Composite plate with electromagnetic shielding and antistatic effects and production process

A technology of electromagnetic shielding and composite boards, applied in the direction of magnetic/electric field shielding, static electricity, electrical components, etc., to achieve the effects of environmentally friendly material selection, broad market prospects, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

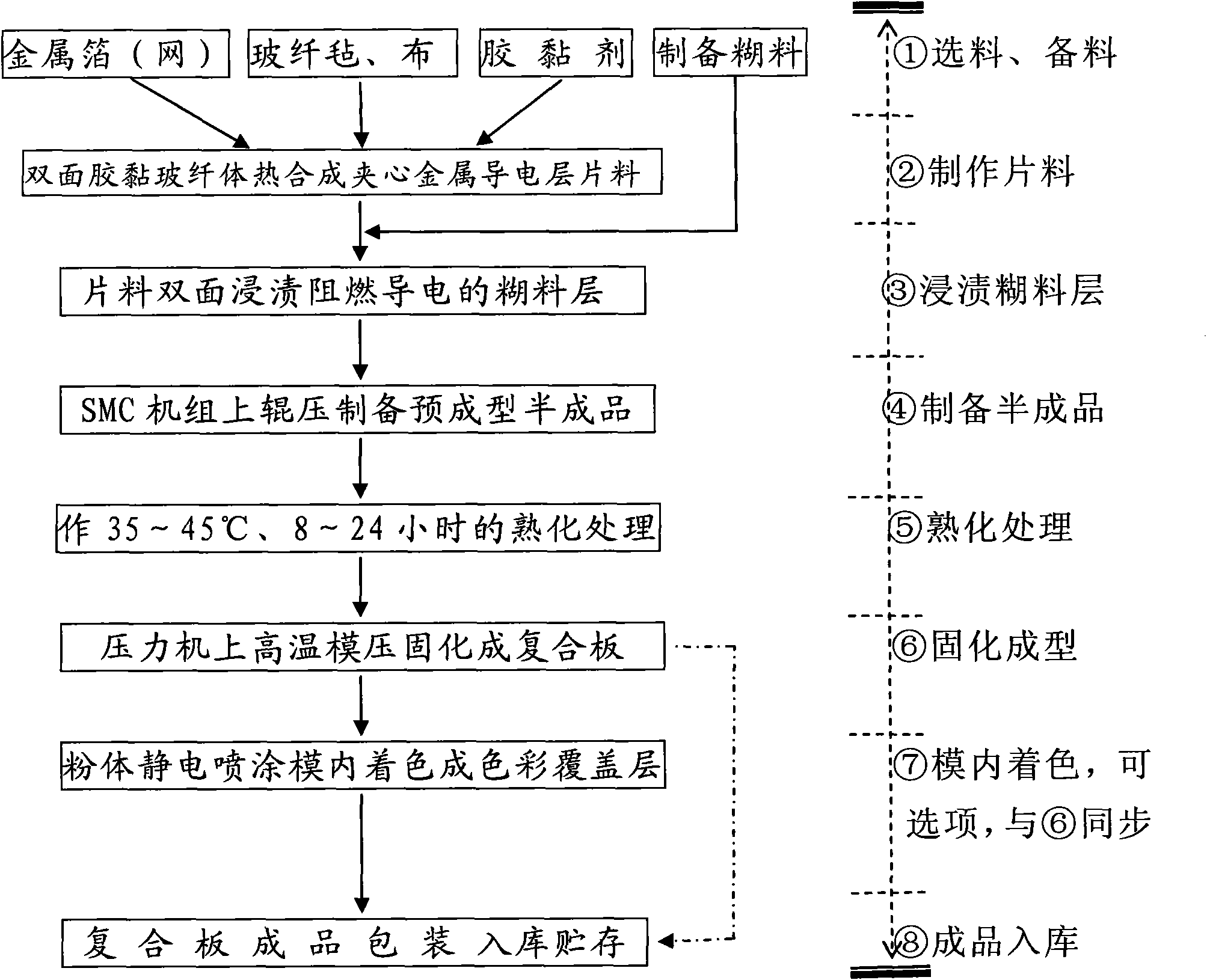

Method used

Image

Examples

Embodiment Construction

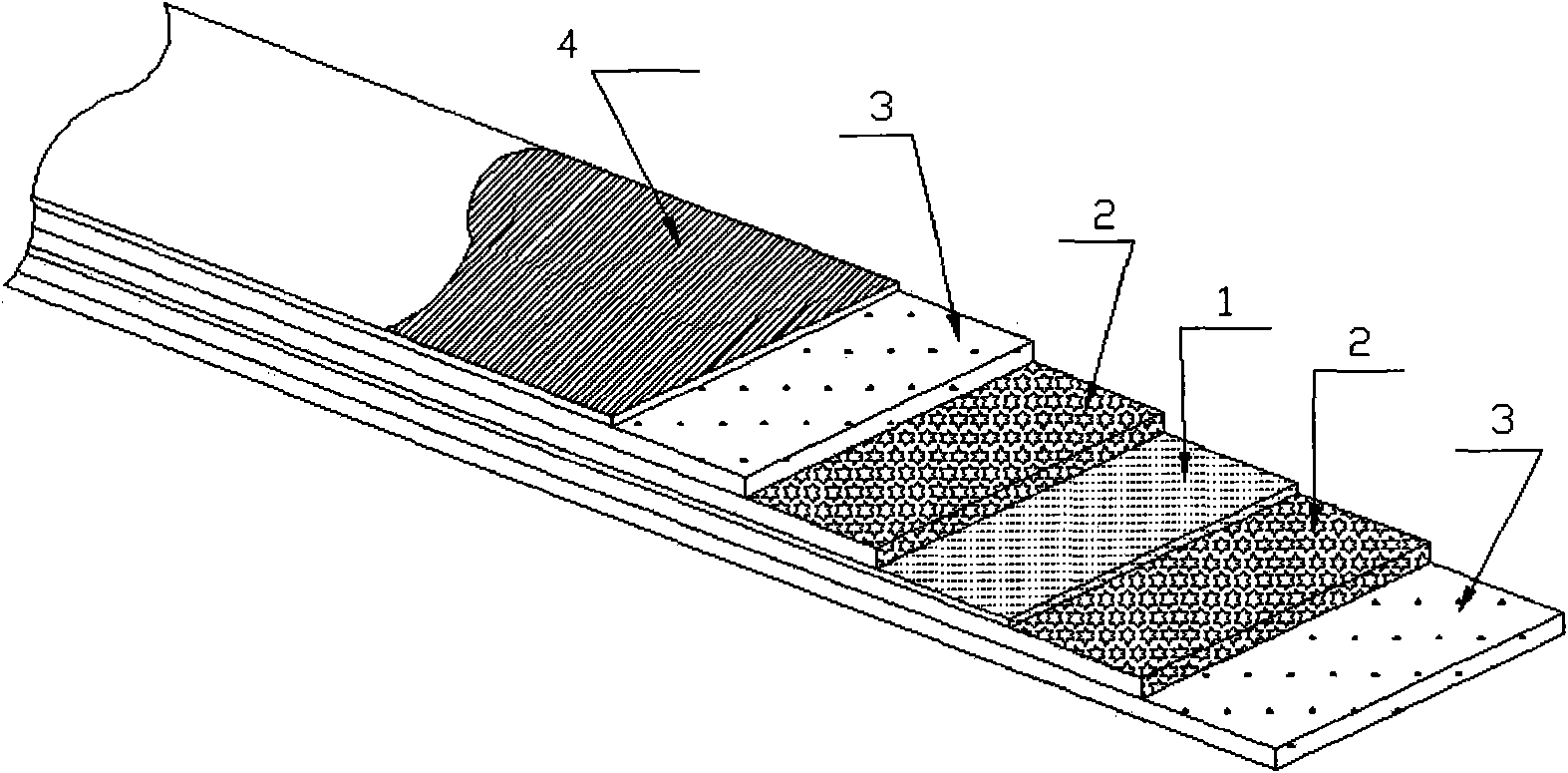

