Patents

Literature

707 results about "Drill floor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

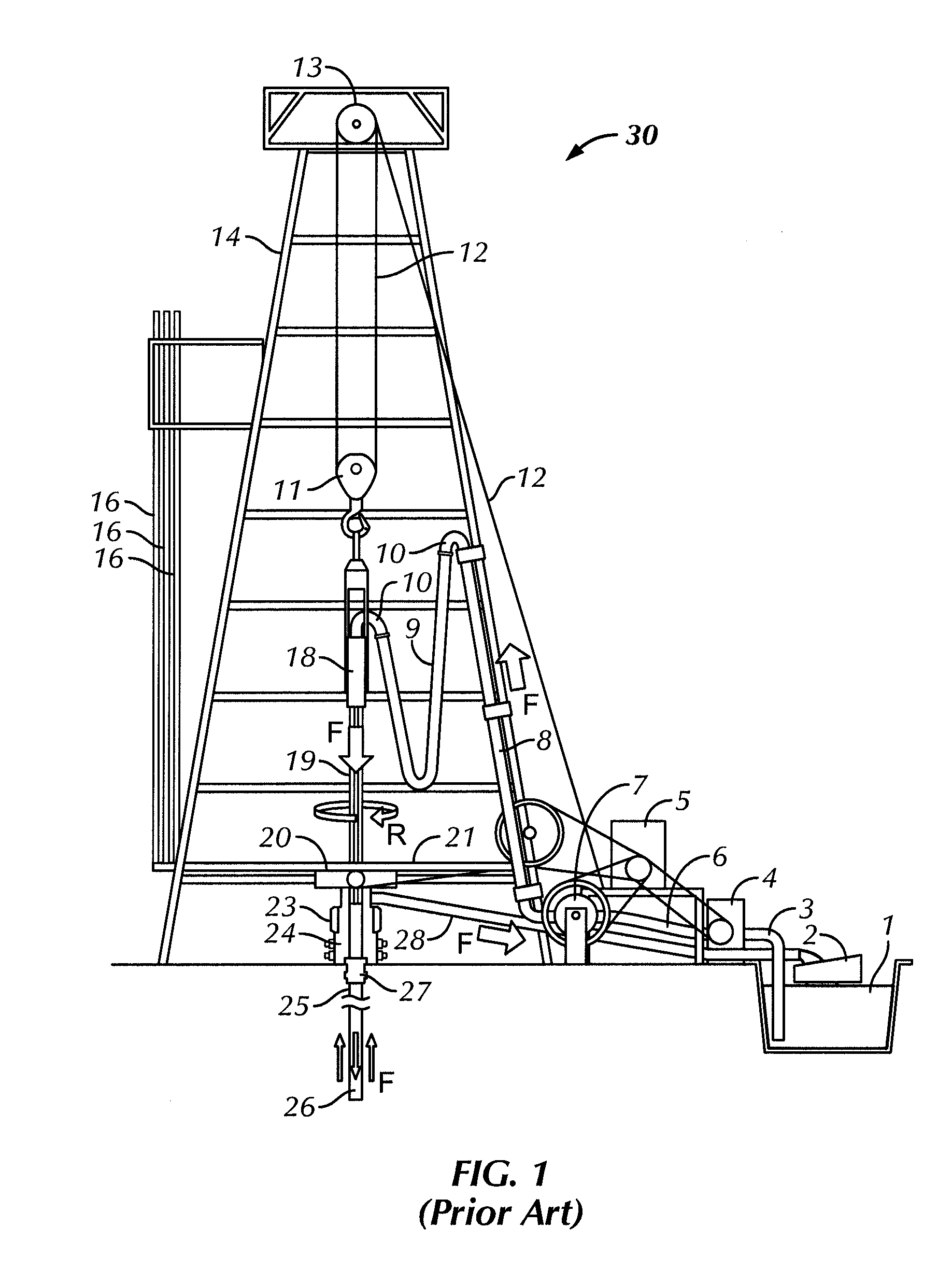

The drill floor is the heart of any drilling rig. This is the area where the drill string begins its trip into the earth. It is traditionally where joints of pipe are assembled, as well as the BHA (bottom hole assembly), drilling bit, and various other tools. This is the primary work location for roughnecks and the driller. The drill floor is located directly under the derrick.

