Patents

Literature

561 results about "Local pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

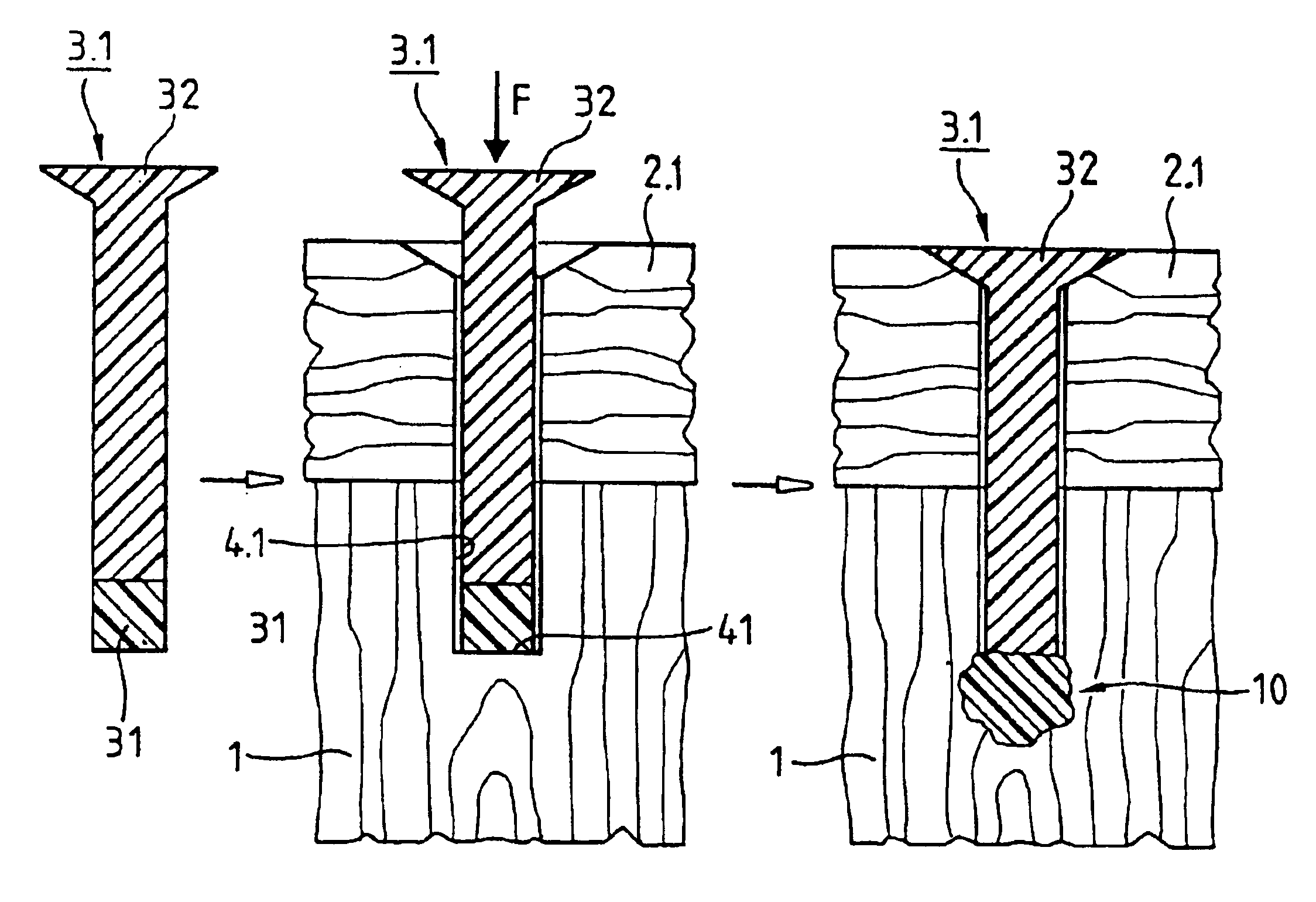

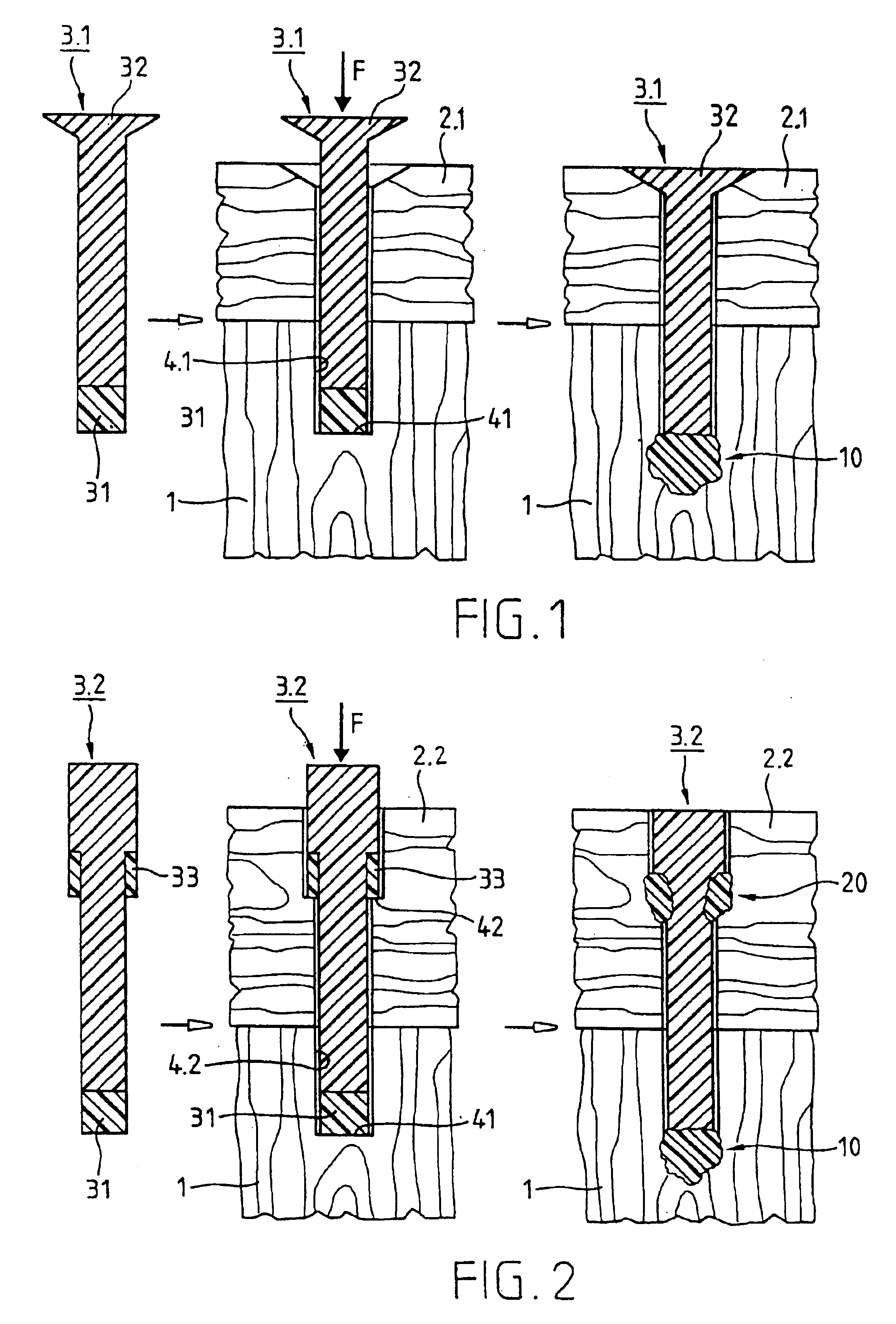

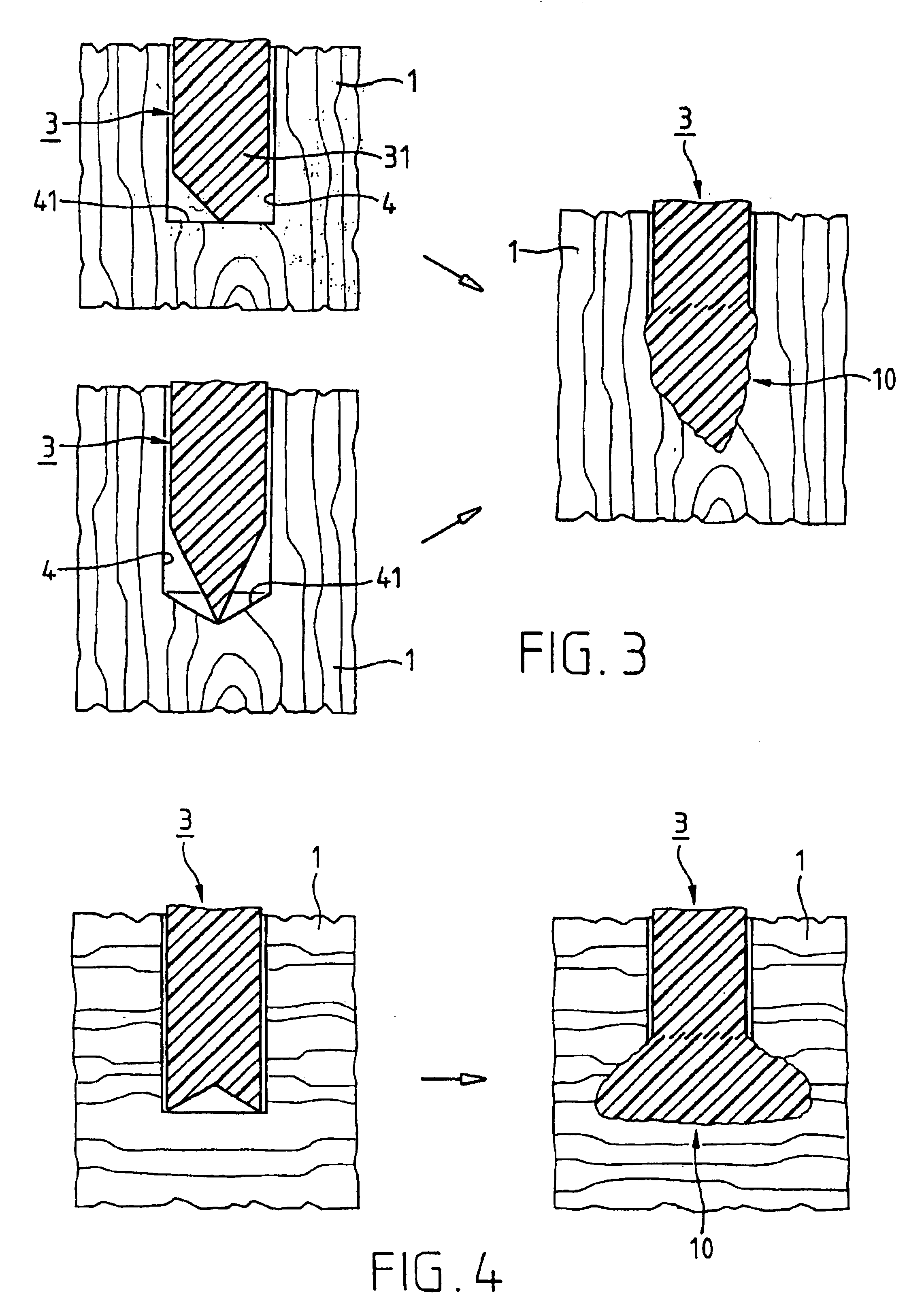

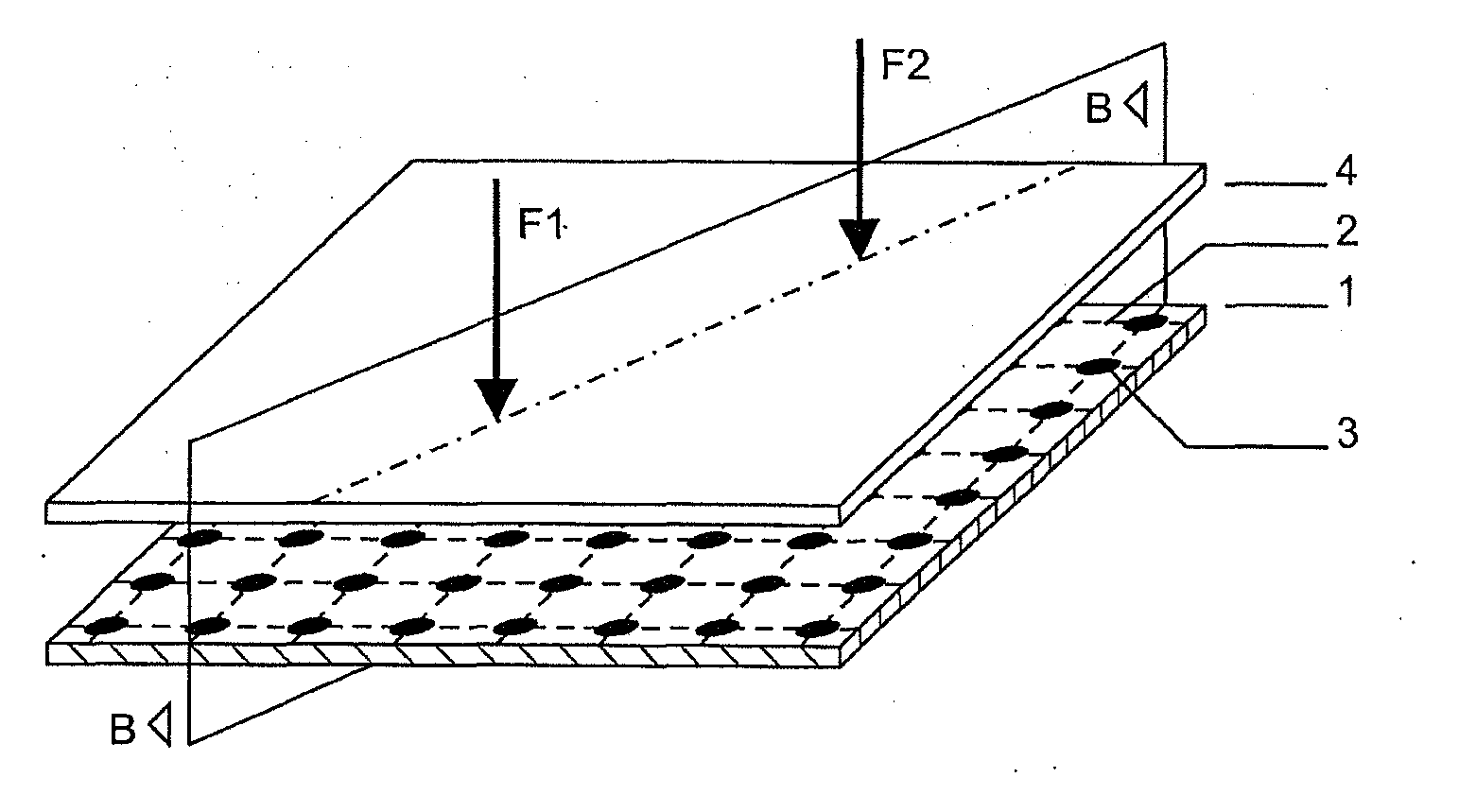

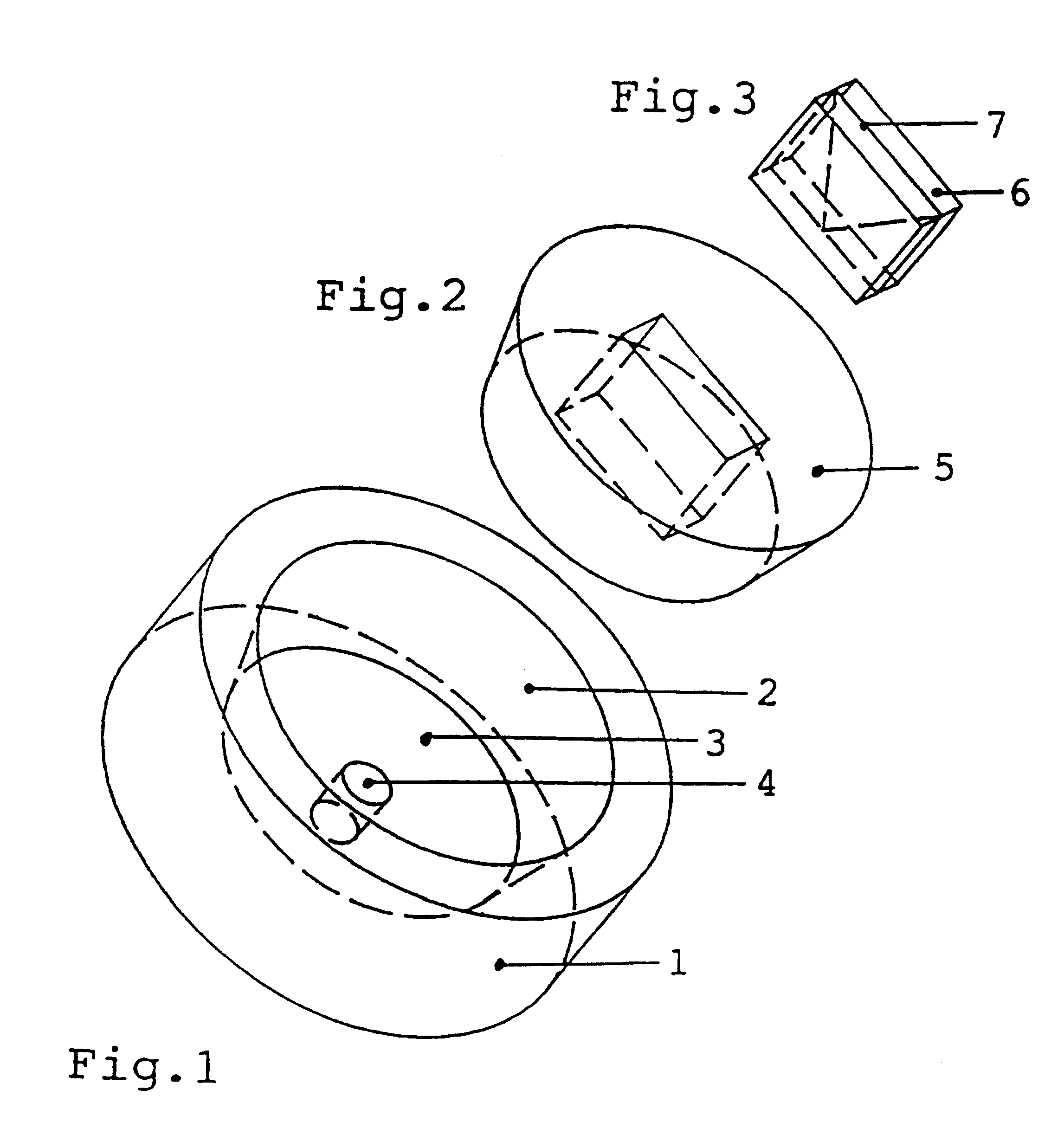

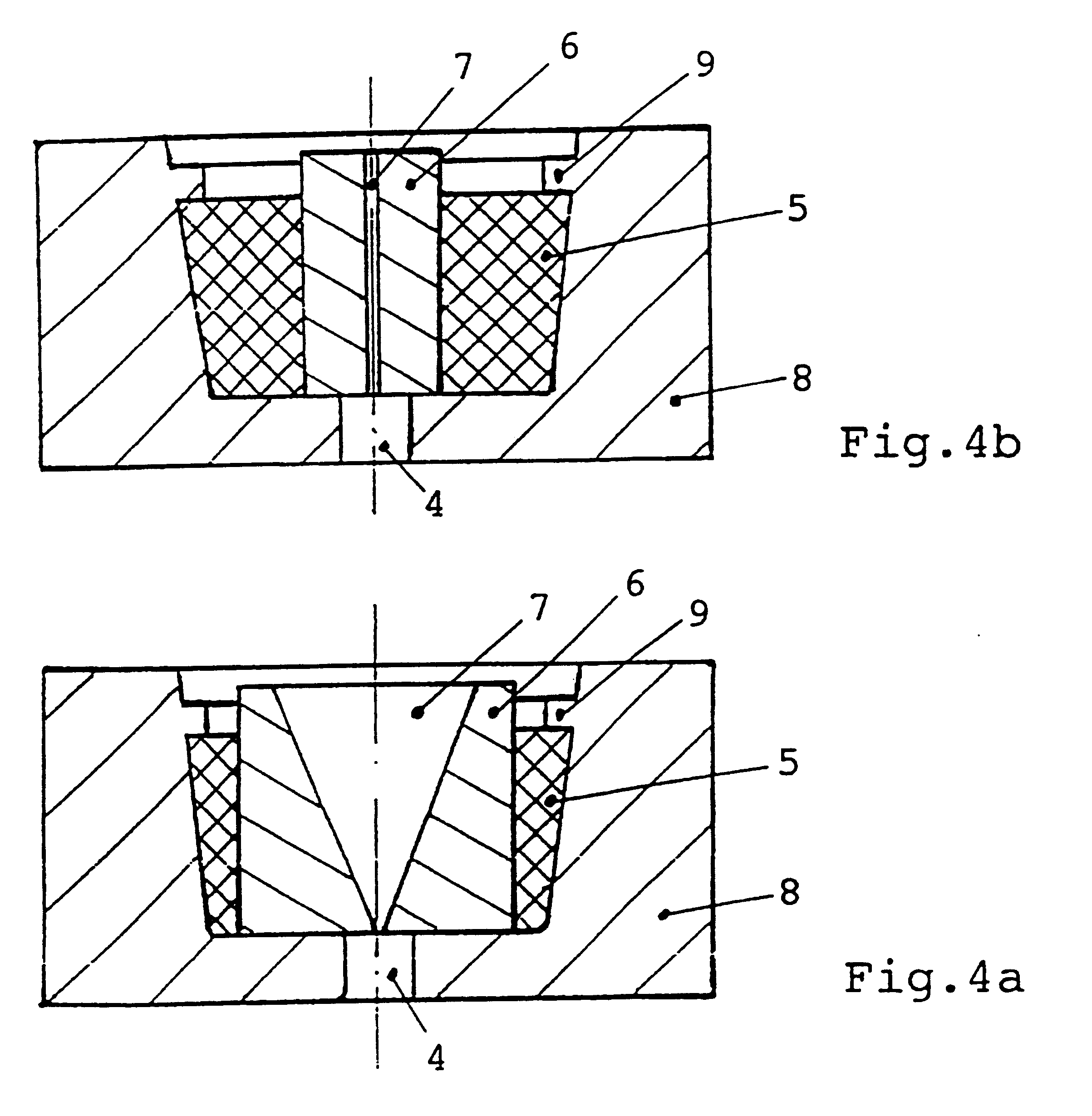

Process for anchoring connecting elements in a material with pores or cavities and connecting elements therefor

InactiveUS6913666B1Easy to reachReduce disadvantagesRivetsCylinder headsEngineeringUltrasonic vibration

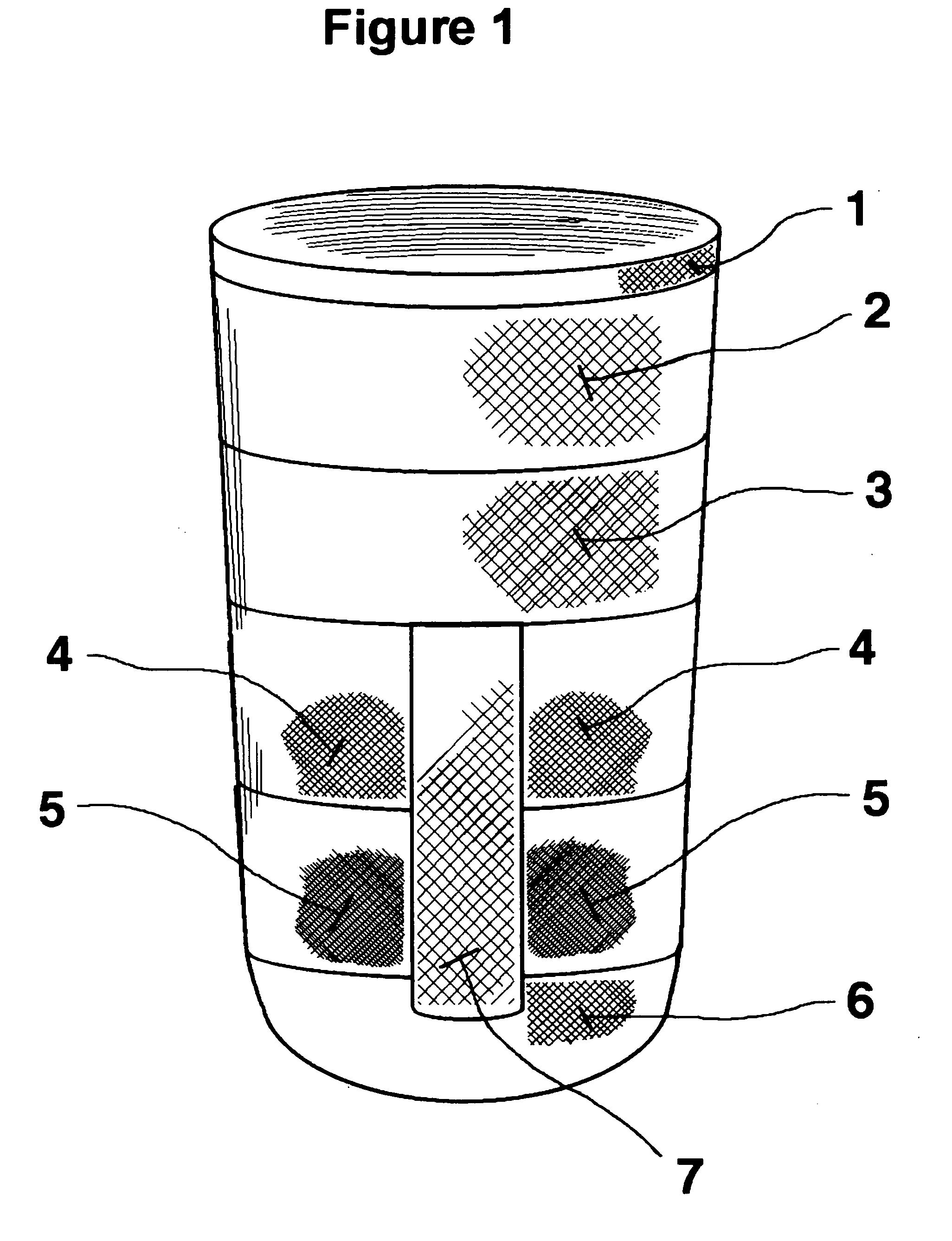

A joining pin (3.2) with which two parts (1 and 2) made from a porous material, particularly wood or a wood-like material, are to be joined together, is anchored in the porous material at predetermined anchoring points (31, 33). For this purpose, a bore (4.2) with a closed inner end (41) is made in the parts (1 and 2). The shape of this bore (4.2) is so matched to the joining pin (3.2) that it can be introduced substantially without force expenditure into the bore and is positionable in a first position. At least one predetermined anchoring point (31, 33) between the joining pin (3.2) and the wall of the bore (4.2) is formed when pressure is built up by pressing the joining pin (3.2) with a pressing force (F) more deeply into the bore to a second position. Energy is supplied in a planned manner to the joining pin (3.2) so that at the predetermined anchoring points (31, 33) the thermoplastic material of the joining pin (3.2) is plasticized. The locally plasticized plastic material is pressed by the local pressure into the porous material of the parts and forms local, macroscopic anchors (10, 20). The joining pin (3.2) is, e.g., made entirely from a thermoplastic material and the energy for plasticizing is supplied thereto by ultrasonic vibration.

