Patents

Literature

647 results about "Furniture manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shaped wooden mould pressing furniture part and manufacturing method thereof

ActiveCN102069523AMitigation resourcesAlleviate the problem of few large-diameter logsWood working apparatusThermal energyAdhesive

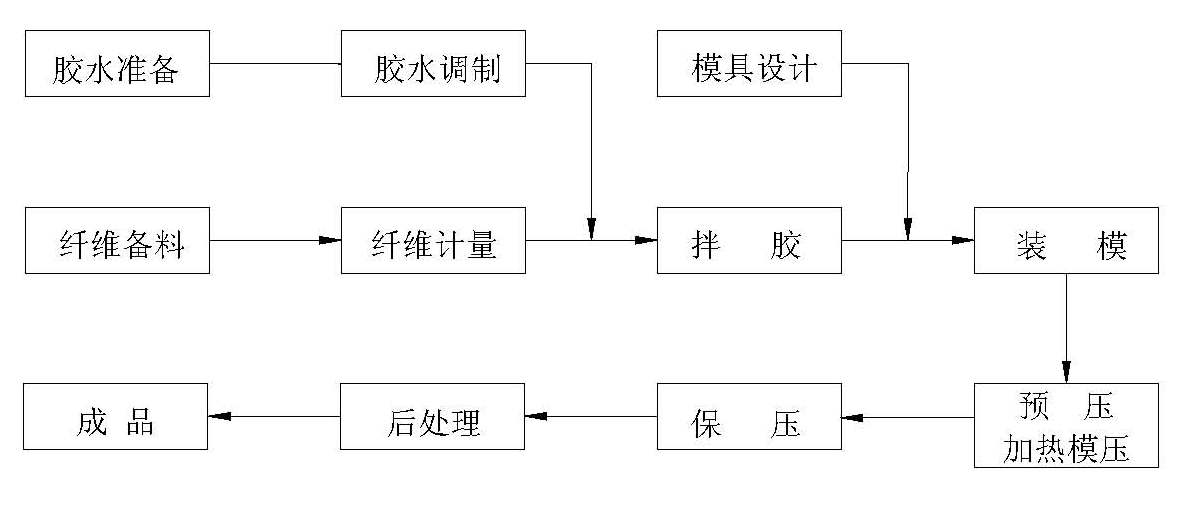

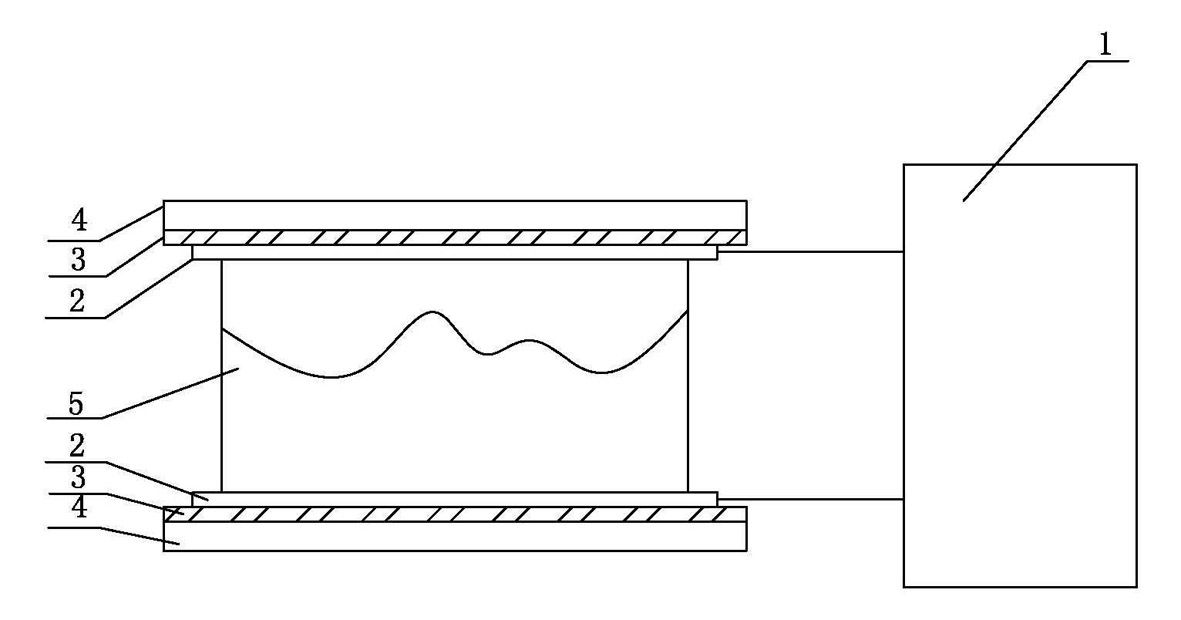

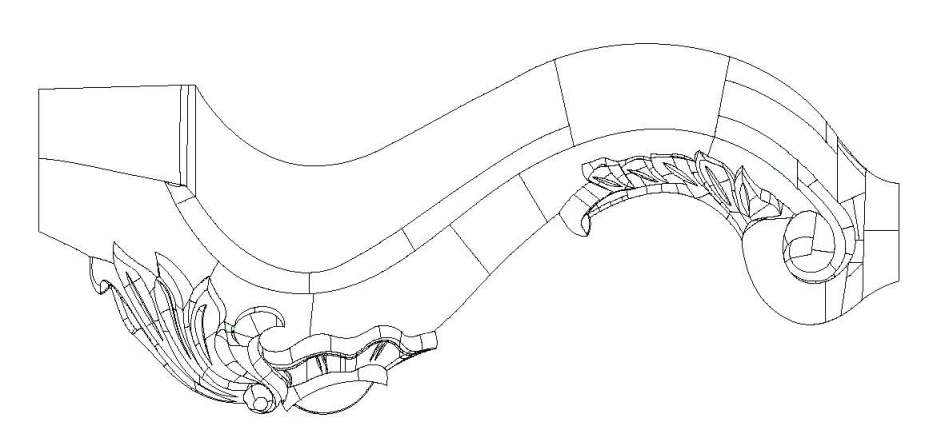

The invention belongs to the technical field of wooden furniture and relates to a shaped wooden mould pressing furniture part and a manufacturing method thereof. The part comprises the following materials in parts by weight: 100 parts of wooden material, 8-25 parts of adhesive, 1-3 parts of curing agent and a proper quantity of waterproofing agent. The manufacturing method comprises the following steps of: mixing the materials and then loading into a mould for pressing; heating by adopting a mode of combining contact type heating and high-frequency electric field heating; and shaping, wherein the mixed materials loaded into the mould are subjected to contact heat transfer by a hot press plate while mould pressing and then shaped after heating and curing. In the invention, the surface of the shaped wooden mould pressing furniture part is provided with obviously convex-concave decorative carved patterns, and the patterns have higher simulation degree and can be compared favorably with a carved and shaped furniture part.

Owner:浙江新木材料科技有限公司

Manufacturing method of surface compressed plate

InactiveCN101664948AHigh densityHigh strengthWood compressionWood treatment detailsPolymer scienceVolumetric Mass Density

The invention relates to a manufacturing method of a surface compressed plate, in particular to solving the technical problem of providing a manufacturing method of a surface compressed plate featuring high surface layer density, high strength, low probability of deformation, simple technology, strong operability and lighter color. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) drying and controlling the water content between 20% and 30%; (2) rolling and controlling the compression ratio between 10% and 30%; (3) impregnating surface layer, namely soaking one or two sides of the plate into light-color water-soluble low molecular weight phenolic resin adhesives at a concentration of 10-25%; (4) softening by steam and controlling thesoftening temperature between 120 DEG C and 140 DEG C and time between 20min and 60min; and (5) compressing surface layer and controlling the compression ratio between 15% and 50%, the hot pressing temperature between 160 DEG C and 180 DEG C and the unit pressure between 1.5MPa and 4.5MPa. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method of producing compound water-proof sheet material of bamboo bits and coal ash

The invention relates to a bamboo cuttings and powder coal composite water-proof plate and a method for manufacturing the same, the composite water-proof plate is made by blending, press molding and polymerizing 20 to 70 potions by weight of bamboo cuttings, 10 to 60 potions by weight of powder coal, 5 to 40 potions by weight of adhesive and TAIC. The compositions of bamboo cuttings and powder coal composite water-proof plate provided by the invention can also comprises 1 to 12 potions by weight of new and old plastic materials. The bamboo cuttings and powder coal composite water-proof plate has high intensity and favorable water-proof performance; most of the raw materials adopted are the scrap products in industry and agriculture, thereby the environment pollution can be degraded. The bamboo cuttings and powder coal composite water-proof plate can be widely used in the floor manufacturing industry, the furniture industry, the decoration and construction material industry as well as the inner decoration material in automobile industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Flame-retardant straw shaving board and manufacturing method thereof

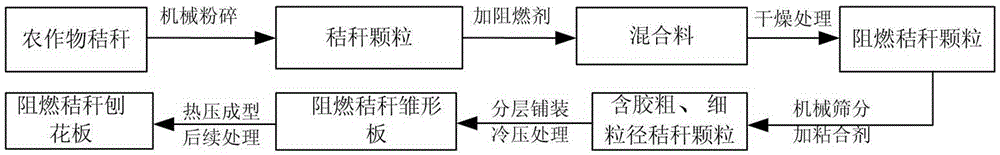

ActiveCN105345911AStable structureWaterproofDomestic articlesFlat articlesPolyvinyl alcoholPhosphoric acid

The invention provides a flame-retardant straw shaving board. The flame-retardant straw shaving board comprises, by weight, 7-9 parts of straw particles, 0.5-1.5 parts of flame retardants and 0.3-1.0 part of binders, wherein the flame retardants comprise magnesium oxide, magnesium chloride, trisodium phosphate, polyvinyl alcohol and ammonium polyphosphate. The flame-retardant straw shaving board is good in flame retardance, water resistance and insect resistance and low in formaldehyde content and has good physical and mechanical performances; a wooden shaving board can be replaced by the flame-retardant straw shaving board which can be applied to the field of decoration of various buildings and manufacturing of furniture. The invention further provides a manufacturing method of the flame-retardant straw shaving board. The hot press molding technology is mainly adopted for modifying and shaping the raw materials, so that not only is the wood resource saved, but also the whole production process is environmentally friendly and free of pollution.

Owner:信阳美丽真好秸秆新材科技有限公司

Compound regenerated environment protecting sheet material and method of preparing the same

InactiveCN101279462AHigh densityImprove wear resistanceDomestic articlesFlat articlesFiberEnvironmental resistance

The invention relates to a composite regenerated environment-friendly plate and a preparation method. The composite regenerated eco-friendly plate consists of 20 percent to 50 percent of plastic and 50 percent to 80 percent of plant fiber in weight percentage; the plastic is a mixture of one or more thermoplactic plastic materials. The preparation method includes the steps that: the plastic and crushed plant fiber are mixed with each other and dried and then are subject to a first high-temperature stirring melting at the temperature ranging from 200 to 350 DEG C for 1 to 2 minutes for extrusion; the extruded mixtures go through second high-temperature stirring melting at the temperature ranging from 150 to 220 DEG C for 1 to 2 minutes and finally are subject to high-temperature oil-pressure molding at the temperature ranging from 80 to 130 DEG C. Being manufactured at the high temperature, the plates of the invention are not deformed at the high temperature ranging from 70 to 100 DEG C, do not swell if immersed in the water for 3 months, are the typical high-temperature resistant plates, have low cost, can be recycled in an economical and environmentally protective way, simultaneously solves the problems of insufficient wood resources and white pollution, can be extensively applied to the furniture manufacturing industry and construction industry, etc.

Owner:北京光耀未名科技有限公司

Manufacturing method of bamboo-Chinese fir composite plate

InactiveCN101664952AHigh strengthIncrease profitNon-macromolecular adhesive additivesWood treatment detailsWood shavingsComposite plate

The invention relates to a manufacturing method of a bamboo-Chinese fir composite plate, in particular to solving the technical problem of providing a manufacturing method of a bamboo-Chinese fir composite plate by comprehensively and efficiently utilizing Chinese fir slabs and bamboo processing residues. The method aims at improving the utilization rate of the bamboos and wood and the composite plate has the characteristics of flat plate surface, high strength, little glue mount and good dimensional stability. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) splicing; (2) flaking and first sorting; (3) Chinese fir flaking and steam-injecting; (4) bamboo flaking and poaching; (5) drying; (6) flaking and sorting; (7) glue blending; (8) paving; (9) prepressing; (10) hot pressing; and (11) post treatment. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

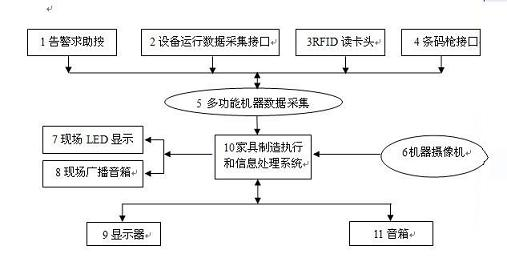

Information acquisition monitoring system and method for large-scale customized furniture manufacturing shop

ActiveCN102193552AIncrease profitReduce consumptionTotal factory controlProgramme total factory controlInformation processingManufacture execution system

The invention relates to an information acquisition monitoring system for a large-scale customized furniture manufacturing shop, which is characterized in that a signal output end of a multifunctional machinery data acquisition device is connected to a signal input end of a furniture manufacturing executing and information processing system; the signal output end of a camera is connected to the signal input end of the furniture manufacturing executing and information processing system; and the signal output end of the furniture manufacturing executing and information processing system is connected to the signal input ends of an on-site LED (light-emitting diode) display screen and an on-site broadcast loudspeaker box. The system has the advantages that the manufacturing process in the whole manufacturing shop is optimized, a new manufacturing shop management mode is established by utilizing an informatization management method, the material use ratio is increased, the cost is lowered,a function of collecting data in real time in the manufacturing process is provided and corresponding analysis and processing are performed, a quick response, elastic and fining manufacturing environment is provided to the furniture enterprises, and the problem that the MES (manufacturing execution system) can realize the enterprise information integration through the continuous information flow of the furniture enterprises by performing information interaction with the plan layer and control layer is solved.

