Patents

Literature

332results about "Specific gravity by measuring pressure differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

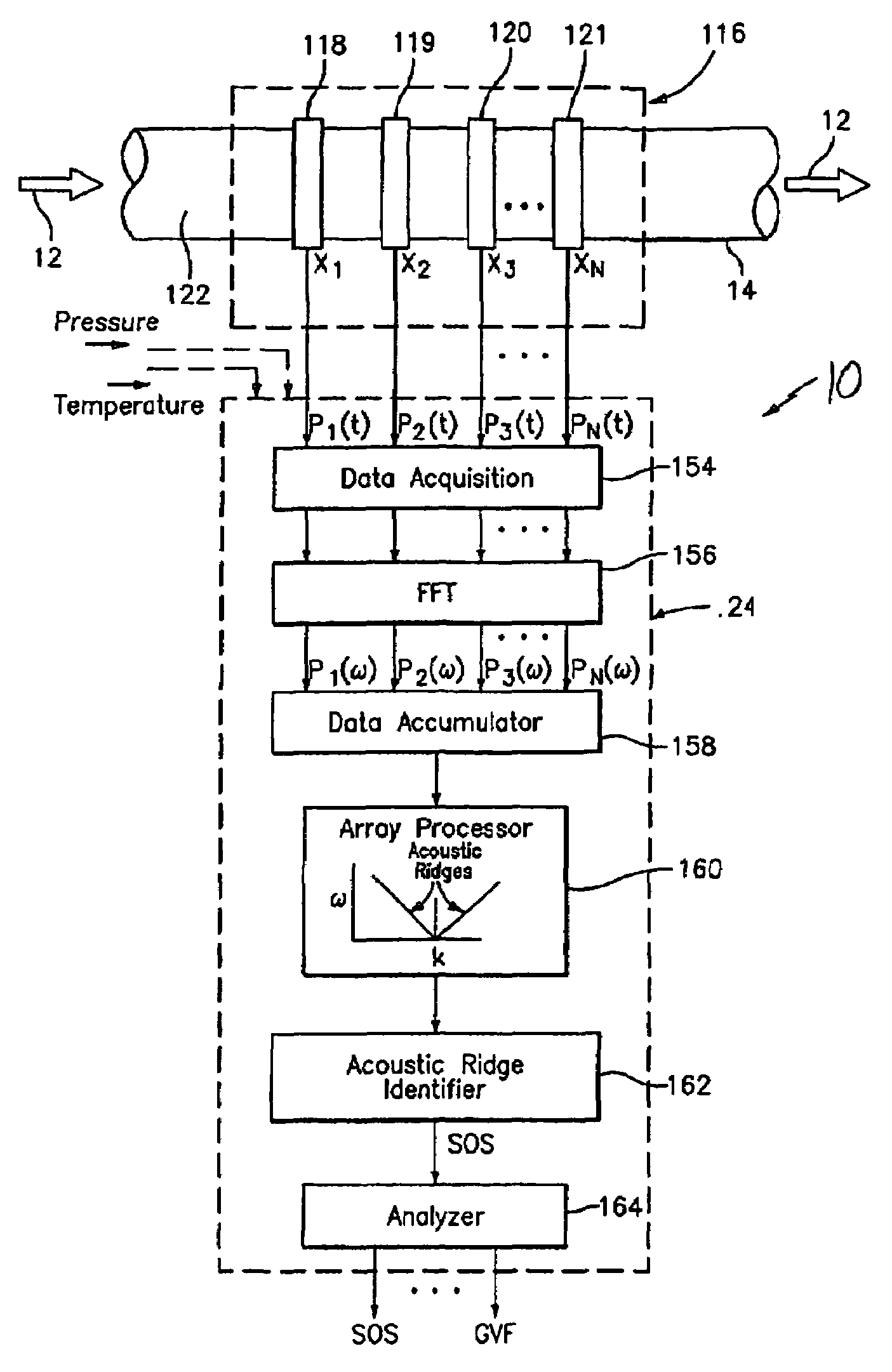

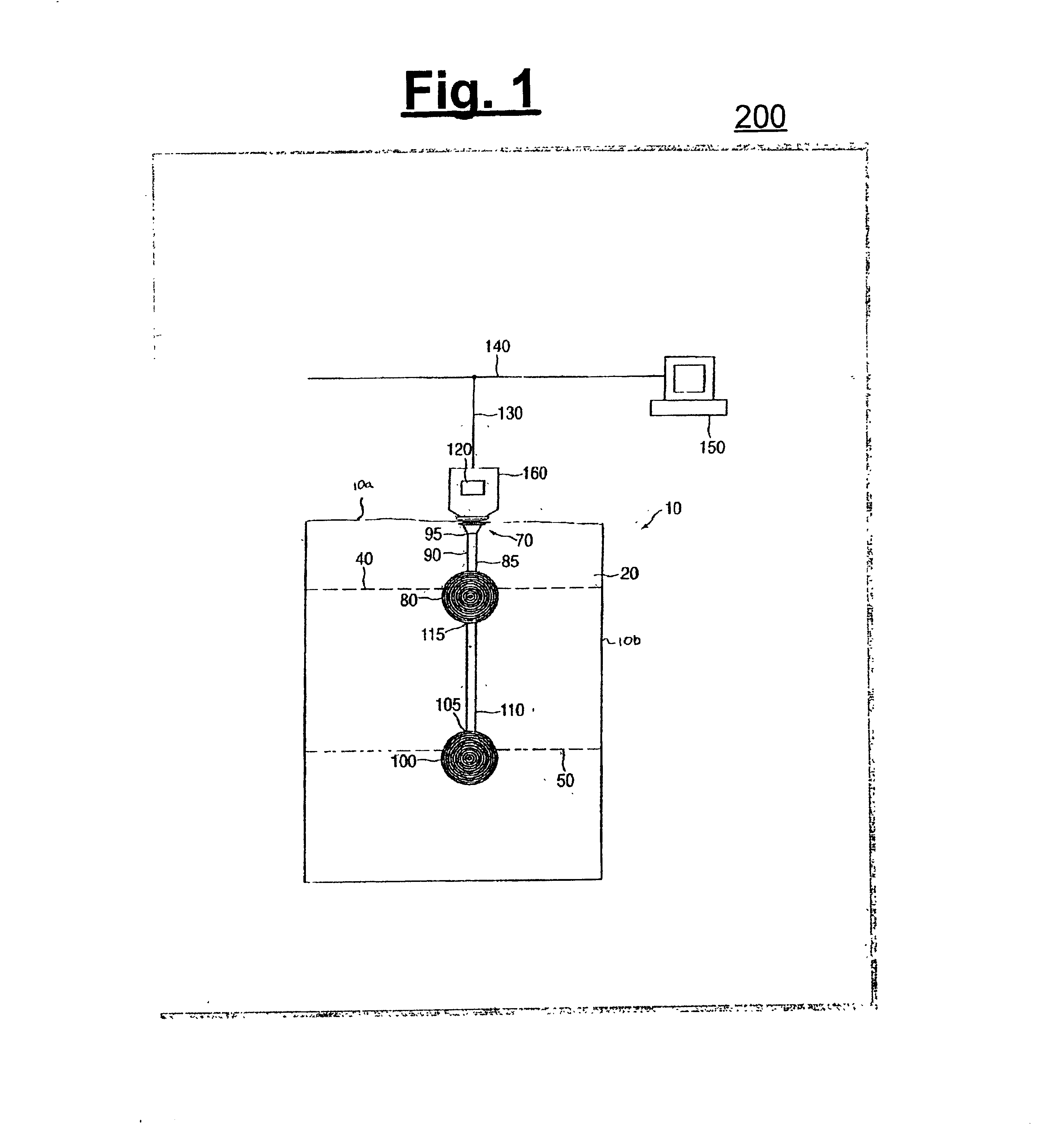

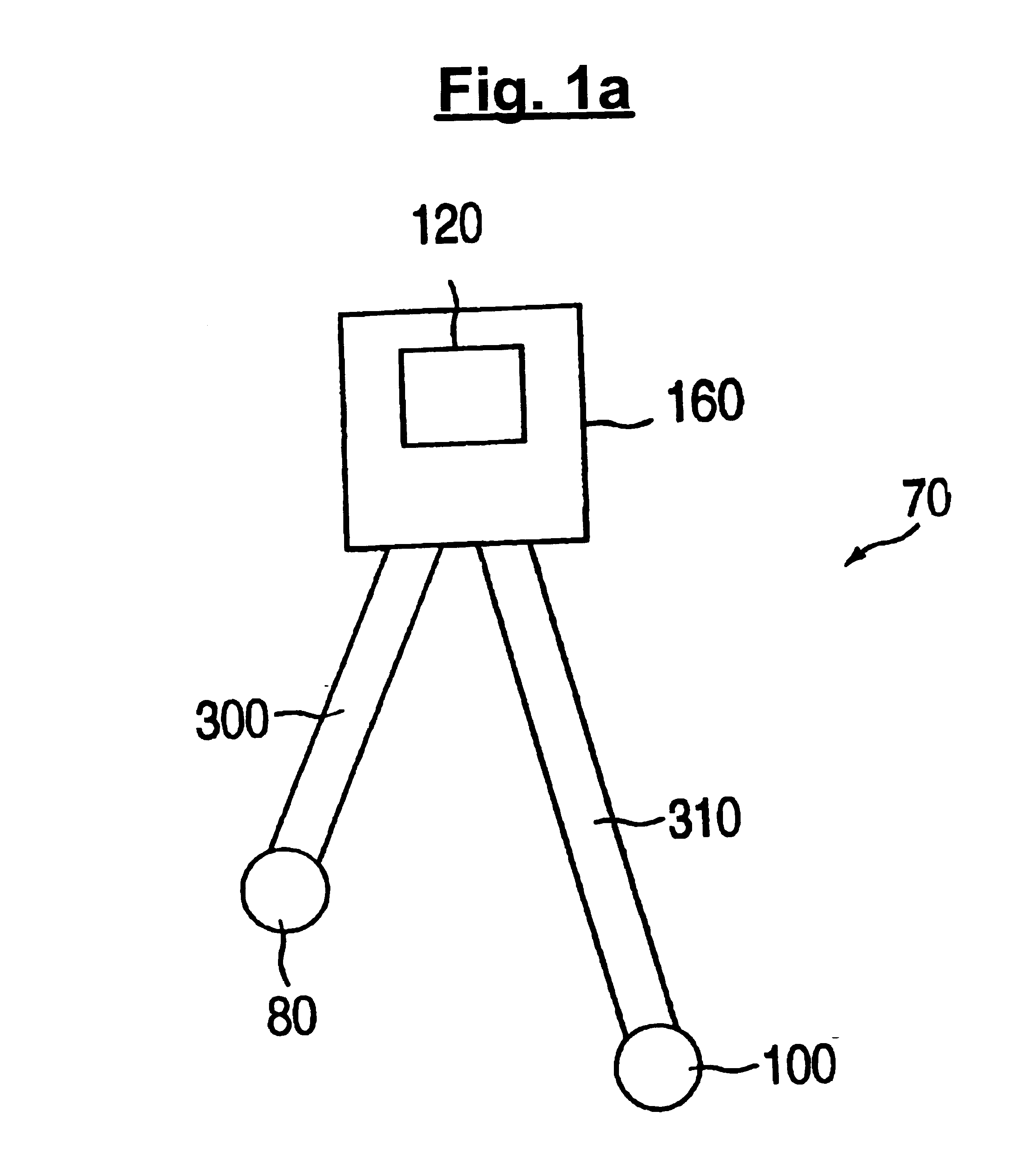

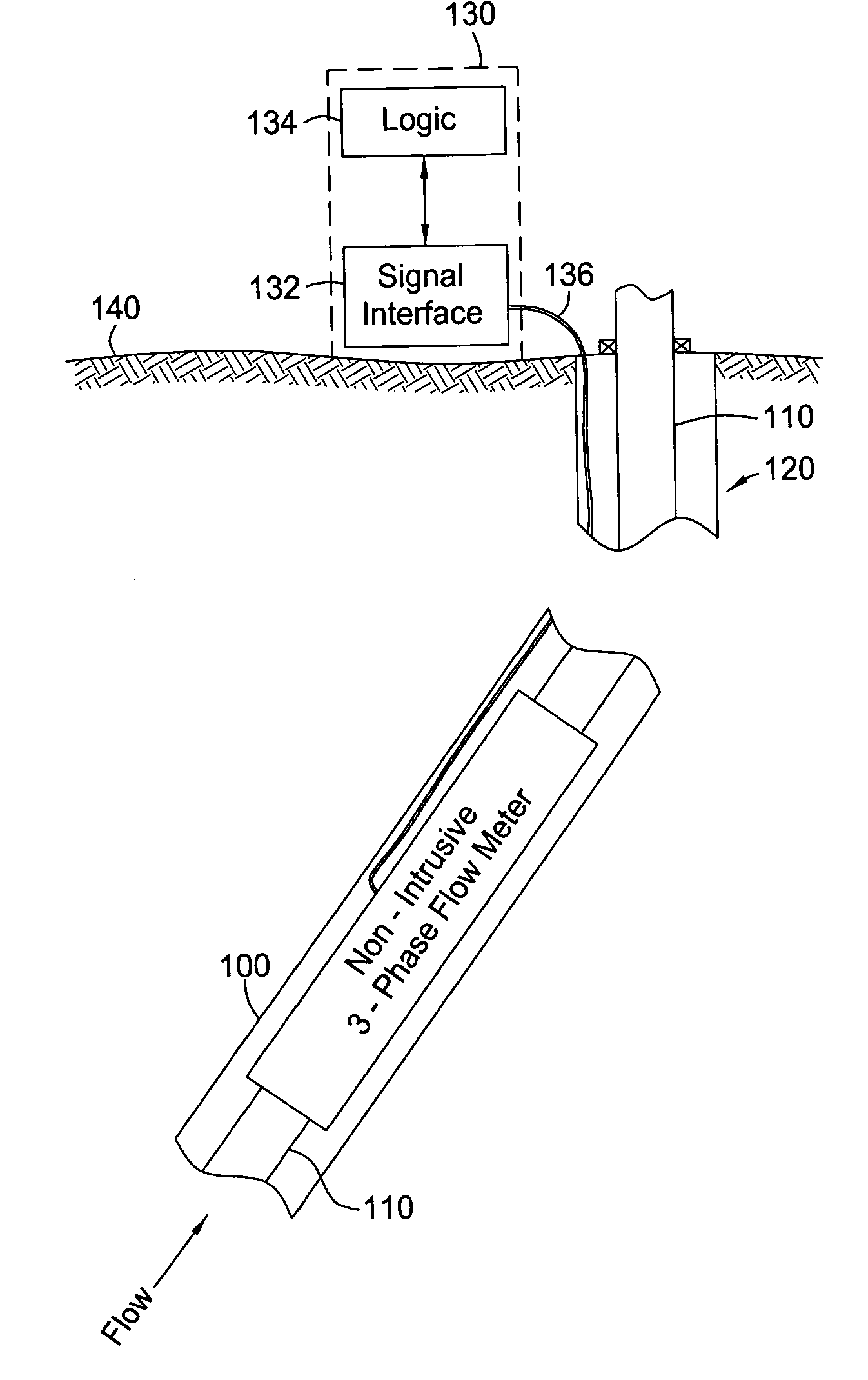

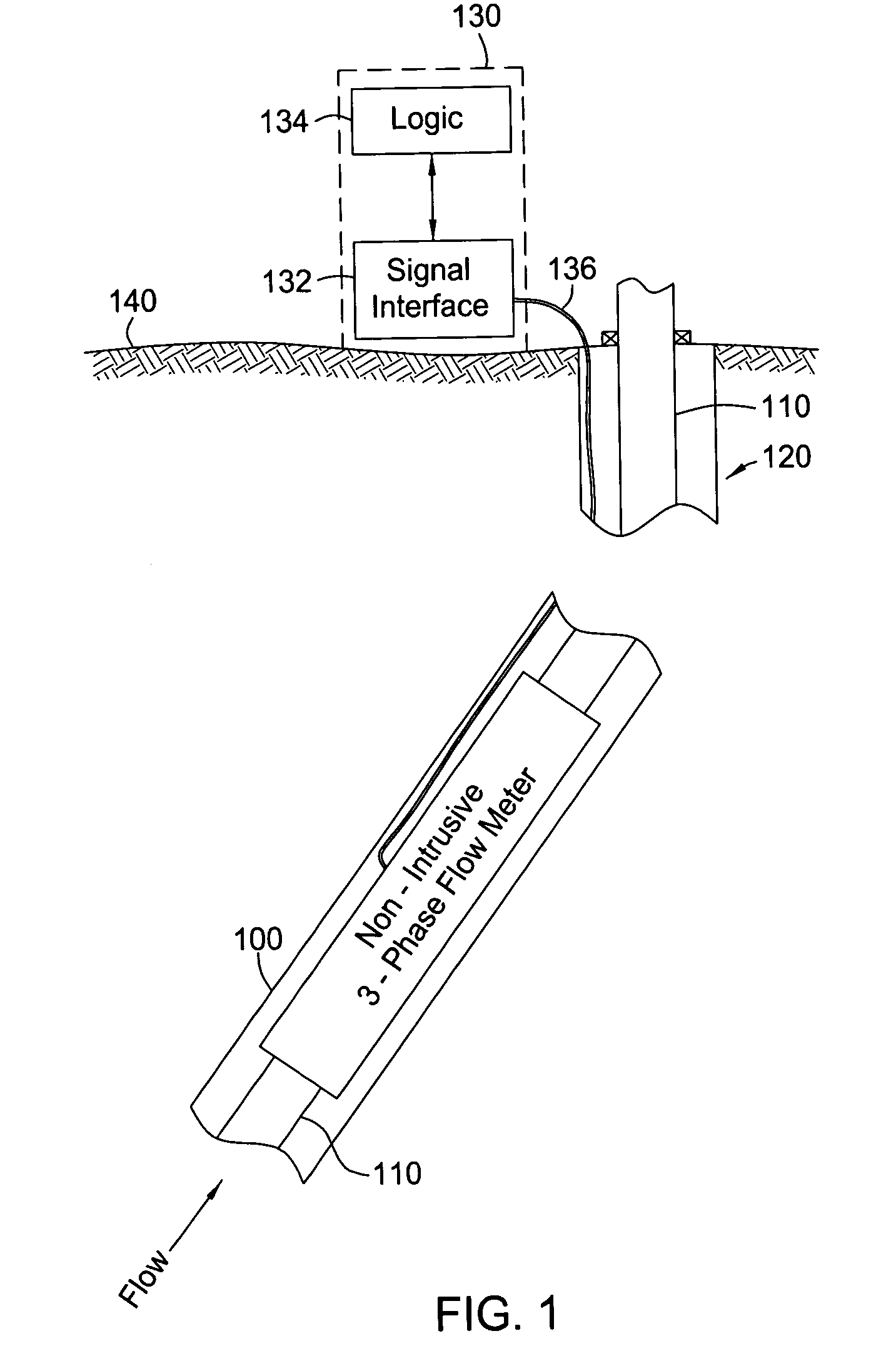

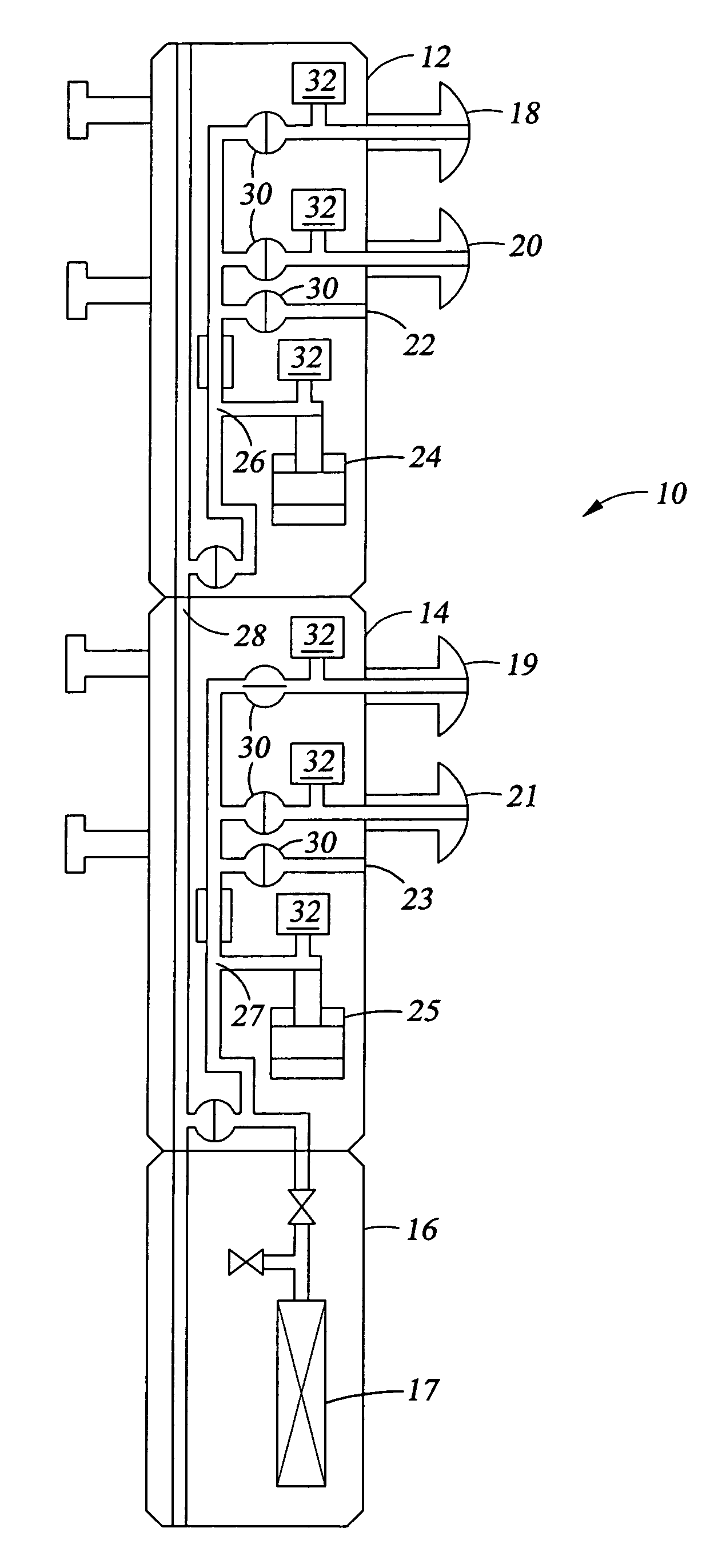

Non-intrusive multiphase flow meter

InactiveUS6945095B2SurveyMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberDifferential pressure

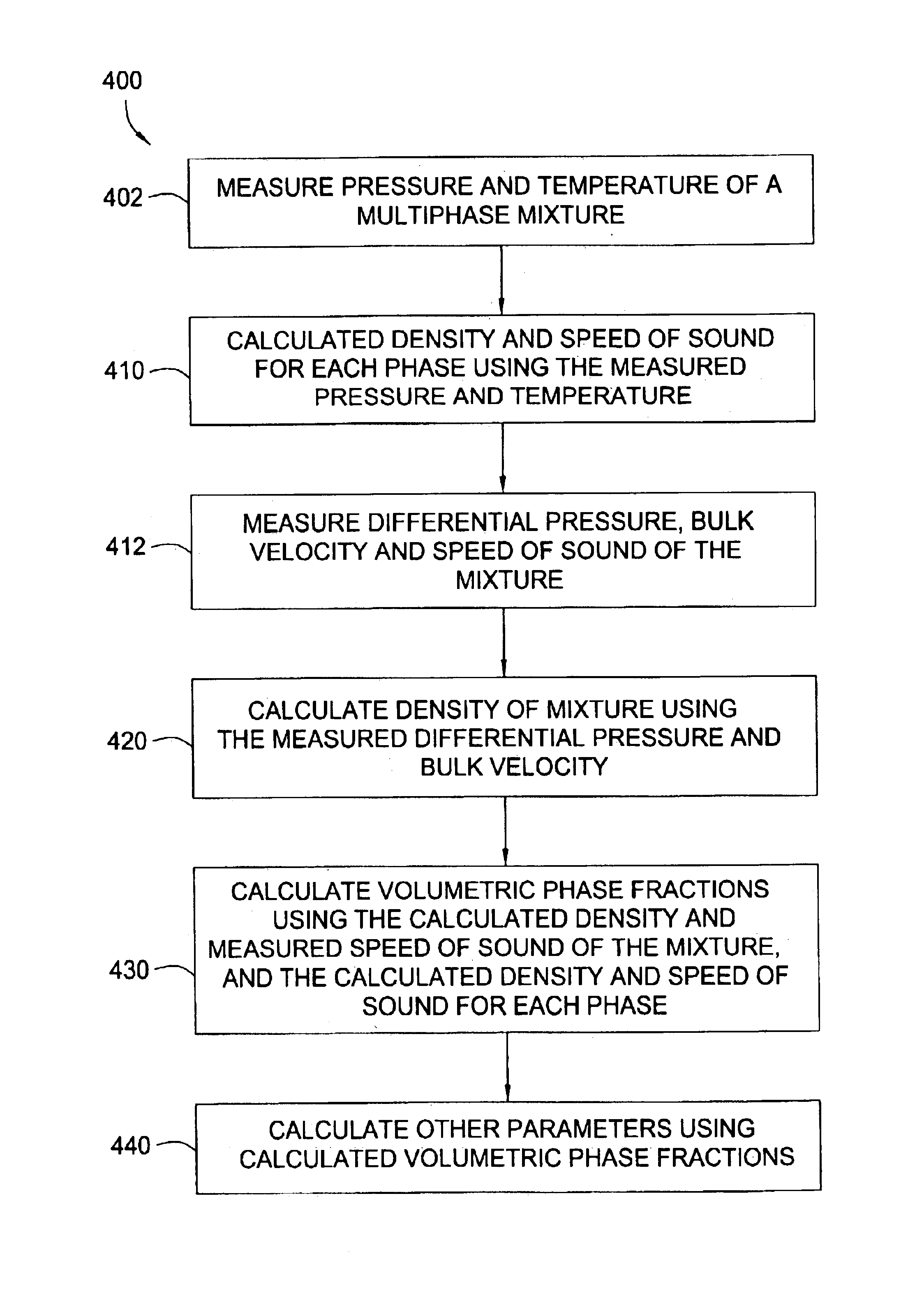

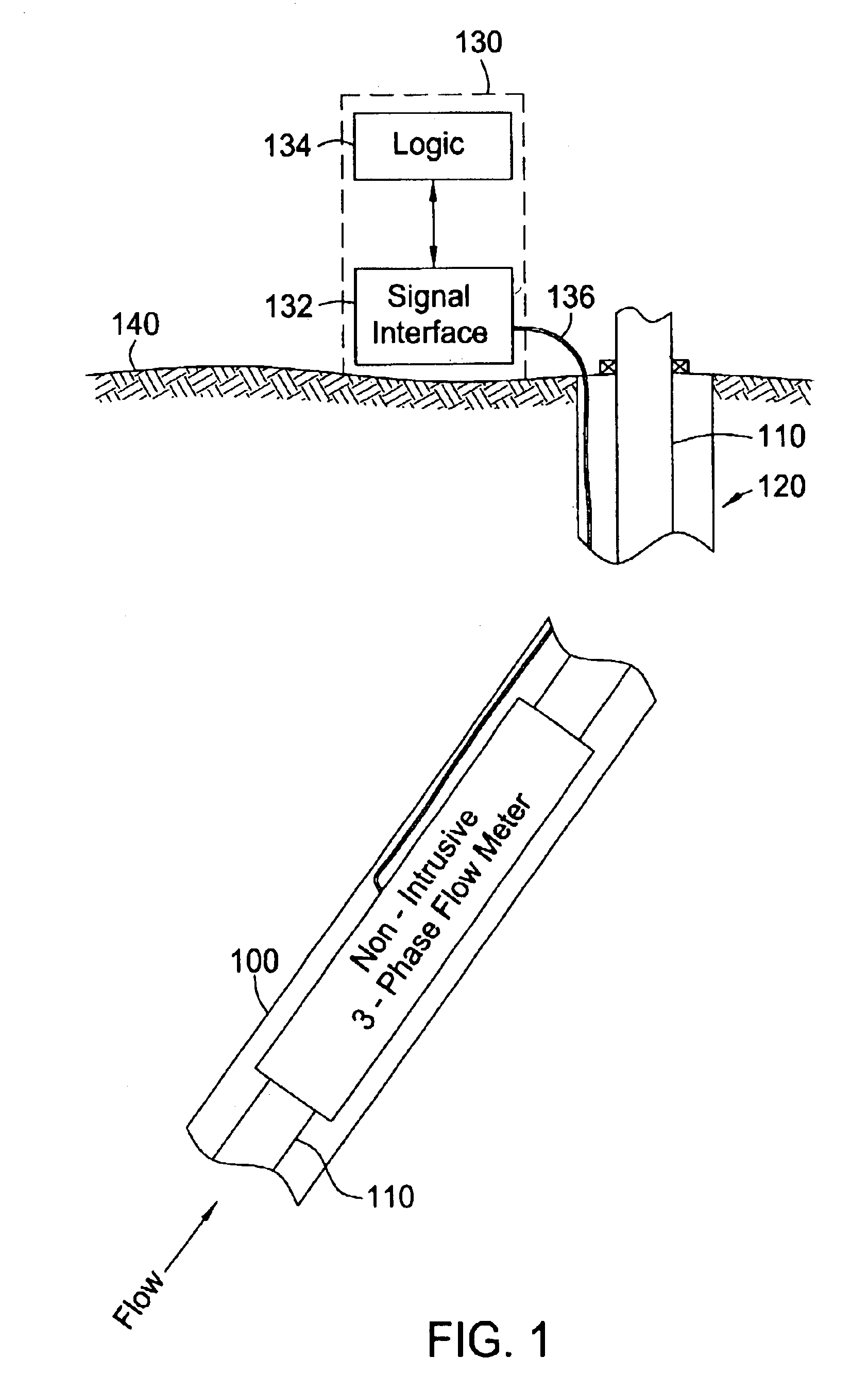

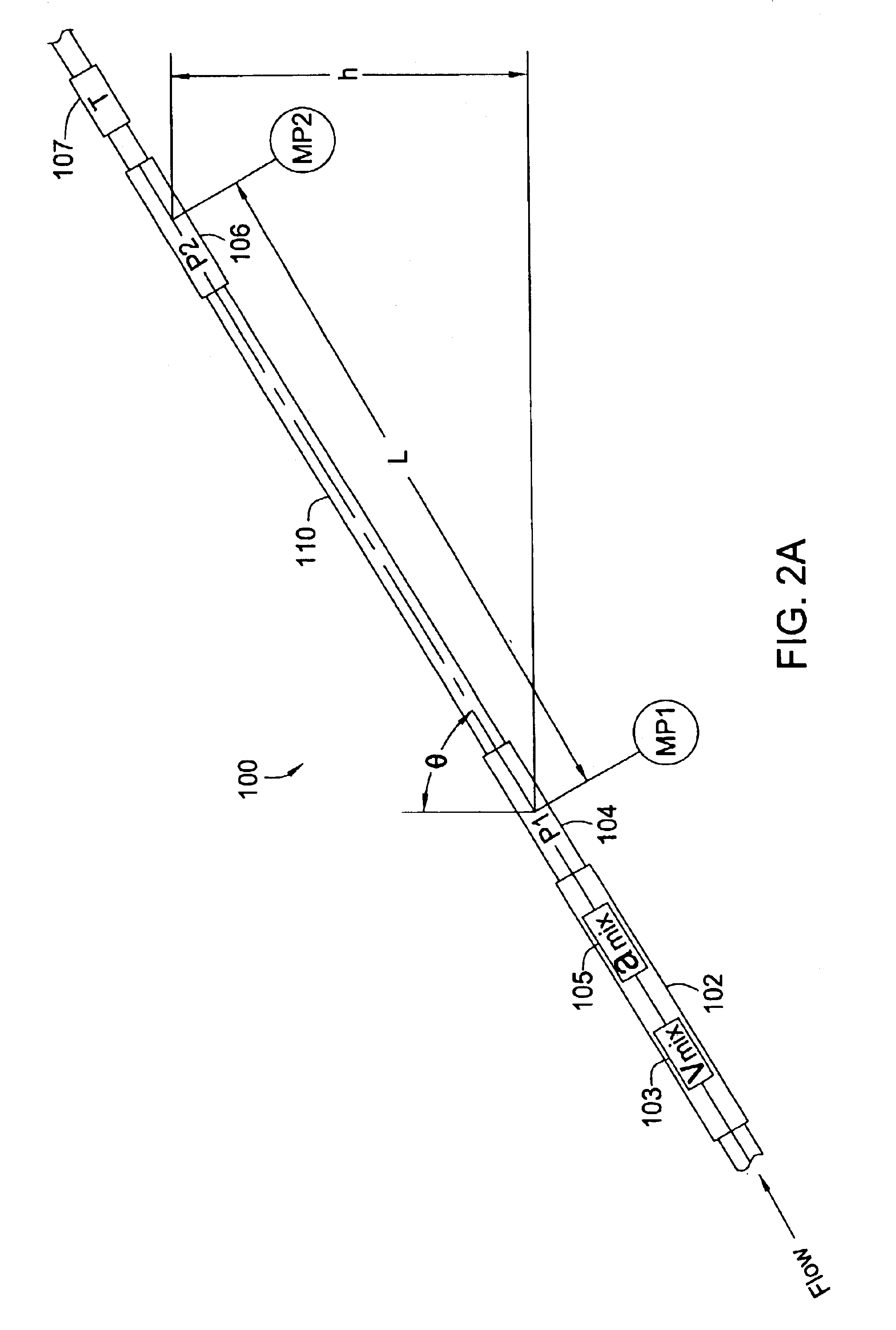

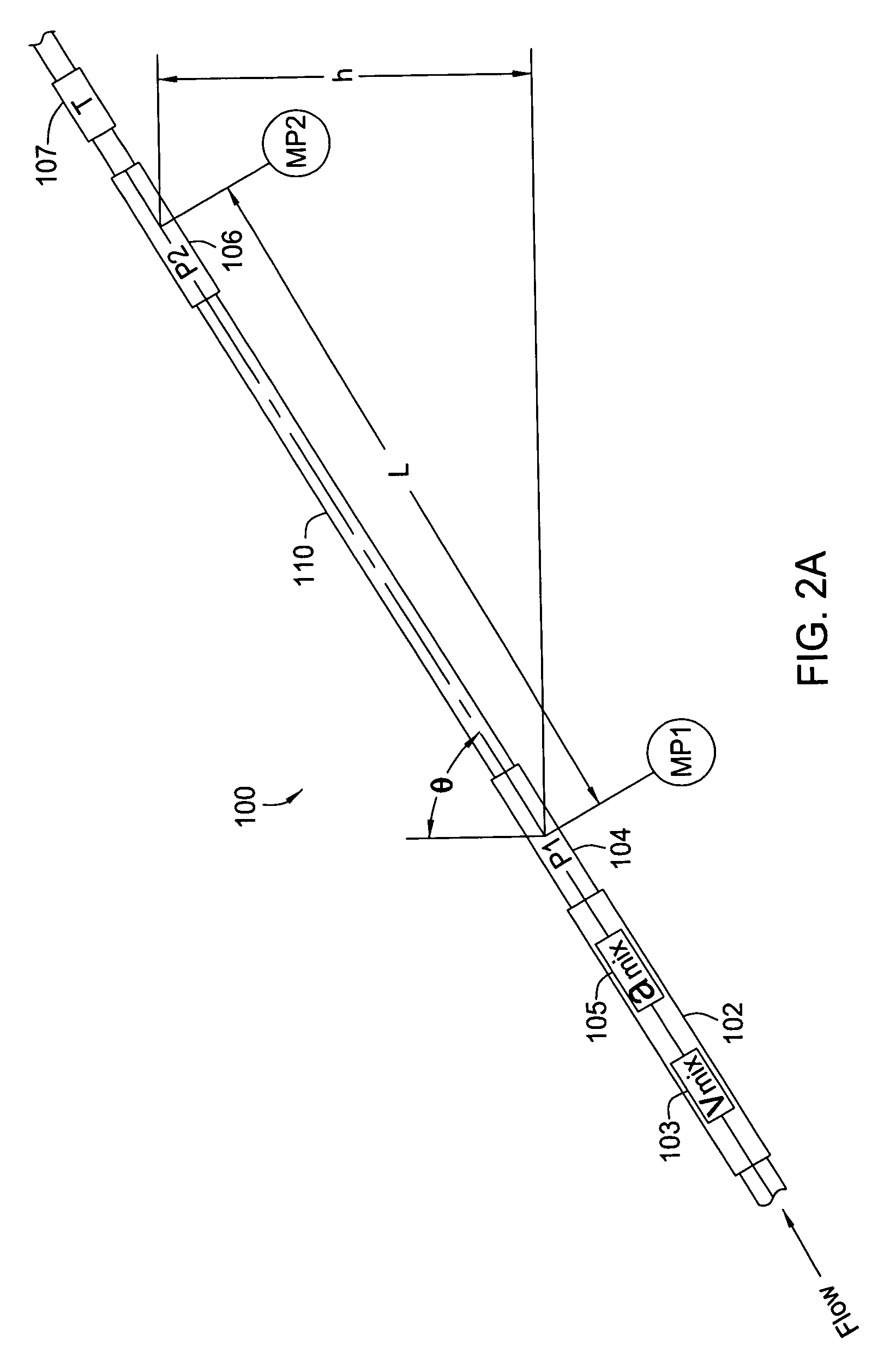

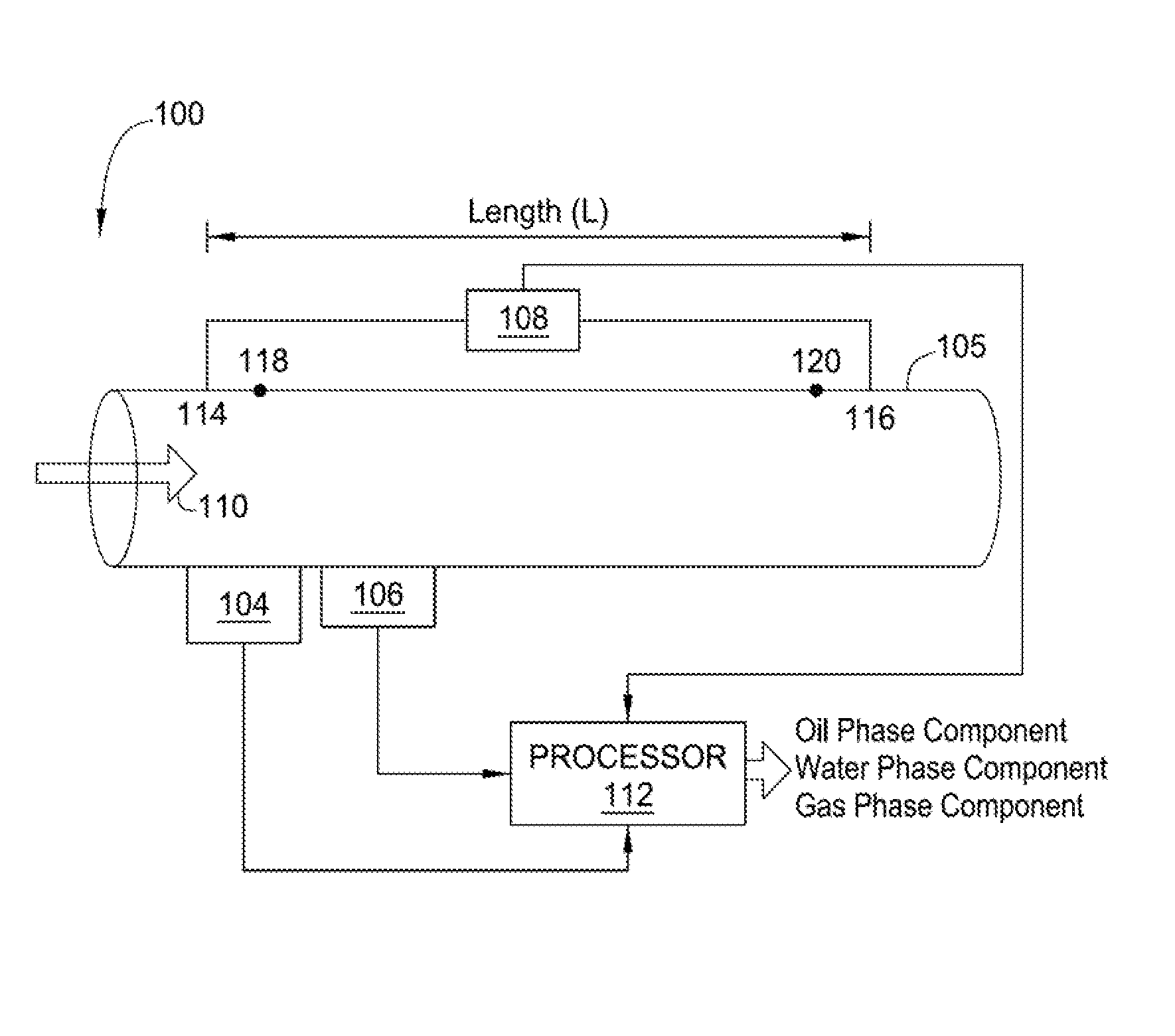

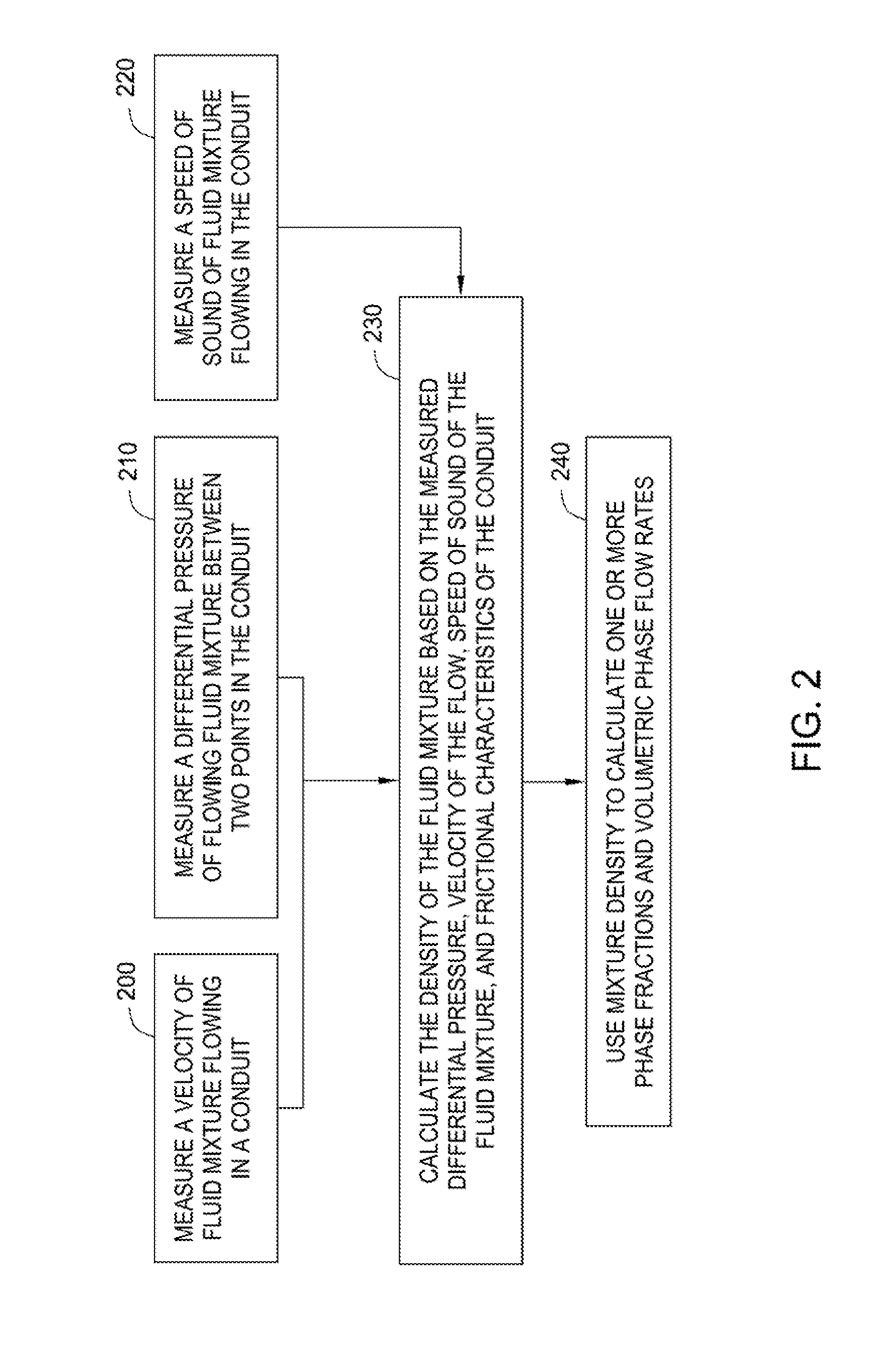

Embodiments of the present invention generally provide methods, apparatus, and systems for determining void fractions of individual phase components of a multiphase mixture. The void fractions may be determined based on measured parameters of the mixture as a whole, such as differential pressure, bulk velocity of the mixture and speed of sound in the mixture. According to some embodiments, the mixture parameters may be measured using non-intrusive fiber optic based sensors. Various other parameters may also be derived from the void fractions, such as individual phase flow rates, liquid holdup and watercut parameters (for oil and gas mixtures).

