Patents

Literature

1005 results about "Liquid column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

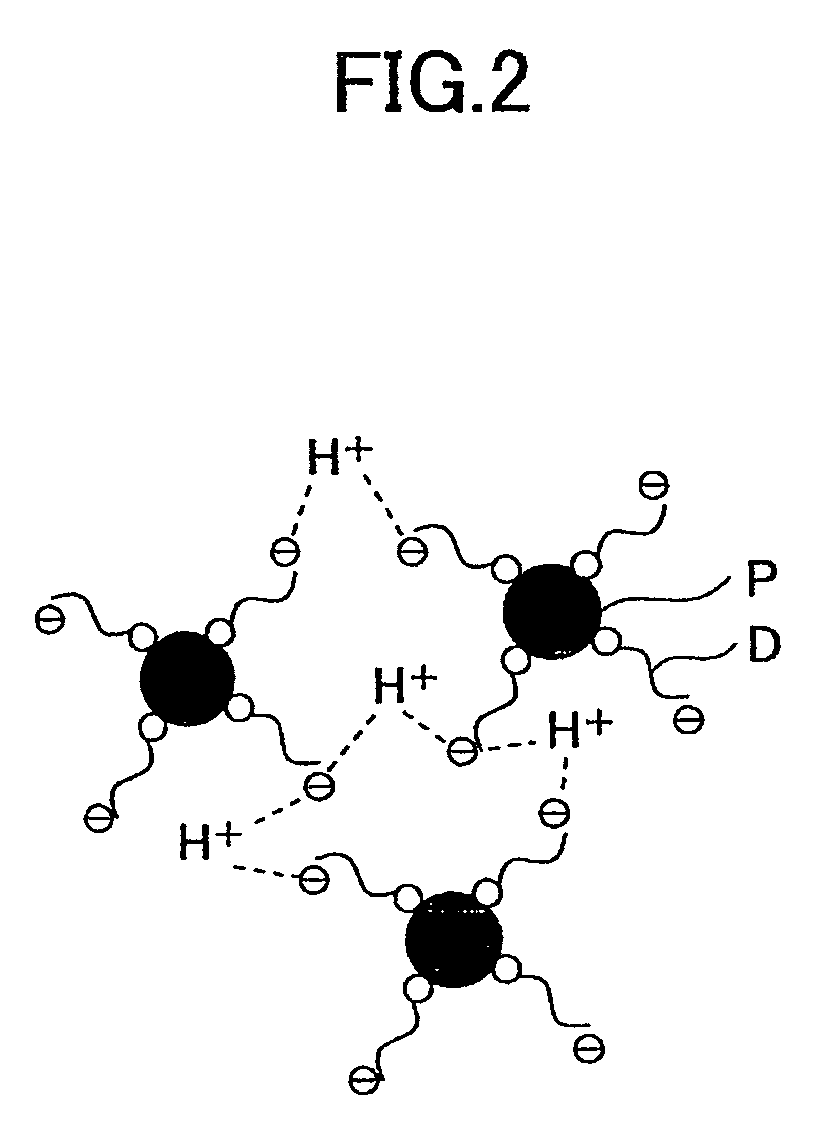

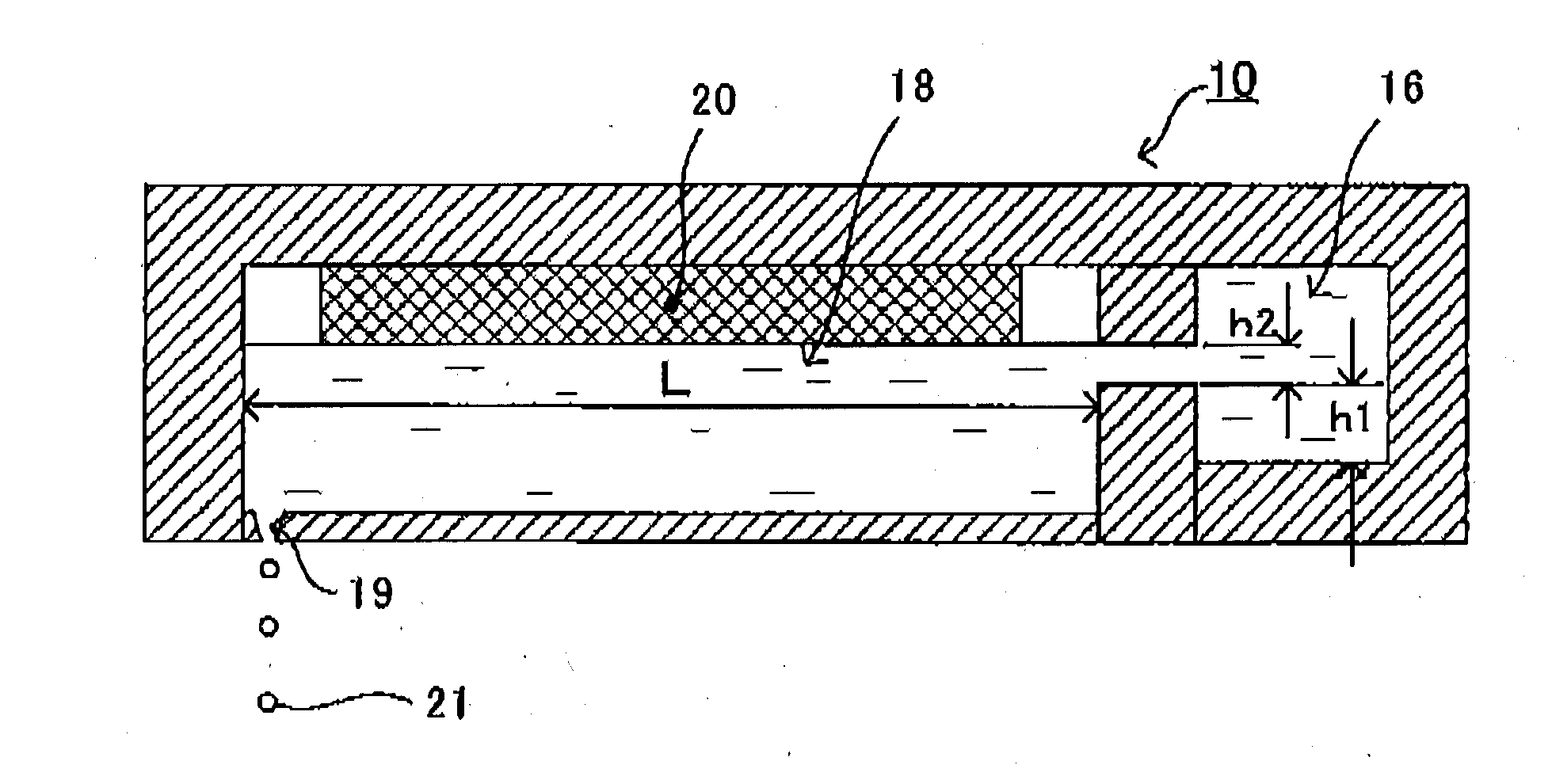

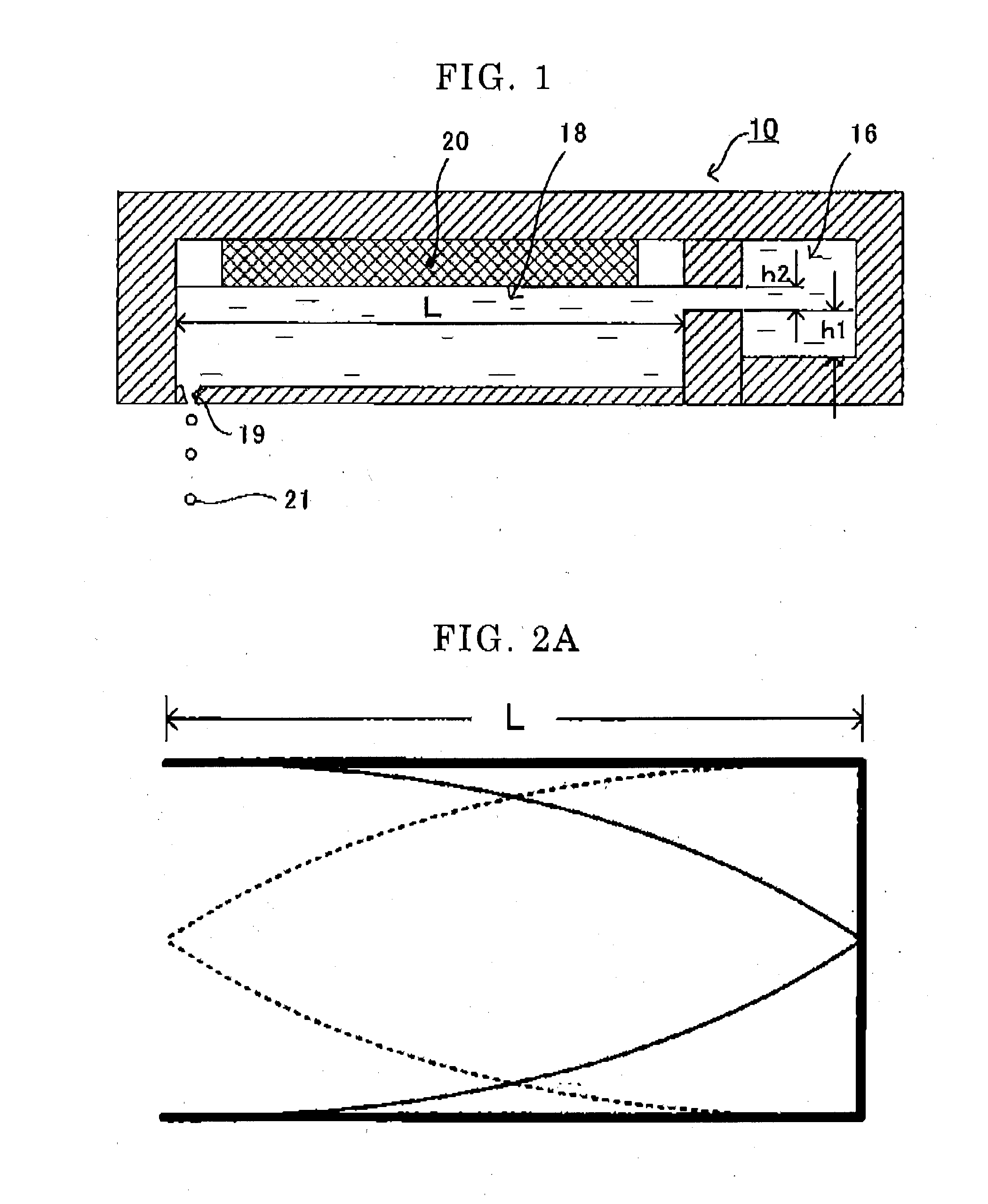

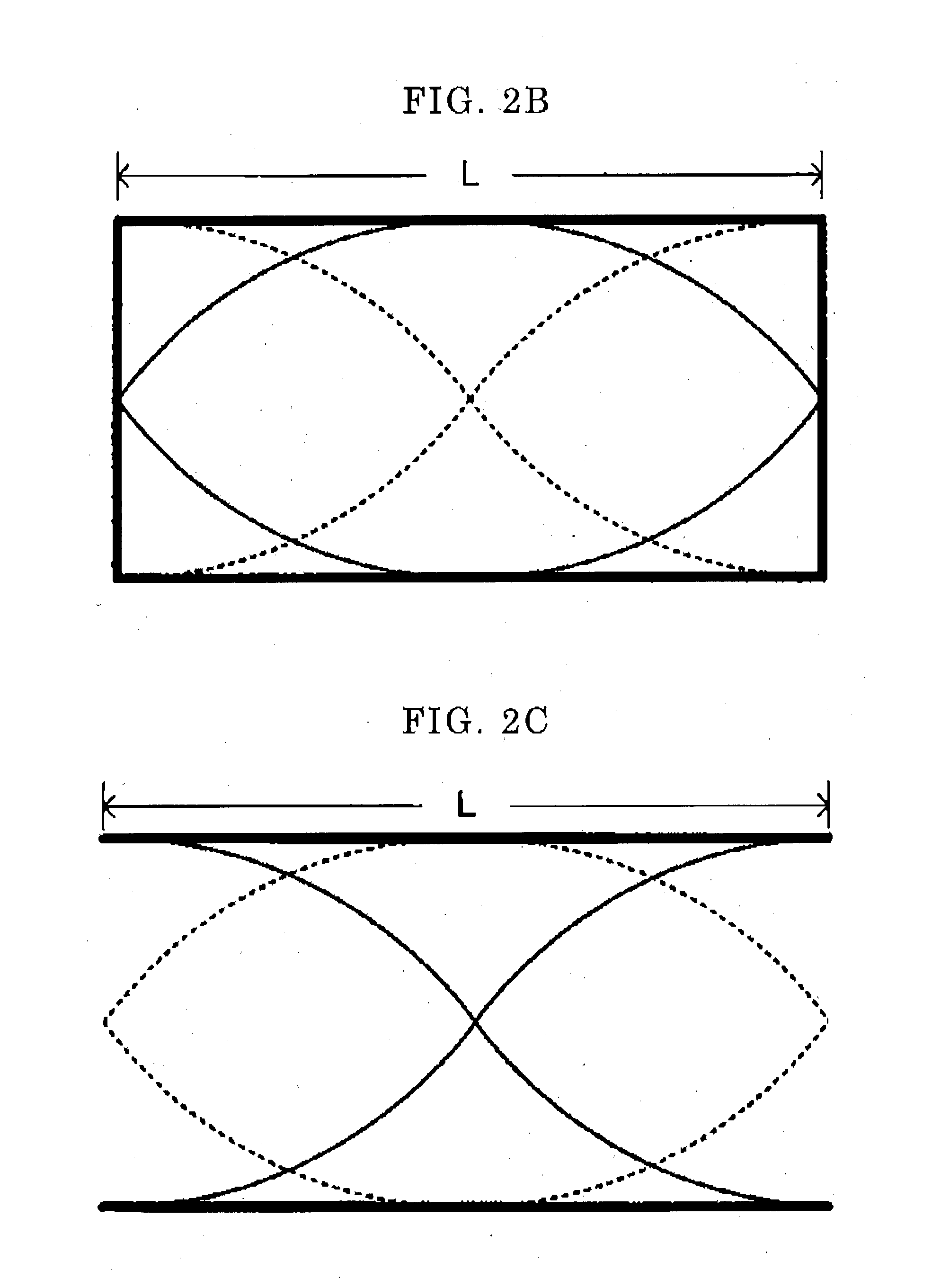

Droplet extraction from a liquid column for on-chip microfluidics

InactiveUS8304253B2Effective drainageAvoid distortionSemi-permeable membranesWithdrawing sample devicesMicrofluidicsDistortion

Owner:ADVANCED LIQUID LOGIC

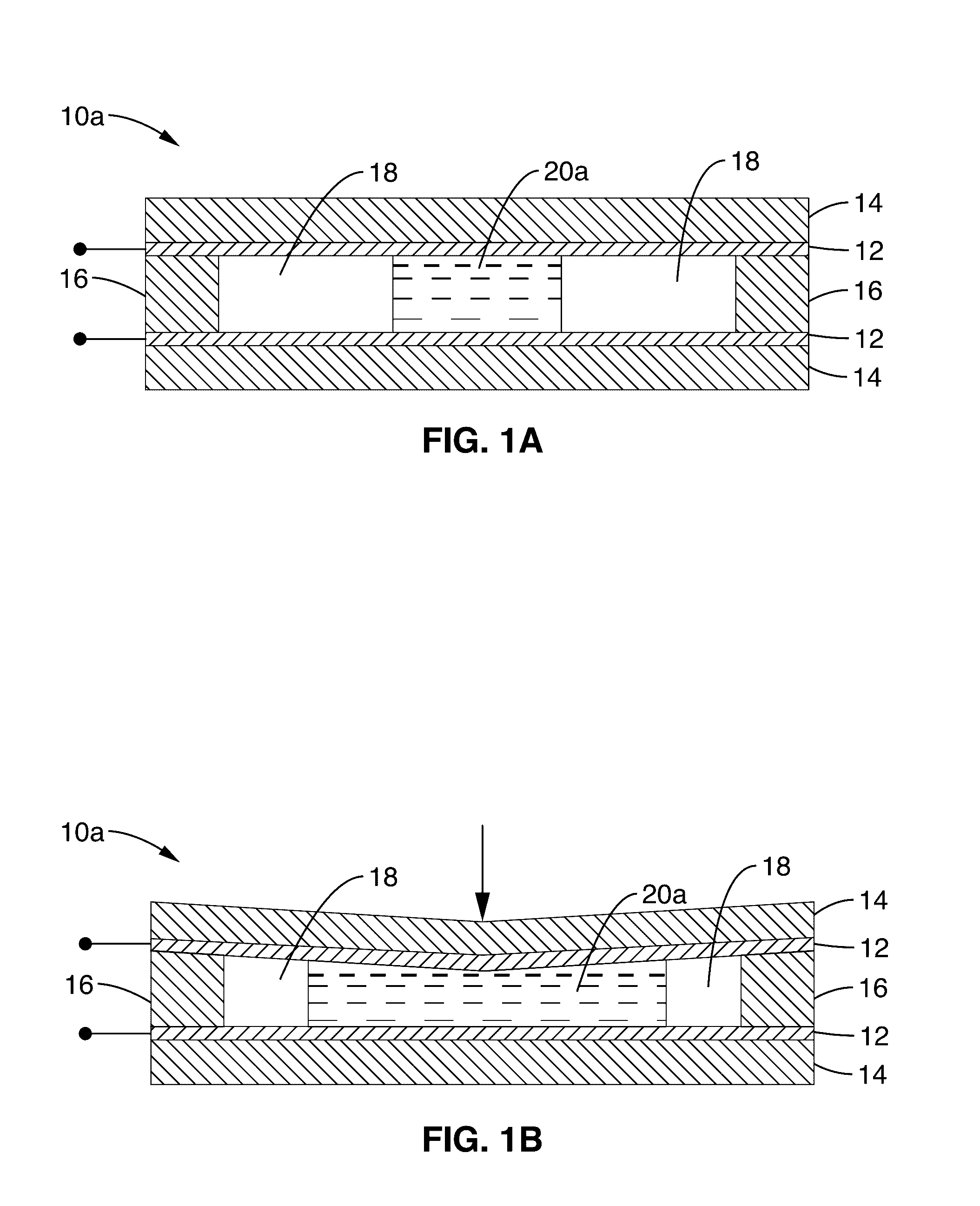

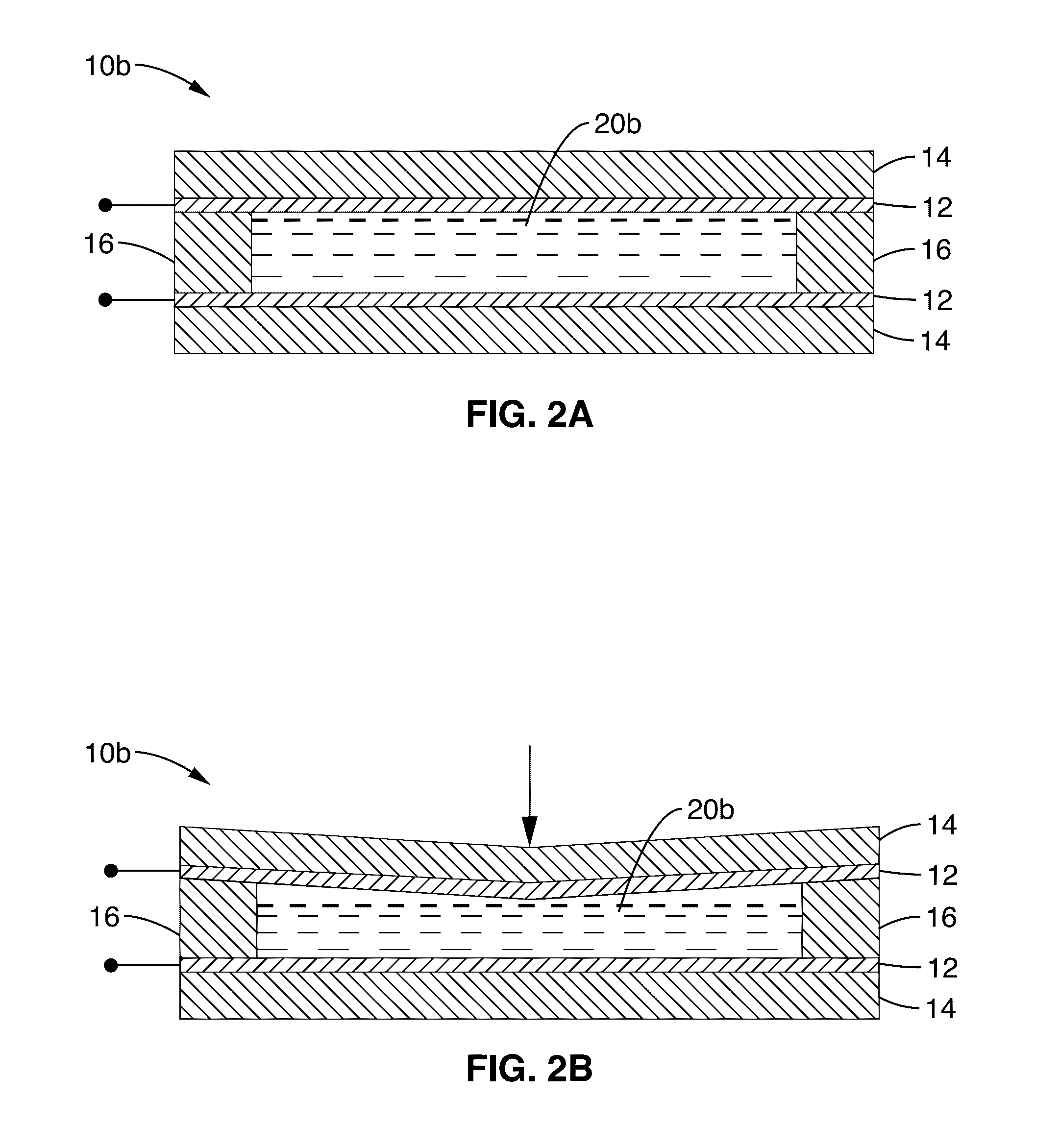

Droplet extraction from a liquid column for on-chip microfluidics

InactiveUS20090014394A1Effective drainageAvoid distortionSemi-permeable membranesWithdrawing sample devicesMicrofluidicsDistortion