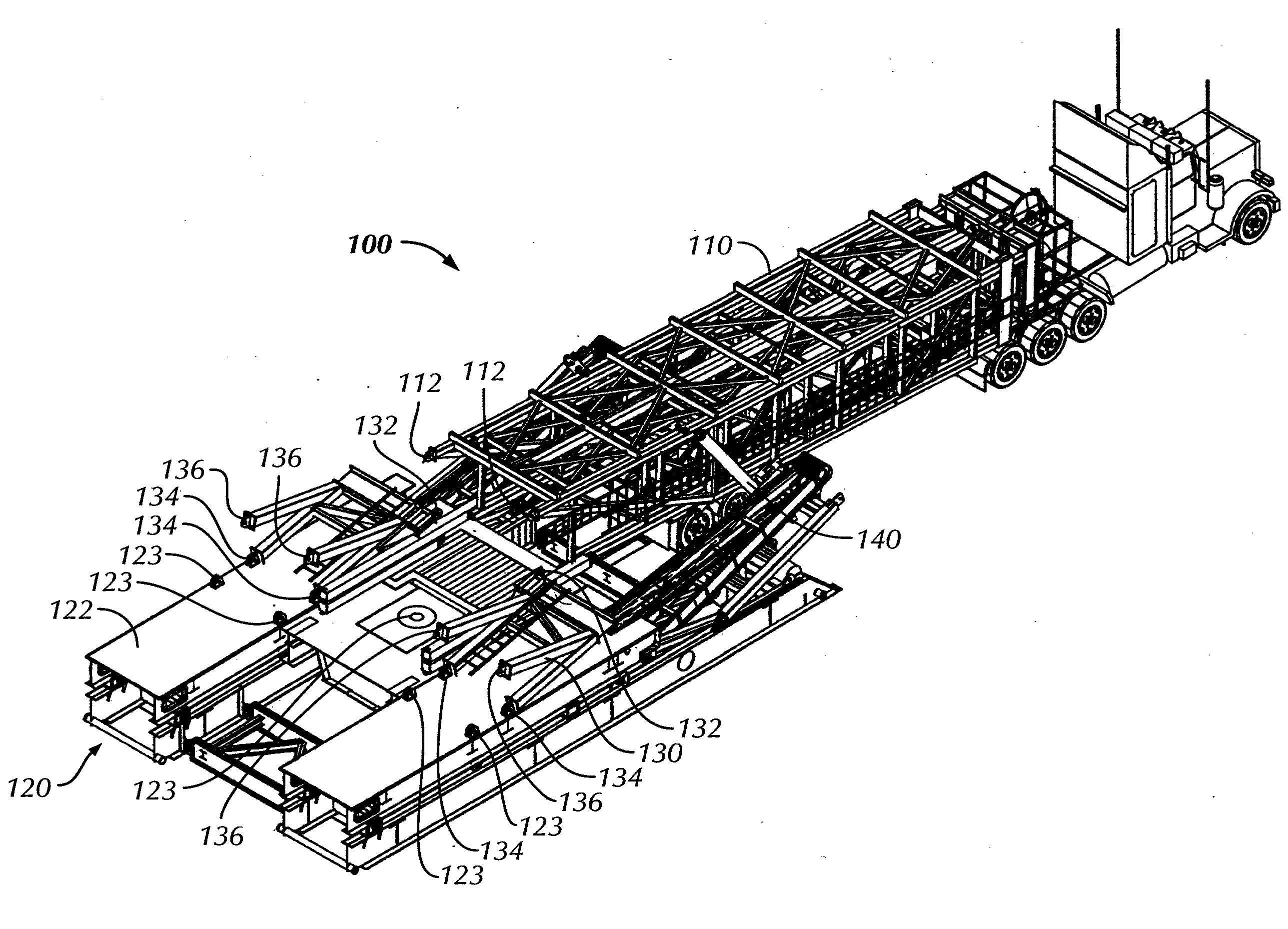

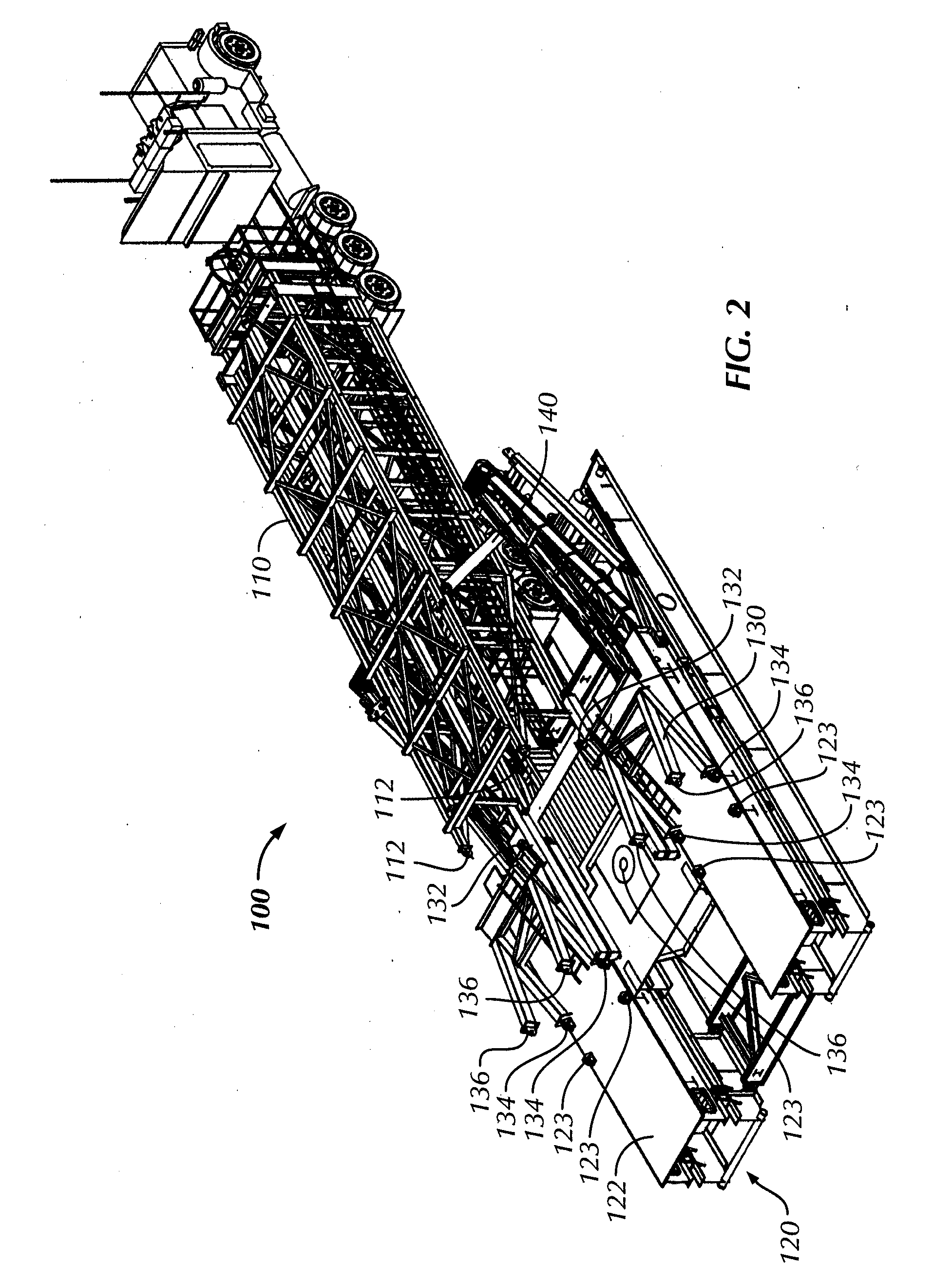

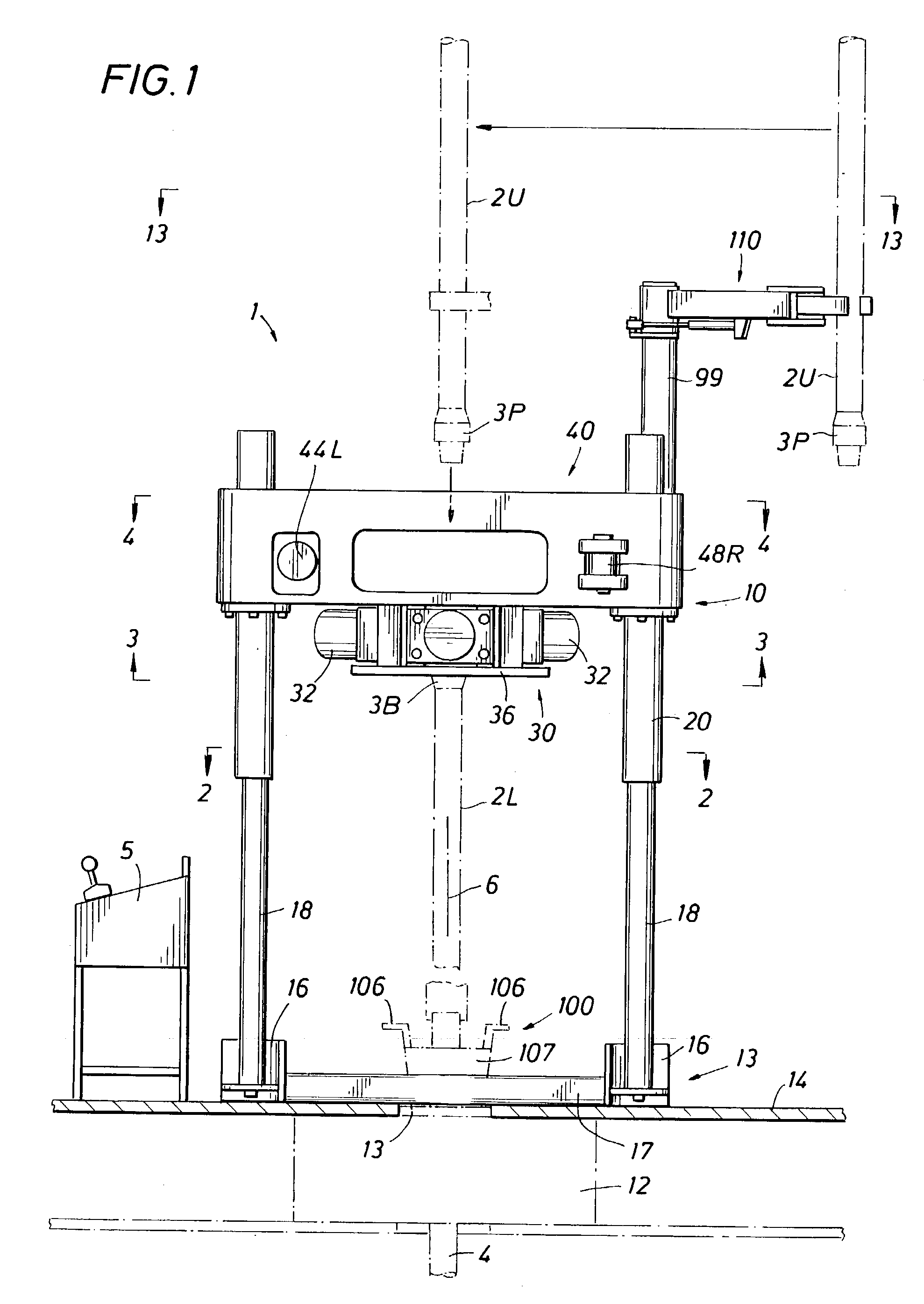

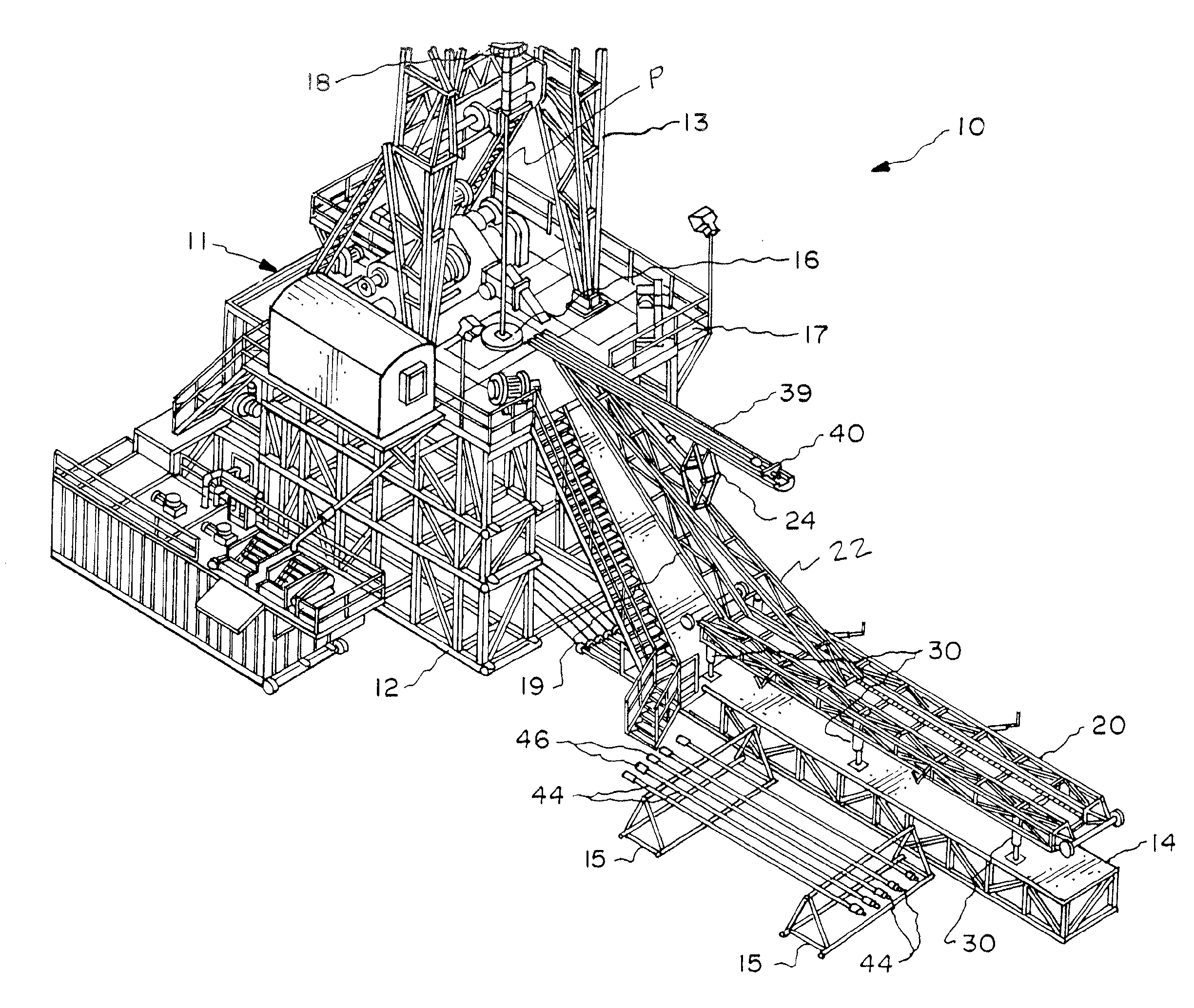

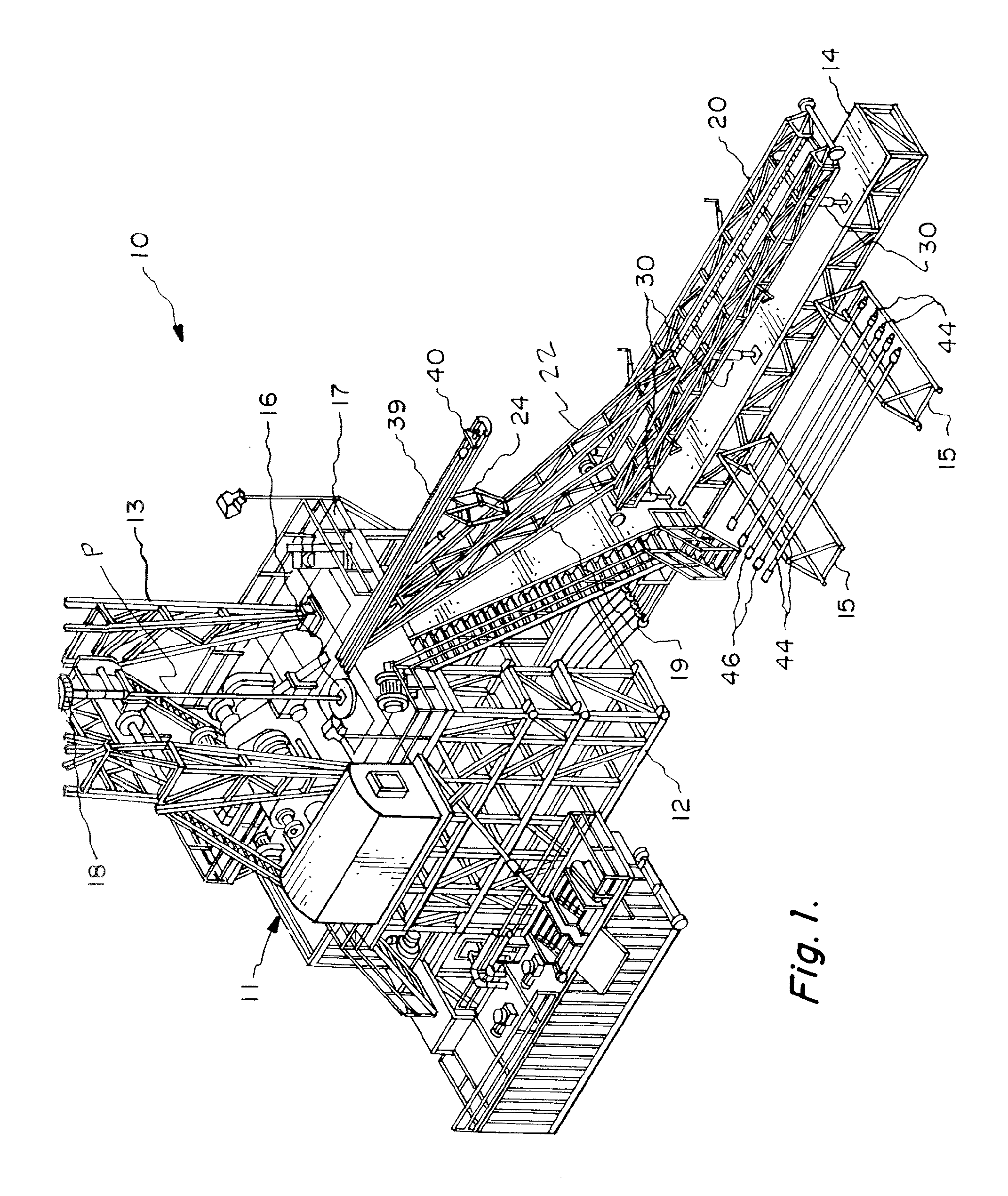

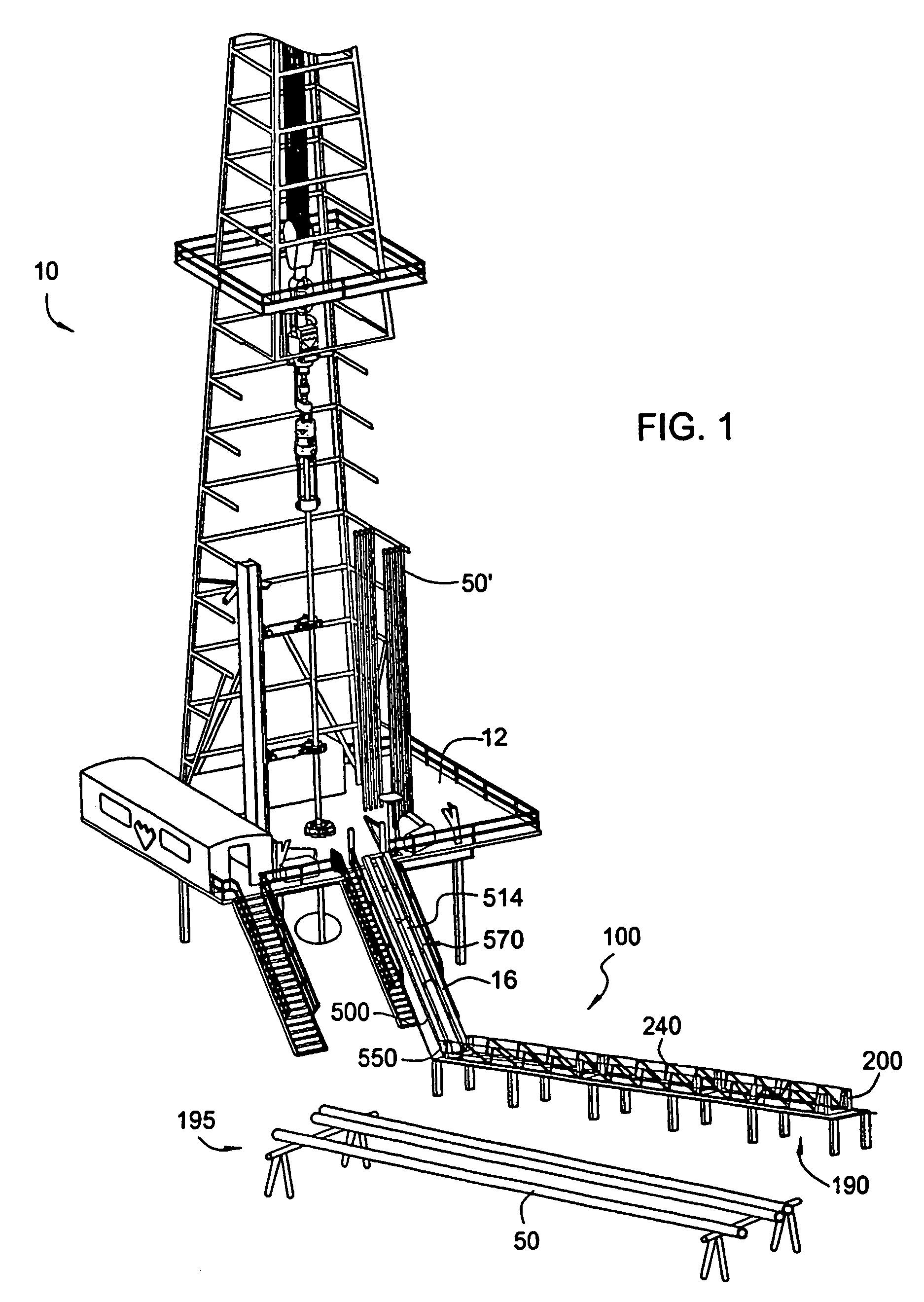

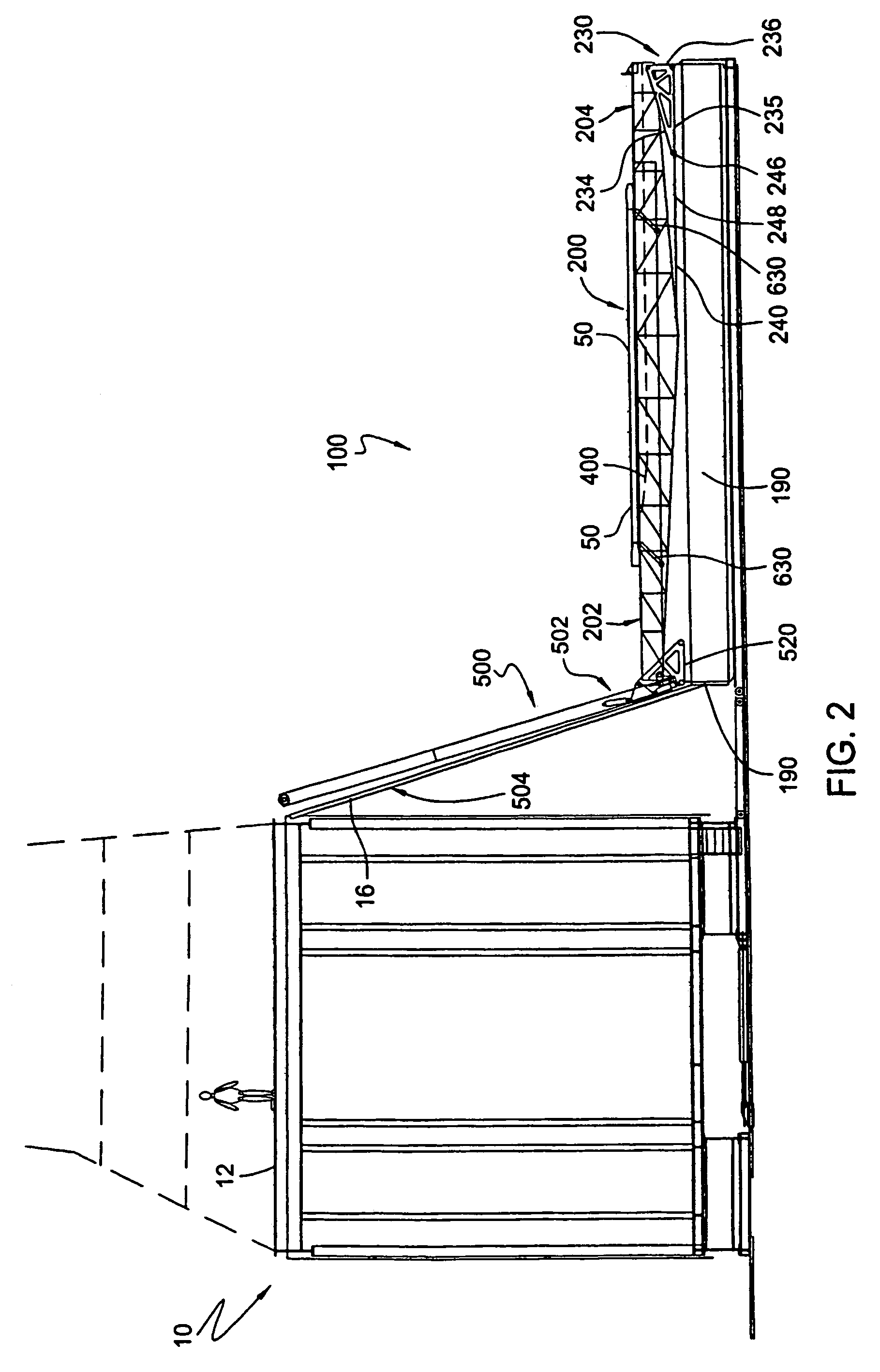

Portable drilling rig apparatus and assembly method

Owner:INTEGRATED DRILLING EQUIP

Drill pipe connecting and disconnecting apparatus

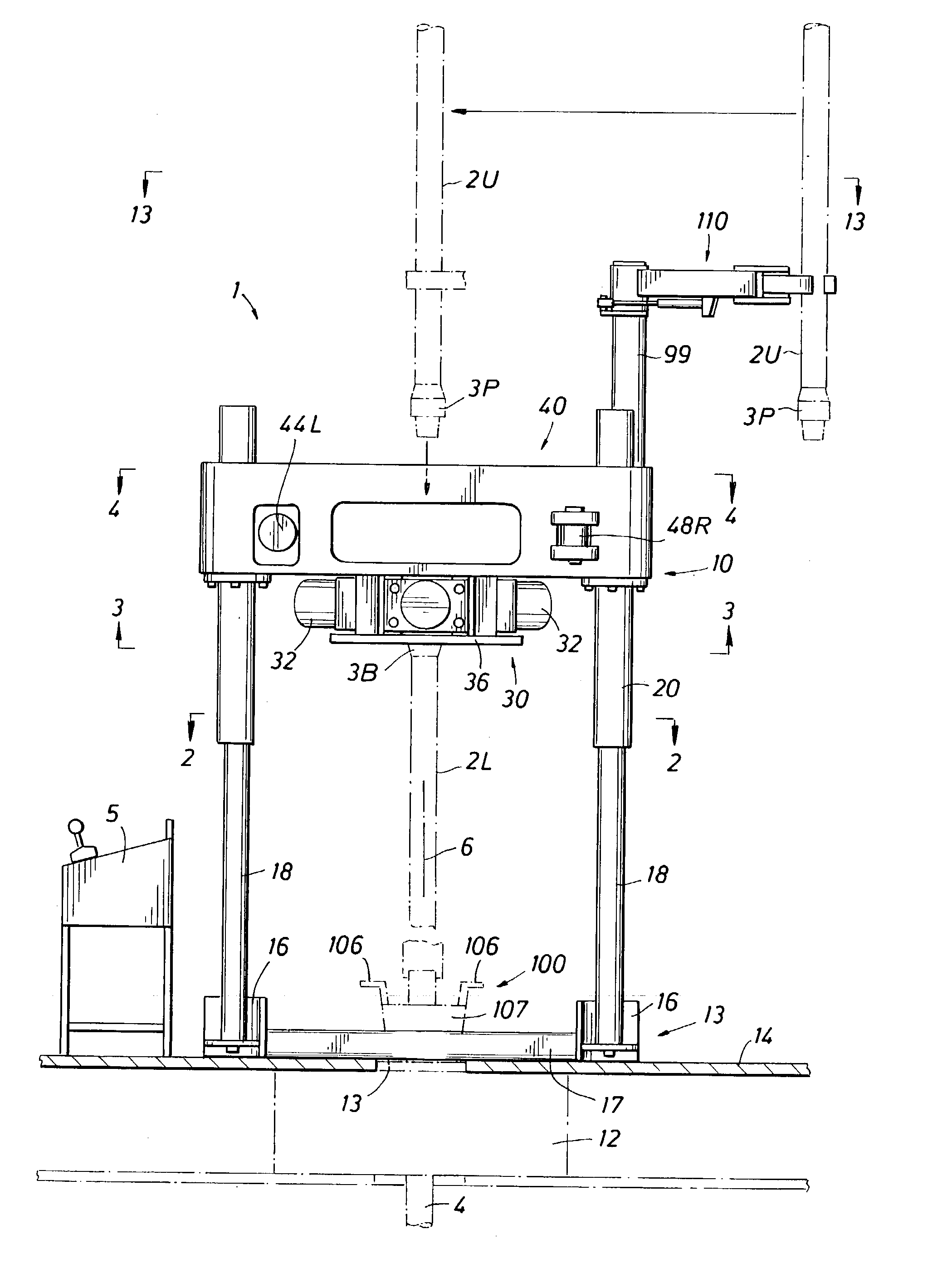

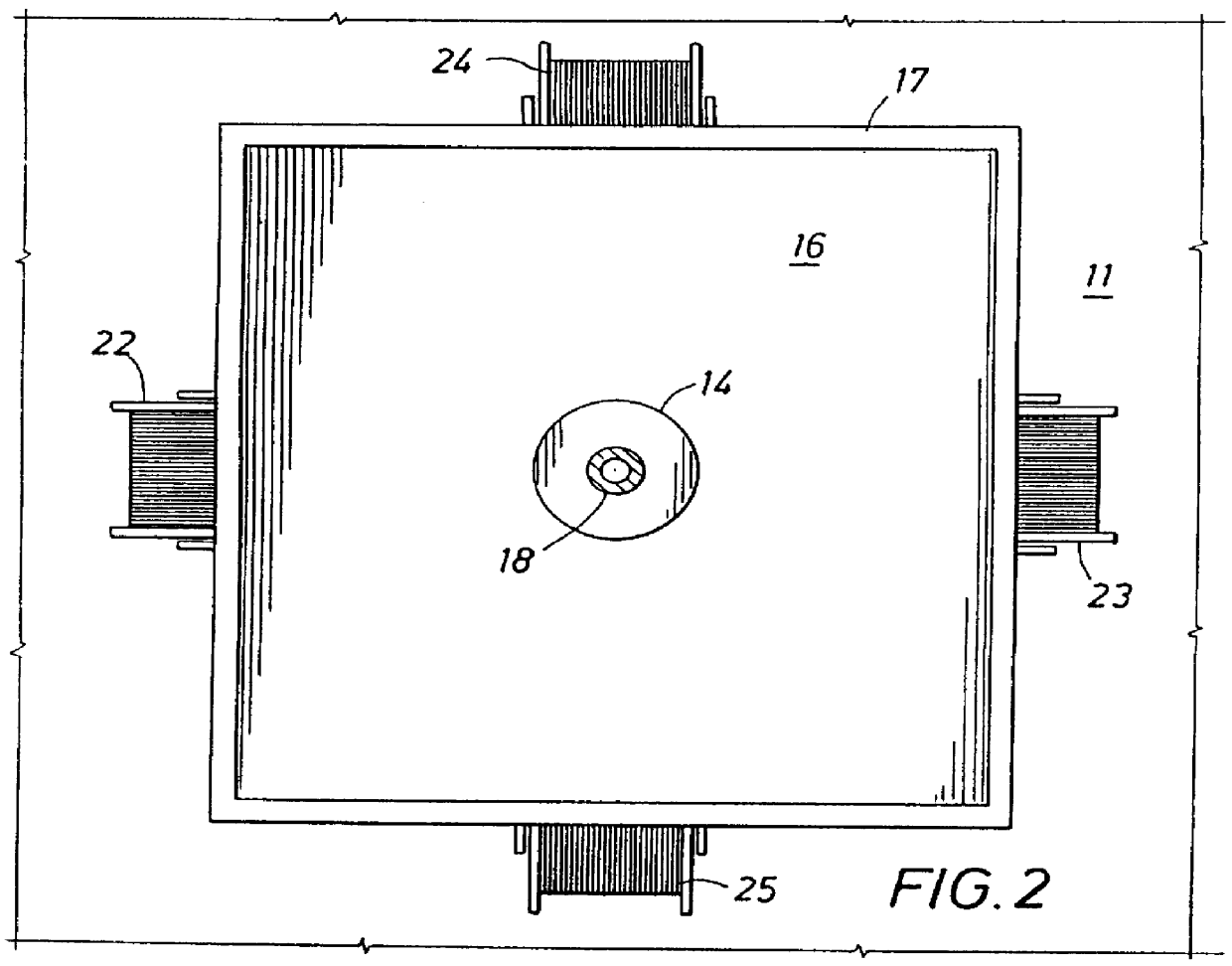

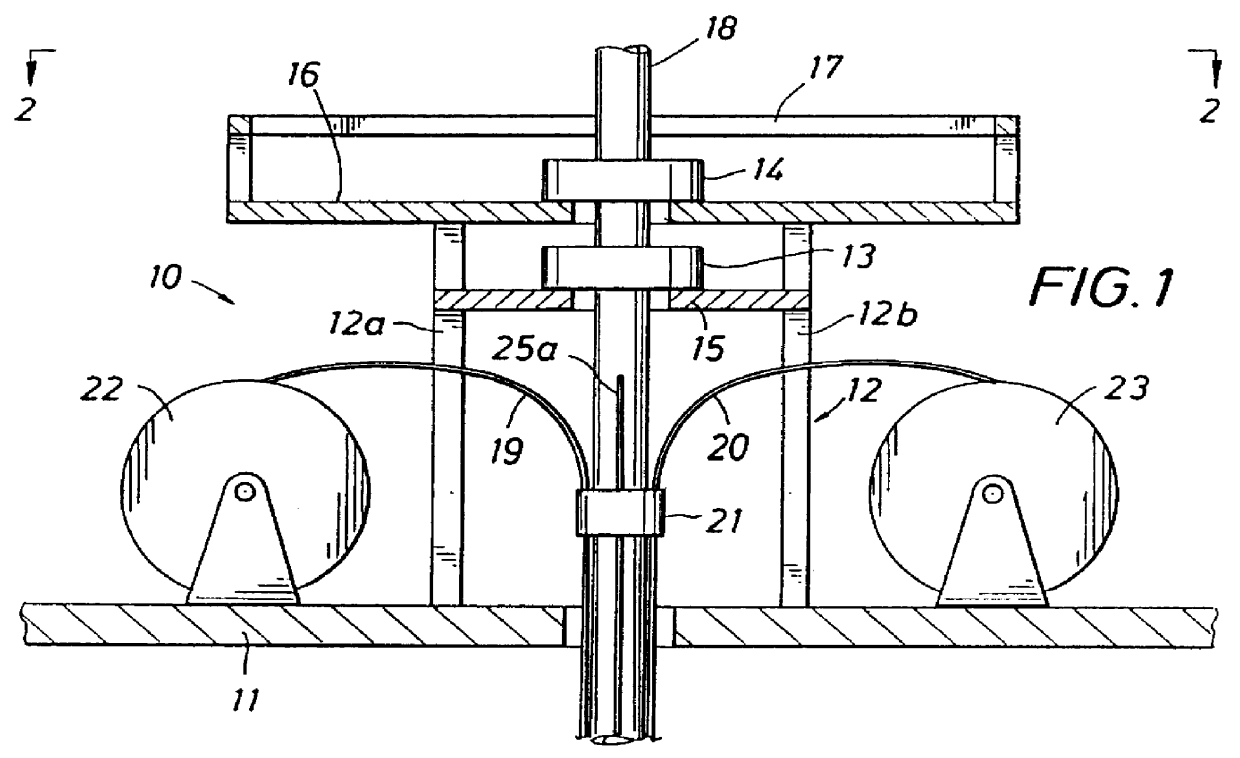

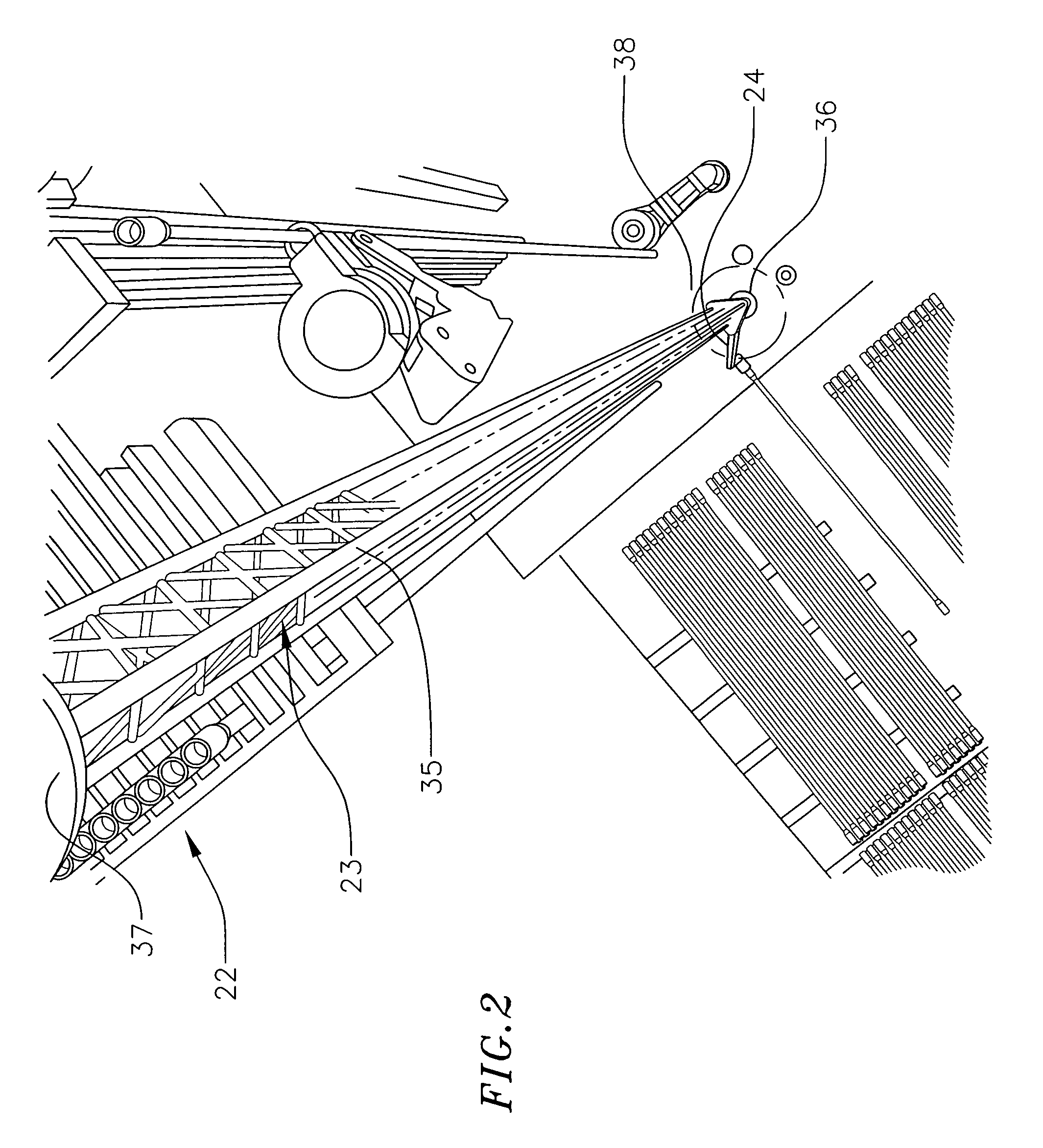

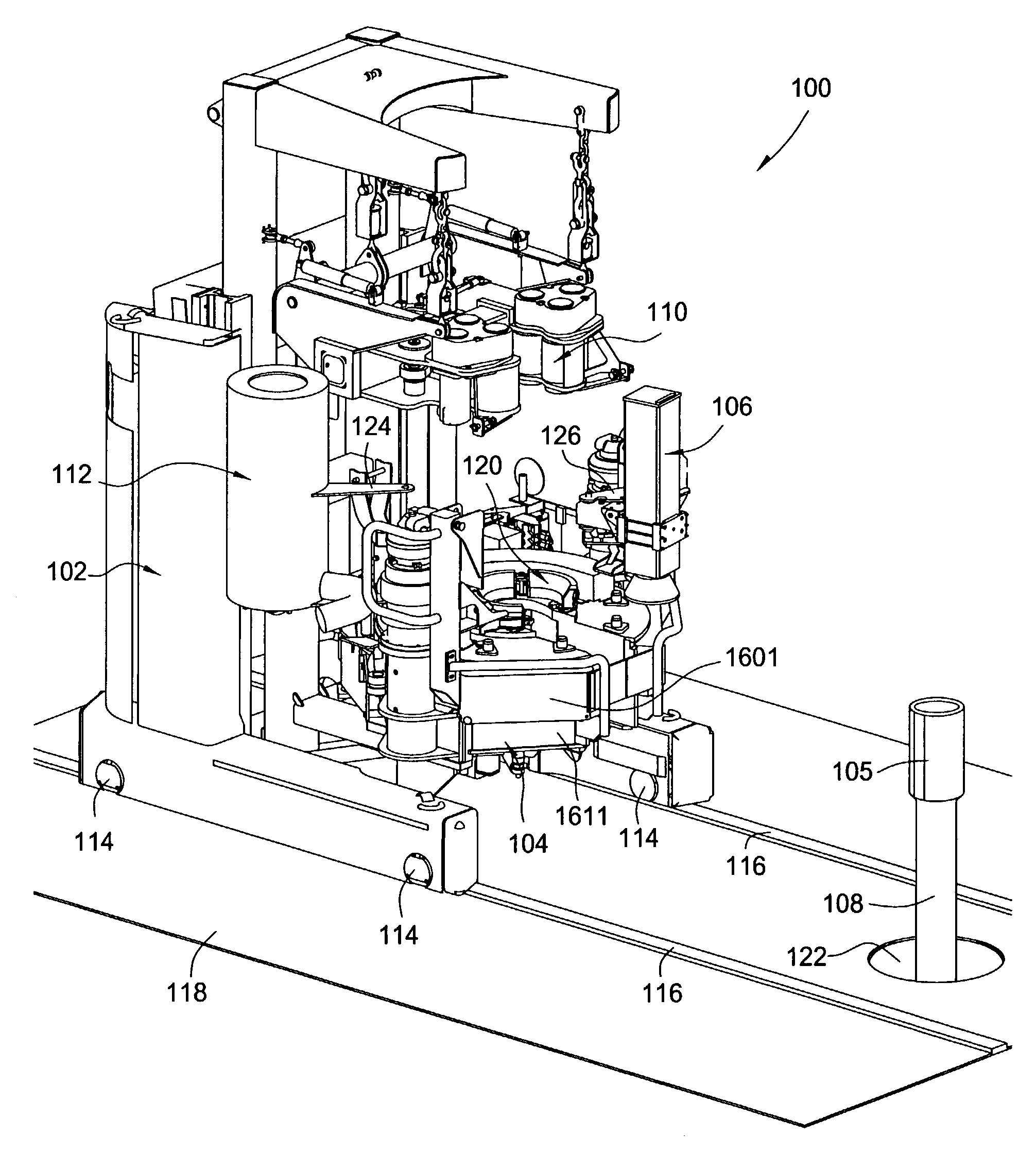

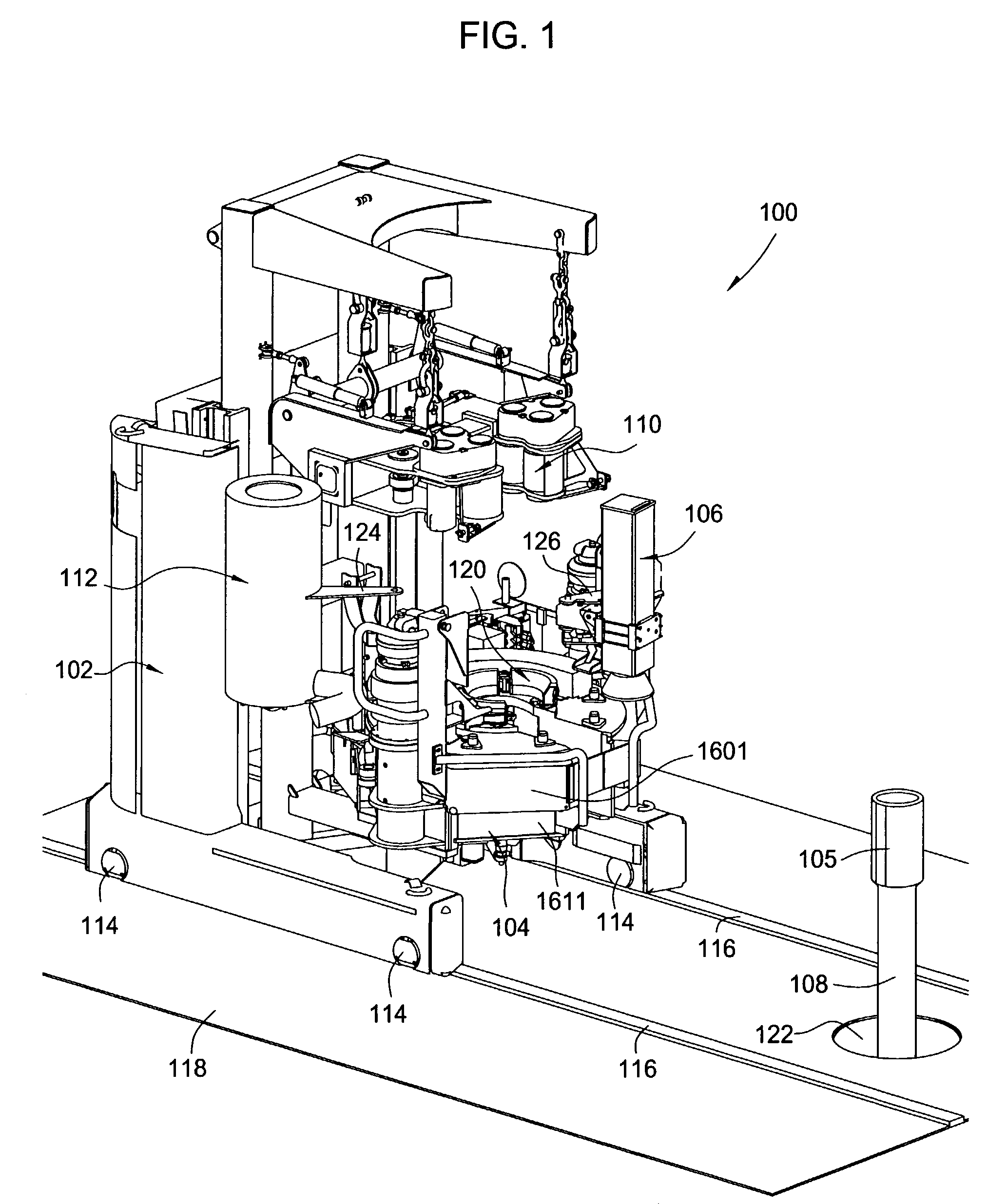

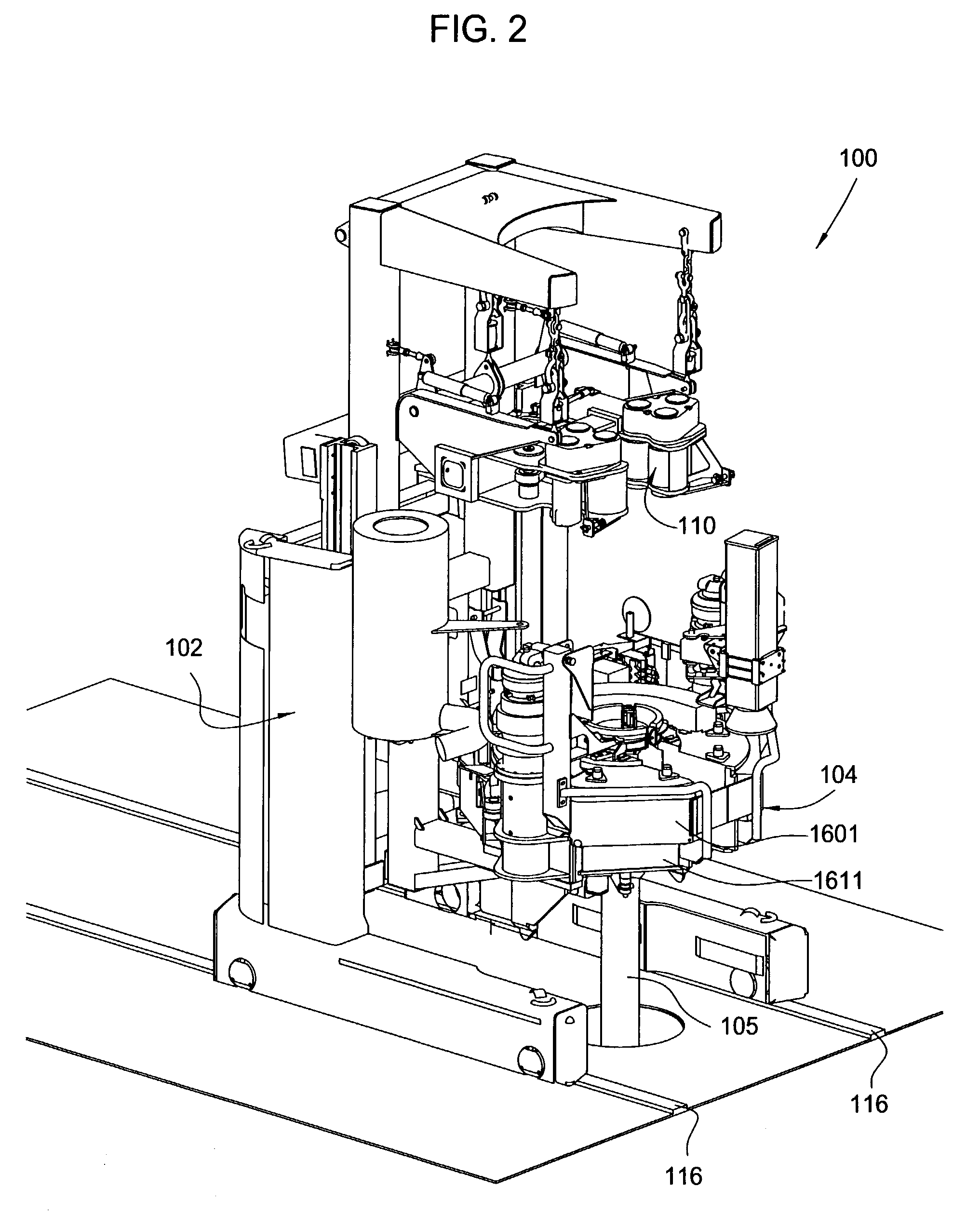

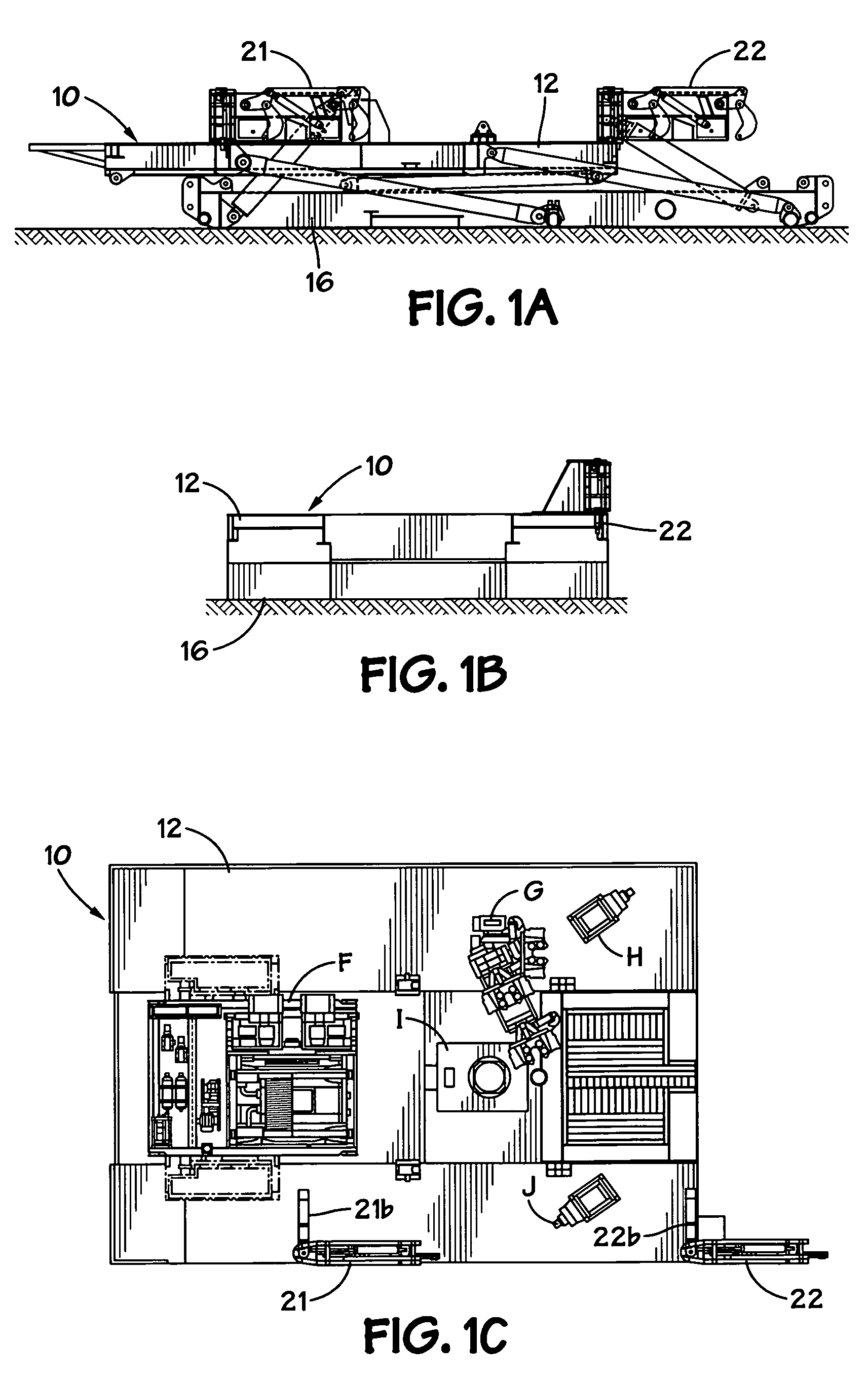

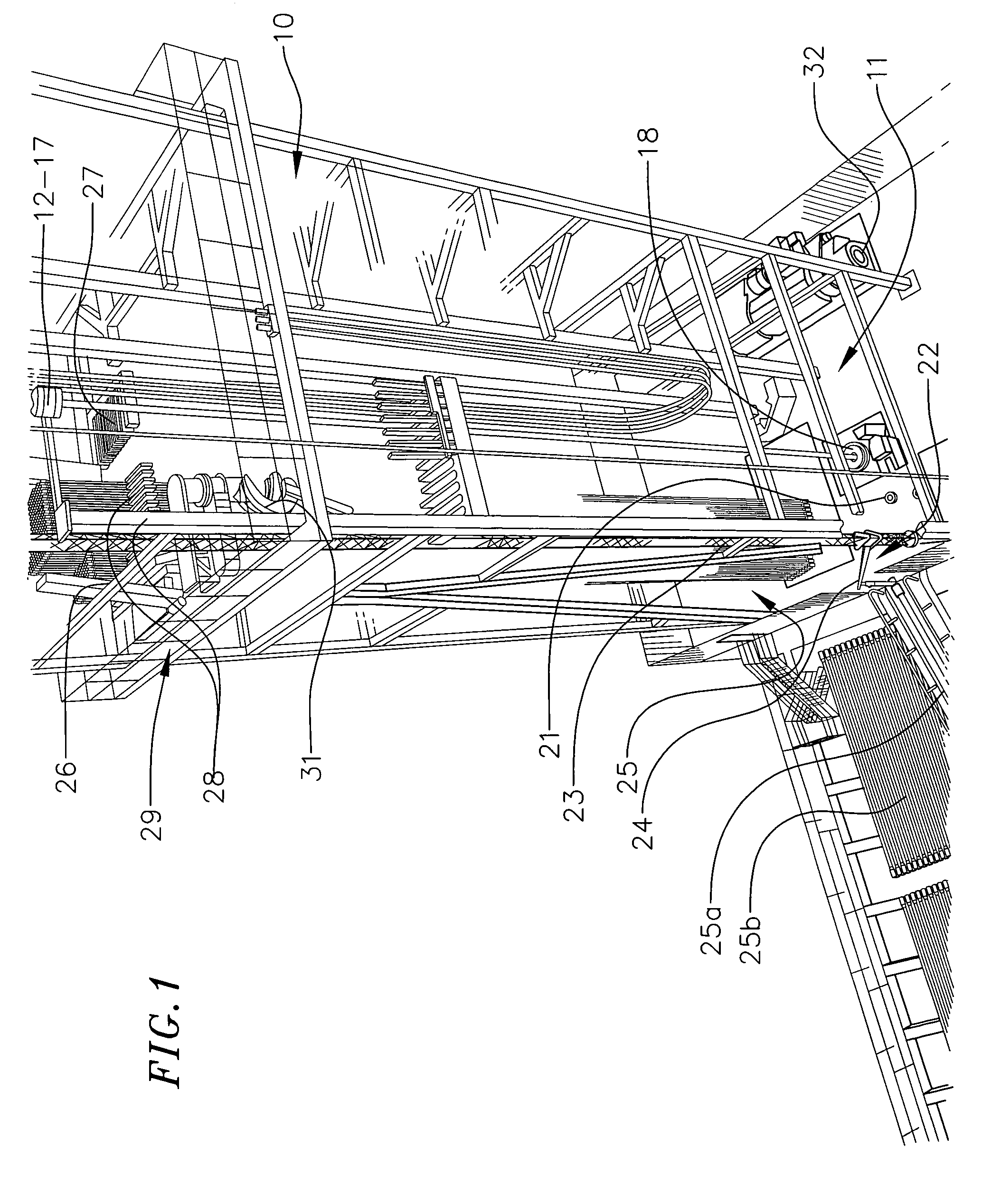

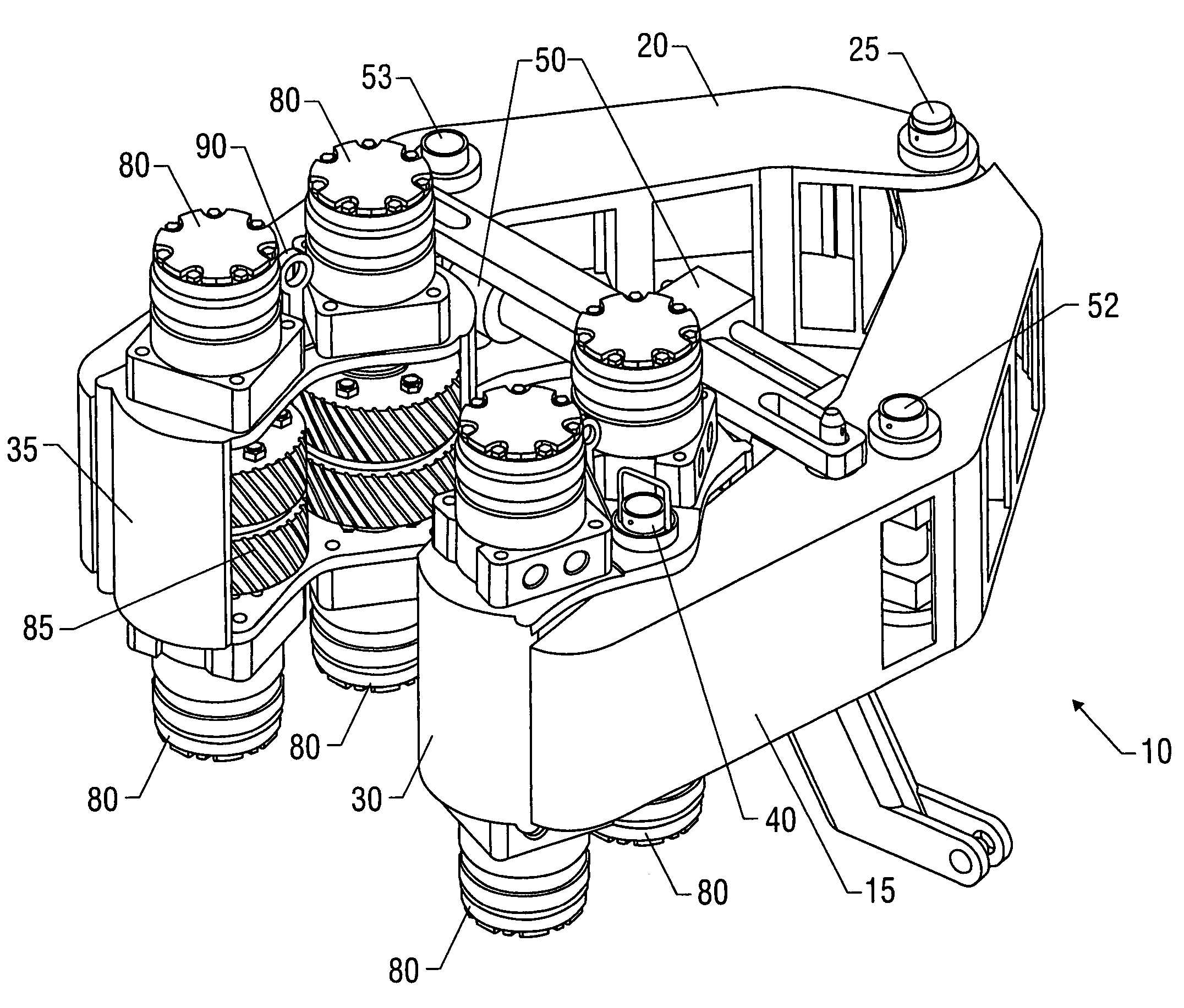

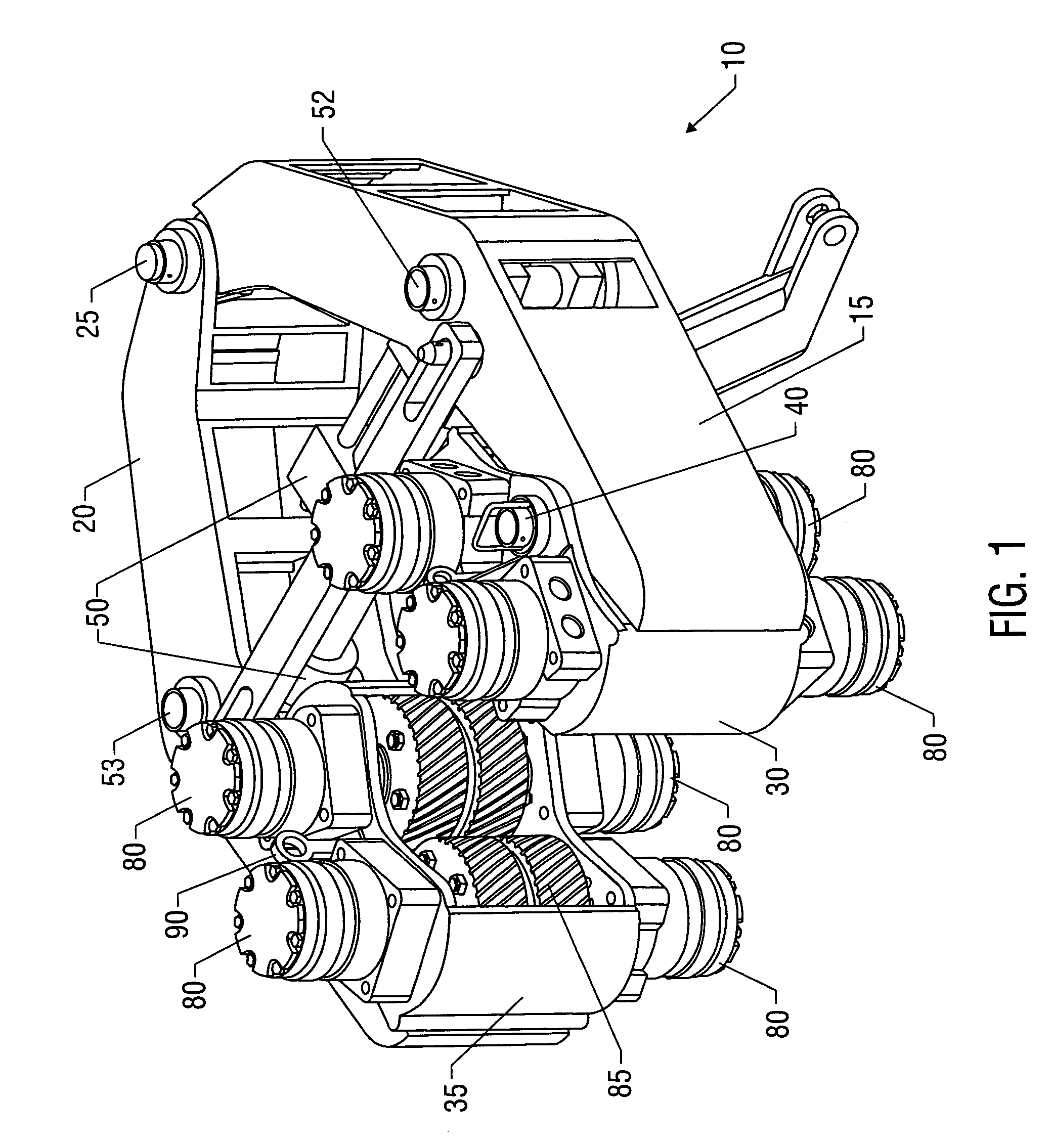

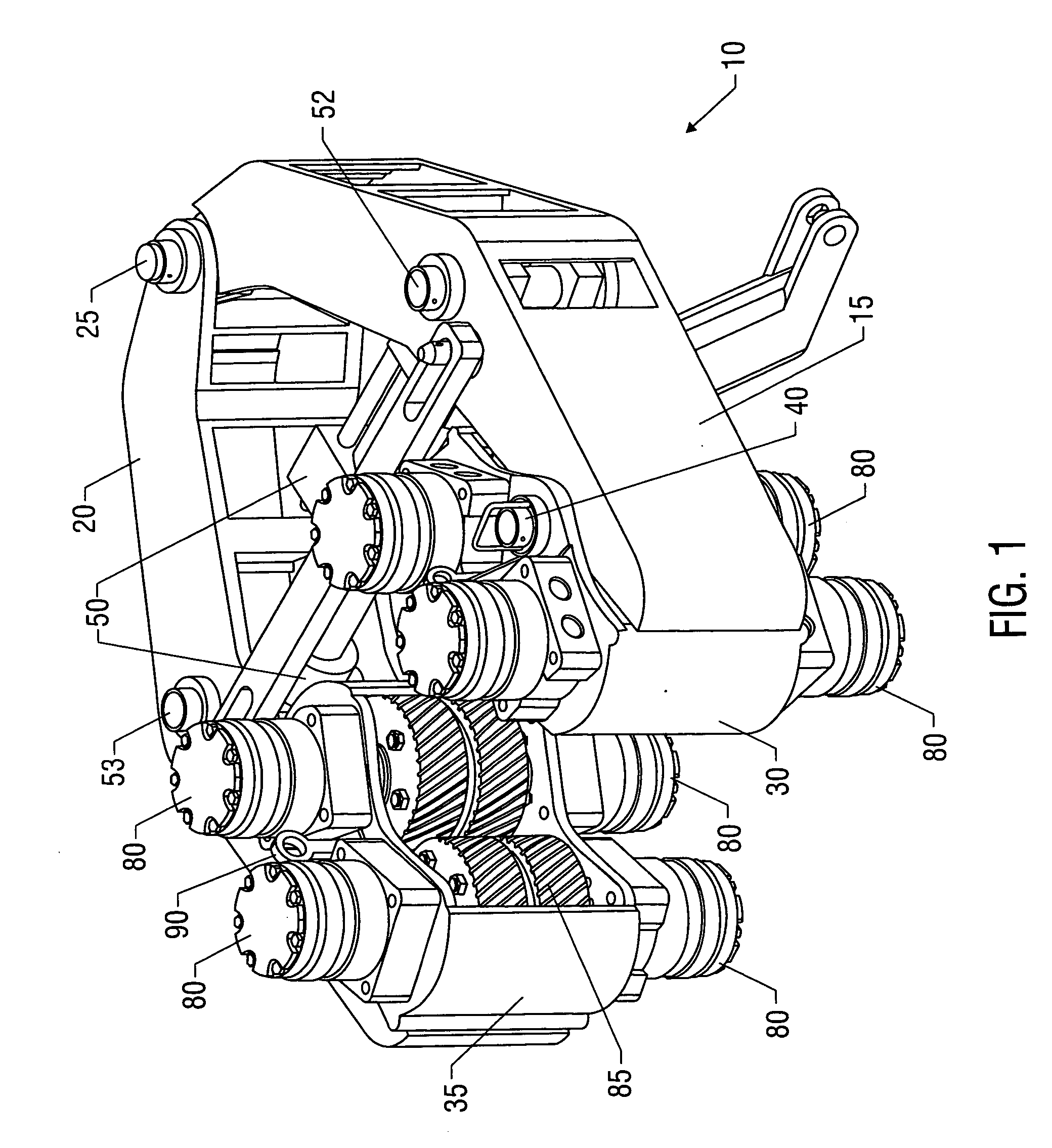

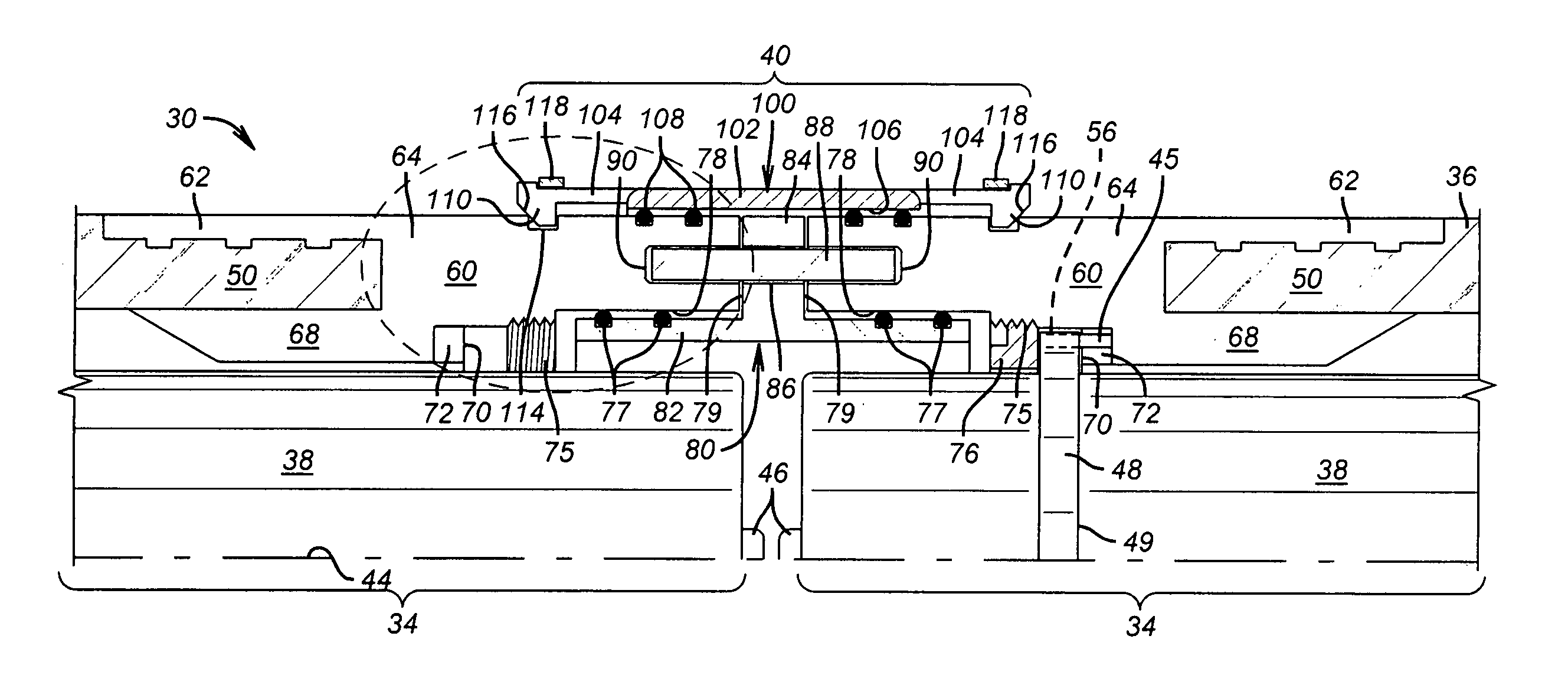

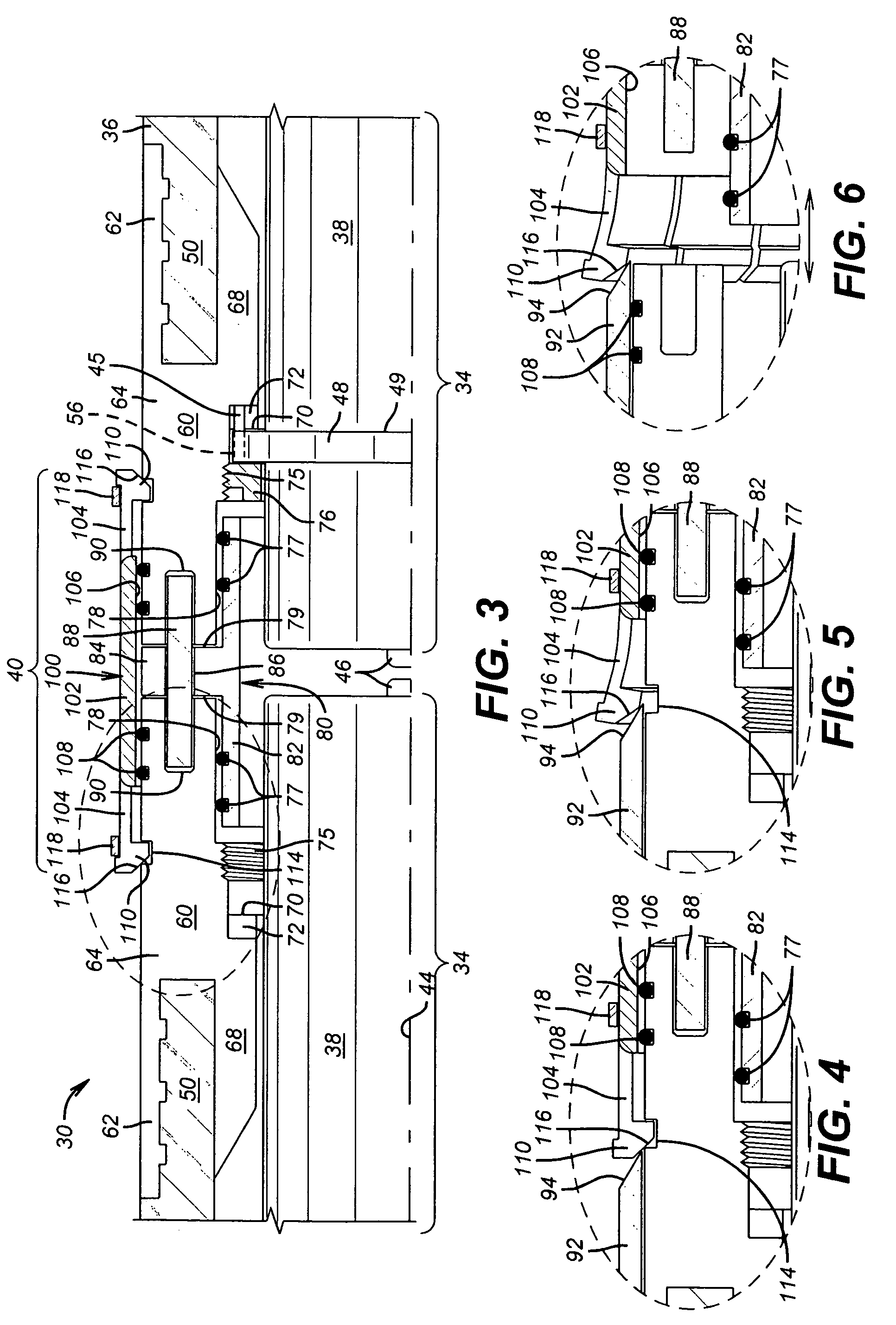

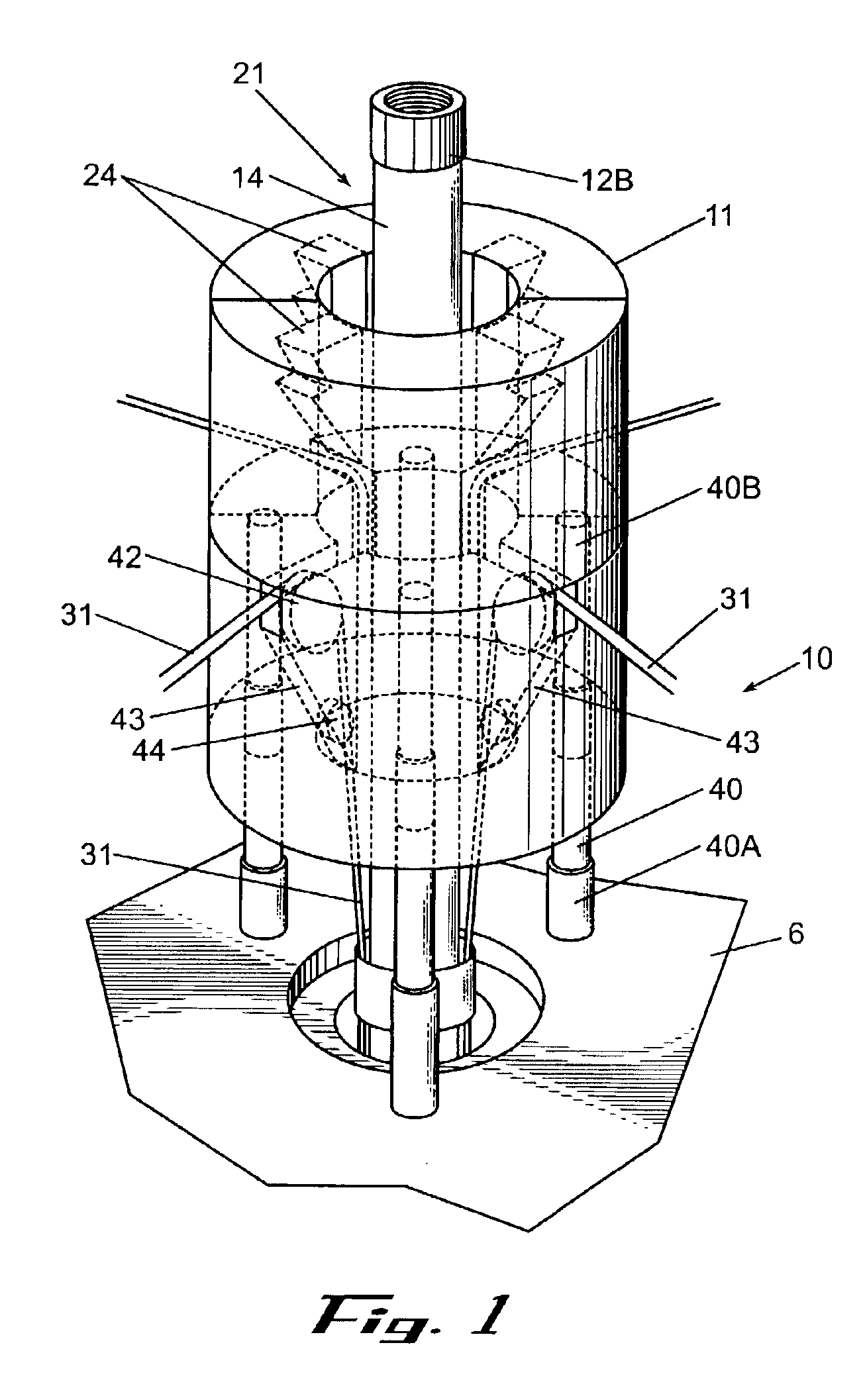

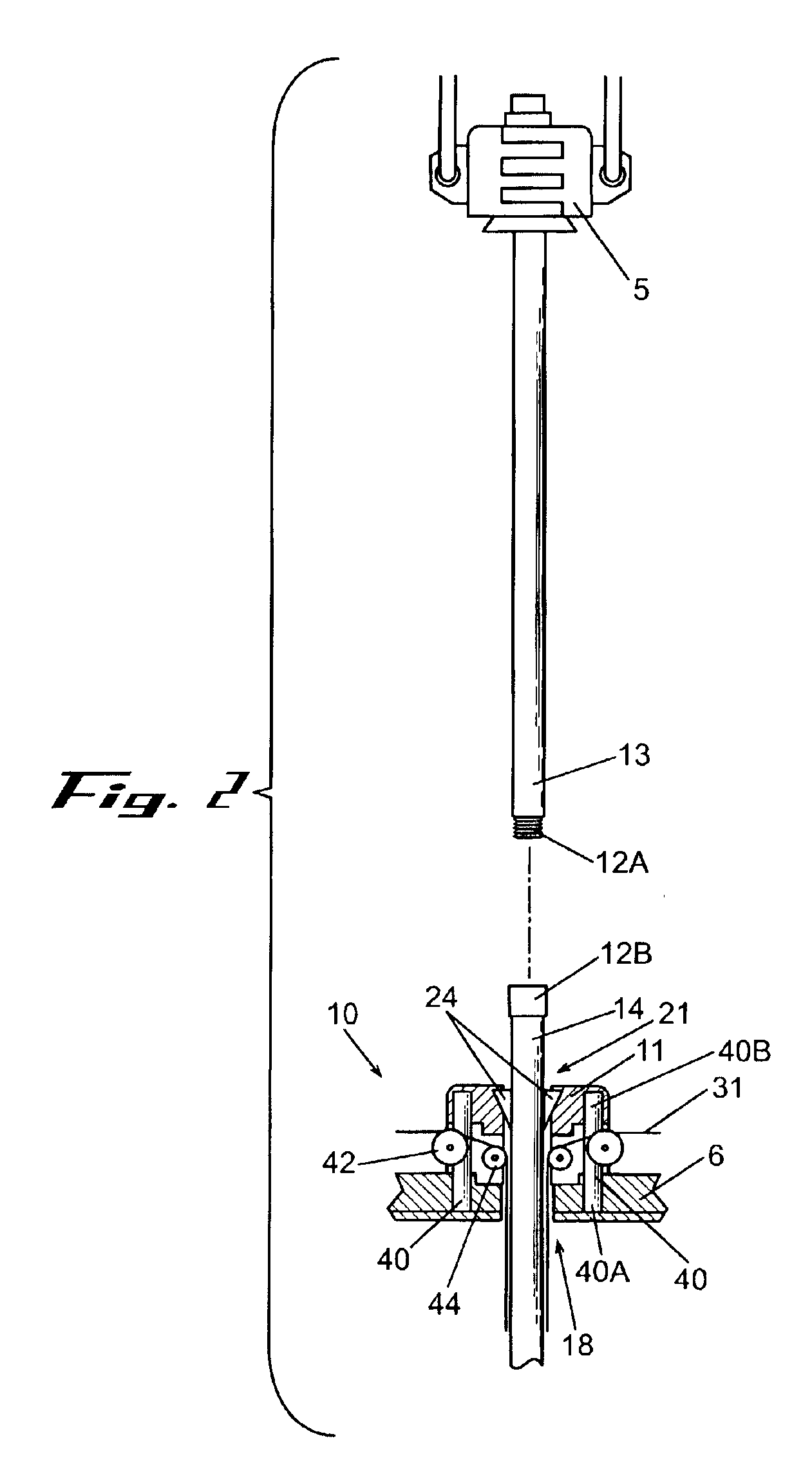

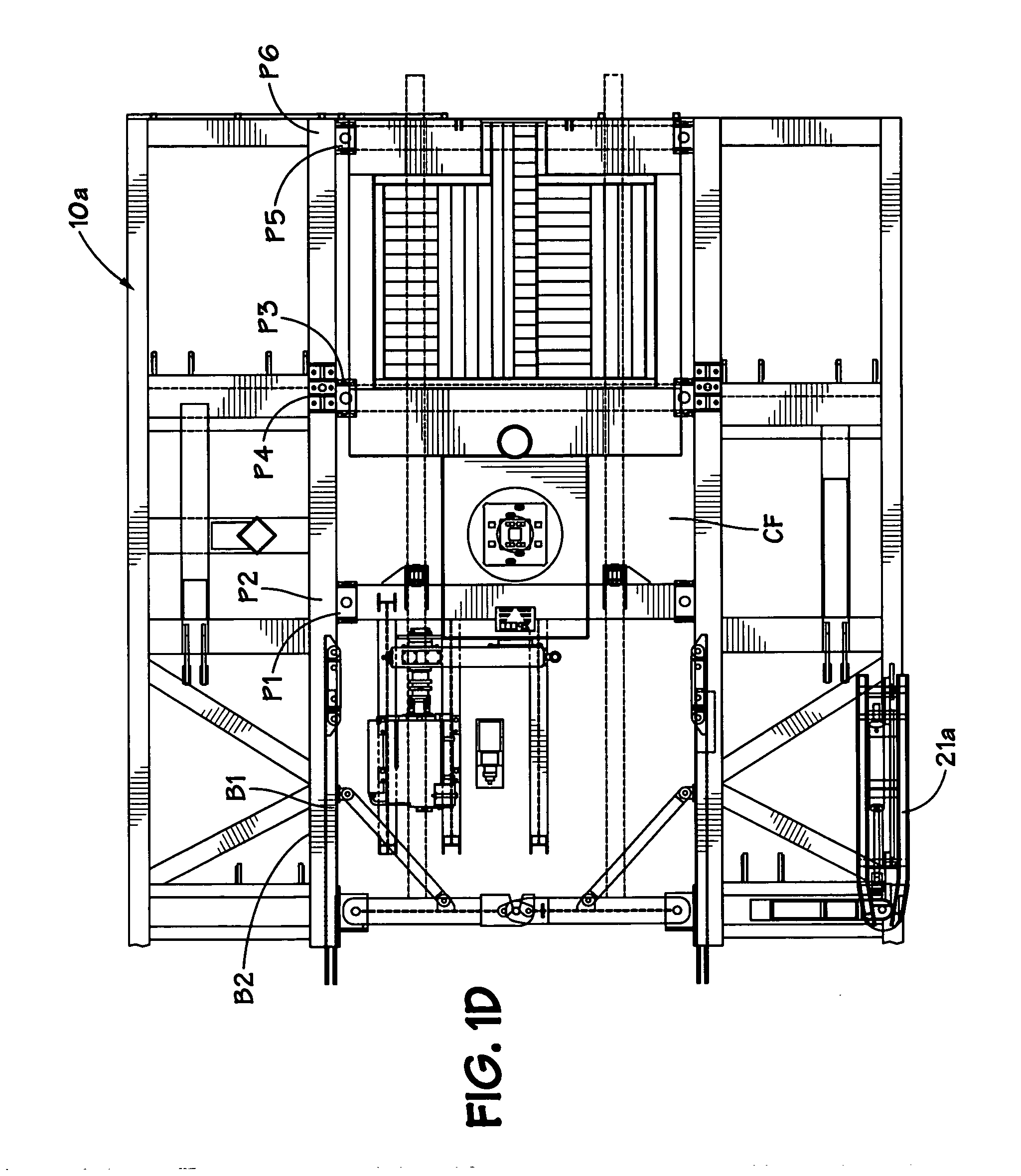

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. The upper wrench has two opposed spinner-roller pairs which translate between open and closed positions for spinning the upper pin coupling when in a closed position. The upper wrench also has two opposed jaw blocks which translate between open and closed positions for gripping the pin coupling in a closed position. The spinner roller pairs and the jaw blocks move in directions perpendicular to each other into and out of a cavity through which the well axis passes vertically. Torque cylinders are provided by which the upper wrench is torqued in a first or "torquing up" direction while the jaw blocks are gripping the pin coupling and in a second or "breaking loose" direction. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator includes a remotely controlled arm and hand assembly which captures a drill pipe section in its hand and transfers the drill pipe while being supported vertically by the drilling rig between the well axis and a position at the side-of the wrench assembly. The drilling rig apparatus includes a bore arranged and designed for placement on the rig floor around the well axis. A slot is provided between frame members for placement of a pneumatically remotely controlled power slip manipulator for setting and releasing slips in the rotary table for supporting the drill pipe string in the well bore during connecting and disconnecting operations of drill pipe sections.

