Patents

Literature

907 results about "Stainless steel fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel fibers are manufactured fibers composed of stainless steel. Composition may include carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), and other elements.

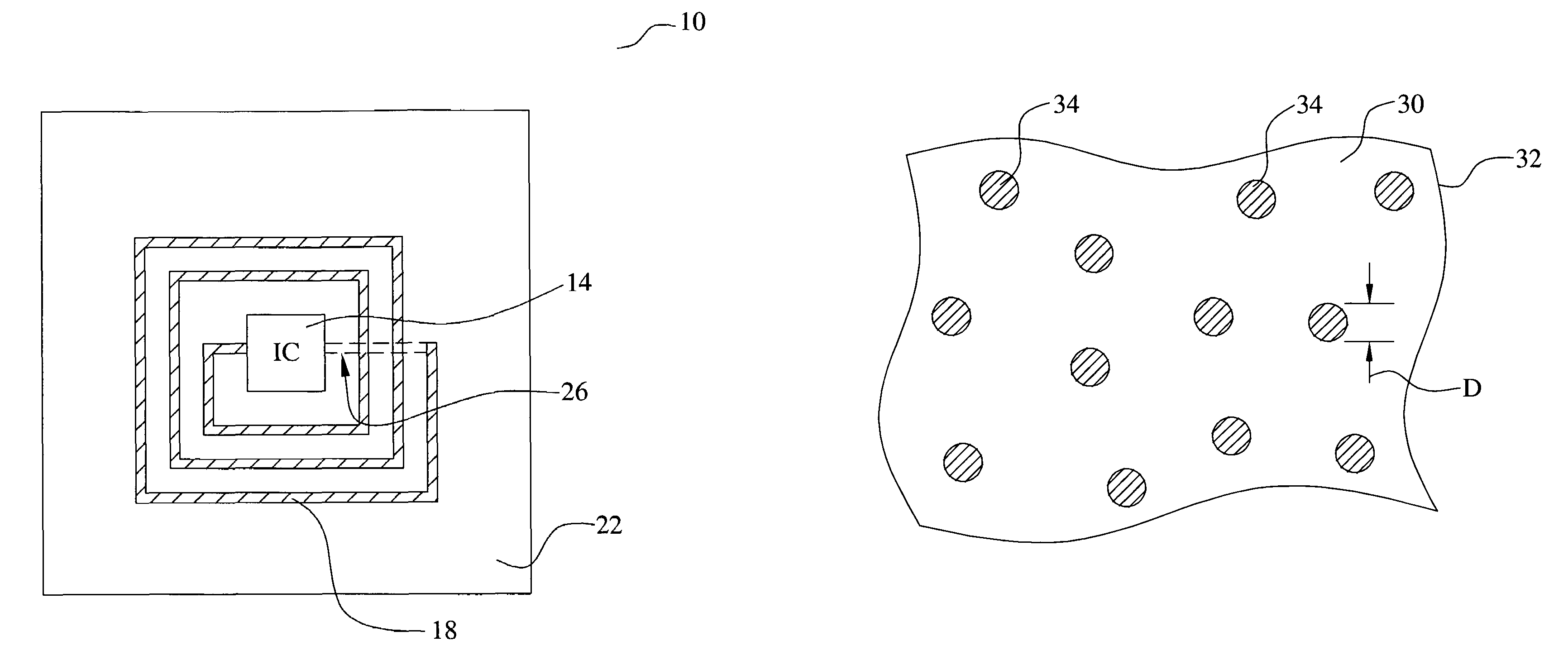

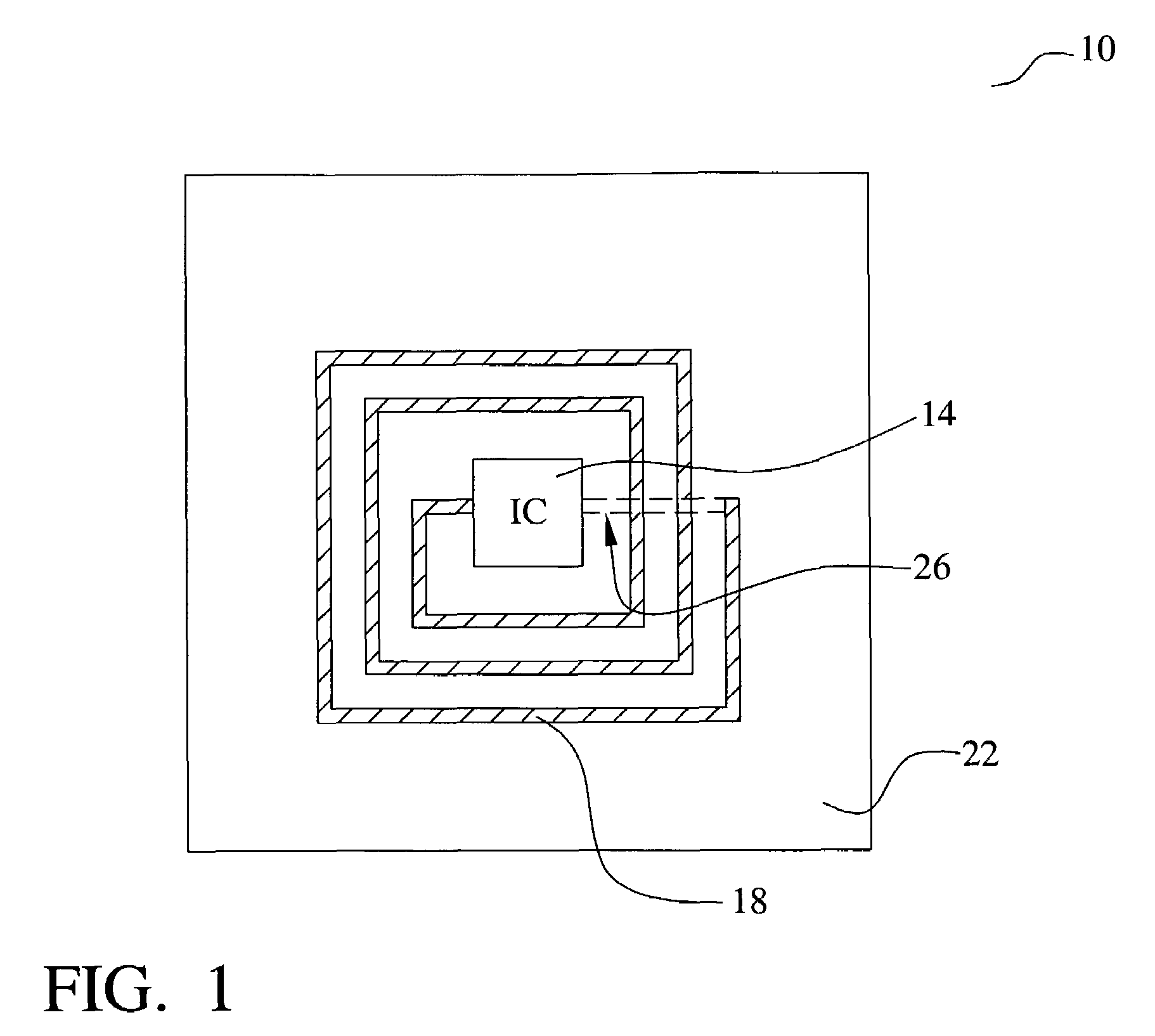

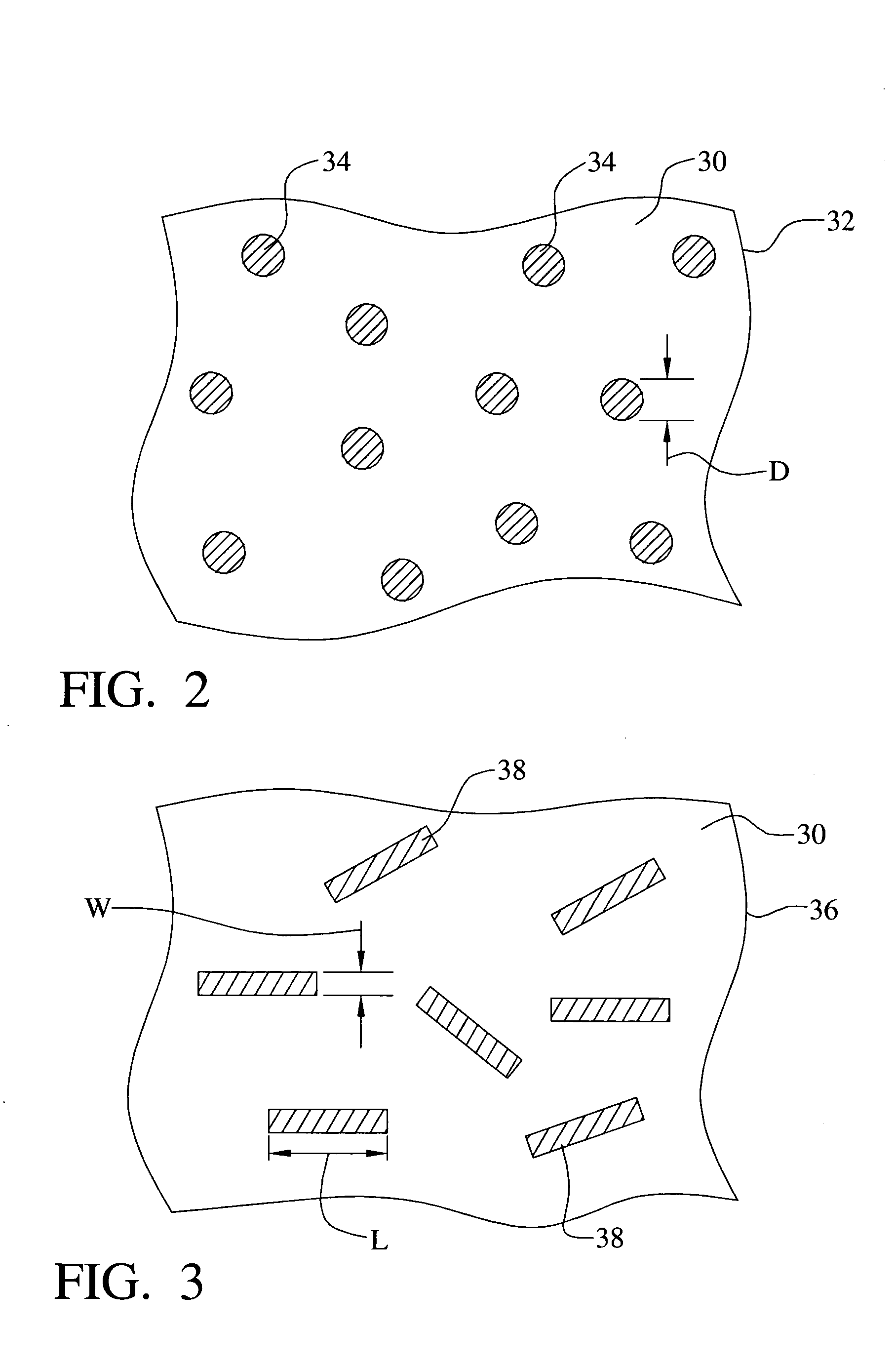

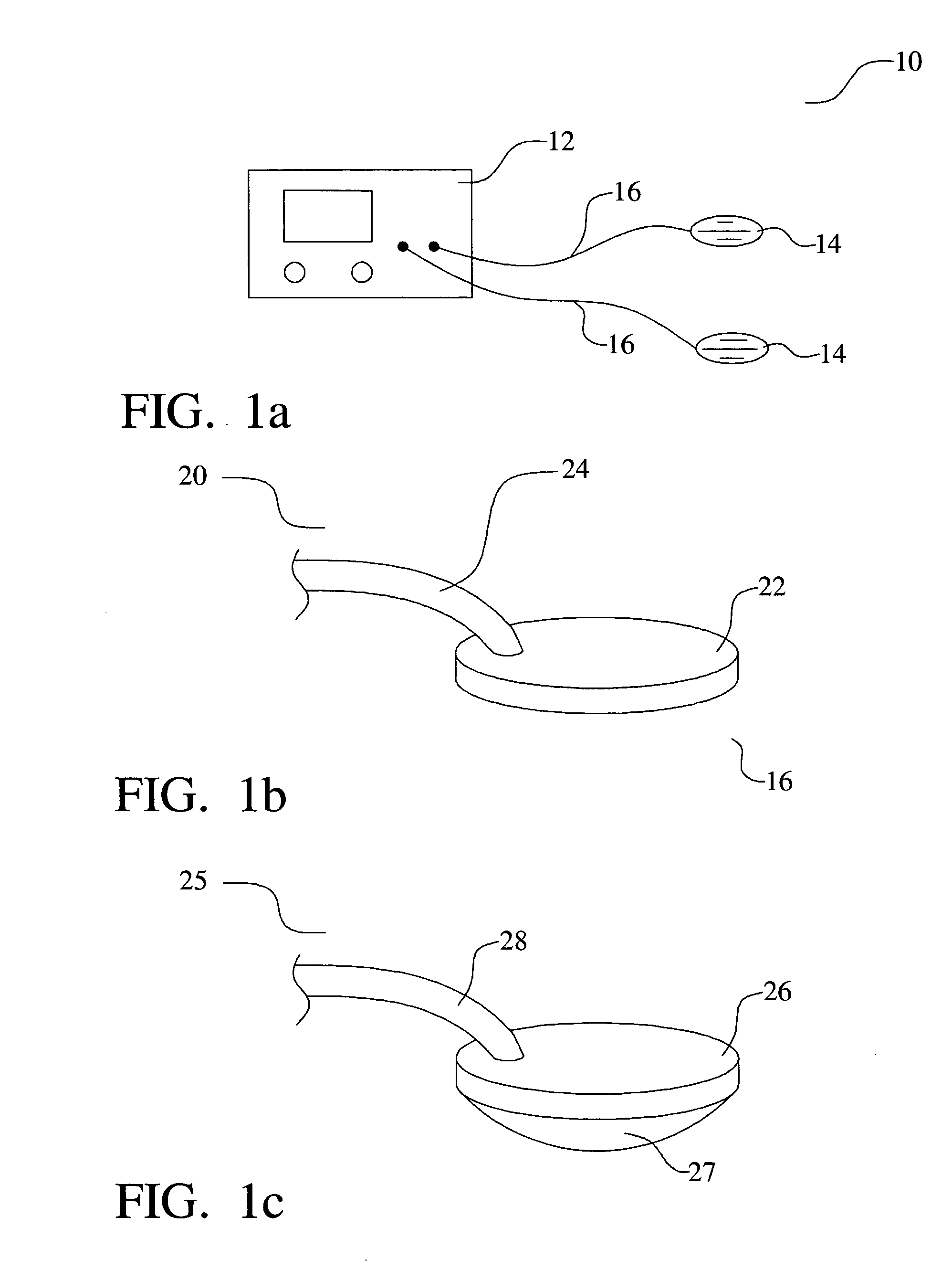

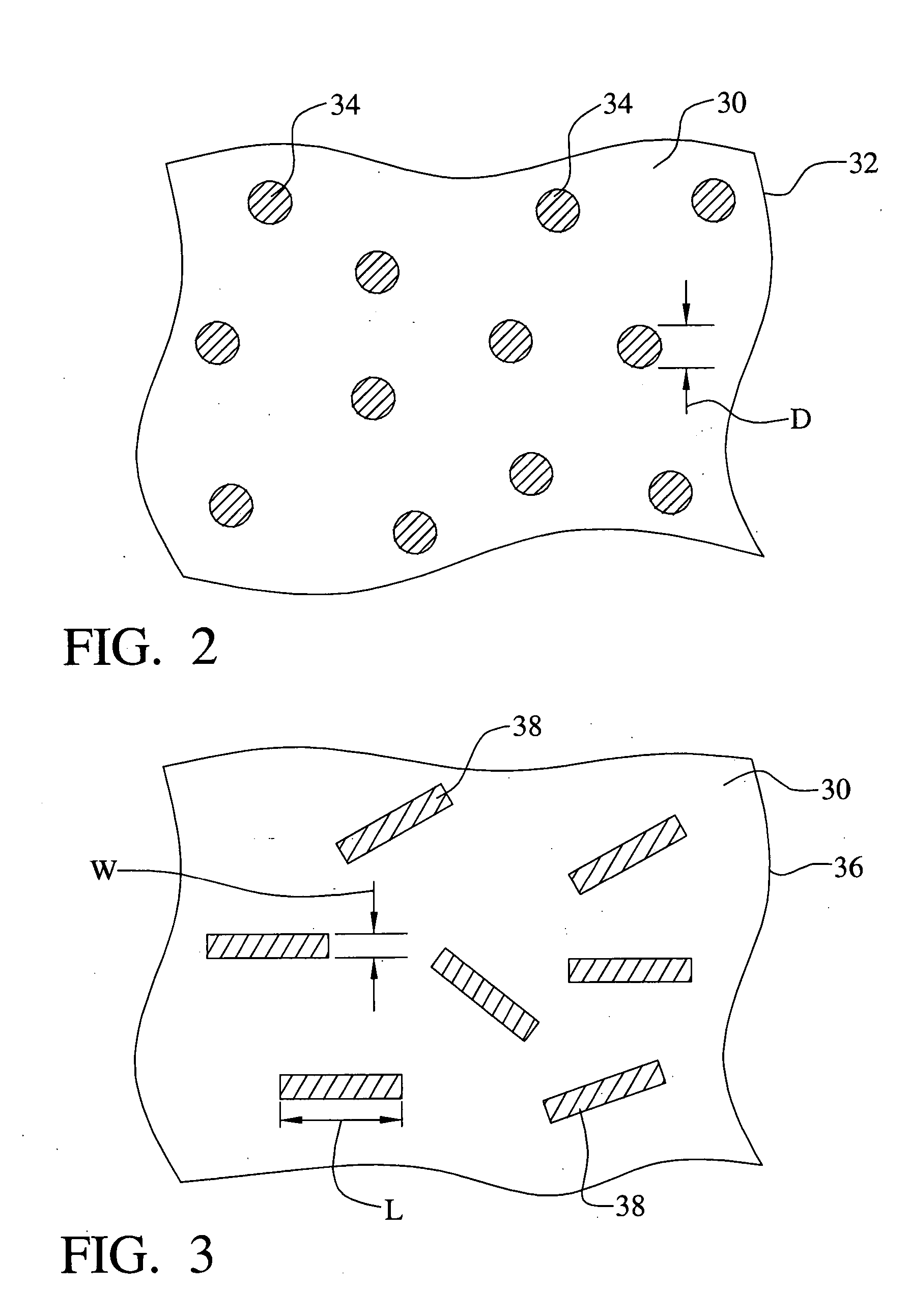

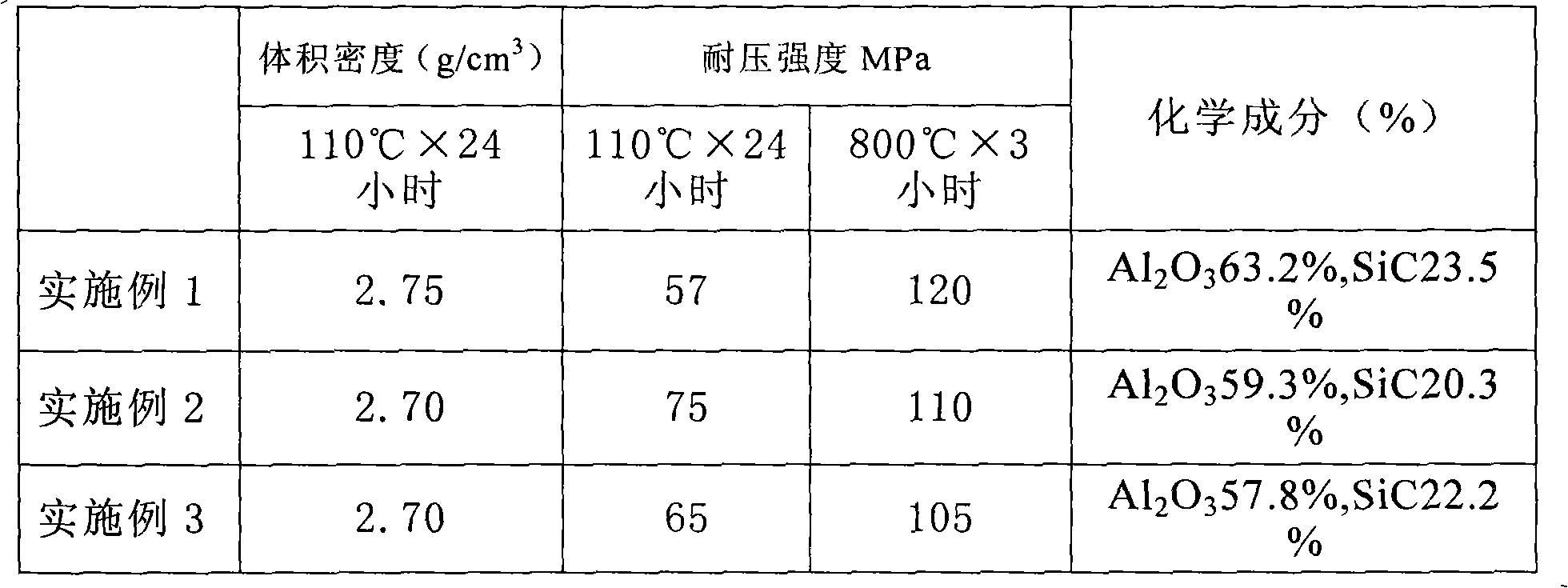

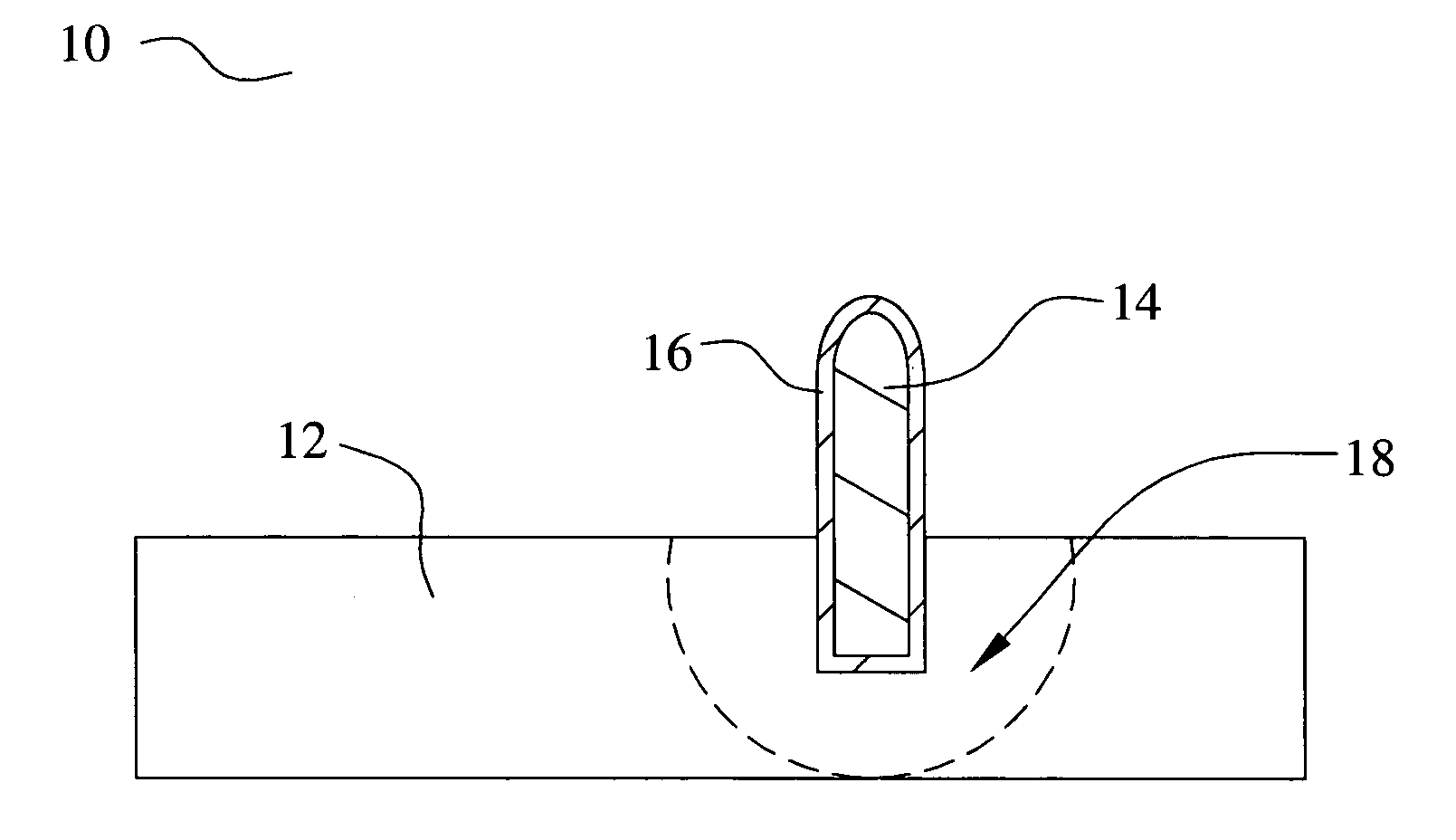

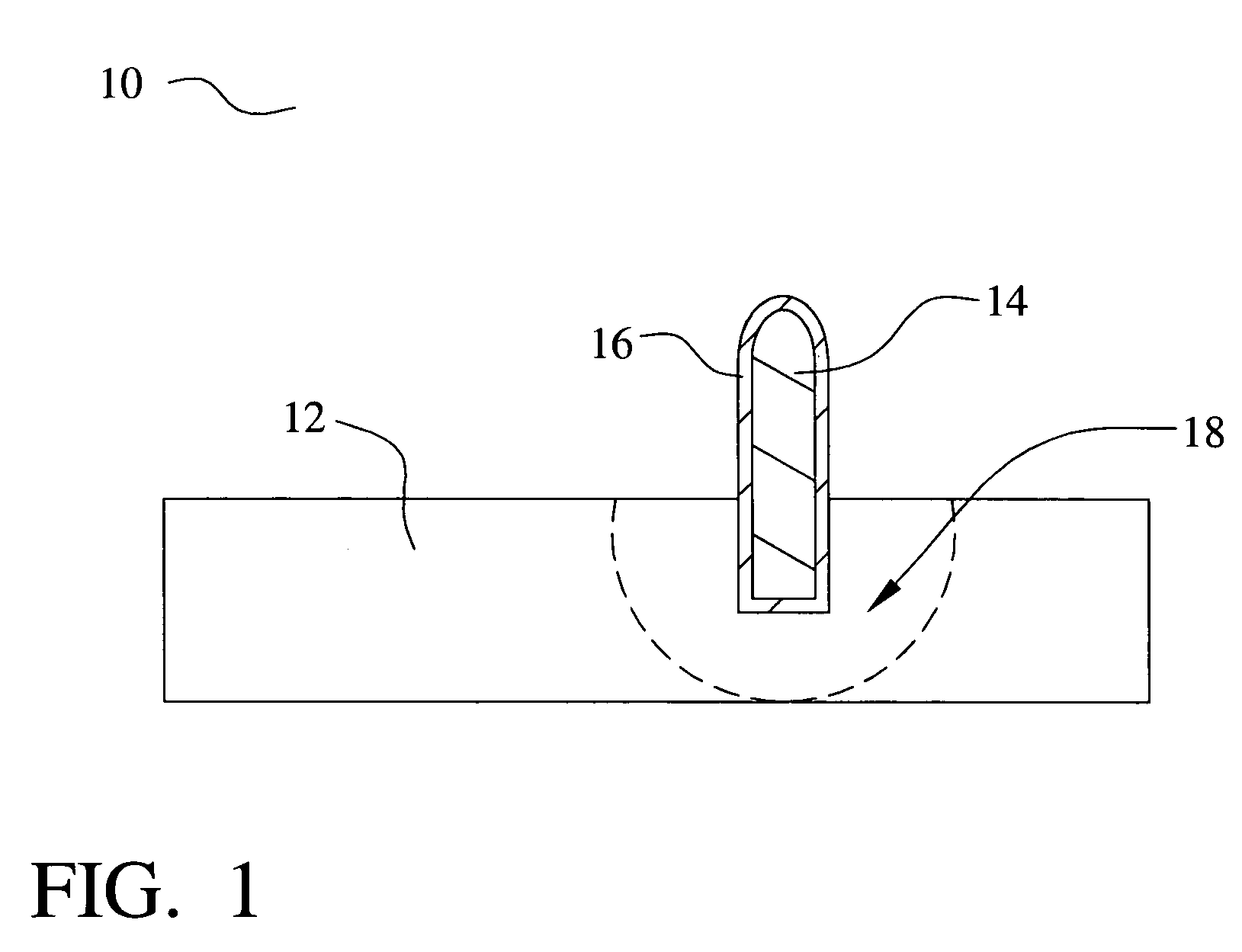