Owner:WOODWELDING

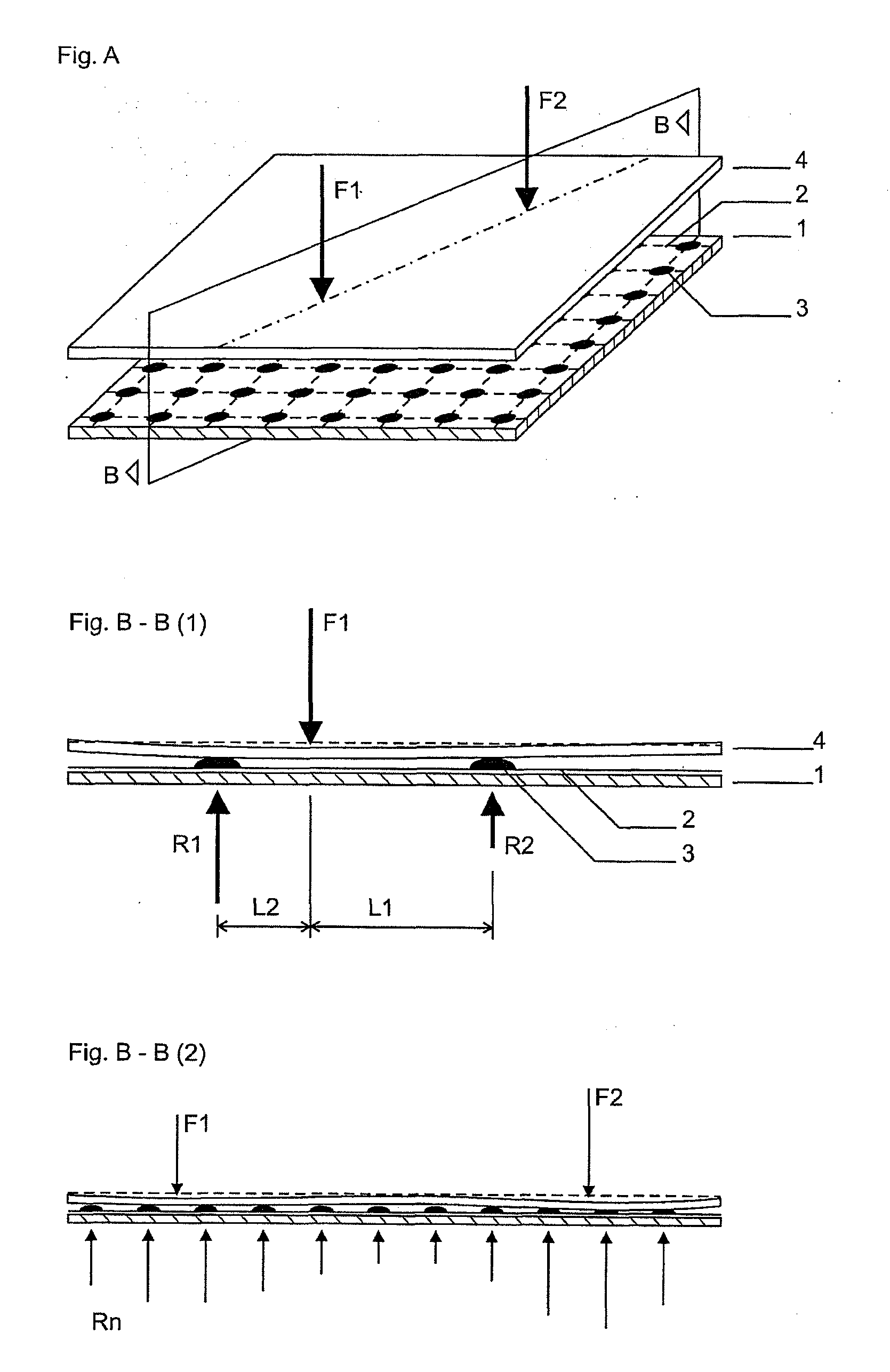

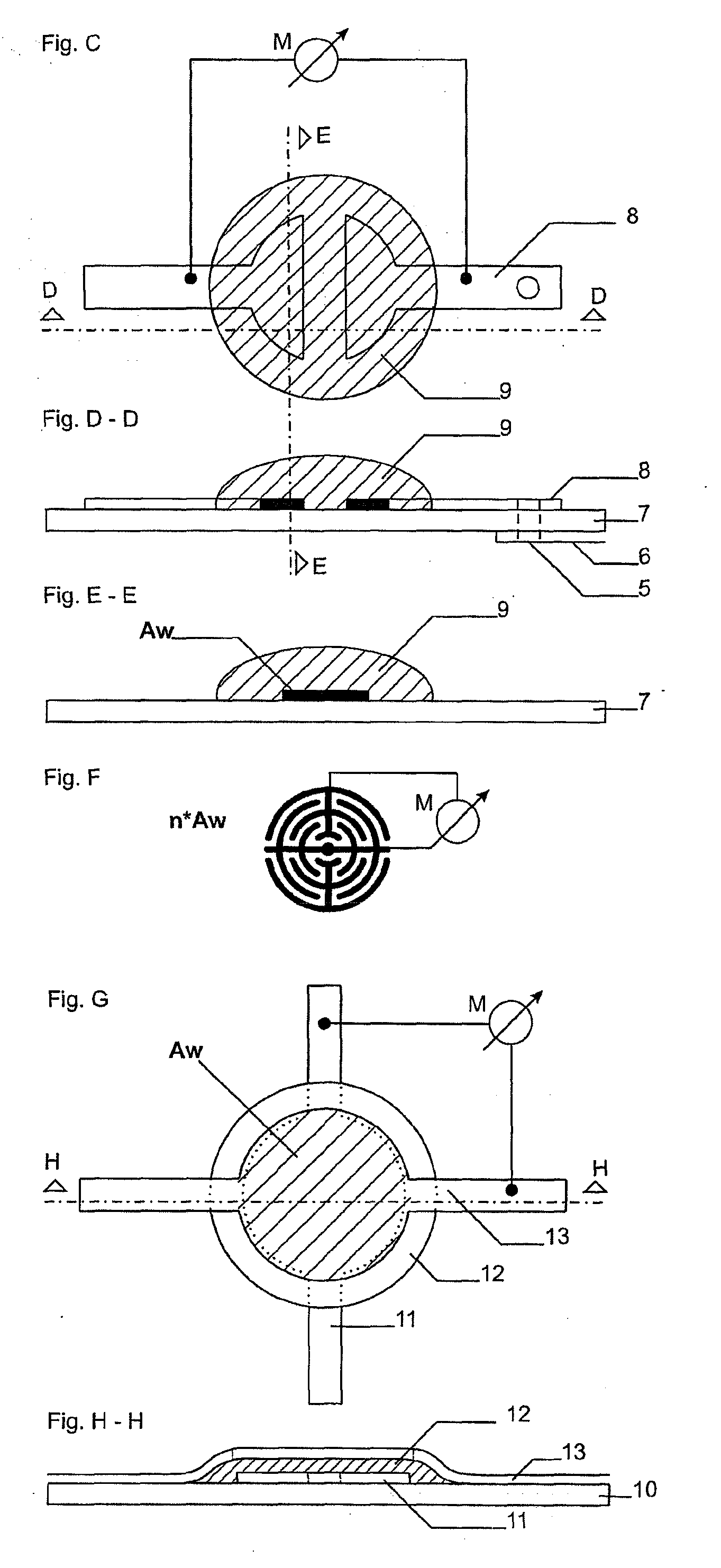

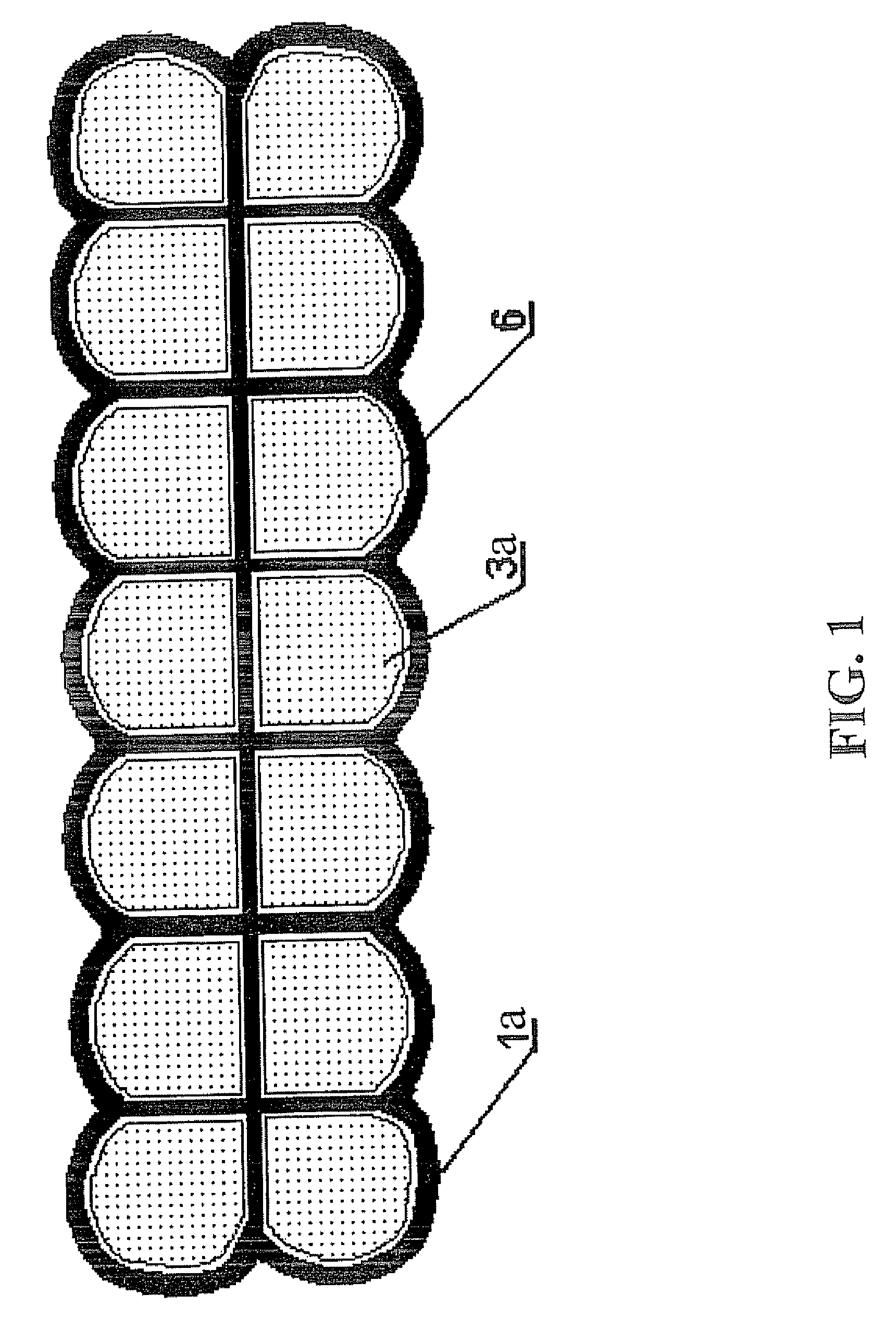

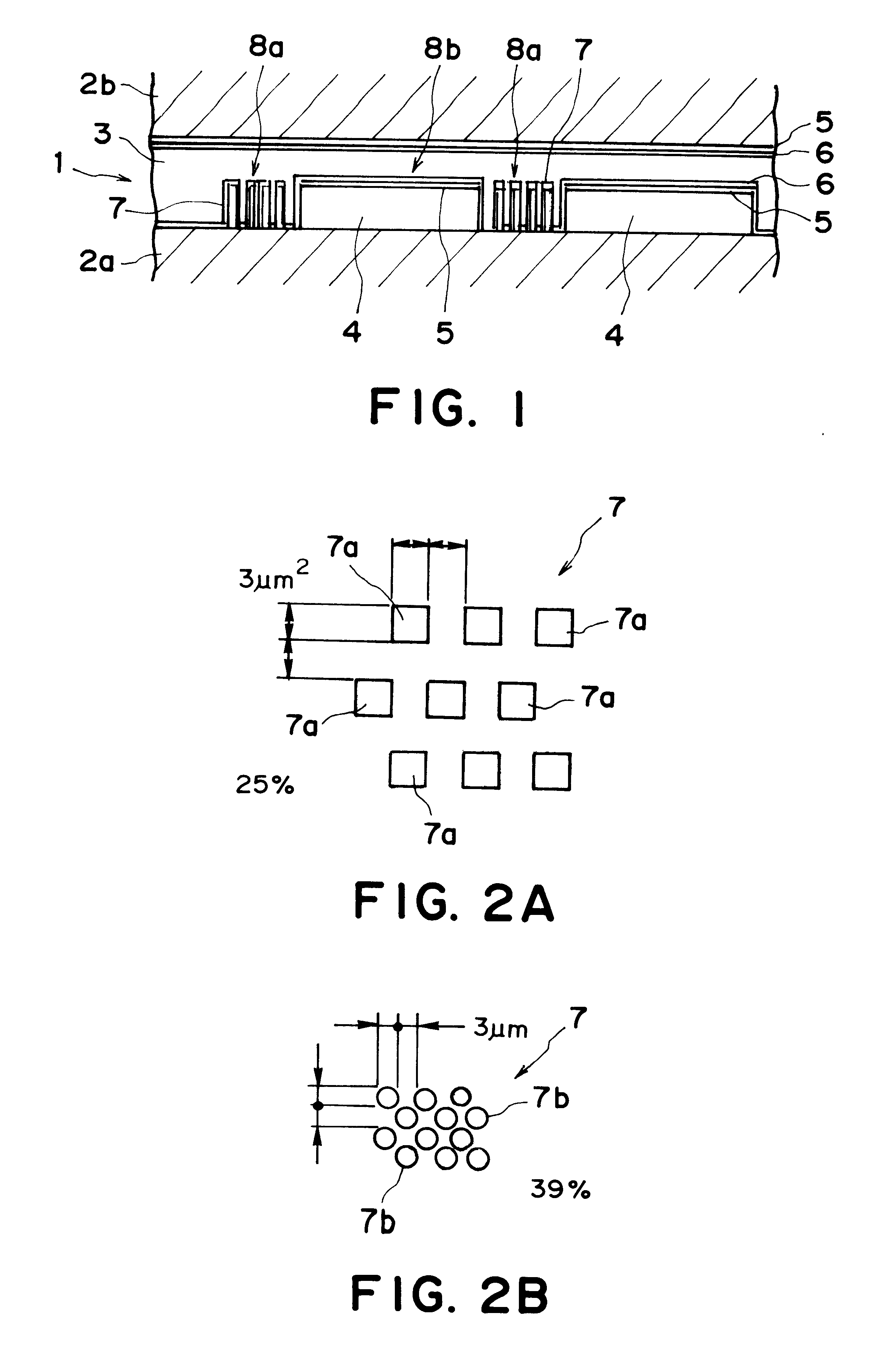

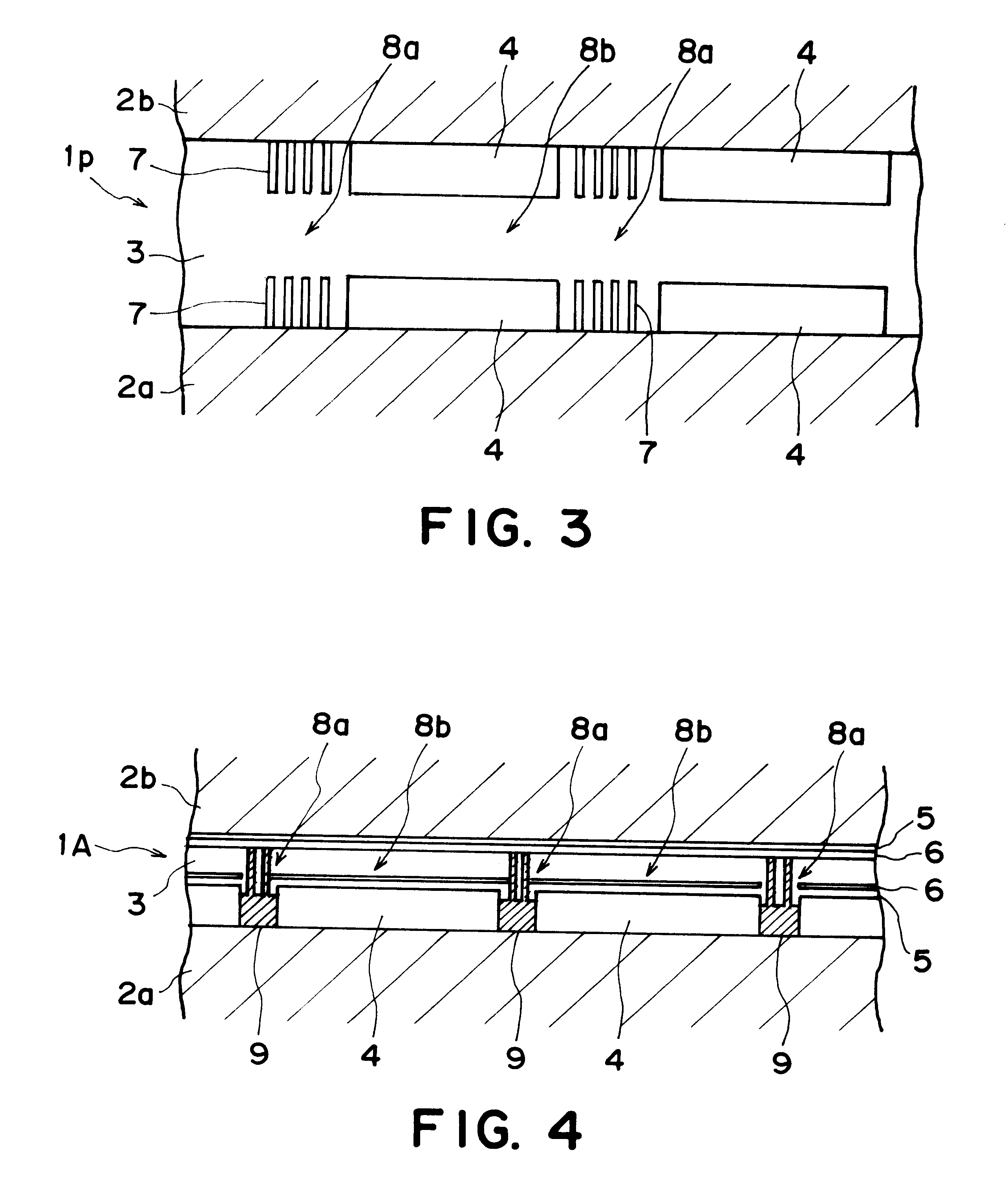

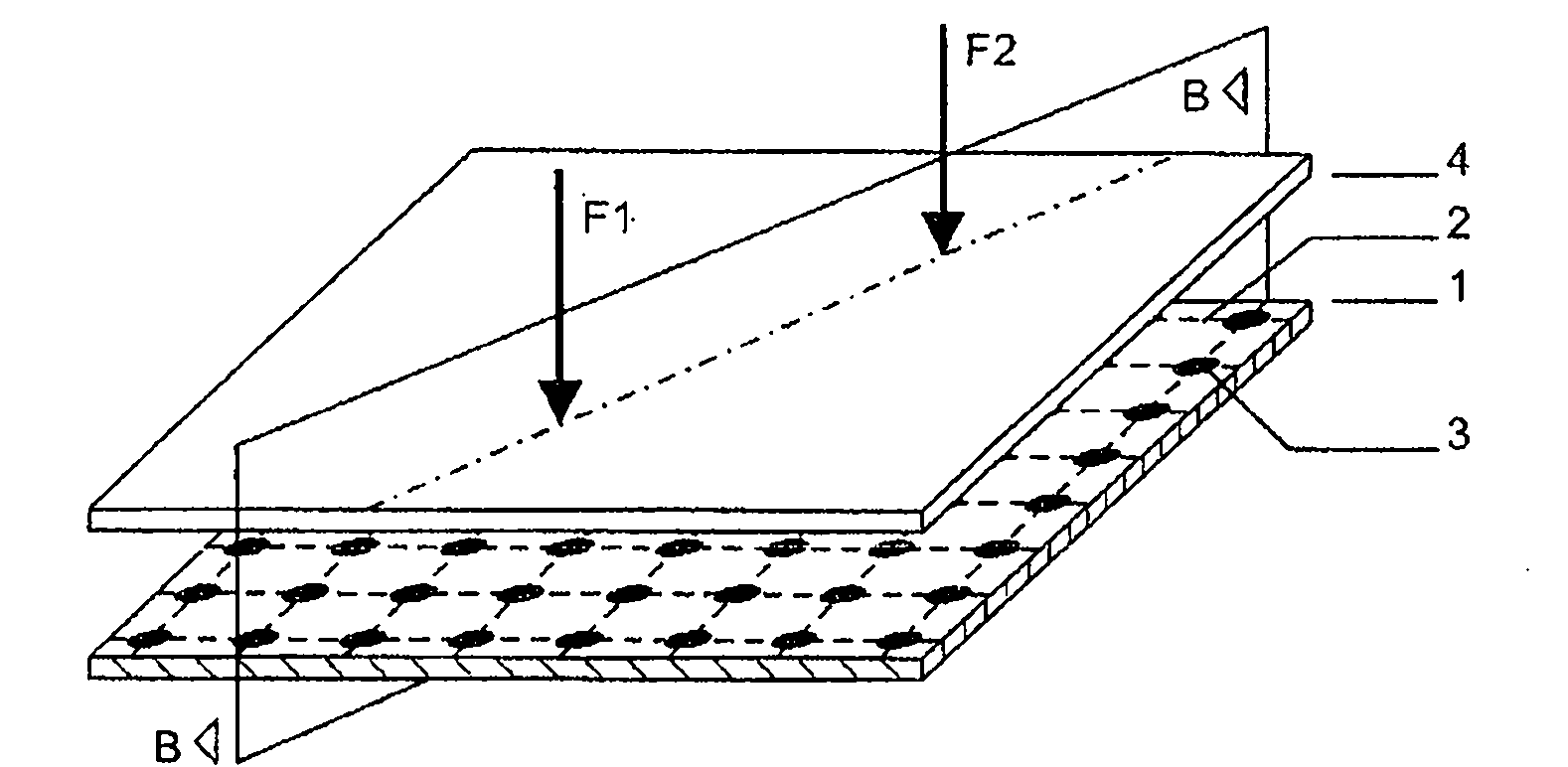

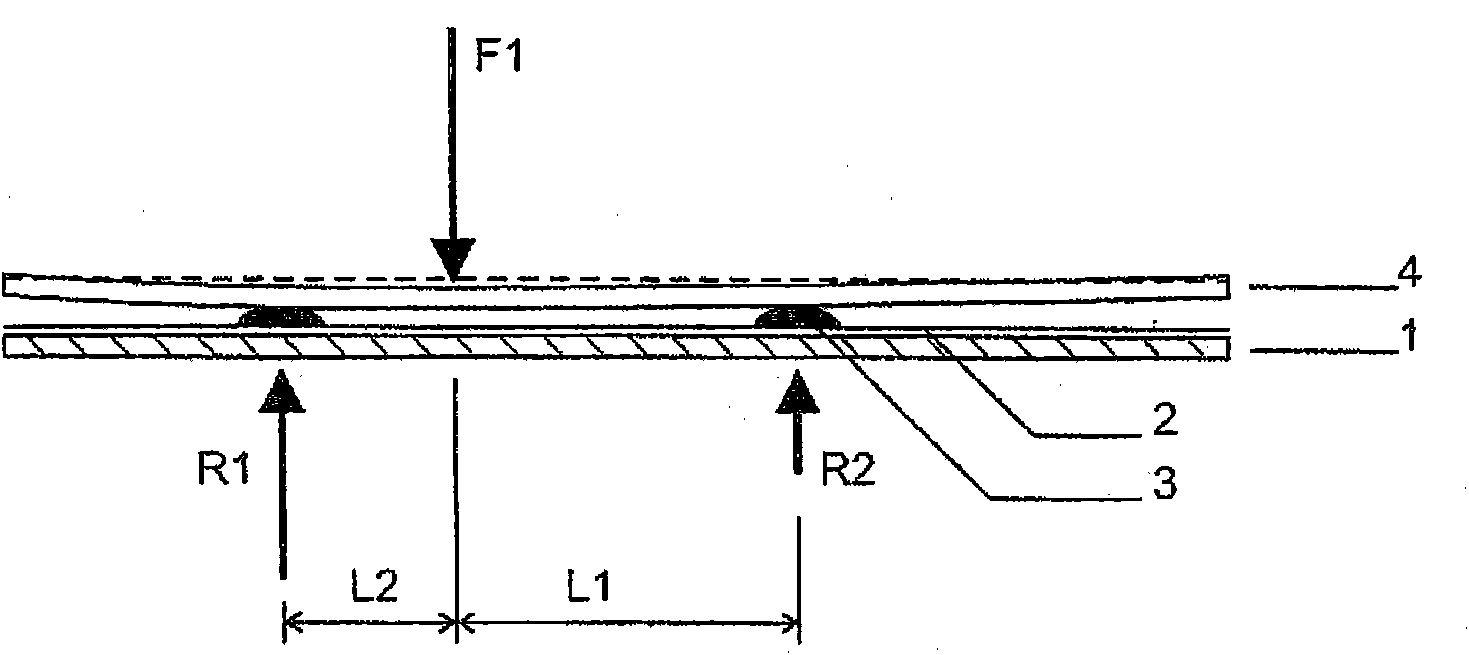

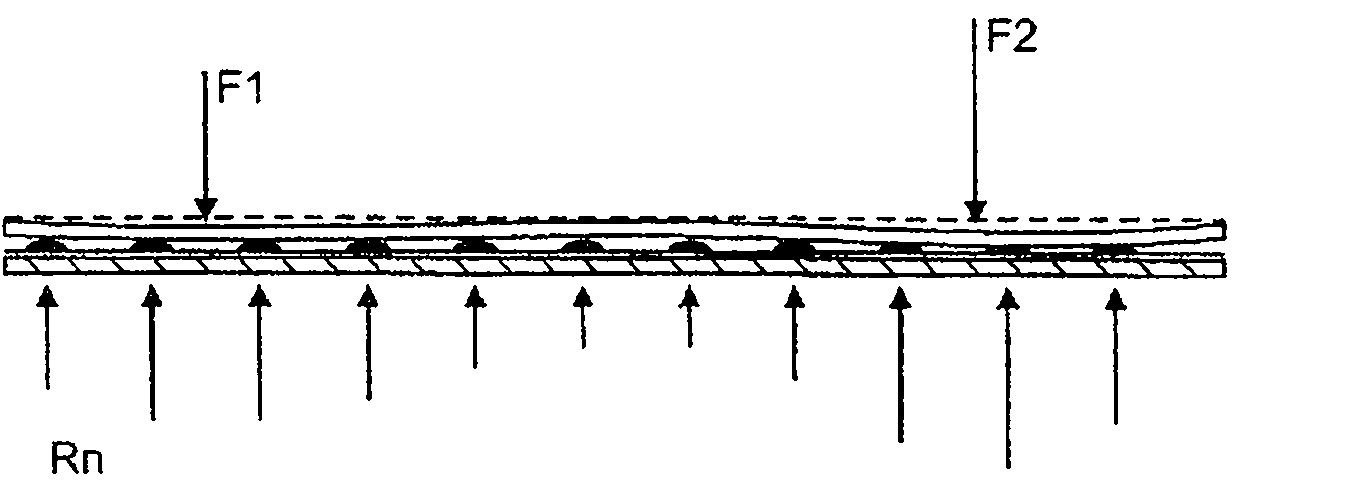

Single or multitouch-capable touchscreens or touchpads comprising an array of pressure sensors and the production of such sensors

InactiveUS20100315373A1Readily be miniaturisedEfficient and inexpensiveForce measurementInput/output processes for data processingPliabilityLocal pressure

A multitouch-capable touchscreen is realized in that a large number of pressure sensors are attached under a flexible surface and thus both the pressure distribution and also the deformation of the surface is measured. Local pressure maxima occur due to the flexibility of the surface material with associated deformation on contact. As several local pressure maxima can exist, it is thus also possible to identify a plurality of contacts simultaneously. It is possible from the strength of pressure and pressure distribution to determine the force that is used for pressing such that this information can also be used in the user interface. Such sensors can be produced very efficiently and inexpensively by printing an ink that changes its resistance under pressure onto PCB tracks designed as sensor surfaces. The PCB tracks and the sensor surfaces can also be printed out using an ink with as low a resistance as possible.

Owner:STEINHAUSER ANDREAS +1

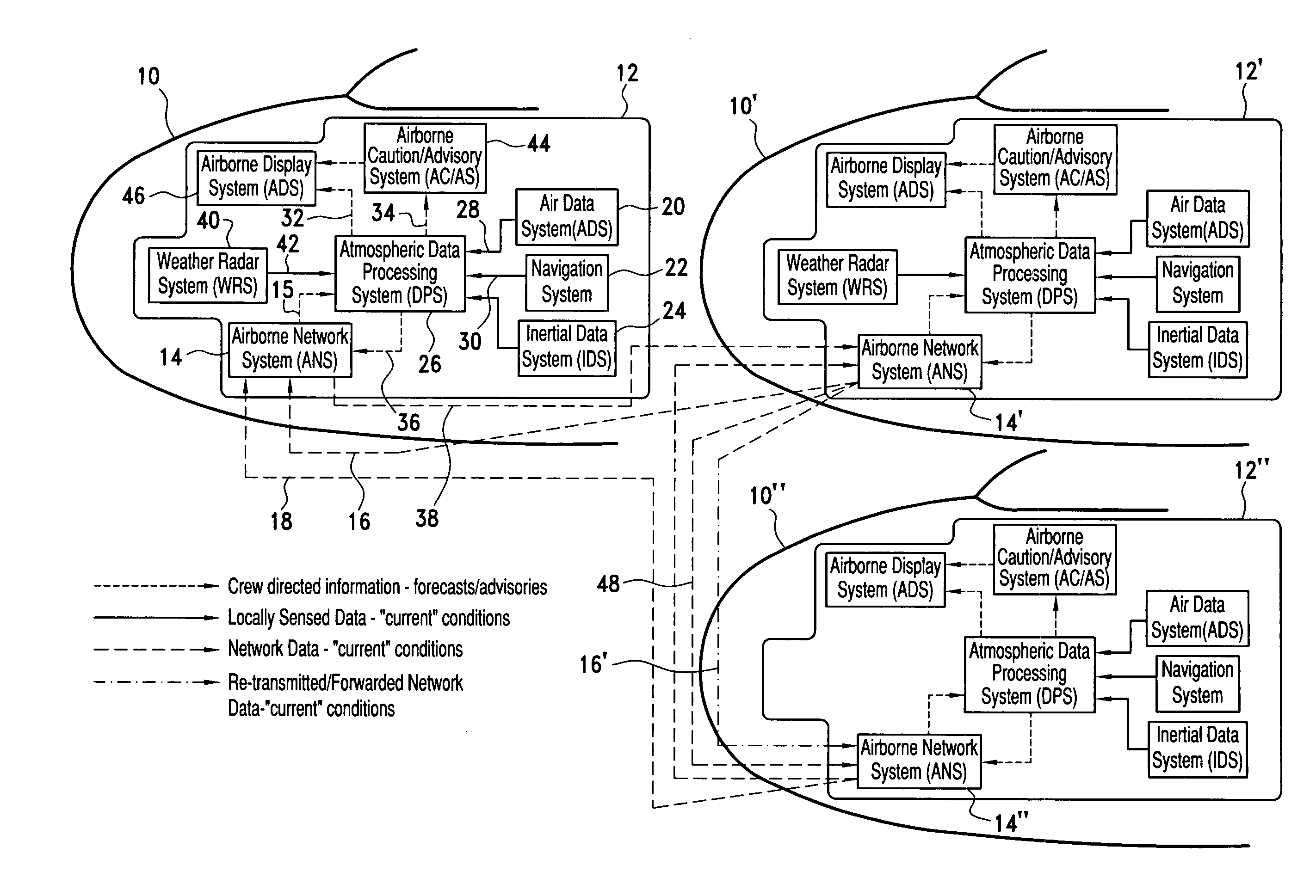

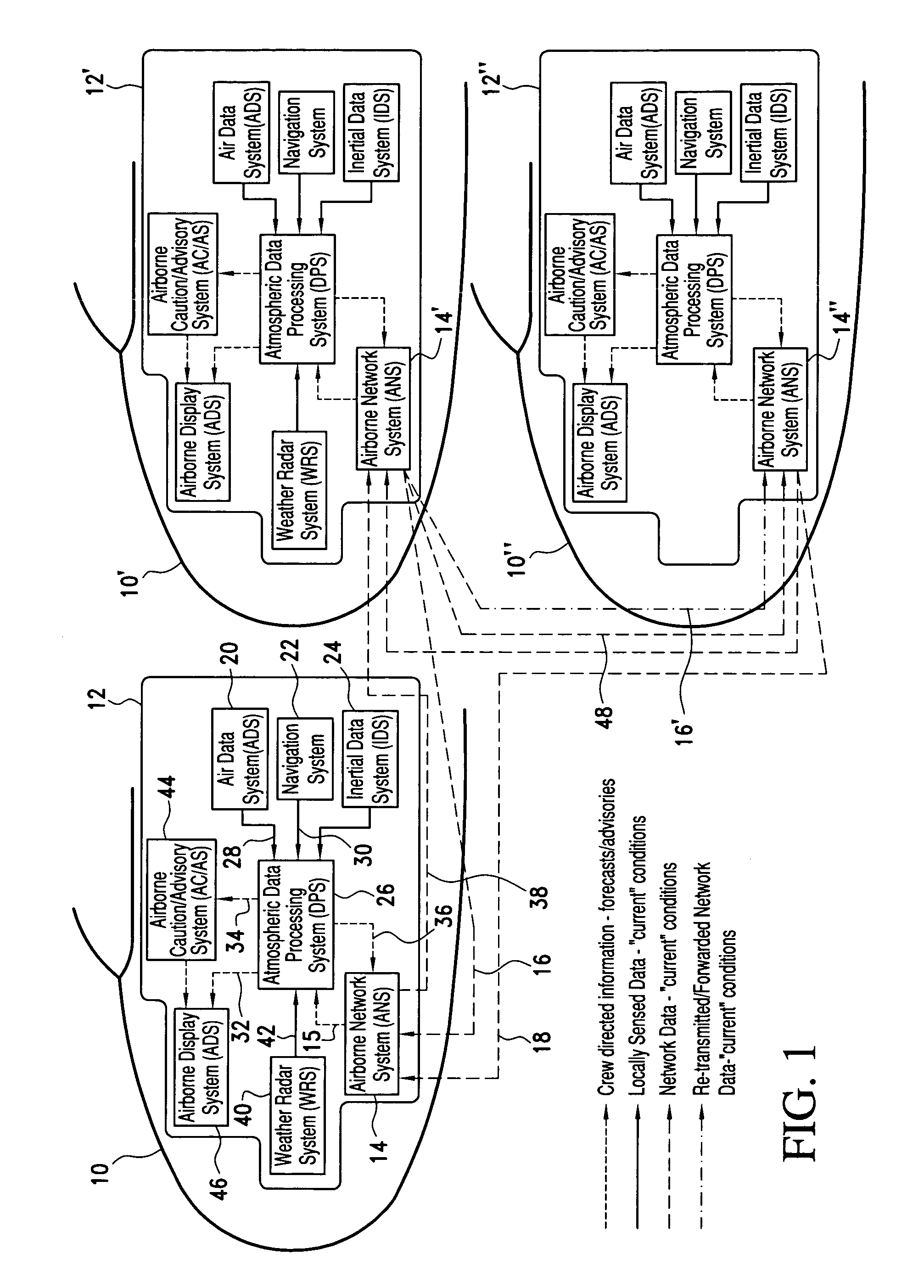

Atmospheric data aggregation and forecasting system

ActiveUS6977608B1Analogue computers for vehiclesAnalogue computers for trafficData aggregatorEngineering

An airborne network system (ANS) on a member aircraft receives incoming geo-referenced atmospheric data regarding atmospheric conditions from other member aircraft and can re-transmit the data to other members. An air data system senses local pressure and temperature conditions. A navigation system calculates geo-referenced aircraft position. An inertial data system senses member aircraft attitude, angular rates and accelerations. A data processing system (DPS) generates the member aircraft's perspective of the atmospheric conditions, based on input data from the above-mentioned systems. Network directed DPS output atmospheric data is provided to the ANS to be transmitted to other airborne network systems positioned on other member aircraft. An airborne display system is adapted to receive crew directed DPS output atmospheric data and in response thereto display desired atmospheric forecast conditions. An airborne caution / advisory system receives the crew directed DPS output atmospheric data and alerts the pilot(s) of hazardous flight conditions.

Owner:ROCKWELL COLLINS INC

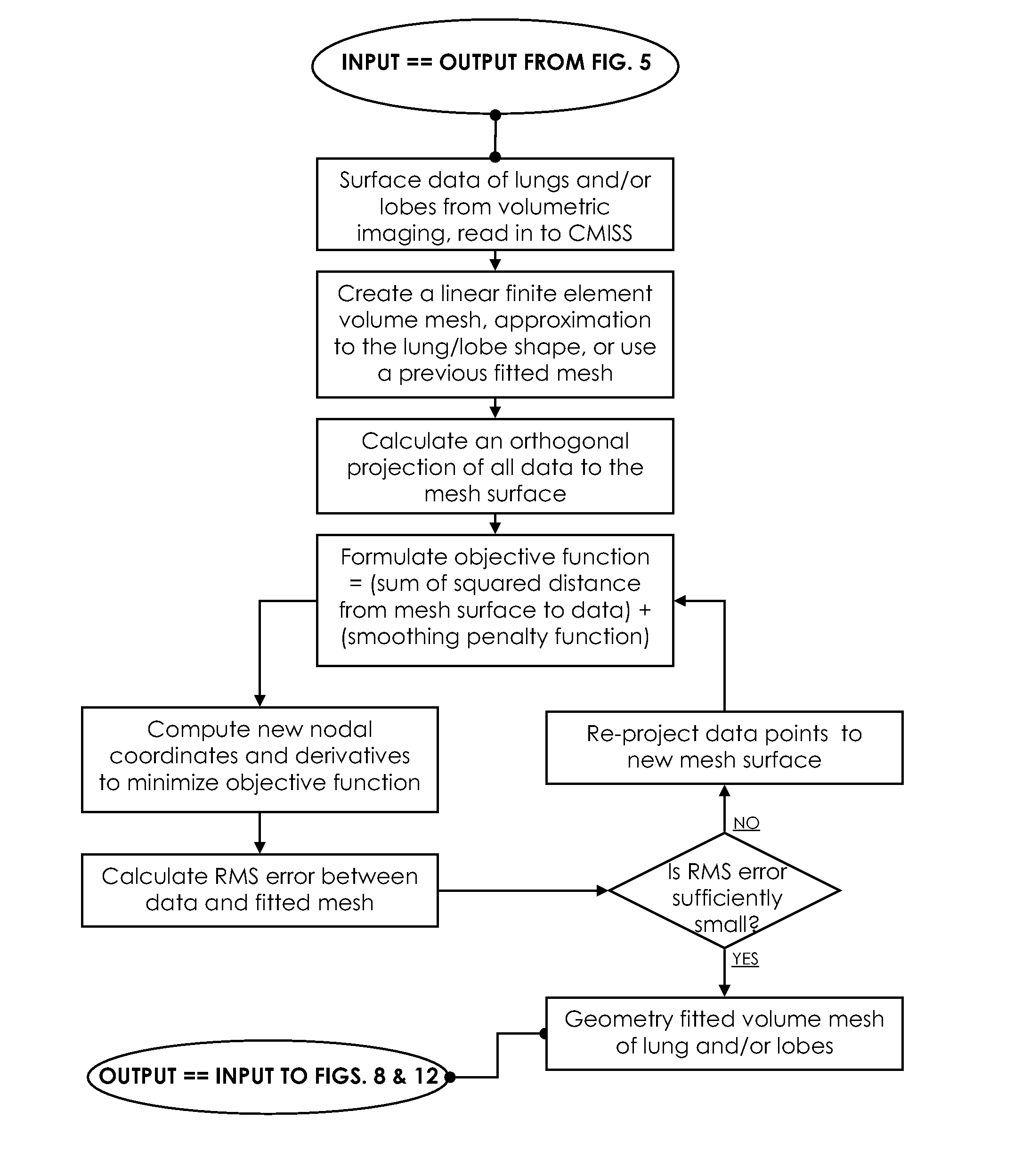

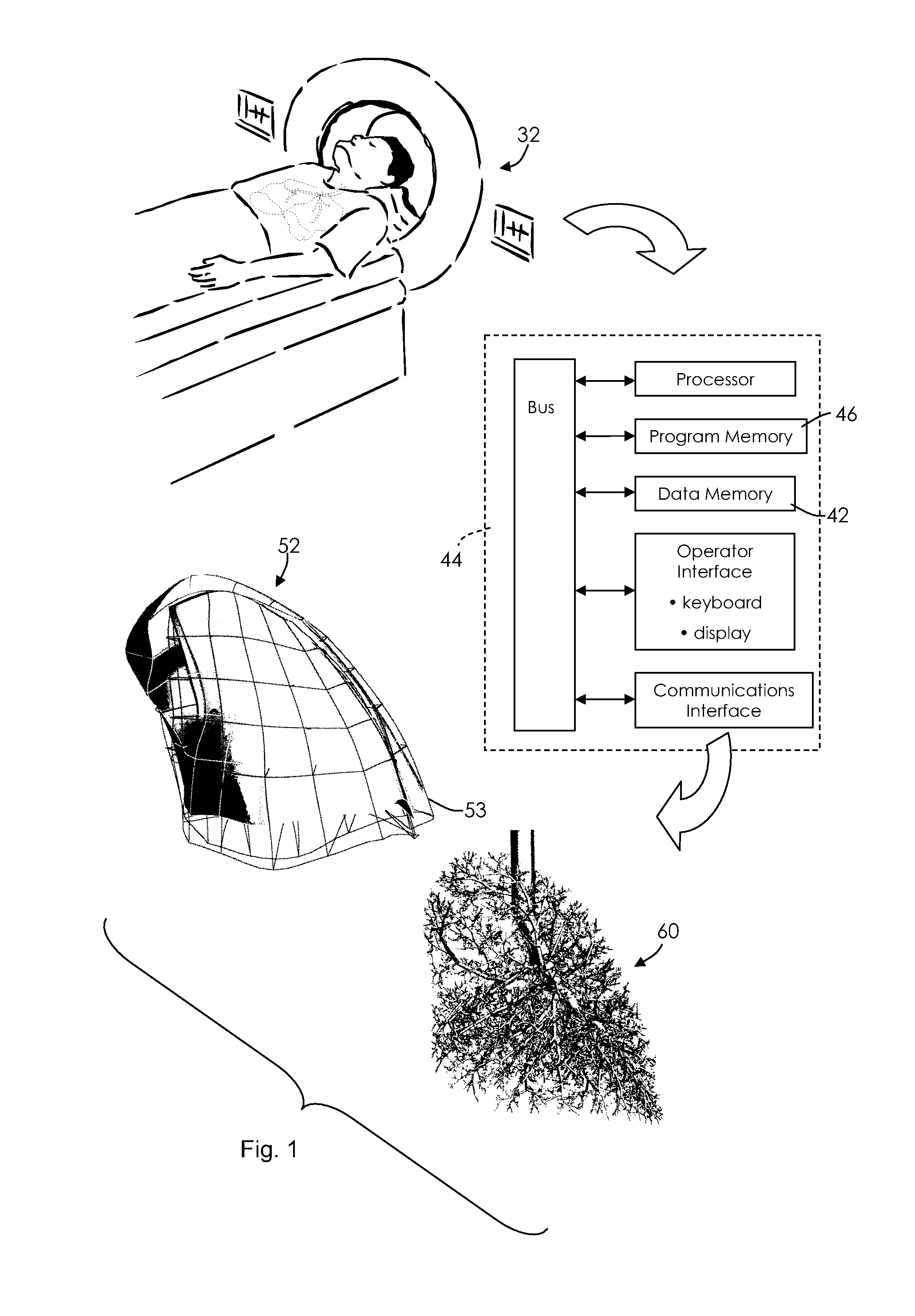

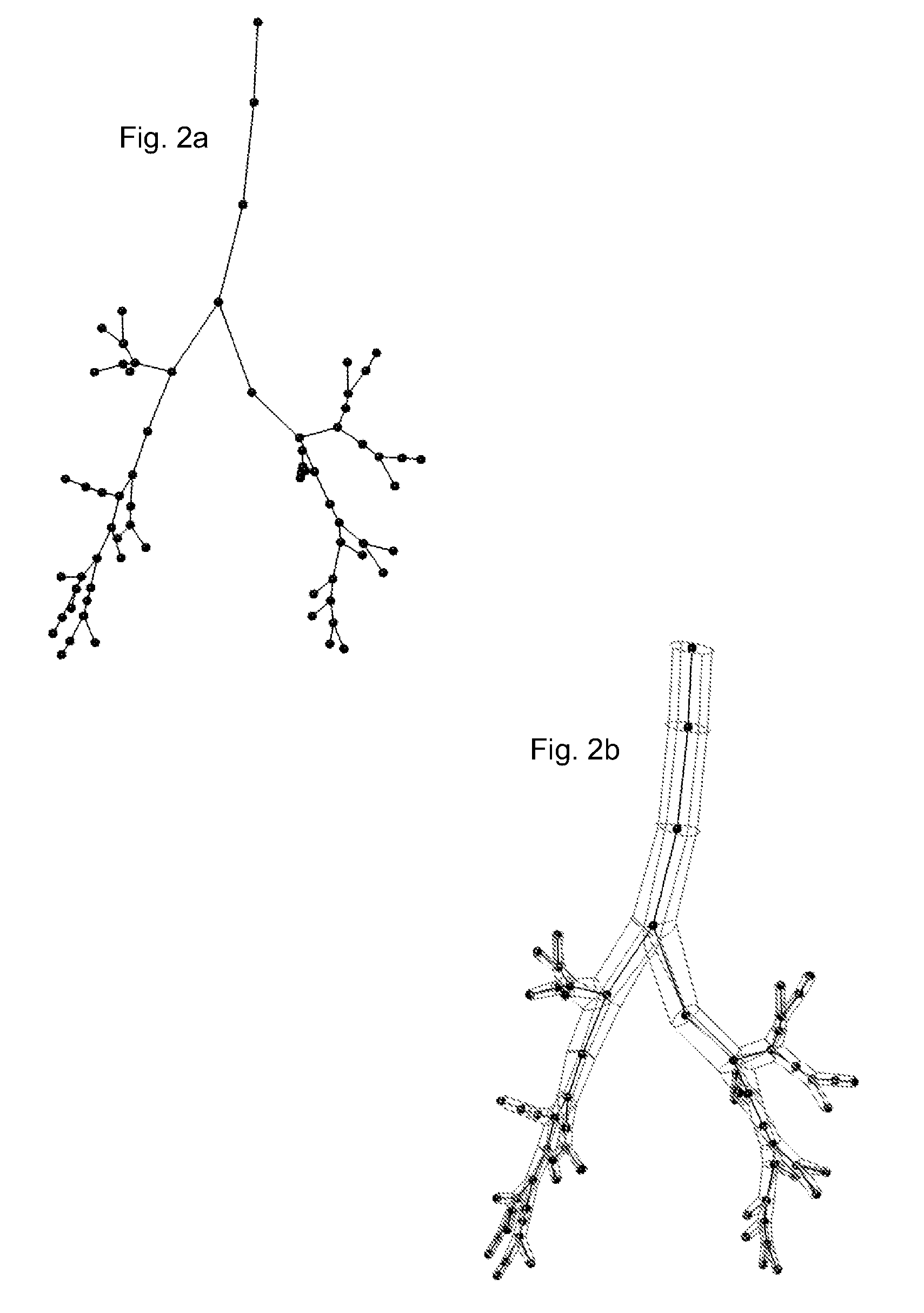

Method for multi-scale meshing of branching biological structures

InactiveUS20110093243A1Good specificationIncrease computing speedMedical simulationImage enhancementLocal pressureGrid partition

A structural and functional model for a lung or similar organ is virtually defined by encoding aspects of branching passageways. Larger passageways that are visible in medical images are surface mesh fitted to the anatomical surface geometry. Smaller distal passageways, beyond a given number of branch generations, are modeled by inference as linear passages with nominal diameters and branching characteristics, virtually filling the space within the outer envelope of the organ. The model encodes finite volumetric elements for elasticity and compliance in passageway walls, and for local pressure and flow conditions in passageway lumens during respiration. The modeling can assess organ performance, help to plan surgery or therapy, determine likely particle deposition, assess respiratory pharmaceutical dosing, and otherwise represent structural and functional organ parameters.

Owner:UNIV OF IOWA RES FOUND +1

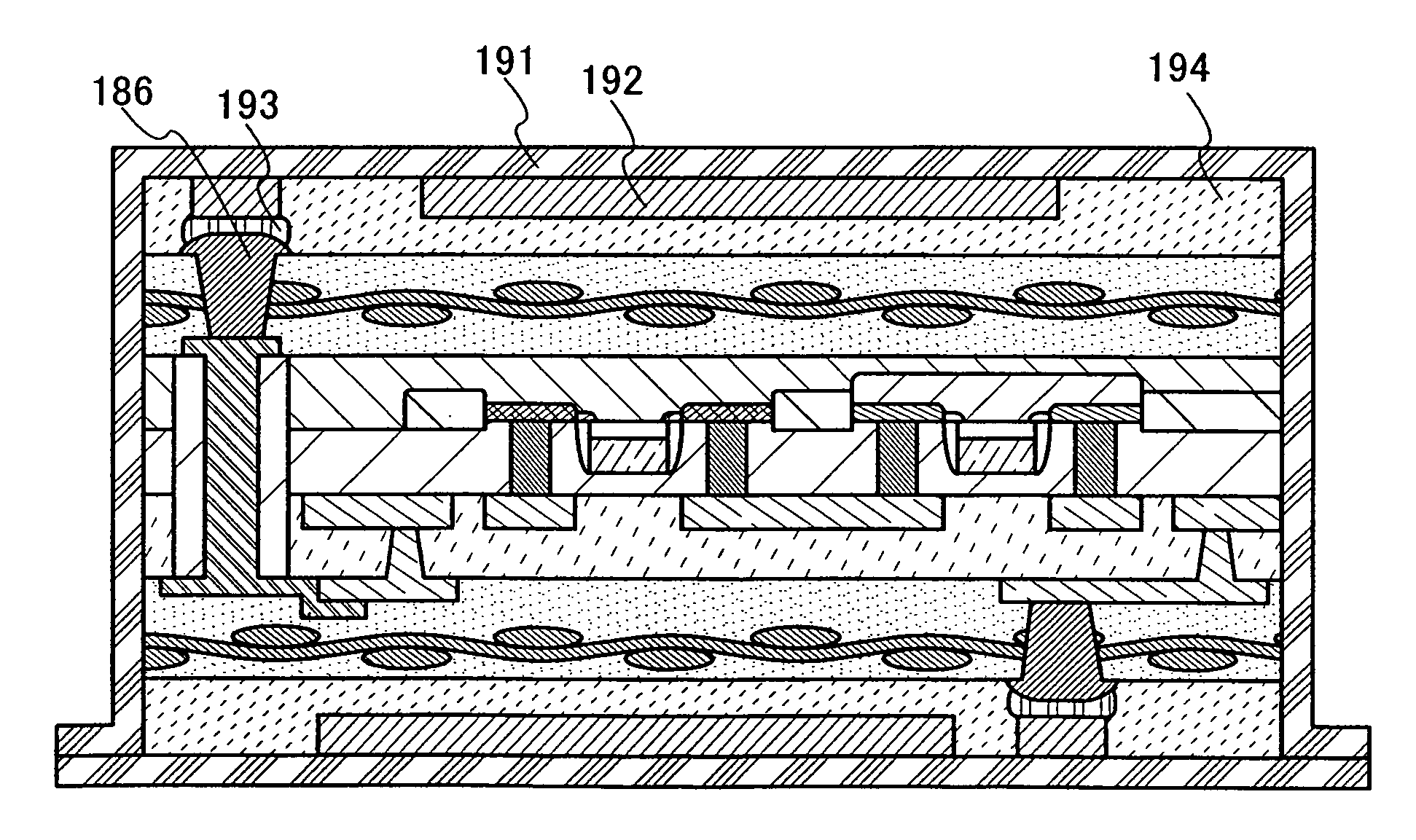

Device for mounting a component exposed to a pressurized fluid

The mounting of a component subjected to pressure from a fluid requires special precautions if the component is made of wear resistant, hard and hence generally brittle material and may be destroyed by locally raised stresses. A fluidic component of this kind, made, for example, of silicon / glass is arranged in an elastomeric shaped component, made, for example, of silicon rubber. The inner contours of the elastomeric shaped component correspond to the outer contours of the fluidic component. The outer contours of the shaped component corresponds to the inner contours of a holder. Due to this "floating mounting" there are no unacceptable local pressure peaks and no deformation of the fluidic component. The device is particularly suitable for mounting a fluidic component made of glass or silicon, or miniature dimensions, subject to high pressure.

