Patents

Literature

3100results about How to "Improve recycling rates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

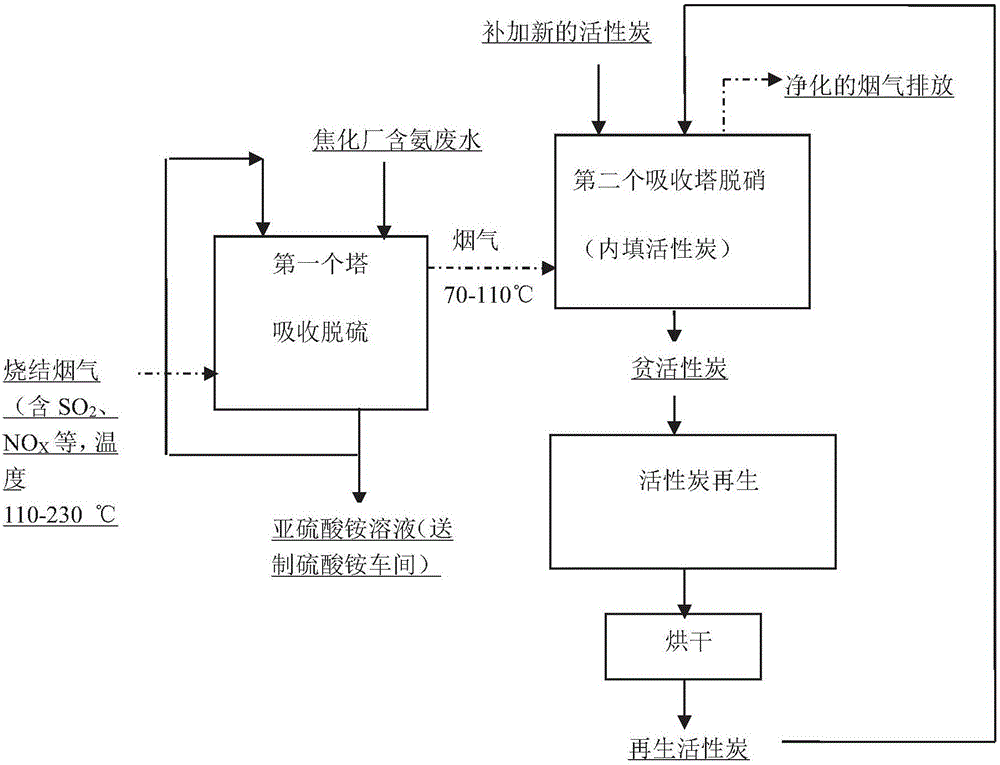

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

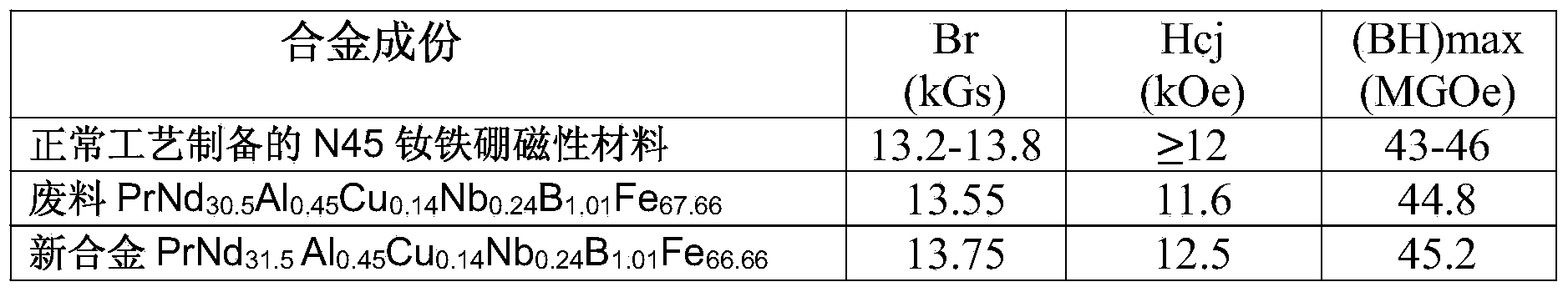

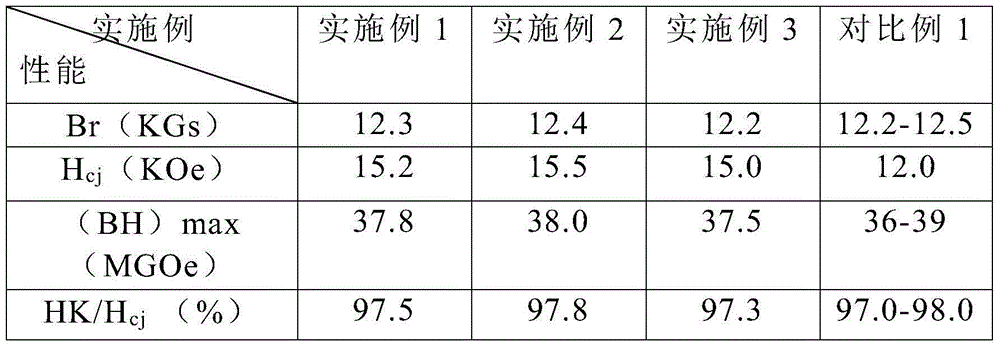

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

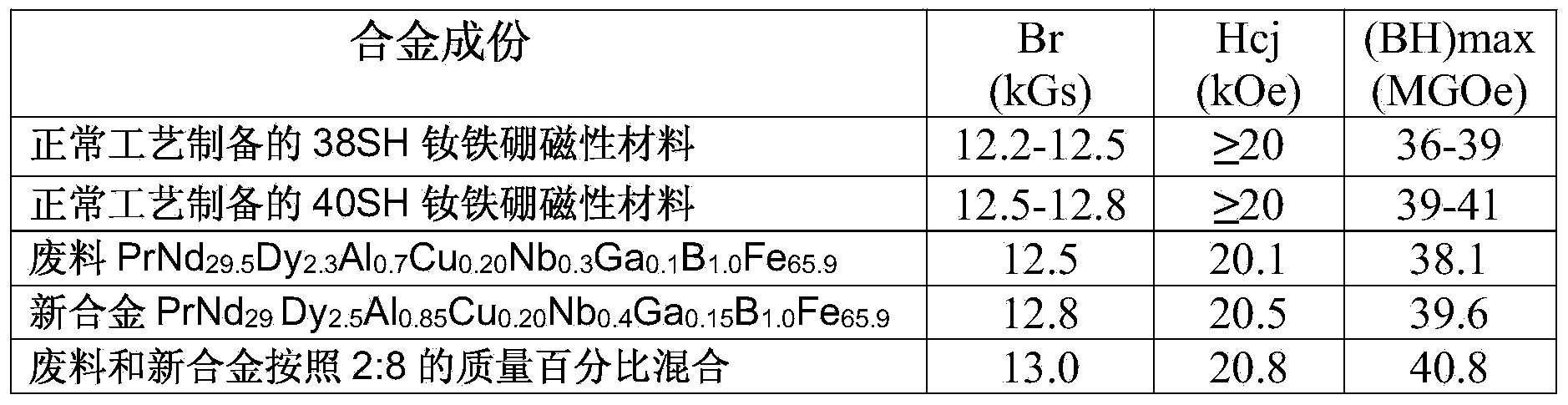

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410ARealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

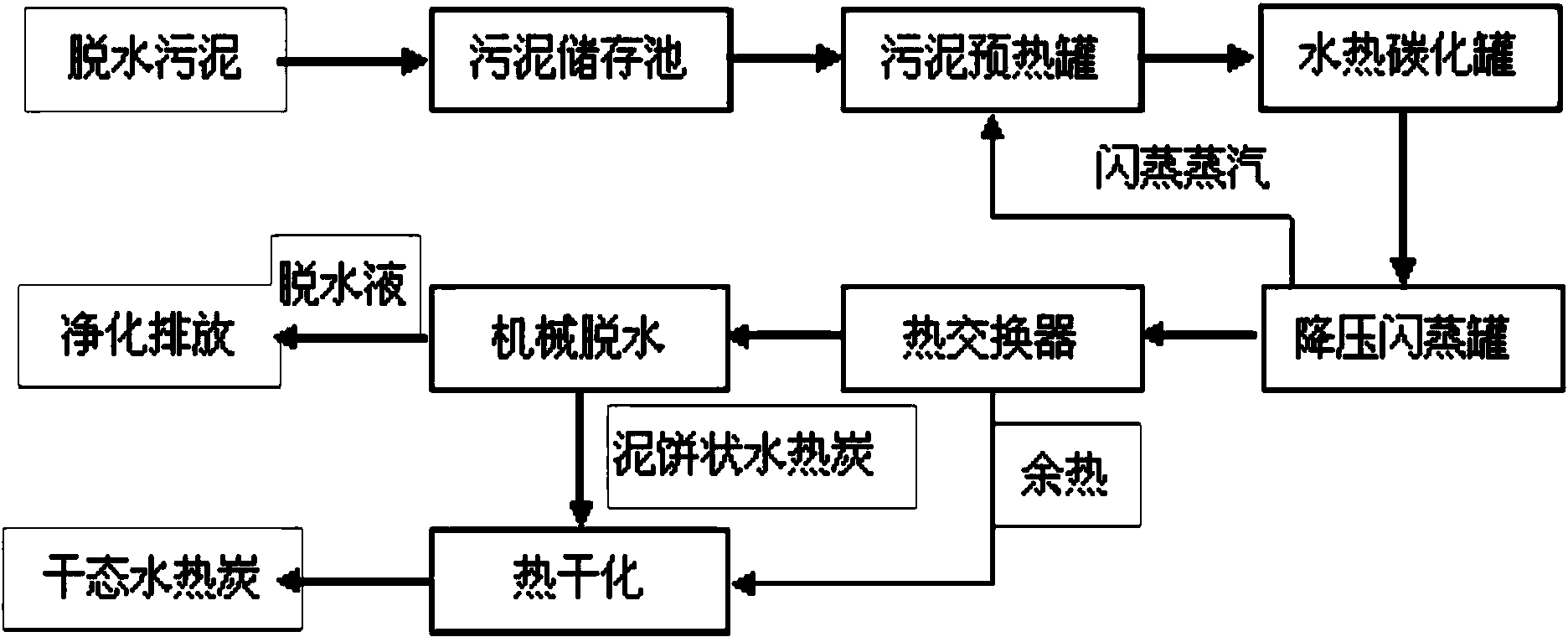

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

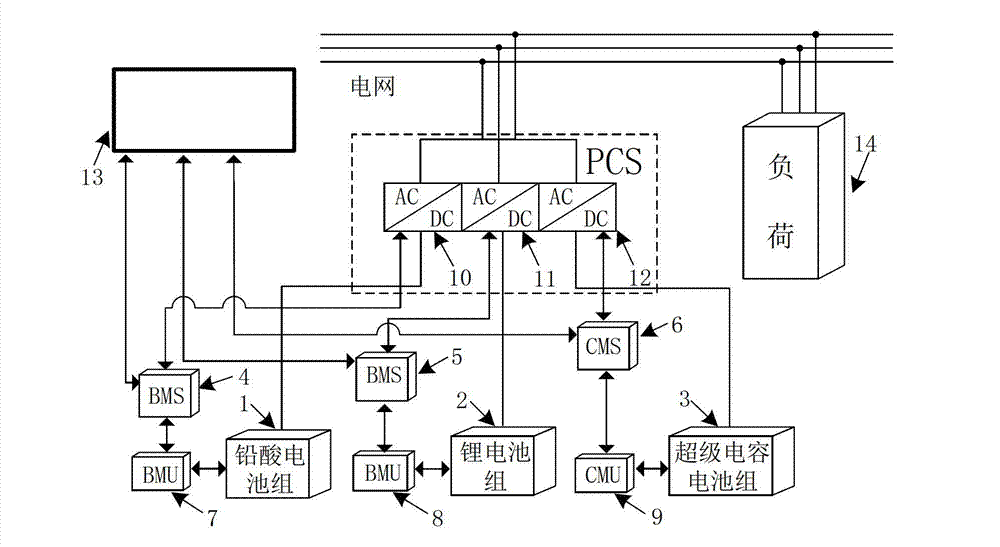

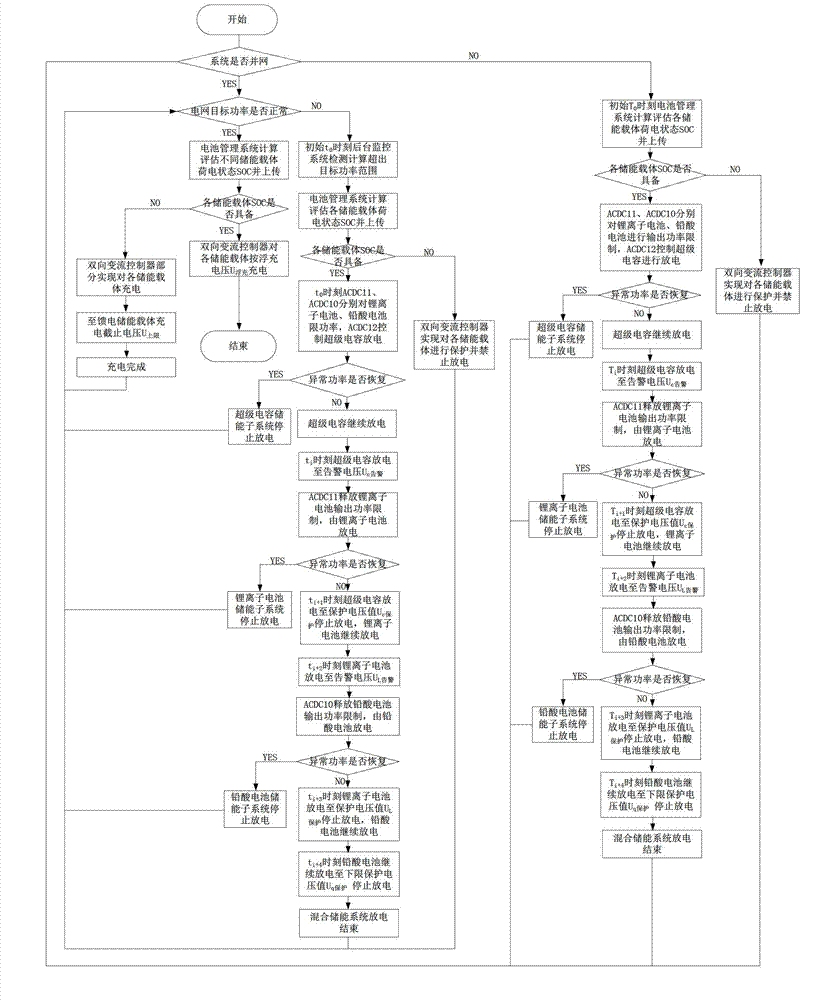

Hybrid energy storage system based on ordered energy control

The invention relates to a hybrid energy storage system comprising various energy storage carriers. The system is mainly based on an ordered energy control strategy, the energy storage carriers are selectively discharged in a current-limiting or power-limiting mode through a pulse width modulation (PWM) closed-loop control principle and a monitoring system selective control principle, the advantages of the energy storage carriers are combined and complemented, the disadvantages of the energy storage carriers are overcome, and the aim of ordered energy utilization of different energy storage carriers is fulfilled according to a discharge priority sequence, namely a third energy storage subsystem, a second energy storage subsystem and a first energy storage subsystem. By the hybrid energy storage system, the phenomenon that the power of a power grid fluctuates because a wind and light power generation system or a high-power load and the like are connected to the power grid is avoided, smoothing compensation is realized, the quality of electric energy is improved, and the stable operation of the power grid is ensured.