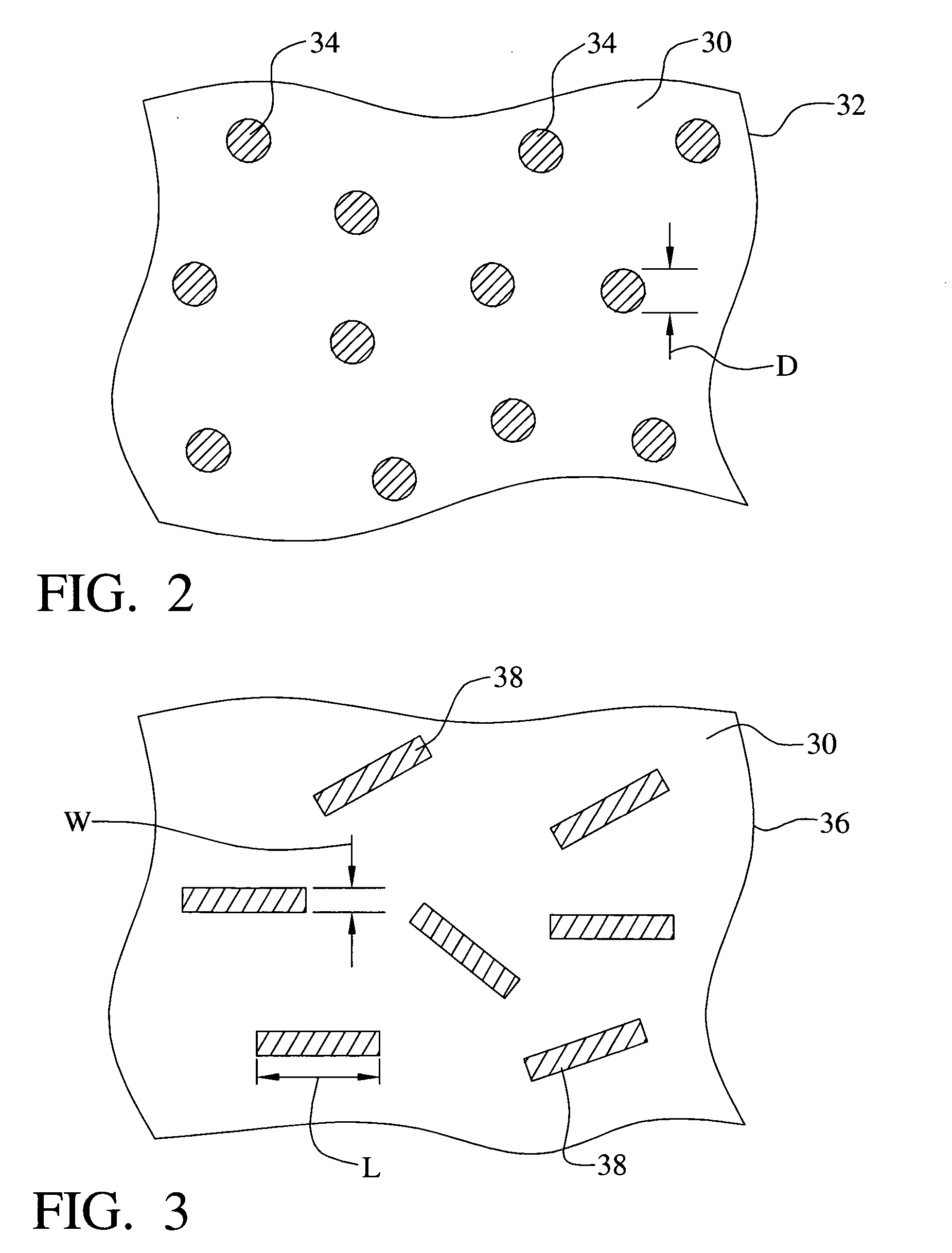

Low cost RFID antenna manufactured from conductive loaded resin-based materials

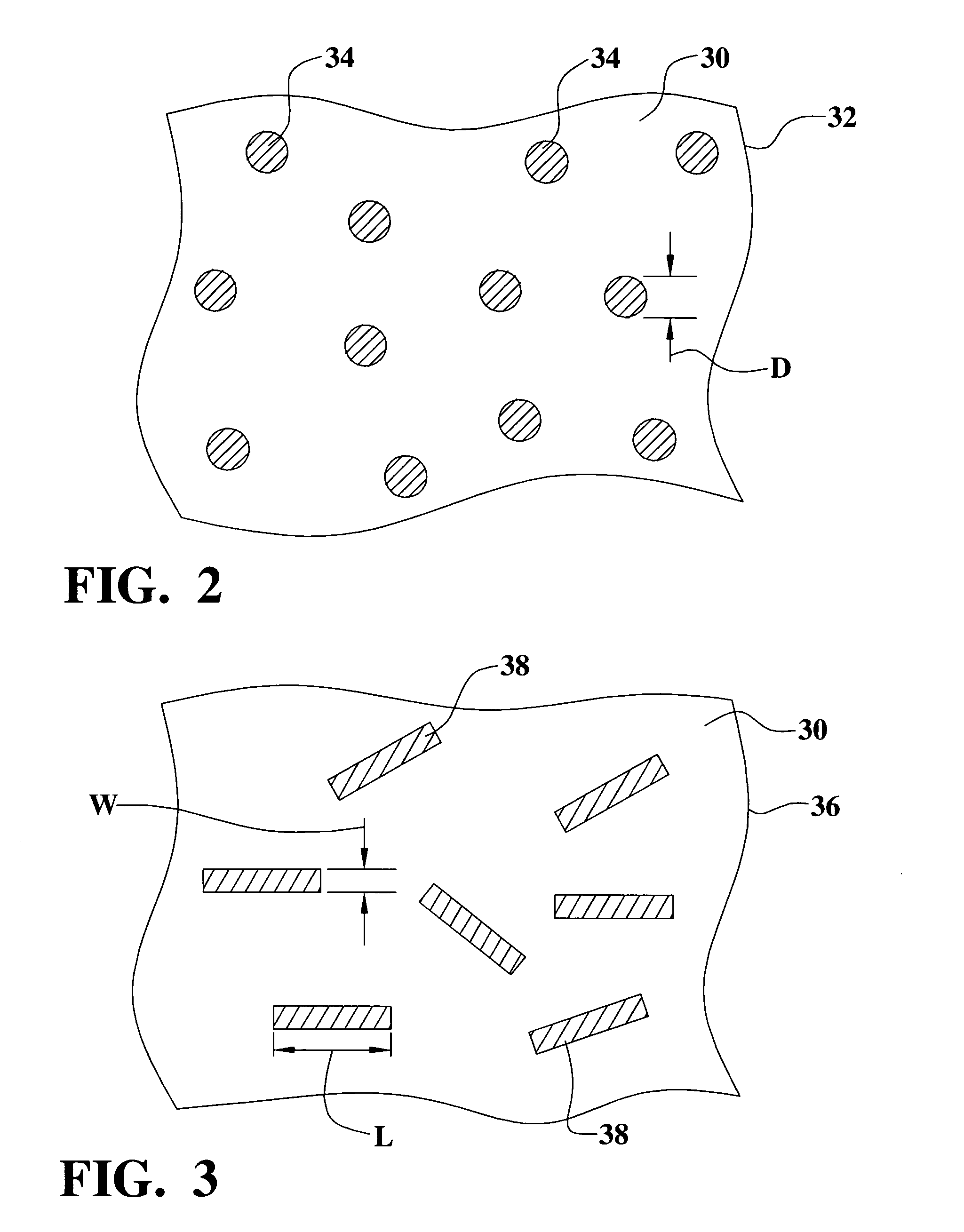

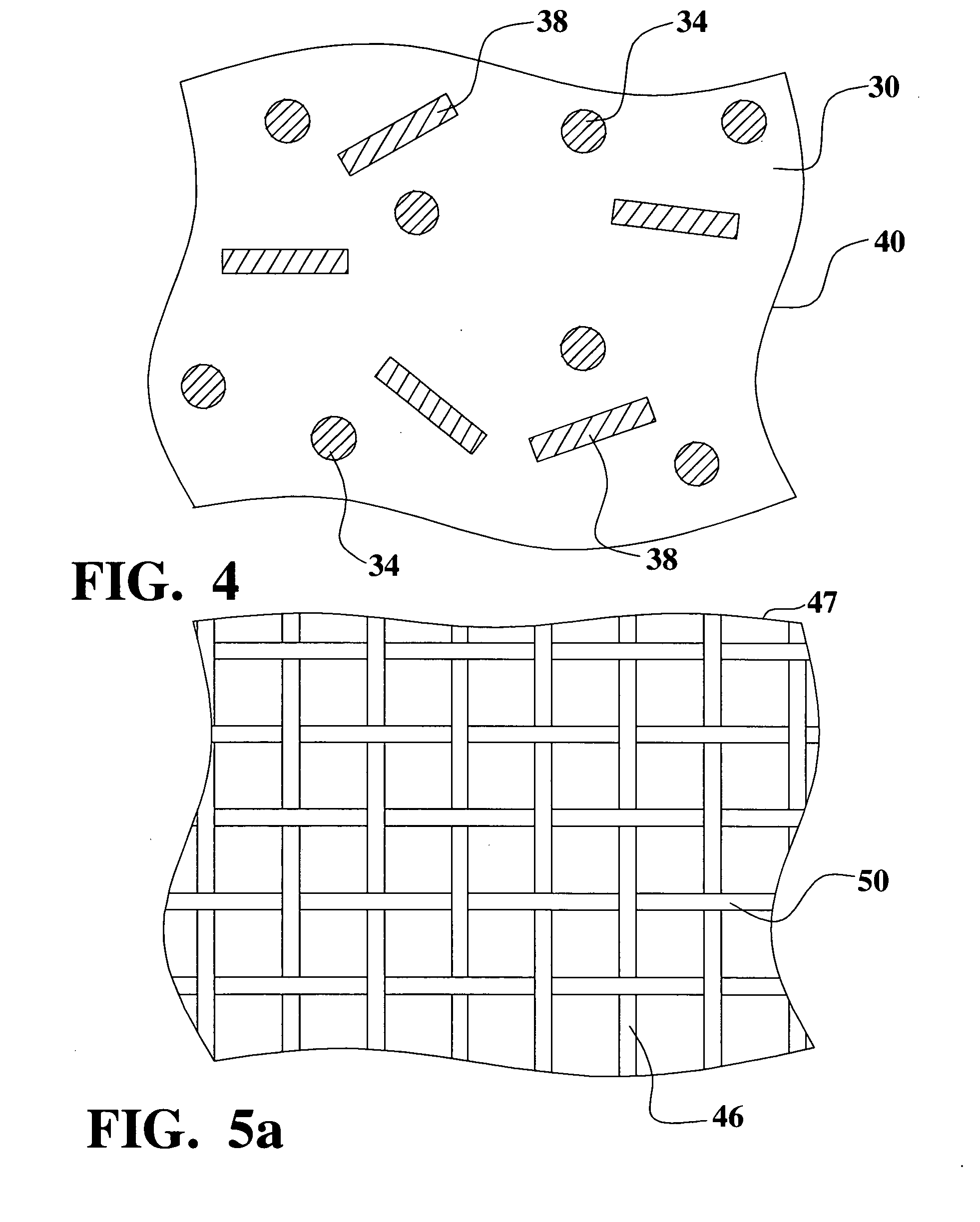

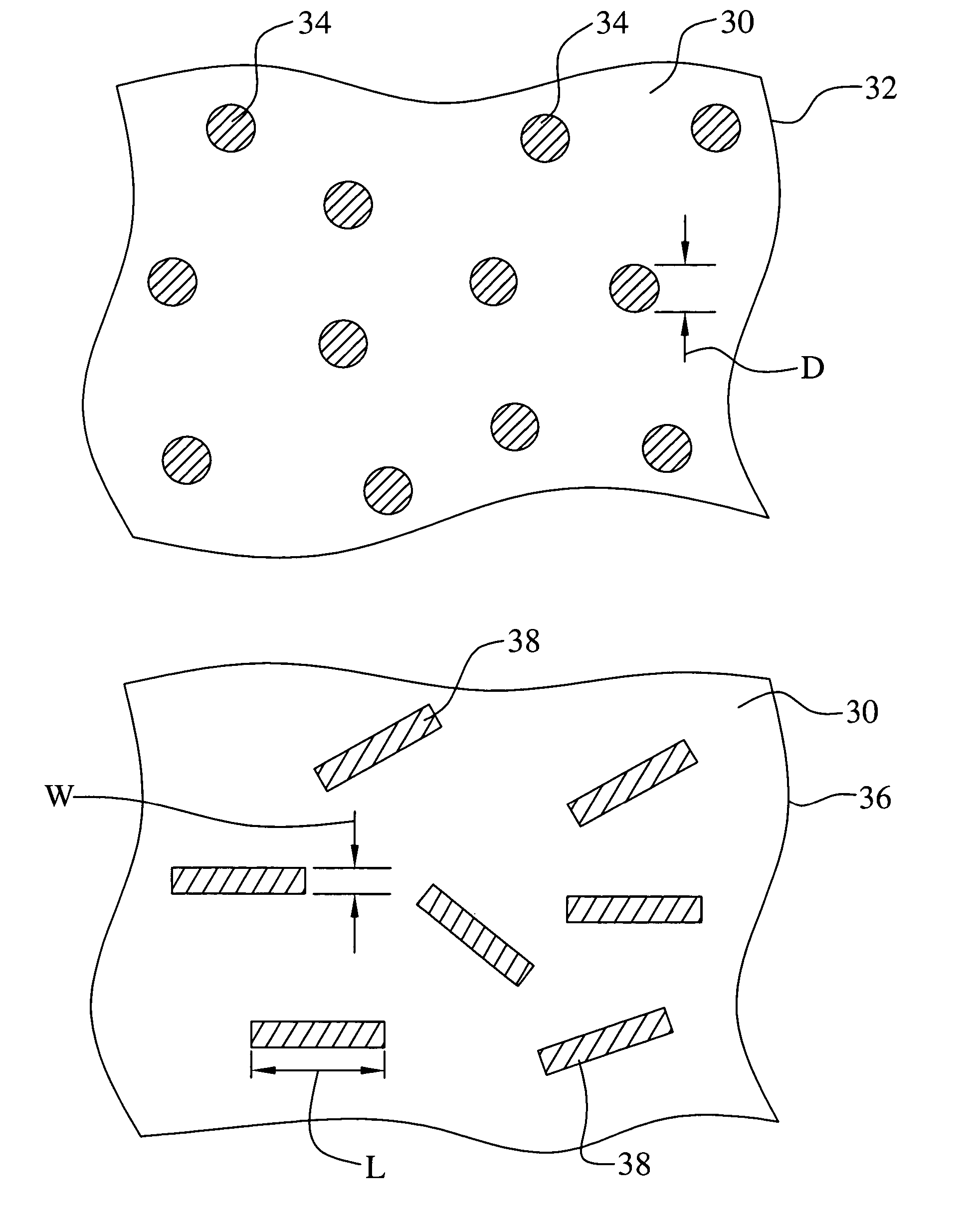

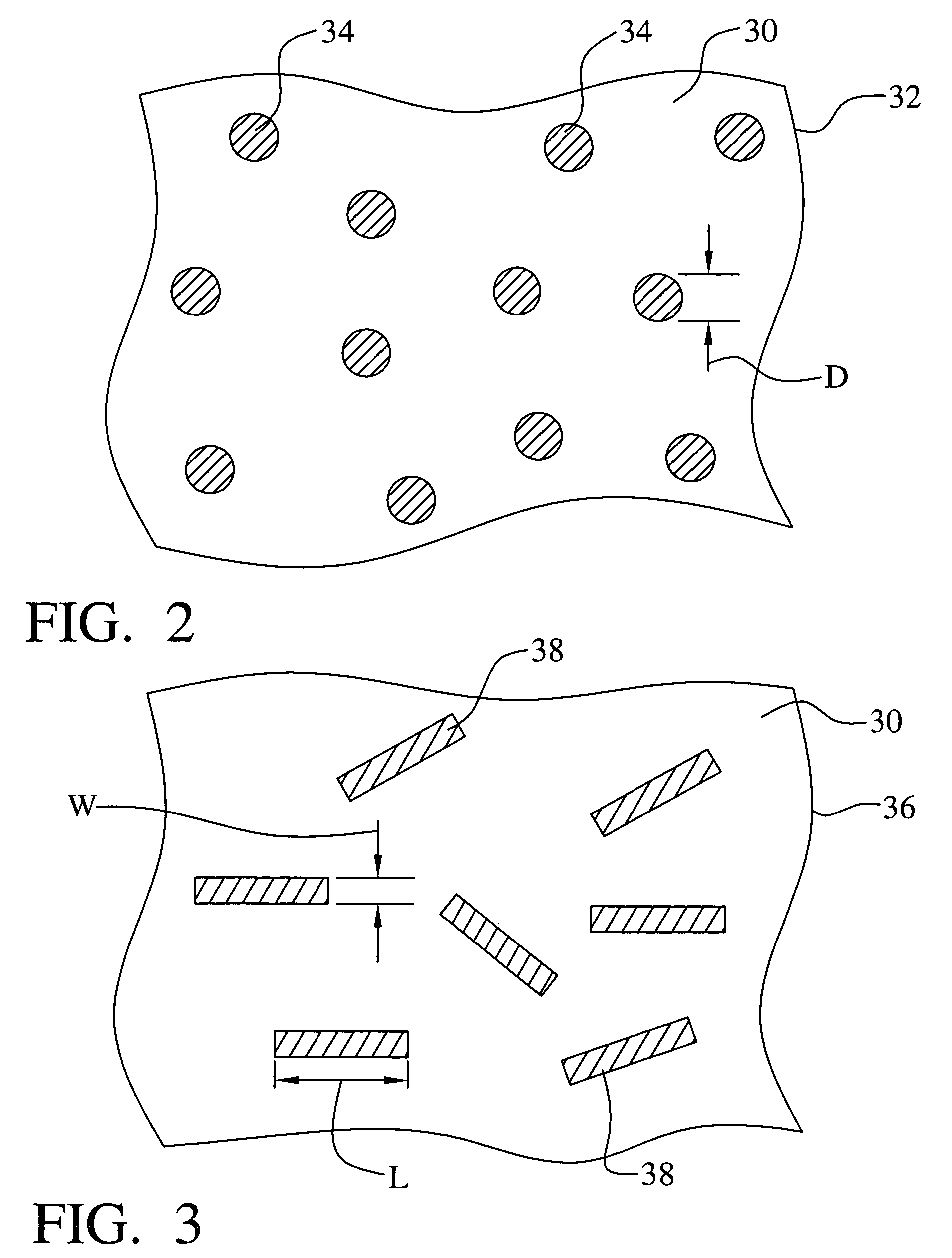

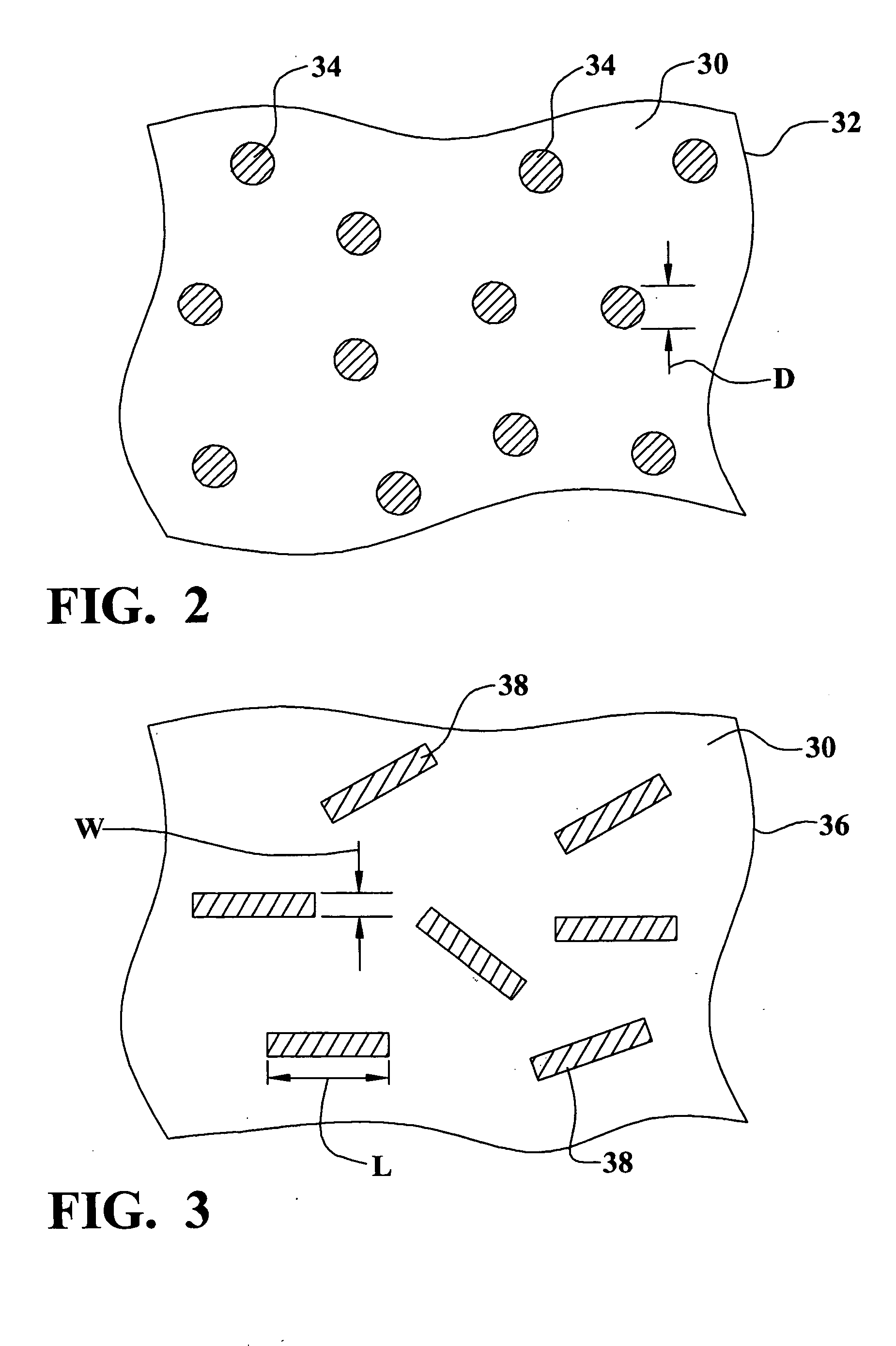

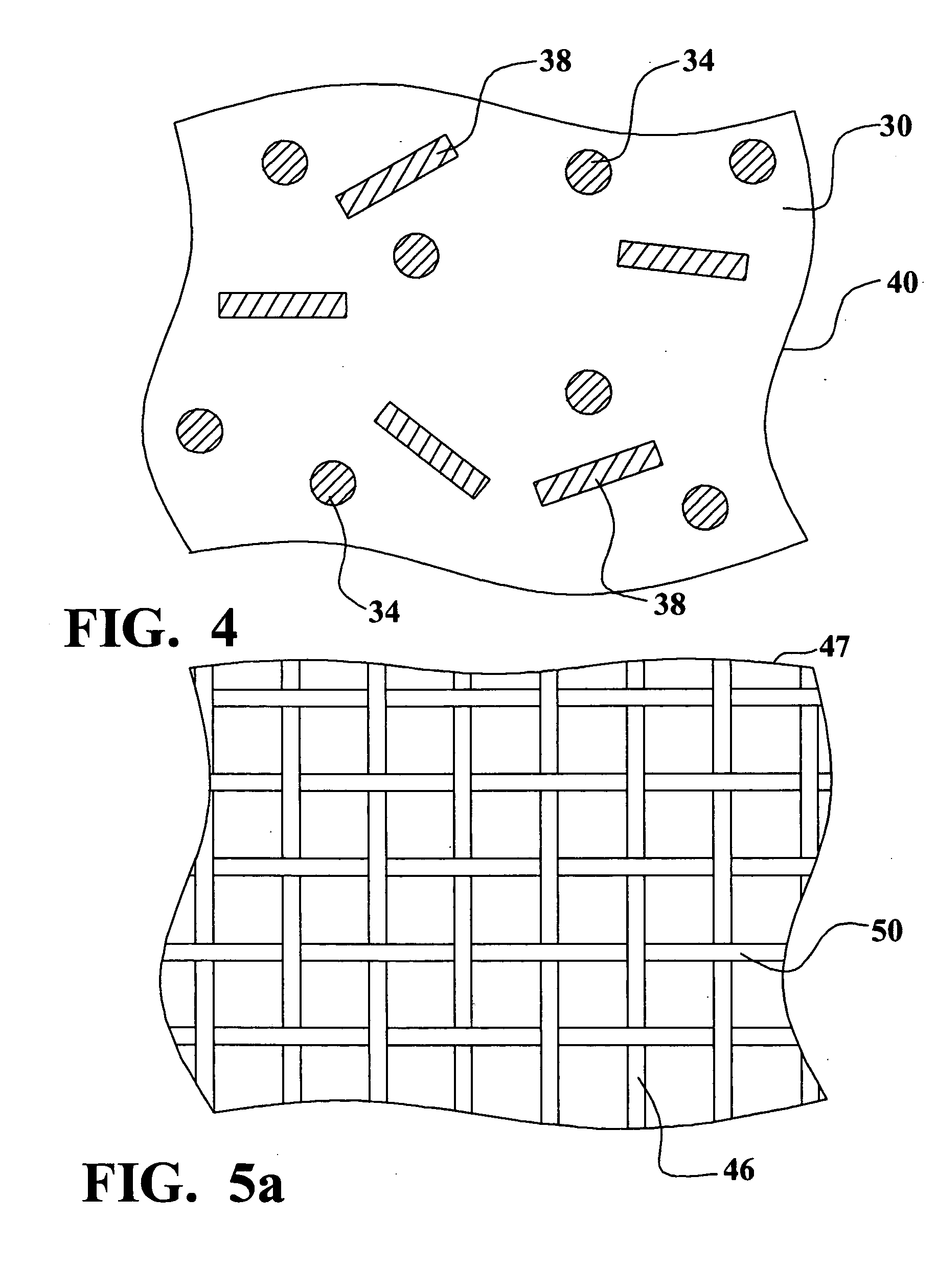

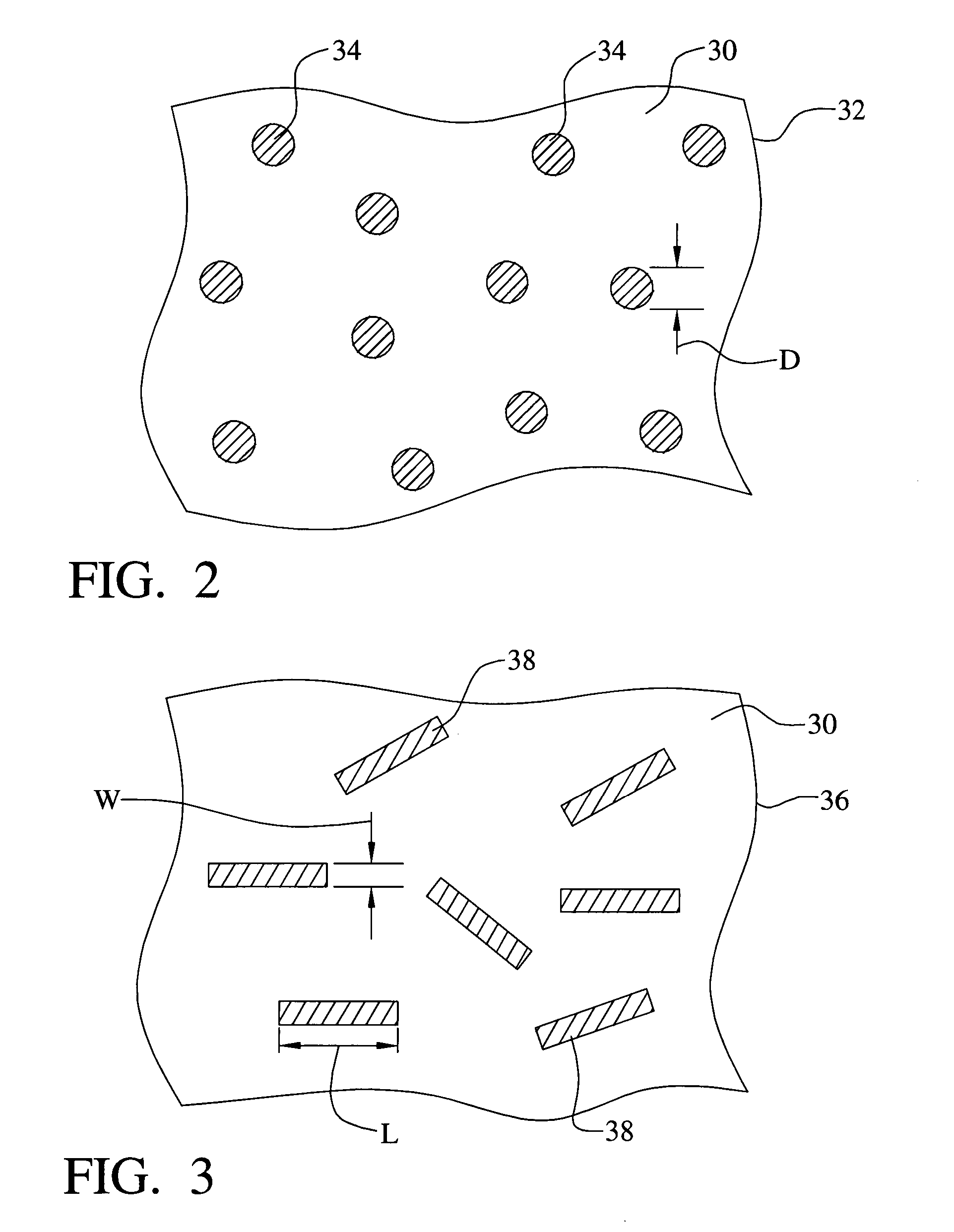

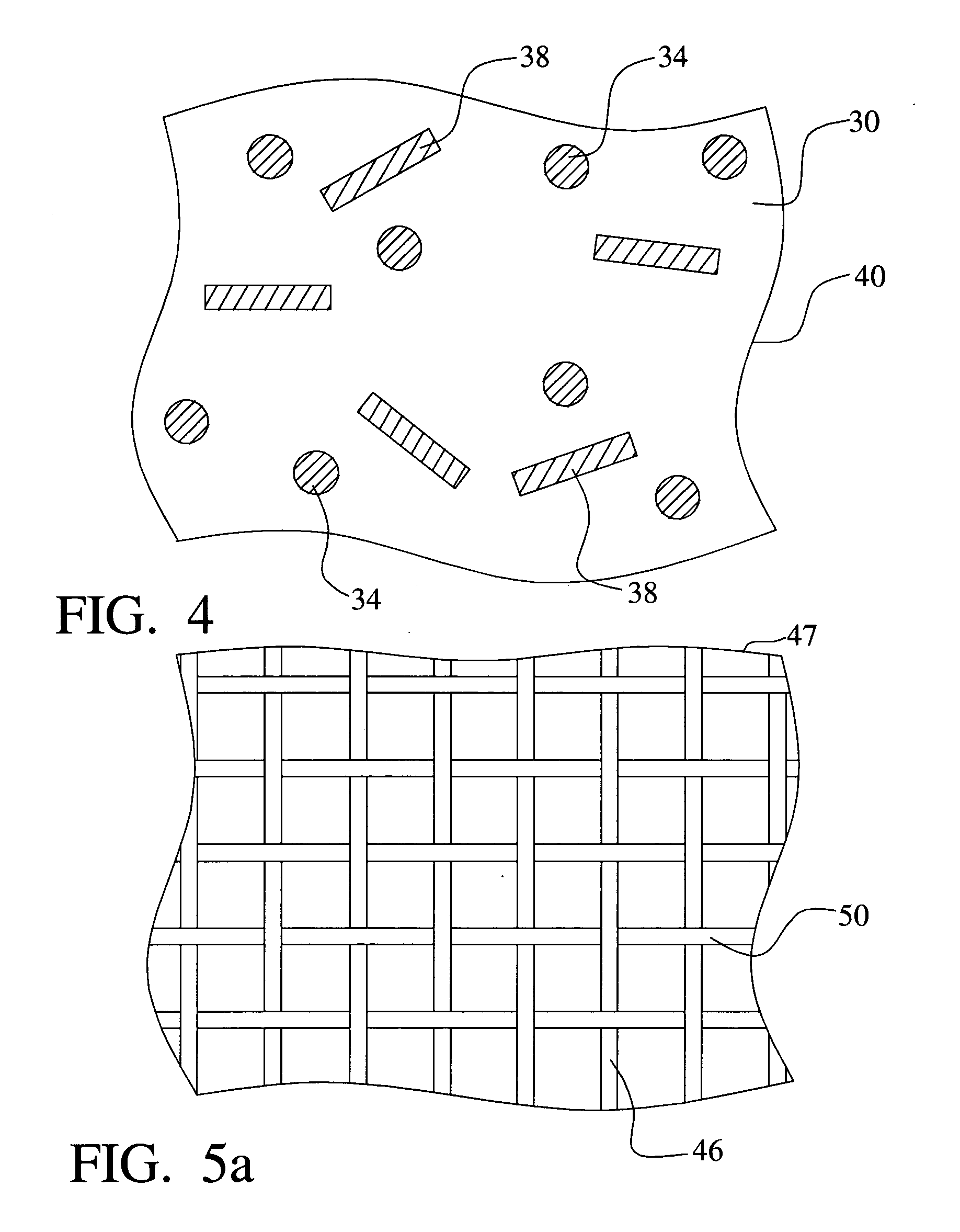

RFID antennas are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Heat resistant separation fabric