Owner:BOEHRINGER INGELHEIM INT GMBH

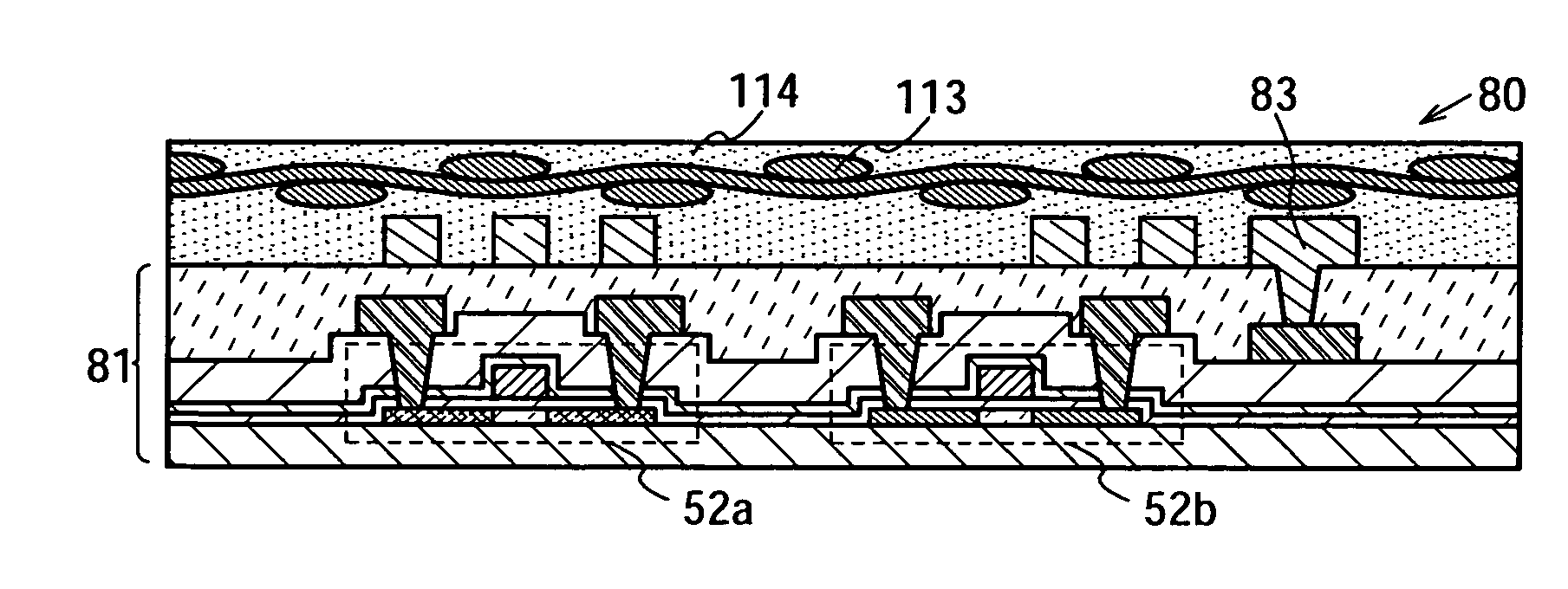

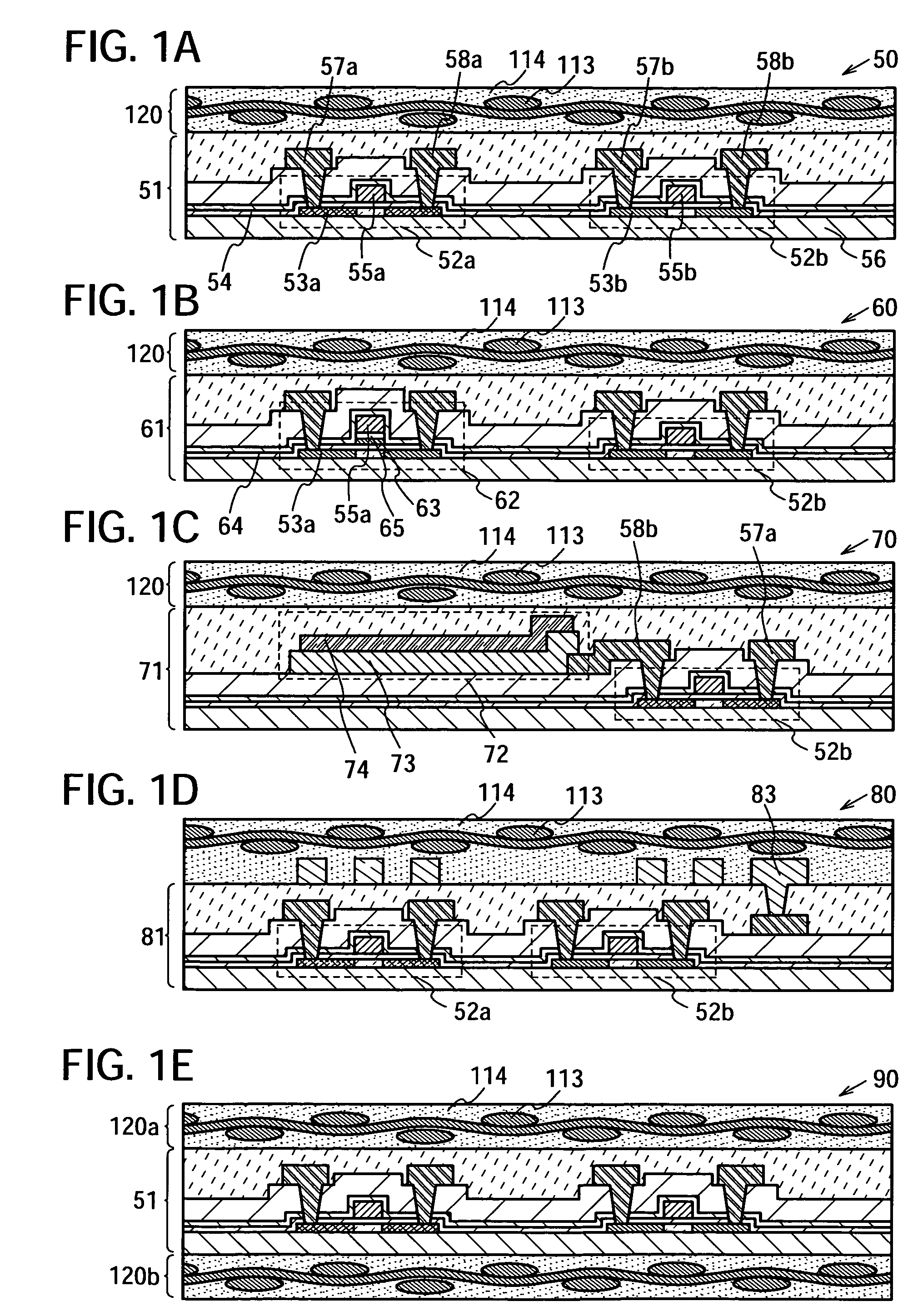

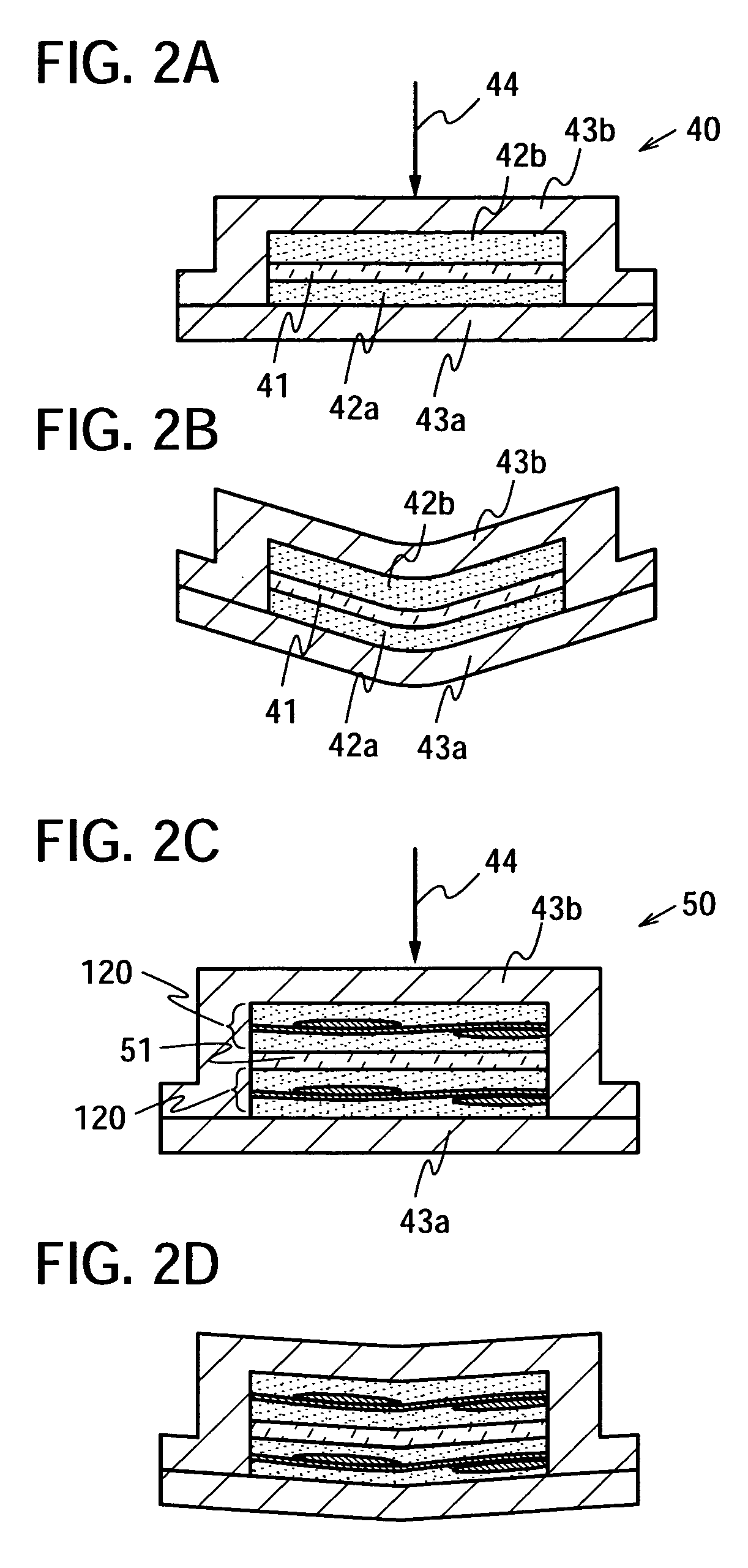

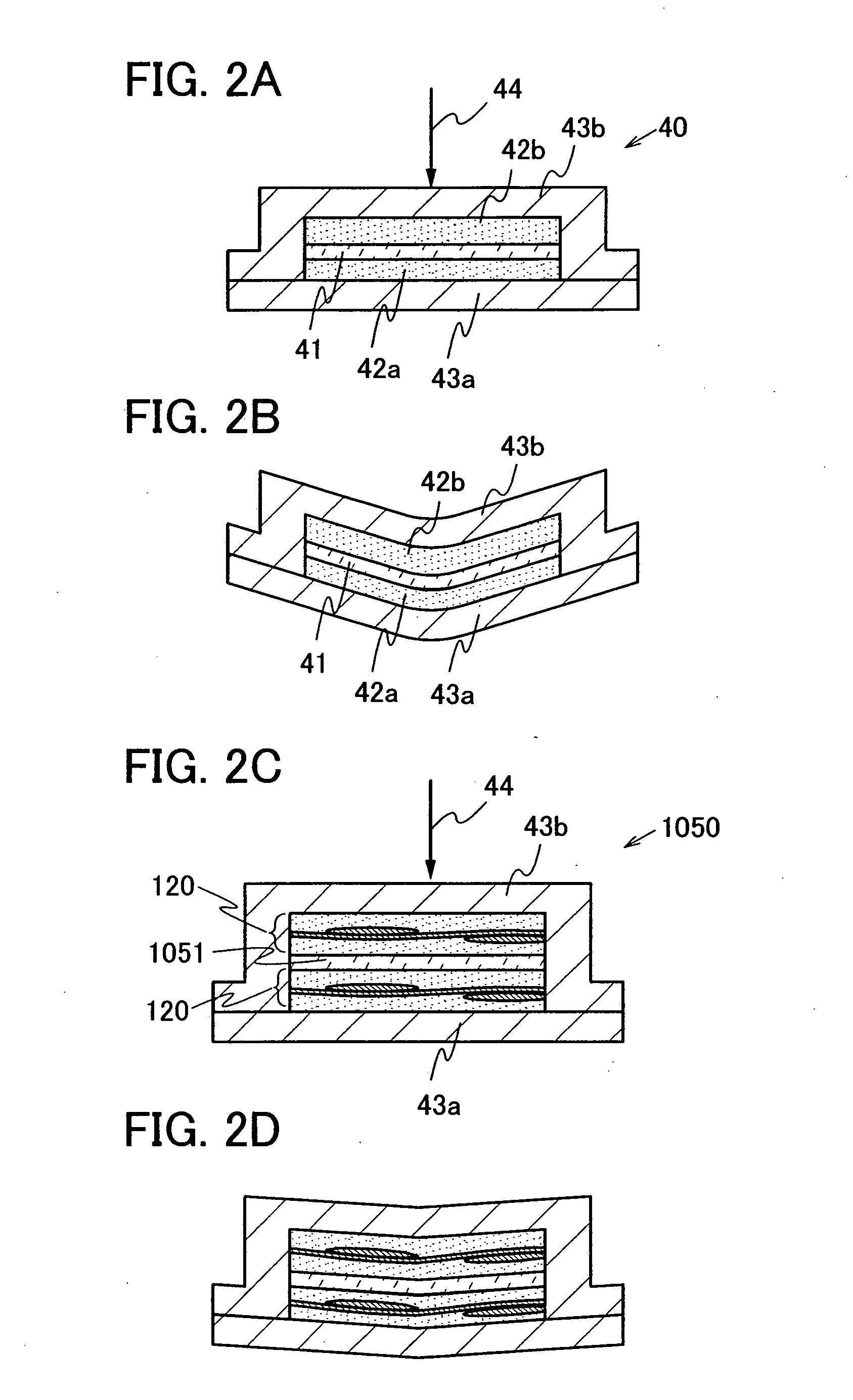

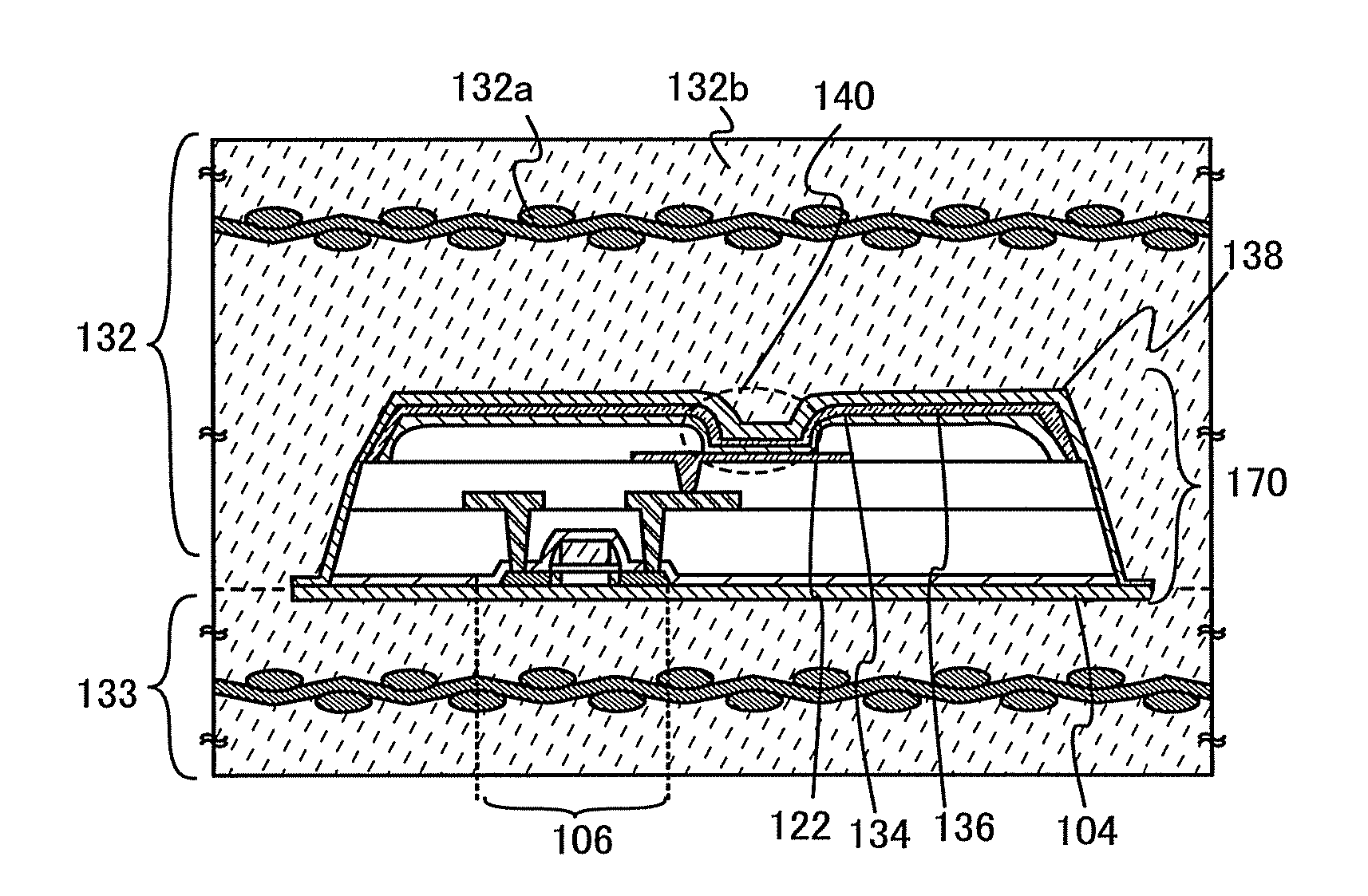

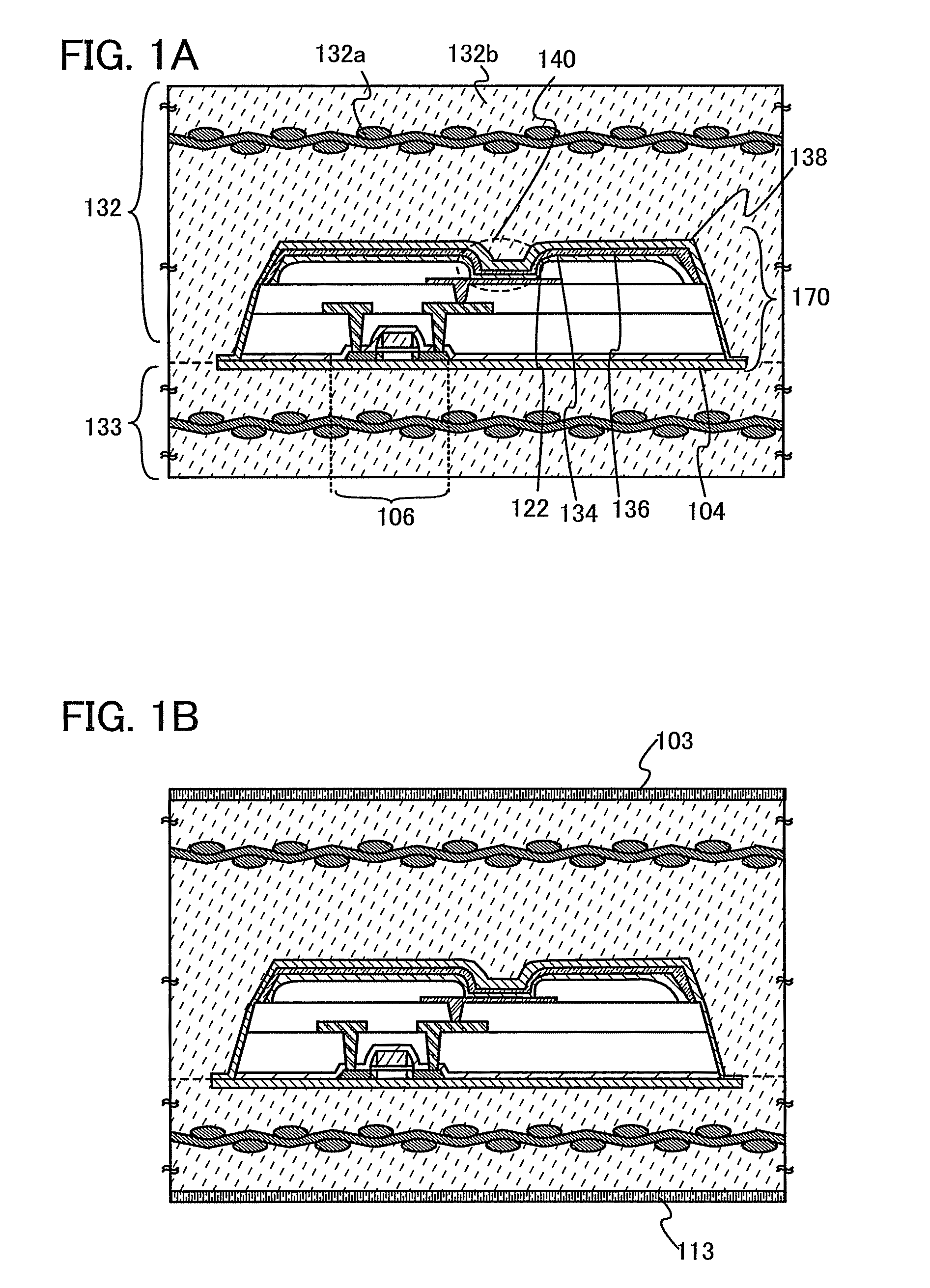

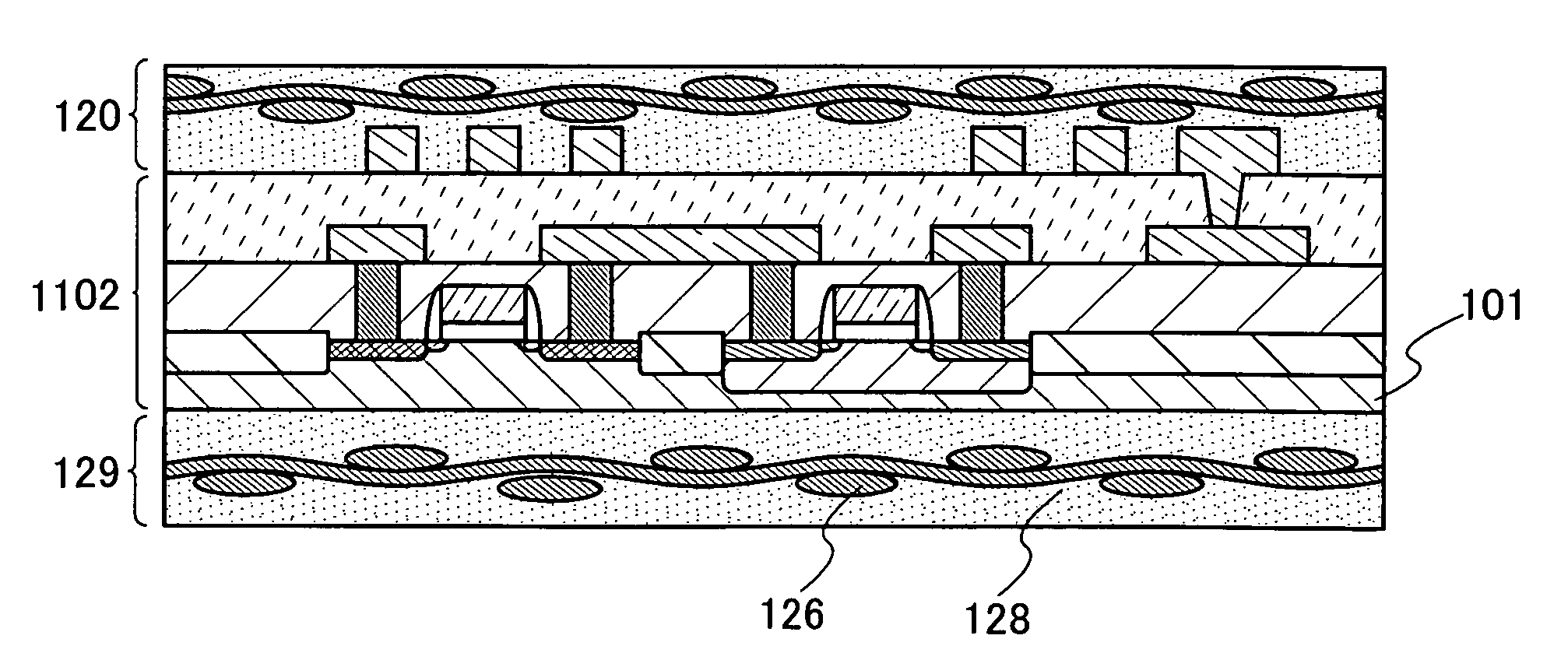

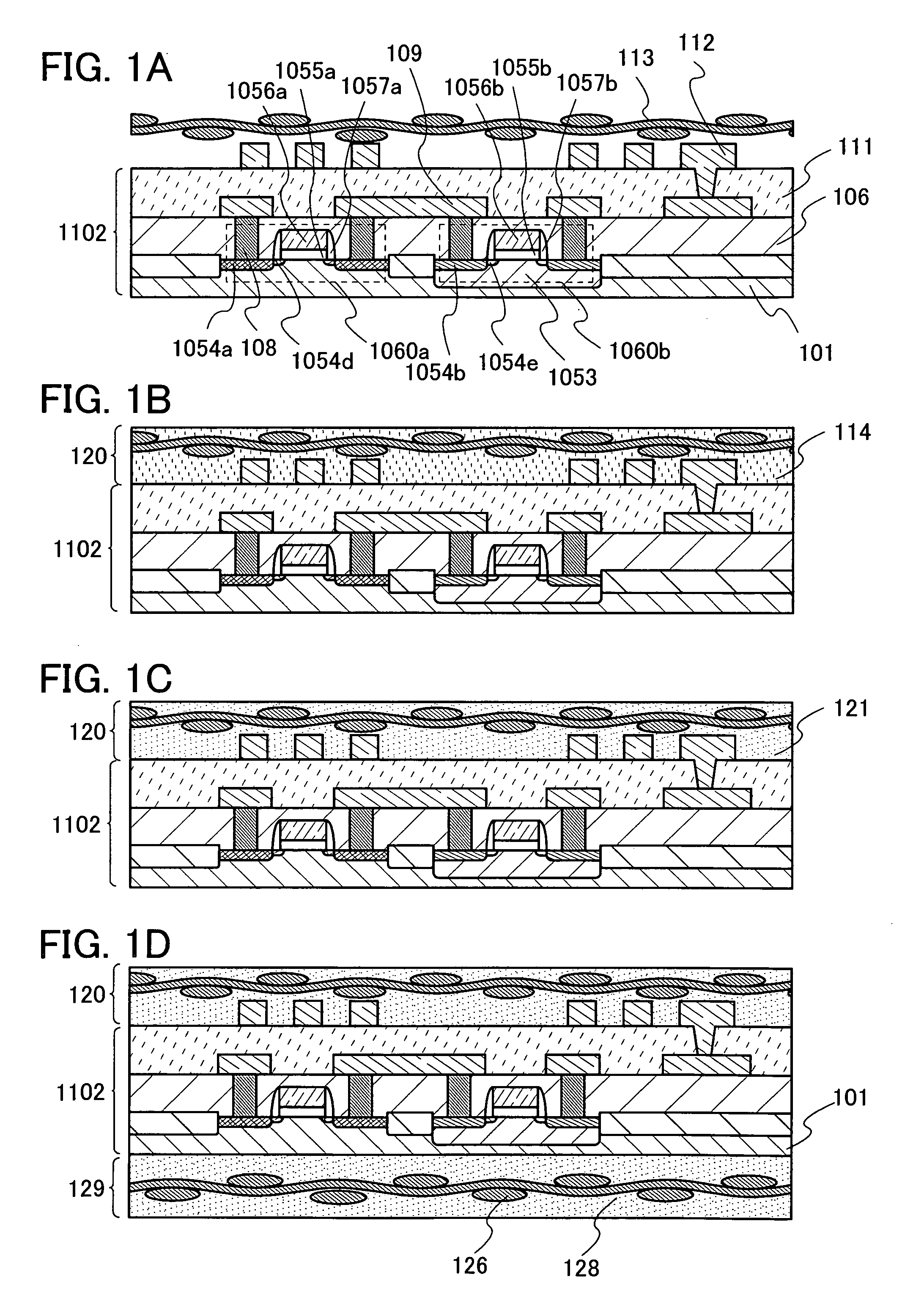

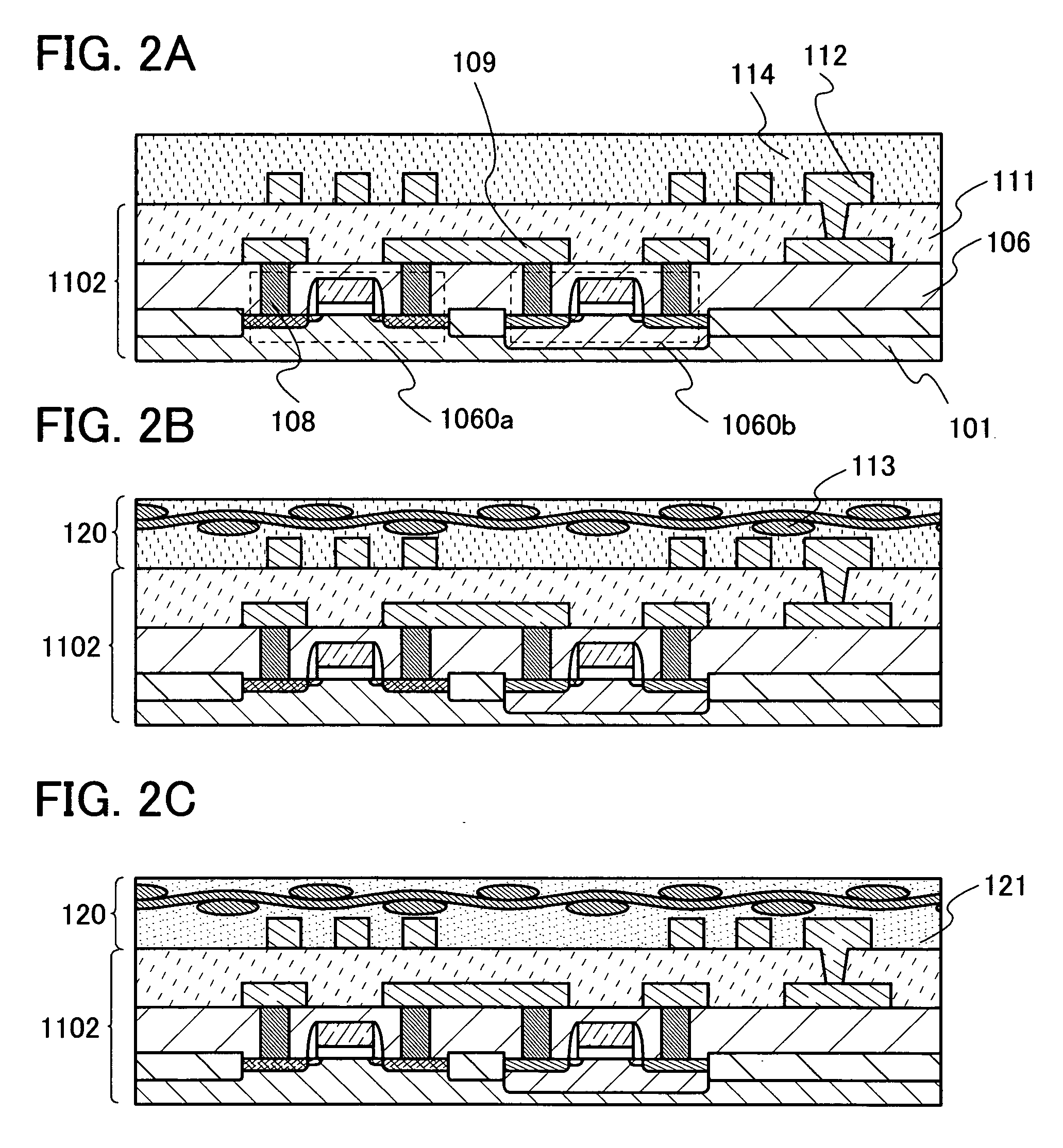

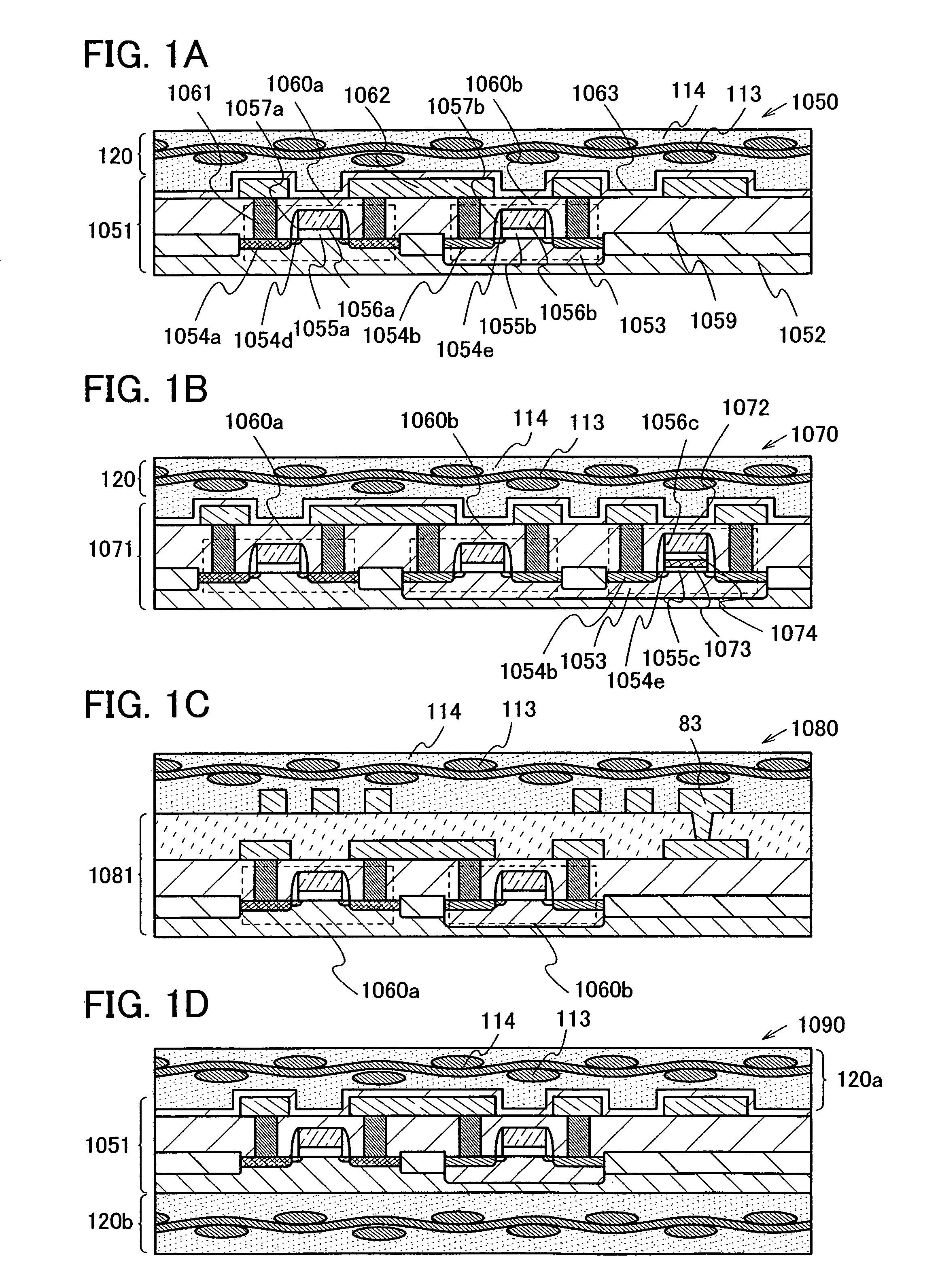

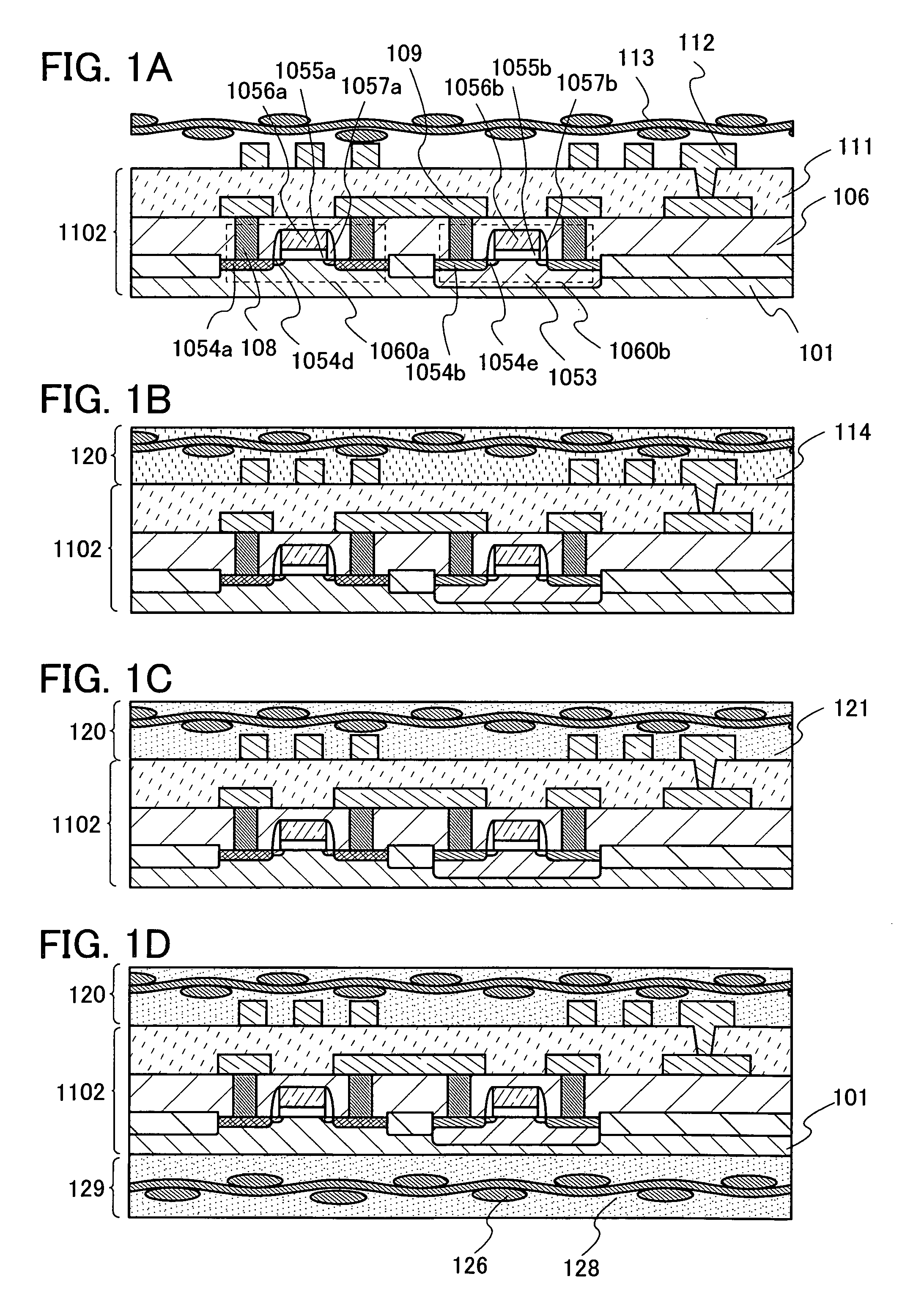

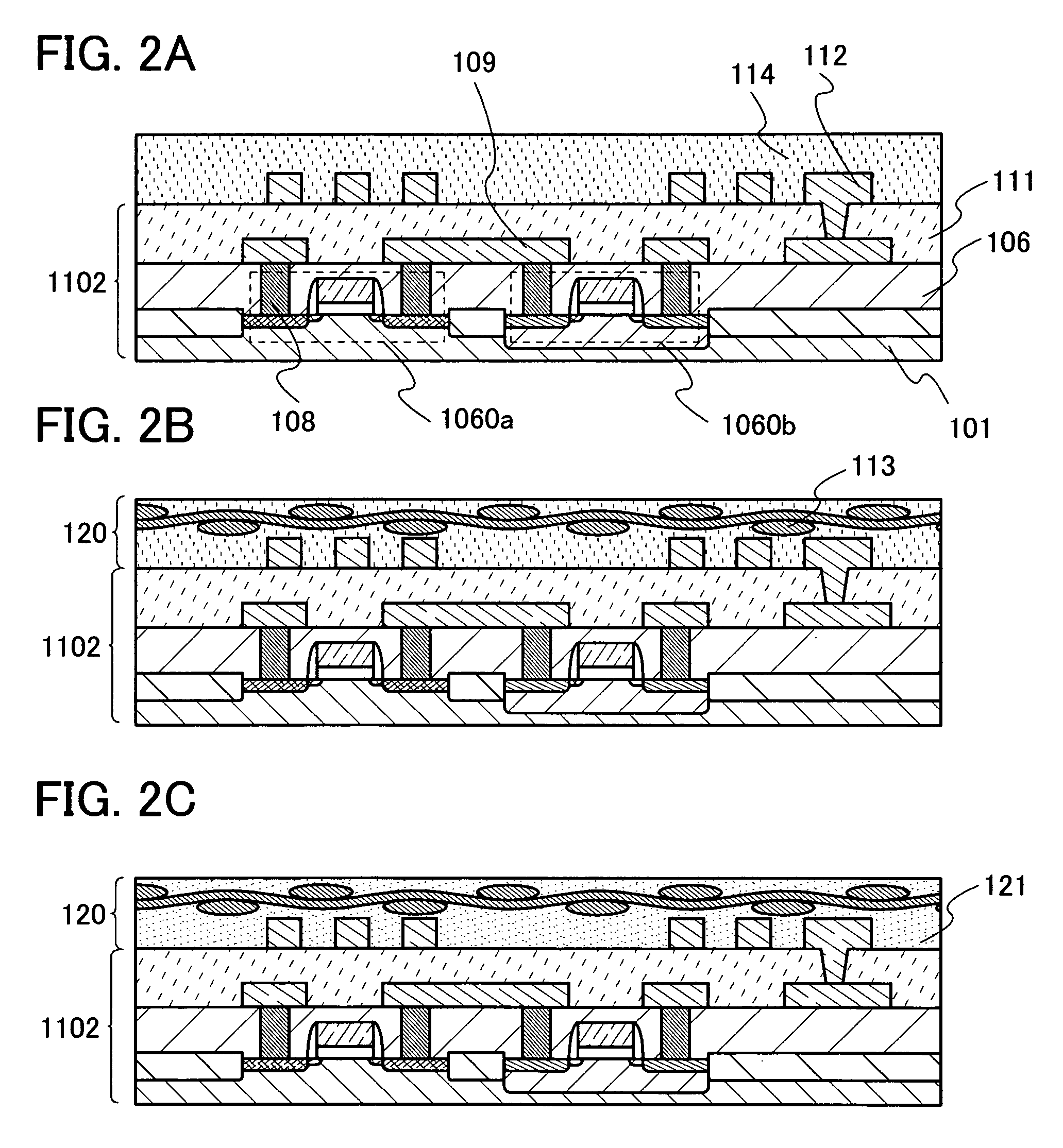

Semiconductor device and manufacturing method thereof

InactiveUS20080224941A1Avoid partialAvoid destructionSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

The present invention provides a semiconductor device which is not easily damaged by external local pressure. The present invention further provides a method for manufacturing a highly-reliable semiconductor device, which is not destructed by external local pressure, with a high yield. A structure body, in which high-strength fiber of an organic compound or an inorganic compound is impregnated with an organic resin, is provided over an element layer having a semiconductor element formed using a non-single crystal semiconductor layer, and heating and pressure bonding are performed, whereby a semiconductor device is manufactured, to which the element layer and the structure body in which the high-strength fiber of an organic compound or an inorganic compound is impregnated with the organic resin are firmly fixed together.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20080224940A1Avoid partialAvoid destructionSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

The present invention provides a semiconductor device which is not easily damaged by external local pressure. The present invention further provides a manufacturing method of a highly-reliable semiconductor device, which is not destroyed by external local pressure, with a high yield. A structure body, in which high-strength fiber of an organic compound or an inorganic compound is impregnated with an organic resin, is provided over an element substrate having a semiconductor element formed using a single crystal semiconductor region, and heating and pressure bonding are performed, whereby a semiconductor device is manufactured, to which the element substrate and the structure body in which the high-strength fiber of an organic compound or an inorganic compound is impregnated with the organic resin are fixed together.