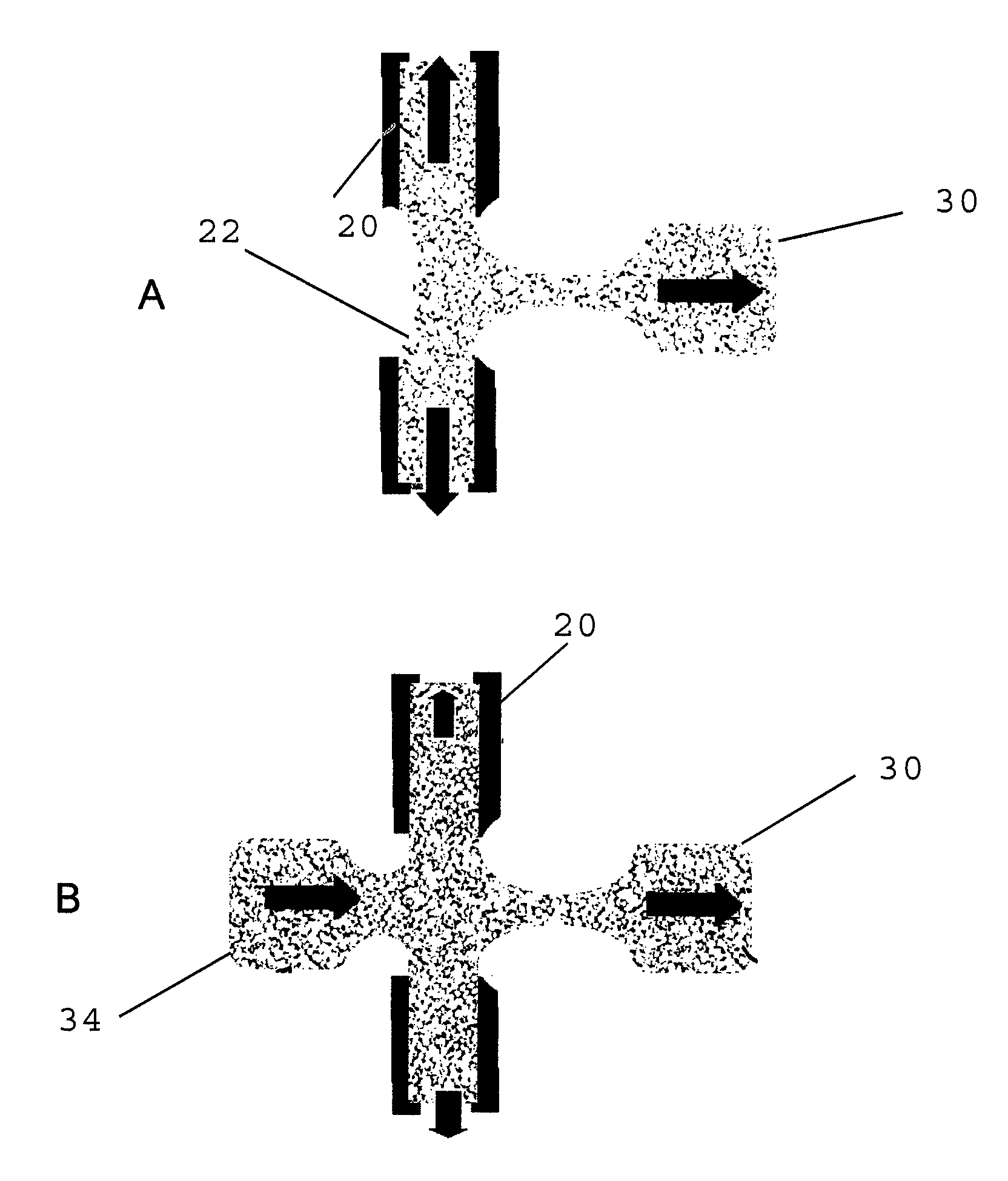

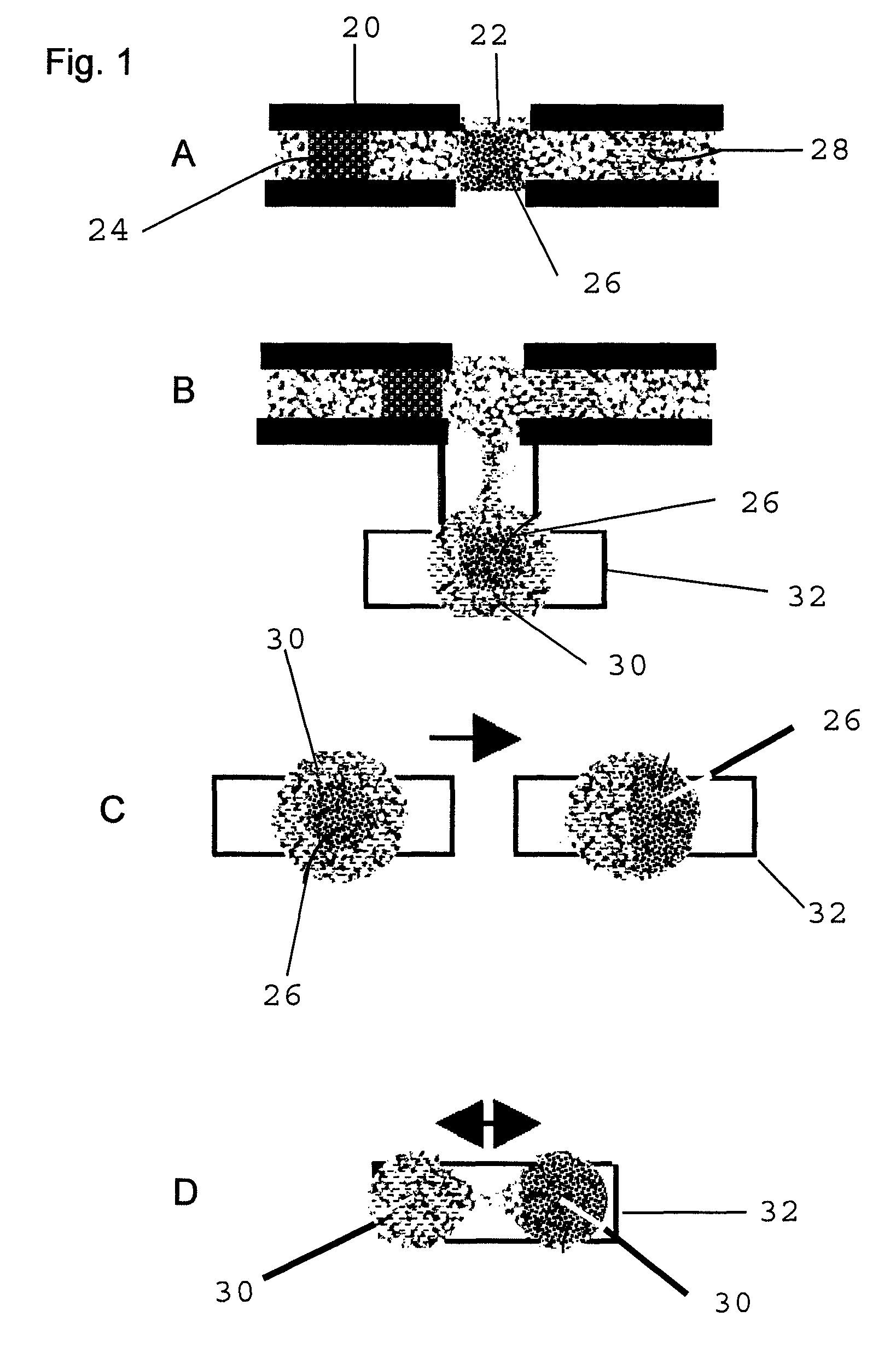

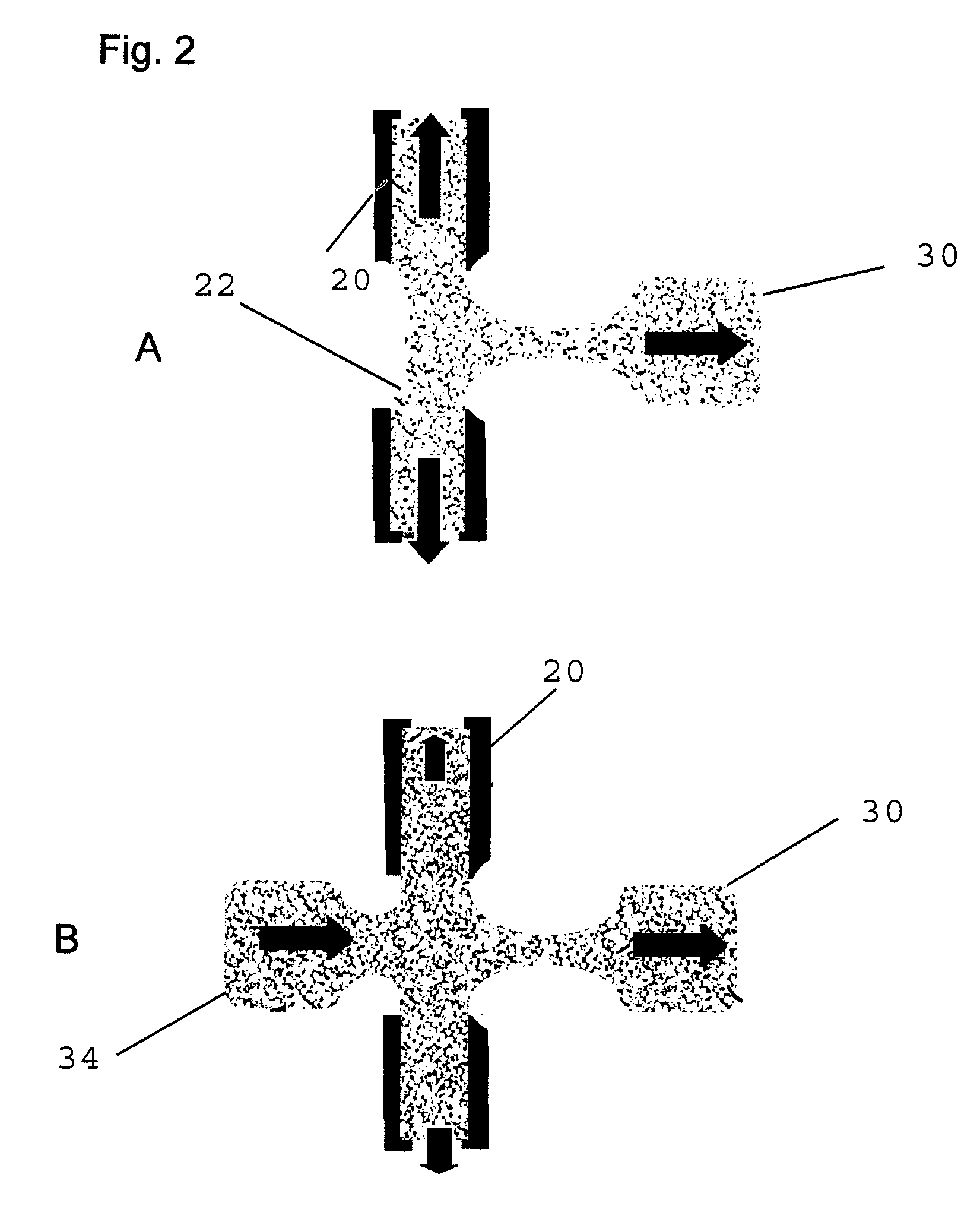

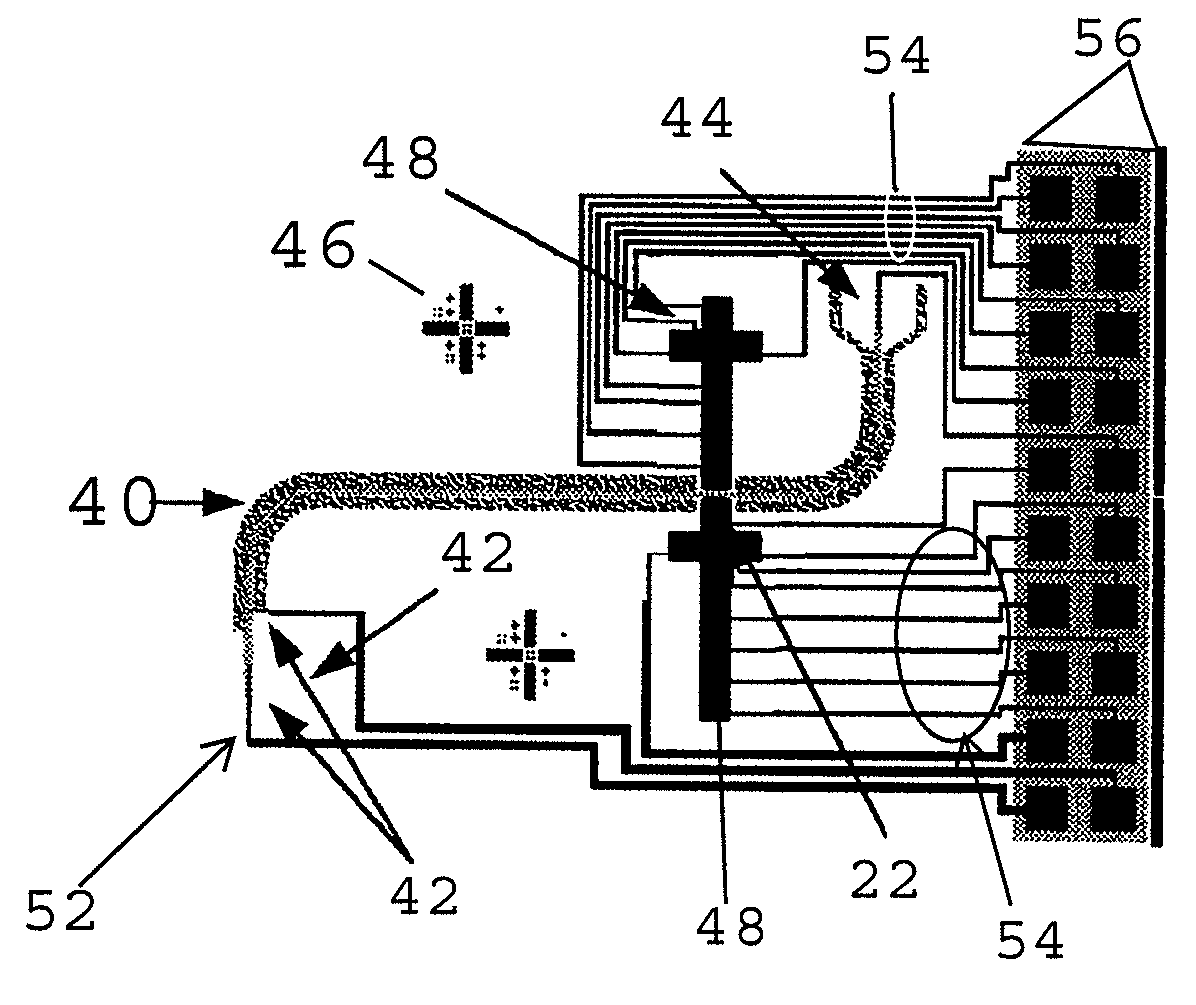

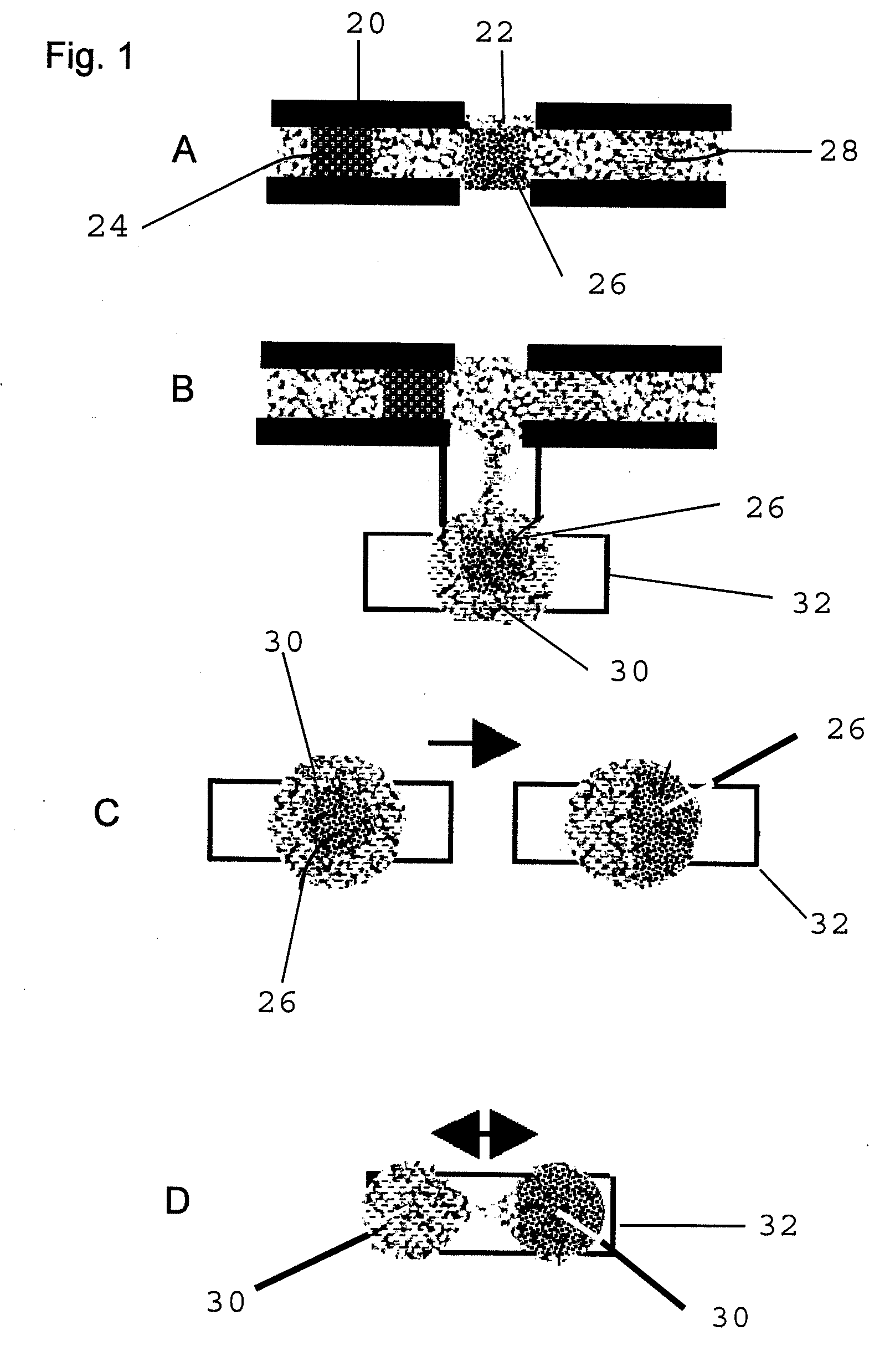

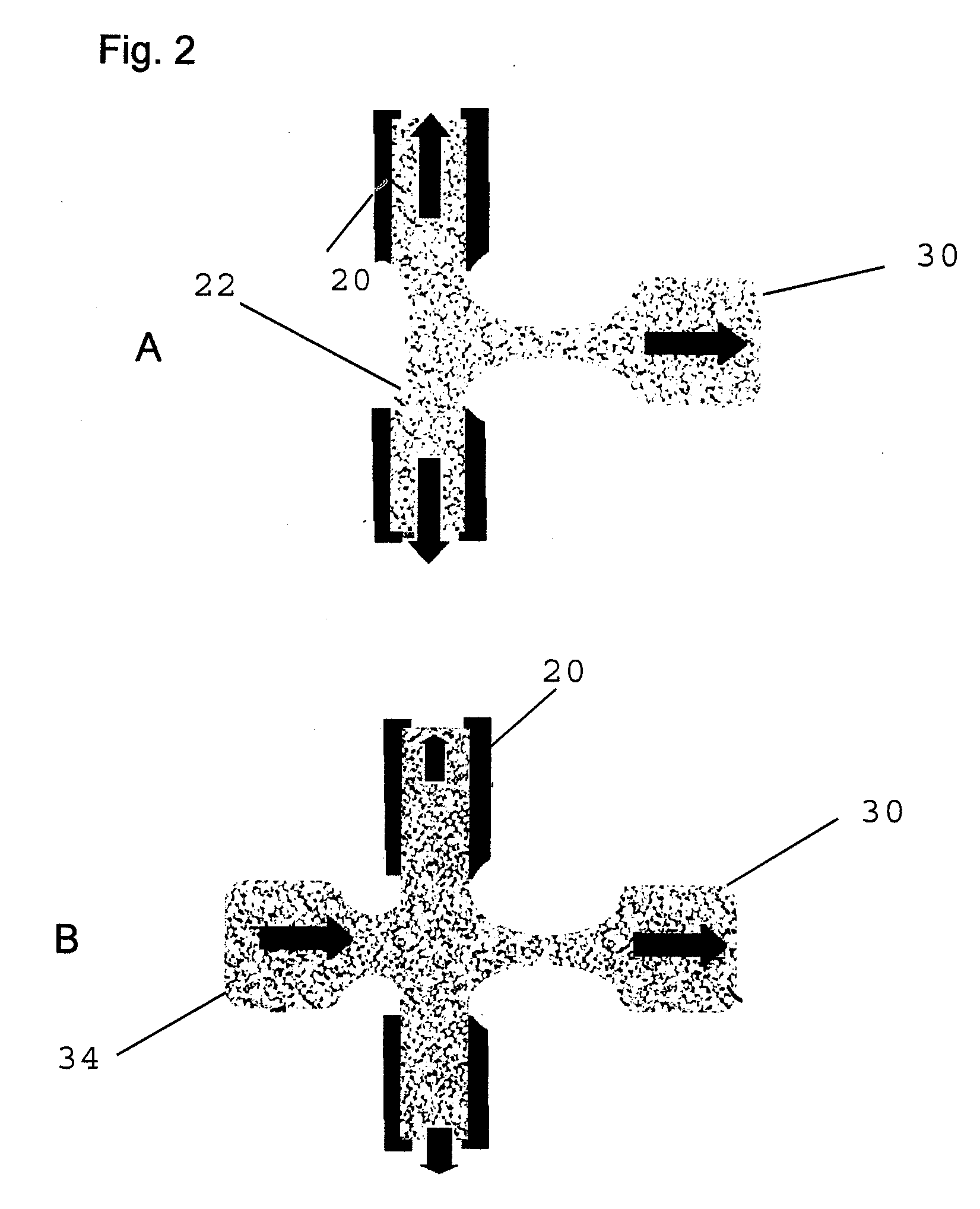

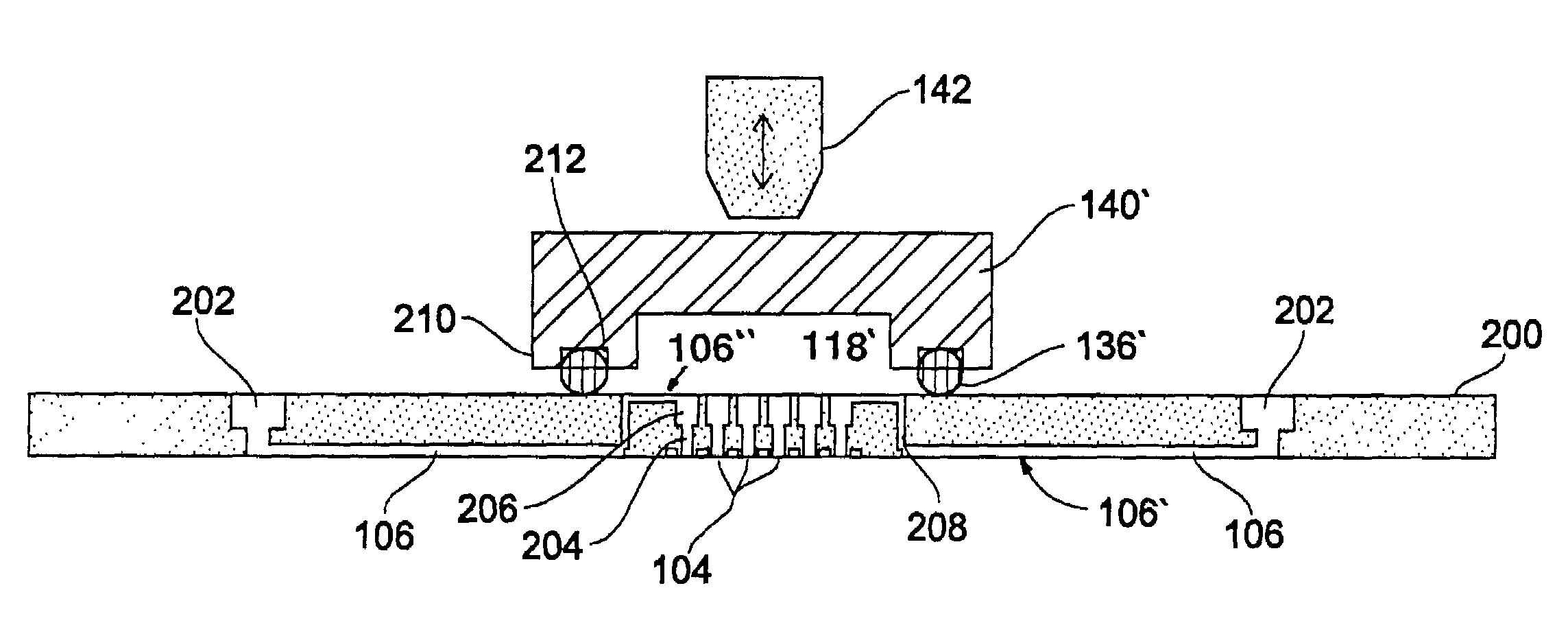

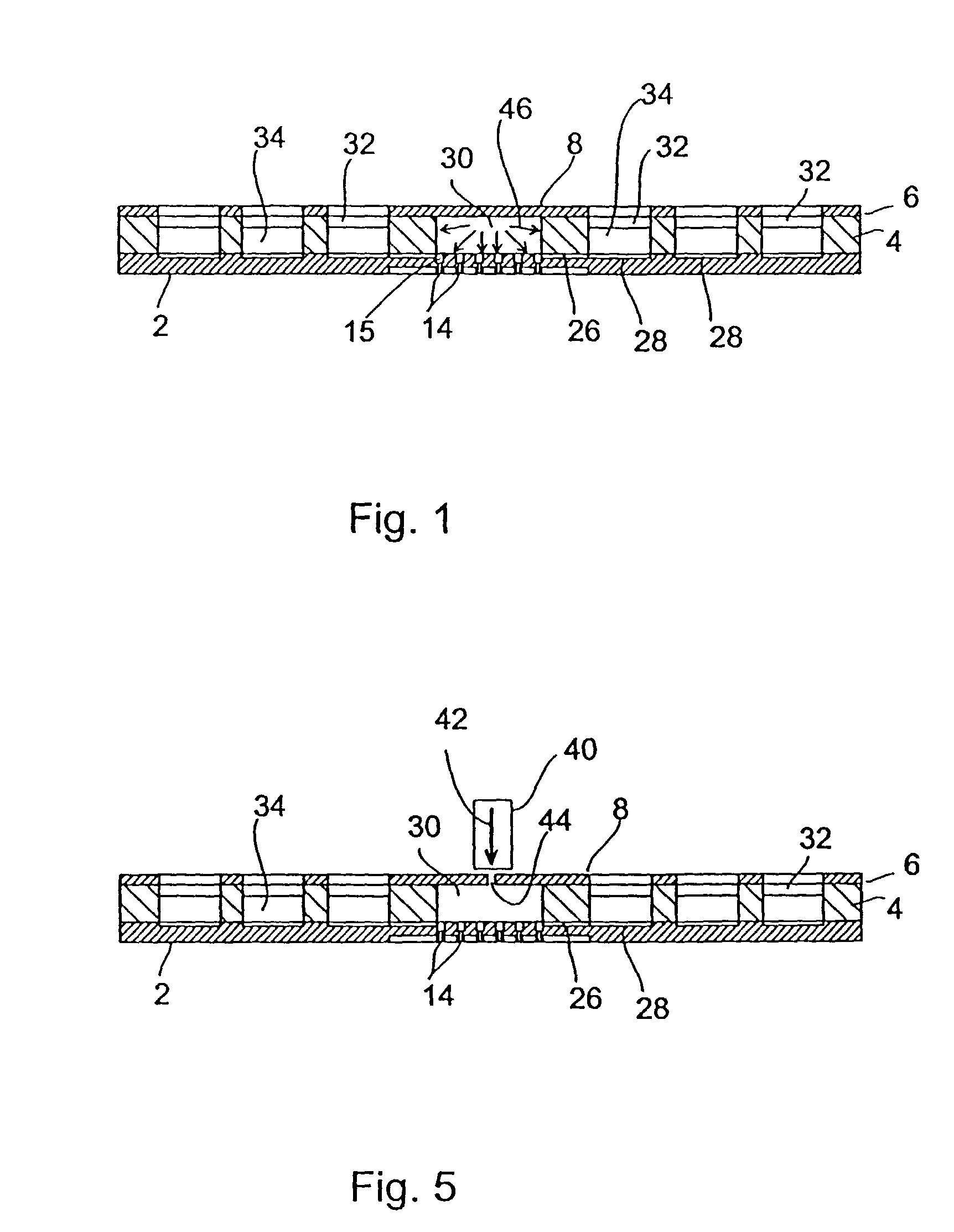

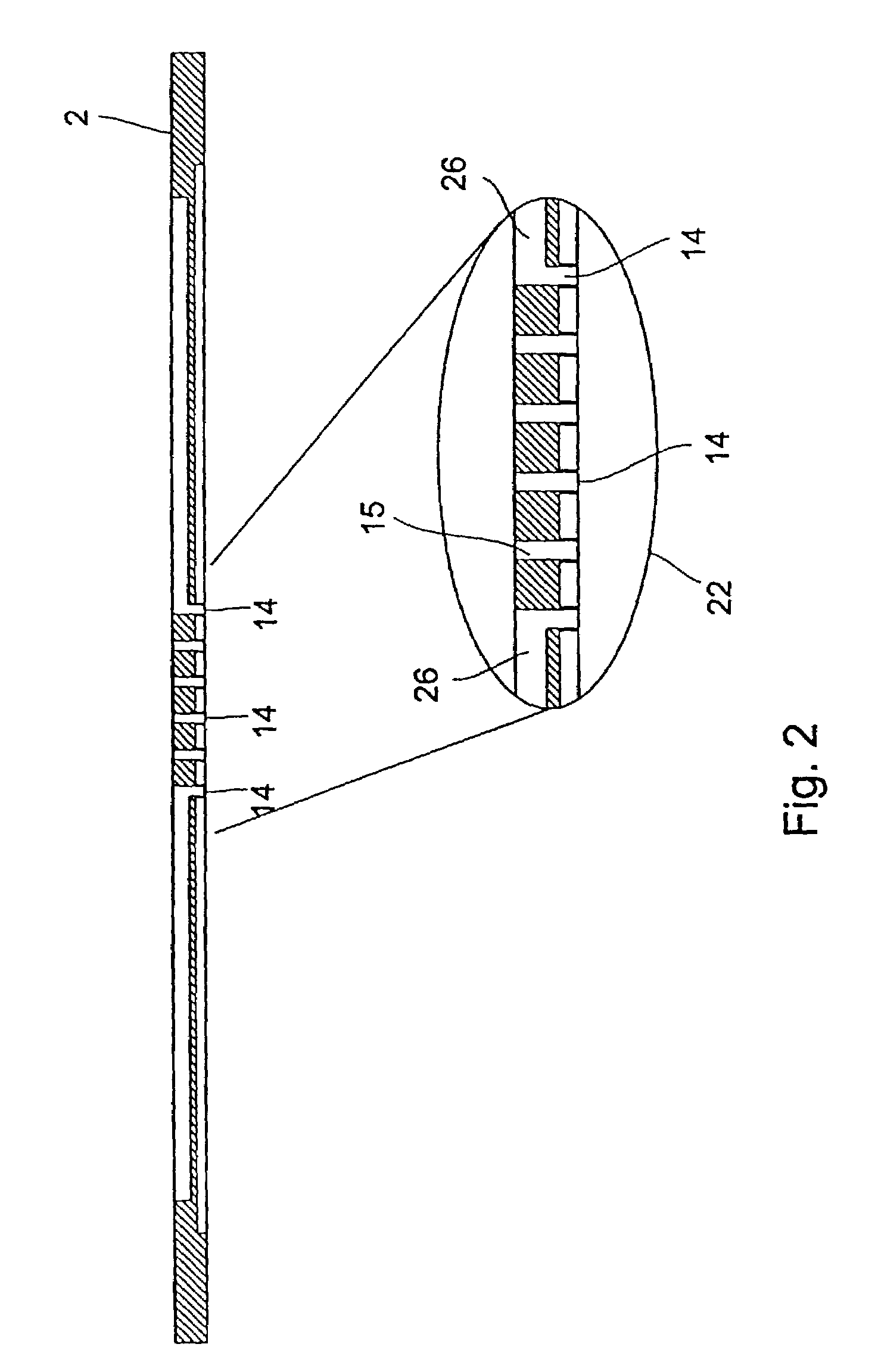

A refill droplet facilitates the extraction of a droplet laterally from a channel in a microfluidic apparatus. Such extraction allows a discrete band of separated particles or solute molecules to be excised from a fluid stream and processed and analyzed separately. An extraction point is located along the length of the channel and includes an EWOD surface or similar microfluidic technology to extract a droplet. An opening in the channel opposite the extraction means is equipped with microfluidic technology to transport a refill droplet to the opening. The refill droplet is moved into the channel or column to occupy the area previously occupied by the extracted droplet. This prevents distortion or mixing of the bands of particles or molecules within the channel and prevents the draining of any portion of the fluidic system.

Owner:ADVANCED LIQUID LOGIC

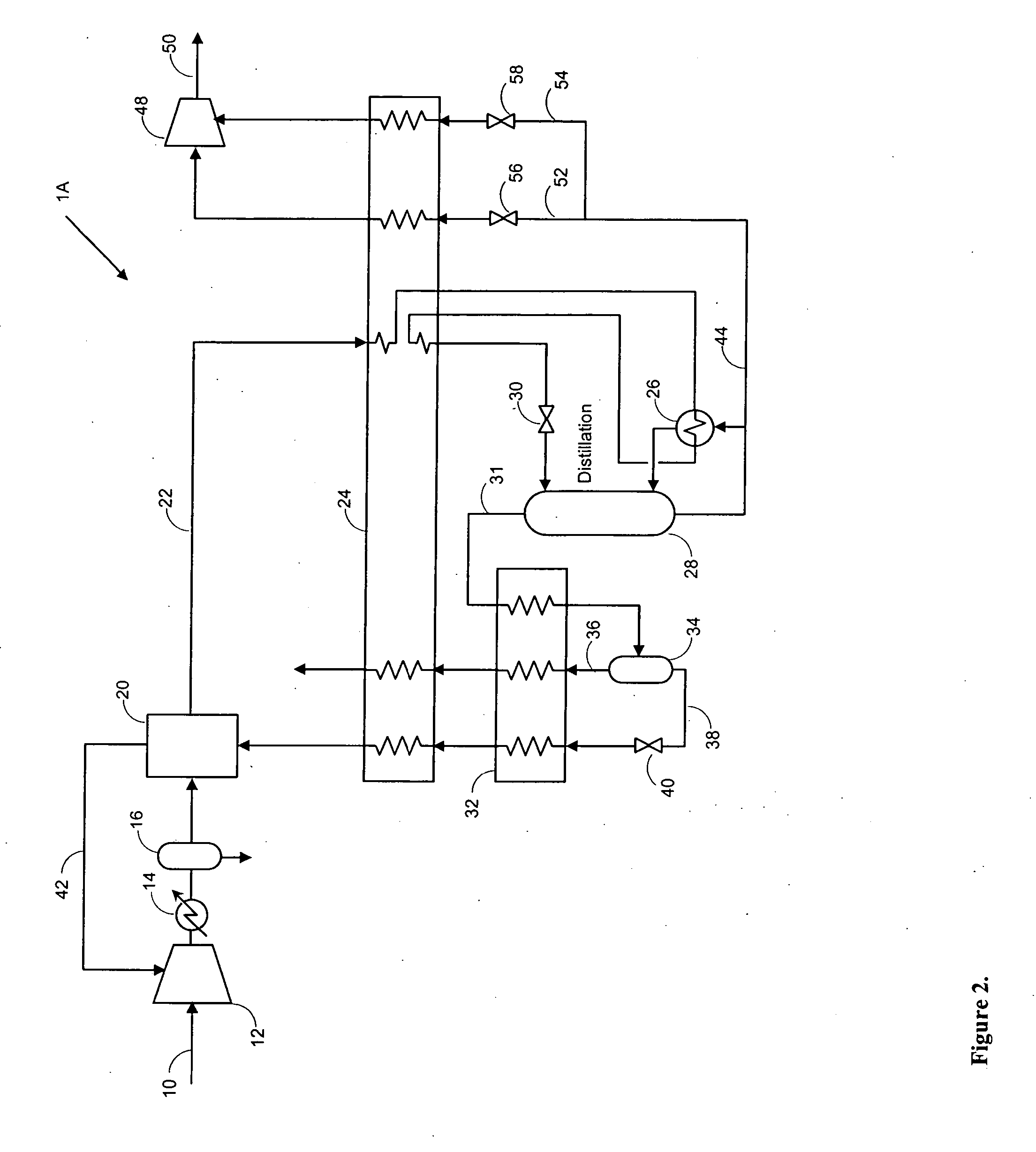

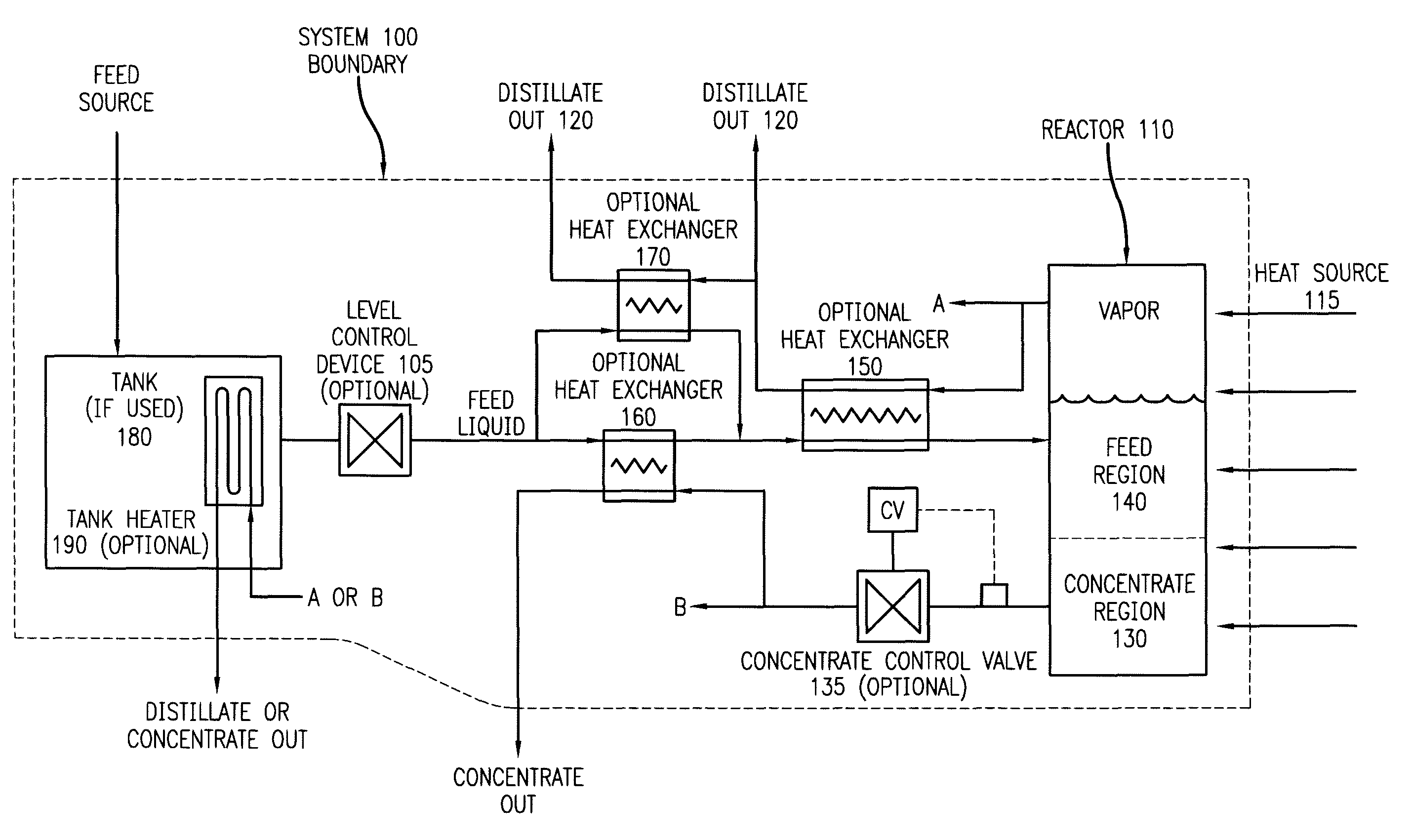

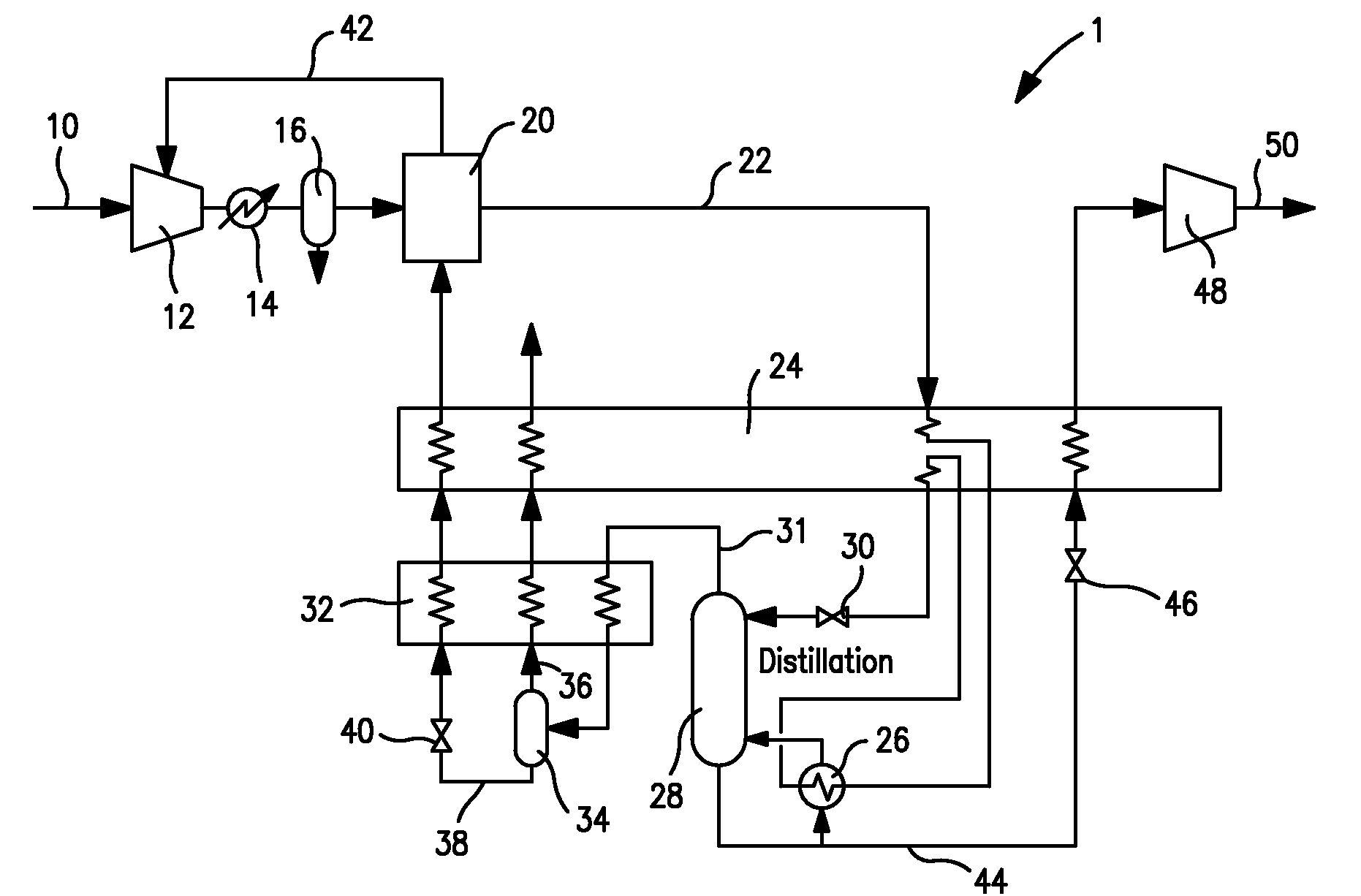

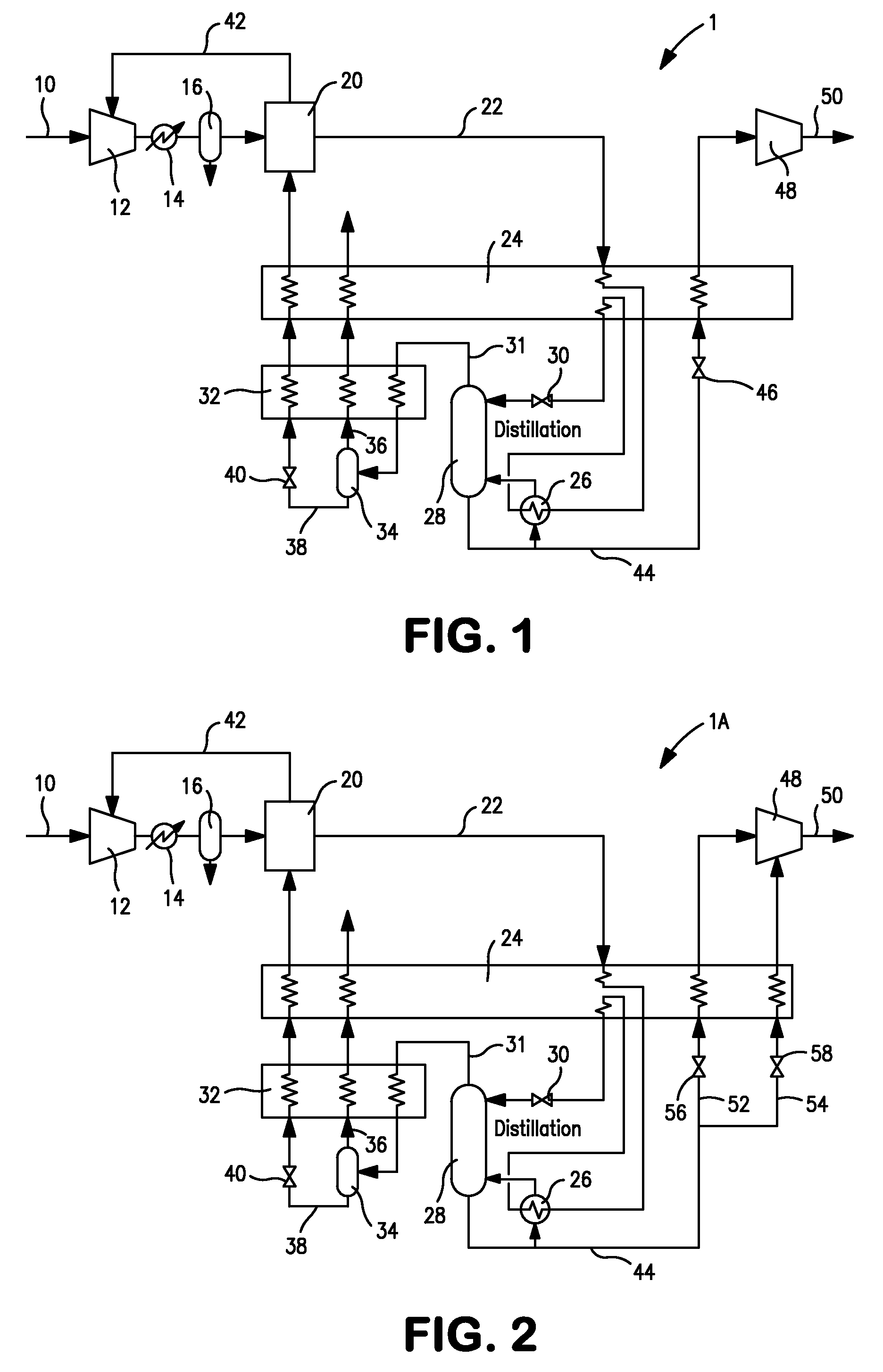

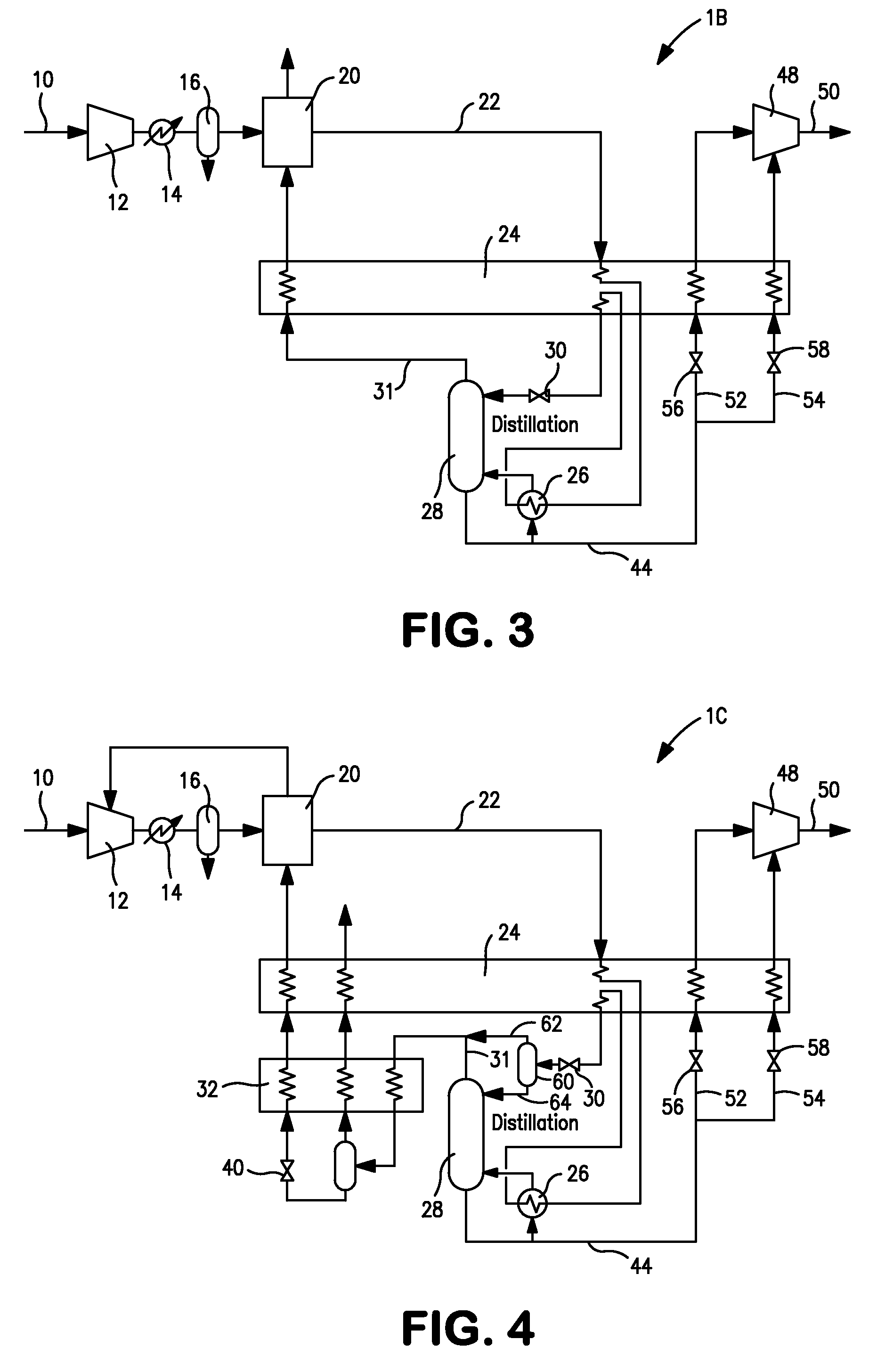

Carbon dioxide purification method

InactiveUS20070231244A1Lower energy requirementsLess refrigerationSolidificationLiquefactionPurification methodsRefrigeration

