Device and method for continuously synthesizing amine-terminated polyether by utilizing fixed bed

An amino-terminated polyether and fixed-bed reactor technology, which is applied in the directions of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems that the continuous production process of amino-terminated polyether has no detailed literature reports, etc. Achieve high heat recovery rate, reduce production costs, and avoid environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

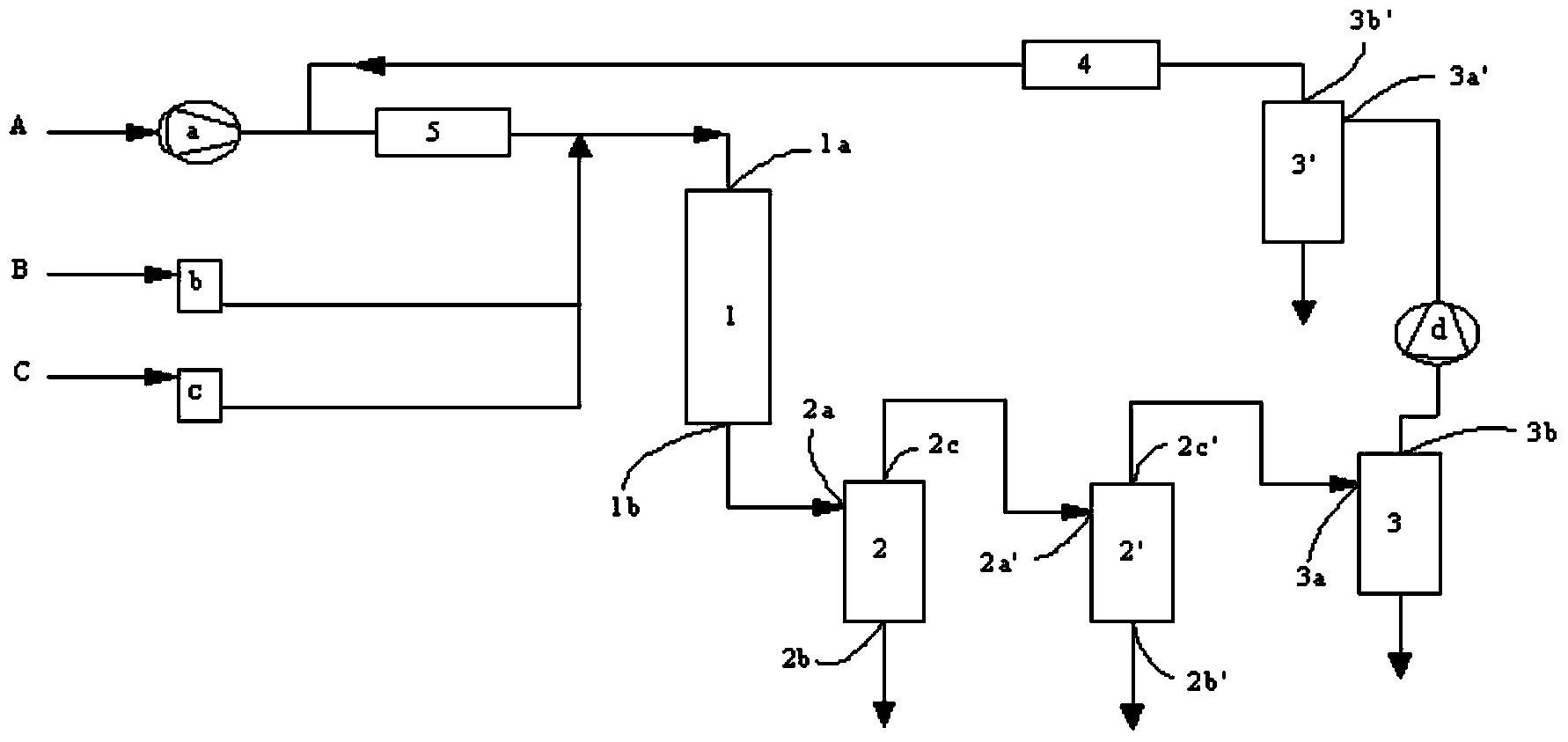

[0053] see figure 1 , the device for continuously synthesizing amino-terminated polyether shown in the figure includes a fixed-bed reactor 1, a preheater 5, a gas-liquid separator 2, 2', a compressor a, a circulating compressor d, a raw material pump b, a liquid Ammonia pump c, buffer tanks 3, 3', hydrogen supply gas source pipeline A, raw material pipeline B and liquid ammonia supply pipeline C.

[0054] The hydrogen gas supplied by the hydrogen supply source pipeline A equipped with a pressure reducing and stabilizing valve and the hydrogen supplied by the compressor a is preheated by the preheater 4, and then the raw material supplied by the raw material pipeline B and the raw material pump b, the liquid ammonia supply pipeline C and the liquid ammonia The liquid ammonia sent by the ammonia pump c is sent into the fixed bed reactor 1 through the feed port 1a at the top of the fixed bed reactor 1; the discharge port 1b at the bottom of the fixed bed reactor 1 is connected to...

