Patents

Literature

356 results about "Technological design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

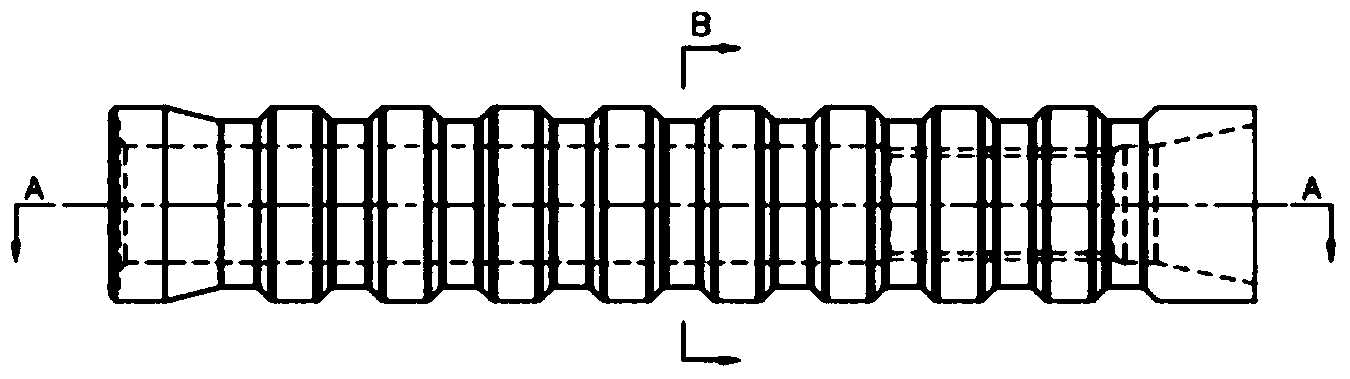

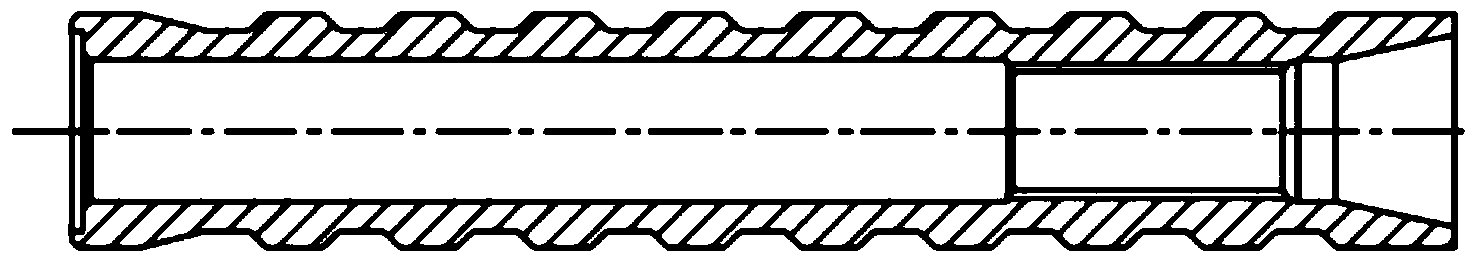

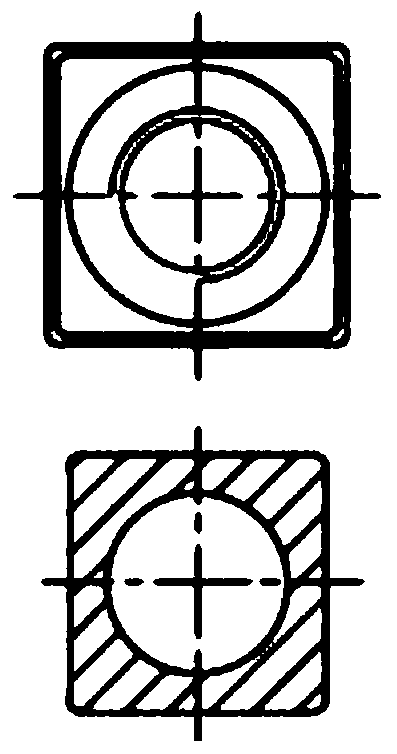

Method for manufacturing root portion of fan blade with square embedded bolt sleeve

ActiveCN104110352AHigh strengthGuaranteed safe operationFinal product manufactureWind energy generationPulp and paper industryMaterial resources

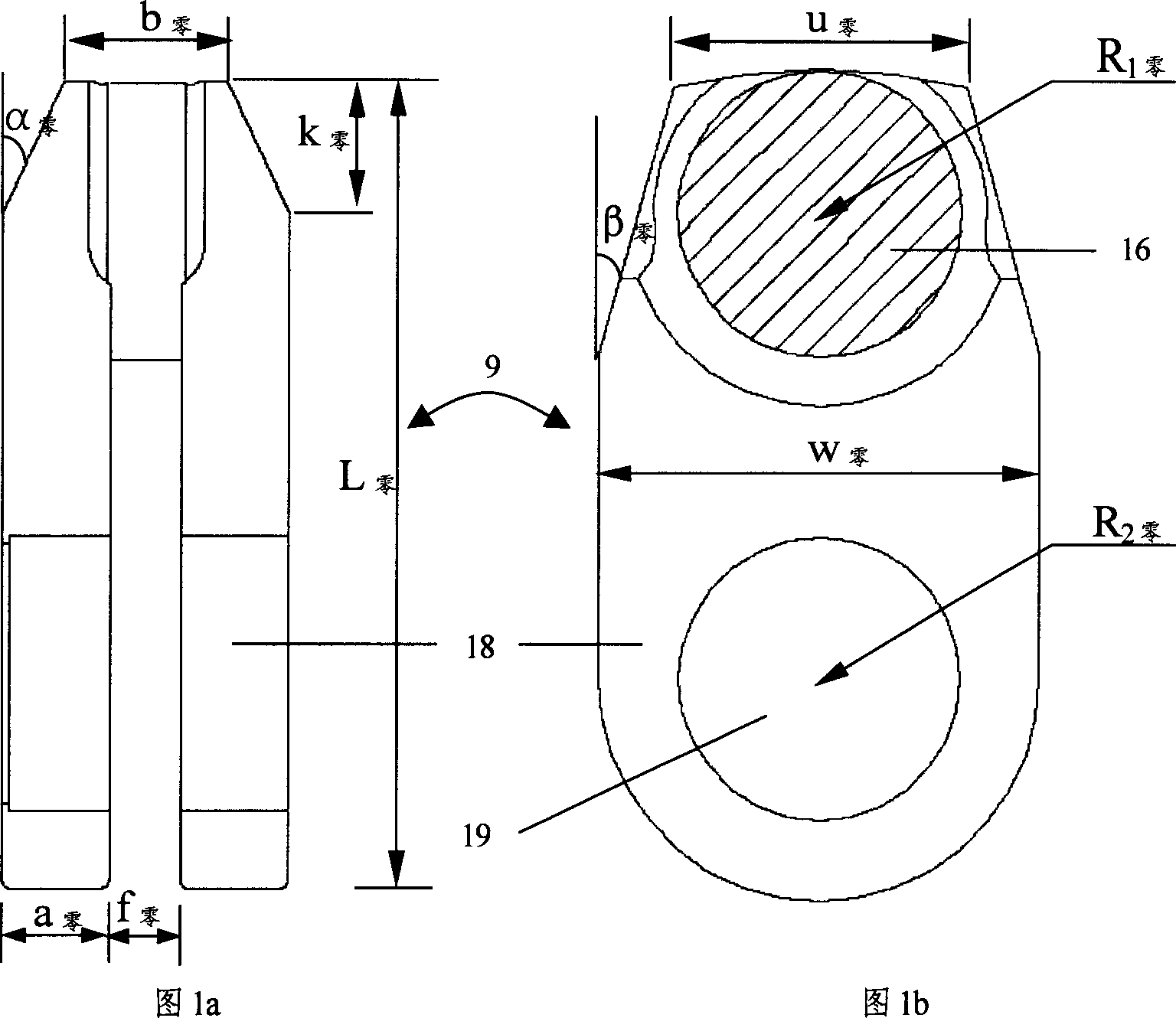

The invention discloses a method for manufacturing the root portion of a fan blade with a square embedded bolt sleeve. The method includes the steps that the square bolt sleeve is manufactured, twistless rovings are wound in a surface groove of the square bolt sleeve, then, optimization technological processing is conducted, and the square bolt sleeve and the root portion of the blade are integrally formed in a vacuum pouring mode so that the root portion of the fan blade can be obtained. According to the method for manufacturing the root portion of the fan blade with the square embedded bolt sleeve, the entire technological design is reasonable, operation is simple and convenient, plenty of manpower and material resources can be saved, and the production efficiency is higher. In particular, the optimized technology is adopted, the square embedded bolt sleeve is obtained, the strength and the firmness degree of the root portion of the blade can be greatly improved, the problem that the periphery of the bolt sleeve is rich in glue can be effectively solved, so that the strength of the fan blade is greatly increased, the dangerous condition that the bolt sleeve is pulled out of a laying layer of the root portion of the blade can be prevented, safe operation of long blade and high load fan blades can be guaranteed, and a good technological effect is achieved.

Owner:中复连众(玉溪)复合材料有限责任公司

Micro-capsule essence with two-layer capsule wall and preparation method and application thereof

ActiveCN101649254AWell mixedHigh mechanical strengthFibre treatmentEssential-oils/perfumesEngineeringTwo layer

The invention discloses a micro-capsule essence with two-layer capsule walls and a preparation method and an application thereof. The essence comprises inner oil essence, a first micro-capsule wall inthe middle and an outer capsule wall located on outermost layer. The micro-capsule essence with two-layer capsule wall of the invention has two-layer capsule wall structure , good mechanical strengthand flexibitity; in addition, when used in cloth the micro-capsule essence has the advantage of strong washing resistance, long fragrance holding time and easy storage. The preparation method of themicro-capsule essence with two-layer capsule walls adopts complex coacervation phase separation method to prepare the essence, the technological design is seasonable, the maneuverability is strong, micro-capsule essence with different fragrances can be designed according to different demands; in the preparation process, the mechanical strength of the micro-capsule essence can be effectively controlled so as to control the duration time and degree of the frangrance of the micro-capsule essence; in addition, the finished product of the micro-capsule essence with two-layer capsule walls preparedin the invention has high qualification rate and the micro-capsule essence with two-layer capsule can realize industrialized production.

Owner:澳华达香精(广州)有限公司

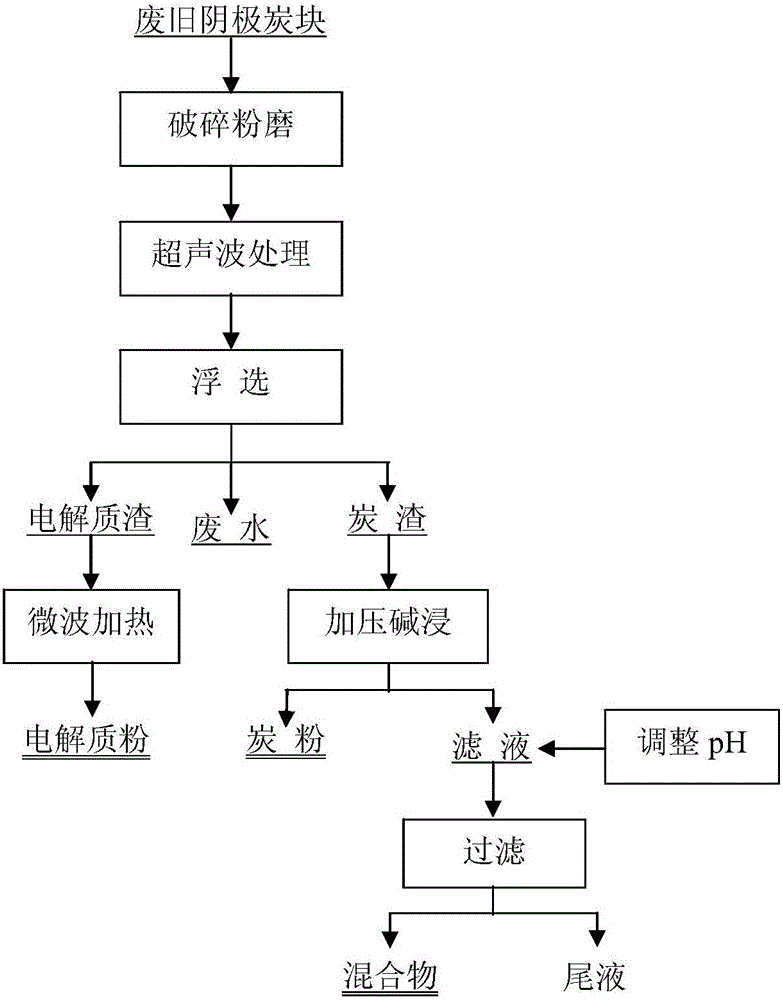

Method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching

ActiveCN106077038AReduce consumptionShorten the alkaline leaching timeSolid waste disposalFiltrationMaterials science

The invention relates to a method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching, and belongs to the technical field of comprehensive utilization of aluminum electrolysis solid waste resources. The method comprises the steps of carrying out ultrasonic pretreatment after crushing and grinding the aluminum electrolysis waste cathode carbon blocks, carrying out floatation on pretreated powder to obtain electrolyte residues and carbon residues, and reusing the wastewater of floatation; removing carbon impurities after the electrolyte residues are subjected to microwave heating to obtain electrolyte powder with high purity, and carrying out pressure alkali leaching on the carbon residues to remove solvend so as to obtain carbon powder with high purity; adjusting the pH of alkali leaching filter liquor to generate sediment, carrying out filtration to obtain electrolyte, and reusing the filter liquor. According to the method, through collaborative assistance action among the ultrasonic pretreatment technology, the microwave heating technology and the pressure alkali leaching technology, the high-efficiency comprehensive recycling of aluminum electrolysis waste cathodes is achieved. The method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching is reasonable in technological design, high in recovery rate of valuable matter, purity of obtained products and processing speed, free of secondary pollutants and applicable to industrial large-scale application.