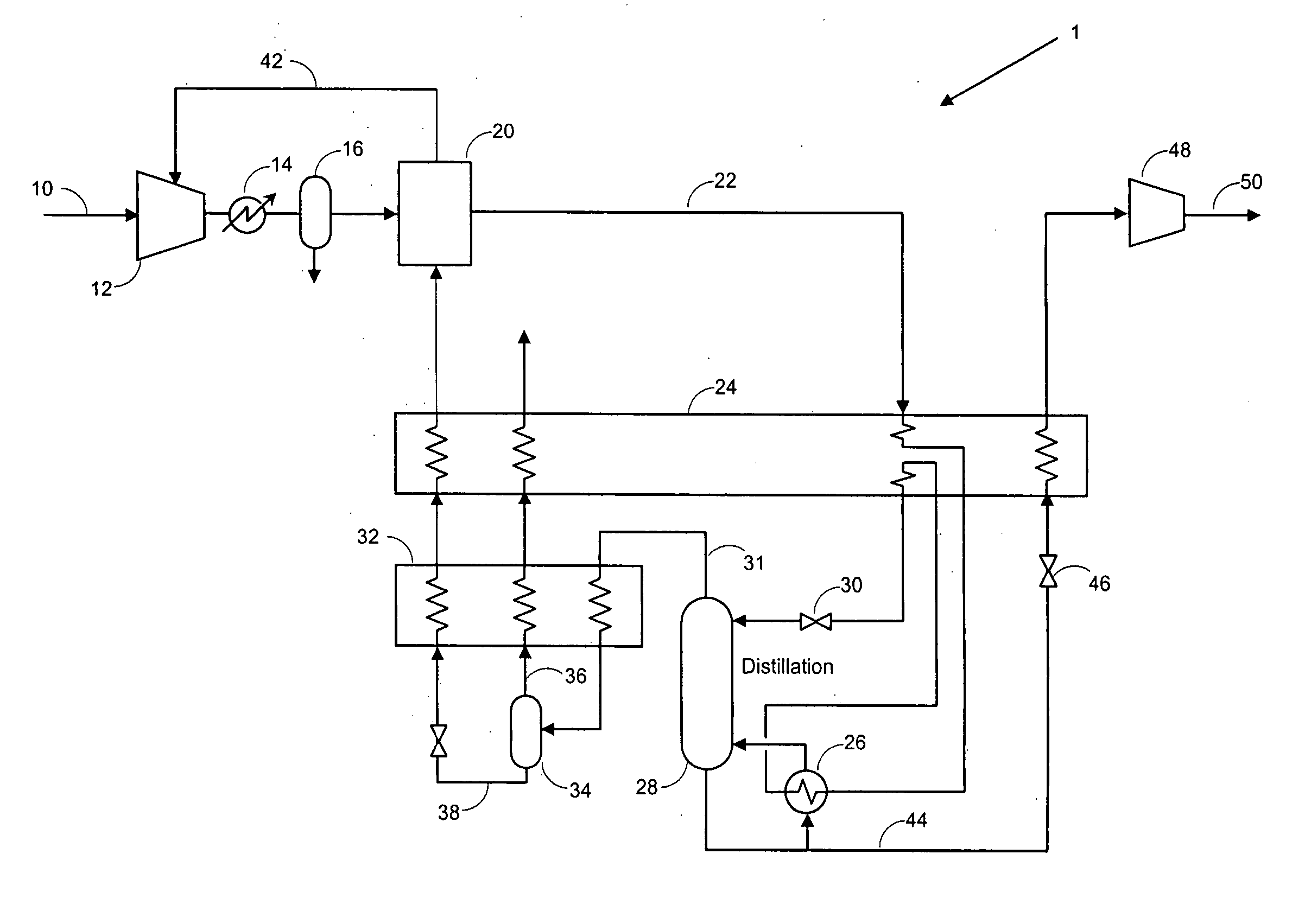

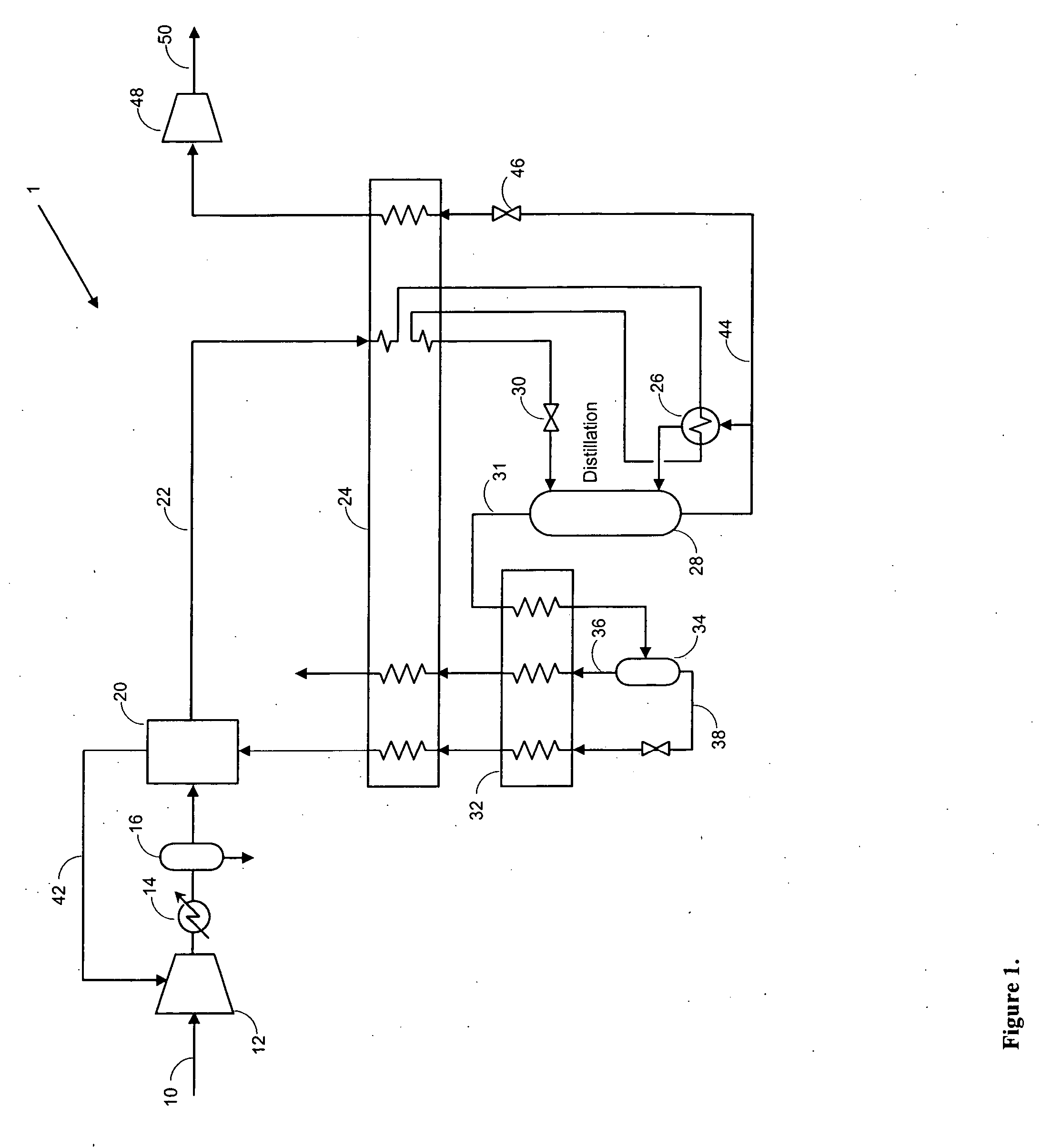

Method of purifying a feed stream containing carbon dioxide wherein the feed stream after having been compressed and dried is partly cooled and then used to reboil a stripping column. Thereafter, the feed stream is further cooled and expanded to a lower operational temperature of the stripping column. A carbon dioxide product stream composed of the liquid column bottoms of the stripping column is expanded at one or more pressures to generate refrigeration, then fully vaporized within the main heat exchanger and compressed by a compressor to produce a compressed carbon dioxide product. Refrigeration is recovered in the main heat exchanger from a column overhead stream extracted from the stripping column within the main heat exchanger either directly or indirectly by auxiliary processing in which carbon dioxide is further separated and optionally recycled back to the main compressor used in compressing the feed stream.

Owner:PRAXAIR TECH INC

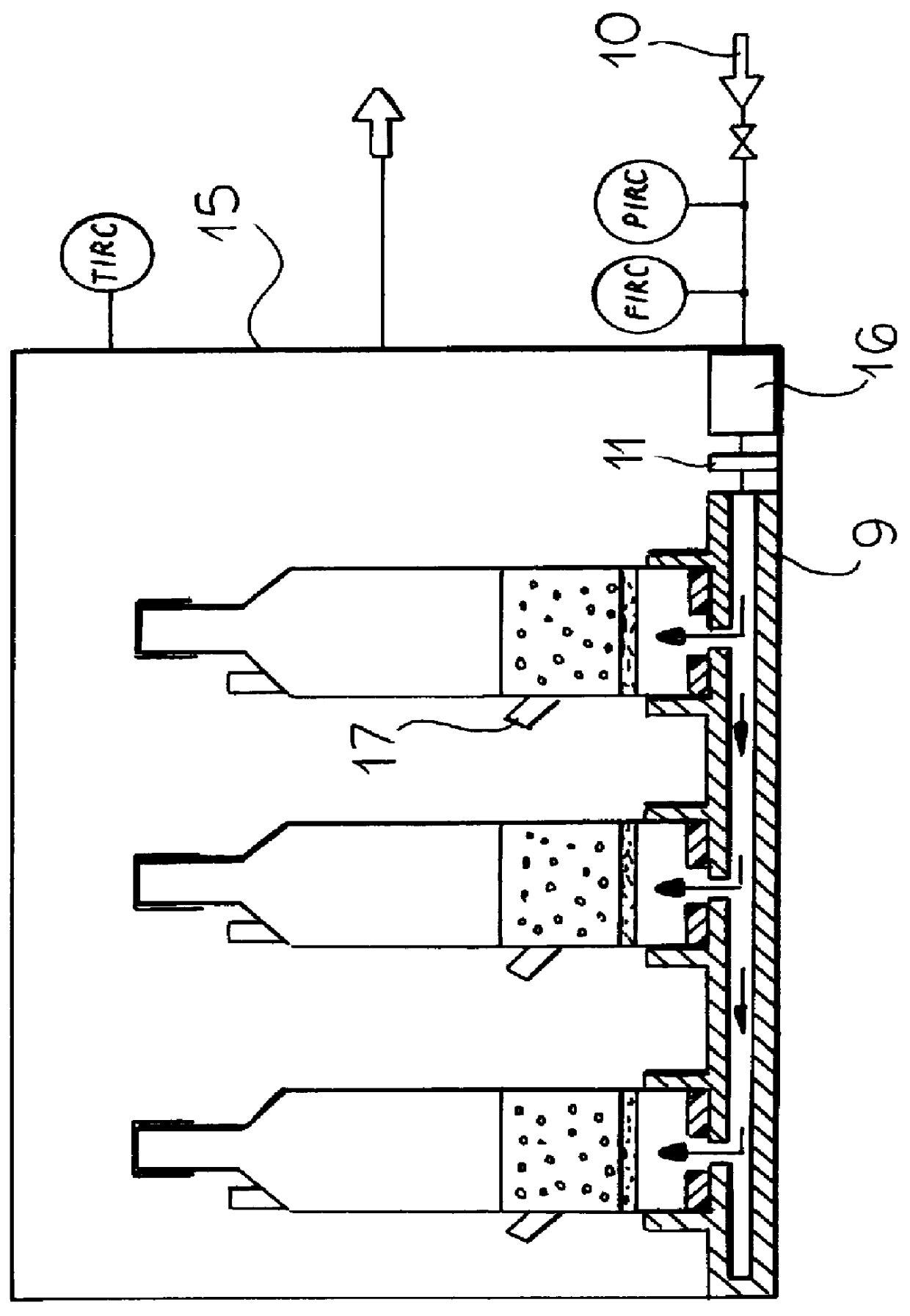

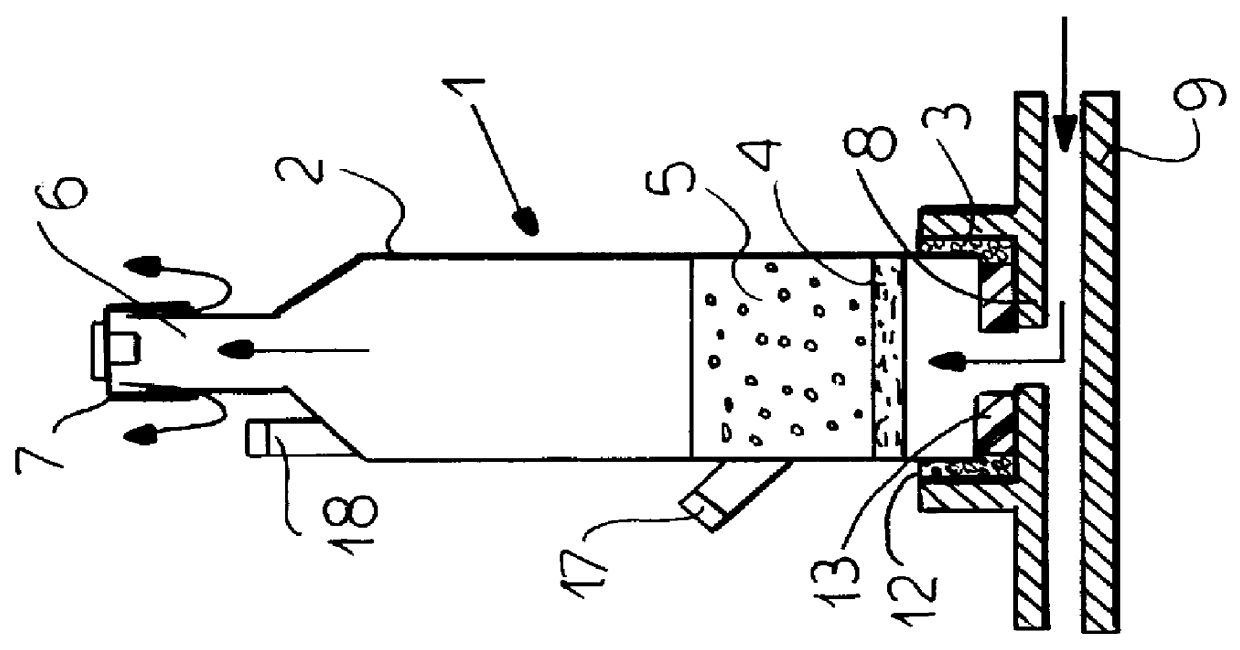

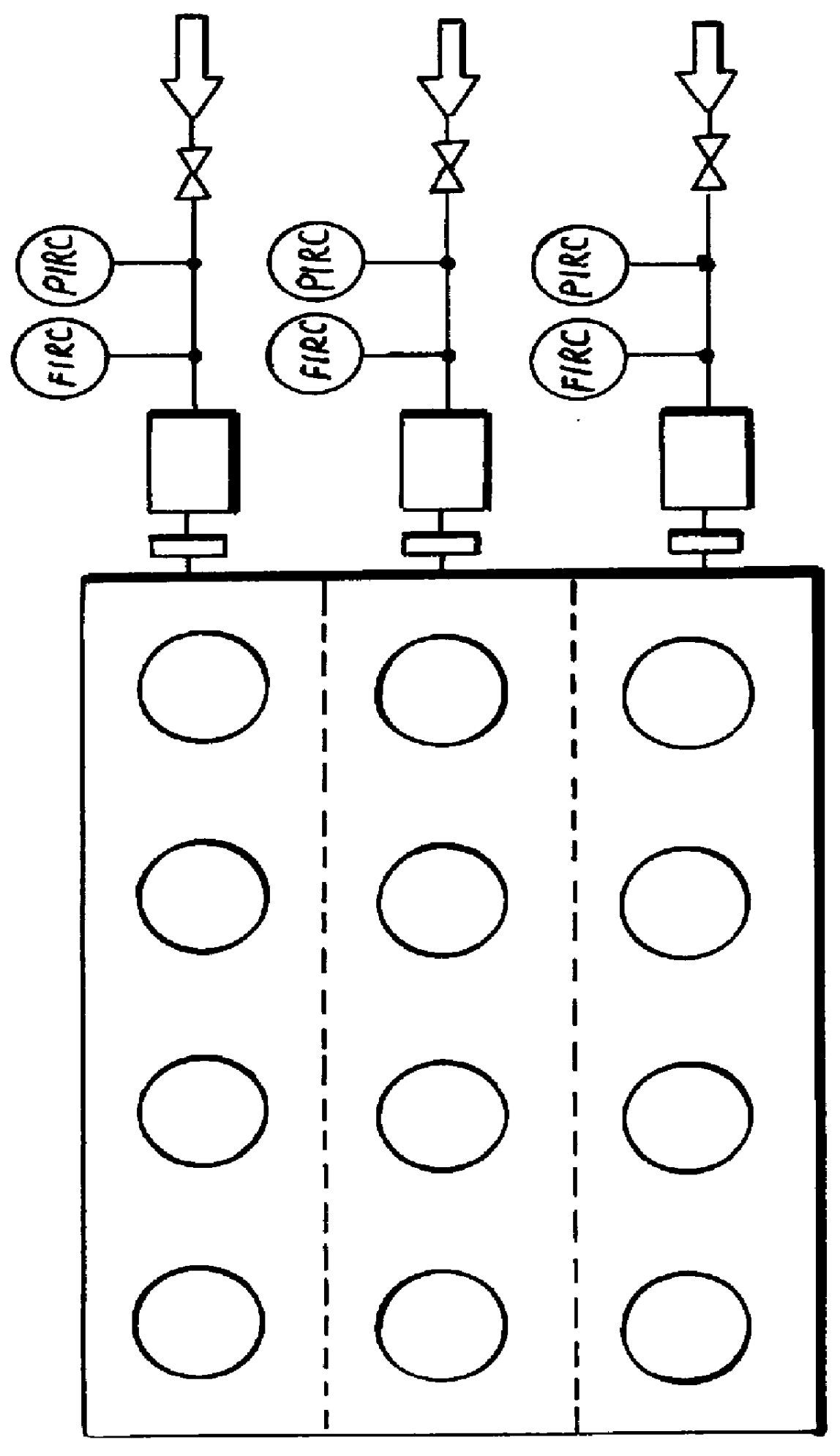

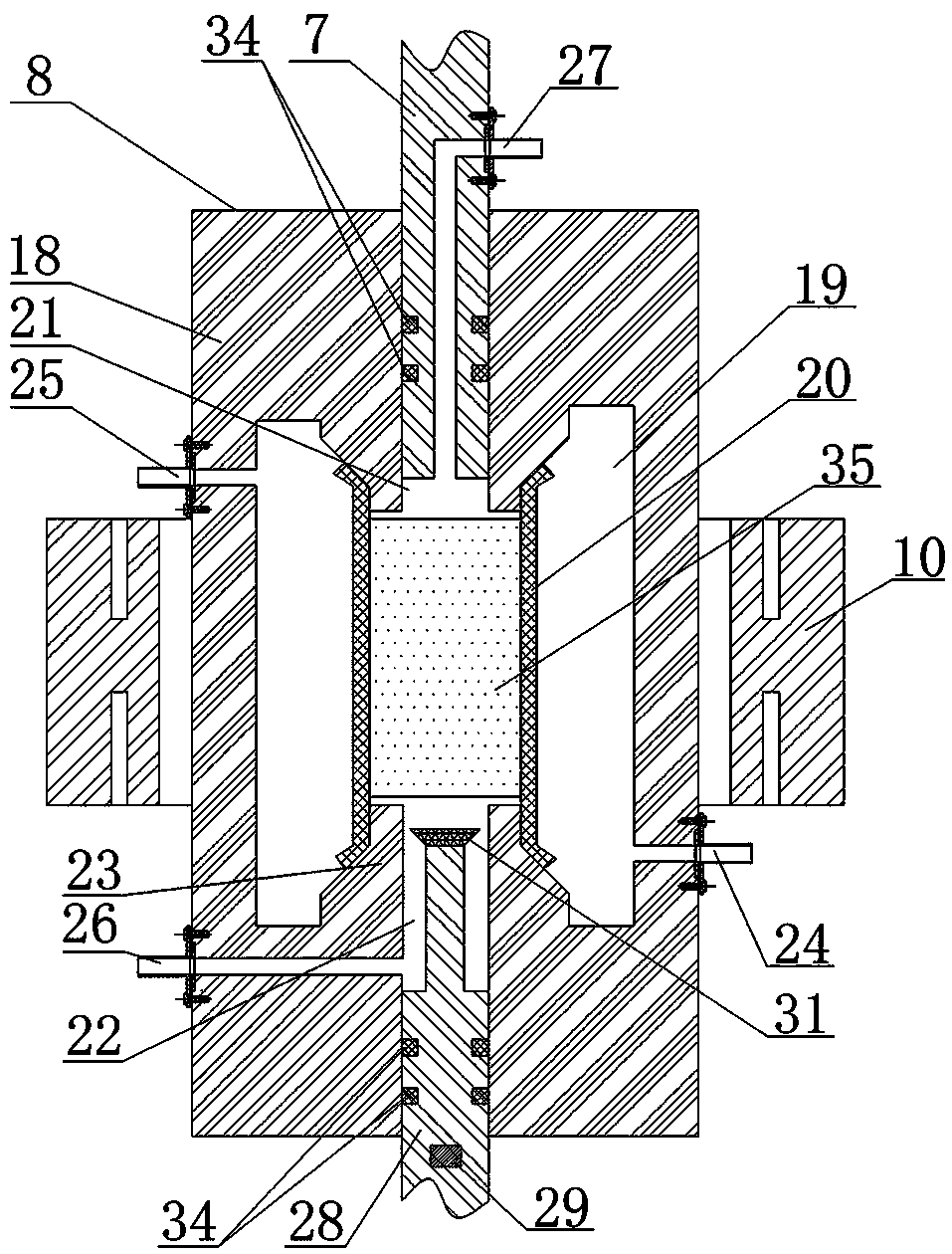

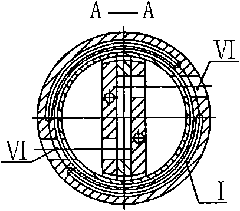

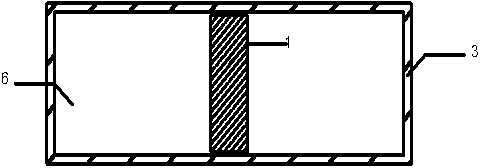

Device for the series cultivation of micro-organisms or cells in gasified liquid columns

InactiveUS6063618AConvenient ArrangementSatisfactory gasificationBioreactor/fermenter combinationsBiological substance pretreatmentsProduct gasEngineering

PCT No. PCT / DE96 / 01485 Sec. 371 Date Feb. 4, 1998 Sec. 102(e) Date Feb. 4, 1998 PCT Filed Aug. 3, 1996 PCT Pub. No. WO97 / 06239 PCT Pub. Date Feb. 20, 1997A reaction apparatus has a plurality of reaction flasks whose bottoms can communicate with a sterile gas source and are provided with porous filter plates which permit the gas to flow into the vessel but prevent the liquid from passing out through the plates. The culture flasks are received in pockets on an upper plate of a double-bottom structure which can communicate through the upper plate between a space within the double bottom and the bottom of the culture flasks. The spiral gas feed is connected to the double-bottom space.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

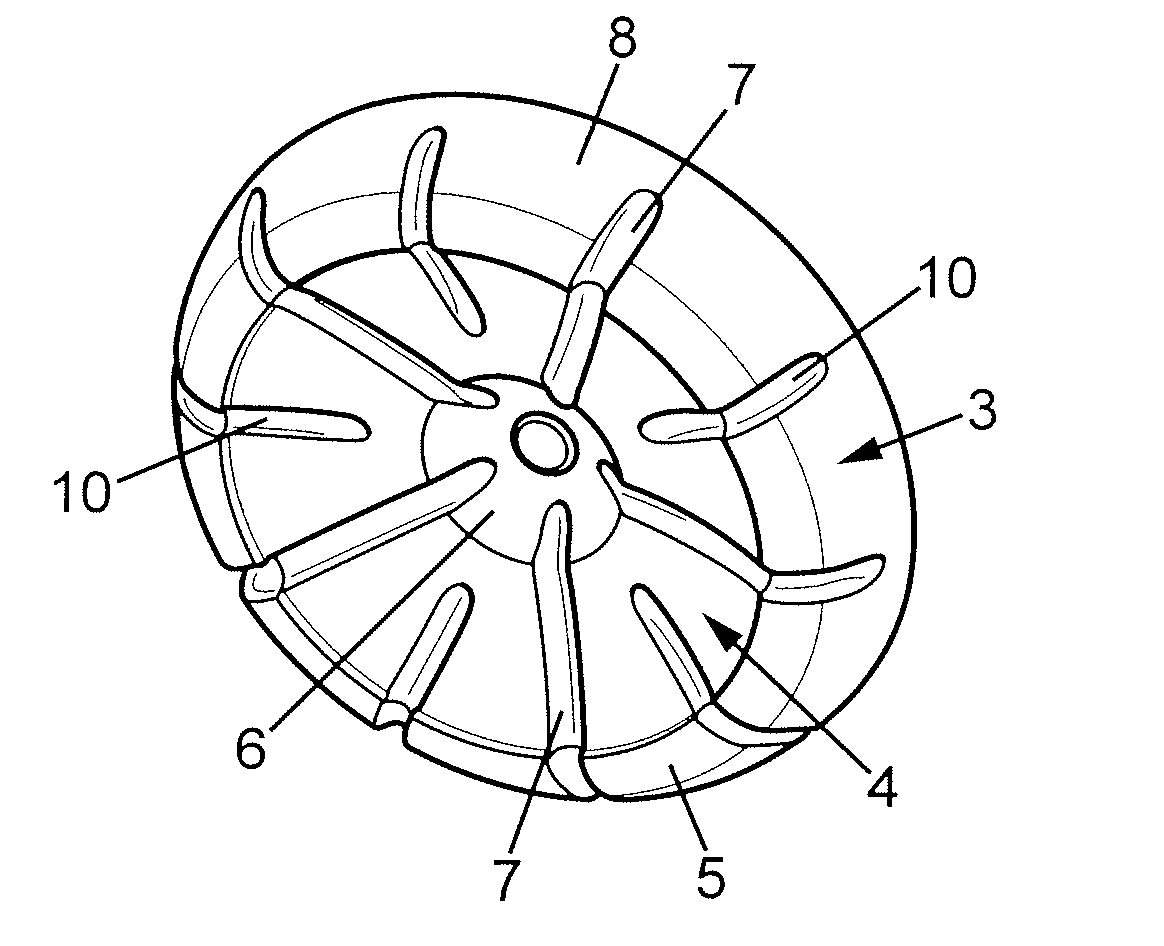

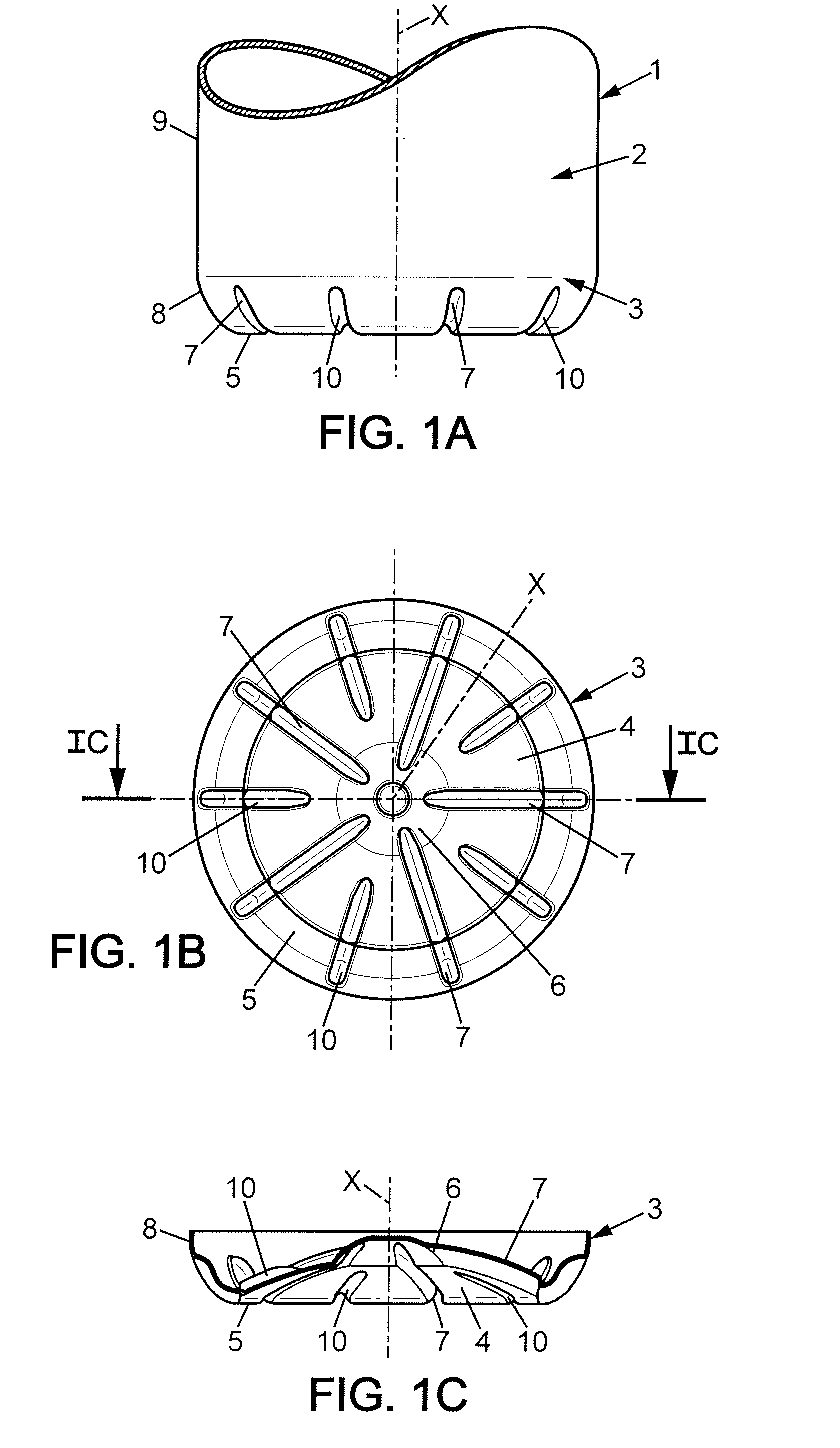

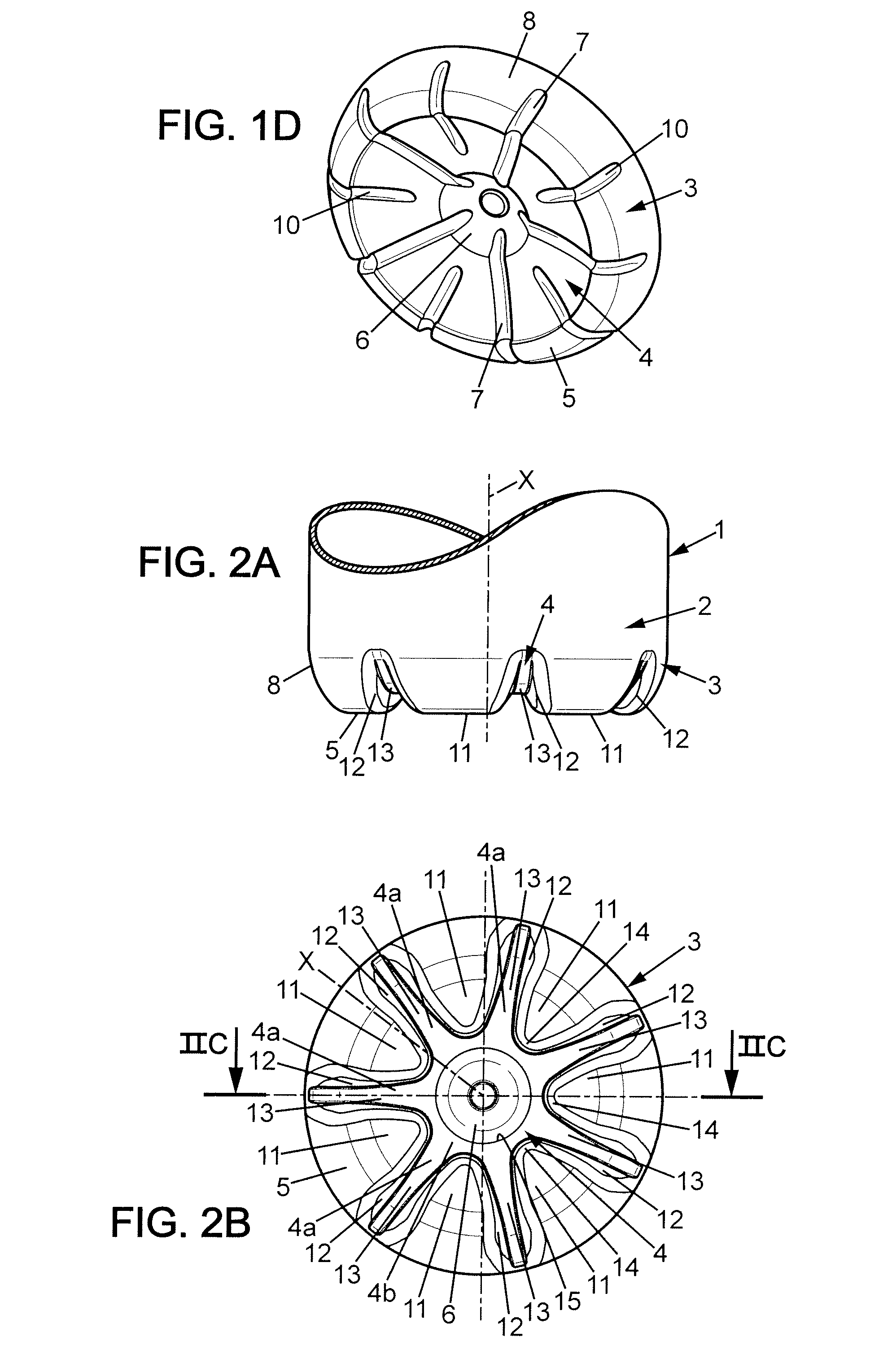

Container, in particular a bottle, made of a thermoplastic material, provided with a reinforced base

InactiveUS20090308835A1Implementation processGreat freedomLarge containersRigid containersHydrostatic pressureBottle

Thermoplastic container (1) having a body (2) and a base (3) comprising: a concave arch (4), a concave dome (6) opening at the centre of said arch (4), an annular zone (5) surrounding the base of said arch and forming a flat foundation, claw-shaped zones (11) radially extending the base of the body (2) and offset projecting outwards relative to the arch, and radial grooves (12) delimited between the zones (11) in the shape of claws, said grooves having bottoms (13) which are formed by radial sections (4a) of the arch and which have a radially variable depth which is maximum in correspondence with said annular zone forming a foundation. Such a base is adapted for withstanding, without marked deformation, the hydrostatic pressure due to the liquid column increased by an excess pressure not exceeding approximately 2×105 Pa.

