Patents

Literature

116 results about "Mass customization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass customization, in marketing, manufacturing, call centres and management, is the use of flexible computer-aided manufacturing systems to produce custom output. Such systems combine the low unit costs of mass production processes with the flexibility of individual customization.

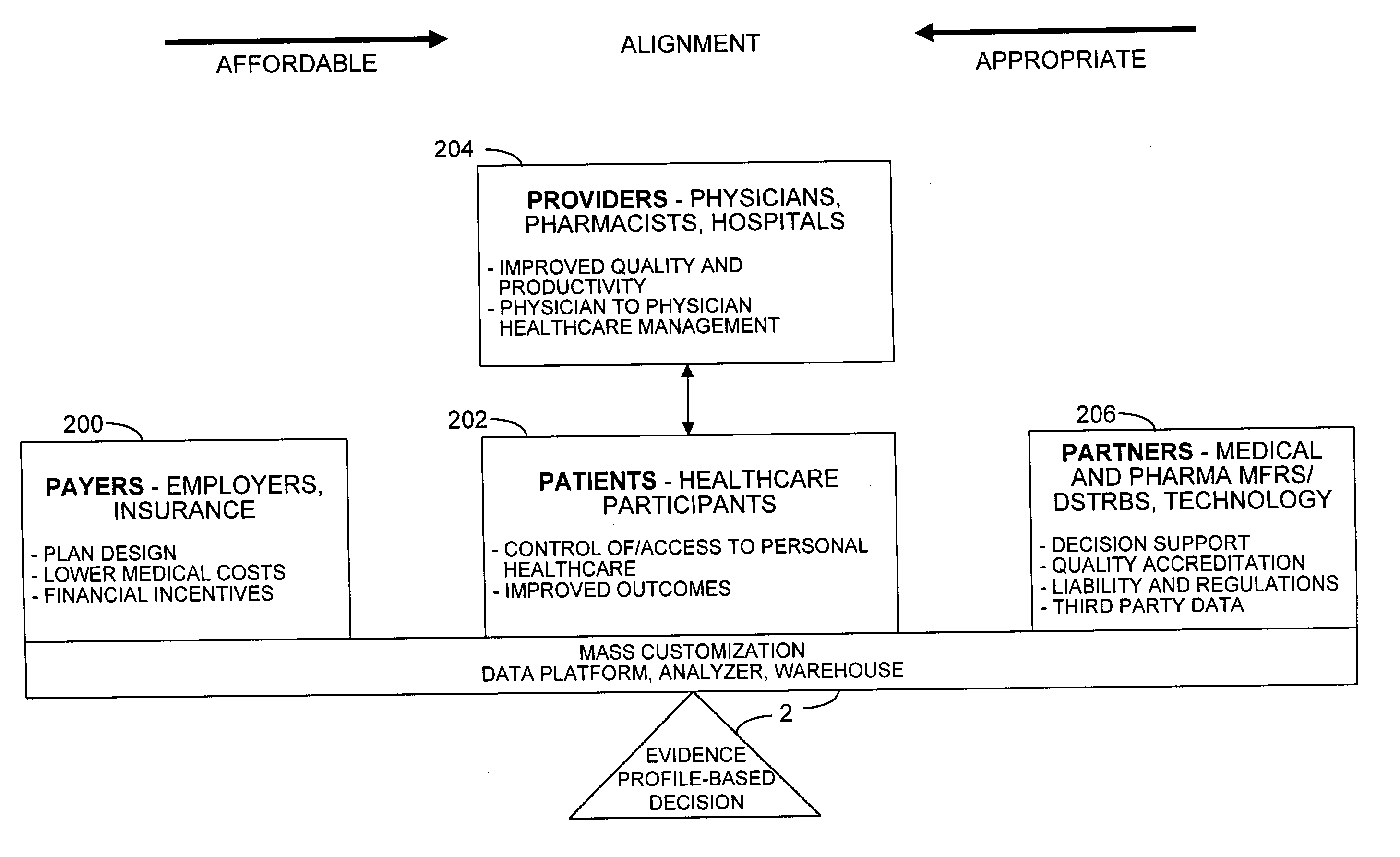

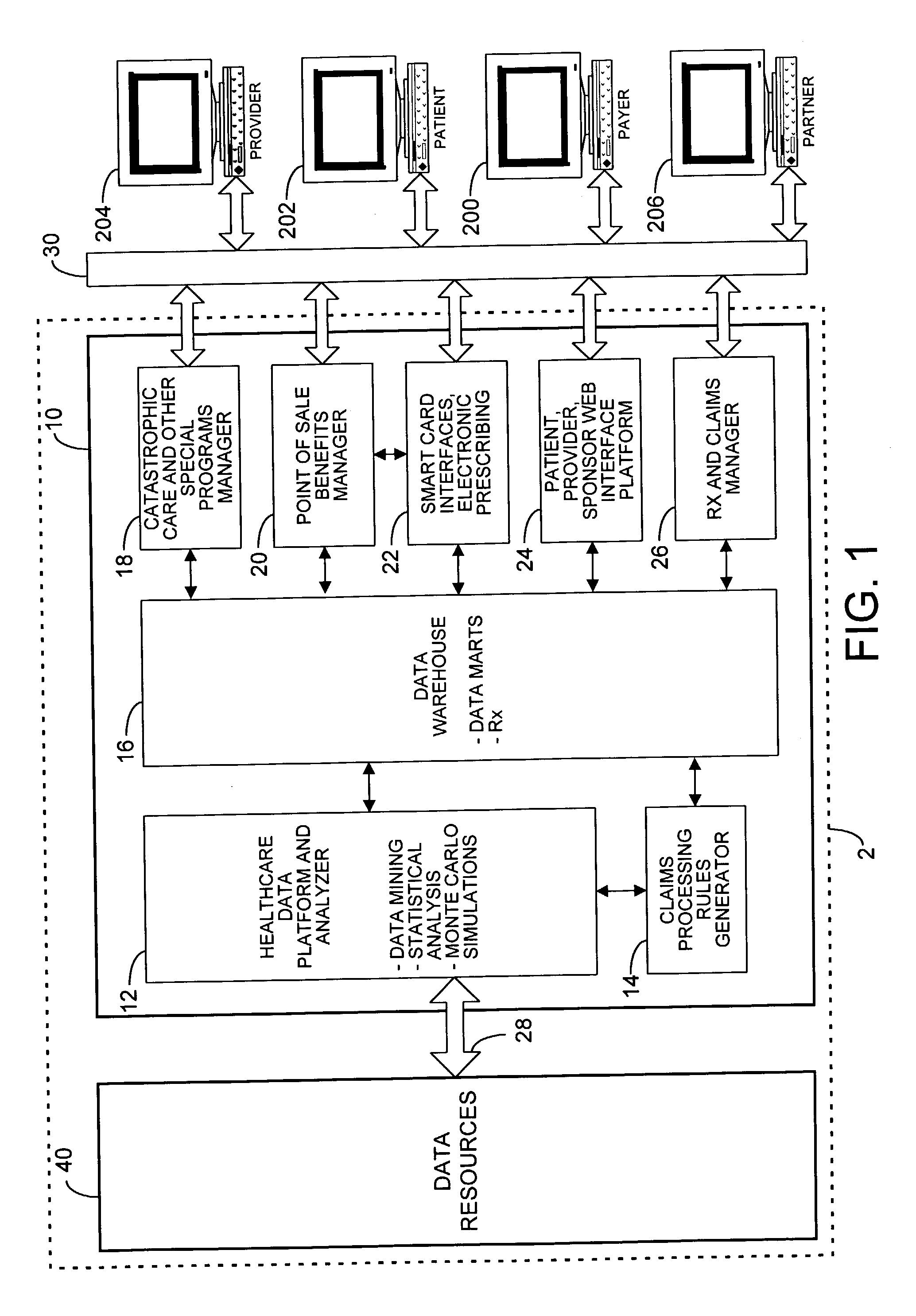

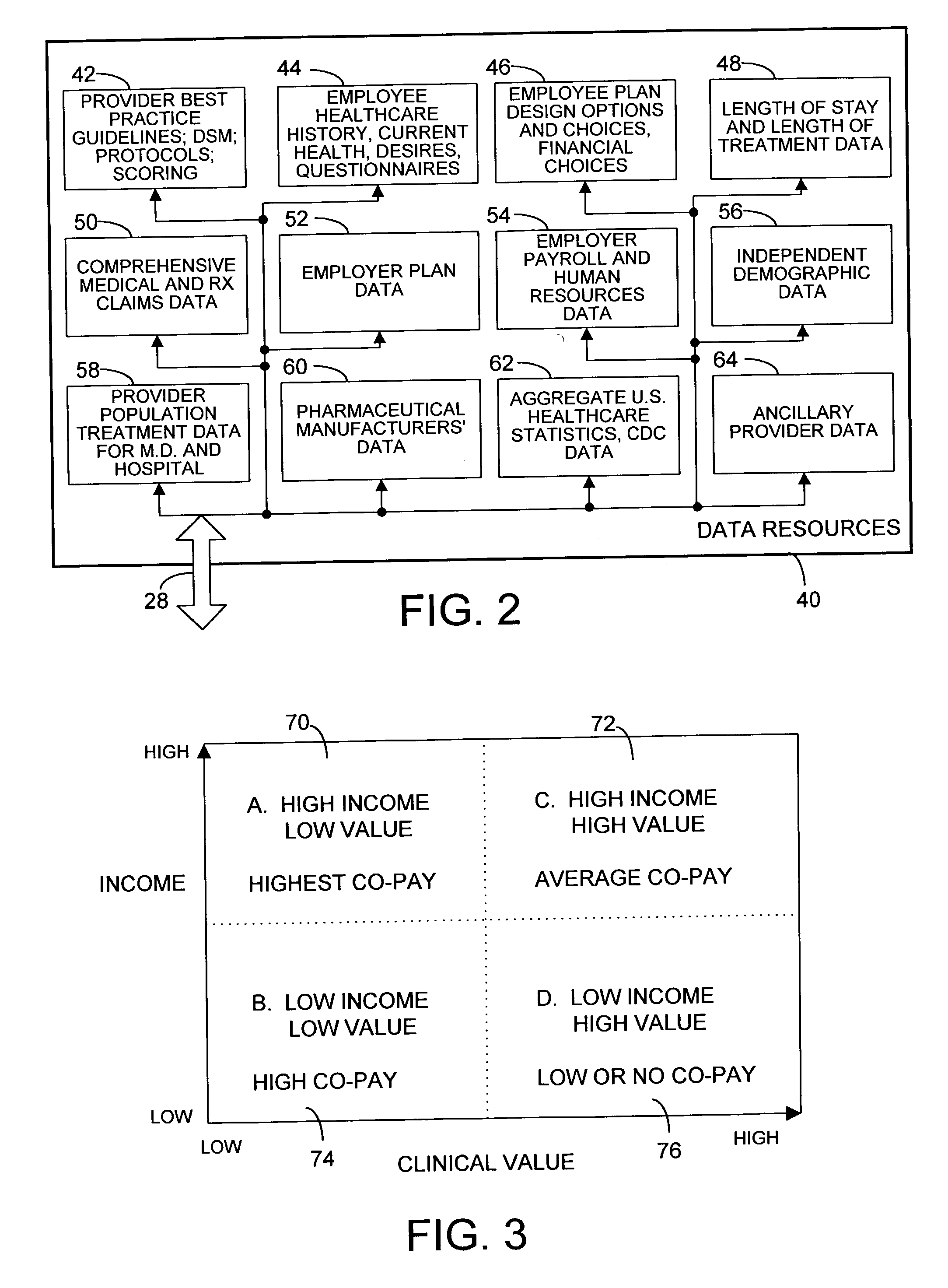

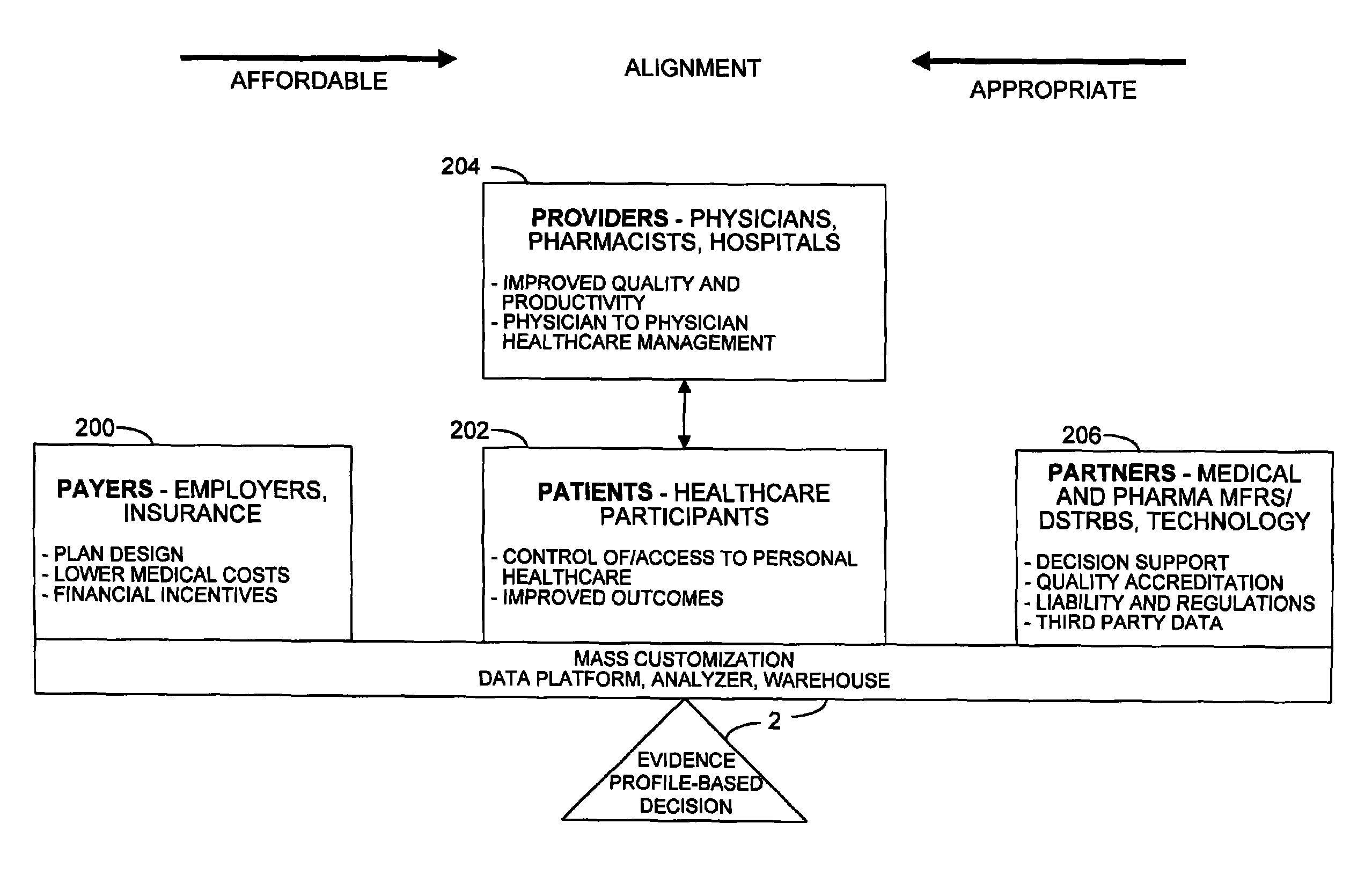

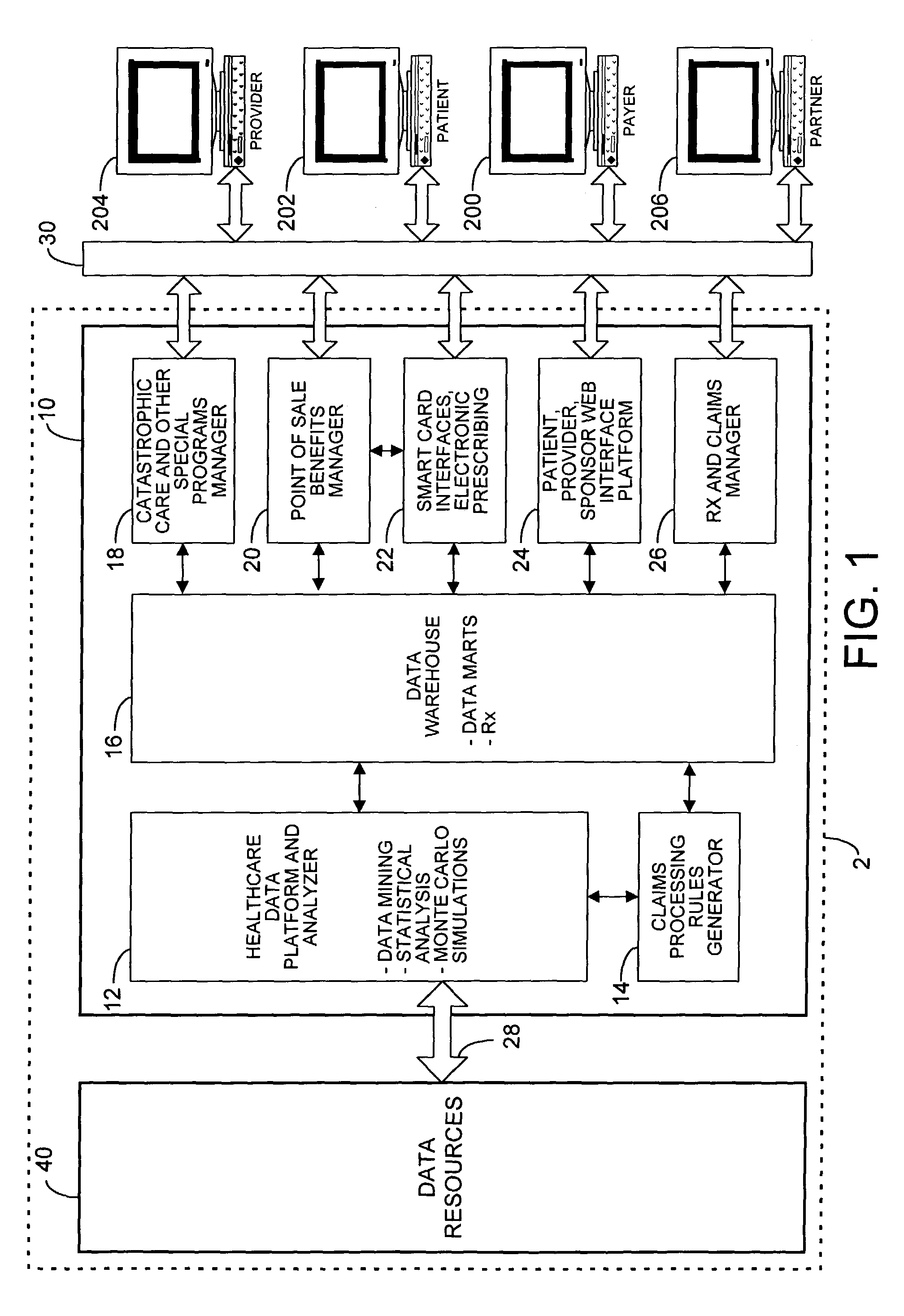

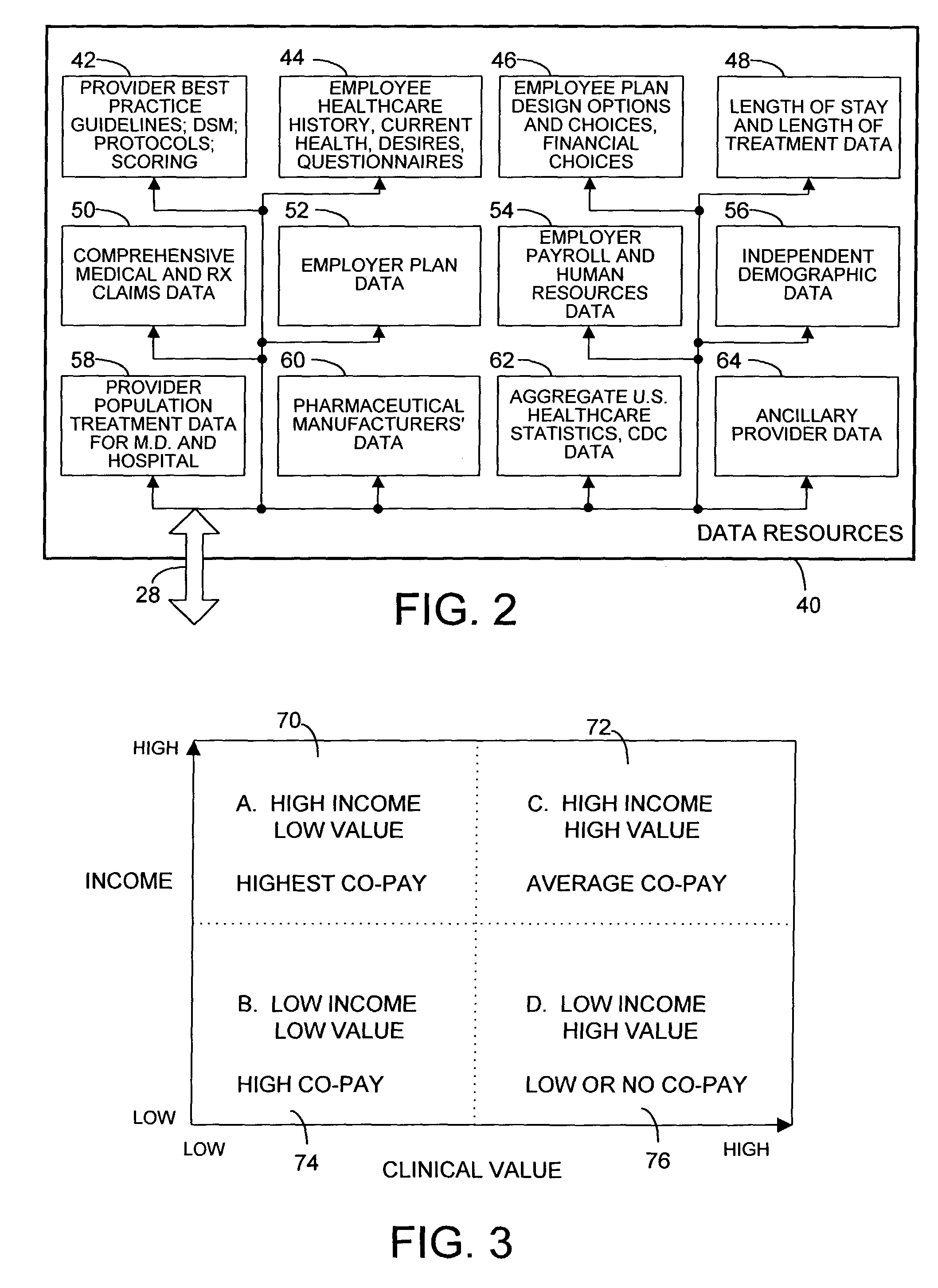

Mass customization for management of healthcare

ActiveUS20060178915A1Deter unnecessary utilizationCost optimizationDiscounts/incentivesDrug and medicationsMass customizationProgram planning

A healthcare mass customization infrastructure individualizes plan designs by incorporating demographics, income, drug history, medical history, lab values, and future genomic information for appropriate and affordable access to medications. The mass customization infrastructure results in quality outcomes for the patients, improved care and productivity for the providers, and lower medical costs for the payers.

Owner:MEDIMPACT HEALTHCARE SYST

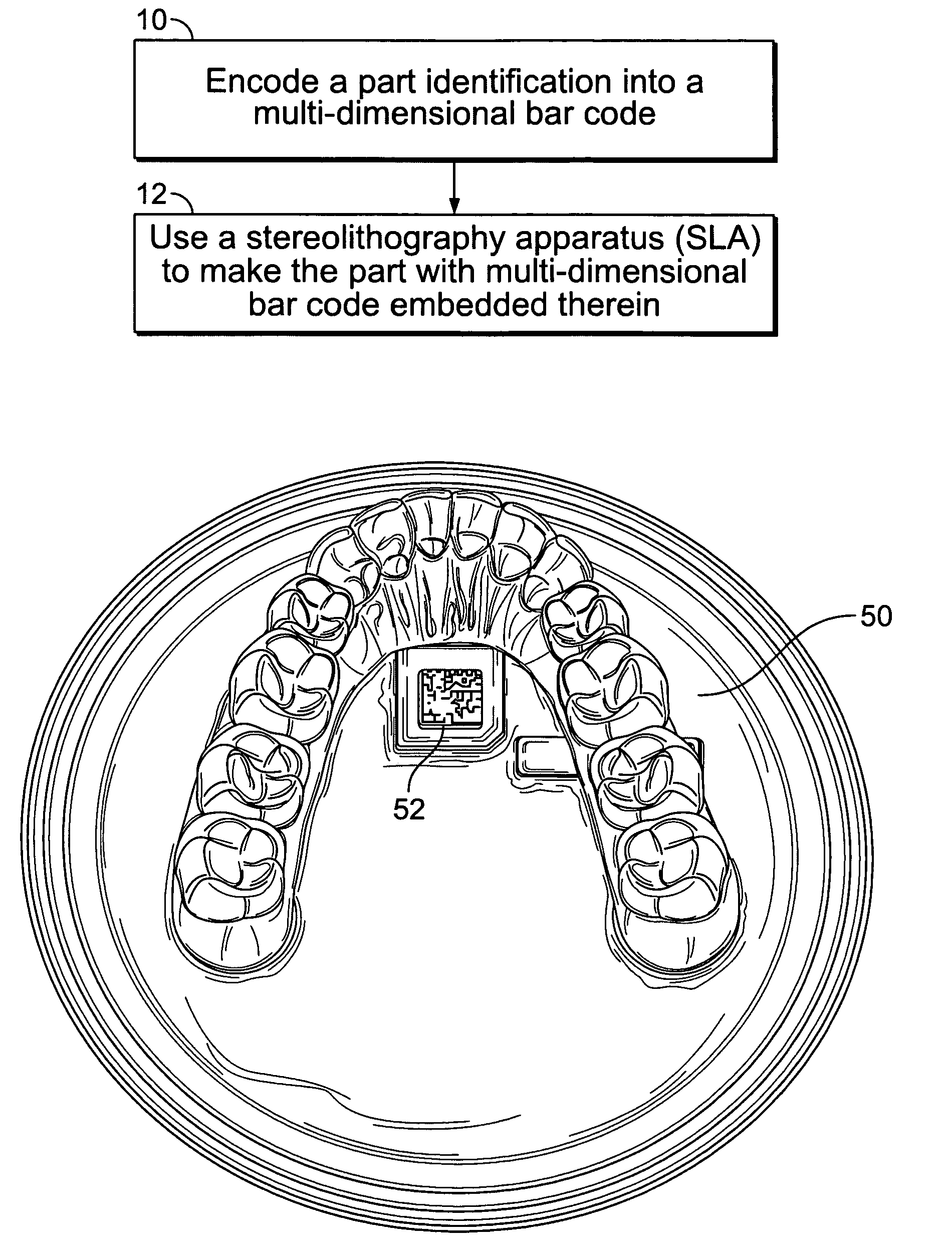

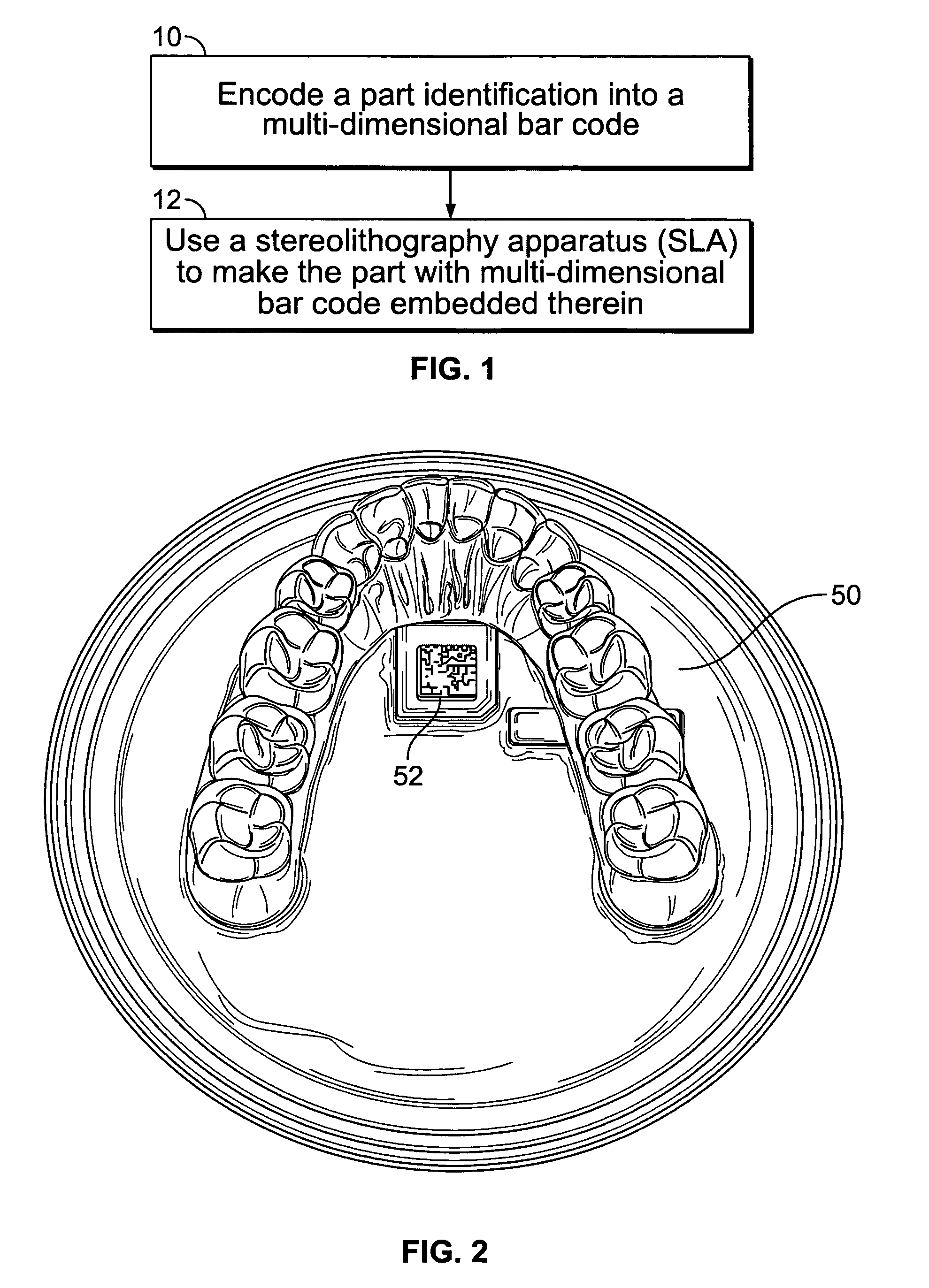

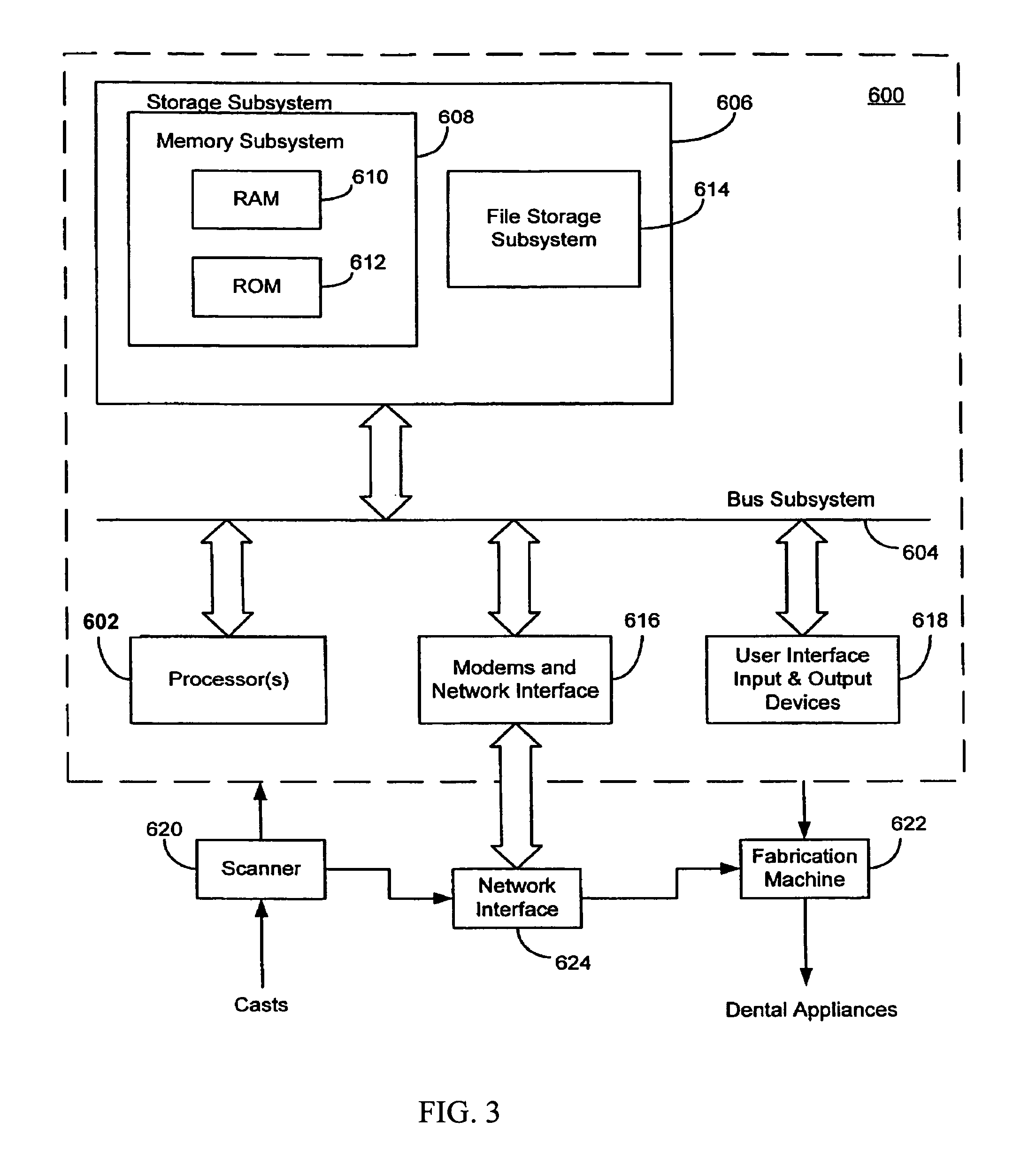

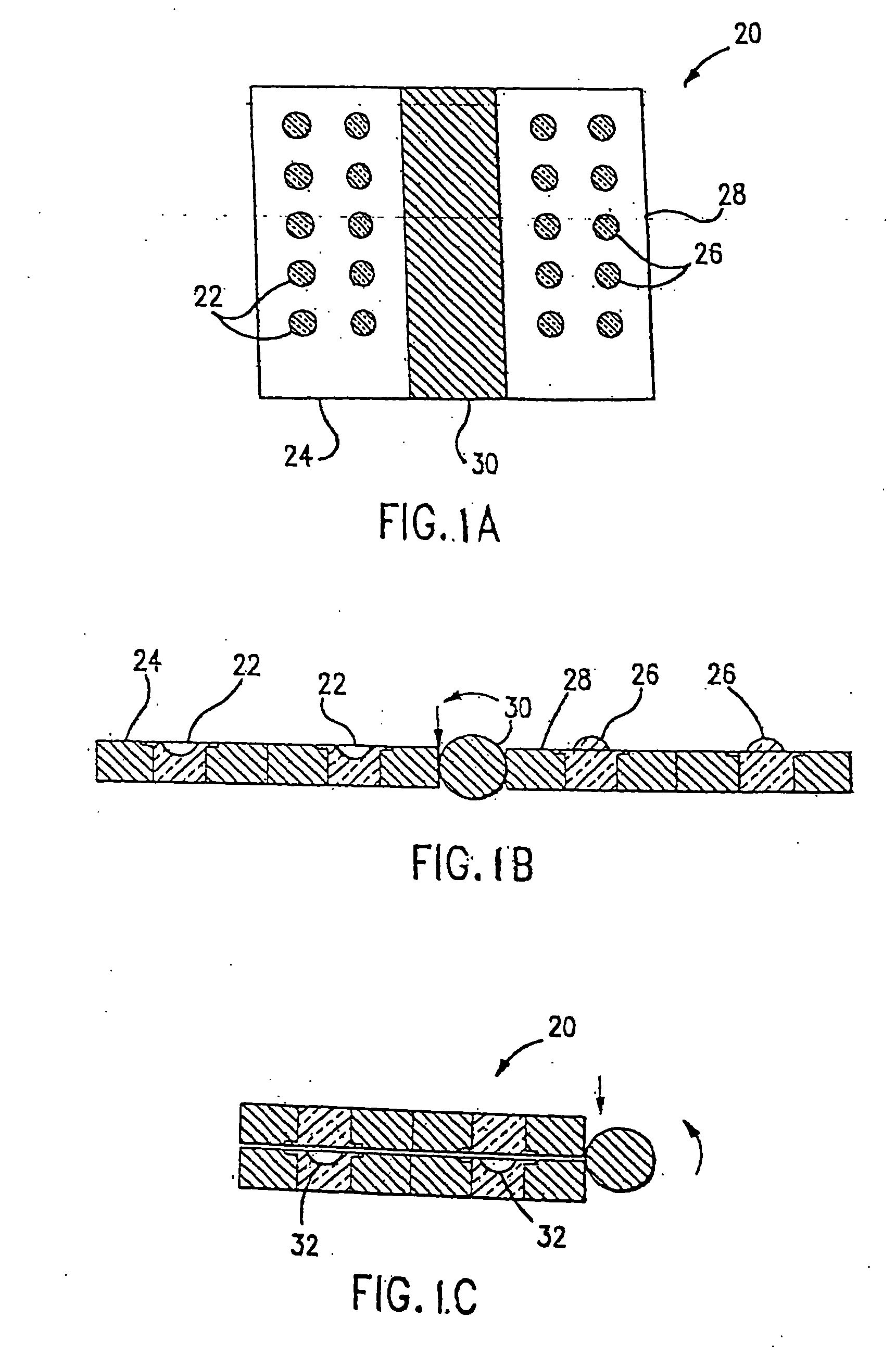

Identification of units in customized production

ActiveUS6976627B1Effective estimateImprove manufacturabilityAdditive manufacturing apparatusCo-operative working arrangementsMass customizationBarcode

Systems and methods are disclosed for identifying a mass-customized part by encoding a part identification into a multi-dimensional bar code; and using a stereolithography apparatus (SLA) to make the part with multi-dimensional bar code embedded therein.

