Patents

Literature

158 results about "Racking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Racking, often referred to as Soutirage or Soutirage traditionnel (meaning racking in French), also filtering or fining, is a method in wine production of moving wine from one barrel to another using gravity rather than a pump, which can be disruptive to a wine. The process is also known as Abstich in German and travaso in Italian.

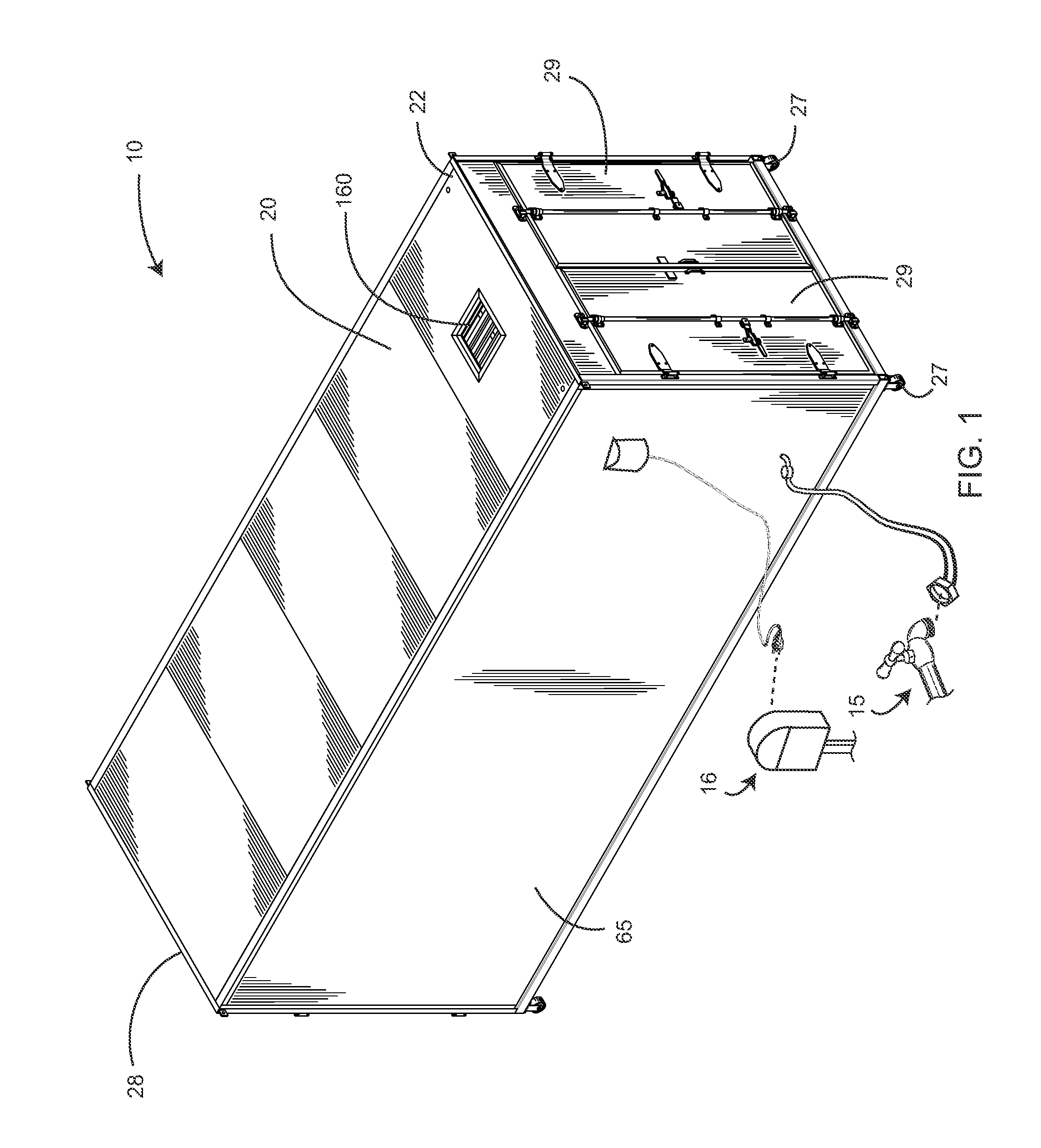

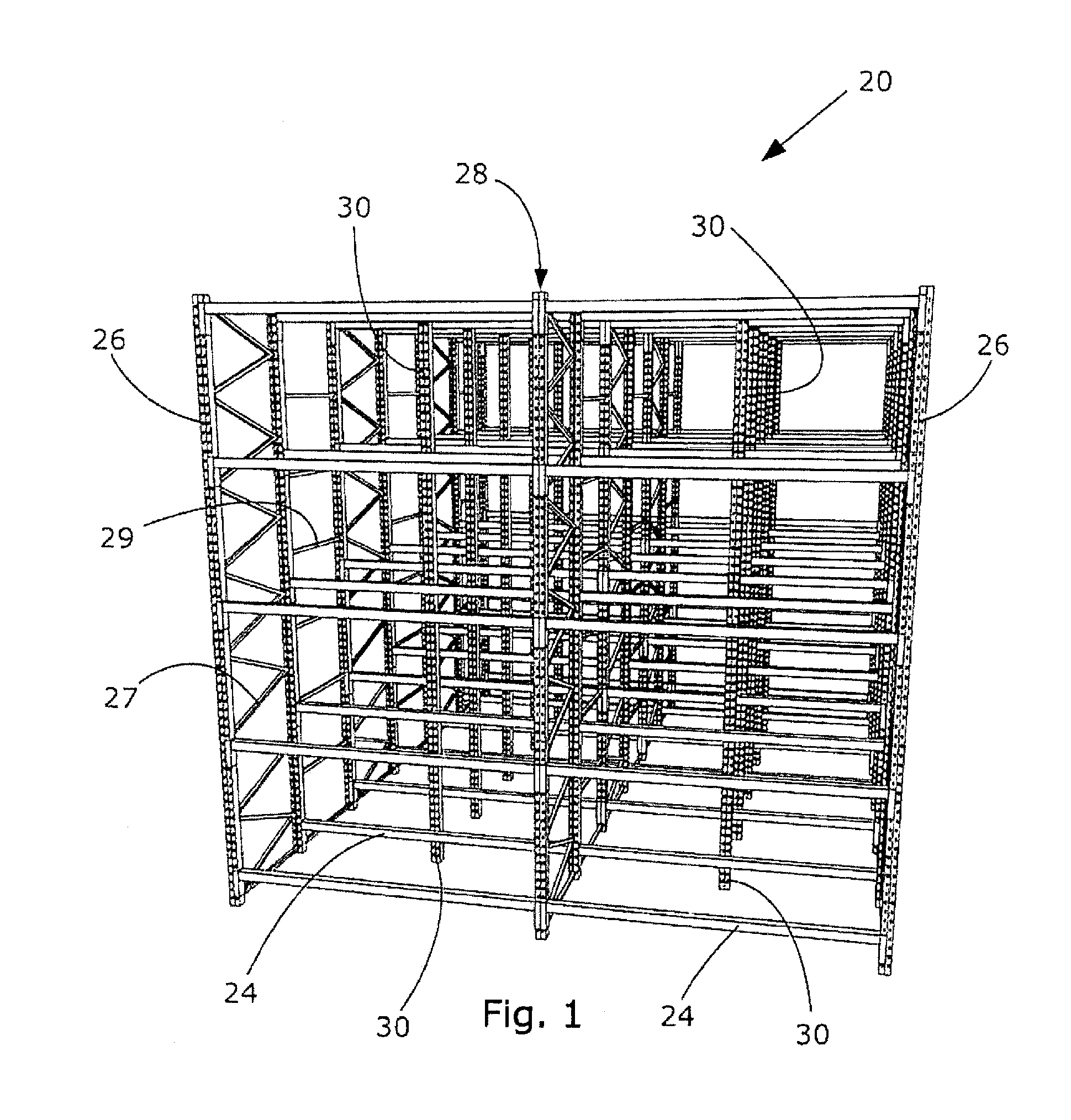

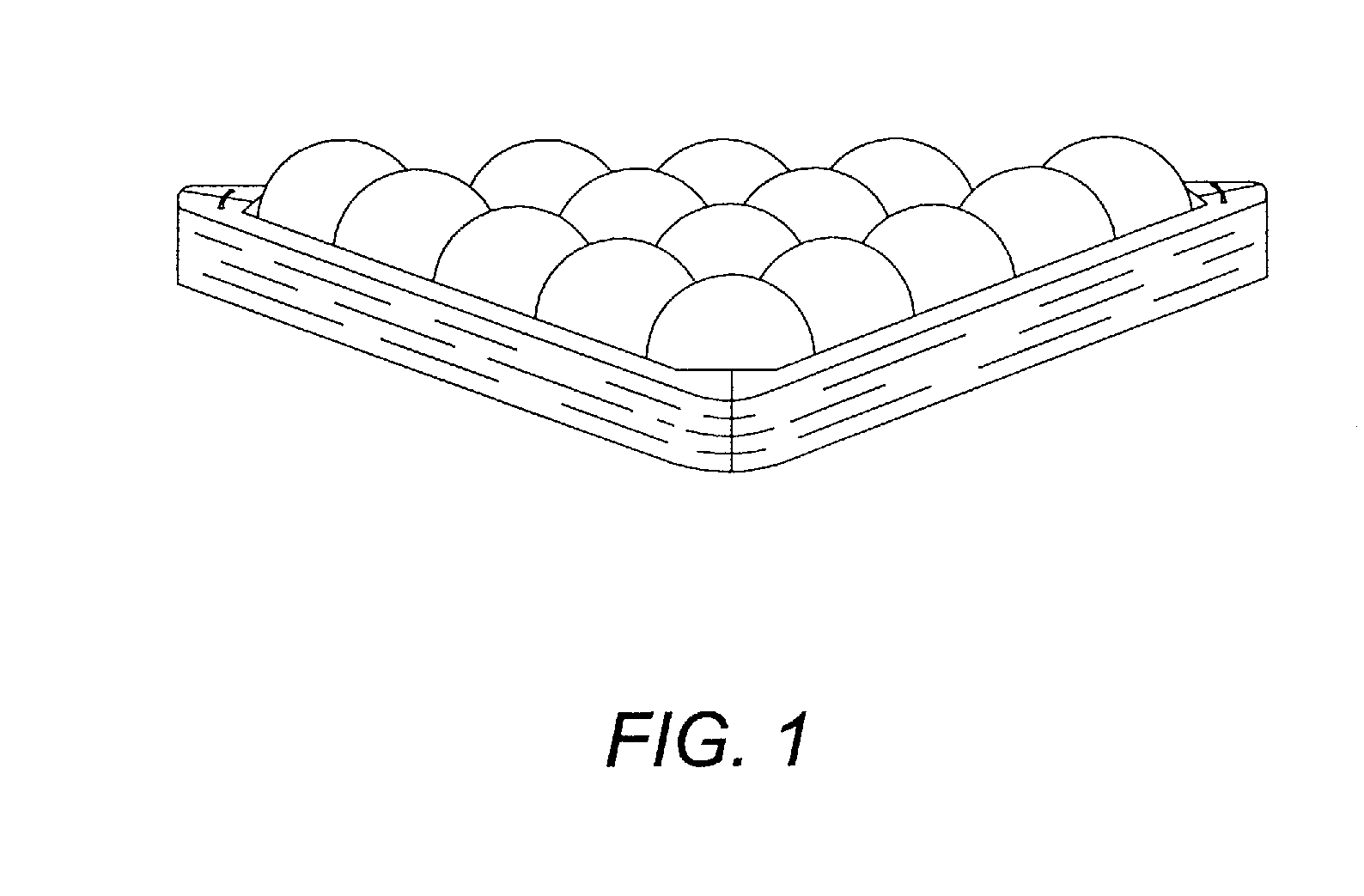

Hydroponic growing enclosure and method for the fabrication of animal feed grass from seed

InactiveUS6578319B1Easy to useAgriculture gas emission reductionCultivating equipmentsSprouted SeedsEngineering