Owner:CENT SOUTH UNIV

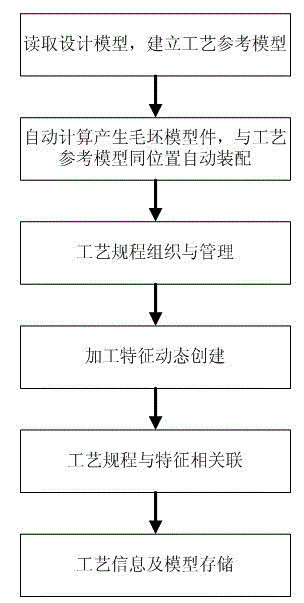

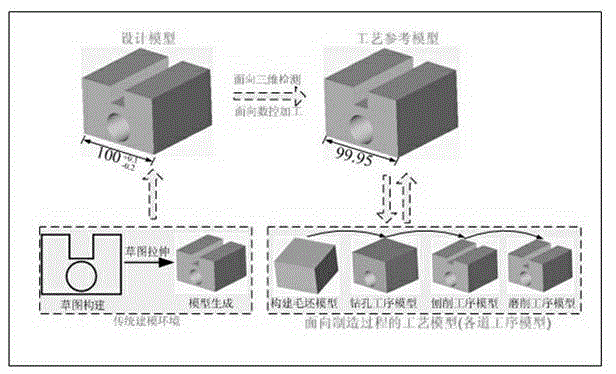

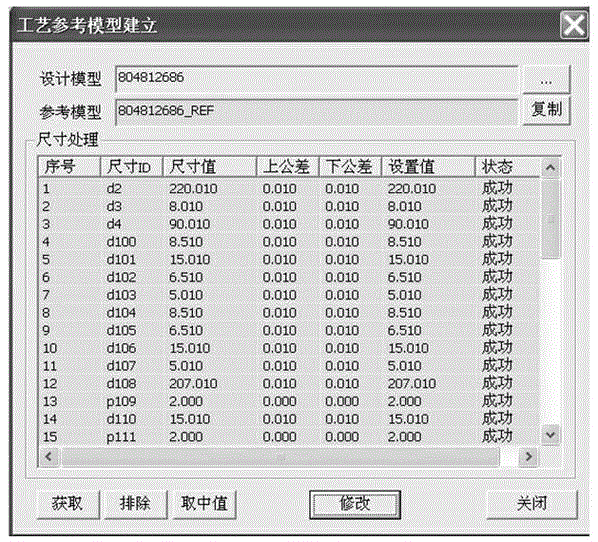

Method for building dynamic three-dimensional process model

ActiveCN102722614AFastImprove interactivitySpecial data processing applications3D modellingReference model3D modeling

The invention belongs to the field of the technological process of a three-dimensional design model, and relates to a method for building a dynamic three-dimensional process model, which is characterized in that the method for building the dynamic three-dimensional process model is carried out according to the following six steps of: reading the design model, and building a technological reference model; automatically calculating the produced blank model, and automatically assembling the produced blank model with the technological reference model at the same position; organizing and managing the technical schedule; dynamically creating processing the characteristic; correlating the technical schedule with the characteristics; and storing the processing information and the model. The method for building the dynamic three-dimensional process model solves the problem that the two-dimensional technological design and the three-dimensional technological design are disjoined at present, and a two-dimensional model is taken to directly guide production and manufacturing, the traditional mode of 'three-dimensional design plus two dimensional' is broken through, and accordingly, the technological design efficiency is obviously improved; and moreover, the manufacturing staff can directly obtain the machining features and the corresponding technological information on the basis of the three-dimensional technological design, so the preparation periods of production and manufacture are greatly shortened, and the production efficiency is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

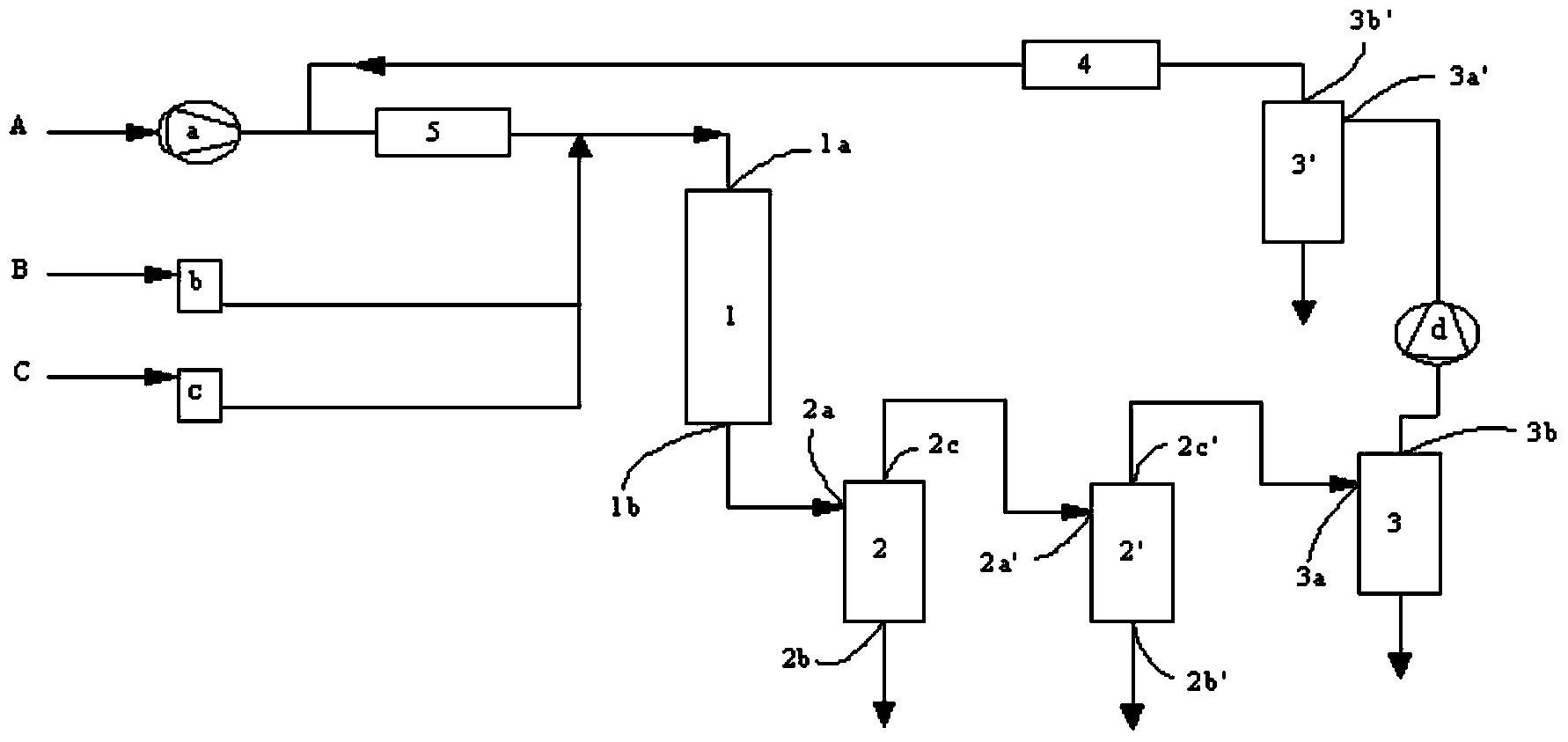

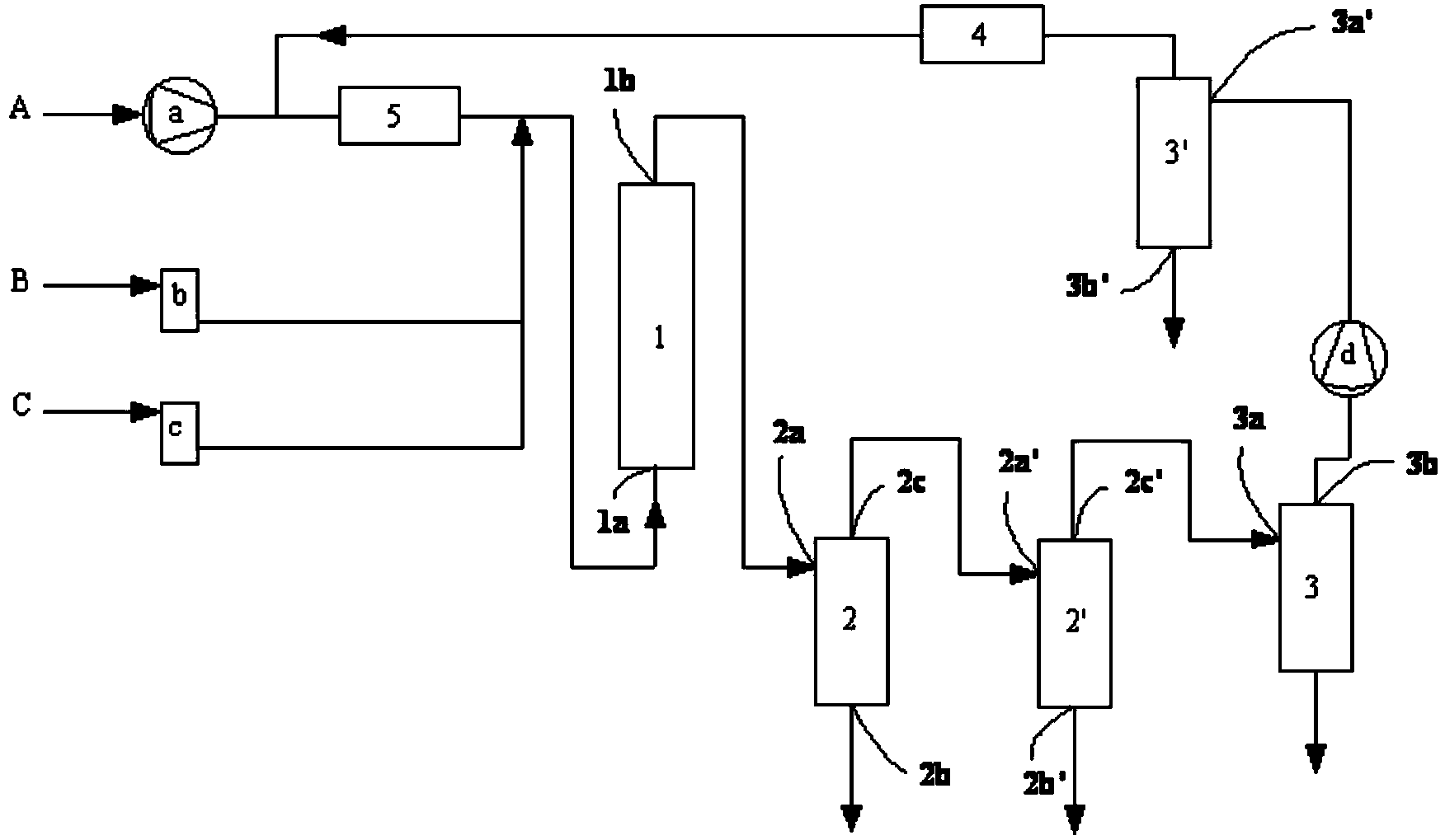

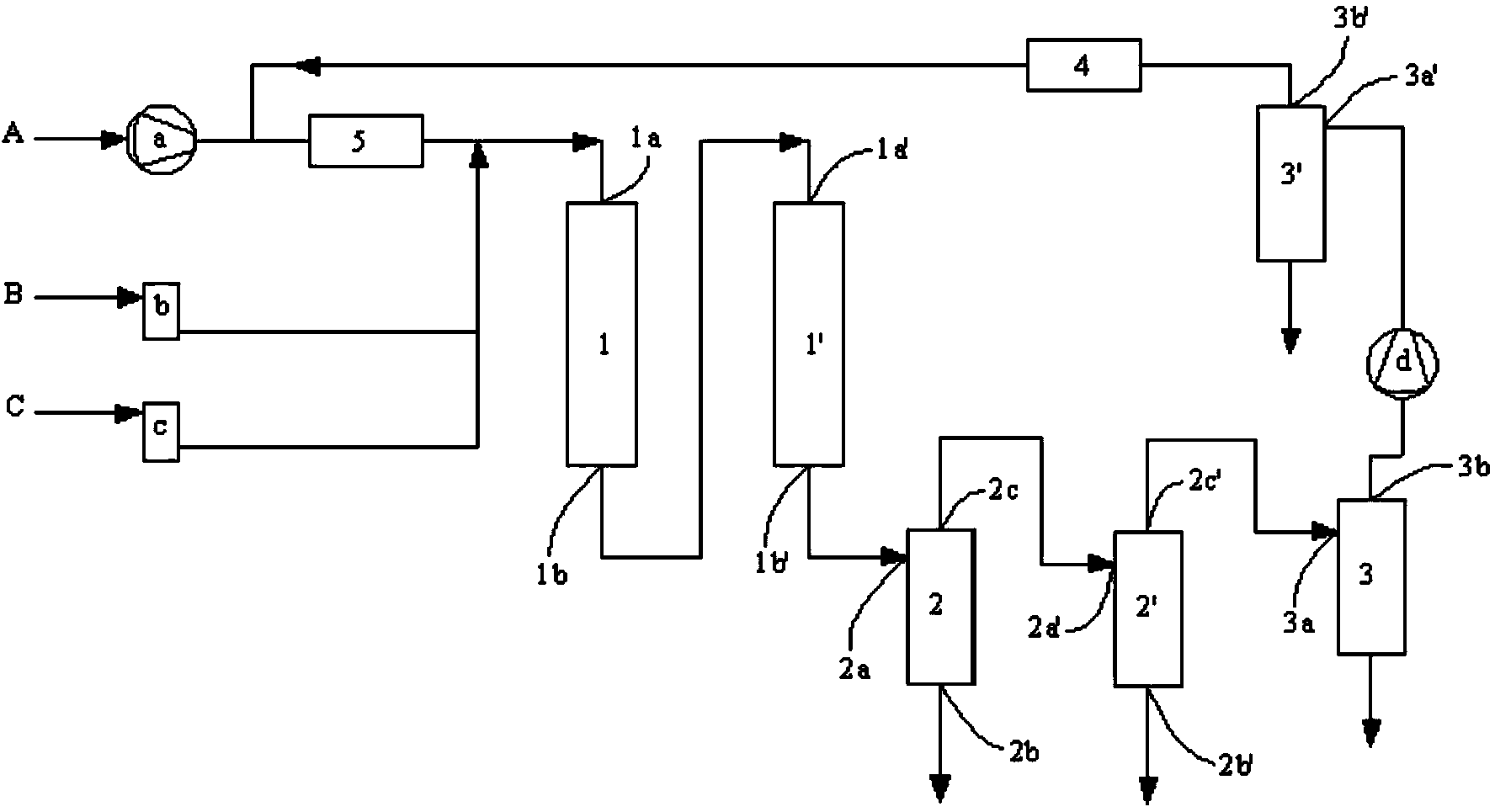

Device and method for continuously synthesizing amine-terminated polyether by utilizing fixed bed

ActiveCN103524725AGood effectContinuous and stable productionChemical recyclingVapor–liquid separatorAlcohol

The invention provides a device and a method for continuously synthesizing amine-terminated polyether by utilizing a fixed bed. The device for continuously synthesizing amine-terminated polyether by utilizing the fixed bed comprises a fixed bed reactor, a preheater, two gas-liquid separators, a compressor, a circulating compressor, a raw material pump, a liquid ammonia pump and two buffer tanks, hydrogen is preheated by virtue of the preheater and is fed into the fixed bed reactor with raw material and liquid ammonia; the amine-terminated polyether is synthesized in a hydrogen atmosphere of the fixed bed; the fixed bed reactor is at the temperature of 150-300 DEG C and the pressure of 1-20MPa, ammonia alcohol ratio is 1-15, and unreacted hydrogen and ammonia are recycled. The device and method for continuously synthesizing amine-terminated polyether by utilizing the fixed bed overcome the defects of tedious operation, unstable product quality, low synthesis efficiency and the like of the existing technology as a batch-type operation is adopted, a continuous reaction technological design is adopted, a technology is simple, performance is stable, yield is high, excessive ammonia and hydrogen are recycled, pollution to the environment is reduced, production cost is reduced, and energy is saved; conversion rate of hydroxyl-terminated polyether or derivative thereof and selectivity of the amine-terminated polyether product are obviously improved, so that production cost of the amine-terminated polyether product is obviously reduced.

Owner:康达新材料(集团)股份有限公司

Preparation method of thermal-sensitive ceramic sputtered film electrode

InactiveCN102503580AImprove bindingExcellent high temperature welding performancePumping vacuumElectronic materials

The invention belongs to the technical field of electronic materials, and particularly relates to a method for sputtering a film electrode on thermal-sensitive ceramic at room temperature, which is characterized by mainly comprising the following steps: cleaning the ceramic, racking a mask, vacuumizing, charging a working gas, and sputtering the electrode film. Compared with the prior art, the invention has the advantages of reasonable technological design, high sputtering film-forming speed, low production cost and pollution-free production process; and the prepared film has the advantages of firm combination, favorable high-temperature welding performance and the like. The invention provides an ideal preparation method of a thermal-sensitive ceramic electrode.