Owner:ALIGN TECH

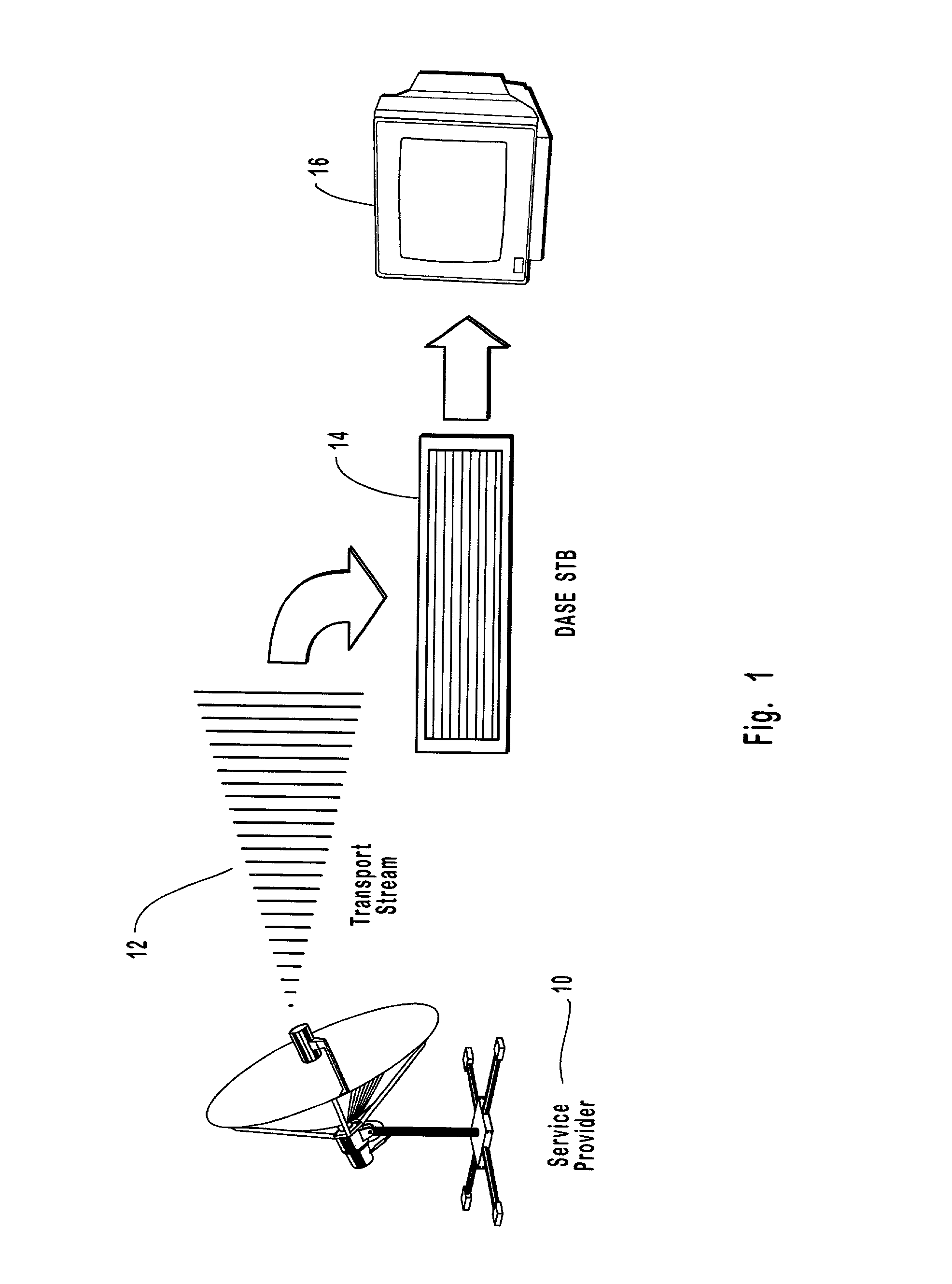

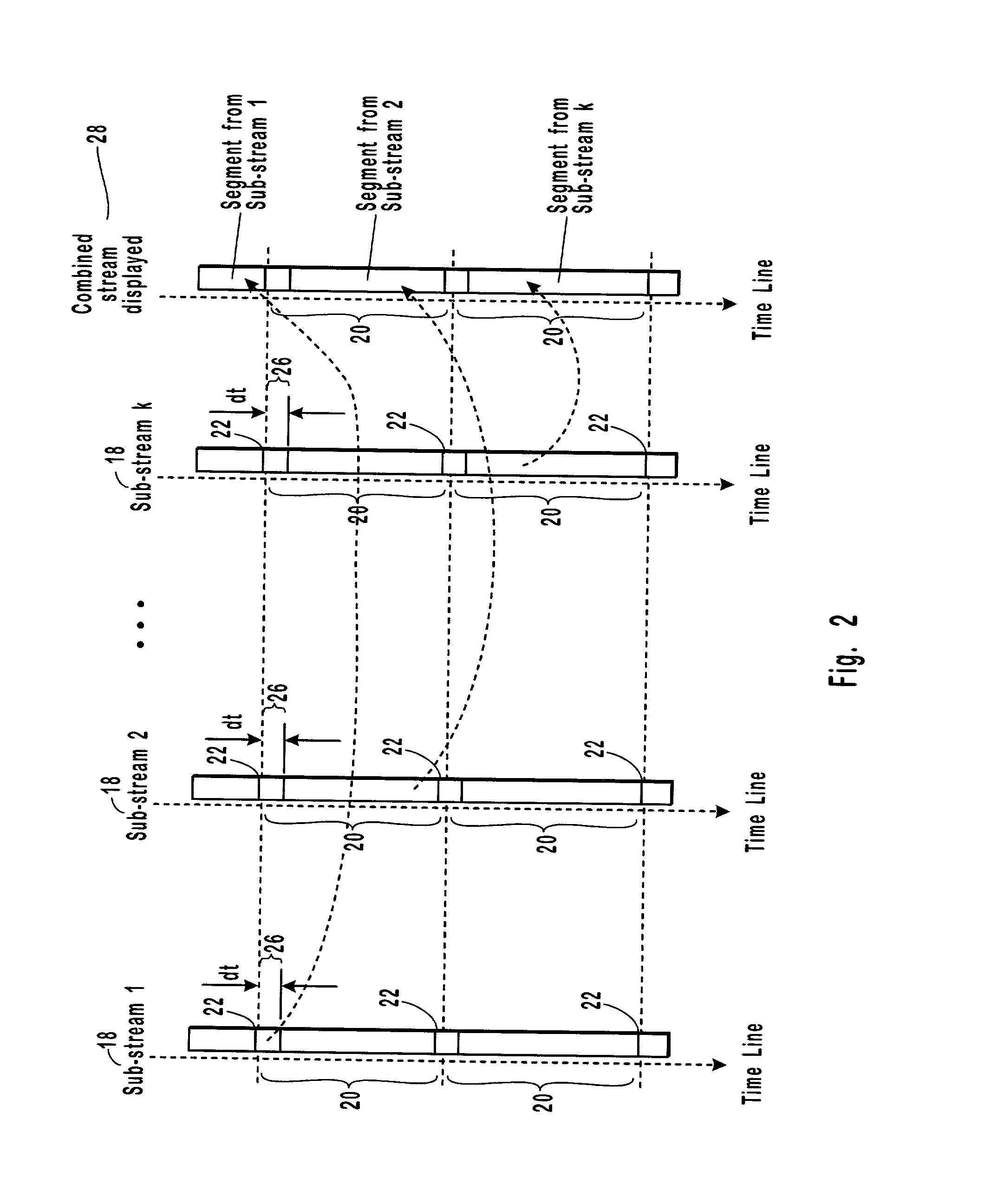

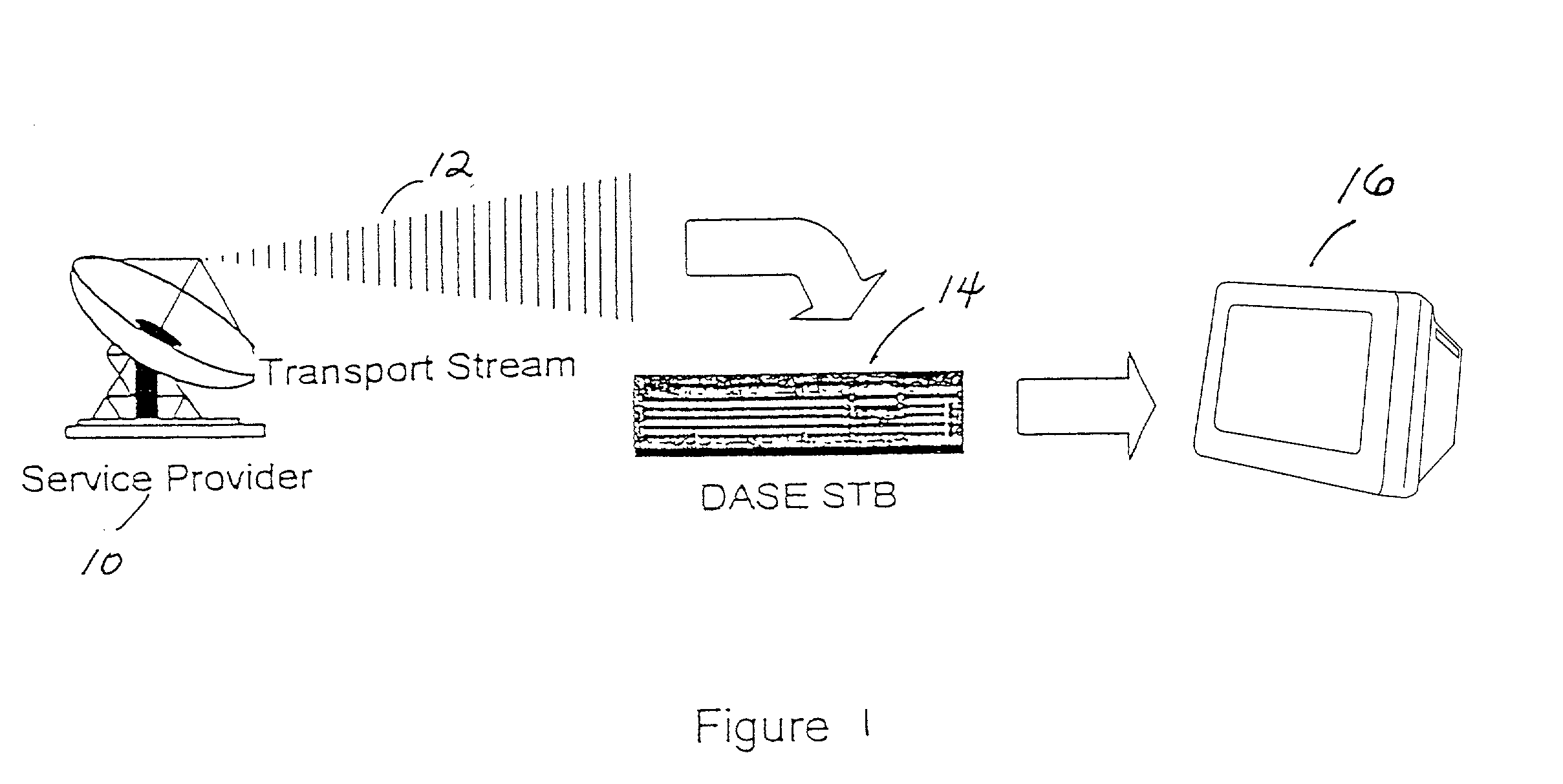

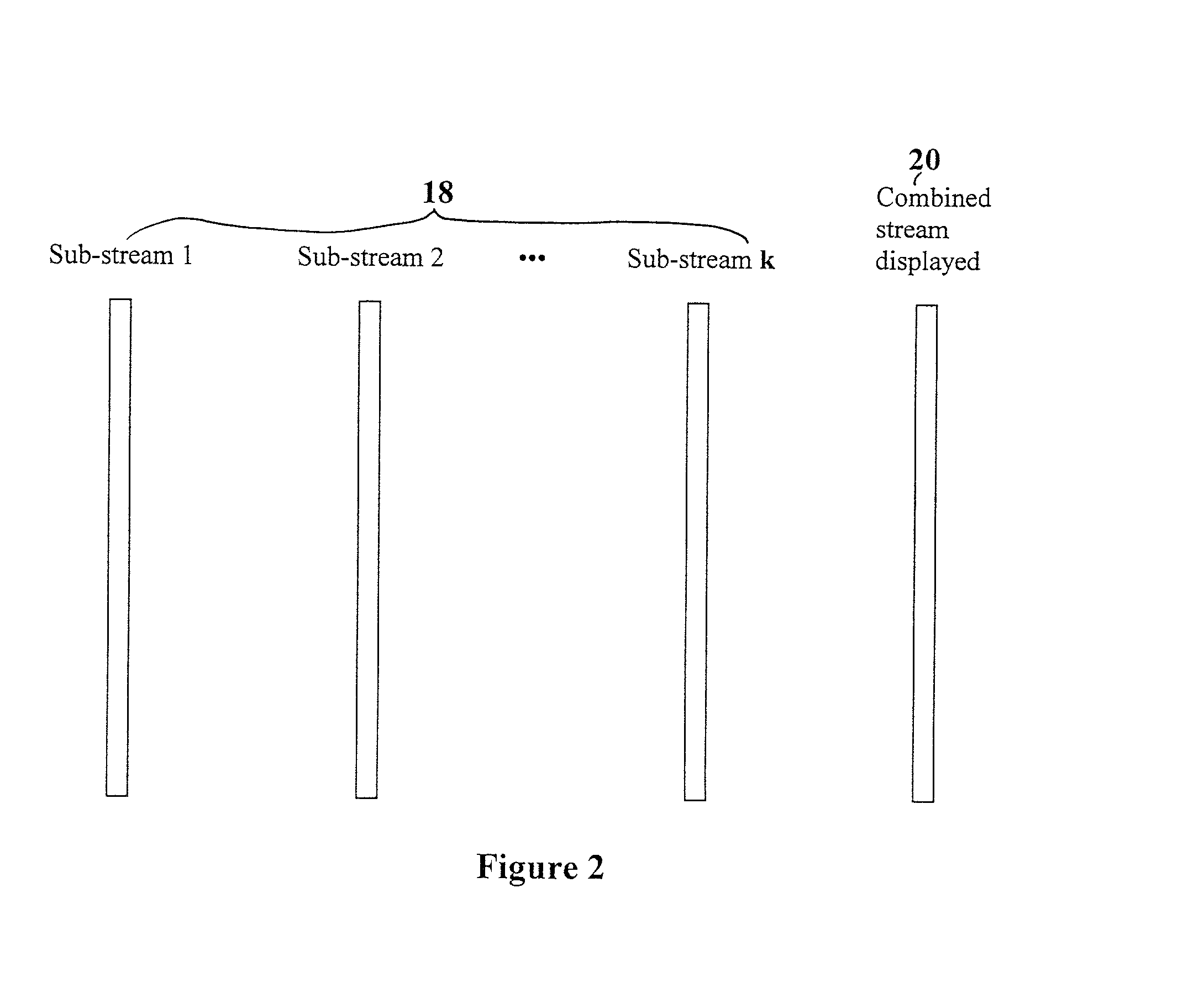

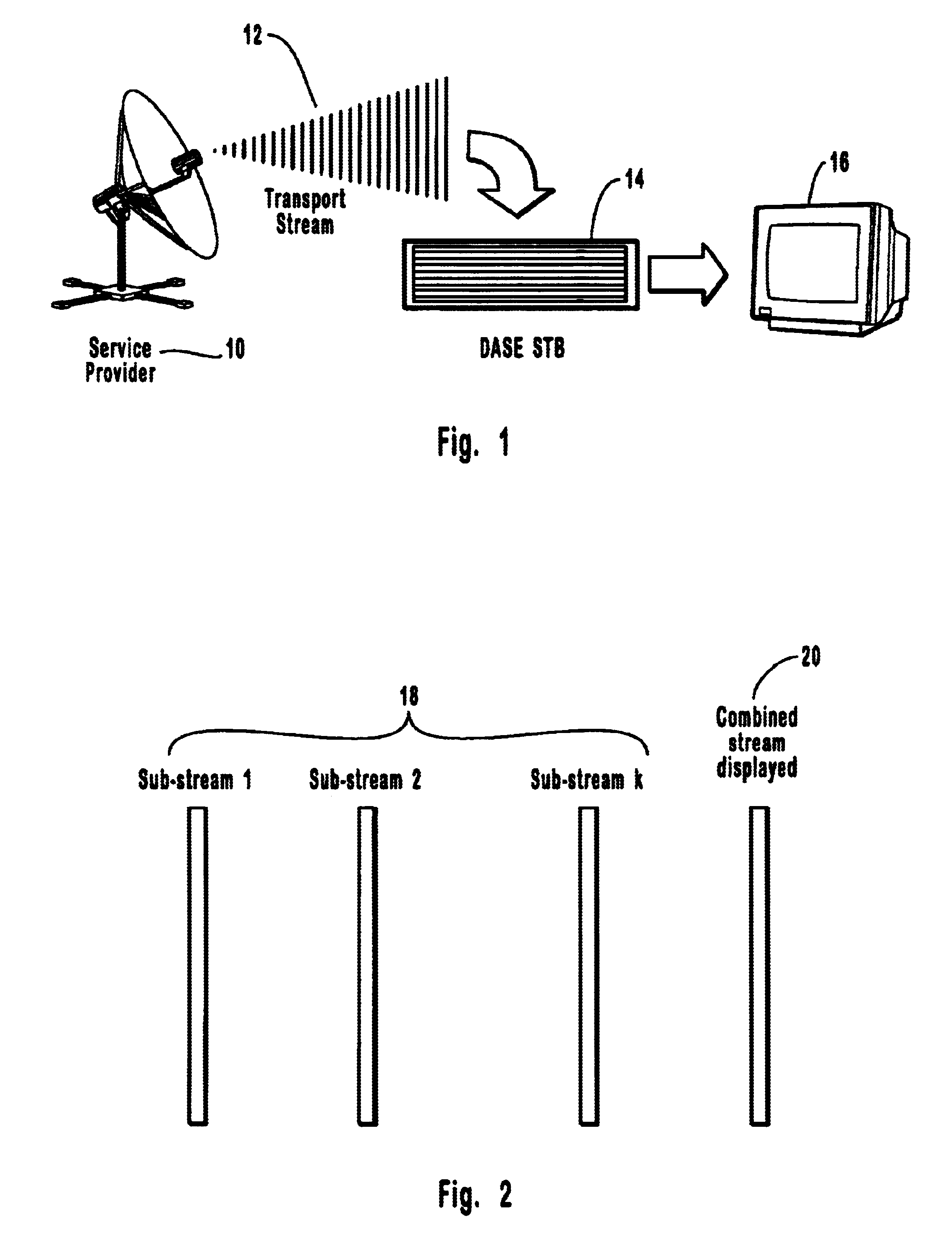

Method and system for mass customization of digital television broadcasts

InactiveUS20020120929A1Improve usabilityBetter targeted commercialsTelevision system detailsMetadata video data retrievalMass customizationClient-side

A method and system for the mass customization of Digital Television broadcasts that involves the broadcasting of synchronized sub-streams. Each sub-stream is divided into segments of equal length and marked by time-stamped tags. The sub-streams include keywords describing the video content, and the sub-stream keywords are compared with viewer keywords at the client-side set-top box to derive a match score. The set-top box then switches to the sub-stream having the best match score. Thus, the client-side set-top box can automatically select commercials that best fit the personal interests of each viewer, resulting in better targeted commercials and simultaneously benefitting the viewer and advertiser.

Owner:SHARP LAB OF AMERICA INC

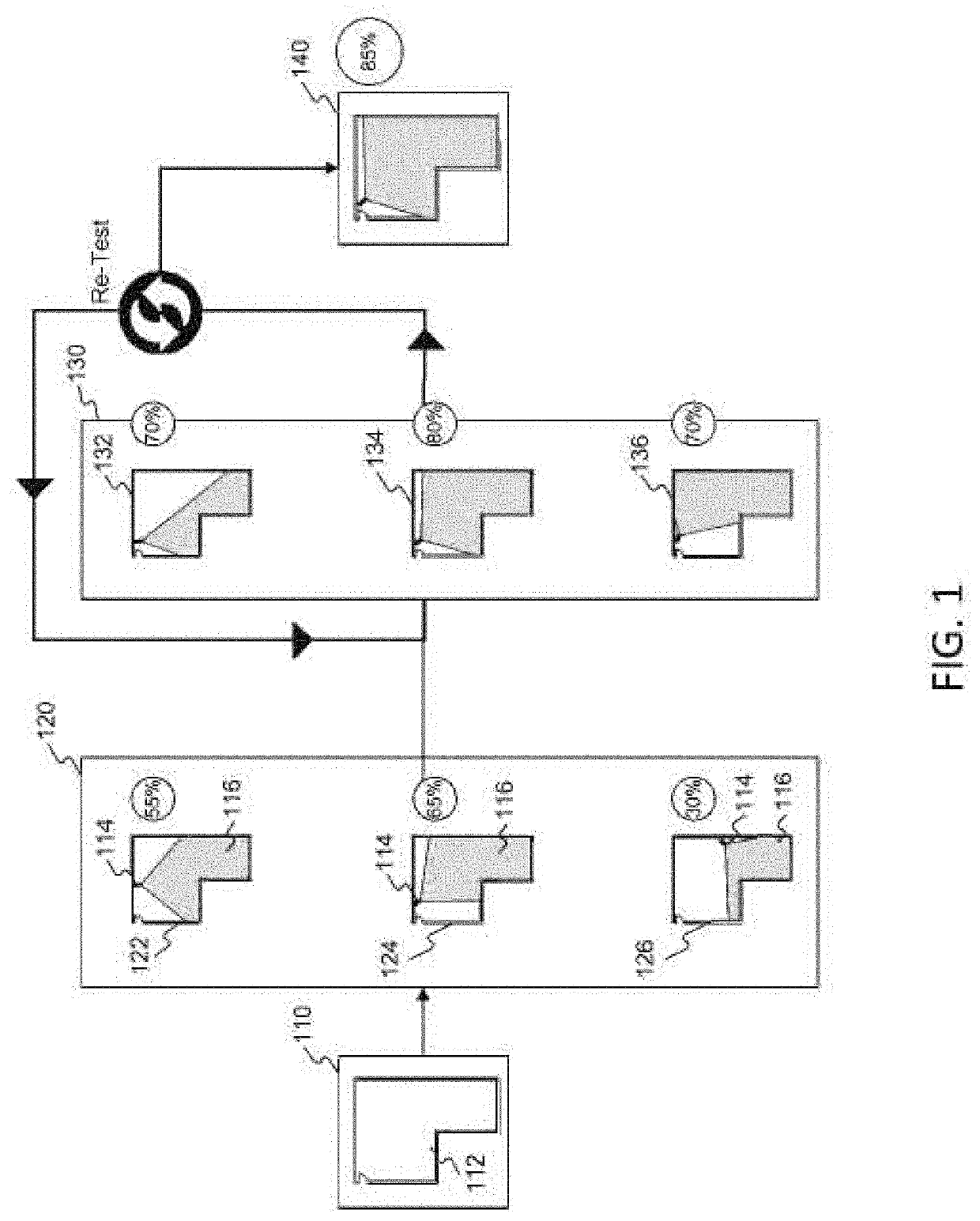

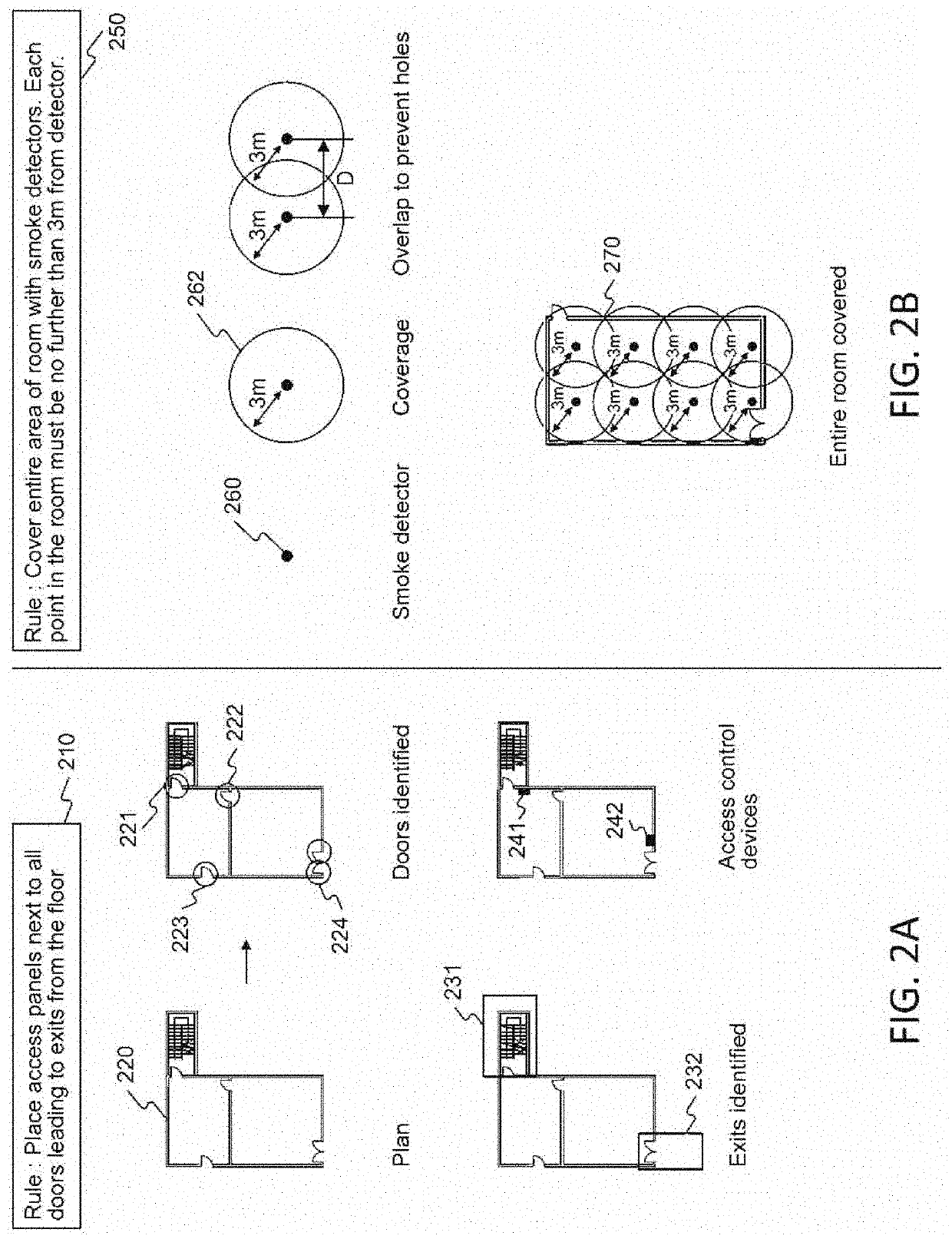

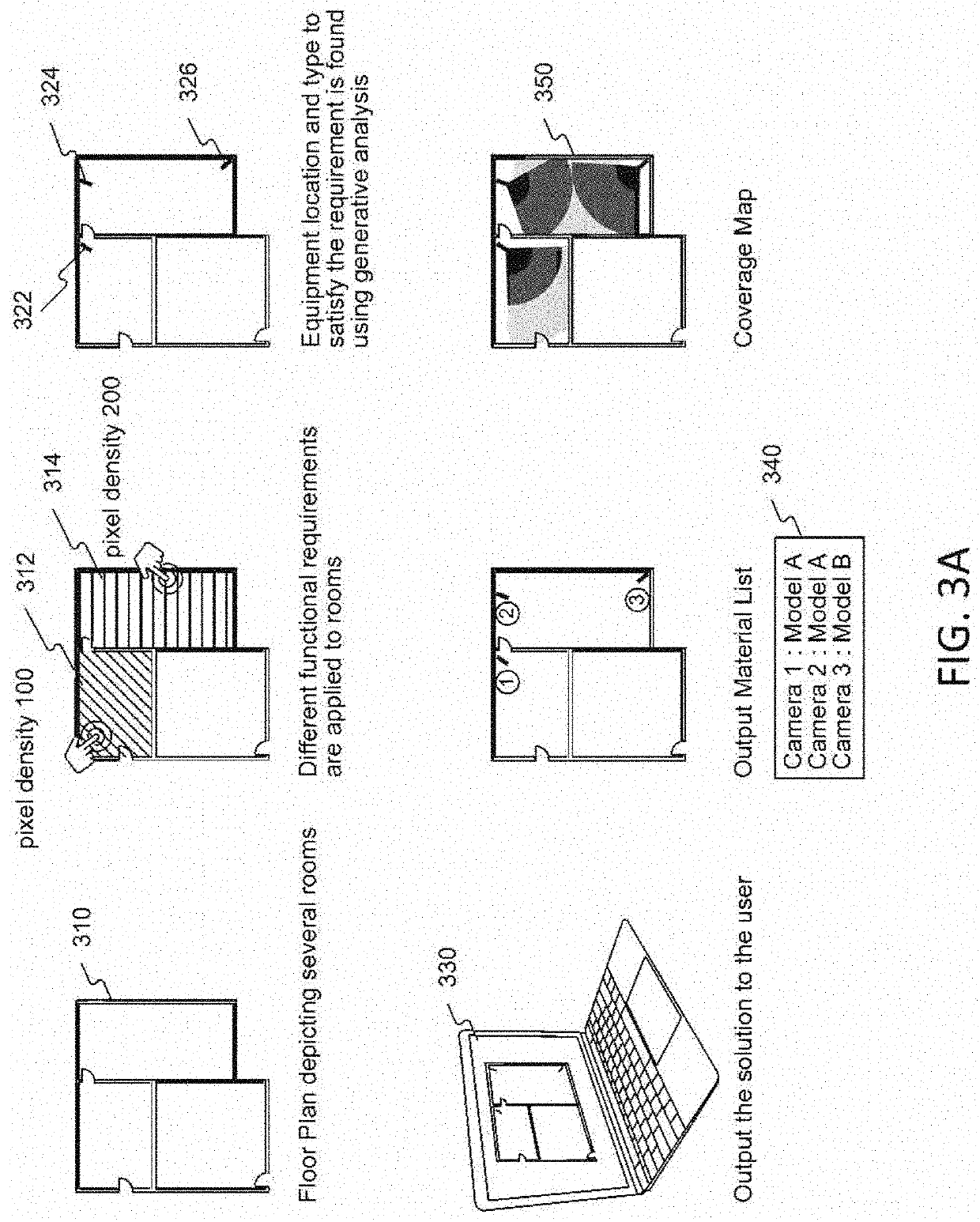

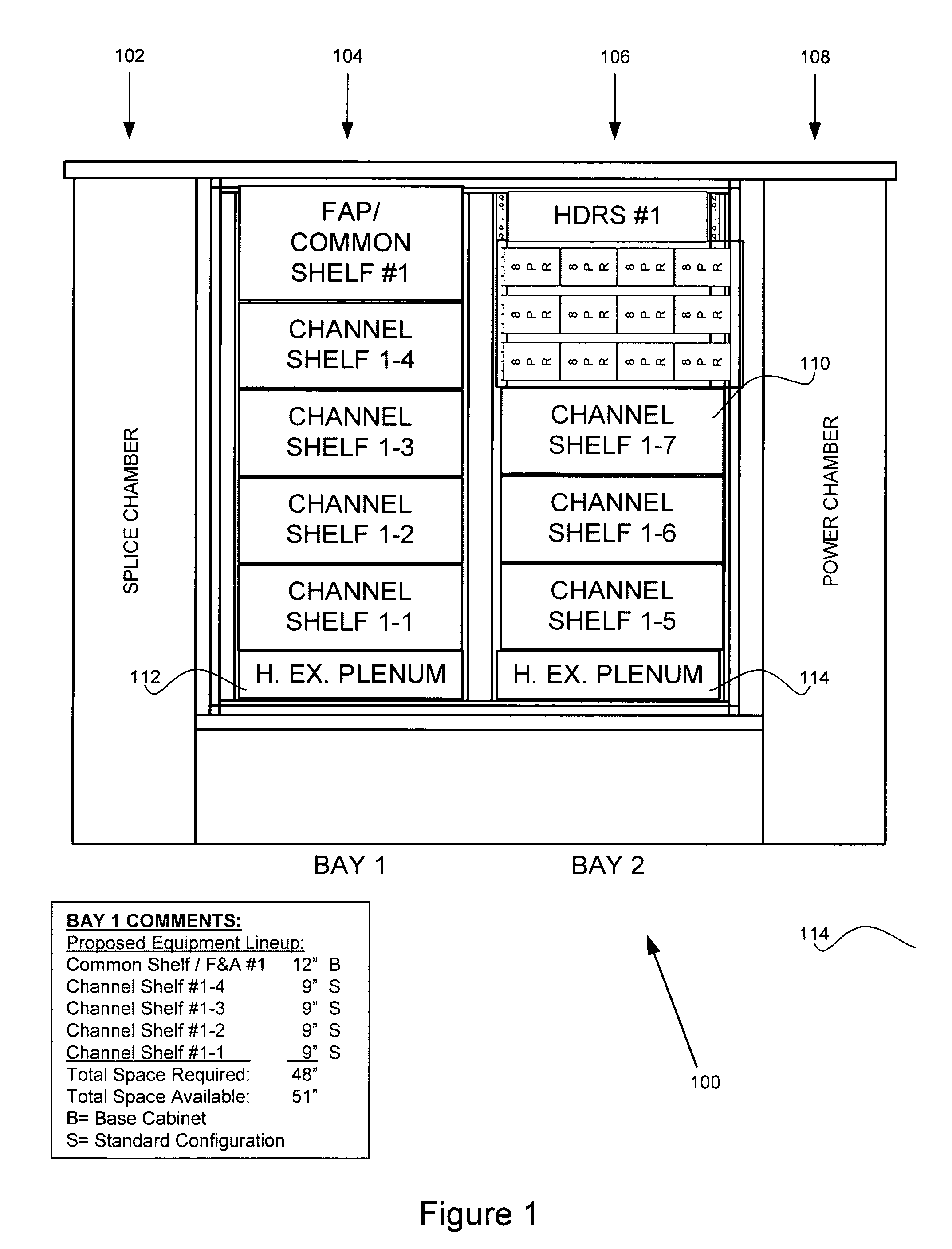

Structural design systems and methods for floor plan simulation and modeling in mass customization of equipment

Systems and methods for selecting equipment for use in buildings are disclosed. The system may include at least one processor configured to perform operations that include accessing a floor plan demarcating a plurality of rooms. The operations further include accessing functional requirements associated with the rooms and accessing technical specifications associated with the functional requirements. The operations include performing floor plan analysis on the floor plan to ascertain room features associated with the functional requirements and technical specifications. The operations include generatively analyzing the room features to determine a customized equipment configuration for at least some of the rooms, and generating a manufacturer dataset including a room identifier, an equipment identifier, and the customized equipment configuration. The manufacturer dataset enables a manufacturer to customize equipment for the rooms and package the customized equipment to display the room identifier.