Owner:STATE GRID CORP OF CHINA +1

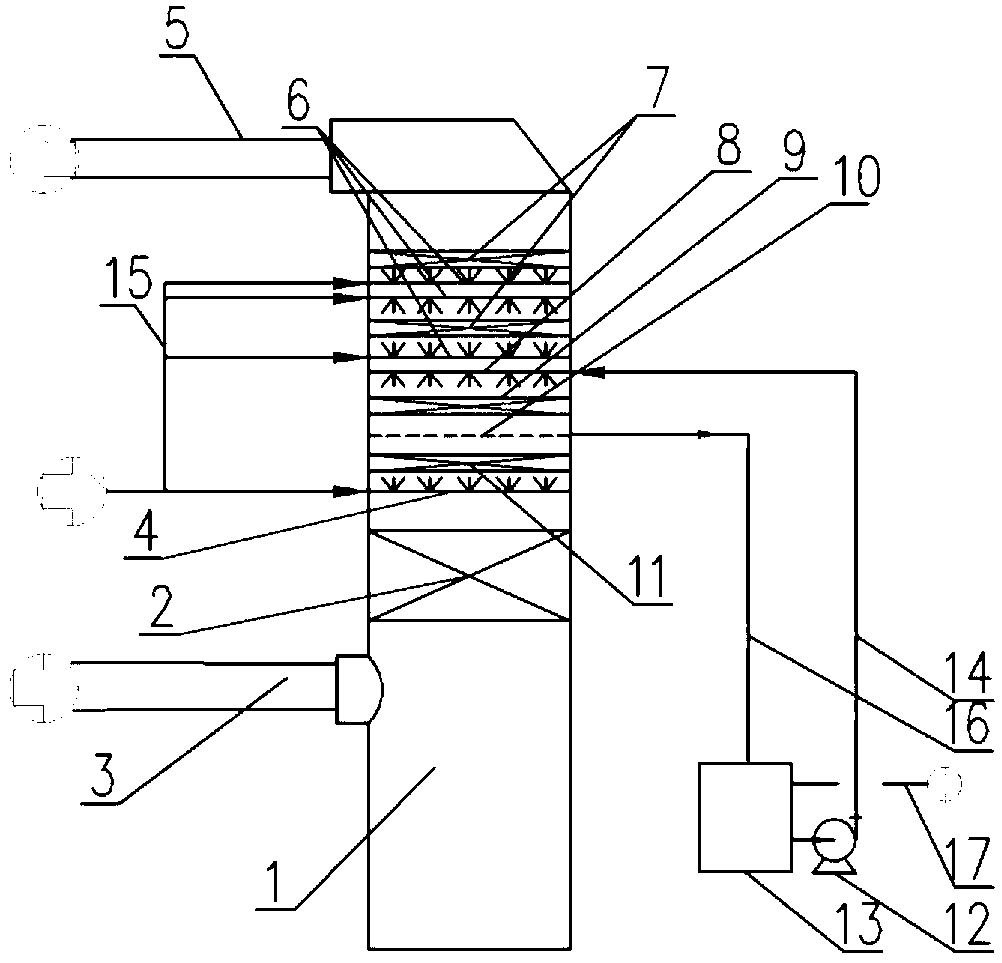

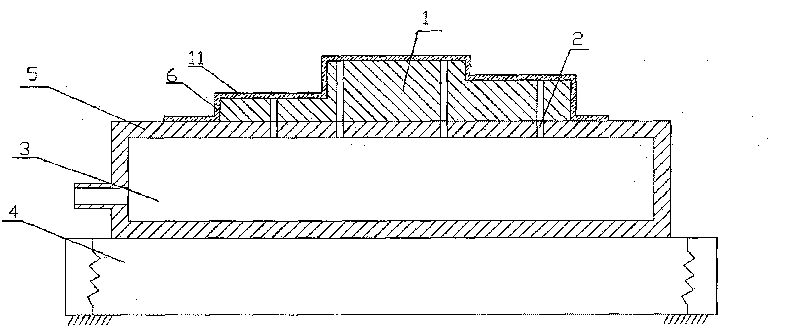

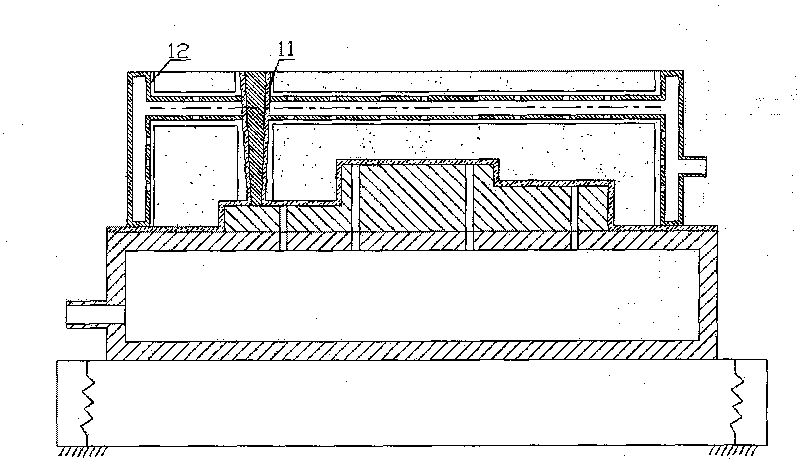

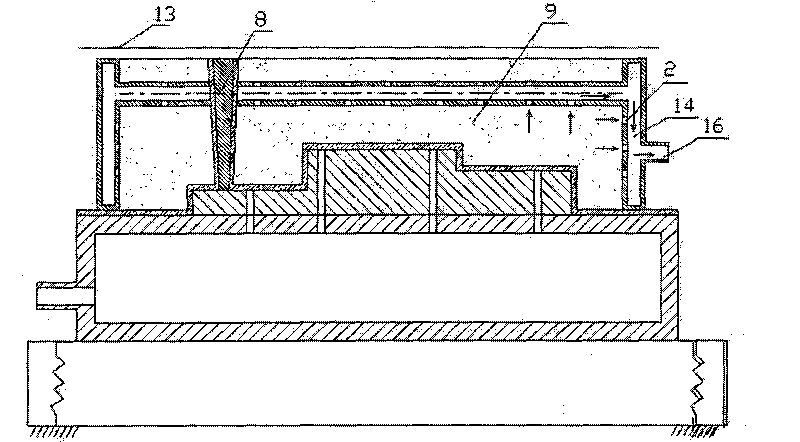

Device and method for controlling fine particulate matter from desulfurized smoke

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

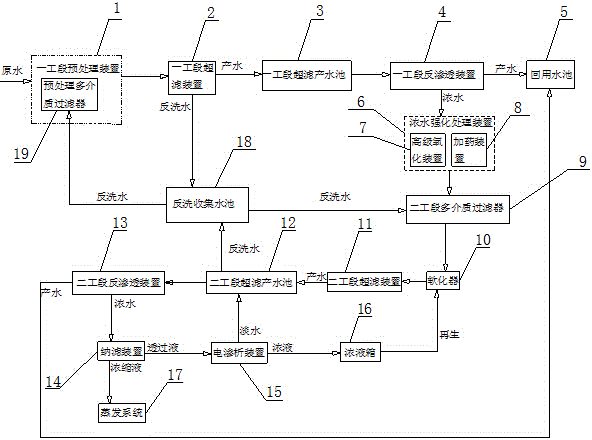

Treatment method for zero discharge of high-hardness high-salinity wastewater

ActiveCN104370405AImprove recycling ratesSolve pollutionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiltrationUltrafiltration

The invention relates to the technical field of water treatment, and particularly relates to and discloses a treatment method for zero discharge of high-hardness high-salinity wastewater. The method comprises the steps of pretreating; ultrafiltering in a first section; carrying out reverse osmosis treatment in the first section; carrying out enhancing treatment on reverse osmosis concentrate in the first section; filtering by multiple mediums, softening, and ultrafiltering and carrying out reverse osmosis treatment in a second section; passing the reverse osmosis concentrate in the second section through a nano-filtration device; passing nano-filtration permeate through an electrodialysis device; introducing fresh water generated by the electrodialysis device into ultrafiltration water of the second section, and taking concentrate in the electroldialysis device for regenerating a softener; feeding nano-filtration concentrate into an evaporation system to obtain a solid matter, and taking water in reverse osmosis treatment of the first and second sections as reuse water. According to the treatment method for zero discharge of high-hardness high-salinity wastewater, physicochemical treatment, membrane integration technology and evaporation technology are combined, so that the problem that the environment is polluted by high-hardness high-salinity concentrate discharge can be effectively solved, the requirement for zero discharge can be met, the effluent water quality is stable, and the water utilization rate is improved.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

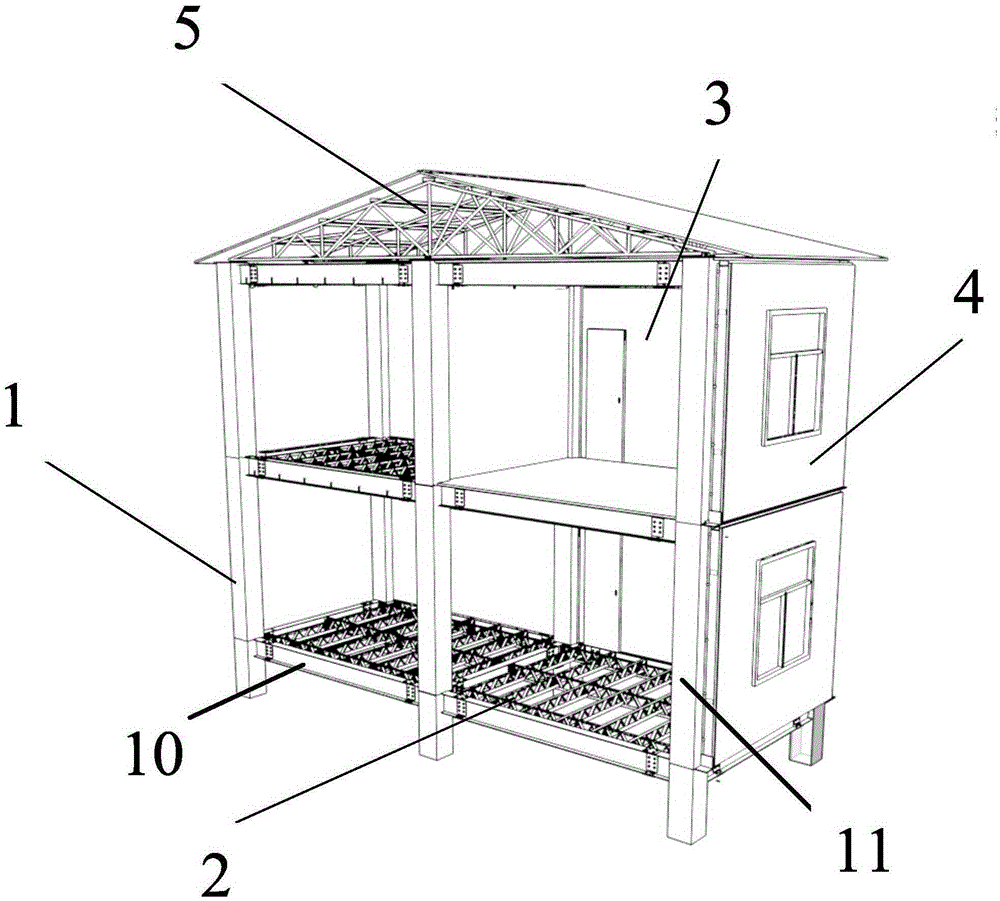

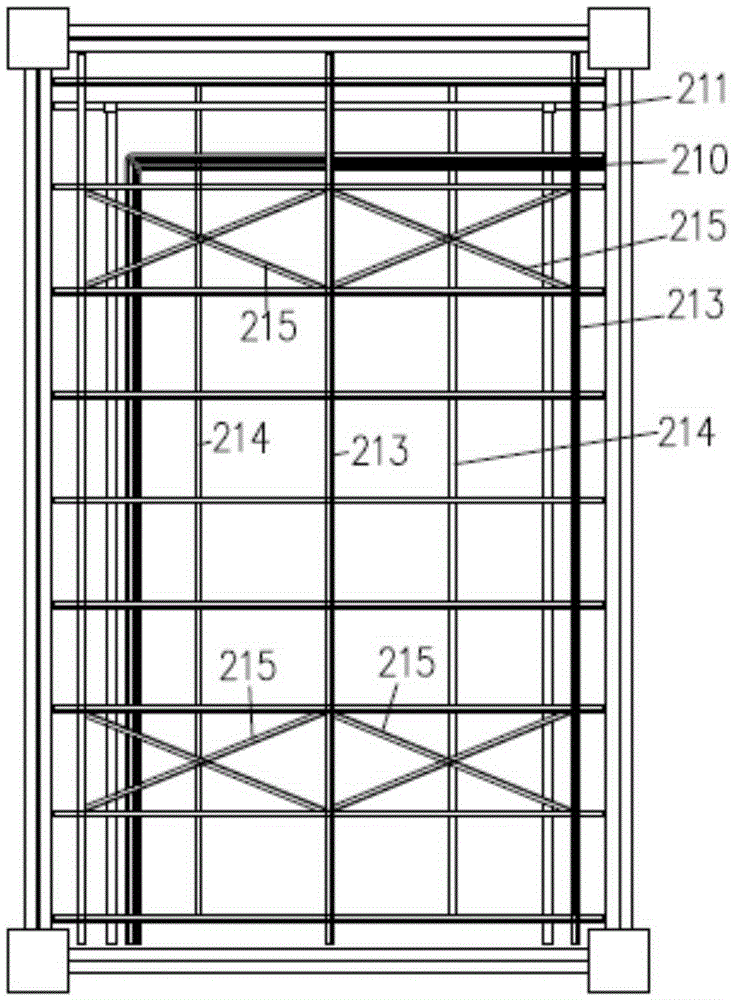

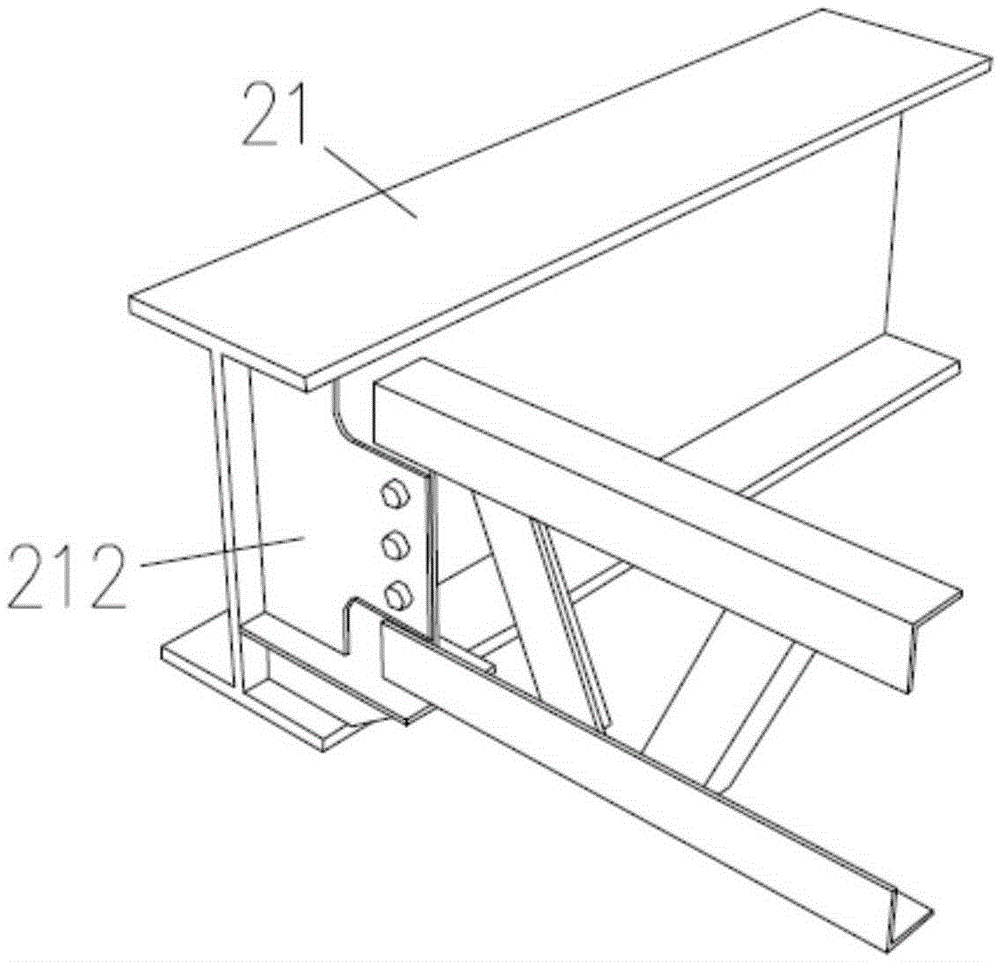

Integrated assembly type steel structure building

InactiveCN105317110AReduce noise pollutionImprove construction efficiencyRoof covering using slabs/sheetsConstruction materialPipingUtilization rate

