Patents

Literature

1384results about "Direct flow property measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for fluid dispersion

Owner:THE GOVERNING COUNCIL OF THE UNIV OF TORONTO +1

System and method for monitoring pressure, flow and constriction parameters of plumbing and blood vessels

InactiveUS6237398B1Ultrasonic/sonic/infrasonic diagnosticsMaterial analysis by optical meansEngineeringPulsatile flow

The present invention provides a system and method of quantifying flow, detecting a location of an obstruction and quantifying a degree of the obstruction in a pipe characterized in pulsatile flow. The method includes the steps of (a) attaching at least two spaced pressure sensors onto inner walls of the pipe; (b) using the at least two spaced pressure sensors for recording pressure records associated with each of the at least two pressure sensors within the pipe; and (c) using the pressure records for quantifying the pulsatile flow in the pipe, for detecting the location of the obstruction in the pipe and for quantifying the degree of the obstruction in the pipe.

Owner:TELESENSE

Multi-reservoir pressure control system

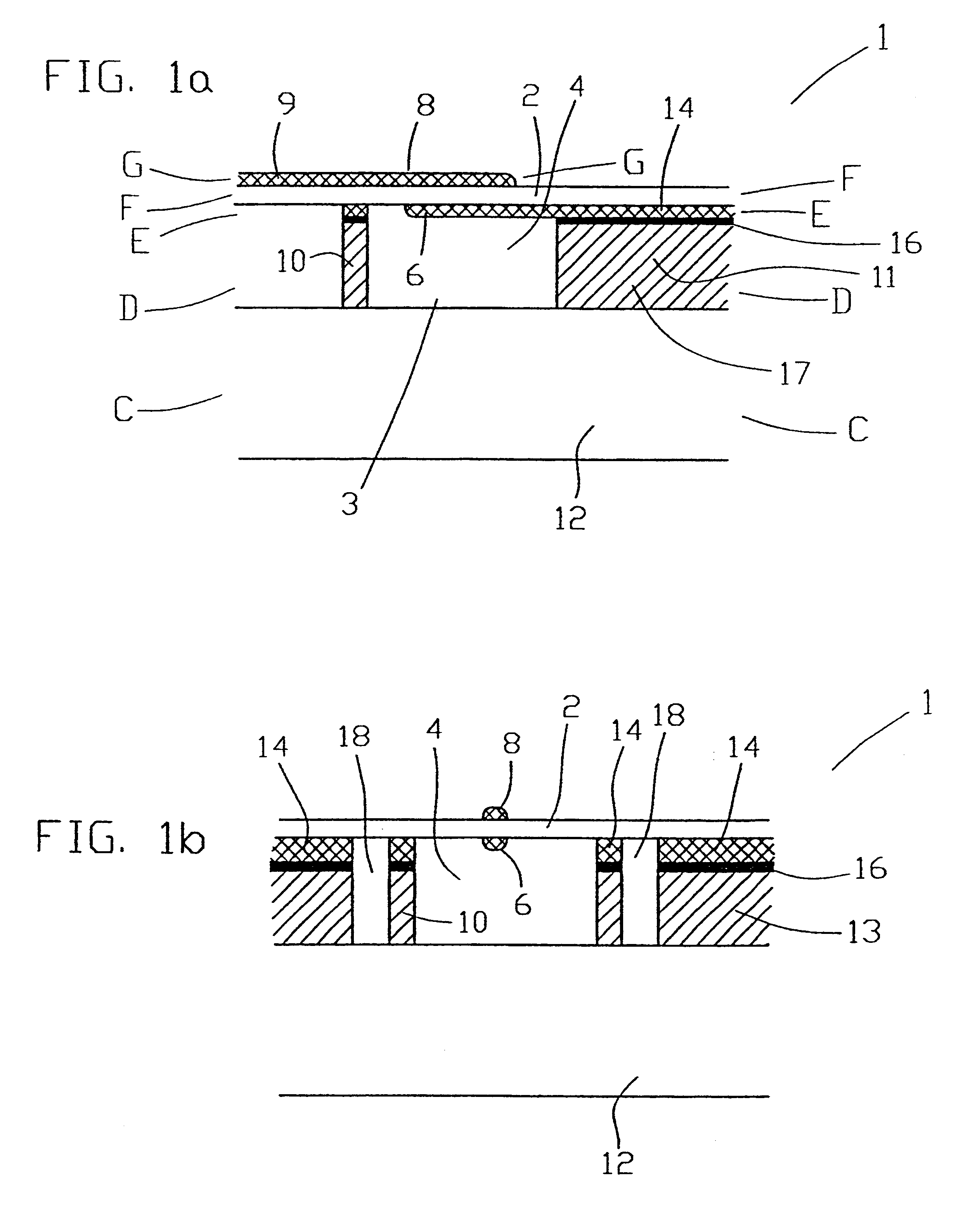

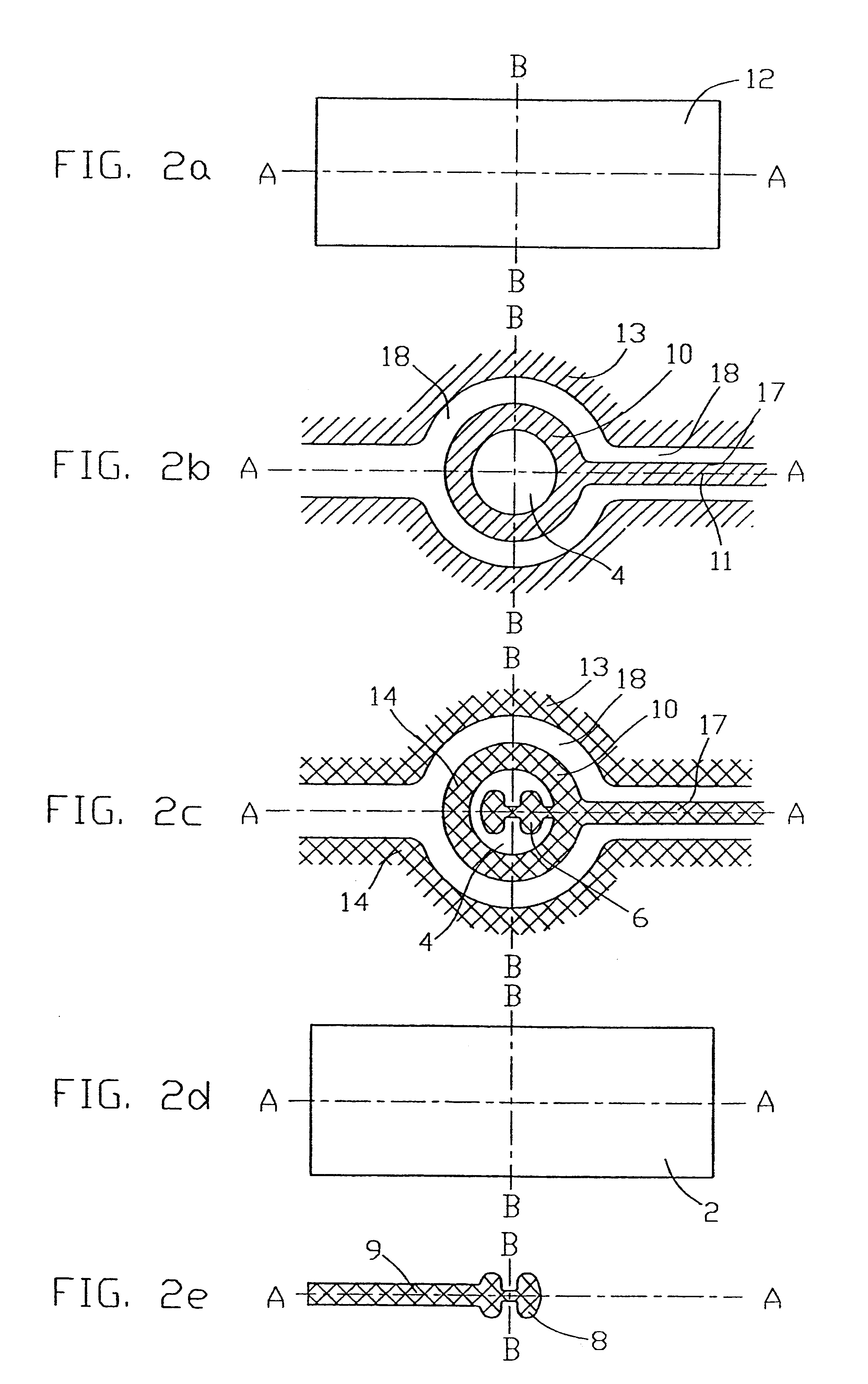

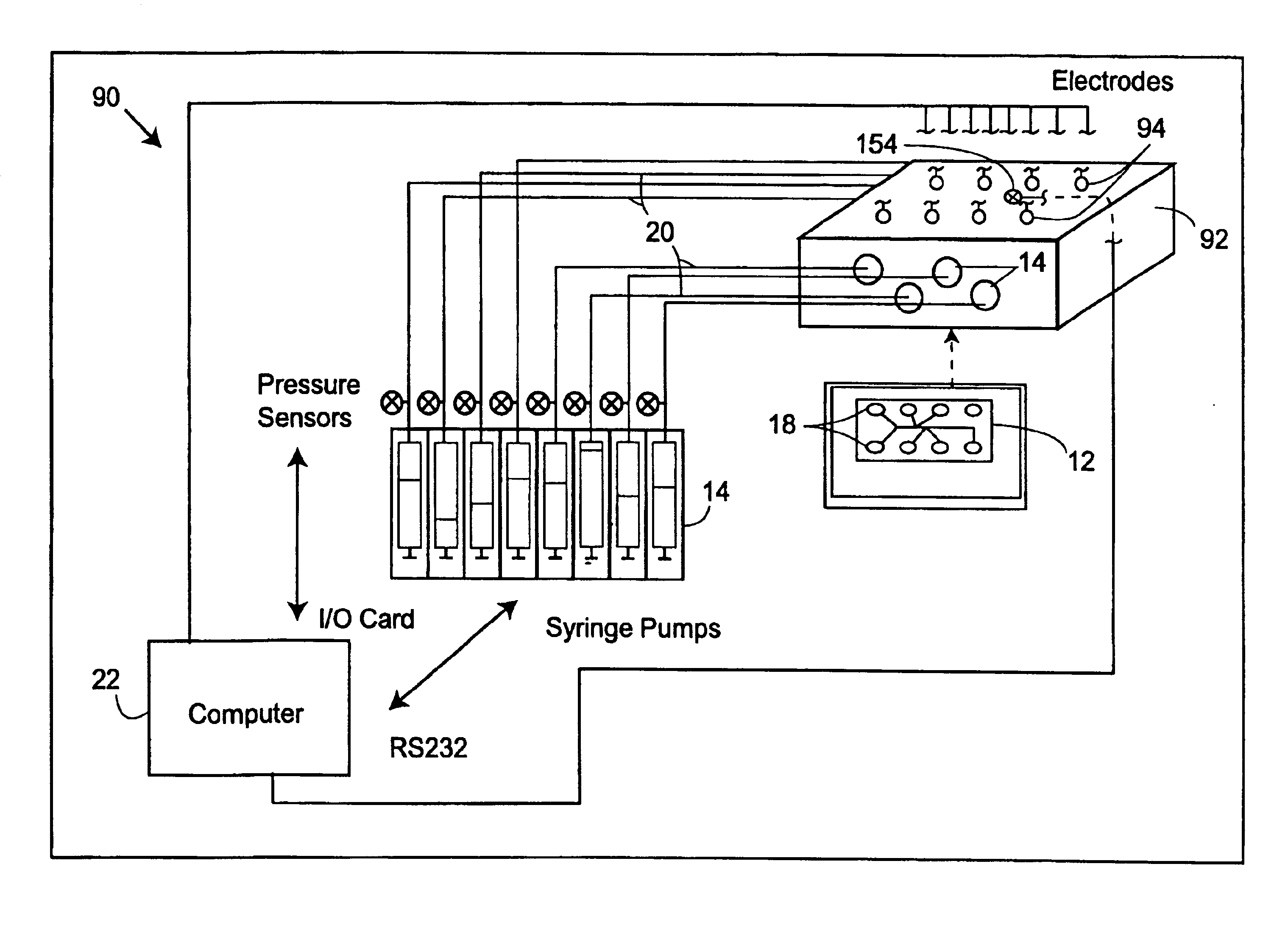

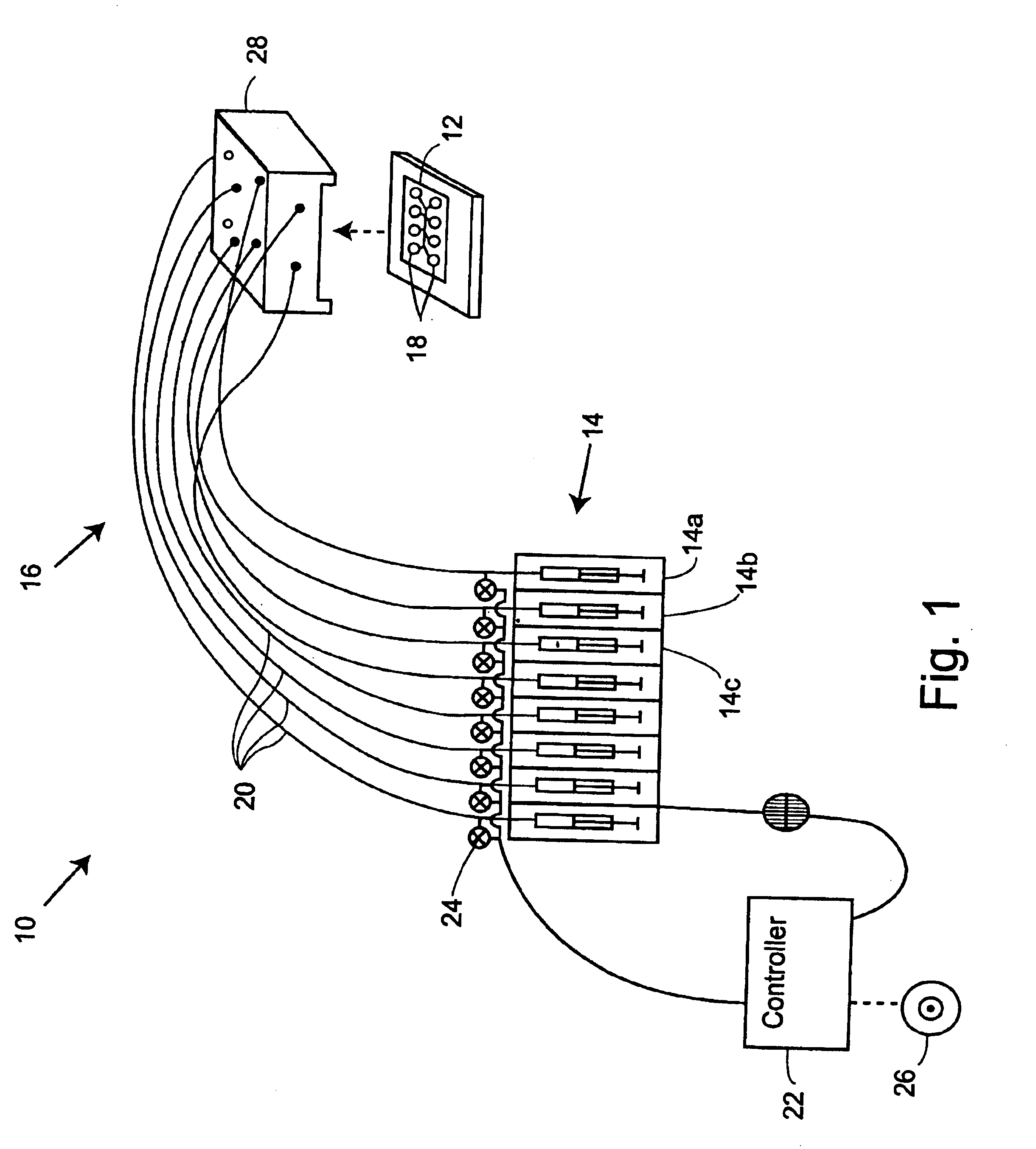

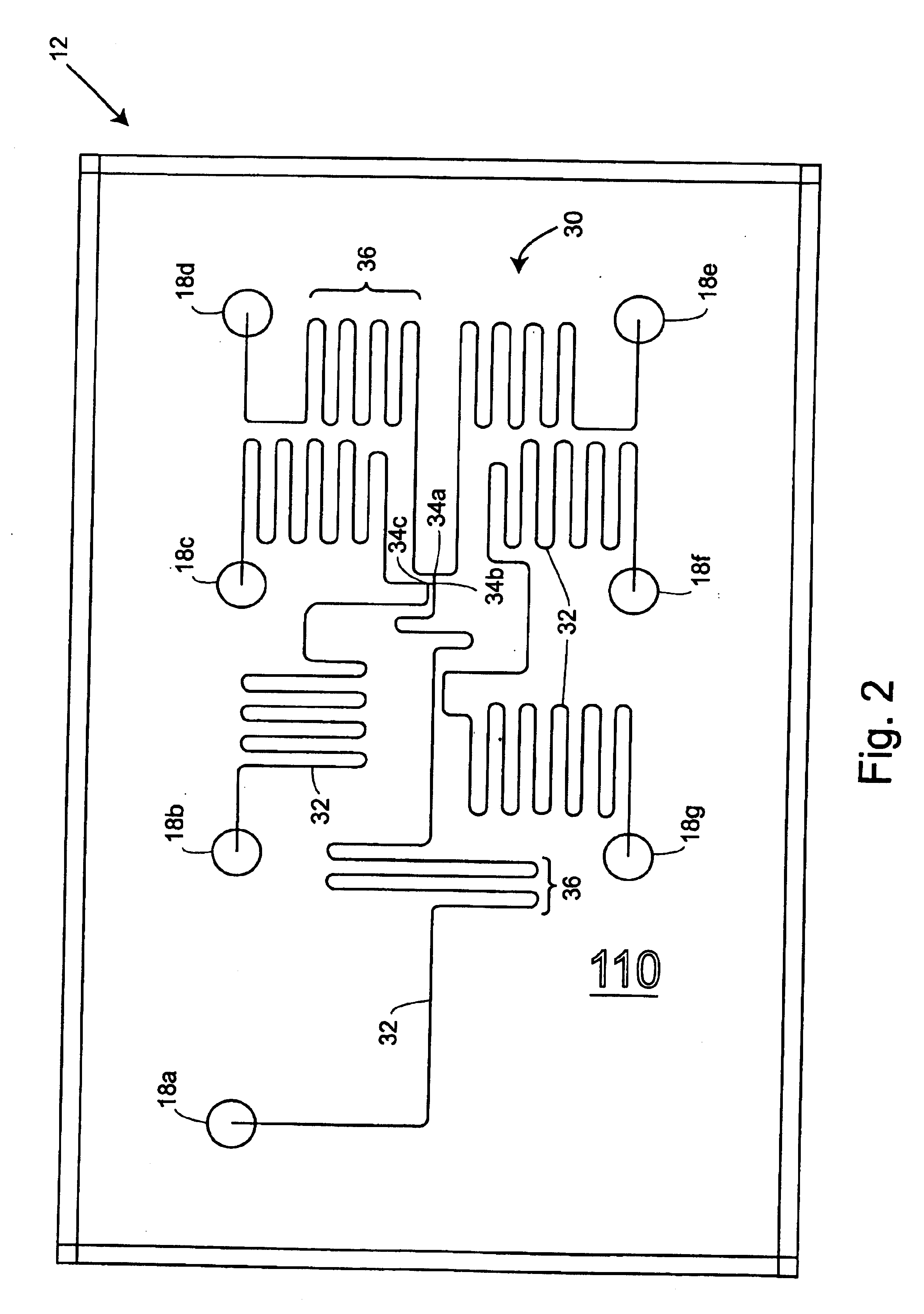

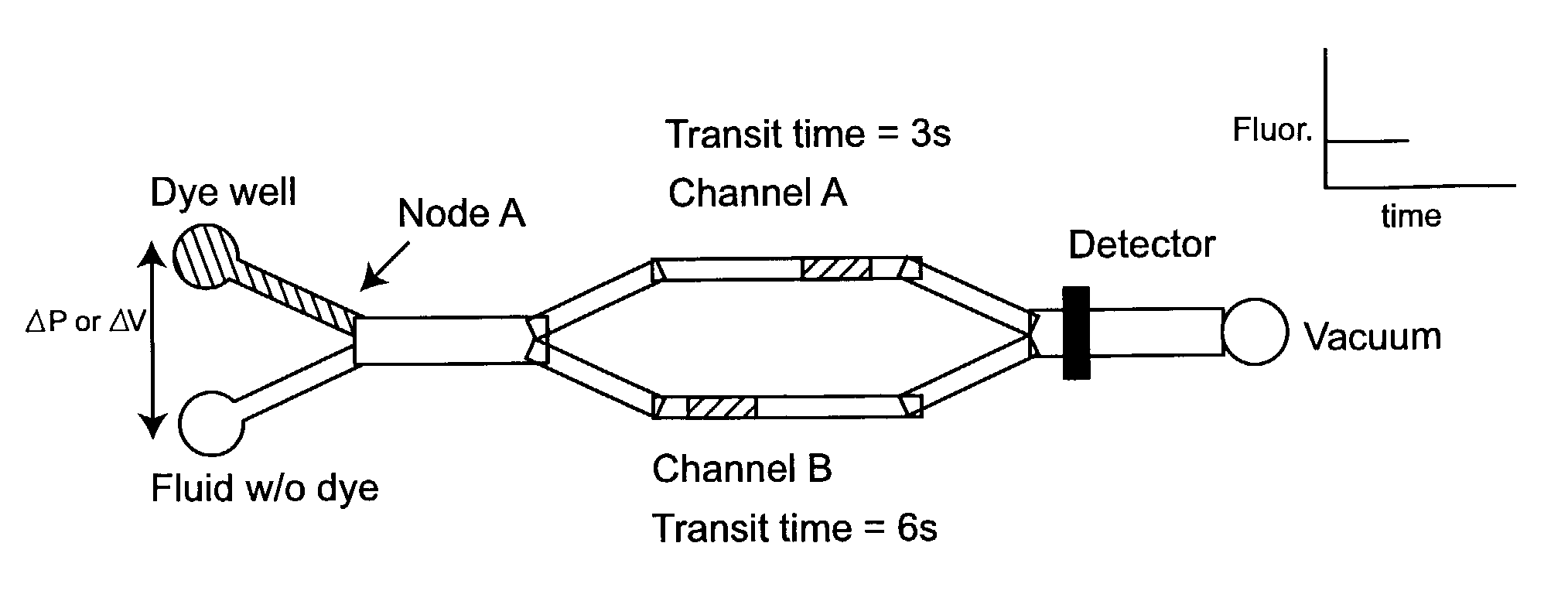

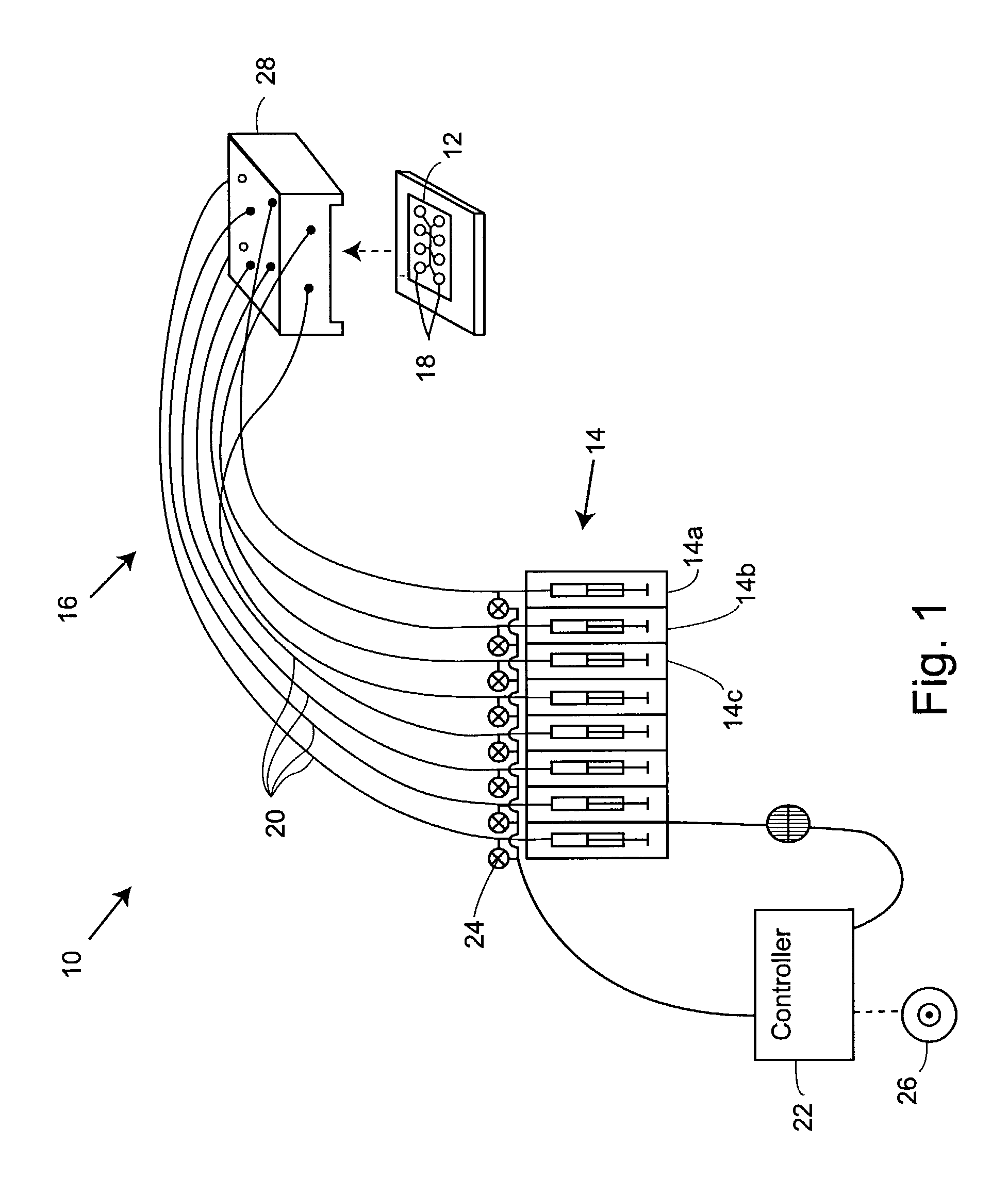

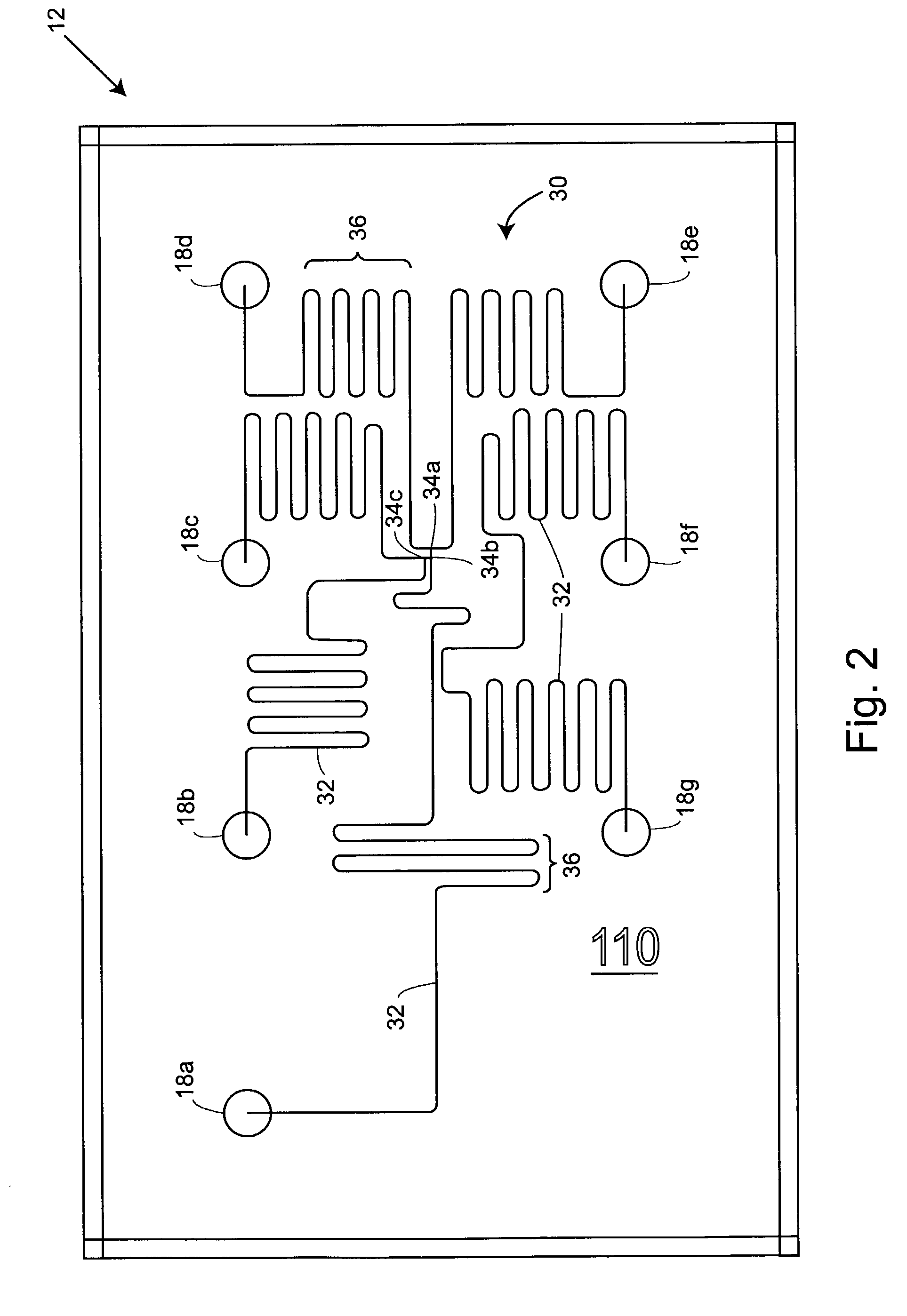

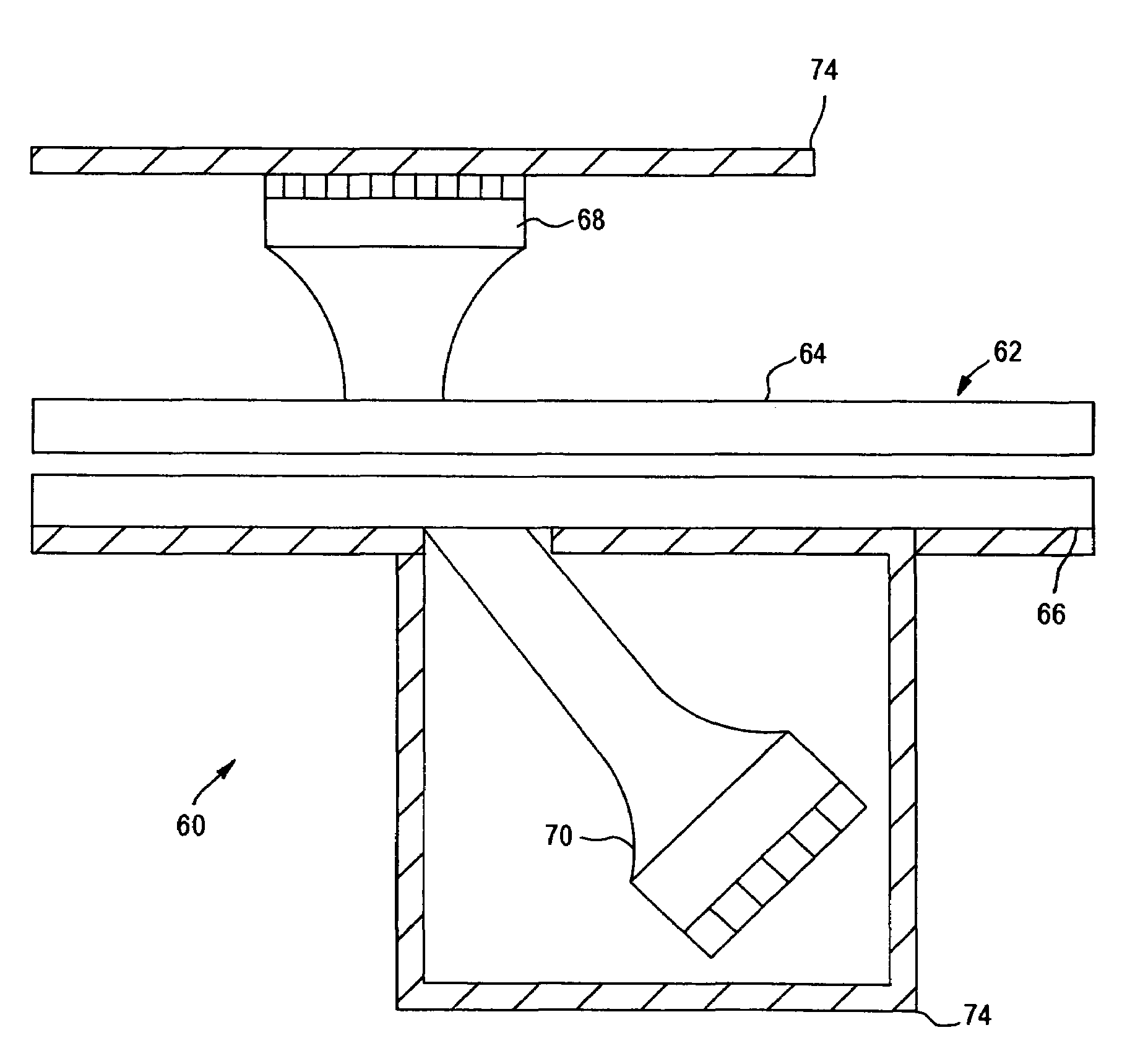

InactiveUS6915679B2Sufficient oscillationAccurate and stable and reliable assayAnalysis by electrical excitationLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