Owner:FORUM US

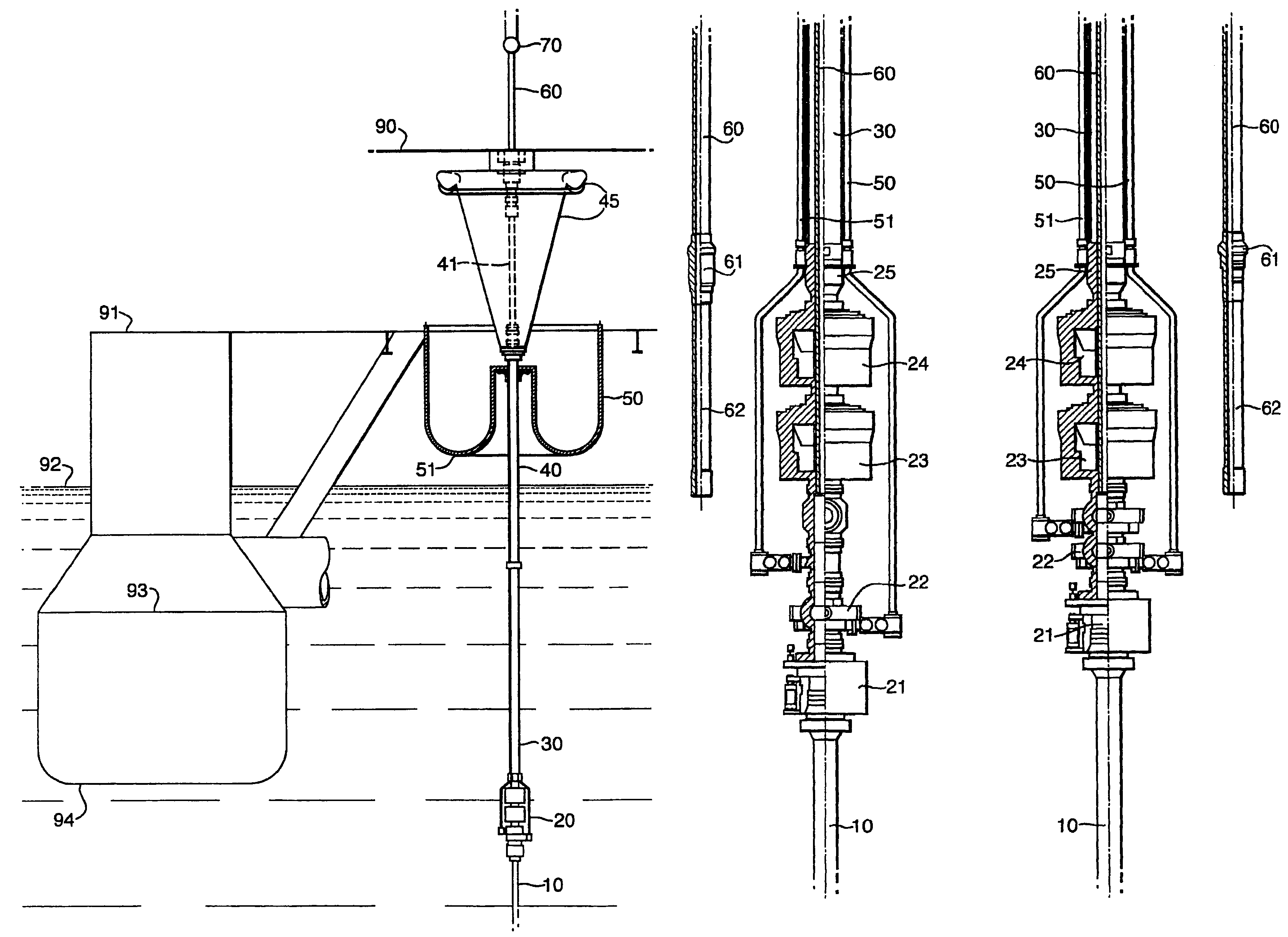

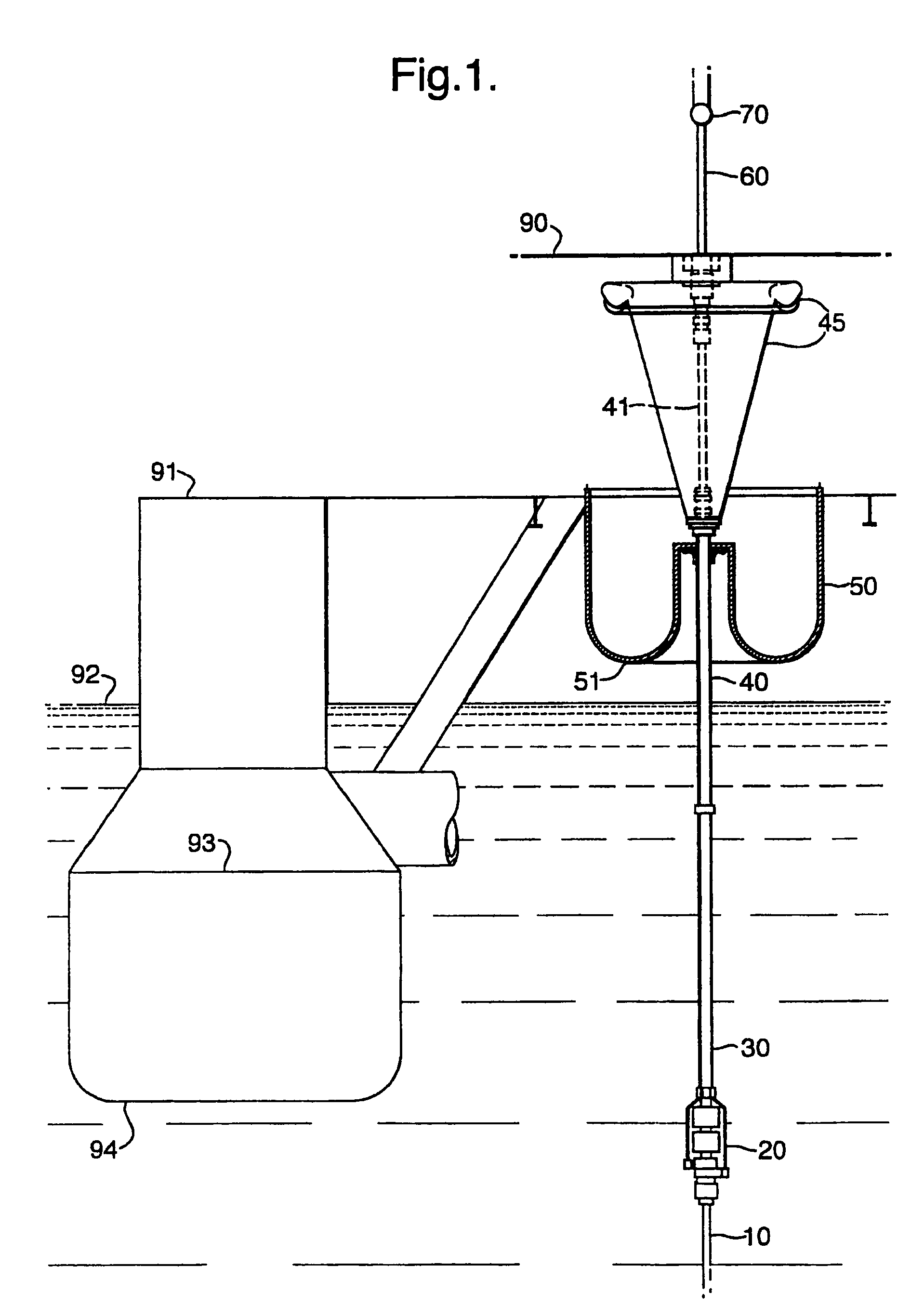

High pressure system

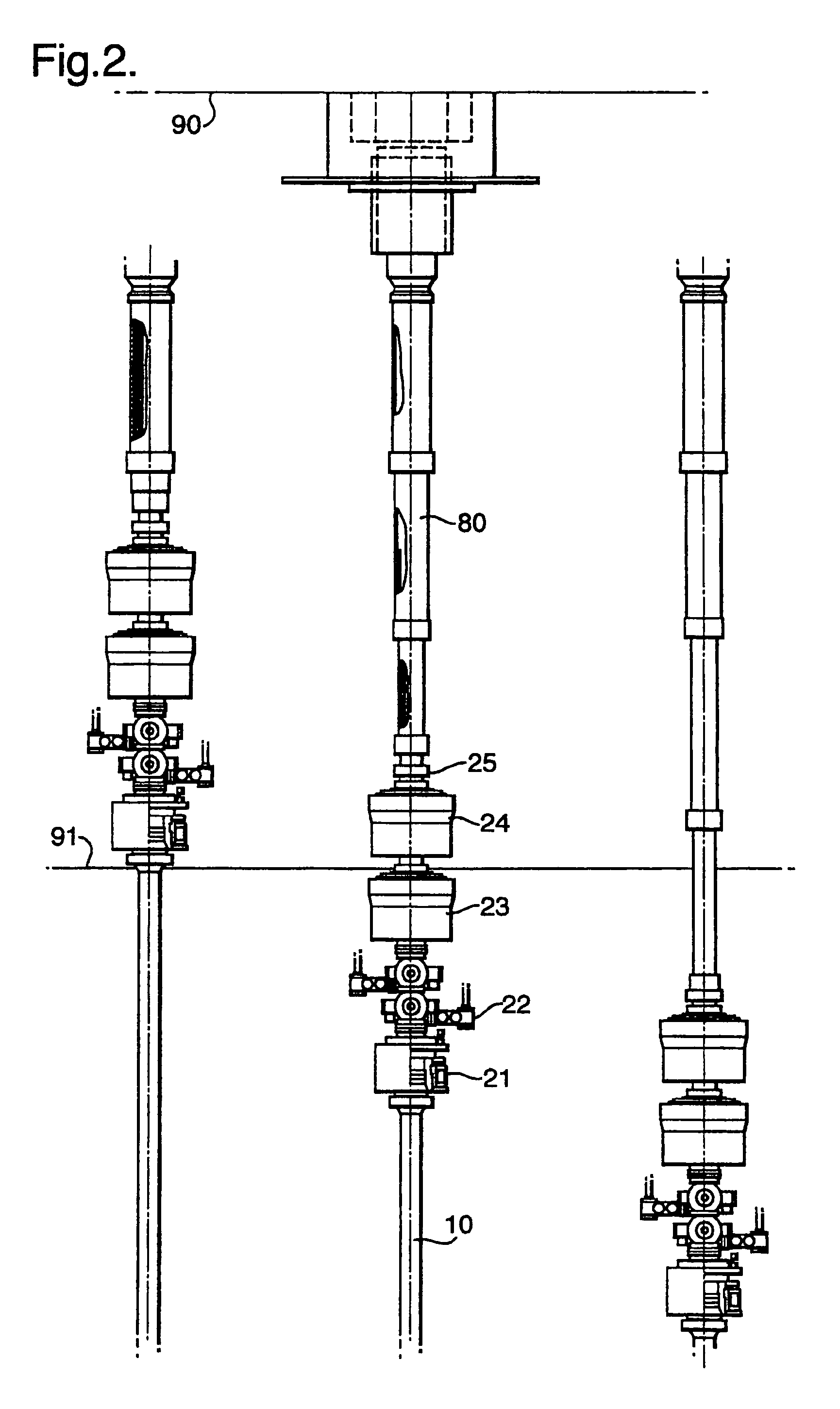

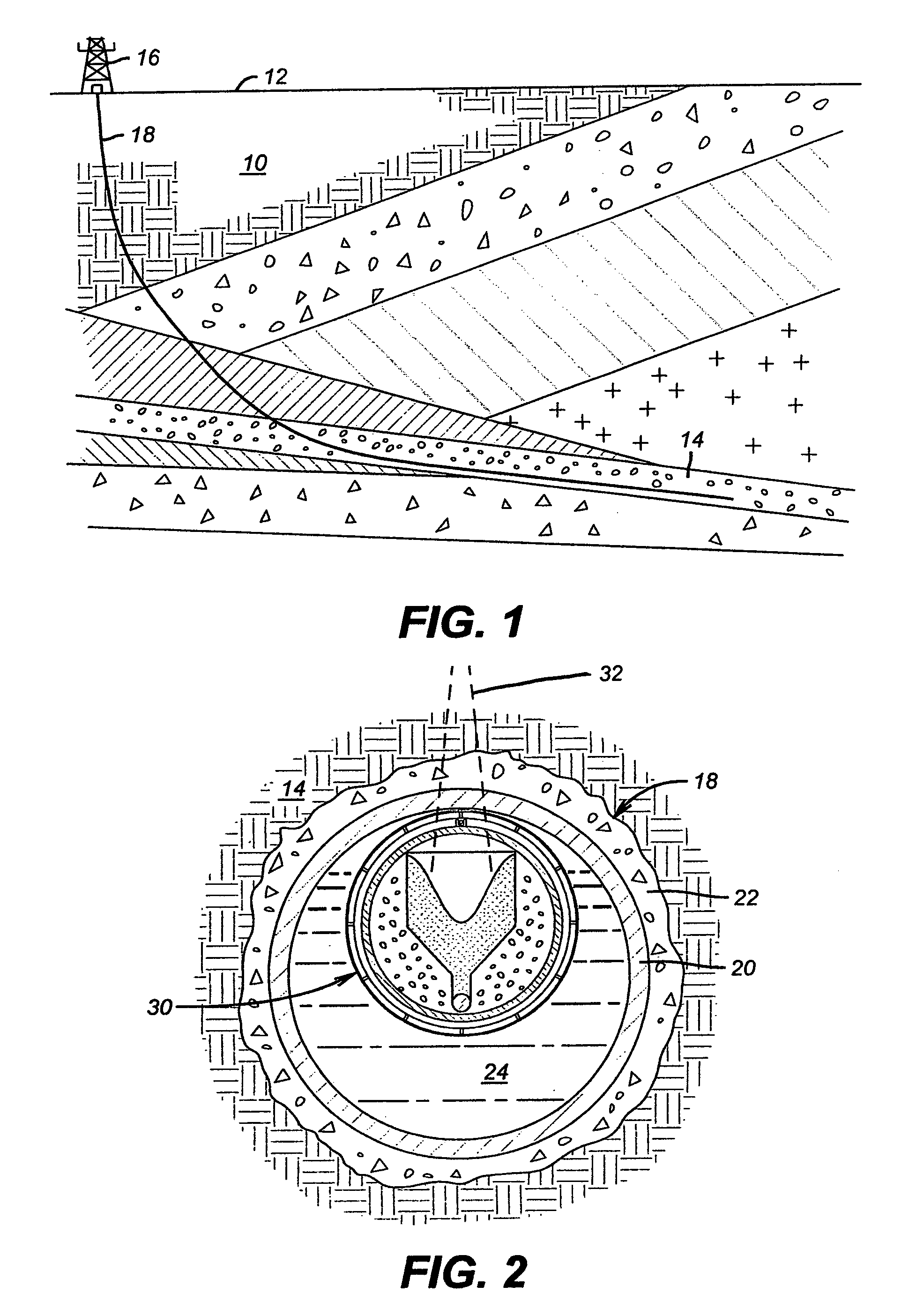

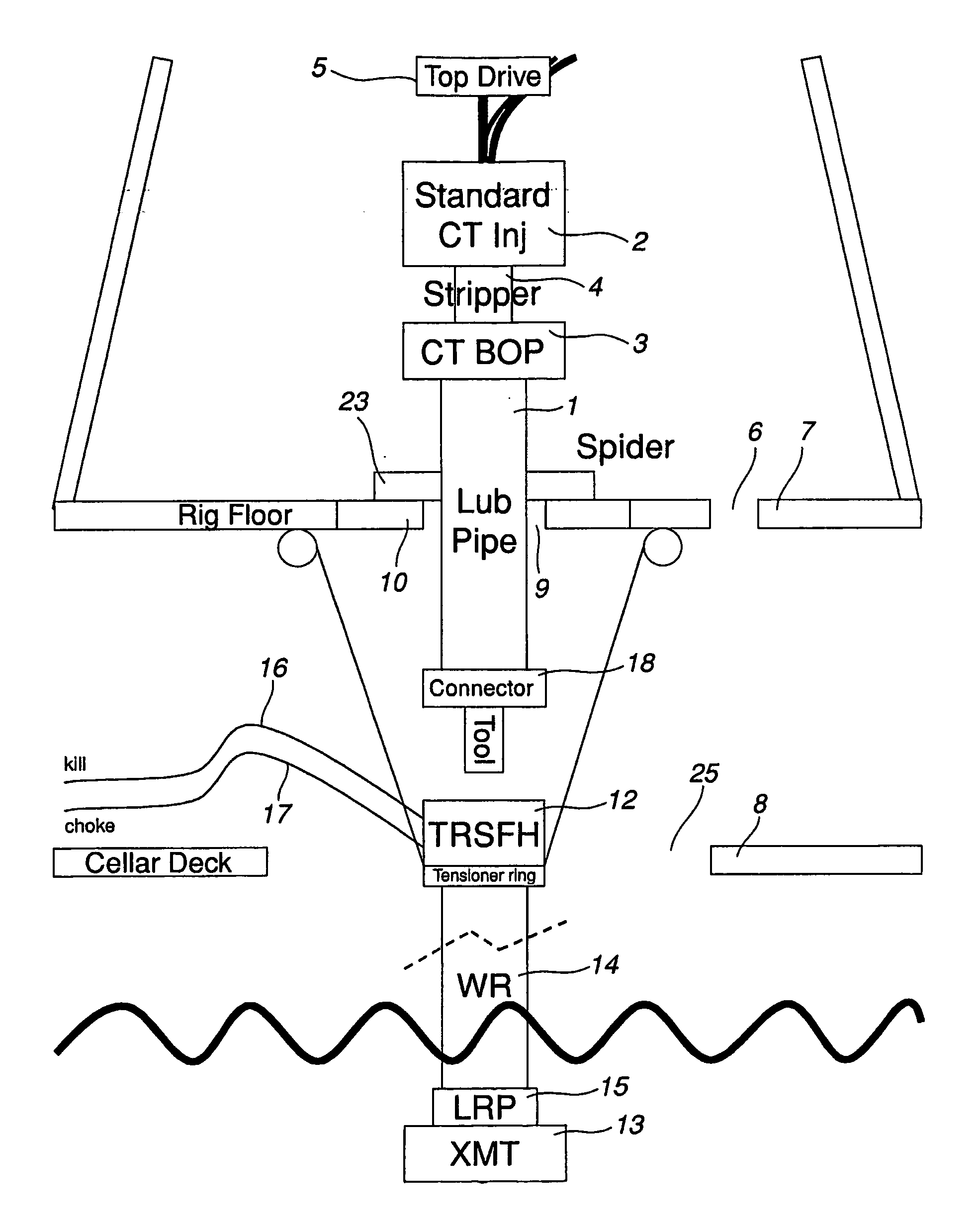

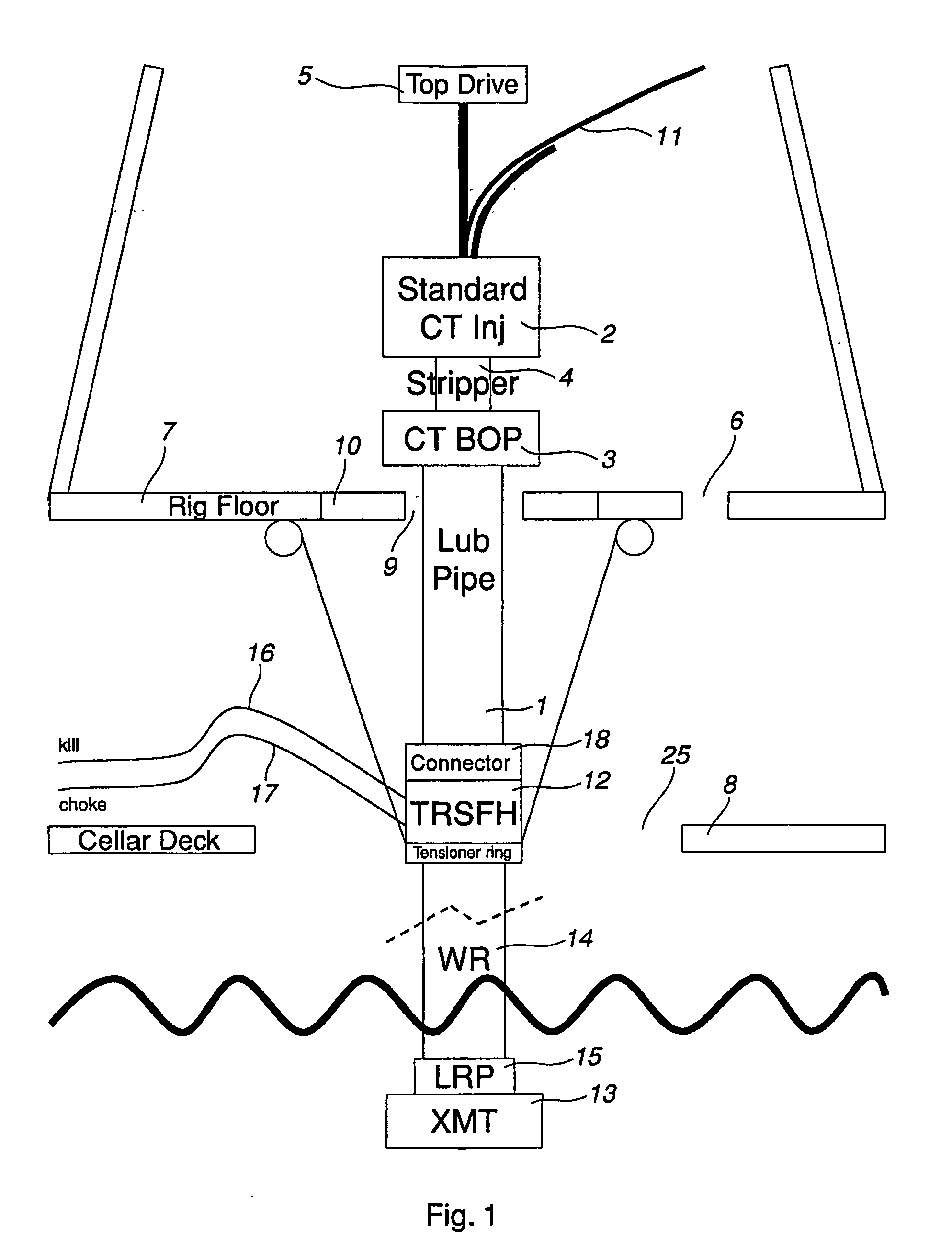

An arrangement and method for integrating a high pressure riser sleeve from the upper end of a high pressure drilling and workover riser terminated by an upper BOP close to sea level in one end and by a sub-sea blowout preventer BOP or a low riser package LRP close to the seabed in the lower end. The high pressure riser sleeve being installed, connected and integrated to the high pressure drilling and workover riser and extending up to and above the drill floor, inside a low pressure drilling riser slip joint which is connected to the drilling and workover riser. This relates to offshore drilling and well activities preformed from a floating drilling or workover rig or vessel. Operations can be switched from drilling with jointed drillpipe in a conventional manner, into performing underbalanced wireline and / or coiled tubing activities with full well pressure, much more effectively than with prior art.

Owner:ENHANCED DRILLING

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for torquing and spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator captures a drill pipe section and transfers the drill pipe section between the well axis and a position at the side of the wrench assembly. A slot is provided between frame members of the base for placement of a power slip manipulator for setting and releasing slips in the rotary table.

Owner:FORUM US

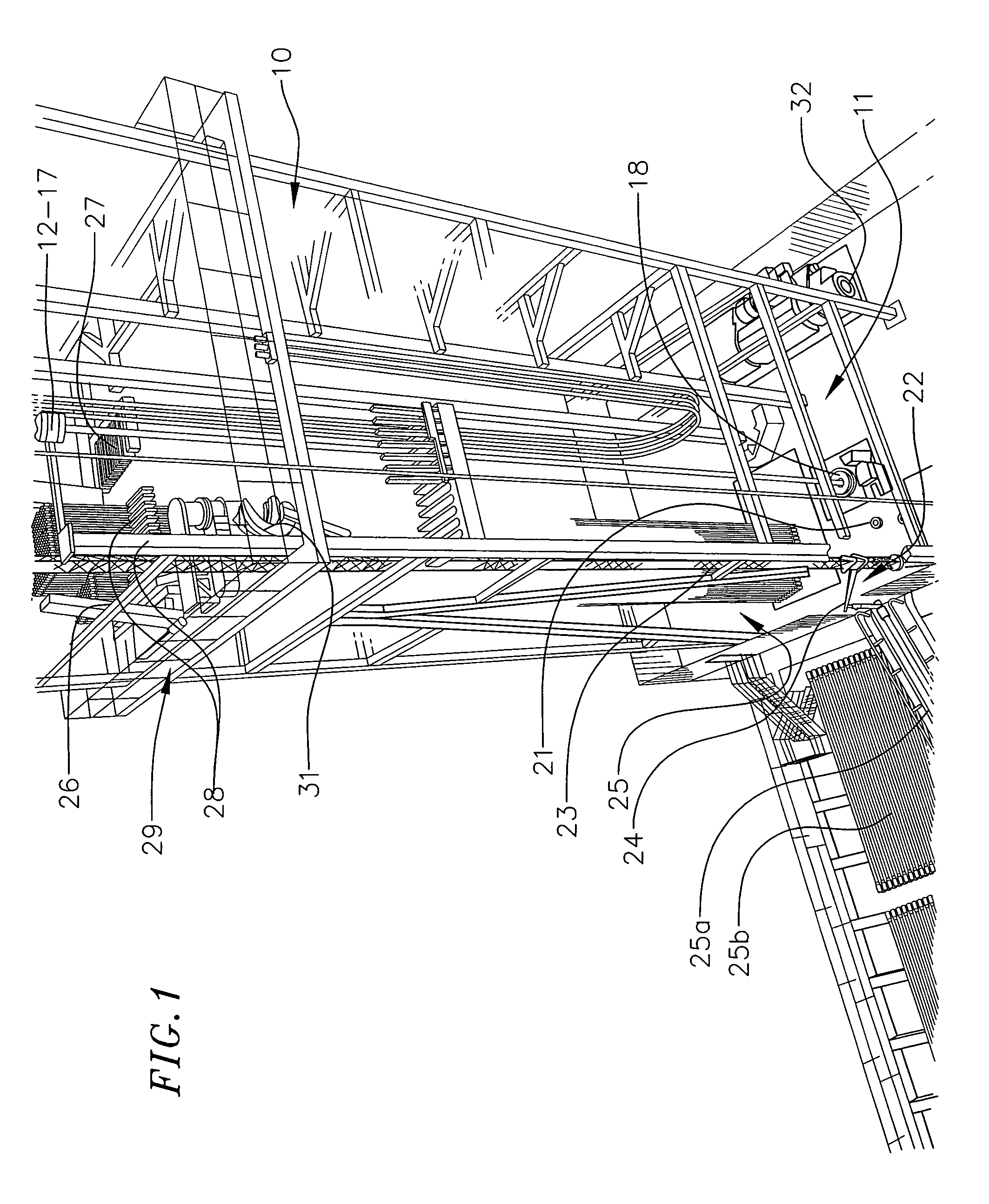

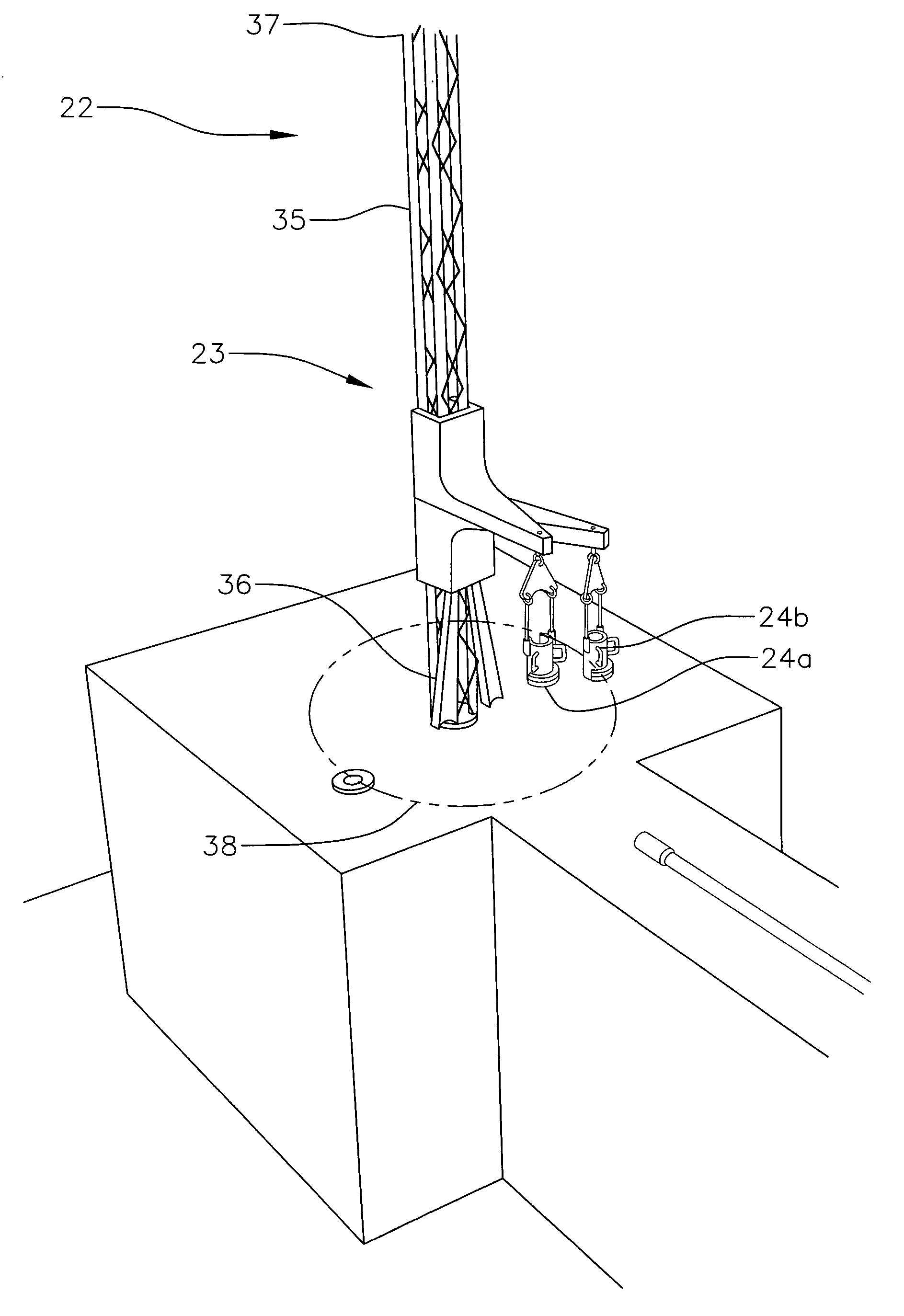

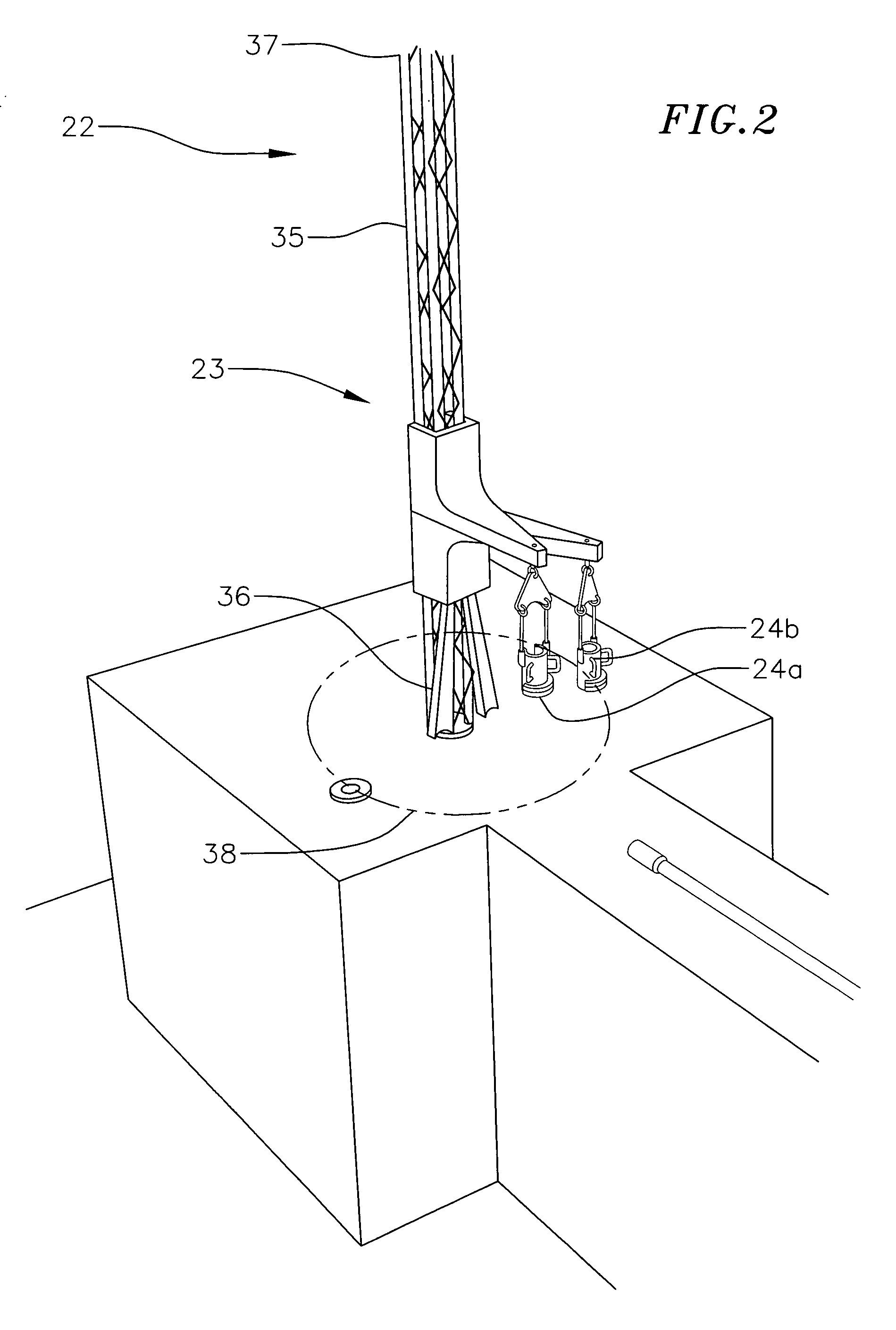

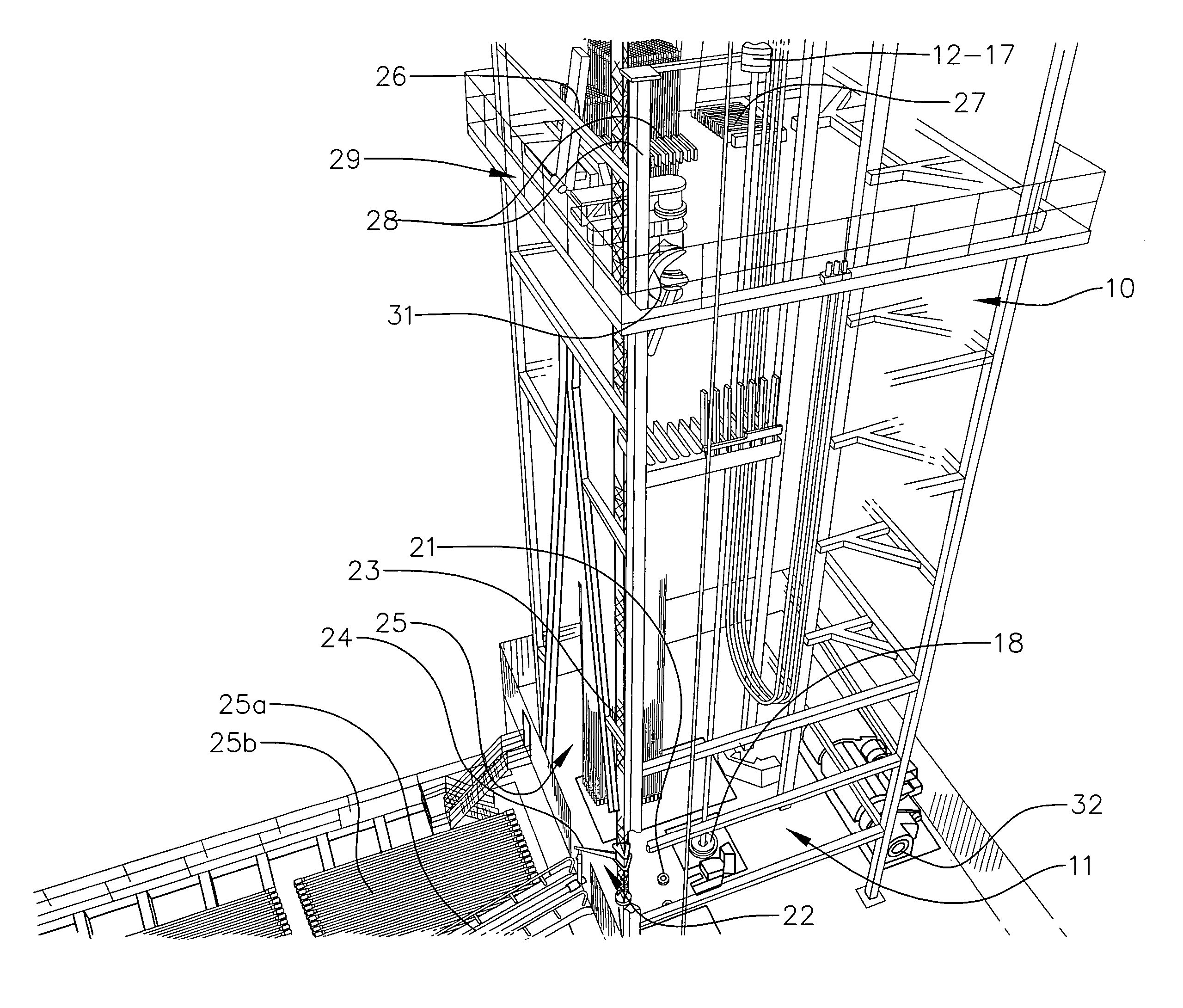

System, apparatus, and method for installing control lines in a well

A method and apparatus for installing control lines and pipe into a well. The work surface for equipment and personnel employed in assembling the pipe is elevated above the rig floor. Personnel operating below the work surface use clamps to attach control lines to the pipe being installed in the well. The pipe-holding spiders that arc normally mounted on the rig floor are mounted on the elevated work surface. Assembling the control lines to the pipe below the work surface permits the control lines to be attached to the pipe without first traveling through the spider.