Owner:WEATHERFORD TECH HLDG LLC

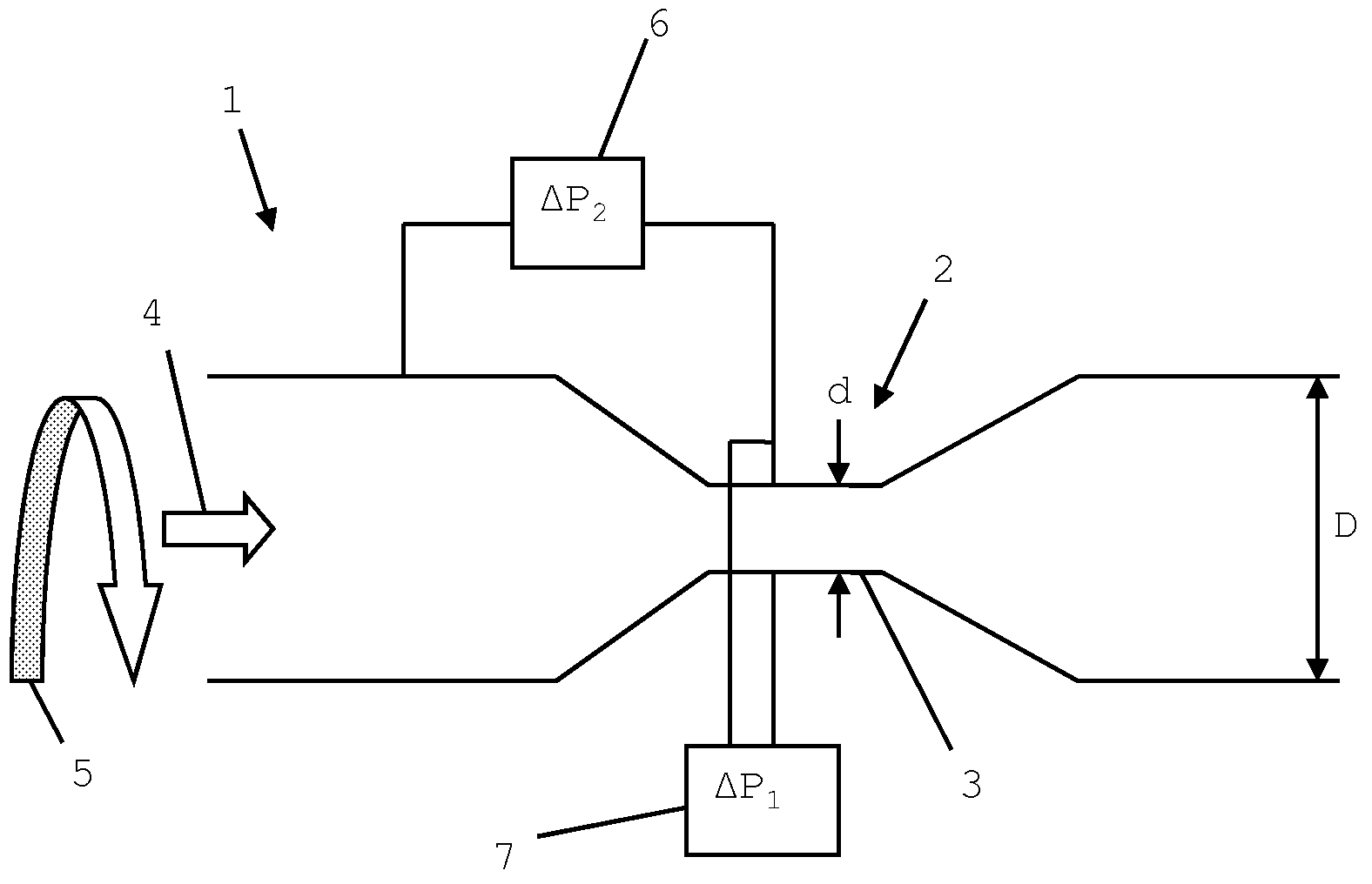

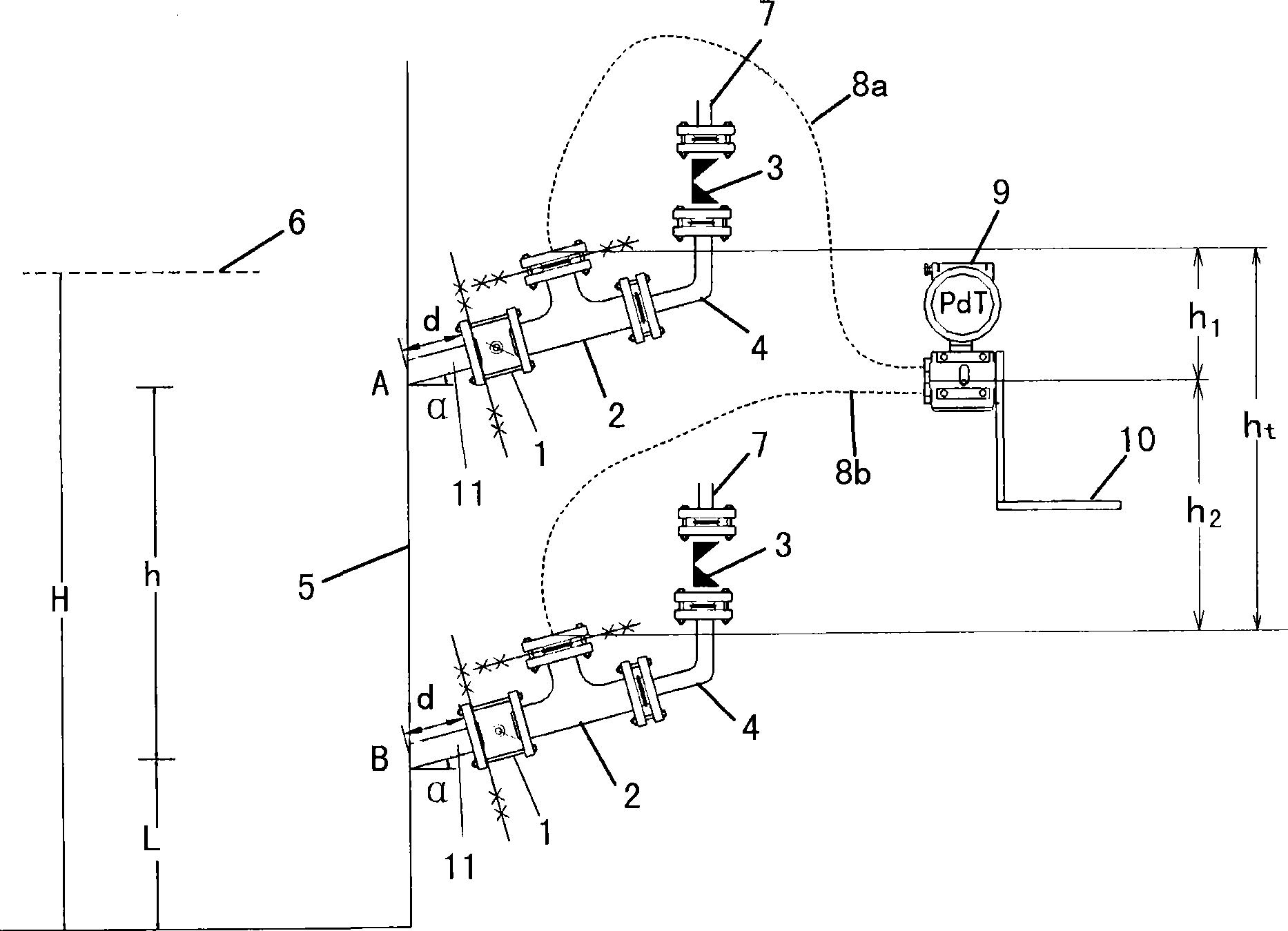

Flow meter

ActiveUS20050188771A1Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansLiquid stateDifferential pressure

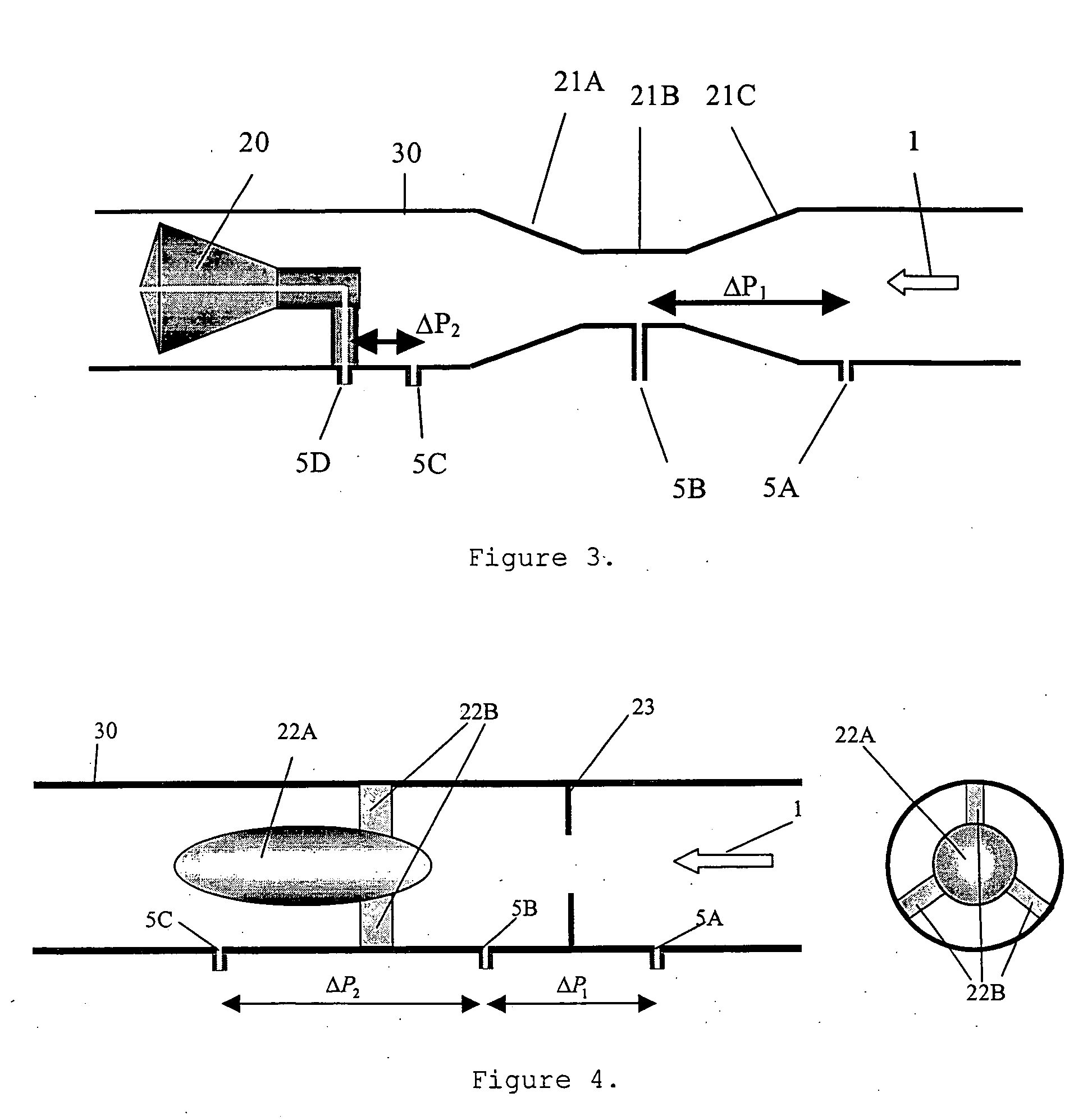

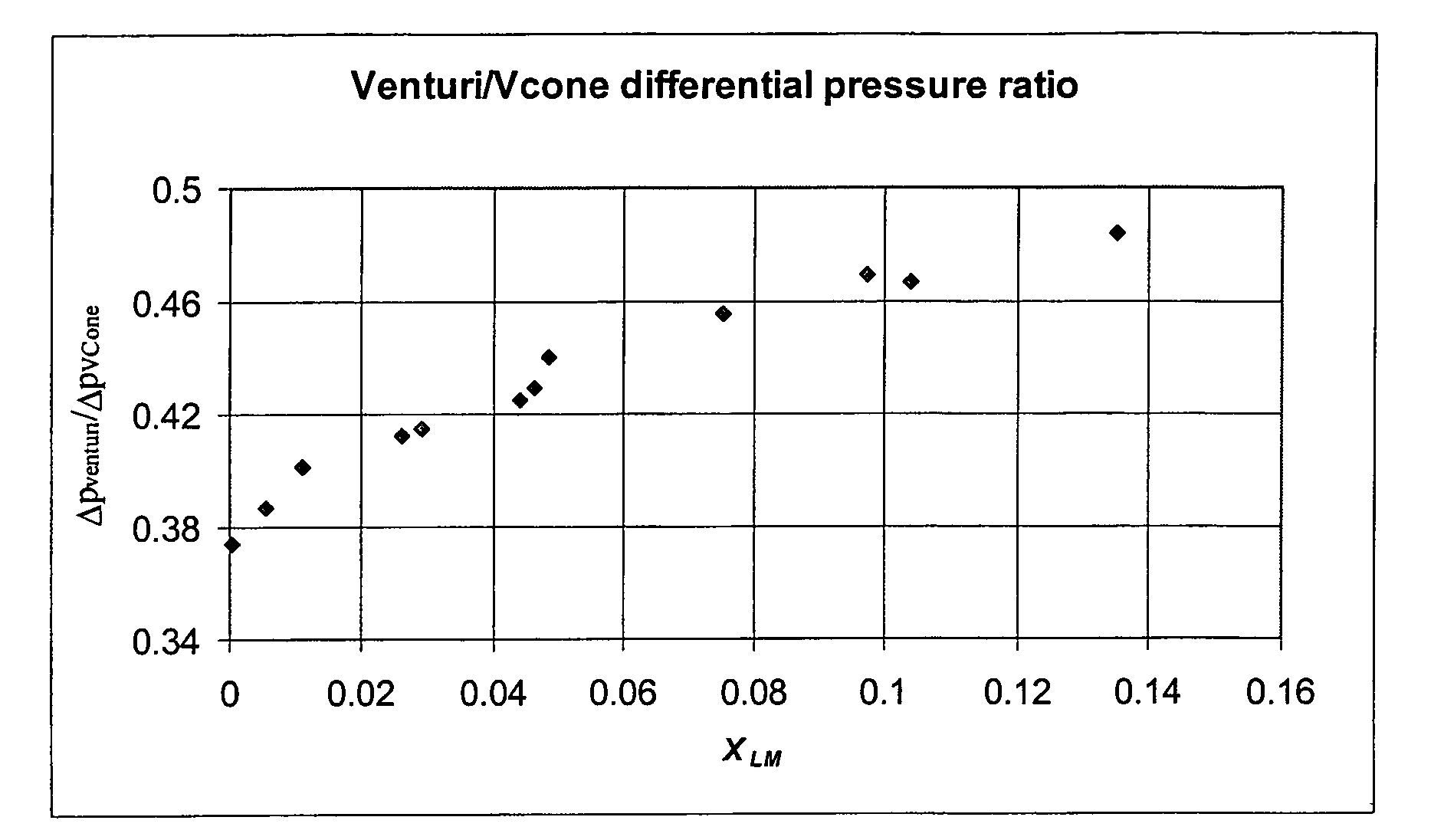

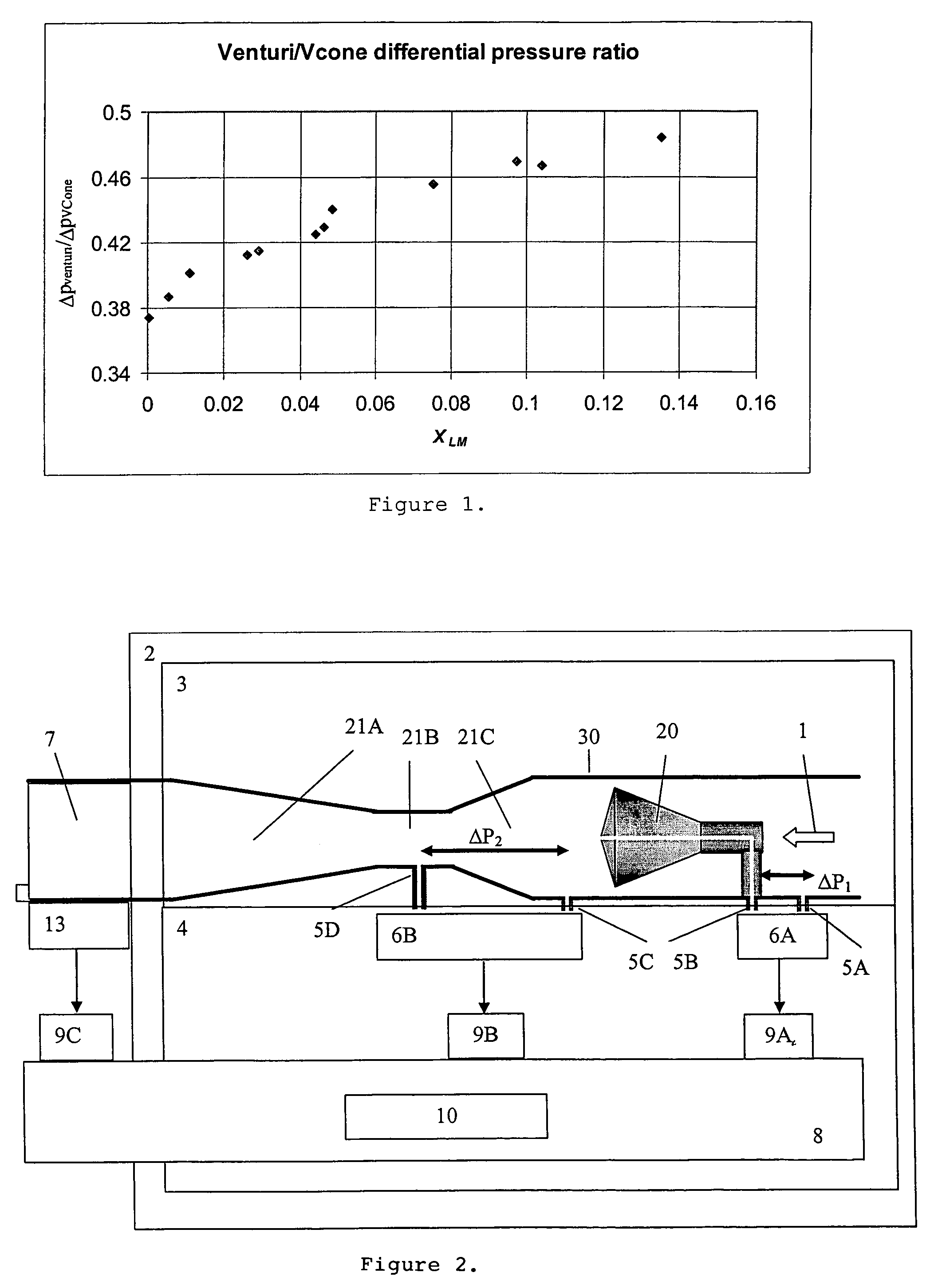

A flow meter obtains the individual flow rates of gas, liquid hydrocarbons, and water in a predominantly gas-containing flowing fluid mixture. The flow meter comprises a water content meter (7) provides a signal representing a measure of the water content of said fluid. It also comprises a double differential pressure generating (3) and measuring (4) structure, denoted a DDP-unit (2), that provides two measurement signals (6A and 6B) representing two independent values of differential pressure (DP) in said fluid (1). In addition to the above, the meter also comprises a signal processing unit (8) having inputs (9A-C) for receiving the measurement signals and the water content signal, and a calculation module (10) which calculates values representing the volumetric flow rates of said gas, liquid hydrocarbons and water in said fluid.

Owner:ROXAR FLOW MEASUREMENT

Flow meter for measuring fluid mixtures

ActiveUS7293471B2Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansDifferential pressureLiquid hydrocarbons

Owner:ROXAR FLOW MEASUREMENT

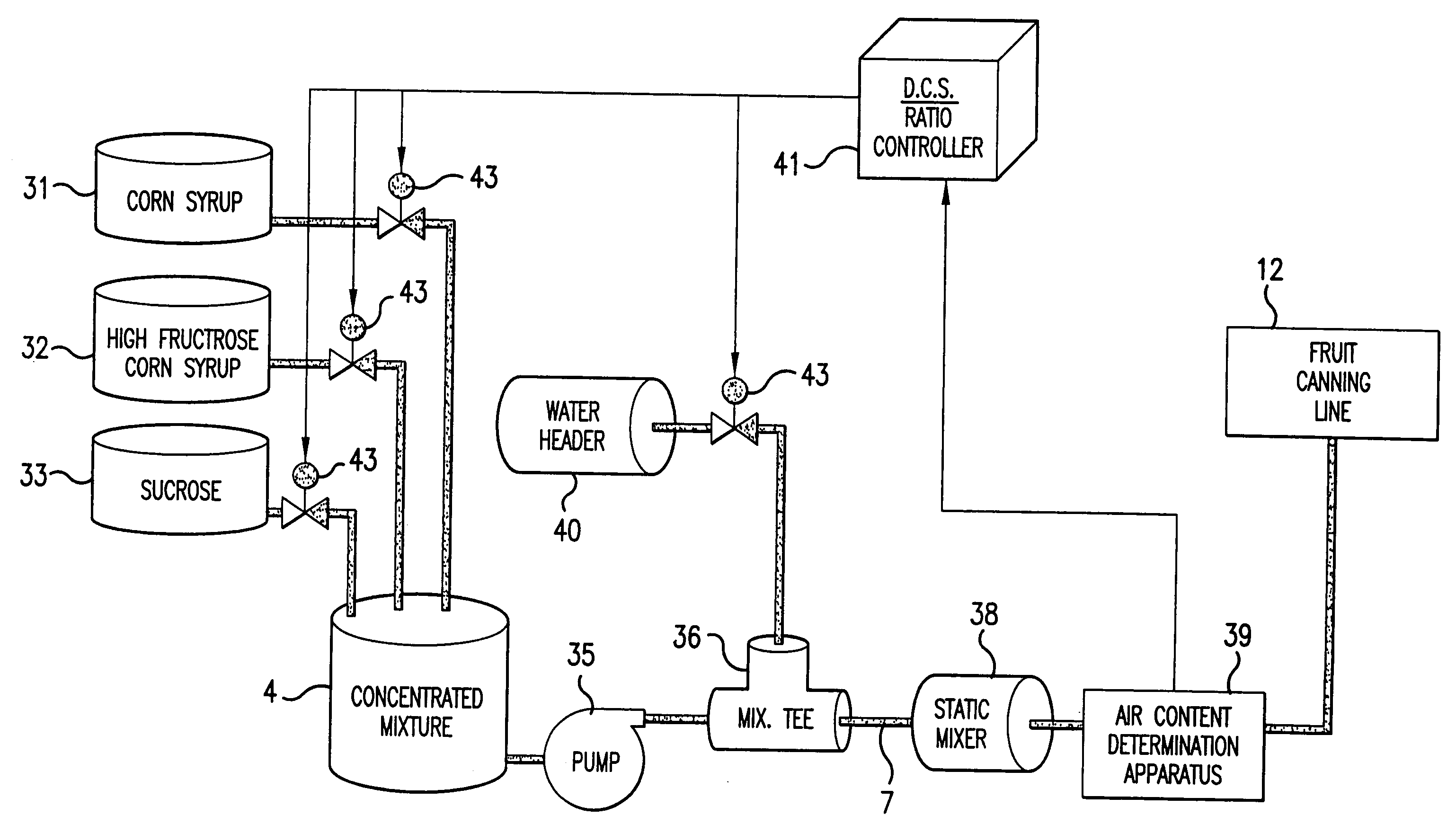

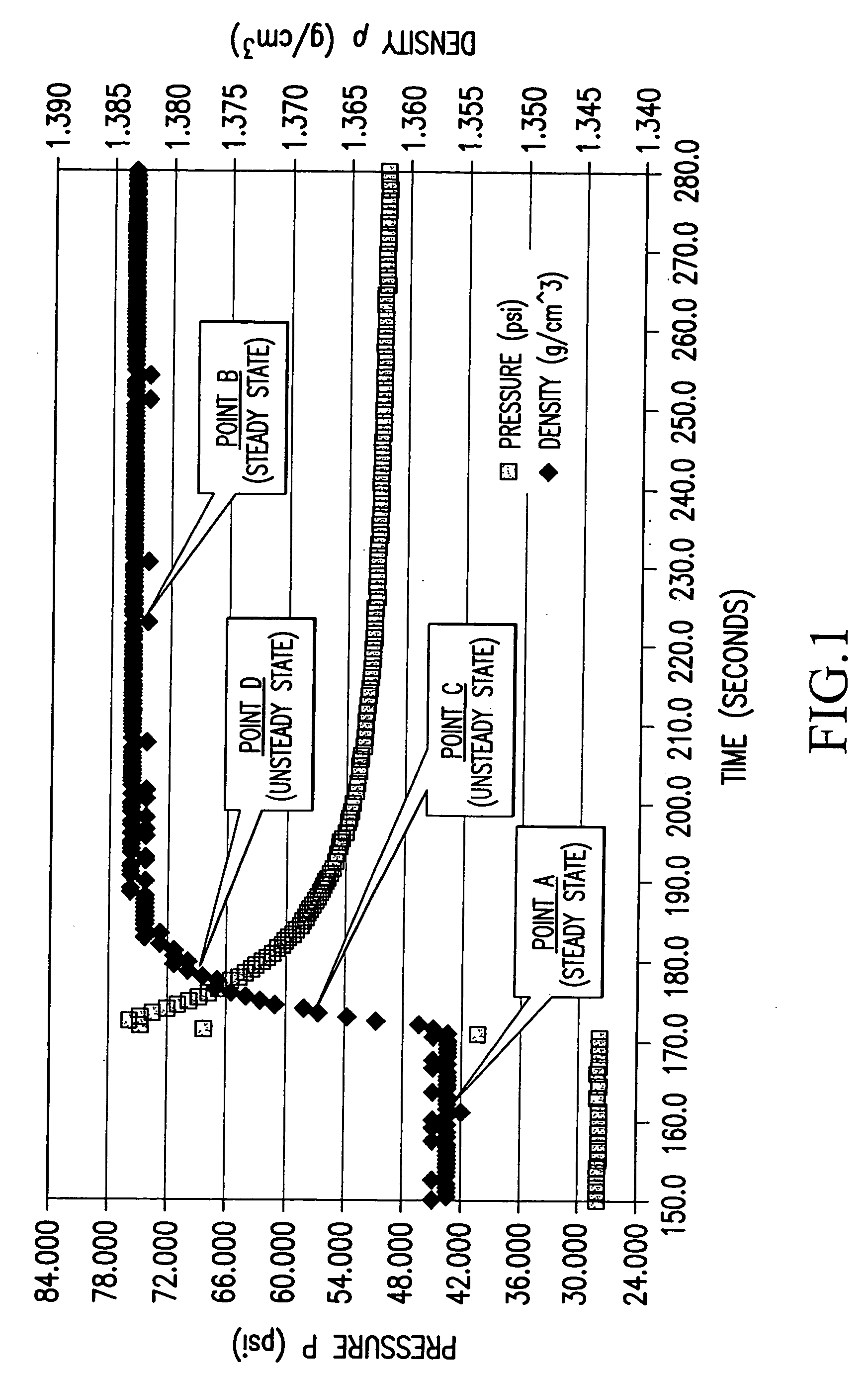

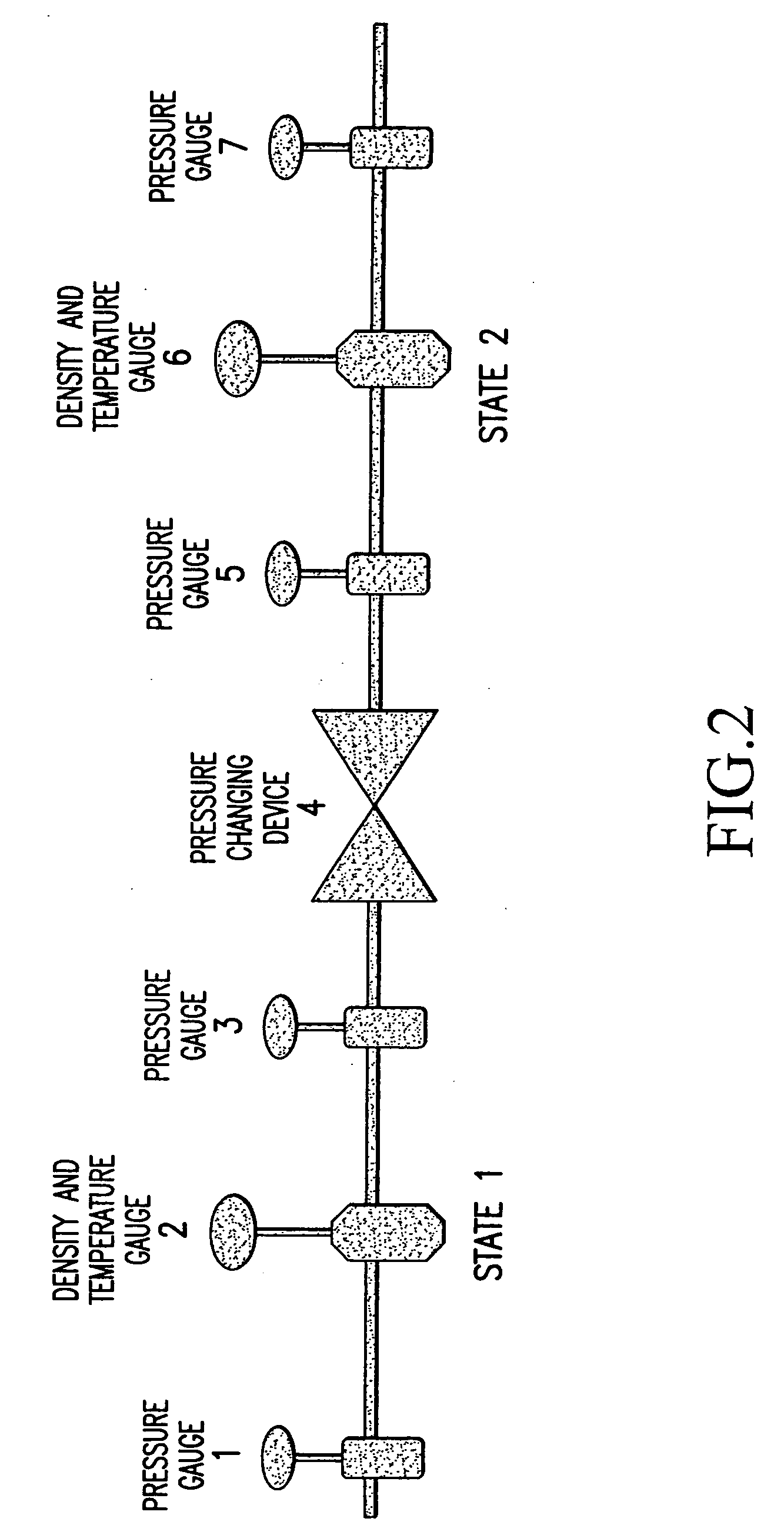

Real time determination of gas solubility and related parameters in manufacturing processes

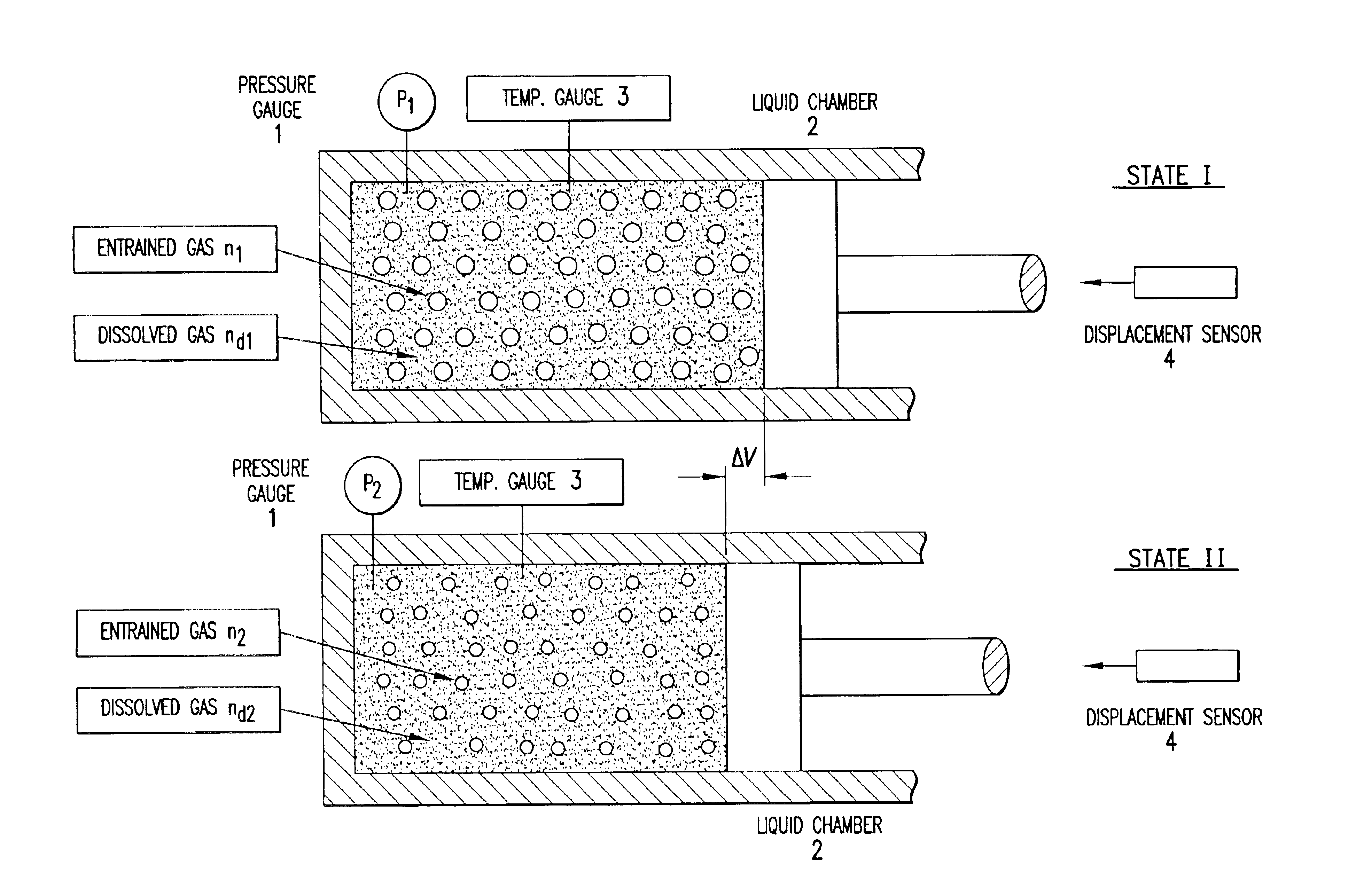

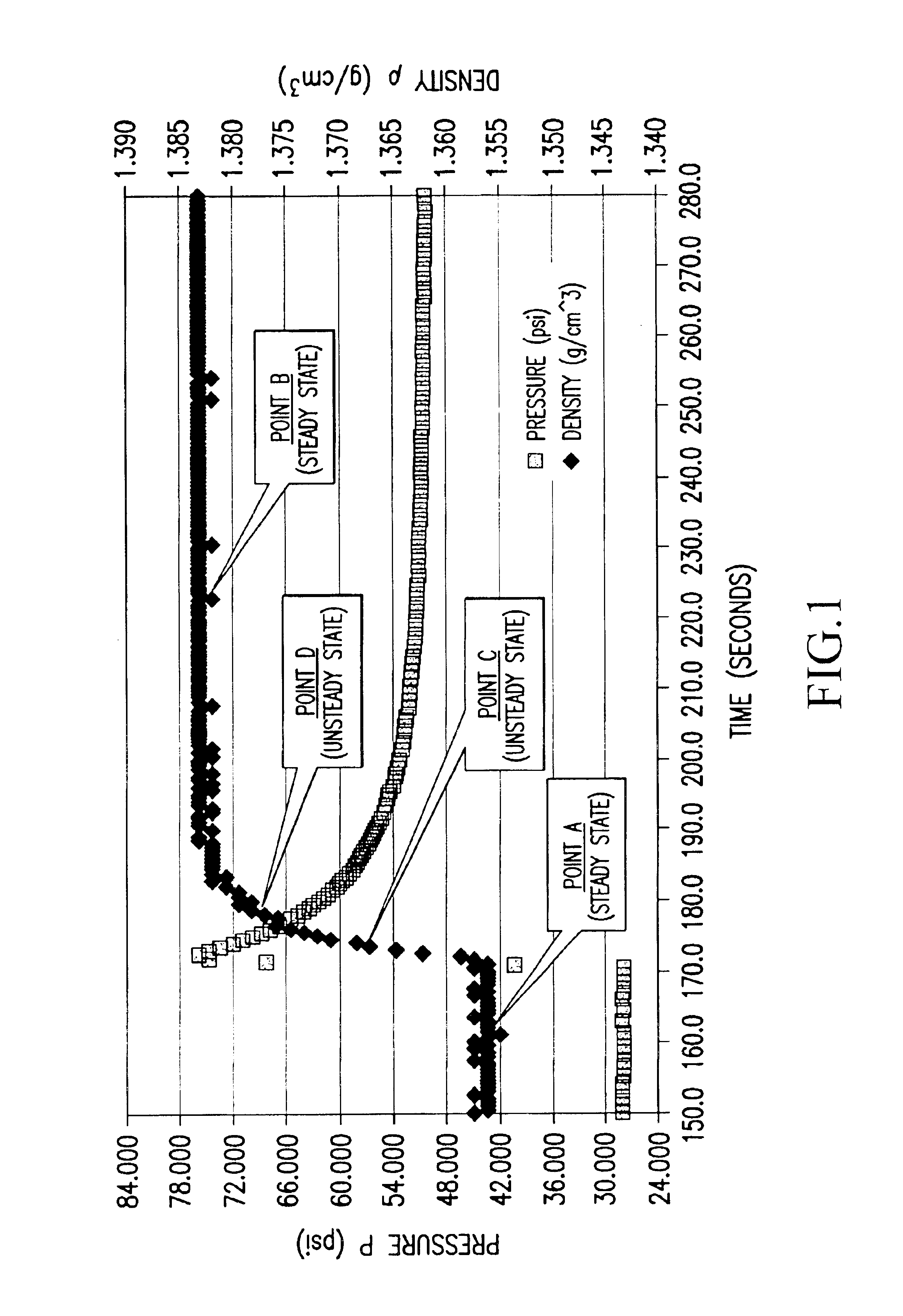

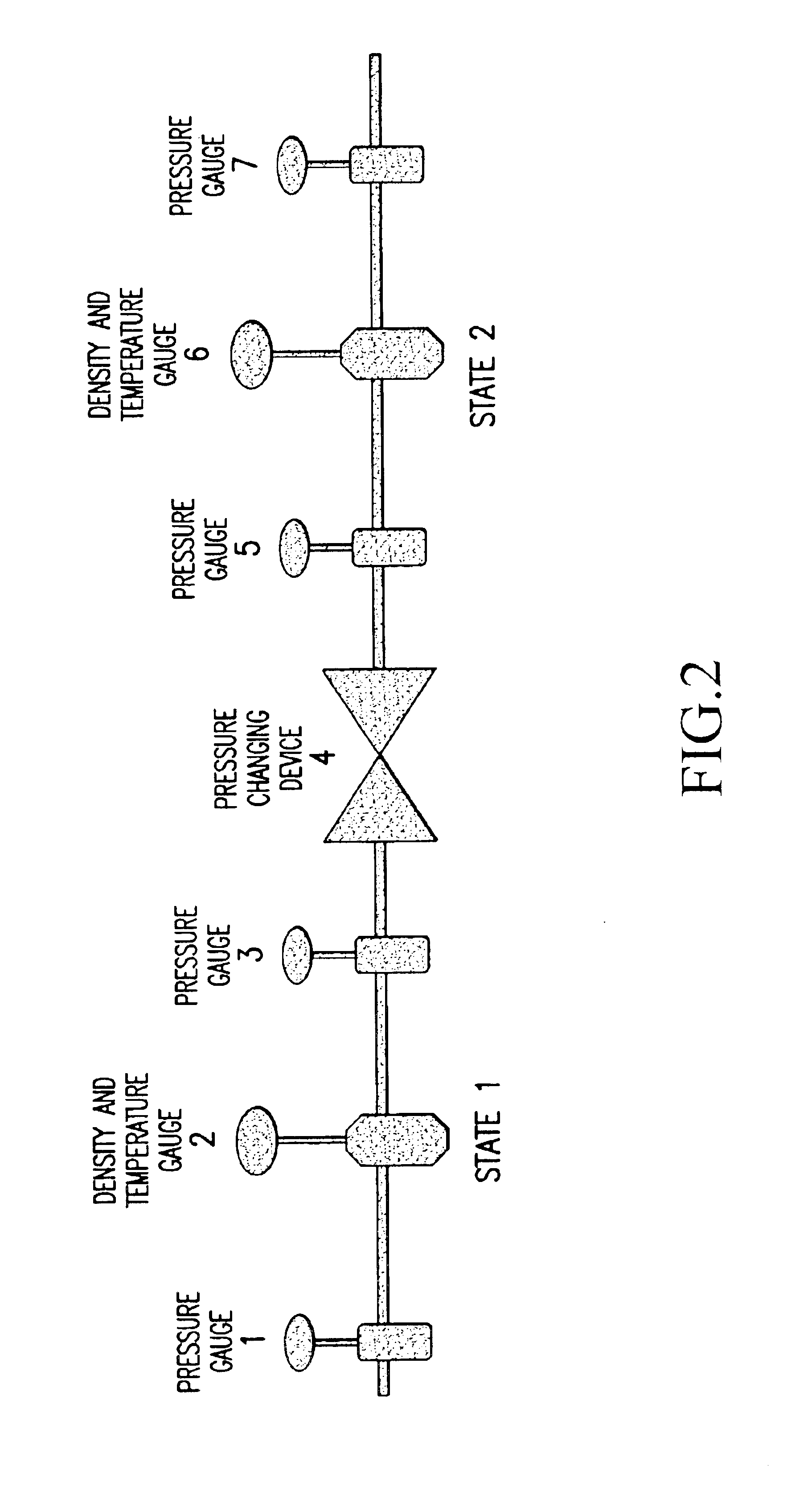

InactiveUS6847898B1Easy to controlEasy to handleTesting beveragesSpecific gravity by measuring pressure differencesSolubilityApparent density