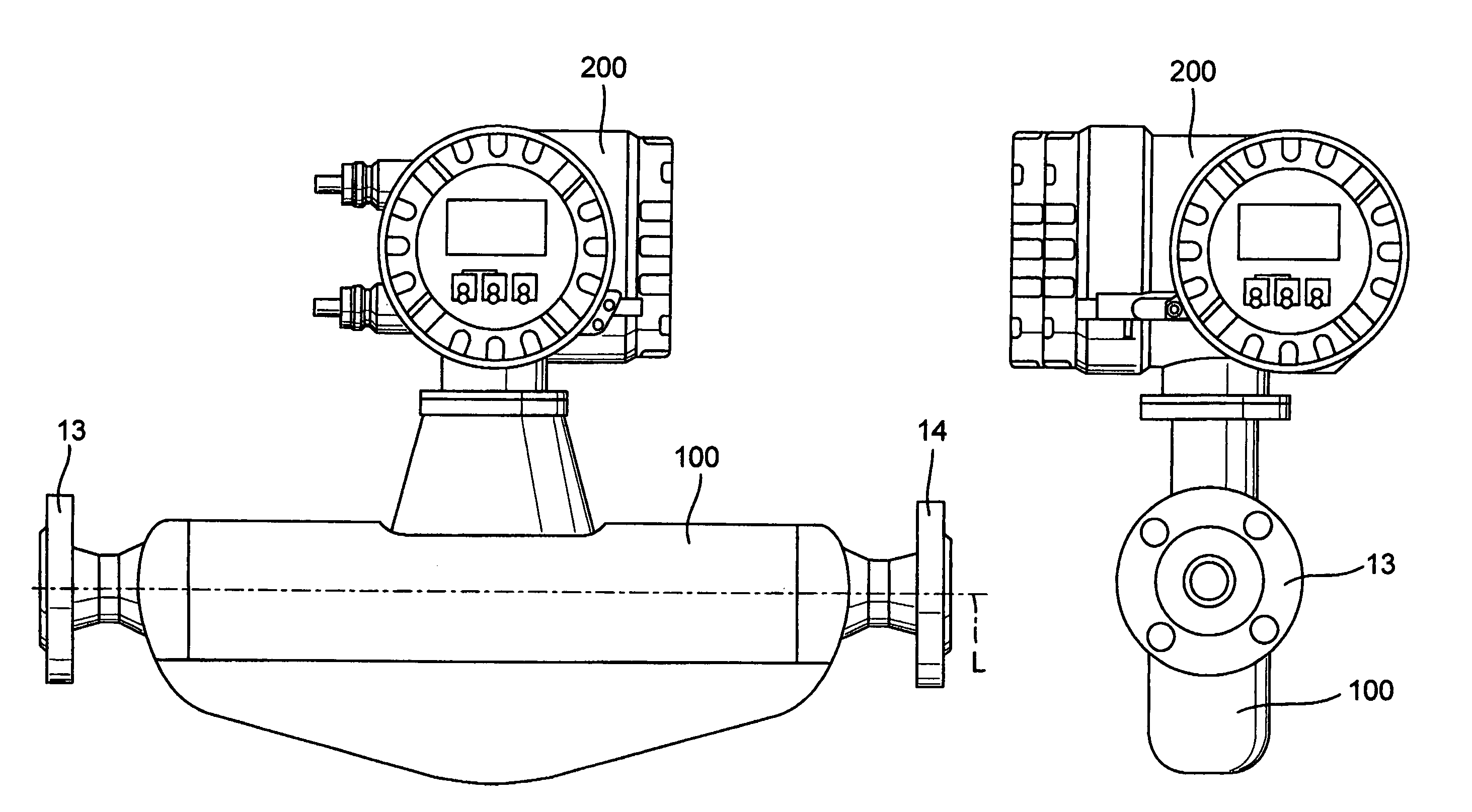

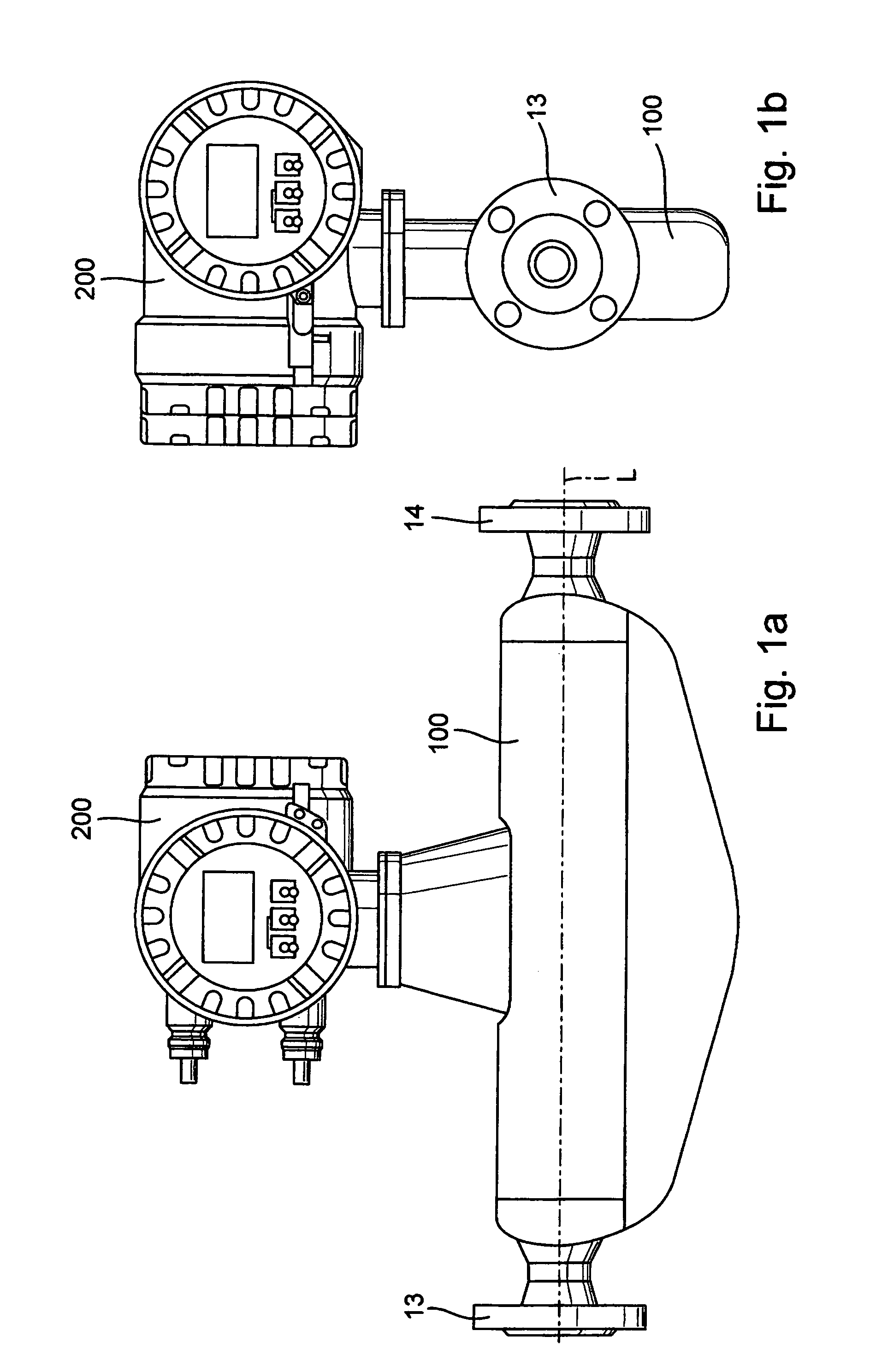

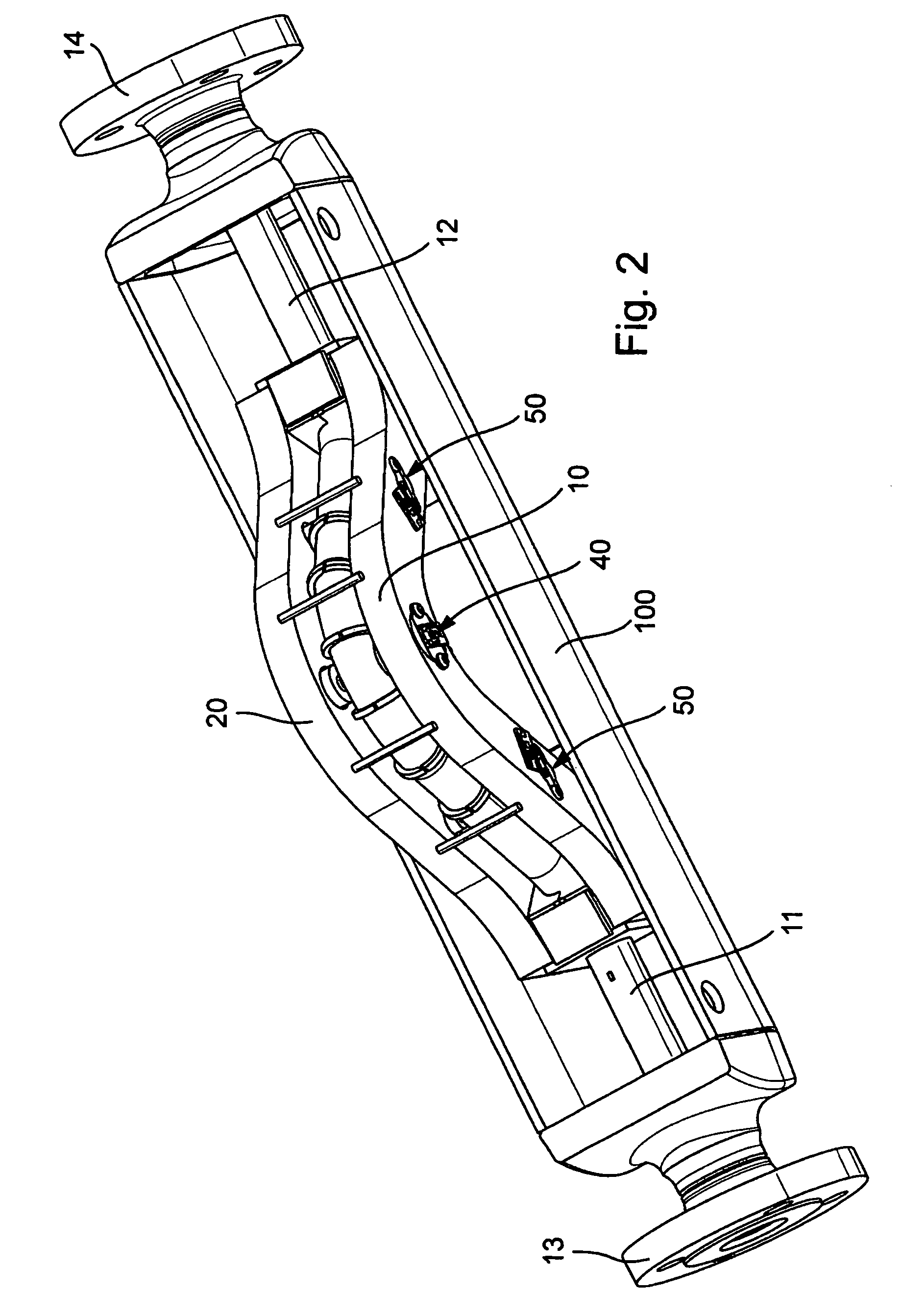

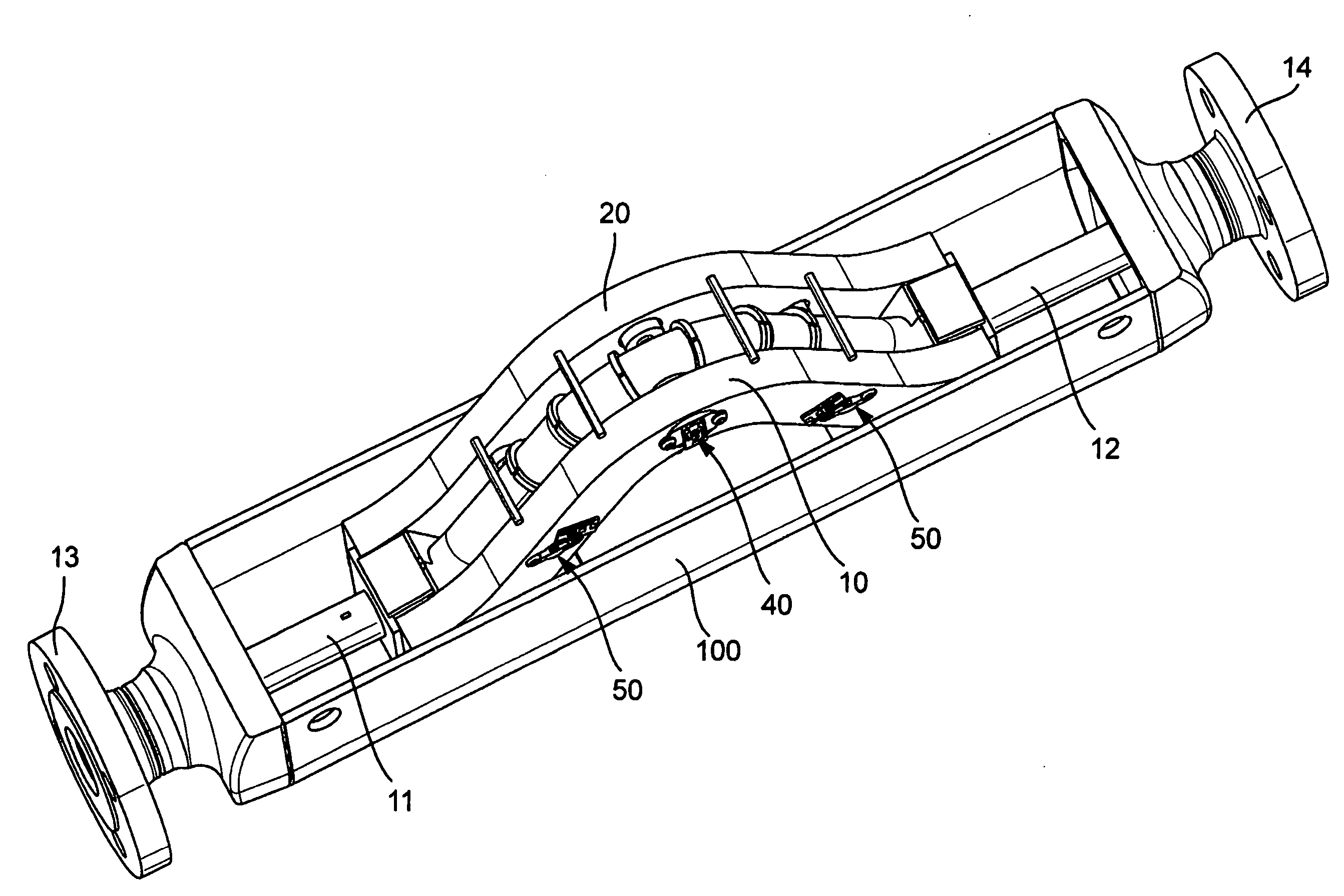

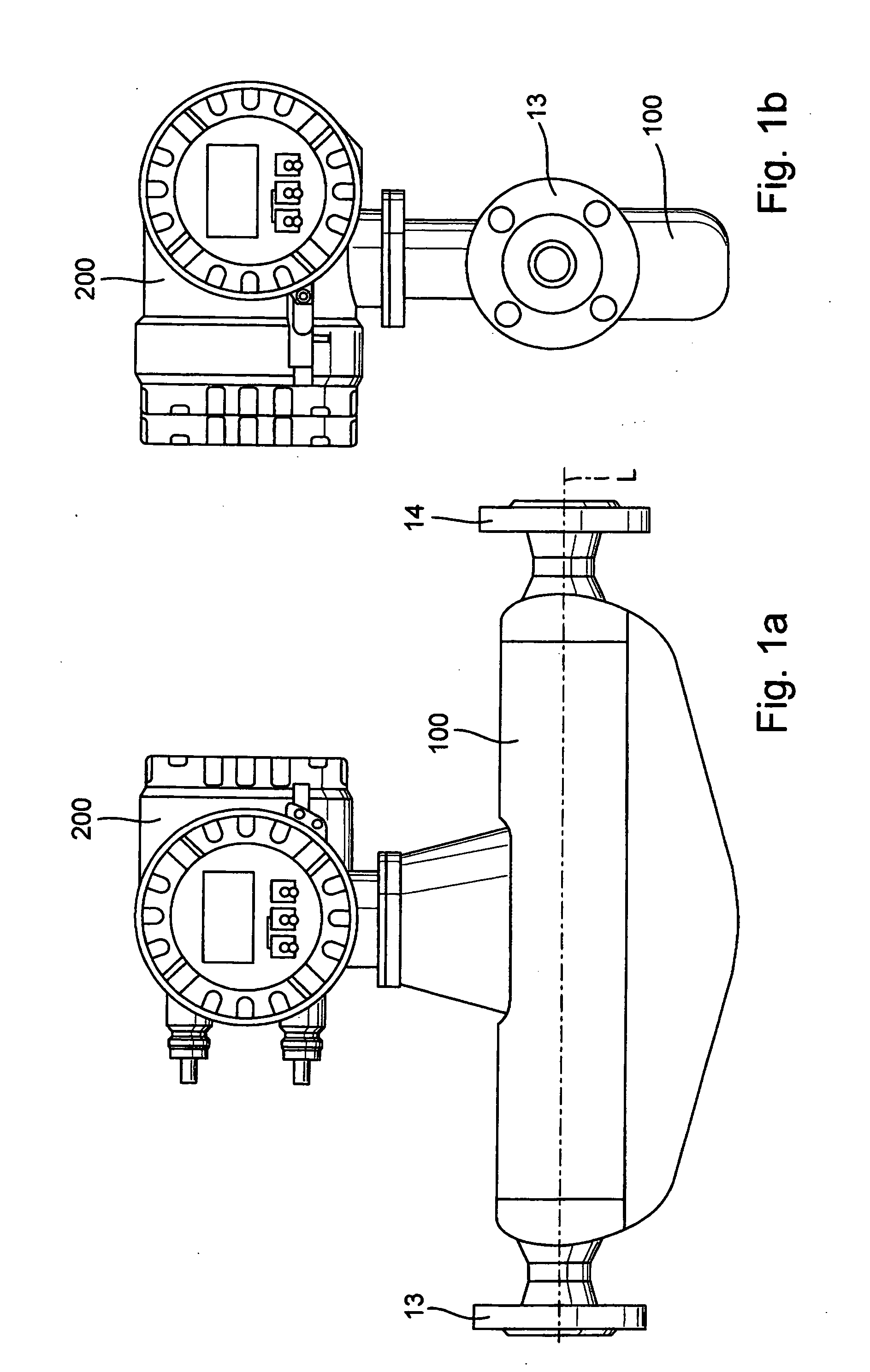

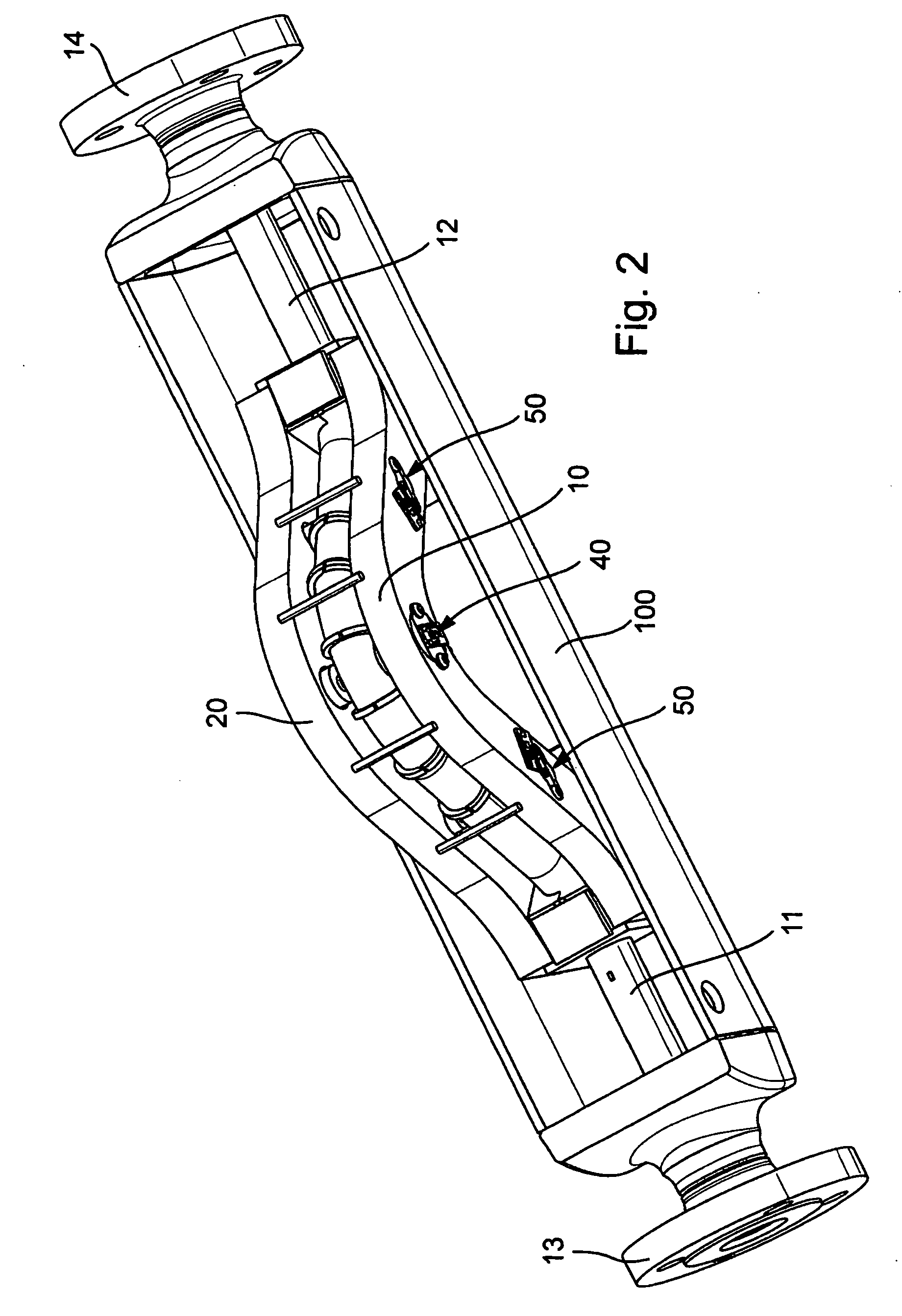

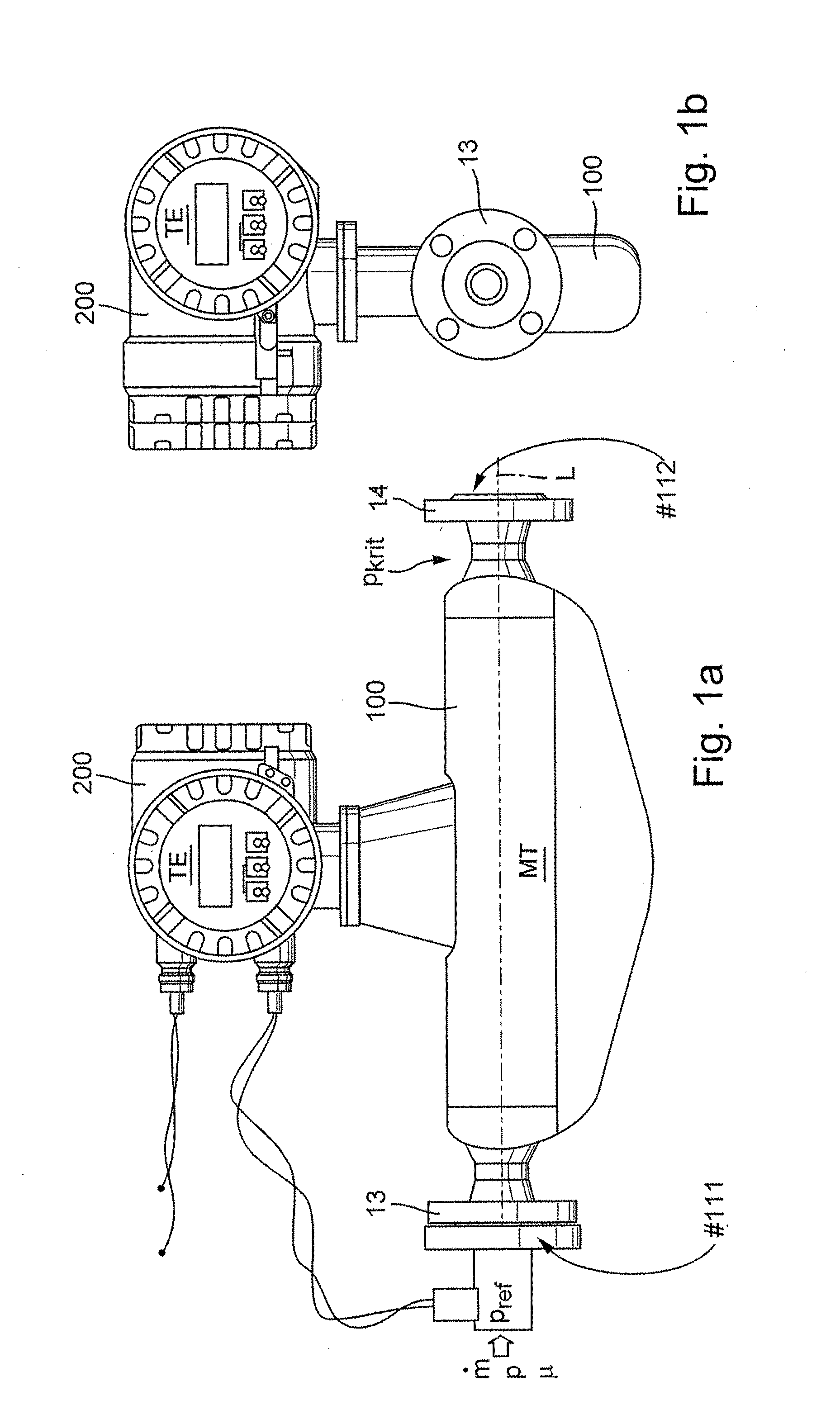

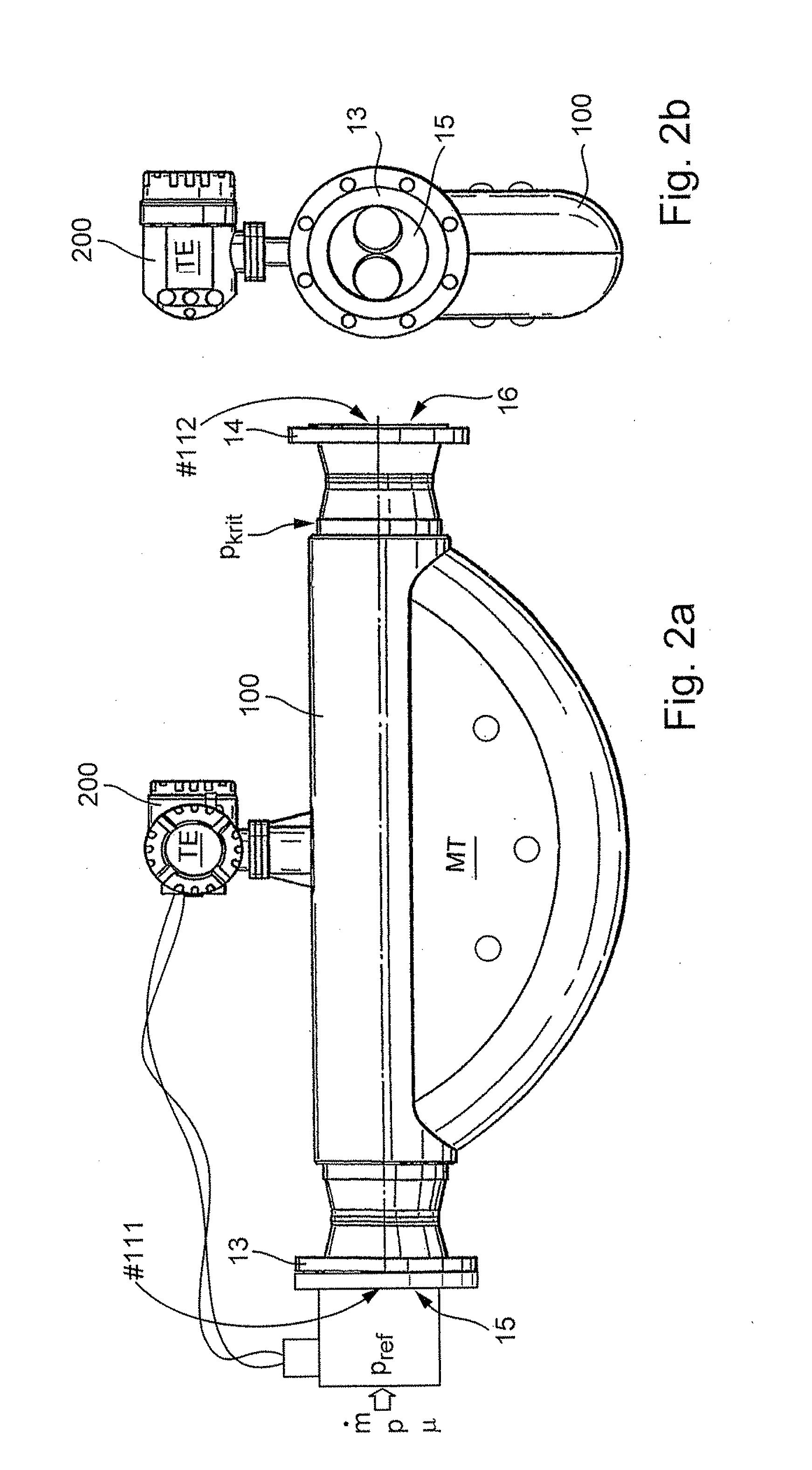

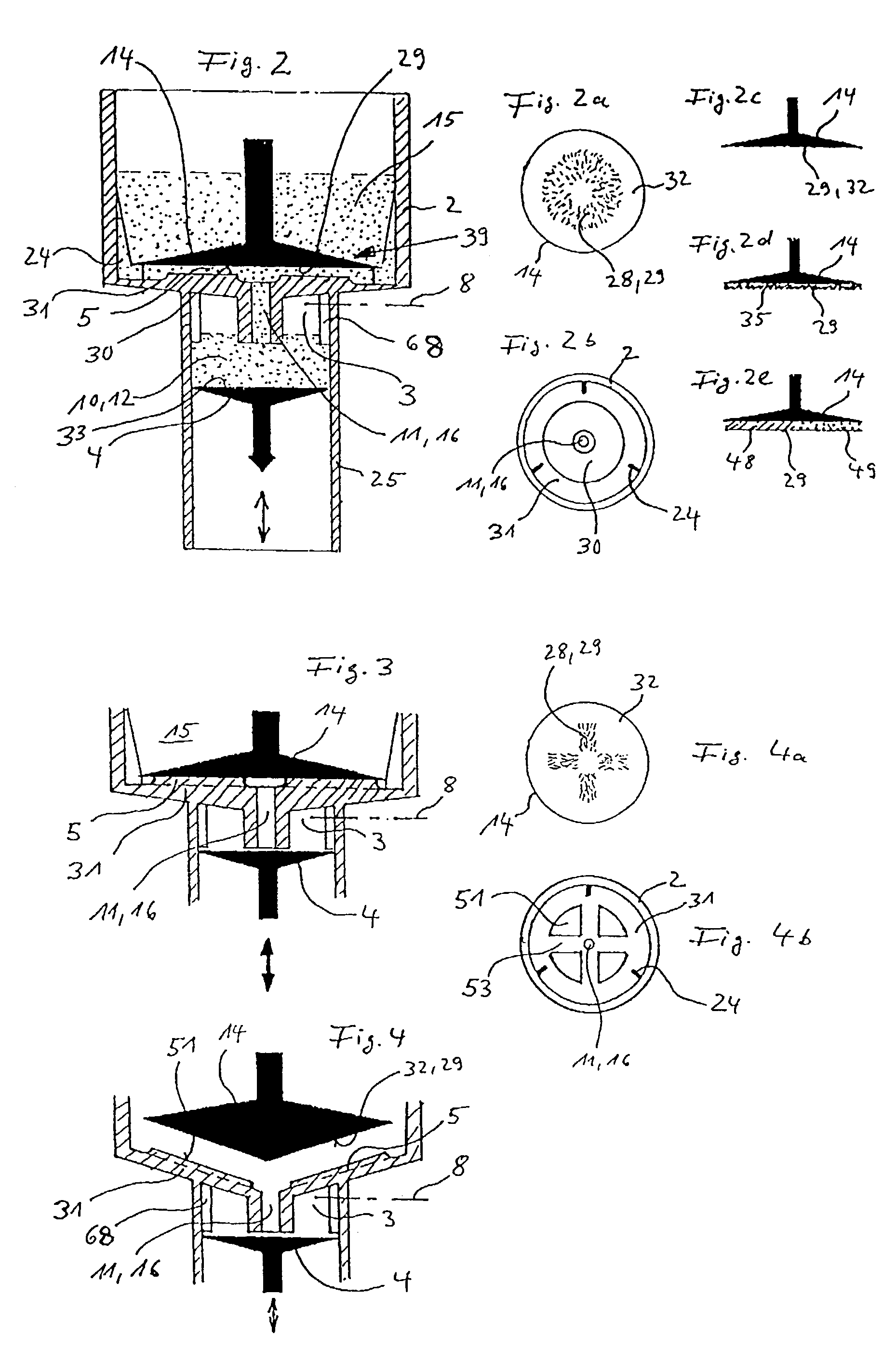

Measuring transducer of vibration-type

ActiveUS7360451B2Improve density dependence of zero-pointWorking range of the measuring transducer can,Direct mass flowmetersDirect flow property measurementCouplingTransducer

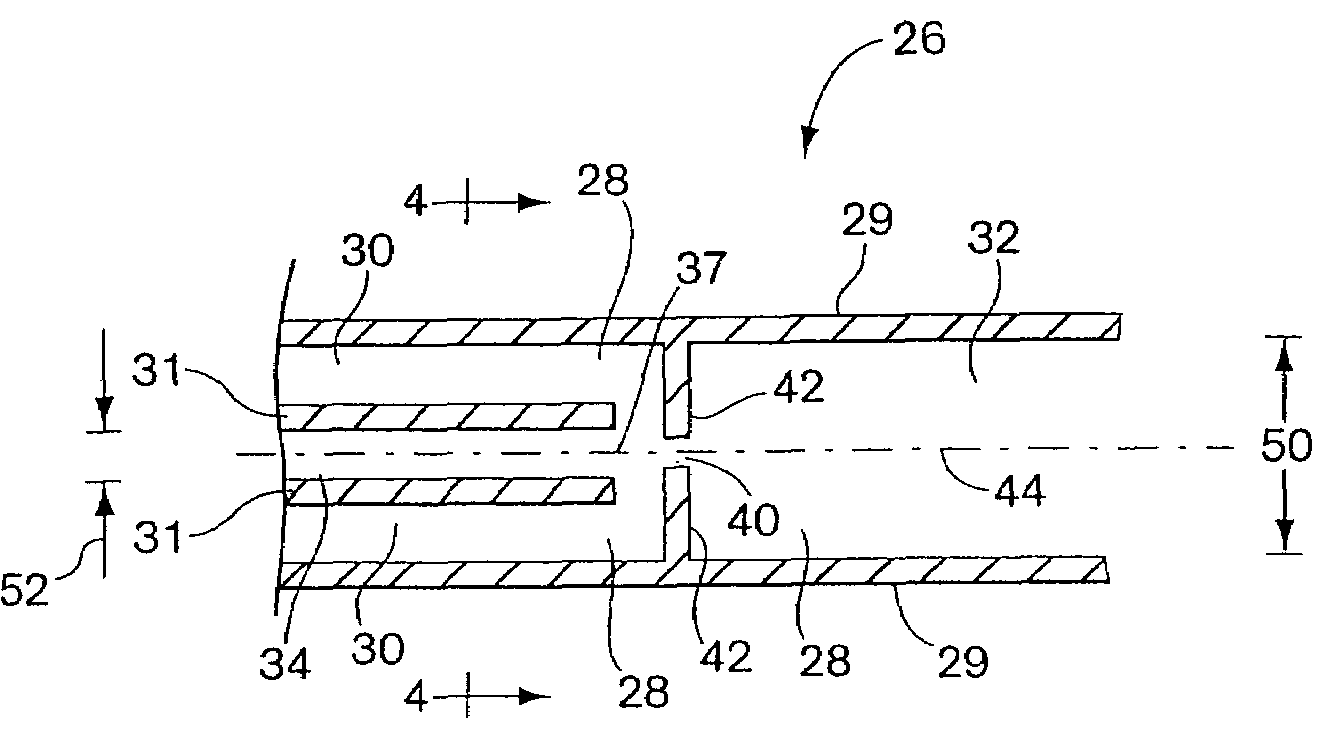

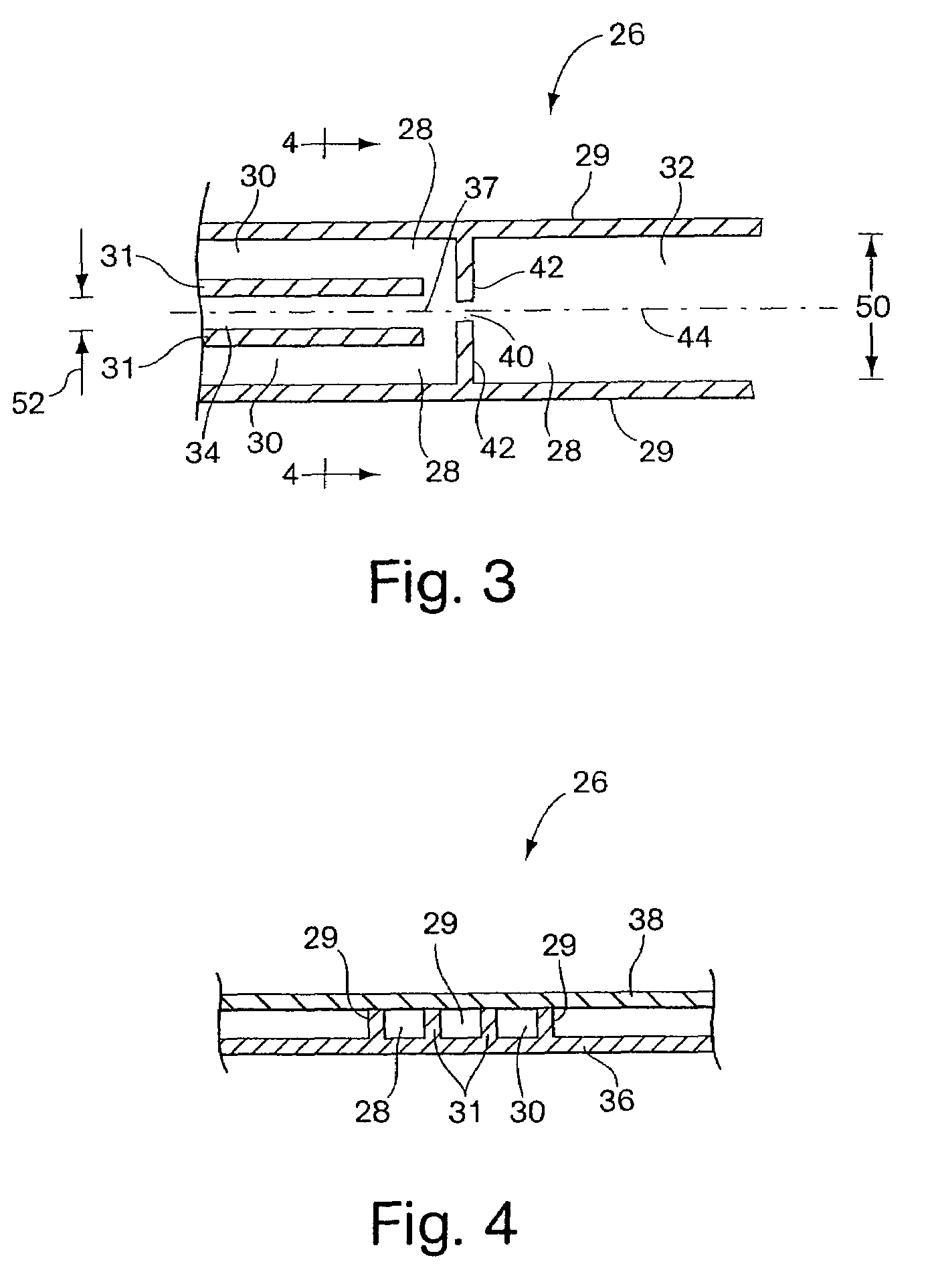

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

Microfluidic viscometer

InactiveUS7040144B2Determine viscosityVolume/mass flow measurementFlow control using electric meansFluid transportEngineering

Microfluidic devices, systems, and methods measure viscosity, flow times, and / or pressures, other flow characteristics within the channels, and the measured flow characteristics can be used to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems, electrokinetic systems and / or other fluid transport mechanisms can generate the flow, controllably mix fluids, and the like.

Owner:CAPLIPER LIFE SCI INC

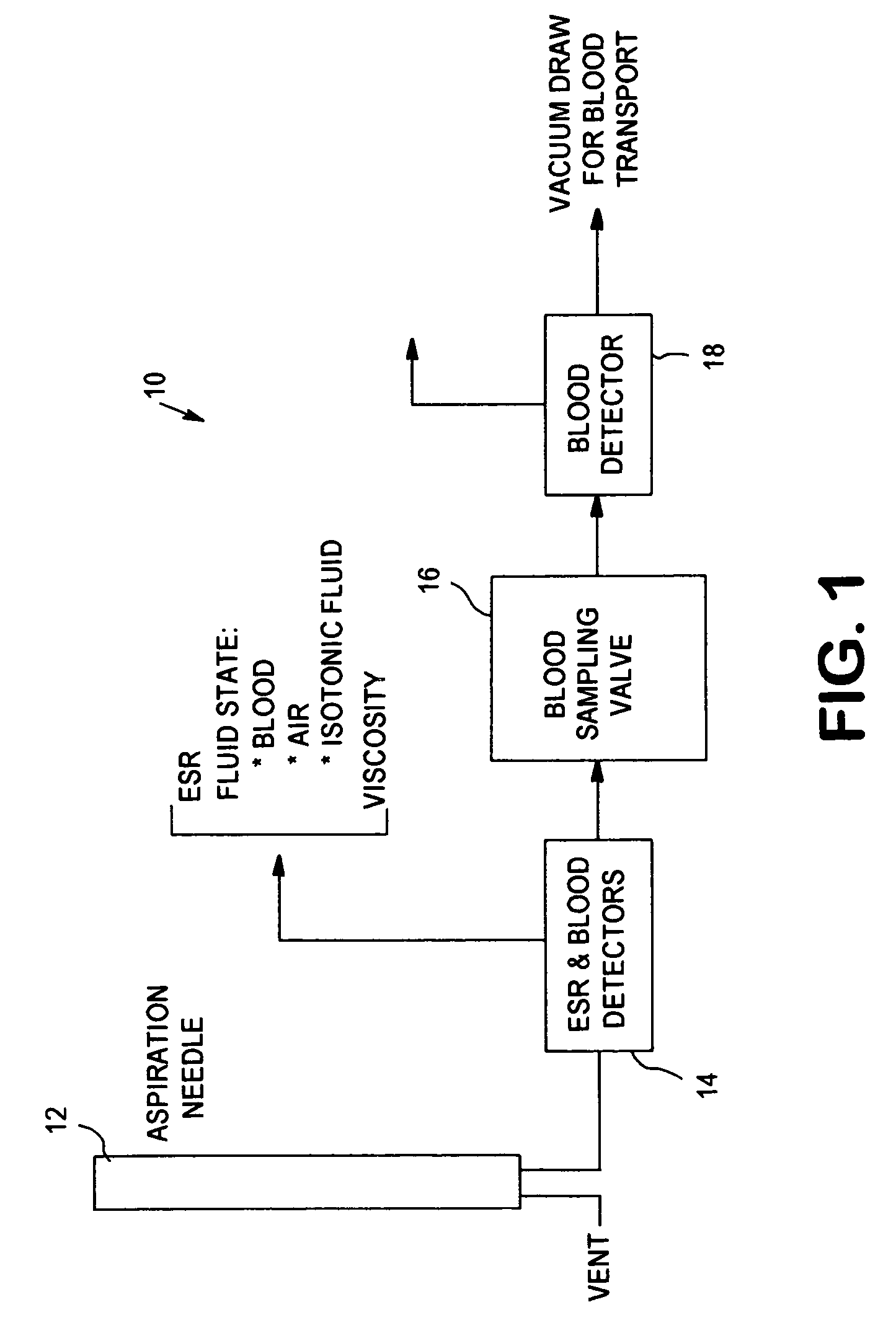

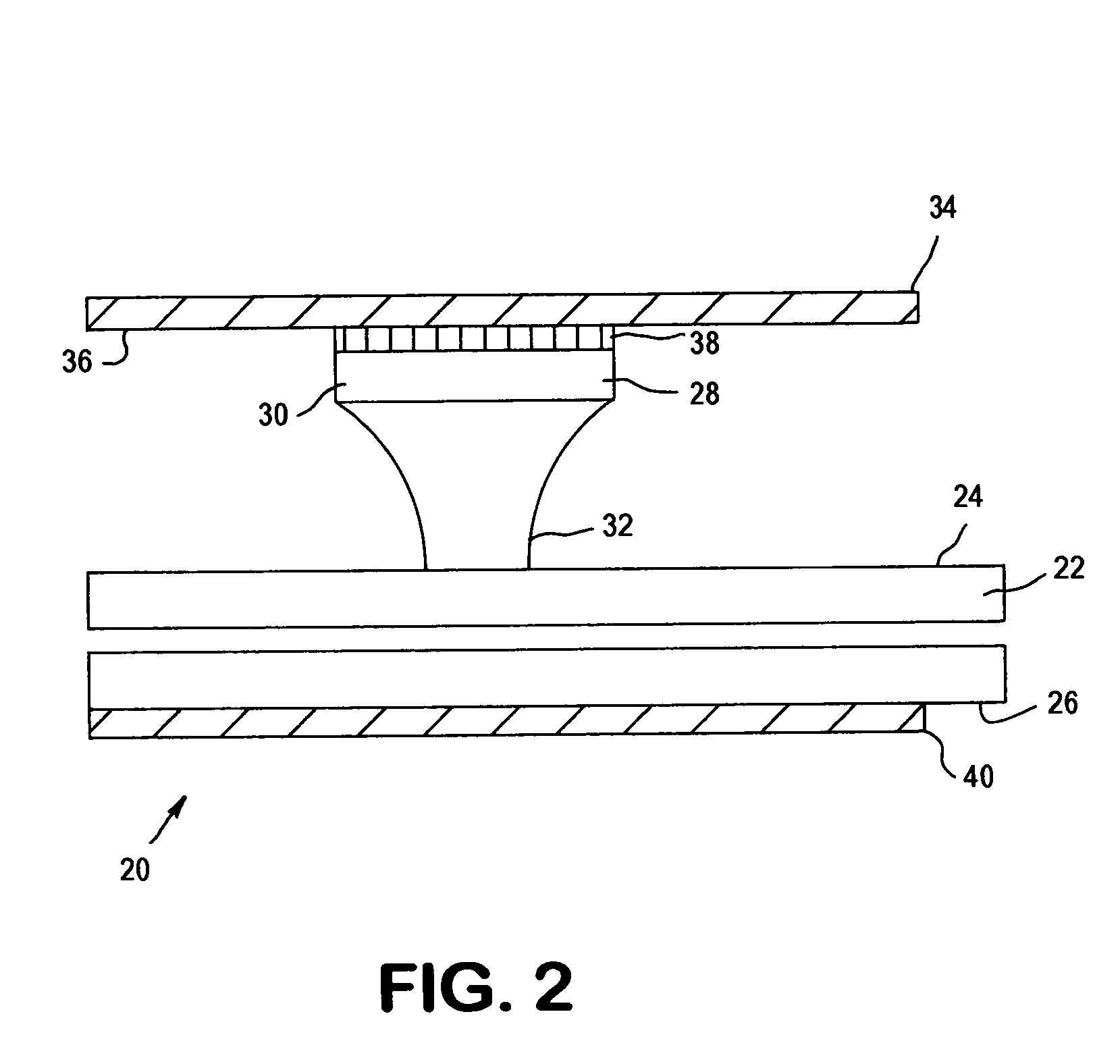

Apparatus and method for analyzing a liquid in a capillary tube of a hematology instrument

InactiveUS7207939B2Ultrasonic/sonic/infrasonic diagnosticsAnalysing fluids using sonic/ultrasonic/infrasonic wavesBlood capillaryHematology

An apparatus and method for determining the density and fluid-type of a fluid flowing in a capillary tube, the velocity and viscosity of a blood sample flowing in a capillary tube, the erythrocyte sedimentation rate (ESR) of a blood sample after flow has been brought to an abrupt stop in a capillary tube, and / or the zeta sedimentation rate (ZSR) of a blood sample after flow has been brought to an abrupt stop in a capillary tube. These measurements are accomplished by directing a waveform pulse, such as an ultrasound pulse, at a pre-determined frequency transversely across the capillary tube and sample fluid, and by determining the flight of time of the pulse through the capillary tube and sample fluid and / or the Doppler shift of the echo signals reflecting off cells moving forwardly or transversely within a flowing, or stationary, blood sample.