Owner:COLE ROBERT +1

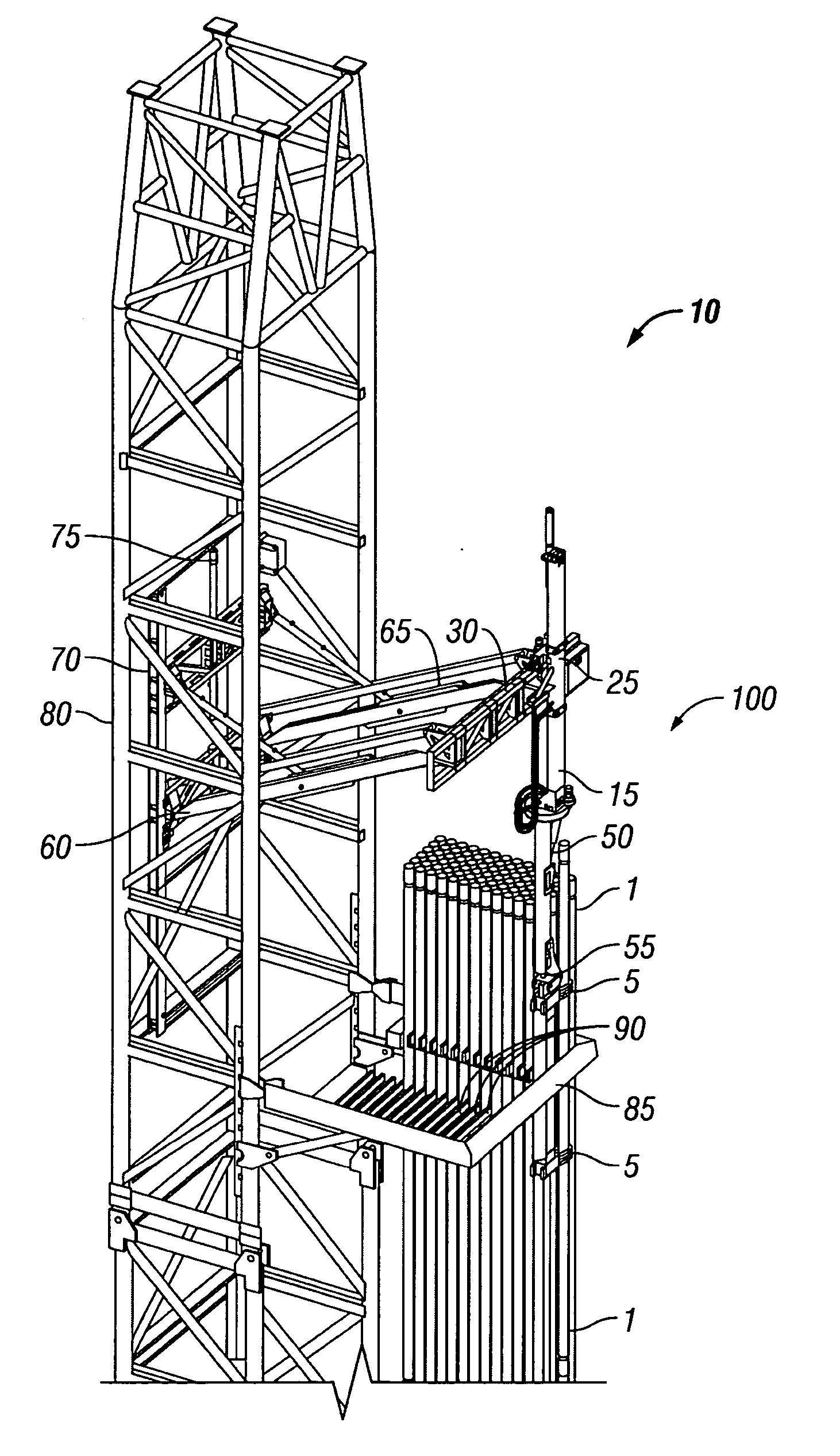

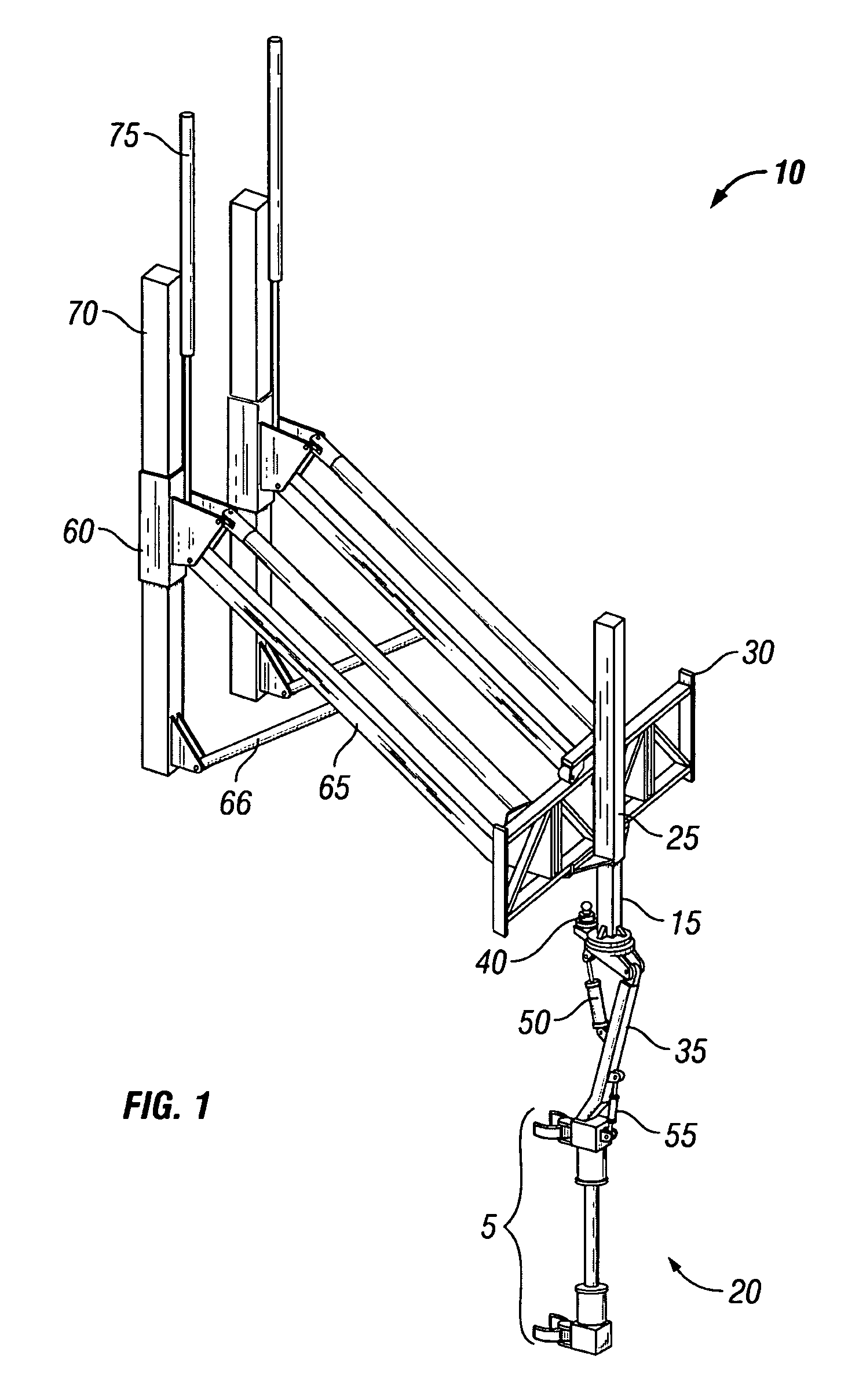

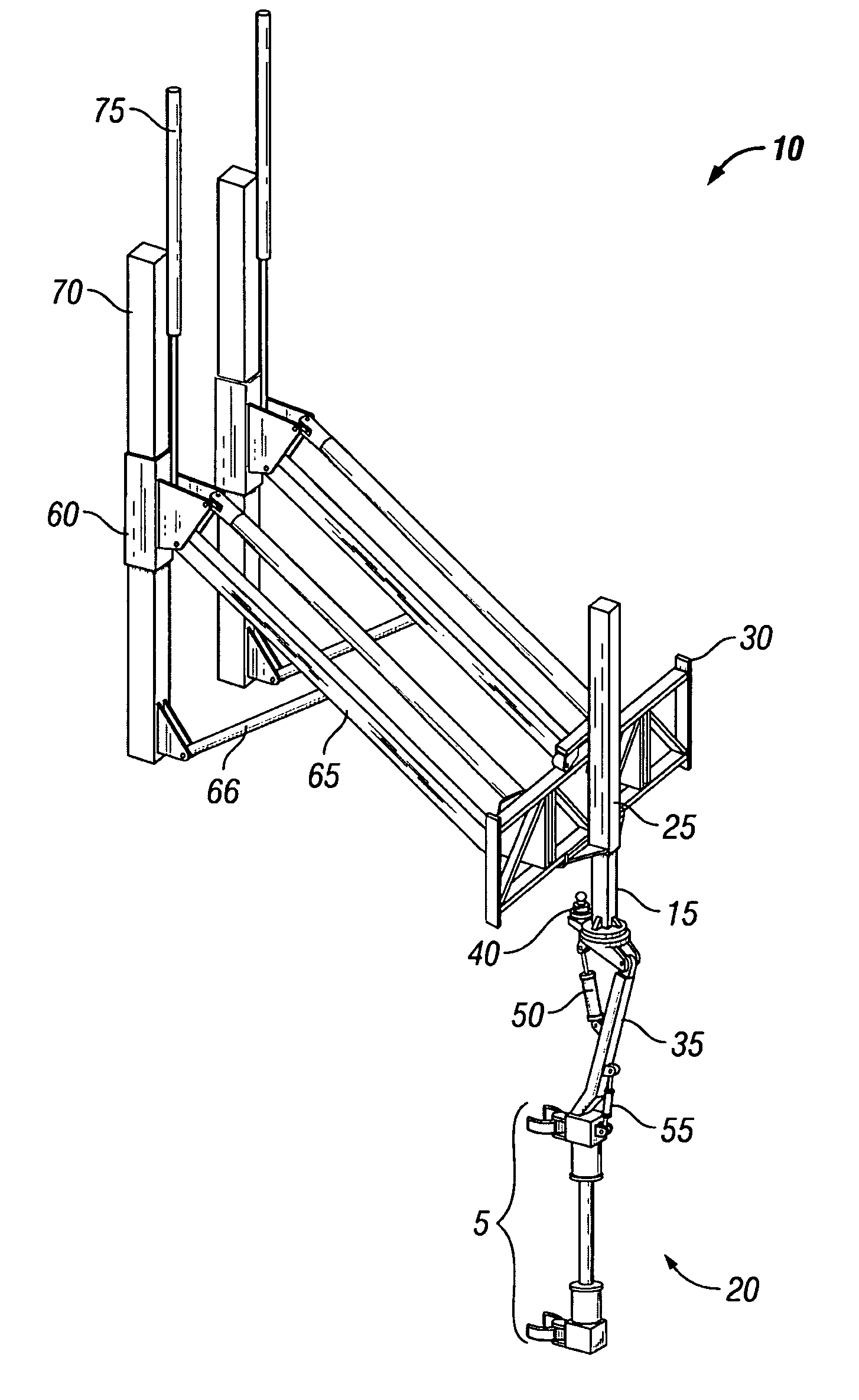

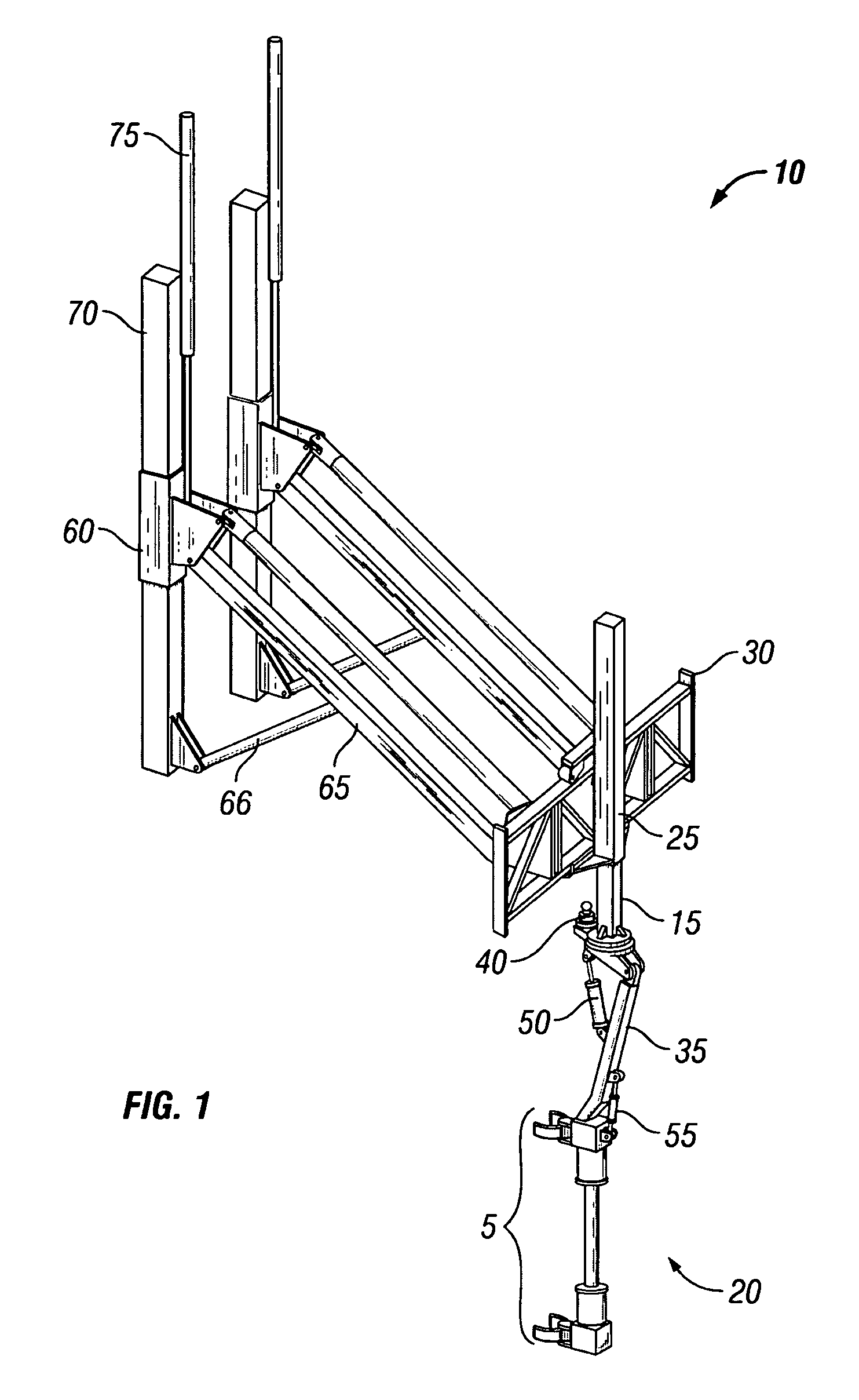

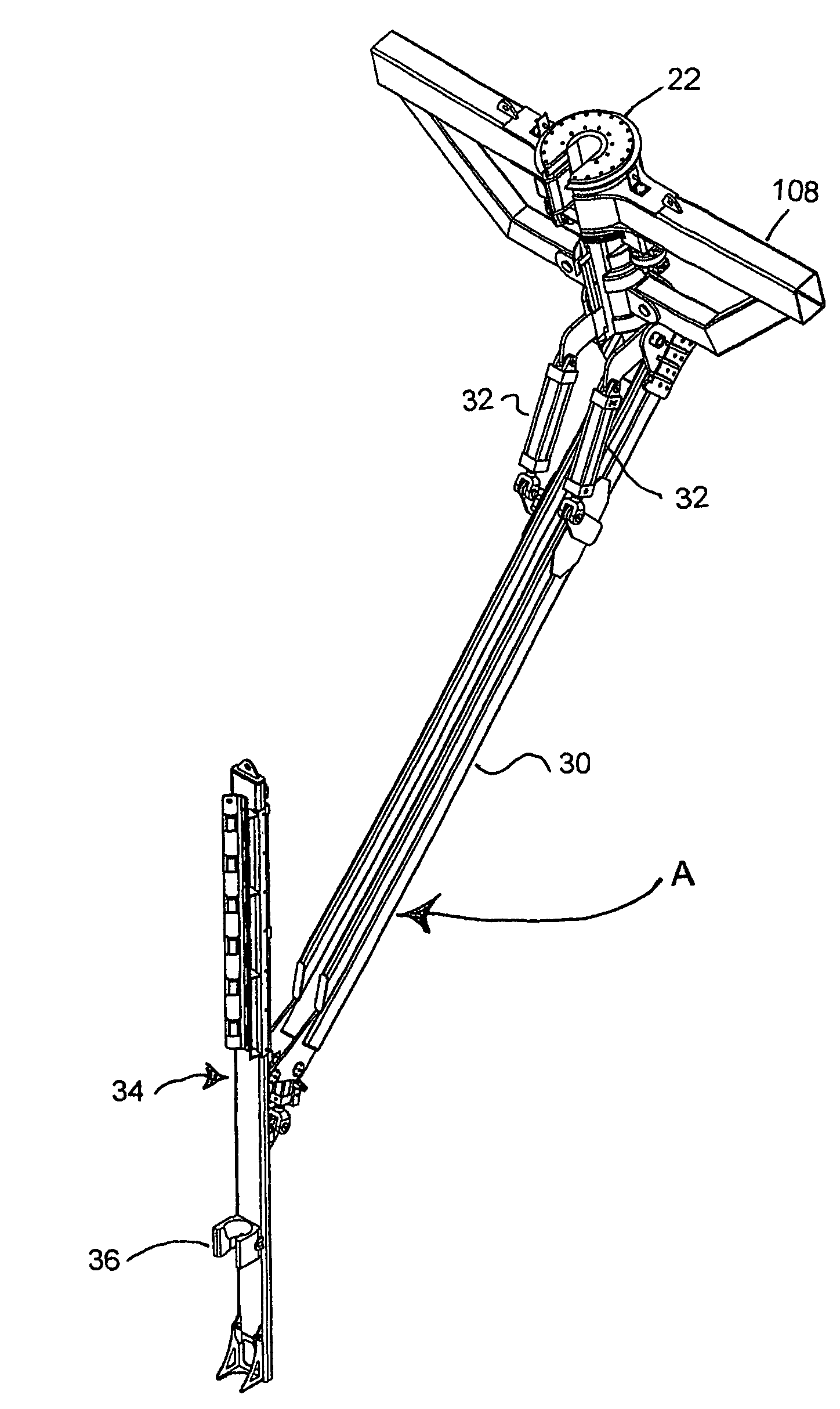

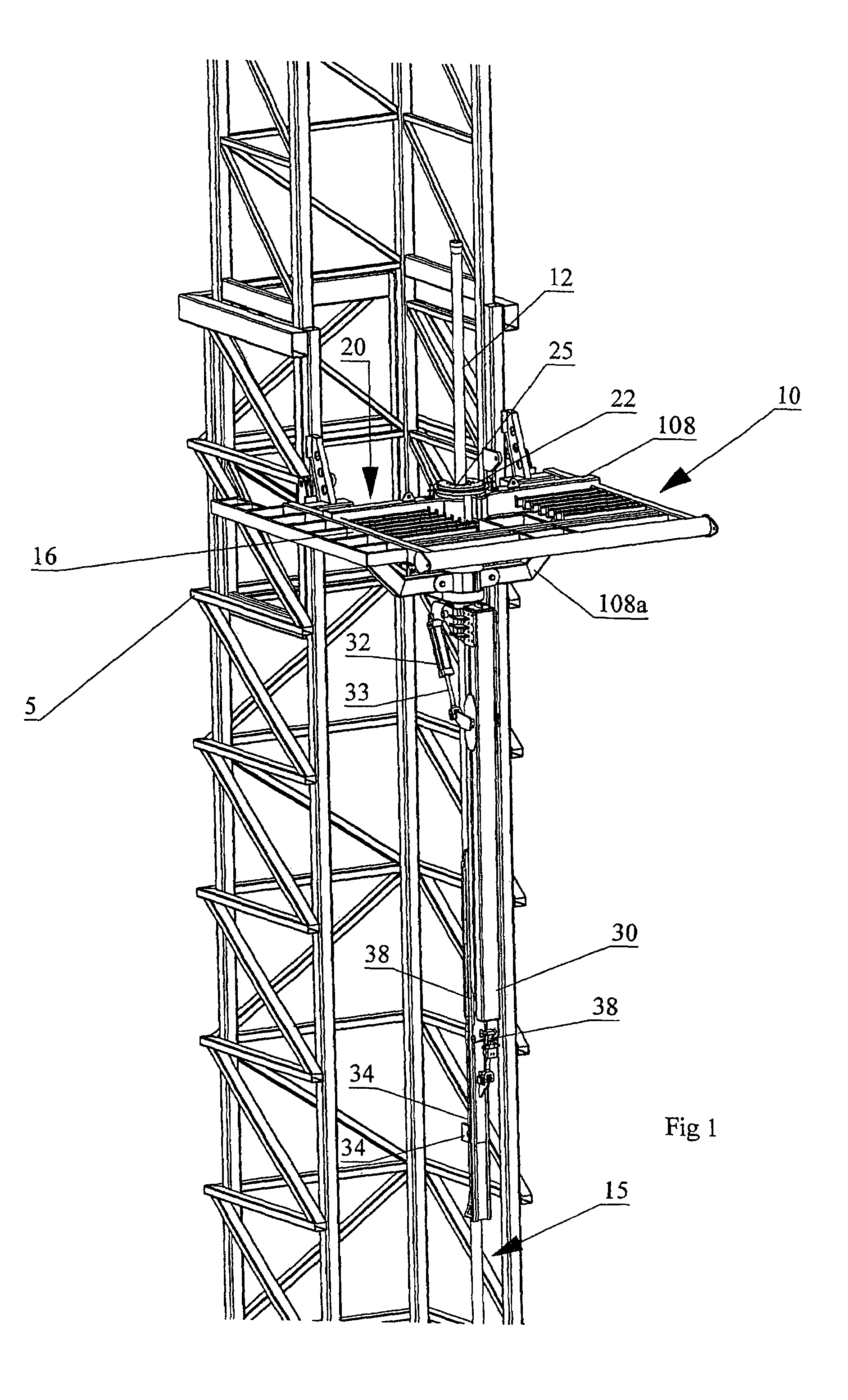

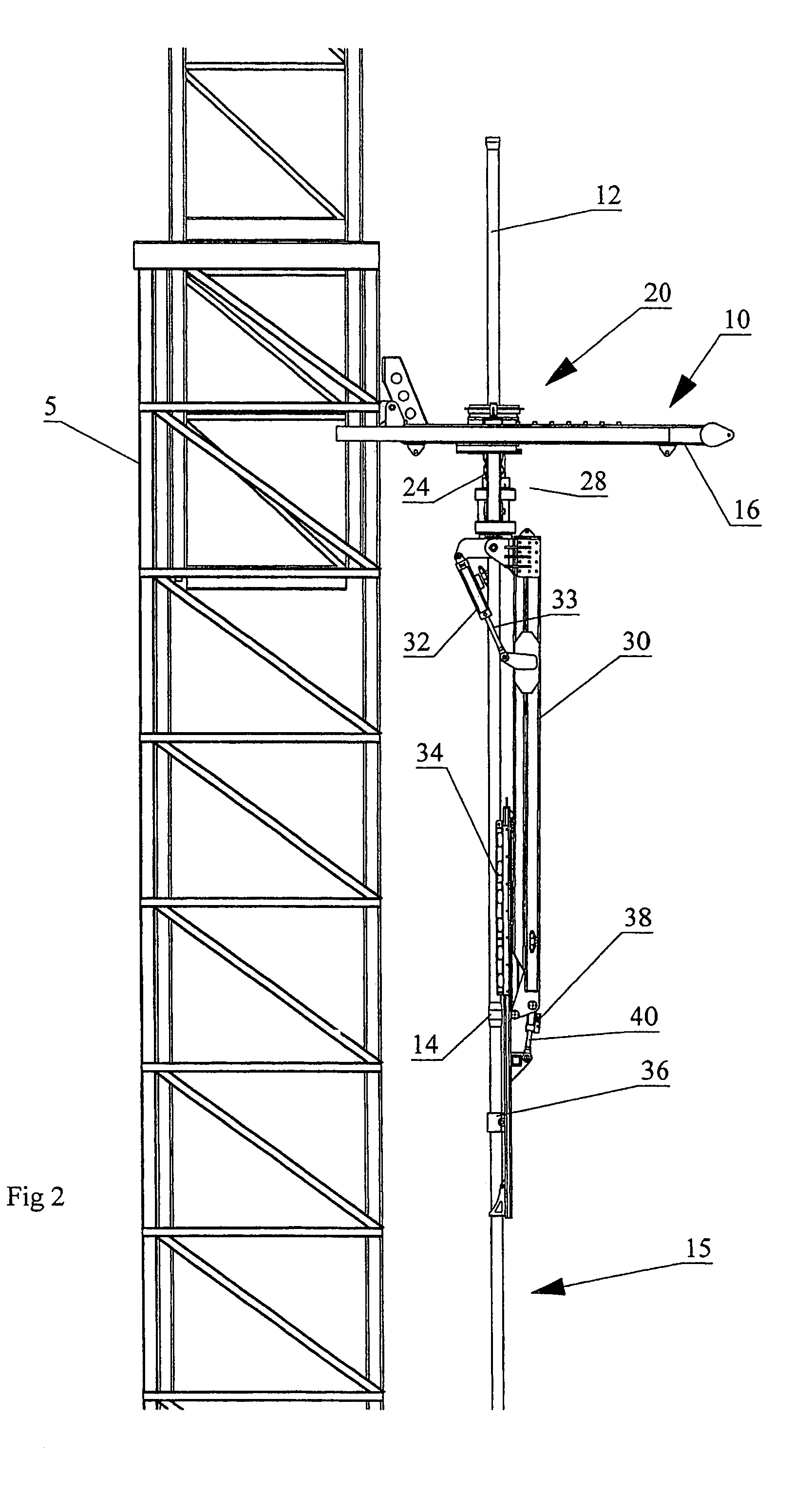

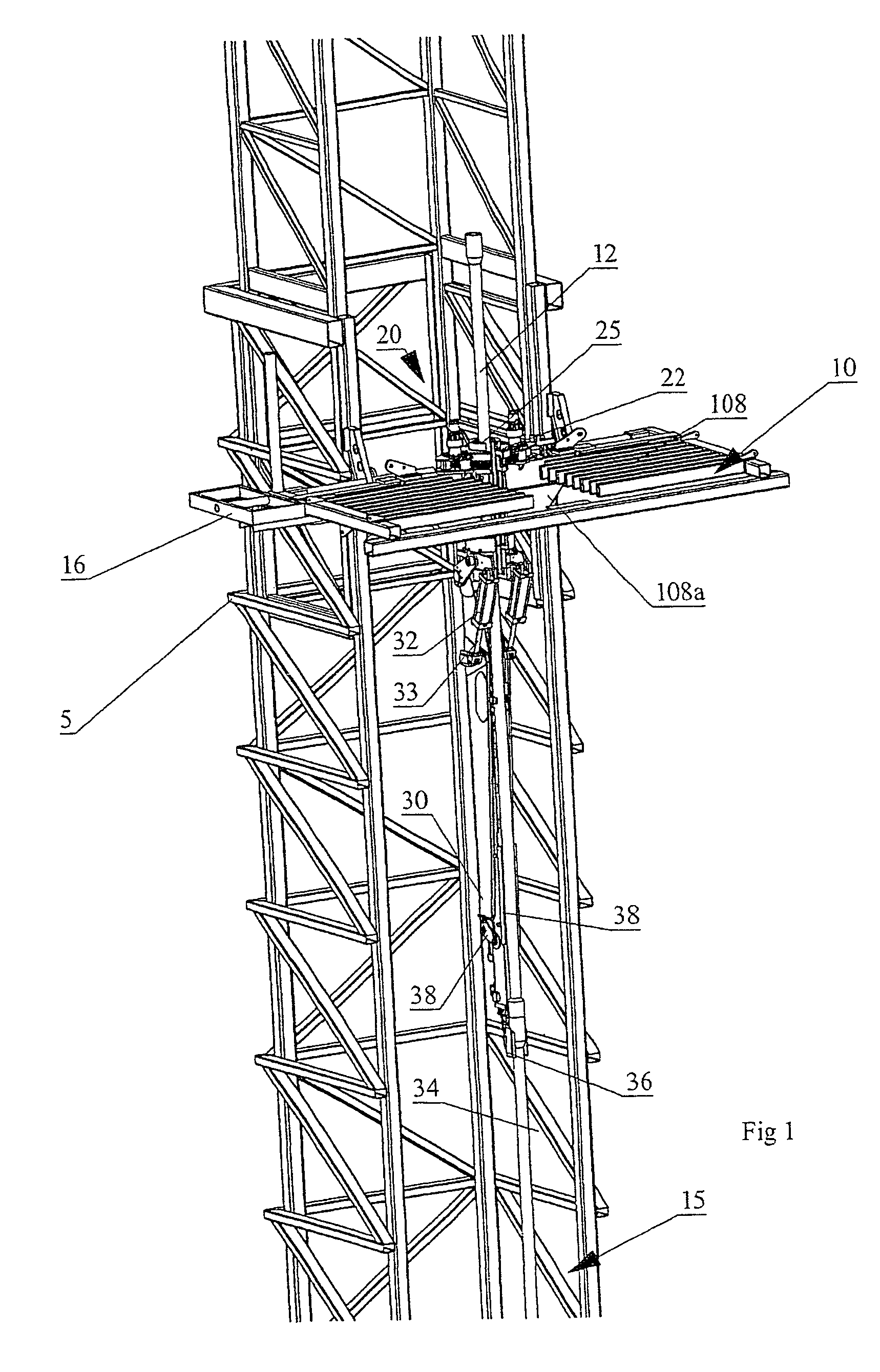

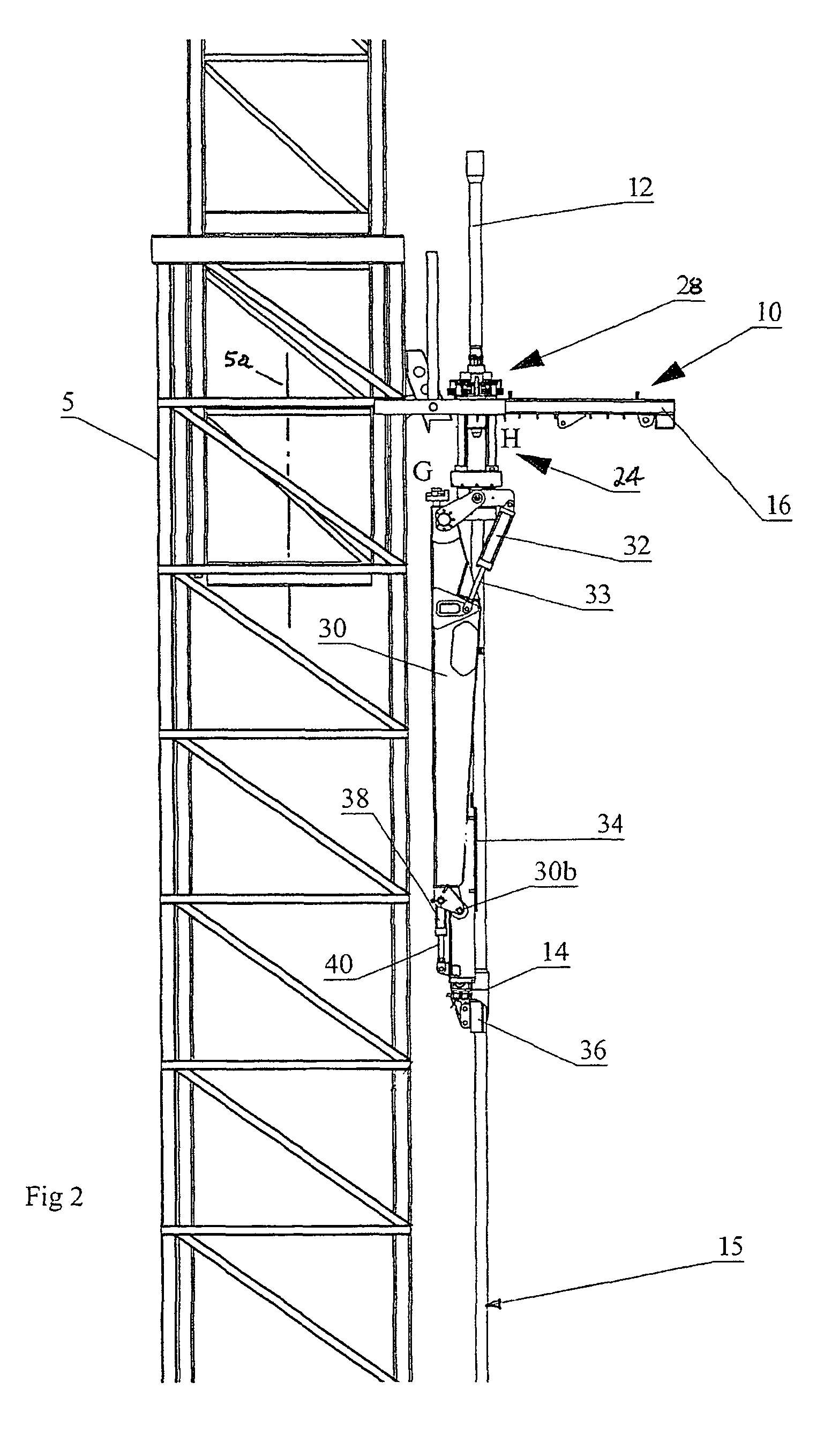

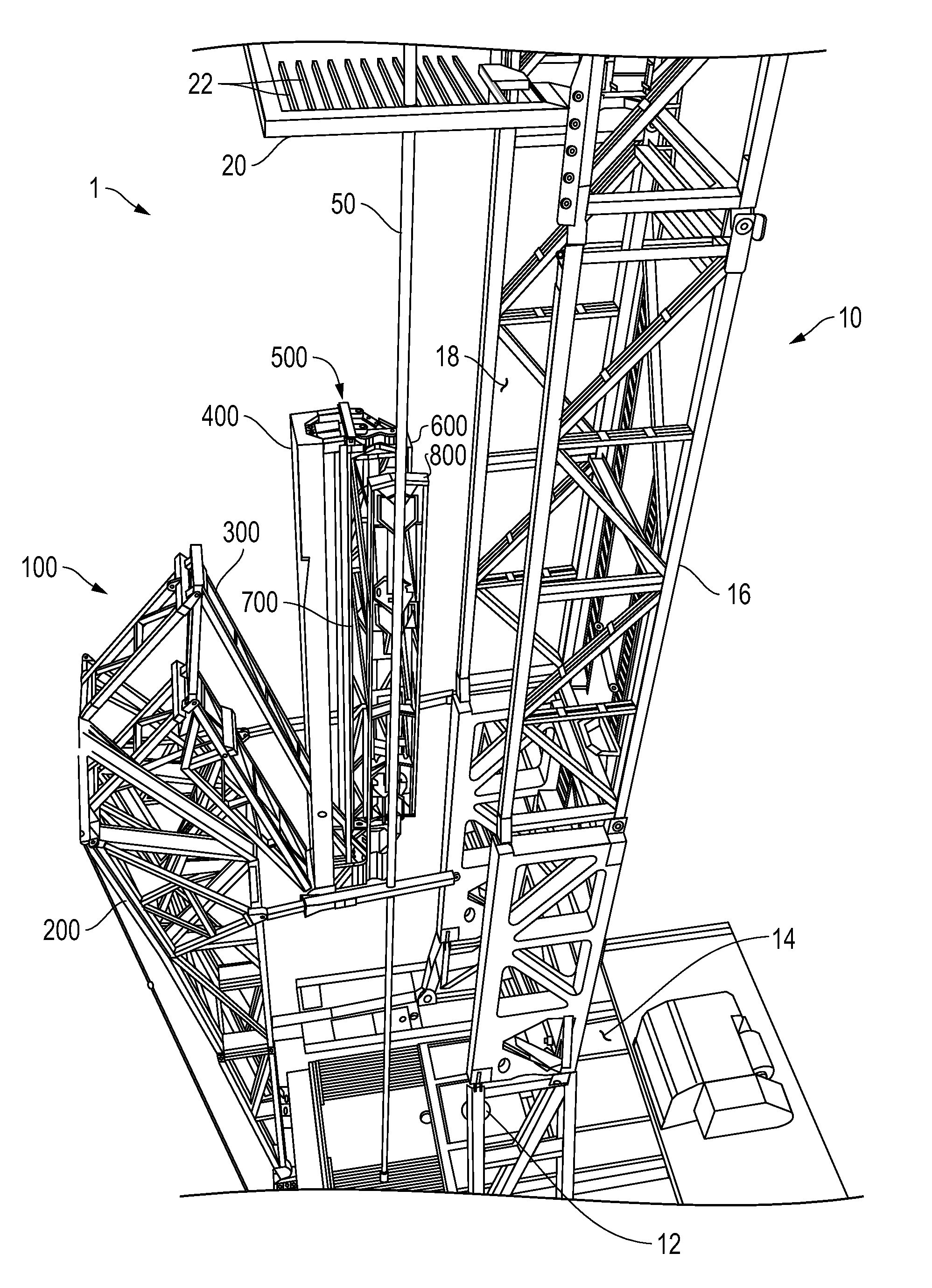

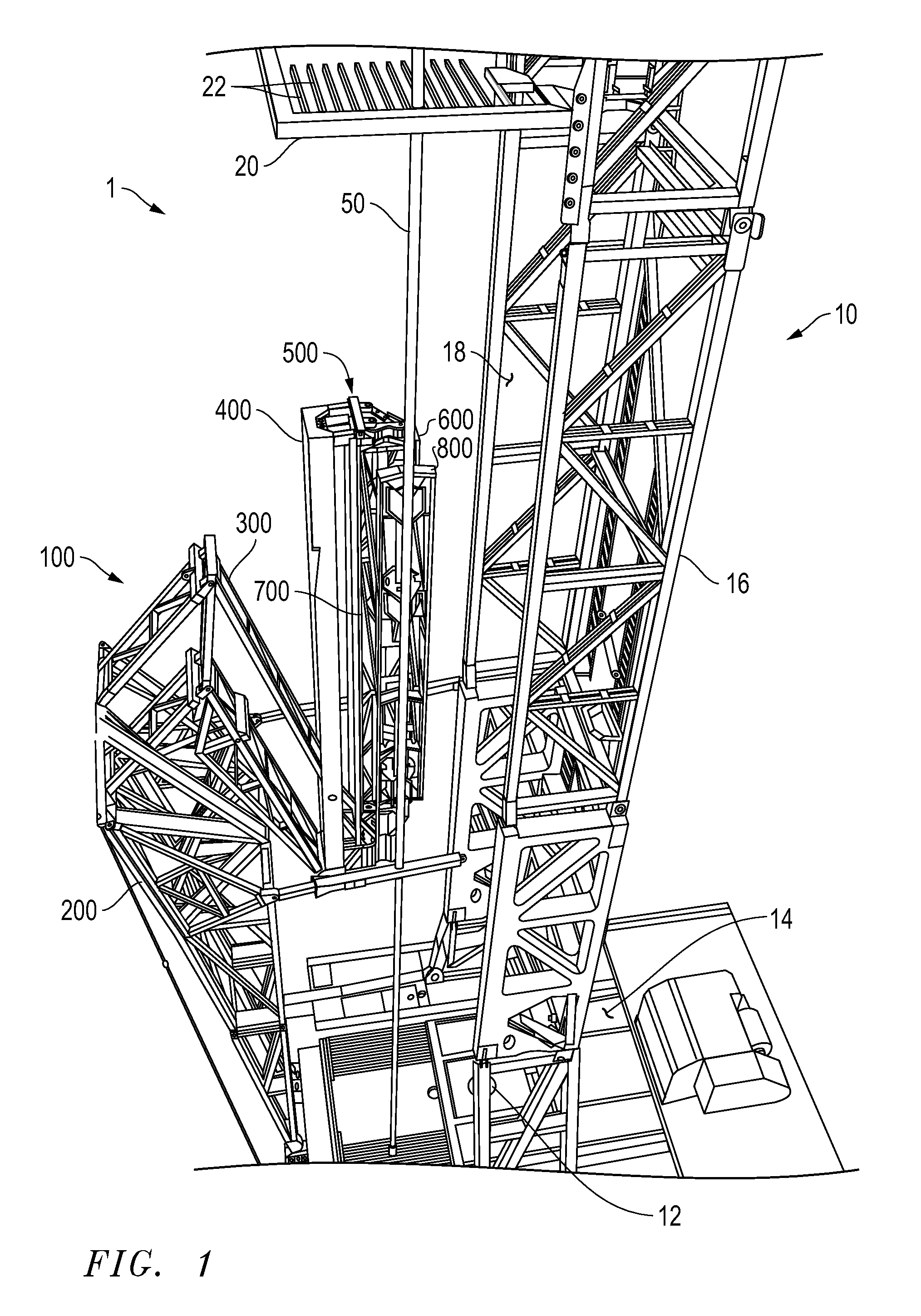

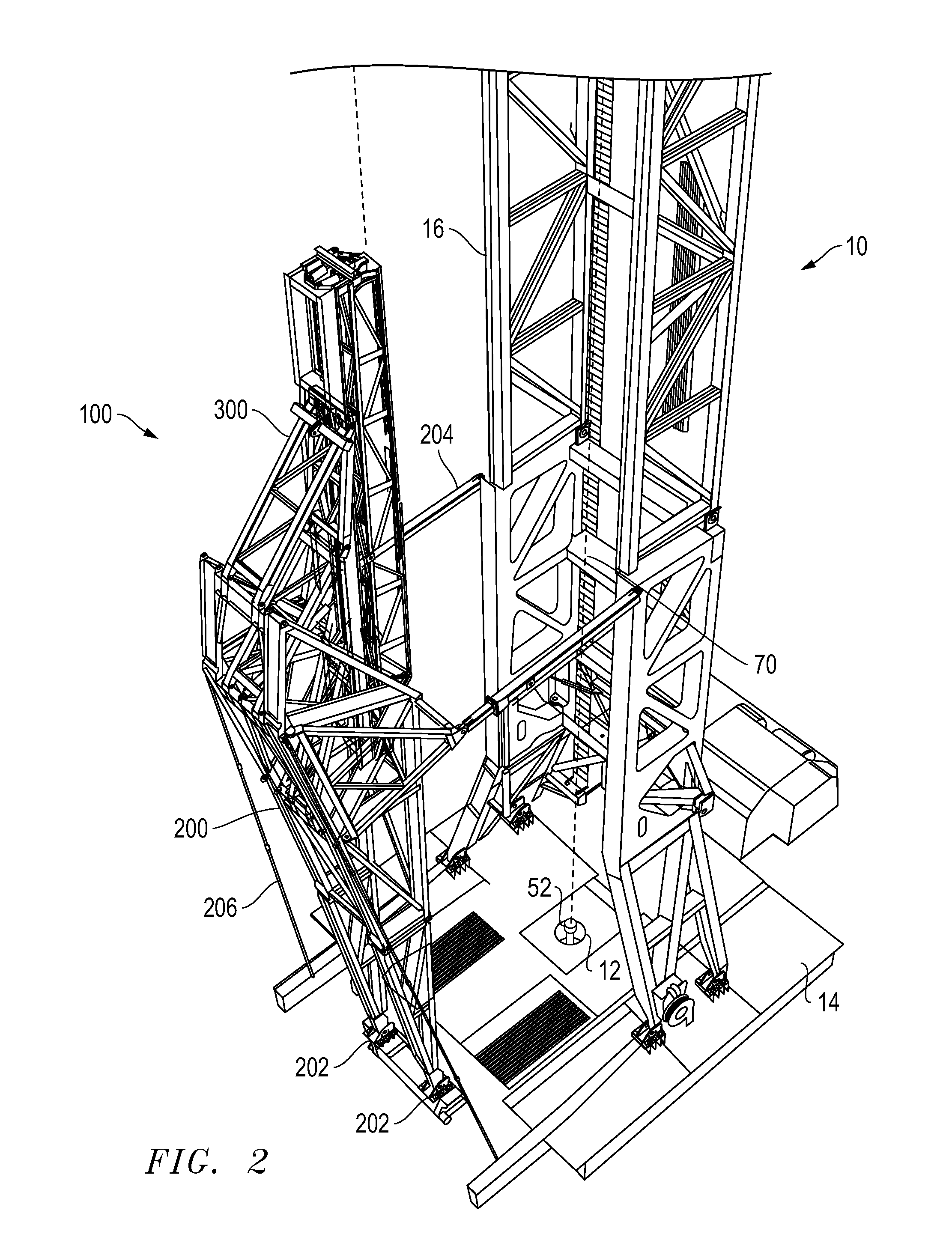

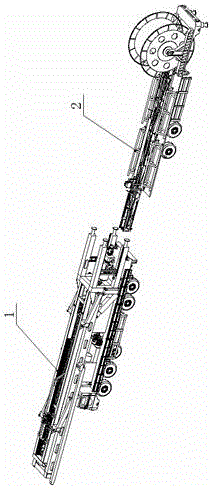

Pipe racking system

ActiveUS20060104747A1Safe and efficient movementReduce the risk of injuryDrilling rodsLifting devicesSystems designWell drilling

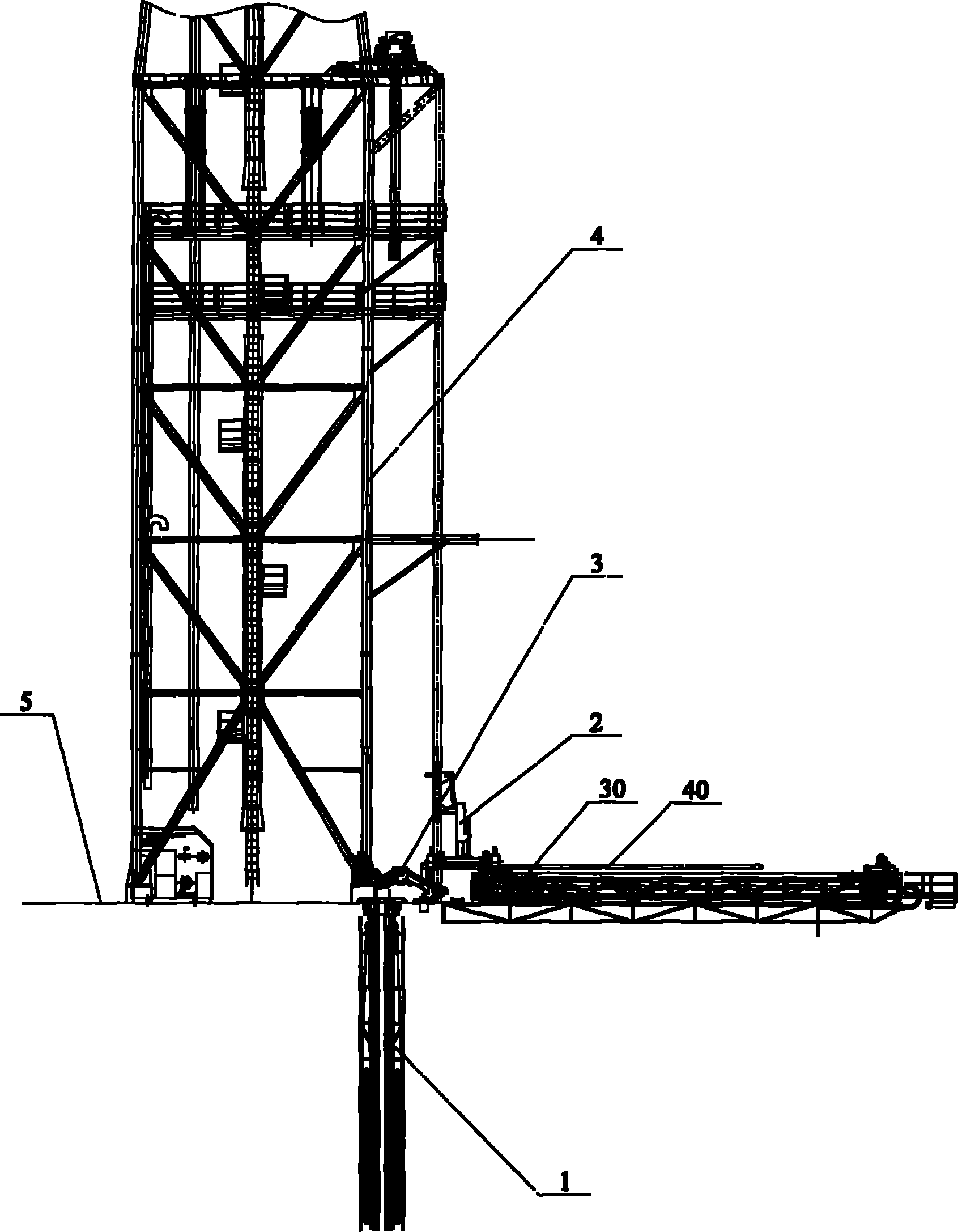

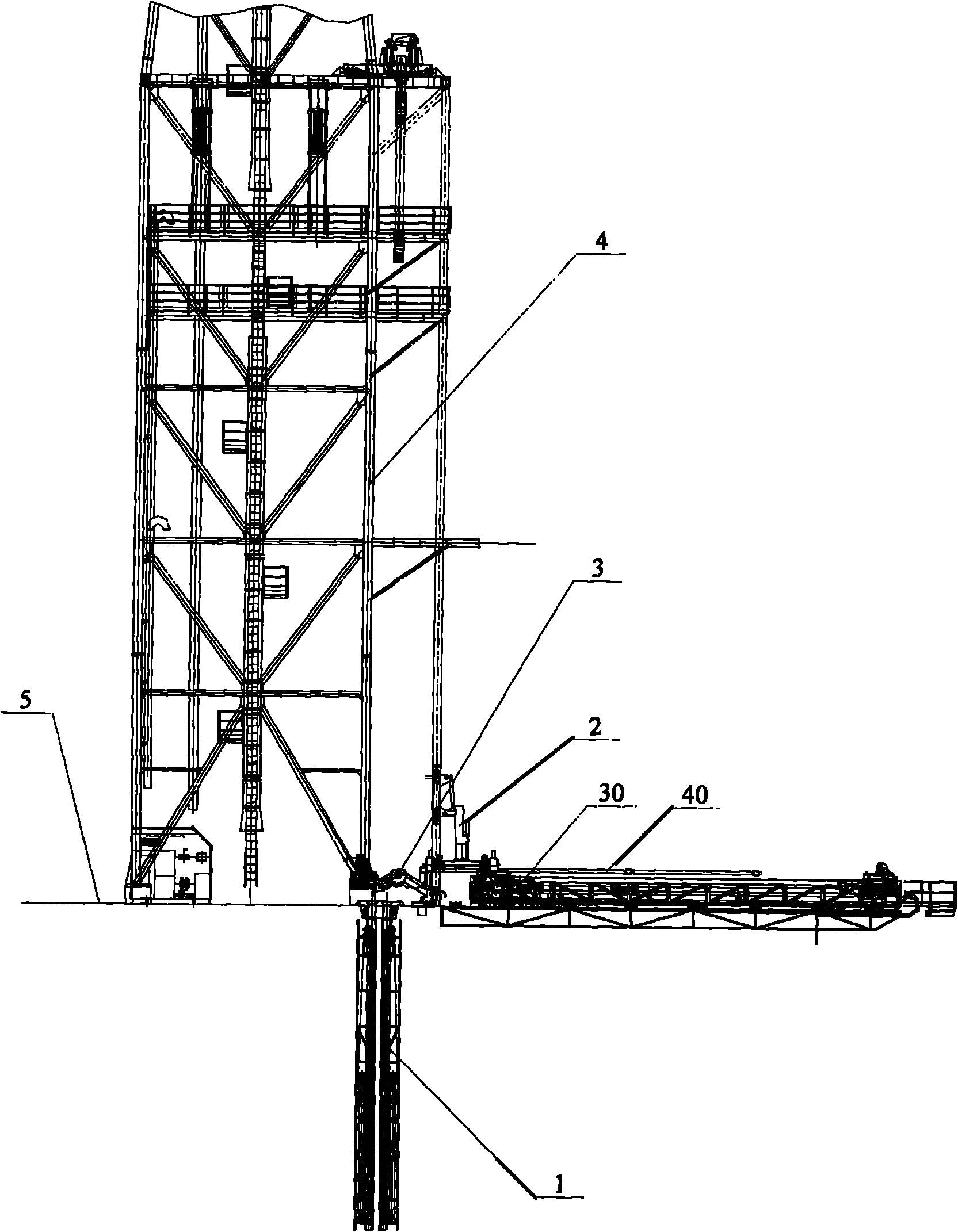

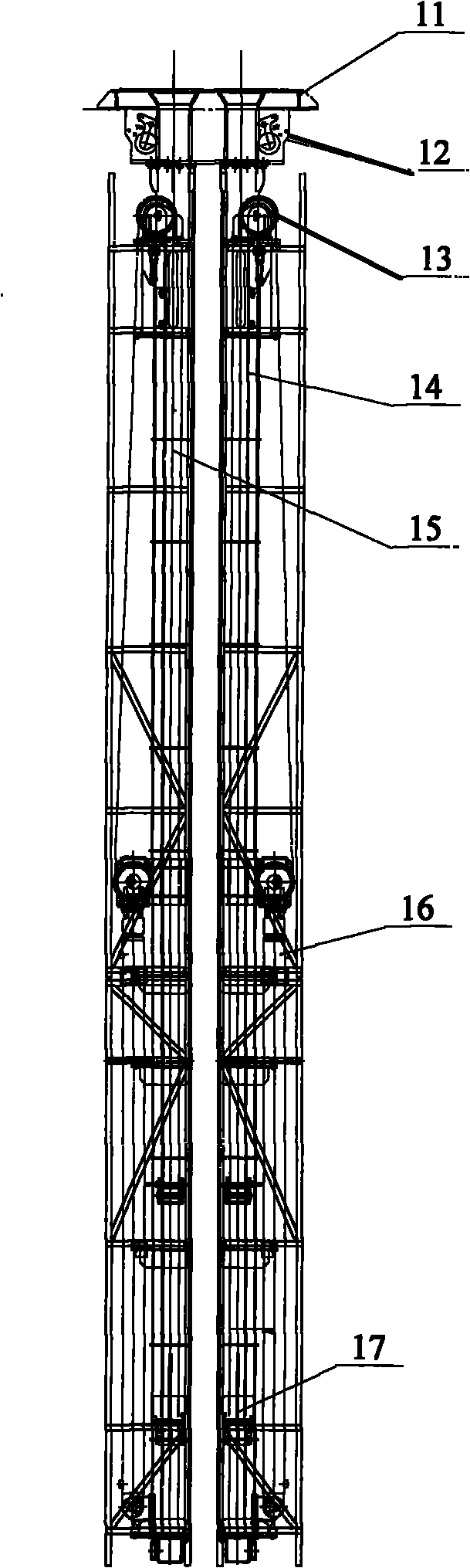

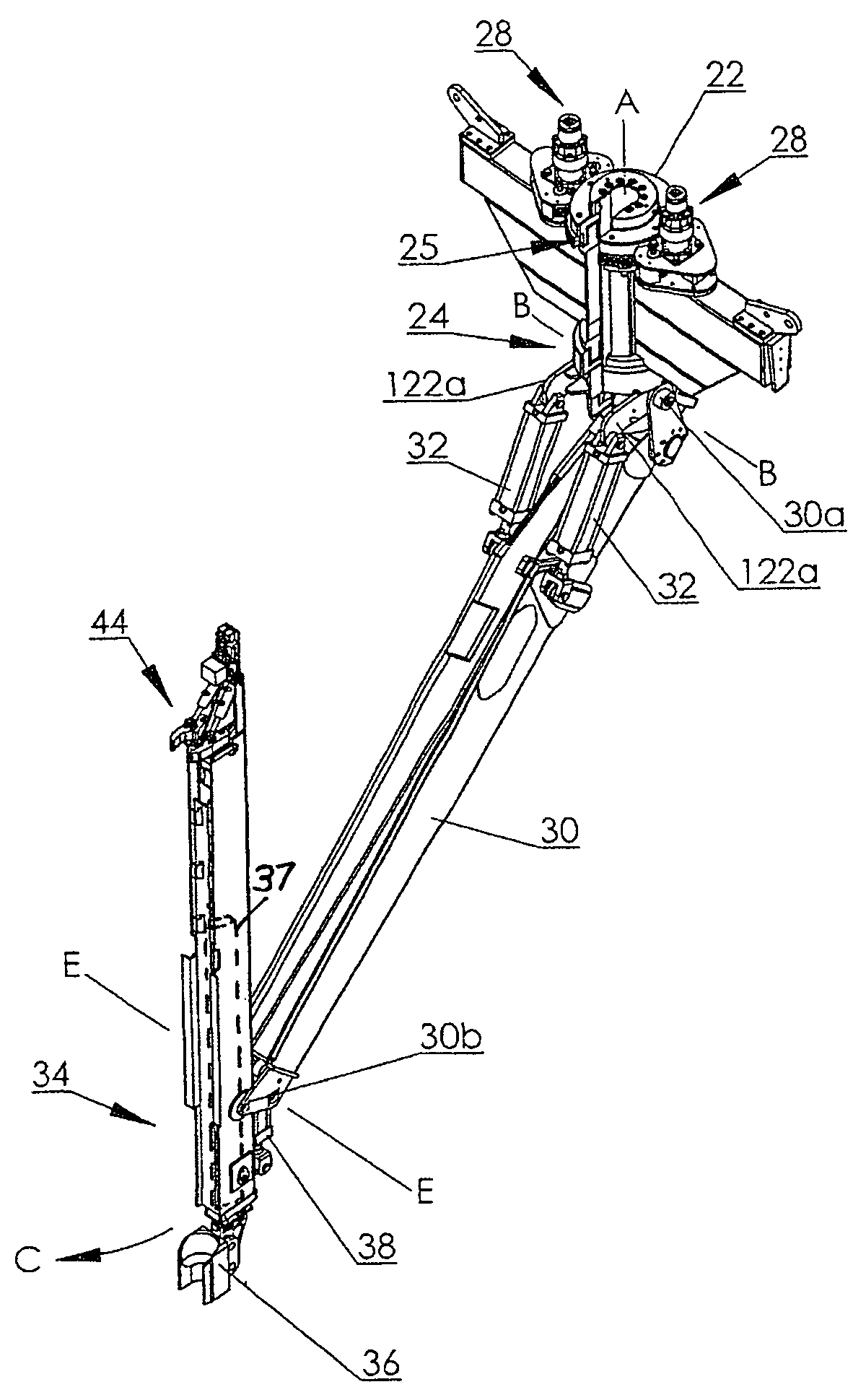

The pipe racking system is designed to handle drilling tubulars (primarily drill pipe and drill collars) between the racked or setback position and the well center. The racking system can mechanically grasp a stand of pipe, lift the pipe sufficient for free movement, and deliver the pipe to either the setback area for storage or to well center to be added to the drilling string. The purpose of this newly developed system is to move pipe safely and efficiently in the vertical position for drilling operations. Together with the use of its mechanized fingerboard, the system automates the process of handling and storing pipe vertically, thus eliminating the need for a worker at the racking board level. The system is capable of being installed within the masts of smaller rigs and may remain installed in the mast during rig moves thus minimizing any disassembly for rig-down.