InactiveUS20160083285A1Improve optical qualityImproved heat resistant separation fabricLiquid surface applicatorsGlass transportation apparatusAlloyStainless steel fiber

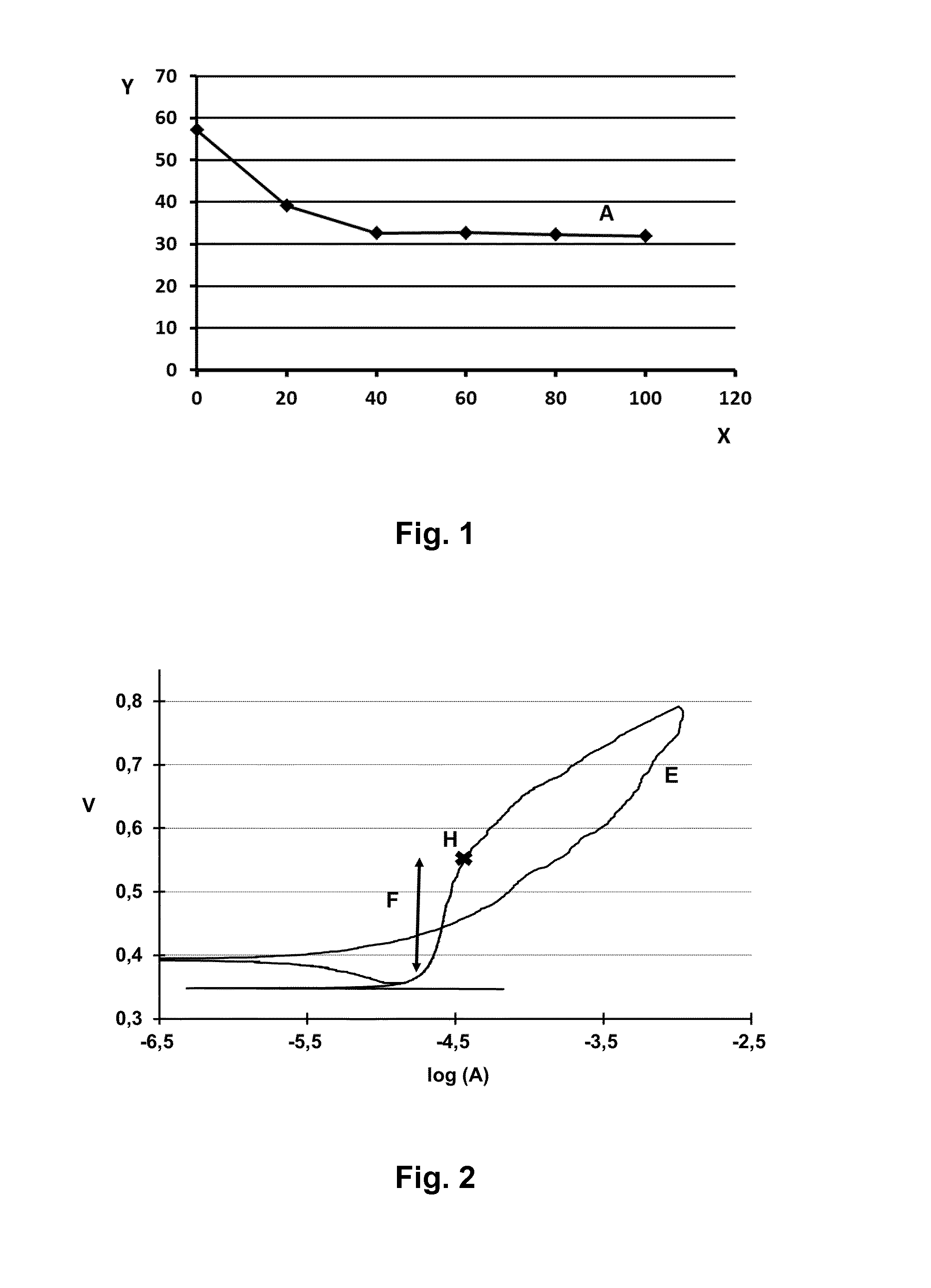

A heat resistant separation fabric including stainless steel fibers. The stainless steel fibers are made out of an alloy comprising more than 12% by weight of chromium. The stainless steel fibers include an oxide skin. The atomic percentage of Cr at 5 nm depth of the oxide skin divided by the sum of the atomic percentages of Cr and Fe at 5 nm depth of the oxide skin, and multiplied with 100 to express as a percentage, is higher than 30%.