Owner:COULTER INTERNATIONAL CORPORATION

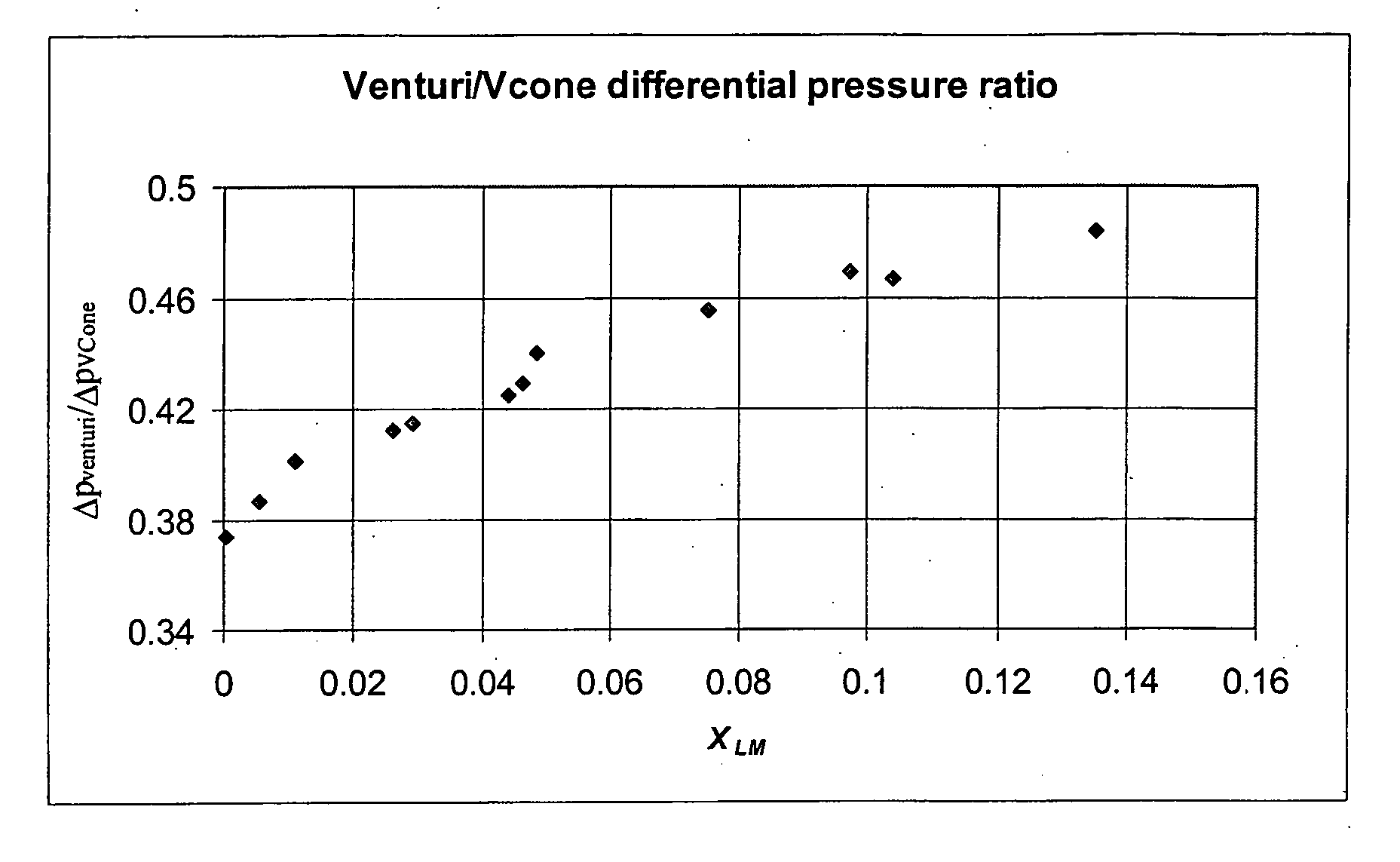

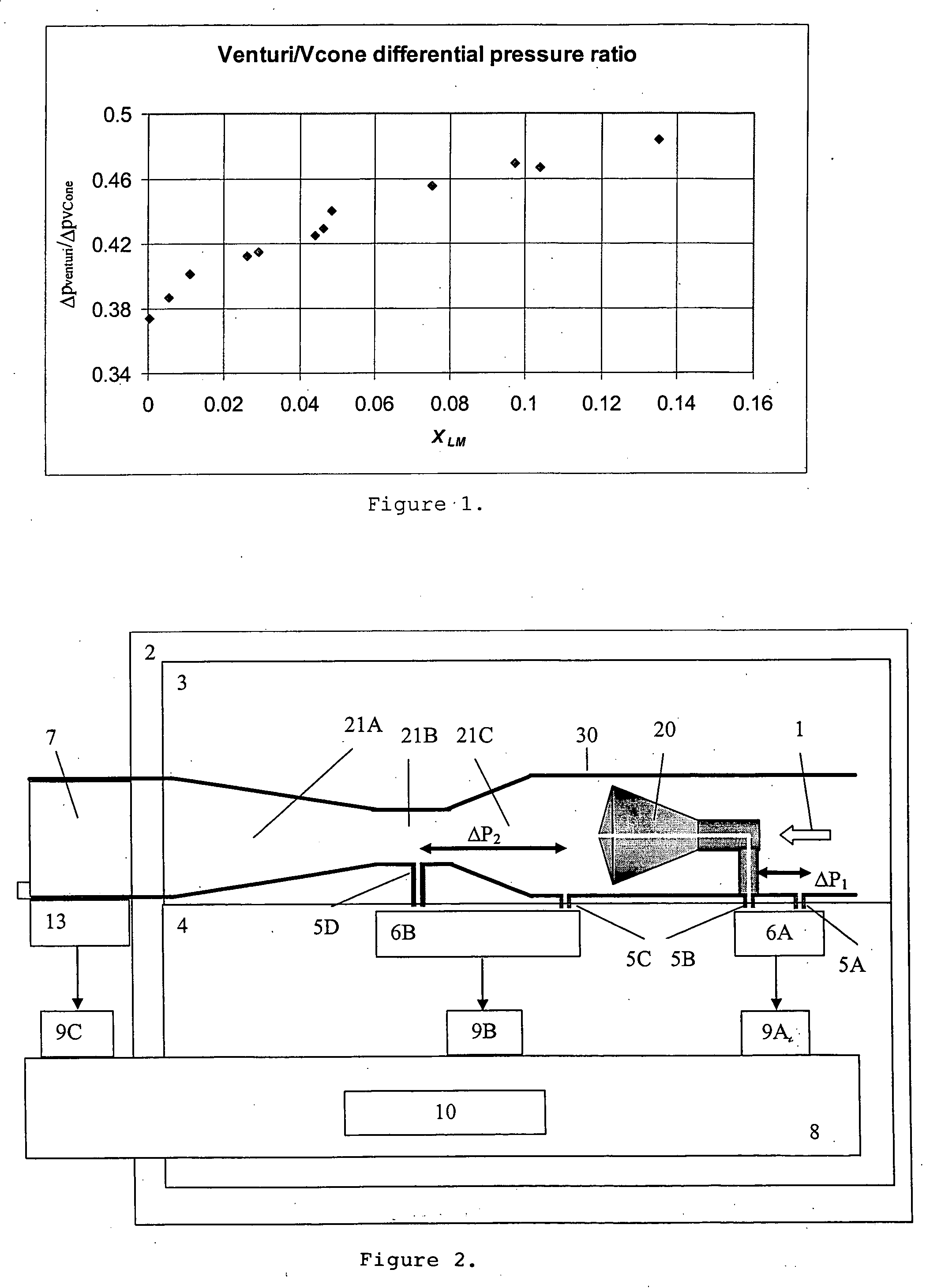

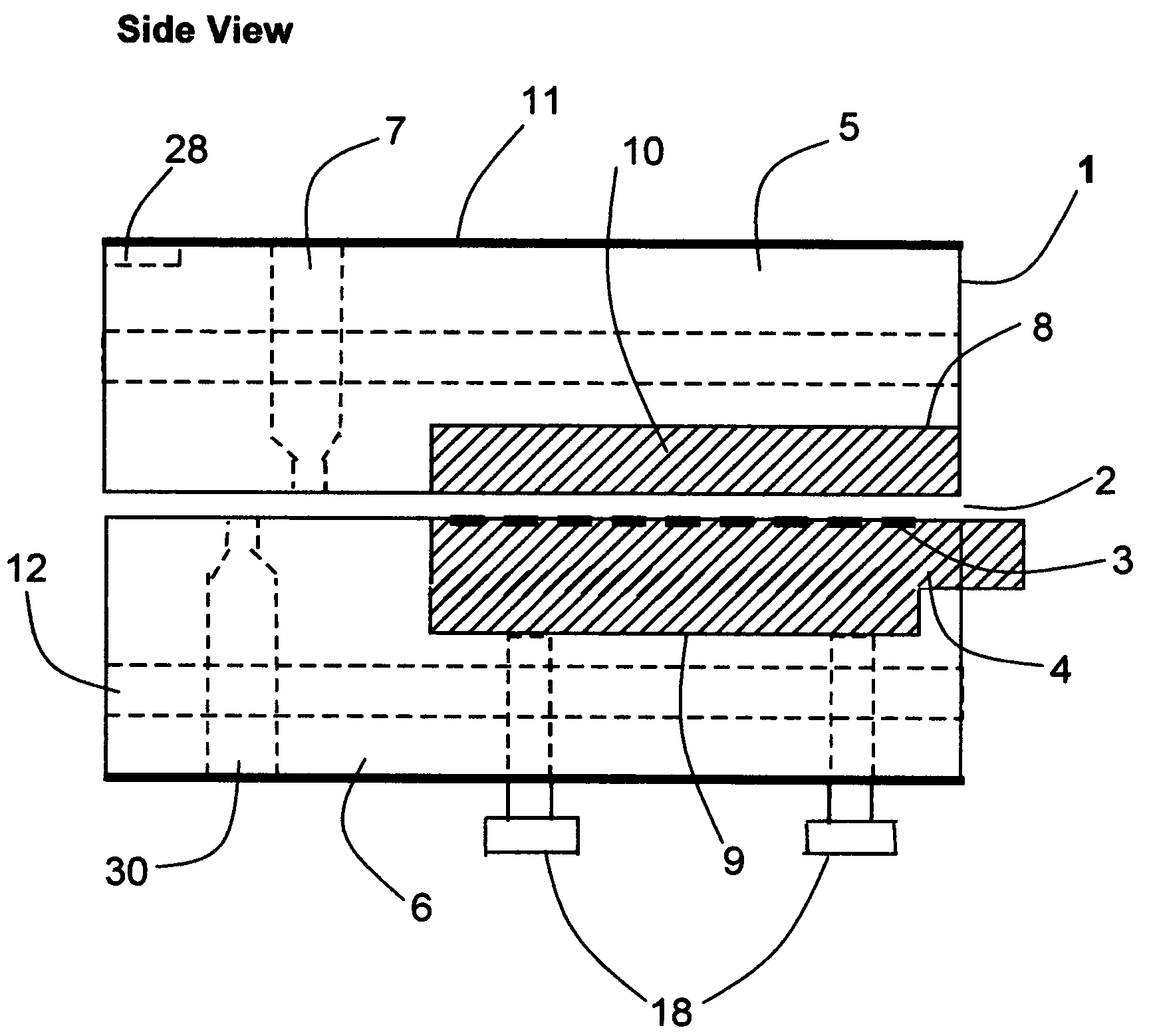

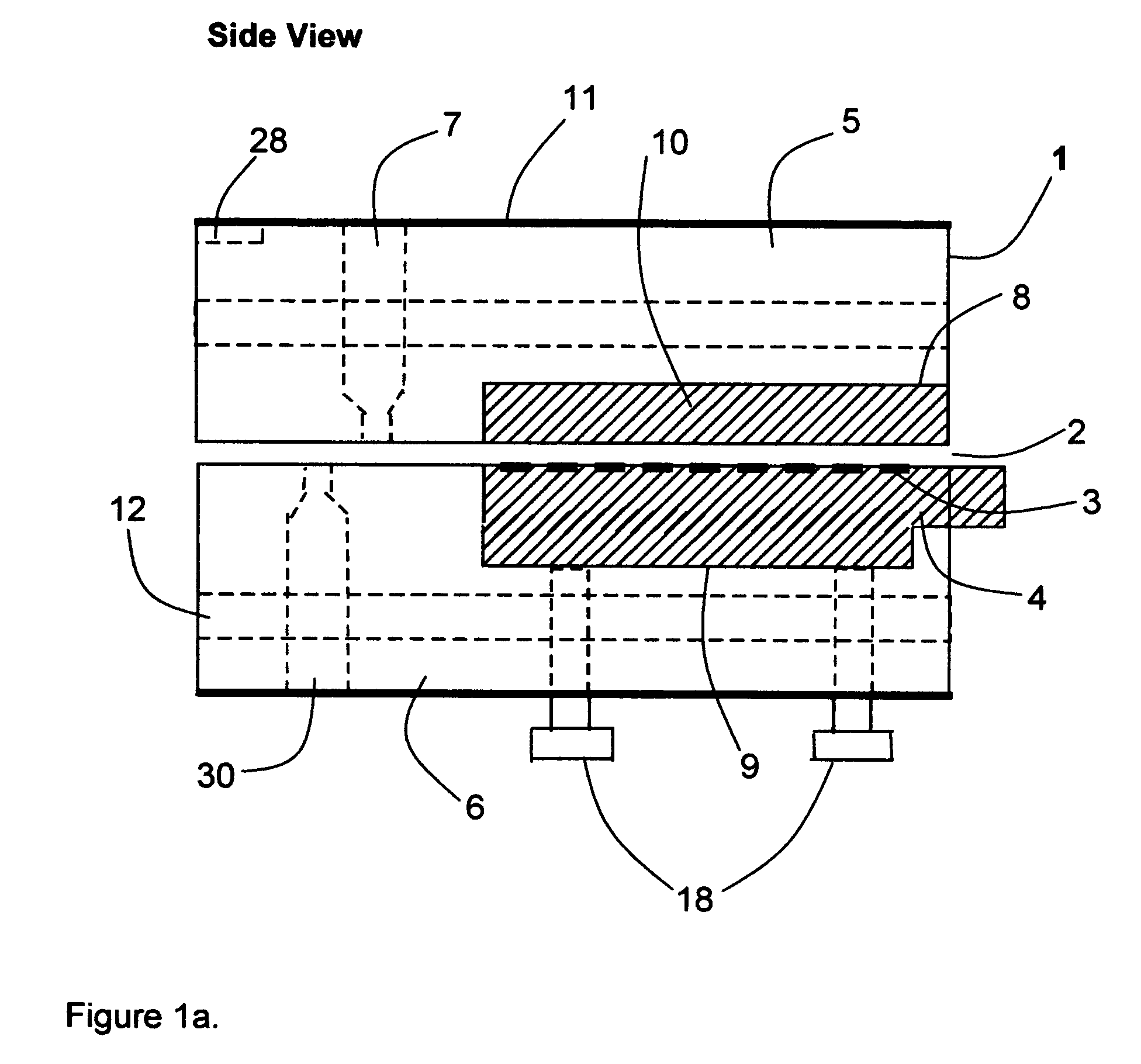

Flow meter

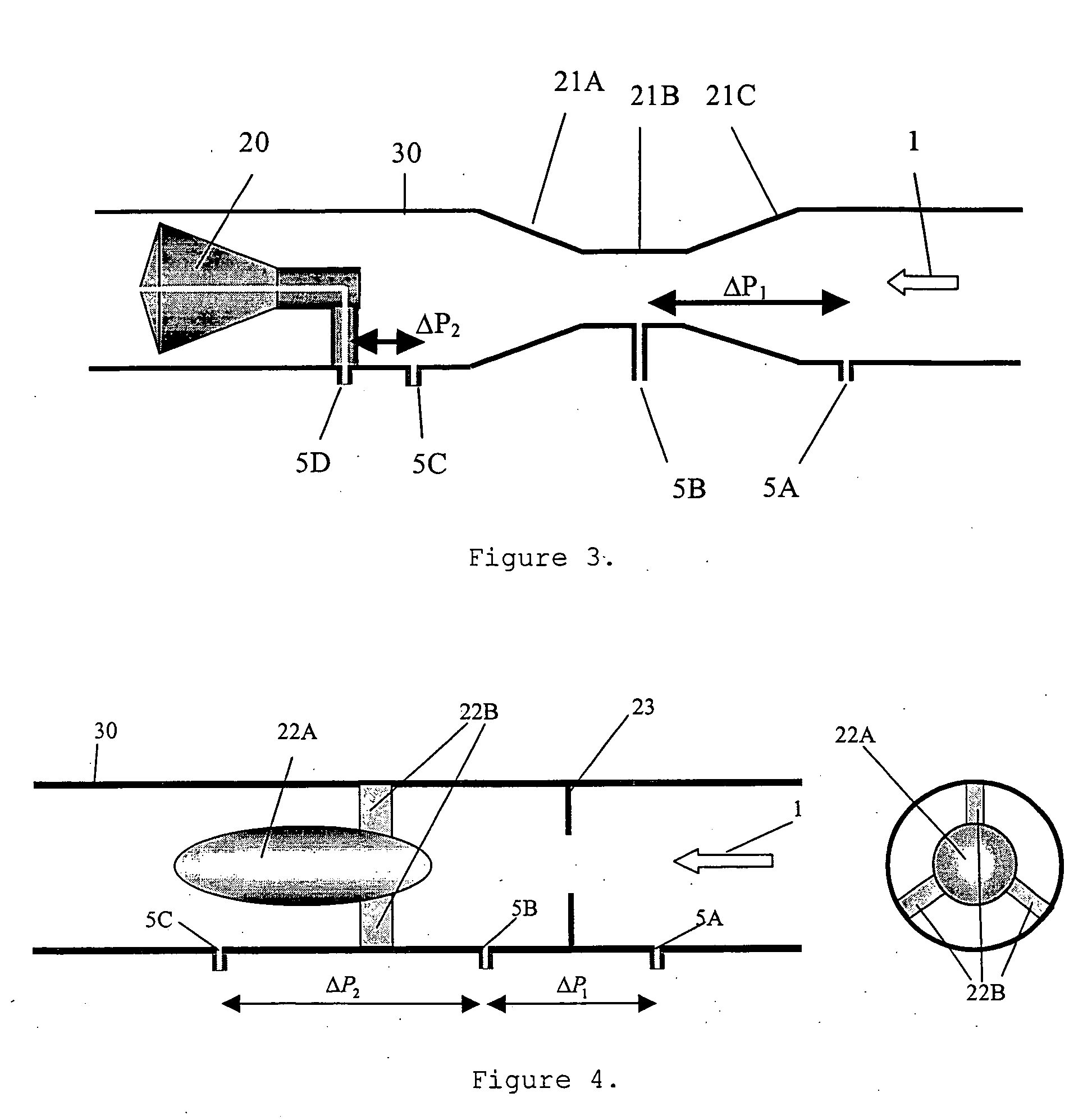

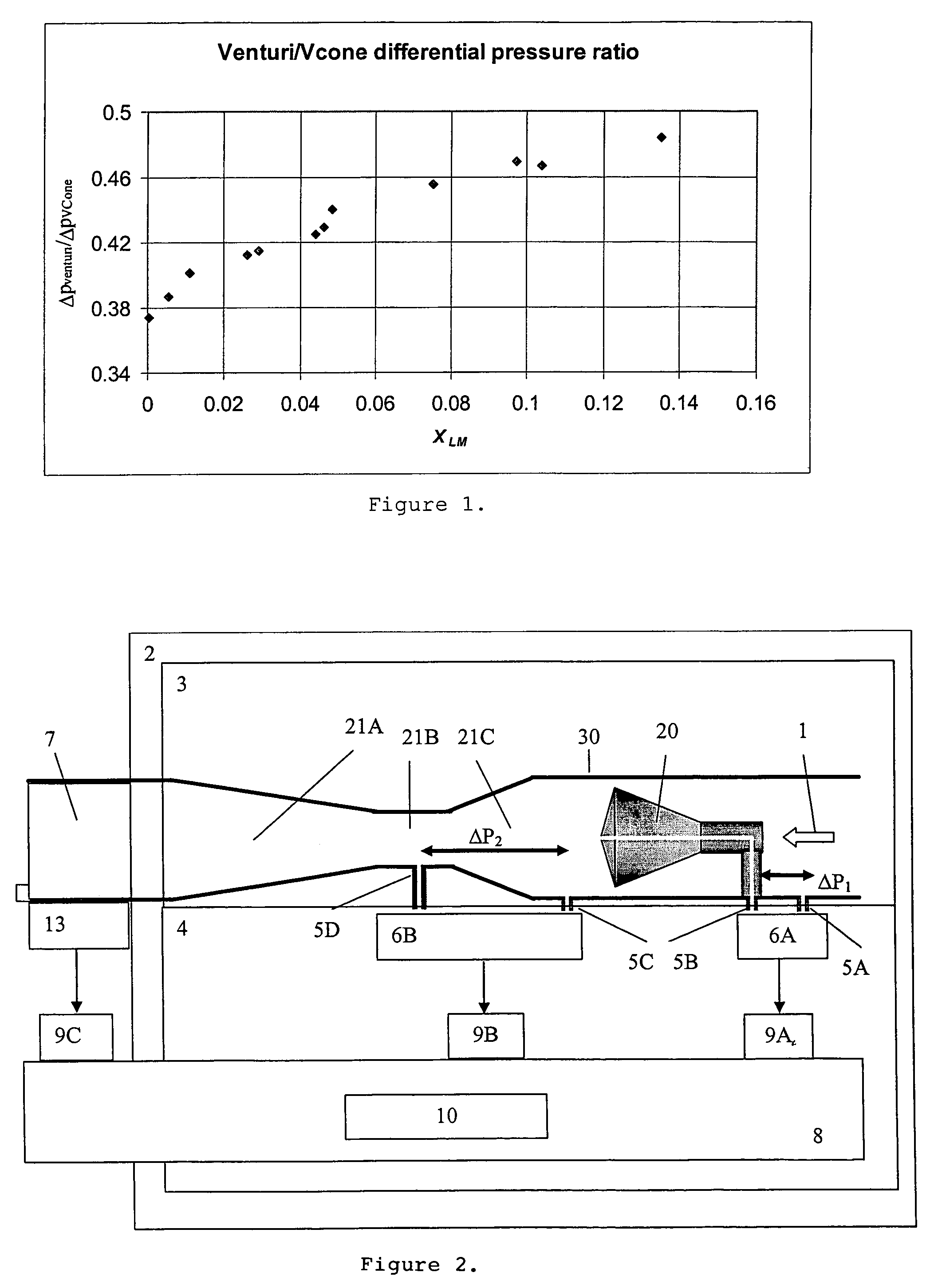

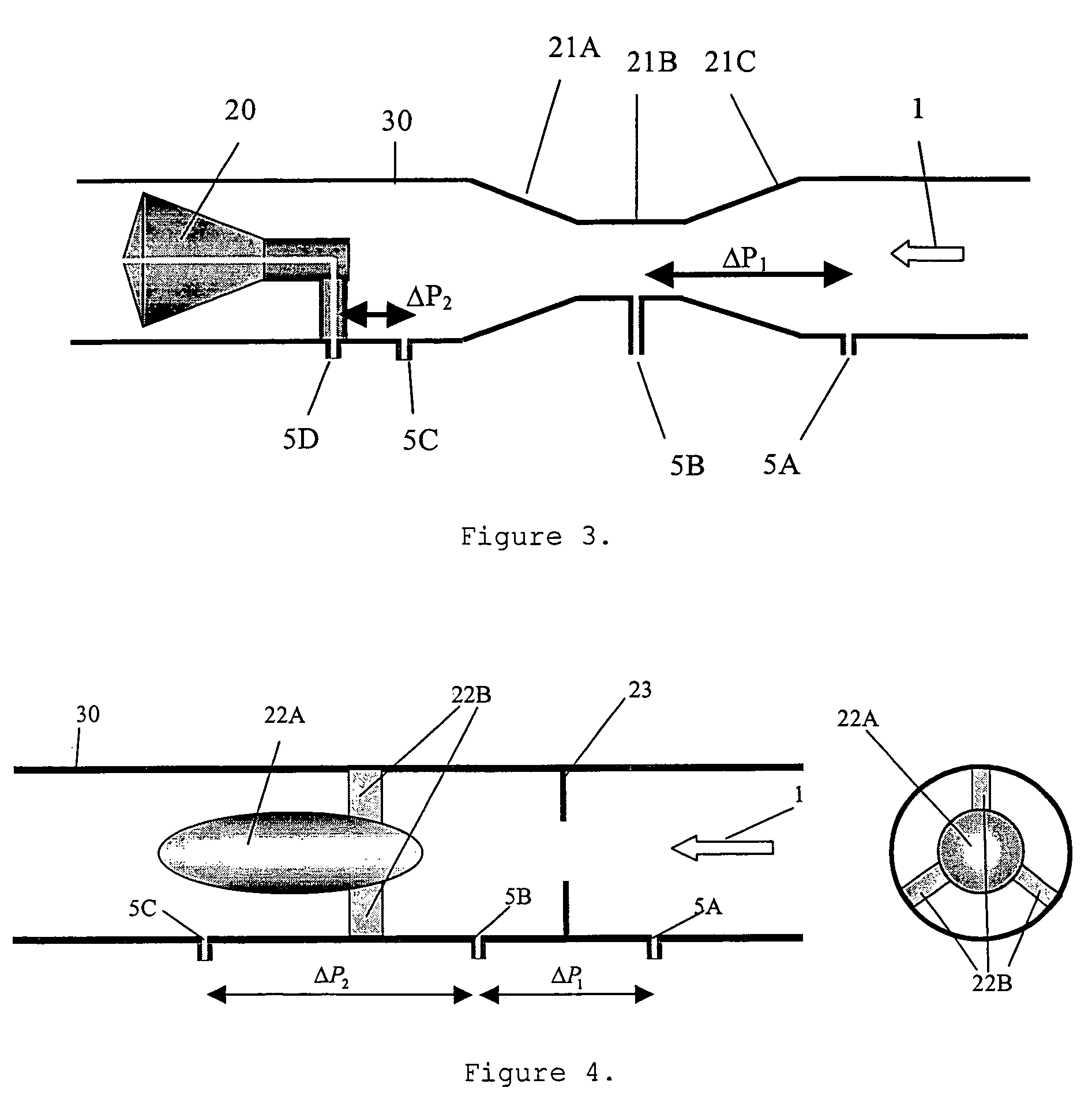

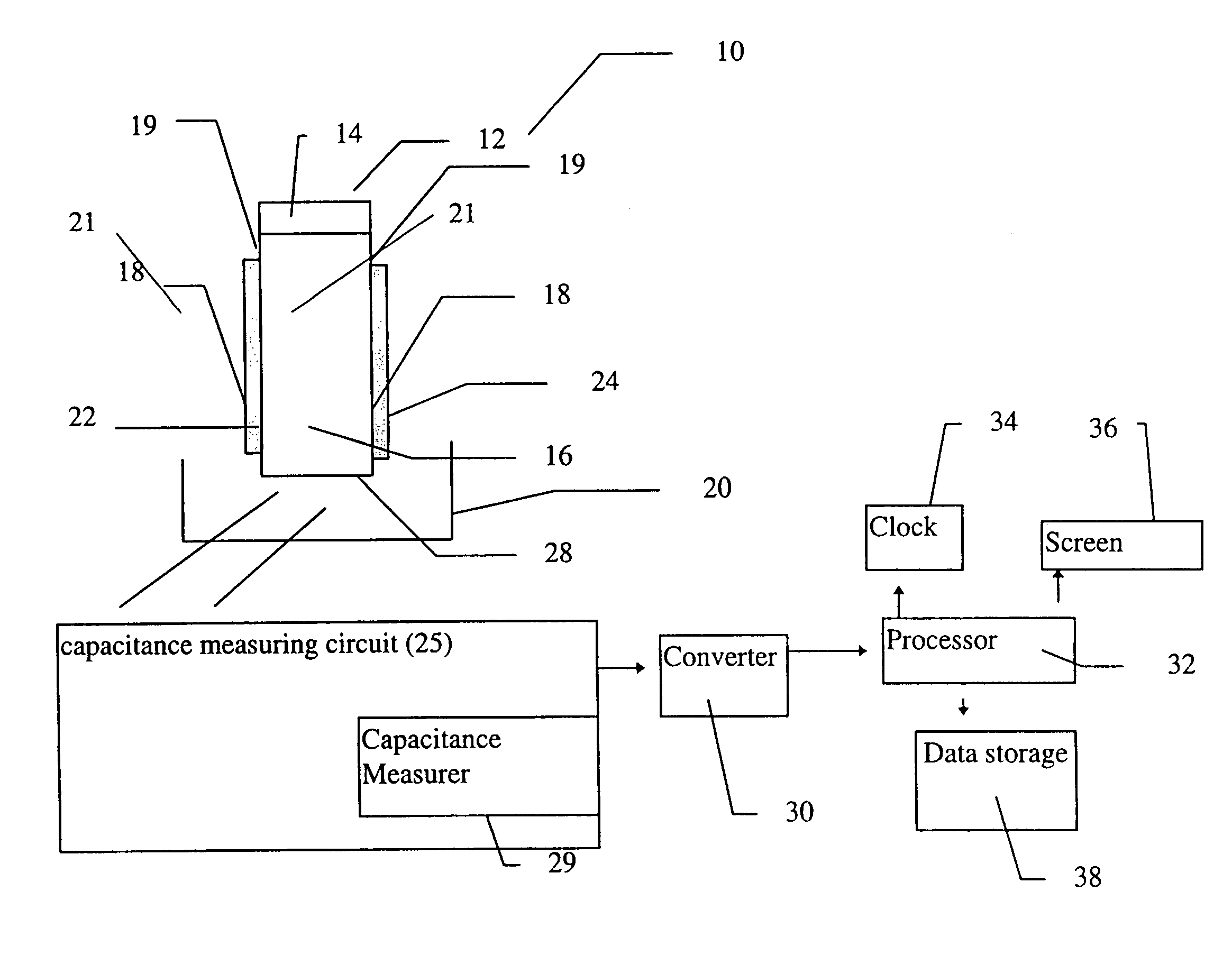

ActiveUS20050188771A1Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansLiquid stateDifferential pressure

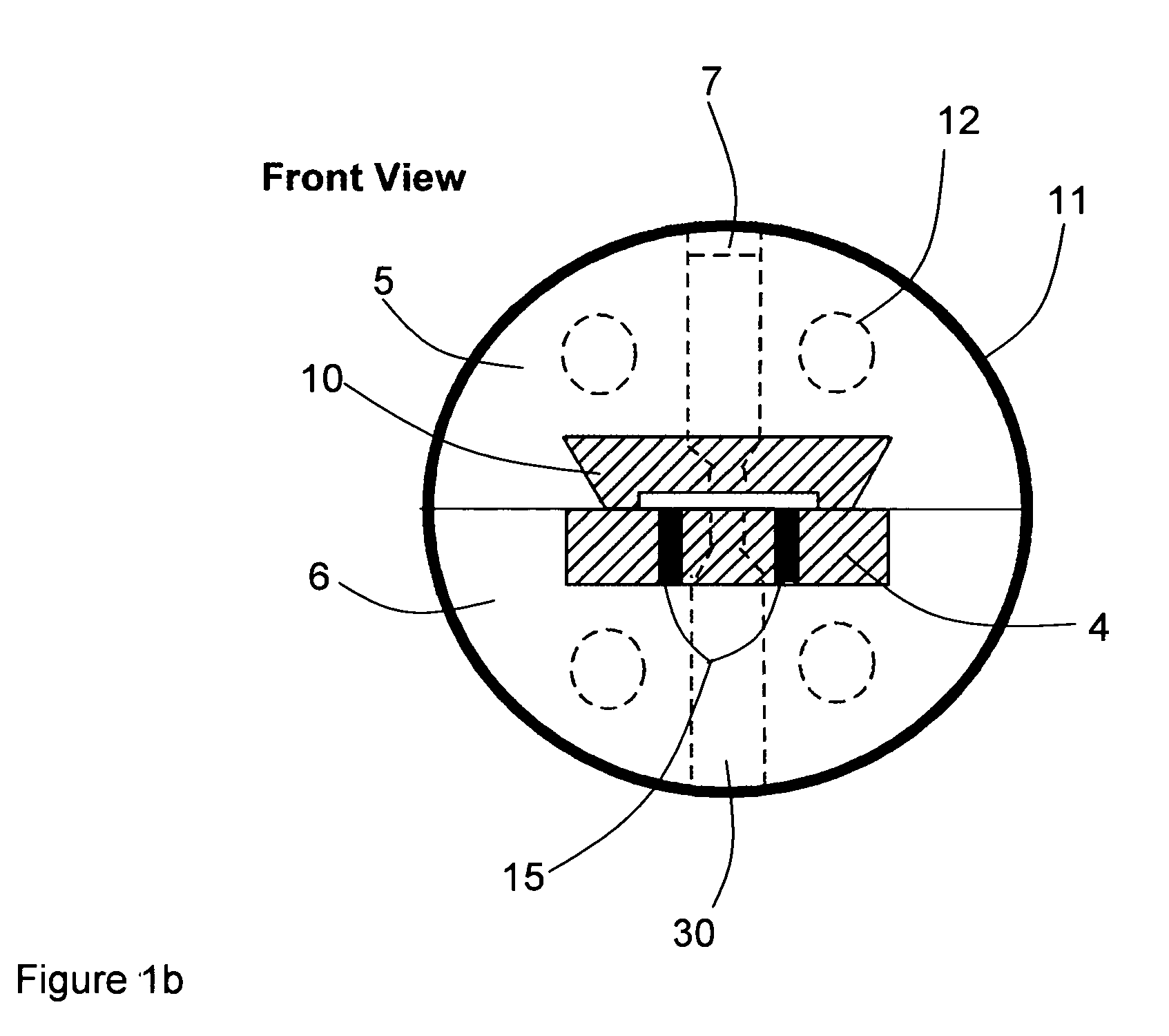

A flow meter obtains the individual flow rates of gas, liquid hydrocarbons, and water in a predominantly gas-containing flowing fluid mixture. The flow meter comprises a water content meter (7) provides a signal representing a measure of the water content of said fluid. It also comprises a double differential pressure generating (3) and measuring (4) structure, denoted a DDP-unit (2), that provides two measurement signals (6A and 6B) representing two independent values of differential pressure (DP) in said fluid (1). In addition to the above, the meter also comprises a signal processing unit (8) having inputs (9A-C) for receiving the measurement signals and the water content signal, and a calculation module (10) which calculates values representing the volumetric flow rates of said gas, liquid hydrocarbons and water in said fluid.