The invention provides an integrated assembly type steel structure building. The integrated assembly type steel structure building comprises a main body framework, floor bearing plates, internal wall bearing plates, external wall bearing plates and a roof; the floor bearing plates, the internal wall bearing plates, the external wall bearing plates and the roof are connected with the main body framework through connecting parts, the internal wall bearing plates are arranged to be adjacent to the external wall bearing plates, the roof is arranged at the upper end of the main body framework, and the outer surfaces of the internal wall bearing plates, the outer surfaces of the external wall bearing plates and the outer surface of the roof are each provided with decoration and fitment plates in an integrated mode, and the interiors of the decoration and fitment plates are correspondingly provided with cable conduits and water pipes in an integrated mode. In this way, the integrated assembly type steel structure building has the advantages of being stronger in integrity, convenient to construct, high in repeating utilization rate, capable of reducing production cost and wide in application range, and integral installation and disassembly of prefabricated part and the connecting parts in a factory can be achieved; meanwhile, large-scale production at a construction site is easy to achieve, and construction waste is greatly reduced.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Method for separating and extracting iron, vanadium and titanium from vanadium-titanium magnetite

ActiveCN1814813AFast responseImprove comprehensive recycling rateProcess efficiency improvementSlagCarbon dioxide

This invention provides a method for separating and extracting Fe, V and Ti from a VTi magnetite including the following steps: 1, making balls with magnetite powder, reducers and a binder or pressing them to blocks to be dried, 2, putting them into a reducing furnace to be heated to 1400-1500deg.C to process metallic pellets, in which, the ratio of partial pressures of CO2 and CO in the gas phase is not greater than 2.0, 3, puuting the pellets into the furnace to be melt under 1560-1700deg.C to separate irons and slags to get the slags with melten iron and Ti, 4, extracting V with pyrogenic process to get melton iron and V slags, 5, processing the V slags to get V205, 6, processing the steel slags with Ti with H2SO4 or chlorination method to get TiO2.

Owner:PANZHIHUA IRON AND STEEL

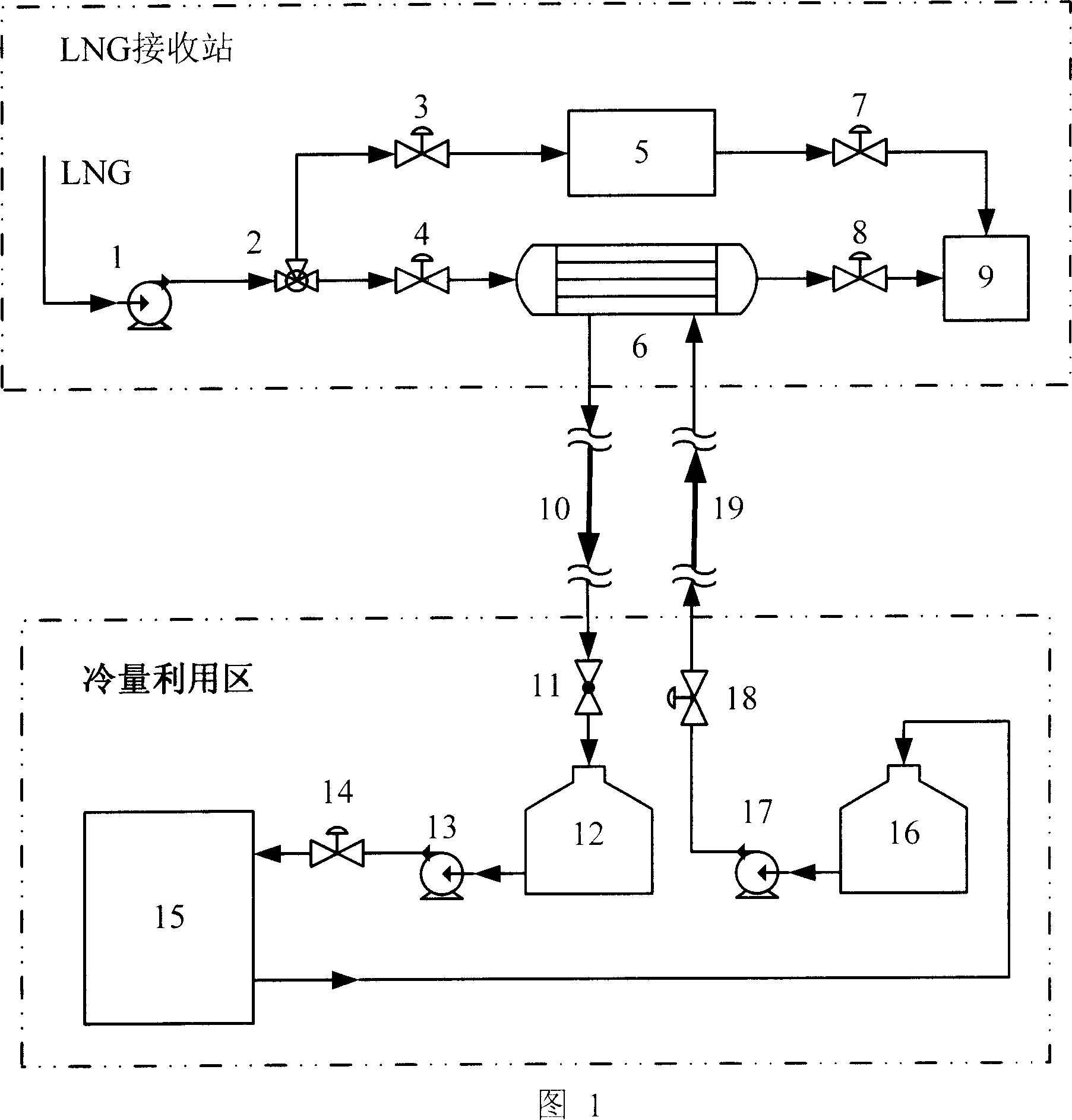

Method for using cooling capacity of LNG with cooling media as medium and apparatus thereof

InactiveCN1963347AGuarantee gas demandNot affected by cooling utilizationDomestic cooling apparatusLighting and heating apparatusNuclear engineeringCarburetor

The utilization of liquefied natural gas with coolant as medium mainly refers to the coolant as the medium to exchange heat with liquefied natural gas in the receiving station, and sending cooled coolant through coolant heat insulation pipe to the cooled energy utilization zone outside the receiving station for customer's use. The equipment applying this method comprises a liquefied natural gas pump, a sea water carburetor, a low temperature heat exchanger, a coolant low temperature reserving tank, a low temperature coolant pump, a coolant normal temperature reserving tank and normal temperature coolant pump. It is simple in operation, convenient to control, feasible to set multi big scale cooled energy utilization to make the best of it.

Owner:SOUTH CHINA UNIV OF TECH

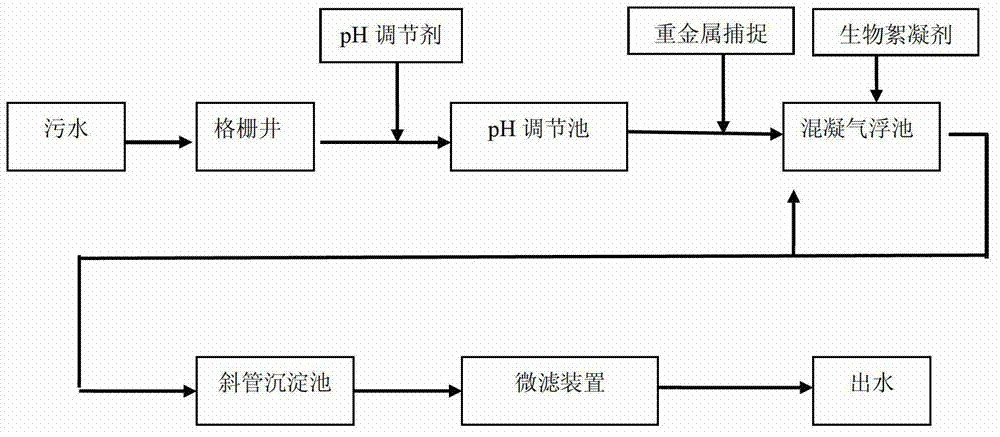

Treatment method of acid heavy metal wastewater

ActiveCN102964014AImprove recycling ratesSignificant technological progressSludge treatment by de-watering/drying/thickeningWater/sewage treatmentViscous liquidCavitation

The invention provides a treatment method of acid heavy metal wastewater, comprising the following steps of: removing massive impurity of the wastewater by the means that the wastewater passes through grids, and adjusting the pH to 8-9; adding 20-80mg / L heavy metal collecting agent before entering a coagulating floatation tank, and adding 0.5-4.0mg / L biological flocculants before entering the floatation tank; removing organic matter, heavy metal and suspended solids by means of cavitation air floatation; subsiding the water discharged in an air floatation way by a wobble plate, and filtering in a continuous microfiltration device to remove suspended solids and colloid; concentrating air floatation slag by the sludge of a floatation slag tank and a sedimentation tank, putting 20-60mg / L cationic polyacrylamide, and recovering in a drying way; and adding 1320kg of deionized water, 400kg of sodium hydroxide and 380kg of polyethylenimine into the reaction kettle, controlling the temperature of the reaction kettle to be below 25 DEG C, slowly and dropwise adding 1008kg of carbon disulfide, and cooling to room temperature to obtain the heavy metal collecting agent of orange viscous liquid.

Owner:URUMQI DEAN DONGSHENG ENVIRONMENTAL PROTECTION EQUIP CO LTD

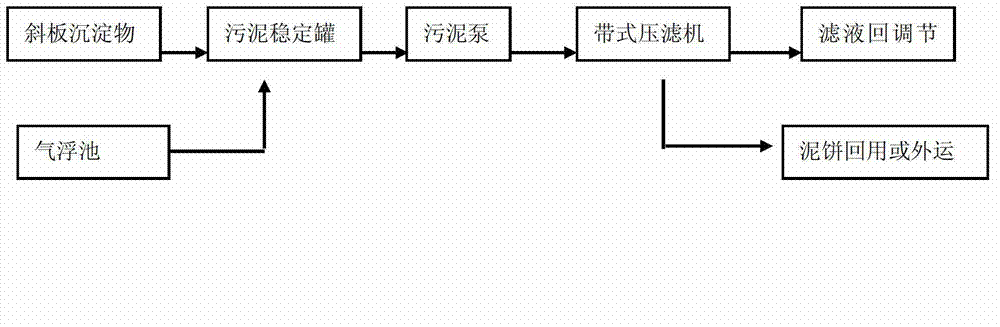

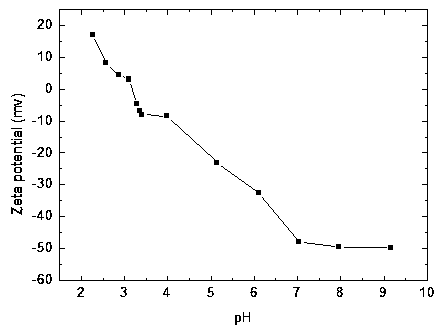

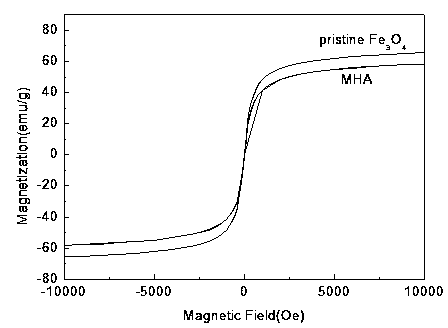

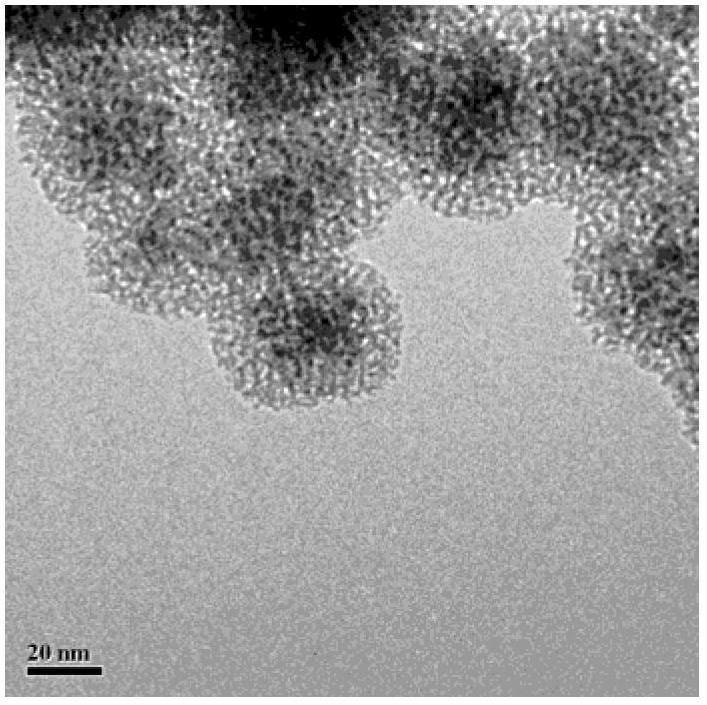

Magnetic humic acid nano material as well as preparation method and application of magnetic humic acid nano material

ActiveCN103752281AImprove removal efficiencyImprove recycling ratesOther chemical processesNanotechnologyDye absorptionNanoparticle

The invention discloses a magnetic humic acid nano material as well as a preparation method and application of the magnetic humic acid nano material. An isoelectric point of the magnetic humic acid nano material is negatively charged when the pH value is 3.2 and the pH value is more than 3.2-9.5; the magnetic induction intensity of magnetic humic acid is 62.88emu / g; the magnetic humic acid is in a torispherical form; the magnetic humic acid contains 22% of humic acid; the structure of the magnetic humic acid is formed by covering humic acid on the outer surface of a magnetic Fe3O4 crystal; in the magnetic humic acid nano material, the humic acid is connected to Fe3O4 mainly through coordination. The magnetic humic acid nanoparticle disclosed by the invention is low in price, environmentally-friendly, high in removal efficiency on cationic dye in wastewater, high in recovery rate and the like; and therefore, the magnetic humic acid nanoparticle can be widely used in dye absorption, water treatment, serving as an adsorbent and other fields, and has the excellent practicability.

