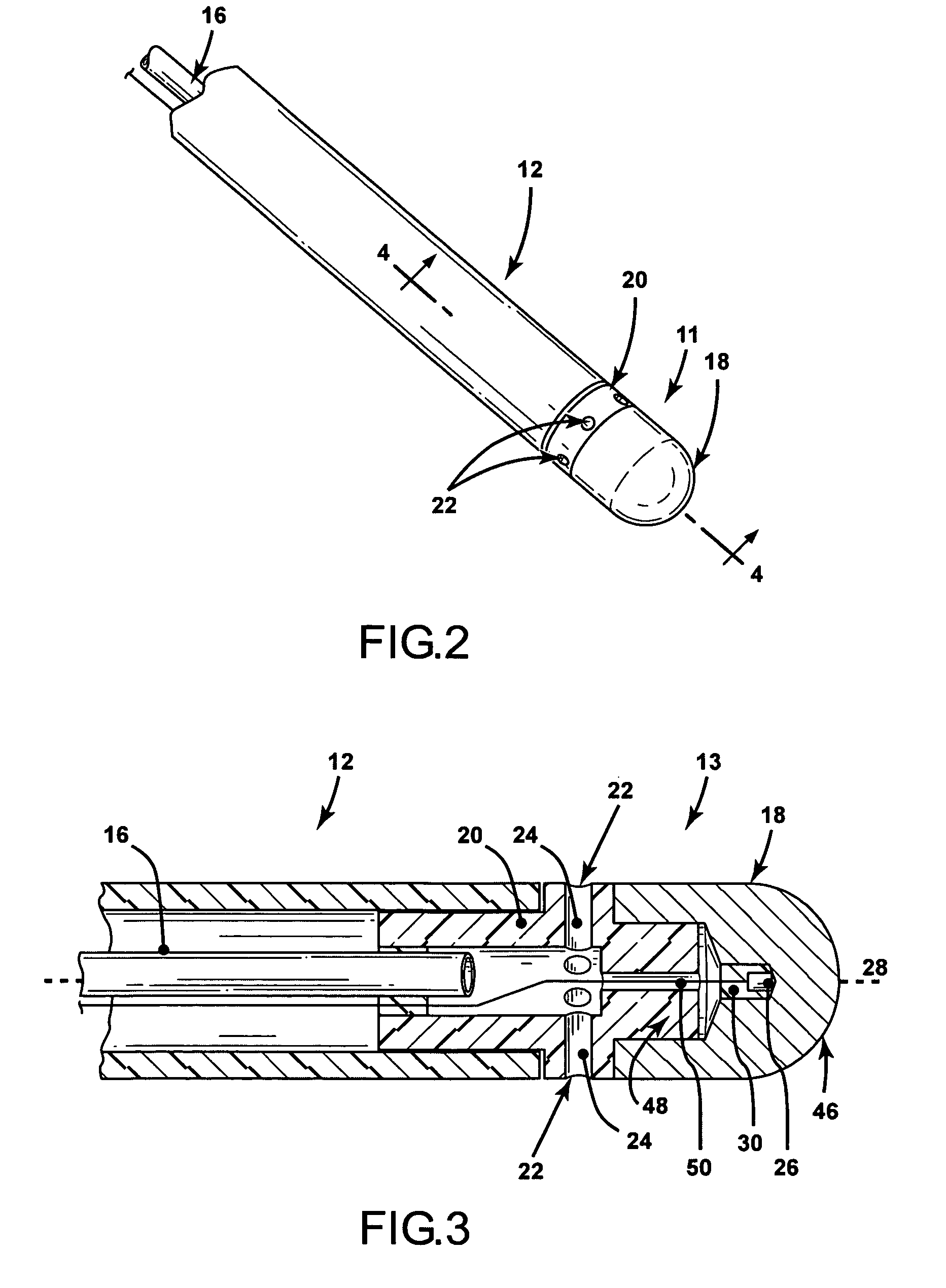

Ablation electrode assembly and methods for improved control of temperature and minimization of coagulation and tissue damage

ActiveUS7857810B2Easy to monitorEasy temperature controlSurgical instruments for heatingSurgical instruments for irrigation of substancesTemperature controlDistal portion

The present invention pertains to multiple piece irrigated ablation electrode assemblies wherein the irrigation channels are insulated or separated from at least one temperature sensing mechanism within the distal portion of the electrode assembly. The present invention further pertains to methods for improved assembly and accurate measurement and control of the electrode temperatures while effectively irrigating the device and target areas.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