Owner:ROXAR FLOW MEASUREMENT

Measuring transducer of vibration-type

ActiveUS20070151371A1Improve density dependence of zero-pointEffective applicationDirect mass flowmetersDirect flow property measurementCouplingTransducer

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

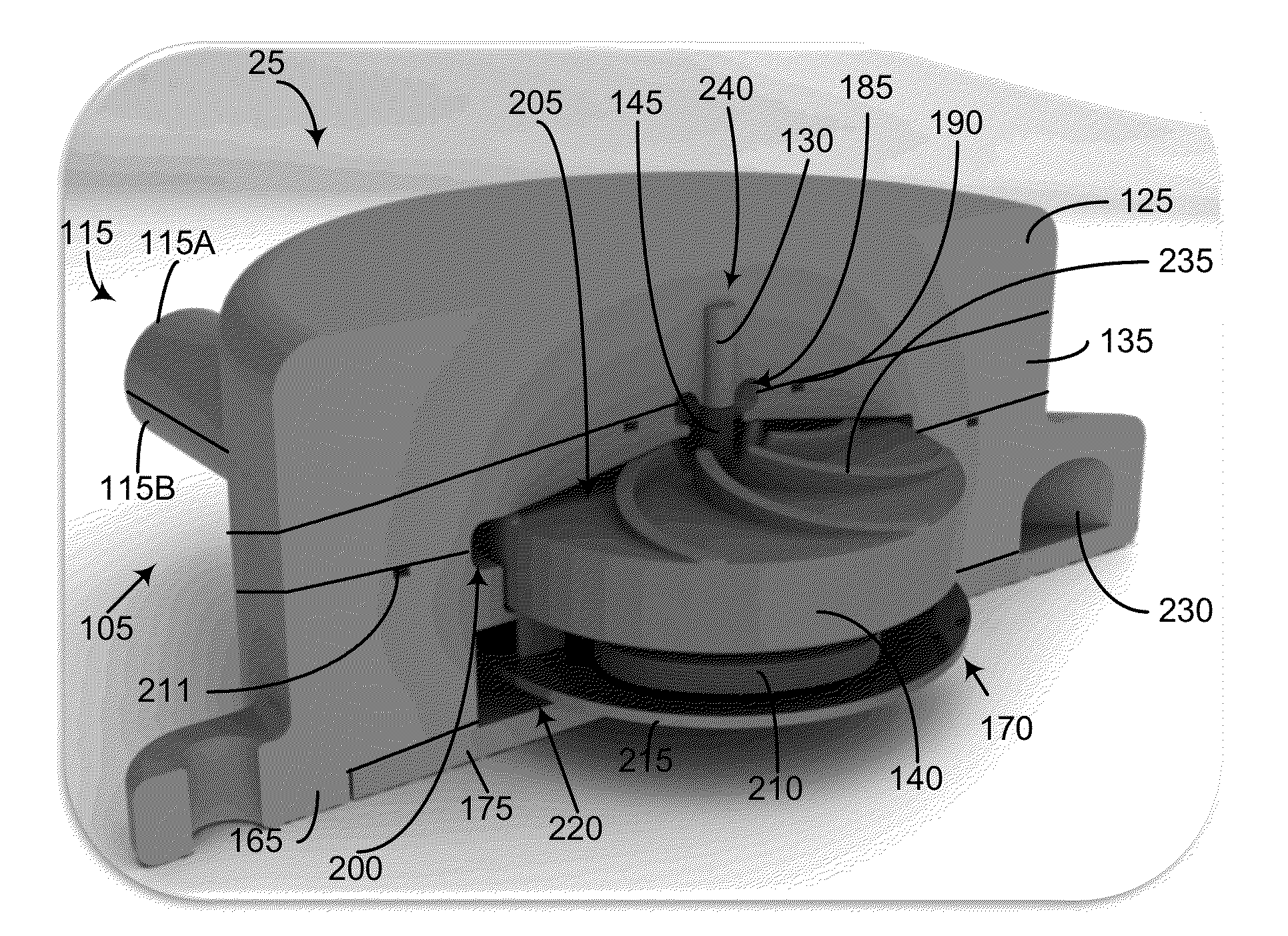

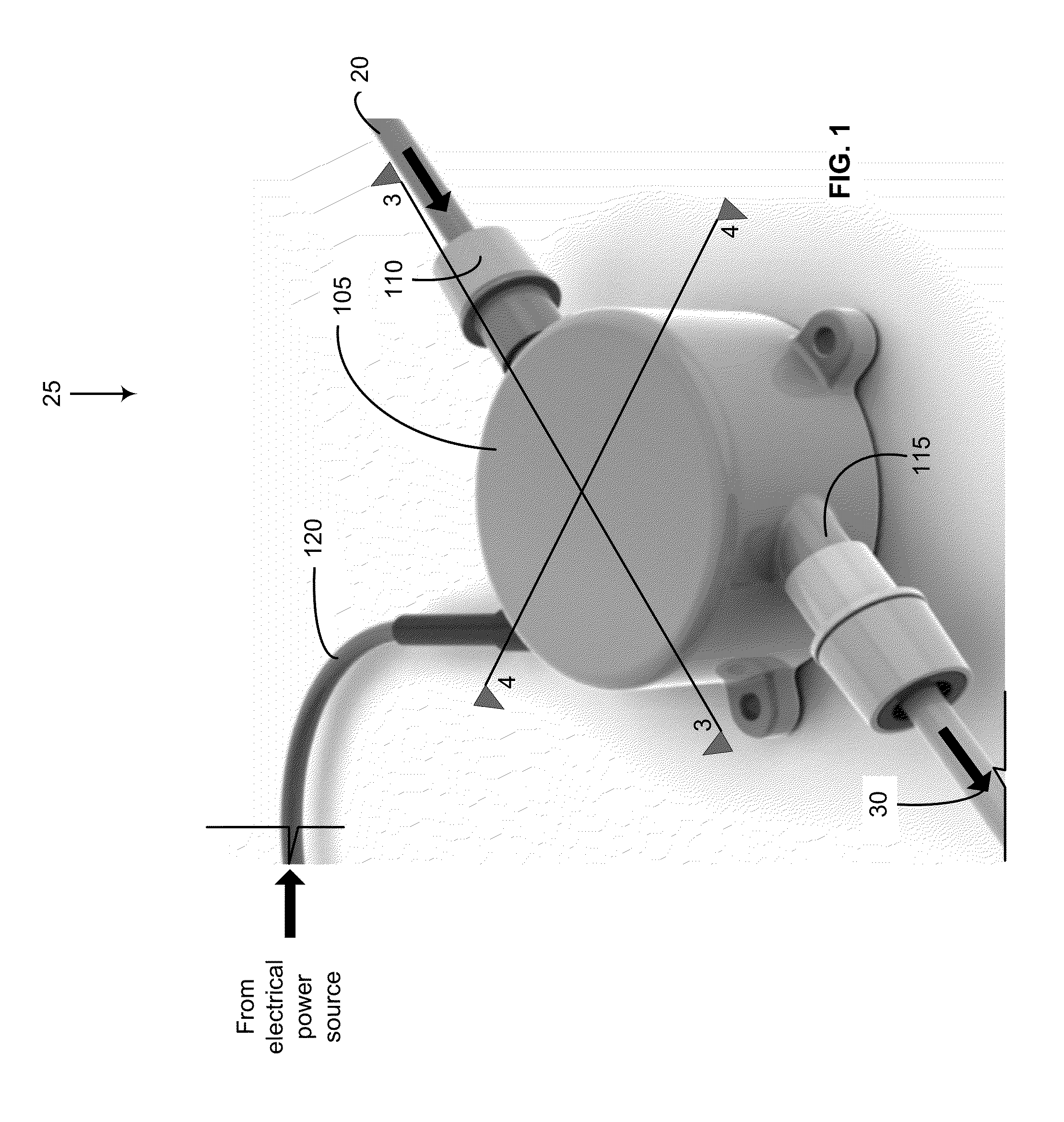

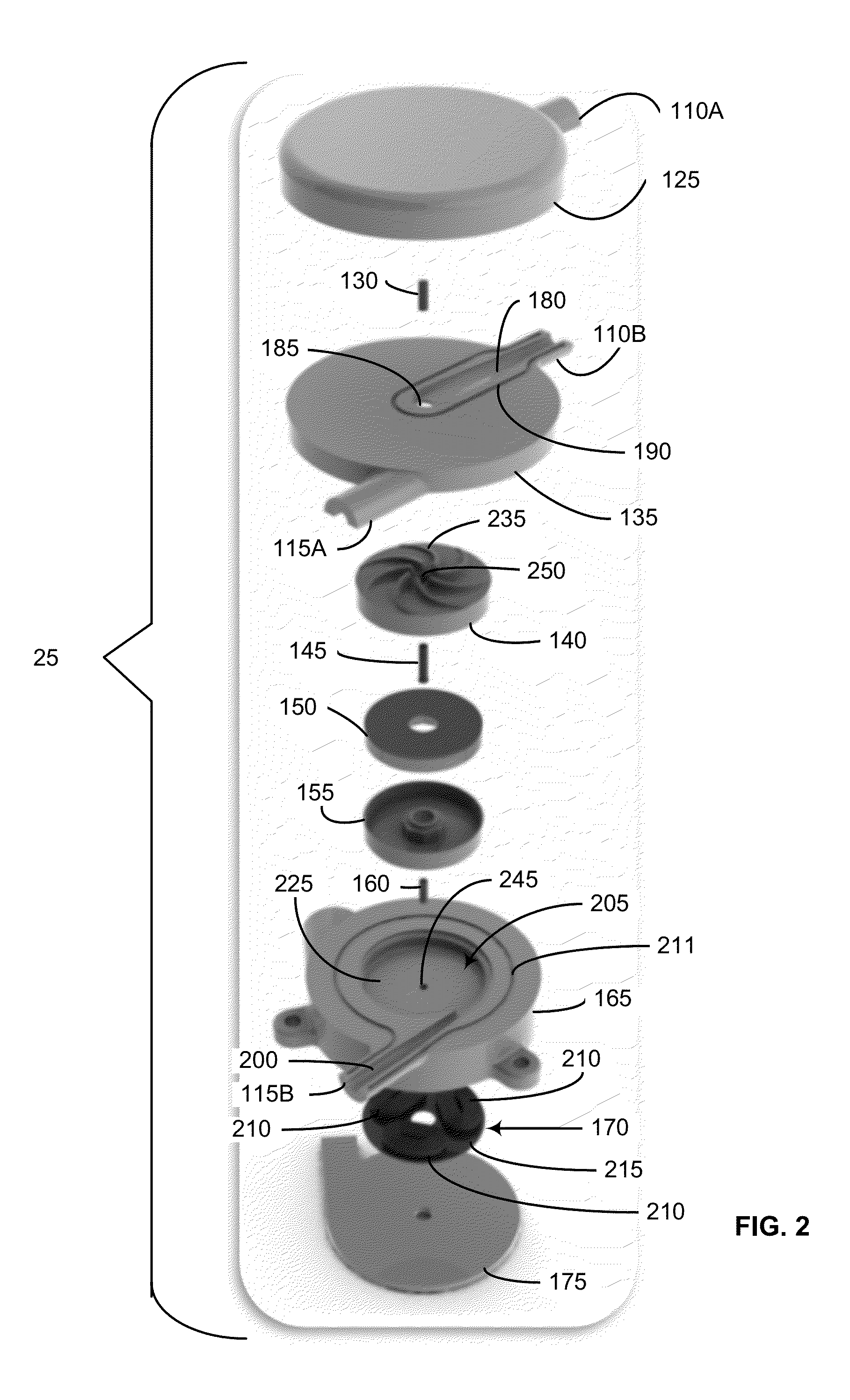

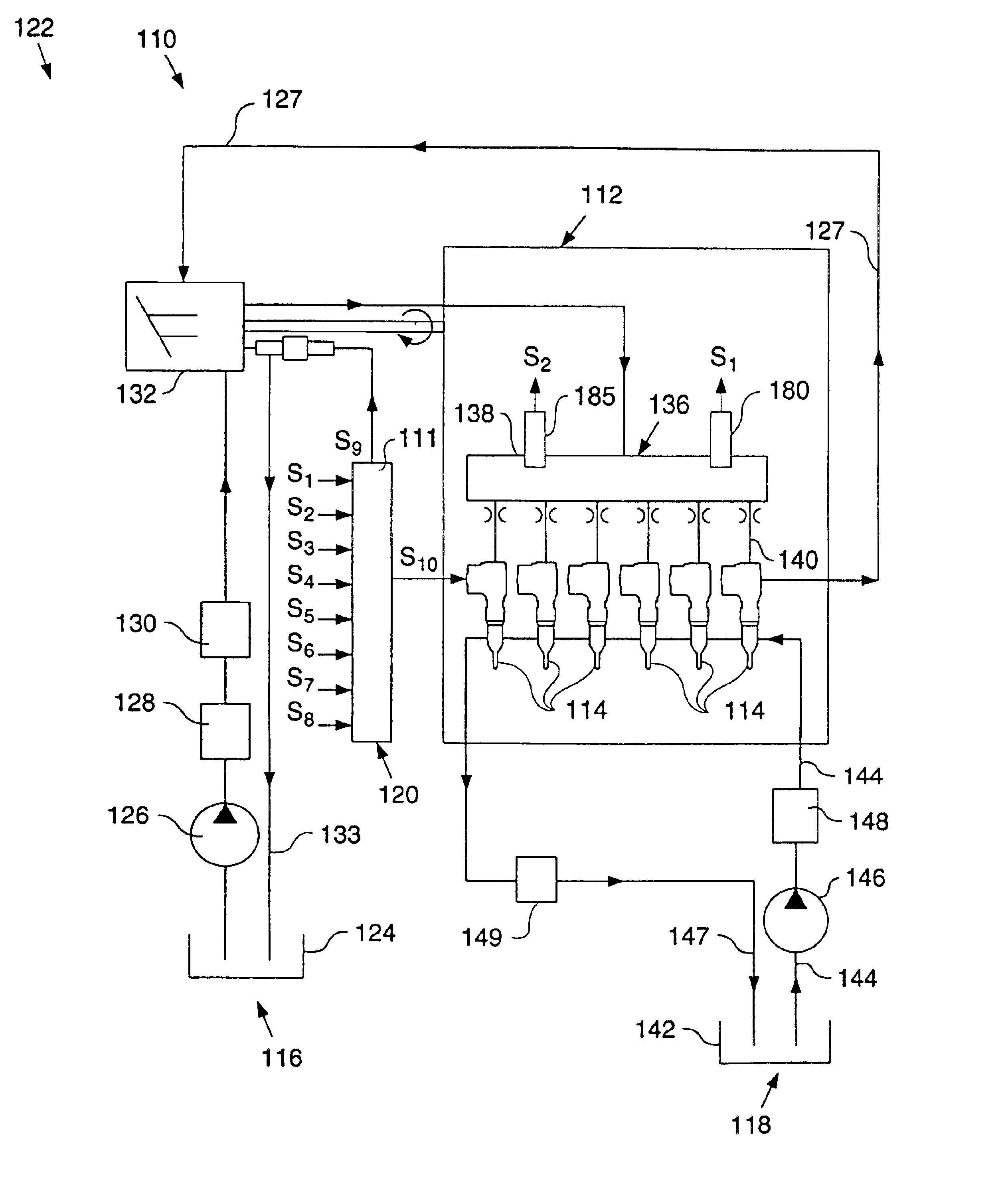

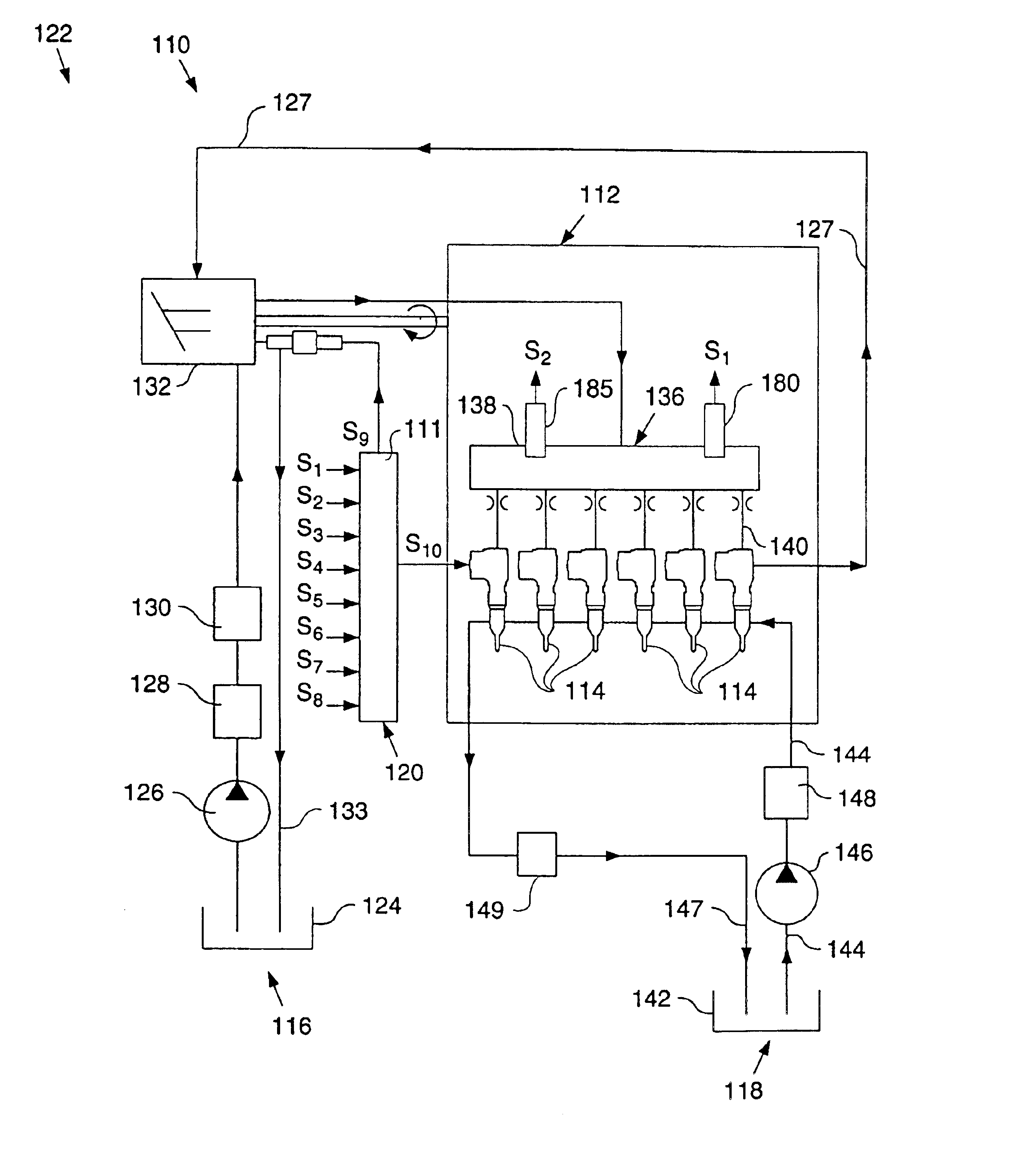

Blood pump systems and methods

A blood pump system for persistently increasing the overall diameter and lumen diameter of peripheral veins and arteries by persistently increasing the speed of blood and the wall shear stress in a peripheral vein or artery for a period of time sufficient to result in a persistent increase in the overall diameter and lumen diameter of the vessel is provided. The blood pump system includes a blood pump, blood conduit(s), a control system with optional sensors, and a power source. The pump system is configured to connect to the vascular system in a patient and pump blood at a desired rate and pulsatility. The pumping of blood is monitored and adjusted, as necessary, to maintain the desired elevated blood speed, wall shear stress, and desired pulsatility in the target vessel to optimize the rate and extent of persistent increase in the overall diameter and lumen diameter of the target vessel.

Owner:ARTIO MEDICAL INC

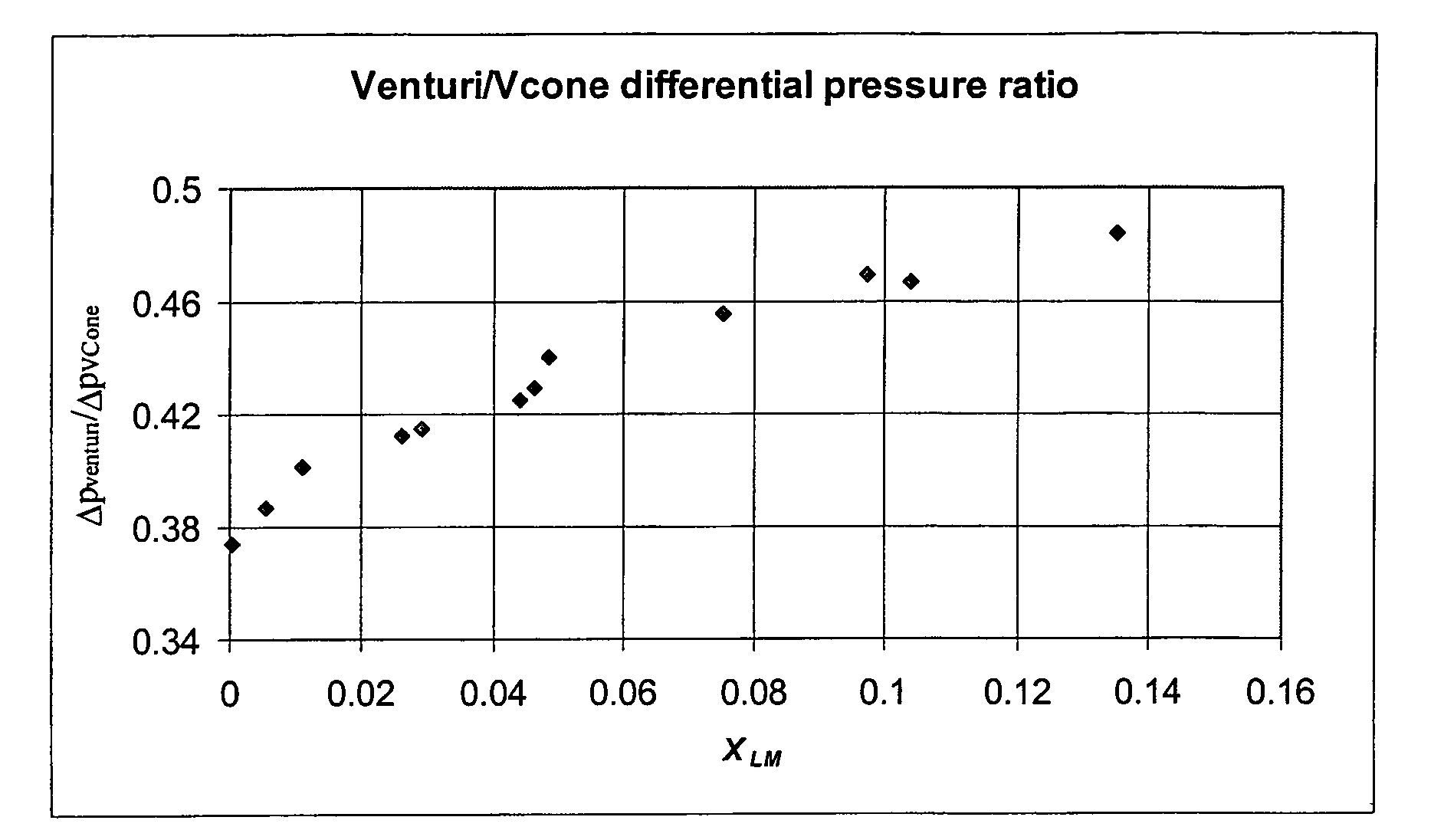

Flow meter for measuring fluid mixtures

ActiveUS7293471B2Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansDifferential pressureLiquid hydrocarbons

Owner:ROXAR FLOW MEASUREMENT

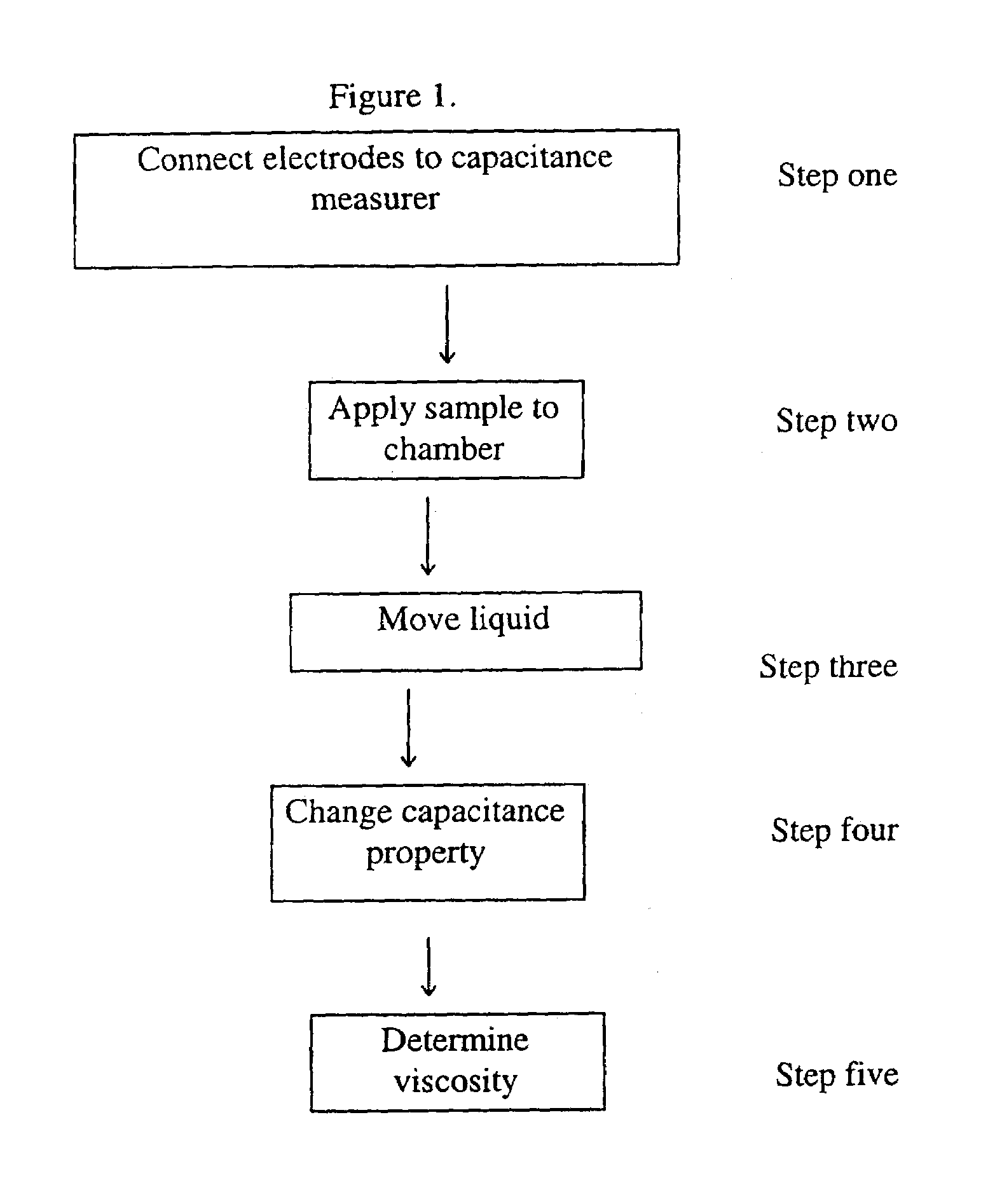

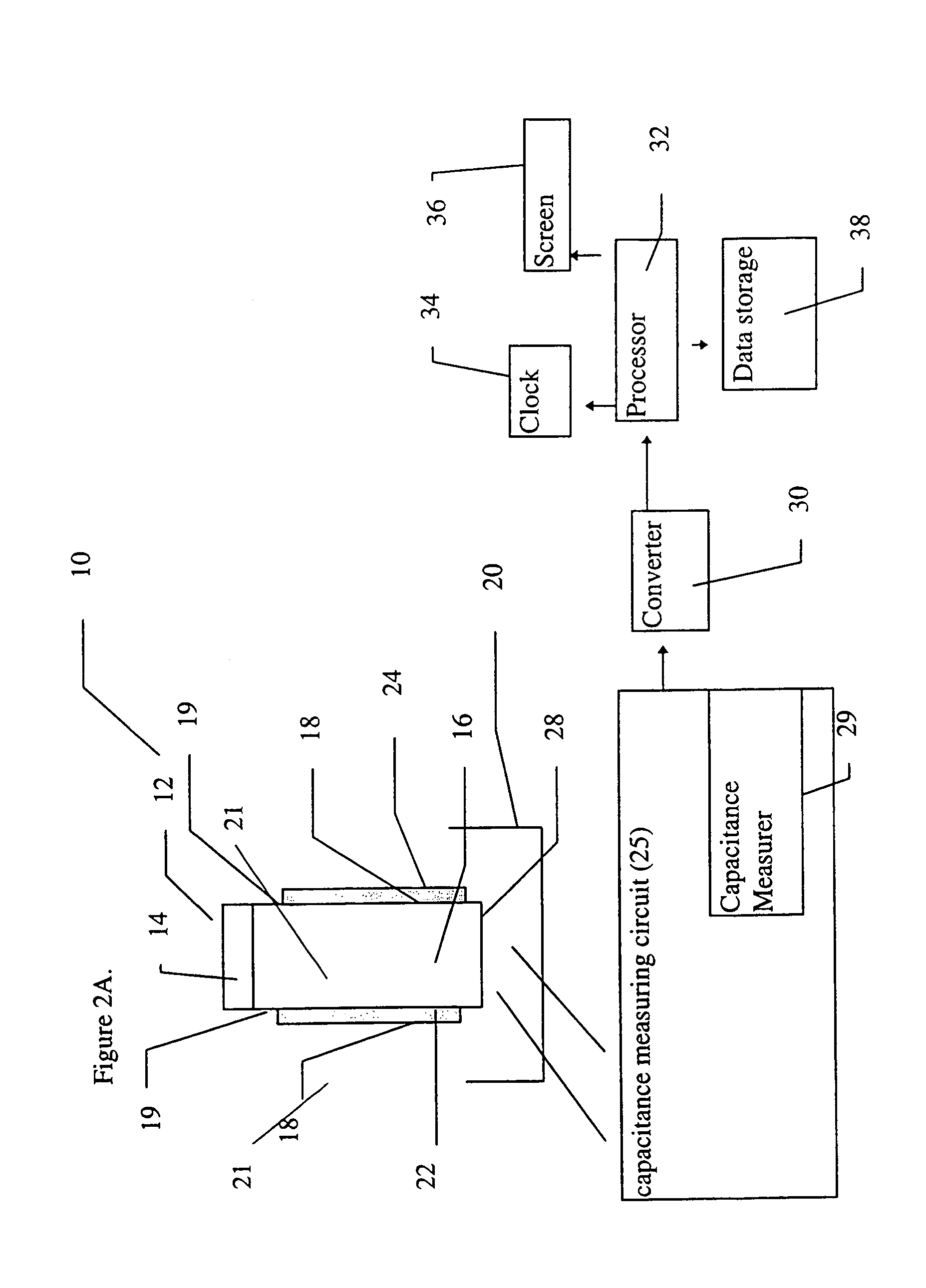

Device for the determination of blood clotting by capacitance or resistance

InactiveUS7021122B1Machines/enginesLubrication indication devicesElectrical resistance and conductanceViscosity

A sensor device (10) and a method for measuring a viscosity of a sample of a liquid. The sensor features a chamber (12) for receiving the sample of the liquid, two electrodes (18) disposed either on the surfaces of the chamber, but possibly isolated from contacting the sample, or electrodes located externally to the chamber, and a capacitance measuring circuit (25). The sensor is used by connecting to a measurer for determining a capacitance on the electrodes, such that the capacitance directly reflects a volume occupied by the sample of the liquid. Preferably, the liquid is blood and the capacitance is used to determine the clotting time of the blood. Also preferably, a cover for the chamber is provided with at least one aperture, which more preferably is a mesh. Alternatively, an electrical property such as the amplitude of current passed through the sample is used to determine clotting time. Also preferably, the time period required for the maximum capacitance to be reached could be measured. Alternatively, the capacitance could be measured after a fixed time period (34) had elapsed. Also alternatively, the time period required for the maximum current to be reached could be measured, or the amount of current could be measured after a fixed time period had elapsed. In preferred embodiments of the present invention, a kit for measuring the clotting time of blood is provided. In other preferred embodiments of the present invention, methods are provided for using the kit and device of the present invention.

Owner:ORGENICS BOISENSORS

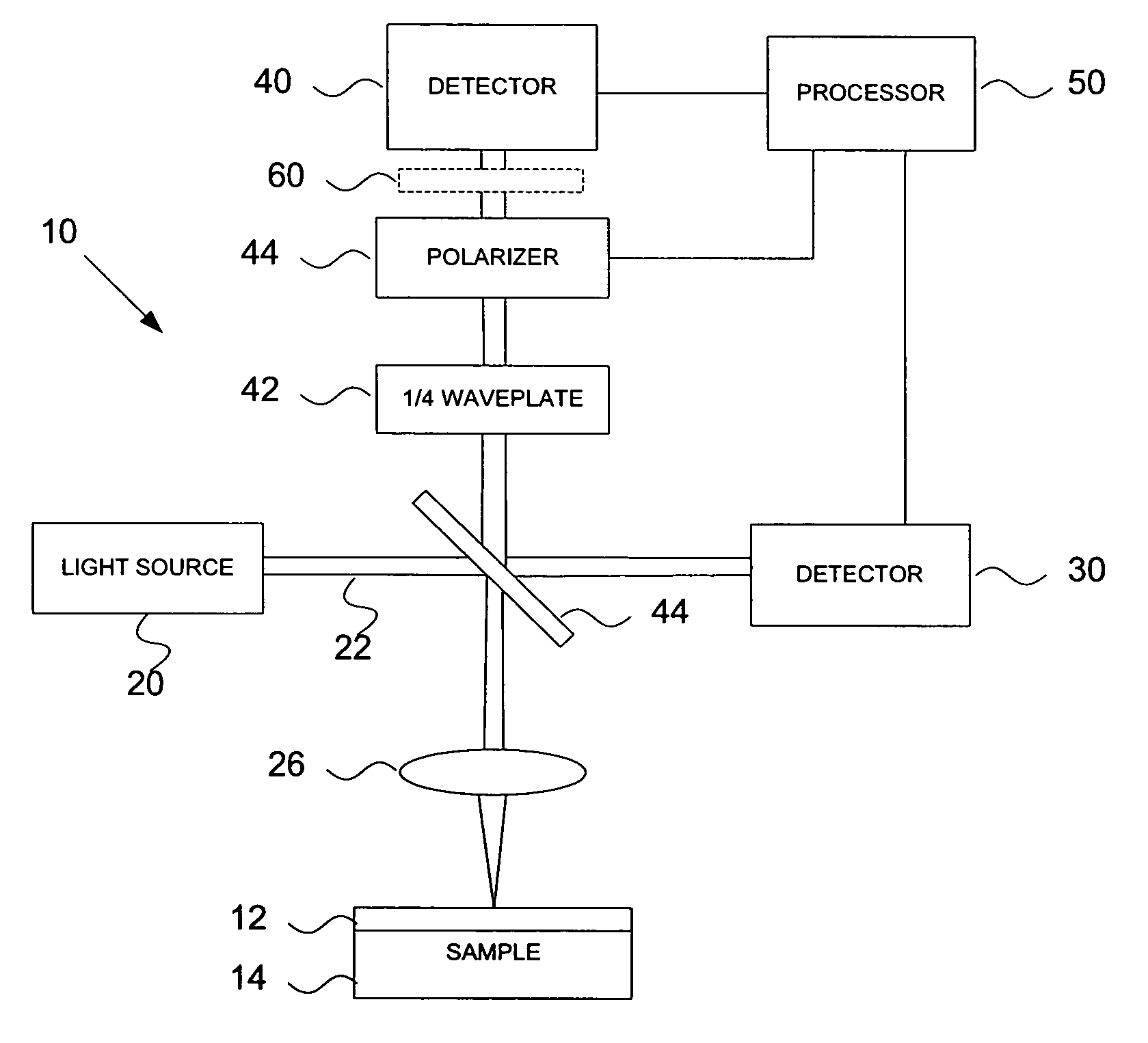

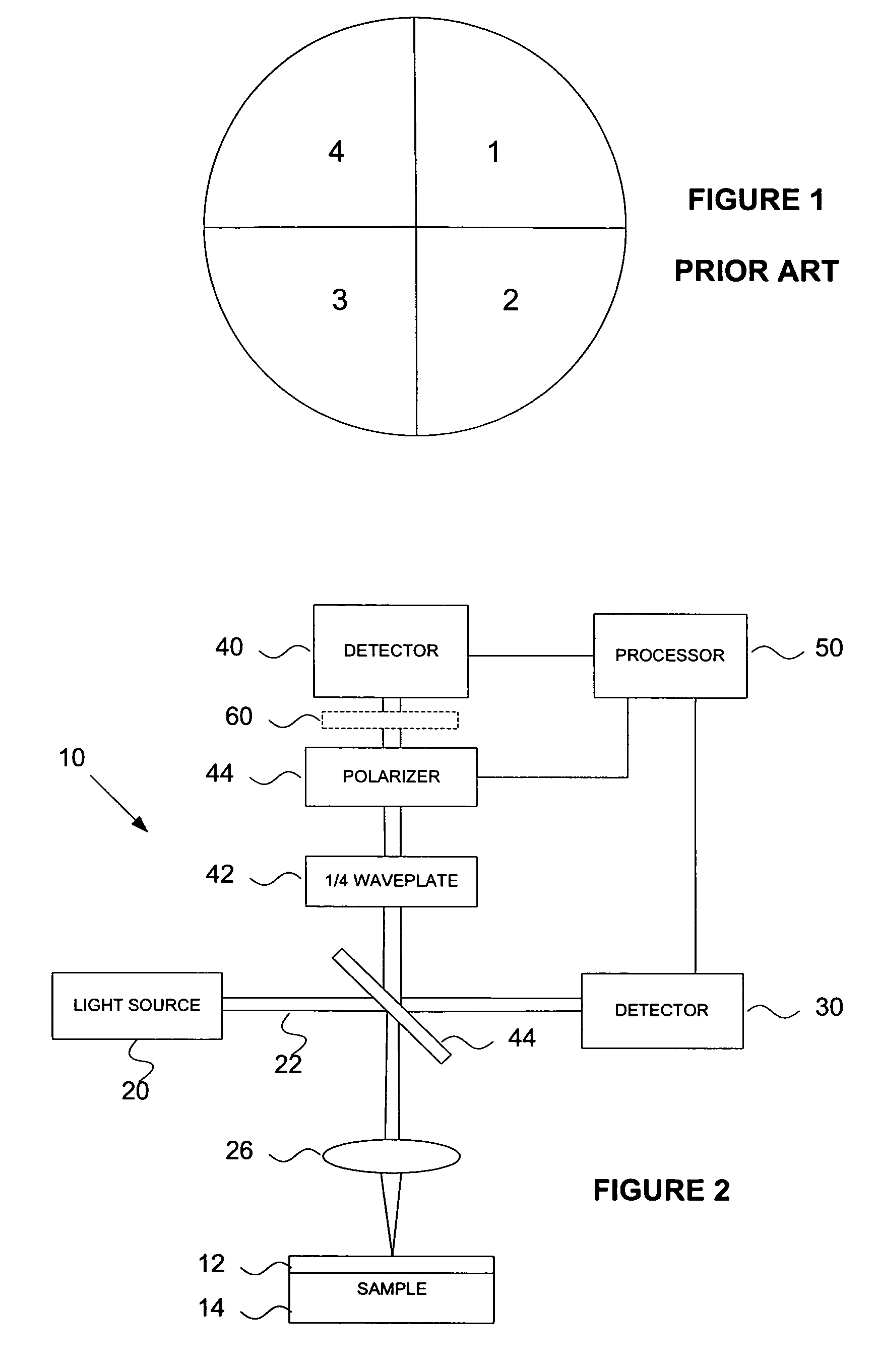

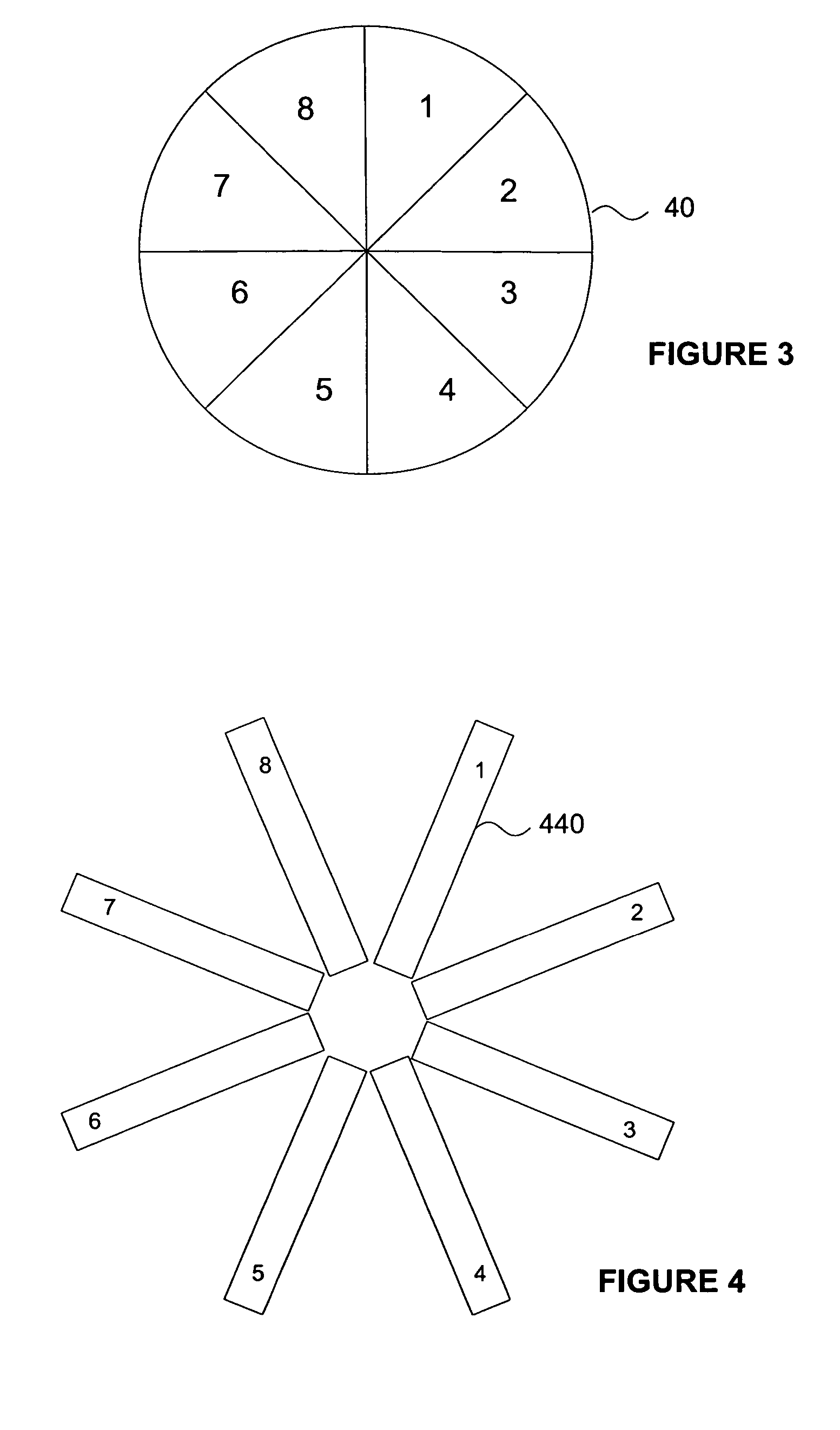

Detector configurations for optical metrology

InactiveUS6995842B2Phase delayAccurate assessmentMaterial analysis by optical meansUsing optical meansAngle of incidenceEllipse

An apparatus is disclosed for obtaining ellipsometric measurements from a sample. A probe beam is focused onto the sample to create a spread of angles of incidence. The beam is passed through a quarter waveplate retarder and a polarizer. The reflected beam is measured by a detector. In one preferred embodiment, the detector includes eight radially arranged segments, each segment generating an output which represents an integration of multiple angle of incidence. A processor manipulates the output from the various segments to derive ellipsometric information.