Owner:TESCO HLDG I

Fill up tool and mud saver for top drives

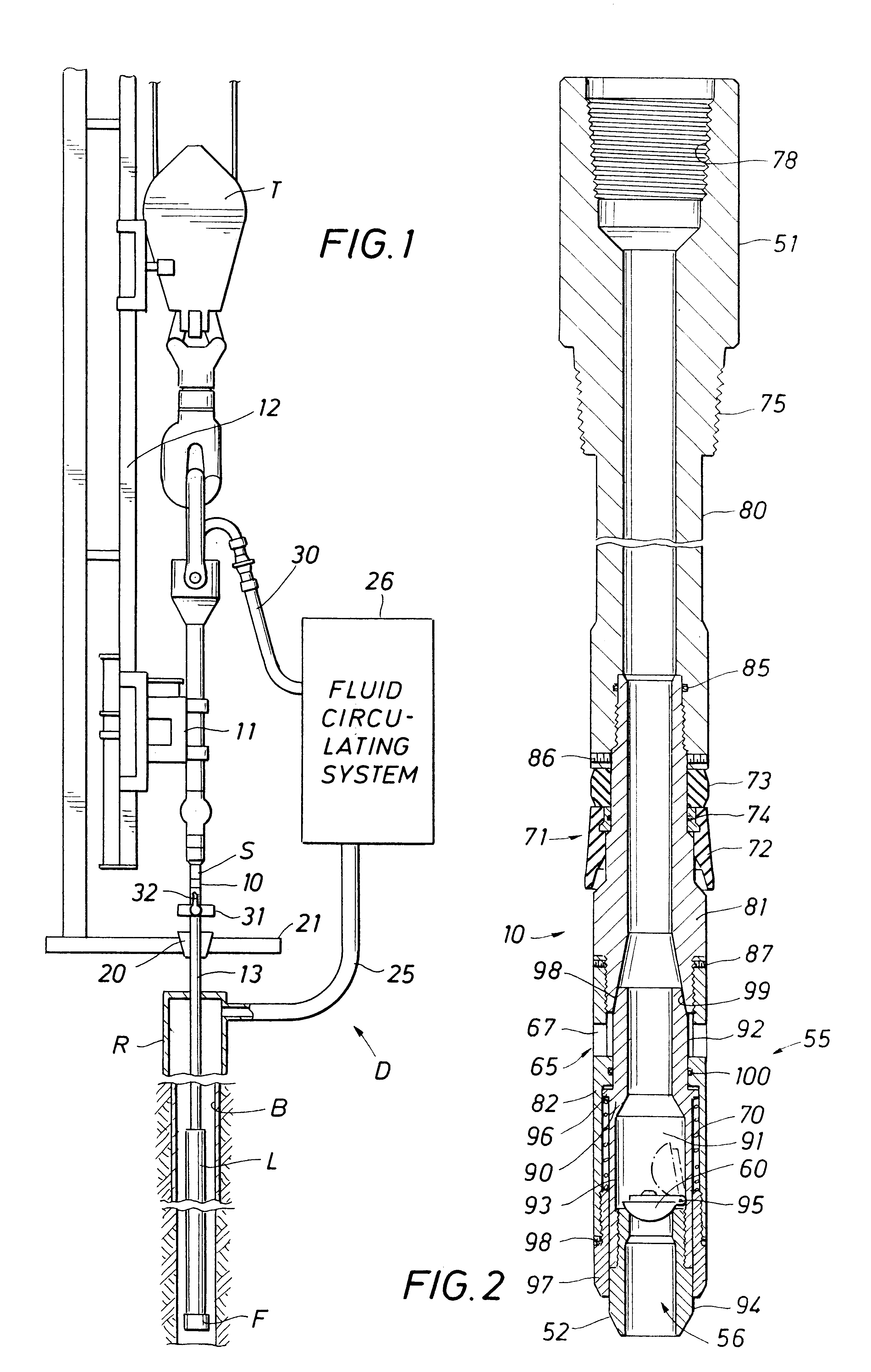

InactiveUS6571876B2Prevent leakageMinimal drilling fluid lossDrilling rodsFluid removalTop driveEngineering

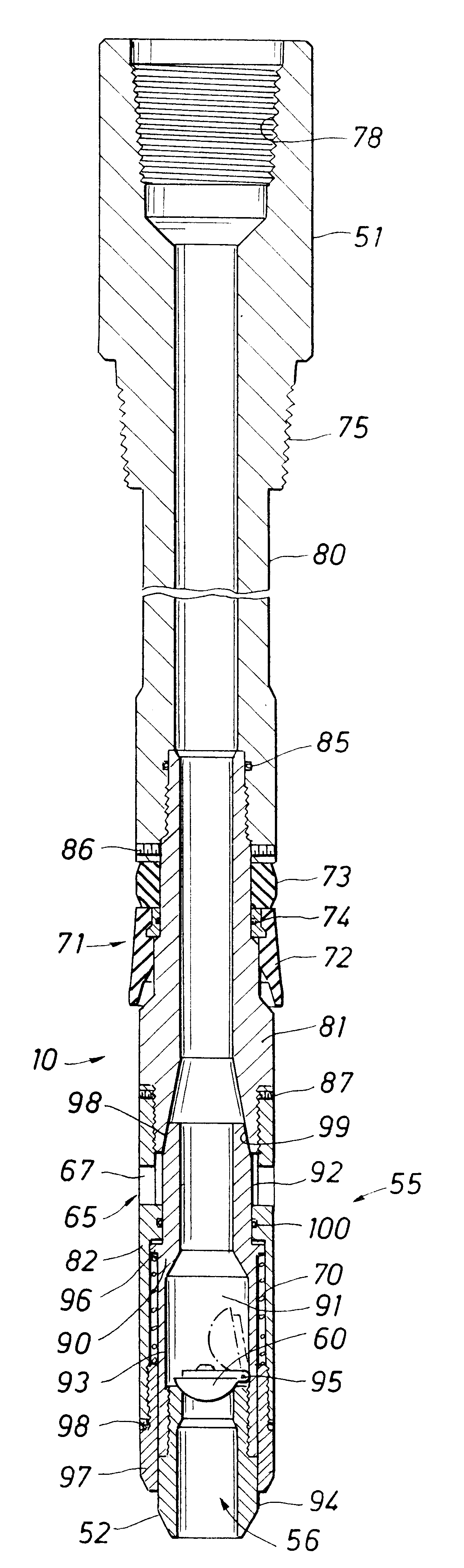

A tubular tool body carried at the end of a drilling rig top drive is received within a drill string being used as a landing string to position casing in a wellbore. External threads on the tool body can be mated with the box threads of the drill string to secure the top drive and drill string together for simultaneous drill string movement and fluid circulation. An annular seal carried about the tool body engages and seals with the internal wall of the drill pipe to prevent drilling fluid leakage when the tool body is received within the drill pipe without thread engagement. The tool has an internal check valve that opens to allow back flow of drilling fluid that may be displaced from the drill pipe as the pipe is lowered into the well. The check valve prevents standing fluid in the top drive from spilling onto the rig floor when the tool is withdrawn from the drill string. Pump pressure applied through the top drive axially moves the check valve against a biasing spring to open a bypass through the wall of the tool to permit forward circulation through the drill string and casing. The spring bias force is sufficient to withstand the hydrostatic force exerted by the standing column of fluid in the top drive and associated piping.

Owner:HALLIBURTON ENERGY SERVICES INC

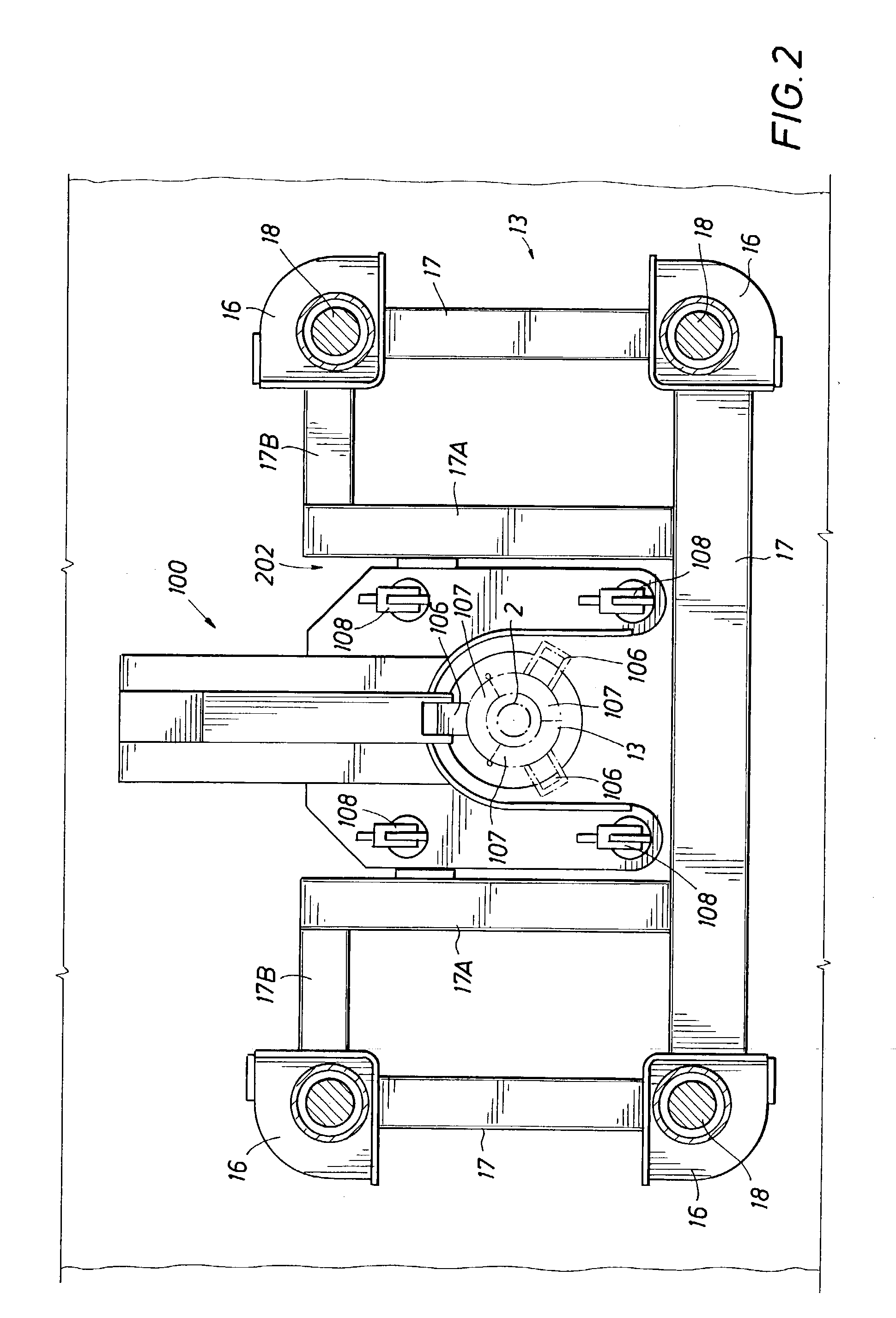

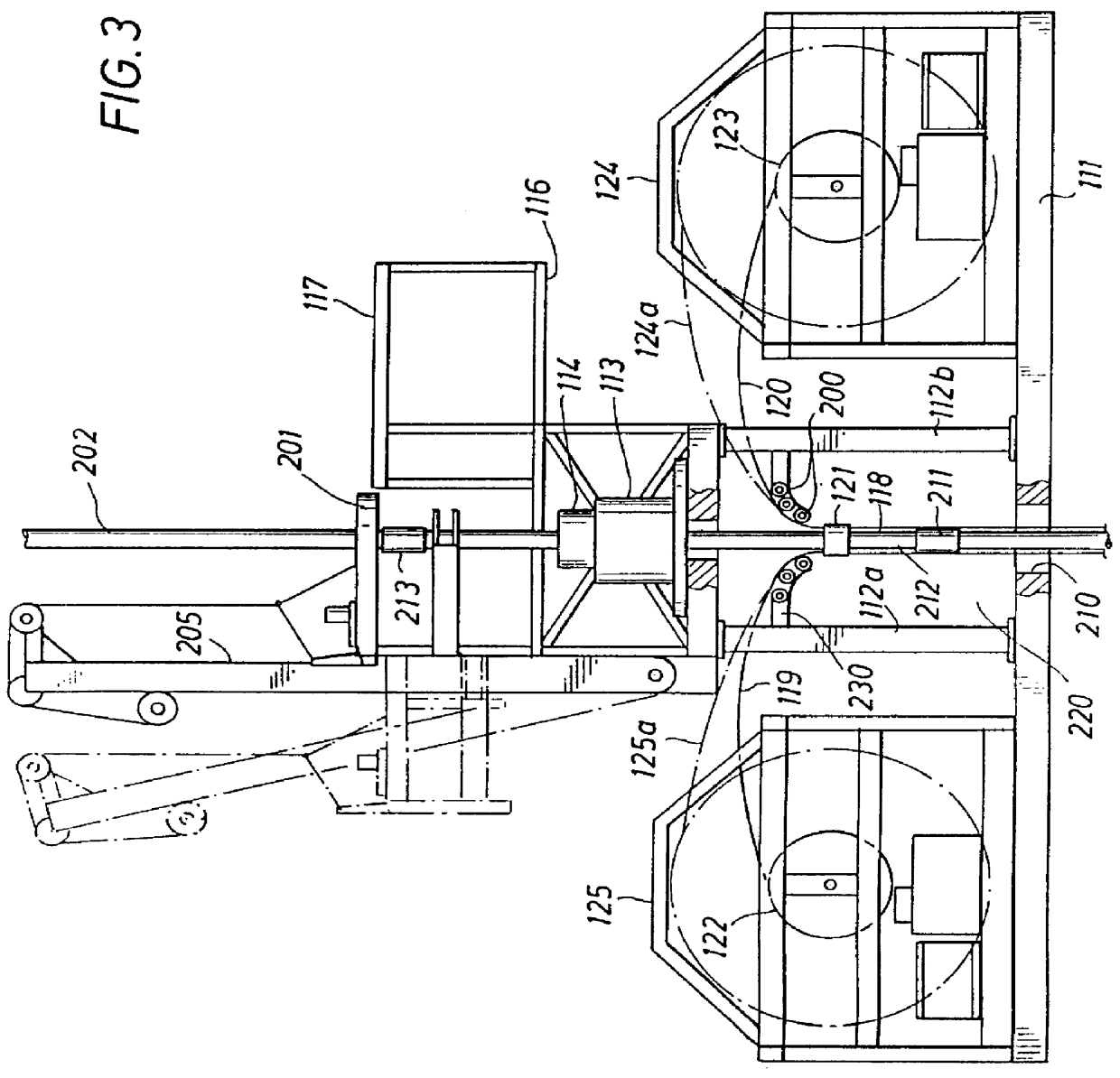

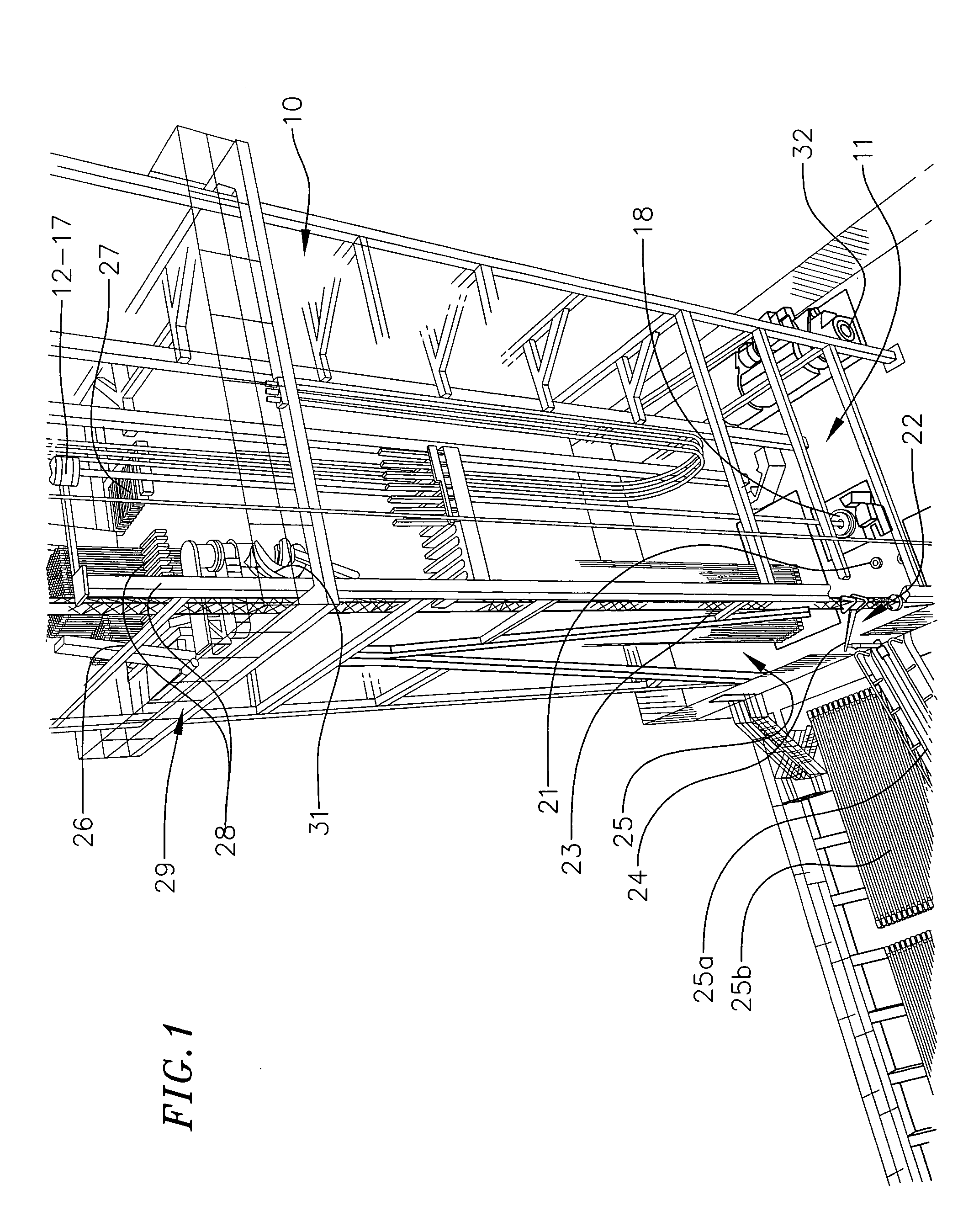

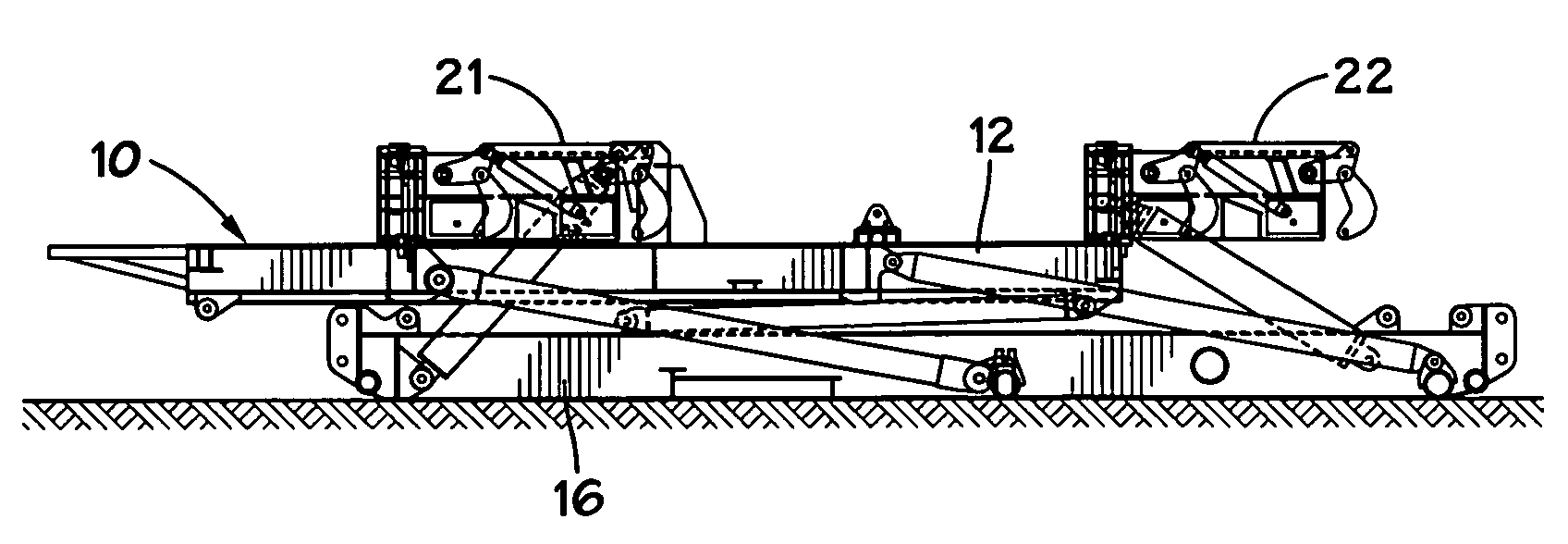

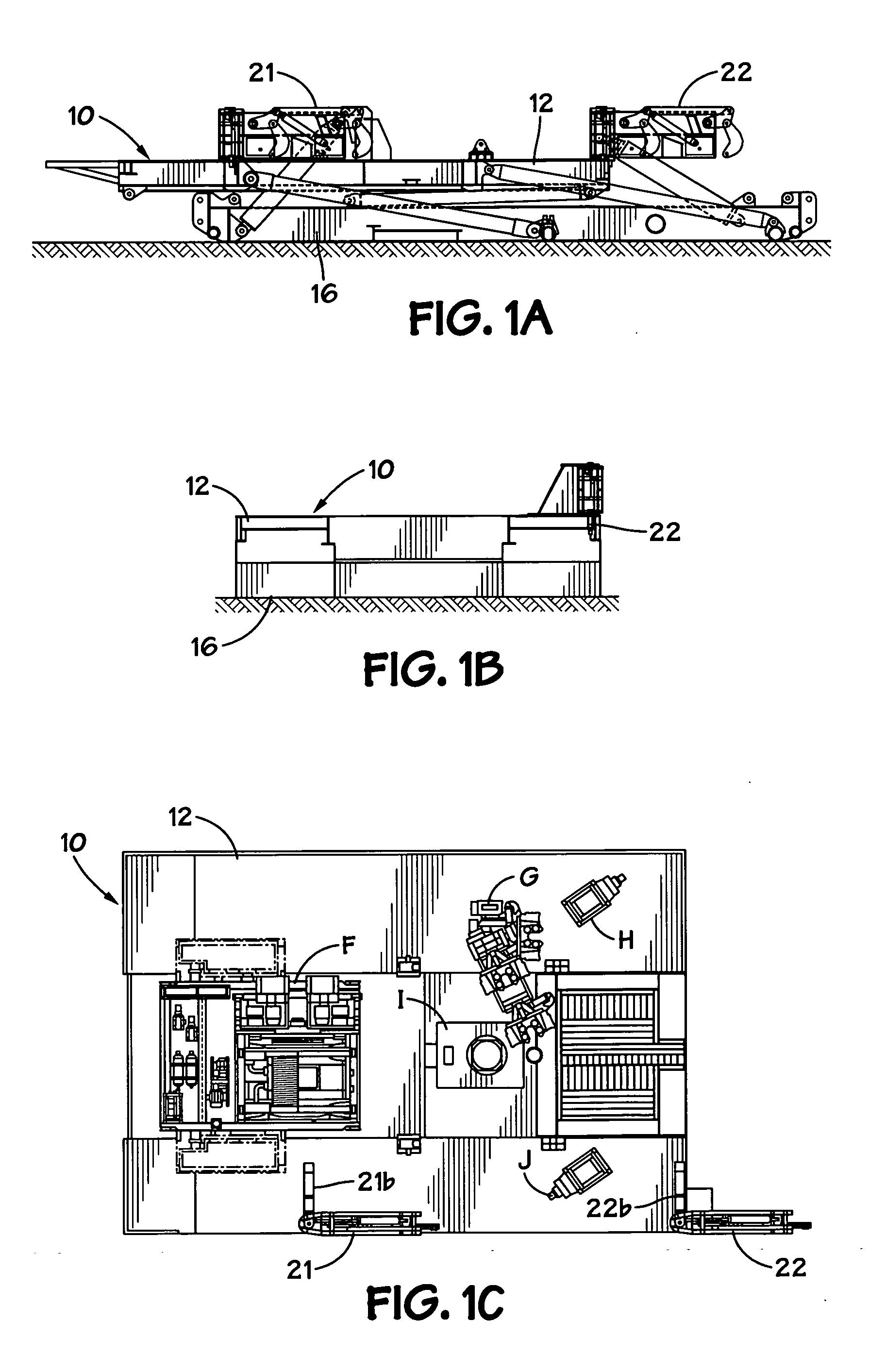

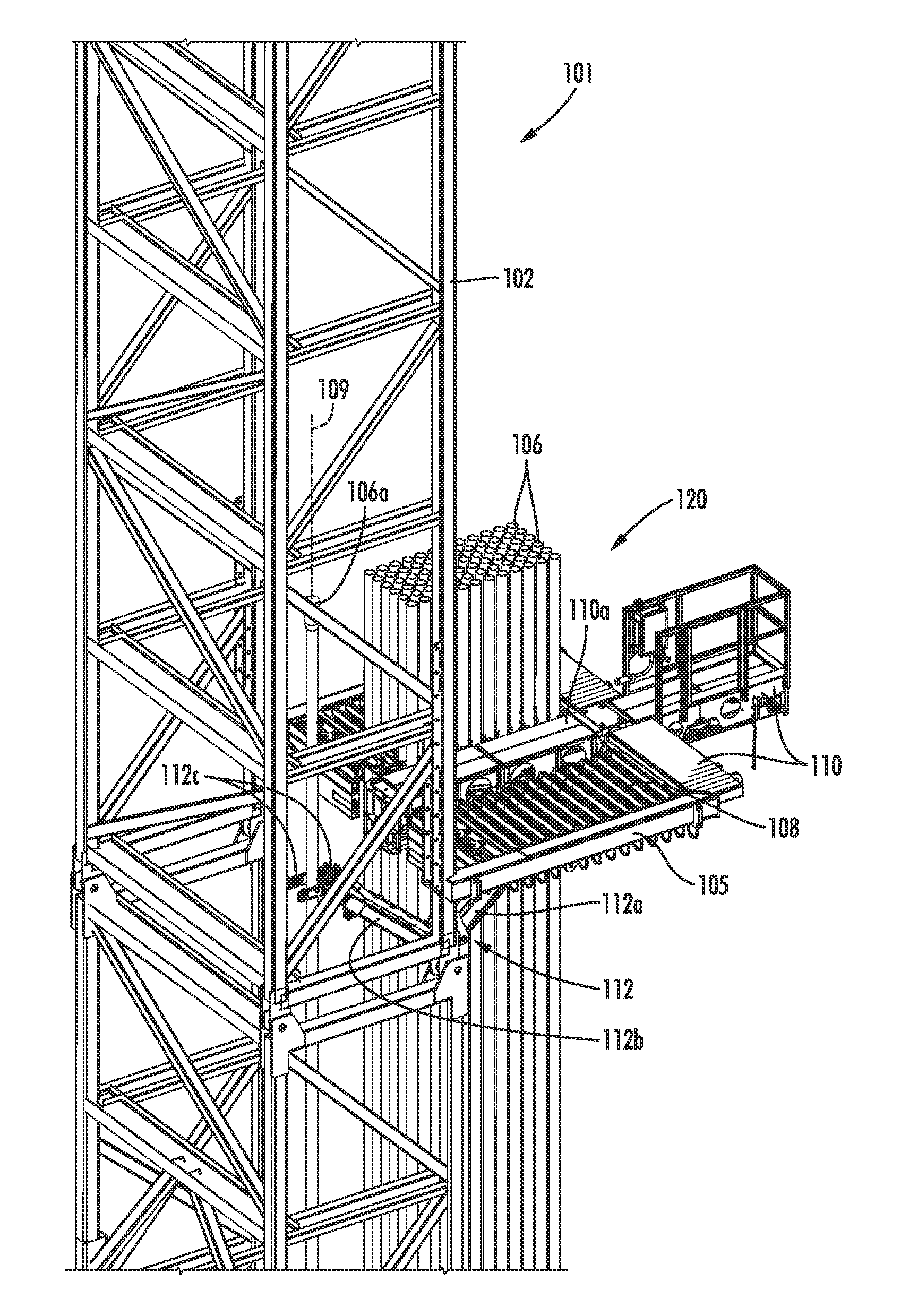

Method and apparatus for offline standbuilding

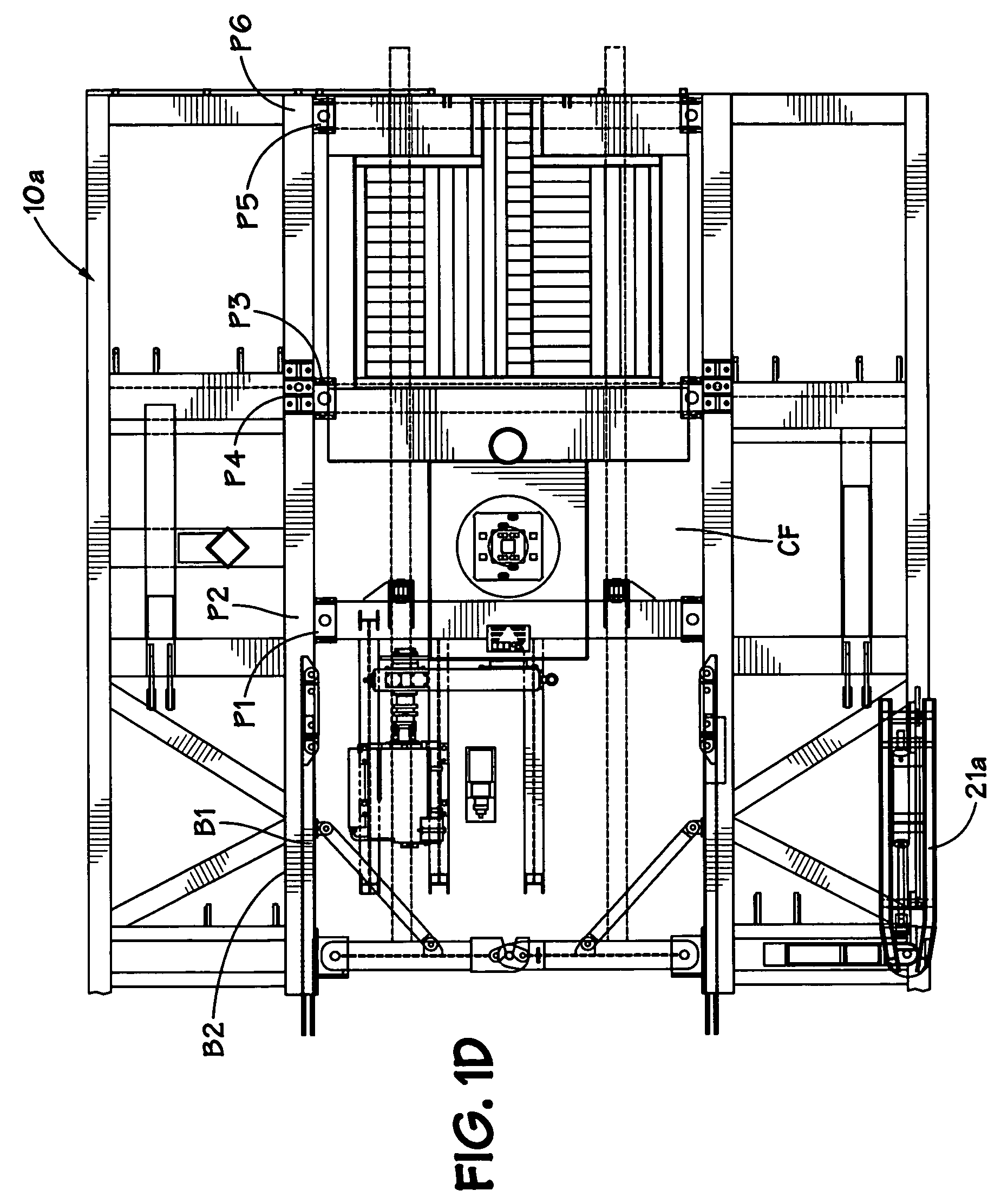

A method and apparatus for moving pipe on a rig floor between a number of different stations are provided. Generally the apparatus includes pipehandling equipment arranged to interact with an off-floor rack, a preparation opening, a borehole, and a storage area, such that tubulars can be loaded onto the drill floor, prepared at the preparation opening, loaded onto or off of the storage rack, and connected to a drill string while drilling is simultaneously conducted at borehole. In one embodiment, the system includes at least two pipehandling devices for communicating pipe between a storage area off the drill floor, a storage area on the drill floor, at least one preparation opening, and a drill opening.

