Measuring system for a medium flowing in a process line

A technology for measuring systems and media, which is applied in mass flow measurement devices, liquid/fluid solids measurement, and fluid flow detection by measuring differential pressure, which can solve the problem of no longer measuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

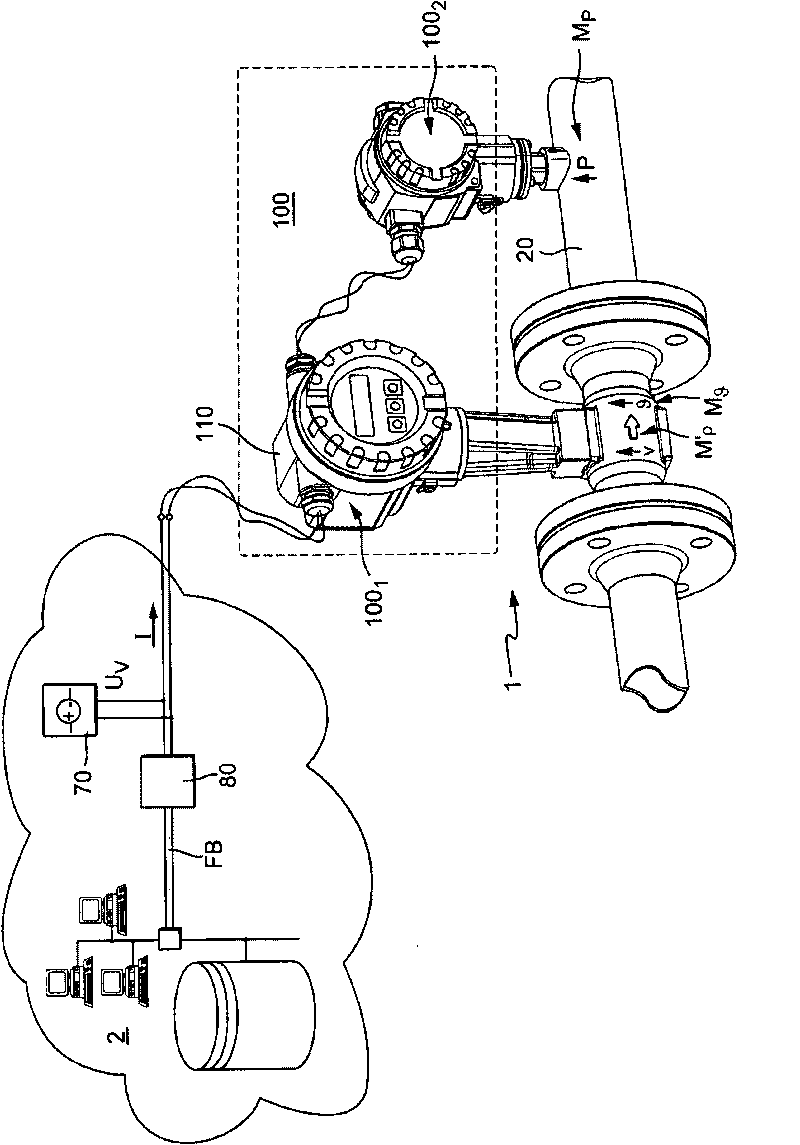

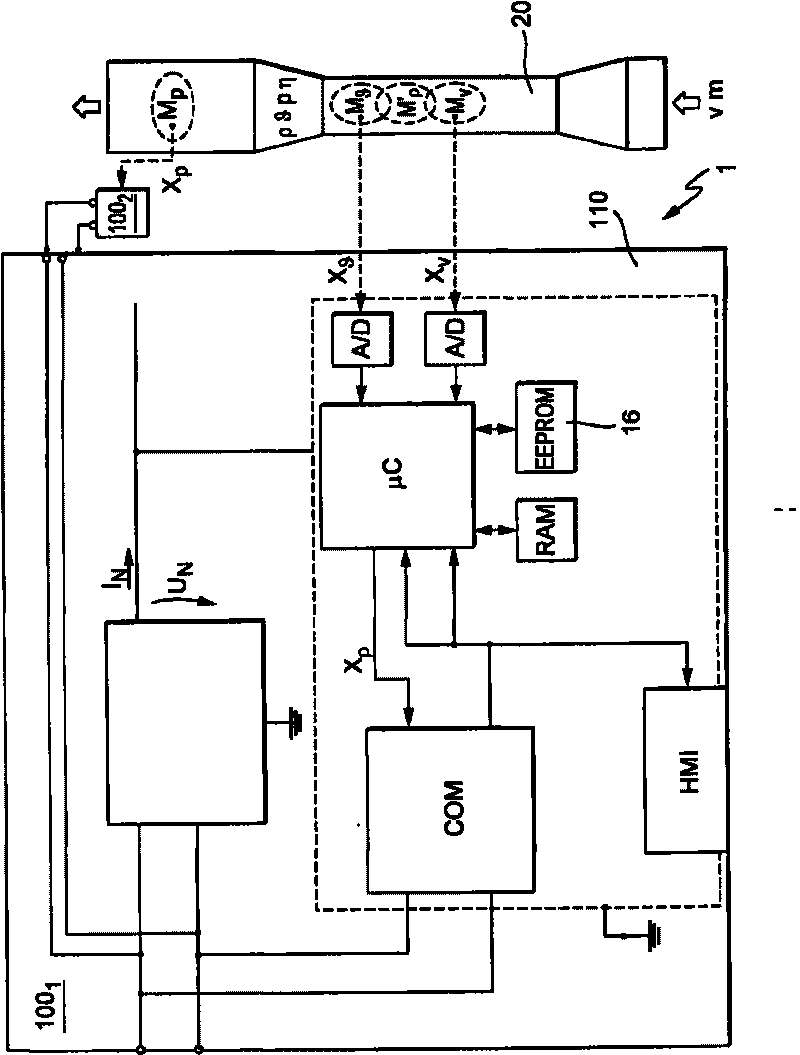

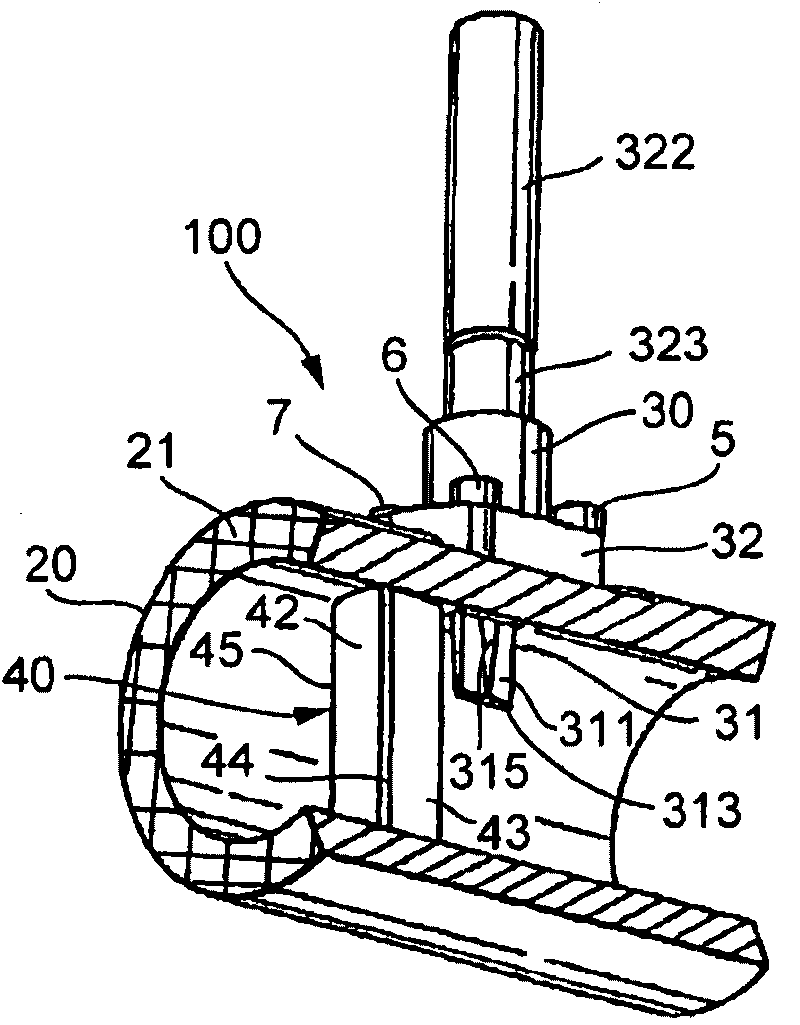

[0110] figure 1 A measuring system 1 is schematically shown, which can be constructed modularly and is suitable for at least intermittently and very precisely and also very robustly determining the density of a medium flowing in a process line 20 and for converting the density (if necessary in real time ground) to corresponding reliable, e.g. digital, density measurements X ρ , the medium here can also be a two-phase or multiphase medium, such as gas, liquid (which may contain gas and / or solid particles), gas containing solid particles and / or liquid droplets, steam (which may be saturated steam or dry steam ),etc. Examples of media include gases such as hydrogen, nitrogen, chlorine, oxygen, helium or complexes and / or mixtures thereof, such as, water, phosgene, air, natural gas or other hydrocarbons.

[0111] In particular, measuring systems are used to measure very precisely the density of flowing media in which the thermodynamic state is variable along the measuring system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com