Positioning spinning method of embedded system

一种嵌入式系统、粗纱的技术,应用在纺纱机、连续卷绕的纺纱机、纱等方向,能够解决很难保证纱线包缠效果、纤维根数少、易发生断头等问题,达到避免纺纱断头、扩大范围、条干优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

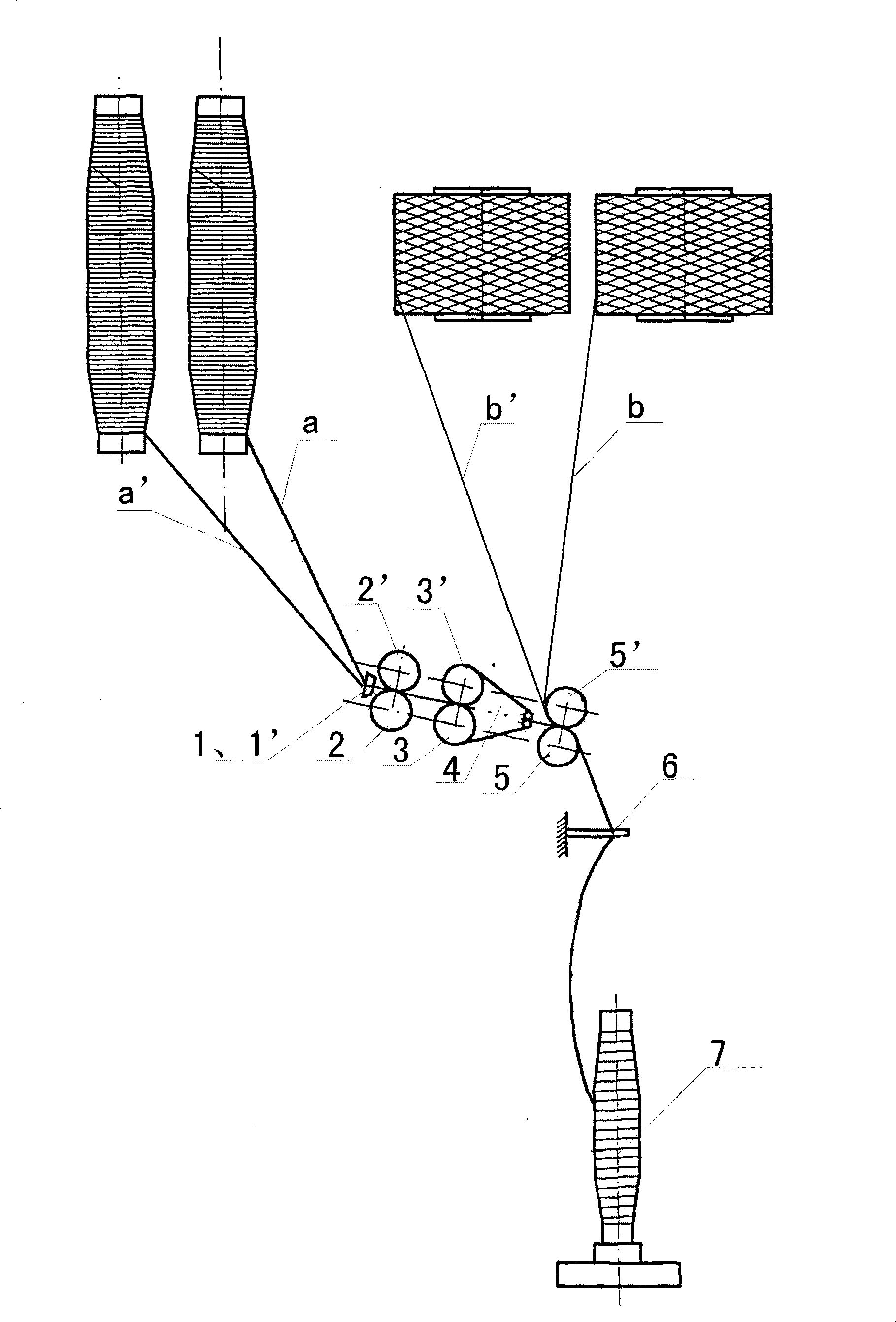

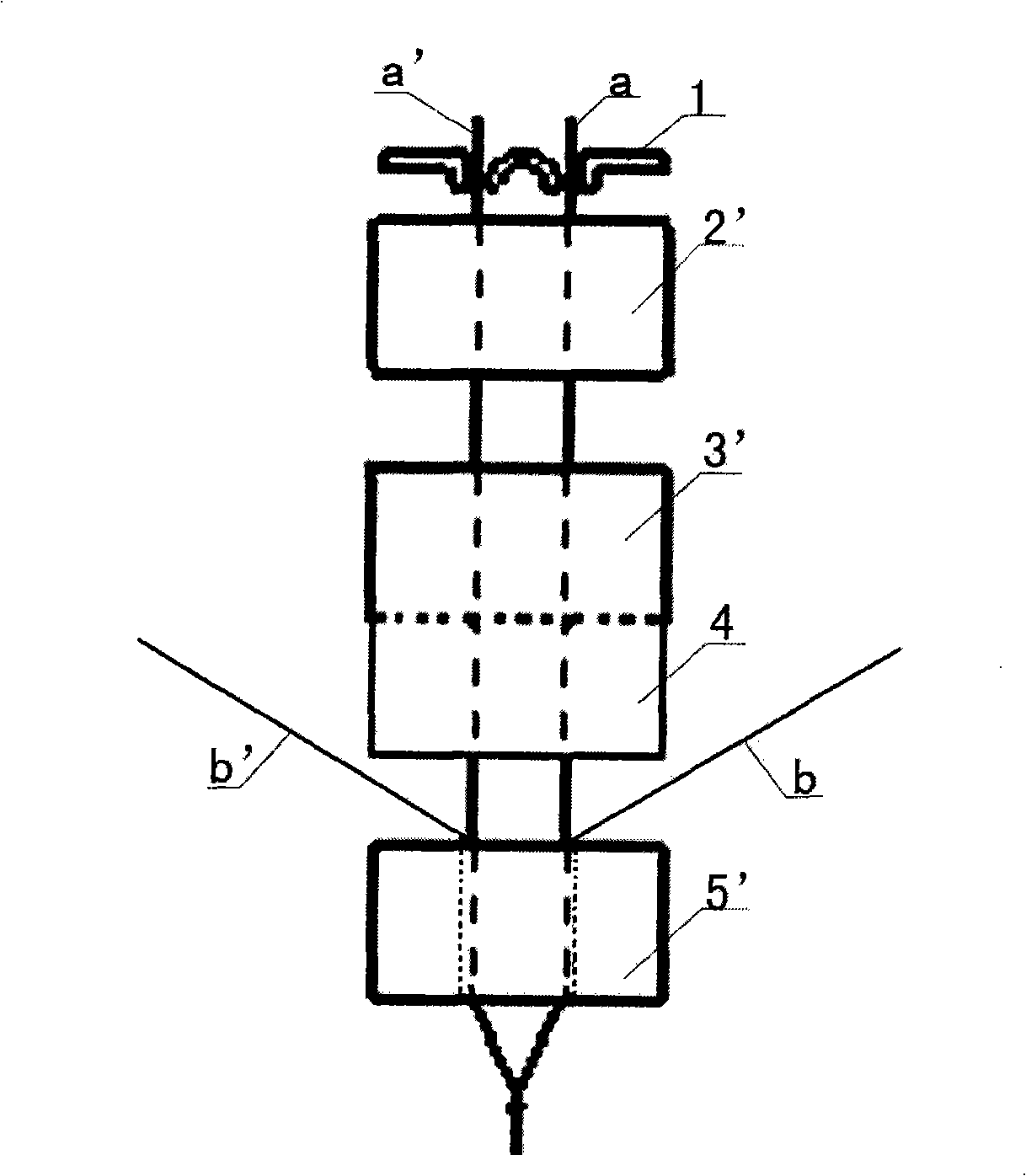

[0018] Example 1 Spinning a silk-like yarn on a cotton ring spinning frame

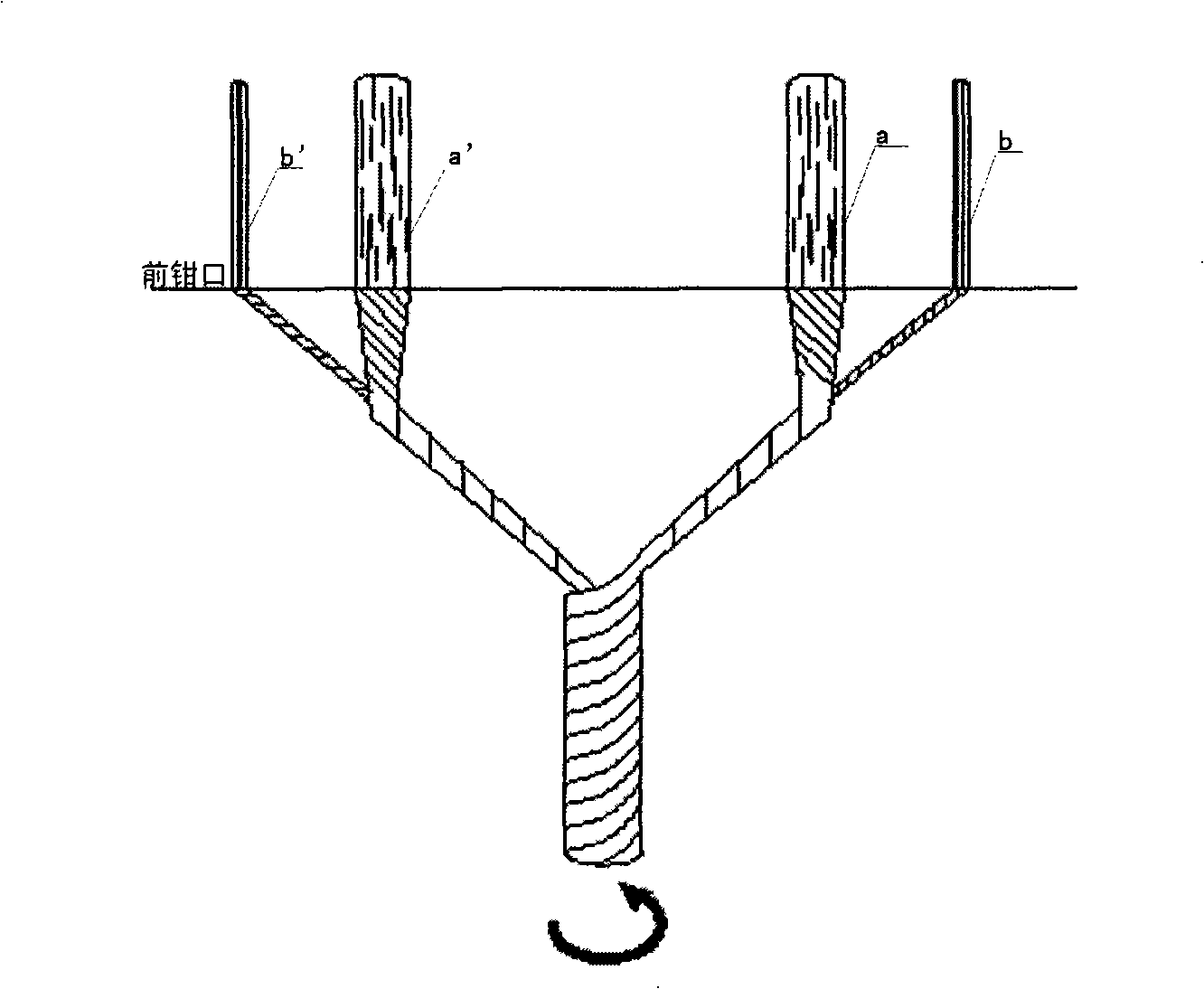

[0019] Two cotton rovings a, a' are unwound from the roving bobbin, respectively enter the drafting area through the guide horn 1 in parallel for drafting; two silk b, b' are guided by the positioning guide wire hook or guide wheel to the front roller 5 Back-end feeding, silk b, b' is parallel to cotton roving sliver a, a', wherein silk b, b' runs on the outer side of cotton roving sliver a, a'; two cotton roving sliver after drafting a, a' and two pieces of silk b, b' are output from the front jaws and enter the twisting triangle area to be twisted, and then wound on the spun yarn bobbin 7 after passing through the yarn guide hook 6 . The yarn spun in this way has silk on the surface and cotton yarn on the inner core. The fabrics made of this yarn not only have the style of real silk, but also reduce the cost.