Owner:NV BEKAERT SA

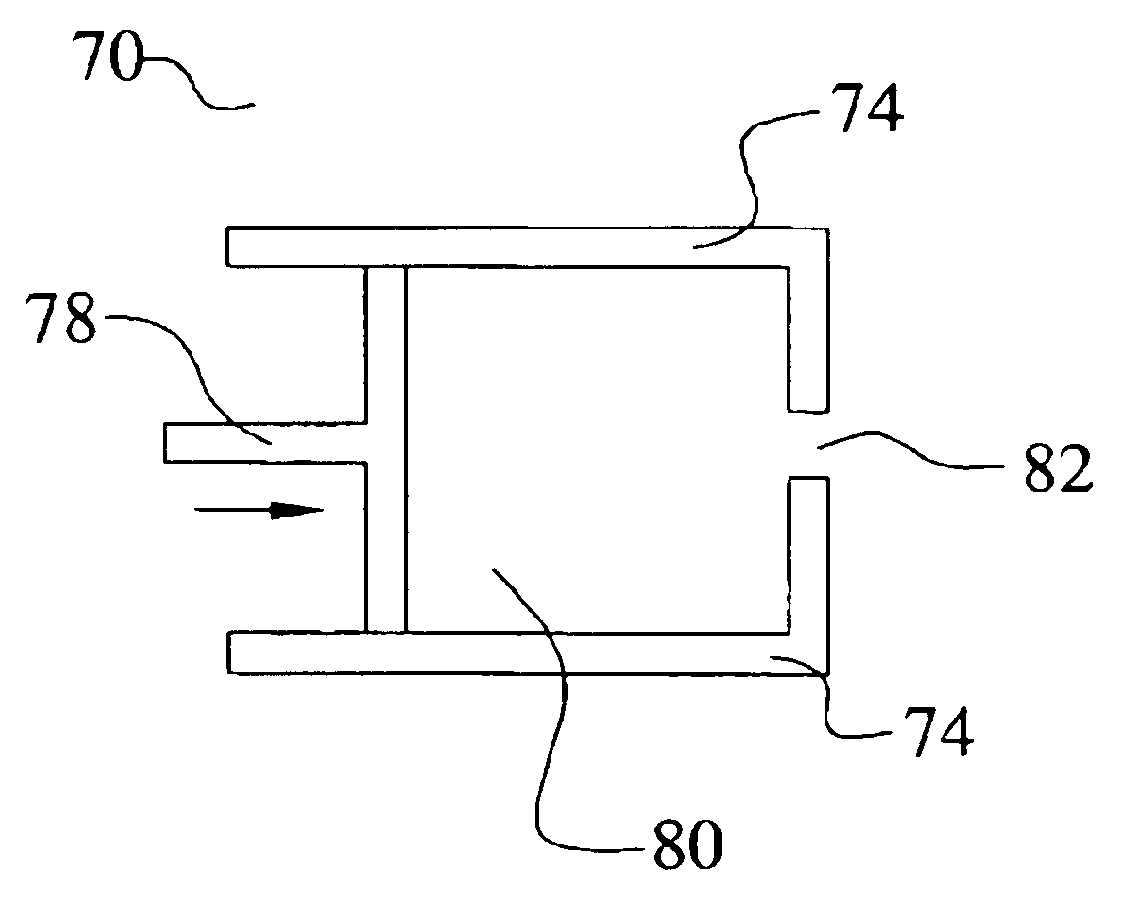

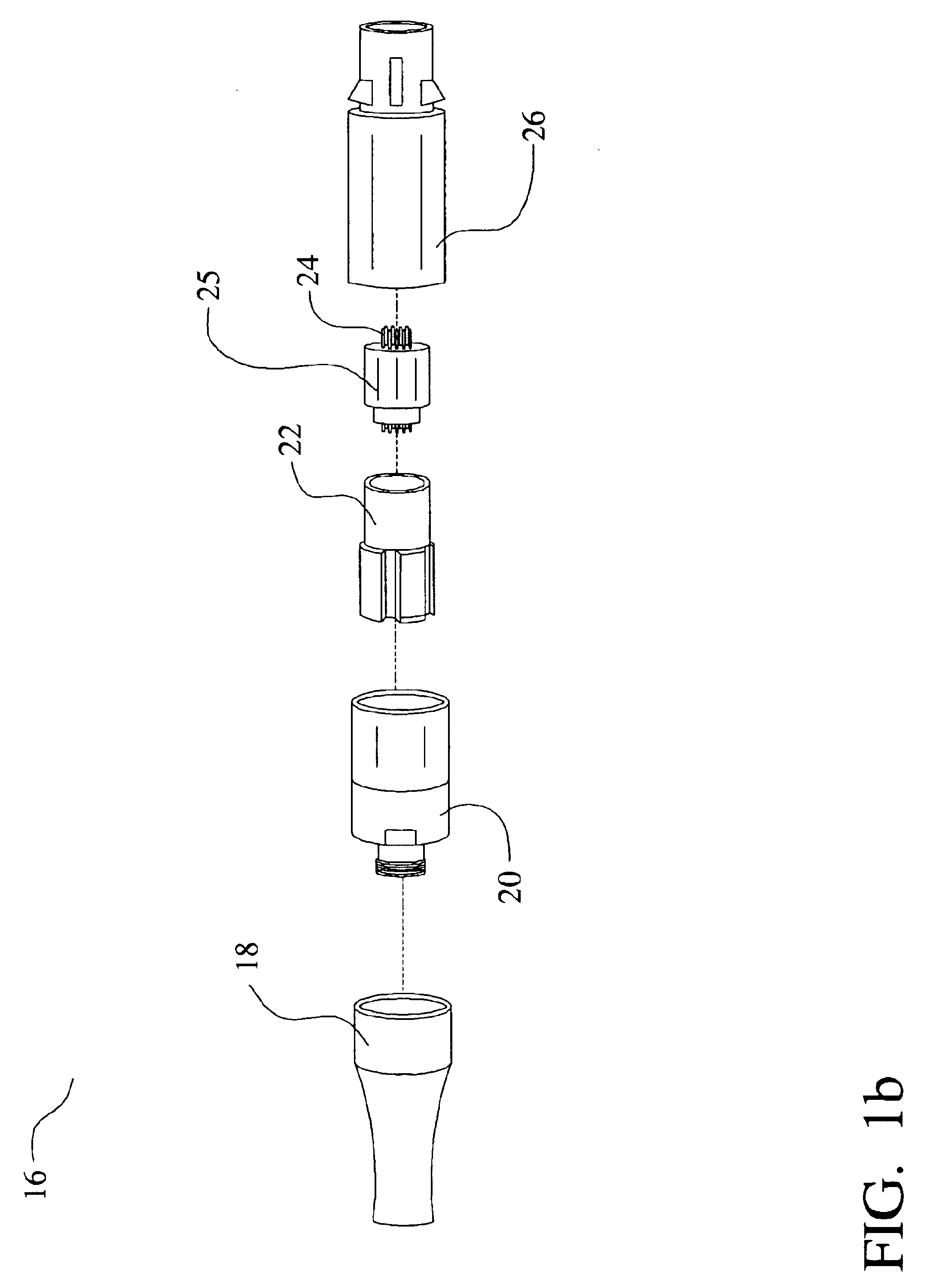

Low cost electrical cable connector housings and cable heads manufactured from conductive loaded resin-based materials

InactiveUS6947012B2Soldered/welded conductive connectionsAntennas earthing switches associationElectrical conductorEngineering

Electrical connector housings are formed of a conductive loaded resin-based material which provides superior protection from EMI and RFI by absorbing such interfering signals. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination thereof, in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 40% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

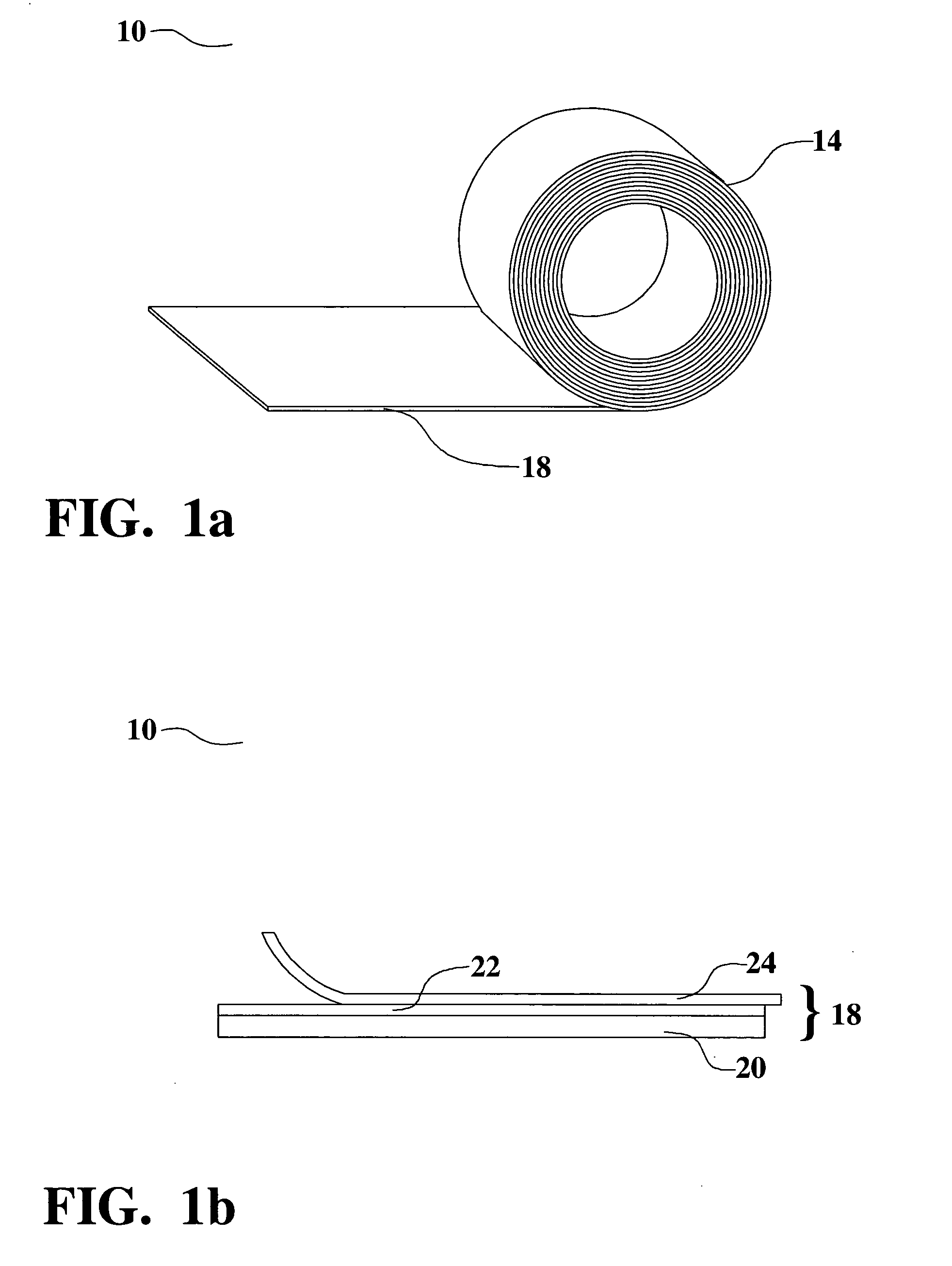

Low cost electrically conductive tapes and films manufactured from conductive loaded resin-based materials

Electrically conductive tapes and films are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