Owner:BEAMUP LTD

Mass customization configurator

InactiveUS7472043B1Accelerate time to marketReducing the engineering life cycleThermometer detailsDigital computer detailsAuto-configurationBill of materials

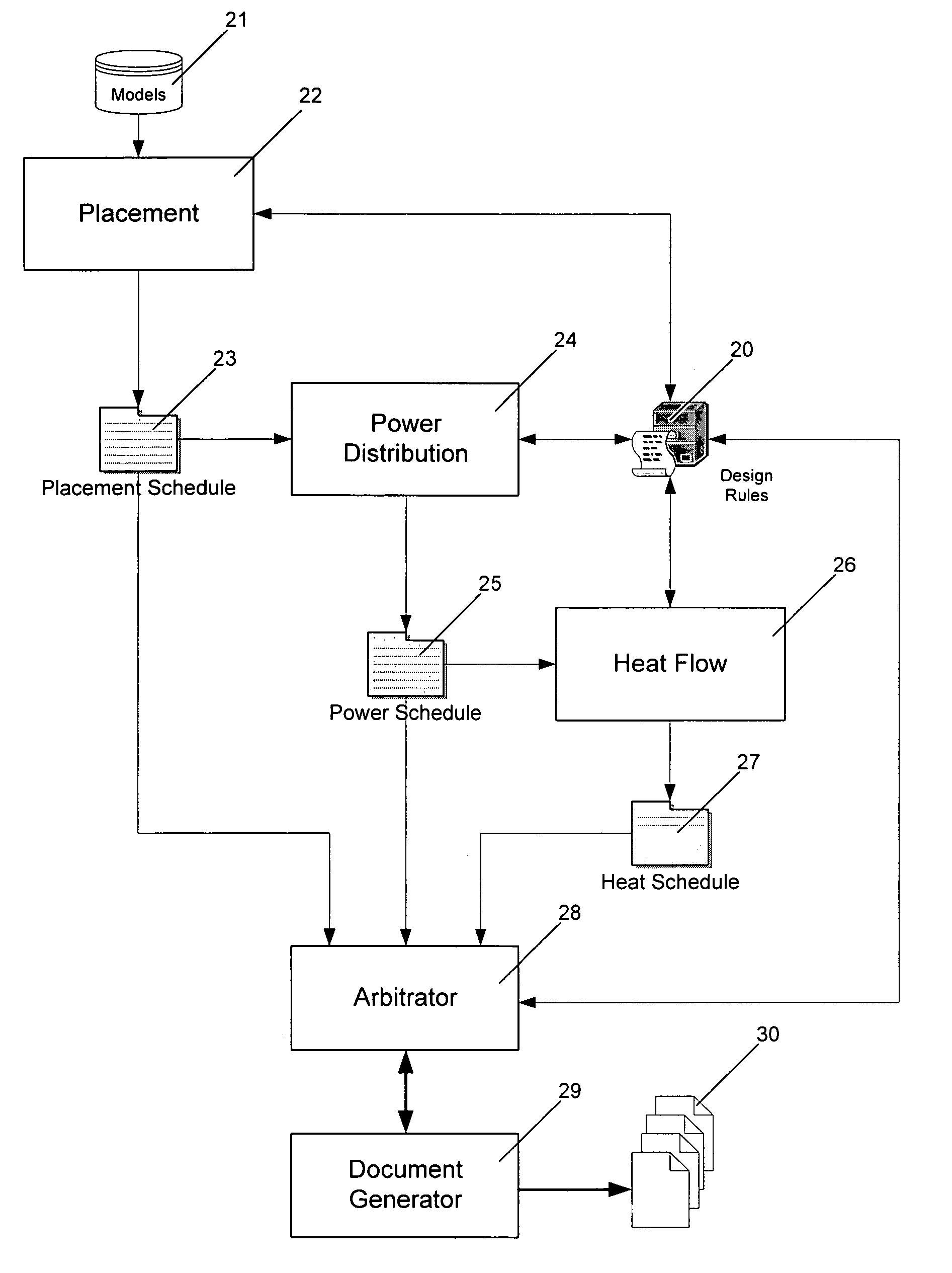

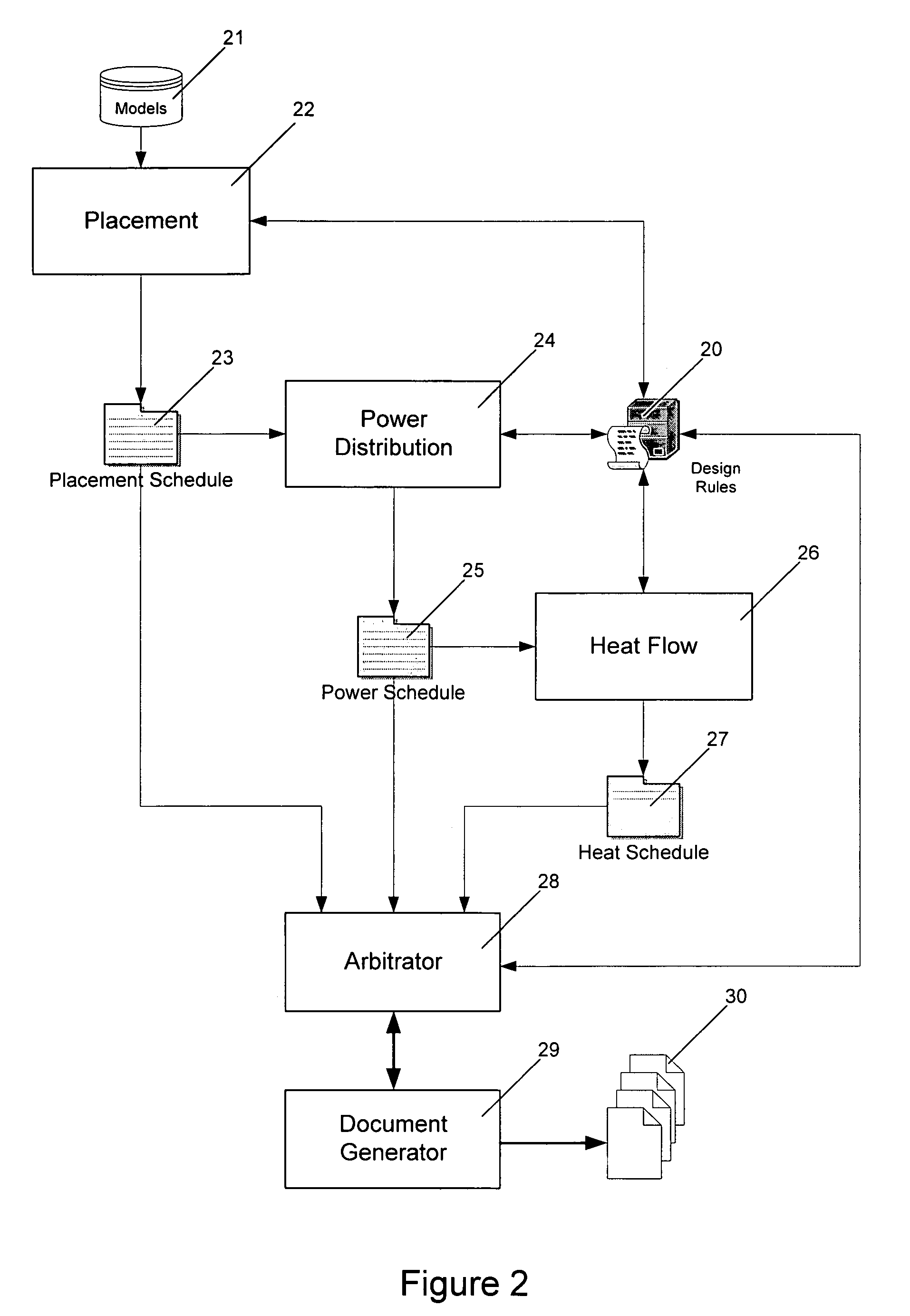

The present invention provides an automated configuration system and method for electronics enclosures. The system receives user requirements generates a configuration including placement schedule, power usage schedules and heat flow schedules. Included as output of the system is a bill of materials, an equipment layout drawing and pricing based on predetermined material and labor pricing. Methods for generating a configuration are described that include iteratively repeating combinations of the steps of generating design rules, deriving a placement schedule, mapping the distribution of power usage within the enclosure and producing a heat flow analysis. Processes used to generate the configuration can be controlled by design rules derived from user requirements.

Owner:TELLABS BEDFORD

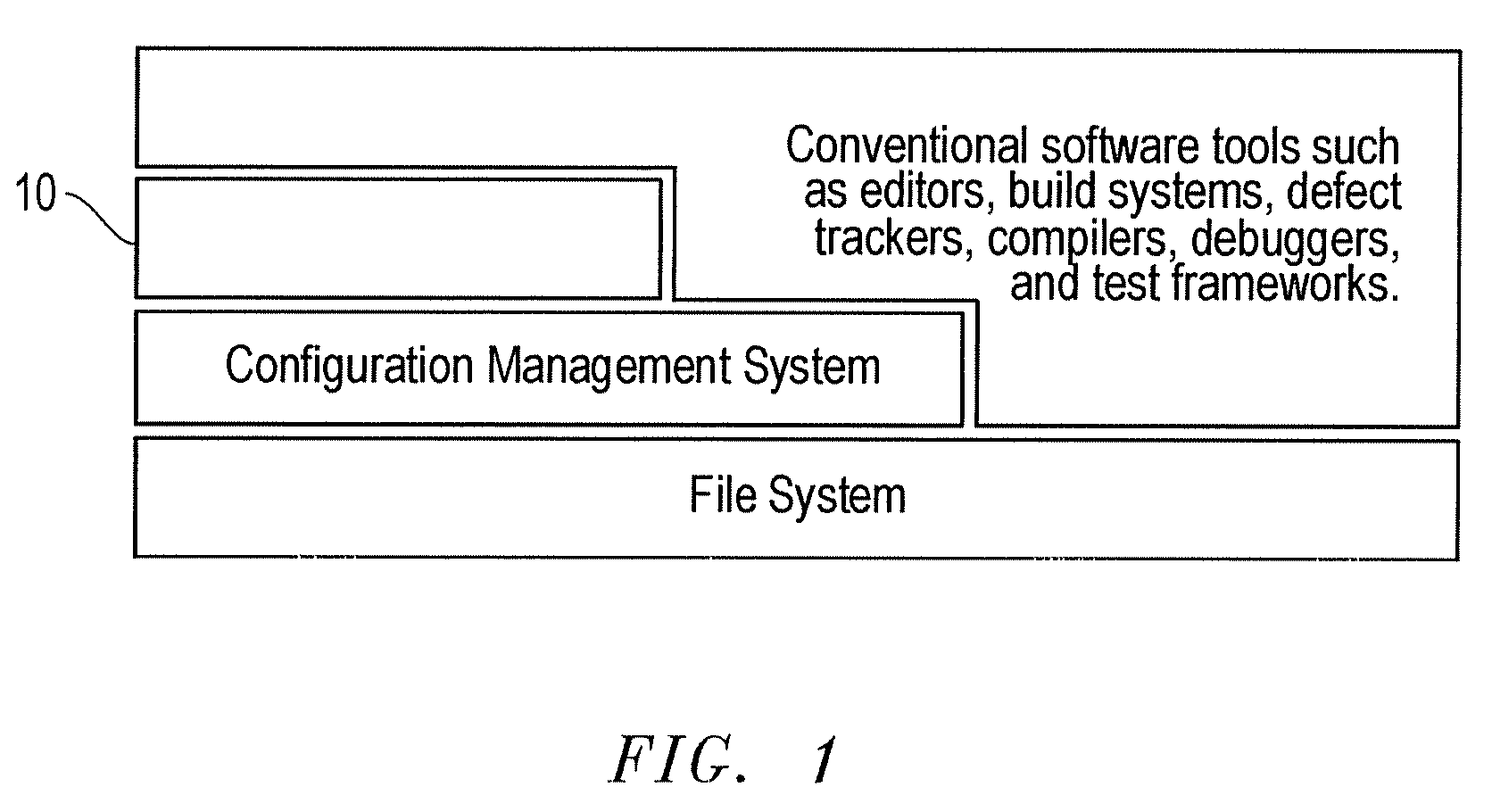

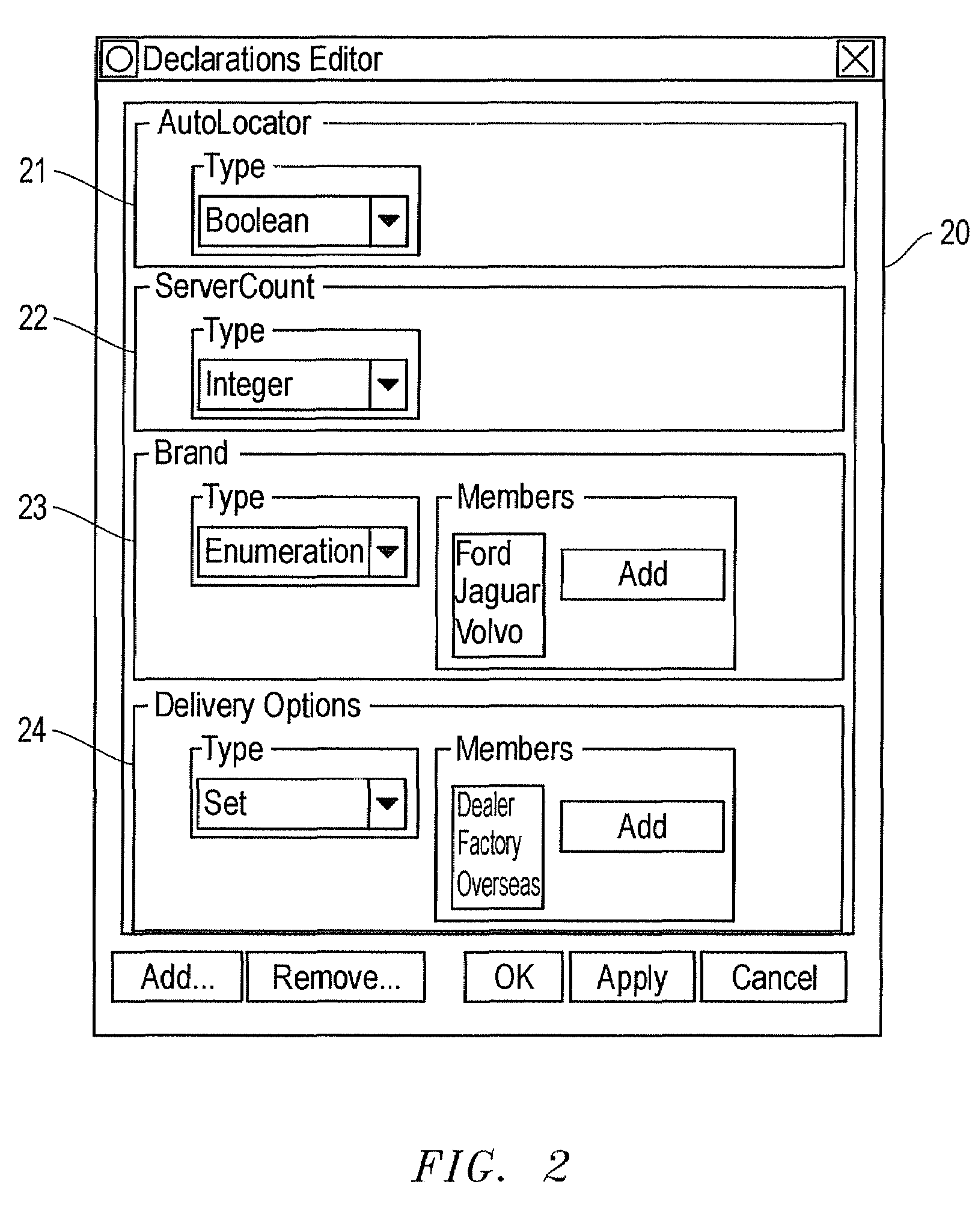

Software customization system and method

InactiveUS7543269B2Maximize reuseMinimize complexityDigital storageSpecific program execution arrangementsMass customizationSoftware engineering

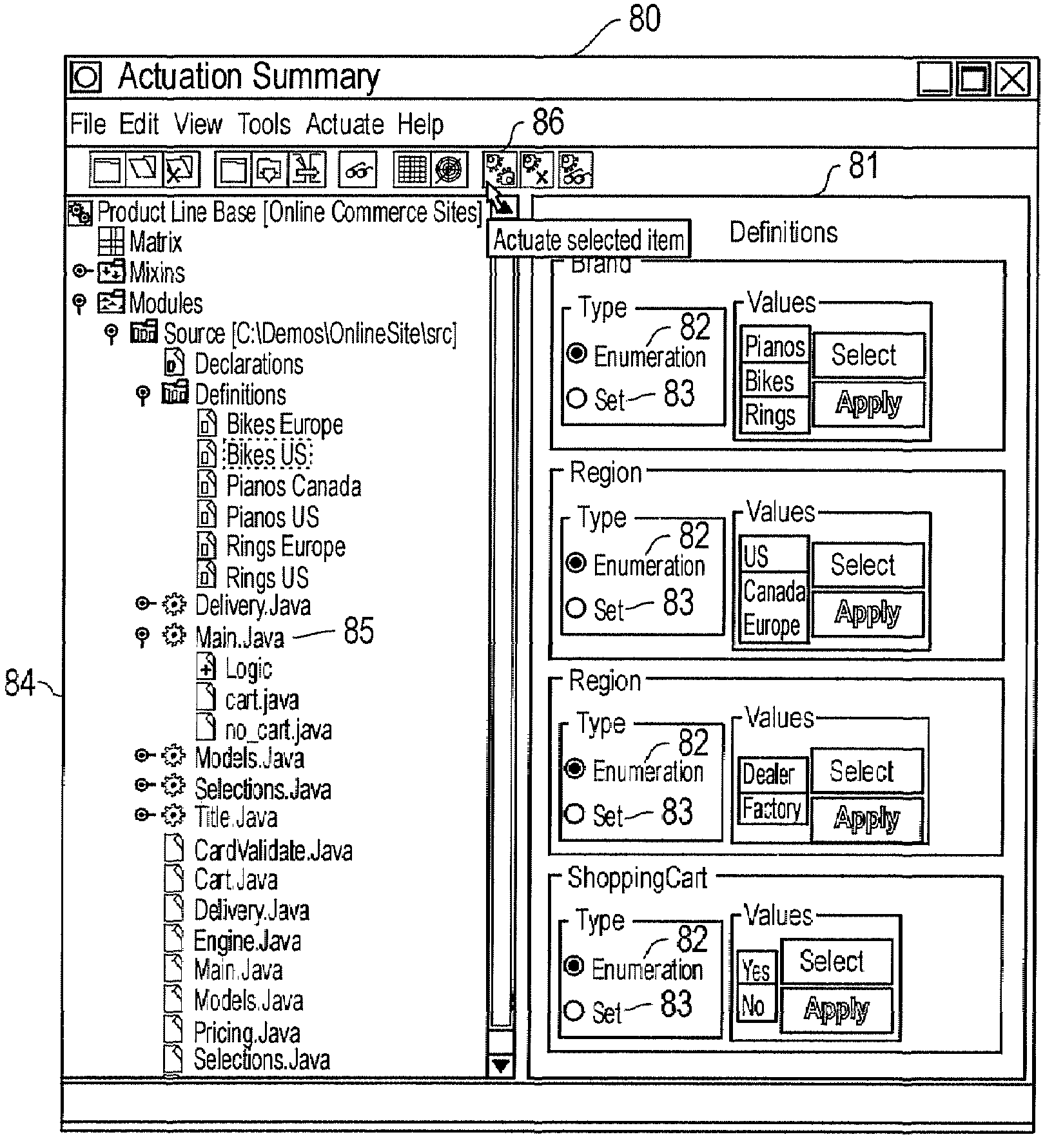

A system and method for the mass customization of software includes a software production line infrastructure, development environment, and actuator. The infrastructure organizes the software production line using a feature declarations component, a product definitions component, an automatons component, and a partition composition component. The development environment browses, displays, organizes, edits, and maintains the infrastructure. The actuator actuates the software production line to produce custom software products.

Owner:BIGLEVER SOFTWARE

Method of manufacturing ophthalmic lenses using modulated energy

InactiveUS20060192310A1Reduce in quantityCost effective productionOptical articlesLensMass customizationEngineering

The present invention is related to a process for efficient manufacture of bifocal, multi-focal, single vision and mass customized ophthalmic lenses by modulating an energy source according to a cure period and a cure pattern to create a maximum number of lenses with a minimum number of molds and associated tooling.