Owner:ZHEJIANG UNIV

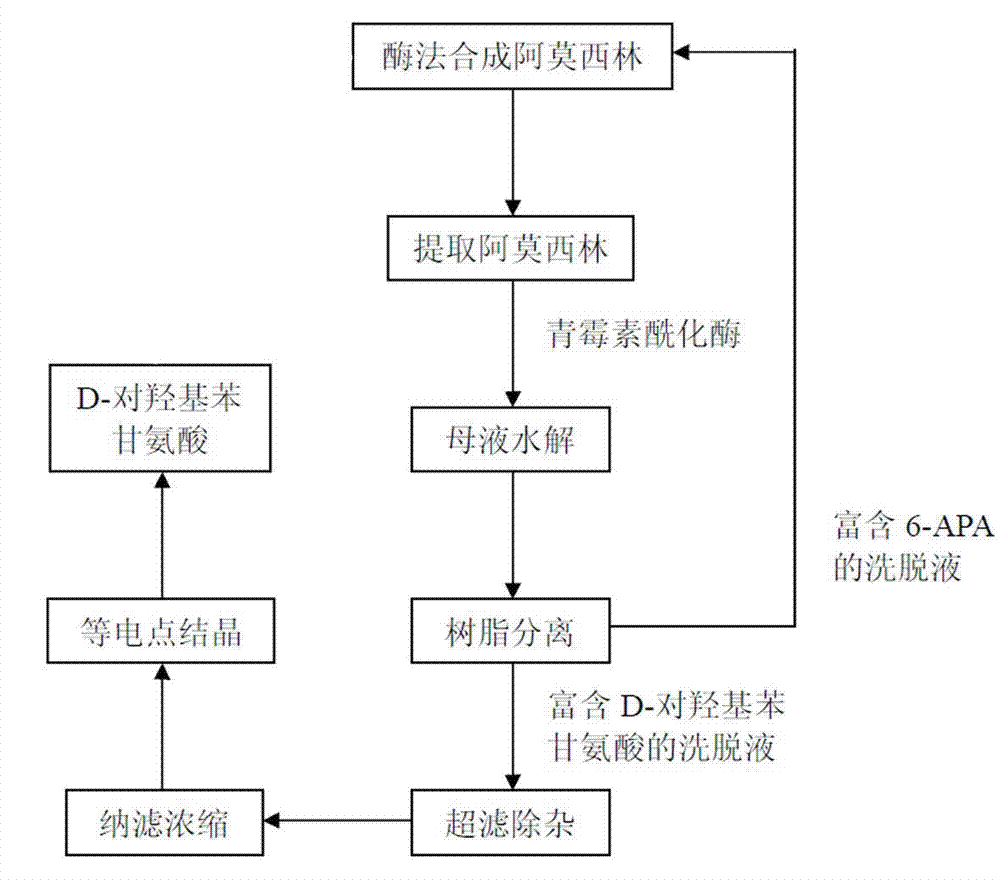

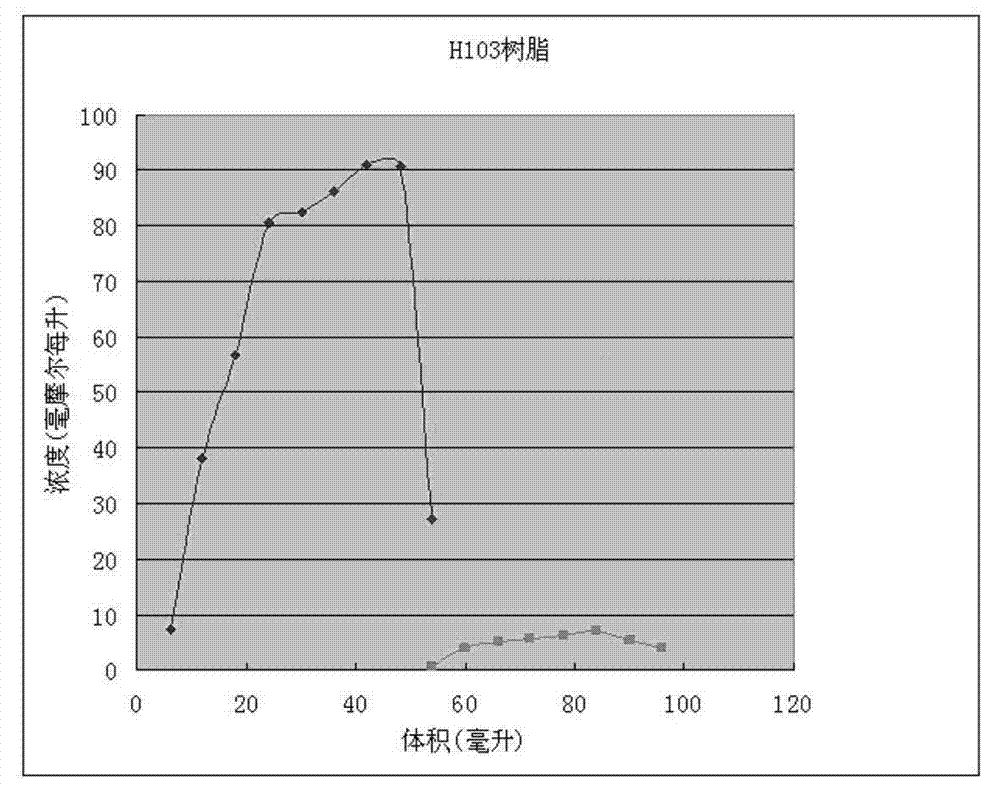

Method for recycling active ingredients in amoxicillin mother liquor synthesized by enzymatic method

ActiveCN102816803AAvoid adverse reactionsRelieve pressureOrganic compound preparationChemical industryBULK ACTIVE INGREDIENTP-hydroxyphenylglycine

The invention discloses a method for recycling active ingredients in the amoxicillin mother liquor synthesized by an enzymatic method. The method includes synthesizing the amoxicillin mother liquor by the enzymatic method; separating the amoxicillin mother liquor through a macro-porous resin column, eluting the separated amoxicillin mother liquor by deionized water, and collecting an eluant rich in D-4-Hydroxyphenylglycine and an eluant rich in 6-amino penicillanic acid (APA) respectively; filtering the eluant rich in D-4-Hydroxyphenylglycine with Daltonian ultrafiltration membranes with a cutoff molecular weight of 150 to 200; performing nanofiltration concentration on the Daltonian ultrafiltration membranes for the filtered liquor with the cutoff molecular weight of 150 to 200, and standing, crystallizing and filtering the concentrated liquor to obtain solids, and drying the solids to obtain the D-4-Hydroxyphenylglycine. According to the method, the technological design is reasonable, the operation is convenient, the recycling effect is good, and energy is saved and the environment is protected.

Owner:NORTH CHINA PHARM GRP SEMISYNTECH CO LTD

Method for quickly cold die-casting aluminium alloy shell

The invention discloses a method for quickly cold die-casting an aluminium alloy shell, which comprises material selecting, material smelting, material refining, degassing with high purity argon after the refining, automatic spraying within a die and ultra-low speed casting of liquid material. Through a modern simulation mode (mold flow analysis), the development cost is greatly lowered, the product percent of pass is high, the porosity is better than a common technological design, the product filling process is stable, the quality is improved, the service life of the die is also improved to a great extent, moreover, the automation is adopted, the manpower and time are greatly saved, and the precision and yield of the product are improved.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

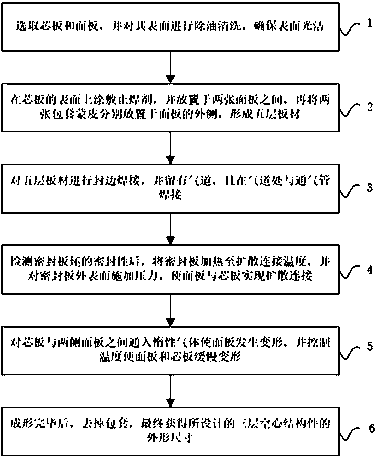

Method for preparing three-layer hollow component through superplastic forming/diffusion connection

ActiveCN108326395AExpand the scope of the designReduce generationArc welding apparatusEngineeringChange control

The invention provides a method for preparing a three-layer hollow component through superplastic forming / diffusion connection. In the process that the three-layer hollow component is prepared throughthe superplastic forming / diffusion connection technology, forming is conducted by combining a hard sheath technological design method and a temperature change process control method. Aiming at the three-layer hollow component, combining of the hard sheath technological design method and the temperature change process control method is put forward, and forming of surface grooves in the forming process of the three-layer hollow component is reduced. According to main improvement points, a hard sheath forming method is adopted, a hard sheath keeps in contact with a face plate all the time in theforming process, under the high-temperature condition, enough surface friction force is provided, the deformation speed of the face plate is coordinated, and thus tensile stress to the face plate inthe inner reinforcing rib forming process is not enough to enable the face plate to deform. Additionally, in the forming process, through temperature change control, control over the forming speed isachieved, forming of the surface grooves of a formed part can be effectively reduced, the design range of the three-layer hollow component is extended, the milling work procedure is reduced, and the material utilization rate is increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

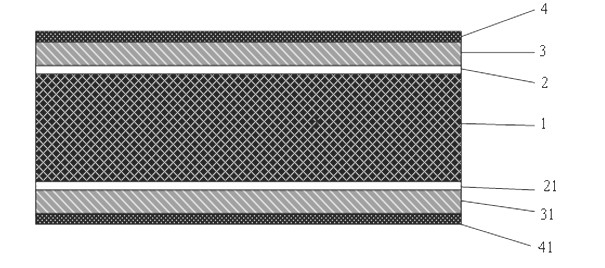

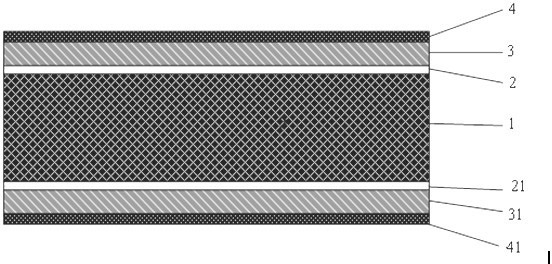

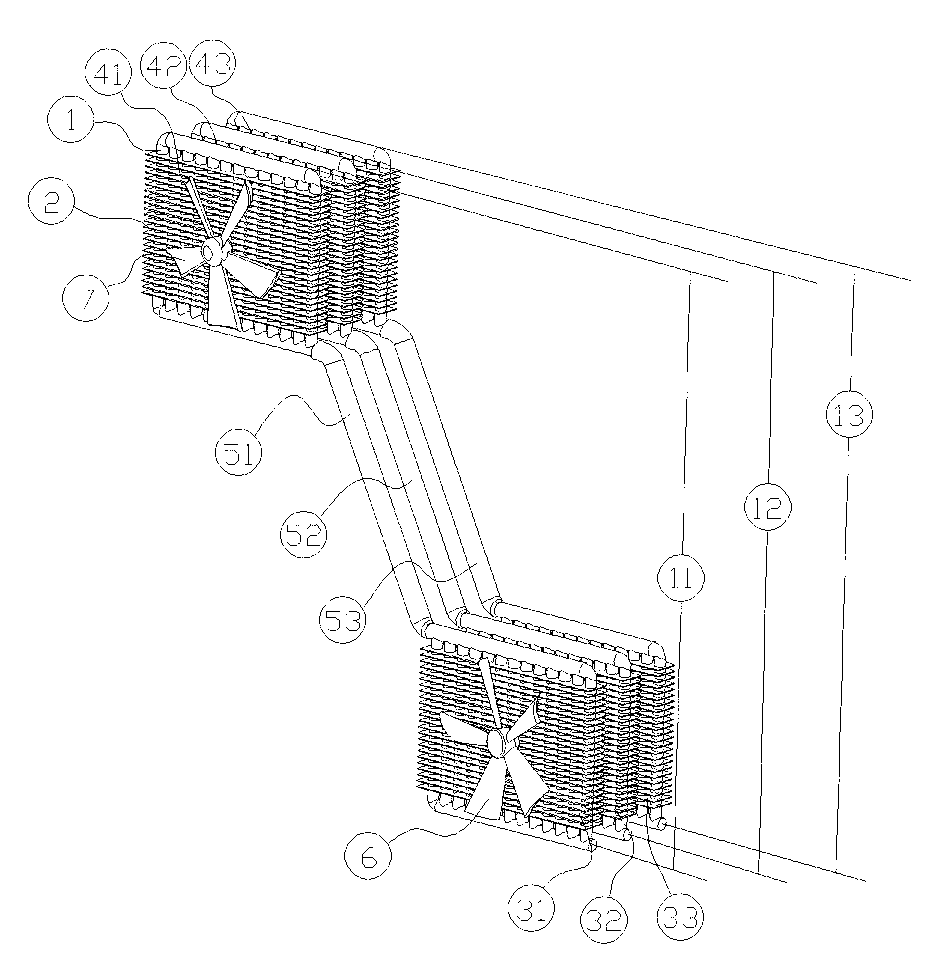

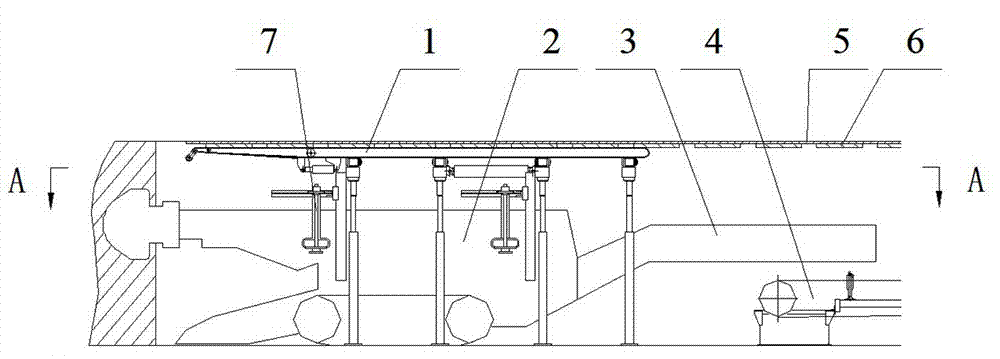

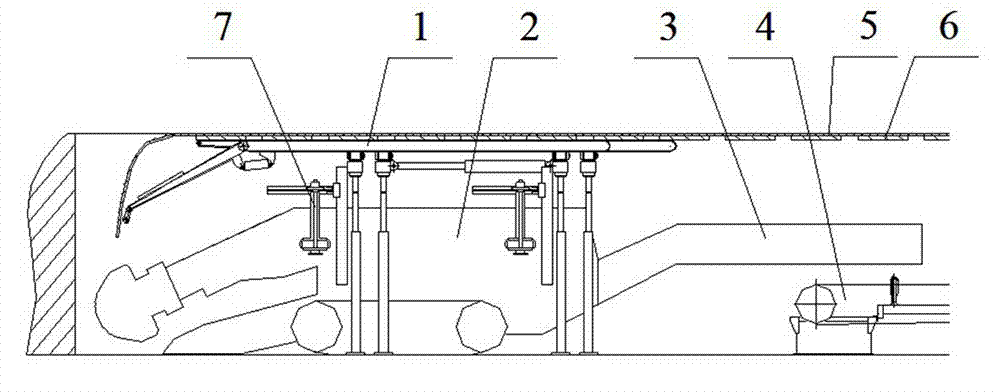

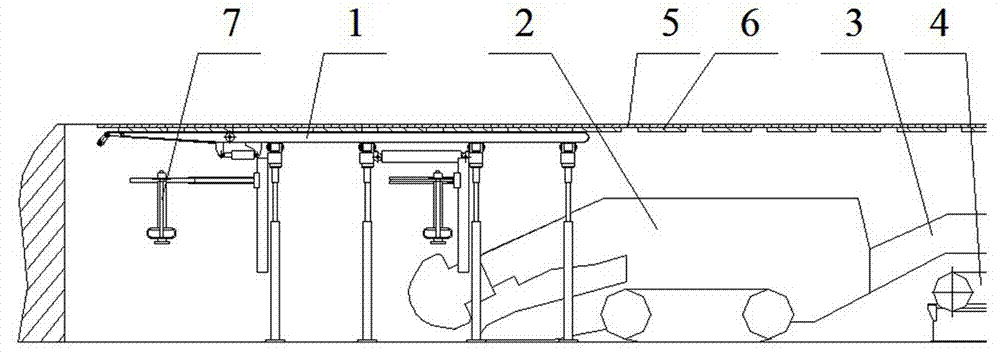

Anti-icing control system of wind turbine blade and manufacturing method of wind turbine blade with anti-icing performance

