Patents

Literature

235 results about "Fibrous body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intervertebral disc treatment devices and methods

InactiveUS7318840B2Promote tissue growthFunction increasePeptide/protein ingredientsBone implantFibrous bodyIntervertebral disk

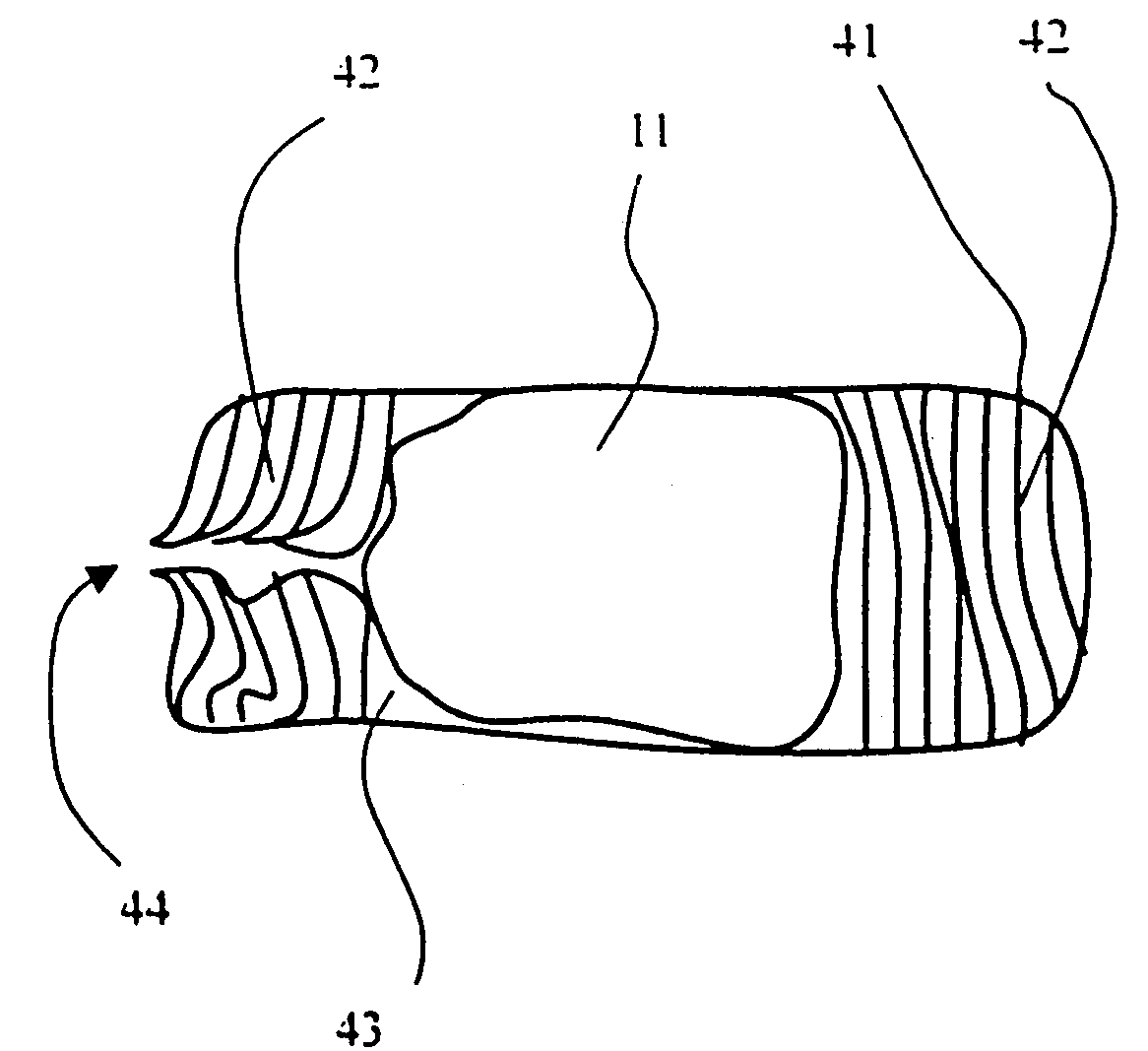

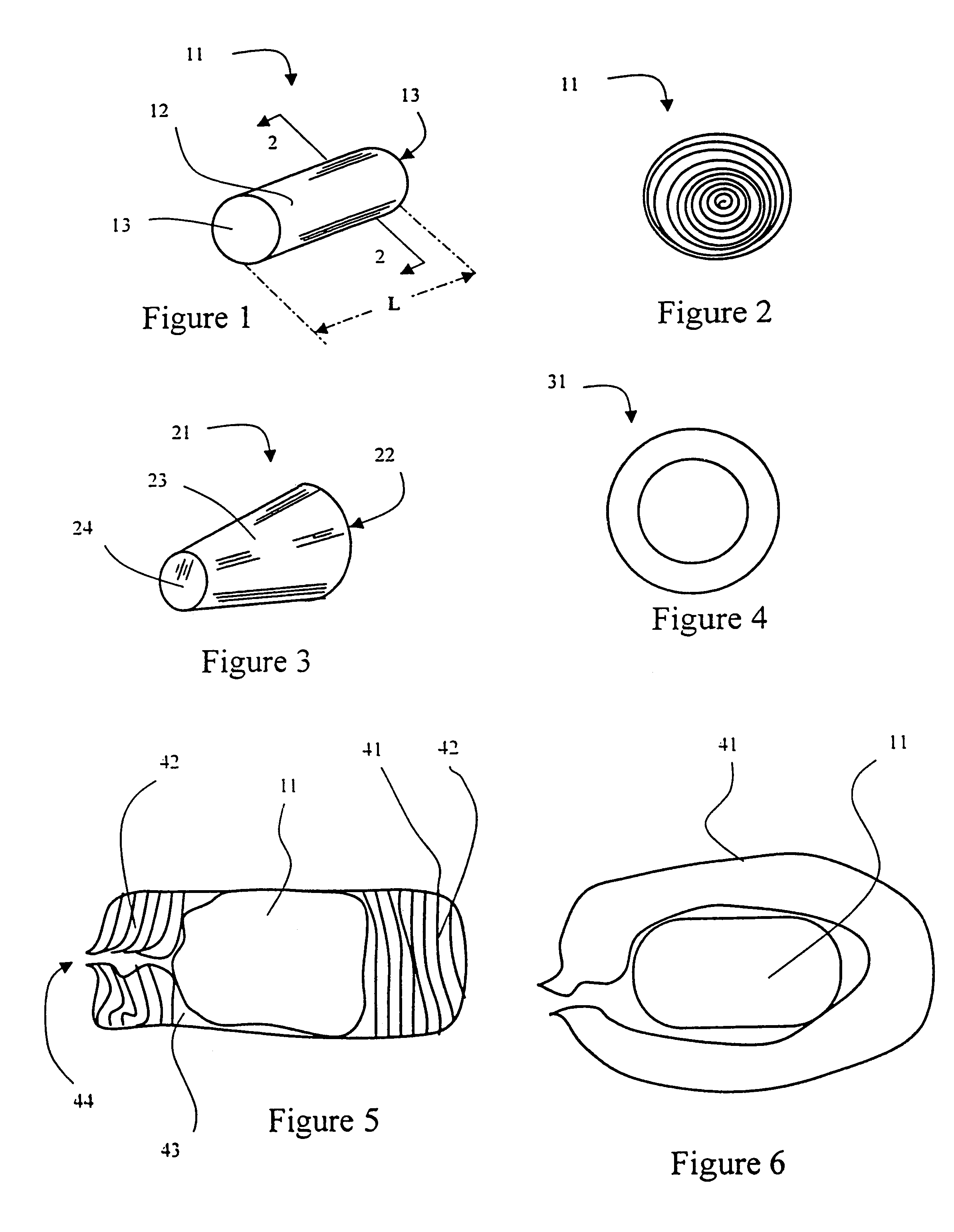

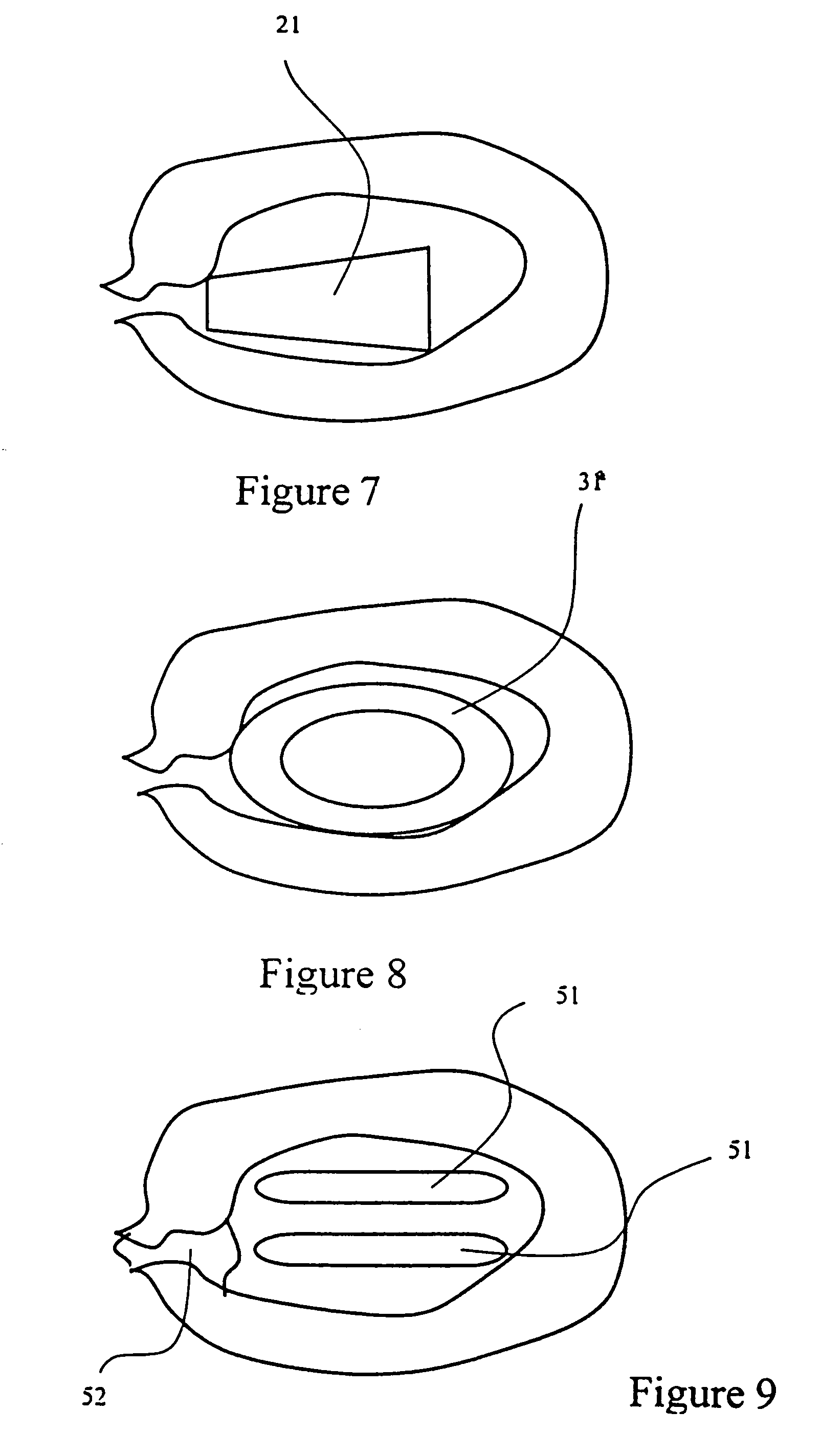

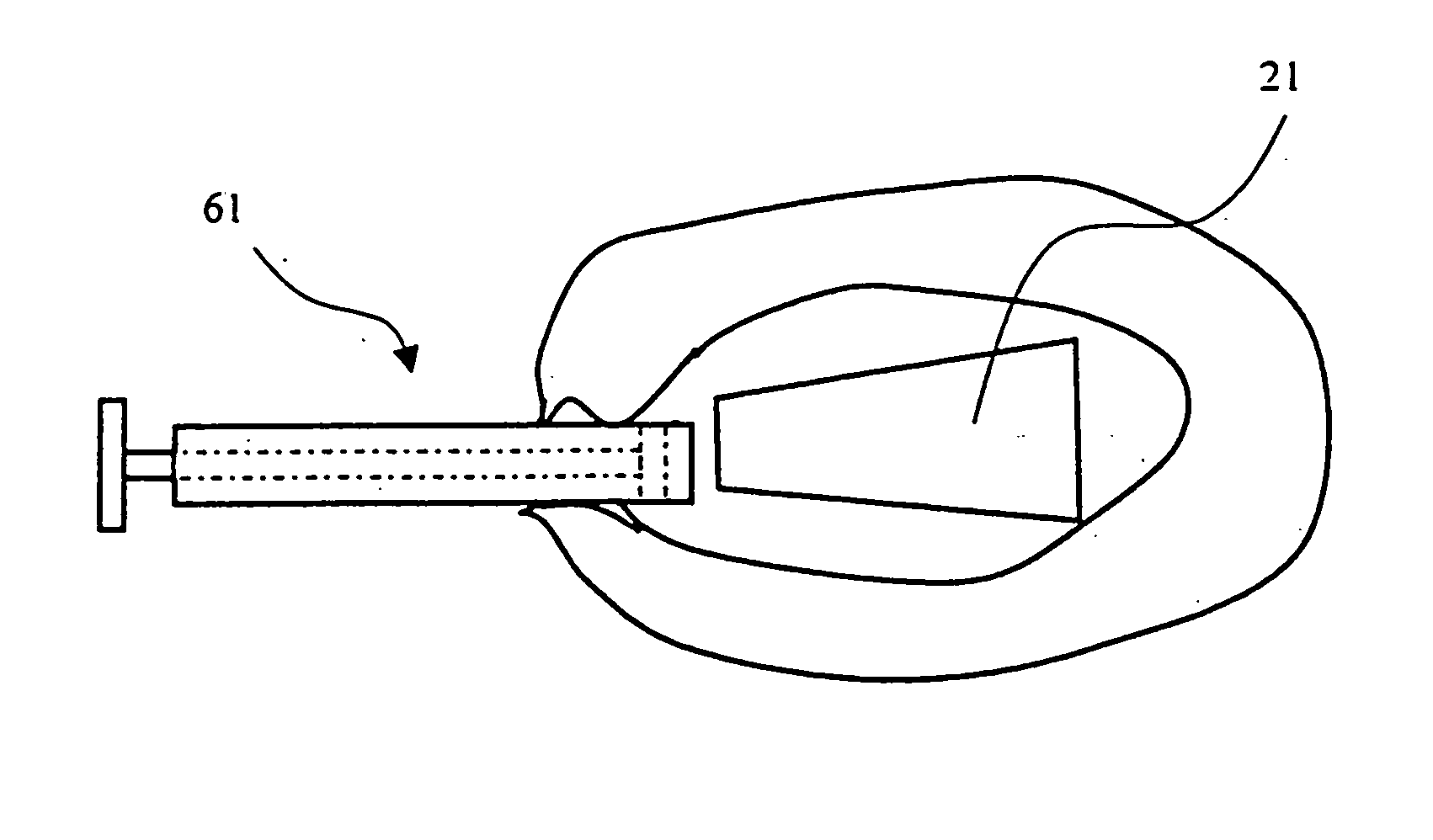

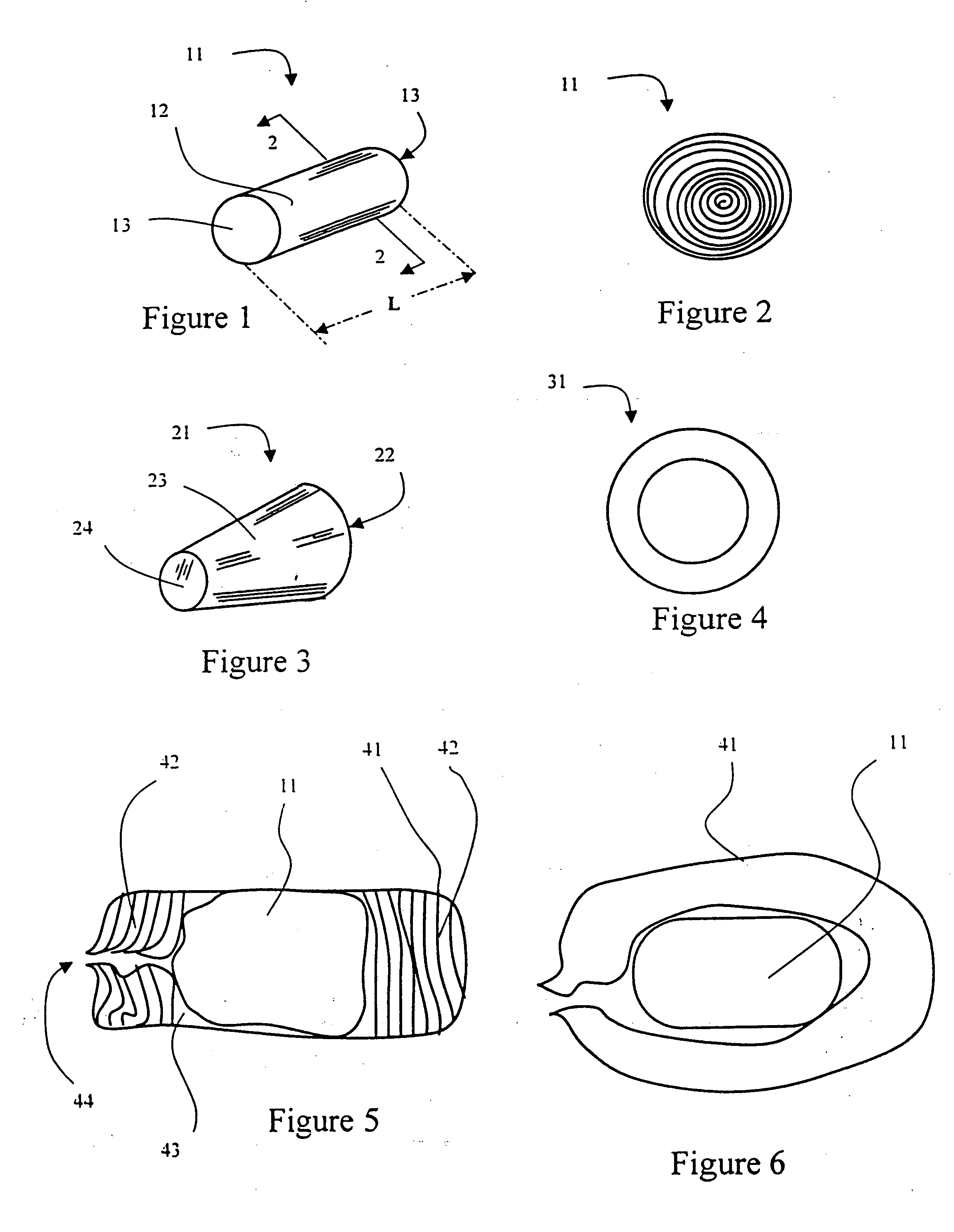

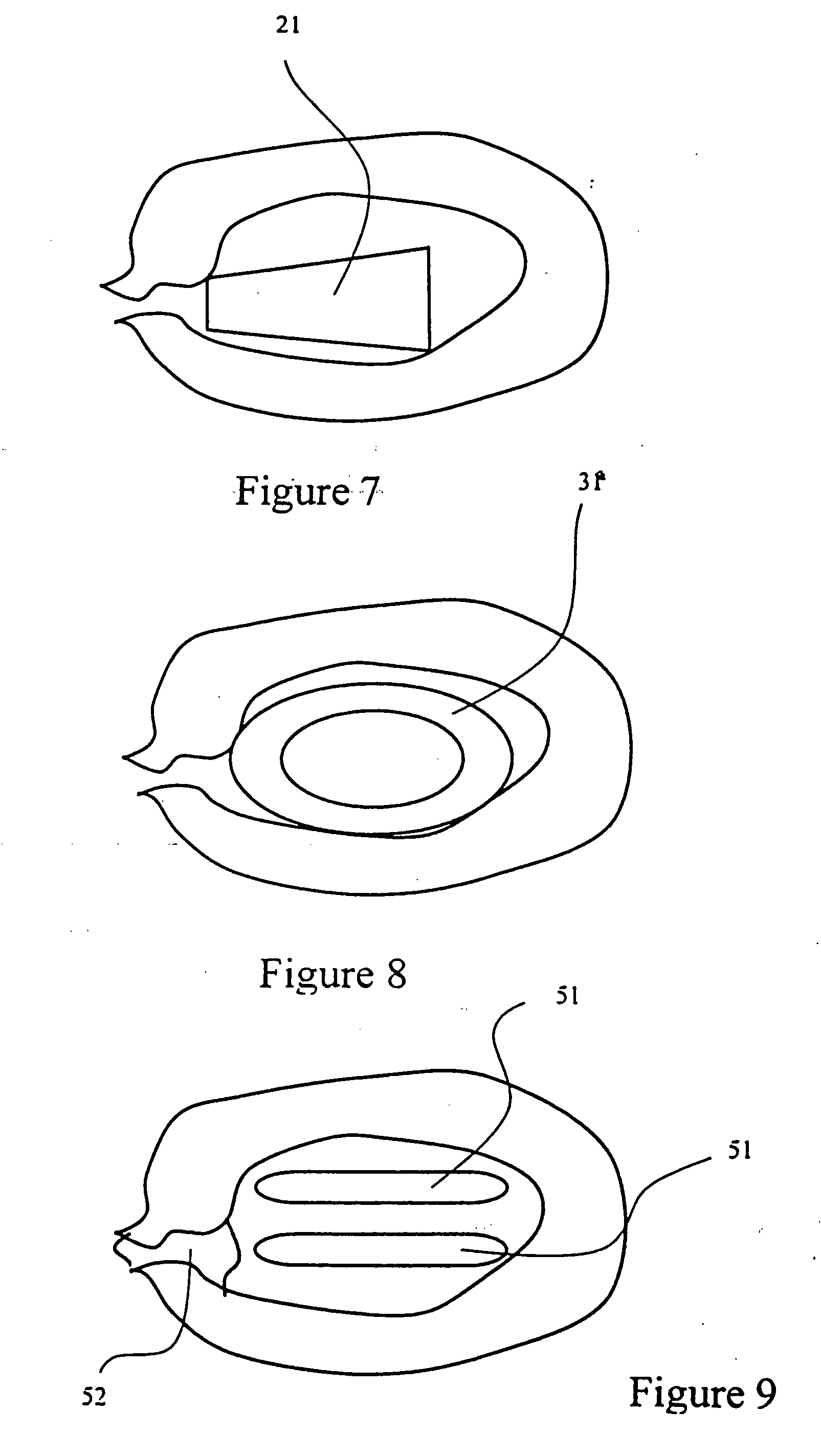

Intervertebral disc treatment devices and methods are provided. An intervertebral disc treatment device includes a fibrous body sized for introduction into a disc cavity of a damaged disc wherein the body incorporates an effective amount of a tissue growth factor. Intervertebral disc treatment apparatuses are also described that include such a disc treatment device in combination with a delivery apparatus for retaining and selectively releasing the device into the disc cavity. Methods for treatment include providing a disc treatment device as described above and inserting the device into an opening in an annulus fibrous and into the disc cavity. The methods further include stimulating tissue growth within the disc cavity of the intervertebral disc.

Owner:SDGI HLDG

Intervertebral disc treatment devices and methods

InactiveUS20060004456A1Prevent outflowPromote tissue growthPeptide/protein ingredientsDiagnosticsFibrous bodyIntervertebral disk

Intervertebral disc treatment devices and methods are provided. An intervertebral disc treatment device includes a fibrous body sized for introduction into a disc cavity of a damaged disc wherein the body incorporates an effective amount of a tissue growth factor. Intervertebral disc treatment apparatuses are also described that include such a disc treatment device in combination with a delivery apparatus for retaining and selectively releasing the device into the disc cavity. Methods for treatment include providing a disc treatment device as described above and inserting the device into an opening in an annulus fibrous and into the disc cavity. The methods further include stimulating tissue growth within the disc cavity of the intervertebral disc.

Owner:SDGI HLDG

Methods, systems and devices for performing gynecological procedures

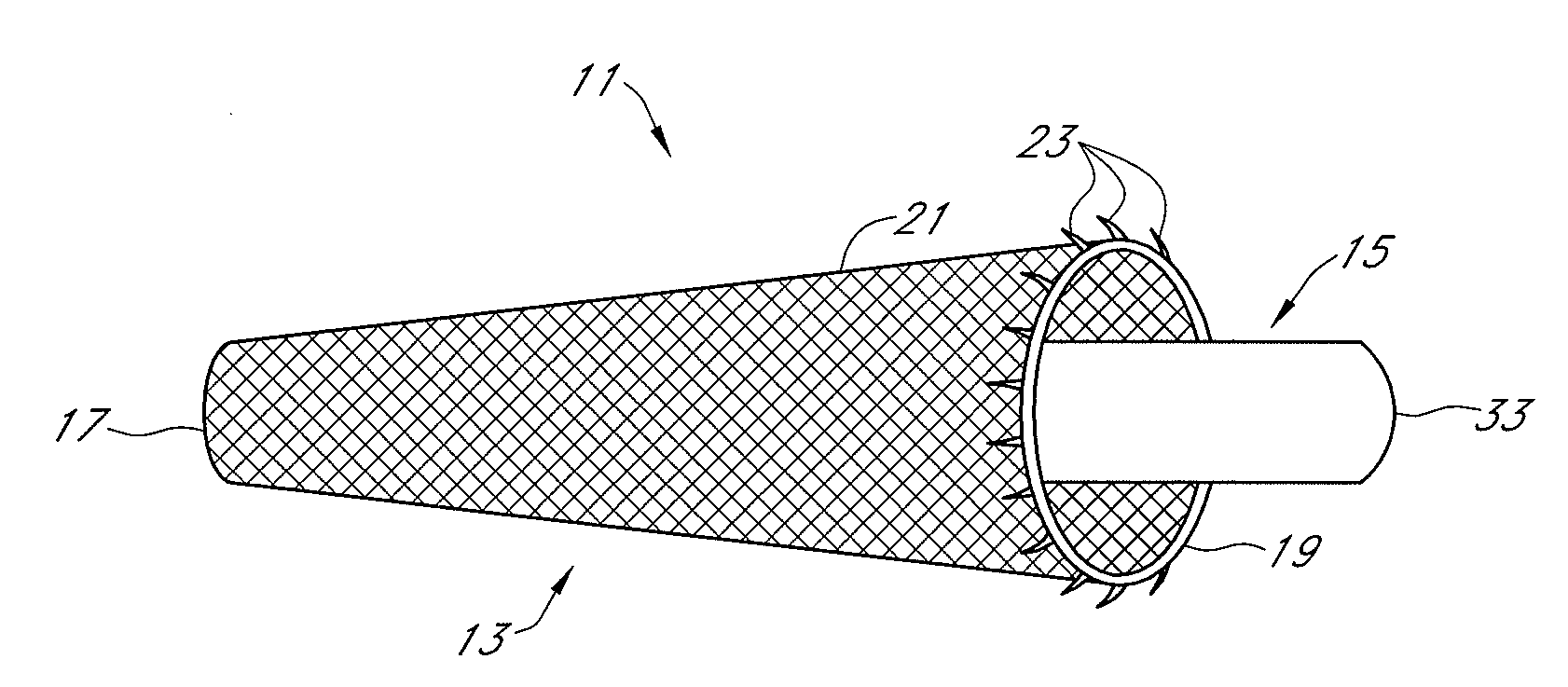

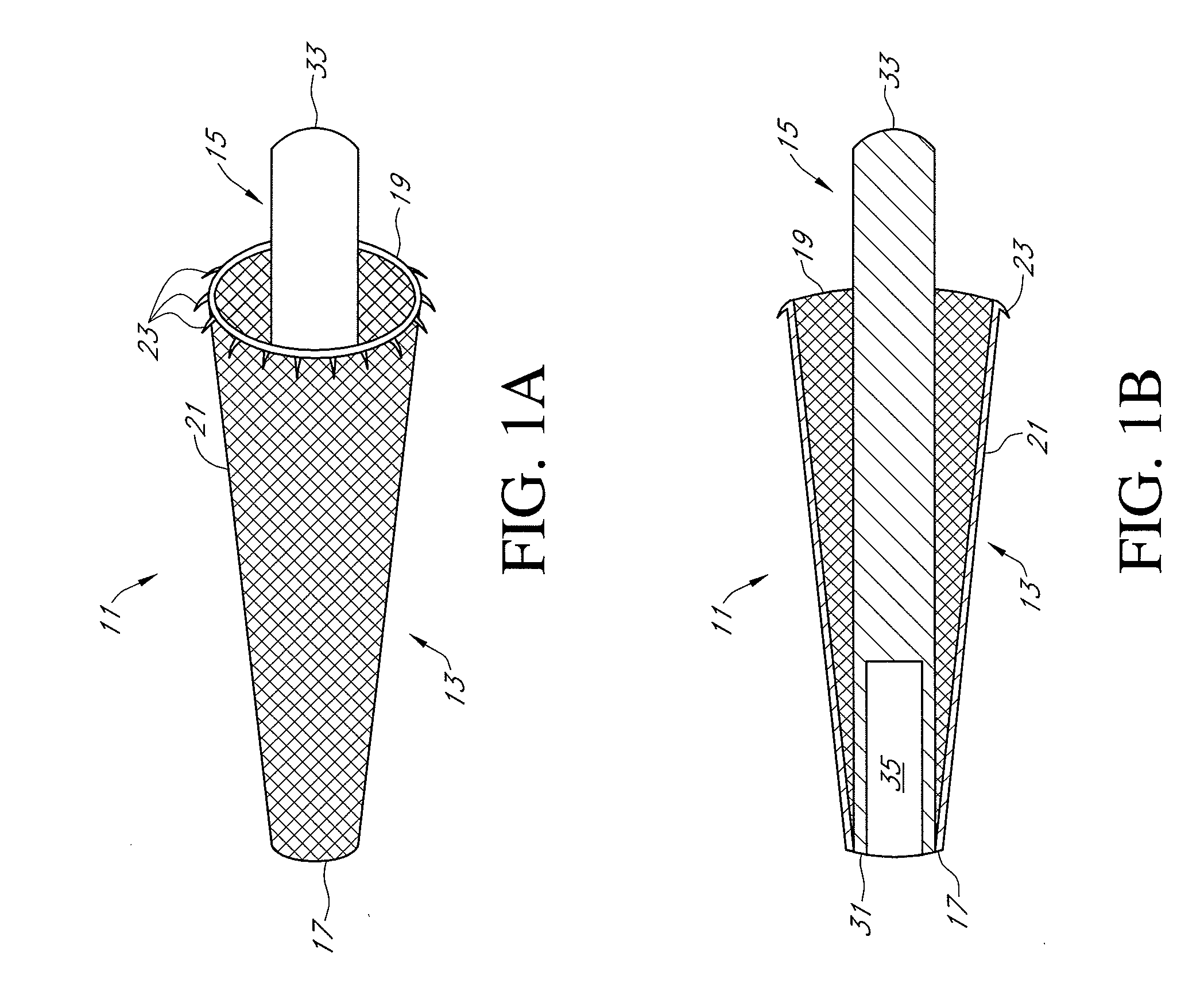

Methods, systems and devices for performing gynecological procedures. According to one embodiment, there is provided a device for occluding a fallopian tube, the device including an outer member and an inner member. The outer member may be a hollow, frusto-conical structure shaped to include an open proximal end, an open distal end, and a side wall. The outer member may be self-expandable such that the distal end is biased radially outwardly. In addition, the side wall may have a porous structure to permit the ingrowth of tissue therethrough. Tines may be provided on the outer surface of the side wall to promote the anchoring of the outer member in a fallopian tube. The inner member, which may be structured to induce scarring, may comprise an elongated fibrous body fixed at its proximal end to the proximal end of the outer member. A bore may extend distally from the proximal end of the inner member to receive a delivery rod. The inner member, which may have pores or interstices to permit the ingrowth of tissue thereinto, is coated or impregnated with a sclerosing agent.

Owner:HOLOGIC INC

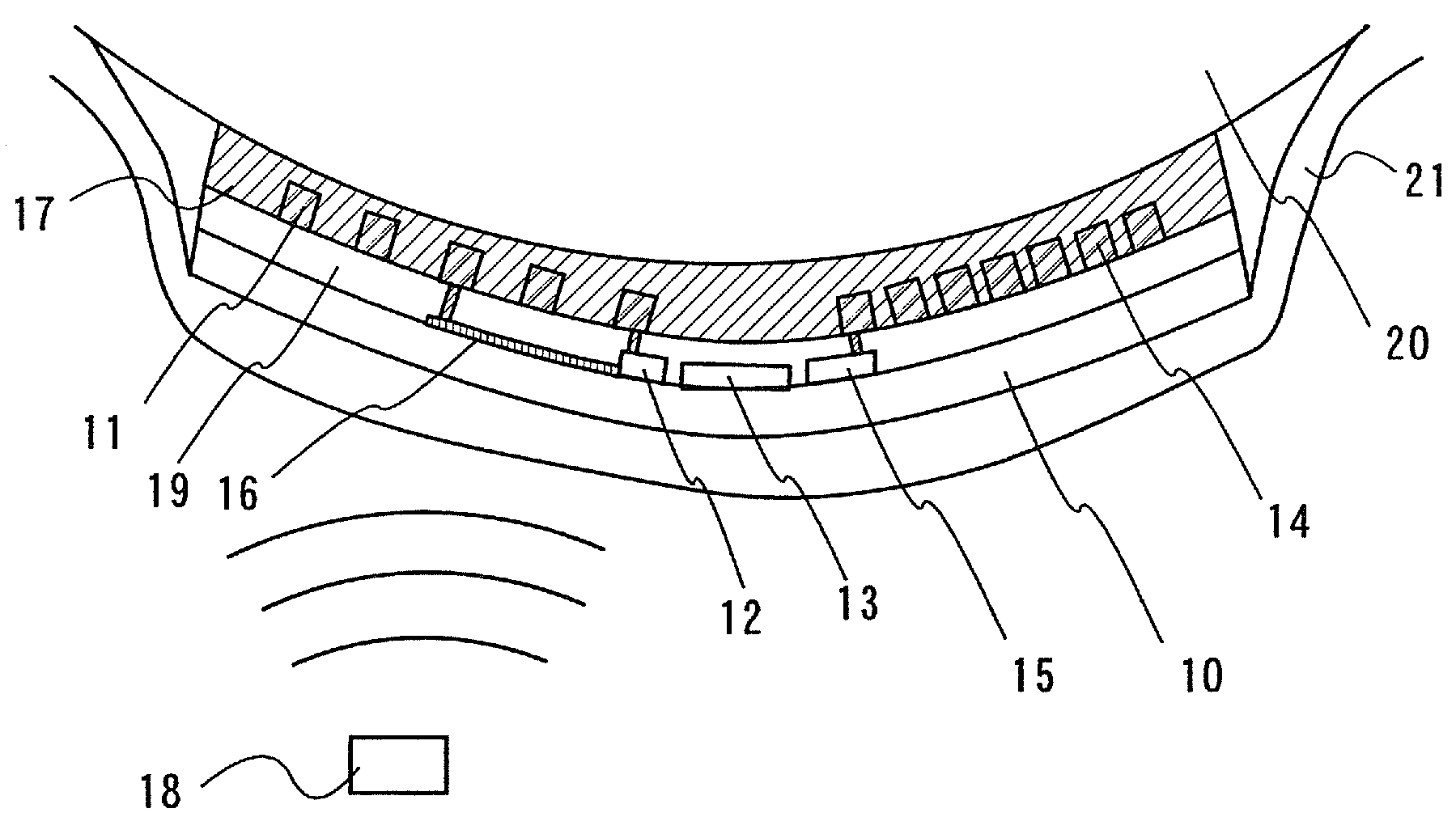

Semiconductor device and heating system

InactiveUS20090071952A1Prevent low temperatureTransistorTransparent/reflecting heating arrangementsFibrous bodyLiving body

A device that warms a surface of a living body required to be warmed at an appropriate timing at any place indoors and outdoors or the sea without causing low temperature burns. A sheet having a heat generating function including a circuit capable of receiving electric power without contact over a sheet containing plastic or a fibrous body, a heat generating circuit, and a circuit that controls the temperature of the heat generating circuit is manufactured. The user with the sheet transmits the radio signal from the transmission device outdoors or indoors to heat the heat generating circuit on the sheet and the heat can be conducted to the skin of the user. Temperature can be automatically adjusted by the circuit for controlling the temperature of the heat generating circuit.

Owner:SEMICON ENERGY LAB CO LTD

Alkaline impregnated filter element, and methods

InactiveUS20060042209A1Extended service lifeSolution to short lifeDispersed particle filtrationMembrane filtersFibrous bodyPotassium iodine

A contaminant-removal filter for removing acidic contaminants from a gas stream, such as air. The filter has a porous or fibrous body that includes a plurality of passages extending from a first, inlet face to a second, outlet face, the passages providing flow paths. The body has a base or alkaline material, such as potassium carbonate, and a promoter, such as potassium iodide, impregnated throughout the substrate. The filter is free of any humectants.