Owner:海太欧林集团股份有限公司

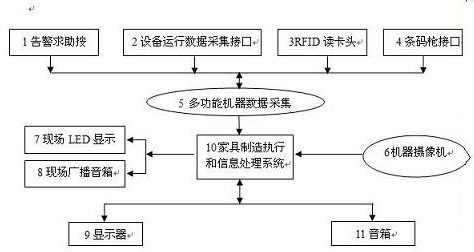

Visual monitoring and display method for wooden furniture manufacture process digital management platform

InactiveCN103823426ATroubleshooting Classified ArchivesSolve collectionTotal factory controlProgramme total factory controlControl layerManufacturing technology

The invention provides a visual monitoring and display method for a wooden furniture manufacture process digital management platform. The method comprises the following steps: 1) the wooden furniture manufacture process digital management platform collects processing information and variation information of components by scanning bar codes of the components through a multifunction machine data acquisition device in a data acquisition system, and collects various on-site process specification information through a camera acquisition device; 2) a data processing and scheduling system is utilized to perform data analysis processing; and 3) the processed information is sent to a background monitoring center. The advantages of the visual monitoring and display method are that wooden furniture manufacture process technical specification digital management can be established through the platform, complete process standardization, process procedure internal correlation, process planning system and typical process module management system of the wooden furniture manufacture process can be established; and digital management is realized, material utilization rate is improved, the cost is reduced, the problem that an MES needs to perform information interaction with a planning layer and a control layer is solved, and enterprise information full integration is realized.

Owner:GUANGDONG YIHUA TIMBER IND +1

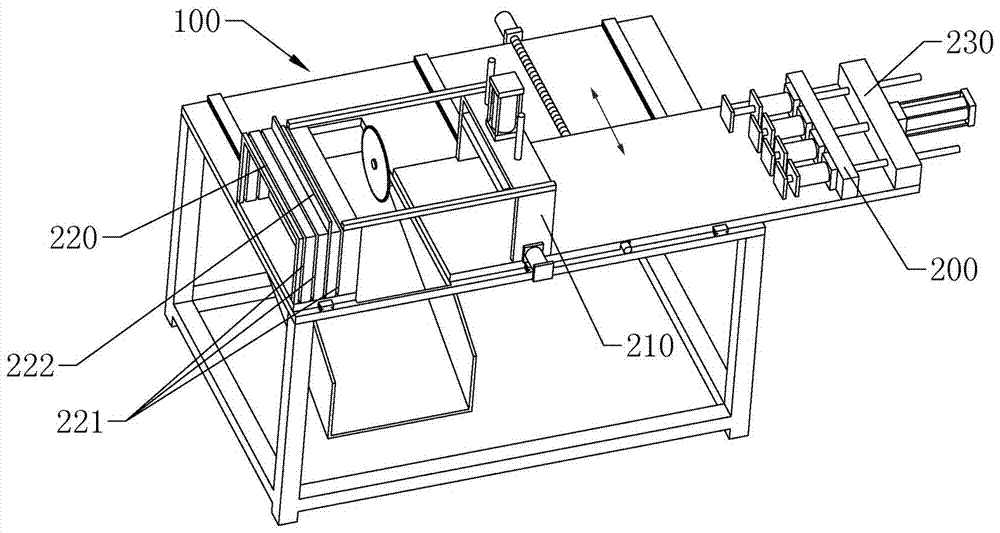

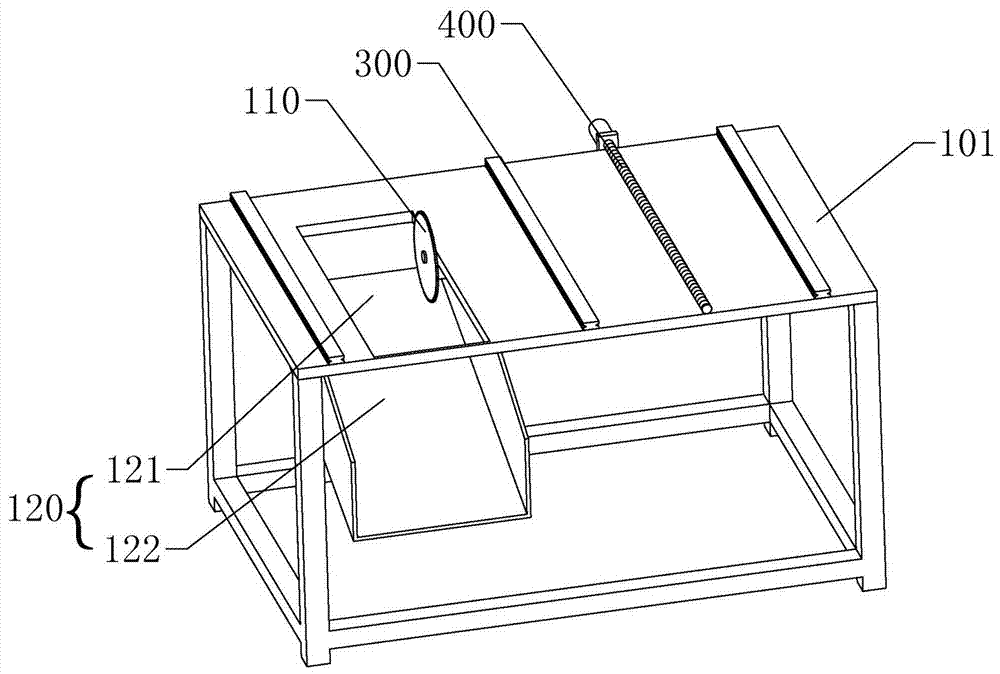

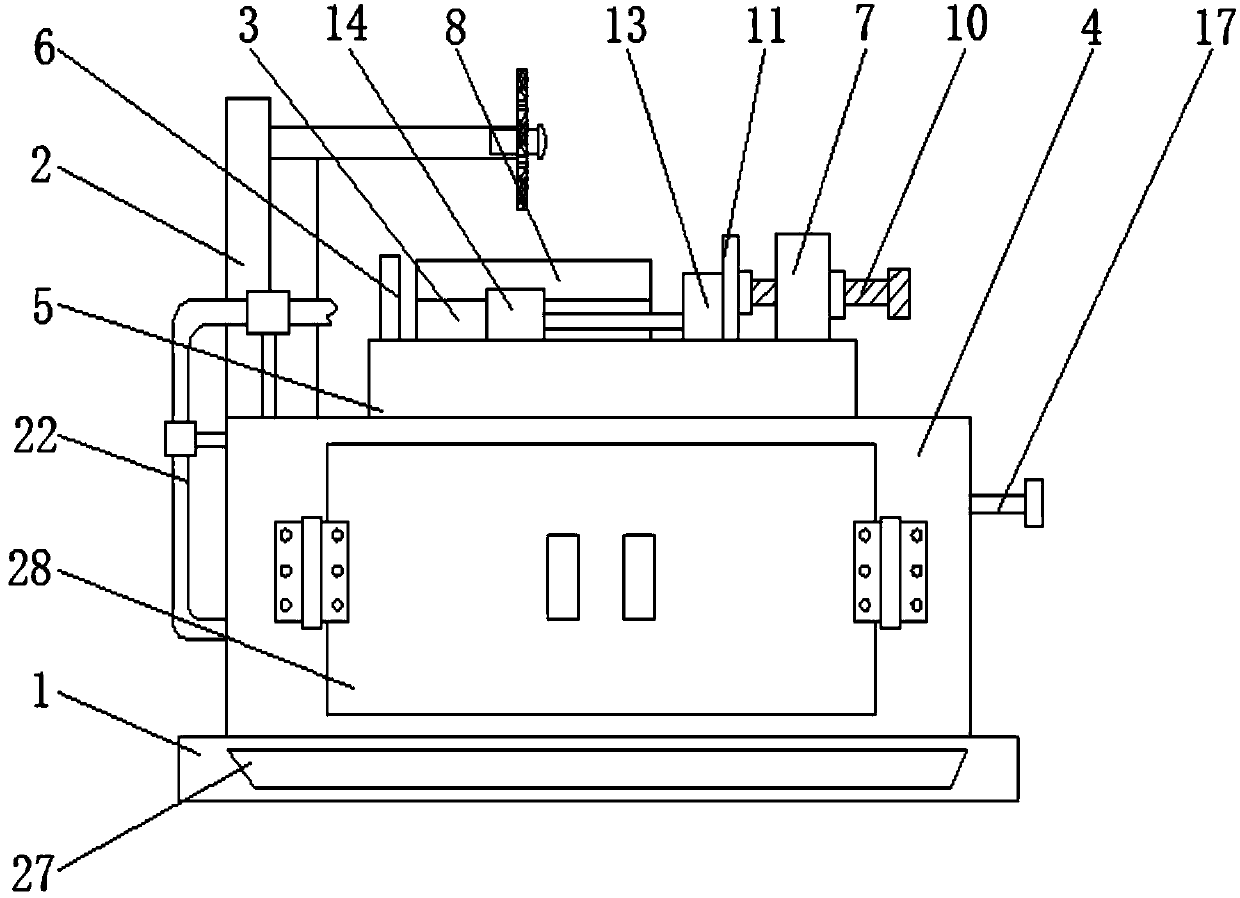

Automatic wood cutting machine

InactiveCN107053344AImprove securityImprove clamping effectFeeding devicesGripping devicesFixed frameSlide plate

The invention relates to the field of furniture manufacturing, in particular to an automatic wood cutting machine. The automatic wood cutting machine comprises a fixed frame and a movable frame. The movable frame is arranged above the fixed frame. A guide rail and a lead screw are arranged between the fixed frame and the movable frame. The fixed frame comprises a top plate, a cutting mechanism and a discharging mechanism. The discharging mechanism comprises a discharging outlet formed in the top plate and a discharging slide. The cutting mechanism is a cutting machine body fixed to the lower portion of the top plate. The top of a cutting blade of the cutting machine body is higher than the top of the top plate. The movable frame comprises a cutting area located above the discharging outlet, a clamping mechanism, a length positioning mechanism and a pushing mechanism. The clamping mechanism, the length positioning mechanism and the pushing mechanism are sequentially arranged. The cutting area is arranged between the clamping mechanism and the length positioning mechanism. The clamping mechanism is connected with the top of the length positioning mechanism through a connecting rod. The clamping mechanism is connected with the bottom of the pushing mechanism through a sliding plate.

Owner:ZOY HOME FURNISHING CORP

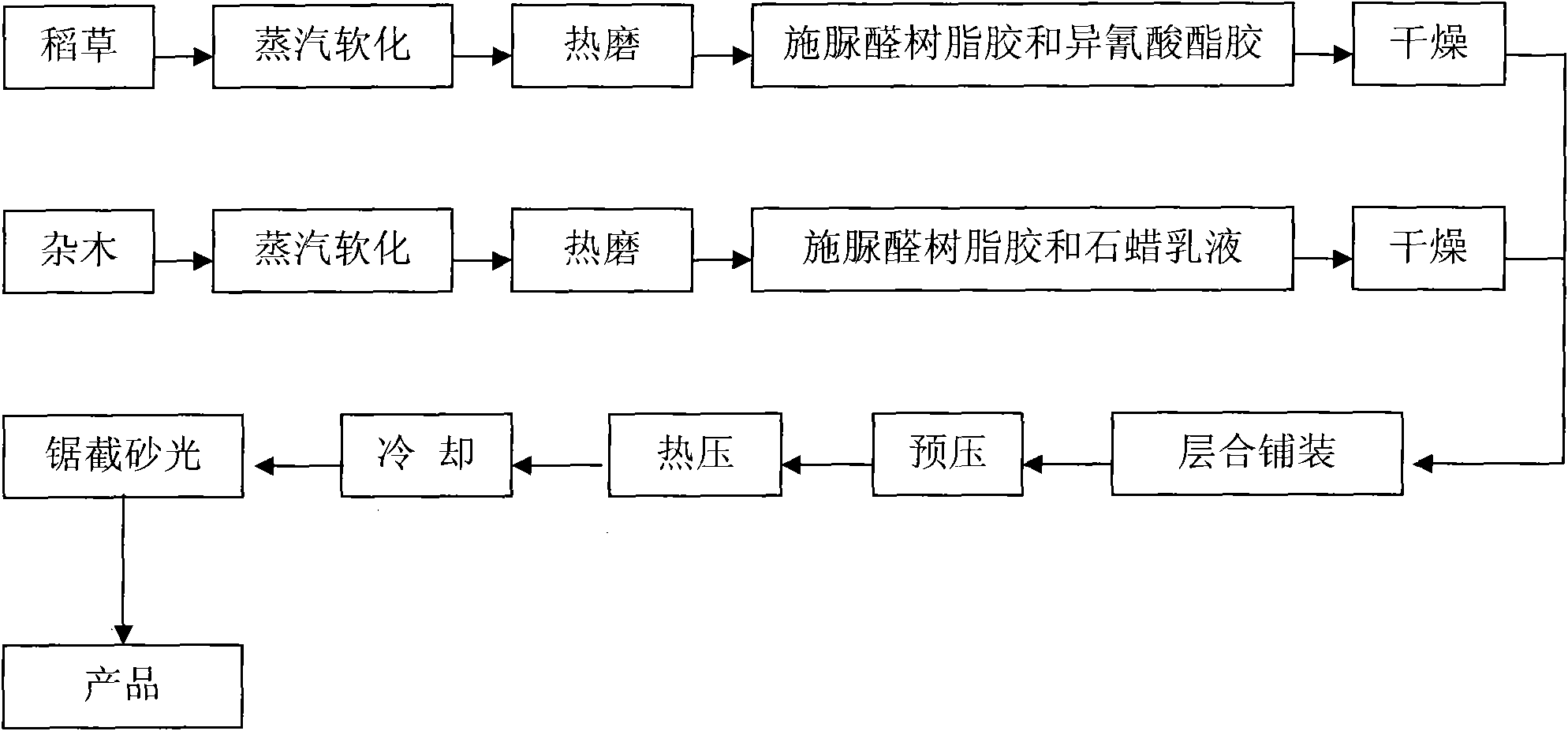

Method for manufacturing weed wood and straw compounding medium density fiberboard with laminated structure

InactiveCN101659074ASave resourcesImprove flexural strengthFlat articlesDomestic articlesEcological environmentFlexural modulus

The invention relates to a method for manufacturing a weed wood and straw compounding medium density fiberboard with a laminated structure. The method adopts straw and weed wood as raw materials, andincludes the following steps: the straw and the weed wood are respectively processed by defibration, and urea formaldehyde resin adhesive and waterproof agent are added, and in the process of formation, straw fibres and wood fibres are proportionally assembled and laminated in the direction of thickness and then are processed by thermocompression to form boards. The method has the advantages thatproved by performance tests, the flexural modulus, the strength and the internal bonding strength of the medium density fiberboard, compared with a pure straw medium density fiberboard, are respectively and obviously increased under the same condition, and the expansion rate of water-absorbing thickness and the water absorption rate are lowered; and the relative performances of the compound material can be increased by changing the mode of lamination. The method efficiently and comprehensively utilizes the agricultural straws and saves wood resources, thereby protecting the ecological environment. The product can be applied to the occasions of furniture manufacturing and production, base materials for interior decoration, and the like.