Owner:SIDEL PARTICIPATIONS SAS

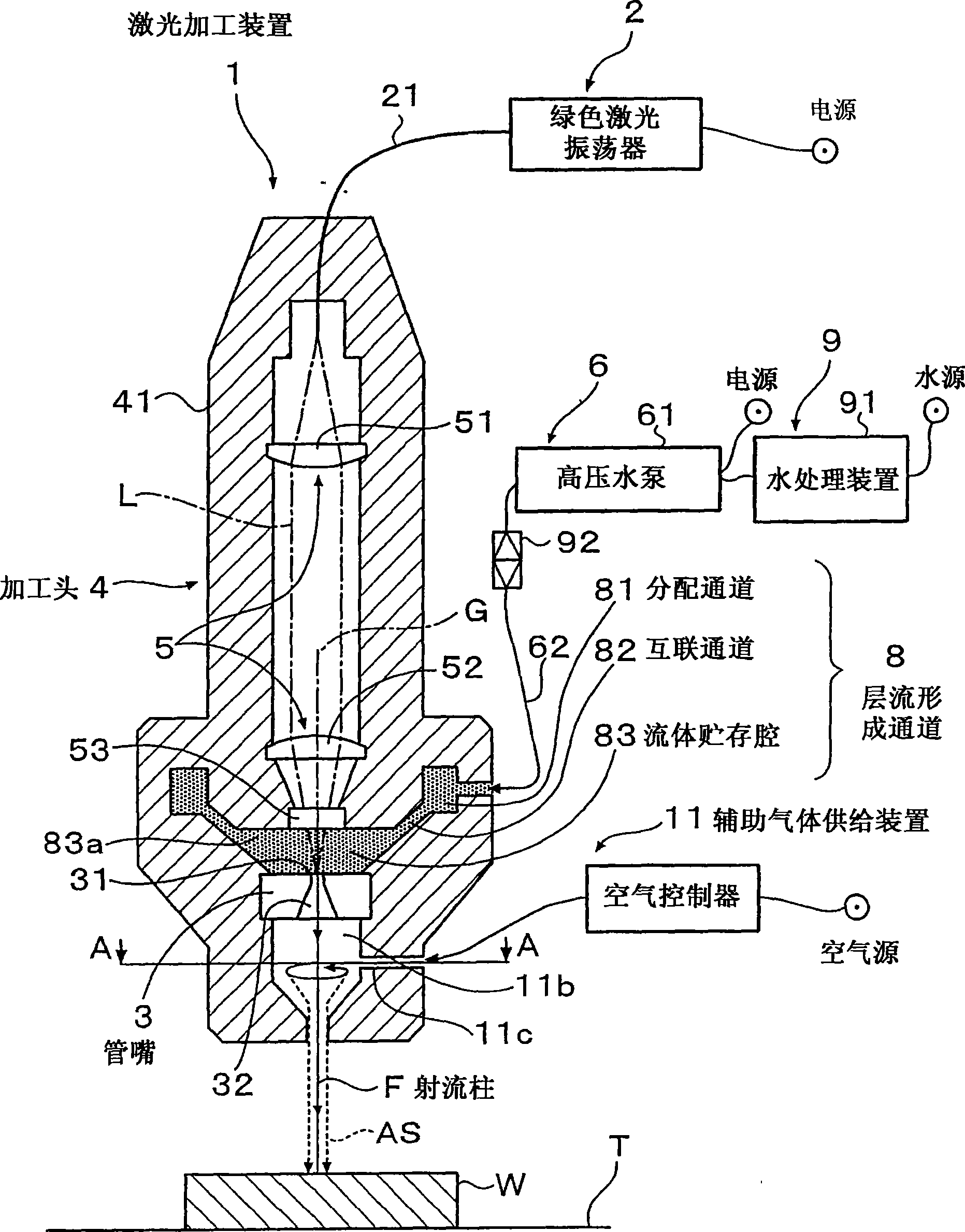

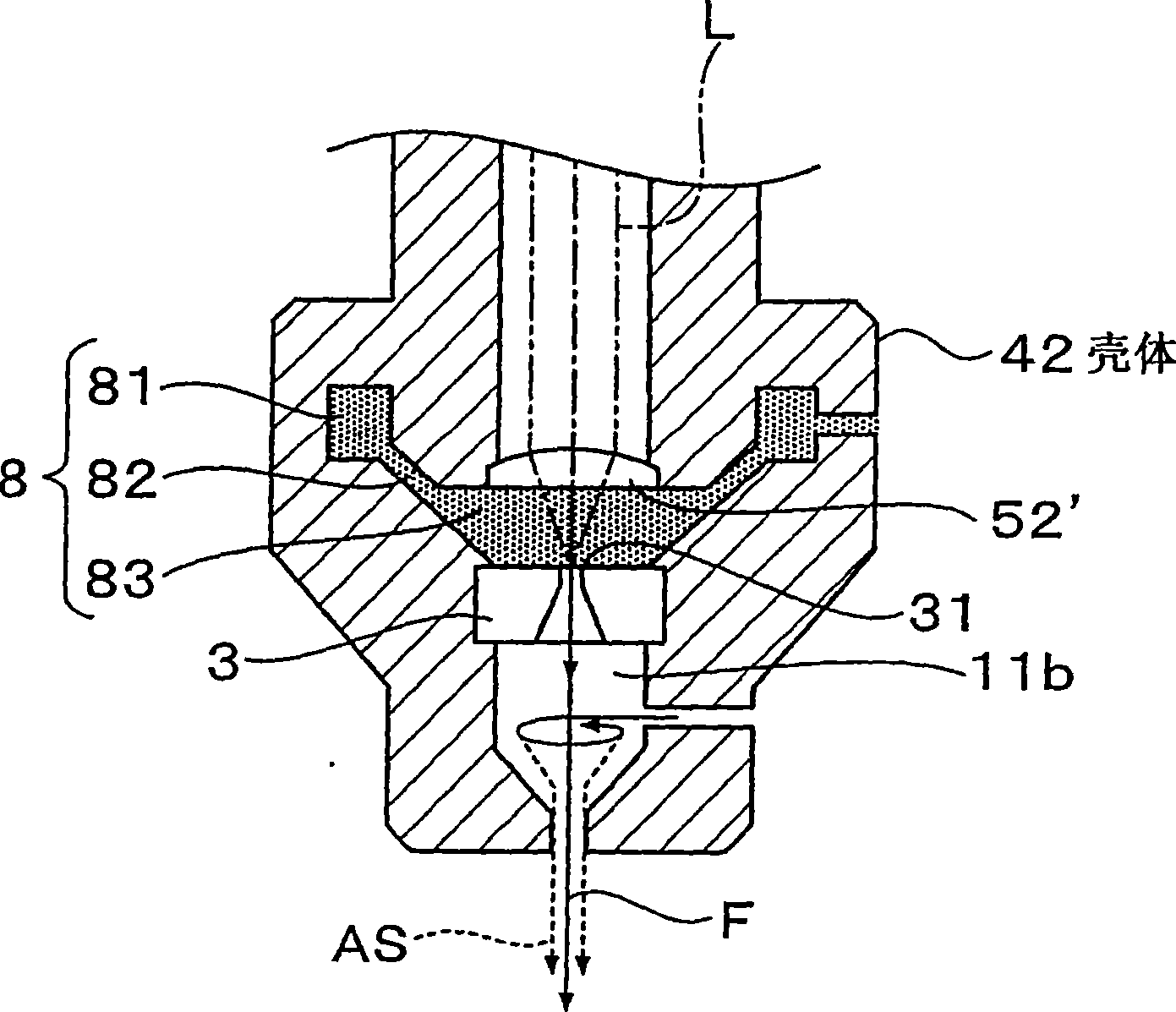

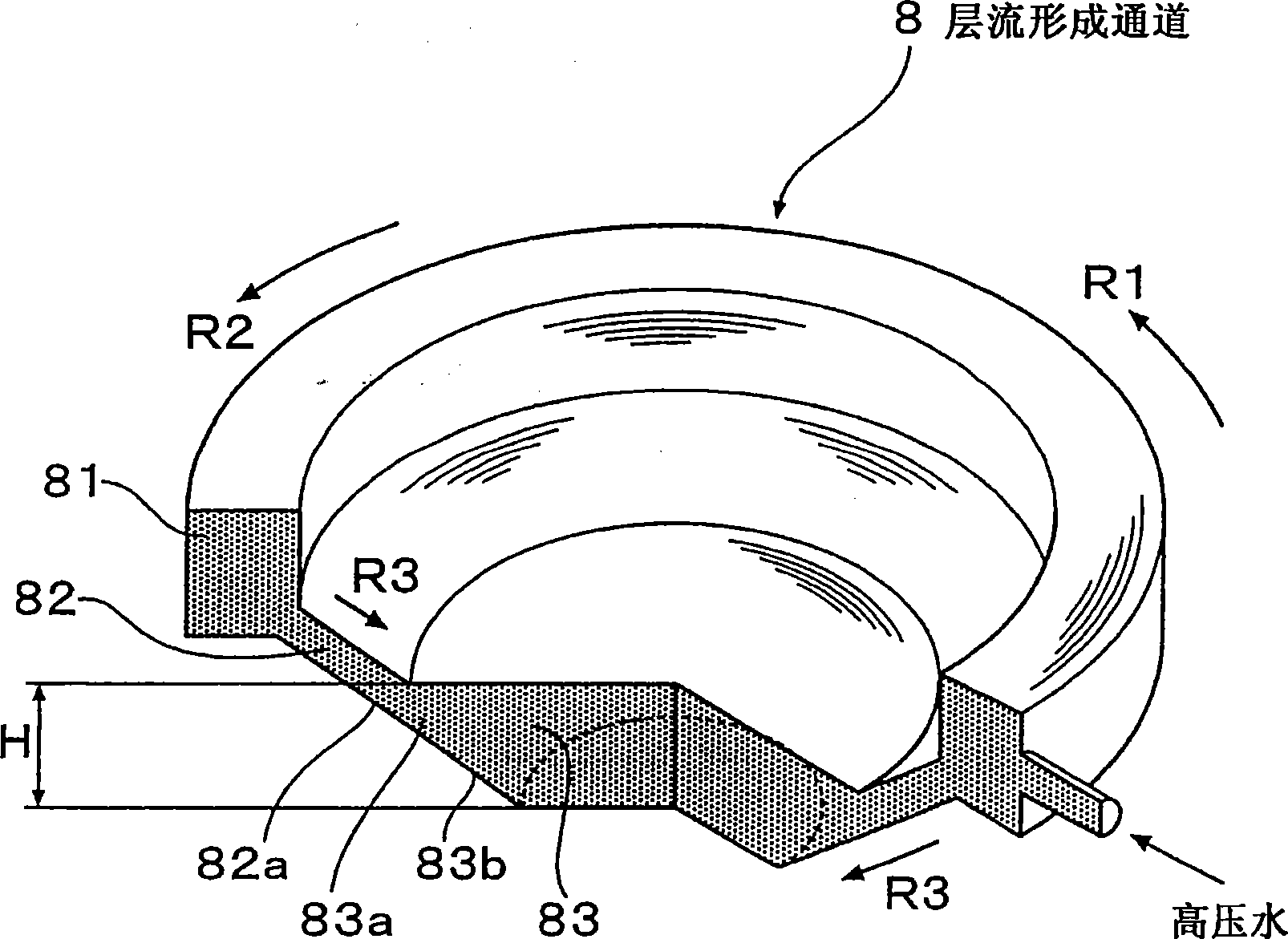

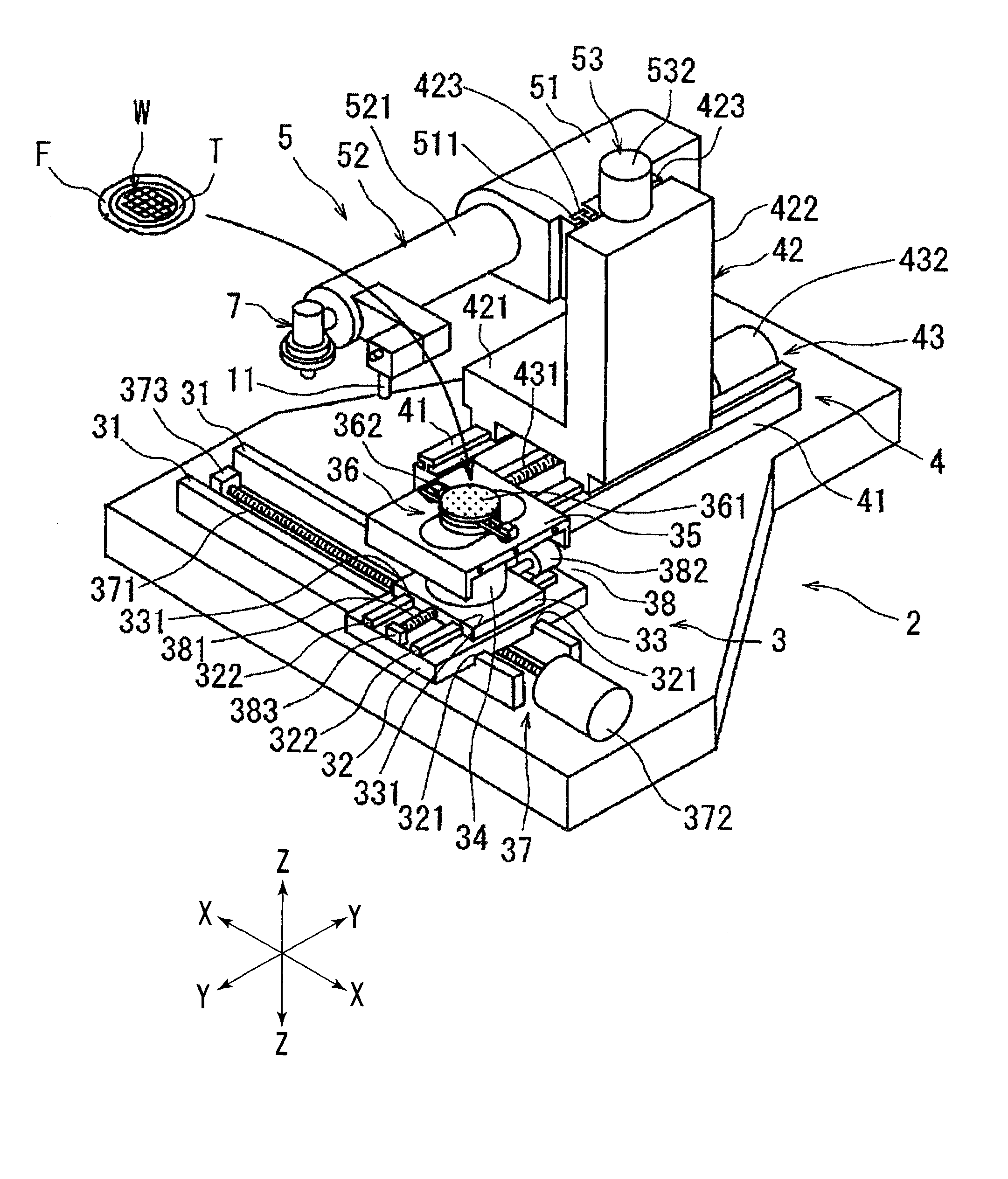

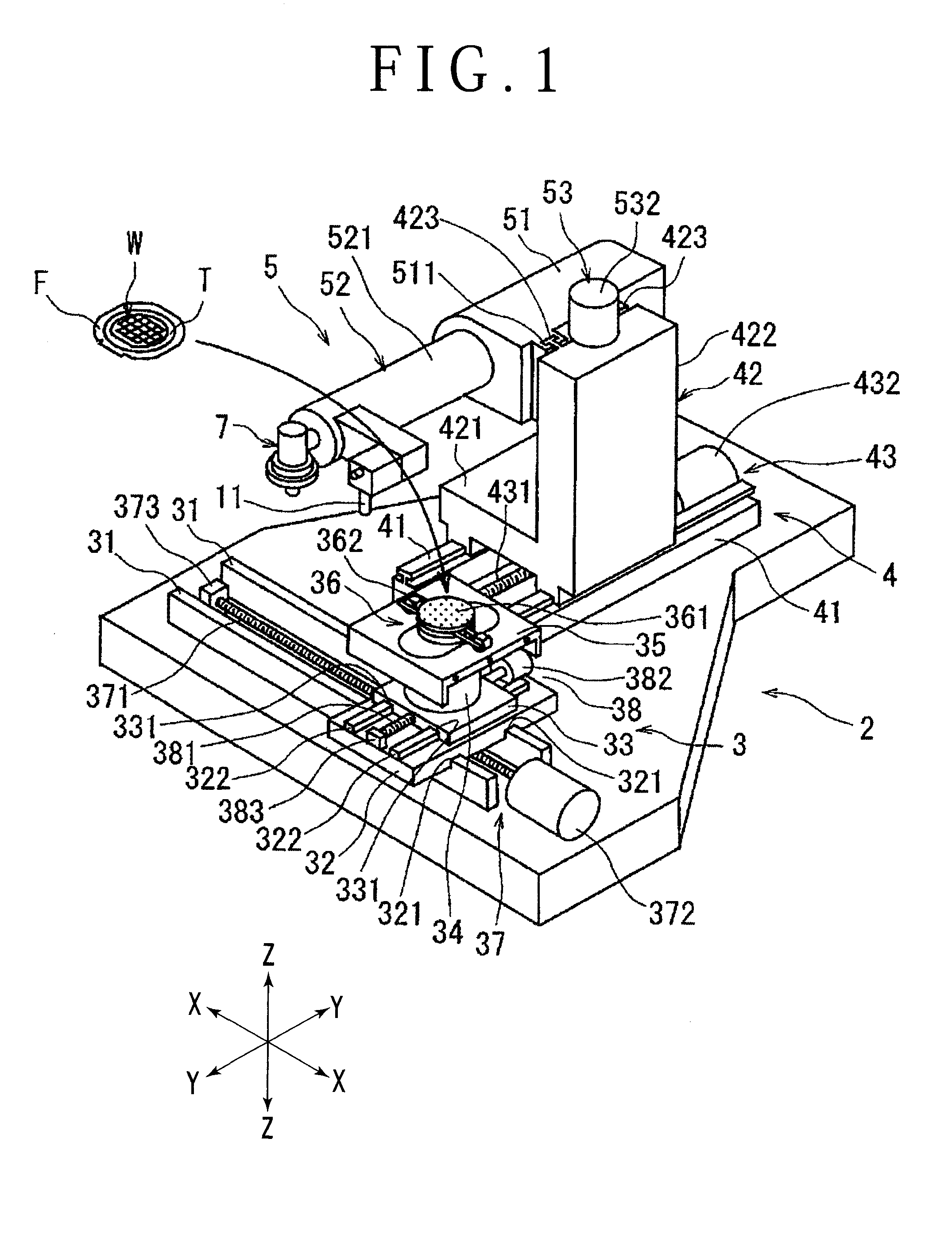

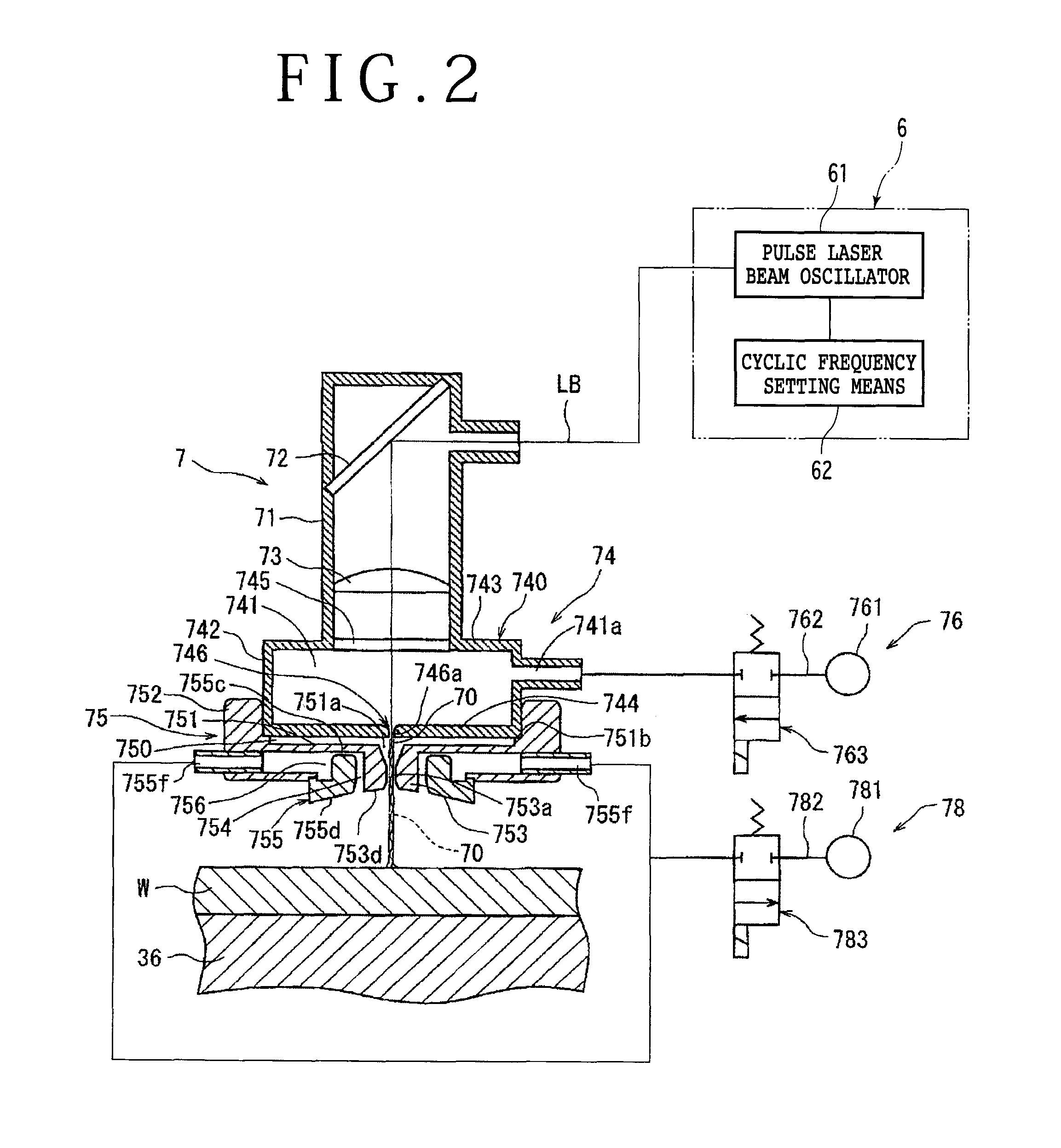

Laser processing device using laser beam induced into jet column

ActiveCN101396768AReduce flow rateSufficient circulation areaLaser beam welding apparatusLaser processingEngineering

A laser machining apparatus comprises a nozzle for ejecting a jet liquid to a workpiece and a liquid supply unit for supplying the jet liquid to the nozzle, while a laser beam is introduced into a jet liquid column ejected from the nozzle. The laser machining apparatus further comprises a laminar flow forming channel for supplying the jet liquid to the nozzle in a laminar state. The laminar flow forming channel includes a distribution channel formed by a cavity for annually distributing the jet liquid, which is supplied from the liquid supply unit, around an axis of the nozzle, an interconnecting channel disposed to be communicated with the distribution channel at the downstream side thereof in an axial direction of the nozzle and formed by an annular cavity around the axis of the nozzle to provide a narrower flow passage than the distribution channel, and a liquid reservoir chamber adjacently disposed upstream of the nozzle in the axial direction thereof and storing the jet liquid tobe supplied to the nozzle. The liquid reservoir chamber has an outer peripheral edge being communicated with the interconnecting channel over an entire circumference of the annular shape thereof.

Owner:SUGINO MACHINE

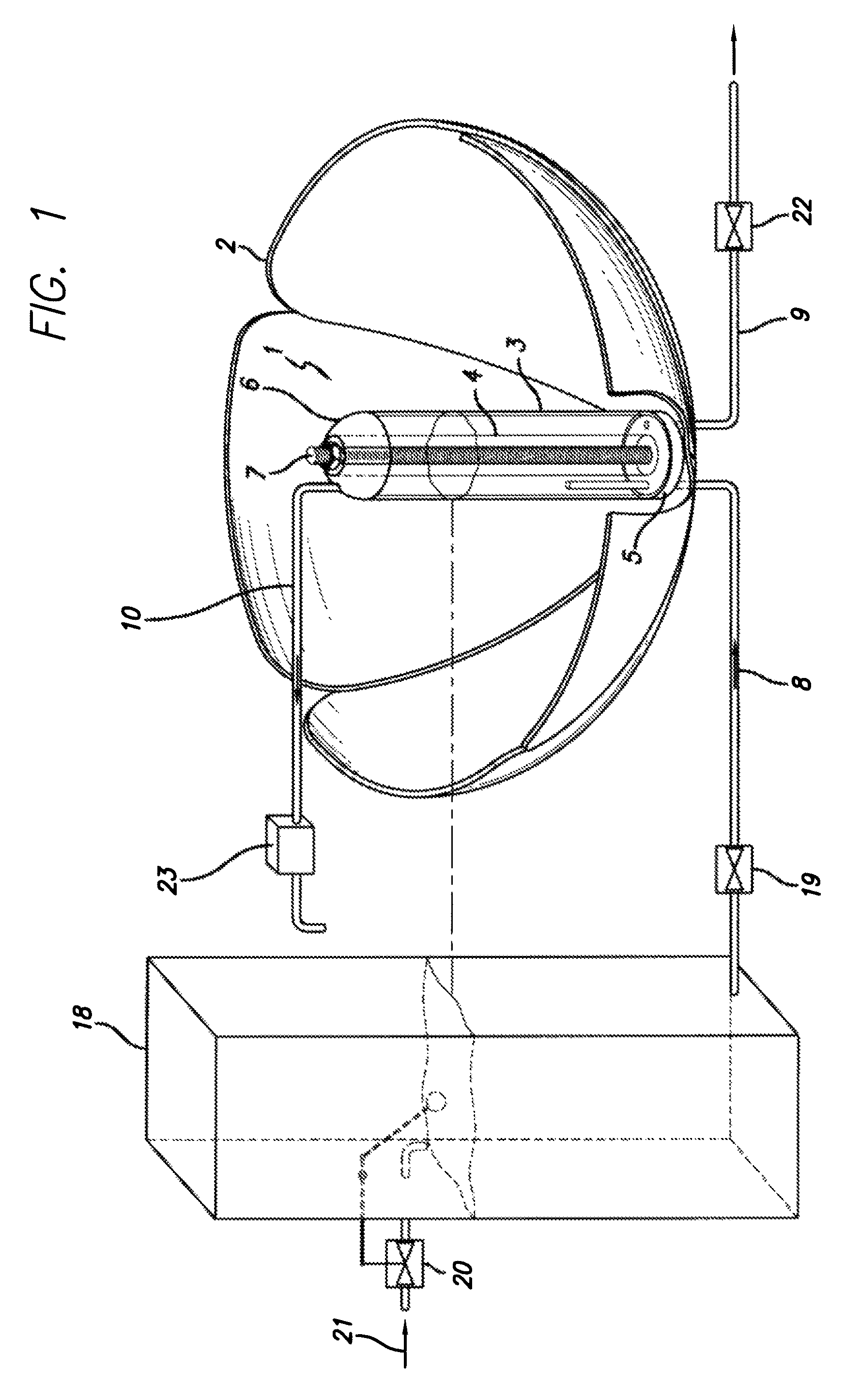

Solar distillation device

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor includes a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

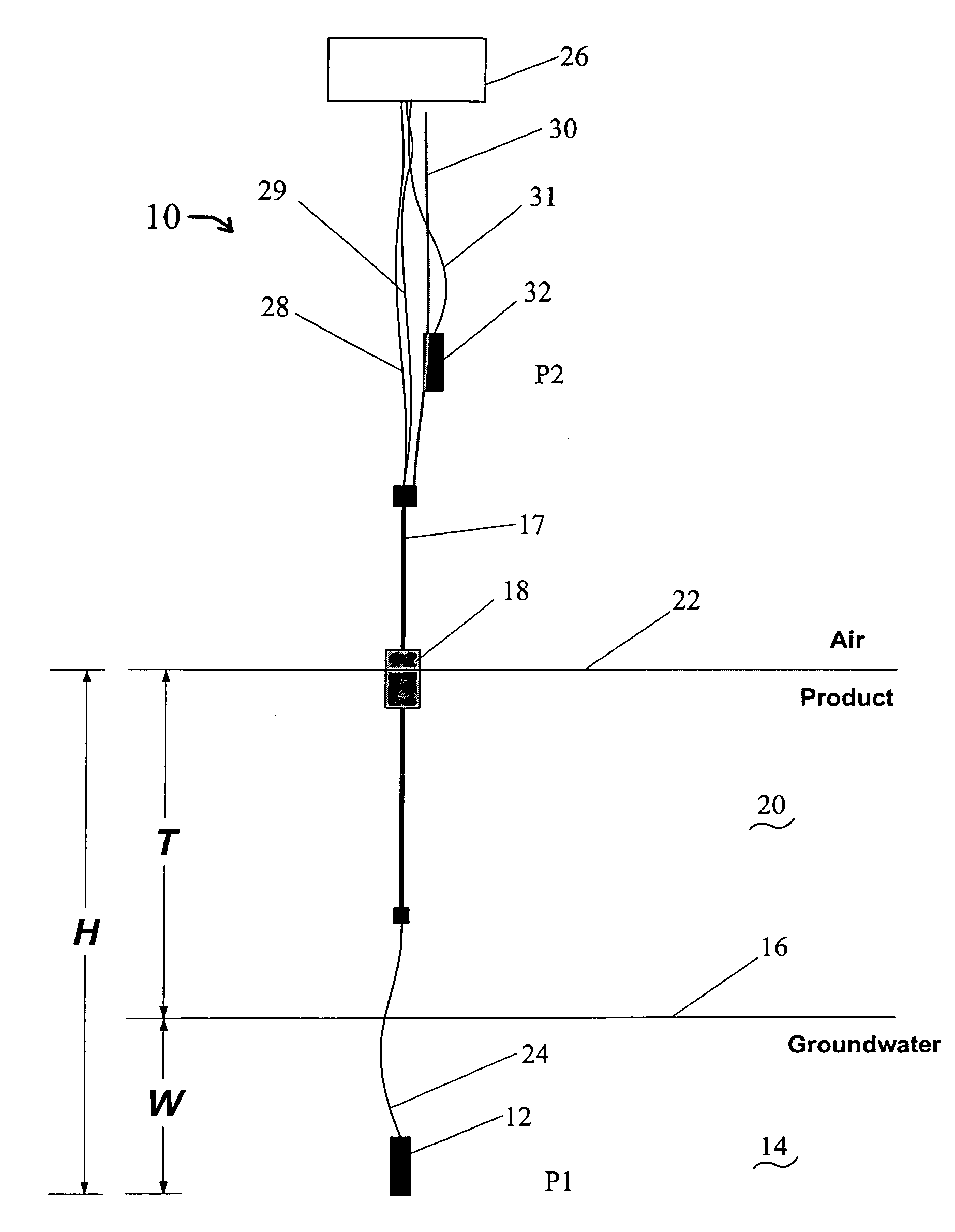

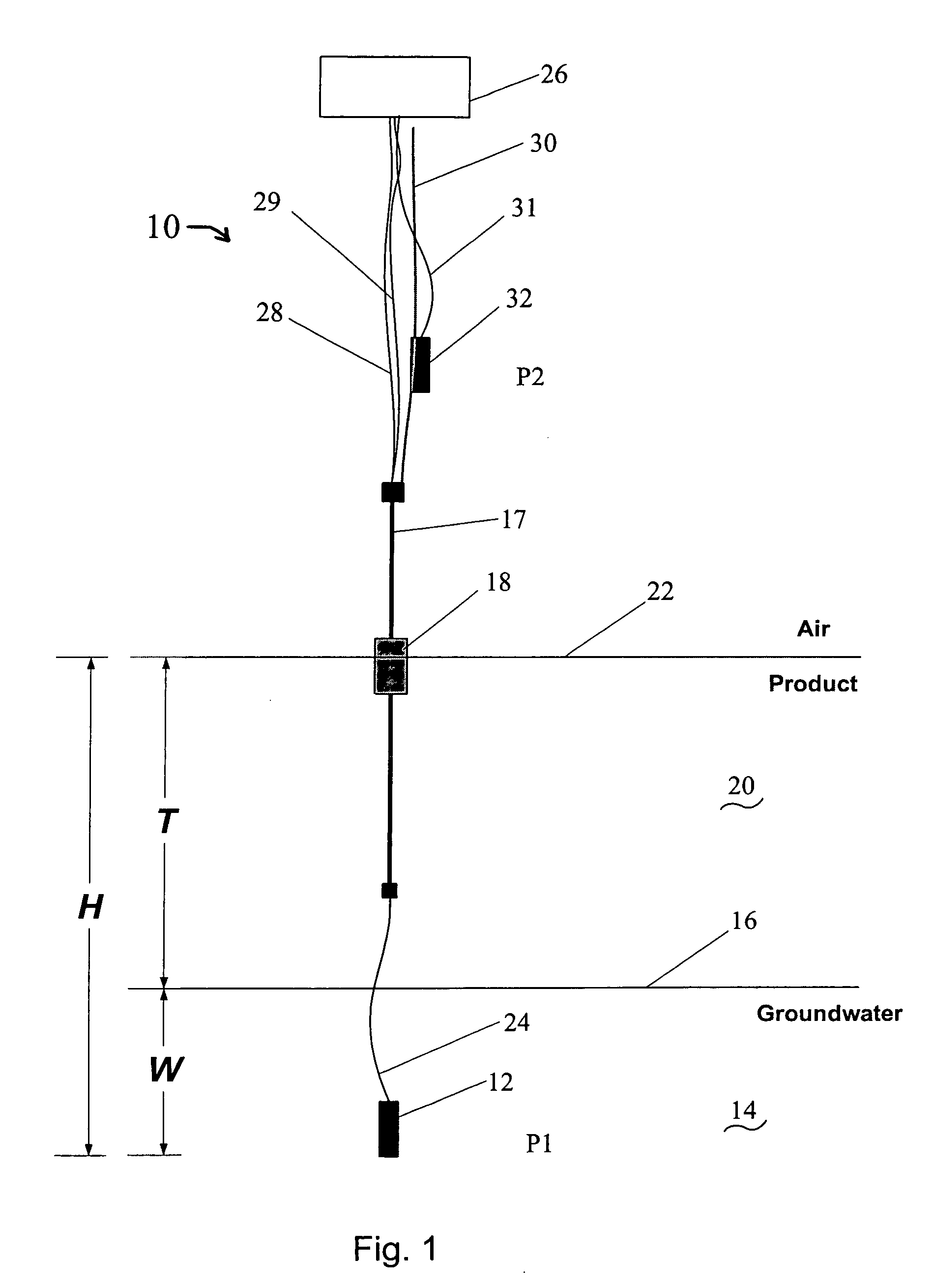

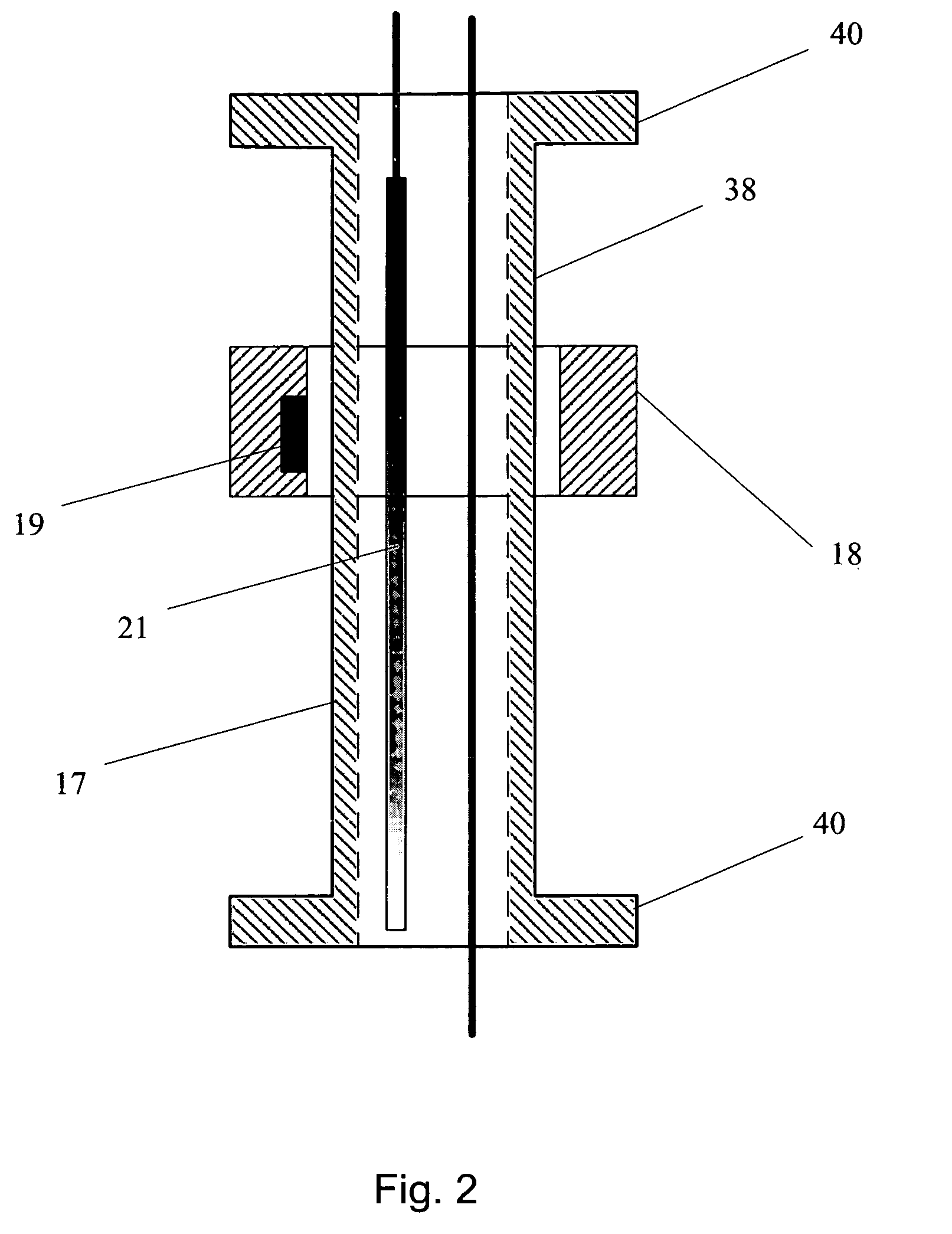

Method of monitoring dual-phase liquid and interface levels

InactiveUS6928862B1Removal from serviceSmall diameterSpecific gravity by measuring pressure differencesSurface/boundary effectSpecific gravityContinuous signal

A dual-phase level monitoring (DPLM) instrument that provides continuous signals that enables determination of the location of the top surface of the lighter of two immiscible fluids (the product) and the hydrostatic pressure below the total fluid column of both immiscible fluids. By knowing the fluid specific gravities, the output signals are processed to yield the location of the air / product and liquid / liquid interfaces, and the depth of the lighter phase. The instrument is intended for use in groundwater monitoring wells with a light non-aqueous phase liquid (product) and tanks or vessels with dual-phase liquids and level monitoring and / or control issues. The DPLM instrument includes a first pressure transducer situated beneath the surface of the liquid with a greater specific gravity, which will typically be ground water. A level element with a float selected so as to be buoyant and float on the surface of the lighter fluid is positioned above the first pressure transducer. A signal from the level element is proportional to the position of the float or the total distance the float is positioned above the bottom of the level element and therefore the total distance above the first pressure transducer, the pressure transducer located in the heaver liquid phase. A second pressure transducer can be deployed above the surface of the liquid if greater accuracy of measurement (as compared to assuming ambient pressure) is desired.