Owner:VARCO I P INC

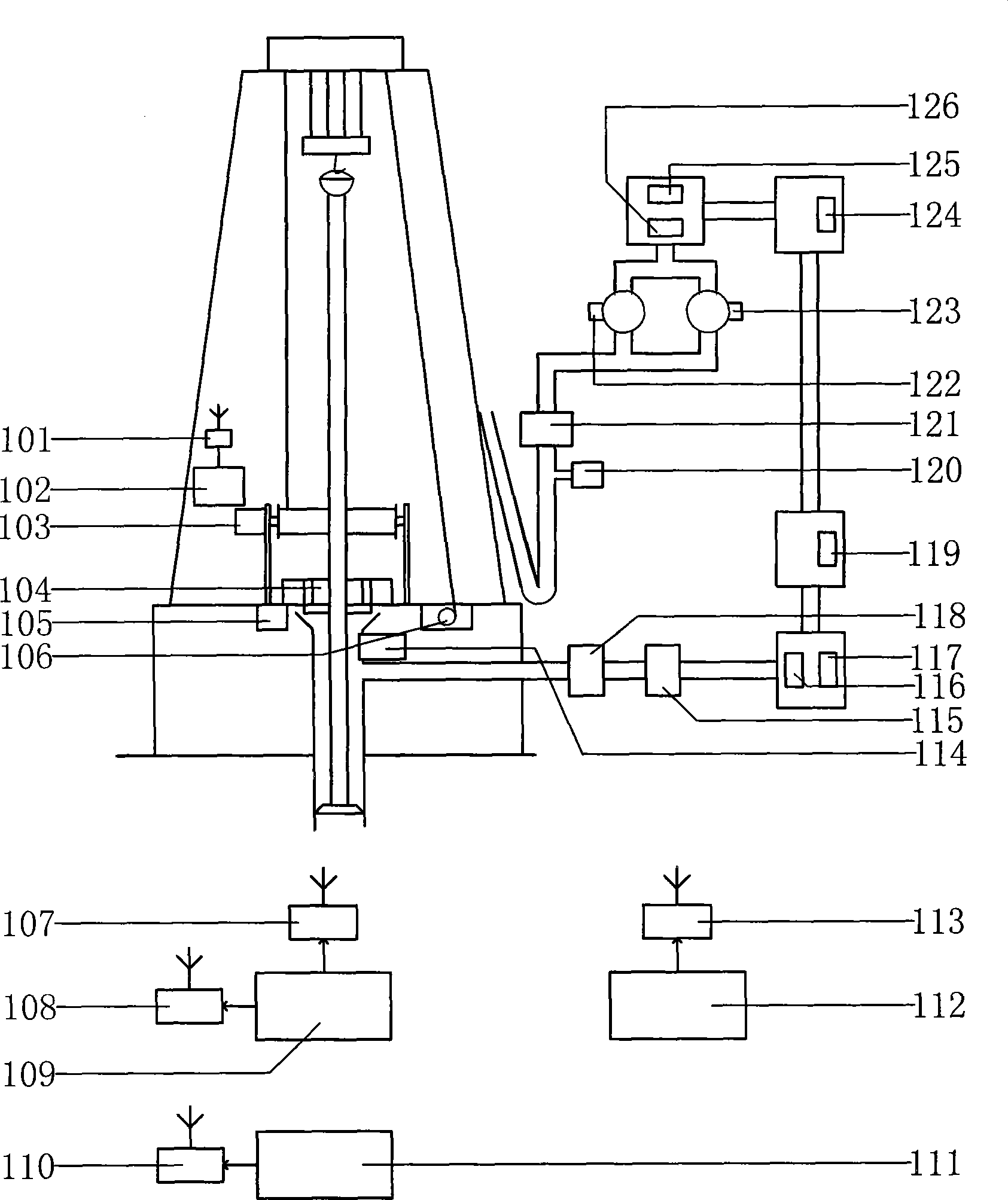

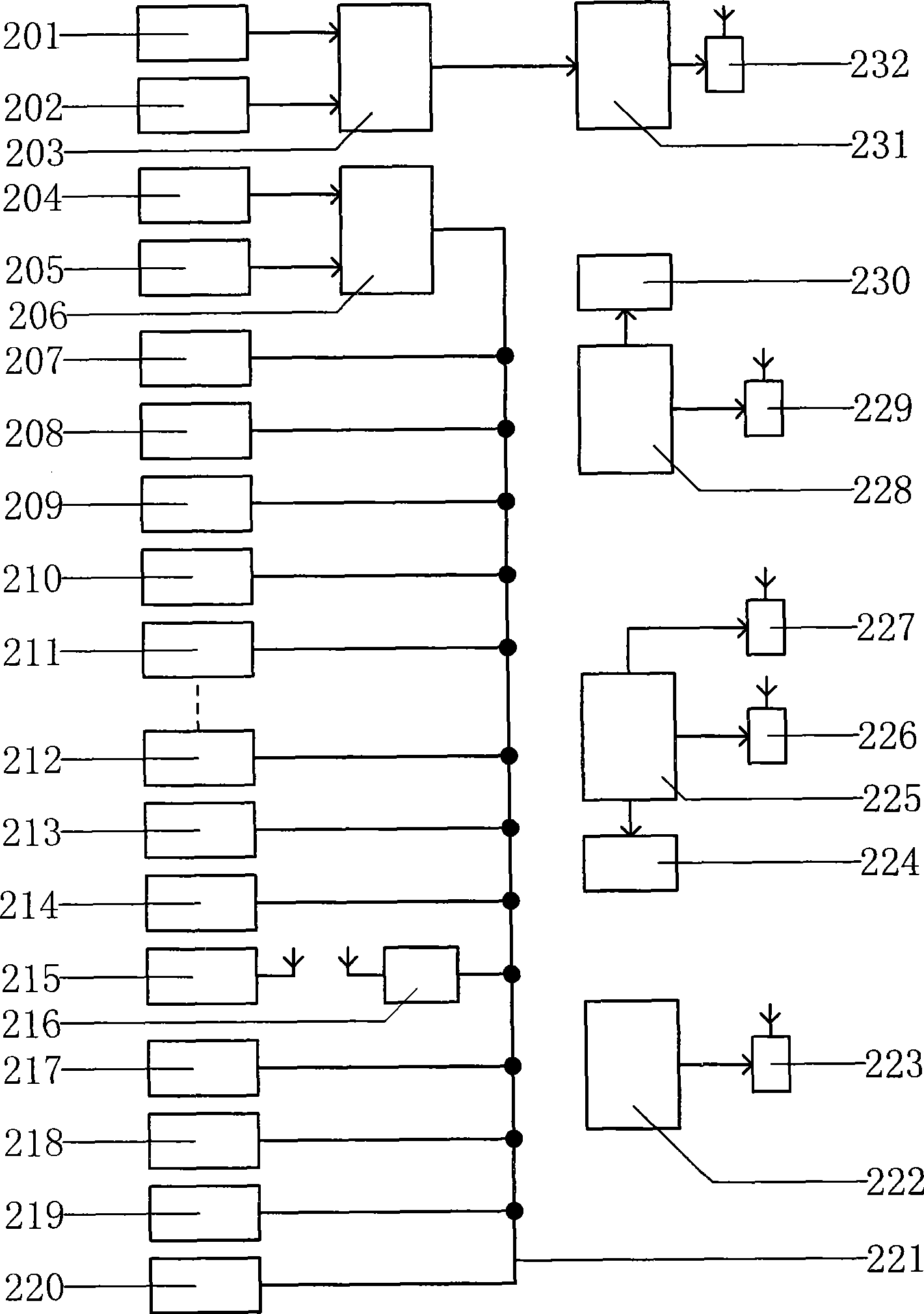

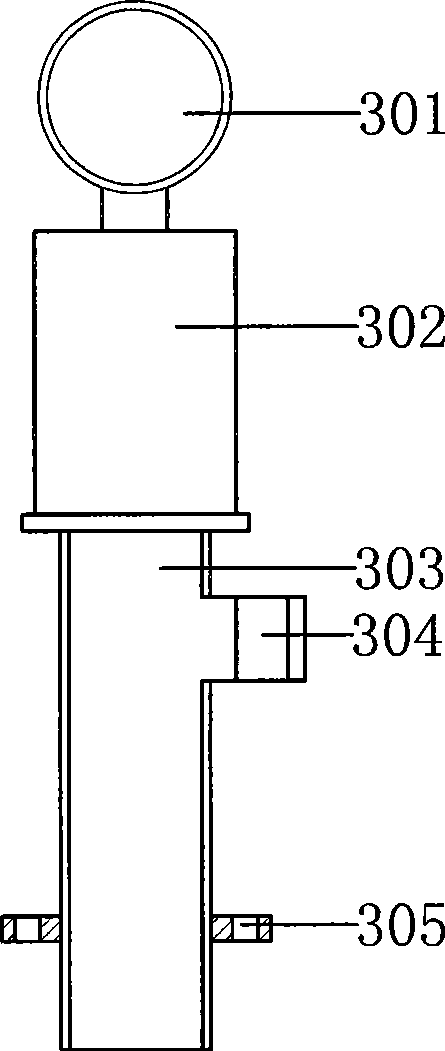

Drilling well control parameter intelligent monitoring system

InactiveCN101446191AJitter Errors Are UniformHigh precisionSurveyFlushingData platformDisplay device

The invention relates to a drilling well control parameter intelligent monitoring system which comprises a monitoring part for drilling fluid cycling volume, a monitoring part for drilling fluid inlet and outlet flow, a monitoring part for drilling fluid inlet density, outlet density, drilling temperature, outlet natural gas, and H2S concentration, a monitoring part for wellhead pitshaft flowing fluid level and table torque, and a collection instrument part. All the signals are transmitted into the collection instrument to be collected through an RS485 network cable; after data processing is carried out, the data is transmitted to a drill floor parameter display device and a central station host computer through a wireless data transmission device; the data storage, display and print are carried out by the host computer, and the data is simultaneously uploaded into a data platform processor of an upper-level command center; finally, remote control realtime processing and monitoring are carried out on all the well control parameters of all the drilling crews. The intelligent monitoring system has the beneficial effects of realizing omnibearing, long-distance and timely drilling well control, safe production, and playing better role in preventing the occurrence of accidents such as well kick, loss circulation, blow-out, etc.

Owner:北京奥林天成科技有限公司

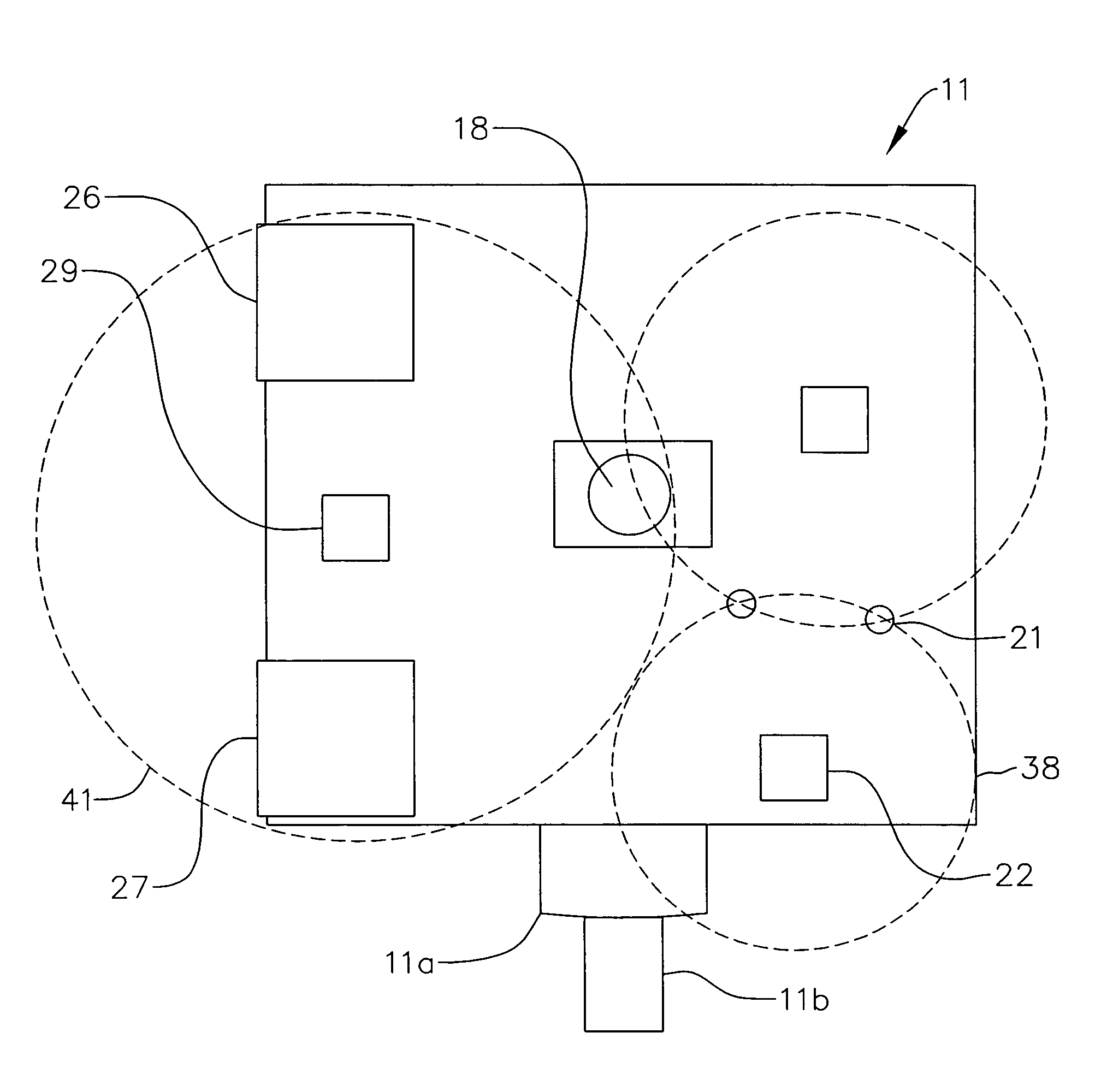

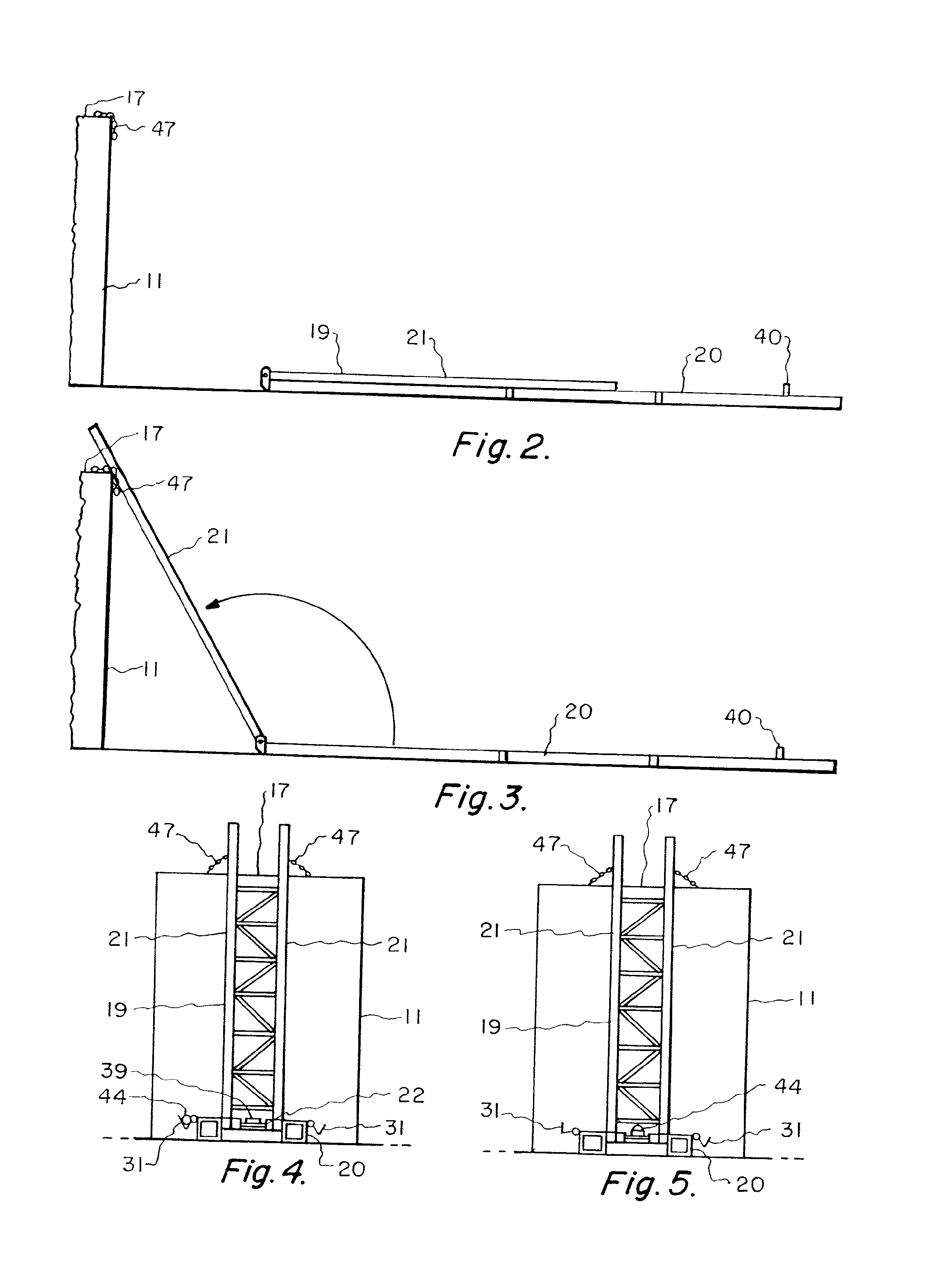

Portable drill pipe handling apparatus for use with oil and gas well drilling rigs

A pipe handling apparatus transfers successive lengths of drill pipe that are stored in a generally horizontal position on a pipe rack, to an elevated position on the rig deck of an oil and gas well drill rig. An elongated frame includes a base section with a folding section that can be inclined. Both the base and folding sections provide toothed racks. A trestle section travels from the base section toward the inclined section. Pinion gears at opposed end portions of the trestle section engage the toothed racks of the base and folding sections. The trestle section gradually increases in inclination as its front end portion travels toward and up hoisting rails of the inclined folding section. While the rear end of the trestle section remains on the base section, the front end portion of the trestle section climbs the toothed racks of the inclined rails.

Owner:MALTBY SCOTT R

Height-adjustable pipe pick-up and laydown machine

Owner:THE TECH ALLIANCE

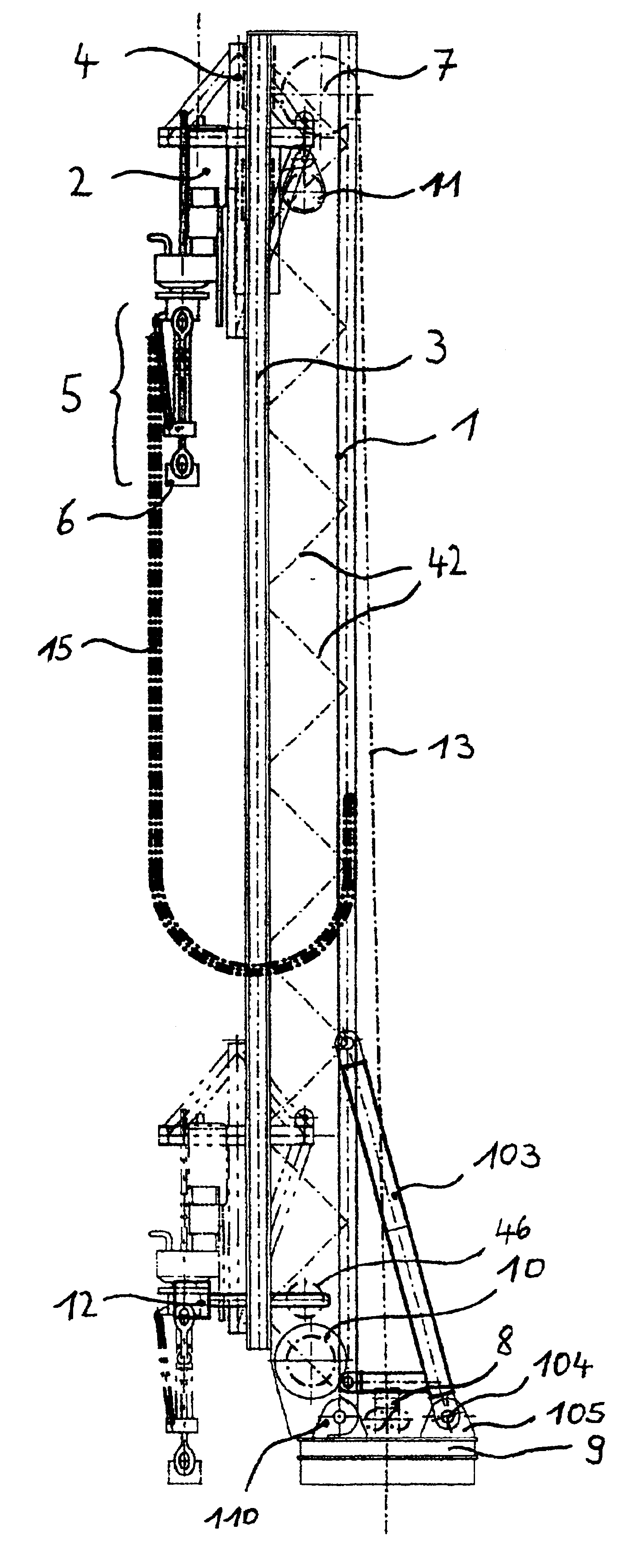

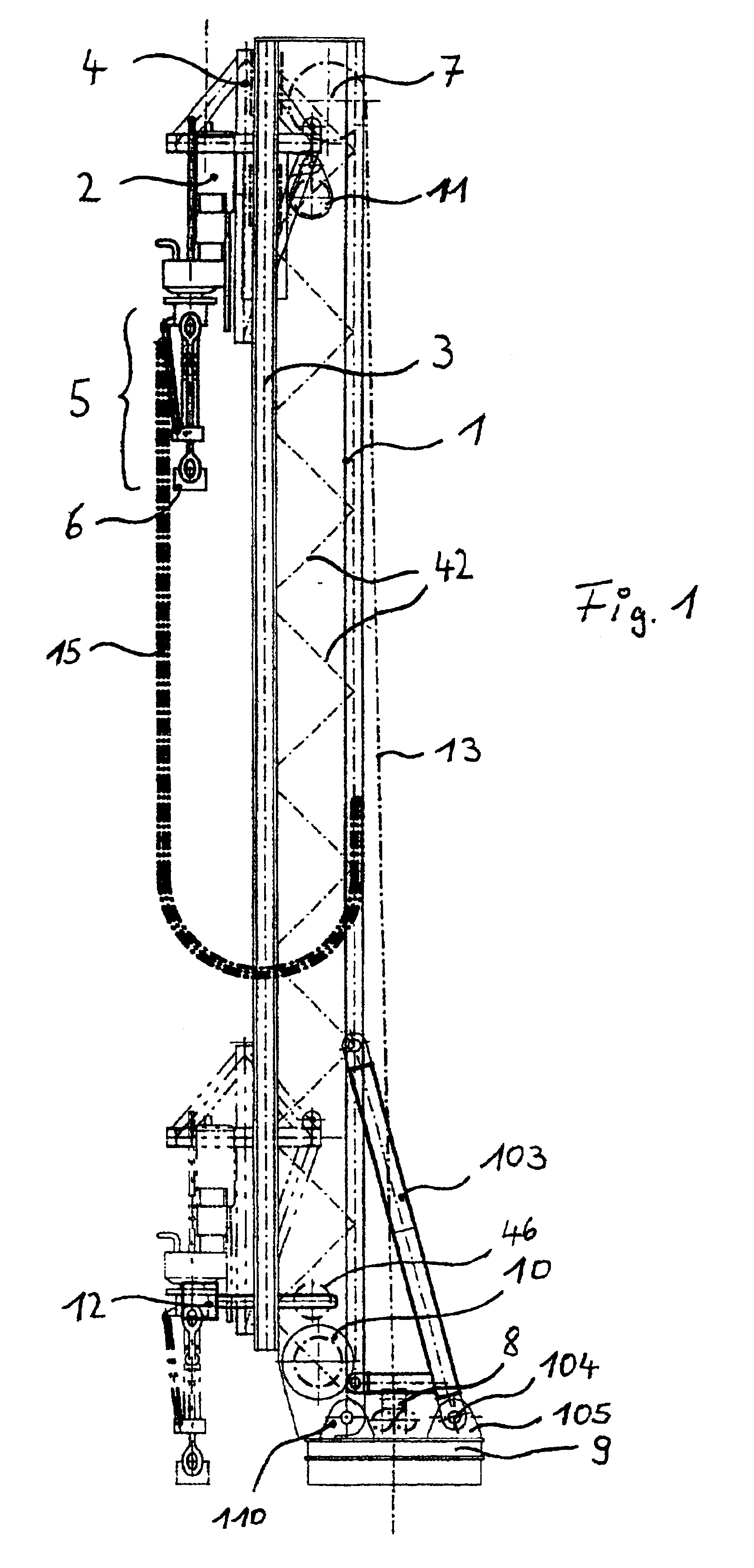

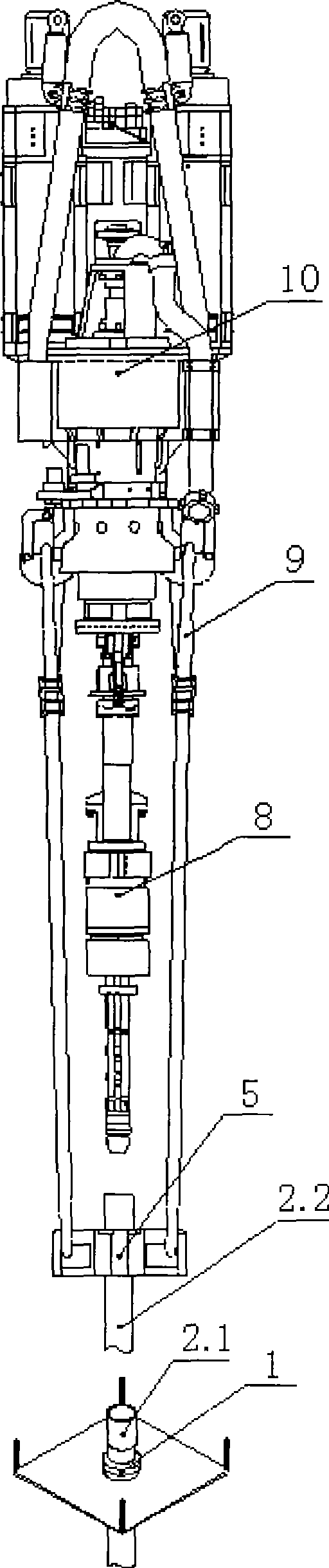

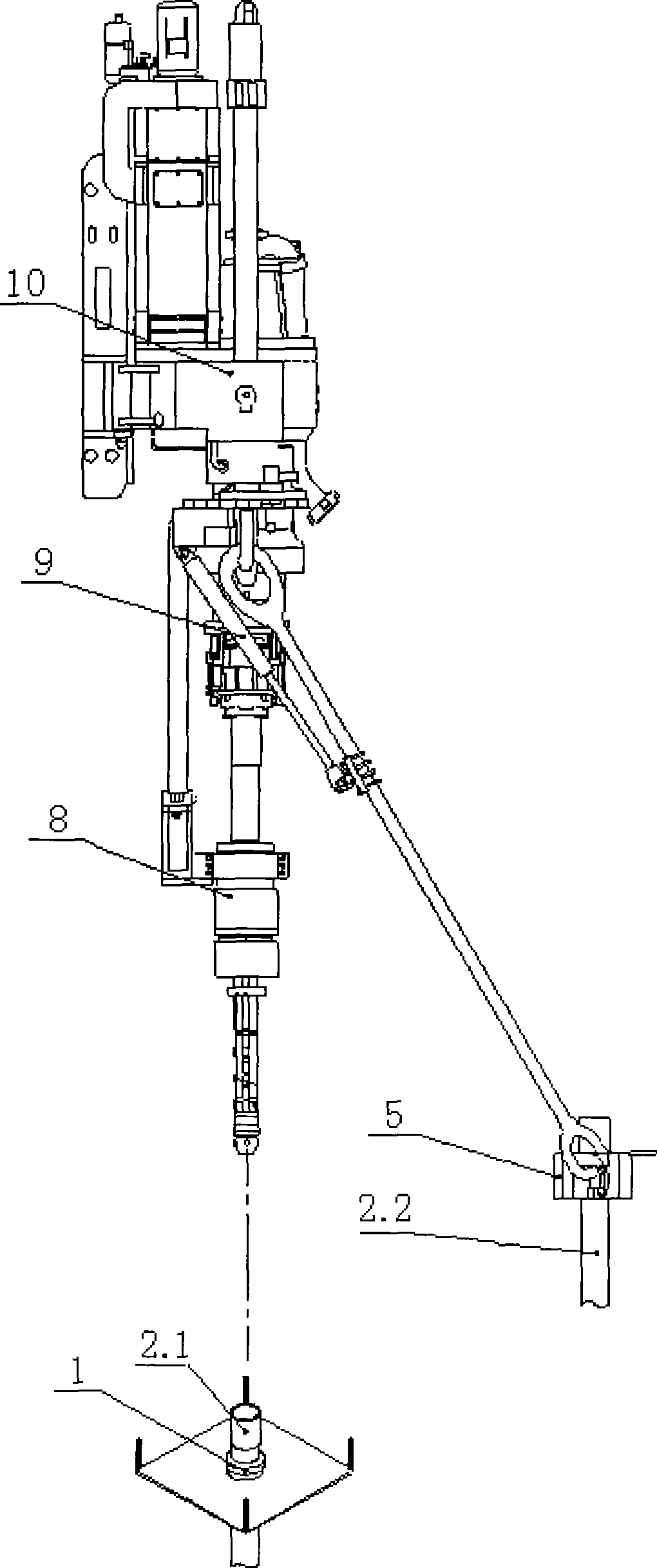

Drilling device and method for drilling a well

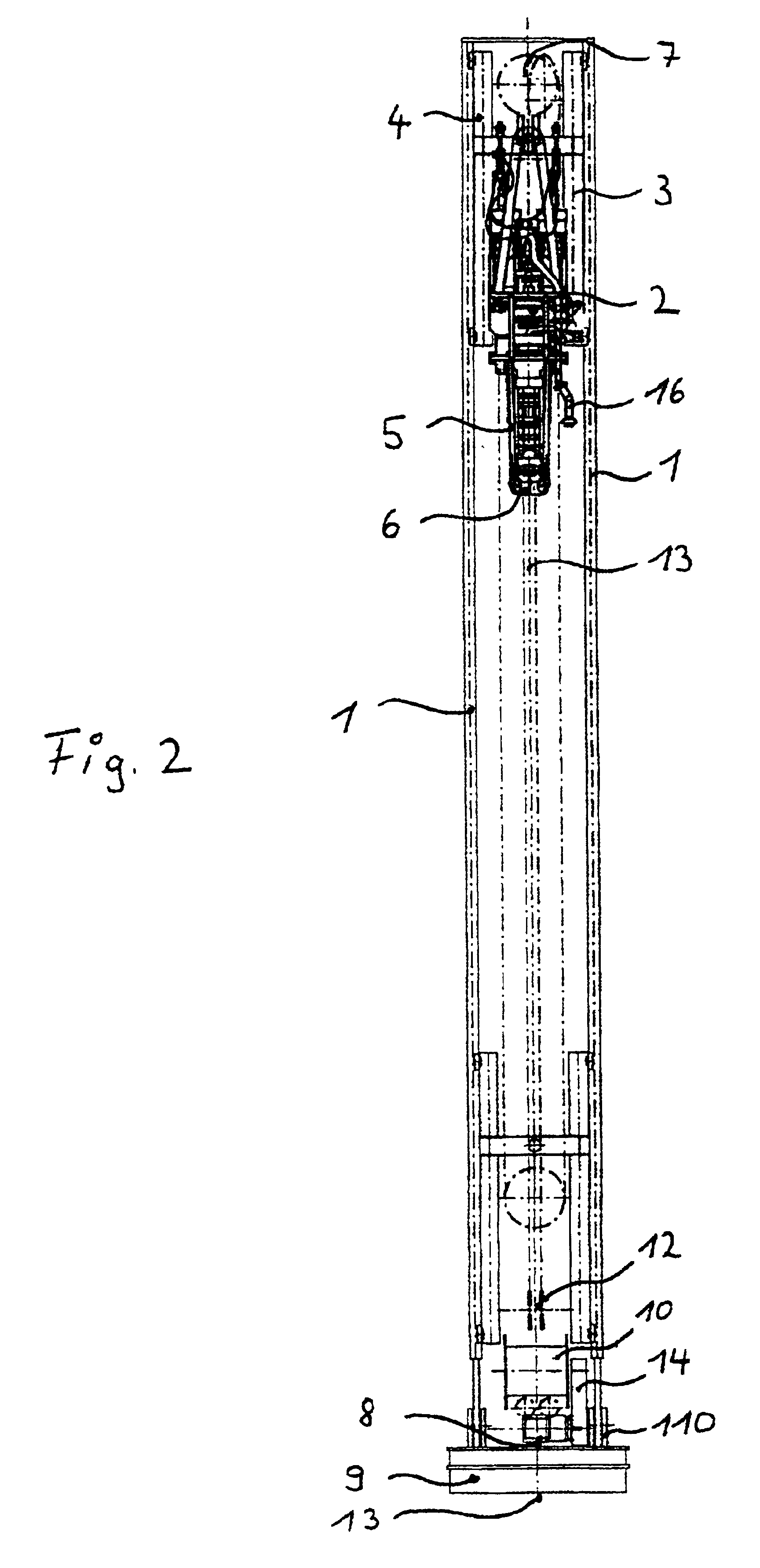

A drilling machine and drilling rig for exploratory drillings and producing wells, include a base mounting atop drive, and a multifunctional gripper for gripping drilling pipe from a stock and to be raised on the base for eventual positions positioning at a well center, an elevator being provided below the top drive. The base can be rotatably mounted and have a live ring at a base lower end region, the base being rotated to the pipe stock location and being rotatable to a well center as well. A drilling pipe upper end when raised on the base can be connected to the top drive, and an iron roughneck on a rig floor can be used to connect a pipe lower end to a pipe section in the well. Where two drilling machine are used, one can be used for actual drilling at the well center, and the second supplied with pipework for the operation.

Owner:BENTEC DRILLING & OILFIELD SYST

Methods and apparatus for drilling with casing

In one embodiment, a method of forming a wellbore includes running a liner drilling assembly into the wellbore, the liner drilling assembly having a liner, a conveying member, one or more connection members, and a drilling member. The method includes temporarily suspending the liner at a location below the rig floor; releasing the conveying member and the drilling member from the liner; re-connecting the conveying member to the liner; releasing the liner from its location of temporary suspension; and advancing the liner drilling assembly.

Owner:WEATHERFORD TECH HLDG LLC

Automated pipe joining system and method

A method and apparatus for making and breaking tubular connections at the surface of a well by utilizing a pipe joining system. The pipe joining system includes a movable support frame for supporting and integrating on a rig floor the tools associated with making and breaking the connection between two tubulars. Tools incorporated in the pipe joining system include combinations of a wrenching assembly for gripping the tubulars and applying torque to the connection, a spinner for spinning the joints of the tubulars into connection, a positioning tool for vertically and / or horizontally aligning the tubulars in the system, a cleaning and doping device for cleaning and doping the threads of the tubulars, a stabbing guide for properly aligning the tubulars before joining, a mud bucket for handling mud spillage during the breaking of the tubulars, and a control system that remotely operates the entire automated system.