Owner:NANJING FORESTRY UNIV

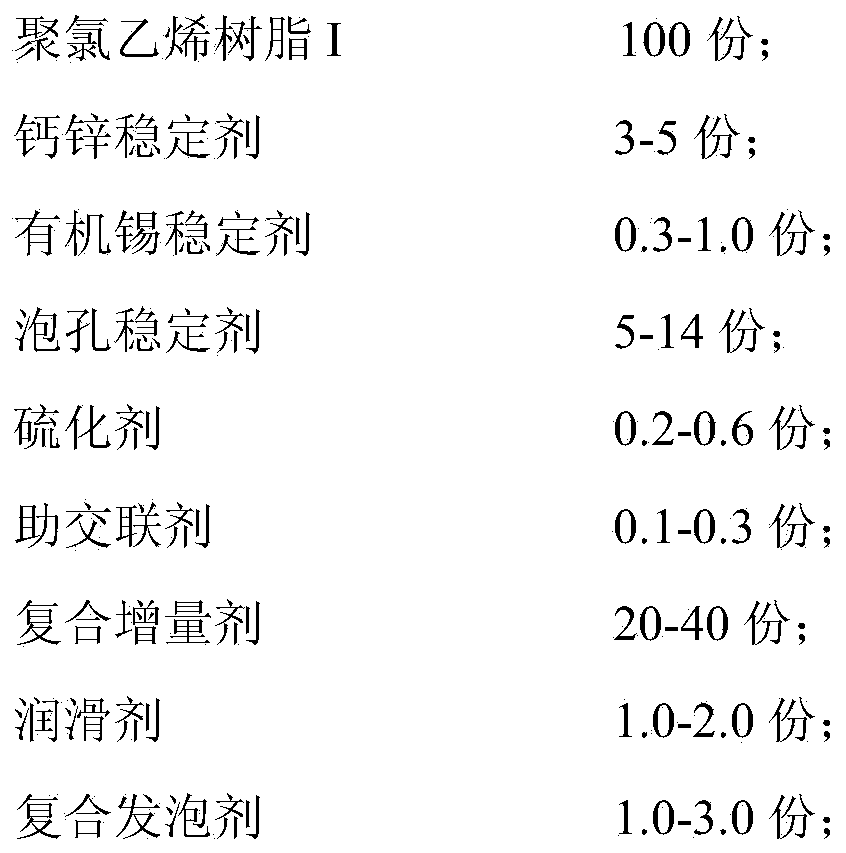

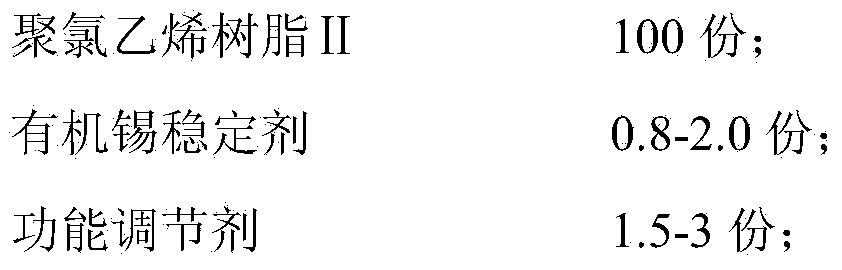

Colored polyvinyl chloride foamed sheet and preparation method thereof

InactiveCN104385735ALow densityFlat surfaceSynthetic resin layered productsLaminationEnvironmental resistancePolymer science

The invention belongs to the technical field of polyvinyl chloride sheets, and particularly relates to a colored polyvinyl chloride foamed sheet and a preparation method thereof. The colored polyvinyl chloride foamed sheet consists of a core layer, an upper surface layer and a lower surface layer, wherein the core layer is prepared from polyvinyl chloride resin I, a calcium-zinc stabilizer, an organic tin stabilizer, a cell stabilizer, a vulcanizing agent, an assistant cross-linker, a composite extender, a lubricant and a composite foaming agent; the upper surface layer and the lower surface layer are made of same raw materials, and each of the upper surface layer and the lower surface layer is prepared from polyvinyl chloride resin II, an organic tin stabilizer, a function regulator, a reinforcing agent, a lubricant, an impact modifier and a cool pigment. The colored polyvinyl chloride foamed sheet has the characteristics that the sheet is high in weather resistance, environment-friendly and good in rigidity, does not deform when heated, does not discolor and the like and can be applied to fields of high-grade advertisements, baking varnish or natural color home decoration, ornament, furniture manufacturing and the like. The preparation method is simple and easy to implement.

Owner:SHANDONG BODO PLASTICS CO LTD

Method for manufacturing re-combined bamboo timber furniture

InactiveCN101879737AAbundant resourcesIncrease profitWood working apparatusSolid woodGeneral assembly

The invention relates to a method for manufacturing re-combined bamboo timber furniture, which is characterized by comprising the following steps of: 1, material proportioning or material cutting; 2, polishing or precision cutting; 3, gluing or veneering decoration; 4, edge precision cutting or irregular milling; 5, tenoning or boring or drilling; 6, molding surface machining; 7, part assembling and machining; 8, surface coating; 9, general assembly; and 10, packaging. The method has the advantages that: the re-combined bamboo timber furniture, which have various types (fixed, detachable, folding and the like) and various structures and are manufactured by using re-combined bamboo timber, replace solid wood furniture, and have the characteristics of high mechanical properties, good textures and colors, abundant material resources, high utilization rate, convenient machining and environmental protection.

Owner:NANJING FORESTRY UNIV

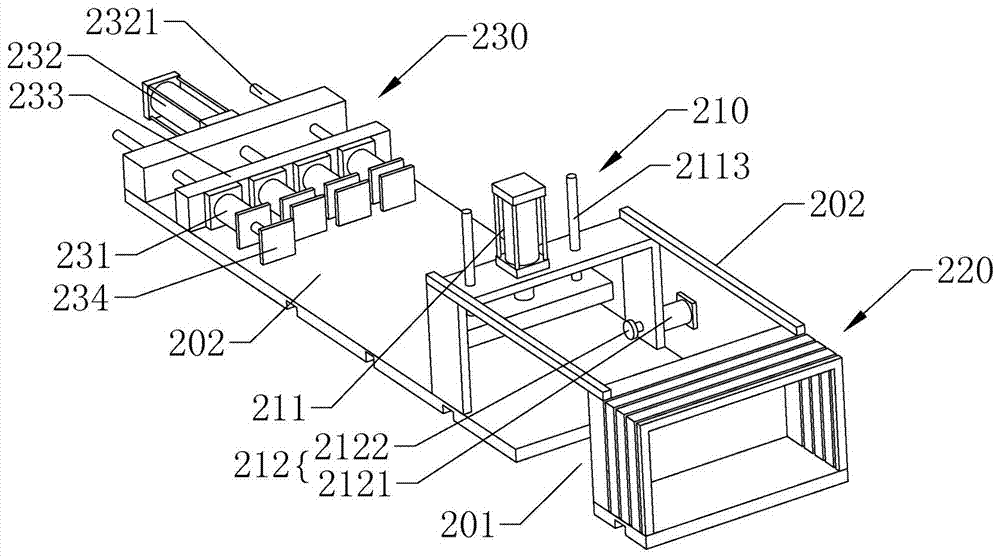

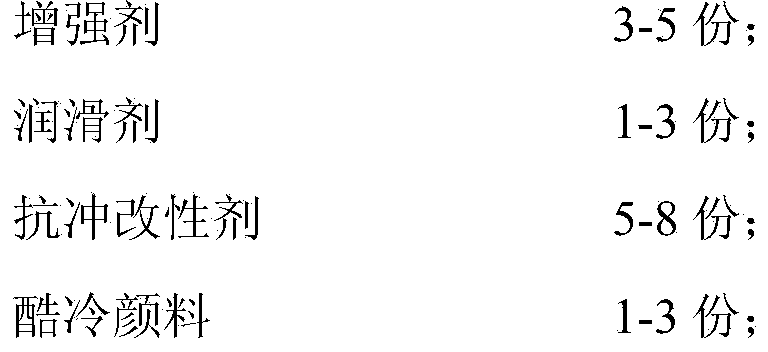

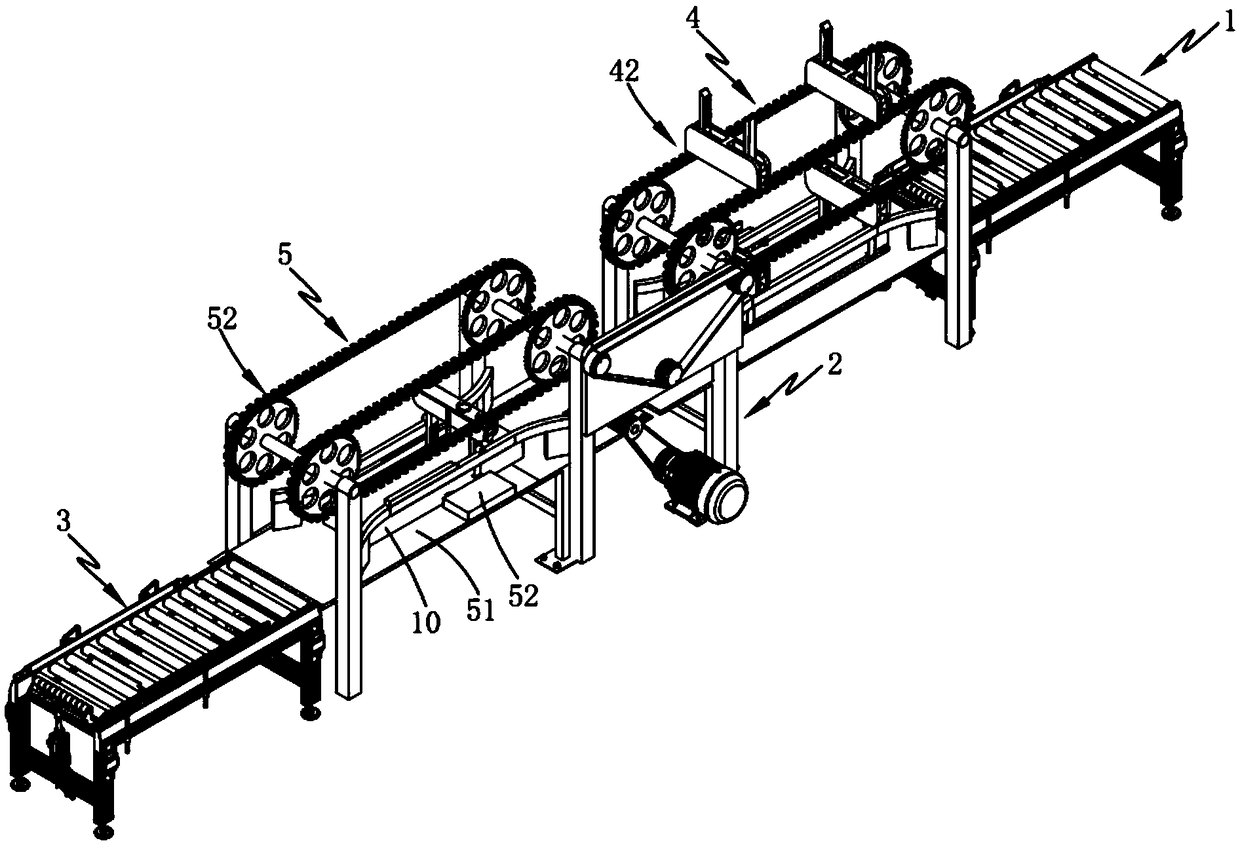

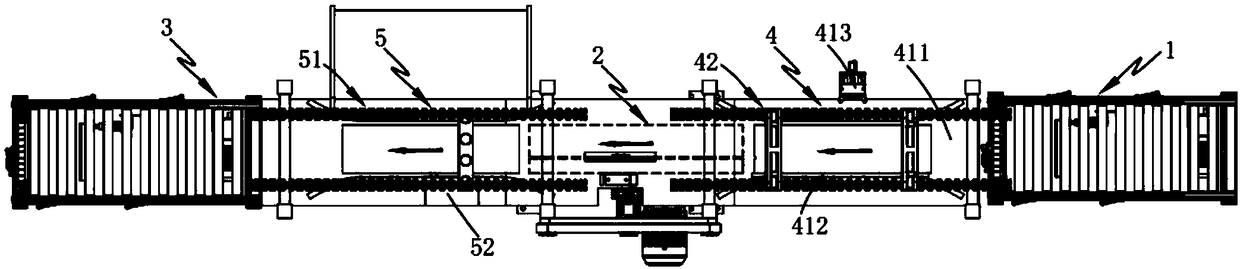

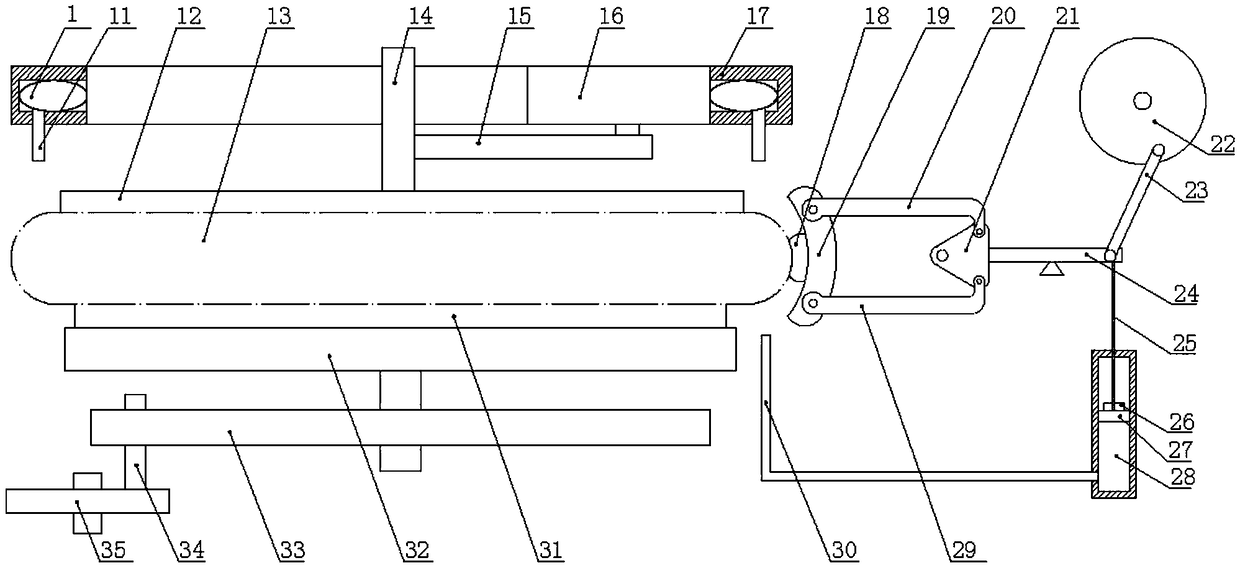

Continuous automatic processing production line for wood of furniture manufacturing

ActiveCN109291140ARealize fully automatic cuttingAchieve separationFeeding devicesGripping devicesProduction lineReciprocating motion

The invention provides a continuous automatic processing production line for wood of furniture manufacturing. The production line comprises a feeding device, a cutting device, an output device, a clamping and feeding device and a waste separating device, wherein the clamping and feeding device is arranged between the feeding device and the cutting device, and comprises a wooden block positioning mechanism and a clamping and transporting mechanism; and the waste separating device is arranged between the cutting device and the output device, and comprises a separating workbench, a clamping staggering mechanism and a separating mechanism. After the clamping and feeding device clamps wooden blocks in a mode of reciprocating motion, the stepwise feeding and cutting are carried out in the cutting device; after the cutting of the wooden blocks is completed, the clamping and feeding device is fitted with the waste separating device to carry out the staggering separation of finished products and waste, so that the full-automatic cutting and the waste separating of the wooden blocks are realized; and in this way, an original manual wooden block feeding and cutting method is replaced, so thatthe problem that the leftward and rightward swaying of the wood results in irregular wood cutting surfaces and the imprecise cutting in the prior art is solved.