Owner:NOVARTIS AG

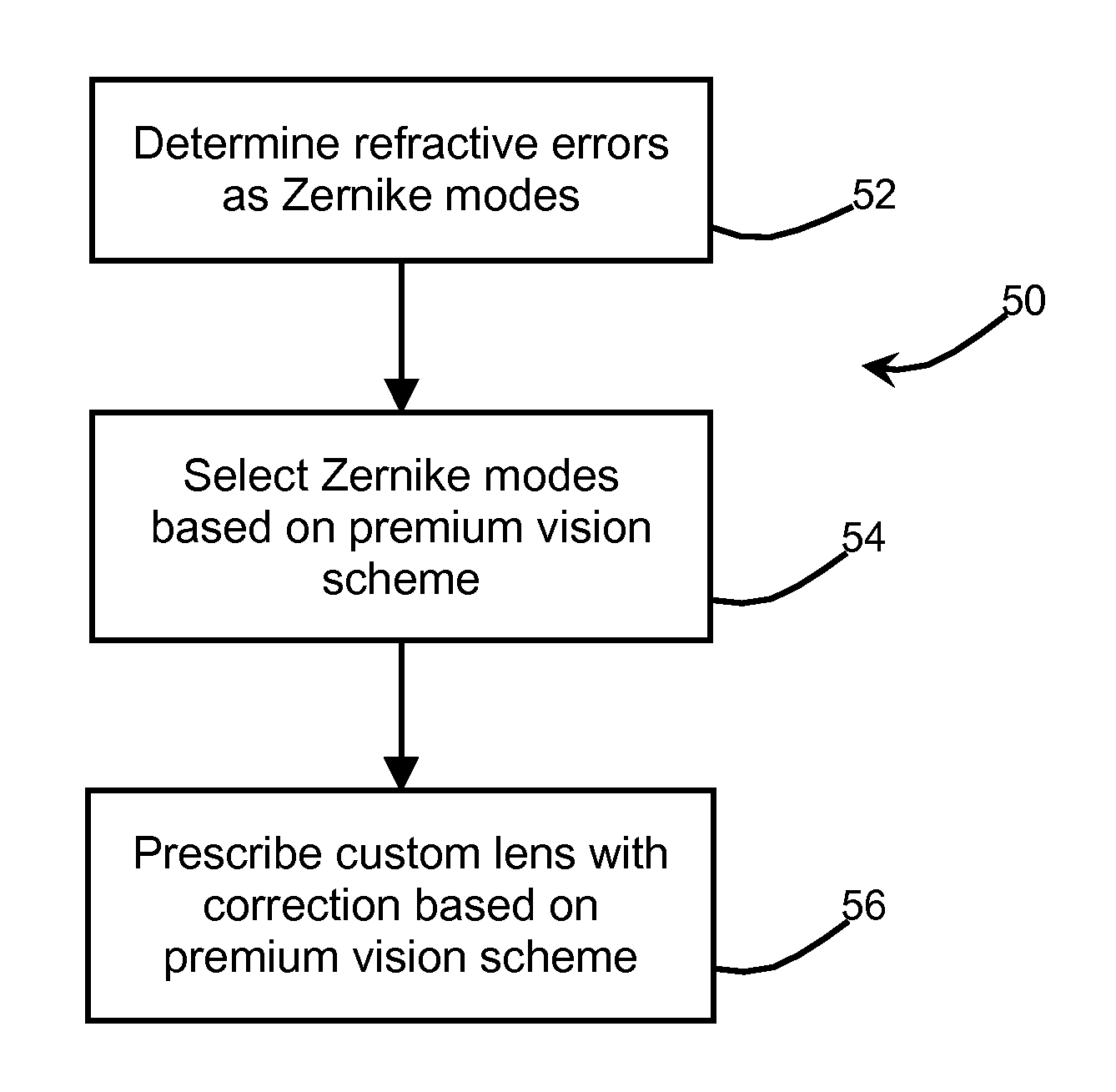

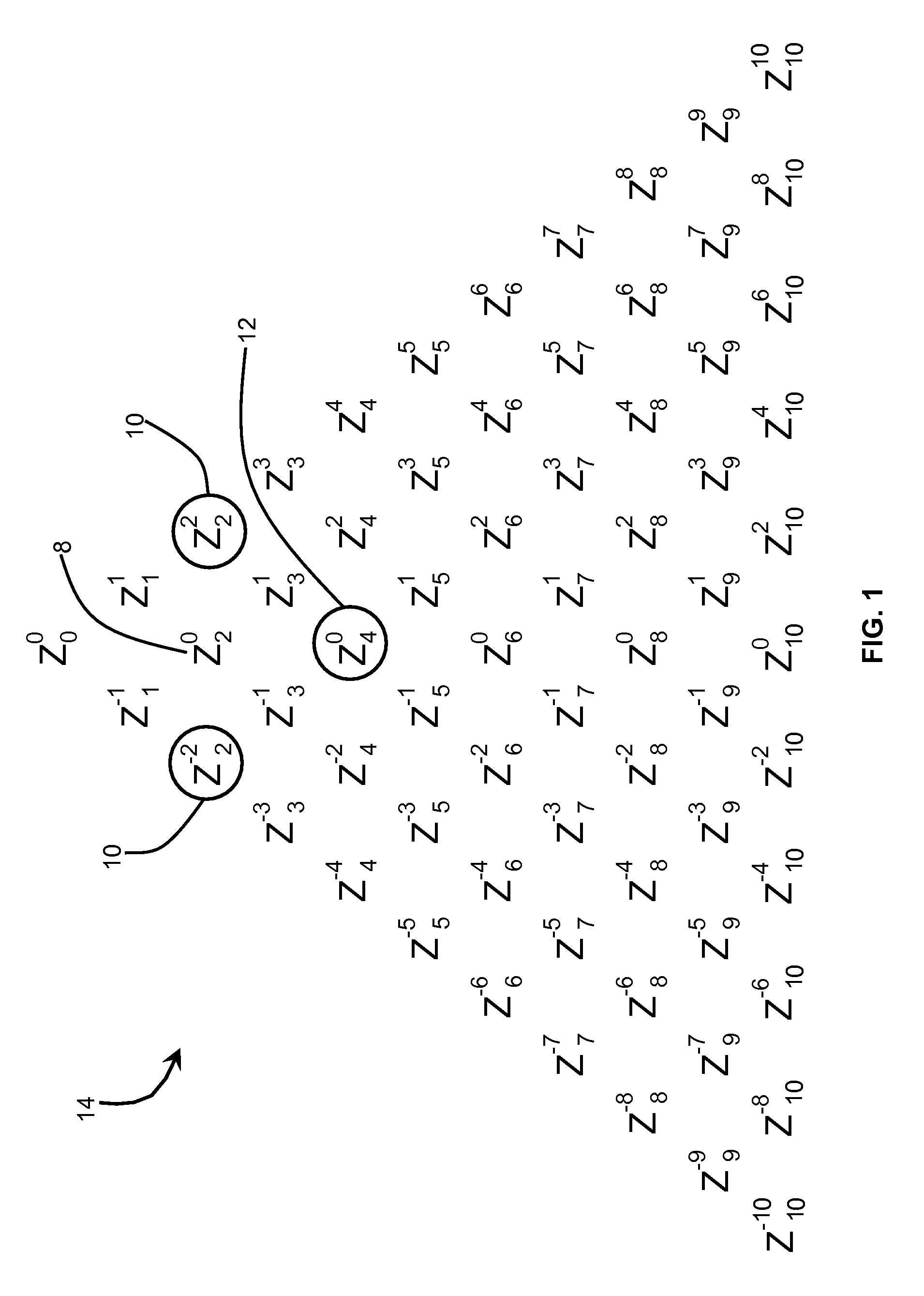

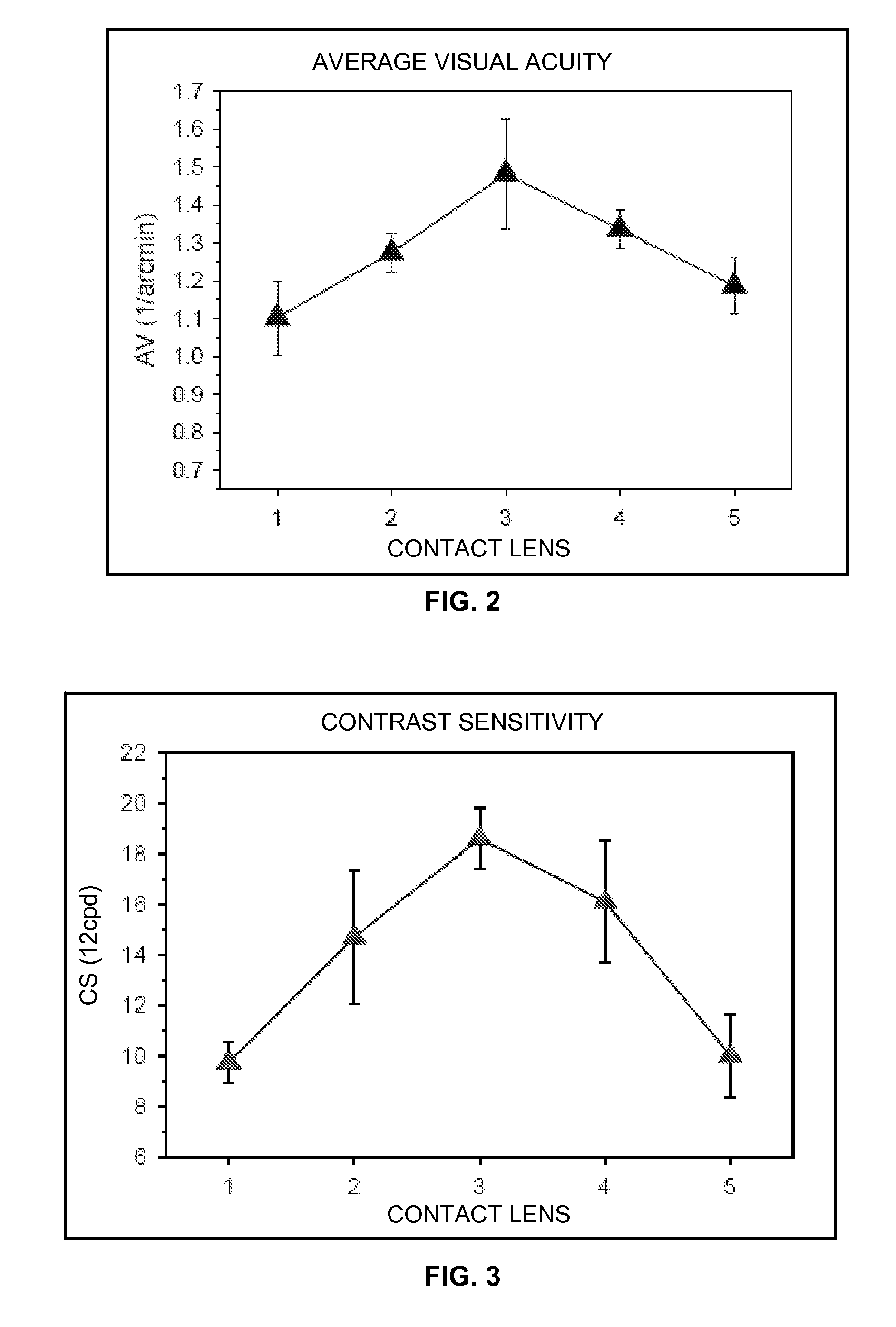

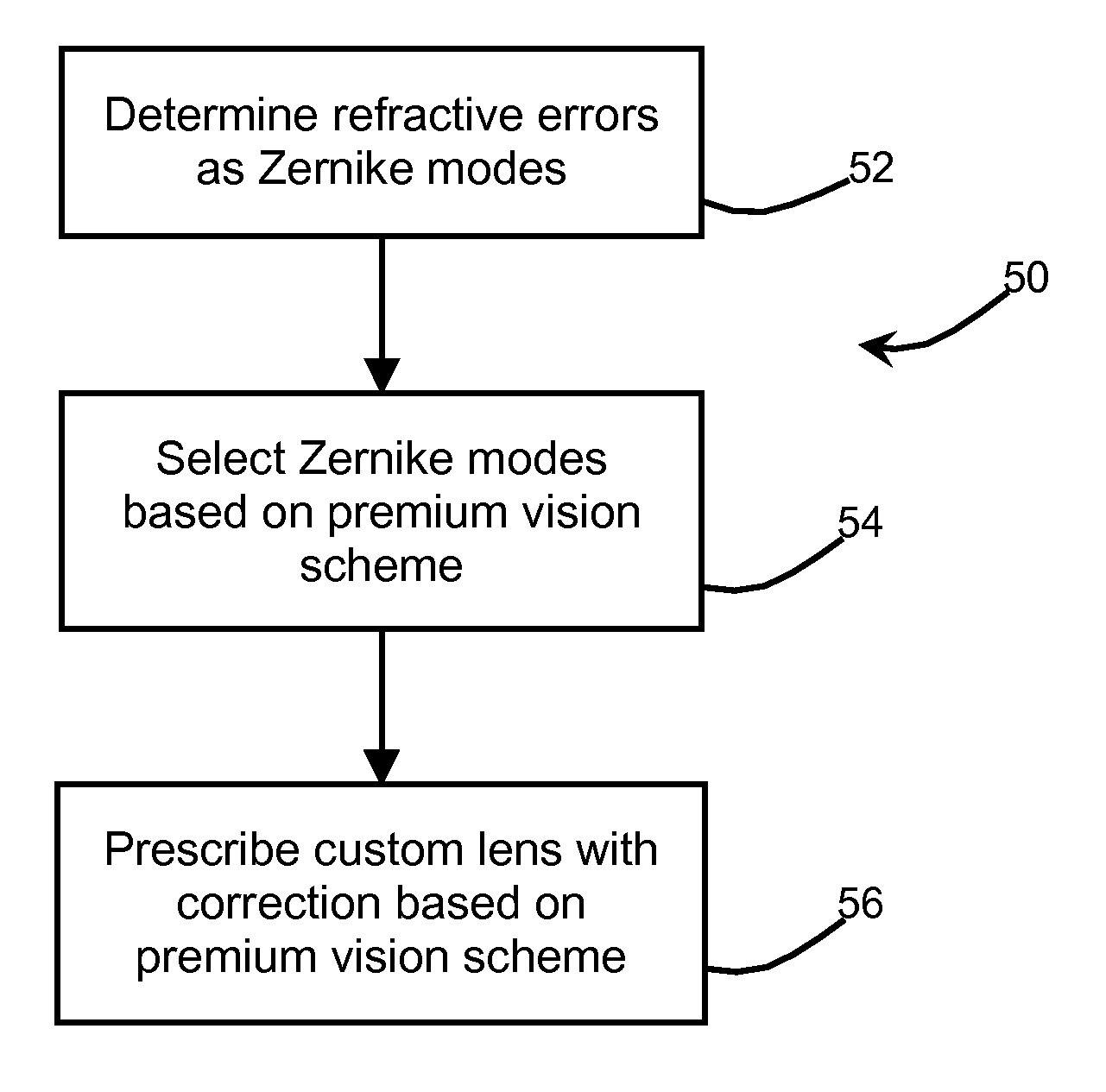

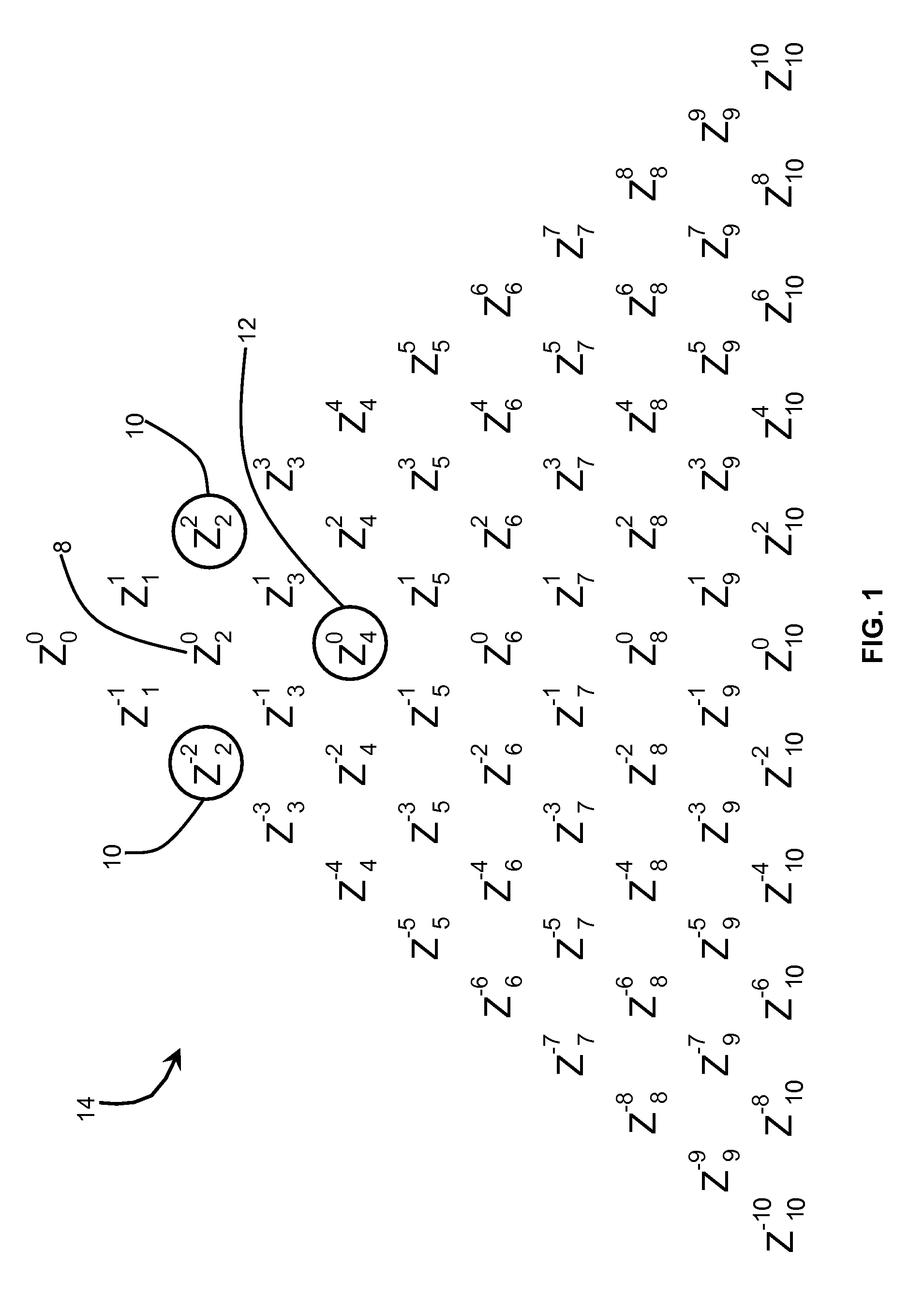

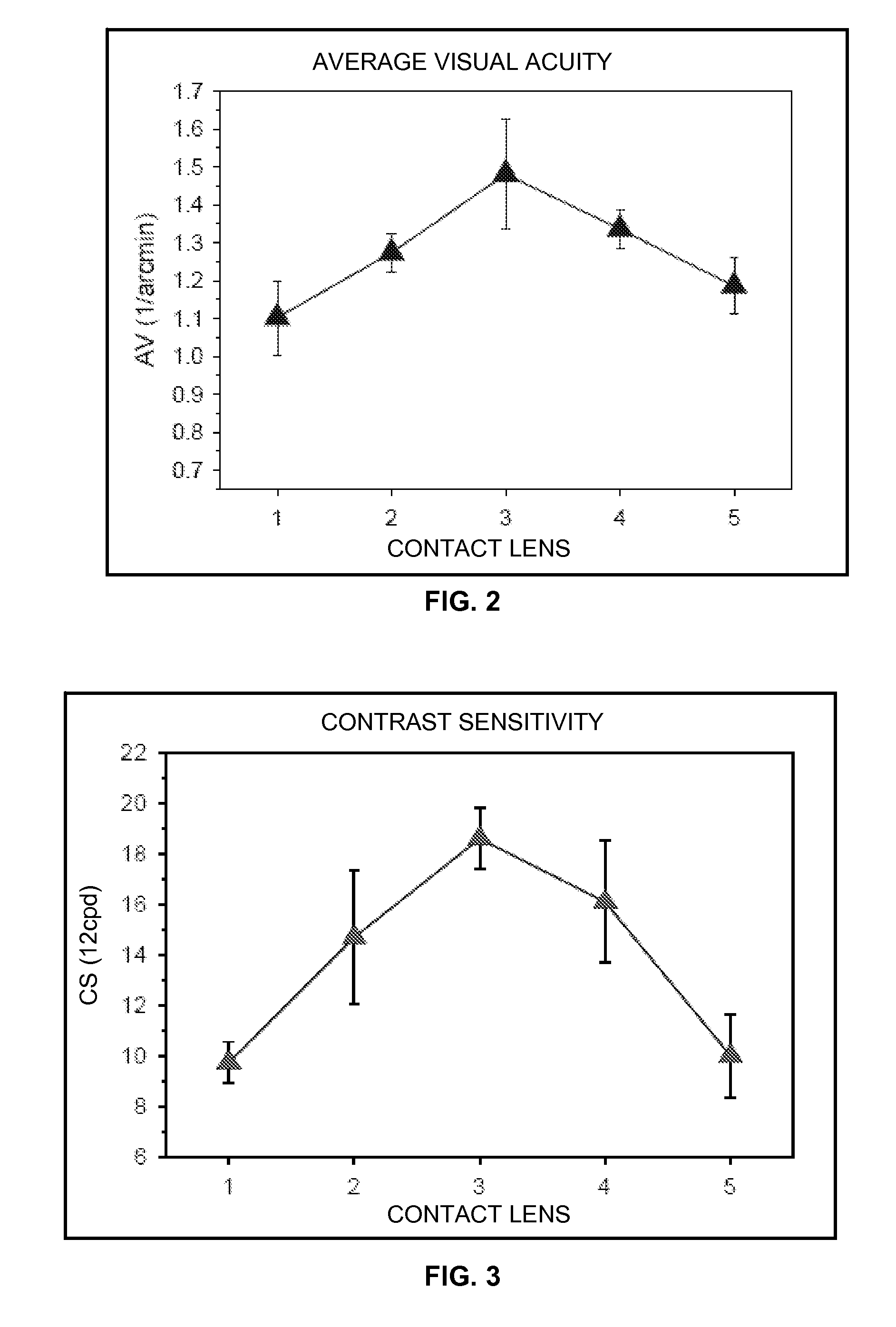

Premium vision ophthalmic lenses

ActiveUS20080143963A1Accurately cancel outImprove visual acuitySpectales/gogglesRefractometersMass customizationStigmatism

An ophthalmic lens with premium vision corrections provides significantly improved visual acuity and contrast sensitivity. The premium vision corrections include precisely correcting for two aberration mode sets simultaneously, second-order astigmatism and fourth-order spherical aberration, instead of correcting for only second-order astigmatism or simultaneously correcting for all aberrations present. Fourth-order astigmatism, sixth-order spherical aberration, and third-order coma are additionally corrected in other premium vision correction schemes. In addition, methods are provided for prescribing and fabricating the premium vision lenses to permit mass customization.

Owner:ALCON INC

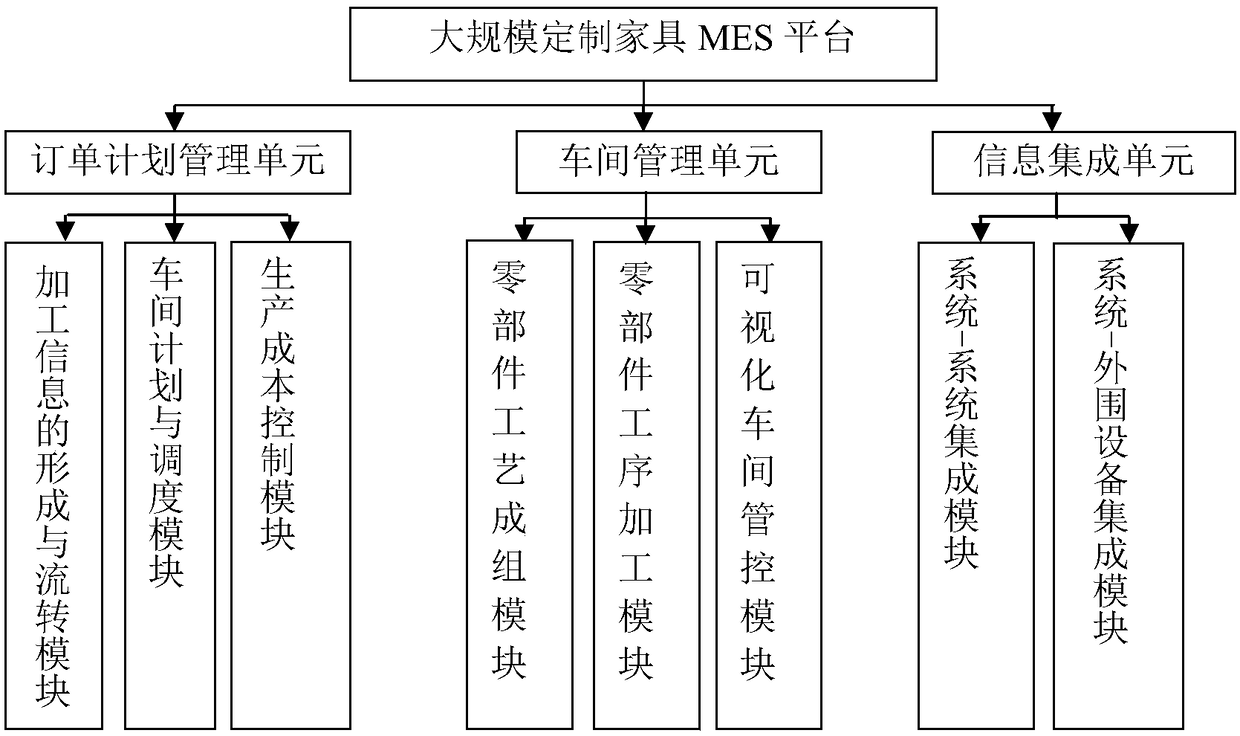

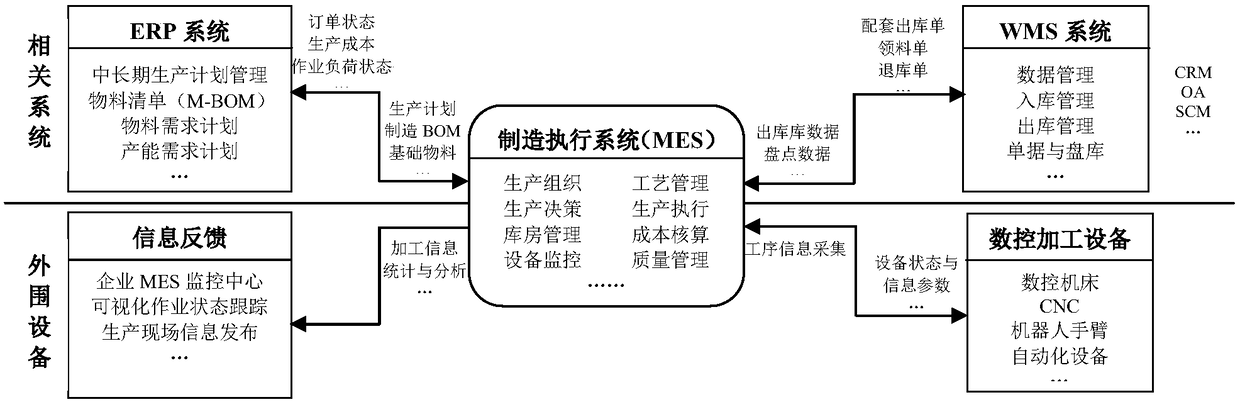

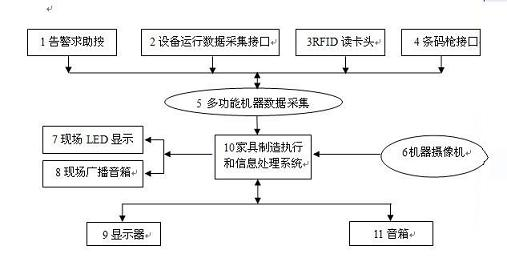

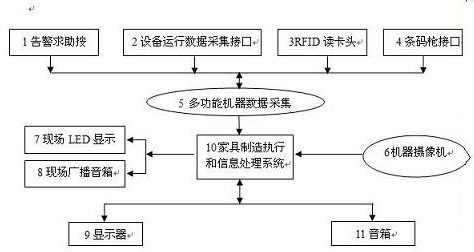

MES platform for mass customization of furniture

InactiveCN108596422AUnderstand and control production equipmentReal-time monitoring of the production siteBuying/selling/leasing transactionsResourcesMass customizationManagement unit

The invention provides an MES platform for mass customization of furniture, and the platform comprises an order planning management unit, a workshop management unit and an information integration unit, wherein the order planning management unit is used for following up the order status and processing process in the management system. The workshop management unit is used for carrying out the real-time monitoring of the various operational specifications and technical requirements of a workshop and corresponding interaction processing, and feeding back various processing results to a productionsite in various modes so as to improve the production scheduling speed of the component processing required by an order. The information integration unit is used for achieving the sharing of the orderdata and the component processing data required for the order between the units and the transmitting of data between the devices. The invention has the beneficial effects that the MES platform improves the production scheduling speed of the component processing by controlling the workshop, overcomes the difficulty of implementing the information management in the processing workshop, and improvesthe labor efficiency.

Owner:NANJING FORESTRY UNIV

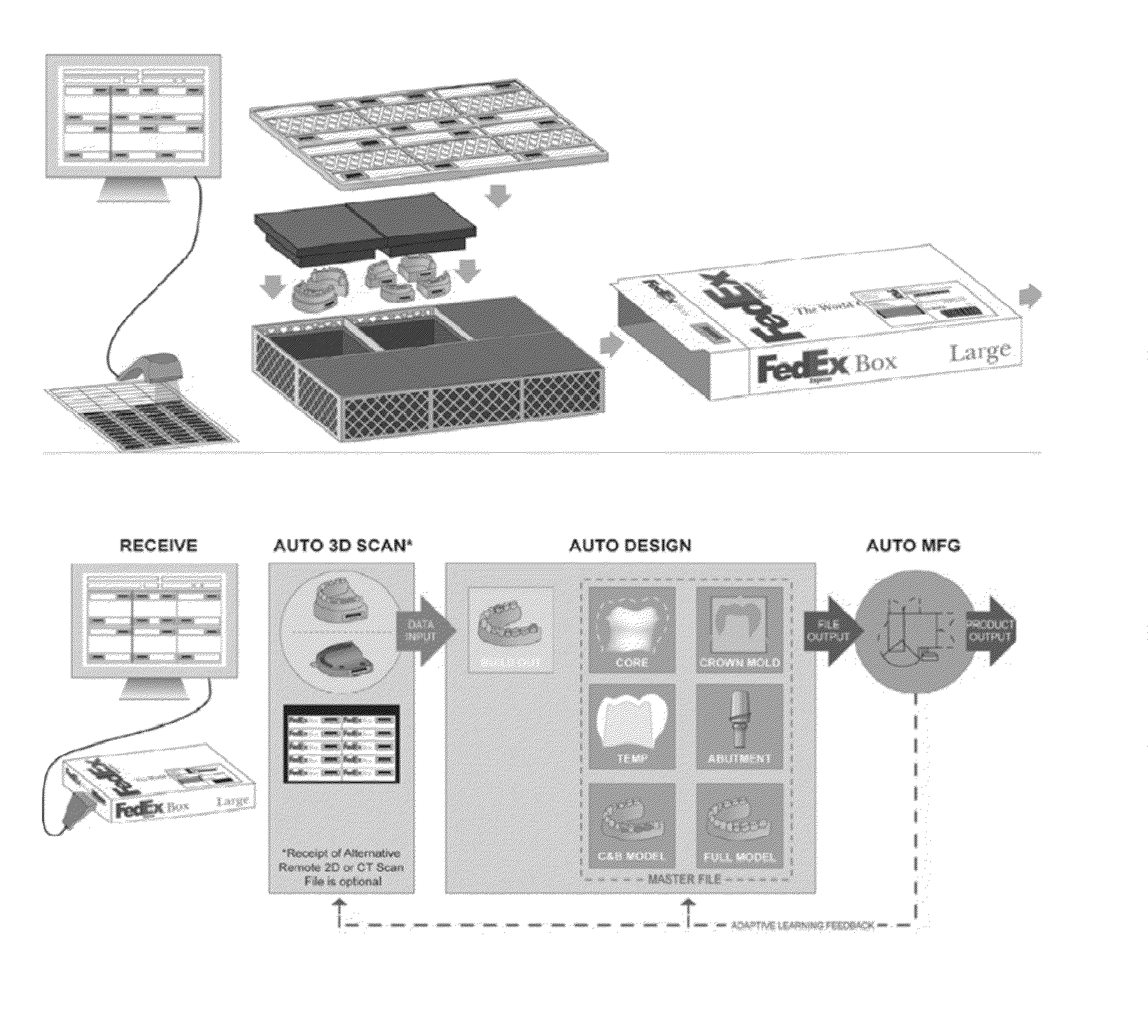

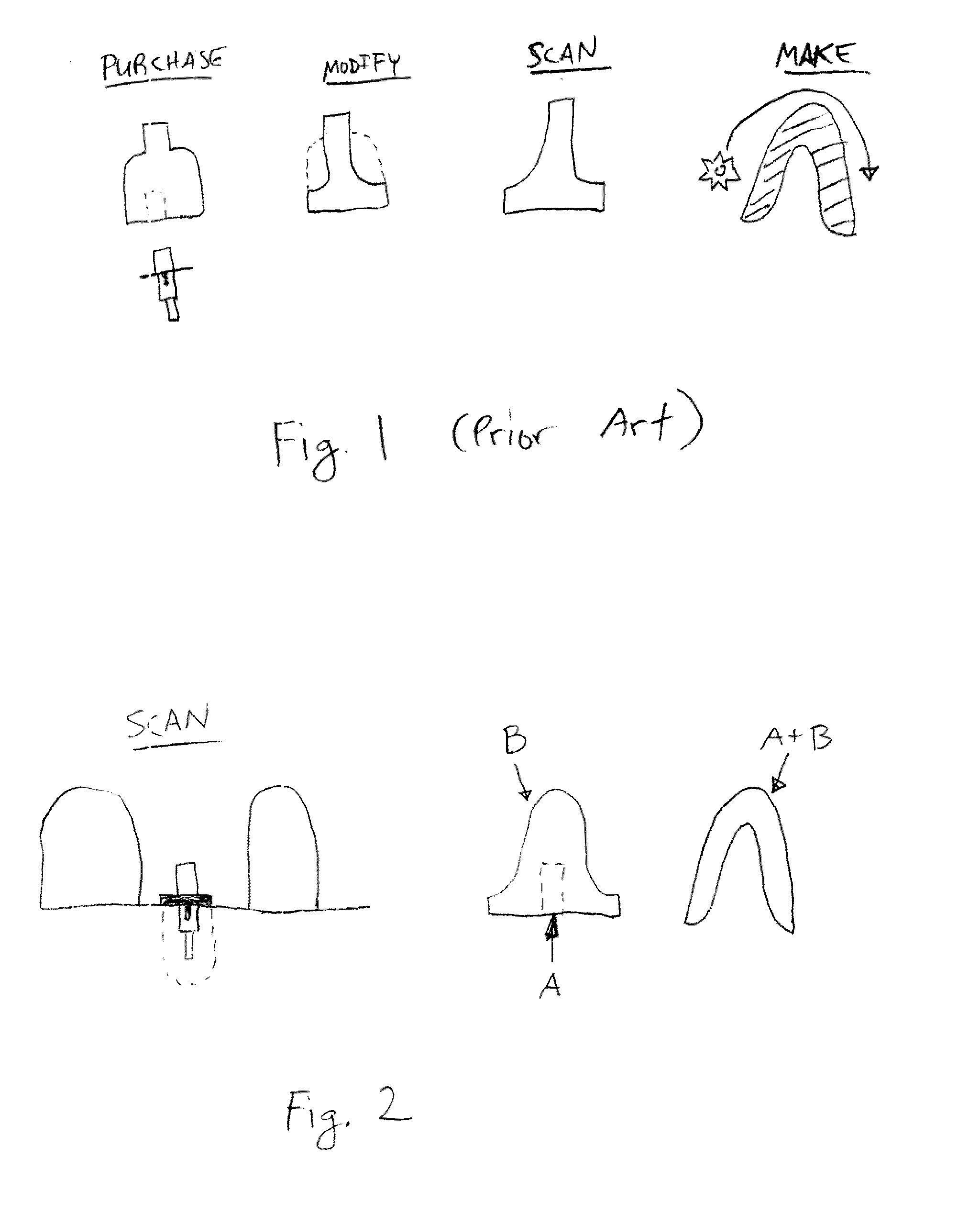

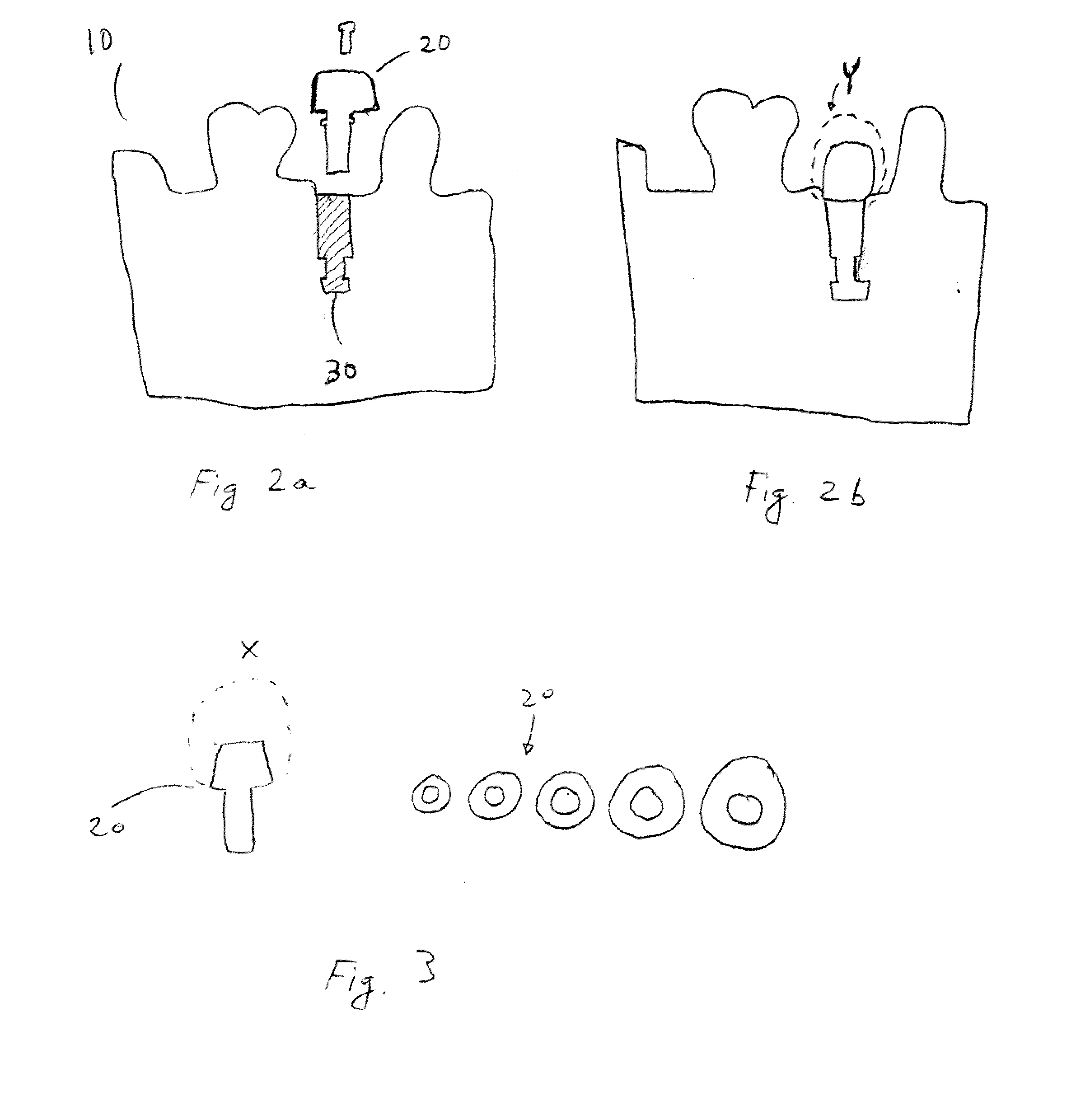

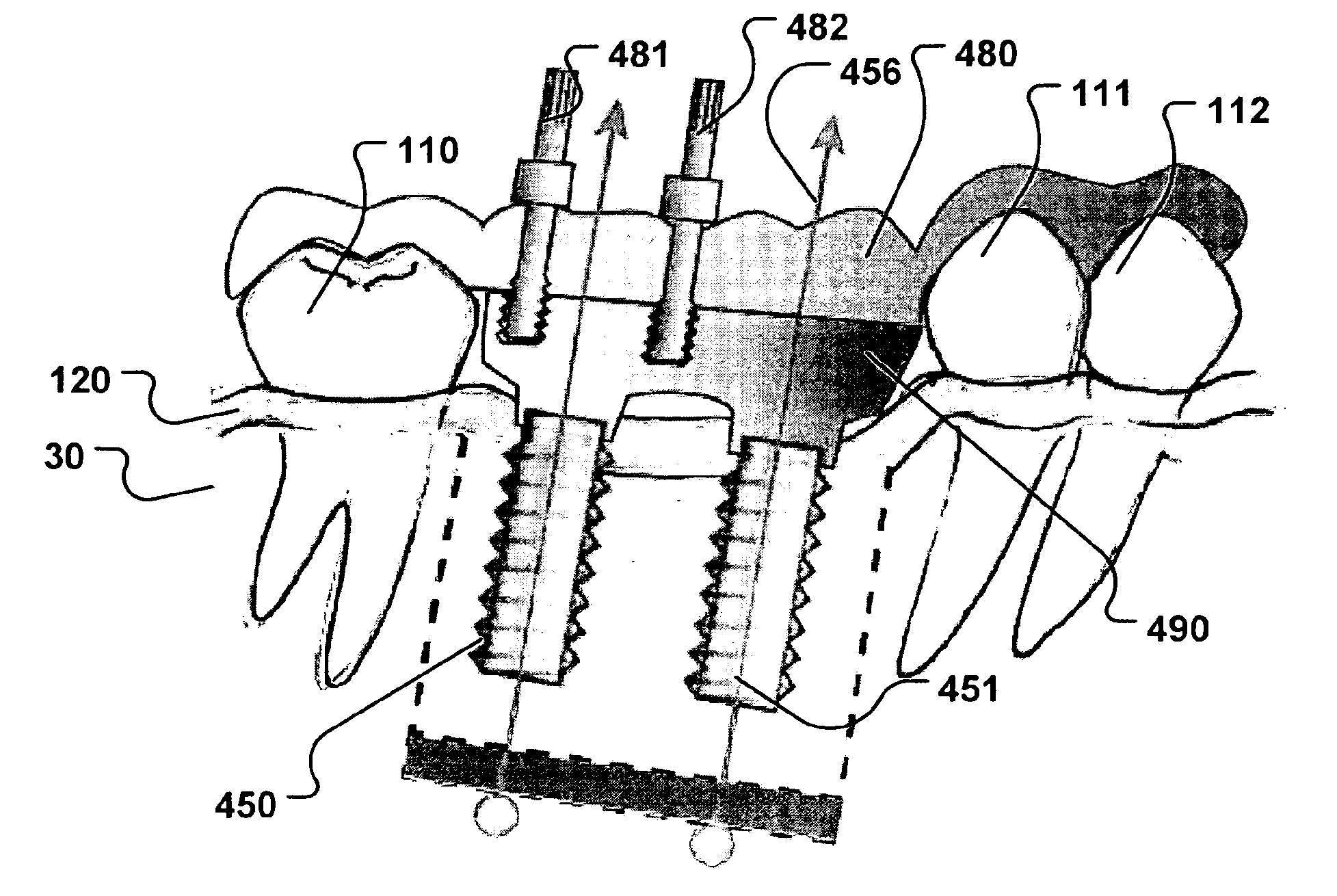

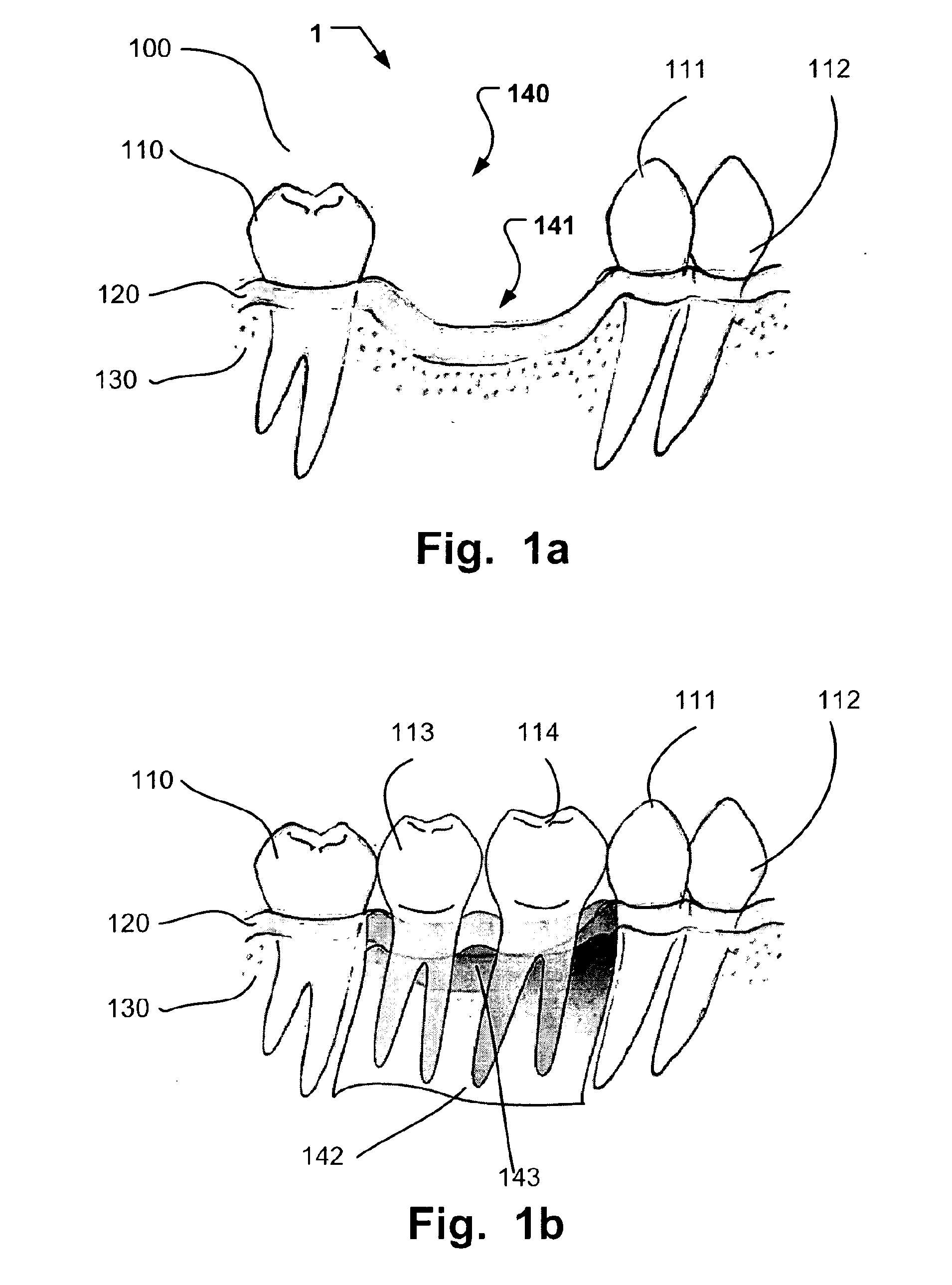

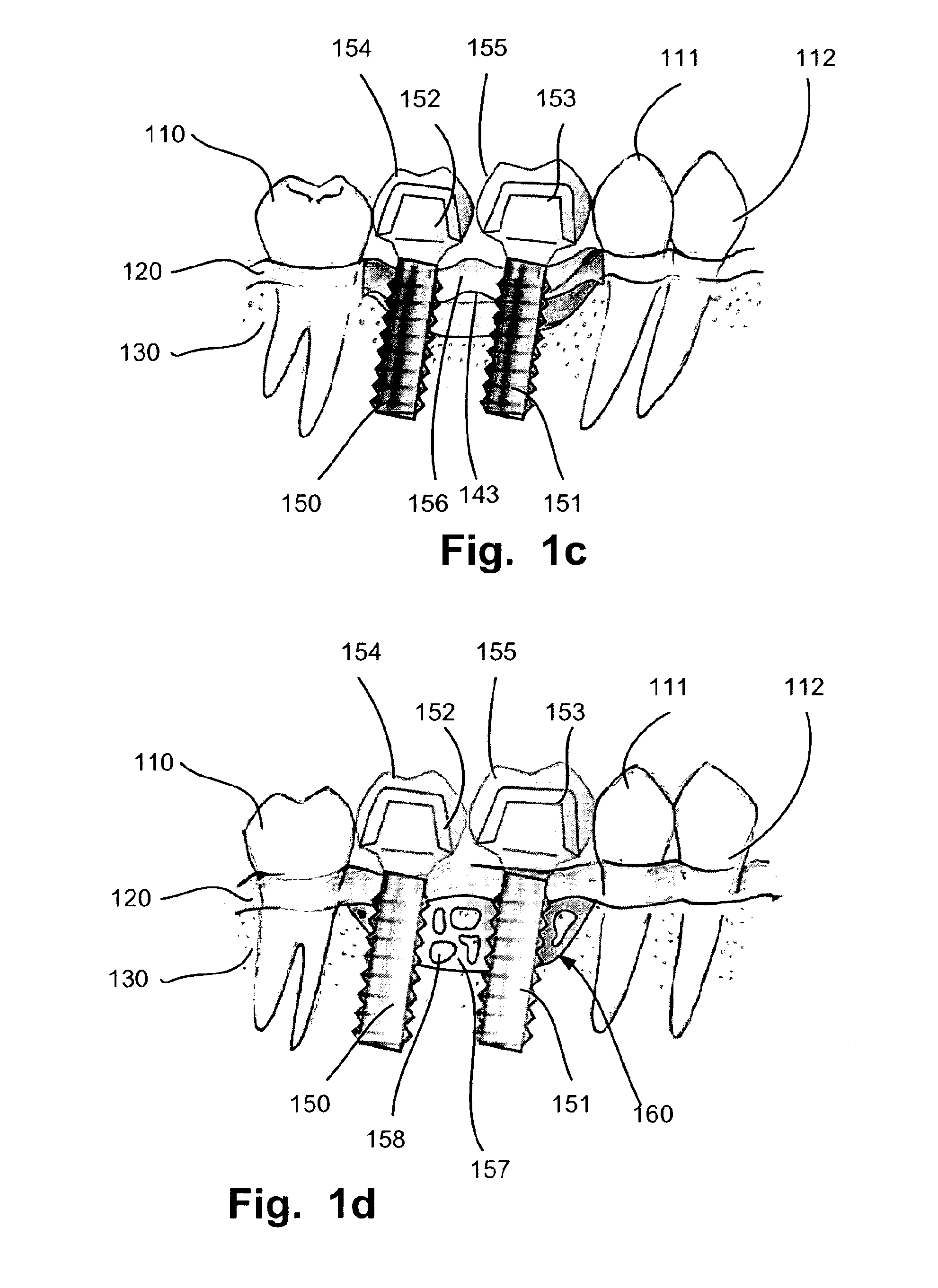

System and method for mass custom manufacturing of dental crowns and crown components

InactiveUS20090319068A1Reduce the amount requiredReduce materialMedical simulationProgramme controlMass customizationDesign phase

A Mass Custom Manufacturing System and methods are provided. A single master file is created for a restoration (or multiple restorations for a single patient) from a scan. Copings / cores, abutments and other companion pieces are designed using the master file through a deconstruction method allowing for simultaneous CAM of those pieces. A centralized system controls design and manufacturing, allowing the system to “learn” from feedback from the CAM operations of prior pieces and incorporate such feedback into the design phase.