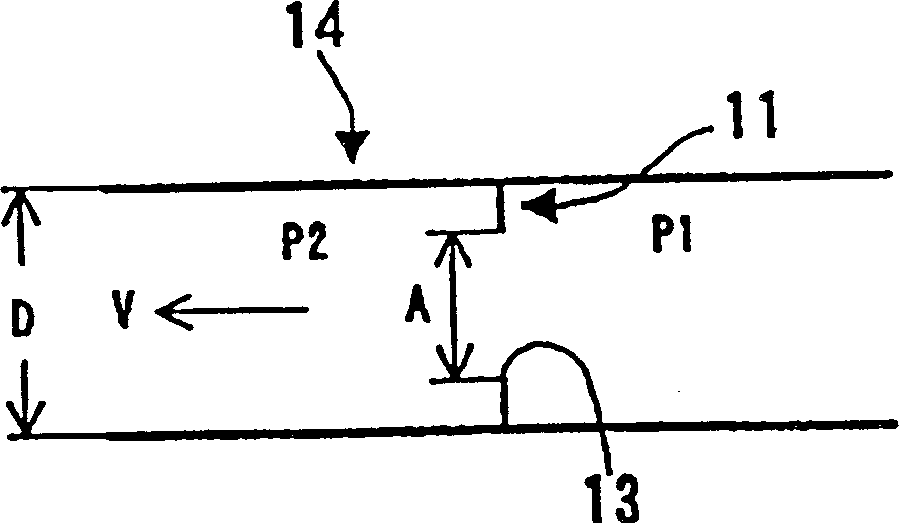

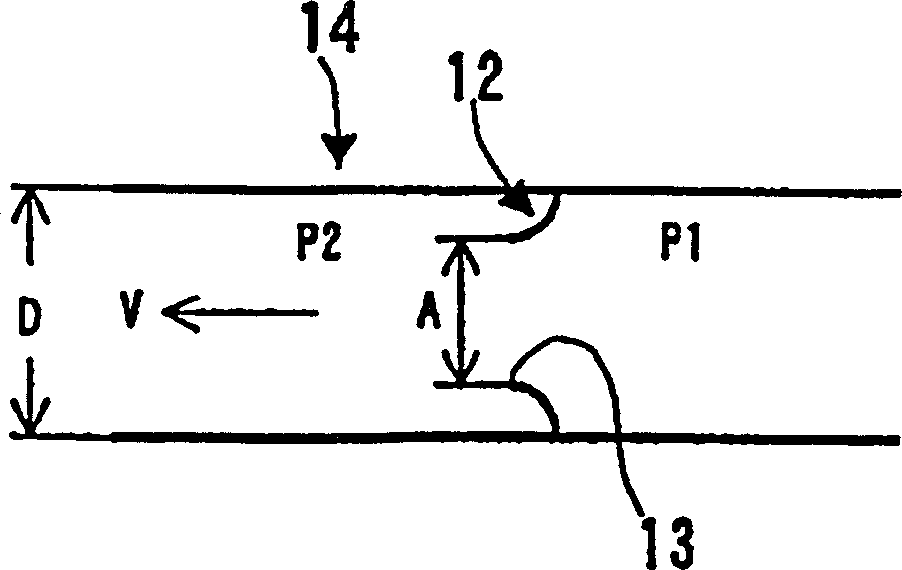

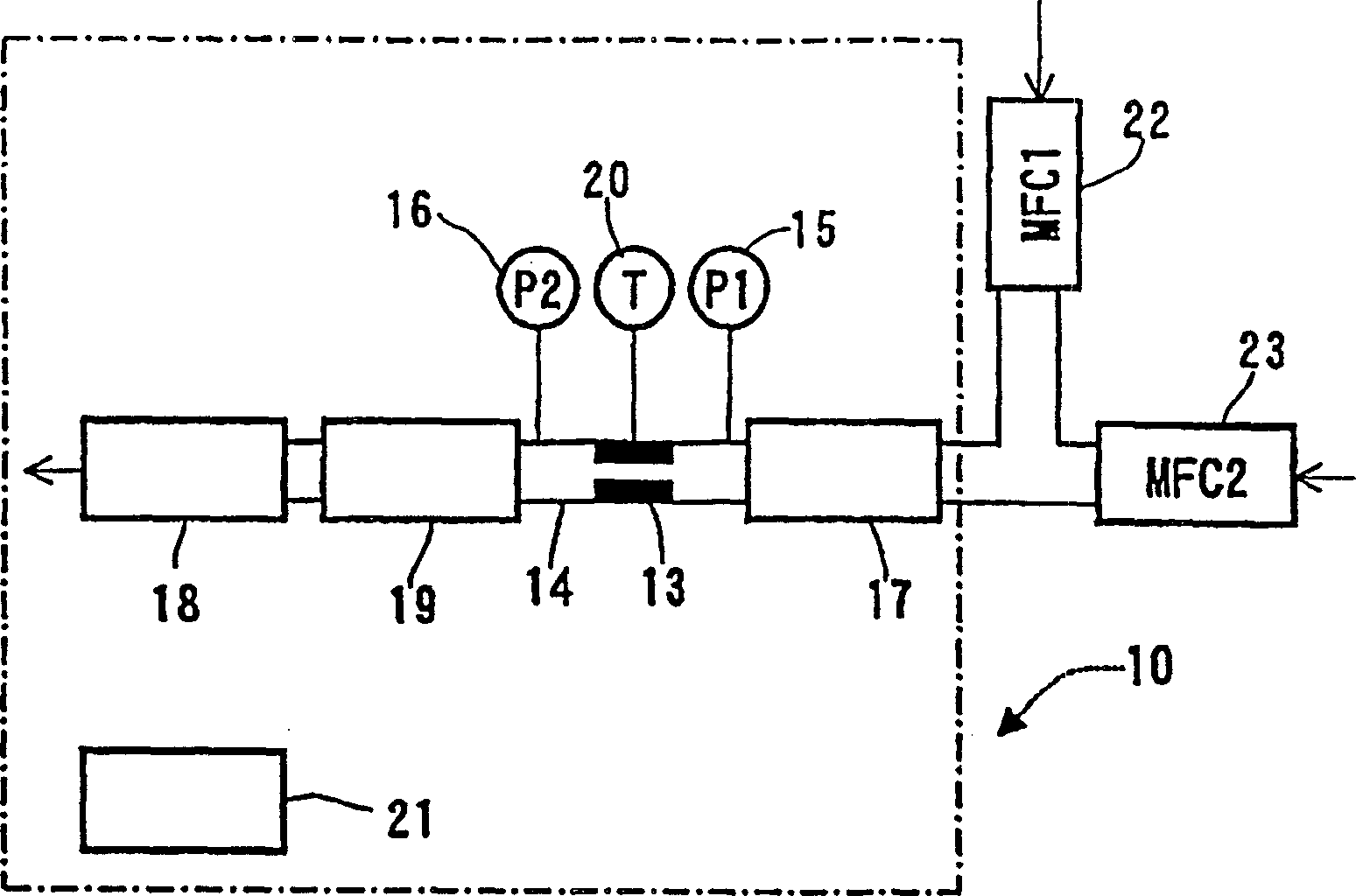

Methods and apparatuses for determining entrained and / or dissolved gas content of gas-liquid mixtures. Data generated is used to control the True (air-free) or Apparent (air-containing) Density or Entrained Air content of liquids within optimum ranges, e.g. in paper coating processes and in the manufacture of food products, personal care products, pharmaceutical products, paints, petroleum blends, etc. For example, an indirect method of continuously determining the amount of gas entrained in a liquid, by: continuously measuring the temperature, flow rate, and apparent density of the mixture at two different pressure states, and calculating the volume percentage of the gas in the liquid by using equation (28) x%=VsVs+V(28)wherein V is the volume of the gas-free liquid calculated by equation (23) V=1ρ1-[P2P2-P1(1ρ1-1ρ2)-RTP2-P1g(Δ PQa)](23)in which P1 and P2 are two different ambient pressures and ΔP=P2−P1, ρ1 and ρ2 are apparent densities of the liquid sample measured at P1 and P2, respectively, R is the constant of the Ideal Gas Law, T is the liquid temperature, Q is the flow rate, g(ΔP / Qa) is a function for determining the amount of gas being dissolved between P2 and P1, and Vs is determined by equation (27) Vs=TsTP1P2Ps(P2-P1)(1ρ1-1ρ2)-RTsPs(P1P2-P1g(Δ PQa)-g(P1-PsQa)).(27)

Owner:APPVION INC

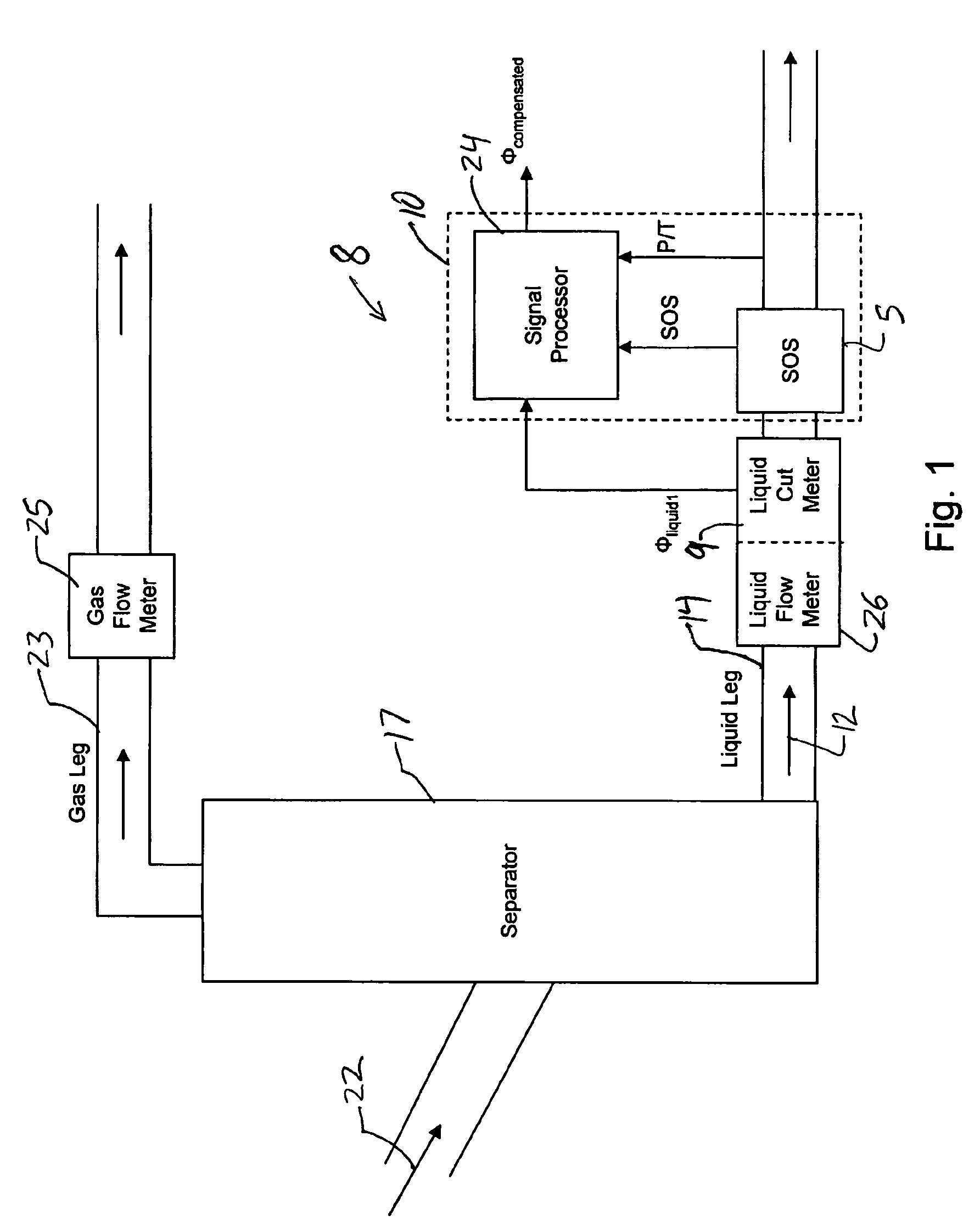

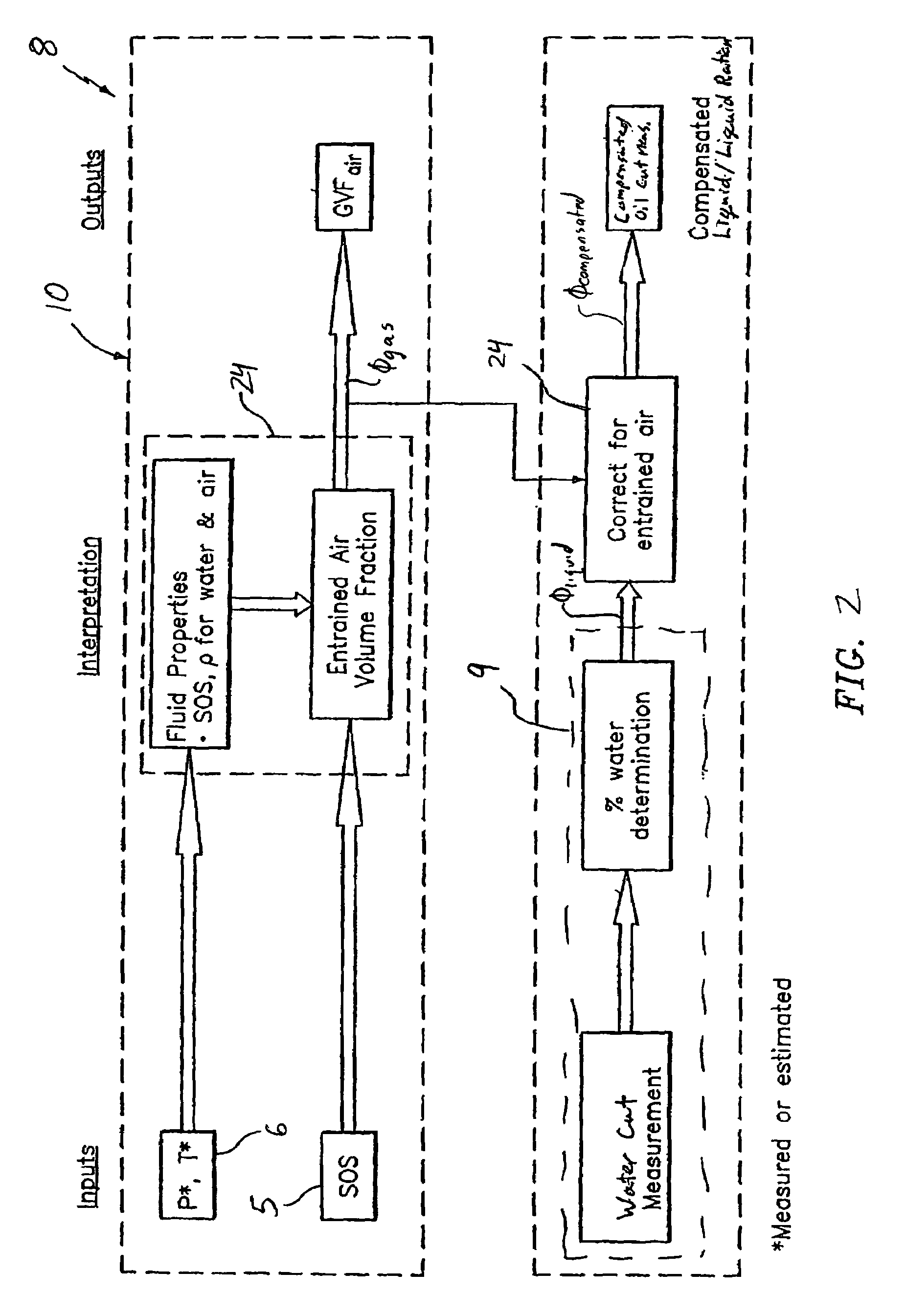

Apparatus and method for providing a fluid cut measurement of a multi-liquid mixture compensated for entrained gas

ActiveUS7380438B2Material analysis using sonic/ultrasonic/infrasonic wavesTesting/calibration apparatusEngineeringPermittivity

An apparatus for determining a fluid cut measurement of a multi-liquid mixture includes a first device configured to sense at least one parameter of the mixture to determine a fluid cut of a liquid in the mixture. A second device is configured to determine a concentration of gas in the mixture in response to a speed of sound in the mixture; and a signal processor is configured to adjust the fluid cut of the liquid using the concentration of the gas to determine a compensated fluid cut of the liquid. The parameter of the mixture sensed by the first device may include a density of the mixture (e.g., by way of a Coriolis meter), a permittivity of the mixture (e.g., by way of a resonant microwave oscillator), or an amount of microwave energy absorbed by the mixture (e.g., by way of a microwave absorption watercut meter). The signal processor may employ different correction factors depending on the type of fluid cut device used. The second device may include a gas volume fraction meter.

Owner:EXPRO METERS

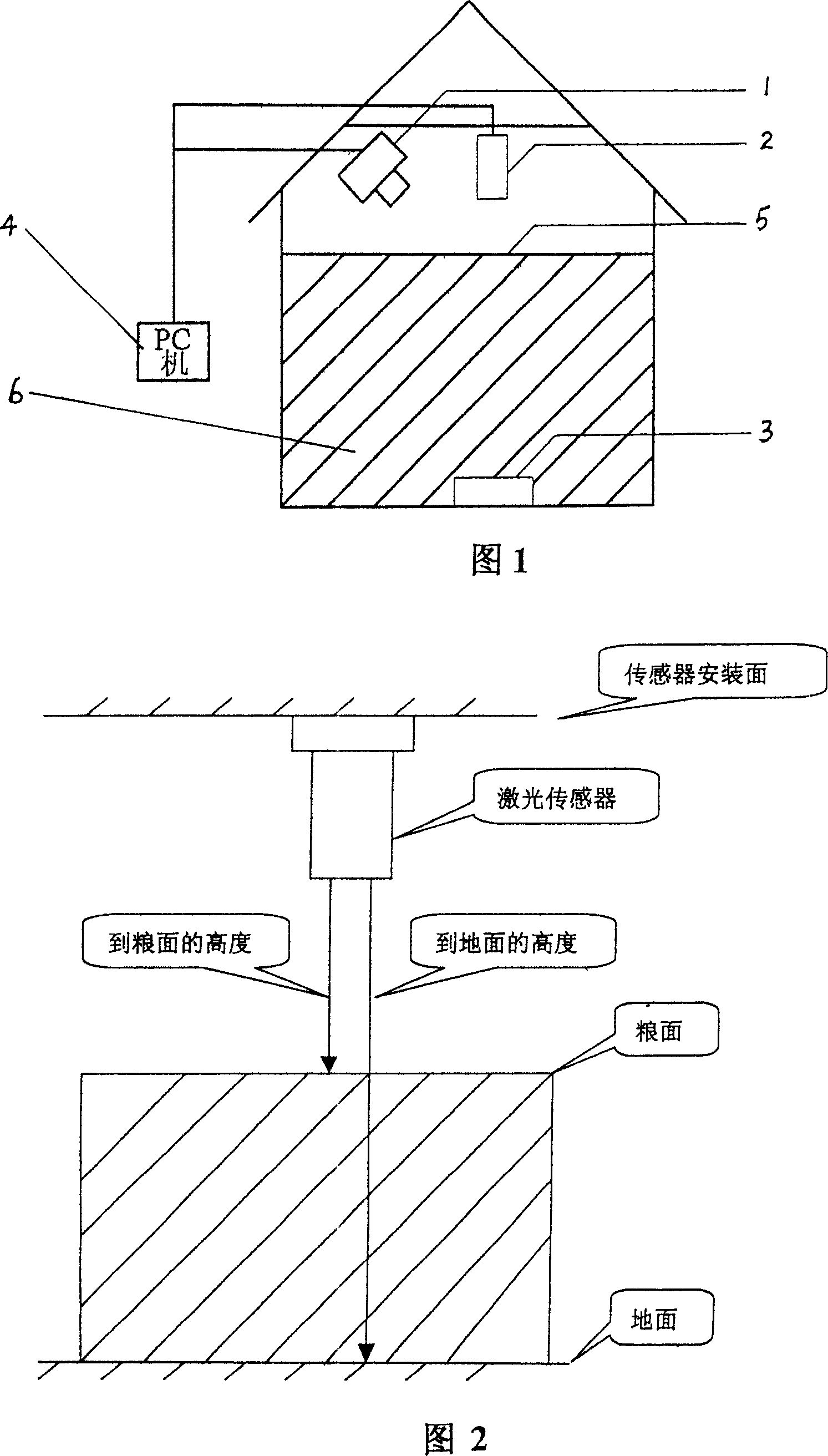

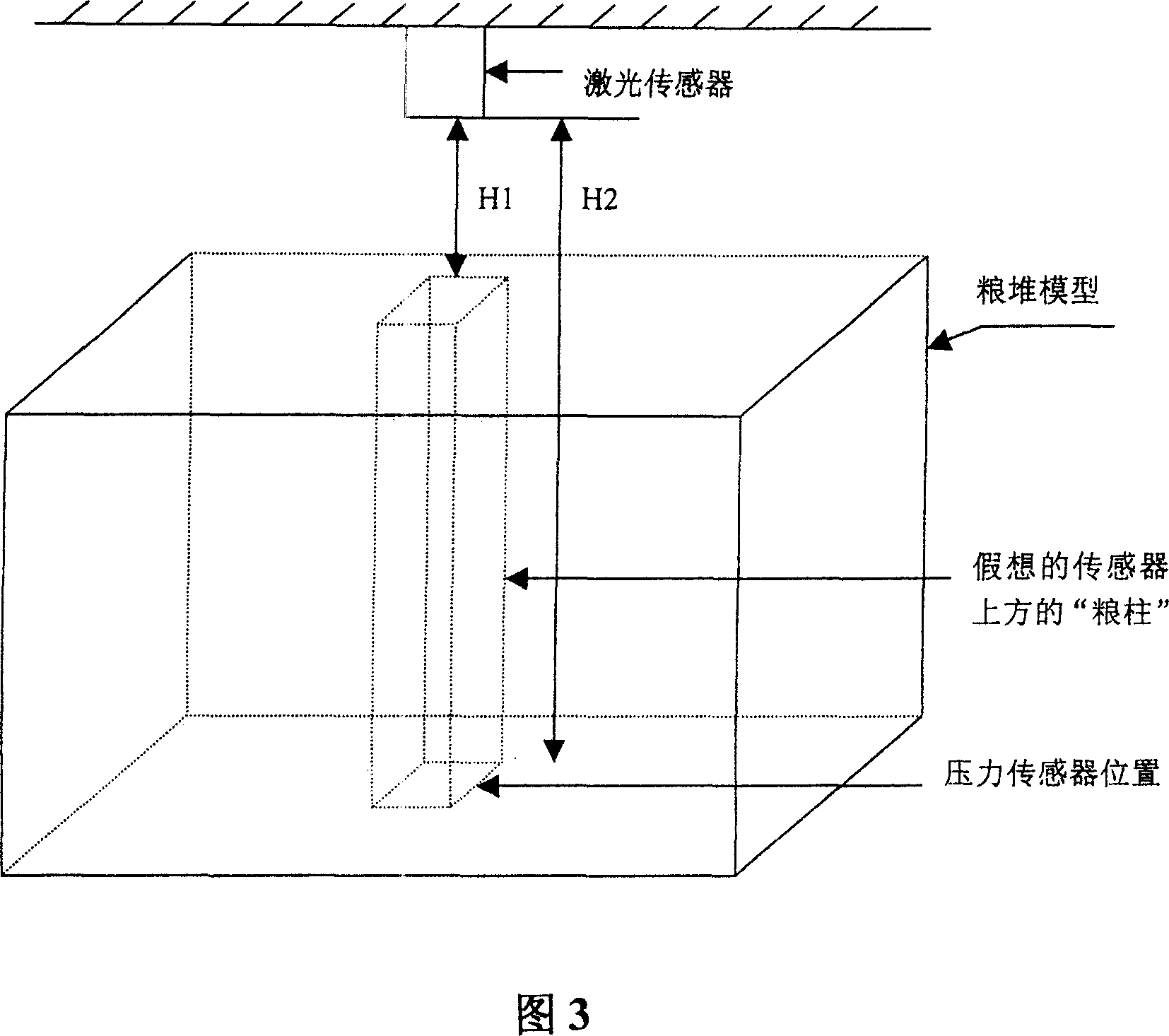

Measuring method for amount of grain reserve in grain depot

InactiveCN1963377AThe measurements are trueAccurate measurementElectric signal transmission systemsVolume measurement apparatus/methodsVolume measurementsStorage management

This invention relates to one food storage volume measurement method, which comprises the following steps: using laser sensor to measure its volume and starting cameral head for shot stored into PC database; correcting according to the volume by laser sensor; measuring food storage intensity by use of pressure sensor to weight sensor above column weight and measuring sensor food column height through laser sensor; computing food column intensity according to the weight, height and pressure area; computing food storage total weight according to the intensity and volume.

Owner:朱阳明

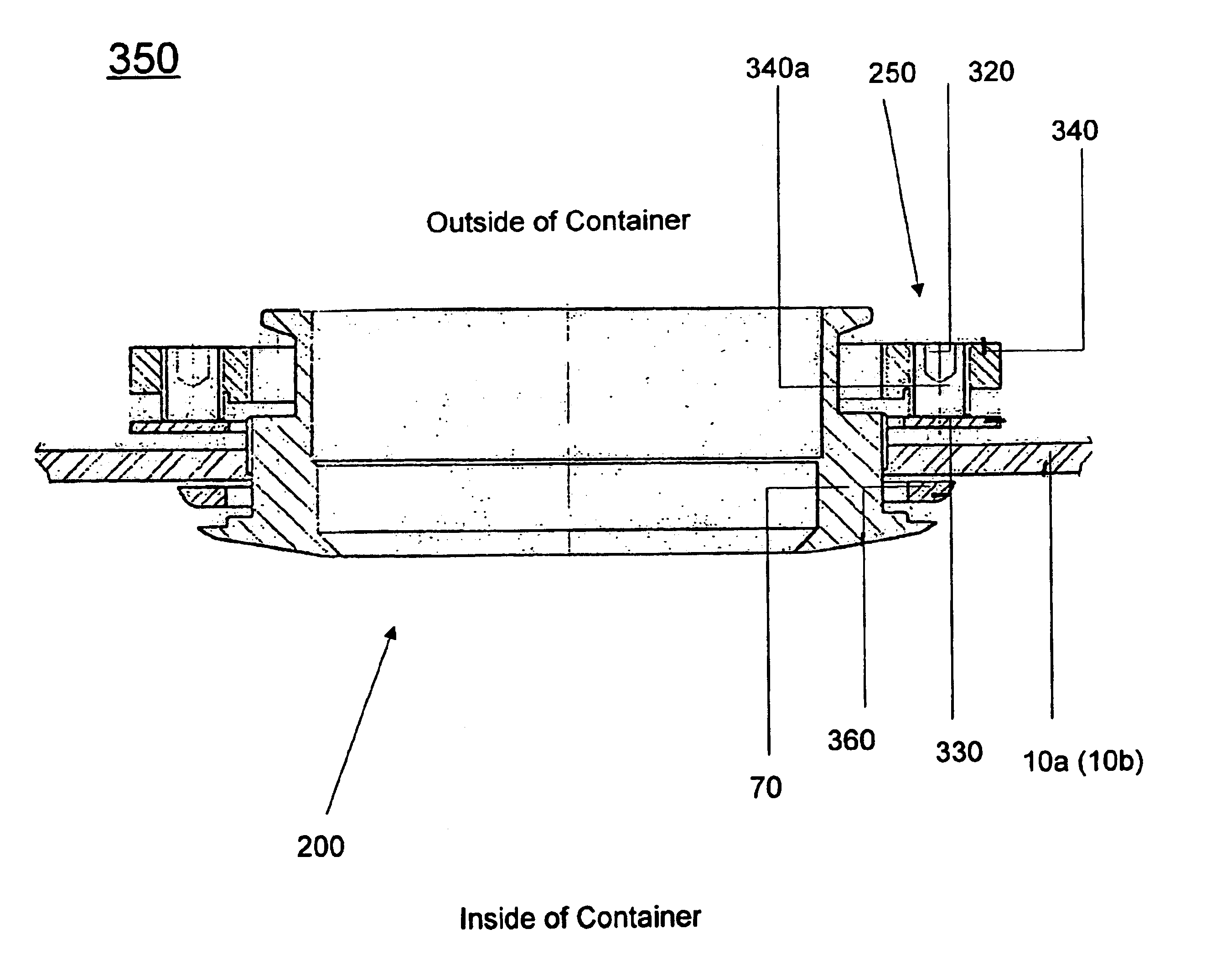

Assemblies adapted to be affixed to containers containing fluid and methods of affixing such assemblies to containers

InactiveUS6854345B2Avoid mixingSamplingMaterial analysis by observing immersed bodiesContact pressureEngineering

An assembly adapted to be affixed to a container which contains a sample fluid, and a method of affixing the assembly to the container, are provided. In particular, a contact pressure can be applied to a surface of the container, such that a particular arrangement, which has a portion situated within an opening of the container, is affixed to the container without piercing the surface of the container. For example, the container can be a tank, the particular arrangement can be a sensor arrangement, and a further arrangement can be used to affix the particular arrangement to the container. Moreover, the contact pressure preferably can be applied to an exterior surface of the container so that the further arrangement may be more accessible to a user of the assembly.