Owner:KLA CORP

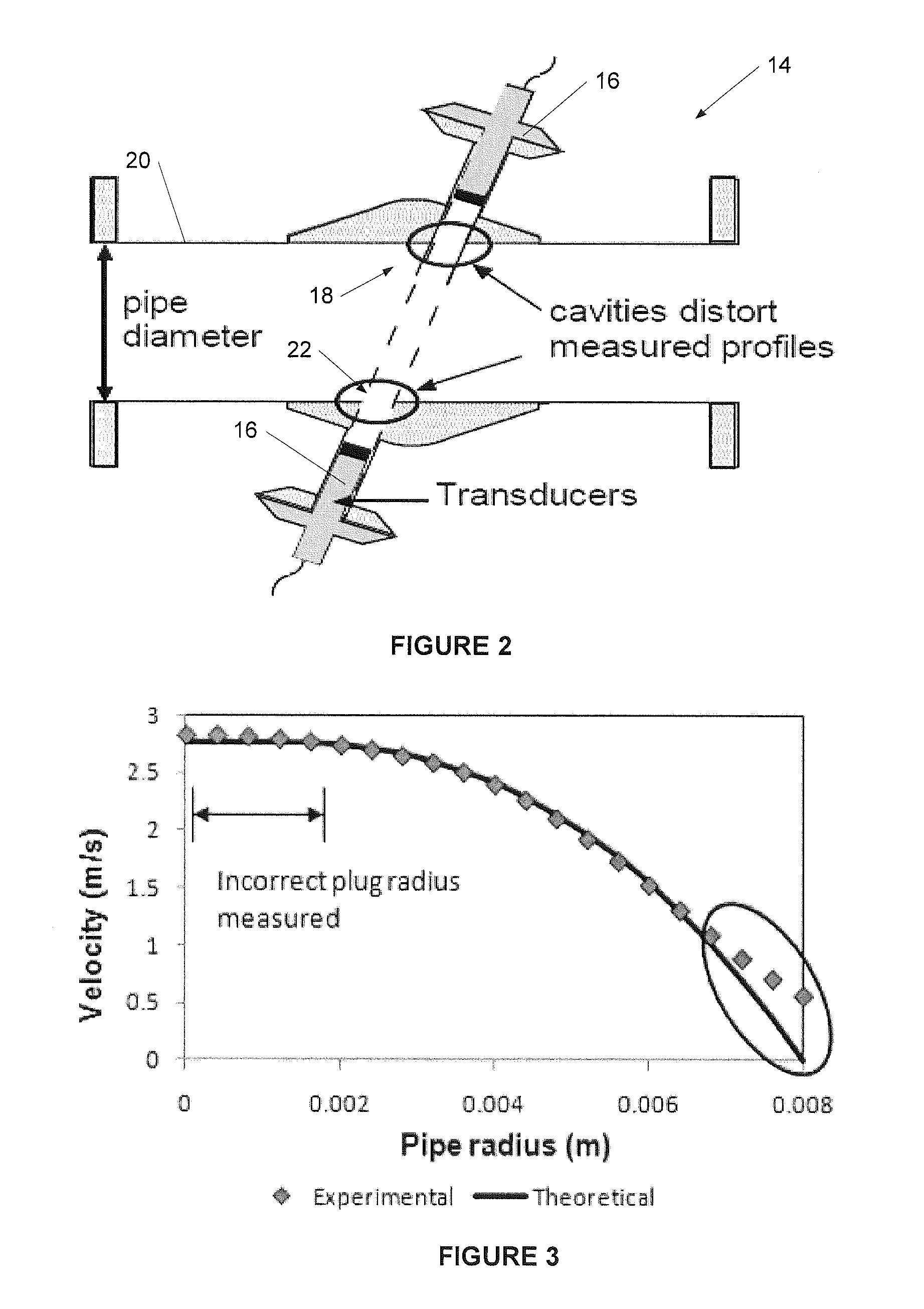

Fluid visualisation and characterisation system and method; a transducer

ActiveUS20130345994A1Reduce sensitivityCanceled outVolume meteringVolume flow measuring devicesSonificationTransducer

A fluid visualization and characterisation system includes a measuring section with a housing defining a fluid flow path for fluid flow. The measuring section includes one or more transducers to emit ultrasonic signals into the fluid flow, and at least one receiver to receive reflections of the ultrasonic signal from reflectors in the fluid flow. The system includes a memory for storing data and a processor operatively connected to the memory. The processor comprises several modules. A velocity estimating module is configured to apply one or more velocity estimation algorithms to received reflections of the ultrasonic signal, or data indicative thereof, to determine a velocity profile of the fluid flow. A deconvolution module is configured to apply a deconvolution algorithm at least to the determined velocity profile to determine a true velocity profile of the fluid flow. A fluid visualization and characterisation module is configured to determine characteristics of the fluid and / or fluid flow in by using the determined velocity profile and / or the true velocity profile.

Owner:SP TECHNICAL RESEARCH INSTITUTE OF SWEDEN +1

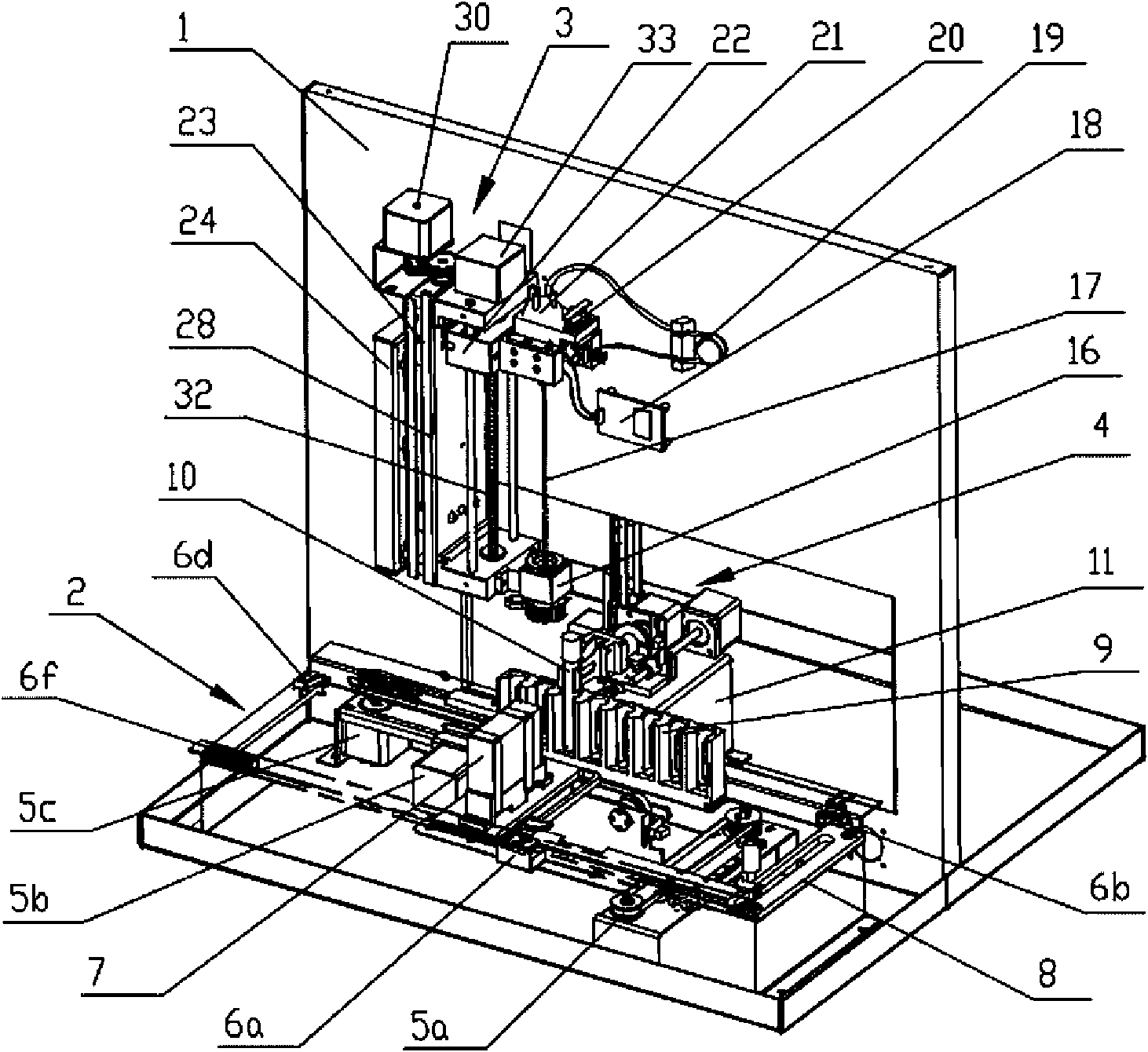

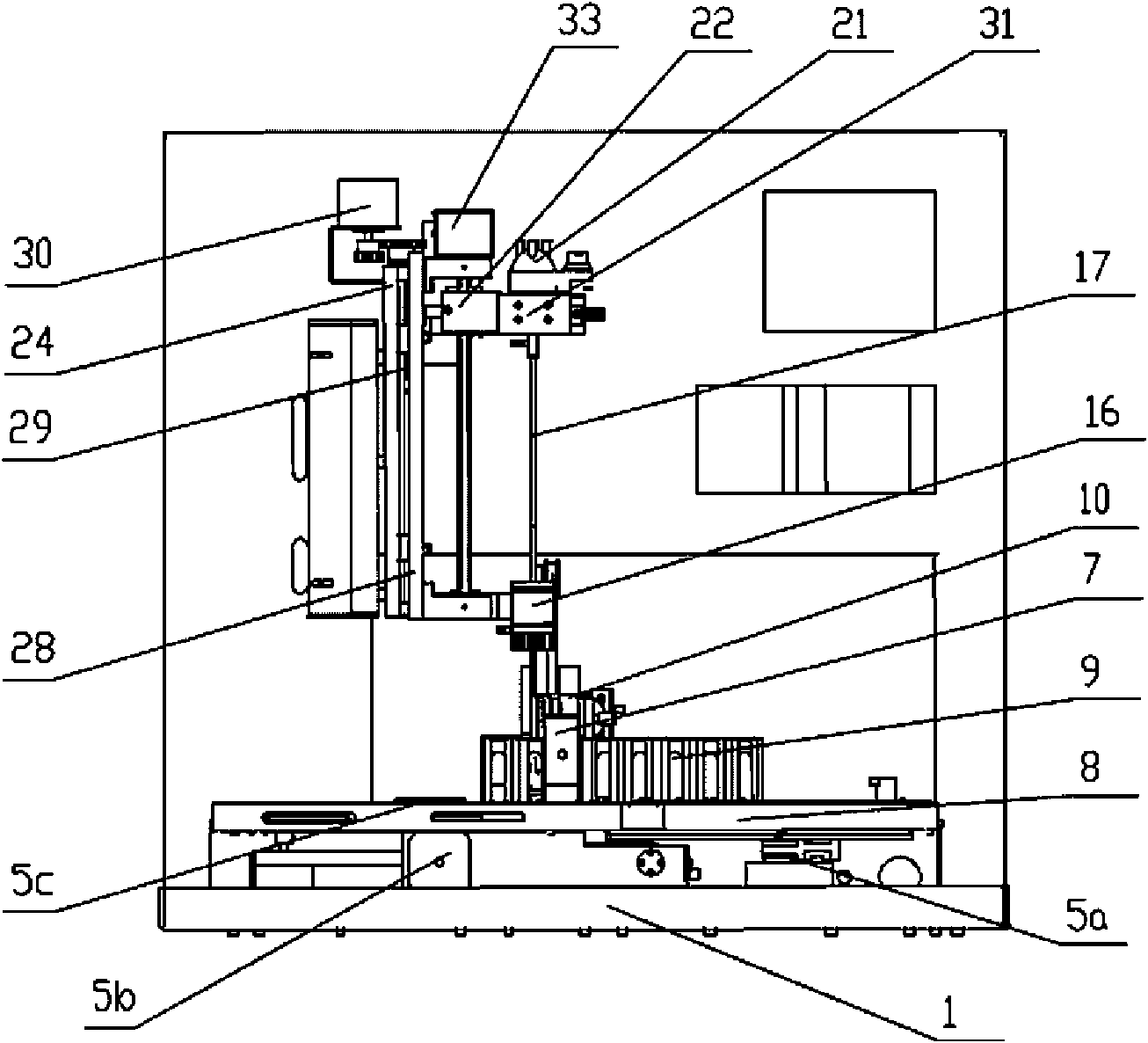

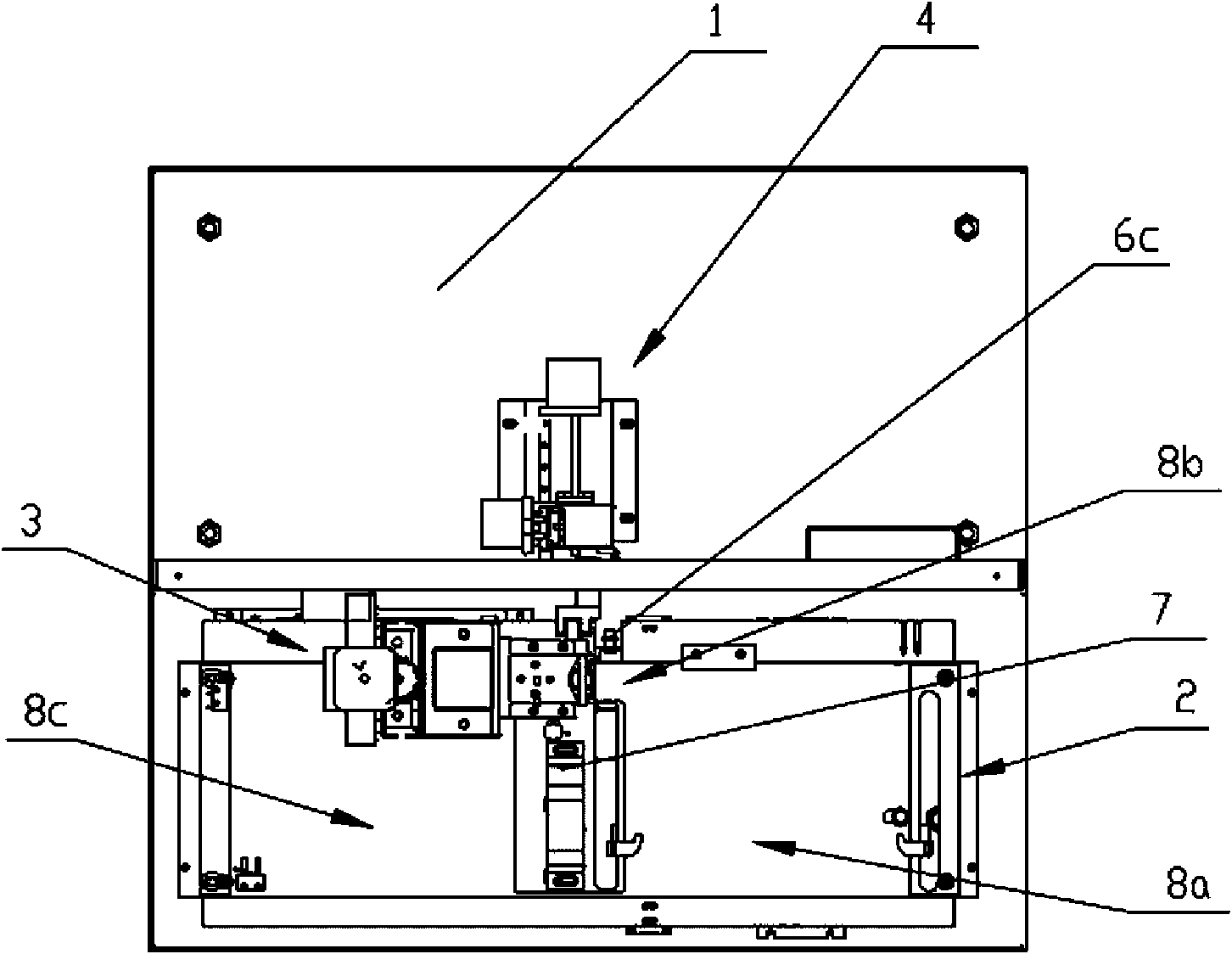

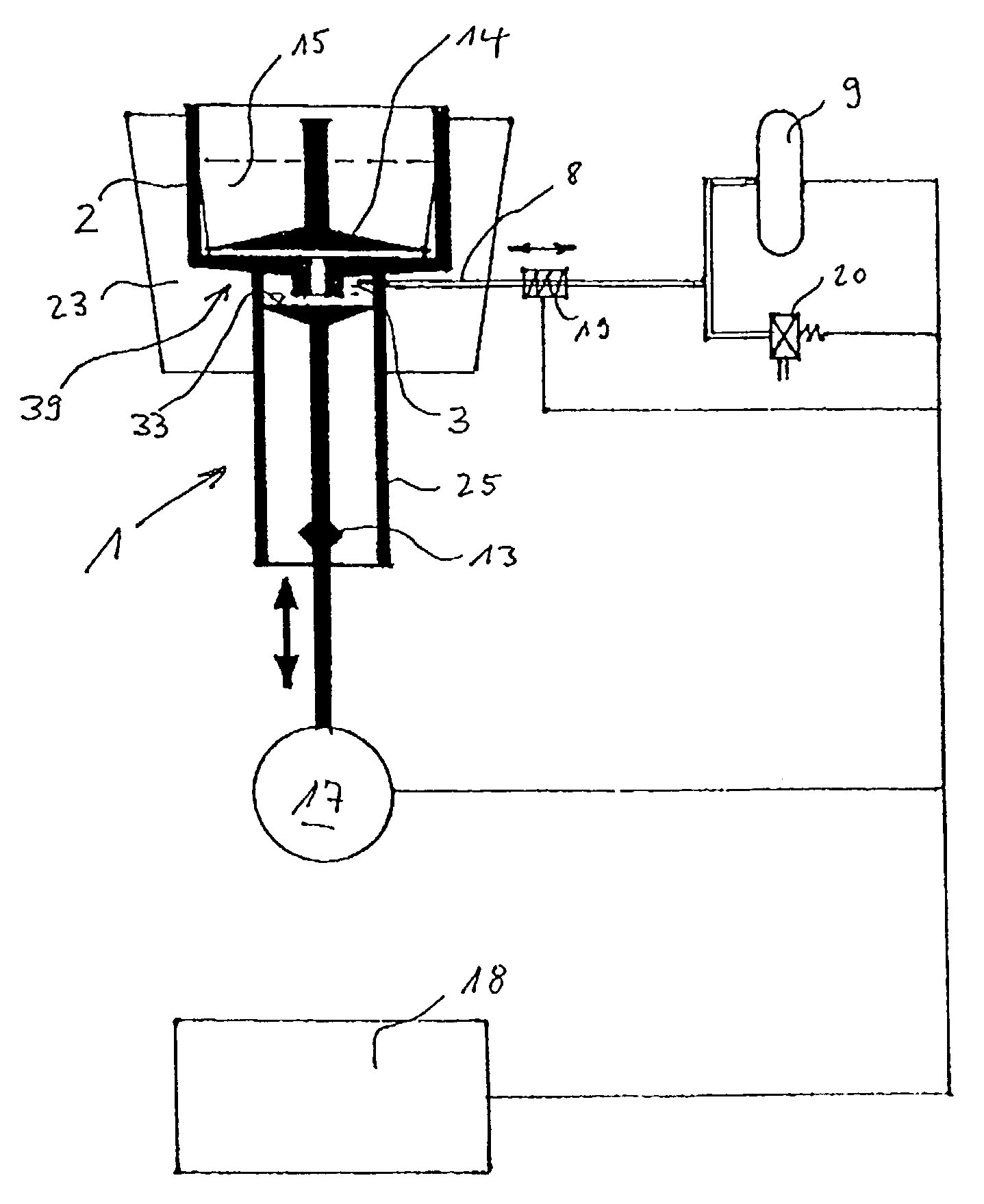

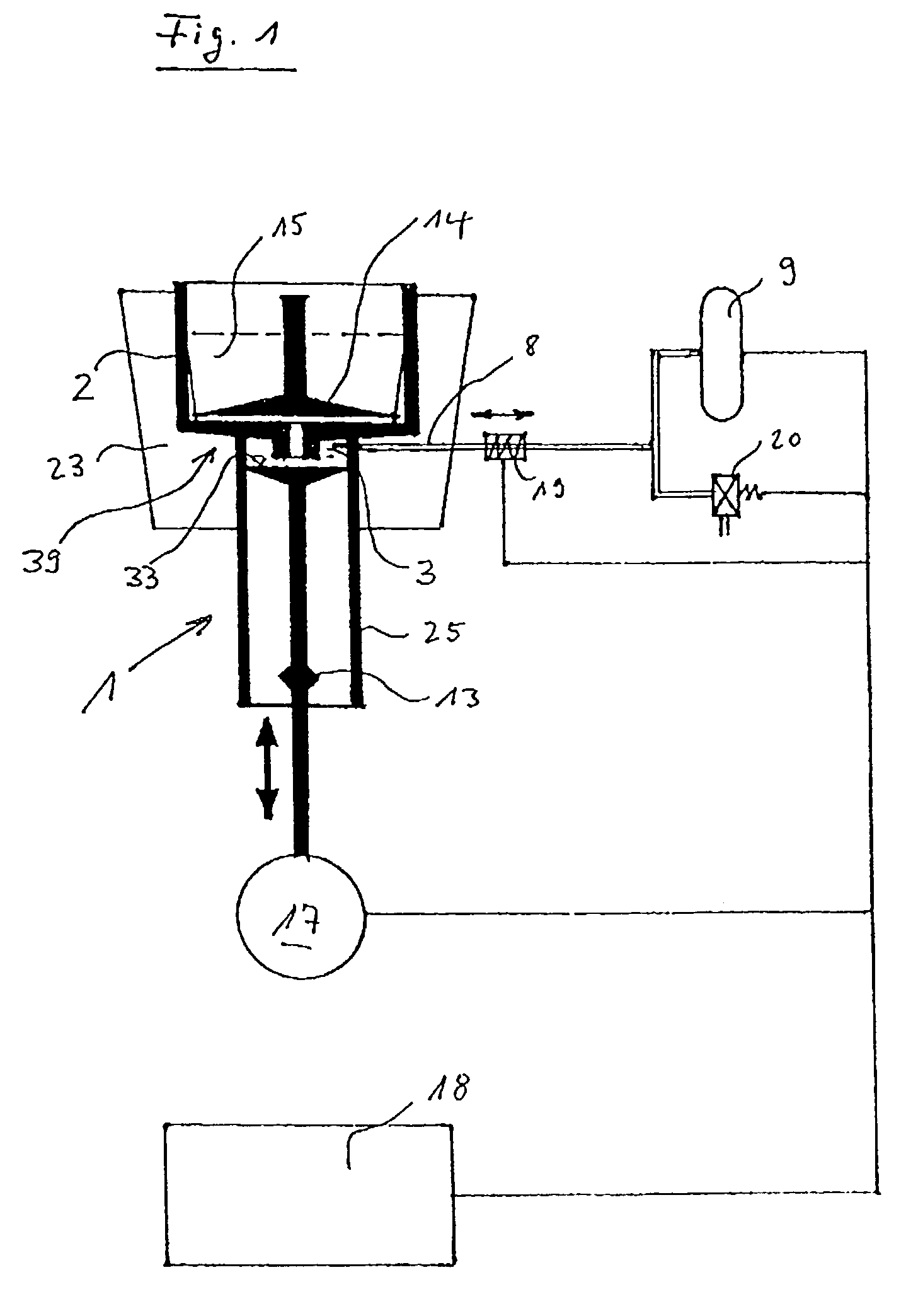

Closed automatic detection device for blood rheology measurement

InactiveCN101603968AAvoids problems that do not require separation from the lidSolve problems that do not require separation from the lidWithdrawing sample devicesUsing optical meansMeasurement deviceAir pump

The invention discloses a closed automatic detection device for blood rheology measurement, which comprises a test tube stand splint, a bar code scanner, a test tube stand moving device, an automatic blood sample transfer device of a test tube stand position monitor, a sampling measurement system comprising a sampling / measuring needle assembly, a needle insertion driving device, a quantitative sampling controller, an upper sphere, a heating module, a washing device and a work station conversion driving device, a blending device comprising an elastic clamping device, an elastic clamping device autorotation driving motor, an up-down moving device and a horizontal moving device, an air pump, a singlechip and the like. The device can ensure that the blood rheology measurement realizes the automatic transfer of a blood sample, automatic reversal of the blending device of the blood sample, automatic quantitative sampling, automatic measurement of the blood sample, automatic washing of a measurement device, and automatic recognition and recording under the condition of not opening a cover, realize the automatic measurement of blood viscosity under the full-closed state, can avoid the cross contamination, can also alleviate the labor intensity of the staff, improve measurement effect, and can also shorten measurement time.

Owner:重庆天海医疗设备有限公司

System and method for determining oil grade

The grade of oil used in a machine or apparatus can be determined by determining a temperature and pressure within an oil supply and determining the oil grade in response to determining the temperature and pressure.

Owner:CATERPILLAR INC

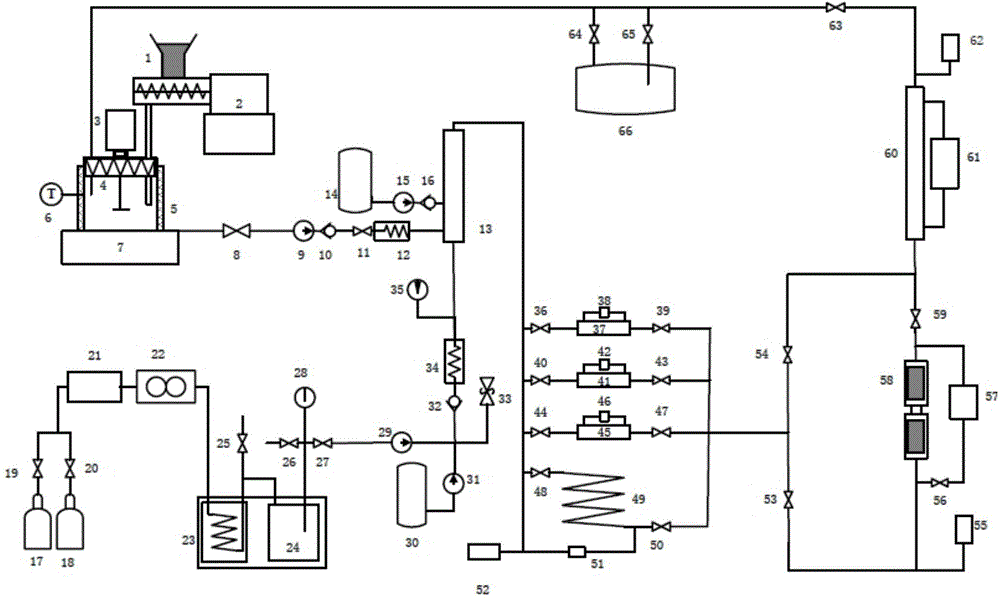

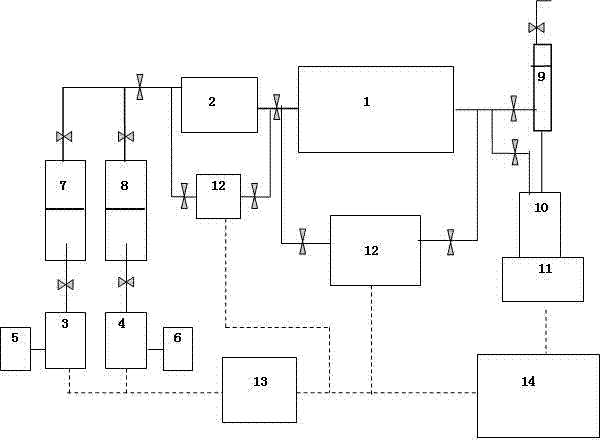

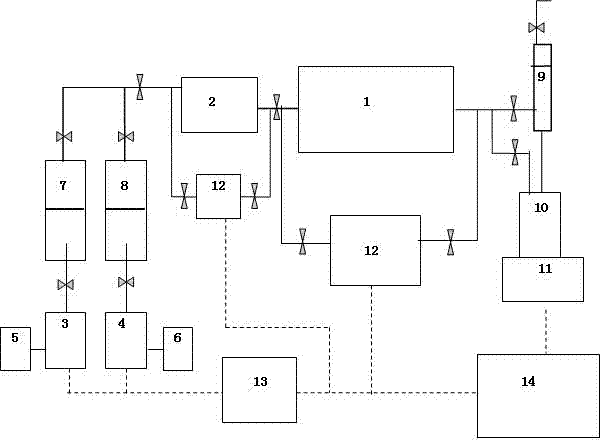

Large multifunctional fracturing fluid experiment system

ActiveCN104007043AControl sand ratioPrevent its subsidenceHydrodynamic testingDirect flow property measurementDifferential pressureFracturing fluid

A large multifunctional fracturing fluid experiment system is characterized in that a drug soup and a gas branch enter a foam generator and are mixed, the obtained mixture enters three straight pipes with different calibers, the influences of the calibers on the frictional resistance of the fracturing fluid are measured, or the soup enters a coil pipe in order to measure the frictional resistance, and two ends of each of the above four pipes are respectively connected with a differential pressure sensor; when the frictional resistance is measured, two ends of the four pipes are respectively provided with a valve; during experiment, the above valves can be switched, and one path can be selectively opened, the suspension state of a propping agent in the fracturing fluid can be observed through a multistage window, the obtained fracturing fluid enters a drug pump and is circulated in order to measure the frictional resistance; or the obtained fracturing fluid enters an outlet separator after the experiment. The system is used for measuring a jelly fracturing fluid, a clear water fracturing fluid and a carbon dioxide foam fracturing fluid, or can be used for researching the rheological characteristic, the frictional resistance and the sand carrying performance of a carbon dioxide dry fracturing fluid at different temperatures under different pressures, and can be used for observing the suspension state of the propping agent in the fracturing fluid through the multistage window.