ActiveCN104018997AReasonable structural designEasy to installFinal product manufactureWind energy generationElectricityGlass fiber

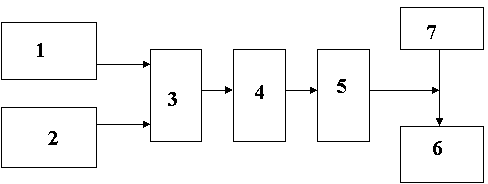

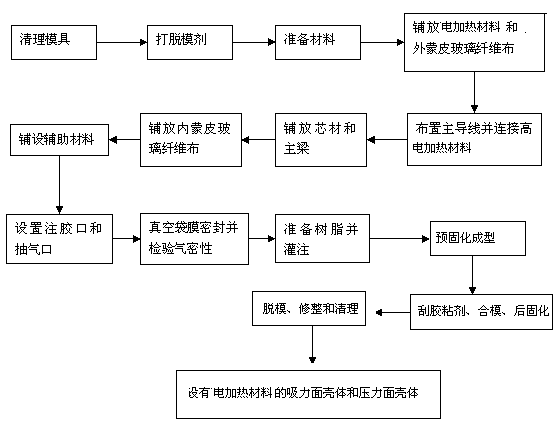

The invention discloses an anti-icing control system of a wind turbine blade and a manufacturing method of the wind turbine blade with the anti-icing performance. The anti-icing control system mainly comprises a monitoring unit, a control unit and a heating unit. The anti-icing control system of the wind turbine blade is reasonable in structural design, convenient to install and high in automation degree and intelligentization degree, can effectively heat the wind turbine blade, can avoid the situation that negative effects are generated on resin and protective coatings of the blade due to the fact that the temperature of the surface of the blade is too high, and can effectively prevent the blade from icing. The manufacturing method is reasonable in technological design, high in maneuverability and stable in technology. A suction surface shell of the wind turbine blade and a pressure surface shell of the wind turbine blade are formed by wrapping middle cores by inner skin and outer skin. Electric heating materials are located on the surface of the blade or between glass fiber cloth of the outer skin of the blade or the inner side of the glass fiber cloth of the outer skin of the blade, the electric heating materials and a surface temperature sensor are integrally formed, and the wind turbine blade with an electric heating system and with the anti-icing performance can be obtained through manufacturing.

Owner:中复连众(玉溪)复合材料有限责任公司

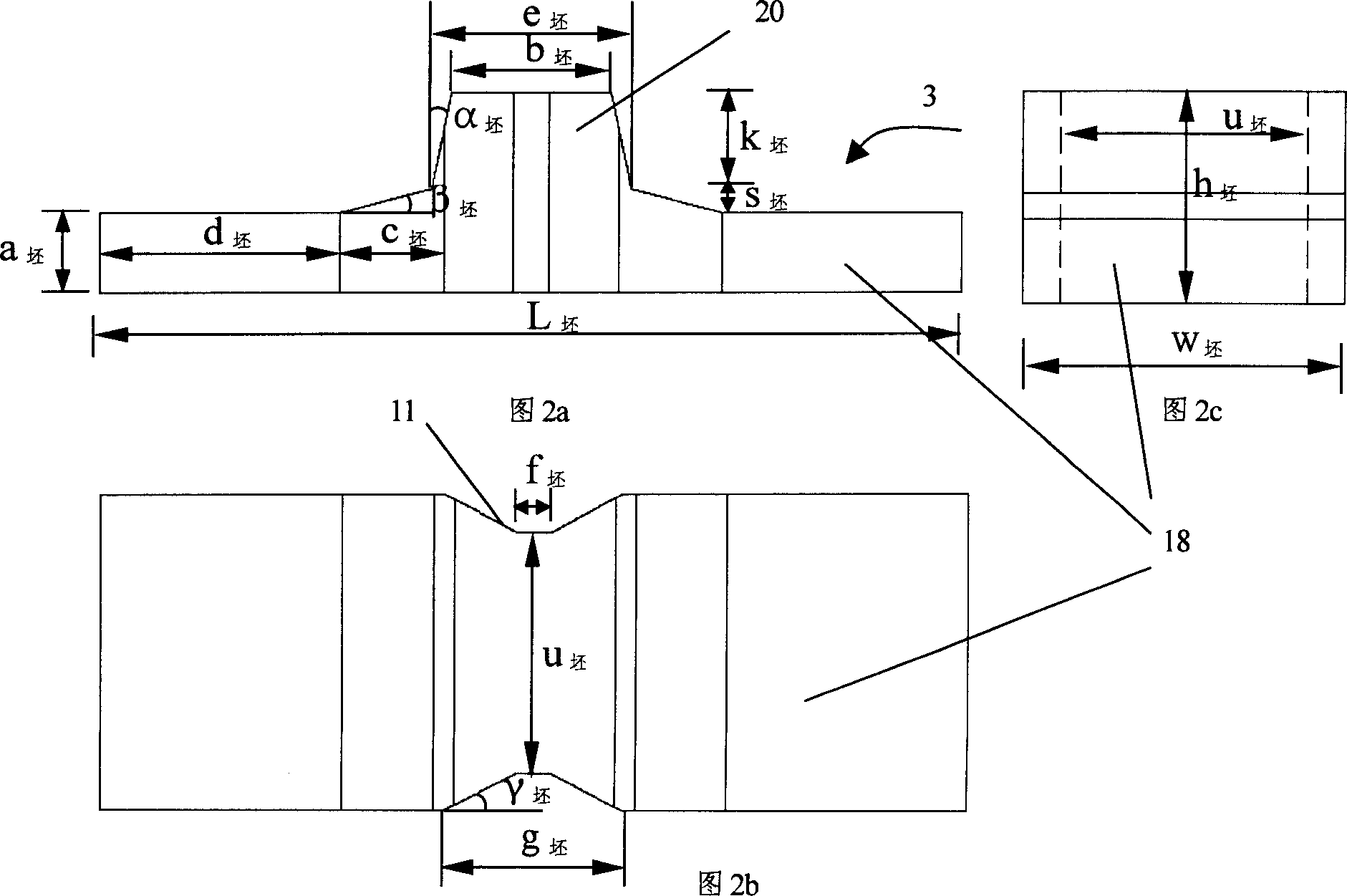

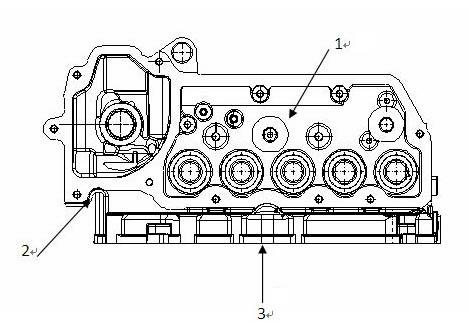

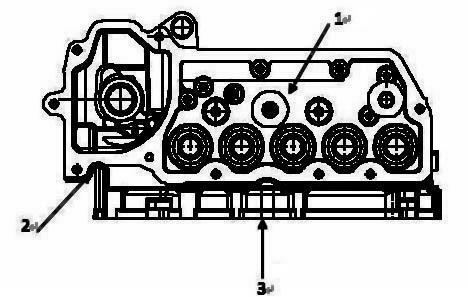

Crankshaft crank throw curved forging mould for large ship and designing method of preformed blank

ActiveCN1949232ASmall machining allowanceReduce difficultyForging/hammering/pressing machinesEngine componentsEngineeringRoughcast

The invention relates to marine type crankshaft bell crank bending swaging dies and preliminary shaping blank design method. It uses computer modeling technique to design preliminary shaping blank, V shape die, bend upper and lower dies, lower cavity die, plug board, and various die matching using methods. The method can save raw materials, shorten production cycle, and reduce admittance. The designed die and preliminary shaping blank can generate total models crankshaft bell crank parts which have good forming quality, symmetrical appearance, uniform flow line and admittance for MANB&, W and WNSD diesel engine patent company.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

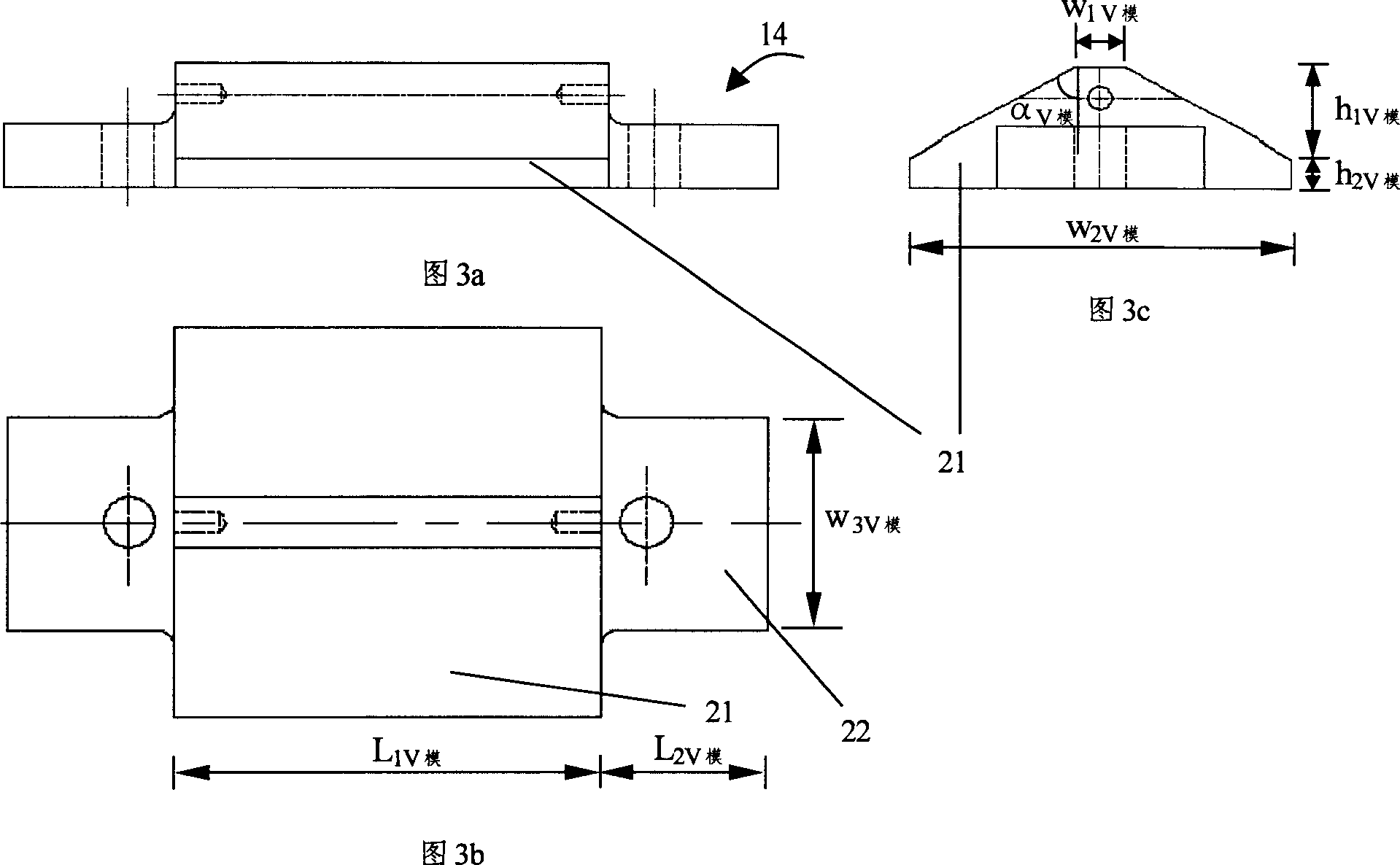

Intelligent auxiliary designing system for sheet metal components

InactiveCN103886119AHigh precisionRealize intelligenceSpecial data processing applicationsControl equipmentMetal

The invention discloses an intelligent auxiliary designing system for sheet metal components. The intelligent auxiliary designing system comprises a model database, a model information reading and writing module, a sheet metal technology generating module and a technologic outcome output module, wherein the model database comprises a technologic database for storing technologic process parameters and a formwork database for storing part parameters, the model information writing and reading module is used for extracting basic model information from the model database and writing formwork files generated by the technology generating module in the model database, the technology generating module generates a technologic formwork file capable of facing normal equipment and numerically controlled equipment according to a pre-edited formwork, and the technologic outcome output module is used for outputting technologic card files to the numerically controlled equipment or an appointed storer and storing a complete technological procedure for the sheet metal into the model database. By the aid of the intelligent auxiliary designing system for the sheet metal components, sheet metal processing precision can be improved, and intelligentization, standardization and practicability of the technological design for the sheet metal are realized.

Owner:SHANGHAI QIZHONG MECHANICAL & ELECTRICAL EQUIP

Production process of glazed devitrified glass tile

InactiveCN1417166AImprove purification effectUse less clayClaywaresHigh wear resistanceTechnological design

The production process of devitrified glass glazed tile includes the preparation of devitrified glass glaze and the production of tile body. The present invention is characterized by the devitrified glass glaze comprising SiO2, CaO, Al2O3, MgO, Na2O, TiO2, Fe2O3 and BaO; and the tile body raw material includes waste glass, sandstone, clay and binder. Compared with prior art, the present inventionhas reasonable technological design, available raw material, waste utilization, low cost, high wear resistance, fine texture, high pollution resistance, natural beauty similar to natural granite and excellent characteristic.

Owner:UNIV OF JINAN

Environment protection baking-free sludge brick and production method thereof

The invention relates to an environment-friendly baking-free sludge brick and a production method thereof. The main compositions of the sludge brick are sludge, sand and cement, and auxiliary chemical raw materials are saturated solvent of potassic salts such as potassium permanganate taken as an oxidant. The invention adopts production processes of waterlogging, oxidation, curing, condensation, moulding and demoulding, fully and effectively utilizes various types of sludge, purifies the environment, does not need to chop hills to unload soil, and protects natural resources; the baking-free technology not only is energy-saving but also reduces the production cost, and has reasonable technological design, simple and convenient operation and no secondary pollution; the brick can be delivered after naturally dried in the air for 15 days, and the quality of the brick completely accords with the national standards; the shaping randomness is strong, and tiles, street bricks and so on can be manufactured only by adoption of different dies; and the environment-friendly baking-free sludge brick has considerable social benefit and economic benefit and obvious promotion value and application value.