Owner:SMAR RES CORP

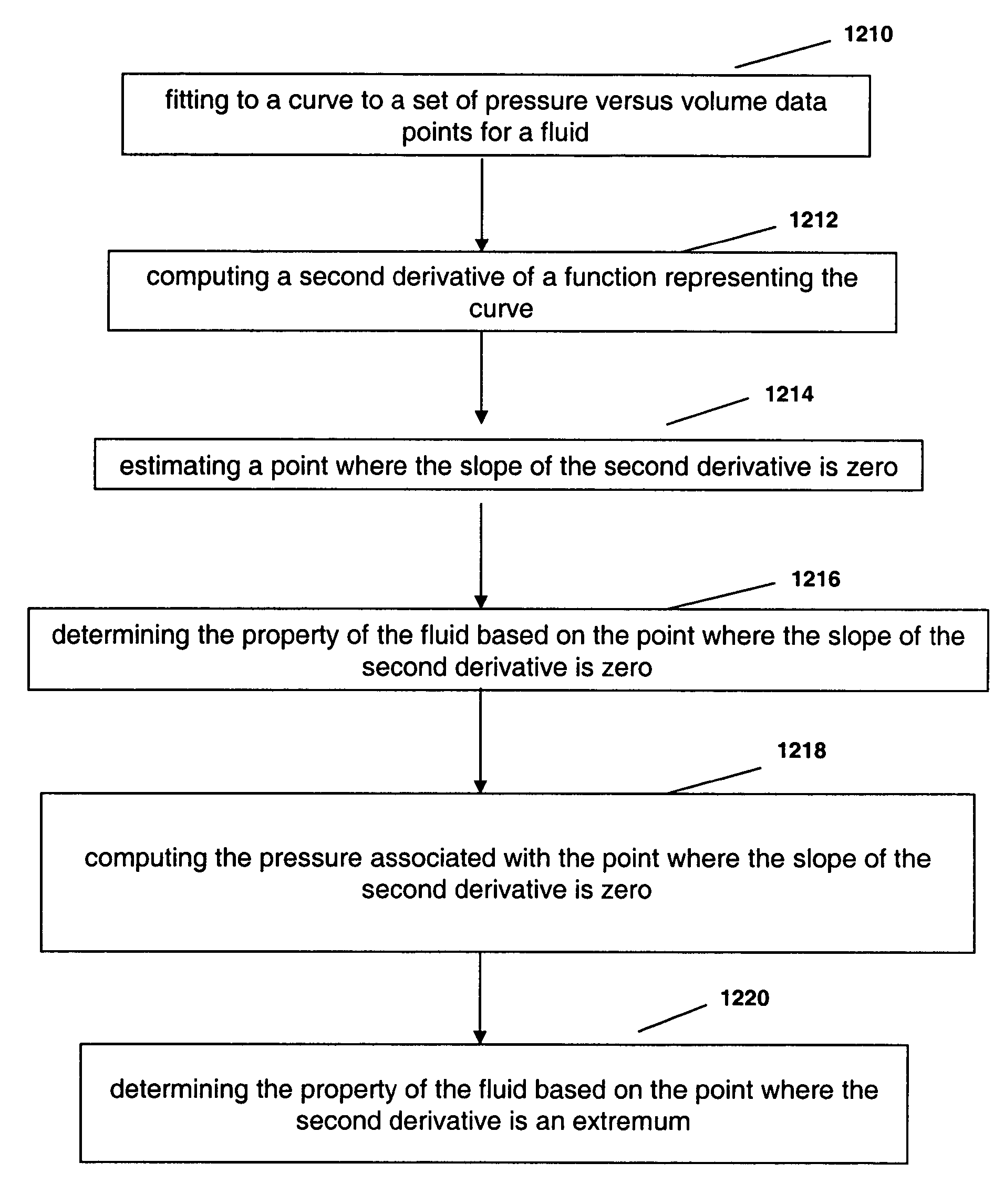

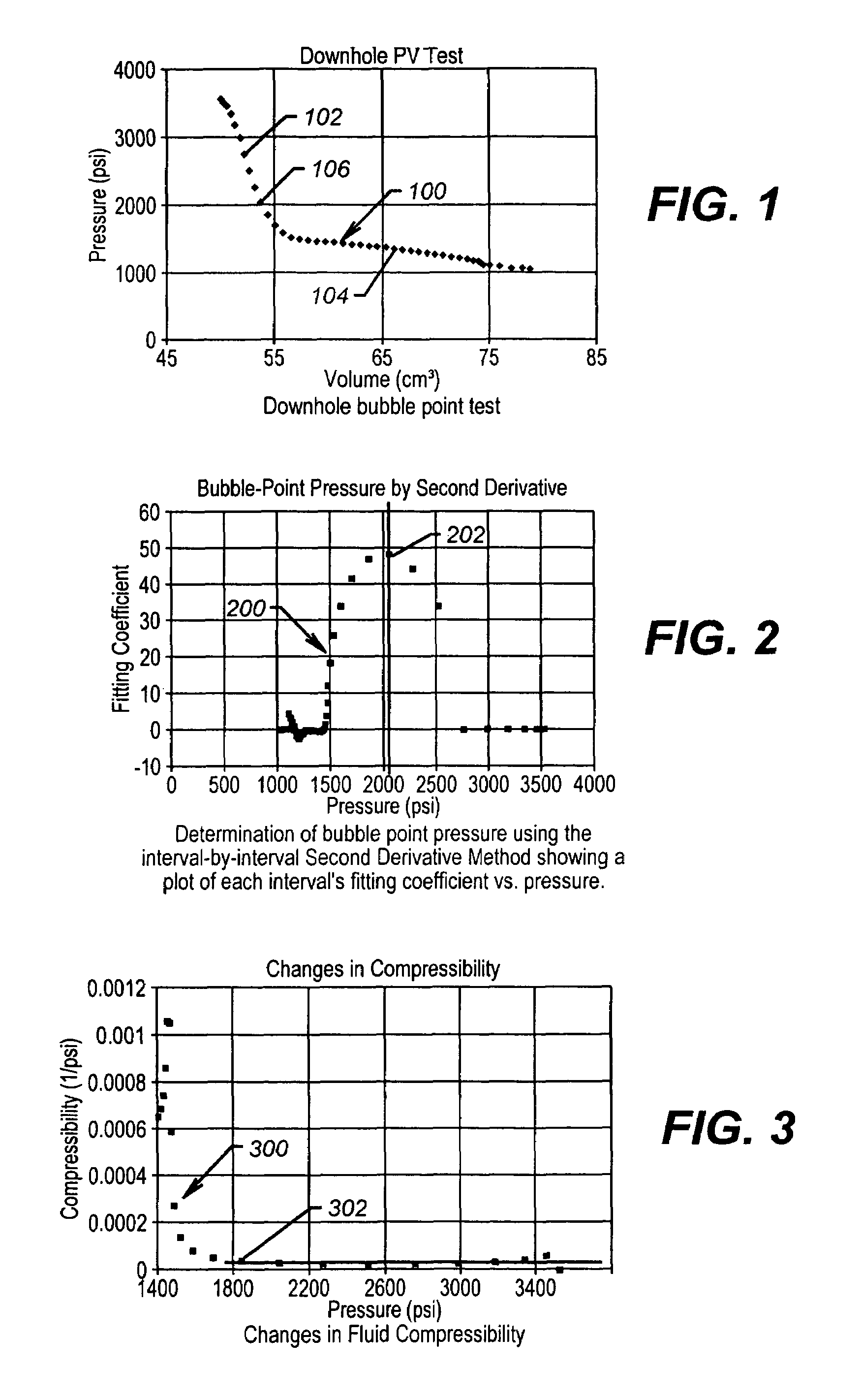

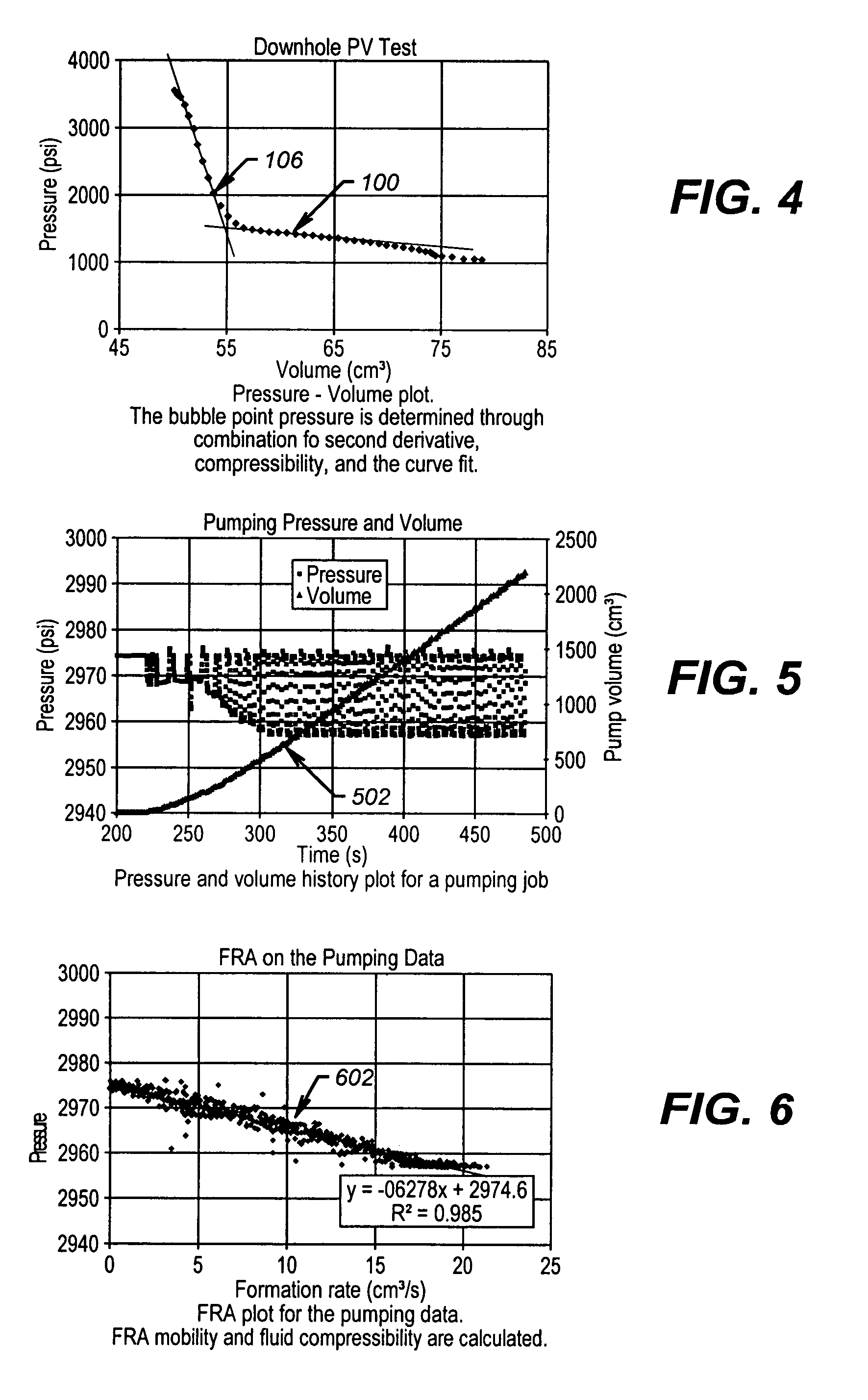

Downhole PV tests for bubble point pressure

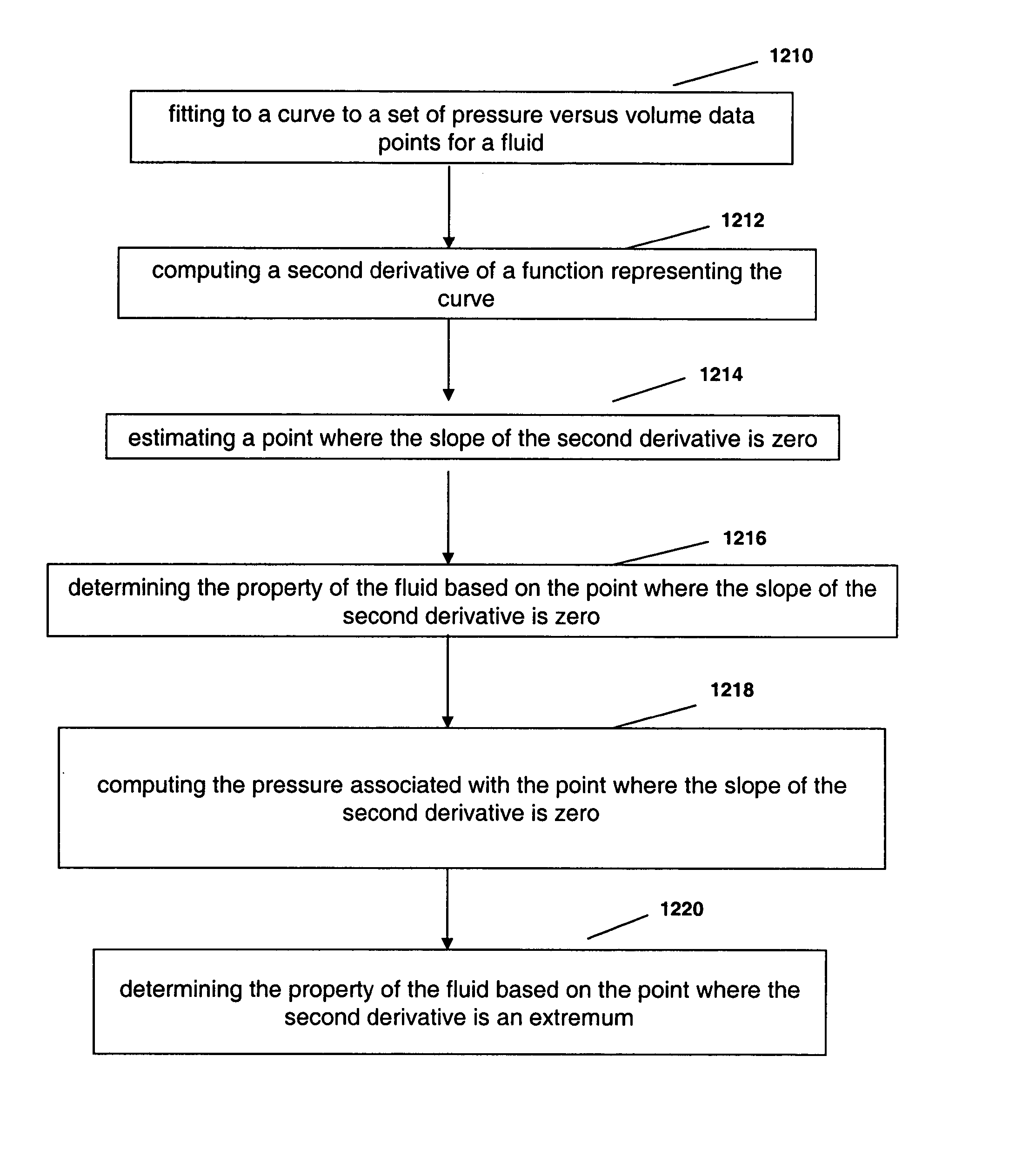

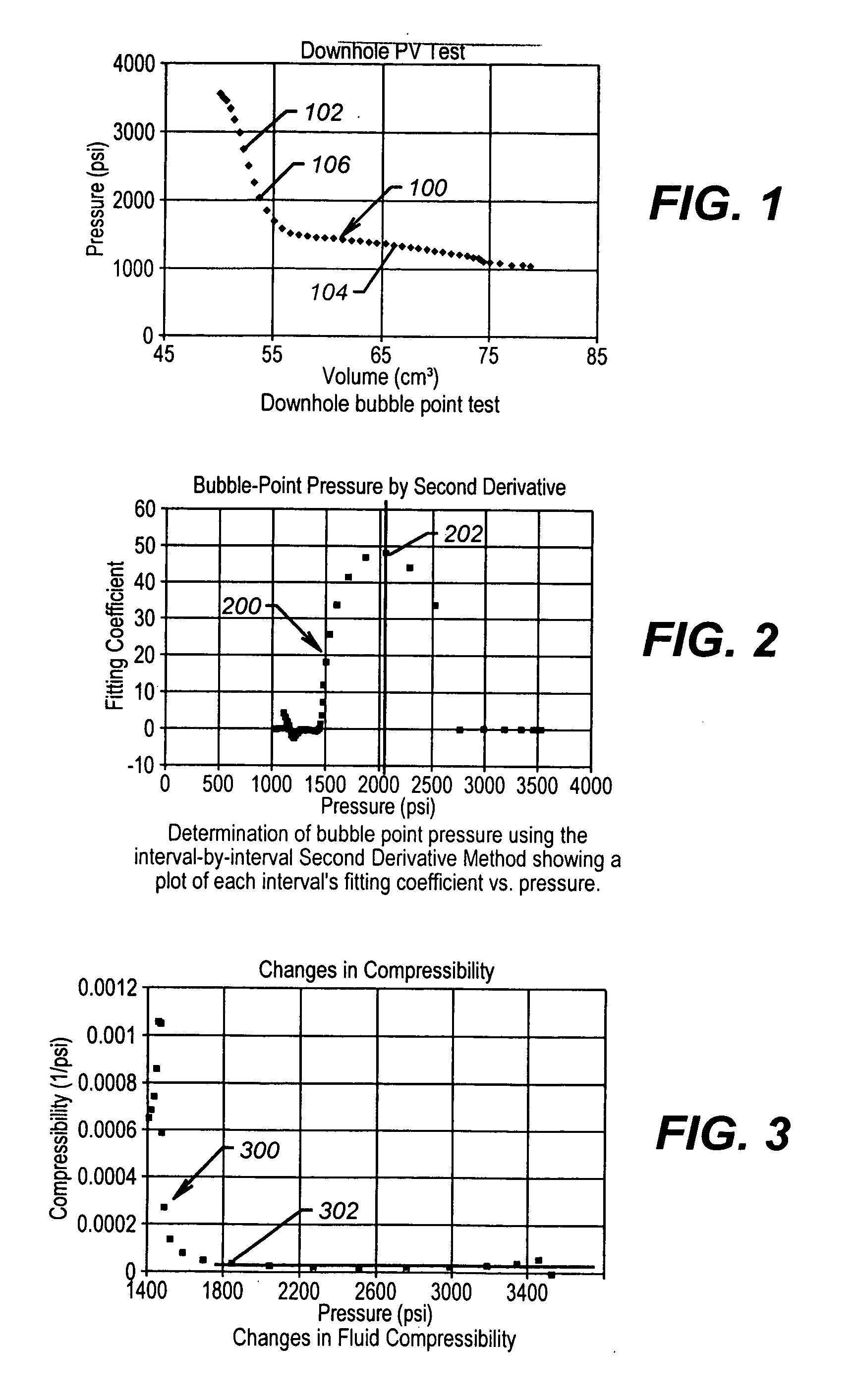

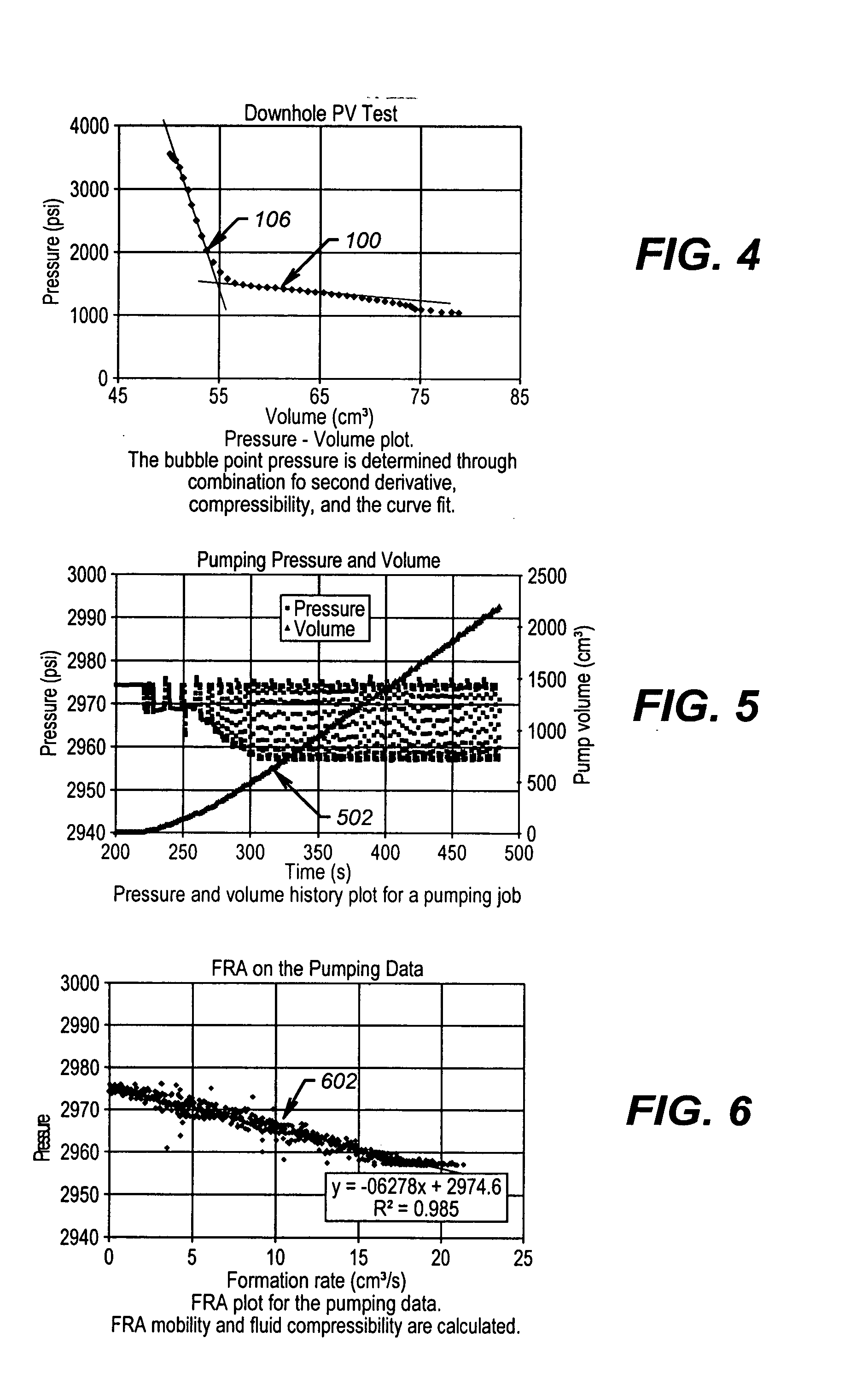

InactiveUS20040260497A1Reduction of filtrateSpecific gravity by measuring pressure differencesFlow propertiesVisual observationQuality control

The present invention provides an objective bubble point pressure determination method enables new applications of downhole PV (Pressure Volume) test results such as in situ measurement of the bubble point pressure for use as a quality control parameter for sampling. The present invention provides a method and apparatus to fit data points to a curve and to smooth these points over an interval of N points. The derivative of the curve is determined to obtain peak acceleration. The peak acceleration represents the bubble point pressure. This bubble point pressure is verified by comparison to changes in fluid compressibility and visual observation of a pressure volume plot history.

Owner:BAKER HUGHES INC

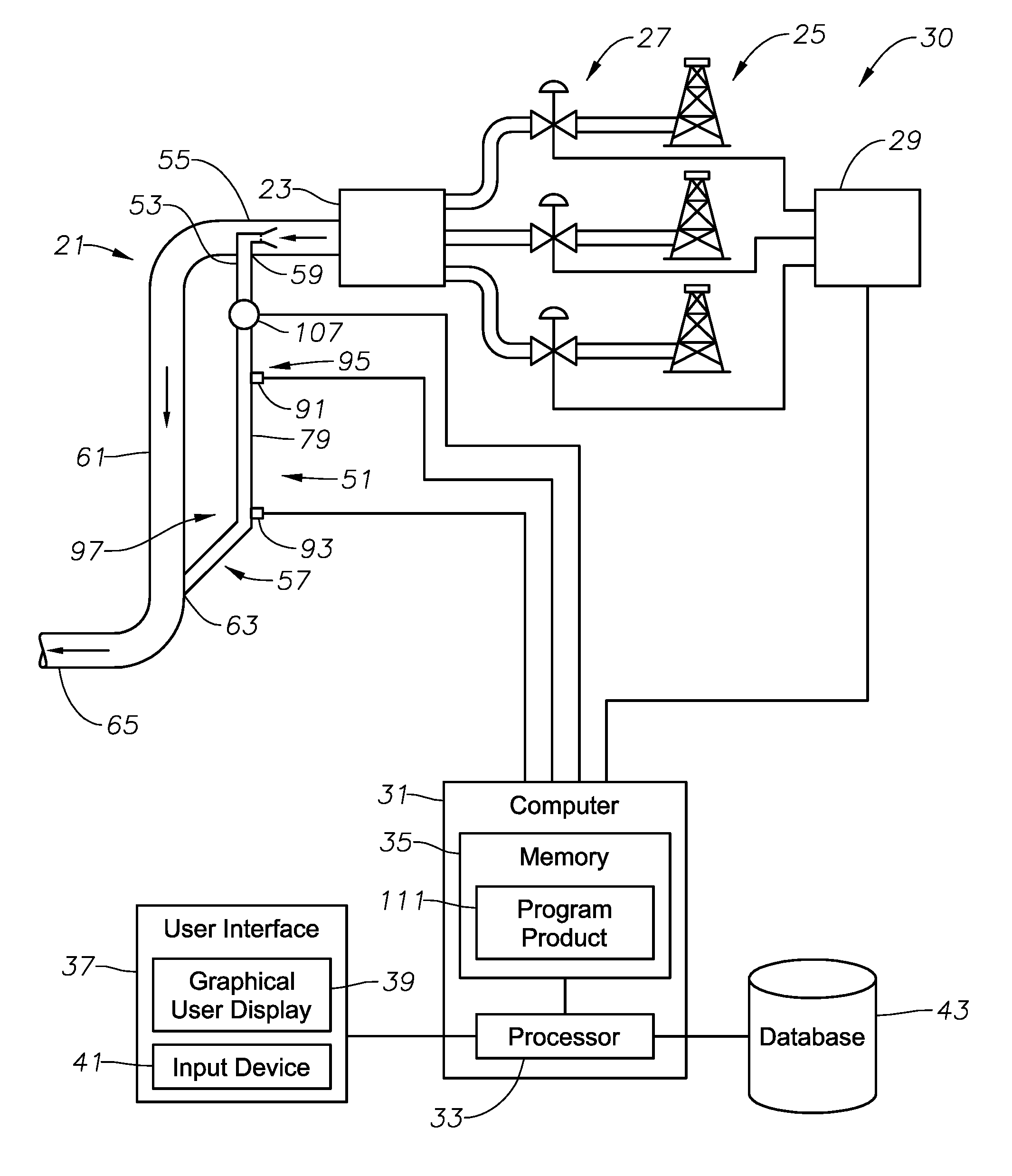

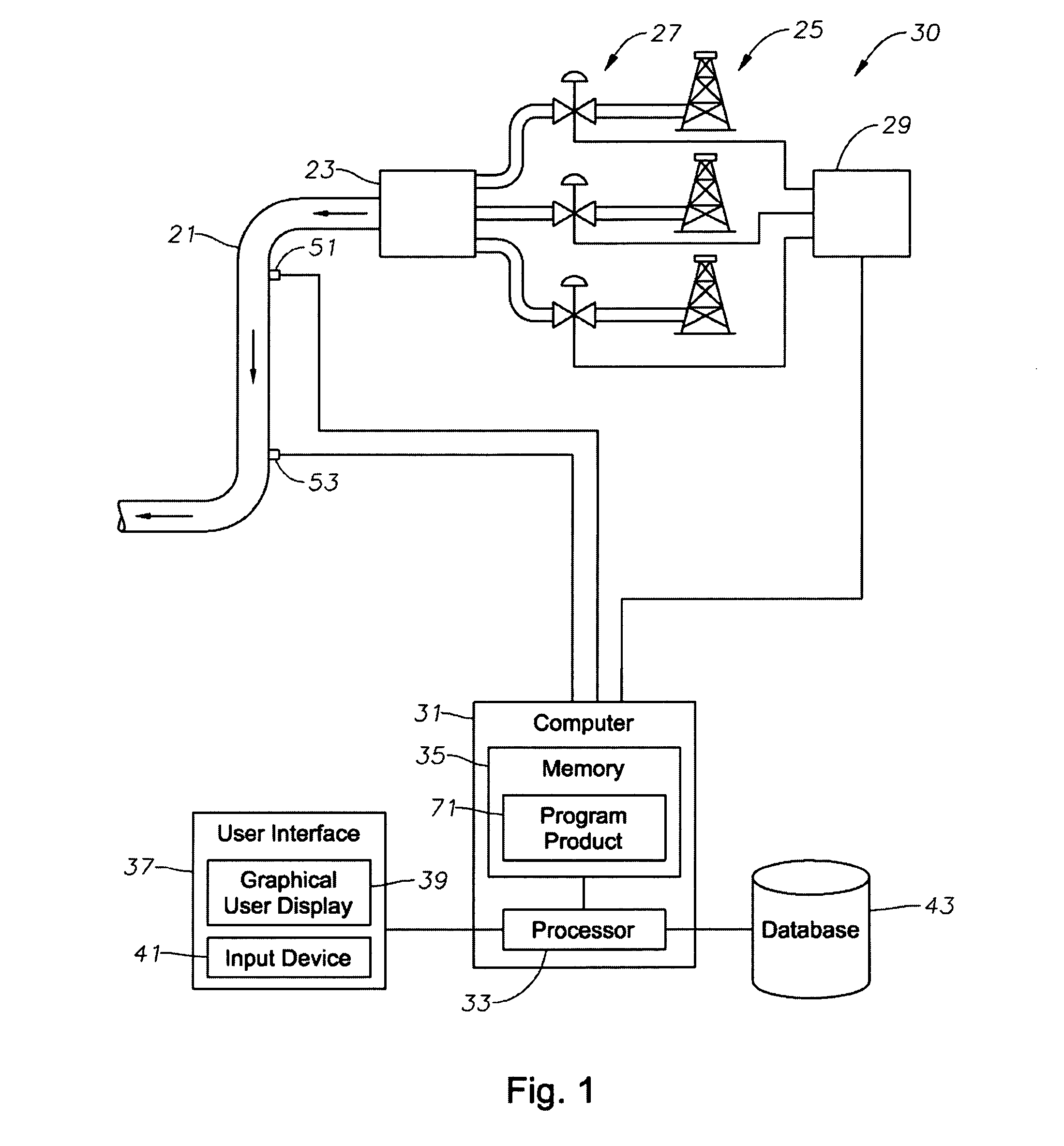

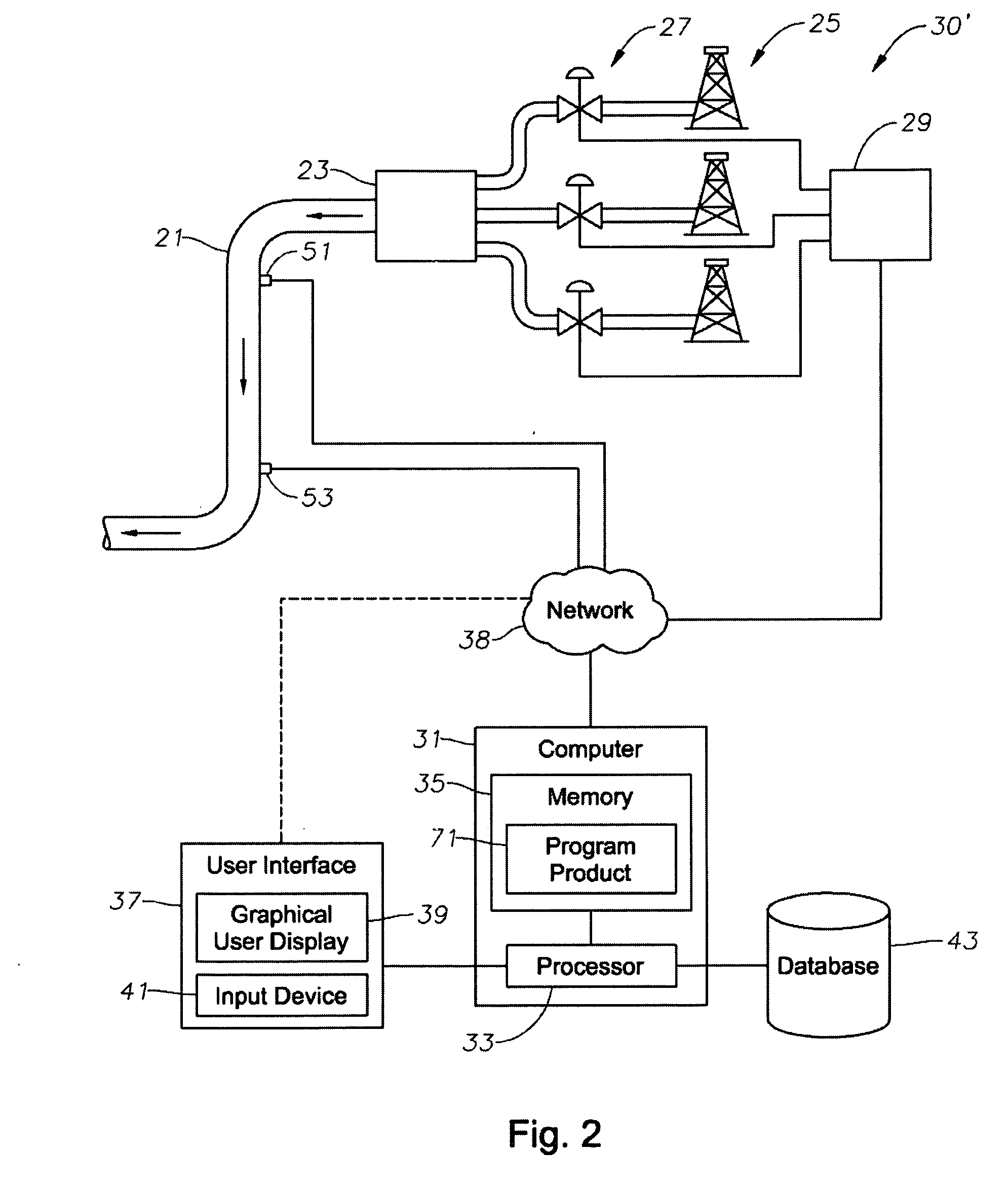

System, program product, and related methods for estimating and managing crude gravity in real-time

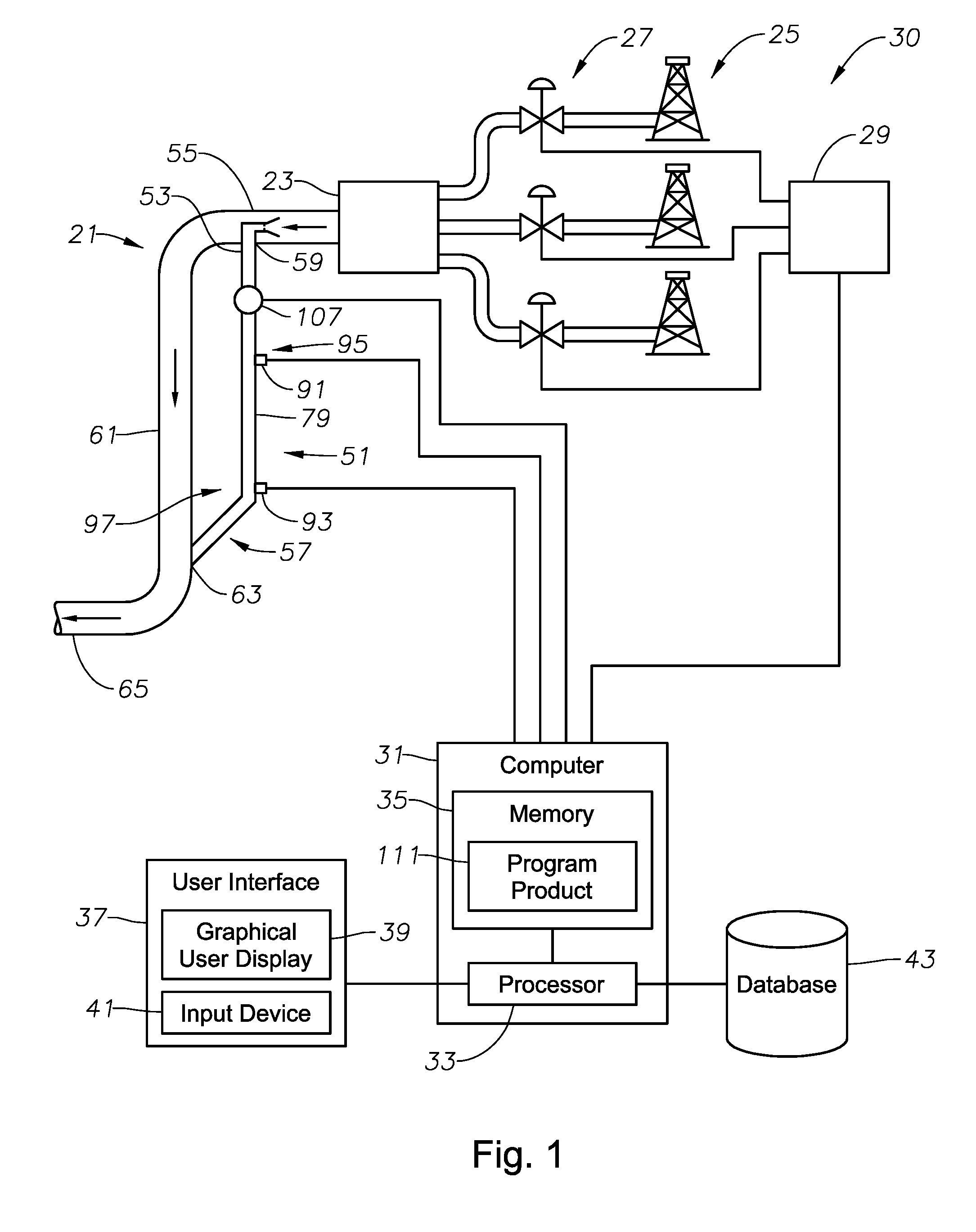

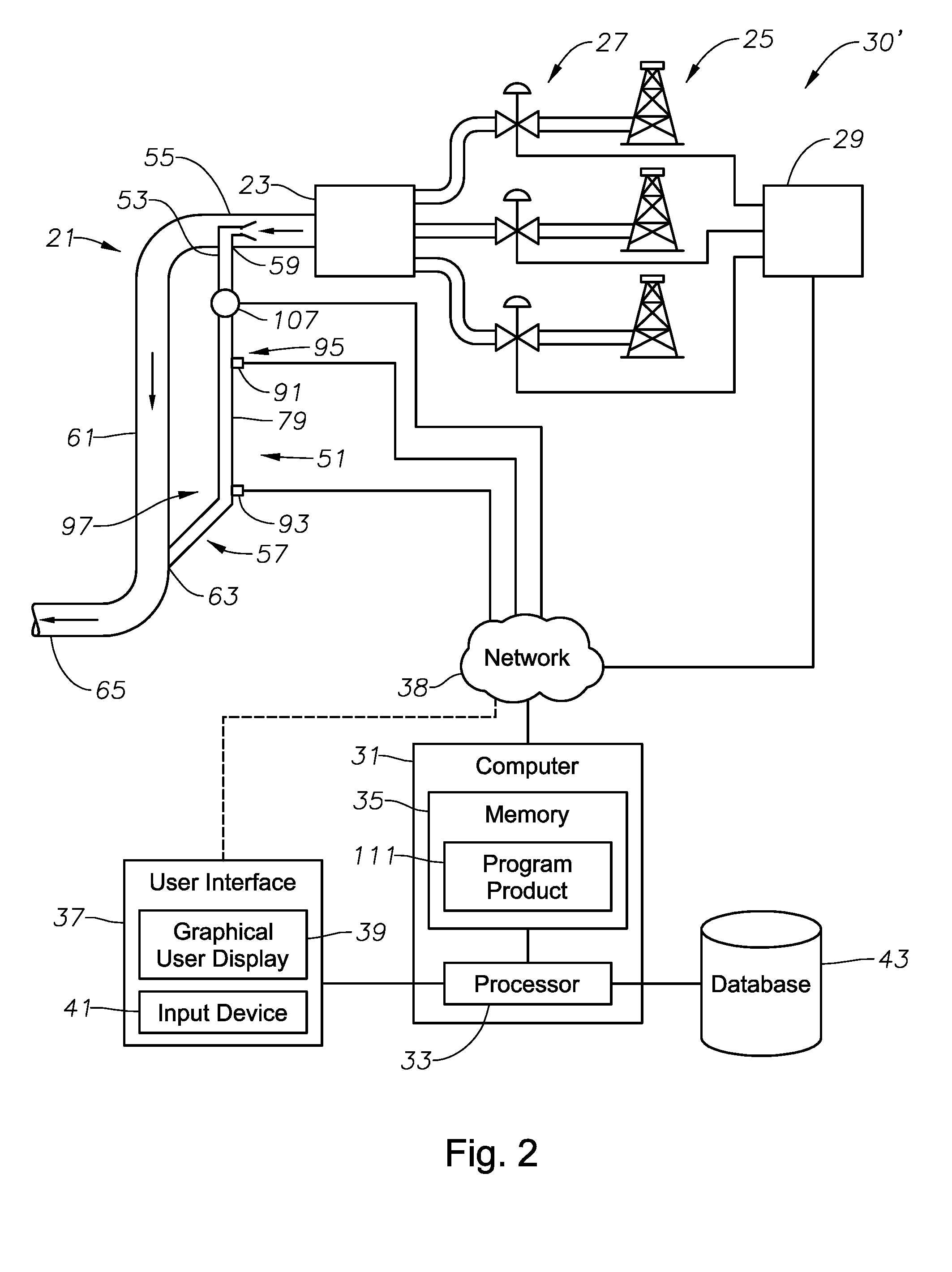

ActiveUS20090312963A1Overcome deficienciesInflated body pressure measurementSpecific gravity by measuring pressure differencesSpecific gravityStream flow

Systems, program product, and methods to estimate and manage flowing fluid characteristics of a fluid stream flowing through a pipeline in real-time, are provided. A system can include a vertically oriented extent of a pipeline for transporting crude oil, a pair of spaced vertically apart sensors or sensor assemblies connected to a bypass line interfaced with or positioned across the vertically oriented extent of the pipeline to obtain pressure and temperature readings of the crude oil flowing through the pipeline, a controller in communication with the pair of sensors or sensor assemblies, and crude oil analysis and management program product stored in the memory of the controller and adapted to determine or estimate density, specific gravity, and API gravity of the crude oil to thereby manage flowing fluid characteristics of the crude oil.