Owner:佛山市顺德区博领家具有限公司

Manufacturing method of cold plasma modified cellulolytic enzyme lignin/plant fiber composite material

ActiveCN101712179AHigh strengthImprove controllabilityWood working apparatusDomestic articlesFiberDry weight

The invention discloses a manufacturing method of a cold plasma modified cellulolytic enzyme lignin / plant fiber composite material. The manufacturing method comprises the following steps of: firstly dehydrating and drying the cellulolytic enzyme lignin to be with a moisture content of 6-10 percent; after processing the cellulolytic enzyme lignin into pulverulent bodies with grain diameters of 200-300 mesh by high-energy ball-milling, placing the pulverulent bodies into a sample chamber of cold plasma modified equipment; vacuumizing the sample chamber to 2-4 Pa; introducing oxygen or nitrogen; controlling a vacuum degree to be 10-30 Pa; starting a radio frequency power supply and adjusting treating power to 100-300 W; modifying the cellulolytic enzyme lignin for 30-150 s; uniformly mixing the modified cellulolytic enzyme lignin with the plant fiber, wherein the oven dry weight of the modified cellulolytic enzyme lignin accounts for 5-25 percent of the oven dry weight of the plant fiber; and spreading the mixed modified cellulolytic enzyme lignin and the plant fiber in a plate blank form for thermo-compression, wherein thermo-compression temperature is 160-210 DEG C, and thermo-compression pressure is 3.0-4.0 MPa, and thermo-compression time is 20-40 s / mm. The material contains no free formaldehyde, and can be widely applied to industries, such as architectural decoration, furniture manufacturing, packaging, children toy manufacturing, and the like.

Owner:NANJING FORESTRY UNIV

Wood cutting device for furniture manufacturing

InactiveCN108789658AEasy to operateImprove working environmentProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningWorking environment

The invention provides a wood cutting device for furniture manufacturing. The device comprises a base plate; support plates are fixedly mounted at the two ends of the base plate; a cover plate is fixedly mounted on the upper sides of the support plates; a motor box is fixedly mounted on the left side of the cover plate; a first servo motor is arranged in the motor box; two bearing bases are arranged on the right side of the first servo motor; a lead screw is arranged between the two bearing bases, and is slidingly connected with a slide block; a first electric extension rod is fixedly mountedat the top of the slide block; a second servo motor is fixedly mounted at the end, far from the slide block, of the first electric extension rod; and the invention relates to the field of wood machining. The wood cutting device for furniture manufacturing is provided with a wood chip collecting box and a wood chip storage box, so that wood chips and dust are sucked into the wood chip collecting box through an electric blower and fall into the wood chip storage box through a discharge pipe, the wood chips are convenient to collect, both time and manpower are saved, and the improvement of the working environment is facilitated.

Owner:刘闪闪

Method for manufacturing surface-carbonized furniture

InactiveCN104526829ANot easy to absorb waterReduce moisture contentWood charring/burningWater basedHazardous substance

The invention relates to the field of furniture manufacturing methods, in particular to a method for manufacturing surface-carbonized furniture. The method includes the following steps that a board is stewed by boiled water, degreased and decolored; the board is soaked and cleaned in circular flowing water; the board is dried under the conditions of shading, normal temperature and ventilation and then enters a hot air drying chamber for drying; the board is spliced and reinforced through water-based glue for the furniture; the furniture is manufactured; the furniture is assembled and then is ground with grinding paper; the furniture is subjected to pressurization and roasting of a blast burner at a uniform speed, and finally the surface is carbonized; floating ashes are brushed away; the furniture is washed by water; the furniture is waxed and polished, and finally the furniture is completed after hardware is installed. The surface-carbonized board is not prone to water absorption, low in water content, resistant to dampness, not prone to deformation, good in corrosion resistance and insect prevention and free of any harmful substance, prolongs the service life of the furniture and will not have any negative effects on human bodies or animals or the environment in the production and use process and the waste treatment process after use.

Owner:ZHENGZHOU RED SUN FURNITURE

Hard polyvinyl chloride foamed sheet

The invention relates to a hard polyvinyl chloride foamed sheet which is characterized by comprising the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 3-5 parts of stabilizing agent, 3-30 parts of acrylate processing modifier, 0-10 parts of impact modifier, 0-100 parts of filler, 0-2 parts of yellow foamer, 0-4 parts of white foamer, 0-4 parts of lubricating agent and 0-2 parts of pigment. The hard polyvinyl chloride foamed sheet is a hard low-density polyvinyl chloride foamed sheet which has the standard size sheet density not more than 600kg / m<3> so as to be widely applied to advertisement material, household, decoration and furniture manufacturing; and in addition, the hard polyvinyl chloride foamed sheet is low in cost, strong in practicability and simple in manufacturing process.

