Patents

Literature

9572 results about "Surface processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

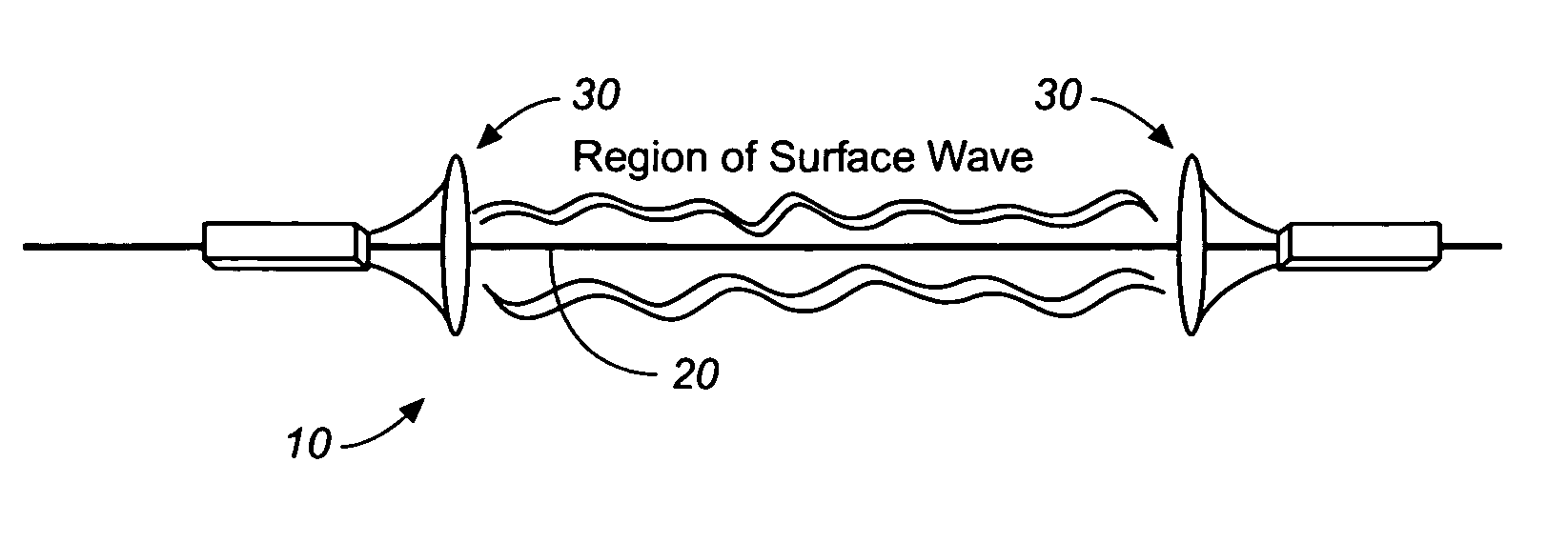

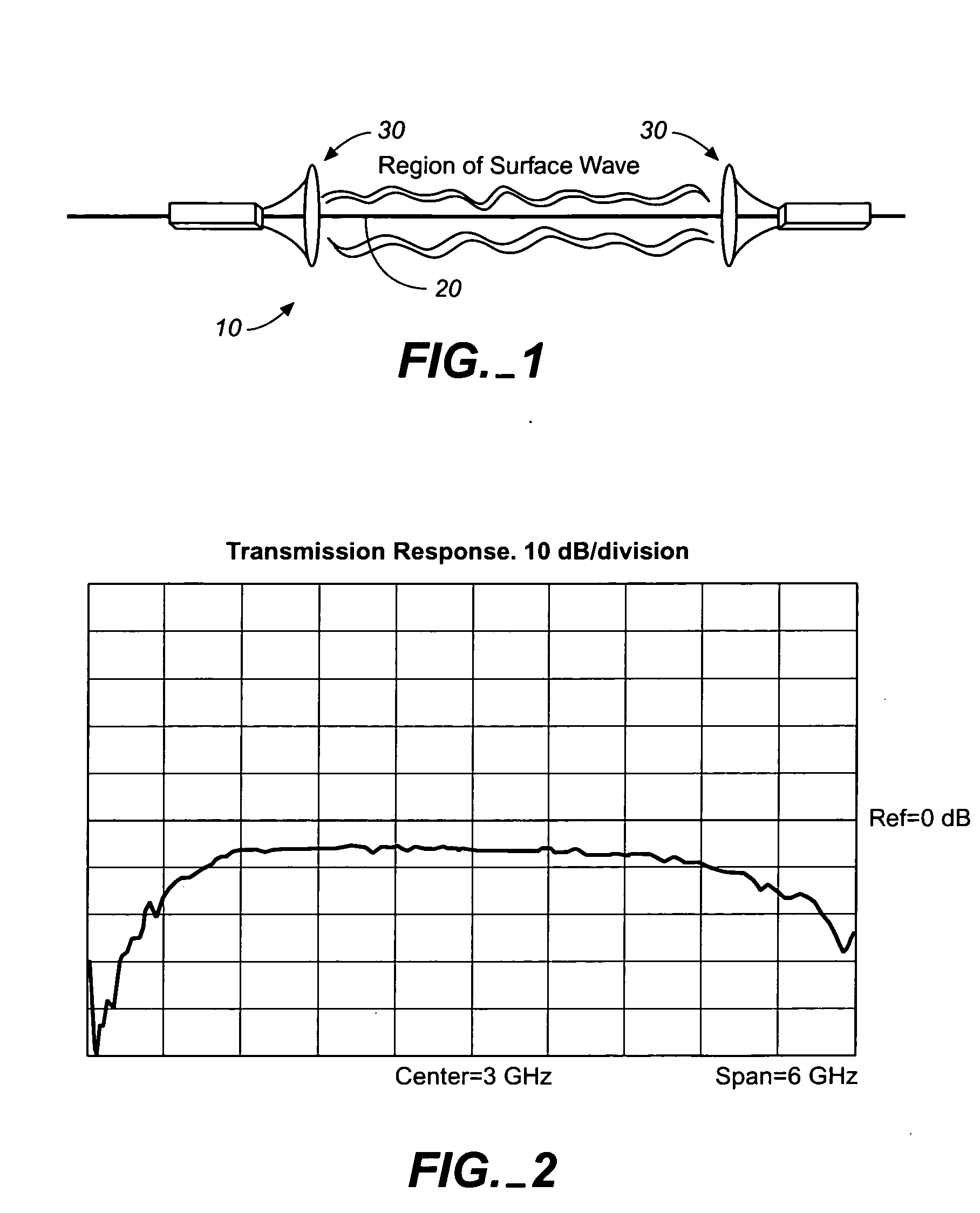

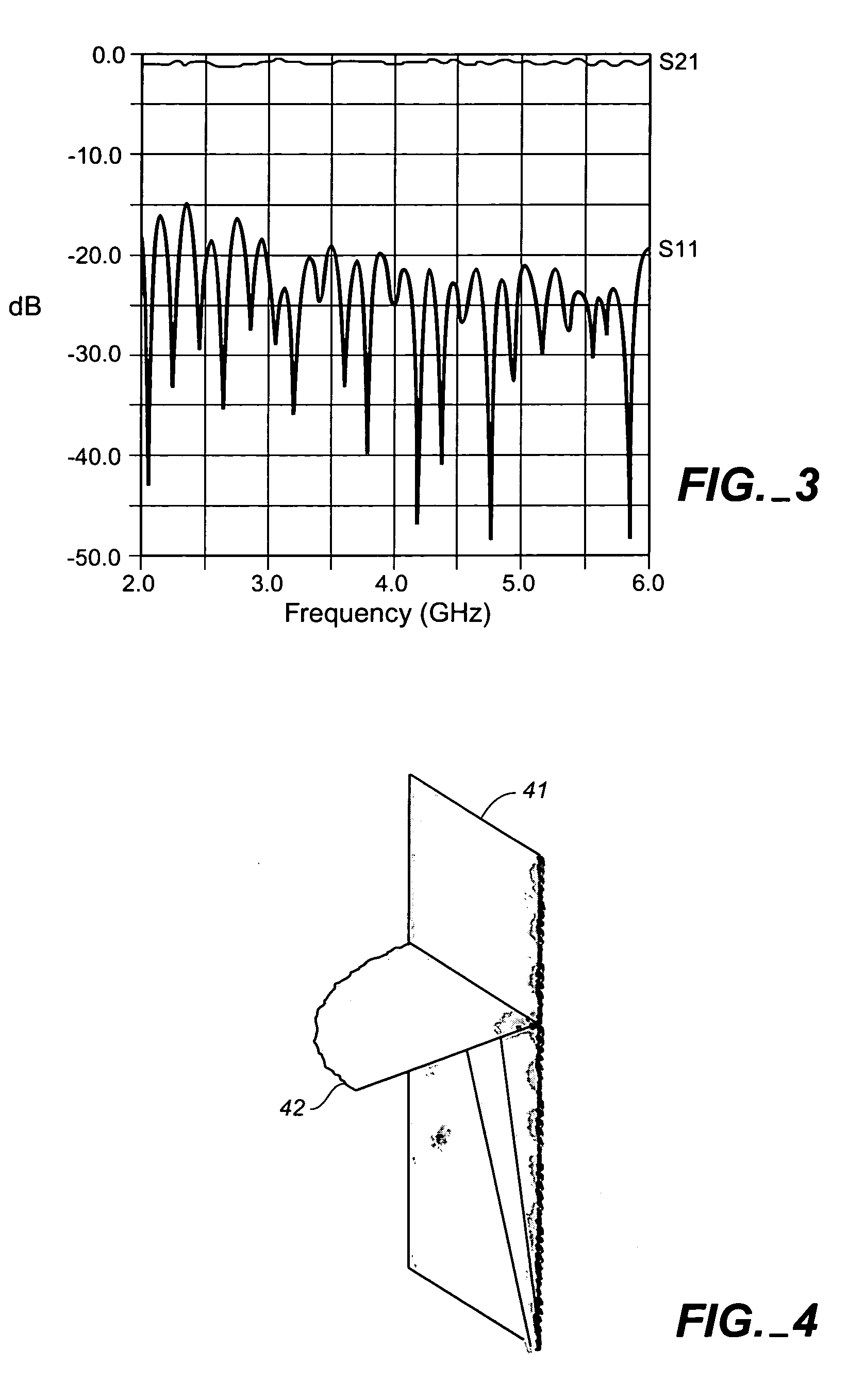

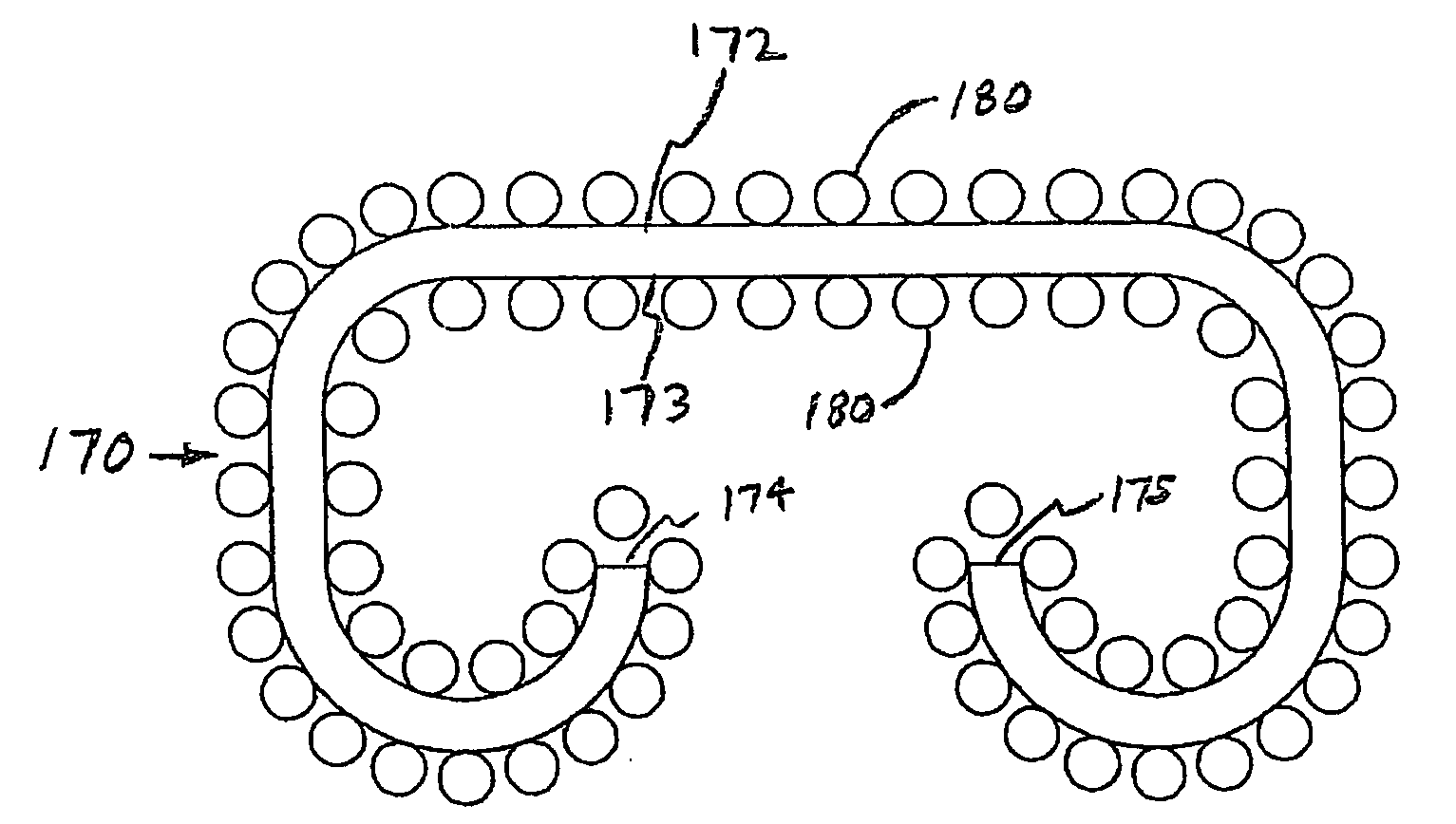

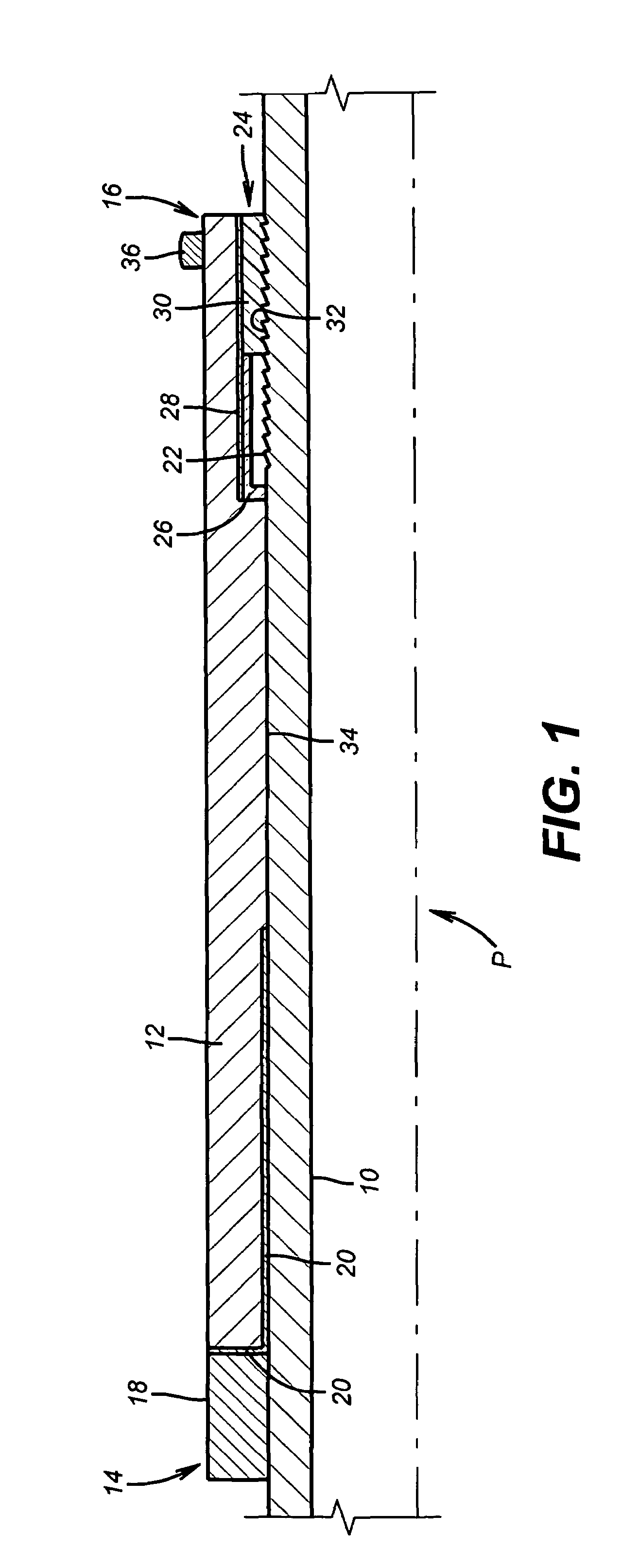

System and method for launching surface waves over unconditioned lines

A low loss transmission system which utilizes a single uninsulated central conducting line segment without any special surface treatment or special enclosing dielectric and having launch devices mounted at each end. The invention provides the use of conductors with circumference approaching and exceeding one wavelength at the propagating frequency. In combination, this invention enables the use of unconditioned and uninsulated conductors and in particular, existing overhead electric power lines which are available worldwide, for the economic and efficient transport of information.

Owner:CORRIDOR SYST INC

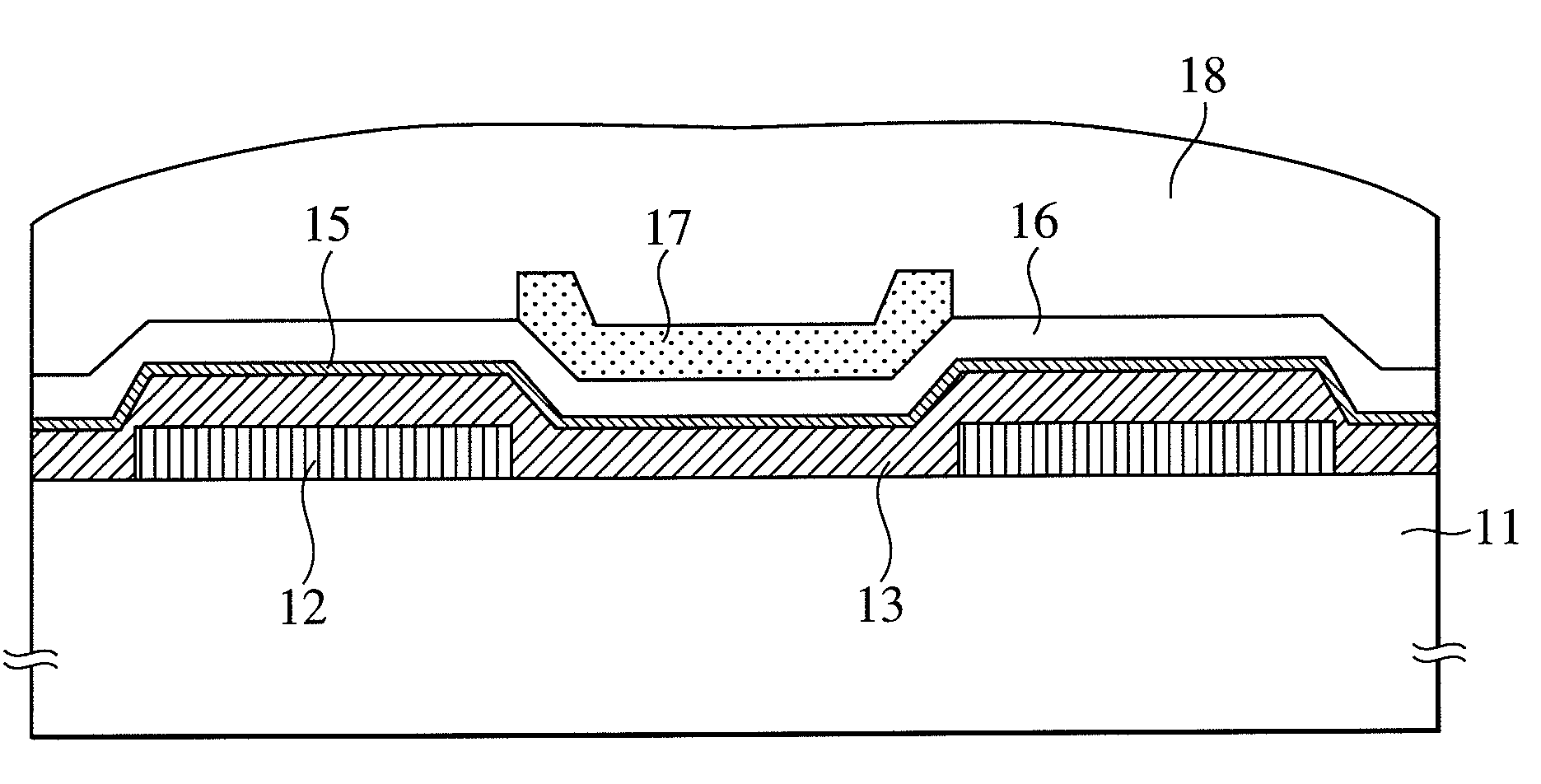

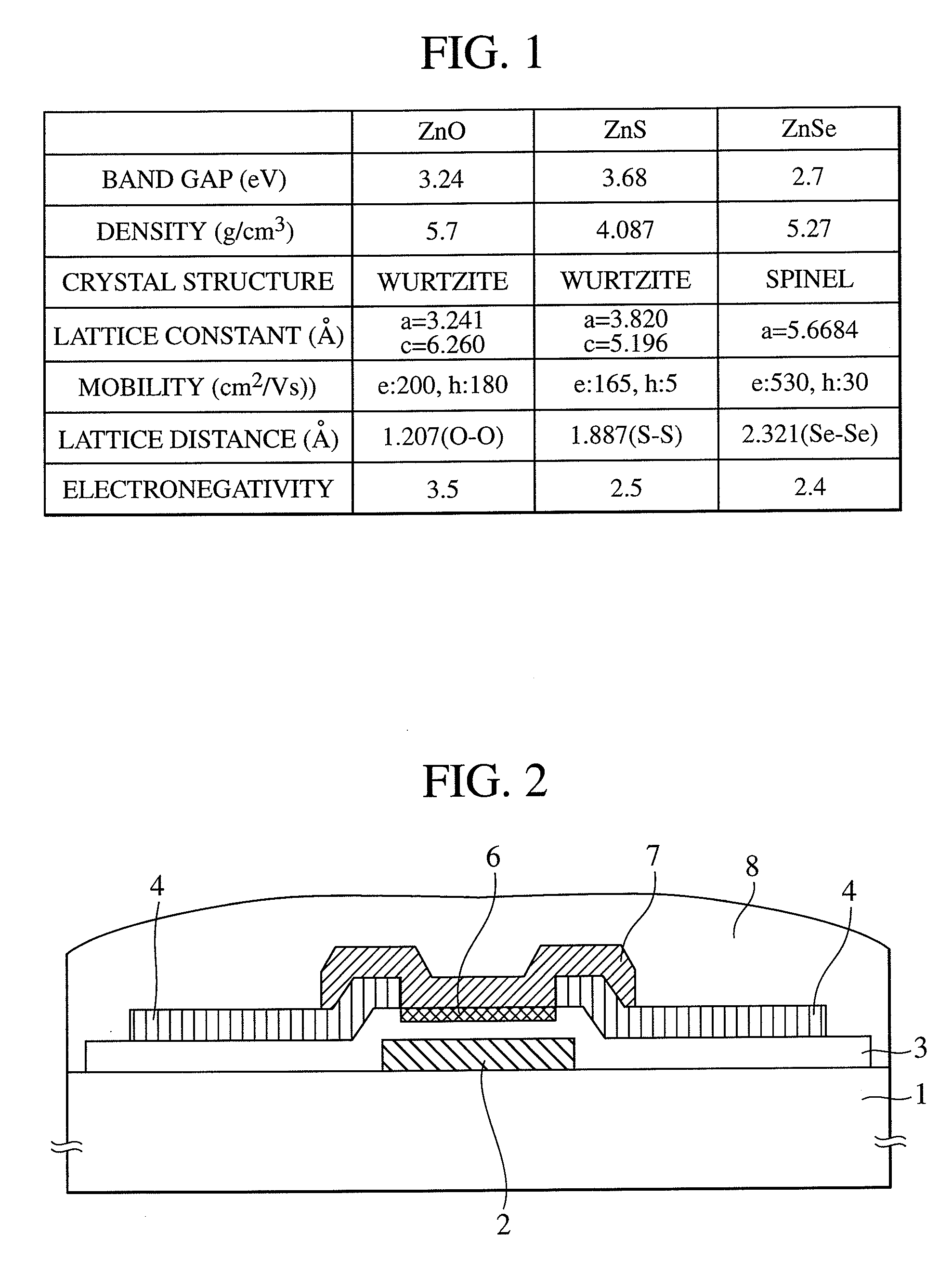

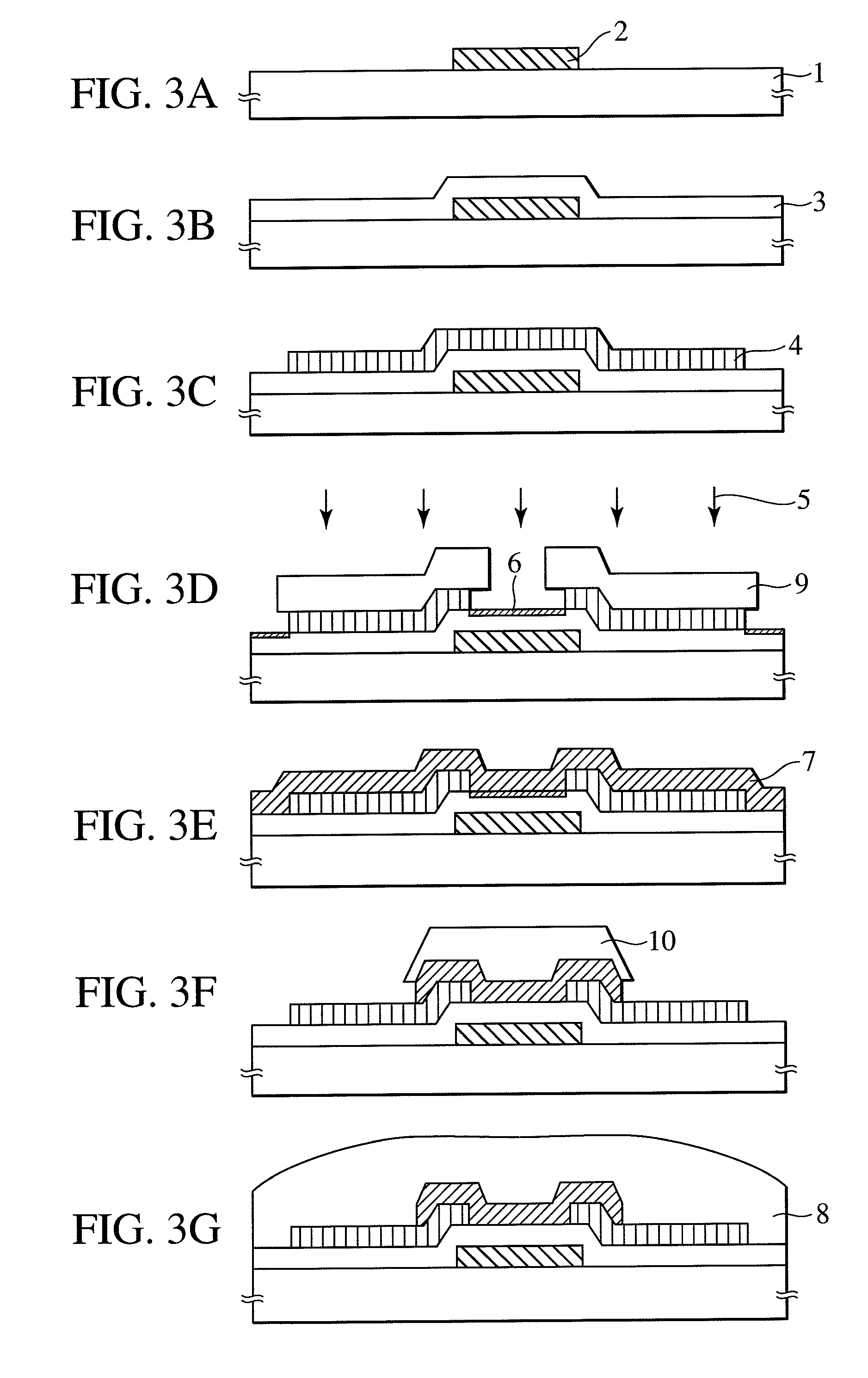

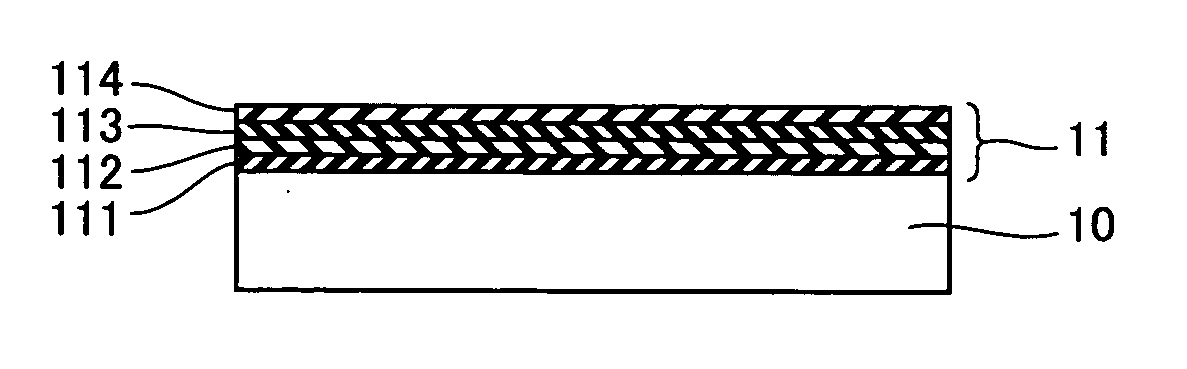

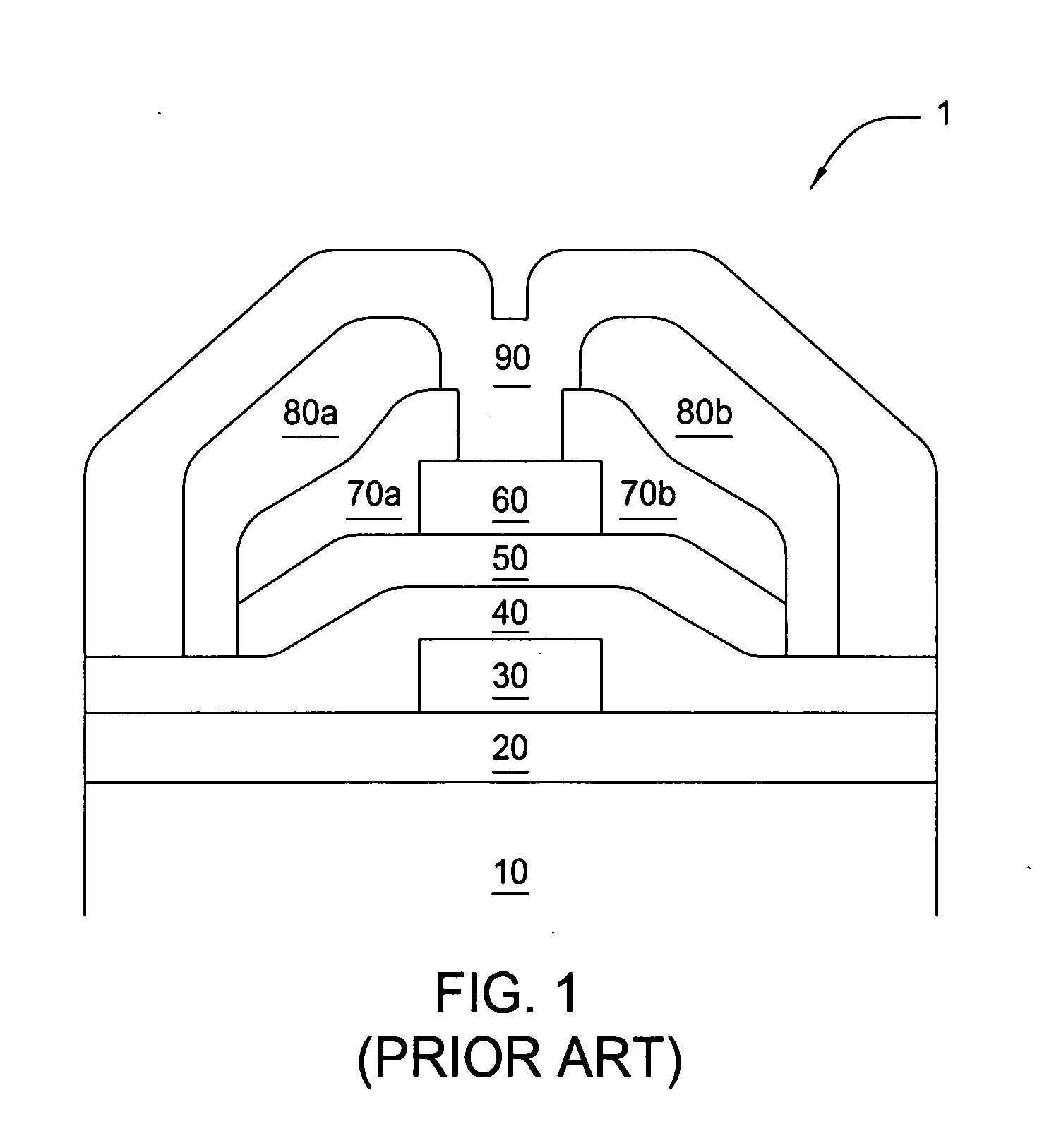

Oxide semiconductor device and surface treatment method of oxide semiconductor

InactiveUS20090166616A1Effectively suppressing the threshold potential shift and occurrence of leak currentPhysical property is lessSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseThreshold potential

Oxygen defects formed at the boundary between the zinc oxide type oxide semiconductor and the gate insulator are terminated by a surface treatment using sulfur or selenium as an oxygen group element or a compound thereof, the oxygen group element scarcely occurring physical property value change. Sulfur or selenium atoms effectively substitute oxygen defects to prevent occurrence of electron supplemental sites by merely applying a gas phase or liquid phase treatment to an oxide semiconductor or gate insulator with no remarkable change on the manufacturing process. As a result, this can attain the suppression of the threshold potential shift and the leak current in the characteristics of a thin film transistor.

Owner:HITACHI LTD

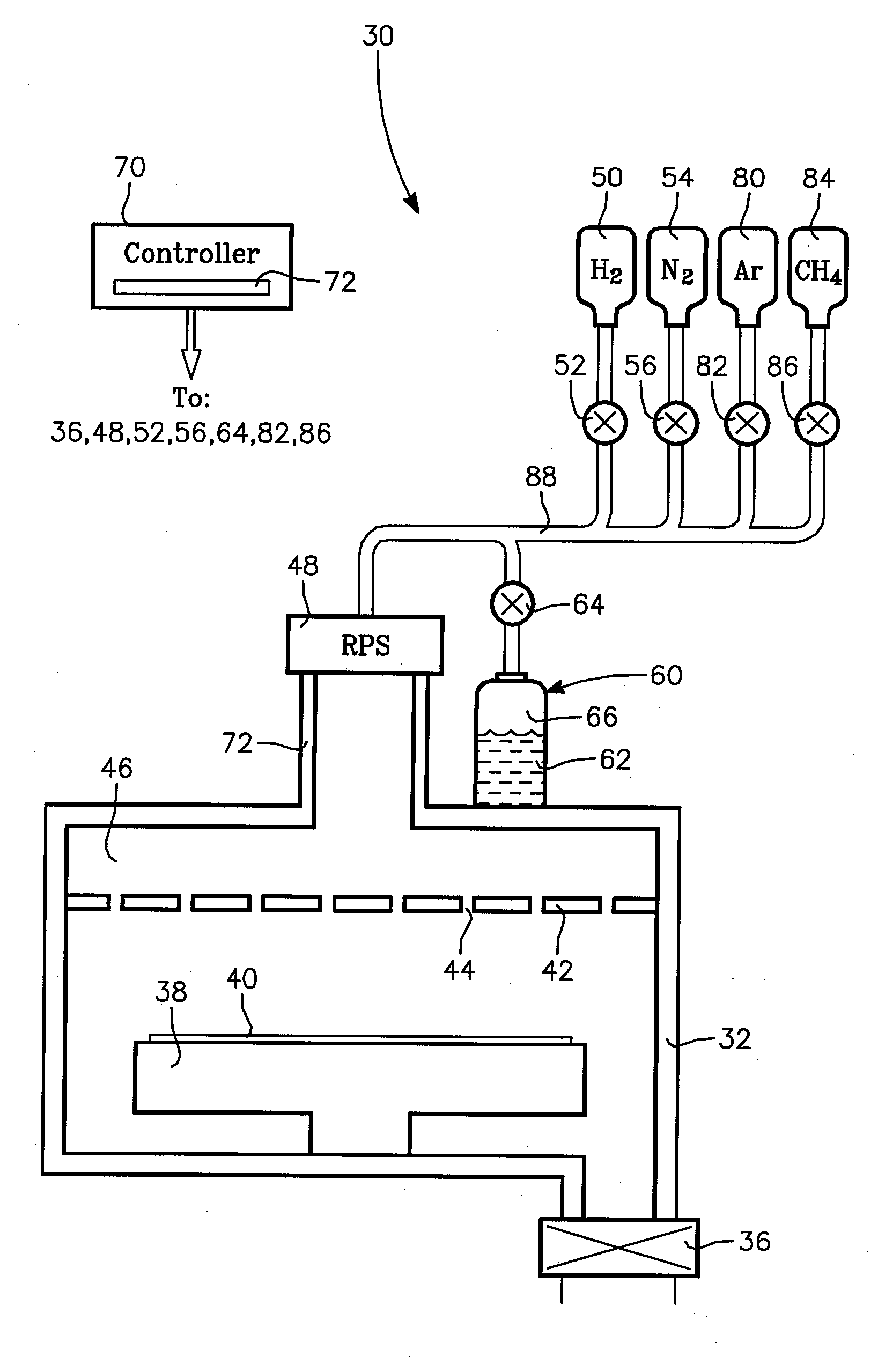

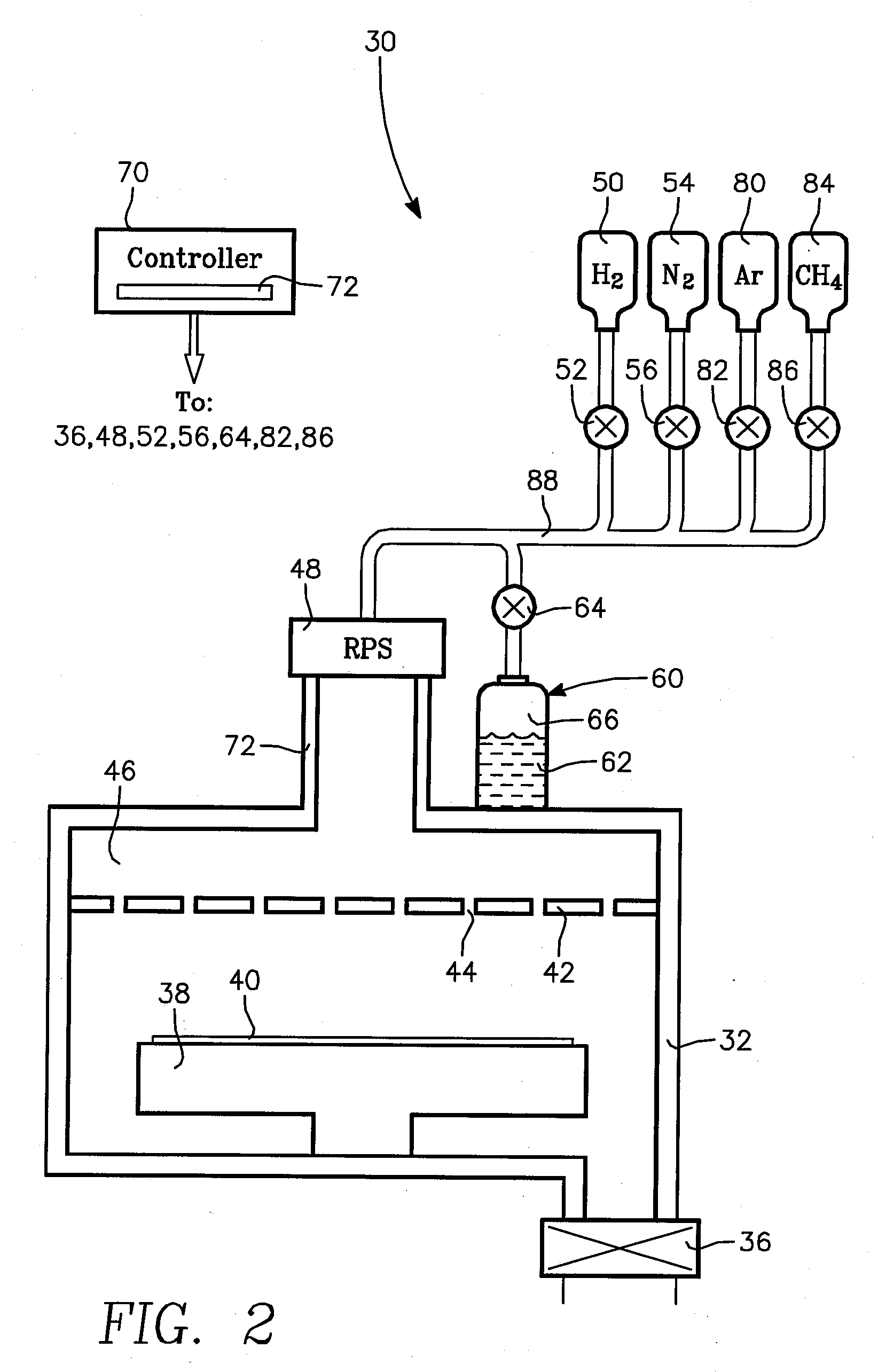

Hydrogen ashing enhanced with water vapor and diluent gas

ActiveUS20080261405A1Decorative surface effectsSemiconductor/solid-state device detailsWater vaporOxygen

An oxygen-free hydrogen plasma ashing process particularly useful for low-k dielectric materials based on hydrogenated silicon oxycarbide materials. The main ashing step includes exposing a previously etched dielectric layer to a plasma of hydrogen and optional nitrogen, a larger amount of water vapor, and a yet larger amount of argon or helium. Especially for porous low-k dielectrics, the main ashing plasma additionally contains a hydrocarbon gas such as methane. The main ashing may be preceded by a short surface treatment by a plasma of a hydrogen-containing reducing gas such as hydrogen and optional nitrogen.