Owner:NAT OILWELL DHT

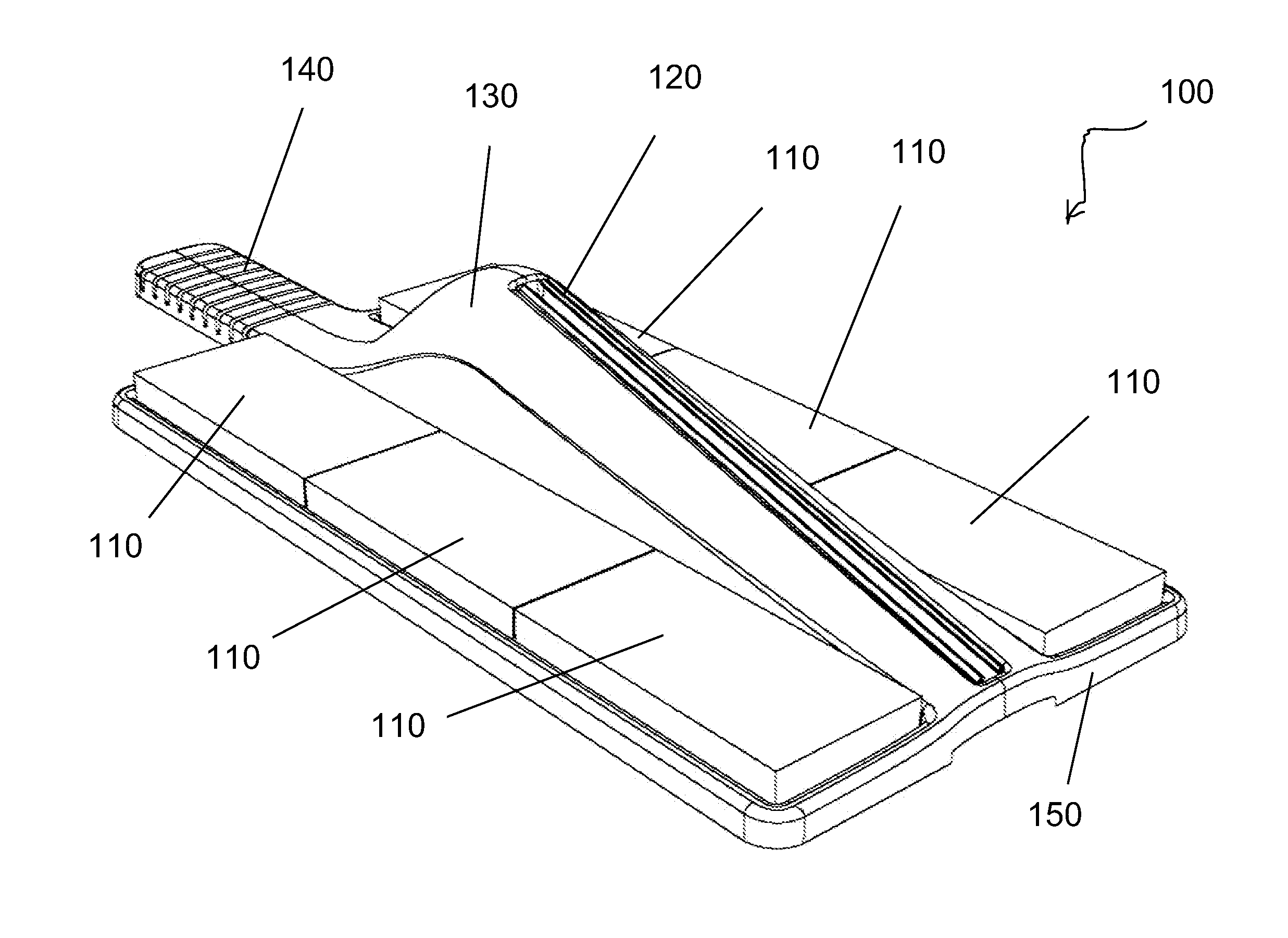

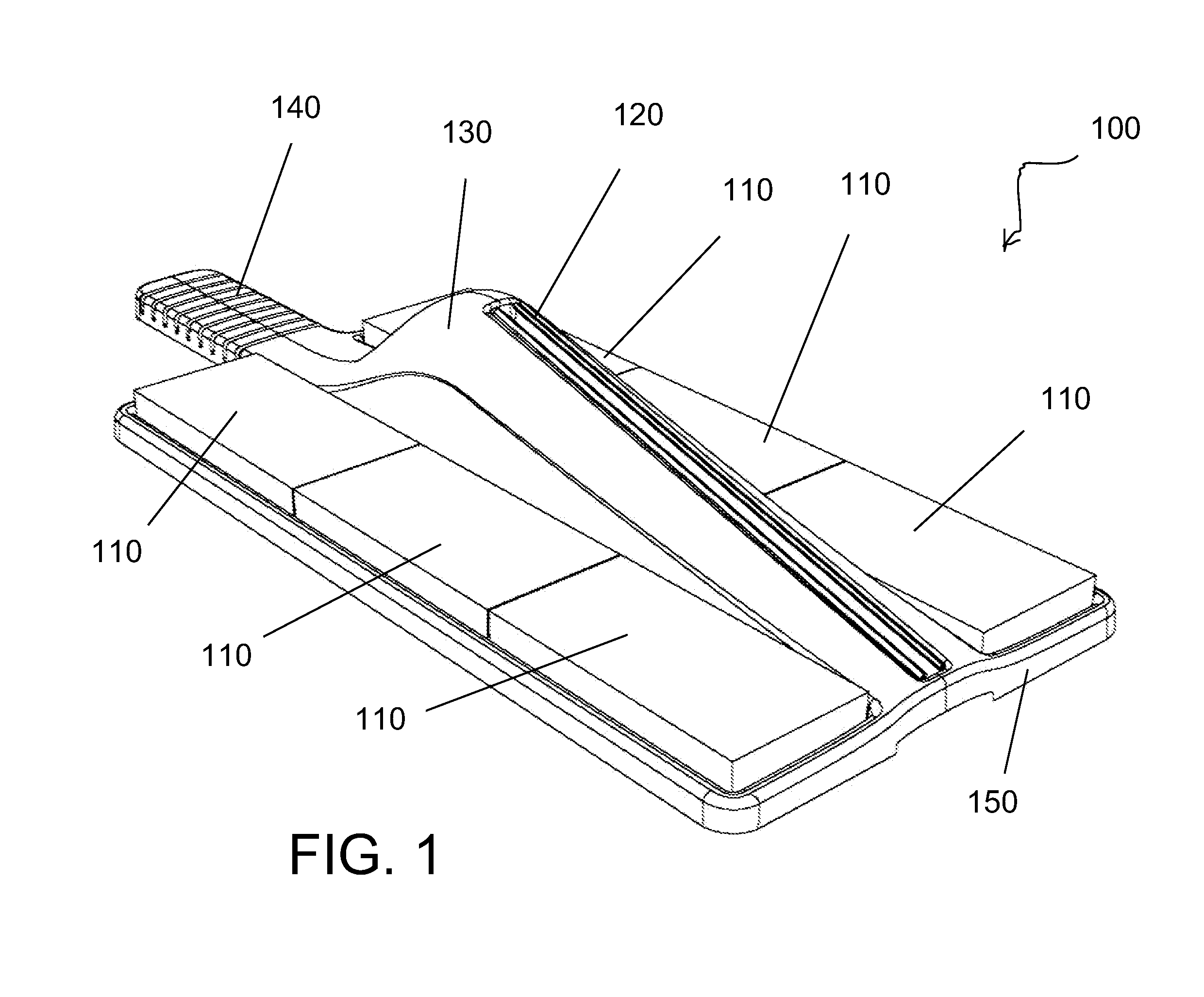

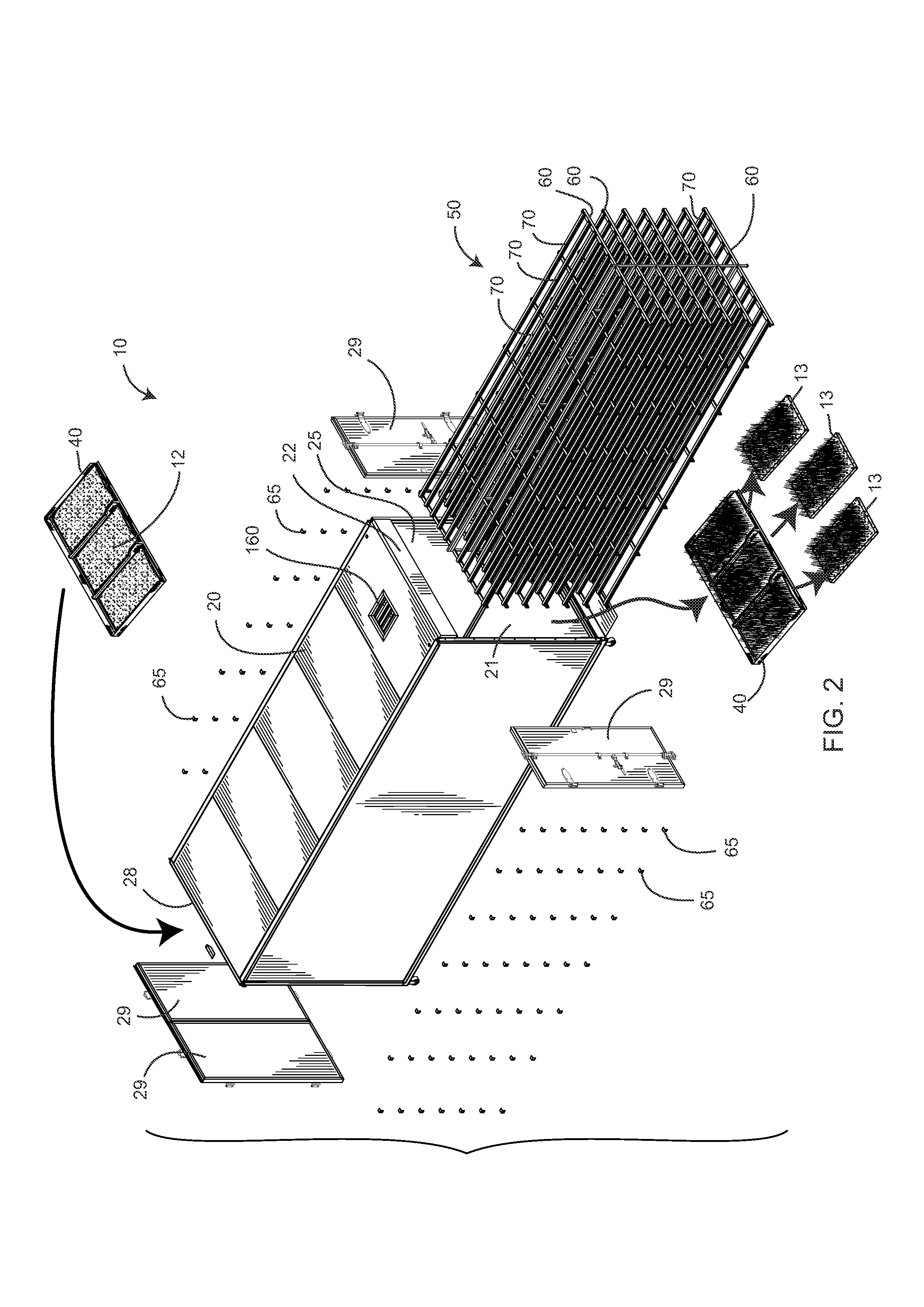

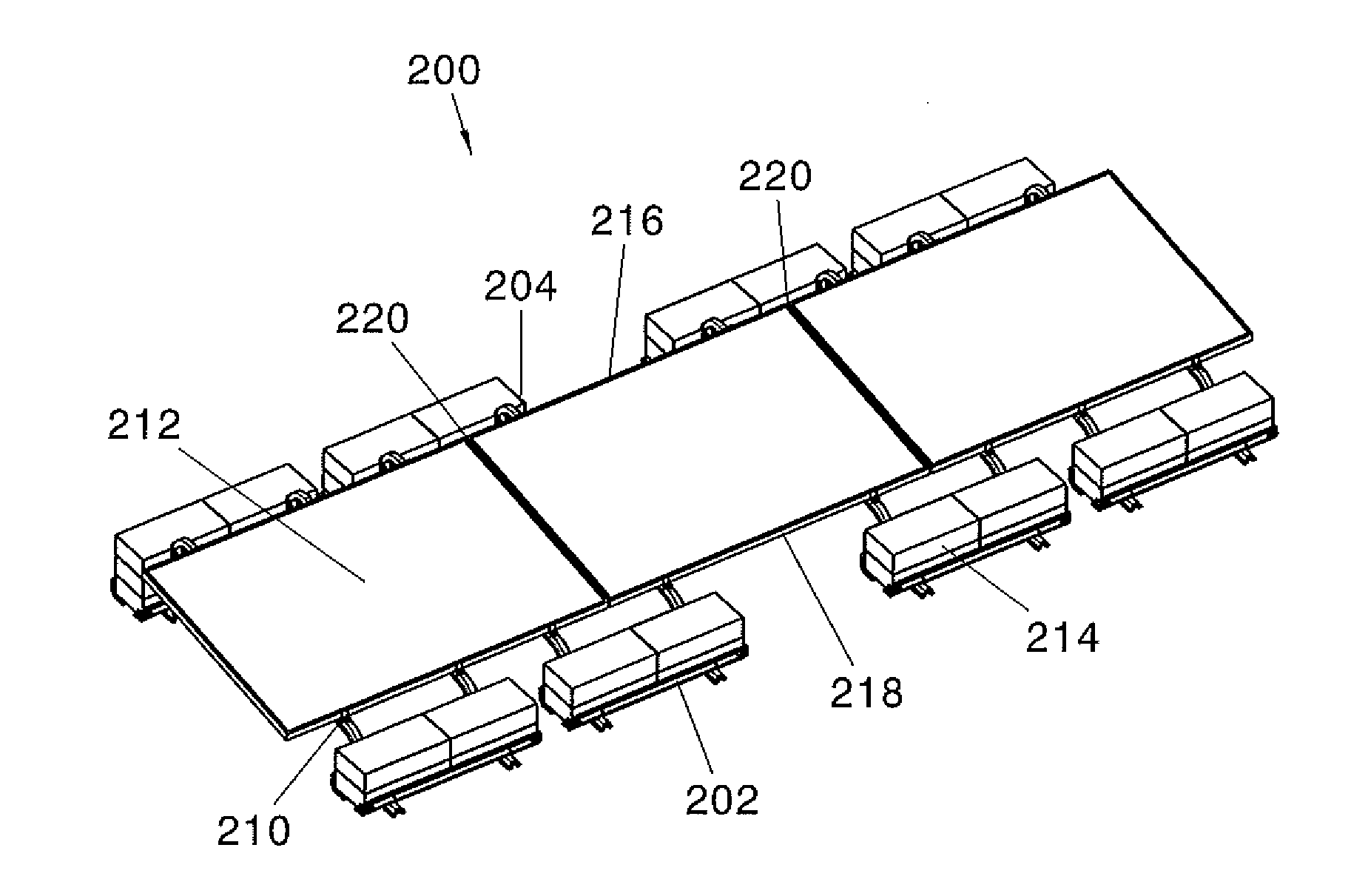

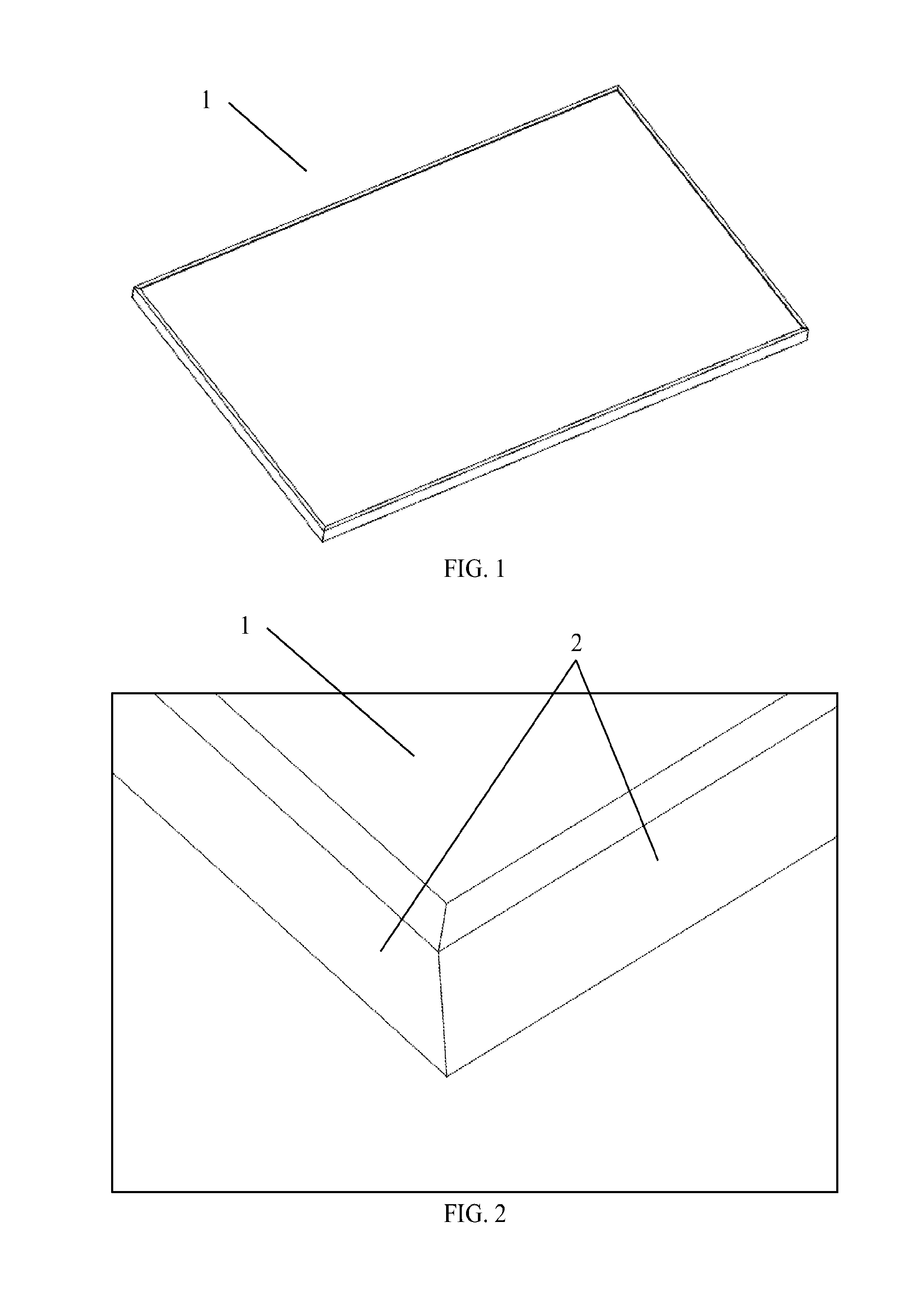

Modular solar racking system

A modular solar racking system comprises a plurality of modular solar rack supports that interconnect to provide a portable, non-invasive solar electrical generation system. One embodiment comprises a plastic modular solar rack support having a base portion, a ballast holding portion, a strut and a wedge portion. Supports are interconnected by fitting within grooves in the strut. Uni-strut frames are attached to the supports and solar panels are mounted thereon. In another embodiment, the supports comprise a base portion, a ballast holding portion, a forward lifting portion, a rearward lifting portion and a strut. Again, supports are interconnected by fitting within grooves disposed in the strut. The supports are stackable and are installed on-site using a torque wrench. Ballast may be used to hold the supports down. In one embodiment, a membrane is applied to the bottom surface which is used to adhere the support to a surface.

Owner:ROTHSCHILD ELIE +2

Pipe racking system

ActiveUS7246983B2Safe and efficient movementPractical, convenient and safeDrilling rodsLifting devicesSystems designDrill pipe

The pipe racking system is designed to handle drilling tubulars (primarily drill pipe and drill collars) between the racked or setback position and the well center. The racking system can mechanically grasp a stand of pipe, lift the pipe sufficient for free movement, and deliver the pipe to either the setback area for storage or to well center to be added to the drilling string. The purpose of this newly developed system is to move pipe safely and efficiently in the vertical position for drilling operations. Together with the use of its mechanized fingerboard, the system automates the process of handling and storing pipe vertically, thus eliminating the need for a worker at the racking board level. The system is capable of being installed within the masts of smaller rigs and may remain installed in the mast during rig moves thus minimizing any disassembly for rig-down.

Owner:NAT OILWELL DHT

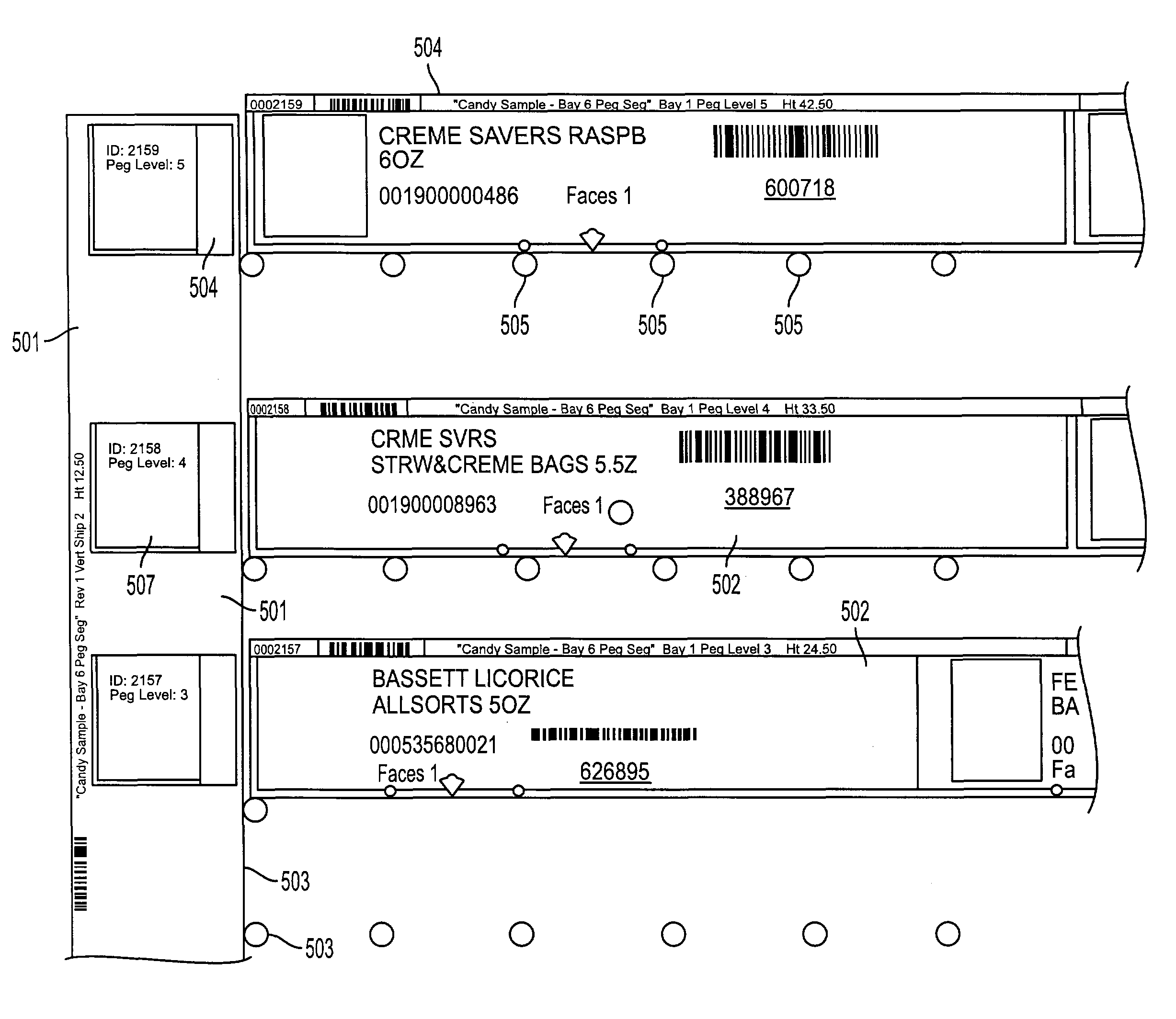

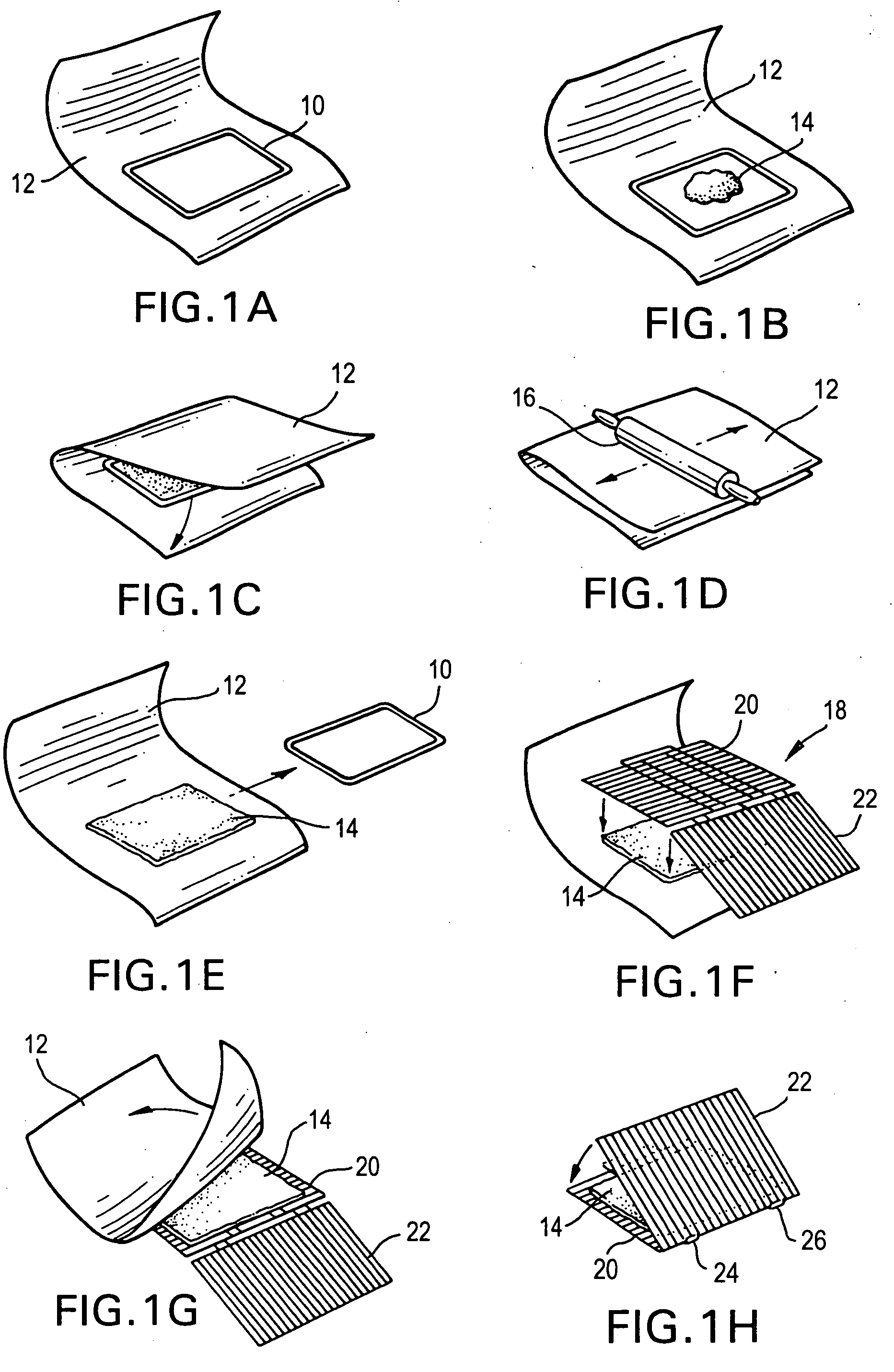

Pegboard stocking and resetting system

ActiveUS8626613B2Address efficiencyAddress executionStampsOther printing matterPlanogramColor marker

Methods and apparatuses for making a stocking strip for pegboard stocking. The stocking strip includes an elongated strip containing information for locating a plurality of different products on a peg board display, a first identification number for identifying the strip, a first text area for identifying a source planogram or print job, a second text area for listing stocking location in a sales establishment which contains the pegboard display, a third text area for listing a height for the product, a demarcation for indicating a span of the position of the product on the pegboard, a product image, a product identifier, a color marker and a peg indicator for locating the peg on the pegboard display.

Owner:INFORMATION PLANNING & MANAGEMENT SERVICE

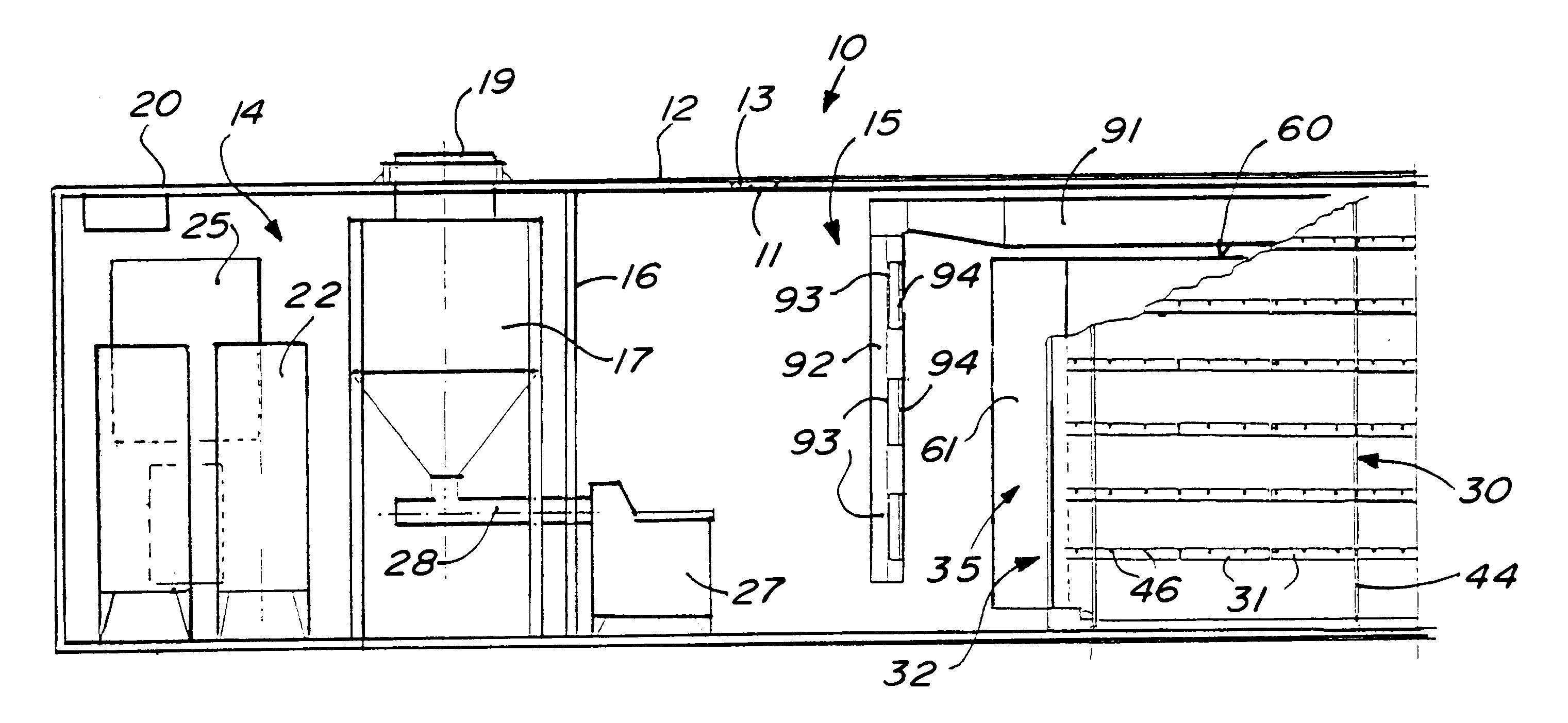

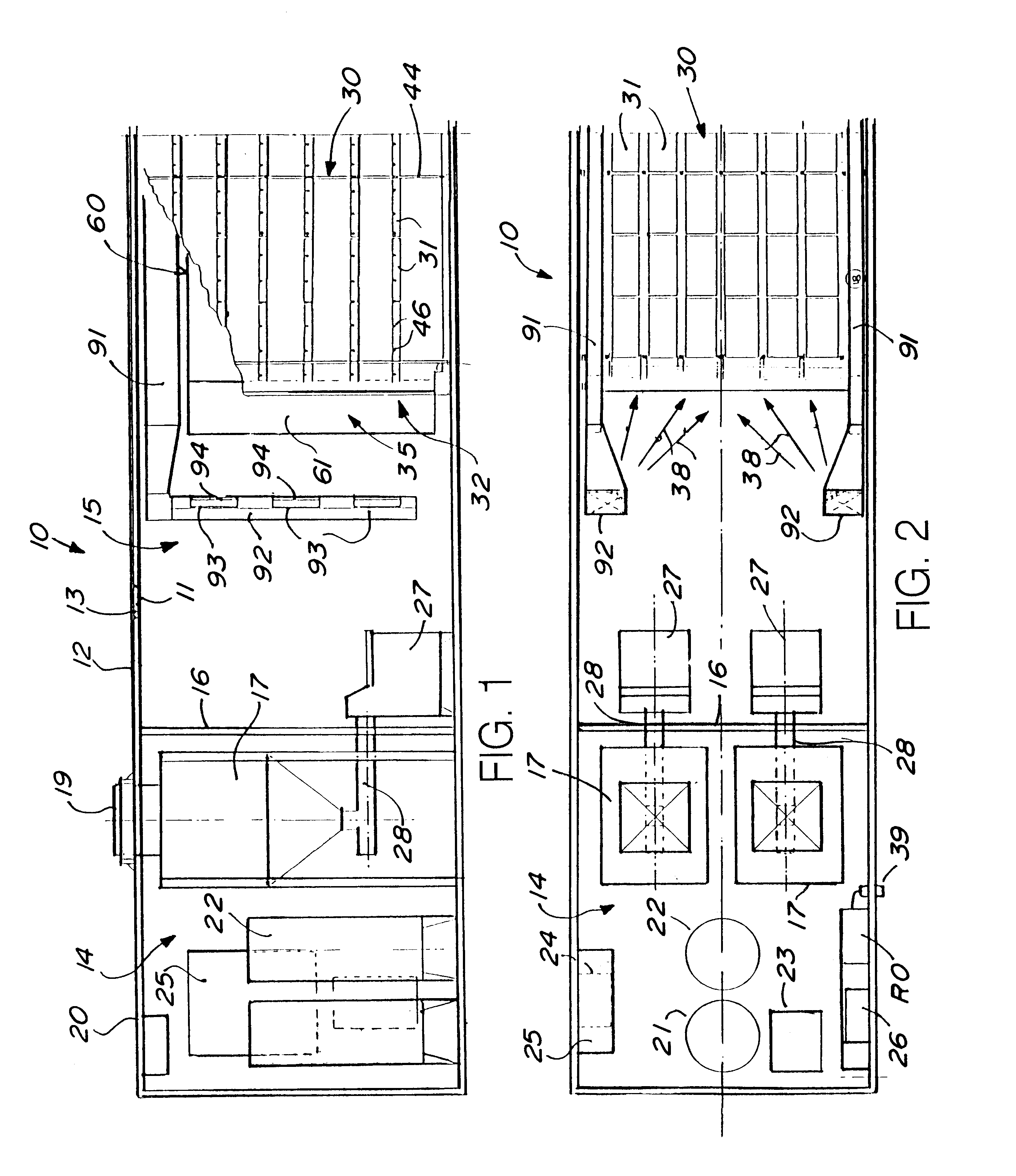

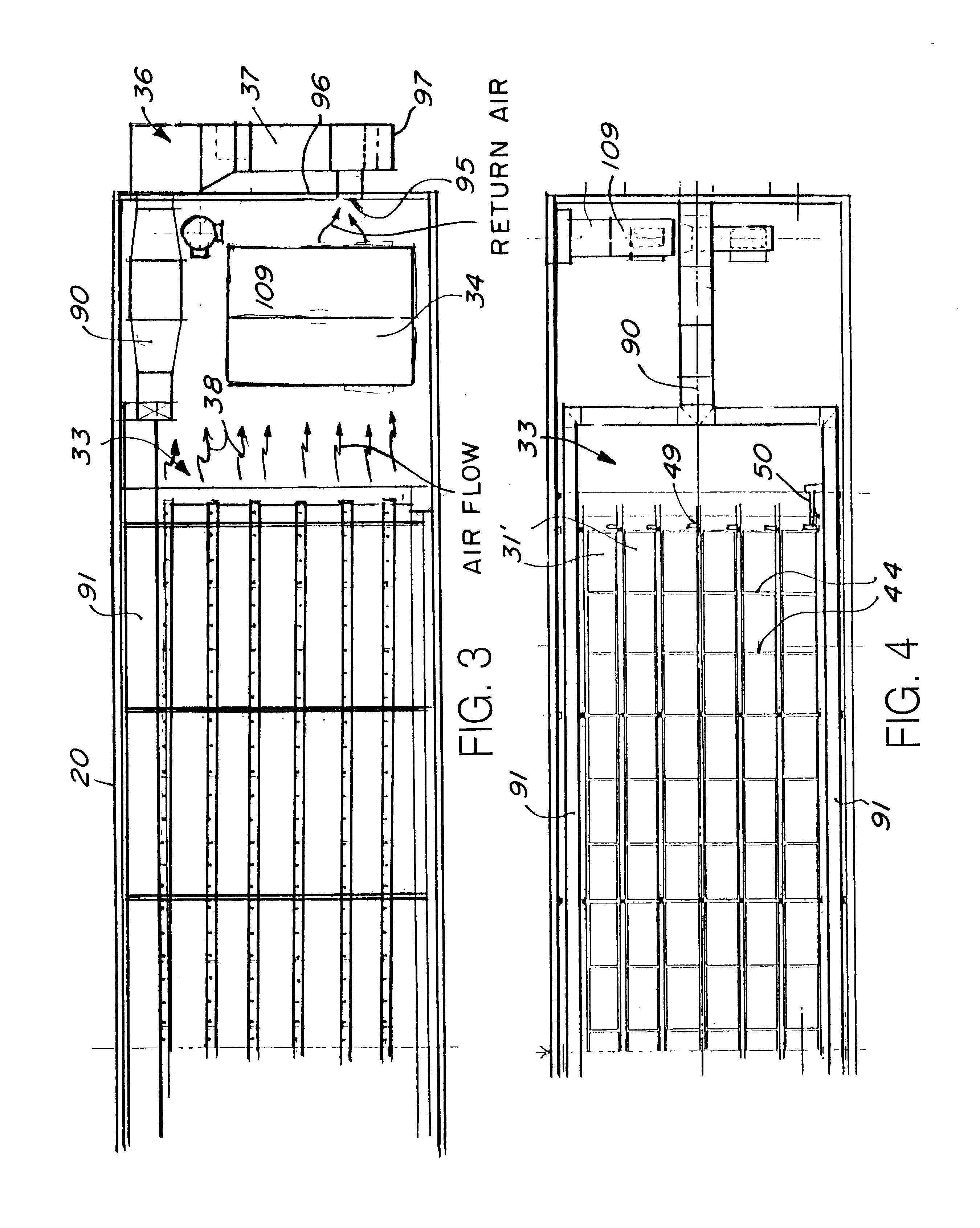

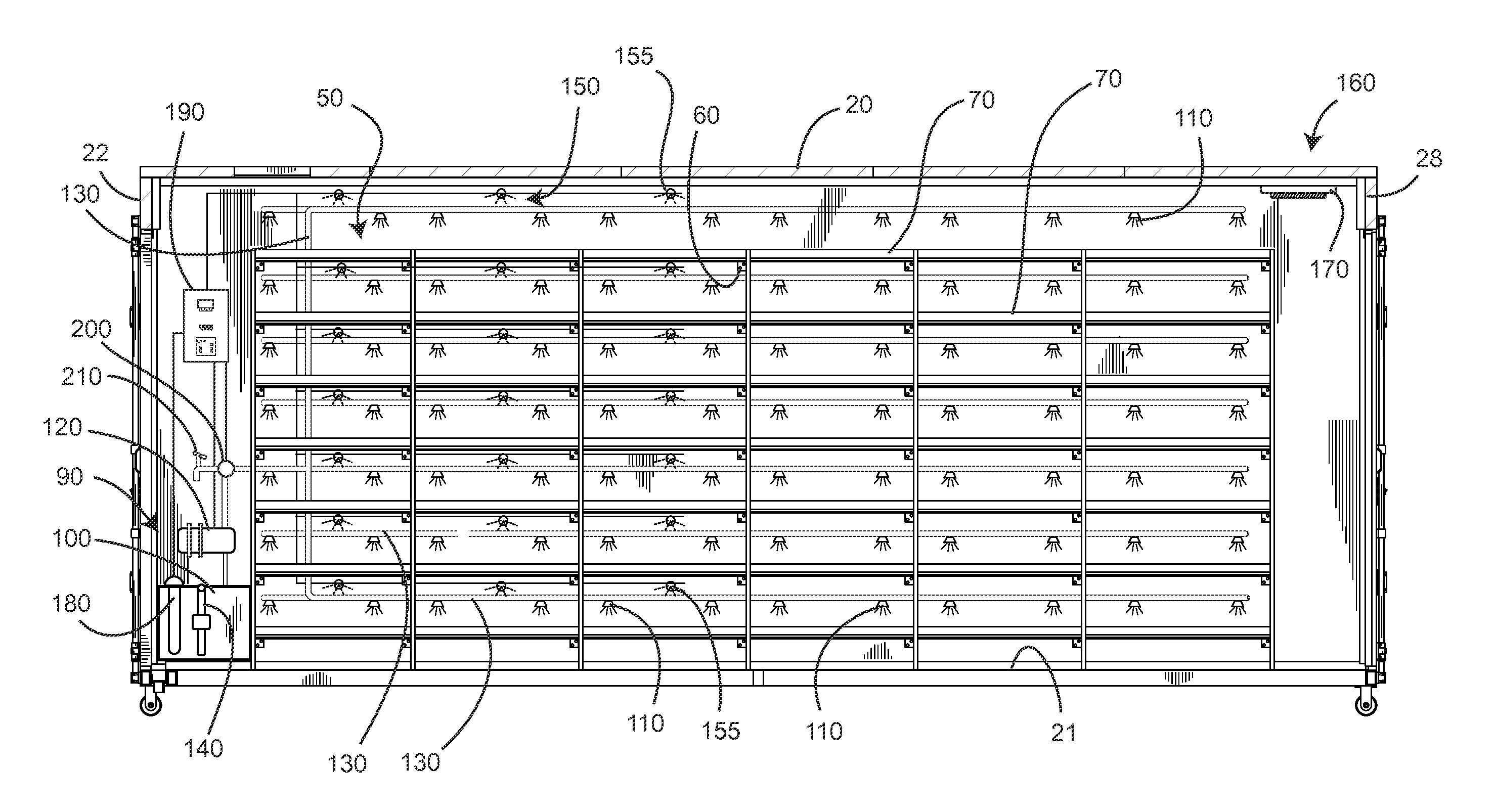

Fodder-growing enclosure

InactiveUS8234812B1Facilitate ready removalEasy to slideClimate change adaptationAgriculture gas emission reductionWater sourceEngineering

A transportable fodder production unit is disclosed that includes an insulated container having a front end and a rear end, a plurality of trays each having drain apertures through a bottom side thereof, a racking system for supporting each of the trays with a plurality of shelves extending from the front end of the container to the rear end of the container, an irrigation system attachable to a water source and having a water tank in fluid communication with a plurality of spray heads through a pump and a plurality of pipes, a lighting system that maintains a predetermined illumination within the container, a thermal control system that maintains the temperature inside the container within a predetermined temperature range, and a central control system for activating the other systems and maintaining electrical load balancing on a power source.