Owner:汉寿县永兴砖厂

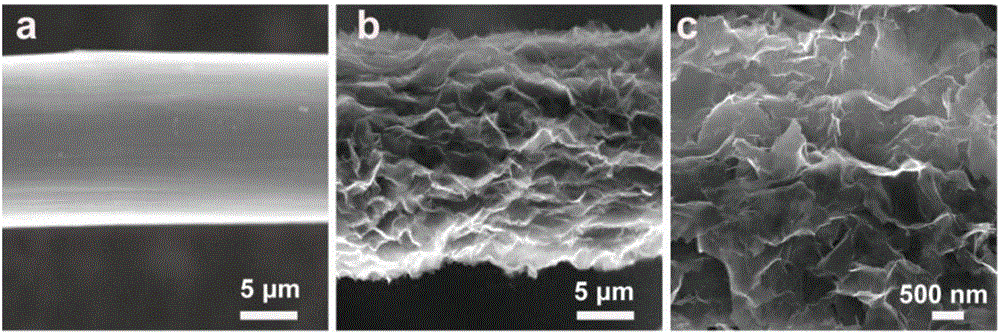

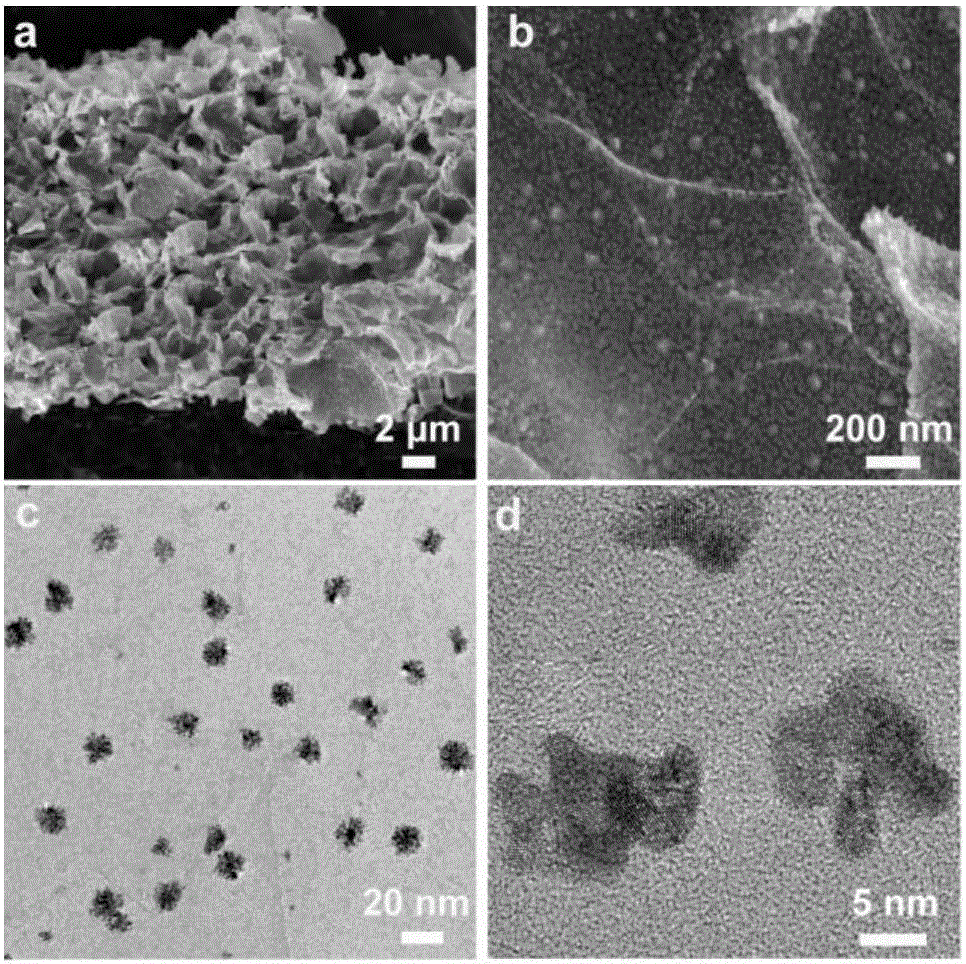

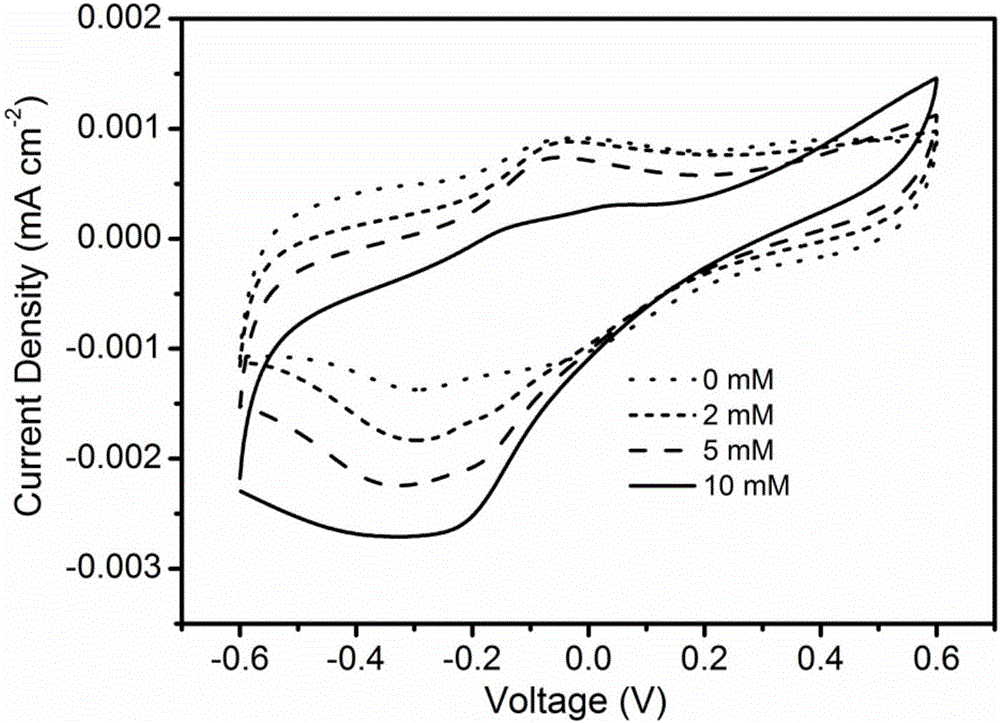

Method for electroplating graphene/carbon fiber by utilizing ionic liquid, product and application

ActiveCN106483172ALarge specific surface areaHigh sensitivityMaterial electrochemical variablesFiberActivated carbon

The invention discloses a method for electroplating graphene / carbon fiber by utilizing ionic liquid, a product and application. The method comprises the following steps: (1) activating carbon fiber and preparing a graphene oxide-ionic liquid dispersion solution; (2) using the activated carbon fiber obtained in step (1) as a working electrode and putting the activated carbon fiber in the graphene oxide-ionic liquid dispersion solution obtained in step (1), and then electroplating, thus obtaining graphene modified carbon fiber, i.e., the graphene / carbon fiber. According to the method disclosed by the invention, through improvement on the whole technological design of a key preparation technology, reaction conditions of each step and the like, the prepared and obtained graphene / carbon fiber has good specific surface area; the graphene / carbon fiber can be used as a self-supporting flexible micro electrode for detecting hydrogen peroxide (such as the concentration of the hydrogen peroxide), and the sensitivity is high.

Owner:HUAZHONG UNIV OF SCI & TECH

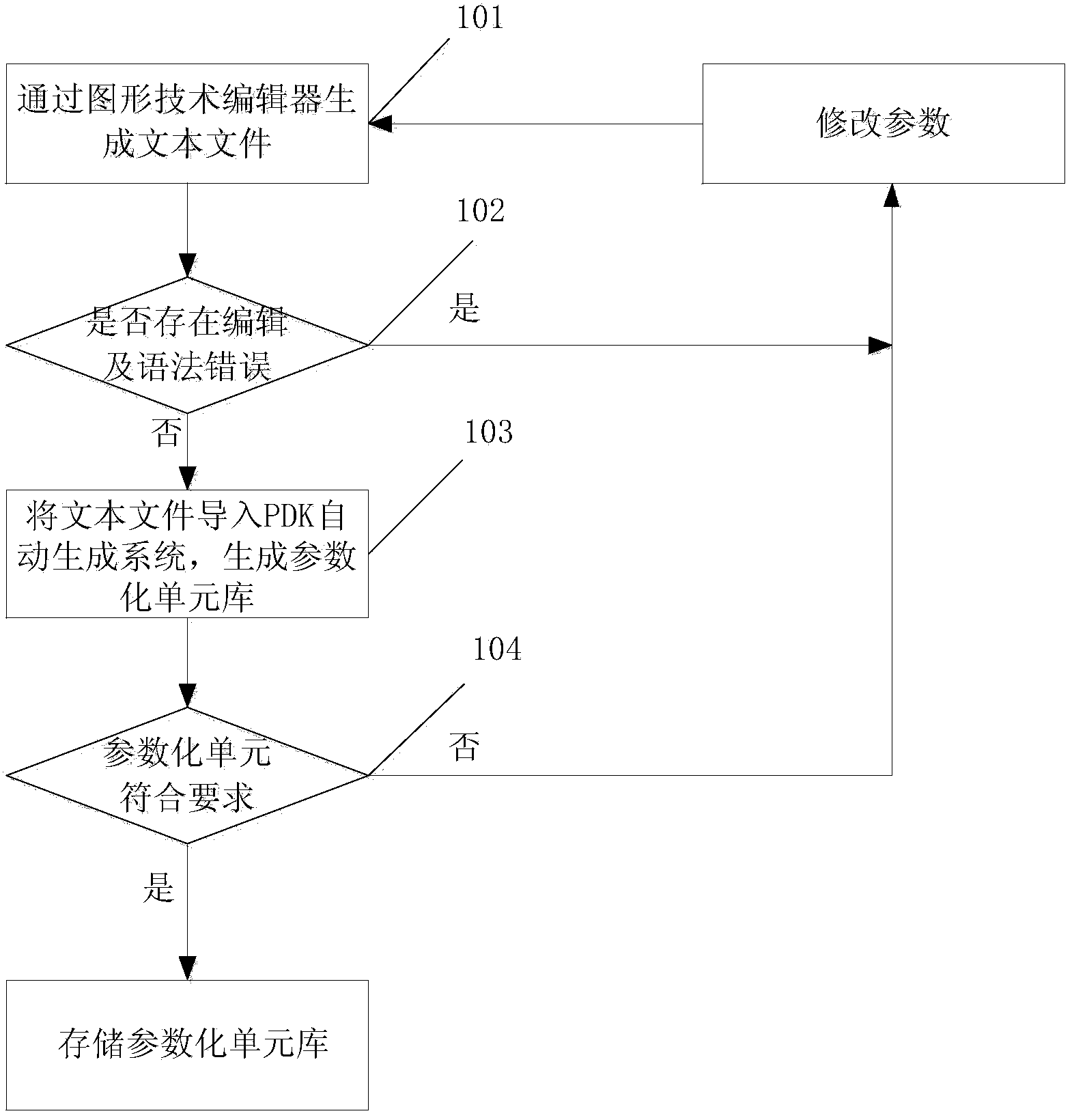

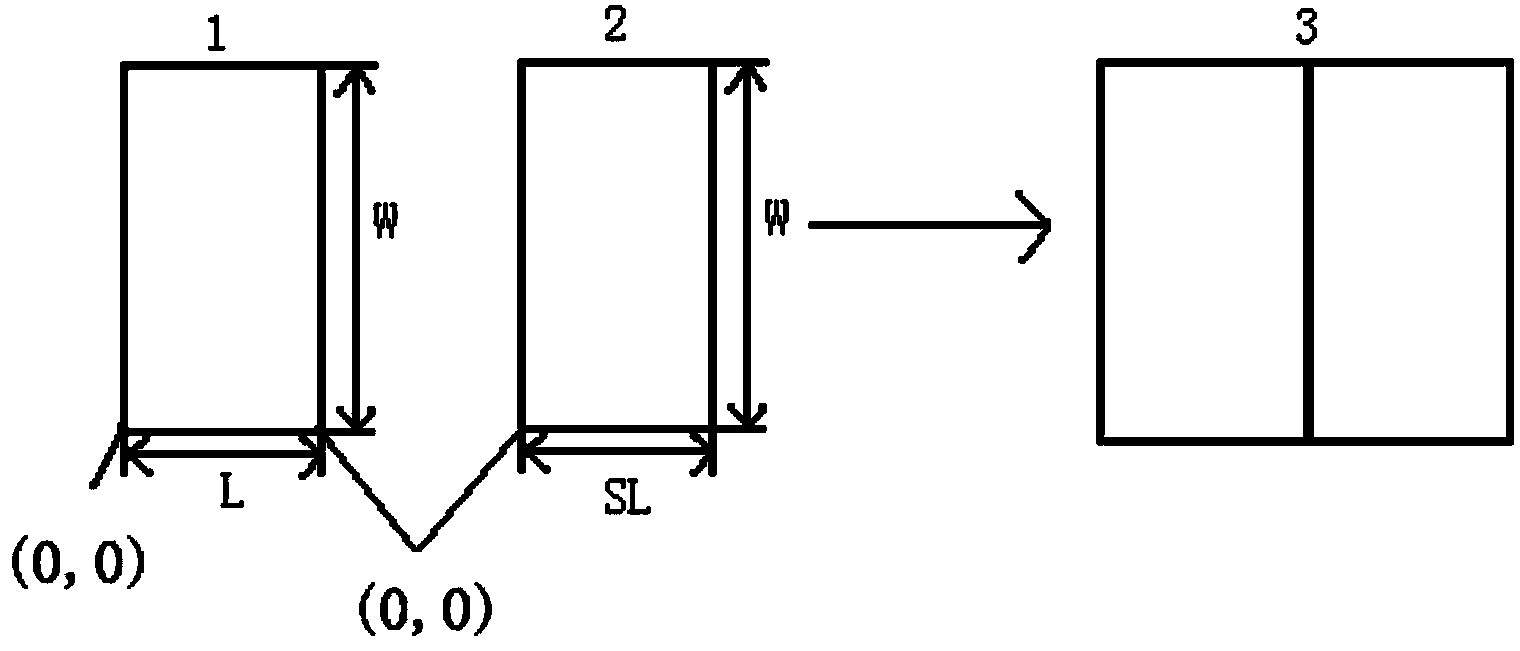

Method and system for implementing parameterization units on basis of technical graph editor

InactiveCN103838930AEasy maintenanceReduce complexitySpecial data processing applicationsGraphicsComputer architecture

The invention discloses a method and a system for implementing parameterization units on the basis of a technical graph editor, and belongs to the technical field of design on integrated circuits. The method comprises the following steps of generating a text file by using the technical graph editor; guiding the text file in an automatic technological design toolkit generating system and generating a parameterization unit library; guiding the parameterization unit library in a layout design platform; and storing the parameterization units meeting requirements on the layout design. The system comprises the technical graph editor, a generating module and the layout design platform. By editing various required graph layers of the parameterization units in the technical graph editor and setting constraint conditions of the graph layers and the positional relation among the graph layers, script files of the parameterization units are not required to be written or described, the complexity of the design is reduced, and the design period is shortened.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for placing chiller in casting process

InactiveCN102744387ALow machining accuracy requirementsReduce processing costsAbnormal shapedProcessing cost

The invention discloses a method for placing a chiller in a casting process. The chiller is manufactured in accordance with a technological design, which is of a frustum-shaped structure; a mould is manufactured in accordance with a casting technology and the position of the mould, corresponding to the position embedded with the chiller, is provided with a high-strength magnet; a small end of the chiller is absorbed on the corresponding high-strength magnet on the mould, and molding sand is filled; and the mould is took out in accordance with a conventional method, and the chiller is left in a sandbox. The cross section of the chiller is round or polygonal or irregularly shaped. By using the method for placing a chiller in the casting process, the processing accuracy requirement for the chiller is reduced greatly, the processing cost of the chiller is lowered, and the effects that the position of a cast, where the chiller is placed, has no burrs, and the chiller is easy to clean after being cast are reached. In the method provided by the invention, the chiller can be placed at any position and is accurately positioned, so that the efficiency of placing the chiller is improved, and the production efficiency of a moulding line is increased largely.