Owner:DONALDSON CO INC

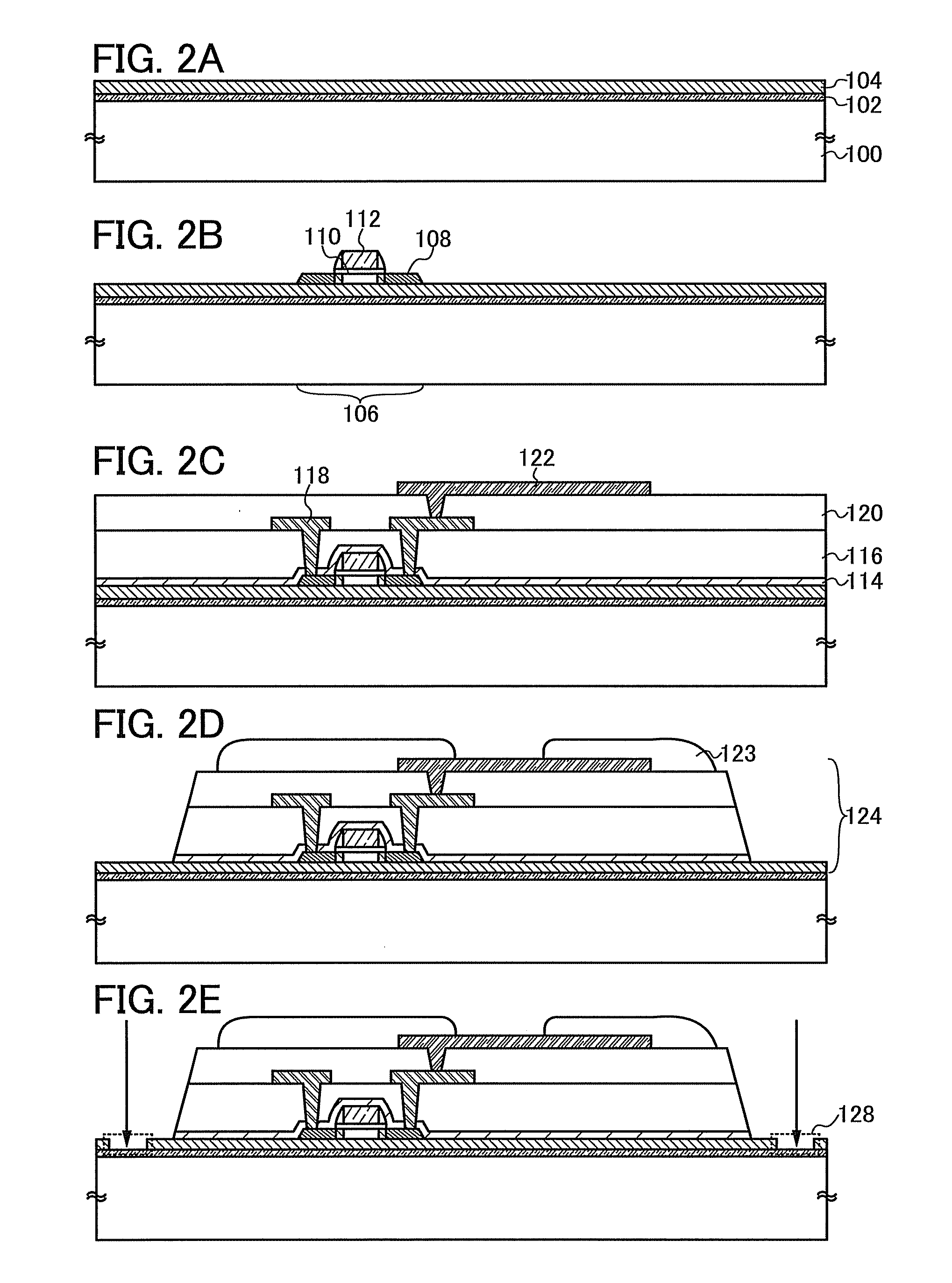

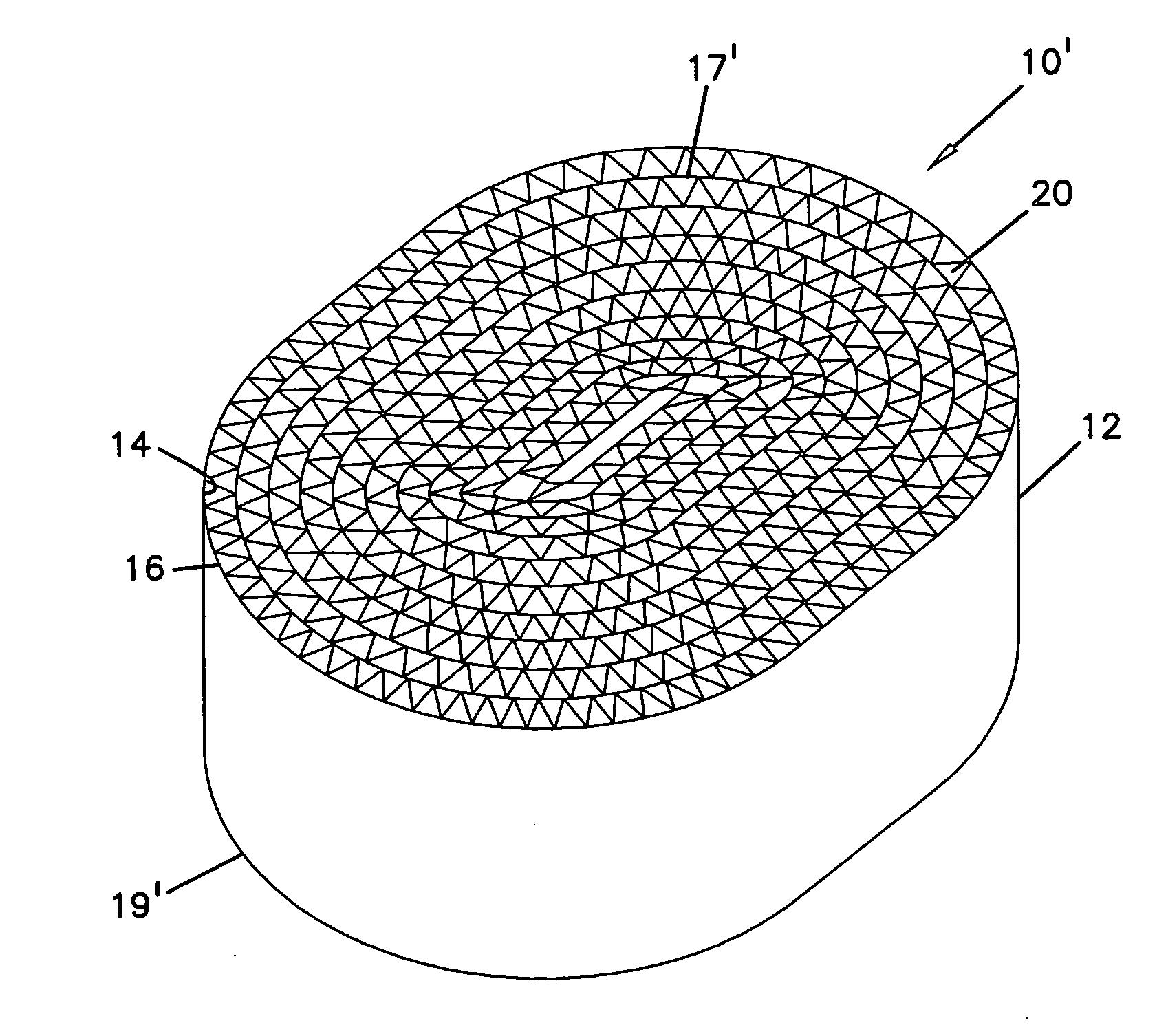

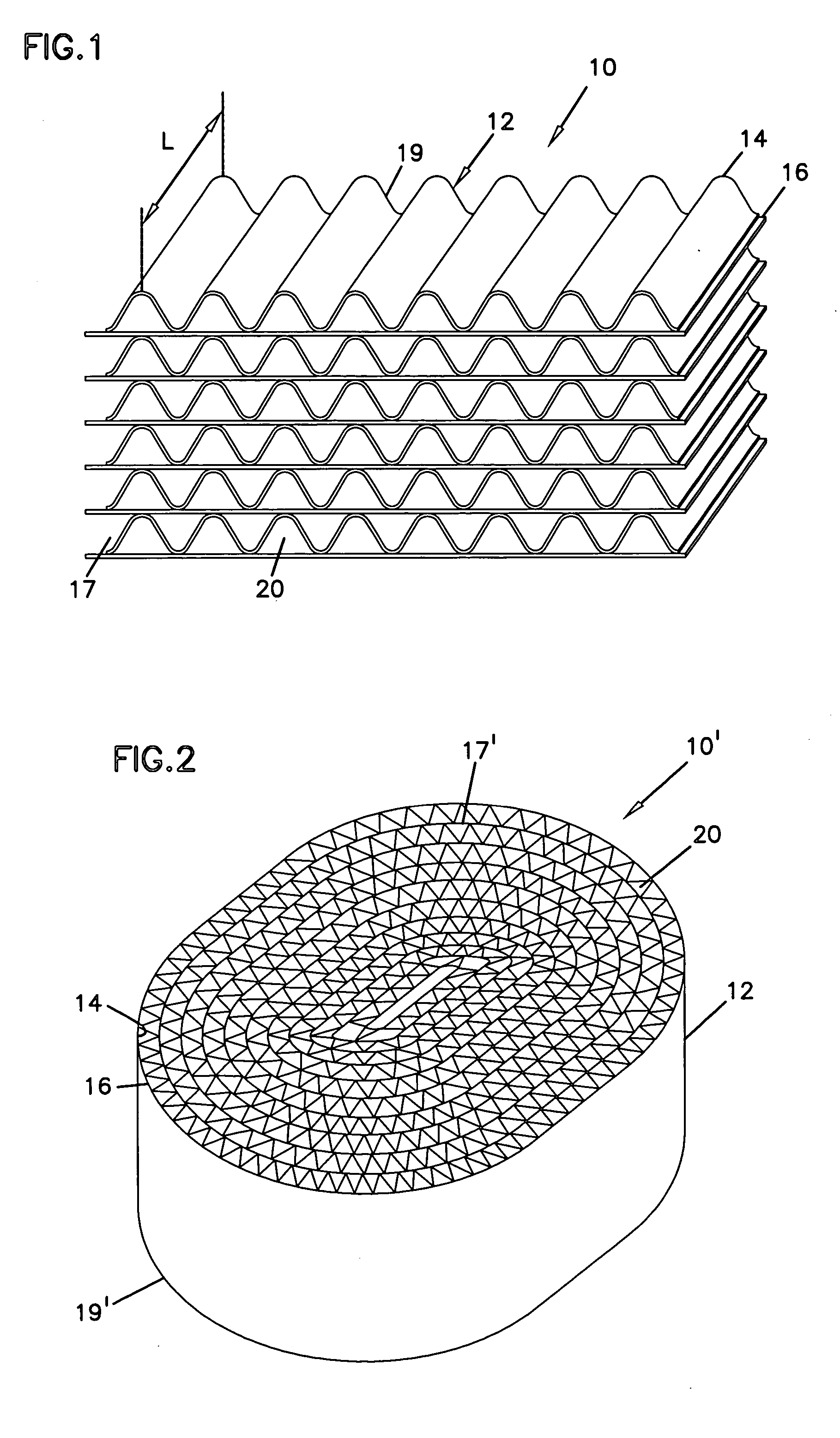

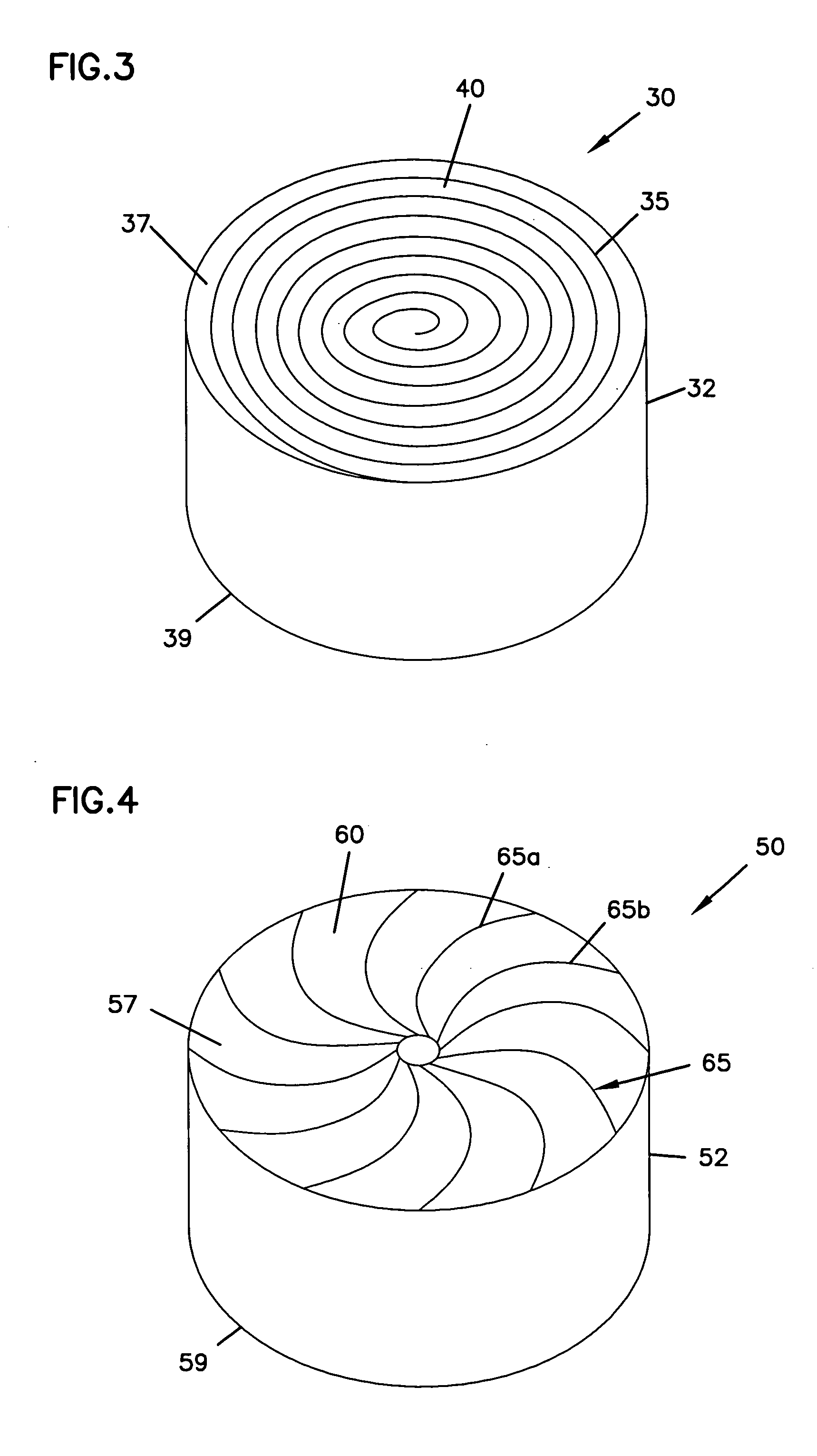

Semiconductor device

InactiveUS20080303140A1Improve reliabilityHigh modulusSemiconductor/solid-state device detailsSolid-state devicesInorganic compoundFibrous body