Owner:APPLIED MATERIALS INC

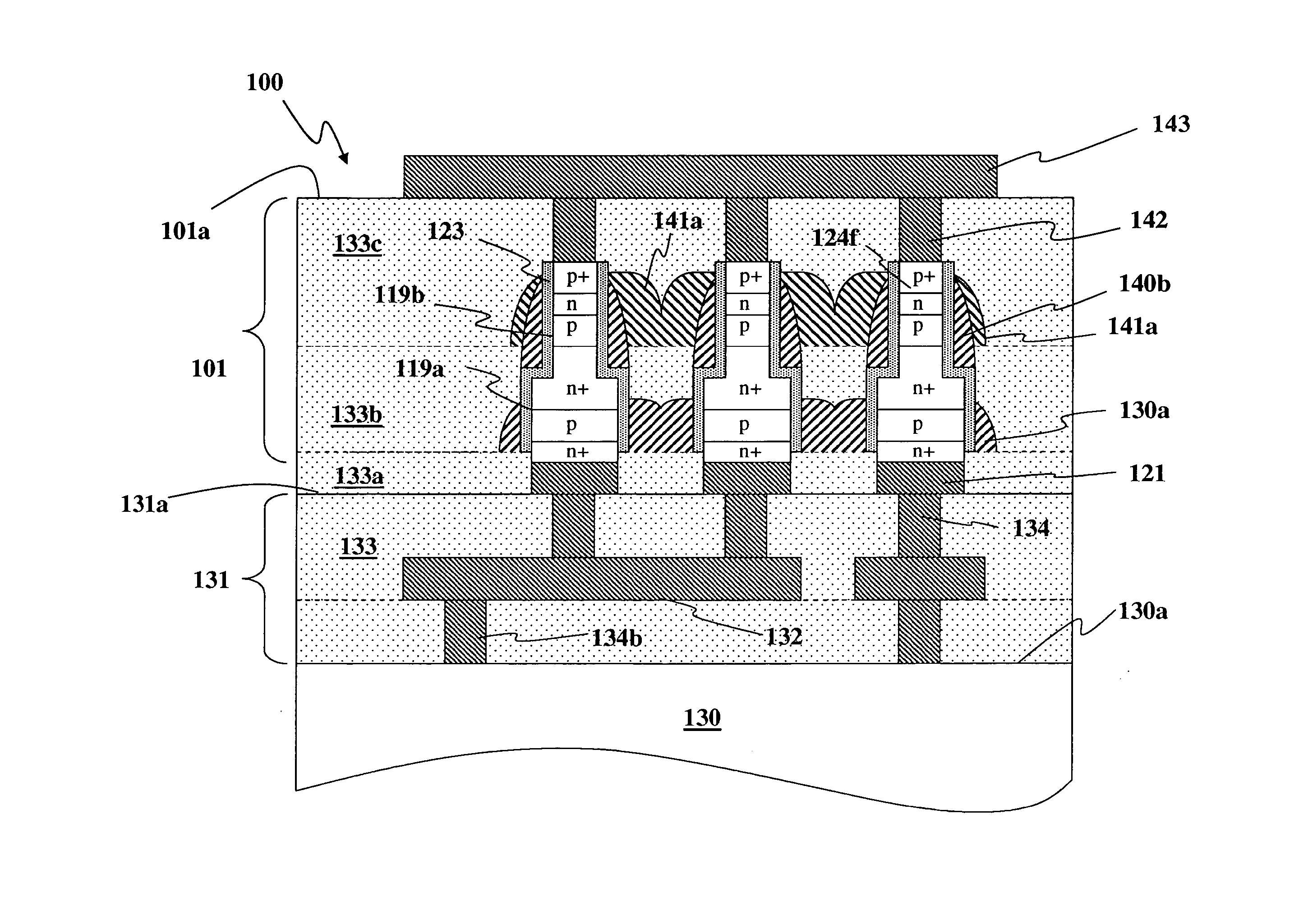

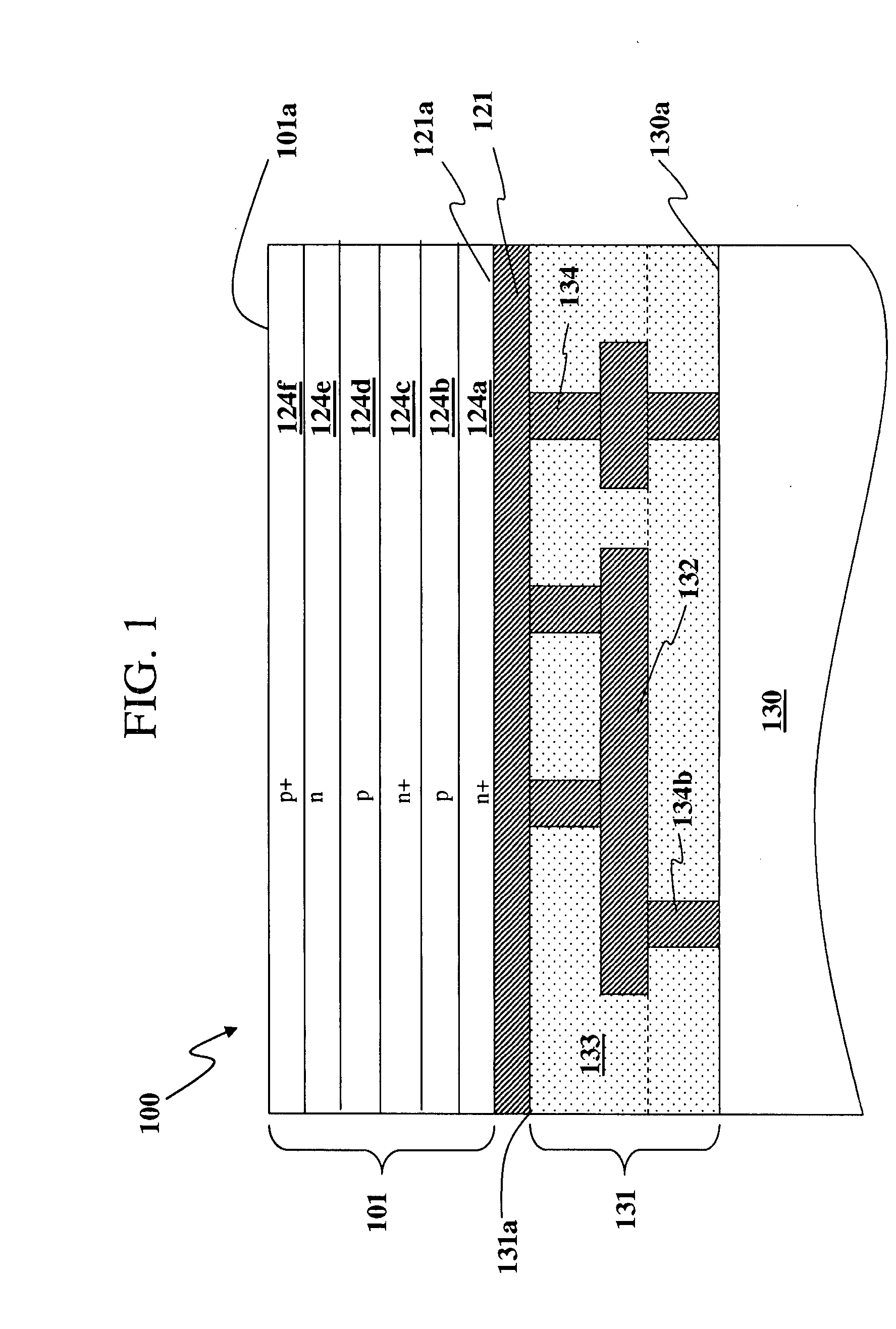

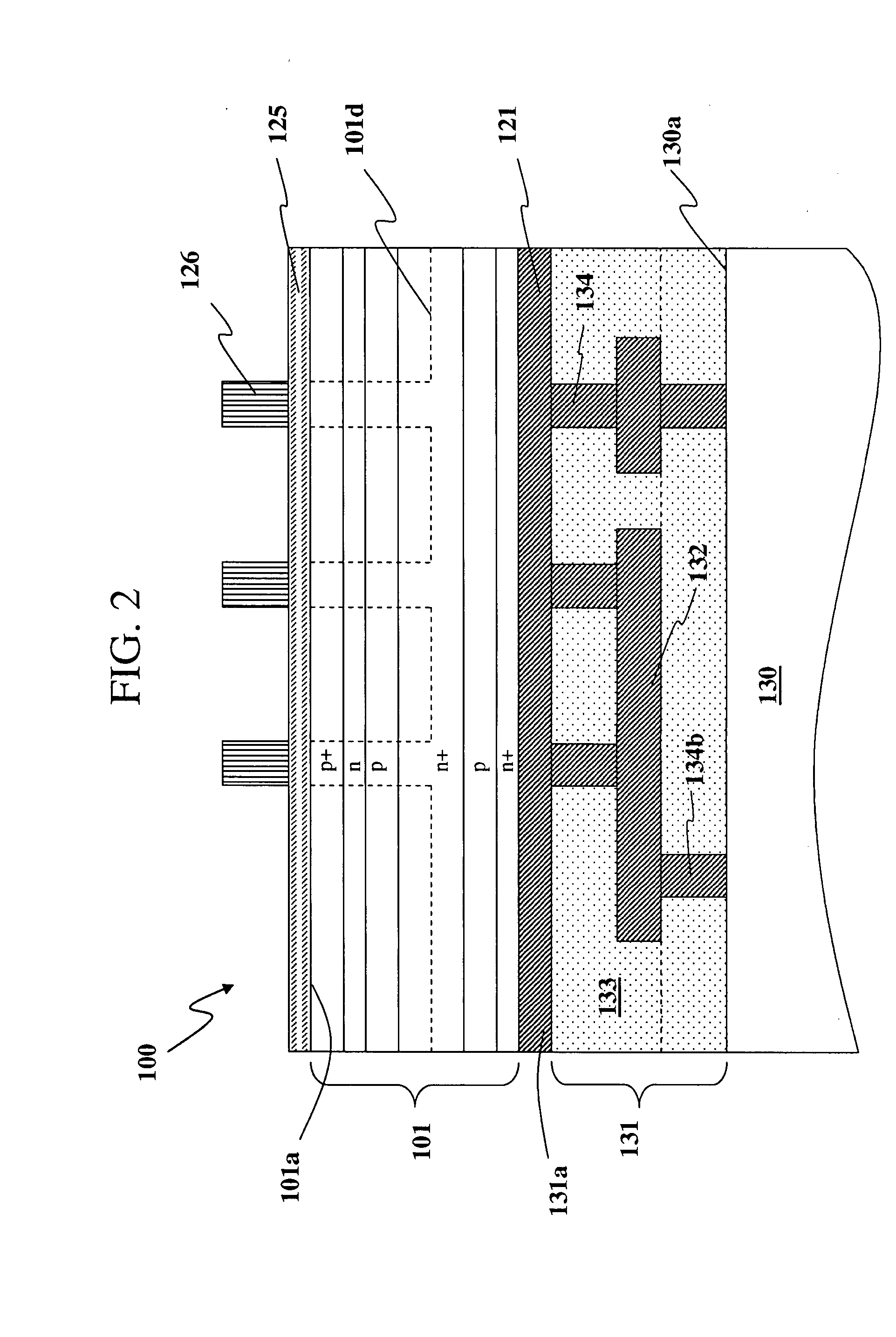

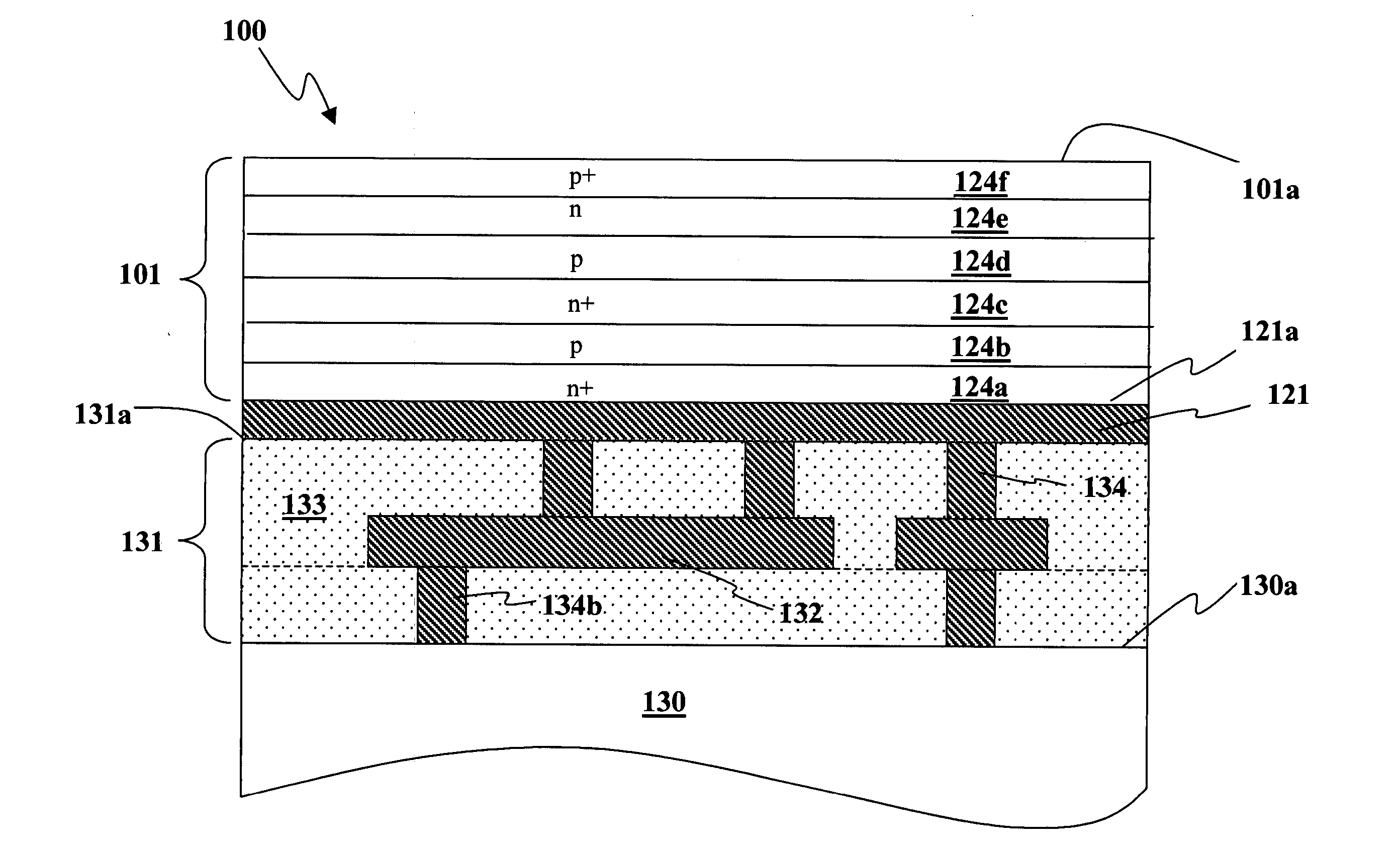

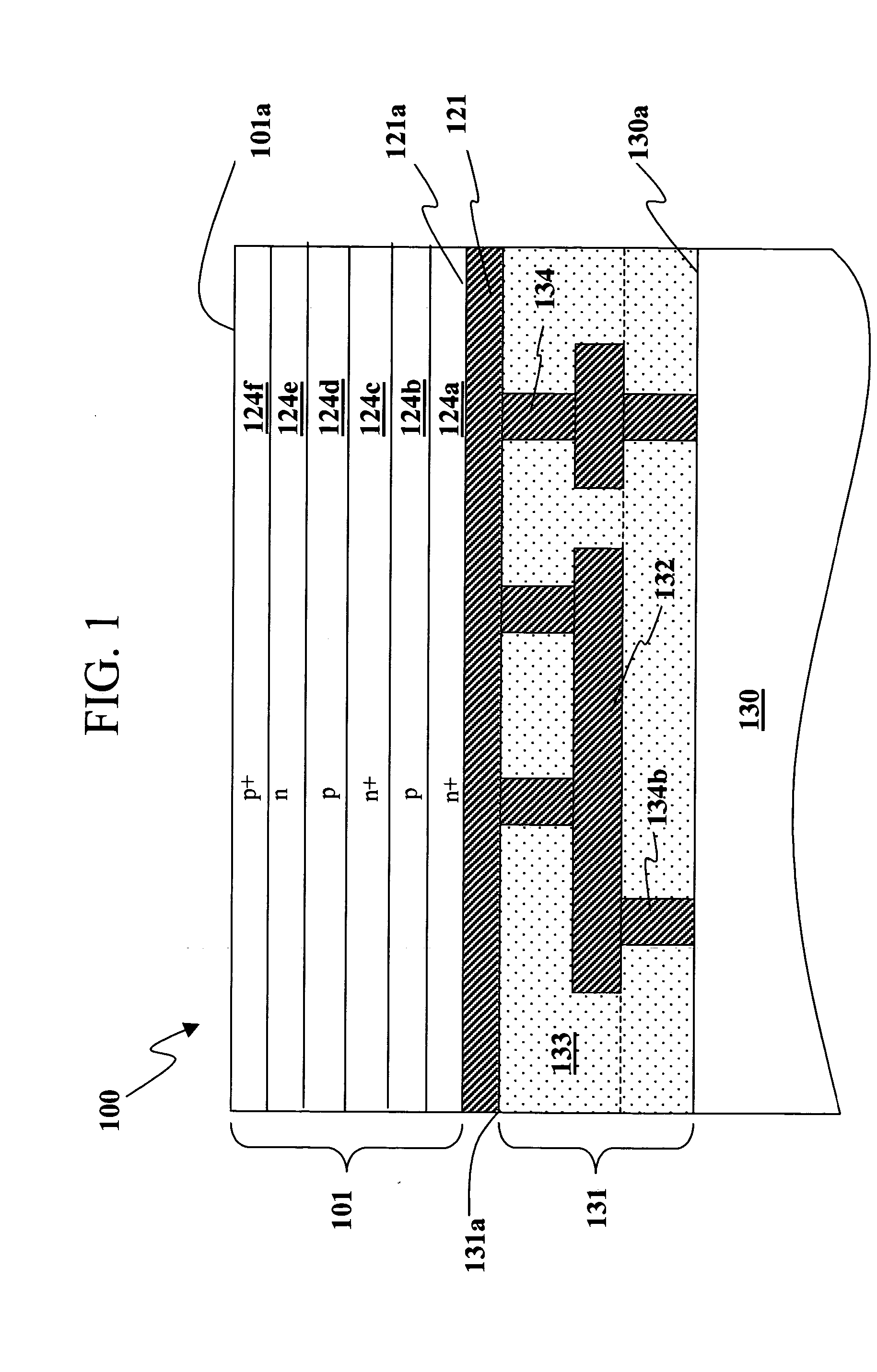

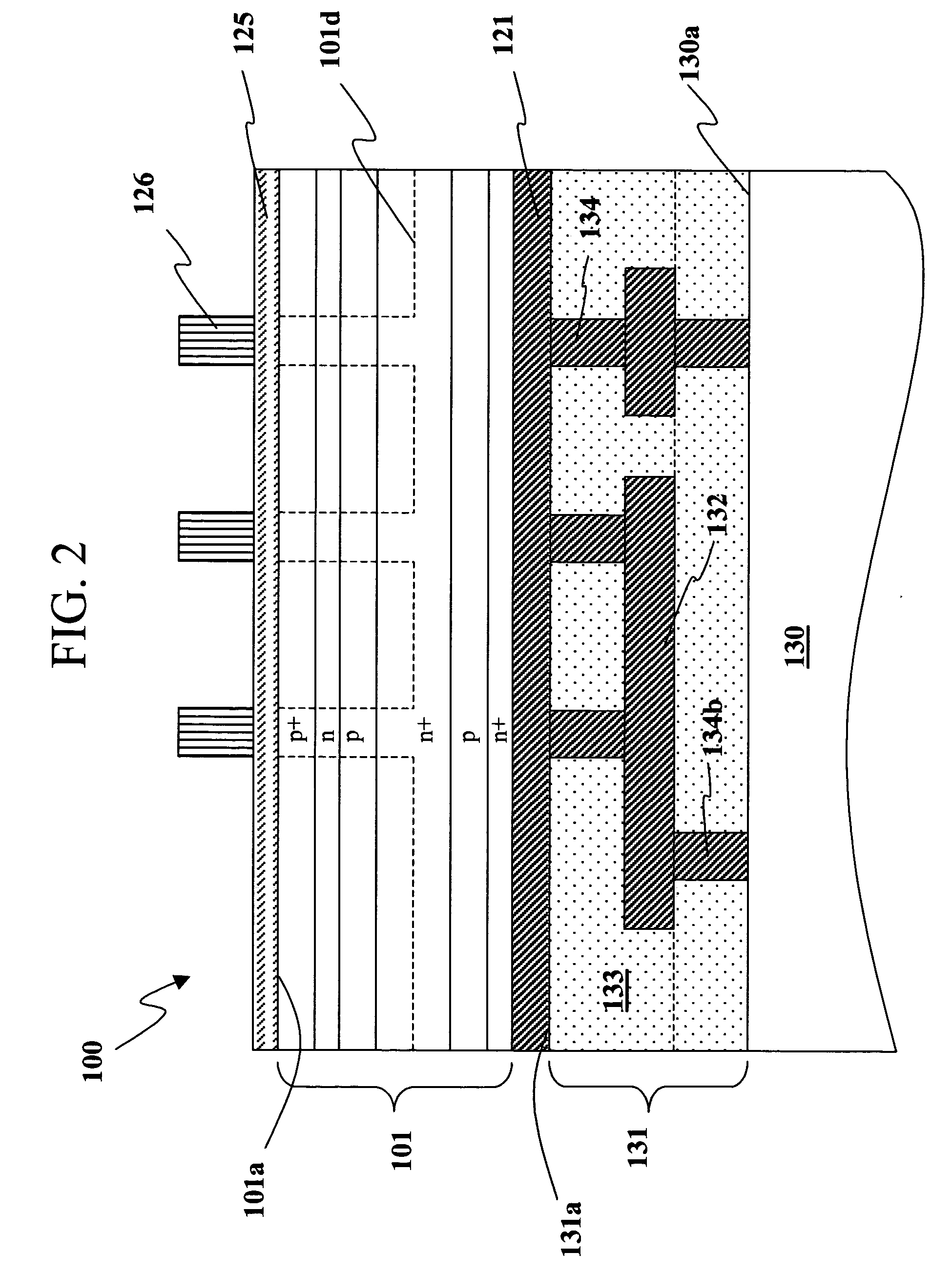

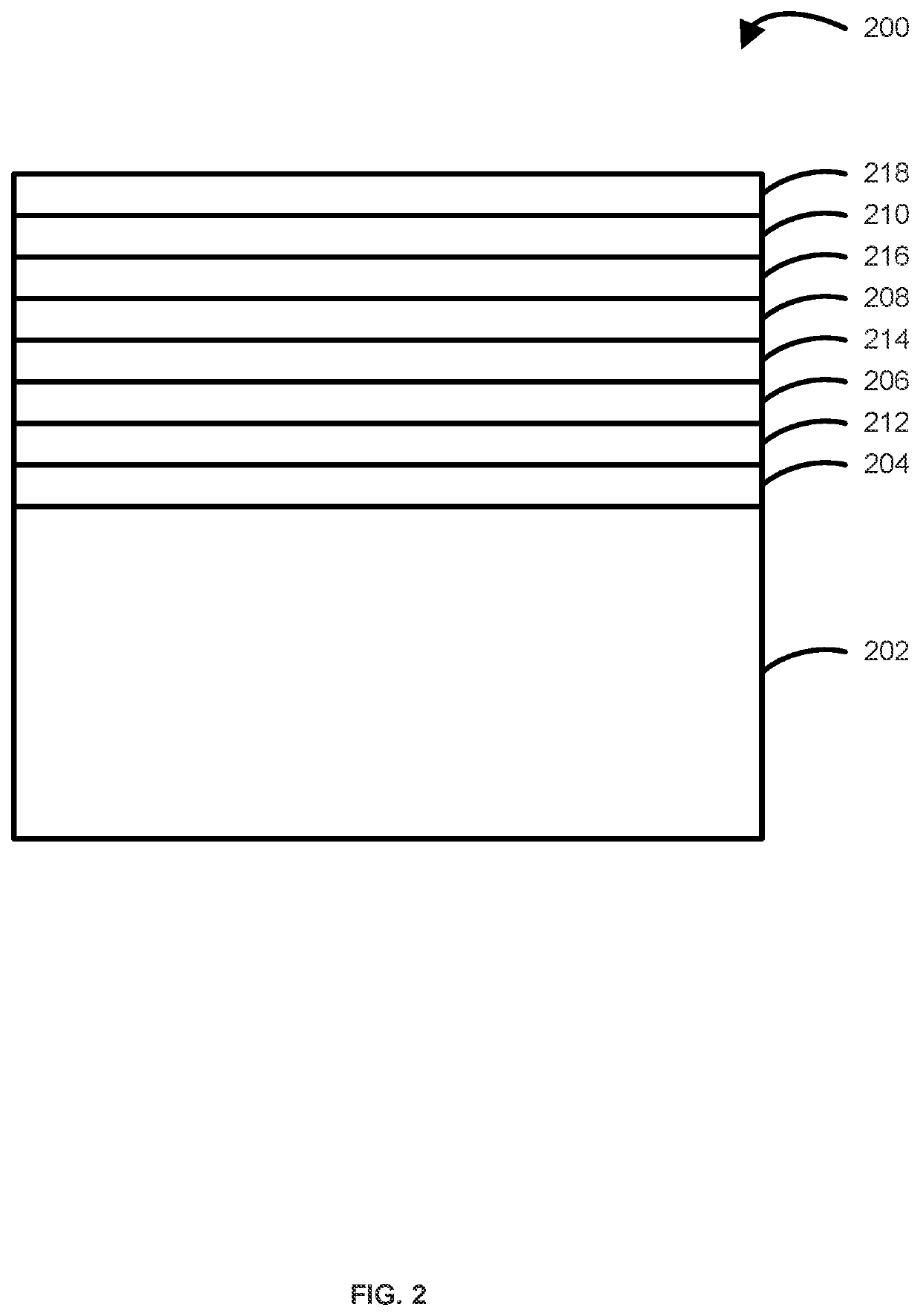

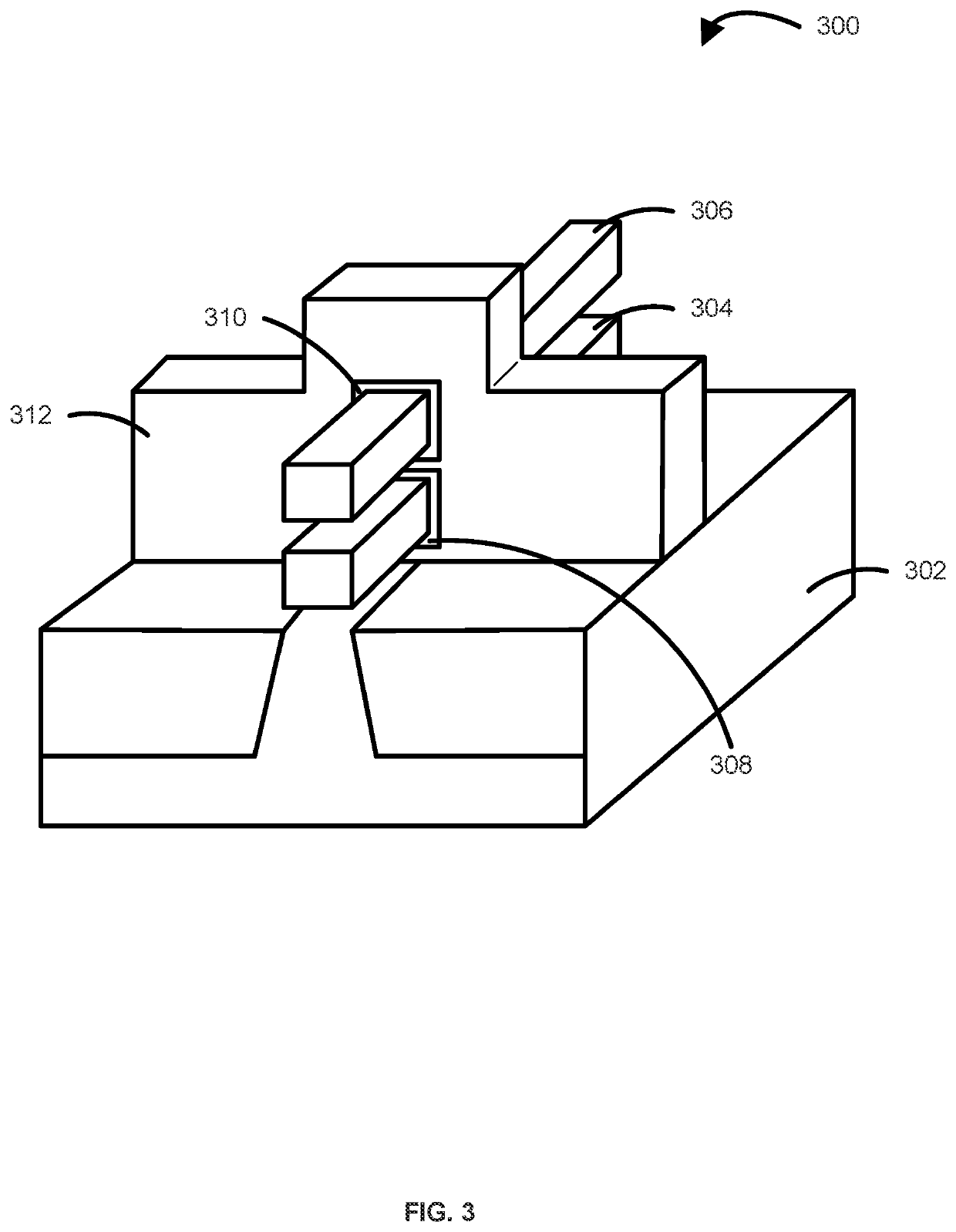

Semiconductor memory device

A method of forming a circuit includes providing a substrate; providing an interconnect region positioned on the substrate; bonding a device structure to a surface of the interconnect region; and processing the device structure to form a first stack of layers on the interconnect region and a second stack of layers on the first stack. The width of the first stack is different than the width of the second stack.

Owner:BESANG

Semiconductor memory device

A method of forming a circuit includes providing a substrate; providing an interconnect region positioned on the substrate; bonding a device structure to a surface of the interconnect region; and processing the device structure to form a first stack of layers on the interconnect region and a second stack of layers on the first stack. The width of the first stack is different than the width of the second stack.