Owner:SHANDONG BODO PLASTICS CO LTD

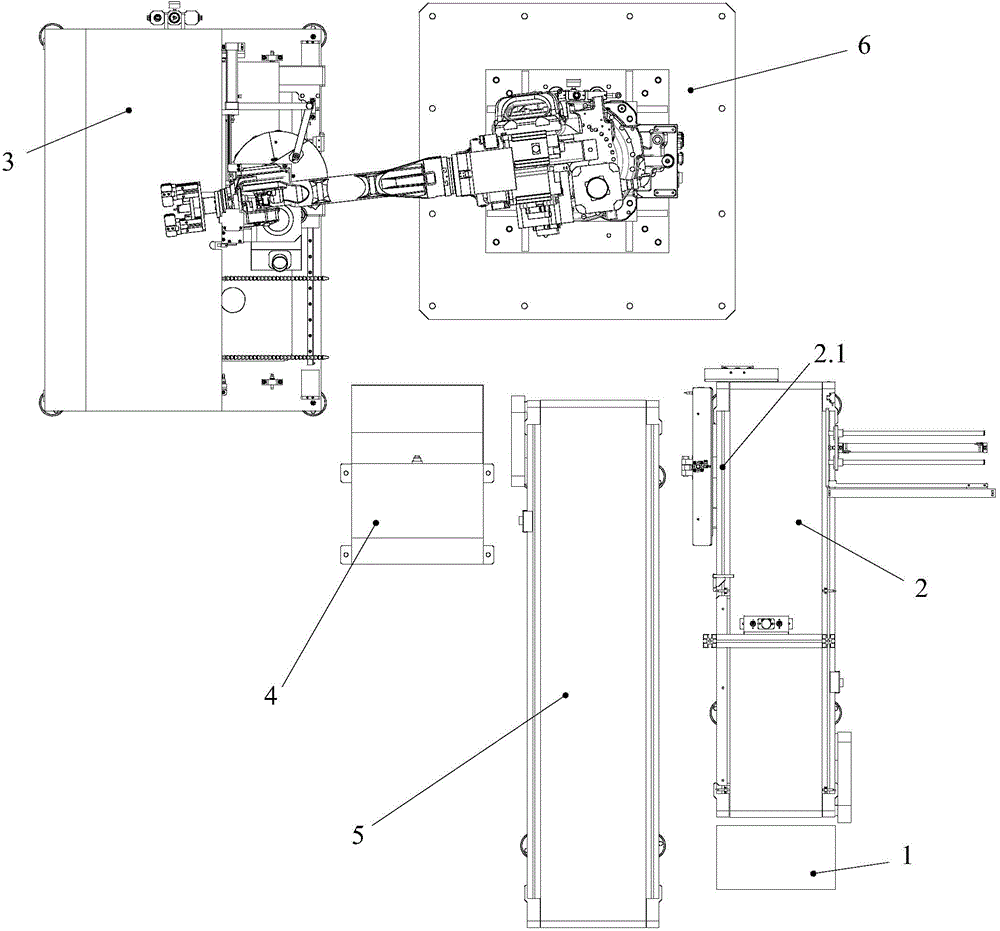

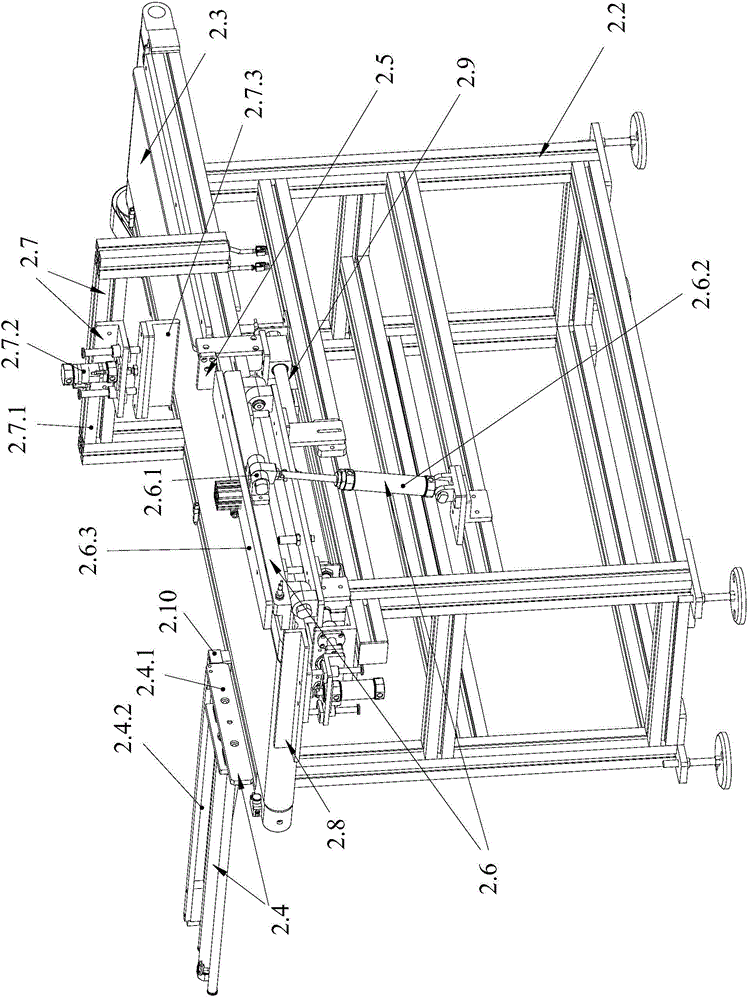

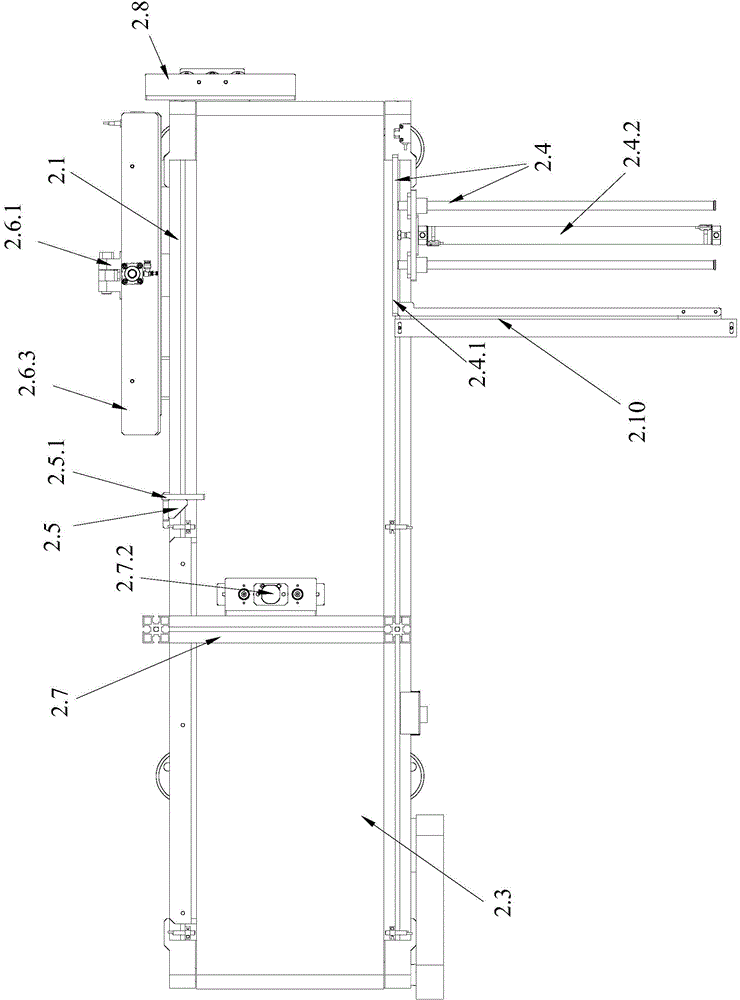

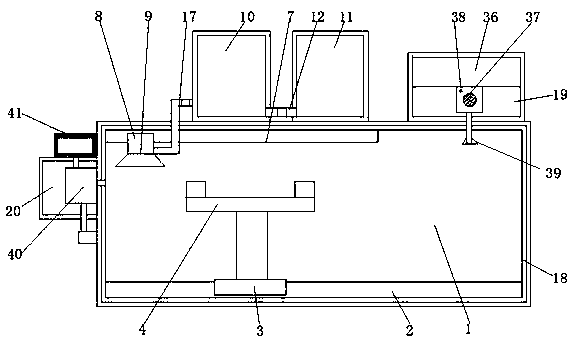

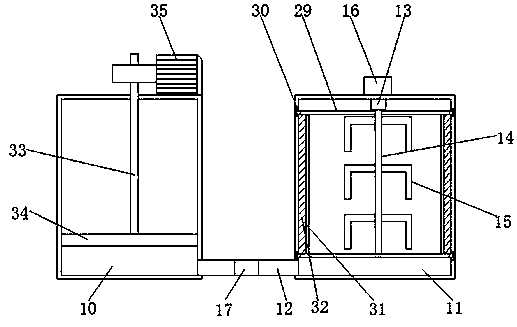

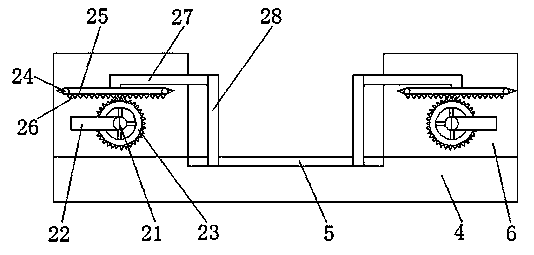

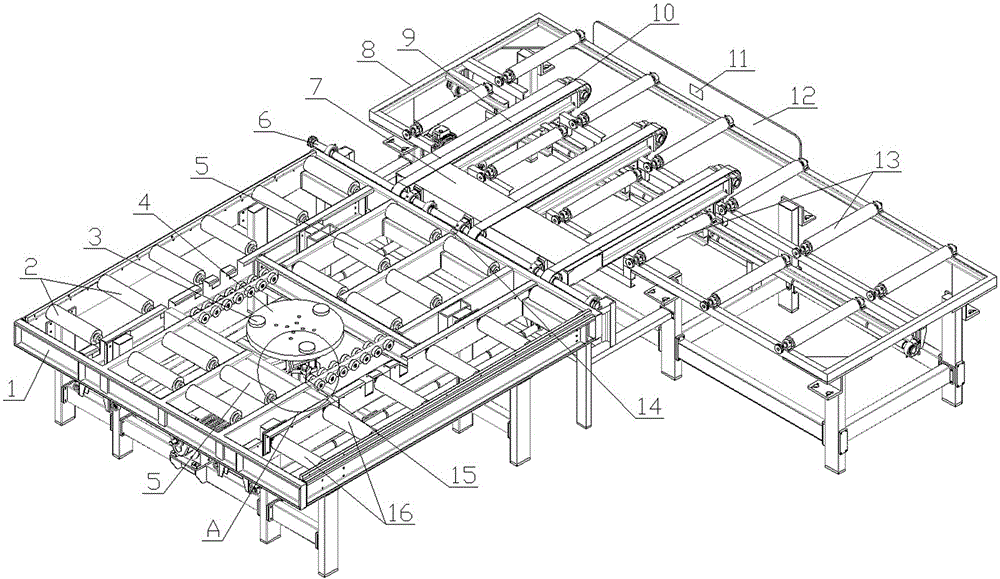

Automatic plate machining device for customizing furniture

ActiveCN104526828AIncrease productivityRealize automatic deliveryBark-zones/chip/dust/waste removalSize measurementComputer module

The invention provides an automatic plate machining device for customizing furniture. The automatic plate machining device comprises a feeding conveying mechanism, a scanning mechanism, a main machining mechanism, a side machining mechanism, a discharging conveying mechanism, a manipulator, a manipulator controller, a control mechanism and an upper computer module, wherein the feeding conveying mechanism is used for conveying the plate to a feeding port after separation, adjustment and size measurement are carried out on the plate; the manipulator is used for grabbing the plate from the feeding conveying mechanism, placing the plate on the main machining mechanism, pushing and turning over the plate for front and back machining, grabbing the plate and moving the plate to the side machining mechanism for side face machining, and then placing the plate on the discharging conveying mechanism; the manipulator controller is in signal connection with the manipulator. The automatic plate machining device for customizing the furniture has high practicality and carries out efficient and stable machining while effectively improves the machining precision, so that plates of various specifications are machined in a full-automatic and standardized mode according to the production demand. The automatic plate machining device for customizing the furniture is suitable for large-scale production and carries out intelligent furniture manufacturing.