Owner:克雷伯氏环保科技(苏州)有限公司

Environment-friendly safe solvent cleaning agent

InactiveCN103468434ANarrow distillation rangeHigh distillation recoveryNon-surface-active detergent solventsAlkaneWater based

The invention relates to an environment-friendly safe solvent cleaning agent which specifically comprises the following components in parts by weight: 0-97 parts of C10-C12 alkanes, 3-100 parts of alcohol ether solvent, 0.00-0.01 part of antioxidant and 0.00-0.01 part of corrosion inhibitor. The environment-friendly safe solvent cleaning agent provided by the invention is narrow in boiling range and the distillation recovery rate of the environment-friendly safe solvent cleaning agent can be above 95%; the environment-friendly safe solvent cleaning agent is also high in clearing ability, and has strong cleaning ability for polar dirt and nonpolar dirt; especially, the environment-friendly safe solvent cleaning agent can be used for thoroughly cleaning various metal working fluids, and oil-based and water-based cutting fluids without any residual and corrosion on metals; moreover, the shortcoming that the previous hydrocarbon type cleaning agents are wide in boiling range and only capable of dissolving and cleaning the nonpolar dirt are overcome. The cleaning agent is perfect in balance of cleaning ability, safety, dryness and reproducibility.

Owner:TIANJIN PRIMETECH CHEM

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

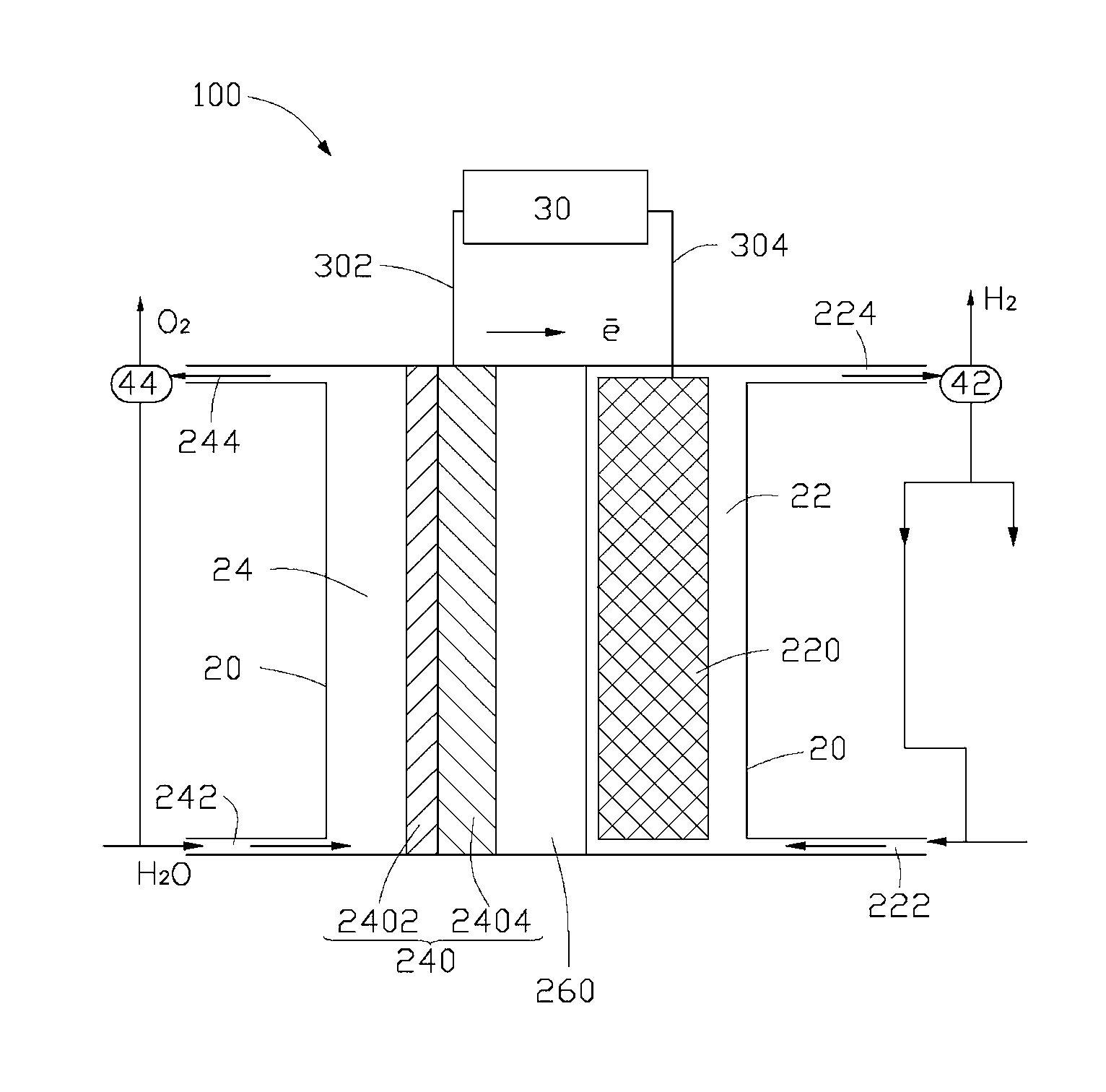

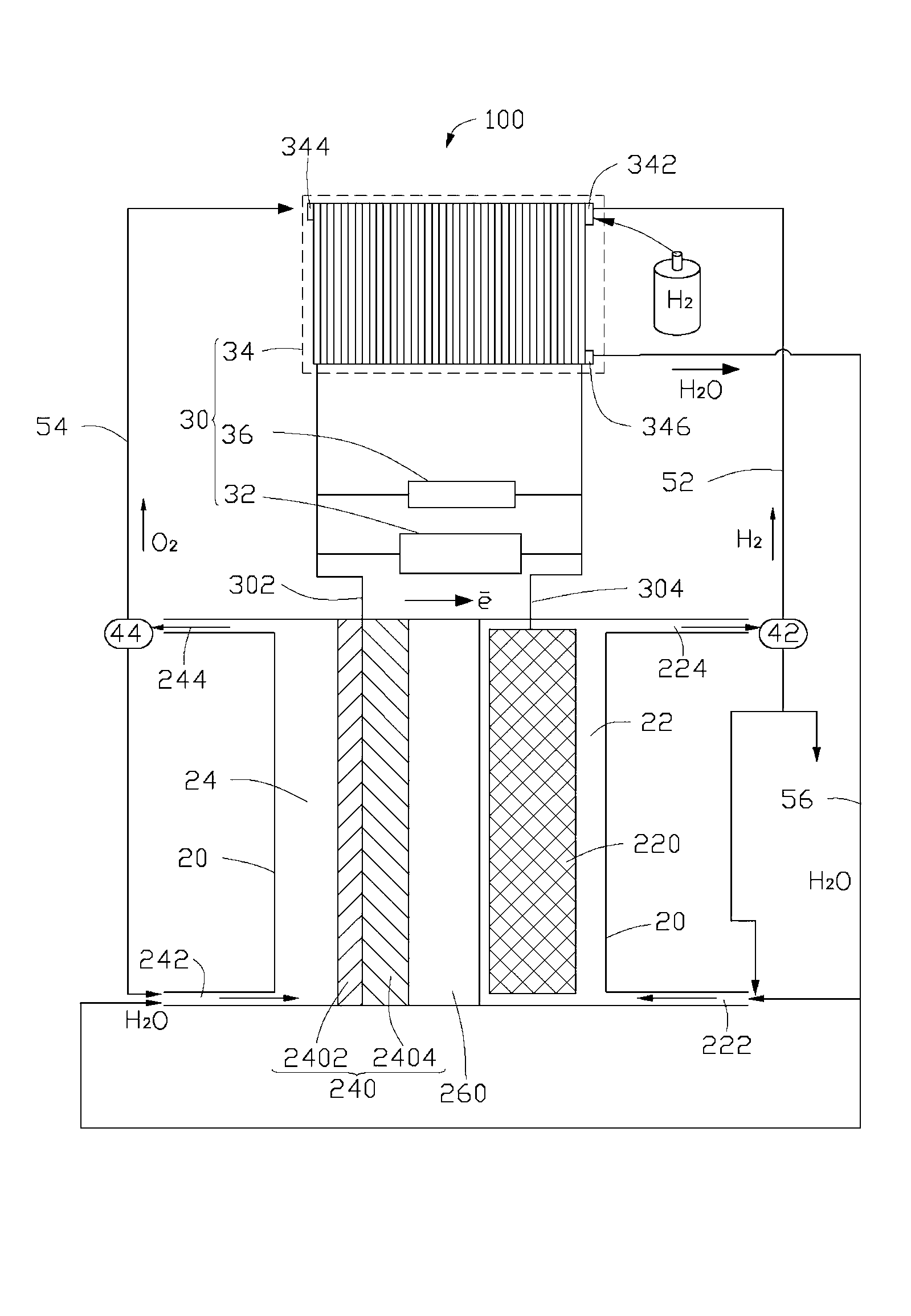

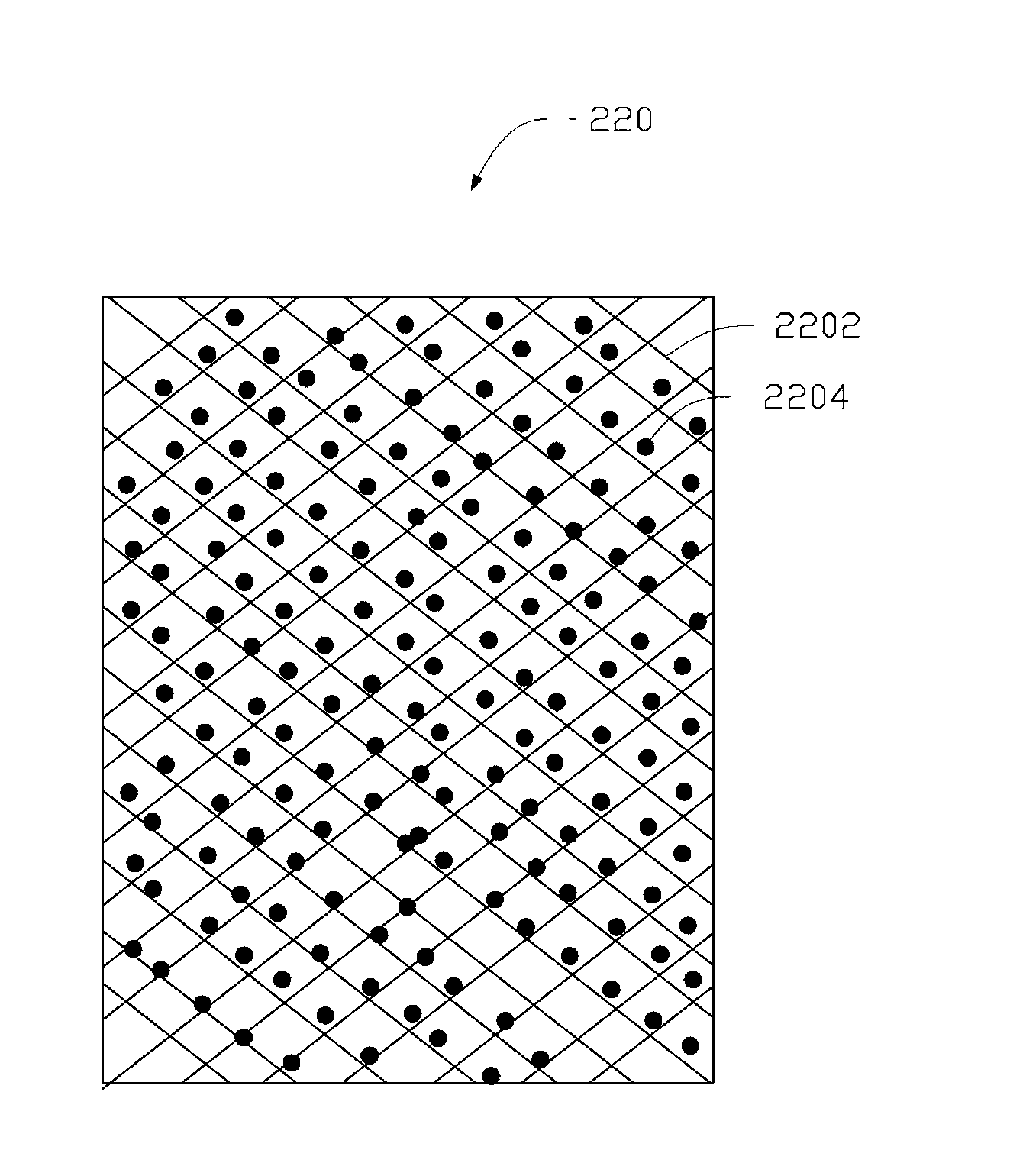

Carbon dioxide electrochemical reduction conversion utilization method

ActiveCN103160849AContinuous processingImprove recycling ratesCellsElectrochemical generatorsElectrolysisFuel cells

The invention relates to a carbon dioxide electrochemical reduction conversion utilization method comprising the steps that: a membrane reactor is provided, wherein the membrane reactor comprises a fuel cell and a cavity; an electrolyte separation membrane is arranged in the cavity, and divides the cavity into a cathode chamber and an anode chamber; an anode is arranged in the anode chamber, and a cathode is arranged in the cathode chamber; a cathode electrolyte and carbon dioxide are continuously and concurrently delivered into the cathode chamber of the membrane reactor, and an anode electrolyte and an anode active substance are continuously delivered into the anode chamber of the membrane reactor; electrolysis voltage is provided between the cathode and anode of the membrane reactor by using the fuel cell, such that carbon dioxide is decomposed, and expected products including hydrogen and oxygen are obtained; and hydrogen and oxygen are delivered into the fuel cell as fuels of the fuel cell, such that electric power can be obtained. The method provides good carbon dioxide conversion rate and energy circulation utilization rate.