Owner:COLLESS TERRY +1

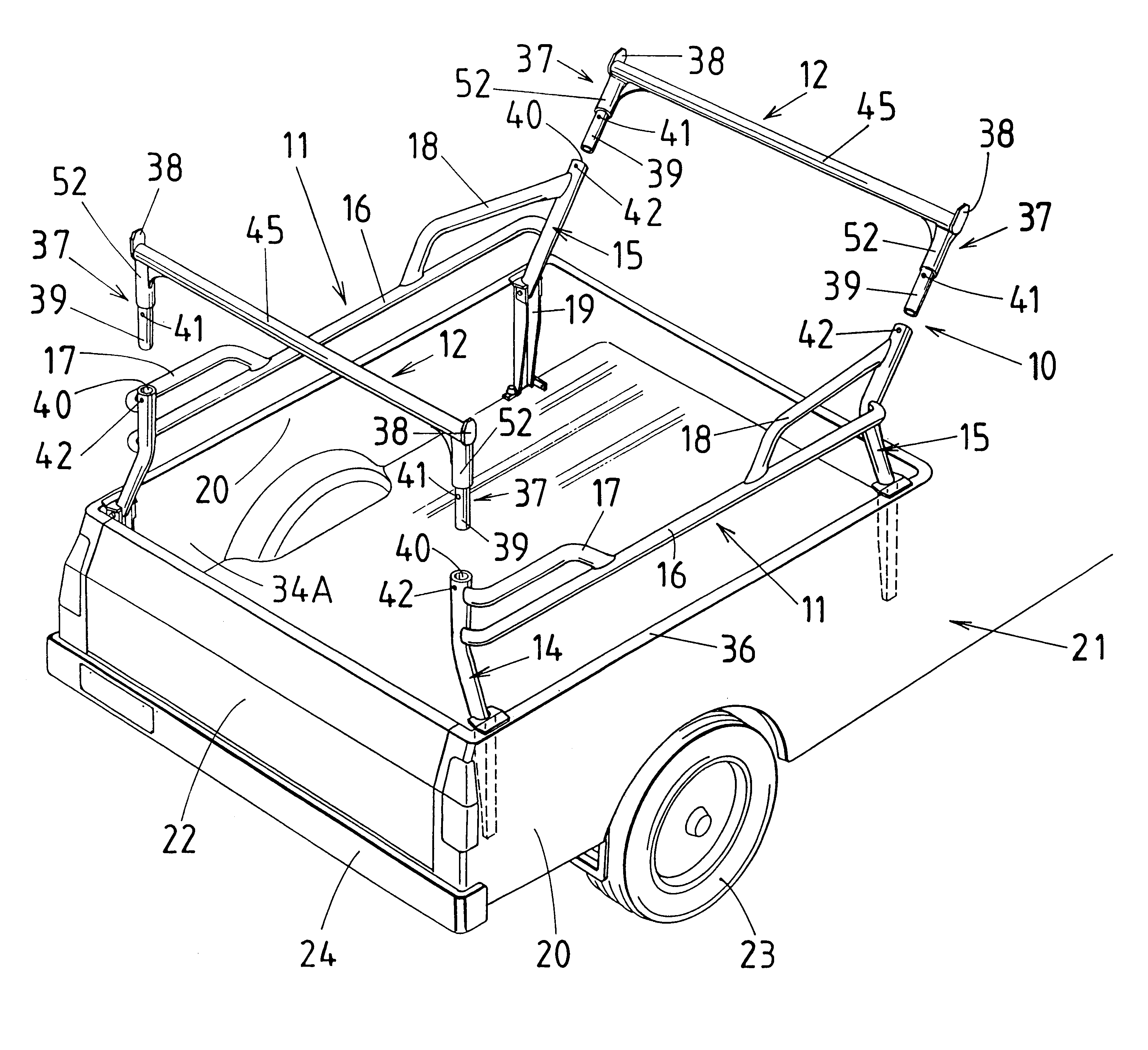

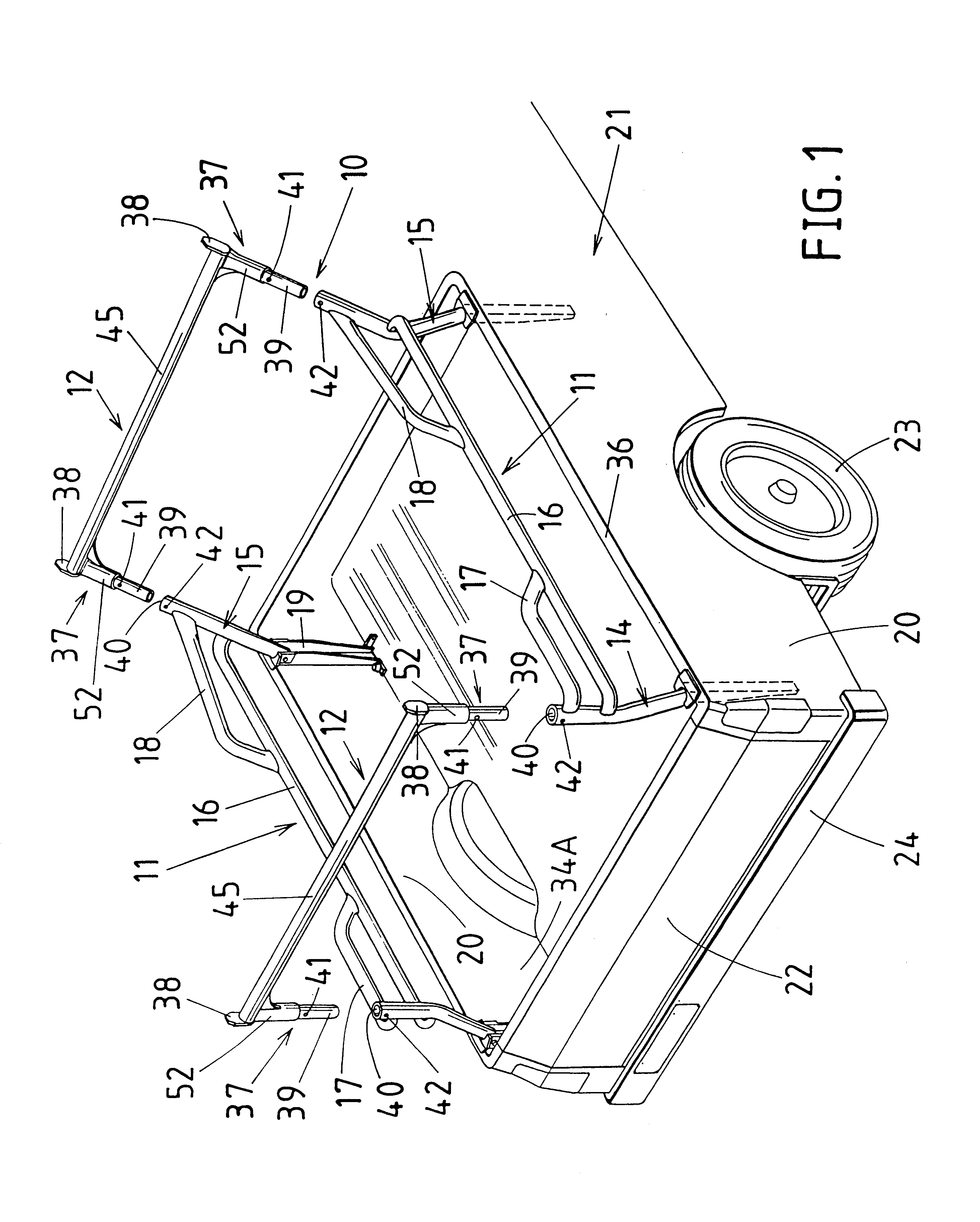

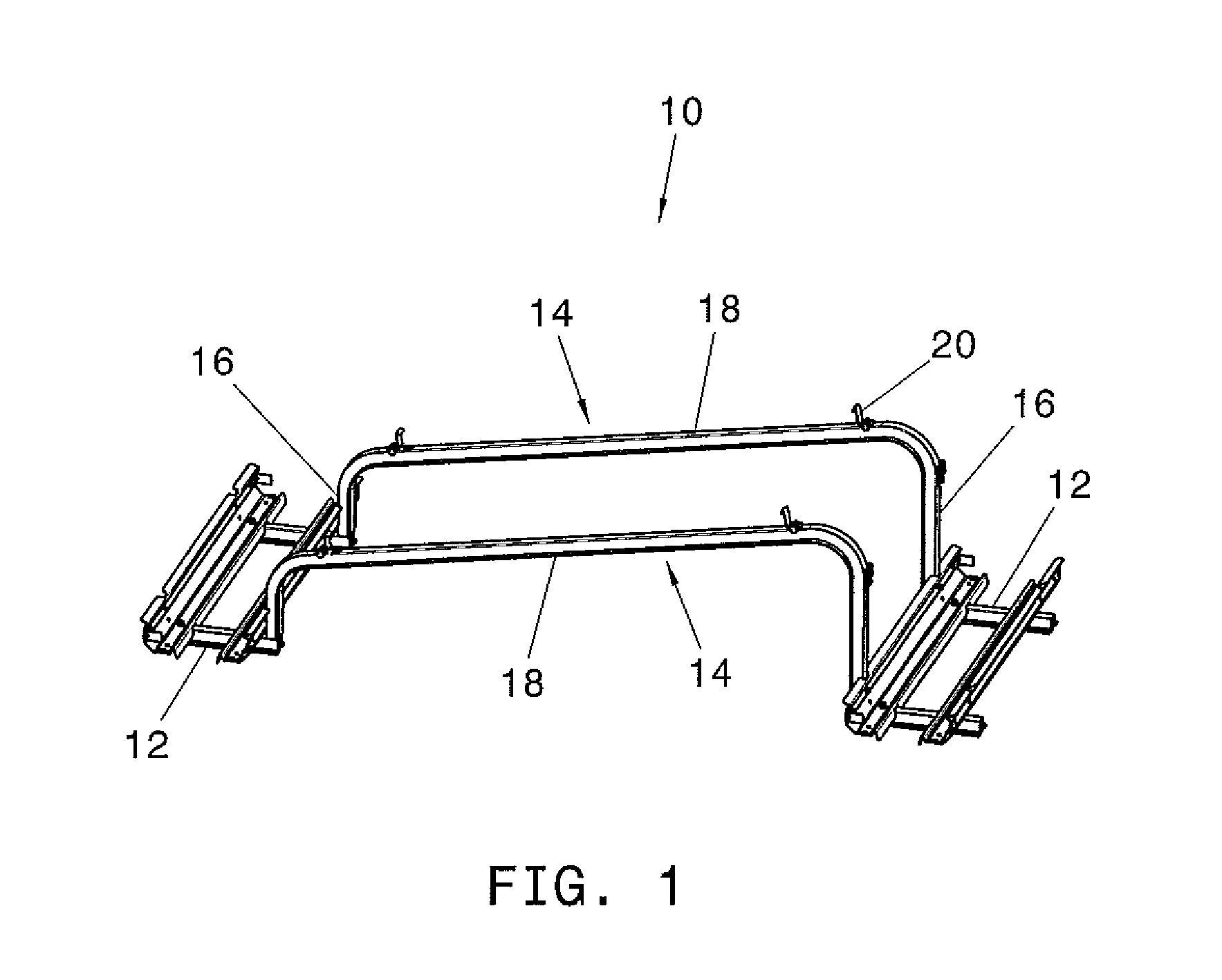

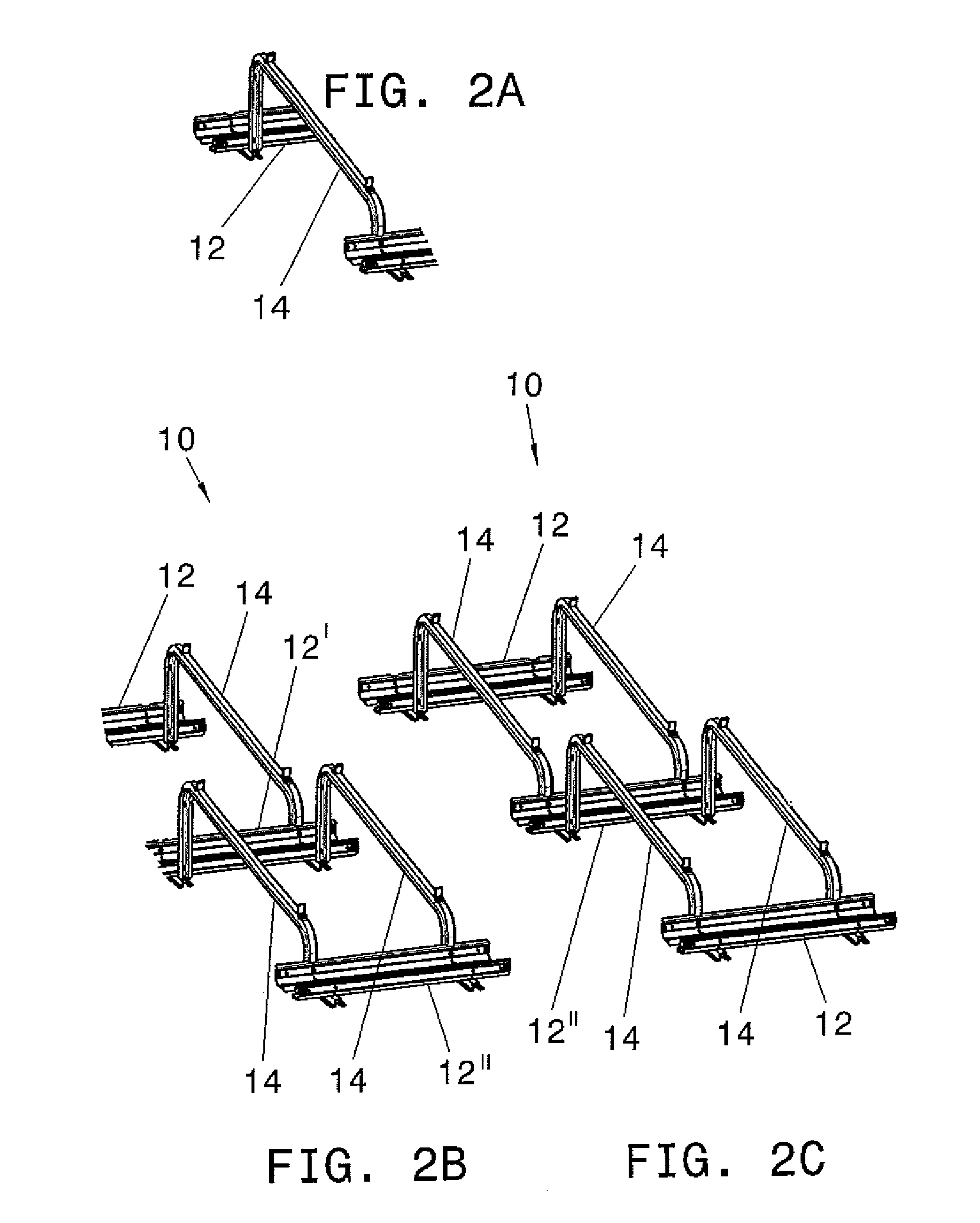

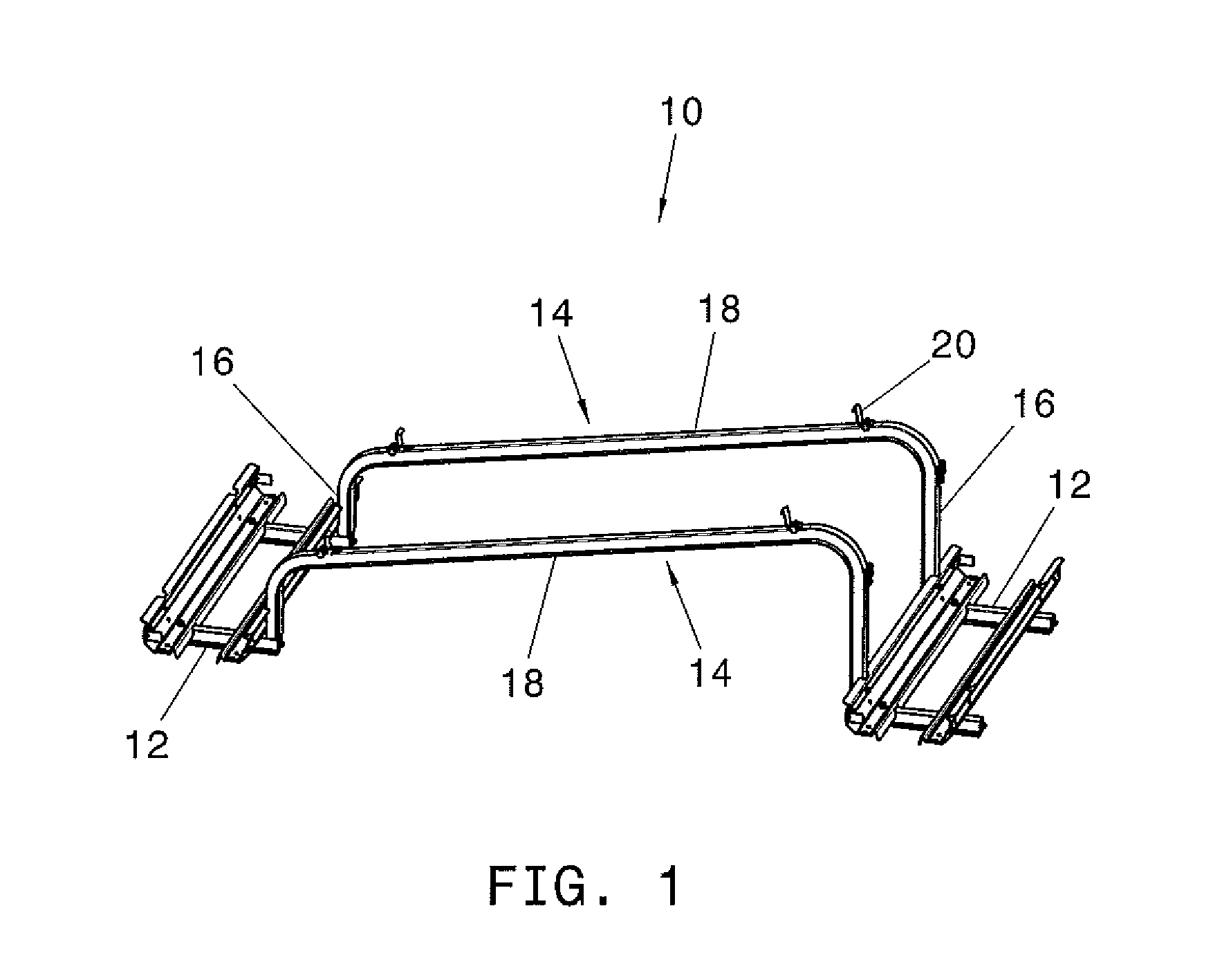

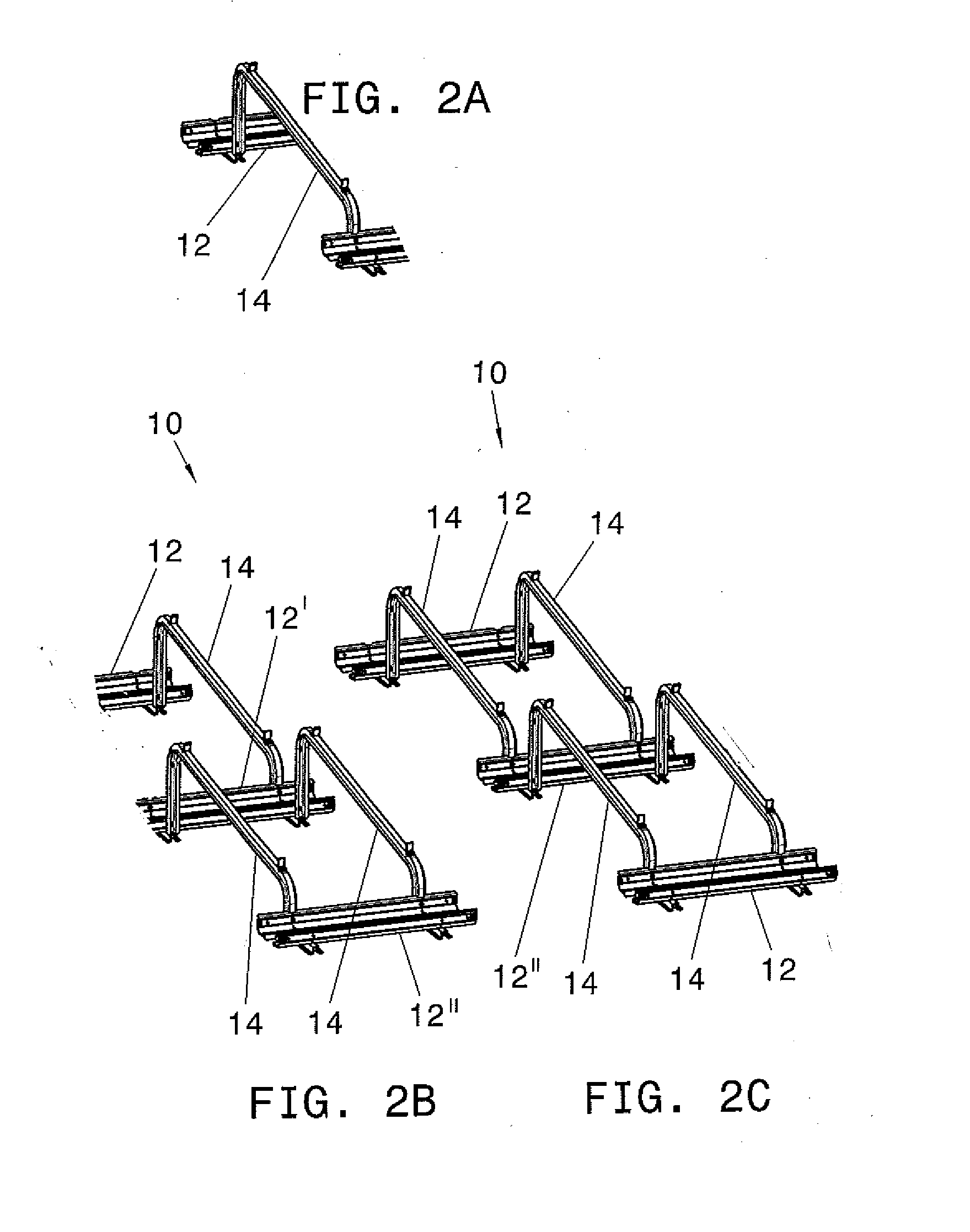

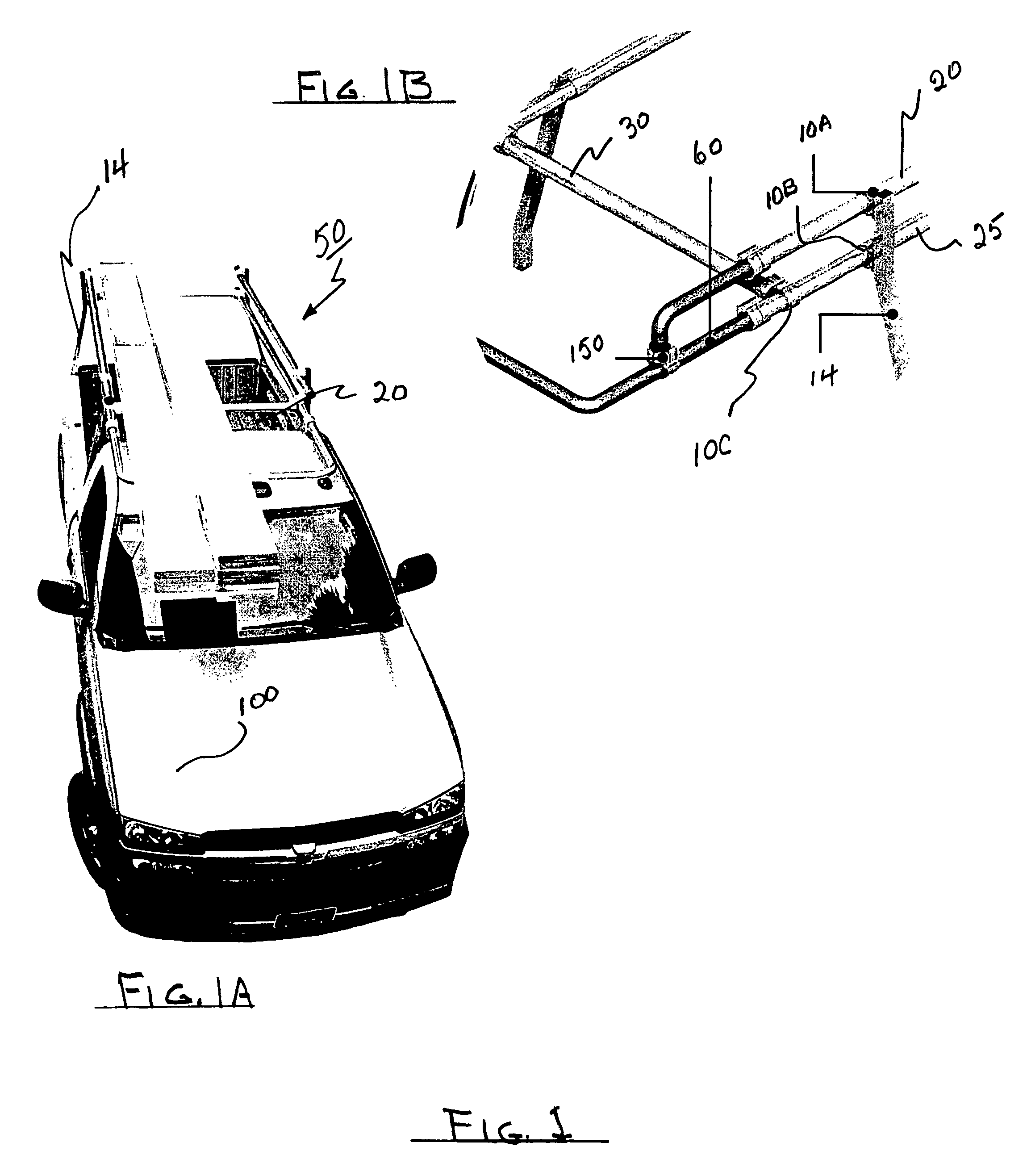

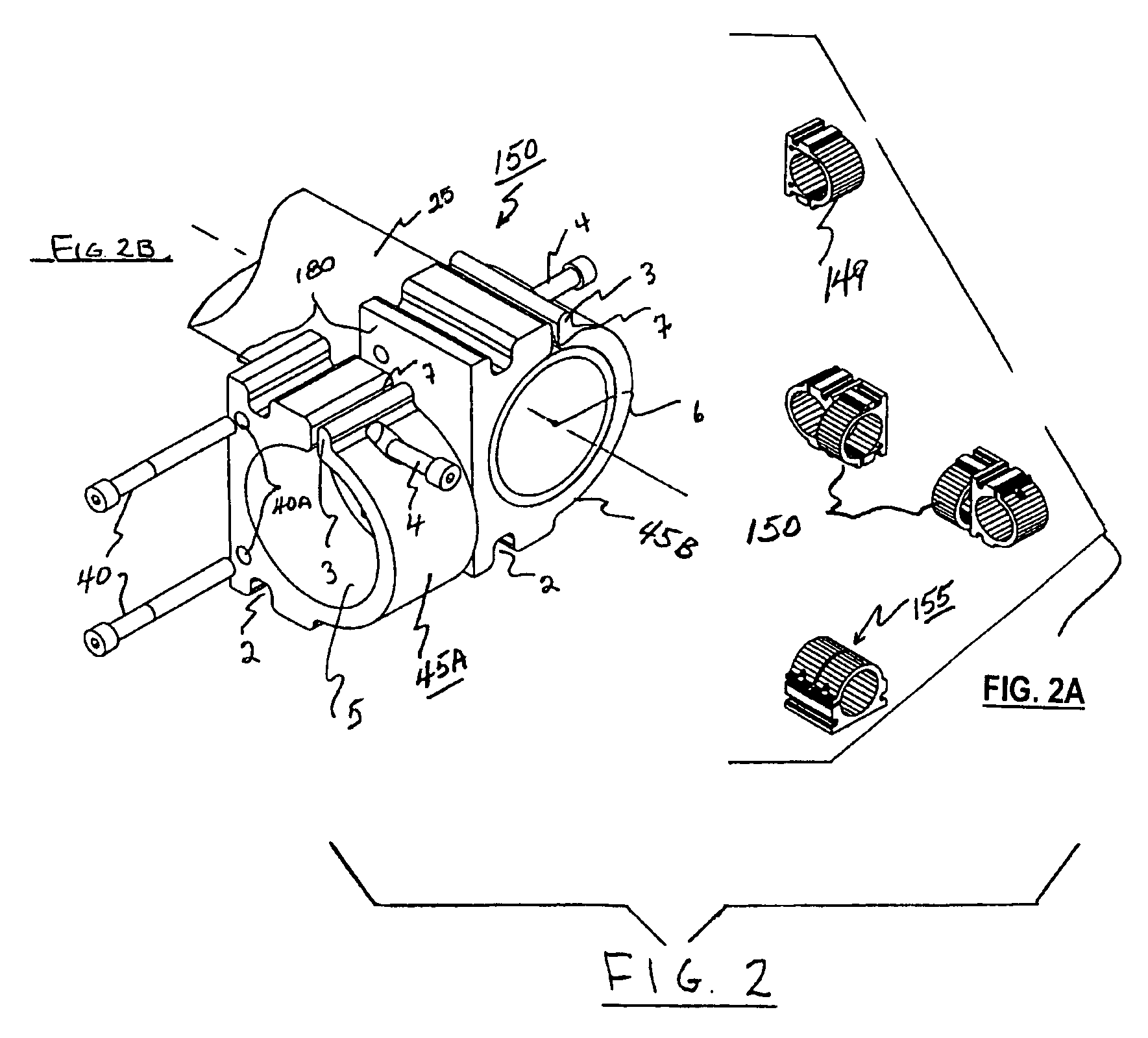

Vehicle racking system

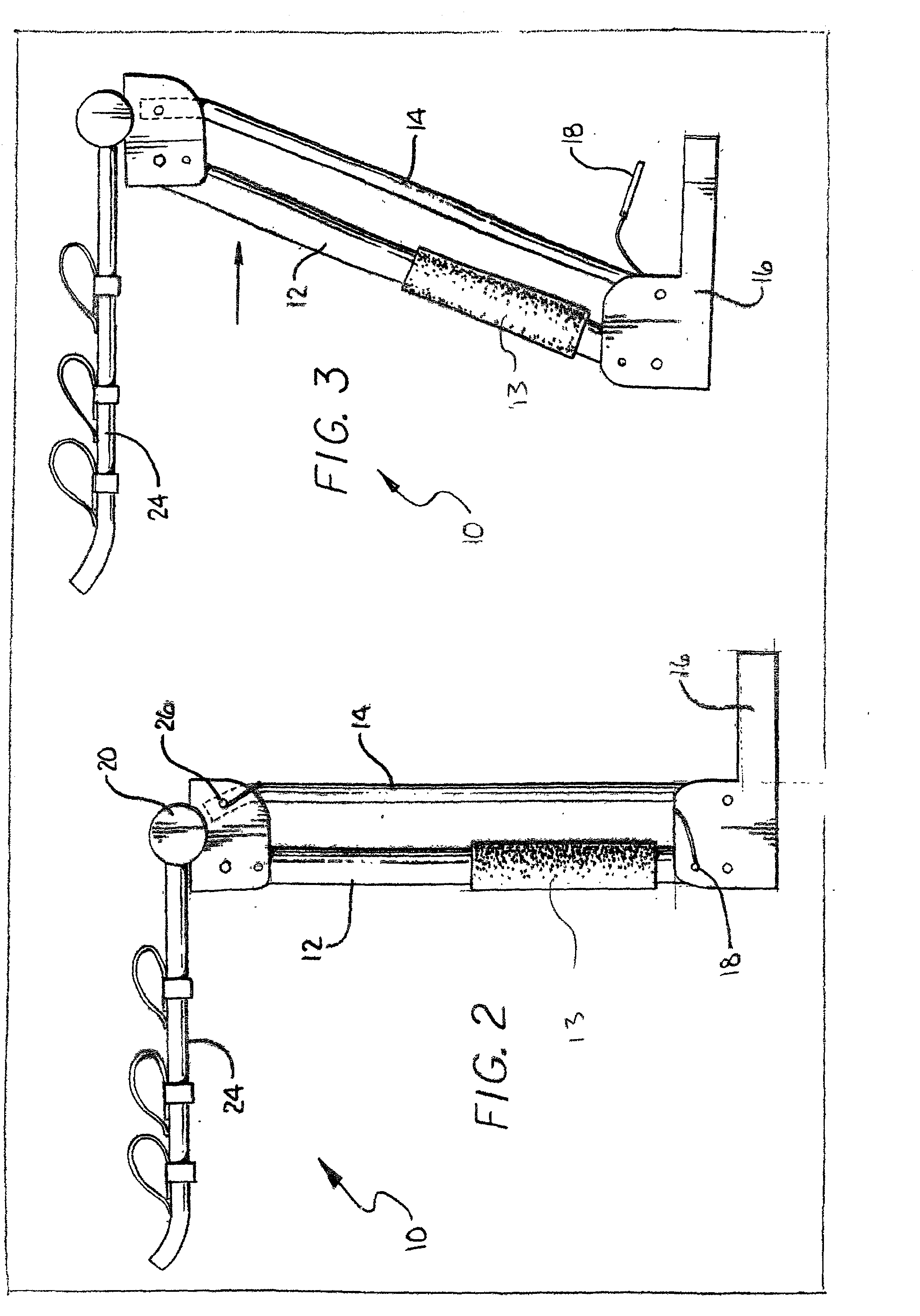

InactiveUS6186571B1Reduce disadvantagesVehicle to carry long loadsSupplementary fittingsEngineeringRacking

A racking system (10) for a pick up vehicle (21) including a pair of side frames (11) which are each mountable to an associated side wall (20) of the pick up vehicle (21) including one or more tie bars (16, 17, 18) and which side frames (11) are each pivotable about a longitudinal axis from an extended position to a lowered position and a pair of end frames (12) wherein each end frame (12) is releasably attachable to respective ends (37) of the pair of side frames (11) wherein the racking system (10) is self-bracing in the extended position.