Owner:HUANENG CLEAN ENERGY RES INST +1

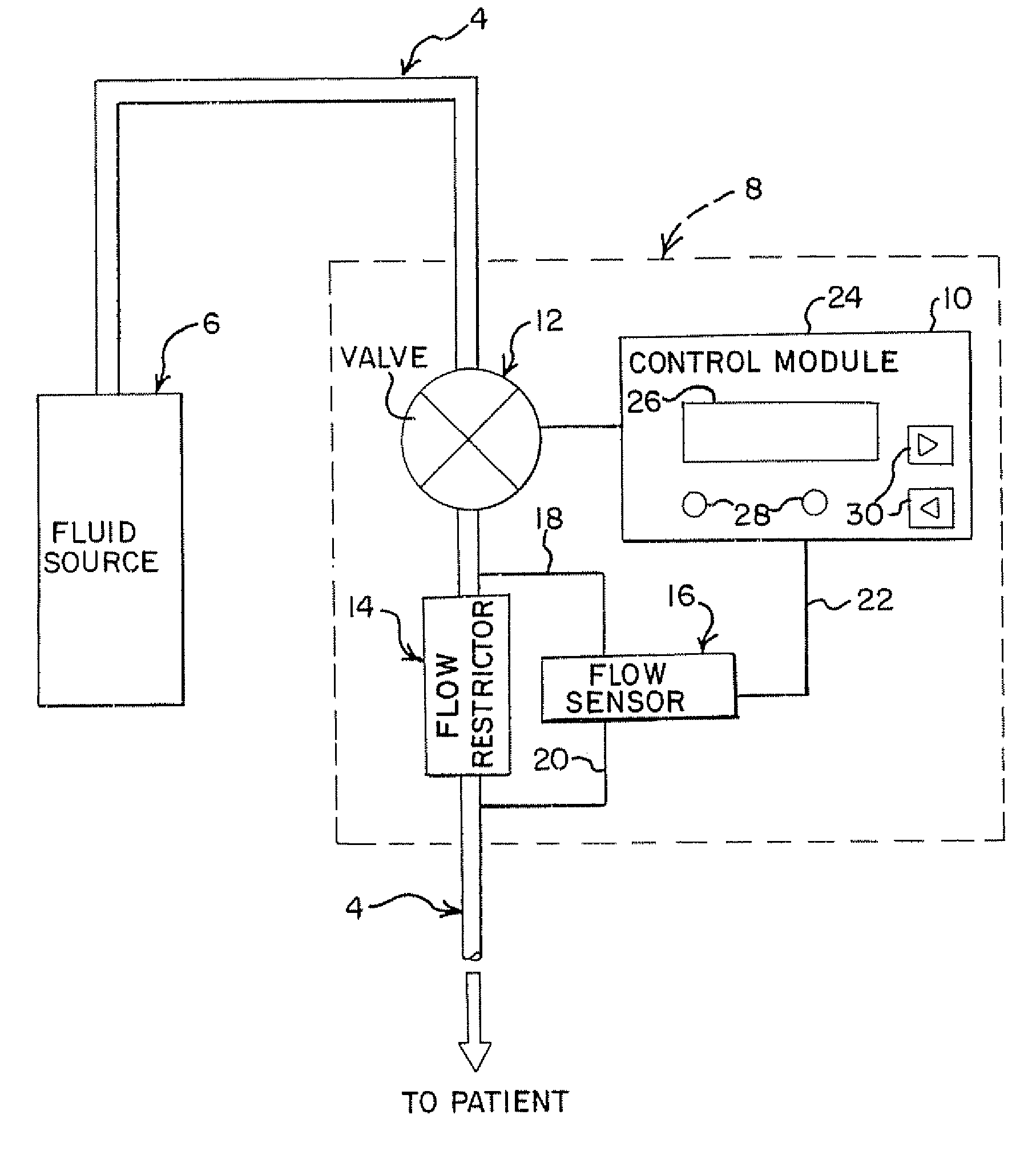

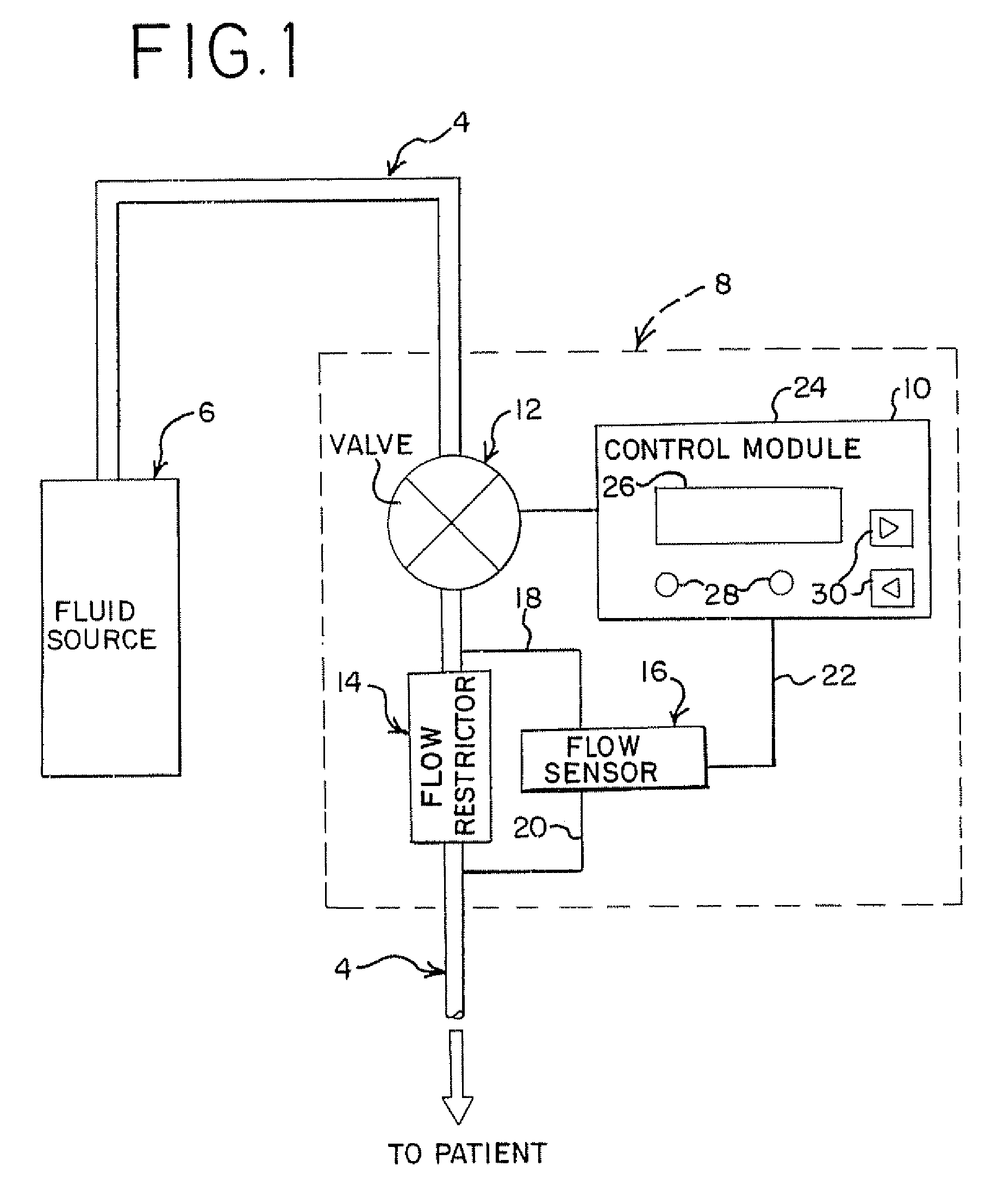

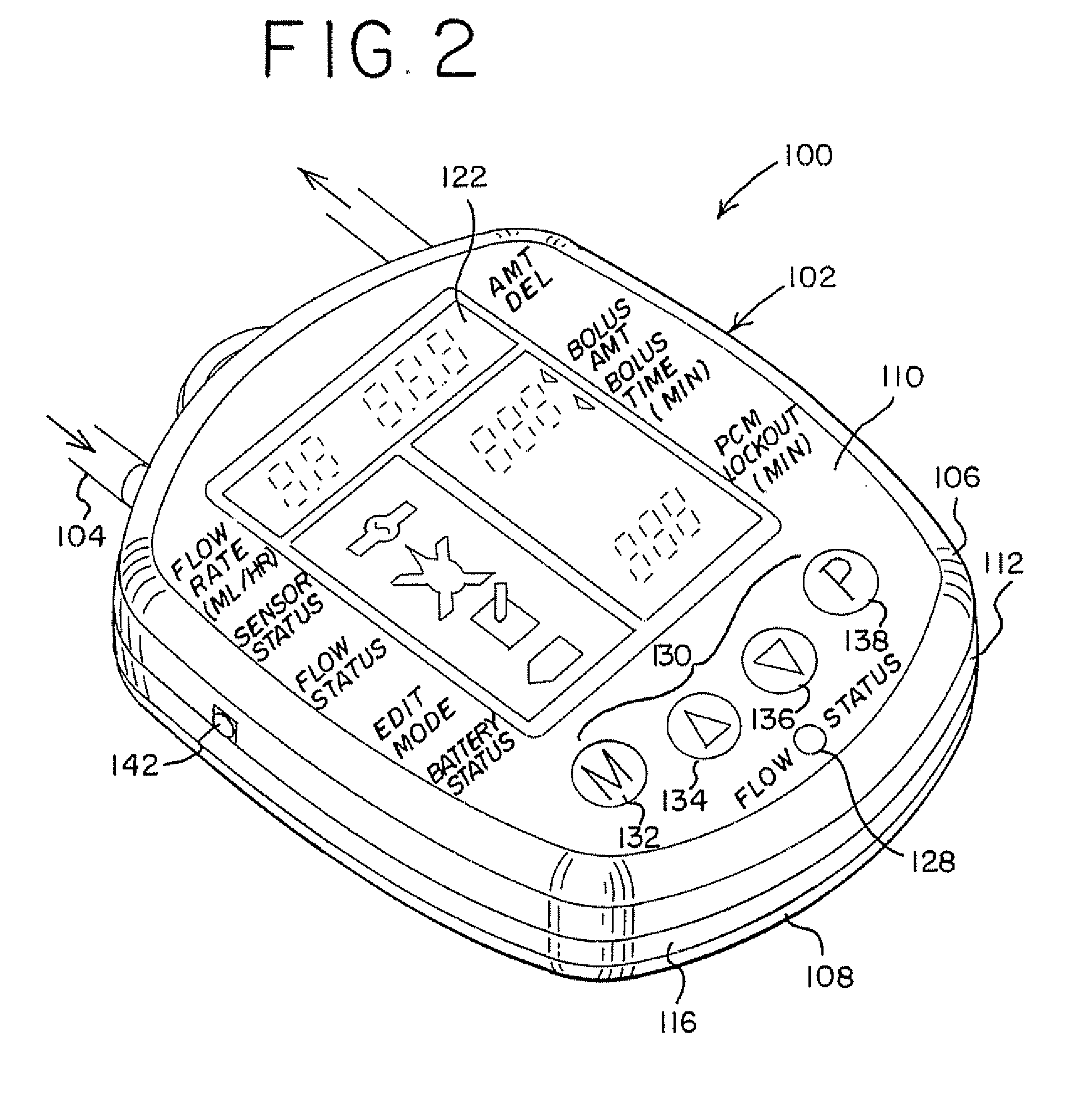

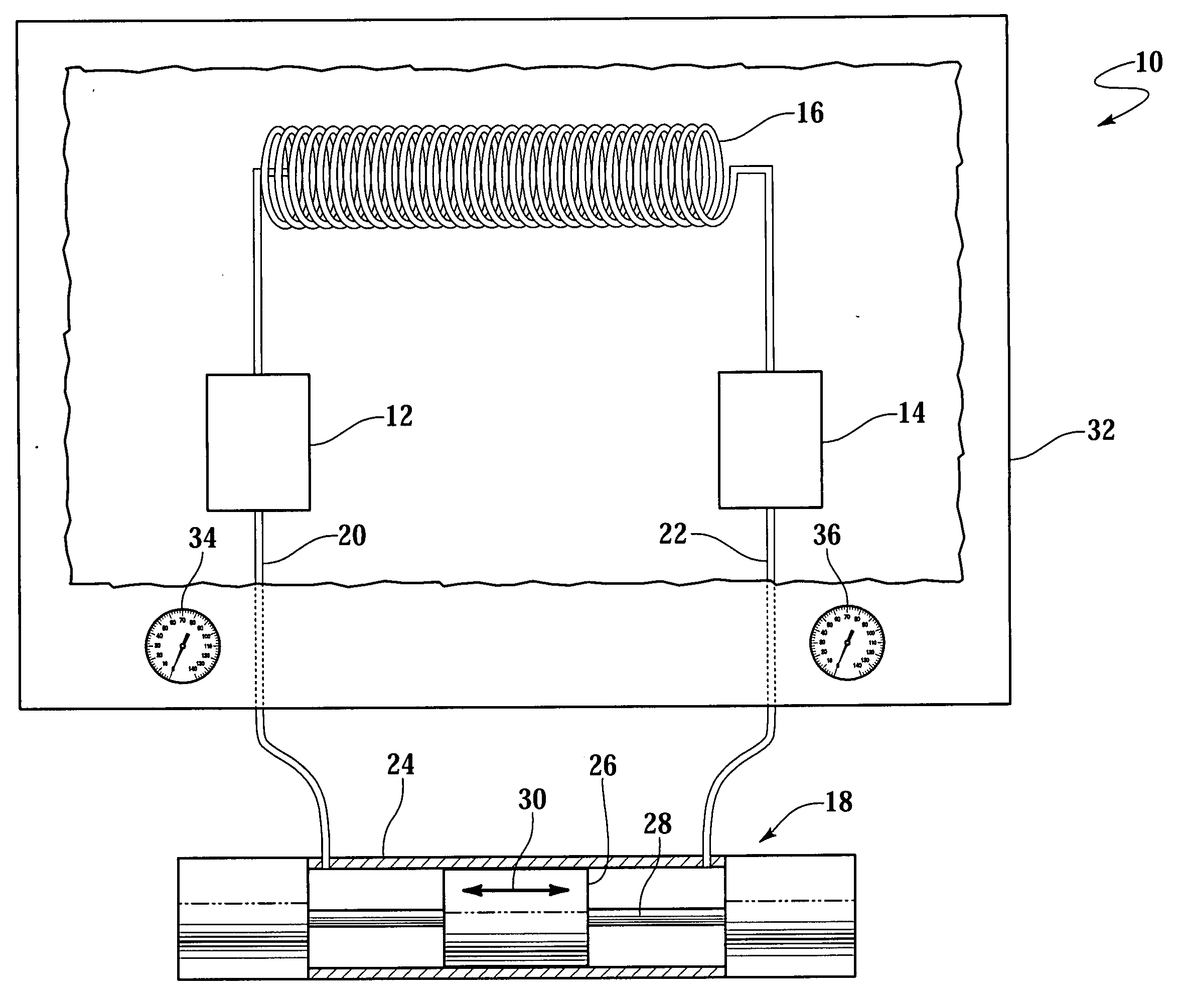

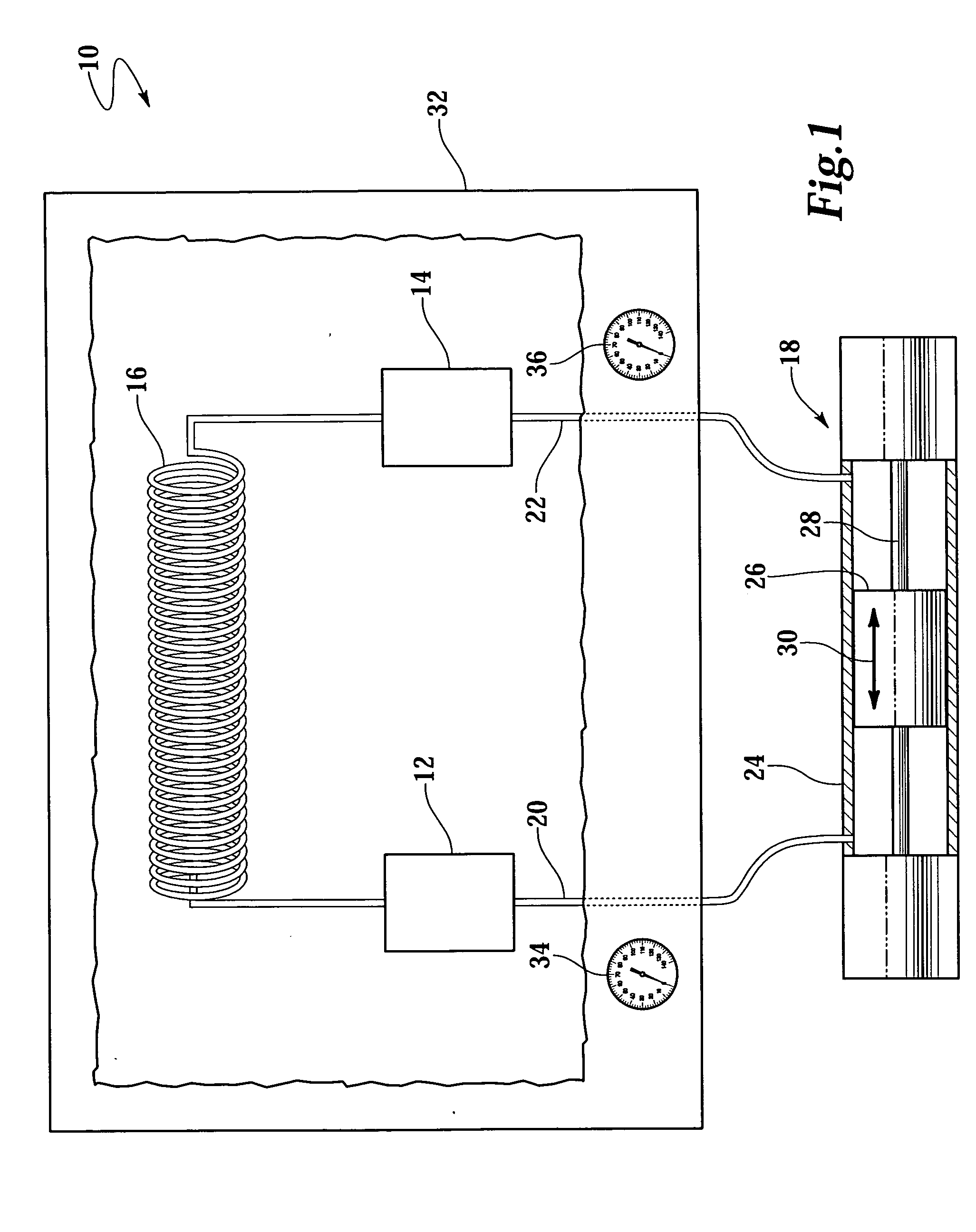

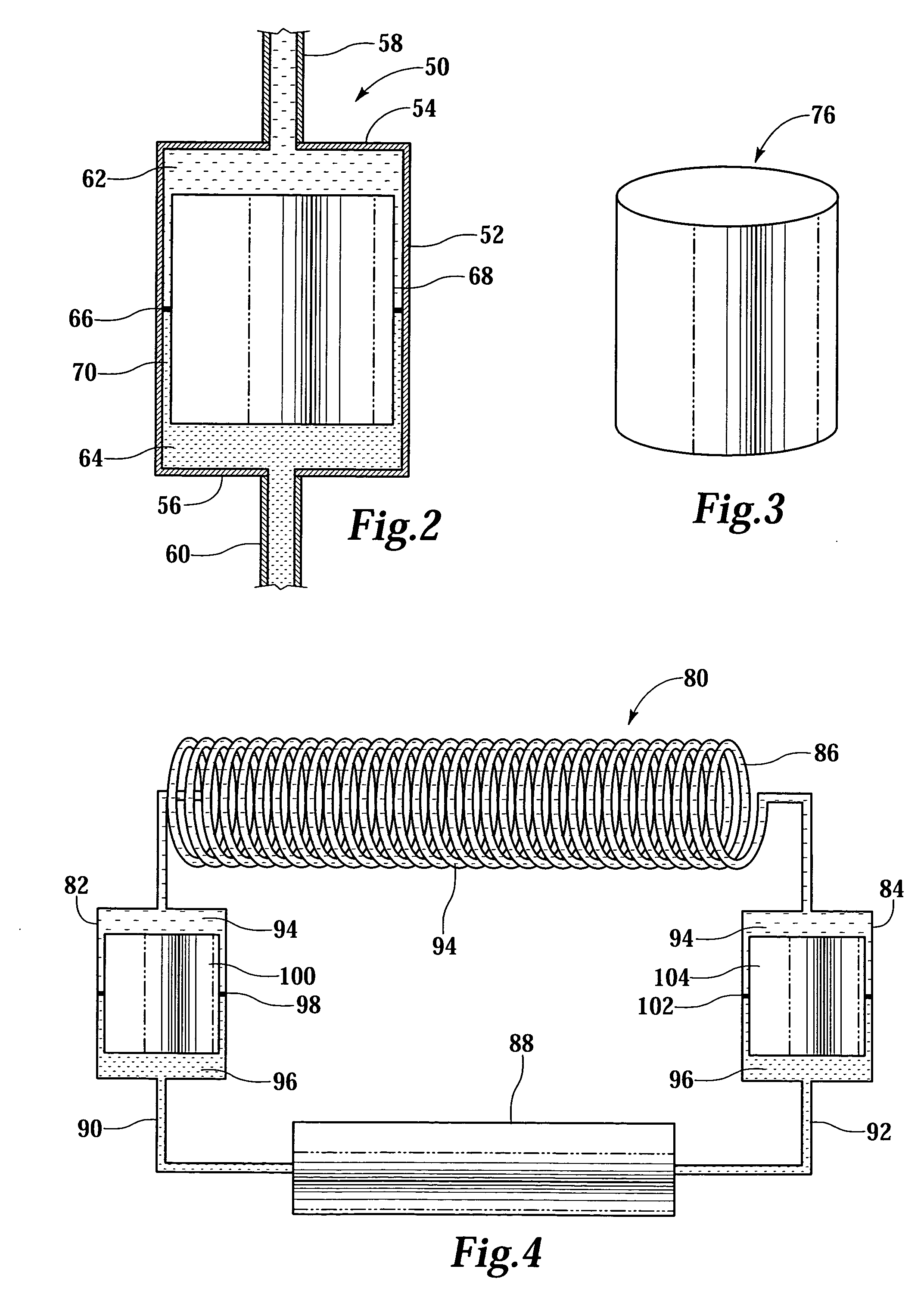

System and method for measuring liquid viscosity in a fluid delivery system

InactiveUS20090113996A1Conveniently performedIntravenous devicesDirect flow property measurementLiquid viscosityFluid viscosity

The present invention includes systems and methods for determining the viscosity of a fluid within a fluid flow path. Such method may comprise flowing fluid through the fluid flow path and past a fixed flow restriction therein. The method may also comprise first sensing of a fluid pressure within the fluid flow path at a selected location upstream of the flow restriction. The method may also include limiting fluid flow in the fluid flow path upstream of such selected location. The method may further comprise second sensing of a fluid pressure within the fluid flow path at such selected location after such limiting. Such method includes determining the viscosity of the fluid based, at least in part, on any pressure difference from such first and second sensing.

Owner:BAXTER INT INC +1

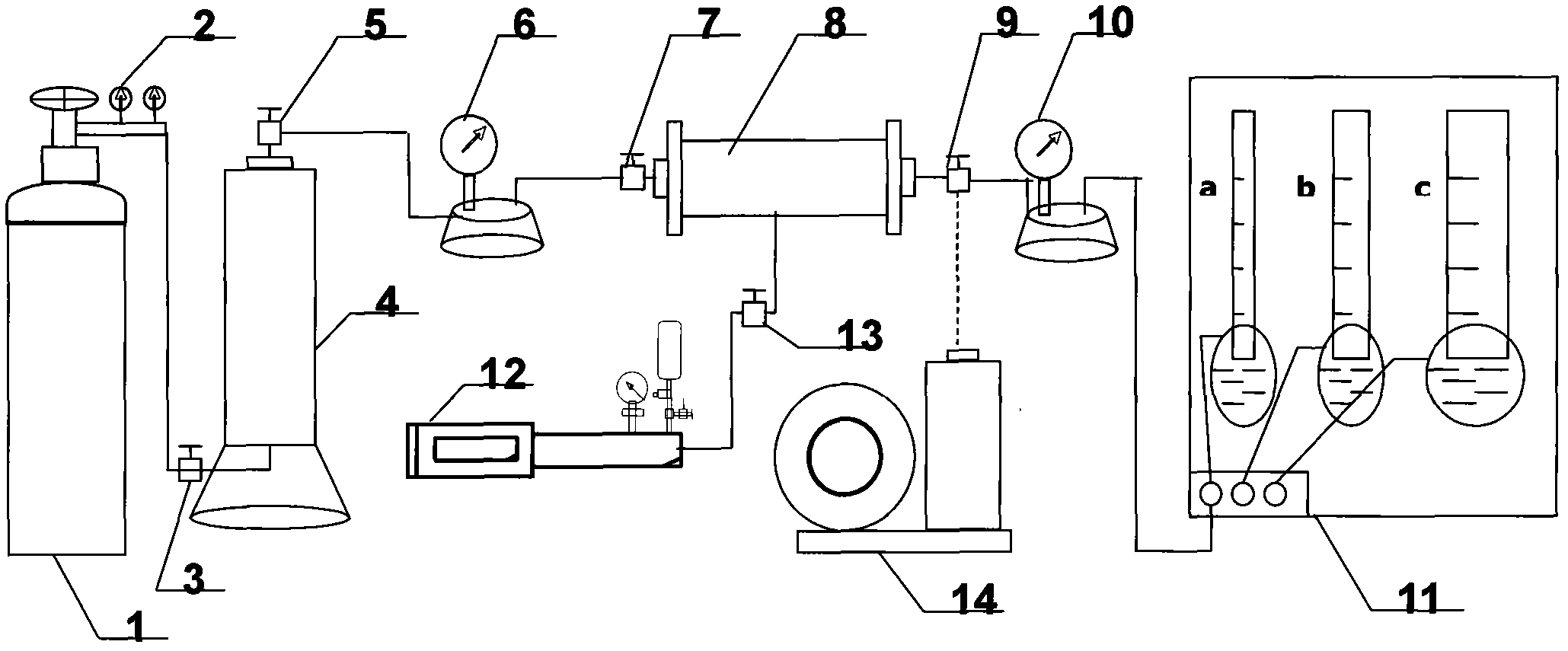

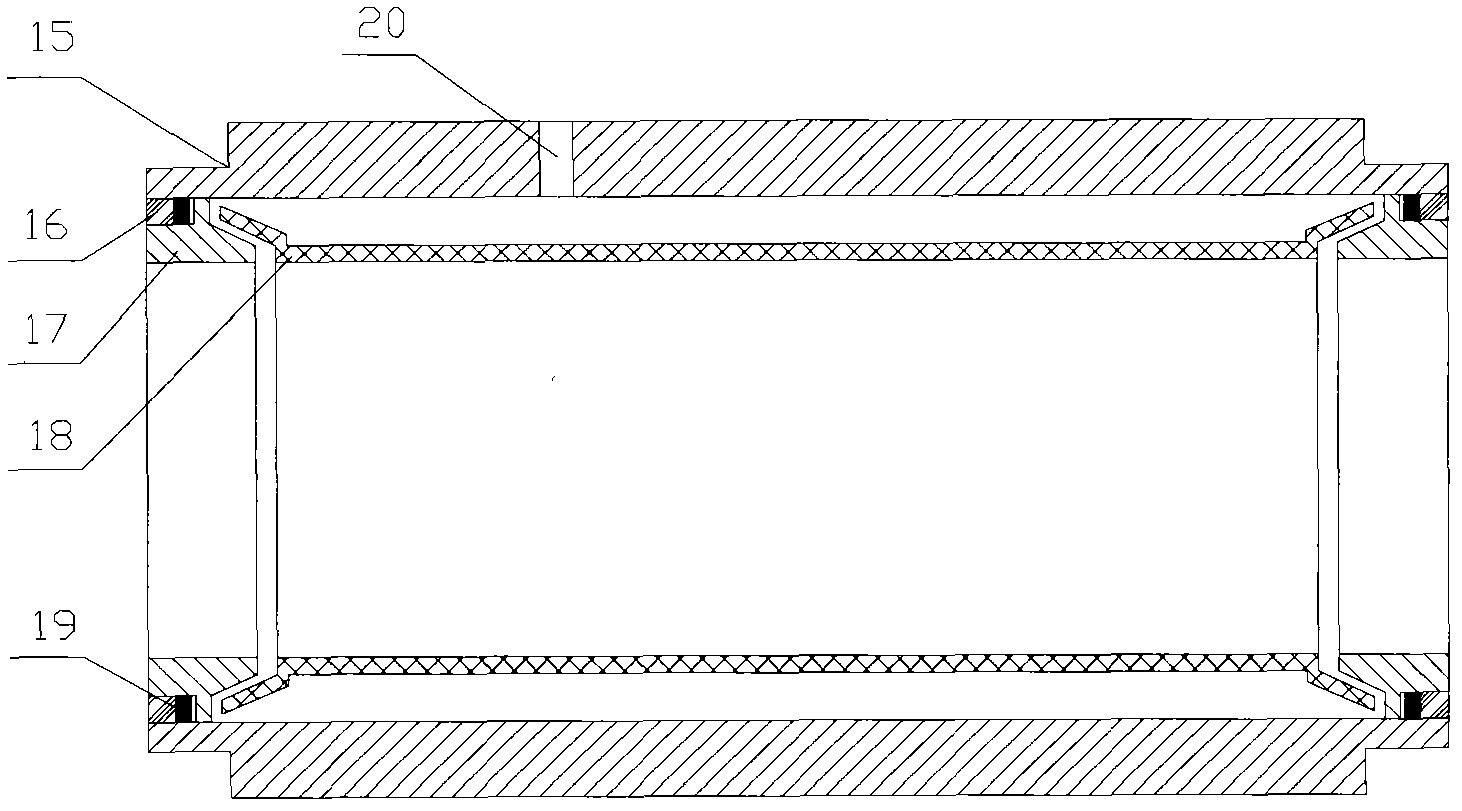

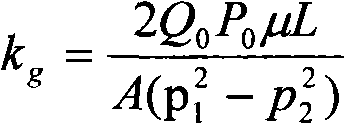

Measuring device for gas permeability of coal rock core

InactiveCN102435537AHigh measurement accuracyEasy to measurePermeability/surface area analysisDirect flow property measurementGas cylinderSoap bubble

The invention discloses a measuring device for gas permeability of a coal rock core. The measuring device mainly comprises a high-pressure gas source module, a core holder module, a circular pressure loading module, a data metering module and a vacuum treating module, which are connected through needle-type valves (3,5,7,9 and 13), wherein the high-pressure gas source module comprises a high-pressure gas bottle (1), a pressure relief valve (2) and a buffer container (4); the core holder module is a core holder (8); the circular pressure loading module is a hand-operated pump (12); the data metering module comprises precision pressure gauges (6 and 10) and a soap bubble flowmeter (11); and the vacuum treatment module is a vacuum pump (14). The measuring device is convenient to operate, has good repeatability of measured data, small experiment error and low cost, and is suitable for the testing field of gas permeability and equivalent liquid permeability of the coal rock core.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

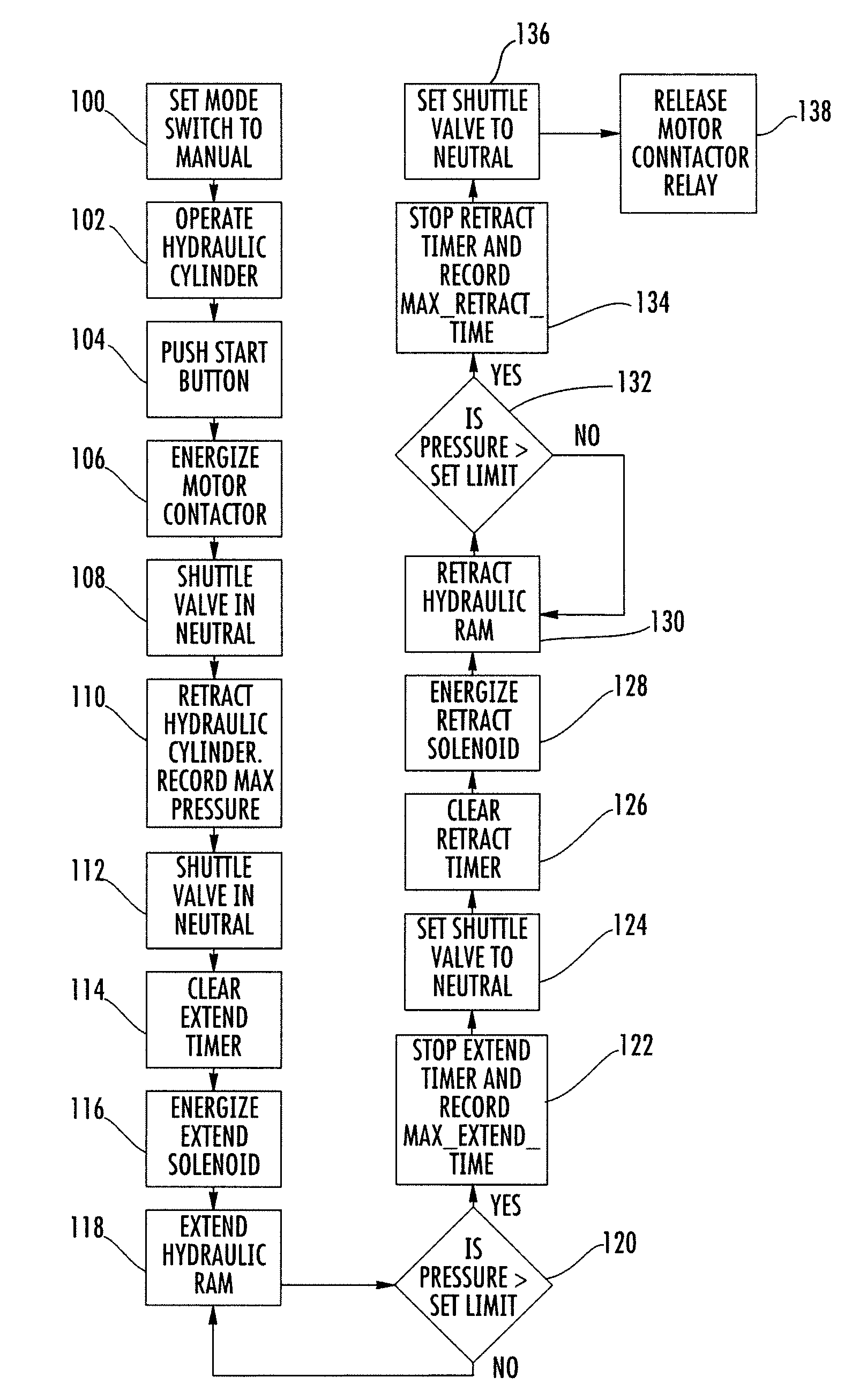

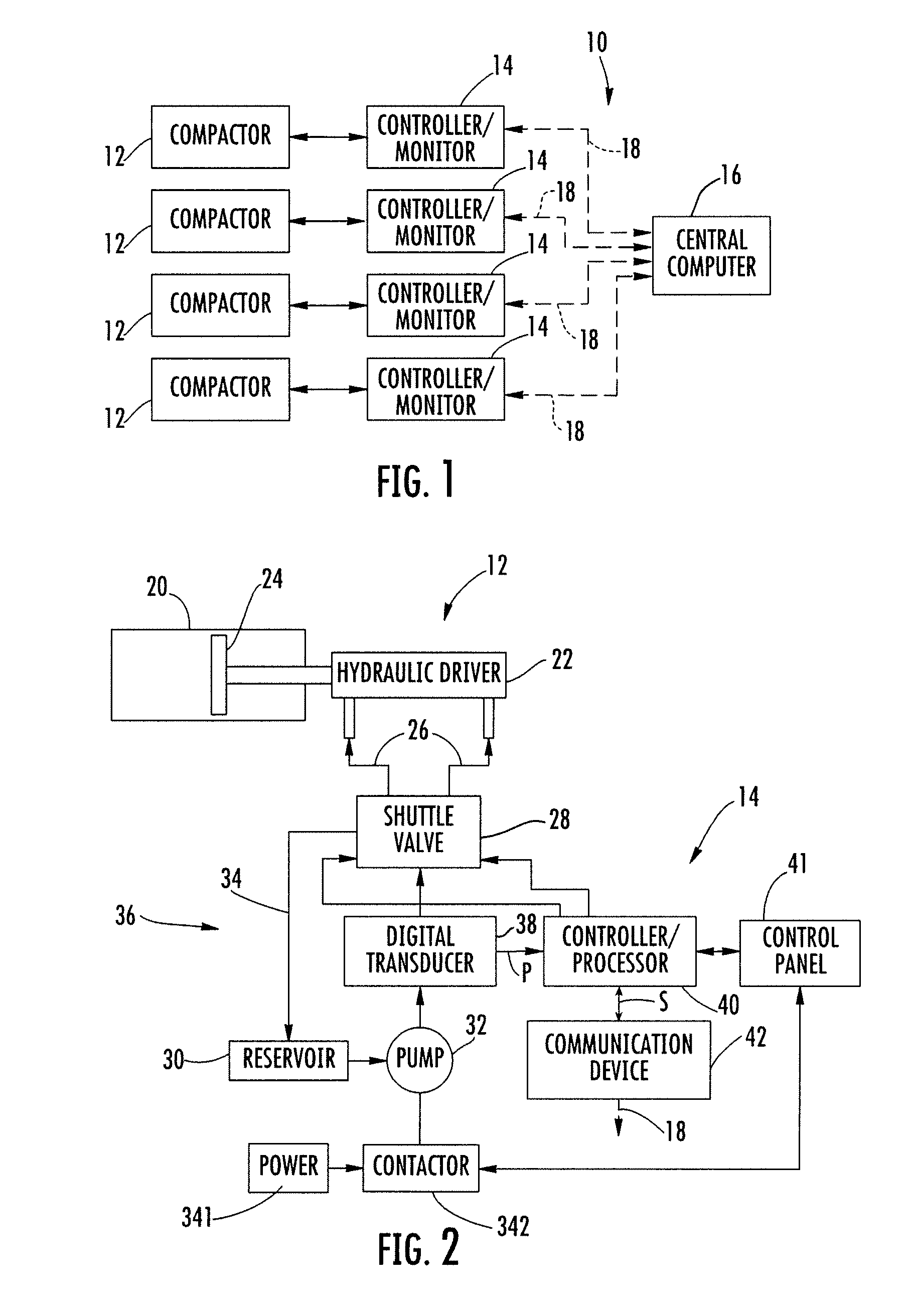

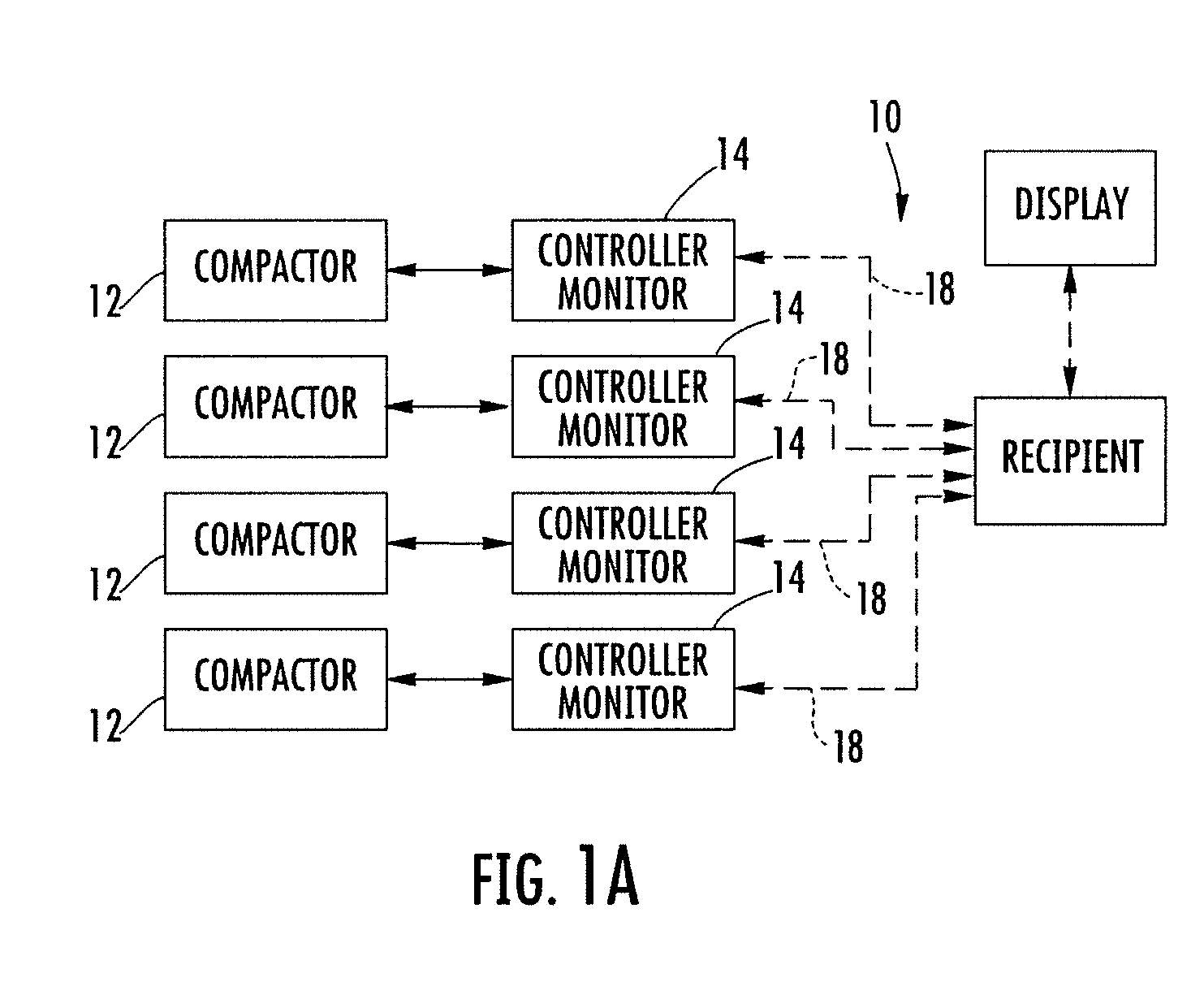

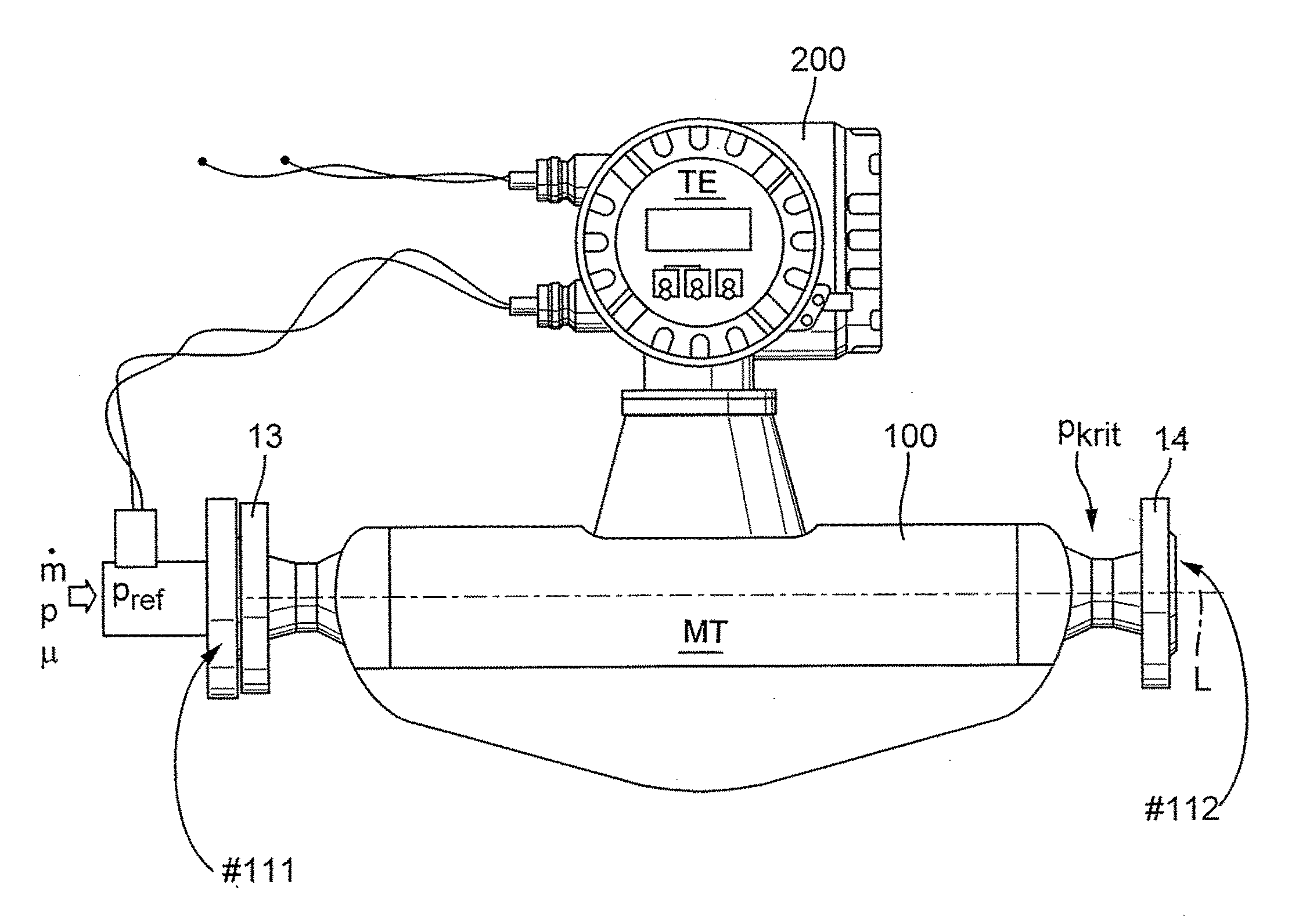

System and method for controlling compactor systems

ActiveUS7481160B1Easy to solveChange viscosityRotary clutchesFluid pressure measurement by mechanical elementsHydraulic ramOil viscosity

An integrated system for: complete waste compactor operational control; remote fullness monitoring; and, remote performance and maintenance diagnostics. Such diagnostic information is transferred wirelessly or otherwise to one or more recipients, so as to directly provide a critical warning in real time.The waste compactor controller / monitor system allows for periodic real-time oil viscosity measurements of the hydraulic fluid to account for changes in such viscosity. The system adjusts the timing of the compactor stroke to permit more efficient operation and inhibit damage to the hydraulic ram and / or container during use.

Owner:WASTE HARMONICS LLC

Measuring system having a measuring transducer of vibration-type

ActiveUS20110161017A1High measurement accuracyVolume/mass flow measurementVolume flow measuring devicesTransducerPressure difference

The measuring system comprises: A measuring transducer of vibration-type, through which medium flows during operation and which produces primary signals corresponding to parameters, especially a mass flow rate, a density and / or a viscosity, of the flowing medium; as well as a transmitter electronics electrically coupled with the measuring transducer for activating the measuring transducer and for evaluating primary signals delivered by the measuring transducer. The measuring transducer includes at least one measuring tube for conveying flowing medium; at least one electro-mechanical, oscillation exciter for exciting and / or maintaining vibrations of the at least one measuring tube, a first oscillation sensor for registering inlet-side vibrations at least of the at least one measuring tube and for producing a first primary signal of the measuring transducer representing vibrations at least of the at least one measuring tube, and a second oscillation sensor for registering outlet-side vibrations at least of the at least one measuring tube and for producing a second primary signal of the measuring transducer representing vibrations at least of the at least one measuring tube. The transmitter electronics, in turn, delivers at least one driver signal for the oscillation exciter for effecting vibrations of the at least one measuring tube and generates, by means of the first primary signal and by means of the second primary signal, as well as with application of a Reynolds number, measured value representing a Reynolds number, Re, for medium flowing in the measuring transducer, a pressure difference, measured value, which represents a pressure difference occurring between two predetermined reference points in the flowing medium.