Owner:TSINGHUA UNIV +1

Method for manufacturing aluminium alloy sheet for automobile fuel tank

ActiveCN104294113AStable mechanical propertiesPrecise dimensional tolerancesFuel tankEconomic benefits

The invention provides a method for manufacturing an aluminium alloy sheet for an automobile fuel tank. The method comprises the steps of batching, smelting, refining, grain refining, degassing, filtering, casting, saw-cutting, milling, homogenized heating, hot-rolling, cold-rolling, cleaning, low-temperature stabilized annealing, transverse shearing, edge straightening, board cutting, inspecting and the like. The aluminium alloy sheet for the automobile fuel tank has the advantages of stable mechanical property, precise dimensional tolerance, finish surface and the like. Compared with the present plastic fuel tank, the automobile fuel tank manufactured by the aluminium alloy sheet produced by the method has the advantages of high strength, sun exposure resistance, aging resistance, breakage prevention, environmental protection and the like, and also has the advantages of corrosion resistance, rusting avoidance, light weight, good economic benefits within the product life cycle, high material reutilization ratio and the like in comparison with a copper fuel tank.

Owner:DALISHEN ALUMINUM

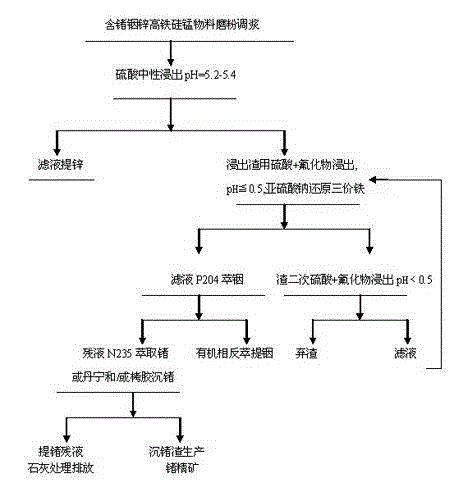

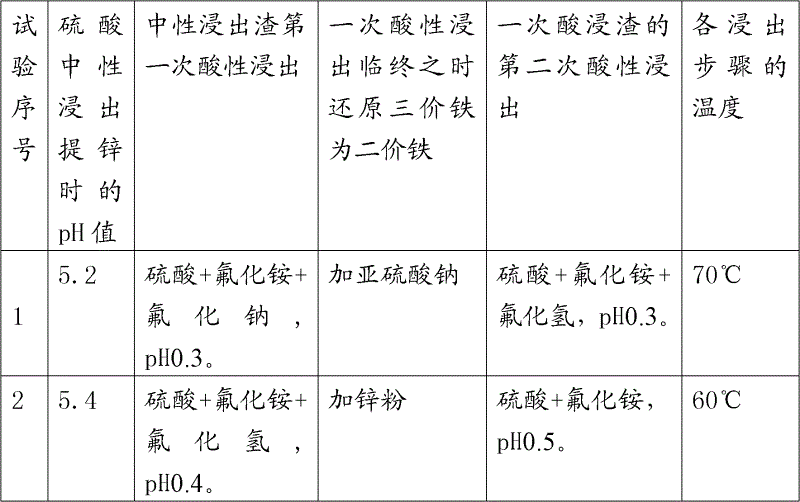

Method for extracting germanium, indium and zinc from high iron, silicon and manganese materials containing germanium, indium and zinc

A method for extracting germanium, indium and zinc from high iron, silicon and manganese materials containing germanium, indium and zinc belongs to the technology of hydrometallurgy. Sulfuric acid and fluoride are adopted for acid leaching for two times, leaching rate of germanium can reach 90% above, and secondary acid leaching slag contains germanium equal to and less than 0.005%. The total leaching rate of indium reaches 95% above, and tailings contain indium equal to and less than 0.003%. Germanium concentrate obtained by germanium extraction through an extraction method contains fluorine less than 1%. Low temperature leaching is performed at 70+-10 DEG C, the structure of iron vitriol slag is damaged as little as possible, and the concentration of ferric iron in leaching liquid is reduced. Ammonium iron hexafluoride produced in the leaching process shields the ferric iron, P204 indium extraction, N235 germanium or tannin extraction and tannin extract germanium deposit are improved, and the poisoning phenomenon in ferric iron of P204 and N235 is reduced. Comprehensive recovery utilization rate of germanium, indium and zinc in high iron, silicon and manganese materials is greatly improved.

Owner:YUNNAN WUXIN IND

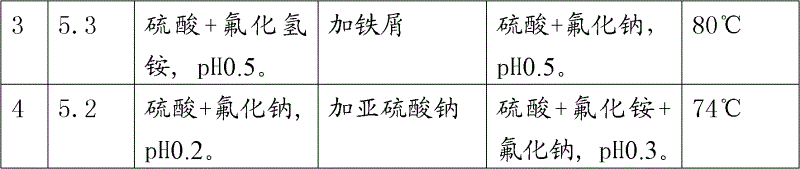

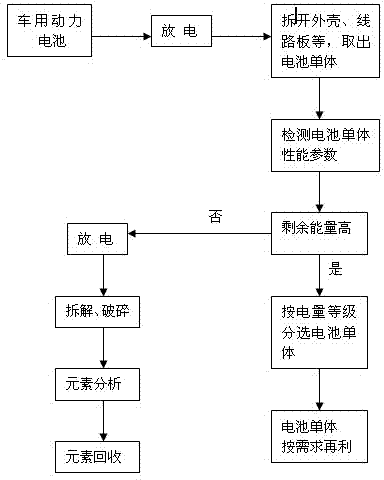

Method for recovering power cells for new energy vehicles

ActiveCN102347520ARealize cascade utilizationAvoid wastingWaste processingSolid waste disposalPower batteryElectrical battery

The invention discloses a method for recovering power cells for new energy vehicles. The method comprises the following steps of: (1) discharging the expired power cells for removing the remaining energy of the power cells to ensure that the subsequent processes can be performed safely; (2) initially partitioning; (3) detecting and classifying the performance parameters of single batteries; (4) disassembling the useless single batteries to take out the positive and negative pole pieces thereof; (5) performing elemental analysis on the obtained positive and negative pole pieces, based on the result of elemental analysis, determining the mixing amount of different batches of raw materials according to the contents of the elements and the proportion of each major element of a target product, and extracting the metal elements by hydrometallurgy to prepare the target product; and (6) sorting the employable single batteries by a battery sorter according to the residual capacitance of the single batteries, grading and classifying based on the capacitance, and then applying to products according to actual requirements.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

Fe3O4/CuO/pSiO2 catalyst and preparation method thereof

InactiveCN102688760AEfficient separation and recoveryReduce catalyst lossOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive agentSurface-active agents

The invention relates to a Fe3O4 / CuO / pSiO2 (porous silica) catalyst, a preparation method thereof and application thereof in olefin epoxidation reaction. The preparation method comprises the following processes of: obtaining Fe3O4 microspheres serving as magnetic cores by adopting a co-precipitation method, and modifying the surfaces of the Fe3O4 microspheres by using polyvinyl pyrrolidone (PVP) in order to improve the adsorption effect of the surfaces of the Fe3O4 microspheres on metal cations; coating a CuO nano shell layer on the surfaces of the Fe3O4 microspheres by using copper acetate as a copper source through hydrothermal synthesis; and finally, coating the porous silicon dioxide shell layer by using cetyl trimethyl ammonium bromide (CTAB) as a surfactant and using ethyl orthosilicate as a silicon source, and thus obtaining a composite catalytic material with a magnetic Fe3O4 / CuO / pSiO2 core-shell structure. The catalytic performance of the composite material is researched by respectively using epoxidation reaction of styrene and cyclooctene as probe reaction, and the results prove that the catalytic material has high reaction activity and selectivity, and the catalytic material is easy to separate and recover by introducing the magnetic ores; and the catalytic material has a good circulating effect, still can keep excellent catalytic performance by dozens of times of circulation, and has a great application prospect.

Owner:UNIV OF SCI & TECH BEIJING

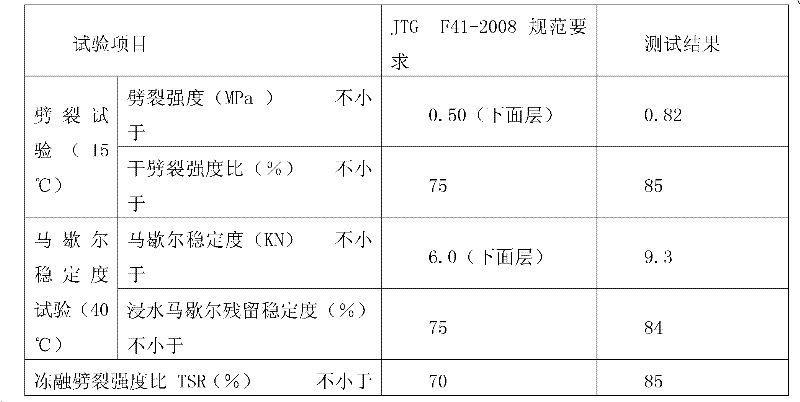

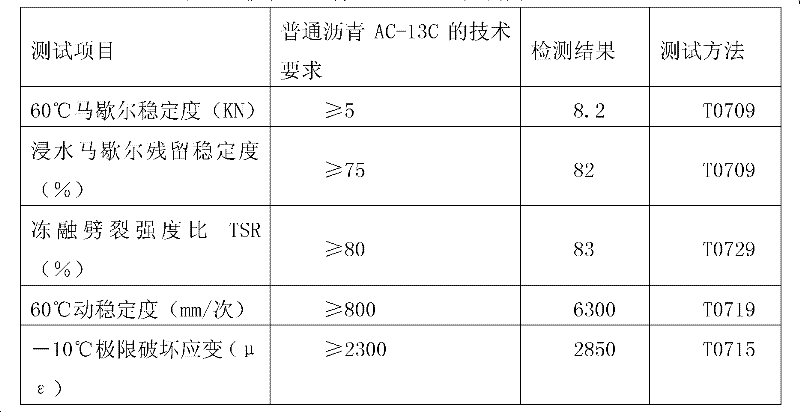

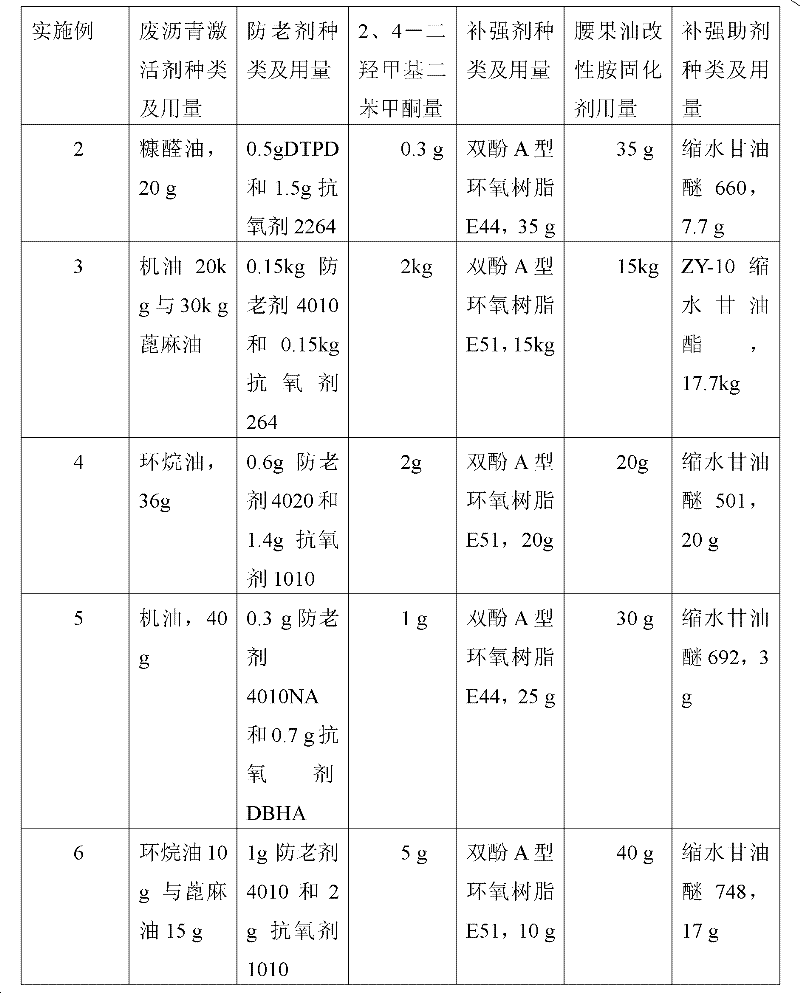

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

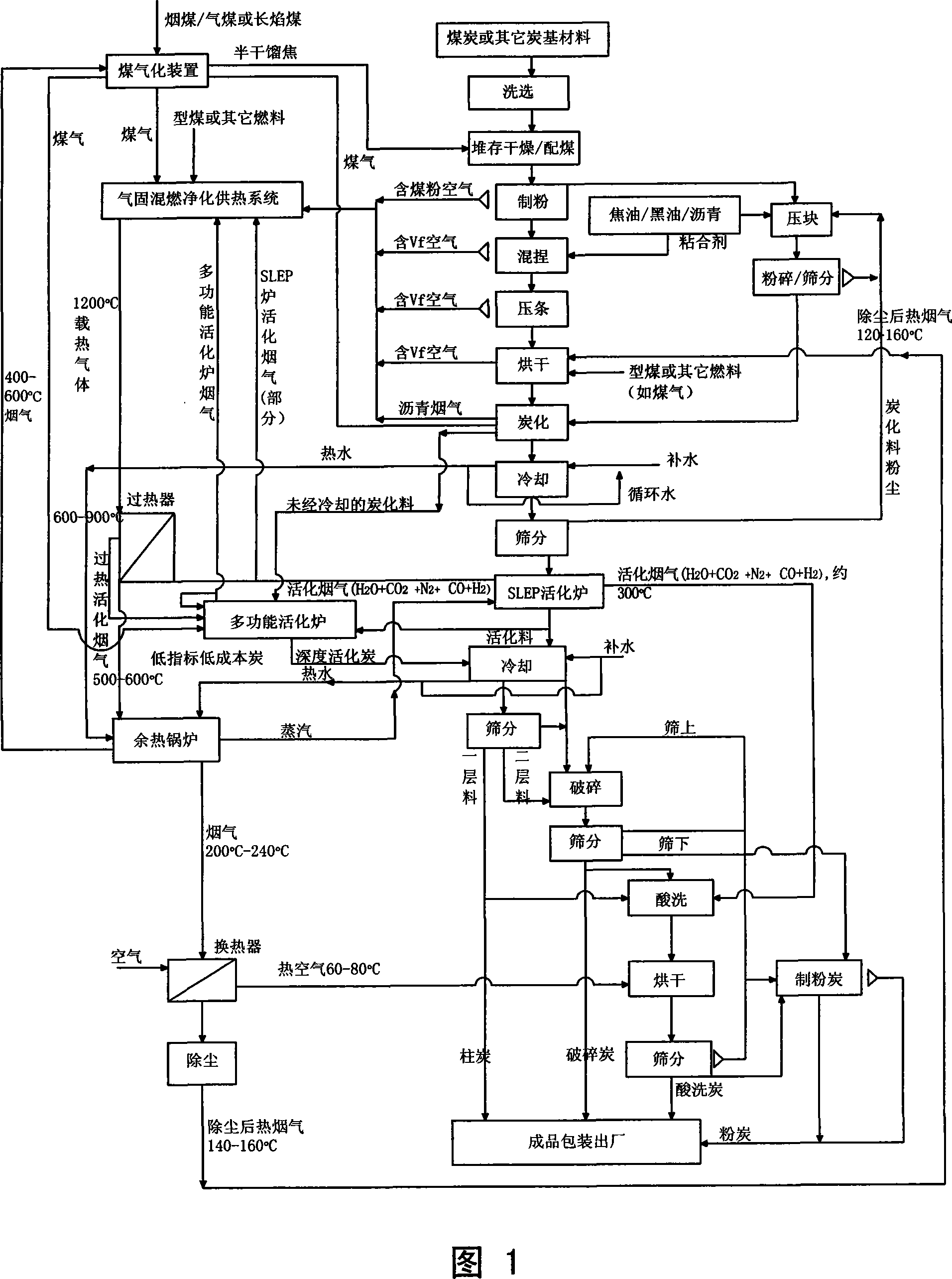

Physical method energy-saving cleaning technique for manufacturing active carbon

The invention relates to a technology for manufacturing activated carbon by a physical method of energy saving and cleaning, which includes the processes of mixing kneading and plating or coal blending and briquetting, airing strip, carbonization, screening, activating, screening and packaging as well as packaging after screening material and making into powder activated carbon to traditional milling, coal powder and tar. The technology adjusts and adds the processes: air with coal powder in the milling workshop, air with Vf (organic volatile) generated in the process of mixing kneading, plating and drying, pitch smoke generated in the process of charring, parts of smoke in a SLEP activated-stove, smoke in a multifunction activated-stove, coal gas out of a coal gasification device or other fuel are sent into a heating system of gas fixing, mixed burning and purifying for burning; through a waste heat boiler, generated heat loading gas generates steam for activating technology to use; tail gas is used for generating coal gas and drying material; after been heated, parts of smoke of the SLEP activated-stove is supplied for the multifunction activated-stove. The technology of the invention increases material yield, power source application which does not pollute the environment.