Embodiment 2

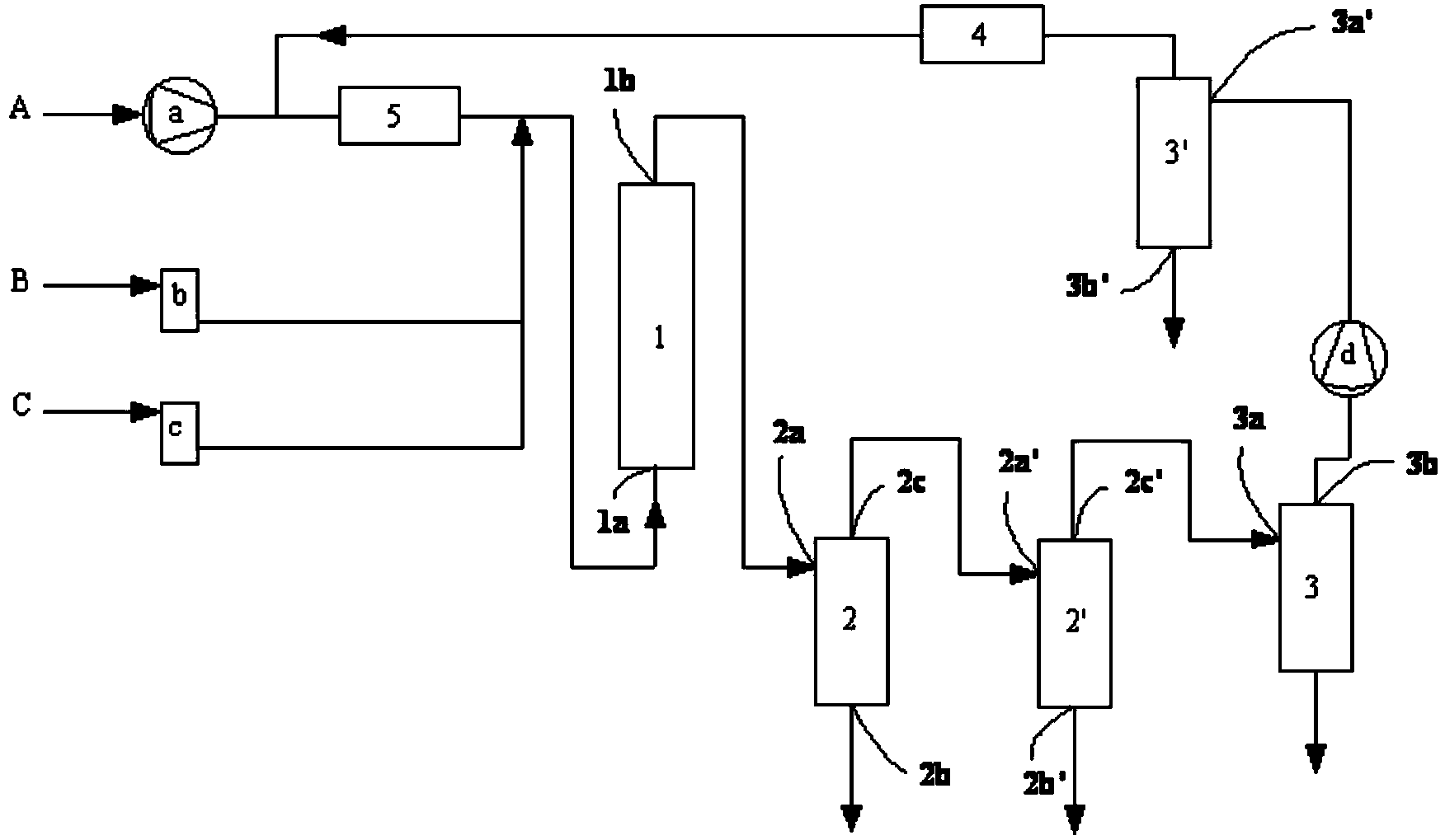

[0057] see figure 2 , the device for continuously synthesizing amino-terminated polyether shown in the figure includes a fixed-bed reactor 1, a preheater 5, a gas-liquid separator 2, 2', a compressor a, a circulating compressor d, a raw material pump b, a liquid Ammonia pump c, buffer tanks 3, 3', hydrogen supply source pipeline A equipped with pressure reducing and stabilizing valves, raw material pipeline B and liquid ammonia supply pipeline C.

[0058] The hydrogen gas supplied by the hydrogen supply source pipeline A equipped with a pressure reducing and stabilizing valve and the hydrogen supplied by the compressor a is preheated by the preheater 4, and then the raw material supplied by the raw material pipeline B and the raw material pump b, the liquid ammonia supply pipeline C and the liquid ammonia The liquid ammonia sent by the ammonia pump c is sent into the fixed bed reactor 1 through the feed port 1a at the bottom of the fixed bed reactor 1; the discharge port 1b a...