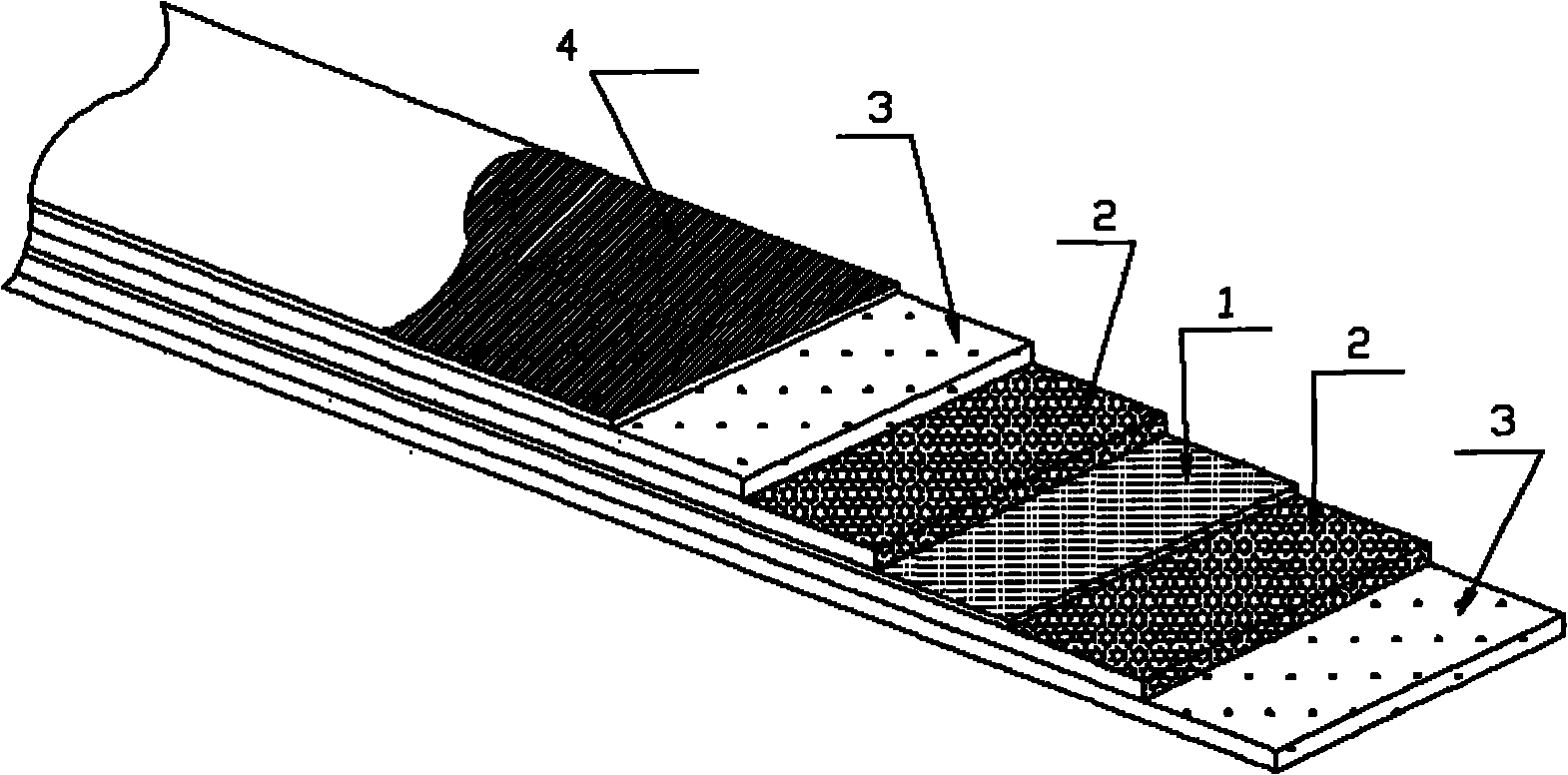

[0034] The product manufactured according to the above technical scheme is a composite board with high electromagnetic shielding and antistatic performance and high longitudinal and transverse tensile strength. With the selection of materials of each layer, it can be used in different frequency ranges. To meet the needs of a variety of environments. Below in conjunction with accompanying drawing, three embodiments of the present invention are described in detail:

[0035] Reference attached figure 1 , 2 , the metal foil (network) 1 of the embodiment of the present invention 1 selects the aluminum foil of 0.1mm for use, the glass fiber body 2 selects SH-100 glass fiber mat and flame-retardant and heat-resistant adhesive for use, and the flame-retardant conductive paste layer 3 selects for use containing 5% Unsaturated polyester of stainless steel fiber as the base paste. In this embodiment, first, on the selected 0.1mm aluminum foil, heat-resistant, flame-retardant adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com