Owner:山西佳净环保工程有限公司

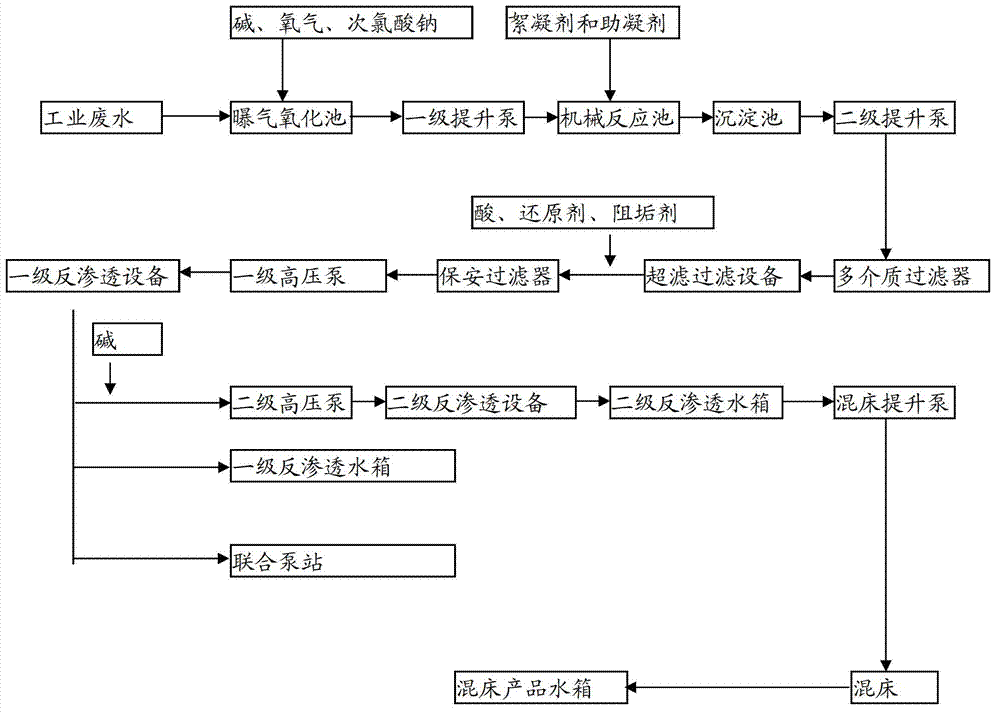

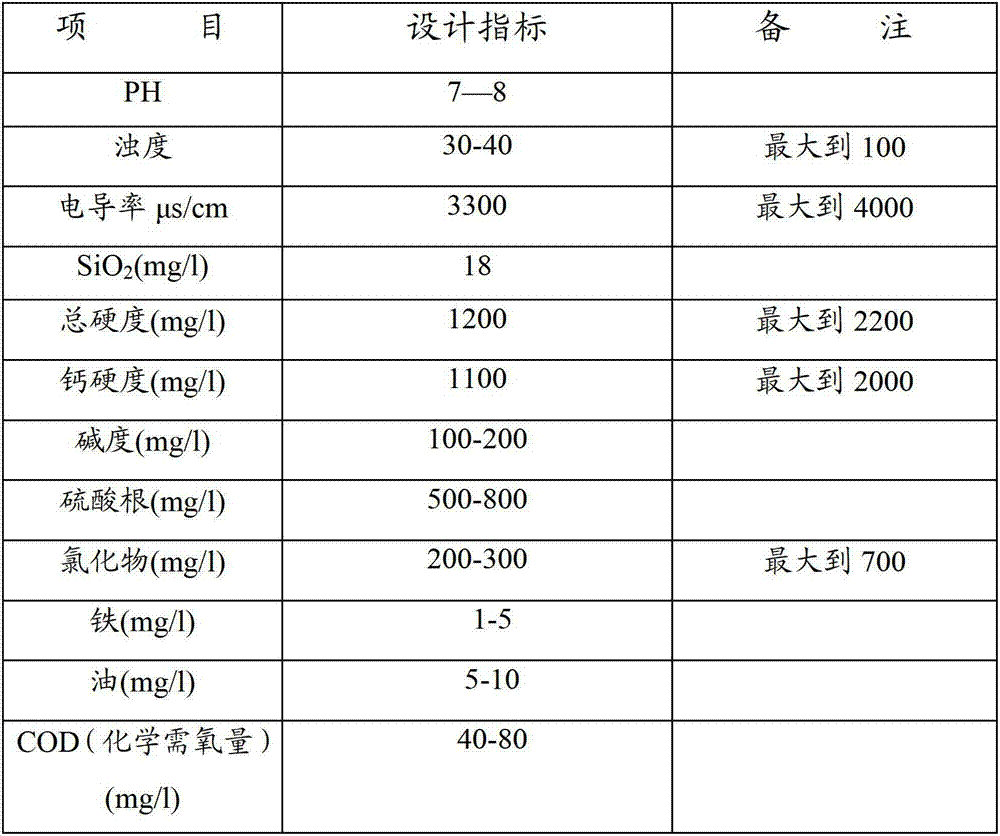

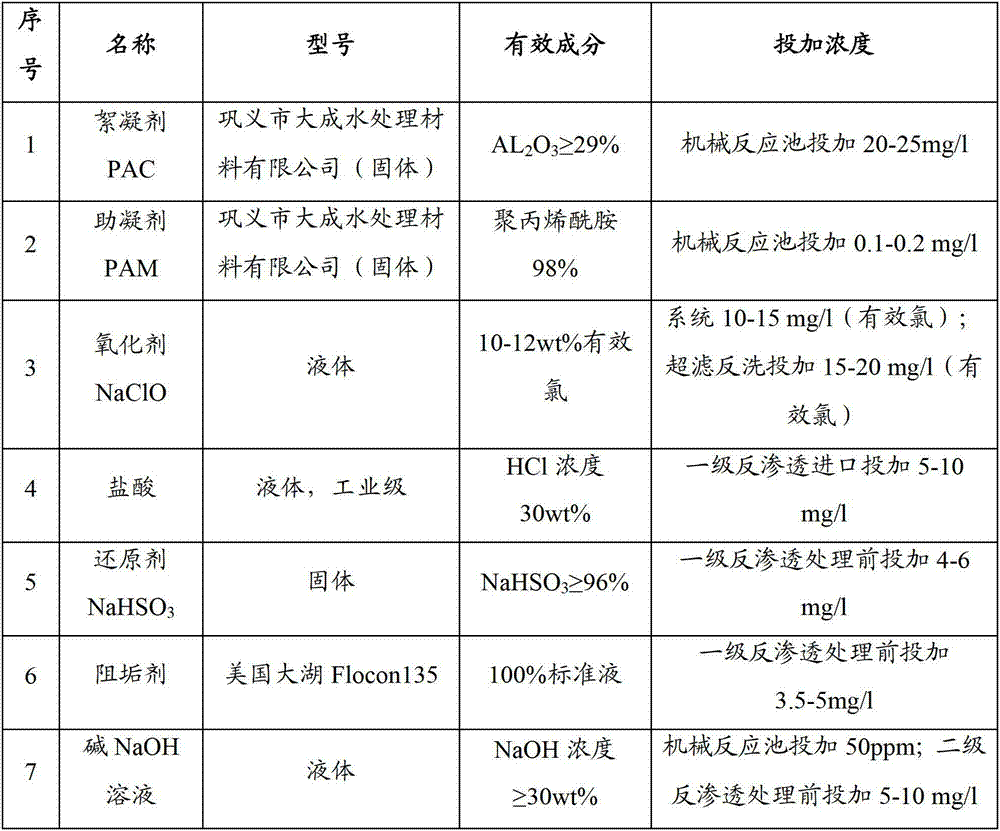

Double-membrane treatment method of iron and steel industrial wastewater

ActiveCN102826686AImprove recycling ratesReduce consumptionWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisSaline waterWater resources

The invention provides a double-membrane treatment method of iron and steel industrial wastewater. The method comprises the following steps that the pH value of the wastewater is regulated to be greater than 7, and then, oxygen gas is introduced into the wastewater until the total iron content in the wastewater is reduced to a value smaller than 0.5mg / l; the pH value of the wastewater is regulated to 8.0 to 8.5, flocculating agents and coagulant aids are added into the wastewater under the stirring condition, and then, the static settlement is carried out; the wastewater subjected to preliminary treatment is subjected to filtering treatment in a filter so that the water outlet turbidity of the wastewater is smaller than 2NTU; the wastewater subjected to filtering treatment is subjected to full flow filtering treatment; the wastewater subjected to pretreatment is subjected to two-stage reverse osmosis treatment; and the wastewater subjected to the two-stage reverse osmosis treatment is subjected to fine treatment through a mixing bed. The double-membrane treatment method has the advantages that the treated wastewater reaches the demineralized water standard, the cyclic utilization rate of water resources is improved, the consumption of new water is saved, and the outward discharge water of a ton of steel is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