Owner:ROBBINS BRYCE V

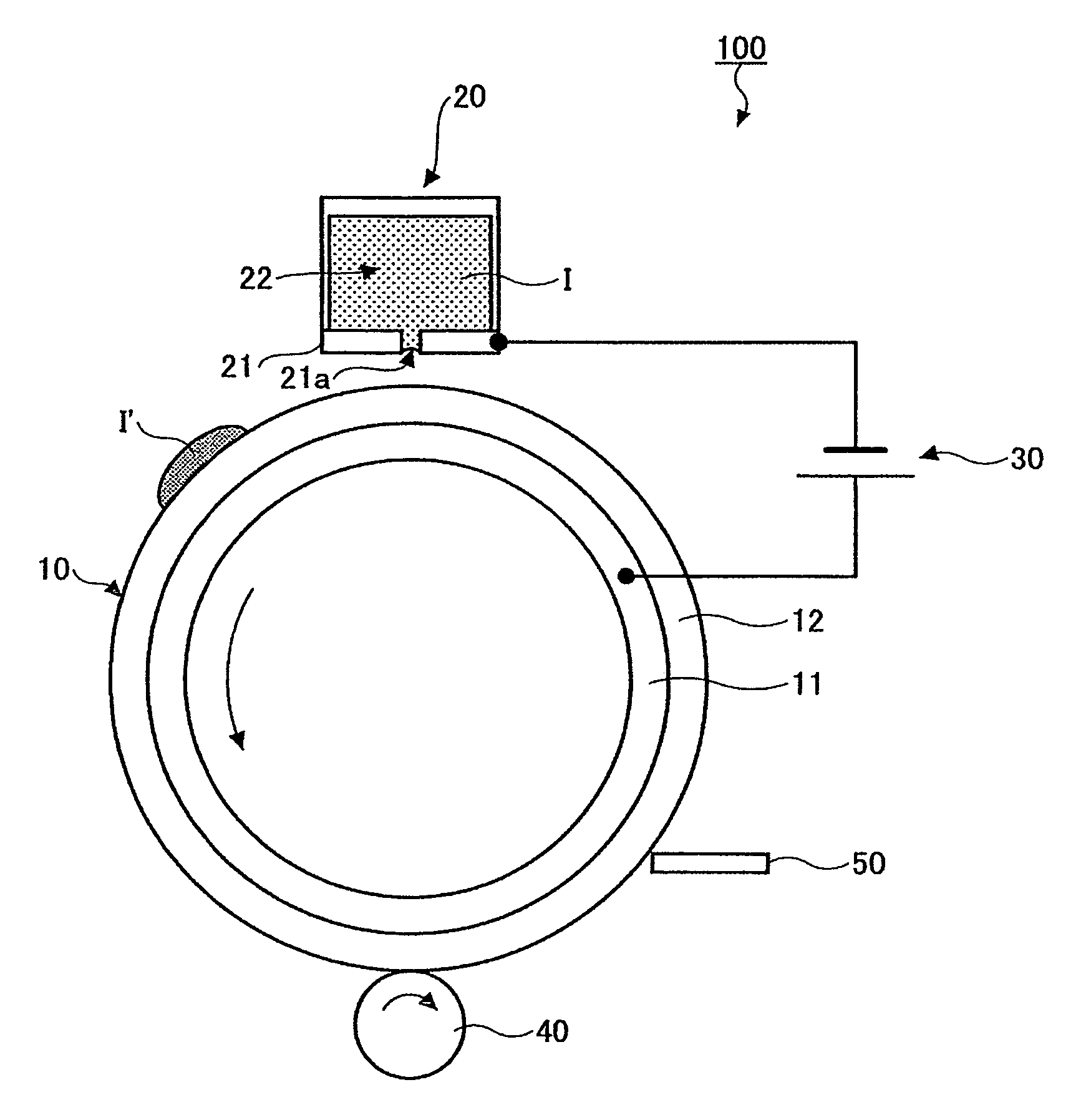

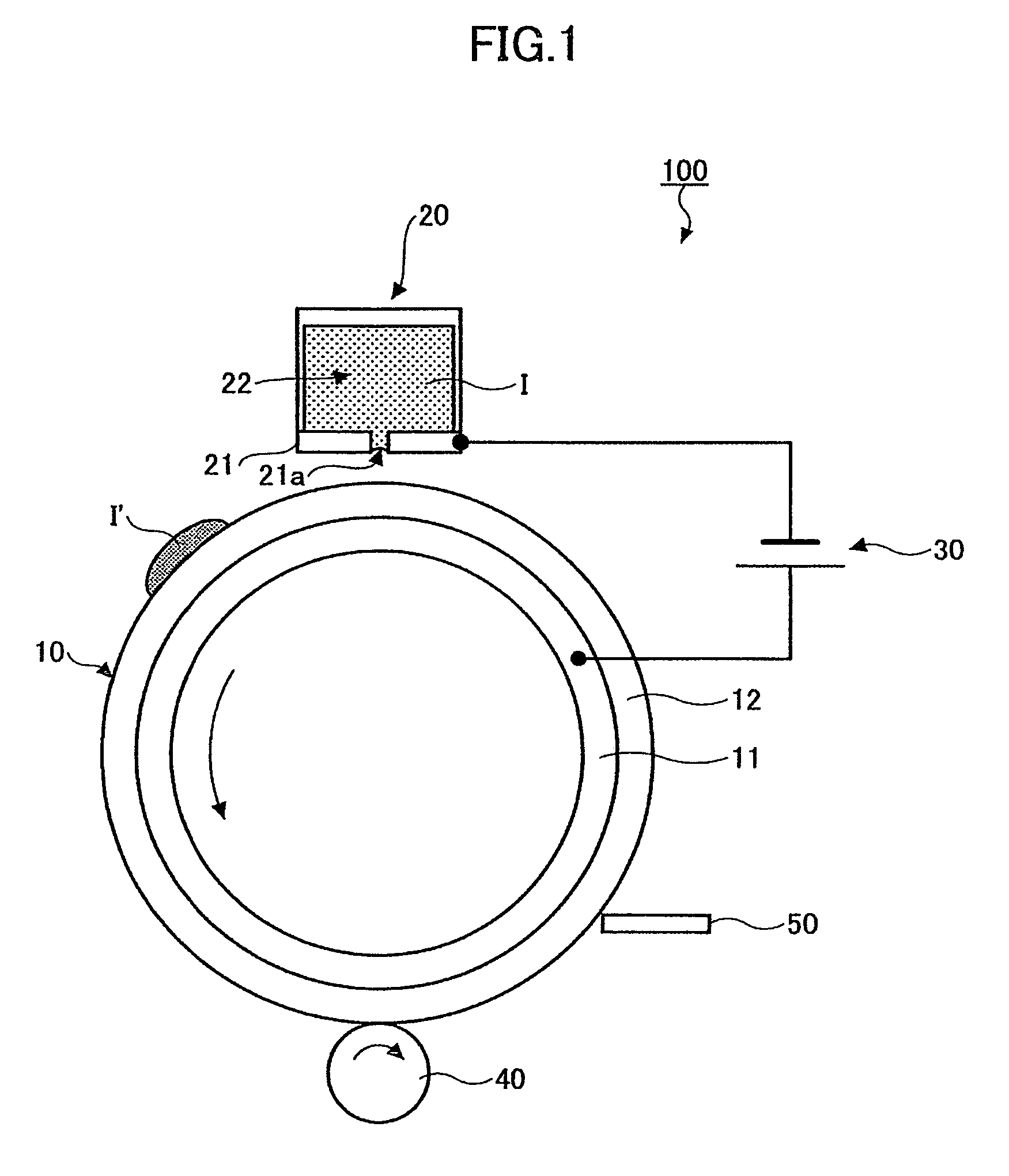

Image forming apparatus and image forming method

A disclosed image forming apparatus includes a recording head having a nozzle capable of ejecting inductive ink including water, a first intermediate transfer body having a conductive surface on which an ink image is to be formed by temporarily forming a liquid-column bridge between the conductive surface and the nozzle, the liquid-column bridge being made of the inductive ink, a voltage application unit applying a voltage between the inductive ink and the conductive surface so that water included in the liquid-column bridge is electrolyzed, and a transfer unit transferring an ink image formed on the first intermediate transfer body to a recording medium.

Owner:RICOH KK

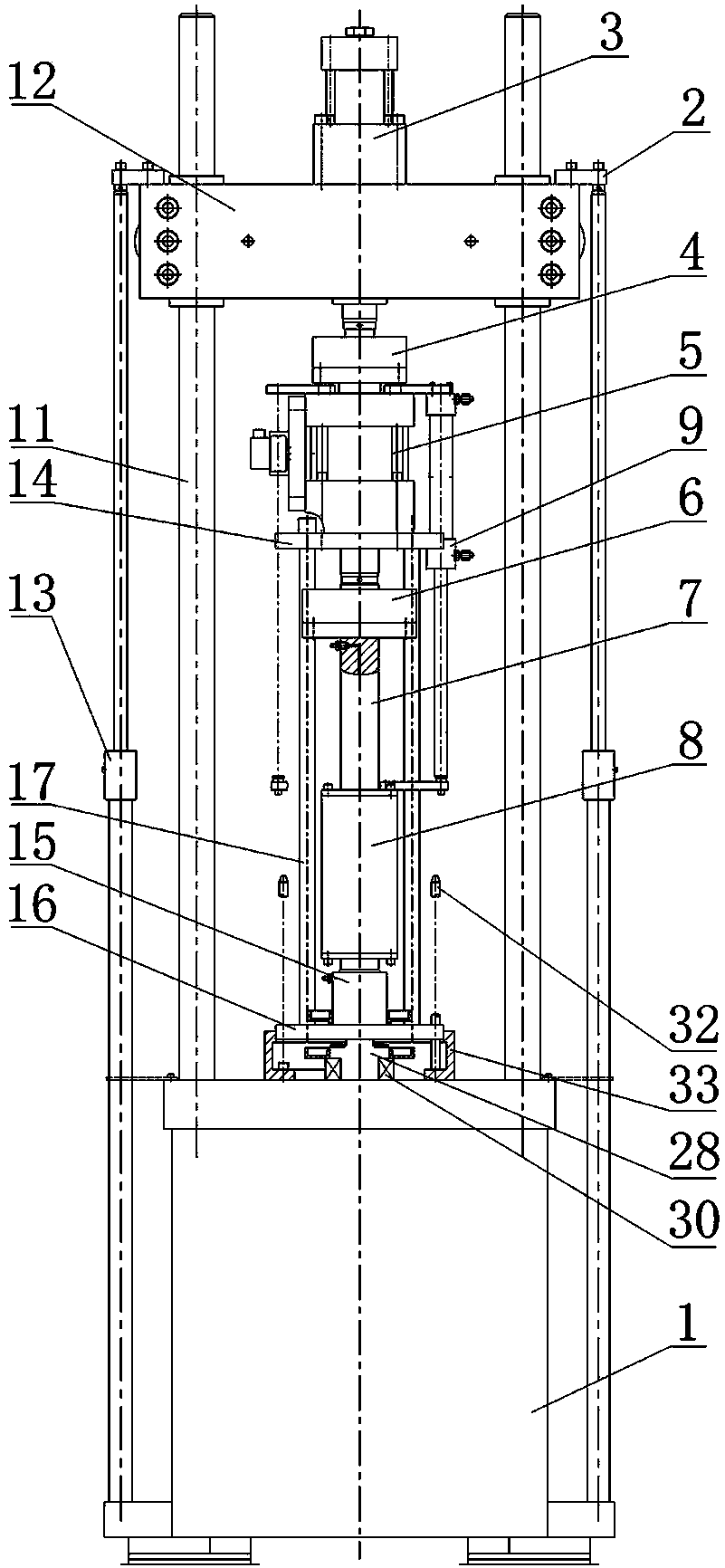

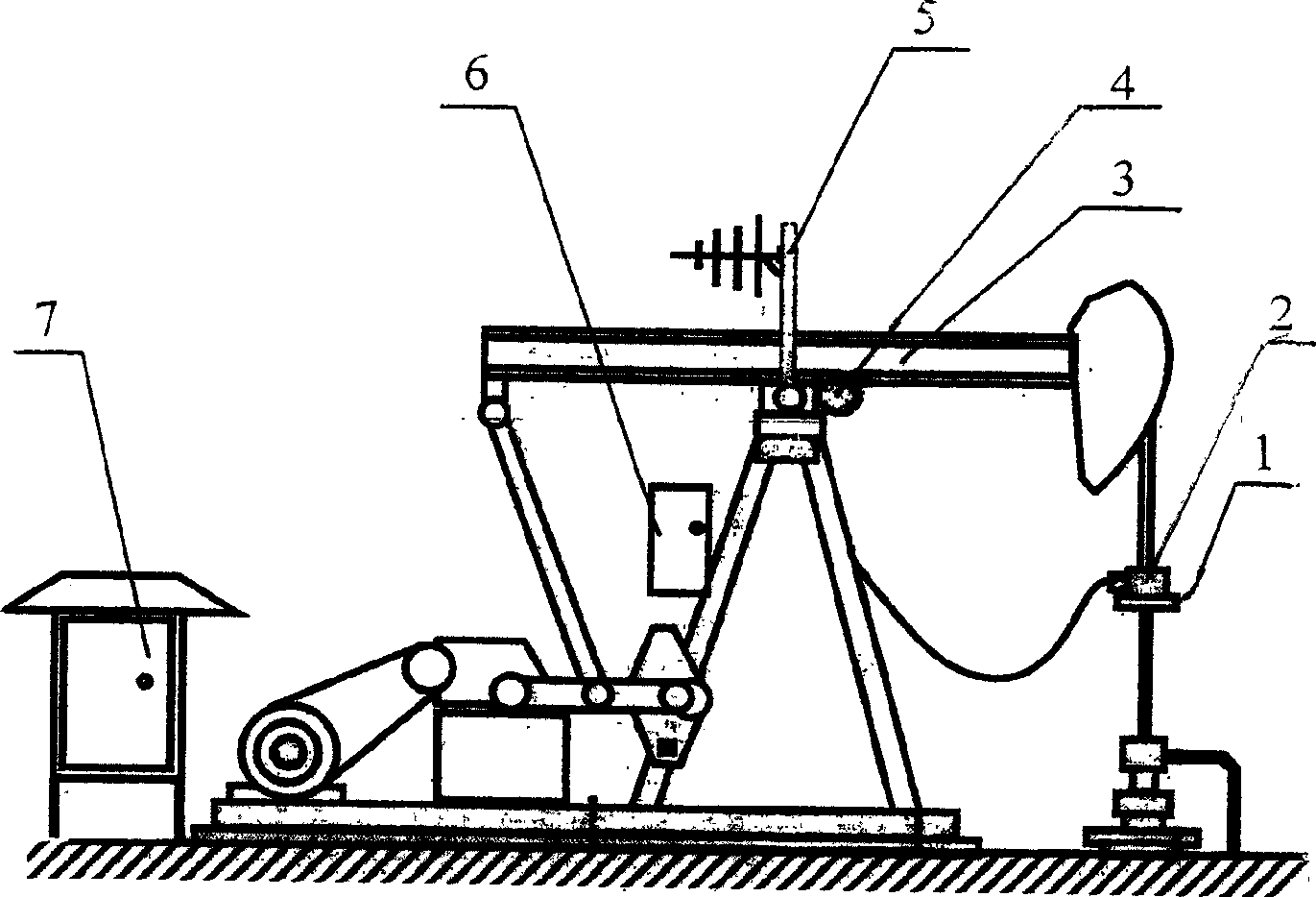

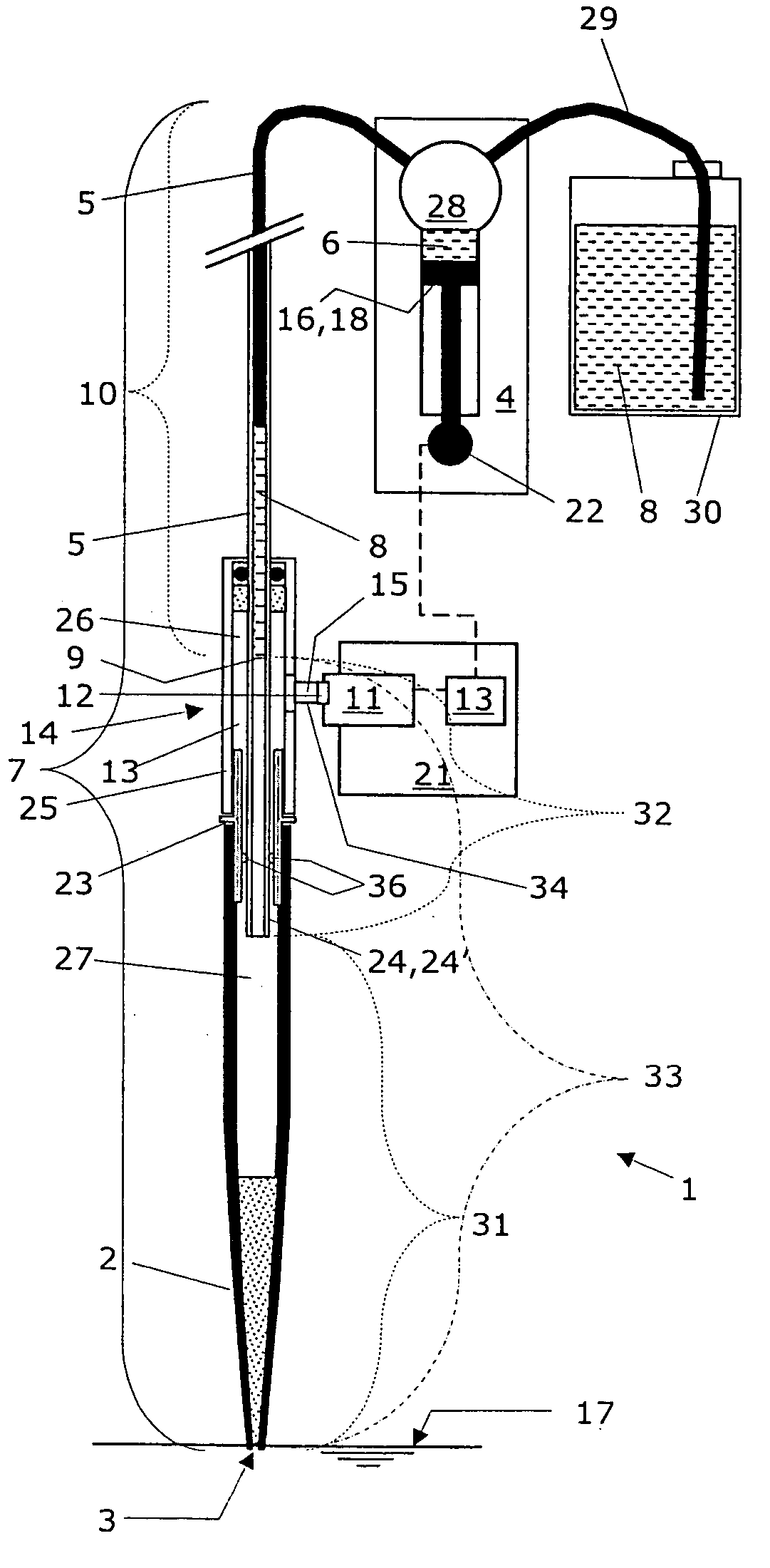

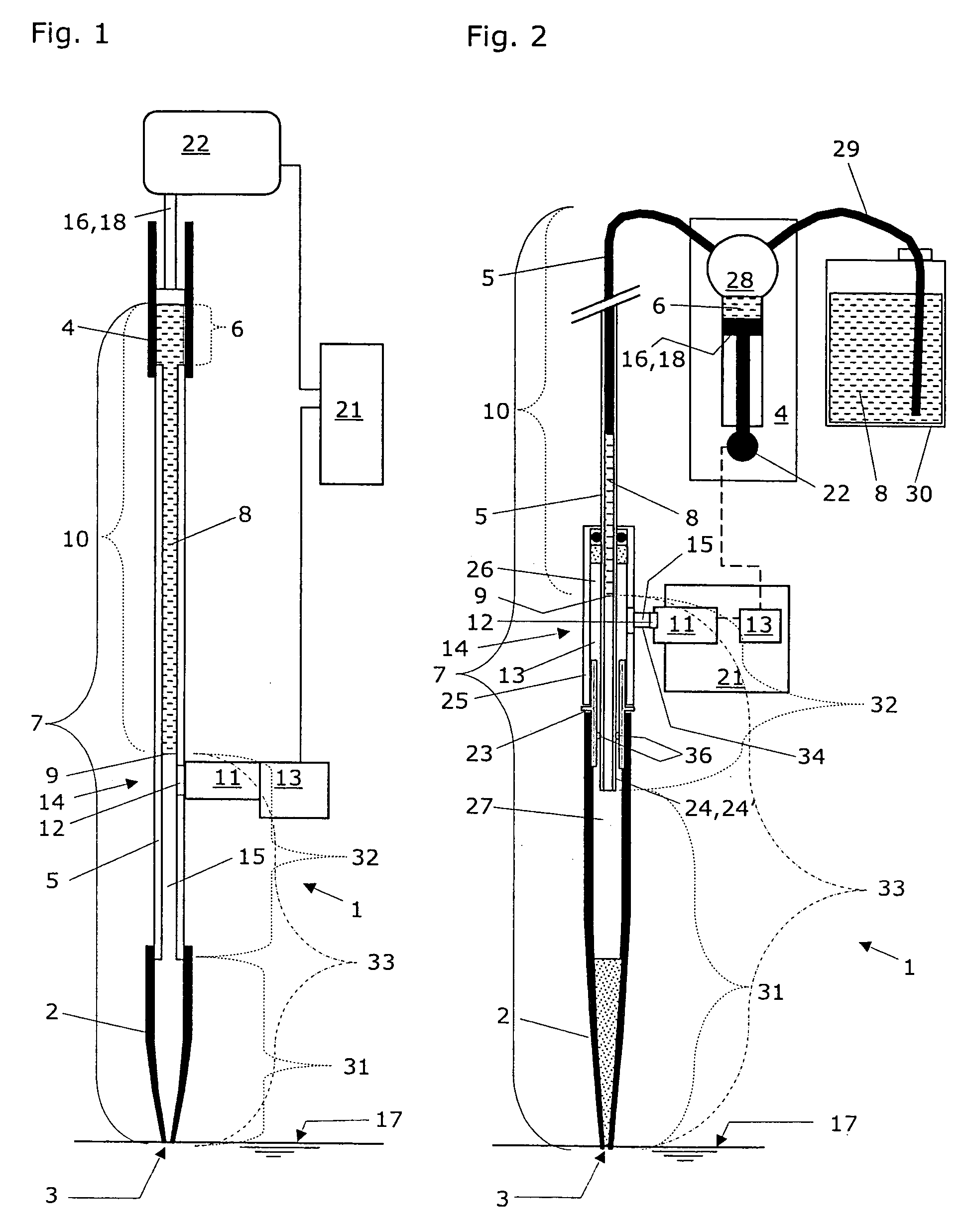

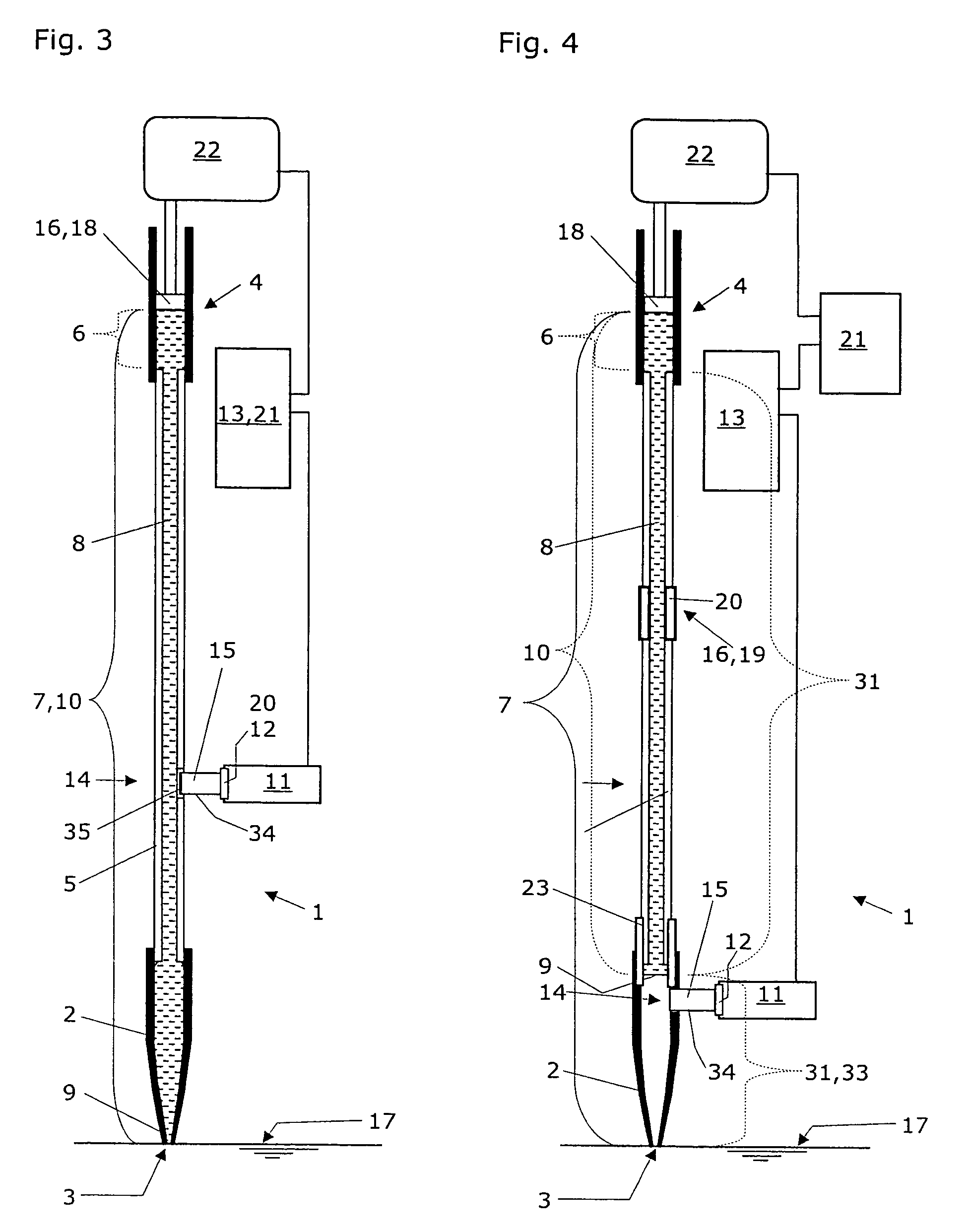

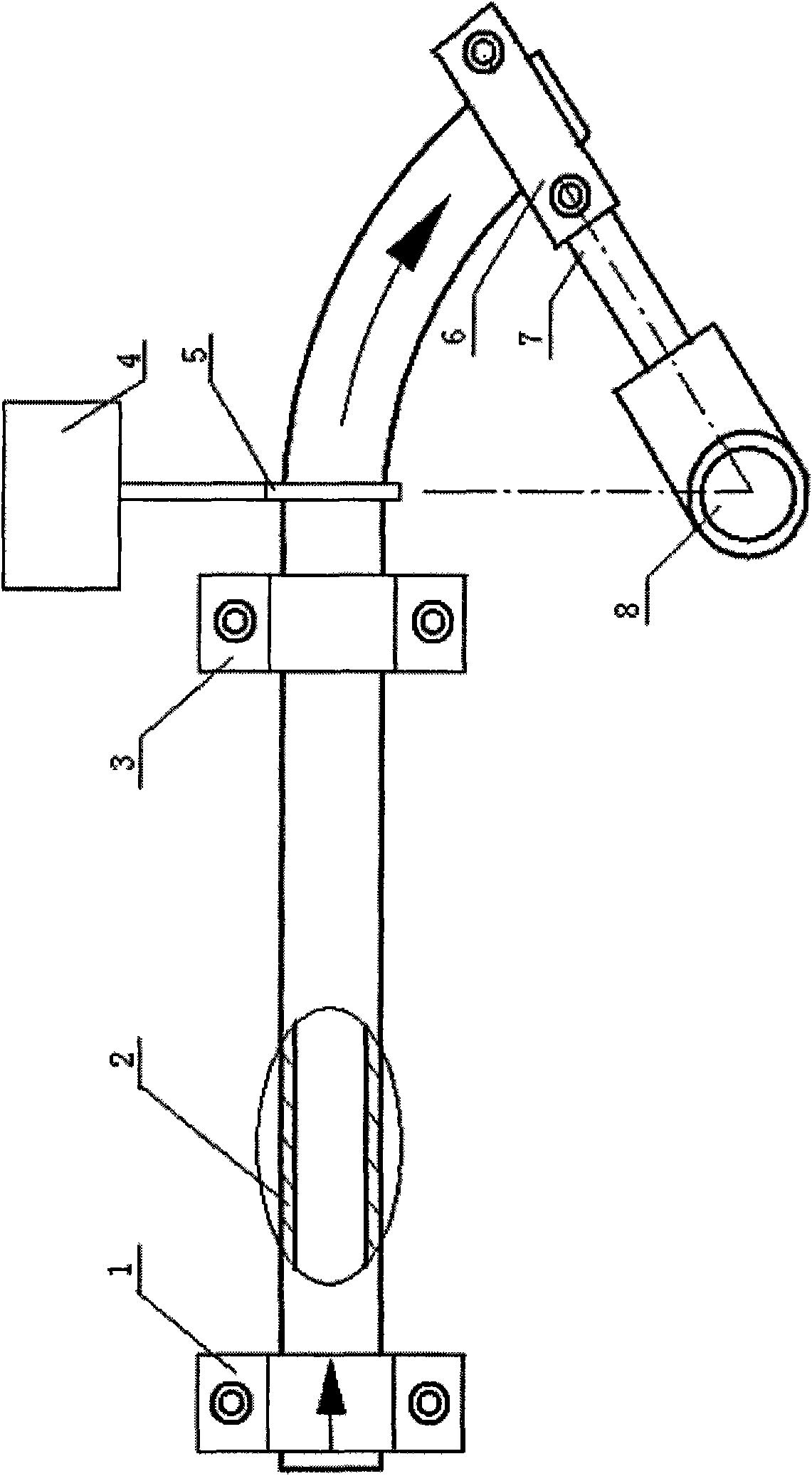

Method and device for testing rock drillability of deep well drilling and extra-deep well drilling

ActiveCN103806907AMeet temperature requirementsMeet pressure requirementsBorehole/well accessoriesExperimental testingWell drilling

The invention discloses a method and device for testing rock drillability of deep well drilling and extra-deep well drilling. The device comprises a machine frame (1), a high temperature and high pressure loading mechanism and a micro drill bit rock breaking drilling depth measurement mechanism, wherein the high temperature and high pressure loading mechanism and the micro drill bit rock breaking drilling depth measurement mechanism are arranged on the machine frame (1). The device exerts confining pressure, pore pressure and fluid column pressure on rock samples in cavities in three axes, overburden pressure is exerted on the rock samples through a hydraulic pump, and therefore the high pressure environment of the stratum of the bottom of a well can be simulated, the relation between the drilling depth and the time is tested through a displacement sensor at the position of a micro drill bit, optimization of the drilling pressure, the rotating speed and the drilling fluid type and drilling machinery drilling speed prediction are achieved. The method and the device have the advantages that the requirements for the bottom hole temperature and the pressure can be met in the deep well drilling process and the ultra-deep well drilling process, the function of testing multiple sets of rock drillability values through a single time of experimental testing of deep well drilling is achieved, the efficiency of the single time of experimental testing is greatly improved, and experimental cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