Owner:FEILONG AUTO COMPONENTS CO LTD

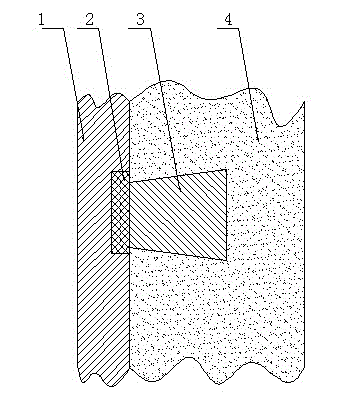

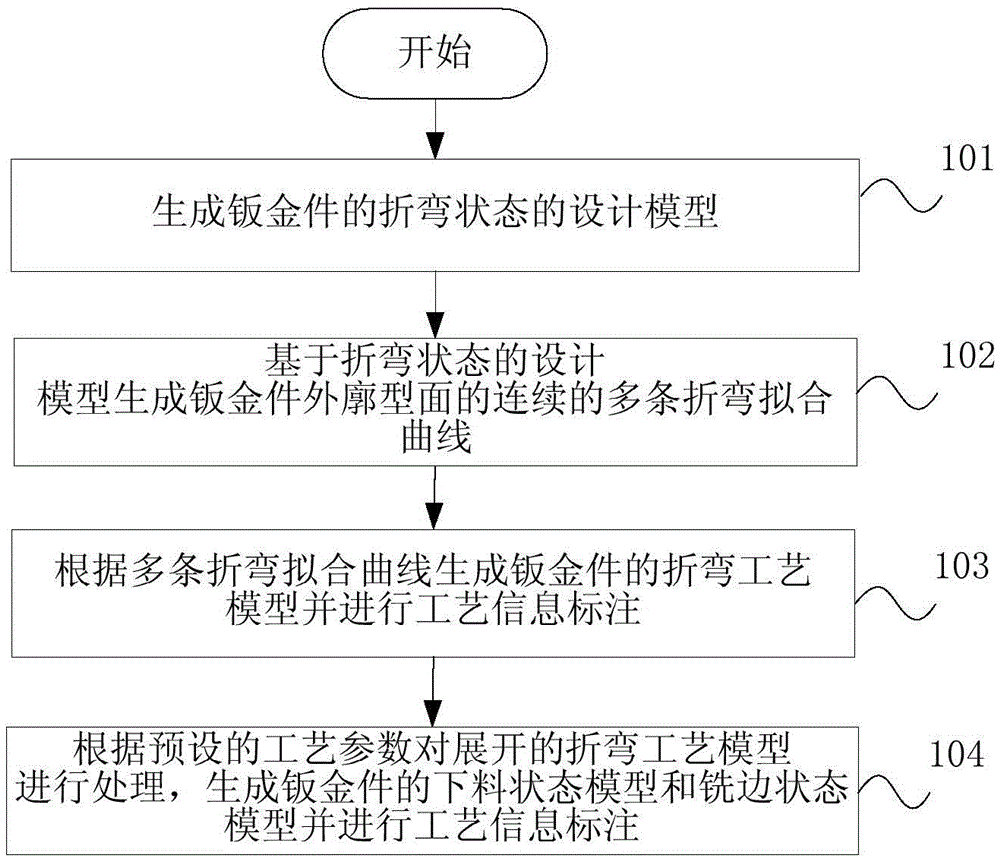

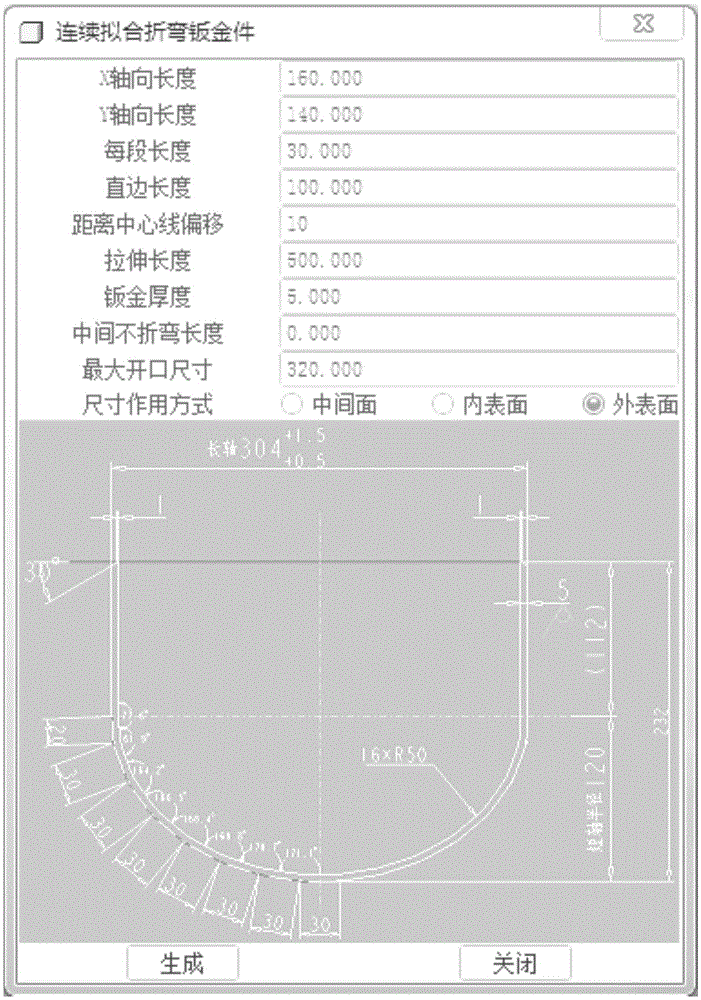

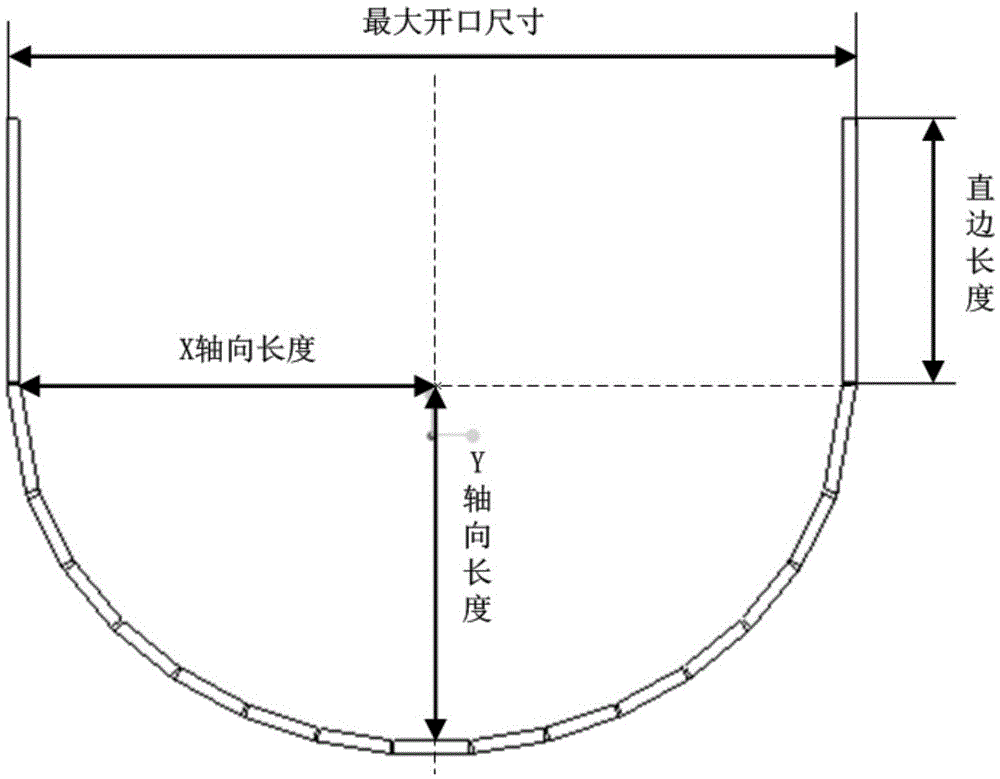

Process model generation method and apparatus for sheet metal process

ActiveCN105550388ARealize automatic fitting lineRealize parameterizationComputer aided designSpecial data processing applicationsState modelSoftware engineering

The invention discloses a process model generation method and apparatus for a sheet metal process. The method comprises the steps of generating a design model of a bending state of a sheet metal part; based on the design model of the bending state, generating multiple continuous bending fit lines of an external profile of the sheet metal part; according to the bending fit lines, generating a bending process model of the sheet metal part and performing process information labeling; and according to preset process parameters, processing an expanded bending process model to generate process state models of the sheet metal part, and performing process information labeling, wherein the process state models include a discharge state model and an edge milling state model. According to the process model generation method and apparatus, automatic fit lineation of the sheet metal part can be realized; the process state models including the bending process model, the discharge state model, the edge milling state model and the like can be automatically generated and the process information labeling is performed; the parameterization, normalization and standardization of a technological design process of the sheet metal part are realized; and the technological design efficiency is improved, so that the workload of manual lineation is reduced and the preparation cycle of a sheet metal manufacturing process is shortened.