Owner:ENDRESS HAUSER FLOWTEC AG

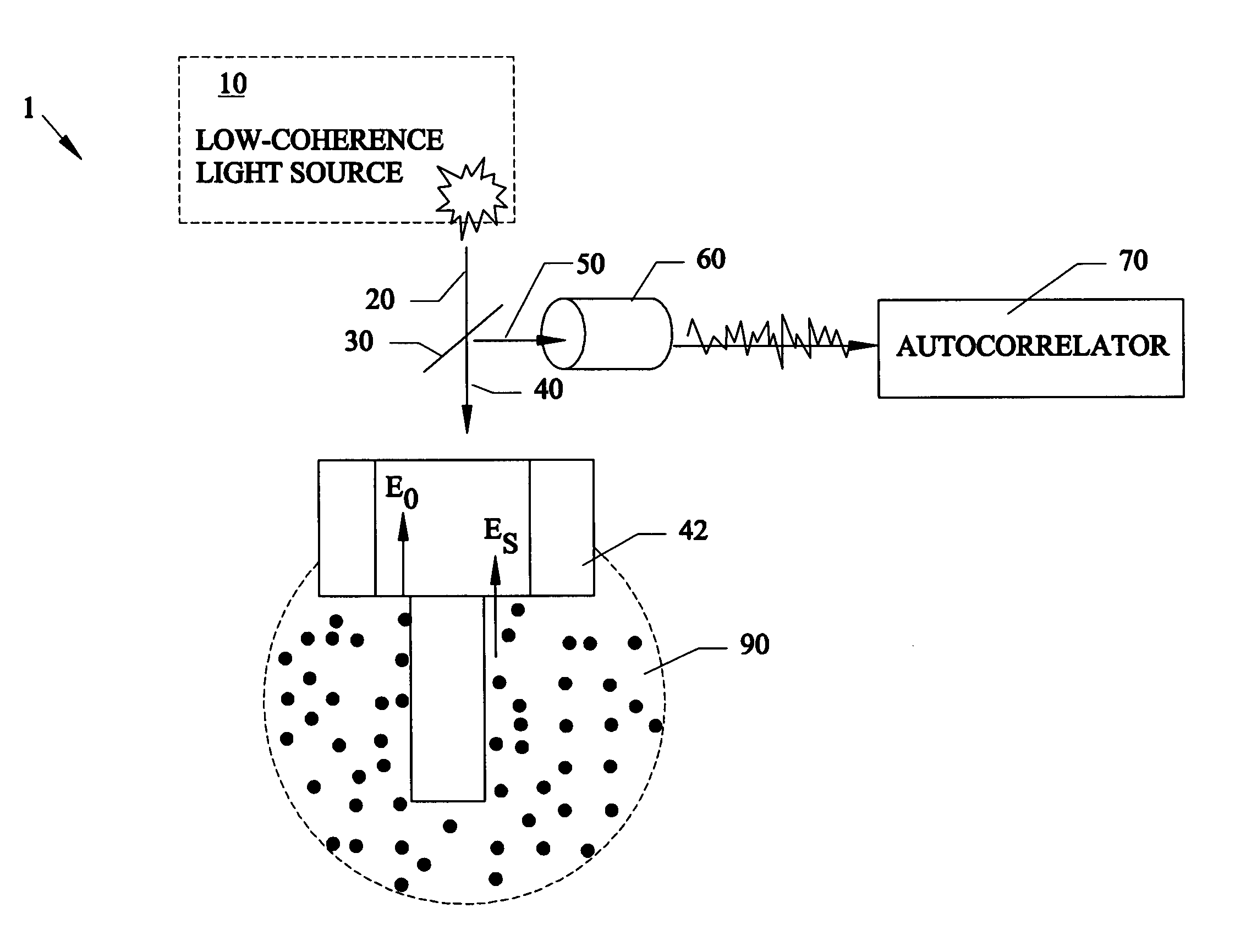

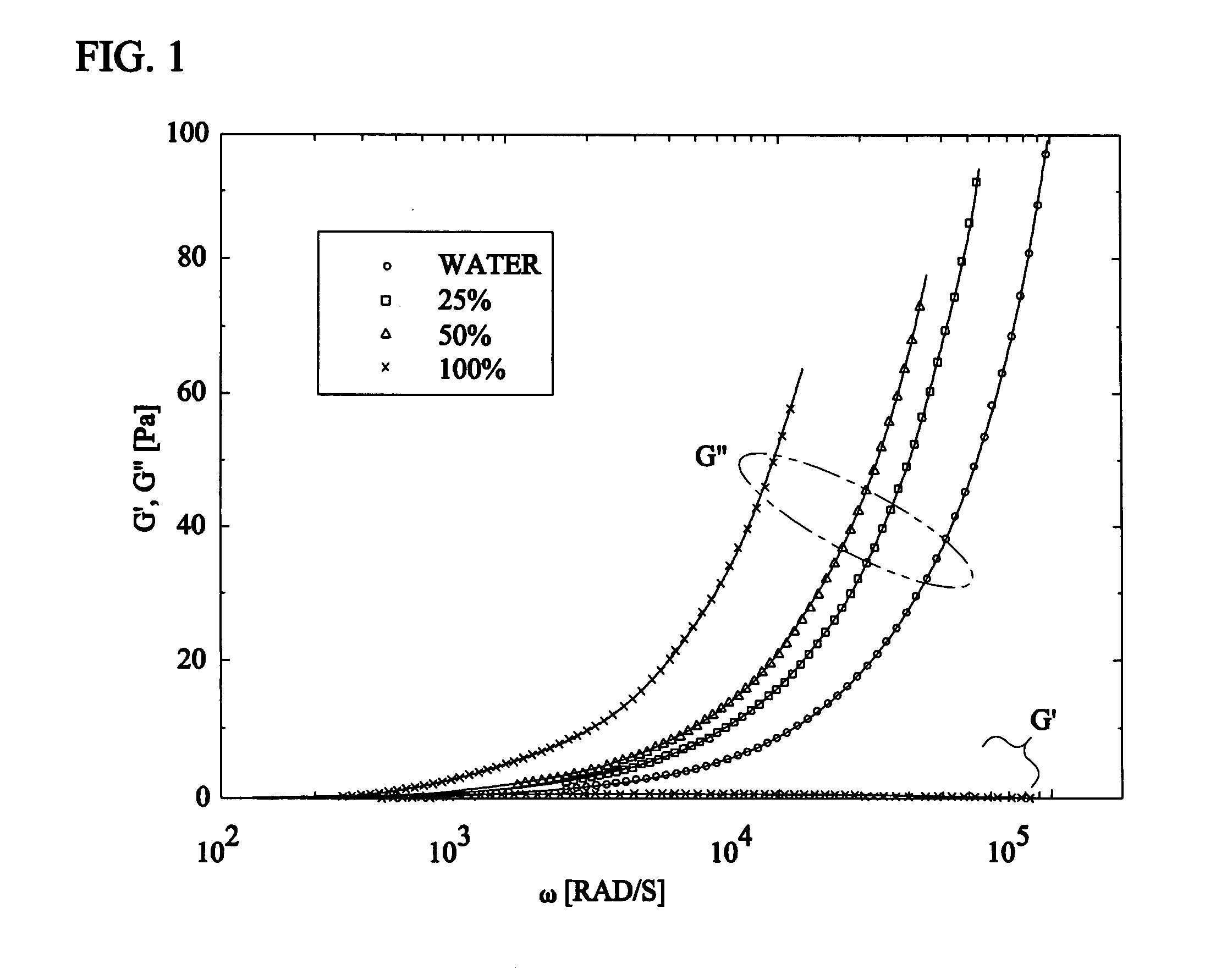

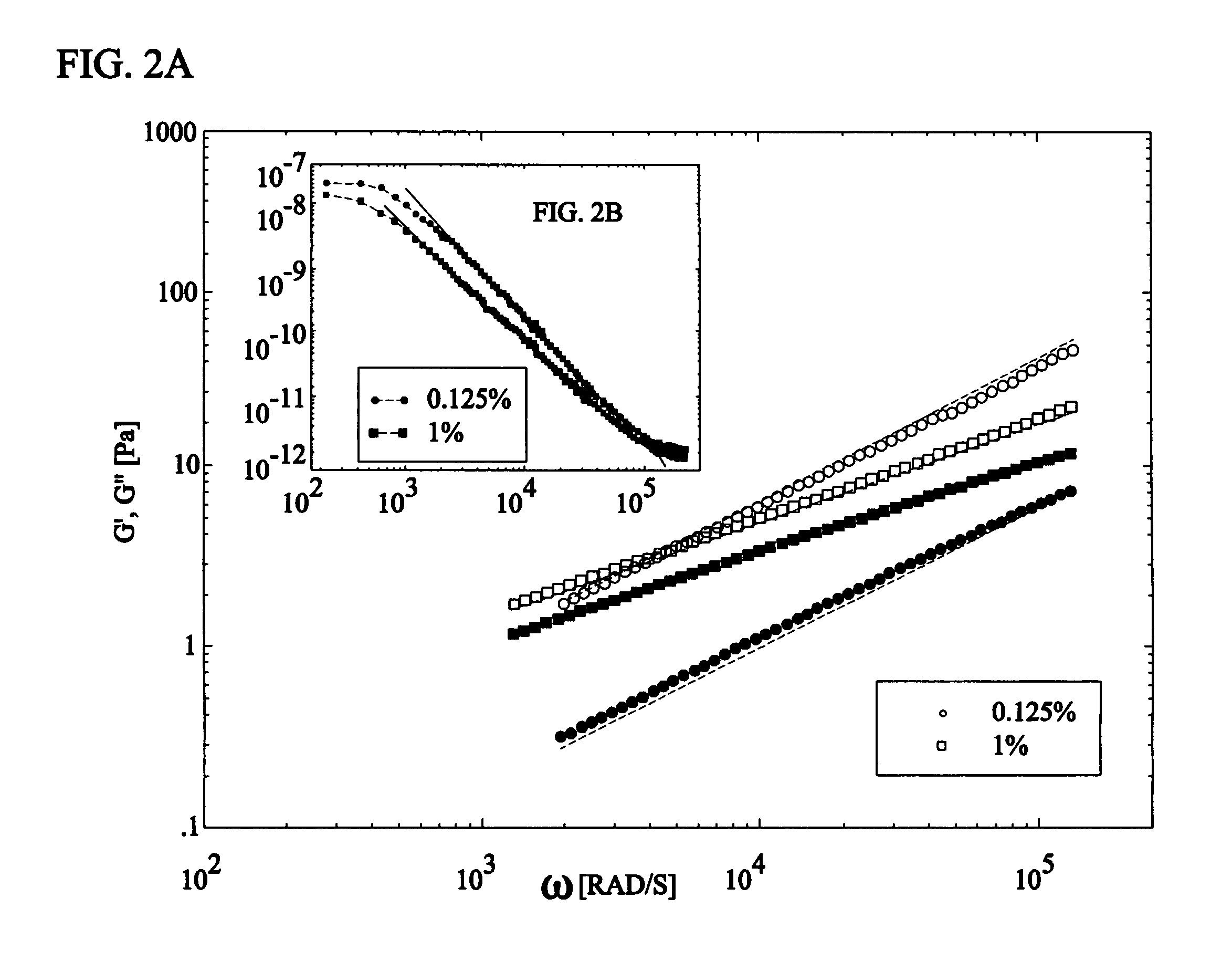

Microrheology methods and systems using low-coherence dynamic light scattering

ActiveUS6958816B1High degree of experimental flexibilityHigh degree of applicabilityScattering properties measurementsUsing optical meansFiberDynamic light scattering

Methods and systems for using dynamic light scattering, for investigating local rheological responses of complex fluids over a frequency range larger than that provided by standard instrumentation. A low-coherence radiation source is used with fiber optics to allow measurements of small volume spacing of up to approximately 1 / 10 of a picoliter. The methods and systems are based on dynamic light scattering, for investigating the local rheological response of a complex fluid over a frequency range larger than that provided by standard mechanical instrumentation. The low-coherence radiation used in a fiber optics configuration allows the measurements to be confined to a small volume around a tenth of a picoliter. The ability of the method to accurately measure both loss and storage moduli has been tested using both simple Newtonian liquids and viscoelastic, complex fluids. Monitoring liquid-gel transitions in polymer solutions has also been demonstrated. The unique capability of the technique to localize the measurement volume can be used for three-dimensional mapping of rheological properties in heterogeneous systems. Other embodiments can use open-air setups instead of optical fibers to transmit and receive the low coherence light.

Owner:CENT FLORIDA UNIV OF +2

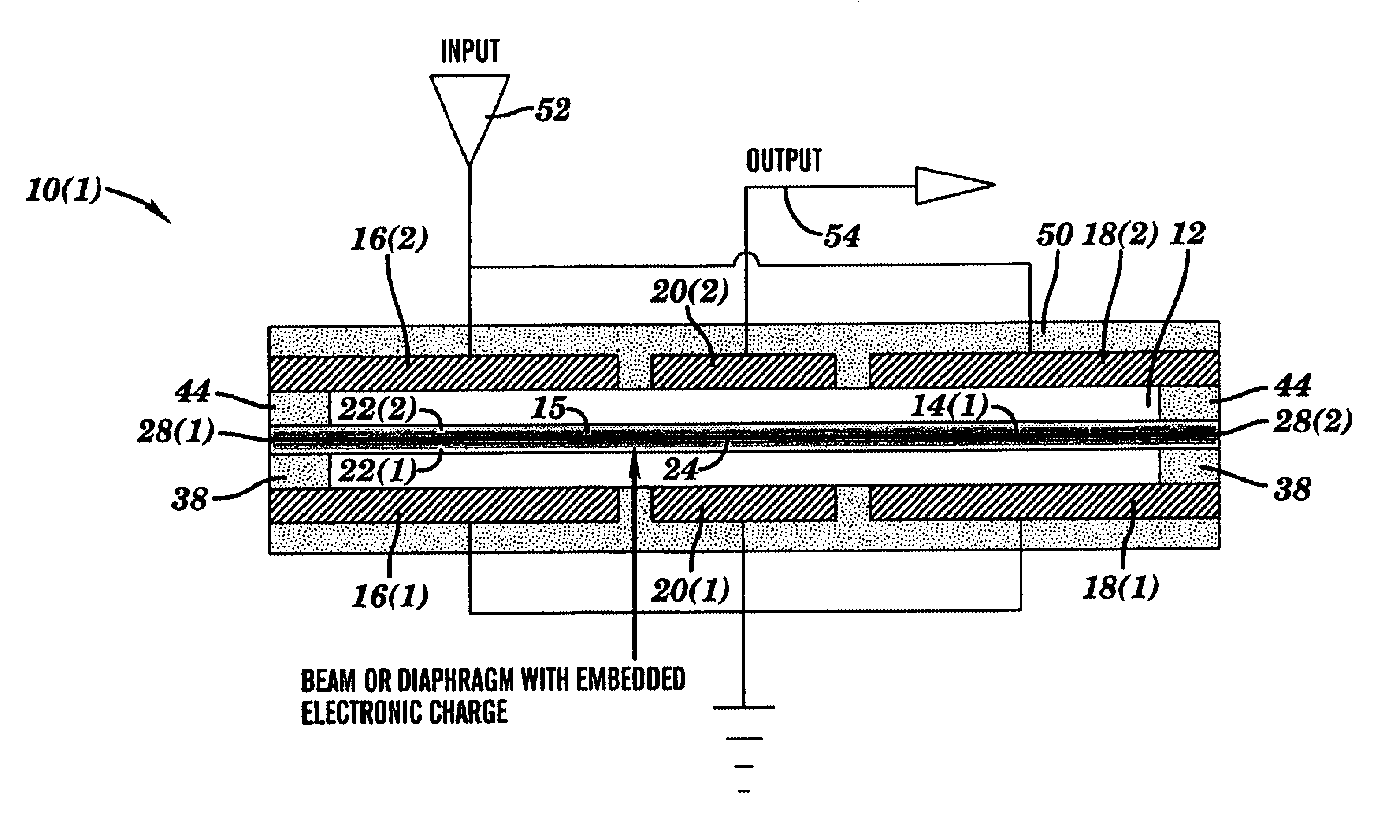

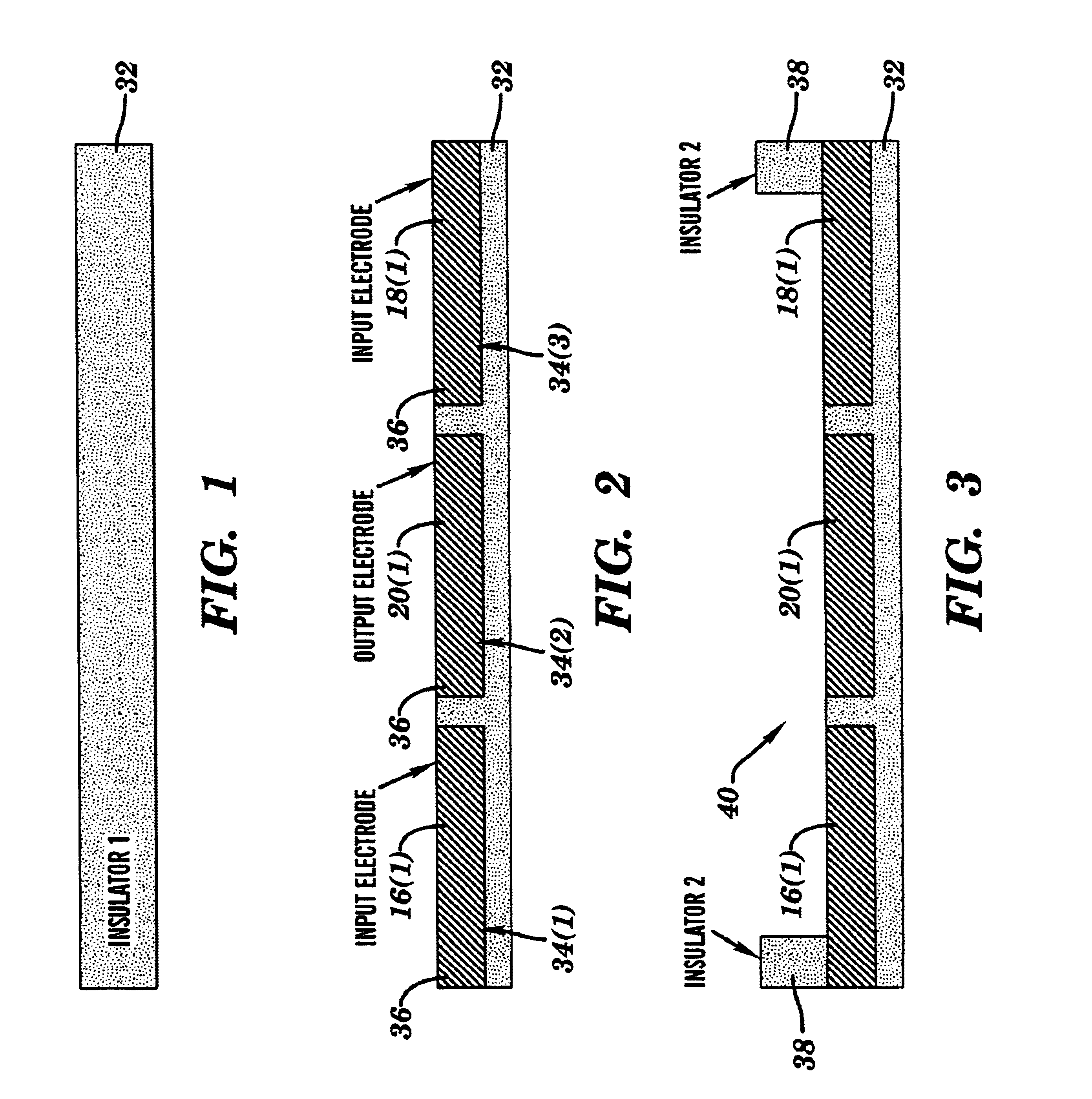

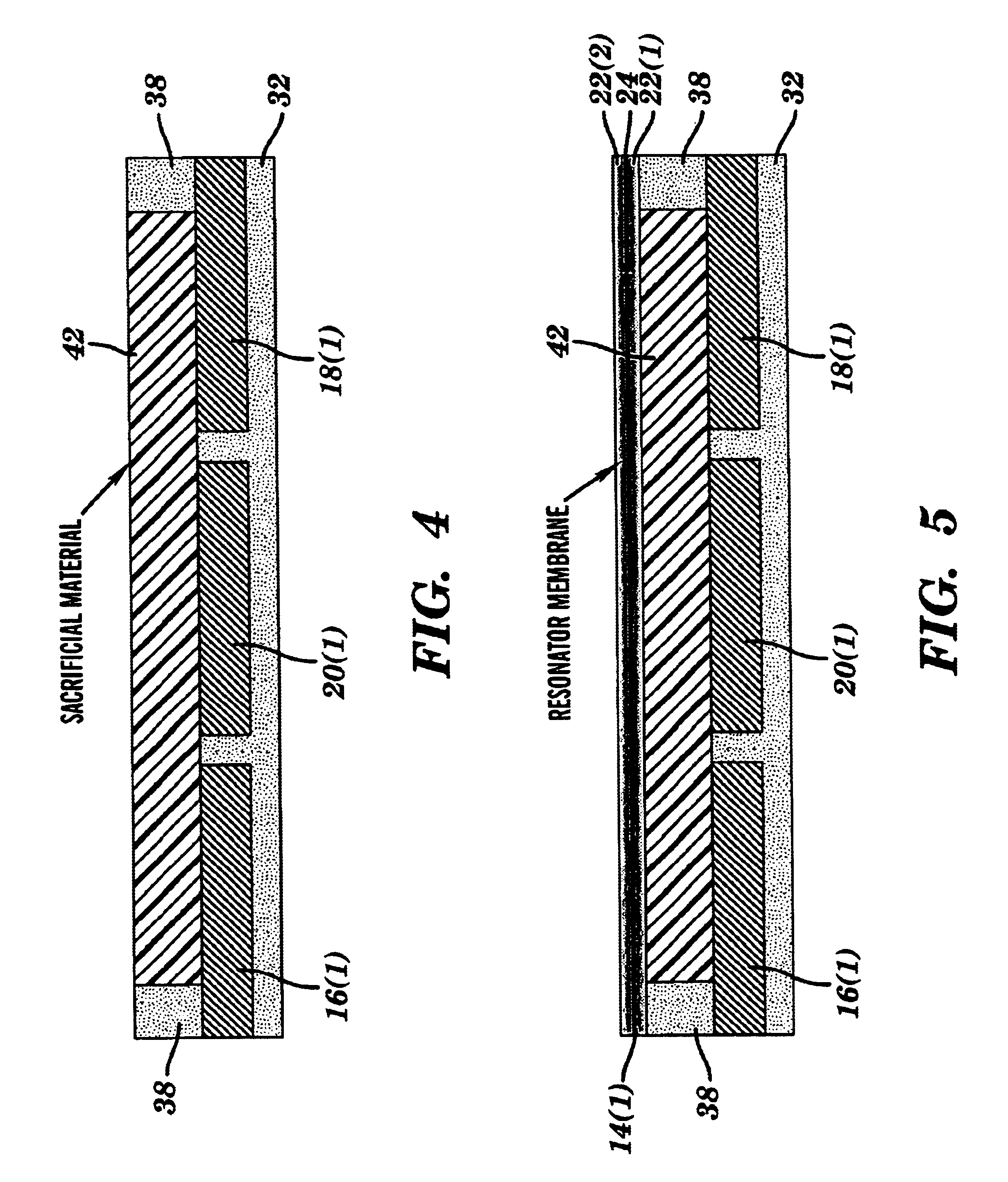

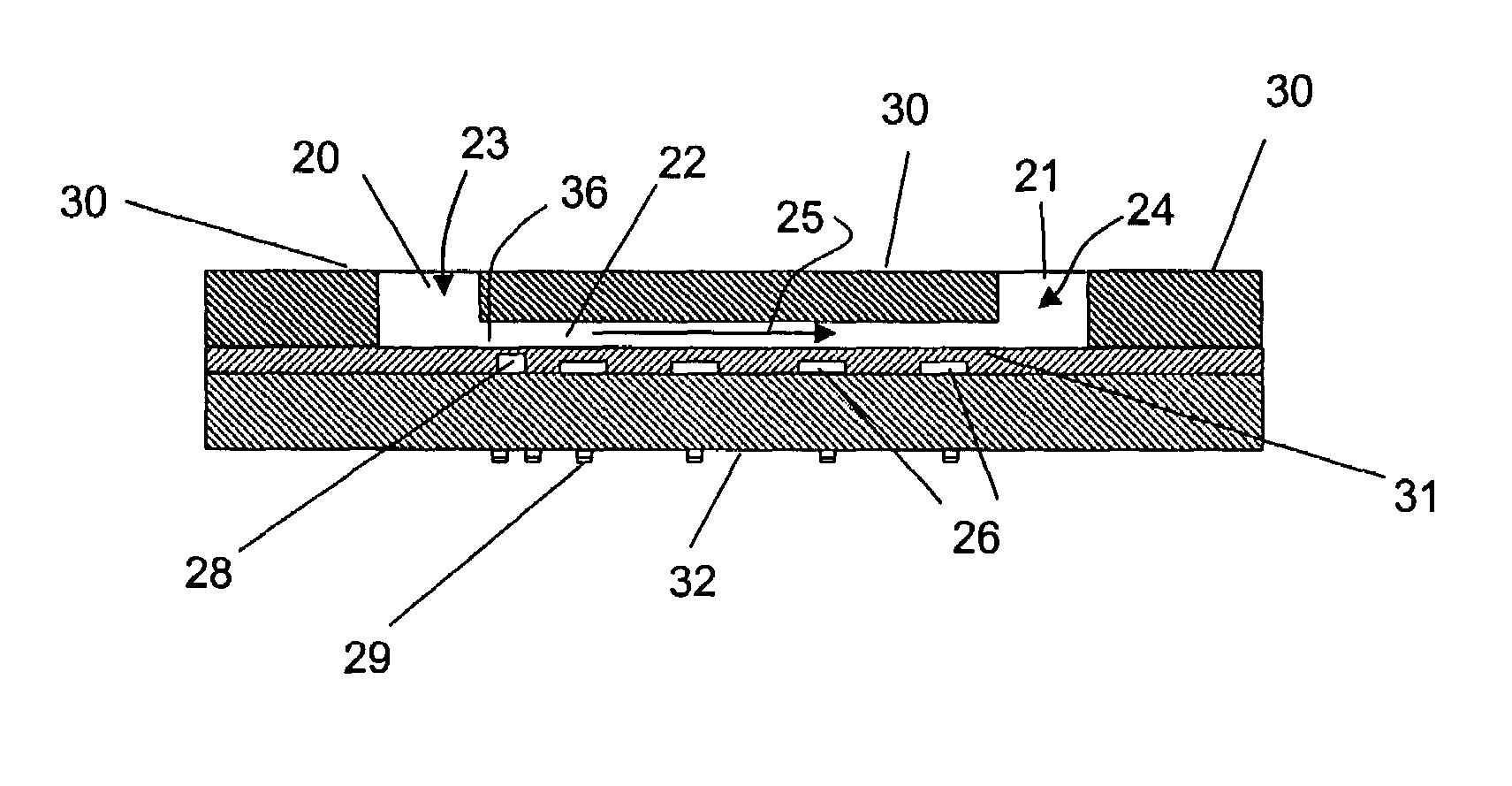

Biohazard sensing system and methods thereof

InactiveUS6842009B2Effective and simple and inexpensiveReduce usageImpedence networksResistance/reactance/impedenceHazardous substanceMonitoring system

A sensing system for a target includes a member with an embedded charge, at least one input electrode, at least one output electrode, at least one common electrode, one or more probes, an input system, and an output monitoring system. The input and output electrodes are spaced from and on substantially opposing sides of the member from the common electrode. At least one of the member and the input and output electrodes is movable with respect to the other. The probes which engage with the target hazardous substance are connected to the at least one of the member and the input and output electrodes which is movable with respect to the other. The input system is coupled between the at least one input electrode and the at least one output electrode and provides an input signal. The output monitoring system is coupled between the at least one output electrode and the at least one common electrode and detects a change in an output signal when the target engages with the movable member or electrode.