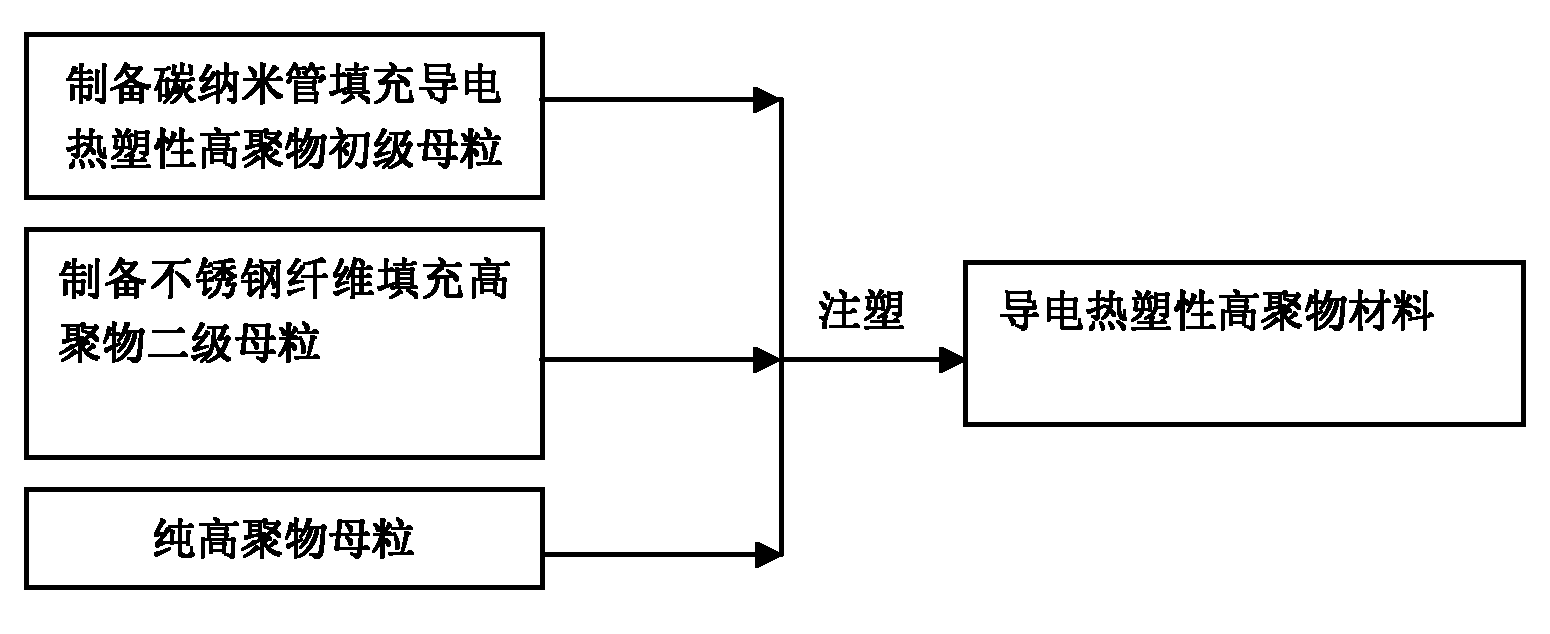

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

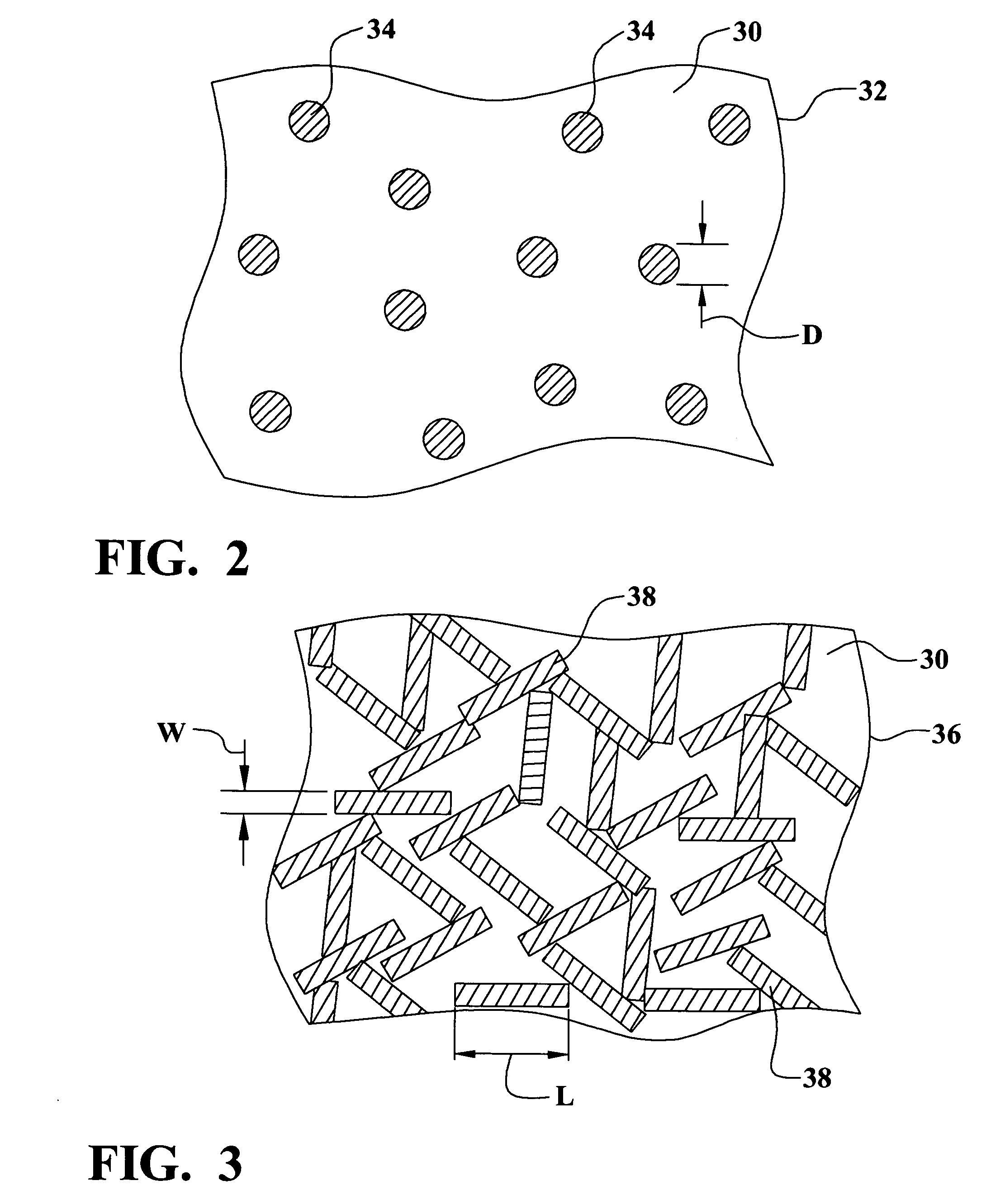

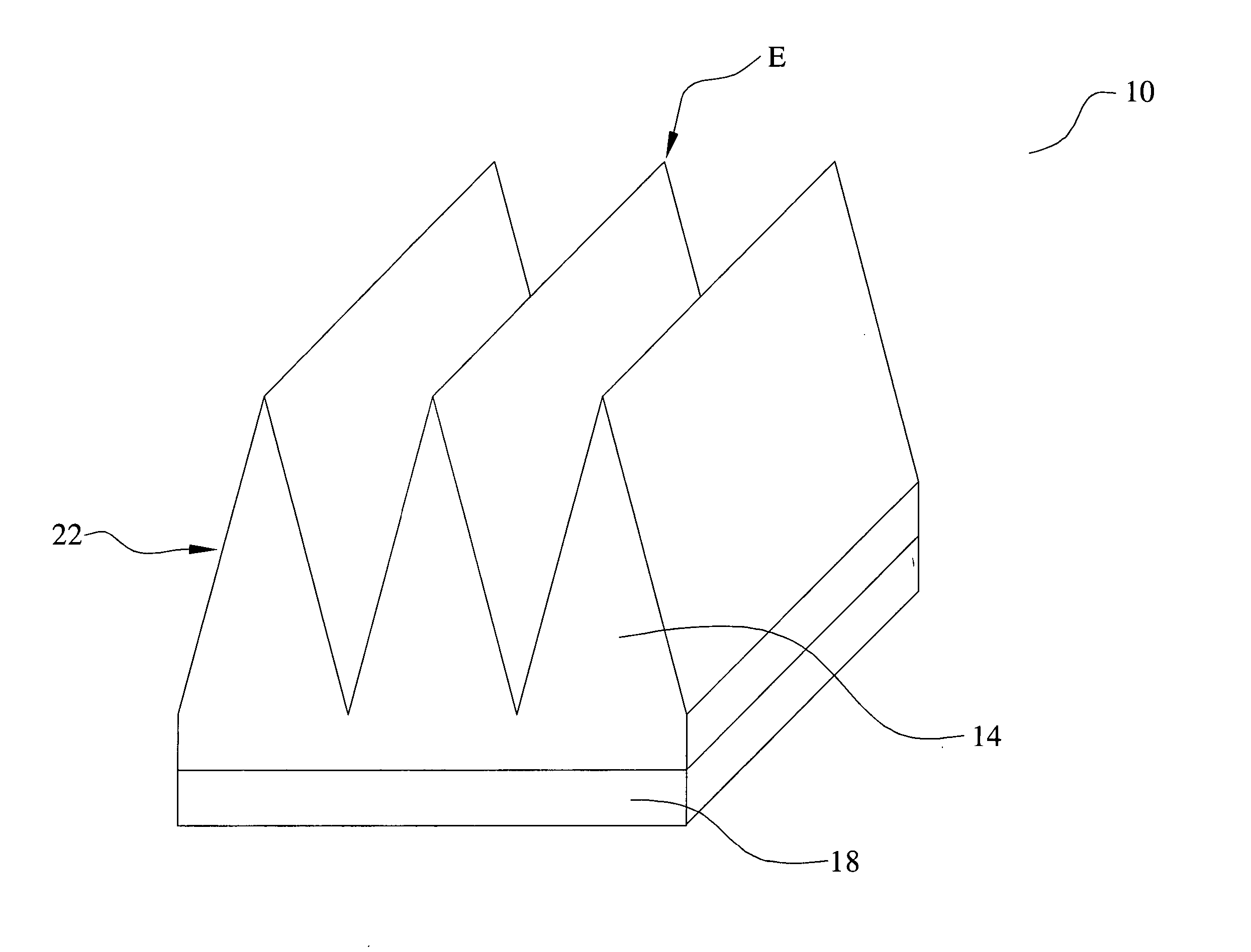

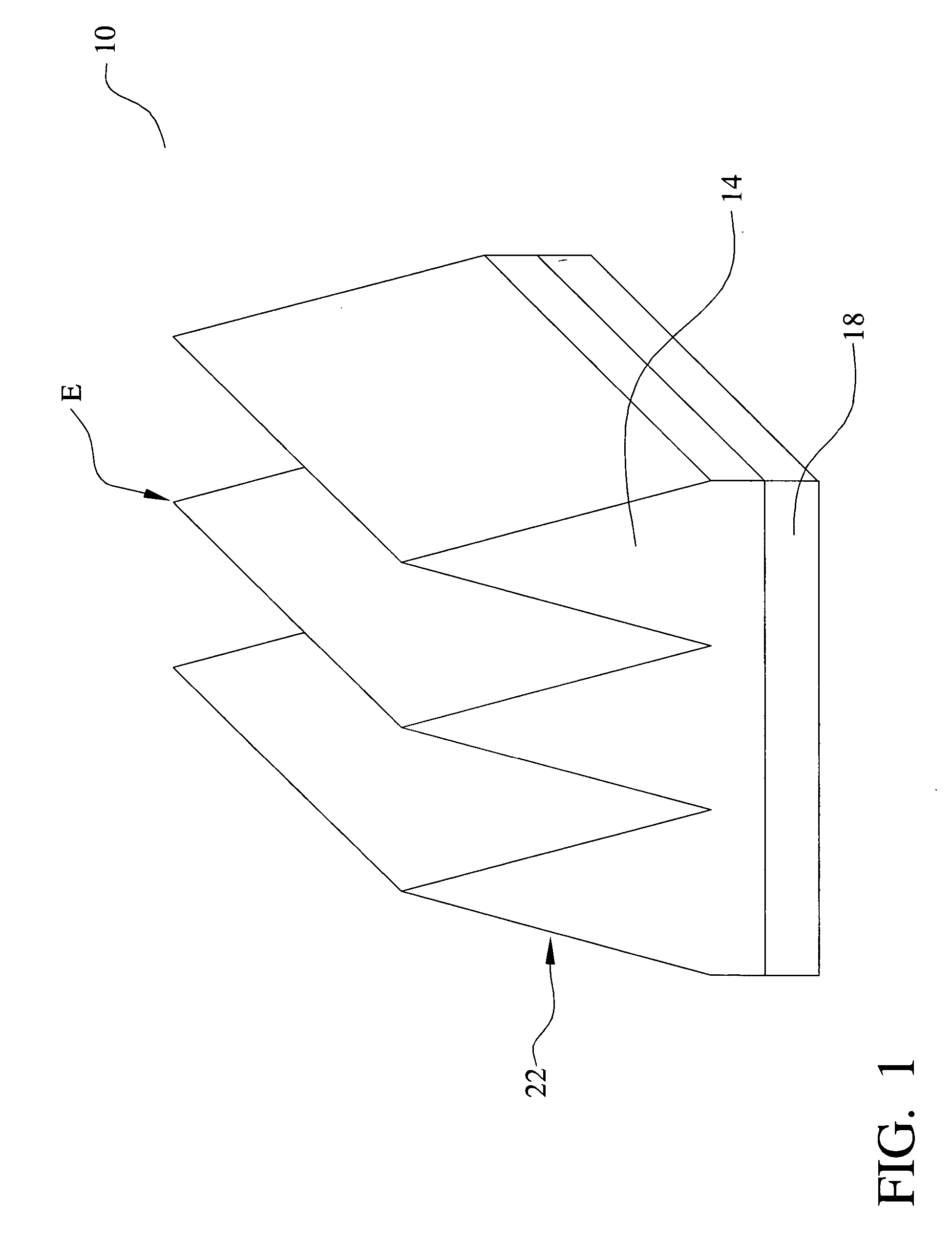

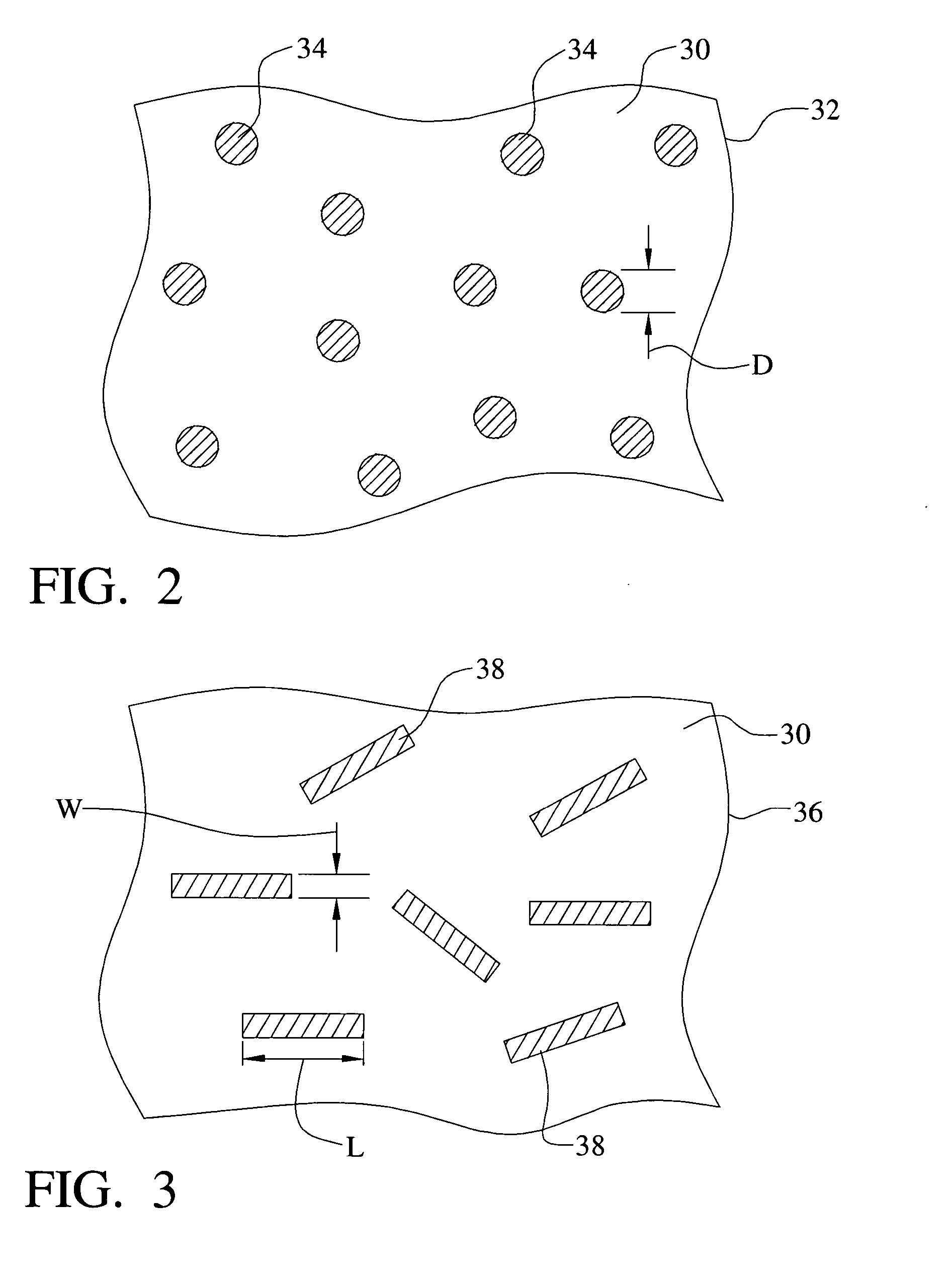

Friction material

InactiveUS20050004258A1Good brake feelingImprove effectivenessBraking element arrangementsOther chemical processesMohs scale of mineral hardnessHardness

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

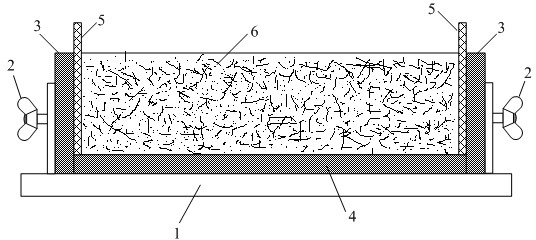

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

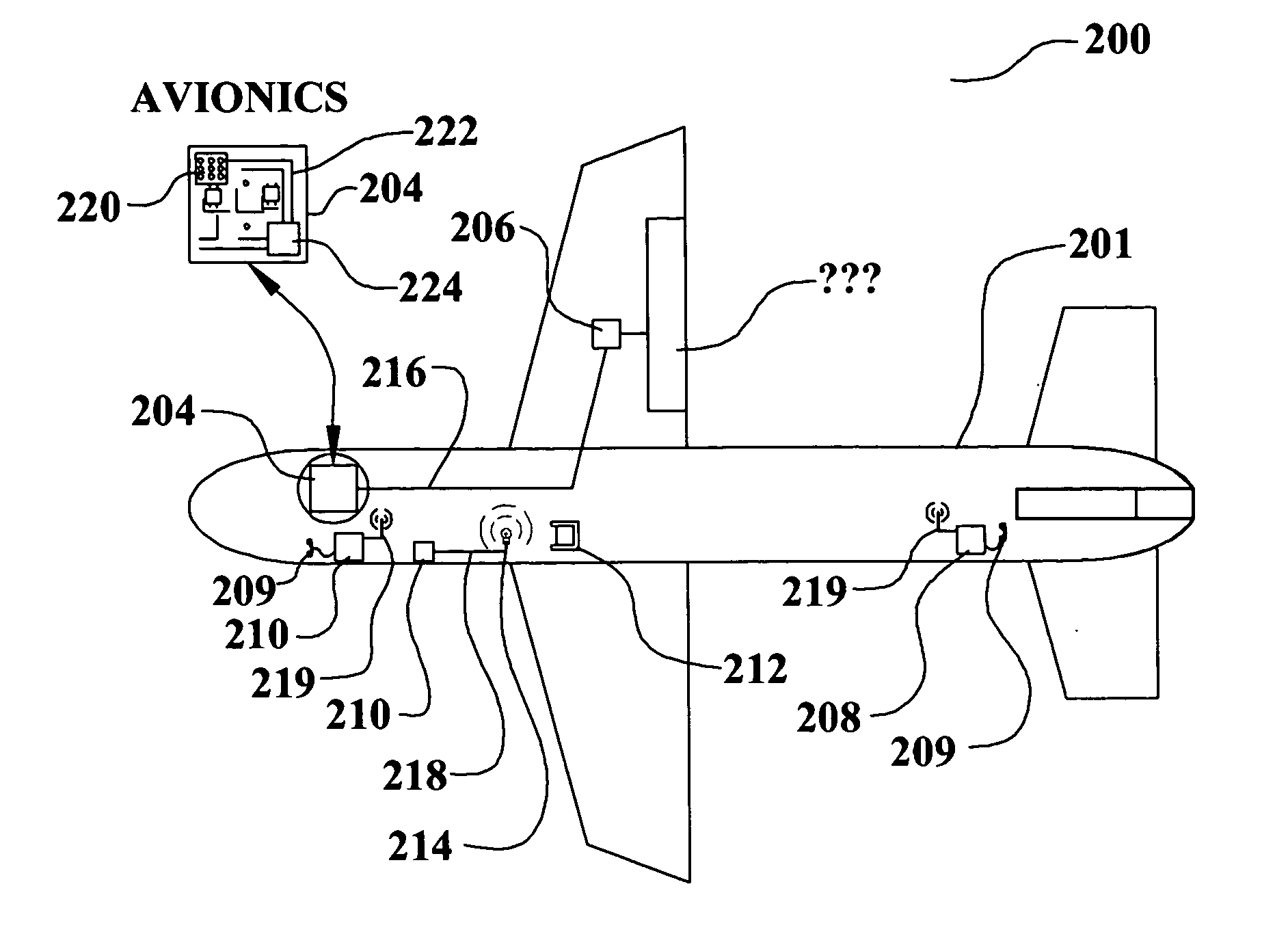

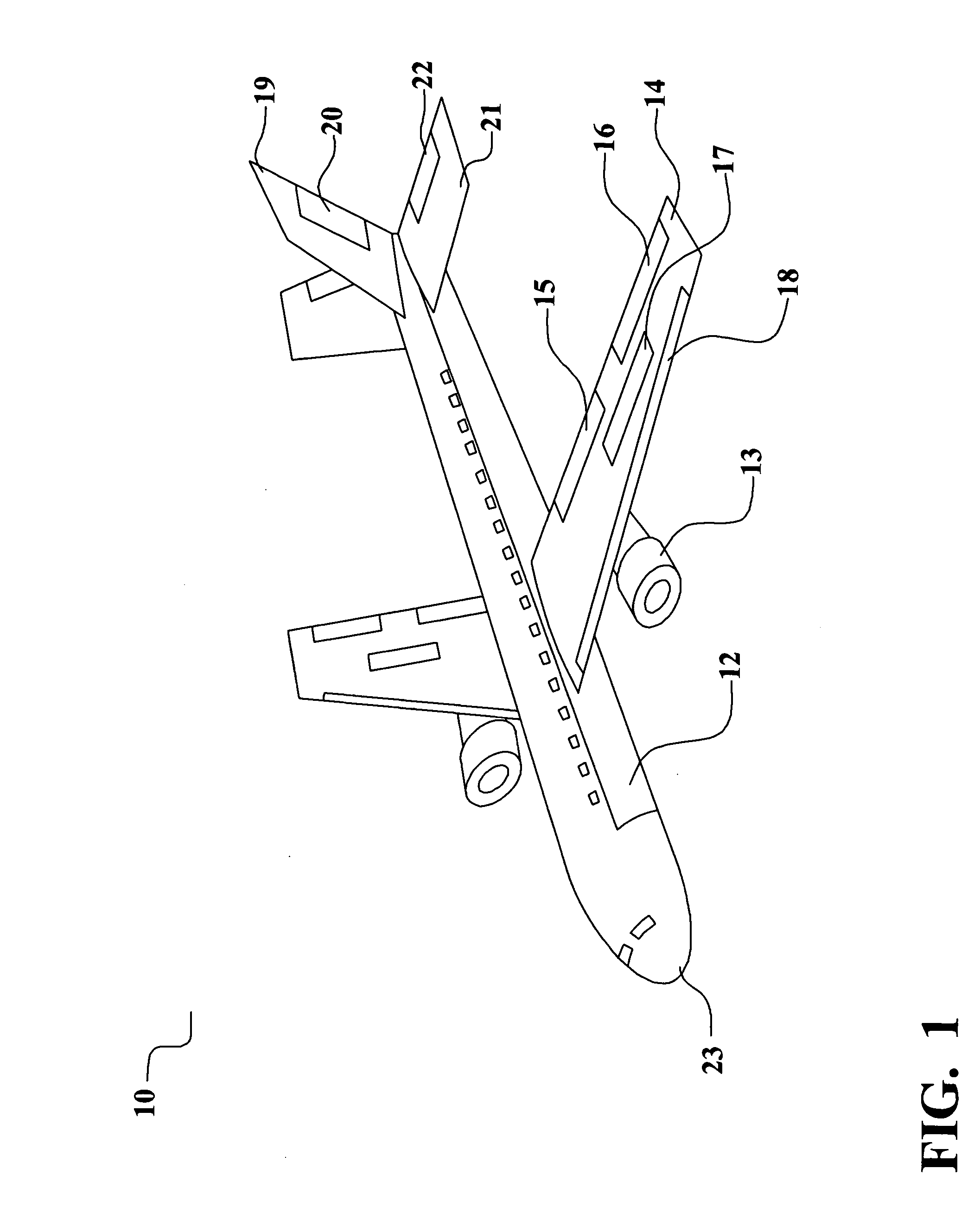

Low cost aircraft structures and avionics manufactured from conductive loaded resin-based materials

InactiveUS20060060690A1Reduce weightImprove performanceNon-insulated conductorsDe-icing equipmentsAviationCarbon fibers

Aircraft structures and avionics are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Low cost electromagnetic energy absorbers manufactured from conductive loaded resin-based materials

Electromagnetic energy absorbing devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The ratio of the weight of the conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers to the weight of the base resin host is between about 0.20 and 0.40. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

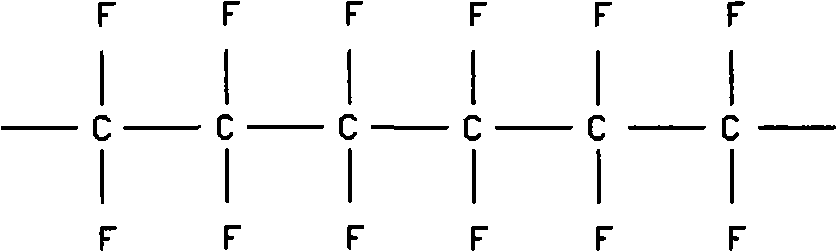

Anti-static polytetrafluoroethylene filter bag and preparation method thereof

InactiveCN103191602AHigh temperature resistantCorrosion resistantDispersed particle filtrationSynthetic resin layered productsChemical industryEngineering

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Owner:南京际华三五二一环保科技有限公司

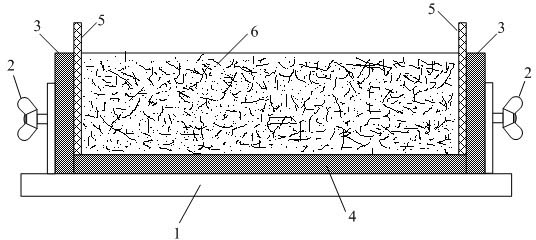

Corrosion-resistant high-strength conductive concrete and preparation method thereof

ActiveCN102432239AHigh strengthLow resistivityCeramic shaping apparatusCarbon fibersElectric power system

The invention discloses corrosion-resistant high-strength conductive concrete and a preparation method thereof. The conductive concrete comprises, by weight, 50-150 parts of cement, 50-150 parts of aggregates, 5-90 parts of graphite, 1-30 parts of a conductive fiber, and 40-180 parts of water, wherein the conductive fiber comprises one or two of a stainless steel fiber and a carbon fiber. According to the conductive concrete, graphite and the conductive fiber are used as conductive fillers, characteristics of strong conductivity and good stability of graphite are utilized, and the conductive fiber, especially the stainless steel fiber and the carbon fiber, is added, so the strength of the concrete is increased, the conductivity and the corrosion resistance of the concrete are very good. The prepared conductive concrete has the advantages of low resistivity, good conductivity, corrosion resistance, high strength and the like. The concrete of the invention can be used for the power system grounding, the electromagnetic shielding and the like, and can be prepared into an earth electrode to replace traditional metal earth electrodes.