Owner:XCMG CONSTR MACHINERY

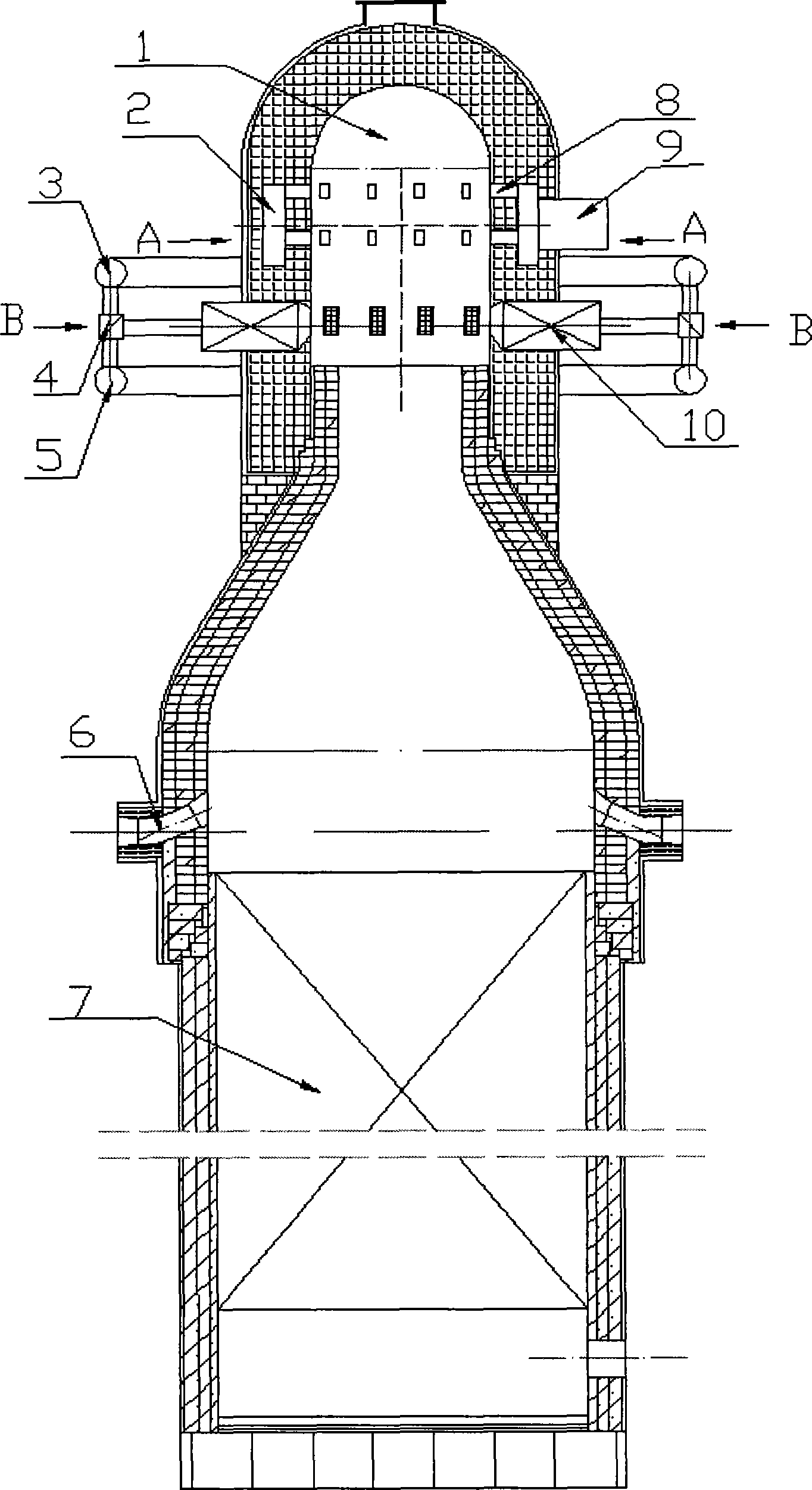

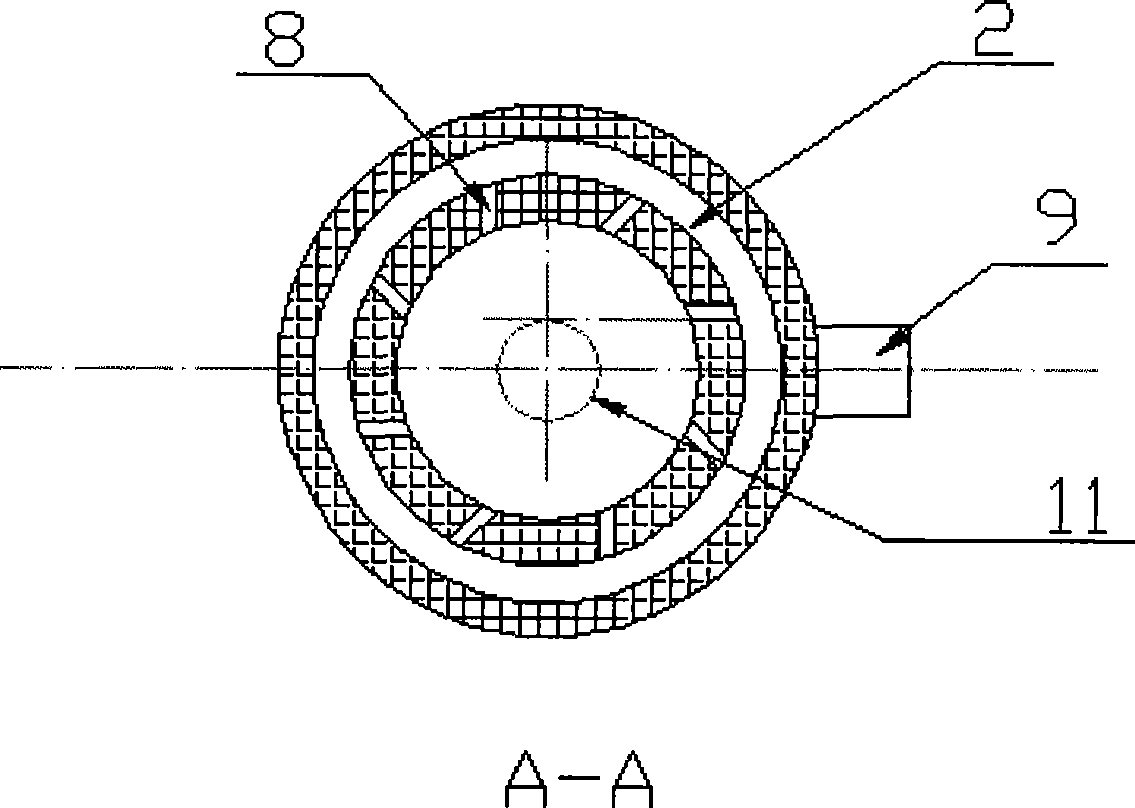

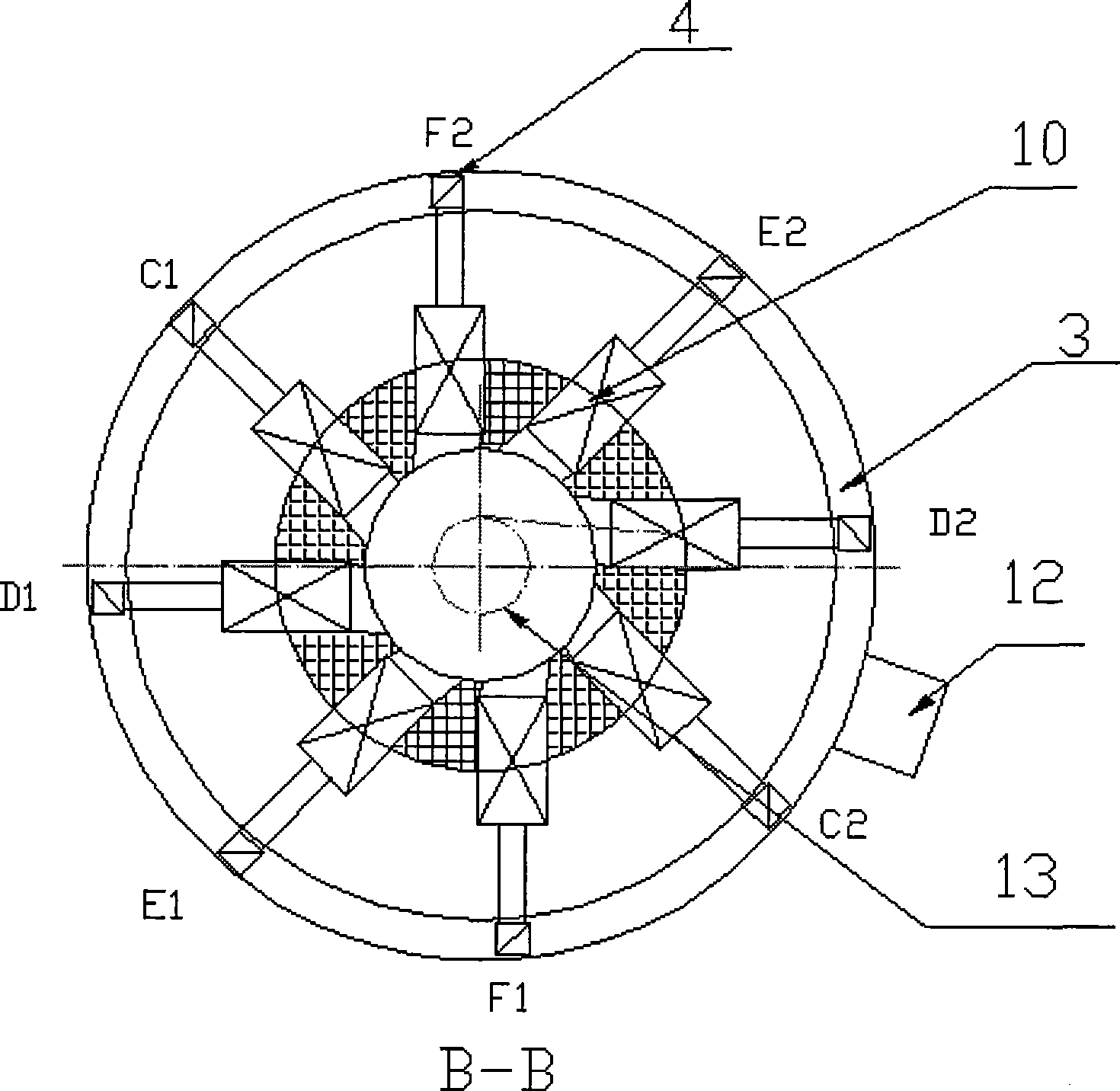

Full BF gas hot blast furnace

ActiveCN101392957ACompact structureEasy to installCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBrickCombustion chamber

The invention relates to a full blast furnace gas fired high blast temperature hot-blast stove, which belongs to the technical field of ironmaking hot-blast stove. The blast furnace gas fired high blast temperature hot-blast stove comprises an arch crown, a combustion chamber, checker bricks, a hot-blast outlet and other parts, and is characterized in that 4 to 20 pairs of pulse burners are arranged on the top of the hot-blast stove; each pulse burner consists of an air channel and a gas flue, wherein a honeycomb heat accumulator is arranged inside the air channel; the gas flue consists of a wall loop and a nozzle orifice; both air and gas are sprayed into the burner for mixed firing respectively; the gas flue and the air channel are arranged up and down or left and right at intervals or in the staggered form; the burners are arranged in a single row or in 2 to 4 rows; the air channel in the front of each burner is provided with a three-way change valve which is externally connected with two circular canals, wherein one circular canal is communicated with the air and the other circular canal is communicated with the gas. The blast furnace gas fired high blast temperature hot-blast stove has the advantages of realization of high blast temperature between 1,250 and 1,600 DEG C of the hot-blast stove, simple technological design, convenient assembly of burner nozzles, small occupied space, low investment cost and reduction of pollution.

Owner:SHOUGANG CORPORATION

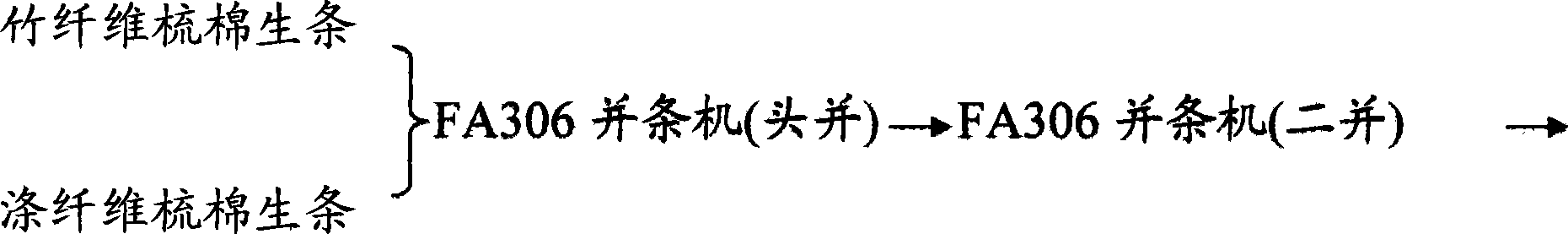

Bamboo / polyester blended fabric and production process thereof

The invention discloses a bamboo / Terylene mixed fabric and a production process thereof. The weight proportion of bamboo fiber to Terylene fiber is 60-80 to 40-20, and mixing and twisting coefficient is between 350 and 375. Mixed fabric technological conditions are strictly controlled to improve spinnability. According to the production process; after mixing, the strength of the fabric can increase by 10 to 20 percent; and according to technological design, gram weight knitted fabric is mastered (shrinkage mass is about between 5 and 8 percent), wherein ball bursting strength NGB / 8878-2001 reaches 325, and the dyed luster of the mixed fabric keeps original style of bamboo fiber fabric, and the strength of the mixed fabric is superior to that of other varieties.

Owner:FUJIAN HONGYUAN GROUP CO LTD

Multistage separated heat pipe

InactiveCN102997728AReduce lossesAchieve stabilityIndirect heat exchangersThermal energyProcess engineering

The invention discloses a multistage separated heat pipe. The multistage separated heat pipe comprises a first stage heat pipe group, a second first stage heat pipe group, a third first stage heat pipe group, a heat pipe unit and a connection pipeline. The pipe can be manufactured into N stage heat pipe groups. A whole system is composed of condensers, evaporators and gas-liquid mixing channels; the evaporators and the condensers of each stage heat pipe group are a group of independent circulation loops formed by parallel connection of an identical number of heat pipe units; and the evaporators of the system are arranged under the condensers, and the gas-liquid mixing channels communicate top ends of the evaporators of each stage with bottom ends of the condensers. The evaporators and the condensers of the system are separated, long-distance heat transfer can be achieved, great flexibility is provided for a technological design, and good conditions are created for large-scale devices, comprehensive utilization of heat energy and optimization of heat energy utilization systems.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

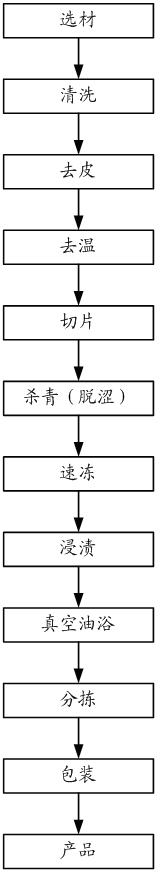

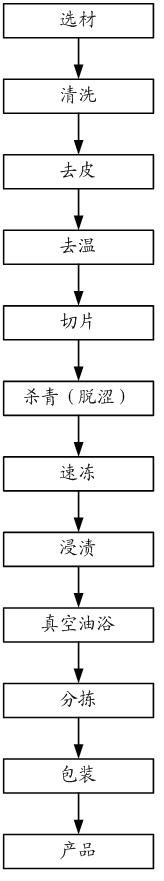

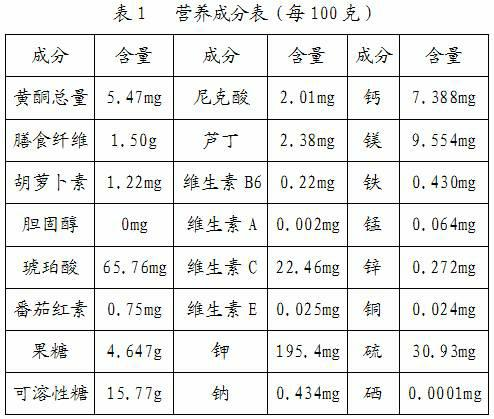

Preparation method of persimmon crisp chip and persimmon crisp chip prepared by adopting preparation method

ActiveCN102578503ASimple operation processShorten the time of exfoliationFood preparationQuick FreezeMillstone

The invention relates to a preparation method of persimmon crisp chip and the persimmon crisp chip prepared by adopting the preparation method. The preparation method provided by the invention comprises the following steps of: sorting, peeling, slicing, removing astringency, quick freezing, refrigerating and low-temperature vacuum oil bath dehydrating. The preparation method provided by the invention adopts a technological design of peeling, slicing and removing astringency, an operating process is simplified, processing time is shortened, astringency removing effect is improved, the quick freezing and refrigerating are carried out after astringency is removed, nutrients of fresh fruit are maintained, no additive is required to be added, especially a colour-protecting process in the priorart is eliminated, and chemical substances harmful to a human body, such as colour retention agents, is not used; besides, the low-temperature vacuum oil bath dehydrating is carried out after a series of treatments in the preparation method provided by the invention, thereby ensuring that the persimmon crisp chip is crisp and tender; the persimmon crisp chip prepared by the invention has the advantages of being green, healthy, nutritional and delicious, and deastringency millstone persimmon crisp chip produced from millstone persimmon is the best.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

In-time supporting method for roadway fully-mechanized excavating operation

InactiveCN103174448AExtension of timeIncrease the step distanceMine roof supportsAnchoring boltsBridge typeEngineering

The invention discloses an in-time supporting method for roadway fully-mechanized excavating operation, and the in-time supporting method is used for solving the problems of ineffective limitation and prevention on wall rock degeneration damage and low working efficiency of the conventional roadway excavating operation. The method comprises steps of temporarily supporting a fresh roof of a roadway fully-mechanized excavating face under the cooperation of a fully-mechanized excavating machine, utilizing a roadway excavating staggered supporting device to assist the permanent supporting operation of a roadway, and conveying coals which are cut off by the fully-mechanized excavating machine through utilizing a bridge type belt reversed loader and a belt conveyor. The method is reasonable in technological design, stable in supporting and moving, and safe and reliable; a small-circulation and frequent operation type switching mode of the original excavating operation is changed into a long-distance and large-circulation mode, the preparation time wasted by switching different processes is reduced, and the cooperation requirements of the roadway supporting and the fully-mechanized excavating machine are satisfied, so that the temporary supporting of the fresh roof of the roadway fully-mechanized excavating face and the permanent supporting of the roadway are mechanically realized in time; and the supporting quality and excavating efficiency of the roadway are obviously increased.

Owner:LIAONING TIAN AN TECH CO LTD

Exposed gear casting no-choke riser-head technique design

InactiveCN101422816AImprove pass rateSimple process designFoundry mouldsFoundry coresRoughcastMechanical property

The invention provides the technological design for manufacturing an unobstructed shrink head for an exposed gear. The technological design includes the following processes of: metal allowance setting; positive quantity correction; sand core; shrink head; shrink head sleeve; chilling block stuccoing; casting system; wood model manufacture; molding and core making; case buckling; casting; heat insulating covering agent adding; heat insulation and cooling of the casting; clearing; heat treatment; burnishing; heat treatment for the second time; mechanical capacity performing; roughcast dispatching; rough machining; UT fault detection; secondary heat treatment; finish machining and tooth washing; and MT fault detection; surface polishing of the casting, and the like. The technological design has simple processes and good feeding effect, which completely overcomes the defect of the shrinkage porosity of the shrinkage cavity under the shrink head and the shrinkage porosity between the shrink heads; and by UT and MT fault detections, the qualification rate reaches 100 percent.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Manufacturing method of compressor volute casing

InactiveCN103042179ACheap manufacturingReduce productionPump componentsFoundry mouldsTRAIL productionNumerical control

The invention relates to a manufacturing method of a compressor volute casing. The method comprises the following steps: establishing a three-dimensional model of the compressor volute casing, introducing the three-dimensional model into rapid molding equipment, directly sintering out a shape of the compressor volute casing of a plastic material instead of a sand core by using a powder sintering technology and a laser numerical control technology, and finishing casting and molding of the compressor volute casing through a traditional investment casting method. As the mold manufacturing and sand core making process is eliminated in the method, the trial period in the production is reduced, the efficiency is increased and the production cost is reduced; and the manufacturing method provided by the invention is especially suitable for trail production in a development phase and medium and small-scale production. Through the adoption of the manufacturing method provided by the invention, the manufacturing period is reduced, and the manufacturing precision of the product can be also guaranteed. Compared with similar domestic methods, the manufacturing method provided by the invention has the advantages as follows: as technological design and manufacture of a wooden mold and the making process of the sand core are eliminated, an energy-saving and environment-friendly effect is taken.