Owner:BURKE MALCOLM ROBERT

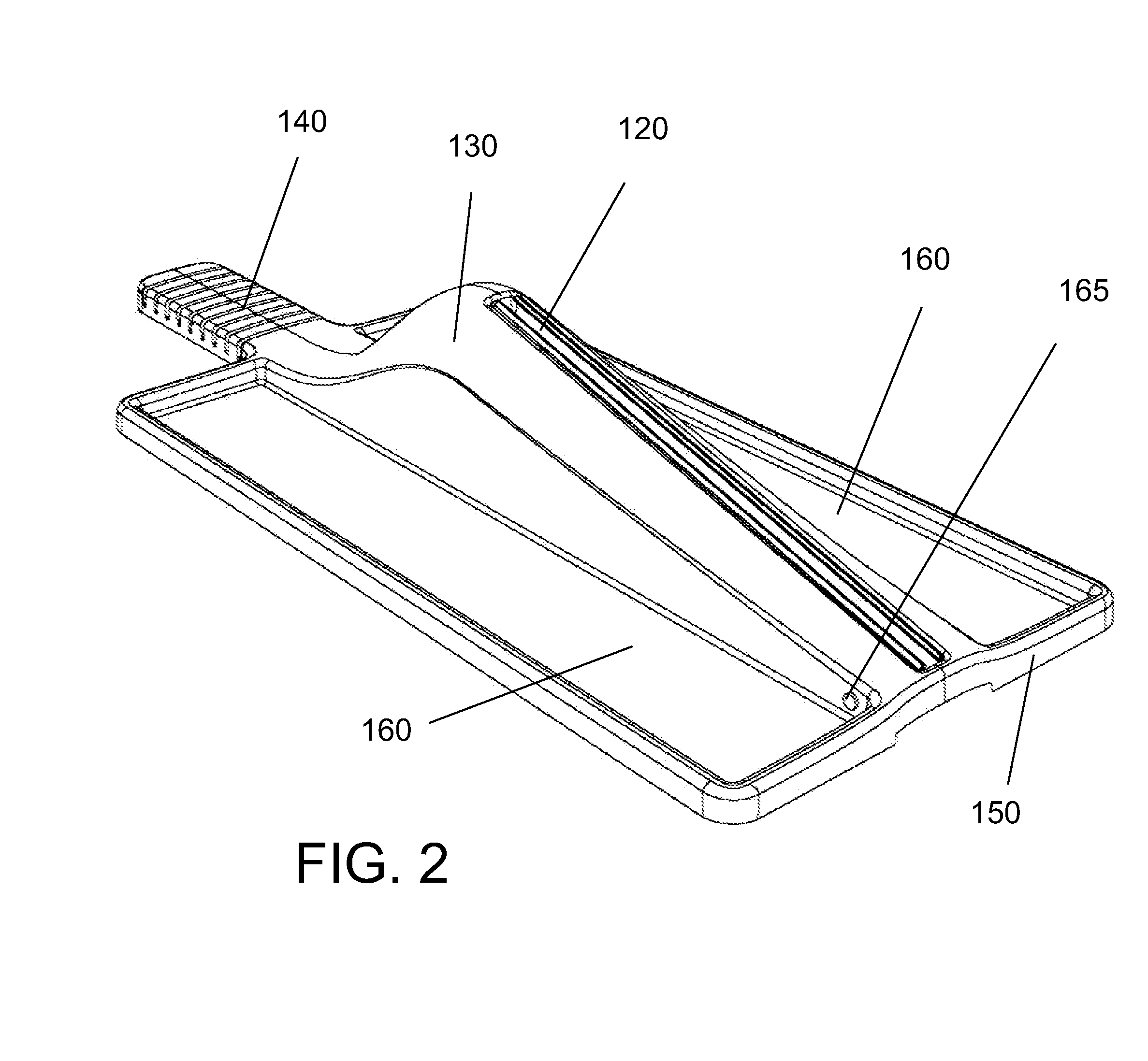

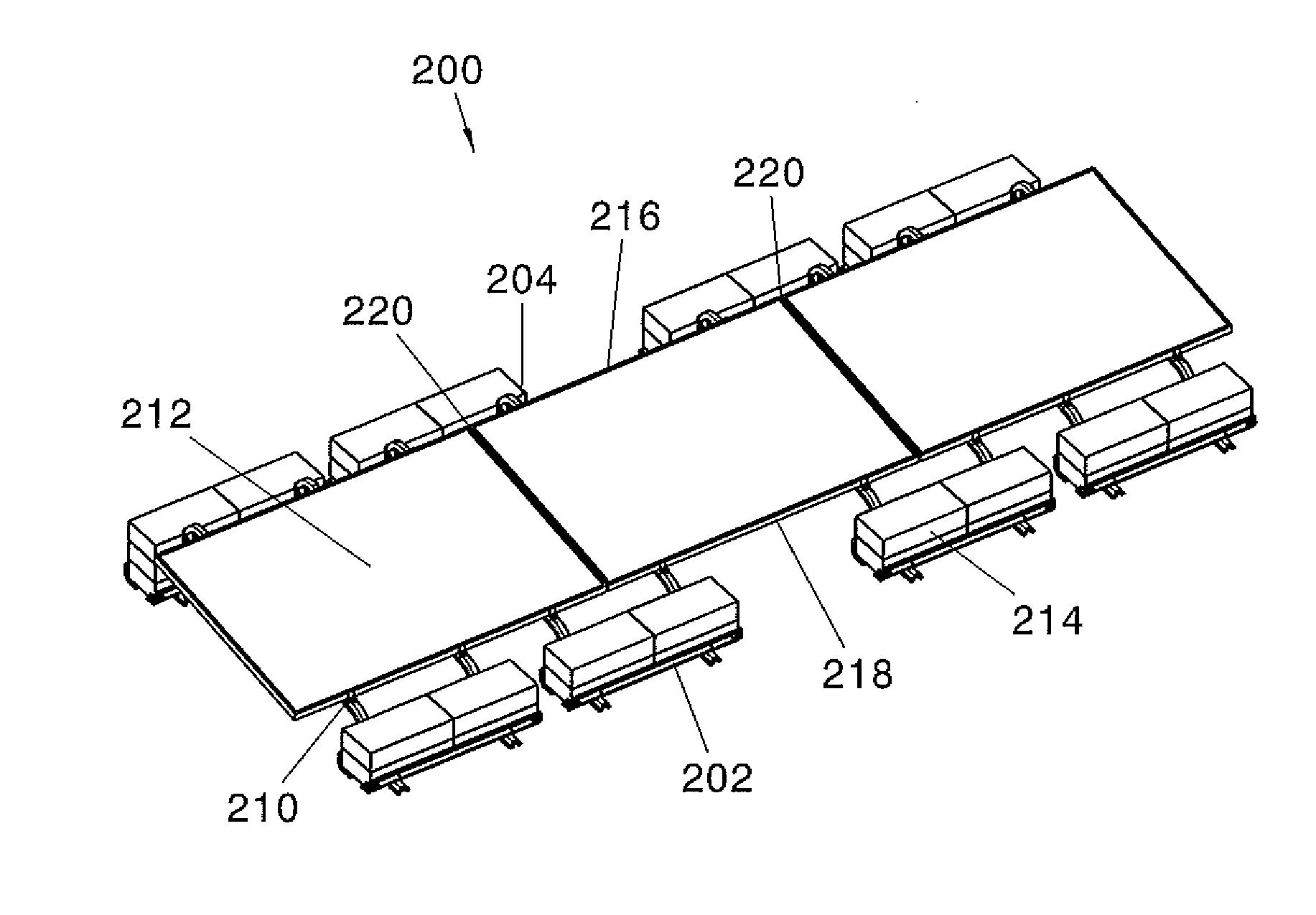

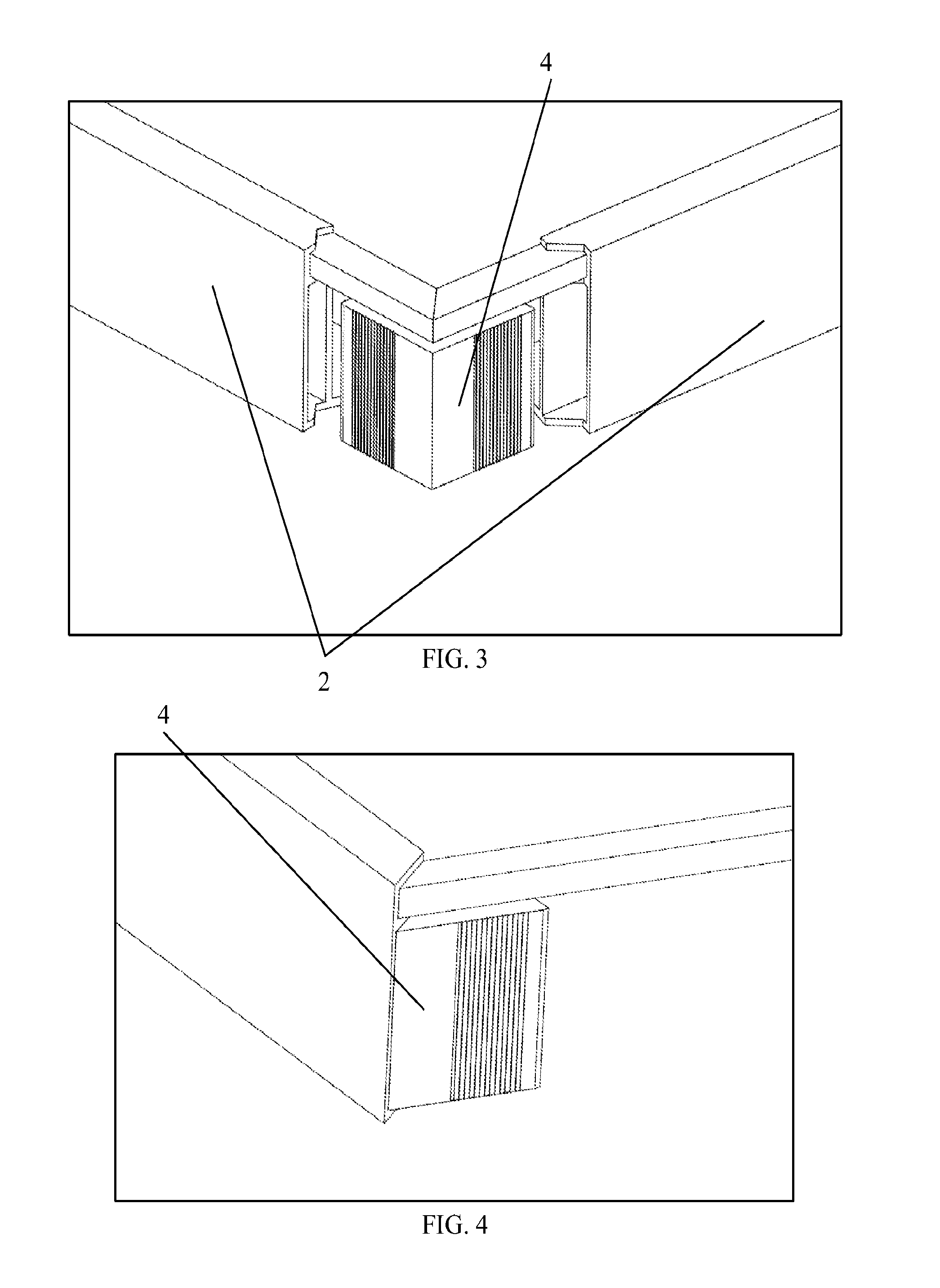

Modular solar panel racking system

Owner:APPLIED ENERGY TECH

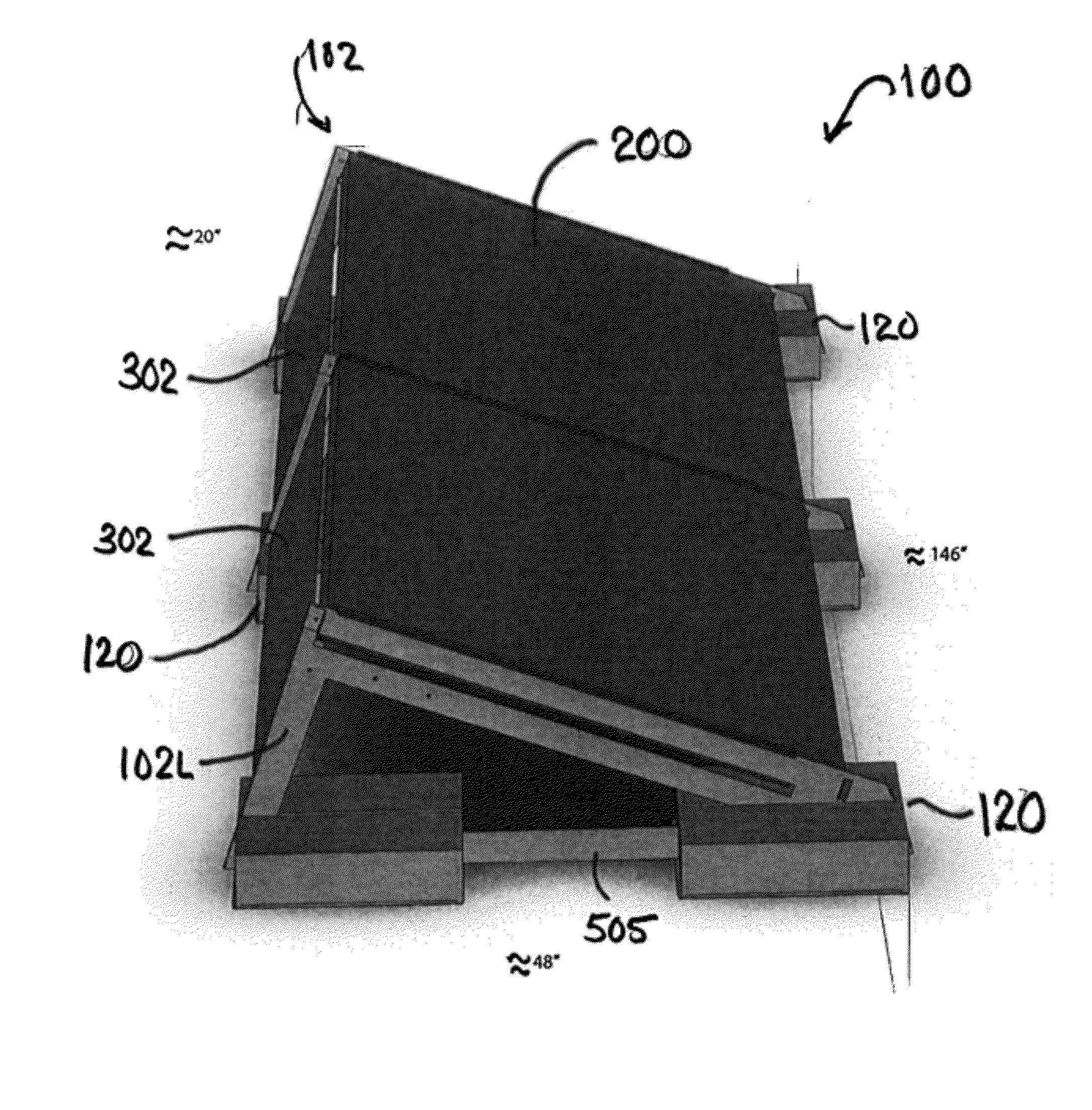

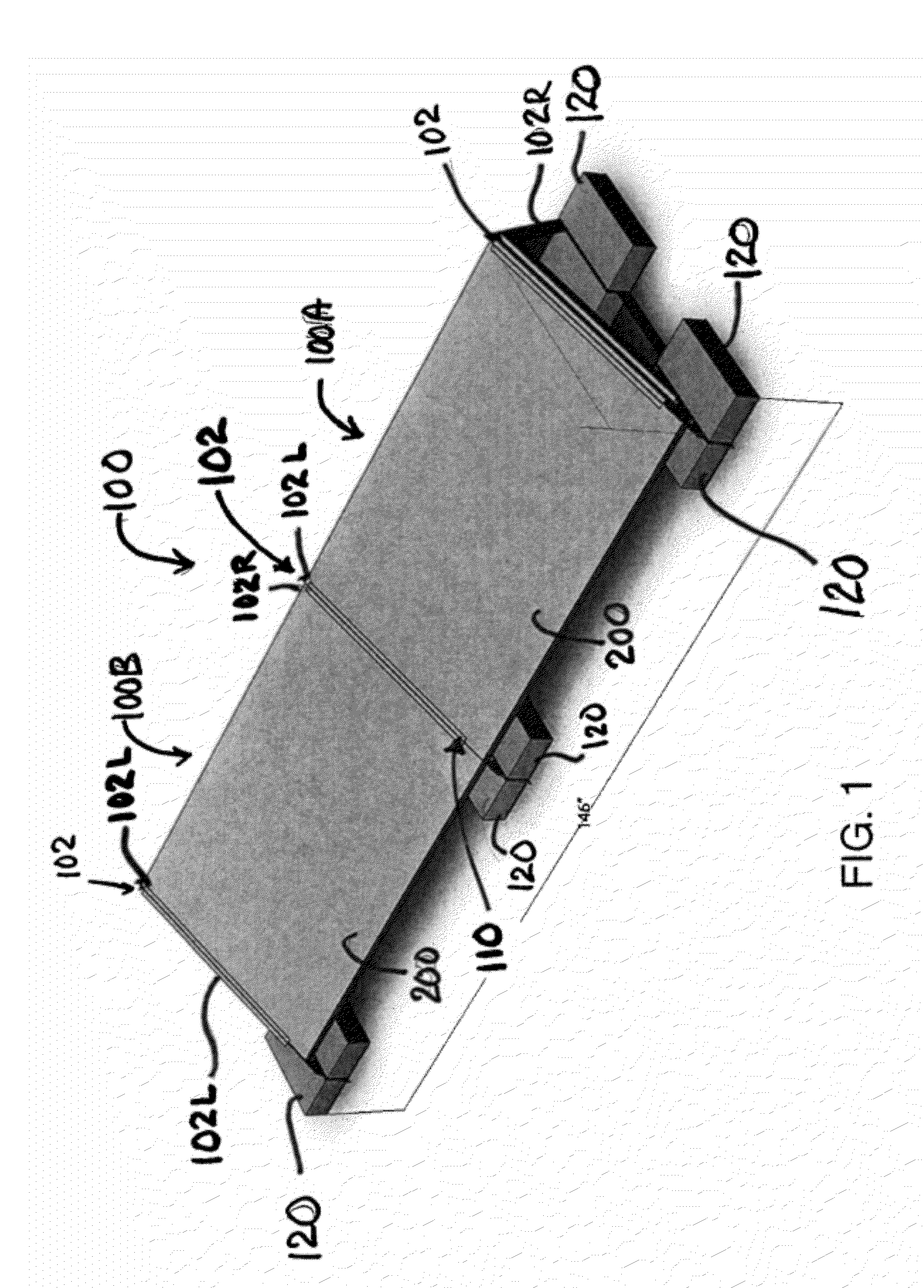

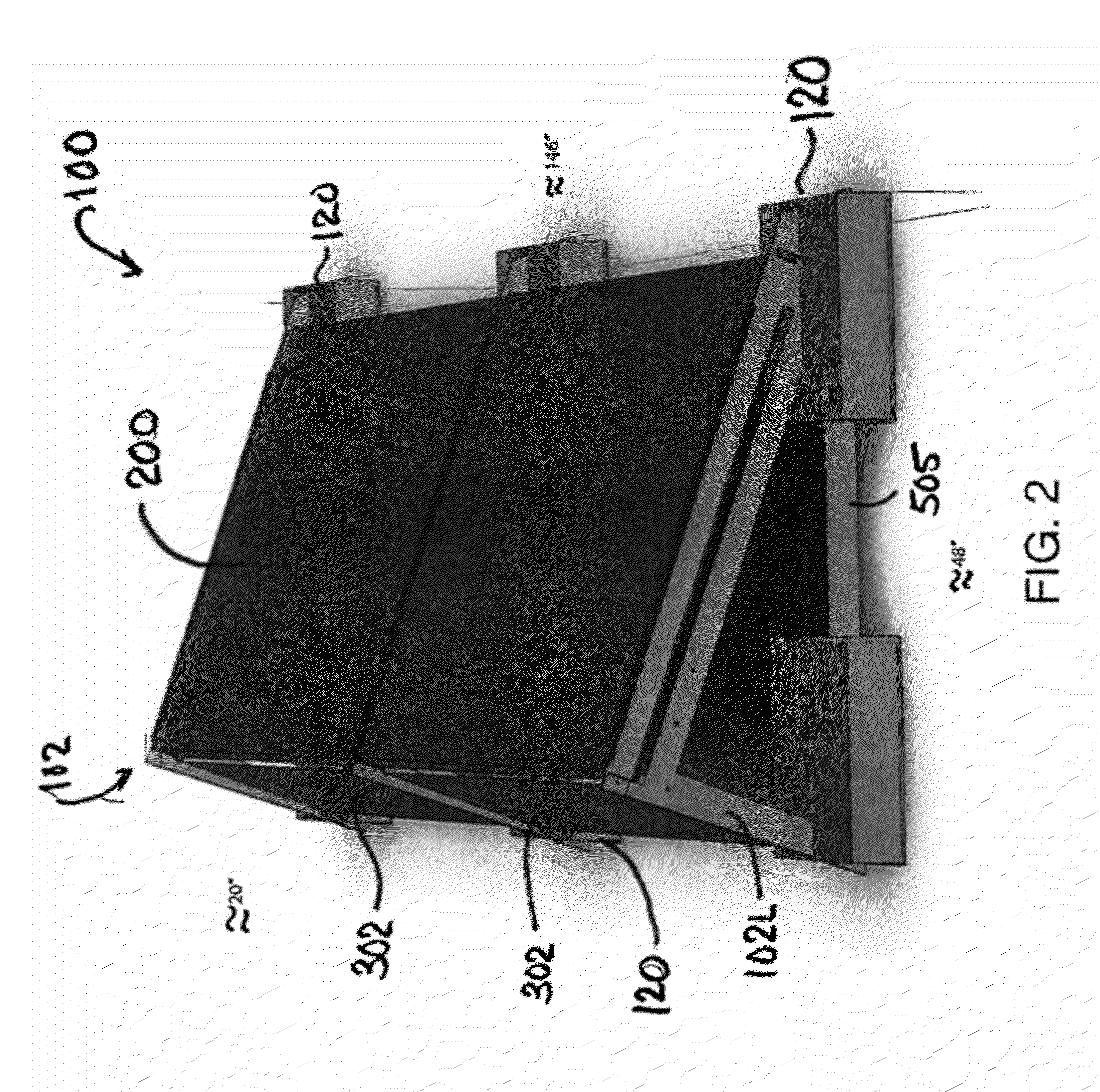

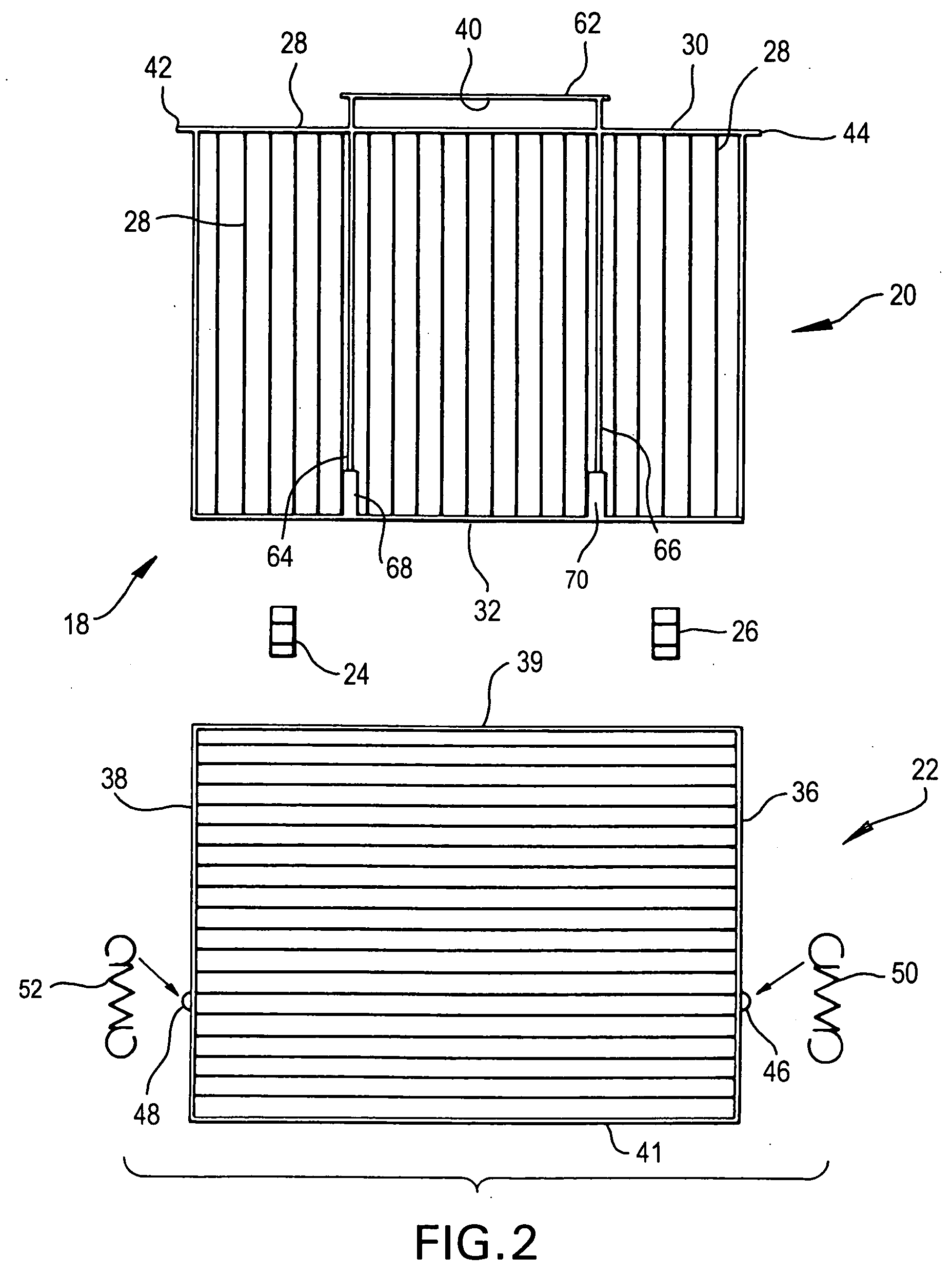

Modular Solar Panel Racking System

Disclosed herein are embodiments of modular racking systems for solar panels and in particular, modular solar panel racks, racking systems, arrays of racks, kits and methods of use. One embodiment of a modular solar panel rack comprises a plurality of discrete ballast holders and a plurality of panel support members each having two upright portions, a transverse portion contiguously connected between the two upright portions, the connection such that the transverse portion is non-perpendicular to the two upright portions, and a retainer attached to the transverse portion and configured to retain a solar panel. Each of the plurality of ballast holders is connected to no more than four panel support members, each ballast holder perpendicularly connected to one of the upright portions.

Owner:APPLIED ENERGY TECH

Apparatus for handling and racking pipes

An apparatus for handling pipes in a derrick and racking the pipes on a pipe racking assembly mounted on the derrick is provided to improve the stability of transferring pipes during a round trip operation. The apparatus includes a rotatable gate assembly mounted on the pipe racking assembly. The rotatable gate assembly includes a collar rotatably mounted to a first end of a shaft and an arm pivotably and rotatably mounted on a second end of the shaft. The collar defines a gate for securing an upper portion of the pipe stand. A first securing means mounted to a second end of the arm secures the mid-portion of the pipe stand and a second securing means mounted to the first securing means secures the lower portion of the pipe stand. After the arm secures the pipe stand from the derrick, a drive mechanism mounted to the shaft rotates the rotatable gate assembly such that the arm may rack the pipe on the pipe racking assembly.

Owner:WEATHERFORD CANADA

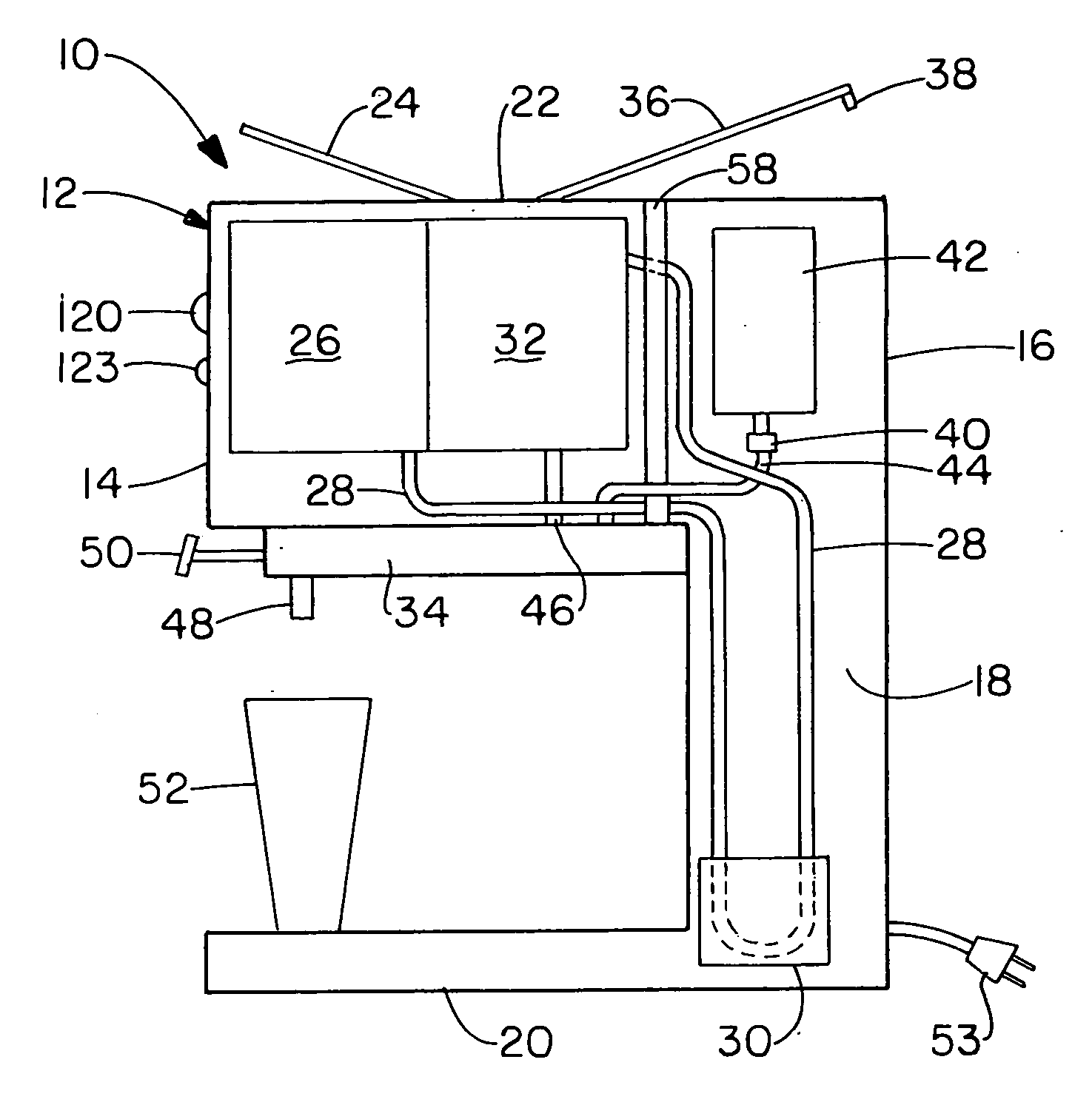

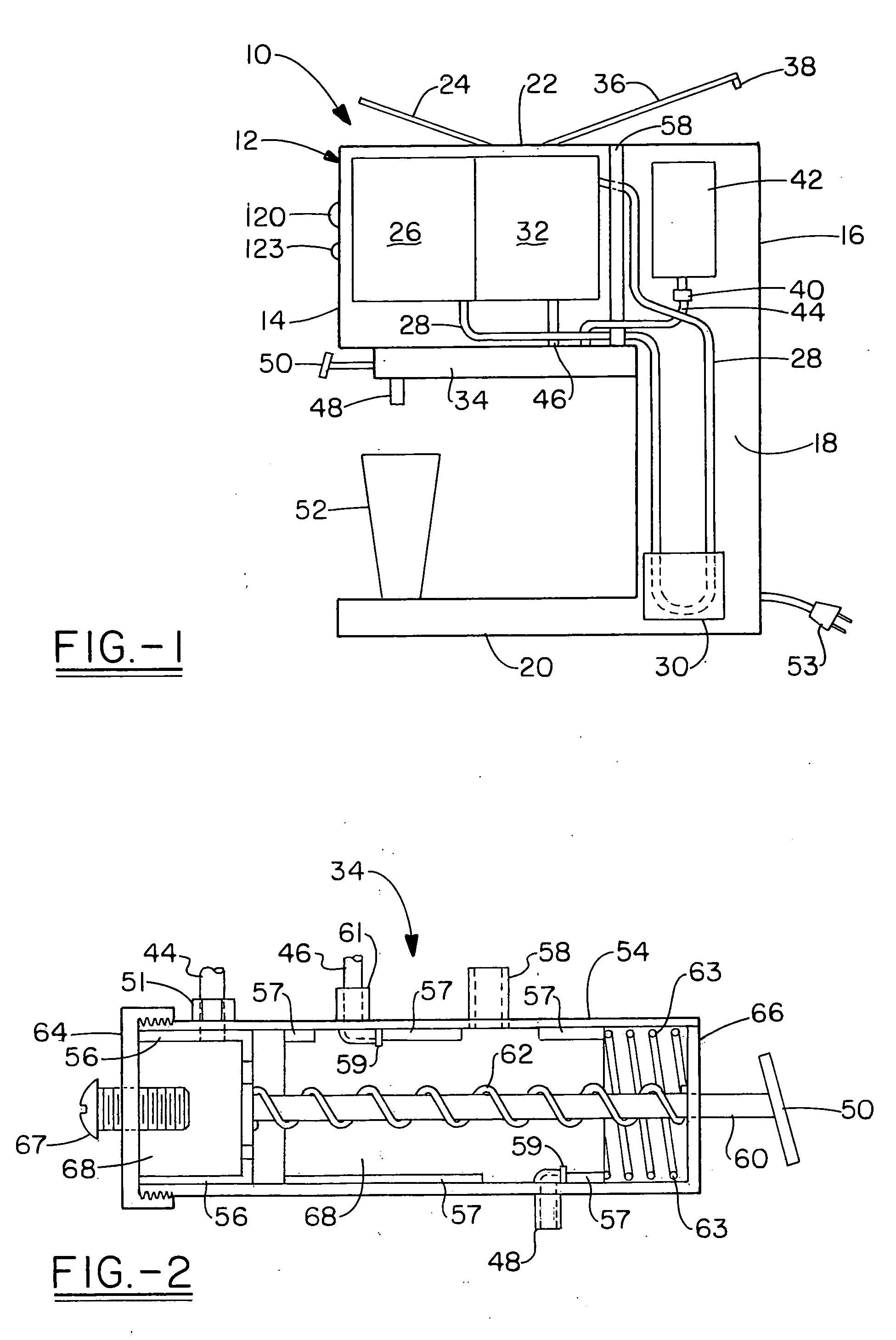

Device for producing small batches of coffee from liquid coffee concentrate

InactiveUS20080148959A1Reducing housekeeping costShorten the timeBeverage vesselsLiquid transferring devicesGuide tubeBrewing

A device for brewing batches, such as, but not limited to, relatively small one or two cup batches, of coffee from water and liquid coffee concentrate, preferably shelf stable. The size of the device, preferably similar to an automatic drip coffee maker, allows the device to be conveniently utilized in the home, an office, a hotel suite, or hospitality area or the like. The device includes a metered volumetric mix valve assembly that, when activated, admits simultaneously or sequentially a finite volume of water and liquid concentrate to a mixing chamber or conduit where they are mixed and then dispensed to a container such as a carafe, cup, mug or the like. Mixing can take place in one or more of the mixing chamber or conduit and the container in which the water and concentrate are dispensed. In this manner, repeatable beverage solutions are obtained. Advantageously, the device is constructed so that the liquid concentrate flows gravimetrically to the volumetric mix valve assembly, and a costly concentrate pump is not necessary. The device can be sealed so that theft of the coffee concentrate can be prevented.

Owner:BOCKBRADER ROBERT H

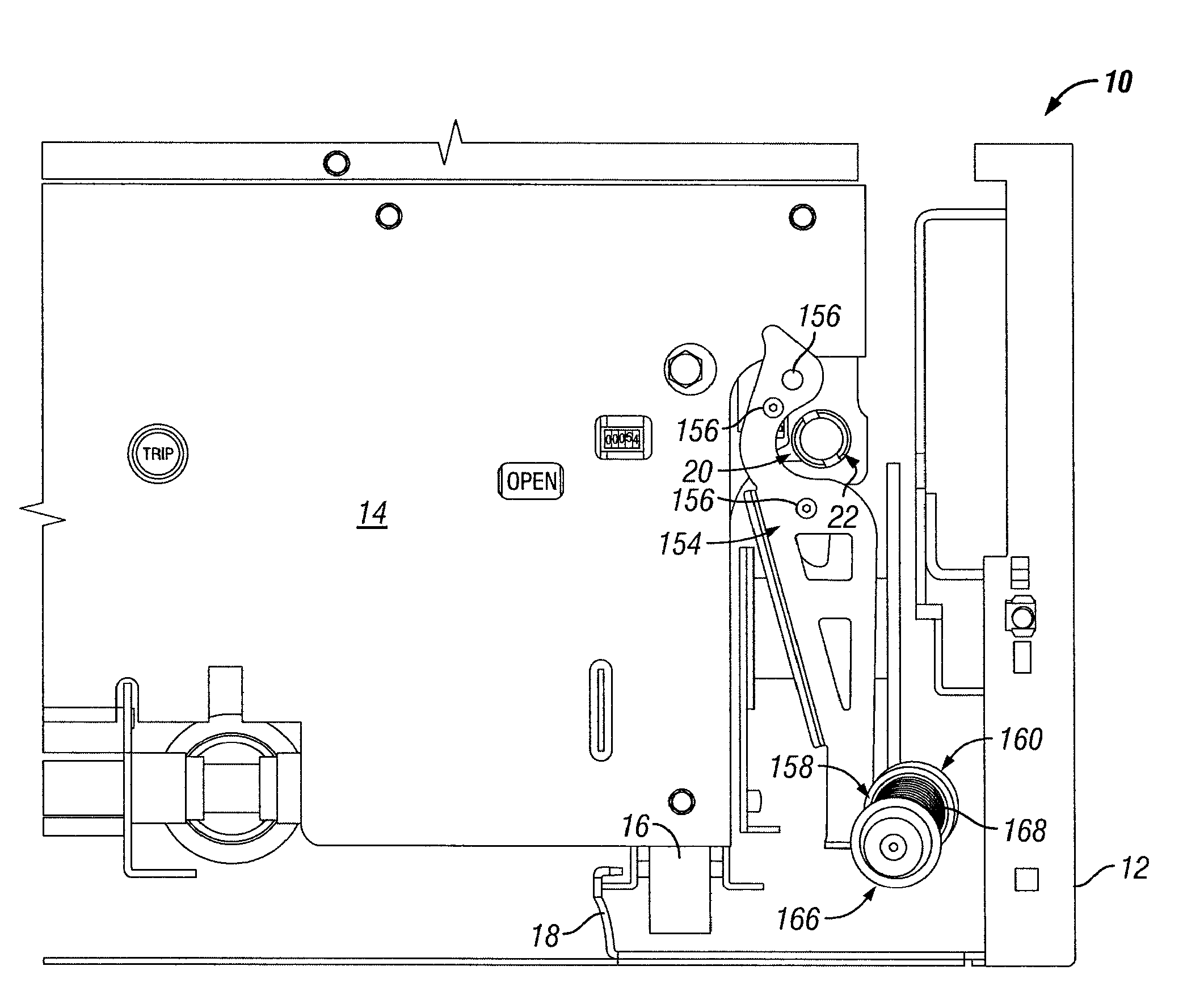

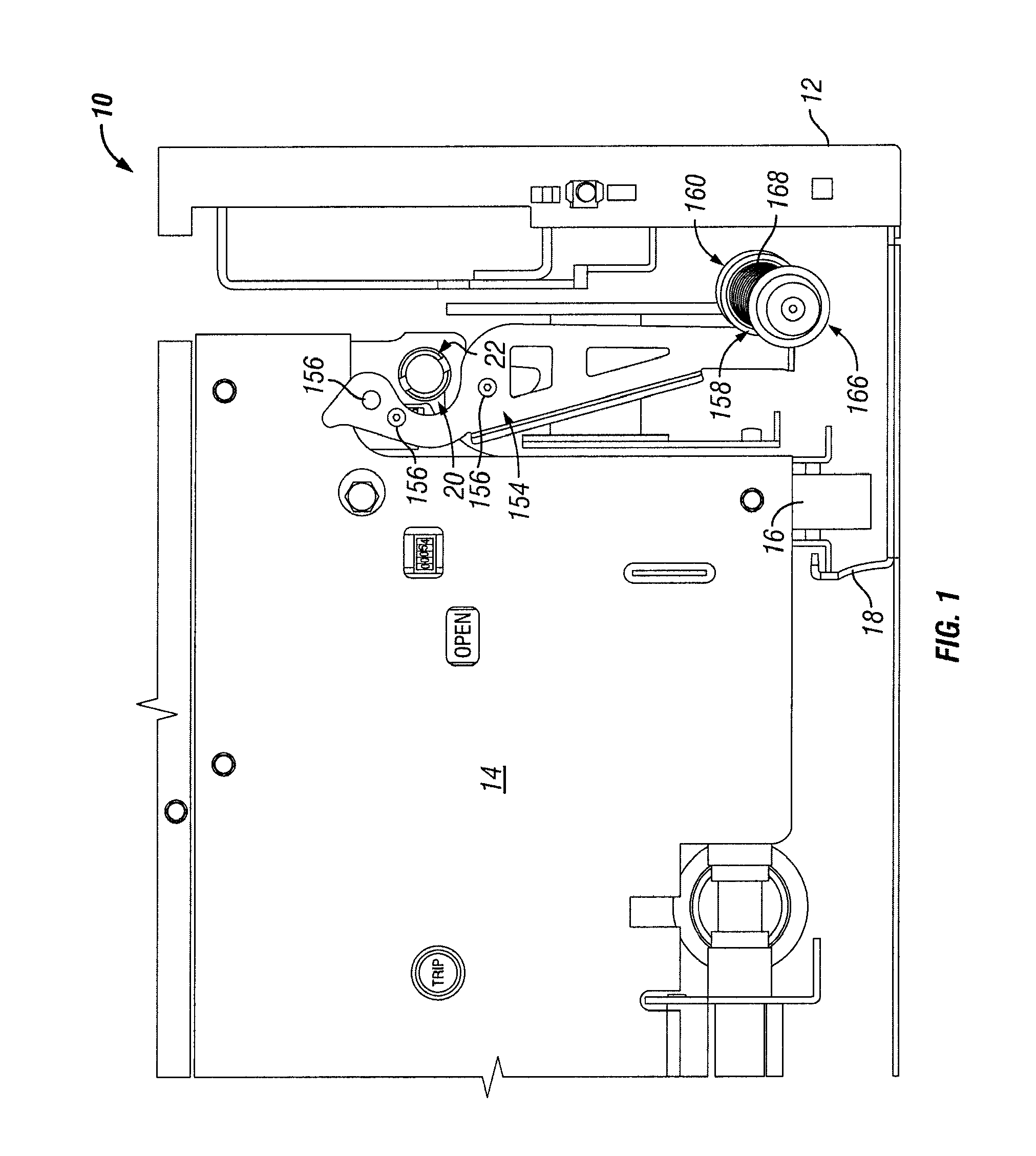

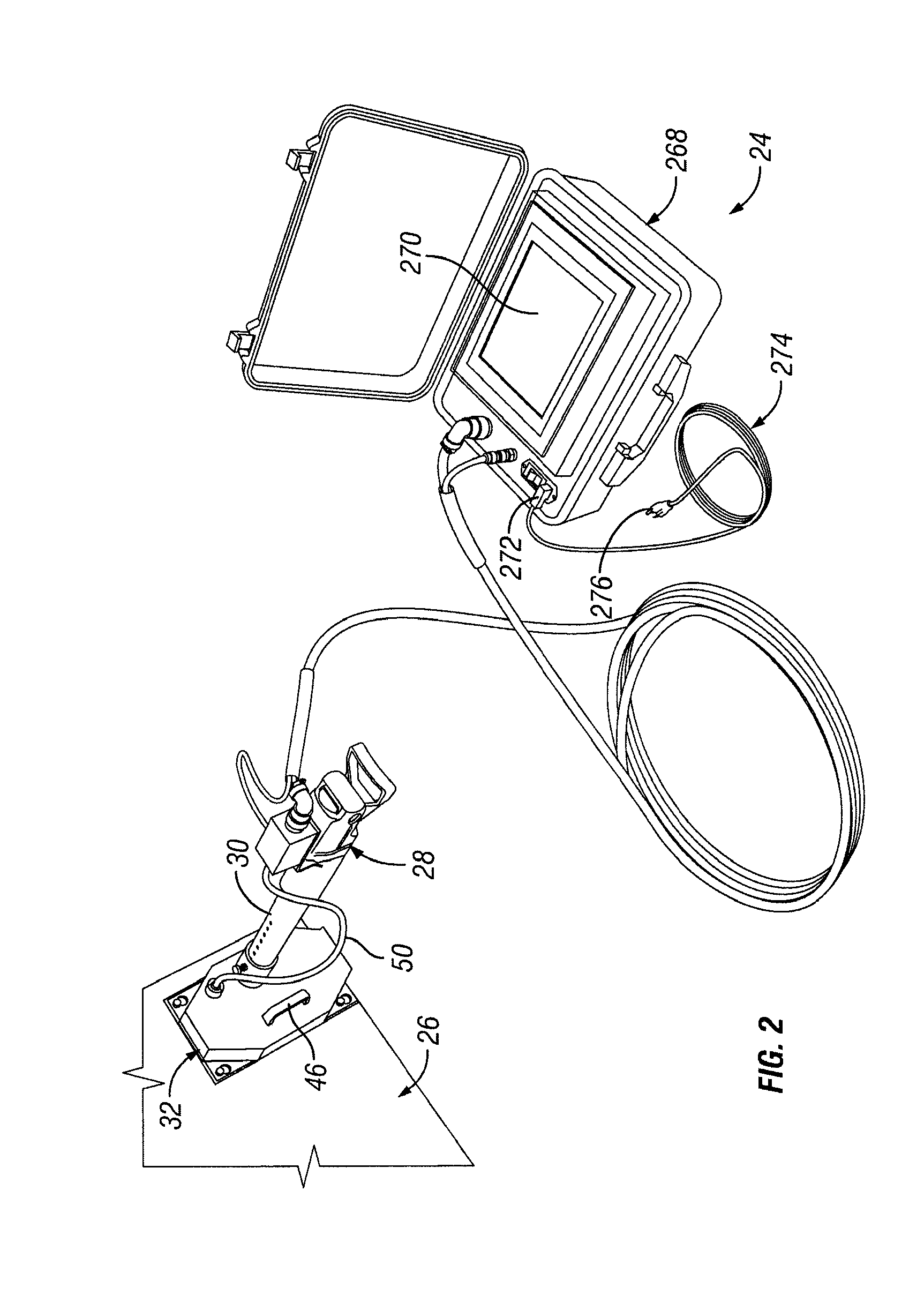

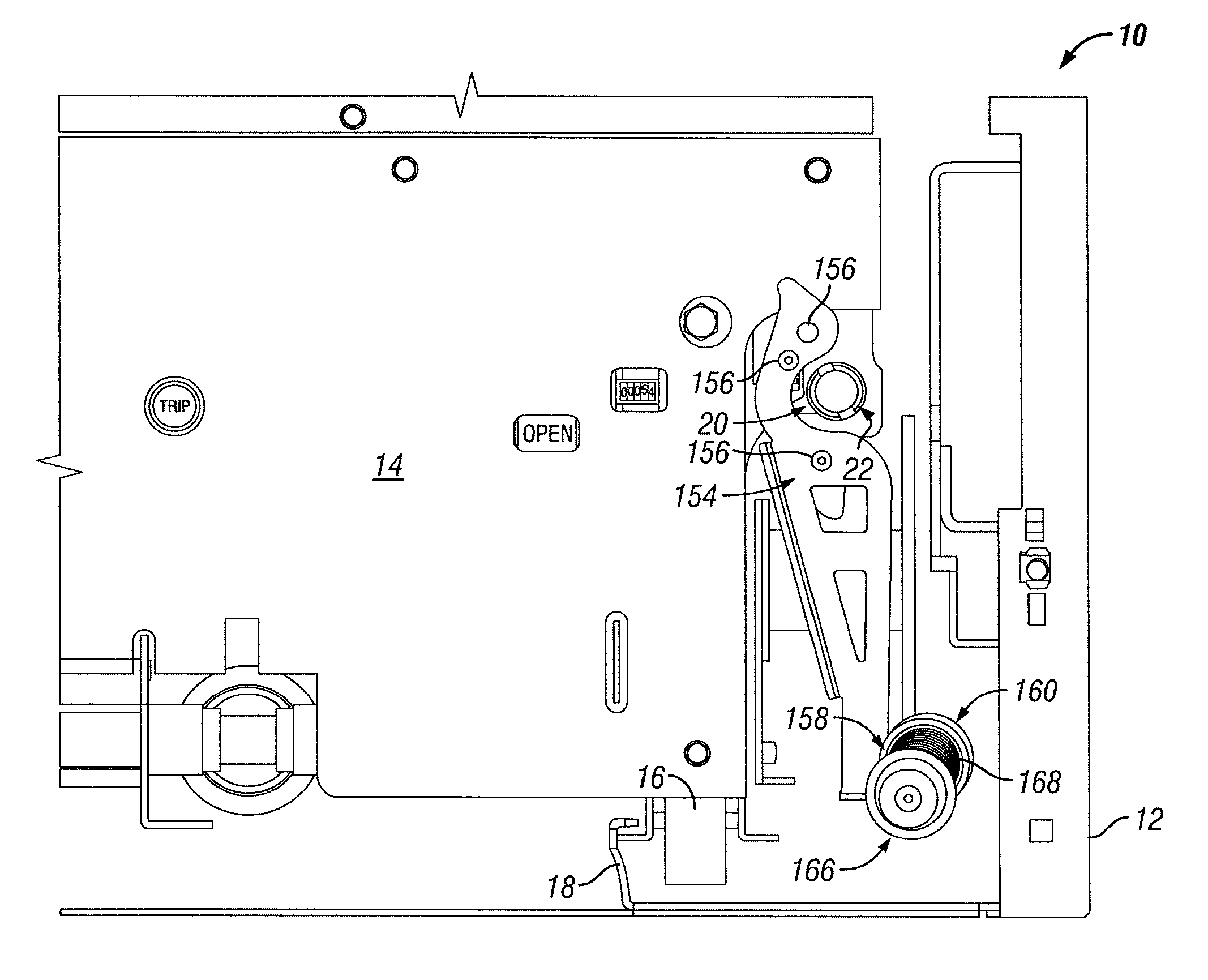

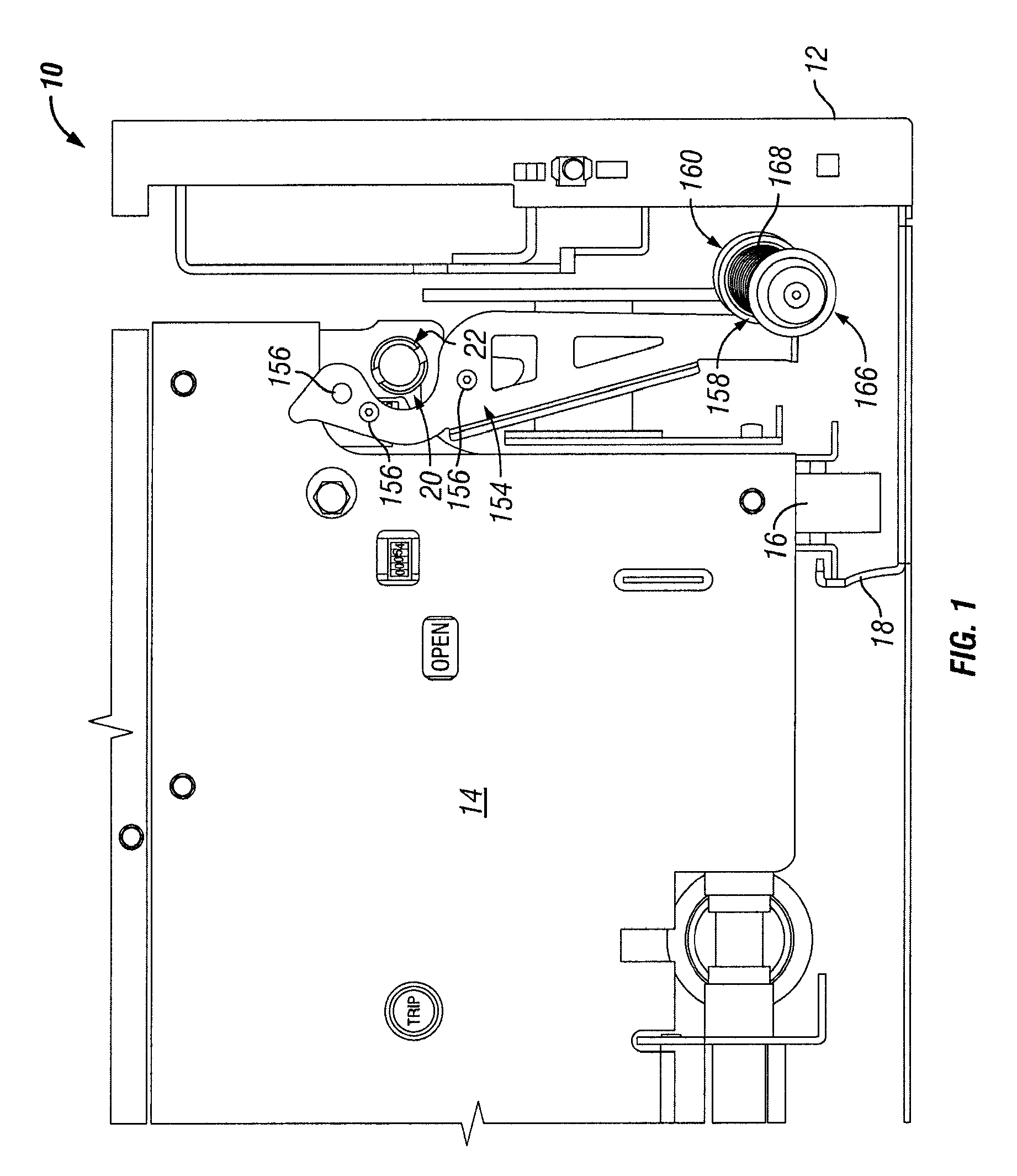

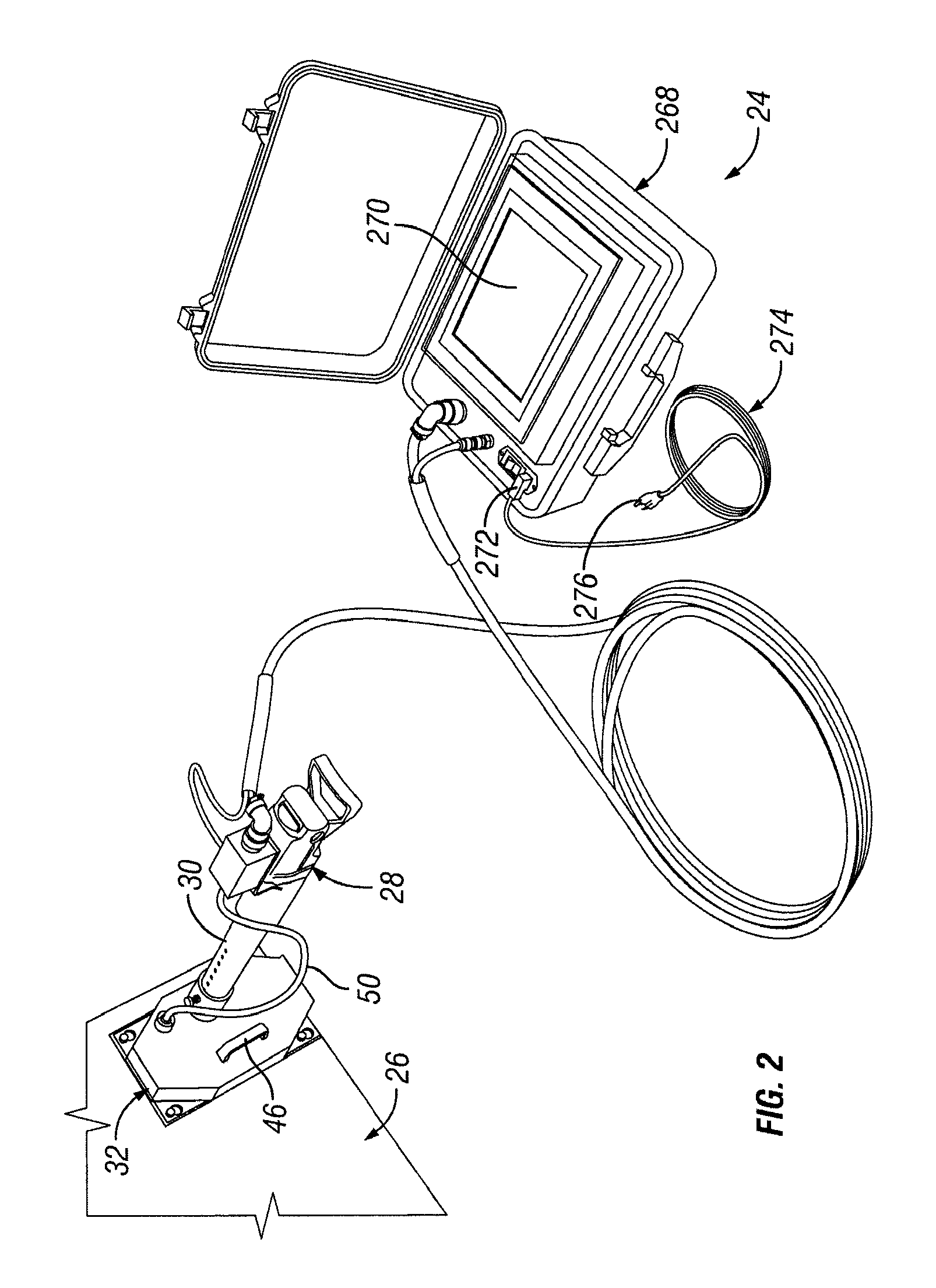

Remote Racking of Horizontally Displaceable Circuit Breakers

ActiveUS20090014291A1Prevent rotationSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesCircuit breakerElectric motor

A system for remotely racking a horizontally movable circuit breaker includes a motor as well as a transmission connectible to the motor and to a racking screw for moving the circuit breaker. The system further includes a mounting bracket for holding the transmission and a controller for controlling the motor from a location remote from the circuit breaker.