Owner:BESANG

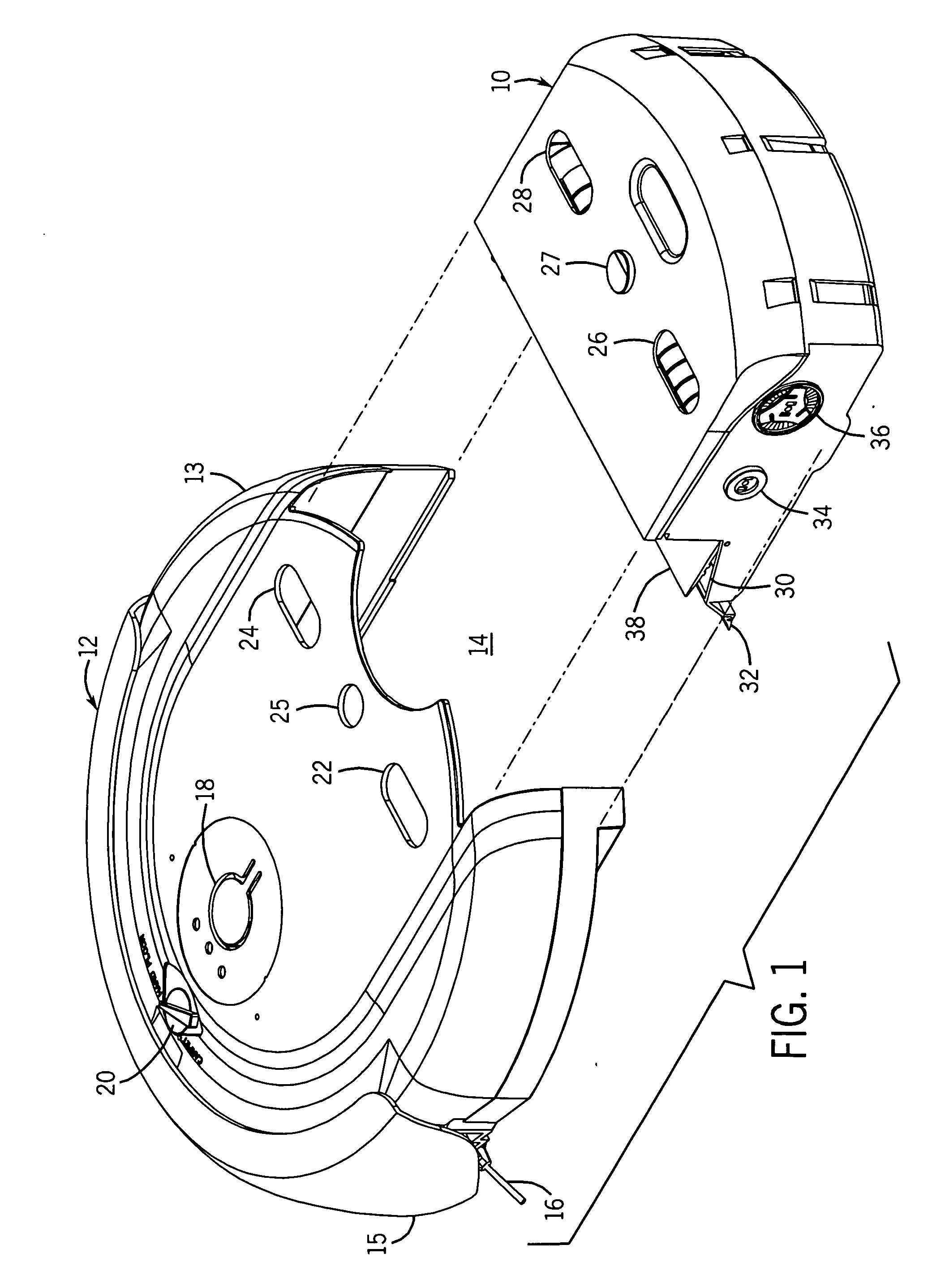

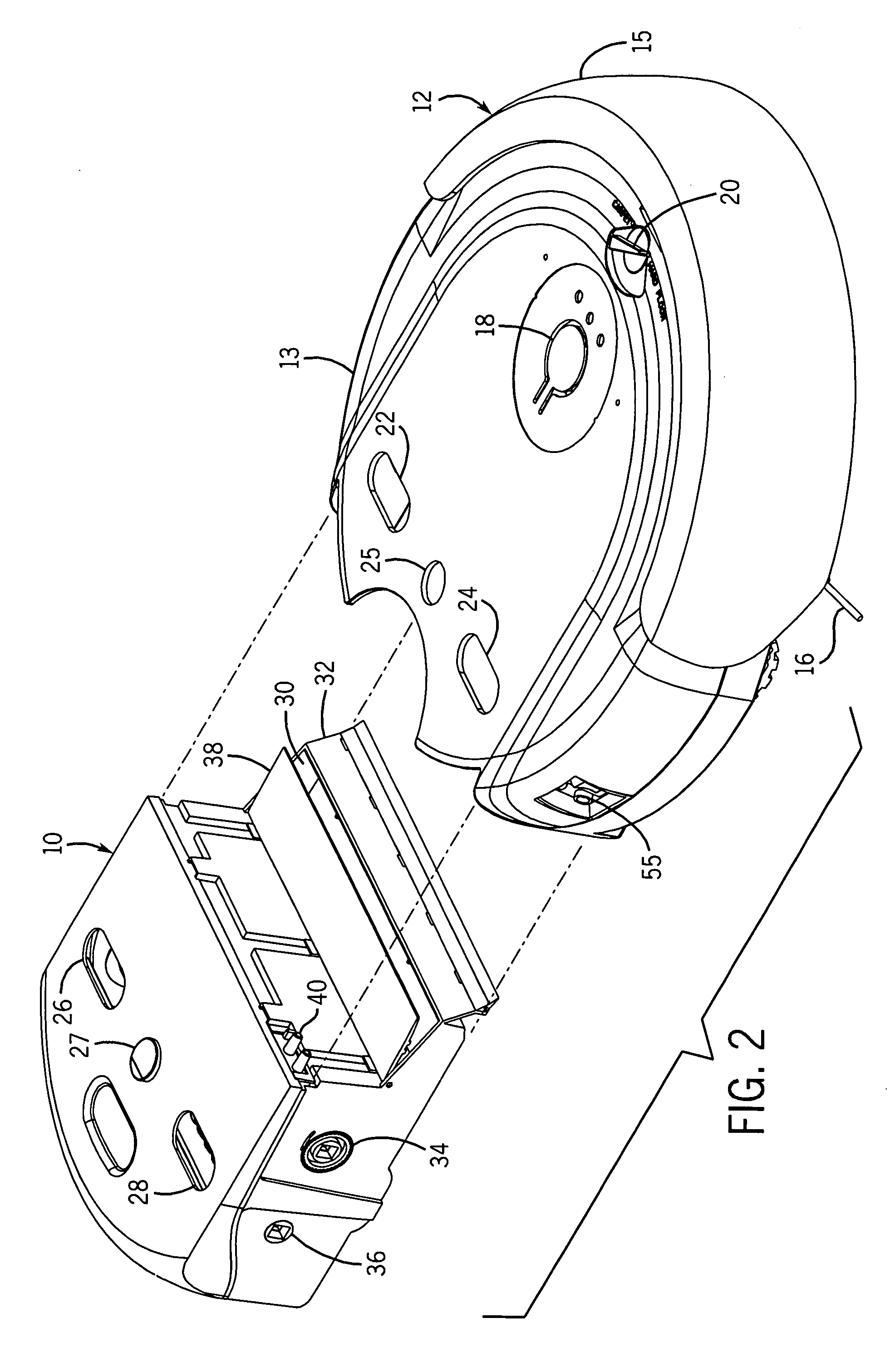

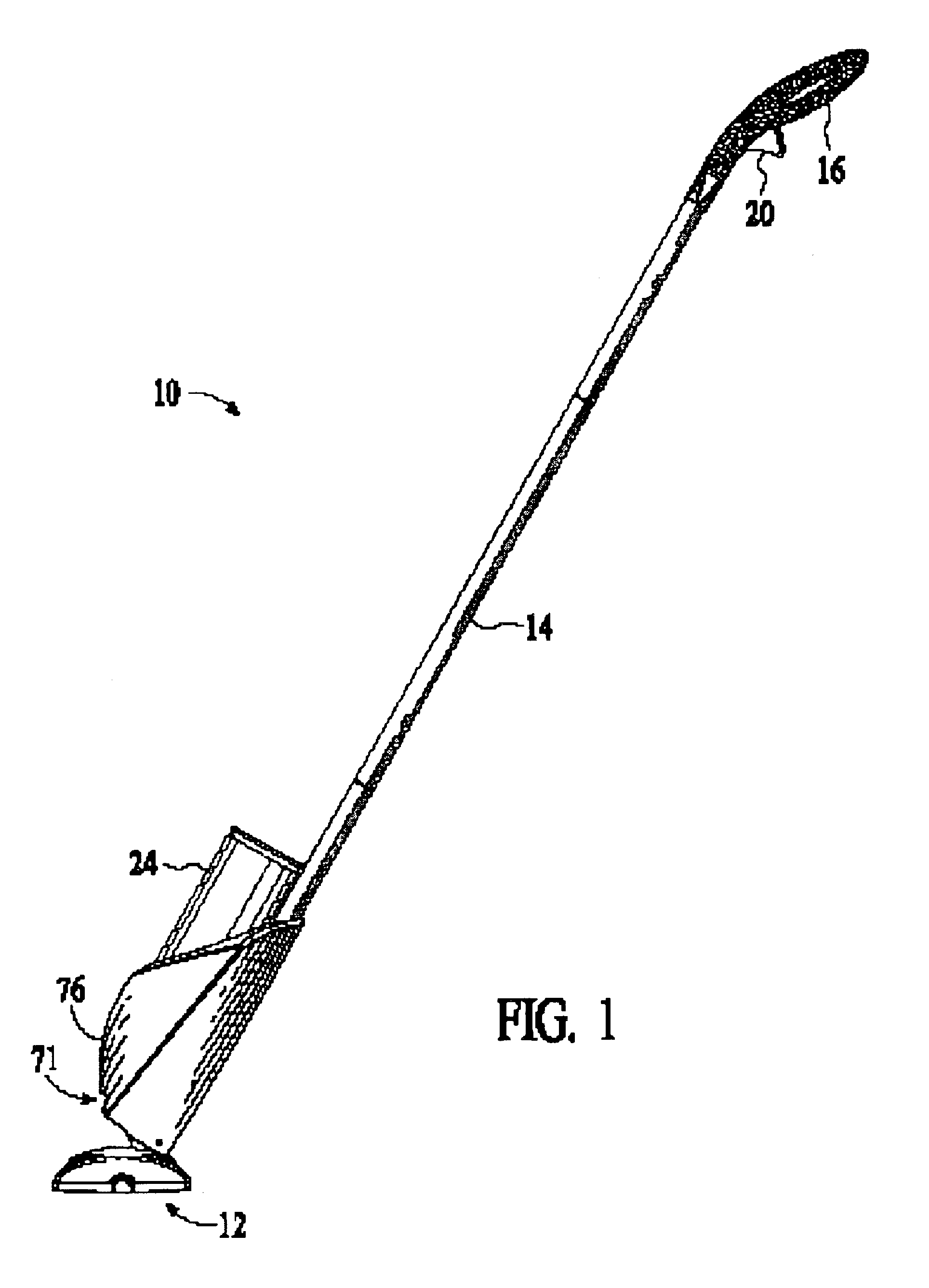

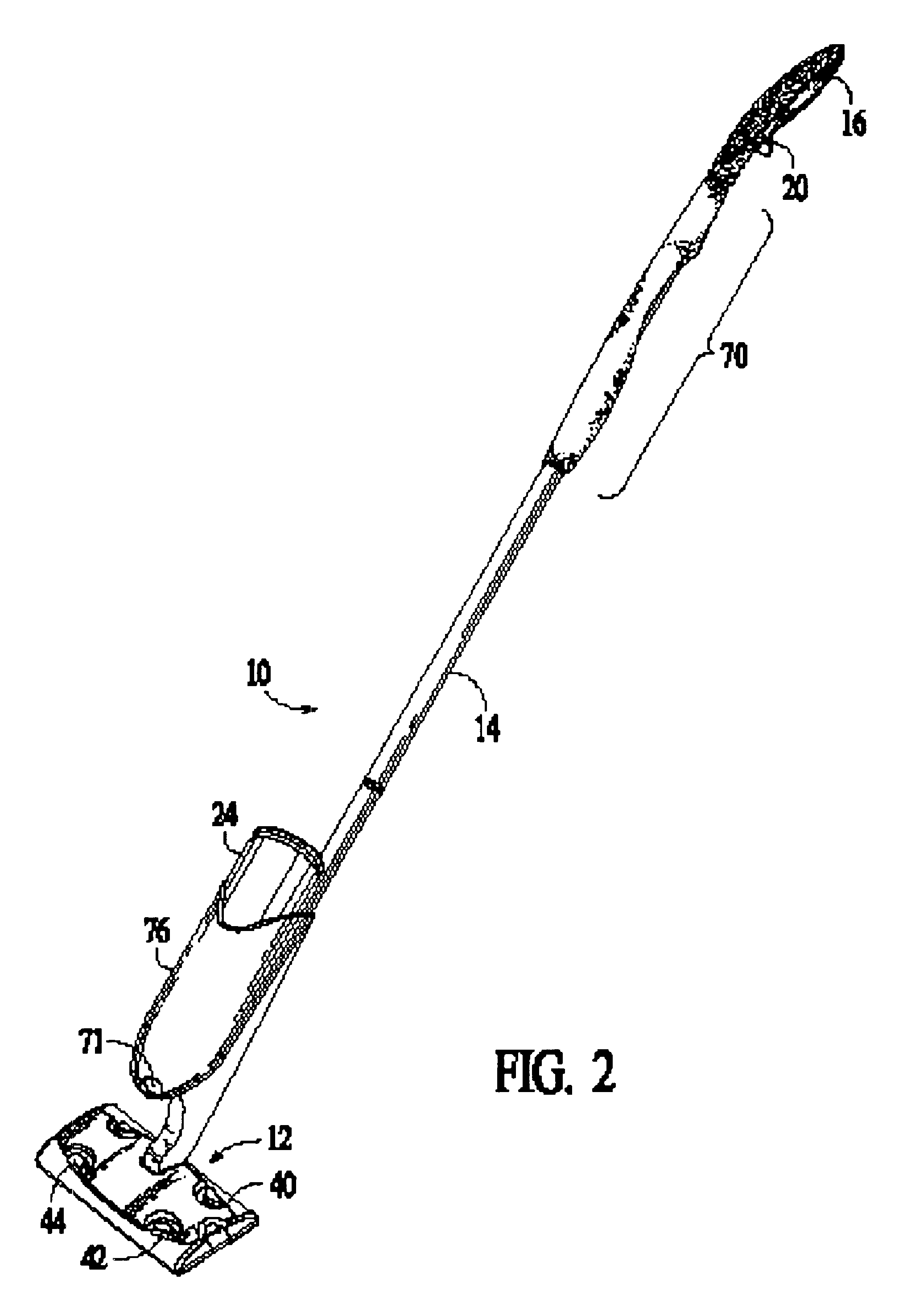

Surface treating device with cartridge-based cleaning system

A cartridge is disclosed comprising a reel-to-reel roll of cleaning material, for use in a hand-held or robotic cleaning device. The cartridge provides either an electrostatic dust cloth or wet mop, and includes a fluid reservoir for maintaining the wet mop cloth during use. A dust bin is also provided on the cartridge, and includes a hinged lid for providing selective access to the dust inside of the bin. A motor, optical sensor, and fluid pump inside of a cleaning apparatus control the operation of the reel-to-reel cloth, and control fluid delivery to the wet cloth.

Owner:SC JOHNSON & SON INC

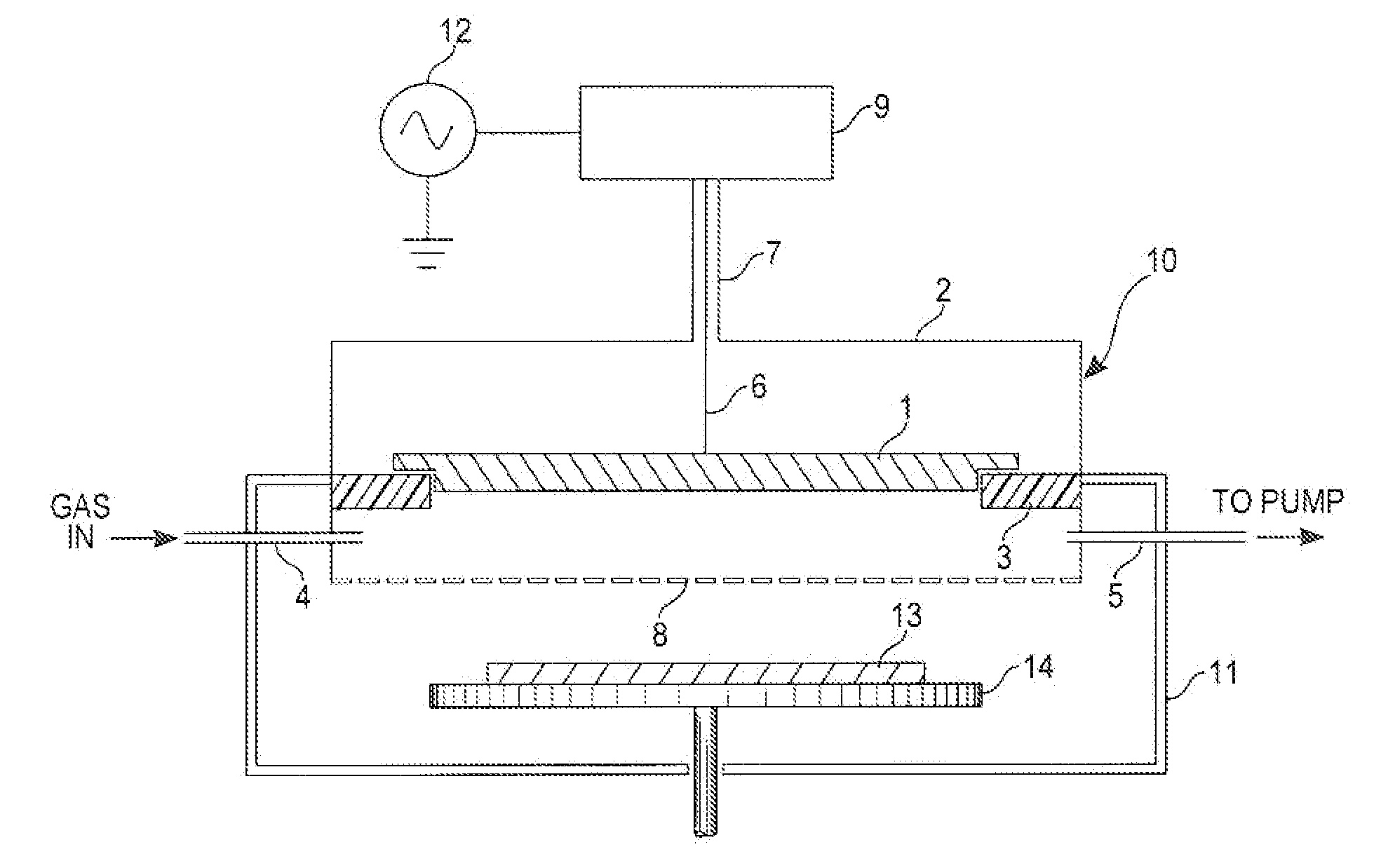

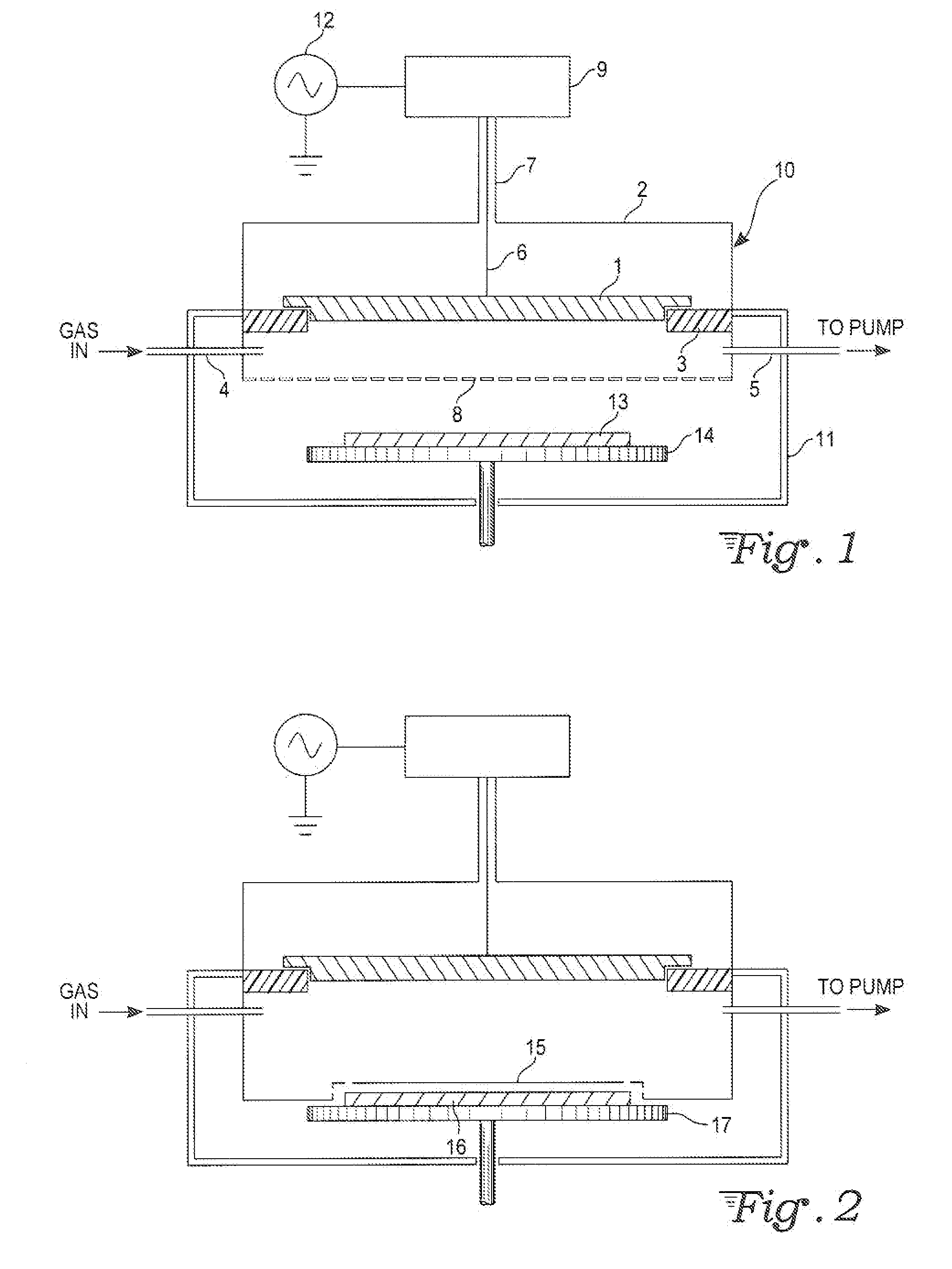

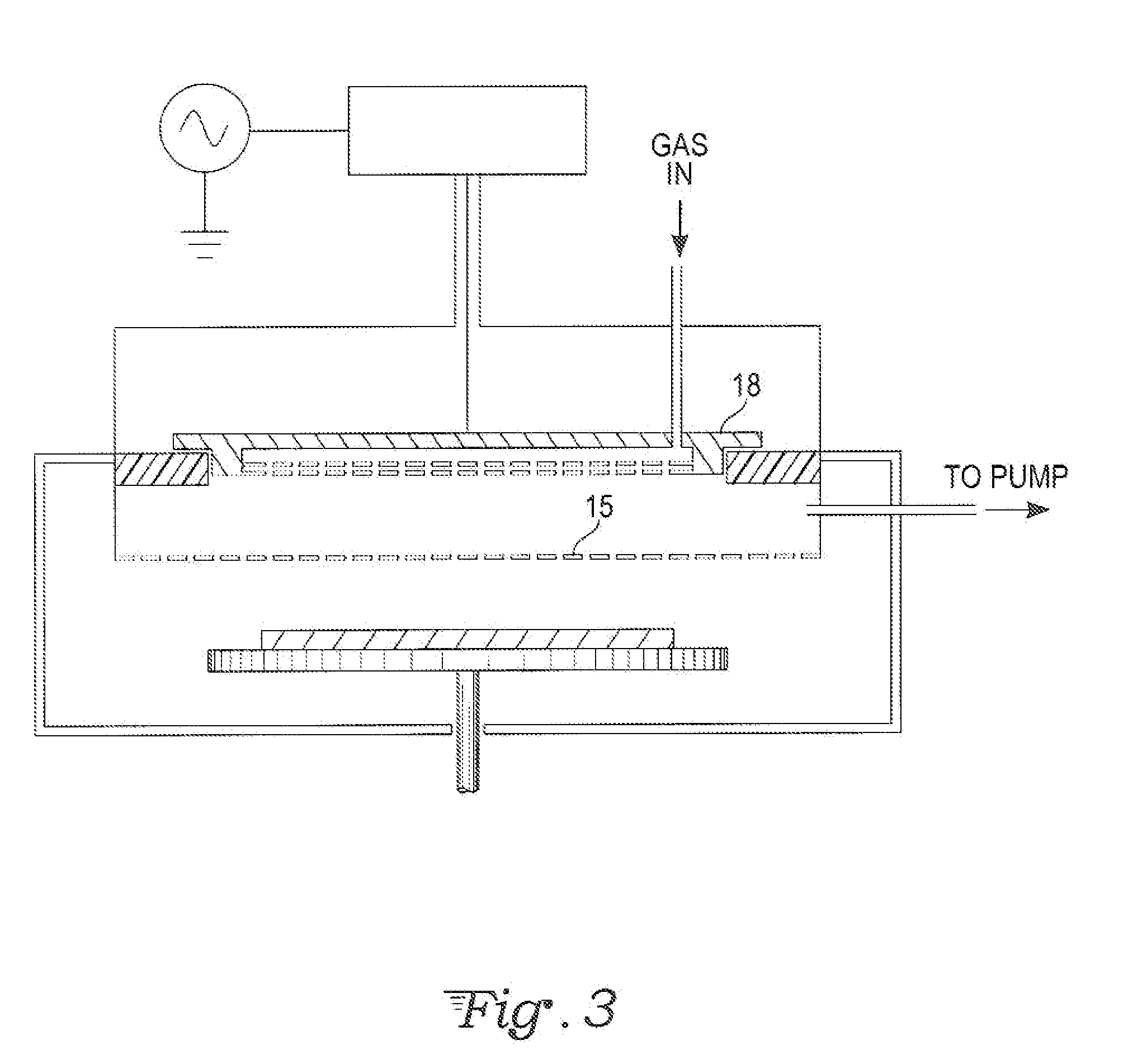

Capacitively coupled remote plasma source with large operating pressure range

InactiveUS20100101727A1System costExtension of timeElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceRadio frequency

A radio frequency (RF) coaxial resonator feeding a saltshaker-like gas distributing electrode assembly forms a capacitively coupled plasma source. This apparatus can generate plasma of high density over a wide pressure range and large process window. The system may be used as a remote radical-rich plasma source for materials surface processing.

Owner:JI HELIN

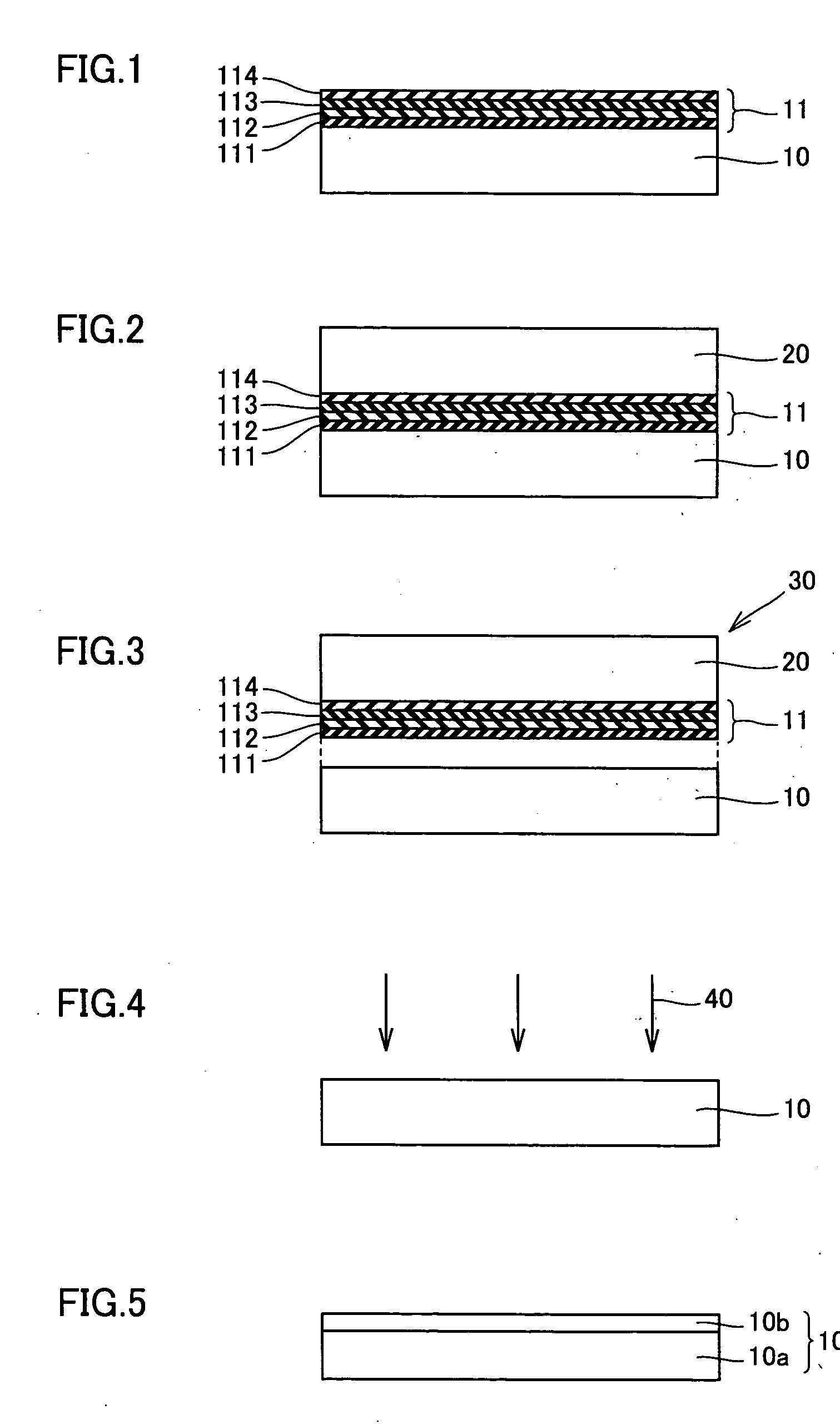

Method of recovering and reproducing substrates and method of producing semiconductor wafers

InactiveUS20050037595A1Efficiently and economically be producedDecrease productivitySemiconductor/solid-state device manufacturingNitrideSemiconductor

A method of recovering a first substrate, including the steps of: sticking a second substrate on a semiconductor layer epitaxially grown on the first substrate; and separating the semiconductor layer and the first substrate. Furthermore, a method of reproducing a first substrate, including the step of surface processing the first substrate separated. Furthermore, a method of reproducing a first substrate, including the step of homoepitaxially growing the first substrate surface processed. Furthermore, a method of producing a semiconductor wafer, including the step of epitaxially growing a semiconductor layer on a first substrate. Thus a group III nitride or similar, expensive substrate can be used to efficiently and economically, epitaxially grow a group III nitride or similar semiconductor layer.

Owner:SUMITOMO ELECTRIC IND LTD

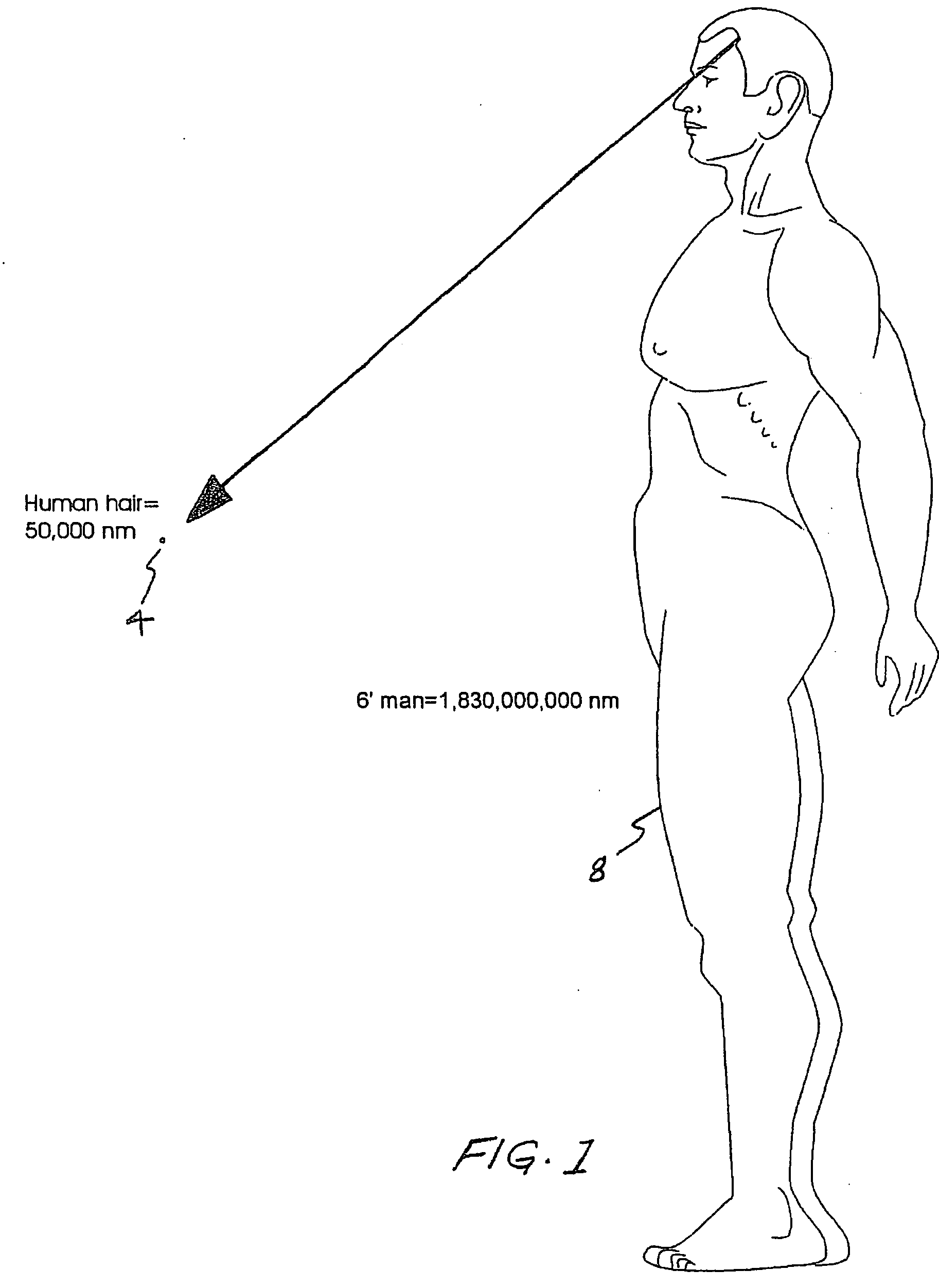

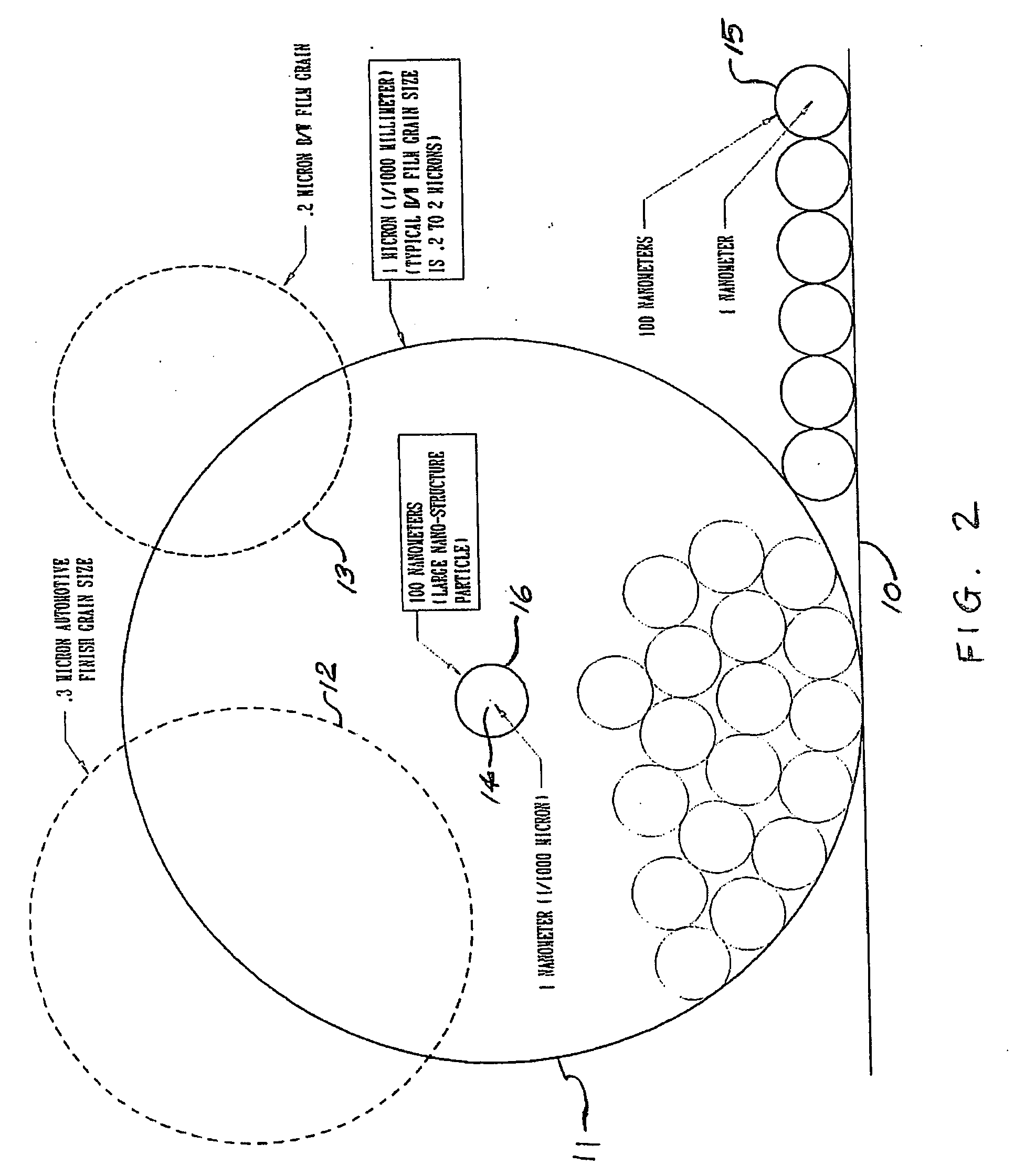

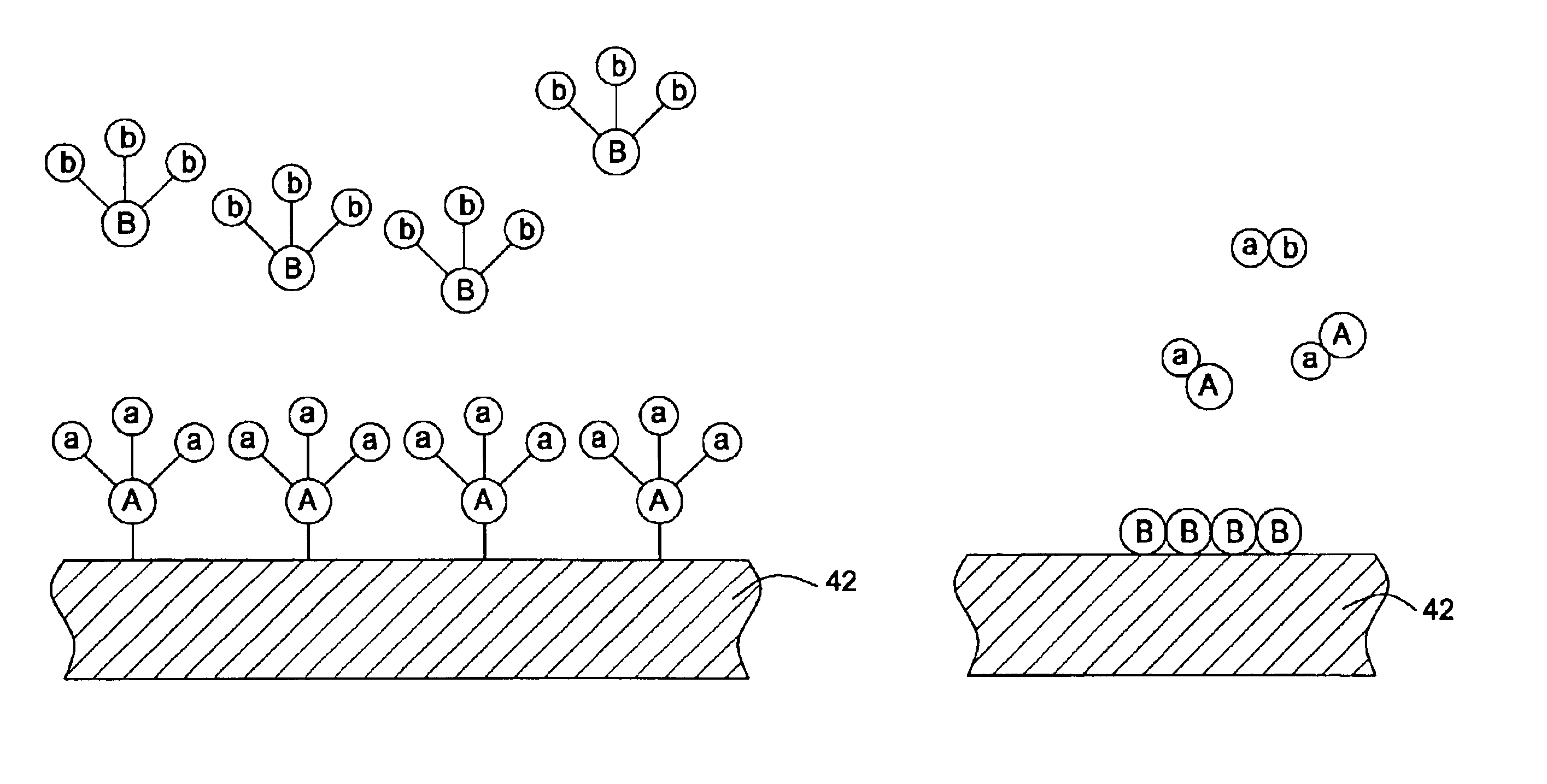

Surface treatments and modifications using nanostructure materials

InactiveUS20050113936A1Reduce surface tensionPromote and inhibit ingrowthSuture equipmentsHeart valvesGas phaseNanostructure

The invention is directed to nanostructure surface treatments, coatings or modifications formed from nanoscale building blocks. The nanostructure surface treatments, modifications or coatings have hydrophobic, hydrophilic and surface adherence properties. The nanoscale building blocks have orientation, geometry, packing density and composition that may be adjusted to control the unique surface characteristics of the desired treatment, coating or modification. Applications of this nanostructure technology include surgical clips, staples, retractors, sutures and manipulators where an improvement in traction, retention or occlusion is desired without excessive material or tissue deformation or where high compressive forces would be undesirable, dangerous or ineffective. In one aspect, a nanostructure surface treatment for a medical device having an external surface is disclosed, wherein the treatment is applied on the external surface to provide a hydrophobic or a hydrophilic surface. With this aspect, the treatment comprises titanium dioxide and provides nanoscopic structures having nearly vertical sidewalls. The treated surface of the device has contact angles greater than or equal to 150 degrees. The vertical sidewalls provide a negative capillary effect and have a width of about 200 nm. The vertical sidewalls attach to a wet surface by the negative capillary effect. The van der Waals forces of the vertical sidewalls enable the treated surface to attach to a dry surface. The treatment may be vapor deposited and cured on the device, or the treatment may be laser blasted on the device.

