Ultrasonic magnetic rheological composite polishing method and polisher thereof

A magnetorheological polishing and composite polishing technology, which is applied in grinding/polishing equipment, optical surface grinders, grinders, etc., and can solve the problems of inability to process concave curved surfaces and deep concave surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Embodiment 1: The steps of the polishing method in this embodiment are as follows: 1. Add magnetorheological polishing liquid mixed with abrasives into the stirring, constant temperature and constant viscosity control device, and fix the workpiece on the fixture of the workpiece numerical control worktable ; Start the pump, so that the magnetorheological polishing liquid mixed with abrasive flows out from the inner hole of the tool head through the circulation pipeline and so on by the pressure of the pump. 2. Start the electric spindle and ultrasonic generating device, and at the same time energize the electromagnet, so that the viscosity of the magnetorheological polishing fluid on the surface of the tool head increases rapidly within milliseconds and becomes semi-solid, forming a flexible polishing head. Rotate and vibrate at high frequency. 3. The spindle CNC workbench controls the position of the polishing head, and the processed workpiece is driven by the workpiec...

specific Embodiment approach 2

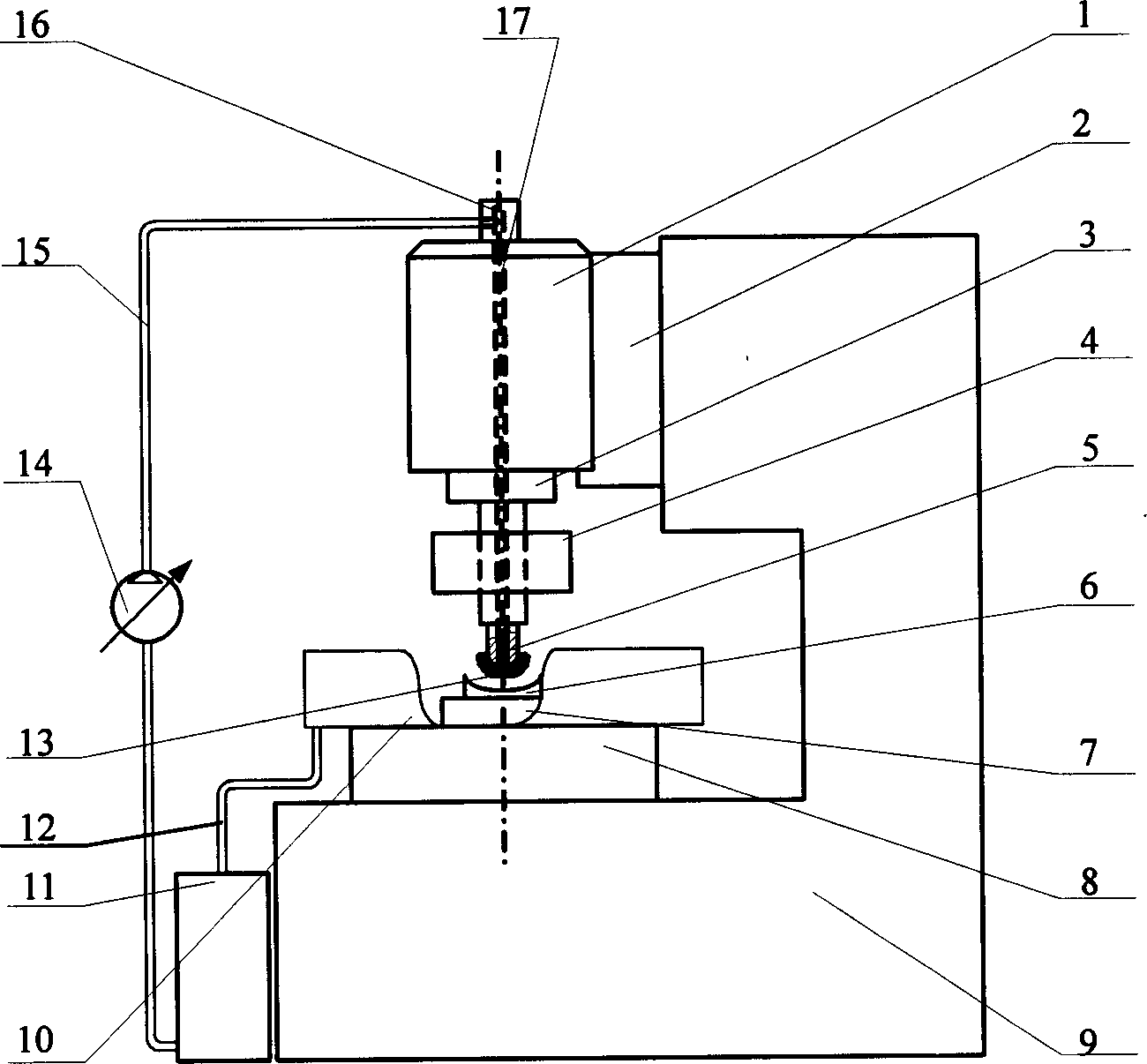

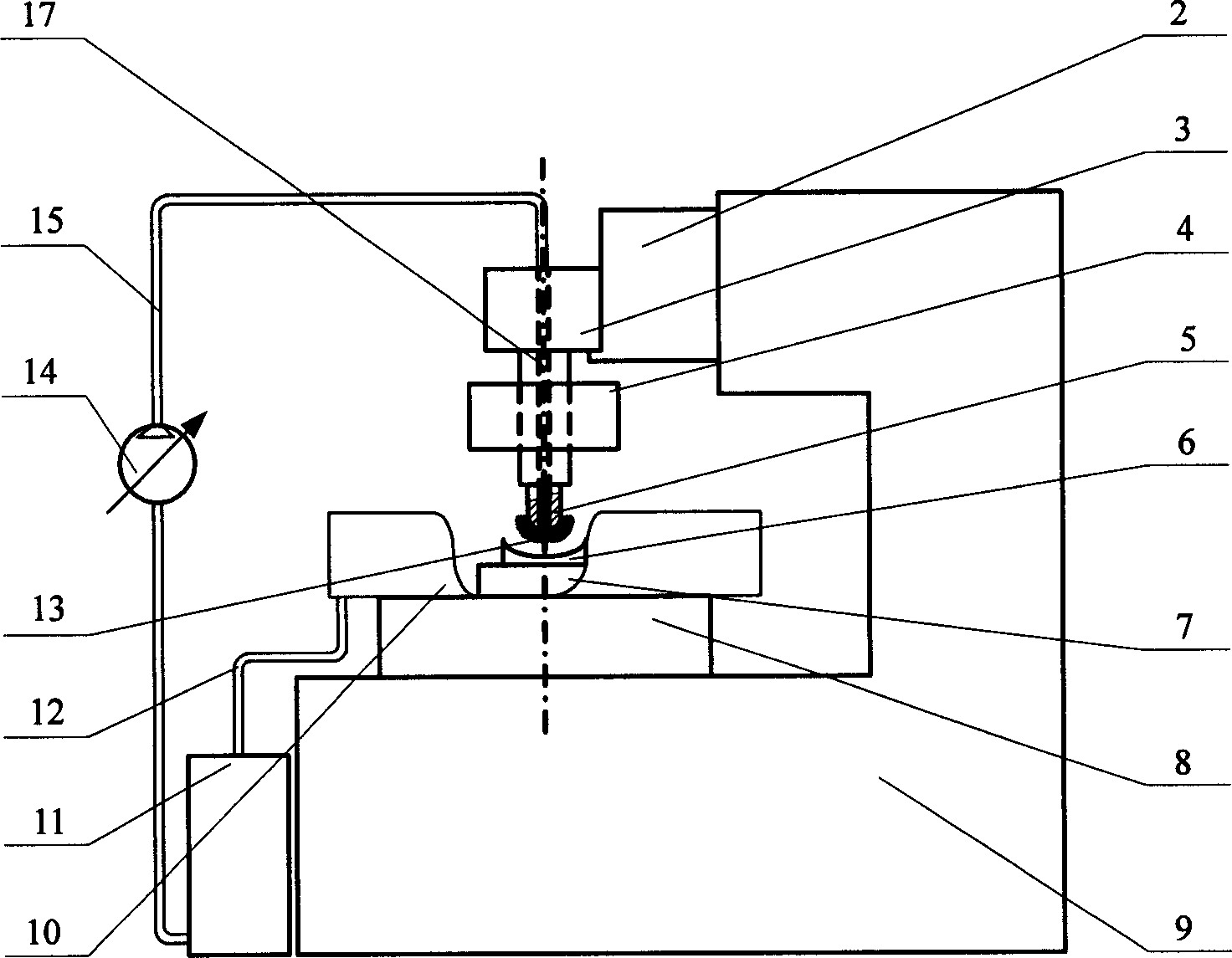

[0006] Specific implementation mode two: (see figure 1 , Figure 4 ) Ultrasonic magneto-rheological composite polishing device, which consists of electric spindle 1, spindle CNC workbench 2, ultrasonic generator 3, electromagnet 4, hollow tool head 5, fixture 7, workpiece CNC workbench 8, bed 9, recycling Tank 10, stirring, constant temperature and constant viscosity control device 11, lower circulation pipeline 12, pump 14, upper circulation pipeline 15, rotary joint 16 and internal passage 17, characterized in that the right end of the spindle CNC workbench 2 and the bed 9 The left end of the upper part is fixedly connected, one side of the electric spindle 1 is fixedly connected with the left end of the spindle CNC workbench 2, the upper end of the ultrasonic generator 3 is fixedly connected with the output end of the electric spindle 1, and the upper end of the hollow tool head 5 is connected with the ultrasonic generator The lower end of the device 3 is fixedly connected...