Owner:ZIRCORE

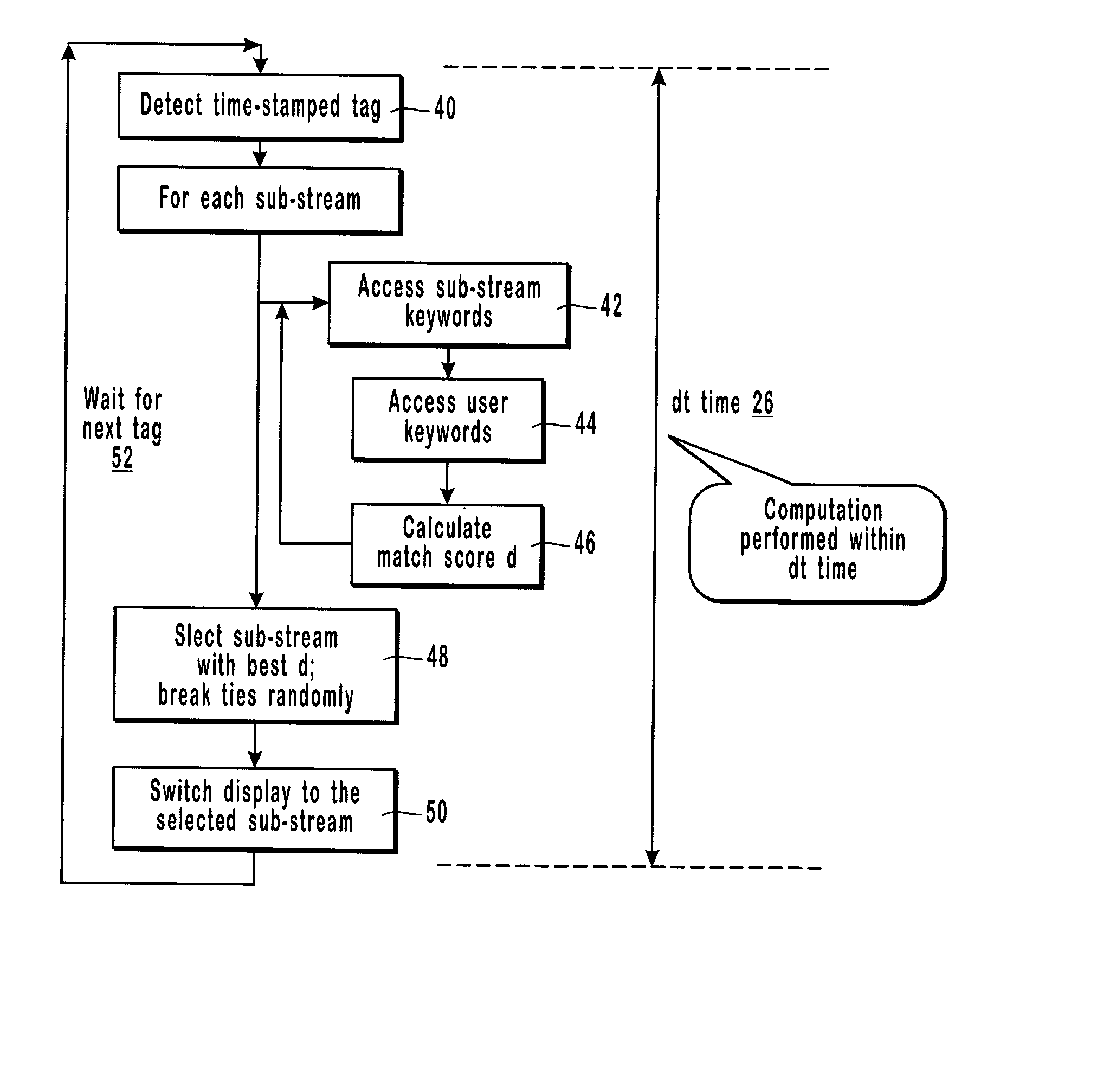

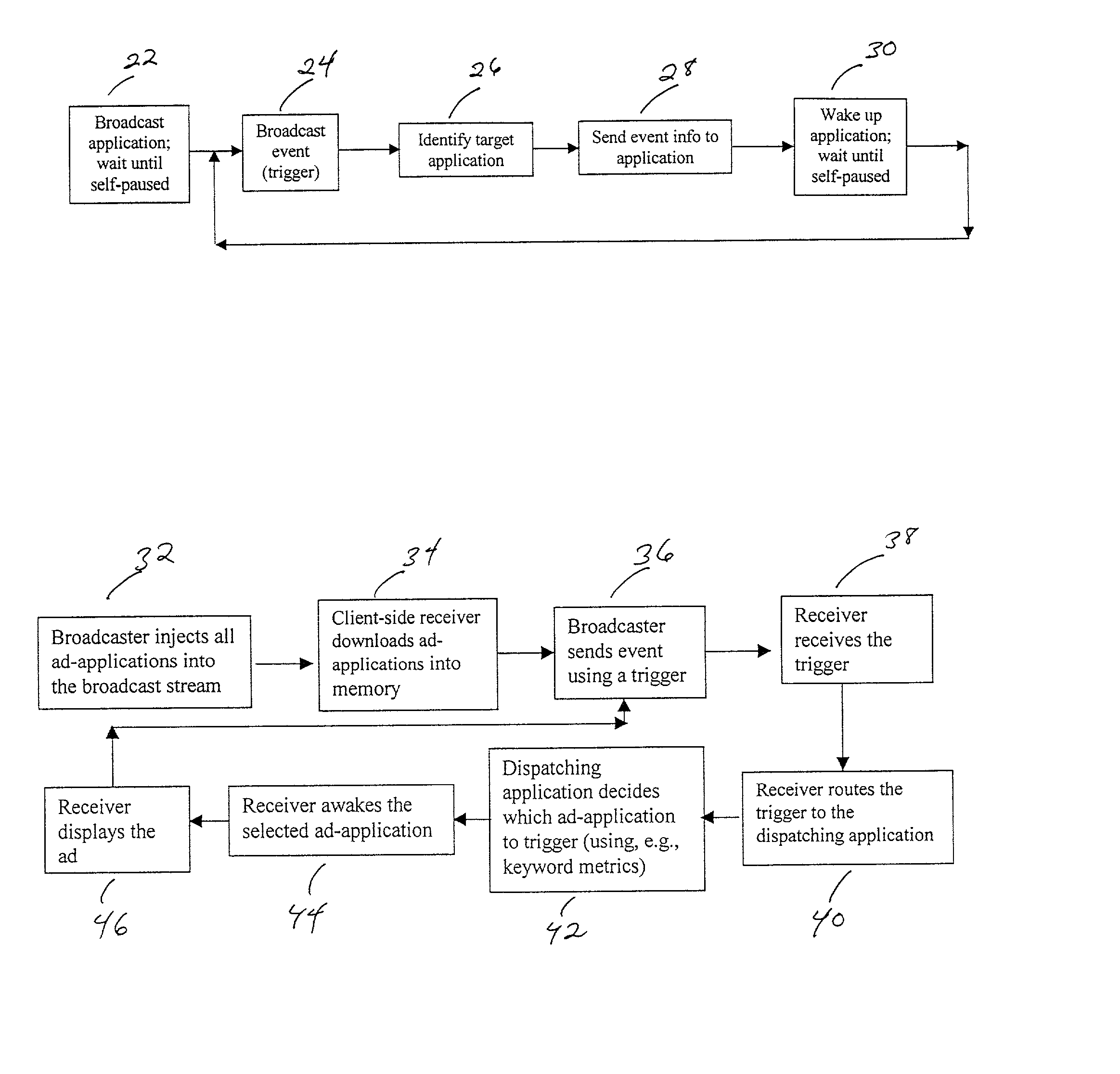

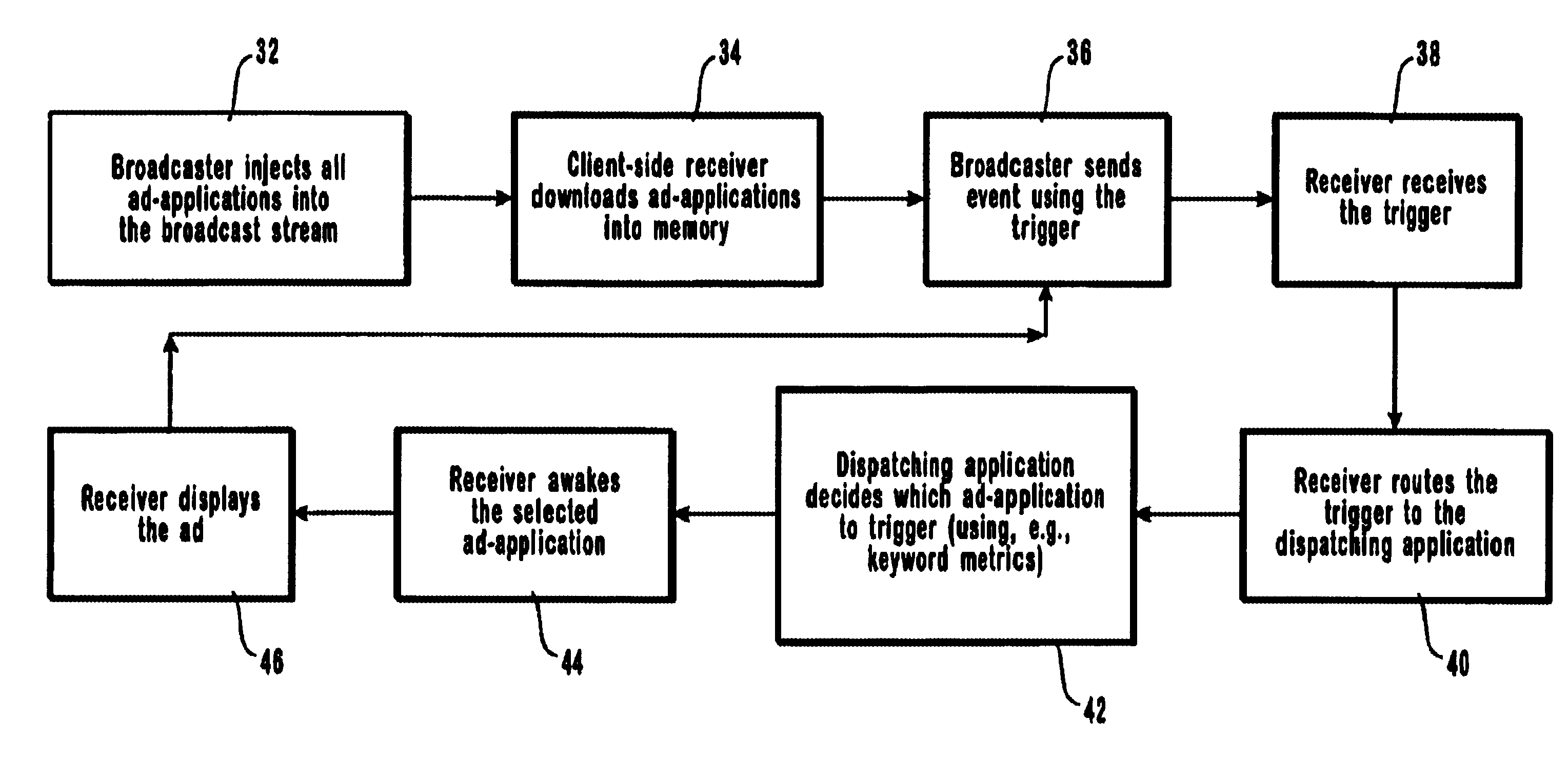

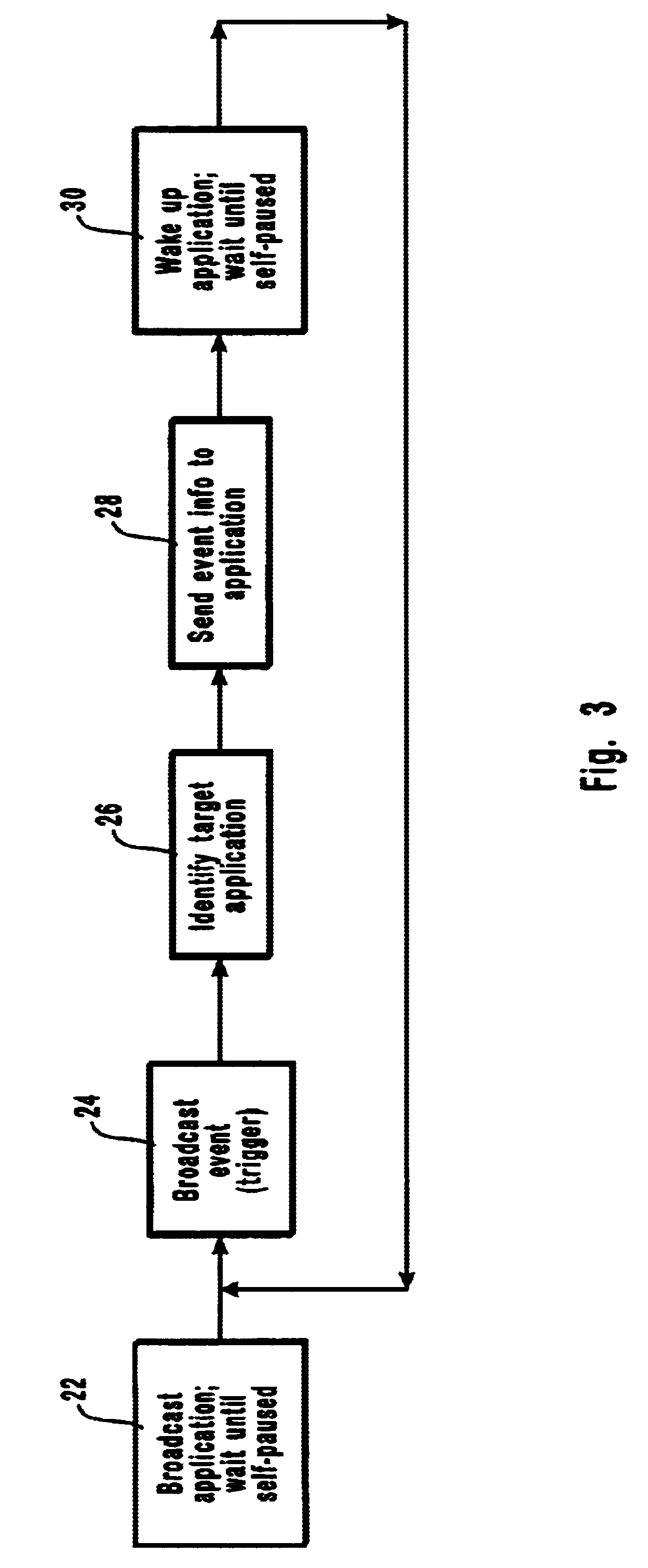

Methods and systems for mass customization of digital television broadcasts in dase environments

InactiveUS20020144261A1Improve experienceIncrease advertisement timeTelevision system detailsAnalogue secracy/subscription systemsMass customizationClient-side

Methods and systems for the mass customization of Digital Television broadcasts through the broadcasting of commercials in the form of software applications. Ad-applications are injected into various sub-streams of the transport stream and received in a dormant state by the client-side set-top box. When a commercial is to be shown, a broadcaster broadcasts a generic time-stamped trigger to a dispatching application that performs a keyword matching algorithm to decide which ad-application among those received at the receiver is to be executed. The dispatching application uses the results of the latter comparison to decide which specific dormant ad-application to route to; it then converts the generic trigger into a chosen-ad trigger that is routed to the chosen ad-application. Upon receipt of the chosen-ad trigger, the chosen ad-application executes, thereby displaying an ad customized to the individual viewer's interests.

Owner:SHARP LAB OF AMERICA INC

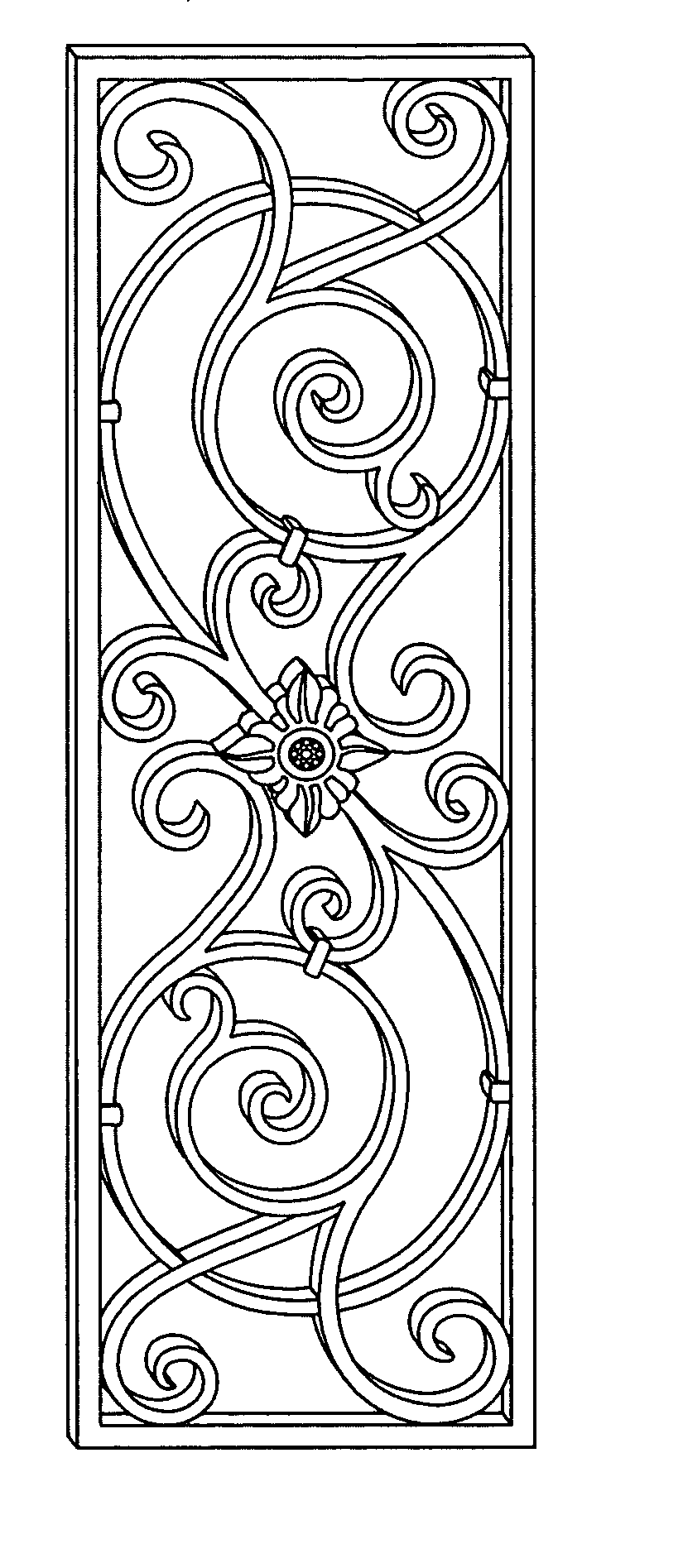

Decorative lattice structure and methods for manufacturing and installing same

InactiveUS20070000195A1High cost lookLow mass production costCovering/liningsFixed grillesFiberMass customization

A decorative lattice that simulates the look and feel of decorative ironwork by combining carving techniques and coating techniques is described. The decorative latticework is made of a sheet material such as a composite wood / fiber board material. The decorative lattice is suitable for a mass customization manufacturing processes.

Owner:LUNA PIENA

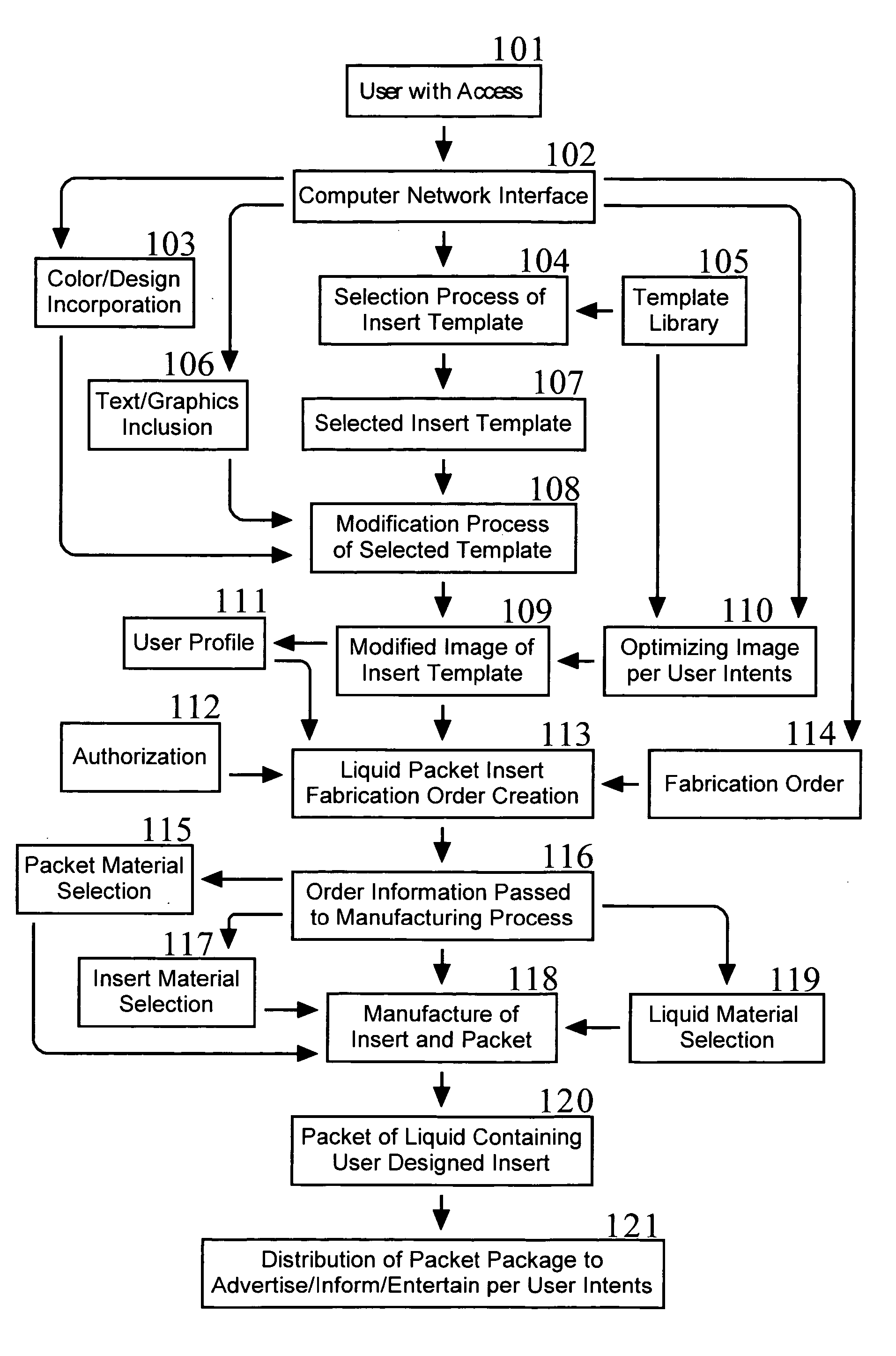

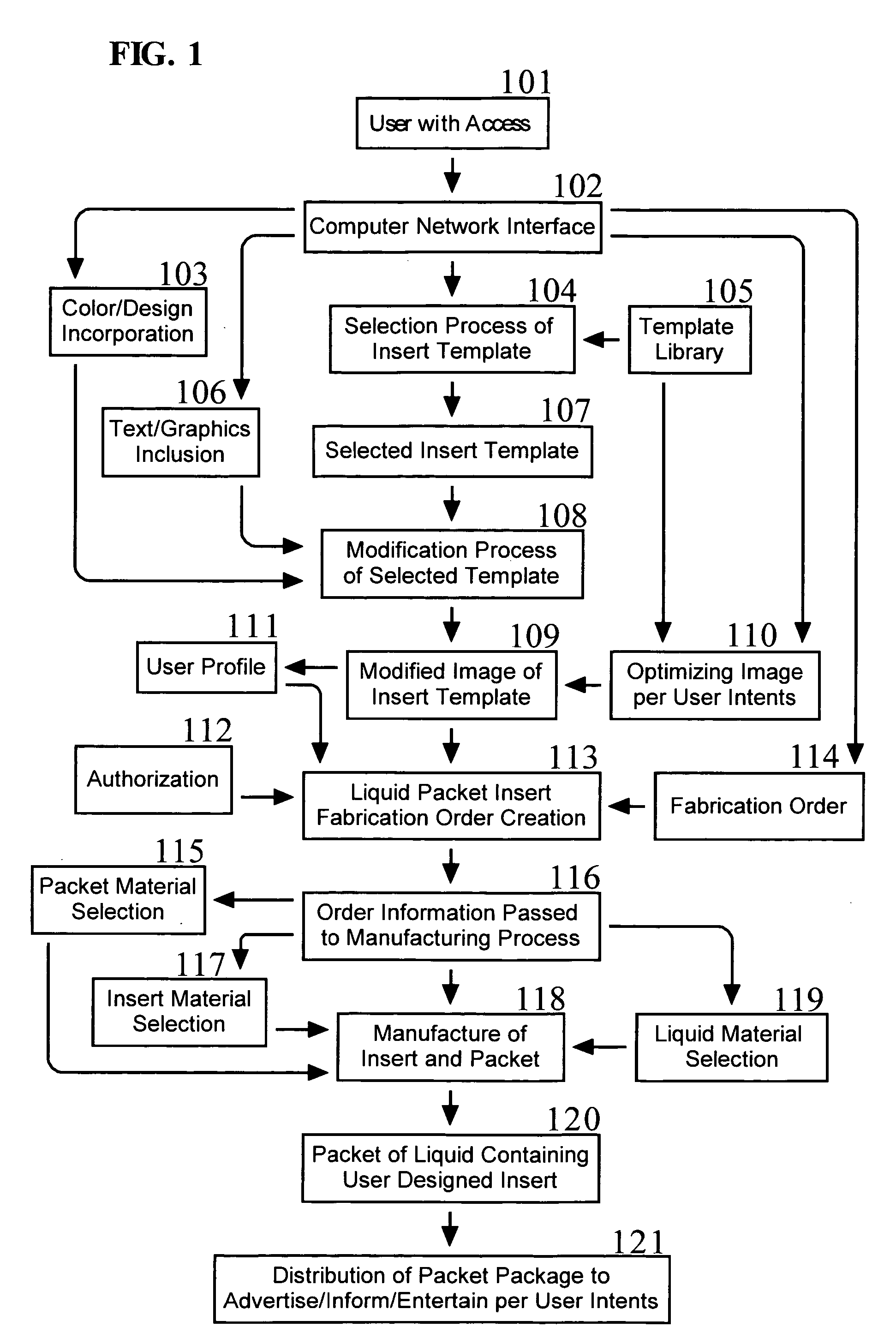

Mass customization of liquid packets

InactiveUS20060155561A1Facilitates online designEasy to orderMarketingExtensibilityMass customization

A method is provided comprising the online design of an insert by a user and the subsequent packaging of the custom insert with liquids. The insert is designed, approved, and ordered by the user through an internet interface that in turn supplies the insert design to an extremely scalable assemblage process within a high volume manufacturing operation which produces a custom finished product quickly, on demand, at low cost, and in quantities determined by the user. By incorporating the custom insert as a changeable modular component within an assembly line a mass produced product, specifically a packet package of hand sanitizer fluid, can be individually characterized by its insert as fully intended by the user who designed, ordered, and receives the packaged liquid packet insert.

Owner:HARPER WILLIAM ANTHONY

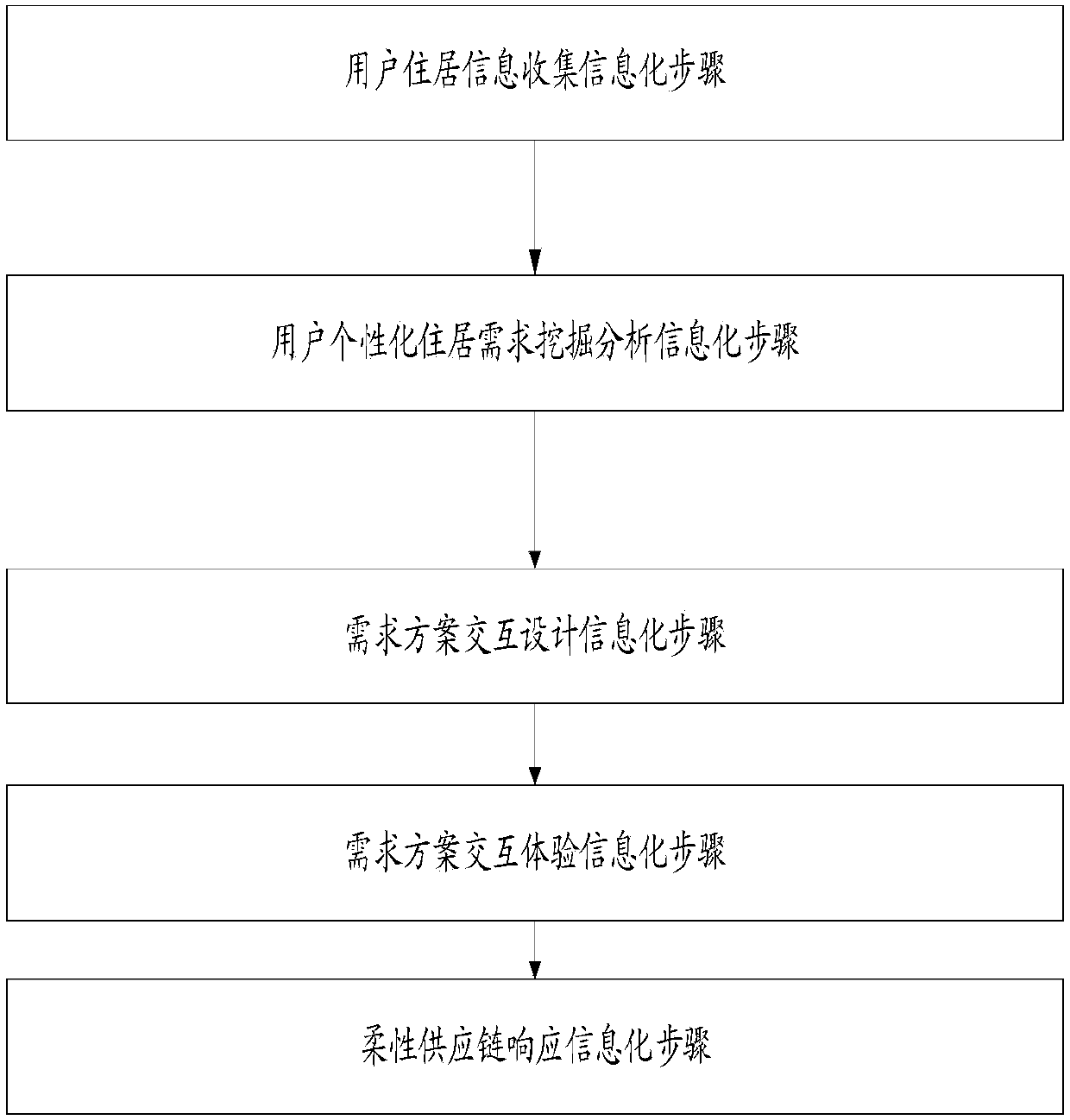

Method for realizing home residence overall solution based on informationized business mode

ActiveCN107657551ARealize acquisitionImplement miningData processing applicationsInformatizationInteractive design

The invention discloses a method for realizing a home residence overall solution based on an informationized business mode. The method comprises the informationization of each process step and operation step of a commercial activity and the realization of personalized product design and mass customized production driven by user requirements by an enterprise. The method concretely comprises the steps that: a user information collection informationization step, a user personalized residential need mining and analysis informatization step including a living room structure modularization sub step,and a demand scheme interaction design informationization step including a step of carrying out the planning layout of a scene object configuration scheme and the interactive design of a scene styleeffect according to a basic scene function design model formed by training in advance, a style effect design scheme library of a basic scene formed by training advance and a preset basic scene productconfiguration standardization database with the combination of building structure characteristics of basic building blocks of the above functional areas and functional structures and user residentialneeds.

Owner:北京玲珑新世纪商贸有限公司 +1

Computer implemented planning and providing of mass customized bone structure

InactiveUS20100332248A1Facilitating medical procedureMedical simulationData processing applicationsBone structuresMass customization

A computer-implemented method, a system and a computer program is disclosed, which comprise virtual planning of a medical procedure of a patient. The medical procedure comprises providing a patient configured bone structure in a body portion of the patient. Based on an input of a final result of the medical procedure, the bone structure may be modified by various tools and methods, such a bone implants, bone distractive methods, etc. Production data based on the virtual planning is generated that is configured for subsequent use in production of the bone structure or a medical product, which medical product is devised for use in the medical procedure, and devised for arrangement in the patient for facilitating the medical procedure. The virtual planning of a medical procedure comprises providing position data for a position of at least a part of a prosthesis component in relation to the body portion, and virtual planning of a modification of a boundary surface at the body portion as a function of the position data.