Owner:SEMICON ENERGY LAB CO LTD

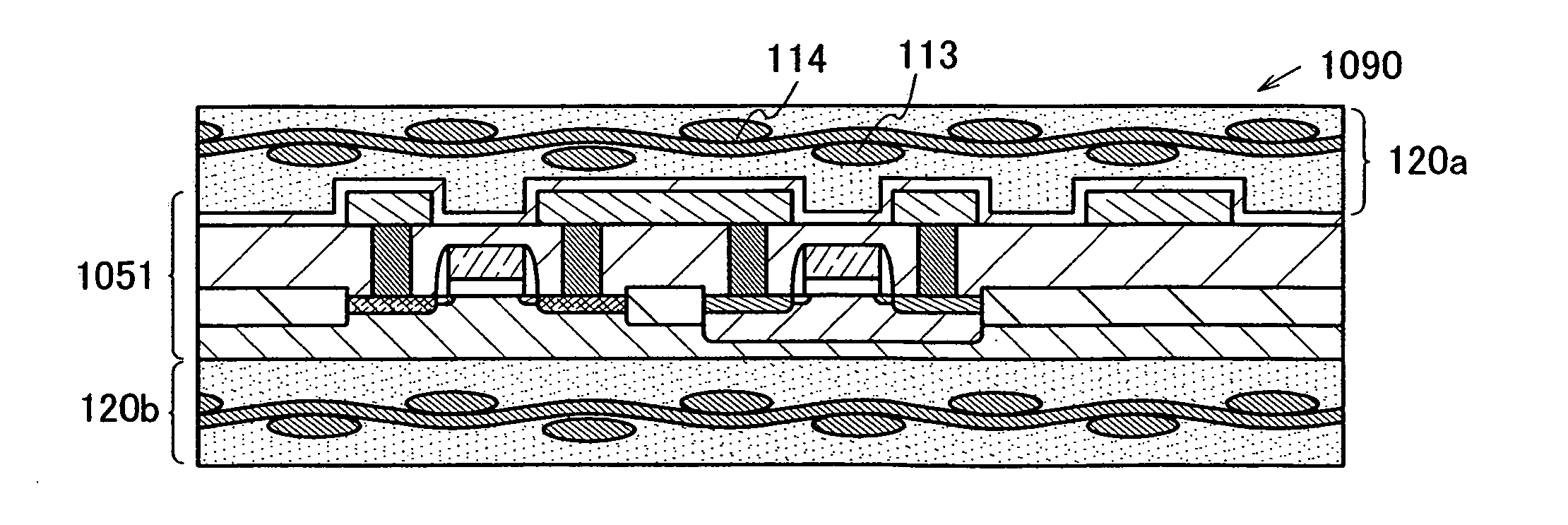

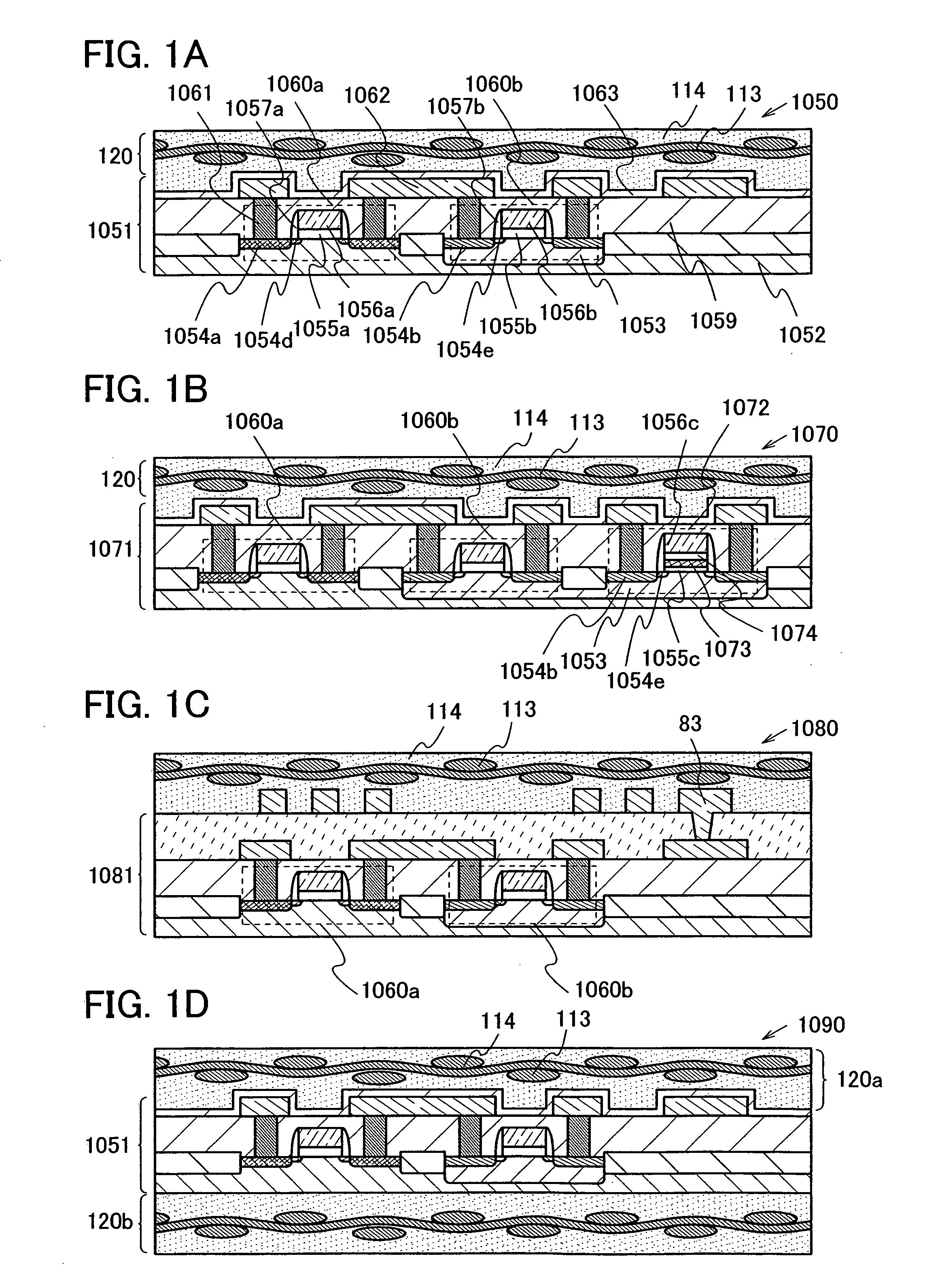

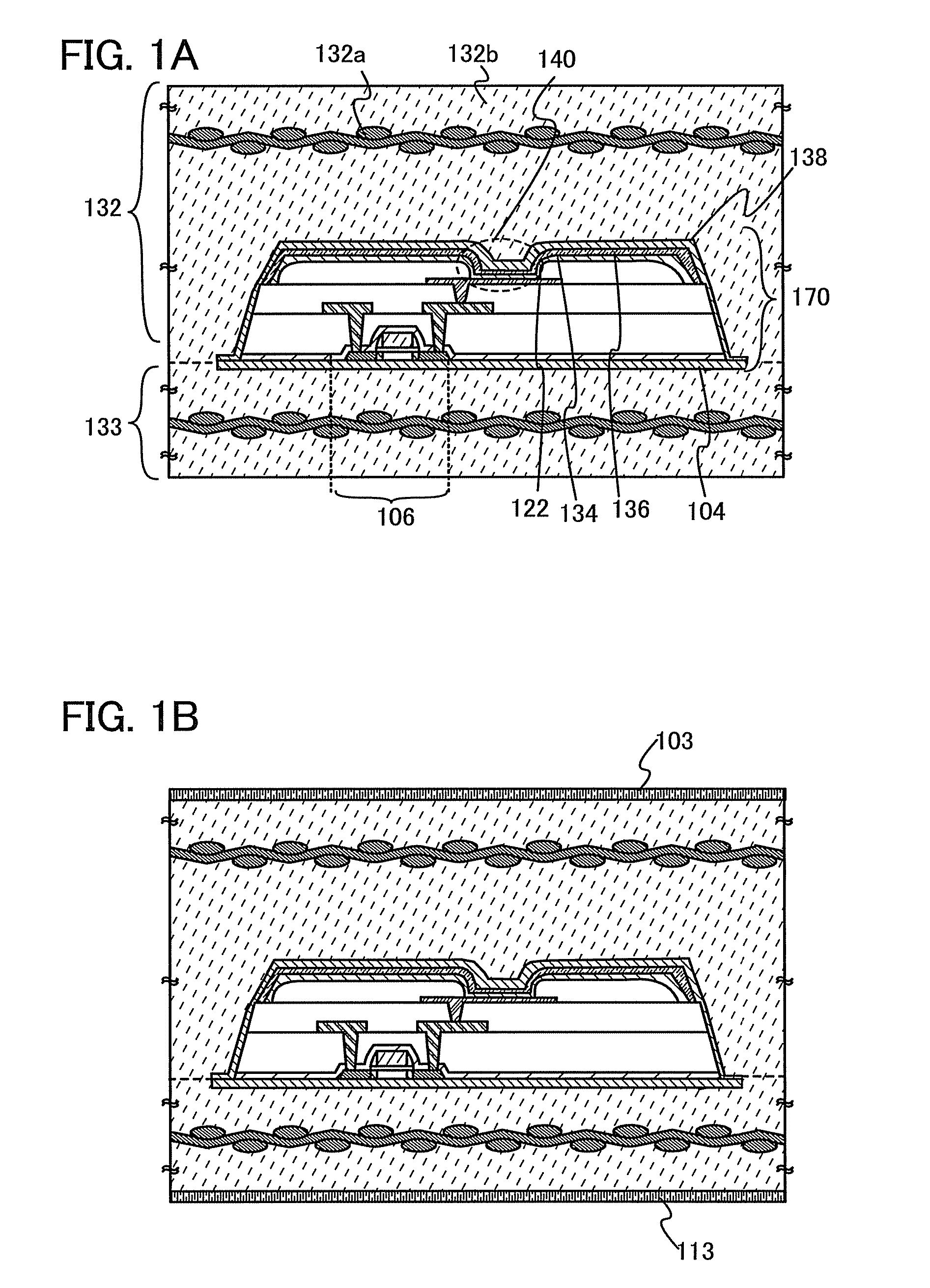

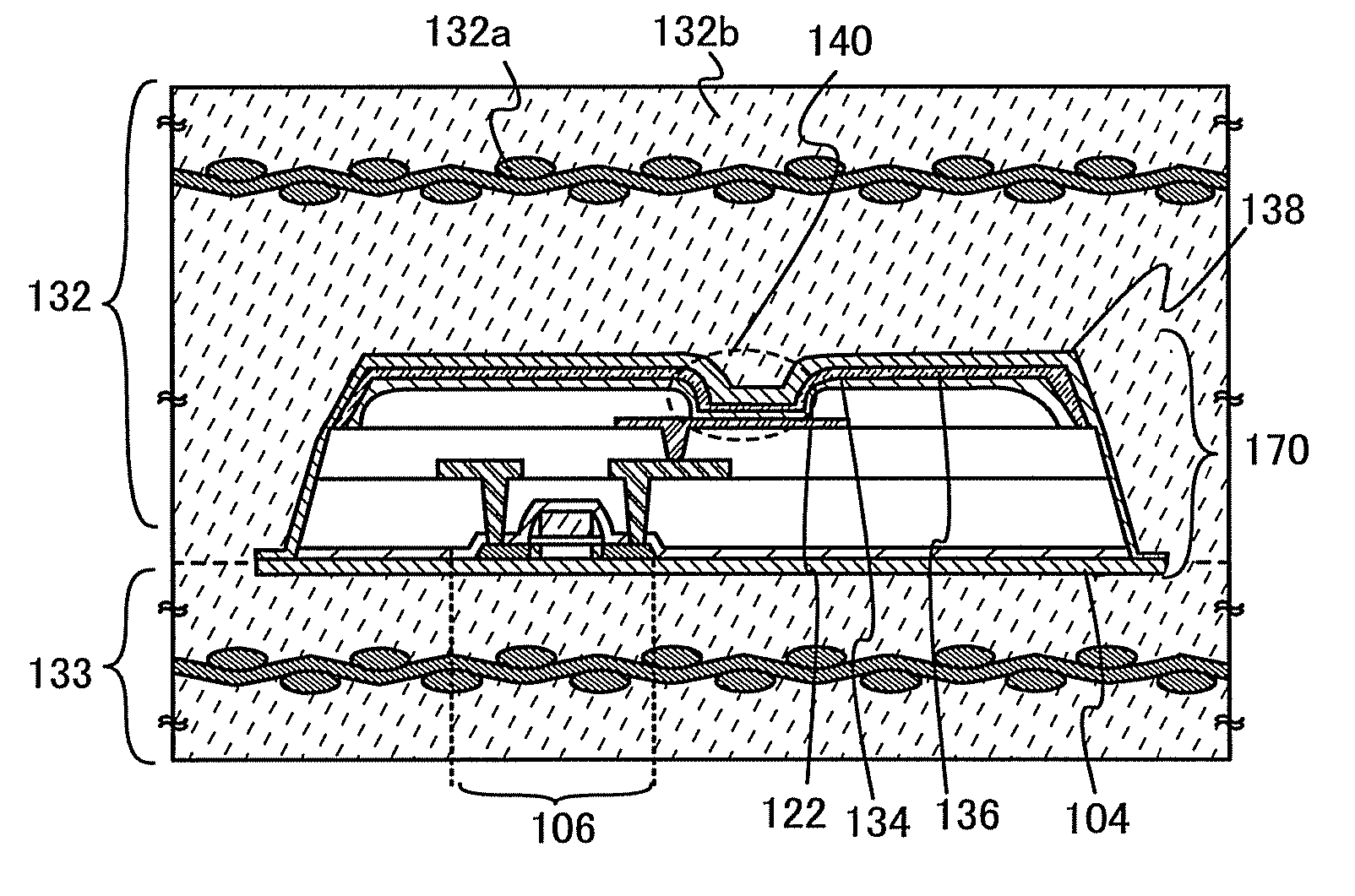

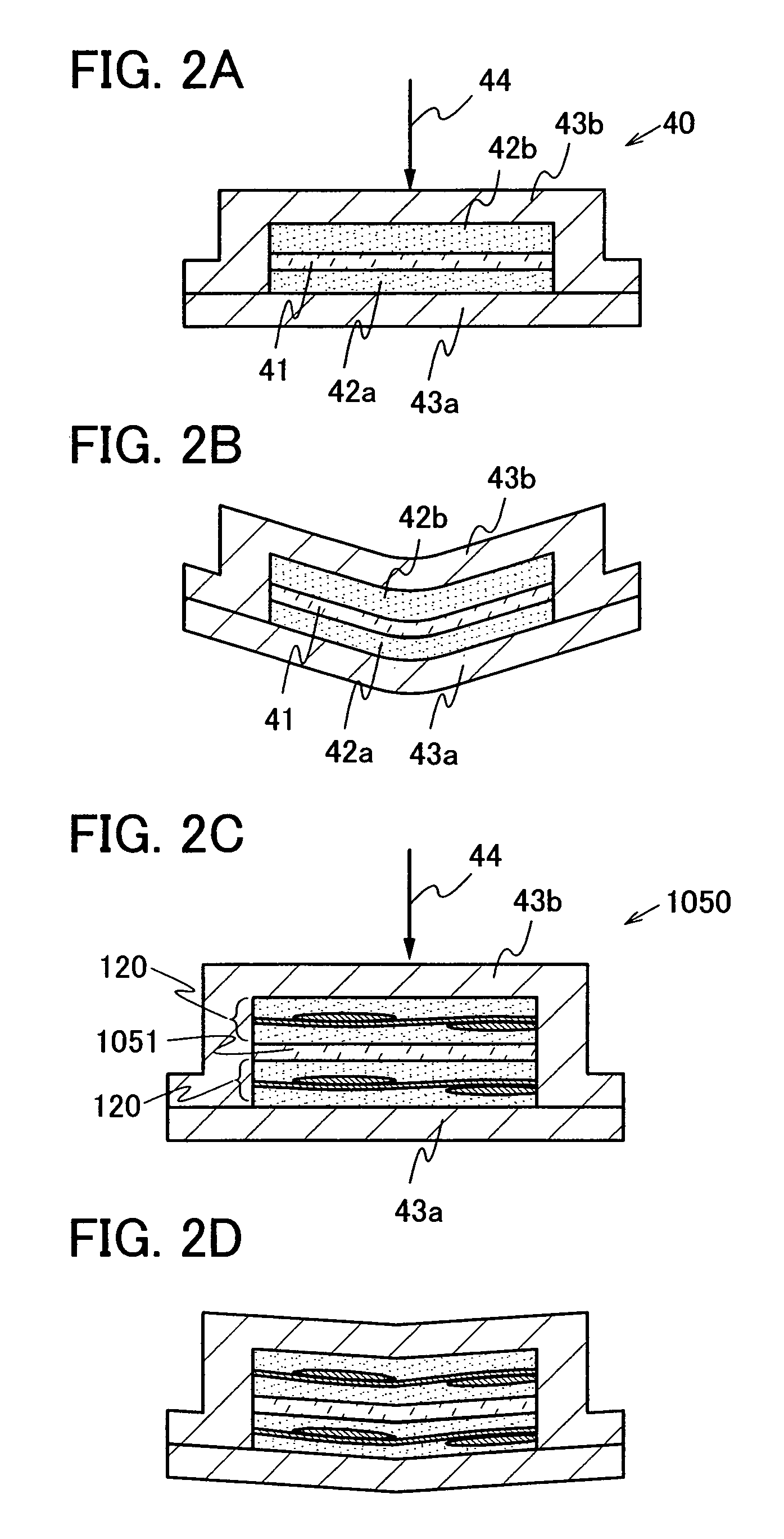

Light Emitting Device and Electronic Device

InactiveUS20100013372A1Improve reliabilityCharacteristic preventedDischarge tube luminescnet screensElectroluminescent light sourcesFibrous bodyLocal pressure

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

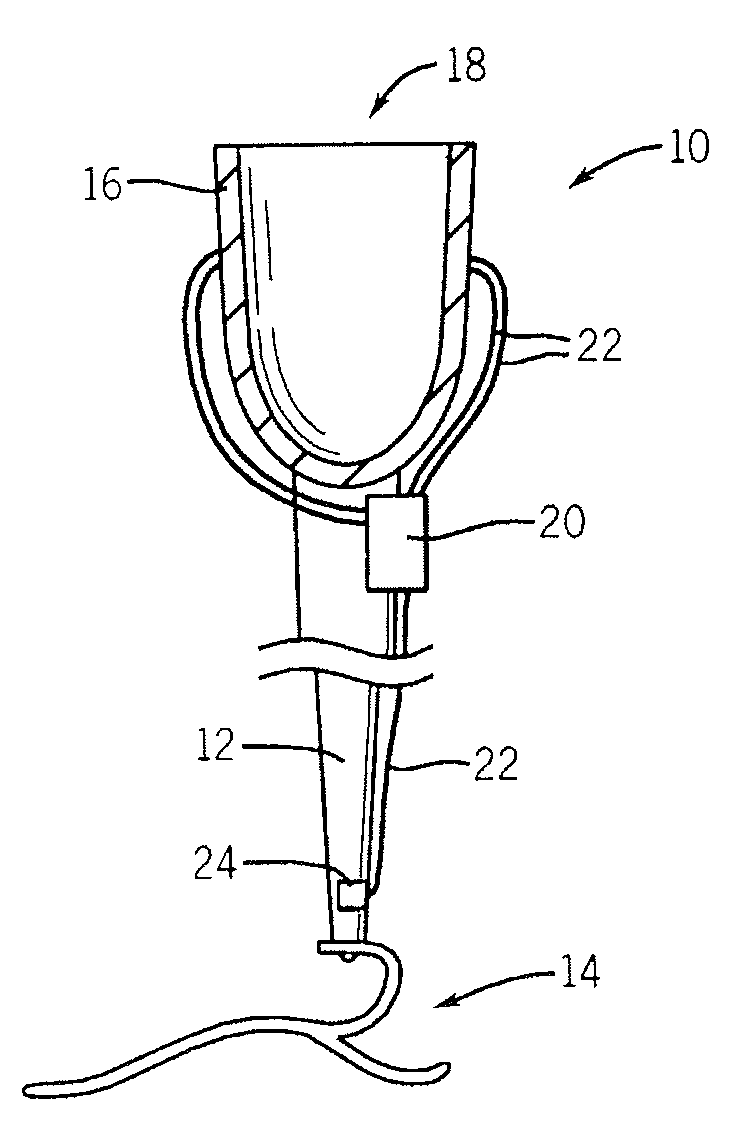

Prosthetic socket with real-time dynamic control of pressure points

An improved socket for a prosthesis uses a liner material providing fluid flow through a porous matrix whose local pressure is adjusted by a control system communicating with multiple valves and pressure sensors. Control of pressure in a viscoelastic material provides an improved trade-off between comfort and stability.

Owner:WISYS TECH FOUND

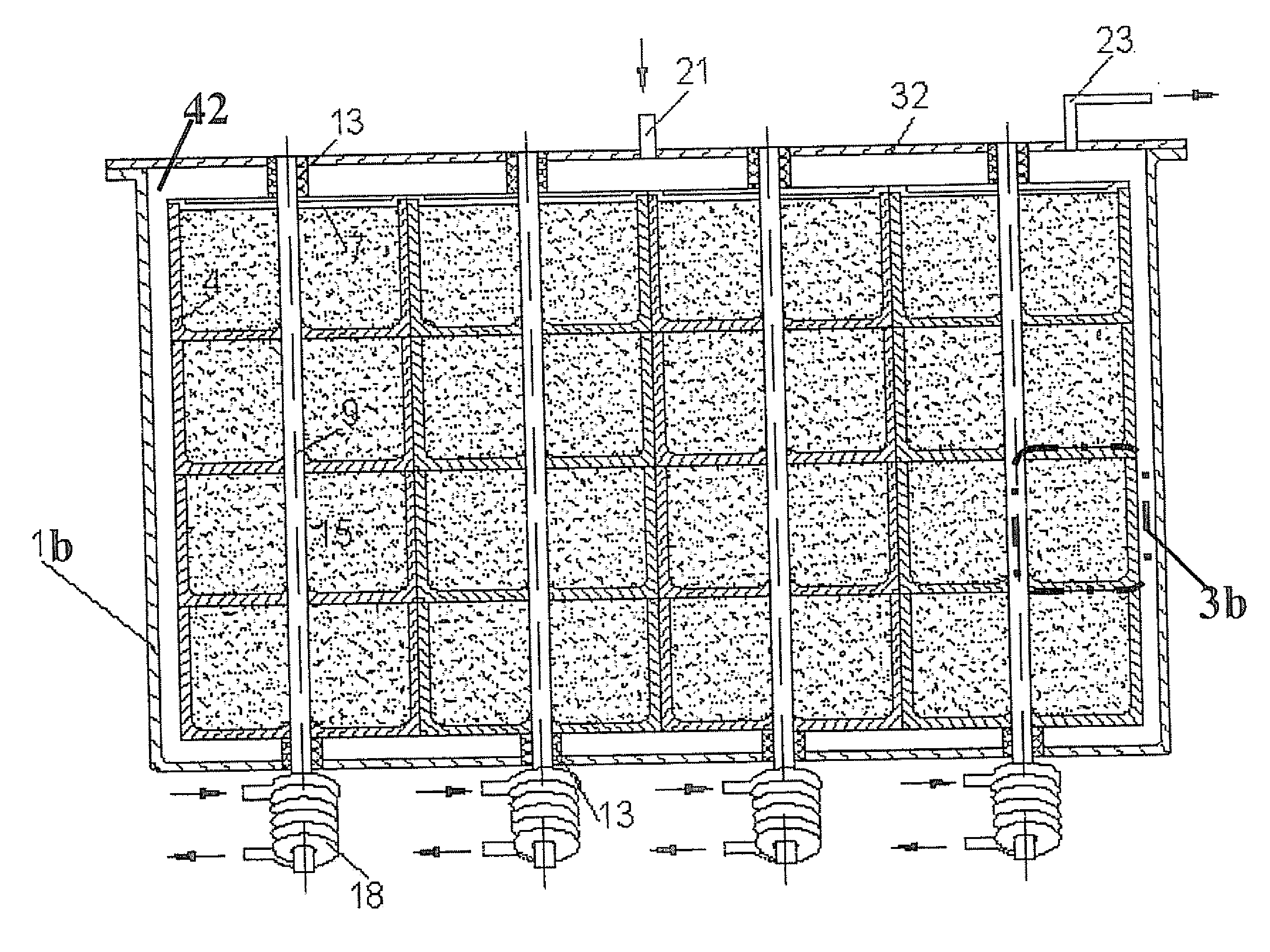

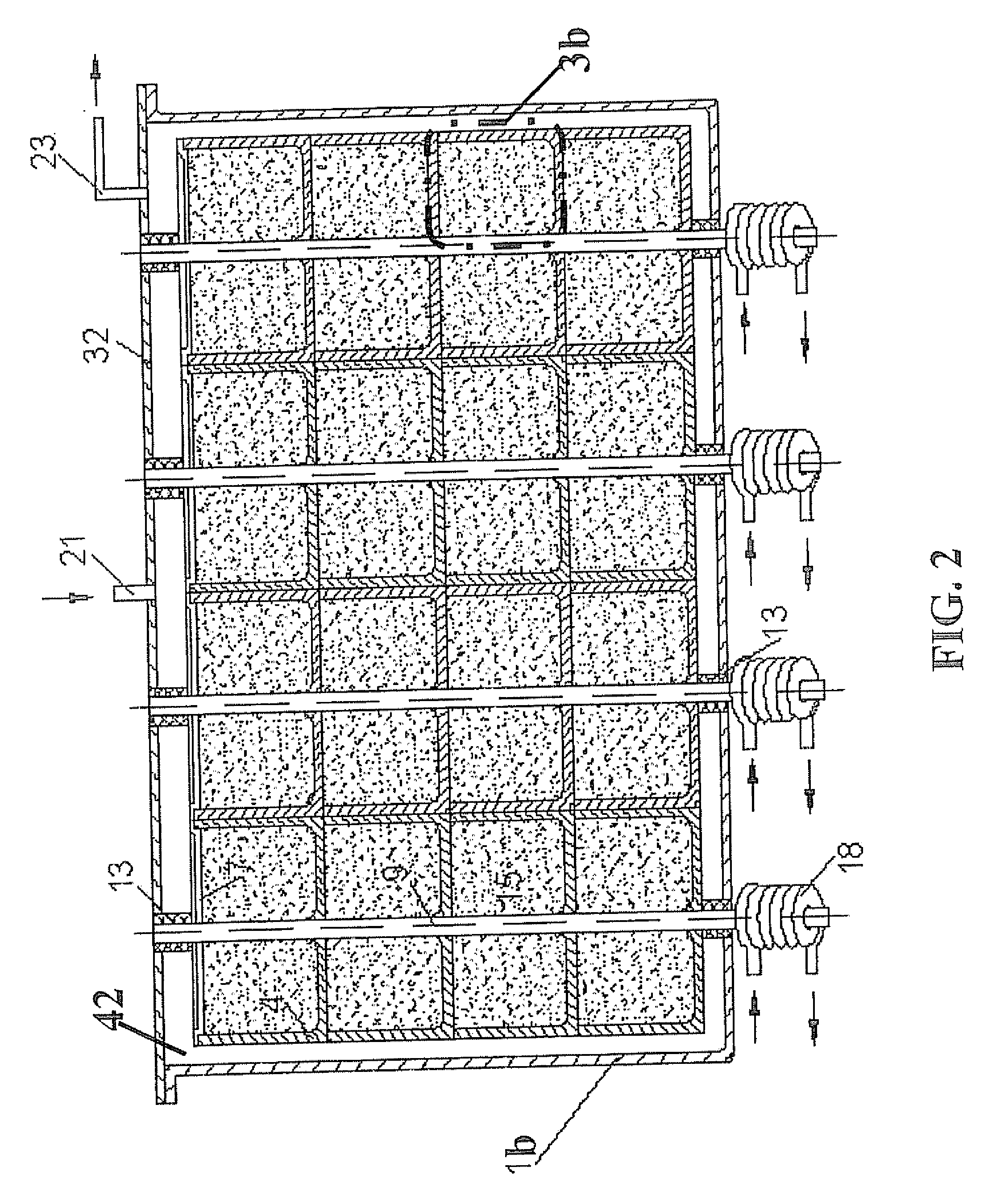

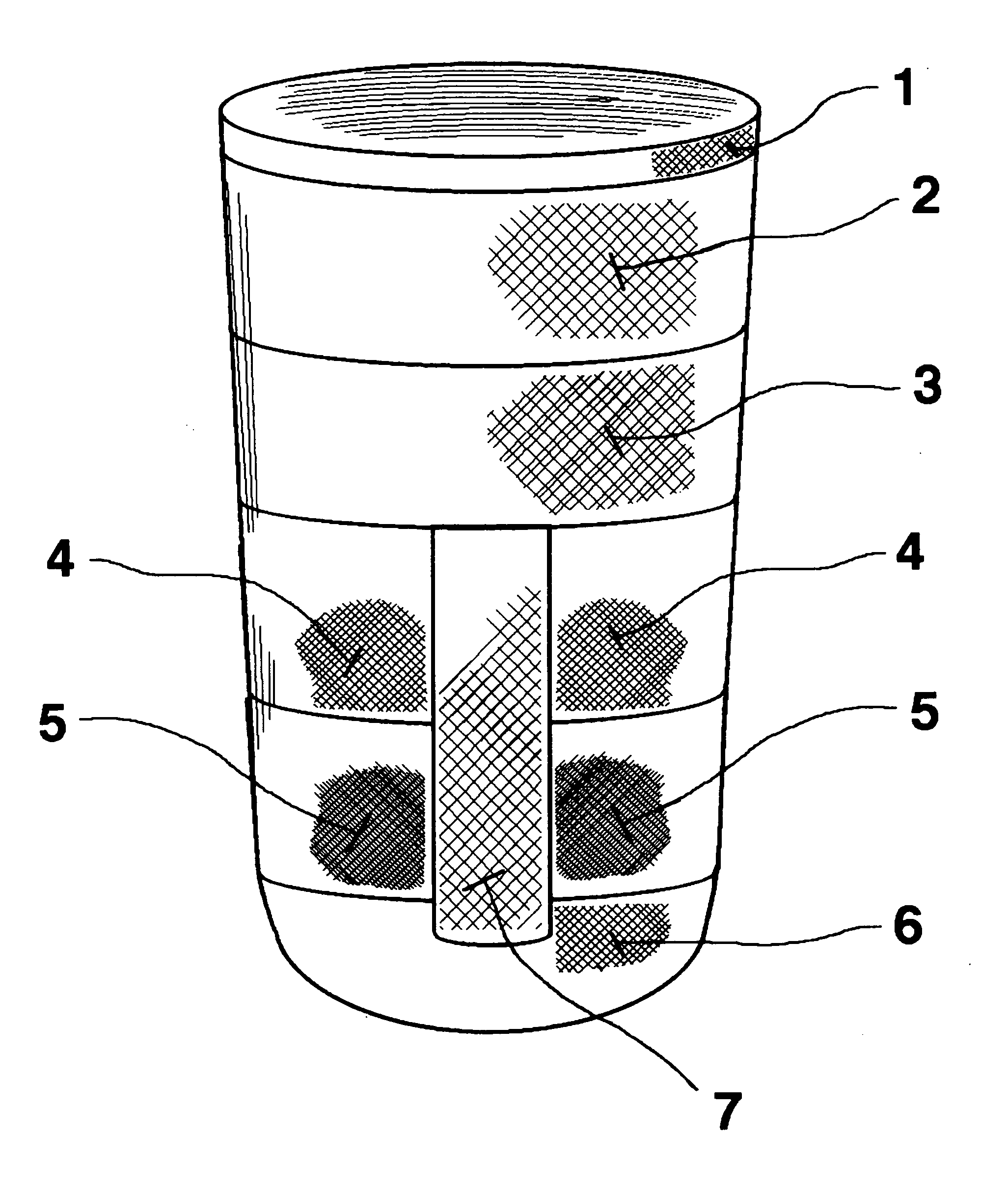

Storage Systems For Adsorbable Gaseous Fuel And Methods Of Producing The Same

InactiveUS20090229555A1Raise transfer toImprove efficiencyGas handling applicationsIsotope separationParticulatesLocal pressure

A storage system for an absorbing gas including a plurality briquette units situated within the storage tank is disclosed. In some embodiments each briquette unit includes a liner or open vessel, and compressed gas-absorbing particulate matter associated with the liner for external support In some embodiments, the liner or vessel maintains the form of the briquette unit. The liner or vessel do not form a pressure tight vessel, and in some embodiments, the local pressure rating of the liner or vessel is less than the gas pressure within the storage tank. Exemplary gas-absorbing materials include but are not limited to methane and hydrogen adsorbing materials such as activated carbon, zeolite, and other appropriate hydrocarbon gas and / or hydrogen adsorbing materials. Optionally, each briquette unit includes a wrapper for preventing circulation of said particulate matter within the storage tank. Optionally, the storage system includes a mechanism for supplying or removing heat to at least one briquette unit. Furthermore, a method for manufacturing any of the aforementioned gas storage systems is disclosed. Some embodiments of the present invention provide methane-powered motor vehicles including but not limited to automobiles, buses, trucks and ships including a storage system with compressed methane-adsorbing particulate matter

Owner:ANGSTORE TECH

Light emitting device and electronic device utilizing fibrous barrier layers impregnated with organic resin

InactiveUS8264144B2High yieldPreventing in characteristicDischarge tube luminescnet screensElectroluminescent light sourcesFiberFibrous body

