Rice cooker having foam overflow preventing function and its preventing method

A rice cooker and foam technology, which is applied in the field of rice cookers, can solve the problems of not being able to completely eliminate foam overflow, high overall cost, and low reliability, and achieve the effect of preventing rice soup foam overflow and rice soup overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

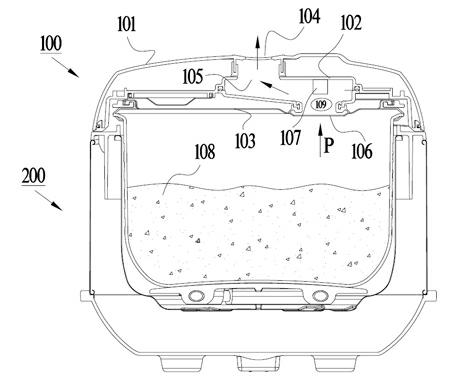

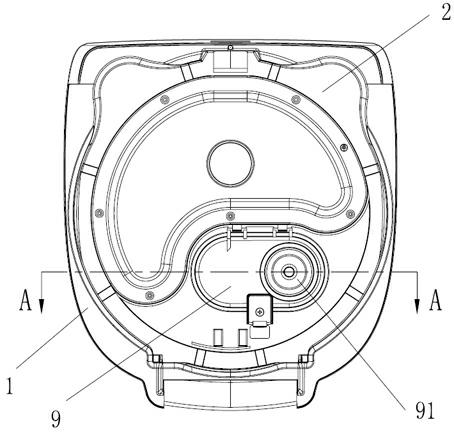

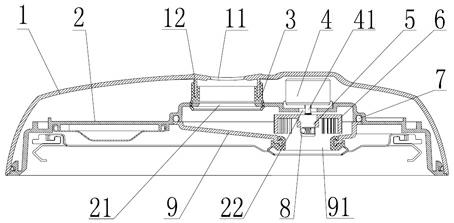

[0036] like figure 2 and image 3 As shown, the electric rice cooker of the present embodiment includes a face cover 1, an inner cover 2, a motor 4, a steam valve seat 9 and a blade 6. The inner cover 2 is installed under the surface cover 1, and the surface cover 1 is provided with an exhaust hole 11, and the lower part of the surface cover 1 is provided with an annular retaining rib 12 protruding toward the direction of the inner cover 2 around the exhaust hole 11, and the inner cover 2 corresponds to A steam hole 21 is provided at the exhaust hole 11 , and a surface cover sealing ring 3 is provided between the annular retaining rib 12 and the inner cover 2 .

[0037] like figure 2 As shown, the upper end of the above-mentioned steam valve seat 9 is open, fastened under the inner cover 2, covering the steam hole 21 and the through hole 22 on the inner cover 2, and a sealing rib is provided at the joint between the steam valve seat 9 and the inner cover 2 7 to seal and f...

Embodiment 2

[0042] like Figure 4 As shown, the electric rice cooker of the present embodiment includes a face cover 1 , an inner cover 2 , a motor 4 , a cover plate 13 and blades 6 . The inner cover 2 is installed under the surface cover 1, and the surface cover 1 is provided with an exhaust hole 11, and the lower part of the surface cover 1 is provided with an annular retaining rib 12 protruding toward the direction of the inner cover 2 around the exhaust hole. A steam hole 22 is provided at the air hole, and a cover sealing ring 3 is provided between the annular retaining rib 12 and the inner cover 2 .

[0043] The motor 4 is installed between the surface cover 1 and the inner cover 2. Specifically, the inner cover 2 is provided with a through hole adjacent to the steam hole, the motor 4 is fixed above the inner cover 2, and the motor shaft 41 of the motor 4 passes through the through hole downward. The hole is rigidly connected with the connector 5, and the connector 5 is fixedly con...

Embodiment 3

[0047] like Figure 5 As shown, the rice cooker provided in this embodiment is substantially the same as that in Embodiment 2, the only difference being that the connector 5 in this embodiment is a plunger connector, and the blade 6 is fixed on the connector 5 through a ball plunger 8 . When the motor 4 is working, the motor shaft 41 drives the blade 6 to rotate through the connector 5, thereby forming a local negative pressure space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com