Stainless steel wrapping yarn and processing method thereof

A processing method and technology of covering yarn, applied in yarn, textile and paper making, etc., can solve problems such as lax covering of stainless steel functional yarn, yarn arching, performance degradation of stainless steel fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one: the specification of stainless steel wire is 32 μm, and the interlining core yarn is polyester fully drawn yarn (Fullydrawnyarn, FDY), 75D / 36f (75D refers to that the total density of multifilament is 75 deniers; Denier is linear density The unit refers to the weight in grams of 9000 meters long fiber or yarn when the moisture regain is determined), 36F means that the 75D yarn is composed of 36 monofilaments), the first outer wrapping yarn is polyester DTY, 100D / 36f, wrapping twist 800 twists / m, wrapping twist direction Z twist; second outer wrapping yarn is pure cotton 60S combed yarn, wrapping twist 544 twists / m, wrapping twist direction S twist. 60S means that the linear density of the yarn is 60 pounds, and the British branch is generally represented by S. The British branch is the unit of linear density of the British yarn, which refers to the multiple of 840 yards of the length of a 1-pound yarn at the British standard moisture regain. The covered...

Embodiment 2

[0055] Embodiment 2: The stainless steel wire specification is 32 μm, the interlining core yarn is a blended yarn with a corn / cotton blending ratio of 30 / 70, the linear density is 40S, the first outer wrapping yarn is polyester DTY, 100D / 36f, and the wrapping twist is 1000 twists / m, wrapping twist to Z twist; the second outer wrapping yarn is 70D / 24f nylon DTY, wrapping twist 680 twist / m, wrapping twist to S twist. The covered yarn is wrapped with polyester and nylon, has good abrasion resistance and comfort, and is suitable for making antistatic and radiation-proof work clothes fabrics that are not worn next to the body.

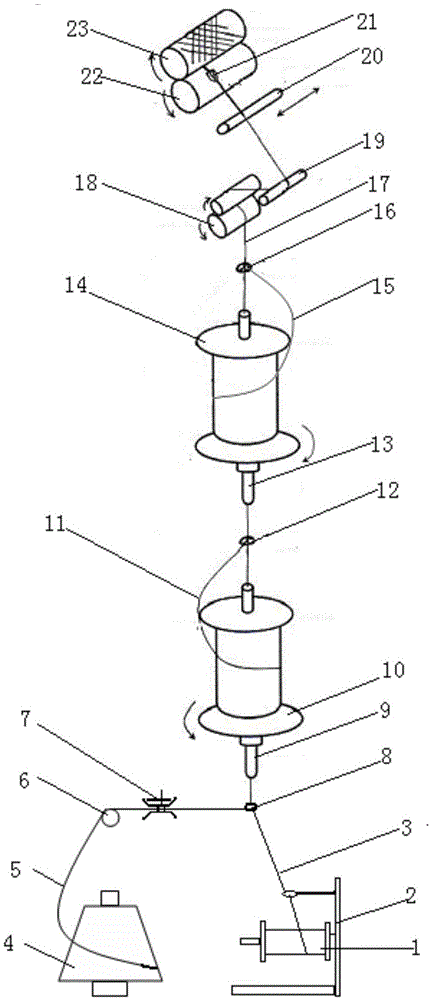

[0056] In summary, the present invention takes the hollow spindle covered spinning machine as the processing equipment, and uses a non-twist / low-twist filament yarn (FDY) or The short-spun yarn is the "interlining core" and the stainless steel wire, which are respectively combined under appropriate tension and passively unwound, and together act as the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com