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

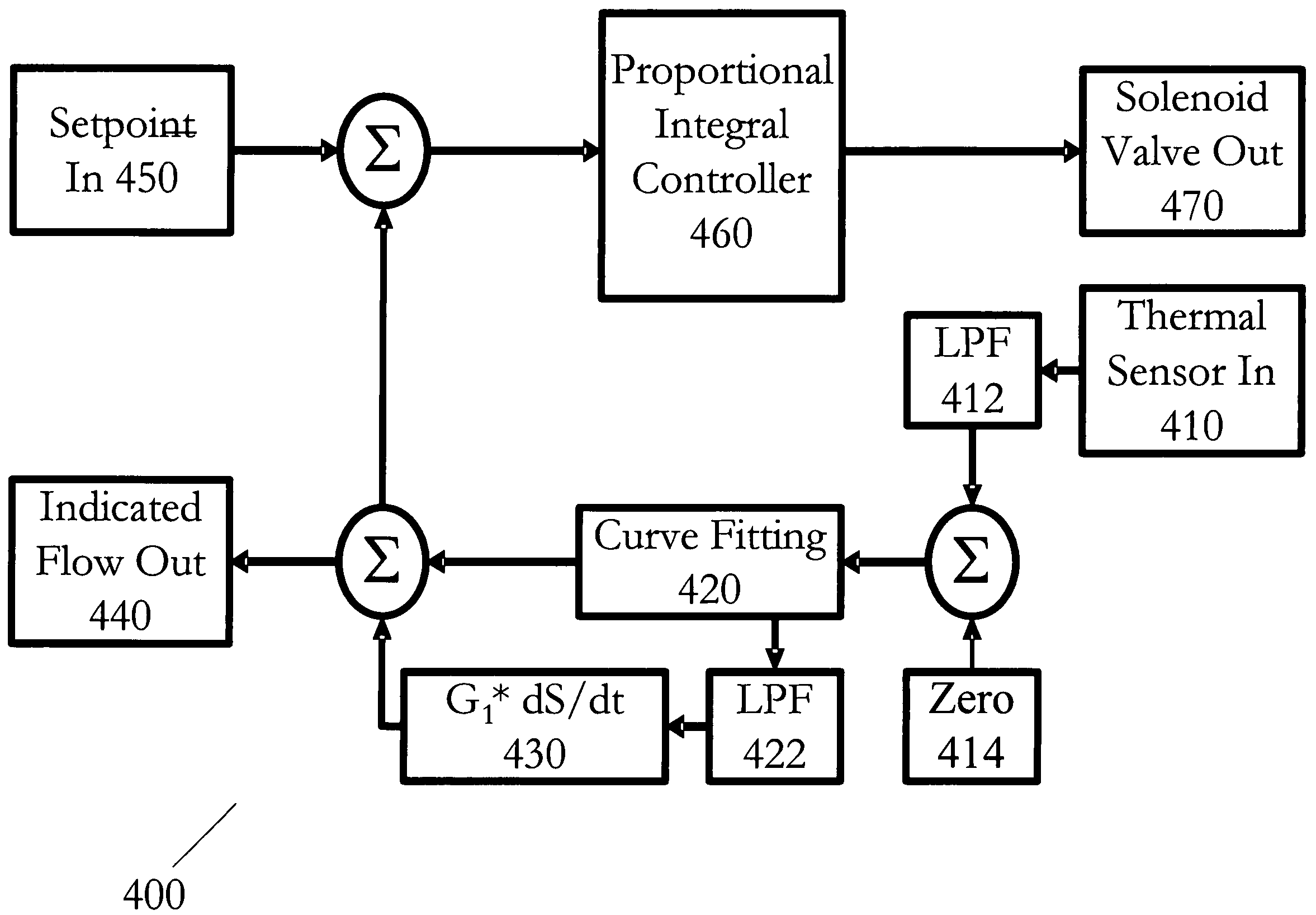

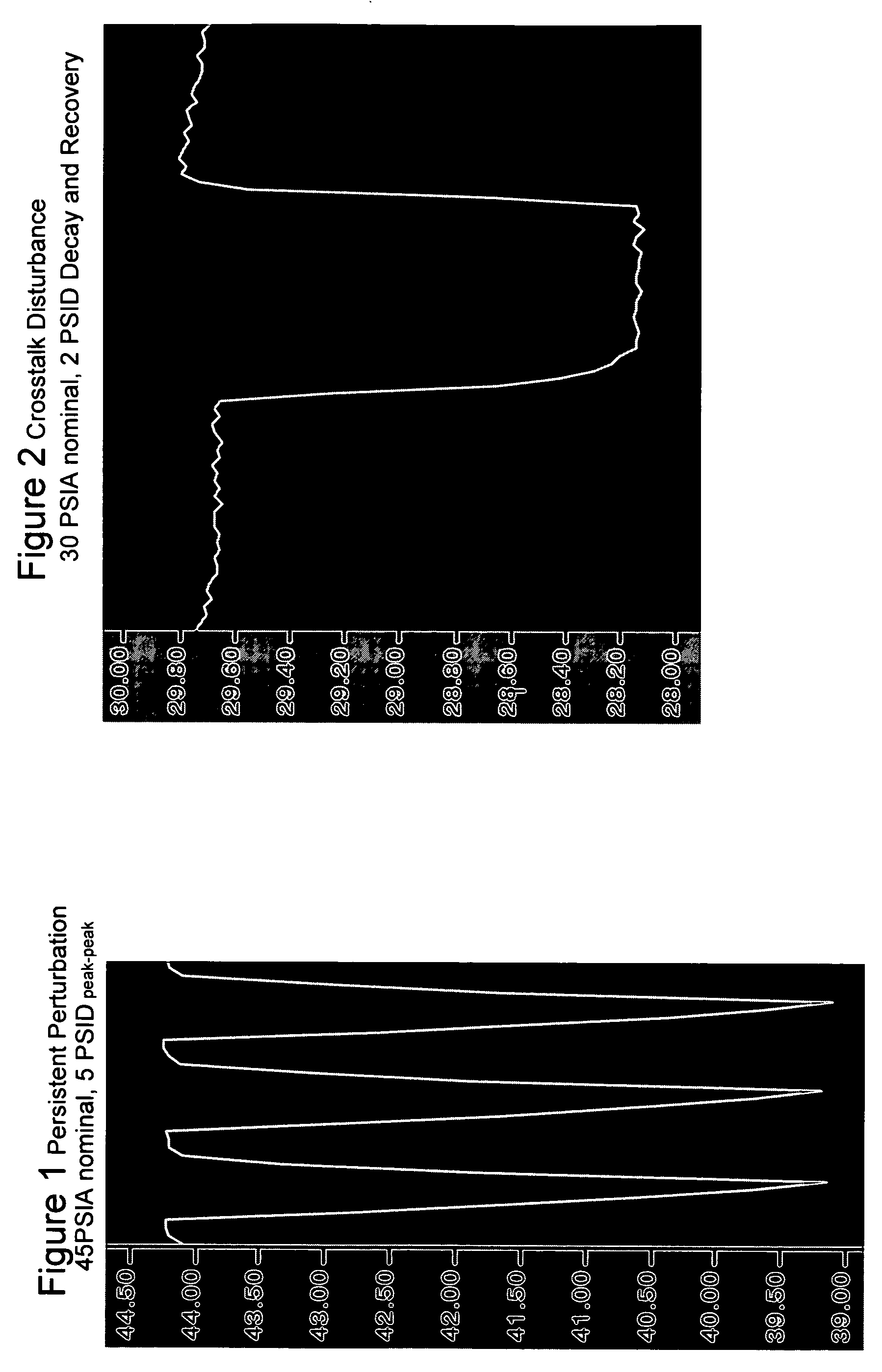

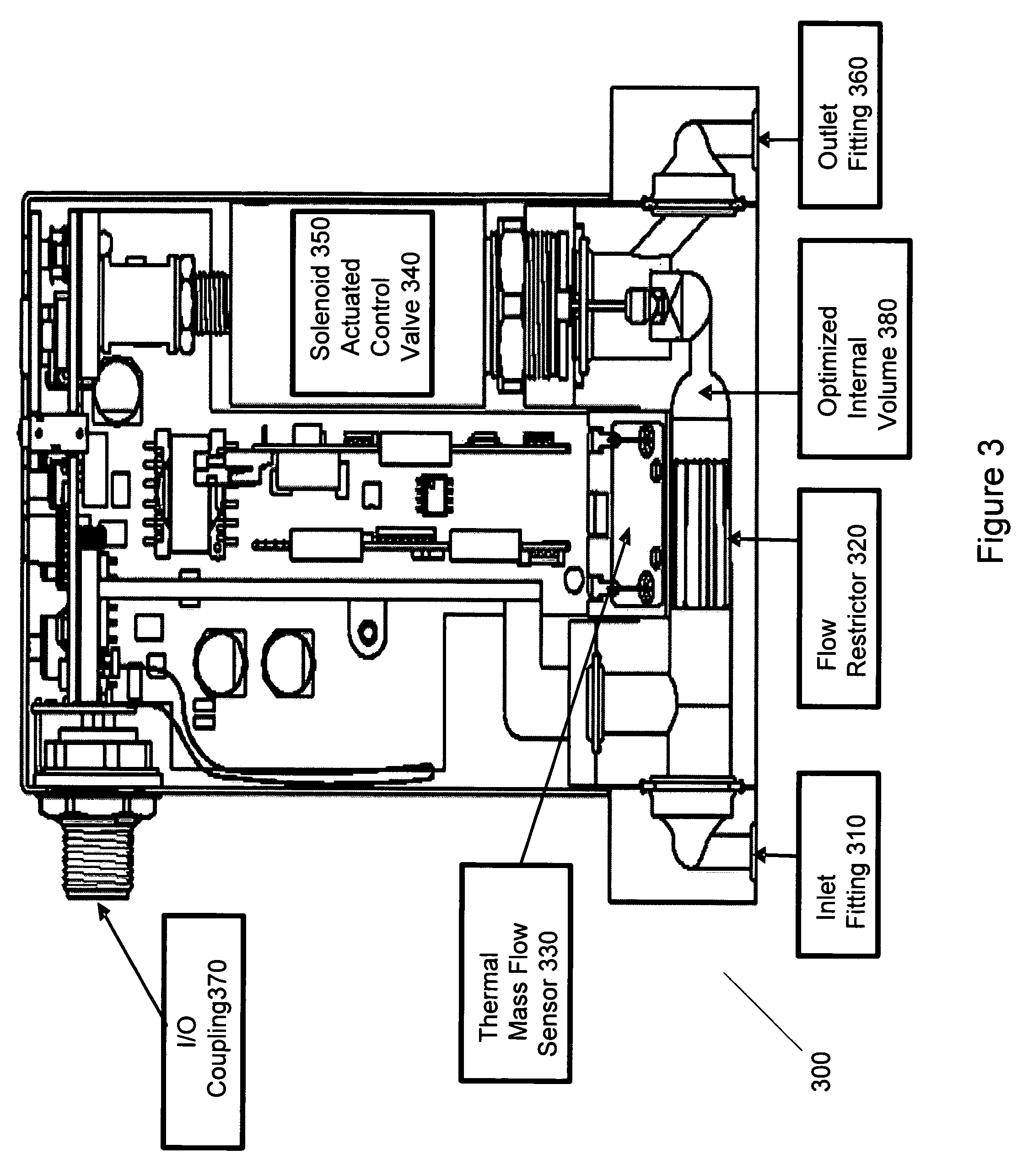

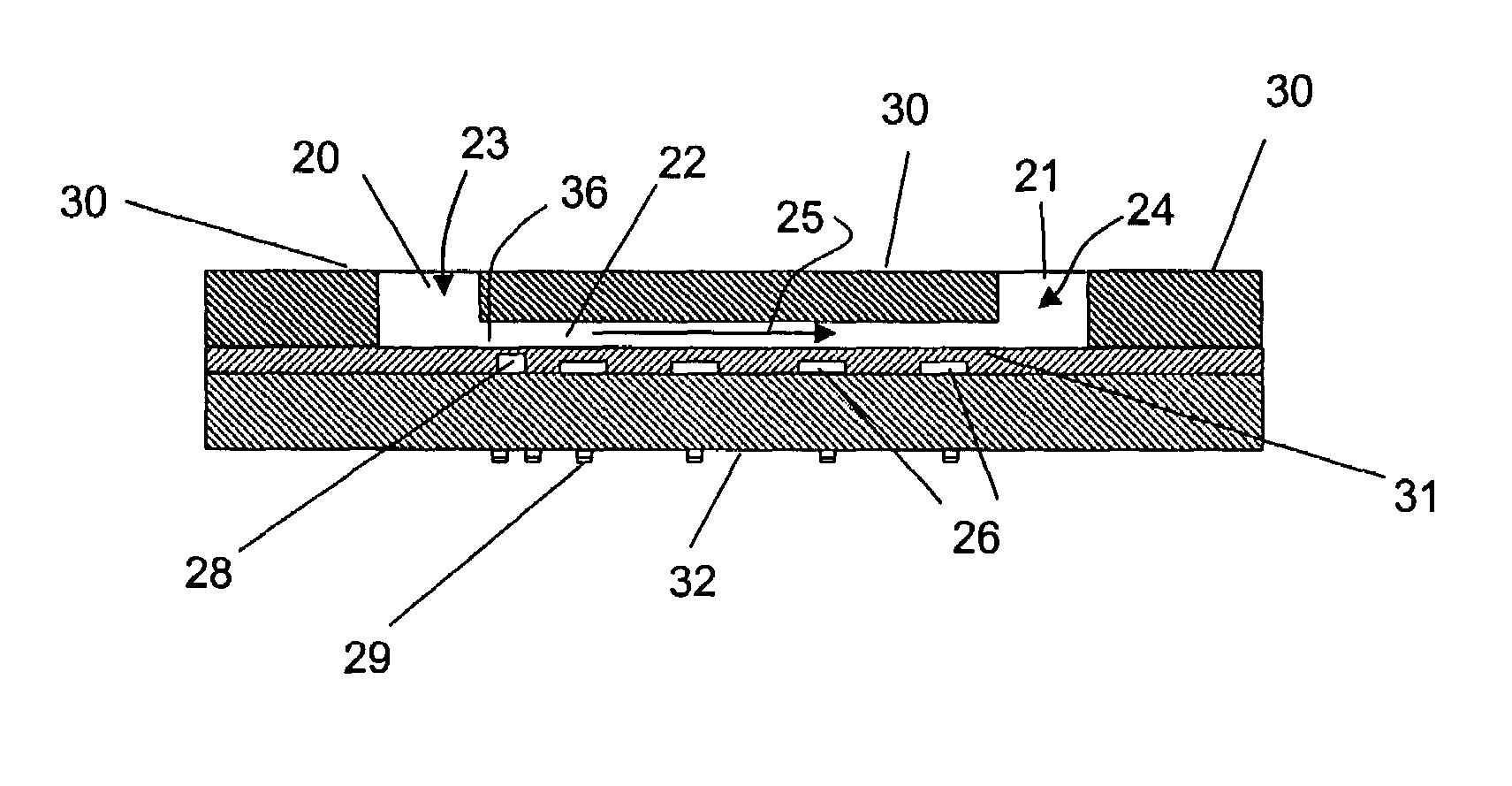

Method and system for a mass flow controller with reduced pressure sensitivity

InactiveUS7216019B2Reduce sensitivityReduce in quantityAnalysing fluids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementIsolation valveTransducer

Systems and methods for mass flow controllers which minimize false flow conditions and display a reduced sensitivity to pressure transients are disclosed. Pressure gradients that exist within the volume of a mass flow controller fluid path are minimized in order to limit the potential energy contained in compressed or pressurized process gas. Additionally, process gas pressure may be monitored using a pressure sensor. This pressure signal is utilized in conjunction with a control algorithm to cancel the detrimental effect of certain flow components. These mass flow controllers may be used as drop in replacements for legacy mass flow controllers and reduce the cost of gas sticks due to elimination of discrete components such as pressure regulators, gas filters, pressure transducers, local pressure displays, isolation valves, seals, etc.

Owner:BROOKS INSTRUMENT +1

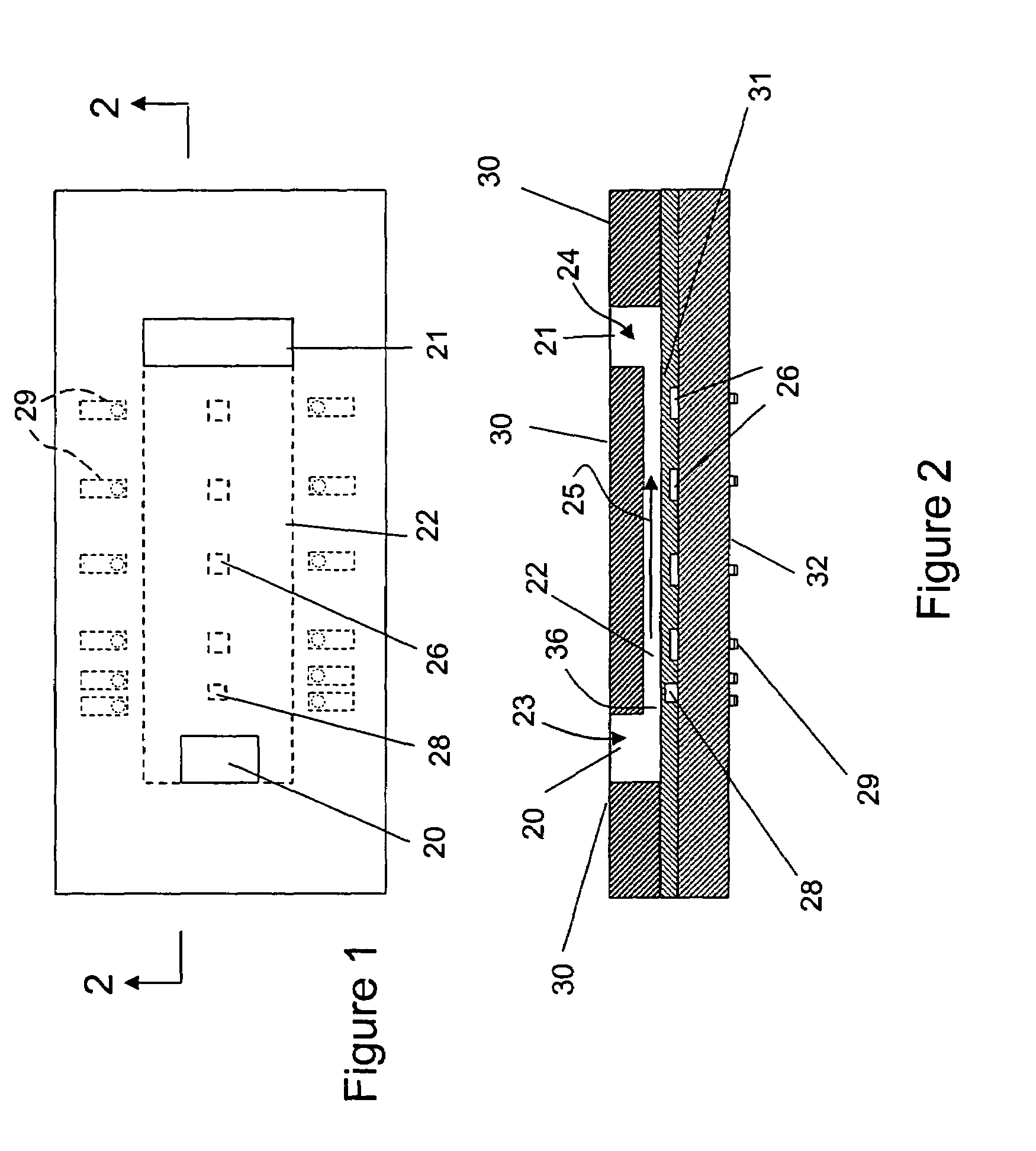

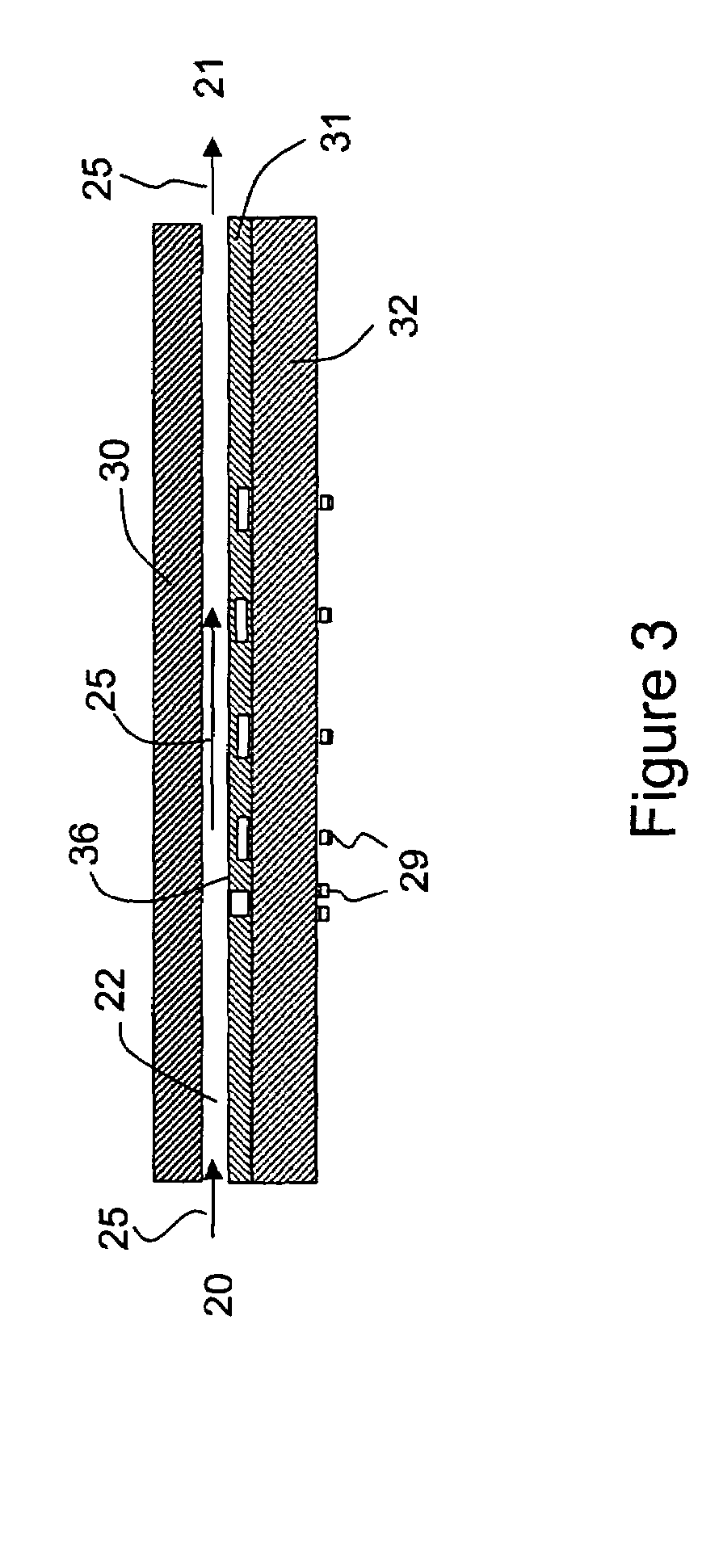

Micro slit viscometer with monolithically integrated pressure sensors

InactiveUS7290441B2Smooth inner surfaceReduce manufacturing costMaterial analysis by optical meansDirect flow property measurementTest sampleMicrometer

An improved micro slit viscometer includes a combined micrometer depth rectangular slit flow channel with monolithically integrated multiple pressure sensors in the flow channels and a pumping system that injects a test sample to the channel at a desired flow rate. Pressure sensing diaphragm of the monolithically integrated pressure sensors is smooth to minimize the flow disturbance thereby measuring accurate local pressures. With the measurement of the pressures at various locations of the channel the true viscosity of test sample can be calculated. The viscometer may consist of multiple flow channels and thus the true viscosity at multiple shear rates can be measured simultaneously for a given flow rate thereby obtaining a full viscosity curve as a function of shear rate of non-Newtonian liquids in a much faster manner. The viscometer needs only a miniscule amount of sample, which minimizes a waste of test material. The flow channels and the monolithically integrated pressure sensors are fabricated using microfabriaction processes on wafers and combined, which greatly reduce the production costs.

Owner:RHEOSENSE

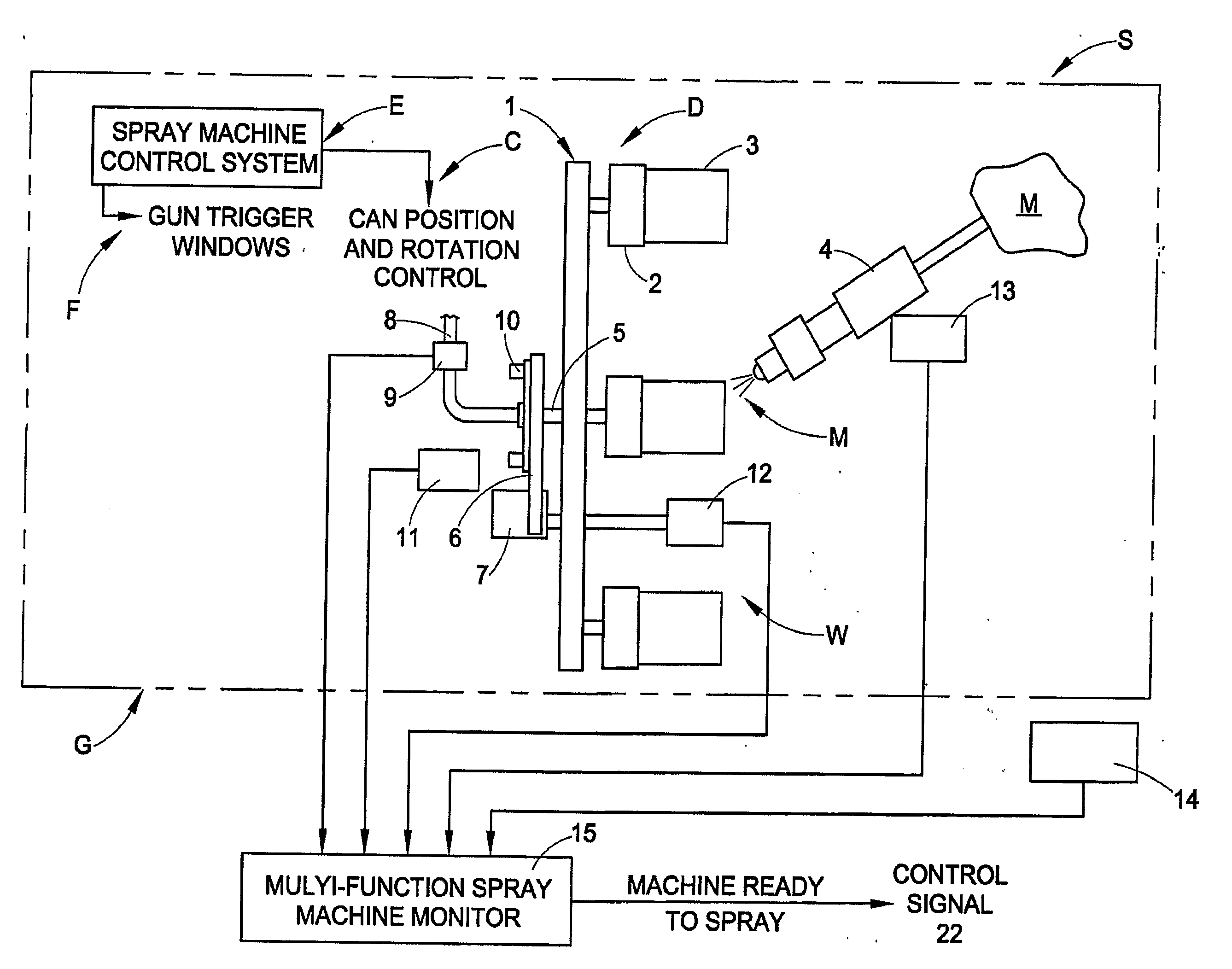

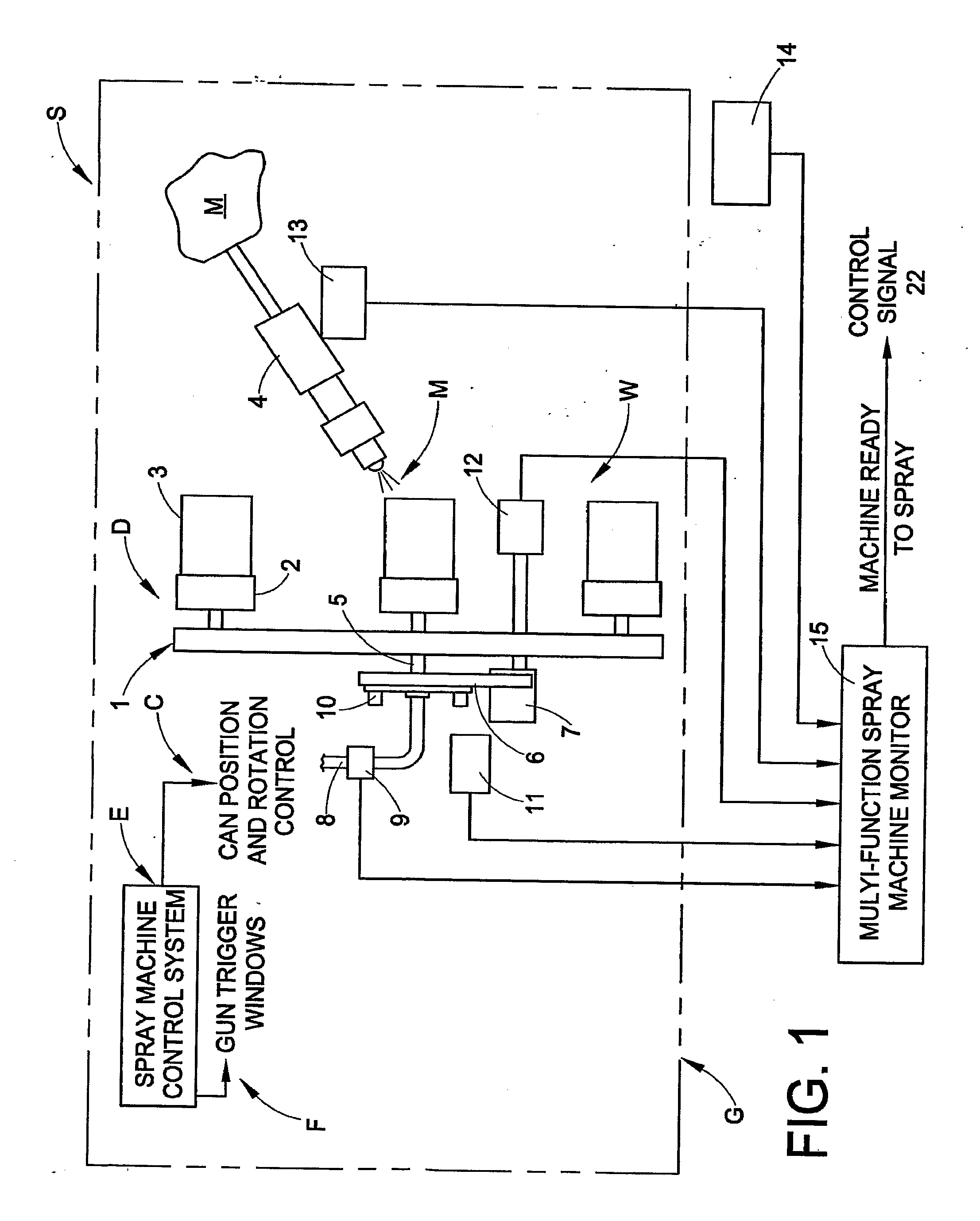

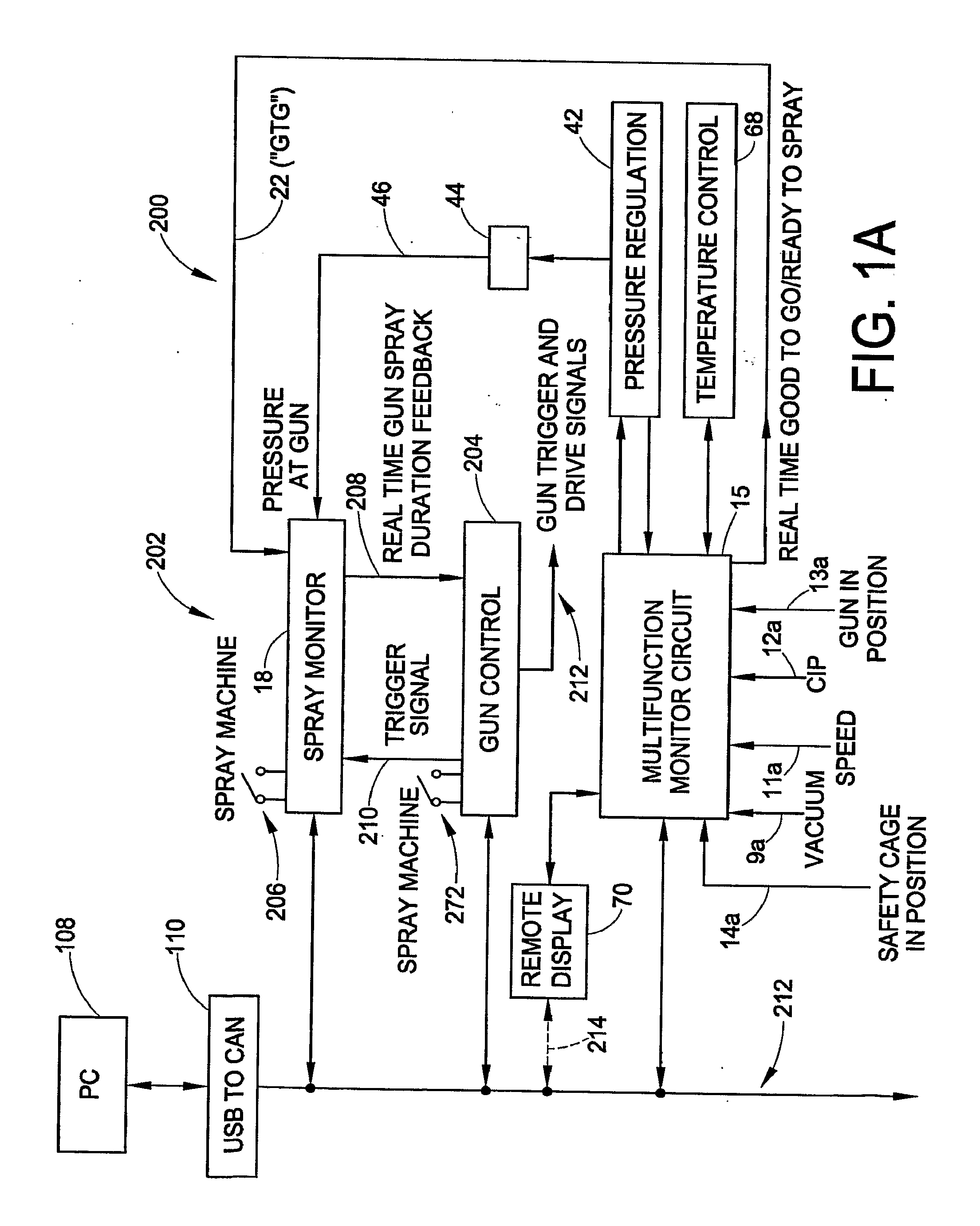

Control system for can coating

ActiveUS20090235864A1Easy to liftLiquid surface applicatorsSpraying apparatusLocal pressureVacuum pressure

A can coating machine control system includes a coating control signal that functions as a go / no-go signal based on a plurality of monitored conditions such as can in position, vacuum pressure, gun in position, guard in position and speed condition. Local pressure regulation of the coating material in the spray gun is provided along with optional control of the material temperature. Local pressure regulation allows for optional spray weight control based on a wrap number derived from speed and gun spray-durations. A CAN to CAN network buffer is provided as well for primary network isolation. A gun control circuit may be used to select specific gun drive signals and to adjust gun drive signals based on real-time feedback of the actual spray duration.

Owner:NORDSON CORP

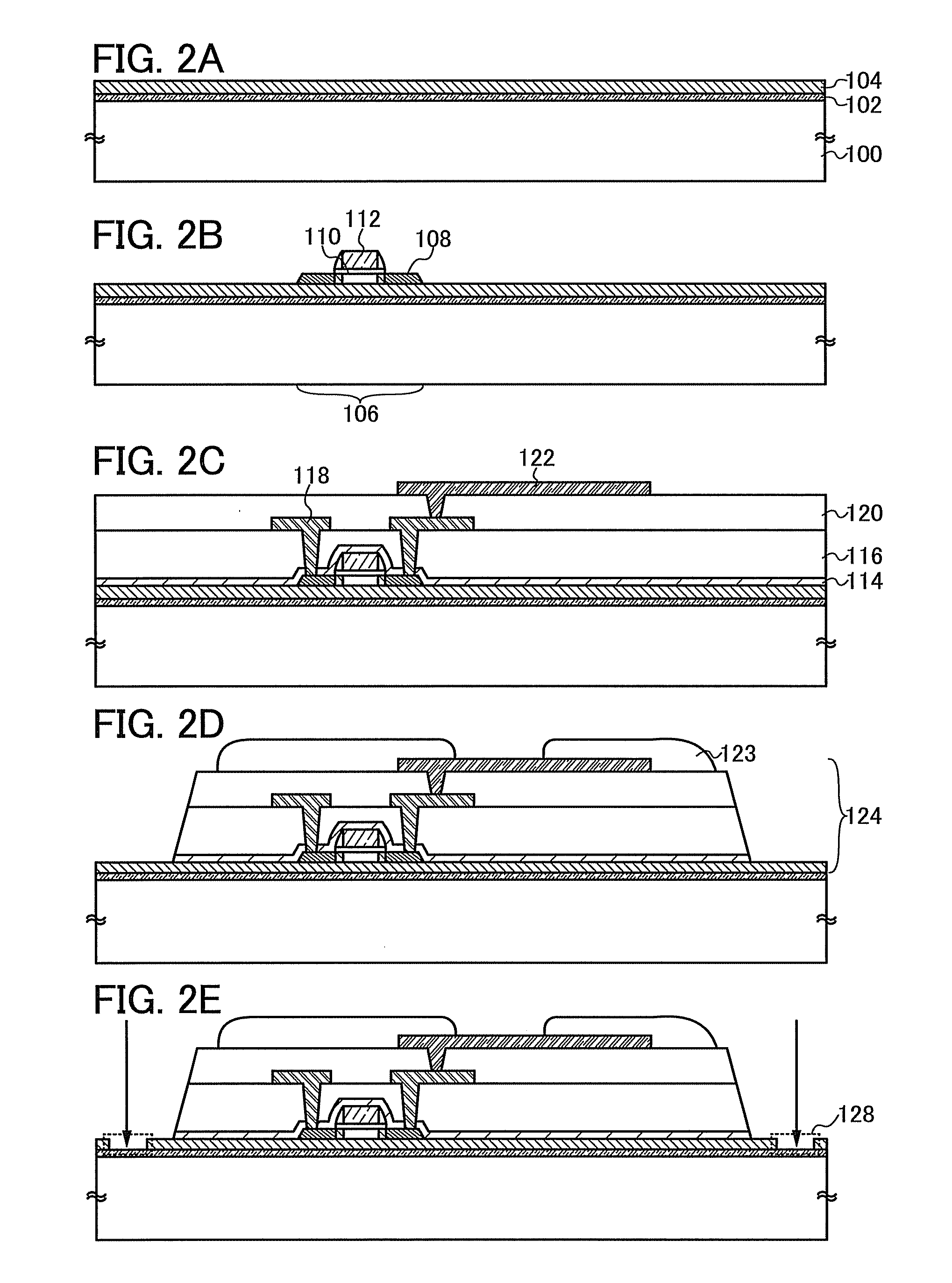

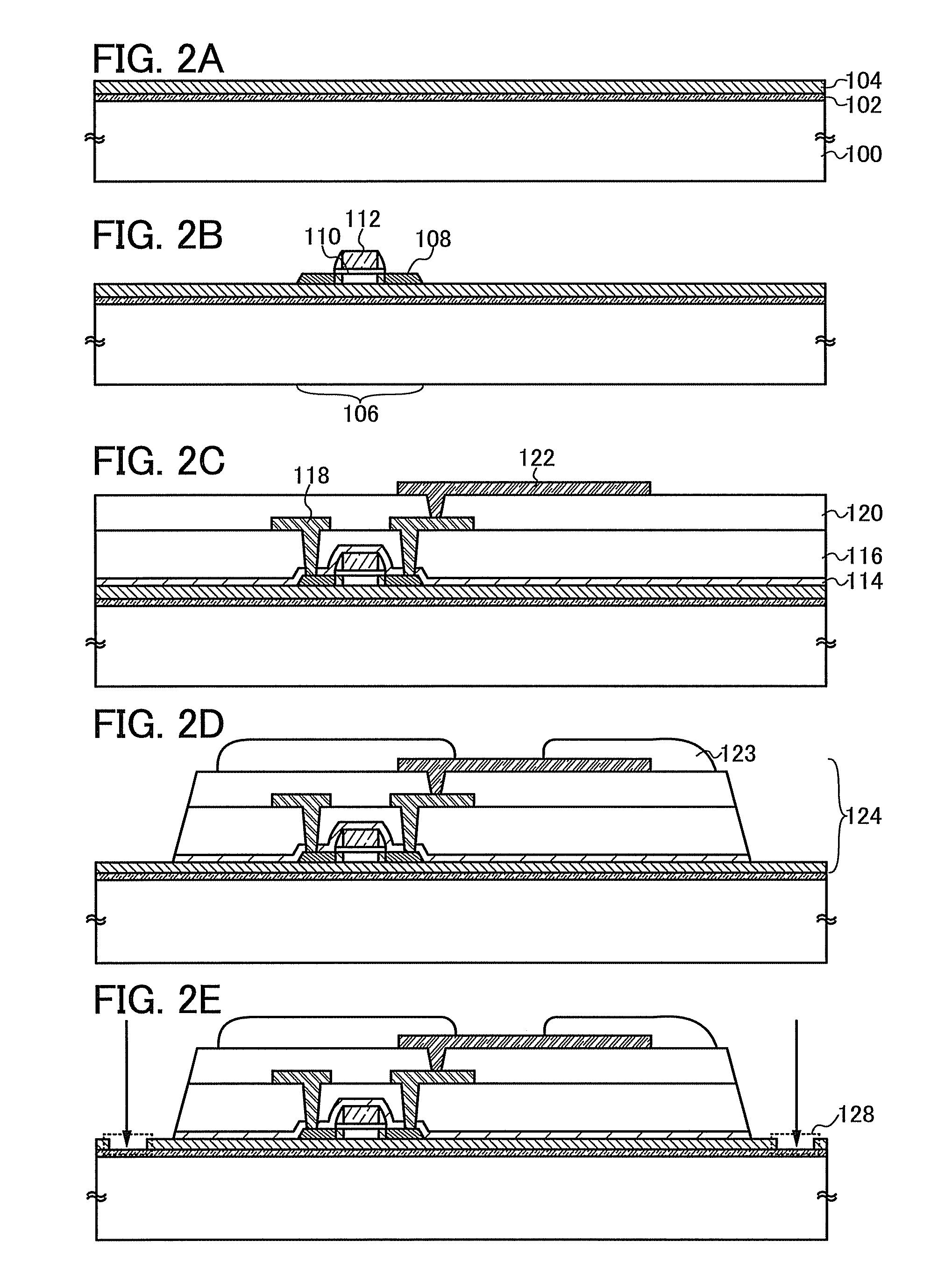

Method for manufacturing semiconductor device

InactiveUS20080311706A1Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

To provide a method for manufacturing a highly-reliable semiconductor device, which is not damaged by external local pressure, with a high yield, a semiconductor device is manufactured by forming an element substrate having a semiconductor element formed using a single-crystal semiconductor substrate or an SOI substrate, providing the element substrate with a fibrous body formed from an organic compound or an inorganic compound, applying a composition containing an organic resin to the element substrate and the fibrous body so that the fibrous body is impregnated with the organic resin, and heating to provide the element substrate with a sealing layer in which the fibrous body formed from an organic compound or an inorganic compound is contained.