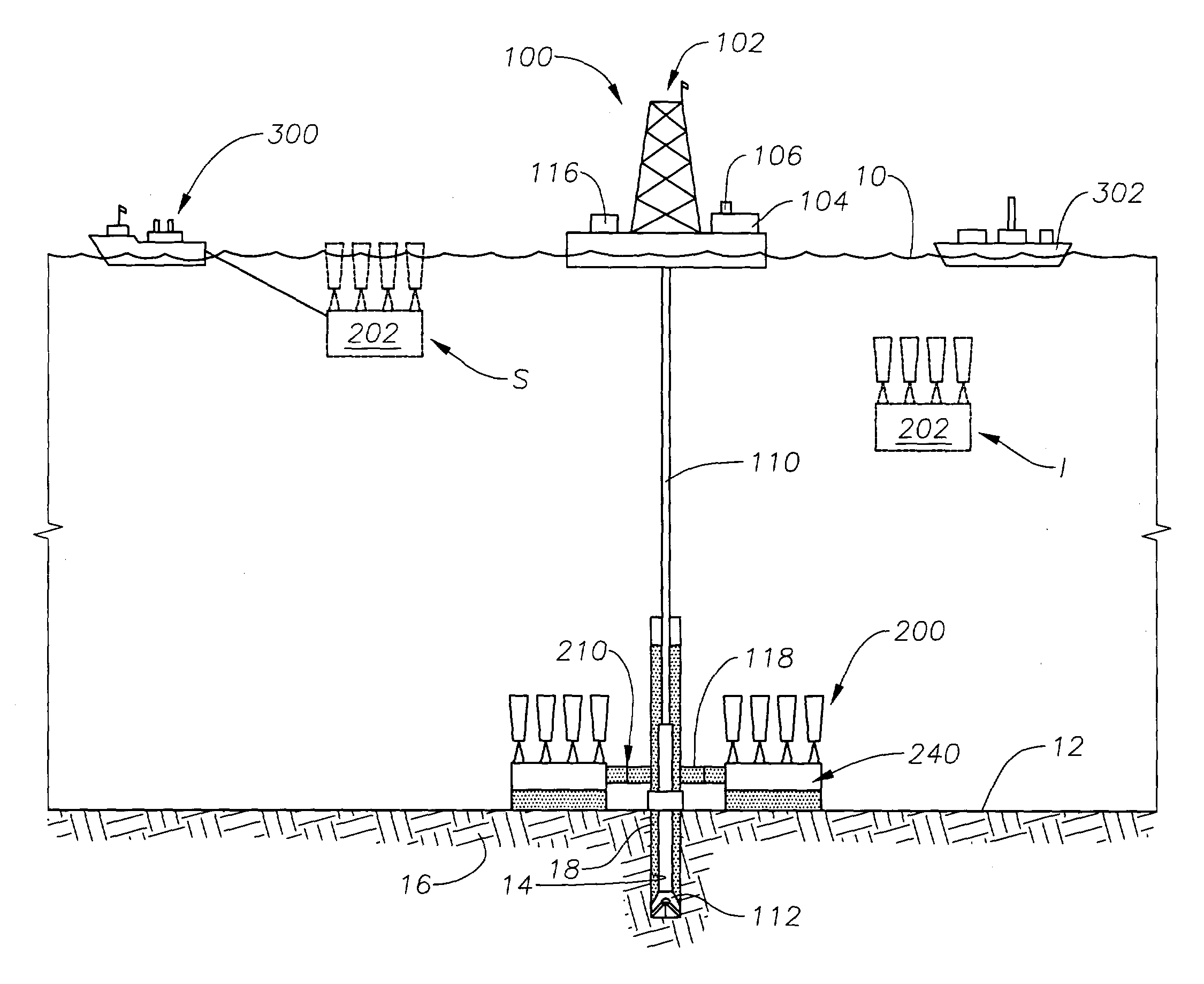

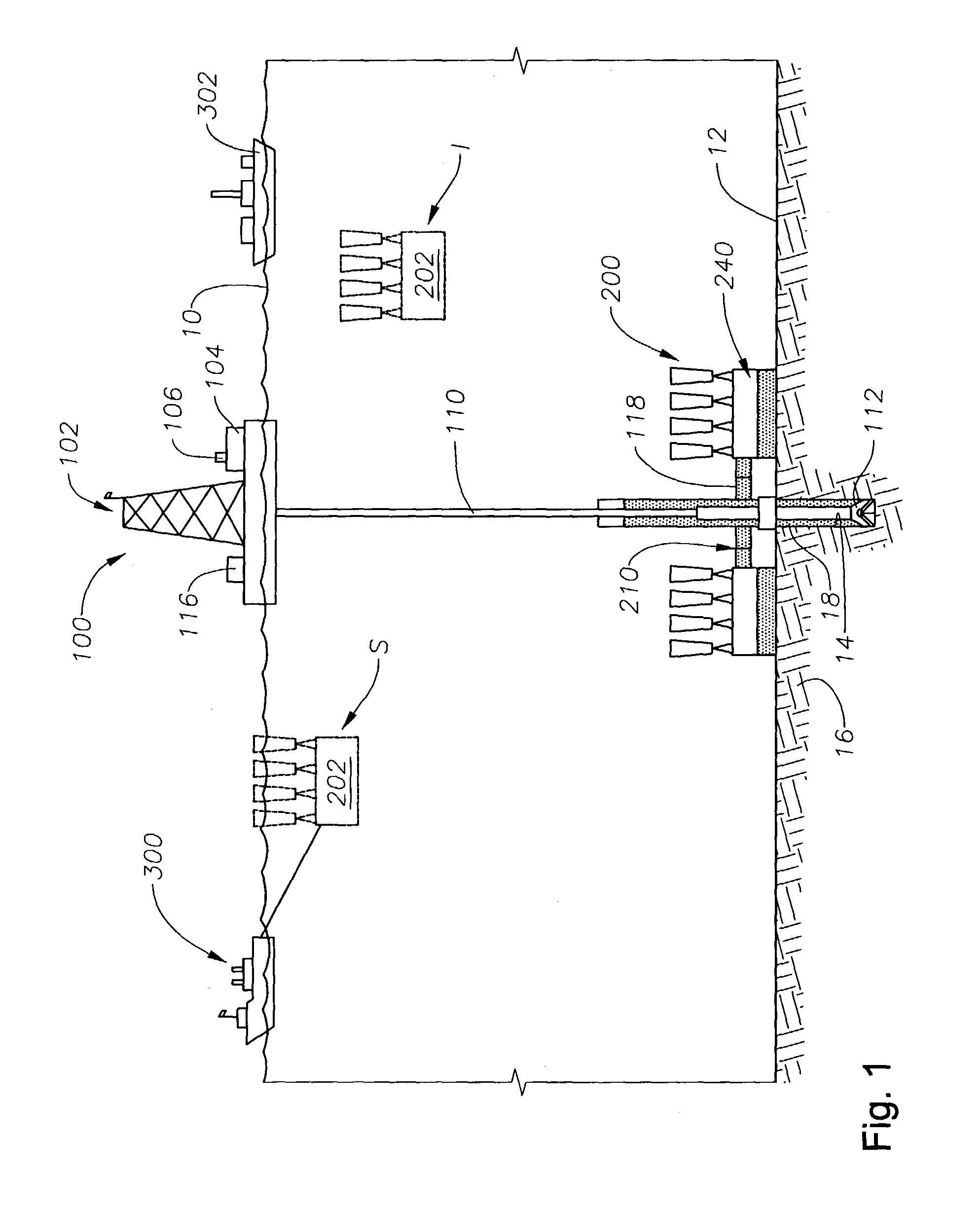

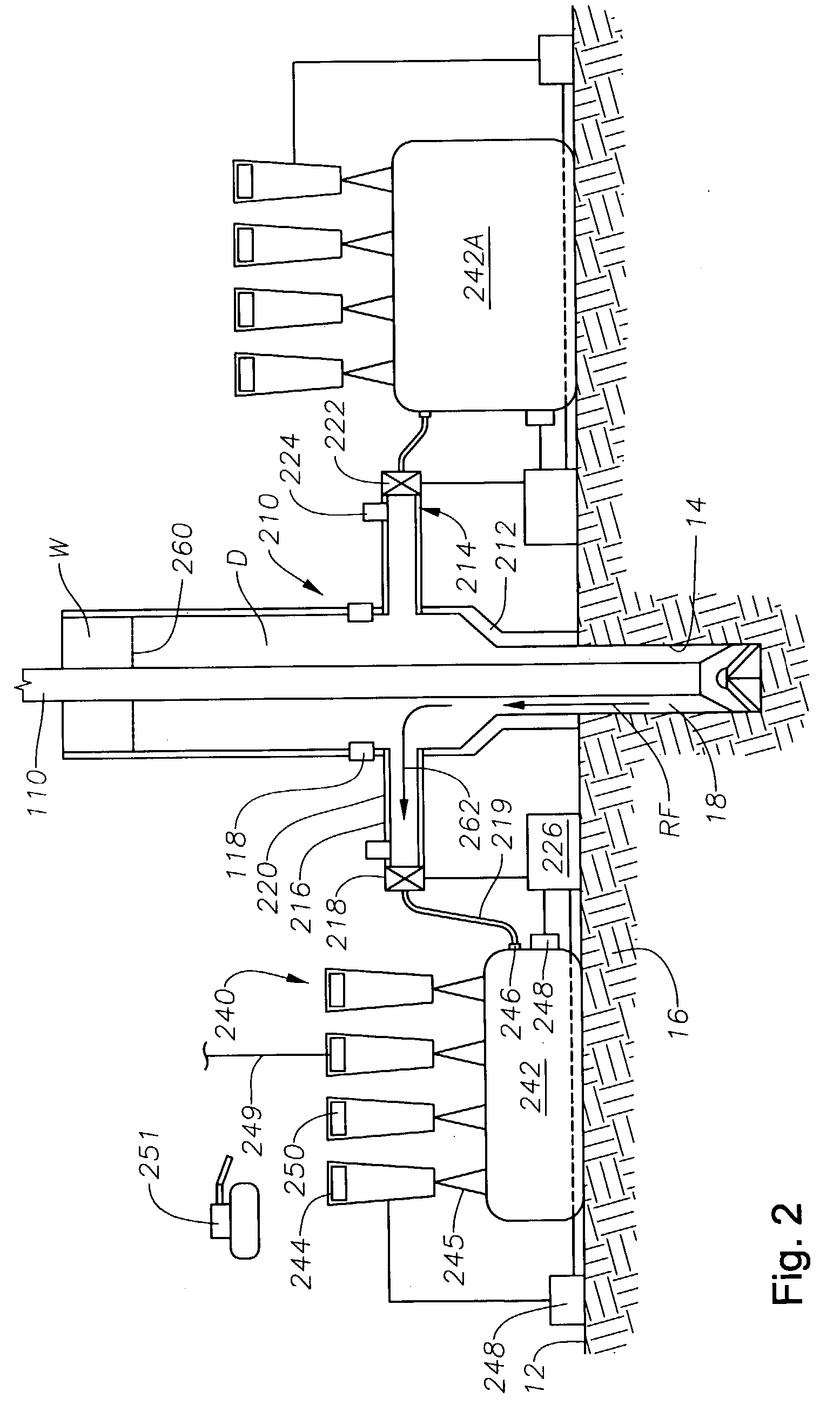

System and method for recovering return fluid from subsea wellbores

InactiveUS7185705B2Recovery system and method be enhanceImprove methodDerricks/mastsFluid removalCritical path methodEngineering

A subsea return fluid recovery system for recovering drilling fluid and cuttings (“return fluid”) from a subsea wellbore in one embodiment includes a hub at the opening of the subsea wellbore that directs fluid into a transport device. In one embodiment, the hub includes a stand pipe that forms a return fluid column, the hydrostatic pressure of which causes return fluid to flow into the transport device rather than up the stand pipe. One or more buoyant members attached to the transport device convey the transport device toward the surface. A preferred recovery method includes collecting return fluid at the seabed, passively transporting the collected fluid to the surface, and processing the collected fluid at a local (offshore) or land based treatment facility. The retrieval and processing of the return fluid is done outside the critical path of the drilling activities at an offshore platform.

Owner:BAKER HUGHES INC

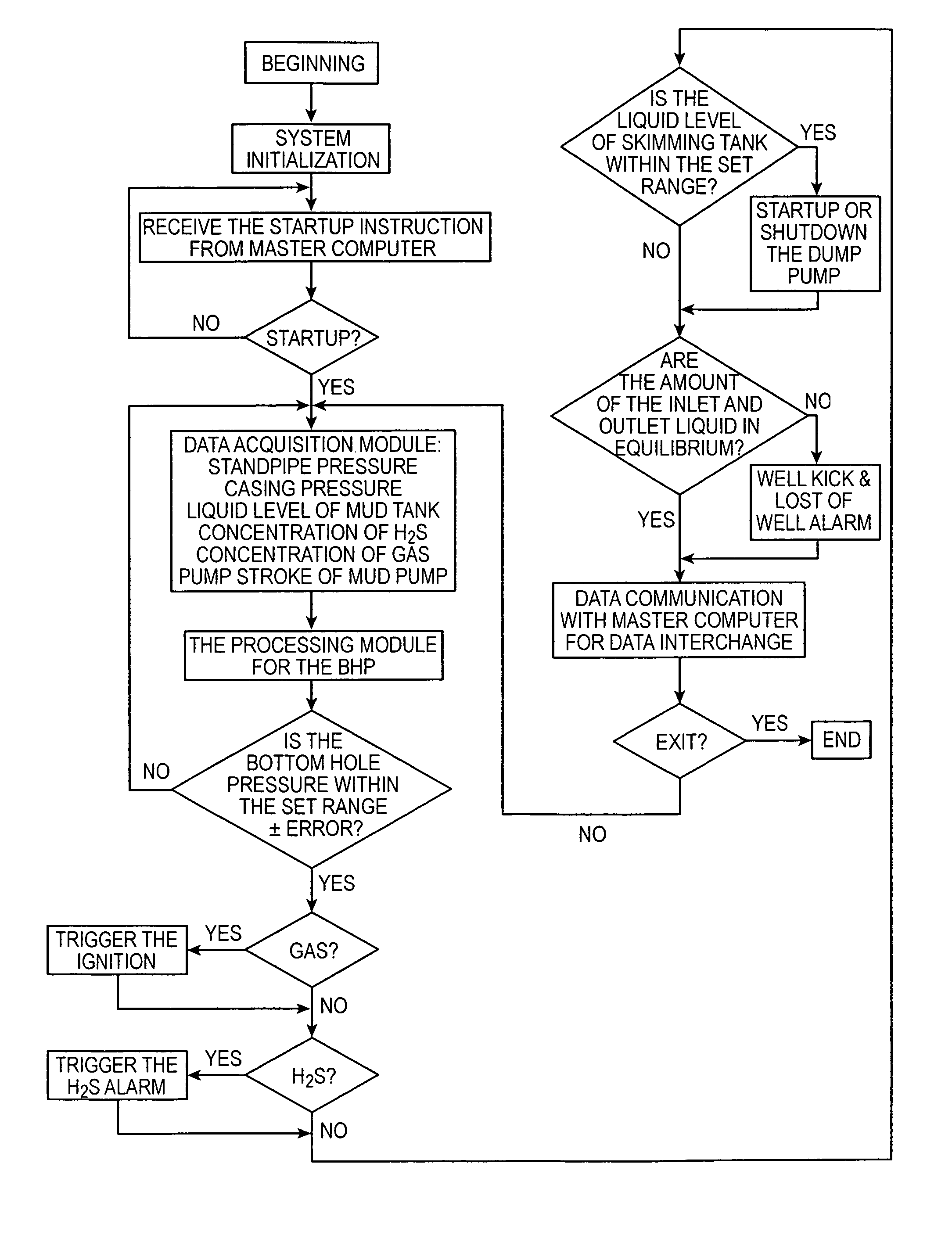

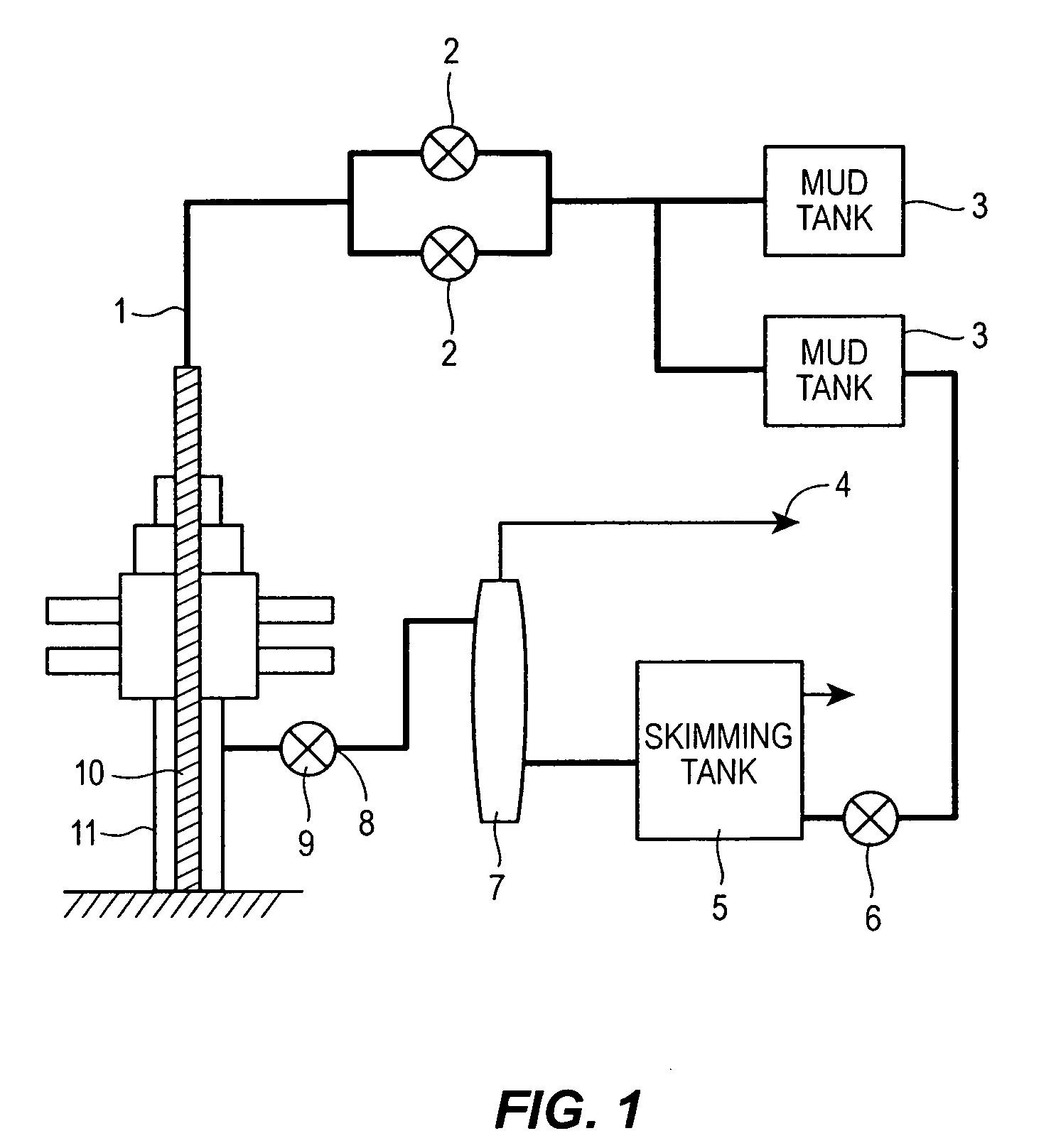

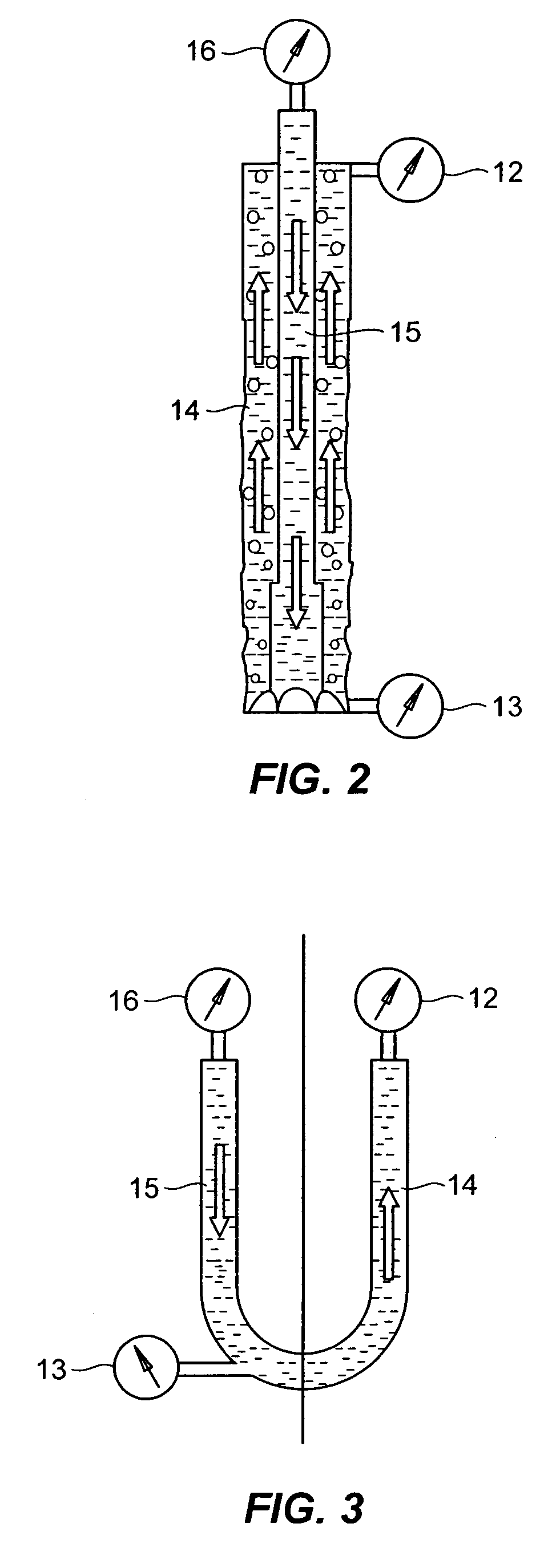

Automatic control system and method for bottom hole pressure in the underbalance drilling

ActiveUS7158886B2Accurate calculationRelatively small errorElectric/magnetic detection for well-loggingConstructionsAutomatic controlAutomated control system

This invention provides an automatic control system and method for bottom hole pressure (BHP) in the underbalanced drilling. It relates to a computer automatic control technology. The automatic control system according to the invention includes a processing module for the BHP based on the mechanisms of hydraulics. The BHP in the underbalanced drilling is calculated from the acquired standpipe pressure (SPP), the calculated circulating pressure loss in the drilling tools, drill bit pressure drop and the fluid colunm pressure in the drill string. The resulting BHP is then compared with the set pressure value of the system. In case that the BHP is higher or lower than the set pressure, an instruction to regulate throttle valve opening will be issued in order to bring the BHP back to the set pressure range and complete BHP monitoring and control.

Owner:CHINA PETROCHEMICAL CORP +1

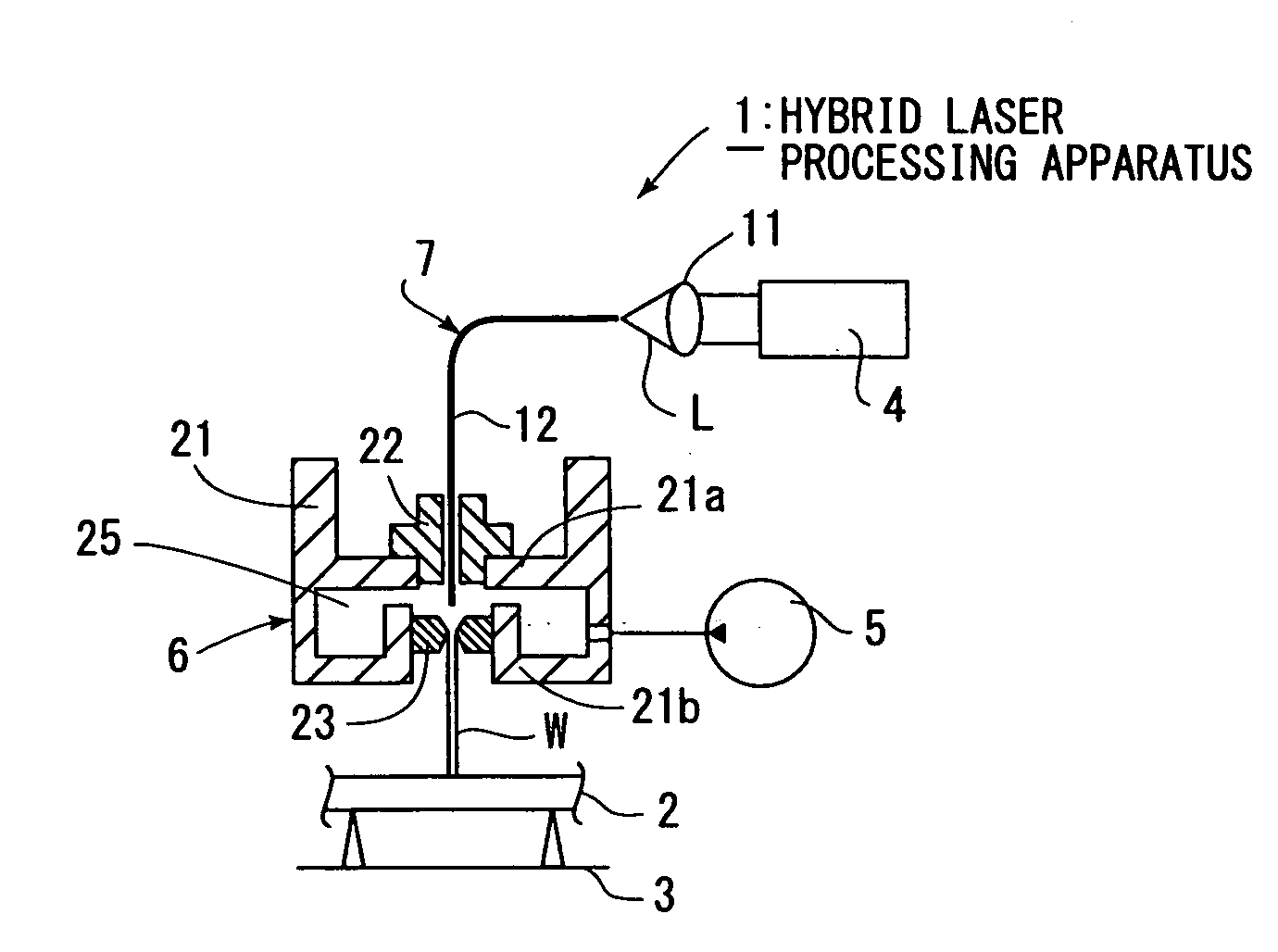

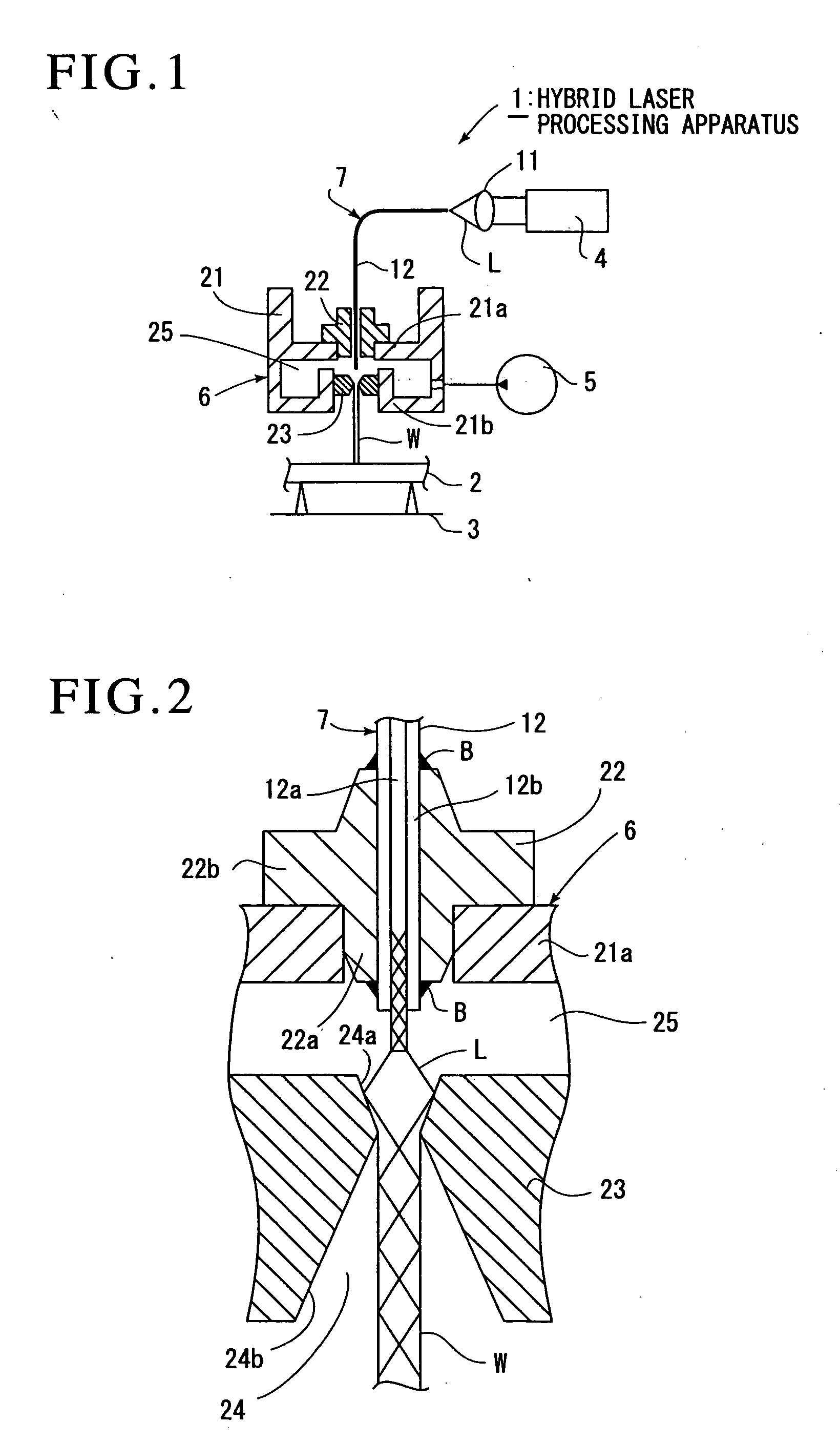

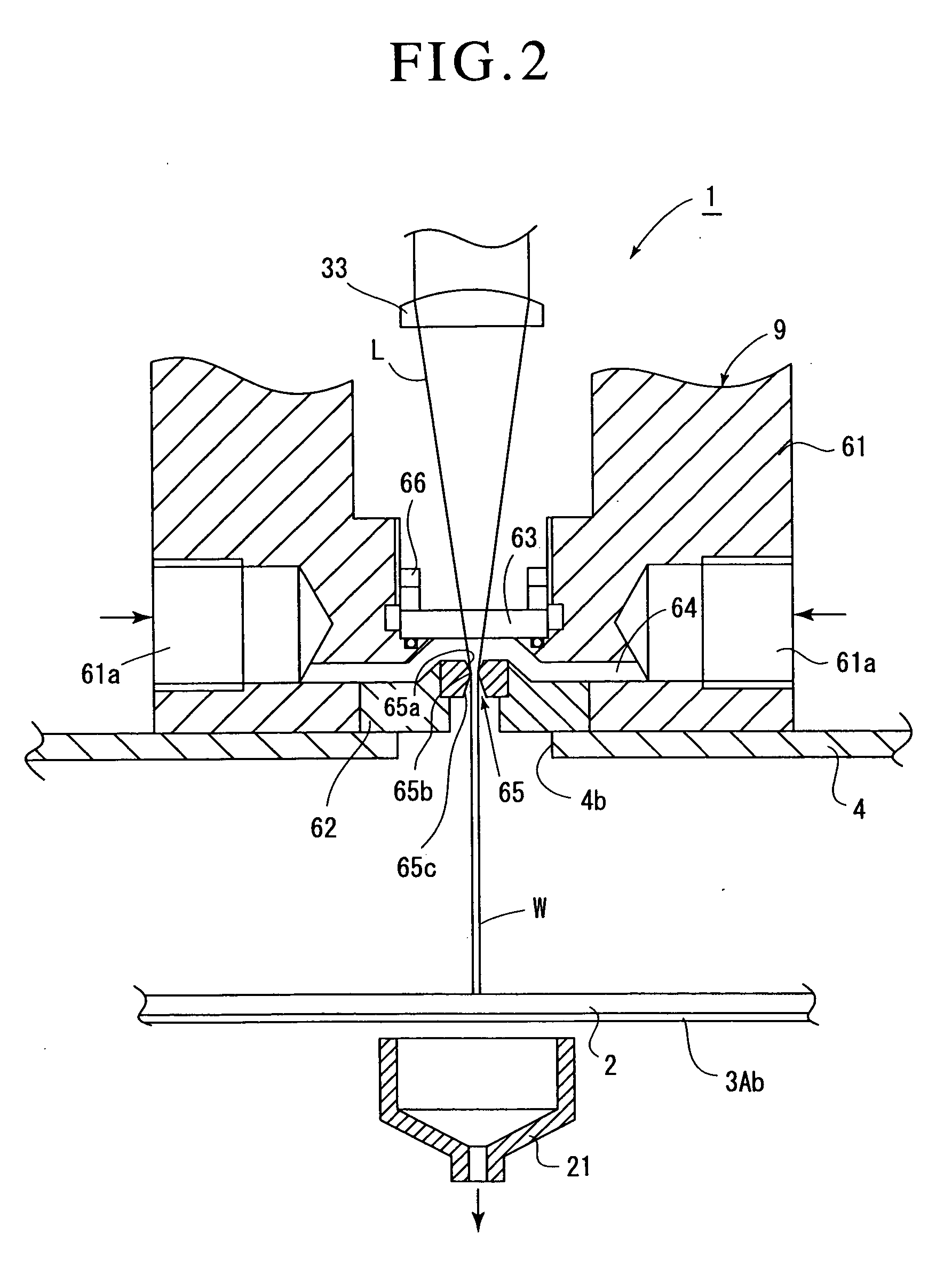

Hybrid Laser Processing Apparatus

InactiveUS20090045177A1Easy to adjustEasily be guidedMetal working apparatusLaser beam welding apparatusFiberLaser processing

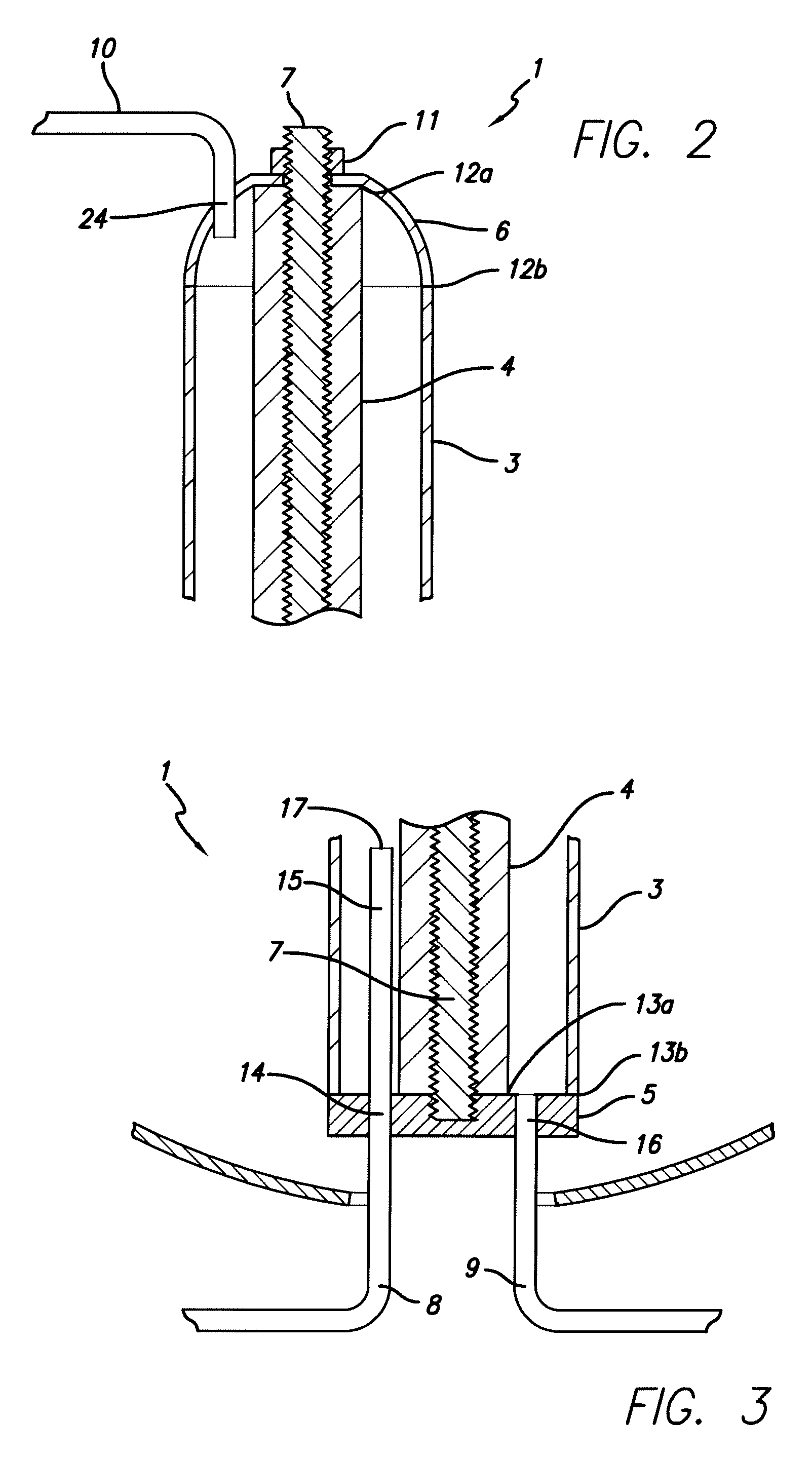

Laser beam L oscillated by a laser oscillator 4 is guided by an optical fiber 12 constituting laser-guiding means 7 to a processing head 6, a liquid passageway 25 to which a high-pressure liquid is supplied by a high-pressure pump 5 is formed in the processing head, and this high-pressure liquid is jetted in the form of a liquid column W from a jet hole 24 of a jet nozzle 23 provided at a lower end of the processing head 6. The optical fiber is exposed inside of the liquid passageway, and a tip of a fiber core 12a of the optical fiber projects beyond a fiber clad 12b, and is close to the vicinity of the jet hole.The laser beam irradiated from the fiber core is guided to the liquid column after it is reflected on a first inclined surface 24a formed on the jet hole, and processing on the workpiece 2 is performed.The laser beam can easily be guided to the liquid column.

