Drilling well control parameter intelligent monitoring system

An intelligent monitoring and drilling technology, applied in the automatic control system of drilling, drilling equipment, wellbore/well components, etc., can solve the problems of large pumping metering flow error, poor repeat stability, high false alarm rate, etc. The effect of surging, ensuring drilling, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, structure and embodiment of the present invention are further described:

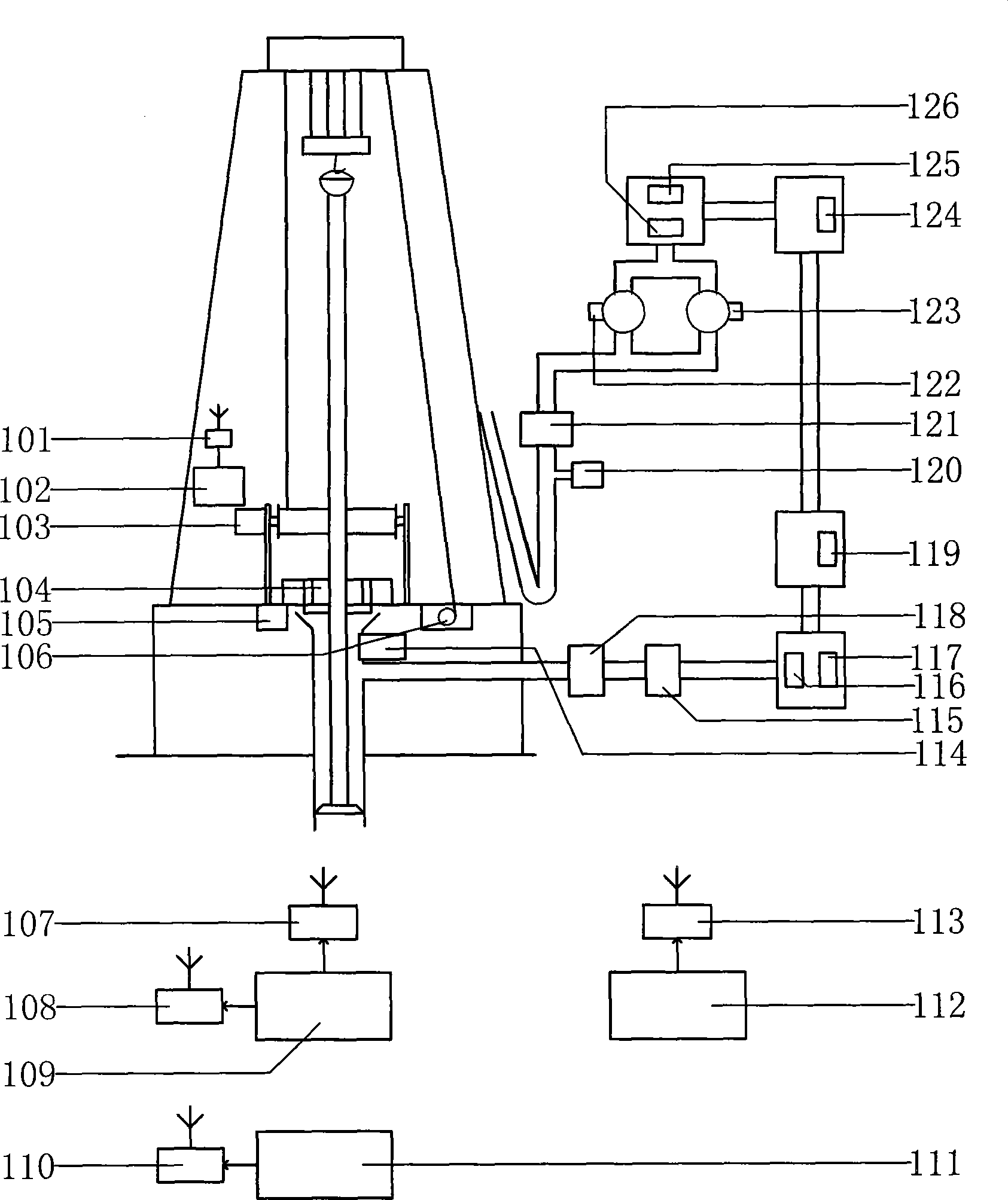

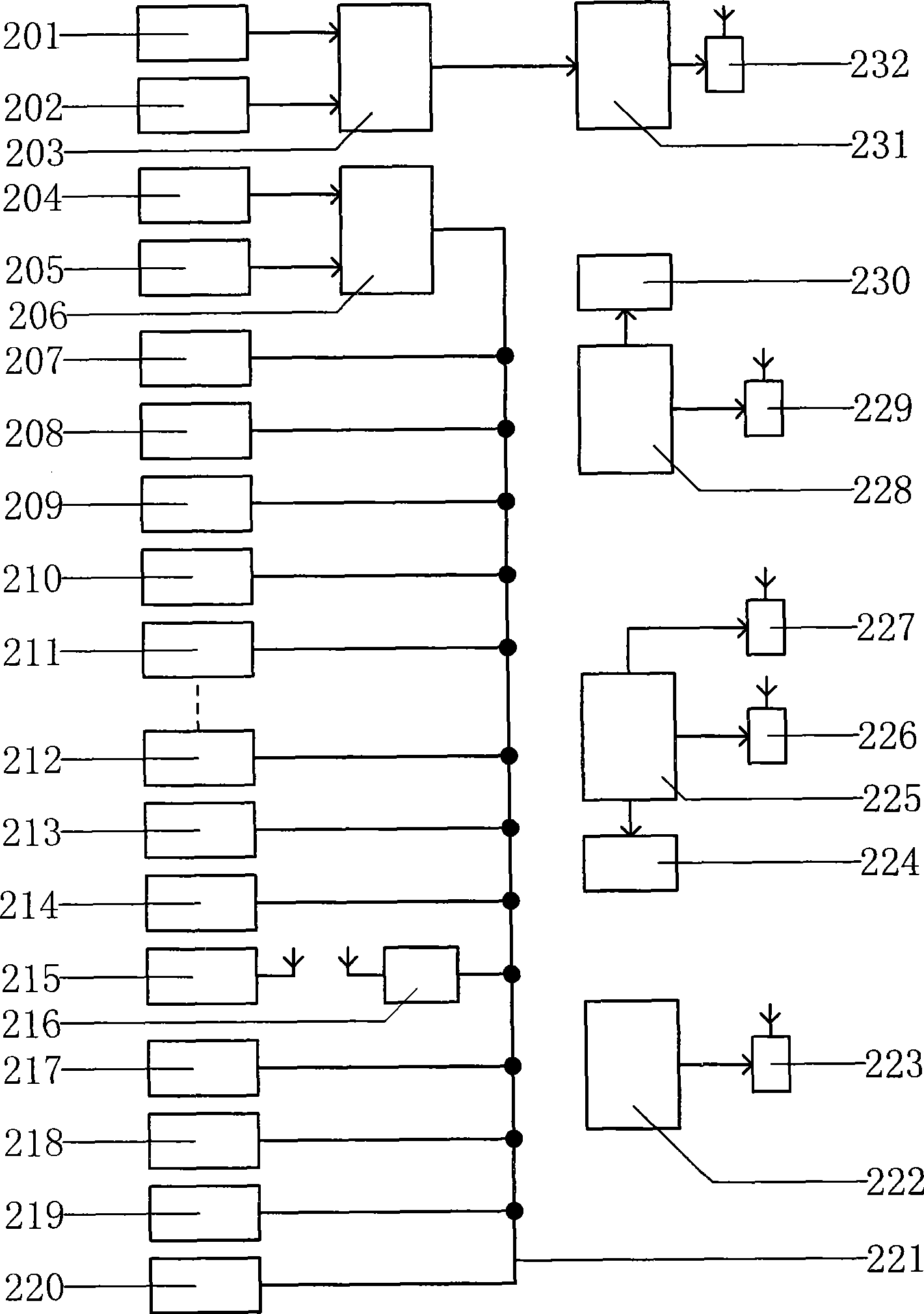

[0041] Such as figure 1 As shown, it is the overall structure diagram of the intelligent monitoring system for drilling well control parameters, in which, the data transmission station 101 of the drill floor parameter display and the drill floor parameter display 102 are installed in the driller's room of the drill floor, and the depth rotary encoder 103 is installed on the shaft of the drawworks drum Above, the square tile type turntable torque meter 104 is installed in the turntable square tile, the turntable torque turntable speed receiver 105 is installed at the bottom of the turntable; the suspension weight sensor 106 is installed on the steel wire dead rope tensioner; the host data transmission station 107, the host GPRS data transmission The radio station 108 and the host computer 109 are installed in the duty room of the well team headquarte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com