Owner:佛山维尚家具制造有限公司

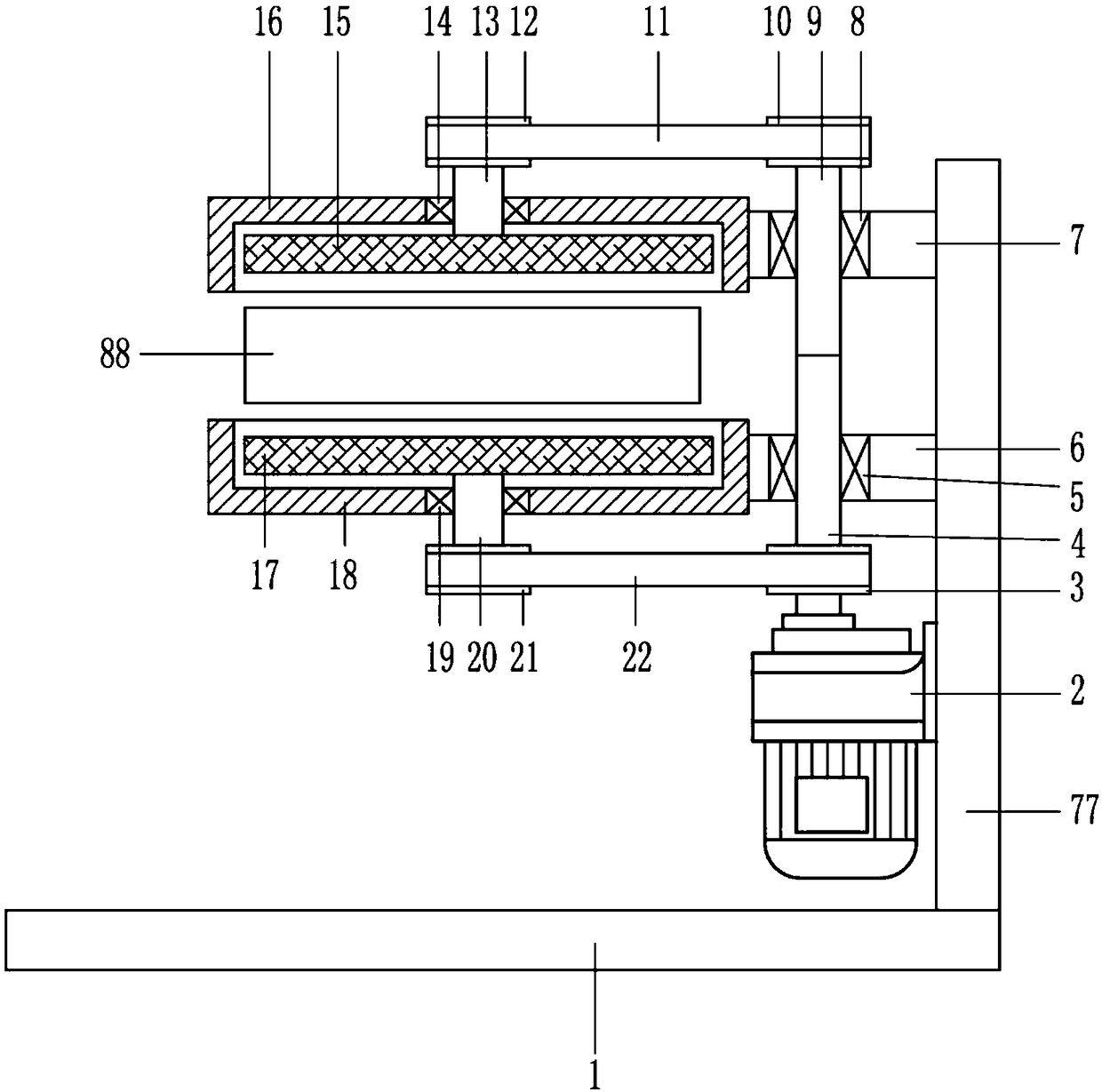

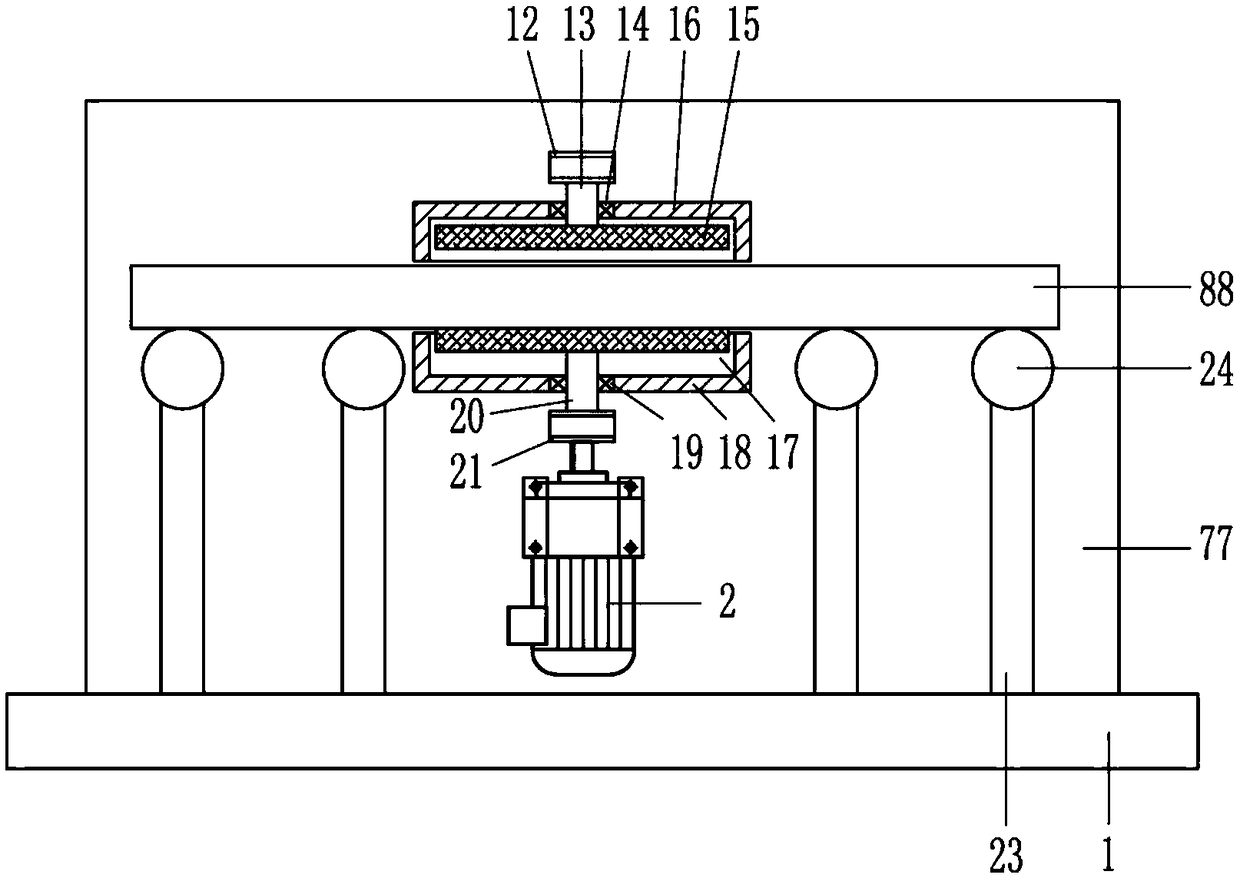

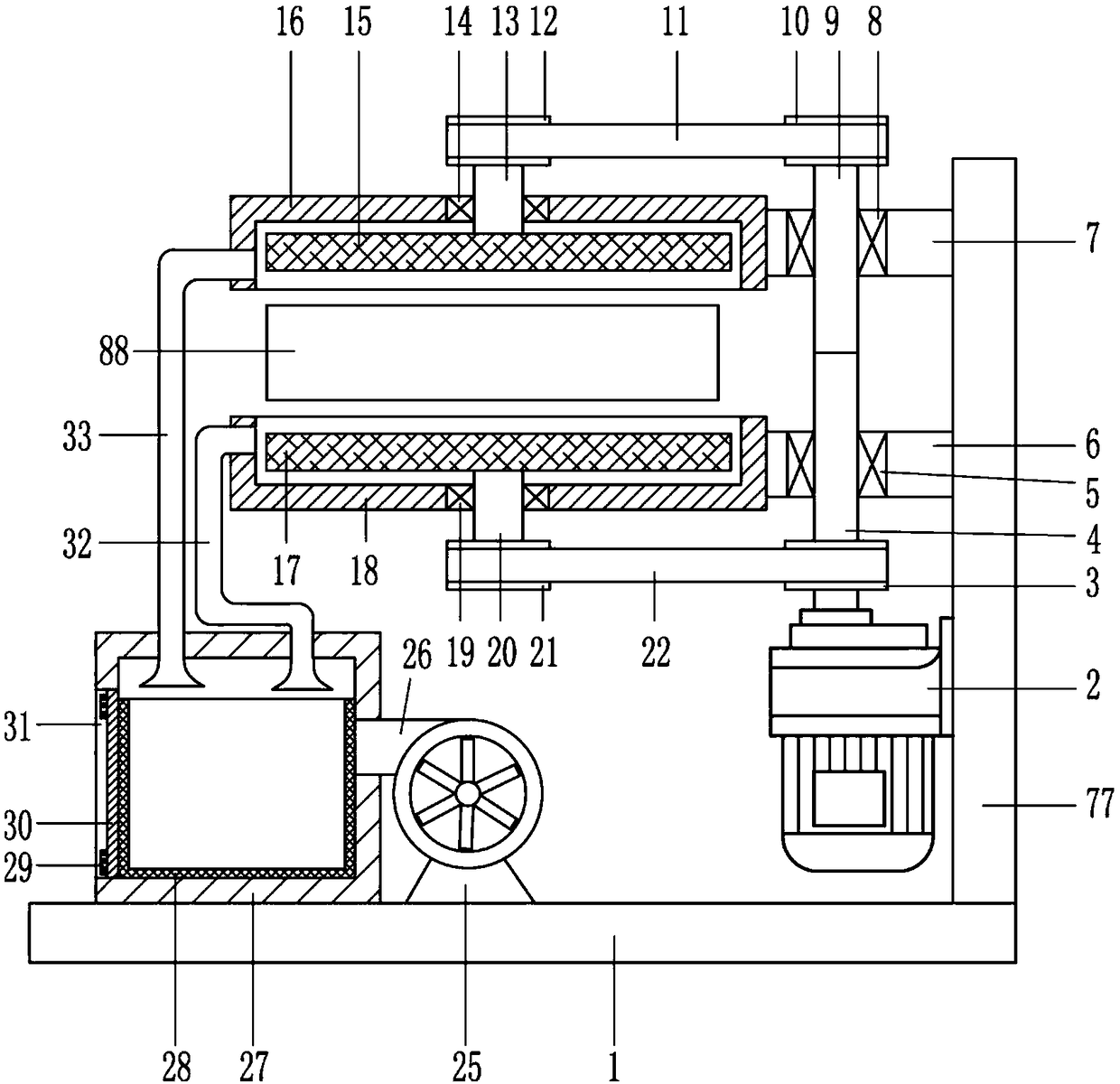

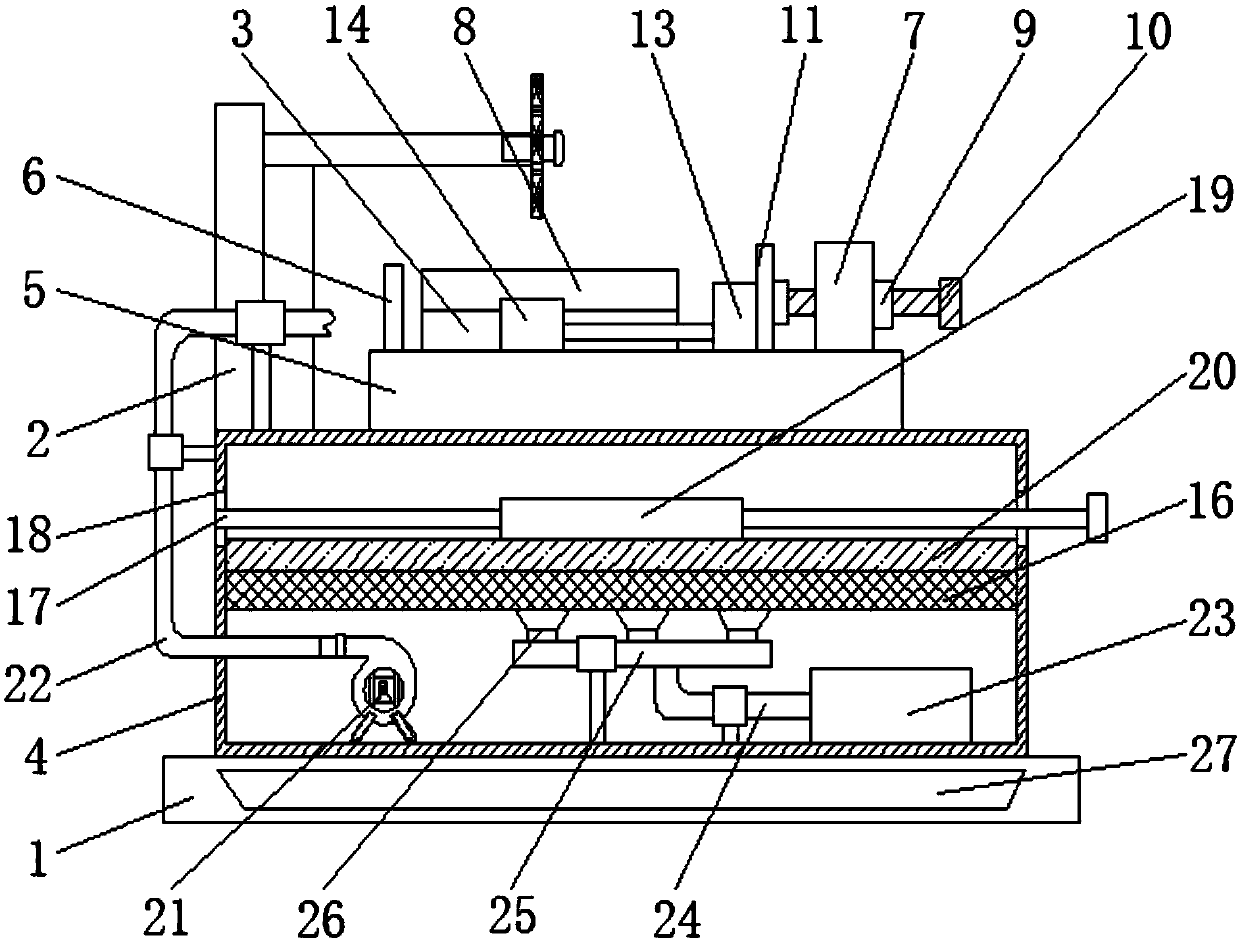

Double-sided polishing machine for wood used for manufacturing furniture

InactiveCN108907936AImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesWood machiningFurniture manufacturing