Owner:APPL MEDICAL RESOURCES CORP

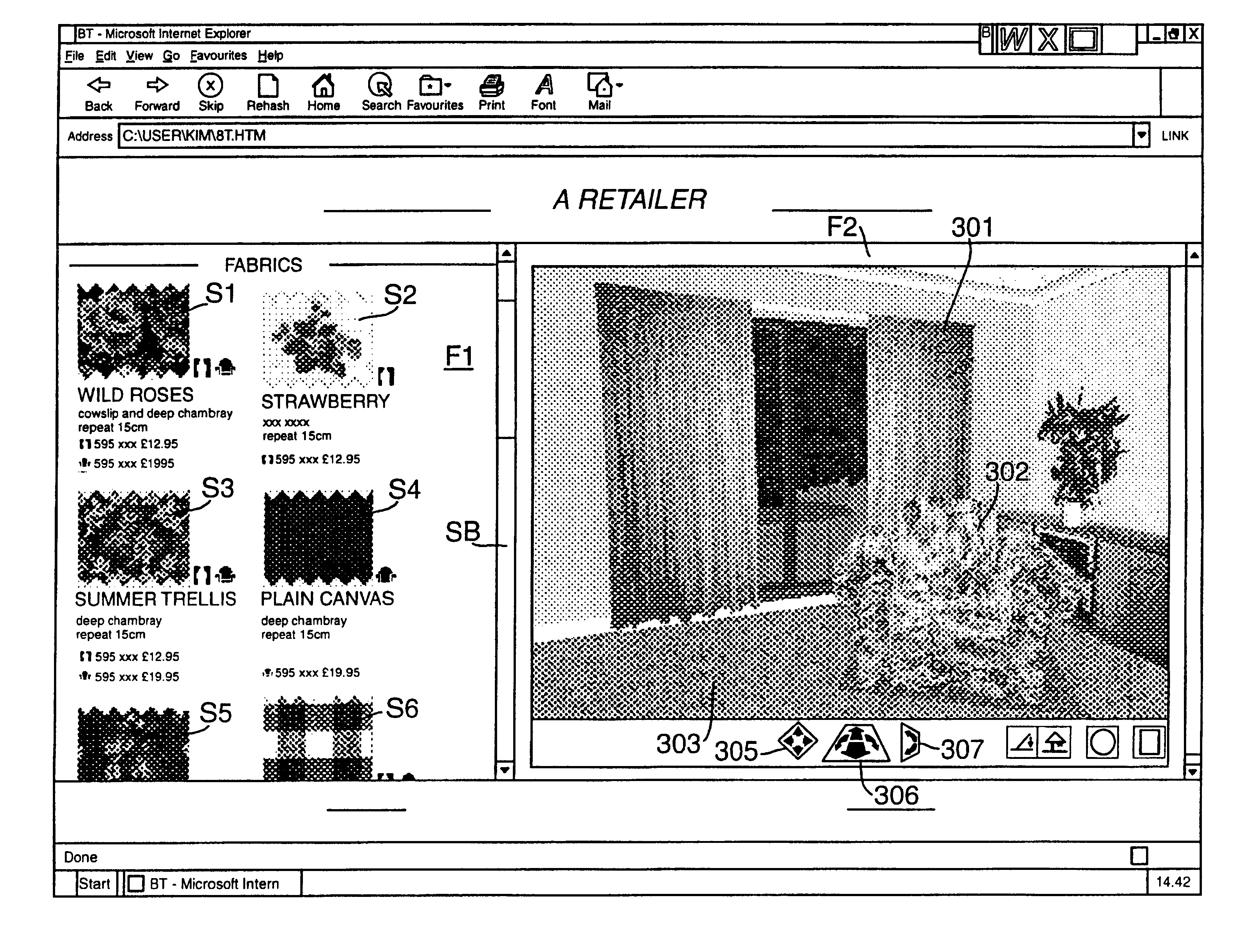

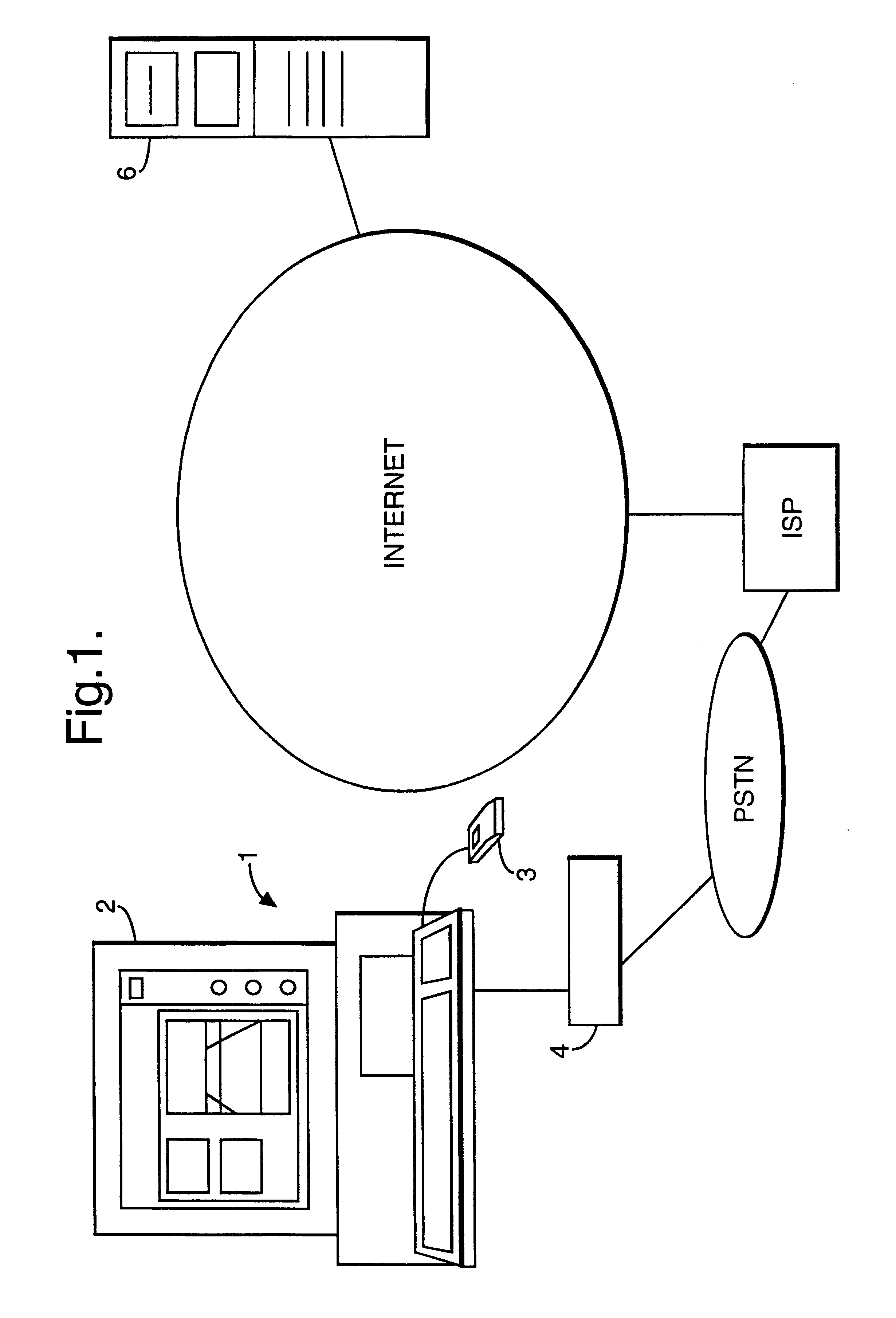

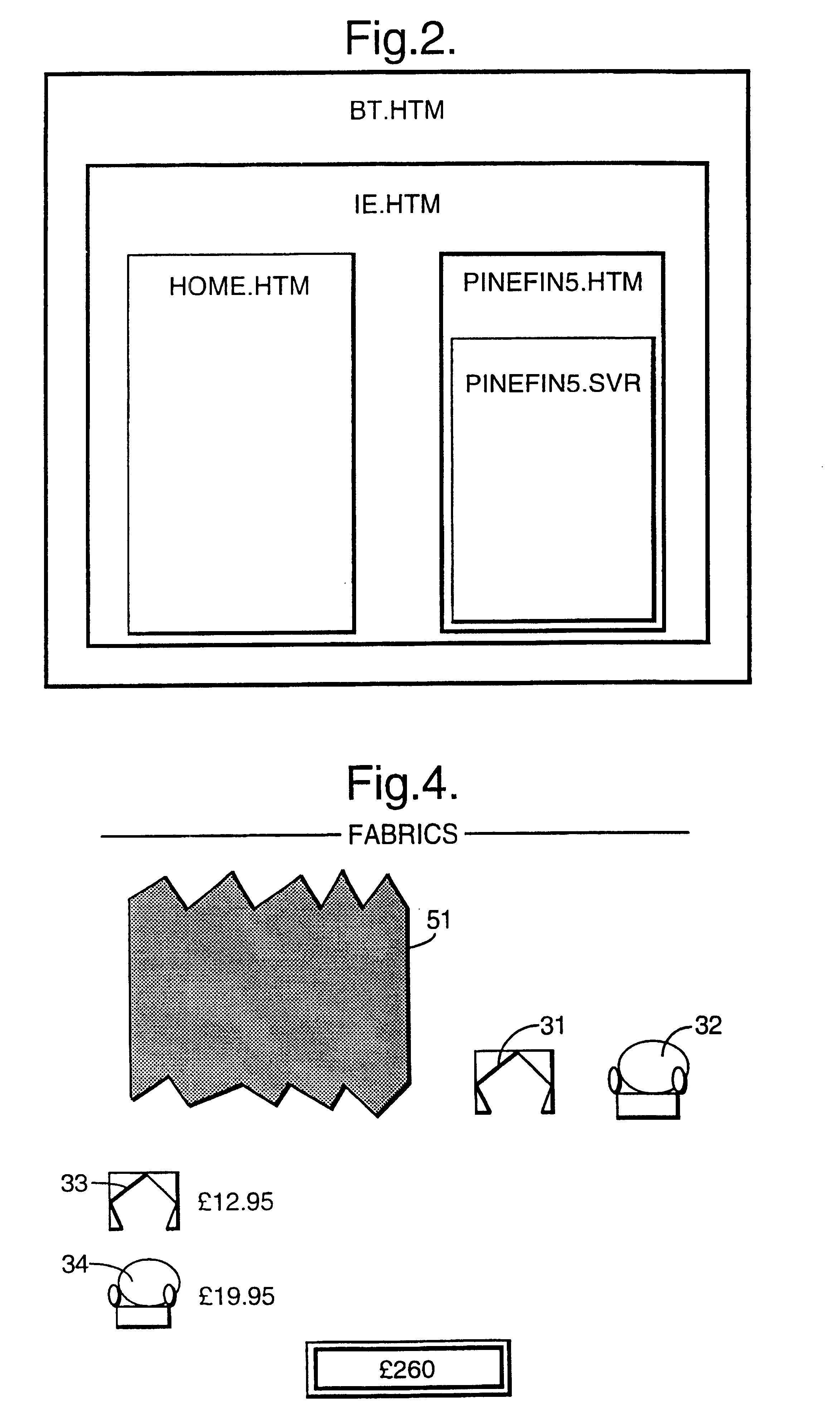

Display terminal user interface with ability to select remotely stored surface finish for mapping onto displayed 3-D surface

InactiveUS6331858B2Realistic assessmentCathode-ray tube indicatorsTwo-way working systemsViewpointsZoom

A user interface on a display terminal, such as a personal computer, includes a 3D display region which shows a scene incorporating a number of objects, such as items of furniture. A surface finish selector is also displayed and is used to select a surface finish from a number of alternatives. In the case of items of furniture, these finishes may correspond to different fabrics for upholstery. A surface texture data for a selected finish is automatically downloaded from a remote source and mapped onto the object in the 3D scene. In a preferred implementation, the surface finish selector is a frame of a web page and generates control data which is passed to another frame containing the 3D scene together with movement controls for changing the viewpoint in the scene.

Owner:BRITISH TELECOMM PLC

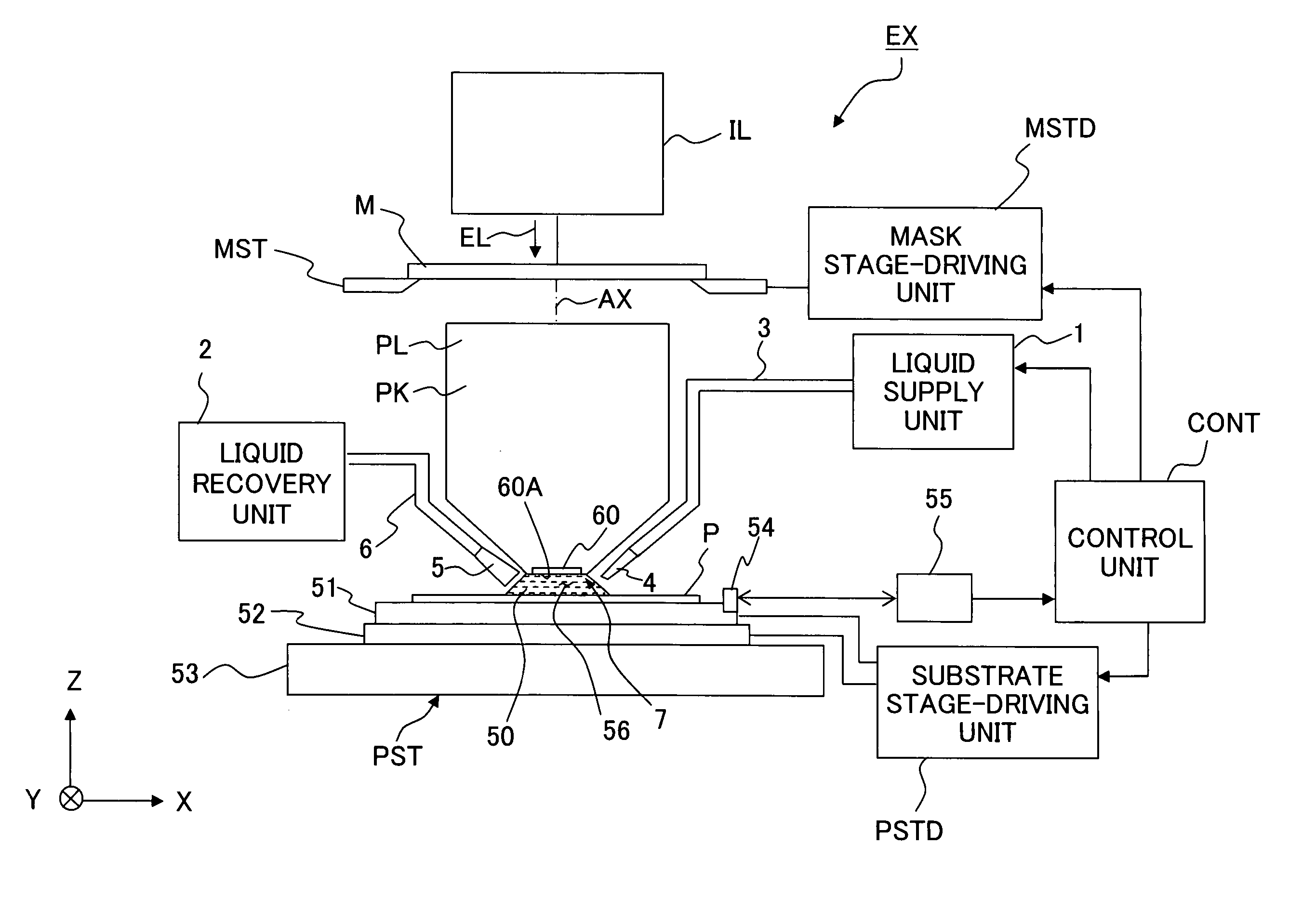

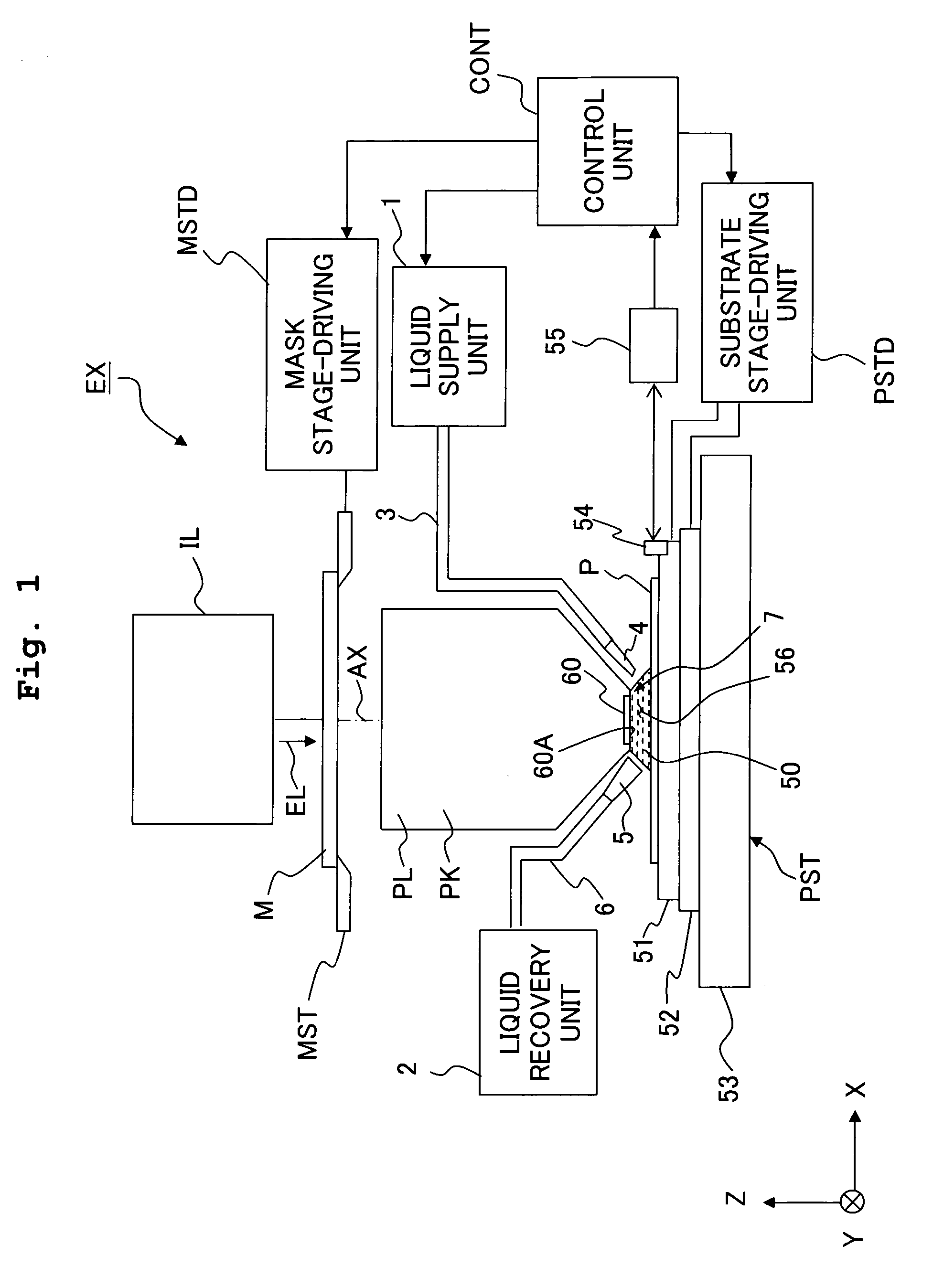

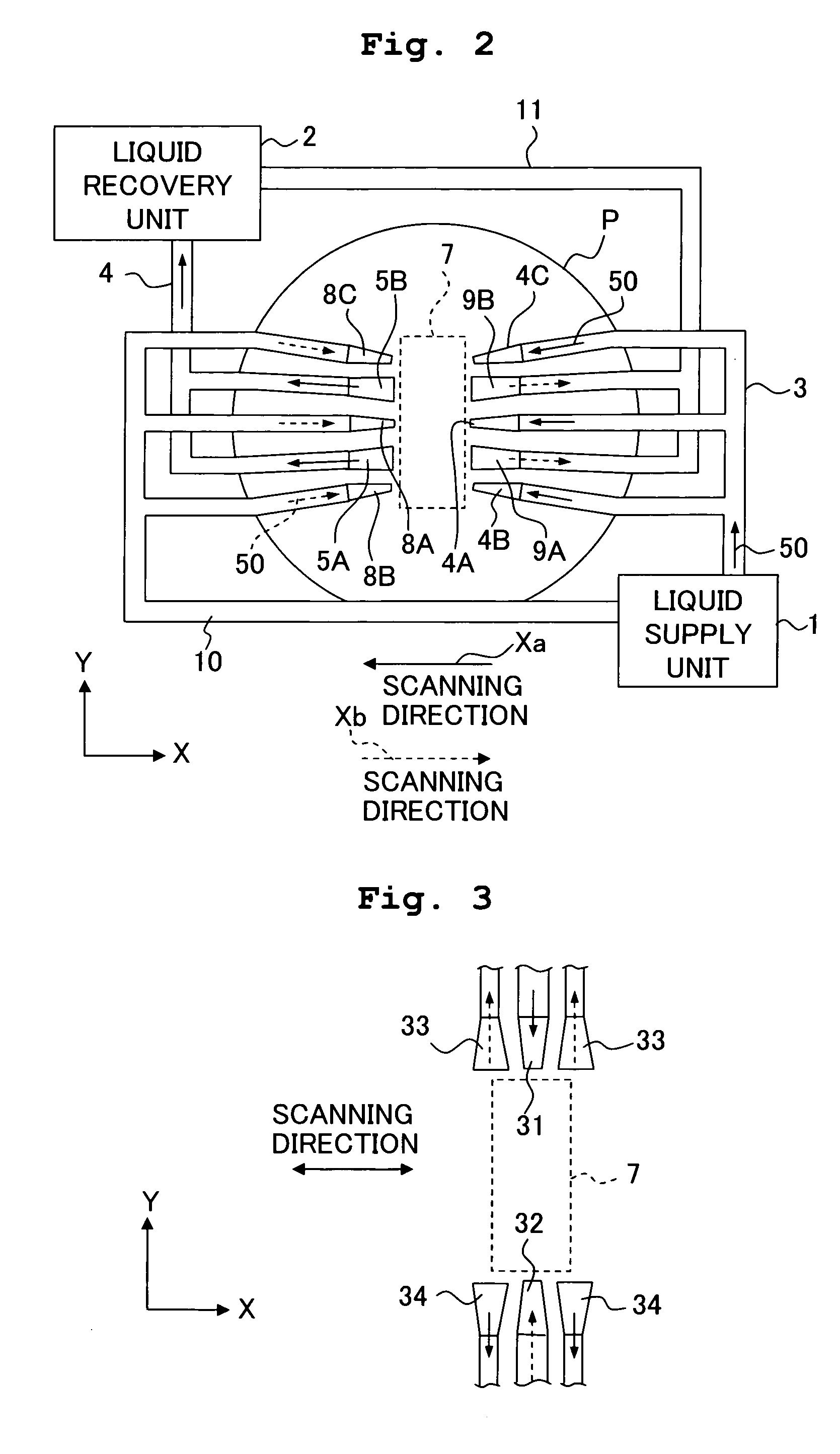

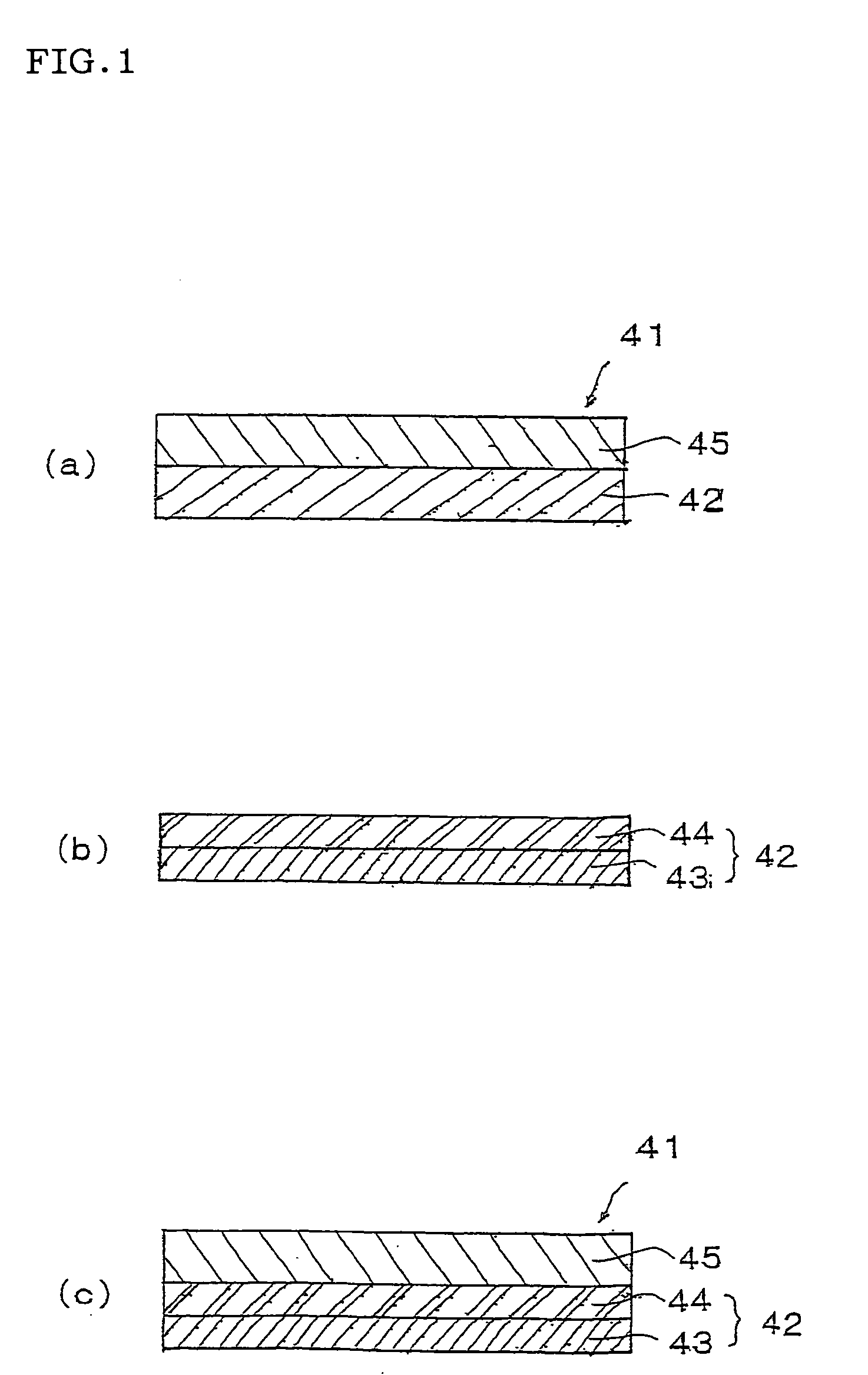

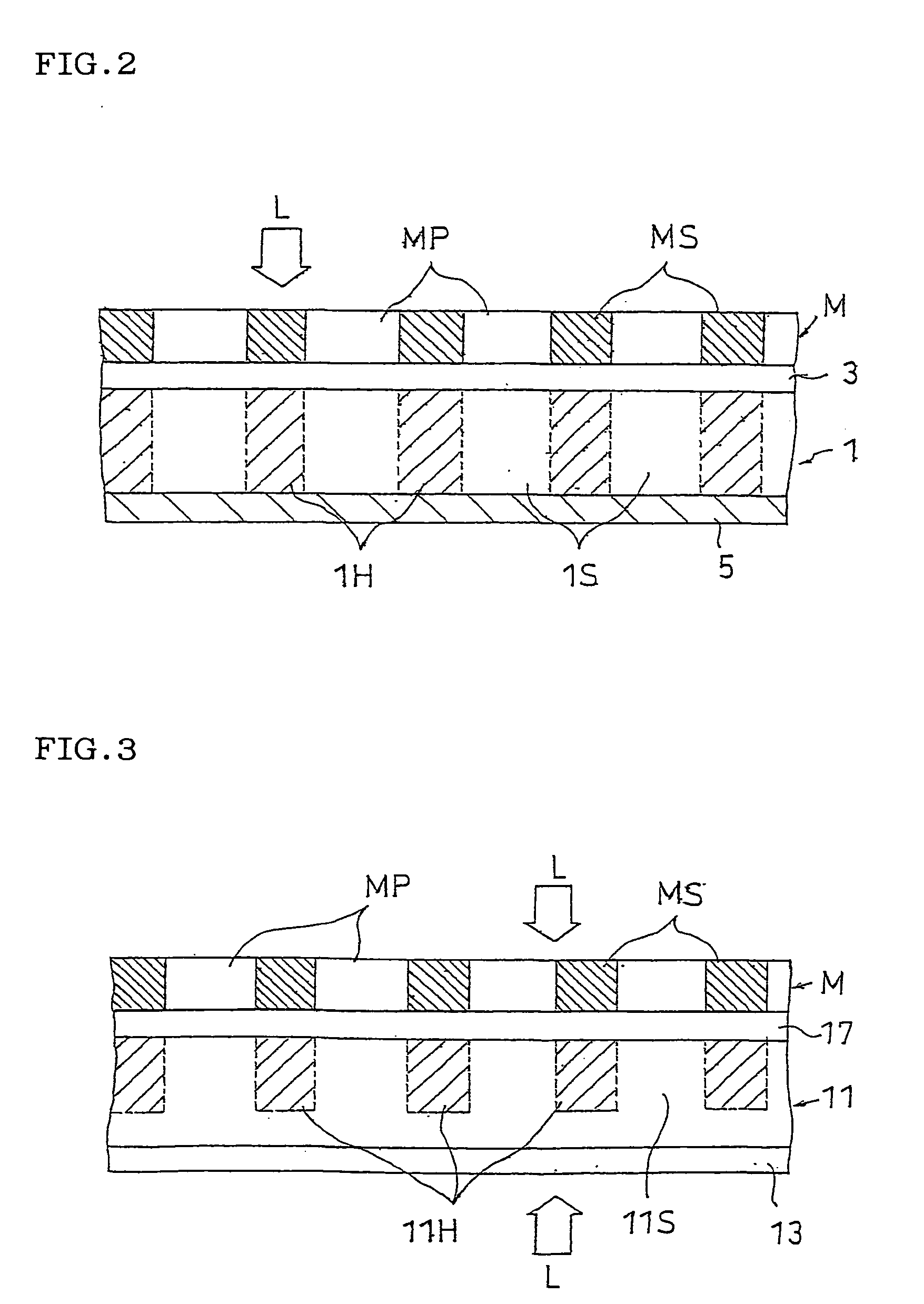

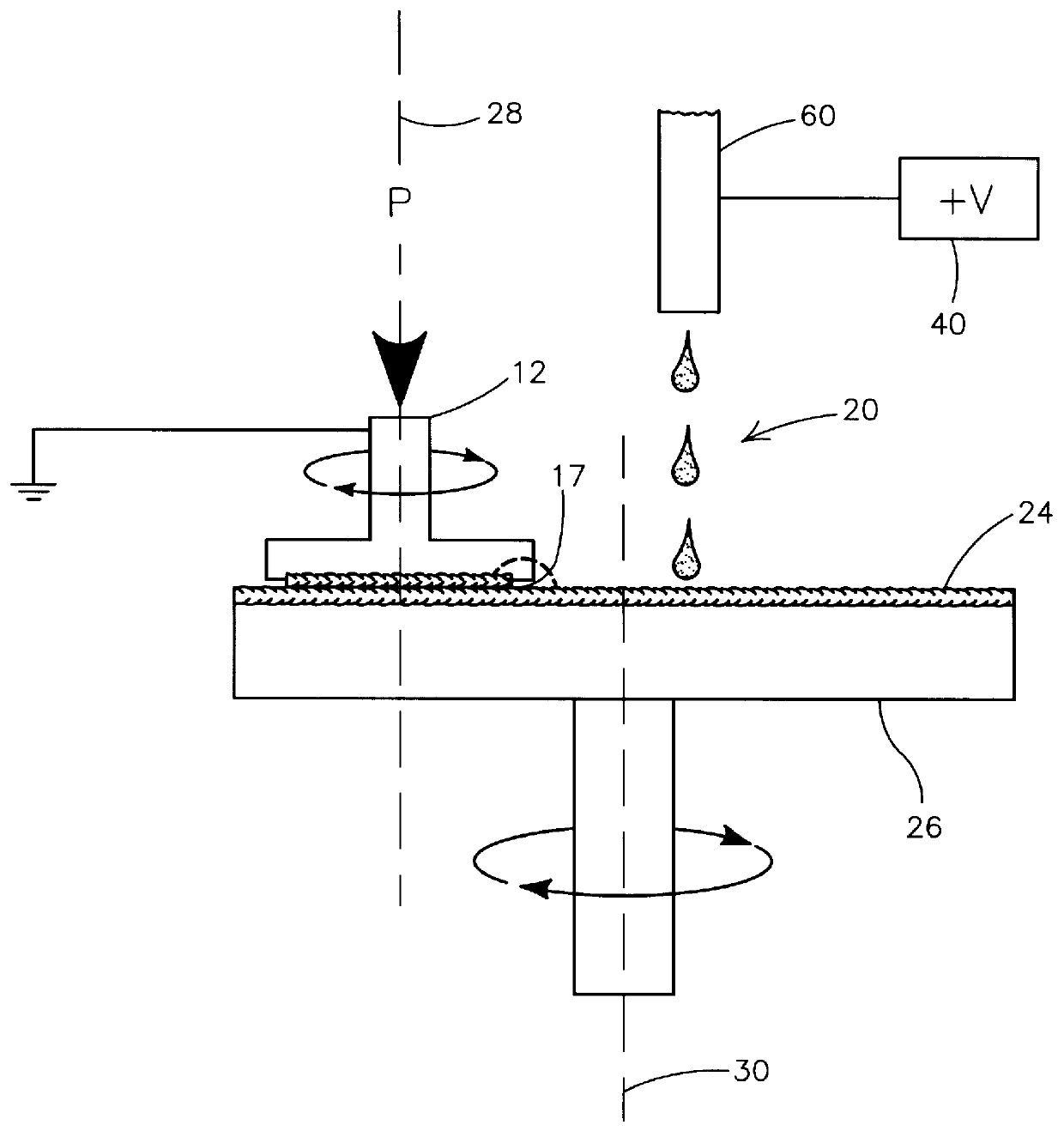

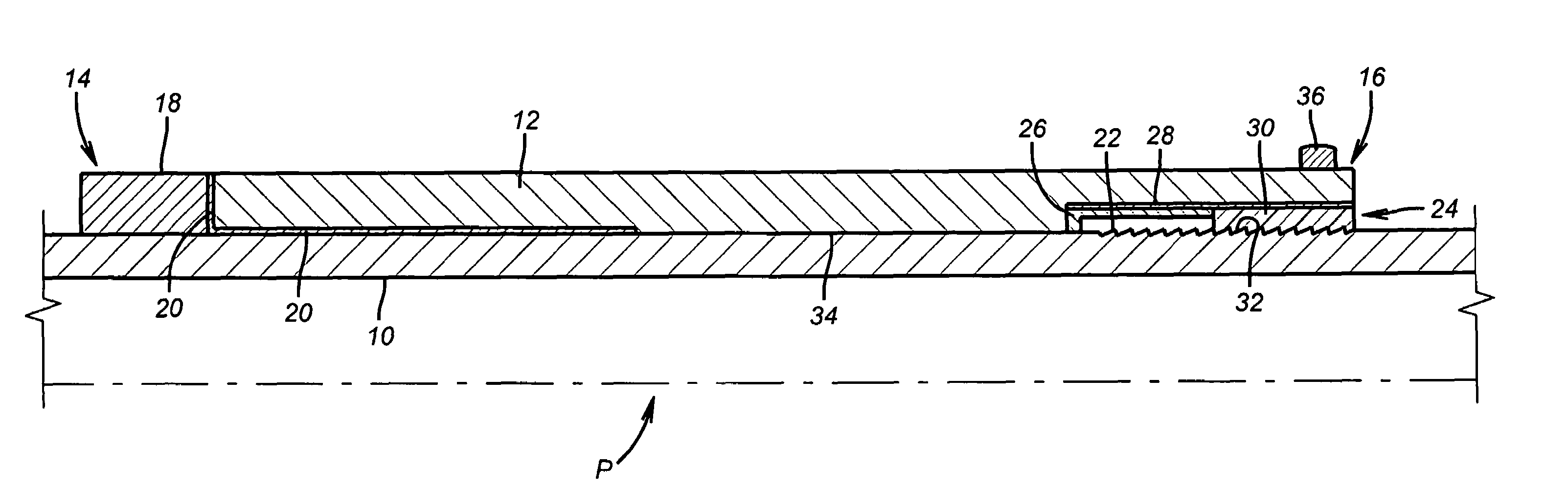

Exposure apparatus, exposure method, and method for producing device

InactiveUS20050237504A1Stable arrangementHigh affinitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOpticsSurface processing

In an exposure apparatus, an exposure of a substrate (P) is carried out by filling at least a portion of the space between a projection optical system (PL) and the substrate (P) with a liquid (50) and projecting the image of a pattern onto the substrate (P) via the projection optical system (PL). An optical element (60) and a barrel (PK), which are in contact with the liquid (50) when the substrate (P) is moved, are surface-treated for adjusting the affinity with the liquid (50). Consequently, generation of bubbles in the liquid between the projection optical system and the substrate is suppressed and the liquid is always retained between the projection optical system and the substrate, thereby creating a good immersion state.

Owner:NIKON CORP

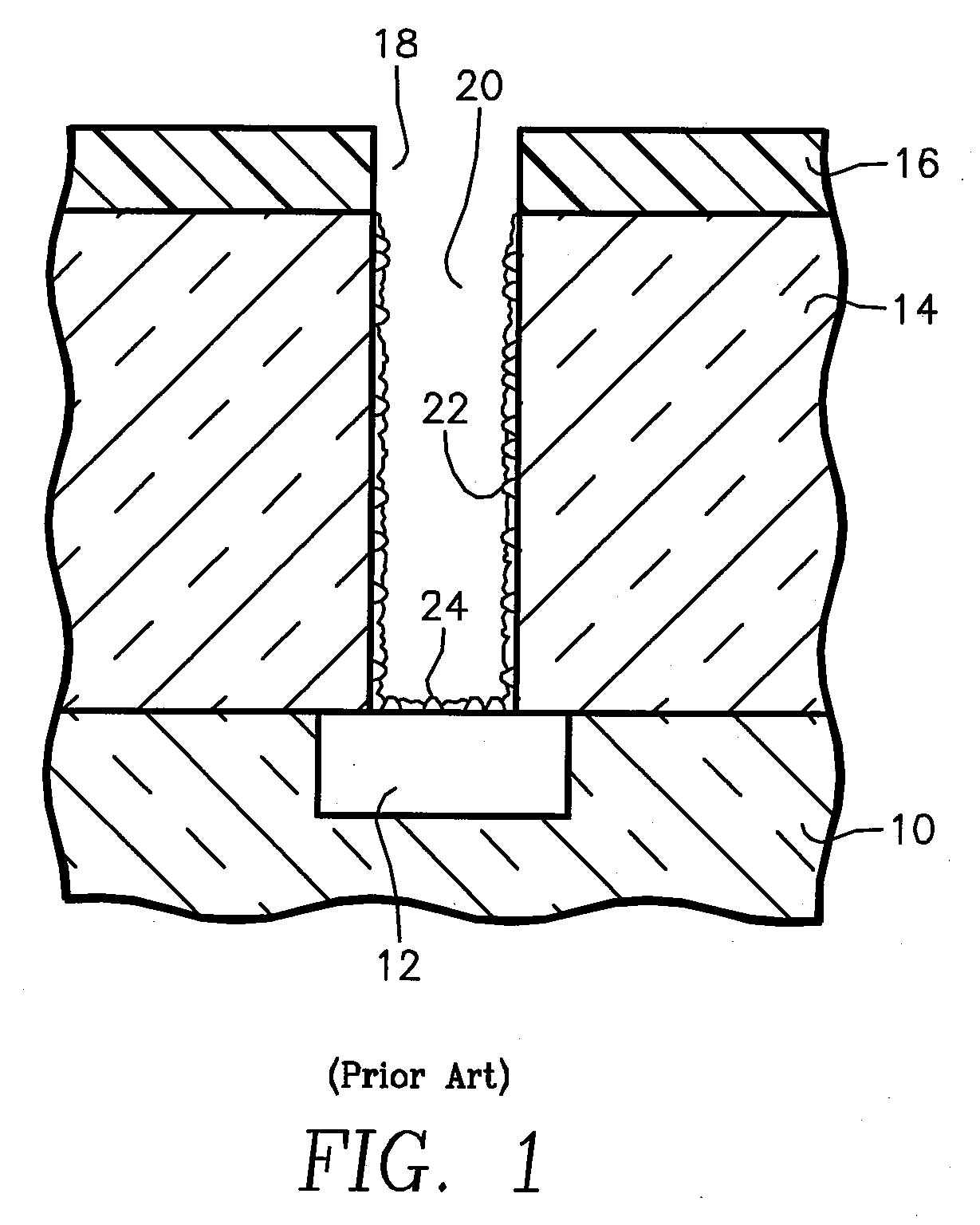

Method and apparatus for depositing tungsten after surface treatment to improve film characteristics

InactiveUS6936538B2Reduce fluorine contentHigh resistivitySolid-state devicesSemiconductor/solid-state device manufacturingChemical speciesNucleation

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer. The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing standard CVD techniques. Alternatively, the formed tungsten layer can be used to fill an aperture.