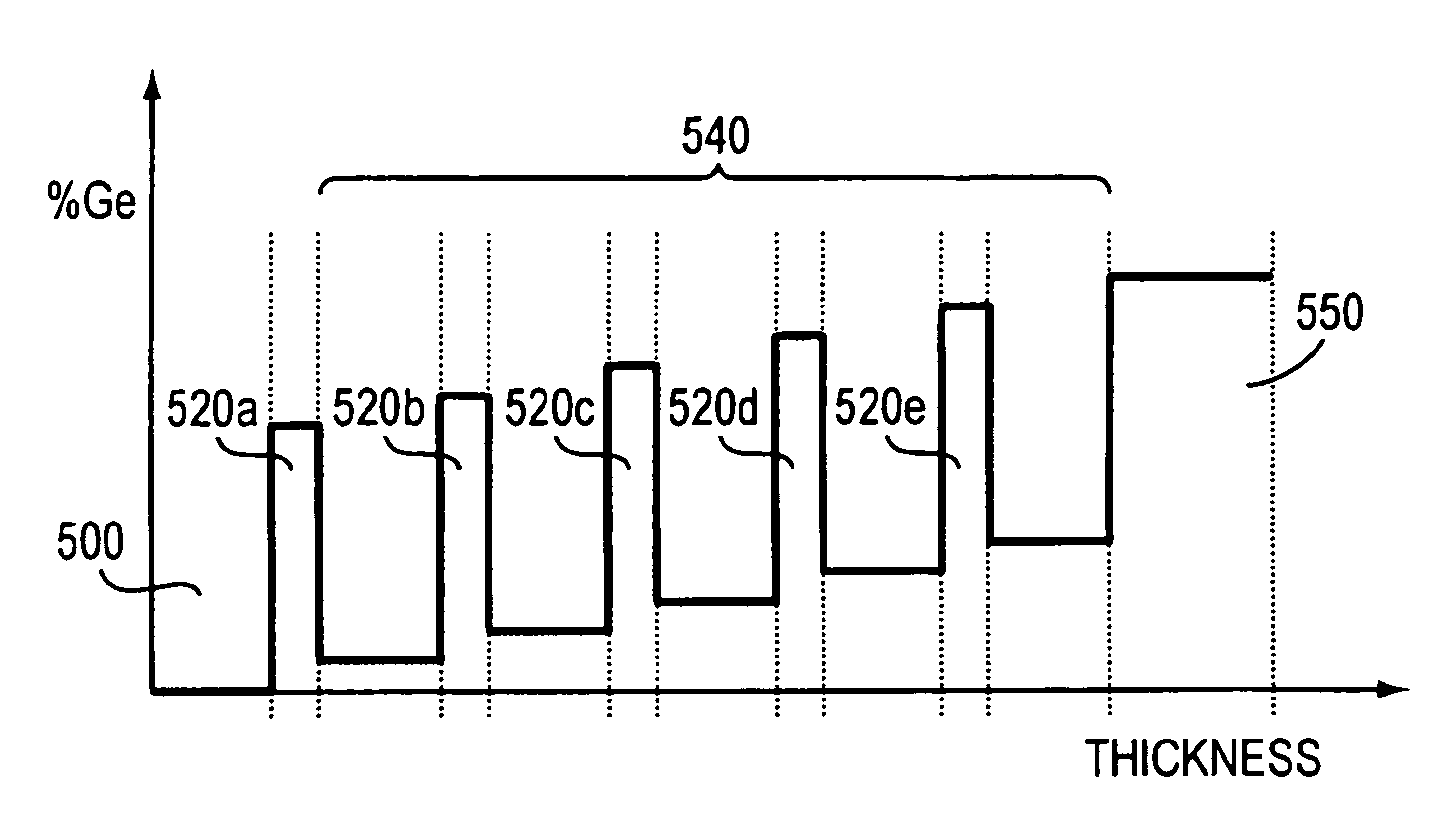

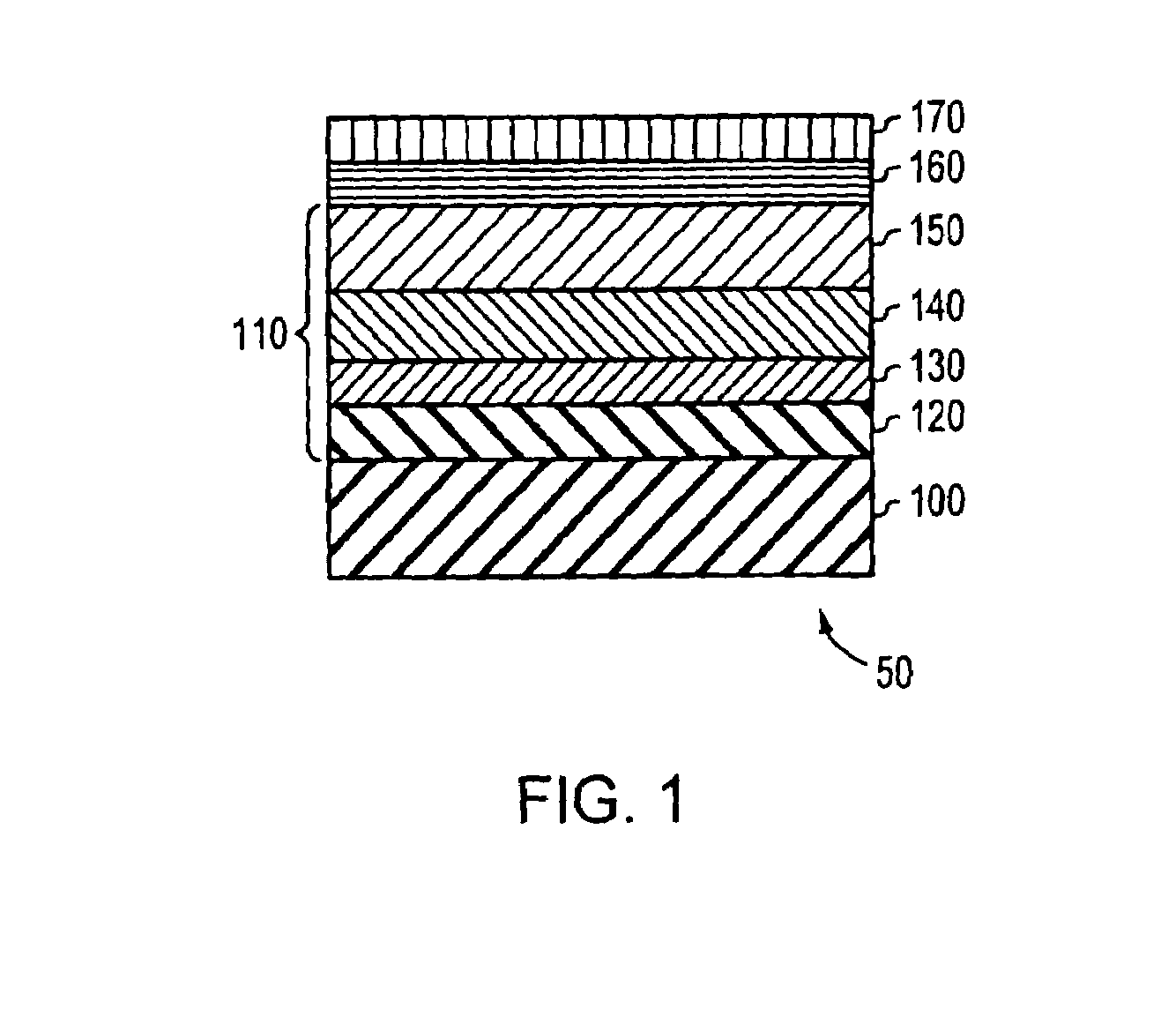

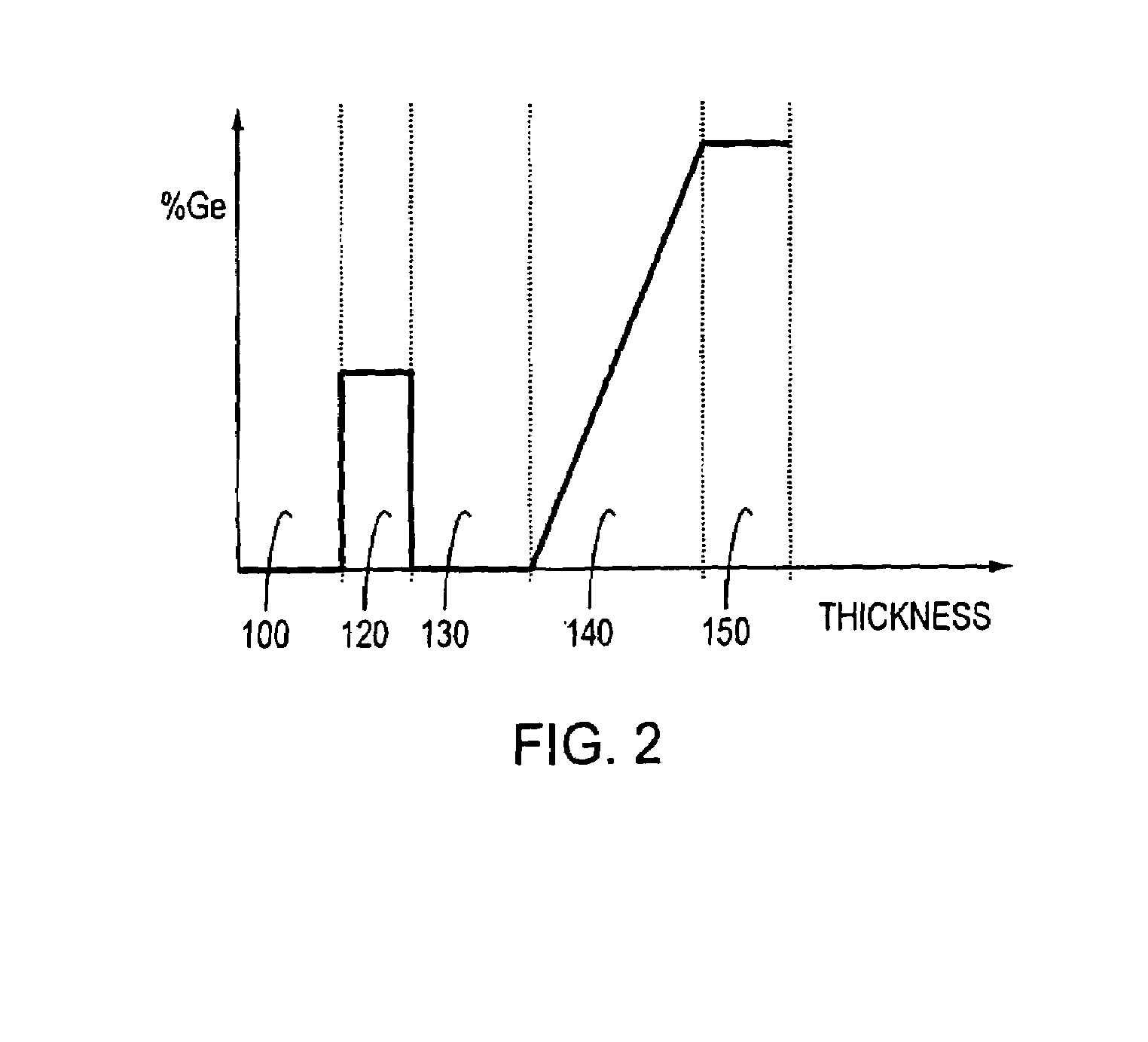

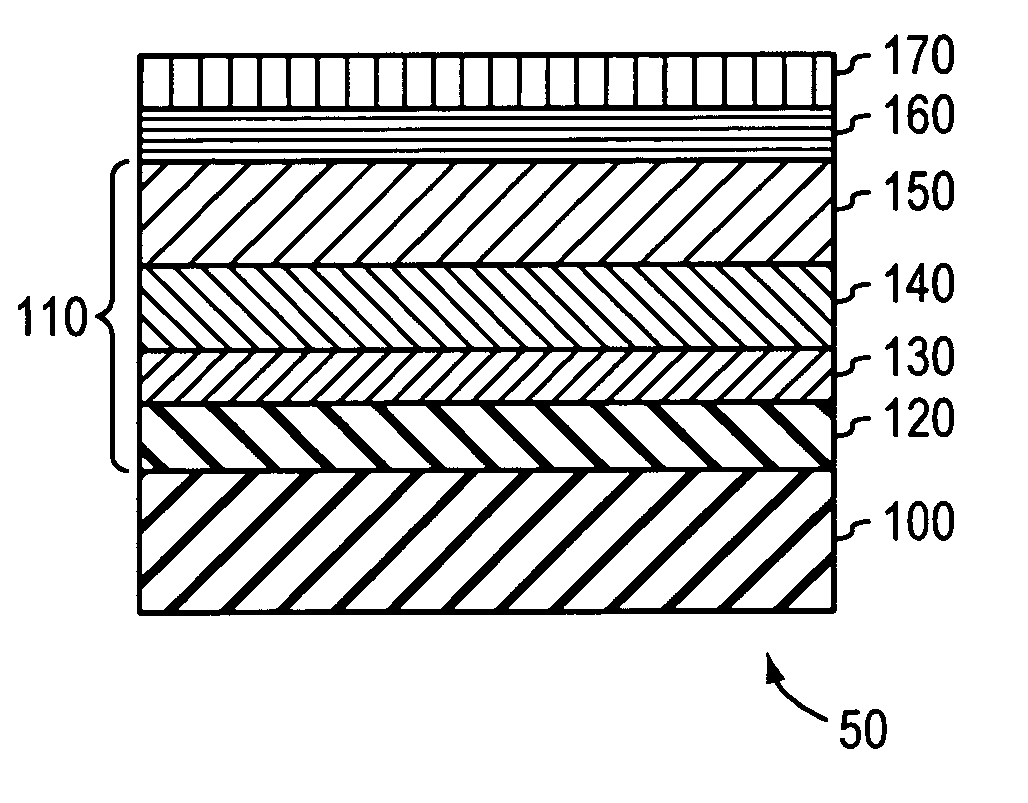

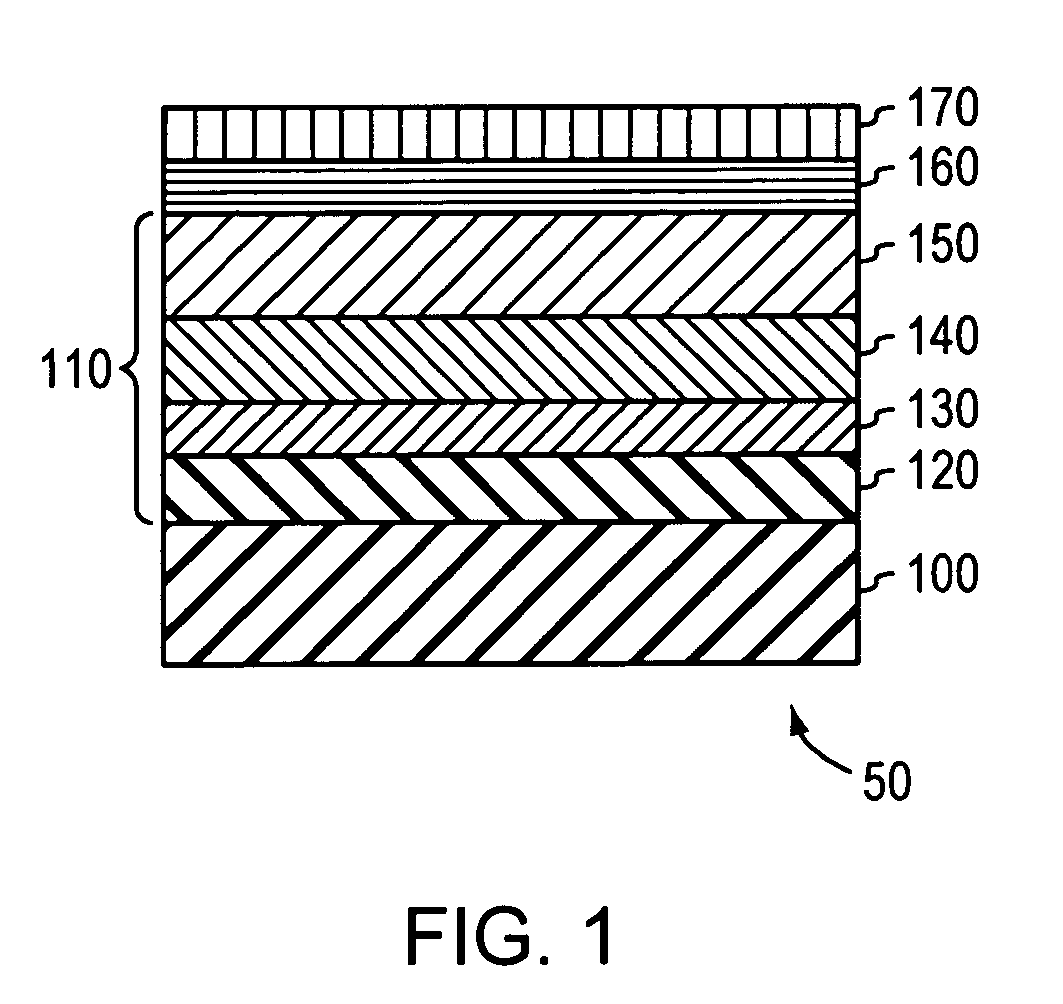

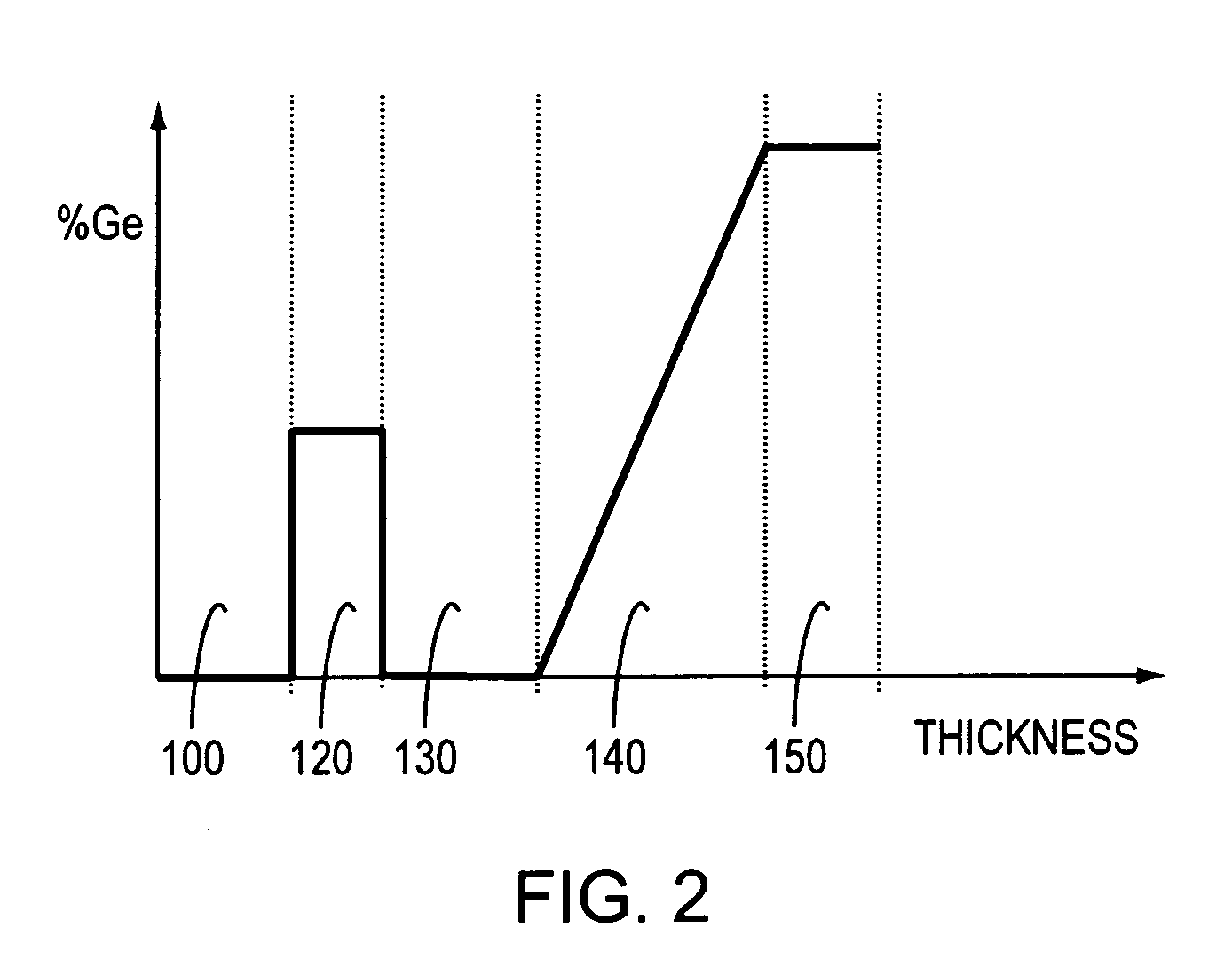

Semiconductor heterostructures and related methods

InactiveUS7049627B2Overcome limitationsImprove manufacturabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingThreading dislocationsInter layer

Dislocation pile-ups in compositionally graded semiconductor layers are reduced or eliminated, thereby leading to increased semiconductor device yield and manufacturability. This is accomplished by introducing a semiconductor layer having a plurality of threading dislocations distributed substantially uniformly across its surface as a starting layer and / or at least one intermediate layer during growth and relaxation of the compositionally graded layer. The semiconductor layer may include a seed layer disposed proximal to the surface of the semiconductor layer and having the threading dislocations uniformly distributed therein.

