Flame-retardant straw shaving board and manufacturing method thereof

A manufacturing method and technology of particleboard, applied in the direction of manufacturing tools, flat products, other household appliances, etc., can solve the problems of difficult adhesive, poor bonding performance of straw particleboard, low fireproof performance, etc., and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a flame-retardant straw particleboard, which has a three-layer structure and a thickness of 12 mm. The flame-retardant straw particleboard and the lower layer are formed by pressing the fine-grained straw particles after modification and sizing. The dense layer, the middle layer is a core layer formed by pressing the straw particles with coarse particle diameter after modification and sizing. The flame-retardant straw particleboard specifically includes the following raw materials: 36Kg of straw particles, 2.4Kg of E0 grade urea-formaldehyde resin, and 2Kg of flame retardant; wherein the 2Kg of flame retardant specifically includes the following raw materials: 0.625kg of magnesium oxide, 0.5kg of magnesium chloride , 0.125kg of trisodium phosphate, 0.625kg of polyvinyl alcohol and 0.125kg of ammonium polyphosphate.

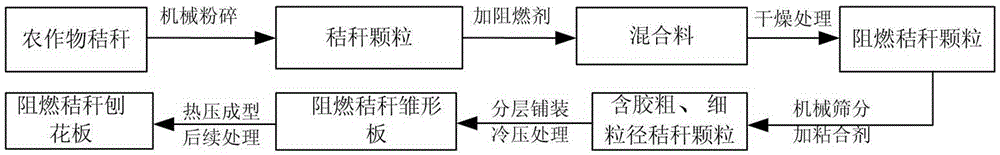

[0030] refer to figure 1 , this embodiment also provides a method for manufacturing the above-mentioned flame-retardant straw par...

Embodiment 2

[0040] This embodiment provides a flame-retardant straw particleboard, which is different from Example 1 in that the flame-retardant straw particleboard specifically includes the following raw materials: 40Kg of straw particles, 5Kg of E0 grade urea-formaldehyde resin, and 2.5Kg of flame retardant; The flame retardant 2.5Kg specifically includes the following raw materials by weight: 0.75kg of magnesium oxide, 0.5kg of magnesium chloride, 0.25kg of trisodium phosphate, 0.75kg of polyvinyl alcohol and 0.25kg of ammonium polyphosphate.

[0041] The performance test of the finished product of the flame-retardant straw particleboard described in Example 2 is carried out below.

[0042] (1) Water resistance test: The flame-retardant straw particleboard with a thickness of 12 mm was placed in boiling water at 73°C for 3 hours and dried at 73°C for 2 hours. Then it was measured that the strength of the flame-retardant straw particleboard was 1 MPa, and the strength before boiling was...

Embodiment 3

[0046] This embodiment provides a flame-retardant straw particleboard, which is different from both Embodiment 1 and Embodiment 2 in that: the flame-retardant straw particleboard specifically includes the following raw materials: 42Kg of straw particles, 1.8Kg of E0 grade urea-formaldehyde resin, and a flame retardant 3Kg; wherein the flame retardant 3Kg specifically includes the following raw materials by weight: 0.9kg of magnesium oxide, 0.6kg of magnesium chloride, 0.3kg of trisodium phosphate, 0.9kg of polyvinyl alcohol and 0.3kg of ammonium polyphosphate.

[0047] The performance test of the finished product of the flame-retardant straw particleboard described in this embodiment is carried out below.

[0048] (1) Water resistance test: The flame-retardant straw particleboard with a thickness of 12 mm was placed in boiling water at 73°C for 3 hours and dried at 73°C for 2 hours. Then it was measured that the strength of the flame-retardant straw particleboard was 0.75 MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com