Owner:APPLIED MATERIALS INC

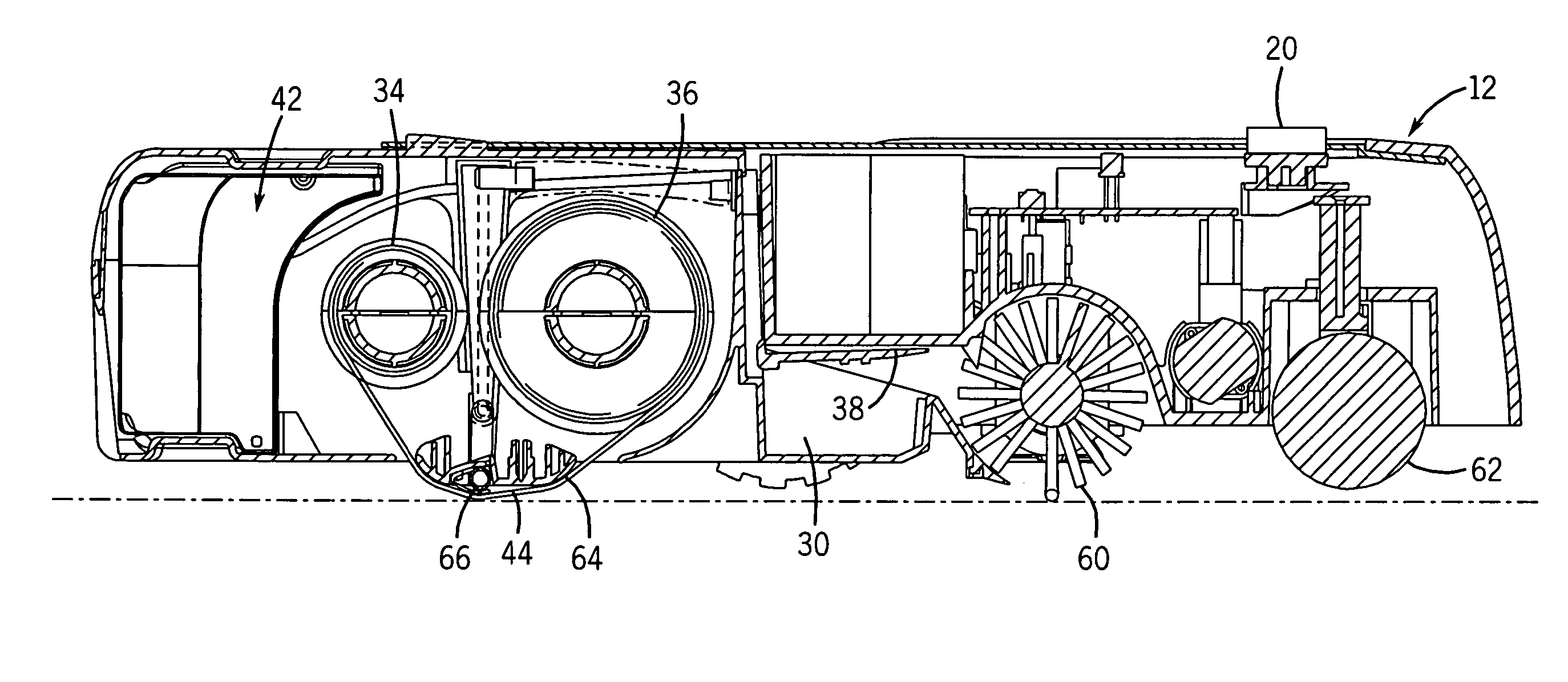

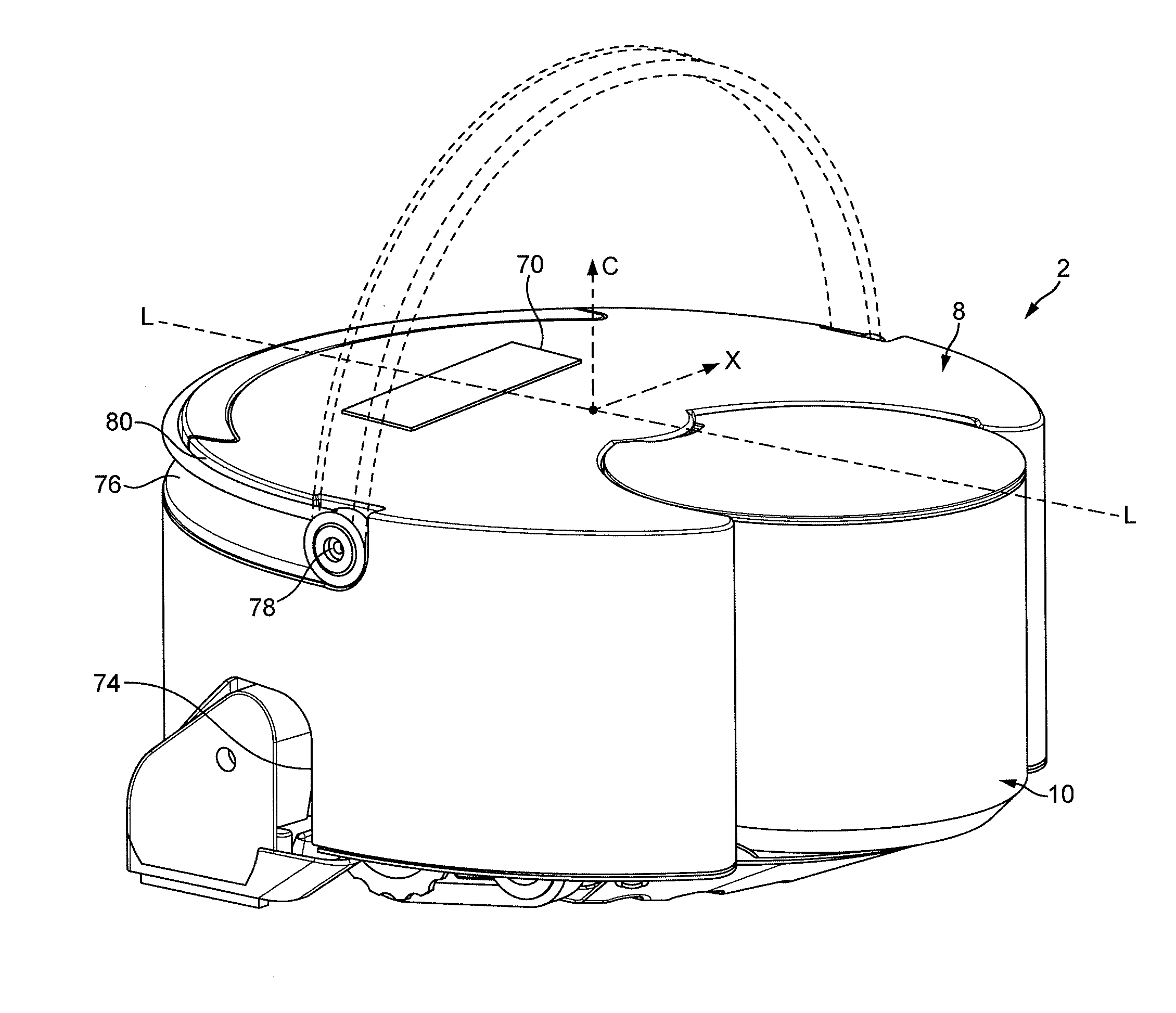

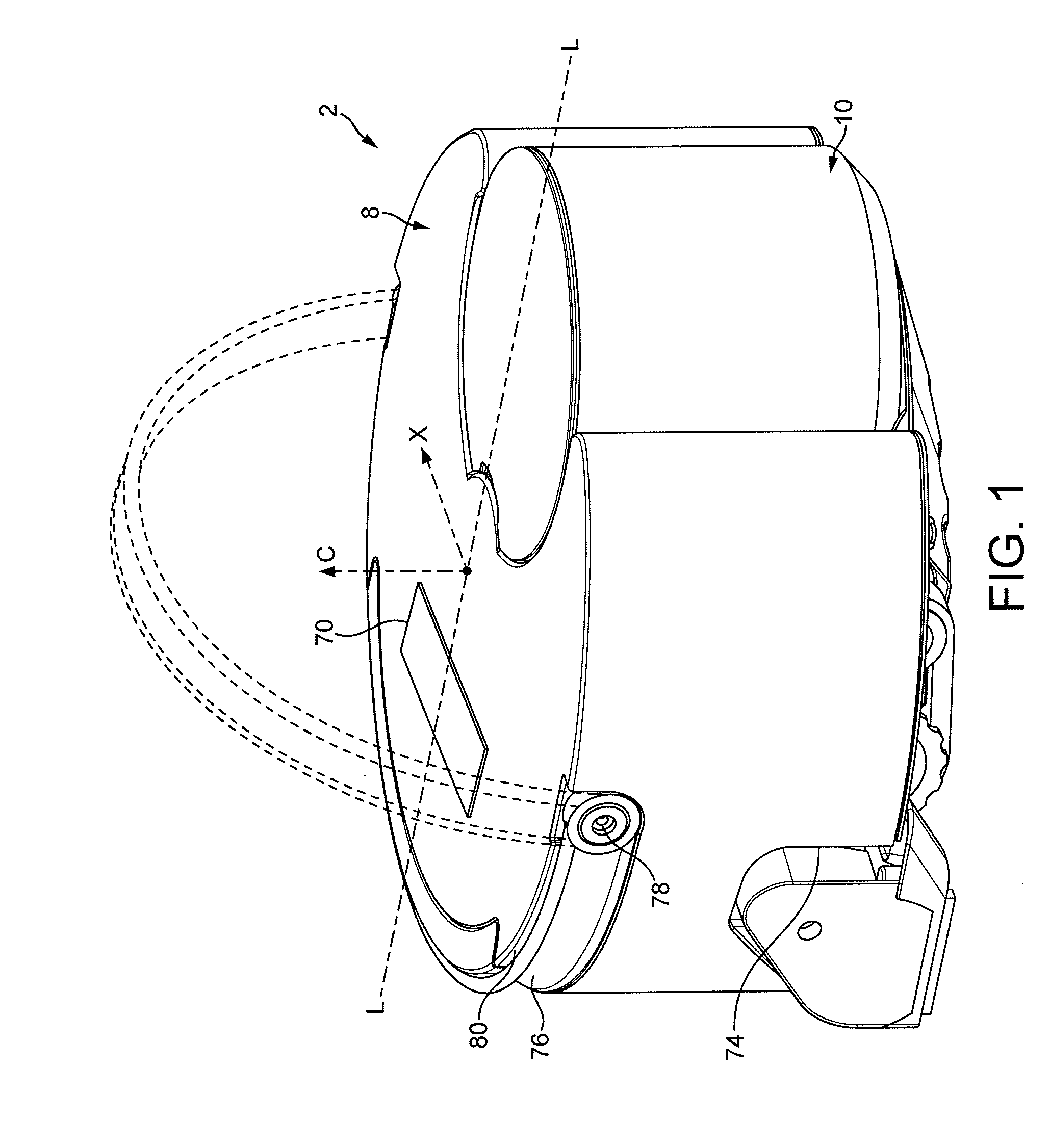

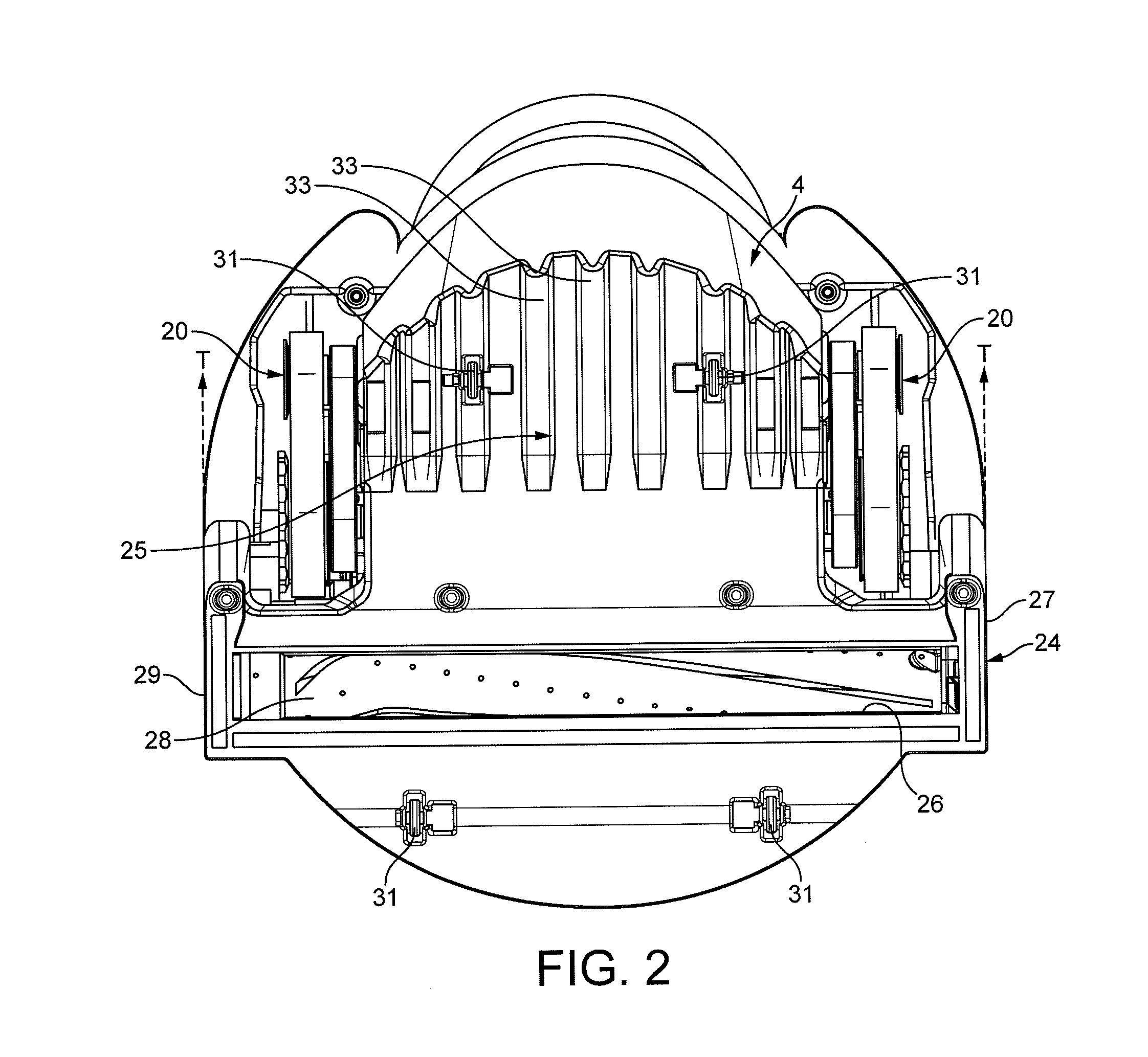

Autonomous surface treating appliance

ActiveUS20130061420A1Good body shapeCleaning machinesCleaning equipmentMarine engineeringSurface processing

An autonomous surface treating appliance comprising a main body defining an outer plan profile, and having a drive arrangement mounted inboard of the outer plan profile of the main body and configured to propel the appliance in a direction of movement across a surface to be cleaned, a surface treating assembly associated with the main body and carried transversely to the direction of movement, the surface treating assembly being generally elongate in form and having side edges extending substantially at a tangent to respective circular portions of the outer plan profile of the main body.

Owner:DYSON TECH LTD

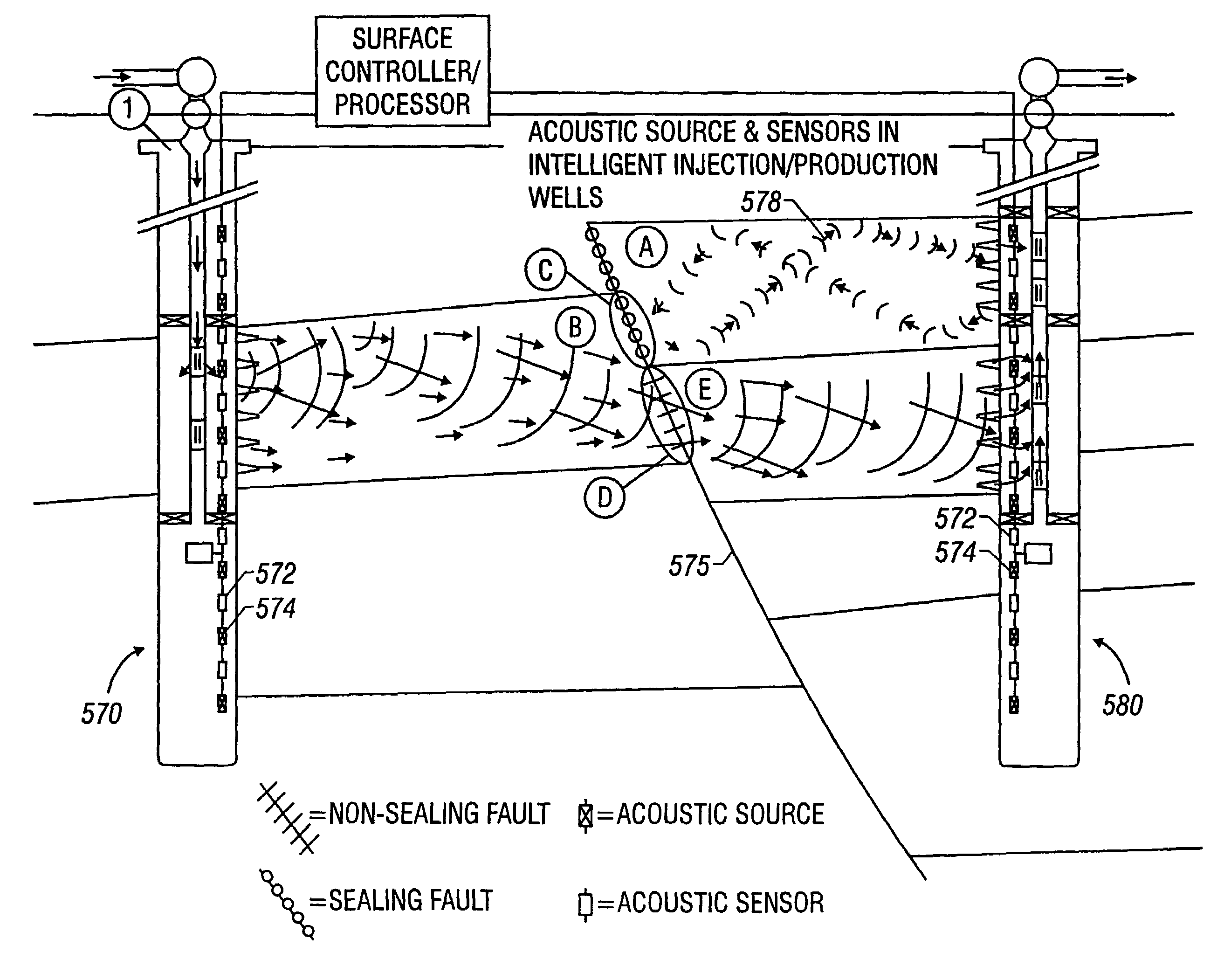

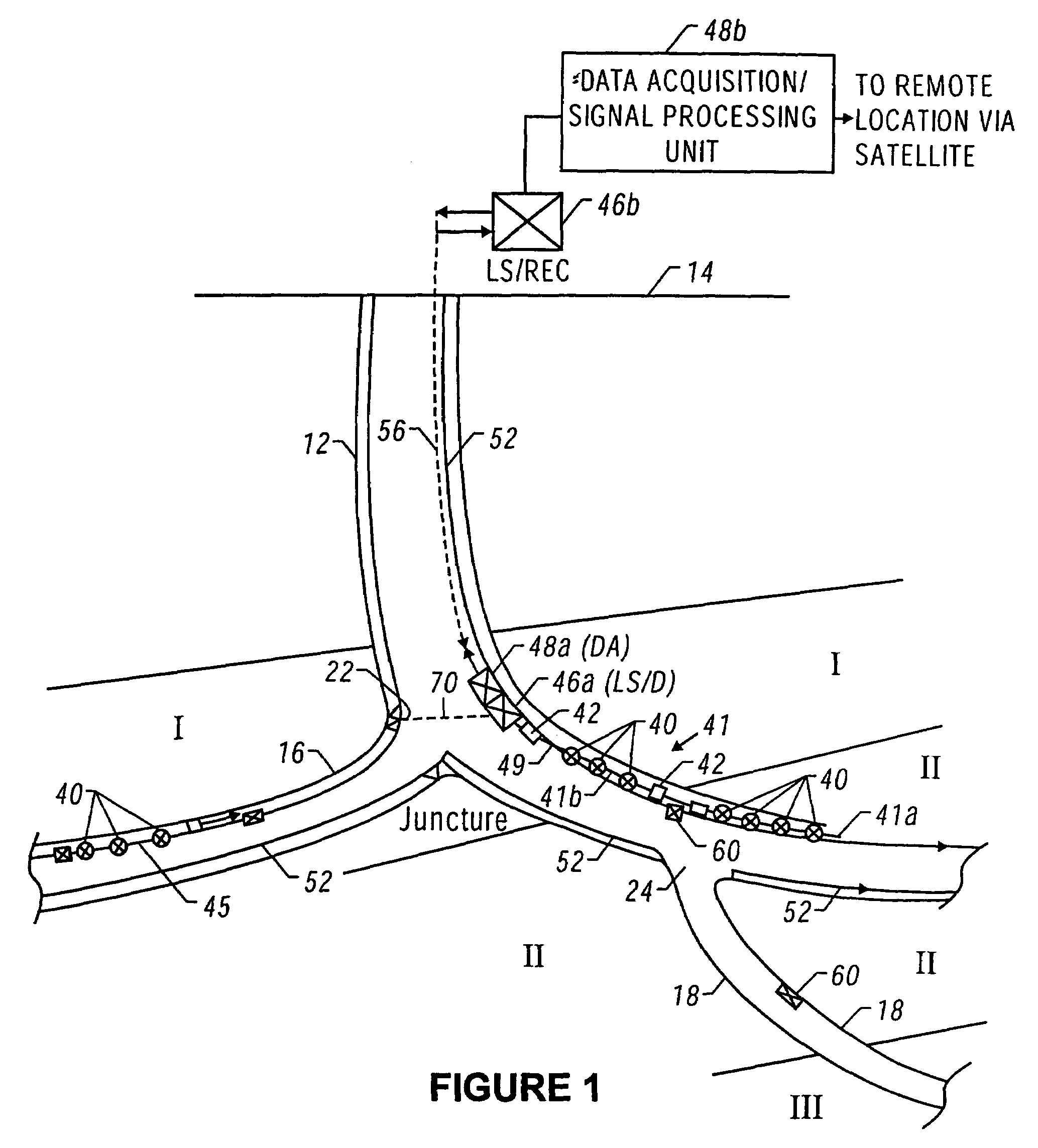

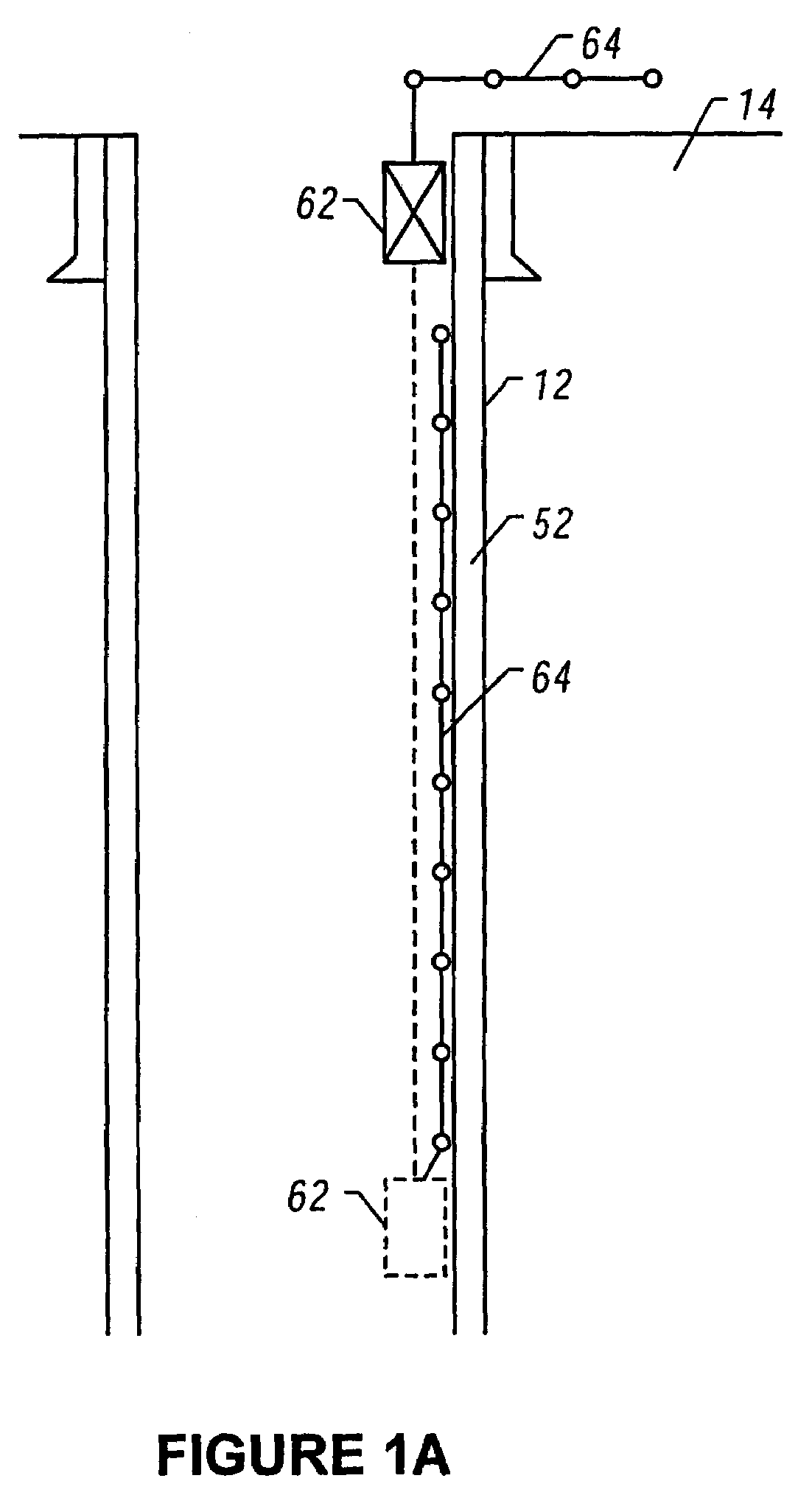

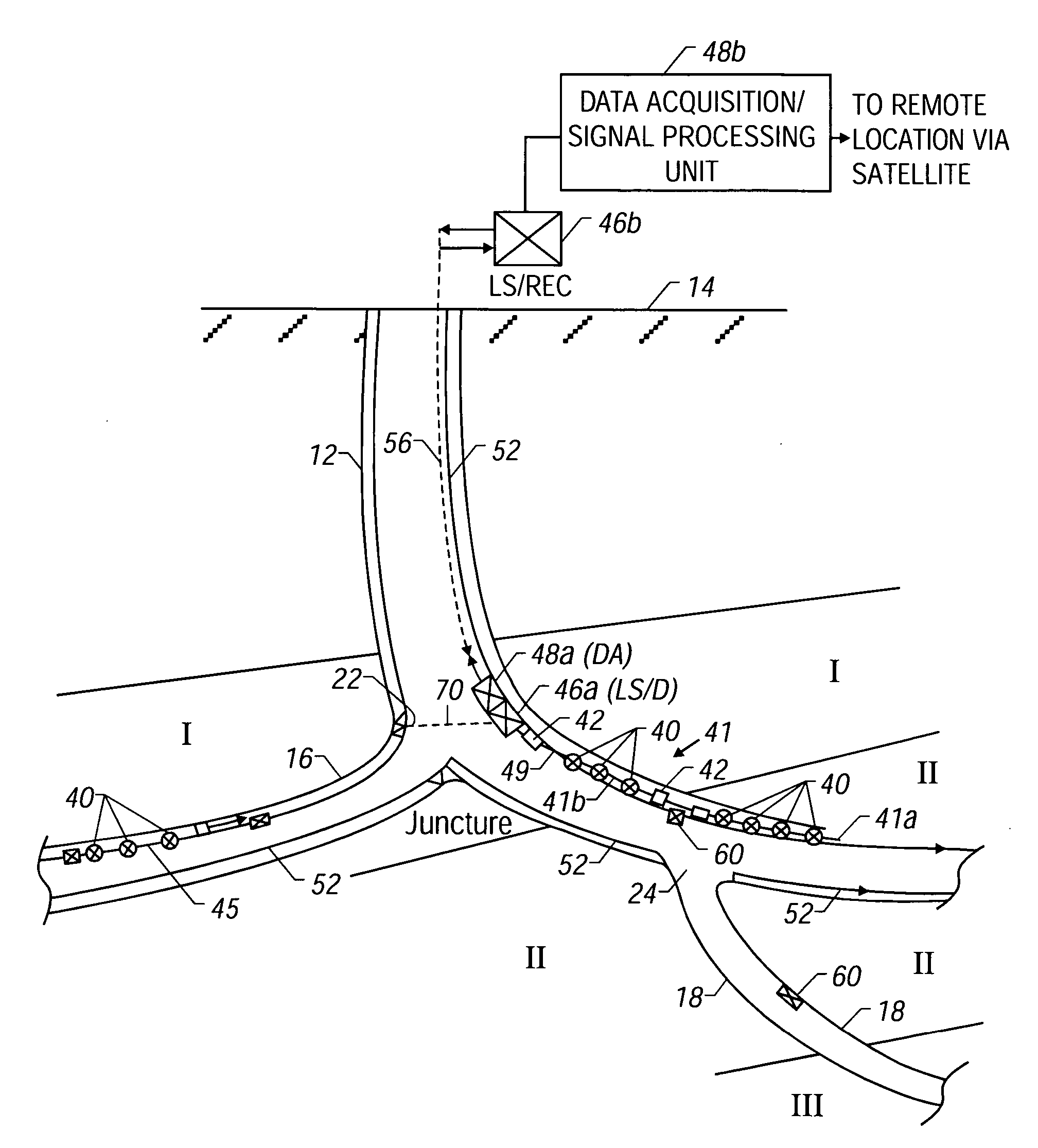

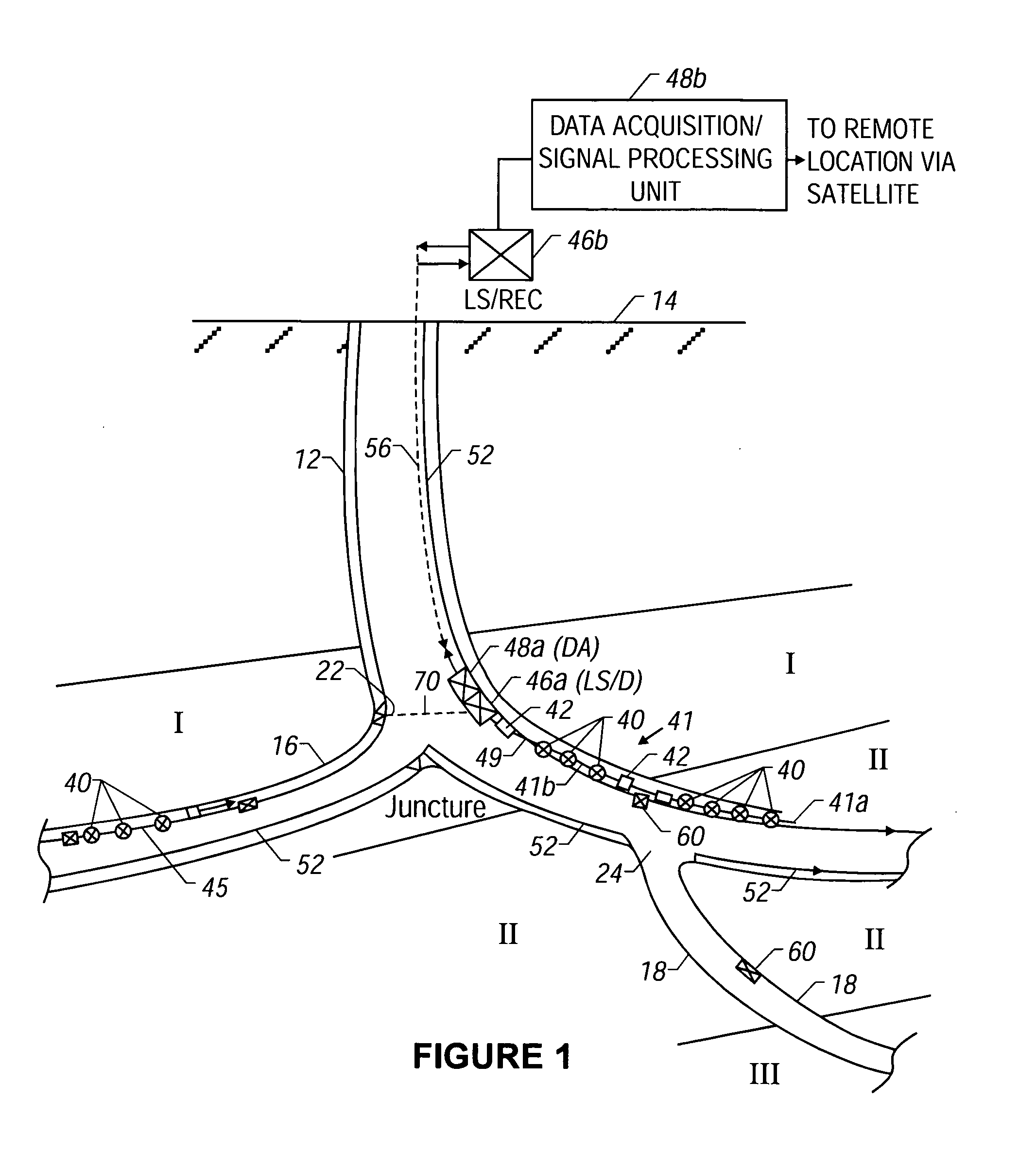

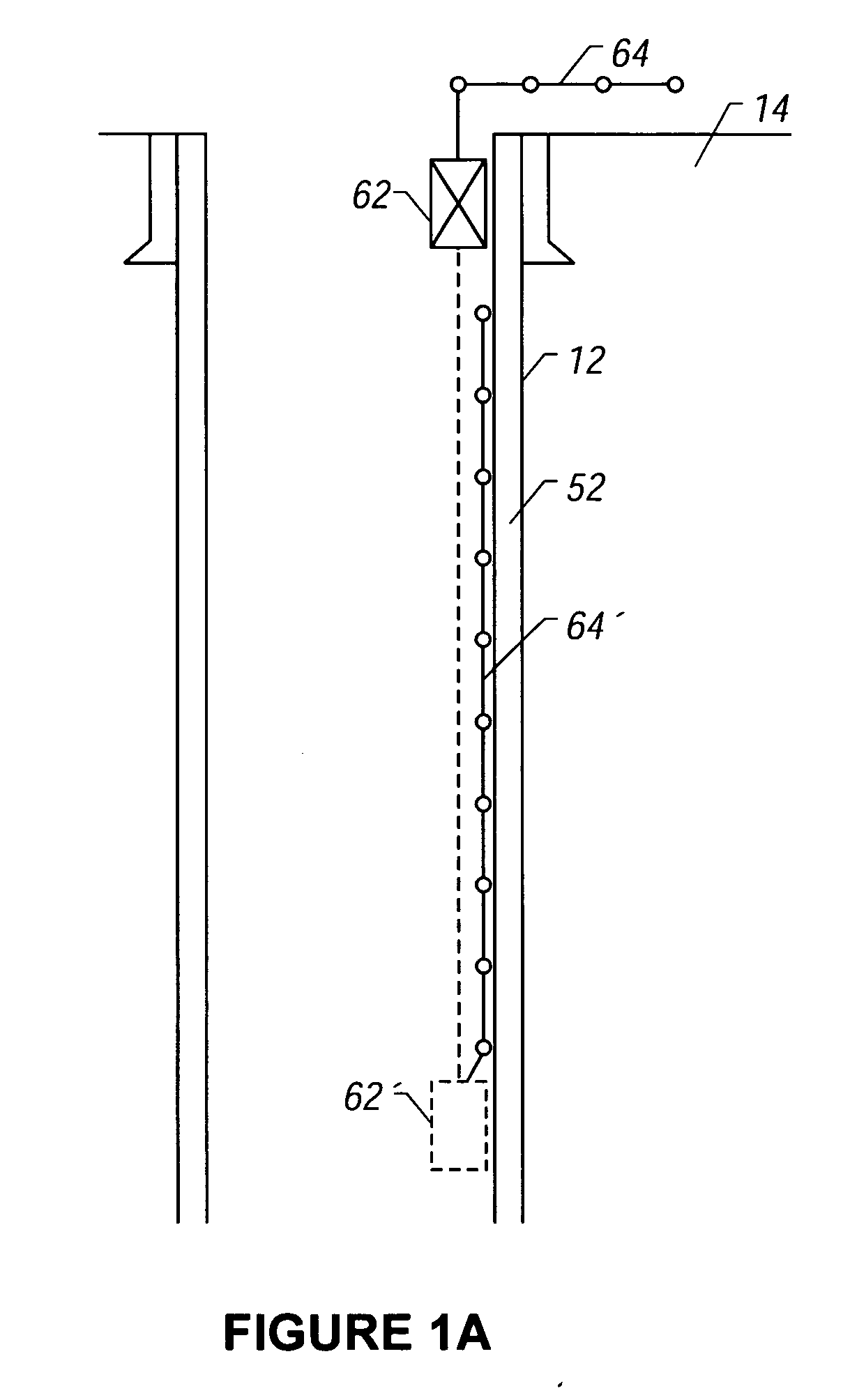

Wellbores utilizing fiber optic-based sensors and operating devices

InactiveUS7040390B2Enhanced overall recoveryEasy to operateConstructionsOptical prospectingForms of energyEngineering

This invention provides a method for controlling production operations using fiber optic devices. An optical fiber carrying fiber-optic sensors is deployed downhole to provide information about downhole conditions. Parameters related to the chemicals being used for surface treatments are measured in real time and on-line, and these measured parameters are used to control the dosage of chemicals into the surface treatment system. The information is also used to control downhole devices that may be a packer, choke, sliding sleeve, perforating device, flow control valve, completion device, an anchor or any other device. Provision is also made for control of secondary recovery operations online using the downhole sensors to monitor the reservoir conditions. The present invention also provides a method of generating motive power in a wellbore utilizing optical energy. This can be done directly or indirectly, e.g., by first producing electrical energy that is then converted to another form of energy.