Owner:NOBEL BIOCARE SERVICES AG

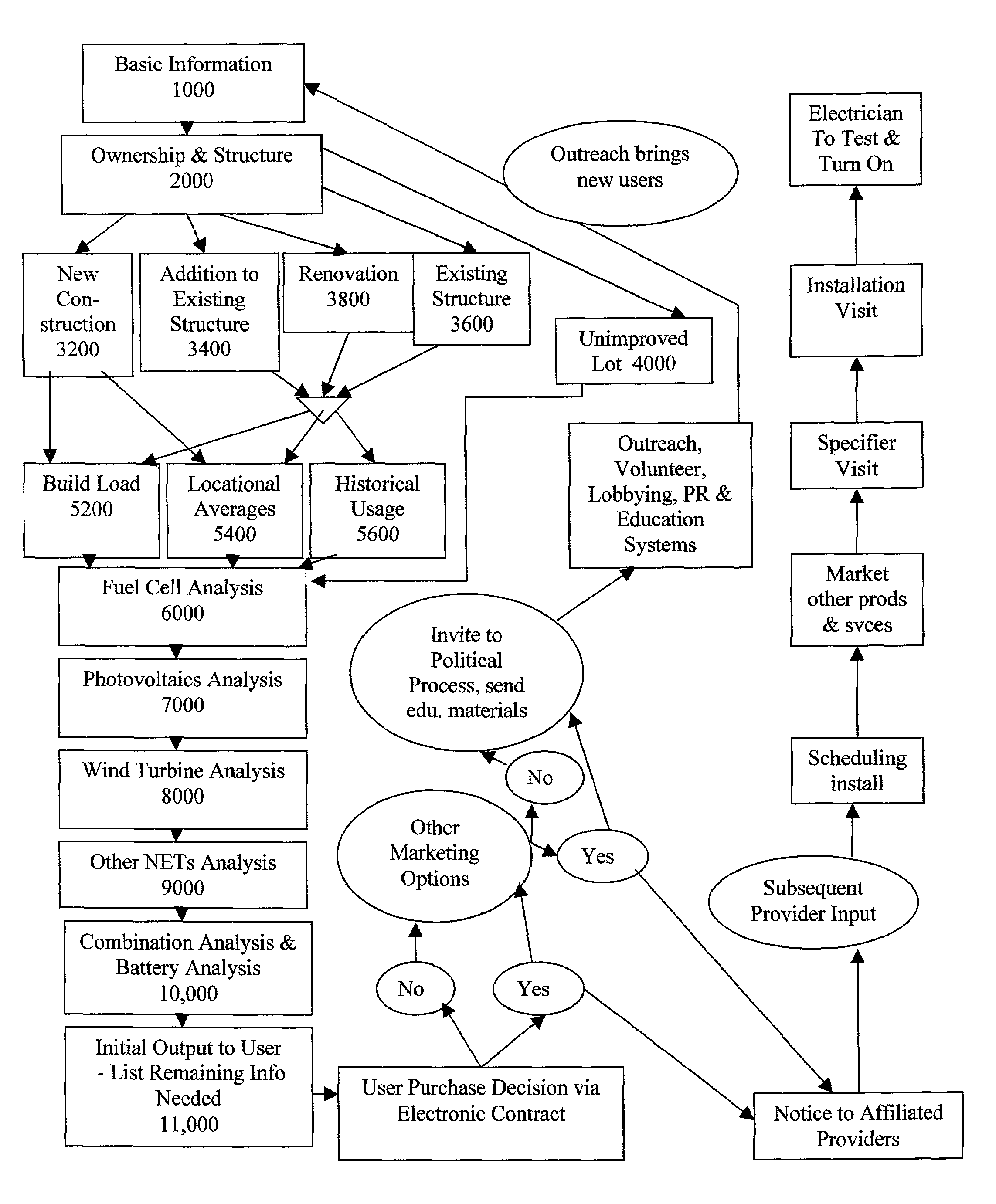

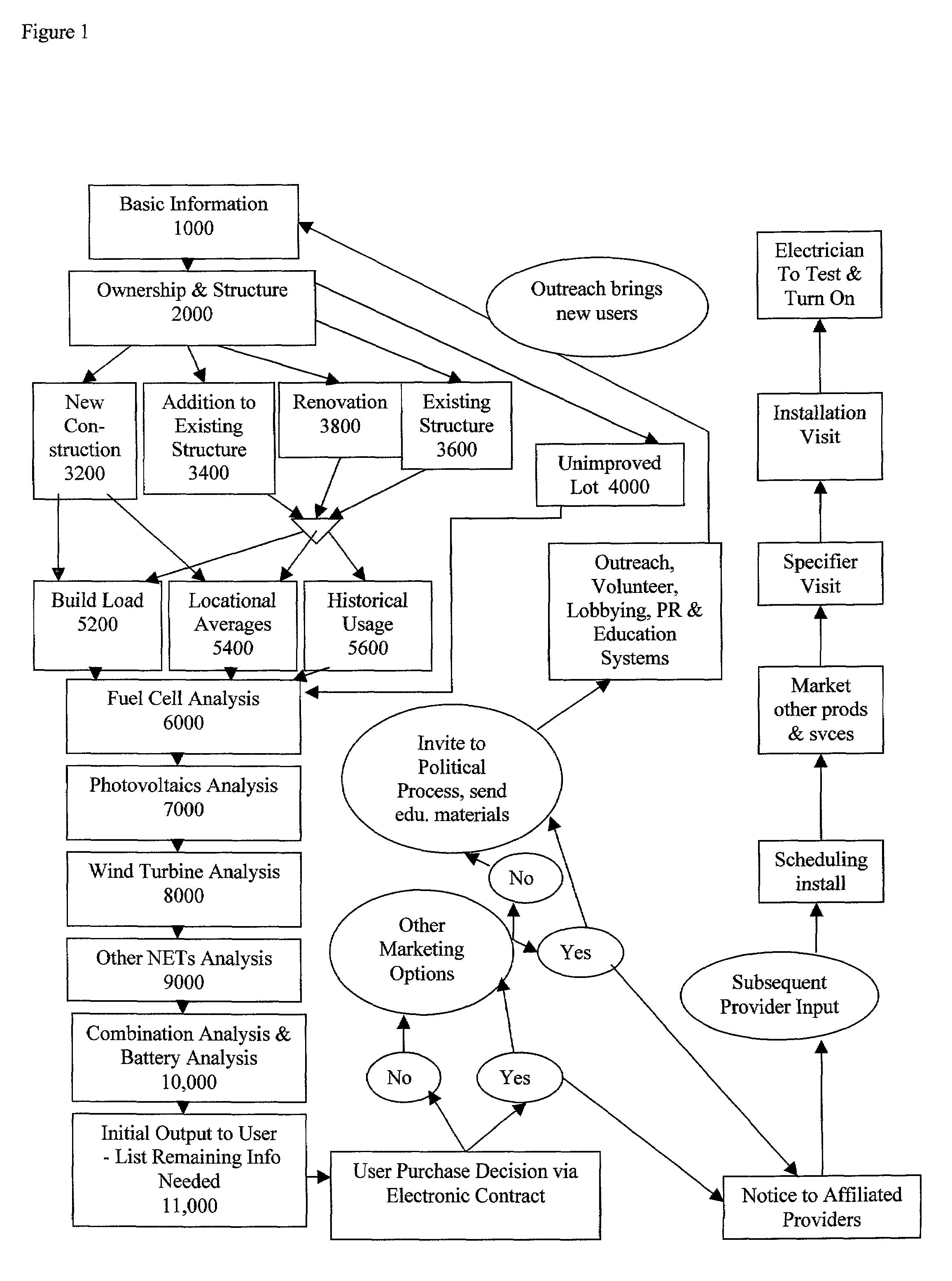

Automated new energy technology consulting and demand aggregation system and method

InactiveUS7512540B2Expanding outreachLow costElectric devicesSpecial tariff metersViral marketingNew energy

An automated energy consulting system and method is provided comprising an interactive input system linked to calculation algorithms and databases of energy-related products and services, affiliated service providers, and climate, financing and regulatory criteria. The system generates proposals of available energy-related products, services and financing options, and obtains and aggregates customer commitments to allow discounted purchasing of the components. Customers can earn referral commissions to encourage customers and volunteers to virally disseminate the access information. For customers not eligible for beneficial products and services because of regulatory deficiencies, the system automates the customer education process to encourage them to advocate politically for the changes that will make them eligible. The automation of the energy consulting and marketing process, mass customization, demand aggregation, and viral marketing reduce customer acquisition and component purchasing costs and reduce the price to consumers, creating new economically viable markets for environmentally friendly energy-related products and services.

Owner:GLUCK DANIEL S +1

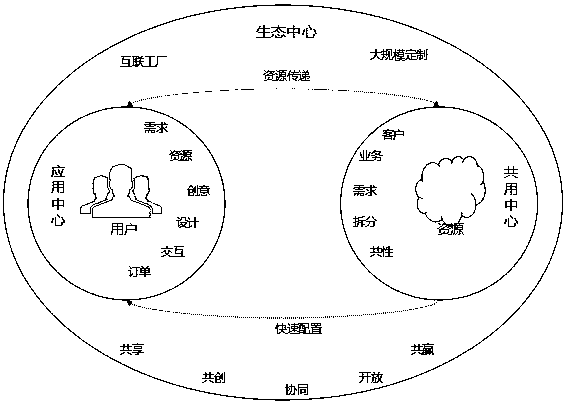

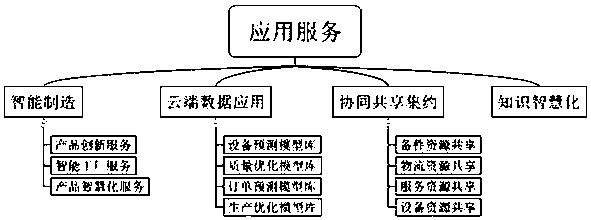

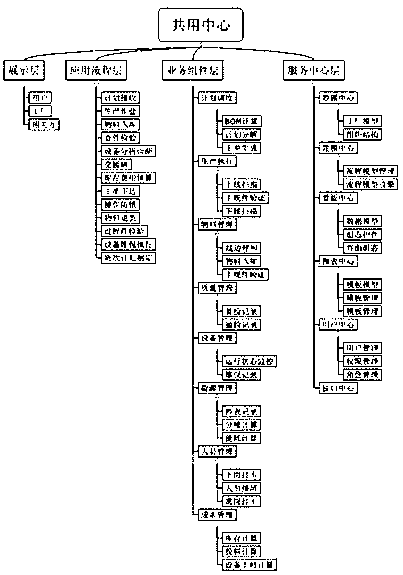

Industrial internet cloud platform

ActiveCN107734059AQuick configurationRealize the integration of product and effectBuying/selling/leasing transactionsResourcesMass customizationThe Internet

An industrial internet cloud platform comprises an application service platform: a small front-end mode for meeting differentiated demands of users; and a common center: a large platform mode for extracting the same service attributes of the manufacturing industry and realizing quick configuration of customers in different industries. The industrial internet cloud platform has the advantages: userlifetime value is created based on user experience; one-off consumption is converted into interactive experience of sustained and deep participation of users by encouraging the users to participate in the whole process of interaction, virtual design, manufacturing, delivery and the like; based on the upgrade from "electrical appliances" to "network devices", a whole-process solution of sustainedand iterative upgrade is provided for the users; the fusion of large-scale customization using internet factories as a carrier and personalized customization solves the contradictions of the both on cost and efficiency, and realizes merit goods; and through parallel and open ecological platforms created by enterprise platforms, the source value is maximized, and parallel and collaborative benign ecological closed loops at resource ends are formed.

Owner:卡奥斯物联科技股份有限公司 +1

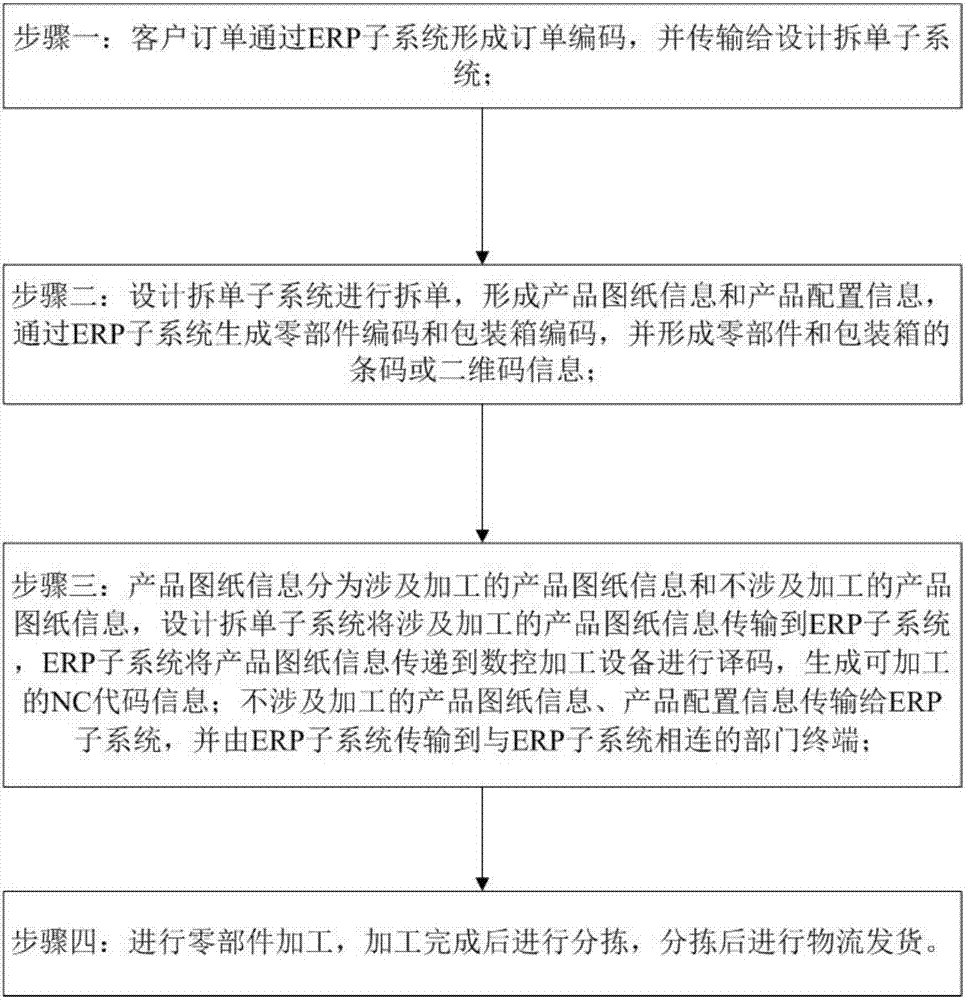

Large-scale customized furniture digital manufacturing information flow circulation method

InactiveCN107967654AImprove circulation efficiencyData processing applicationsAutomatic testing and analysing marked record carriersNumerical controlMass customization

The invention discloses a large-scale customized furniture digital manufacturing information flow circulation method. An order code is formed through an ERP subsystem for a client order and is transmitted to a design order analyzing subsystem; the design order analyzing subsystem is used for analyzing the order code to acquire the product drawing information and the product configuration information, a part code and a packing case code are generated through the ERP subsystem, and bar codes or the two-dimensional code information of a part and a packing case are generated; the product drawing information comprises the product drawing information related to processing and the product drawing information not related to processing, the product drawing information is transmitted by the ERP subsystem to numerical control processing equipment for decoding, and the NC code information which can be processed is generated; the information is further transmitted through the ERP subsystem to a department terminal connected with the ERP subsystem, and part processing is carried out. The method is advantaged in that circulation efficiency of the customized furniture information in the manufacturer product processing process is improved.

Owner:NANJING FORESTRY UNIV

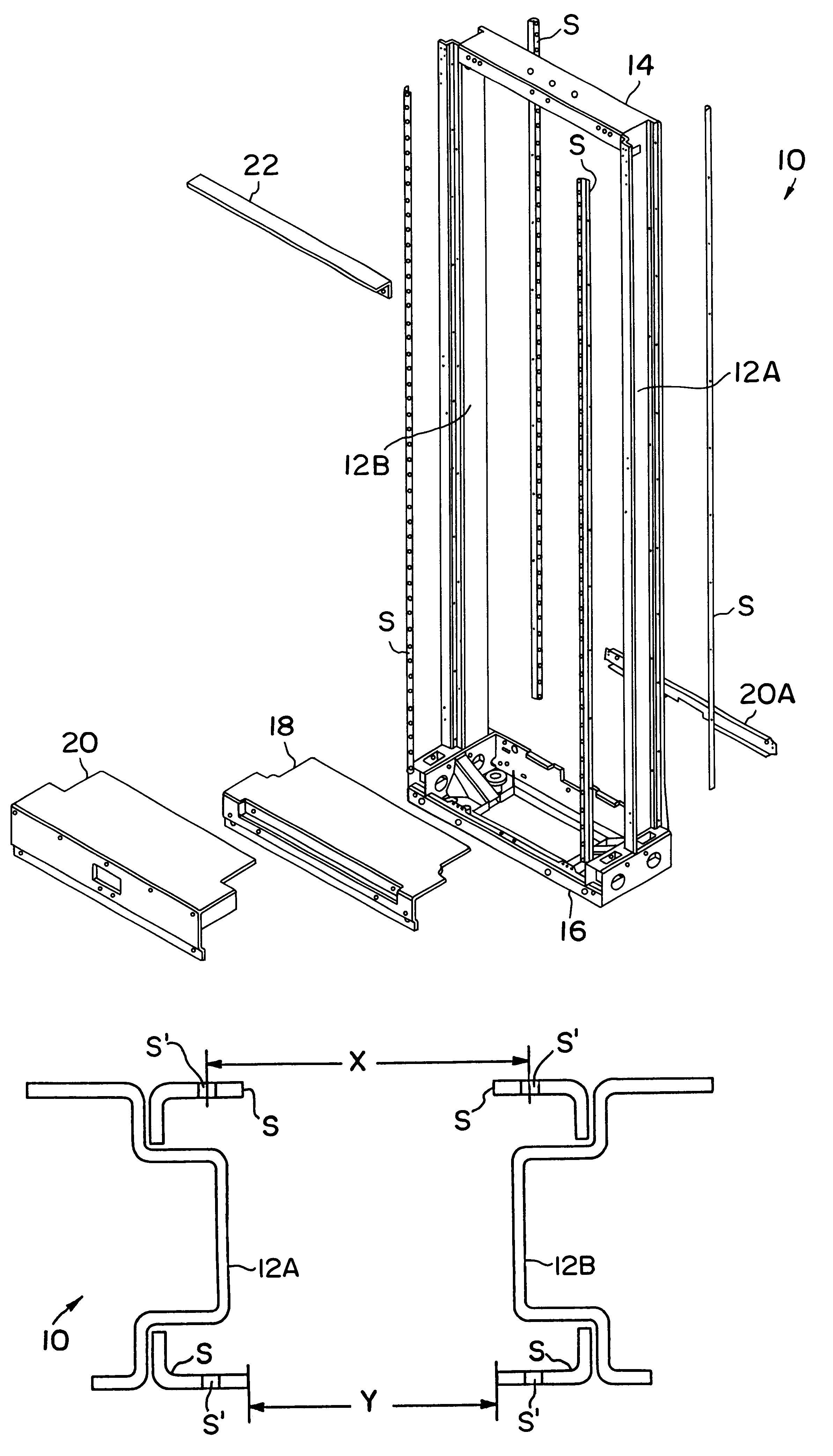

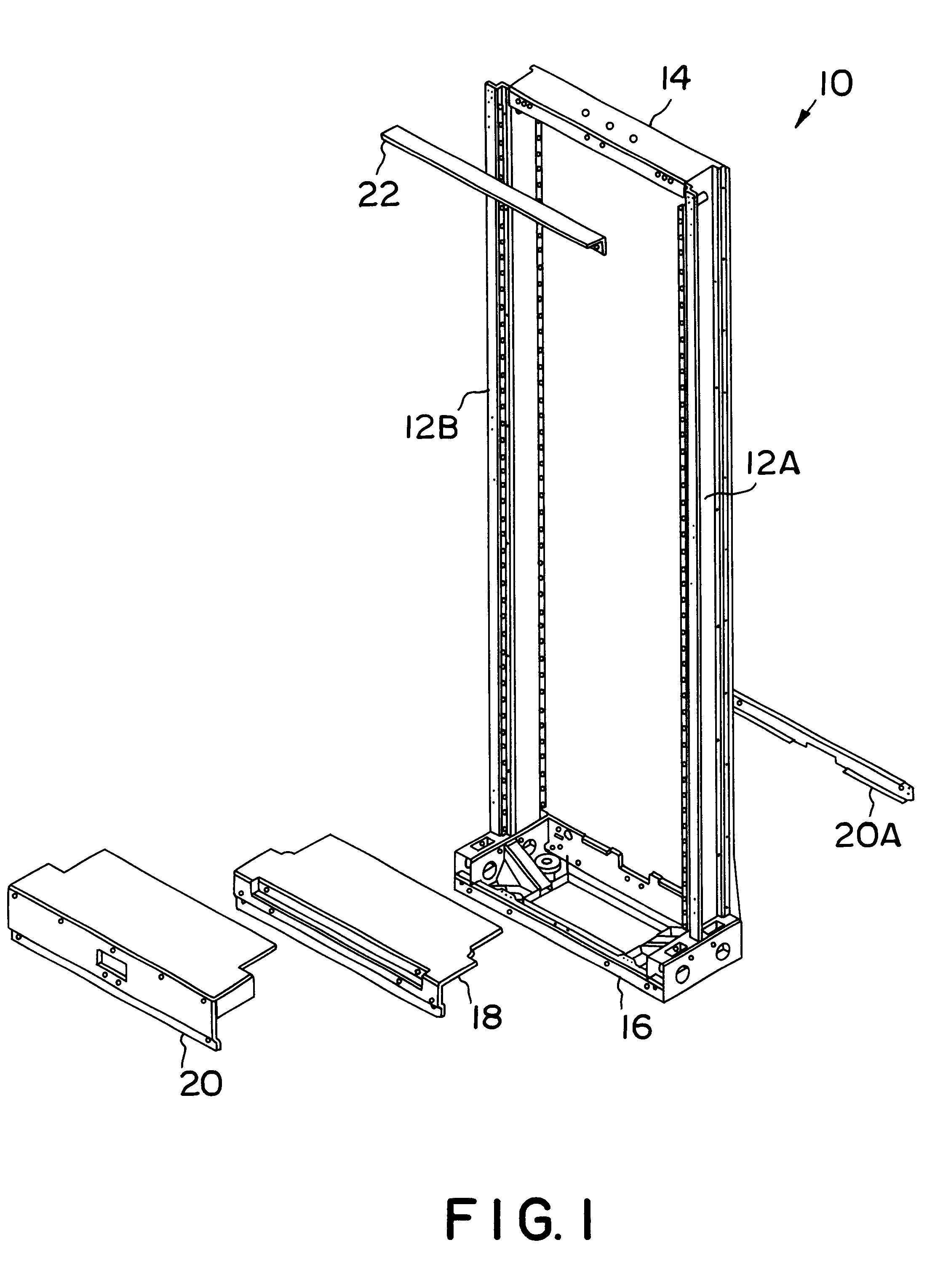

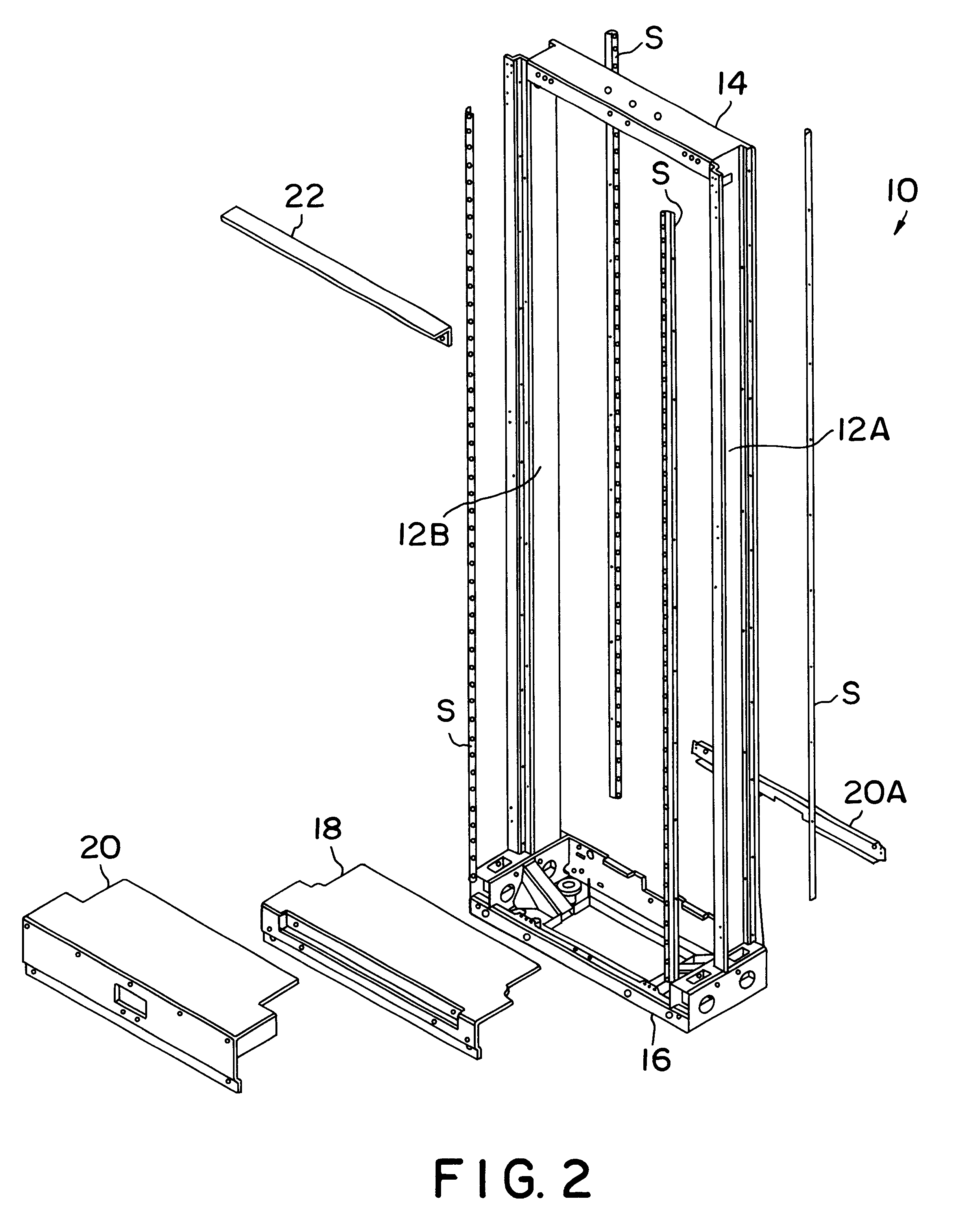

Mass customization telecommunications equipment rack

InactiveUS6338413B1Shorten the timeSimplify the manufacturing processSubstation/switching arrangement detailsDigital data processing detailsMass customizationTelecommunications equipment

A rack assembly for mounting telecommunications equipment is provided which will accommodate both Network Bays and UFER Bays and which provides mounting strips secured at the front and rear comers of the upright channels to better accommodate mounting digital equipment in the rack assembly.

Owner:NEWTON INSTR

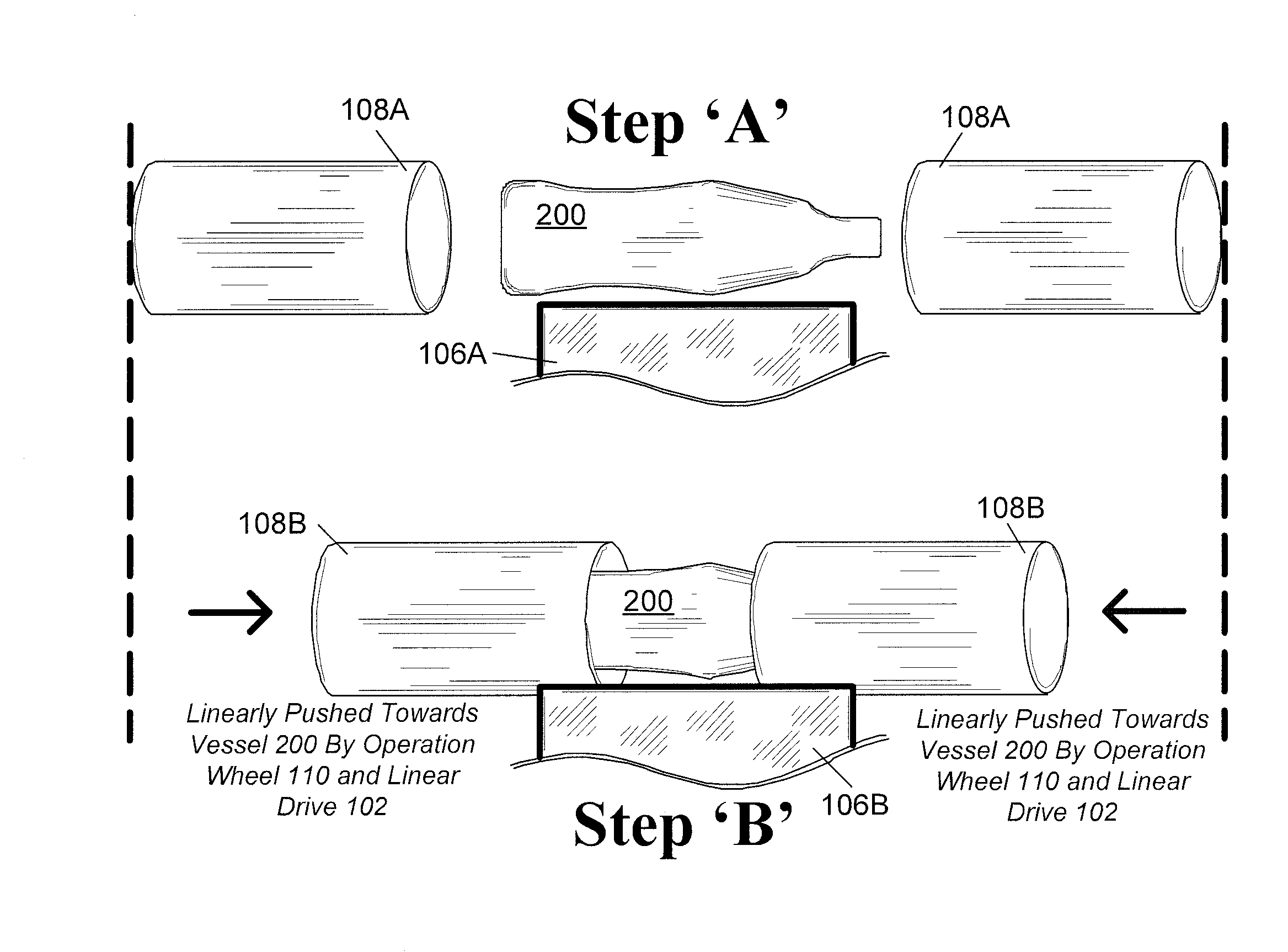

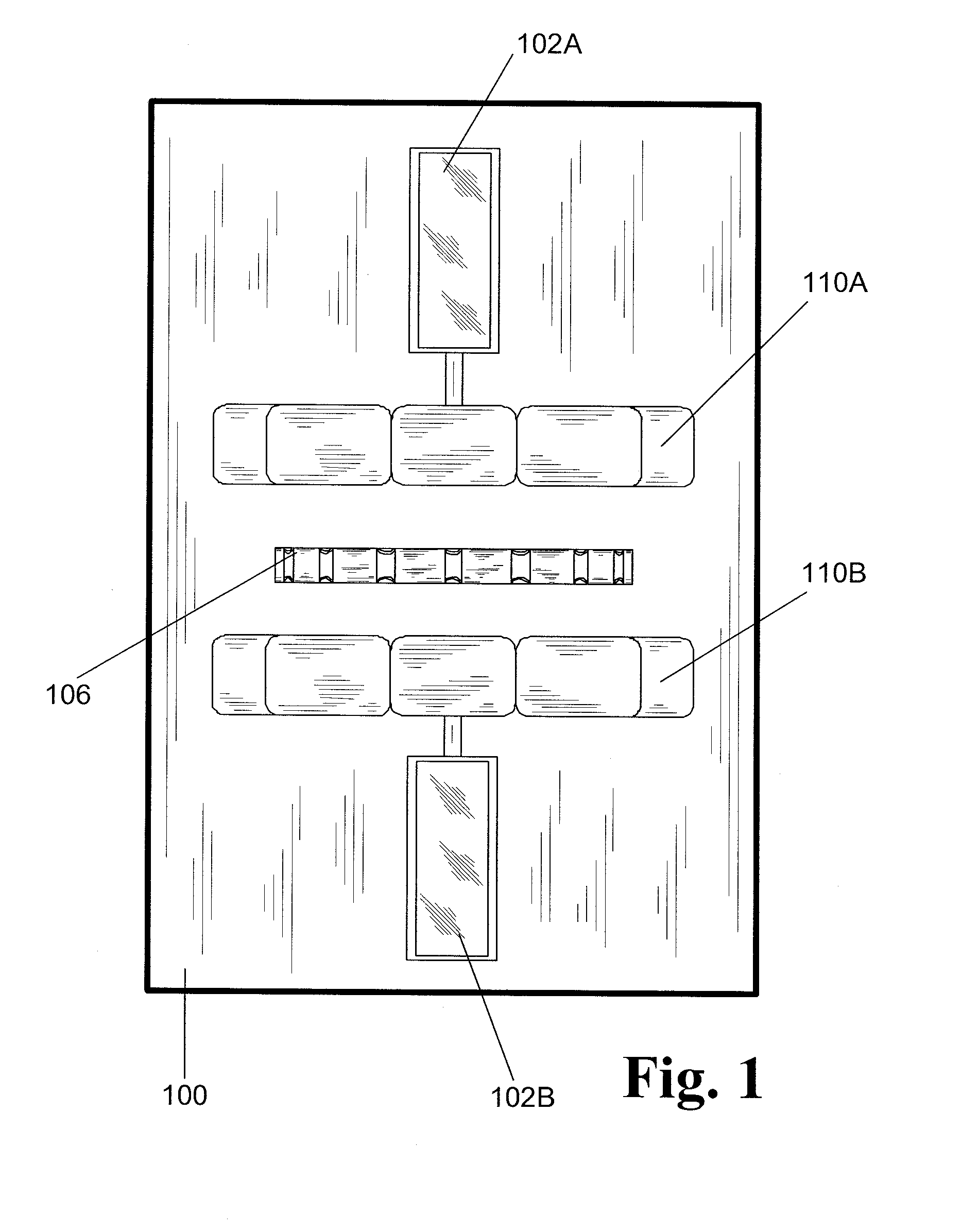

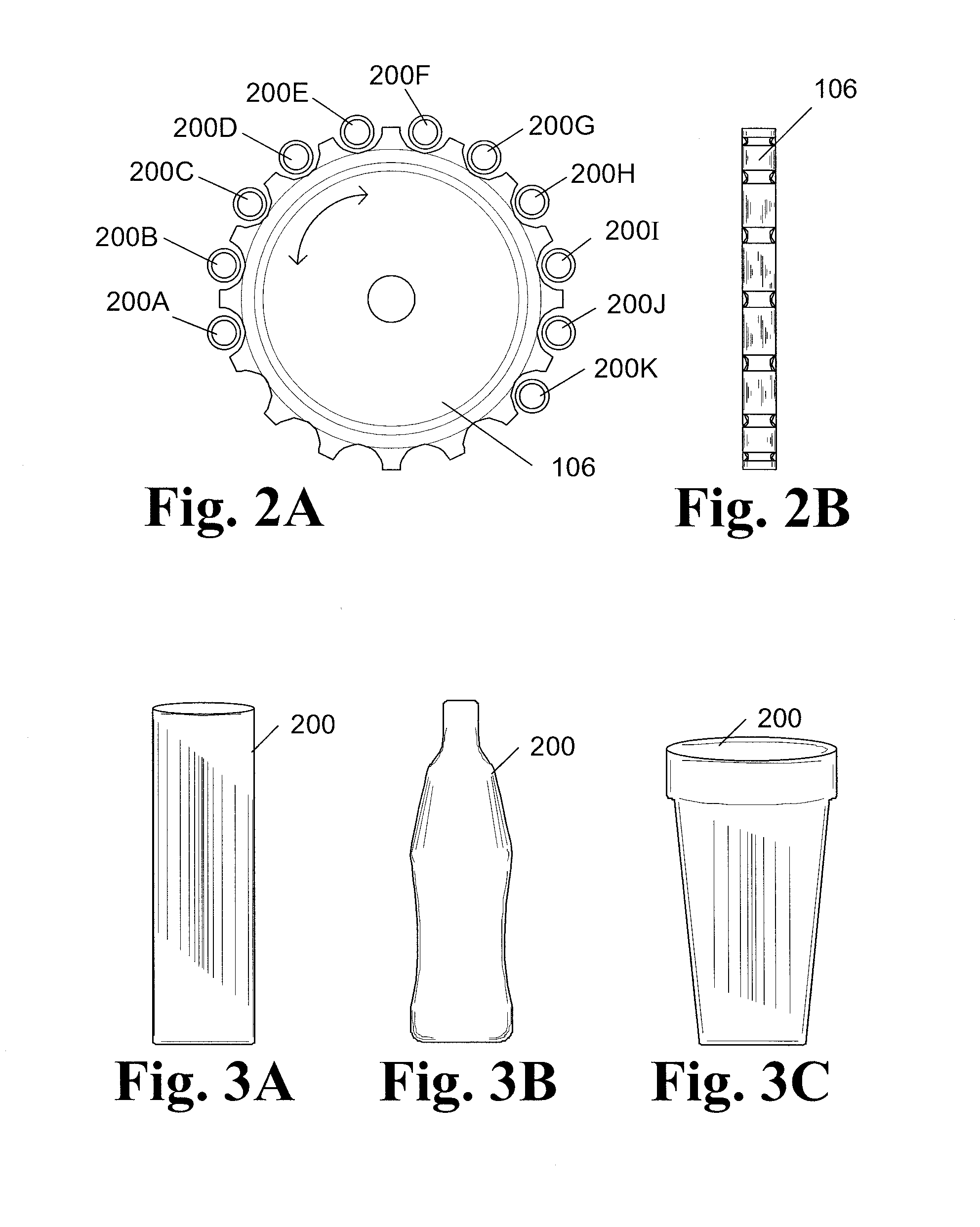

Method of configuring a production line to mass customize shaped vessels

ActiveUS20100095502A1Efficient and accurate manufactureEasy to operateProgramme controlOther manufacturing equipments/toolsProduction lineMass customization

An embodiment of the present invention is a method of configuring a production line to mass customize shaped vessels, the method comprising receiving a plurality of consumer or event data, configuring a plurality of vessel forming stations based in part on received plurality of consumer or event data, and shaping a plurality of vessels by indexing the plurality of vessels through the plurality of vessel forming stations.Other embodiments include shaping by contouring length of each of the plurality of vessels, selecting a decoration style to be applied to the plurality of vessels based in part on received plurality of consumer or event data, and configuring a top-forming station based in part on received plurality of consumer or event data.