Owner:TAIWAN SEMICON MFG CO LTD

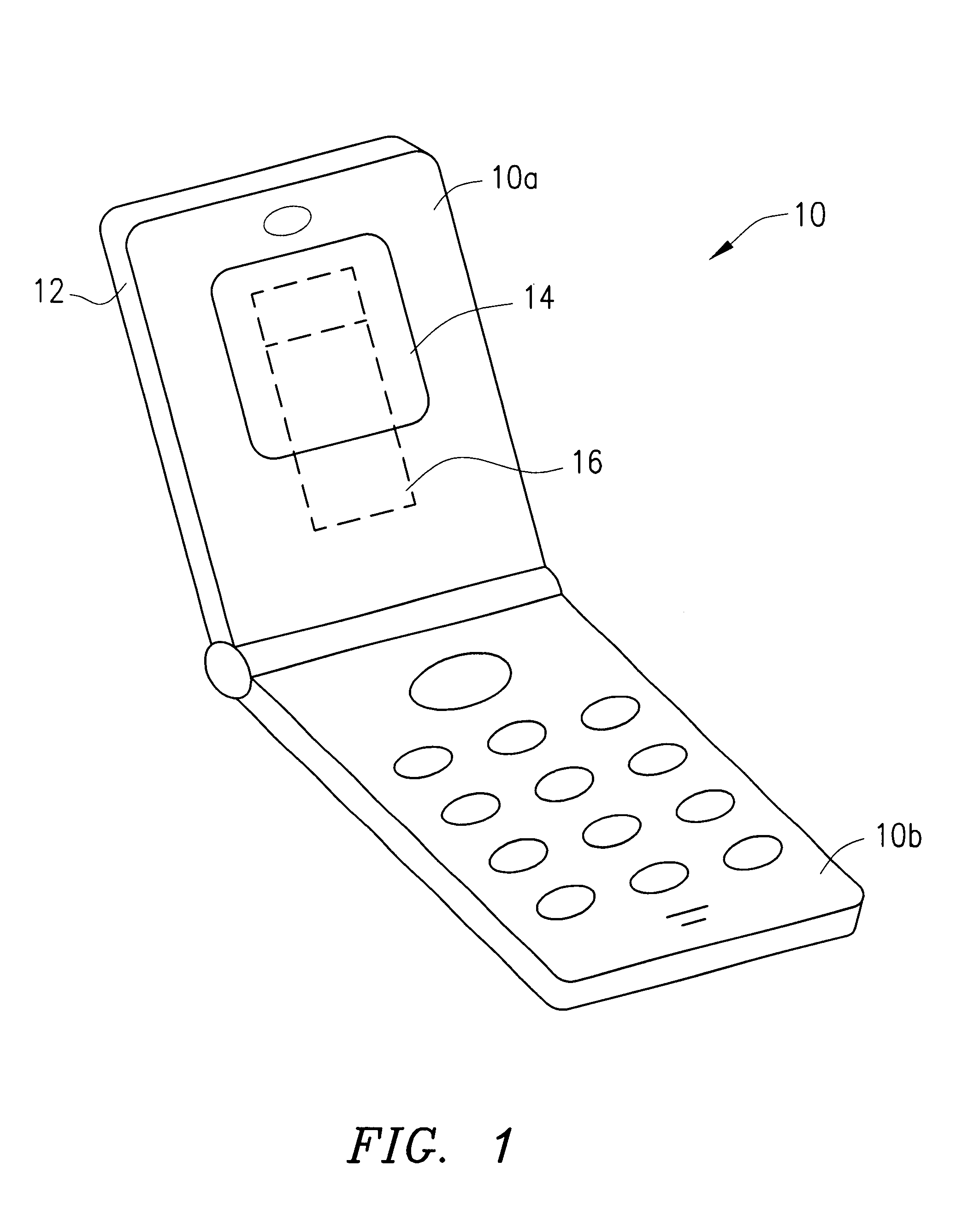

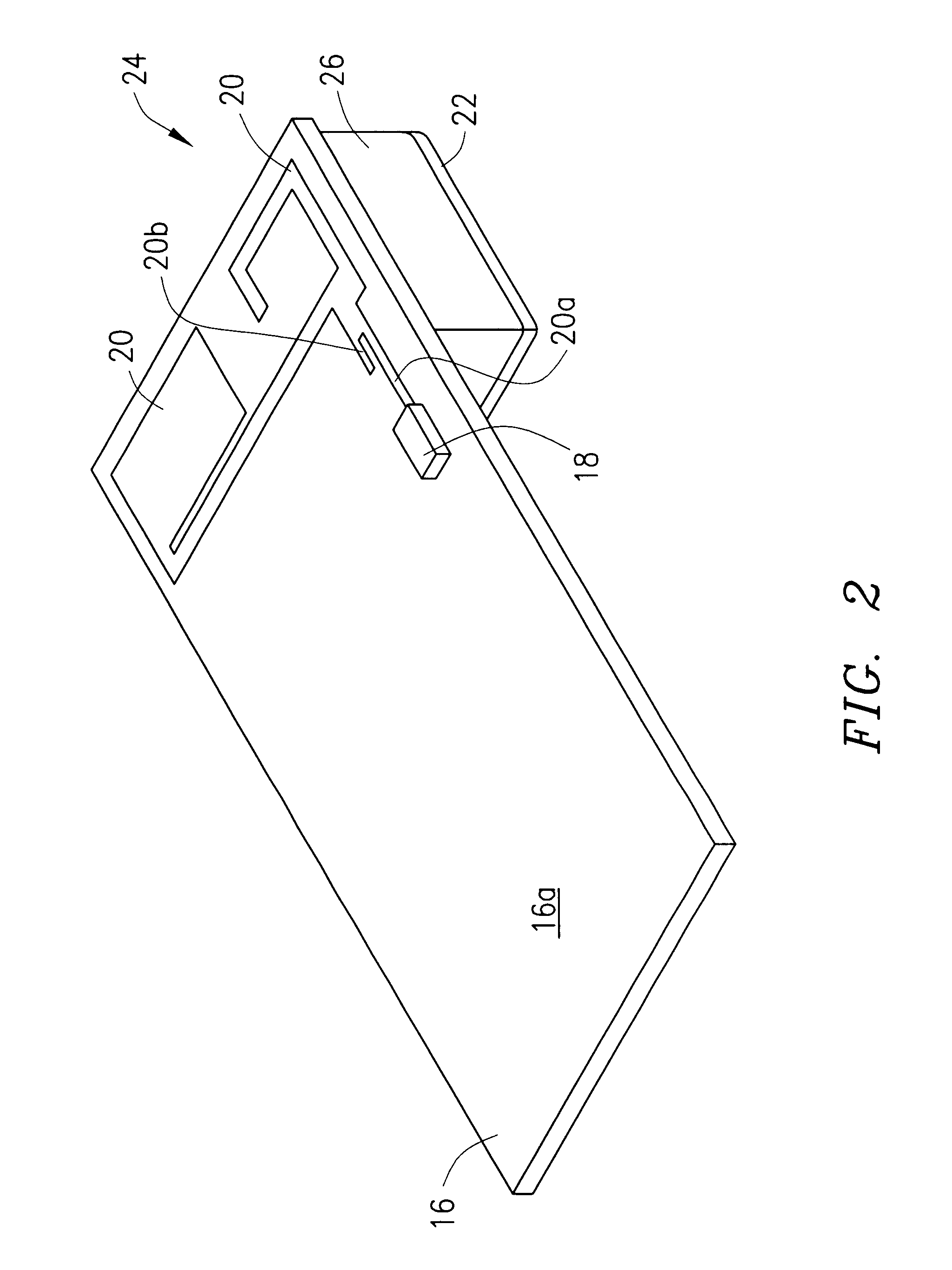

In-built antenna for mobile communication device

InactiveUS6879849B2Cost lossImprove manufacturabilityInterconnection arrangementsSimultaneous aerial operationsSurface mountingElectrical connection

An in-built antenna is provided for a mobile phone or other communication device having a main printed circuit board contained within a case, wherein components for transmitting and receiving radio signals are mounted on the main circuit board. An antenna pattern or radiator is etched on the printed circuit board surface mounting the components, in electrical connection with the components, using the same process employed to form the components and connections between them. A ground plane is mounted to the opposing surface of the main printed circuit board, in facing, spaced-apart parallel relationship with the antenna pattern and in spaced-apart parallel relationship with the main printed circuit board.

Owner:TELEFON AB LM ERICSSON (PUBL)

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS6946173B2Improve performanceImprove adhesionEnvelopes/bags making machineryMouldsElastomerTetrafluoroethylene

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is a silicone-polyurethane copolymer elastomer or a diene polymer elastomer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:ABBOTT CARDIOVASCULAR

Methods of fabricating semiconductor heterostructures

InactiveUS20060009012A1Overcome limitationsImprove manufacturabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingThreading dislocationsDevice material

Dislocation pile-ups in compositionally graded semiconductor layers are reduced or eliminated, thereby leading to increased semiconductor device yield and manufacturability. This is accomplished by introducing a semiconductor layer having a plurality of threading dislocations distributed substantially uniformly across its surface as a starting layer and / or at least one intermediate layer during growth and relaxation of the compositionally graded layer. The semiconductor layer may include a seed layer disposed proximal to the surface of the semiconductor layer and having the threading dislocations uniformly distributed therein.