Owner:BAKER HUGHES INC

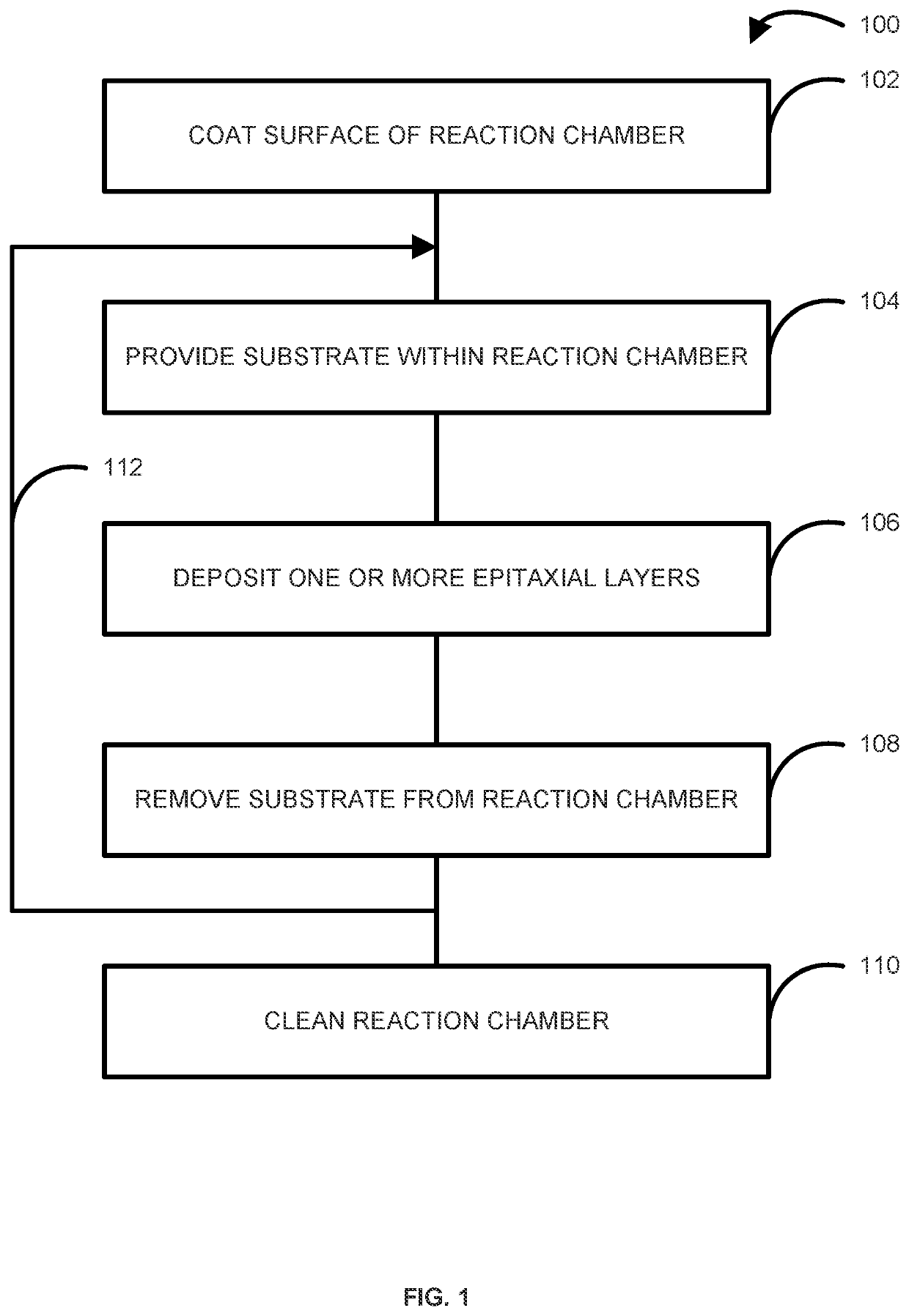

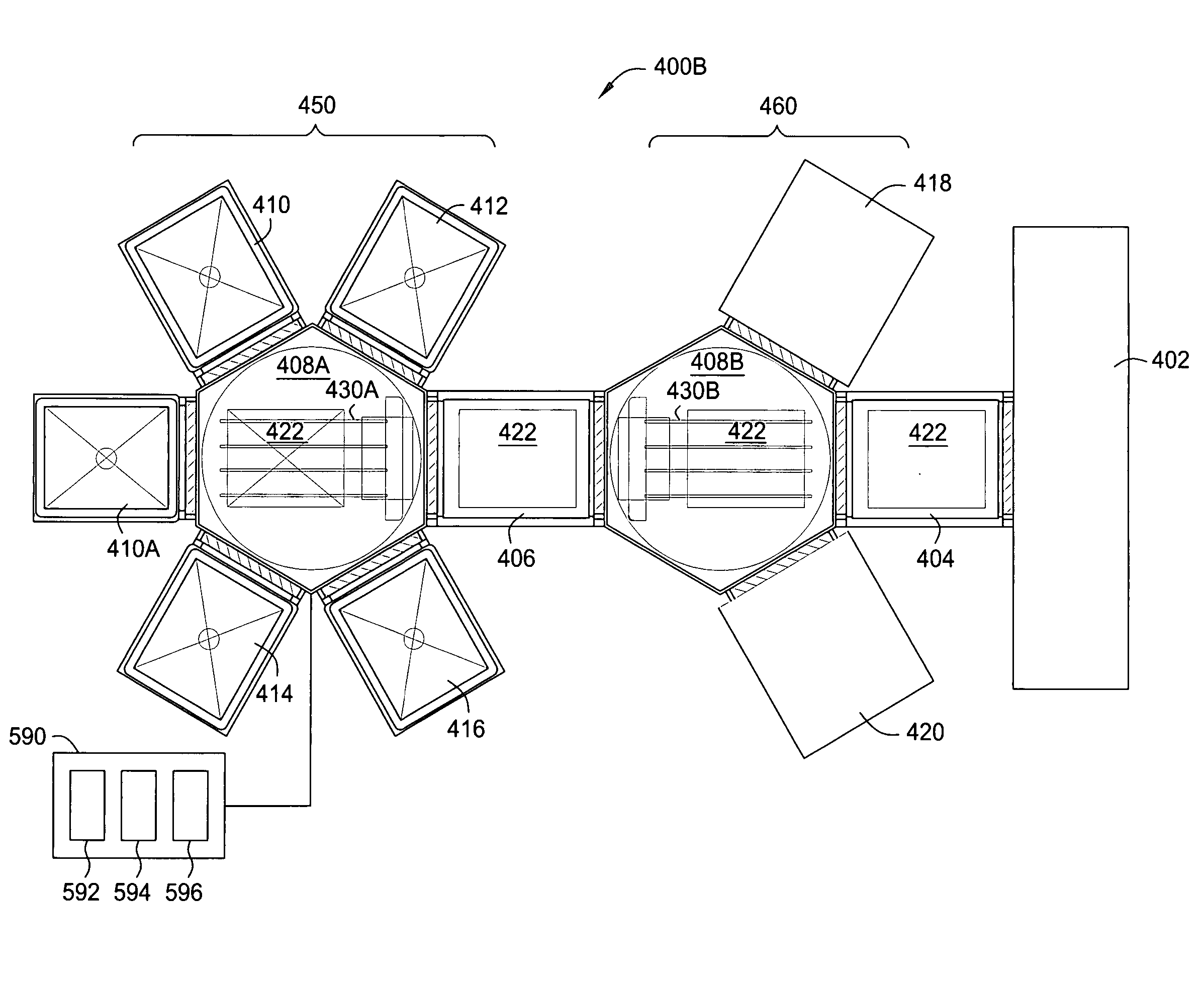

Method of depositing epitaxial material, structure formed using the method, and system for performing the method

PendingUS20210292902A1Improve throughputThe material is lowPolycrystalline material growthSemiconductor/solid-state device manufacturingEpitaxial materialEngineering

A method of depositing one or more epitaxial material layers, a device structure formed using the method and a system for performing the method are disclosed. Exemplary methods include coating a surface of a reaction chamber with a precoat material, processing a number of substrates, and then cleaning the reaction chamber.

Owner:ASM IP HLDG BV

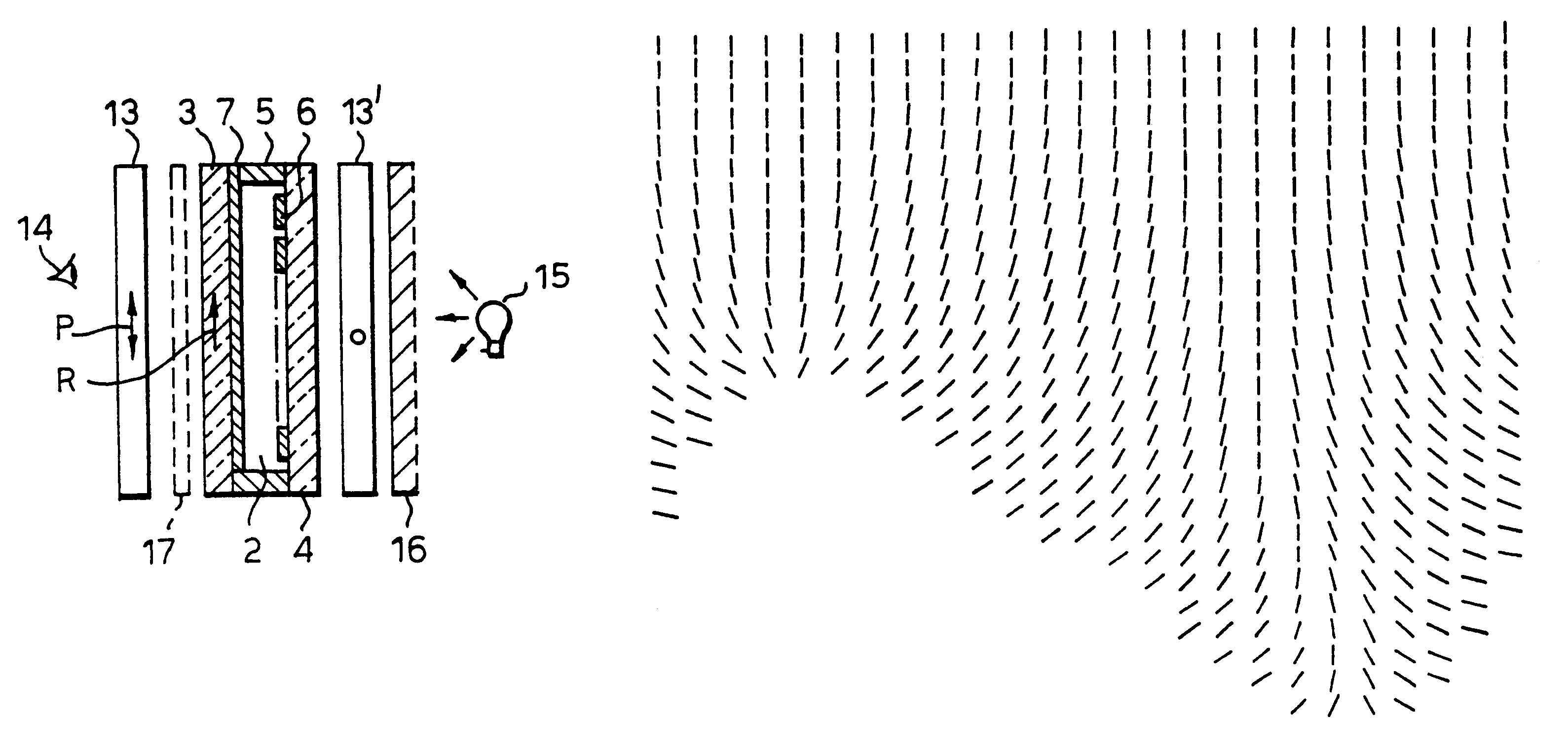

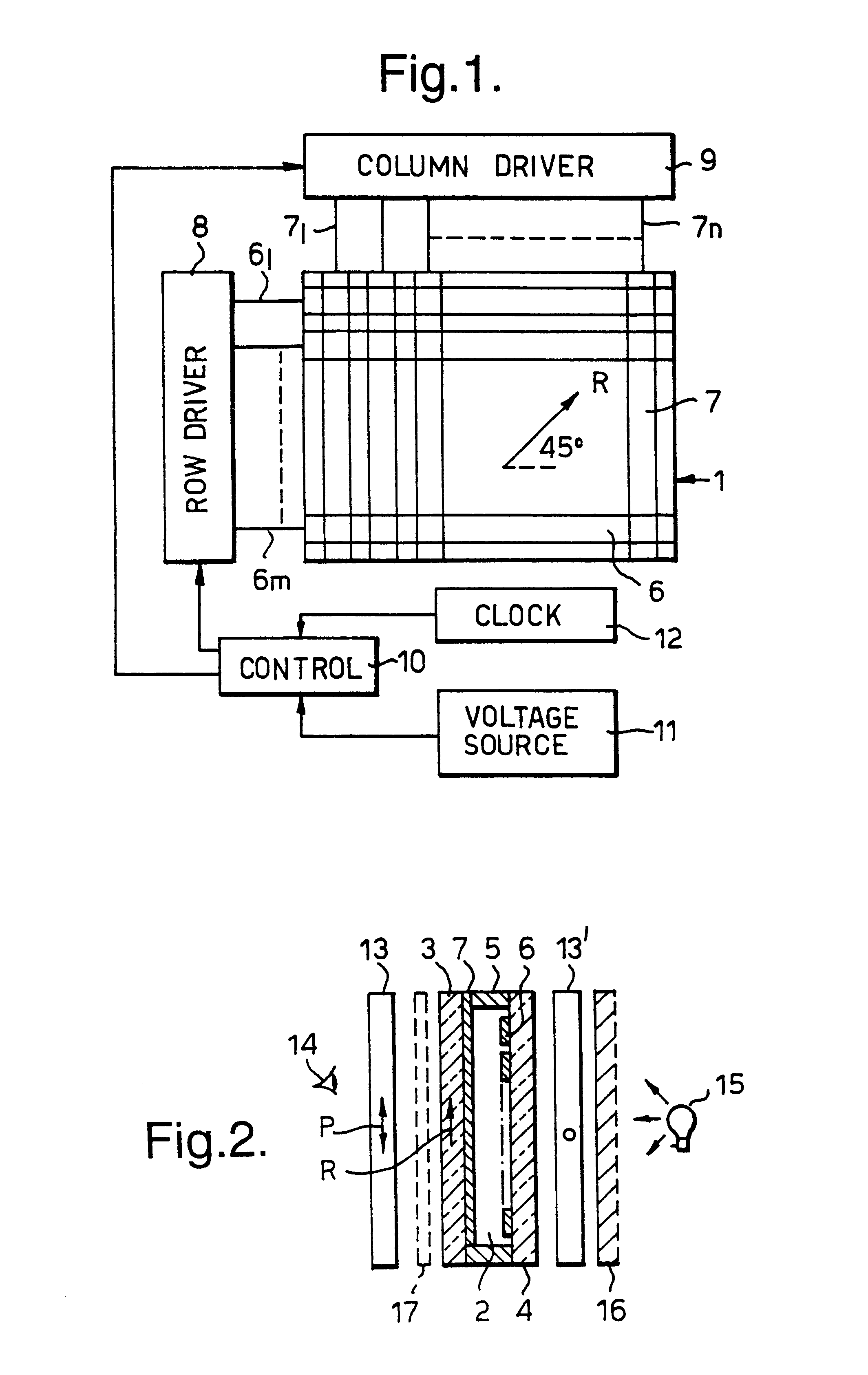

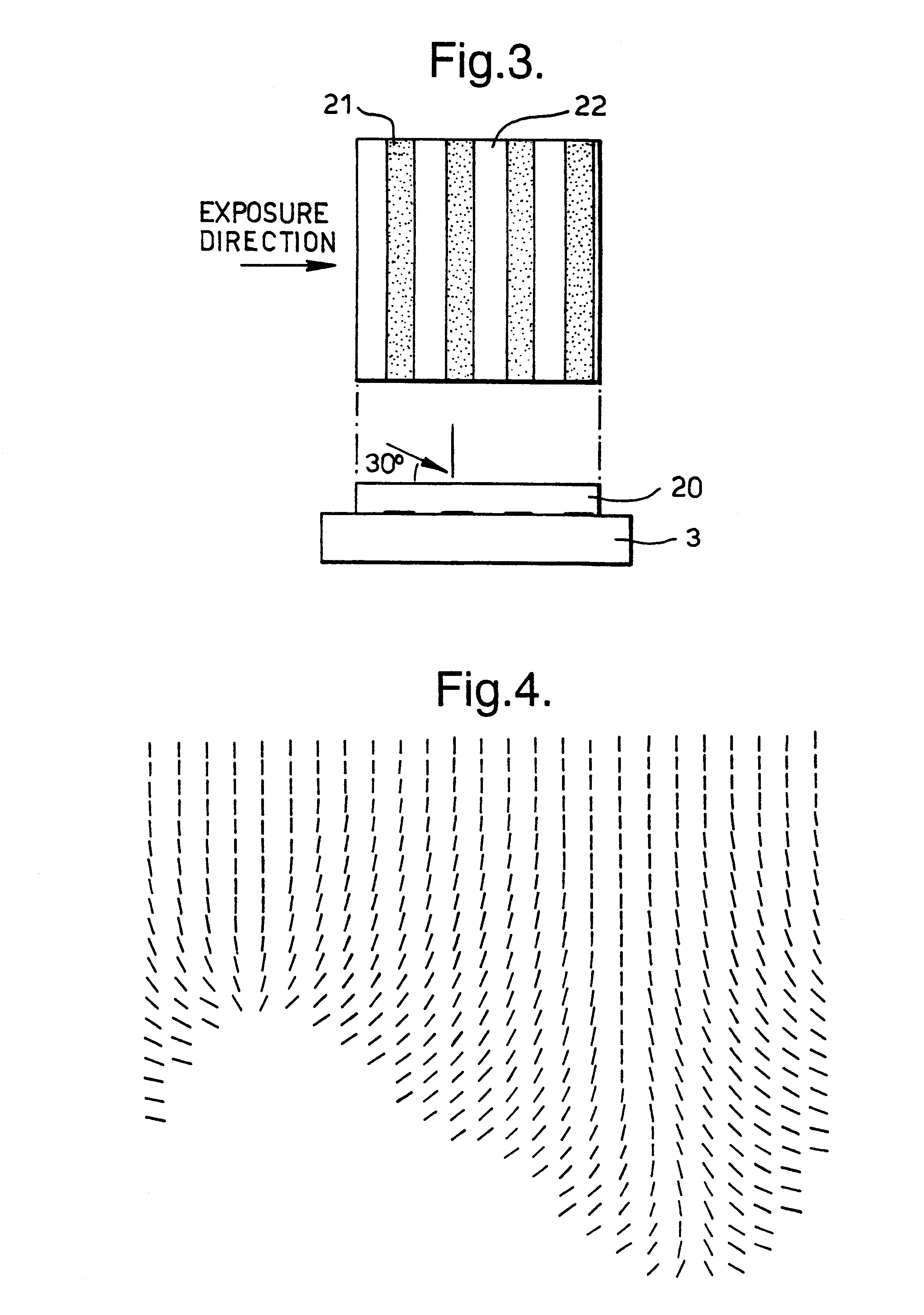

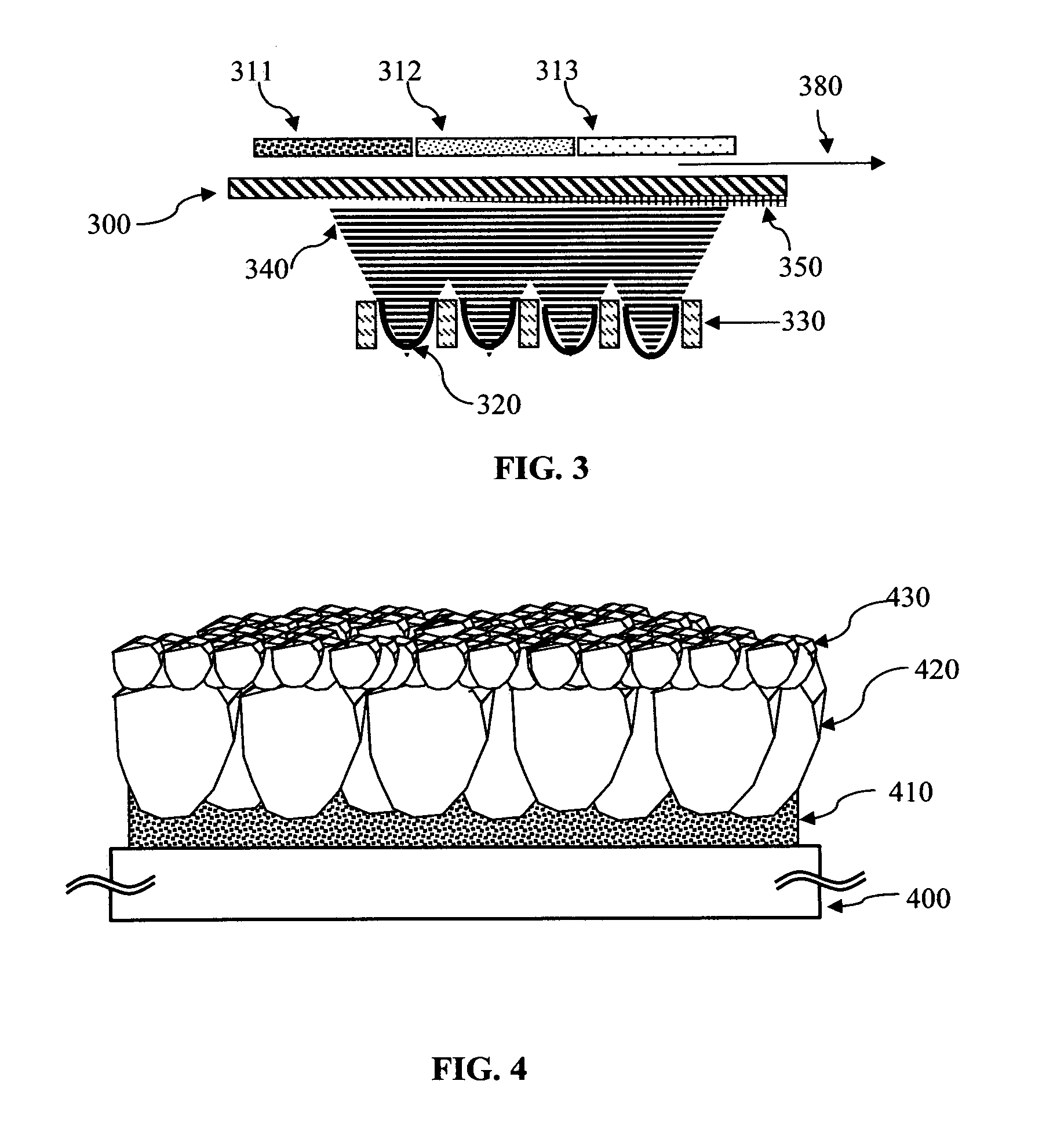

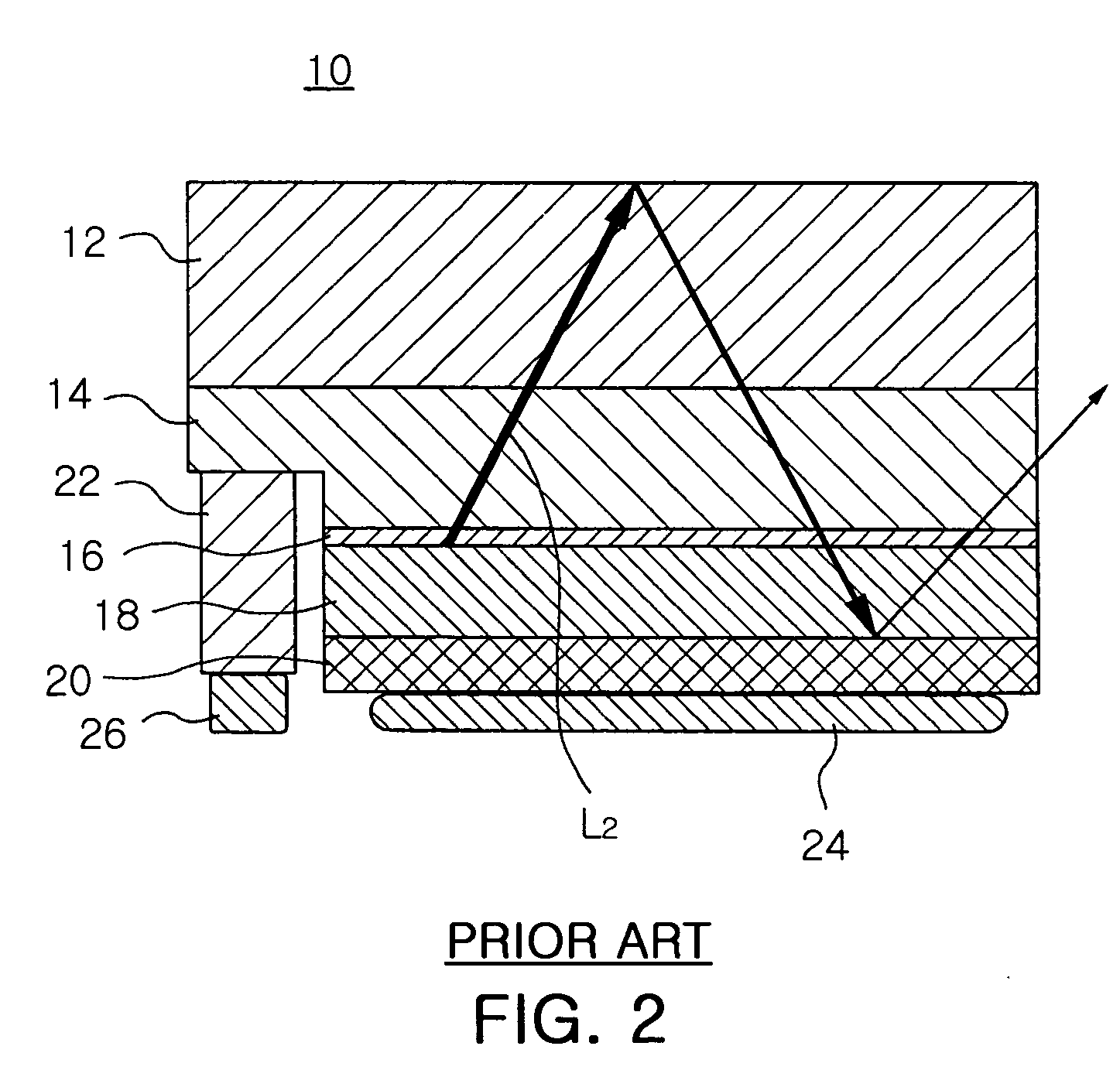

Bistable nematic liquid crystal device

A bistable nematic liquid crystal device cell (1) is provided with a surface alignment grating on at least one cell wall (3) and a surface treatment on the other wall (4). Such treatment may be a homeotropic alignment or a planar alignment with or without an alignment direction, and zero or a non zero pretilt. The surface profile on the monograting is asymmetric with its grove height to width selected to give approximately equal energy within nematic material (2) in its two allowed alignment arrangements. The monograting may be formed by a photolithographic process or by embossing of a plastics material. The cell (1) is switched by dc pulses coupling to a flexoelectric coefficient in the material (2), or by use of a two frequency addressing scheme and a suitable two frequency material. Polarizers (13,13') either side of the cell (1) distinguish between the two switched states. The cell walls (3,4) may be rigid or flexible, and are coated with electrode structures (6,7), e.g. in row and column format giving an x,y matrix of addressable pixels on the cell (1).

Owner:ZBD DISPLAY LTD

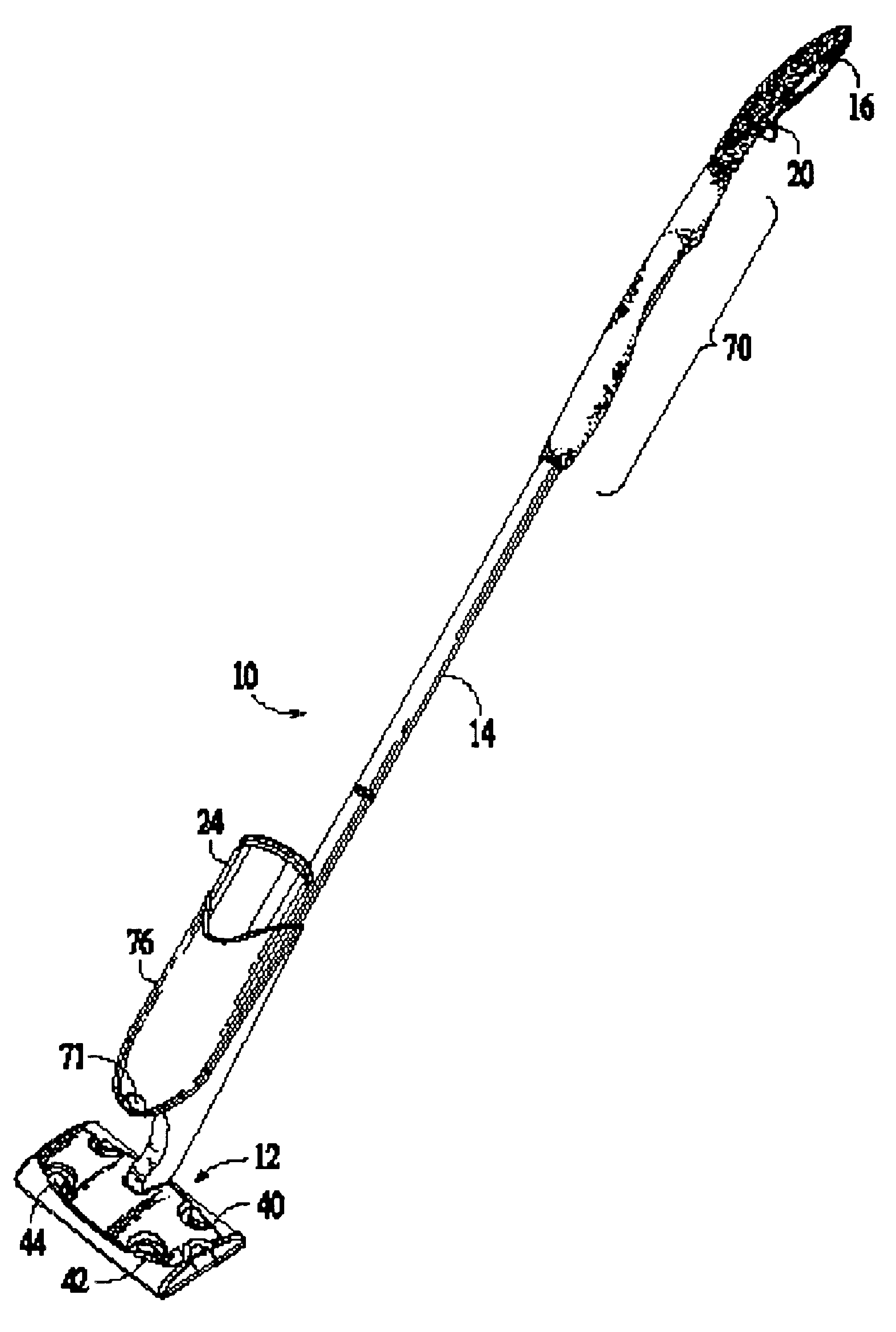

Cleaning implement with interchangeable tool heads

A system for treating a work surface including a handle portion, a first tool head adapted for use with a removable pad and a second tool head, both connectable to the handle portion, and a first fluid reservoir is disclosed. In some arrangements, the second tool head can be used with a removable pad or can include an electric motor. A controller can be provided for releasing and stopping fluid flow from the first fluid reservoir. An optional second fluid reservoir can also be used. The first tool head and the first fluid reservoir can include a first indicium that can be characterized by a feature such as color, shape, picture, text, or sound. The indicium can signify a work surface, a purpose for surface treatment, a mode of operation or instructions. Surface treatments include applying, cleaning, scrubbing, waxing, polishing, disinfecting, killing mites, killing fleas, detoxifying, neutralizing allergens, painting, removing liquids, and fertilizing.

Owner:THE CLOROX CO

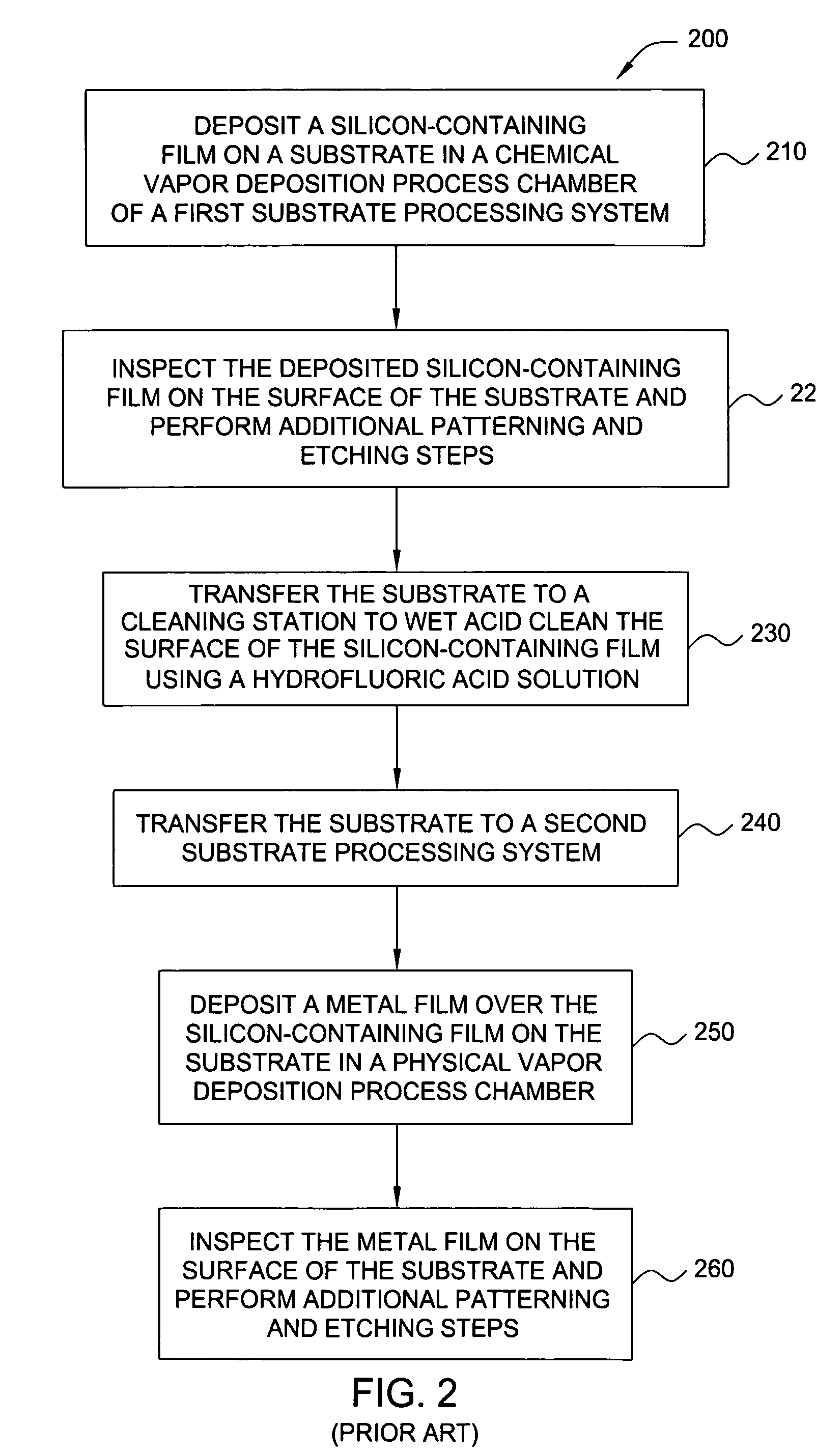

Hybrid PVD-CVD system

A method for making a film stack containing one or more silicon-containing layers and one or more metal-containing layers and a substrate processing system for forming the film stack on a substrate are provided. The substrate processing system includes one or more transfer chambers coupled to one or more load lock chambers and two or more different types of process chambers. The two or more types of process chambers are used to deposit the one or more silicon-containing layers and the one or more metal-containing layers in the same substrate processing system without breaking the vacuum, taking the substrate out of the substrate processing system to prevent surface contamination, oxidation, etc., such that additional cleaning or surface treatment steps can be eliminated. The substrate processing system is configured to provide high throughput and compact footprint for in-situ substrate processing and carry out different types of processes.

Owner:APPLIED MATERIALS INC

Wellbores utilizing fiber optic-based sensors and operating devices

InactiveUS20060272809A1Enhanced overall recoveryEasy to operateSurveyConstructionsForms of energyCompound (substance)

This invention provides a method for controlling production operations using fiber optic devices. An optical fiber carrying fiber-optic sensors is deployed downhole to provide information about downhole conditions. Parameters related to the chemicals being used for surface treatments are measured in real time and on-line, and these measured parameters are used to control the dosage of chemicals into the surface treatment system. The information is also used to control downhole devices that may be a packer, choke, sliding sleeve, perforating device, flow control valve, completion device, an anchor or any other device. Provision is also made for control of secondary recovery operations online using the downhole sensors to monitor the reservoir conditions. The present invention also provides a method of generating motive power in a wellbore utilizing optical energy. This can be done directly or indirectly, e.g., by first producing electrical energy that is then converted to another form of energy.