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

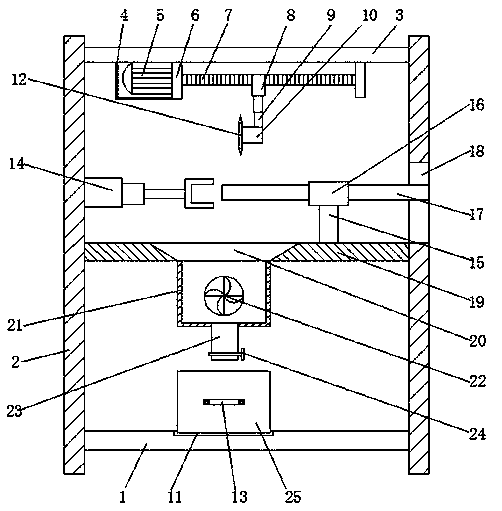

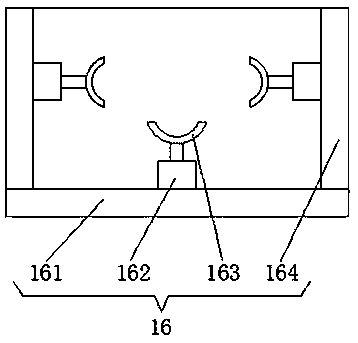

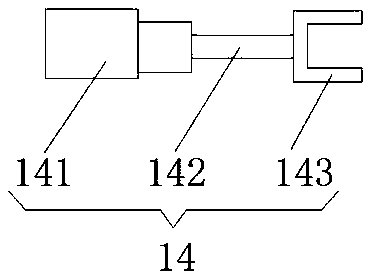

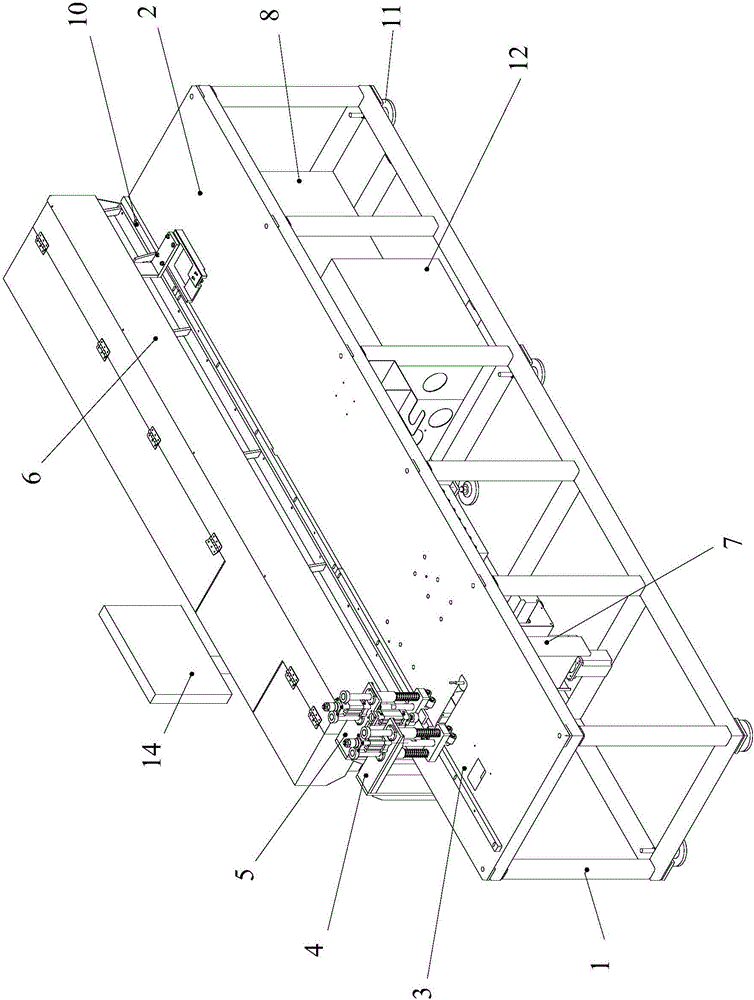

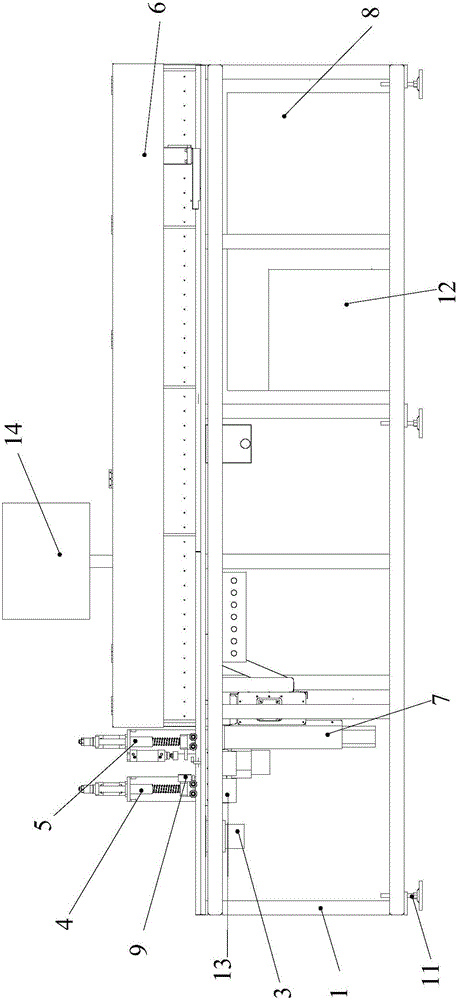

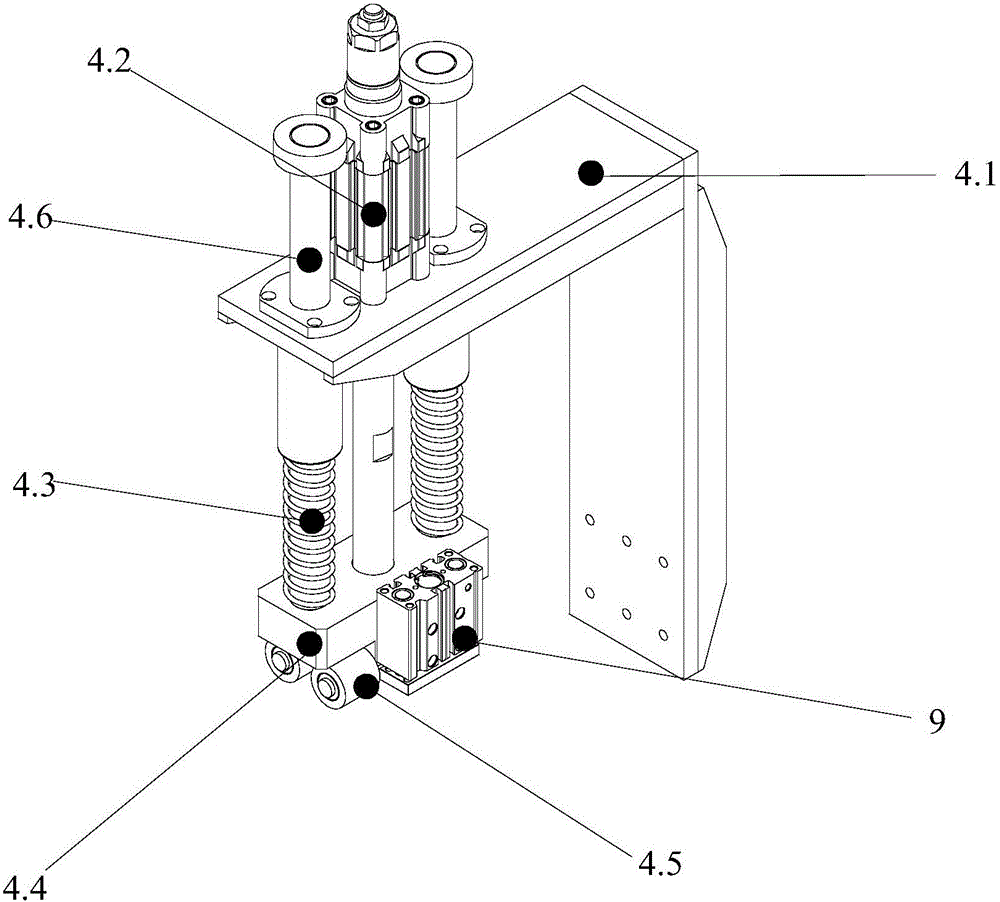

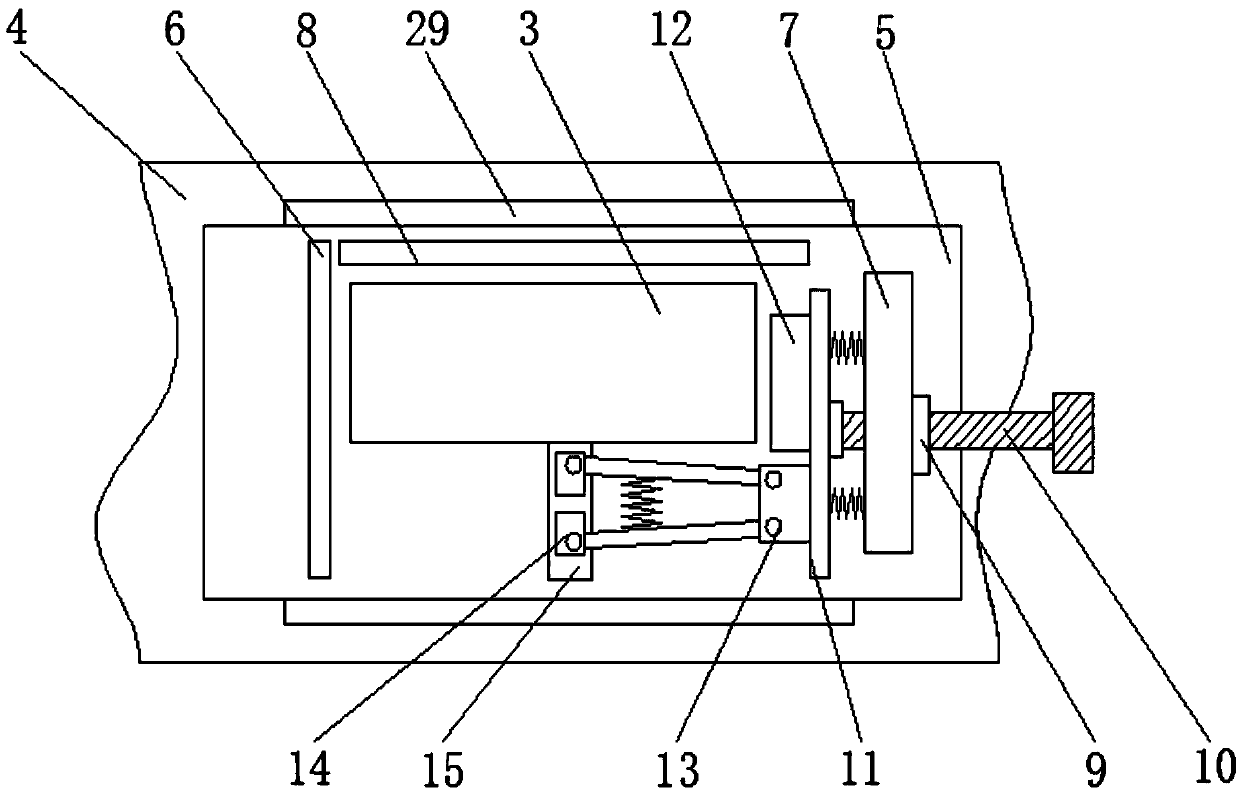

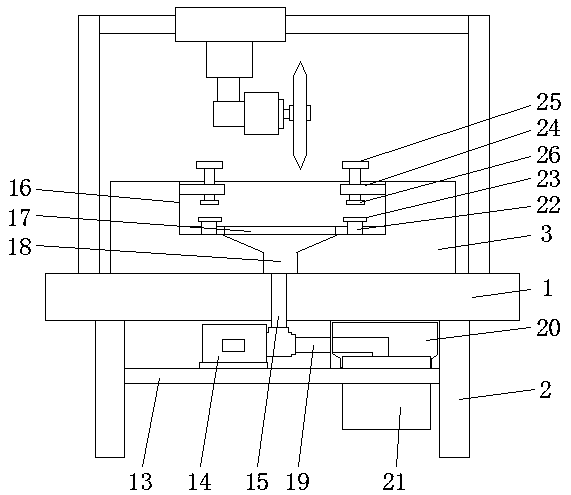

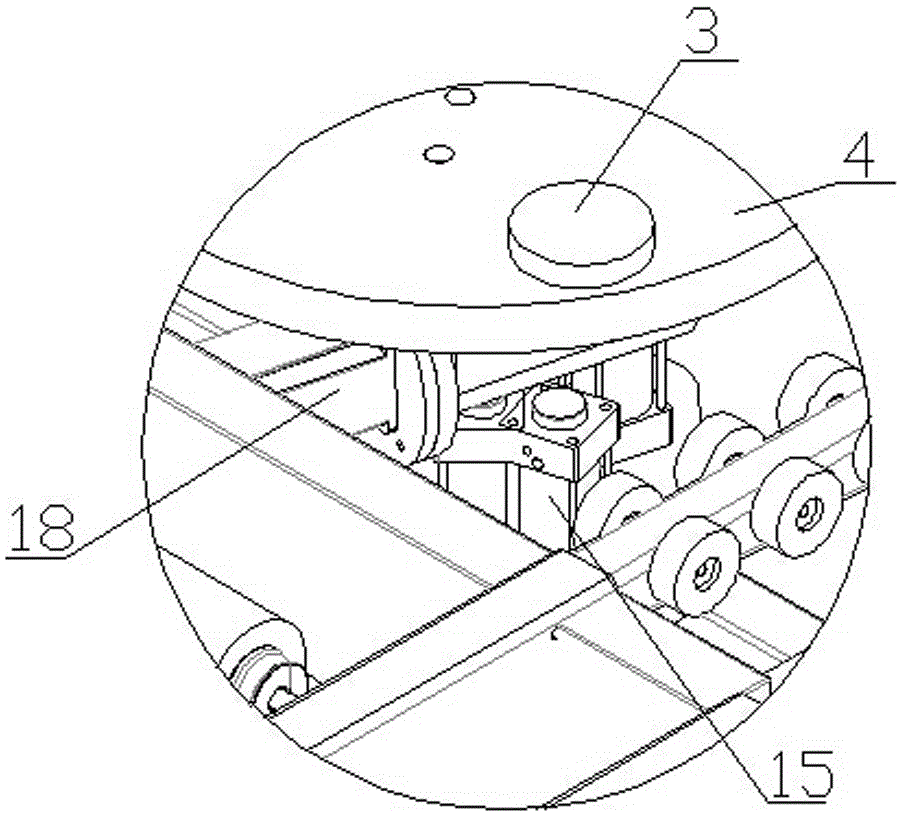

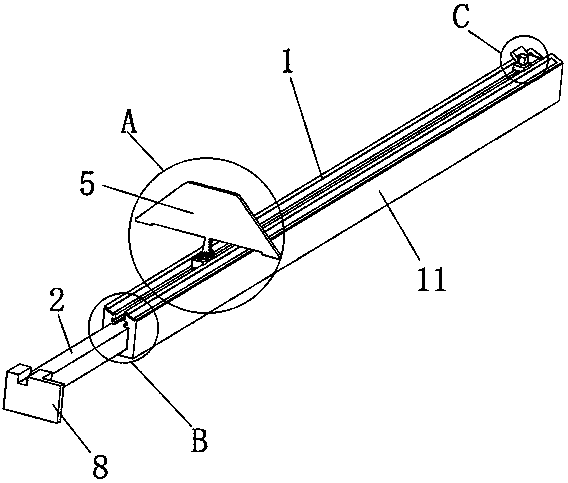

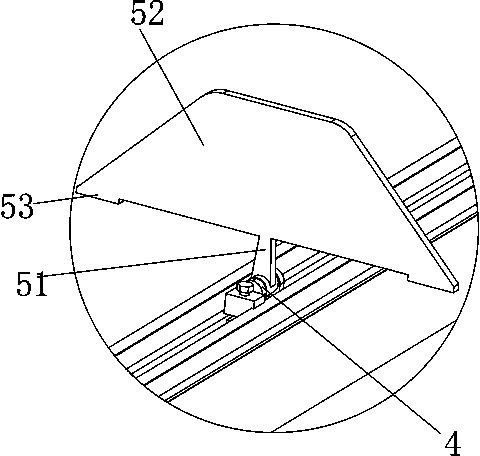

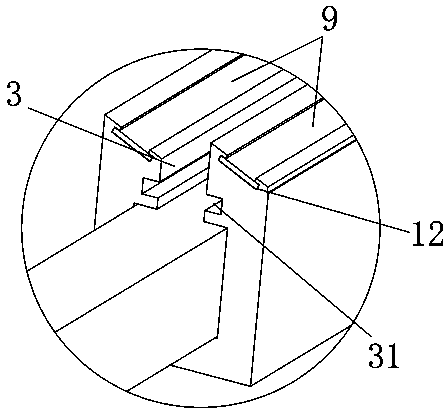

Numerical control groove broaching equipment for customized furniture board processing

ActiveCN105856342AImprove efficiencyHigh precisionMulti-purpose machinesBark-zones/chip/dust/waste removalNumerical controlEngineering

The invention provides a numerical control groove broaching equipment for customized furniture board processing. The numerical control groove broaching equipment comprises a rack, a scanning device, a measuring device, an electric spindle processing device, an x-axis board pushing device, a front pressing device, a rear pressing device and a control device, wherein the electric spindle processing device is used for adjusting the groove broaching processing initial position according to the board groove broaching position and carrying out groove broaching processing, the x-axis board pushing device is used for positioning boards and pushing the boards for groove broaching, and the control device is in signal connection with the scanning device, the measuring device, the electric spindle processing device, the x-axis board pushing device, the front pressing device and the rear pressing device. A platform of the rack is provided with a processing area, the electric spindle processing device is located below the processing area, the front pressing device and the rear pressing device are located on the two sides above the processing area respectively, and the x-axis board pushing device is arranged on the platform of the rack. The numerical control groove broaching equipment is high in groove broaching processing efficiency, capable of replacing traditional manual processing to improve production efficiency and suitable for large-scale production for intelligent furniture manufacturing.

Owner:佛山维尚家具制造有限公司

Painting device for furniture manufacturing

The invention provides a painting device for furniture manufacturing. The device comprises a processing box, wherein a first guide rail is fixedly mounted at the bottom part of an inner cavity of theprocessing box; a mounting seat is arranged on the surface of the first guide rail; a working platform is fixedly mounted on the top part of the mounting seat, and a chute is formed in the surface ofthe working platform; fixing boxes are fixedly mounted at the left side and the right side of the chute; a second guide rail is fixedly mounted on the top part of the inner cavity of the processing box; and a painting head is in thread connection with the surface of the second guide rail. According to the painting device for the furniture manufacturing, a water-air separator is mounted and is capable of pumping air from the processing box to realize water and air separation, and air in the processing box can be purified and exhausted, so that the drying effect of painted furniture boards can be improved, and the production efficiency is improved; smell can be filtered through a filtering cover; nitrogen in a refrigerating box is exhausted to decrease the temperature; the nitrogen exhausting volume can be adjusted through a boost air pump, so that the inside of the processing box can be rapidly refrigerated, and as a result, the painting effect is improved.

Owner:张雪燕

Wood cutting device with sawdust removing function

InactiveCN107718197AEase of workShorten the timeGripping devicesClamping devicesBiochemical engineeringWood cutting

A wood cutting device with a sawdust removing function mainly comprises a bottom plate, a cutter body and a wood body. The top of the bottom plate is fixedly connected with a box body, the top of thebox body is fixedly connected with a workbench, one side of the top of the workbench is fixedly connected with a first limiting plate, the other side of the top of the workbench is fixedly connected with a fixing plate, the top of the workbench is fixedly connected with a second limiting plate located between the first limiting plate and the fixing plate, and one side of the fixing plate is fixedly connected with a thread sleeve. By means of the wood cutting device with the sawdust removing function, easy and rapid fixation can be achieved in the wood cutting process, meanwhile, the fixing effect is good, in this way, the working difficulty is lowered for workers, time is saved, the working efficiency is improved, damage caused during wood cutting is also avoided, and the situations that resources are wasted and the manufacturing cost of furniture is increased are avoided.

Owner:刘毓玉

Wood plate grooving machine for furniture manufacturing

InactiveCN108638234APrevent splashEasy to cleanWood mortising machinesBark-zones/chip/dust/waste removalFixed framePulp and paper industry

The invention provides a wood plate grooving machine for furniture manufacturing, and relates to the field of furniture manufacturing equipment. The wood plate grooving machine for furniture manufacturing comprises a base. Four supporting legs are fixedly connected to the bottom of the base. The top of the base is fixedly connected with a working table. Brackets are fixedly connected to the positions, on the two sides of the working table, of the top of the base. The tops of the brackets are fixedly connected with a cross beam. The surface of the cross beam is movably connected with a slidingseat in a sleeved mode. The bottom of the sliding seat is fixedly connected with an air cylinder. The bottom of the air cylinder is fixedly connected with a fixing frame. A motor is fixedly mounted onthe right side of the fixing frame. According to the wood plate grooving machine for furniture manufacturing, a wood flour collecting device is arranged, a wood plate is placed in a working groove during grooving, and thus wood flour can be effectively prevented from splashing; the wood flour generated during grooving of the wood plate can be collected into a flour collecting bottle through a fan, and the flour collecting bottle can be taken down from a flour collecting box, so that the wood flour in the flour collecting bottle can be recycled and treated unitedly and conveniently, and thus clearing is more convenient for workers.

Owner:芜湖市涵润智能科技有限公司

Polishing device for furniture plate

PendingCN108705438AAchieve polishImprove processing efficiencyEdge grinding machinesGrinding carriagesEngineeringFurniture manufacturing

The invention relates to the technical field of furniture manufacturing, in particular to a polishing device for furniture plates. The polishing device comprises a processing table. A sucker is arranged on the processing table. A grooved wheel is rotationally connected to the lower portion of the processing table. A rotating wheel is rotationally arranged at one side of the grooved wheel. A roundpin is arranged on the rotating wheel. The round pin is intermittently and slidably connected with a groove of the grooved wheel. A turntable is rotationally arranged at one side of the processing table. An upper connecting rod and a lower connecting rod are correspondingly arranged at the upper part and the lower part of the turntable. Both the upper connecting rod and the lower connecting rod are hinged with the turntable. An arc-shaped polishing plate is arranged at one side of the turntable. A polishing wheel is arranged on the polishing plate. The free end of the upper connecting rod andthe free end of the lower connecting rod are correspondingly hinged with the two ends of the polishing plate. A driving mechanism is arranged on the other side of the turntable. The driving mechanismis connected with the turntable. The polishing device solves the problems of troublesome operation and low efficiency of edge polishing of circular plates in the prior art.