Owner:SEMICON ENERGY LAB CO LTD

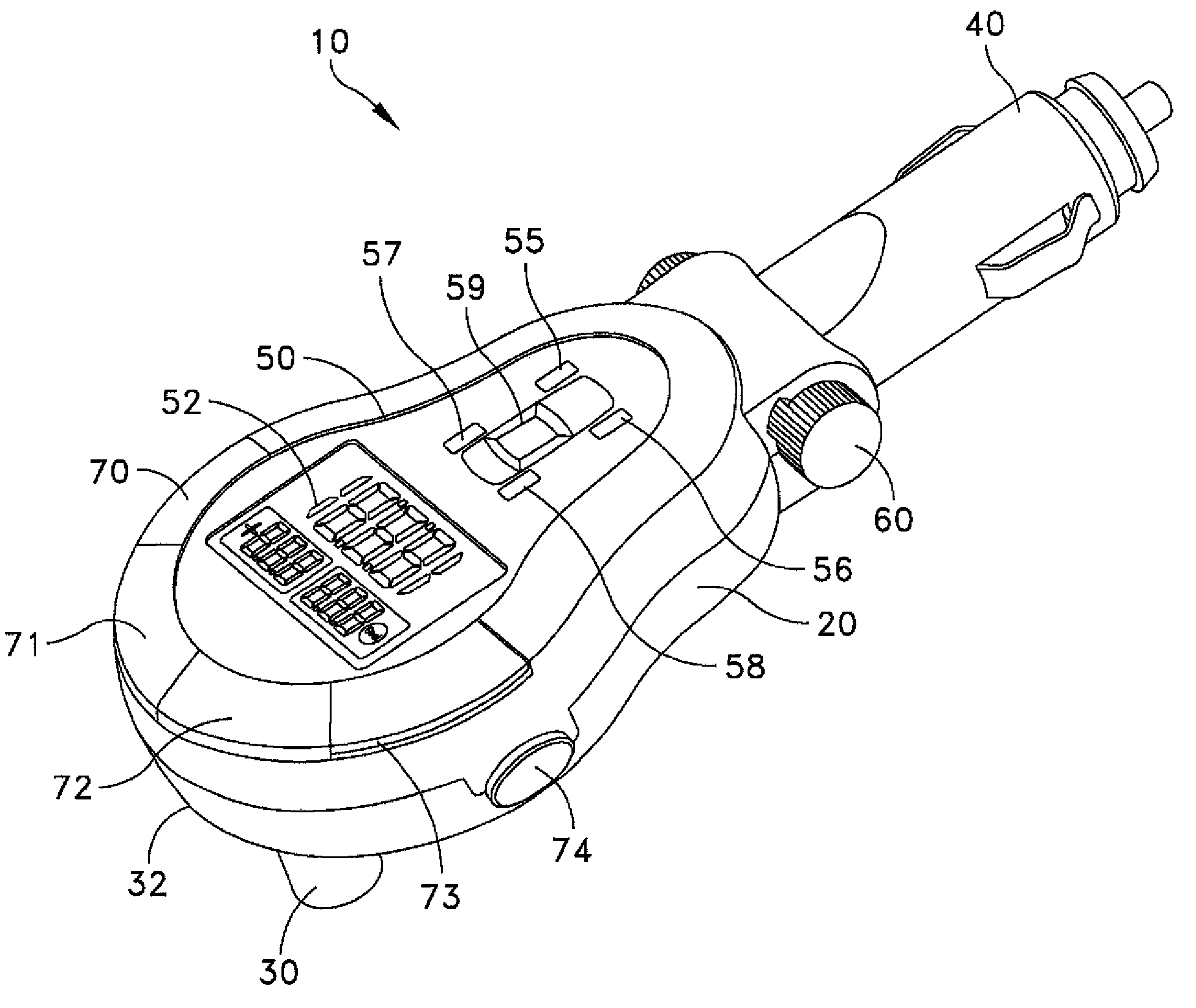

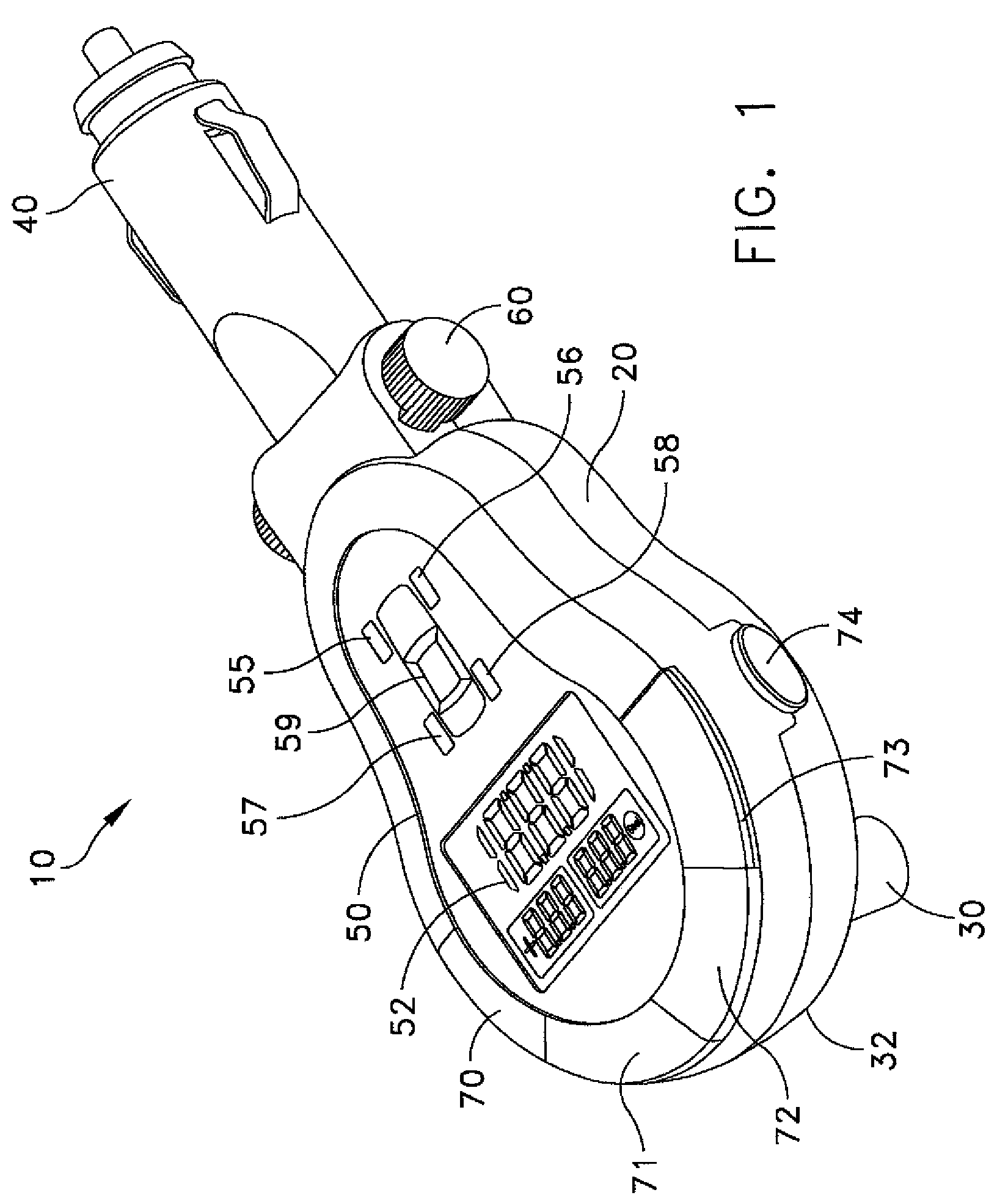

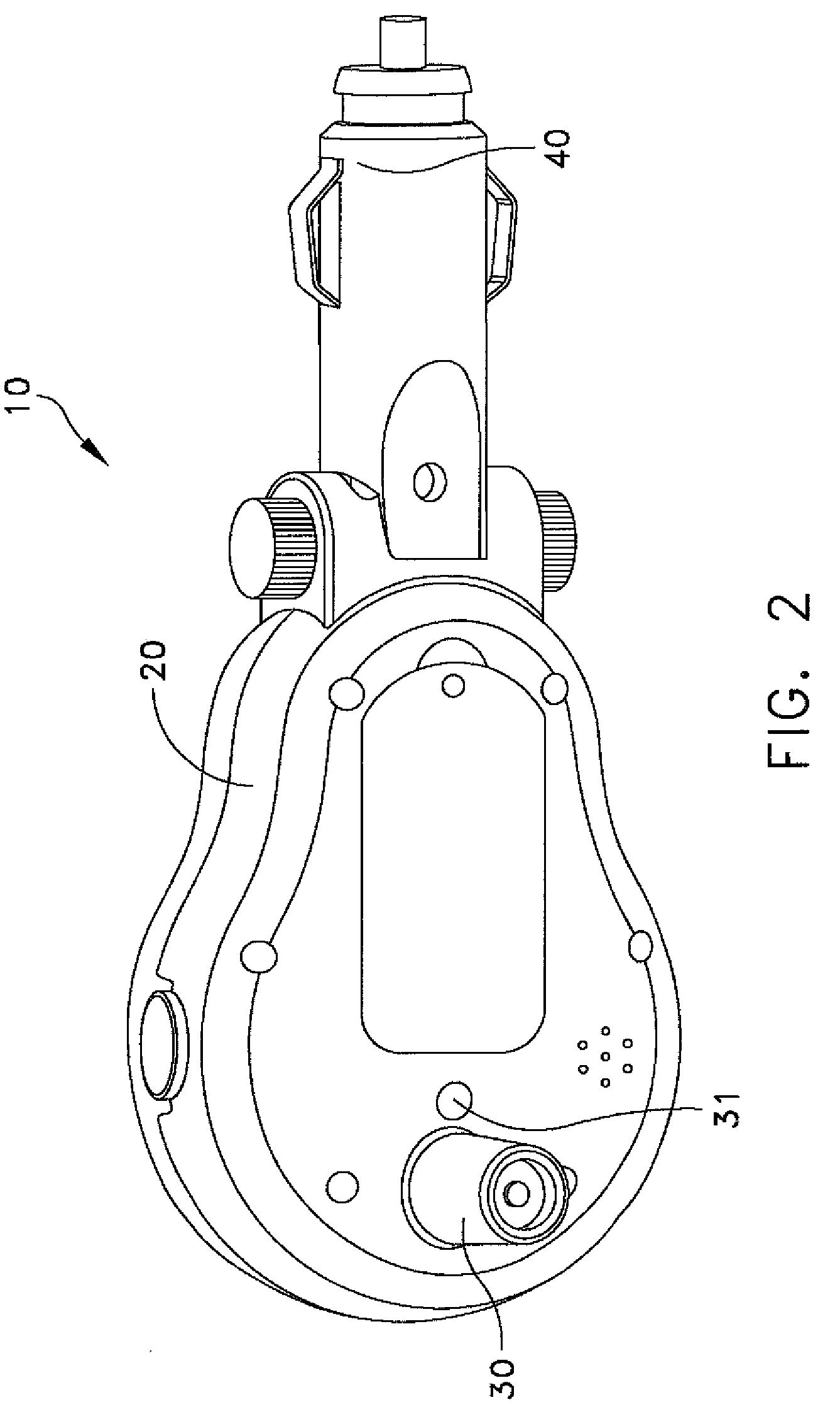

Combined tire pressure gauge and remote tire pressure display

InactiveUS20090109012A1Inflated body pressure measurementTyre measurementsTire-pressure gaugeDisplay device

A combined tire pressure gauge and remote tire pressure display includes a port adapted to couple to a vehicle tire valve stem and to open a valve in the valve stem; a chamber in physical communication with the port; a local pressure transducer in the chamber for detecting a pressure of a fluid within the vehicle tire and providing an output signal representative of the detected pressure; a wireless receiver for receiving a signal identifying a tire pressure sensor and having a detected tire pressure and for providing an output signal; a processor for receiving the output signal from the pressure transducer and the output signal from the wireless receiver, and for providing a processor output signal indicative of an identified tire and a value of the detected pressure, in a remote tire display mode, and for providing a processor output signal indicative of a detected tire pressure, in a tire pressure gauge mode; and a display coupled to the processor for providing a visible indication of detected pressure value and identified tire in accordance with the processor output signal in the remote tire display mode, and for providing a visible indication of detected pressure value in the tire pressure gauge mode.

Owner:MEASUREMENT

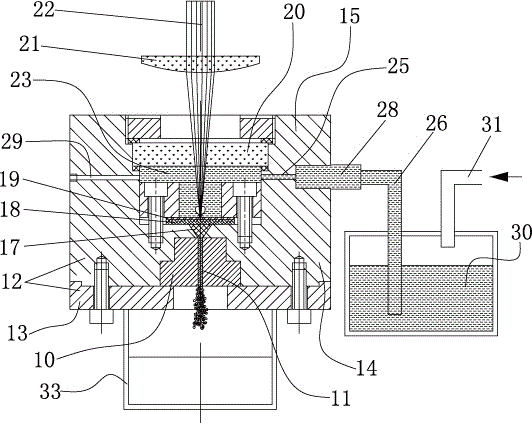

Abrasive flow micropore polishing device and polishing process thereof

InactiveCN104440584AAchieve polishReduce roughnessAbrasive feedersAbrasive machine appurtenancesCavitationWear particle

The invention discloses an abrasive flow micropore polishing device, comprising a clamping tool, a base plate, a cavity, a separation device, a laser high-transparency protective lens, a laser, a focusing lens, a flow guiding passage and a one-way valve, wherein the clamping tool is used for clamping a workpiece and locating micropores of the workpiece; the base plate is arranged on the clamping tool; the cavity is arranged in the base plate and the clamping tool and correspondingly communicate with the micropores; the separation device is arranged in the cavity and divides the cavity into a cavitation cavity and a liquid storage cavity; the laser high-transparent protective lens covers the cavitation cavity; the laser can generate laser beams facing to the cavitation cavity; the focusing lens is arranged between the laser and the laser high-transparent protective lens and is used for focusing laser beams in the cavitation cavity; the flow guiding passage can guide deionized water into the caviation cavity; the one-way valve is arranged in the flow guiding passage. According to the abrasive flow micropore polishing device, lasers are focused to cavitate the deionized water to form a large local pressure and impact the separation device, and the abrasive fluid flows and is pushed into the micropores at high speed and rubs the pore walls of the micropores to reduce the roughness of the inner surface of the micropores, so as to achieve the polishing on the micropores. The invention further discloses an abrasive flow micropore polishing process for highly effectively and ultra-precisely polishing the micropores.

Owner:GUANGDONG UNIV OF TECH

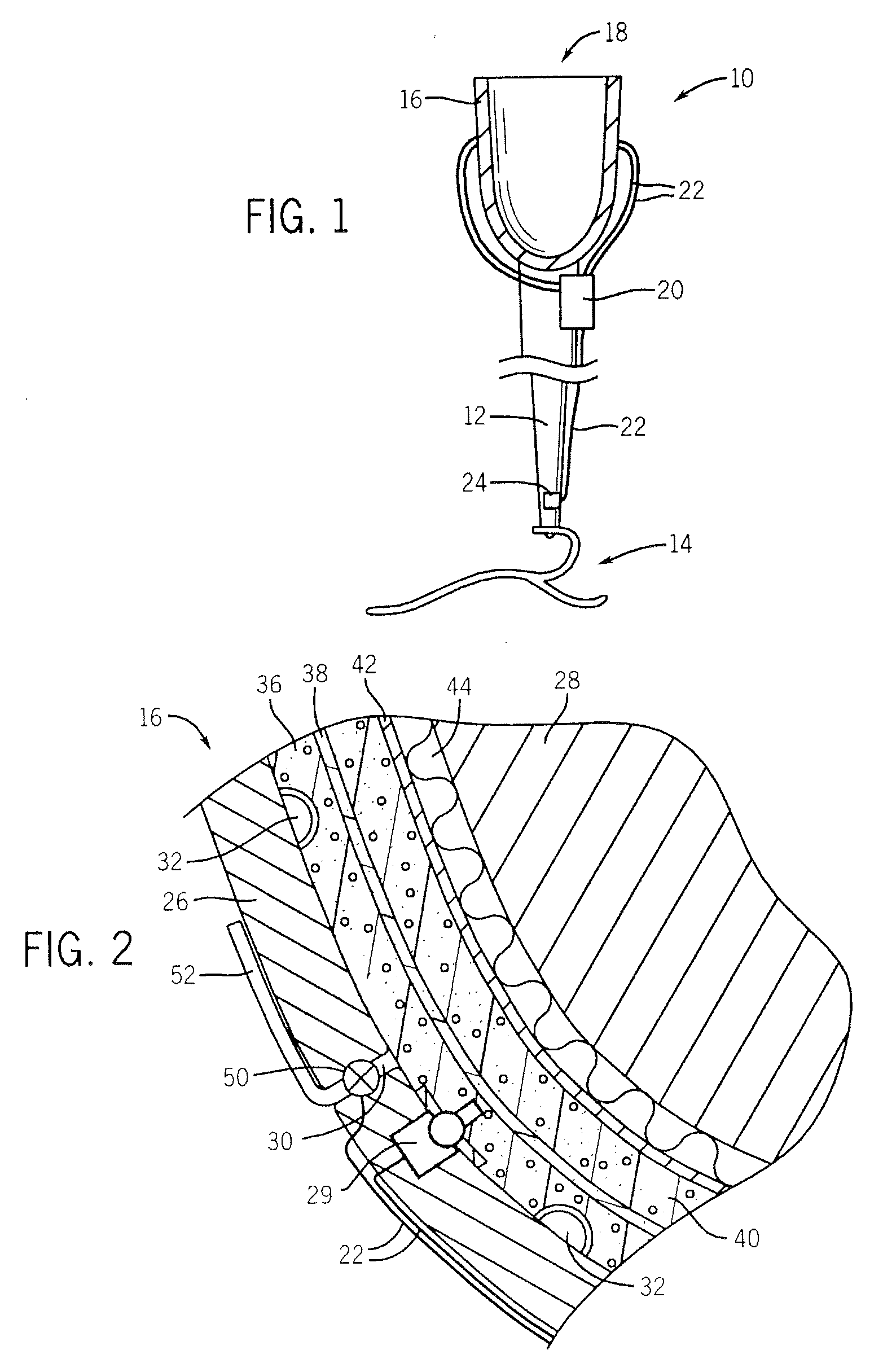

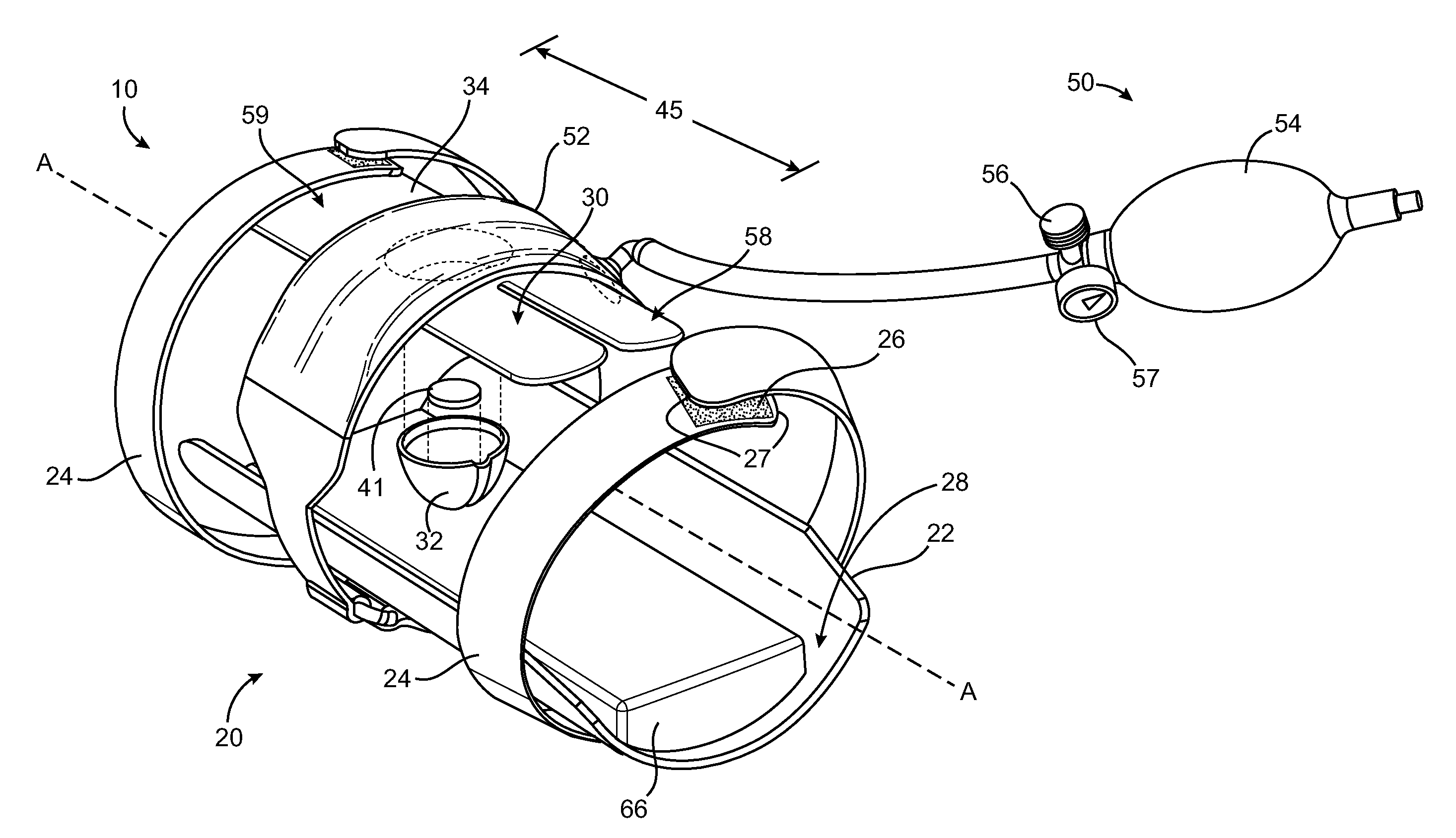

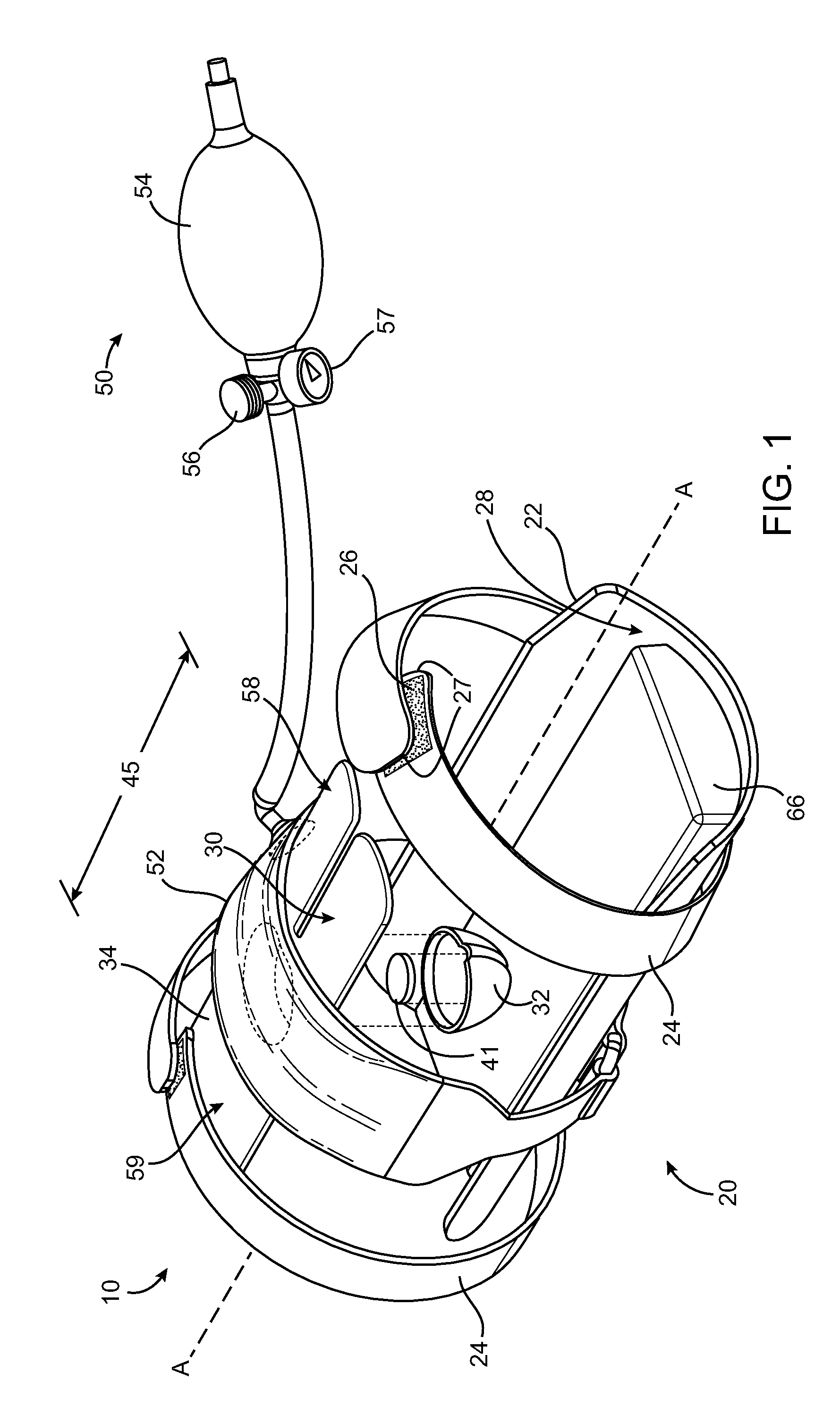

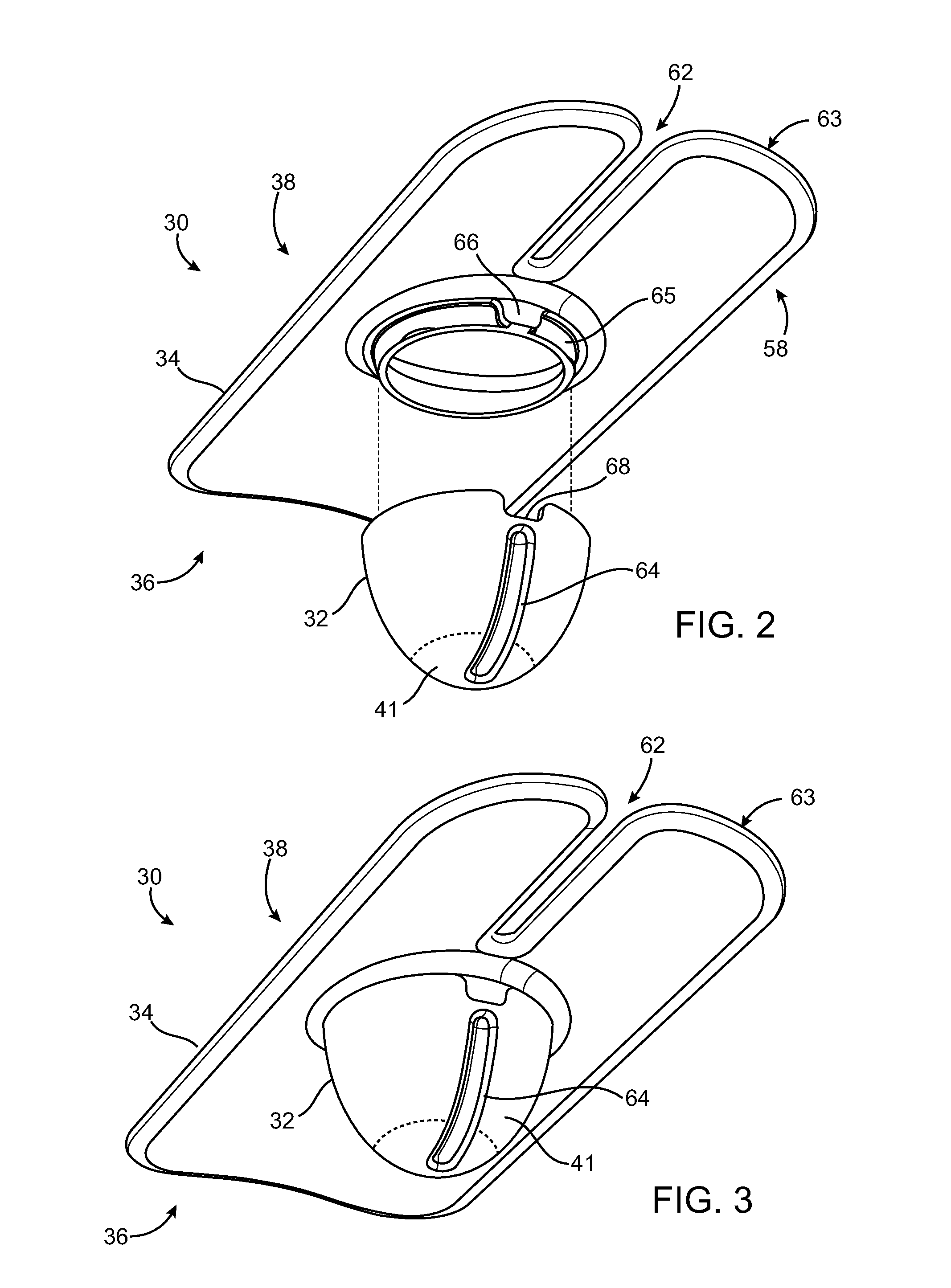

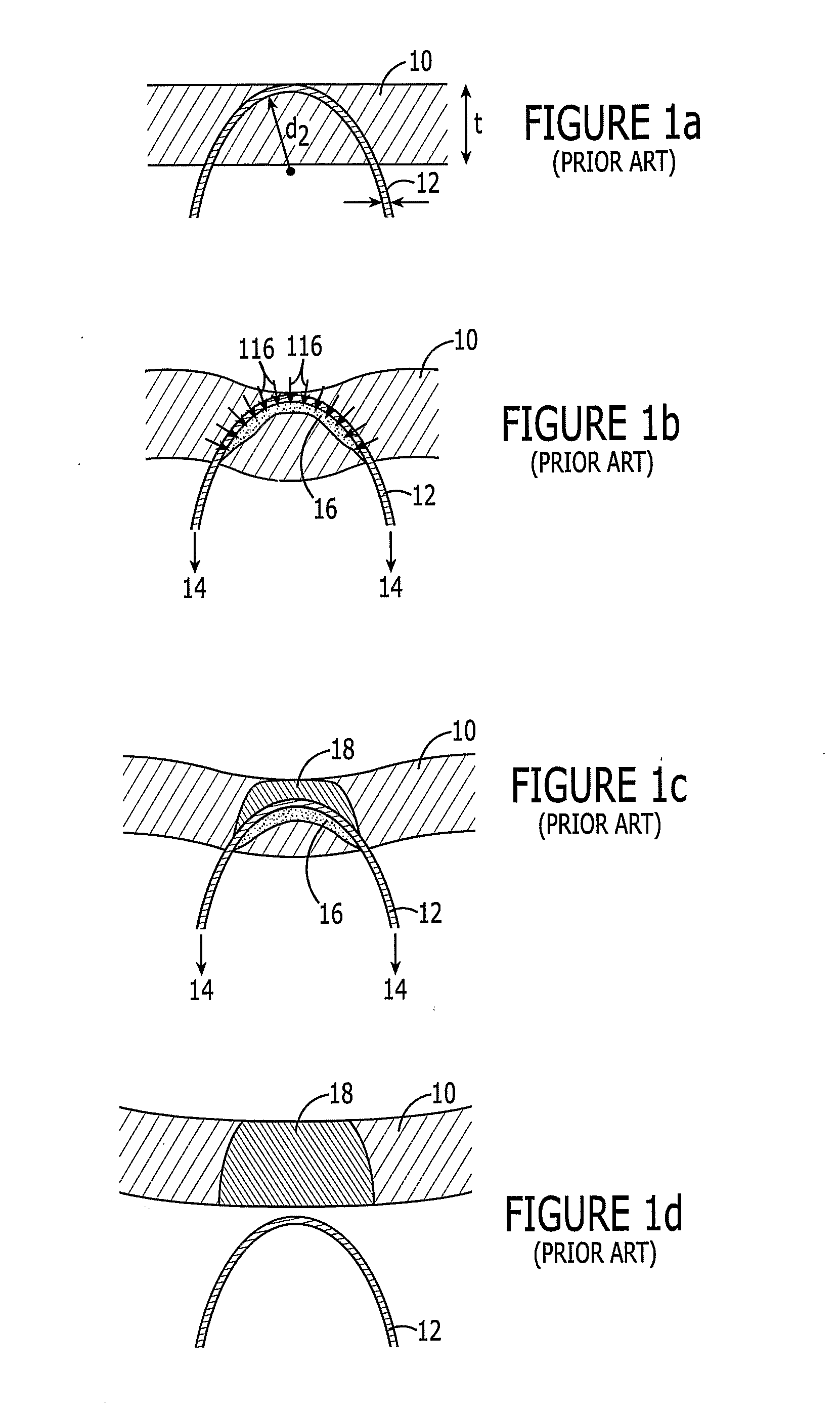

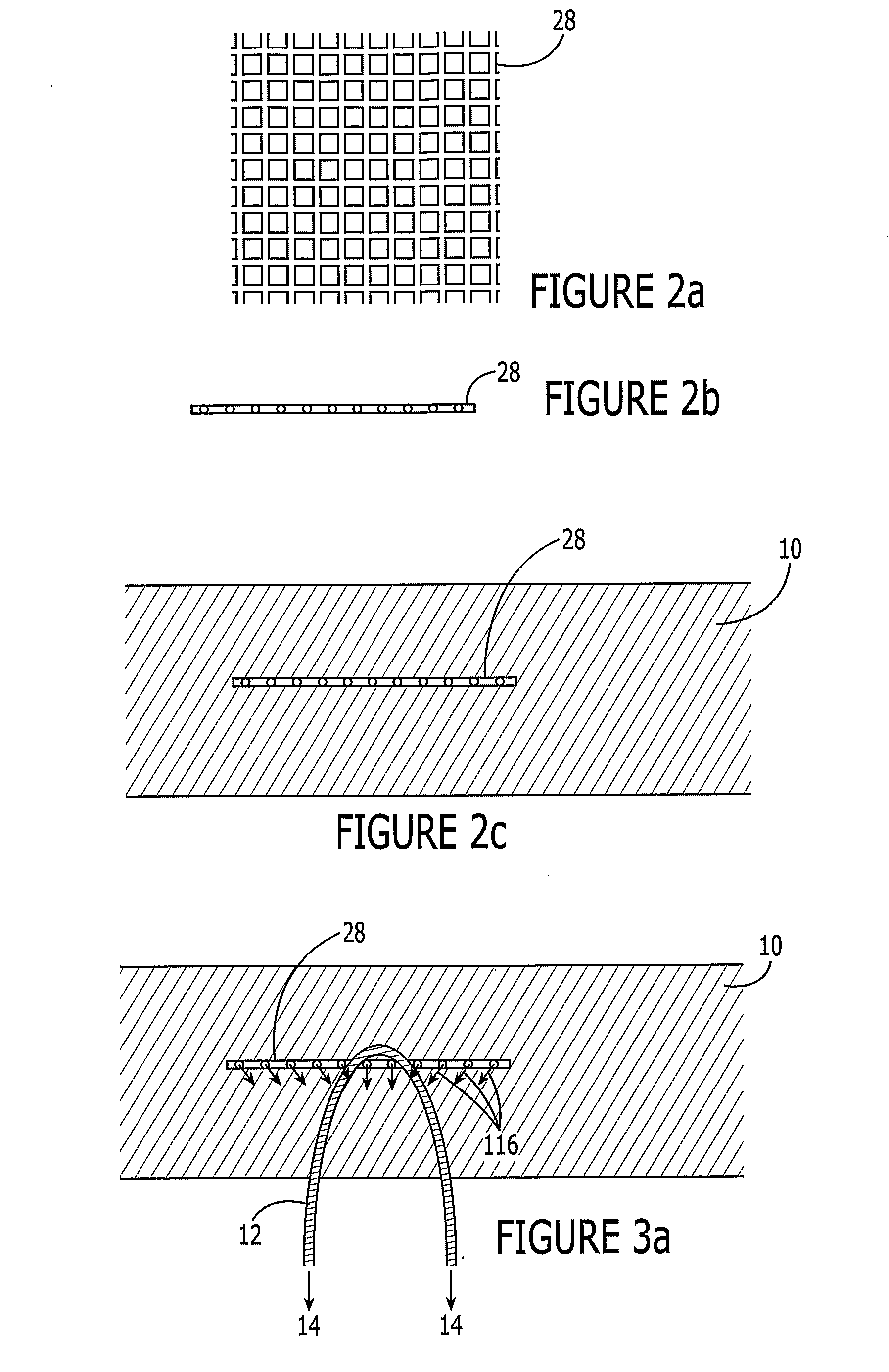

Apparatuses and methods for treating wounds

InactiveUS20120116444A1Avoid bendingAvoid strangulationDiagnosticsTourniquetsWound siteLocal pressure

A clamp apparatus is particularly configured for controlling bleeding by applying localized pressure to a wound site without strangulating the body member. A restraint supports the body member and inhibits bending thereof. A clear pressure pad having a protuberance is applied to the wound site. The protuberance may include a magnifying lens to magnify the wound site. Slots may be formed in the protuberance and a backing and aligned to receive a needle so that the transparent, magnifying pressure pad may be applied to a patient while undergoing an injective procedure, e.g., angiography. A pressure source provides force to the pressure pad. Strangulation is either prevented by wrapping an inflatable pressure cuff around the restraint or facilitated by wrapping the cuff directly around the body member without a restraint. An inflatable pressure pad is also provided to be applied to a wound site without a restraint.