Owner:SAUDI ARABIAN OIL CO

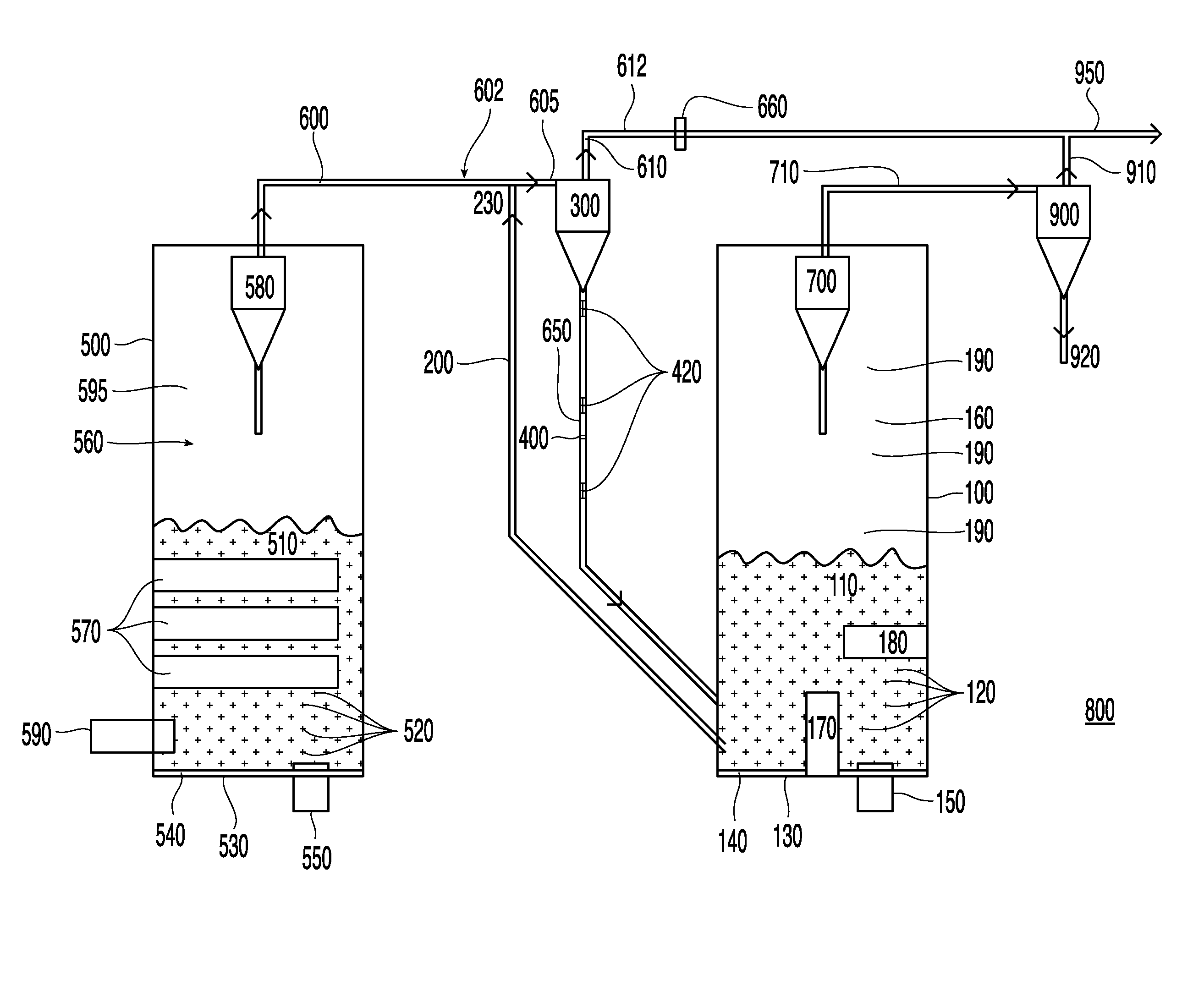

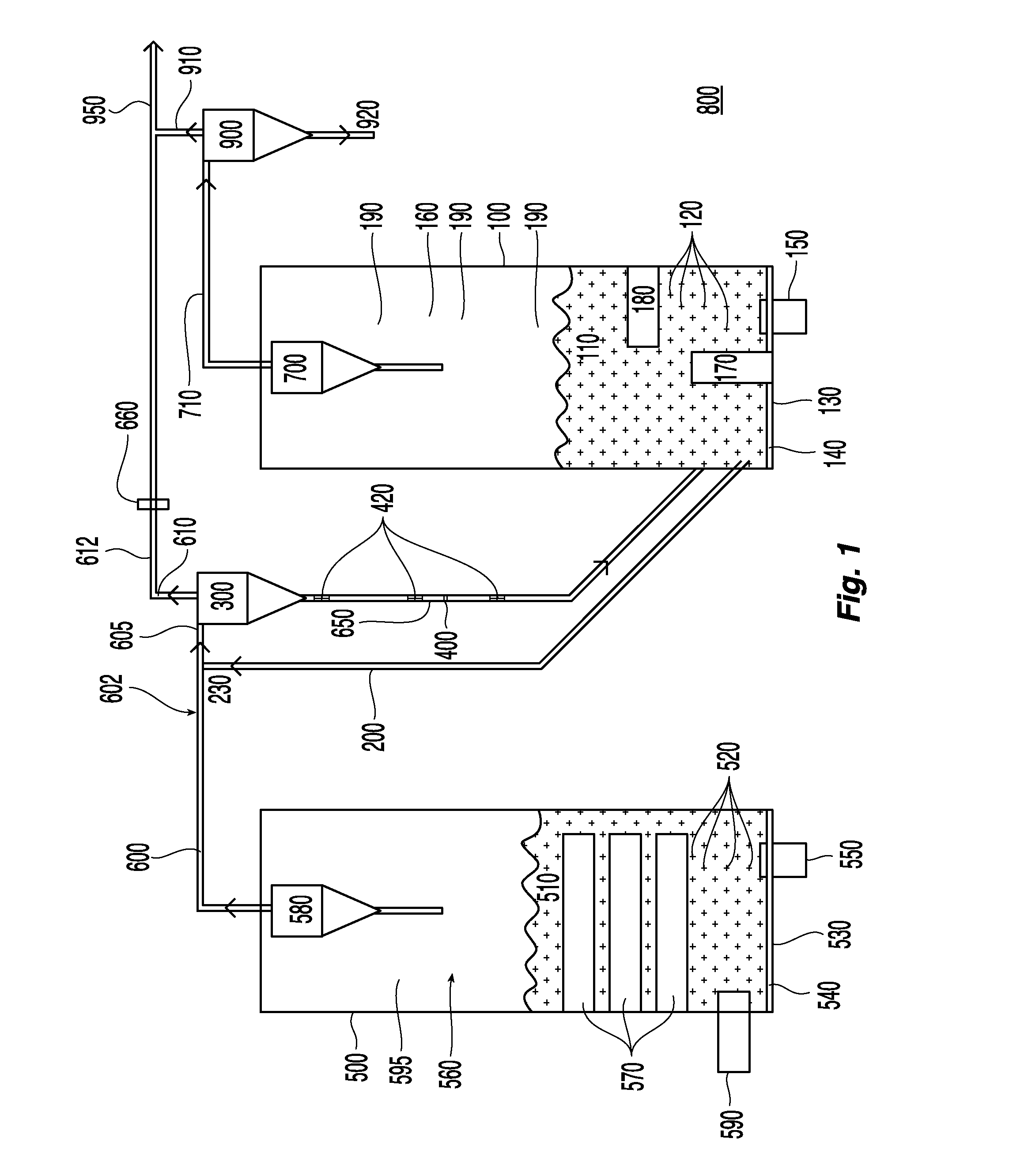

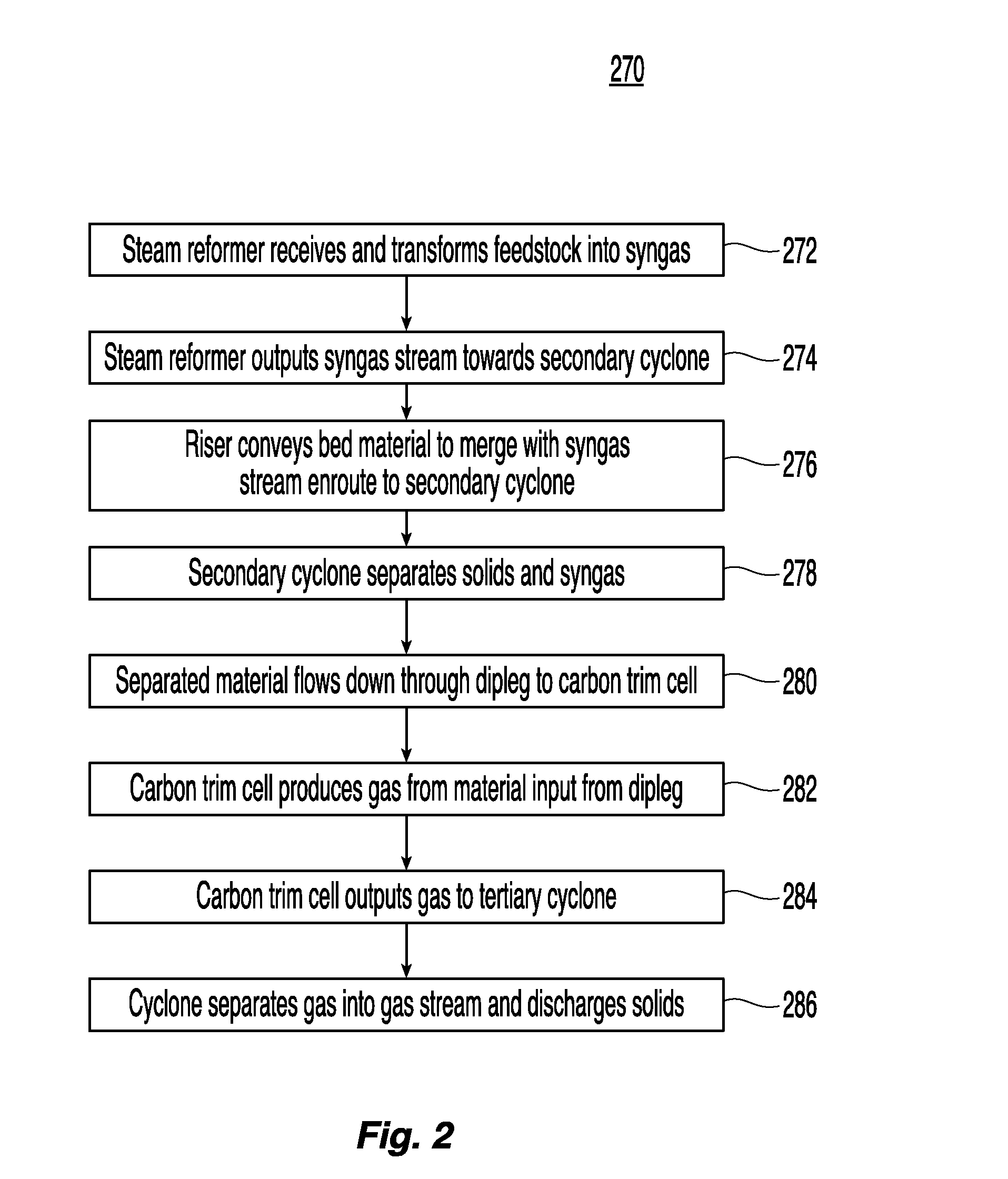

Solids Circulation System and Method for Capture and Conversion of Reactive Solids

ActiveUS20120111109A1Specific gravity by measuring pressure differencesGasifier mechanical detailsCycloneFluid transport

A solids circulation system receives a gas stream containing char or other reacting solids from a first reactor. The solids circulation system includes a cyclone configured to receive the gas stream from the first reactor, a dipleg from the cyclone to a second reactor, and a riser from the second reactor which merges with the gas stream received by the cyclone. The second reactor has a dense fluid bed and converts the received materials to gaseous products. A conveying fluid transports a portion of the bed media from the second reactor through the riser to mix with the gas stream prior to cyclone entry. The bed media helps manipulate the solids that is received by the cyclone to facilitate flow of solids down the dipleg into the second reactor. The second reactor provides additional residence time, mixing and gas-solid contact for efficient conversion of char or reacting solids.

Owner:THERMOCHEM RECOVERY INT

Downhole PV tests for bubble point pressure

InactiveUS7346460B2Reduction of filtrateFlow propertiesSpecific gravity by measuring pressure differencesVisual observationEngineering

The present invention provides an objective bubble point pressure determination method enables new applications of downhole PV (Pressure Volume) test results such as in situ measurement of the bubble point pressure for use as a quality control parameter for sampling. The present invention provides a method and apparatus to fit data points to a curve and to smooth these points over an interval of N points. The derivative of the curve is determined to obtain peak acceleration. The peak acceleration represents the bubble point pressure. This bubble point pressure is verified by comparison to changes in fluid compressibility and visual observation of a pressure volume plot history.

Owner:BAKER HUGHES INC

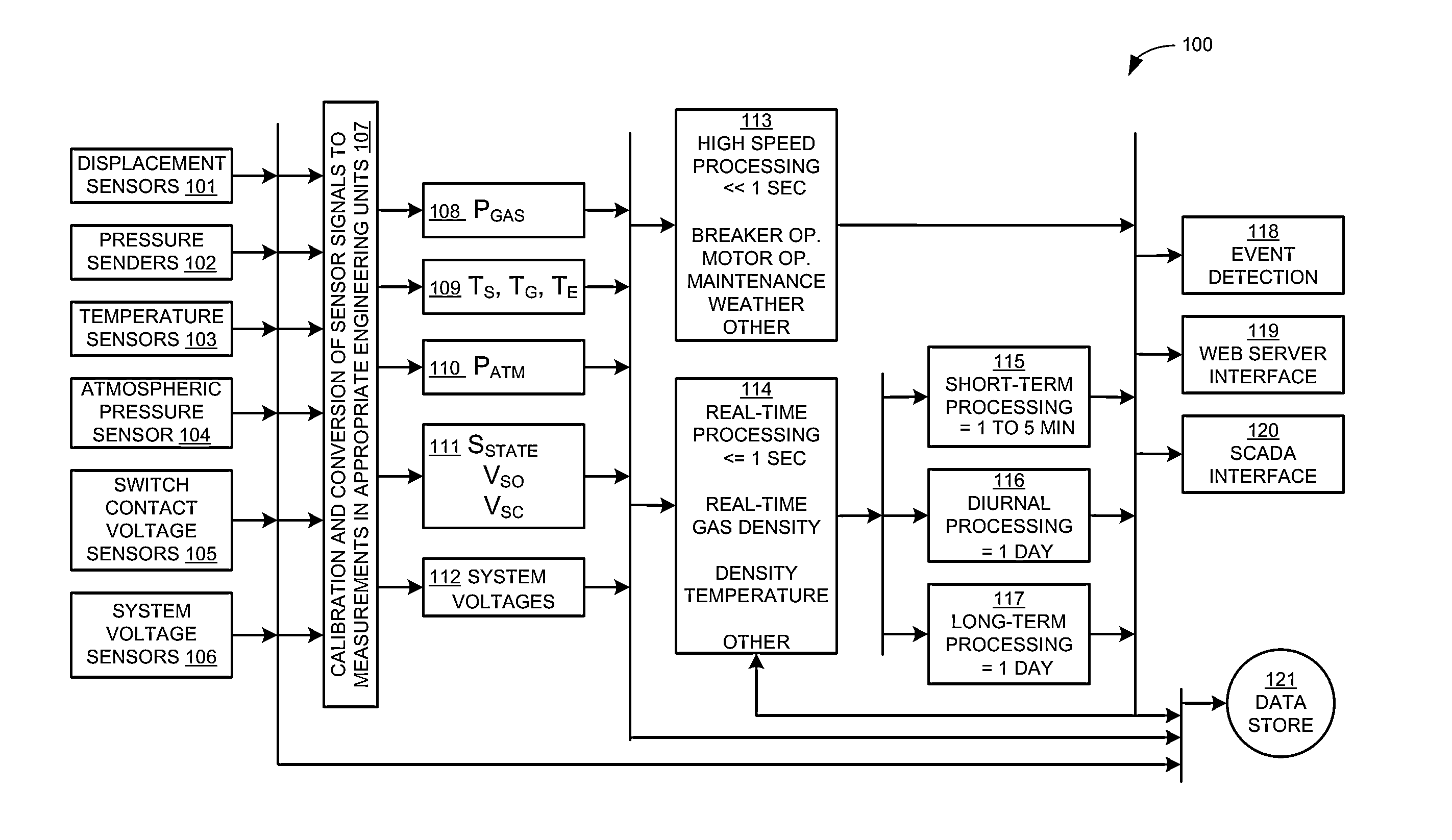

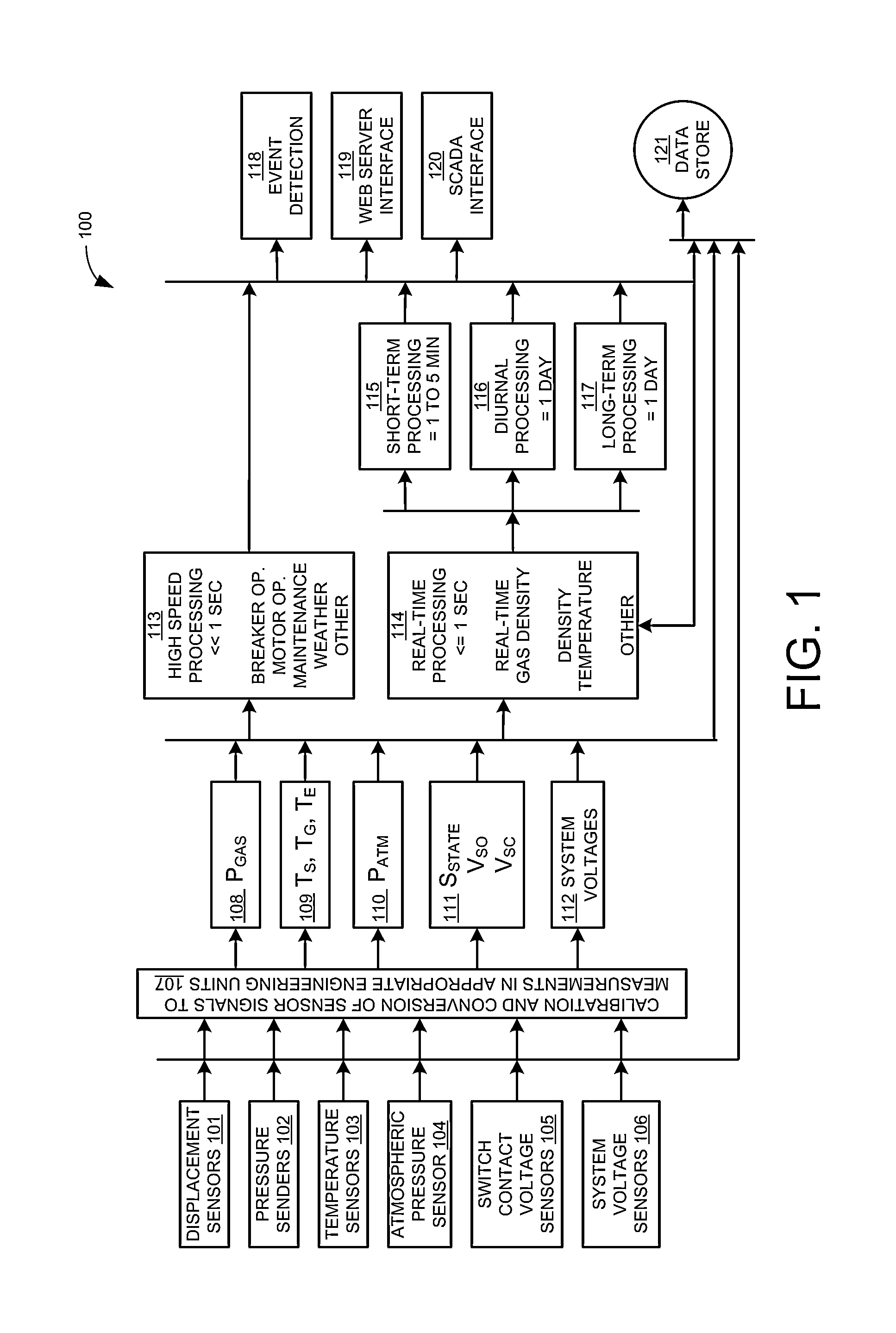

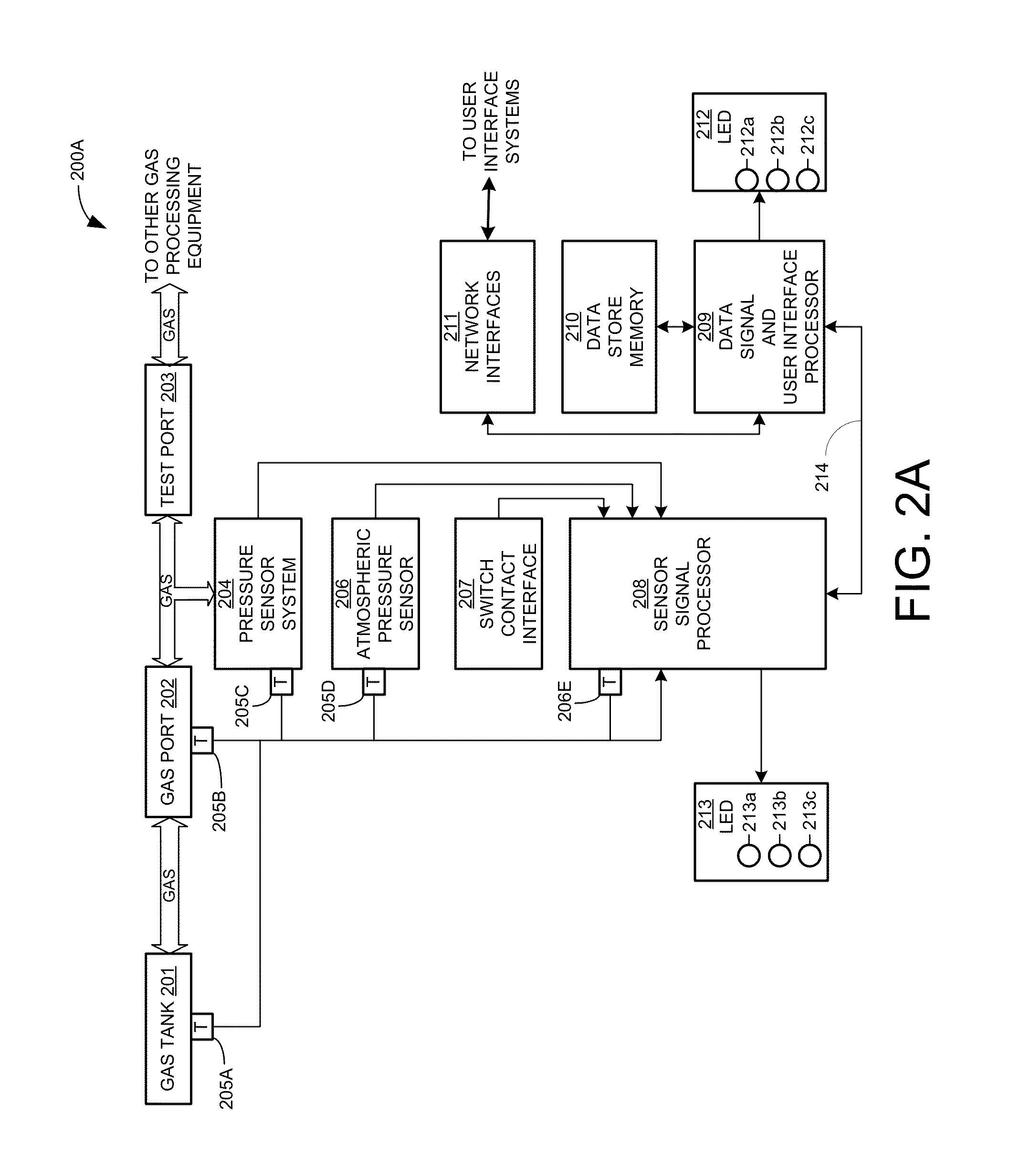

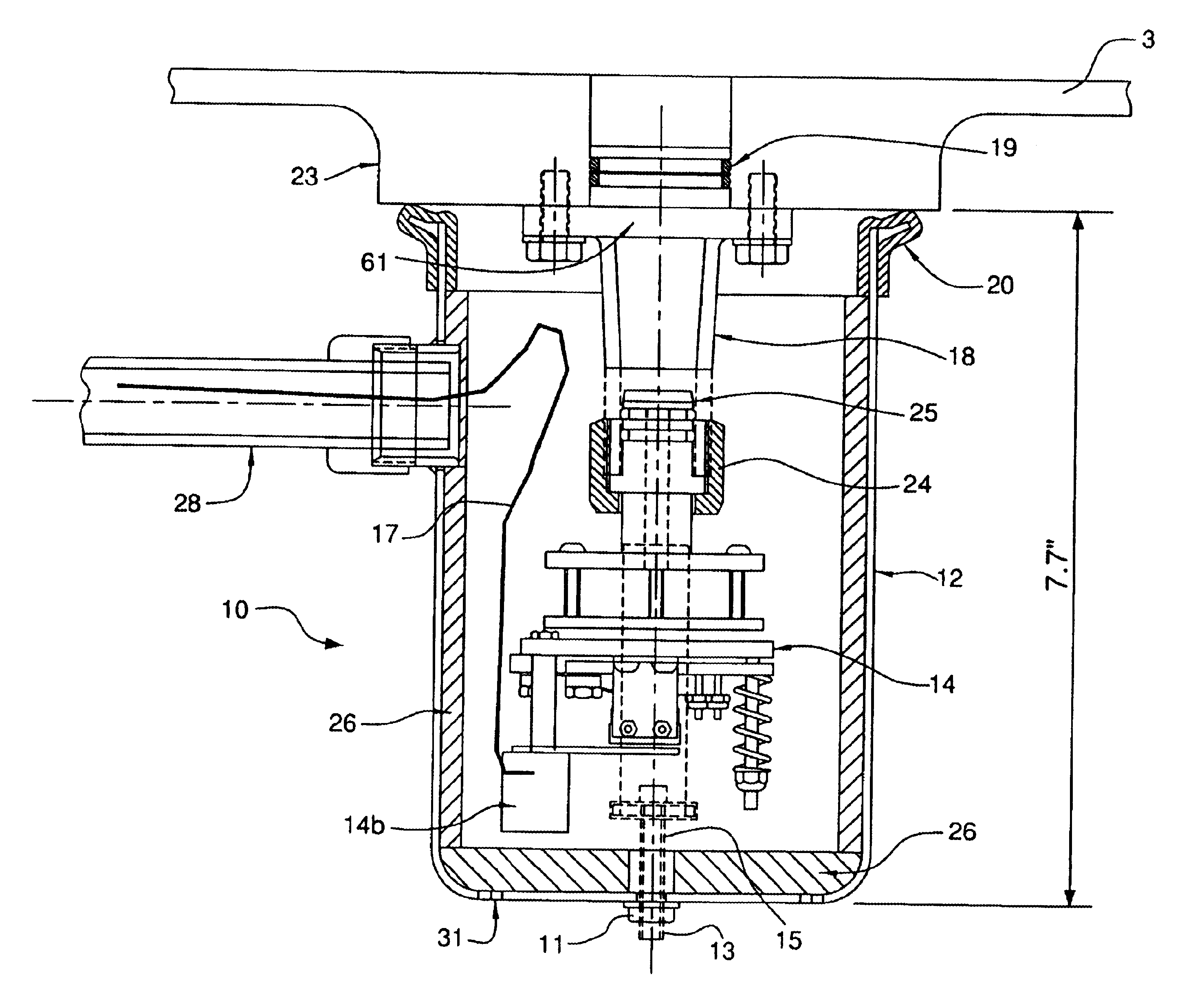

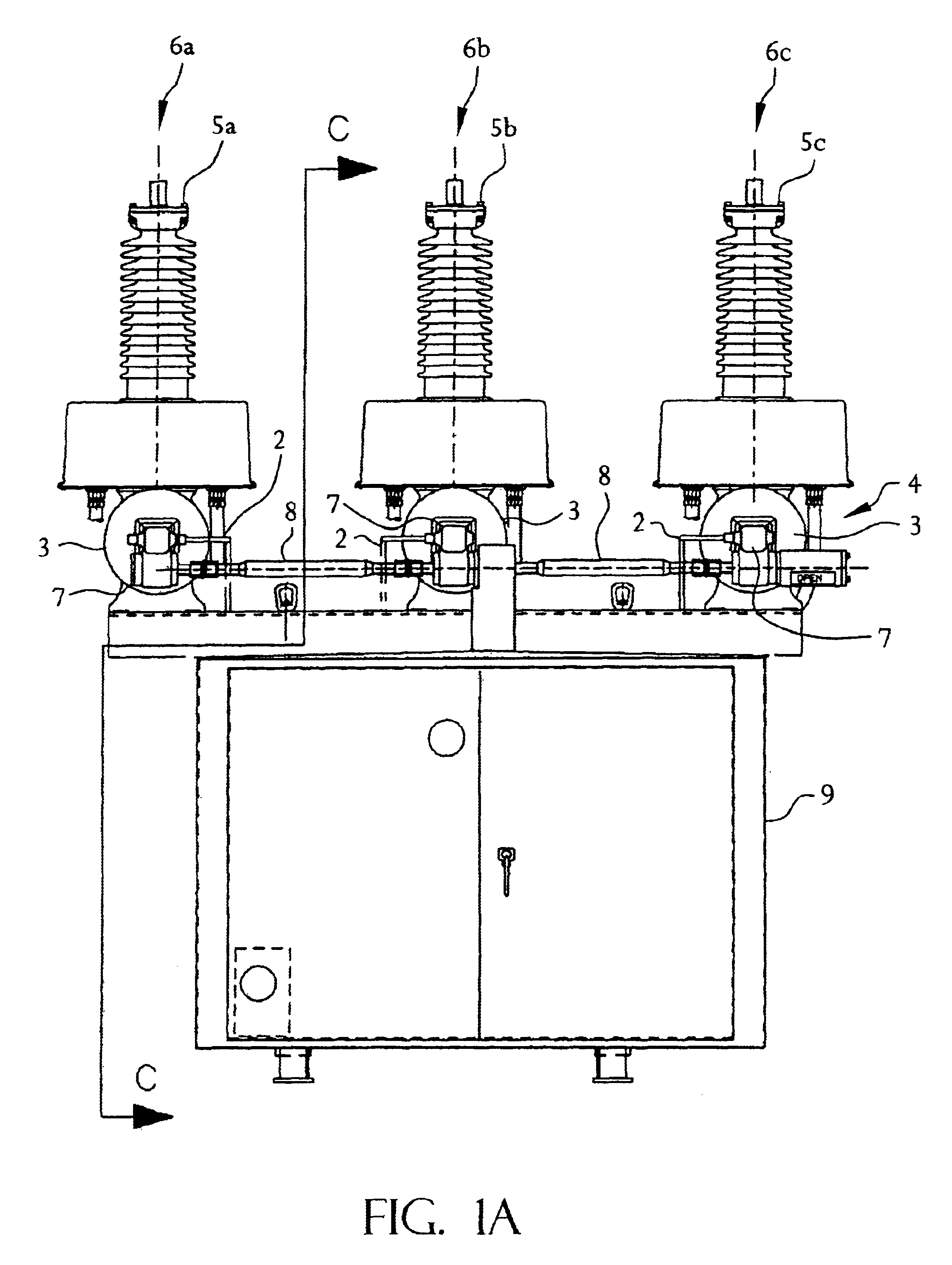

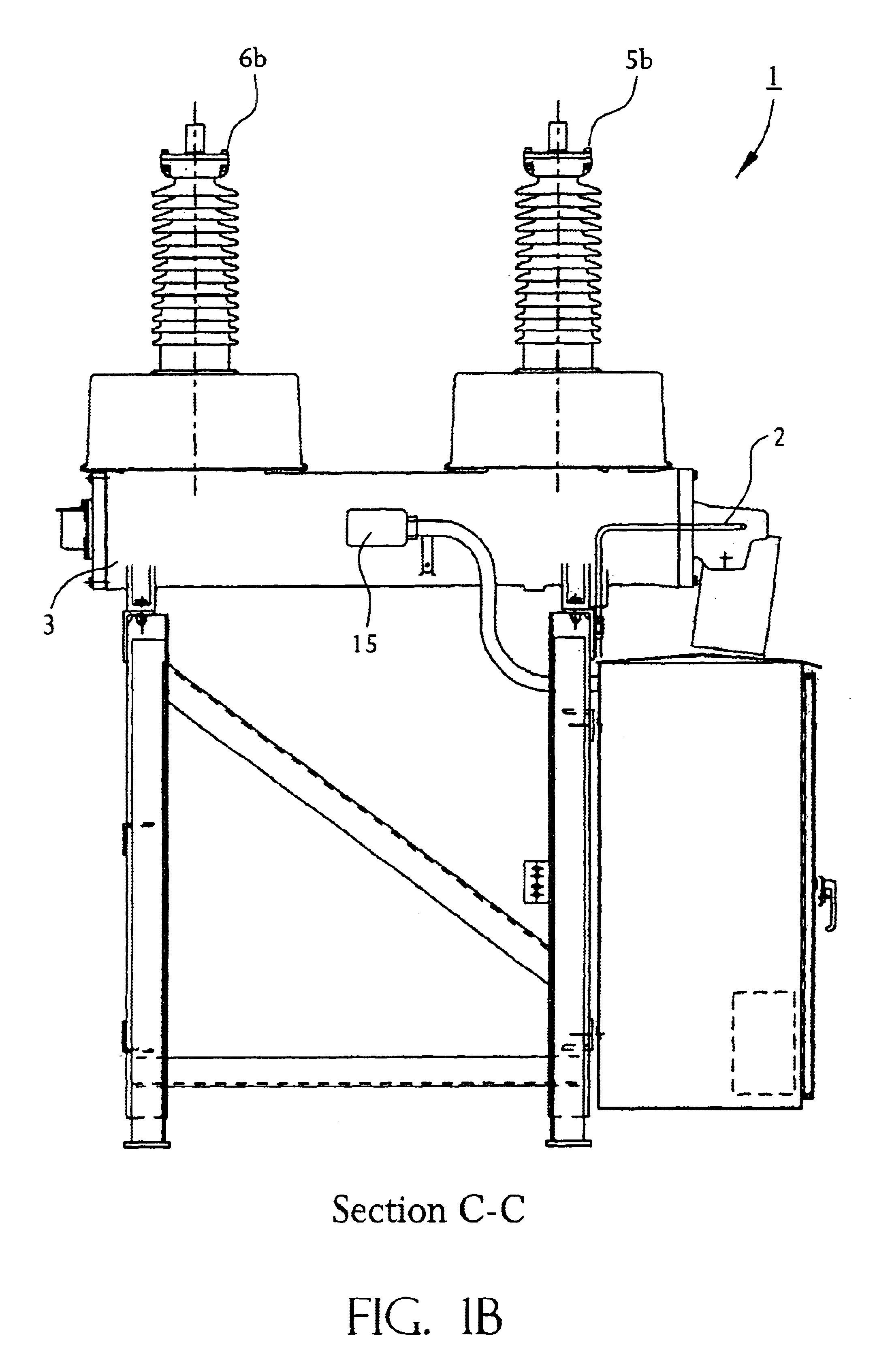

Gas insulated switchgear monitoring apparatus and method

ActiveUS20150308938A1Easy to adaptFacilitate communicationSwitchgear arrangementsSpecific gravity by measuring pressure differencesMass storageObservational error

Mechanical, electronic, algorithmic, and computer network facets are combined to create a highly integrated advanced sensor that monitors the gas density, state-of-repair, and events associated with switchgear. Measurements of gas pressure, atmospheric pressure, gas temperature, are used with models of the non-ideal behavior of a particular gas to realistically estimate gas density. A hierarchical system of signal processing optimizes measurements working within high-frequency, real-time, short-term, medium-term, diurnal, long-term, and historical timeframes and overcomes measurement errors present in real-world applications. The time at which a condition such as gas density will reach a particular level is calculated. Events such as threshold attainments and switchgear operation are detected. A large memory stores all raw data values allowing flexible re-processing and verification at any future time. Instantaneous as well as logged information is communicated in convenient formats over a selected digital network. An embedded web server provides a familiar graphical user interface.

Owner:MODTECH

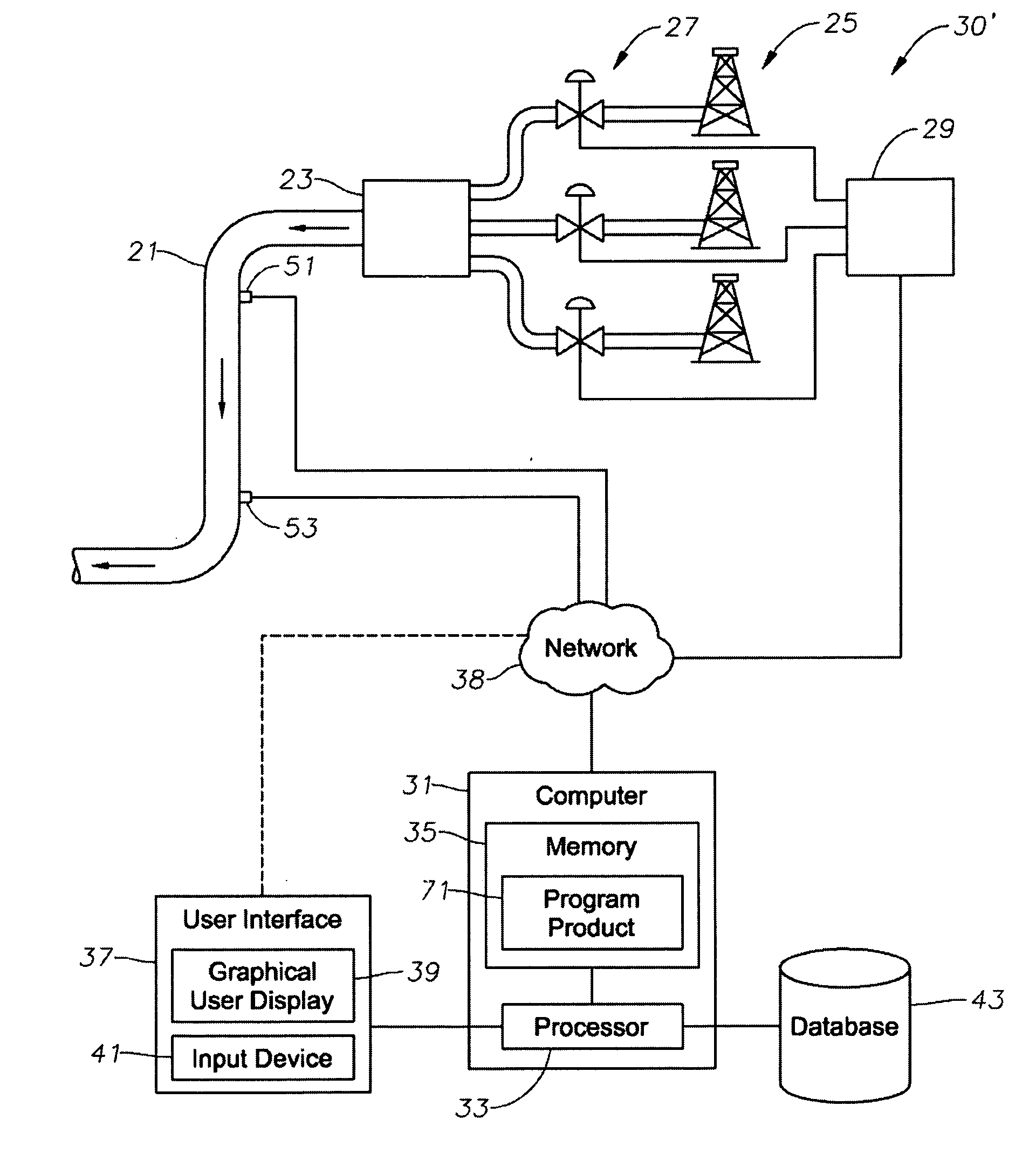

System, program product, and related methods for estimating and managing crude gravity in flowlines in real-time

ActiveUS20090312964A1Flow propertiesSpecific gravity by measuring pressure differencesStream flowAPI gravity

Systems, program product, and methods to estimate and manage flowing fluid characteristics of a fluid stream flowing through a pipeline in real-time, are provided. A system can include a vertically oriented extent of a pipeline for transporting crude oil, a pair of spaced vertically apart sensors or sensor assemblies connected to the vertically oriented extent to obtain pressure and temperature readings of the crude oil, a controller in communication with the pair of sensors or sensor assemblies, and crude oil analysis and management program product stored in the memory of the controller and adapted to determine or estimate density, specific gravity, and API gravity of the crude oil to thereby manage flowing fluid characteristics of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Non-intrusive multiphase flow meter

InactiveUS20050268702A1Material analysis using sonic/ultrasonic/infrasonic wavesSurveyFiberDifferential pressure

Owner:WEATHERFORD TECH HLDG LLC

Low leak gas density monitor assembly

InactiveUS6651483B1Little gas lossFail safeAnalysing fluids using sonic/ultrasonic/infrasonic wavesSpecific gravity by measuring pressure differencesElectrical and Electronics engineeringPressure monitors

An apparatus is provided for monitoring the fluidic contents of a tank. The tank includes a quick disconnect valve and an assembly includes a monitor device, such as, for example, a gas density monitor, a pressure monitor, a temperature monitor, etc., and a quick disconnect fitting. The monitor device is coupled to the quick disconnect fitting. The quick disconnect fitting is adapted to couple to the quick disconnect valve such that the interior of the quick disconnect fitting is in fluidic communication with the interior of the monitor device for reducing the chance of leakage upon connection / disconnection.