Owner:CHINA NORTH IND GRP NO 70 RES INST

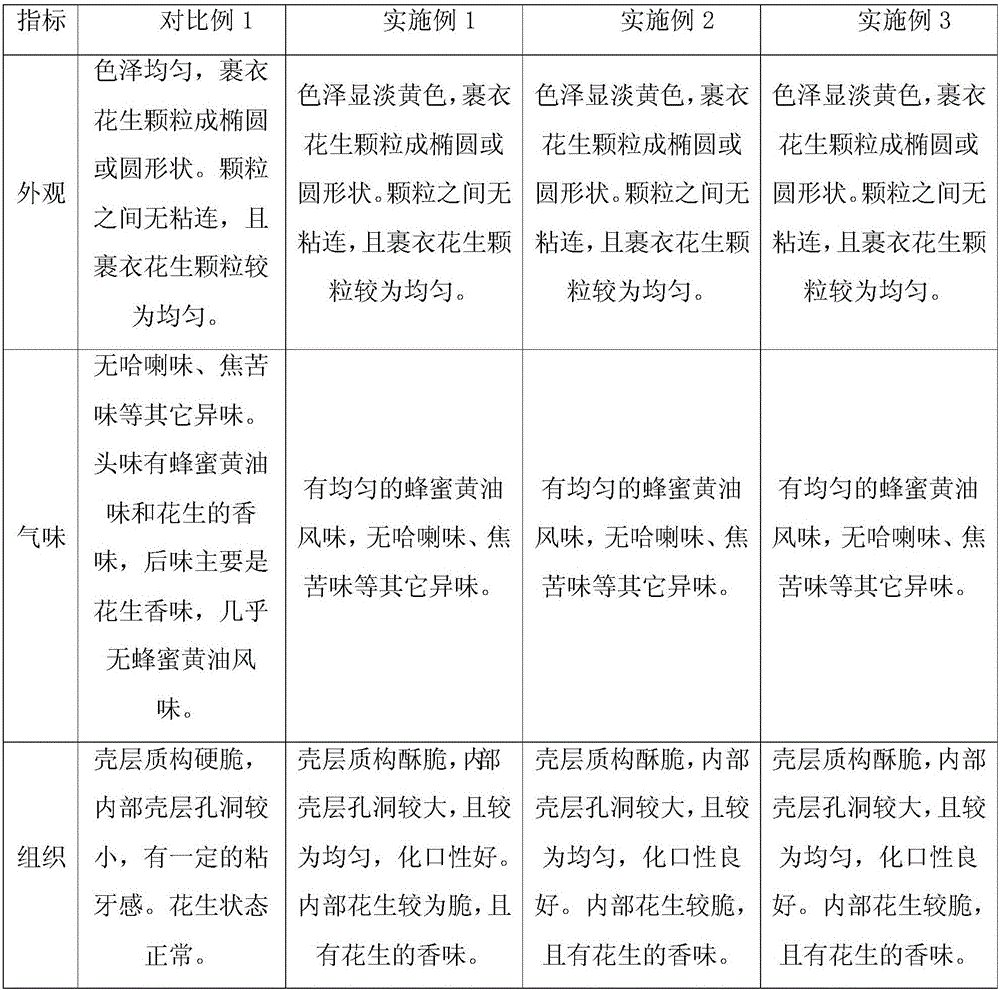

Coating formula, honey and butter coating peanuts and peanut preparation method

InactiveCN106578285AImprove crispnessControl stickinessConfectionerySweetmeatsFood flavorProduct processing

The invention discloses a coating formula, honey and butter coating peanuts and a peanut preparation method, and belongs to the technical field of food processing. The coating formula consists of coating liquid and coating powder, wherein the honey and butter coating peanuts made by the coating formula are obtained through the following steps of (1) preparing the coating liquid; (2) preparing the coating powder; (3) performing coating shaping; (4) performing baking; and (5) performing seasoning. The qualified honey and butter peanuts are obtained through the five steps, and the honey and butter coating peanuts prepared by the method disclosed by the invention have good crisp feel and good honey and butter flavor, the technological design is scientific and reasonable, not only is rich flavor of products guaranteed, but also the industrial processing feasibility of the products is guaranteed, the nutrition of the peanut products is strengthened, the application range of the peanuts is widened, and the comprehensive utilization value of nut resources is increased.

Owner:无锡赞匠生物科技有限公司

Traditional Chinese medicine compound preparation used for treating colpitis and tinea manus and pedis and preparation method thereof

InactiveCN101559188AKeep active ingredientsSignificant effectAntimycoticsHydroxy compound active ingredientsAdditive ingredientFiltration

The invention relates to a traditional Chinese medicine compound preparation used for treating colpitis and tinea manus and pedis and a preparation method thereof. The preparation is made from oriental bittersweet, Common Cnidium Fruit, Herba Oldenlandiae, kuh-seng, dandelion, angelica dahurica, phellodendron, giant knotweed, Cortex Dictamni, Radix Stemonae, fructus kochiae, radix cyathulae, ginkgo and borneol. The preparation method adopts the process that part of the impurities are precipitated by water cooking and ethanol solution, alkali liquor is used for adjusting pH value, the borneol is added and finally filtration and sterilization are implemented. With the organic combination of the drugs as well as scientific refinement and being directly acting on a part invaded by pathogenic bacteria, the compound preparation can effectively bring the efficacies of clearing away heat and toxic material, dehumidifying, killing insects and relieving itching into play, has notable treatment effect on trichomonas vaginitis, colpomycosis, gonorrhoea and mycetogenous tinea pedis as well as certain effect on tinea manus and pedis with the treatment rate being up to over 90 percent, and is convenient for administration. The preparation method is simple and convenient in operation, and rational in technological design and retains the effective ingredients of drugs to the maximum extent.

Owner:甘肃益尔药业股份有限公司

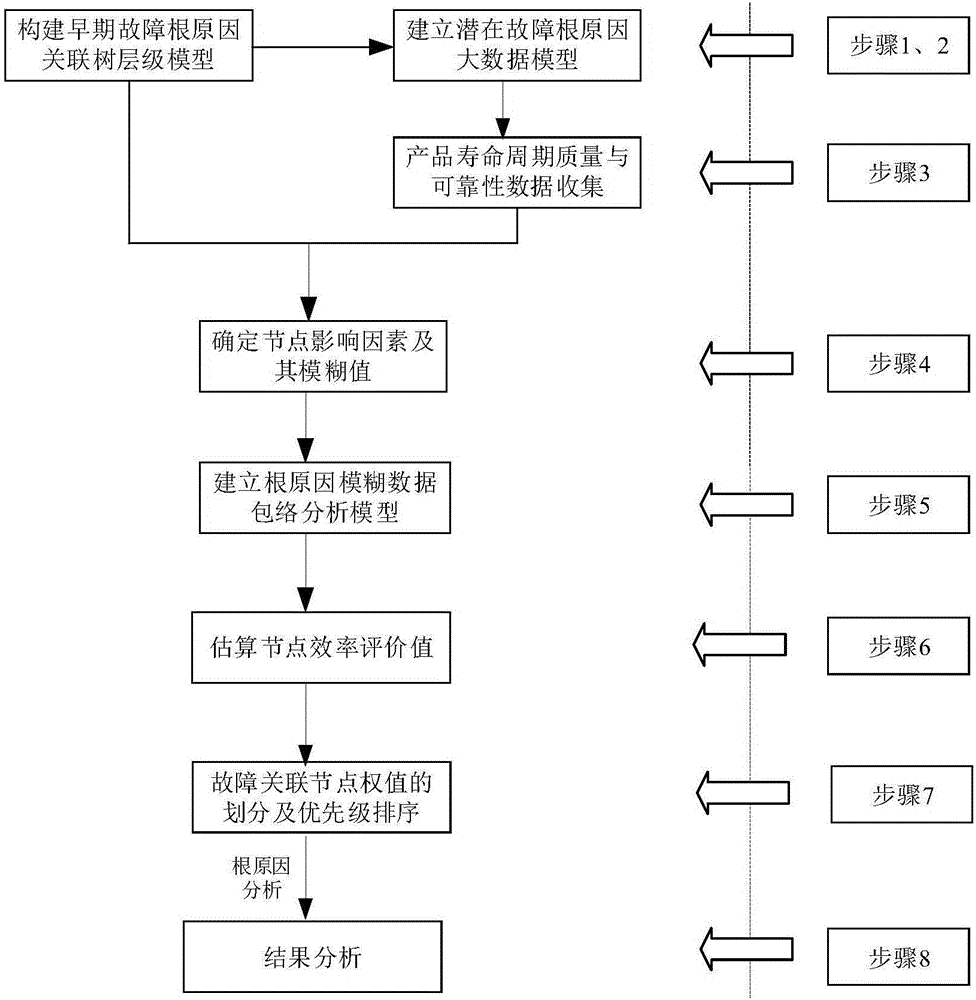

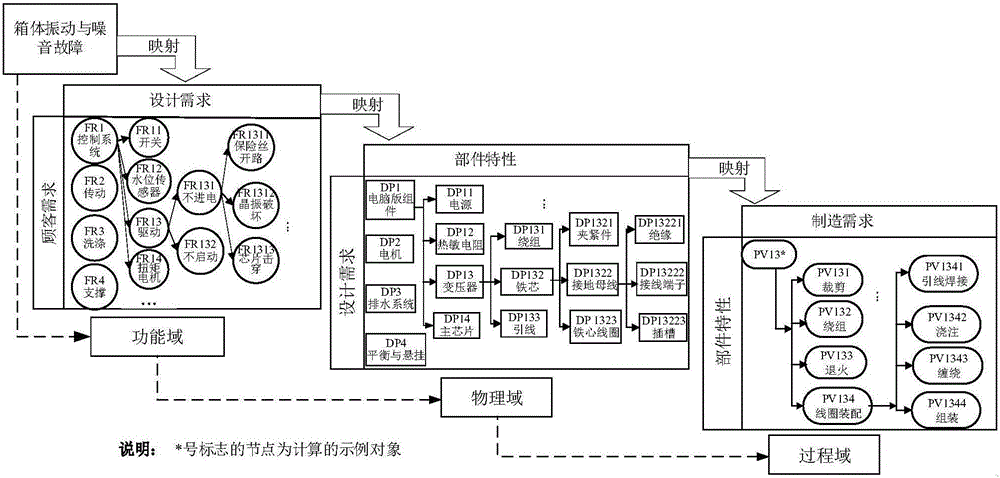

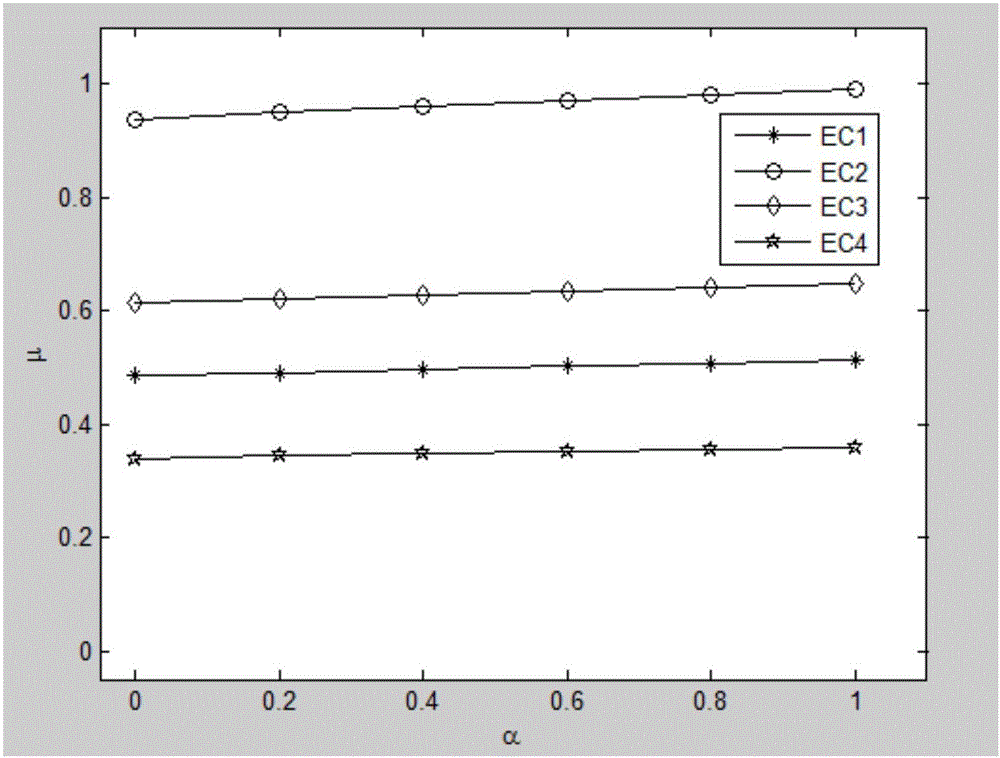

Product early-fault root cause recognition method based on fuzzy data processing

ActiveCN105975797ASolve misjudgmentConducive to preventive measuresSpecial data processing applicationsInformaticsNODALData treatment

The invention discloses a product early-fault root cause recognition method based on fuzzy data processing. The method comprises the following steps of 1, constructing a product early-fault root cause relevance tree layer model; 2, constructing a potential fault root cause data model; 3, collecting product service life period quality and reliability data; 4, on the basis of the fault relevance tree layer model, a process target node and data fuzziness analysis are determined, and then node influence factors and fuzzy values are determined; 5, constructing a product early-fault root cause fuzzy data envelopment analysis model; 6, estimating an efficiency evaluation value of a fault relevance tree node; 7, fault relevance node relative weights are divided, and node priorities are ranked; 8, results are analyzed, and fault root cause recognition is completed. Development of the early fault root cause recognition technology under the early fault mechanism recognition cognition fuzzy environment is broken through, prevention measures are adopted for product design, technological design stage and other early fault forming stages, afterward treatment is changed into beforehand prevention, and the new idea is provided for early fault prevention and rectification.

Owner:BEIHANG UNIV

Method for producing double-clutch valve

The invention discloses a method for producing a double-clutch valve. The method includes batching, smelting, refining, degassing, die-casting and the like to finally form the double-clutch valve. The development cost is greatly reduced by a modern simulation means (mold flow analysis), the qualified rate of the product is high, the porosity is superior to that of a common technological design, afilling process of the product is stable, the quality is improved, and the service life of a mold is prolonged to a great extent. In addition, the problem of air holes and gas leakage are solved by ultracold technology, the problem of low production efficiency is solved by automatic peripheral equipment, productivity is improved by 20% nearly, and labor intensity is reduced.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

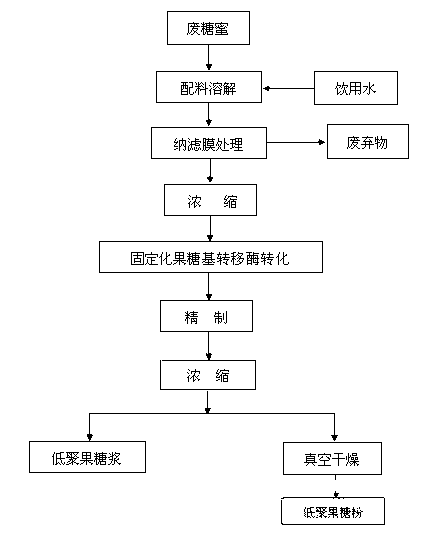

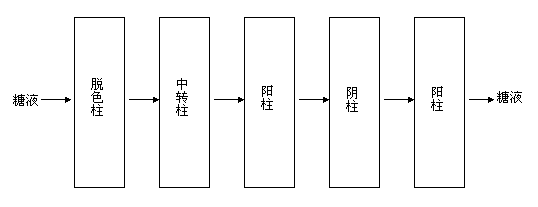

Method for preparing fructooligosaccharide by taking waste molasses as raw material

The invention belongs to the technical field of deep processing of agricultural products, and particularly discloses a method for preparing fructooligosaccharide by taking waste molasses as a raw material. The method is characterized in that the method comprises the steps of taking the waste molasses produced during the sucrose refining production course, preparing a waste molasses solution with a mass concentration of 15-20%, dialysing with a 500Da nanofiltration membrane, concentrating a dialysate, adding the dialysate to immobilized transfructosylase directly, adjusting a pH value to be 5-6, saccharifying at 38-42 DEG C for 10-20h, filtering, decolorizing, hybridizing, concentrating, drying, and obtaining the finished solid fructooligosaccharide. According to the method, the waste molasses raw material replaces sucrose for preparing the fructooligosaccharide; the method is abundant in raw material source, simple and easy to operate, low in production cost and reasonable in technological design; the product quality meets a national standard of the fructooligosaccharide; the method is suitable for industrial production; economic benefits can be remarkably increased; and an additional value of a byproduct can be increased.

Owner:山东星光首创生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com