Owner:CHONGQING UNIV

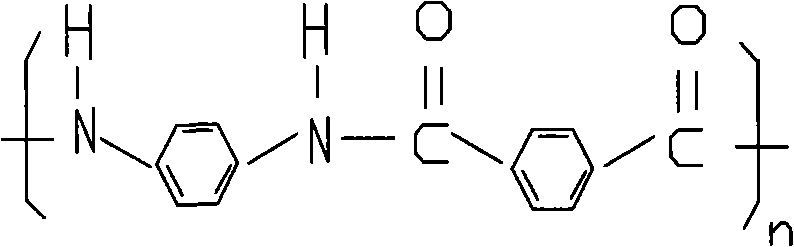

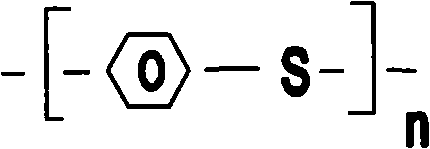

Multifunctional macromolecule filter material and preparation method thereof

InactiveCN101314091ALow costMoisture resistantSynthetic fibresFiltration separationGlass fiberPrice ratio

The invention relates to a multifunctional polymer filtering material which comprises 70 to 85 percent of glass fiber, the balance being one or a plurality of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, p-aramid, ceramic fiber, stainless steel fiber and copper fiber. The invention also discloses a method for preparing the multifunctional polymer filtering material. The method comprises the following steps: mixing the 70 to 85 percent of glass fiber and at least one of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, para-aramid, ceramic fiber, stainless steel fiber, copper fiber into a synthetic fabric; and puncturing and shaping the synthetic fabric and a base fabric to obtain a finished product. The filtrating material produced by the method has the advantages of low cost, water proofing, temperature resistance, corrosion resistance and high performance to price ratio.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

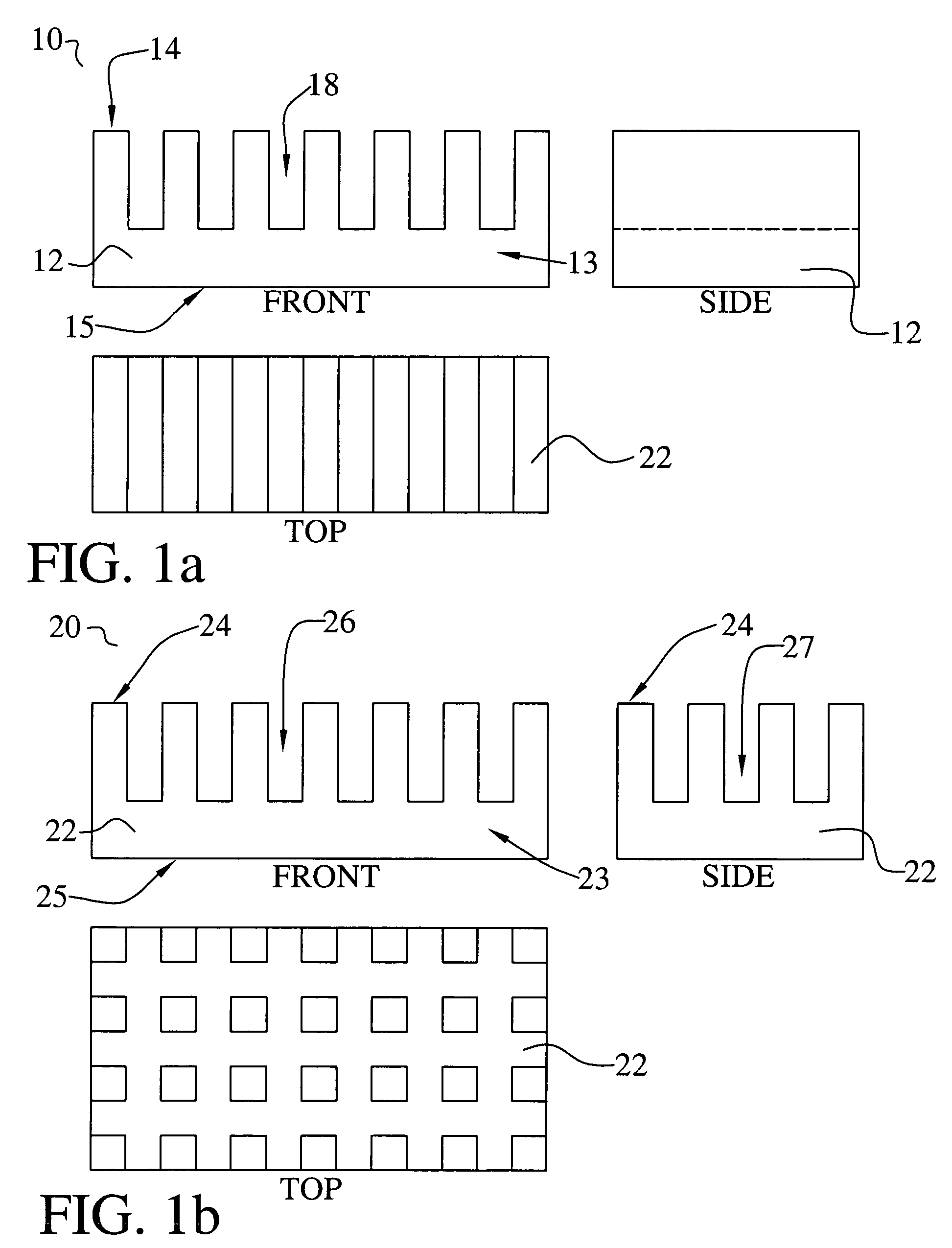

Low cost thermal management device or heat sink manufactured from conductive loaded resin-based materials

Heat sinks, heat pipes, and other thermal management devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The ratio of the weight of the conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers to the weight of the base resin host is between about 0.20 and 0.40. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

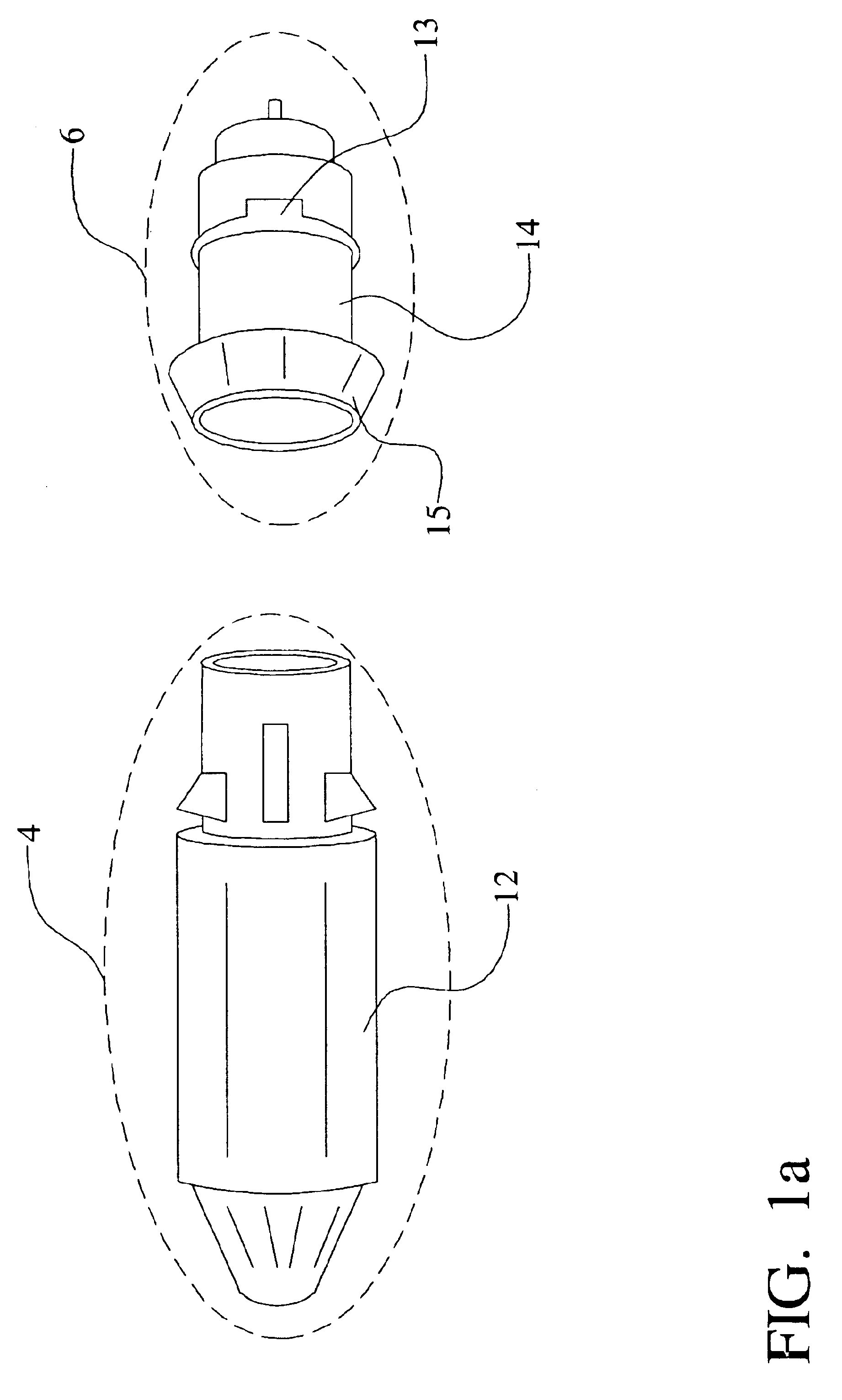

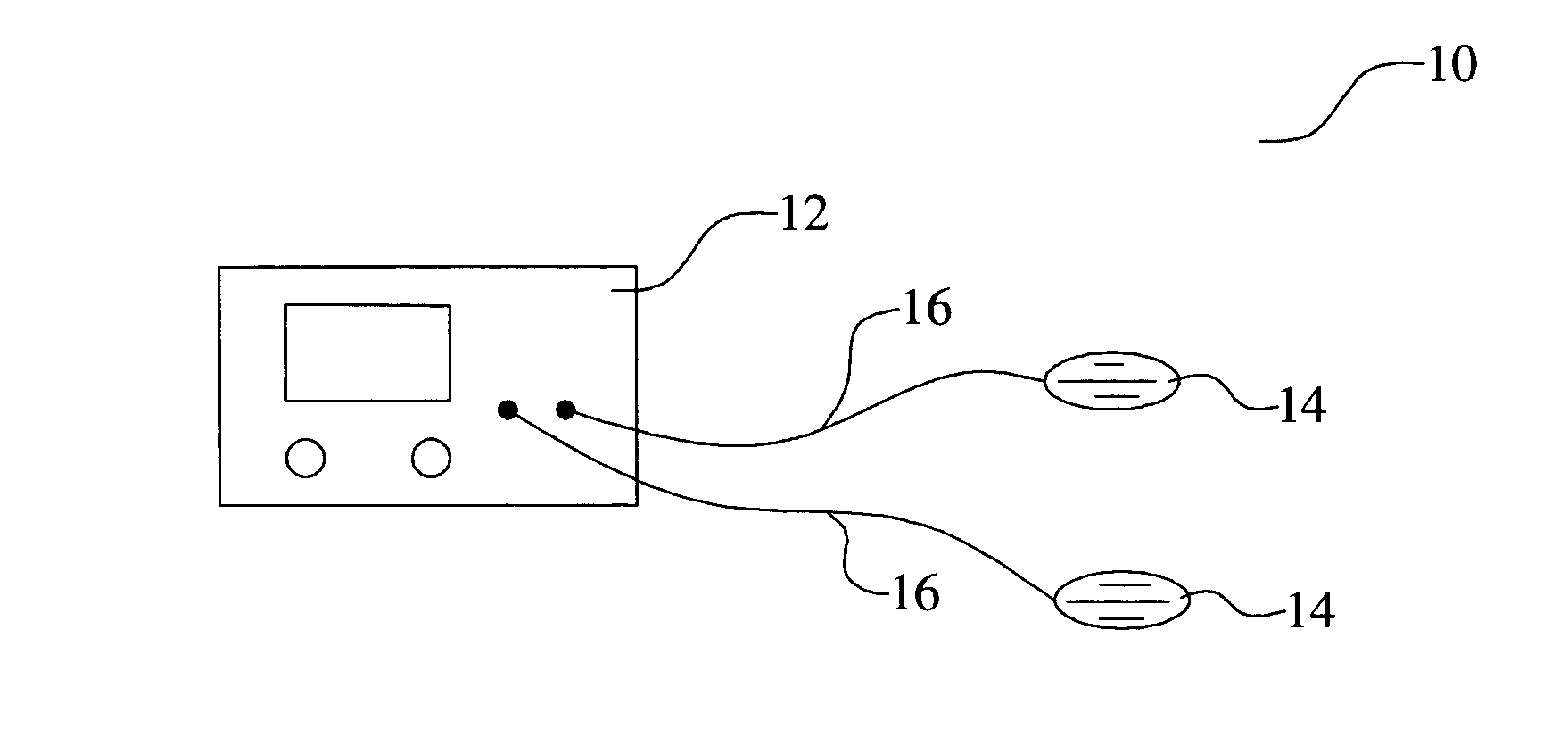

Low cost electrical stimulation and shock devices manufactured from conductive loaded resin-based materials

Electrical stimulators and shocking devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

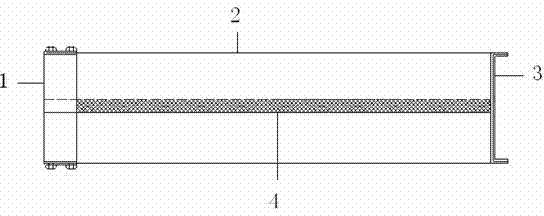

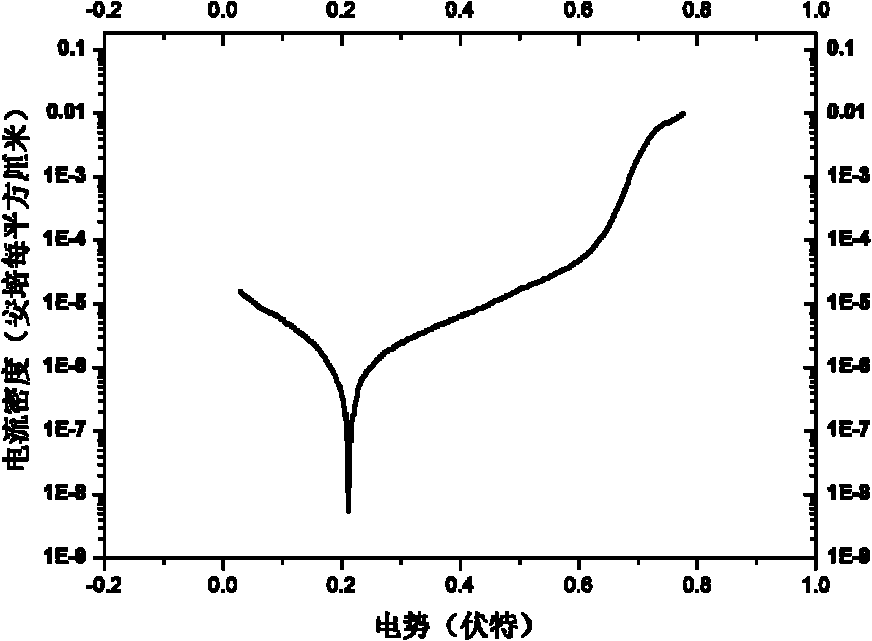

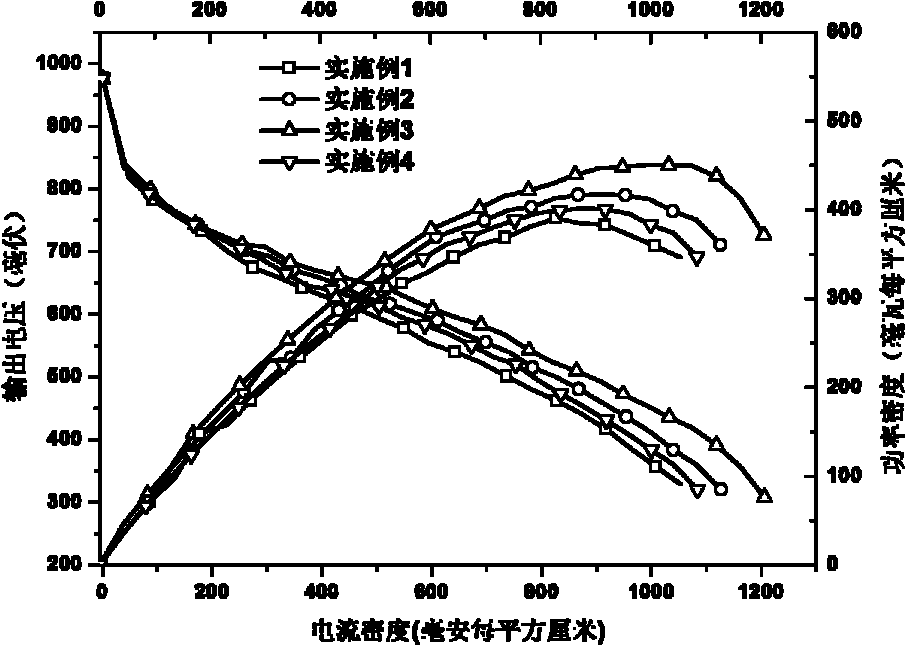

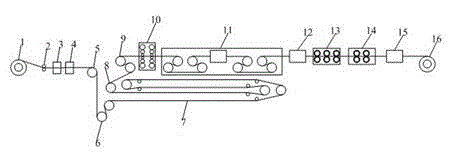

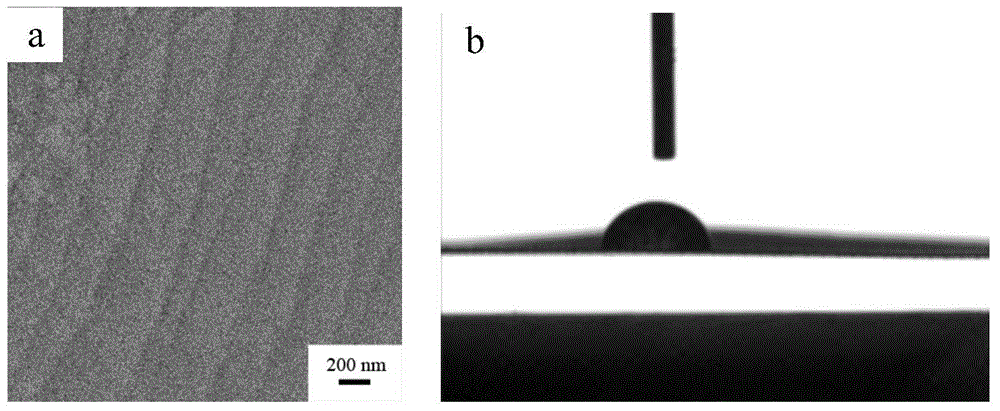

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277AImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:上海氢晨新能源科技有限公司

Method for producing cold-rolled stainless steel annealing and pickling brand steel

ActiveCN102744277AReduce thicknessReduce roughnessWork treatment devicesGrinding machinesNitrogenSlurry

The invention relates to a method for producing cold-rolled stainless steel annealing and pickling brand steel, comprising the following steps: (1) uncoiling and welding brand steels and then directly rolling the processed brand steels on two online six-high cluster mills without being lubricated, with the screw-down rate being 30-60%; (2) performing tension levelling and scale breaking on the brand steel, with the percentage of elongation being 2-7%; (3) performing shot blasting on the brand steels, wherein slurries formed by mixing water with abrasive materials are jetted in the shot blasting, and the30-40% abrasive materials are contained in the slurries; (4) using a scrubbing unit to grind and scrub the brand steel, wherein four pairs of grinding and scrubbing rollers are used for eliminating scales remaining on surfaces of the brand steels; (5) using two pairs of scrubbing rollers to polish and scrub the brand steel, thereby reducing the roughness of the brand steels; and (6) drying and coiling the brand steel. According to the method for producing cold-rolled stainless steel annealing and pickling brand steel, the production cost is lowered and energy conservation and environmental protection are realized as well as improve the surface quality of the cold-rolled stainless steel annealing and pickling brand steel is improved without adoption of an annealing furnace, a pickling section and a nitrogen-removing device.

Owner:WISDRI ENG & RES INC LTD

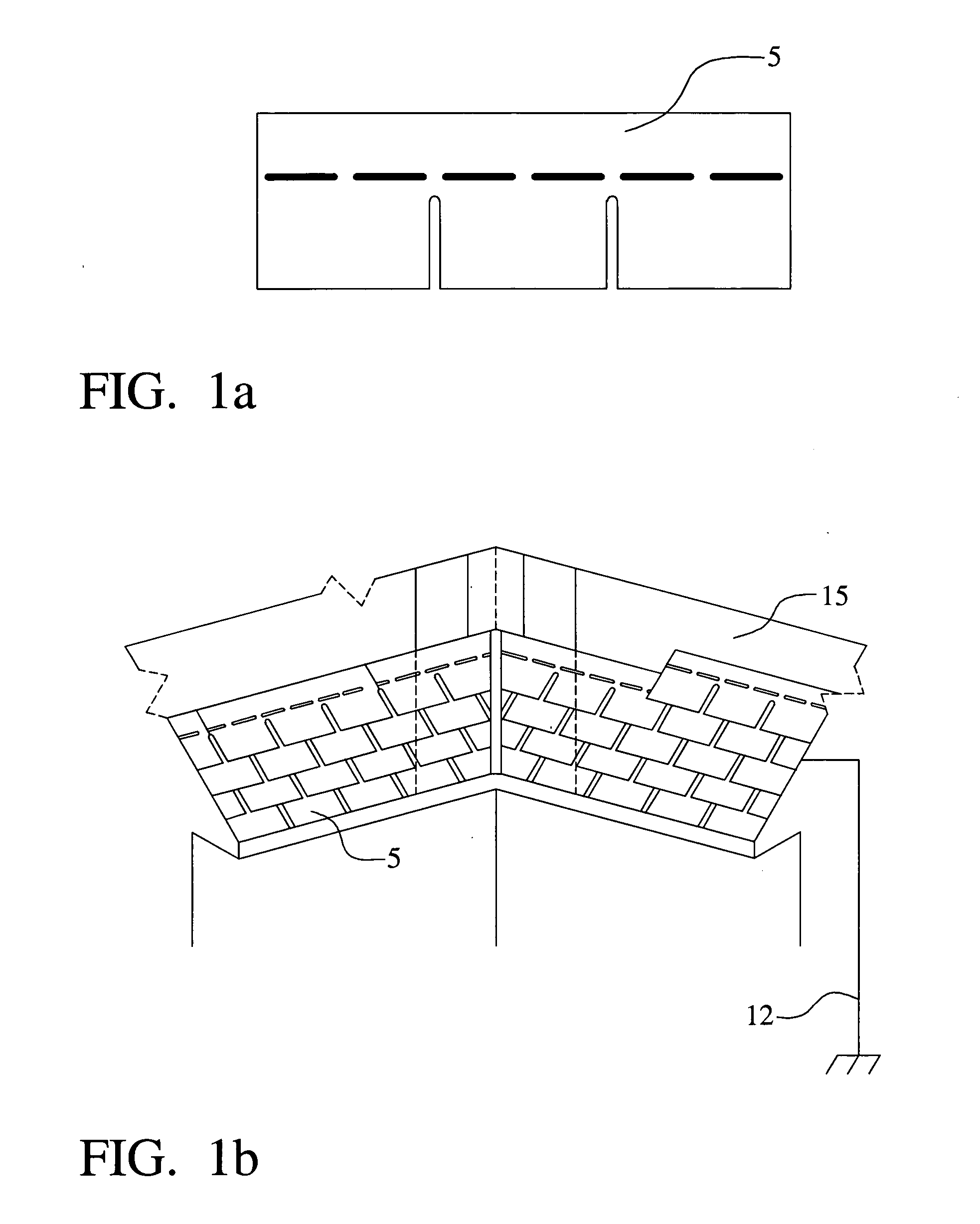

Low cost roofing shingles manufactured from conductive loaded resin-based materials

InactiveUS20050166956A1Efficient conductionEfficiently conductedAntenna arraysAntenna supports/mountingsElectrical conductorCarbon fibers

Conductive roofing materials are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Dry coke quenching furnace circular passage tilt channel regional patching material

InactiveCN101618967AImprove volume stabilityMake up for the defect of medium temperature strength dropAluminateHeat resistance

The invention relates to a dry coke quenching furnace circular passage tilt channel regional patching material, comprising 65wt% of aggregate part and 35wt% of substrate part; the formula is as follows: 5-42 parts of fused brown aluminium oxide, 10-30 parts of mullite, 5-13 parts of silicon carbide, 8-15 parts of active alpha-Al2O3 powder, 3-8 parts of active silicon dioxide micropowder, 5-11 parts of silicon carbide powder, 3-7 parts of silicon carbide ultrafine powder, 3-9 parts of high purity aluminate, 0.2-0.4 part of composite dispersant and 1-3 parts of heat resistance stainless steel fiber. The invention has the advantage that the optimization of grain composition of particles in the aggregate part and the substrate part and the use of the composite dispersant ensure that the self-flow patching material has good flowing property in the simple and fast way and the patching material has good workability.