Owner:STEVENSON ROBERT L

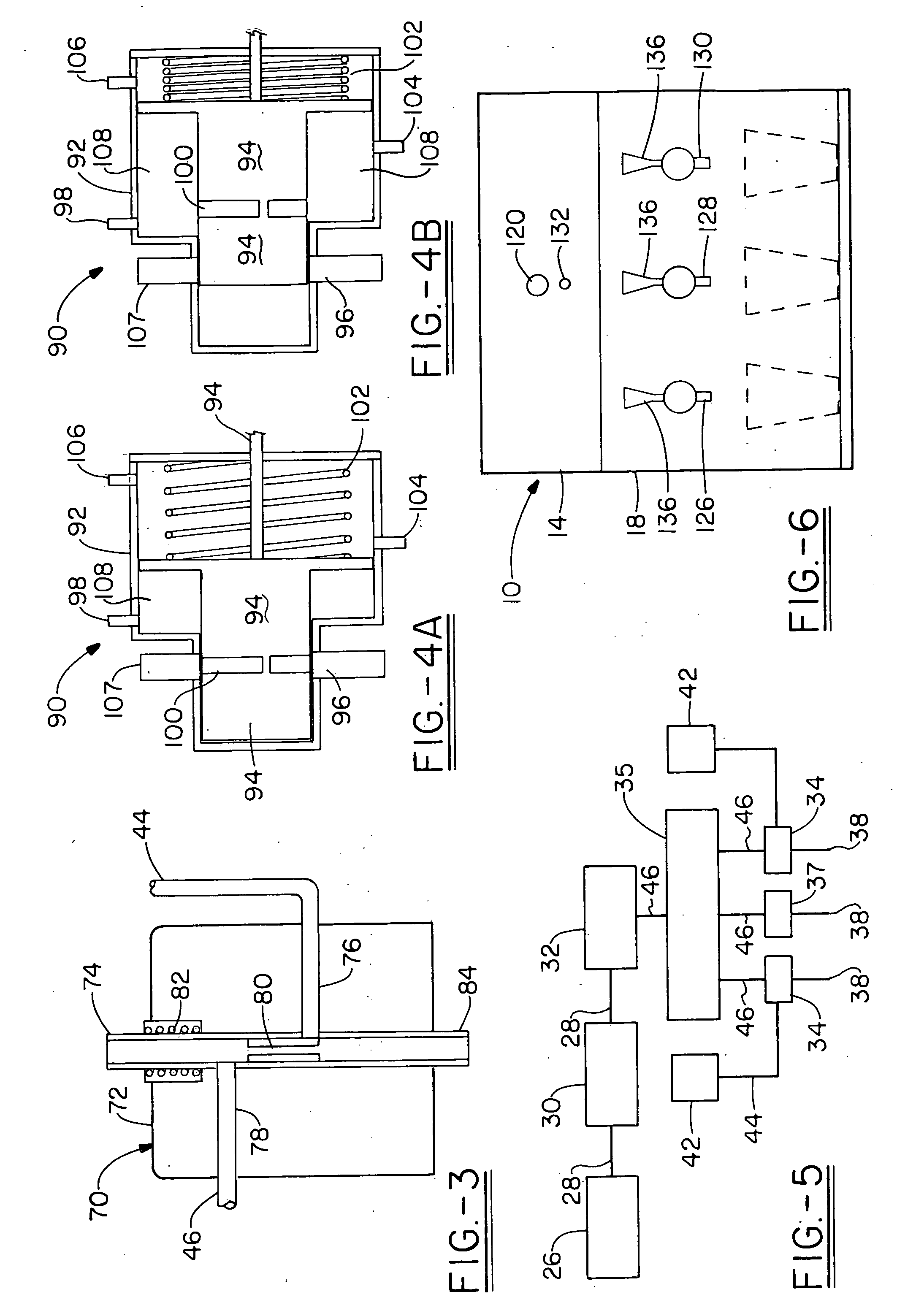

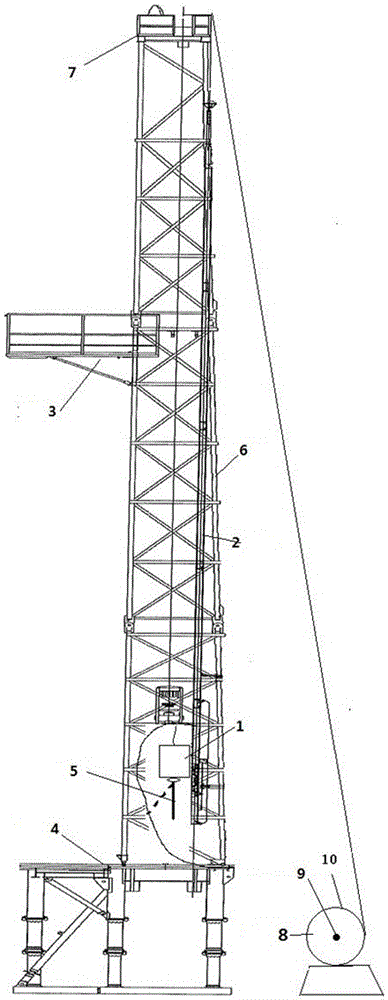

Drilling platform pipe racking system and method

InactiveCN101812977AIncrease productivityIncrease profitDrilling rodsDrilling casingsWell drillingRoughneck

The method disclose a drilling platform pipe racking system, which comprises a multi-station mouse hole, a derrick, a pipe grabbing mechanical hand and an iron roughneck, wherein the multi-station mouse hole at least provides two mouse hole-body drill stem insertion stations; a drill stem aligning device, a lifting cylinder, a drill steam buffer and a lifting pulley block are correspondingly arranged in the mouse hole body one to one; the pipe grabbing mechanical hand grabs drill stems in turn, puts the drill stems into the mouse hole body and joints the stems after the drill stems are pulled outside the mouse holes. The invention also discloses a method for racking pipes by the system. In the invention, a multi-station mouse hole structure providing at least two pipe racking stations is adopted, so two single pipes can be arranged in the mouse holes simultaneously; when the third single pipe is jointed, the third pipe can be directly connected with the rest single pipes; and thus, the production efficiency is greatly improved. Besides, the drill stem can be changed from a horizontal state into a vertical state by only one piece of equipment, namely the pipe holding mechanical hand, so the equipment use ratio is greatly improved, the space is saved and the equipment operation is simplified.

Owner:天时海洋工程及石油装备研究院(青岛)有限公司

Apparatus for handling and racking pipes

An apparatus and method for handling pipes in a derrick and racking the pipes on a pipe racking assembly mounted on the derrick. The apparatus includes a rotatable gate assembly rotatably mounted on the pipe racking assembly. The rotatable gate assembly includes a collar rotatably mounted to a first end of a rotatable pipe support. A pipe manipulator arm is pivotably mounted on a second end of the rotatable gate assembly. The collar defines a gate for securing an upper portion of the pipe stand. A pipe mount is mounted to a distal end of the arm for holding the pipe stand for transport between the derrick and the gate, and between the gate and the pipe rack. After the arm secures the pipe stand into the gate from the derrick, a drive mechanism rotates the rotatable gate assembly to a rack facing position from the derrick facing position such that the arm may transport the pipe between the gate and the pipe rack.

Owner:WEATHERFORD CANADA

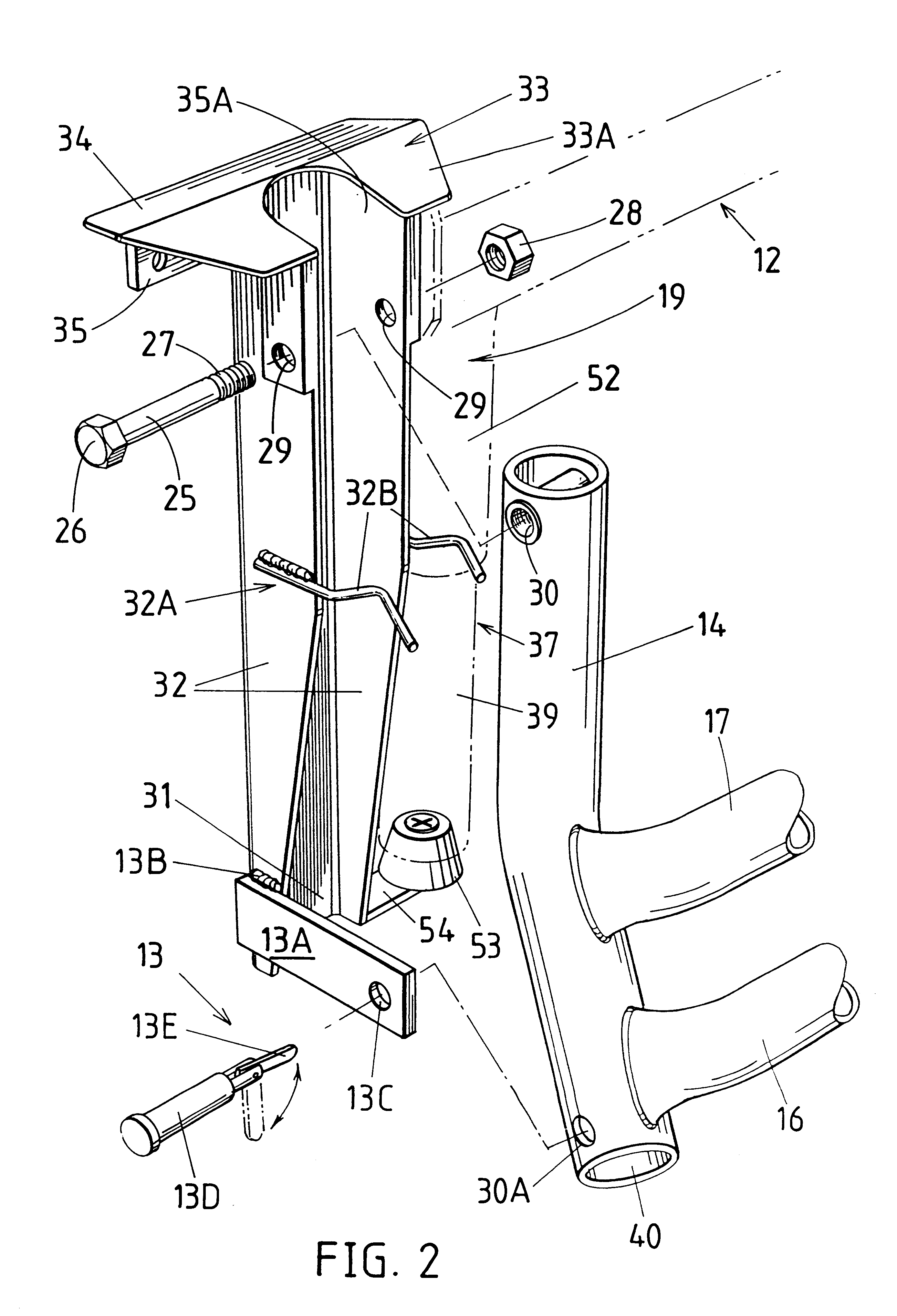

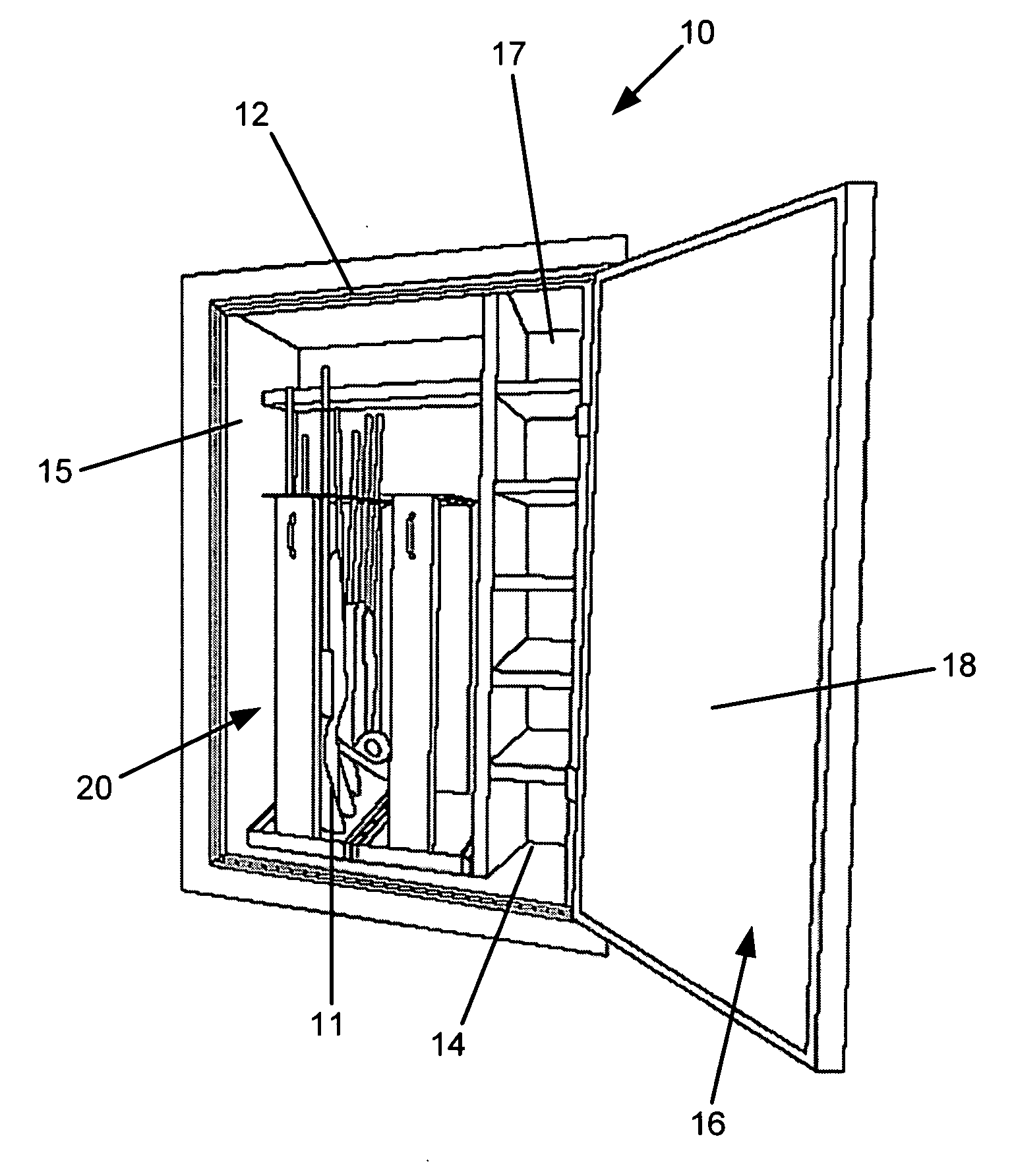

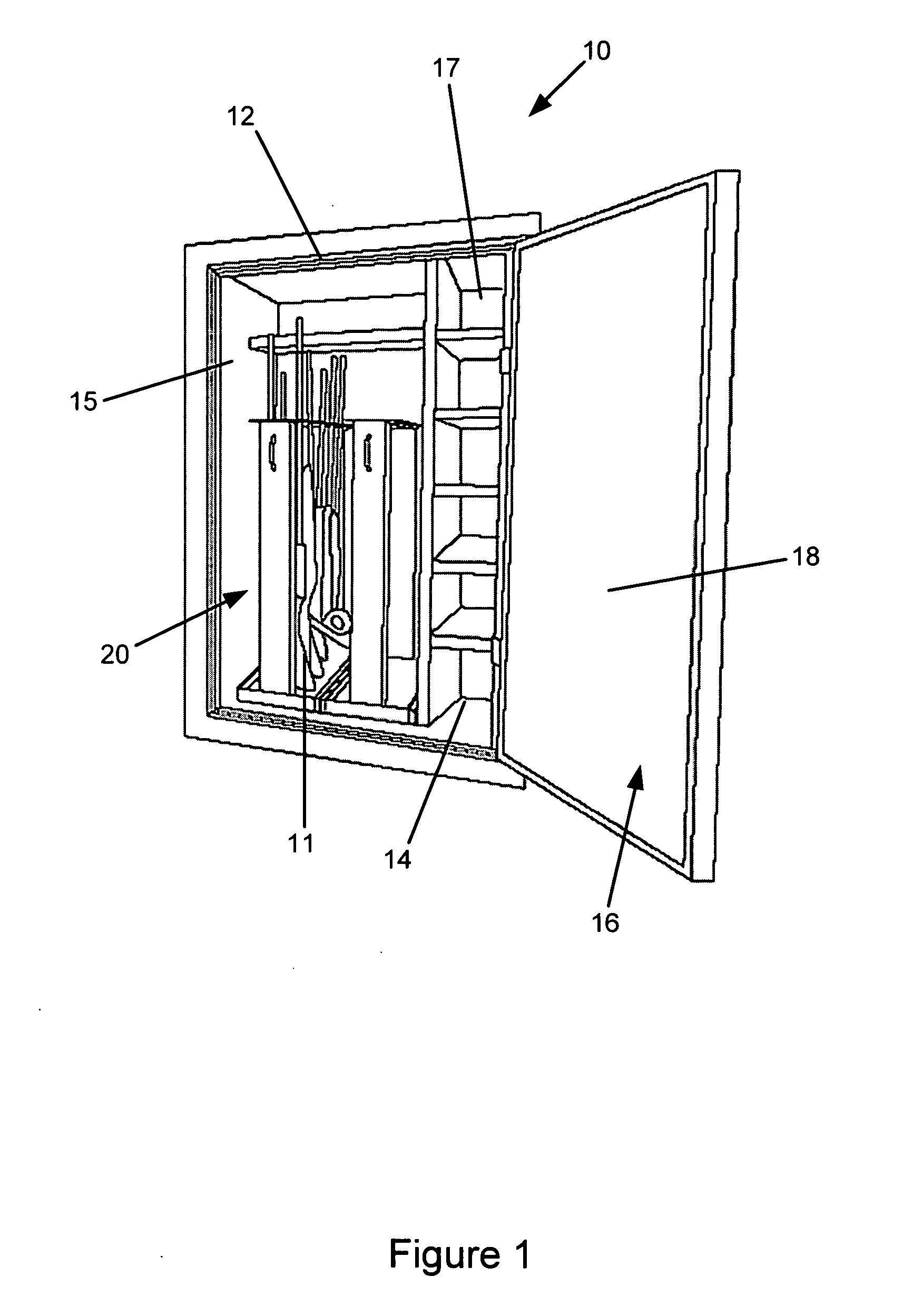

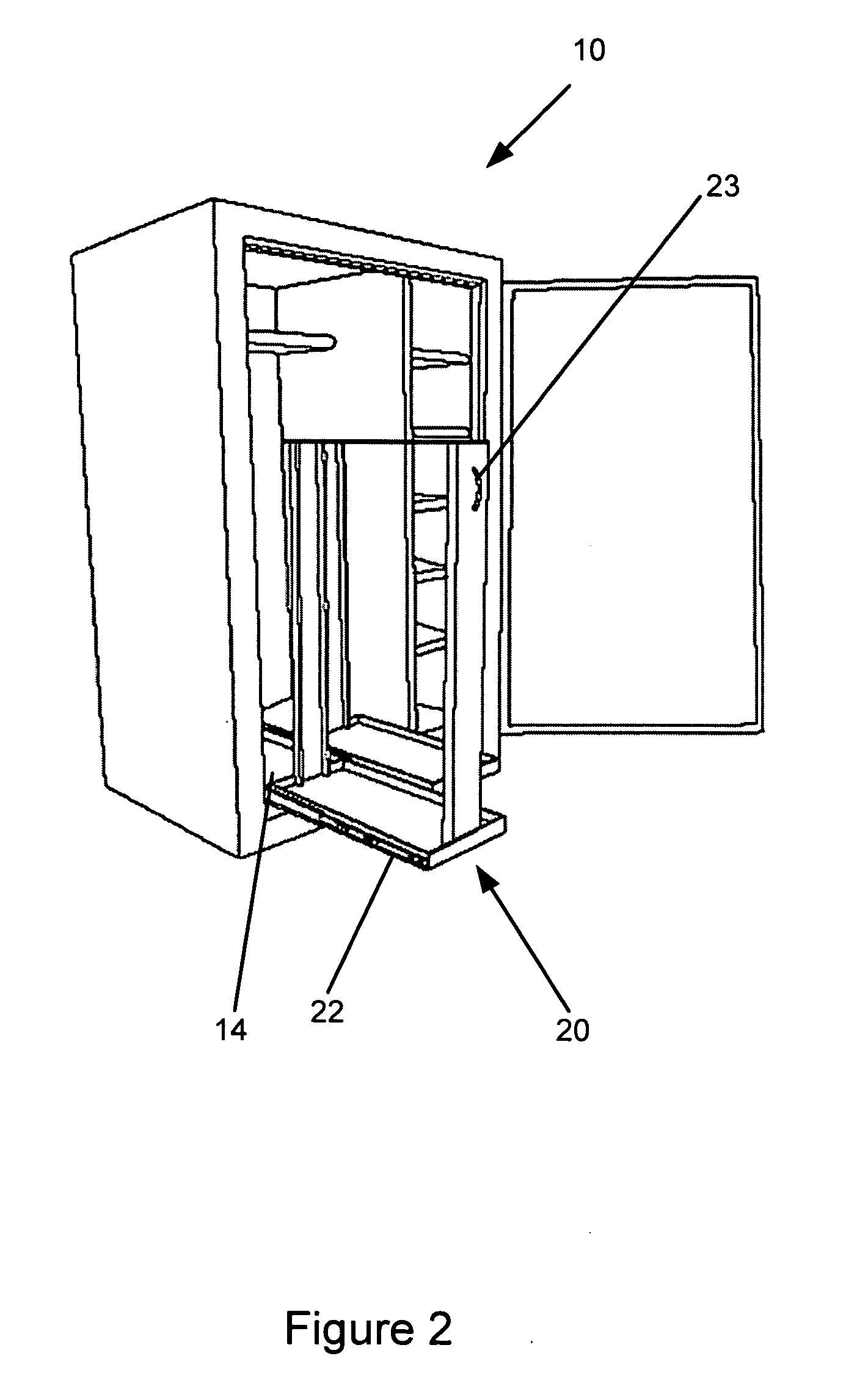

Pull-out gun racking system

A enclosure including a racking system for storing firearms and other valuables is disclosed. The racking system can include a first rail where the first rail can be secured to a bottom interior surface of an enclosure. The racking system can also include a rack secured to the first rail so that the rack is slidably attached to the enclosure. The rack can include a bottom for supporting firearms, a top having a plurality of openings, and a set of arms connecting the bottom and the top. The racking system can also include a second rail where second rail is secured to a top interior surface of the enclosure. A drawer can be secured to the second rail so that the drawer is slidably attached to the enclosure and can independently move in relation to the rack.

Owner:APX ENCLOSURES

Remote racking of horizontally displaceable circuit breakers

ActiveUS7825344B2Prevent rotationSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesCircuit breakerElectric motor

A system for remotely racking a horizontally movable circuit breaker includes a motor as well as a transmission connectible to the motor and to a racking screw for moving the circuit breaker. The system further includes a mounting bracket for holding the transmission and a controller for controlling the motor from a location remote from the circuit breaker.

Owner:STEVENSON ROBERT L

Solar panel racking assembly and system

A racking system for a solar panel includes a solar panel support rack assembly, the solar panel support rack assembly being configured to be coupled to another solar panel support rack assembly. Each solar panel support rack assembly includes a first arm having a first end and a second end, the first arm configured to be coupled to a base structure, a second arm having a first end and a second end, the first end of the second arm coupled to the first end of the first arm, the second arm being disposed at an angle from the first arm, and a third arm having a first end and a second end, the first end of the third arm coupled to the second end of the first arm and the second end of the third arm coupled to the second end of the second arm. The second arm includes a first channel member and a second channel member, the first and second channel members being disposed on opposing sides of the second arm, and a stop member at the first end.

Owner:REYES RENE +1

Telescoping racking system with ramps and platforms

InactiveUS7753615B1Improve securityImprove easeCorner/edge jointsVehicle to carry long loadsCouplingEngineering

Long load racking system for vehicles, adjustable runners horizontal and vertical with telescoping members—both single rail, double rail; and trombone shaped; multi-functional, split and corner couplings with accessible transverse to coupling base friction adjustments, ramping ground to bed and bed to elevated locations.

Owner:SPRAGUE DONALD G

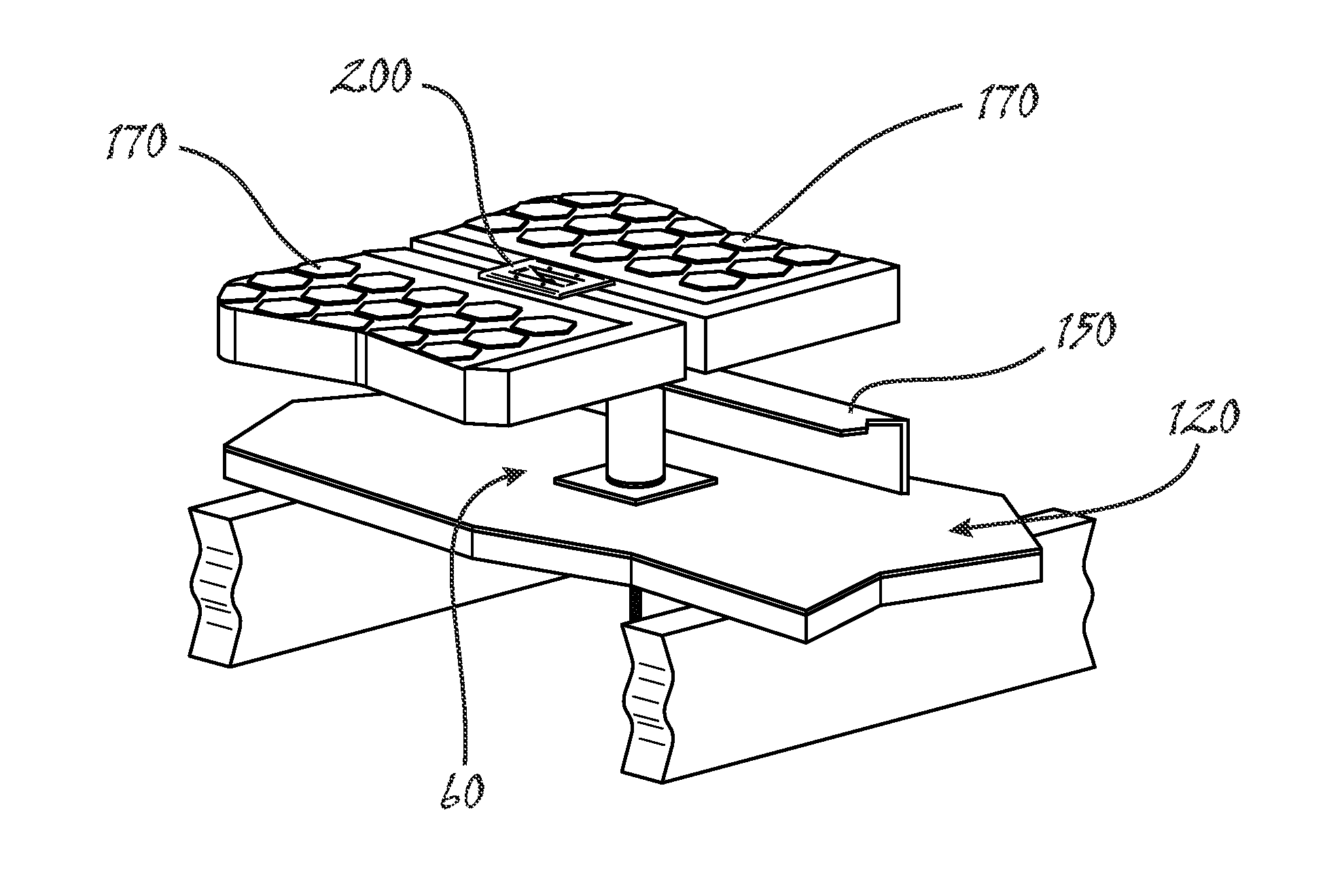

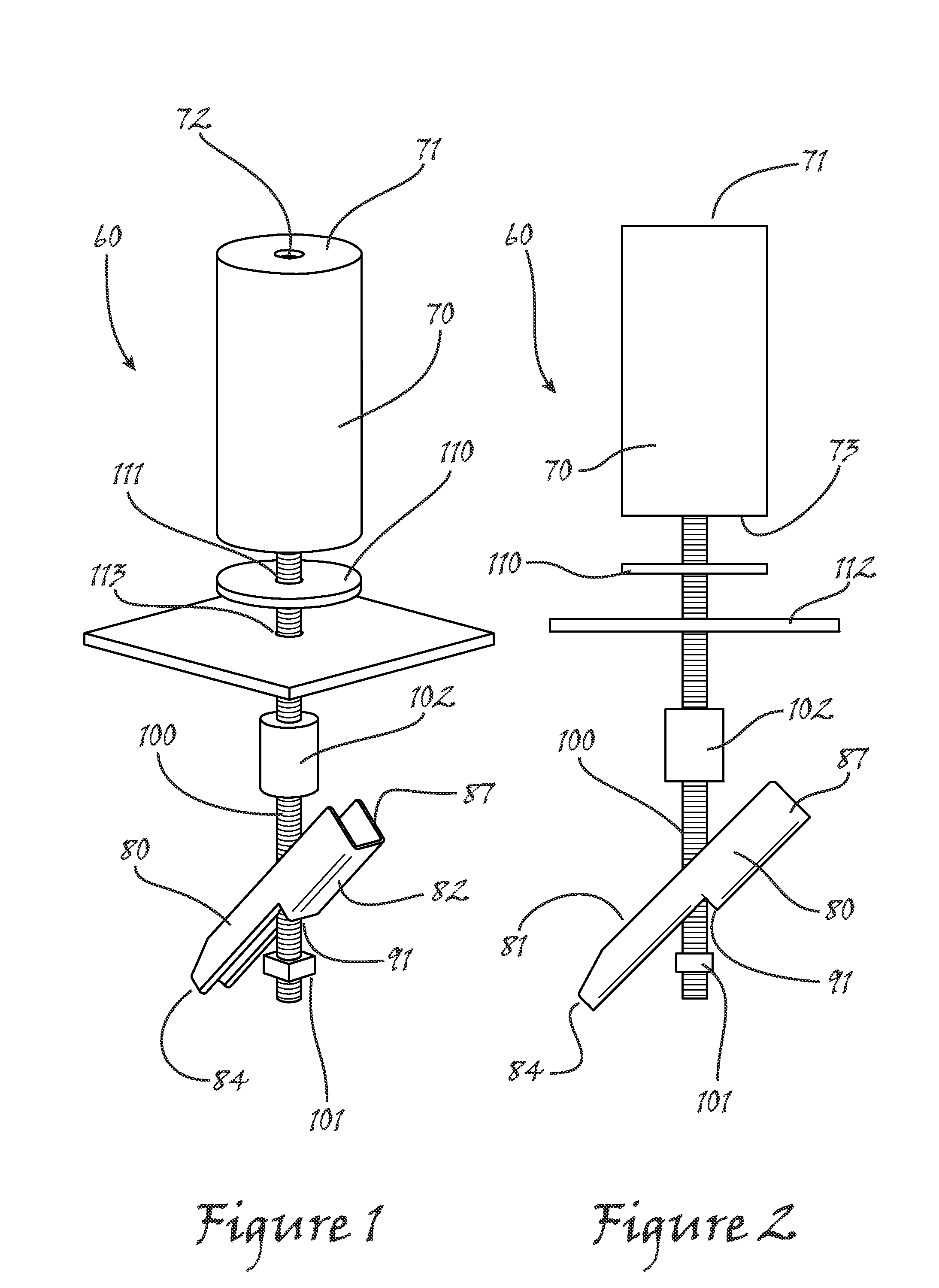

Photovoltaic panel racking assembly for use in connection with roof installation of panels

InactiveUS20130240466A1Help positioningImprove sealingPhotovoltaic supportsSolar heating energyAsphalt shingleEngineering

A photovoltaic panel racking assembly (60) includes a cylindrically shaped standoff (70) cooperatively adjoined to a specially formed toggle (80) through an all thread rod (100). A nut (101) is sized and shaped to operatively engage with the toggle (80) to fix the relative position of the toggle (80) and the nut (101). A rubber gasket (110) is provided in order to promote watertight sealing upon installation and during use of the racking assembly (60). A relief plate (112) may be provided in order to prevent installation damage to more generally fragile roofing materials such as asphalt shingles or like composite roofing (128). A rubber sleeve (102) is provided in order to facilitate positioning of the toggle (80) during installation of the racking assembly (60). Brackets (180, 200) are described for affixing one or more photovoltaic panels (170) to the racking assembly (60).