Owner:HITACHI ENERGY SWITZERLAND AG

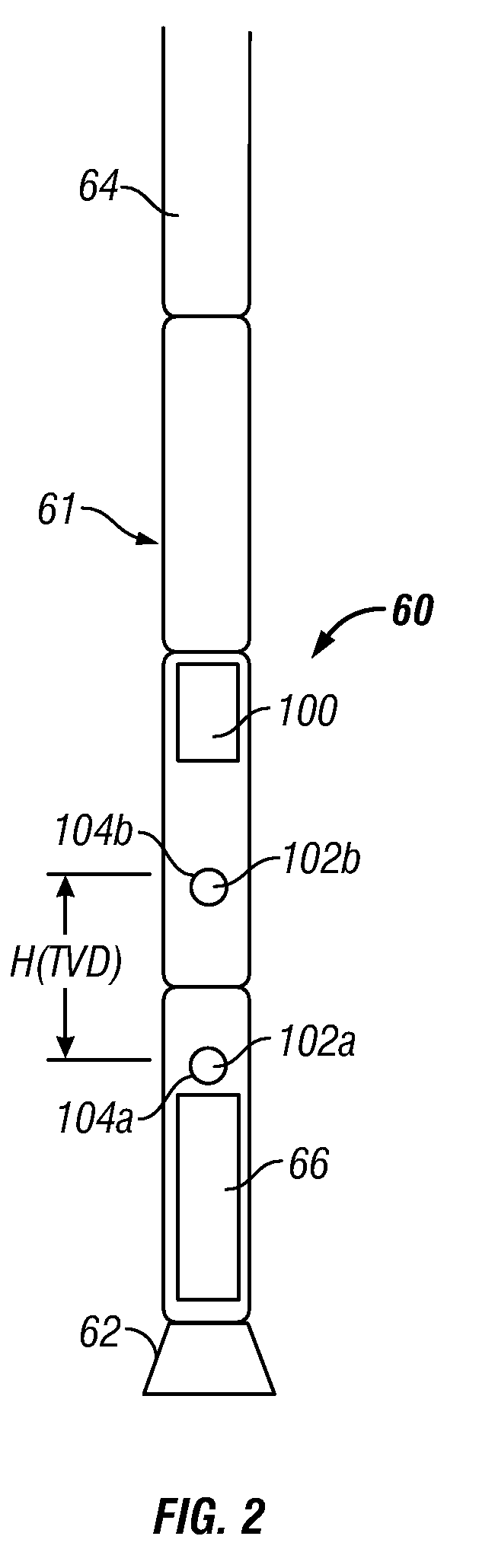

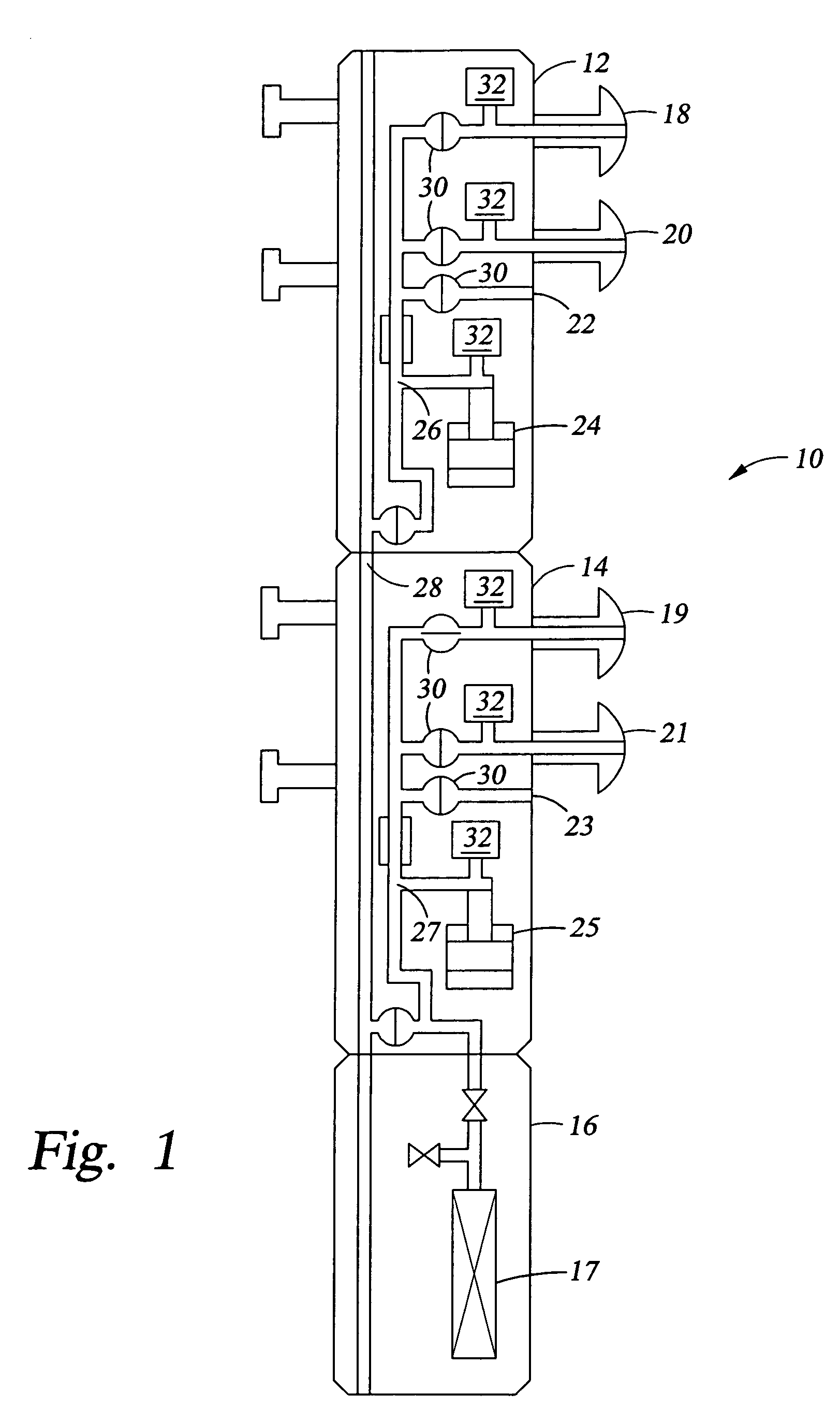

In-well full-bore multiphase flowmeter for horizontal wellbores

ActiveUS20140012507A1Electric/magnetic detection for well-loggingMaterial analysis using sonic/ultrasonic/infrasonic wavesMomentumSurface roughness

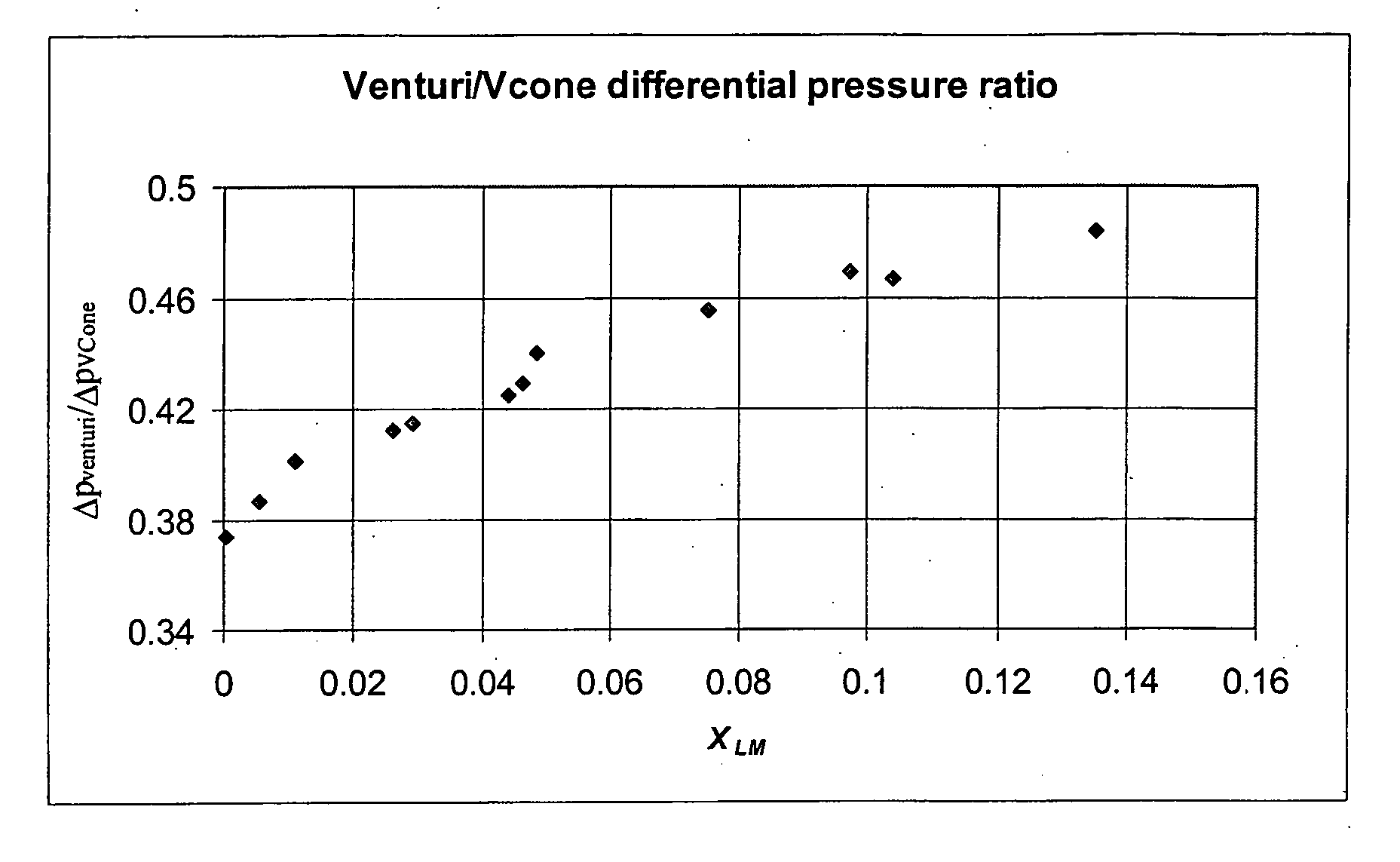

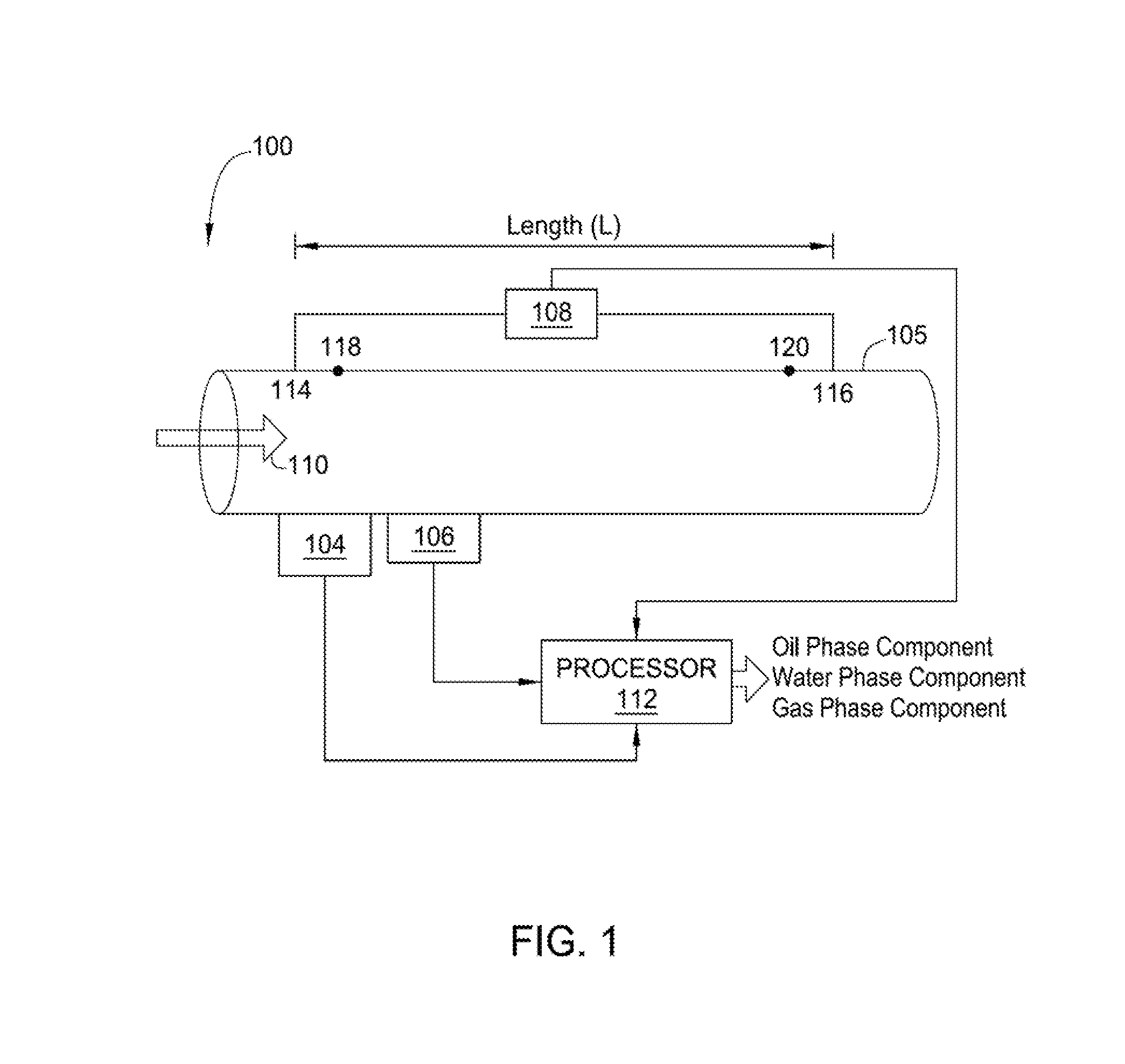

Methods and apparatus for measuring individual phase fractions and phase flow rates in a multiphase flow based on velocity of the flow, speed of sound through the fluid mixture, and the density of the fluid mixture. Techniques presented herein are based on measuring frictional pressure drop across a flowmeter conduit, determining a surface roughness term for the conduit during initial flow tests or through other mechanical means, implementing a correction method to balance the momentum equation, and calculating the fluid mixture density using the measured pressure drop. The techniques may be applicable to measuring flow parameters in horizontally oriented conduits and, more generally, conduits of any orientation.

Owner:WEATHERFORD TECH HLDG LLC

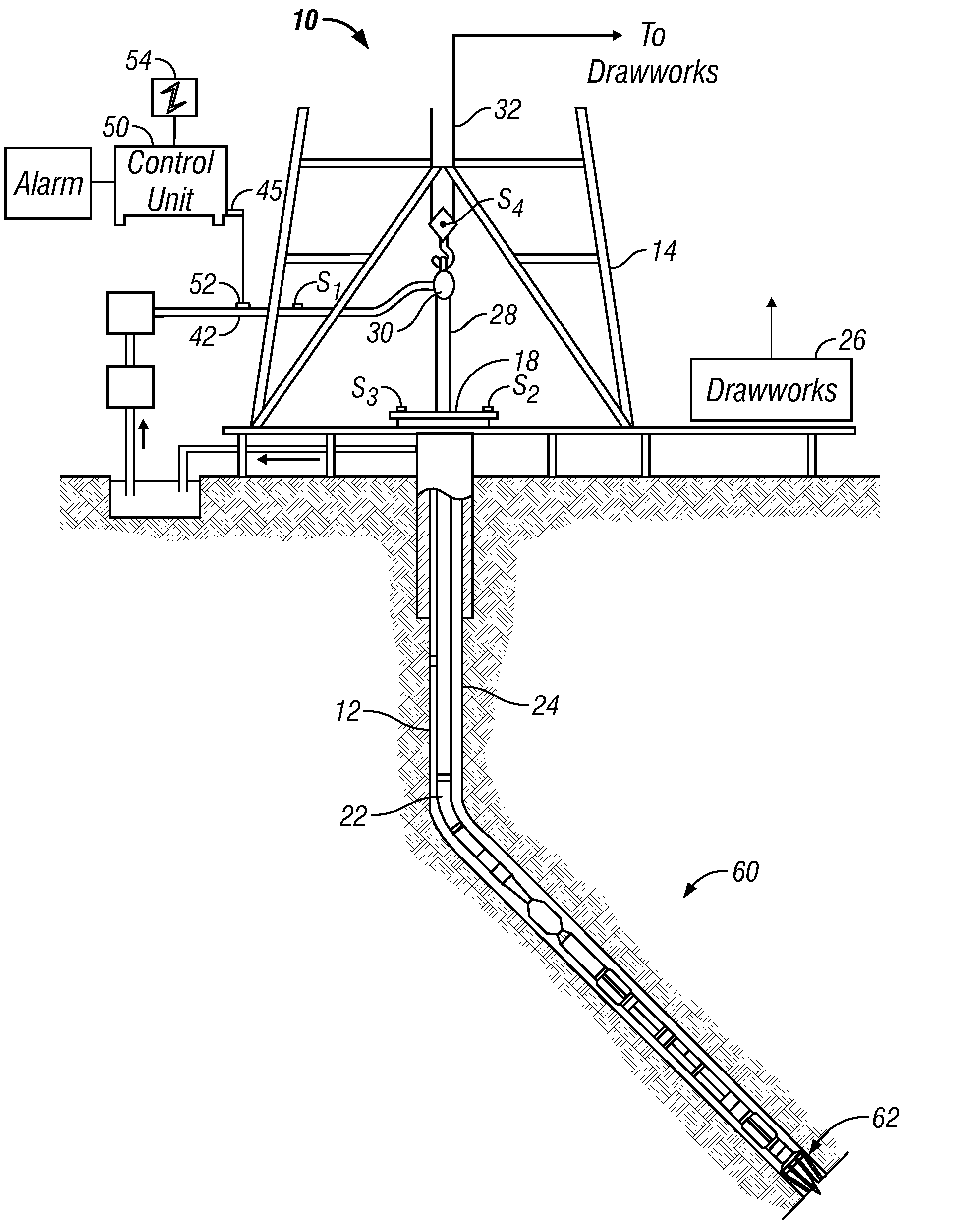

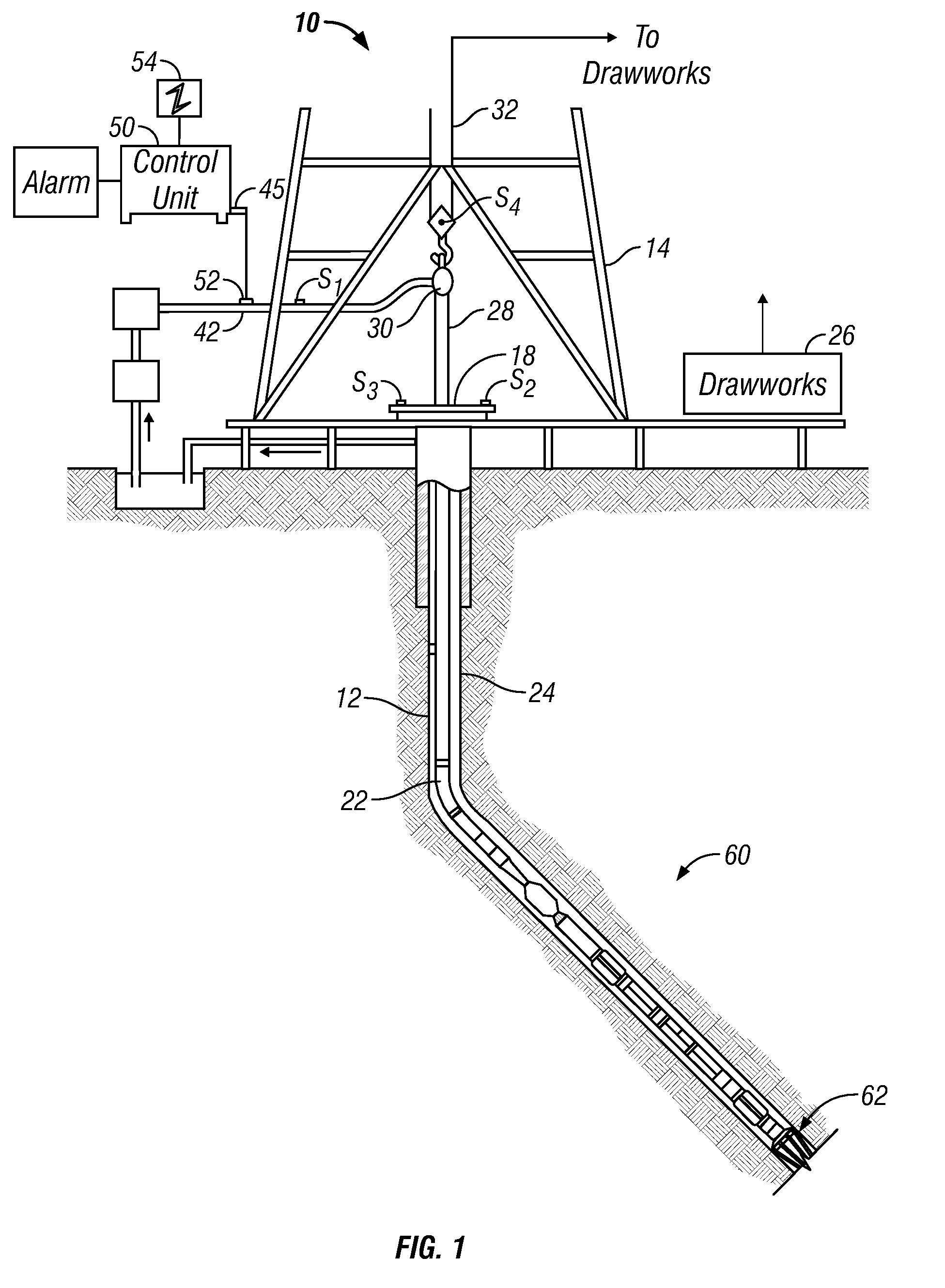

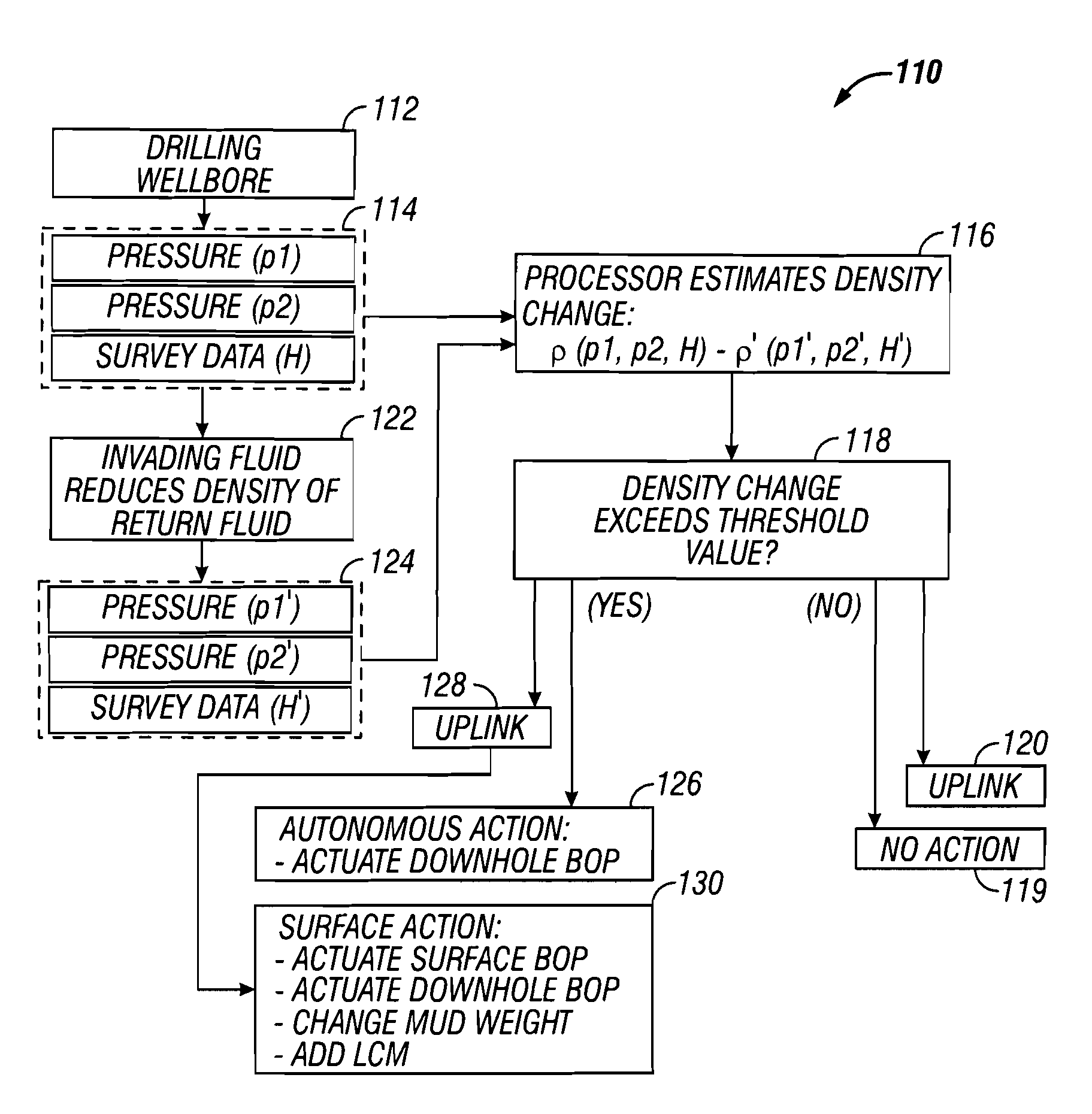

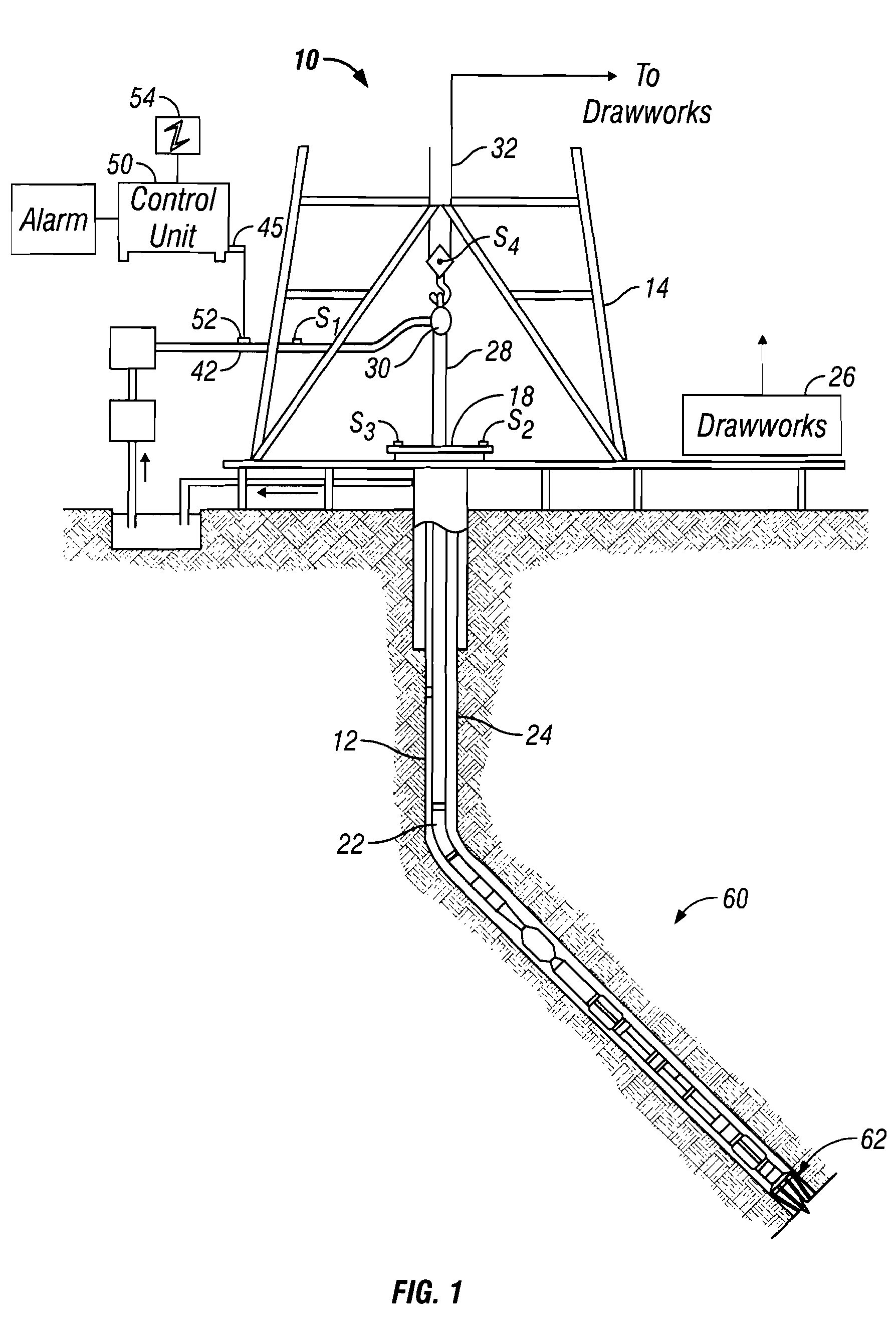

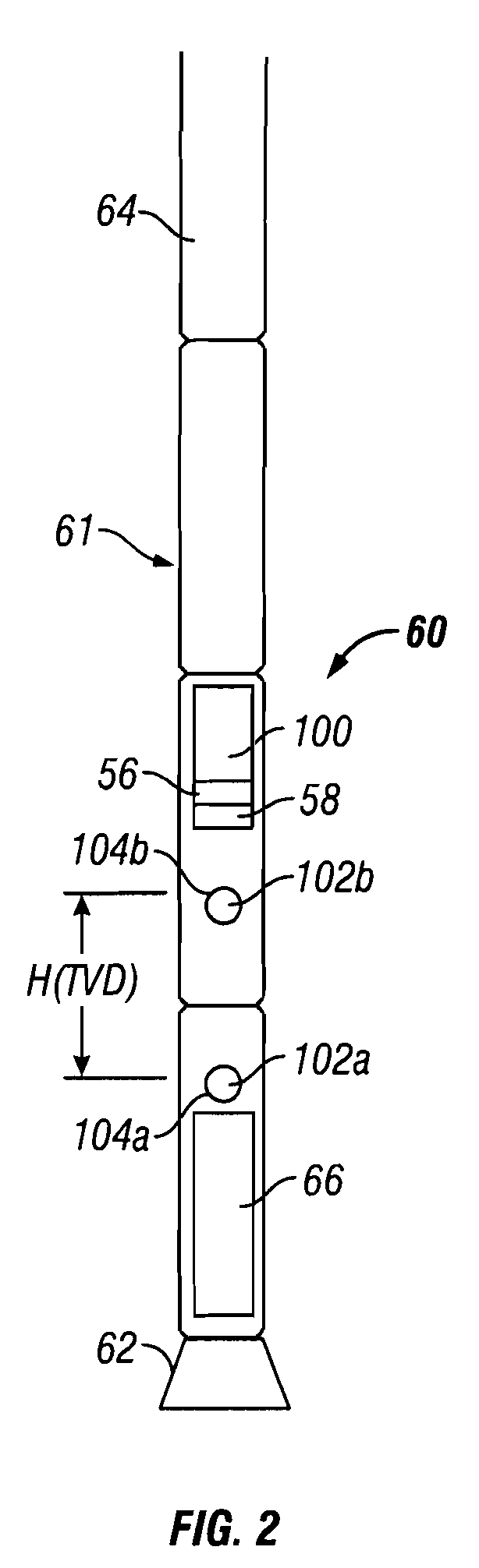

Downhole Local Mud Weight Measurement Near Bit

ActiveUS20090205822A1Reduce offsetElectric/magnetic detection for well-loggingSurveyVolumetric Mass DensityPressure difference

A method for detecting a change in a wellbore fluid includes estimating at least two pressure differences in the wellbore fluid and estimating a change in a density of the fluid using the at least two pressure differences. The density change may be estimated by the equation, Δρ=(ΔPbefore<sub2>—< / sub2>influx−ΔPafter<sub2>—< / sub2>influx) / (g×ΔTVD), wherein ΔP is a fluid pressure difference between two points along the wellbore, ρ is a mean value of density of the fluid between the two points, g is gravity and ΔTVD is a vertical distance between the two points. The method may include estimating a density change using an estimated inclination of the wellbore. An apparatus for estimating density changes includes at least two axially spaced apart pressure sensors. The sensor positions may be switched to estimate a correction term to reduce a relative offset between the two pressure sensors.

Owner:BAKER HUGHES INC

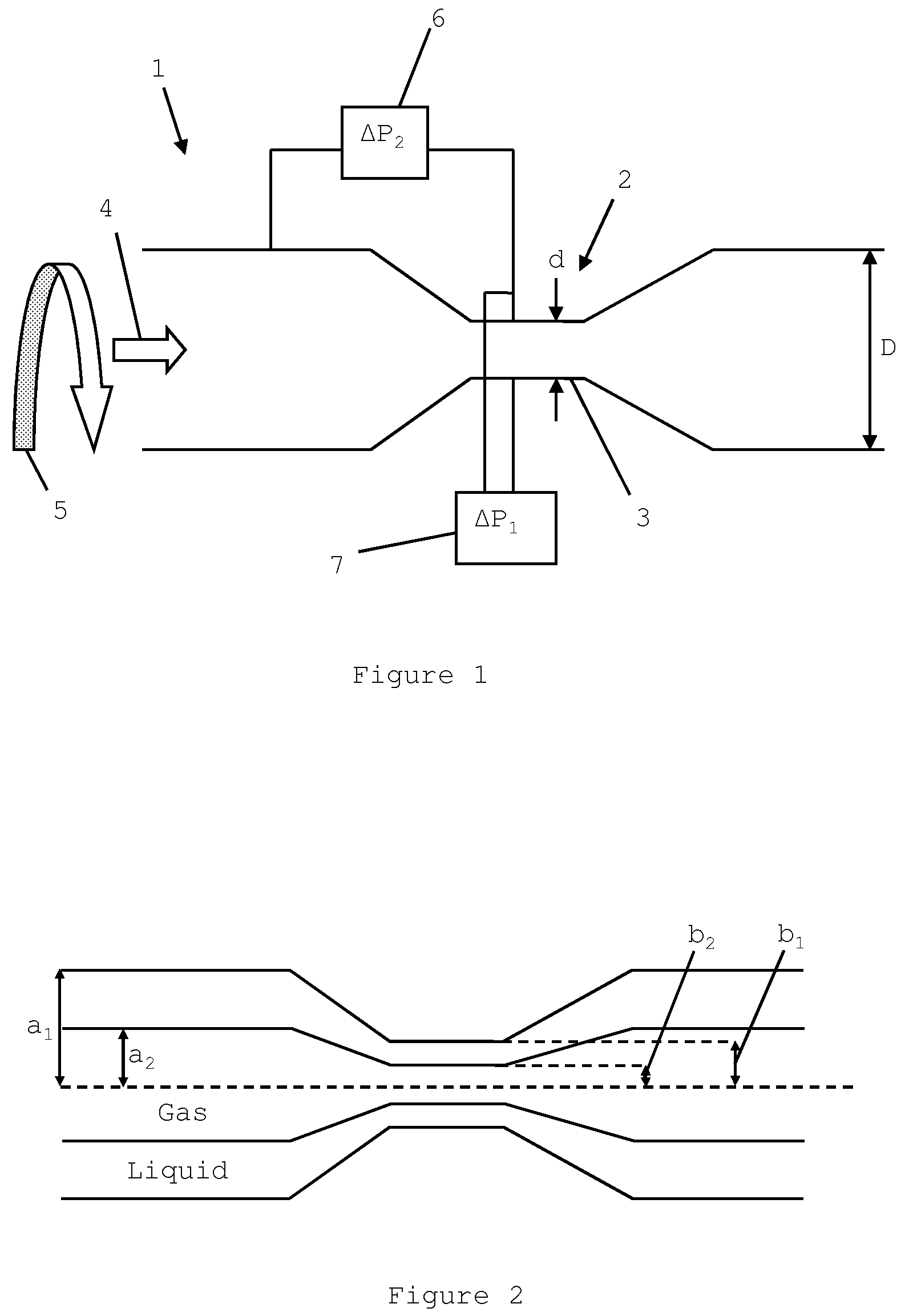

Determination of density for metering a fluid flow

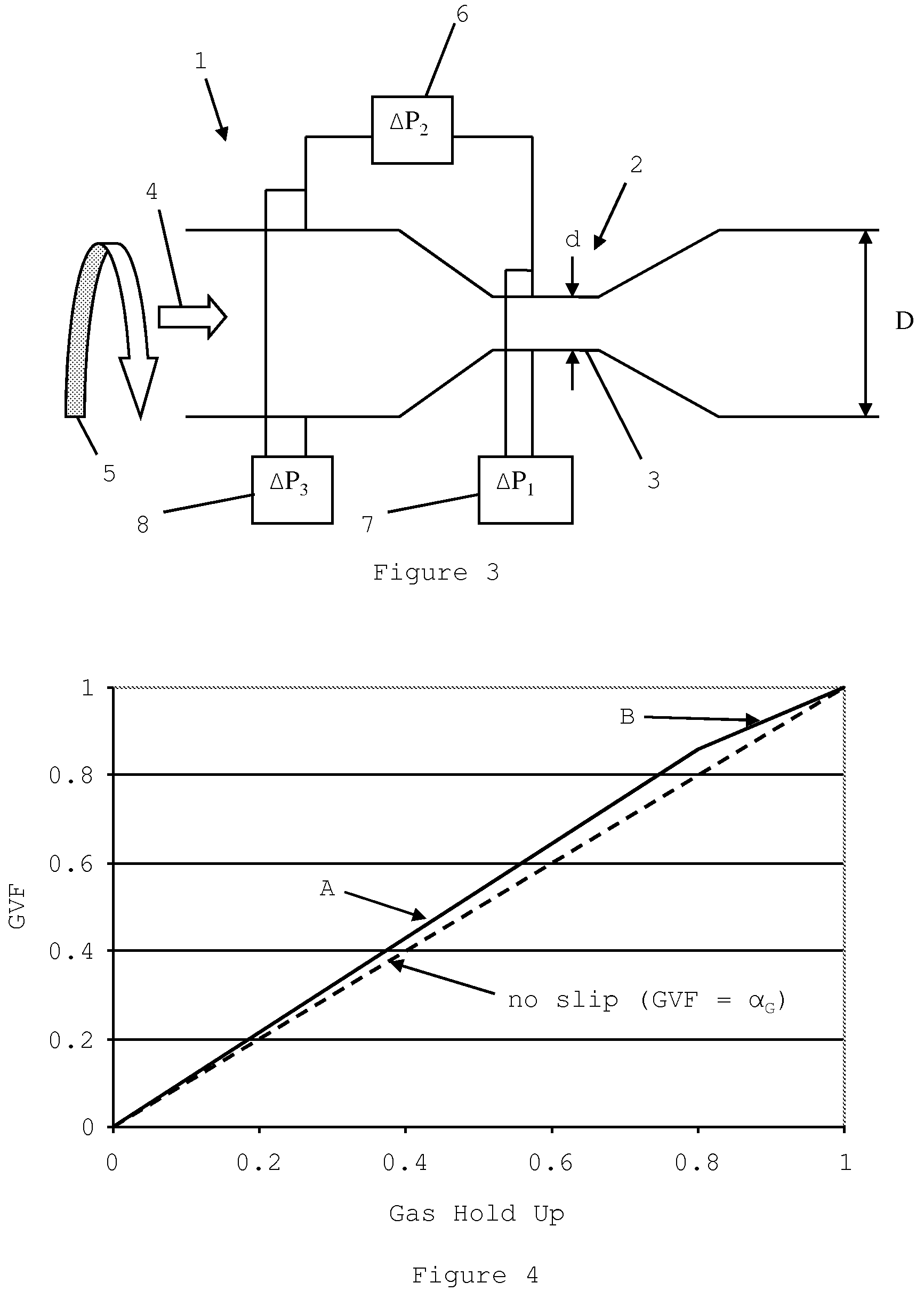

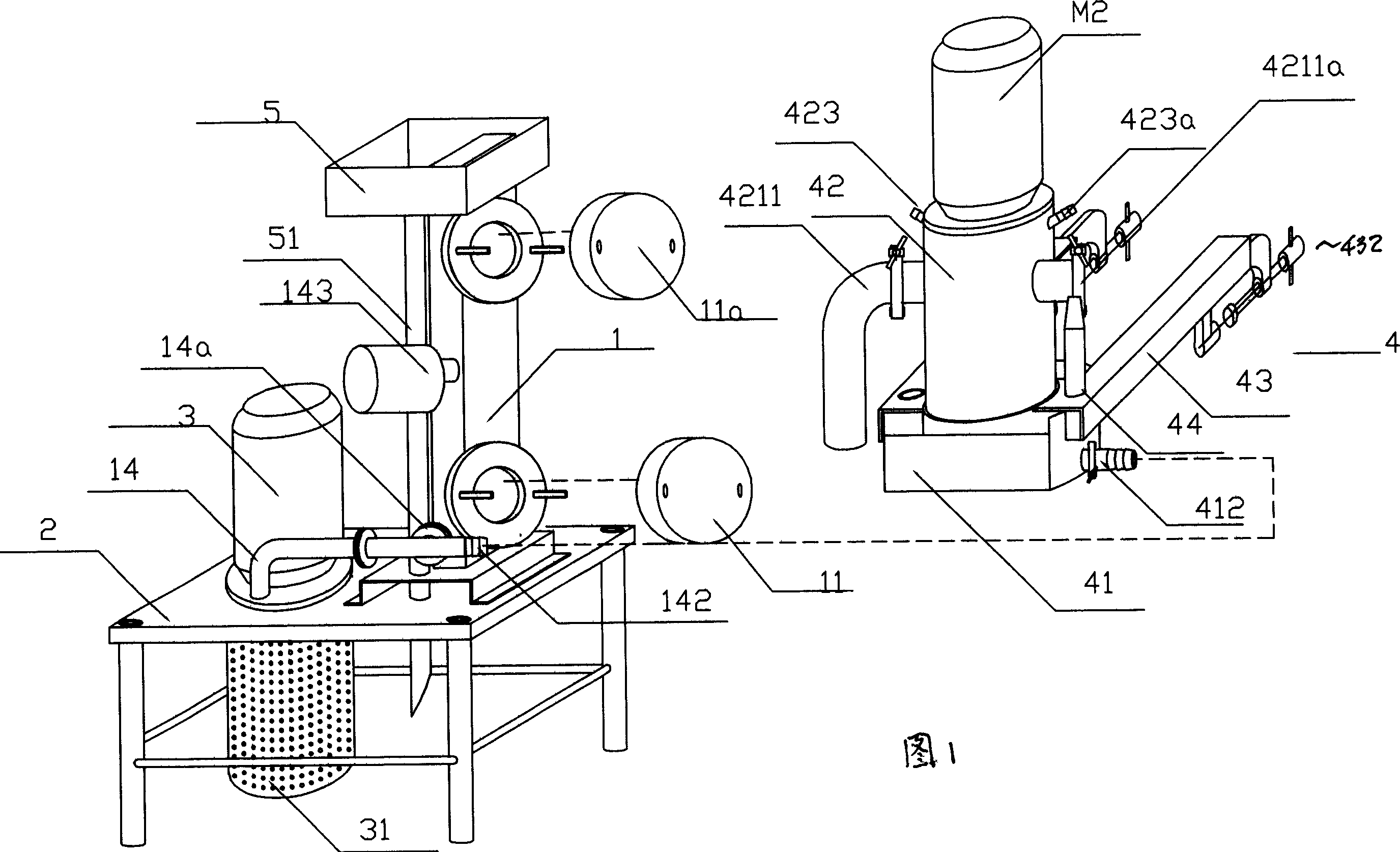

InactiveUS7562587B2Specific gravity by measuring pressure differencesVolume meteringPressure differenceGuide tube