Embodiment 3

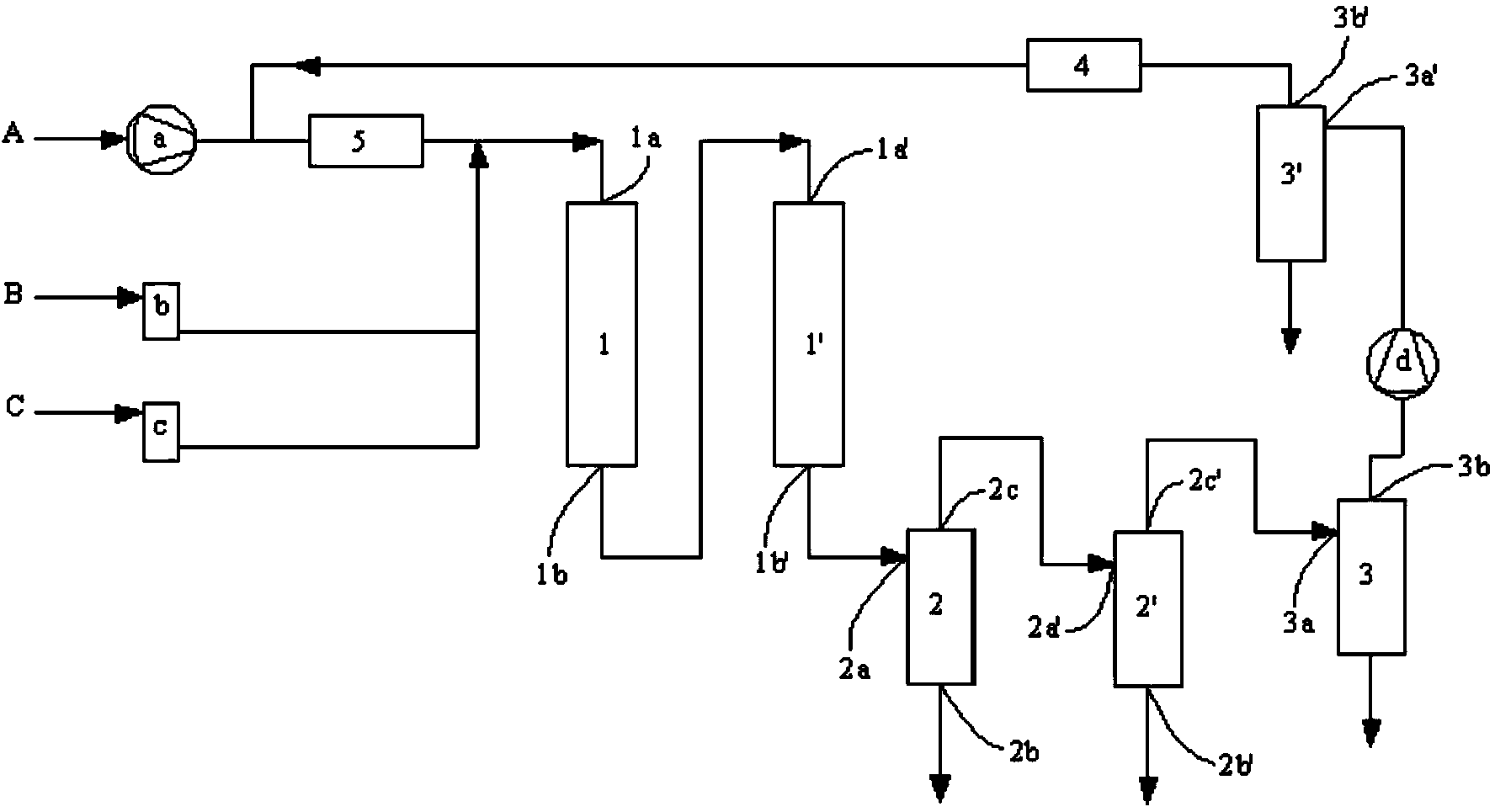

[0061] see image 3 , the device for continuous synthesis of amino-terminated polyether shown in the figure, including fixed bed reactor 1, 1', preheater 5, gas-liquid separator 2, 2', compressor a, circulation compressor d, raw material pump b. Liquid ammonia pump c, buffer tanks 3, 3', hydrogen supply gas source pipeline A, raw material pipeline B and liquid ammonia supply pipeline C installed with pressure reducing and stabilizing valves.

[0062] The hydrogen gas supplied by the hydrogen supply source pipeline A equipped with a pressure reducing and stabilizing valve and the hydrogen supplied by the compressor a is preheated by the preheater 4, and then the raw material supplied by the raw material pipeline B and the raw material pump b, the liquid ammonia supply pipeline C and the liquid ammonia The liquid ammonia sent by the ammonia pump c is sent into the fixed bed reactor 1 through the feed port 1a at the top of the fixed bed reactor 1; the discharge port 1b at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com