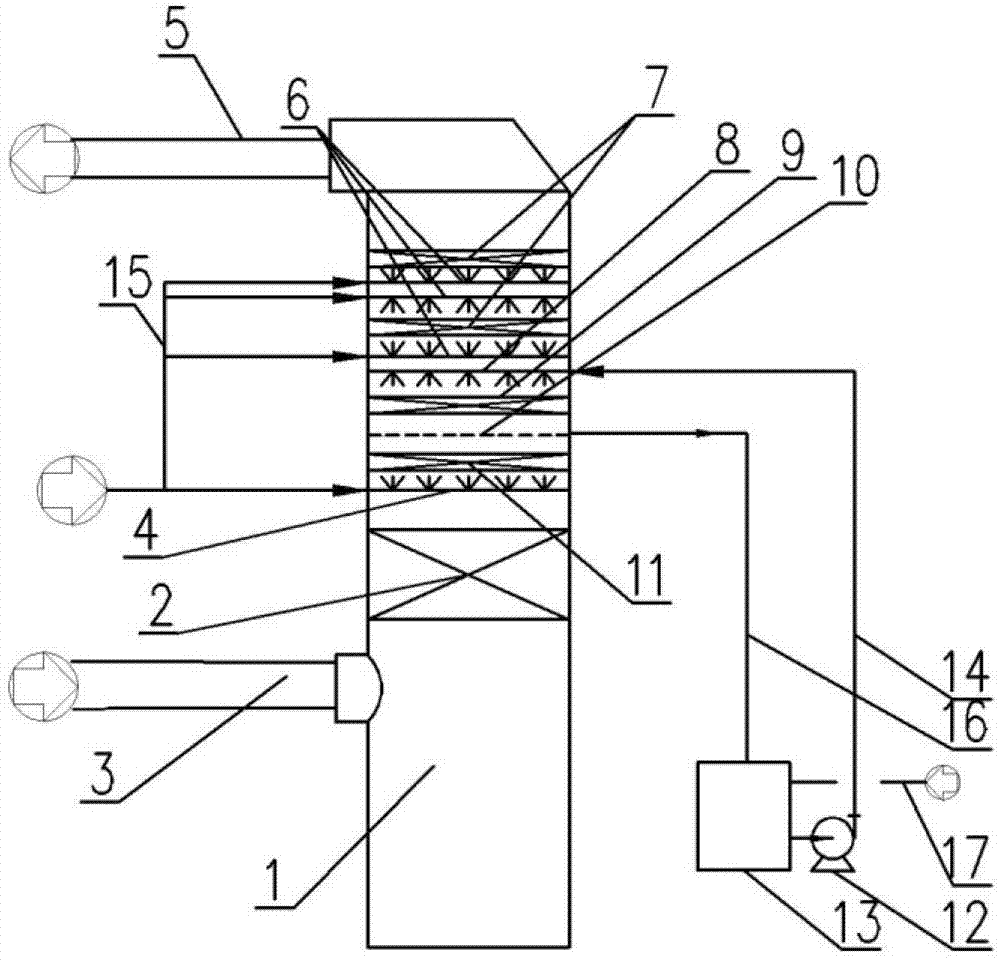

Device and method for controlling fine particles in desulfurization flue gas

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

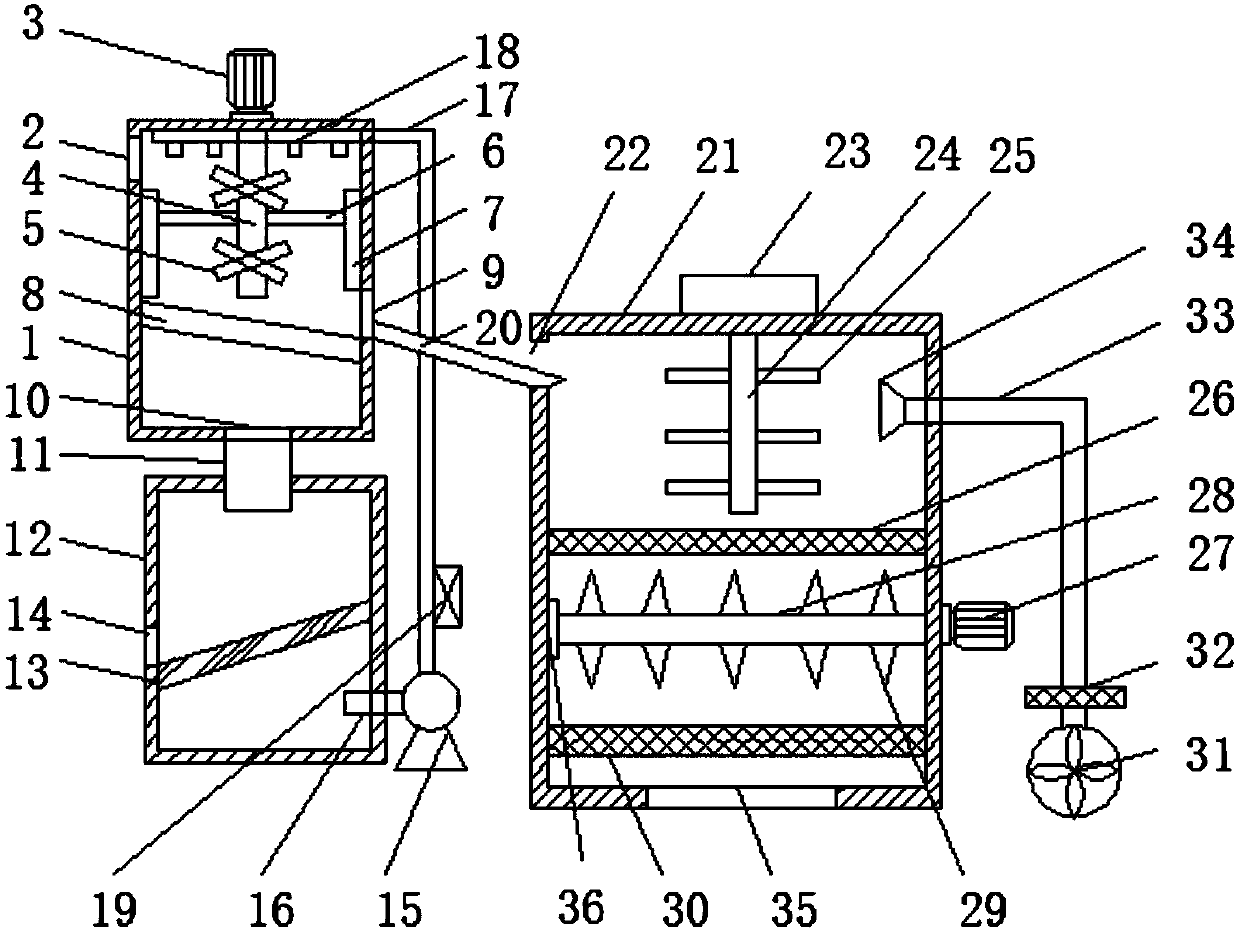

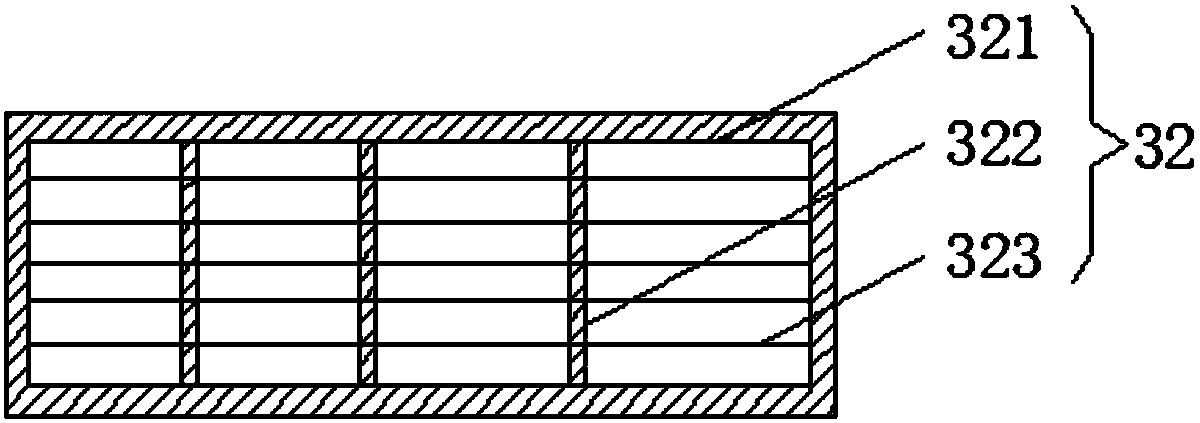

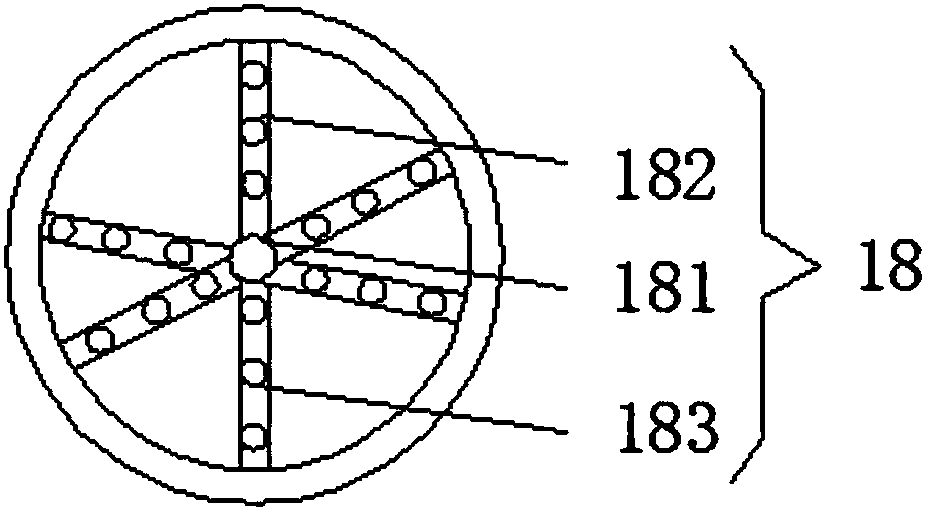

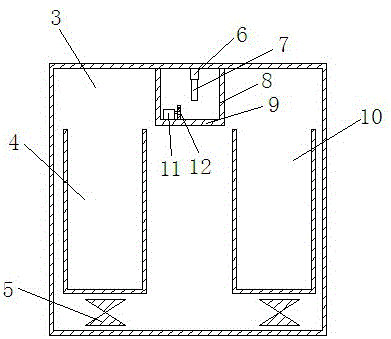

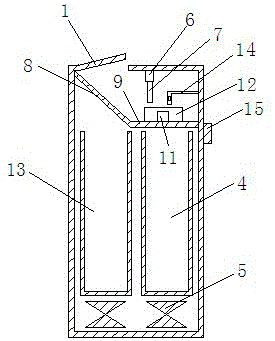

Waste and old plastic product recovering apparatus and use method thereof

ActiveCN107891546AImprove recycling ratesSimple structurePlastic recyclingGrain treatmentsTemperature treatmentEngineering

The invention discloses a waste and old plastic product recovering apparatus, and belongs to the technical field of waste and old plastic products. The apparatus comprises a cleaning chamber. The topof a grinding chamber is provided with a motor (A). The output shaft of the motor (A) is provided with a blade shaft. Blades are arranged on the outer wall of the blade shaft. A first screen is arranged right under the blade shaft. A motor (B) is arranged on the right side of the grinding chamber. The outer wall of a grinding shaft is provided with grinding blades. A second screen is arranged right under the grinding shaft. Two different sets of blades are arranged in the grinding chamber so as to process waste and old plastic products with different shapes and degrees. A draught fan and a heating device are provided. When waste and old plastic products are grinded, the draught fan and the heating device can carry out a high temperature treatment on the waste and old plastic products. Thesubsequent treatment on grinded waste and old plastic products becomes more convenient. The sieve pores of the first screen are larger than sieve pores of the second screen. The grinded plastic products can be grinded for another time. The grinding efficiency is improved and the plastic products are more radically grinded.

Owner:PINGHU DAKE BABY CARRIER

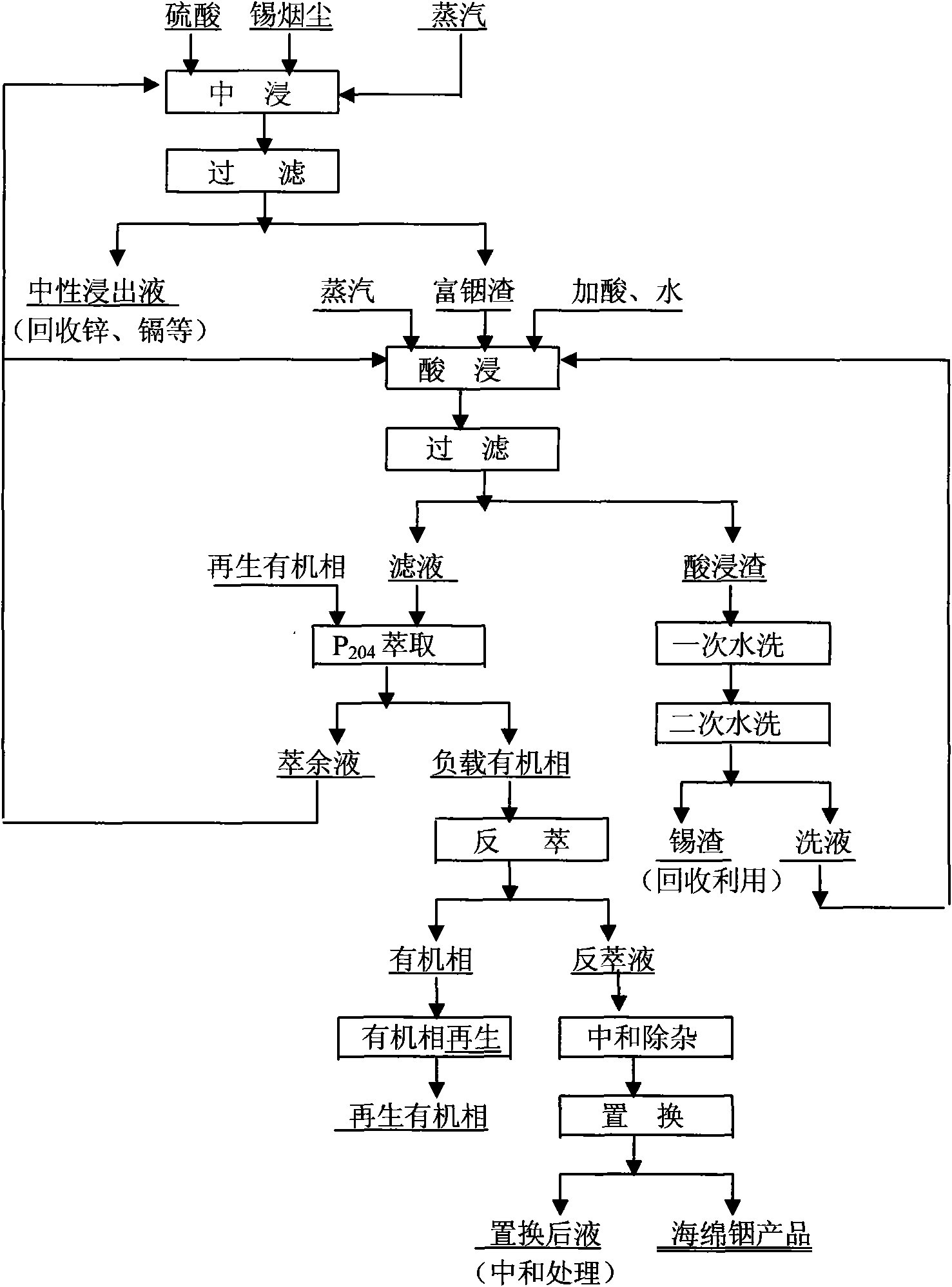

Method for extracting indium and recovering valuable metals from flue dust of tin

ActiveCN101643853AReduce contentRaise the gradePhotography auxillary processesProcess efficiency improvementPregnant leach solutionIndium

The invention relates to a method for extracting indium and simultaneously recovering valuable metals such as tin, lead, zinc, cadmium and the like from flue dust of smelted tin. The method comprises:adopting twice leaching: neutral leaching-acid leaching, and firstly leaching part of impurity elements such as arsenic, cadmium, zinc and the like in the flue dust of tin into the neutral leaching liquid under the condition of neutral normal temperature or low temperature; then, acidic twice leaching neutral leaching residue, leaching indium and residual part of impurity elements again, and entering high temperature leaching liquid; washing high temperature leaching residue, and then recovering tin and lead. P204 is adopted for extracting the indium in the high temperature leaching liquid, hydrochloric solution is used for back-extraction enrichment, and zinc blocks are used for replacing, so that the product sponge indium can be obtained and has the indium content of 92.70%; raffinate obtained after the indium is extracted by the P204 returns to neutral leaching or acid leaching to be taken as leaching preparation liquid; zinc in the neutral leaching liquid is extracted by P507, sulfuric acid solution is processed by back-extraction enrichment, evaporation, concentration and crystallization, so that industrial first-grade product ZnSO4.7H2O can be obtained.

Owner:YUNNAN TIN GROUP HLDG

Garbage compression leachate comprehensive waste water treatment device and technological method

ActiveCN104529093AIncreased hydraulic shear strengthStable fluxWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningWater storage tankFiltration

The invention provides a garbage compression leachate comprehensive waste water treatment device and technological method. The device comprises a grille, a waste water storage tank, an ultrasonic Electro-Fenton reactor, an intermediate water storage tank, an ultrasonic vibration film reactor and a vortex vibration film filtration system, wherein the grille, the waste water storage tank, the ultrasonic Electro-Fenton reactor, the intermediate water storage tank, the ultrasonic vibration film reactor and the vortex vibration film filtration system are sequentially connected. The device further comprises a sludge dewatering drying pool which is connected with a vortex energy-saving heat pump flash evaporator of the vortex vibration film filtration system and provided with a circuit connected with the ultrasonic vibration film reactor. Waste water sequentially flows through the grille, the waste water storage tank, the ultrasonic Electro-Fenton reactor, the intermediate water storage tank, the ultrasonic vibration film reactor and the vortex vibration film filtration system for redox reactions and filtration. The device is high in operability, high in regeneration cycle use rate and low in operation cost.