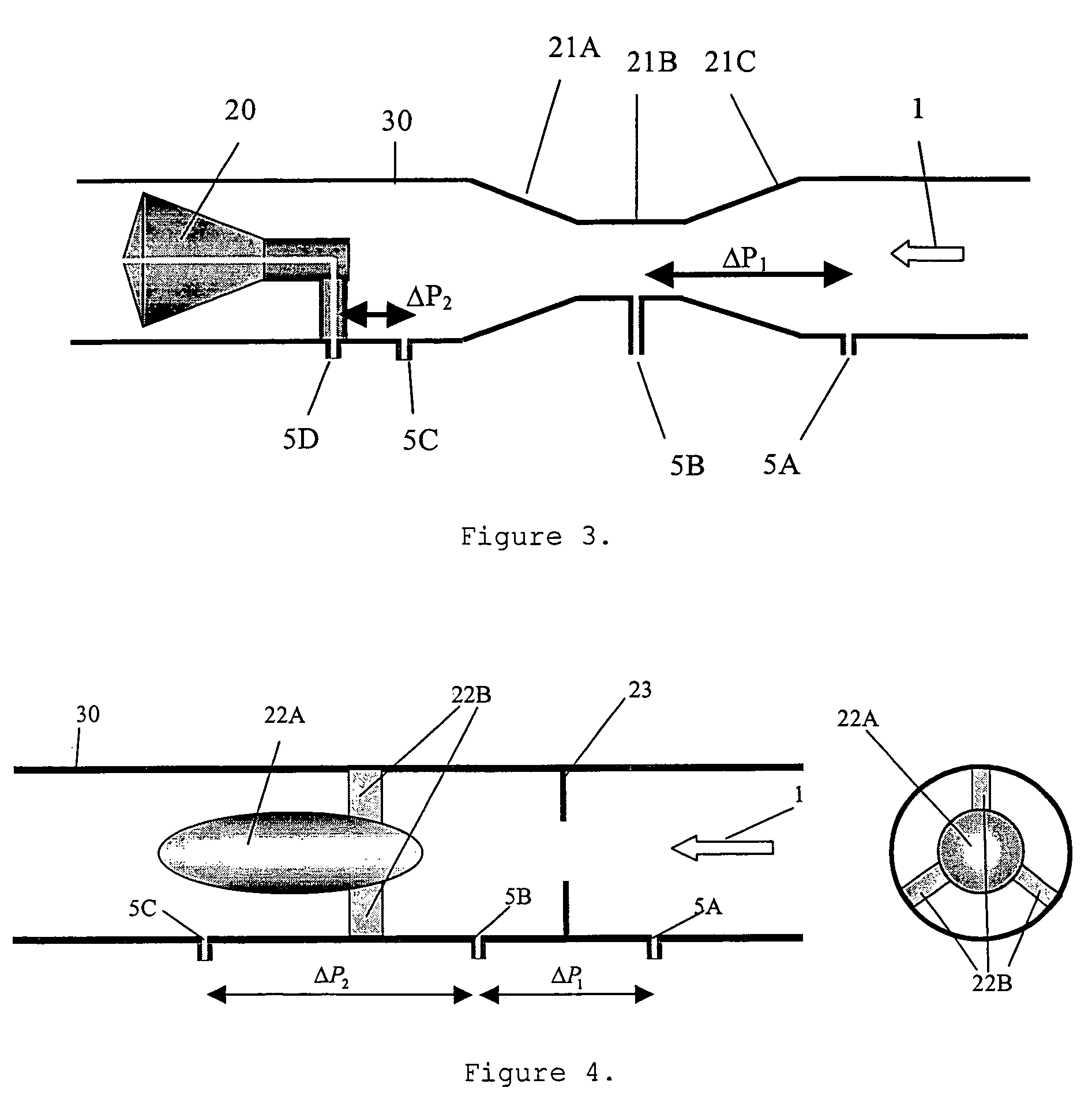

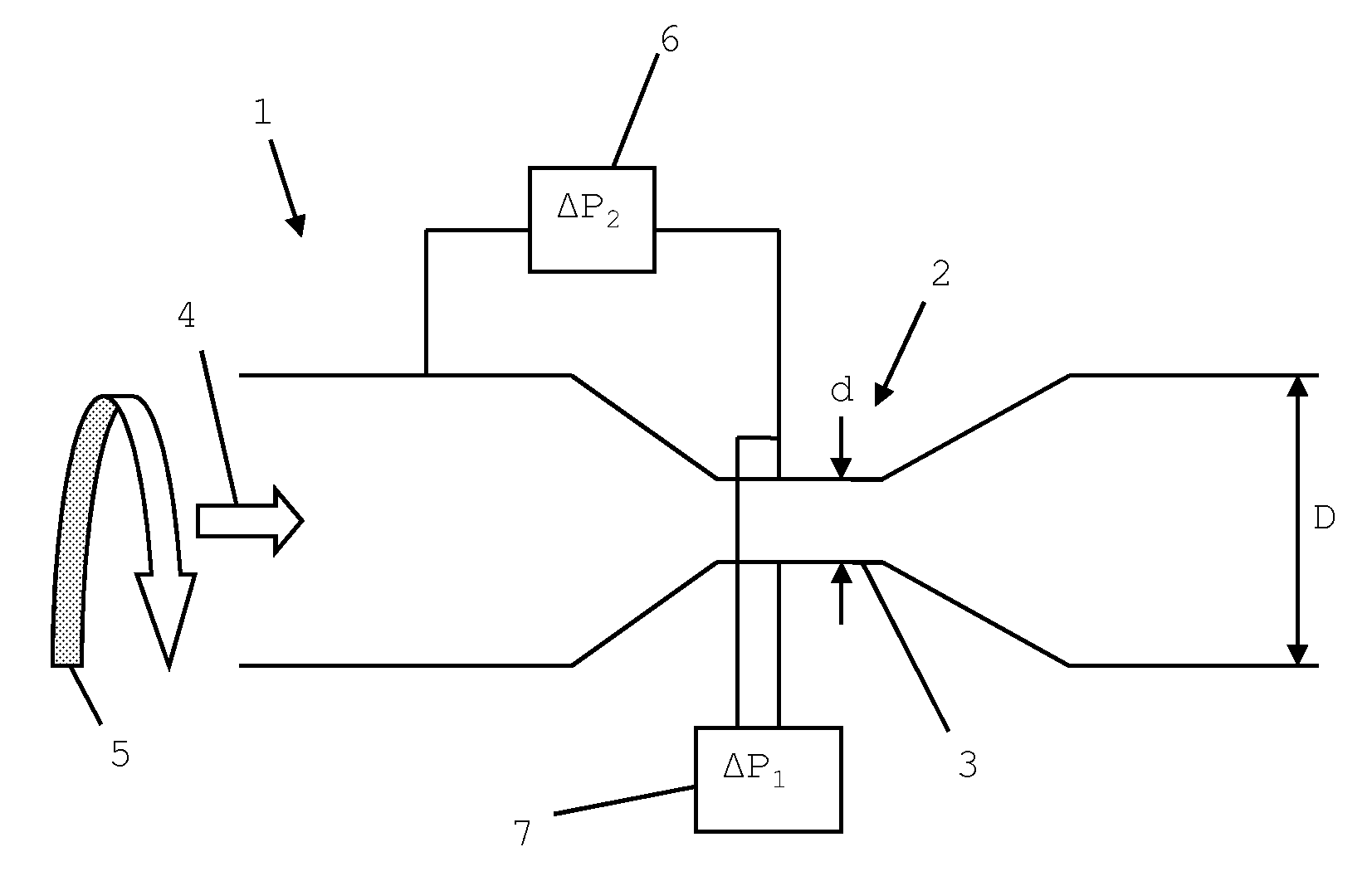

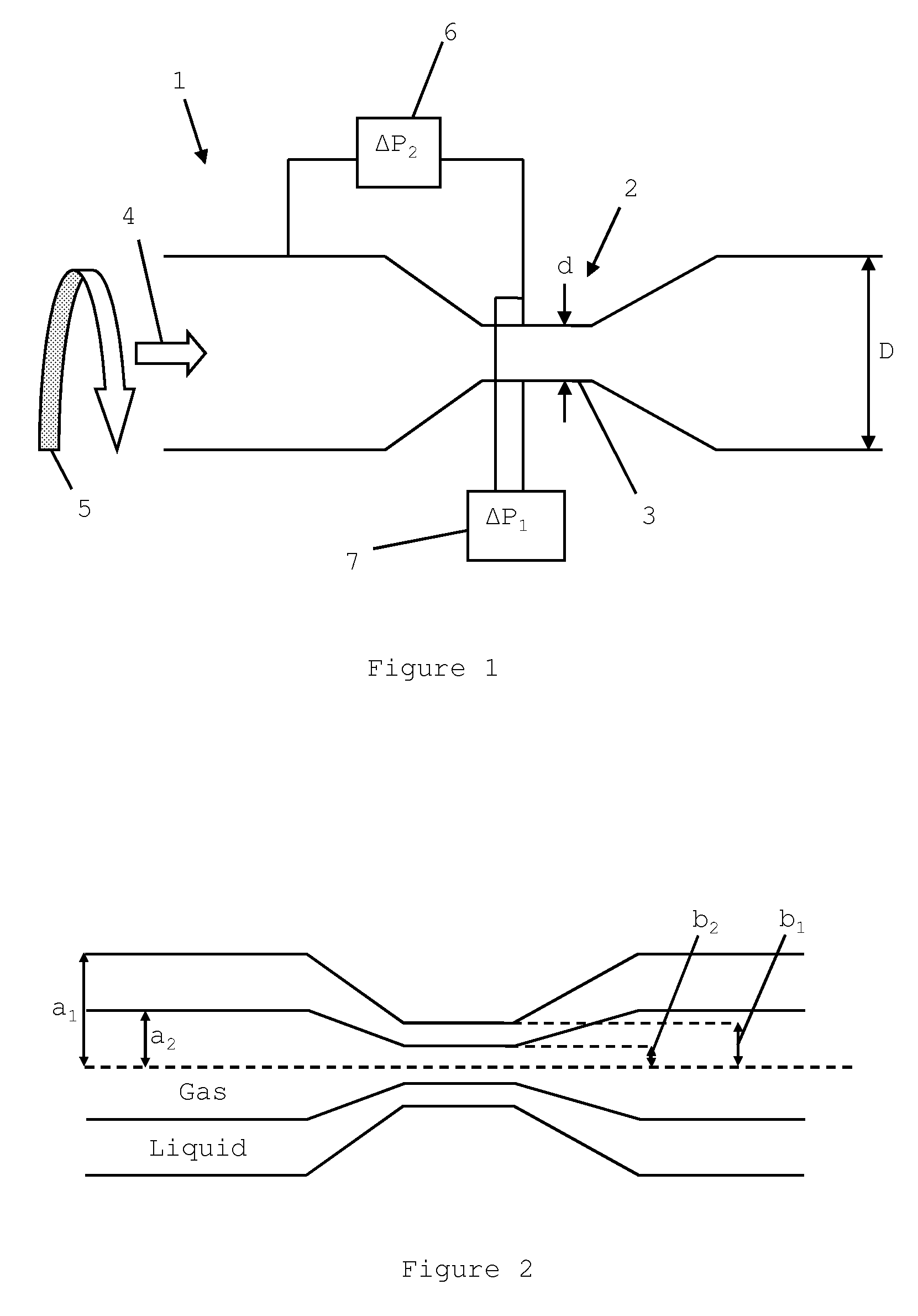

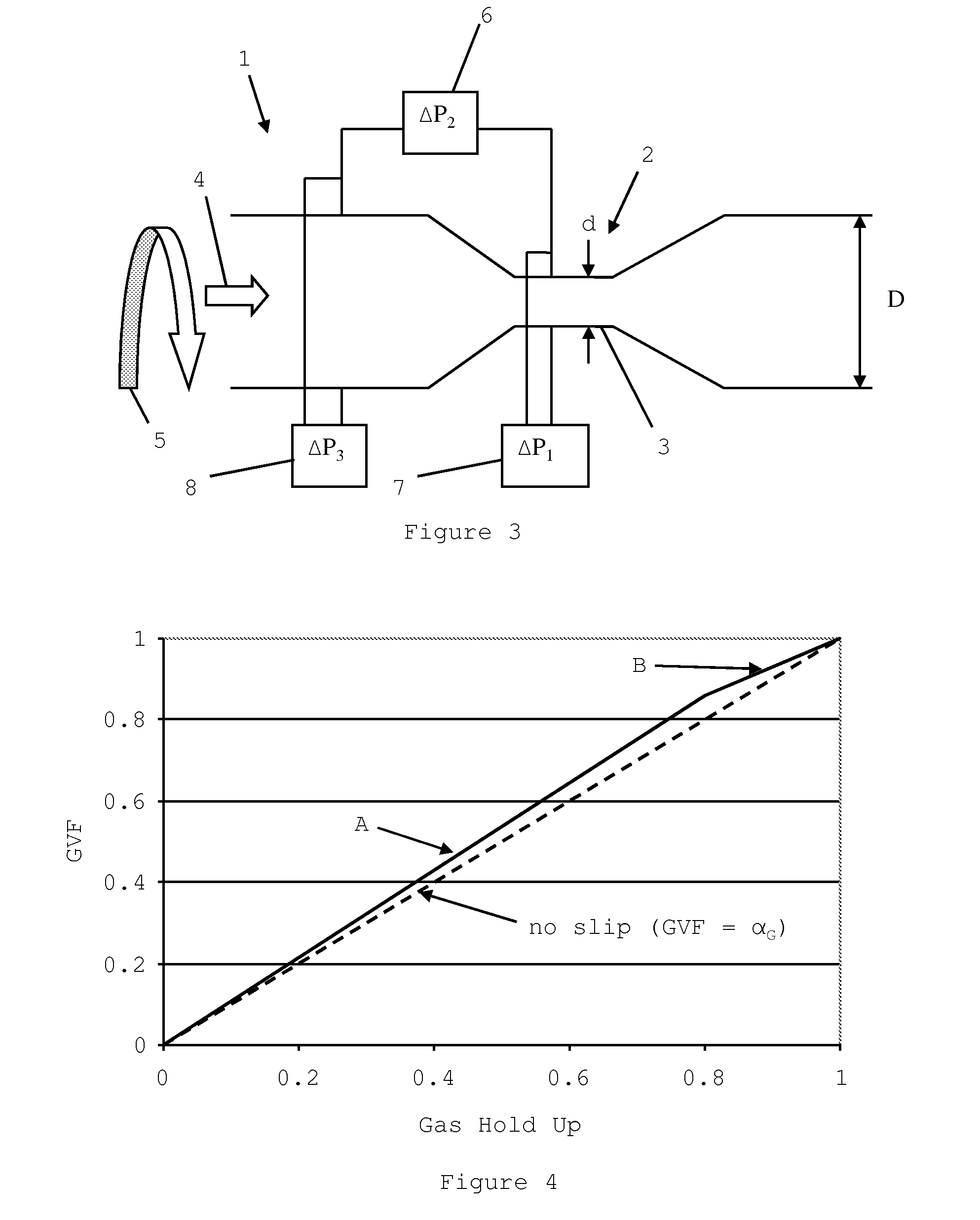

Systems and methods are disclosed for measuring densities and flow rates of gas-liquid fluid mixtures. In the systems and methods, the fluid mixture is caused to exhibit swirling flow as it flows through a conduit that includes a constriction, a first pressure difference is measured between two vertically-spaced measurement positions in the conduit, a second pressure difference is measured between two horizontally-spaced measurement positions in the conduit, the first horizontally-spaced measurement position being at the constriction region and the second horizontally-spaced measurement position being upstream or downstream of the constriction region, and one or more of the pressure differences is used to determine a density or a flow rate of the gas-liquid fluid mixture.

Owner:SCHLUMBERGER TECH CORP

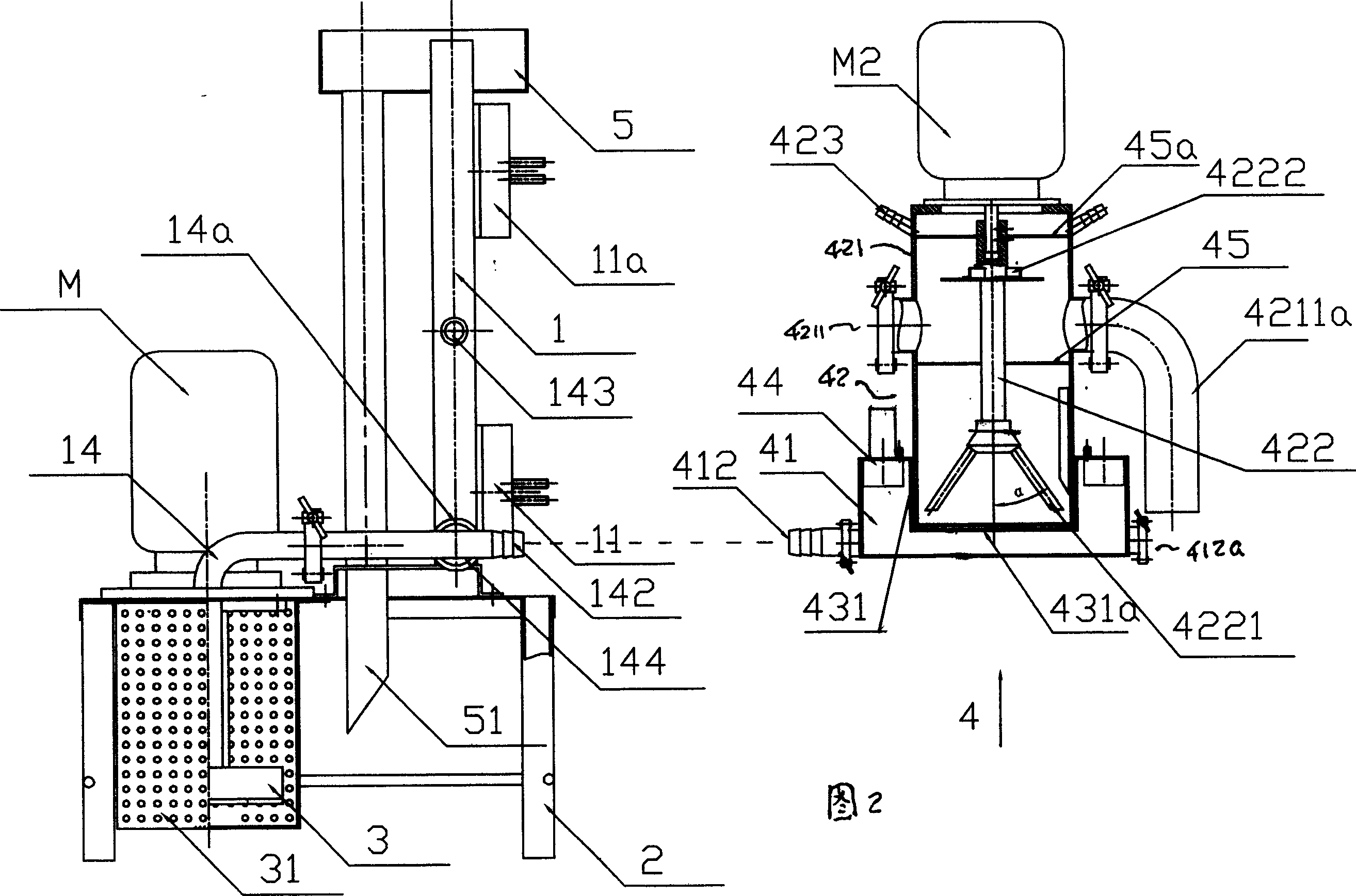

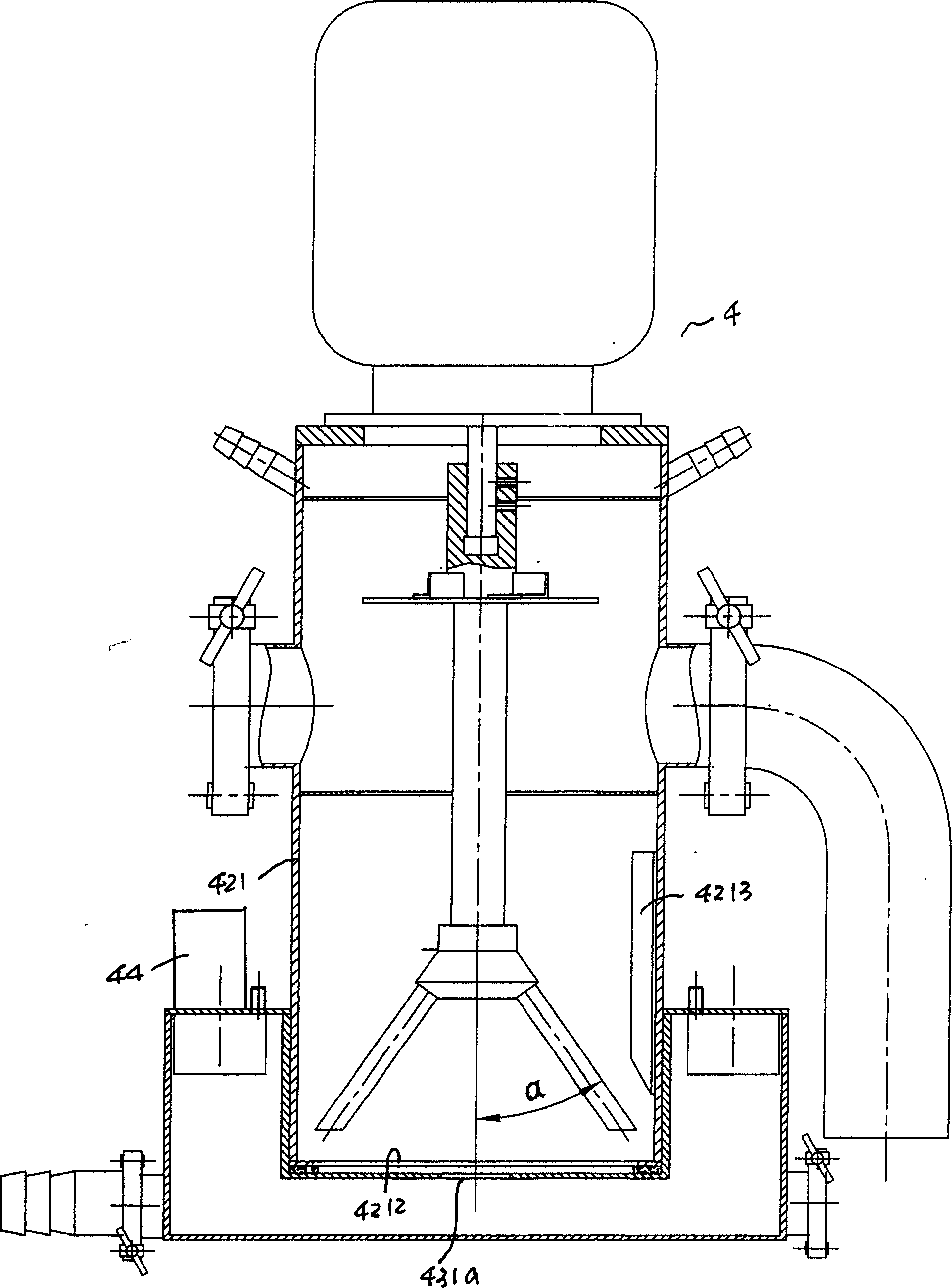

Combined type sensor devices and quantitative degassing apparatus

InactiveCN1687562ASignificant advantagesSignificant beneficial effectSurveySpecific gravity by measuring pressure differencesDegasserEngineering

The invention is a composite sensing device and its quantitative degas device. The density sensor and the temperature sensor connect with the detecting container, the slurry pump transmits the waiting detected well liquid by the conveying tube, and the conveying device connects the quantitative degas device. The quantitative box of the degas device is set at the bottom of the degasser, and the bottom of its side wall has the inlet snout and connects the conveying tube, the bracket is on the quantitative box and has the tray of degasser, and the tray has the limiting slurry inlet, the conductive sensing device is equipped on the bracket and can contact the raw liquid position of the quantitative box. The invention can online correctly detects the density of the well liquid, the conductive ratio and the temperature.

Owner:天津港保税区鑫利达石油技术发展有限公司

Determination of density for metering a fluid flow

InactiveUS20090114038A1Avoid using forceSpecific gravity by measuring pressure differencesVolume meteringPressure differenceGuide tube

Systems and methods are disclosed for measuring densities and flow rates of gas-liquid fluid mixtures. In the systems and methods, the fluid mixture is caused to exhibit swirling flow as it flows through a conduit that includes a constriction, a first pressure difference is measured between two vertically-spaced measurement positions in the conduit, a second pressure difference is measured between two horizontally-spaced measurement positions in the conduit, the first horizontally-spaced measurement position being at the constriction region and the second horizontally-spaced measurement position being upstream or downstream of the constriction region, and one or more of the pressure differences is used to determine a density or a flow rate of the gas-liquid fluid mixture.

Owner:SCHLUMBERGER TECH CORP

Downhole local mud weight measurement near bit

ActiveUS7950472B2Reduce offsetSurveySpecific gravity by measuring pressure differencesVolumetric Mass DensityPressure difference

A method for detecting a change in a wellbore fluid includes estimating at least two pressure differences in the wellbore fluid and estimating a change in a density of the fluid using the at least two pressure differences. The density change may be estimated by the equation, Δρ=(ΔPbefore<sub2>—< / sub2>influx−ΔPafter<sub2>—< / sub2>influx) / (g×ΔTVD), wherein ΔP is a fluid pressure difference between two points along the wellbore, ρ is a mean value of density of the fluid between the two points, g is gravity and ΔTVD is a vertical distance between the two points. The method may include estimating a density change using an estimated inclination of the wellbore. An apparatus for estimating density changes includes at least two axially spaced apart pressure sensors. The sensor positions may be switched to estimate a correction term to reduce a relative offset between the two pressure sensors.

Owner:BAKER HUGHES HLDG LLC

Method for measuring slurry density of desulfurizing absorption column

ActiveCN101477020AReduce inherent errorEasy to clean and maintainSpecific gravity by measuring pressure differencesDifferential pressureAbsorption column

The invention relates to a method for measuring density of slurry in a desulfurization absorption tower, which comprises the following steps: firstly selecting a low-pressure side pressure sampling point and a high-pressure side pressure sampling point in the vertical direction of an absorption tower body, then leading out sampling pipe sections from the high-pressure side pressure sampling point and the low-pressure side pressure sampling point respectively, next connecting a high-pressure side capillary tube and a low-pressure side capillary tube of a double-flange diaphragm differential pressure transmitter to a sampling pipe section respectively, and finally calculating a density value by a measured value delta P of the double-flange diaphragm differential pressure transmitter according to a formula rho1=(delta P + rho2 gh) / (gh), wherein in the formula, rho1 is the density of the slurry in the absorption tower, rho2 is the density of the filling liquid in the capillary tube, g is gravitational acceleration, and h is the altitude difference between the high-pressure side pressure sampling point and the low-pressure side pressure sampling point. The method can measure more conveniently and accurately, needs no complex operation or measures, can simply maintain corresponding used measuring equipment and devices with low cost, and ensure stable and reliable running of the measuring equipment and the devices.

Owner:江西井冈山博奇环保科技有限公司

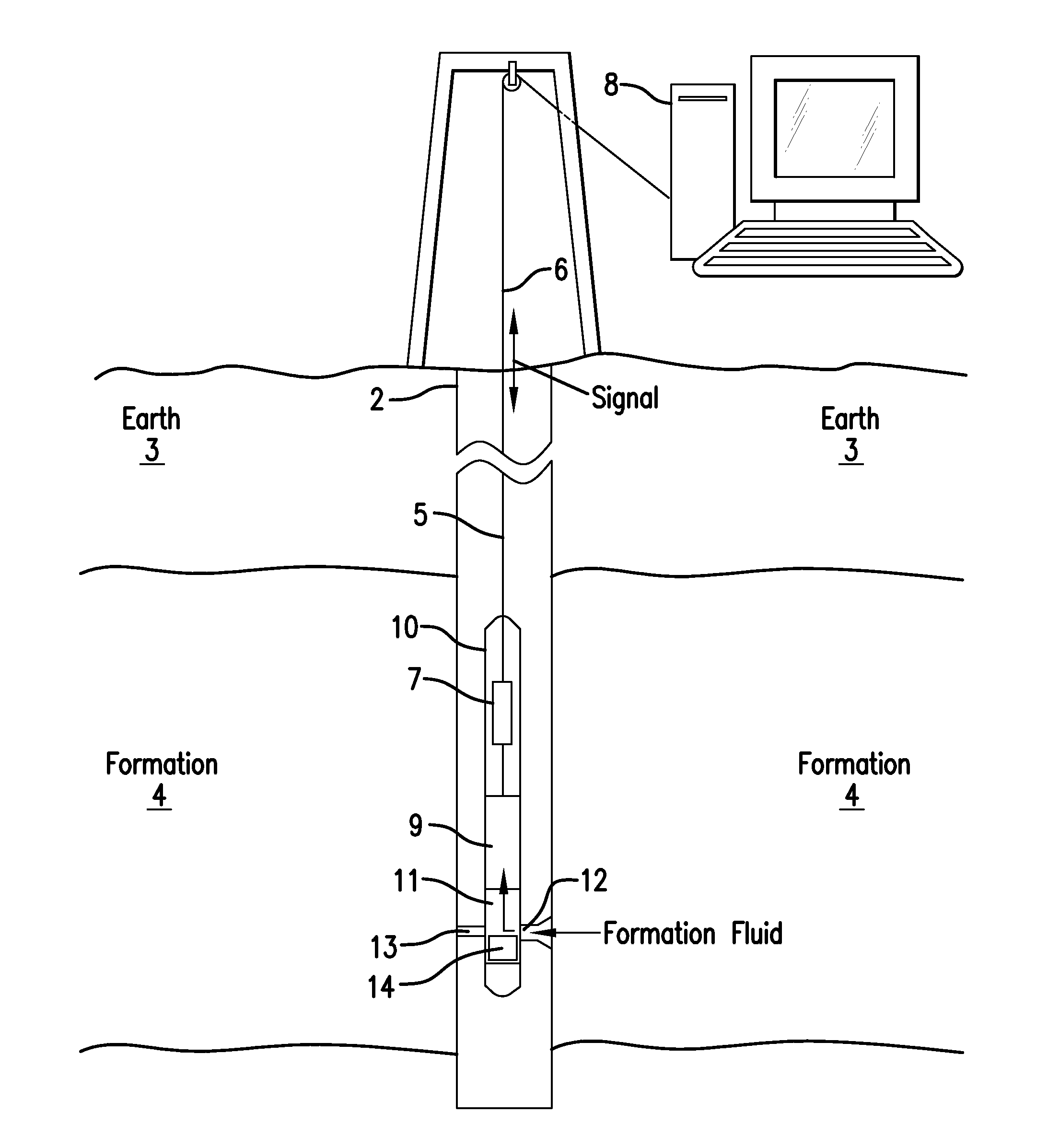

Determining gradients using a multi-probed formation tester

InactiveUS7021405B2Electric/magnetic detection for well-loggingConstructionsFormation fluidFluid density

Methods for operating multi-probed formation testers to determine a fluid density gradient in the formation. The probes of the multi-probed formation tester are connected to a pressure gauge through a flowline that establishes a differential height between the probes. In some embodiments, a gradient of the fluid density in the flowline is determined as a function of the gradient of fluid density in the wellbore. The flowline fluid density gradient is then used to determine a formation fluid density gradient as a function of the flowline fluid density gradient.

Owner:HALLIBURTON ENERGY SERVICES INC

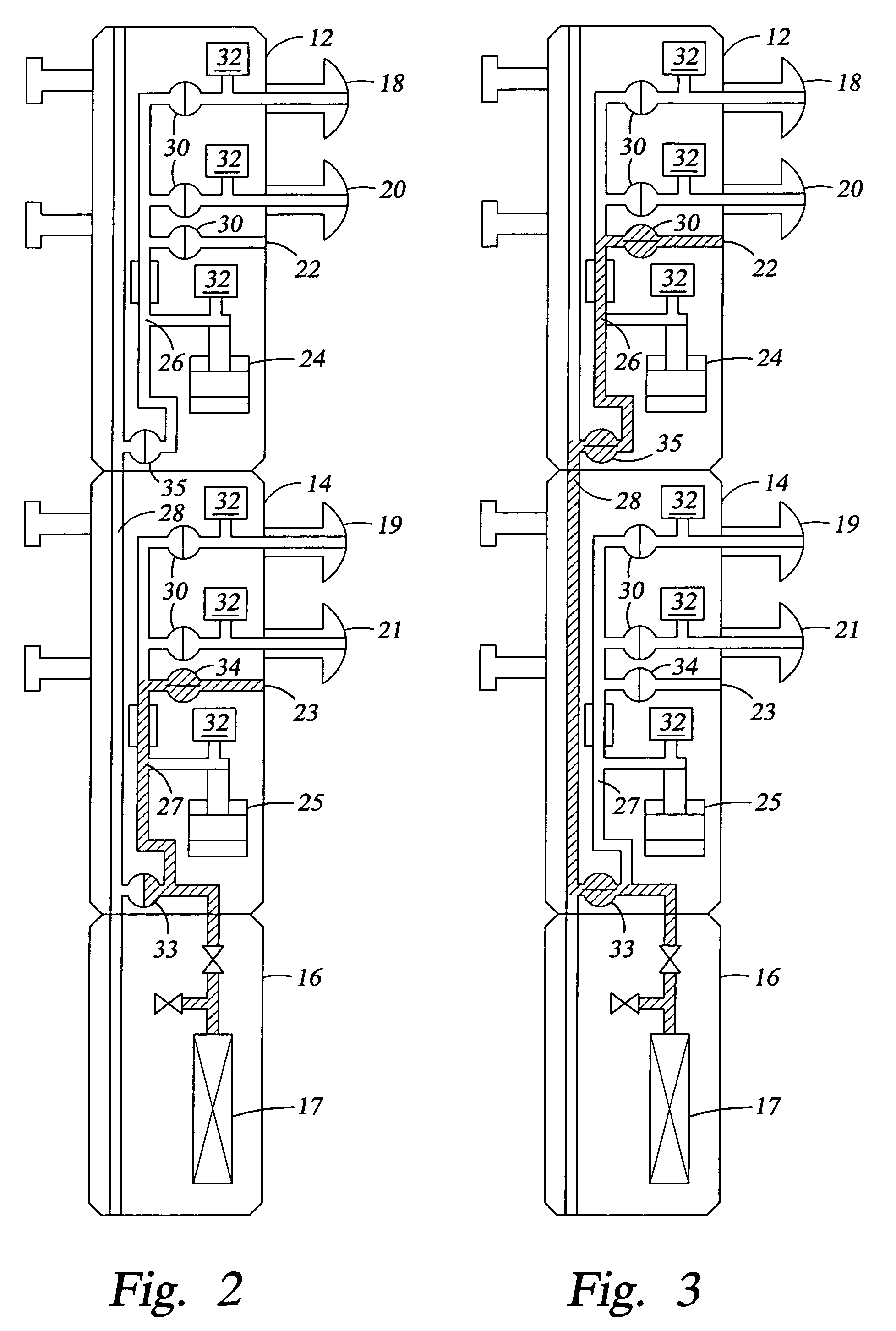

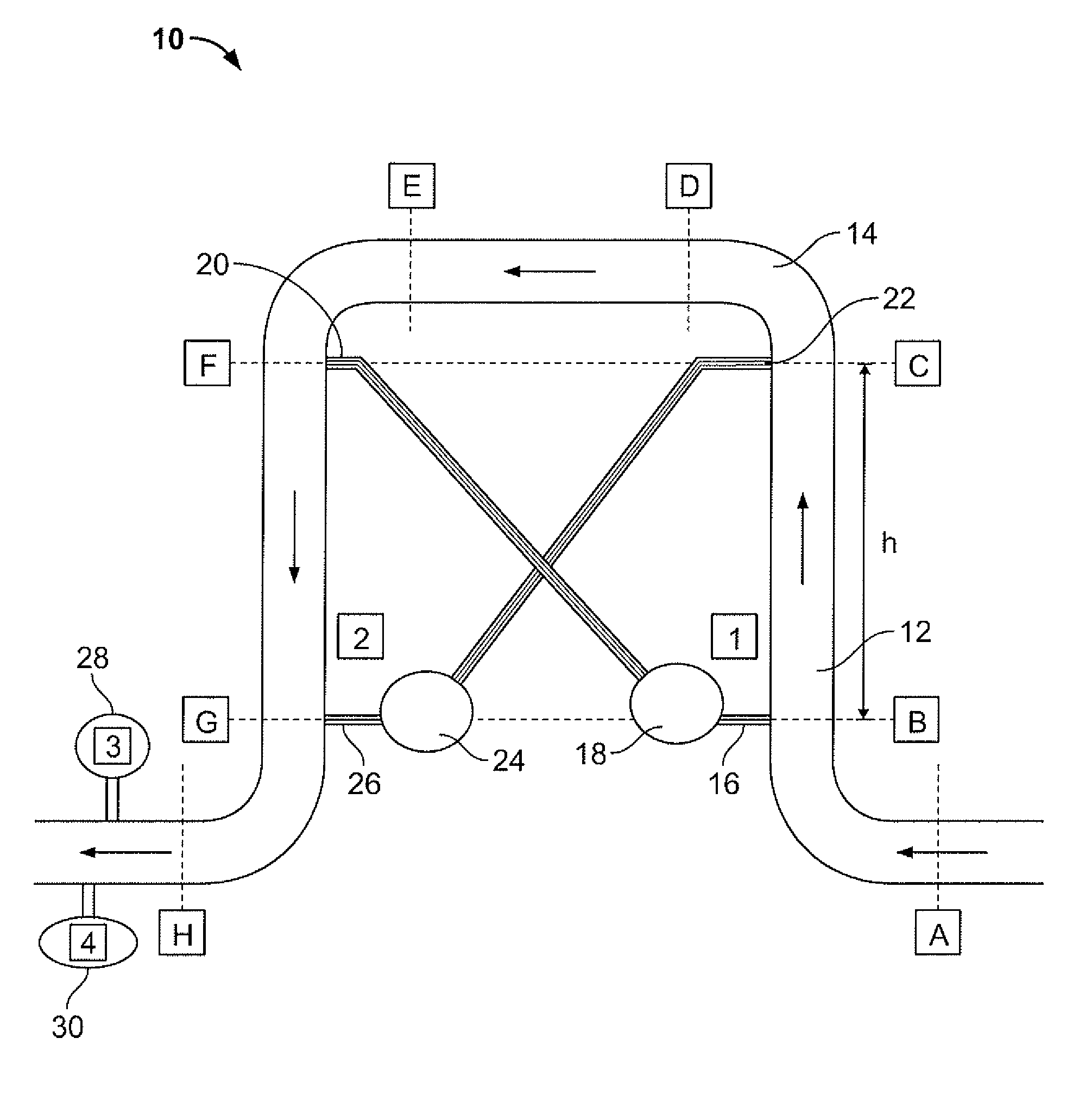

Method and apparatus for measuring the density of a flowing fluid in a conduit using differential pressure

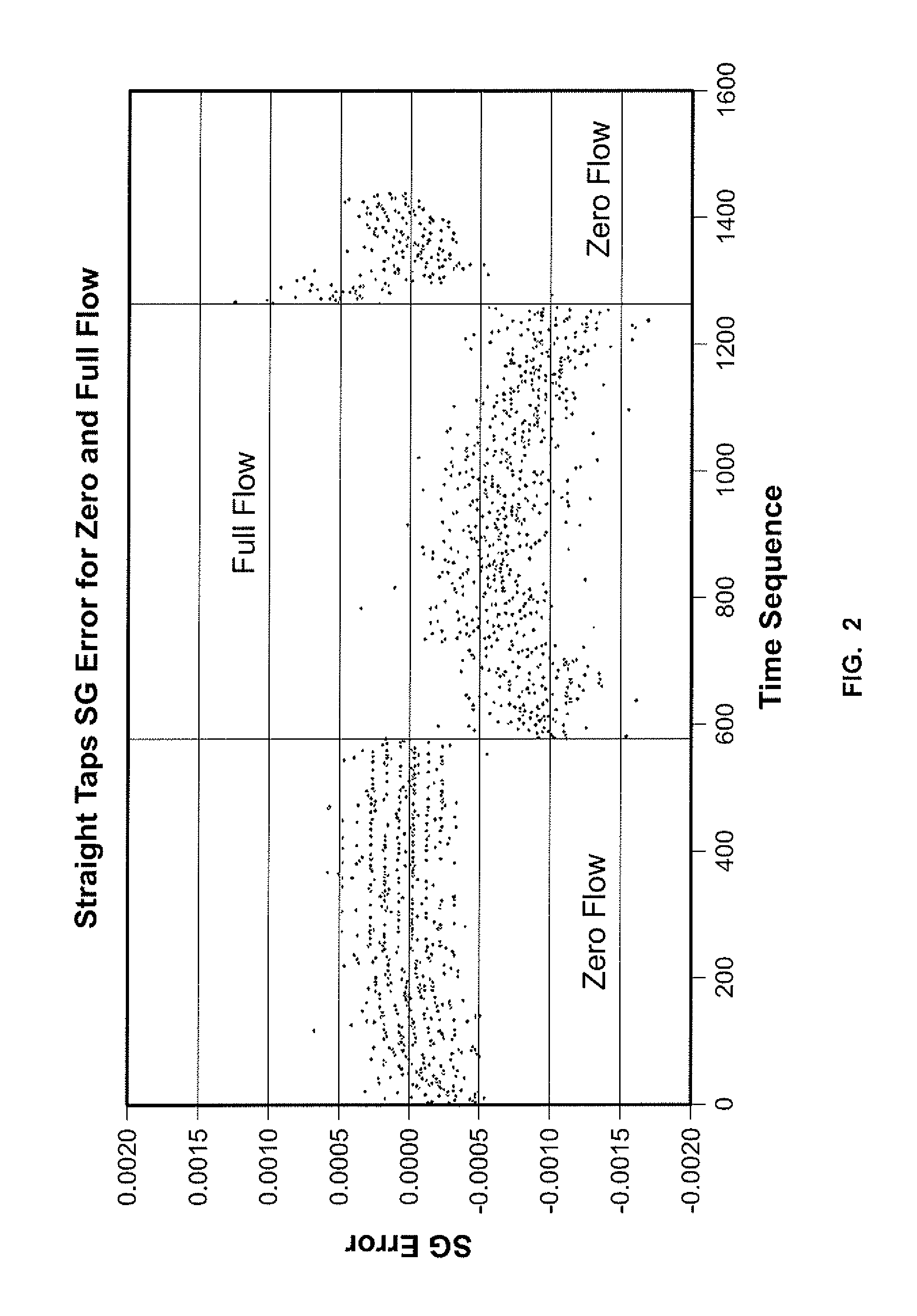

InactiveUS20110296911A1Eliminates elbow effectAvoid the needSpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesDifferential pressureEngineering

A method and apparatus for determining the specific gravity of a monophasic or polyphasic fluid flowing in a conduit. The apparatus employs an square wave shaped tube known for its effectiveness in differential pressure measurements. The apparatus is configured such that the differential pressure is measured in crosswise manner Pressure taps comprising high and low pressure taps for a respective pressure sensing device are associated with a different leg. The apparatus has also been found to be effective for determining flow rate of the fluid in the conduit using differential pressure measurements.