Owner:BAKER HUGHES HLDG LLC

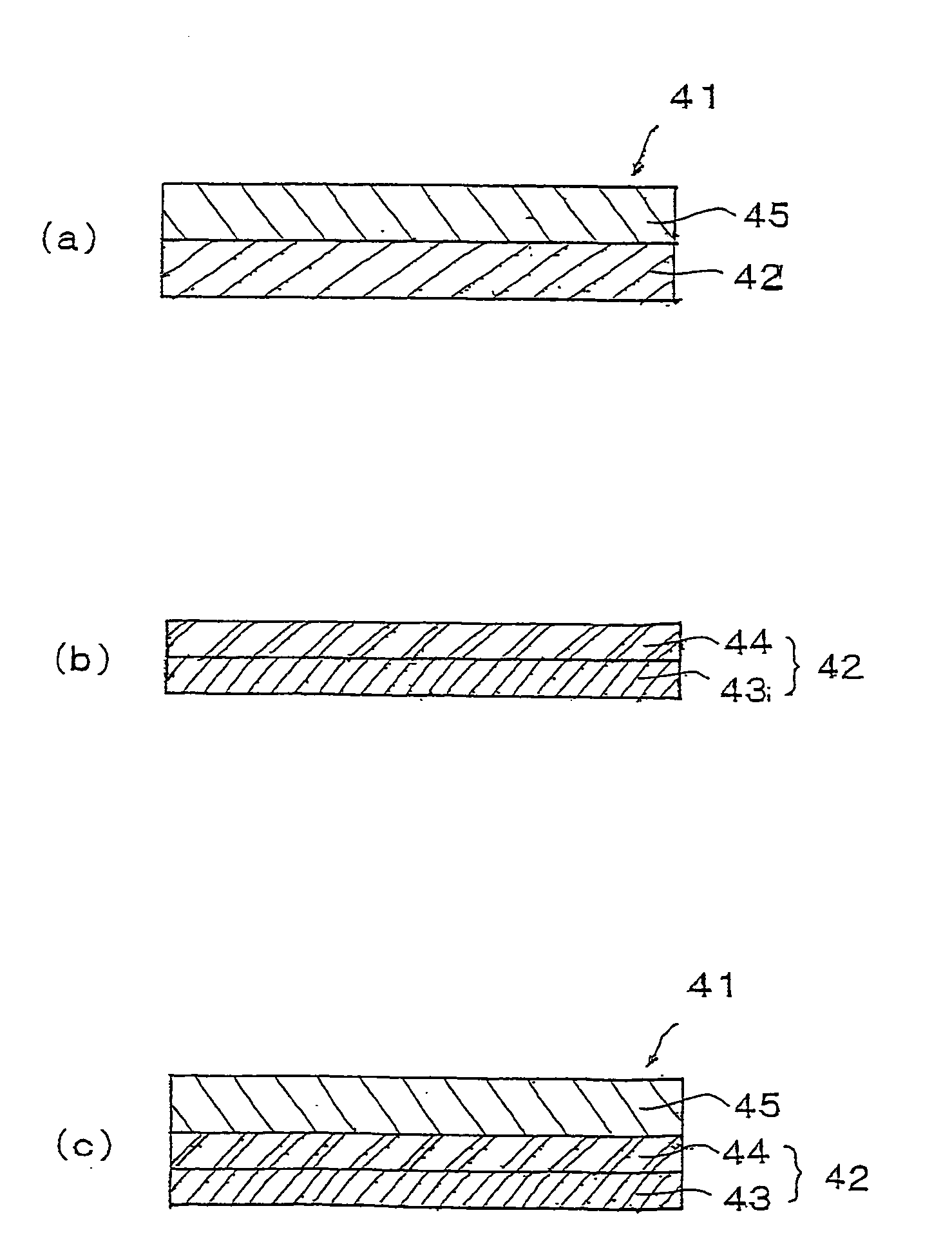

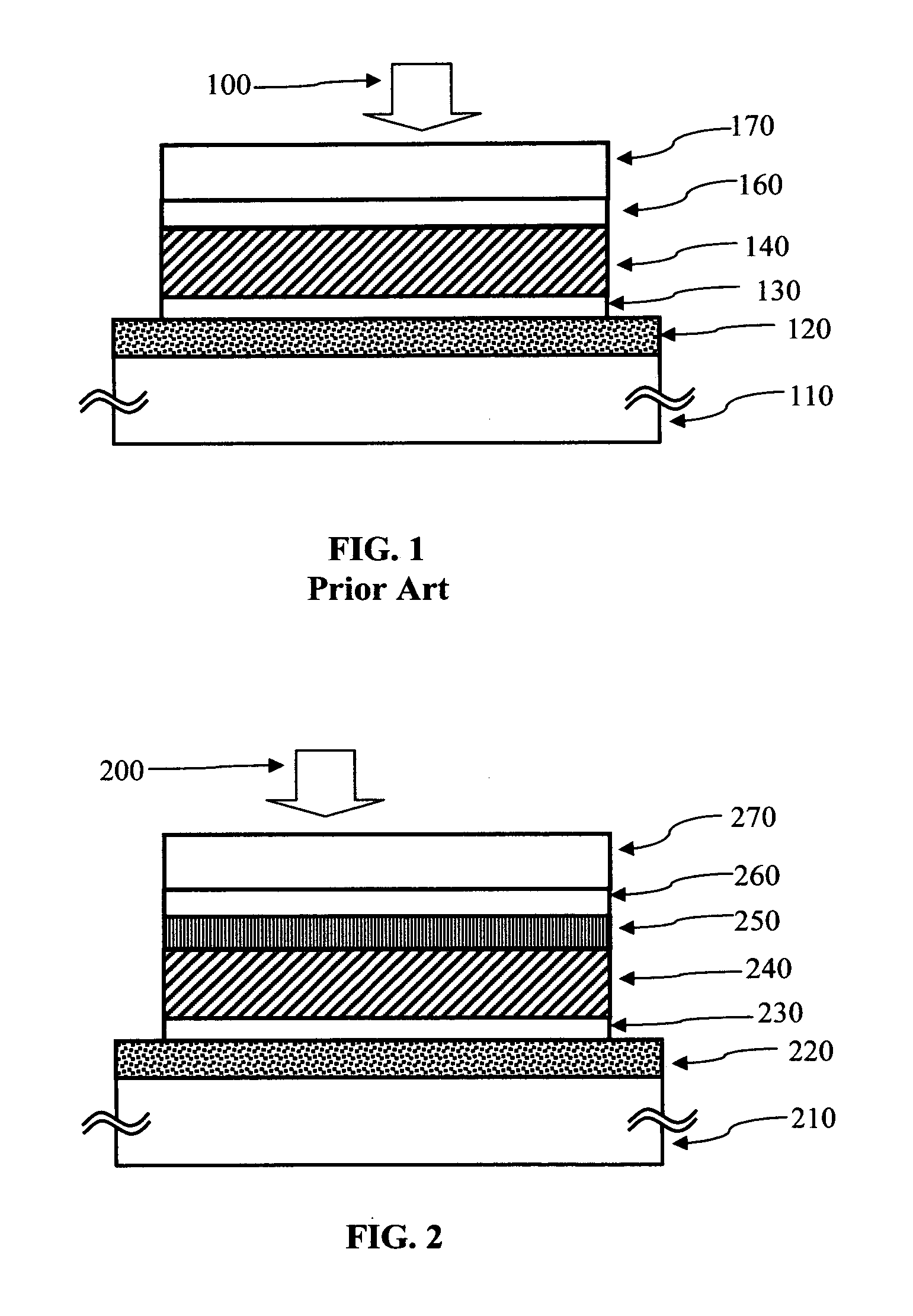

Polishing pad, method of manufacturing the polishing pad, and cushion layer for polishing pad

InactiveUS20040055223A1Easy to processHigh thickness accuracyOther chemical processesAbrasion apparatusSurface patternEngineering

The polishing pad of this invention is a polishing pad effecting stable planarizing processing, at high polishing rate, materials requiring surface flatness at high level, such as a silicon wafer for semiconductor devices, a magnetic disk, an optical lens etc. This invention provides a polishing pad which can be subjected to surface processing to form a sheet or grooves, is excellent in thickness accuracy, attains a high polishing rate, achieves a uniform polishing rate, and also provides a polishing pad which is free of quality variations resulting from an individual variation, easily enables a change the surface patterns, enables fine surface pattern, is compatible with various materials to be polished, is free of burrs upon forming the pattern. This invention provides a polishing pad which can have abrasive grains mixed at very high density without using slurry, and generates few scratches by preventing aggregation of abrasive grains dispersed therein. The polishing pad of this invention has a polishing layer formed from a curing composition to be cured with energy rays, the polishing layer being formed surface pattern thereon by photolithography. The polishing pad of this invention comprises a polishing layer resin having abrasive grains dispersed therein, the resin containing ionic groups in the range of 20 to 1500 eq / ton.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

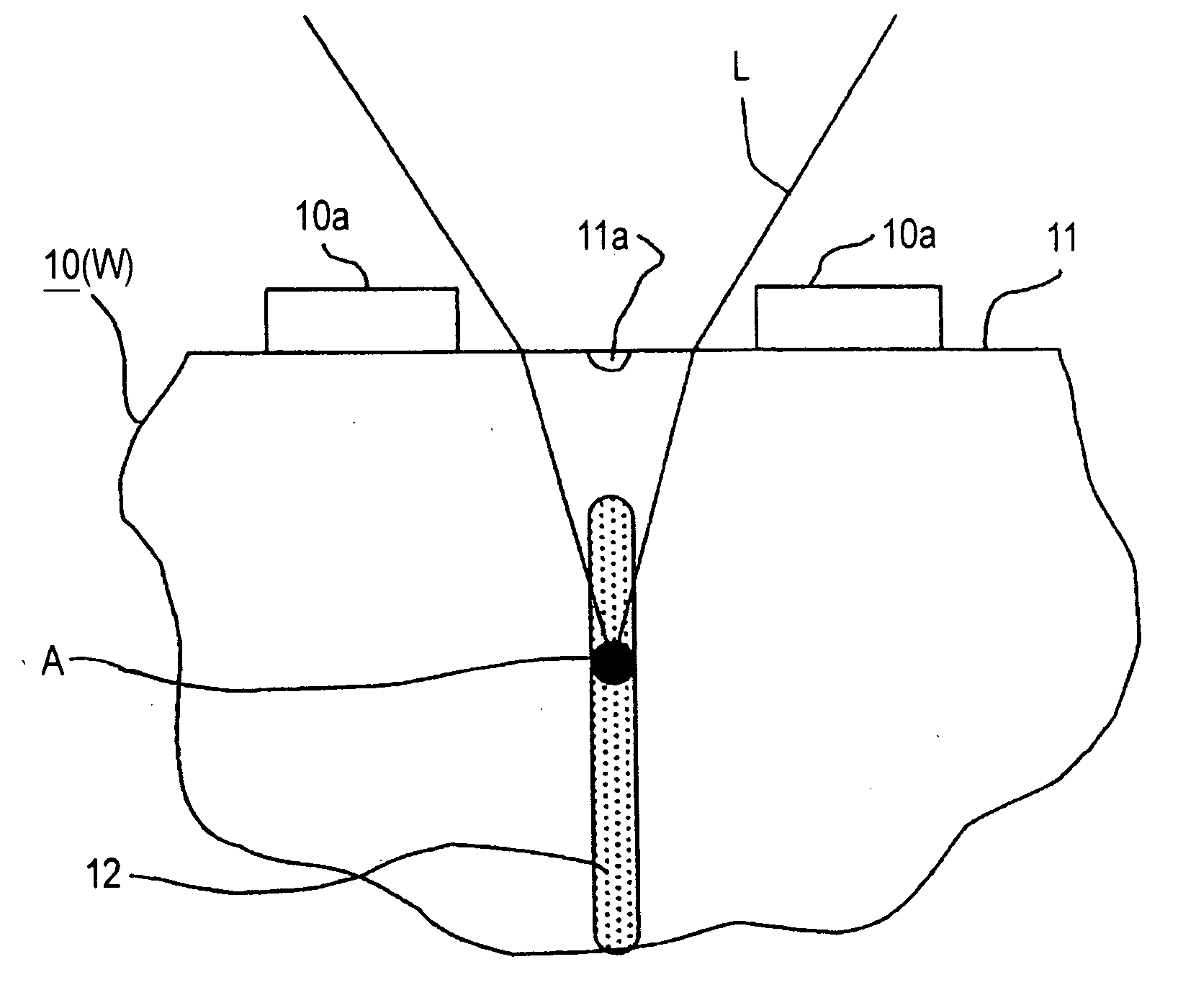

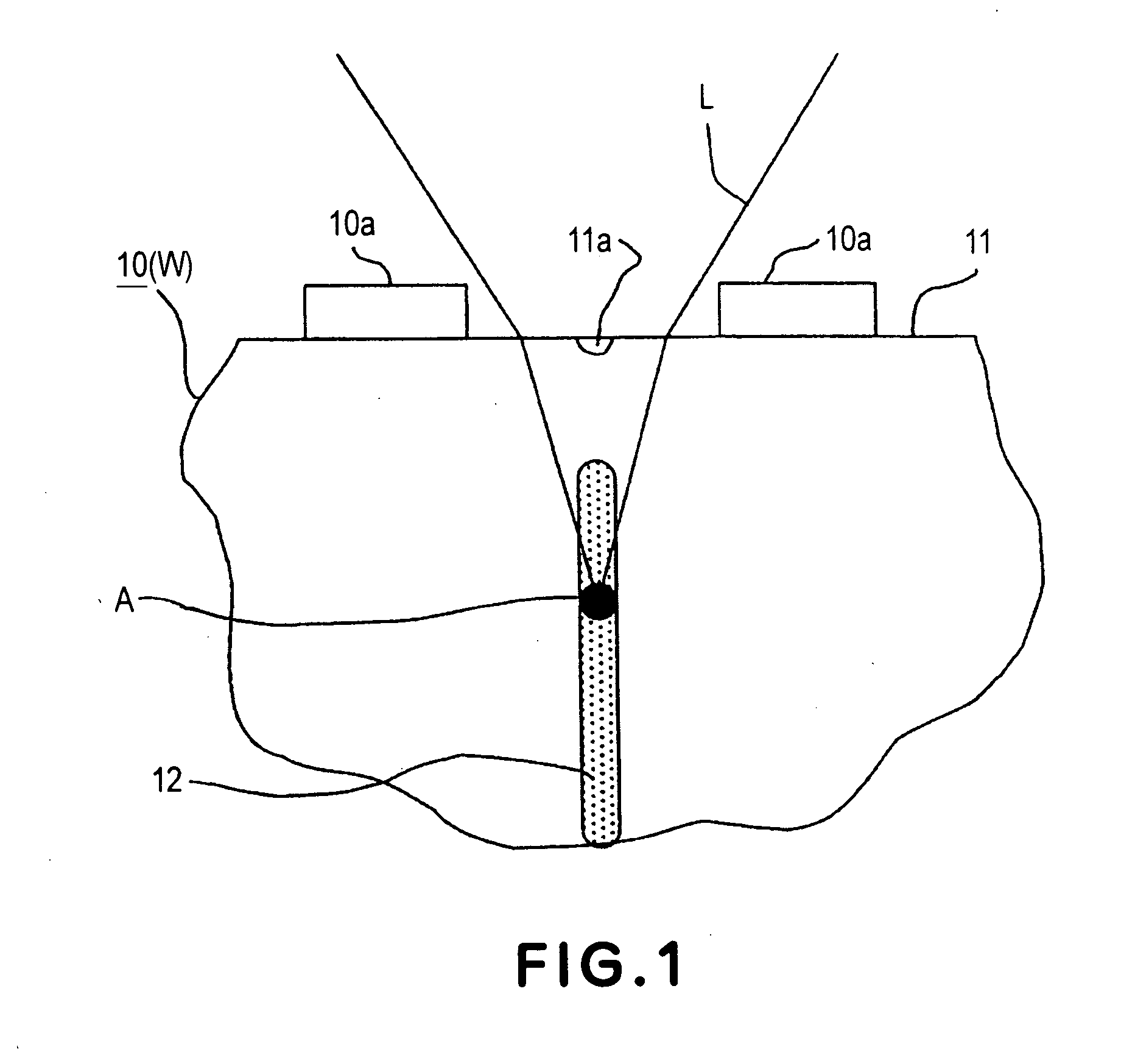

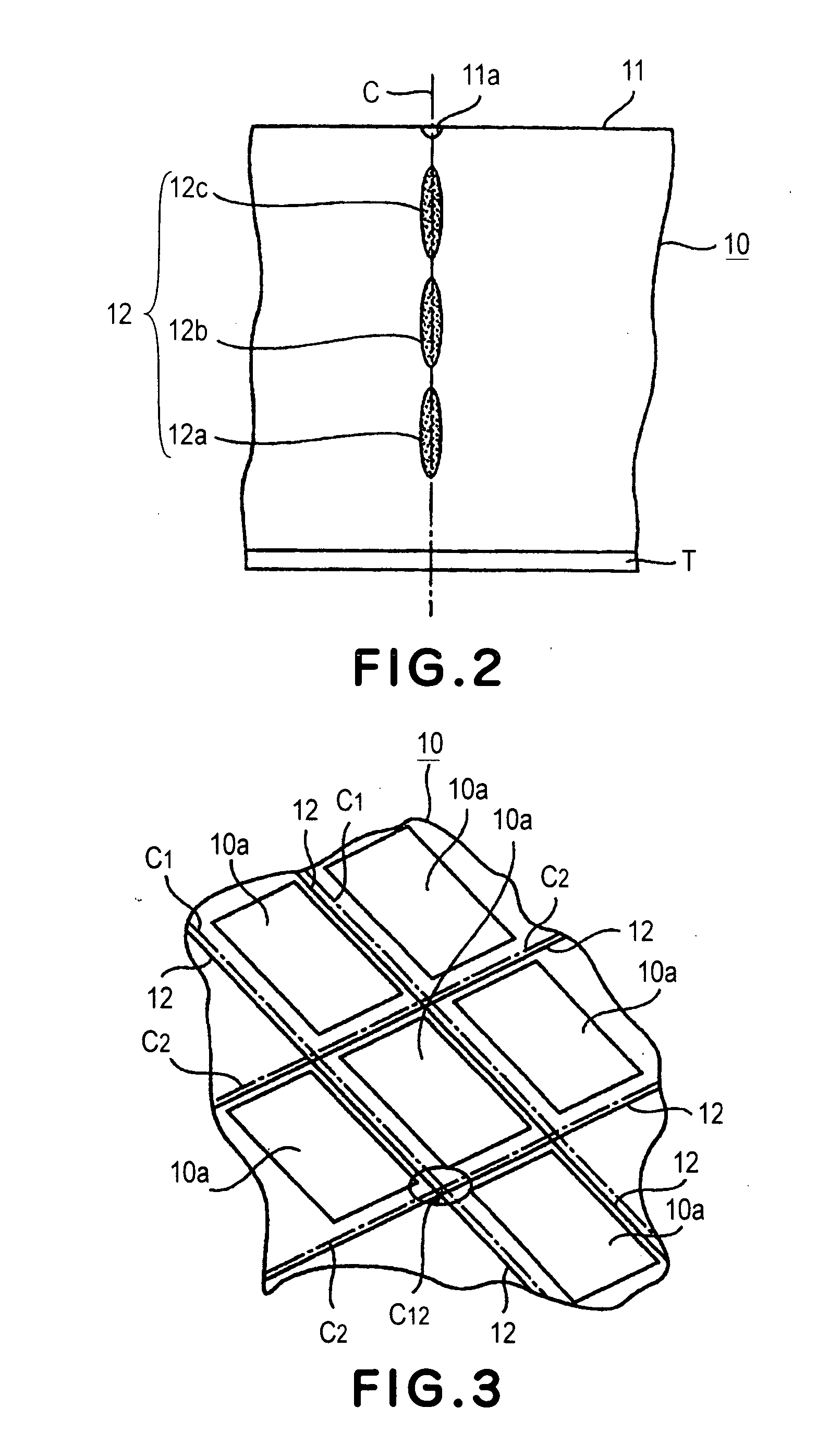

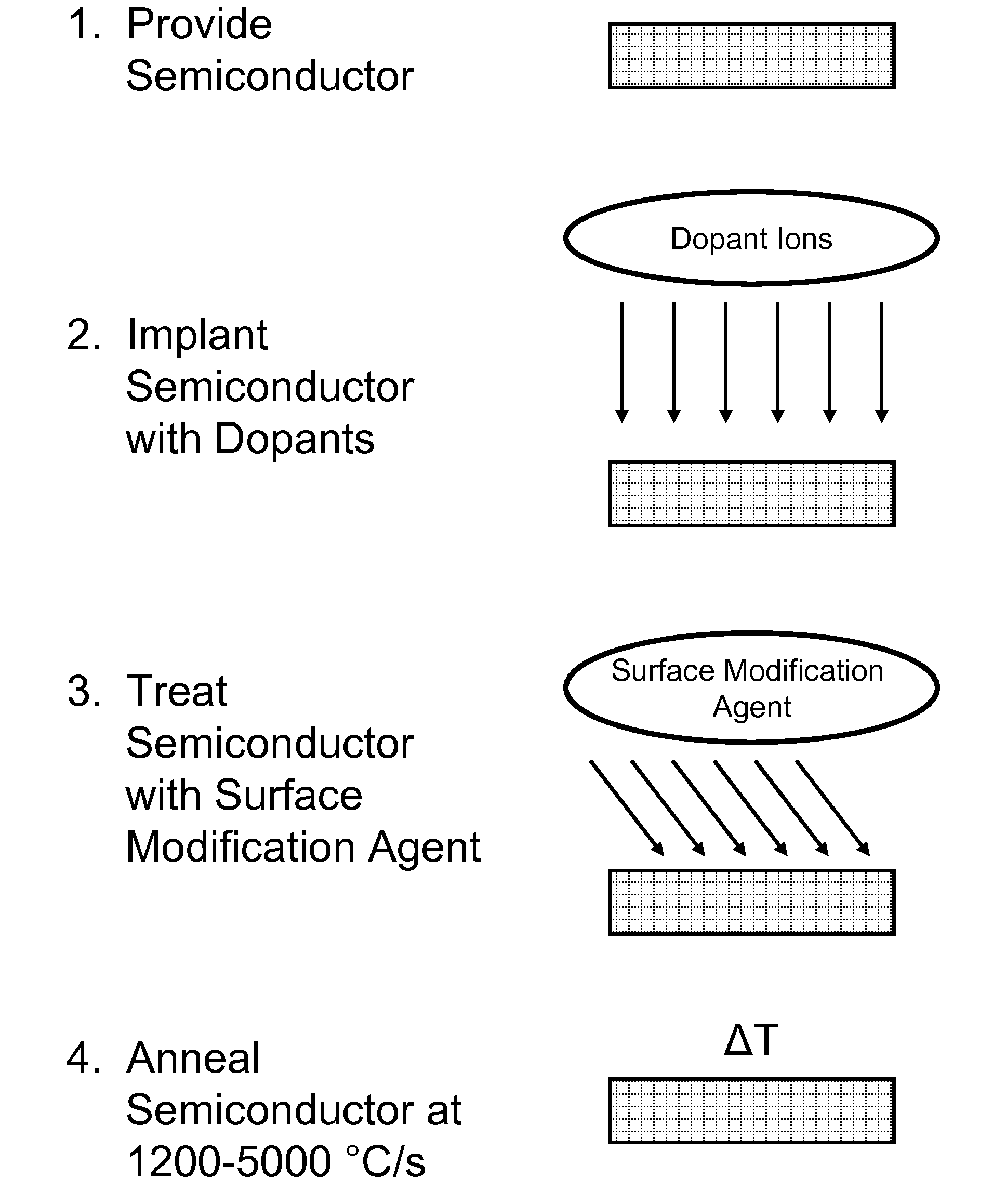

Laser based splitting method, object to be split, and semiconductor element chip

ActiveUS20050199592A1Improve the level ofImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesStress concentrationProcess region

A laser splitting method for splitting off a segment from an object to be split using a laser beam, includes a surface processing step of processing the object by forming a linear recessed portion in a surface of the object, the linear recessed portion being effective to cause a stress concentration at the surface of the object; an internal processed-region forming step of forming an internal processed-regions at a depth of the object in a line along which a laser beam scans the surface of the object by a relative motion therebetween, the laser beam being converged adjacent the depth, wherein the thus formed internal processed-regions extend in a direction substantially perpendicular to the surface of the object; and an external force applying step of applying an external force to the object to form cracks between the recessed portion and the internal processed-regions.

Owner:CANON KK

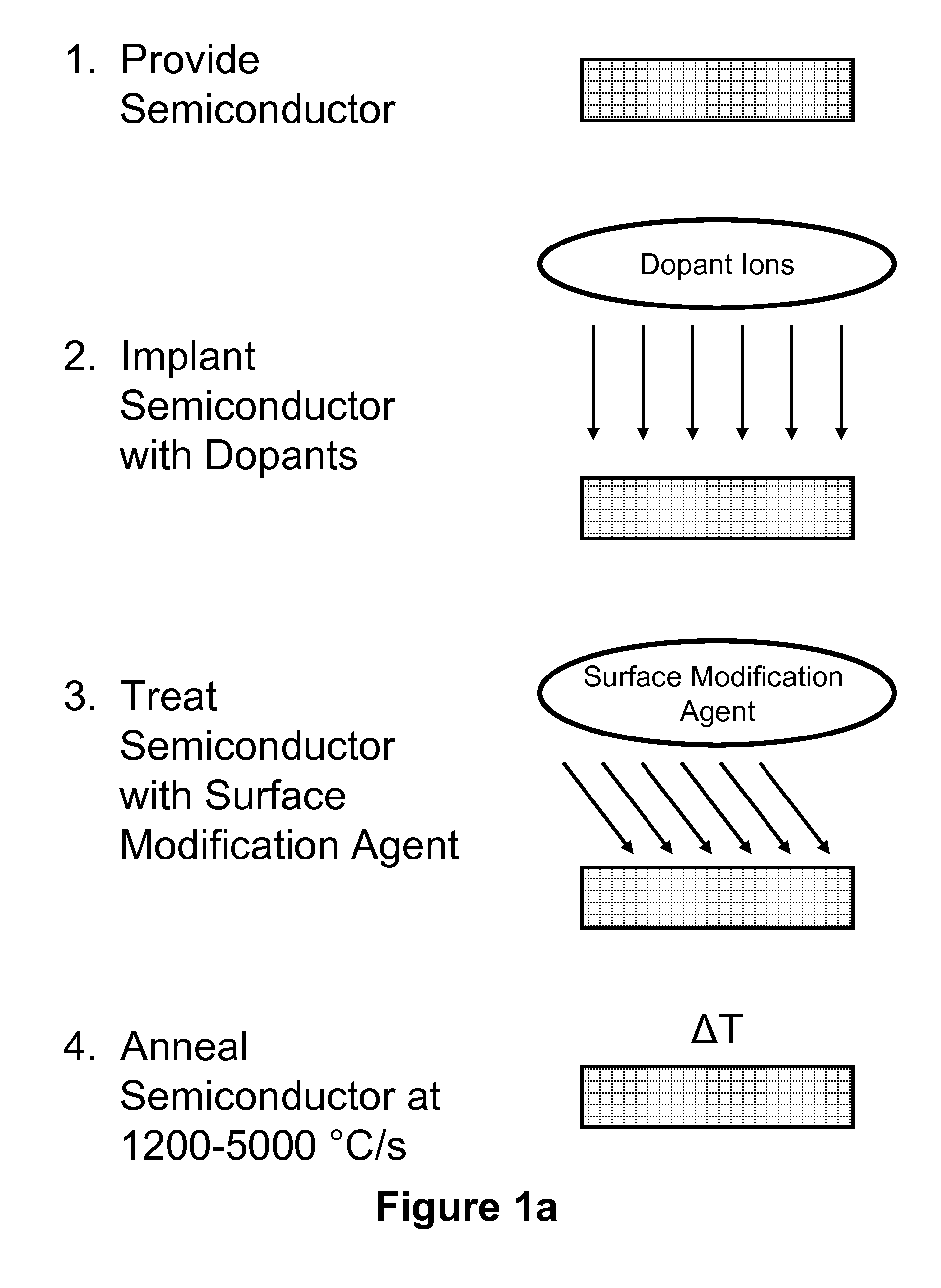

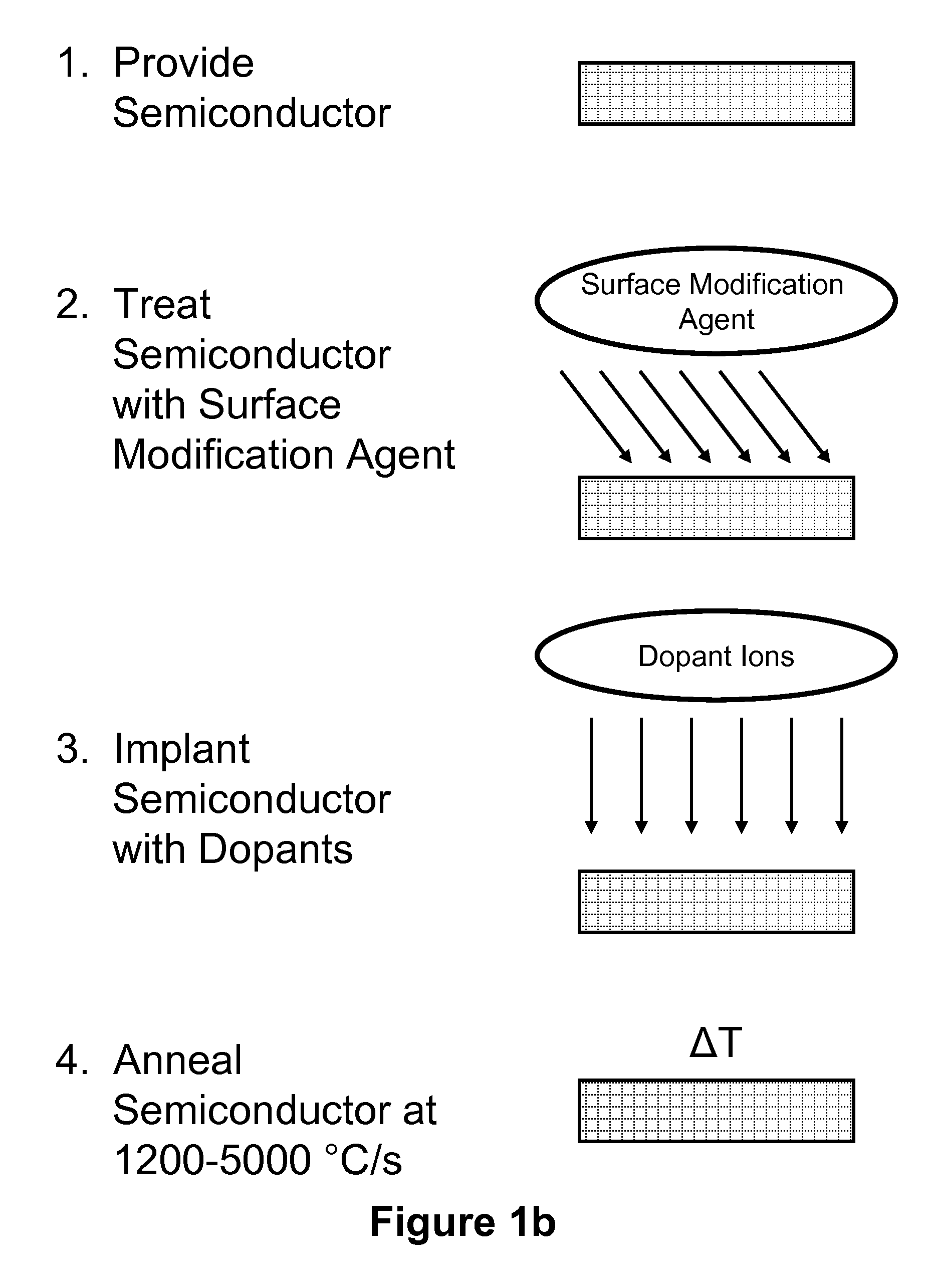

Preparation of ultra-shallow semiconductor junctions using intermediate temperature ramp rates and solid interfaces for defect engineering

ActiveUS7968440B2Increase and decrease loss rateSemiconductor/solid-state device manufacturingDopantDiffusion

Described herein are processing conditions, techniques, and methods for preparation of ultra-shallow semiconductor junctions. Methods described herein utilize semiconductor surface processing or modification to limit the extent of dopant diffusion under annealing conditions (e.g. temperature ramp rates between 100 and 5000° C. / second) previously thought impractical for the preparation of ultra-shallow semiconductor junctions. Also described herein are techniques for preparation of ultra-shallow semiconductor junctions utilizing the presence of a solid interface for control of dopant diffusion and activation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