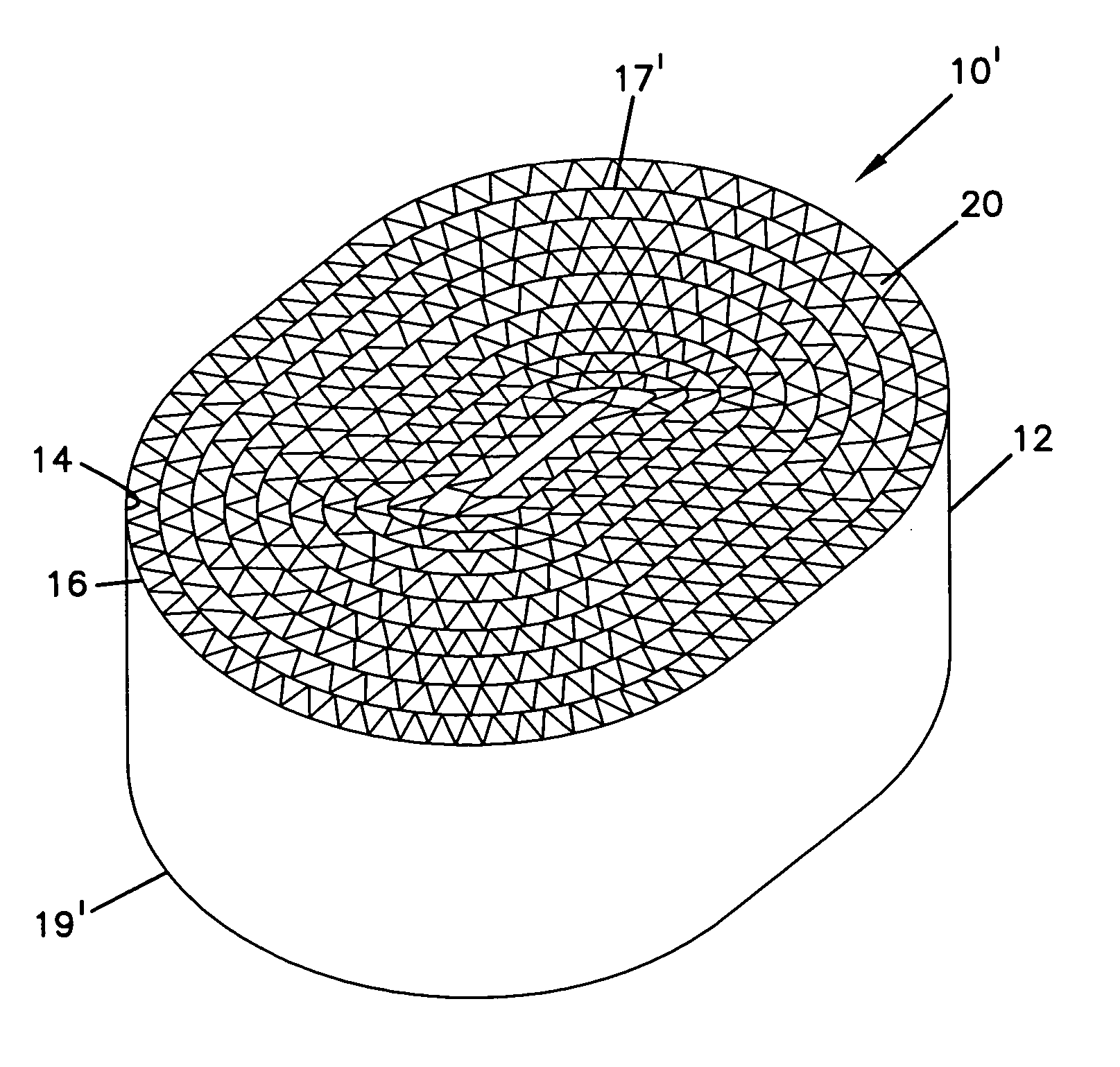

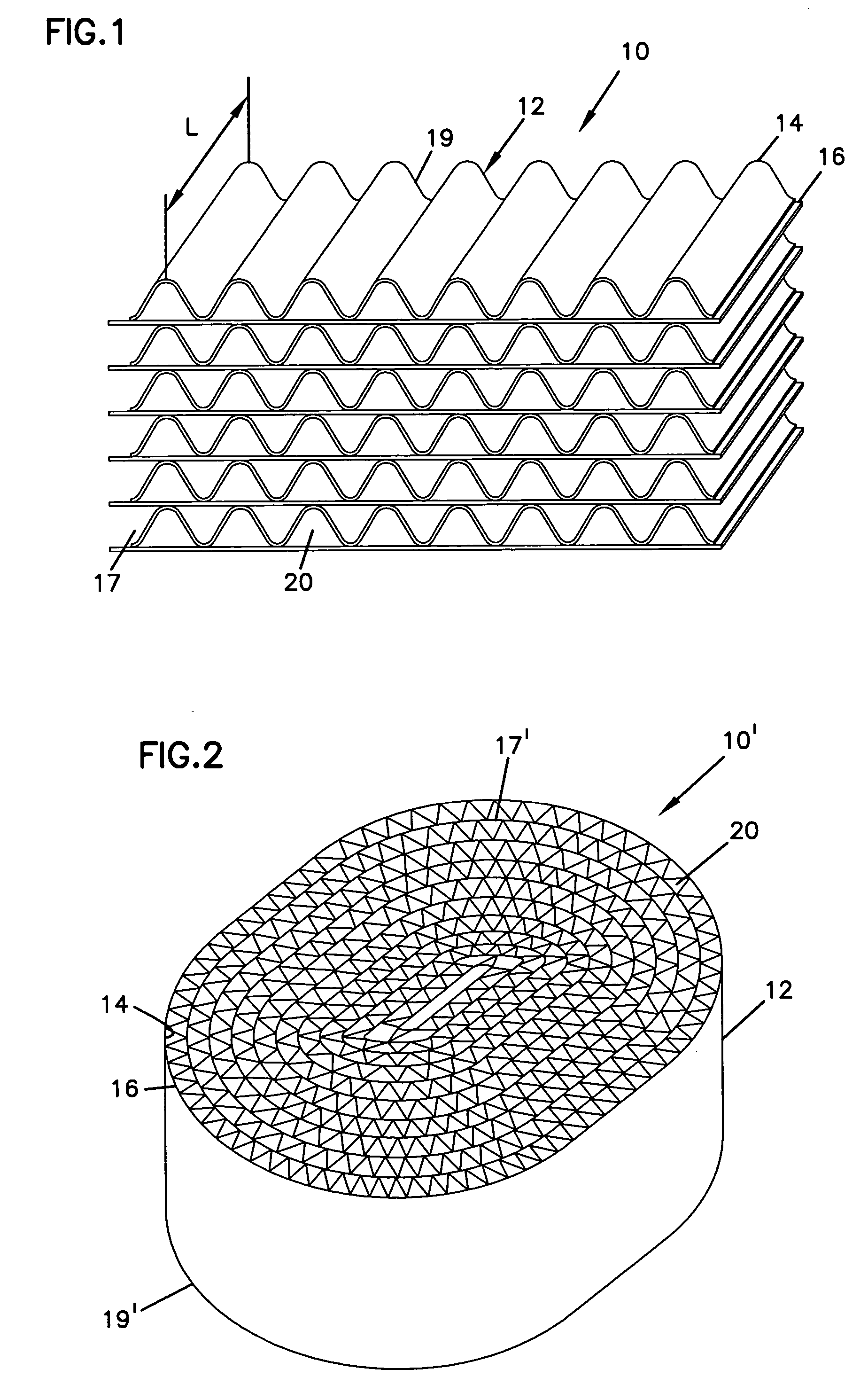

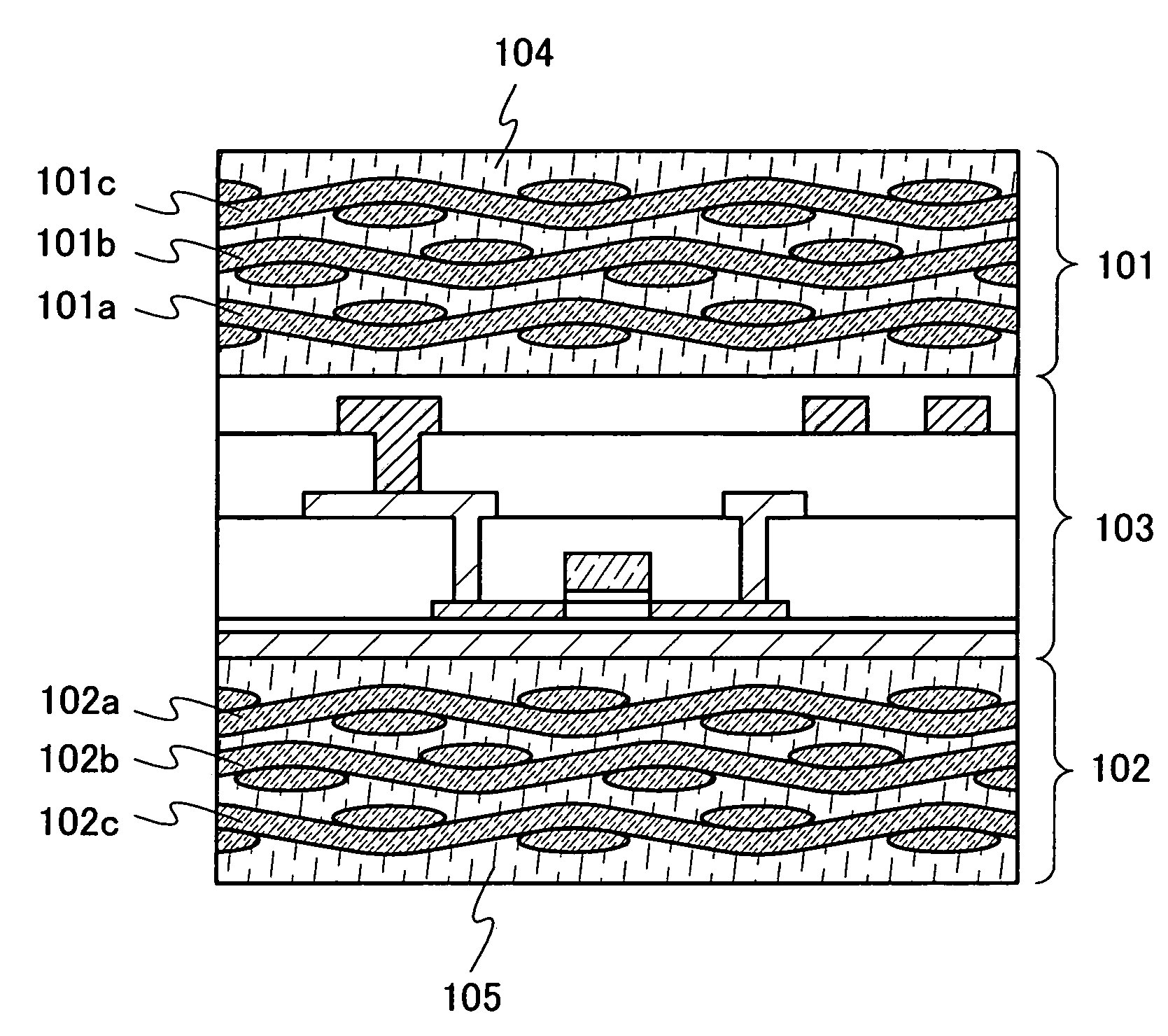

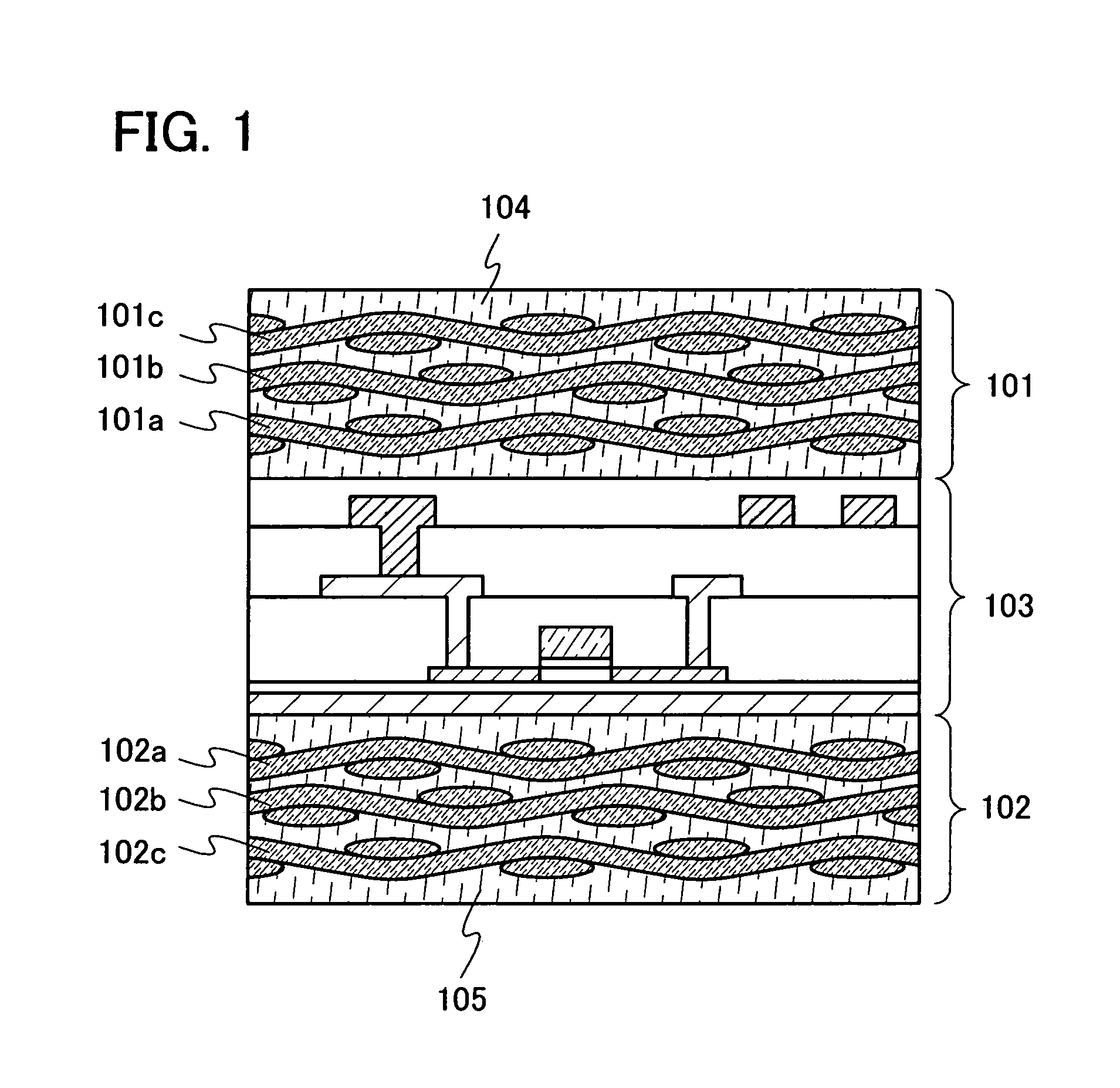

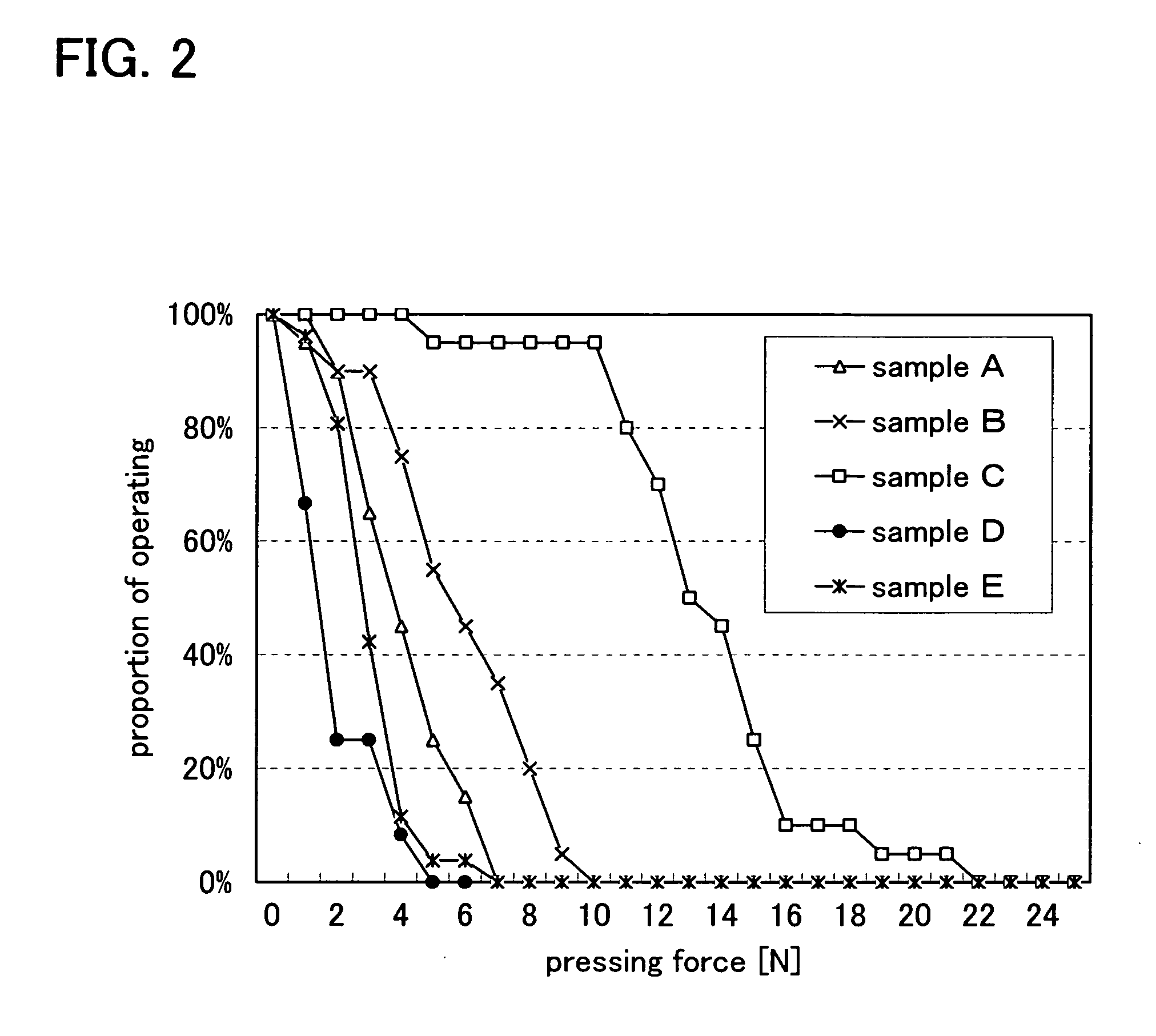

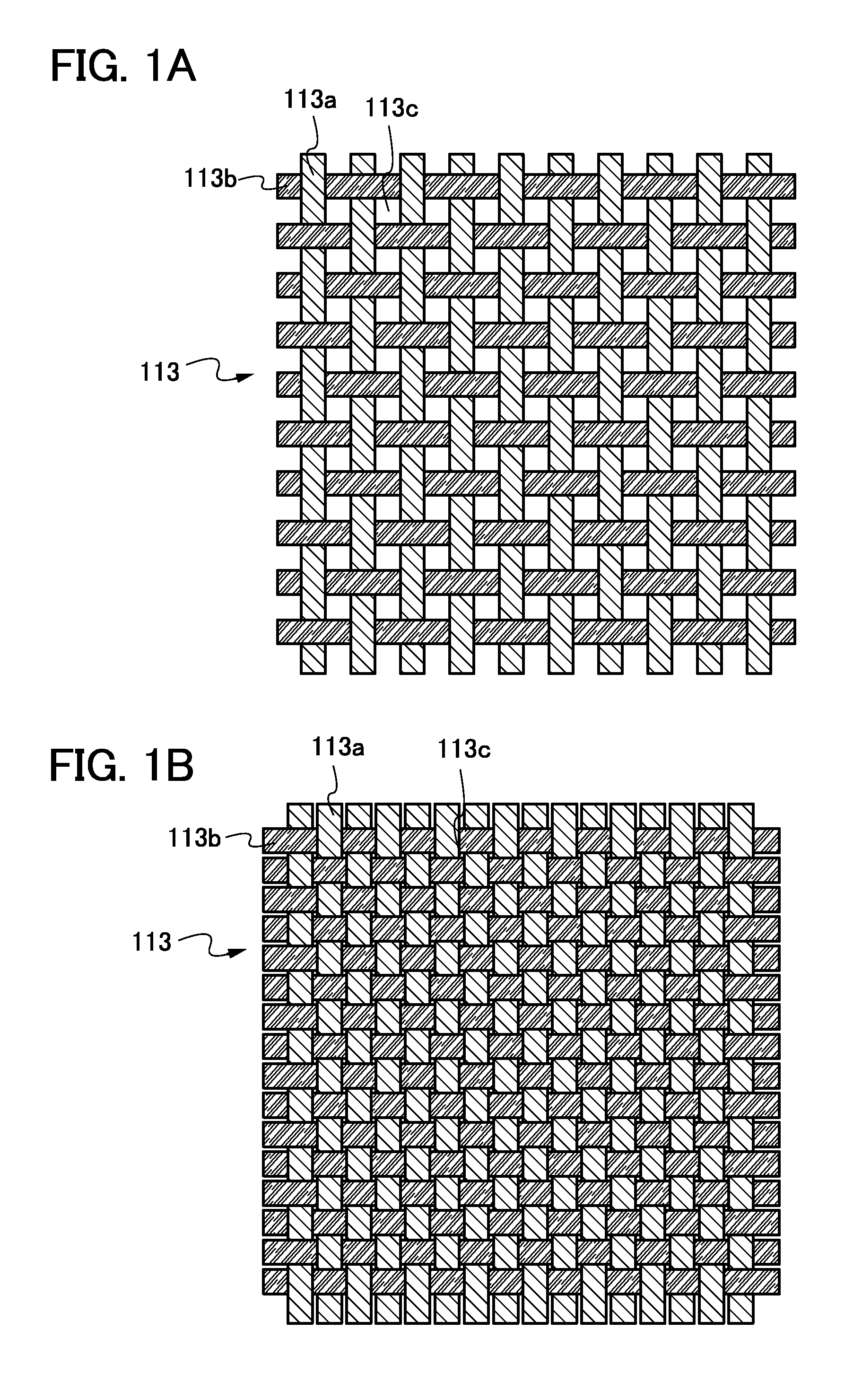

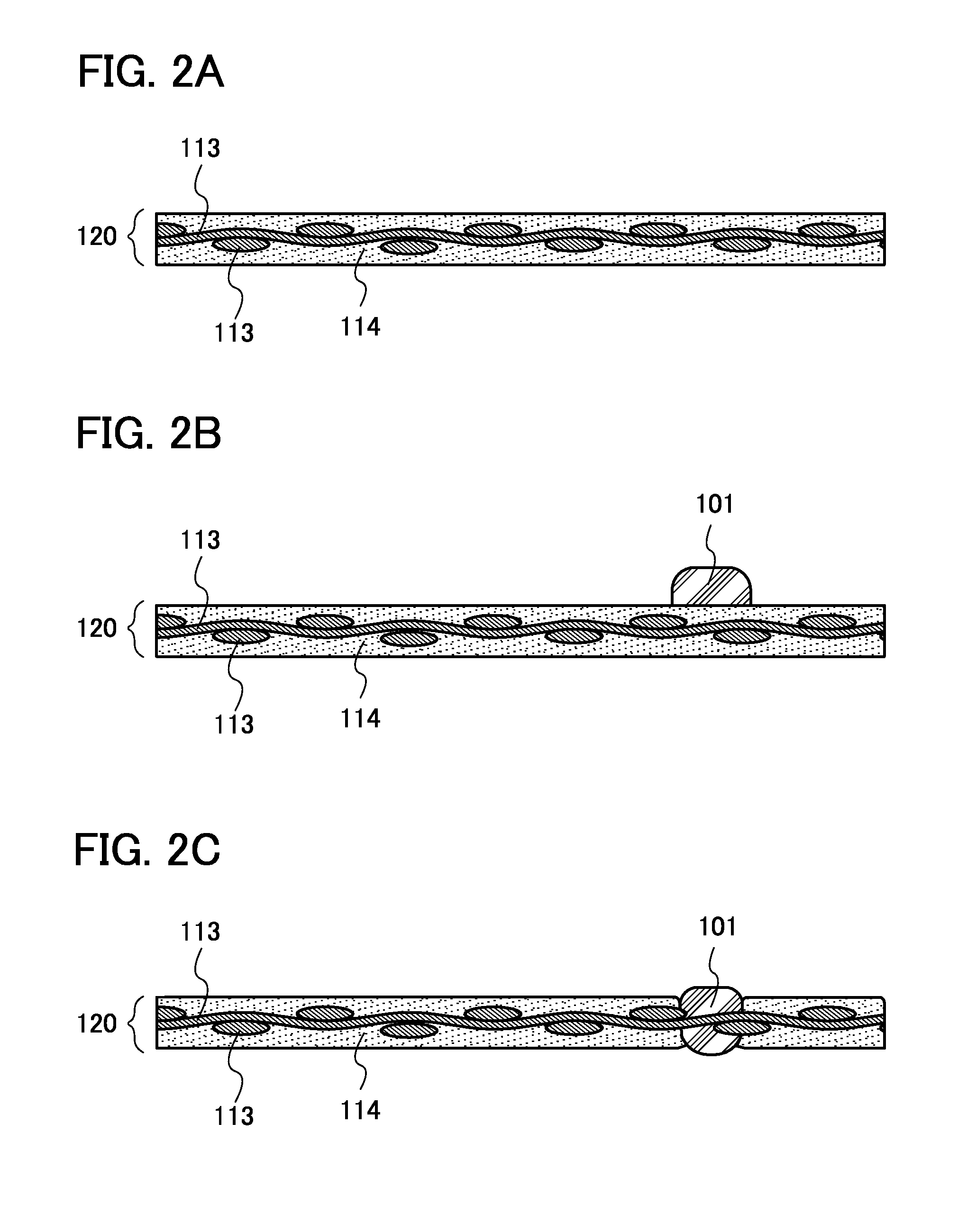

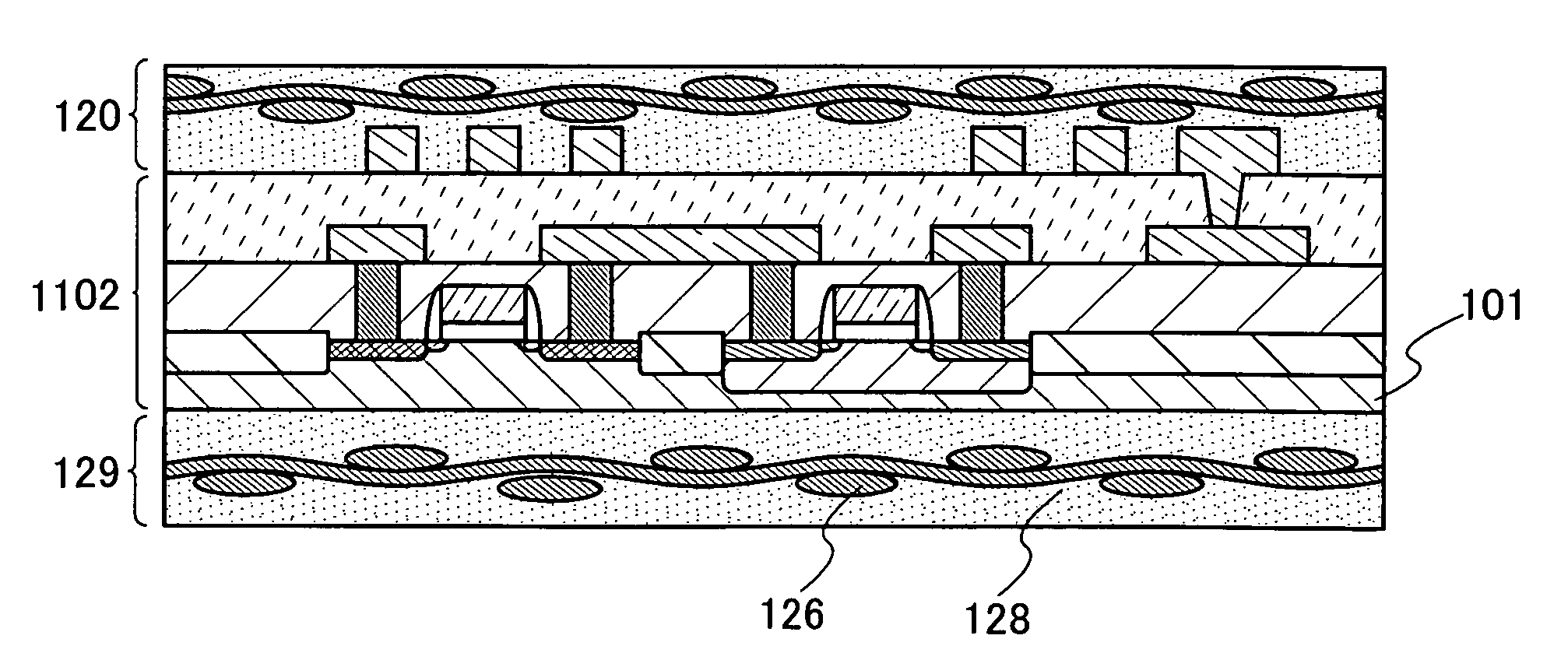

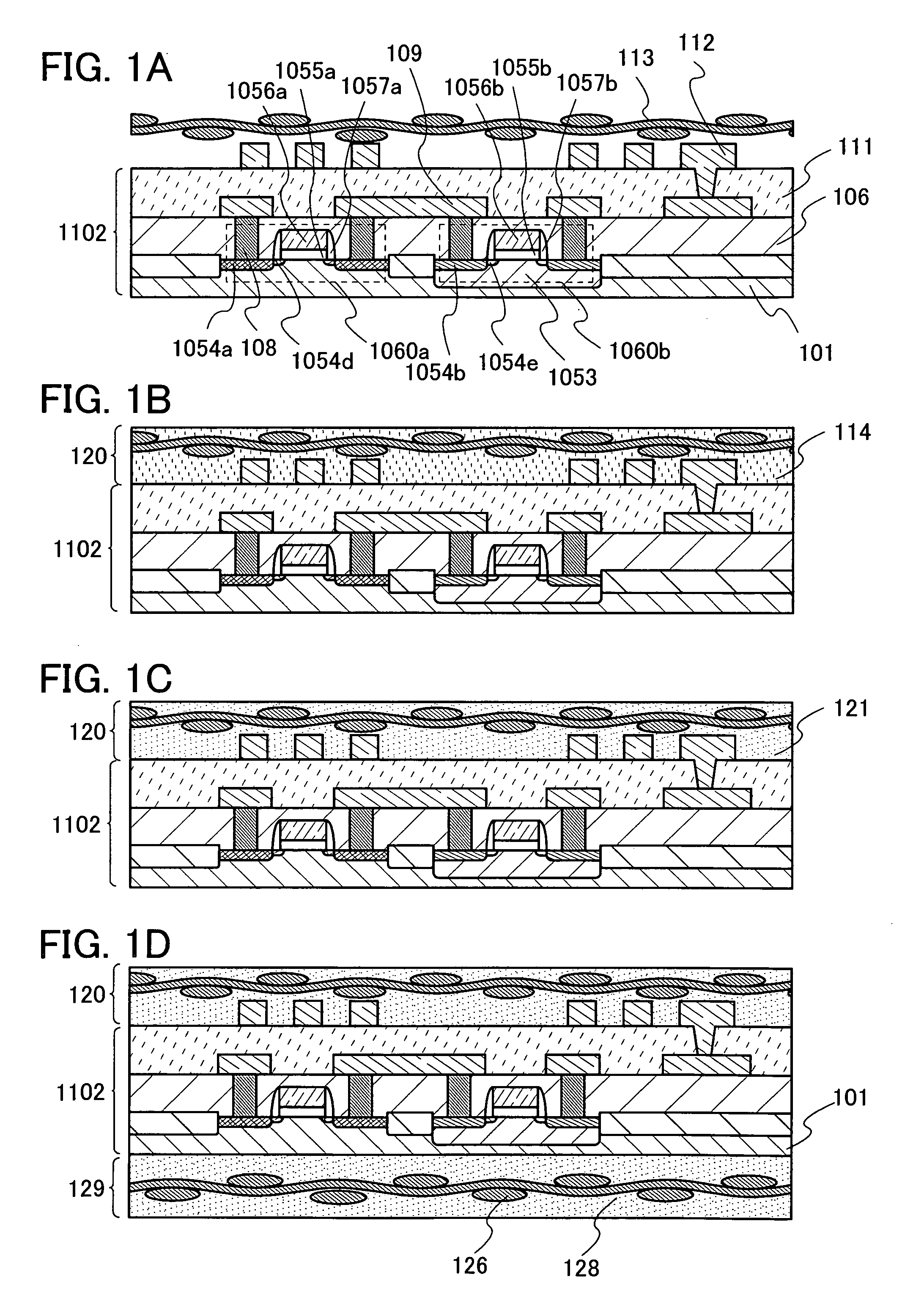

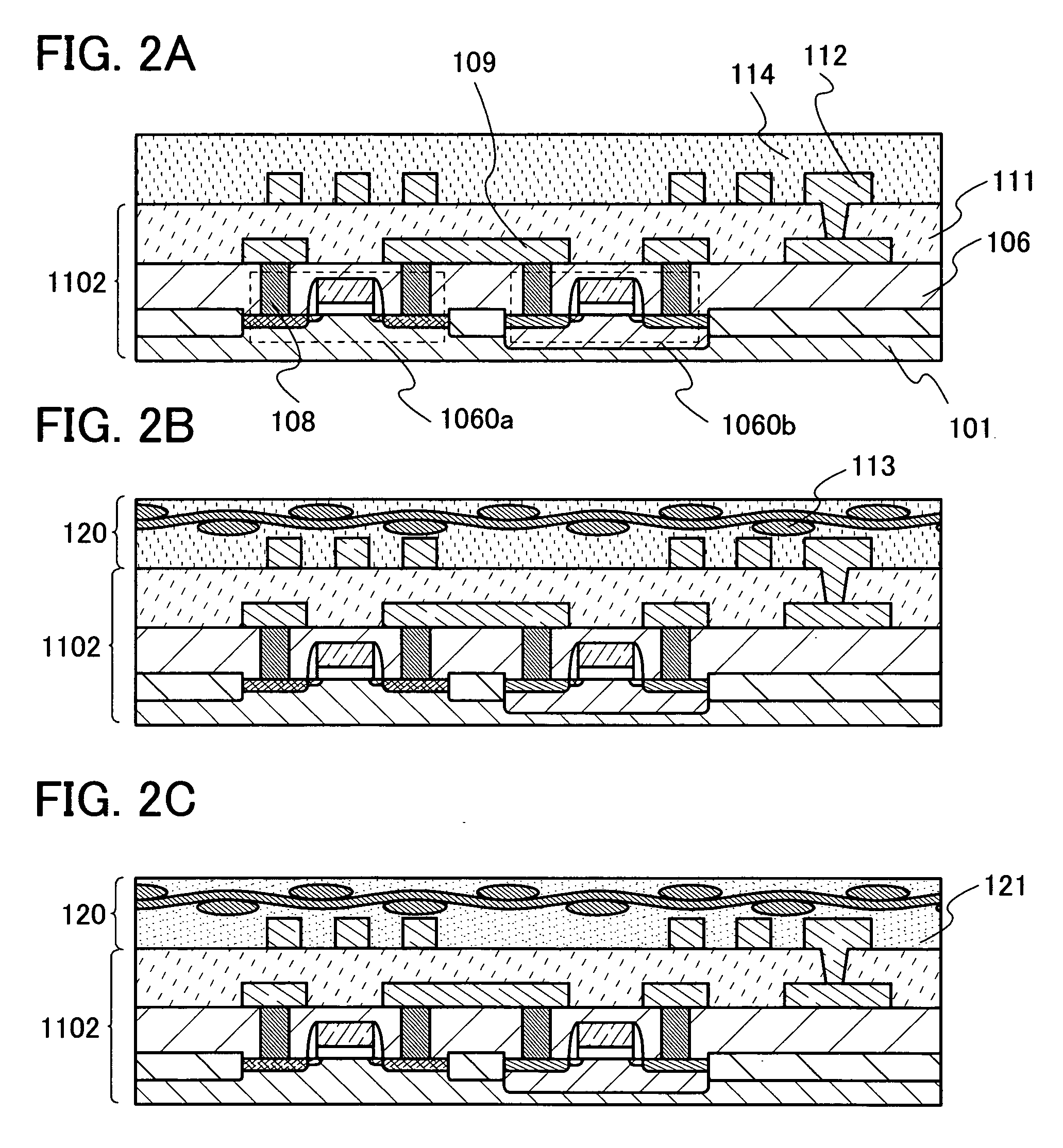

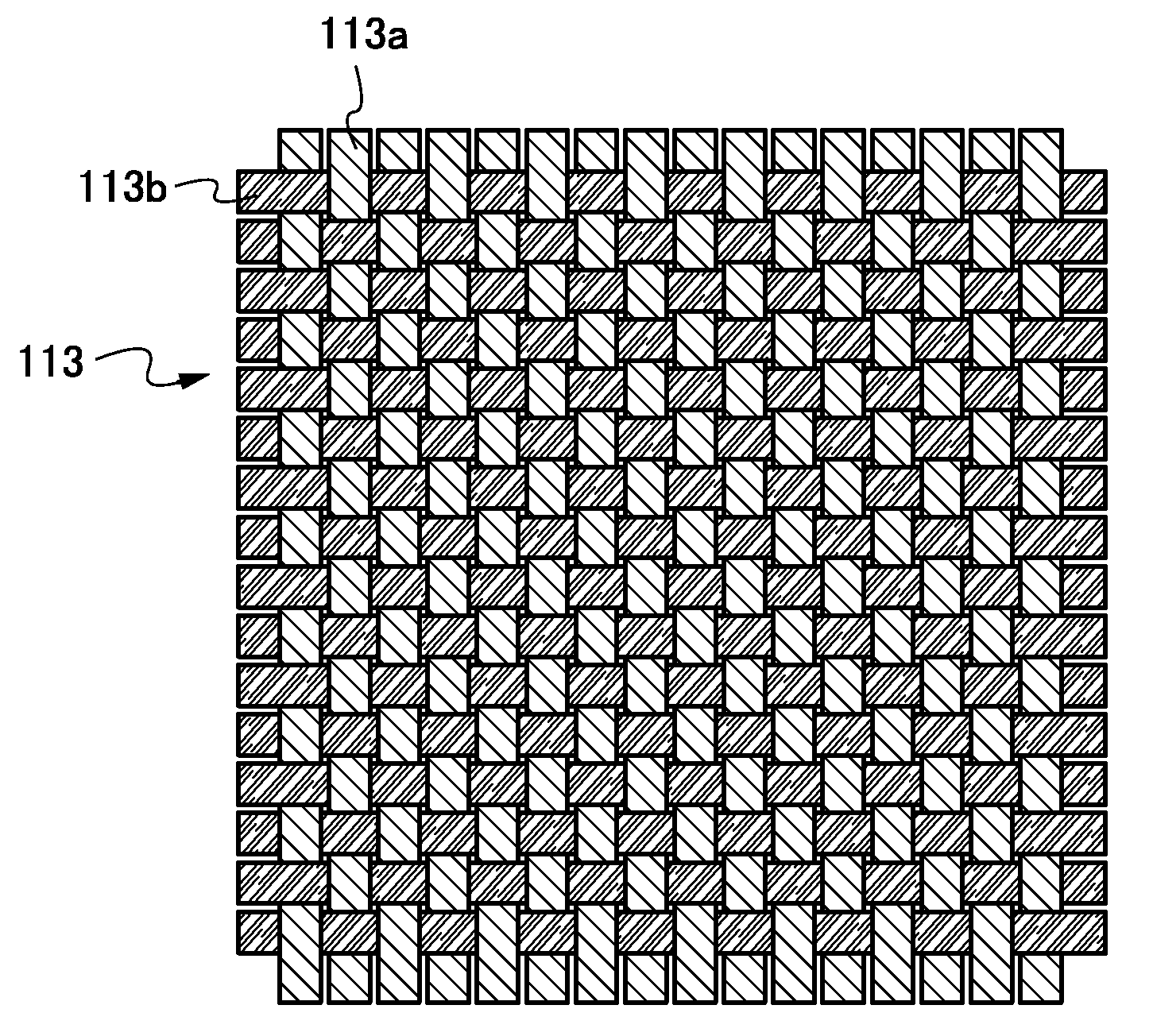

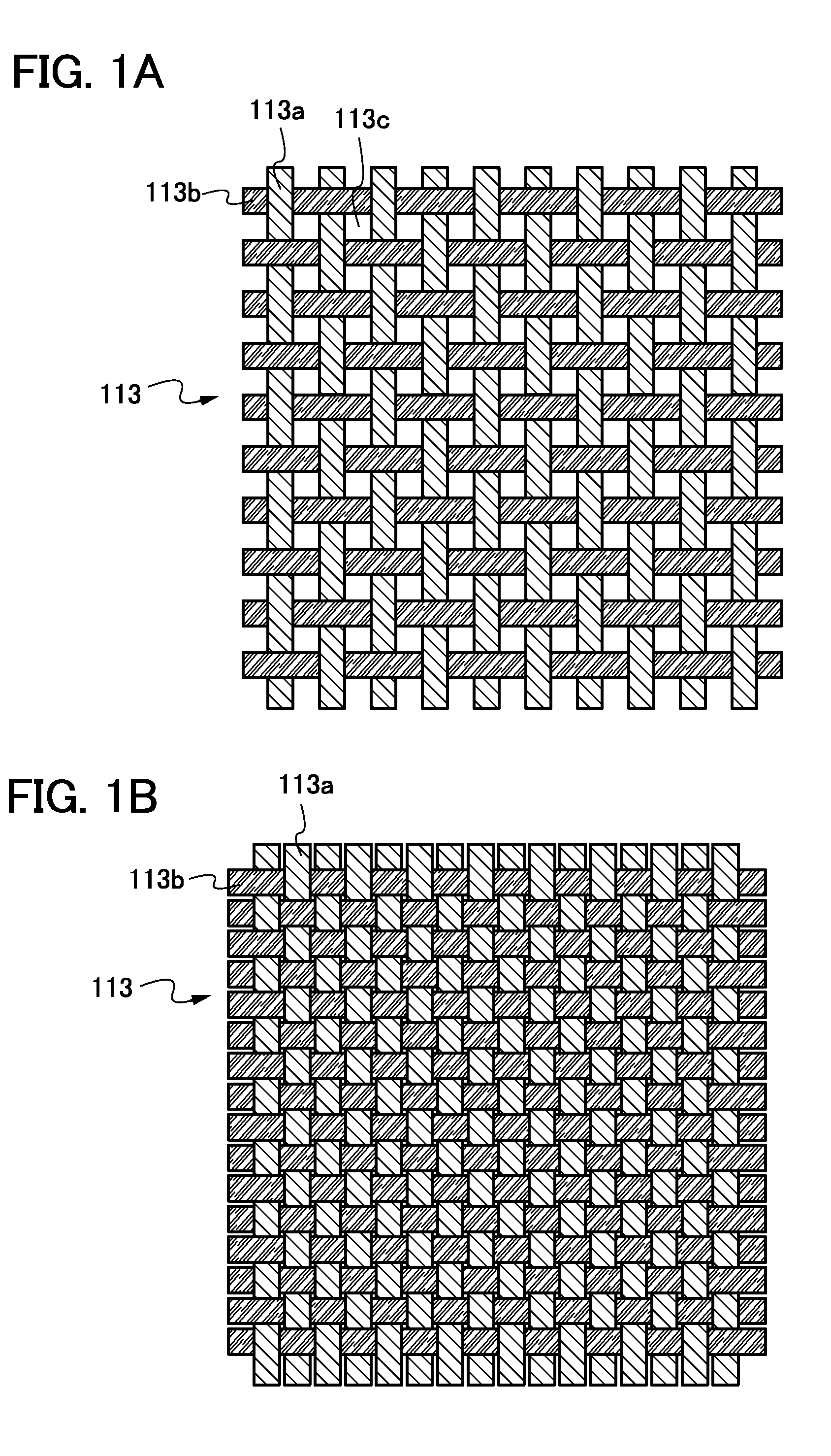

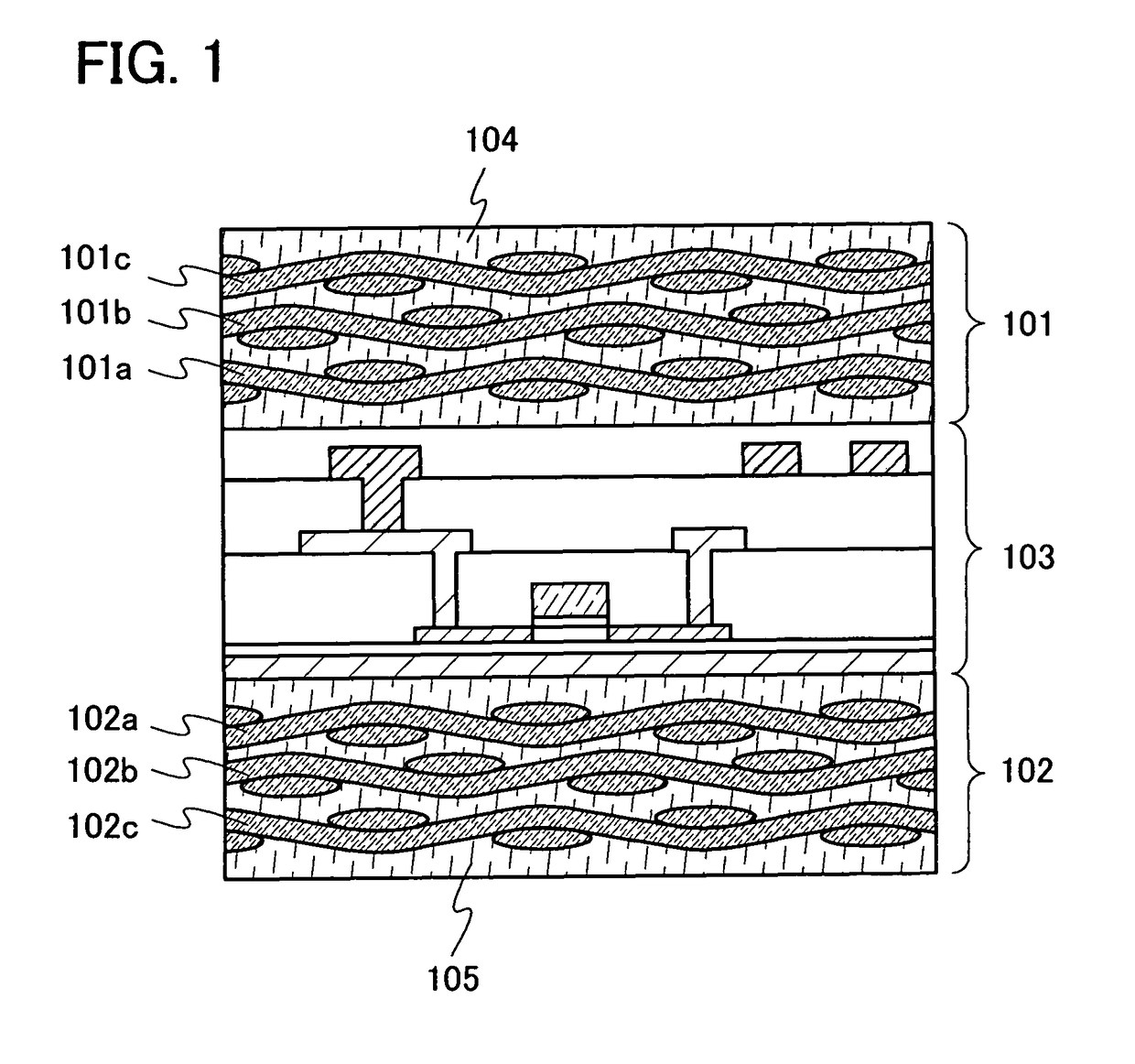

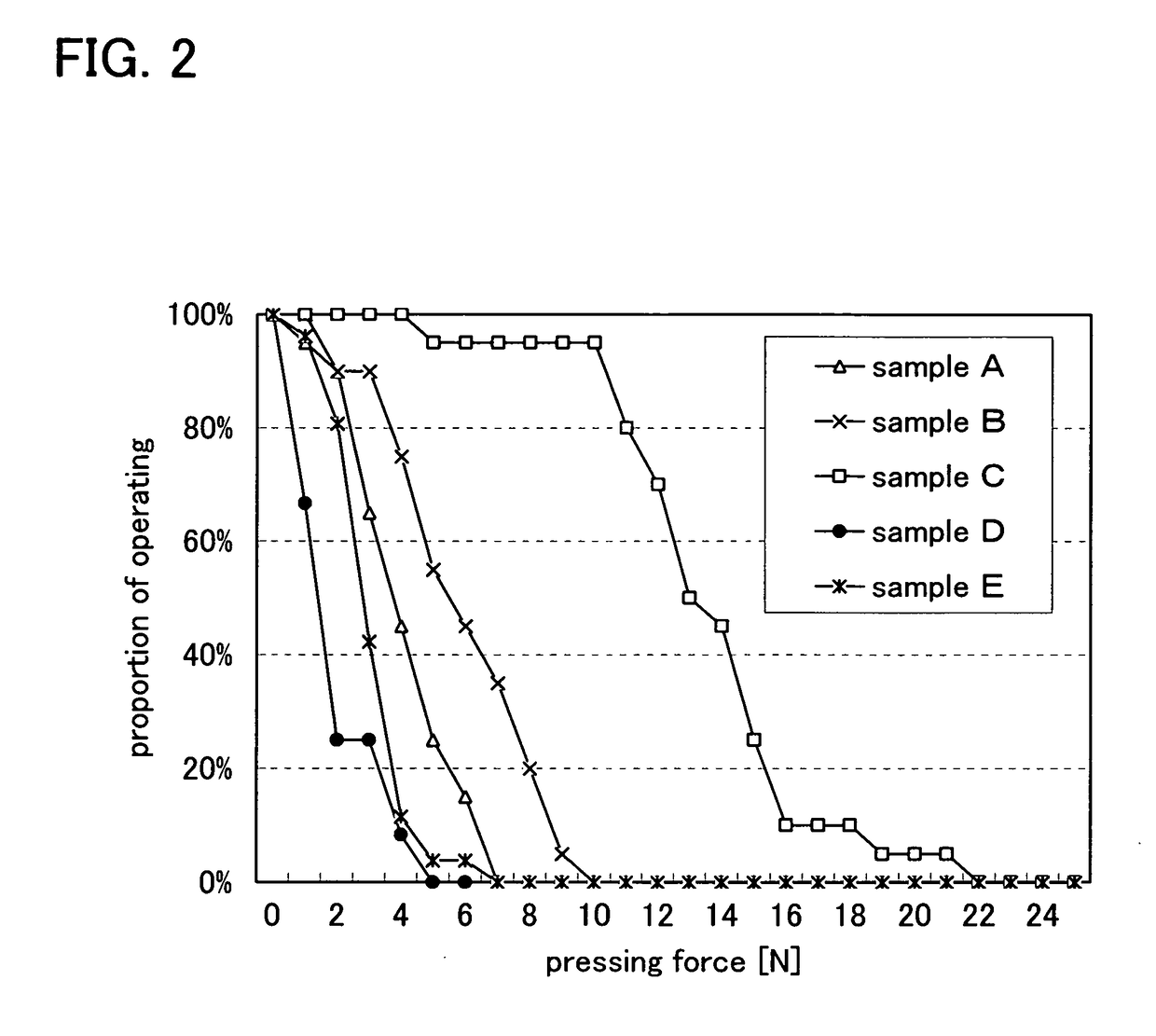

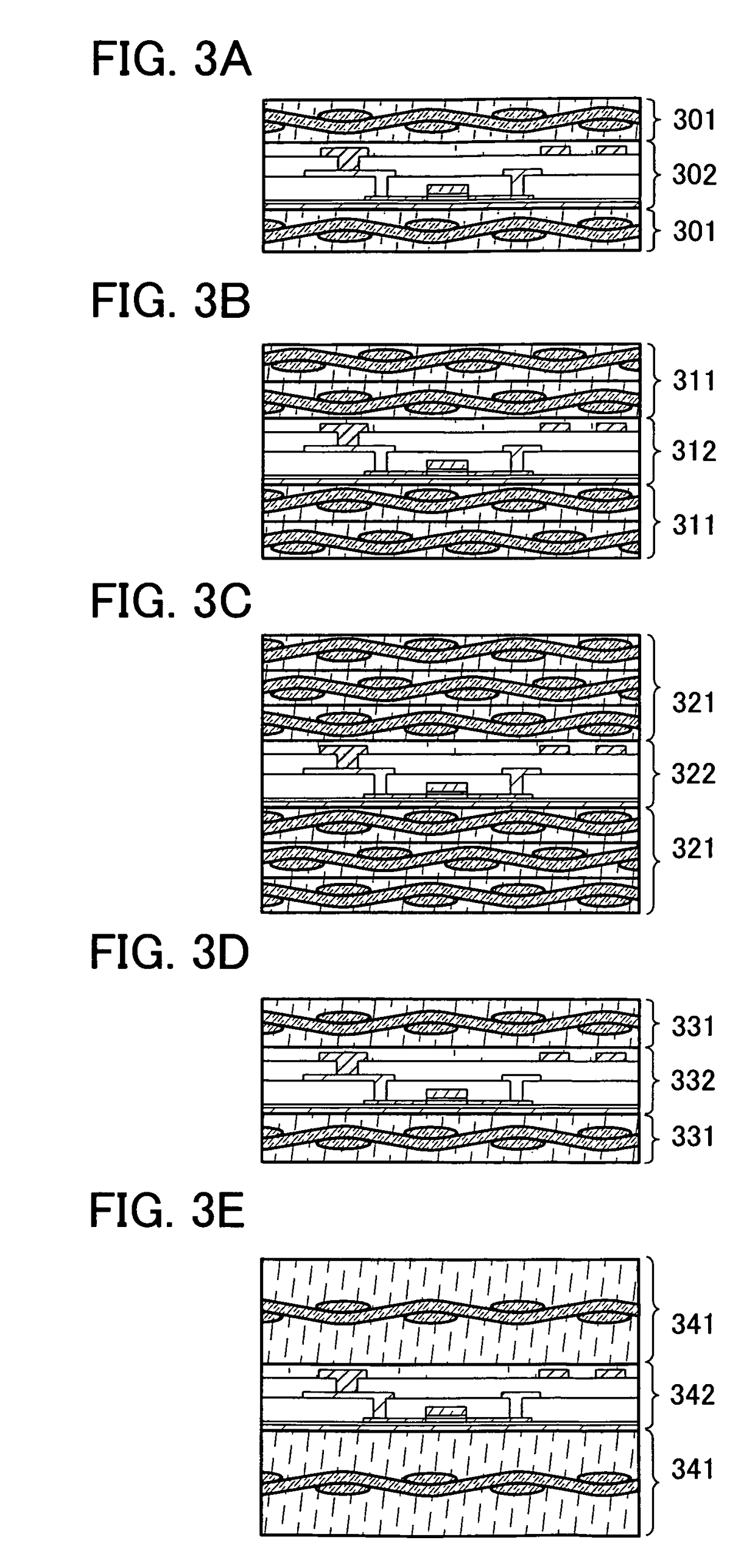

To provide a semiconductor device which can increase reliability with respect to external force, especially pressing force, while the circuit size or the capacity of memory is maintained. A pair of structure bodies each having a stack of fibrous bodies of an organic compound or an inorganic compound, which includes a plurality of layers, especially three or more layers, is impregnated with an organic resin, and an element layer provided between the pair of structure bodies are included. The element layer and the structure body can be fixed to each other by heating and pressure bonding. Further, a layer for fixing the element layer and the structure body may be provided. Alternatively, the structure body fixed to an element layer can be formed in such a way that after a plurality of fibrous bodies is stacked over the element layer, the fibrous bodies are impregnated with an organic resin.

Owner:SEMICON ENERGY LAB CO LTD

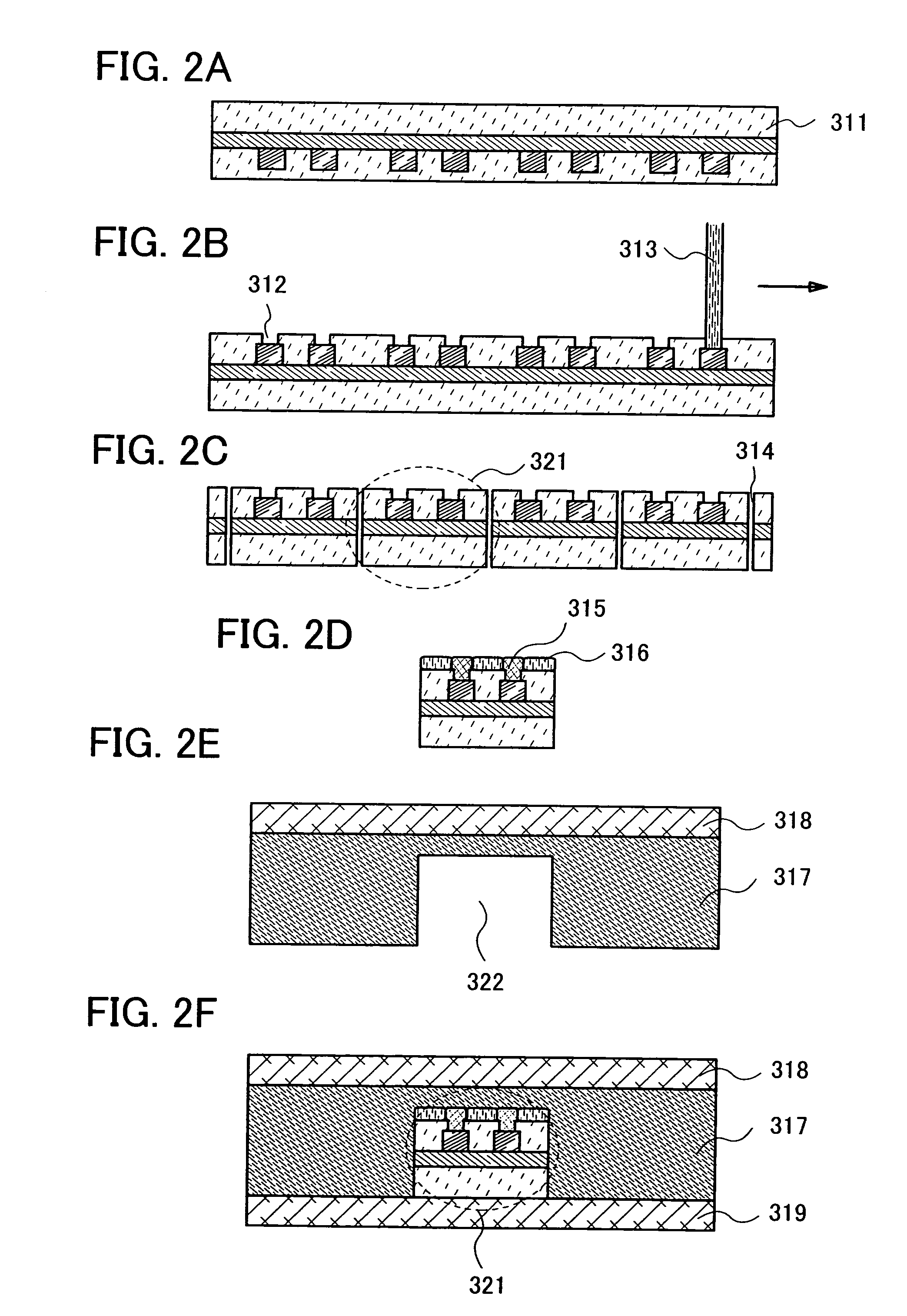

Semiconductor device and method for manufacturing semiconductor device

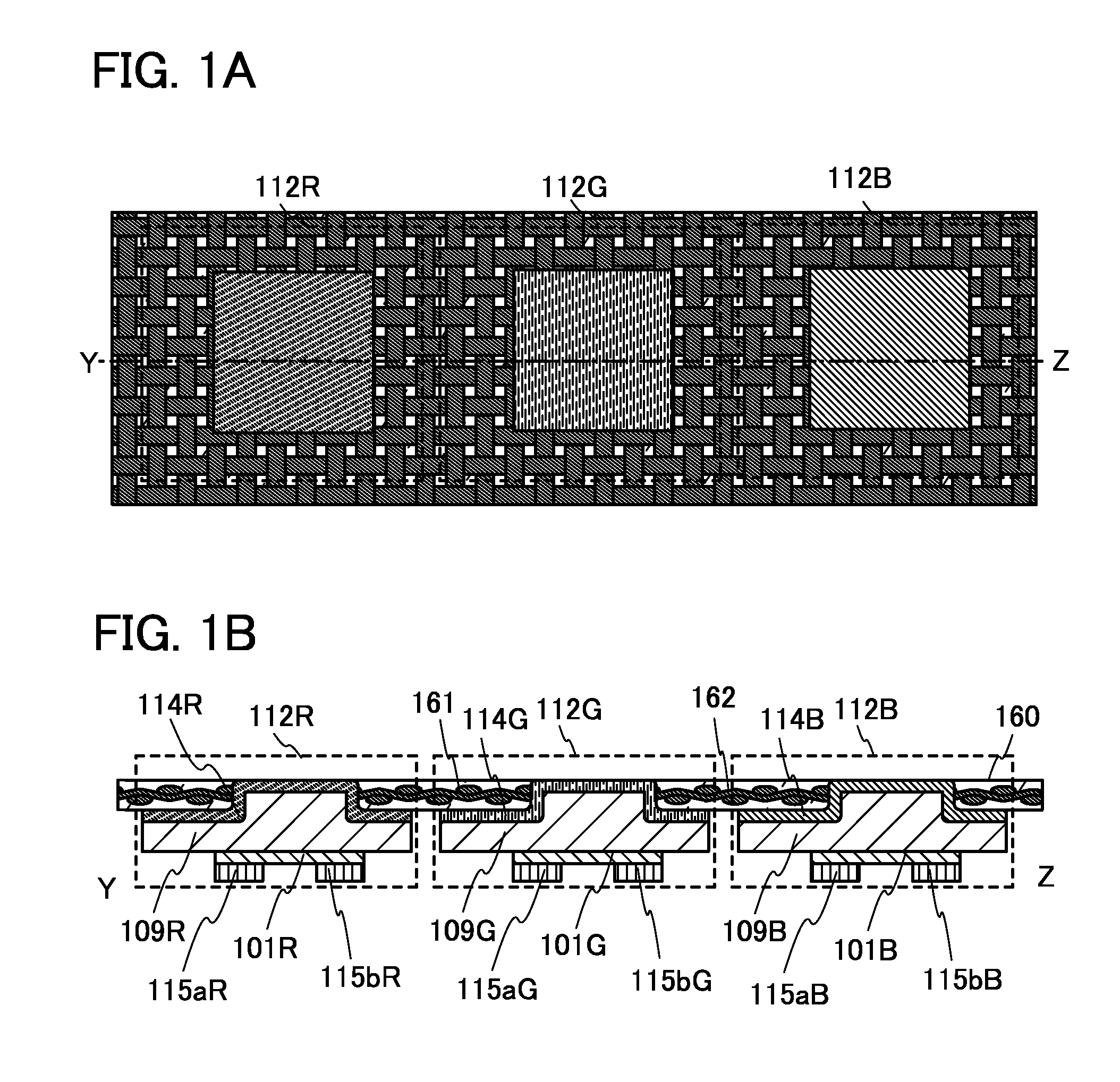

InactiveUS20090267173A1Easy to distinguishReduce misidentificationSolid-state devicesSemiconductor/solid-state device manufacturingFibrous bodyEngineering

A semiconductor device includes a plurality of semiconductor integrated circuits bonded to a structure body in which a fibrous body is impregnated with an organic resin. The plurality of semiconductor integrated circuits are provided at openings formed in the structure body and each include a photoelectric conversion element, a light-transmitting substrate which has stepped sides and in which the width of the projected section on a first surface side is smaller than that of a second surface, a semiconductor integrated circuit portion provided on the second surface of the light-transmitting substrate, and a chromatic color light-transmitting resin layer which covers the first surface and part of side surfaces of the light-transmitting substrate. The plurality of semiconductor integrated circuits include the chromatic color light-transmitting resin layers of different colors.

Owner:SEMICON ENERGY LAB CO LTD

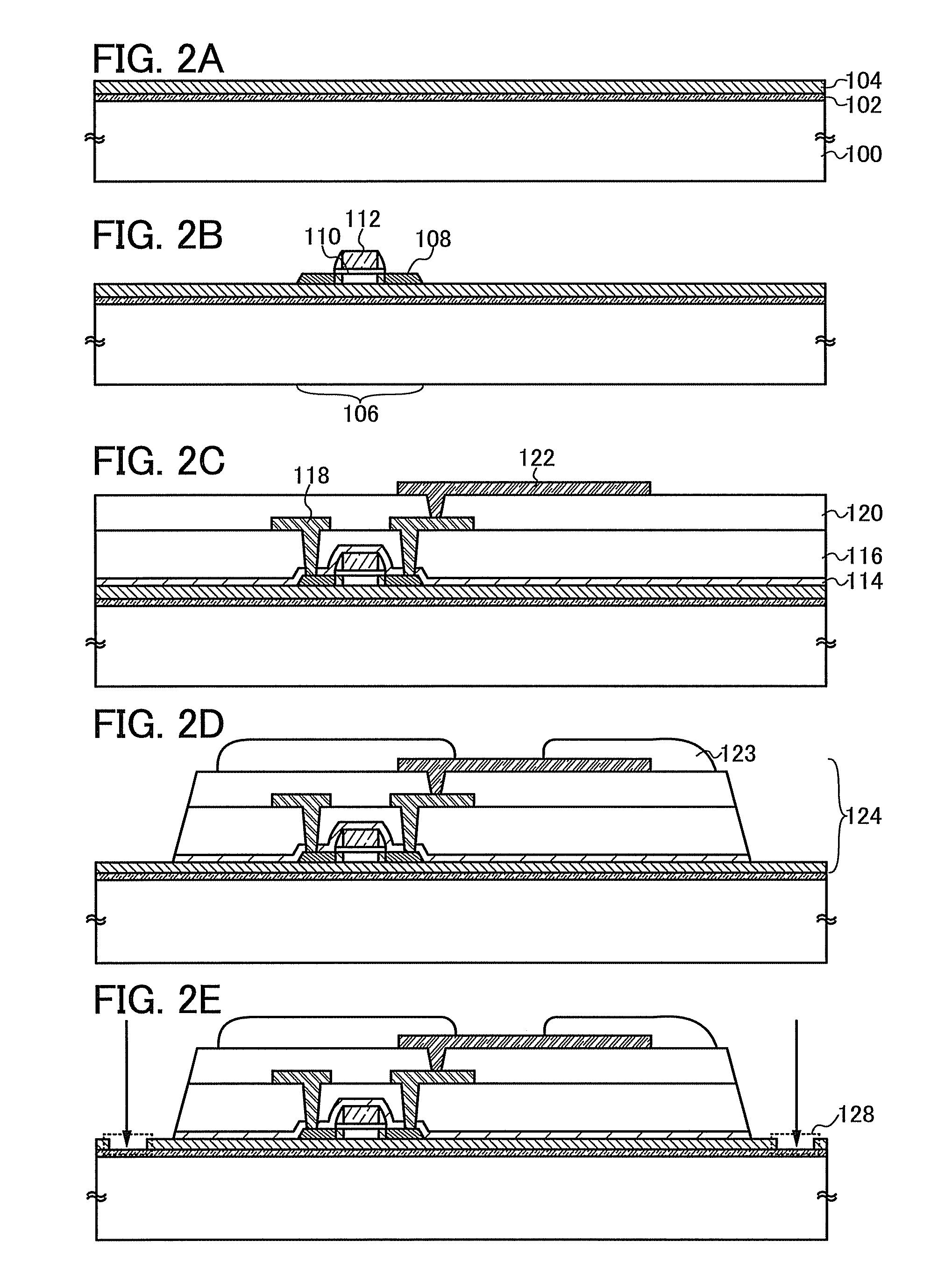

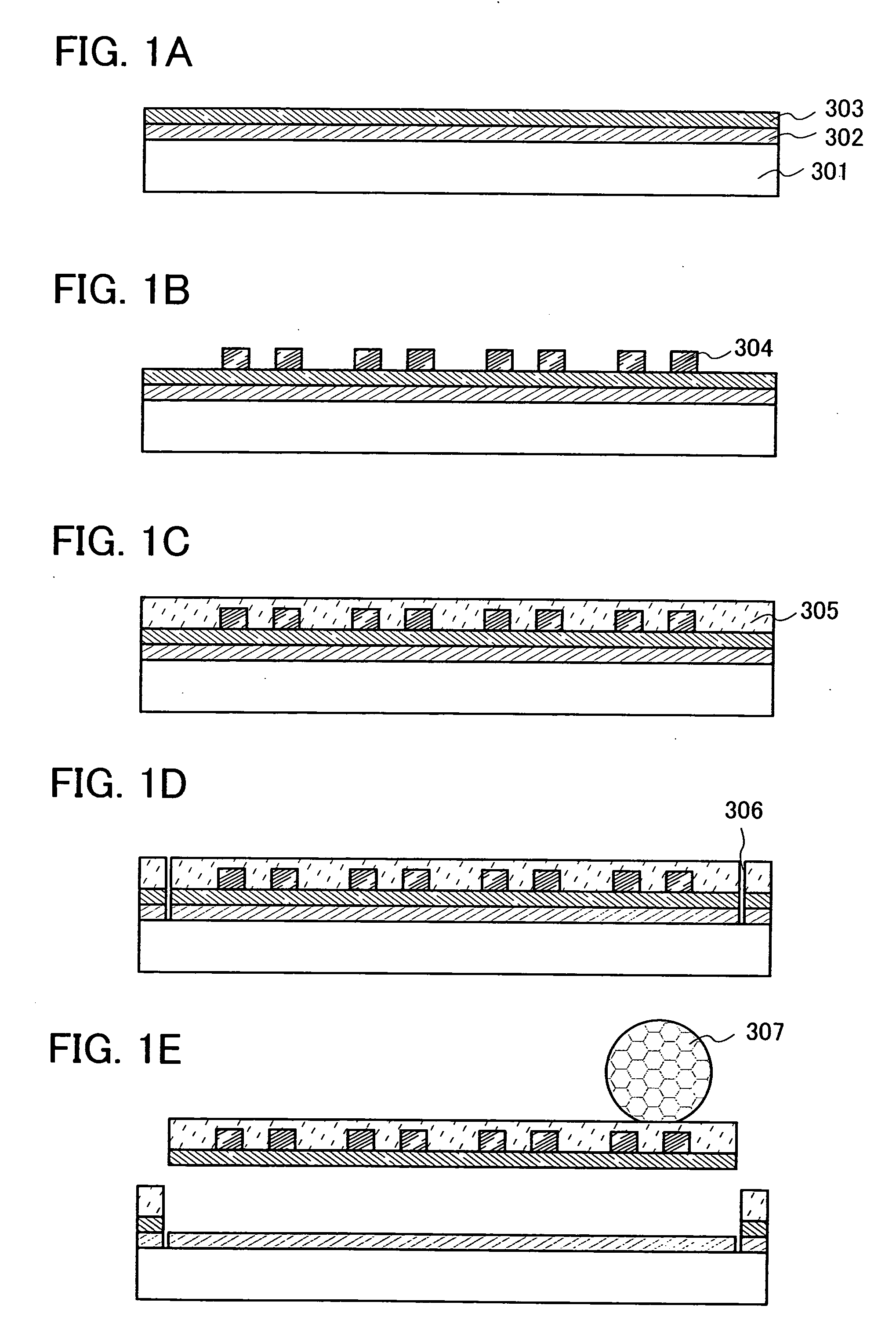

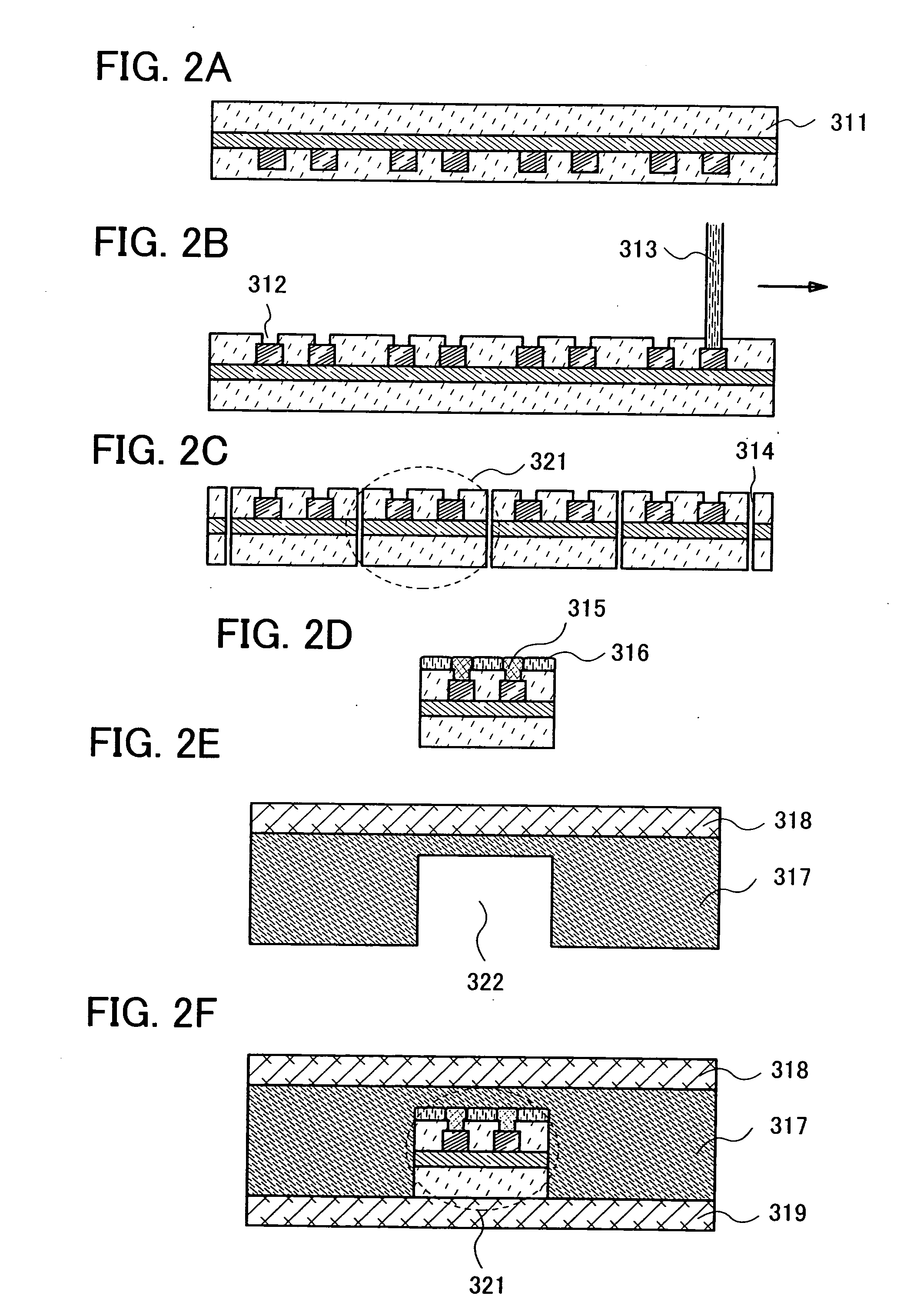

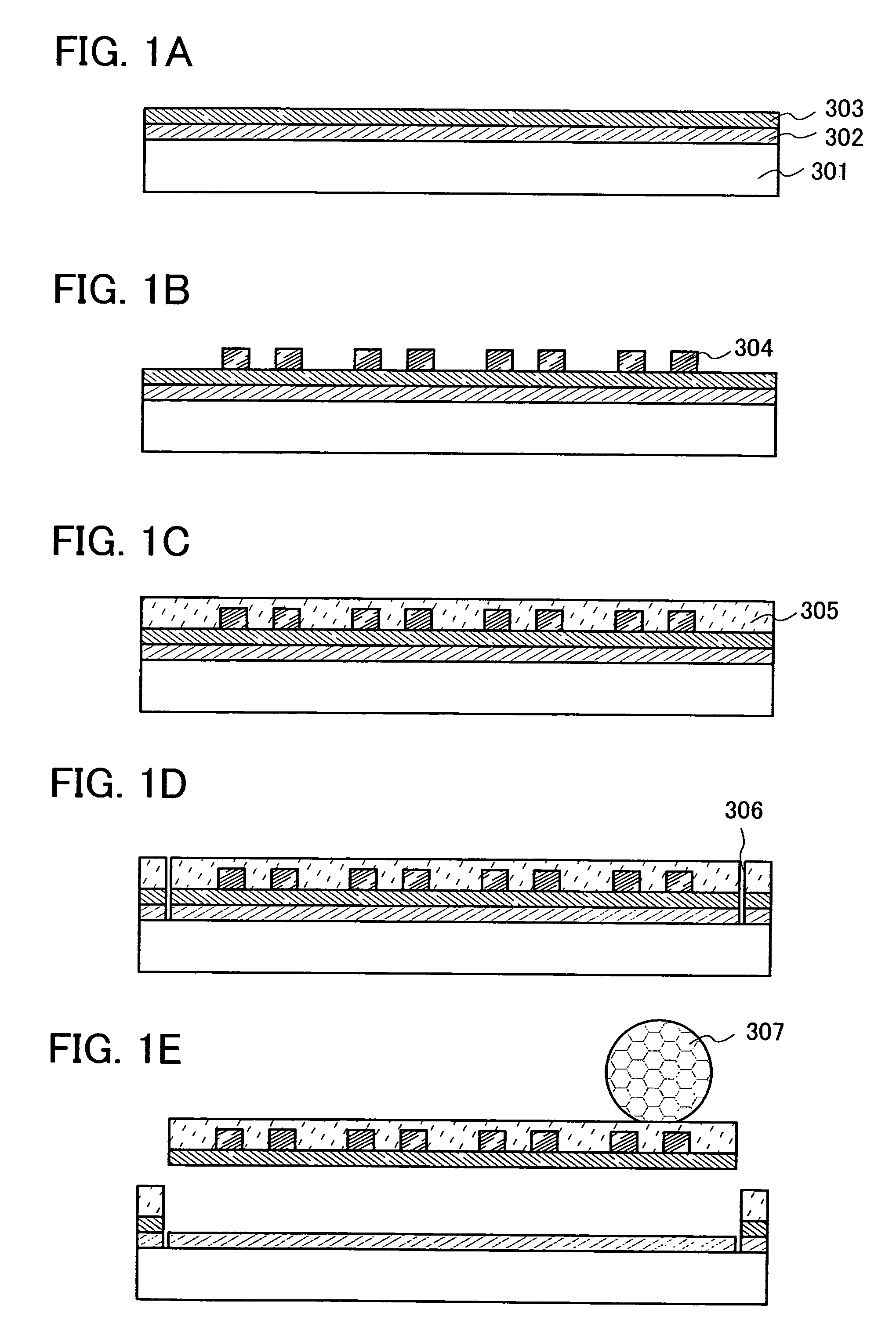

Method for manufacturing semiconductor device

InactiveUS20080242005A1Reduce communicationReduce connectionsSolid-state devicesSemiconductor/solid-state device manufacturingInorganic compoundSingle crystal