Owner:WEATHERFORD TECH HLDG LLC

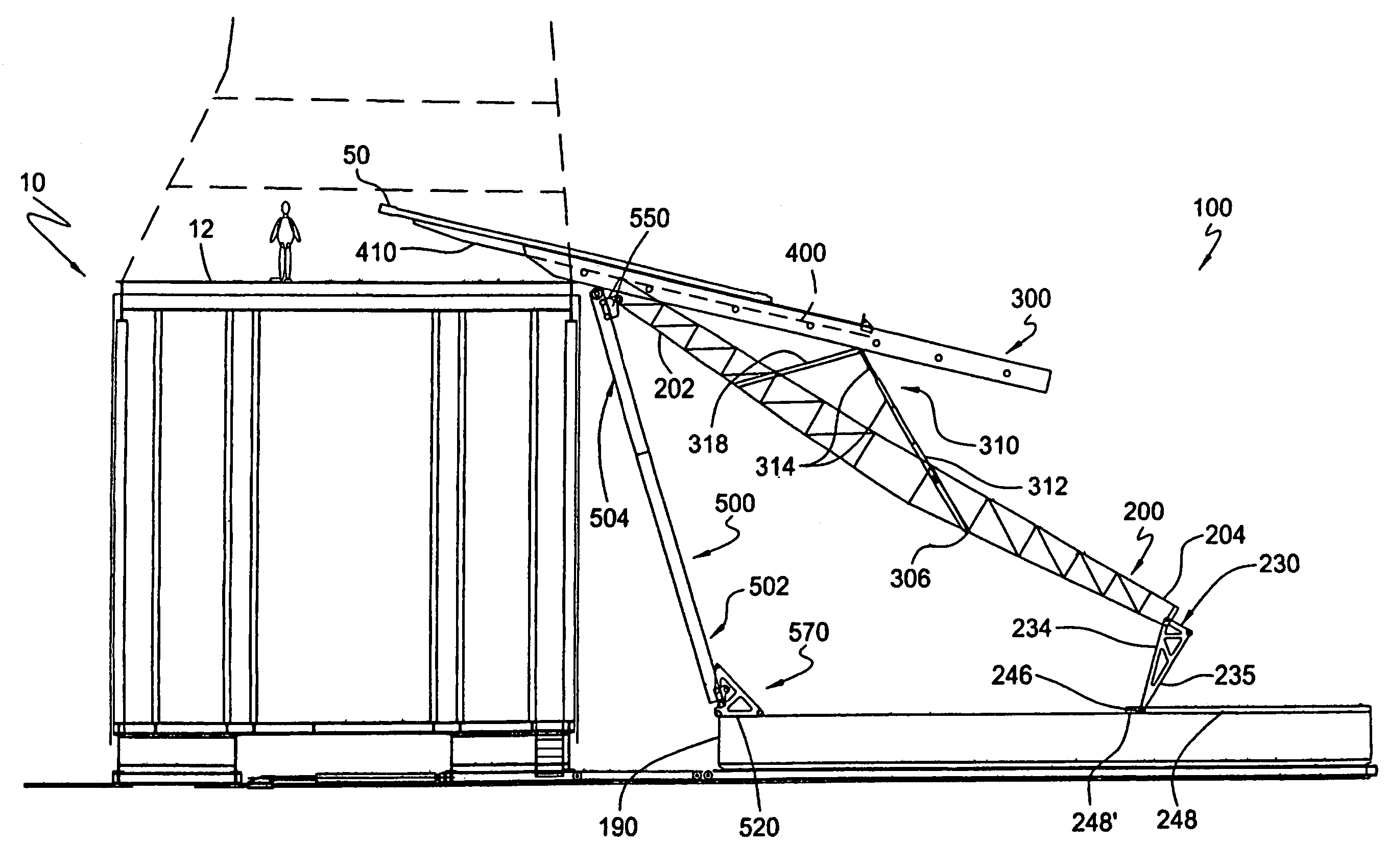

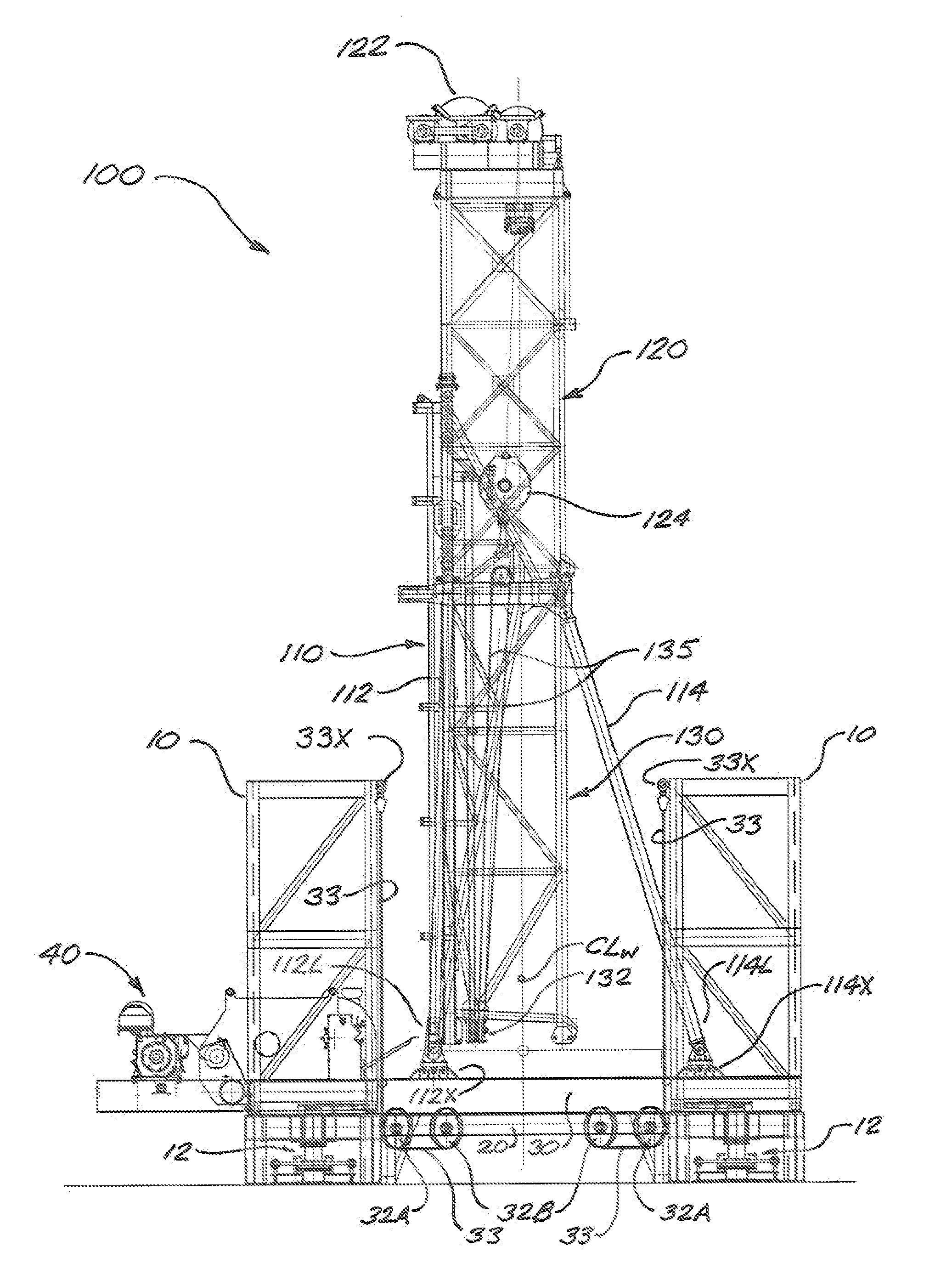

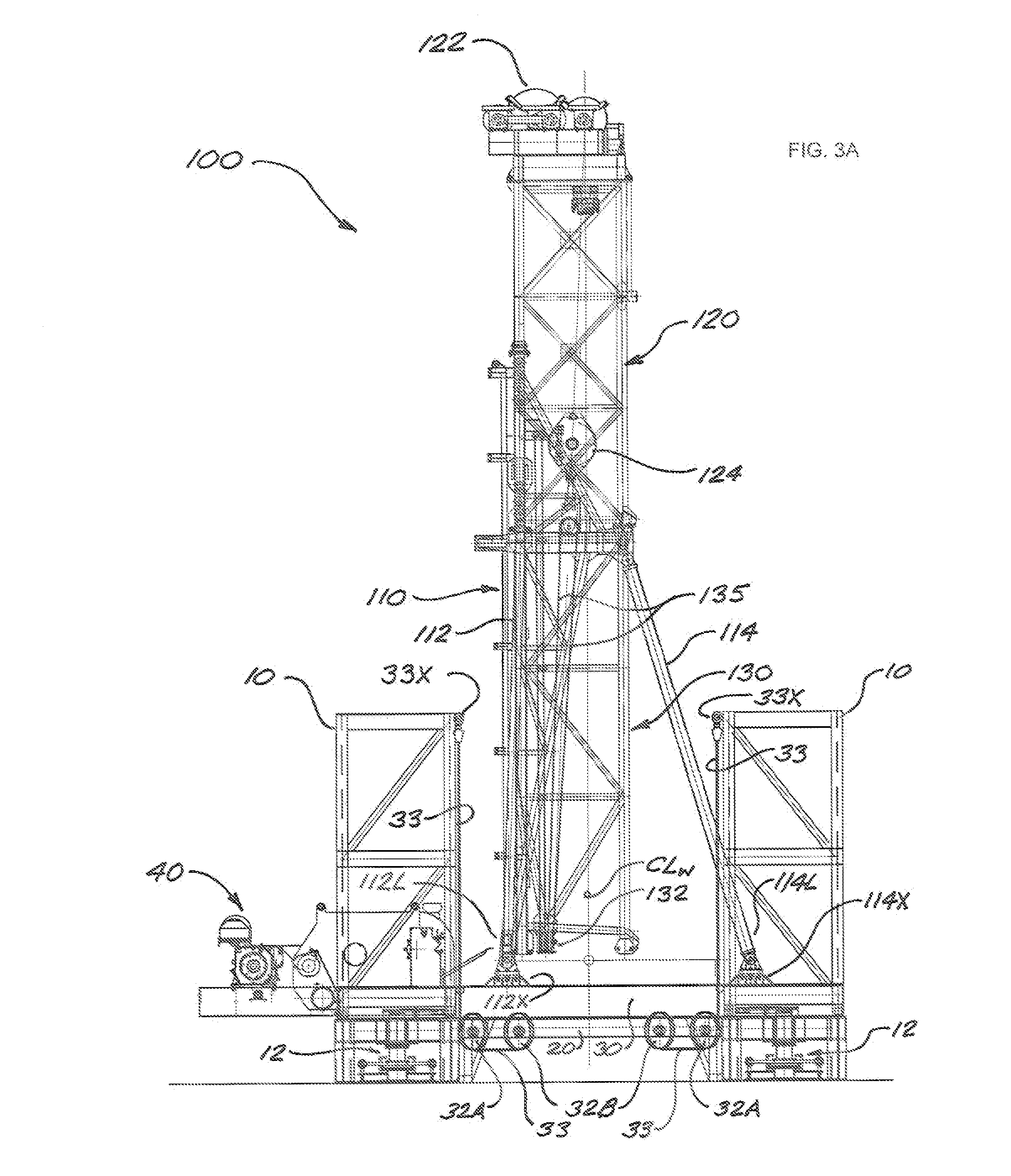

Drilling rig structure installation and methods

Owner:NAT OILWELL VARCO LP

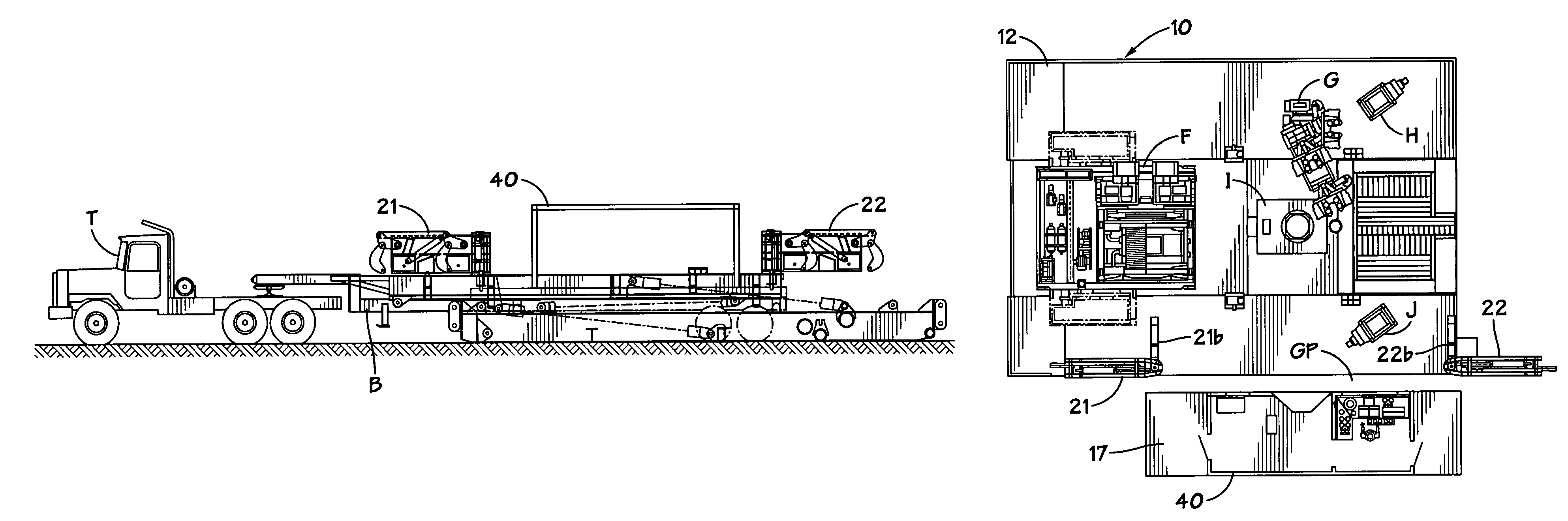

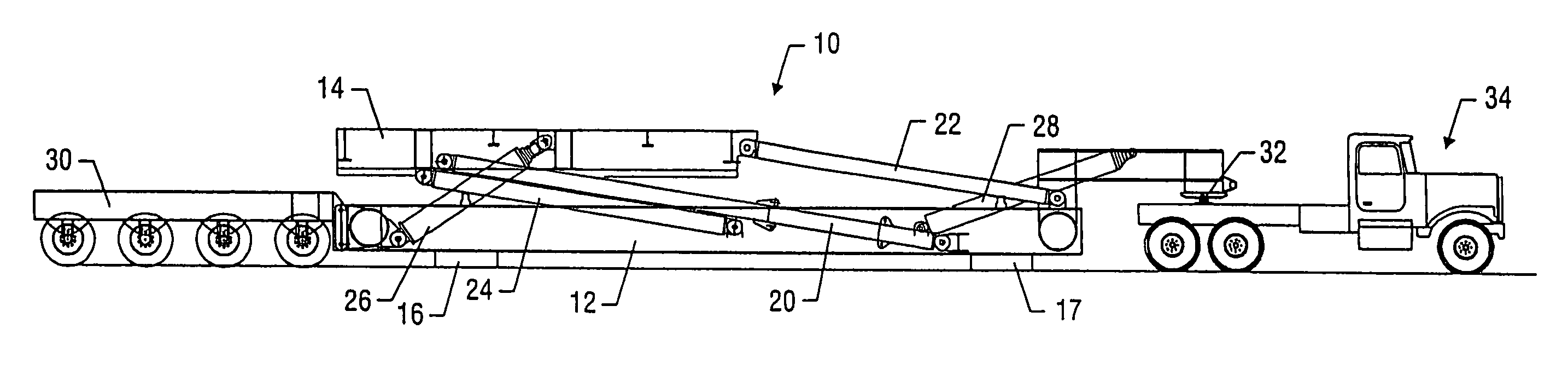

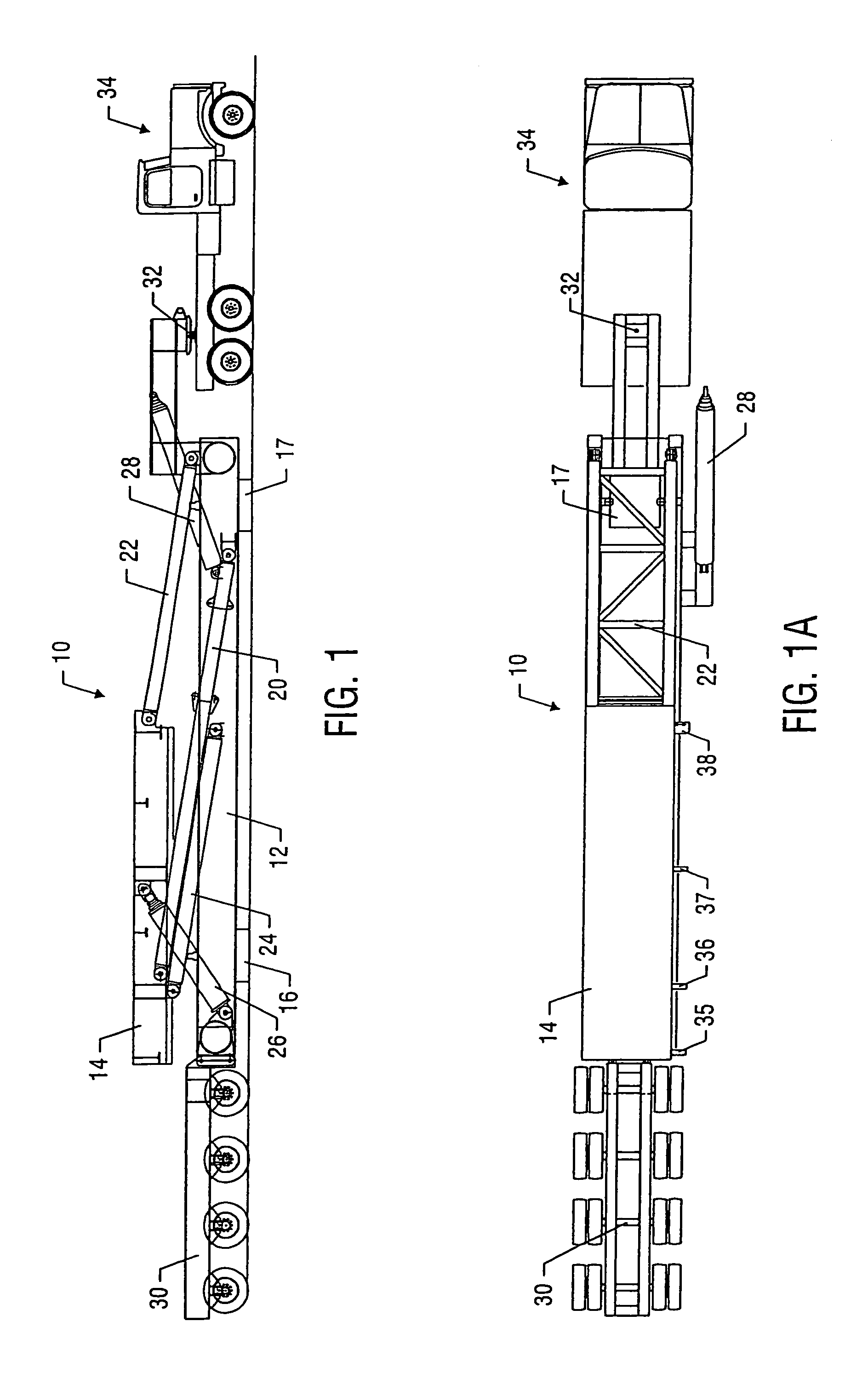

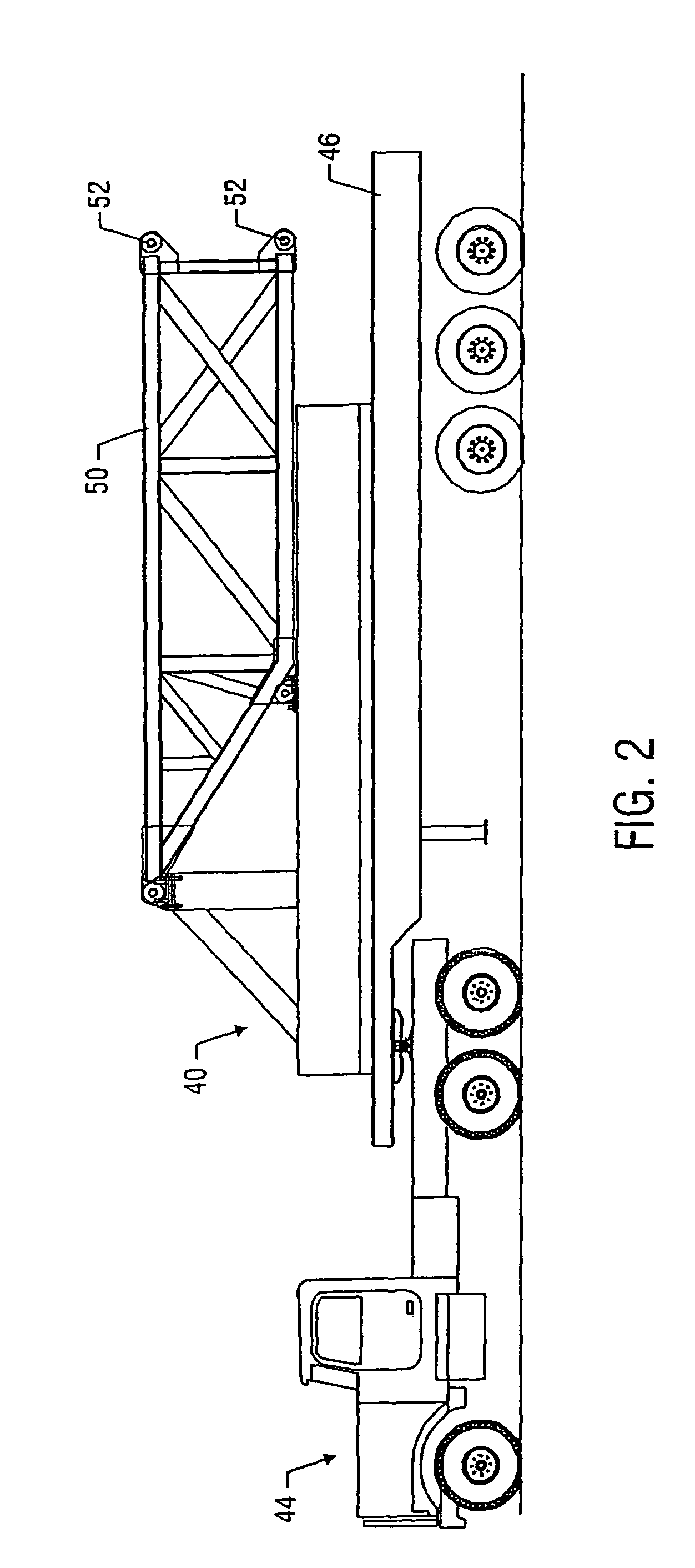

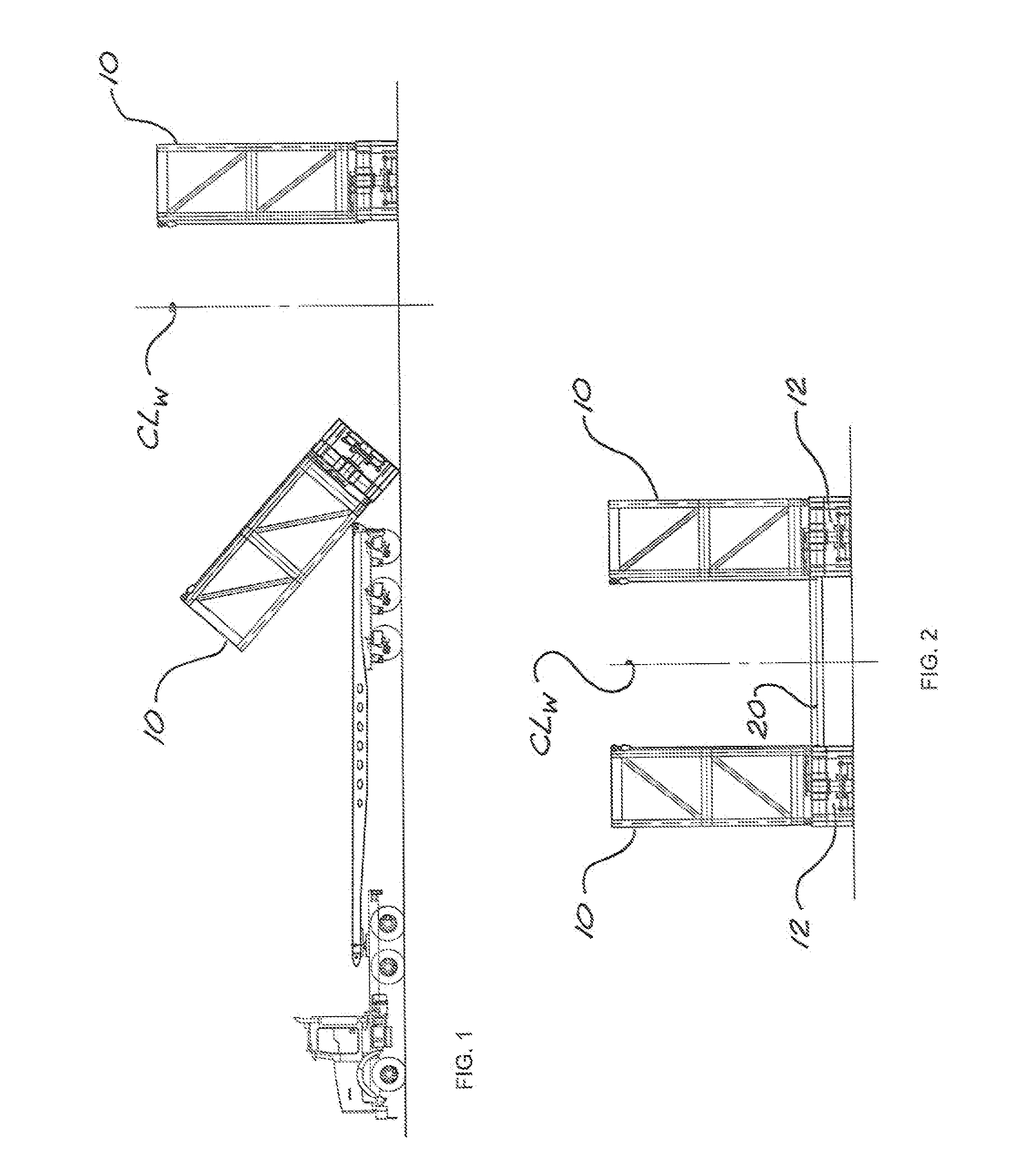

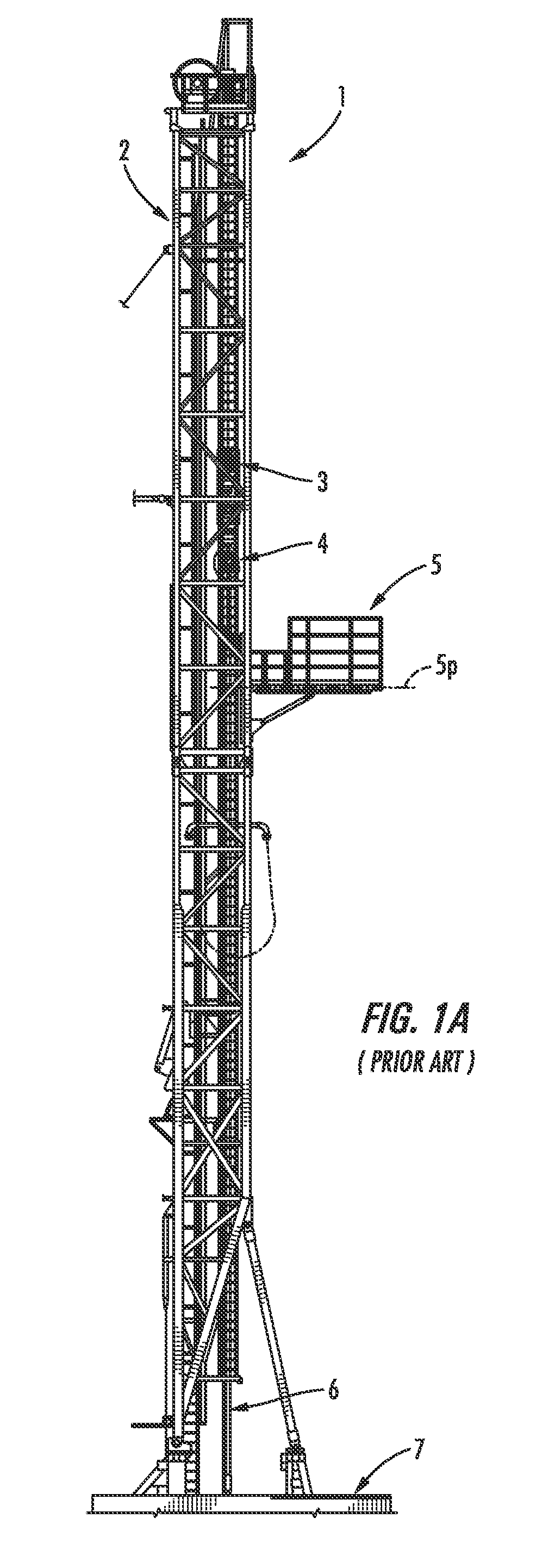

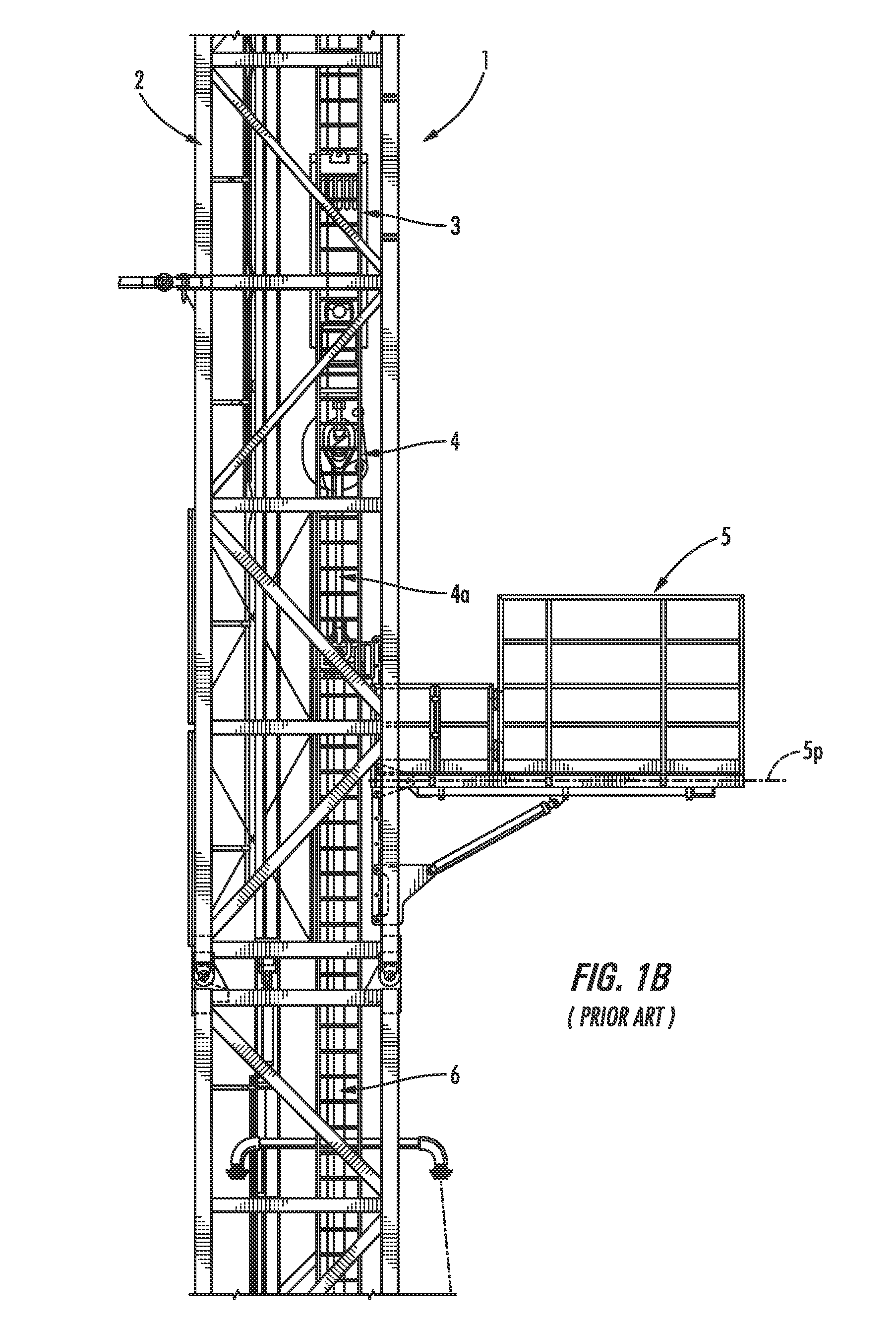

Fast moving drilling rig

A method and apparatus for transporting and assembling a drilling rig is disclosed. The drilling rig of a preferred embodiment of the present invention utilizes specialized positioning pads integral to the side boxes of the drilling rig to facilitate the connection of the center drill floor of the drilling rig to the side boxes of the rig. A preferred embodiment of the present invention may also utilize a specialized positioning dolly and an adjustable fifth-wheel truck connection for transporting the mast to the drill site, assembling the mast sections together, and positioning the mast for connection to the drill floor of the rig. The result is a unique drilling rig design and sequence for assembly that significantly reduces the time required to transport the rig from location to location and to assemble the rig at the drill site.

Owner:NAT OILWELL DHT

Method and apparatus for offline standbuilding

A method and apparatus for moving pipe on a rig floor between a number of different stations including an off-floor rack, a preparation opening, a borehole, and a storage area, such that tubulars can be loaded onto the drill floor, prepared at the preparation opening, loaded onto or off of the storage rack, and connected to a drill string while drilling is simultaneously conducted at the borehole, comprising at least two pipehandling devices, at least one of the pipehandling devices having multiple independent gripping arms, the pipehandling devices being arranged for communicating pipe between a storage area off the drill floor, a storage area on the drill floor, at least one preparation opening, and a drill opening are provided.

Owner:VARCO I P INC

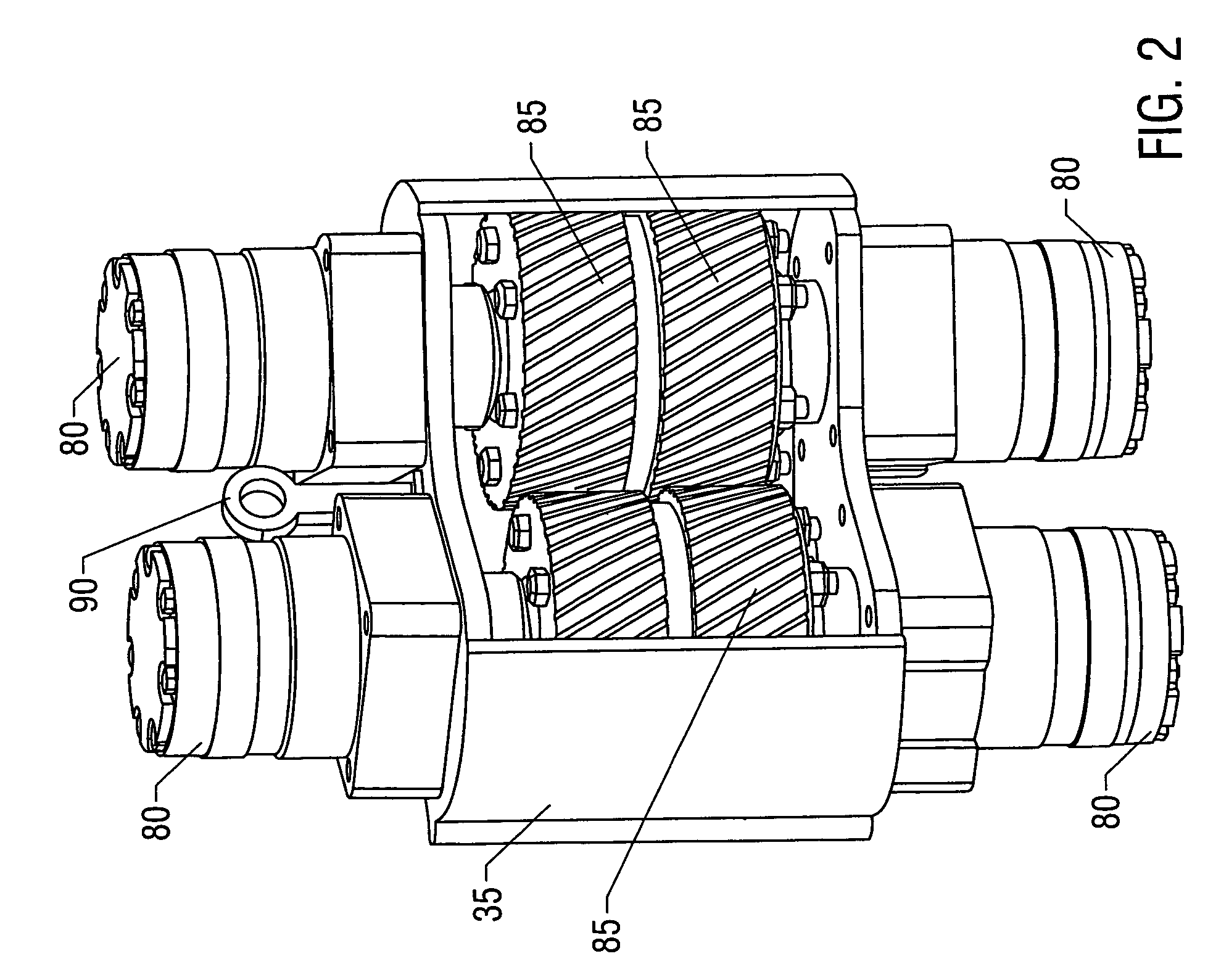

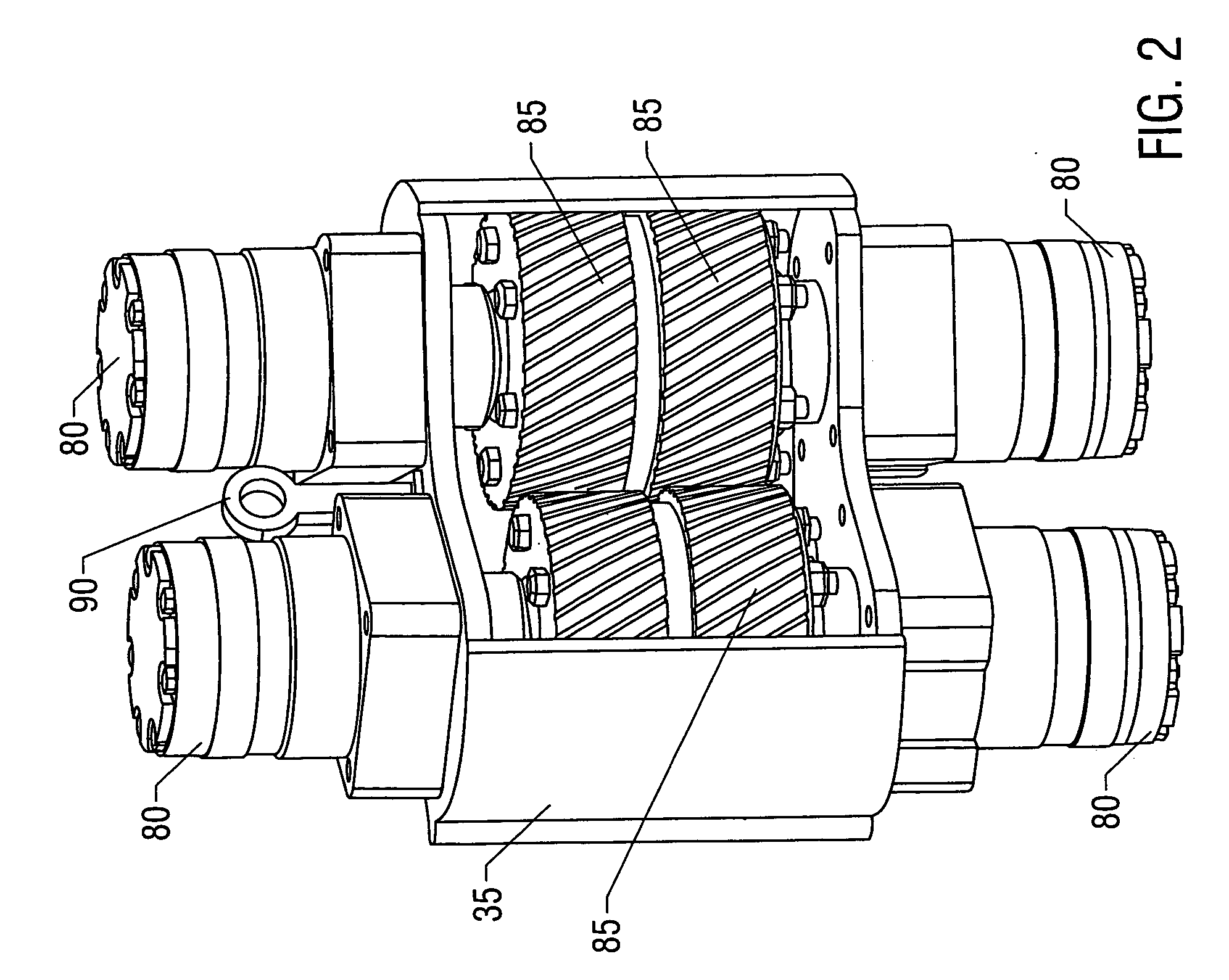

Drillpipe spinner

The invention relates to an improved drill pipe spinner. The improved spinner may be used as a stand-alone piece of pipe handling equipment or may be used in an Iron Roughneck. The spinner comprises a pair of clamping arms that are movable between an open position and a closed position, wherein in the closed position, the arms will clamp about a pipe to be made up or broken out and in the open position, the spinner may be moved away from or towards the pipe. The arms are preferably moved between the open and closed positions by a hydraulically actuated clamping cylinder. Attached to the distal ends of each arm is a roller bracket. The roller brackets are preferably attached to the clamping arms by a roller bracket pin. Each roller bracket includes a pair of drive roller assemblies, which together form the spinning unit. Each drive roller assembly preferably comprises a pair of drive rollers, with each roller rotated by a pair of hydraulic motors. If the rollers of the spinner have to be repaired, serviced or replaced, the arm brackets are easily removed by simply pulling the roller bracket pin and removing the roller bracket. A new roller bracket may then be picked up, aligned with and pinned to the arm by reinserting the roller bracket pin. The spinning unit can easily be removed and replaced on the rig floor by changing out the roller bracket.

Owner:NAT OILWELL DHT

Drillpipe spinner

The invention relates to an improved drill pipe spinner. The improved spinner may be used as a stand-alone piece of pipe handling equipment or may be used in an Iron Roughneck. The spinner comprises a pair of clamping arms that are movable between an open position and a closed position, wherein in the closed position, the arms will clamp about a pipe to be made up or broken out and in the open position, the spinner may be moved away from or towards the pipe. The arms are preferably moved between the open and closed positions by a hydraulically actuated clamping cylinder. Attached to the distal ends of each arm is a roller bracket. The roller brackets are preferably attached to the clamping arms by a roller bracket pin. Each roller bracket includes a pair of drive roller assemblies, which together form the spinning unit. Each drive roller assembly preferably comprises a pair of drive rollers, with each roller rotated by a pair of hydraulic motors. If the rollers of the spinner have to be repaired, serviced or replaced, the arm brackets are easily removed by simply pulling the roller bracket pin and removing the roller bracket. A new roller bracket may then be picked up, aligned with and pinned to the arm by reinserting the roller bracket pin. The spinning unit can easily be removed and replaced on the rig floor by changing out the roller bracket.

Owner:NAT OILWELL DHT

Perforating gun connector

Controlled Buoyancy Perforating technology for highly deviated and substantially horizontal wellbores may include long perforating guns assembled on a rig floor from a multiplicity of light weight and highly engineered shaped charge carrier joints. Tubular housings for such light weight joints may be fabricated from composite materials having steel transition collars. The collars are designed for an angularly coordinated, bayonet assembly and, in most cases, rapid disassembly. The internal volume of each joint is environmentally sealed by a plurality of O-rings. Barbs carried by collet fingers projecting from opposite ends of a sealing sleeve that externally bridges a transition collar union plane secures the union by meshing with detent channels in the respective collars. Individual shaped charge units and cooperative fusing are assembled in a light weight inner loading tube having an alignment collar to secure the angular and axial position of the loading tube relative to the transition collars.

Owner:SCOTT BRUCE DAVID

Method and apparatus for offline standbuilding

A method and apparatus for moving pipe on a rig floor between a number of different stations including an off-floor rack, a preparation opening, a borehole, and a storage area, such that tubulars can be loaded onto the drill floor, prepared at the preparation opening, loaded onto or off of the storage rack, and connected to a drill string while drilling is simultaneously conducted at the borehole, comprising at least two pipehandling devices, at least one of the pipehandling devices having multiple independent gripping arms, the pipehandling devices being arranged for communicating pipe between a storage area off the drill floor, a storage area on the drill floor, at least one preparation opening, and a drill opening are provided.

Owner:VARCO I P INC

Drilling rig system with self-elevating drill floor

InactiveUS20120304553A1Improve the level ofFor lateral movementCeilingsDerricks/mastsTowerTraveling block

A transportable drilling rig having a self-elevating drill floor includes a base structure comprising multiple base towers that can be transported to a wellsite and positioned around an intended wellbore location. A horizontal base frame is installed between lower regions of the towers to form a stable rig base structure, and a drill floor can then be constructed over the base frame and between the base towers. A suitable rig mast can then be erected on the drill floor. Floor-lifting cables are anchored to upper regions of the base towers and disposable around corresponding sheave assemblies associated with the drill floor. The free ends of the floor-lifting cables can be engaged by the traveling block in the rig mast, whereupon the rig's drawworks can be actuated to elevate the drill floor and mast as required and then locked to the base towers.

Owner:NAT OILWELL VARCO LP

Method and apparatus for installing control lines in a well

InactiveUS6889772B2Improve securityAvoid impairmentDrilling rodsFluid removalLine tubingControl line

A method and apparatus are provided for installing control lines and pipe into a well. The pipe-holding spider that is normally mounted on the rig floor is supportably retained in a vertically movable retainer. The retainer is adapted for controllably elevating the spider above the rig floor when the pipe slips within the spider are not engaged with the outer surface of the pipe string, thereby providing personnel access to a portion of the length of the pipe string below the elevated spider and above the rig floor. Personnel are provided with access to the pipe string for applying a fastener to secure the control line to the pipe string.

Owner:FRANKS INT

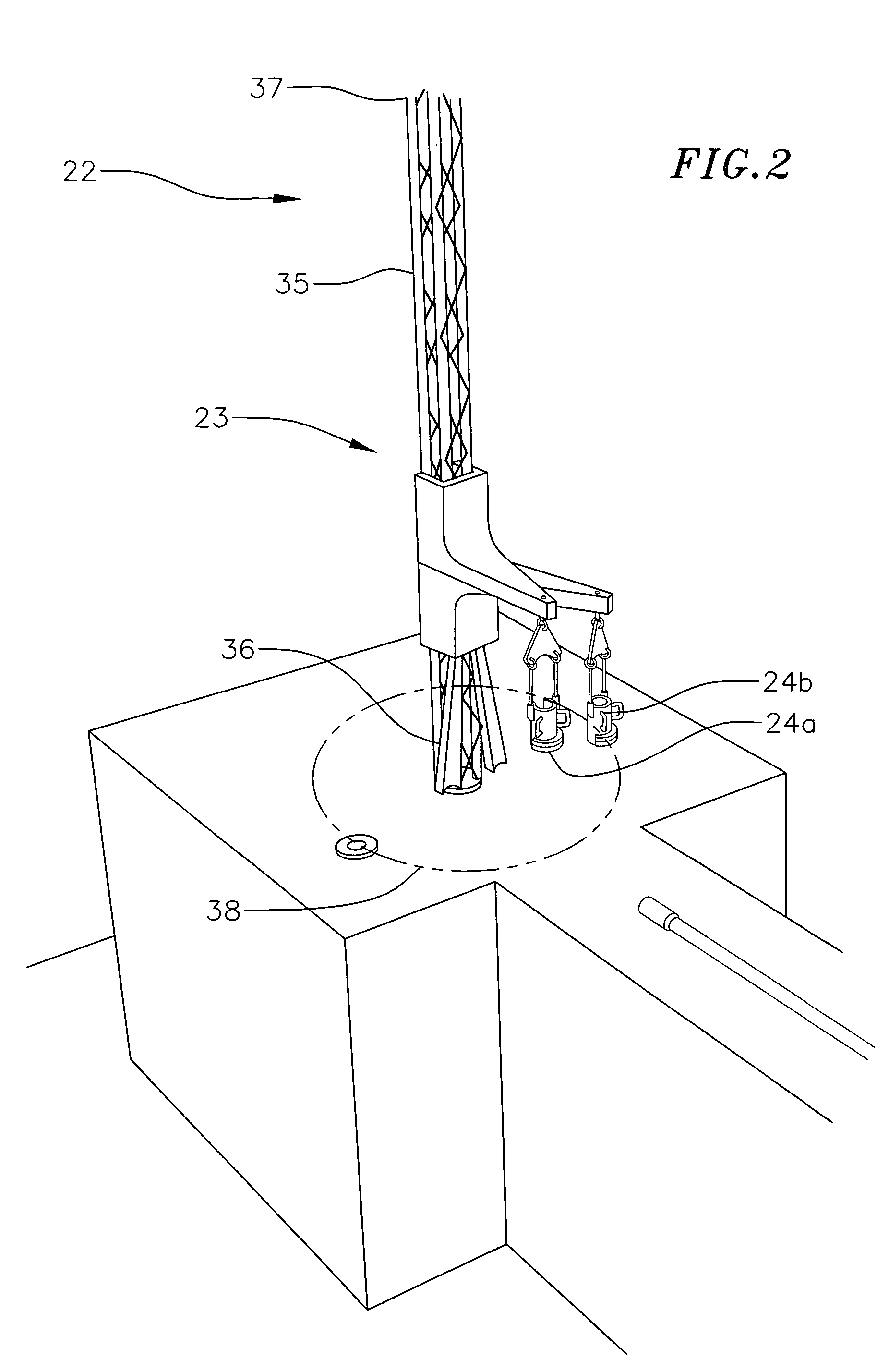

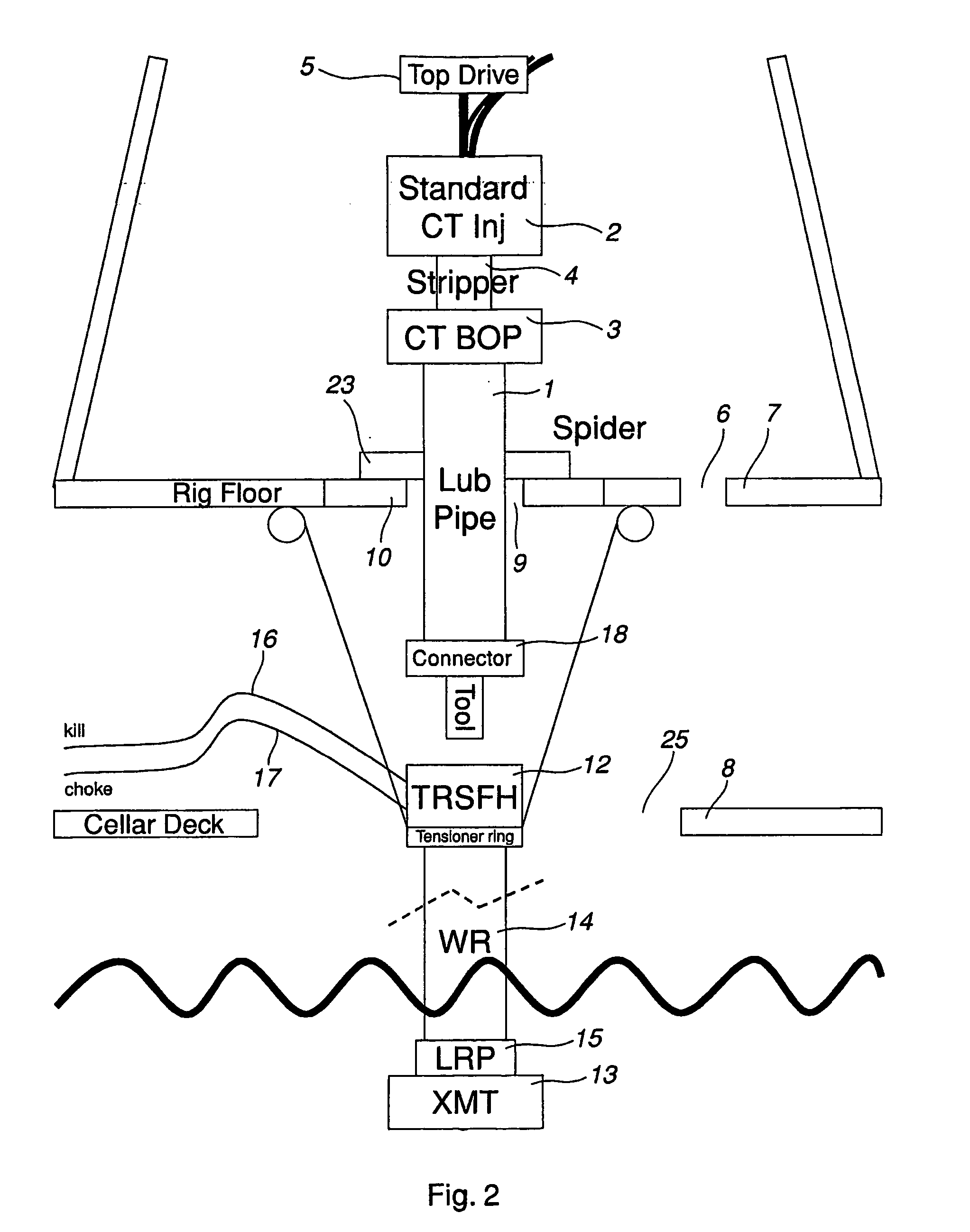

System And Method For Rigging Up Well Workover Equipment

InactiveUS20070284113A1Facilitate riggingSimple and safe processDrilling rodsFluid removalVertical tubeCoiled tubing

A gas and oil recovery system including a vessel, platform or rig, with a rig floor, a riser including a pipe that extends from the vessel, platform or rig to a x-mas tree on top of a well head and via which a wire or coiled tubing is fed down into a well. The riser is movable through an opening in the rig floor, and a surface flow head connected to the riser and to a wire line or coiled tubing equipment. The surface flow head is arranged to be run through the opening in the rig floor.