Embodiment 2

[0020] Embodiment 2 spinning wool core-spun yarn

[0021] The two wool rovings a and a' are unwound from the roving bobbin, respectively enter the drafting area through the guide horn 1 in parallel for drafting; the two polyester filaments b and b' are guided by positioning guide hooks or guide wheels Feed from the rear end of the front roller 5, the filaments b, b' are parallel to the wool roving strands a, a', wherein the filaments b, b' run on the inside of the wool roving strands a, a'; Wool roving strands a, a' and two polyester filaments b, b' are output from the front jaws and entered into the twisting triangle area for twisting, and then wound on the spun yarn bobbin 7 after passing through the yarn guide hook 6 . The yarn spun in this way has the surface of wool and the inner core of polyester filament. The yarn has the style and characteristics of wool yarn, but also improves the strength and reduces the cost.

Embodiment 3

[0022] Embodiment 3 spinning ramie high-count yarn

[0023] Two ramie rovings a, a' are unwound from the roving bobbin, respectively enter the drafting zone through the guide horn 1 in parallel for drafting; two fine denier (50-120 denier) polyester filaments b, b' pass through the positioning The guide hook or guide wheel is fed from the rear end of the front roller 5, the filaments b, b' are parallel to the hemp roving strands a, a', wherein the filament b overlaps with the roving a, and the filament b' overlaps with the roving a' Coincident; two ramie roving strands a, a' after drafting and two polyester filaments b, b' are output from the front jaws and enter the twisting triangle area for twisting, and then are wound on the spun yarn after passing through the yarn guide hook 6 On bobbin 7.

[0024] Ramie is difficult to weave high-count yarns due to its thick fibers, high stiffness, and poor cohesion. Although sirofil spinning can be used to spin high-count yarns of more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com