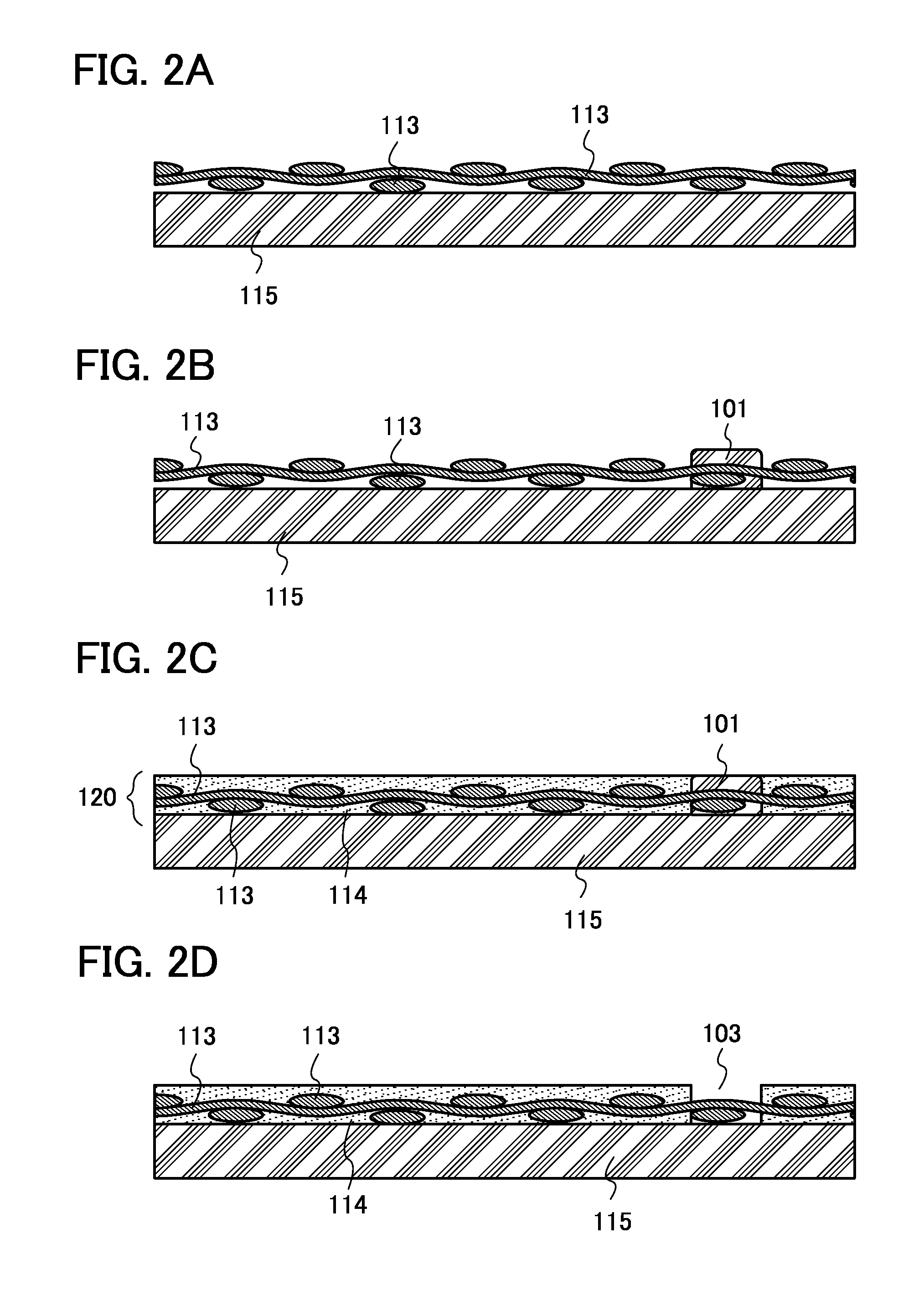

In the present application, is disclosed a method of manufacturing a flexible semiconductor device having an excellent reliability and tolerance to the loading of external pressure. The method includes the steps of: forming a separation layer over a substrate having an insulating surface; forming an element layer including a semiconductor element comprising a non-single crystal semiconductor layer, over the separation layer; forming an organic resin layer over the element layer; providing a fibrous body formed of an organic compound or an inorganic compound on the organic resin layer; heating the organic resin layer; and separating the element layer from the separation layer. This method allows the formation of a flexible semiconductor device having a sealing layer in which the fibrous body is impregnated with the organic resin.

Owner:SEMICON ENERGY LAB CO LTD

Method and apparatus for implanting an occlusive structure

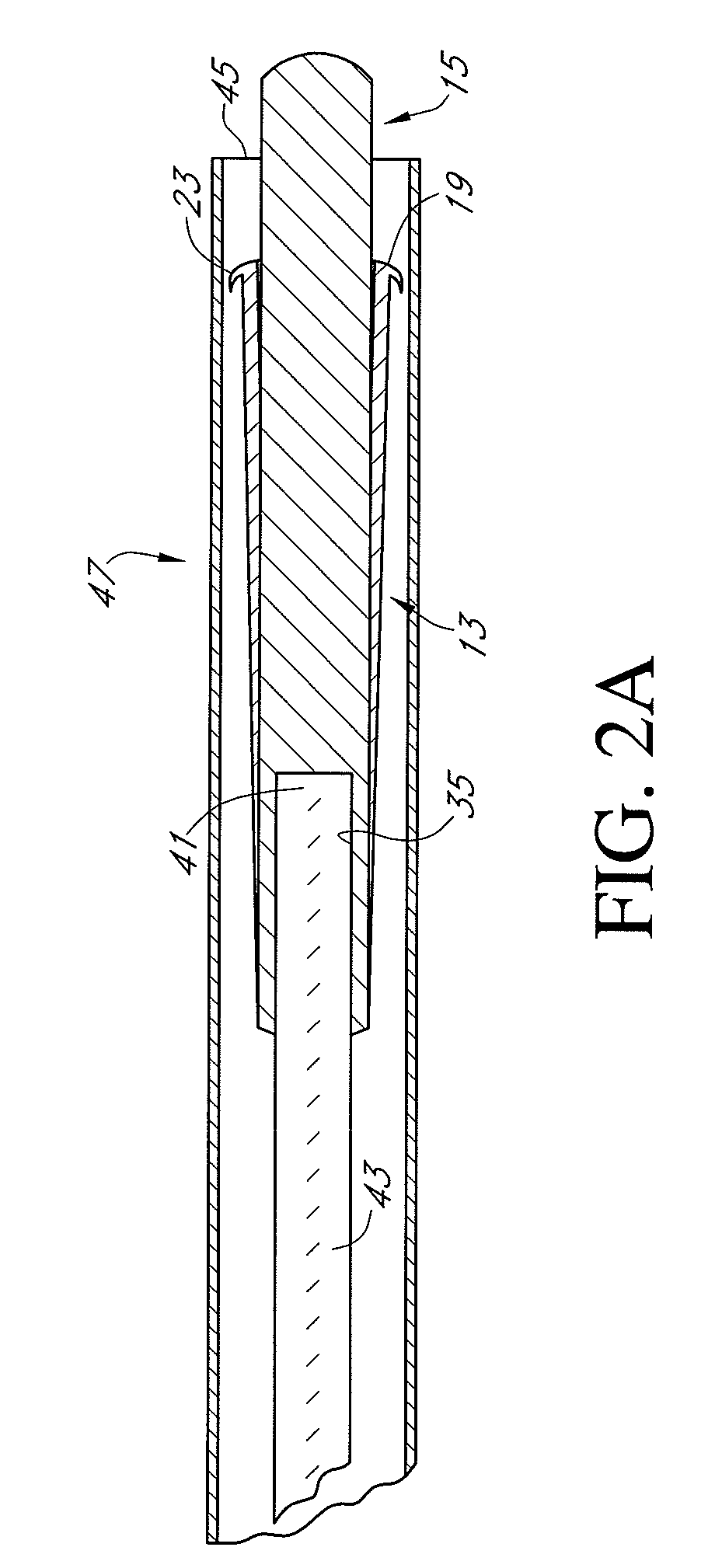

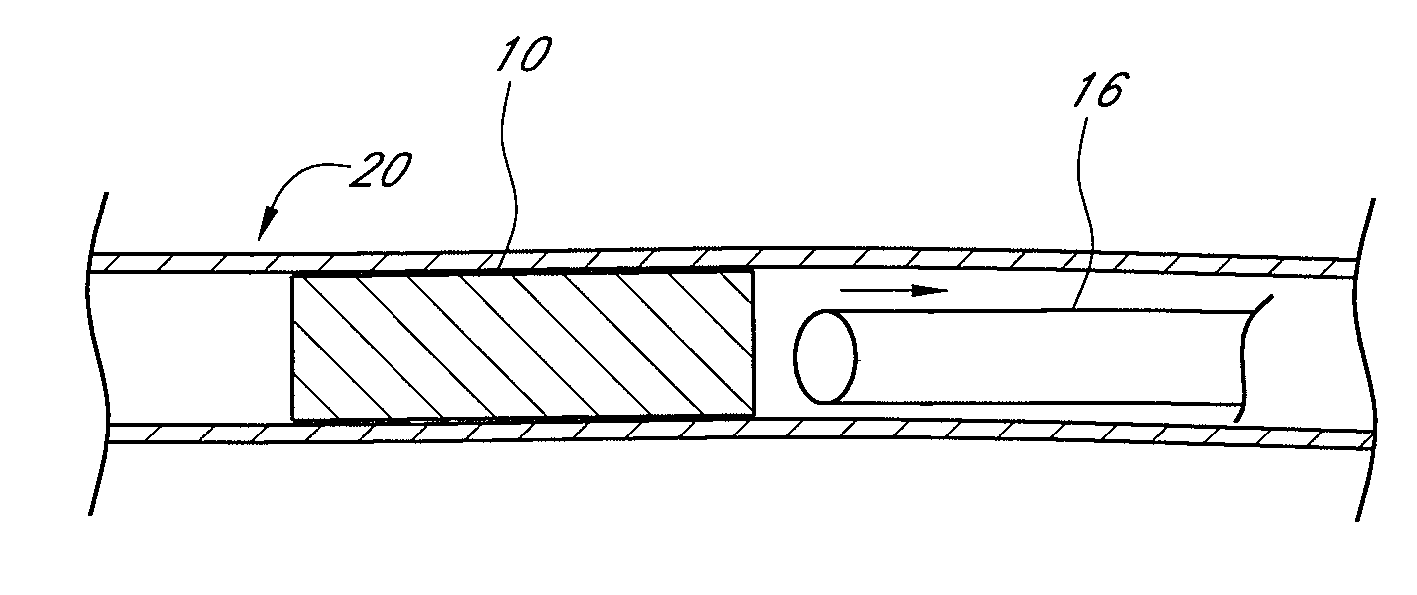

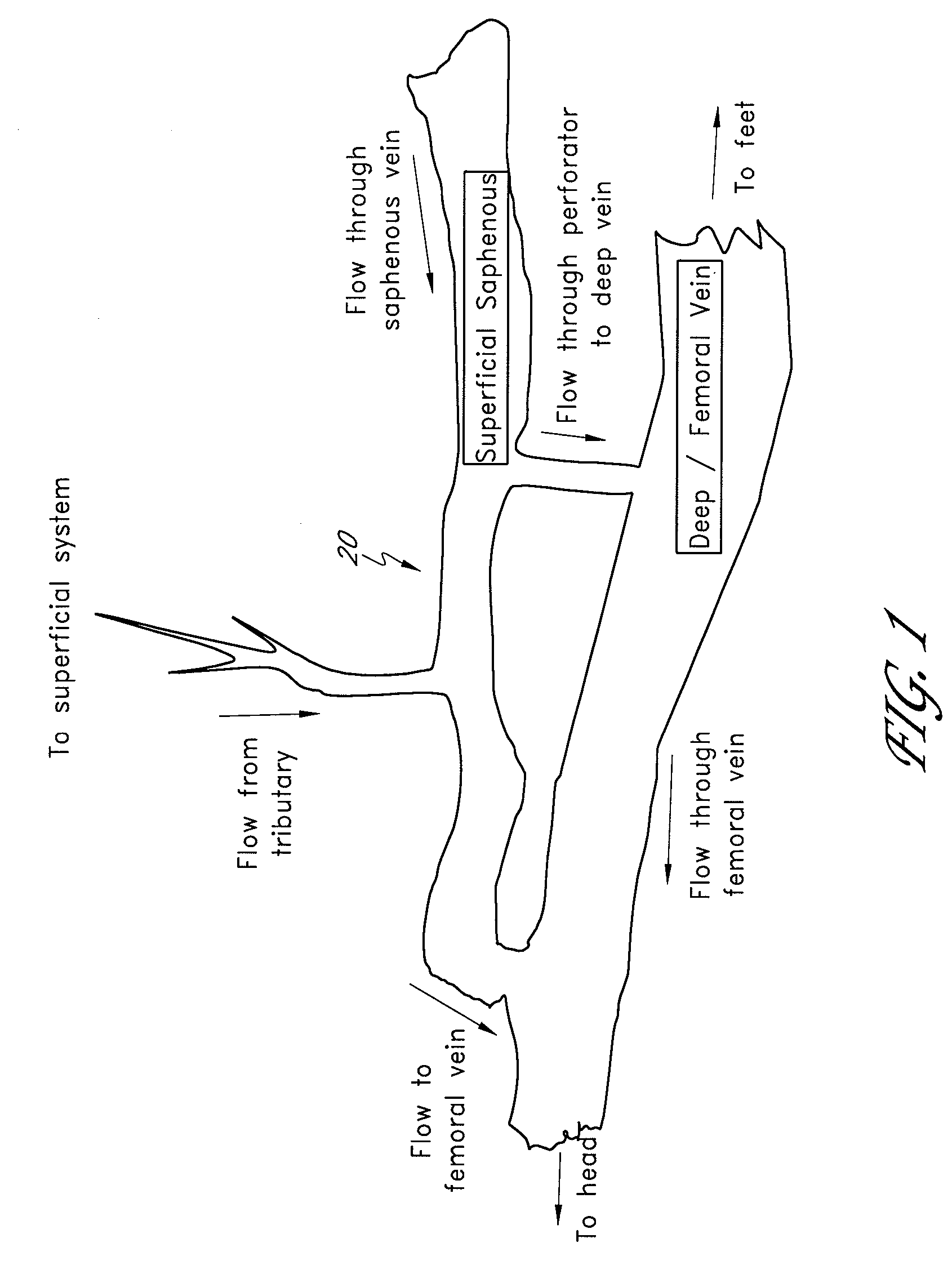

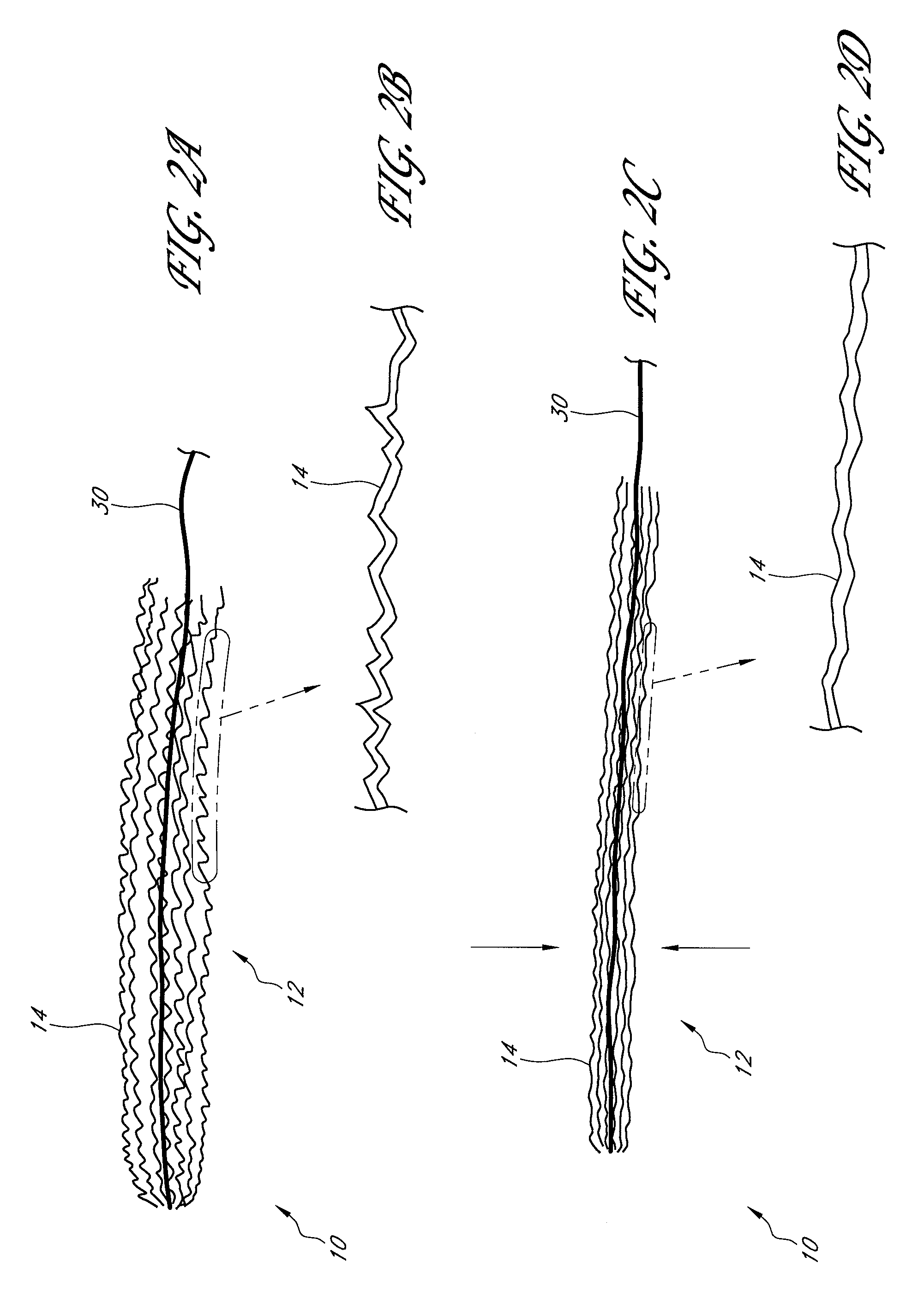

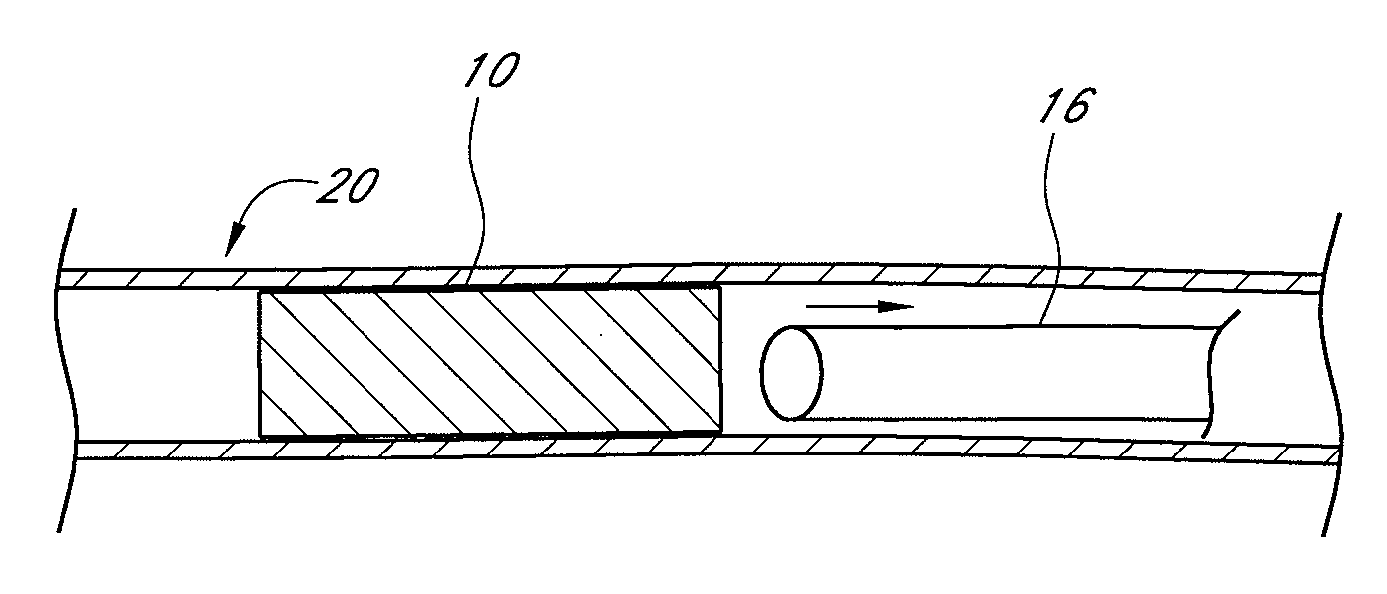

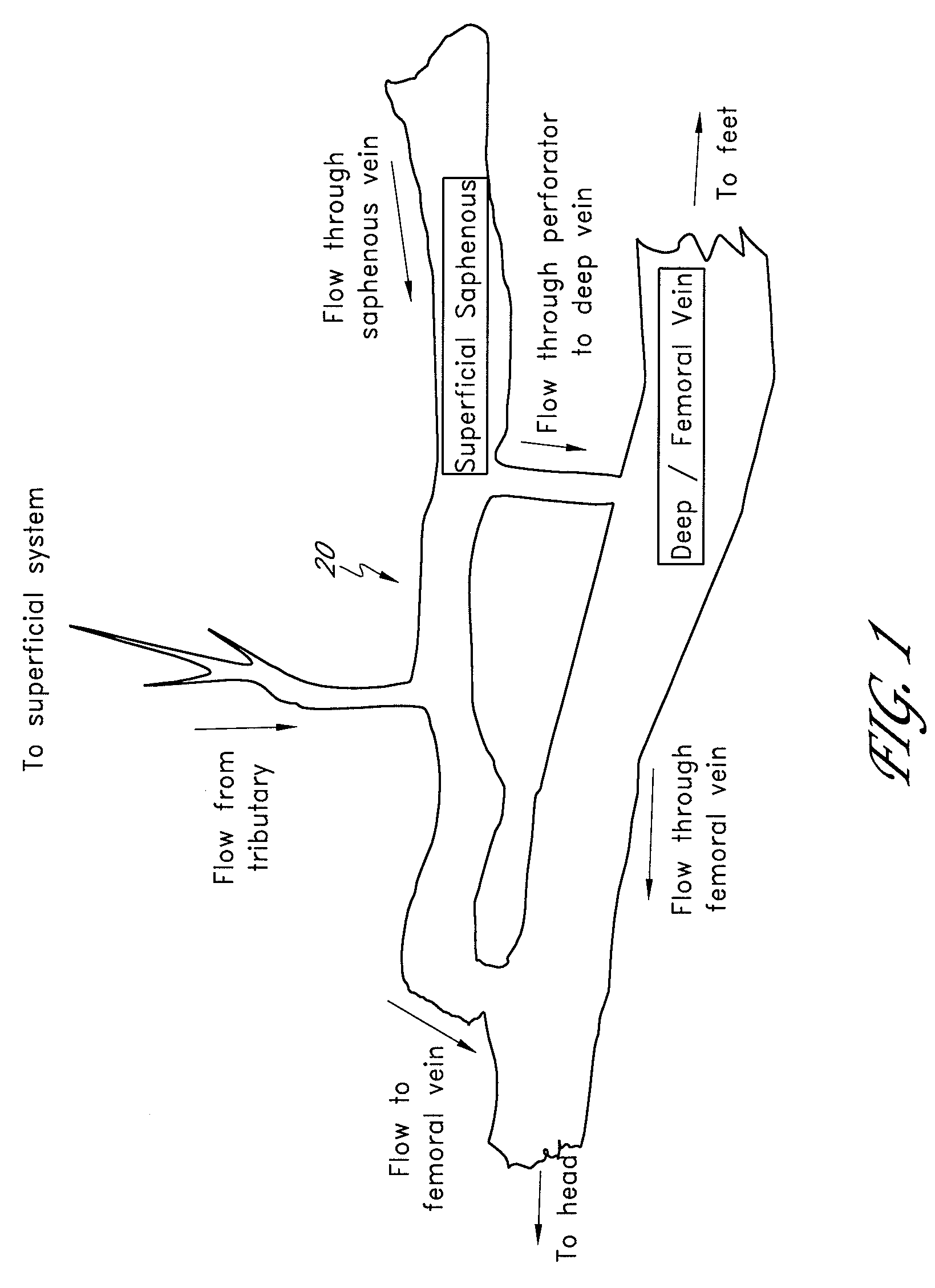

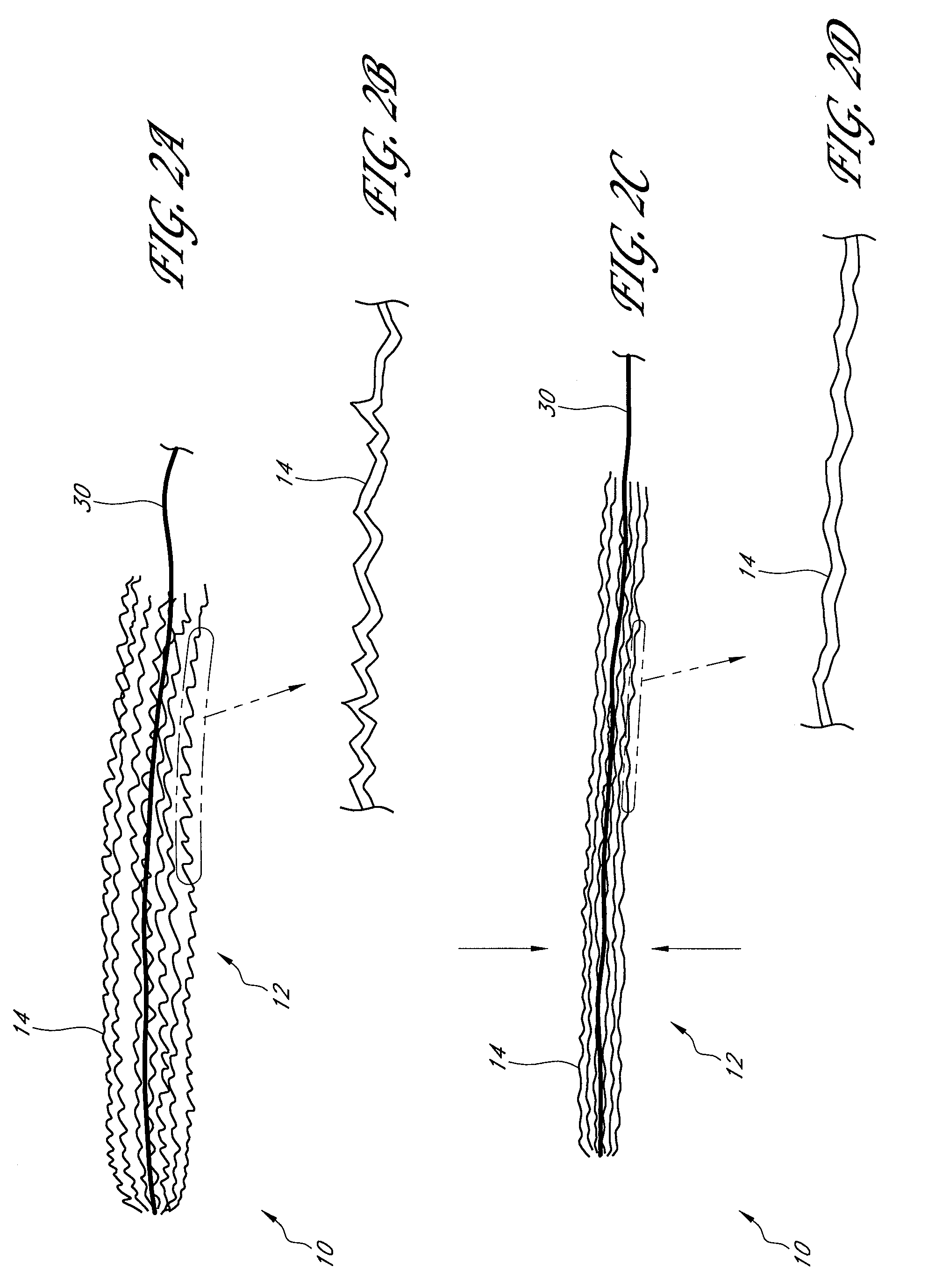

ActiveUS20060229669A1Promoting occlusive ingrowthReduced structureSuture equipmentsBronchoscopesVeinMedicine

A method of treating a vein comprises accessing a vein at an access point spaced from a sapheno-femoral junction. A bioabsorbable fibrous body is implanted into the vein through the access point. The body is moved in the vein toward the sapheno-femoral junction.

Owner:TYCO HEALTHCARE GRP LP

Method and apparatus for impeding migration of an implanted occlusive structure

InactiveUS20060229668A1Promoting occlusive ingrowthReduced structureSuture equipmentsSurgical needlesAnatomical structuresFibrous body

A method of treating a hollow anatomical structure of a patient comprises implanting a bioabsorbable fibrous body in a hollow anatomical structure. The body is secured in the hollow anatomical structure to limit migration of the body within the hollow anatomical structure.