Owner:BEIJING RUIPU TONGCHUANG TECH DEV

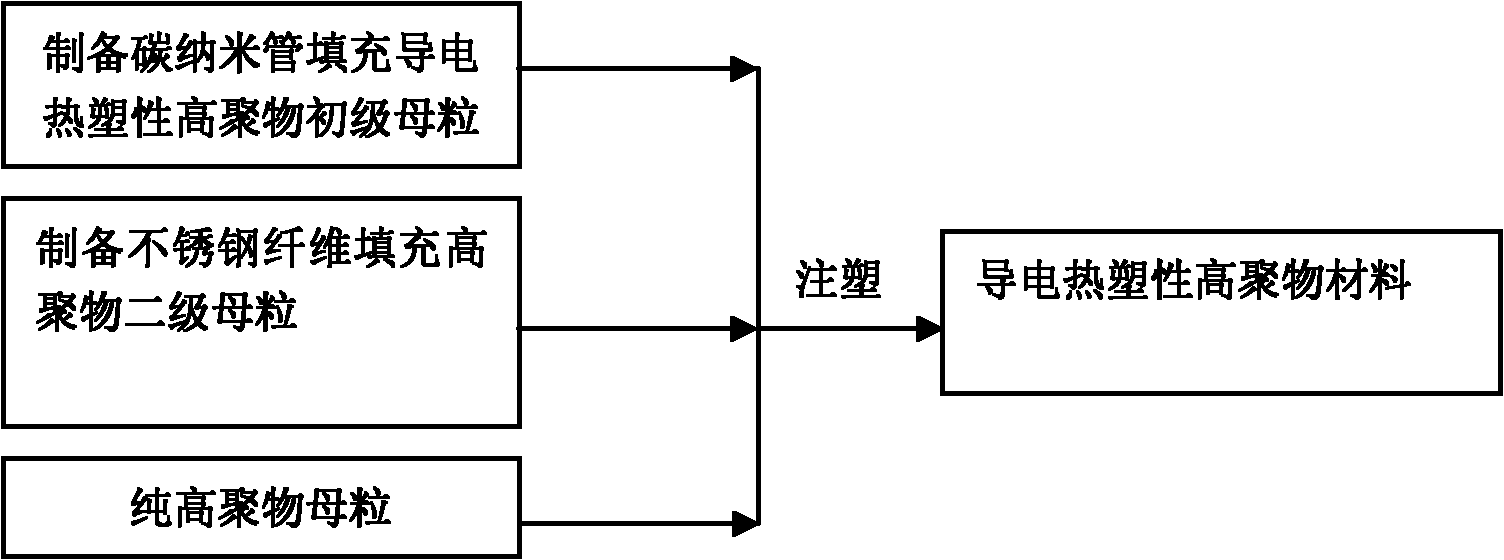

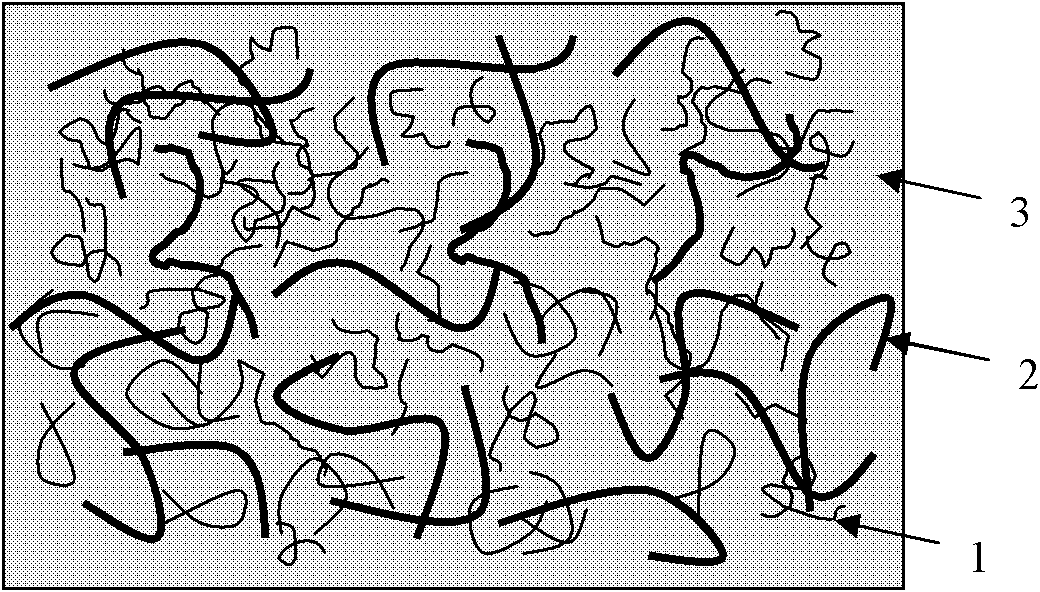

Method for preparing particle-filled conductive thermoplastic polymer

InactiveCN101812239ANo reunionImprove performanceNon-conductive material with dispersed conductive materialExplosion protectionCarbon nanotube

The invention provides a method for preparing a particle-filled conductive thermoplastic polymer, which belongs to the field of electromagnetic shielding material preparation. The method comprises the following steps of: firstly, preparing primary master batch of a carbon nanotube filled conductive thermoplastic polymer; secondly, preparing secondary master batch of a stainless steel fiber filled polymer; and finally, mixing the primary master batch, the secondary master batch and pure polymer master batch and performing co-injection molding on the mixture to obtain the conductive thermoplastic polymer material. The method has the characteristics of simple technical condition, easily controlled process, no residual impurities or reactant, low cost, high yield and convenient batch production. No agglomeration phenomenon occurs in the mixing process of the carbon nanotube primary master batch and the stainless steel fiber secondary master batch, so the composite material has uniformly distributed conductive filler, and the performance of the composite material is greatly improved. The method can be widely applied in the fields of civil and electric consumer products, such as consumer electronics, electrical appliance, communication devices, explosion protection safety products, information transfer and security, anti-static electricity, petrochemical industry and the like.

Owner:PEKING UNIV

Low density fire resistant pouring material for KR stirring paddle

The invention provides a KR stirring paddle desulfuration used low density fireproof casting material, which belongs to the field of a fireproof material used for pretreatment of ladle desulfuration and desilication before pneumatic steelmaking. The volume density of the fireproof casting material is 2.3 to 2.7g / cm<3>; the granule is primarily prepared with superfine flint clay, silica and carborundum. The casting material further comprises alumina powder, carborundum, silica micropowder and alundum cement of less than 0.074mm. The components and the mass percentages of the KR stirring paddle desulfuration used low density fireproof casting material are as follows: 60 to 80 percent of aggregate; 20 to 40 percent of fine powder; an additive of 0.03 to 0.35 percent of the total weight of the aggregate and the fine powder; a detonation inhibitor of 0.02 to 0.5 percent of the total weight of the aggregate and the fine powder; and stainless steel fiber of 0 to 7 percent of the total weight of the aggregate and the fine powder. After the raw materials are mixed, water is added, the mixture is beaten, cast and moulded. After the moulded mixture is cured, and molded mixture is baked at moderate temperature, thus getting the KR stirring paddle desulfuration used low-density fireproof casting material. The KR stirring paddle desulfuration used low density fireproof casting material has the advantages of low cost, high wear resistance at high temperature, high service life and so on.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

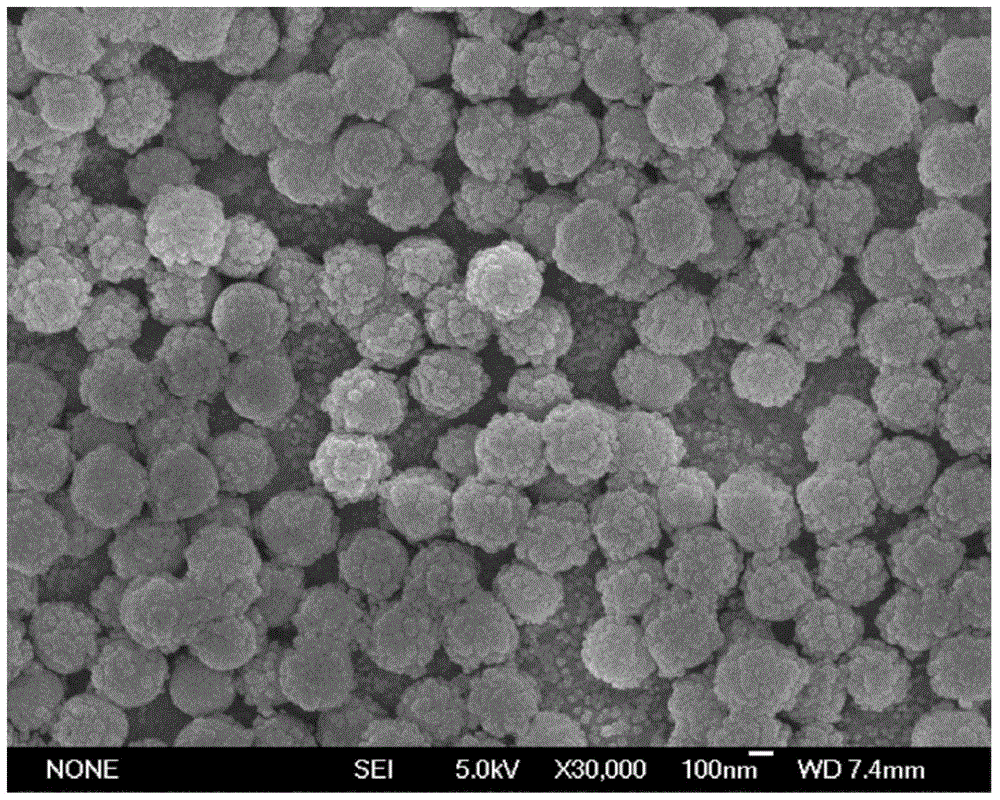

Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

ActiveCN104802488AEasy to separateSimple processLayered productsCoatingsChemical industryOil water emulsion

The invention belongs to the technical field of preparation of nano-materials, and relates to a super-hydrophobic oil-water separation material containing a hierarchical structure coating layer. The hierarchical structure coating layer is formed by a layer of solid spherical SiO2 nano-particles with the particle size of 10-50nm and the particle size of 70-500nm, and the surface of the coating layer is provided with a layer of a low surface energy substance. The coating layer is obtained through layer-by-layer electrostatic in situ self-assembling, and can be used on stainless steel wire nets, stainless steel fiber sintered felts and other metal net products. The water contact angle of the stainless steel sintered nets coated with the hierarchical structure coating layer can exceed 150DEG. The material is simple to prepare, can be used to process filter core materials in coalescence separators, can be repeatedly used in oil-water separation, especially has a good separation effect on an oil-water emulsion, and can be widely used in oil-containing sewage treatment in the petroleum chemical industry, the metallurgy industry, the chemical engineering industry, the beverage industry, the food industry and the pharmacy industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

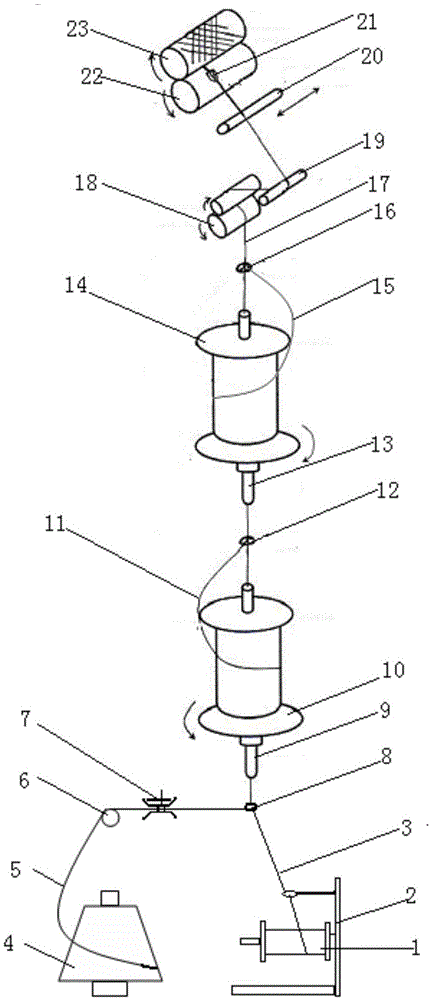

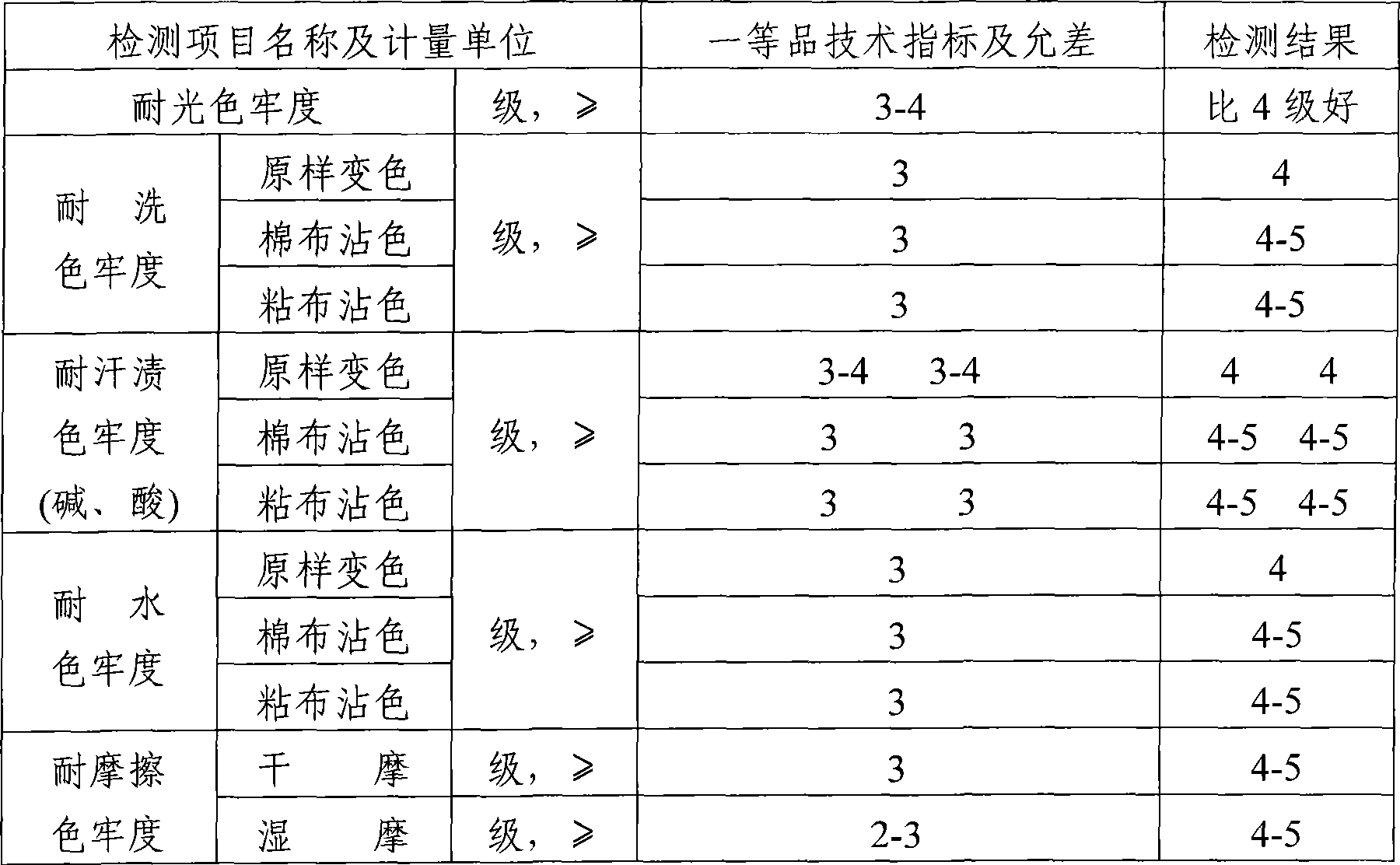

Method for producing electrostatic resistance and ray-proof worsted cloth

ActiveCN101250787AMeeting urgent needsSuitable for worsted processing needsDry-cleaning apparatus for textilesWoven fabricsPolyesterWorsted

The invention relates to method for manufacturing antistatic ray-proof worsted fabric, which successively comprises the following steps: firstly, carrying out the cleaning treatment and the sizing and film mulching treatment to rust-less steel fiber, secondly, blending by selecting treated rust-less steel fiber with wool, polyester fiber, bamboo fiber, tenel, modal fiber or spun silk, manufacturing mixed sliver with homogeneous mix, thirdly, spinning the mixed sliver and obtaining the worsted spinning yarn, fourthly, warping, weaving and obtaining the grey fabric, fifthly, carrying out birth repairing, dyeing and finishing and post-processing to the grey fabric, namely obtaining the antistatic ray-proof worsted fabric, wherein the materials feeding proportion by weight of the wool, the polyester fiber, the bamboo fiber, the tenel, the modal fiber, the spun silk, viscose or cashmere are respectively that the rust-less fiber 15-45 parts, the wool 45-75 parts, the polyester fiber 5-50 parts, the bamboo fiber, the tenel, the modal fiber, the spun silk, the viscose or the cashmere 5-20 parts. The method of the invention selectes length and fineness of the rust-less fiber and carries out the prophase film mulching treatment to the fiber, which enables the performances of the fiber is suitable for the requirements of the worsted process and enables the fiber to achieve the goal of being applied at high proportion.

Owner:山东希努尔男装有限公司

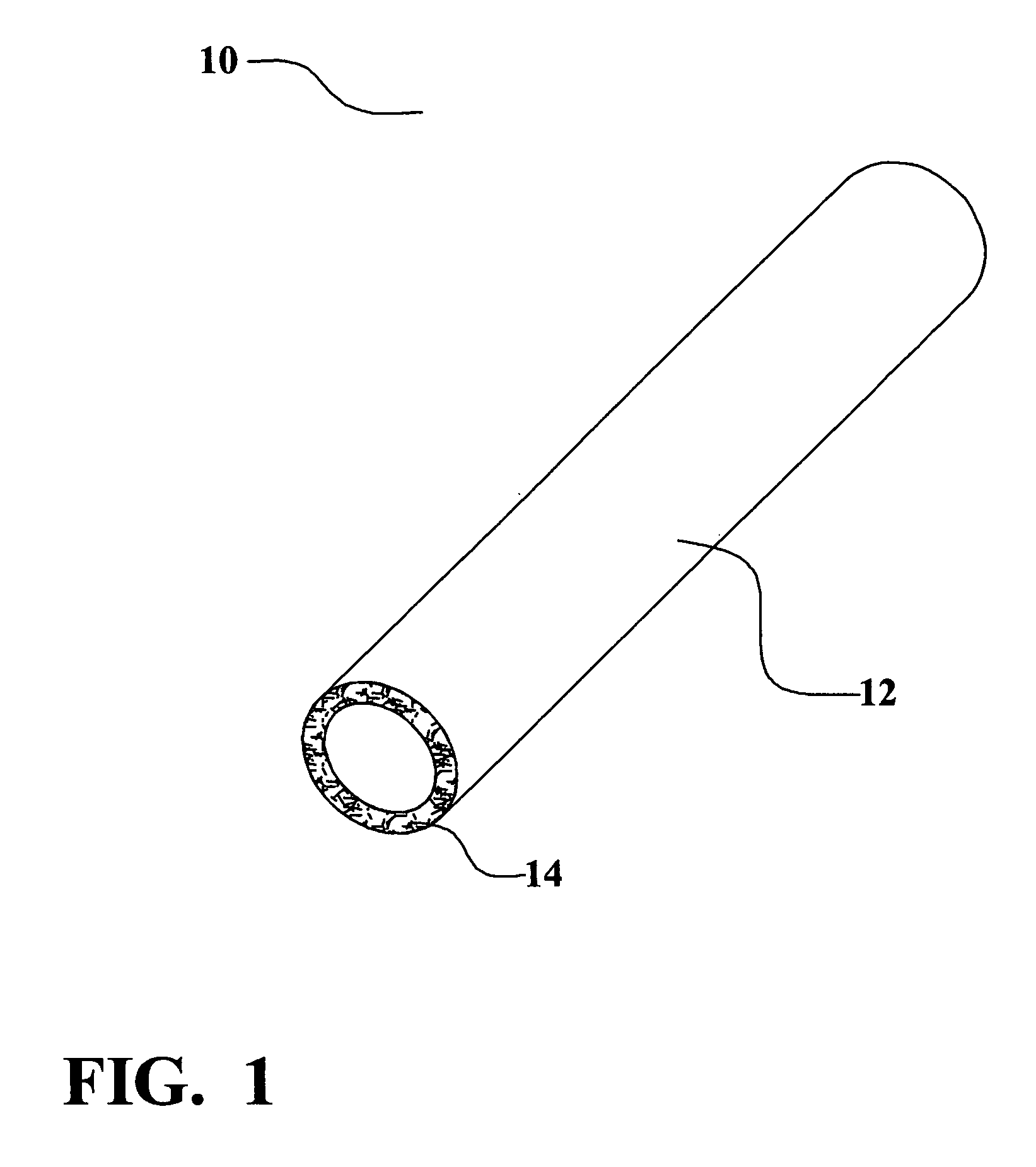

Low cost conductive pipe manufactured from conductive loaded resin-based materials

InactiveUS20050212161A1Characteristic can be alteredLayered productsWood working apparatusCarbon fibersElectrical conductor

Conductive pipe are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Low cost roofing shingles manufactured from conductive loaded resin-based materials

InactiveUS20050140042A1Efficiently conductedAntenna arraysAntenna supports/mountingsElectrical conductorCarbon fibers

Conductive roofing materials are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Stainless steel wrapping yarn and processing method thereof

The present invention discloses a stainless steel wrapping yarn and a processing method thereof. The stainless steel wrapping yarn comprises a stainless steel wire; the stainless steel wire and a lining yarn are combined together to form a twin-core yarn; the diameter of the lining yarn is greater than the diameter of the stainless steel wire; outer wrapped yarns are disposed outside the twin-core yarn; the outer wrapped yarns comprise the first outer wrapped yarn and the second outer wrapped yarn; the first outer wrapped yarn and the second outer wrapped yarn are wound outside the twin-core yarn and wrap the twin-core yarn; and winding directions of first outer wrapped yarn and the second outer wrapped yarn are opposite. The lining yarn is introduced to compose the twin-core yarn with the stainless steel wire, then the twin-core yarn is intercrossed and wound in positive and negative directions for two times, the stainless steel wrapping yarn of a lining-wrapped structure is formed, so that the problems that wrapping of a stainless steel functional yarn is not sealed and a core is exposed, performance of stainless steel fiber is degraded due to twisting and torsion, slip is performed between a stainless steel core wire and a wrapping component core sheath, and the yarn is arched when stretched and the like are solved.