Owner:TAIWAN SEMICON MFG CO LTD

System for designing integrated circuits with enhanced manufacturability

ActiveUS20050188338A1Improve manufacturabilityLittle interferencePressersMattress sewingData conversionIntegrated circuit

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

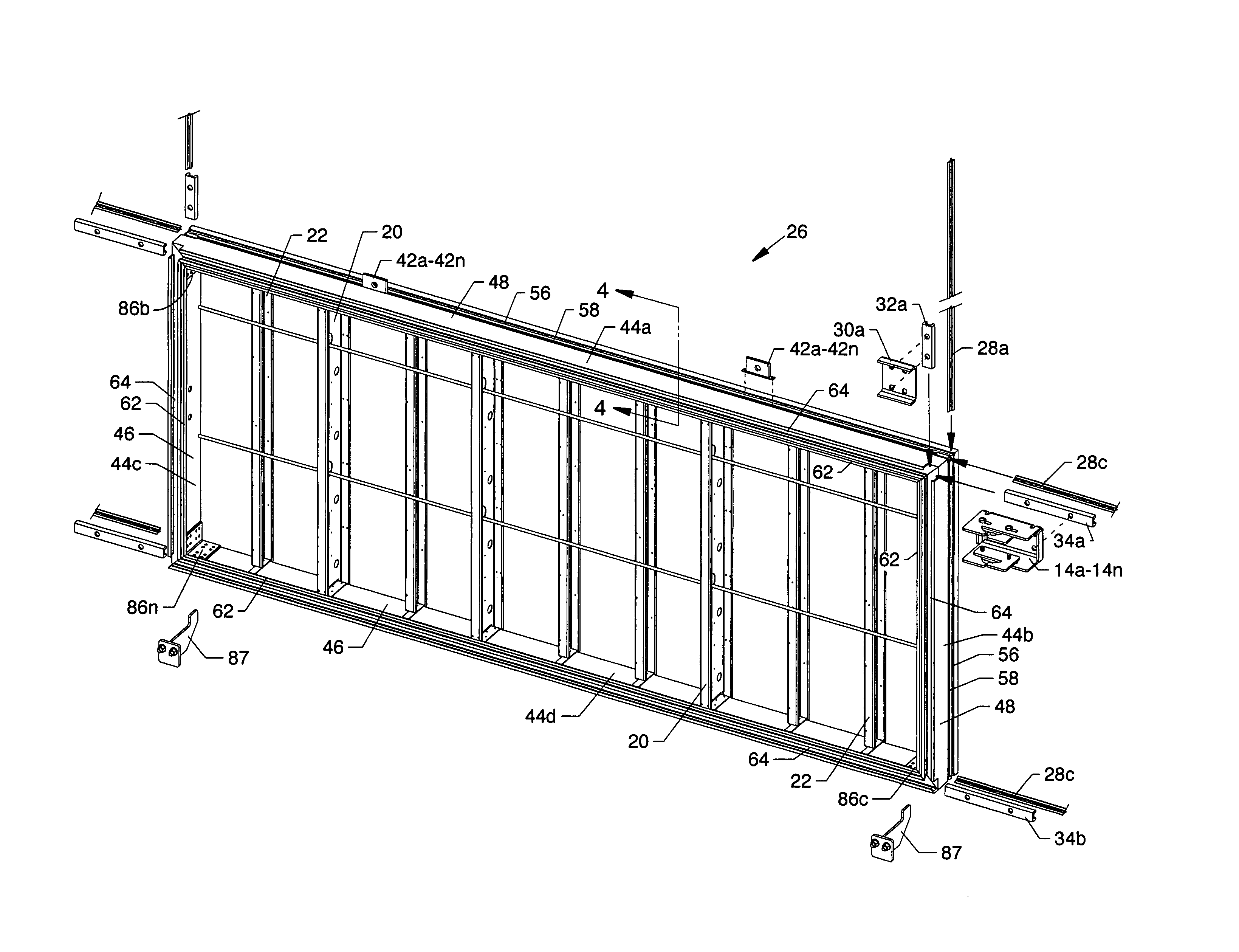

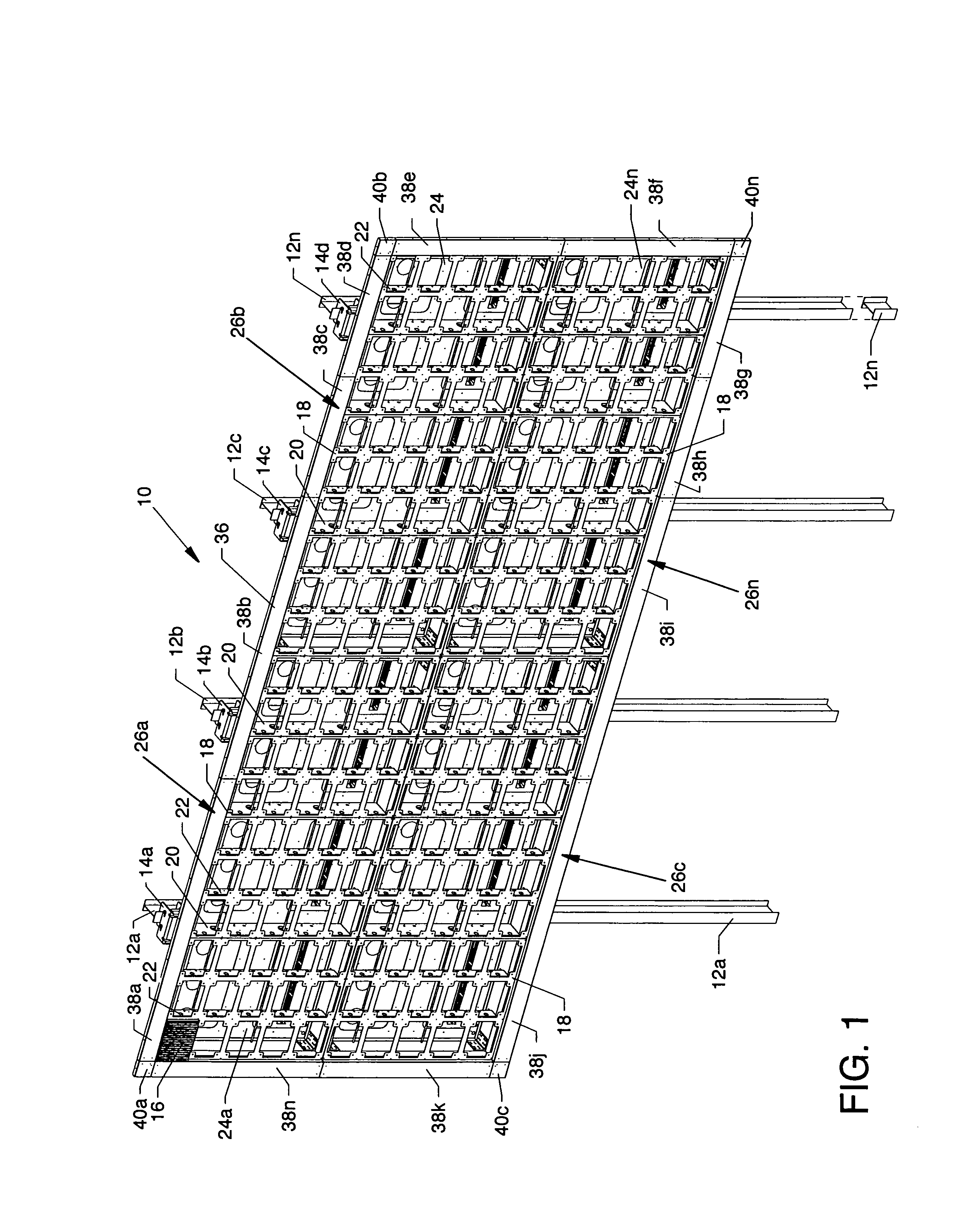

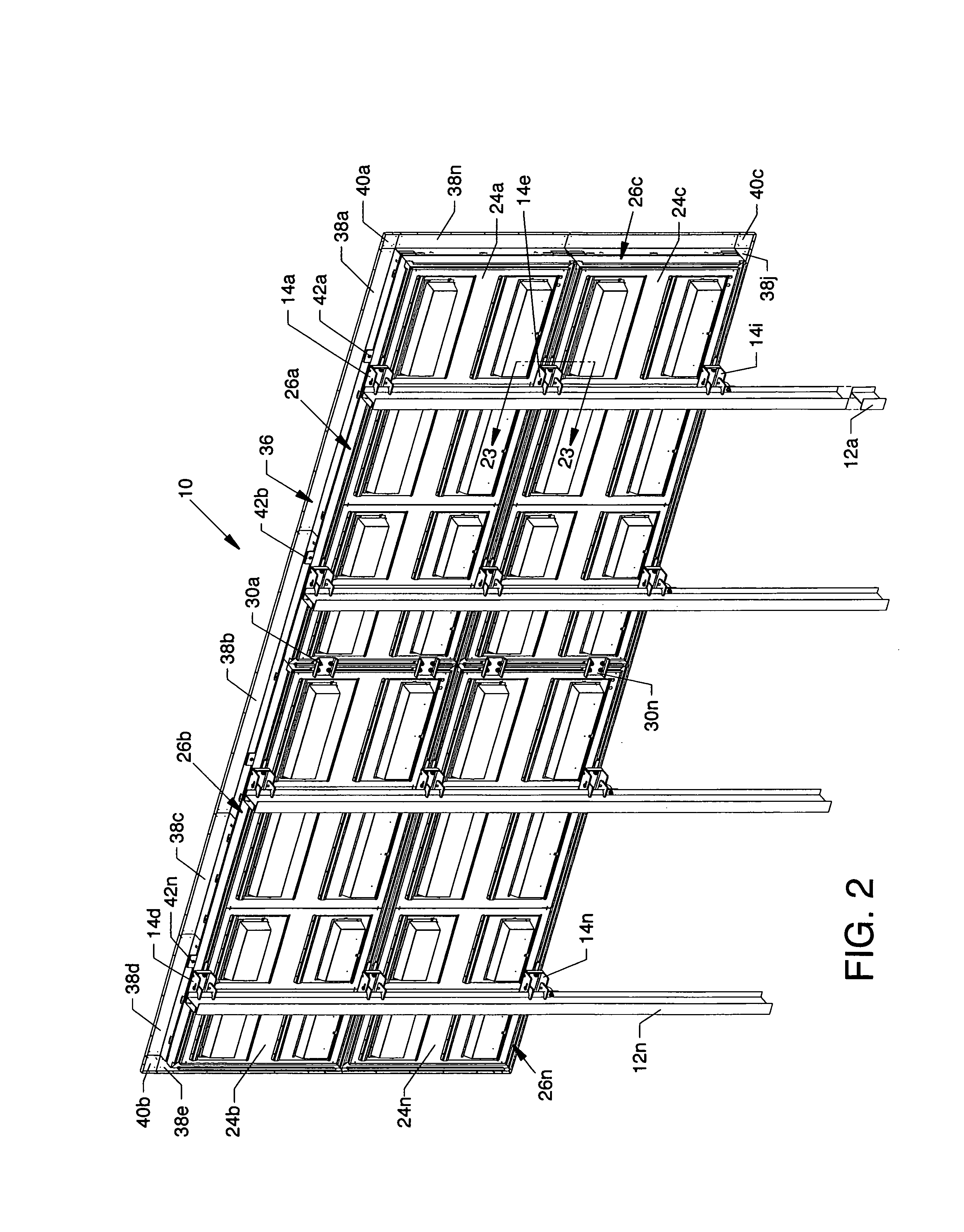

Electronic sign having slotted frame cabinets

ActiveUS7926213B1Improve efficiencyImprove manufacturabilityTelevision system detailsSide-by-side/stacked arrangementsLED displayEngineering

An electronic sign having slotted frame cabinets whereby each slotted frame cabinet can conveniently be attached to one or more vertically or horizontally positioned adjacent slotted frame cabinets by using connecting components which are generally located around the periphery of one or more slotted frame cabinets. Connecting components including splice bars, splice plates, and mounting clamps are aligned in, positioned along and secured to backing bars which are co-located in backing bar slots in one or more of the slotted frame cabinets. Lift eyes can be variably located in one or more lift eye slots. The use of externally located connecting components, which do not extend through the cabinetry, minimize the entry of environmental elements into the interior of the electronic sign. Multiple slotted frame cabinets can be connected without the removal of LED display panels.

Owner:DAKTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com