Owner:COVIDIEN LP

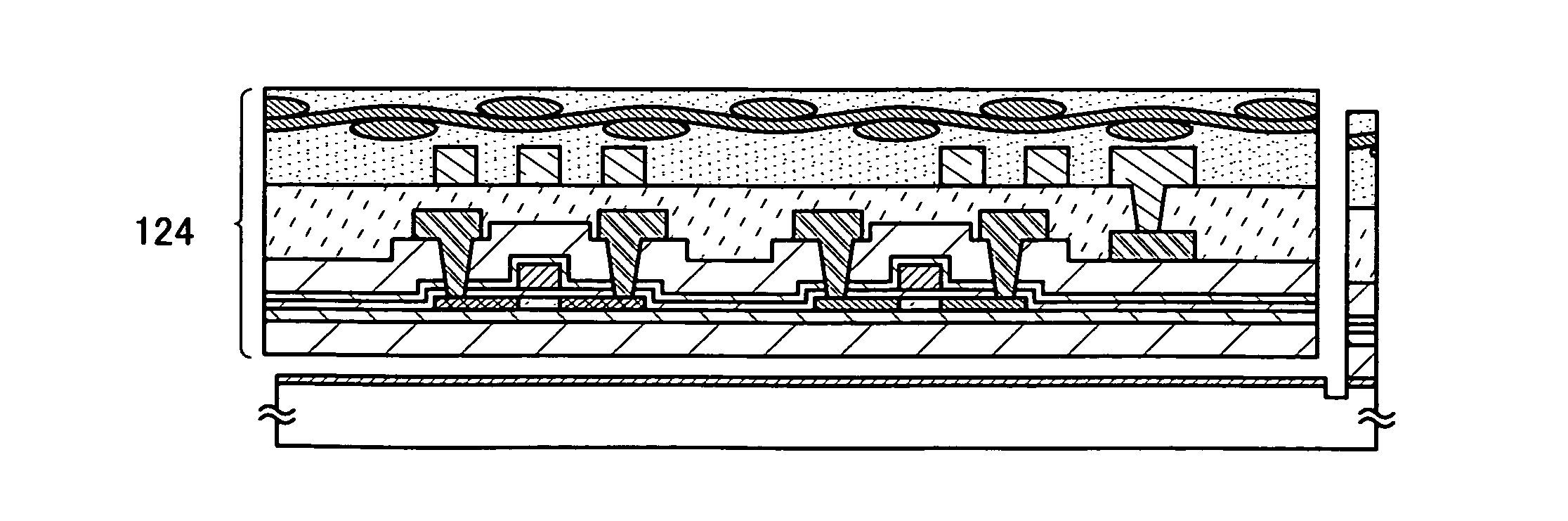

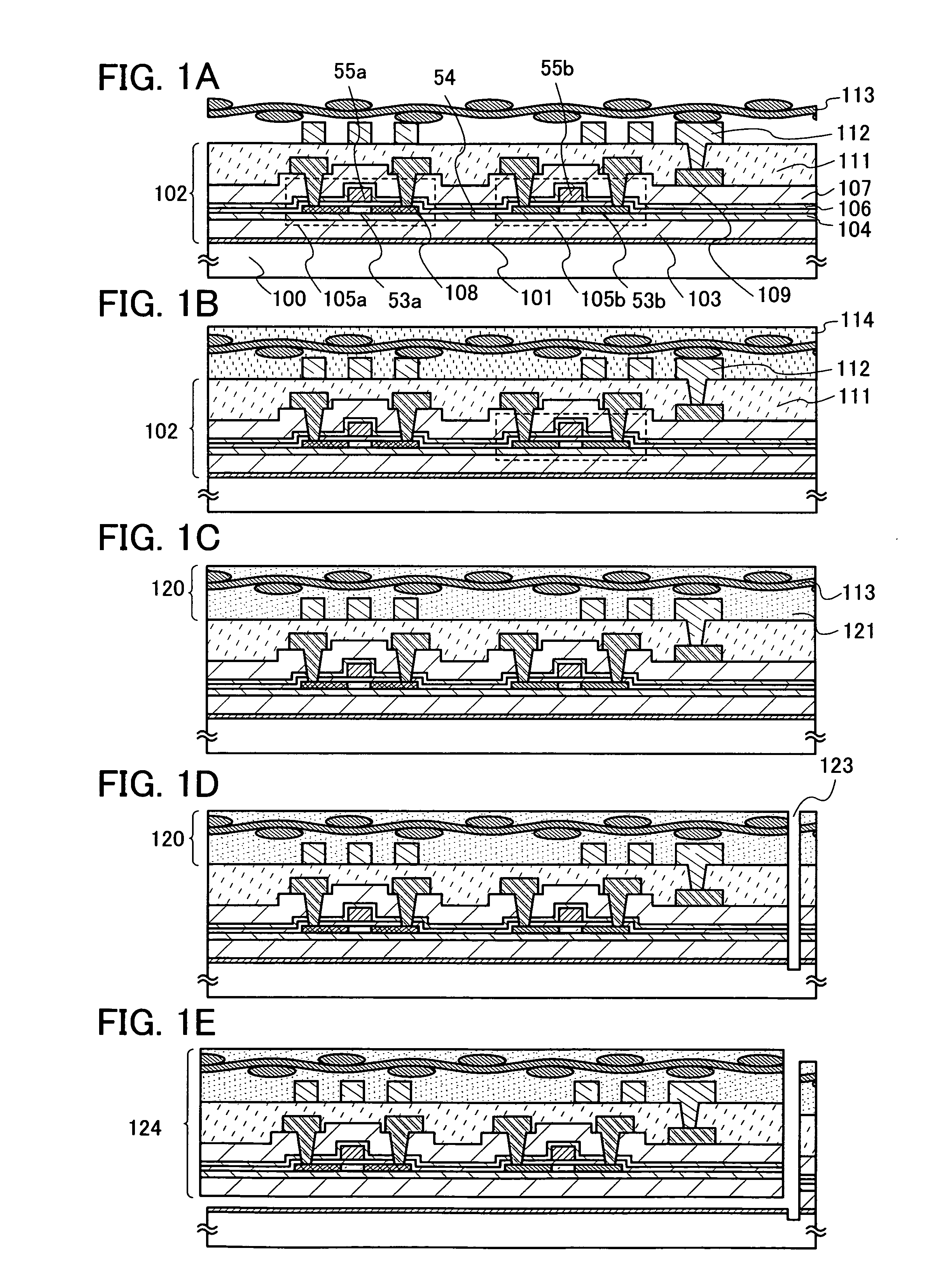

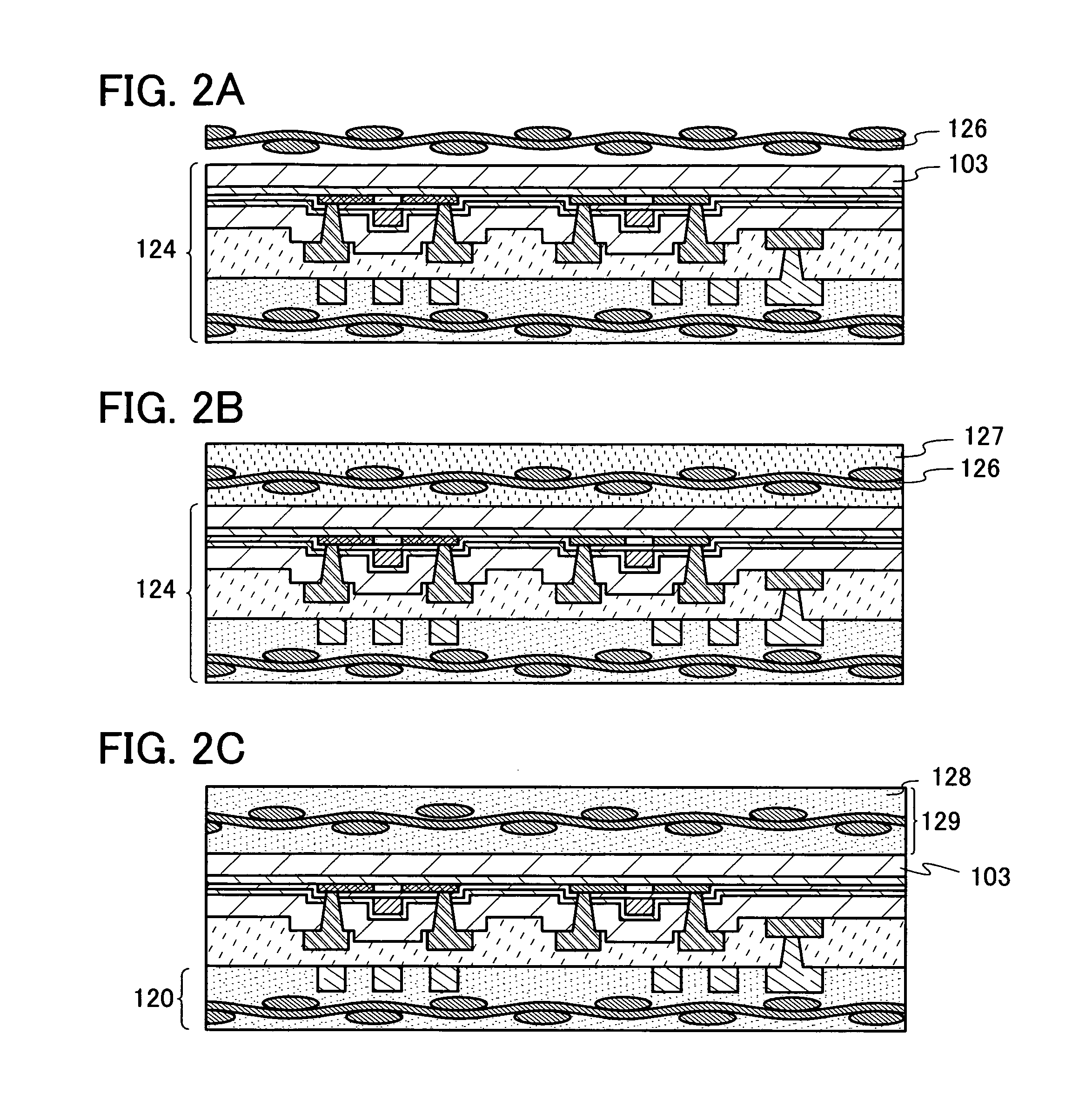

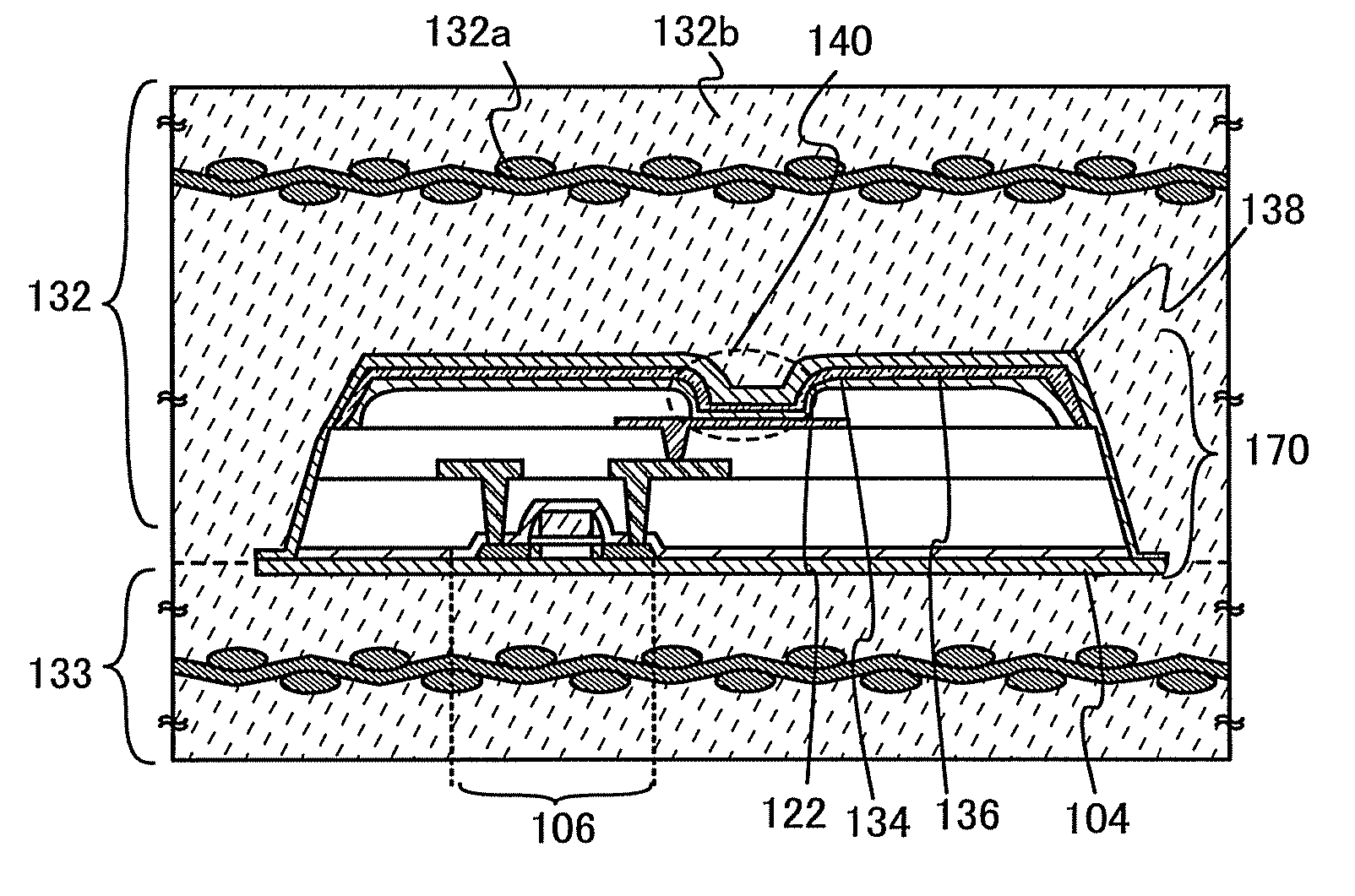

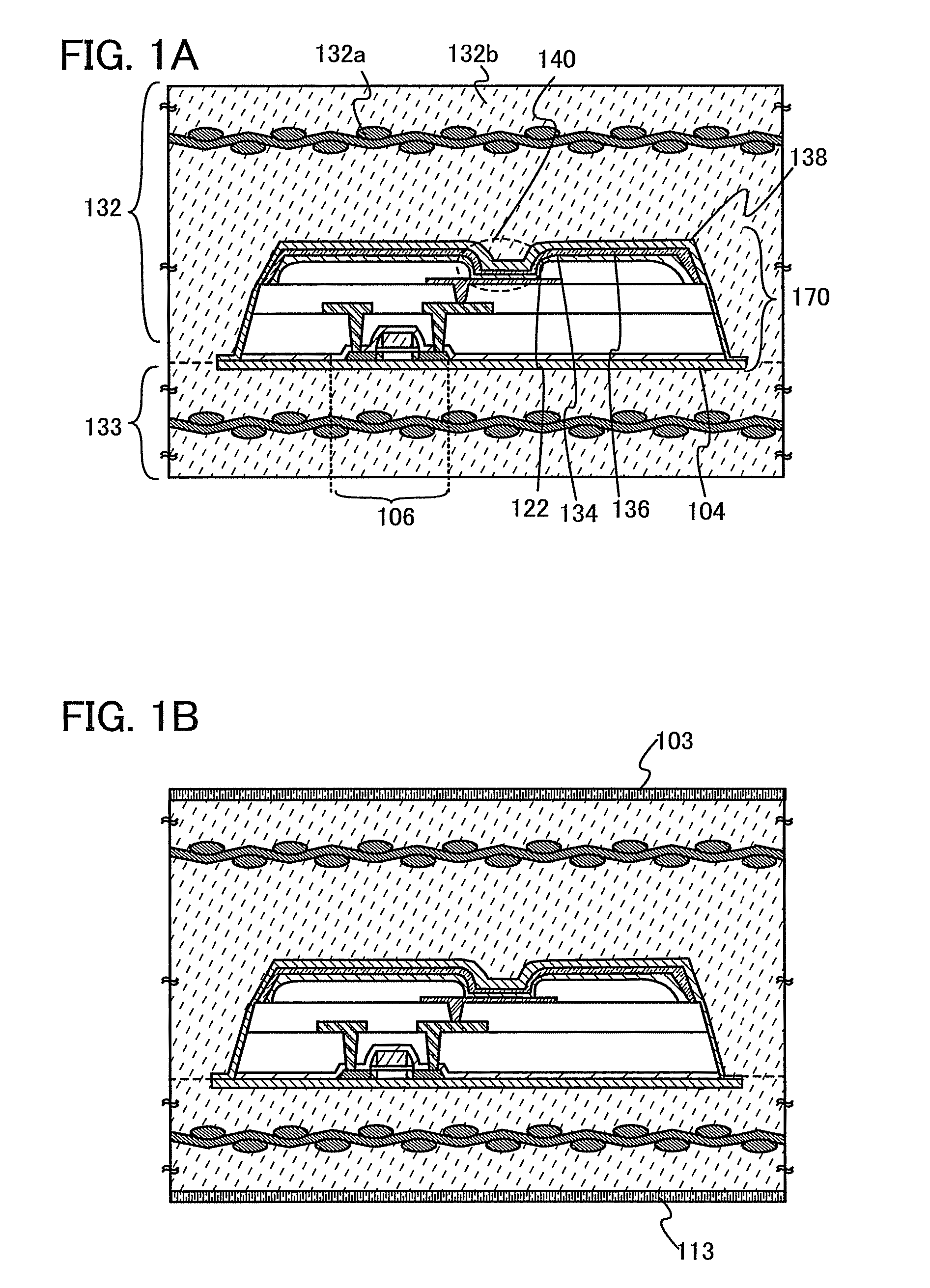

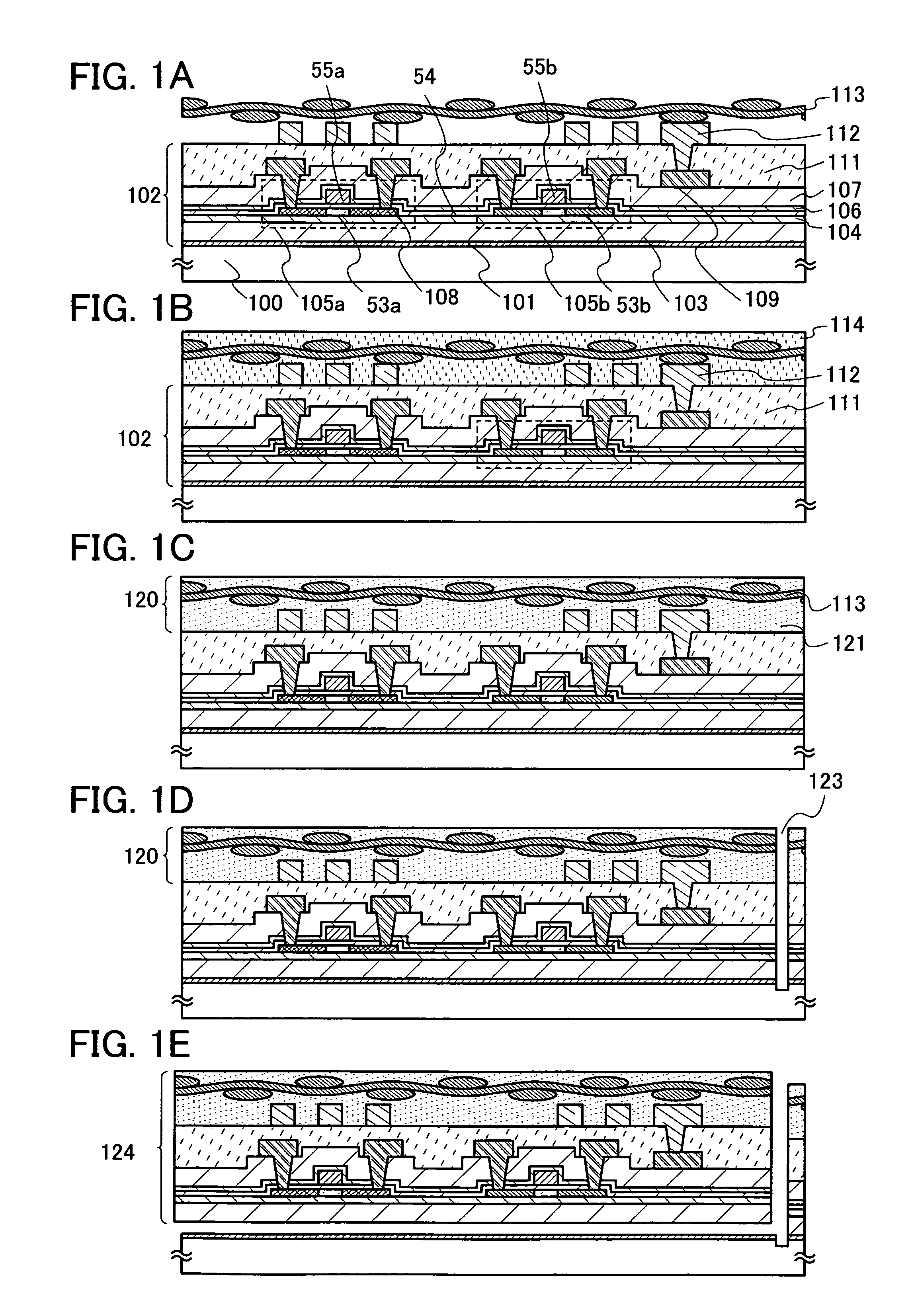

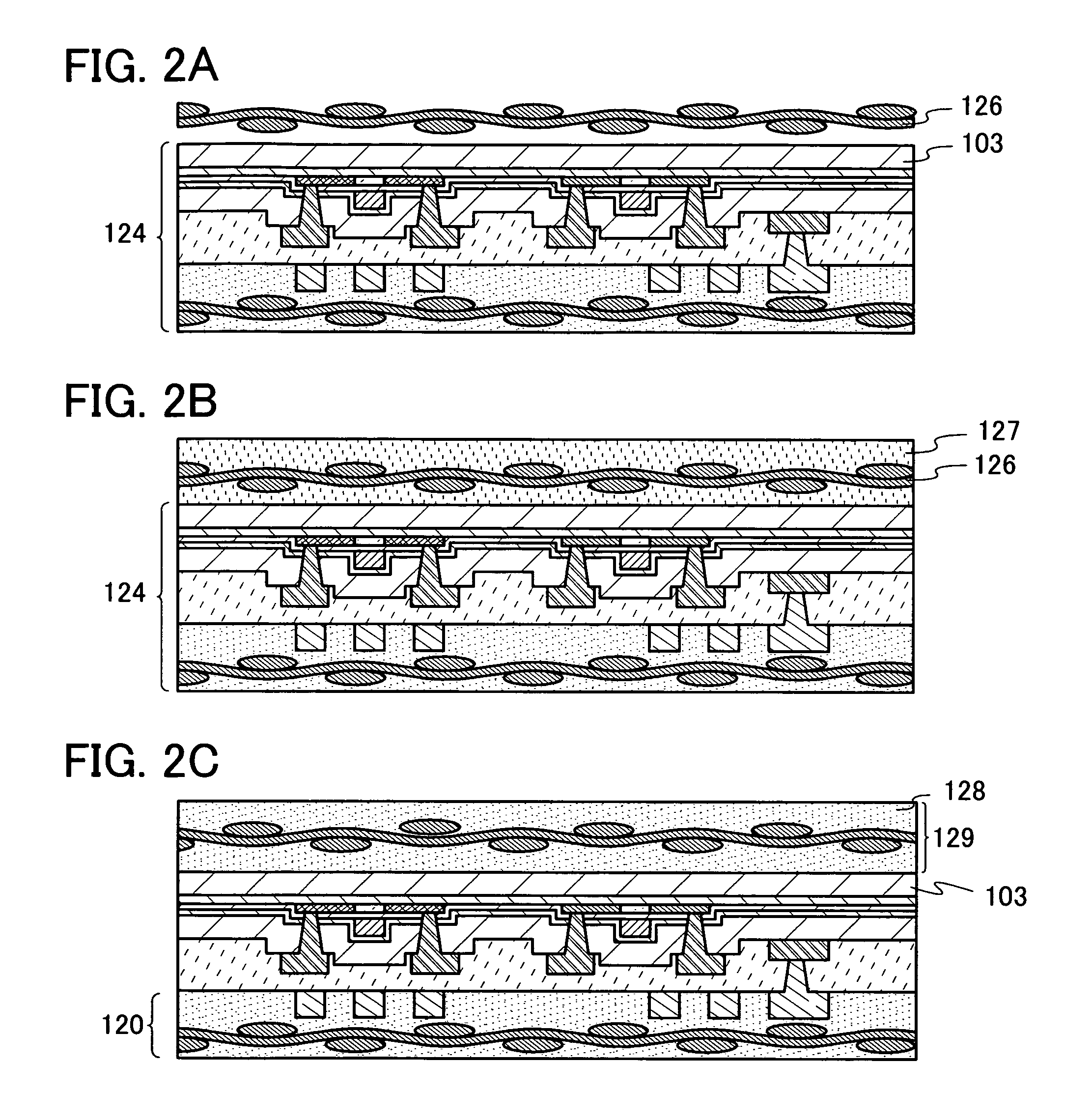

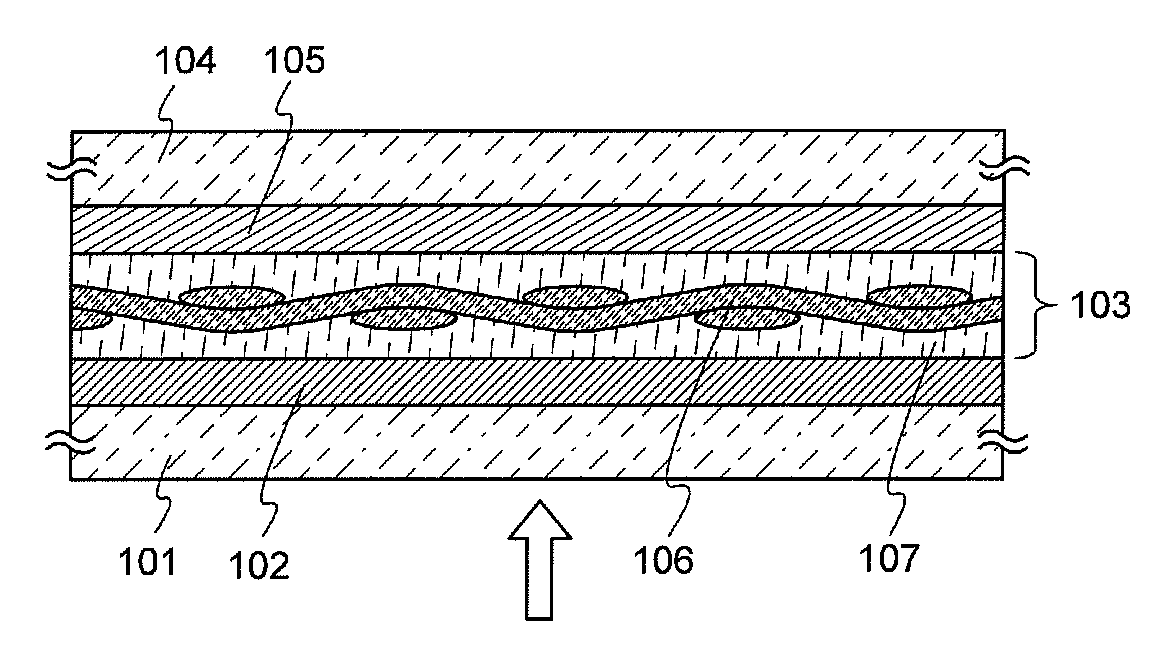

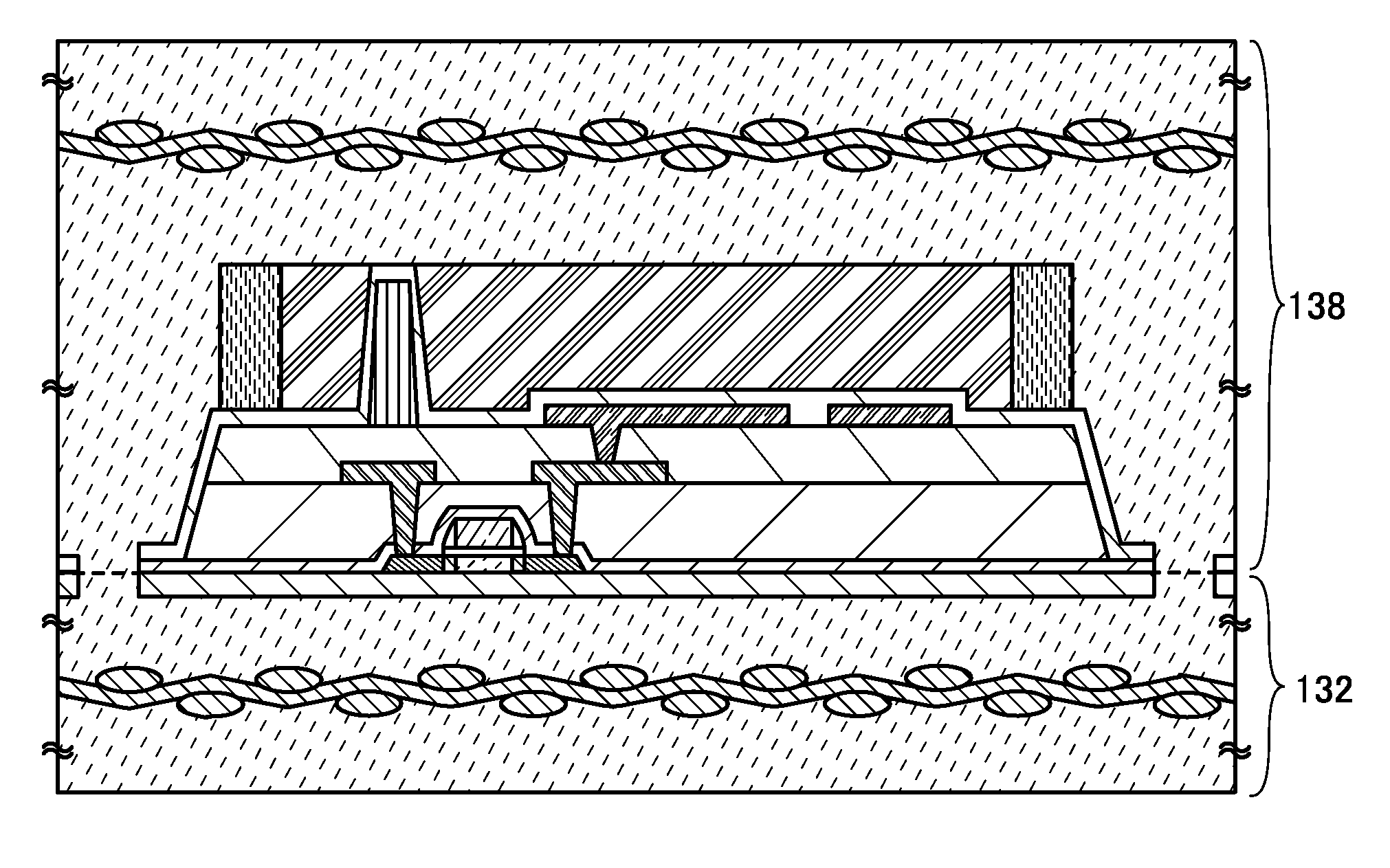

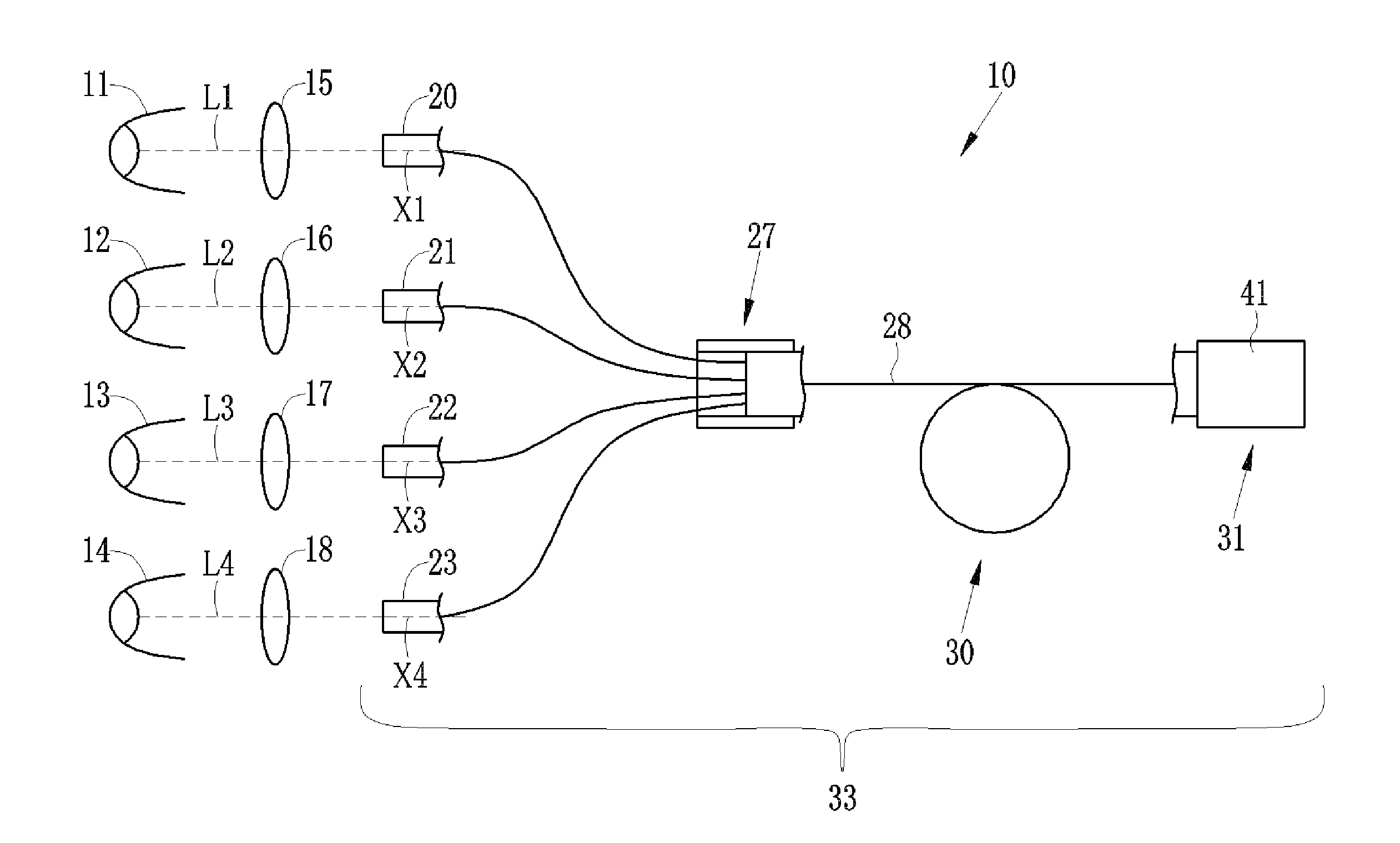

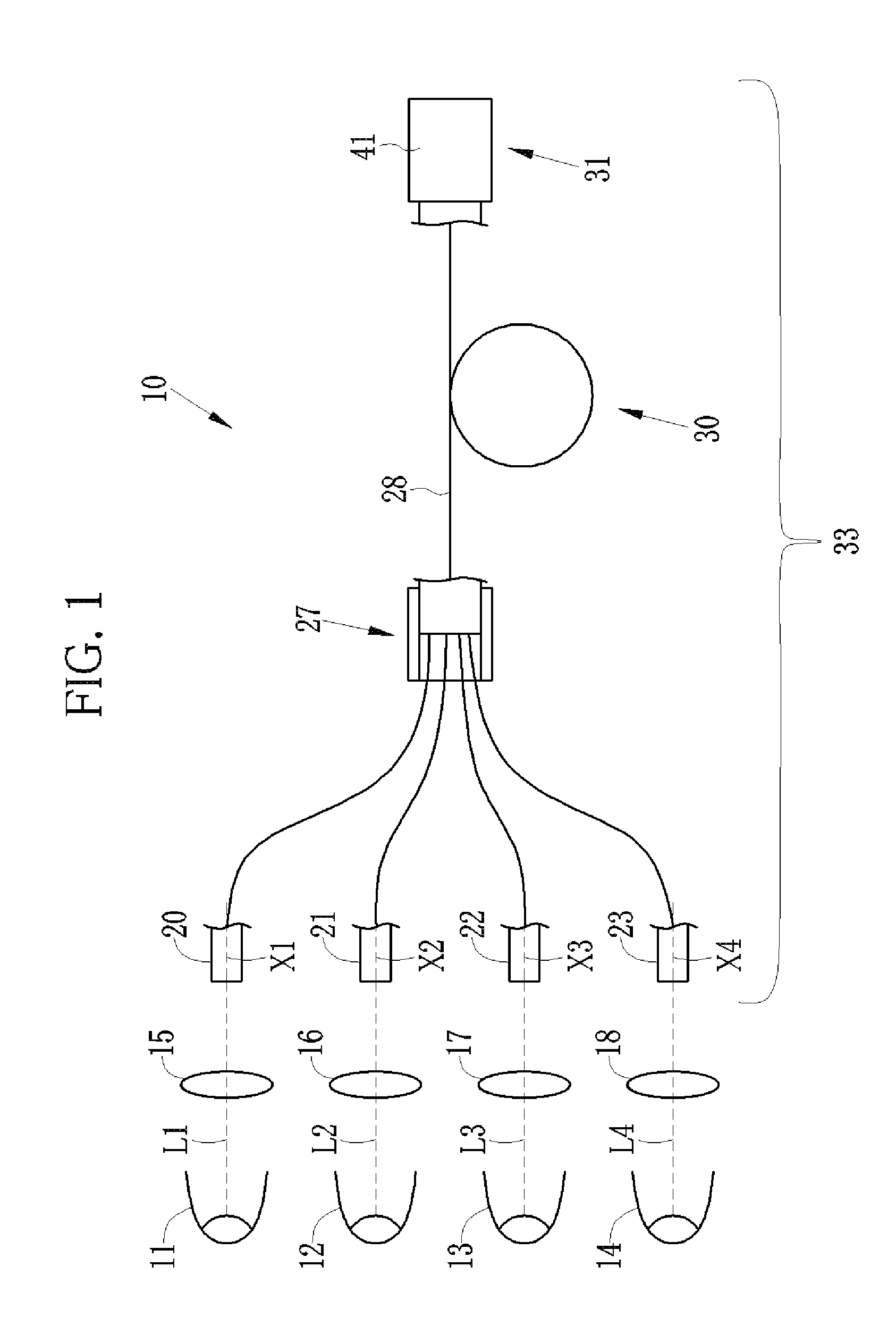

Light Emitting Device and Electronic Device

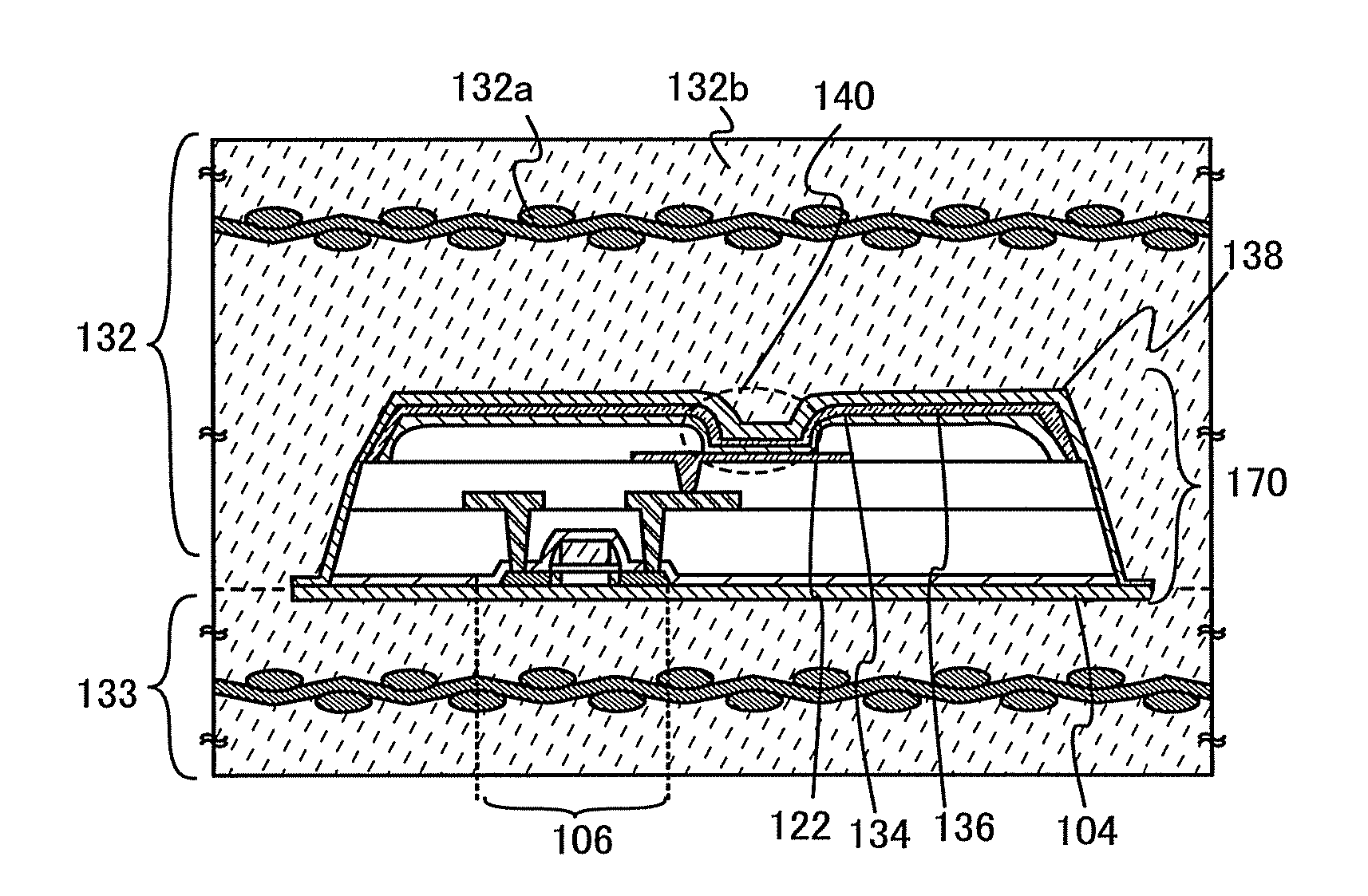

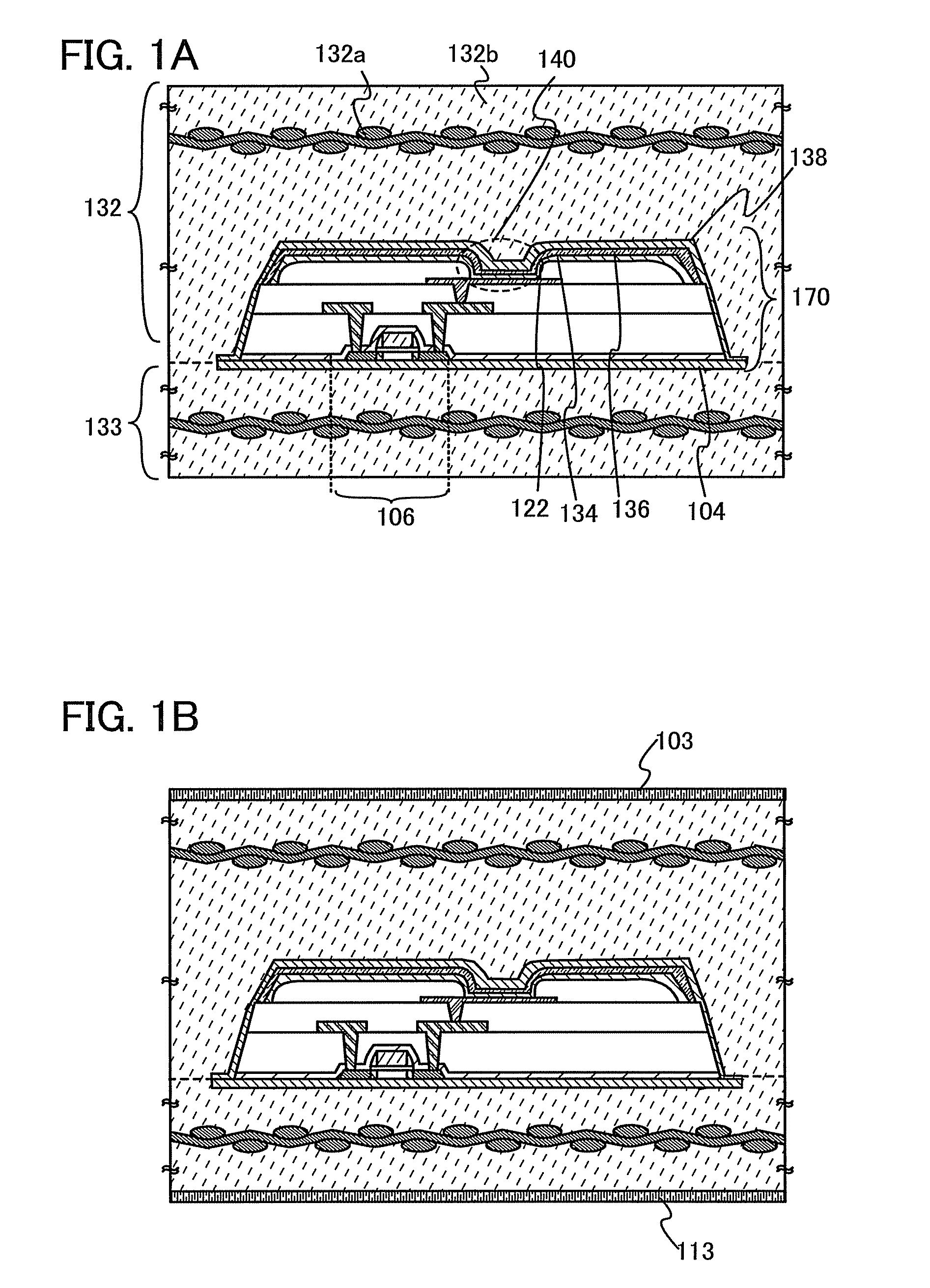

InactiveUS20100013372A1Improve reliabilityCharacteristic preventedDischarge tube luminescnet screensElectroluminescent light sourcesFibrous bodyLocal pressure

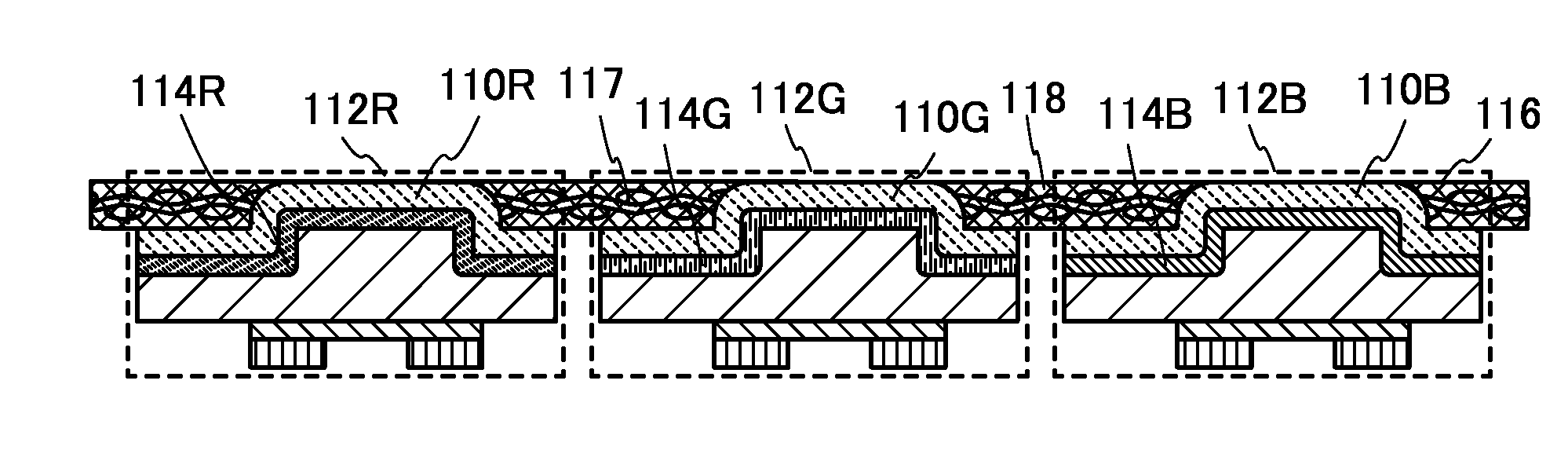

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

Acidic impregnated filter element, and methods

InactiveUS20060042210A1Extended service lifeSolution to short lifeMembrane filtersLoose filtering material filtersPreservativeFibrous body

A contaminant-removal filter for removing basic contaminants from a gas stream, such as air. The filter has a porous or fibrous body that includes a plurality of passages extending from a first, inlet face to a second, outlet face, the passages providing flow paths. The body has an acidic material, such as citric acid, and at least one of a preservative and a stabilizer impregnated throughout the substrate. The filter is free of any humectants.