Owner:THE COCA-COLA CO

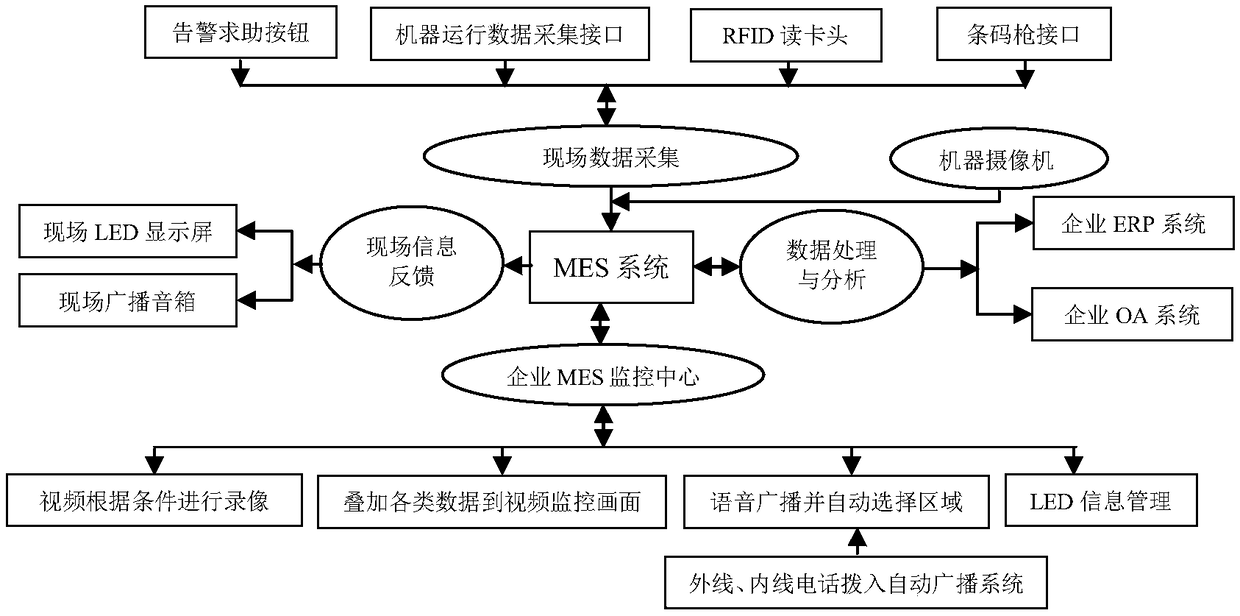

Information acquisition monitoring system and method for large-scale customized furniture manufacturing shop

ActiveCN102193552AIncrease profitReduce consumptionTotal factory controlProgramme total factory controlInformation processingManufacture execution system

The invention relates to an information acquisition monitoring system for a large-scale customized furniture manufacturing shop, which is characterized in that a signal output end of a multifunctional machinery data acquisition device is connected to a signal input end of a furniture manufacturing executing and information processing system; the signal output end of a camera is connected to the signal input end of the furniture manufacturing executing and information processing system; and the signal output end of the furniture manufacturing executing and information processing system is connected to the signal input ends of an on-site LED (light-emitting diode) display screen and an on-site broadcast loudspeaker box. The system has the advantages that the manufacturing process in the whole manufacturing shop is optimized, a new manufacturing shop management mode is established by utilizing an informatization management method, the material use ratio is increased, the cost is lowered,a function of collecting data in real time in the manufacturing process is provided and corresponding analysis and processing are performed, a quick response, elastic and fining manufacturing environment is provided to the furniture enterprises, and the problem that the MES (manufacturing execution system) can realize the enterprise information integration through the continuous information flow of the furniture enterprises by performing information interaction with the plan layer and control layer is solved.

Owner:海太欧林集团股份有限公司

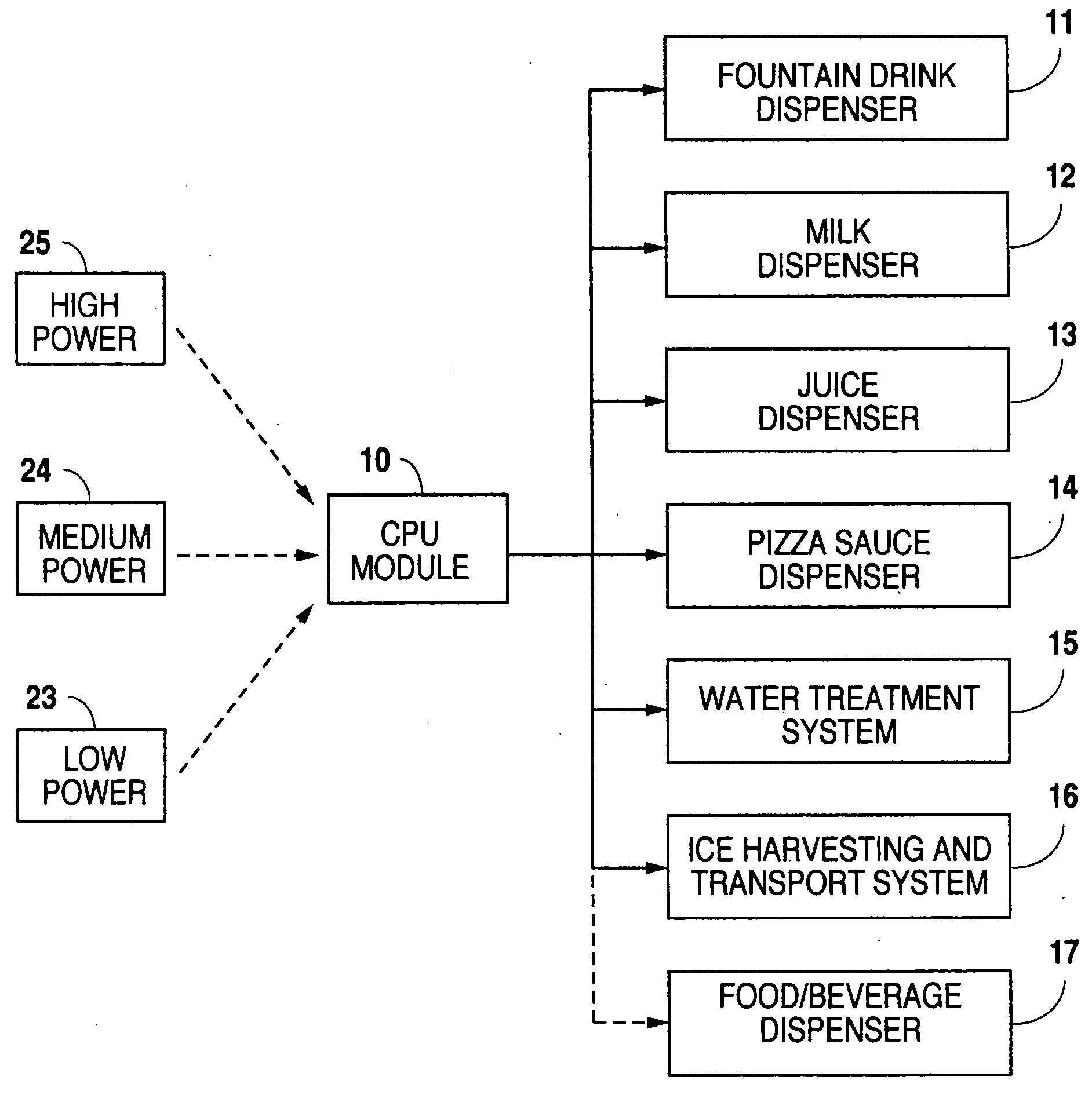

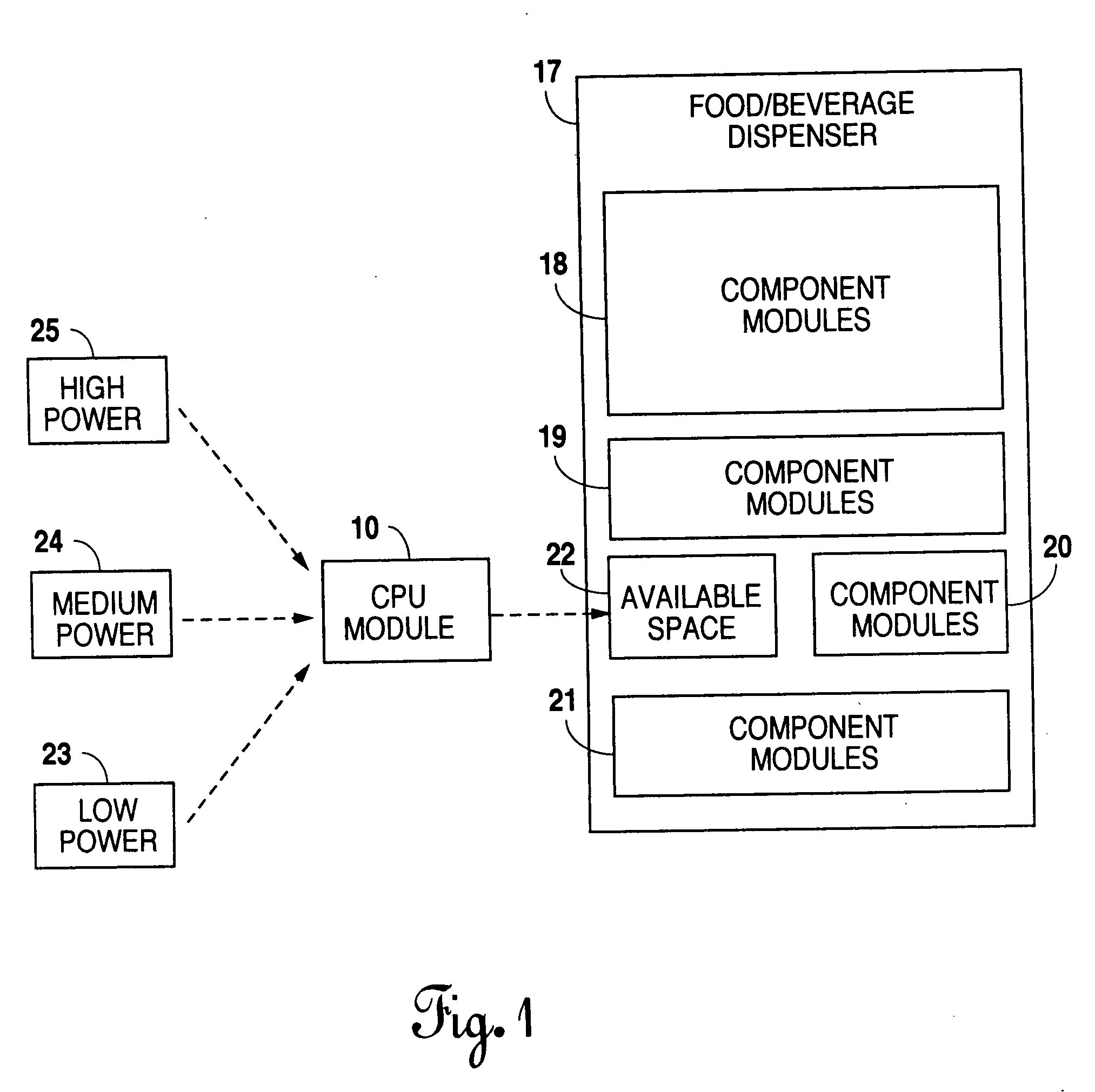

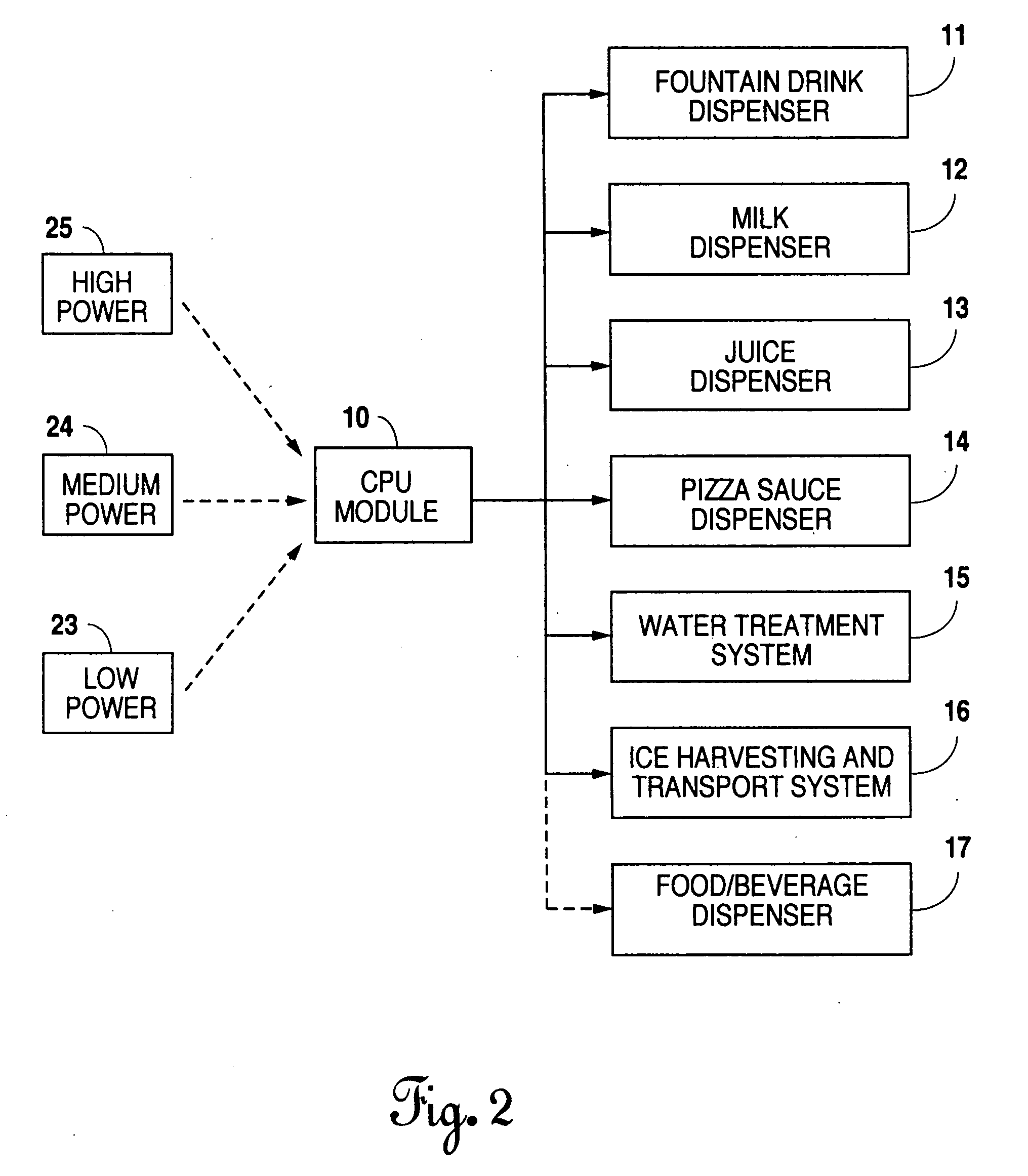

Distributed architecture for food and beverage dispensers

InactiveUS20050061837A1Overcomes limited space issueTime indicationElectric windingMass customizationDesign cycle

A method and apparatus wherein traditional design methodologies directed toward obtaining minimized component costs are largely set aside in favor of mass customization, reduced design and ownership costs, and shorter design cycles. The distributed architecture contemplates widespread distribution of monitoring and control functions for most device-specific hardware under the direction of a CPU module. In implementation of the distributed architecture, various component modules are placed in communication with the CPU module through at least one and preferably multiple communication busses.

Owner:LANCER PARTNERSHIP

Mass customization for management of healthcare

ActiveUS8799023B2Cost optimizationQuality improvementMedical communicationMedical data miningMass customizationProgram planning

Owner:MEDIMPACT HEALTHCARE SYST

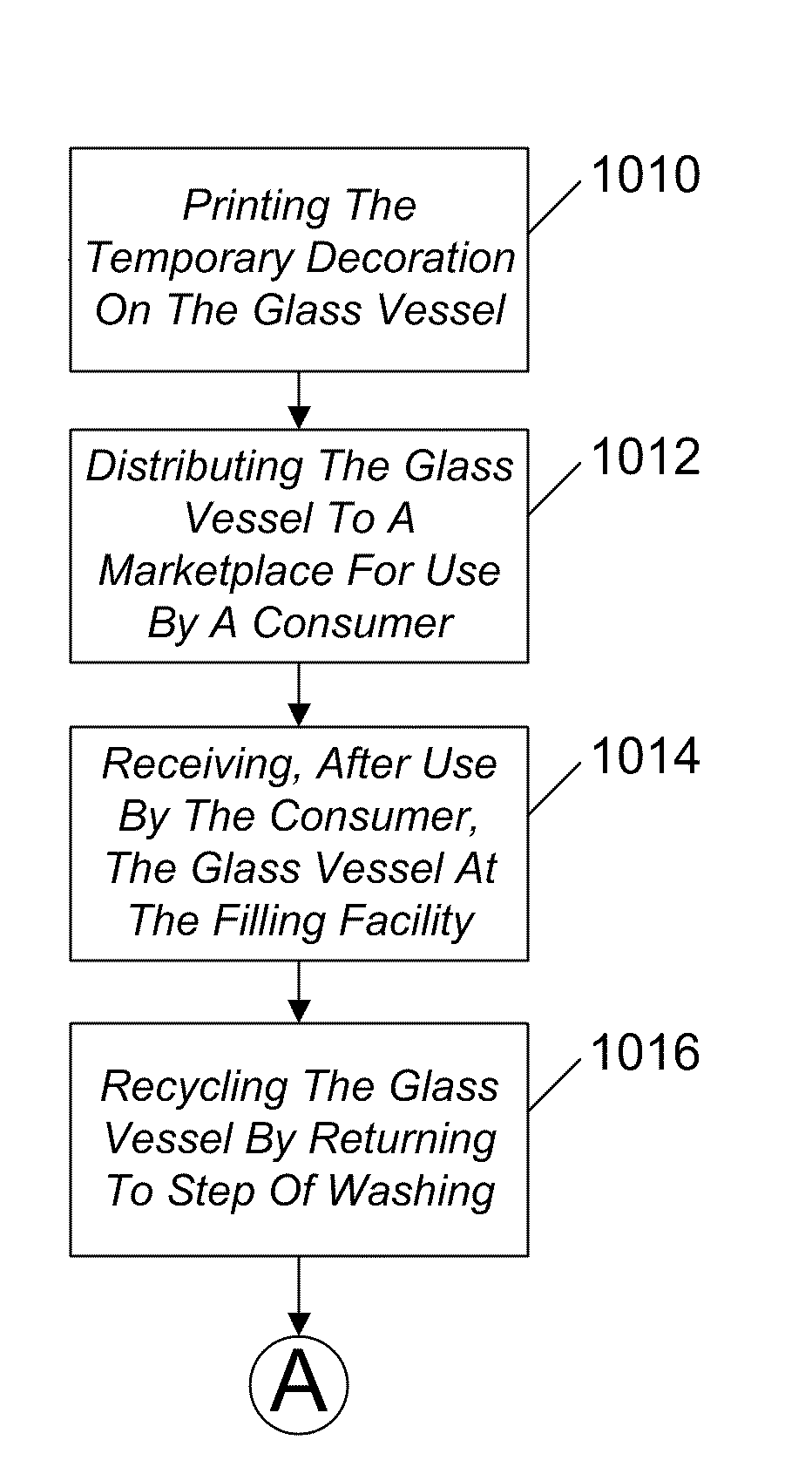

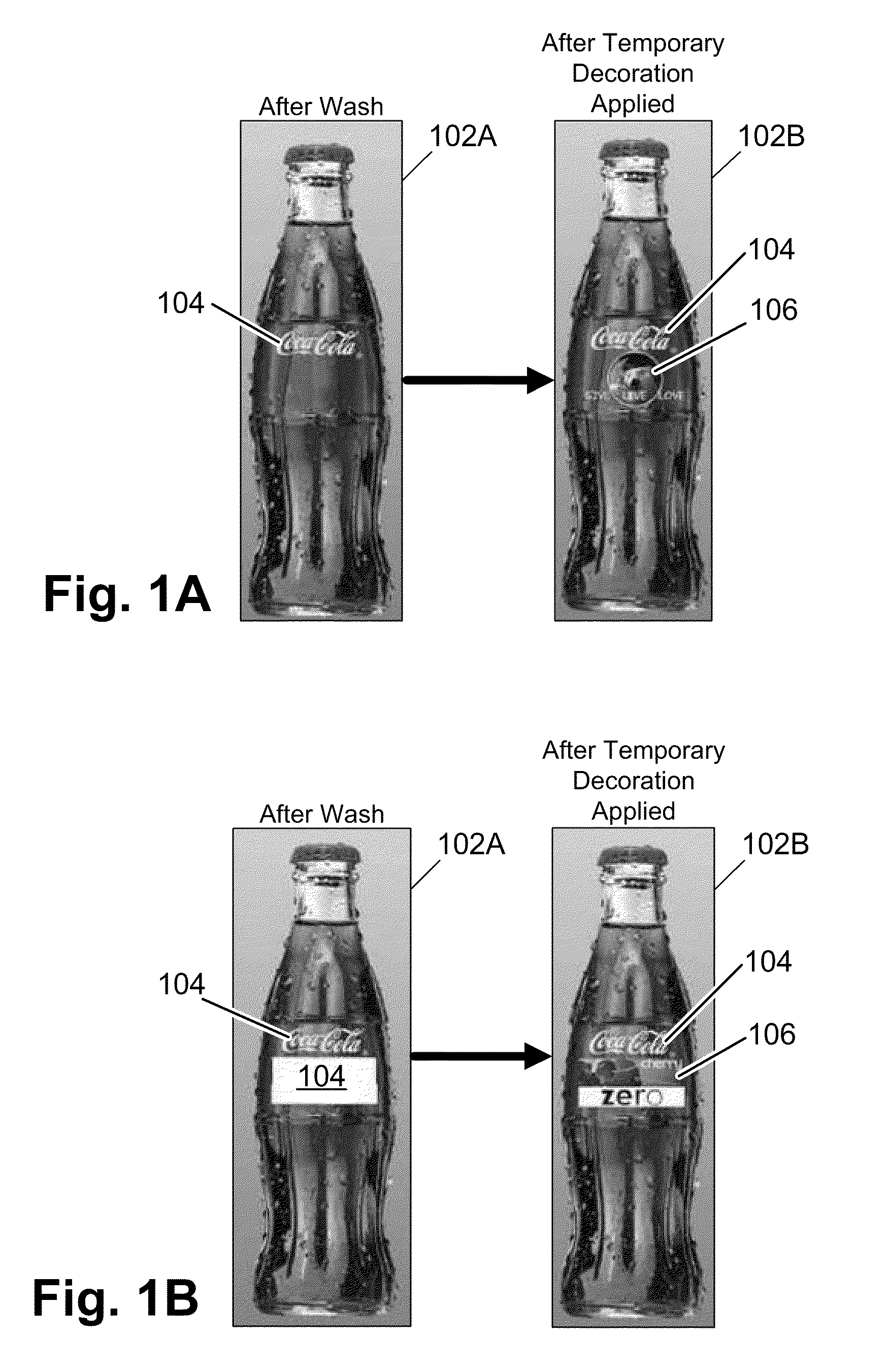

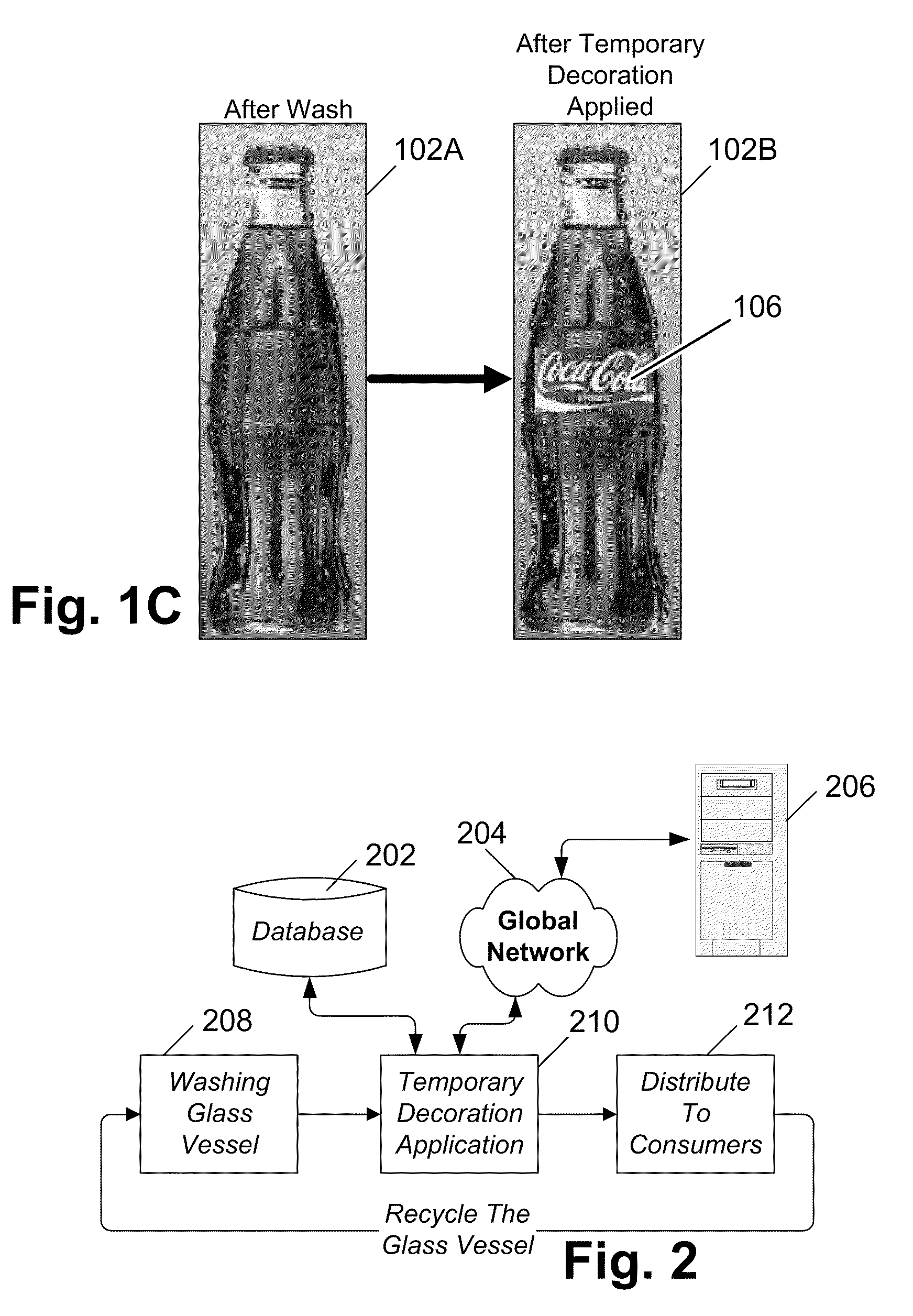

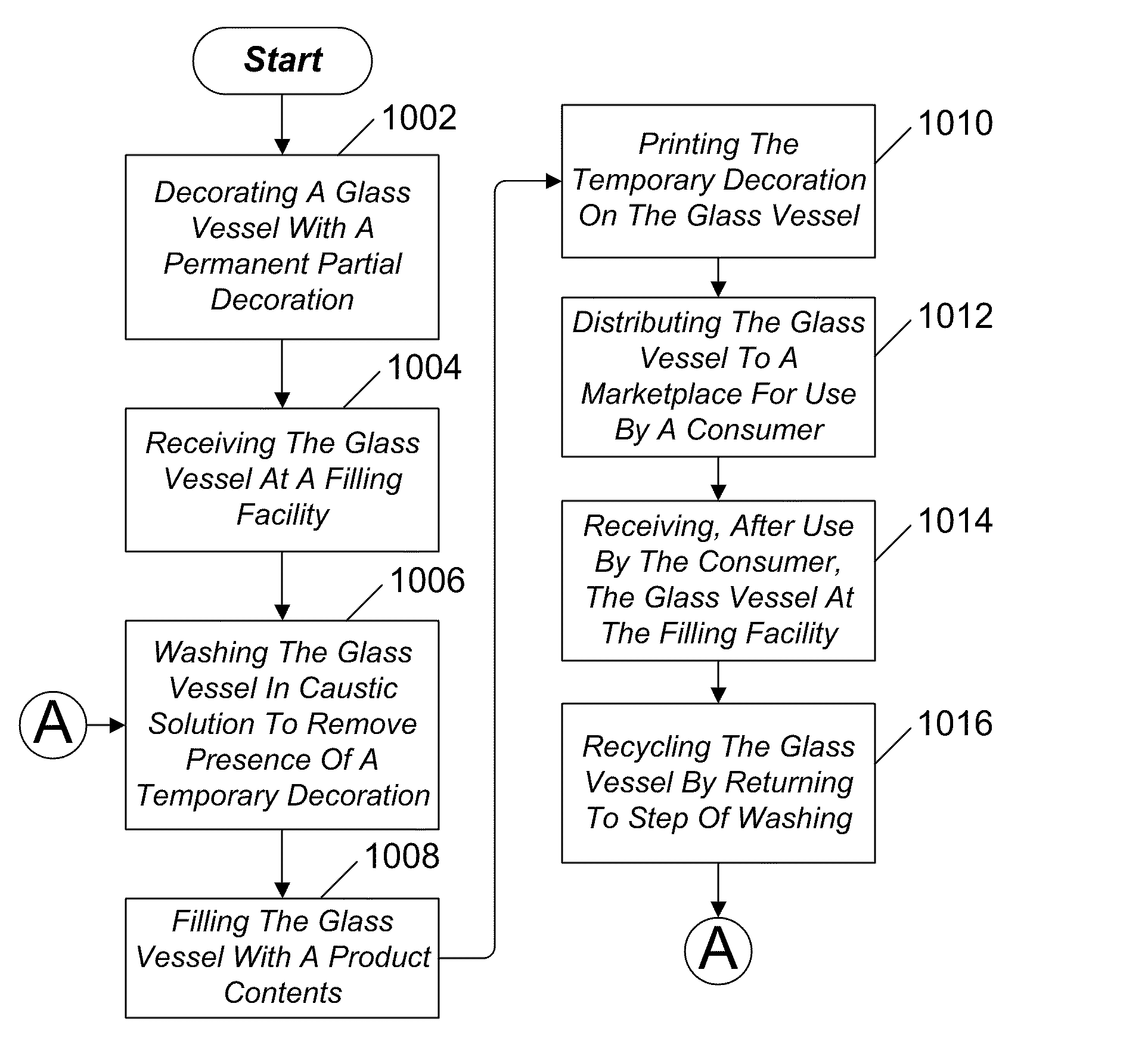

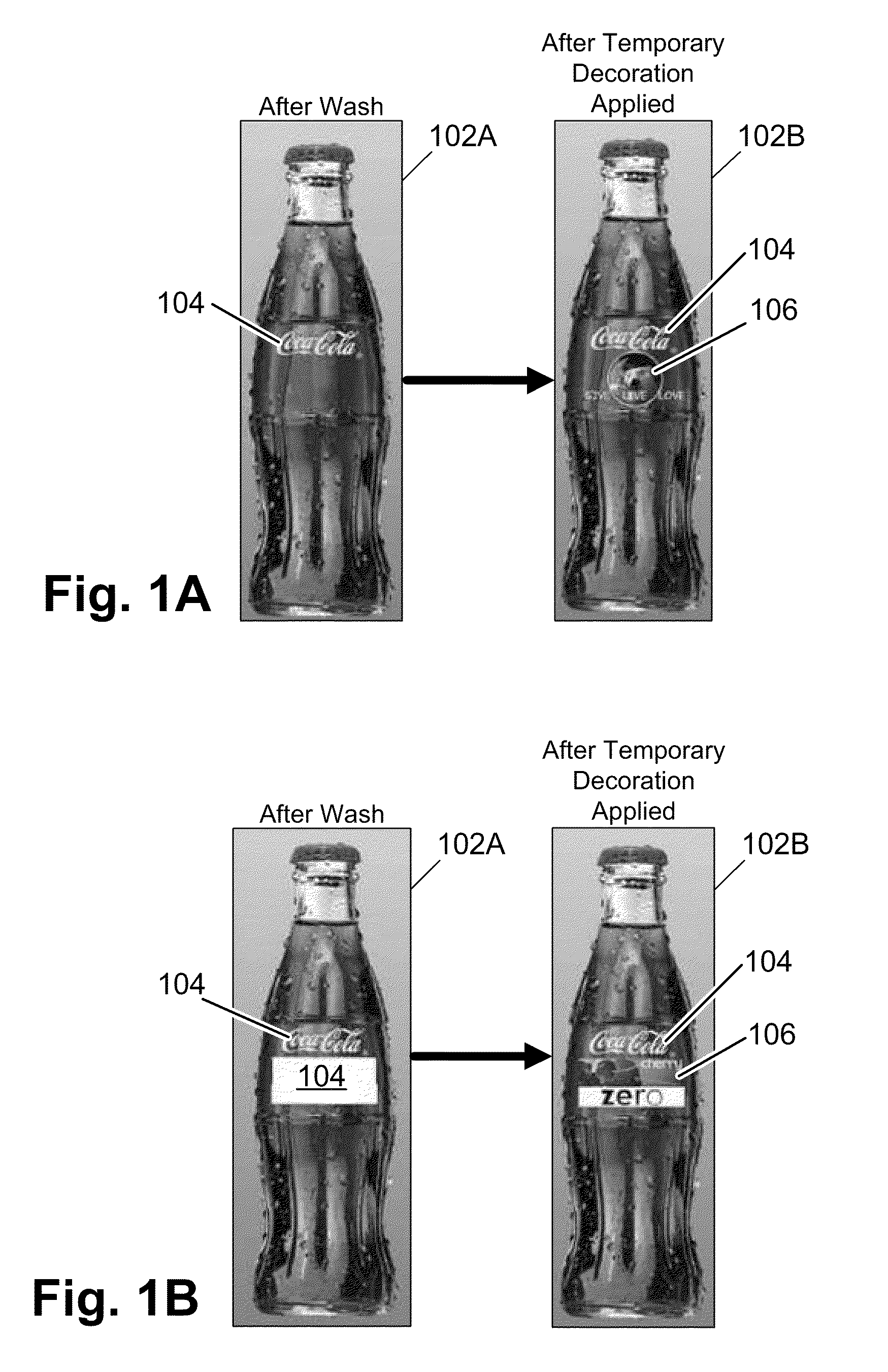

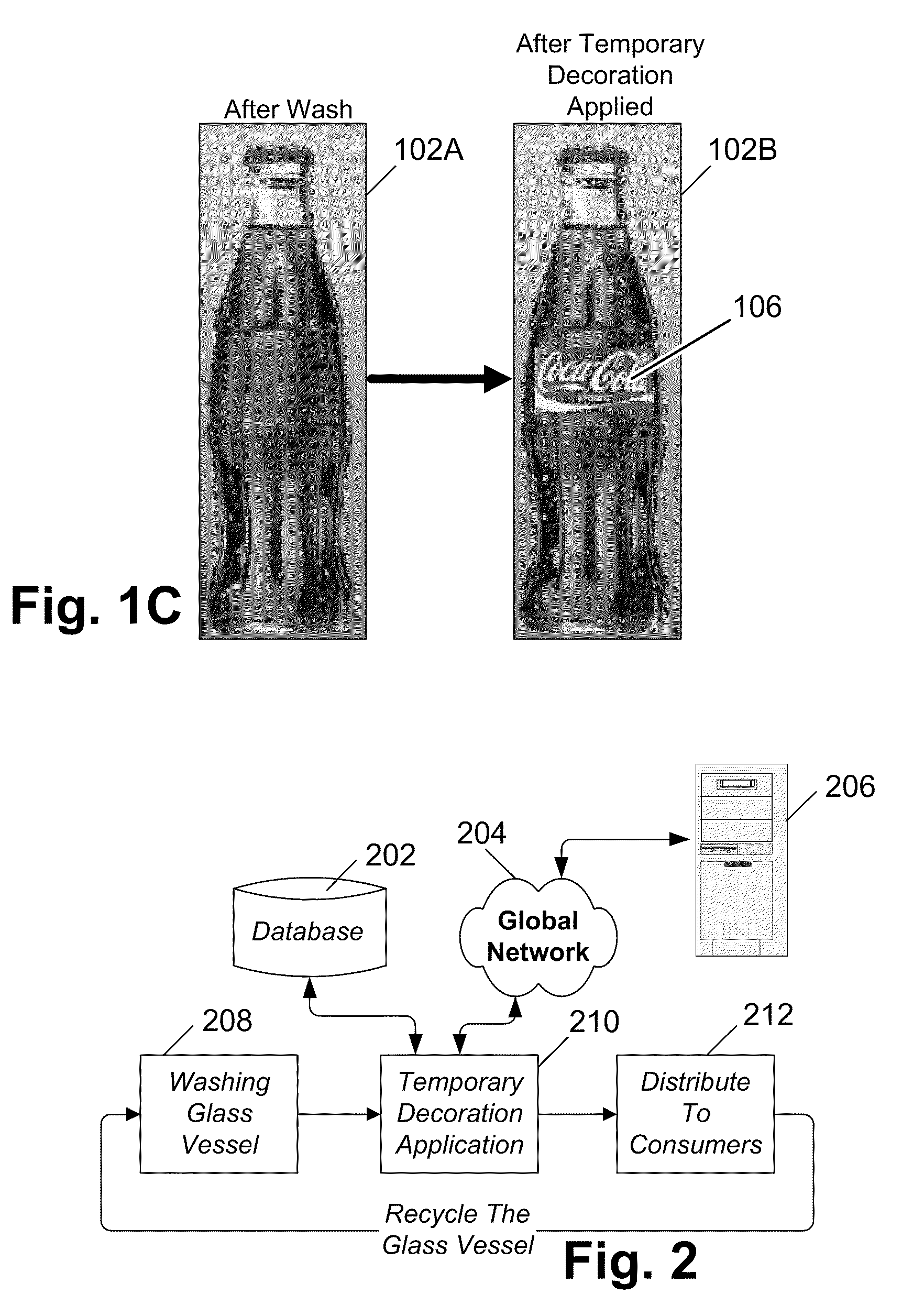

Method of using temporary decoration to mass customize refillable glass vessels

ActiveUS20100281833A1Improve brightness qualityOvercomes shortcomingPower operated devicesScreen printersMass customizationGlass vessel

The present invention relates to a method of using a combination permanent partial decoration and temporary decoration to mass customize refillable glass vessels. The method comprising: decorating a glass vessel with a permanent partial decoration, receiving the glass vessel at a filling facility, washing the glass vessel in caustic solution to remove presence of a temporary decoration, filling the glass vessel with a product contents, printing the temporary decoration on the glass vessel, distributing the glass vessel to a marketplace for use by a consumer, receiving the consumer used glass vessel at the filling facility, and recycling the glass vessel by returning to the step of washing. Other embodiments include not using the permanent partial decoration and printing the temporary decoration on the glass vessel, wherein at least some of the temporary decoration is printed on top of a background region to increase the luminance qualities of the temporary decoration.