Owner:樊利华

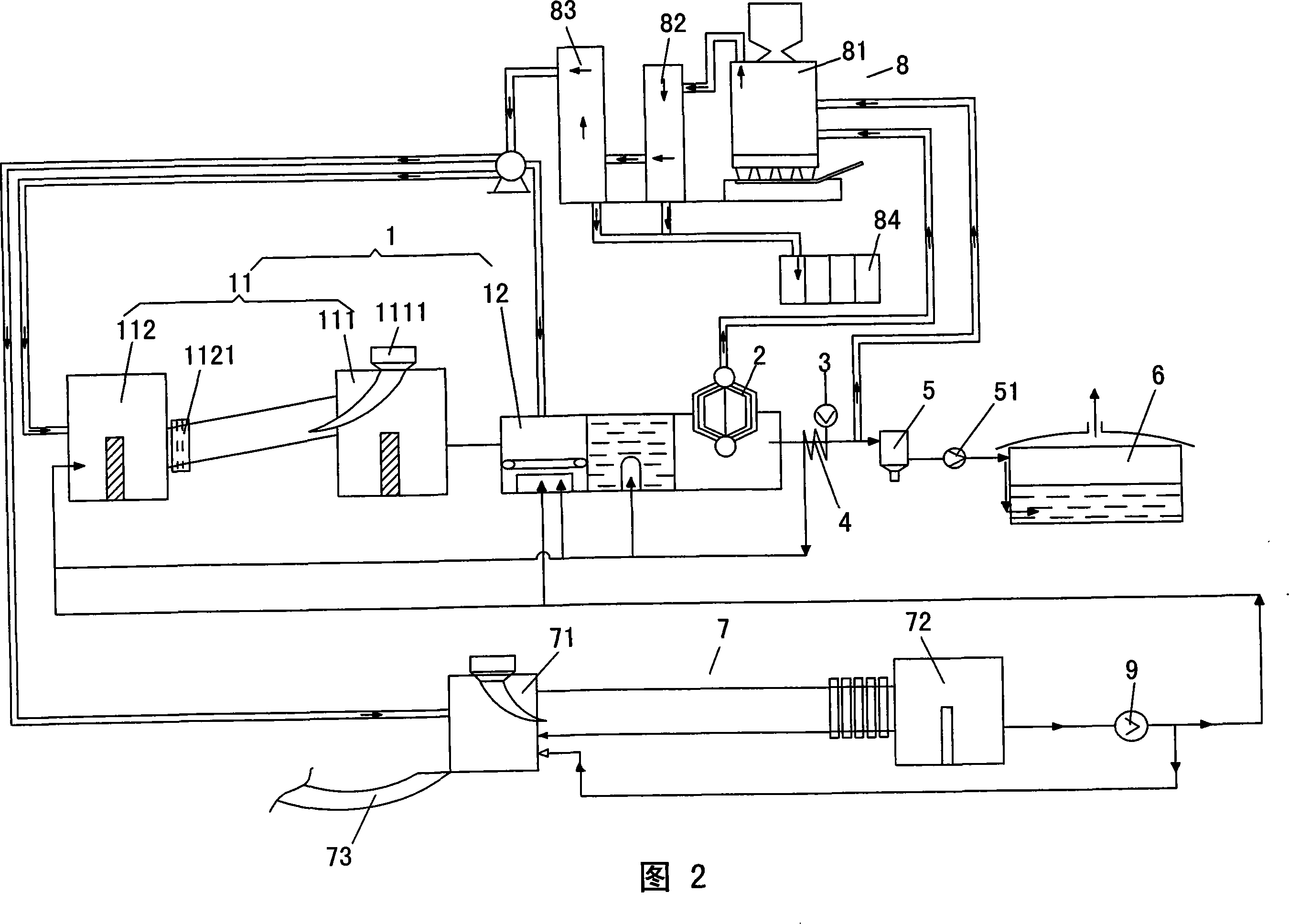

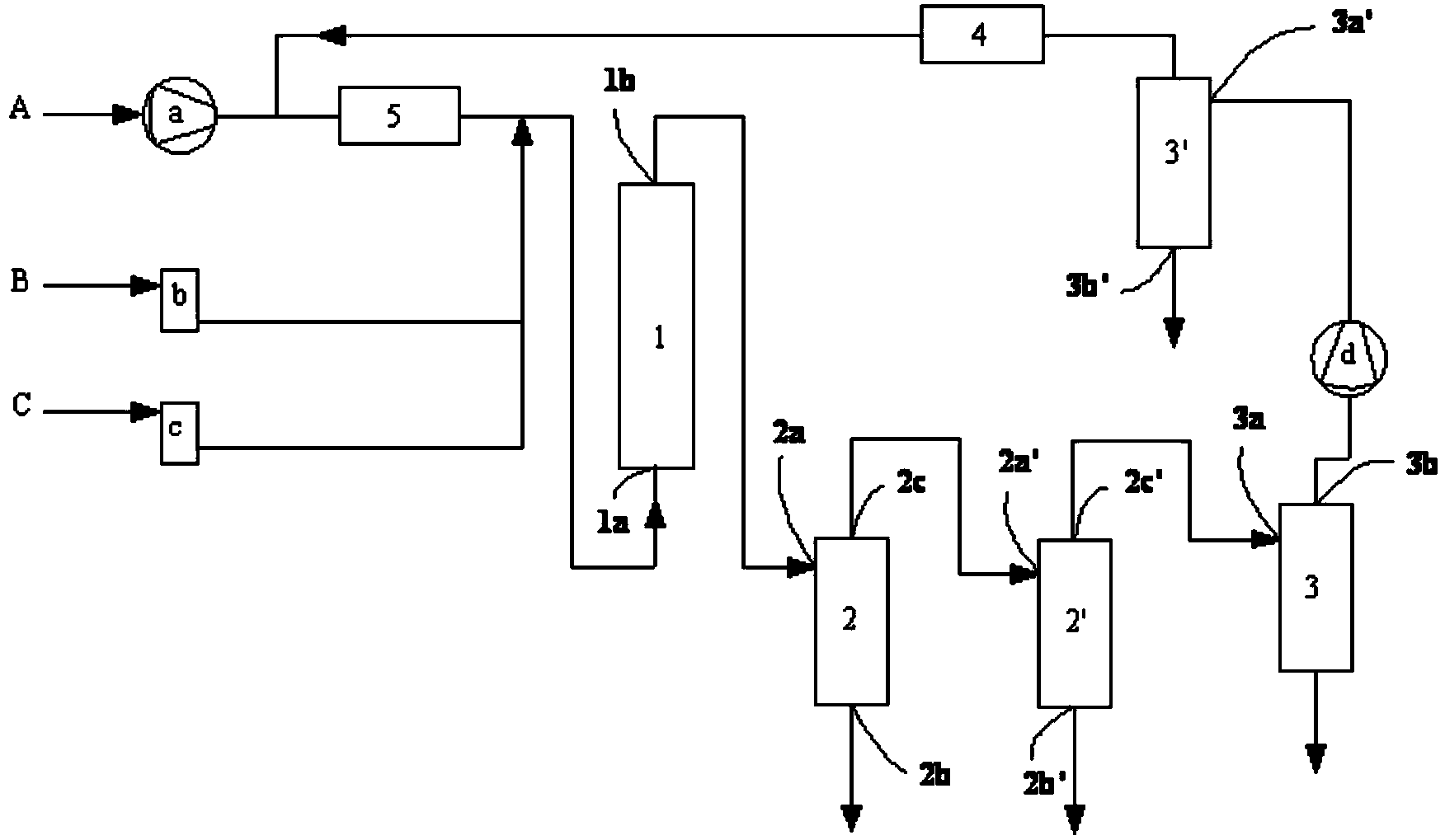

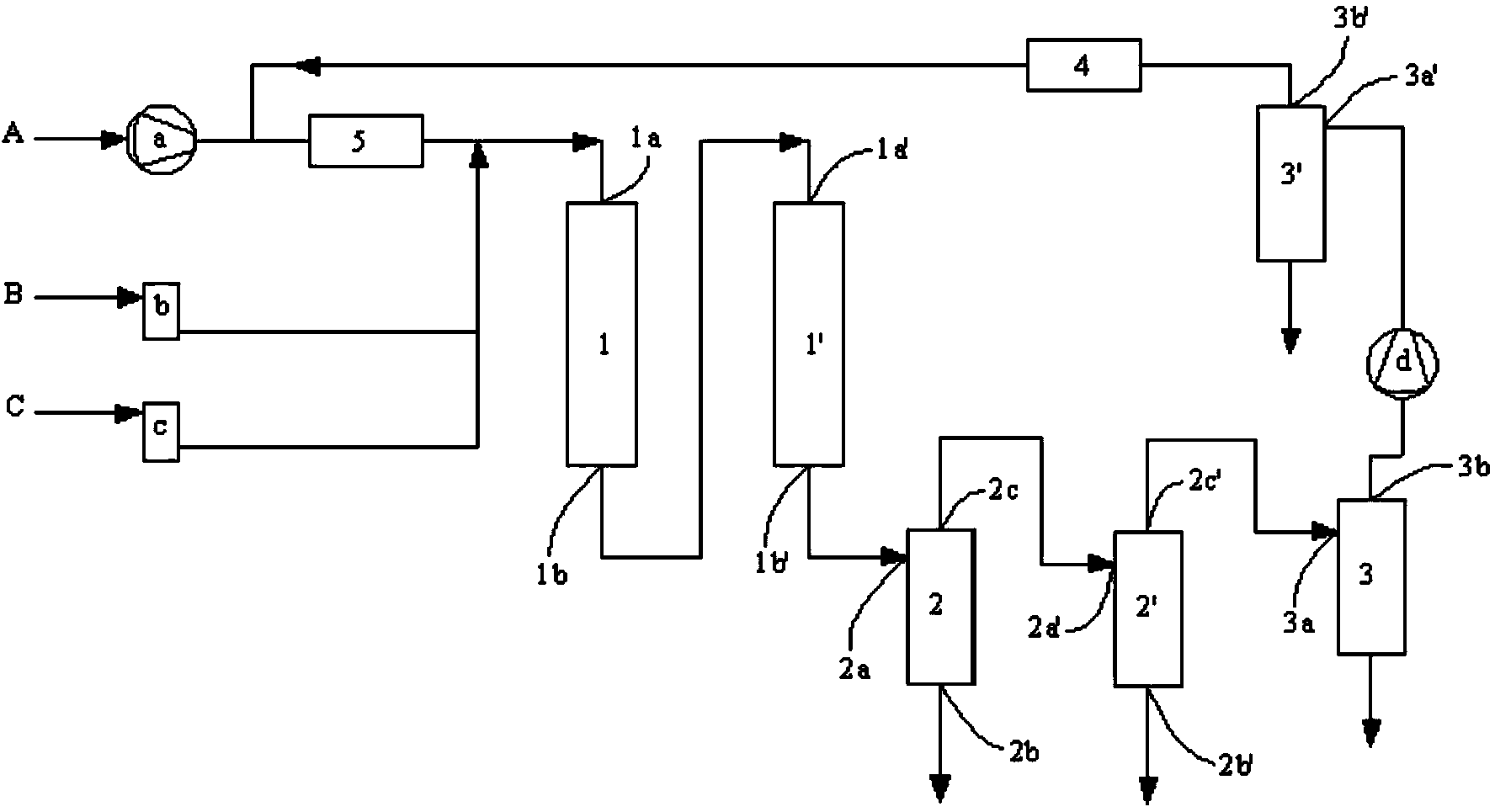

Device and method for continuously synthesizing amine-terminated polyether by utilizing fixed bed

ActiveCN103524725AGood effectContinuous and stable productionChemical recyclingVapor–liquid separatorAlcohol

The invention provides a device and a method for continuously synthesizing amine-terminated polyether by utilizing a fixed bed. The device for continuously synthesizing amine-terminated polyether by utilizing the fixed bed comprises a fixed bed reactor, a preheater, two gas-liquid separators, a compressor, a circulating compressor, a raw material pump, a liquid ammonia pump and two buffer tanks, hydrogen is preheated by virtue of the preheater and is fed into the fixed bed reactor with raw material and liquid ammonia; the amine-terminated polyether is synthesized in a hydrogen atmosphere of the fixed bed; the fixed bed reactor is at the temperature of 150-300 DEG C and the pressure of 1-20MPa, ammonia alcohol ratio is 1-15, and unreacted hydrogen and ammonia are recycled. The device and method for continuously synthesizing amine-terminated polyether by utilizing the fixed bed overcome the defects of tedious operation, unstable product quality, low synthesis efficiency and the like of the existing technology as a batch-type operation is adopted, a continuous reaction technological design is adopted, a technology is simple, performance is stable, yield is high, excessive ammonia and hydrogen are recycled, pollution to the environment is reduced, production cost is reduced, and energy is saved; conversion rate of hydroxyl-terminated polyether or derivative thereof and selectivity of the amine-terminated polyether product are obviously improved, so that production cost of the amine-terminated polyether product is obviously reduced.

Owner:康达新材料(集团)股份有限公司

Method for preparing NdFeB (neodymium-iron-boron) magnet by waste materials

InactiveCN104576019AImprove coercive forceImprove remanenceInductances/transformers/magnets manufactureRecycling and recovery technologiesAntioxidantRare earth

The invention relates to an NdFeB (neodymium-iron-boron) magnet, in particular to a method for preparing the NdFeB magnet by waste materials, and belongs to the technical field of magnetic materials. The preparing method of the NdFeB magnet comprises the following steps that firstly, NdFeB magnet waste materials are cleaned and are dried through being blown, the NdFeB magnet waste materials are crushed into particles being 10 to 15mm by a crushing machine, rare earth metal is added into the particles, then, hydrogen crushing treatment is carried out to obtain crushed powder, and next, antioxidants are added for airflow grinding to obtain fine powder with the average particle diameter being 3.0 to 4.0 mu. m; next, lubricating agents are added, orientation is carried out under the protection atmosphere of nitrogen gas, in addition, pressing forming is carried out, and finally, NdFeB magnet finished products are obtained through discharging plasma sintering, secondary tempering heat treatment and surface treatment. The method has the advantages that waste materials are used as major raw materials, the simple and feasible preparing method is adopted, the recovery and utilization rate of the waste materials is effectively improved, in addition, Tb, Dy, Nd and Ce are added and compounded in the preparing process, and the obtained NdFeB magnet has better coercive force, residual magnetism and magnetic energy product.

Owner:NINGBO GERONGLI MAGNETIC IND

Intelligent garbage classifying and sorting device

ActiveCN106115106AEasy to sort and recycleImprove recycling ratesWaste collection and transferRefuse receptaclesUtilization rateWaste management

The invention discloses an intelligent garbage sorting and sorting device, which comprises: a garbage box body, the lower part of which is buried underground, and a garbage dropping port and a box body sliding door are arranged on the top of the garbage box body; A garbage temporary storage board connected to the garbage disposal port, at least two trash cans are set around the garbage temporary storage board; a mechanical arm is set on the inner wall of the garbage box body, and a garbage attribute detector is set on the mechanical arm; it also includes: a controller; garbage attribute The detector and the mechanical arm are respectively electrically connected to the controller. The invention automatically completes the sorting of the garbage without manpower sorting of the garbage, facilitates the sorting and recycling of the garbage, and improves the recycling rate of the garbage.

Owner:山东同其智能科技有限公司

Vacuum sealed molding casting method production process for front bridge and rear bridge of automobile

InactiveCN101722298ALow investment costReduce labor intensityFoundry mouldsFoundry coresVacuum pumpingSurface layer

The invention relates to a vacuum sealed molding casting method production process for a front bridge and a rear bridge of an automobile. The front bridge and the rear bridge of the automobile are characterized by being produced by the following steps that: (1) a model is provided with a longitudinal air hole by which the model is divided into an upper half body and a lower half body; (2) the upper half body of the model is flatly placed on an air exhaust box, a film is roasted to be soft and then covered on the surface layer of the model, and after air exhaust, the film is closely adhered to the model and a top plate; (3) the film, covered on the circumference of the gating and risering model, is jointed with an in gate in the half body of the model, the film on the model is sprayed with a coating, and then a sand box is covered, the sand box is filled with dry sand, a vibrating table is started to tamp the dry sand, the surface of the sand layer is scraped to be smooth, and an upper opening is covered by a sealing cover; (4) the dry sand is agglomerated and hardened by vacuum pumping, the air exhaust box stops air exhaust, but the sand box is continuously vacuumized, the sand box is lifted up, the upper half body models is taken out, the gating and risering model is drawn out, and the upper sand box is formed; (5) the lower half body of the model repeats the steps to form the lower sand box; and (6) the bottom surfaces, where the mould cavities of the half body models are formed, of the upper sand box and the lower sand box are closed, and the molten metal is poured in from the gating and risering, and after cooling, the blanks of the front bridge and the rear bridge of the automobile are produced. The products produced by the process are high in accuracy and low in cost.

Owner:薛立华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com