Owner:DONALDSON CO INC

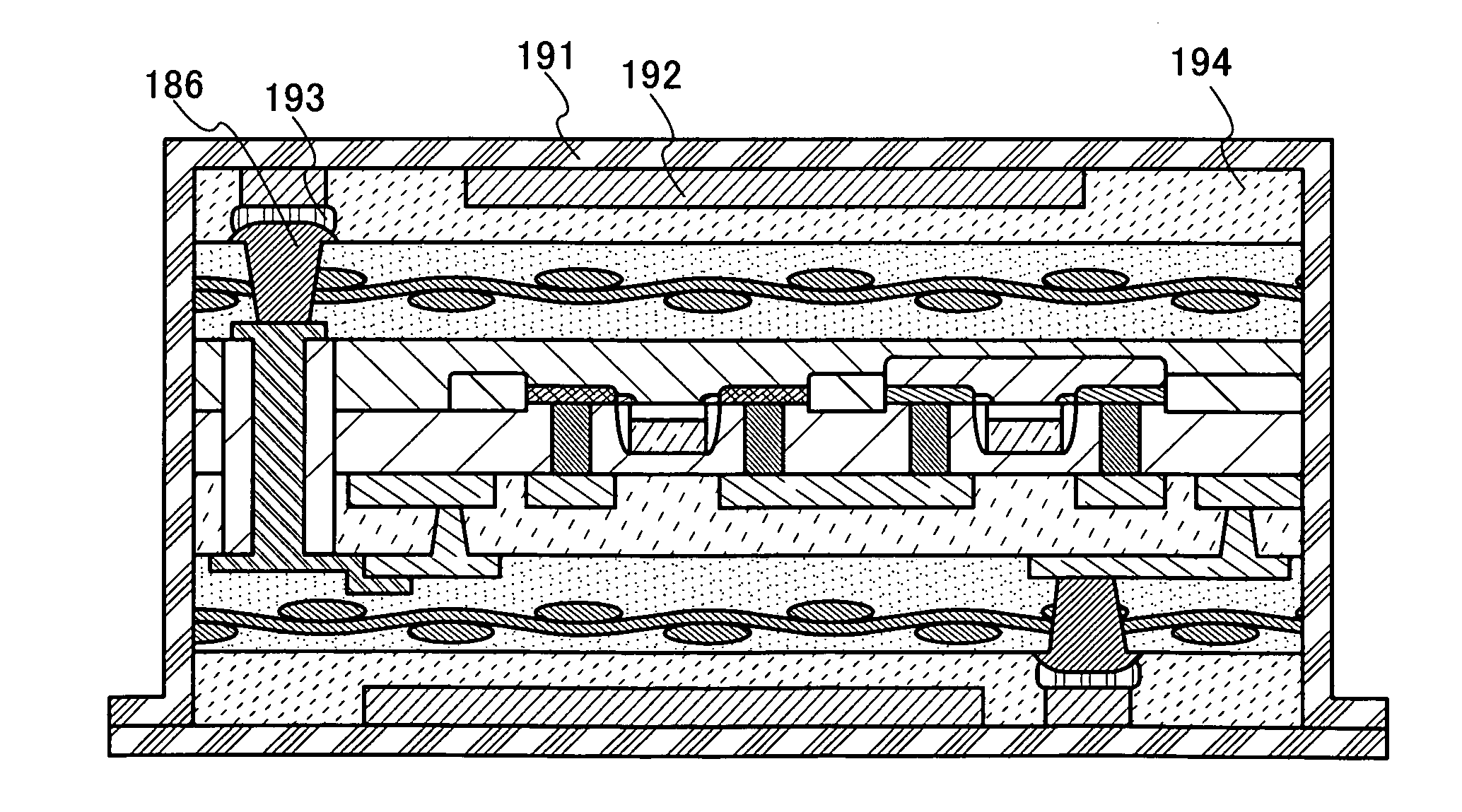

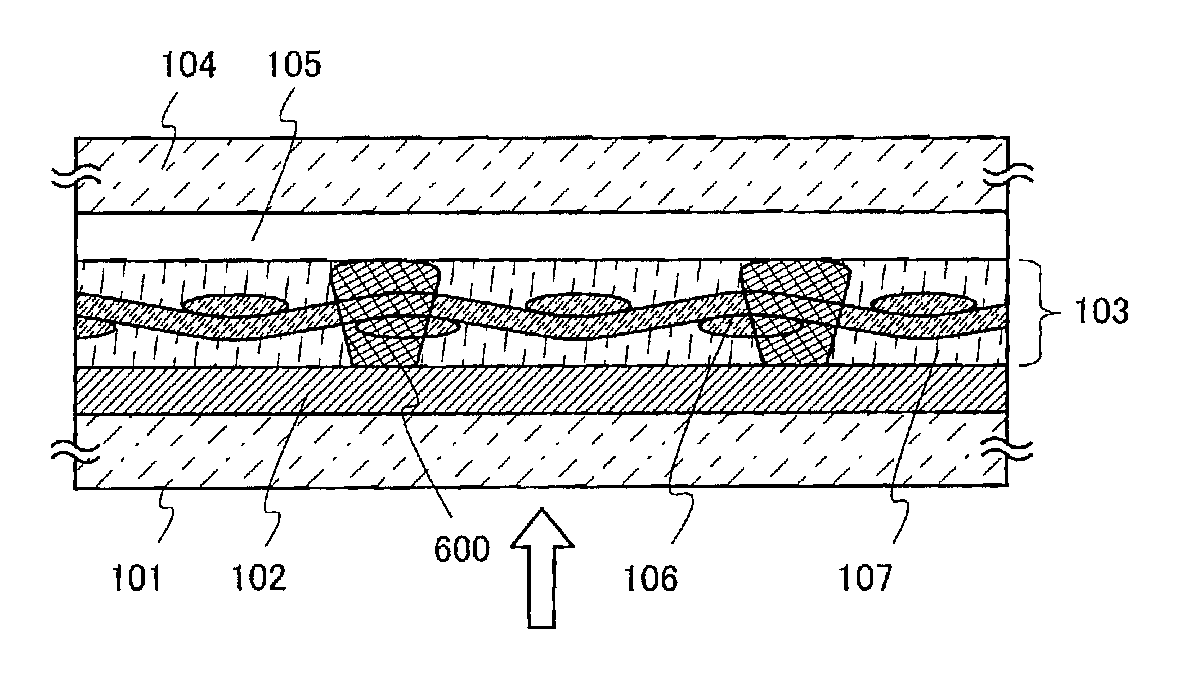

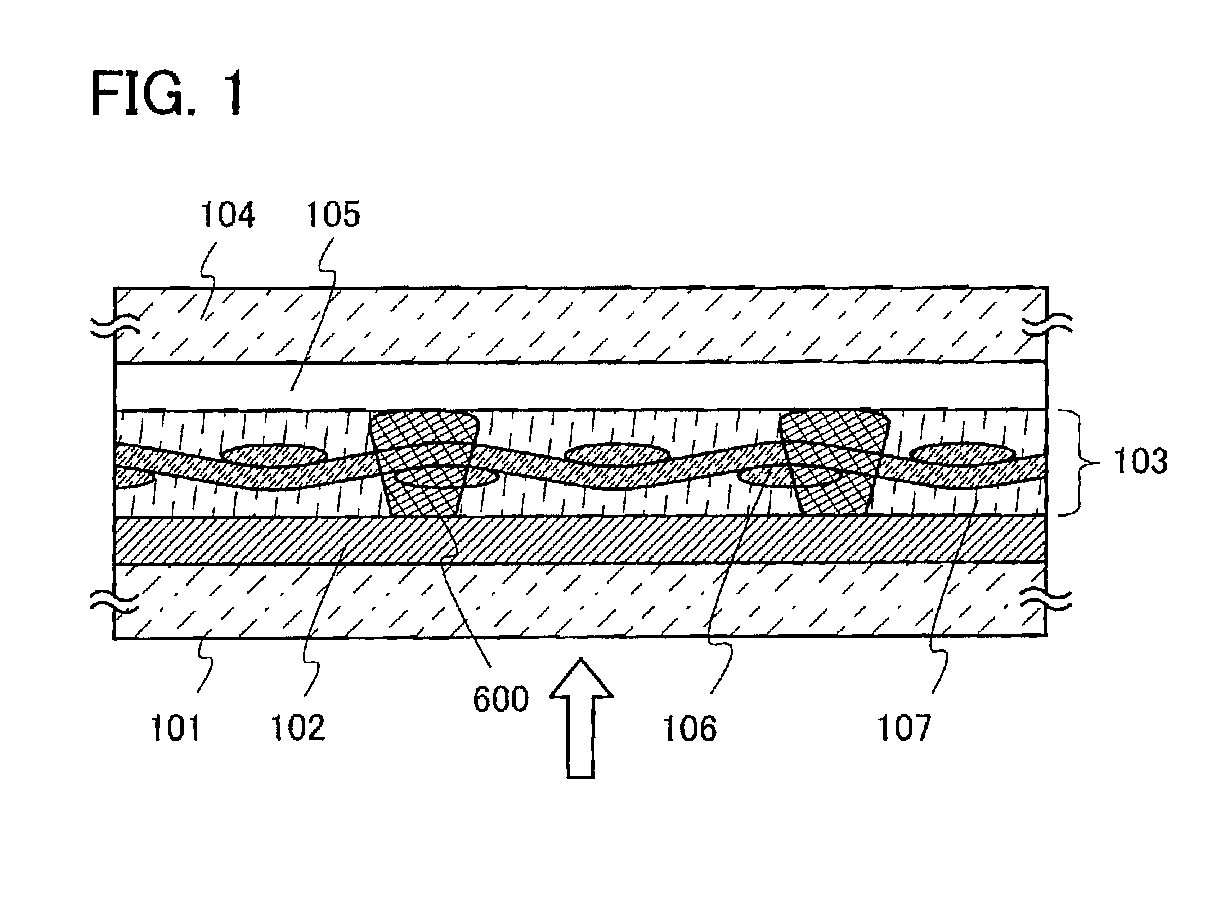

Light emitting device and electronic device utilizing fibrous barrier layers impregnated with organic resin

InactiveUS8264144B2High yieldPreventing in characteristicDischarge tube luminescnet screensElectroluminescent light sourcesFiberFibrous body

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

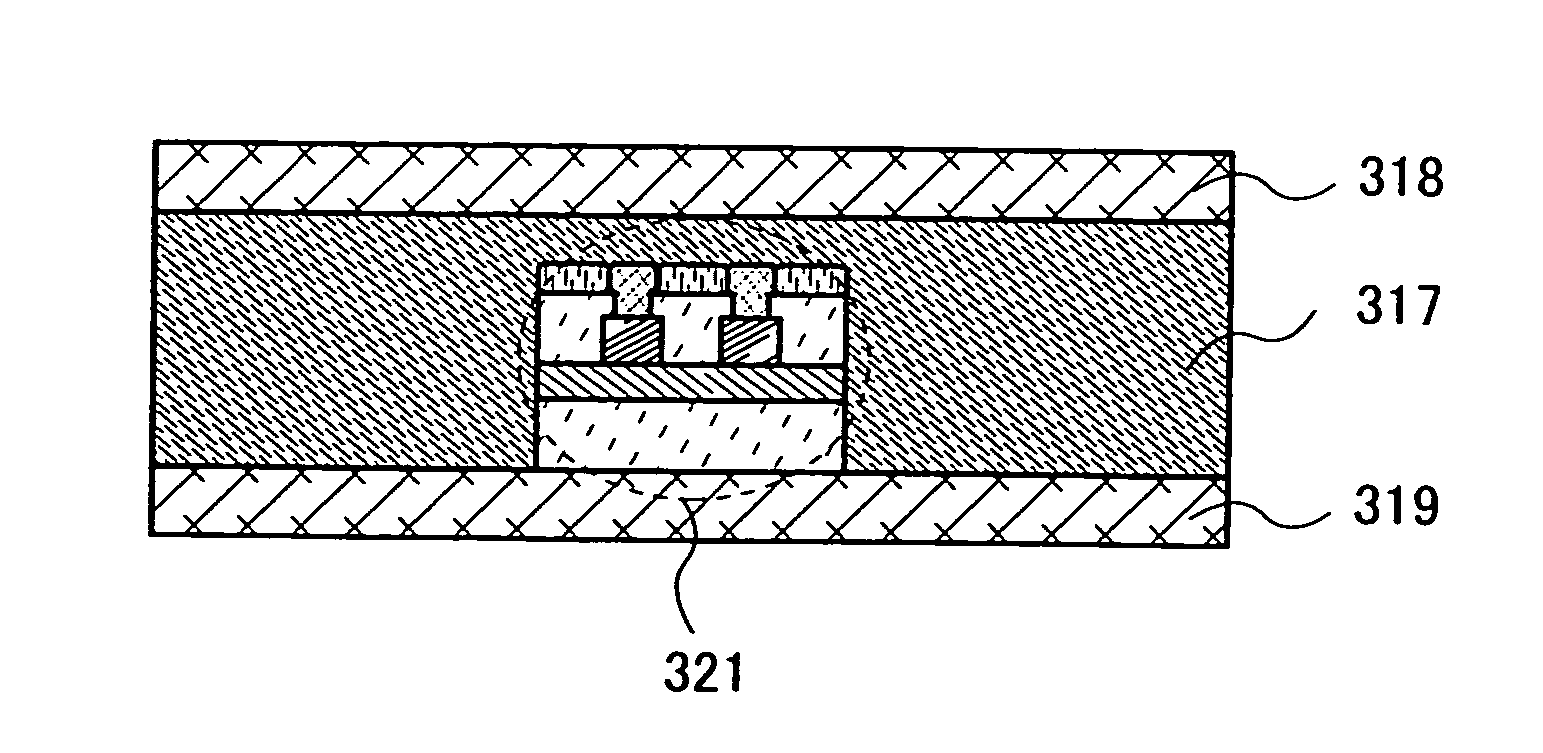

Semiconductor device and manufacturing method thereof

InactiveUS20090314527A1Maintain mechanical strengthMaintenanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialFibrous body

To form a conductive region in a prepreg without opening a through hole in a fibrous body. A wiring substrate is provided, including: an organic resin layer and a fibrous body, wherein the fibrous body is impregnated with the organic resin layer; and a wiring with which the fibrous body is impregnated and which is formed by dissolving the organic resin layer. The wiring is exposed on both surfaces of the organic resin layer and penetrates the fibrous body so that the fibrous body is positioned in the through wiring. Further, a semiconductor device is provided by adhering an integrated circuit chip having a bump to the wiring substrate so that the bump is in contact with the wiring.

Owner:SEMICON ENERGY LAB CO LTD

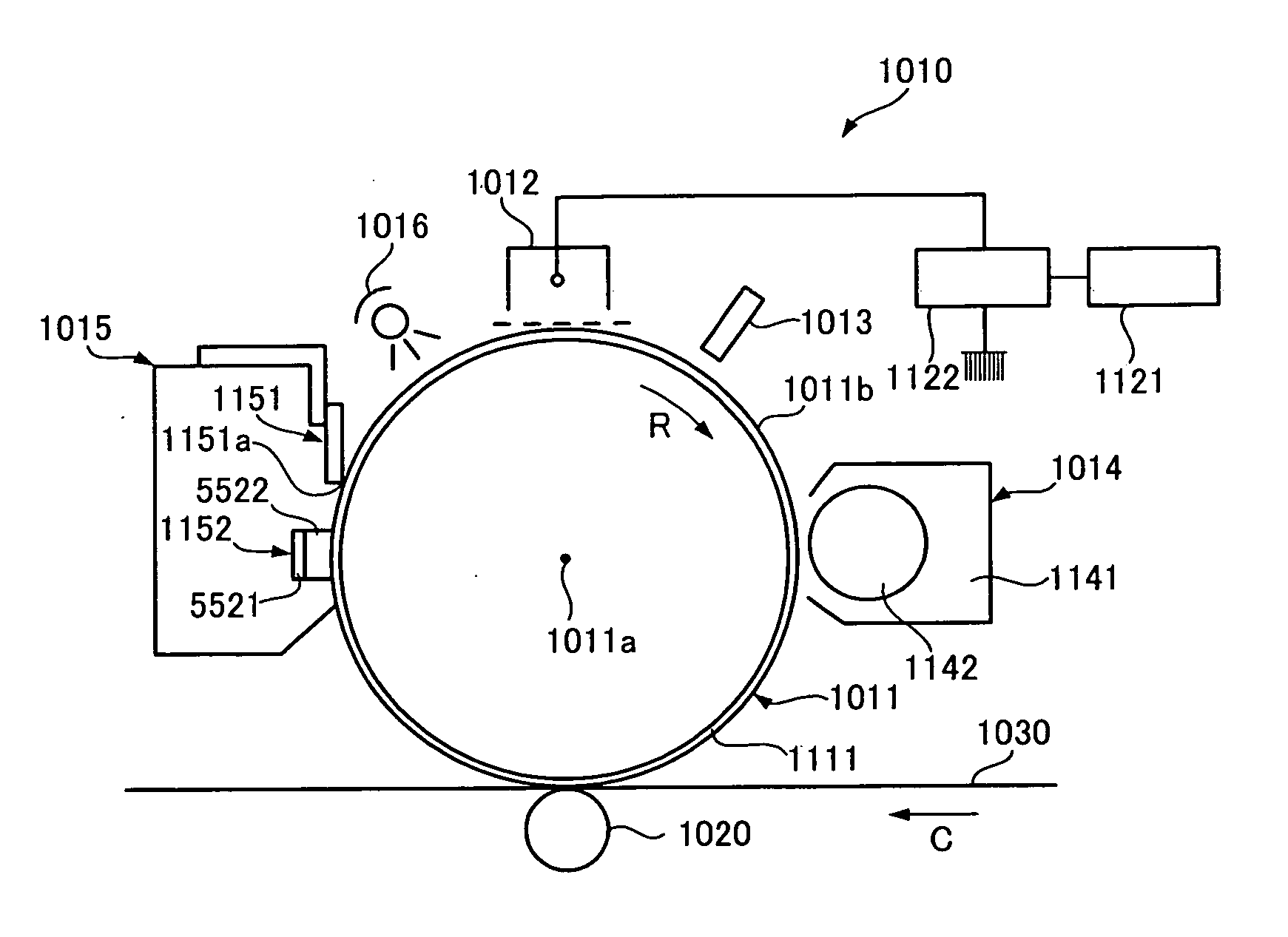

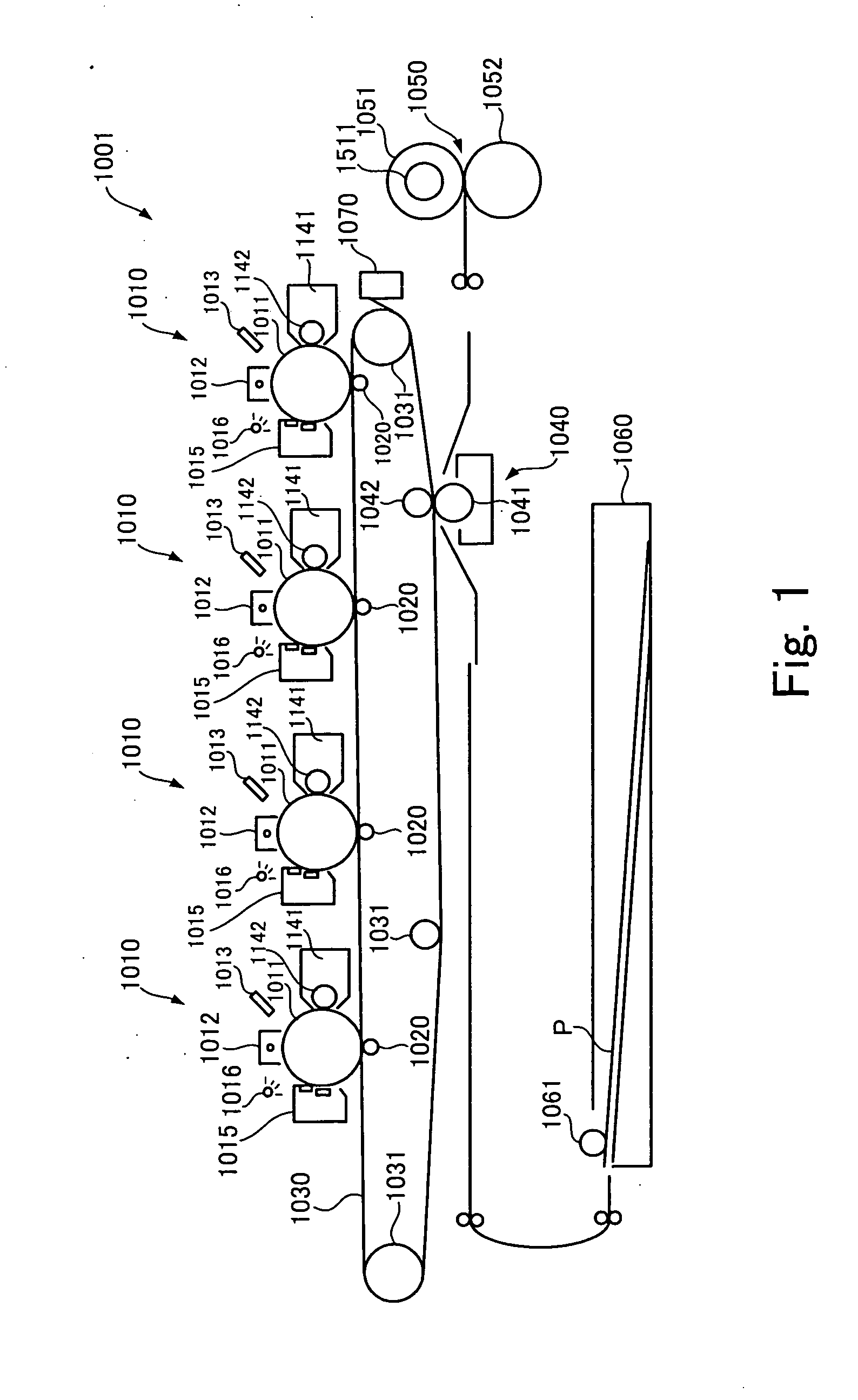

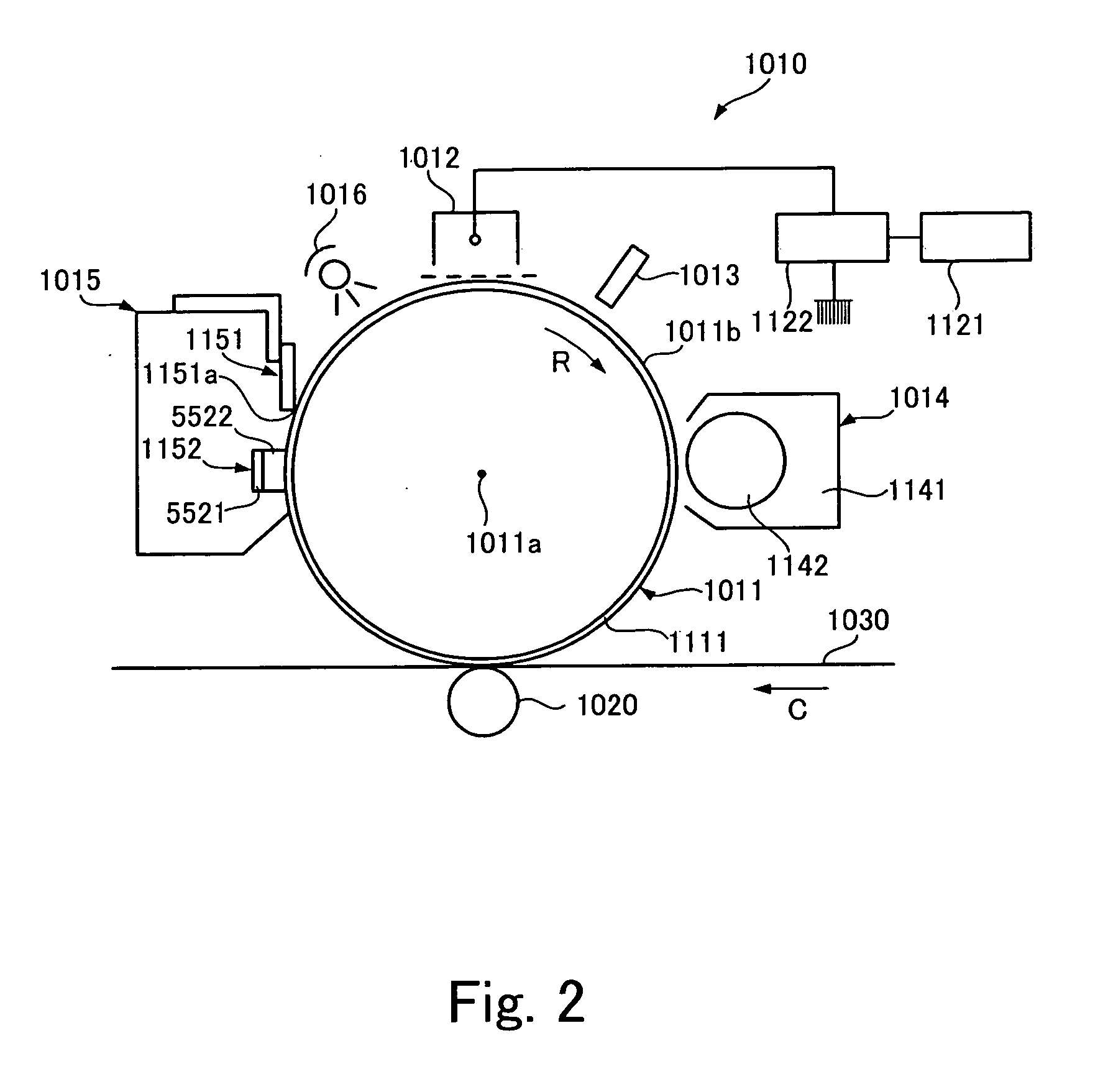

Cleaning unit and image forming apparatus

This invention relates to a cleaning unit comprising: a cleaning blade that keeps a front end of rubber material in contact with the surface with a pressure so as to scrape residual toner left on the surface of the photoreceptor and a fiber body having multiple fibers in contact with the surface of the photoreceptor in the upstream in the cyclic moving direction of the surface of the photoreceptor with respect to the cleaning blade, wherein the cleaning blade satisfies conditions A≧−2.5×B+102 and 6.3≦B≦19.6, where A designates a contact angle (°) with pure water under 23° C., 55% RH and B designates 100% modulus (MPa) at 23° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method for manufacturing semiconductor device

InactiveUS7736958B2Reduce communicationReduce connectionsSolid-state devicesSemiconductor/solid-state device manufacturingInorganic compoundFibrous body

In the present application, is disclosed a method of manufacturing a flexible semiconductor device having an excellent reliability and tolerance to the loading of external pressure. The method includes the steps of: forming a separation layer over a substrate having an insulating surface; forming an element layer including a semiconductor element comprising a non-single crystal semiconductor layer, over the separation layer; forming an organic resin layer over the element layer; providing a fibrous body formed of an organic compound or an inorganic compound on the organic resin layer; heating the organic resin layer; and separating the element layer from the separation layer. This method allows the formation of a flexible semiconductor device having a sealing layer in which the fibrous body is impregnated with the organic resin.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing semiconductor device

InactiveUS20080311706A1Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

To provide a method for manufacturing a highly-reliable semiconductor device, which is not damaged by external local pressure, with a high yield, a semiconductor device is manufactured by forming an element substrate having a semiconductor element formed using a single-crystal semiconductor substrate or an SOI substrate, providing the element substrate with a fibrous body formed from an organic compound or an inorganic compound, applying a composition containing an organic resin to the element substrate and the fibrous body so that the fibrous body is impregnated with the organic resin, and heating to provide the element substrate with a sealing layer in which the fibrous body formed from an organic compound or an inorganic compound is contained.