Owner:VETCO GRAY SCANDINAVIA

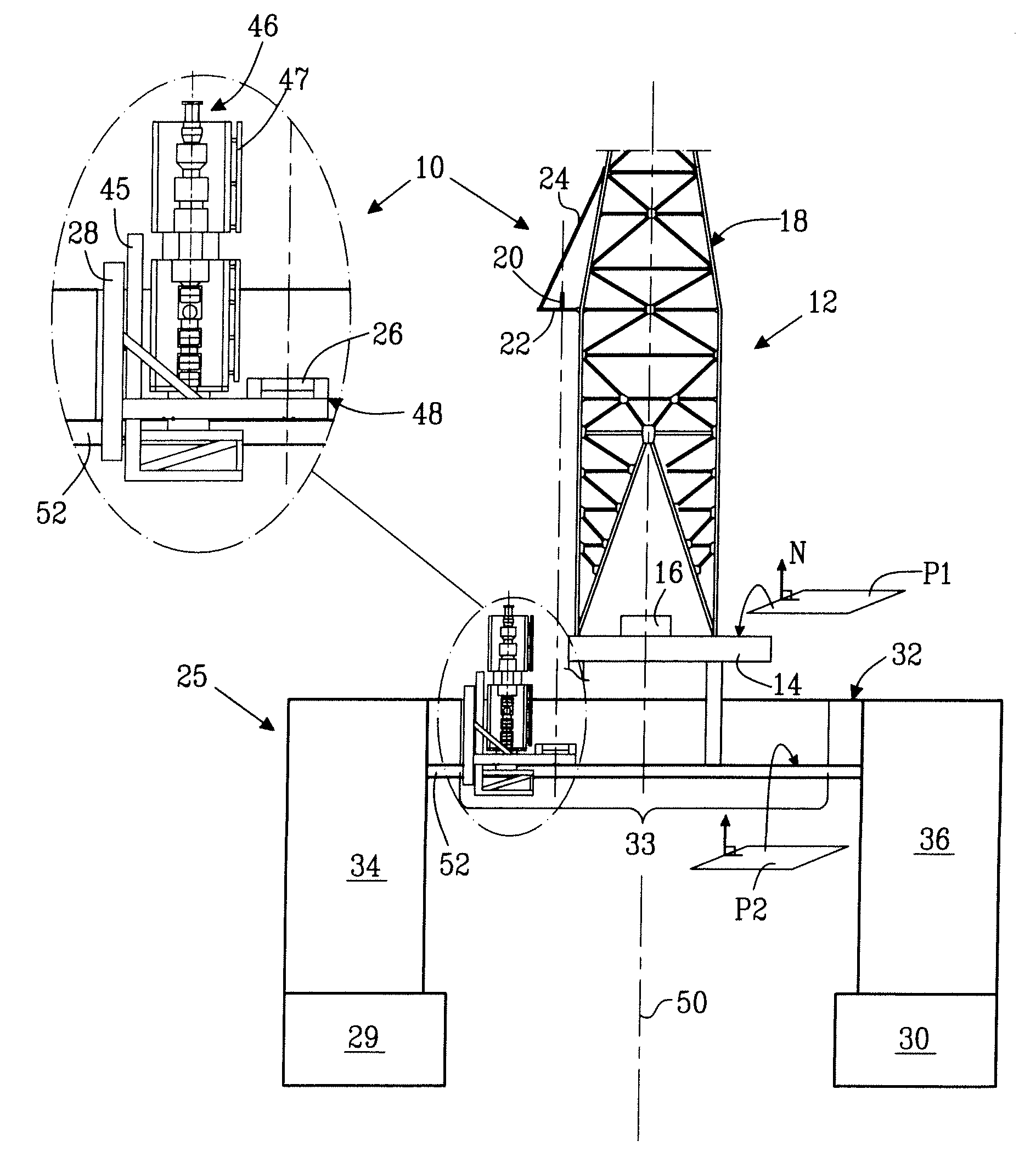

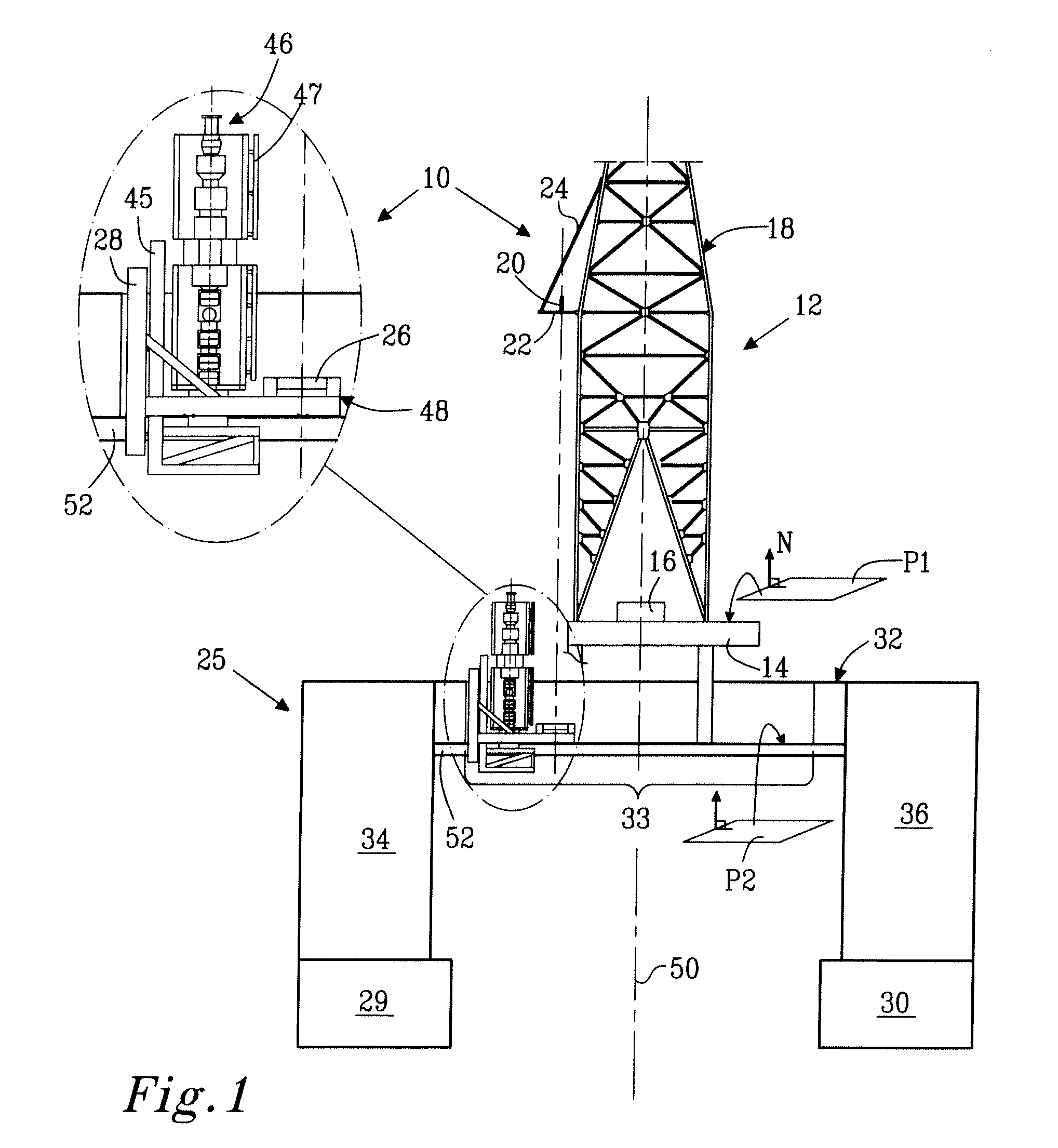

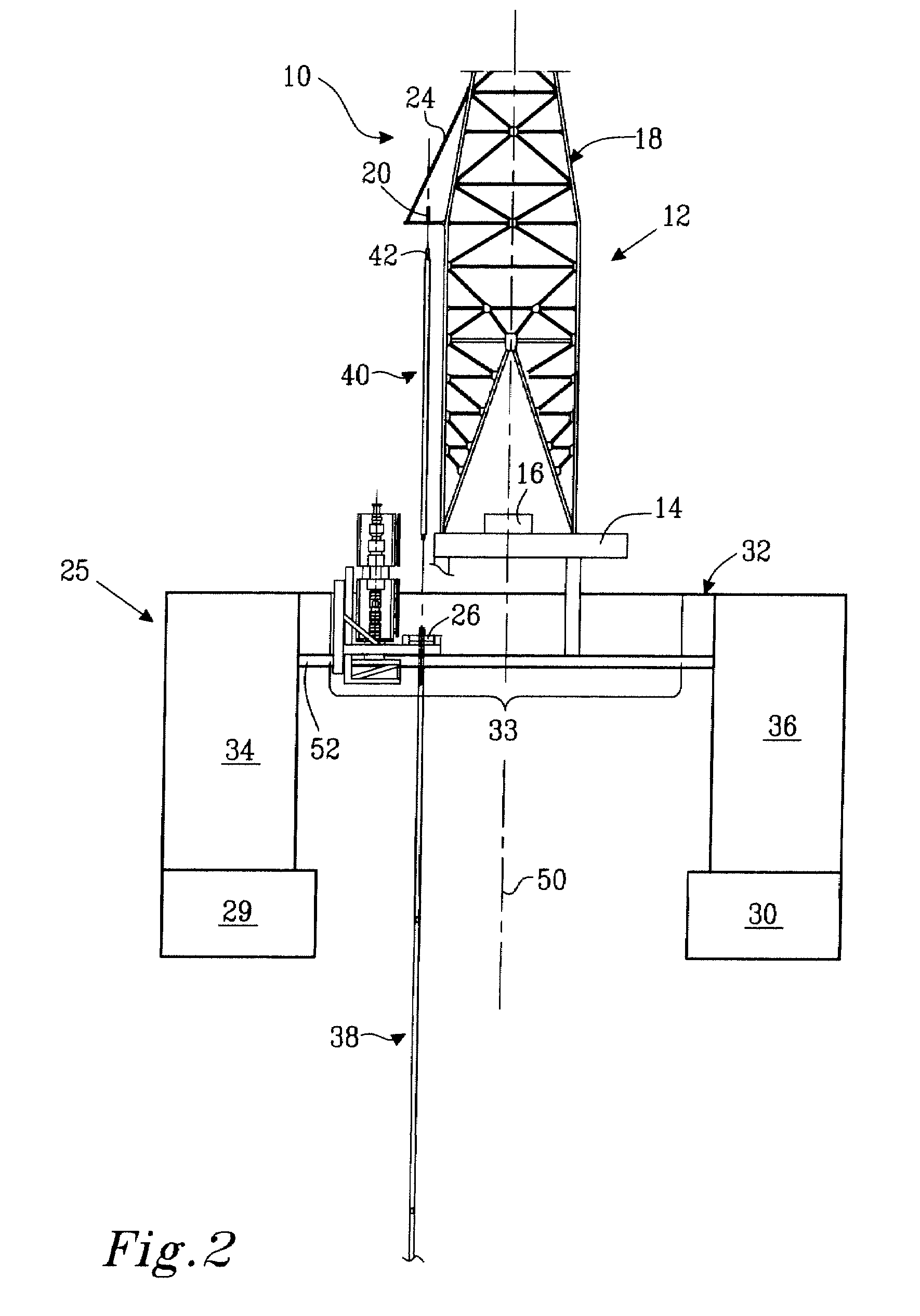

Drilling device

The present embodiments relate to systems for building and / or handling a tubular string of a drilling device. The drilling device comprises a drill floor and a drilling derrick extending from the drill floor. The drill floor has an extension in a first plane (P1) being substantially perpendicular to a first direction (N). The system comprises a suspension device being fixedly attached to the drilling derrick, wherein a projection of the suspension device, in the first direction, onto the first plane (P1), is situated outside the drill floor. The present embodiments also relate to drilling device trolleys arranged to transport a component to and from a drilling center of a drilling device. The present embodiments relate to a use of a drilling device having a drill floor, wherein the drilling device has a suspension device being situated outside the drill floor.

Owner:GVA CONSULTANTS

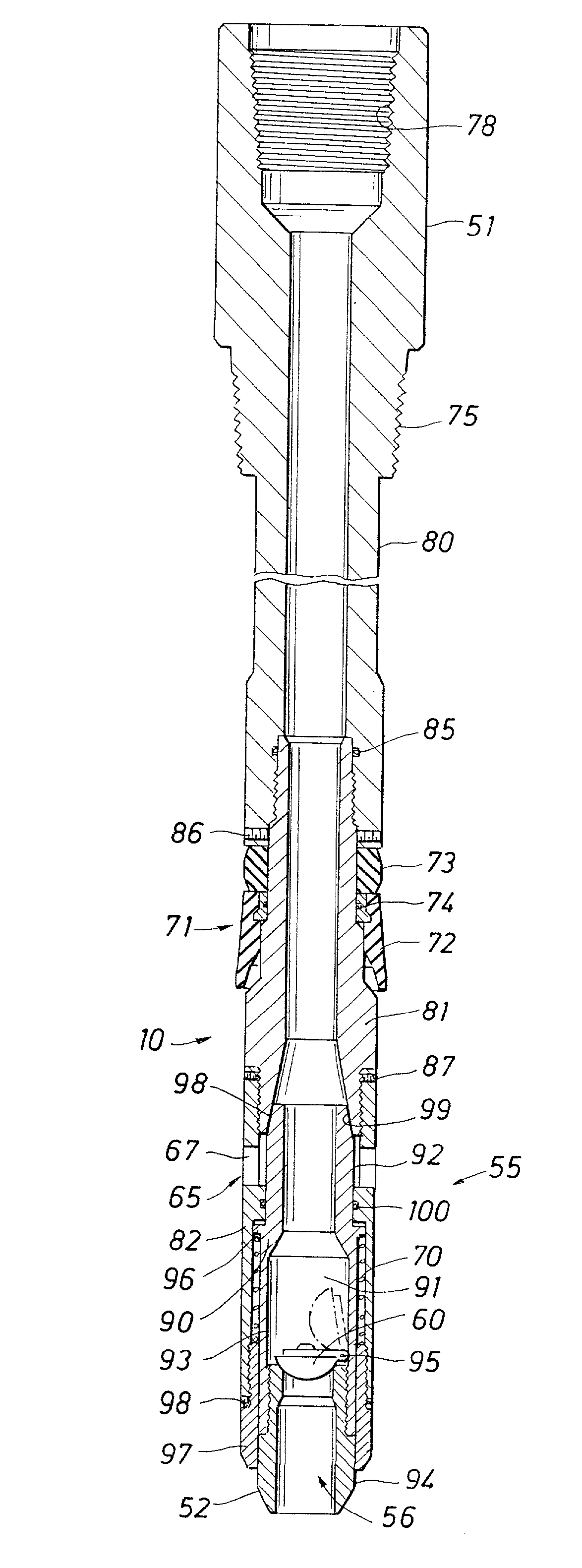

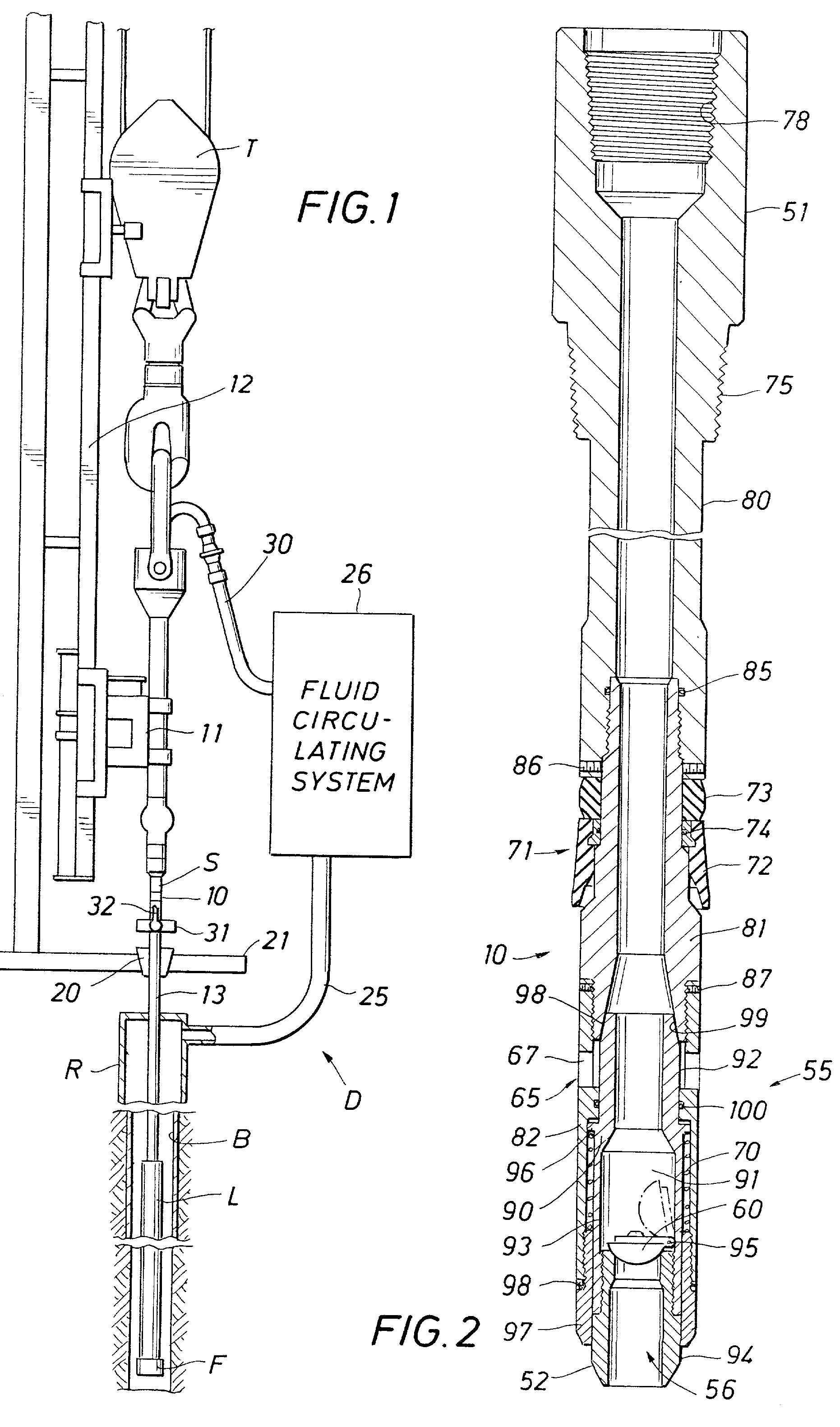

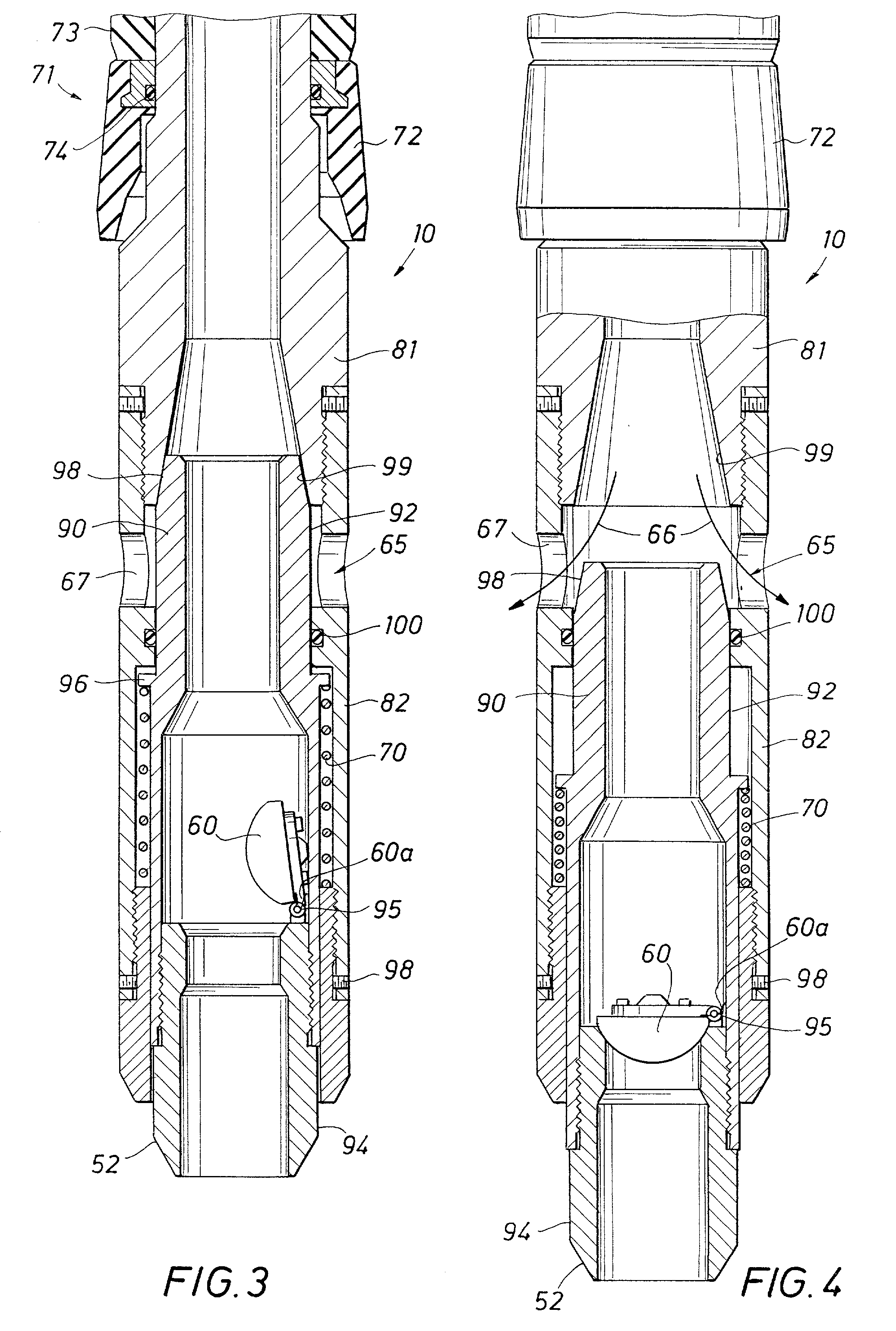

Fill up tool and mud saver for top drives

InactiveUS20020174988A1Prevent leakageMinimal drilling fluid lossDrilling rodsFluid removalTop driveEngineering

A tubular tool body carried at the end of a drilling rig top drive is received within a drill string being used as a landing string to position casing in a wellbore. External threads on the tool body can be mated with the box threads of the drill string to secure the top drive and drill string together for simultaneous drill string movement and fluid circulation. An annular seal carried about the tool body engages and seals with the internal wall of the drill pipe to prevent drilling fluid leakage when the tool body is received within the drill pipe without thread engagement. The tool has an internal check valve that opens to allow back flow of drilling fluid that may be displaced from the drill pipe as the pipe is lowered into the well. The check valve prevents standing fluid in the top drive from spilling onto the rig floor when the tool is withdrawn from the drill string. Pump pressure applied through the top drive axially moves the check valve against a biasing spring to open a bypass through the wall of the tool to permit forward circulation through the drill string and casing. The spring bias force is sufficient to withstand the hydrostatic force exerted by the standing column of fluid in the top drive and associated piping.

Owner:HALLIBURTON ENERGY SERVICES INC

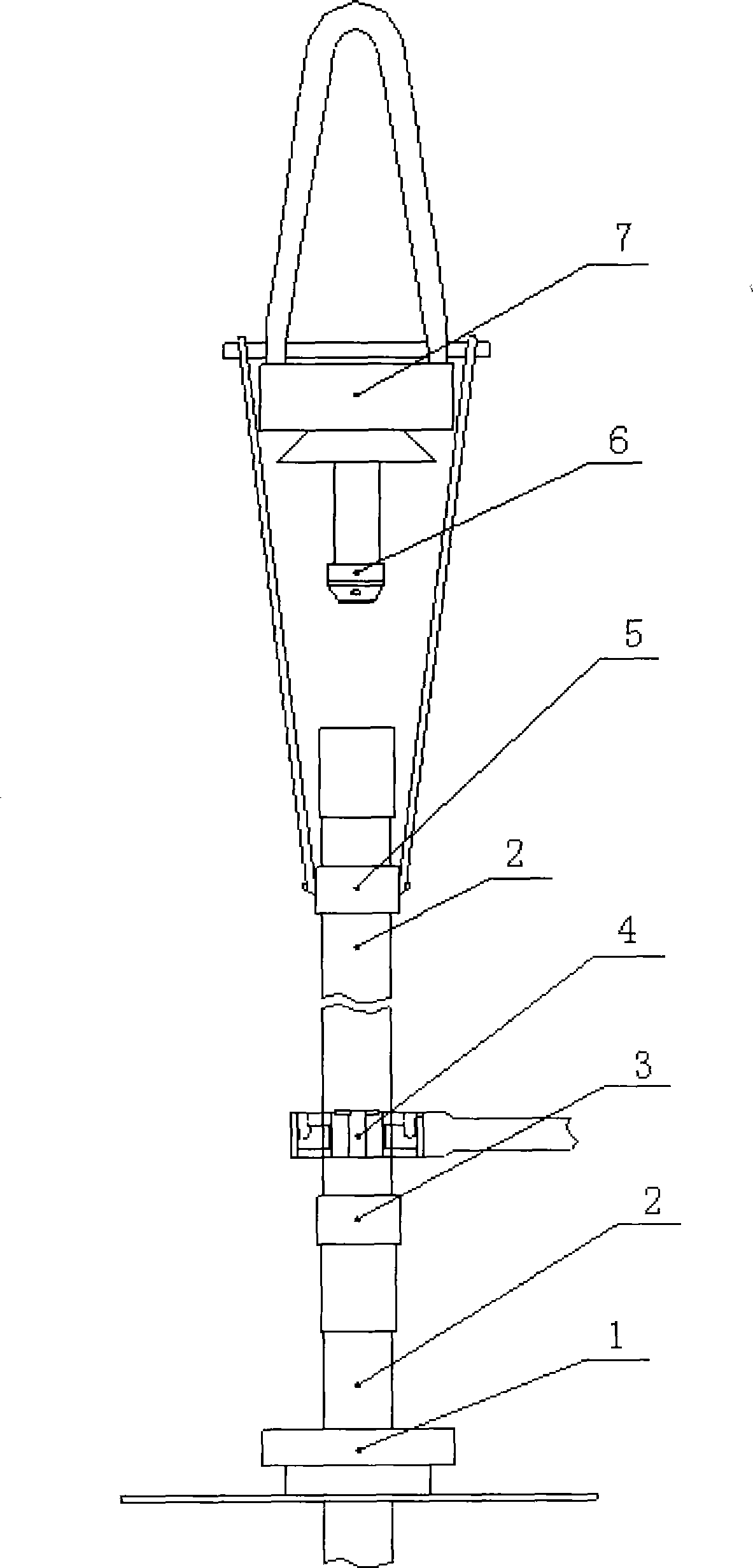

Method for top-driving casing job of drilling apparatus

ActiveCN101487377AHigh degree of automationSimplify the work processDrilling machines and methodsTop driveWell drilling

A method for casing job by using a top drive drilling unit is applied to the petrol cementing technique field, and is characterized in that a casing elevator is used for lifting a single casing which is buckled with a casing string oppositely; a top-driven casing device is driven to tightly clamp the single casing; the top drive drilling unit is driven to revolve, which allows the single casing to be connected with the casing string; an air slips of a drill stand is loosed, which allows a top-driven flying ring and the casing elevator to support the single casing and the casing string; the single casing and the casing string are lowered; the air slips of the drill stand is used for fixing the single casing; slurry is poured to the interior cavities of the single casing and the casing string through a chief axis hydrophthalmia of the top drive drilling unit and a central spindle hydrophthalmia of the top-driven casing device; and finally, all the casing strings are lowered to the well bottom. The method has the advantages of reducing working equipments, simplifying working process, being capable of revolving casing string and cycling slurry timely according to the actual needs, increasing the automatic degree of the casing job, and improving the production efficiency and safety.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling rig structure installation and methods

A method for installing rig structure (e.g. cabin, house, a doghouse) on a drilling rig, the method including: connecting support apparatus to a substructure of a drilling rig, supporting a drilling floor; moving a movement apparatus supporting a rig structure to position it adjacent the support apparatus, by moving movement apparatus on ground adjacent the substructure, moving the support apparatus into a connecting orientation with respect to the structure; connecting raising apparatus to the structure, the raising apparatus connected to the support apparatus; raising the structure up to the drill floor with the raising apparatus; and securing the structure to the support apparatus. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

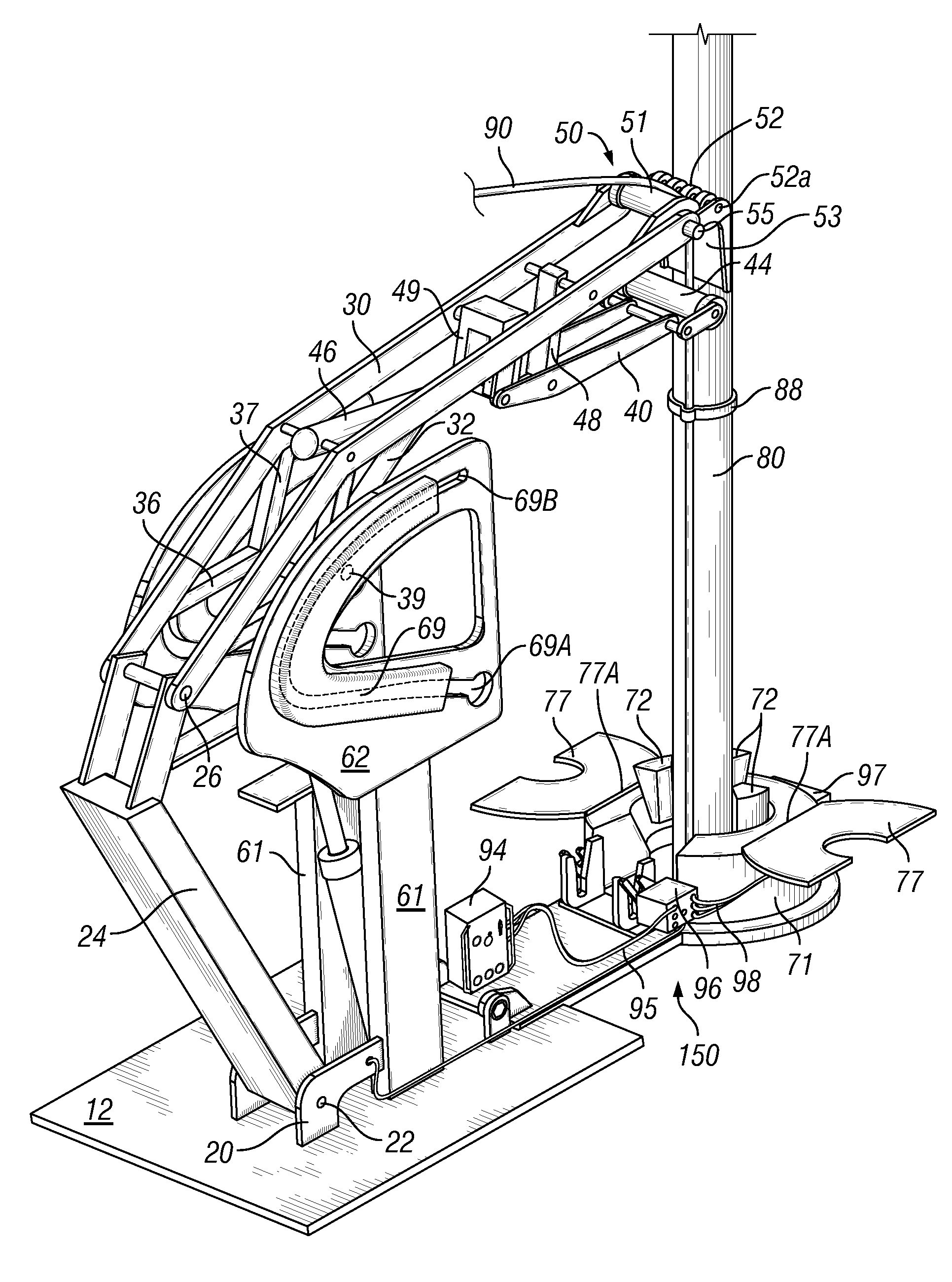

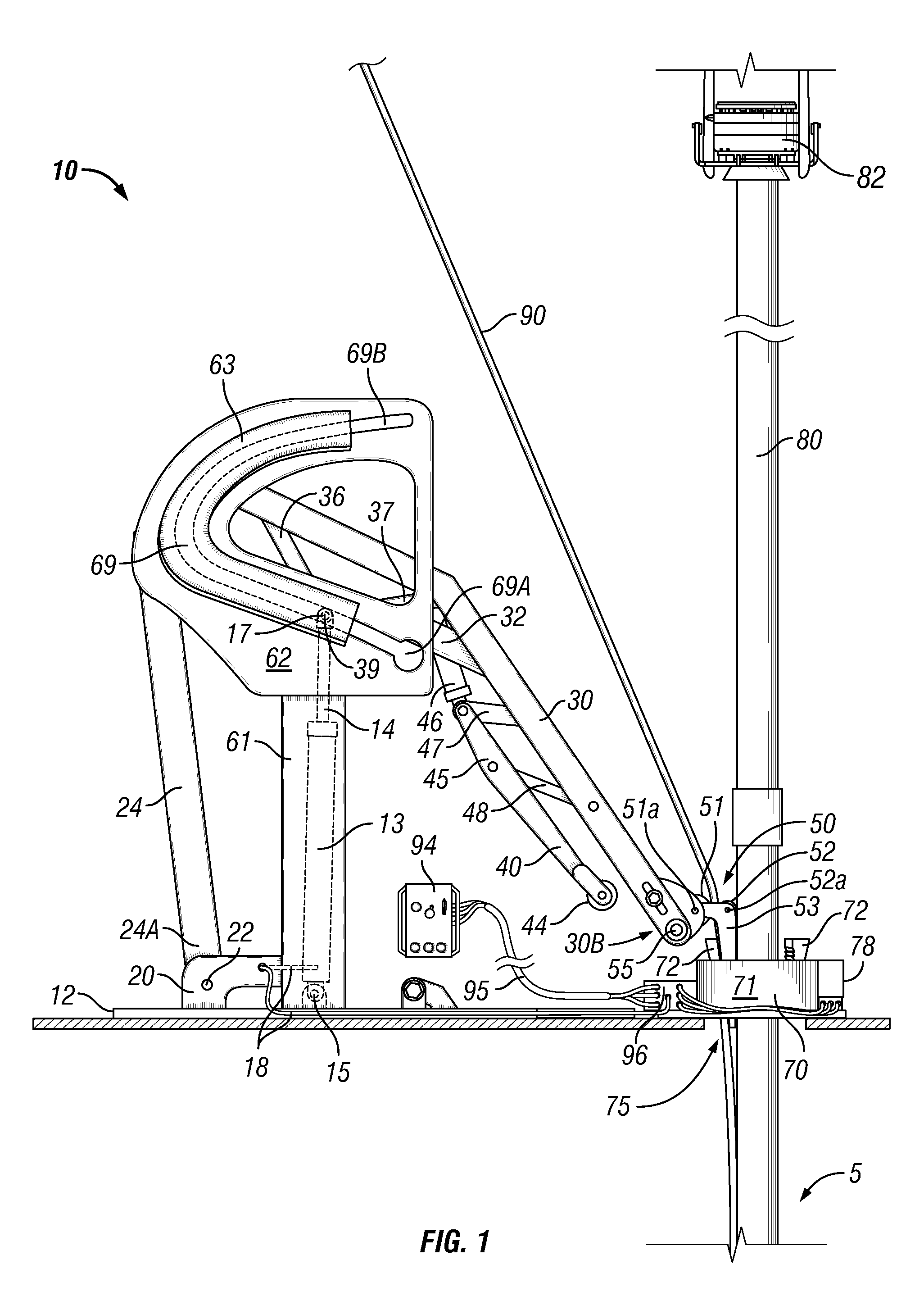

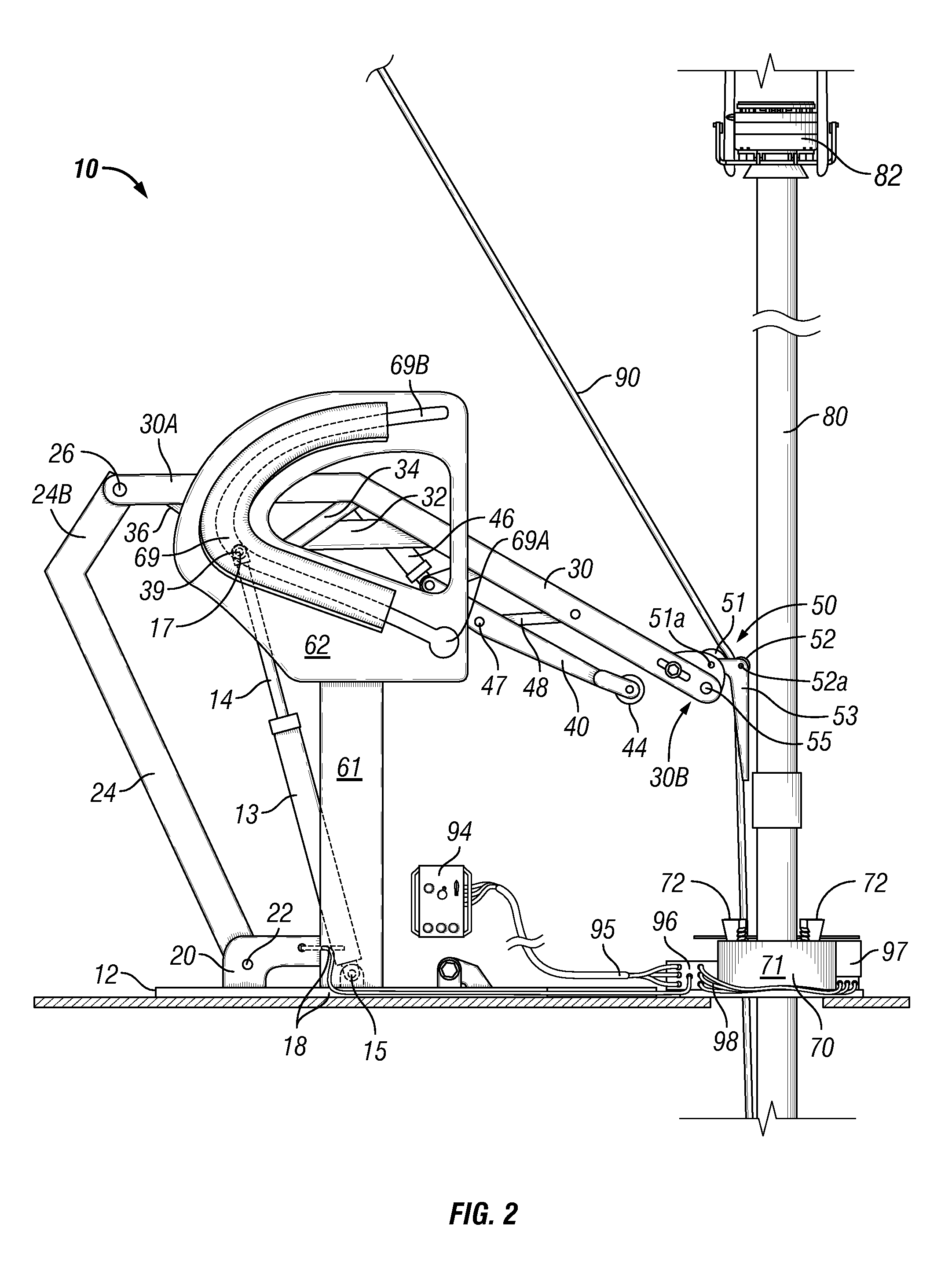

Floor mounted racking arm for handling drill pipe

ActiveUS20160160586A1Well formedDrilling rodsSemiconductor/solid-state device manufacturingHorizontal axisDevices fixation

A racking arm assembly is adapted to be mounted on a drill floor of a drilling rig and includes a lift arm assembly having a first arm that is movably coupled to a vertical support column, wherein the lift arm assembly is adapted to be raised and lowered along a vertical length of the vertical support column during a pipe handling operation. A lift jaw assembly is pivotably coupled to a second arm of the lift arm assembly and includes a lift jaw assembly having a lift jaw gripping apparatus that is adapted to grip and fixedly hold a drill pipe stand proximate a pin end of the drill pipe stand during the pipe handling operation. The lift jaw gripping apparatus is further adapted to be rotated relative to the lift arm assembly about a substantially horizontal axis while the lift jaw gripping apparatus is fixedly holding the drill pipe stand.