specific Embodiment approach 3

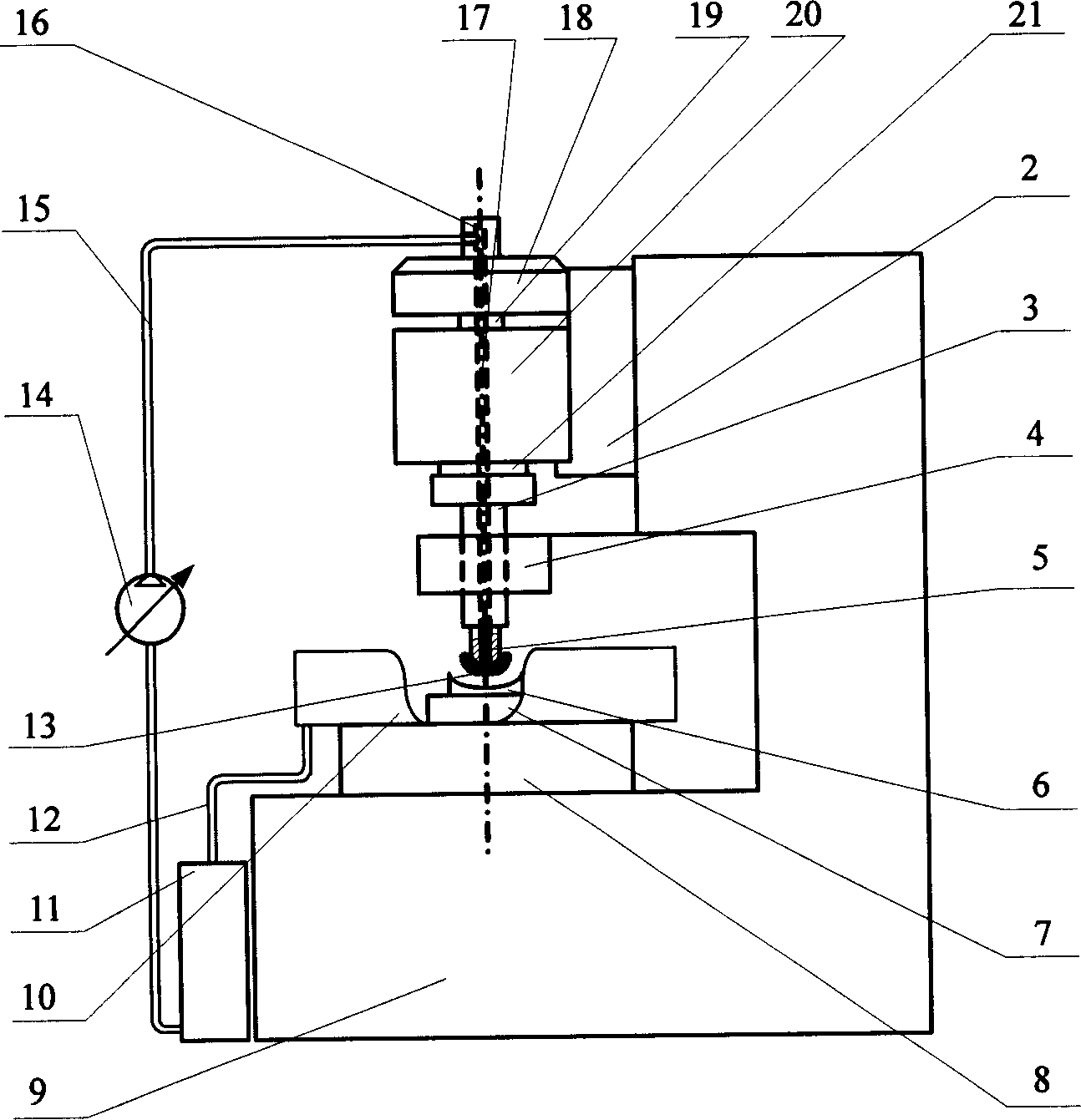

[0007] Specific implementation mode three: (see figure 2 ) The difference between this embodiment and the first embodiment is that the electric spindle 1 is replaced by the motor 18, the shaft coupling 19, the headstock 20, and the main shaft 21, and the output end of the motor 18 and the input end of the headstock 20 are connected by a coupling. The shaft device 19 is connected, the main shaft 21 on the headstock 20 is fixedly connected with the ultrasonic generator 3, and other components and connection relations are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com