Owner:ZODNIK RICHARD C +2

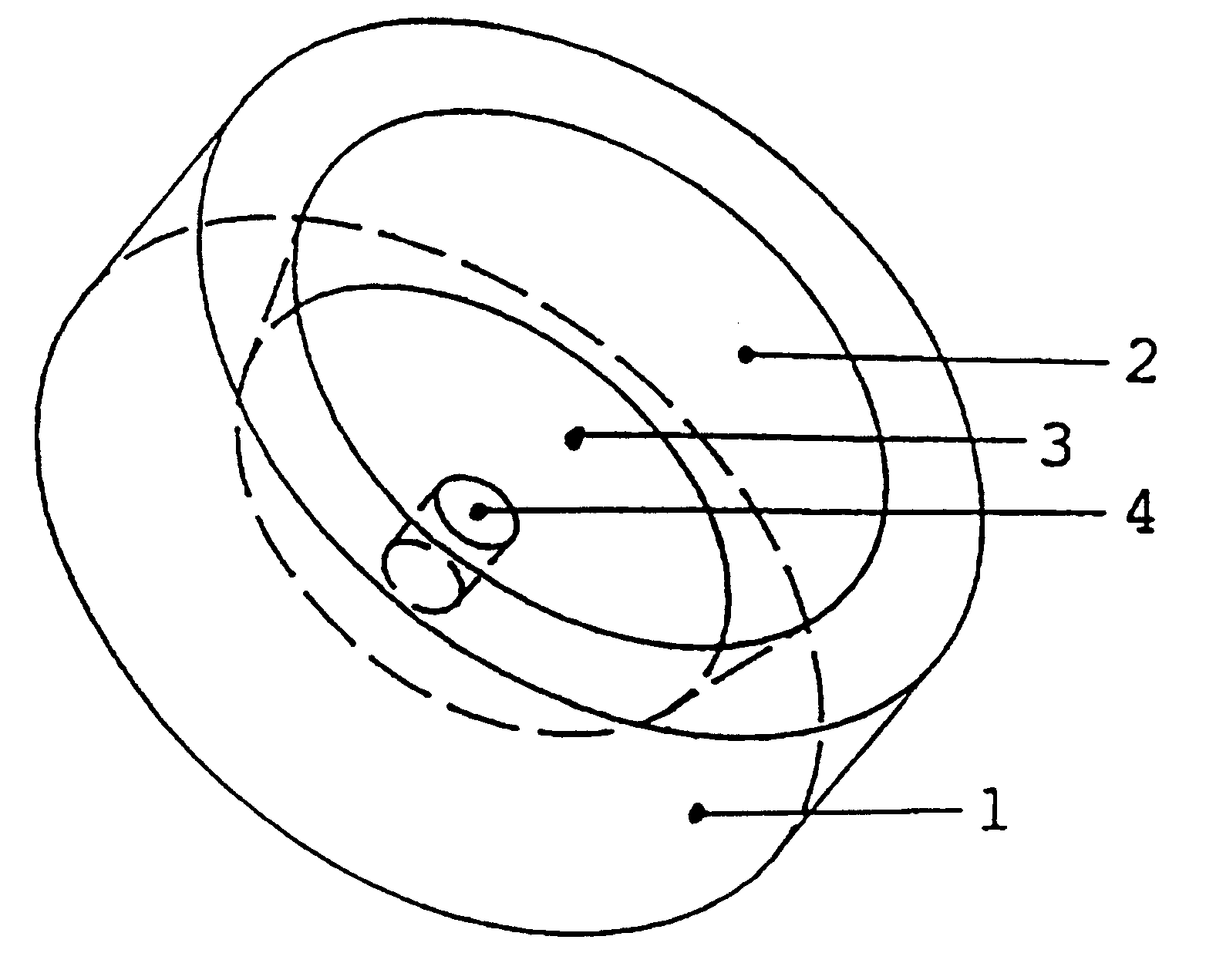

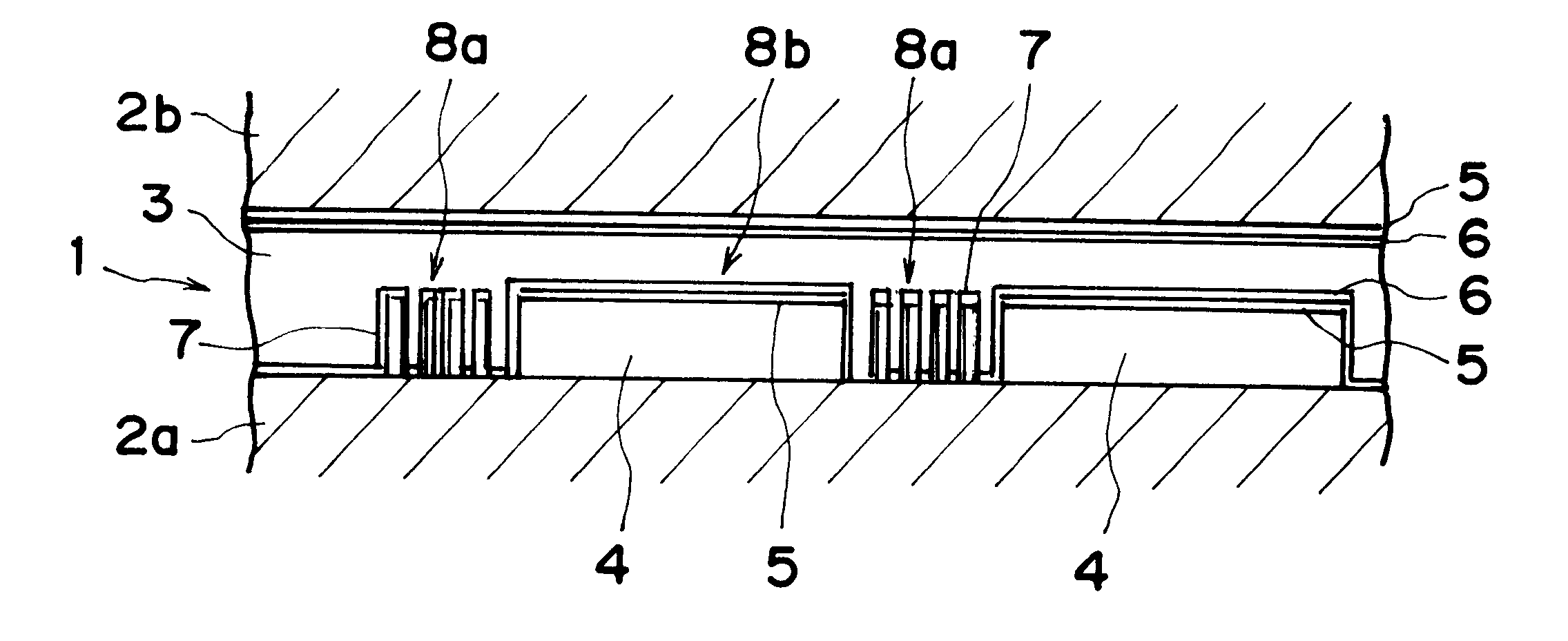

Liquid crystal device and process for production thereof

A matrix-type liquid crystal device is formed so as to have a matrix of pixels defined by and isolated from each other by an outside-pixel region. The liquid crystal in the outside-pixel region in placed in an alignment state, typically a homeotropic state or one close thereto, which is different from an alignment state, typically a homogeneous uniform alignment state, at the pixel region. As a result, the liquid crystal device is provided with improved display qualities due to suppression of irregularities at the outside-pixel region and / or a local pressure distribution.

Owner:CANON KK

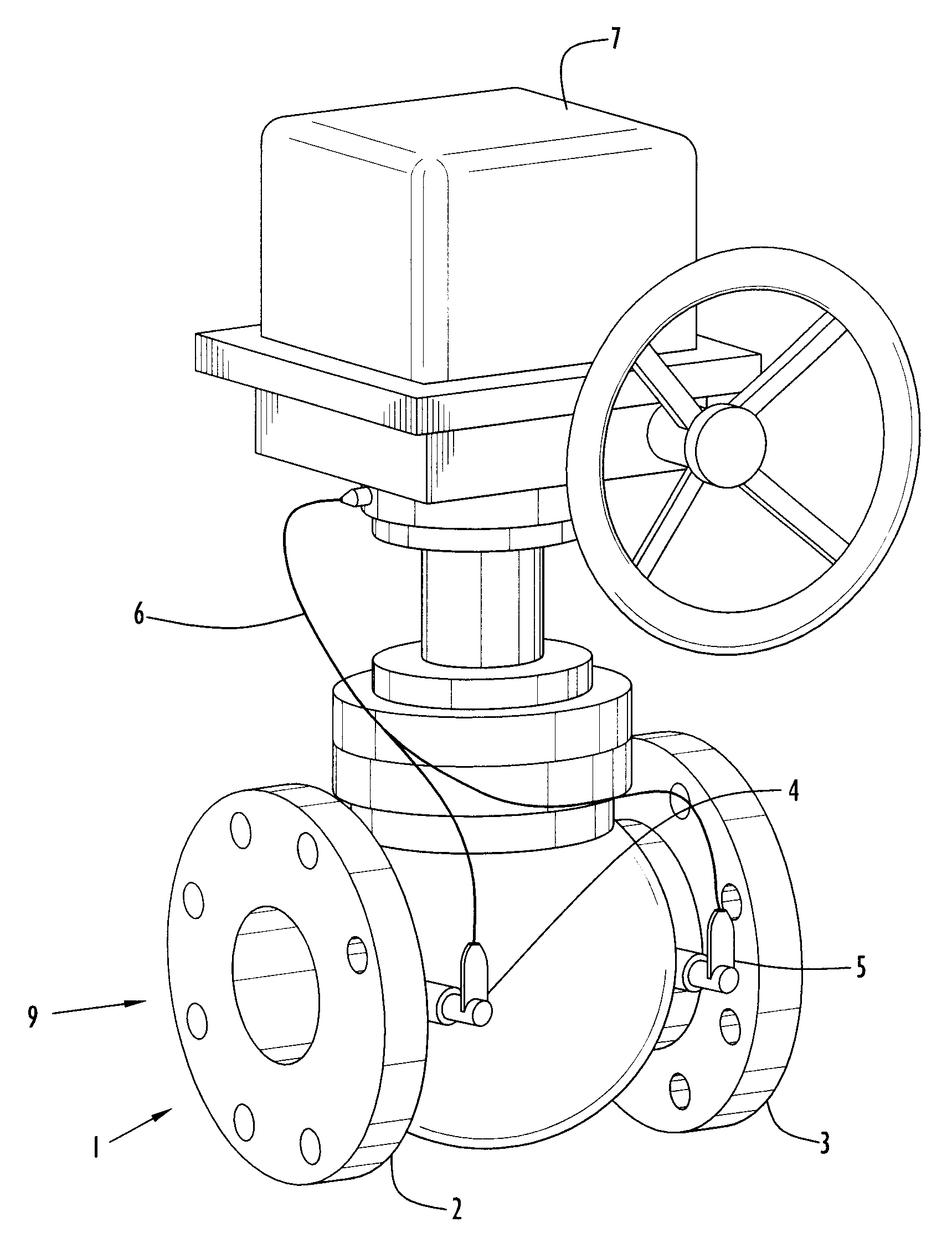

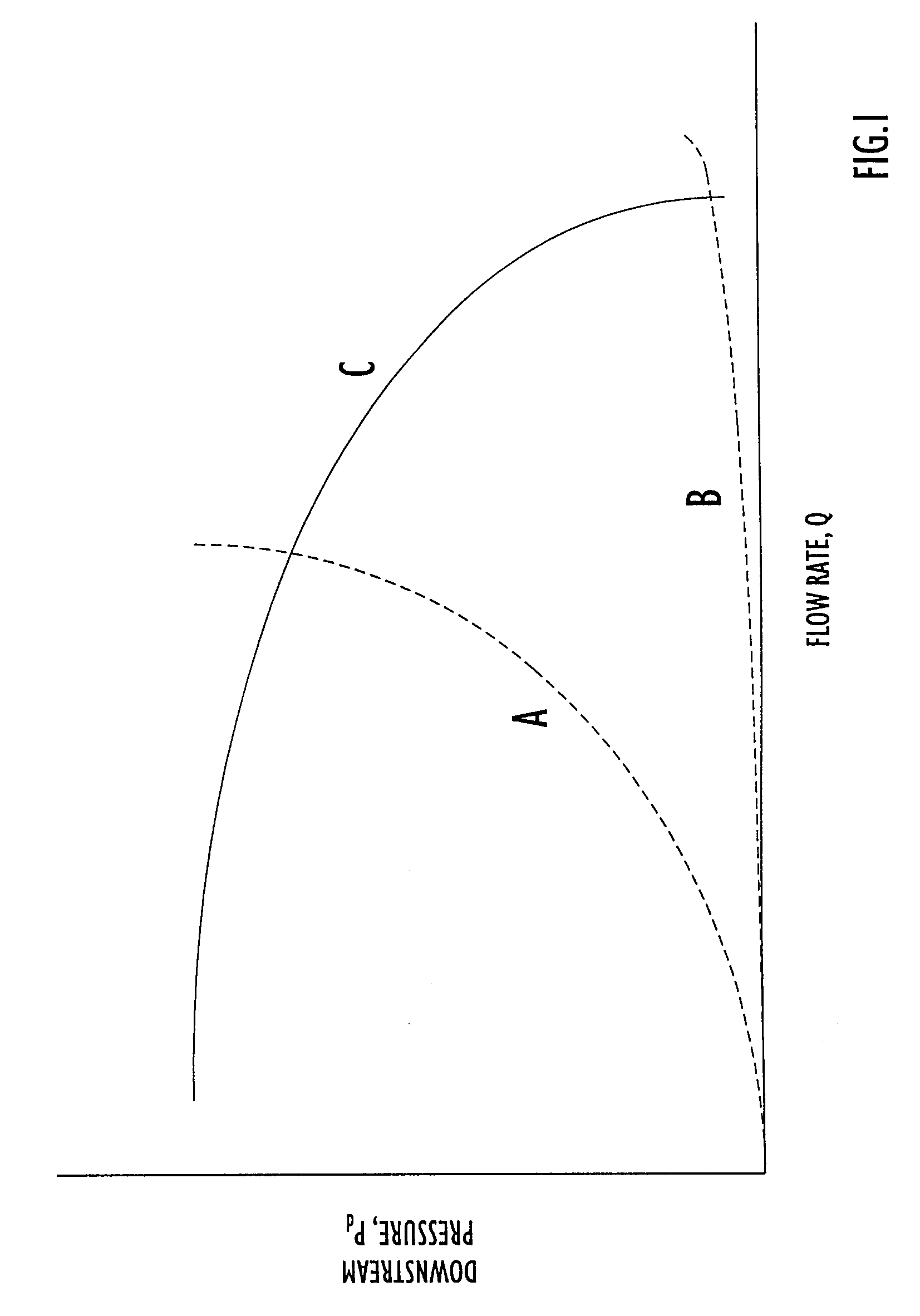

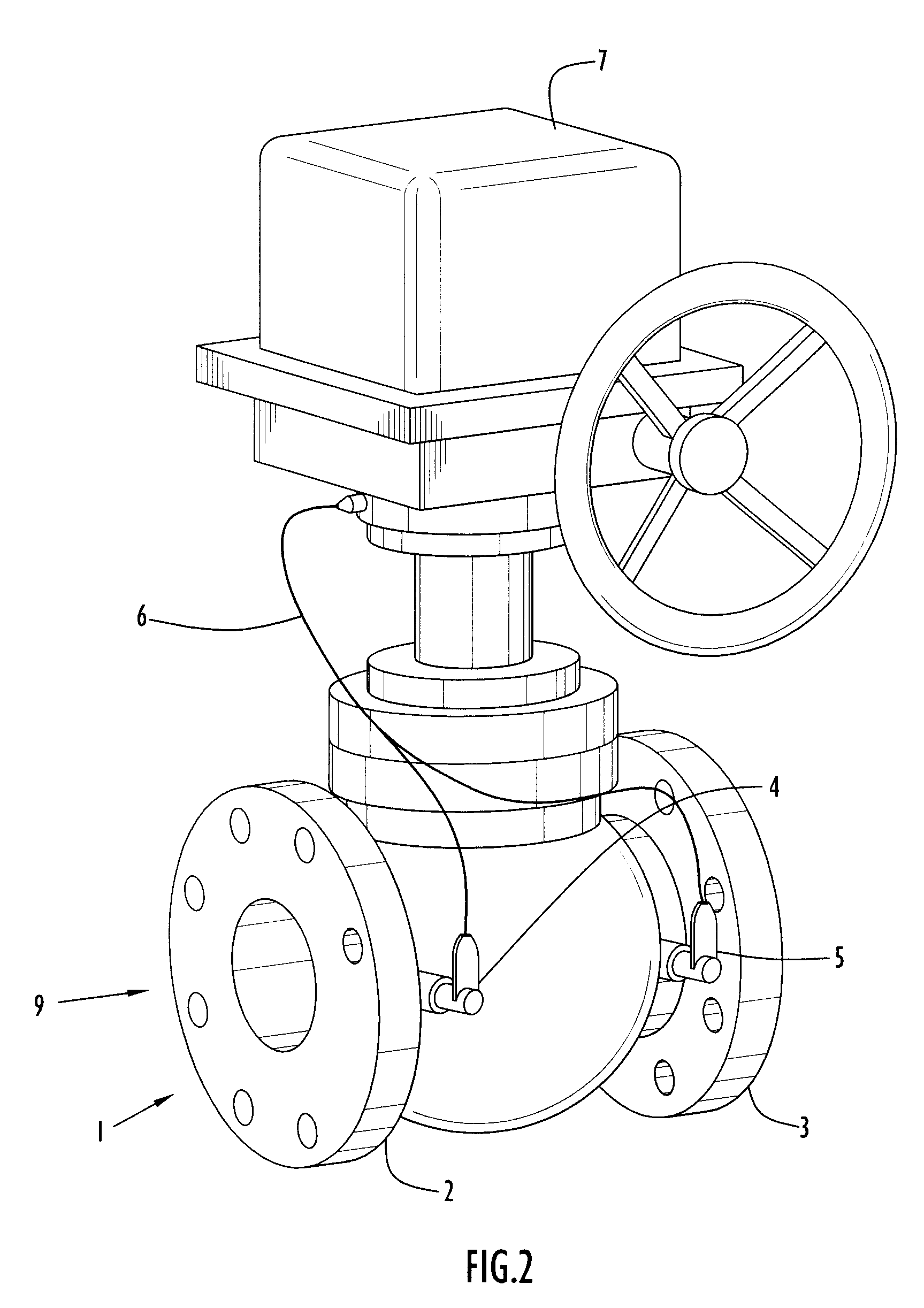

Method and apparatus for detecting and isolating a rupture in fluid distribution system

InactiveUS6535827B1Short response timeImprove system reliabilityMeasurement of fluid loss/gain rateTesting/calibration apparatusDischarge measurementsEngineering

Rupture path logic methods of detecting, locating and isolating ruptures within a fluid piping system are disclosed, wherein a rupture within a piping system can be detected and isolated based solely upon local pressure and flow rate measurements at individual valves within the system without the need for communication of measured fluid data between valves at various locations throughout the system. A fluid characteristic is determined individually for each valve based upon the pressure and flow rate measurements at the valve, and that fluid characteristic is compared with set point fluid characteristic information to determine whether each valve is on a fluid path between a fluid supply source and a rupture. Upon detecting a rupture, valves detected as being on such a fluid path are automatically closed within the system in an order of valves furthest from all online fluid supply sources closing first, thereby ensuring eventual isolation of the rupture while allowing intact sections of the piping system to remain open and operational. An automatic rupture detection and isolation fluid piping system is also disclosed that utilizes rupture path logic methods to isolate detected ruptures within the system.

Owner:MPR ASSOC

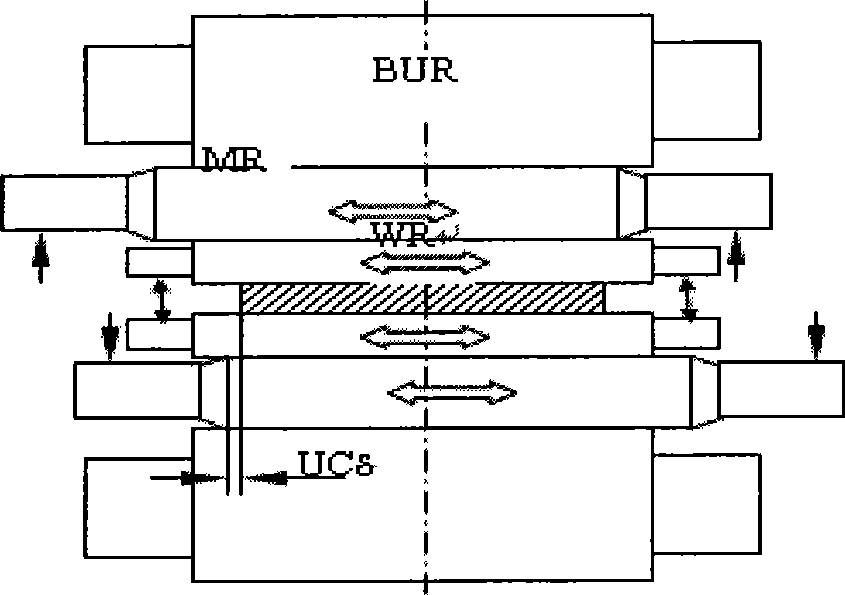

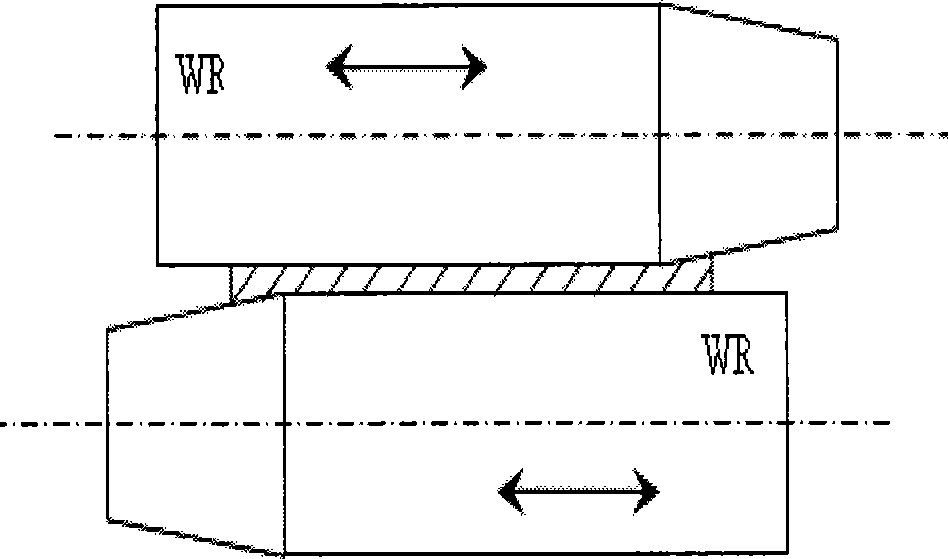

Working roll technique for controlling edge drop of cold-rolled steel

InactiveCN101367092AImproved shape controlPrevent peelingRollsProfile control deviceElectrical steelContact pressure

The invention relates to a working roll technology for controlling the edge drop of cold rolled steel. With the special high-order curve working roll forming technology, the technology solves the disadvantages that a rolling machine with a working roll which can not axially move has weak capacity of controlling the edge drop when electric steel is rolled. The technology can control the edge drop of the electric steel below 10 mu m, simultaneously improve the control performance of the plate shape of the rolling machine, increase the transverse rigidity for bearing roll gap, improve the state of contact pressure between rolls and prevent the roll from shelling off caused by local pressure peak. The technology is suitable for the cold rolling machine with the working roll which can not axially move, in particular for the rolling machine which infrequently changes the rolling width and the rolling specification.

Owner:UNIV OF SCI & TECH BEIJING

Semiconductor device and manufacturing method thereof

InactiveUS7808098B2Improve reliabilityNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

The present invention provides a semiconductor device which is not easily damaged by external local pressure. The present invention further provides a manufacturing method of a highly-reliable semiconductor device, which is not destroyed by external local pressure, with a high yield. A structure body, in which high-strength fiber of an organic compound or an inorganic compound is impregnated with an organic resin, is provided over an element substrate having a semiconductor element formed using a single crystal semiconductor region, and heating and pressure bonding are performed, whereby a semiconductor device is manufactured, to which the element substrate and the structure body in which the high-strength fiber of an organic compound or an inorganic compound is impregnated with the organic resin are fixed together.

Owner:SEMICON ENERGY LAB CO LTD

Prosthetic sock providing graduated thickness and tibial crest load reduction for an amputee limb remnant

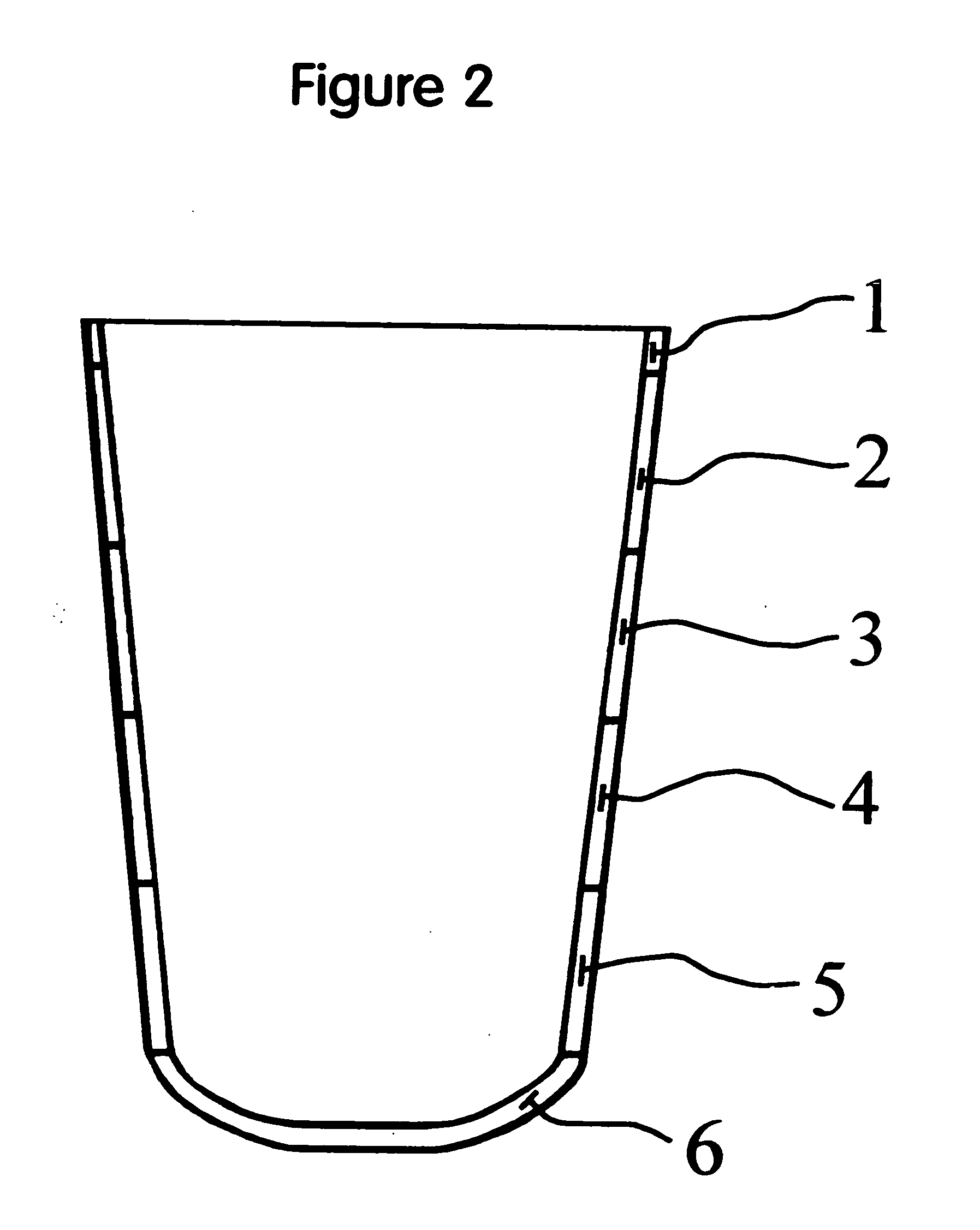

InactiveUS20070162153A1Great distal thicknessReduced sock thicknessProsthesisTibiaTrans tibial amputation

A prosthetic sock configured to accommodate a transtibial amputee's residuum volume reductions which occur over time and are greater distally than proximally. It is also applicable to other amputee limbs and other levels of amputation of the leg and arm. The sock provides better compensation for the increased distal volume shrinkage and it reduces discomfort from localized loading on the stump by providing a knitted thickness that is greater distally and then tapers to a lesser proximal knitted thickness. A transtibial amputee's residuum is more sensitive to pressure over the tibial bone and this sock also provides a reduced local thickness over the tibial crest area which decreases the localized pressure in this region. Since the sock accommodates the loss of tissue volume in the distal end of the prosthetic socket, it thereby provides improved stump stability inside the prosthetic socket and improves amputee control and stability in walking.

Owner:BARNES LESLIE JAMES +1

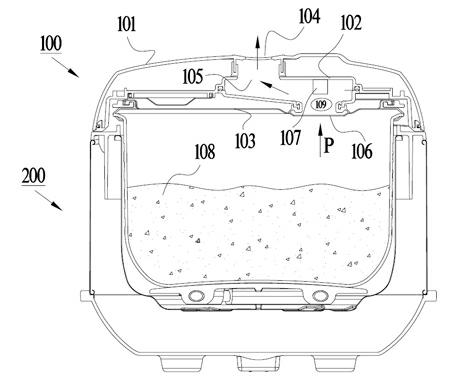

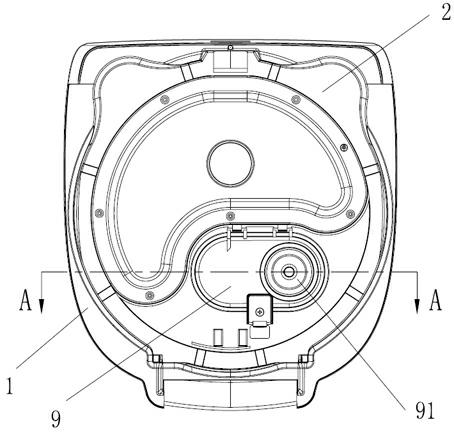

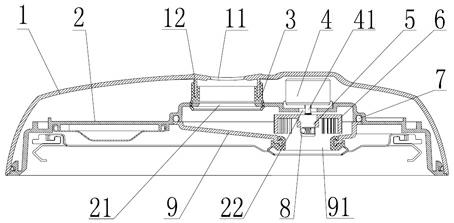

Rice cooker having foam overflow preventing function and its preventing method

The invention provides a rice cooker having a foam overflow preventing function. The rice cooker has an axially sealed steam passage provided with a negative pressure generation device in the position corresponding to a steam inlet hole. Also provided is a method for preventing foam overflow, which comprises forming an axially sealed steam passage and generating a negative pressure at the position of the steam passage corresponding to the steam inlet hole. With the invention, a negative pressure generation device is arranged in a steam flowing passage of the cooker body, and rapid suctioning is carried out so that the steam in the cooker body has no time to supplement the space where gas is suctioned by the device, to form, nearby the negative pressure generation device, a local low pressure space with a local pressure lower than the internal pressure inside the cooker body, so as to physically avoid rice water foam overflow during rice cooking and porridge cooking processes of the rice cooker.

Owner:MIDEA GRP CO LTD

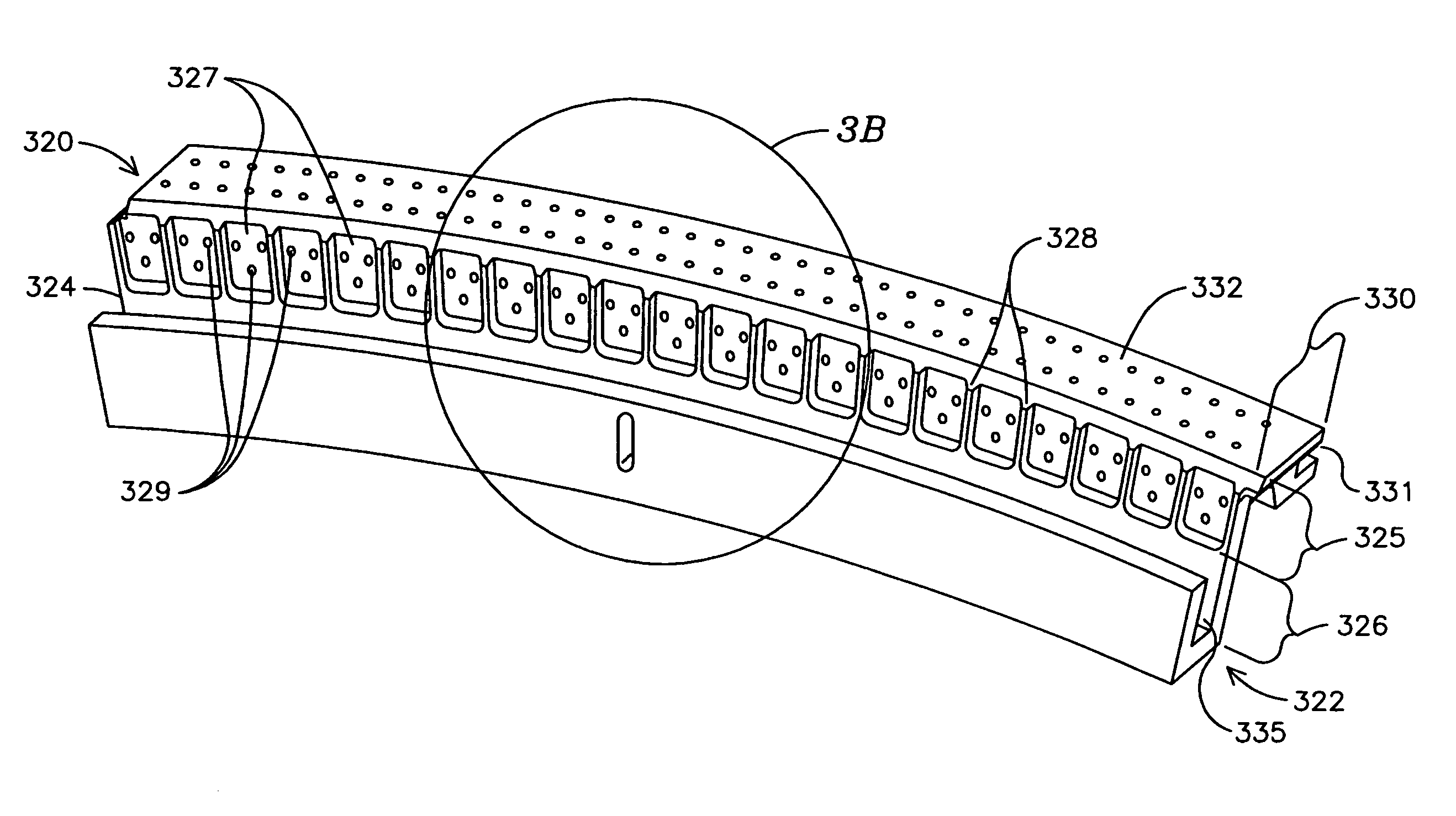

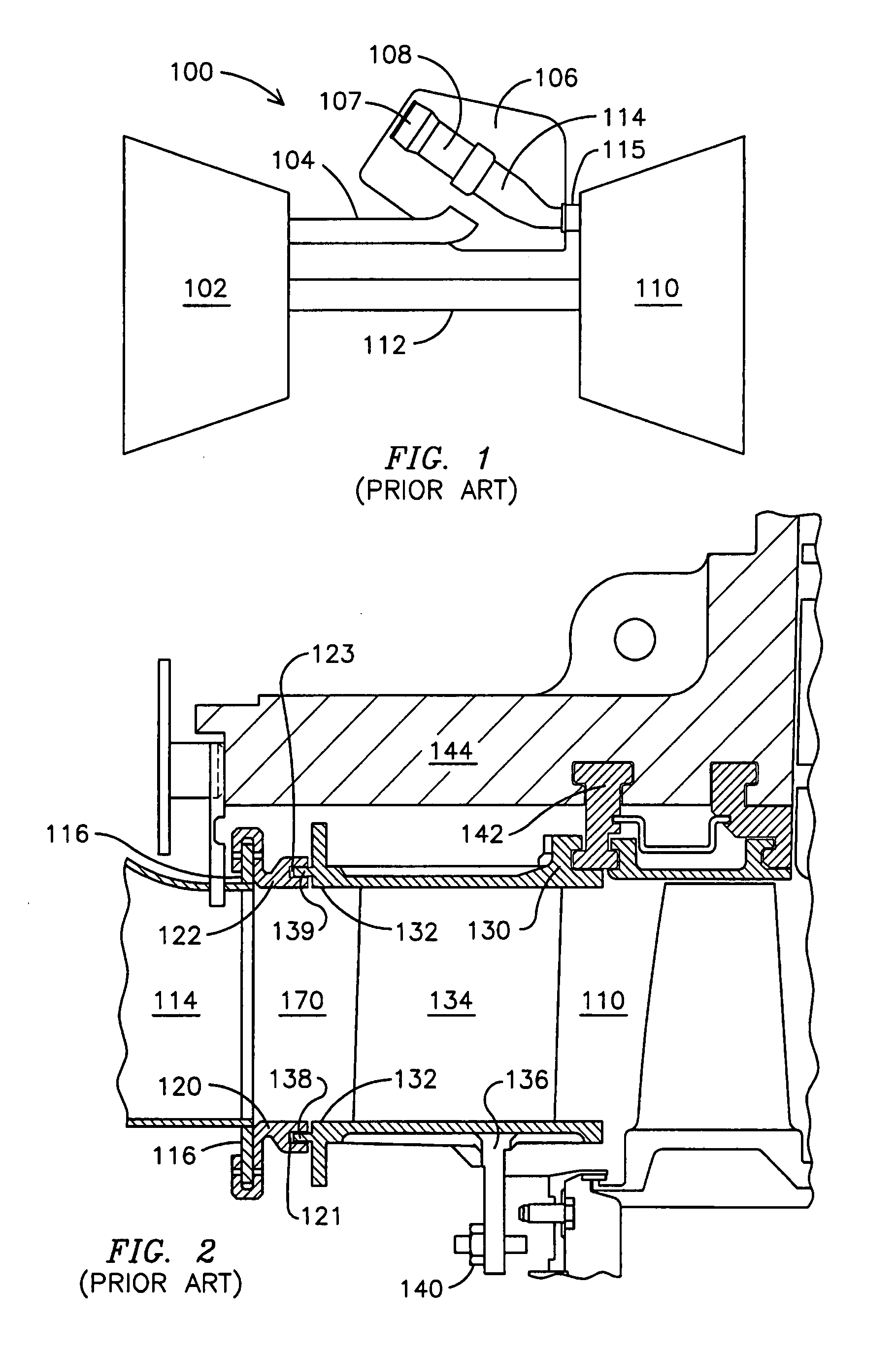

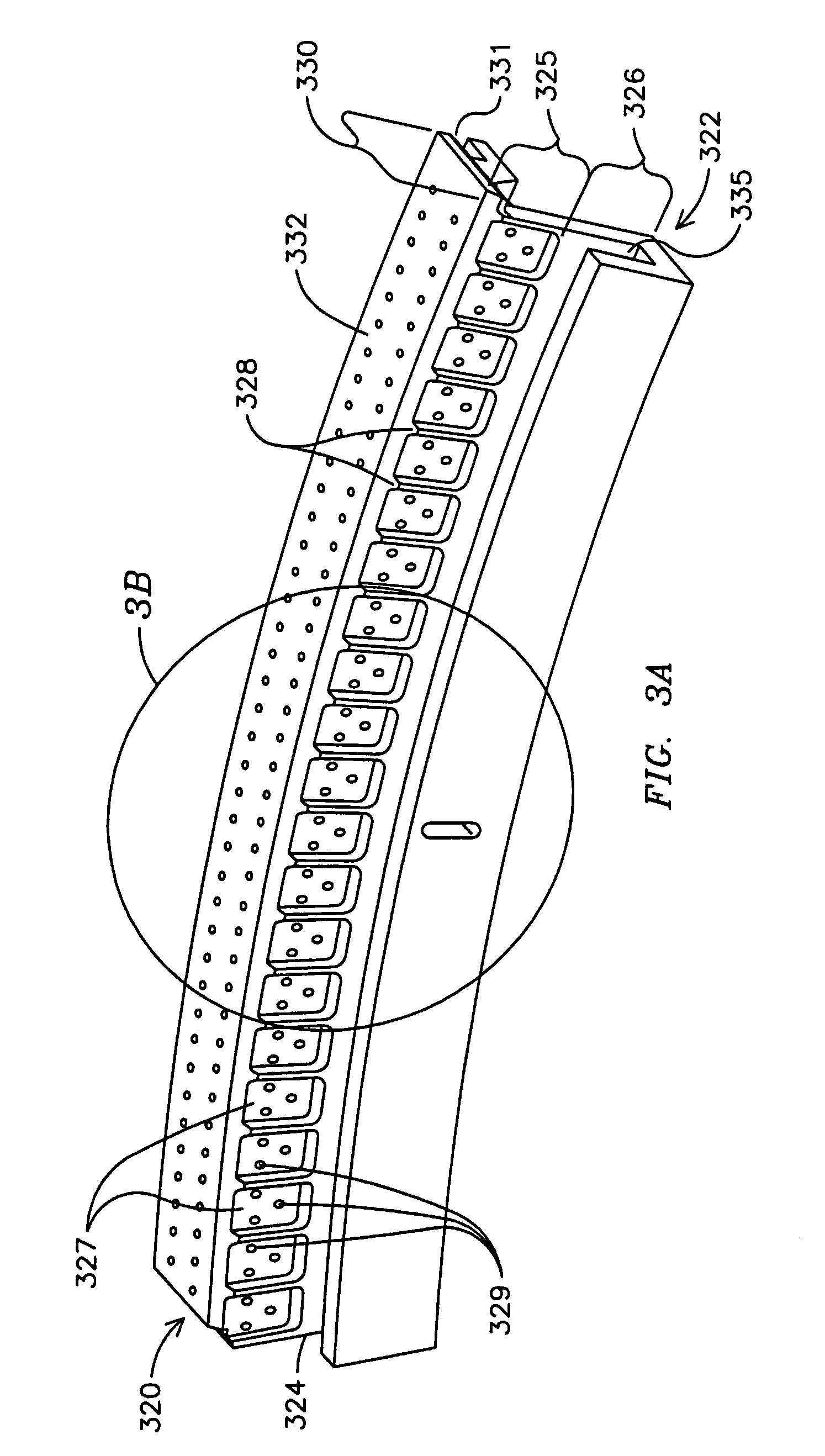

Transition-to turbine seal apparatus and transition-to-turbine seal junction of a gas turbine engine

One embodiment of a transition-to-turbine seal (320) comprises an upstream portion (322) adapted to engage a flange (416) of a transition (400). The upstream portion (322) may be U-shaped in cross-sectional profile and comprises a primary wall (324) that comprises a proximal section (325) and a distal section (326) relative to a hot gas path (170). The proximal section (325) comprises a plurality of recesses (327) which are spaced apart and separated by intervening wall (328). In each recess (327) is provided one or more outlets (329) of cooling fluid holes (339). The outlets (329) communicate via the cooling fluid holes (339) with a supply of compressed cooling fluid, such as compressed air that is provided from the compressor. During operation the outlets (329) release this fluid into the respective recesses (327). The flow of cooling fluid through such outlets (329) in the respective recesses (327) provides for a more uniform cooling effect that includes impingement and convective cooling. Further, the outlets and recesses reduce the likelihood of hot gas ingestion due to local pressure gradients. Toward its downstream end, the seal (320) also comprises a downstream groove (321) which is adapted to engage a lip (138, 139) of a row 1 vane segment (130). Variations of the transition-to-turbine seal are described.