Owner:NAT OILWELL VARCO LP

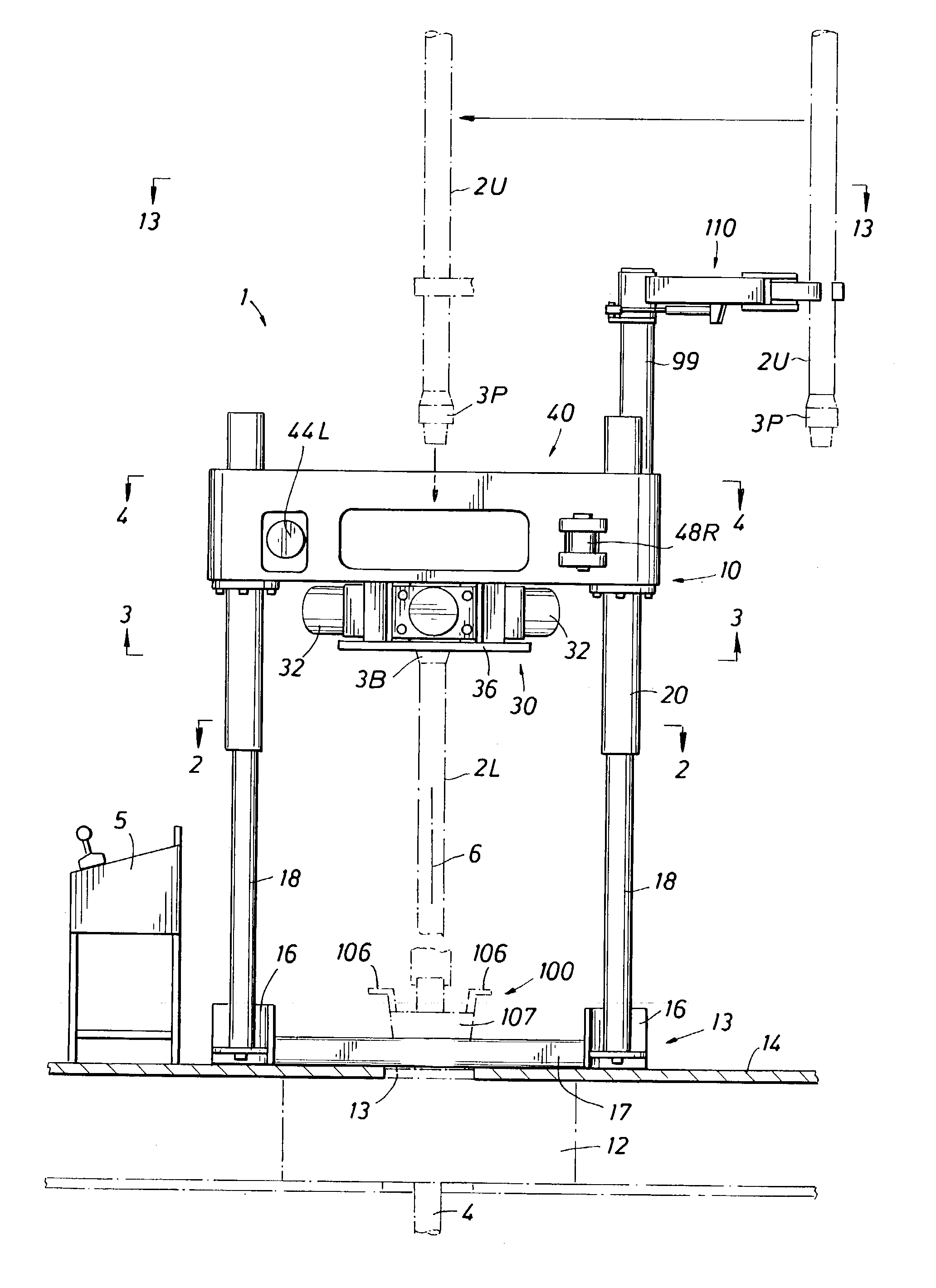

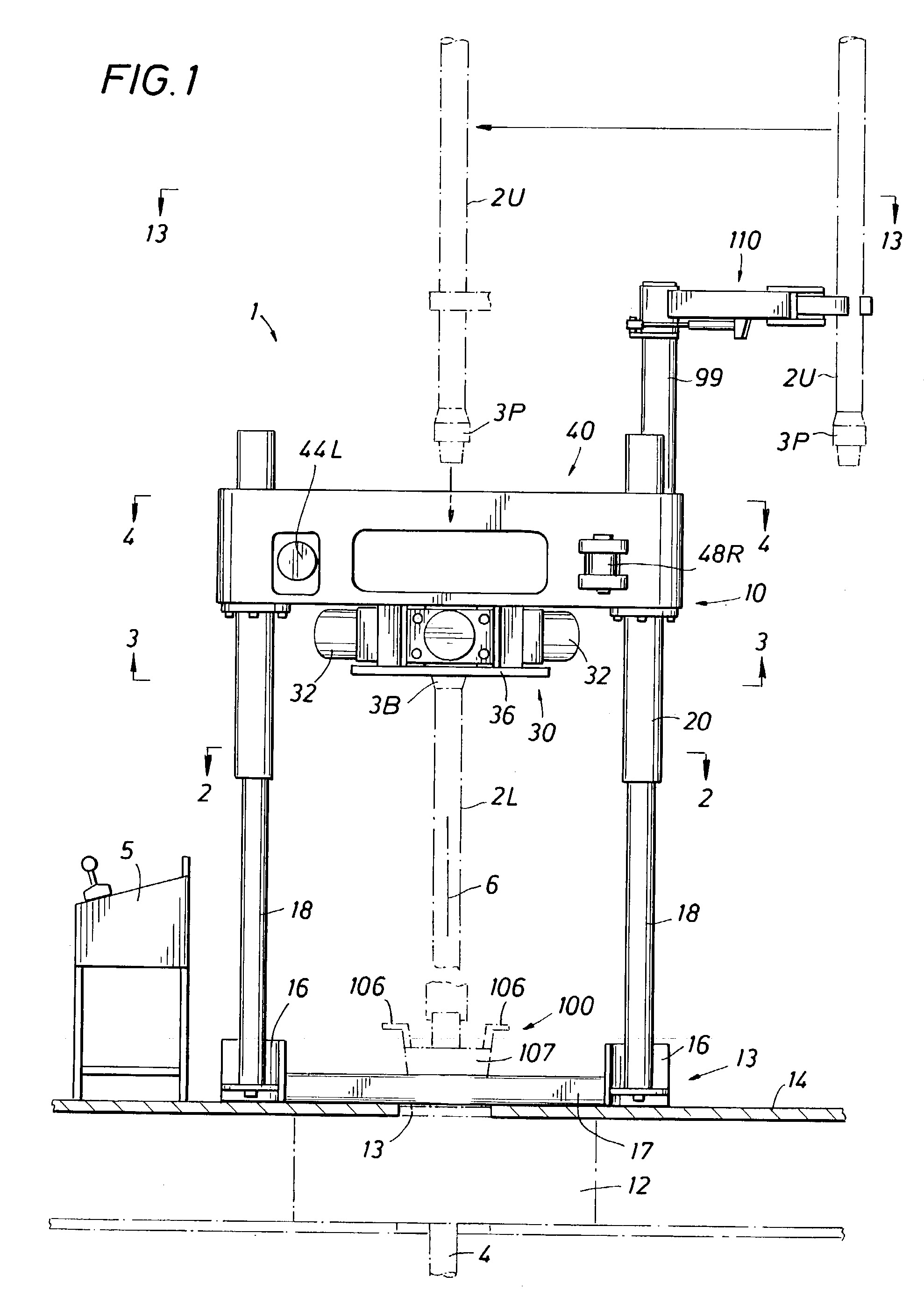

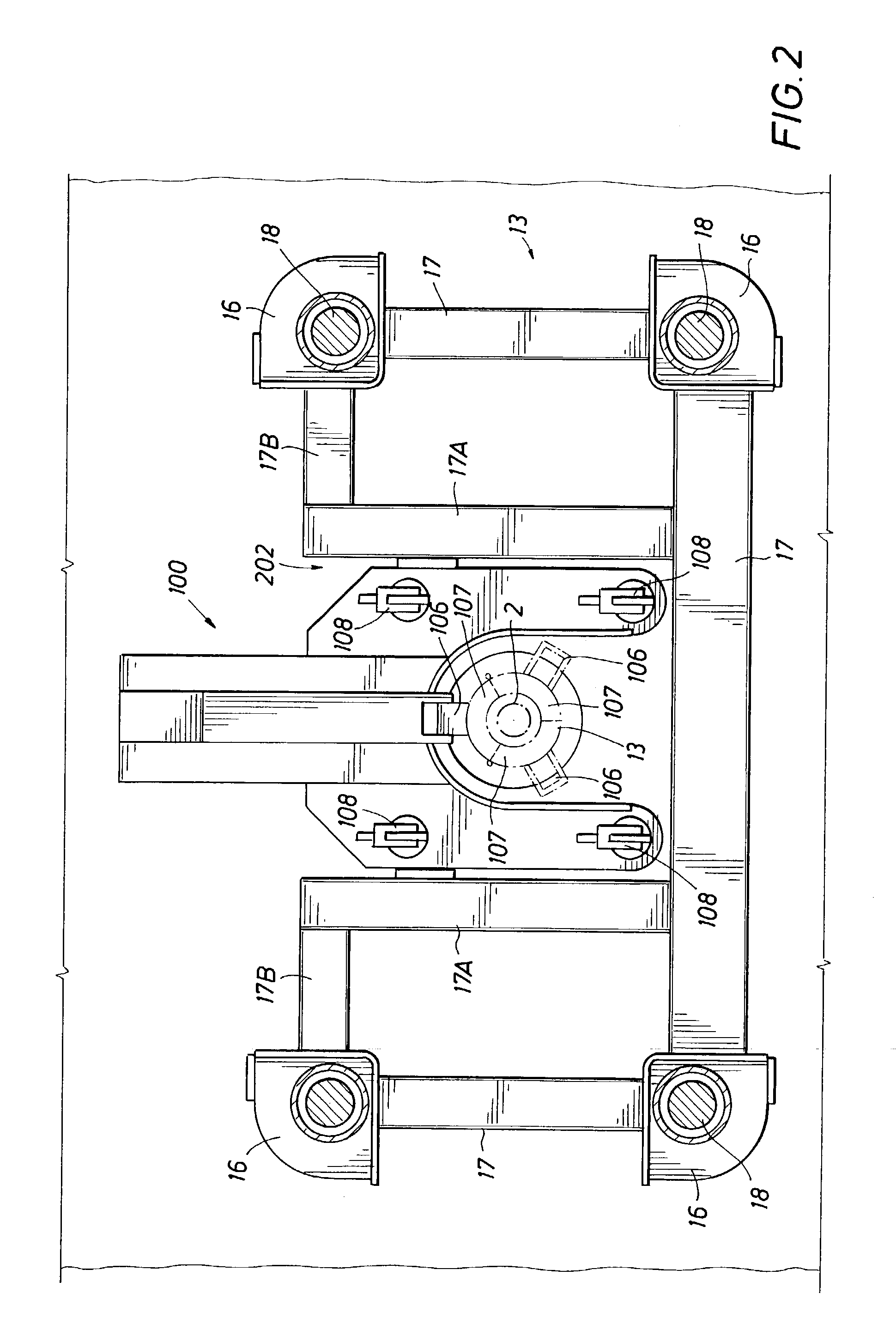

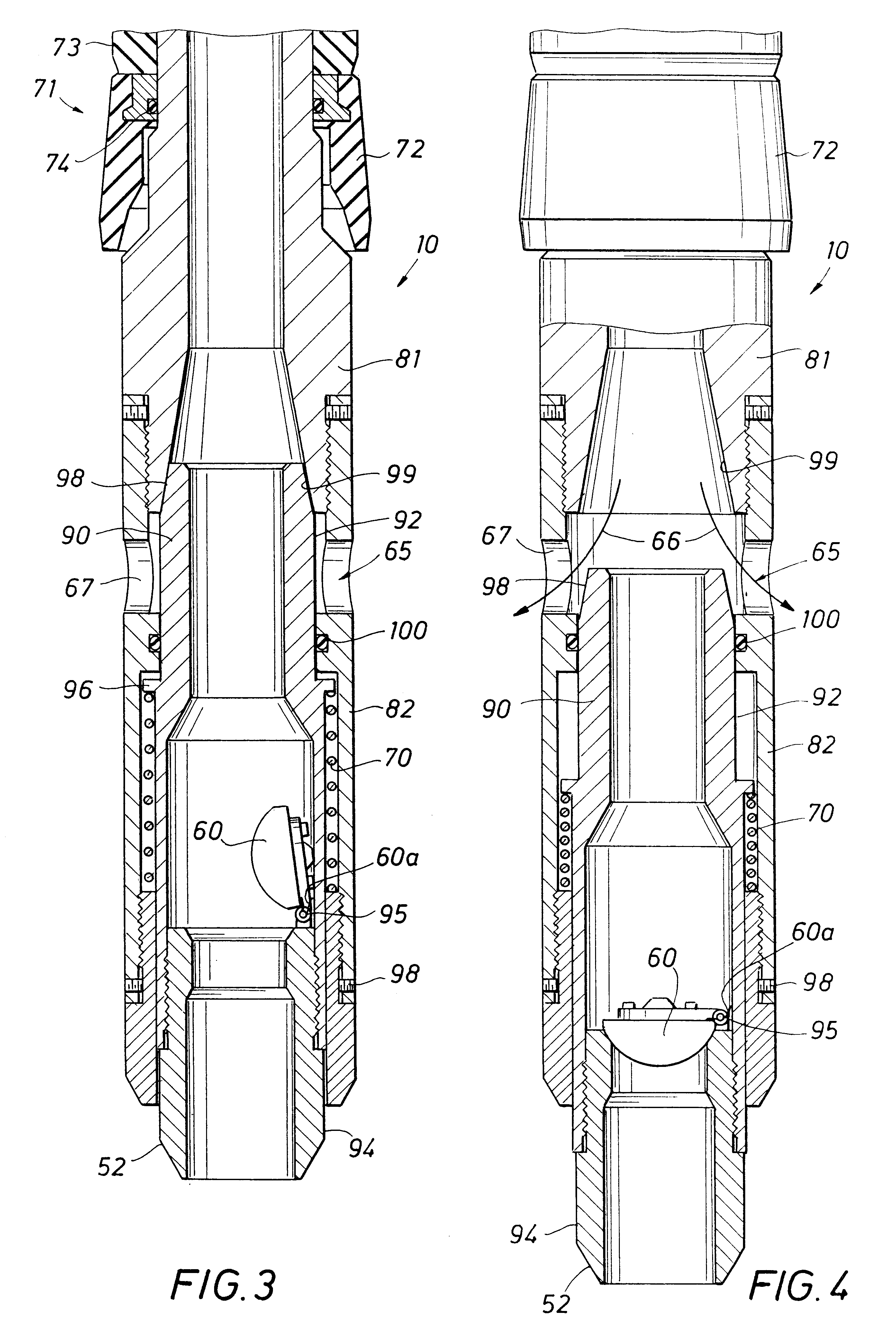

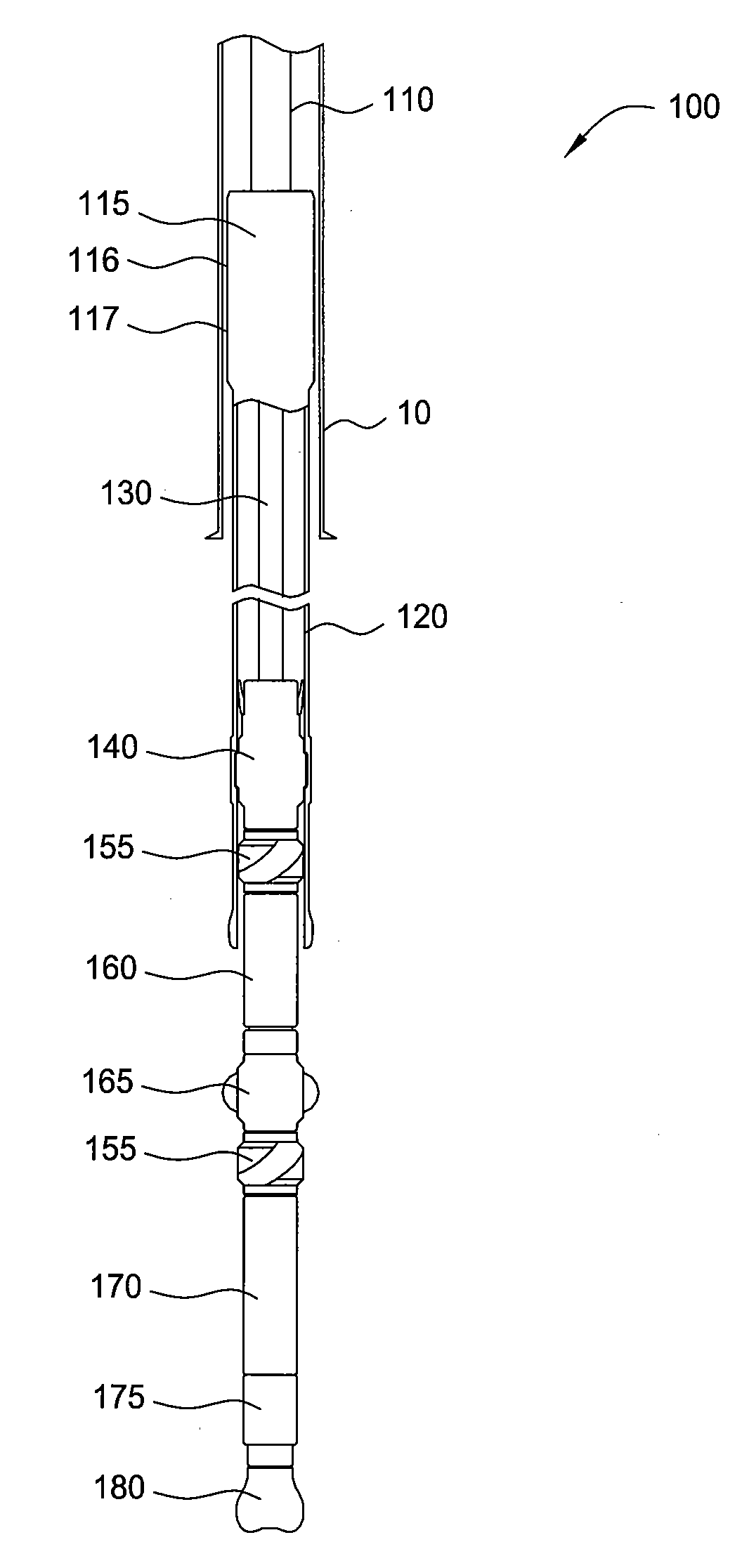

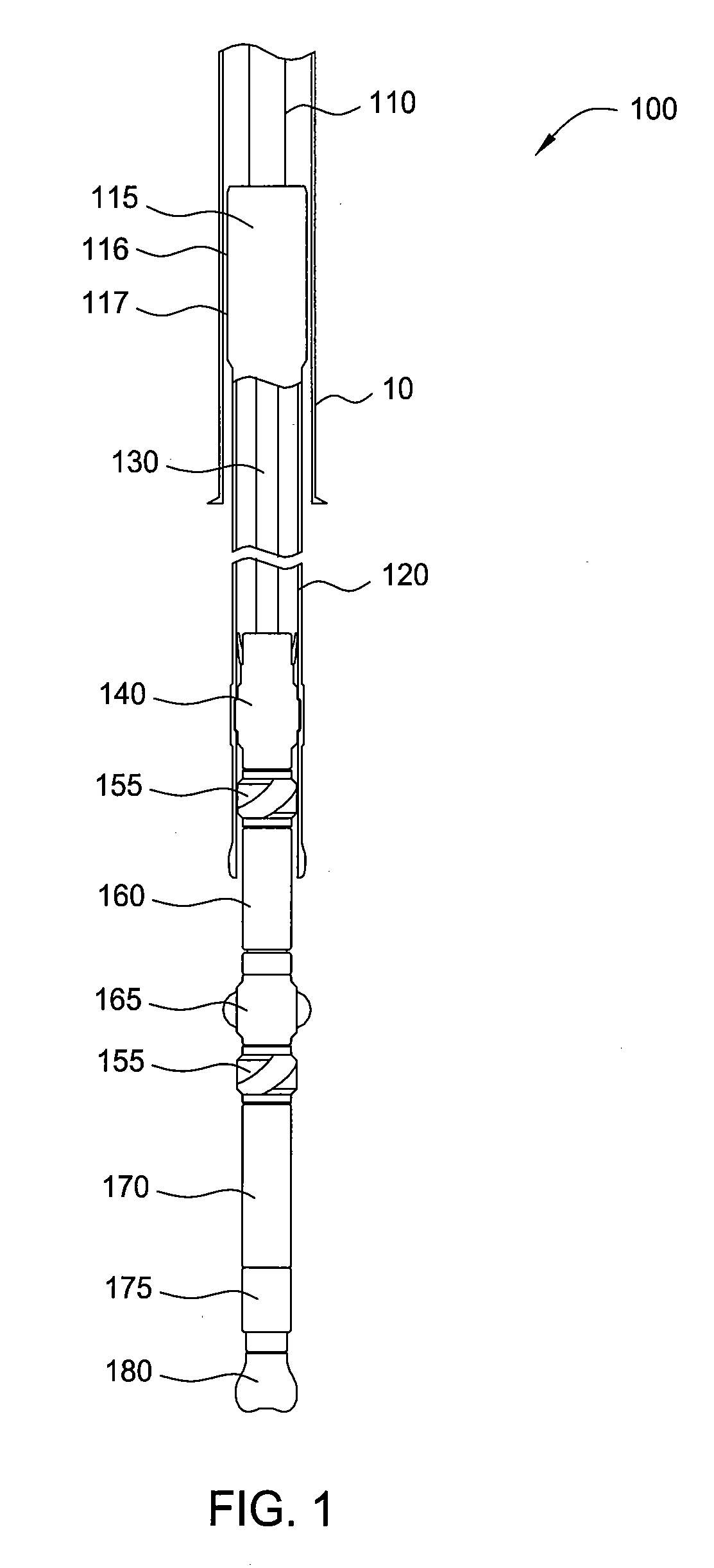

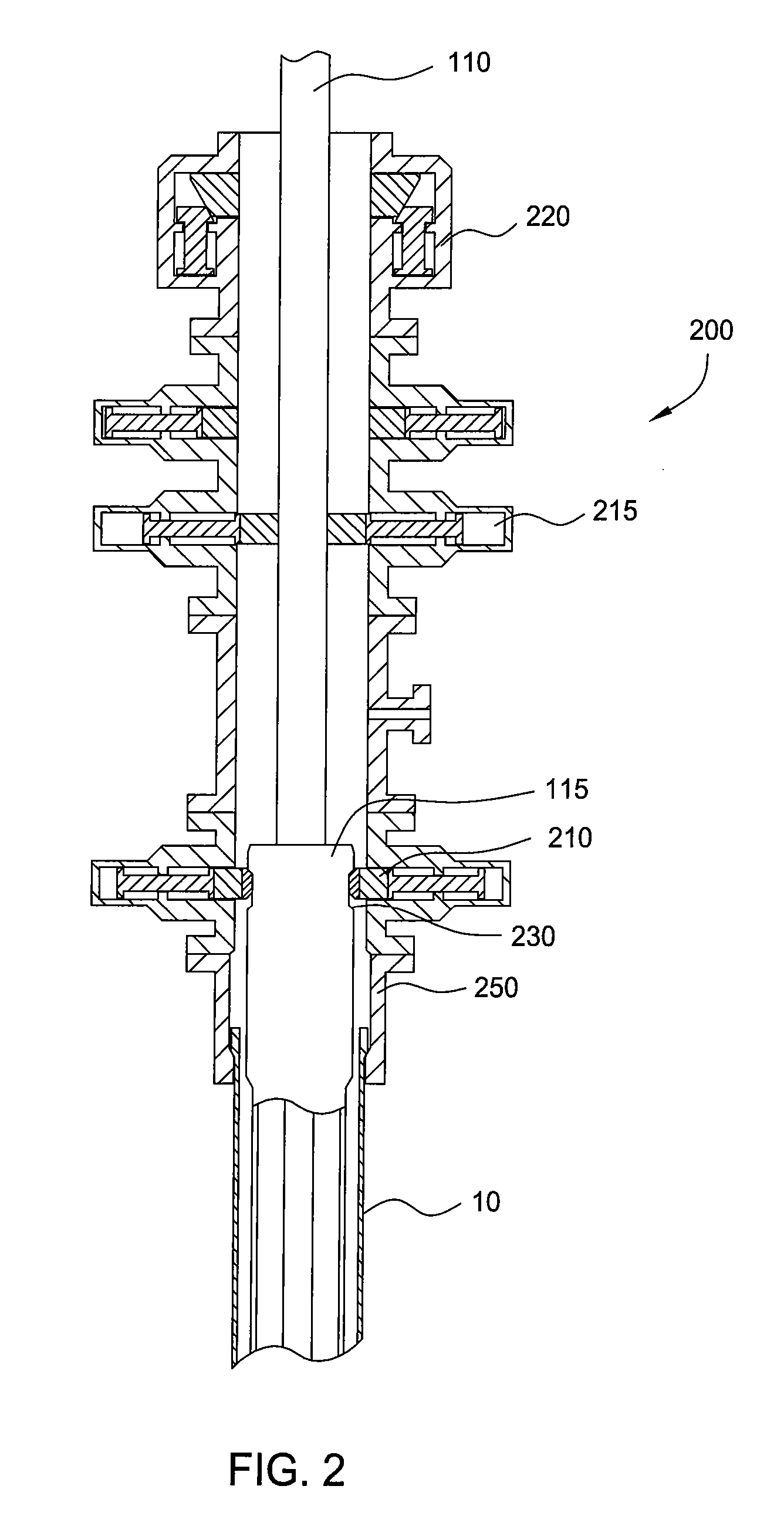

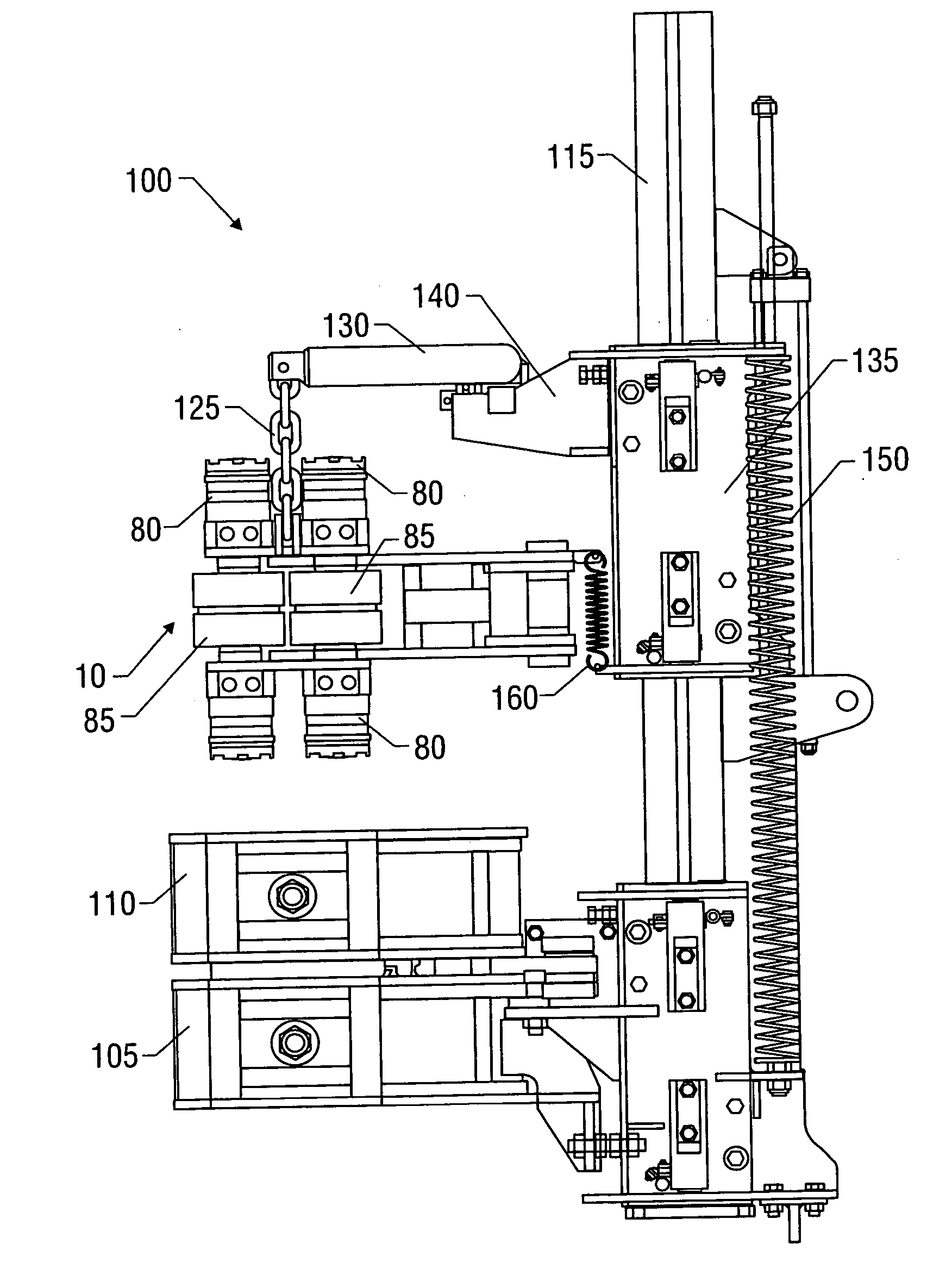

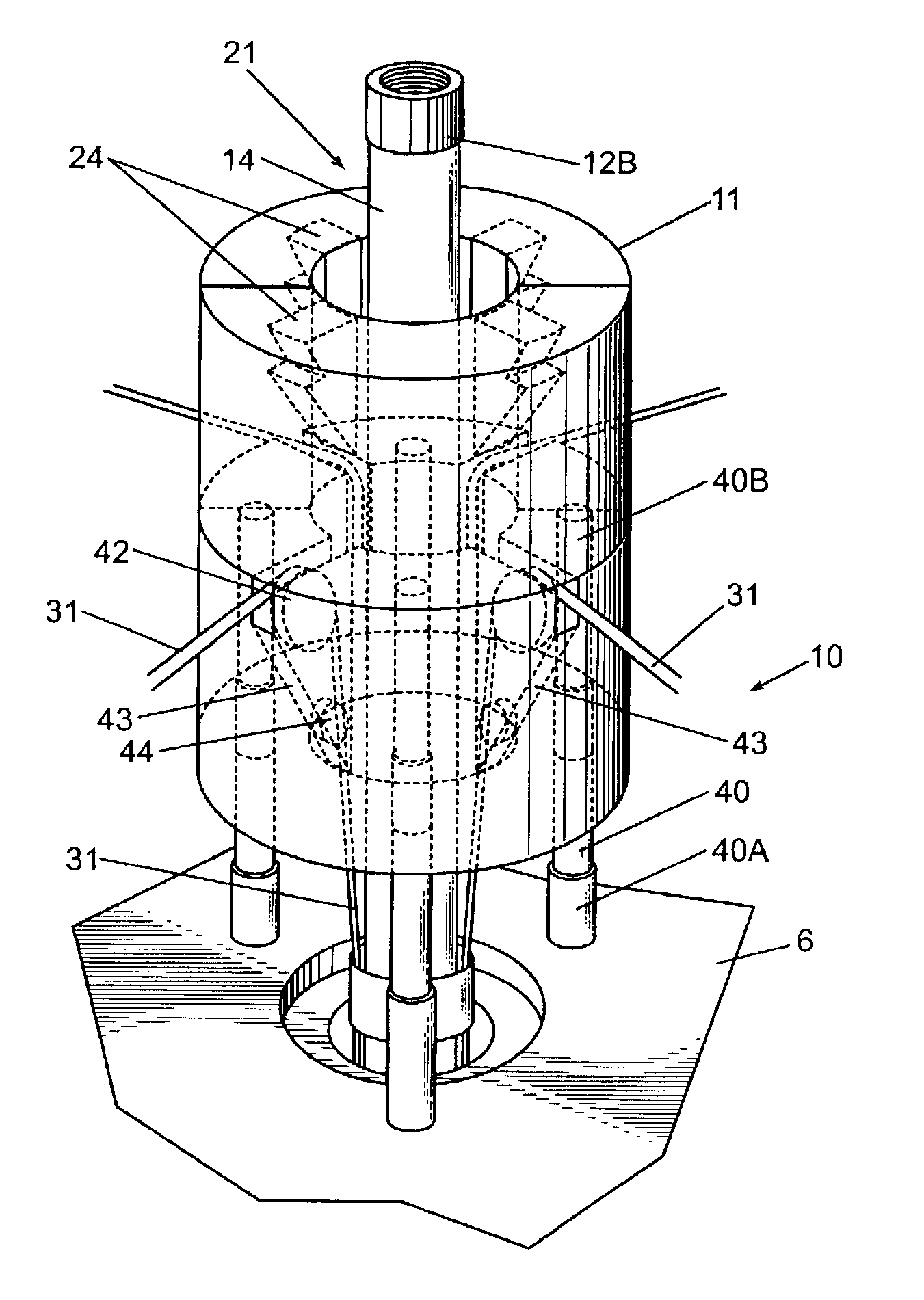

Method And Apparatus To Position And Protect Control Lines Being Coupled To A Pipe String On A Rig

A control line positioning apparatus (10) comprising a retainer arm (30), having a control line retainer thereon, is driven between a removed position with the retainer arm (30) positioned adjacent to a base and adjacent to a rig floor and a raised position with the retainer arm (30) raised by a drive member to a raised position to hold one or more control lines (90) along a portion of the length of a pipe string (80) to facilitate application of a clamp to secure the control lines to the pipe string (80). In one embodiment, the retainer arm (30) may be releasably secured to a docking assembly (50) disposed adjacent to the pipe engaging apparatus and adjacent to a rig floor. In one embodiment, the control line positioning apparatus may comprise an ascending control line pathway (112) comprising a plurality of rolling members to direct one or more control lines to a retainer assembly.

Owner:FRANKS INT

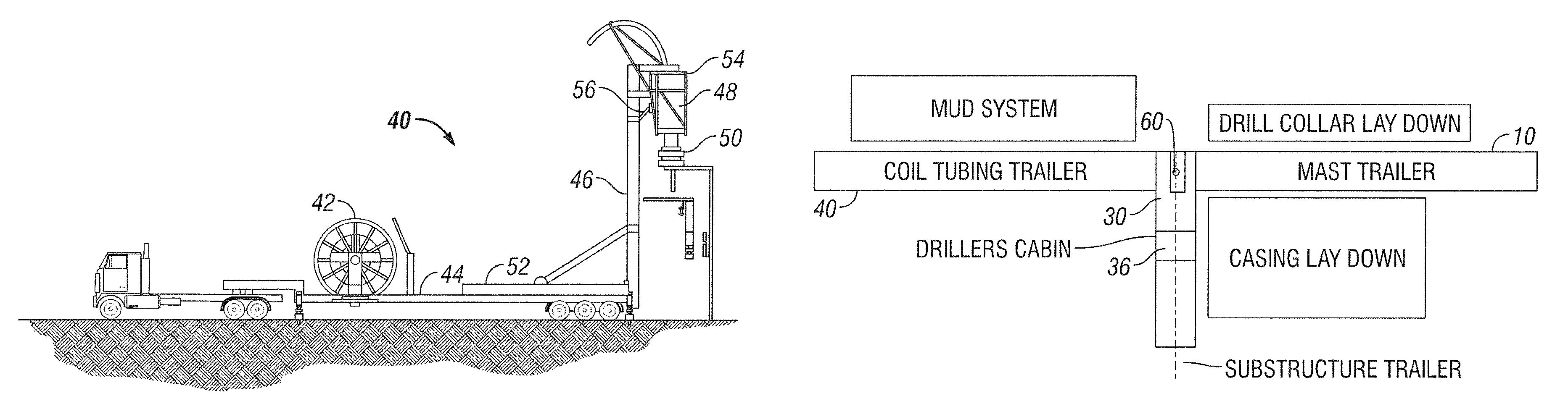

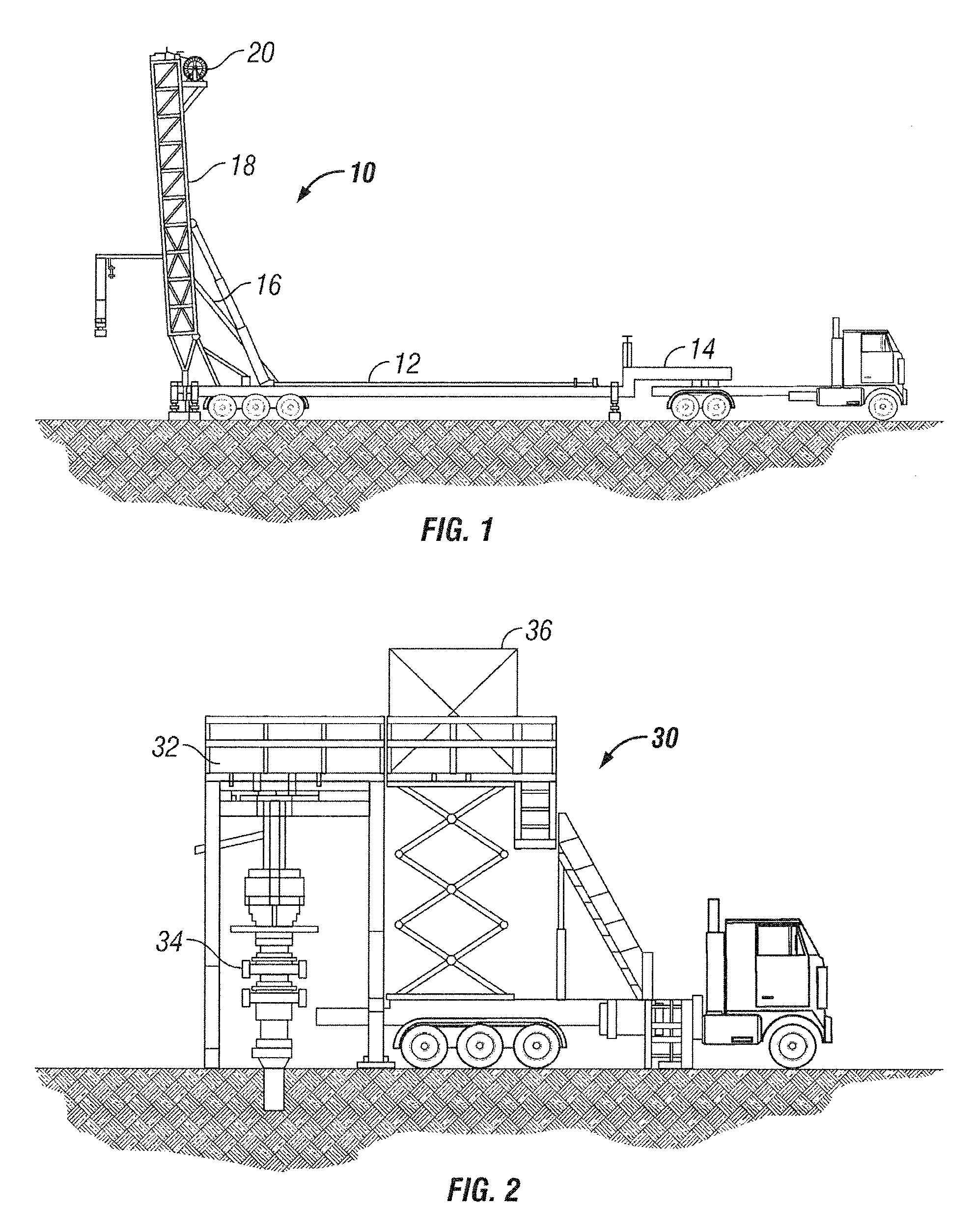

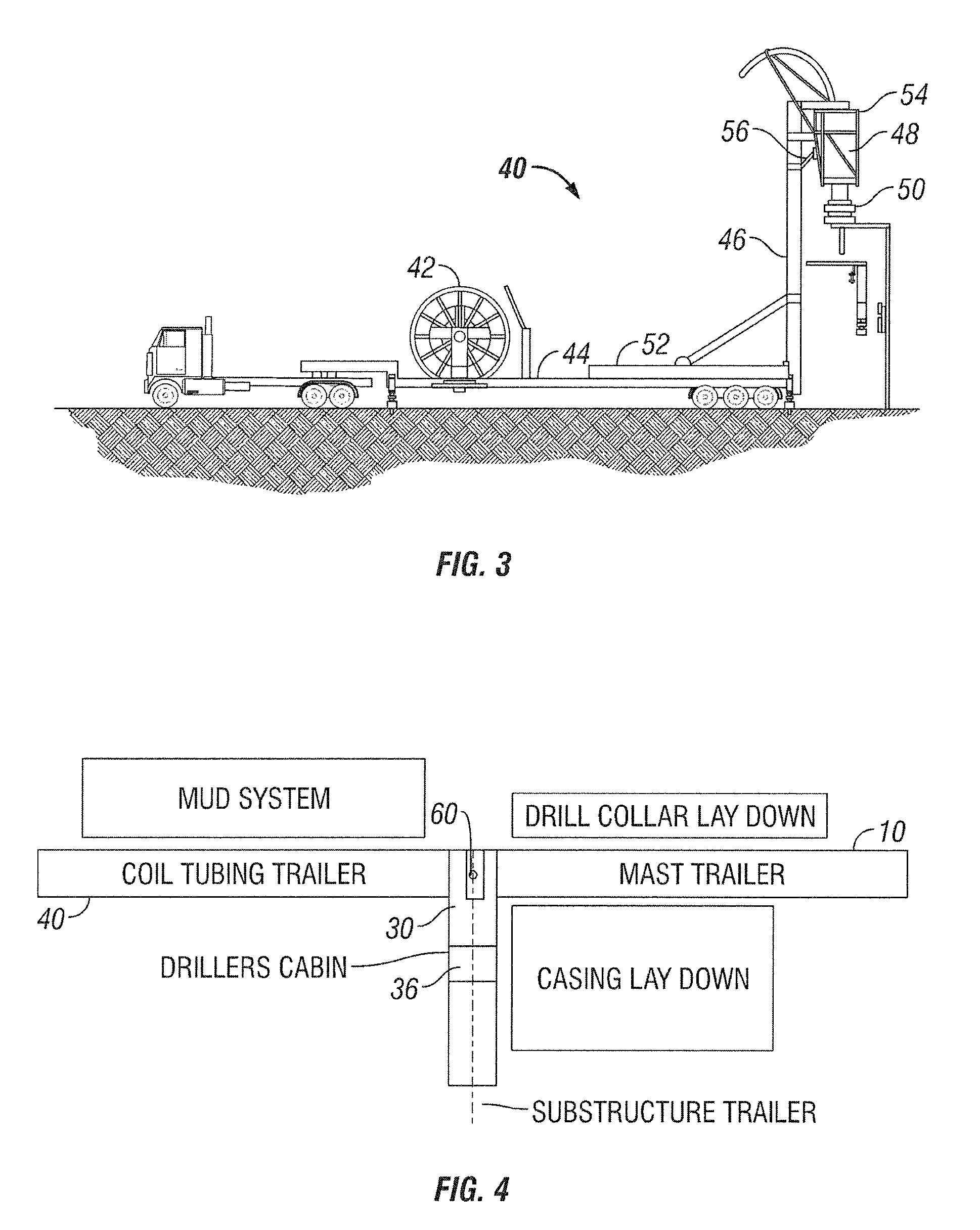

Coiled tubing drilling rig

The present invention provides a rig capable of both coiled tubing and conventional drilling. The rig comprises a mast unit having a drilling mast and a catwalk. The mast unit is adapted for rotary drilling and casing operations. The rig further comprises a drill floor unit adapted to house a drilling cabin and hold a drilling BOP stack while in transport. The rig additionally comprises a coiled tubing unit that is controllable from the drilling cabin.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com