Owner:SPONSELLER GREGORY W

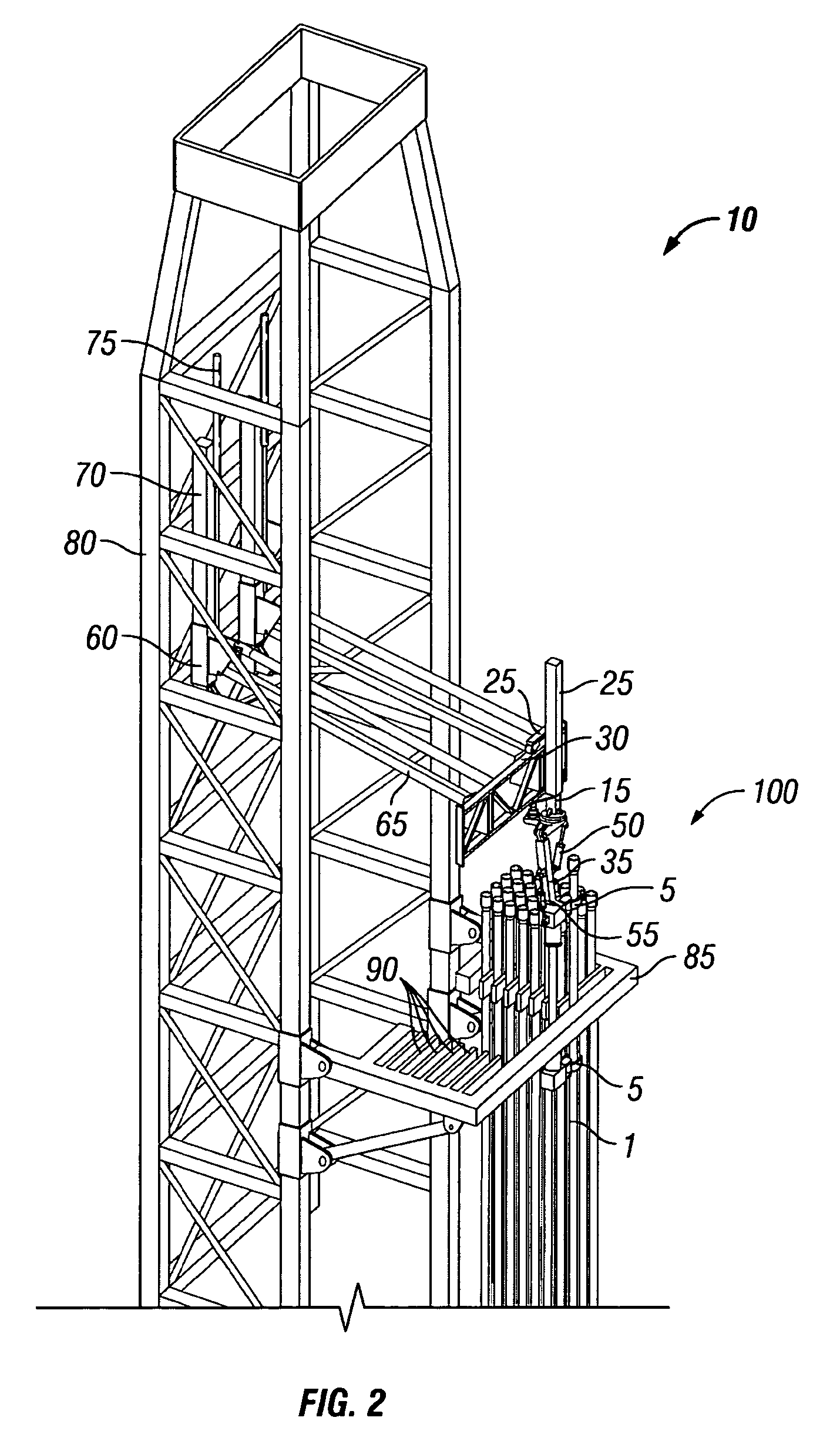

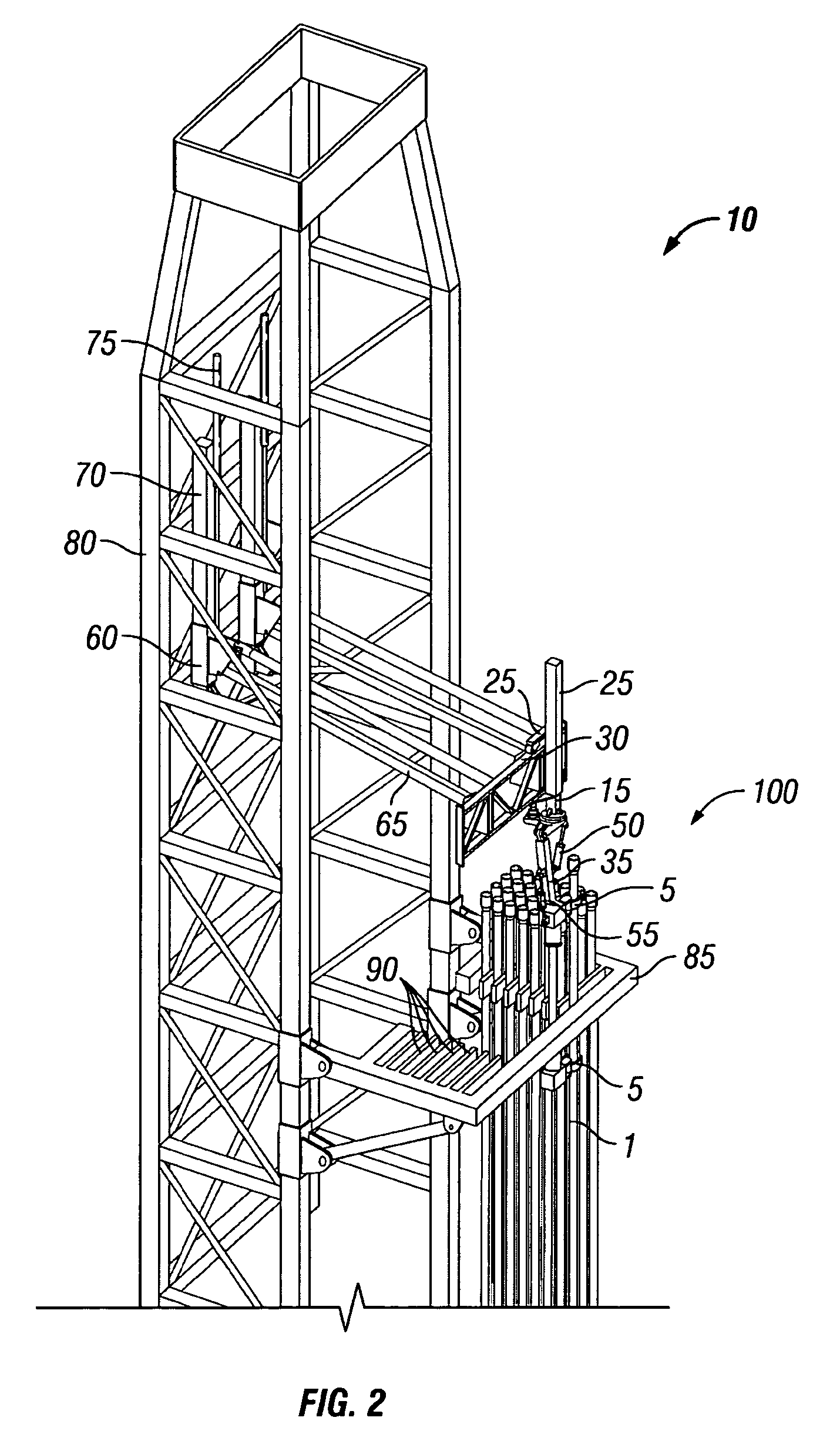

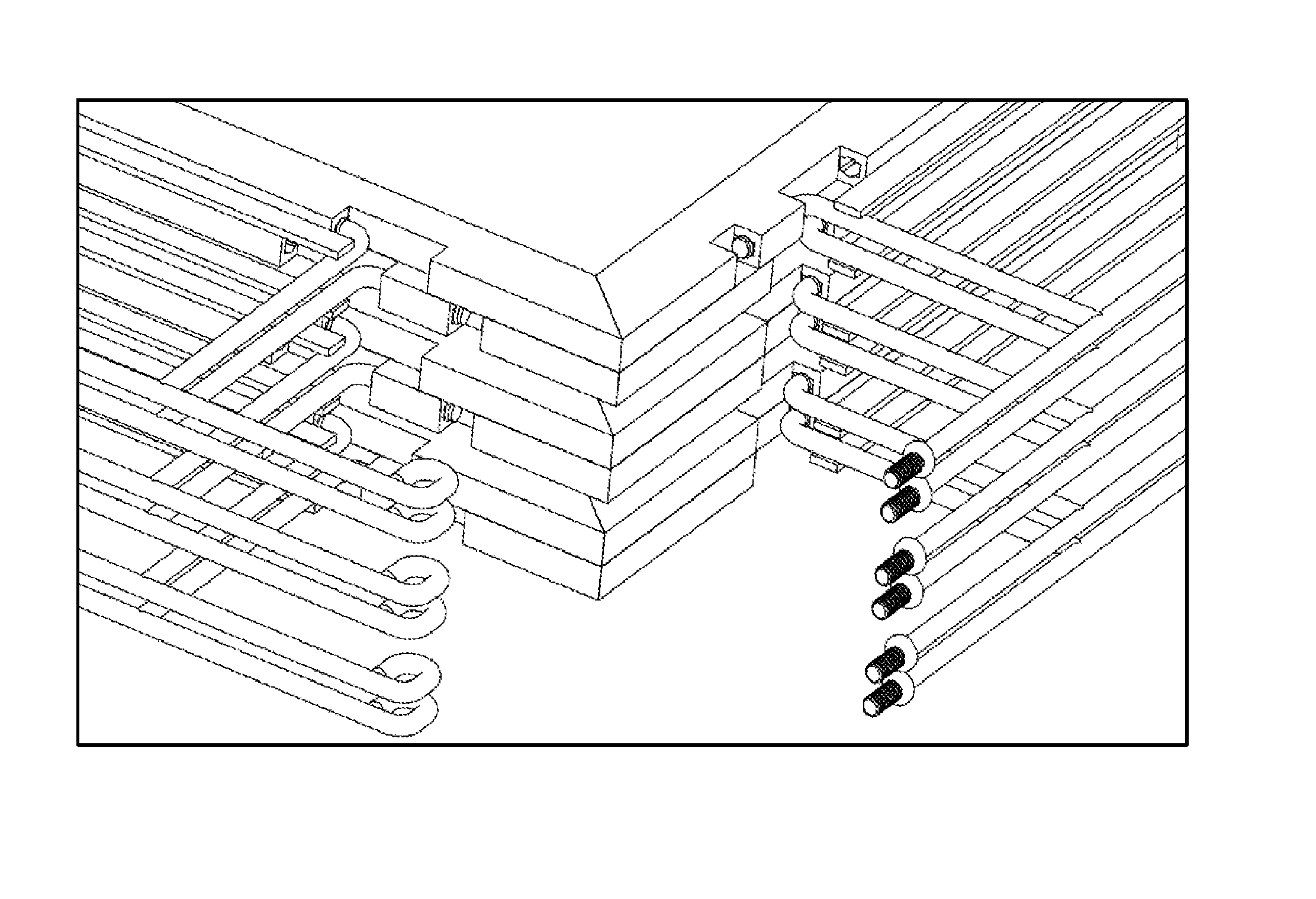

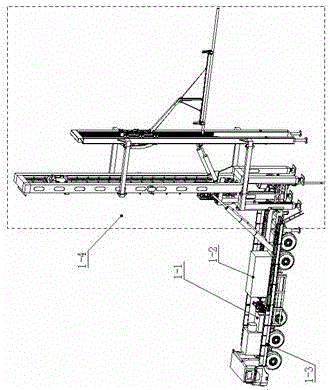

Tubular Stand Building and Racking System

The present invention provides a rapid rig-up and rig-down pipe stand building and racking system that is capable of being retrofit to an existing drilling rig. In particular, the invention relates to a horizontal to vertical pipe delivery machine that is mountable to a drilling rig. The horizontal to vertical machine delivers sections of pipe to a pair of drilling rig mounted elevators. The elevators receive and vertically translate the sections of pipe. A power tong may be used to make connections between the sections of pipe to form a pipe stand, and may also break the connections of the pipe stand. A drill floor mounted pipe racking system receives the connected drill pipe from the elevators. A pipe racking system that may be used in conjunction with the stand building system is capable of controlled, rapid, and precise movement of multiple connected sections of pipe.

Owner:T & T ENG SERVICES

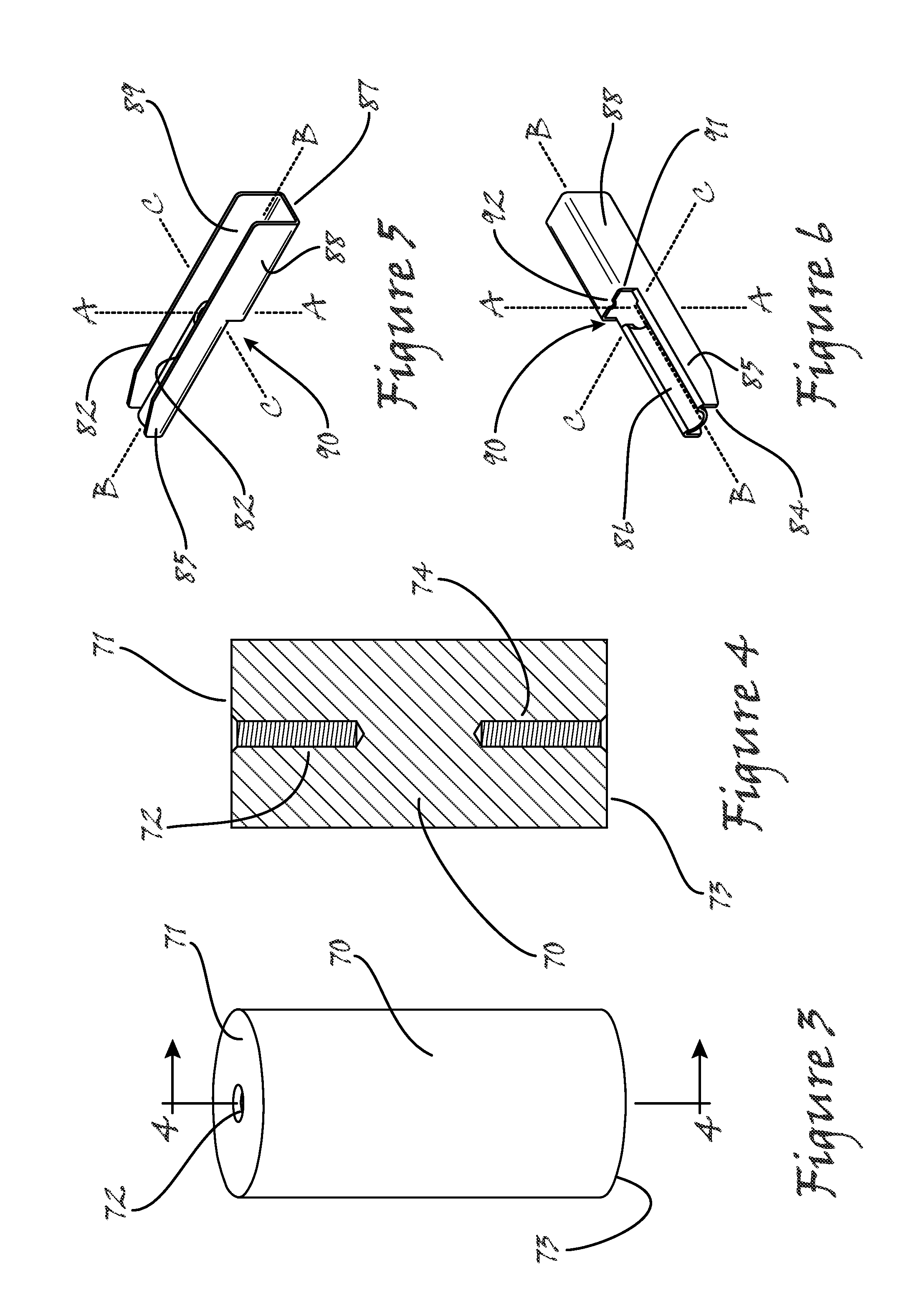

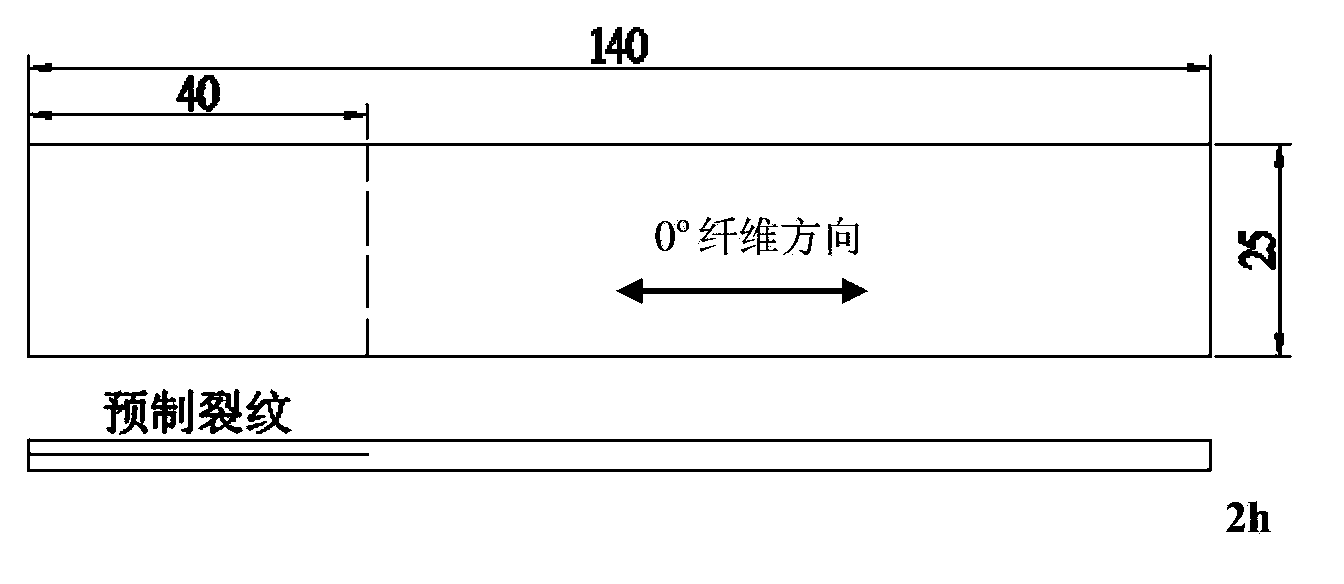

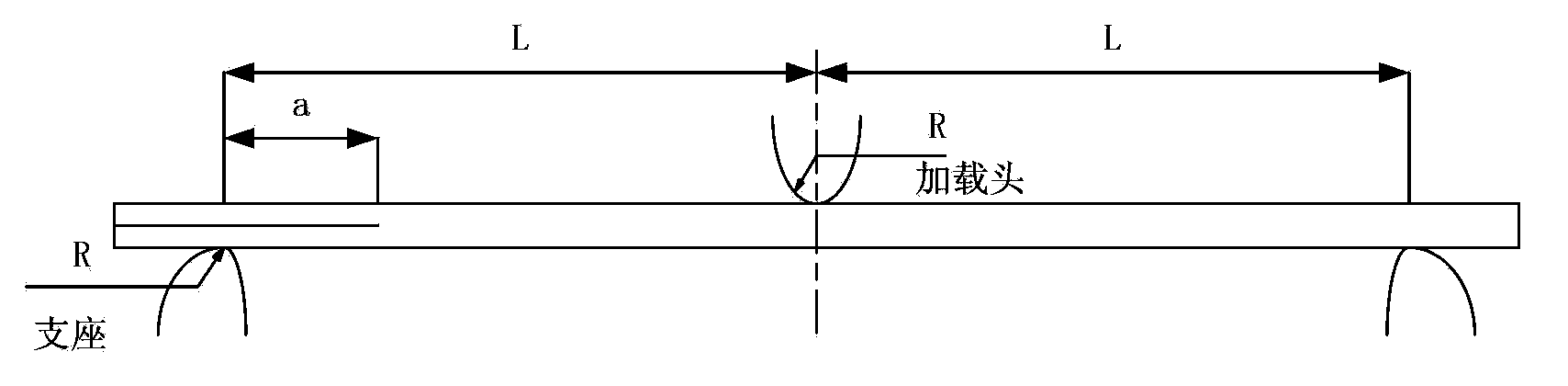

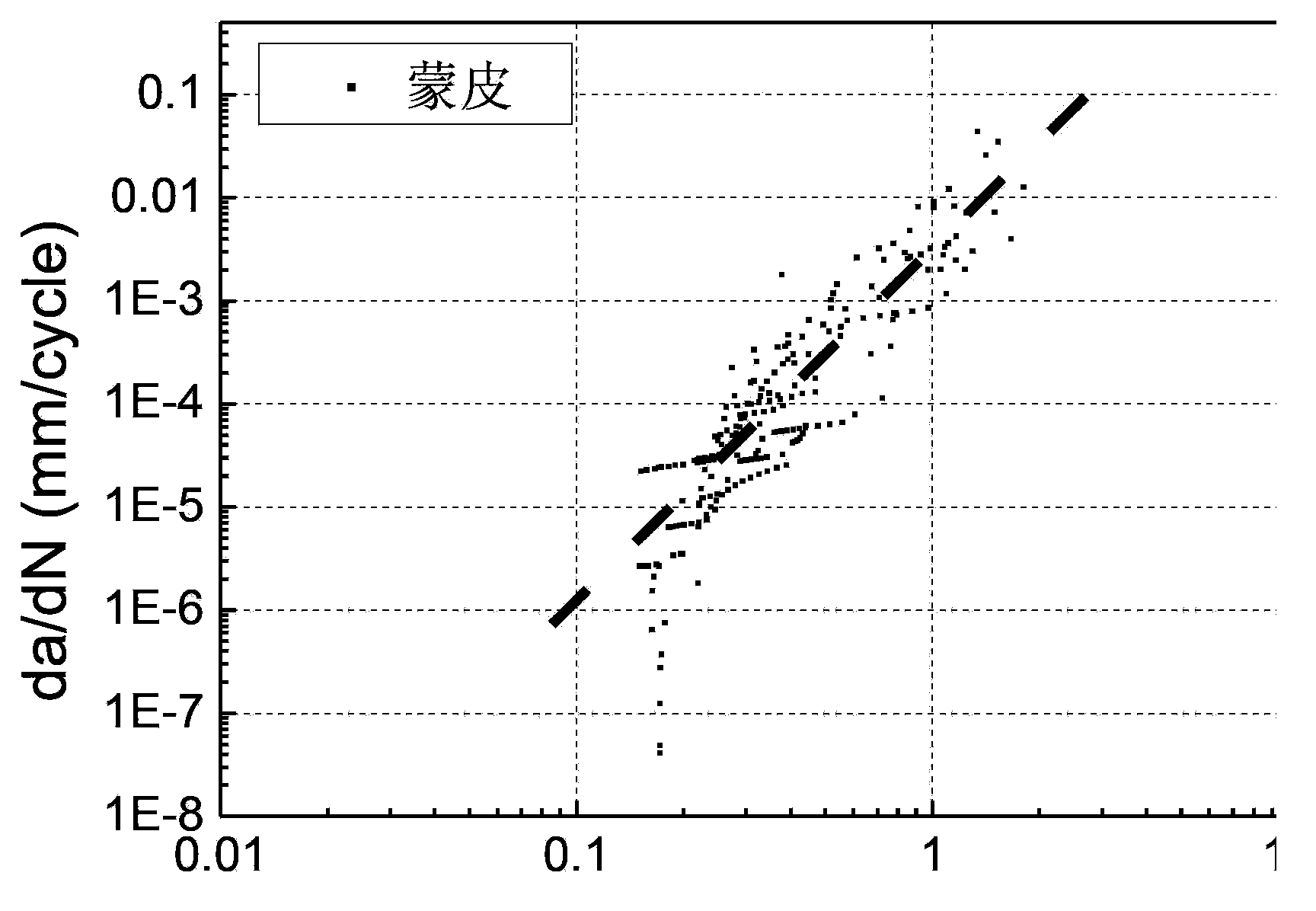

Determination method of composite material II-type cracking threshold value and S-N curve

ActiveCN103884610ASimplified Determination Method of Cracking ThresholdReduce testing costsPreparing sample for investigationMaterial strength using repeated/pulsating forcesConstant loadLoad cycle

The invention relates to a determination method of composite material fatigue performance, and particularly relates to determination of a composite material II-type cracking threshold value. The method adopts an end-notched flexure (ENF) sample under constant-load and increasing-K control, and is carried out at several stress levels. In the test process, the racking length a, the sample deflection value [delta]max, and the corresponding load cycle number N are recorded at regular intervals. An a-N curve of the sample is obtained by double-growth exponential function fitting, and da / dN-[delta]GII scatter diagrams are further obtained; da / dN-[delta]GII scatter diagrams at different stress levels are superposed and fitted to obtain a full-range crack growth da / dN-[delta]GII curve, so as to obtain the cracking threshold value. Since the maximum stress between layers are constant at the same stress level group, the test can also be used for determining a fatigue S-N curve. When compared with G-decreasing methods under load control, the determination method is simple in operation, and obtains more information on material fatigue performance.

Owner:CHINA HELICOPTER RES & DEV INST

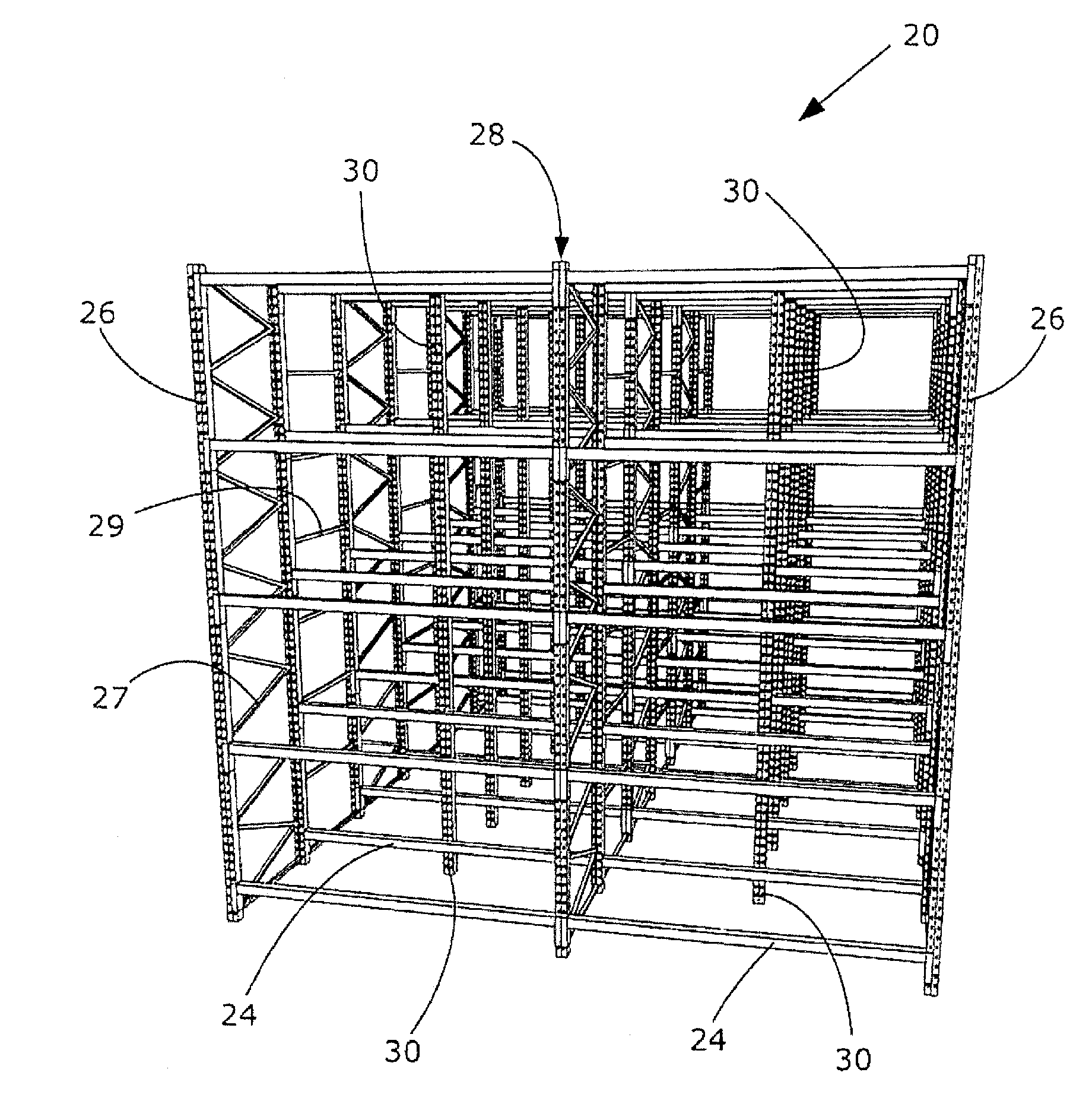

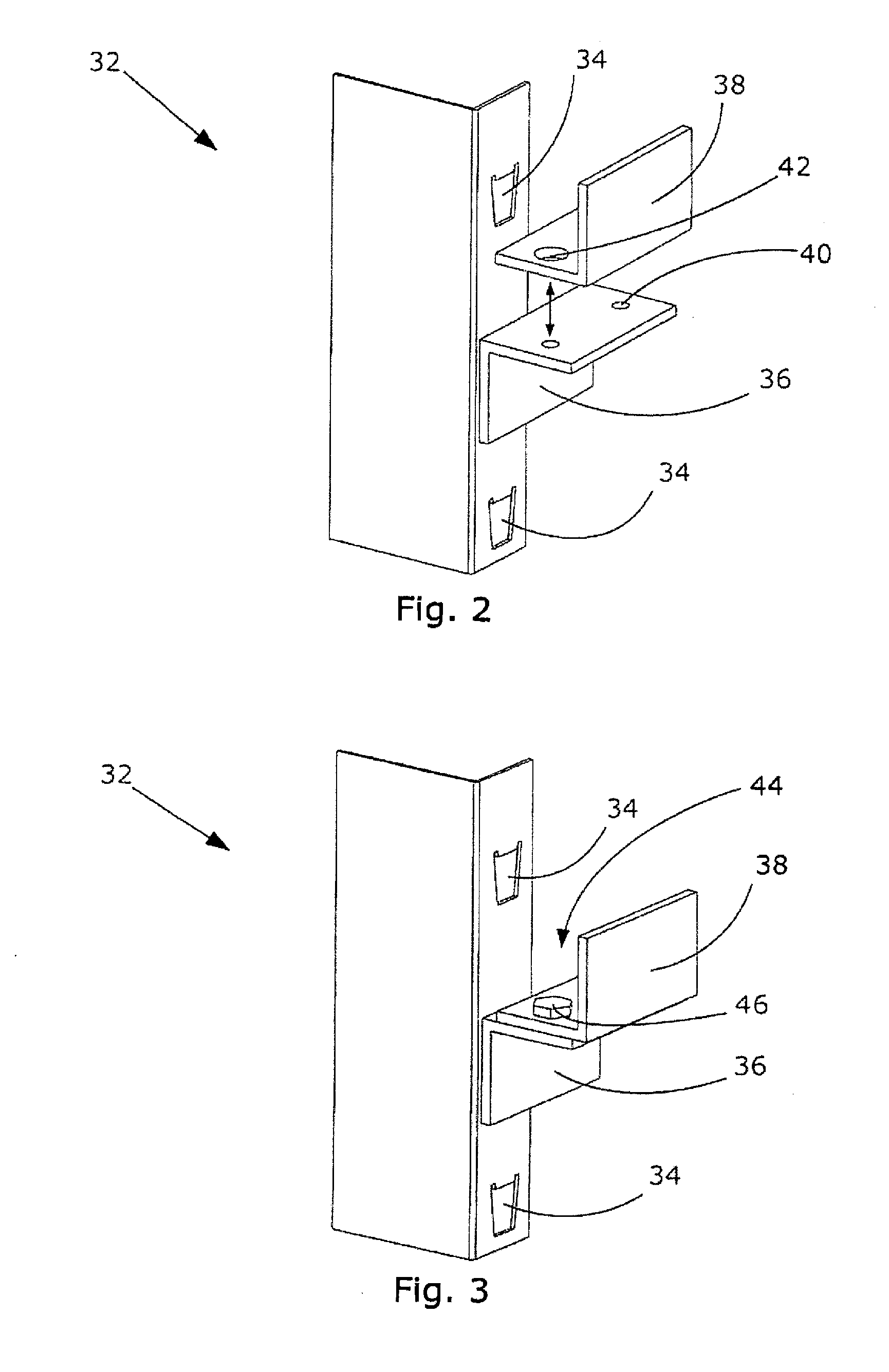

Upright support configuration for a pallet racking system

InactiveUS20130068705A1Prevent movementPromote sportsFurniture partsStorage devicesEngineeringDistortion

The present invention relates to an upright reinforcing assembly for use with a pallet racking system, and racking system incorporating the same. The support configuration consists of an upright support and attached a bracket containing two L-shaped platforms which form a pocket. The upright support configuration is placed between two frame assemblies to support the beam, which is held in the pocket created by the bracket, thereby providing additional support to the beam and preventing rotation, bowing or distortion of the beam. Such a configuration lowers the cost of pallet racking as lower capacity beams can be used, or otherwise less frame assemblies are required in the racking.

Owner:GLIDESTORE FREETRACK PTY LTD

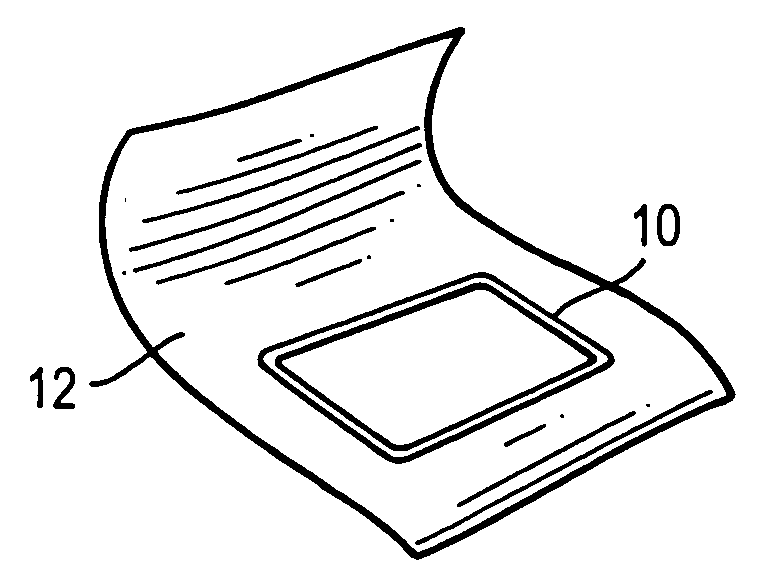

Vertically oriented jerky dehydrator

InactiveUS20050172835A1Minimize timeSuccessful operation of the dehydration processMilk preservationMeat processingEngineeringTrailing edge

A jerky dehydrator comprises several baskets for receiving and retaining the product to be dehydrated and a racking grid for retaining several baskets in a vertical orientation. The racking grid is inserted into a metal tray, and the tray is inserted into the oven of a household range. The oven is preheated, prior to inserting the tray and its contents. Subsequently, the oven is maintained at a low temperature, about 200°, and the door of the oven is held open, slightly, to allow moisture to escape. Each basket comprises a first grate and a second grate, retained in pivotal relation by a pair of hinge clips. Tension springs, secured to an anchor on one grate and an extension on the other grate, urge the grates togther to form a basket and retain the jerky therebetween during the dehydration process. Receptacles at the trailing edge of one grate slip over upstanding pins on the racking grid and lock each basket in its vertical orientation. A form may be used to mold the jerky into a patty or square, of desired dimensions, prior to inserting same into the basket.

Owner:LAMASTER ALAN L +1

Shelving system

InactiveUS20050224427A1Low costIlluminance (contrast)Show cabinetsCabinetsMotion detectorEngineering

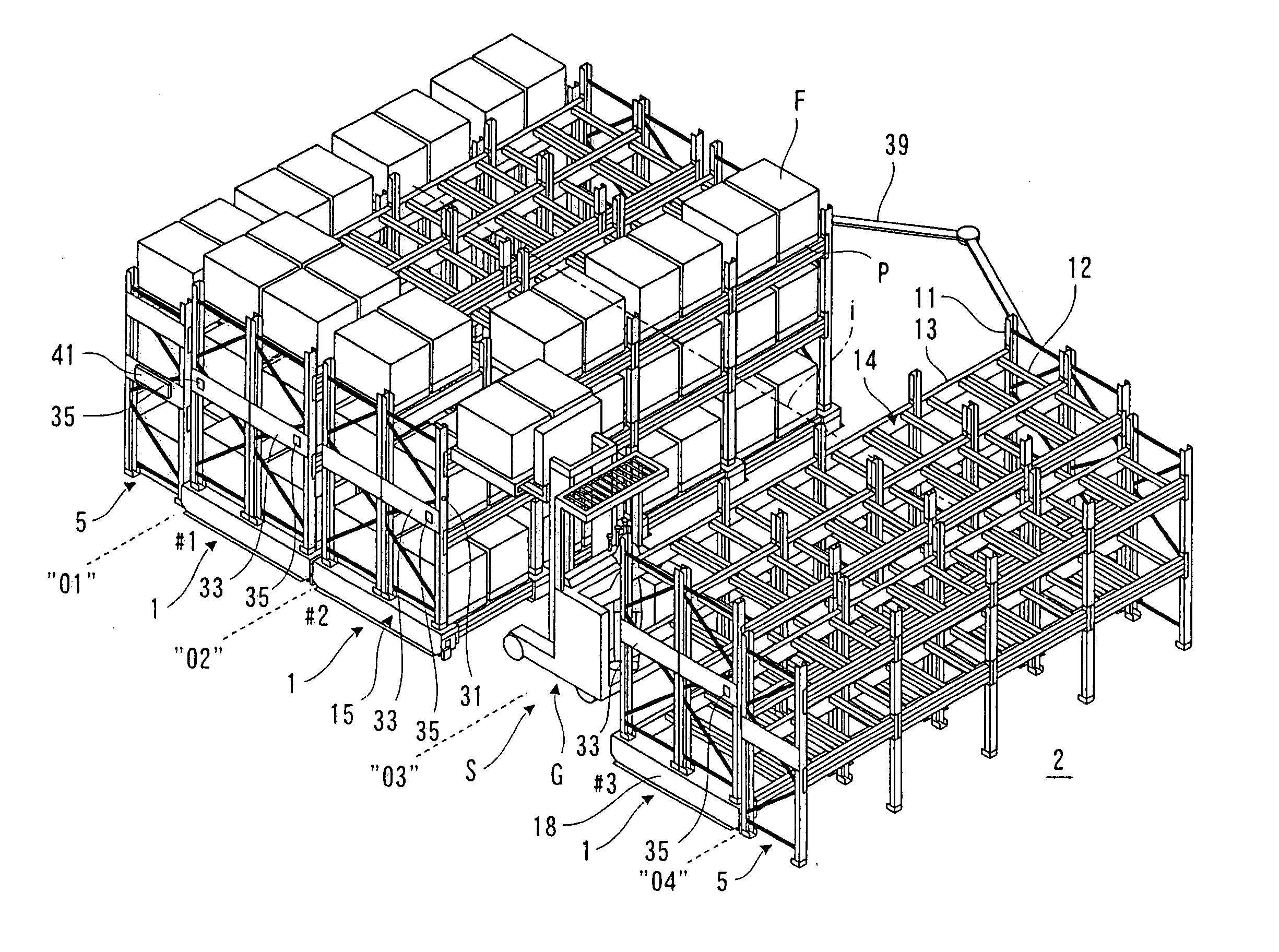

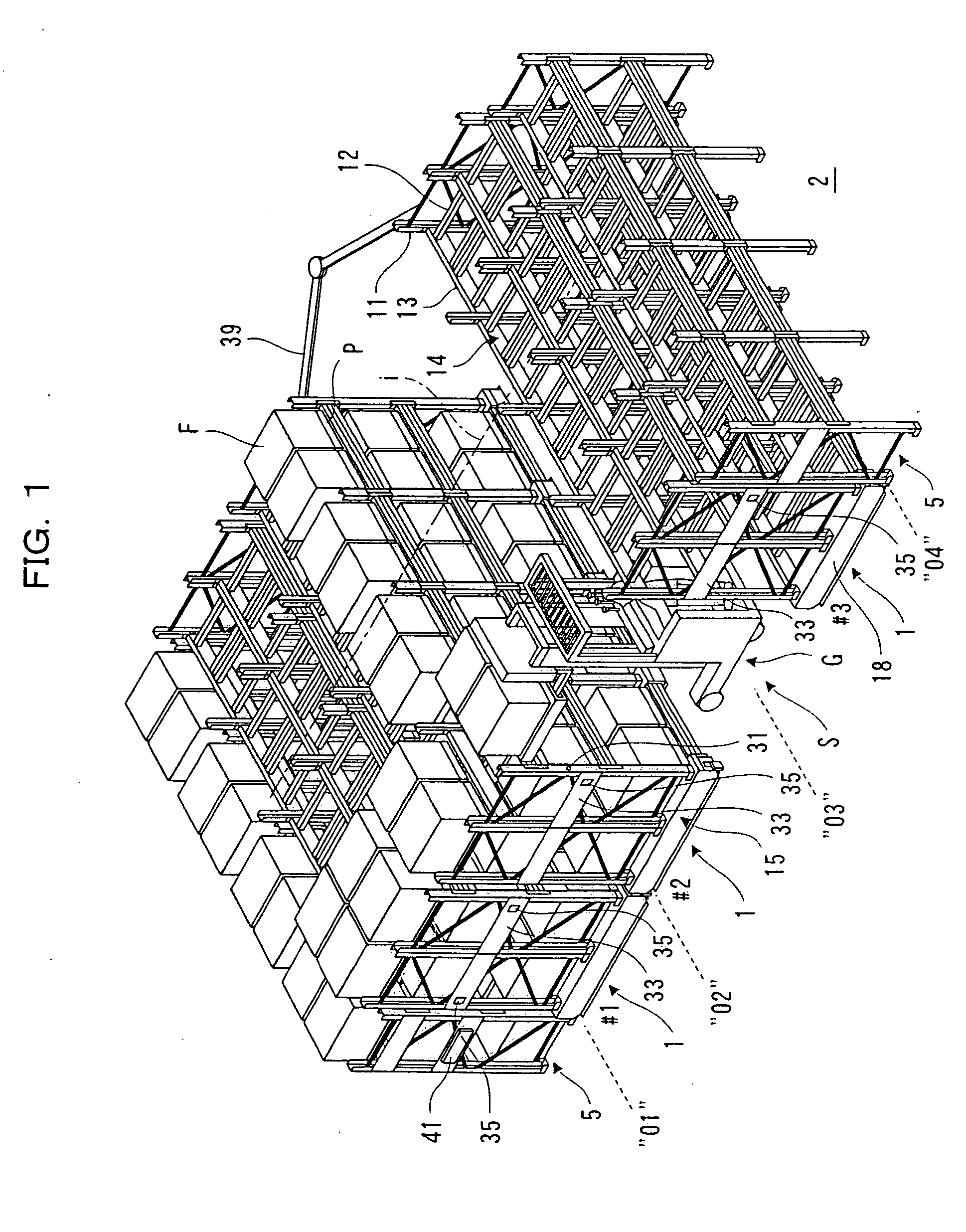

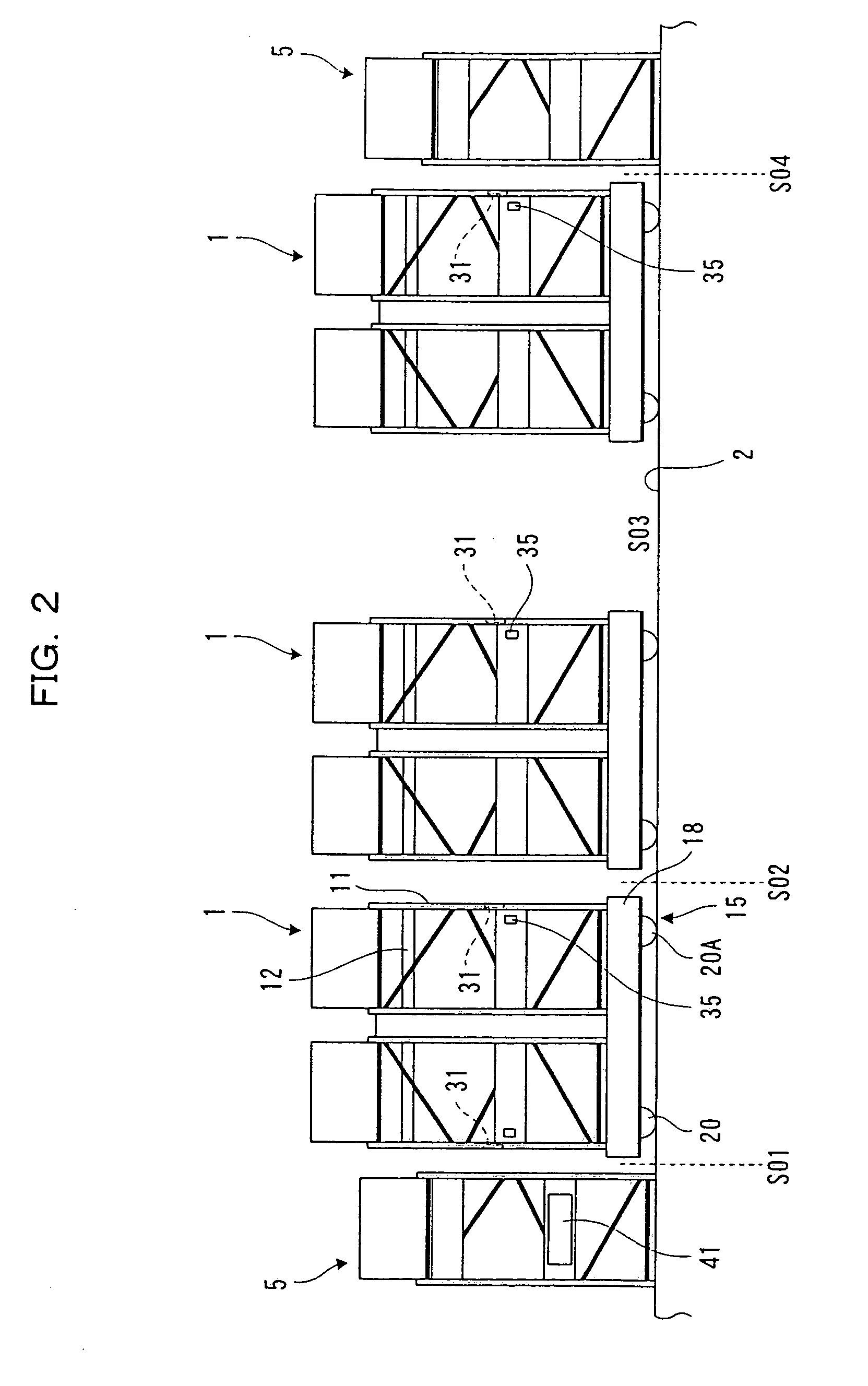

A shelving system including a plurality of movable shelves (1) installed for back-and-forth movement on a travel path through a travel support device, thereby to handle articles with respect to the movable shelves (1) opposed to a working aisle (S) by using the working aisle (S) opened between the movable shelves (1). Each movable shelf (1) includes a pair of movement detectors (19) disposed in a left-right direction (B) perpendicular to the travel direction (A) of the movable shelves (1). Absolute coordinates of each movement detector (19) are found based on detection signals from the pair of movement detectors (19) of each movable shelve (1). The amount of left-right directional deviation from the travel path (i) of the movable shelves (1) is corrected based on the amount of deviation of the absolute coordinates in the left-right direction (B). Further, the attitude of the movable shelves (1) is corrected to be perpendicular to the travel direction (A) based on positional deviation of the absolute coordinates in the travel direction (A), i.e. traveled distance deviation.