Owner:SHIBUYA IND CO LTD

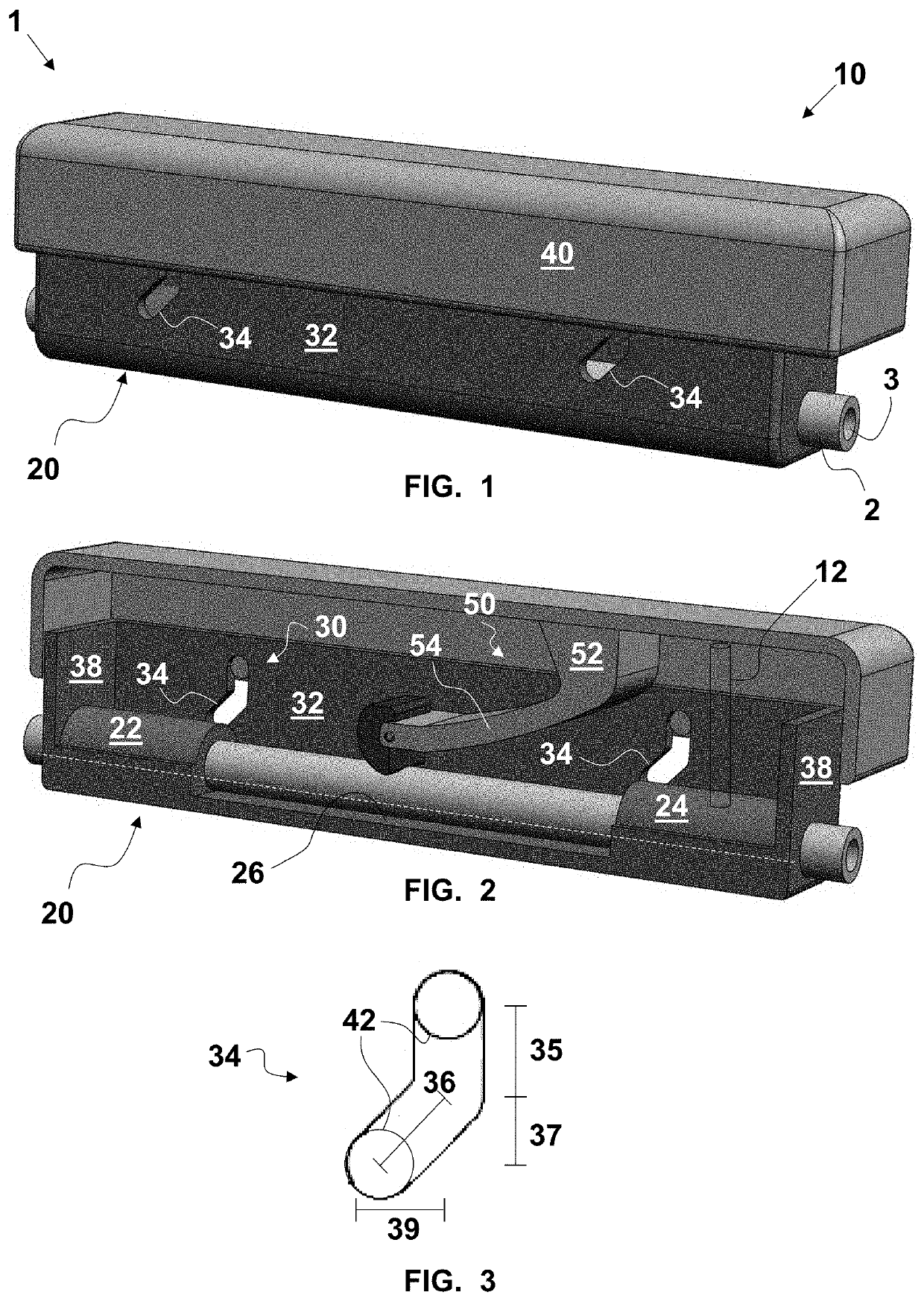

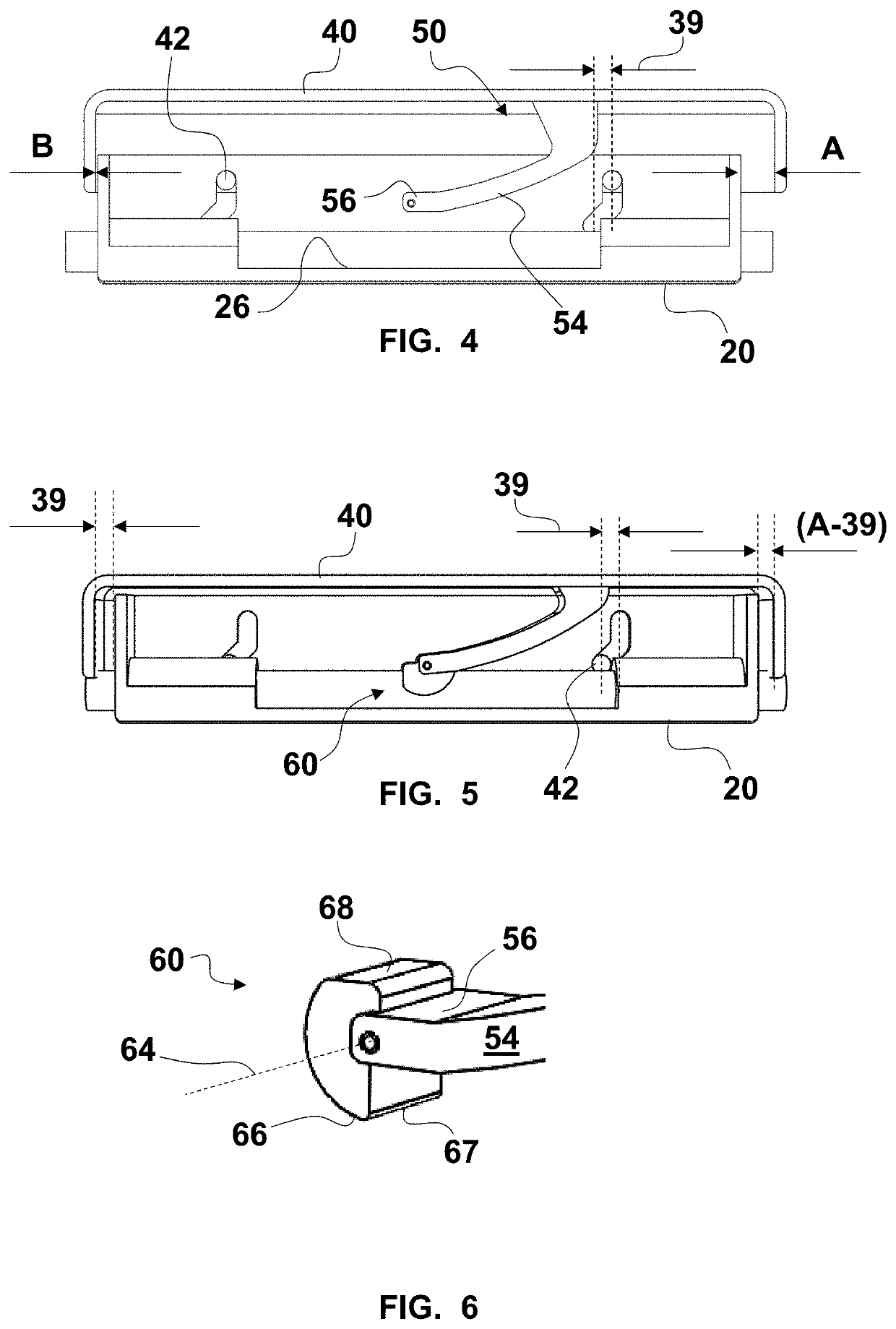

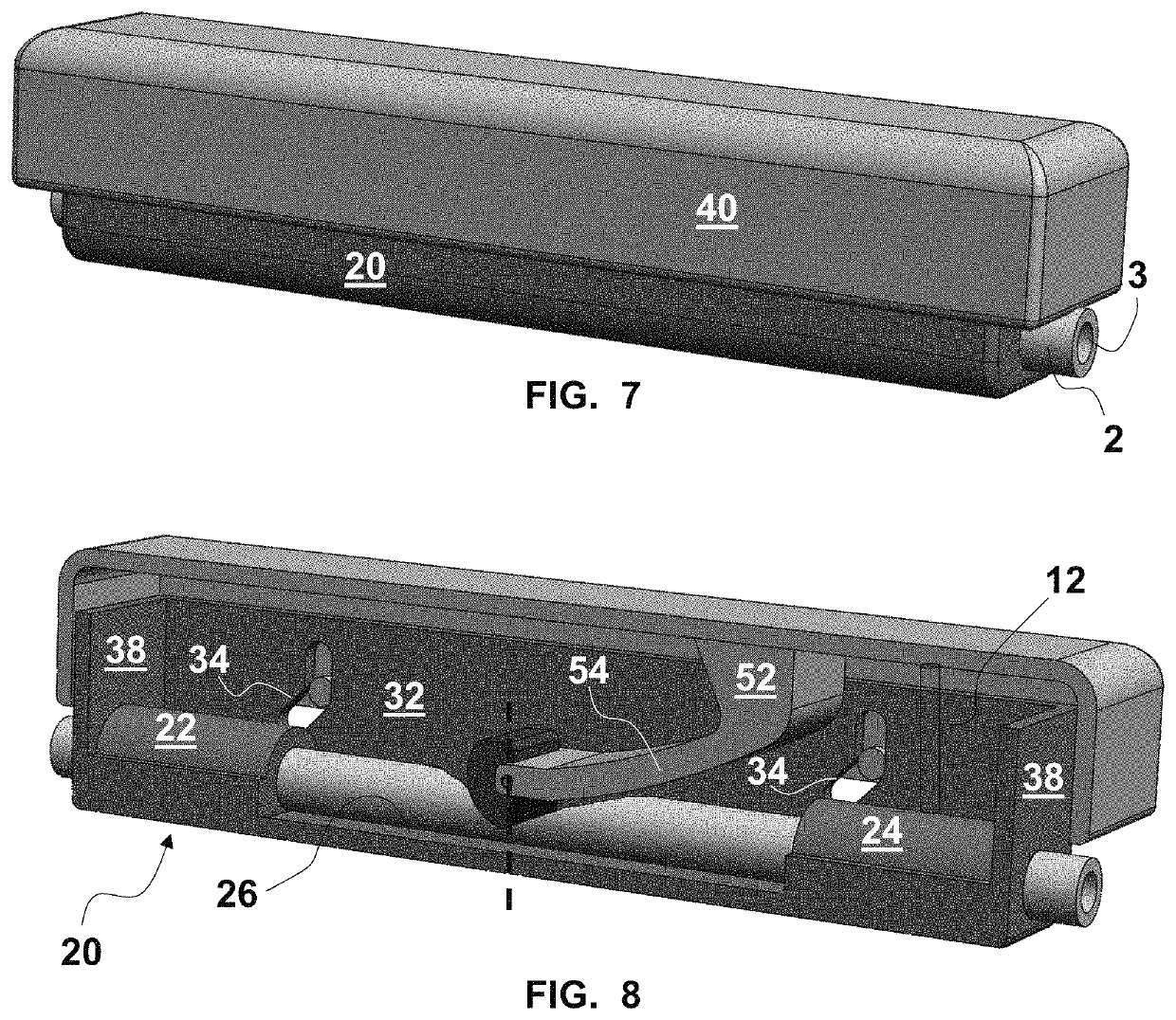

Aspiration thrombectomy system and methods for thrombus removal with aspiration catheter

ActiveUS10531883B1Increased first-pass recanalization rateReduces instanceBalloon catheterSurgeryBiomedical engineeringAspiration catheter

A thrombectomy removal system includes a catheter having a distal end and defining a lumen filled with a liquid column having a proximal portion and a distal portion, a vacuum source, a vent liquid source, and a vacuum and vent control system configured to cyclically connect or disconnect the vacuum source and the vent liquid source to change a level of vacuum at the distal end and substantially prevent forward flow. The vacuum source and the vent source are respectively fluidically connected to the vacuum and vent valves. A manifold connects the proximal portion to the vacuum and vent sources through the valves. Control of the valves prevents forward flow of the distal portion out from the distal end during each cycle. Each cycle can have states including vacuum-only, first double-closed, vent-only, and second double-closed. A time of the double-closed states can be no greater than 30 ms.

Owner:RAPIDPULSE INC

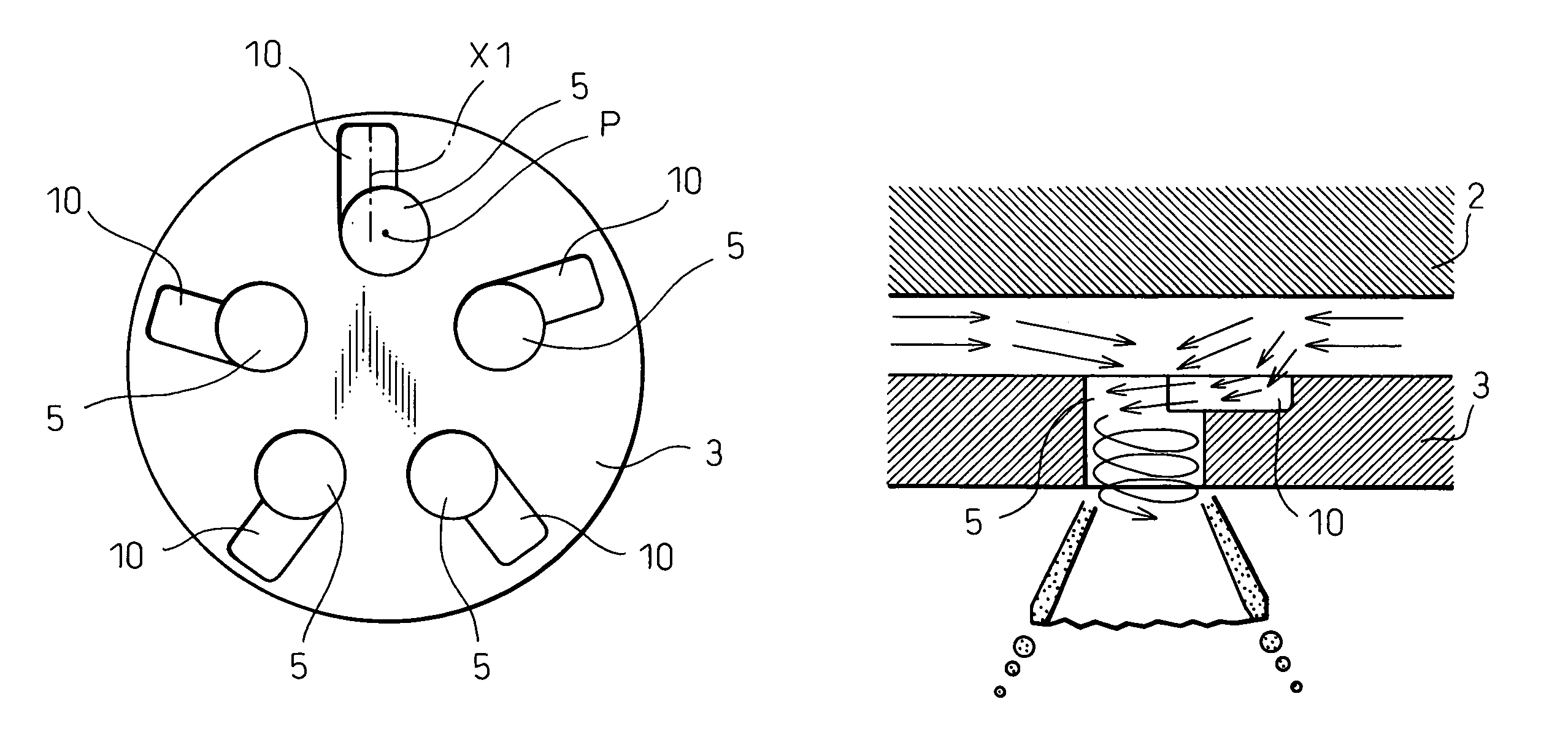

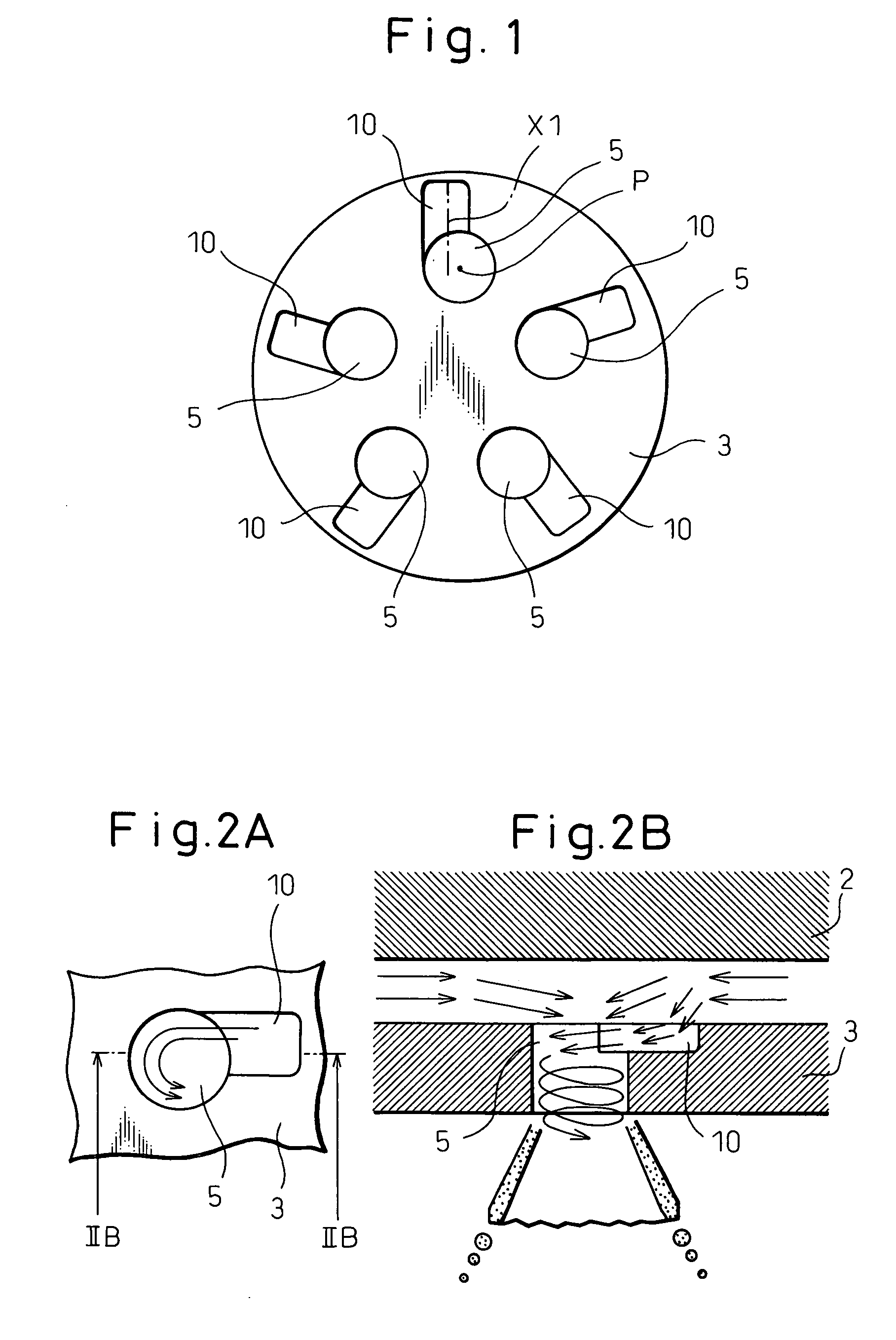

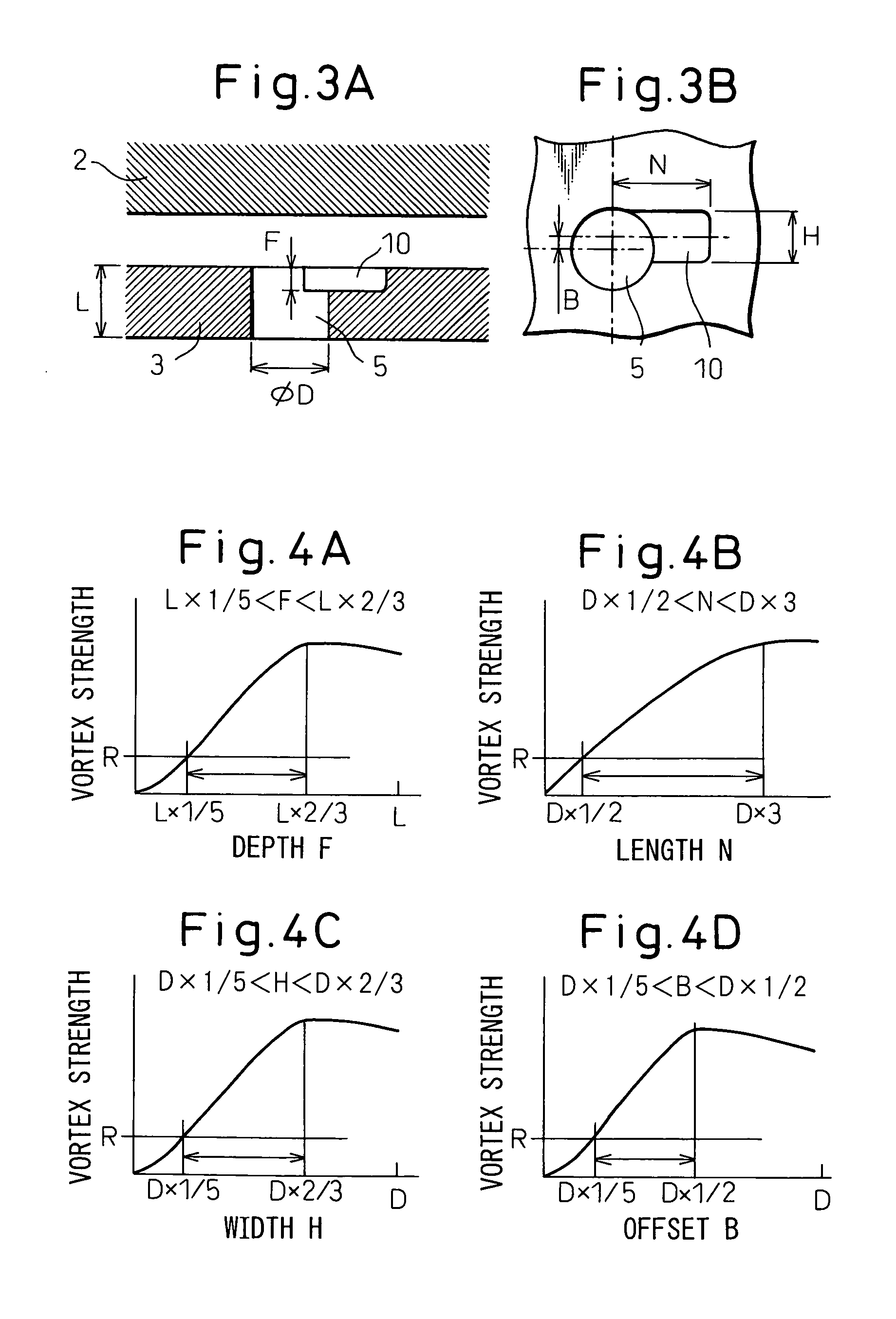

Fuel injection valve

There is provided a fuel injection valve in which nozzle holes are formed on a metering plate and fuel flowing on a face of the metering plate on the upstream side is injected outside of a face of the metering plate on the downstream side through the nozzle holes. The fuel injection valve includes a vortex flow generator means for changing a flow of fuel passing in each nozzle hole into a vortex flow, wherein the vortex flow generator means is provided on the upstream side of the metering plate. The vortex flow means is a vortex flow generator groove provided on an upper face of the metering plate and connected with a wall face of an entrance of the nozzle hole, and a main stream of fuel flowing in the groove is directed to a position shifted from the center of the nozzle hole. Alternatively, the vortex flow means is a protrusion formed on an upper face of the metering plate. A flow of fuel is changed into a vortex flow in the nozzle hole and injected from the nozzle hole. Therefore, fuel can be excellently atomized and diffused as a megaphone-shape without being formed into a liquid column spray.

Owner:TOYOTA JIDOSHA KK +2

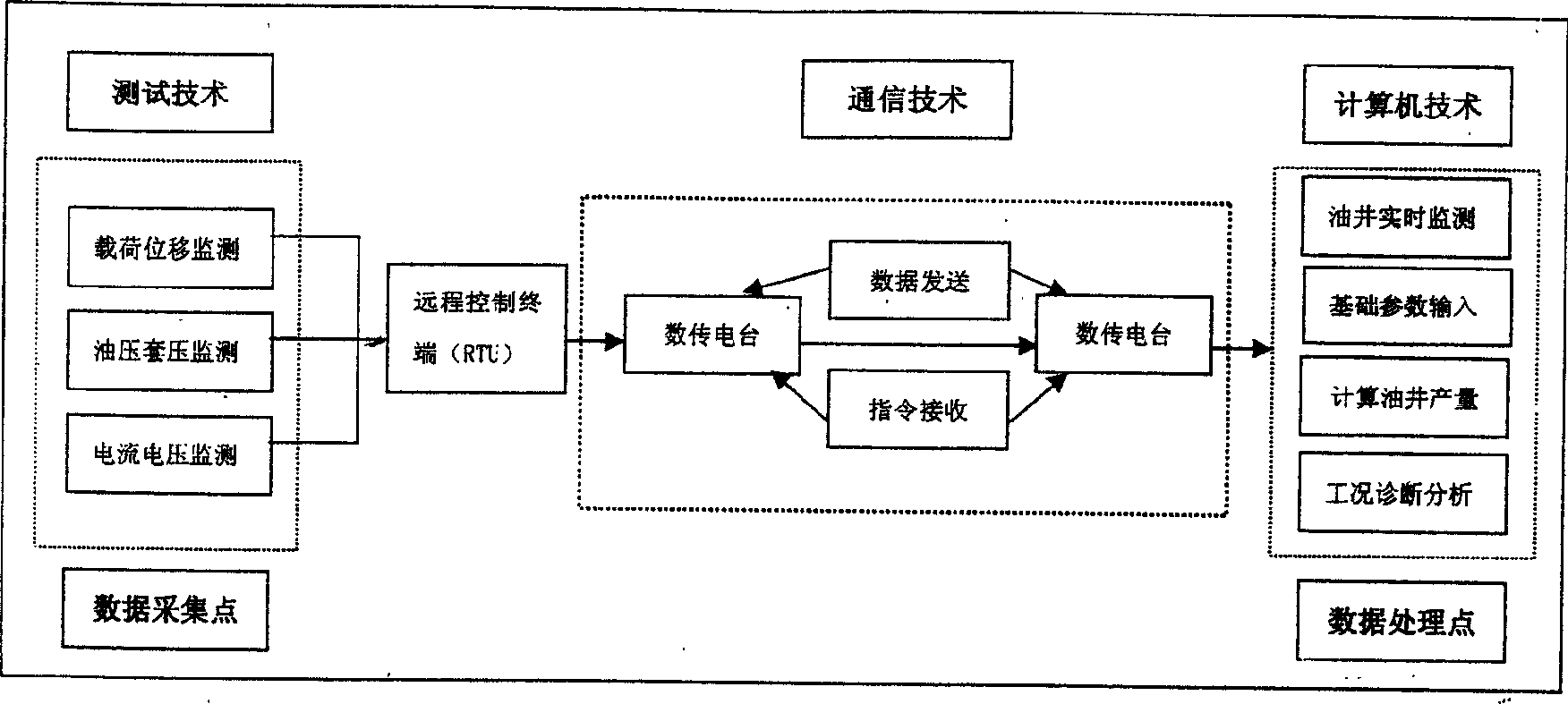

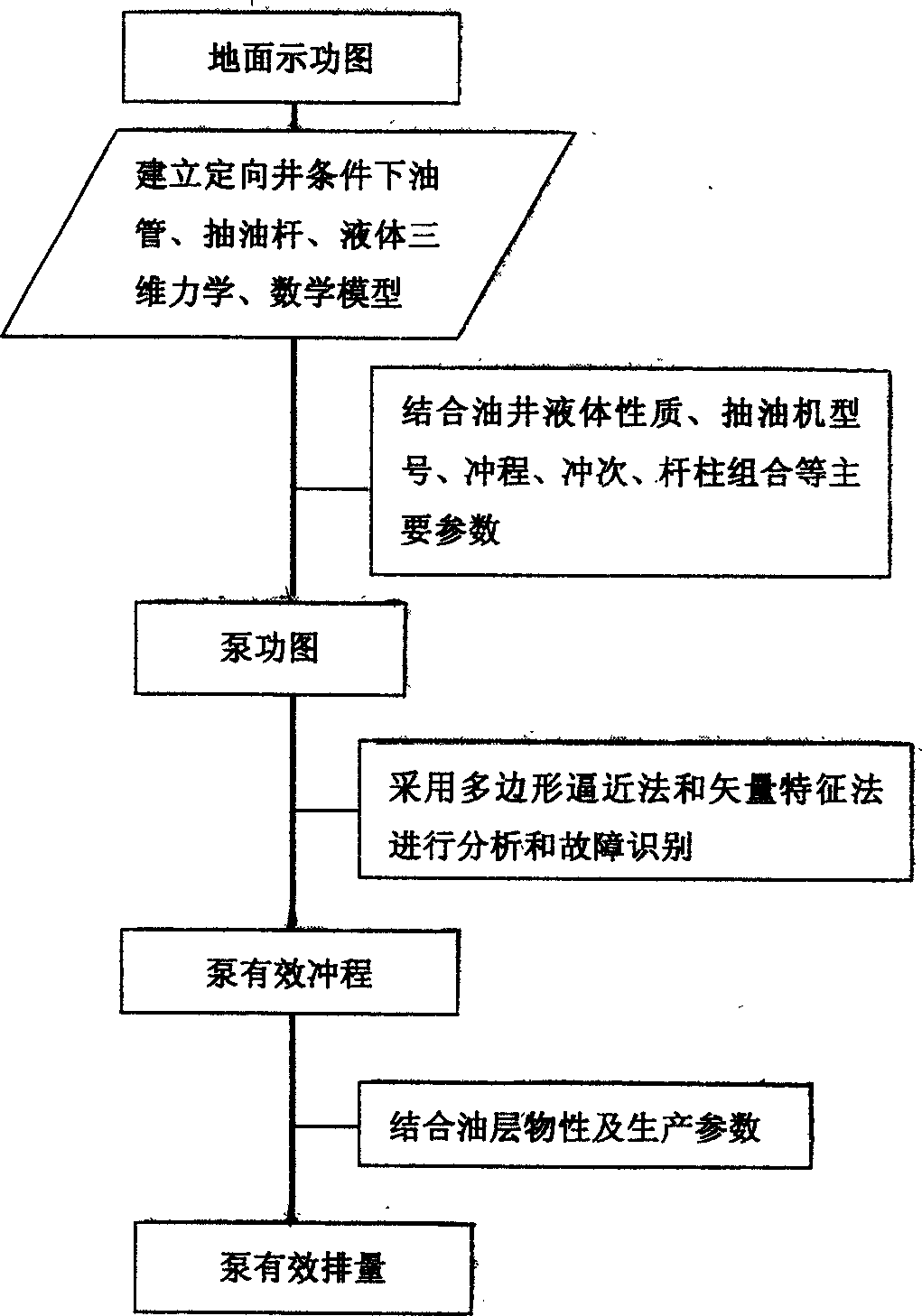

Well logging power graph method and device

ActiveCN1740515ARealize automatic start and stopAchieve meteringSurveyConstructionsCouplingWell logging

The present invention relates to oil well output liquid measuring power graph method and device. Oil well liquid output is measured through analysis of the 3D vibration of oil pumping rod column, oil pipe column and liquid column and the time relationship of their displacement, speed, strain, stress and load, research of the mutual coupling of the force and displacement of these three sys, acquiring oil well relating data with load and displacement sensors, and computer treatment to calculate the effective stroke of the oil pump. Meanwhile, the present invention also performs the diagnosis and analysis of oil well work state and the remote monitoring of oil well.

Owner:PETROCHINA CO LTD

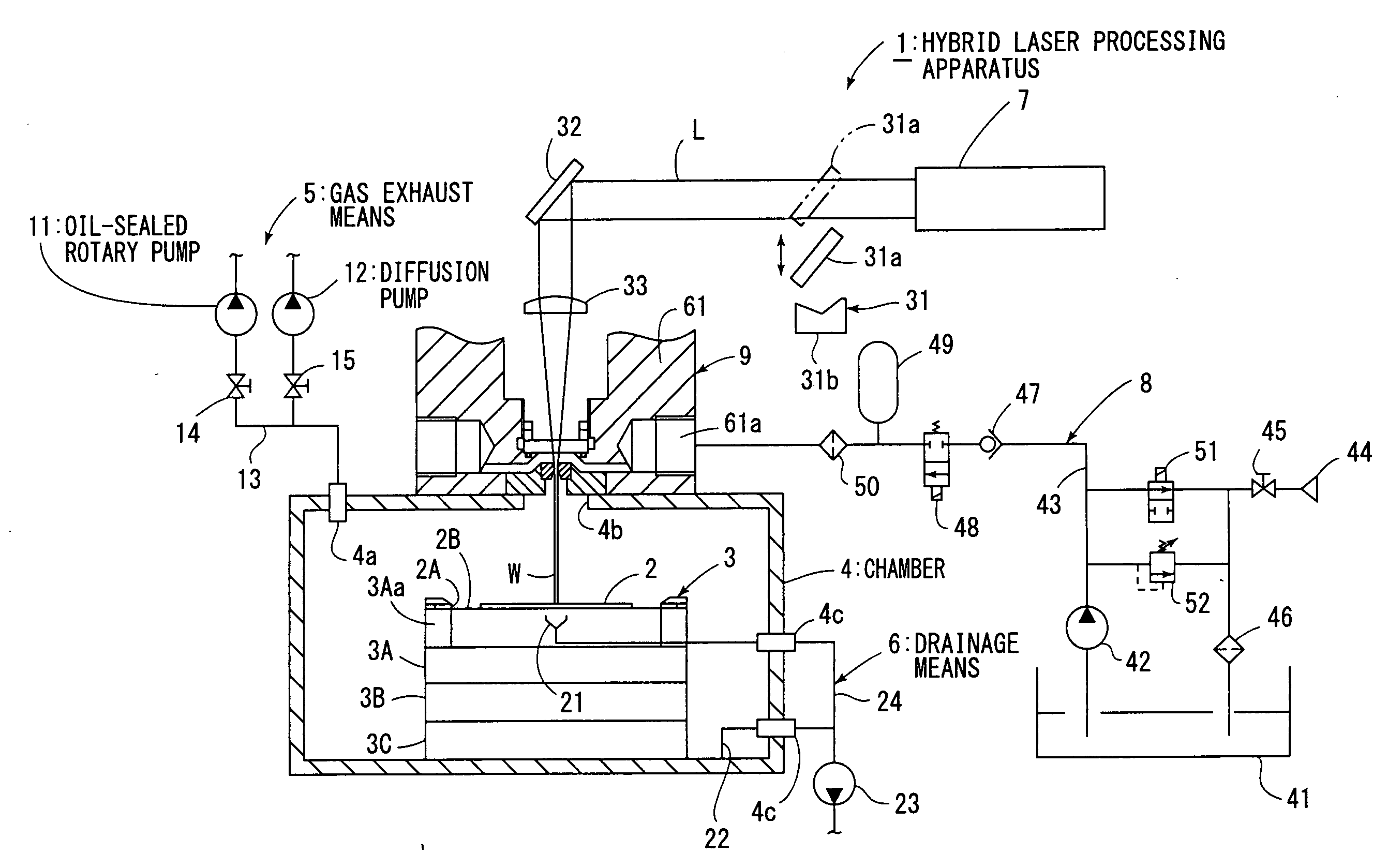

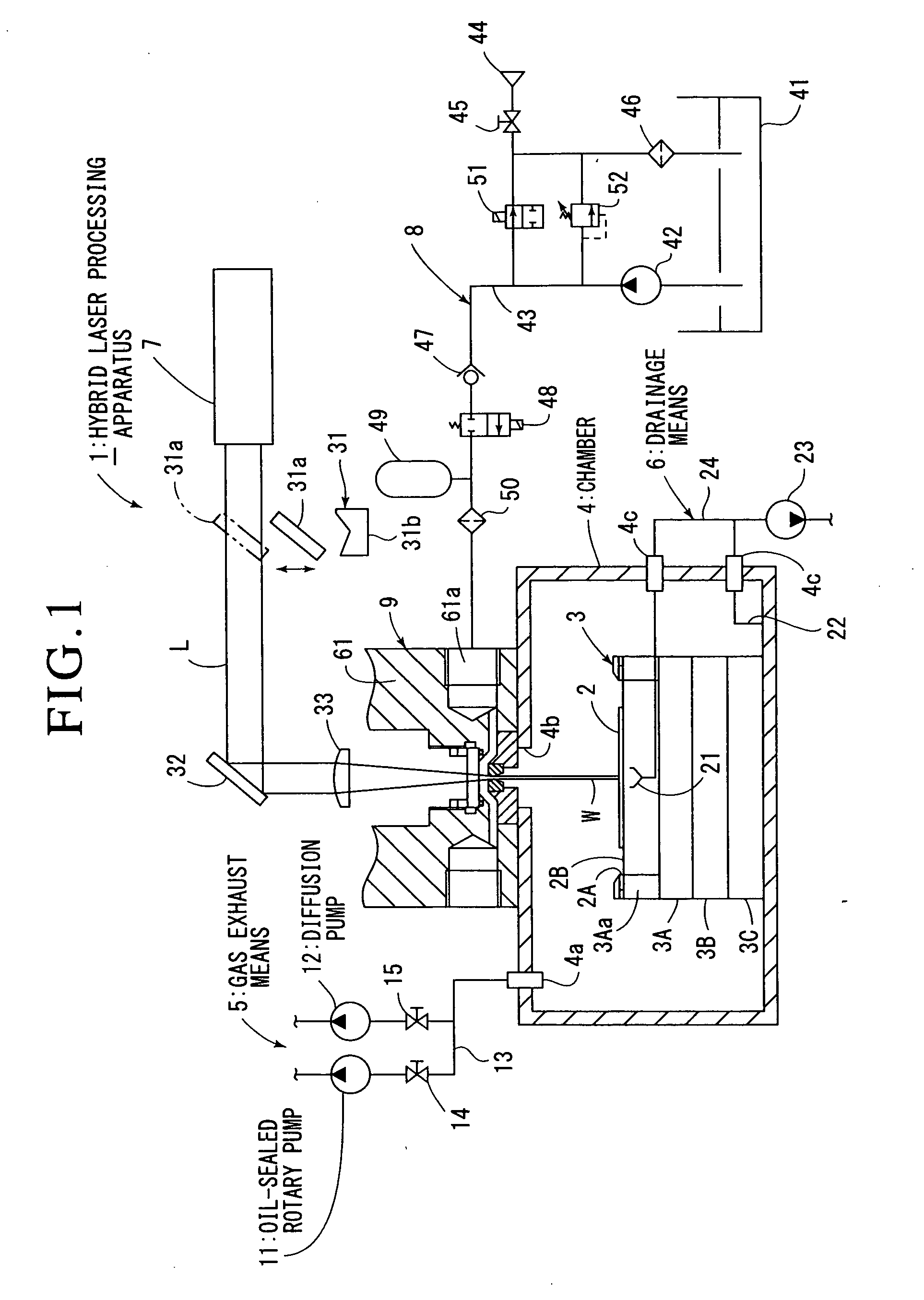

Hybrid laser processing apparatus

InactiveUS20100108648A1LengthReduce diffuseElectrostatic cleaningCleaning using liquidsStable stateLaser processing

A processing table 3 holding a workpiece 2 is accommodated in a chamber 4 with a gas-tight condition kept, and a liquid column W is jetted to an upper surface of this chamber 4, and a processing head 9 that guides laser beam L to the liquid column W is secured to the upper surface of this chamber 4. Gas exhaust means 5 in which an oil-sealed rotary pump 11 and a diffusion pump 12 are provided in parallel is connected to the chamber 4, and the diffusion pump 12 is actuated after the actuation of the oil-sealed rotary pump 11, brining the inside of the chamber 4 into a vacuum state.Bringing the inside of the chamber 4 into a vacuum state, no gas current is generated around the liquid column W jetted from the processing head 9, making it possible to prevent turbulence of the liquid column W due to turbulence of the gas current.A liquid column having a small diameter can be jetted in a stable state.