Owner:SIEMENS ENERGY INC

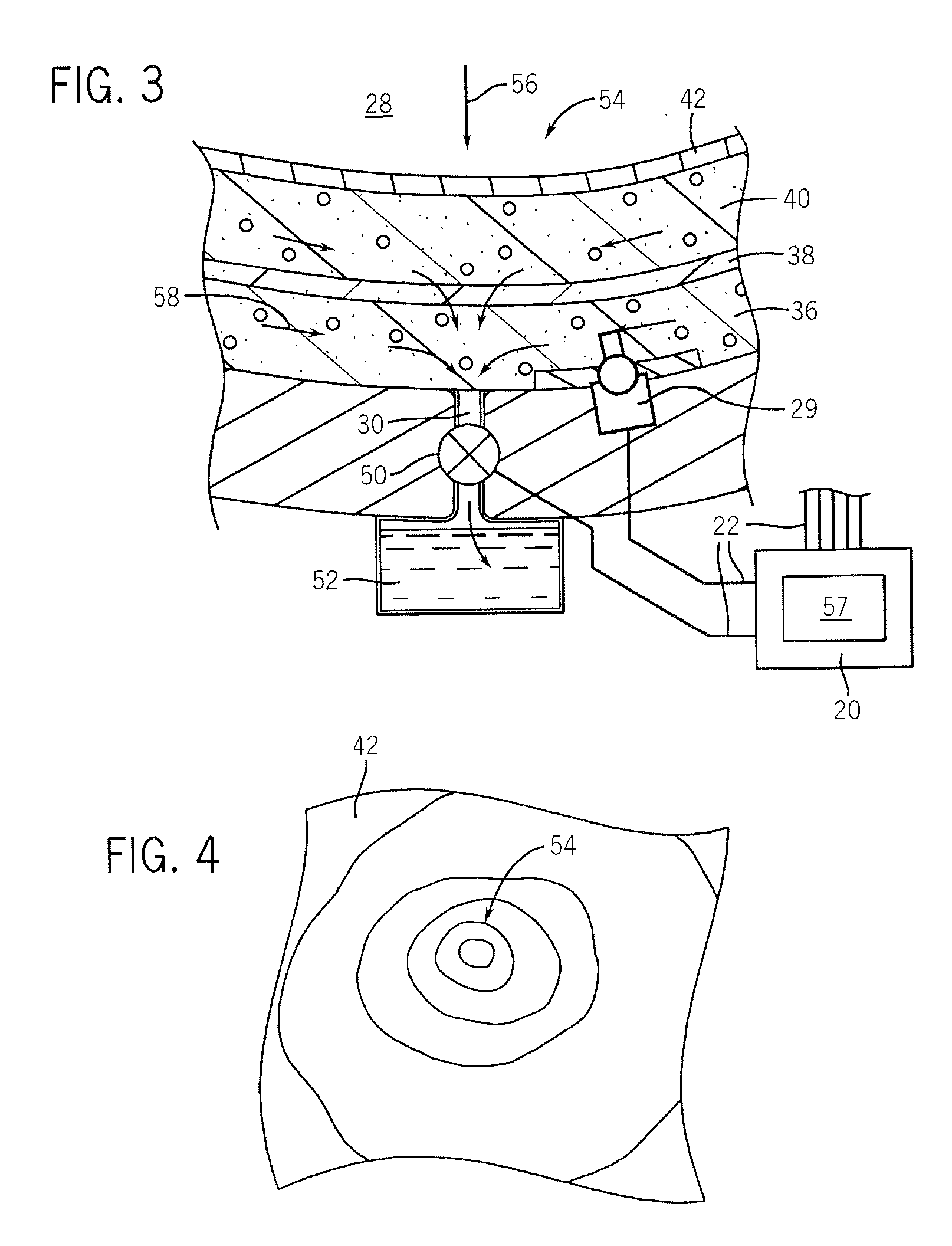

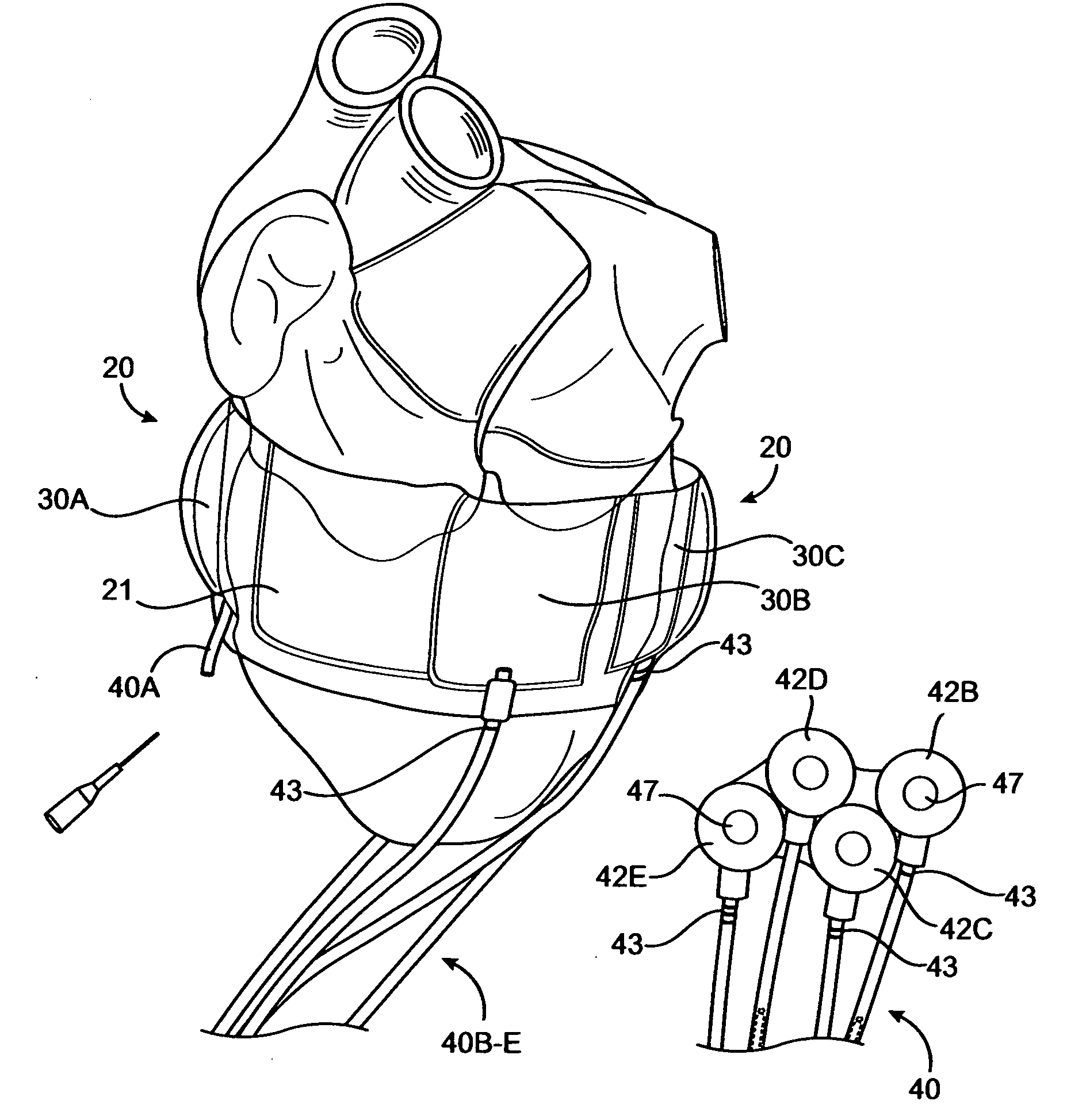

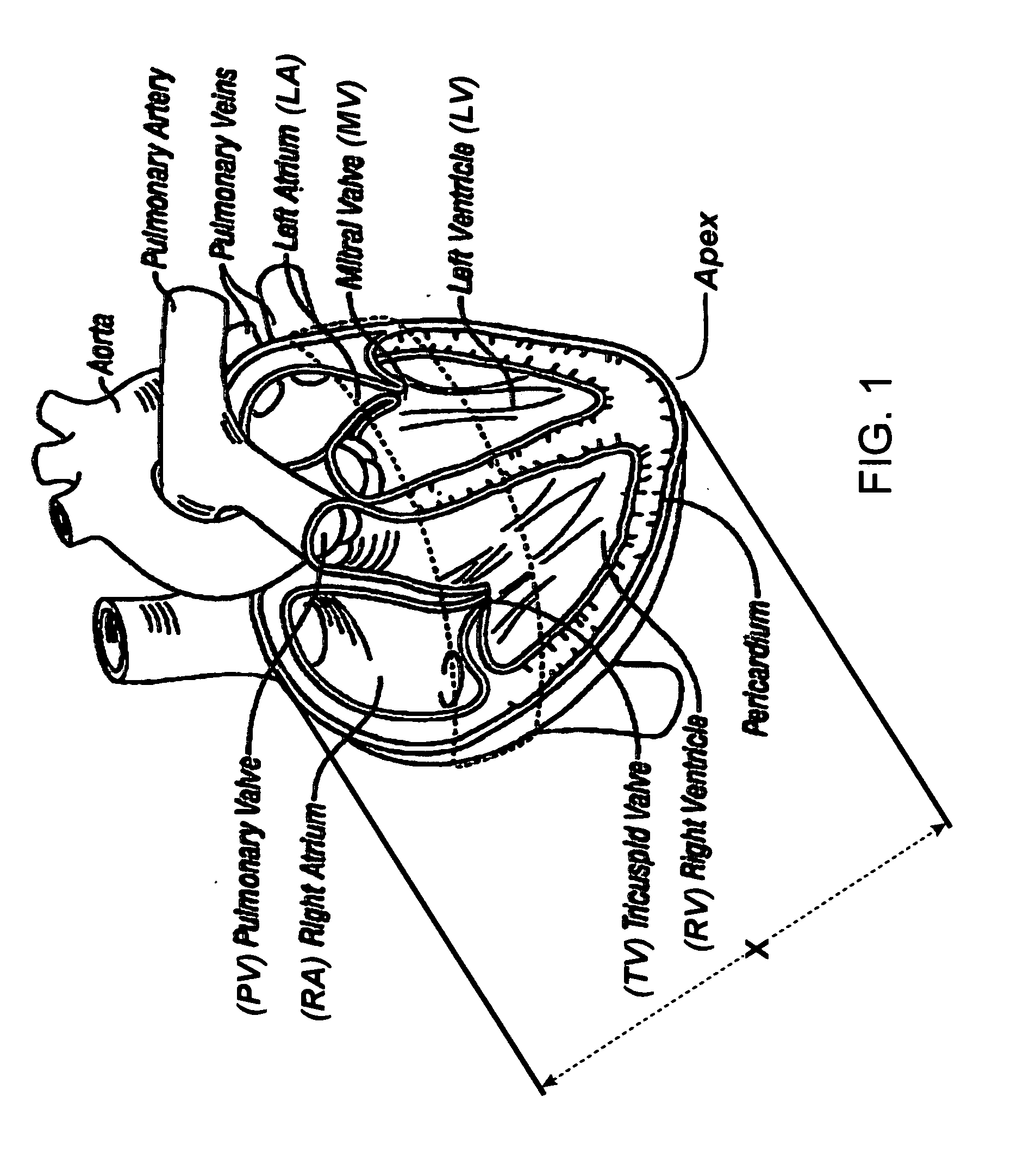

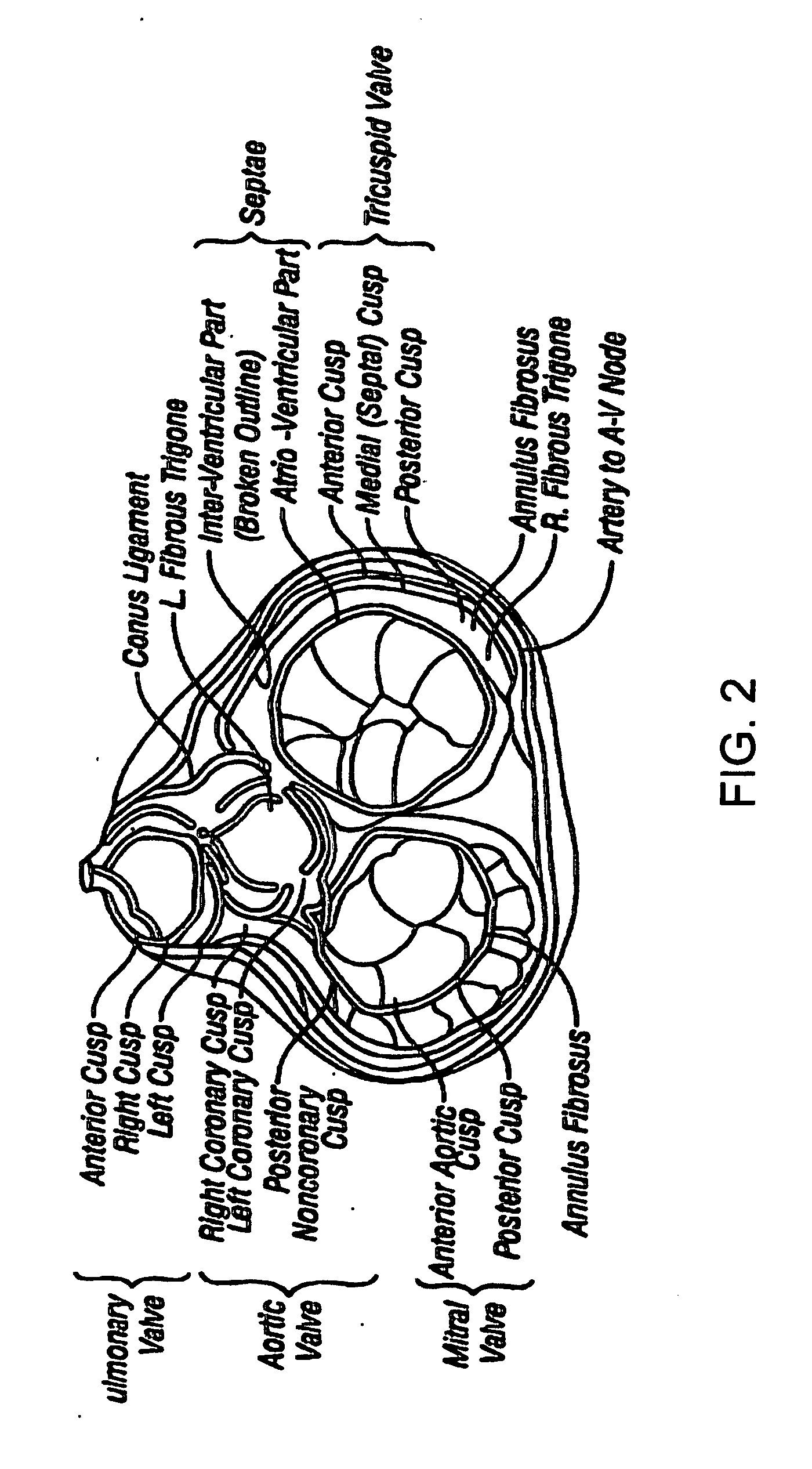

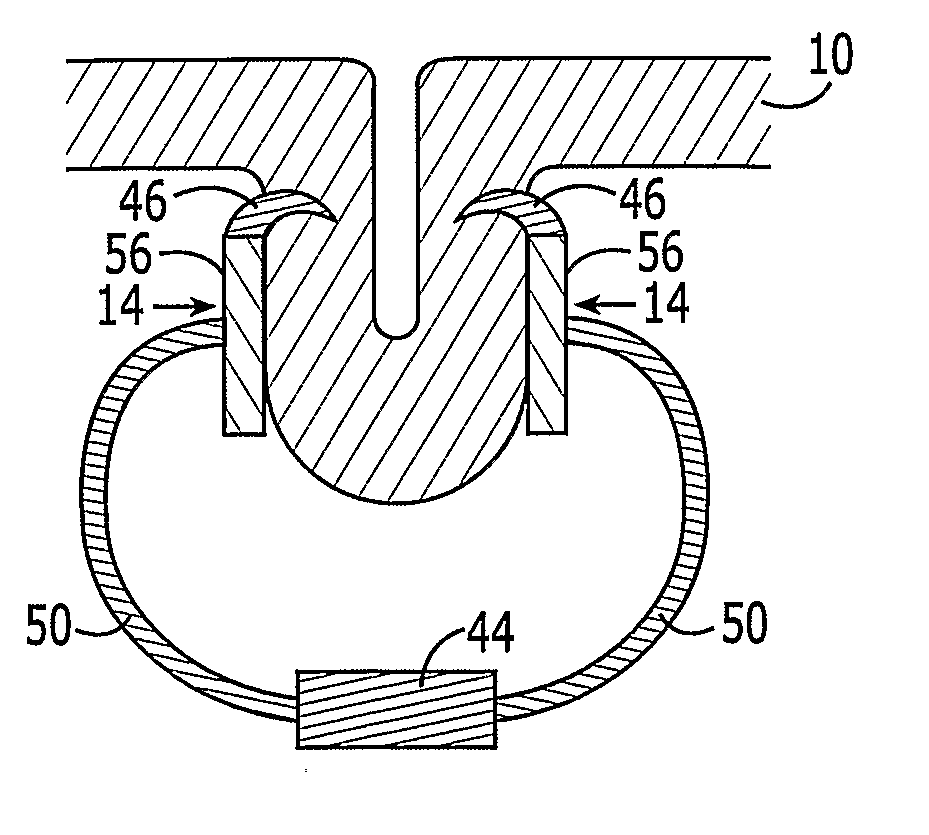

Heart band with fillable chambers to modify heart valve function

The present invention relates to an external heart device, having a layered band dimensioned to be received around a patient's heart, which also includes at least one fillable chamber between the layers in the band that functions to apply localized pressure to the outside of the heart when filled. More particularly, the fillable chambers are positioned such that they exert an inward radial force on a heart valve. Areas between the fillable chambers may also be sized and positioned to form a bridge of little to no pressure over the vascular structures of the heart.

Owner:MUPPIRALA GOPAL

Soft Tissue Anchoring Methods and Devices

InactiveUS20110098730A1Smoother featureSuture equipmentsObesity treatmentLocal pressureTissue fixing

Novel devices (120) and methods for soft tissue anchoring and securement are disclosed, such devices and methods offering the advantage of enabling secured tissue to withstand significant forces after such securement is complete. The novel tissue anchoring elements (28) include a force-distributing device that has a large surface area relative to conventional tissue securement devices such as sutures and staples. The force-distributing device (28) may be implanted to a controlled depth into the tissue mass by forming a pocket in a tissue mass and inserting the device, or by slowly driving the device into tissue means of an erosion mechanism such as local pressure necrosis (56). The erosion process may be driven by a force-producing element that may also include a tissue-grasping element (144).

Owner:KELLEHER BRIAN

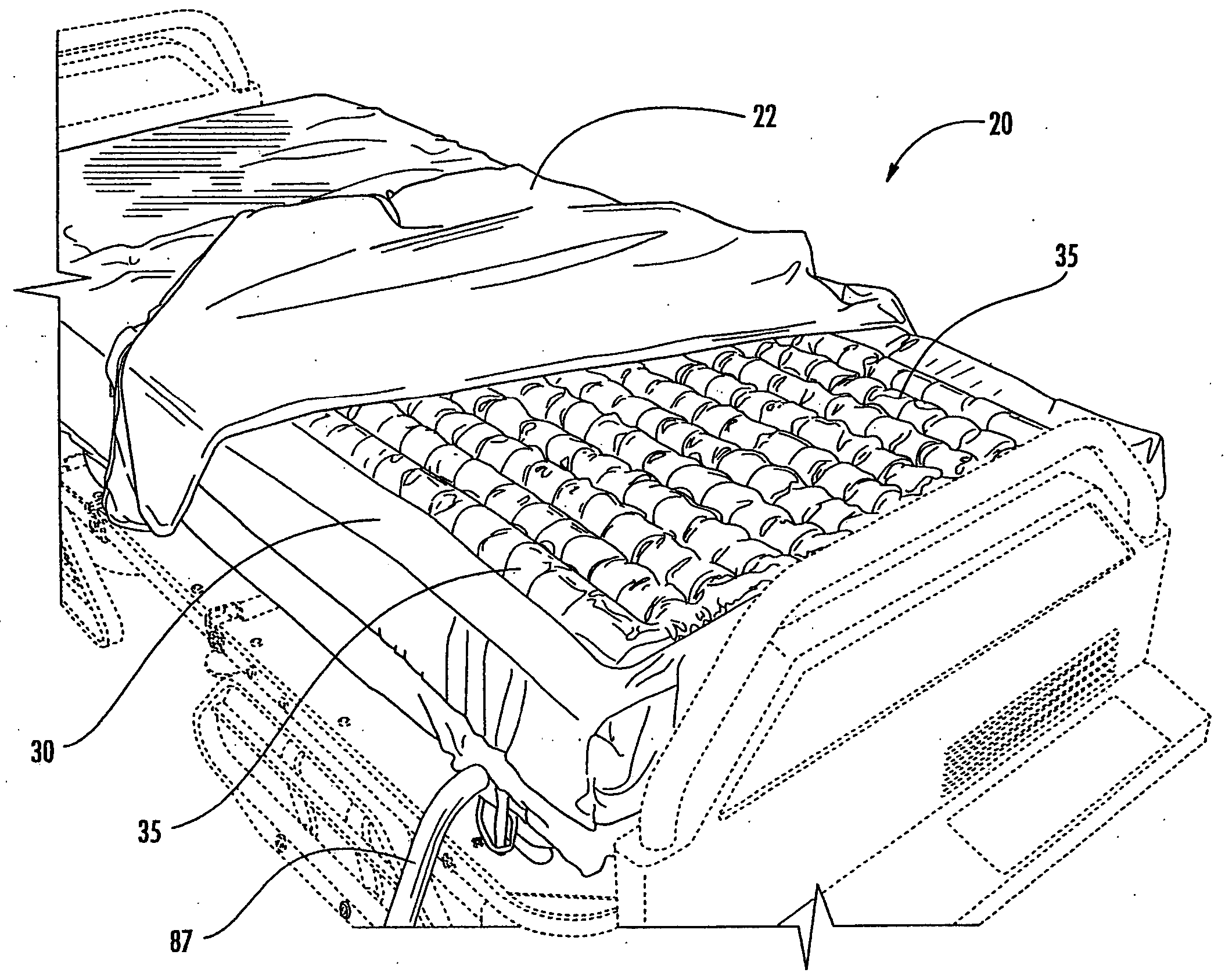

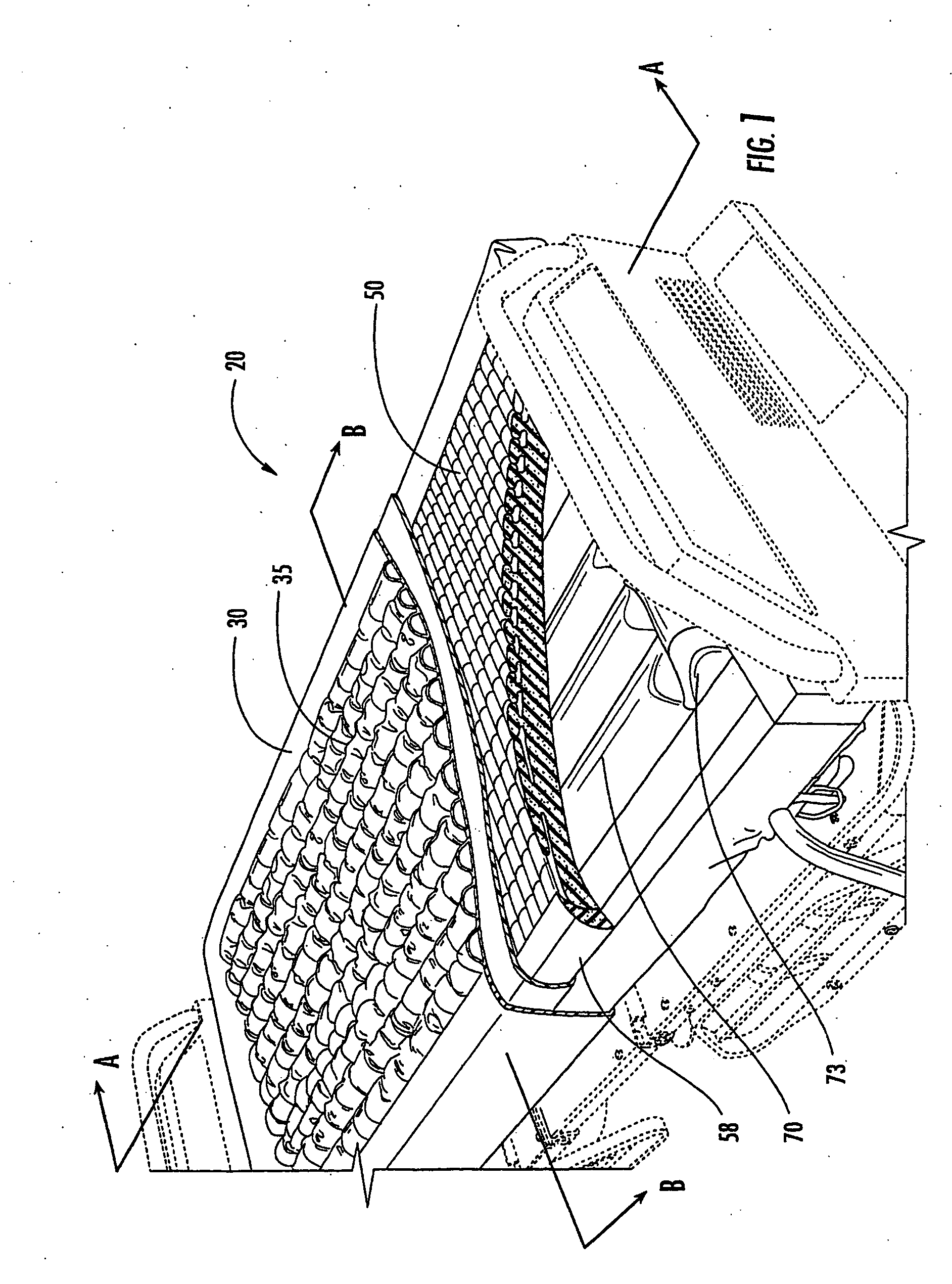

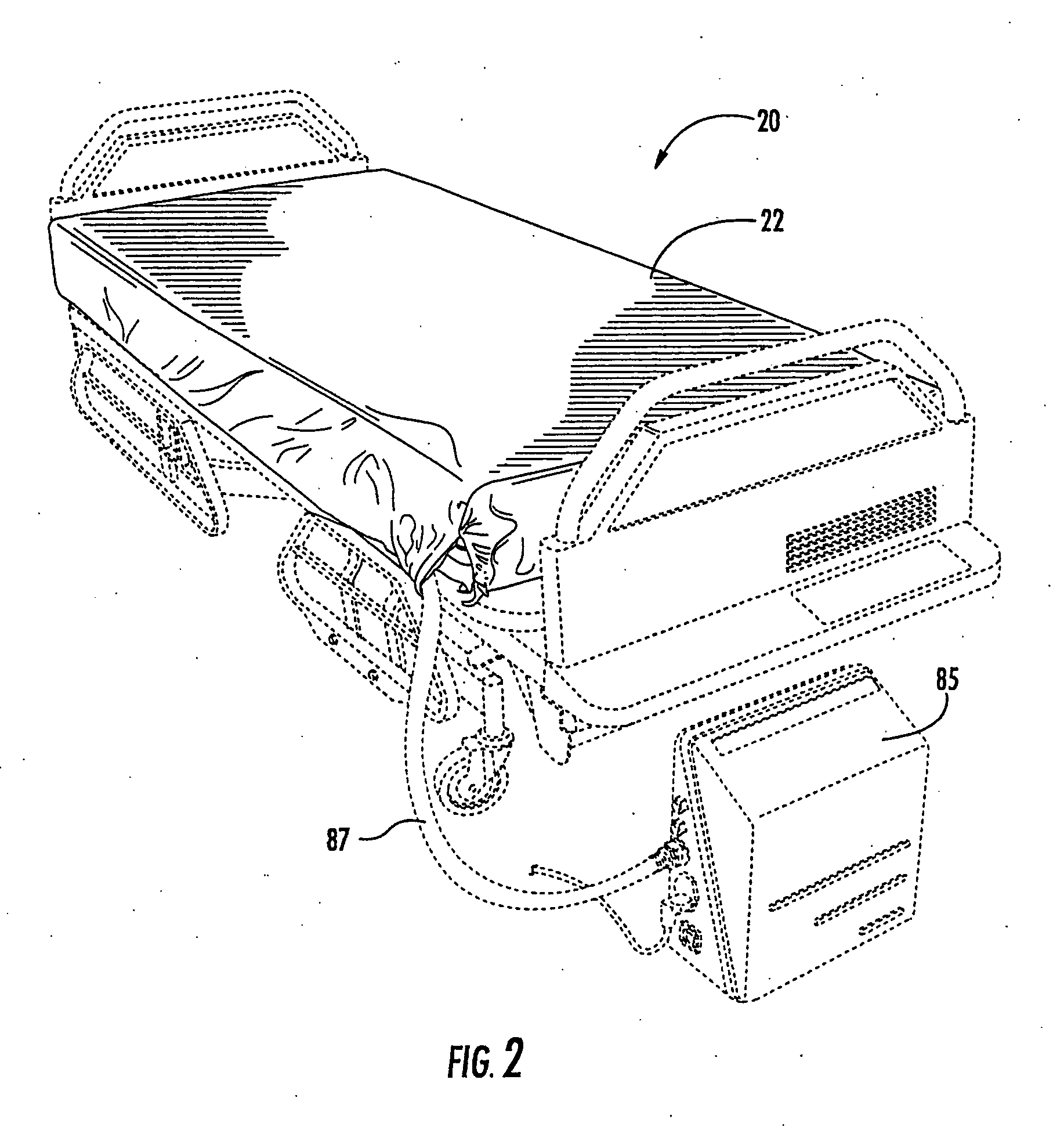

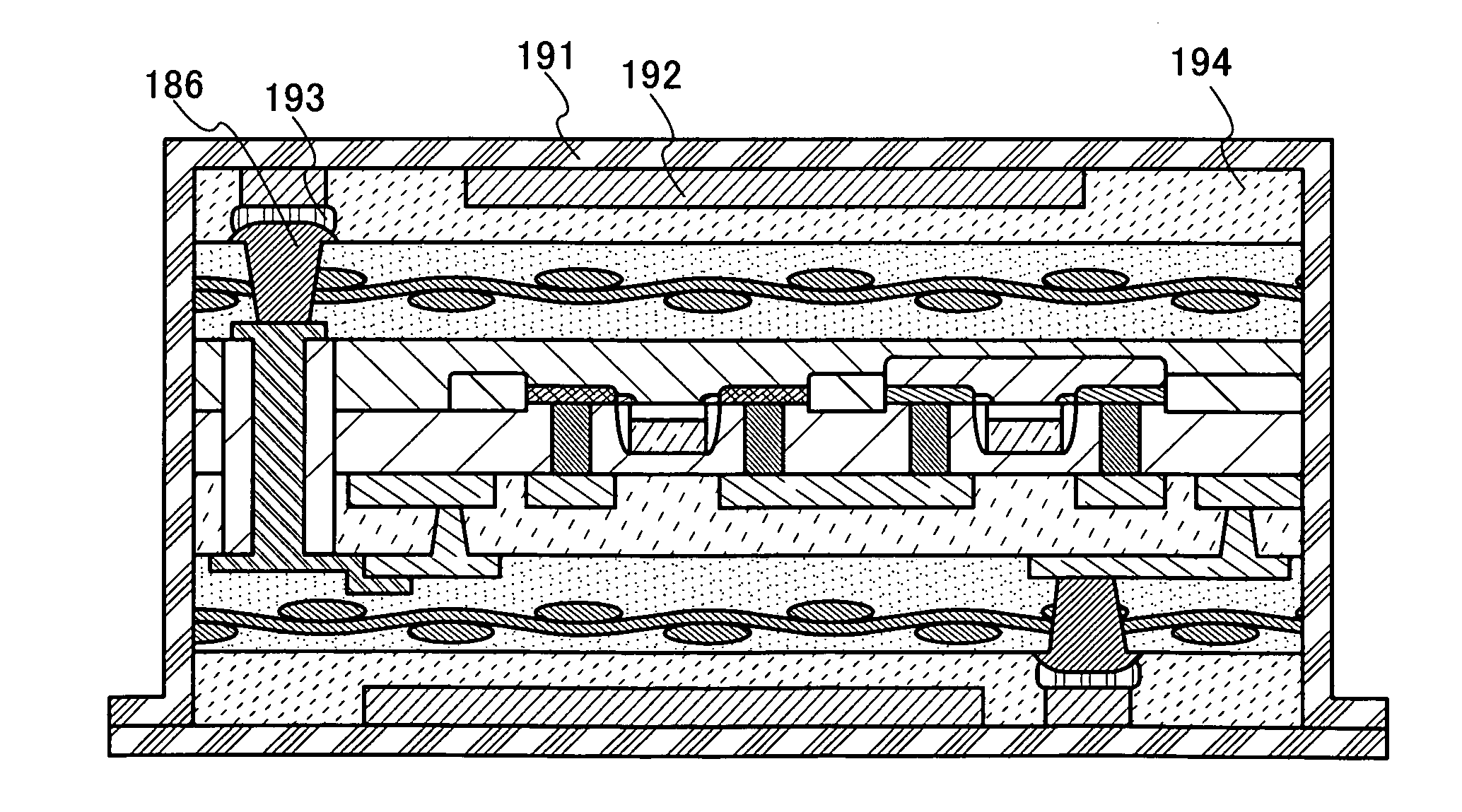

Two-mode therapeutic mattress system

InactiveUS20050081300A1Improved heel comfortEasy and fast setupStuffed mattressesSpring mattressesDual modeEngineering

A two-mode therapeutic mattress system is provided, including a non-powered air mattress, a pressure dispersion cushion, and a selectively operable air diffusion coverlet in a common modular assembly for improved medical management of skin care. The non-powered air mattress includes longitudinal air cylinders providing a static air support system inflated to predetermined pressure. The longitudinal air cylinders are in pressure communication with elasticized reservoirs, in that the air level in the elasticized reservoirs dynamically reacts to changes in pressure in the longitudinal air cylinders, for example upon receipt of a patient upon the mattress system. The pressure dispersion cushion facilitates pressure relief with a number of lateral and longitudinal cuts resulting in a plurality of separate upright support cells, the size and construction of which may vary over the surface of the pressure dispersion cushion so as to provide selective support characteristics. The air diffusion coverlet contains a plurality of air pockets. The air diffusion coverlet operates in two modes: a “therapy mode” such that compressed air from an air compressor is pumped to the air diffusion coverlet, and an “off” mode in which the air pockets collapse to provide a suitable and relatively smooth bedding component to the therapeutic mattress system. The non-powered air mattress, pressure dispersion cushion, and selectively operable air diffusion coverlet cooperate to provide a single product that addresses localized pressure, maceration, shear stress, and dynamic changes in a patient's condition during the course of time.

Owner:SPAN-AMERICA MEDICAL SYSTEMS

Method for manufacturing semiconductor device

InactiveUS7785933B2Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

Owner:SEMICON ENERGY LAB CO LTD

Single-touch or multi-touch capable touch screens or touch pads comprising an array of pressure sensors and production of such sensors

A multi-touch capable touch screen or touchpad is implemented in that a large number of pressure sensors are attached below a flexible surface and both the pressure distribution and also the deformation of the surface are measured. Local pressure maxima arise due to the flexibility of the surface material with the attendant deformation upon contact. Because multiple local pressure maxima may exist, multiple contacts may thus also be recognized simultaneously. The force with which pressure is applied may additionally be ascertained from the pressure strength and the pressure distribution, so that this information may likewise be used in the user interface. Such sensors may be produced very efficiently and cost-effectively in that an ink, which changes the resistance thereof under pressure, is imprinted on printed conductors implemented as the sensor surfaces. Likewise, the printed conductors and the sensor surfaces may also be printed using an ink having the lowest possible resistance.

Owner:安德烈亚斯‧施泰因豪泽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com