Owner:DAIFUKU CO LTD

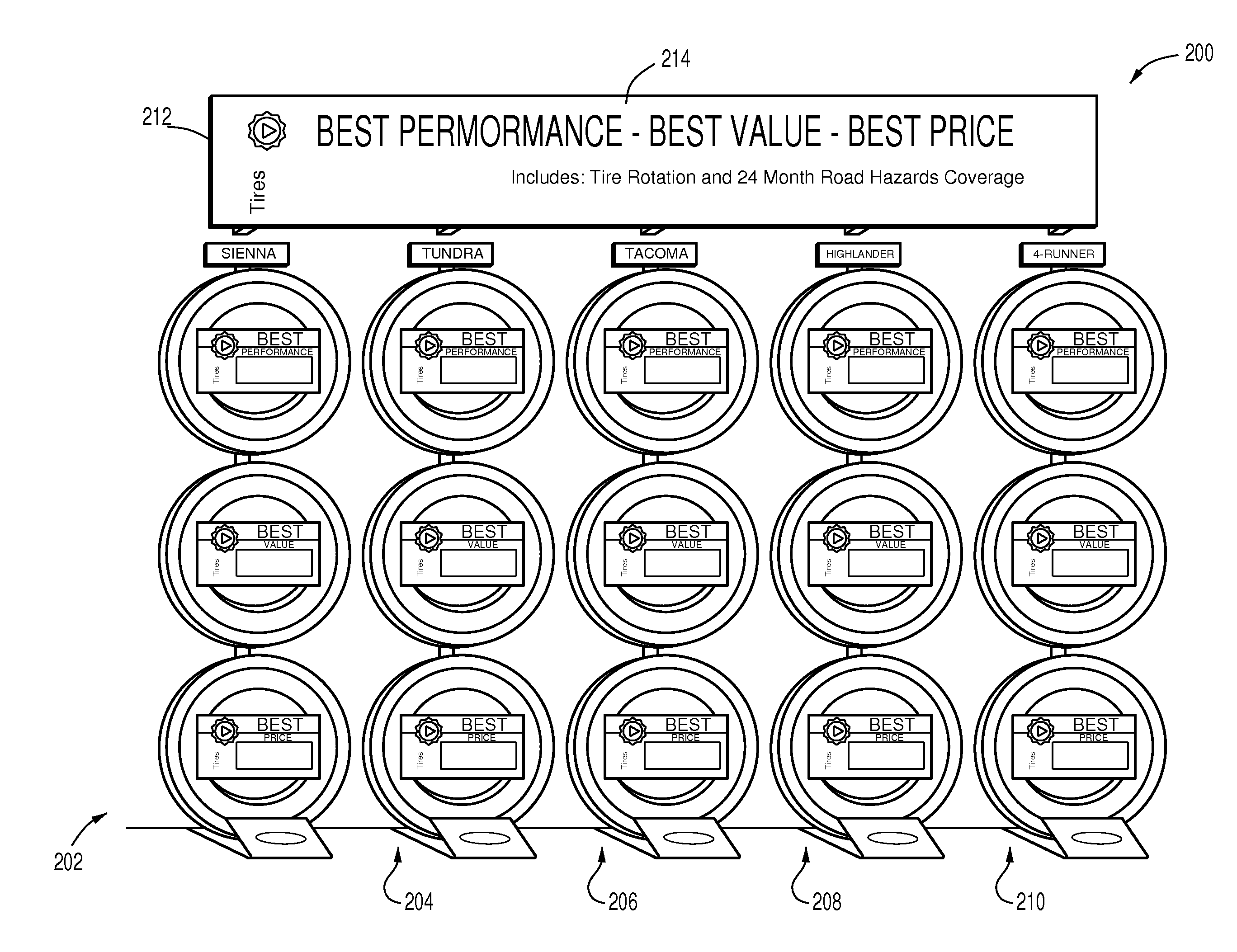

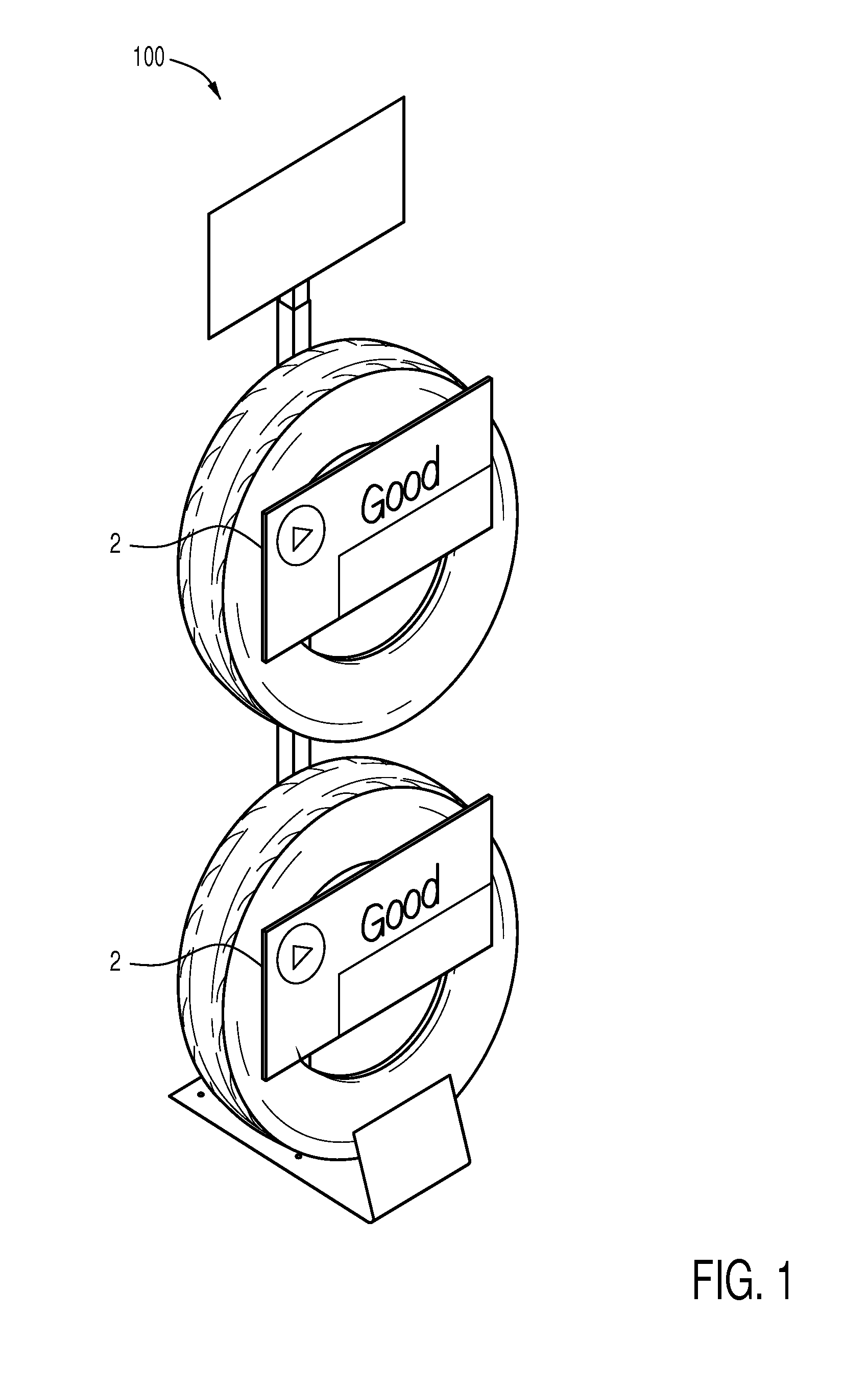

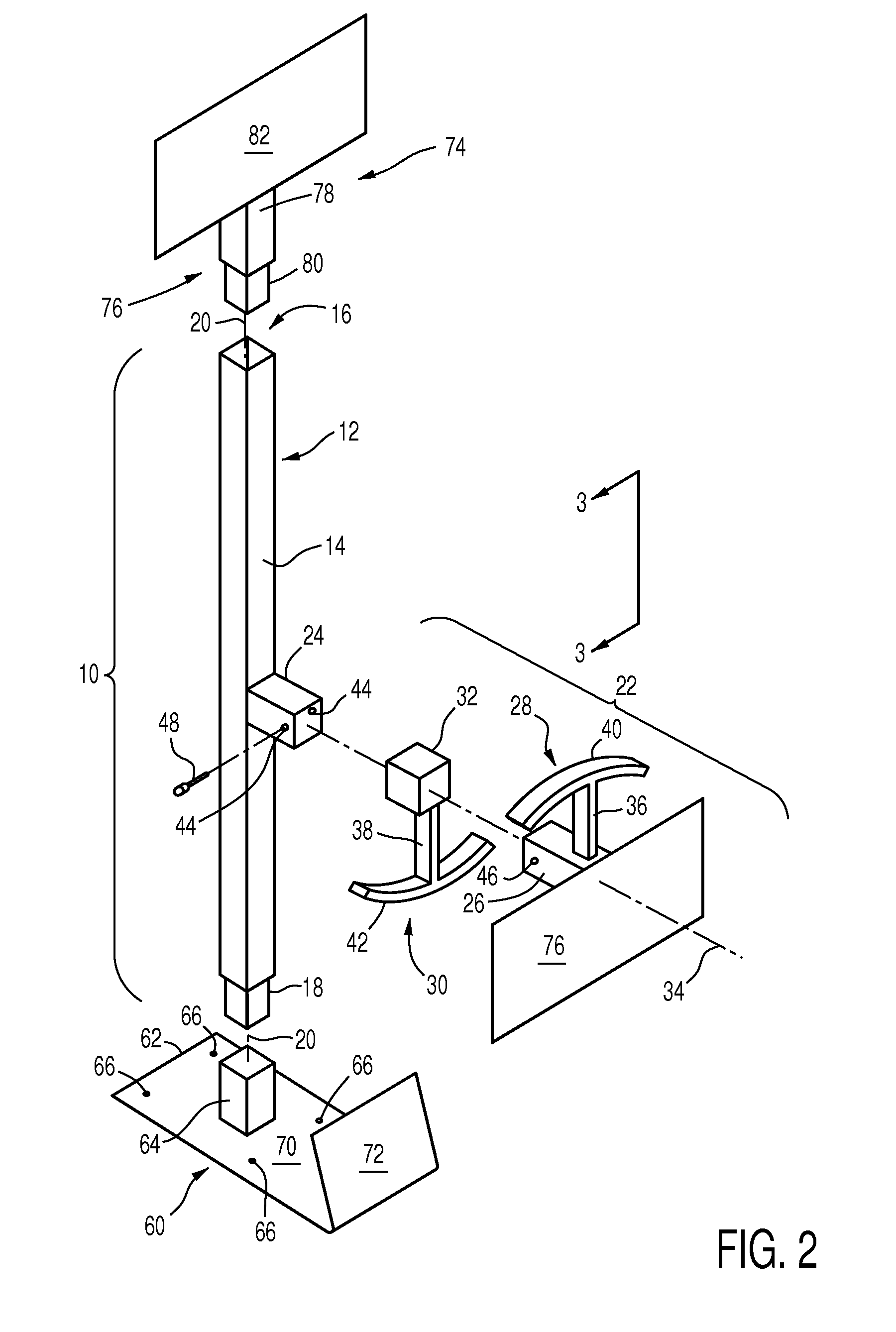

Modular locking tire merchandising display racking system

InactiveUS20130008066A1Versatile convenientSecurely holdLocks for portable objectsWheel holding meansEngineeringCaster

A modular tire rack which engages tires from the open interior of each tire. The rack may be formed in modular sections which can be assembled in vertically or horizontally adjustable numbers. The rack may incorporate a lock to prevent casual removal of tires. Tires are supported with their full faces available for inspection by potential buyers. Tires are engaged by structure which after assembly occupies the open interior of each tire. The rack may include a floor base accommodating either permanent bolting to a floor or the like or alternatively, attachment of caster wheels. Supports for holding signage may be provided.

Owner:DE MARTIGNY CHARLES

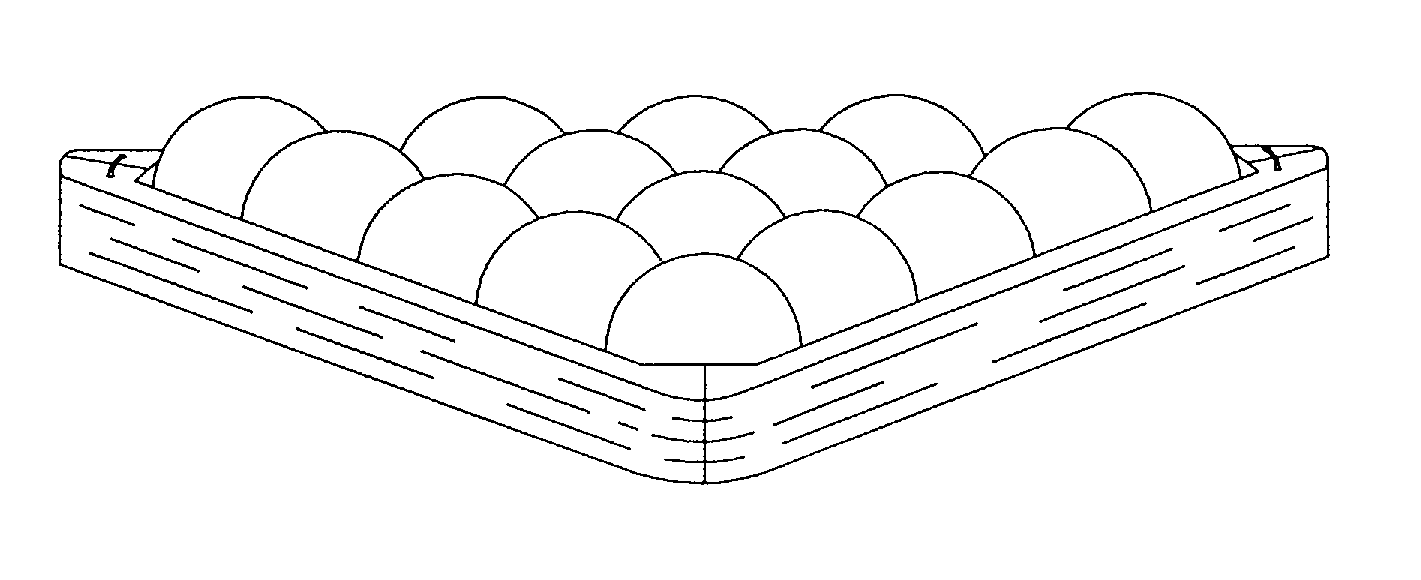

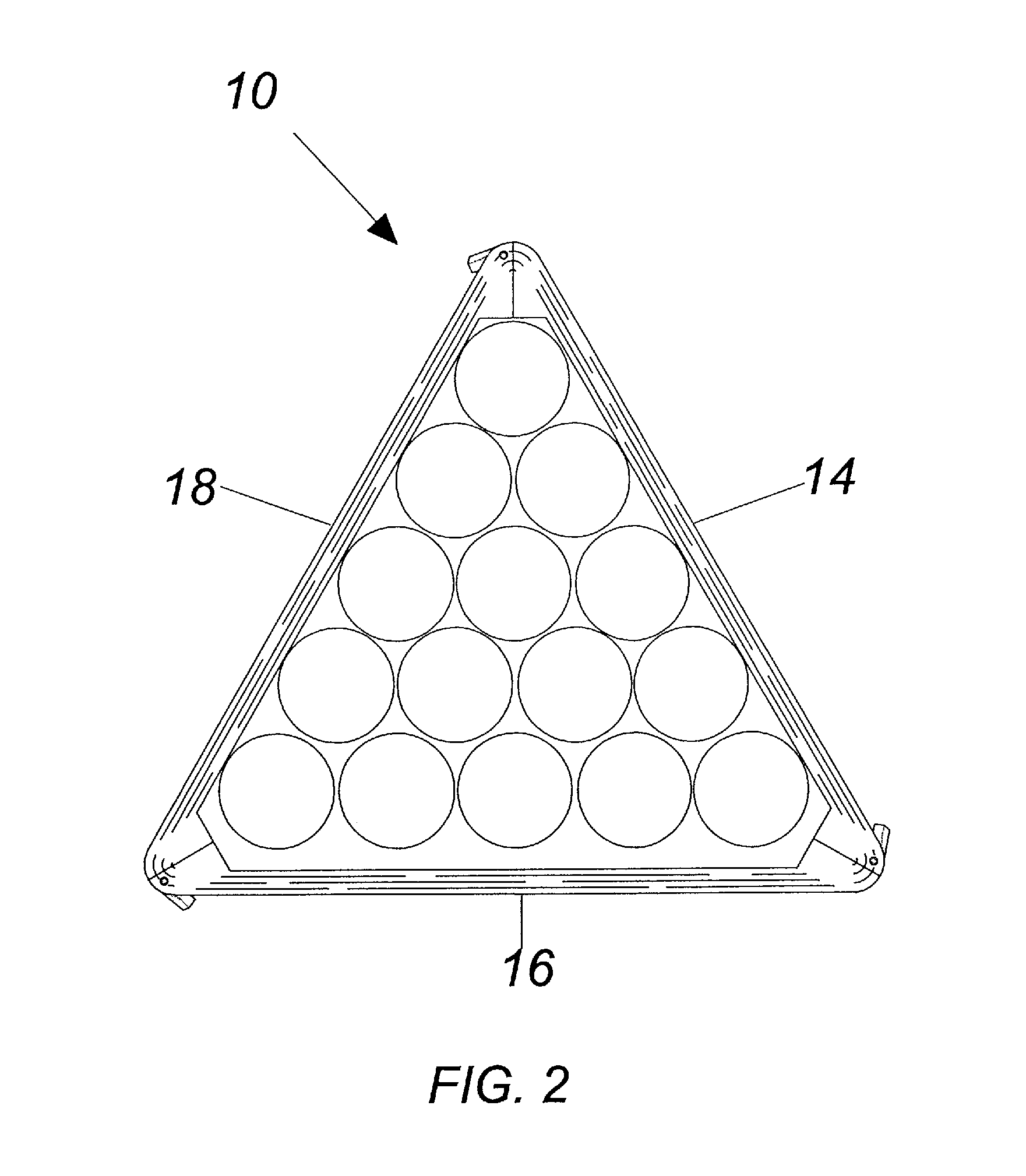

Racking frame kit

A racking frame kit including a storage container housing three shaped side members that can assembled into an equilateral triangular enclosure for receipt of a group of balls in a compressed position. The racking frame providing a portable device that allows pool players to obtain the repeatability necessary from location to location. The kit further provides for the tightening of the formation of balls to obtain the maximum transfer of energy from a cue ball impact which will allow a predictable and disperse spread of balls across a playing surface. Various embodiments include a latching release, a magnet release, a tongue & groove release, and an elastic band.

Owner:KAPLAN MATTHEW

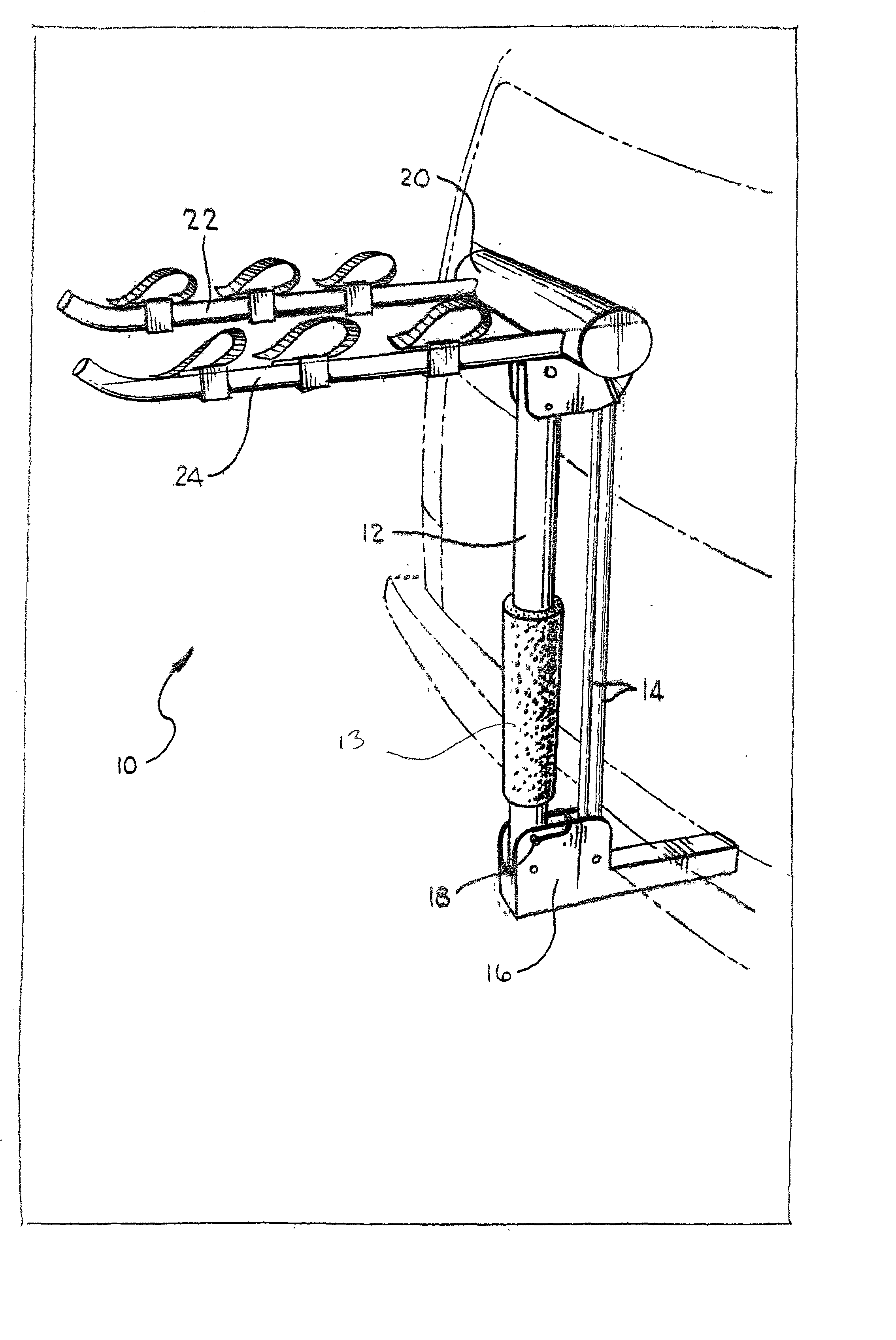

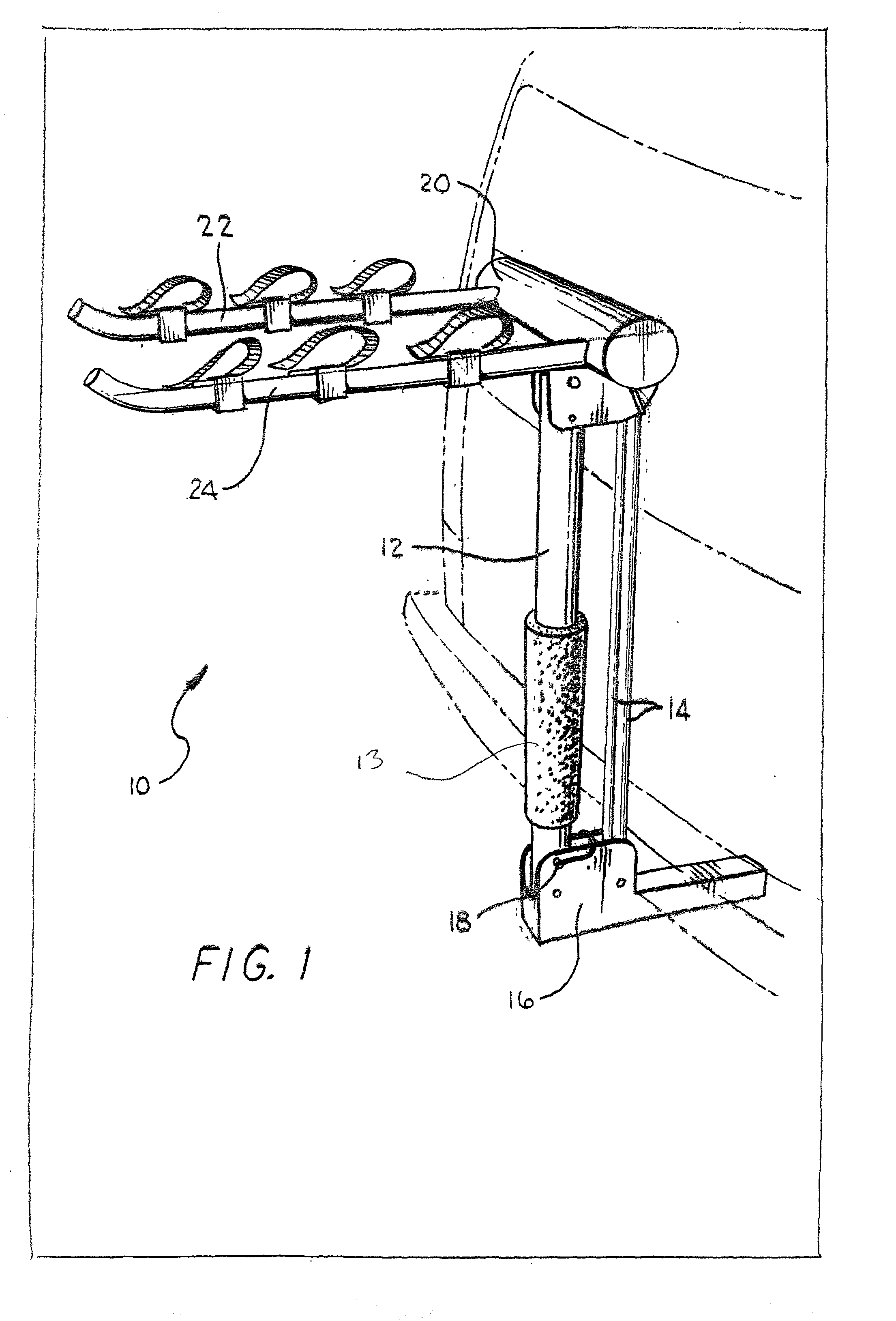

Hitch-mounted pivotable racking assembly

InactiveUS20020050502A1Large spacingPlace safeTravelling carriersSupplementary fittingsRECREATIONAL EQUIPMENTEngineering

A racking assembly for securely storing and transporting recreational equipment on vehicles includes a hitch mount, an equipment support assembly, and pair of support members having lower ends pivotally coupled to the hitch mount and upper ends pivotally coupled to the equipment support assembly. The support members are configured to allow the racking assembly to collapse away from a user placing equipment thereon so that injury is prevented from the weight of the equipment causing the racking assembly to collapse onto a user.

Owner:VIGOR SPORTS

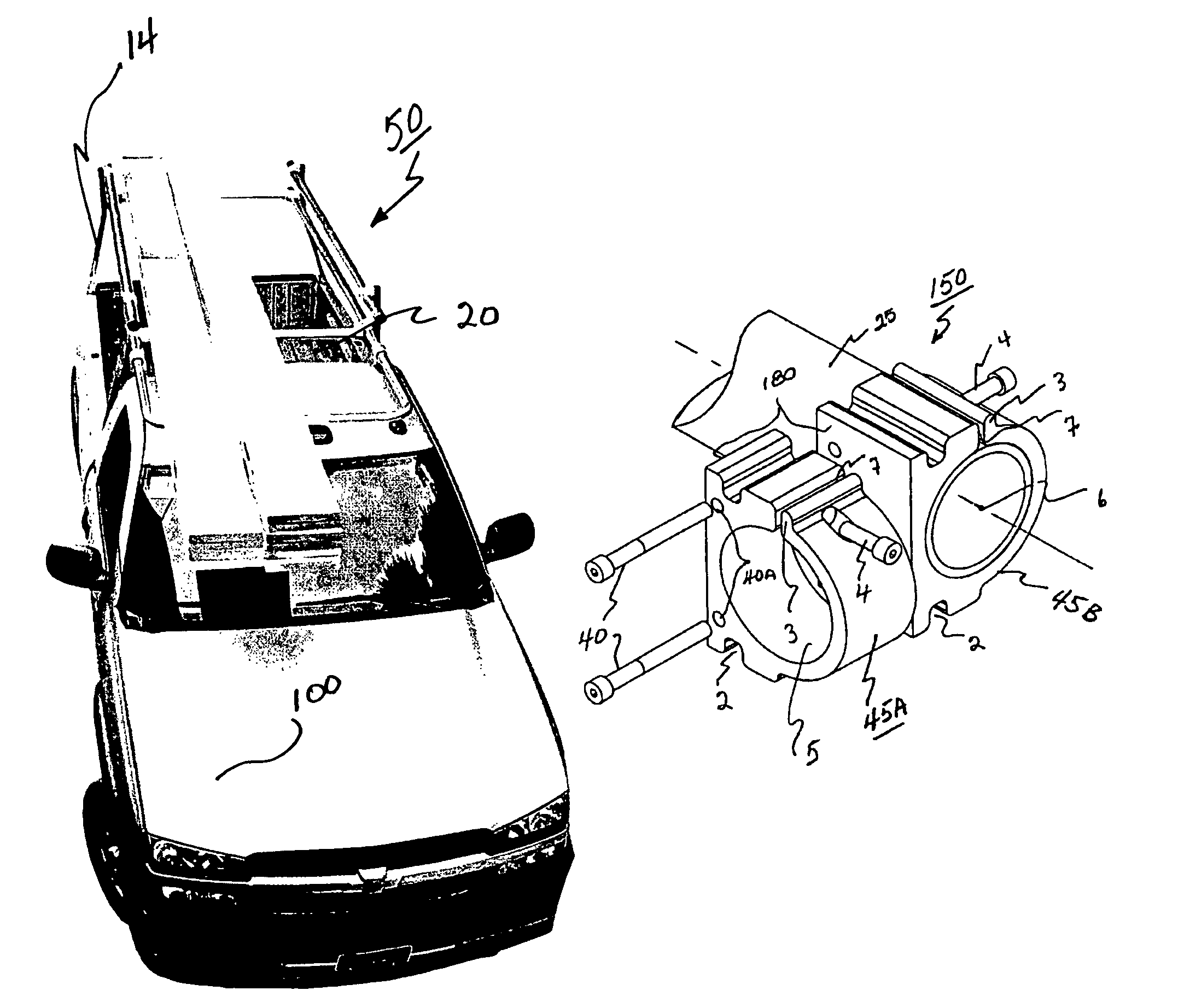

Solar Panel with Pivoting Side Supports

ActiveUS20160315580A1Reduce expensesReduce laborPhotovoltaic supportsSolar heating energyEngineeringSolar energy harvesting

A folded down support (12) allows for stronger solar panels (10) and the support replaces most of the solar racking required for solar installation which further reduces the cost of the photovoltaic solar system. The solar panels (10) can be arranged so that solar panels form a solar collector solar panel array. The solar panel (10) can be set on a surface by itself or with ballast (43). It can also be attached to the surface by fastening the solar panel to the side supports. If the solar panel frame and supports are electrically conductive, the design allows for self electrical grounding between these conductive parts when the side supports are pivoted to the down position. The folded up support allows for high density storage and shipping.

Owner:PATTON ENG

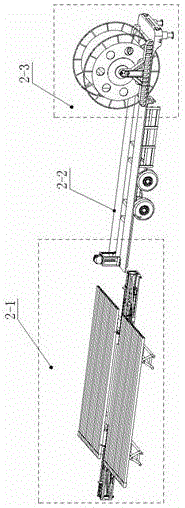

Multifunctional full-automatic coiled tubing drilling rig

ActiveCN105822223AAdjust working posture at willFulfill the needs of the work environmentDrilling rodsDerricks/mastsWell drillingControl system

The invention discloses a multifunctional full-automatic coiled tubing drilling rig, which comprises a main vehicle unit and an auxiliary vehicle unit, wherein the main vehicle unit comprises a vehicular chassis, a vehicular power system, a combination type derrick system and a main vehicle vehicular operation and control system; the auxiliary vehicle unit comprises a semi-mounted vehicular chassis, a drill pipe racking and moving system tubing racking part, a coiled tubing discharging and injecting system and an auxiliary vehicle vehicular operation and control system; the combination type derrick system comprises a drilling rig platform, a drill floor supporting leg, a main bracket, an auxiliary bracket, a derrick amplitude varying and posture adjusting system, a well head tubular column fastener processing system, a well head protecting system, a pinion-and-rack hoisting system, a coiled tubing injecting system and a drill pipe racking and moving system tubing moving part; the main vehicle unit can independently complete conventional single drill pipe drilling, super single drill pipe drilling and slant and vertical well drilling work; the auxiliary vehicle unit is combined with the main vehicle unit to be capable of completing a coiled tubing drilling work; the main vehicle unit cooperates with the auxiliary vehicle unit to realize single drill pipe drilling, slant and vertical well drilling and coiled tubing drilling work.

Owner:SHANDONG SHENGLI PETROLEUM EQUIP IND TECH RES INST

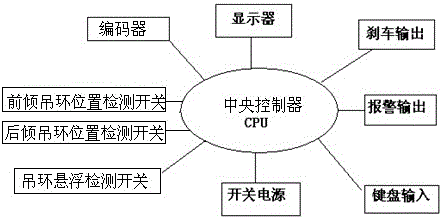

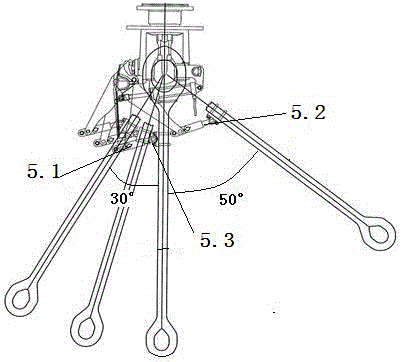

Anti-collision protective device and method for drilling top drive and derrick racking platform

InactiveCN105672870AReduce labor intensityDegree of reductionDrilling rodsConstructionsTop drivePulse number

The invention relates to an anti-collision protective device and method for a drilling top drive and a derrick racking platform. Hang ring position detecting switches are installed at the forerake position and the hypsokinesis position of a top drive hang ring respectively, and a hang ring suspension detecting switch is arranged in the middle suspension position to judge the position state of the top drive hang ring. An encoder is installed on a winch and can output multiple pulse records when a roller on the winch is rotated by a circle; a central control unit indicates the height of the top drive in a derrick according to the pulse number recorded by the encoder, the position of the top drive hang ring and the height of the top drive are processed and compared in the central control unit to achieve collision prevention of the racking platform position. The anti-collision protective device has the advantages that the independent top drive and the winch are systematically and organically combined together, defects of respective designs are overcome, safety of equipment operation is greatly improved, and the situation that the top drive hang ring collides with the racking platform due to human errors and other serious related accidents caused by collision is effectively prevented.

Owner:李峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com