Owner:SHIBUYA IND CO LTD

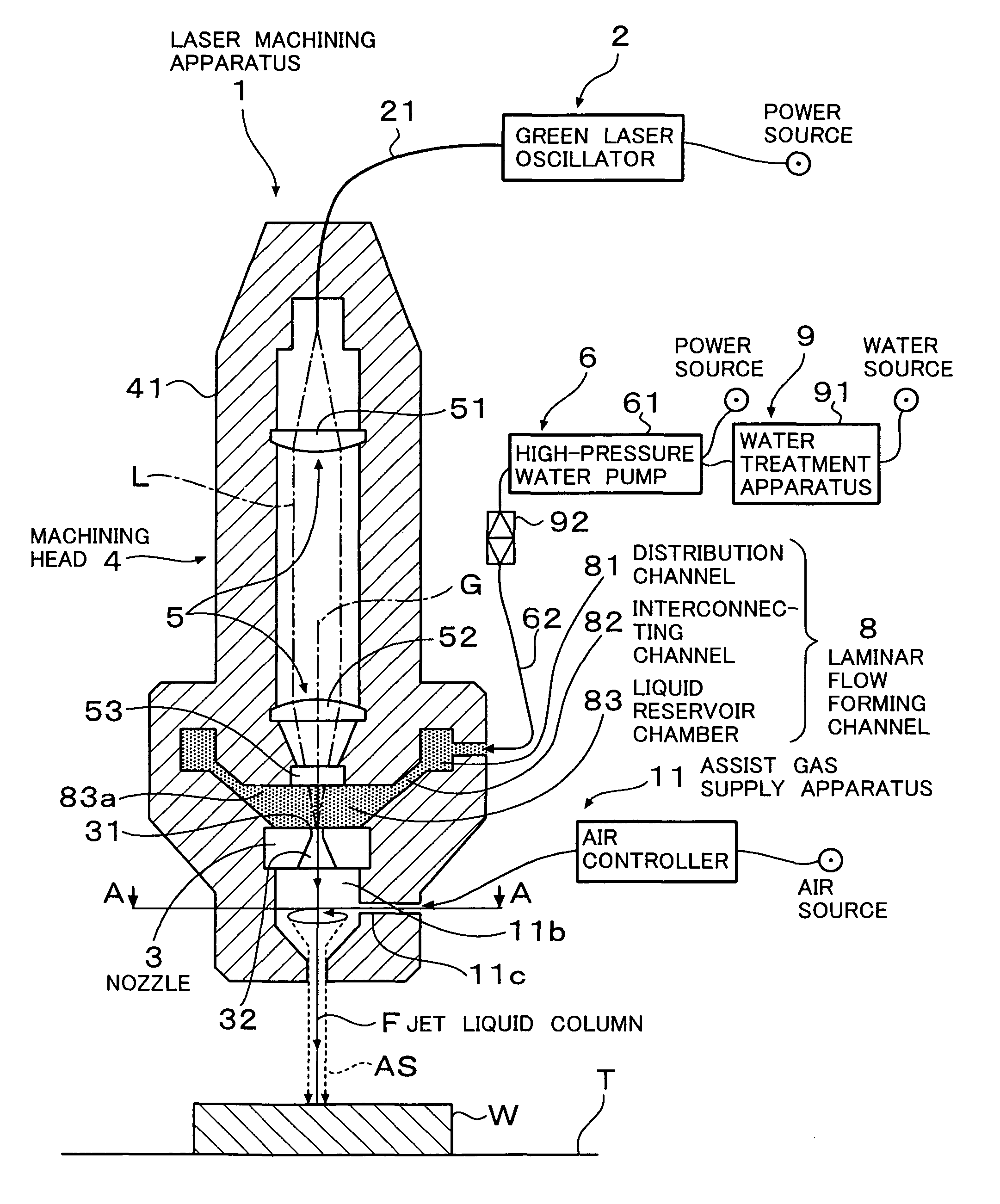

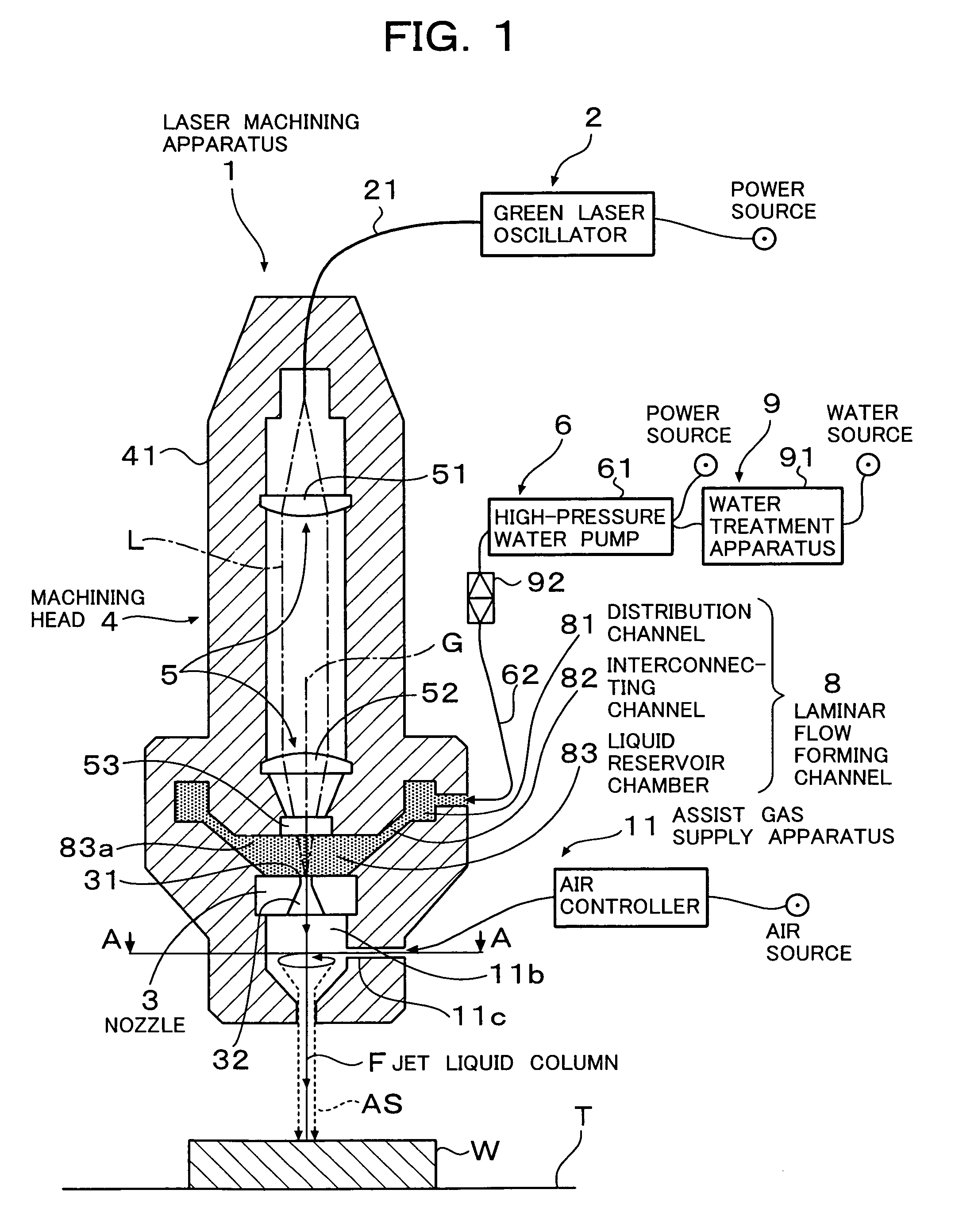

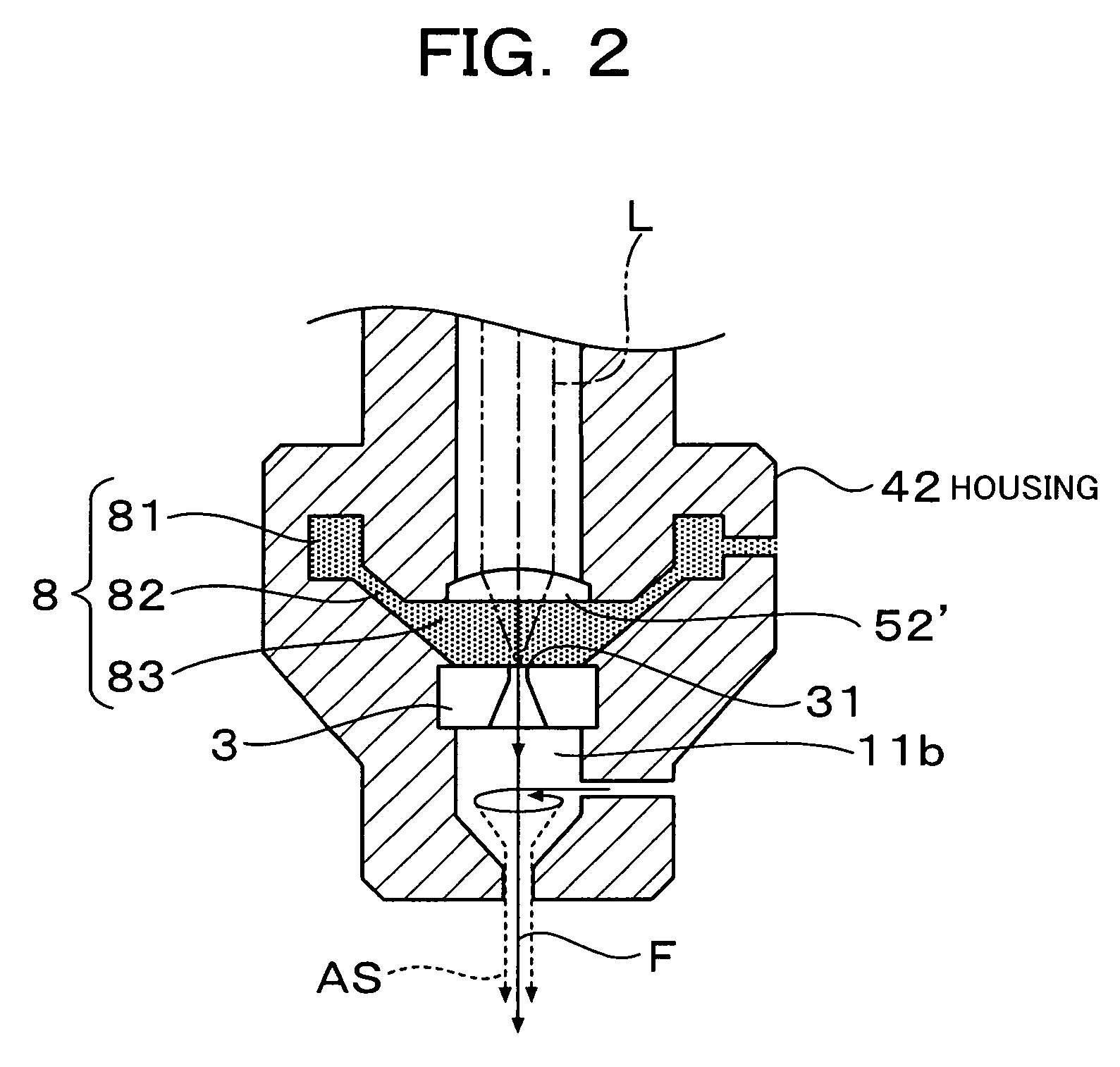

Laser machining apparatus using laser beam introduced into jet liquid column

ActiveUS8134098B2Stable generationImprove transmission efficiencyLaser beam welding apparatusLight beamSpray nozzle

A laser machining apparatus comprises a nozzle for ejecting a jet liquid to a workpiece and a liquid supply unit for supplying the jet liquid to the nozzle, while a laser beam is introduced into a jet liquid column ejected from the nozzle. The laser machining apparatus further comprises a laminar flow forming channel for supplying the jet liquid to the nozzle in a laminar state. The laminar flow forming channel includes a distribution channel formed by a cavity for annually distributing the jet liquid, which is supplied from the liquid supply unit, around an axis of the nozzle, an interconnecting channel disposed to be communicated with the distribution channel at the downstream side thereof in an axial direction of the nozzle and formed by an annular cavity around the axis of the nozzle to provide a narrower flow passage than the distribution channel, and a liquid reservoir chamber adjacently disposed upstream of the nozzle in the axial direction thereof and storing the jet liquid to be supplied to the nozzle. The liquid reservoir chamber has an outer peripheral edge being communicated with the interconnecting channel over an entire circumference of the annular shape thereof.

Owner:SUGINO MACHINE

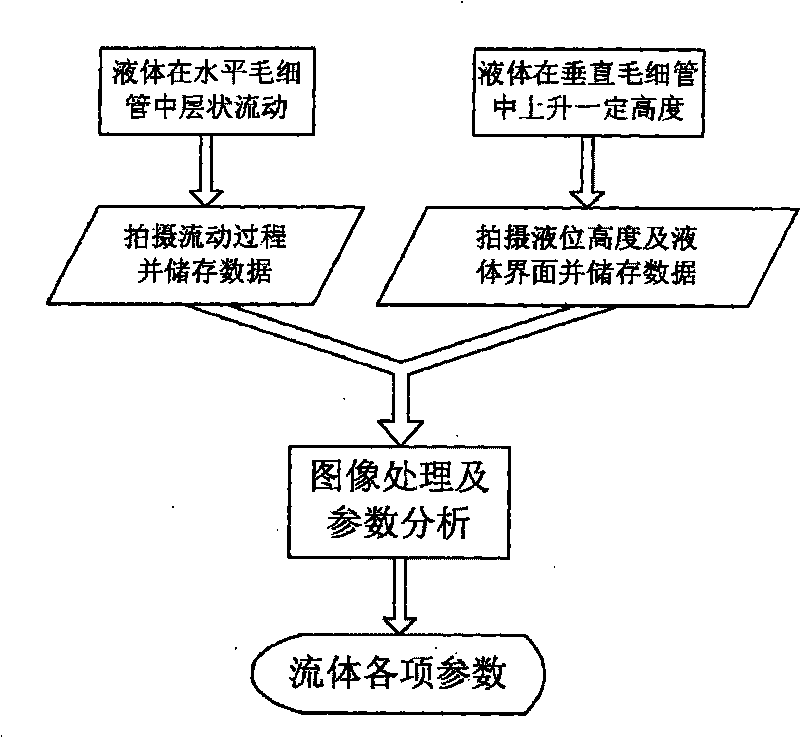

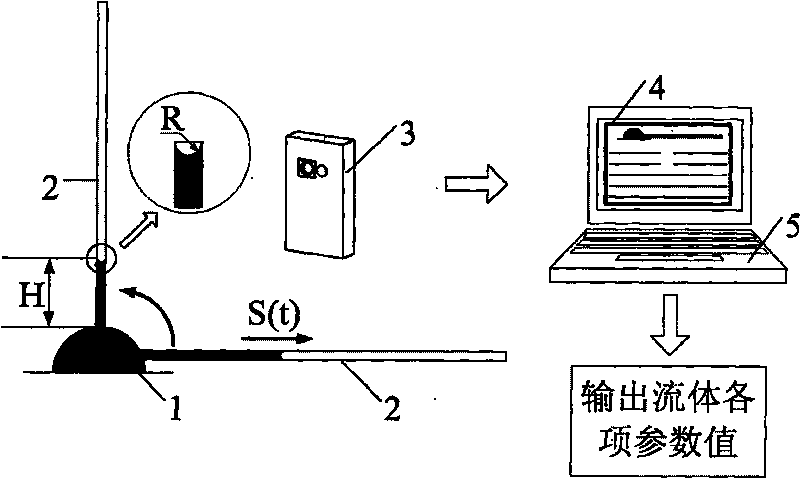

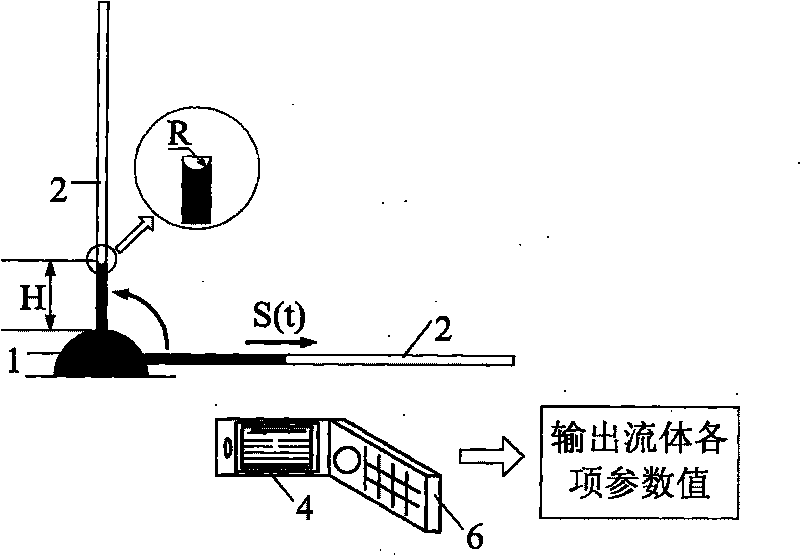

Non-contact measurement method for measuring liquid parameter

InactiveCN101750515AReduce dosageMeasurement made easyFluid speed measurementDirect flow property measurementComputer scienceImaging data

The invention provides a non-contact measurement method for measuring a liquid parameter, which comprises the following steps: 1) horizontally putting one end of a transparent capillary into the measured liquid; 2) recording image data of a layered flowing process of the measured liquid in the capillary; 3) vertically placing the capillary; 4) shooting an image of a liquid column with high stability; 5) calibrating a corresponding relationship between the number of pixels in an image device and the length of a shot object, processing the image of the image data to acquire the radius alpha of the capillary, the change process of liquid interface displacement S (t) along with the change of time t, the height H of the liquid column formed in the capillary and the curvature radius R of the liquid interface; and 6) calculating the fluid dynamic parameter of the measured liquid according to the data acquired by processing the image in the step 5). The method does not depend on large equipment, is simple and feasible, has low cost and uses a small amount of samples. The method can easily realize the measurement of a capillary array, and also can measure different liquid parameters.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

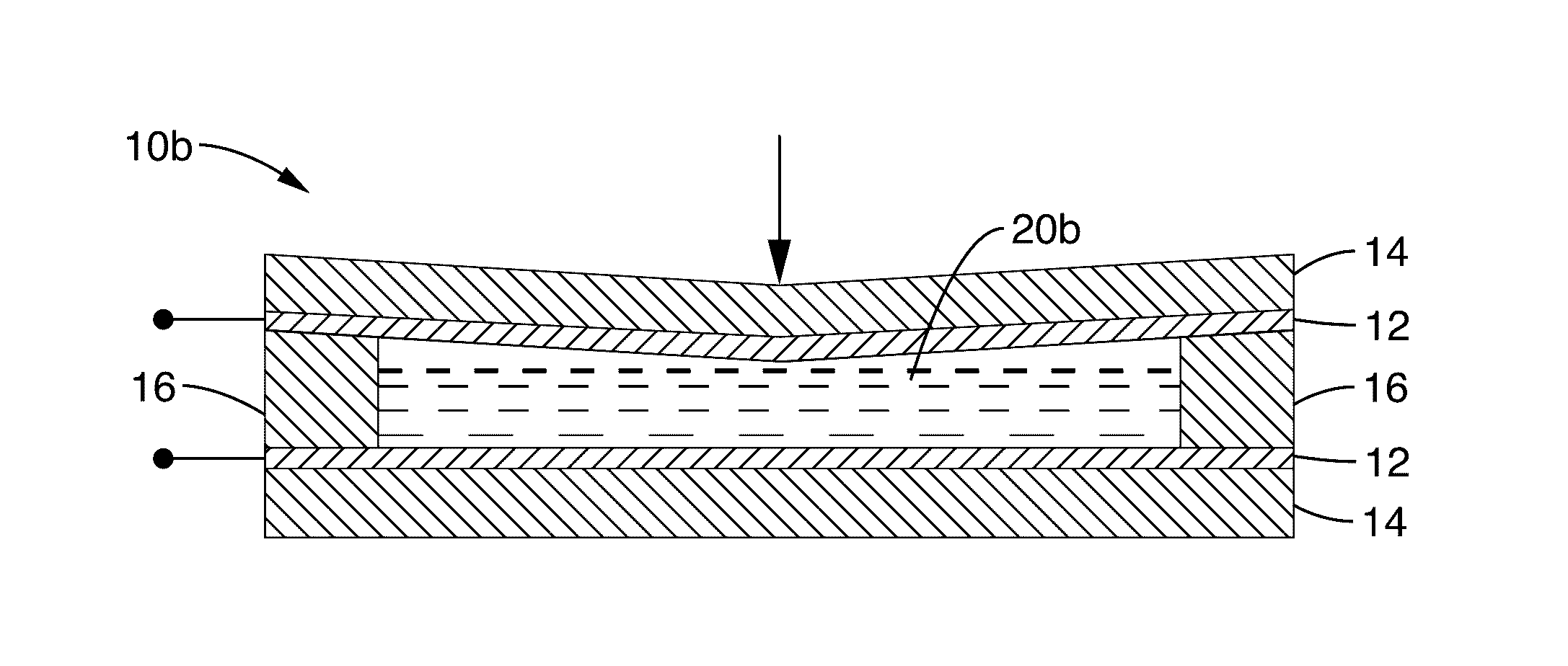

Liquid column-based capacitive sensors

InactiveUS20160365198A1Good flexibilityHigh sensitivityCapacitor collector combinationsMultiple capacitorsCapacitanceImage resolution

A liquid column-based normal / shear pressure / force sensing device having an elastic electrolyte-electrode contact with large interfacial capacitance to achieve high sensitivity and resolution with flexible and transparent constructs.

Owner:RGT UNIV OF CALIFORNIA

Icebound type pressure-maintaining and temperature-preserving sampler

InactiveCN101798924AEasy accessTroubleshoot startup problemsWithdrawing sample devicesBorehole/well accessoriesSlurry iceEngineering

The invention relates to an icebound type pressure-maintaining and temperature-preserving sampler. The icebound type pressure-maintaining and temperature-preserving sampler comprises a drilling in / sampling switching mechanism, a refrigerating fluid circulating system, a slurry ice valve and core valve in-situ generation mechanism, a core accommodating pipe single acting mechanism and channels I, II, III, IV, V and VI; the slurry ice valve and the core valve which are generated by freezing are used to replace mechanical valves of a ball valve or a plate valve and the like to close an upper port and an lower port of a sampling drilling tool, solid impurities in a hole have no influence on the closing process, thereby the sampler has high reliability and solves the problems of difficult starting, difficult closing caused by easy blockage of sundries in the hole and the like of the tradition mechanical valves and improves pressure-maintaining reliability and success ratio; and moreover, radial dimension can be smaller so as to be beneficial to acquiring cores with larger diameters and improving hydrate coring recovery factor. Tests prove that the ice valve can realize the sealing of 25MPa, which is suitable for drilling on hydrate with an inner hole liquid column reaching 2500m; and a hydro hammer drives a reciprocating pump, which utilizes the slurry as dynamic medium, thereby avoiding the complexity brought by an electric structure and having simplicity and reliability.

Owner:JILIN UNIV

Pipetting apparatus with integrated liquid level and/or gas bubble detection

Owner:TECAN TRADING AG

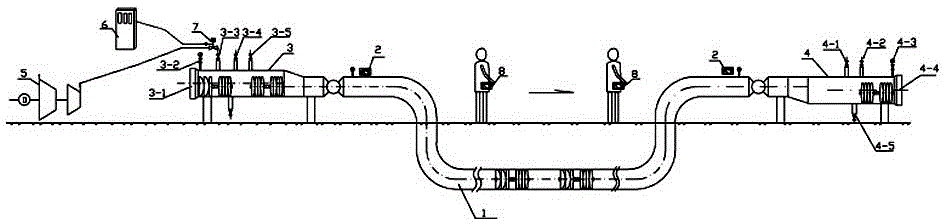

Continuous casting method of large-length hollow ductile cast iron sections and method for arcing hollow ductile cast iron sections after local continuous heating

InactiveCN101638748ASolve technical problems that are difficult to produceCorrosion resistancePhysical fieldVolumetric Mass Density

The invention relates to a continuous casting method of large-length hollow ductile cast iron sections and a method for arcing the hollow ductile cast iron sections after local continuous heating. Thesection comprises the following components by weight percent: 3.4-3.6% of C, 2.8-3.2% of Si, 0.40-0.60% of Mn, S less than or equal to 0.1%, P less than or equal to 0.1% and the balance Fe. Molten iron is subjected to shaping and continuous casting under multiple physical fields to become the hollow sections. The molten iron in heat preserving furnaces is separated from dross, sand and gas in twoways, thus completely solving the defects of dross inclusion, sand inclusion and pores; liquid column cores in a crystallizer carry out continual feeding on condensing tube shells, thus eliminating the possibility of shrinkage porosity inside the tube walls, obtaining highly dense cast structure of (ferritic matrix+spherical graphite) and eliminating crack initiation origins in thermoplastic deformation to be carried out later. The intense cooling speed in the crystallizer enables the volumes of eutectic cells to be only 1 / 15-1 / 25 of the volumes of traditional sand mould casts. The density ofthe graphite balls reaches around 500 / mm<2>. In plastic deformation, the micro slip orientation is increased and the ductility is enhanced, therefore, the hollow cast iron sections can be arced by medium frequency induction heating and bending.

Owner:SHAN XI TONGXIN LIANZHU PIPE IND

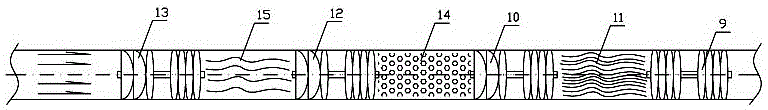

Waste crude oil pipe harmless cleaning process

ActiveCN106733964AIntelligent adjustment of travel speedAccurate determination of dissolution timeHollow article cleaningLiquid wasteWax

The invention discloses a waste crude oil pipe harmless cleaning process. A pipe cleaning train consisting of four sets of pipe cleaners, and special detergent liquid columns, compressed nitrogen gas columns and clean water liquid columns formed among the four sets of pipe cleaners slowly moves in a pipe to fully dip and thoroughly clean residues attached on the inner wall of the pipe. The process adopts a physical and chemical combined cleaning method to clean a waste crude oil pipe, can remotely monitor and intelligently adjust the traveling speeds of the pipe cleaners, accurately determines the dissolving time of detergent in the pipe to the residues, and guarantees the pipe cleaning effect; and the residues and the cleaning waste liquid in the pipe are respectively collected in a manner of not falling to the ground, so that the pollution is prevented from the source. The special detergent can guarantee efficient, quick and thorough dissolving of the firm residues in the waste crude oil pipe, is matched with clean water for cleaning to enable the waste pipe to achieve the effects of no wax, no oil stains and no scales in the pipe after cleaning, and can show natural color of metal.

Owner:RICH HIGH TECH CO LTD

Carbon dioxide purification method

InactiveUS7666251B2Lower energy requirementsCompression requirementSolidificationLiquefactionPurification methodsRefrigeration

Method of purifying a feed stream containing carbon dioxide wherein the feed stream after having been compressed and dried is partly cooled and then used to reboil a stripping column. Thereafter, the feed stream is further cooled and expanded to a lower operational temperature of the stripping column. A carbon dioxide product stream composed of the liquid column bottoms of the stripping column is expanded at one or more pressures to generate refrigeration, then fully vaporized within the main heat exchanger and compressed by a compressor to produce a compressed carbon dioxide product. Refrigeration is recovered in the main heat exchanger from a column overhead stream extracted from the stripping column within the main heat exchanger either directly or indirectly by auxiliary processing in which carbon dioxide is further separated and optionally recycled back to the main compressor used in compressing the feed stream.

Owner:PRAXAIR TECH INC

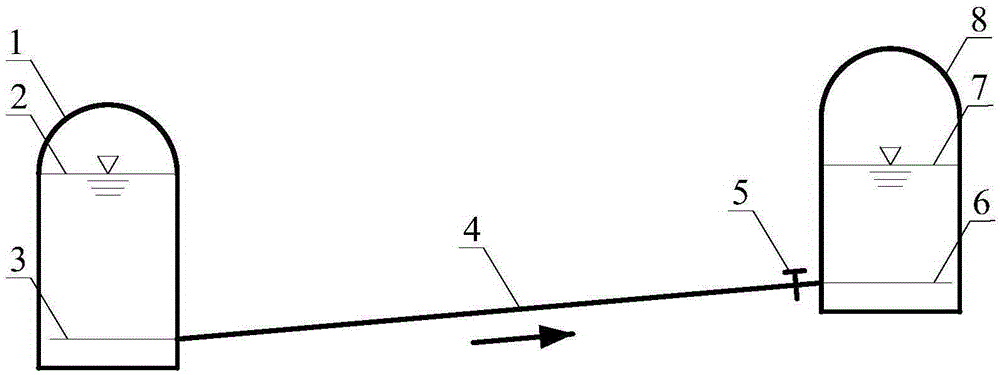

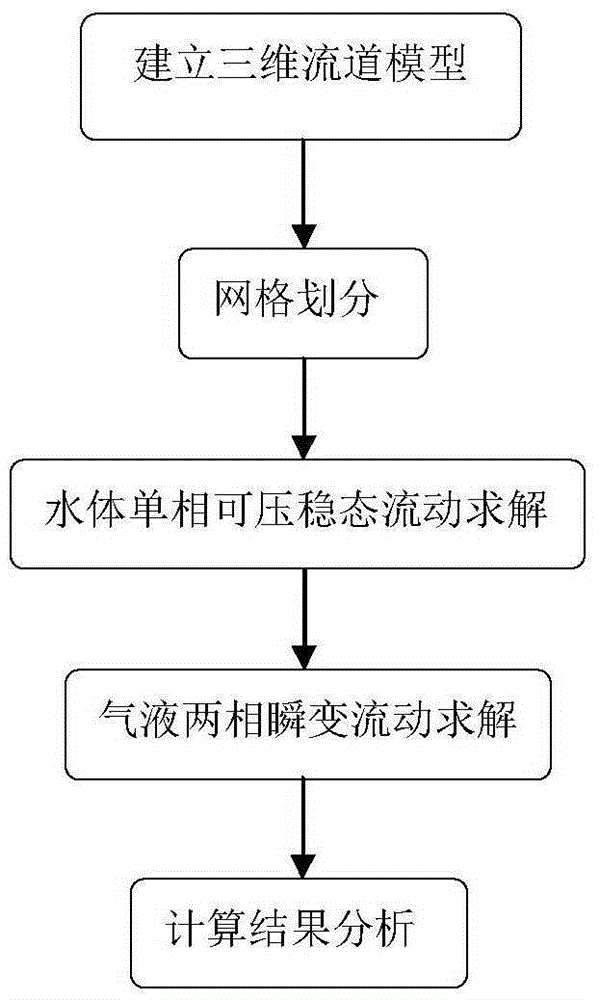

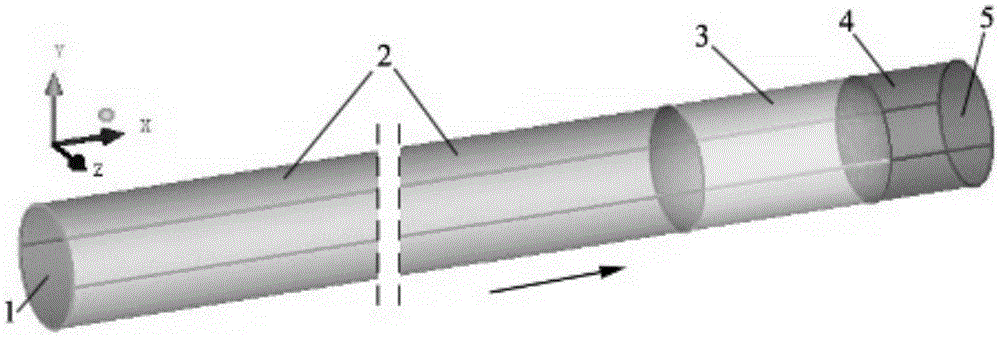

Liquid column separation-bridged water hammer simulation method based on three-dimensional CFD (Computational Fluid Dynamics)

ActiveCN105302997AThe solution method is simpleHigh precision solutionSpecial data processing applications3D modellingDimensional simulationMathematical model

The invention discloses a liquid column separation-bridged water hammer simulation method based on three-dimensional CFD (Computational Fluid Dynamics). The liquid column separation-bridged water hammer simulation method comprises the following steps: by carrying out three-dimensional modeling and mesh generation, firstly, carrying out single-phase compressible stable-state calculation of a water body to obtain a stable-state fluid field; then carrying out liquid column separation gas-liquid two-phase transient flowing calculation; and finally, processing a computed result by using post-processing software. According to the liquid column separation-bridged water hammer simulation method, on the basis of simultaneously considering the compressibility of the water body and steam, the mass transfer between gas and liquid is considered, and liquid column separation types do not need to be distinguished, so that a mathematical model and a solving method thereof are simplified to a certain extent and the simulation accuracy is relatively high; and unreal pressure pulse similar with one-dimensional simulation is not formed, and visualization of primary formation, development and collapsing processes of a hollow hole in a liquid column separation process is realized.

Owner:HOHAI UNIV +1

Laser beam processing machine

ActiveUS20110042362A1Avoid skewAccurate directionLaser beam welding apparatusLight beamLaser beam machining

A laser beam processing machine is provided which includes a laser beam irradiation unit including a laser beam oscillation unit and a processing head provided with a condenser lens condensing a laser beam oscillated from the laser beam oscillation unit. The processing head includes a liquid column forming mechanism provided with a jet nozzle adapted to jet liquid along an optical path for the laser beam condensed by the condenser lens, and a water droplet suction mechanism disposed below the liquid column forming mechanism and provided with an insertion passage through which a liquid column jetted from the jet nozzle is passed and with an annular suction port formed to surround the insertion passage and communicate with suction means.

Owner:DISCO CORP

Liquid droplet ejecting method, liquid droplet ejection apparatus, inkjet recording apparatus, production method of fine particles, fine particle production apparatus, and toner

ActiveUS20130010035A1High-density printingImprove productivityInking apparatusMovable spraying apparatusResonanceEngineering

A liquid droplet ejecting method for ejecting a liquid from at least one ejection hole to form the liquid into liquid droplets, the method including: applying a vibration to the liquid in a liquid column resonance-generating liquid chamber, in which the ejection hole is formed, to form a standing wave through liquid column resonance, and ejecting the liquid from the ejection hole, which is formed in a region corresponding to an antinode of the standing wave, to form the liquid into liquid droplets.

Owner:RICOH KK

Method and device for applying a plurality of microdroplets onto a substrate

InactiveUS7479256B1Avoid mixingAnalysis using chemical indicatorsSequential/parallel process reactionsEngineeringLiquid column

A device for device for applying a plurality of microdroplets onto a substrate has a plurality of nozzle orifices in a dosing head. In addition to walls for defining a liquid column of a medium to be dosed on each nozzle orifice, a pressure chamber is provided, which is adapted to be filled with a buffer medium and which is arranged in such a way that said buffer medium can simultaneously be used for applying a pressure to the liquid-column ends which are spaced apart from the nozzle orifices. A pressure generator is provided for applying a pressure to said buffer medium in such a way that a plurality of microdroplets will simultaneously be applied onto the substrate through said plurality of nozzle orifices. Finally, liquid reservoirs for the media to be dosed, which are in fluid communication with the liquid columns on the nozzle orifices are provided.

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV +1

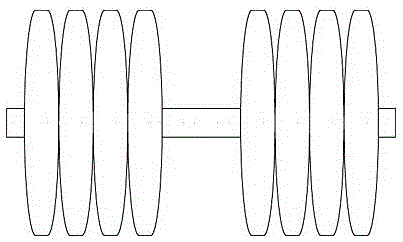

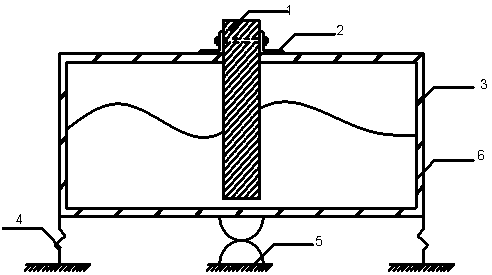

Novel TLD (Tuned Liquid Damper)

InactiveCN103541458AVarious ways of energy consumptionImprove energy consumptionShock proofingEngineeringShock absorber

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com