Owner:MOORE BARRY +1

Real time determination of gas solubility and related parameters in manufacturing processes

InactiveUS20050109078A1Easy to controlEasy to handleAnalysing fluids using sonic/ultrasonic/infrasonic wavesTesting beveragesApparent densitySolubility

Owner:APPVION OPERATIONS INC

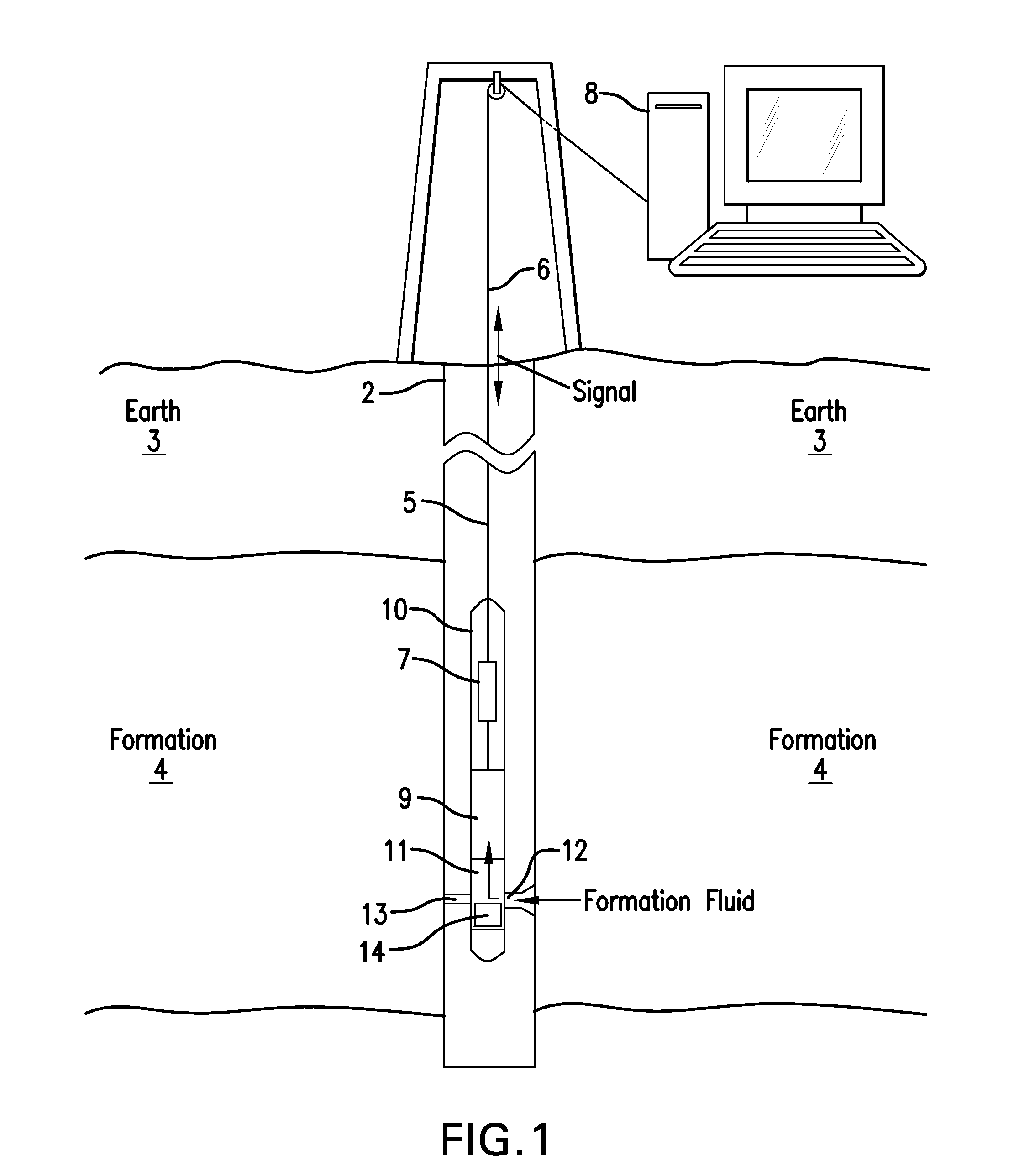

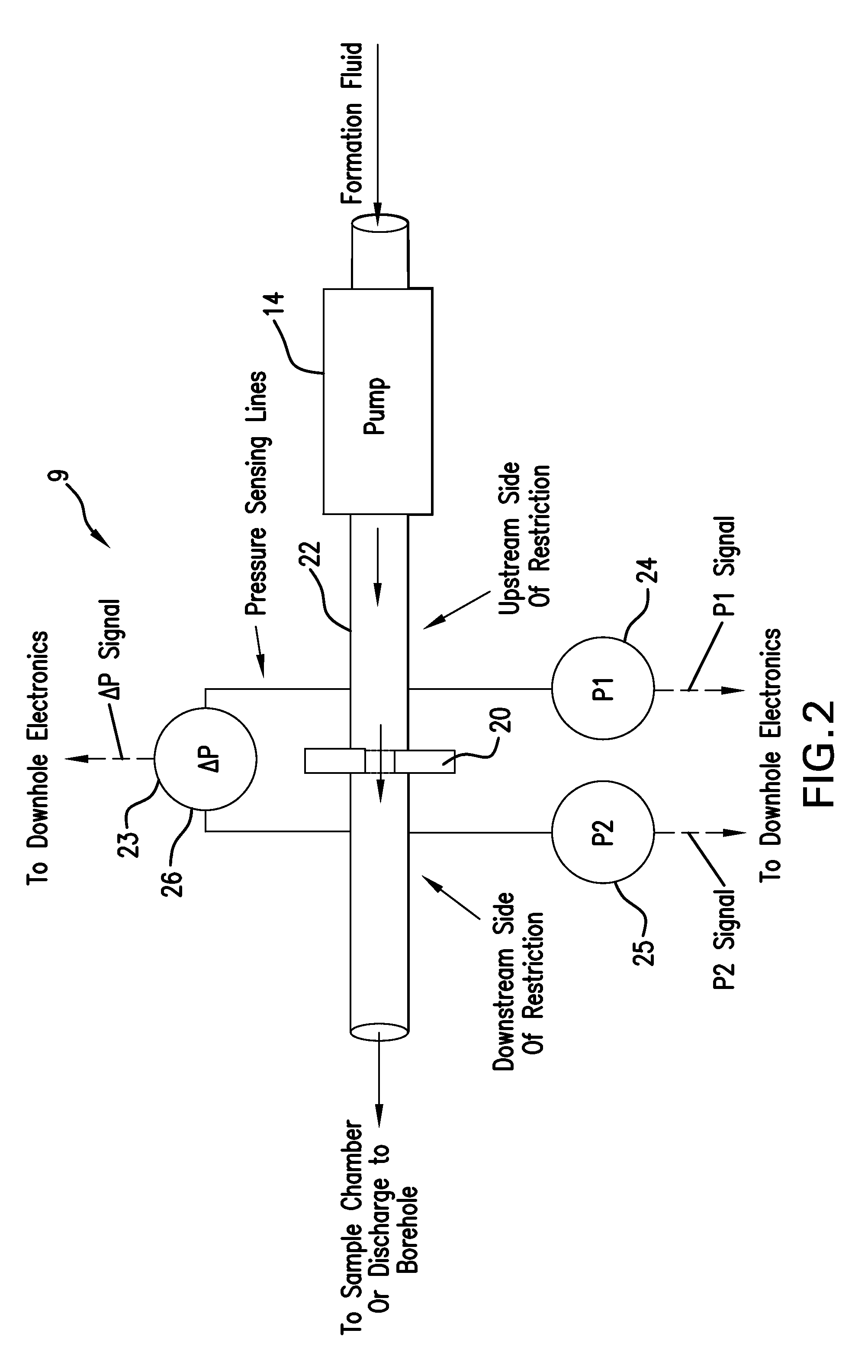

Viscosity measurement in a fluid analyzer sampling tool

ActiveUS20130019673A1Reduce pressureSurveySpecific gravity by measuring pressure differencesDifferential pressureEngineering

An apparatus for estimating a viscosity or density of a fluid downhole includes a carrier configured to be conveyed through a borehole penetrating the earth. A pump is disposed at the carrier and configured to pump the fluid. A flow restriction element is configured to receive a flow of the fluid pumped by the pump and to reduce pressure of the fluid flowing through the flow restriction element. A sensor is configured to measure a differential pressure across the flow restriction element and to provide an output that is used to estimate the viscosity or density.

Owner:BAKER HUGHES INC

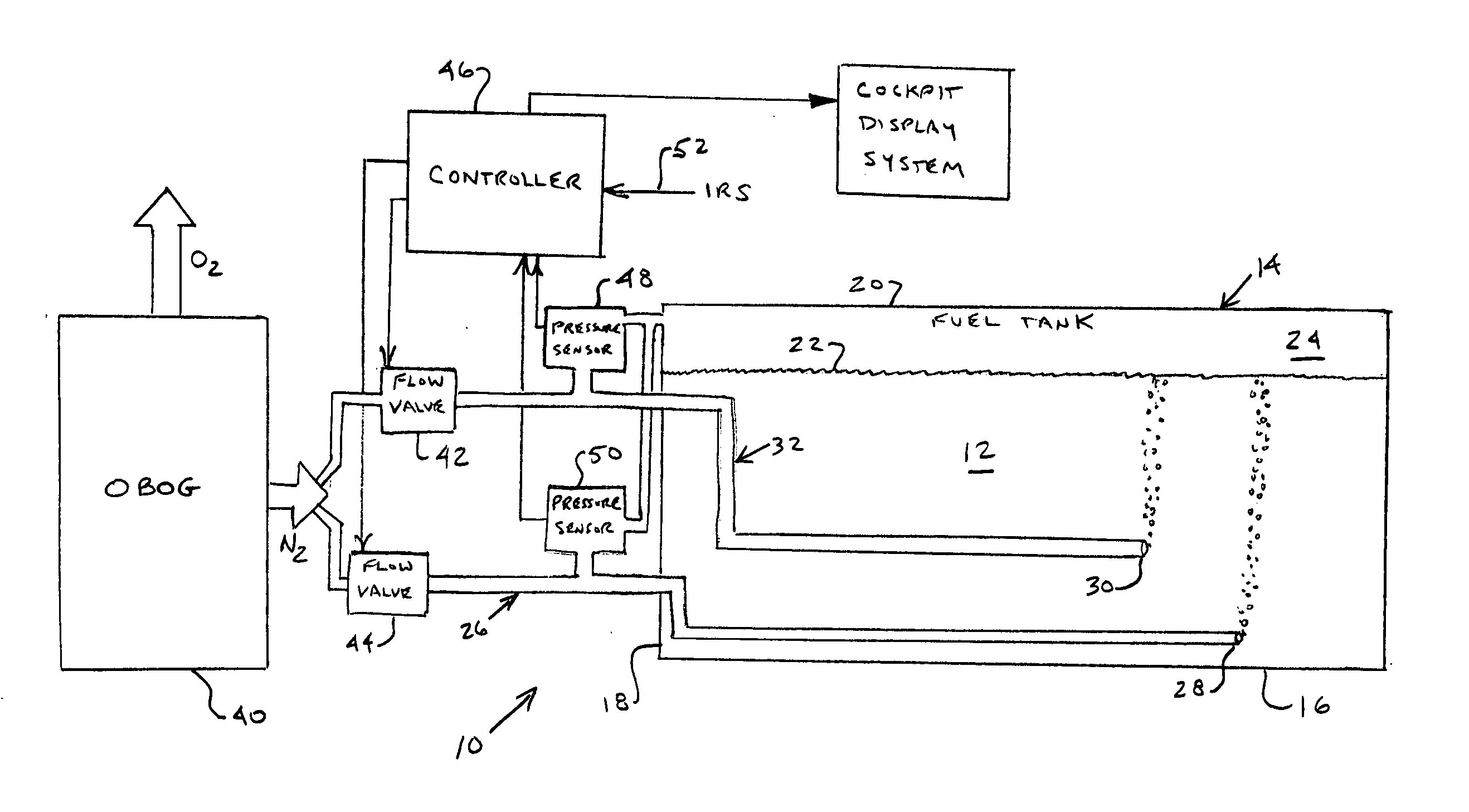

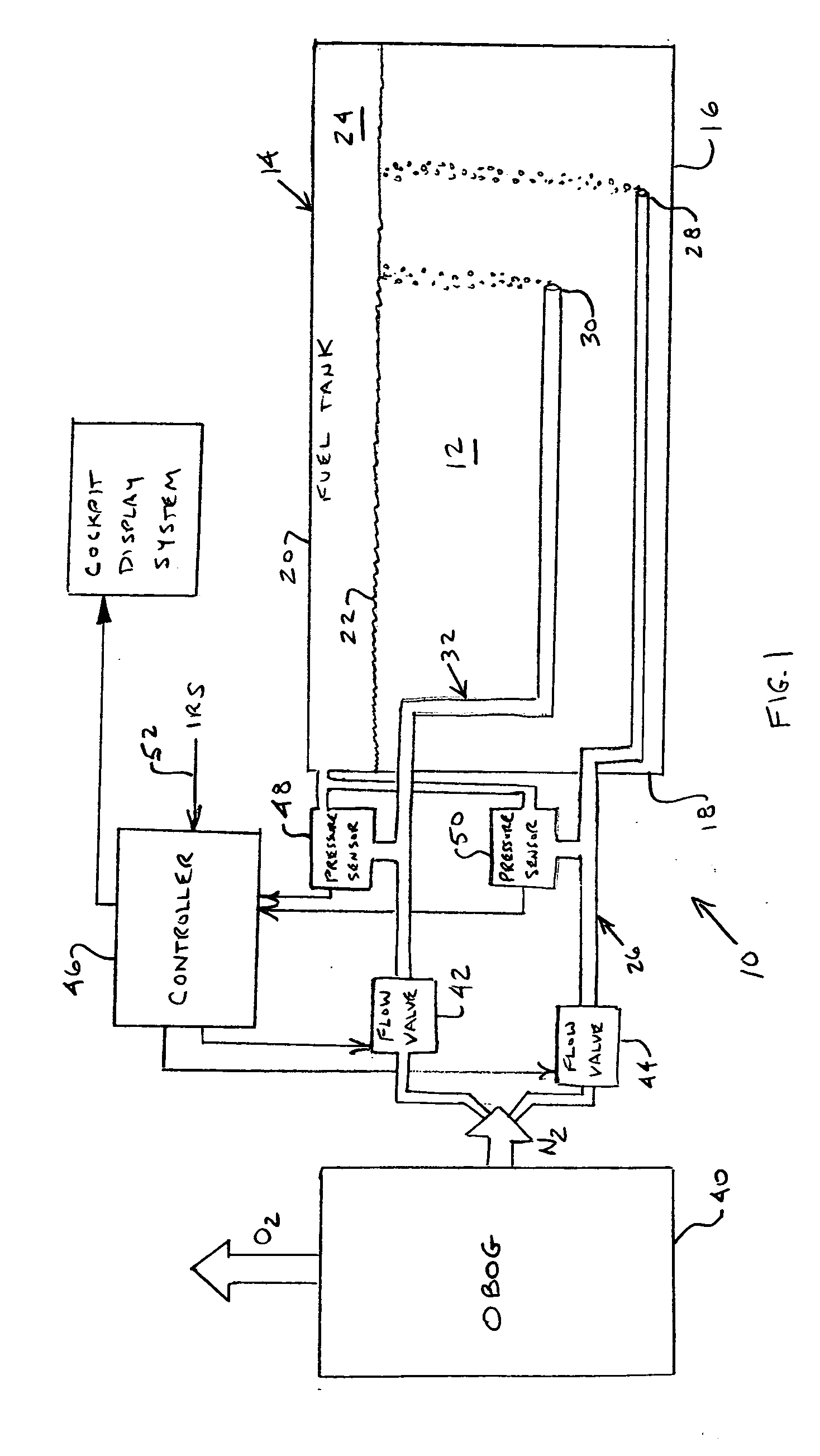

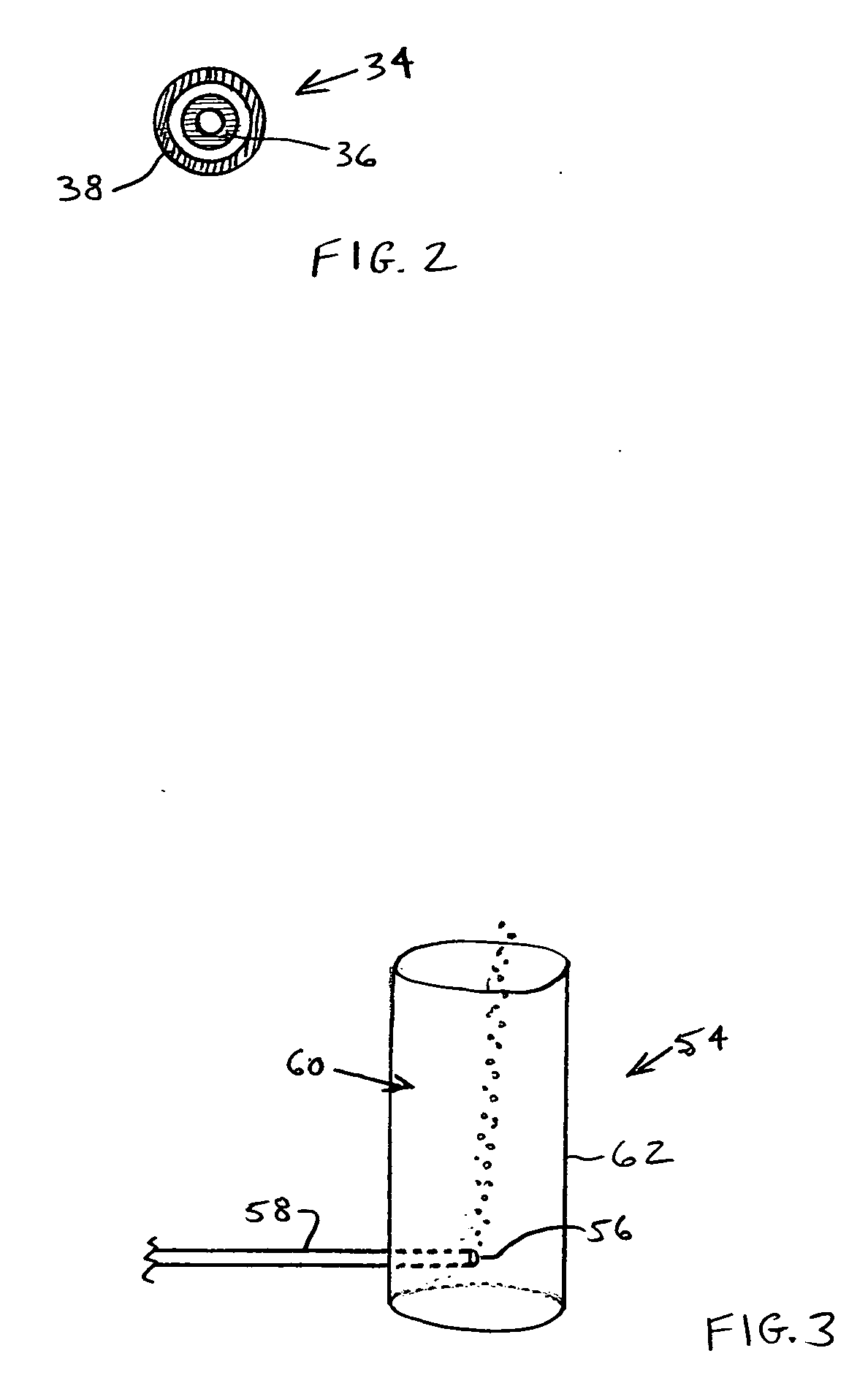

Pressure-based aircraft fuel capacity monitoring system and method

ActiveUS20060260392A1Specific gravity by measuring pressure differencesFlow propertiesMonitoring systemDynamic monitoring

Dynamic monitoring of the amount of fuel remaining in an aircraft fuel tank is effected by delivering a constant volume flow of an inert gas into the fuel through the respective open distal ends of a sensor conduit tube and a reference conduit tube, each of which extends from a proximal end exterior of the tank to its respective distal open end located within the fuel tank. The sensor conduit tube distal end is fixed closely proximate the bottom of the tank, and the reference conduit tube distal end is fixed proximate but at a vertical spacing h from the sensor conduit tube distal end. The pressure at which the gas is delivered into the fuel at the constant volumetric rate through each of the sensor and reference conduit tubes is monitored. The pressure difference between the monitored pressure in the sensor conduit tube and the pressure in the free space in the fuel tank above the surface of the remaining fuel is directly proportional to the weight of the fuel lying above the sensor conduit tube distal end. The density of the fuel is proportional to the monitored pressure difference between the sensor and reference conduit tubes, divided by the vertical spacing h. The calculated weight of the fuel, divided by the calculated density of the fuel, is proportional to the volume of the fuel remaining in the tank.

Owner:INNOVATIVE SOLUTIONS & SUPPORT

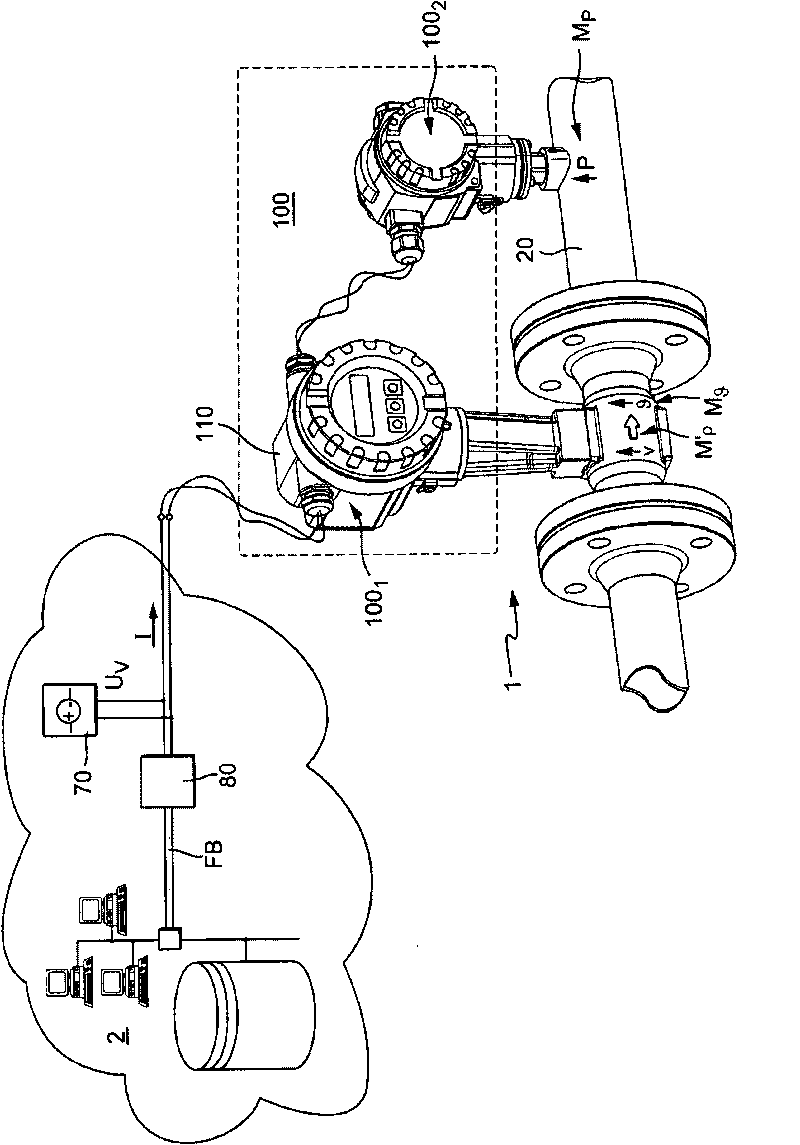

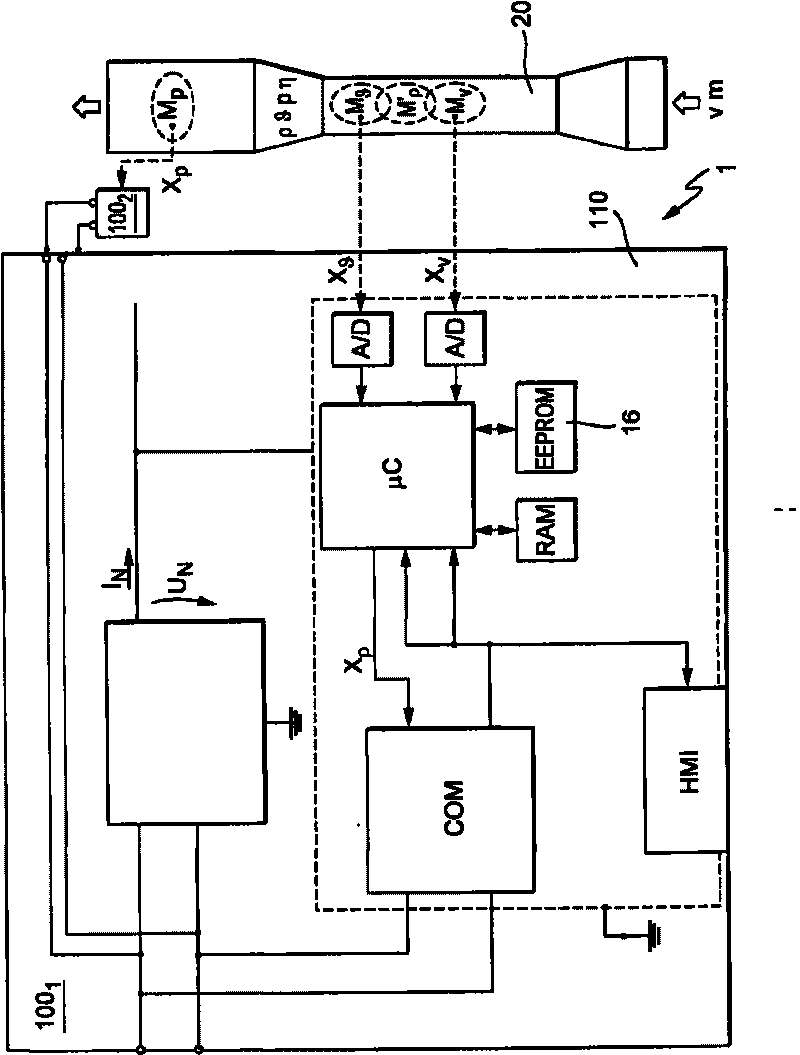

Measuring system for a medium flowing in a process line

ActiveCN101711351AHigh measurement accuracySpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesLine tubingMeasurement point

The invention relates to a measuring system for measuring a density of a medium flowing in a process line, said medium being variable regarding its thermodynamic state, especially at least being proportionally compressible, along an imaginary axis of flow of the measuring system. The measuring system comprises at least one temperature sensor that is located in a temperature measuring point and that primarily reacts to a local temperature, theta, of a medium flowing past, said temperature sensor supplying at least one temperature measurement signal that is influenced by the local temperature of the medium to be measured, at least one pressure sensor that is located in a pressure measuring point and that primarily reacts to a local, especially static, pressure, p, of a medium flowing past, said pressure sensor supplying at least one pressure measurement signal that is influenced by the local pressure, p, in the medium to be measured, and at least one electronic measuring unit that at least temporarily communicates with at least the temperature sensor and the pressure sensor. The electronic measuring unit generates a provisional density value, using the temperature measurement signal and at least the pressure measurement signal, said density value representing a density which the flowing medium only apparently has in a virtual density measuring point that is especially interspaced from the pressure measuring point and / or the temperature measuring point along the axis of flow at a defined distance. The electronic measuring unit further generates at least temporarily at least one especially digital density value, which is different from the provisional density value, using the provisional density value and at least one correctional density value that depends on a flow speed of the medium and on the local temperature prevailing in the temperature measuring point, said correctional value being determined during operation time.

Owner:ENDRESS HAUSER FLOWTEC AG

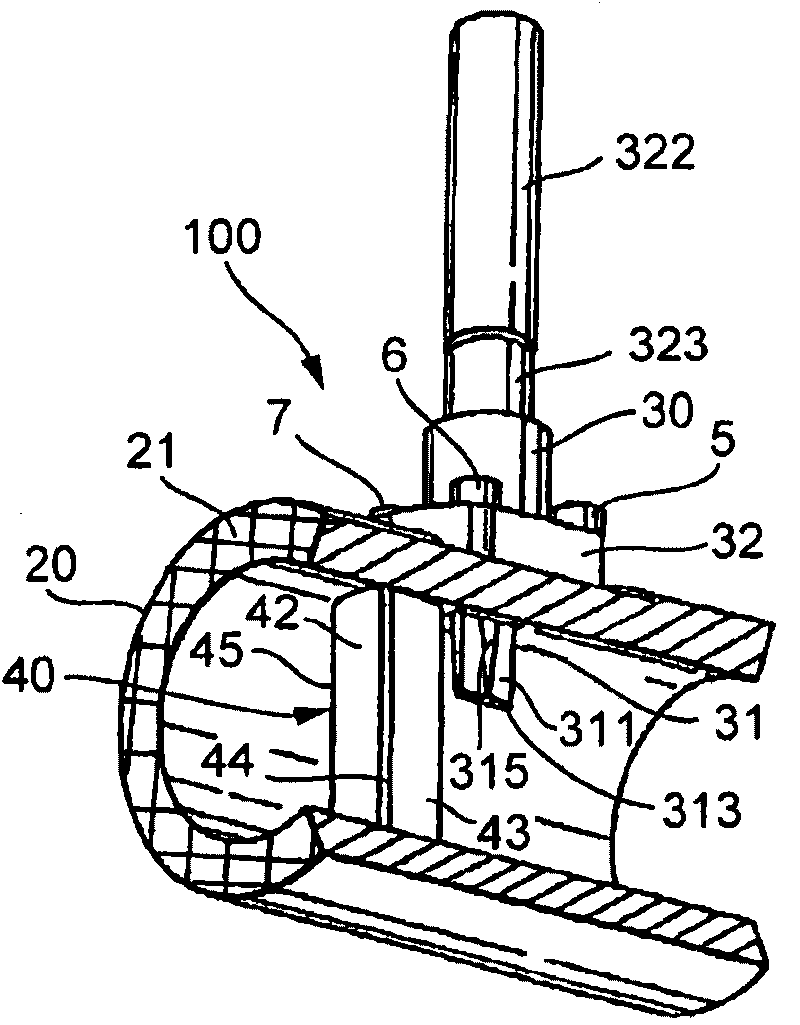

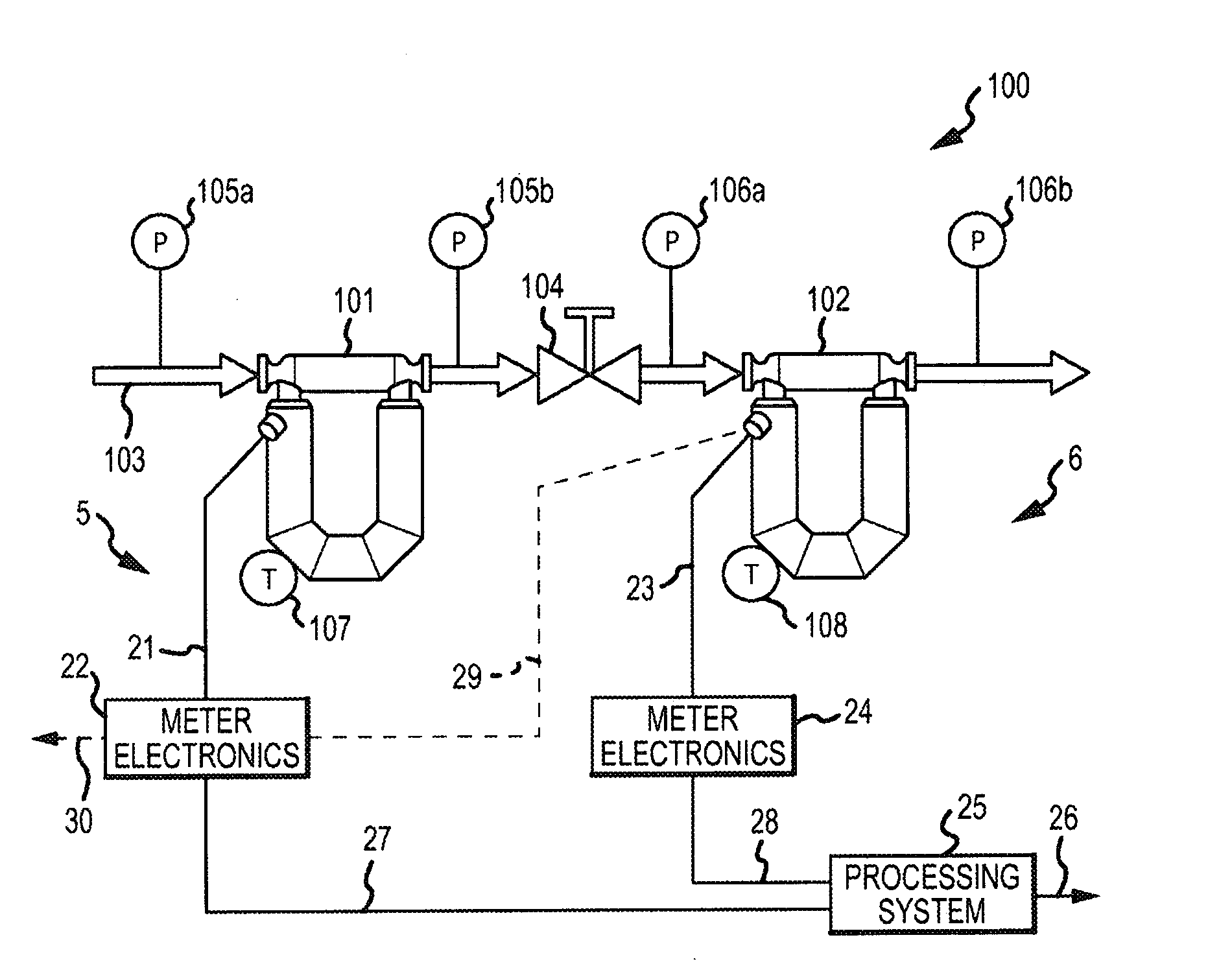

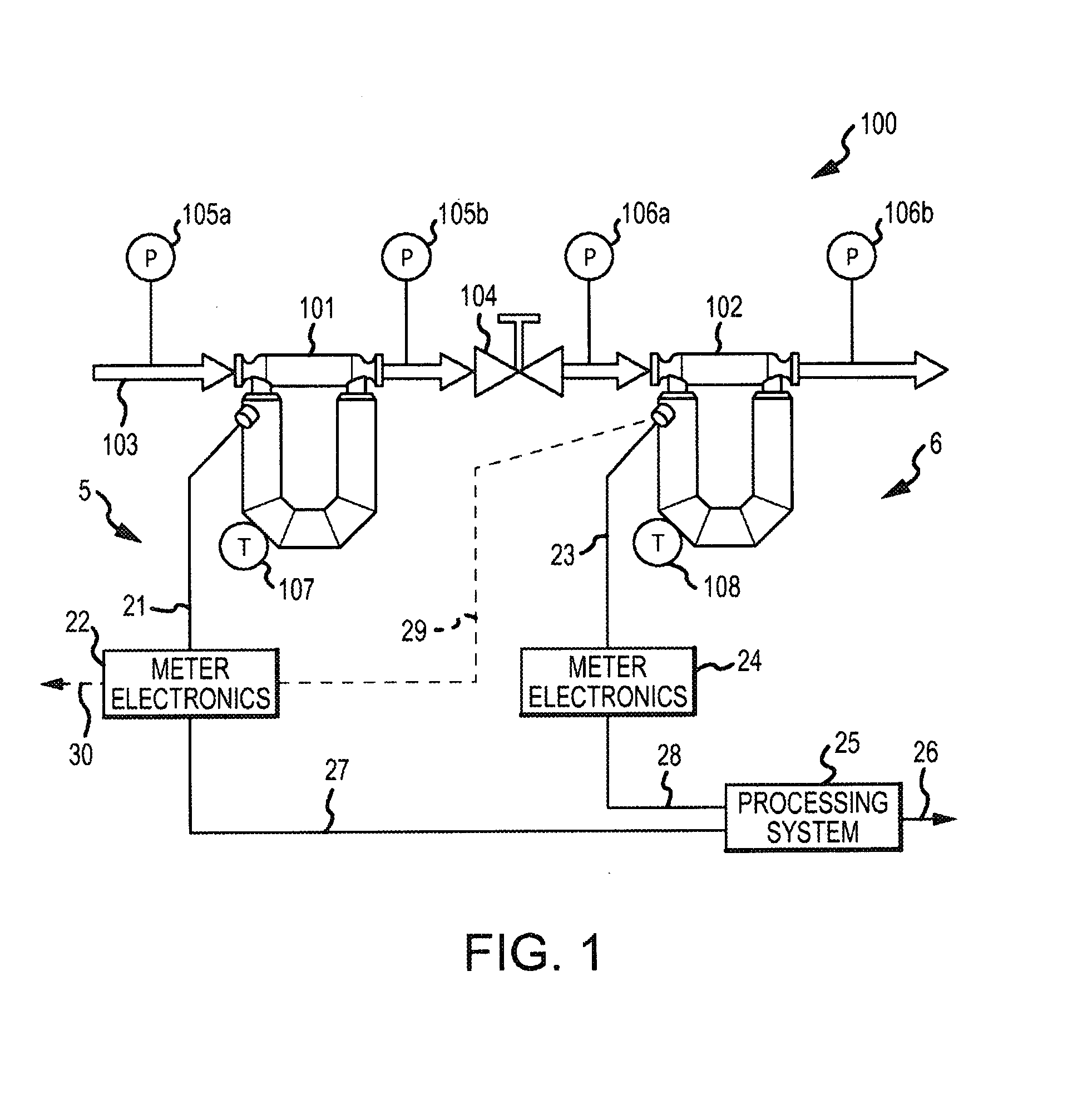

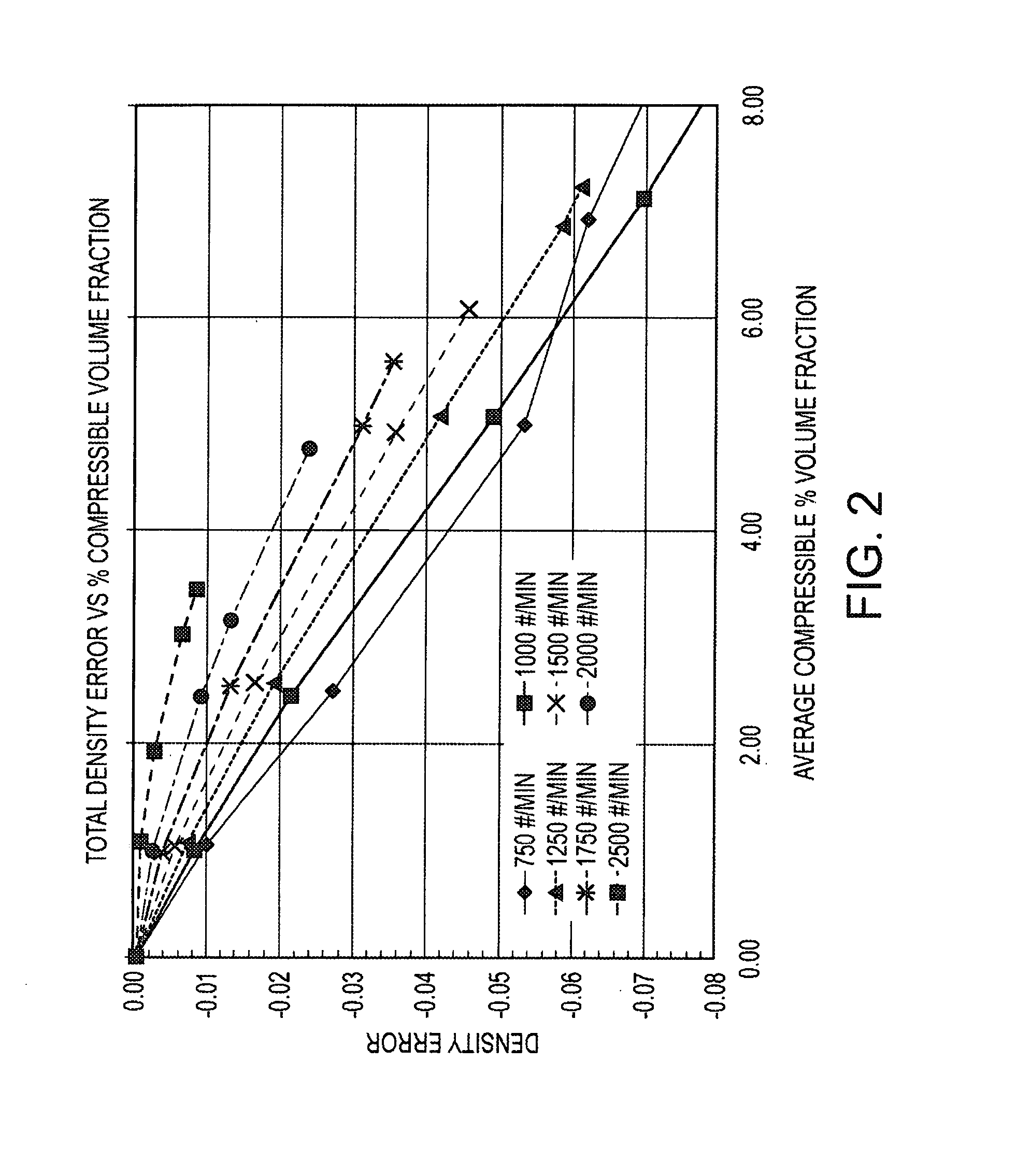

Fluid characteristic determination of a multi-component fluid with compressible and incompressible components

ActiveUS20150160056A1Specific gravity by measuring pressure differencesSpecific gravity using flow propertiesEnvironmental geologyFluid property

Owner:MICRO MOTION INC

Fluid composition concentration test method and device thereof

InactiveCN1407328AReal-time and continuousComponent separationVolume/mass flow by thermal effectsFluid compositionPressure difference

A method and an apparatus for measuring the concentrations of the components of a fluid are described, which can be used to measure the concentrations of the components continuously in real time and to monitor a high pressure gas, and is suitably used for in-line monitoring. In the method and the apparatus, a fluid sample is conducted through a measuring tube, wherein the measuring tube has a small aperture with a constant diameter in a fluid flow path. The pressure difference (P1-P2) between the upstream and the downstream of the small aperture and the flow rate at the downstream of the small aperture are measured to determine the concentrations of the components of the fluid.

Owner:NIPPON SANSO CORP

Popular searches

Testing metals Material analysis by optical means Biological testing Volume/mass flow by dynamic fluid flow effect Volume/mass flow by differential pressure Moisture content investigation using microwaves Chemical methods analysis Direct flow property measurement Indirect mass flowmeters Digital computer details

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com