Non-contact measurement method for measuring liquid parameter

A non-contact, measurement method technology, applied in the field of biochemistry and medical detection, can solve the problems of complex image processing principles, large volume, complex structure, etc., and achieve the effect of small sample amount, low cost, and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

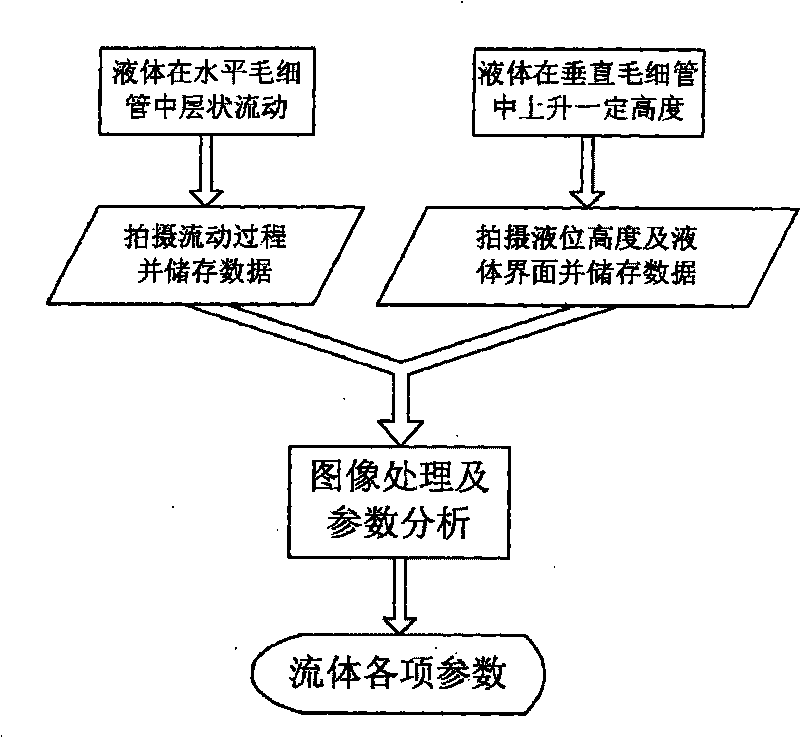

[0042] figure 1 It is a schematic diagram of the working process of the method for measuring non-contact liquid flow parameters according to an embodiment of the present invention.

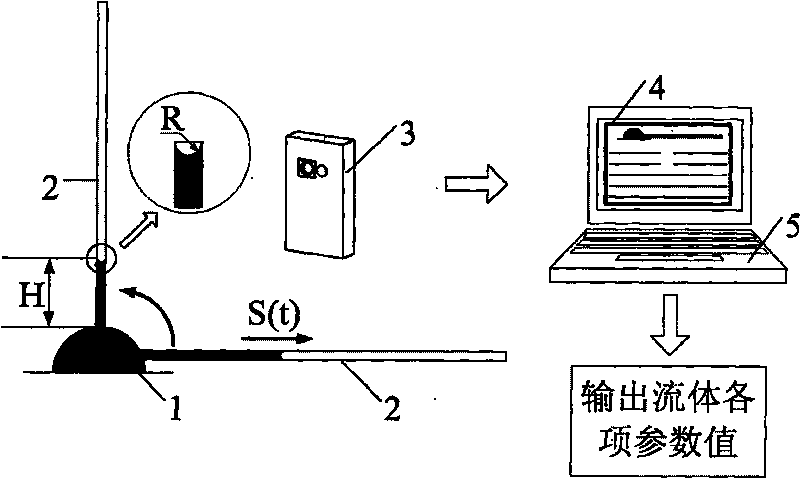

[0043] figure 2 It is a schematic diagram of the system structure of the method for measuring non-contact liquid flow parameters in an embodiment. When the portable household imaging device 3 is an ordinary mobile phone, digital camera or digital video camera, the image processing and parameter analysis software 4 is installed in the computer 5 .

[0044] refer to figure 1 and figure 2 , the liquid parameters are measured as follows:

[0045] Put one end of the transparent capillary 2 horizontally into the measured liquid 1. At this time, the measured liquid undergoes capillary phenomenon in the transparent capillary and starts to flow laminarly. At the same time, the portable household imaging device 3 is turned on to record the whole process of the flow. Then place the transparent capillar...

Embodiment 2

[0053] Figure 4 is another embodiment of the present invention. In order to quickly and efficiently complete the parameter measurement of various liquids, various measured liquids 1 can be caused to undergo capillary phenomena in the array of horizontally placed transparent capillary tubes 2 due to capillary action and start laminar flow, and at the same time use portable household imaging equipment 3 to record the The entire process of the flow and storage of image data. Then the above-mentioned array of transparent capillary tubes 2 is vertically placed, and its inlet end is still immersed in the liquid to be measured. After the height of the liquid column is reached, the portable image device 3 is used to take images of various measured liquids 1 forming a fixed-height liquid column at the bottom of the transparent capillary 2 array. When applying this embodiment, the axis of the lens of the portable home imaging device 3 must be perpendicular to the capillary array plan...

Embodiment 3

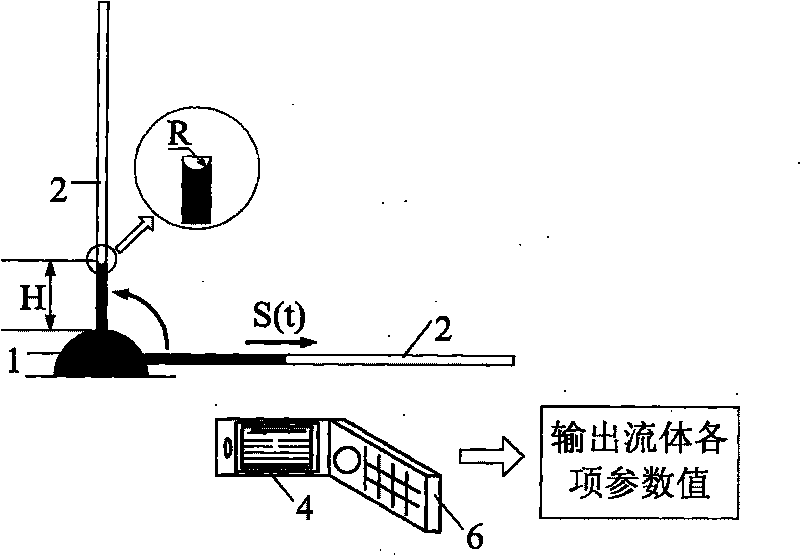

[0055] This embodiment is an embodiment that only needs to measure the density of the liquid. As shown in Figure 5, when the present invention is used to realize the measurement of liquid density, the transparent capillary 2 is vertically inserted into the measured liquid 1, and when the liquid interface of the measured liquid 1 stops rising after the transparent capillary 2, the portable household imaging device 3 Carry out image acquisition on the transparent capillary 2, and use the image processing function in the image processing and parameter analysis software 4 to obtain relevant data in the image data, such as: the radius a of the transparent capillary 2, the measured liquid 1 in the transparent capillary 2 The radius of curvature R of the interface, and the height H of the liquid column formed by the measured liquid 1 in the transparent capillary 2; and then using the liquid parameter analysis function in the image processing and parameter analysis software 4, accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com