Owner:SEMICON ENERGY LAB CO LTD

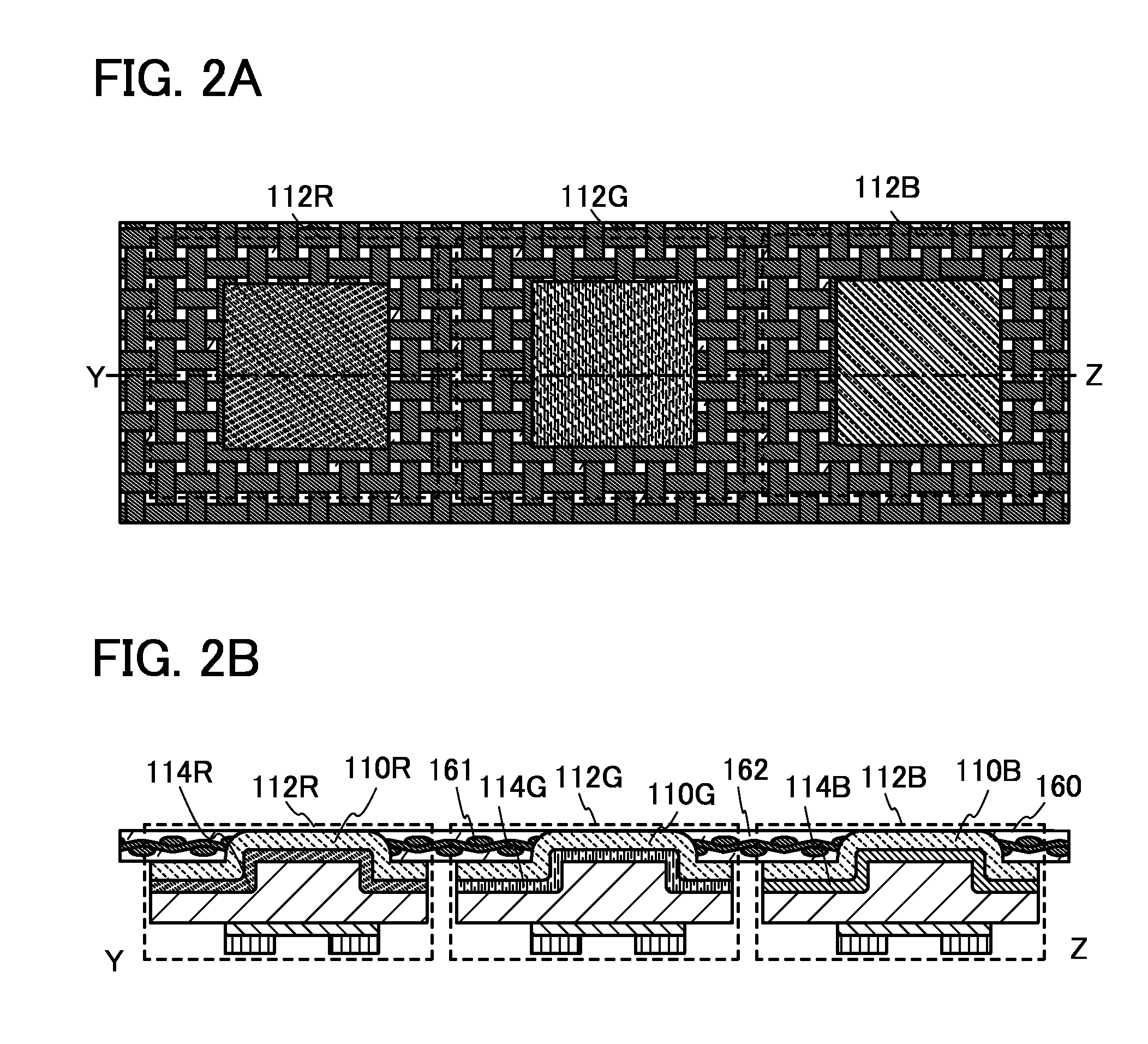

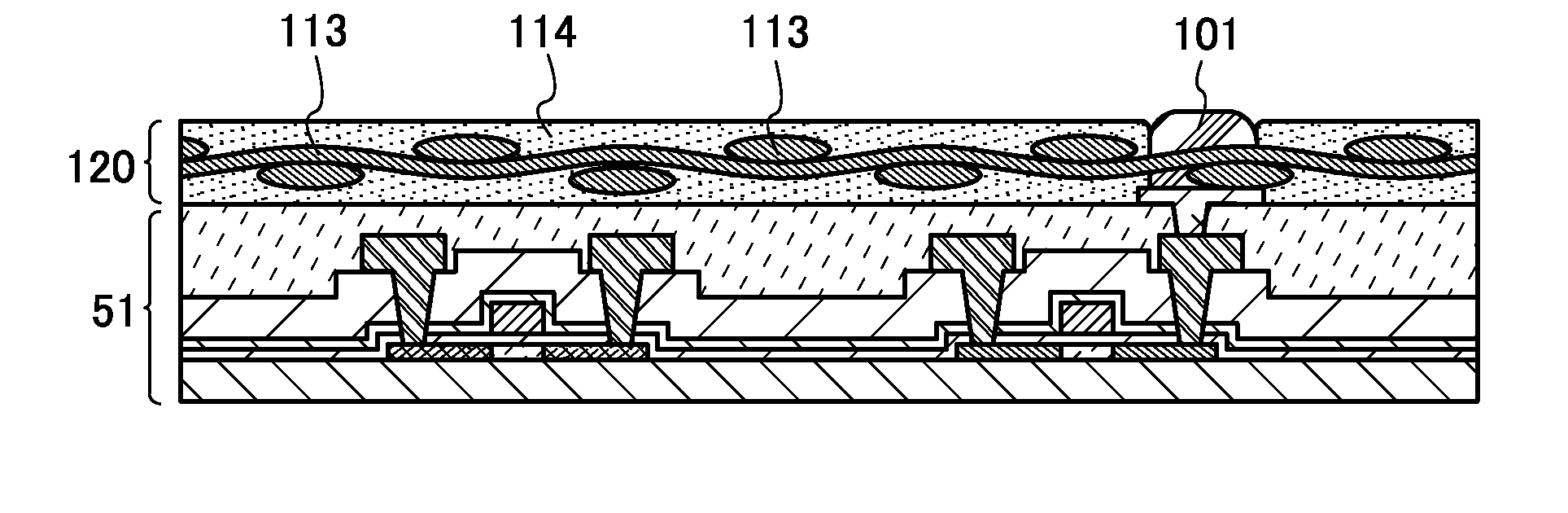

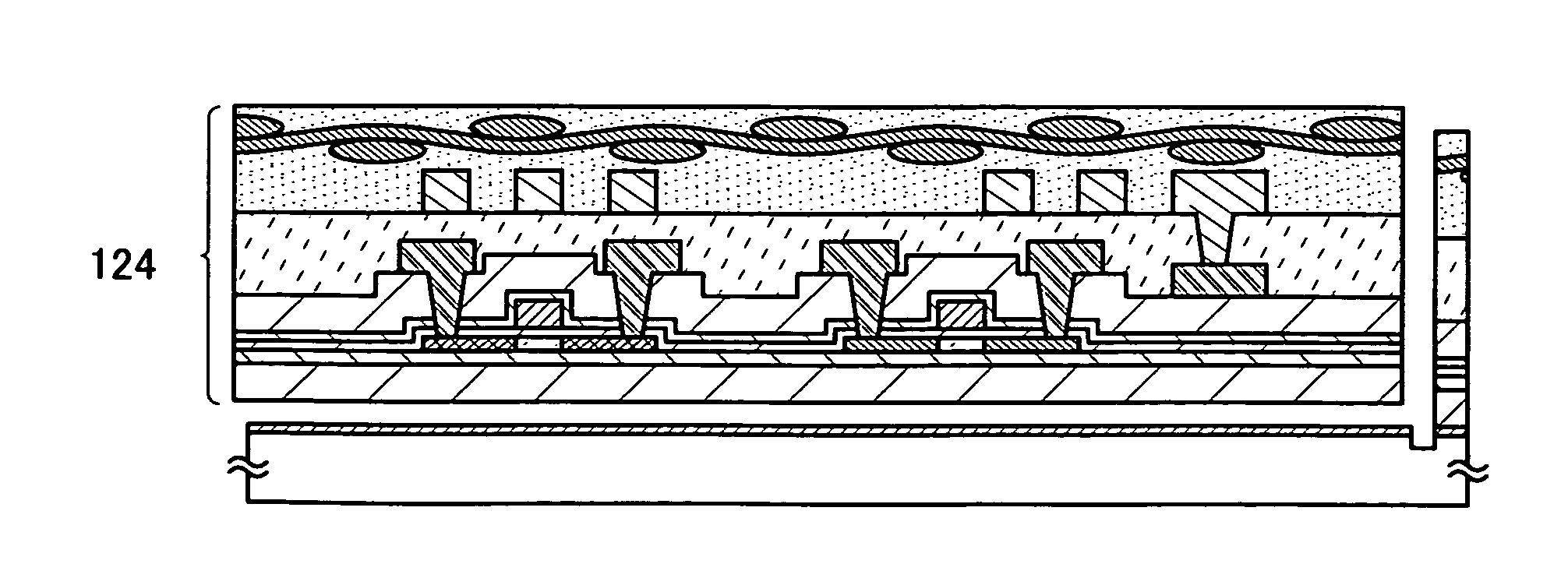

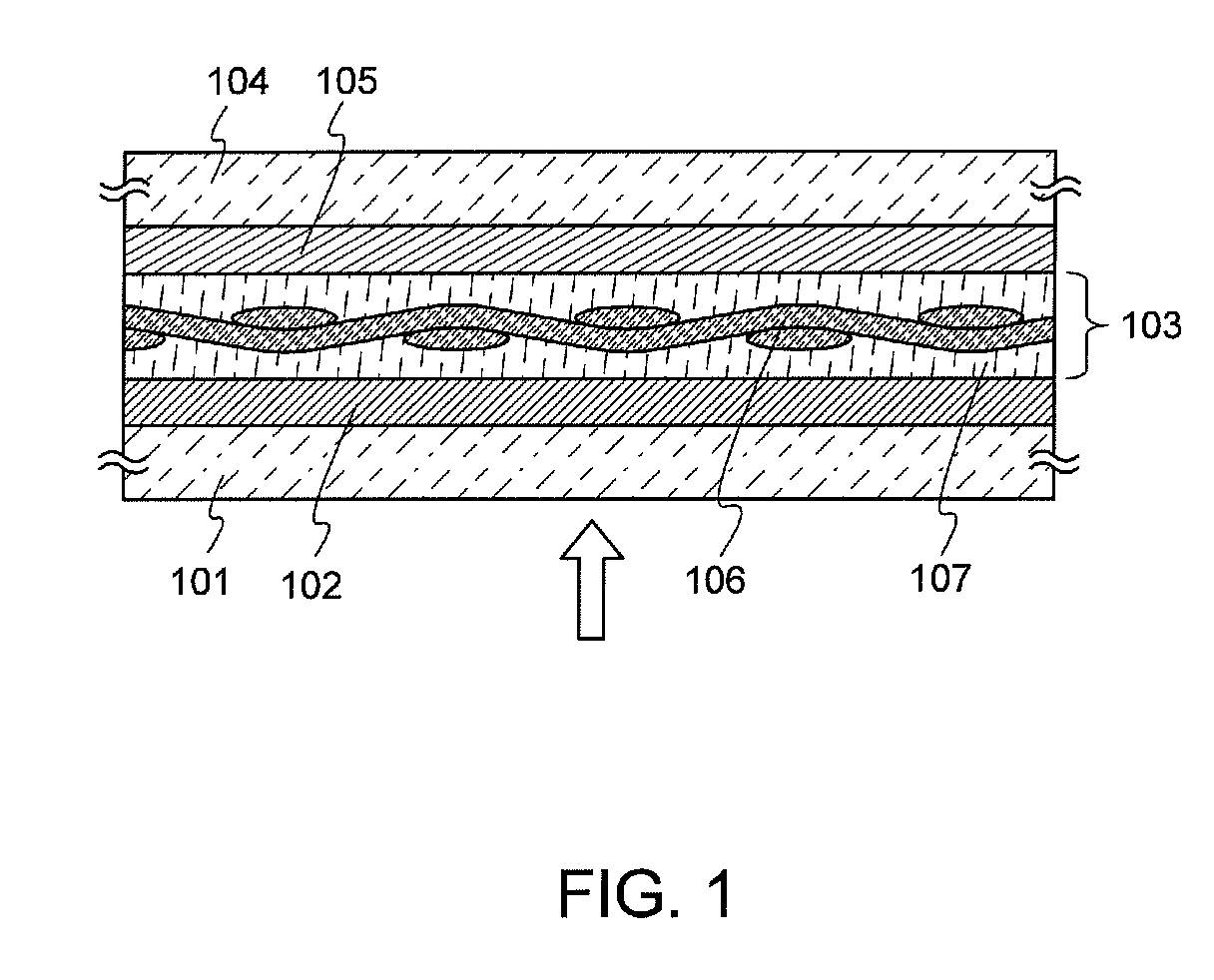

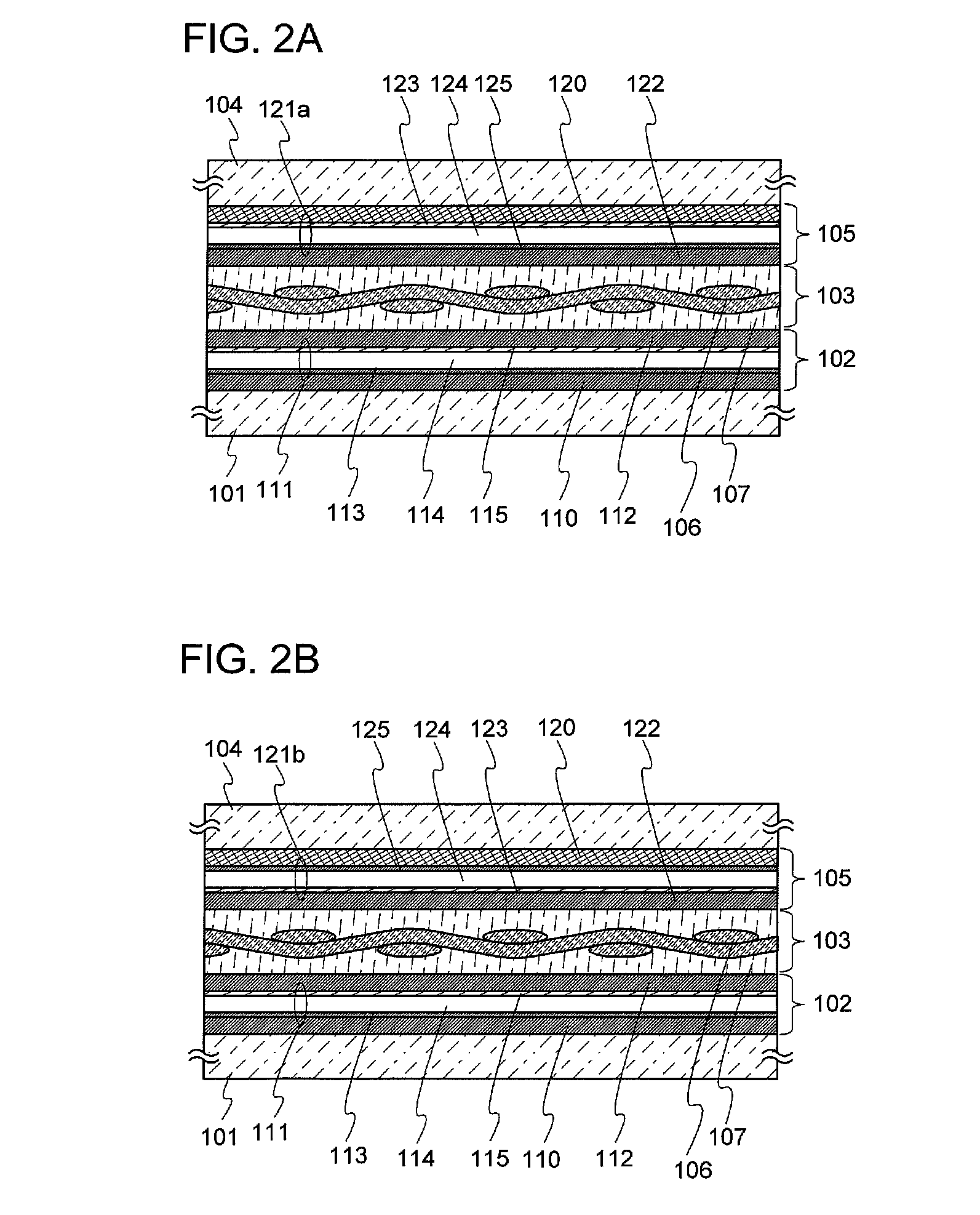

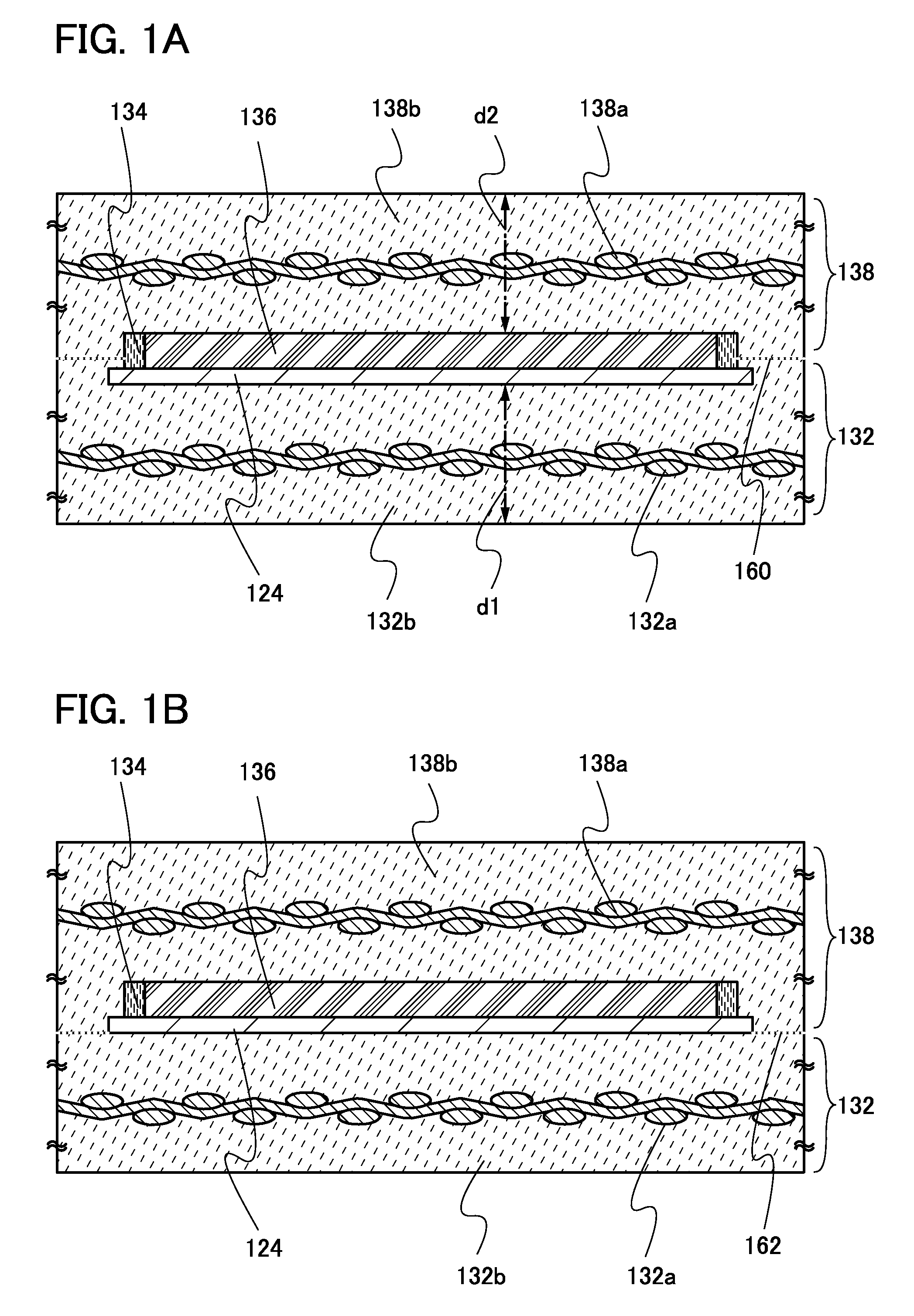

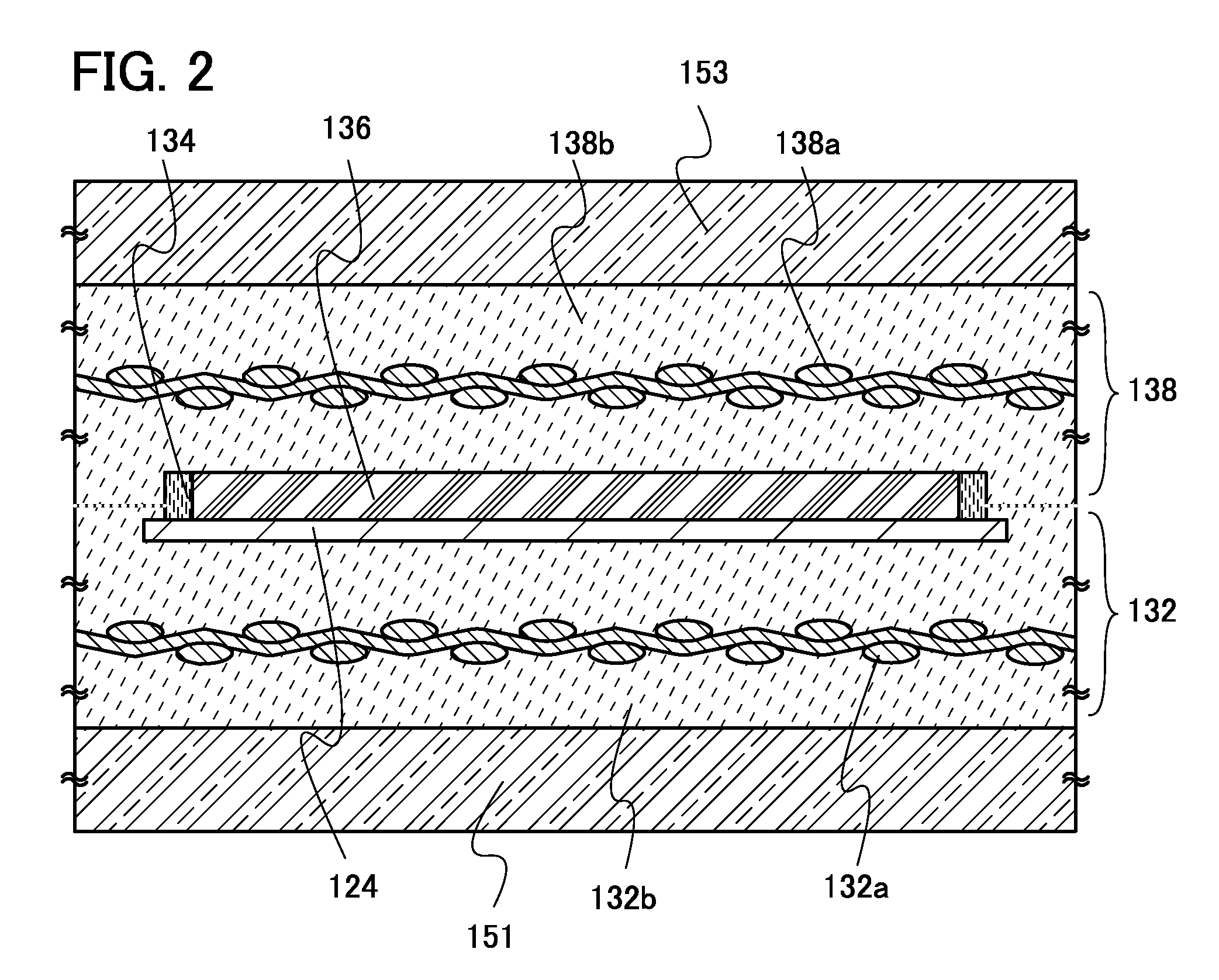

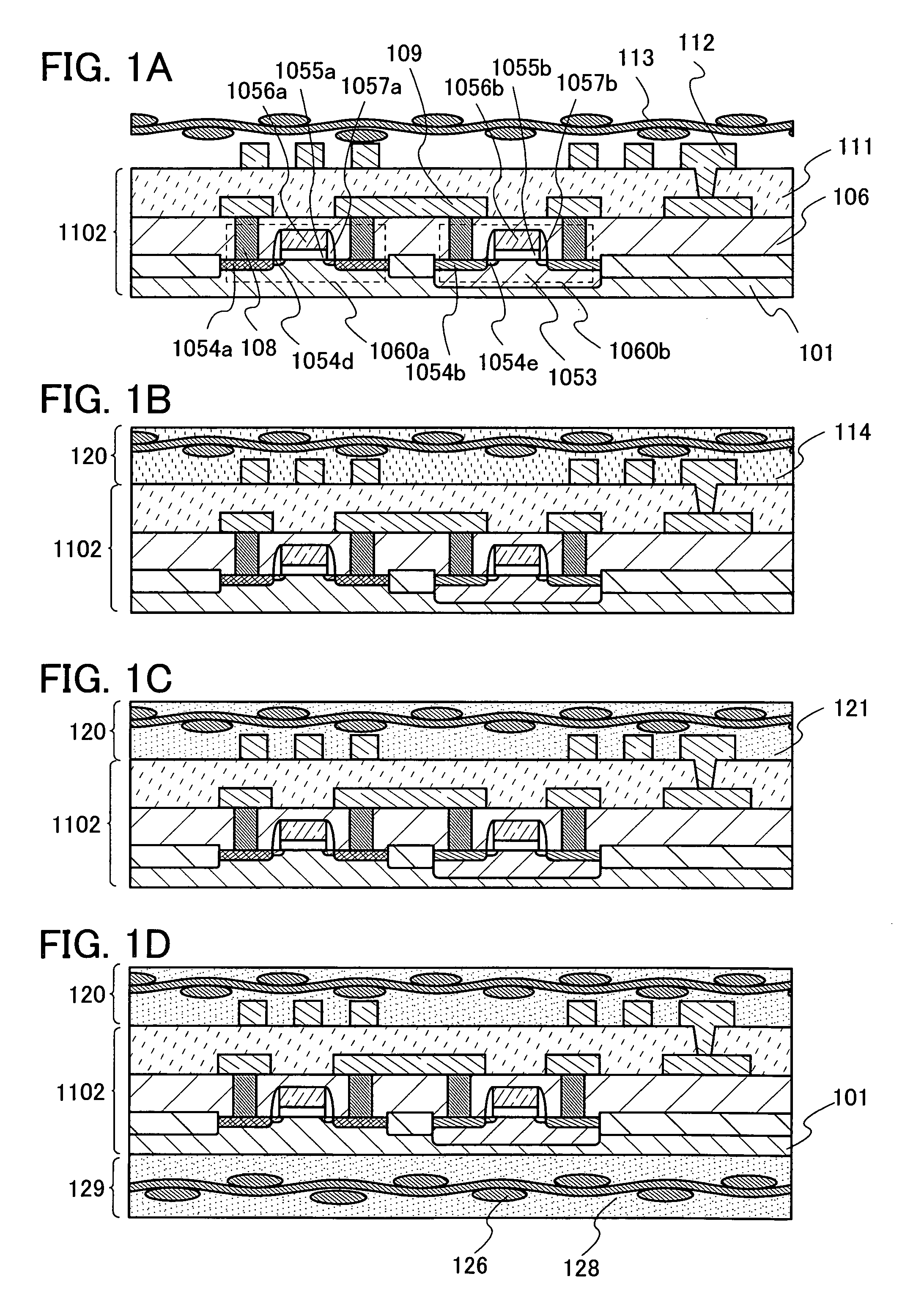

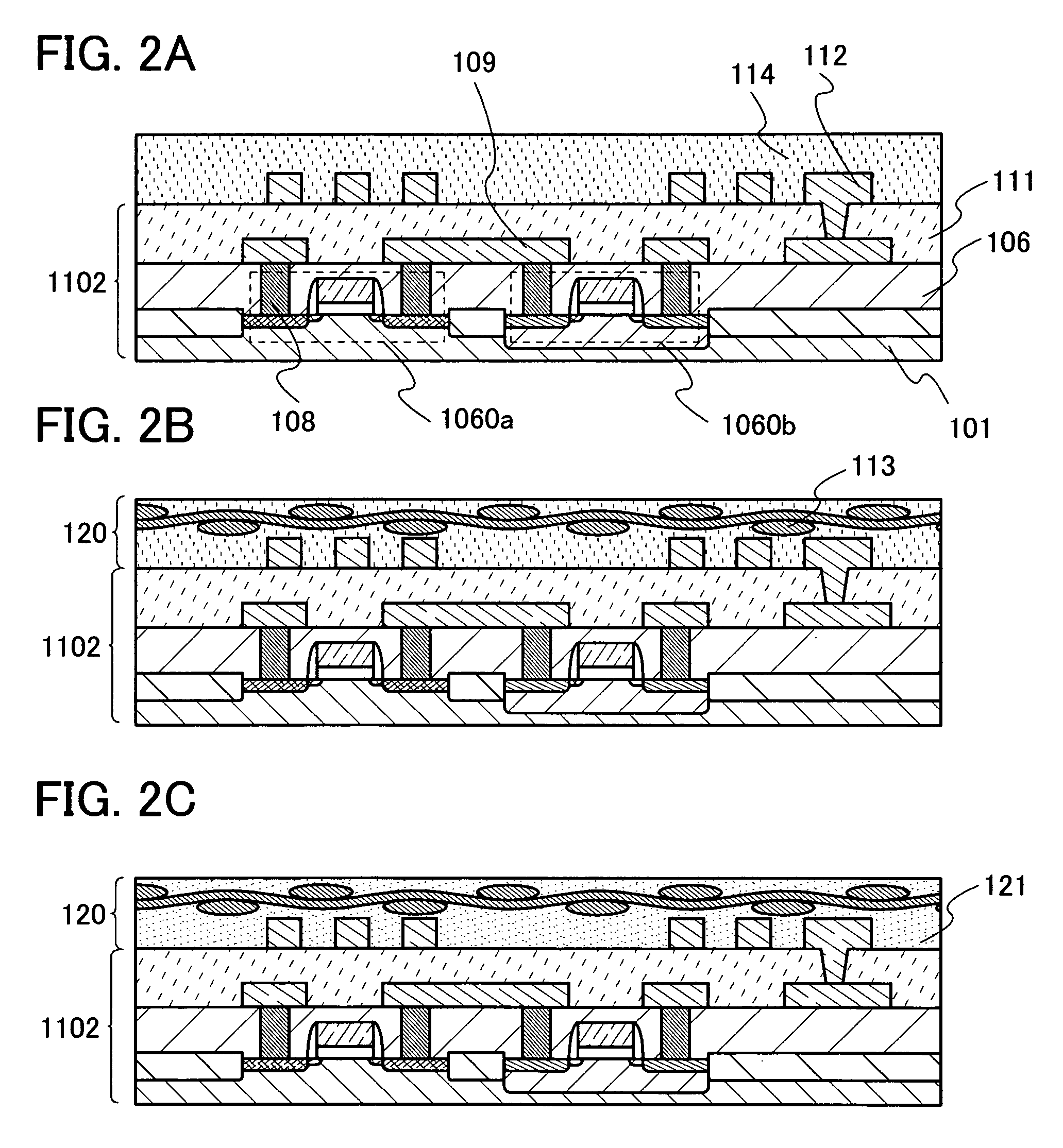

Liquid crystal display device and method for manufacturing the same

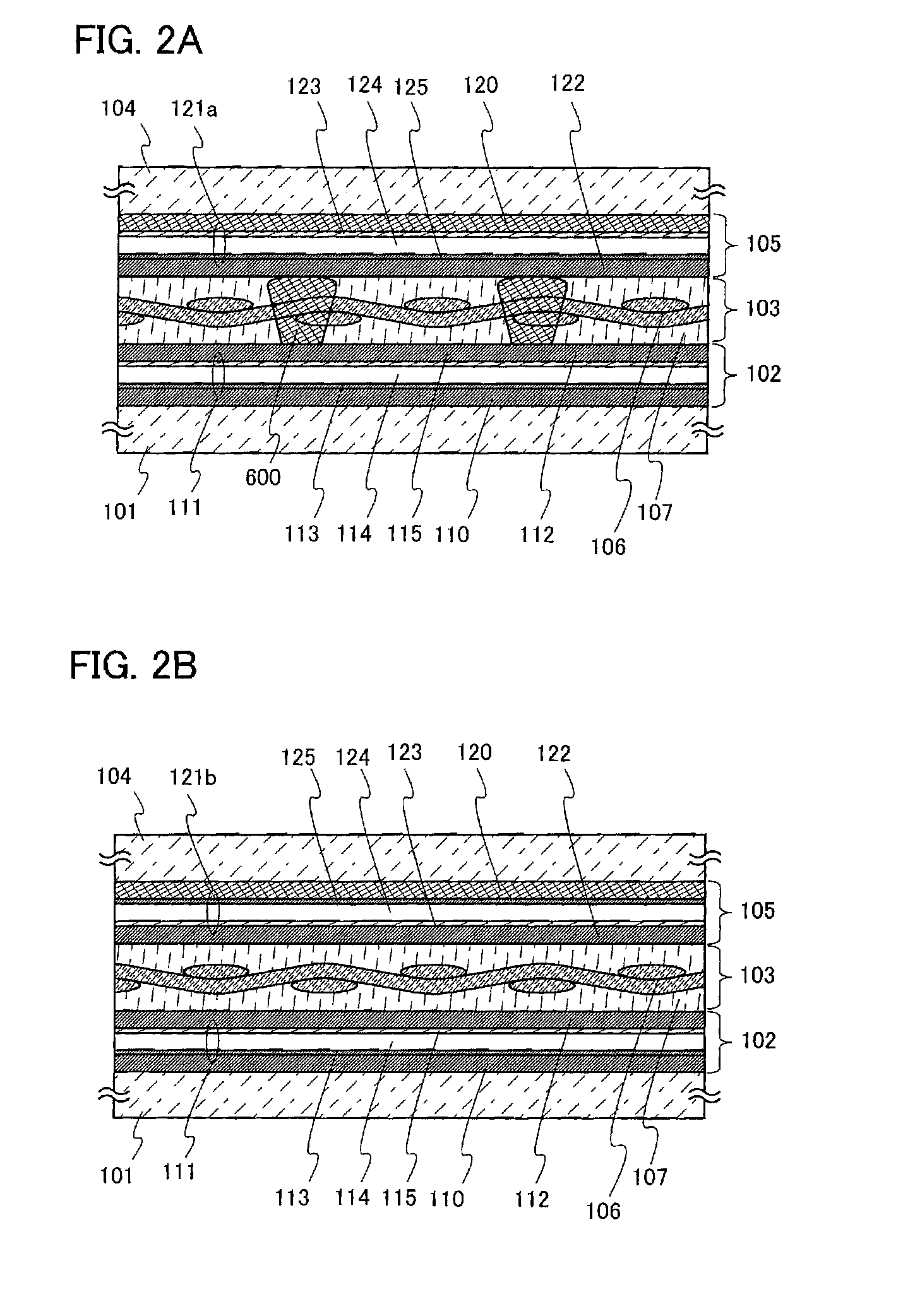

InactiveUS20100007829A1Reduce image qualityReduce harmNon-linear opticsLiquid-crystal displayEngineering

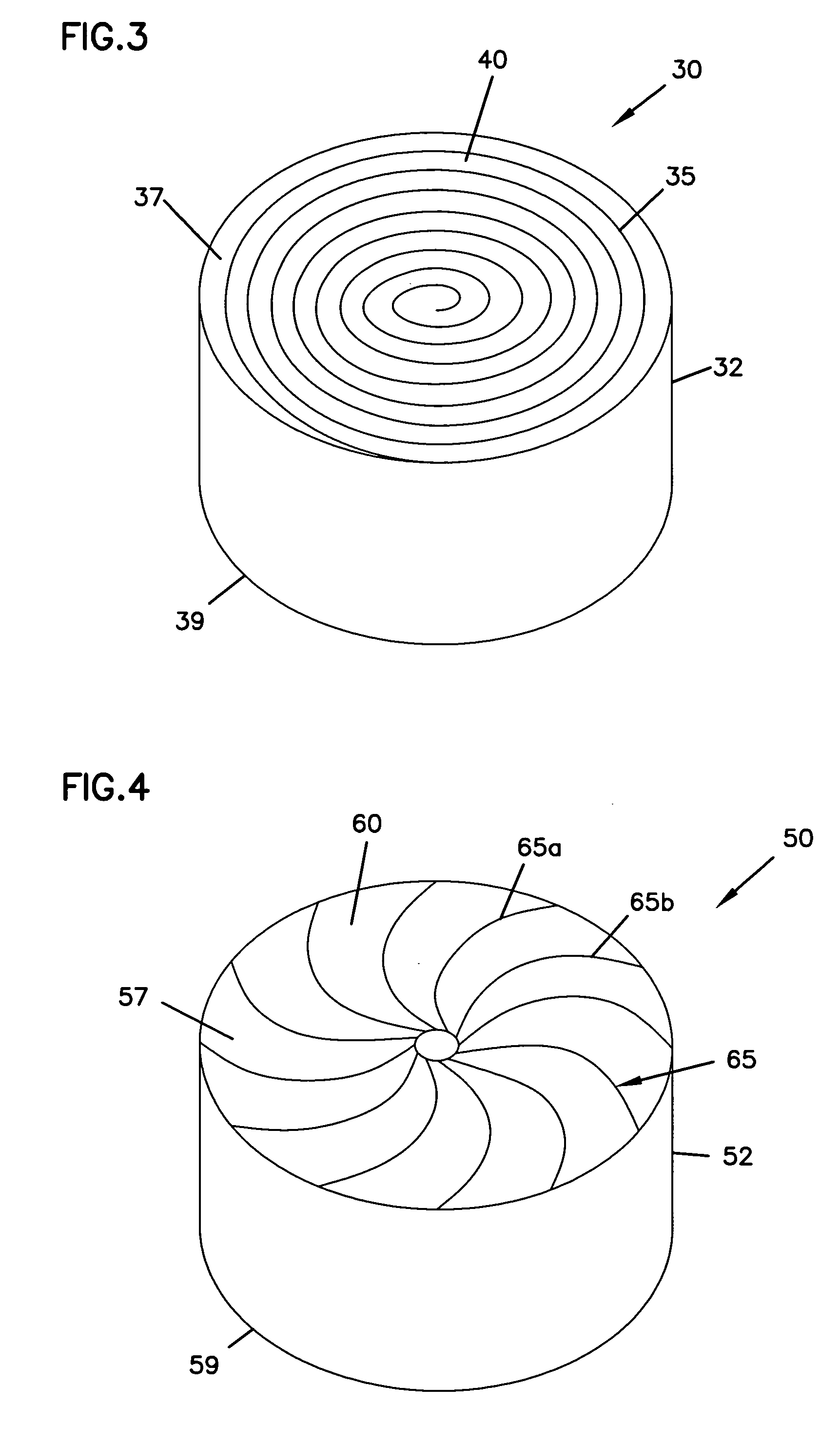

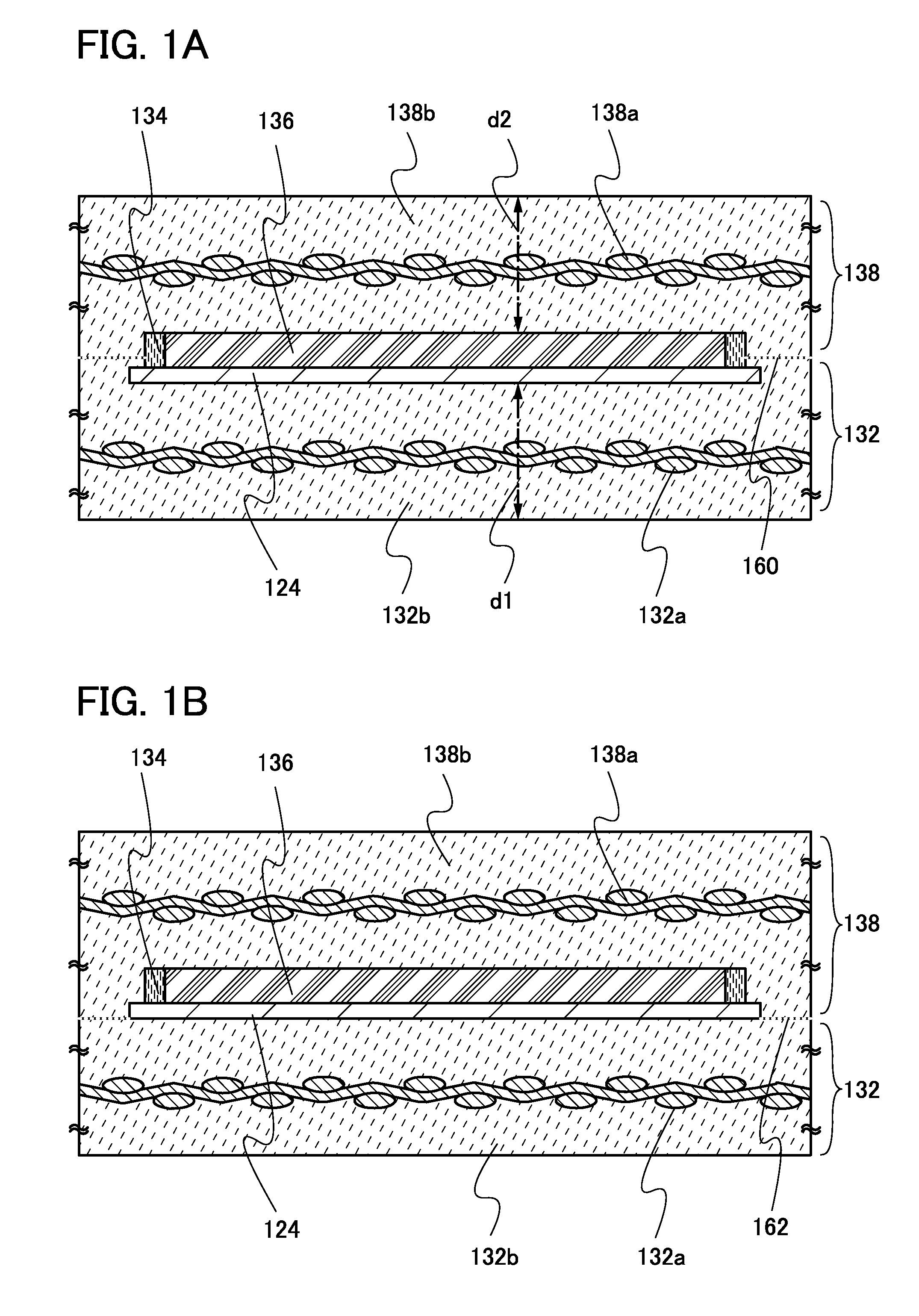

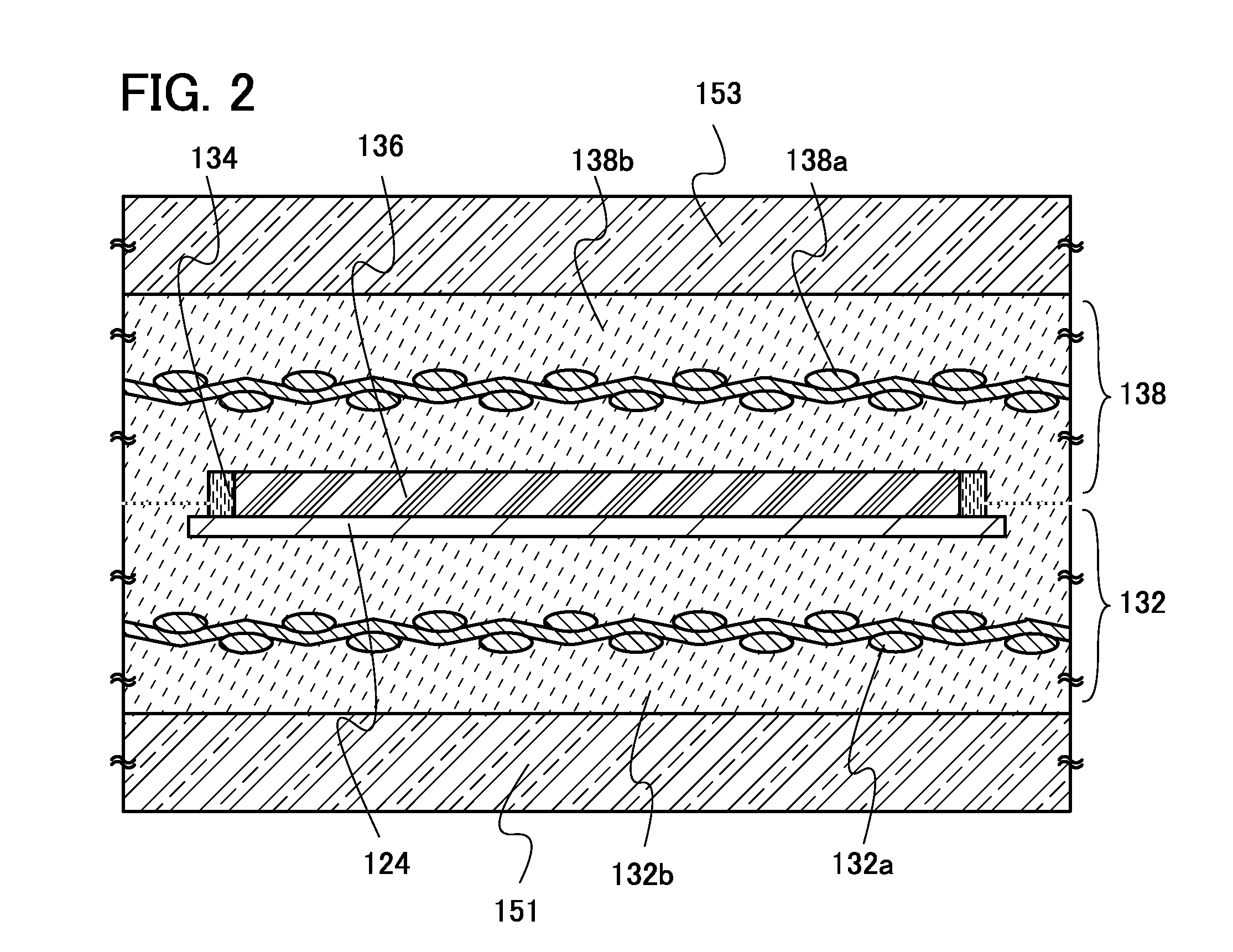

A flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is provided. A method for manufacturing, with high yield, a flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is also provided. A liquid crystal display device including a first structure body including a first fibrous body and a first organic resin, a second structure body including a second fibrous body and a second organic resin, a liquid crystal interposed between the first and second structure bodies, and a seal member for fixing the first and second structure bodies and for enclosing the liquid crystal. The first and second fibrous bodies are impregnated with the first and second organic resins, respectively, and the first structure body and the second structure body are in contact with each other.