Owner:ZHEJIANG KAIFA NEW MATERIAL

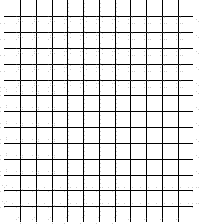

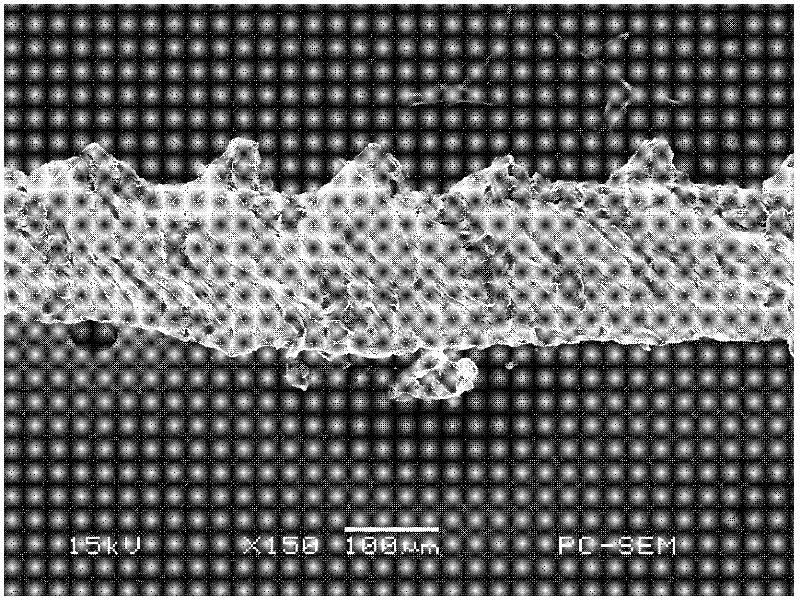

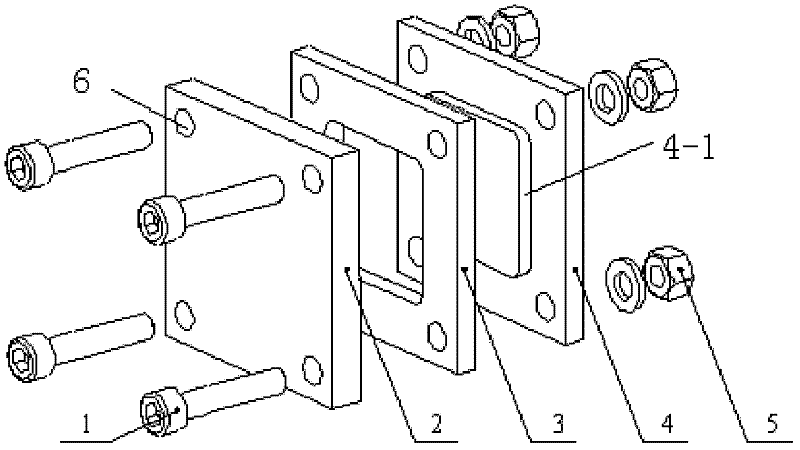

Preparation method of composite filtering net of stainless steel net and metal fiber felt

ActiveCN1785557AImprove filtering effectHigh strengthLaminationLamination apparatusMetal fiberComposite filter

A composite filter net is prepared from the stainless steel mesh with square holes and the stainless steel fiber felt through overlaying, two-roller rolling, and vacuum sintering. Its advantages are high filter power, high strength and high adhesion.

Owner:WESTERN METAL MATERIAL

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

Friction material

InactiveUS7297728B2Improve effectivenessExcellent brake feelBraking element arrangementsOther chemical processesMohs scale of mineral hardnessShell molding

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

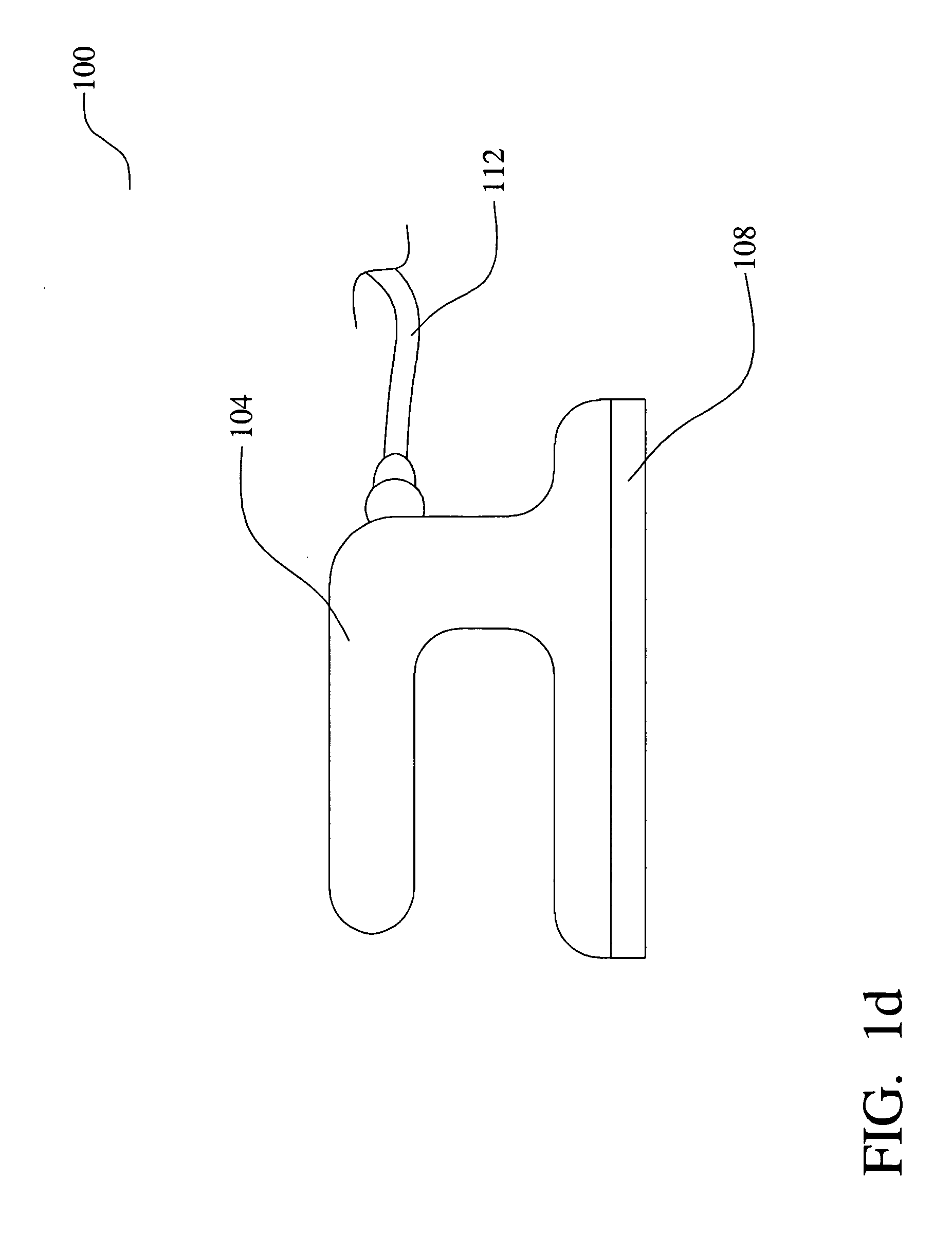

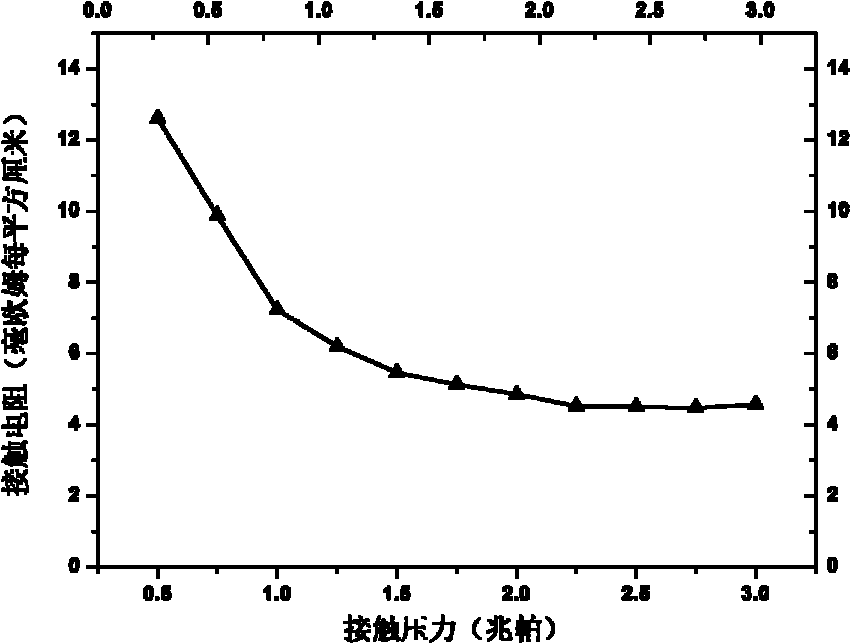

Very low resistance electrical interfaces to conductive loaded resin-based materials

InactiveUS20050024291A1Characteristic can be alteredContact member assembly/disassemblyLaminationElectrical conductorCarbon fibers

Electrical interfaces formed into a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

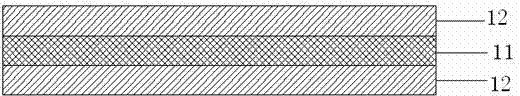

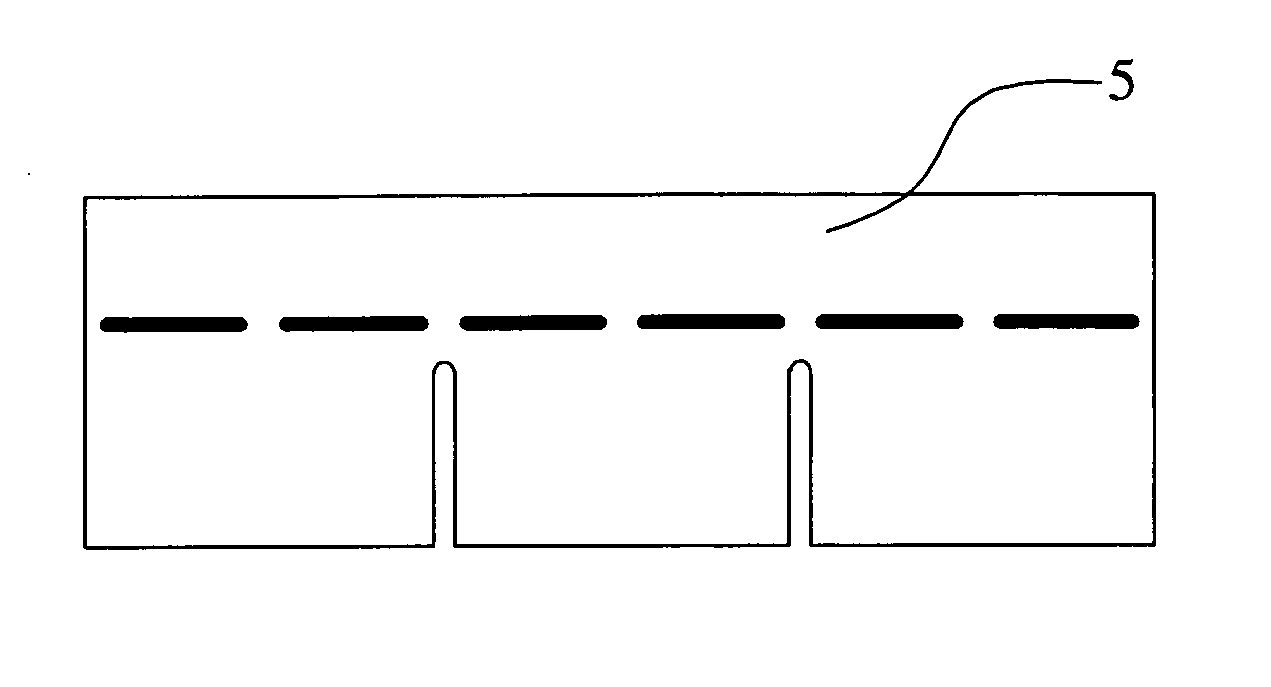

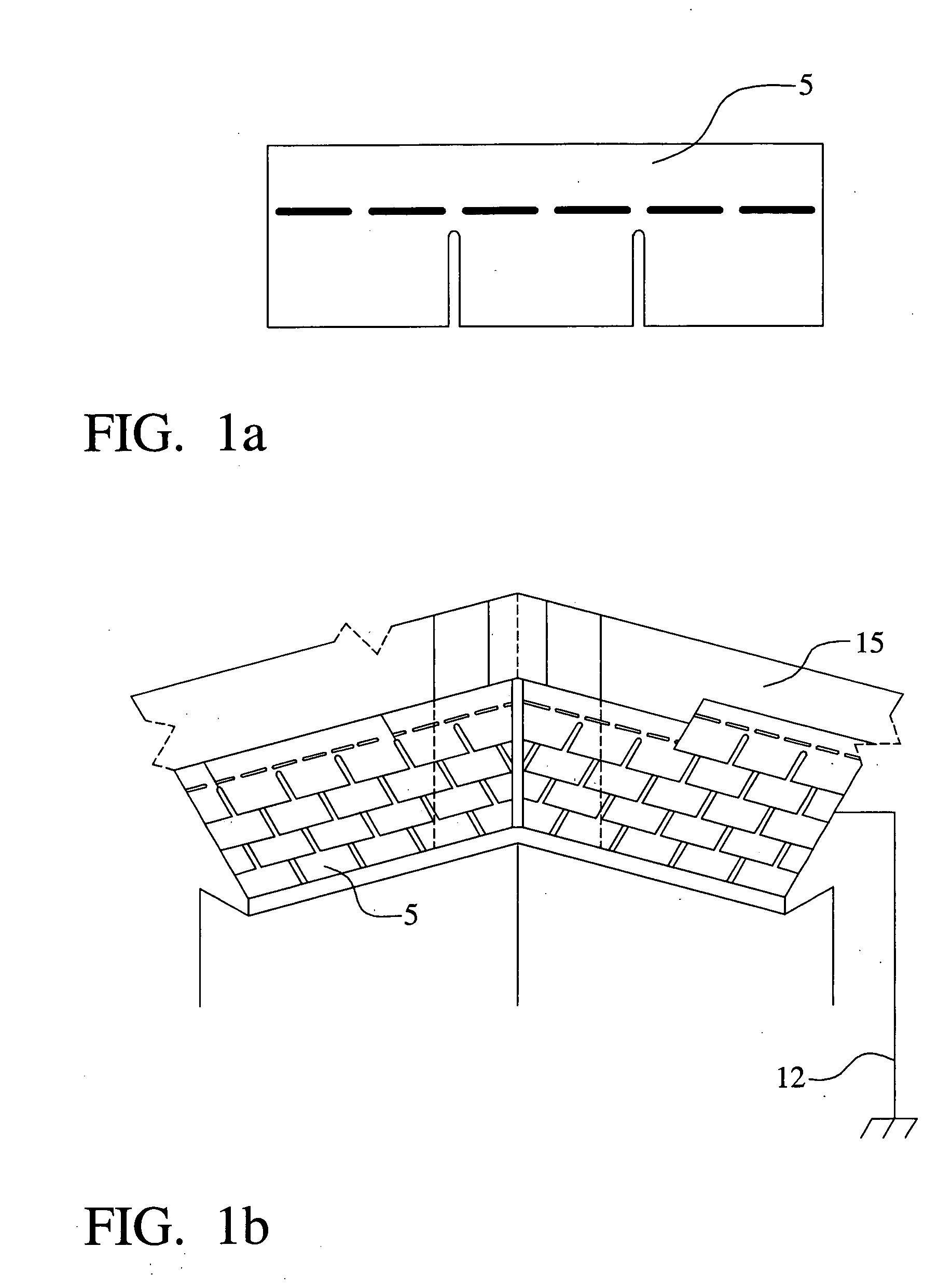

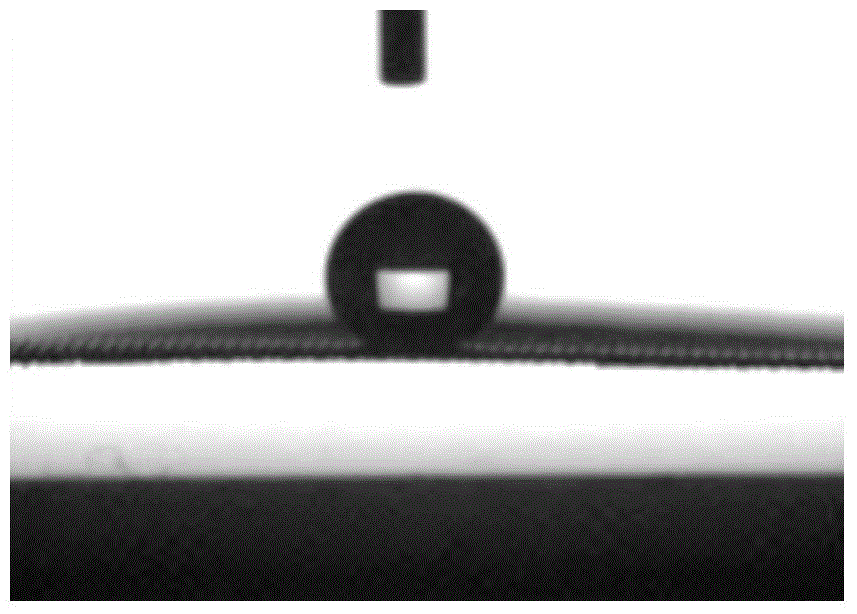

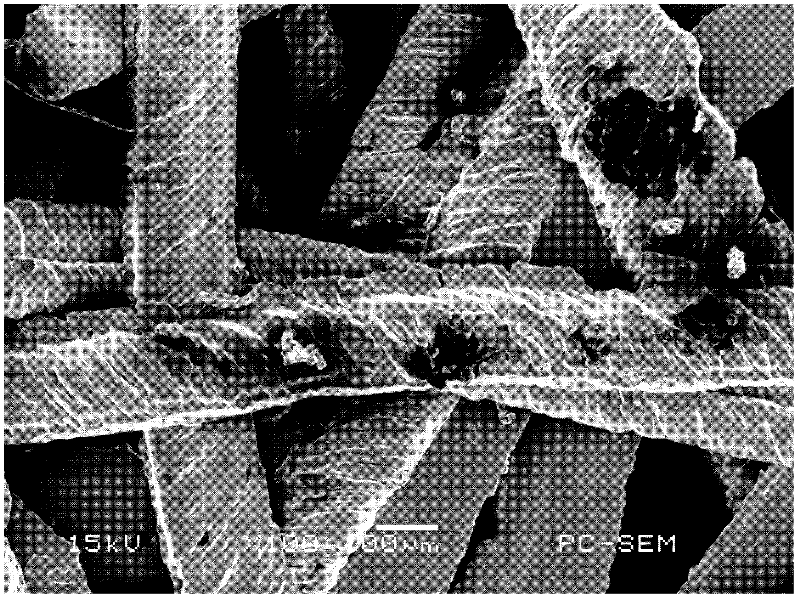

A kind of stainless steel fiber felt used for fuel cell bipolar plate and its manufacturing method

InactiveCN102290582AImprove structural uniformityGood heat and mass transfer performanceCell electrodesMetal fiberFuel cells

The invention discloses a stainless steel fiber felt used for fuel cell bipolar plates and a manufacturing method thereof, belonging to the technical field of fuel cell bipolar plate flow fields. The manufacturing method of stainless steel fiber mat can be divided into four steps: processing stainless steel fiber by cutting method, pretreatment of stainless steel fiber, molding of fiber mat, and high-temperature solid-state sintering. After the metal fibers are sintered, metallurgical bonding is achieved between the fibers, forming a large number of multi-scale pore structures. The manufactured stainless steel fiber felt has the advantages of high porosity, high specific surface area, good heat and mass transfer performance, surface hydrophobicity, simple manufacturing process and low cost. This method is applicable to manufacture various metal porous materials, and its pore size and porosity can be controlled.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com