Owner:四川三虎家居有限公司重庆分公司

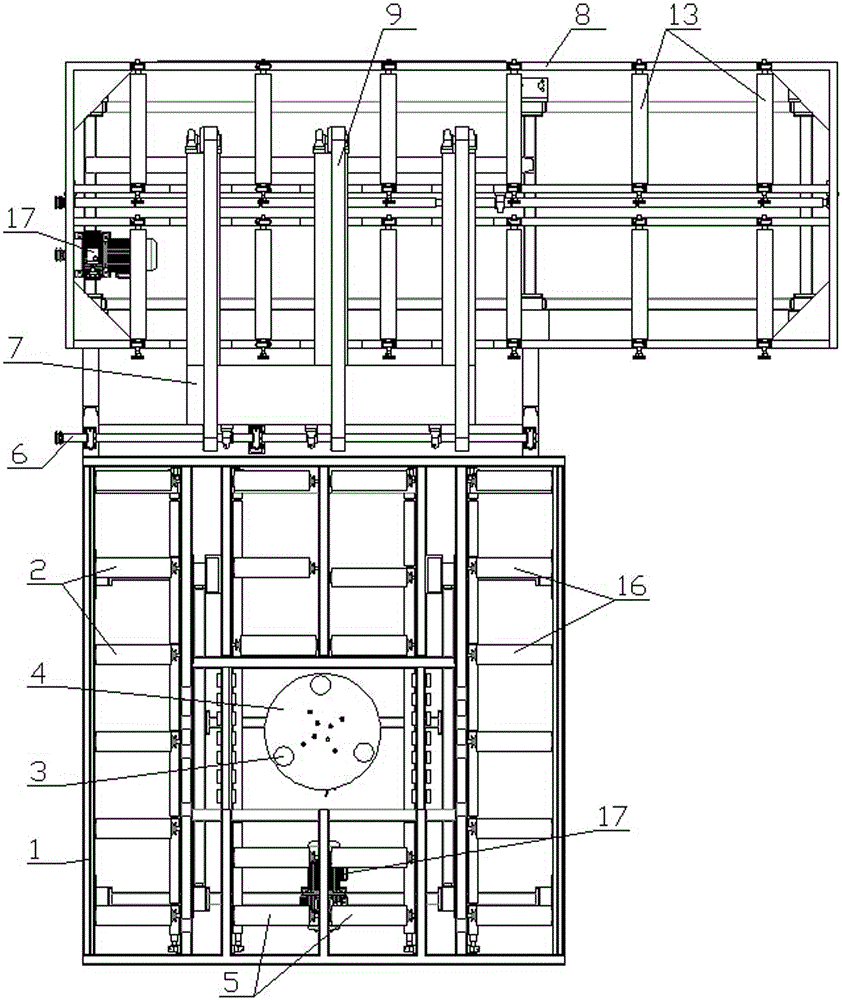

90-degree plate rotating machine

The invention belongs to the technical field of furniture manufacturing, and discloses a 90-degree plate rotating machine which is used for solving the problems that an existing plate rotating device is complex in structure and not suitable for rotating and conveying large-size plates. The 90-degree plate rotating machine comprises a plate rotating machine frame and a conveying machine frame. The plate rotating machine frame is provided with first rubber coated rollers driving the plates to move along the plate rotating machine frame, and the plate rotating machine frame is further provided with a plate rotating disc used for driving the plates to rotate. The conveying machine frame is provided with second rubber coated rollers driving the plates to move along the conveying machine frame, and a transition conveying device is arranged between the plate rotating machine frame and the conveying machine frame and used for conveying the plates on the plate rotating machine frame to the conveying machine frame.

Owner:QUANYOU FURNITURE

Positioning guiding rule

InactiveCN104290145AHigh dimensional accuracyEasy to observe whether the displacementGuide fencesCircular sawsEngineeringFurniture manufacturing

The invention belongs to the field of furniture manufacturing and specifically relates to a positioning guiding rule. The positioning guiding rule comprises a main rule bar, an auxiliary rule bar, a positioning baffle plate assembly and a scaleplate, wherein the upper parts of two walls of a sliding groove project towards each other to form a limiting leg for preventing the auxiliary rule bar from dropping out of the opening of the groove, and the sliding groove is divided into a lower sliding groove and an upper sliding groove by the limiting step; the positioning baffle plate is arranged on the upper sliding groove, and comprises a limiting locking structure and a baffle plate structure; the baffle plate structure comprises a slider and a reversal baffle plate; the inner end, inserted into the sliding groove, of the auxiliary rule bar is fixedly connected with a rule observing component; the rule observing component comprises a sliding lug and a rule observing plate; the limiting locking structure is arranged on one side of the outer end, facing the auxiliary rule bar, of the sliding lug; a marking line is formed on the rule observing plate. According to the positioning guiding rule, due to the cooperation of the auxiliary rule bar and the main rule bar, the measurement range of machines of the same volume can be greatly increased; the baffle plate and the scaleplate are capable of realizing visual reading on two scales; the positioning guiding rule is convenient to operate and adjust, and accurate in positioning; the displacement of a reverse plate can be observed easily, the cut plate is high in dimension accurate, and less plate scrap is generated.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

Neoprene adhesive subjected to secondary graft modification and preparation method of neoprene adhesive

InactiveCN103865451AImprove environmental protection requirementsImprove performanceGraft polymer adhesivesShoe industryPolymer science

The invention discloses a neoprene adhesive subjected to secondary graft modification and a preparation method of the neoprene adhesive. The neoprene adhesive comprises the following raw materials (in percentage by weight): 10%-15% of neoprene, 6.3%-13% of grafted monomers, 0.1%-0.5% of initiating agents, 5%-10% of acetone, 15%-30% of butanone, 10%-20% of ethyl acetate, 10%-20% of dimethyl carbonate, 8%-20% of methyl cyclohexane, 5%-10% of thickening agents and 0.3%-1% of terminating agents. The preparation method comprises the following steps of sequentially adding acetone, butanone, ethyl acetate, dimethyl carbonate and methyl cyclohexane, and uniformly mixing and stirring; adding neoprene, and stirring for 2-4 hours; adding a part of the initiating agents, further stirring, then dropping first grafted monomers to react for 0.5-1 hour, and adding second grafted monomers and the rest of initiating agents; adding a terminating agent, and then adding tackifying resin; regulating viscosity, and then discharging. The neoprene adhesive disclosed by the invention is subjected to the secondary graft modification through multiple monomers. The product has the characteristics of high comprehensive property and good environmental friendliness and is suitable for industries, such as furniture making, shoe making and luggage.

Owner:ZHUHAI YUTIAN CHEM PROD

Regenerated composite plastic brick environmental-protection plate and preparation method thereof

The invention relates to a regenerated composite plastic brick environmental-protection plate and a preparation method thereof. The regenerated composite plastic brick environmental-protection plate comprises 20-60% by weight of a plastic and 40-80% by weight of building garbage, wherein one or a plurality of materials selected from meltable plastic materials are mixed to obtain the plastic. According to the present invention, the waste plastic and the building garbage are subjected to crushing, mixing, hot melting and extrusion pressing to obtain the regenerated composite plastic brick environmental-protection plate, and barium sulfate can be selected to enhance the toughness; the waste plastic and the building garbage are used to prepare the regenerated composite plastic brick environmental-protection plate, such that the currently-existing white pollution problem is solved, a large amount of soil resources are saved, the production cost is reduced, and the advantages of economy and environmental protection are provided; and the regenerated composite plastic brick environmental-protection plate is the typical high-temperature-resistant plate, has characteristics of high density and easily available raw materials, and can be widely used in a variety of outdoor municipal decorations, furniture manufacturing, build industry, and the like.

Owner:黄永培

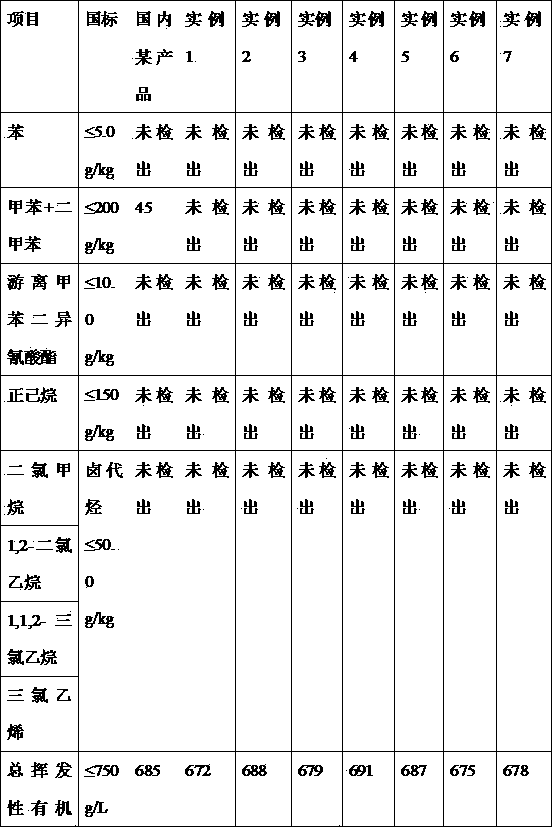

Environmental protection adhesive

InactiveCN101260286AMeet the performanceFulfil requirementsStarch adhesivesWax adhesivesAdhesiveTackifier

The invention provides environmental protection adhesive and is characterized in that the invention is formed by the raw materials (mass proportion): mother liquor 40-60, acrylic acid 10-20, water 15-35, thickening agent 5-15, surfactant 3-10, tackifier 0.1-2, modifying agent 0.1-2, evocating agent 0.4-1, plasticiser 0.1-1, and preservative 0.1-1. Solid paraffin is taken as the main raw material, then a small quantity of chemical additive is added, thus the environmental protection adhesive which has good performance and low cost and does not contain harmful components such as formaldehyde and so on can be produced; the requirements of product performance and use of the environmental protection adhesive can be satisfied by adjusting the proportion of the compositions to produce the environmental protection adhesive which is applicable to industries such as sheet materials, furniture manufacturing, building industry, decoration industry and so on. The environmental protection adhesive has easy-obtaining raw materials, a simple preparation method, short process flow, low production cost, low energy consumption, no pollution discharge and no toxicity discharge, and does not bring any harm to producers and users.

Owner:KUNMING UNIV OF SCI & TECH

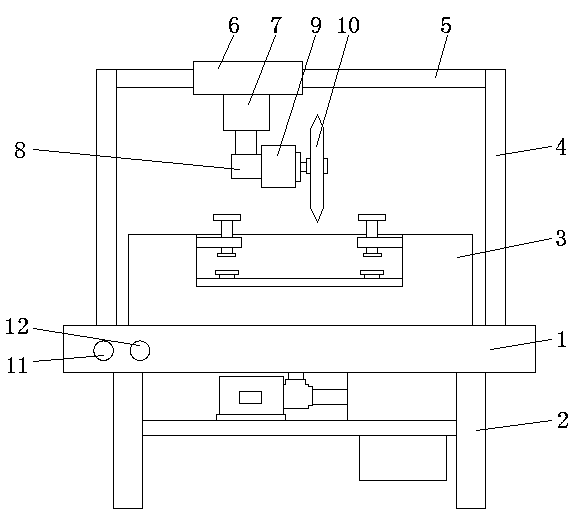

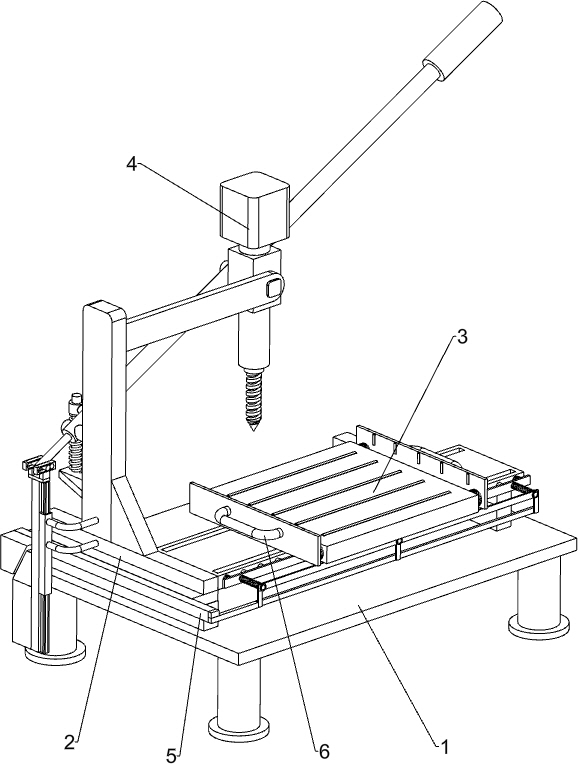

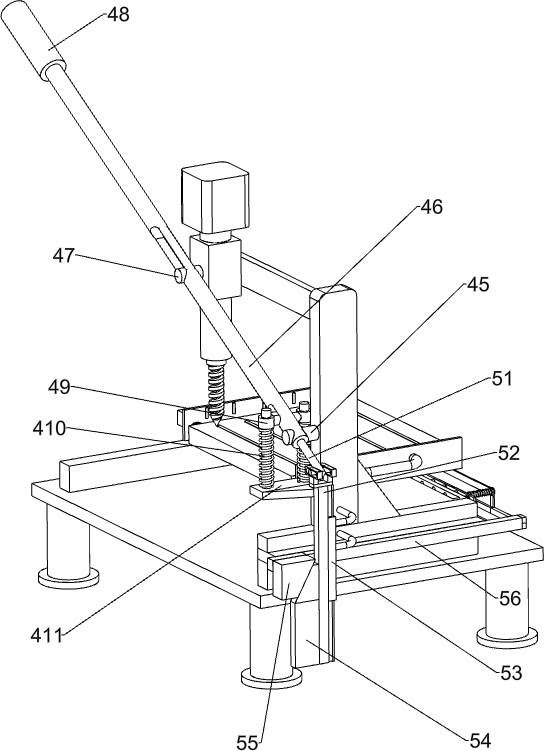

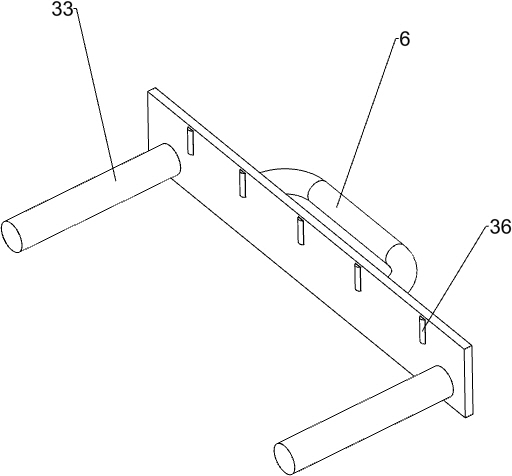

Plate punching device for furniture manufacturing

ActiveCN111923155AEasy to moveReduce labor intensityStationary drilling machinesPunchingStructural engineering

The invention relates to a plate punching device, and particularly relates to a plate punching device for furniture manufacturing. The plate punching device for furniture manufacturing can reduce thelabor intensity of workers and improve the punching efficiency. The plate punching device for furniture manufacturing comprises a bottom plate base, a plate moving mechanism and a punching mechanism,wherein a mounting frame is connected to the bottom plate base, the plate moving mechanism is arranged on the bottom plate base, and the punching mechanism is arranged on the mounting frame. Accordingto the plate punching device, the punching mechanism can punch a plate on the plate moving mechanism, the plate can be conveniently moved through the plate moving mechanism, and therefore the punching mechanism can punch all positions of the plate, the plate does not need to be punched by manually holding an electric drill for a long time, and the effects of reducing the labor intensity of the workers and improving the punching efficiency are achieved.

Owner:山东凯迪威家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com