Owner:SEMICON ENERGY LAB CO LTD

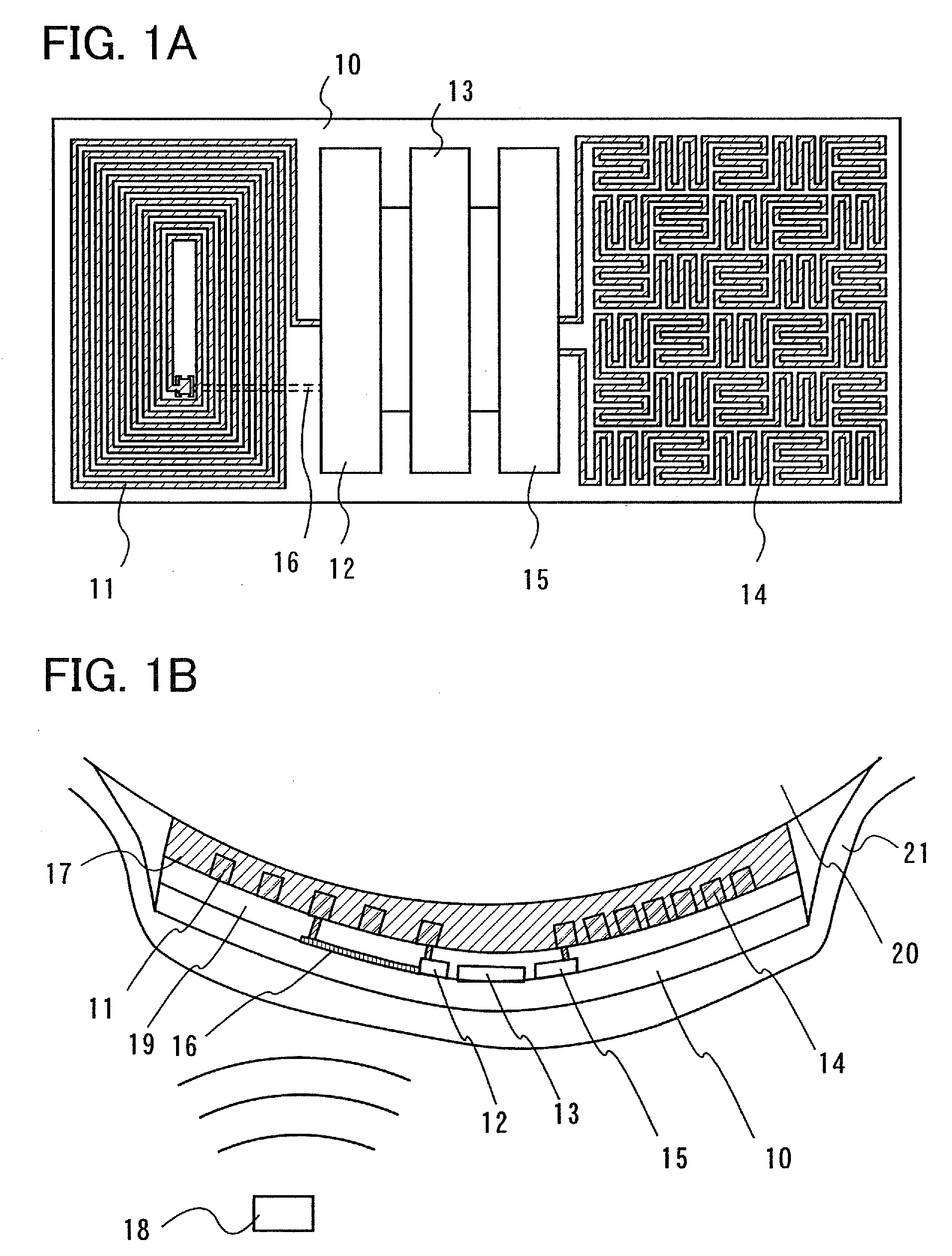

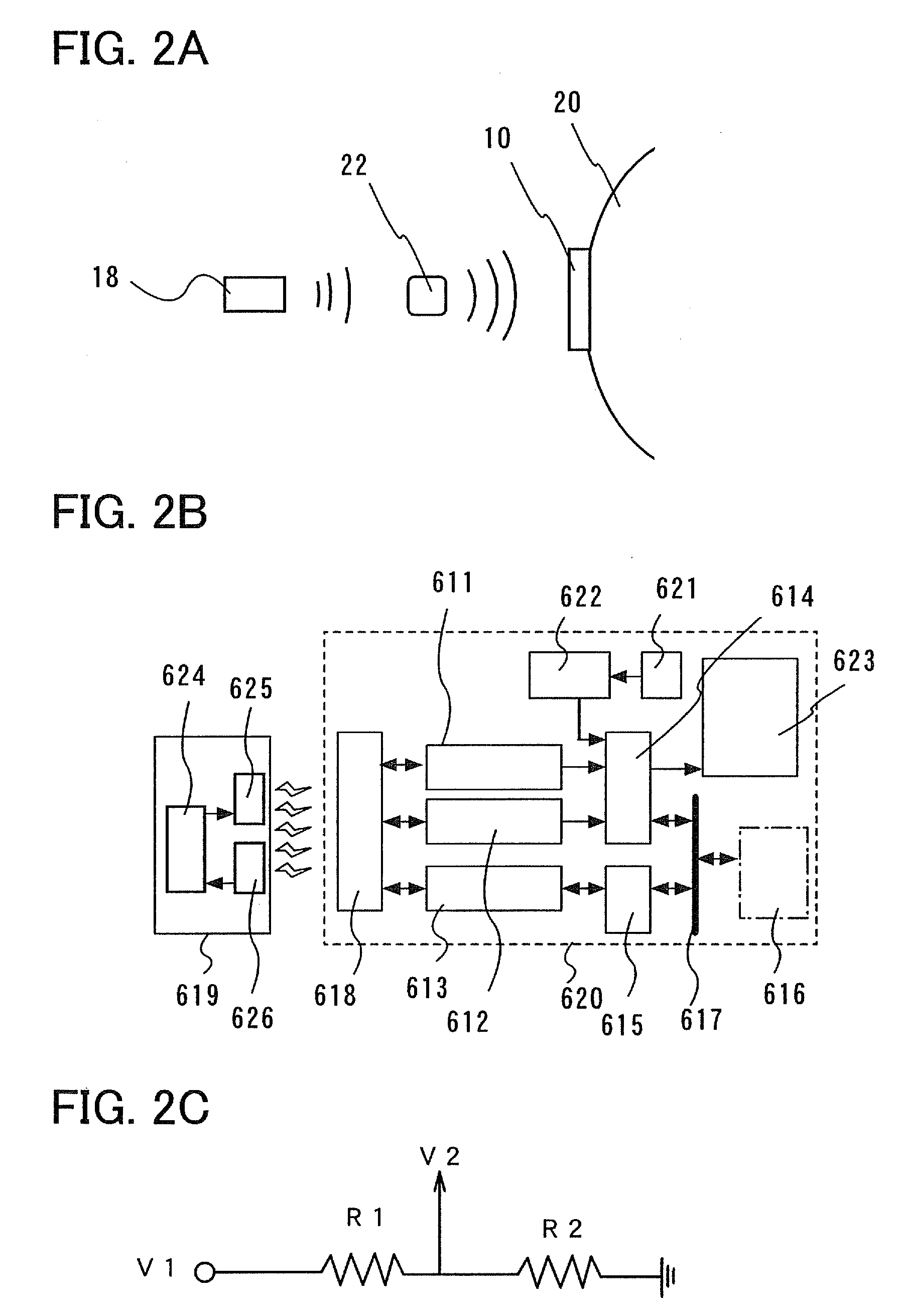

Semiconductor device

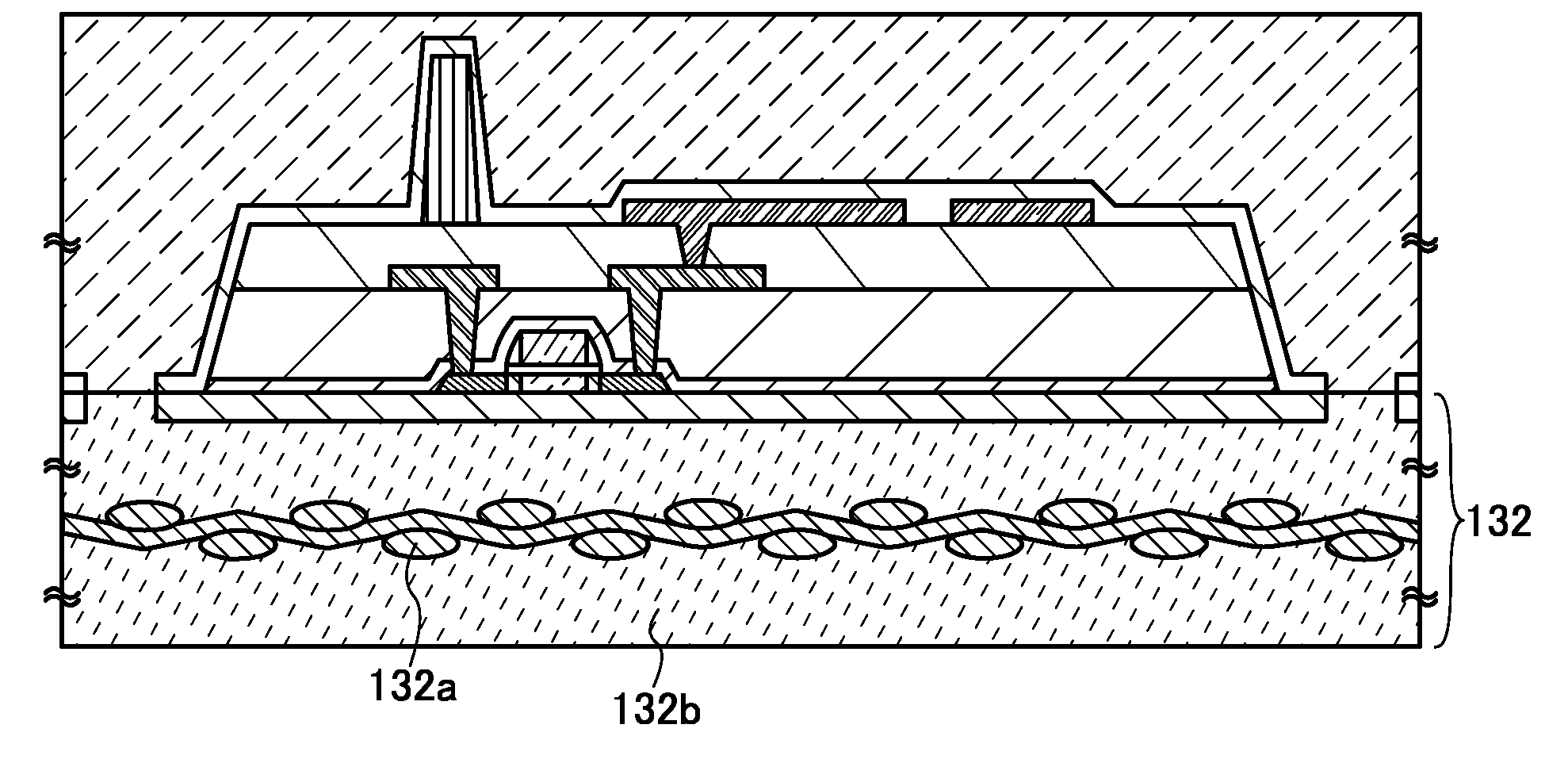

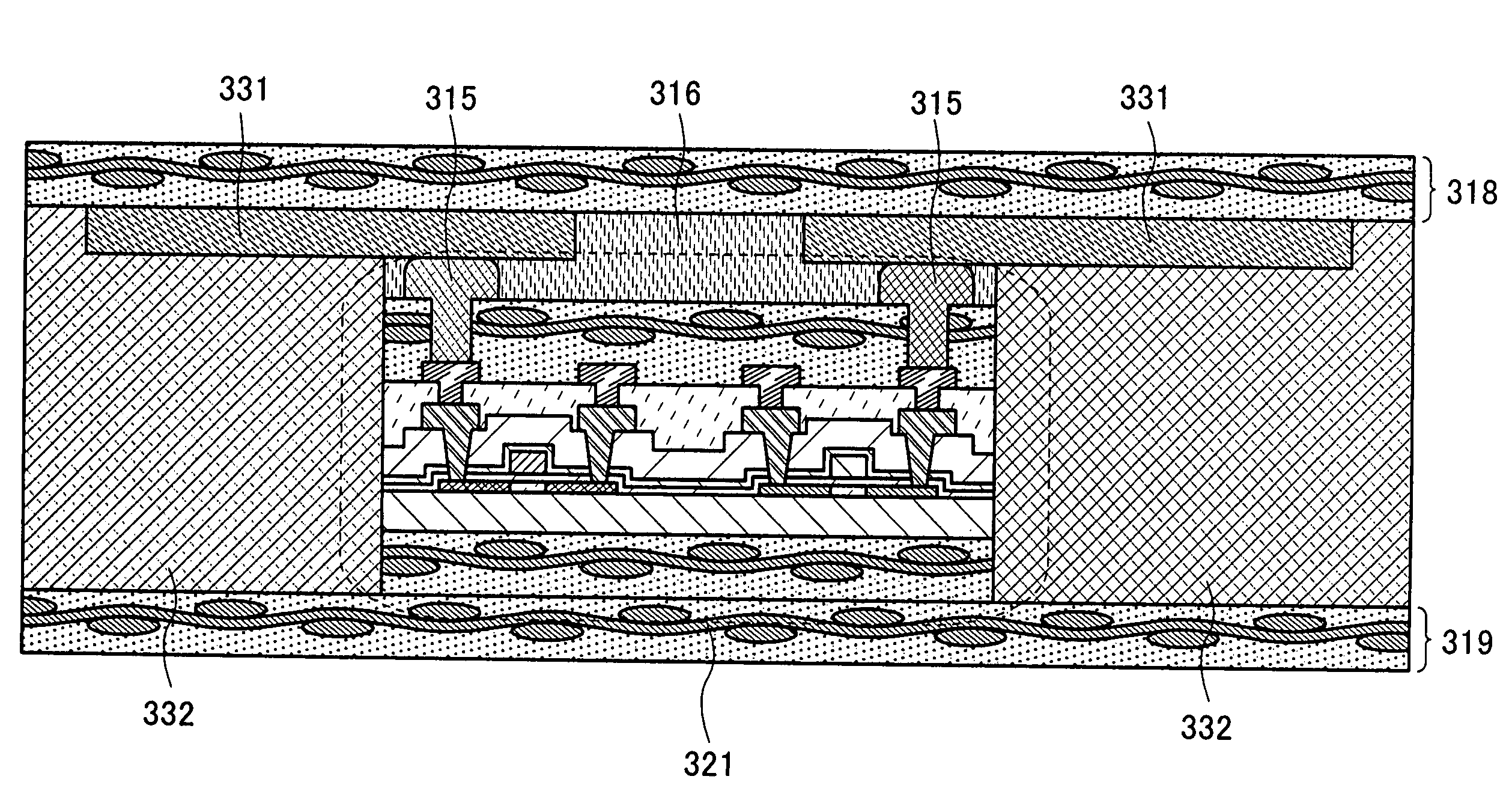

InactiveUS20090057875A1Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberEngineering

A highly reliable semiconductor device which is not damaged by local pressing force from the outside and in which unevenness of a portion where an antenna and an element overlap with each other is reduced. The semiconductor device includes a chip and an antenna. The chip includes a semiconductor element layer including a thin film transistor; a conductive resin electrically connected to the semiconductor element layer; and a sealing layer. The sealing layer in which a fiber body is impregnated with an organic resin covers the semiconductor element layer and the conductive resin, and has a thickness of 10 to 100 μm. The antenna has a depressed portion and is electrically connected to the semiconductor element layer through the conductive resin. The chip is embedded inside the depressed portion. The thickness of the chip is equal to the depth of the depressed portion.

Owner:SEMICON ENERGY LAB CO LTD

Photoelectric conversion device and method for manufacturing the same

InactiveUS20100307559A1High mechanical strengthReduce manufacturing costPV power plantsSolid-state devicesManufacturing cost reductionPhotoelectric conversion

An object is to provide a photoelectric conversion device whose mechanical strength is increased without complicating a manufacturing process. The photoelectric conversion device includes a first cell having a photoelectric conversion function, a second cell having a photoelectric conversion function, and a structure body including a fibrous body which firmly attaches the first cell and the second cell. As a result, p-i-n junctions are bonded with the structure body in which the fibrous body is impregnated with an organic resin, which is a so-called prepreg. Thus, a photoelectric conversion device whose mechanical strength is increased can be realized while the manufacturing cost is reduced.

Owner:SEMICON ENERGY LAB CO LTD

Liquid crystal display device and method for manufacturing the same

A flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is provided. A method for manufacturing, with high yield, a flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is also provided. A liquid crystal display device including a first structure body including a first fibrous body and a first organic resin, a second structure body including a second fibrous body and a second organic resin, a liquid crystal interposed between the first and second structure bodies, and a seal member for fixing the first and second structure bodies and for enclosing the liquid crystal. The first and second fibrous bodies are impregnated with the first and second organic resins, respectively, and the first structure body and the second structure body are in contact with each other.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device

InactiveUS7759788B2Improve reliabilityReduce unevennessSemiconductor/solid-state device detailsSolid-state devicesFiberEngineering

A highly reliable semiconductor device which is not damaged by local pressing force from the outside and in which unevenness of a portion where an antenna and an element overlap with each other is reduced. The semiconductor device includes a chip and an antenna. The chip includes a semiconductor element layer including a thin film transistor; a conductive resin electrically connected to the semiconductor element layer; and a sealing layer. The sealing layer in which a fiber body is impregnated with an organic resin covers the semiconductor element layer and the conductive resin, and has a thickness of 10 to 100 μm. The antenna has a depressed portion and is electrically connected to the semiconductor element layer through the conductive resin. The chip is embedded inside the depressed portion. The thickness of the chip is equal to the depth of the depressed portion.

Owner:SEMICON ENERGY LAB CO LTD

Plant culture soil and processing method thereof

InactiveCN106986682AImprove firmnessHigh porosityCalcareous fertilisersMagnesium fertilisersMonopotassium phosphateBiology

The invention provides plant culture soil. The plant culture soil comprises, by weight, 20-36 parts of chicken manure, 10-48 parts of pig manure, 100-300 parts of potassium nitrate, 20-120 parts of fibrous bodies, 50-88 parts of calcium chloride, 46-97 parts of magnesium sulfate, 44-118 parts of monopotassium phosphate, 28-46 parts of ferric salt, 8-10 parts of decavitamin, 250-350 parts of agar, 2-5 parts of beer paste, 0.1-1 part of Chinese photinia leaf, 2-6 parts of water-retaining agents, 90-110 parts of potatoes, 40-60 parts of carbon powder and 11-22 parts of bean pulp. The invention further provides a processing method of the culture soil. The plant culture soil has good water and fertilizer retaining performance and high water and air permeability, the pH value of the culture soil can be stabilized, and a certain inhibition effect on reproduction of pathogenic bacteria is achieved; the processing method of the culture soil is simple, and industrialized production is easily realized.

Owner:新昌县天姥园艺发展有限公司

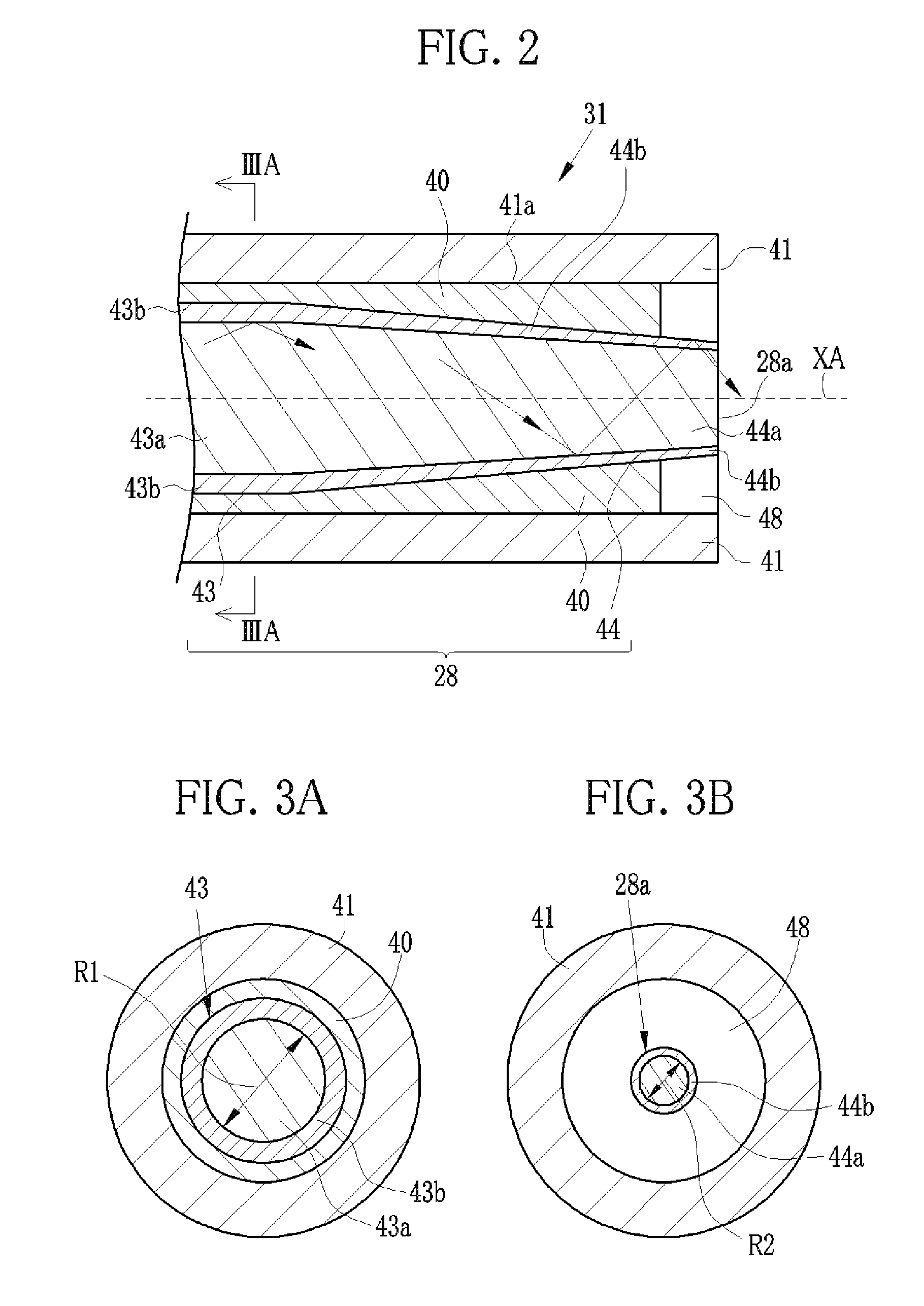

Light guide, light source apparatus and endoscope system

A large diameter fiber is composed of a multimode optical fiber and provided with a fiber body having a constant diameter in an optical axis direction XA and a tapered section tapered in diameter toward a light exit surface. An adhesive member attaches the large diameter fiber inside a retaining hole of a tubular housing such that an outer circumferential surface of a tapered clad of the tapered section is entirely exposed to air to a predetermined depth from the light exit surface. A light passing space is a ring-like space formed between the exposed outer circumferential surface of the tapered clad and an inner circumferential surface of the tubular housing. Light in the tapered section is output from the light exit surface and partially leaked to the tapered clad. A part of the leaked light is released from the light passing space.

Owner:FUJIFILM CORP

Method for manufacturing semiconductor device

InactiveUS7785933B2Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

Owner:SEMICON ENERGY LAB CO LTD

Wiring substrate, manufacturing method thereof, semiconductor device, and manufacturing method thereof

InactiveUS20090302457A1Maintain mechanical strengthMaintenanceSemiconductor/solid-state device detailsPrinted circuit aspectsDevice materialEngineering

A wiring substrate is provided, including an insulating resin layer which is provided on both surfaces of a sheet-like fibrous body and with which the sheet-like fibrous body is impregnated, and a through wiring provided in a region surrounded by the insulating resin layer. The through wiring is formed using a conductive material, the conductive material is exposed on both surfaces of the insulating resin layer, the sheet-like fibrous body is positioned in the conductive material, and the sheet-like fibrous body is impregnated with the conductive material. A manufacturing method of the wiring substrate is also provided.

Owner:SEMICON ENERGY LAB CO LTD

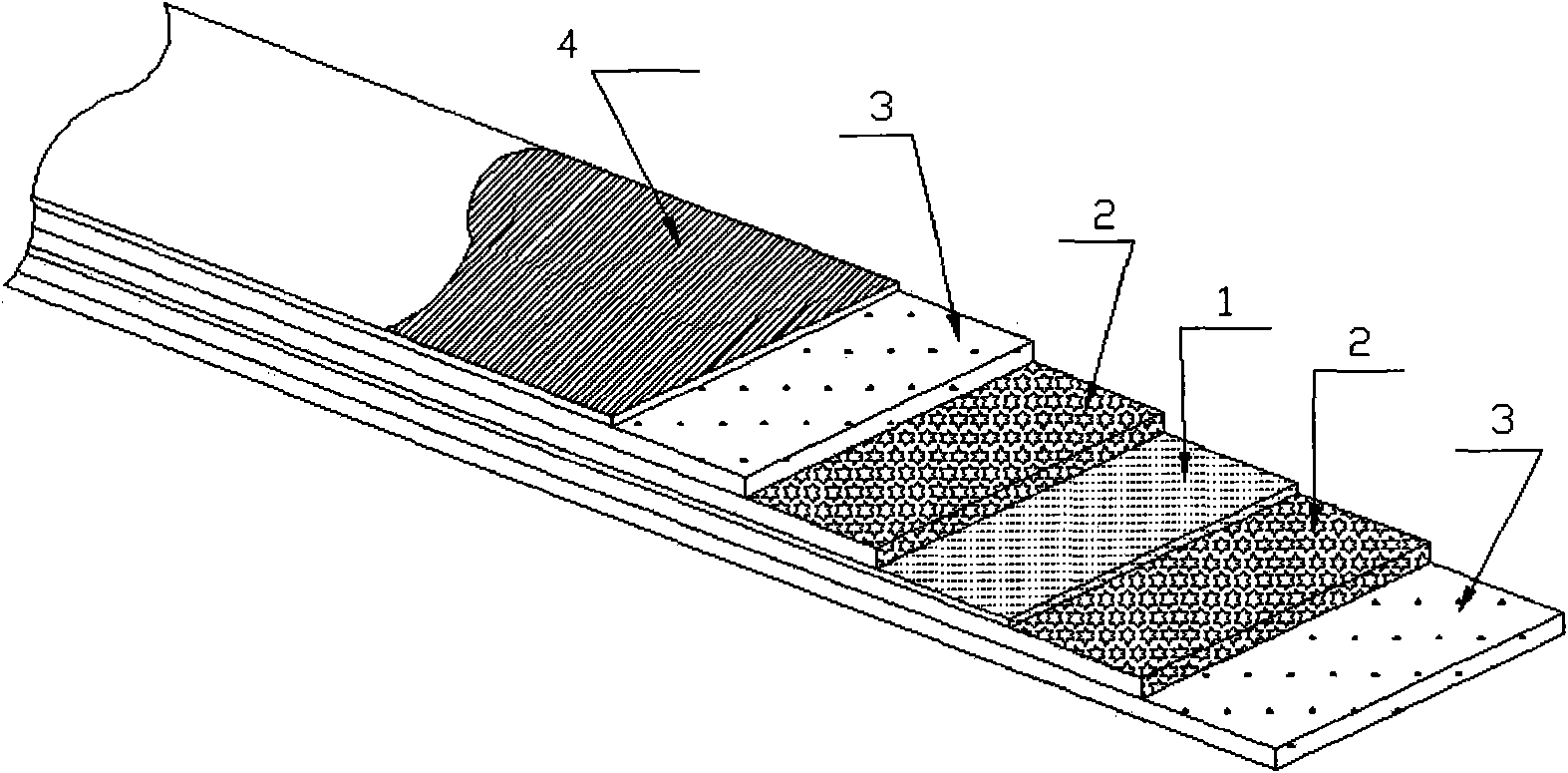

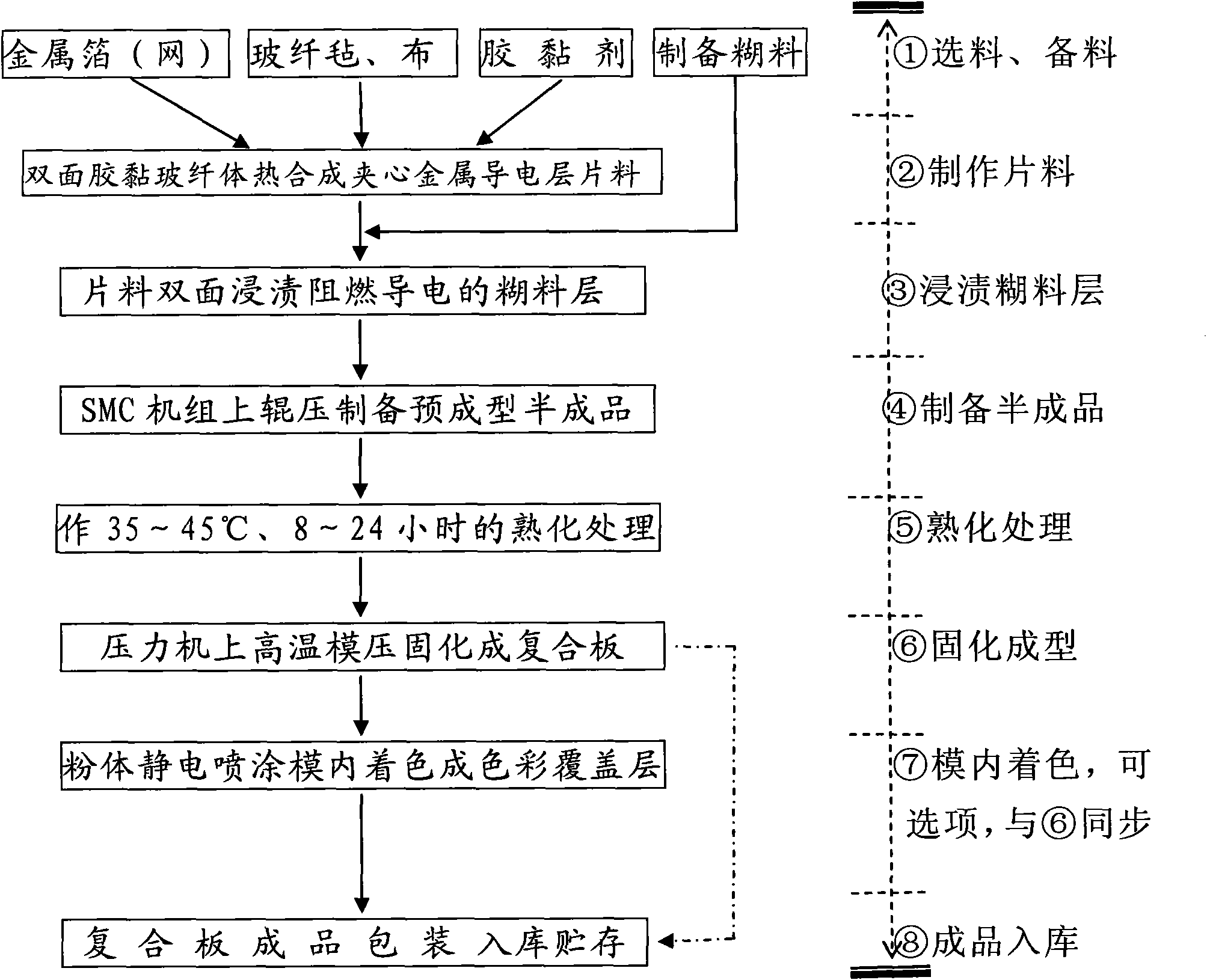

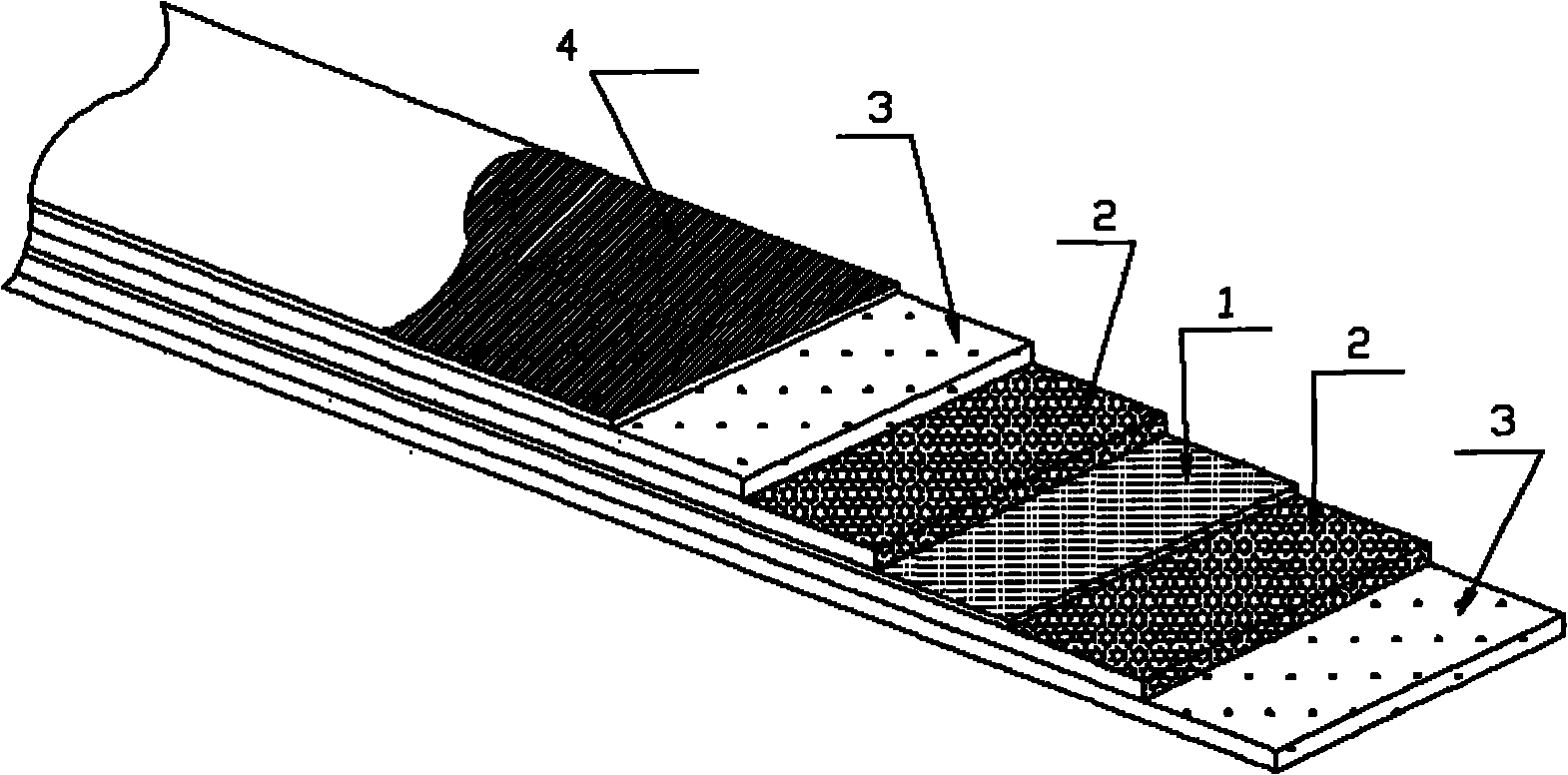

Composite plate with electromagnetic shielding and antistatic effects and production process

InactiveCN101808498AHigh specific strengthImprove flame retardant performanceMagnetic/electric field screeningGlass/slag layered productsPolyesterFiber

The invention discloses a composite plate with electromagnetic shielding and antistatic effects and a production process, the product is formed by combining a metal foil (or net) 1, a glass fibrous body 2, a flame-retardant and conducting paste layer 3, a color overlay layer 4 and flame-retardant and heat-resistant adhesive, and the production process comprises eight steps, namely (1) selecting and preparing materials, (2) making sheet stocks, (3) impregnating the paste layer, (4) preparing semi-finished products, (5) aging processing, (6) curing molding, (7) in-mold coloring and (8) warehousing finished products. The composite plate is a glass-fiber fabric reinforced sandwiched metal foil (or net) composite plate which is molded by impregnating and pressing unsaturated polyester, which has good electromagnetic shielding function, polymerized substance on the surface layer is doped with conducting particles and conducting fiber, thus forming a permanently antistatic working surface of the electric resistivity between 105ohm and 109ohm, the longitudinal tensile strength and the transverse tensile strength are higher than that of an aluminum alloy plate and are equivalent to that of a stainless steel plate, the excellent flame retardancy can achieve UL94 to V0 grade, and the composite plate can be used as inner decoration of a machine room of precise microelectronic equipment. When the color is coated on the surface, no solvent is contained, and the color coating is in synchronization with mold pressing, compared with coating paint after molding, the production process is energy-saving and environmental-friendly, and selection of the layer material is various and free, thus meeting the demands of various environments and having wide market prospect.

Owner:QINGDAO HUACI MARINE EQUIP TECH CO LTD

Photoelectric conversion device and method for manufacturing the same

ActiveUS20100307557A1Improve performanceReduce manufacturing costBraking element arrangementsPV power plantsElectrical connectionFibrous body

A multi junction photoelectric conversion device that can be manufactured by a simple method is provided. In addition, a photoelectric conversion device whose mechanical strength is increased without complicating a manufacturing process is provided. A photoelectric conversion device includes a first cell having a photoelectric conversion function, a second cell having a photoelectric conversion function, and a structure body including a fibrous body, which firmly attaches and electrically connects the first cell and the second cell to each other. Accordingly, a multi-junction photoelectric conversion device in which semiconductor junctions are connected in series and sufficient electrical connection between p-i-n junctions is ensured can be provided.

Owner:SEMICON ENERGY LAB CO LTD

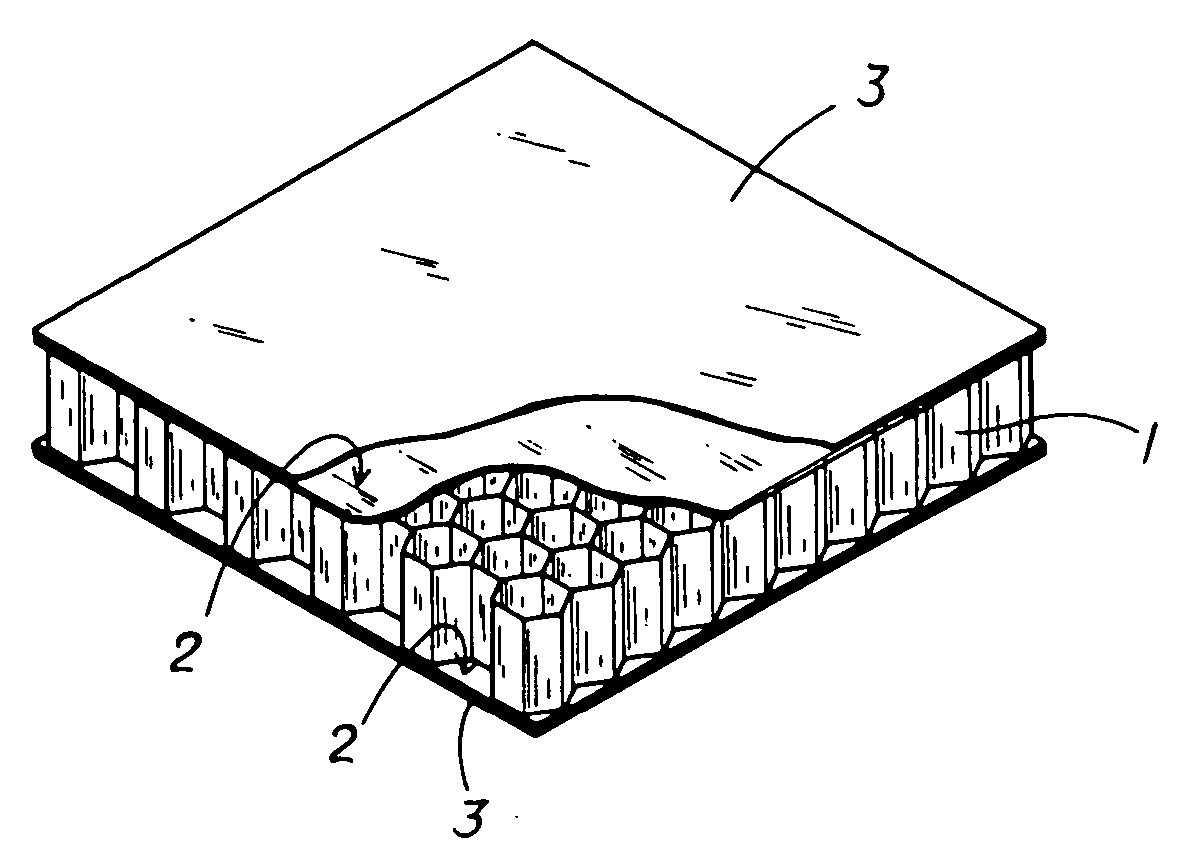

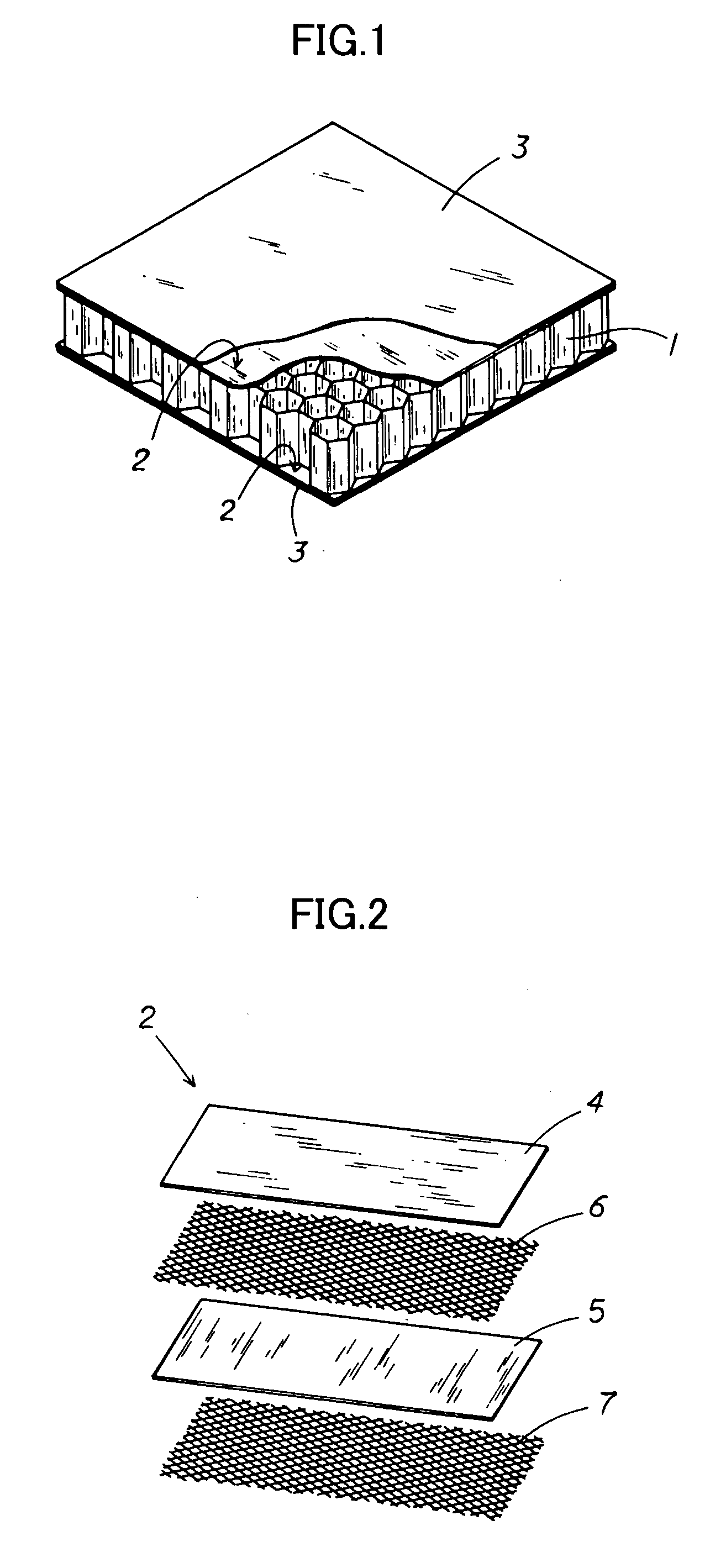

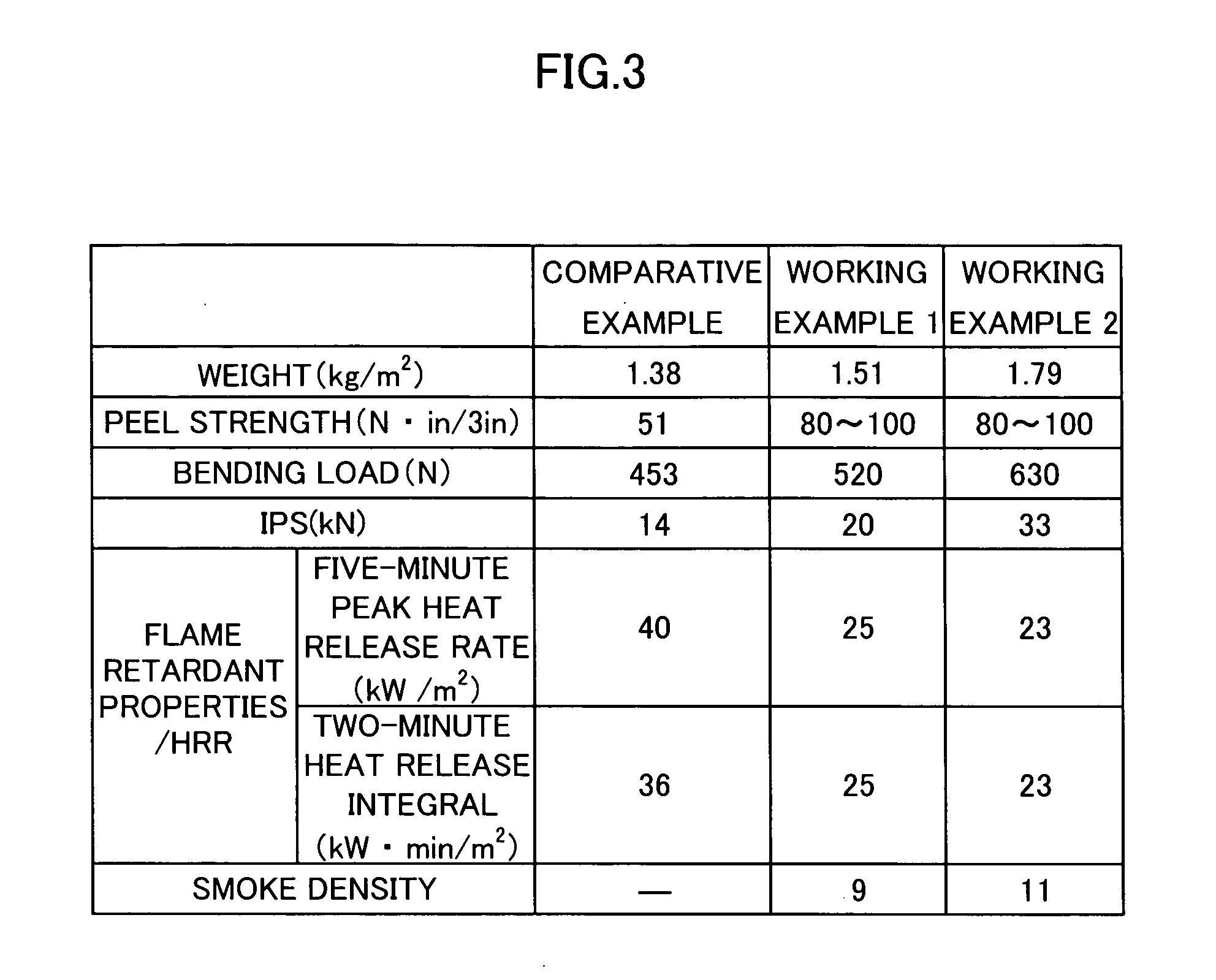

Sandwich panel

ActiveUS20080131645A1Improve practicalityReduce weightSynthetic resin layered productsBuilding componentsFiberSandwich board

A sandwich panel that has excellent practicality as an inner wall material used in aircraft, for example, whereby the abovementioned requirements of flexural strength, peel strength, and in-plane shear strength can be satisfied while having reduced weight. A sandwich panel in which a middle material 2 and a surface material 3 that are each formed by laminating a plurality of fiber bodies are laminated from inside to outside on the upper and lower surfaces of a hollow columnar core 1, wherein the middle material 2 is composed of a set of unidireactional fiber bodies 4, 5 whose fibers are aligned in one direction, fibers in a first unidireactional fiber body 4 are in a direction that is substantially parallel to an edge of the sandwich panel, fibers in a second unidireactional fiber body 5 are in a direction that is substantially orthogonal to an edge of the sandwich panel, and bonding layers 6, 7 having a resin content ratio of 50% or higher are provided between the unidireactional fiber bodies 4, 5 and between the hollow columnar core 1 and an inside unidireactional fiber body 5.

Owner:JAMCO +1

Semiconductor device

InactiveUS7906847B2Improve reliabilityHigh modulusSemiconductor/solid-state device detailsSolid-state devicesSimple Organic CompoundsPower semiconductor device

To provide a semiconductor device which can increase reliability with respect to external force, especially pressing force, while the circuit size or the capacity of memory is maintained. A pair of structure bodies each having a stack of fibrous bodies of an organic compound or an inorganic compound, which includes a plurality of layers, especially three or more layers, is impregnated with an organic resin, and an element layer provided between the pair of structure bodies are included. The element layer and the structure body can be fixed to each other by heating and pressure bonding. Further, a layer for fixing the element layer and the structure body may be provided. Alternatively, the structure body fixed to an element layer can be formed in such a way that after a plurality of fibrous bodies is stacked over the element layer, the fibrous bodies are impregnated with an organic resin.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com