Owner:THE COCA-COLA CO

Premium vision ophthalmic lenses

ActiveUS8152300B2Improve visual qualitySpectales/gogglesEye diagnosticsMass customizationMedical prescription

An ophthalmic lens with premium vision corrections provides significantly improved visual acuity and contrast sensitivity. The premium vision corrections include precisely correcting for two aberration mode sets simultaneously, second-order astigmatism and fourth-order spherical aberration, instead of correcting for only second-order astigmatism or simultaneously correcting for all aberrations present. Fourth-order astigmatism, sixth-order spherical aberration, and third-order coma are additionally corrected in other premium vision correction schemes. In addition, methods are provided for prescribing and fabricating the premium vision lenses to permit mass customization.

Owner:ALCON INC

Methods and systems for mass customization of digital television broadcasts in DASE environments

InactiveUS6925649B2Improve usabilityBetter targeted commercialsTelevision system detailsPulse modulation television signal transmissionMass customizationApplication software

Methods and systems for the mass customization of Digital Television broadcasts through the broadcasting of commercials in the form of software applications. Ad-applications are injected into various sub-streams of the transport stream and received in a dormant state by the client-side set-top box. When a commercial is to be shown, a broadcaster broadcasts a generic time-stamped trigger to a dispatching application that performs a keyword matching algorithm to decide which ad-application among those received at the receiver is to be executed. The dispatching application uses the results of the latter comparison to decide which specific dormant ad-application to route to; it then converts the generic trigger into a chosen-ad trigger that is routed to the chosen ad-application. Upon receipt of the chosen-ad trigger, the chosen ad-application executes, thereby displaying an ad customized to the individual viewer's interests.

Owner:SHARP LAB OF AMERICA INC

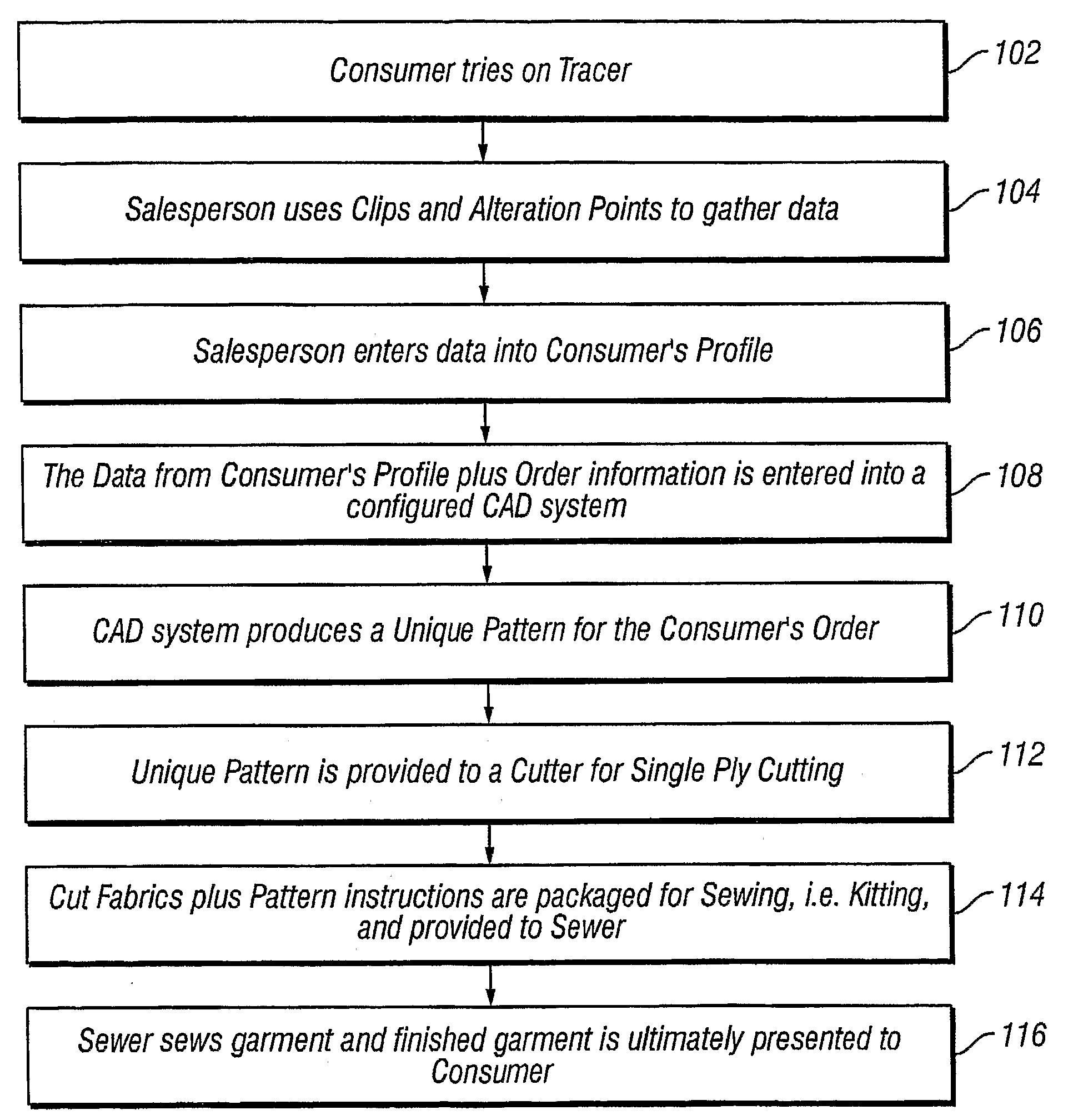

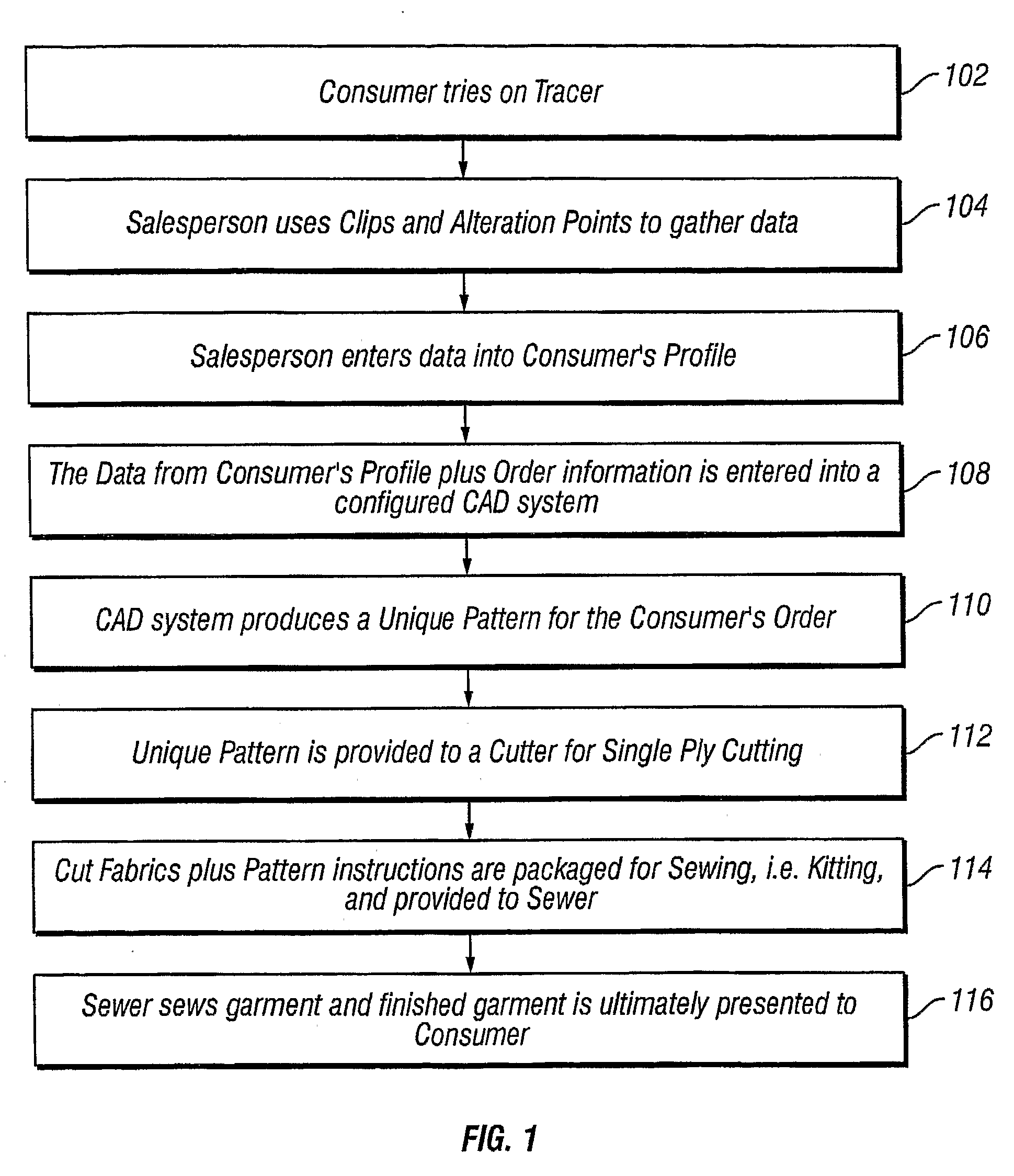

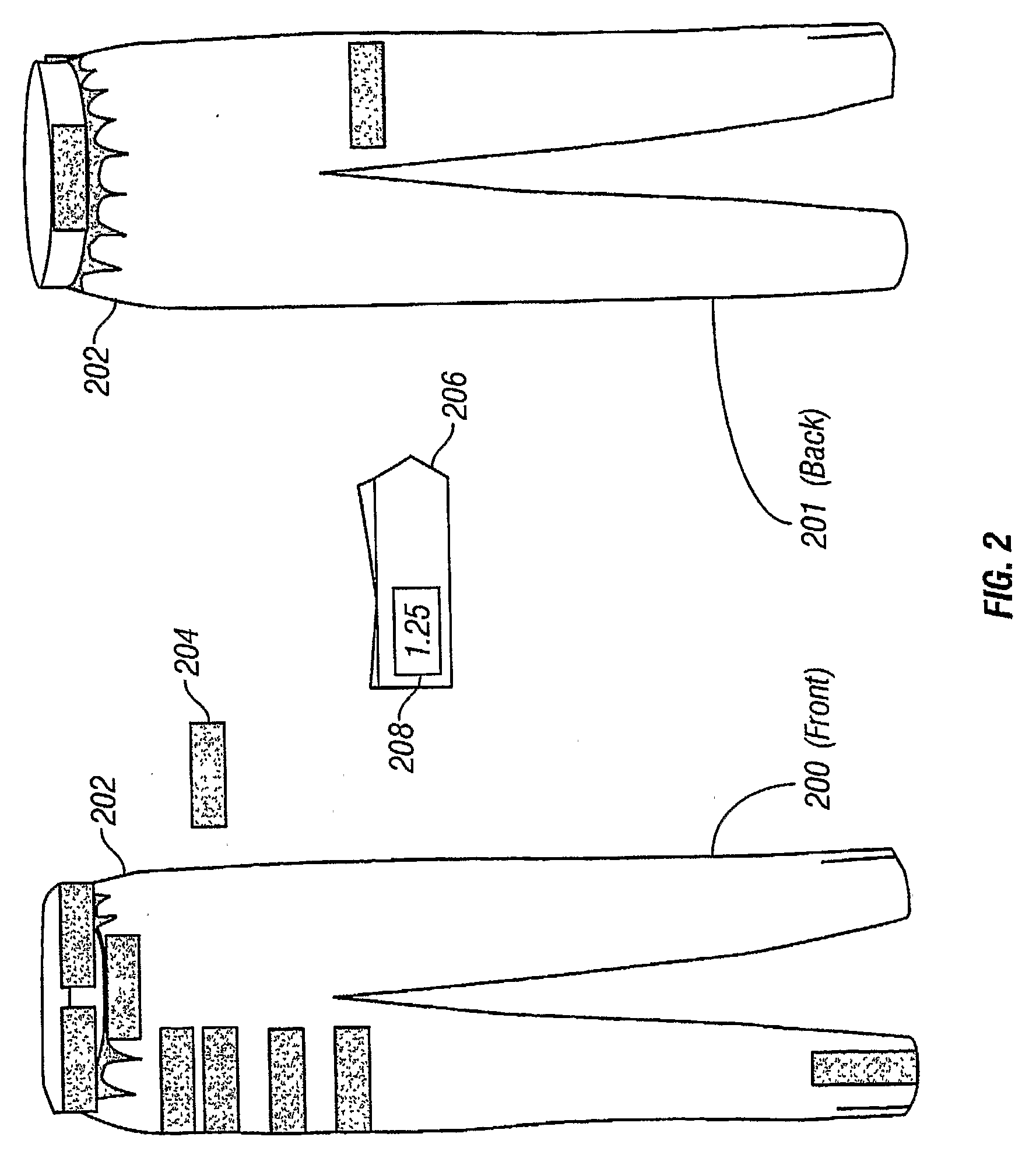

Method and Apparatus for Apparel Customization

InactiveUS20080249652A1Cost-effective and rapid one-at-a-time apparel creationExemption stepsBuying/selling/leasing transactionsSpecial data processing applicationsMass customizationSystem usage

A unique methodology for apparel mass-customization is provided. Tracers, precision garments designed for fitting at a store site, are provided. Tracers work in conjunction with a unique Clip and Alteration Point relationship. A database of customers' unique digital fit data is provided. Such data are used by a configured system to generate patterns reflecting a customer's personal size as well as level of comfort. [Virtual inventory is enabled by such stored data and are applied to electronic patterns with no shelf life.] The database allows customers to reorder additional pants in new styles and fabrics at any time. Automated patternmaking algorithms are used that dynamically adjust patterns to the data; core style patterns are adjusted to fabric specifications. A sophisticated manufacturing process provides separates and independent sub-processing, such as kitting, enabling cost-effective and rapid one-at-a-time apparel creation. An exemplary channel kiosk and channel kiosk with scanning are provided.

Owner:LUCY & LILY

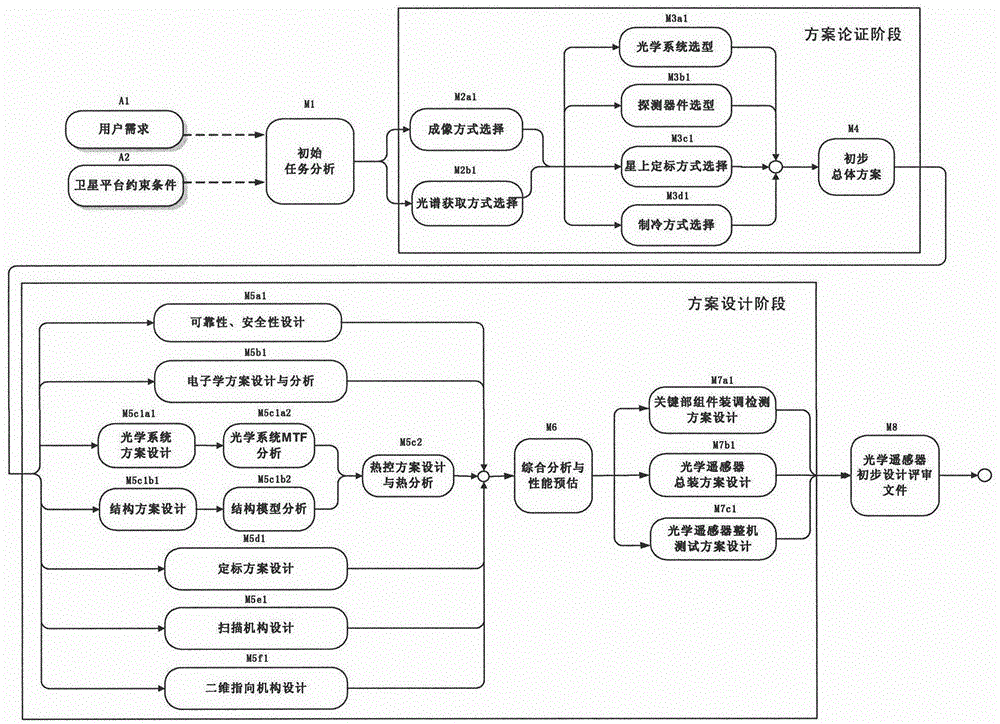

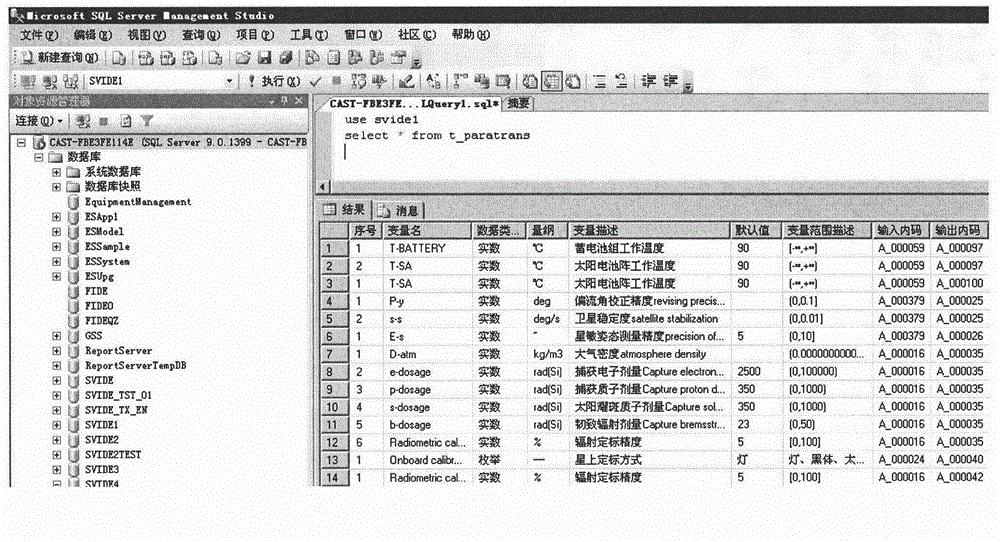

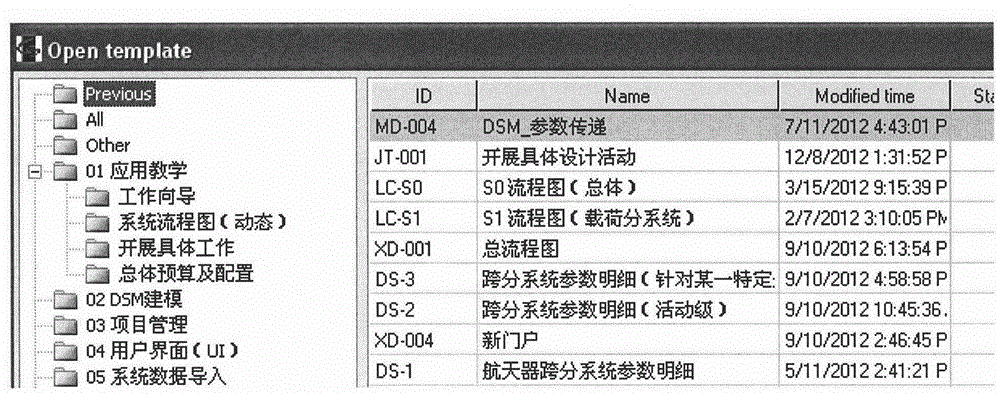

Spreadsheet-based fast customization and integration method for satellite design system

InactiveCN103942348AEasy to optimizeImplement strand analysisSpecial data processing applicationsMass customizationElectronic form

The invention relates to a spreadsheet-based fast customization and integration method for a satellite design system and belongs to the field of design of spacecrafts. The method includes the first step of sorting and summarizing the general flow of designing remote sensing satellites or other types of spacecrafts on the basis of a traditional process expression mode, the second step of conducting mapping to generate a DSM matrix, conducting statistics on DSM items and conducting structured quantitative analysis item by item to obtain a perfect parameter correlation list, and the third step of utilizing the spreadsheet-based middleware technology to achieve storage of a spreadsheet in a database, establishing four modules through existing functions of middleware of the spreadsheet and then achieving fast customization of the spacecraft design system, wherein the four modules are an engineering application module, a DSM modeling module, a project management module and an import and export module. According to the method, the existing spacecraft design process is mapped to generate a DSM, the DSM is stored into the database for maintenance, the Excel spreadsheet is used as a front-end interface, and consequently a foundation is laid for follow-up optimization.

Owner:中国空间技术研究院神舟学院

Method of using temporary decoration to mass customize refillable glass vessels

ActiveUS8020359B2Overcomes shortcomingPower operated devicesScreen printersMass customizationGlass vessel

The present invention relates to a method of using a combination permanent partial decoration and temporary decoration to mass customize refillable glass vessels. The method comprising: decorating a glass vessel with a permanent partial decoration, receiving the glass vessel at a filling facility, washing the glass vessel in caustic solution to remove presence of a temporary decoration, filling the glass vessel with a product contents, printing the temporary decoration on the glass vessel, distributing the glass vessel to a marketplace for use by a consumer, receiving the consumer used glass vessel at the filling facility, and recycling the glass vessel by returning to the step of washing. Other embodiments include not using the permanent partial decoration and printing the temporary decoration on the glass vessel, wherein at least some of the temporary decoration is printed on top of a background region to increase the luminance qualities of the temporary decoration.

Owner:THE COCA-COLA CO

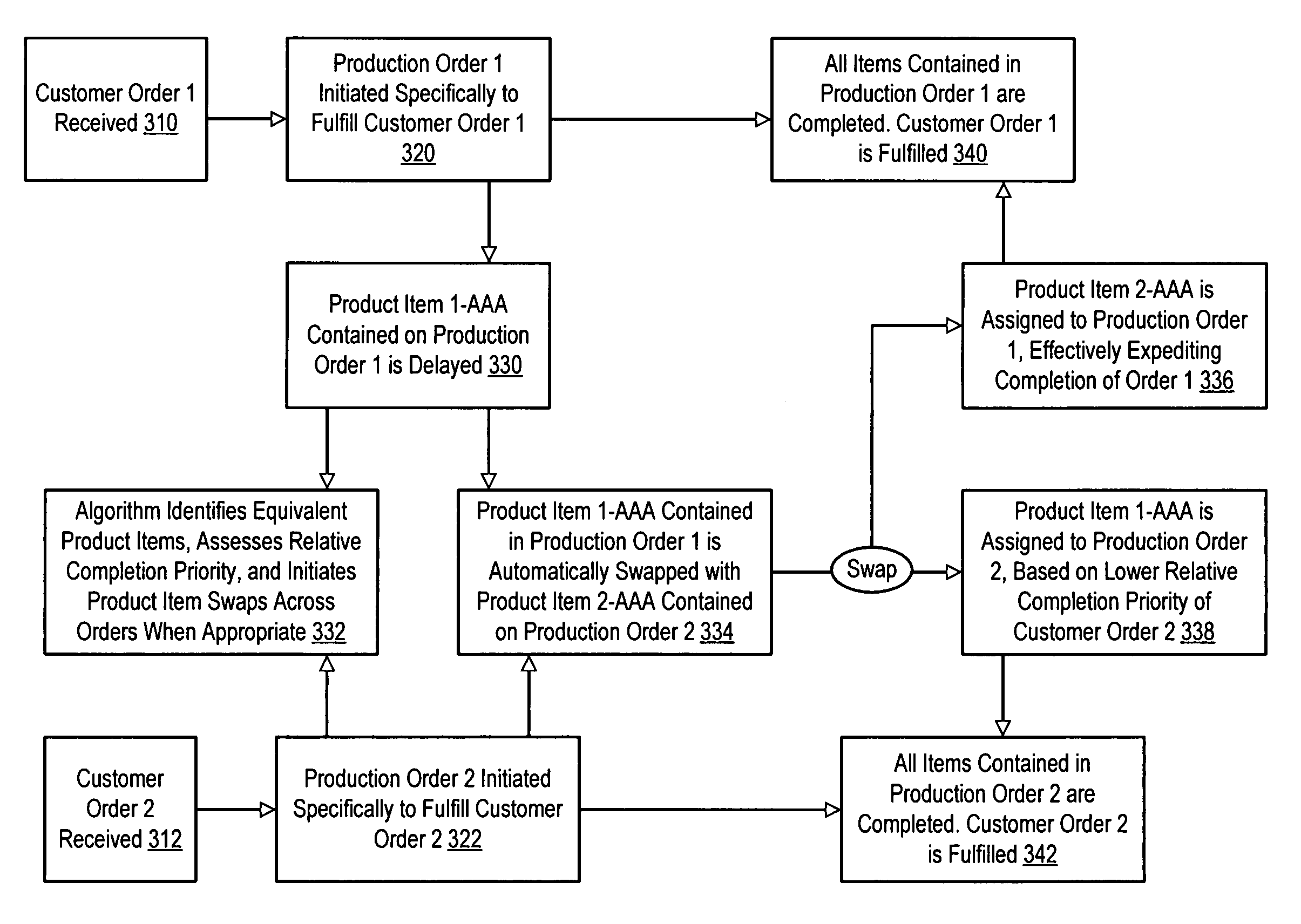

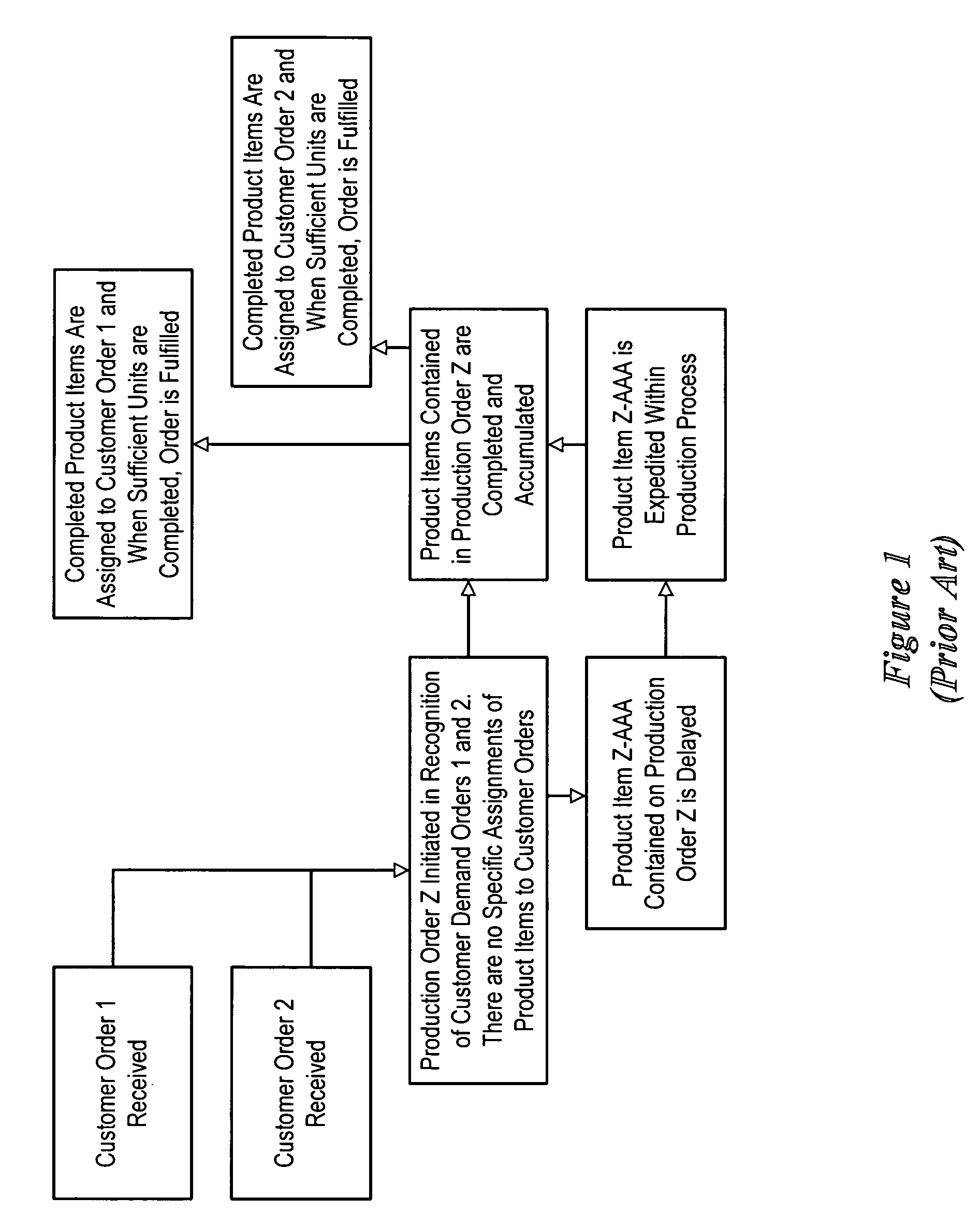

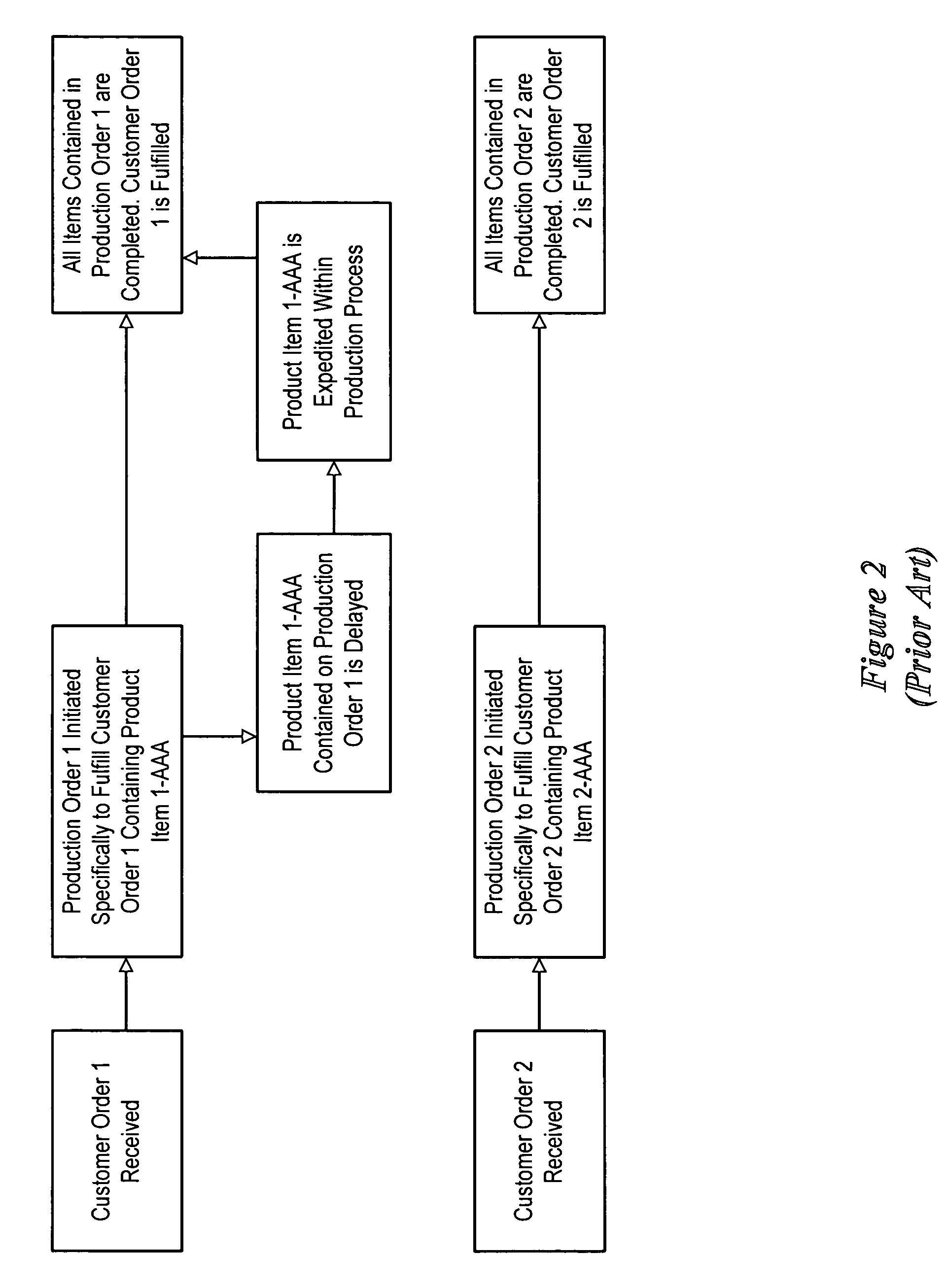

Dynamic order swapping in BTO environment

ActiveUS7308330B2Improve throughputImprove the level ofHand manipulated computer devicesDigital data processing detailsProduct orderMass customization

A method for addressing process variability in a build-to-order, mass customization production environment. The method includes receiving an order for a product having a particular configuration defined by the order, initiating a production order specifically assigned to the order, fabricating the product based upon the production order, determining if an unrelated product order contains an identical product item configuration and automatically swapping identical product items contained on unrelated production orders to optimize overall production process objectives.

Owner:DELL PROD LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com