Multifunctional full-automatic coiled tubing drilling rig

A coiled tubing, fully automatic technology, applied in drill pipe, drill pipe, casing, etc., can solve the problems of wasting manpower, material and financial resources, increasing engineering volume, and insufficient performance of drilling rigs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

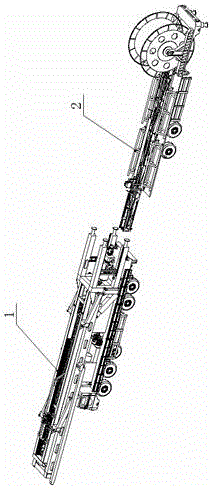

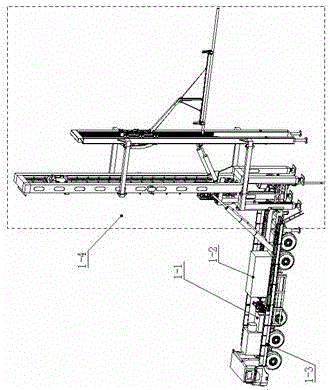

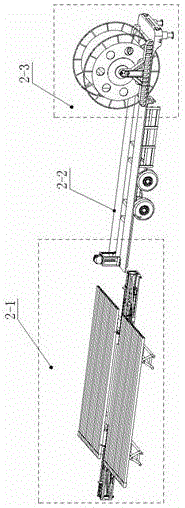

[0044] Such as Figure 1-12 In the illustrated example, as Figure 1-3 As shown, a multifunctional fully automatic coiled tubing drilling rig includes a main vehicle unit 1 and an auxiliary vehicle unit 2, the main vehicle unit 1 includes a vehicle chassis 1-3, a vehicle power system 1-1, a combined derrick system 1-4, Main vehicle on-board control system 1-2, auxiliary vehicle unit 2 includes semi-trailer vehicle-mounted chassis 2-2, drill pipe row and rod moving system pipe part 2-1, coiled tubing drainage system 2-3, auxiliary vehicle on-board control system , the main vehicle unit 1 can independently complete conventional single drilling, super single drilling and inclined vertical well drilling operations, the auxiliary vehicle unit 2 and the main vehicle unit 1 can complete the coiled tubing drilling operation, the main vehicle unit 1 and the auxiliary vehicle unit 2 are two The trolley cooperates to realize three kinds of drilling operations: single drilling, inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com