Owner:NTH TECH

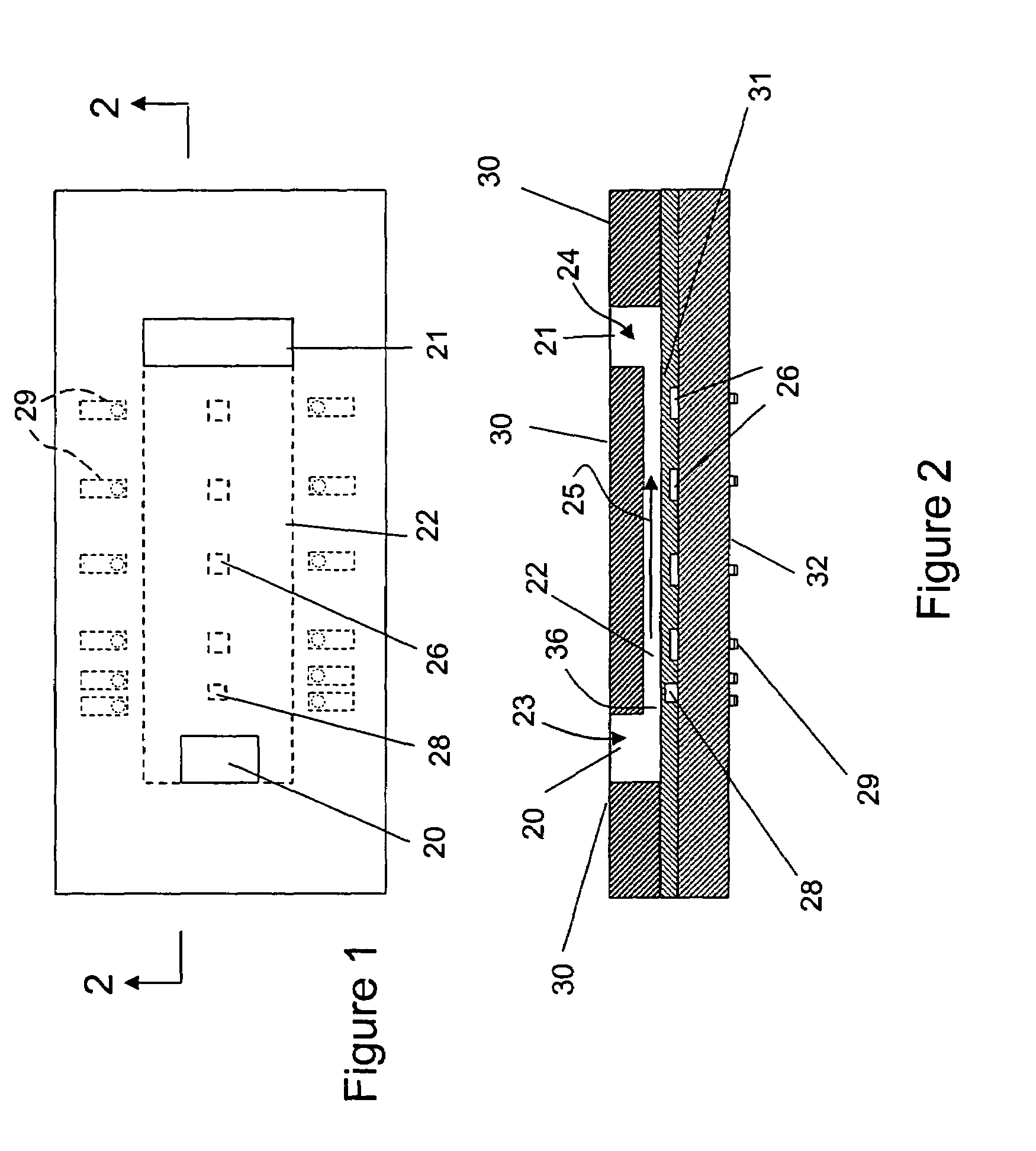

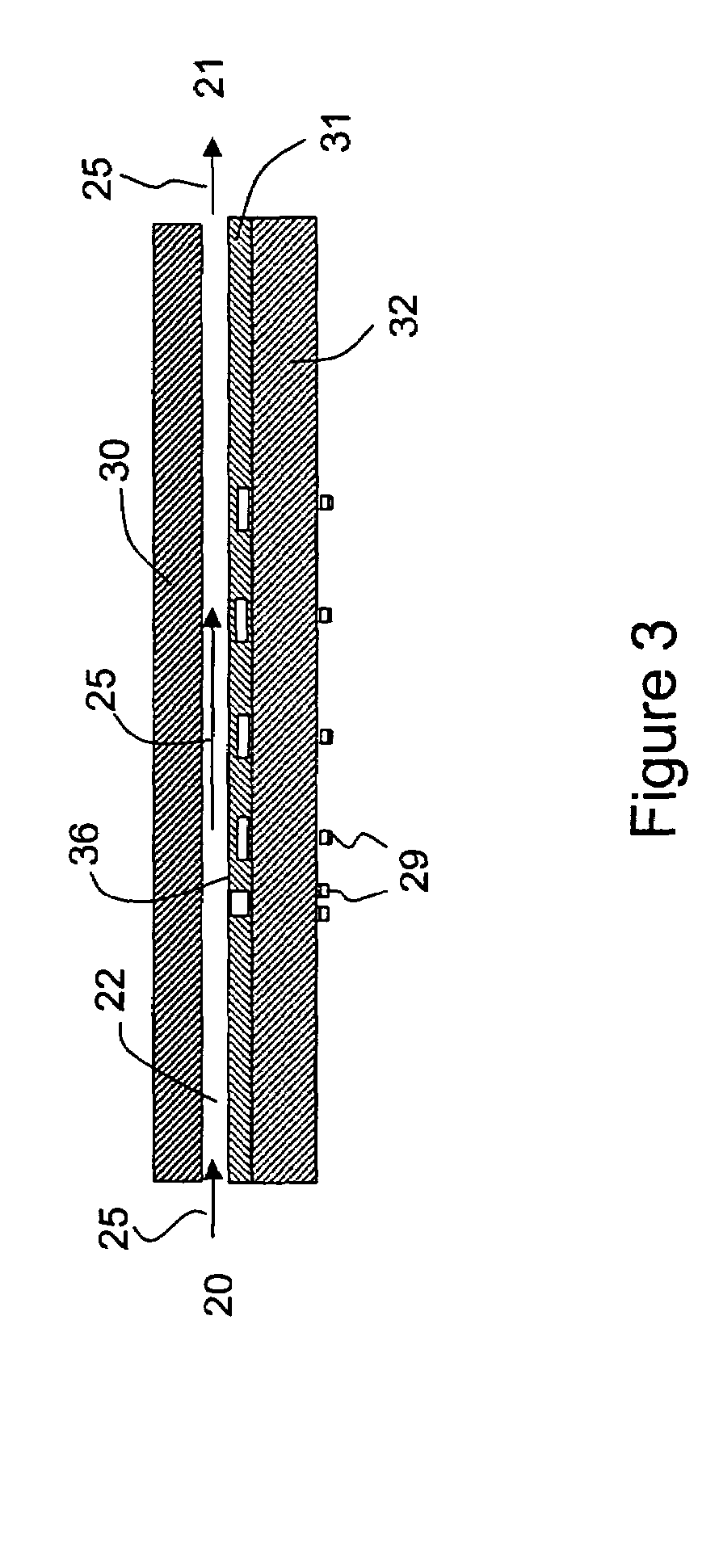

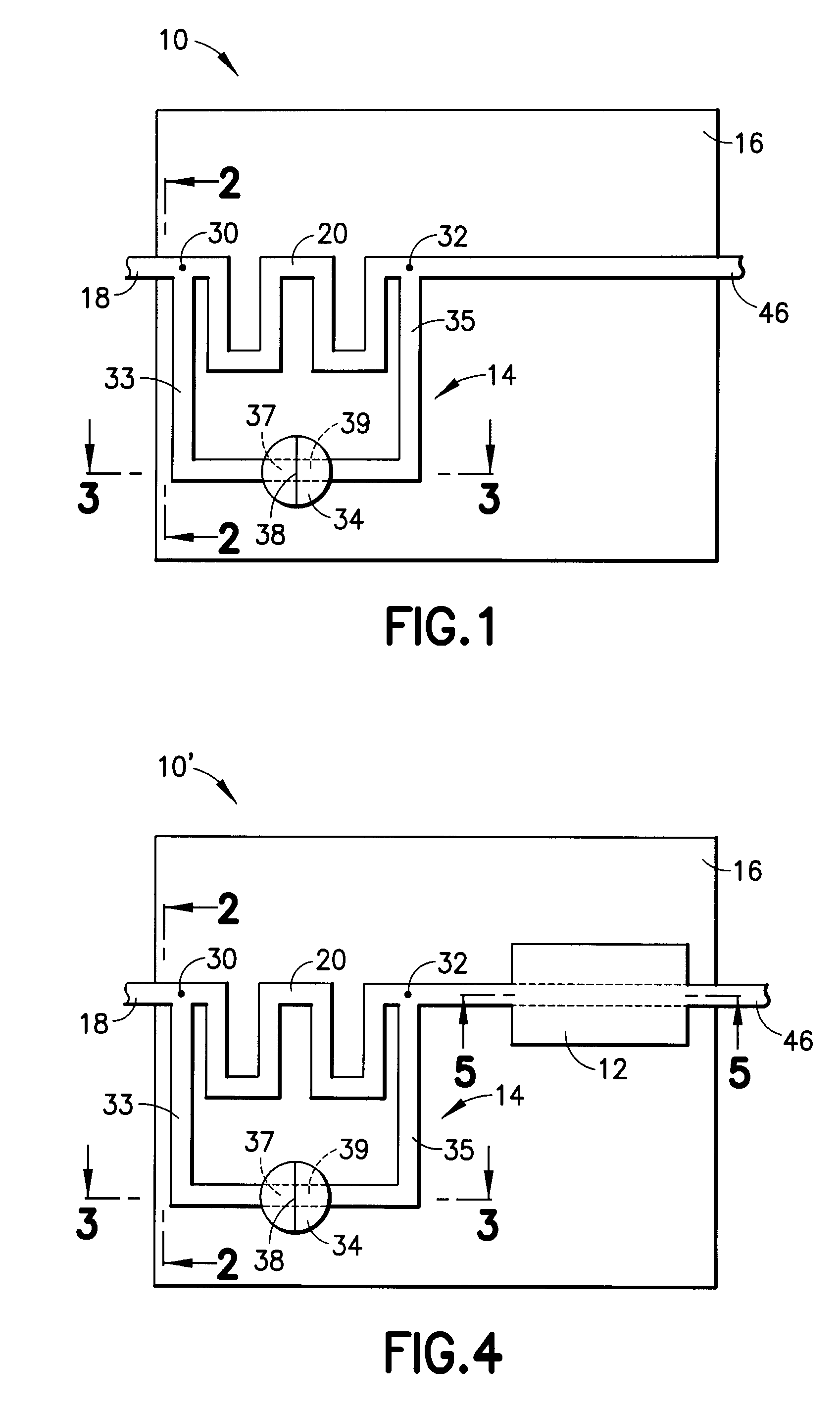

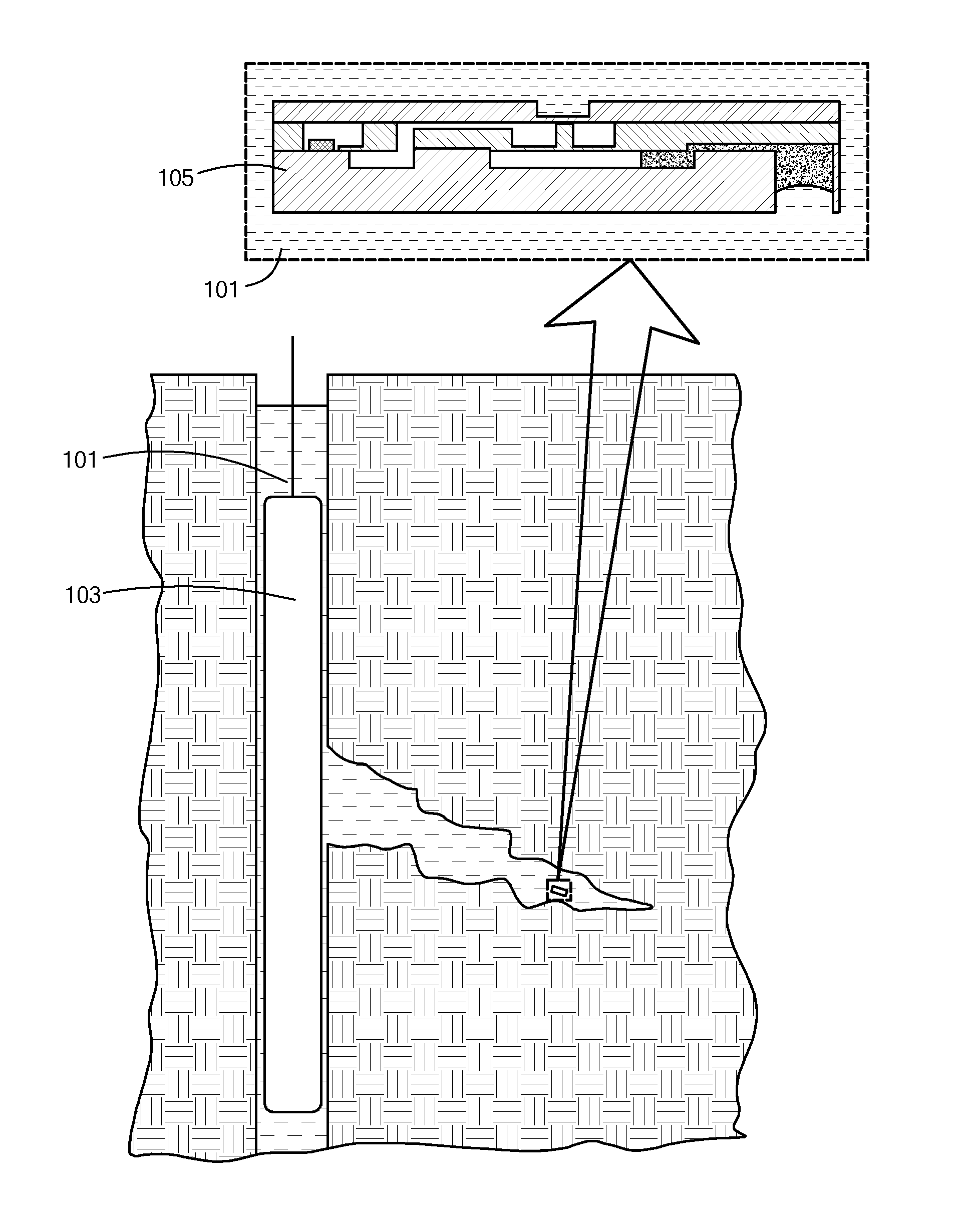

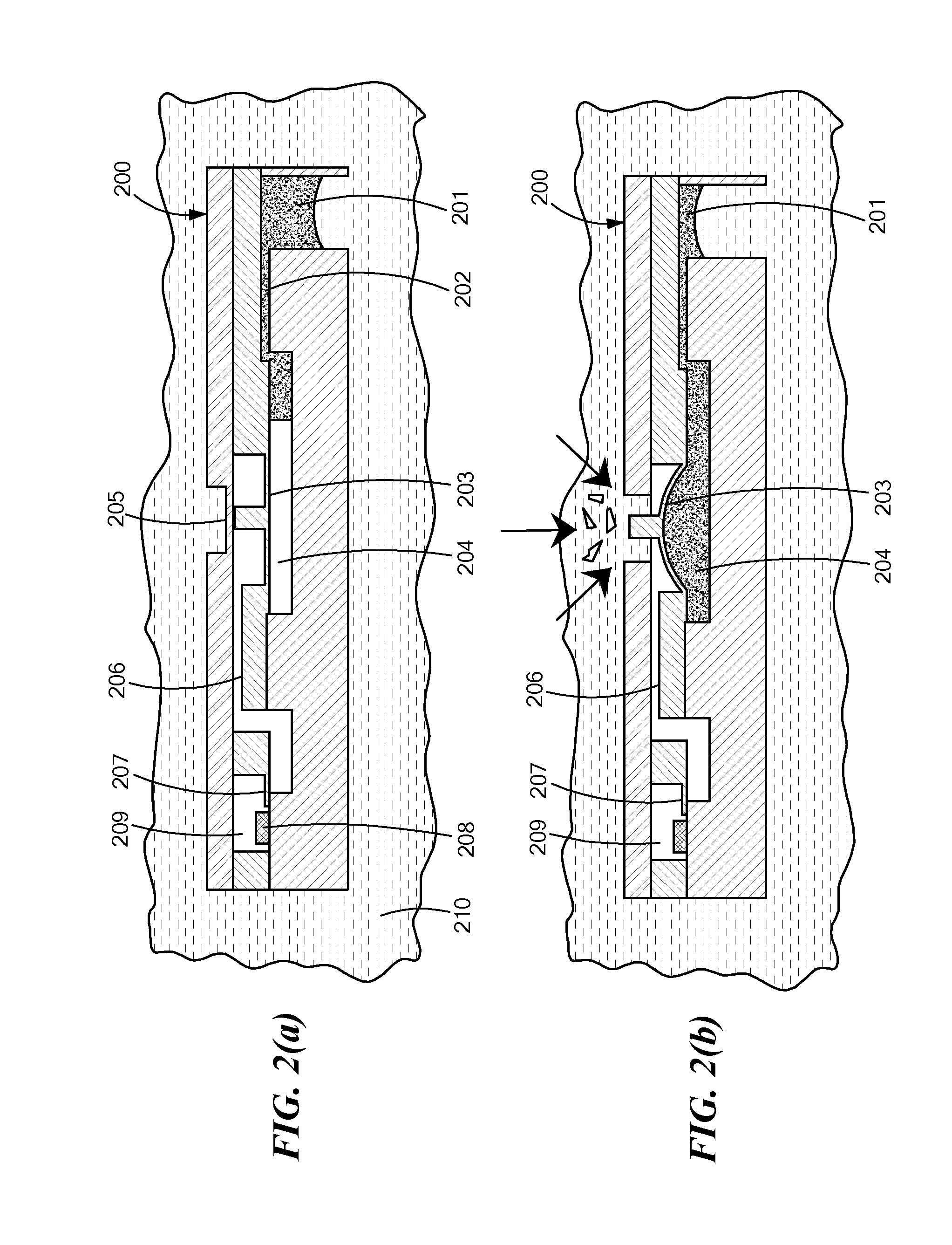

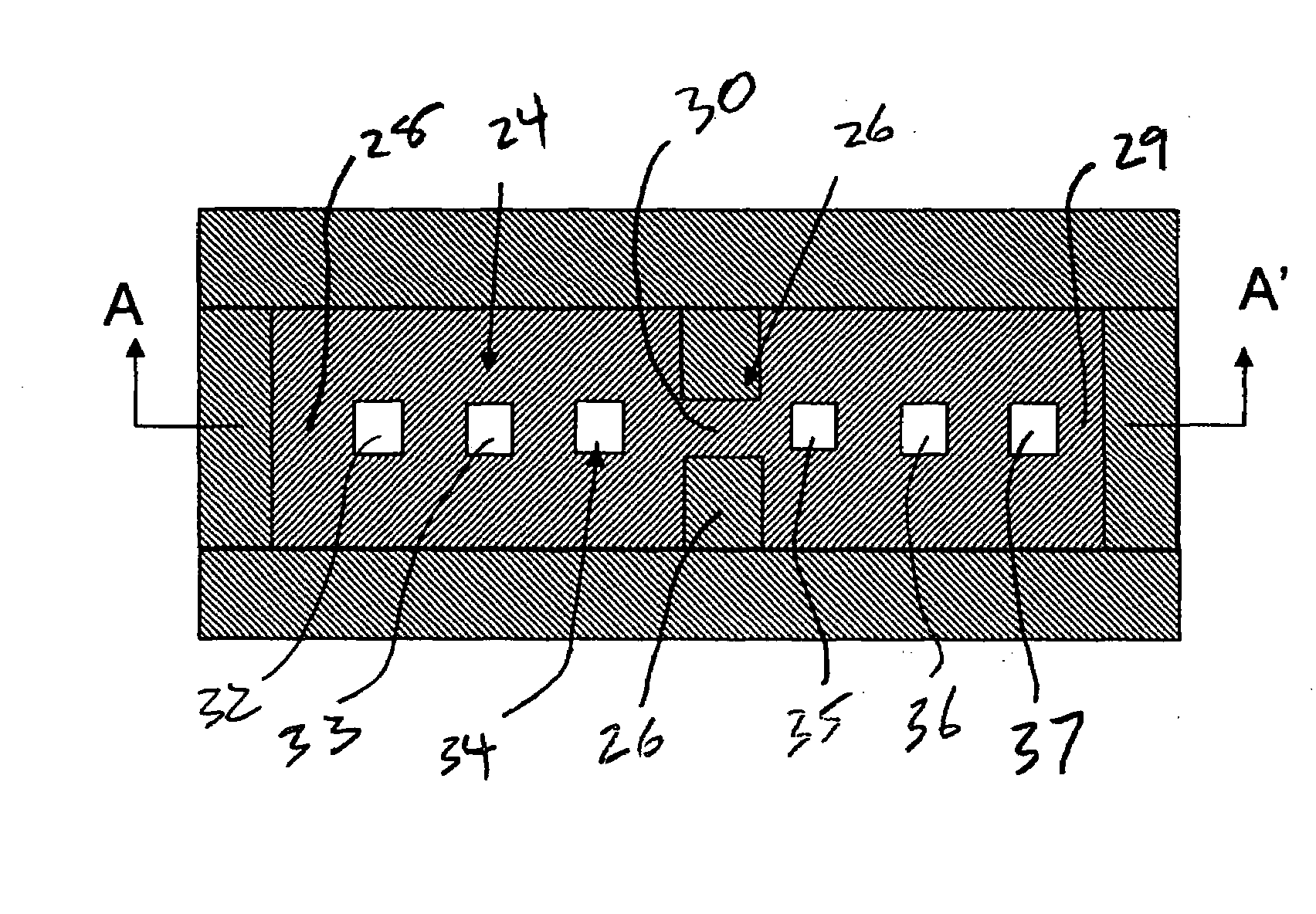

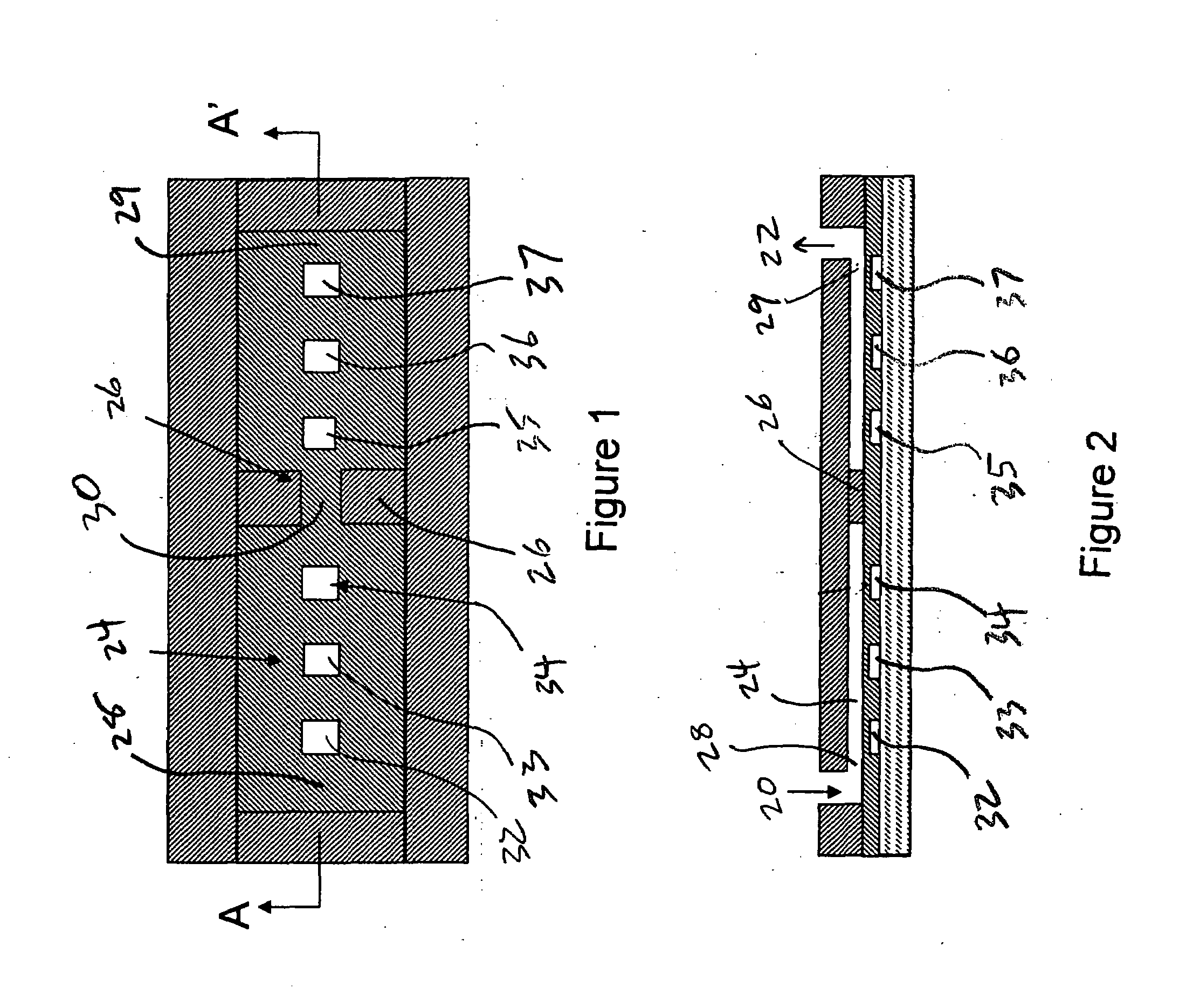

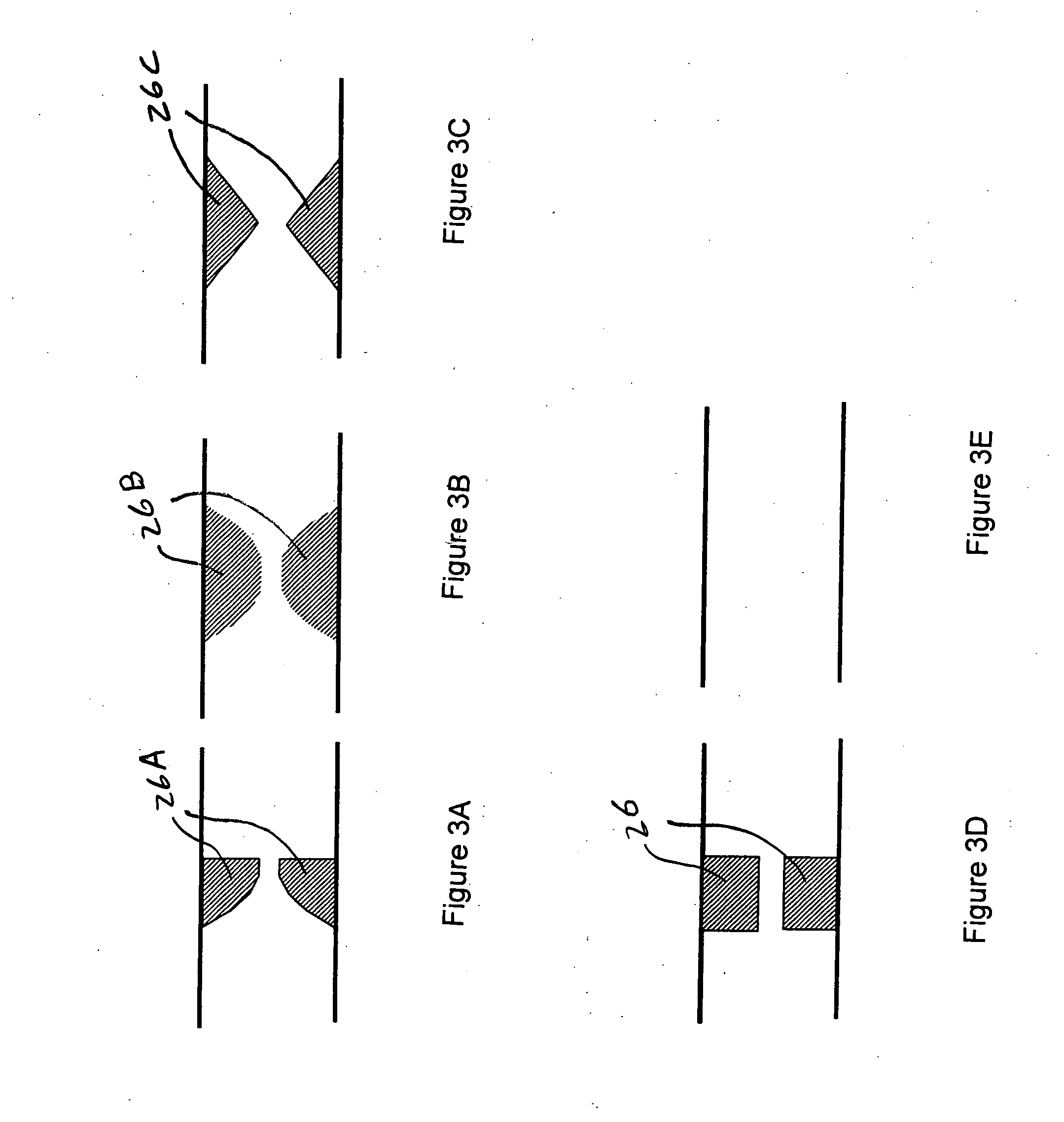

Micro slit viscometer with monolithically integrated pressure sensors

InactiveUS7290441B2Smooth inner surfaceReduce manufacturing costMaterial analysis by optical meansDirect flow property measurementTest sampleMicrometer

An improved micro slit viscometer includes a combined micrometer depth rectangular slit flow channel with monolithically integrated multiple pressure sensors in the flow channels and a pumping system that injects a test sample to the channel at a desired flow rate. Pressure sensing diaphragm of the monolithically integrated pressure sensors is smooth to minimize the flow disturbance thereby measuring accurate local pressures. With the measurement of the pressures at various locations of the channel the true viscosity of test sample can be calculated. The viscometer may consist of multiple flow channels and thus the true viscosity at multiple shear rates can be measured simultaneously for a given flow rate thereby obtaining a full viscosity curve as a function of shear rate of non-Newtonian liquids in a much faster manner. The viscometer needs only a miniscule amount of sample, which minimizes a waste of test material. The flow channels and the monolithically integrated pressure sensors are fabricated using microfabriaction processes on wafers and combined, which greatly reduce the production costs.

Owner:RHEOSENSE

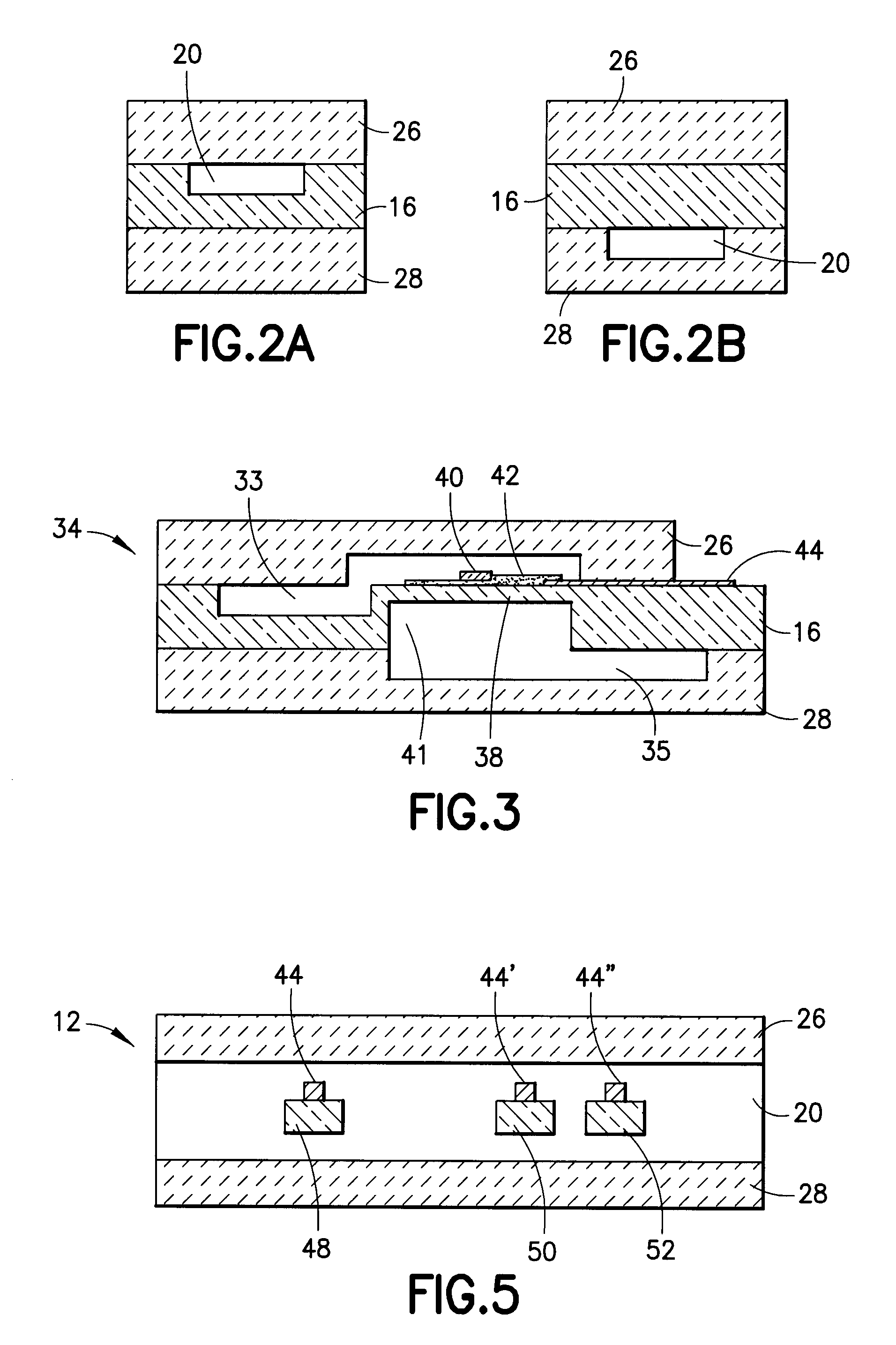

Device and method for detecting the coagulation functions of global, especially primary hemostasis

InactiveUS7223365B2Low cost of measurementSimple and low-maintenance techniqueUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsBlood plasmaPlasma rich platelet

A method and a device are provided for examining the properties of the global, in particular the primary, hemostasis functions in whole blood or platelet-rich plasma. A volumetric blood flow is preferably adjusted, depending on the measured pressure of the volumetric flow, so that the shear rate or the shear force, whose action in the reaction opening causes blood components, in particular thrombocytes, to deposit, follows a predetermined characteristic curve and in particular is held constant.

Owner:FREIHERR VON DER GOLTZ VOLKER

Viscosity measurement

ActiveUS7784330B2Material analysis by optical meansFluid pressure measurement by mechanical elementsDifferential pressureEngineering

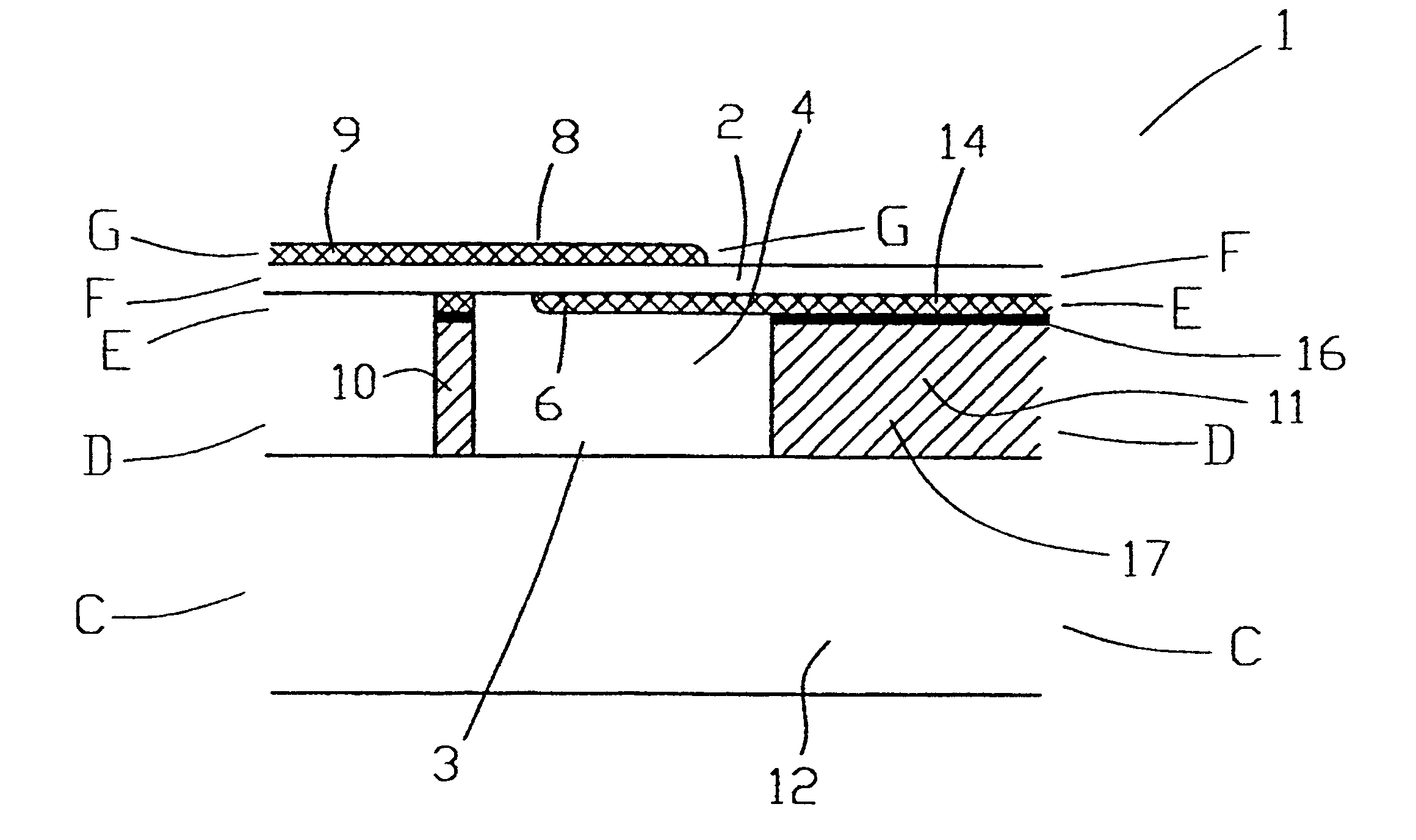

A micro-fluidic device and methods for measuring one or more rheologic properties of a fluid. The micro-fluidic device includes a substrate and at least one cover bonded to a surface of the substrate with a fluid channel formed in at least one of the cover or the substrate. Further, the micro-fluidic device includes a first differential pressure gauge that can have a first differential pressure sensor in fluid communication with both a first pressure site and a second pressure site. Further still, the micro-fluidic device includes the first pressure site and the second pressure site that can be spaced apart by a first section of the fluid channel. Also, the micro-fluidic device includes a data processor communicatively coupled to the first differential pressure sensor, so as to receive data generated by the first differential pressure sensor.

Owner:SCHLUMBERGER TECH CORP

Apparatus and method for measuring viscosity

InactiveUS20050087001A1Preserve integrityEliminate useDirect flow property measurementViscosityEnvironmental geology

An apparatus and method for measuring the viscosity of a sample fluid are disclosed. In one embodiment, a holding vessel (82) receives the sample fluid (94) and a weighted fluid (96). The weighted fluid (96) has a greater specific gravity than the sample fluid (94). A floating spacer (100) is buoyantly disposed in the weighted fluid (96) such that an interface (116) between the sample fluid (94) and the weighted fluid (96) is defined between the holding vessel (82) and the floating spacer (100). A capillary tube 86 is positioned in fluid communication with the holding vessel (82) such that a pressure drop is created across the capillary tube (86) when at least a portion of the sample fluid (94) is forced therethrough. The viscosity of the sample fluid (94) may be determined by utilizing Hagen-Poiseuille's Law.

Owner:HALLIBURTON ENERGY SERVICES INC

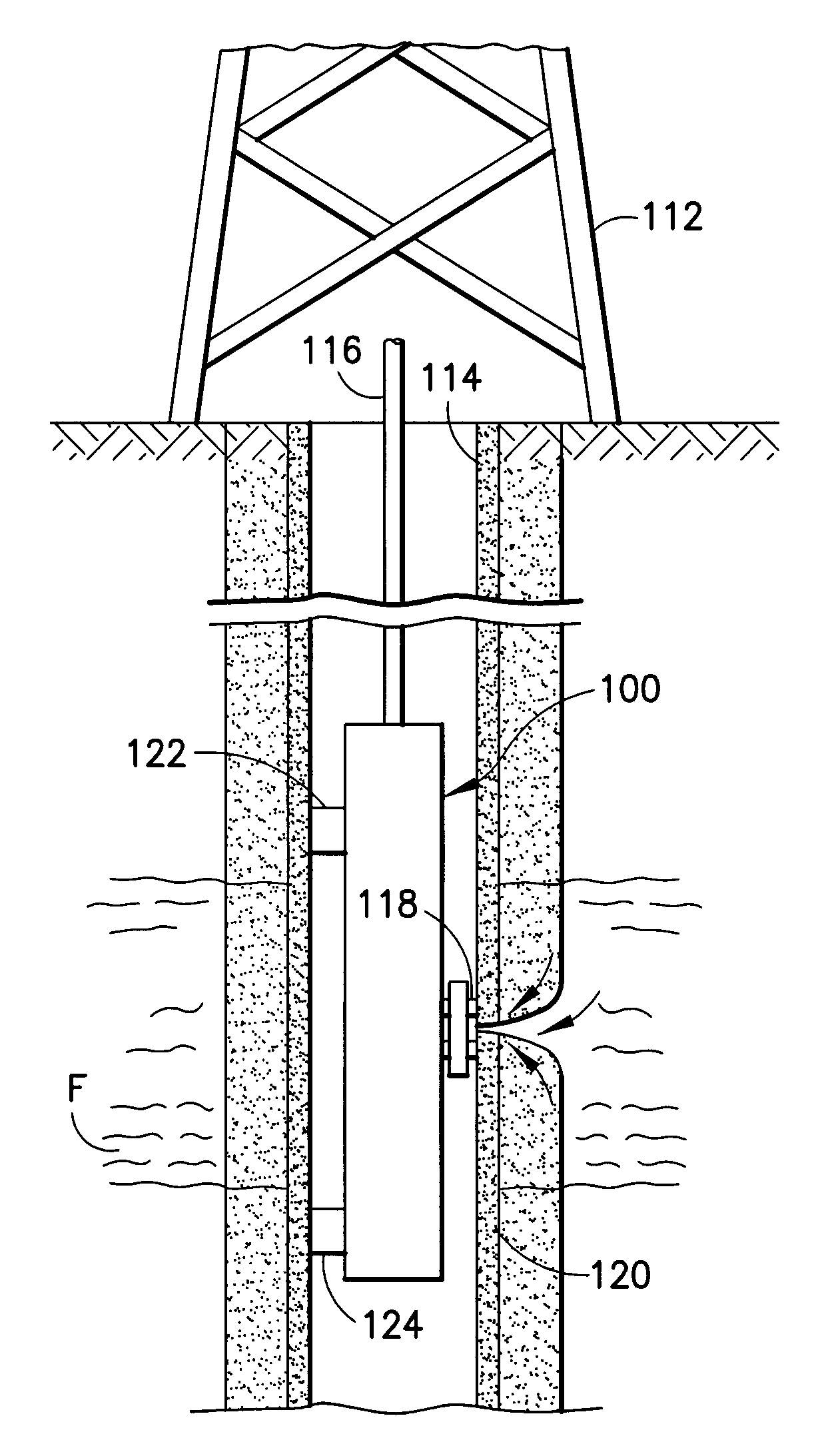

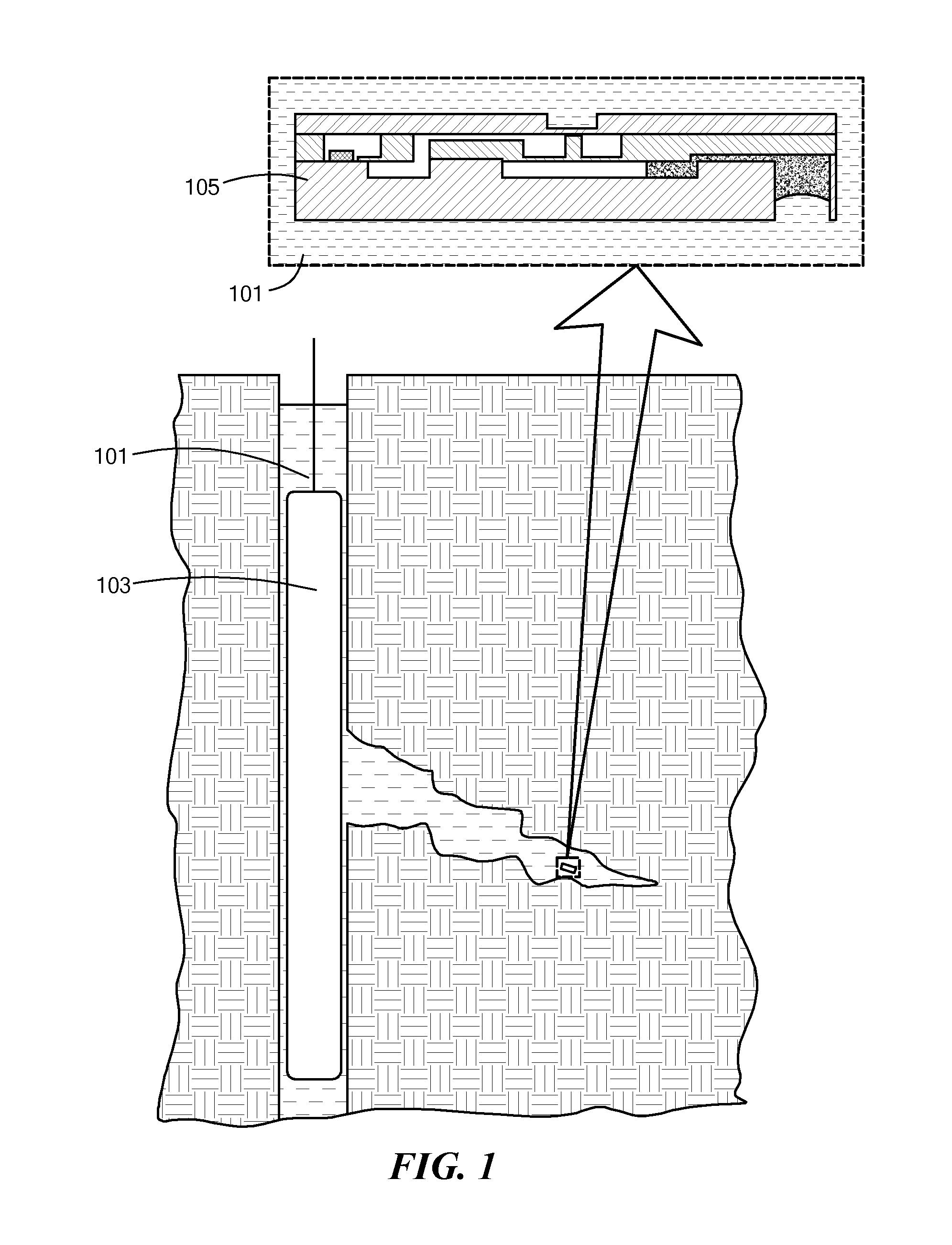

Passive Micro-vessel and Sensor

An electrically passive device and method for in-situ acoustic emission, and / or releasing, sampling and / or measuring of a fluid or various material(s) is provided. The device may provide a robust timing mechanism to release, sample and / or perform measurements on a predefined schedule, and, in various embodiments, emits an acoustic signal sequence(s) that may be used for triangulation of the device position within, for example, a hydrocarbon reservoir or a living body.

Owner:ANGELESCU DAN

Dielectric slit die for in-line monitoring of liquids processing

InactiveUS7143637B1Cutting can not be obtainedUniform sizeMaterial analysis by electric/magnetic meansIndirect flow property measurementElectricityDielectric

The dielectric slit die is an instrument that is designed to measure electrical, rheological, ultrasonics, optical and other properties of a flowing liquid. In one application, it is connected to the exit of an extruder, pump or mixing machine that passes liquefied material such as molten plastic, solvents, slurries, colloidal suspensions, and foodstuffs into the sensing region of the slit shaped die. Dielectric sensing is the primary element of the slit die, but in addition to the dielectric sensor, the die contains other sensing devices such as pressure, optical fiber, and ultrasonic sensors that simultaneously yield an array of materials property data. The slit die has a flexible design that permits interchangeability among sensors and sensor positions. The design also allows for the placement of additional sensors and instrumentation ports that expand the potential data package obtained.

Owner:MCBREARTY MICHAEL +1

Micro rheometer for measuring flow viscosity and elasticity for micron sample volumes

InactiveUS20080134765A1Small sample sizeCost-effectiveMaterial analysis by optical meansMaterial thermal analysisMeasurement precisionMechanics

A micro-rheometer for measuring flow characteristics such as viscosity, elasticity, and flow rate of a sample liquid combines well defined micro-fabricated flow channels having geometry changes forming a constriction region therein to a monolithically fabricated pressure sensor arrays. The pressure sensor array positions pressure sensors to measure the viscosity of the sample liquid while flowing in a uniform length of the flow passage and to measure the extensional viscosity while flowing through the constriction region of the passage. The invention can improve the measurement accuracy of the flow rate, viscosities, or elasticities over a wide range of shear rate. The accuracy of the viscosity over a broader range of shear rate or flow rate measurement over broader range of flow rates can be accomplished by employing monolithically integrated pressure sensors fabricated with different sensitivities disposed in a known manner. The invention further includes necessary components such as a display, a pumping system, valve manifolds, and software for a portable or laboratory measurement instrument, process control, and high throughput measurements.

Owner:RHEOSENSE

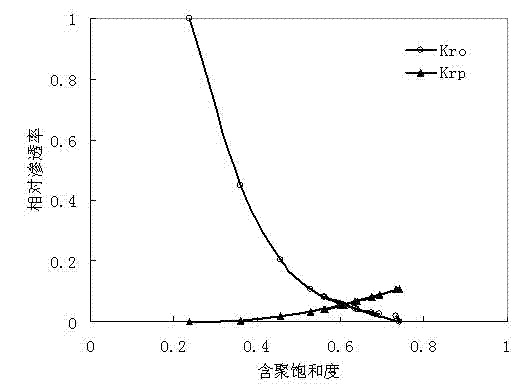

Joint testing device and method of rheological property of polymer solution and relative permeability of core

InactiveCN102221514ARheology hasGuaranteed stabilityPermeability/surface area analysisDirect flow property measurementLine tubingShear rate

The invention relates to a joint testing device and method of the rheological property of a polymer solution and the relative permeability of a core. The device provided by the invention comprises a polymer injection unit, an oil injection unit, an online rheometer, a core holder, an oil-liquid separator, a pressure difference sensor and an electronic weighing instrument which are connected through pipelines and control valves. The method provided by the invention comprises the following steps: placing a core into the core holder; injecting a polymer solution sample into the core in the core holder by utilizing the polymer injection unit; collecting pressure difference and flow data; computing the viscosity of the polymer solution under different flows; obtaining the rheological curve of the polymer solution by combining the relation of the shear rate and flow in the online rheometer according to the relationship between the shearing rate and flow in the online rheometer; injecting oil by utilizing the oil injection unit to remove the polymer solution out of the core; injecting the polymer solution into the core by utilizing the polymer injection unit so as to remove the oil; in the removing and substituting process, measuring the change of the oil quantity in real time by utilizing the oil-liquid separator, and measuring the change of the total liquid quantity of the oil and the polymer in real time by utilizing the electronic weighing instrument; and finally, computing the relative permeability of the polymer solution and the oil by utilizing the obtained data such as the flow, the oil yield, the solution yield, the pressure difference and time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com