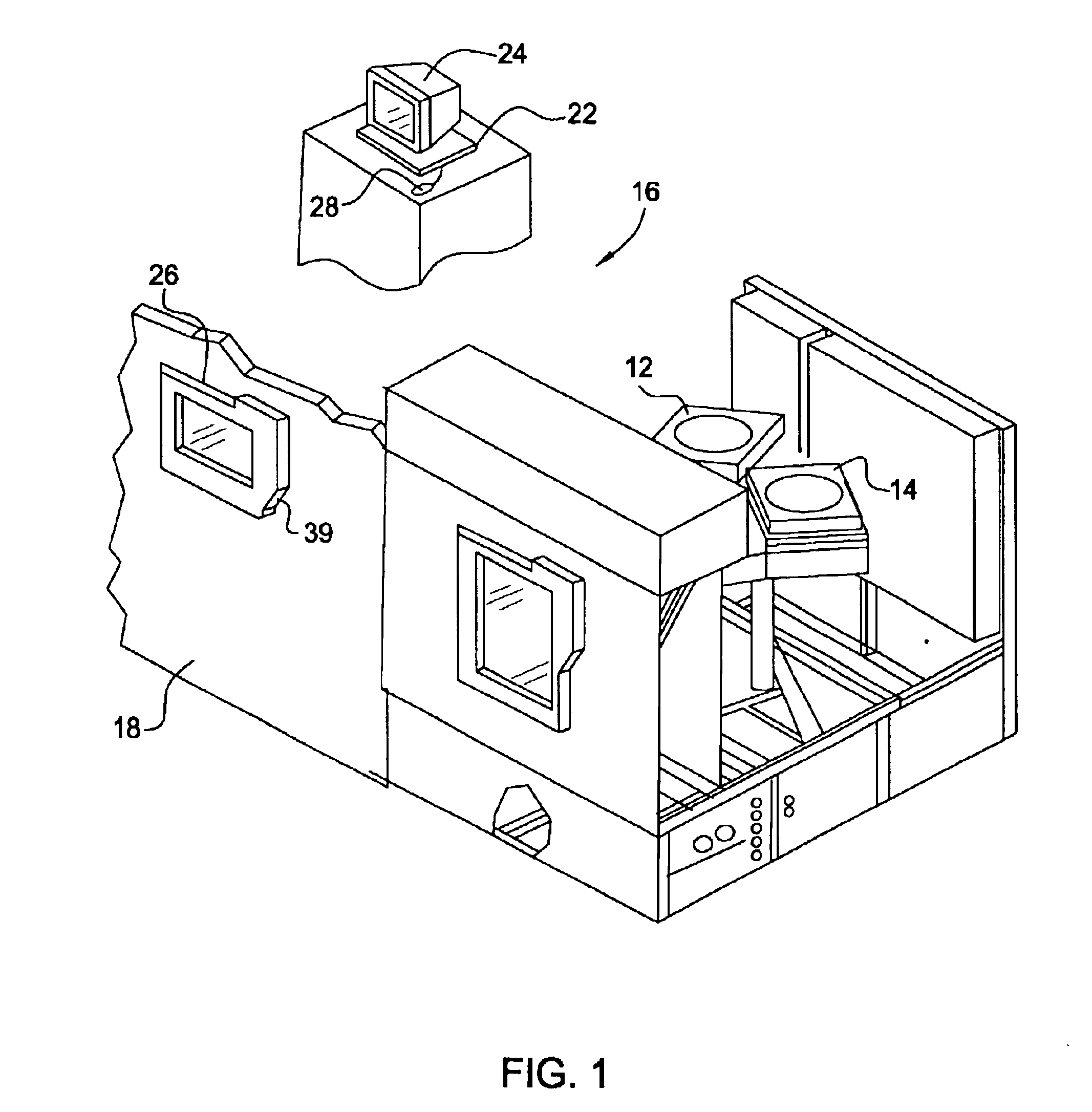

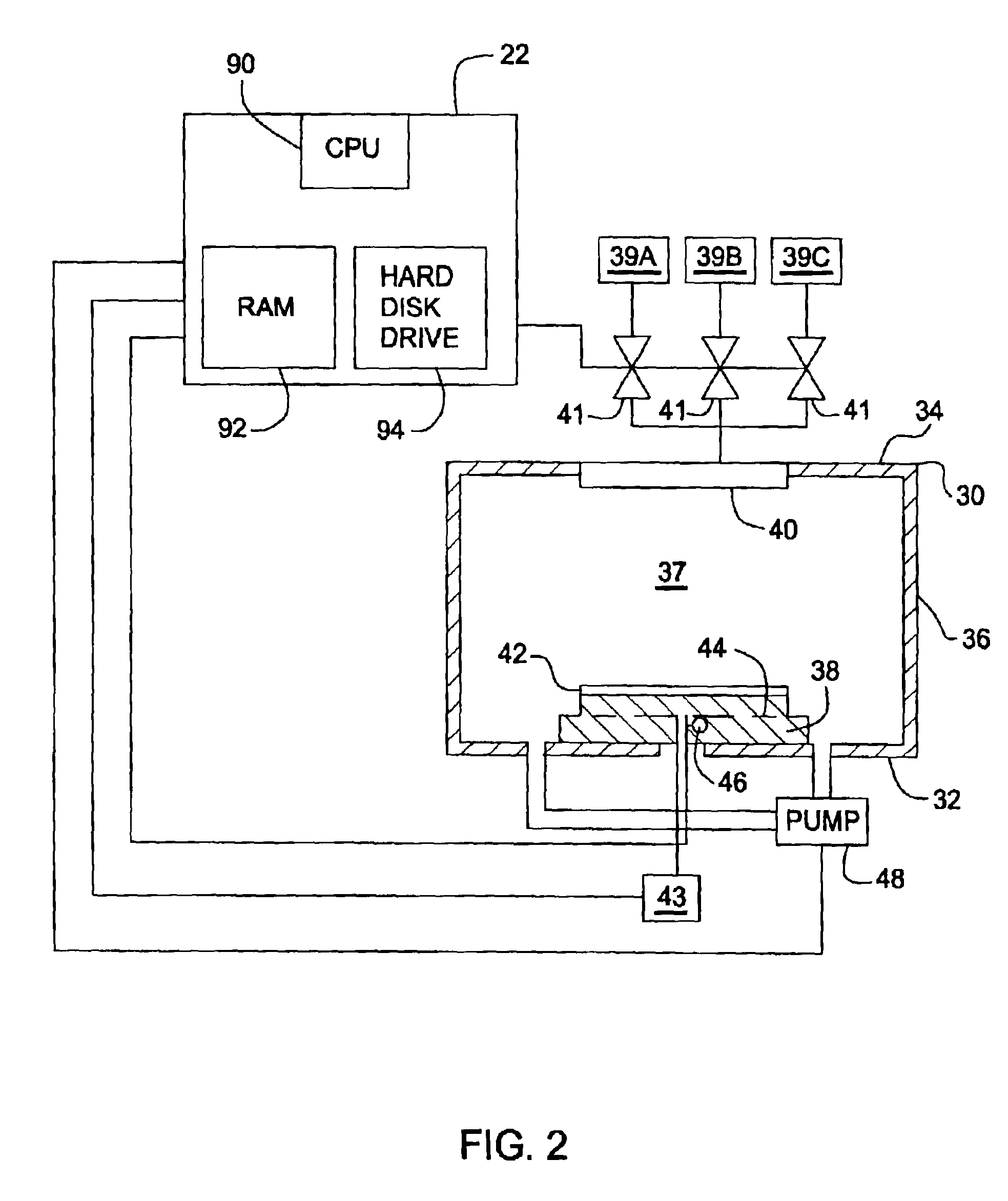

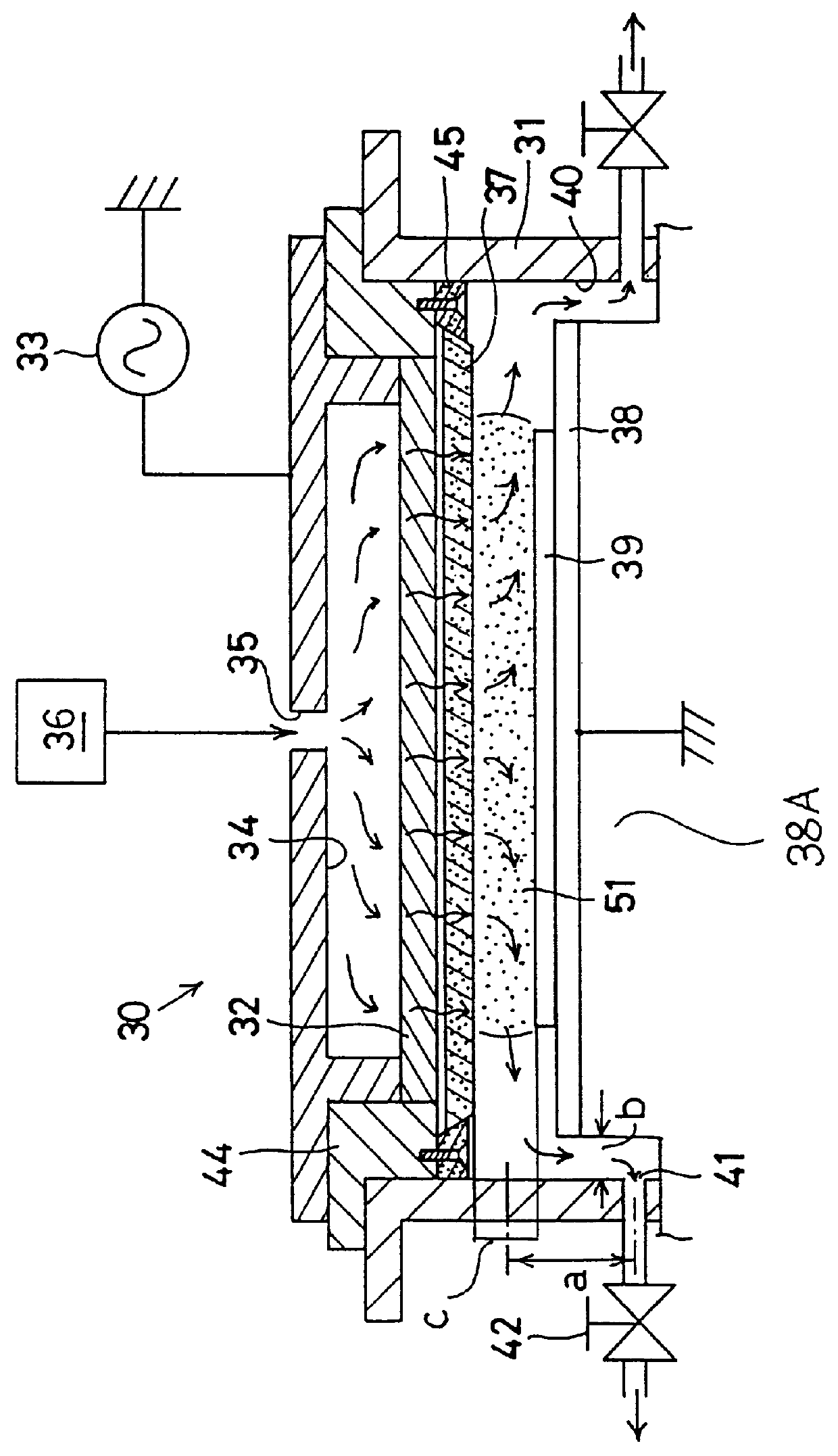

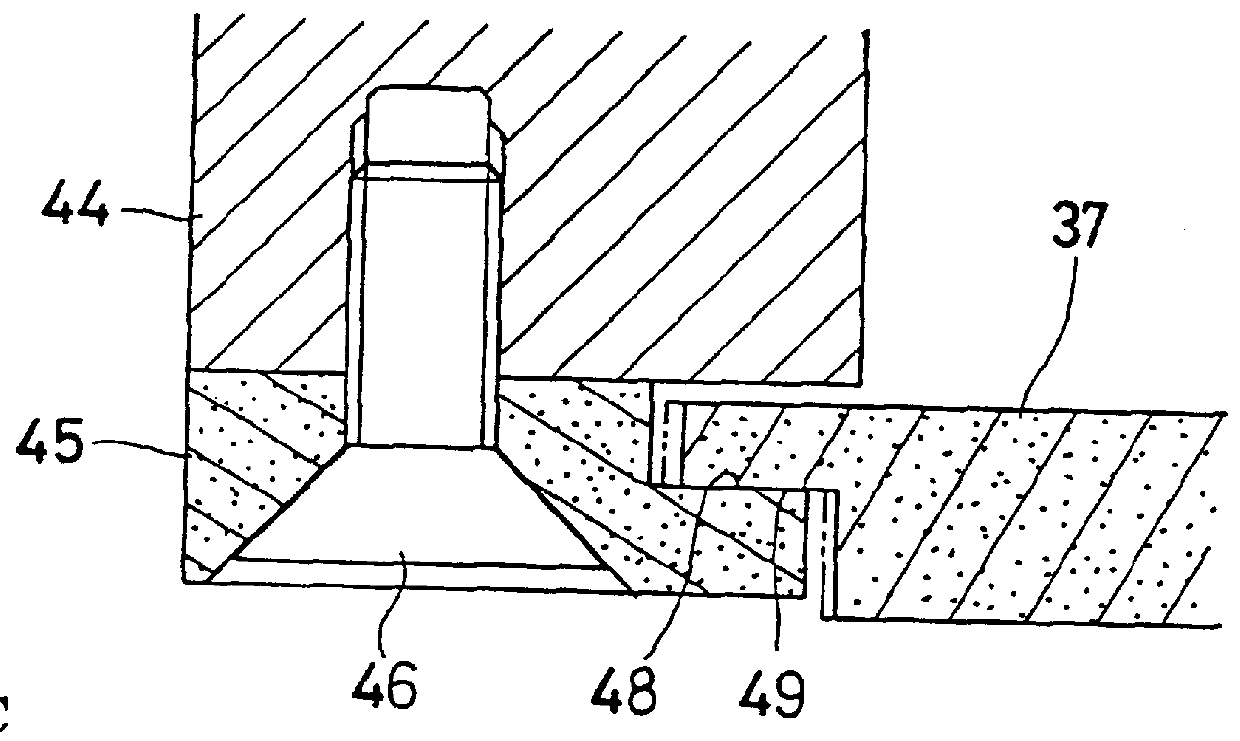

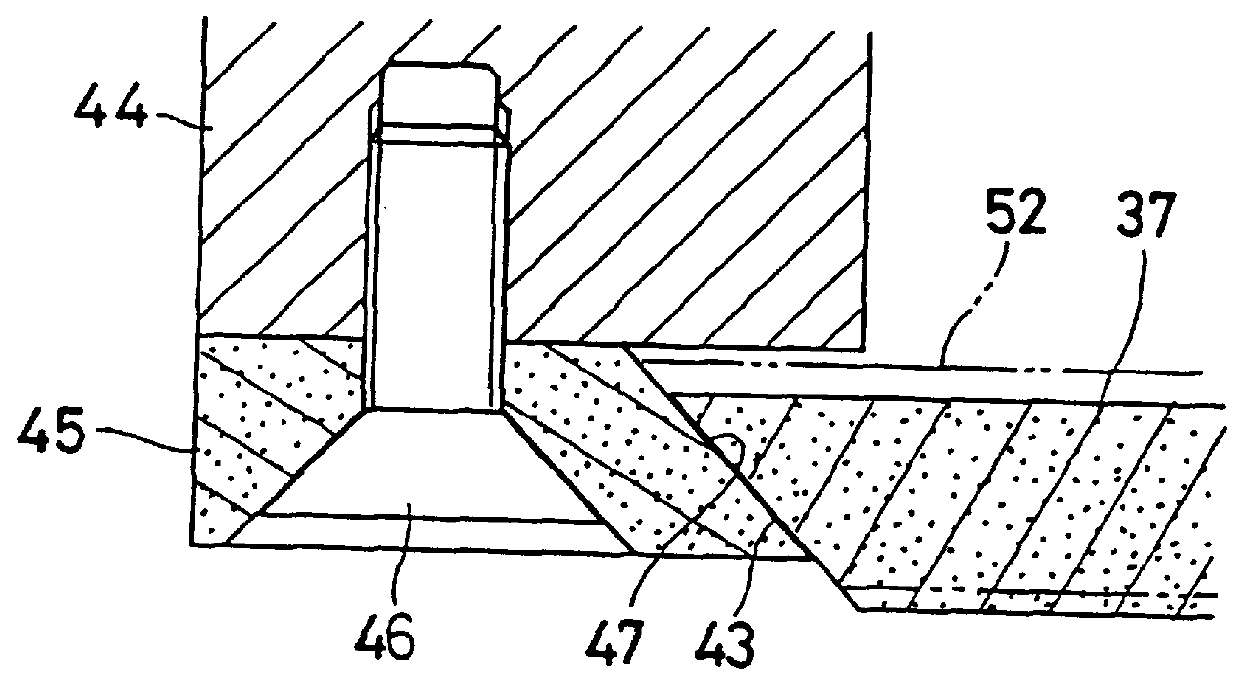

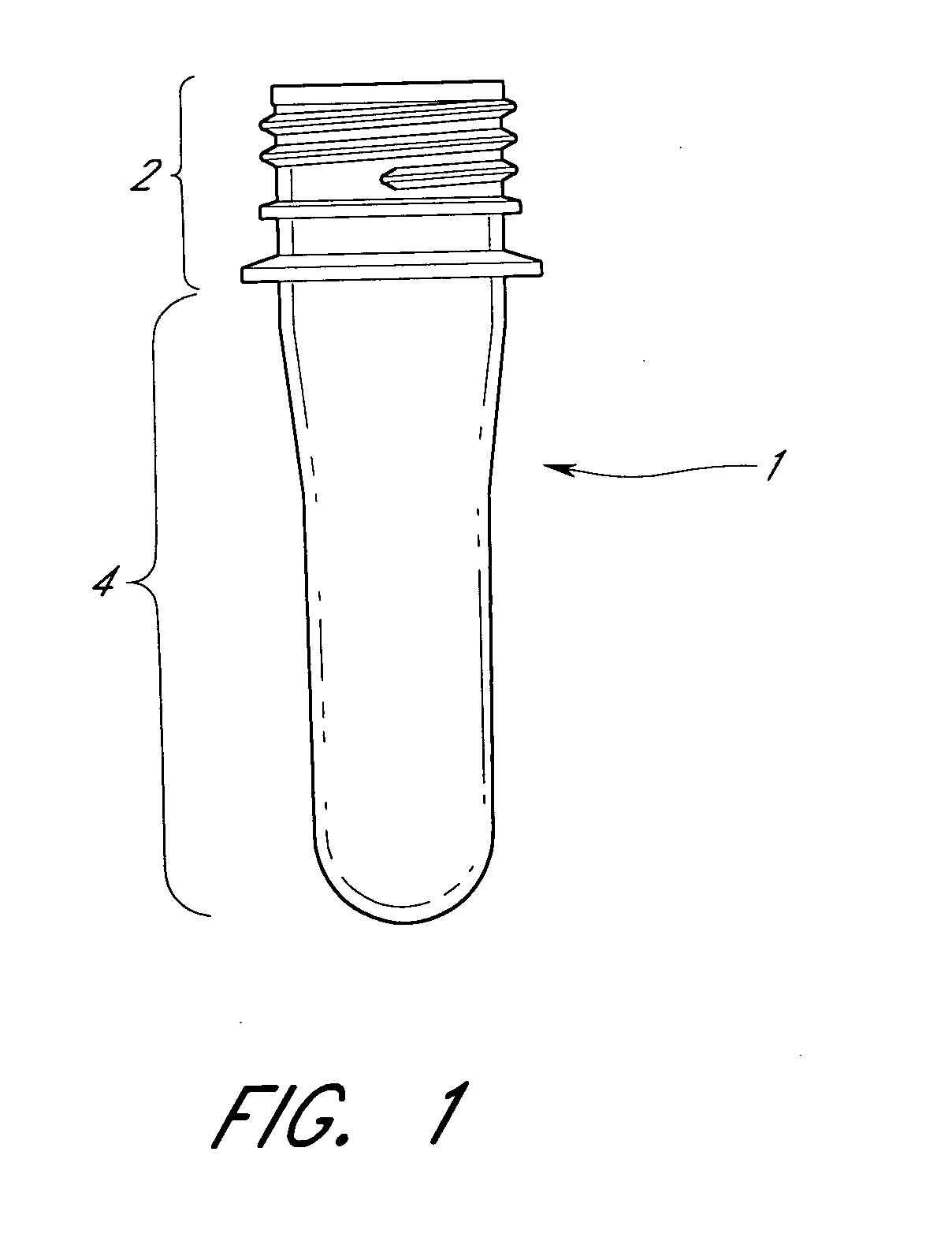

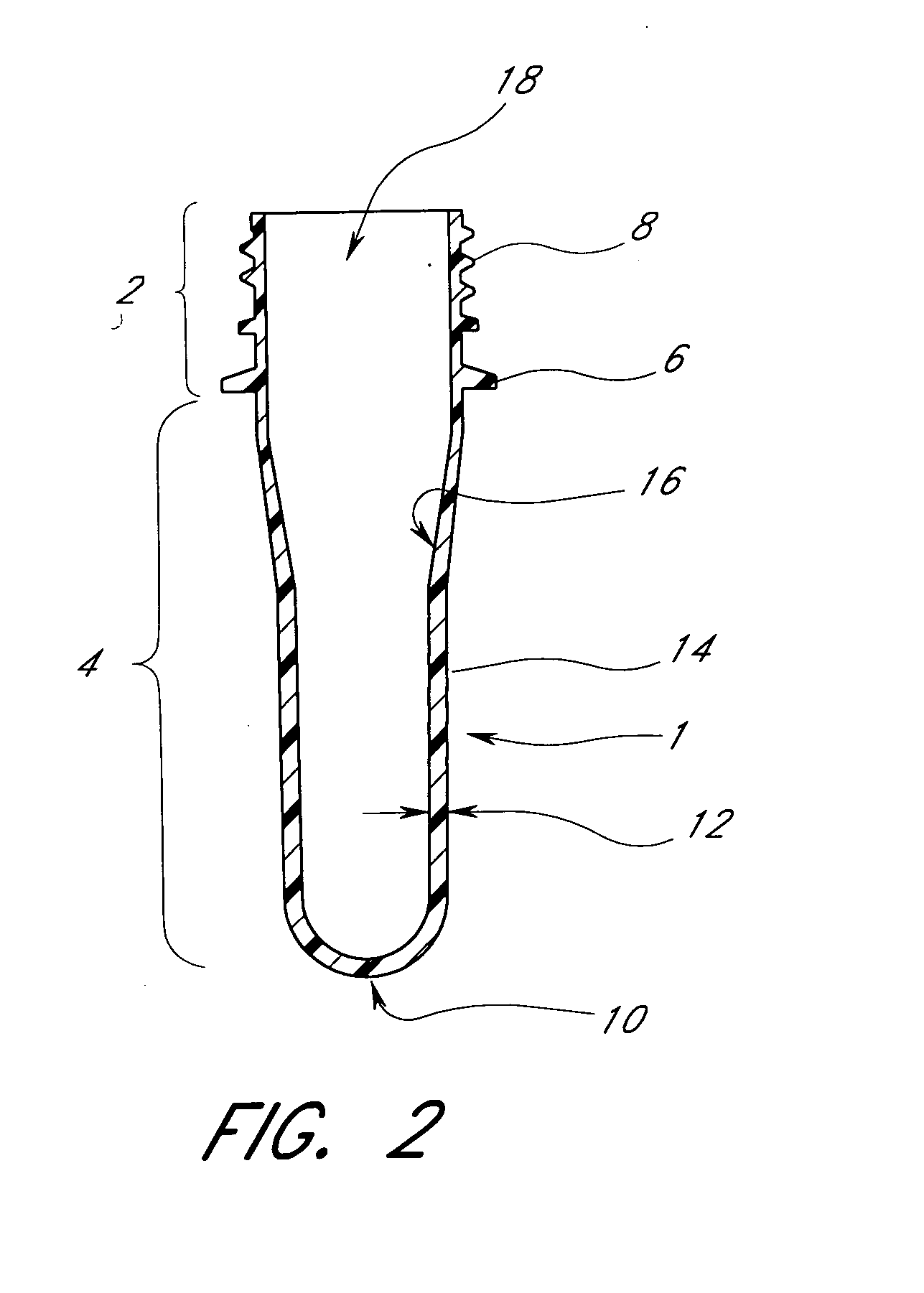

Surface treatment apparatus

InactiveUS6086710AEffective treatmentAvoid mixingElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricThermal expansion

PCT No. PCT / JP96 / 00935 Sec. 371 Date Dec. 6, 1996 Sec. 102(e) Date Dec. 6, 1996 PCT Filed Apr. 5, 1996 PCT Pub. No. WO96 / 31997 PCT Pub. Date Oct. 10, 1996In a surface treatment apparatus (30) of the face type, a porous dielectric (37) is supported by the outer periphery portion of the supporting member (45) under the bottom surface of a porous electrode (32). The dielectric can be supported by the supporting member to permit the thermal expansion deformation of the dielectric by forming an upward inclined-face (47) and a downward inclined-face (43) on the supporting member (45) and the dielectric (37), respectively. Further, a discharge gas can be supplied uniformly to a discharge region (51) through the electrode (32) and the dielectric (37), both of which are porous. Many gas exhaust ports (41), by which the flow rate of the gas can be regulated, are provided around the discharge region (51). Thus, the gas is uniformly exhausted around the discharge region (51). Especially, if the gap between the dielectric (37) and a work (39) depends on mounting accuracy or the like and varies with location, the gas can be exhausted uniformly around the discharge region (51).

Owner:SEIKO EPSON CORP

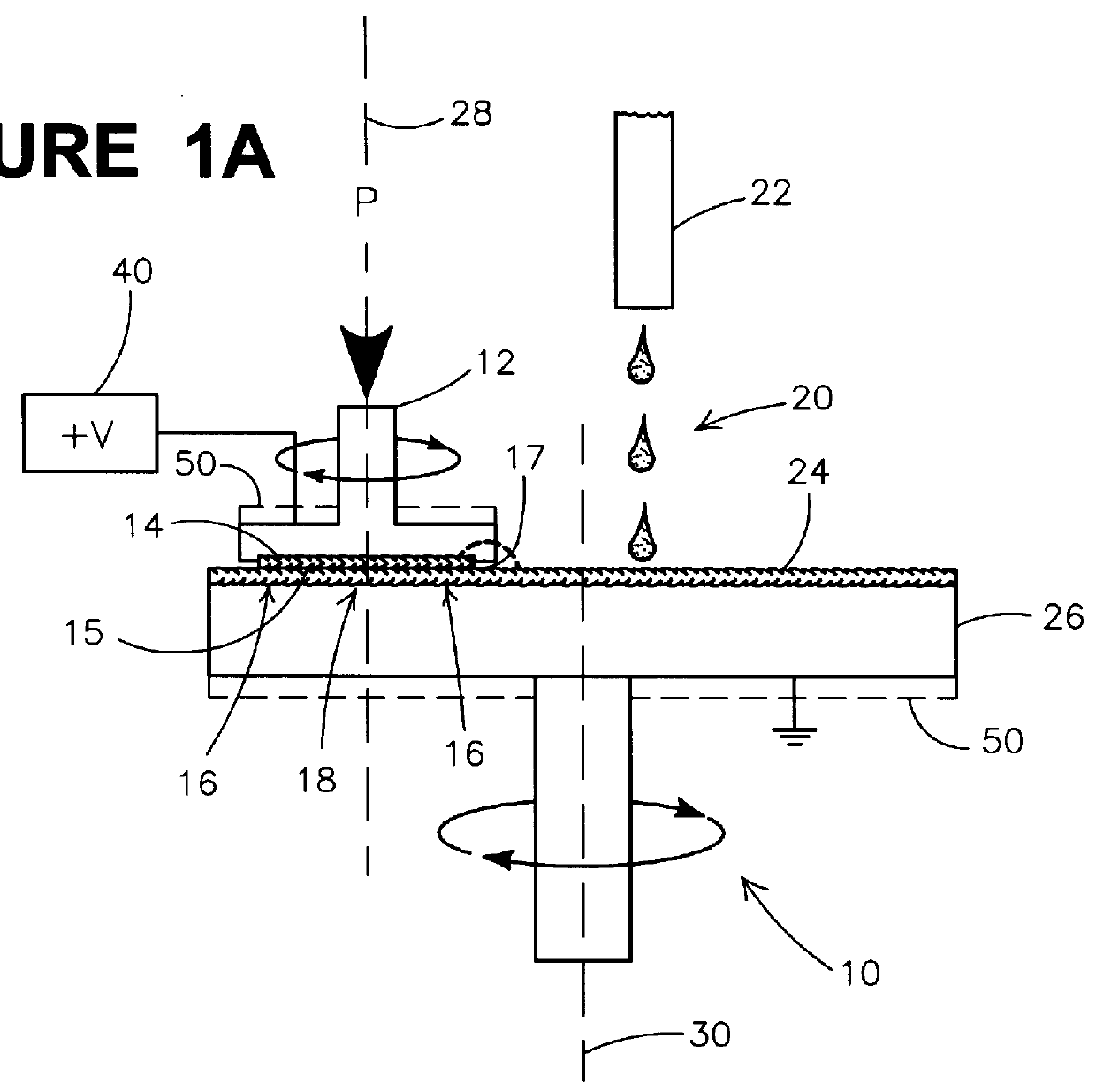

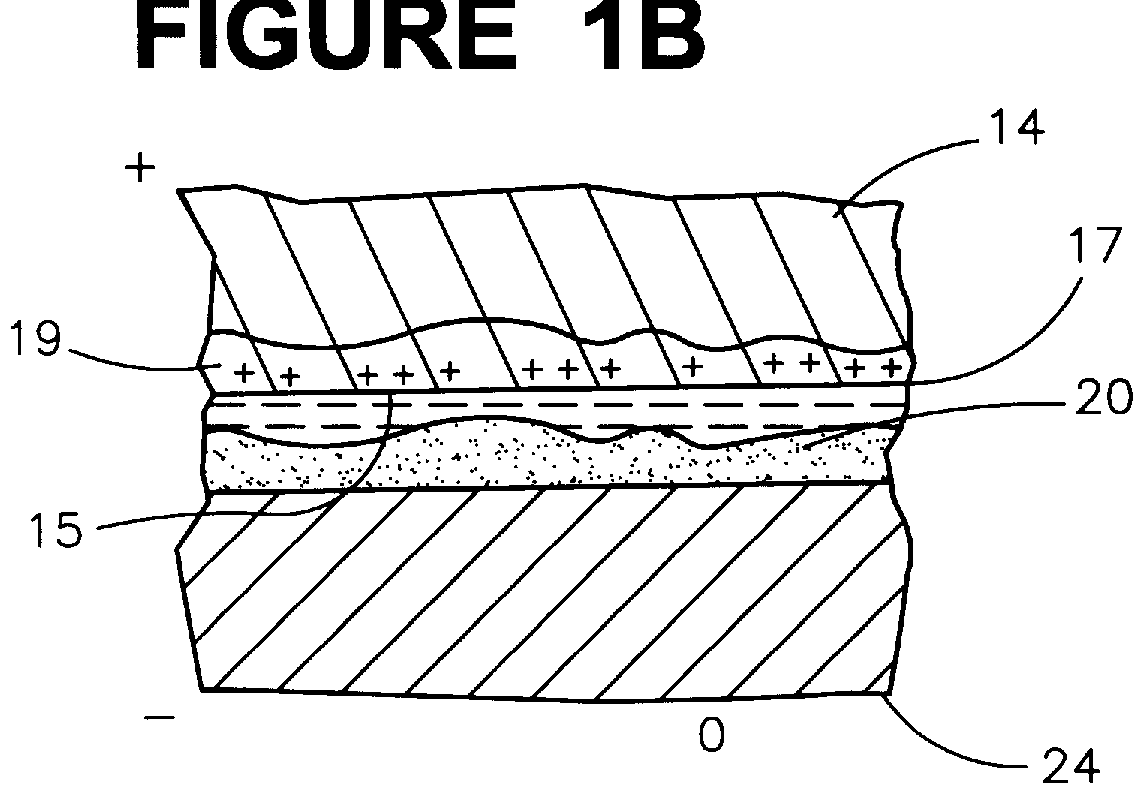

Wafer surface treatment methods and systems using electrocapillarity

InactiveUS6010964ADecorative surface effectsPhotomechanical apparatusBiomedical engineeringElectric potential

A surface treatment method for use in integrated circuit fabrication includes providing a substrate assembly having a surface. A liquid is provided adjacent the surface resulting in an interface therebetween. An electrical potential difference is applied across the interface and the surface is treated as the electrical potential difference is applied across the interface. The liquid may be a planarization liquid when the treatment of the surface includes planarizing a substrate assembly or the liquid may be a coating material when the treatment of the surface includes applying a coating material on the surface.

Owner:MICRON TECH INC

Self boosting packing element

ActiveUS7392841B2Increase frictionIncrease forceFluid removalSealing/packingSingle elementLocking mechanism

A packer assembly features one or more elements that preferably swell when in contact with well fluids and have a feature in them that responds to an applied load in a given direction by retaining such a boost force with a locking mechanism. A single element can have two such mechanisms that respond to applied forces from opposed directions. Friction force for adhering the element to the mandrel is enhanced with surface treatments between them that still allow the locking mechanisms to operate.

Owner:BAKER HUGHES INC

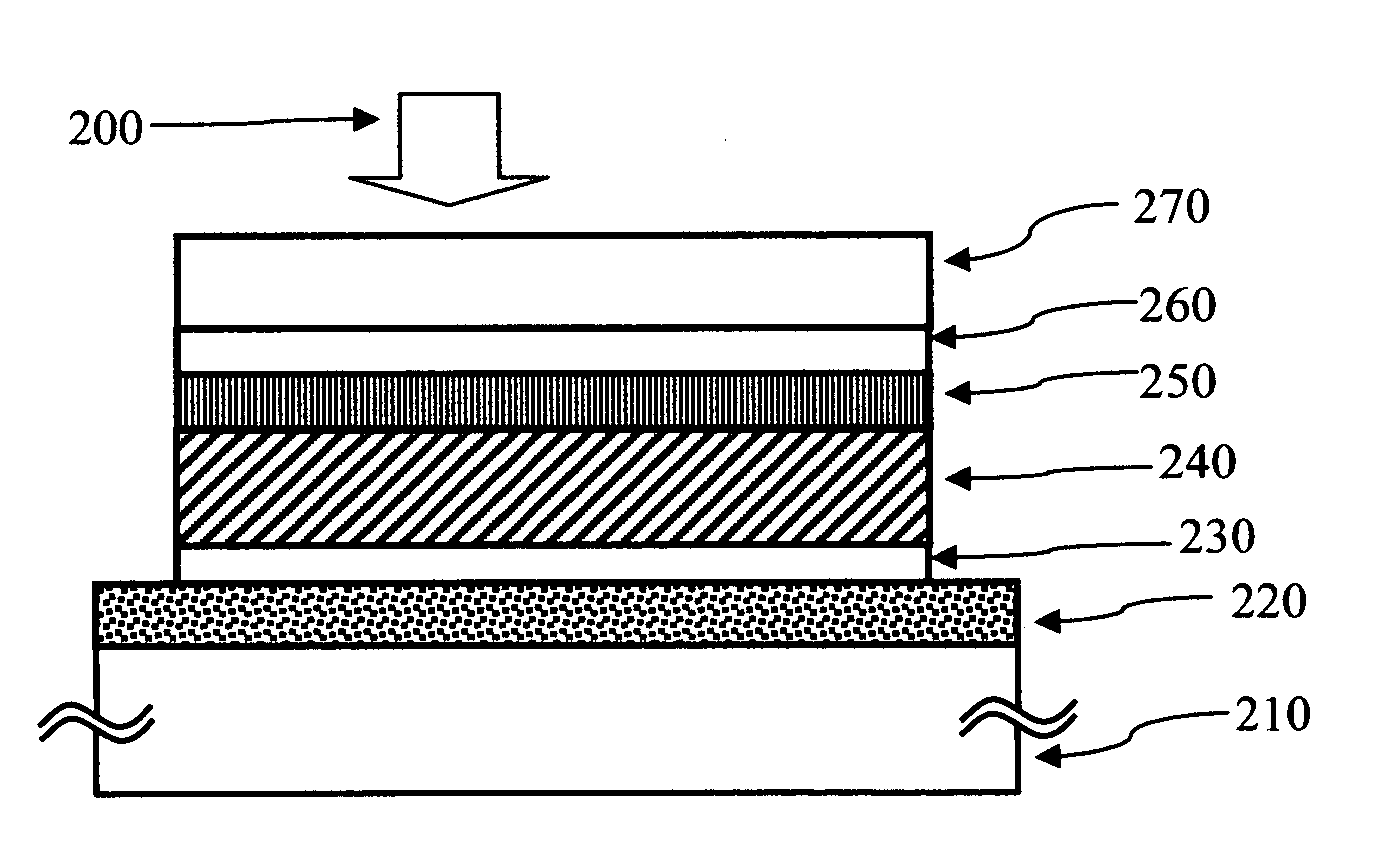

Junctions in substrate solar cells

The present invention discloses thin film photovoltaic devices comprising Group II-VI semiconductor layers with a substrate configuration having an interface layer between the absorber layer and the window layer to create improved junctions.The present invention also discloses methods for making and surface treatments for thin film photovoltaic devices comprising Group II-VI semiconductor layers with a substrate configuration to create devices with improved junctions.

Owner:FIRST SOLAR INC (US)

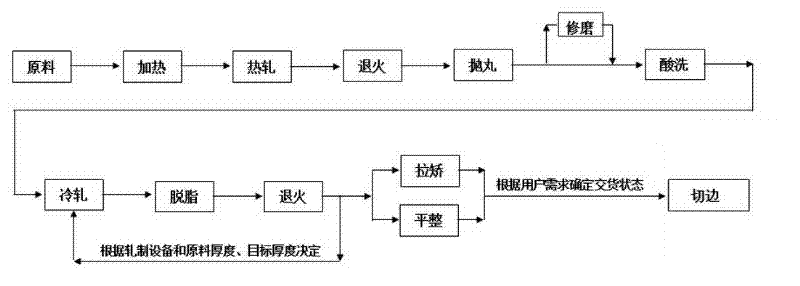

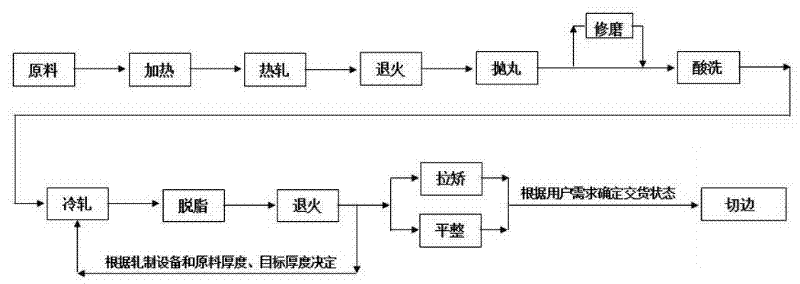

Processing method of titanium and titanium alloy strip coils

ActiveCN102310314ASolve the shortage of titanium-free surface processing technologyImprove processing efficiencyWork treatment devicesMetal rolling arrangementsSingle plateTitanium

The invention provides a processing method of titanium and titanium alloy strip coils, which comprises the steps of raw material preparation, heating, rolling, annealing, shot blasting treatment, coping, pickling, cold rolling, derosination, annealing, straightening or flattening, edge scraping, and product obtaining. According to the method, existing large steel rolling equipment of various types in the steel processing industry is fully utilized, the defect that no titanium material surface processing and treatment technology exists in the steel processing industry is overcome, the advantages of the steel processing industry are combined with the uniqueness of the titanium material processing industry, and the essential leap of titanium material processing from single plate rolling to long strip rolling plus collection and coiling is completed. By using the method, goods can be delivered in a coiled state as well as a flat plate state, the titanium material processing efficiency is improved, the titanium material processing yield is increased, and conditions are created and high quality raw materials are provided for the processing of titanium welded pipes with various diametersand longer lengths, so high efficiency, energy conservation and economization of titanium material processing are realized.

Owner:YUNNAN TITANIUM IND

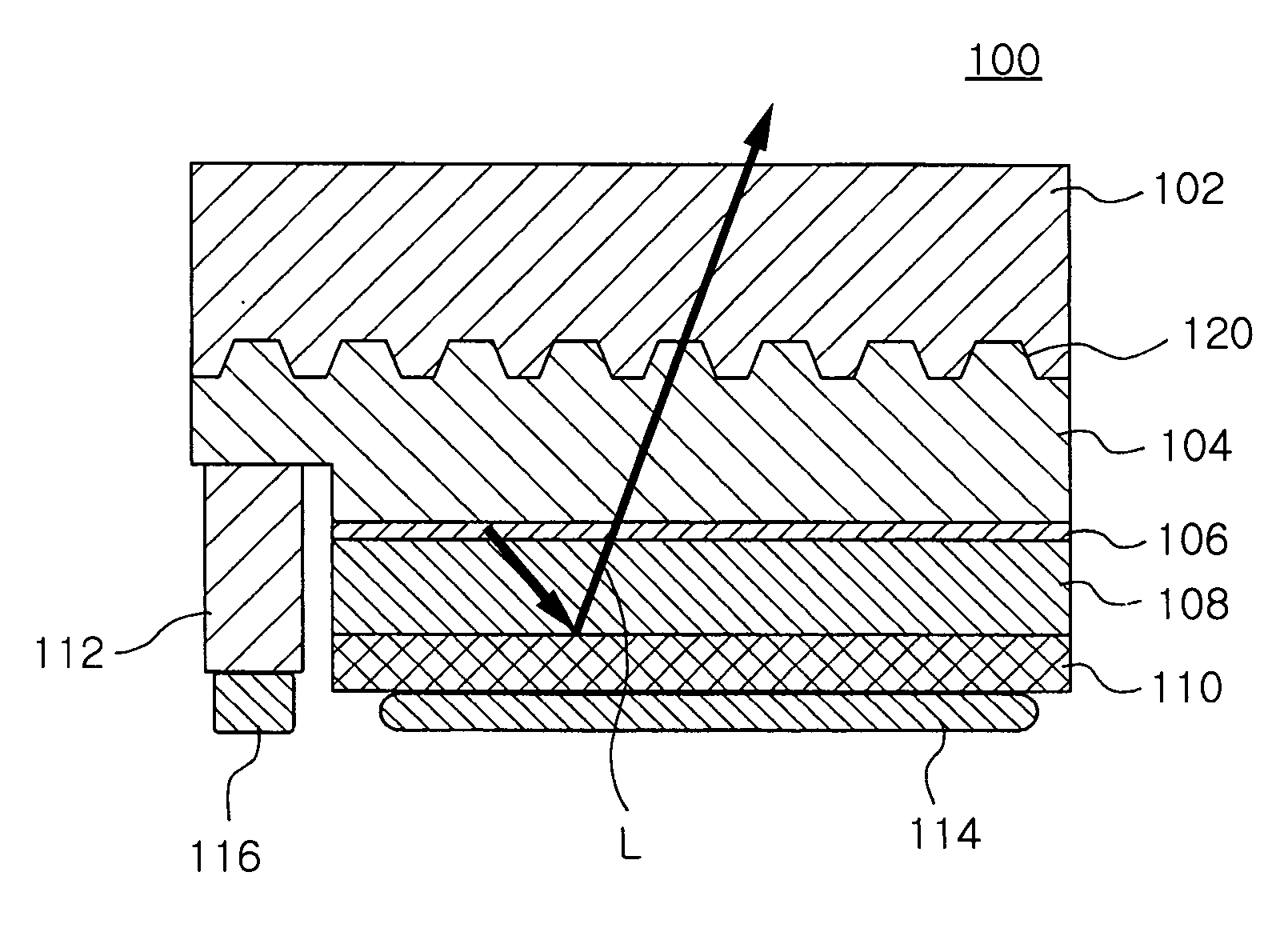

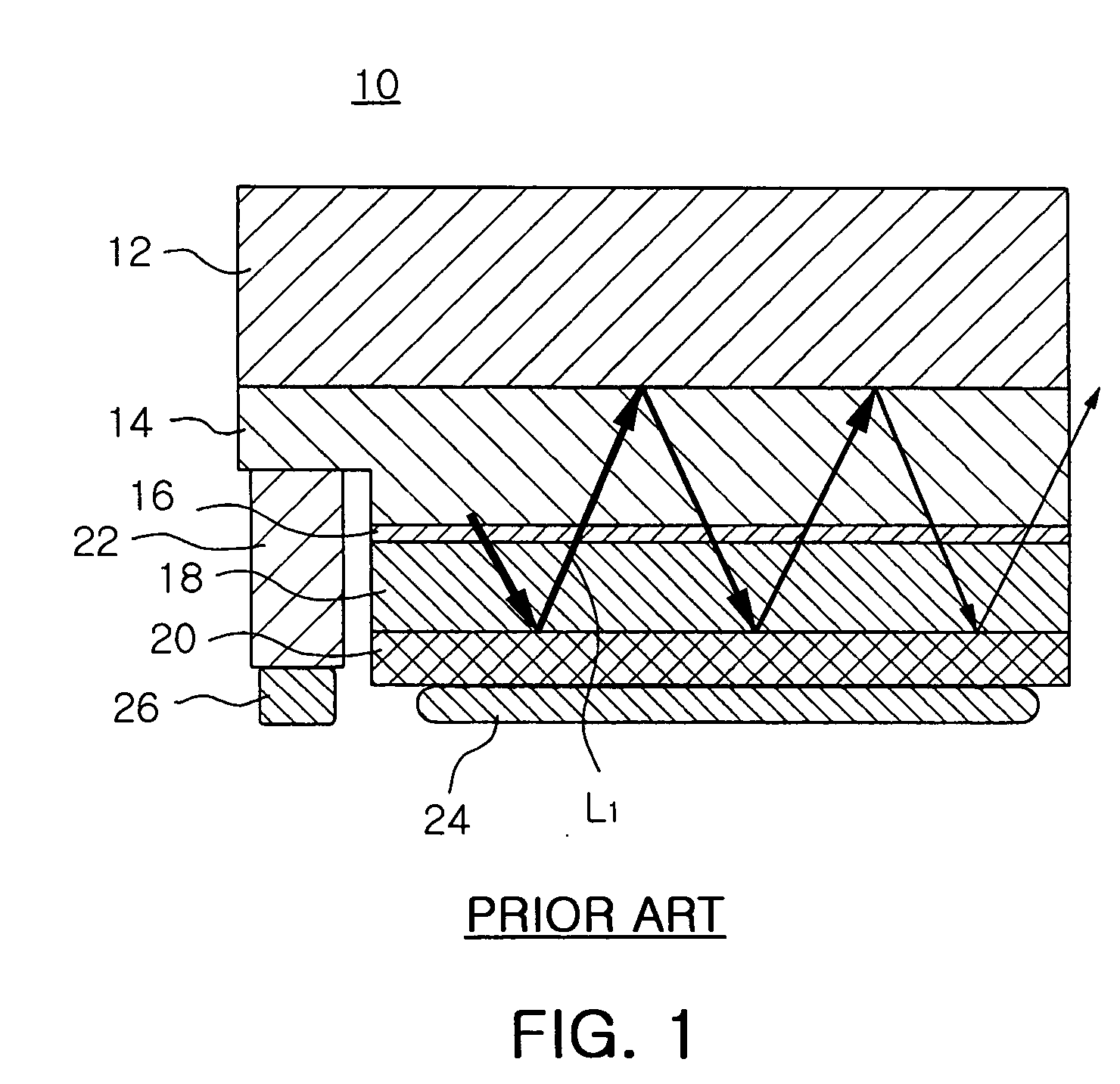

Fabrication method of light emitting diode incorporating substrate surface treatment by laser and light emitting diode fabricated thereby

InactiveUS20060038190A1Light extraction efficiencyChronic problemSemiconductor/solid-state device manufacturingSemiconductor devicesState of artOptoelectronics

The present invention relates to a fabrication method of LEDs incorporating a step of surface-treating a substrate by a laser and an LED fabricated by such a fabrication method. The present invention can use a laser in order to implement finer surface treatment to an LED substrate over the prior art. As a result, the invention can improve the light extraction efficiency of an LED while protecting the substrate from chronic problems of the prior art such as stress or defects induced from chemical etching and / or physical polishing.

Owner:SAMSUNG ELECTRONICS CO LTD

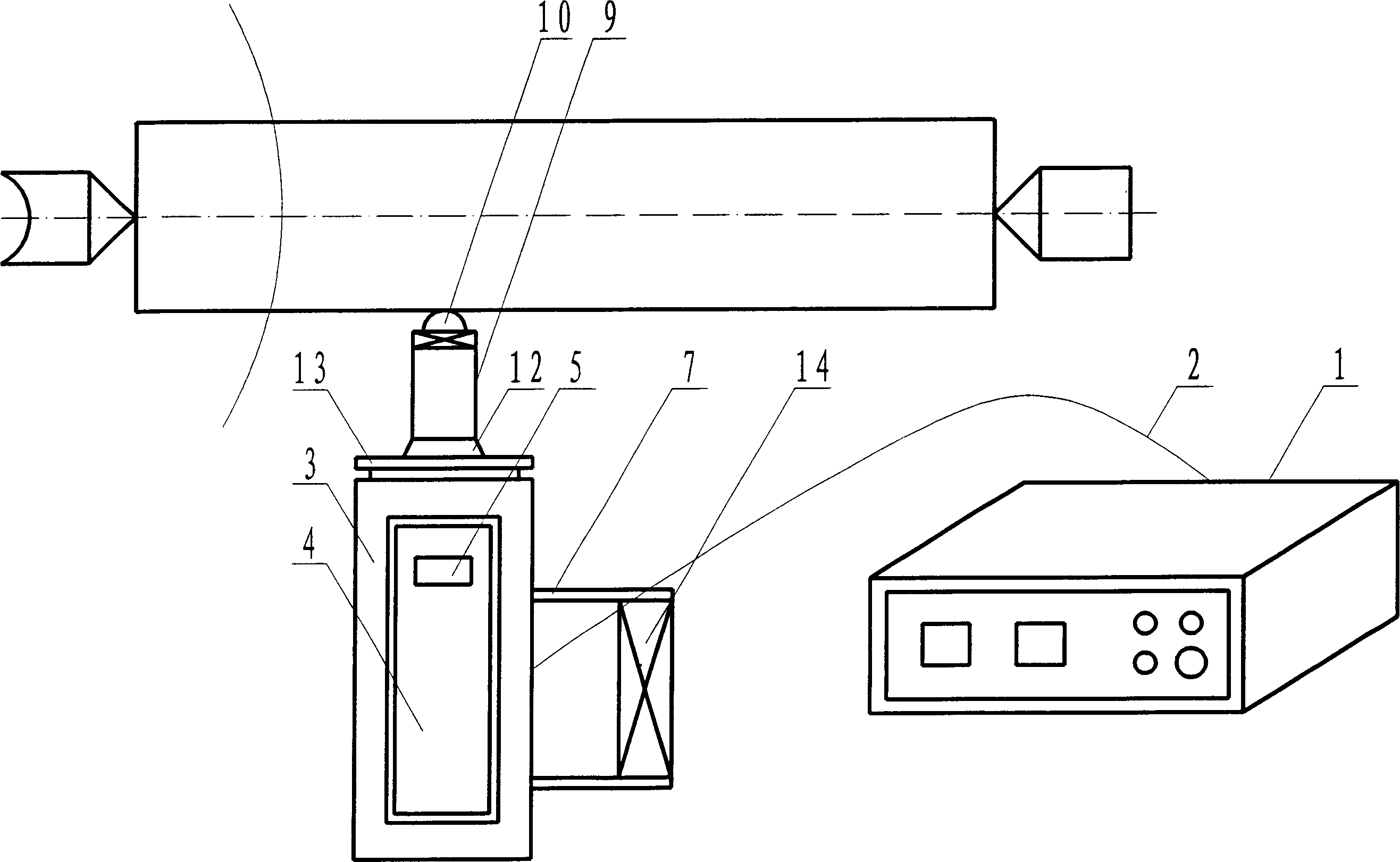

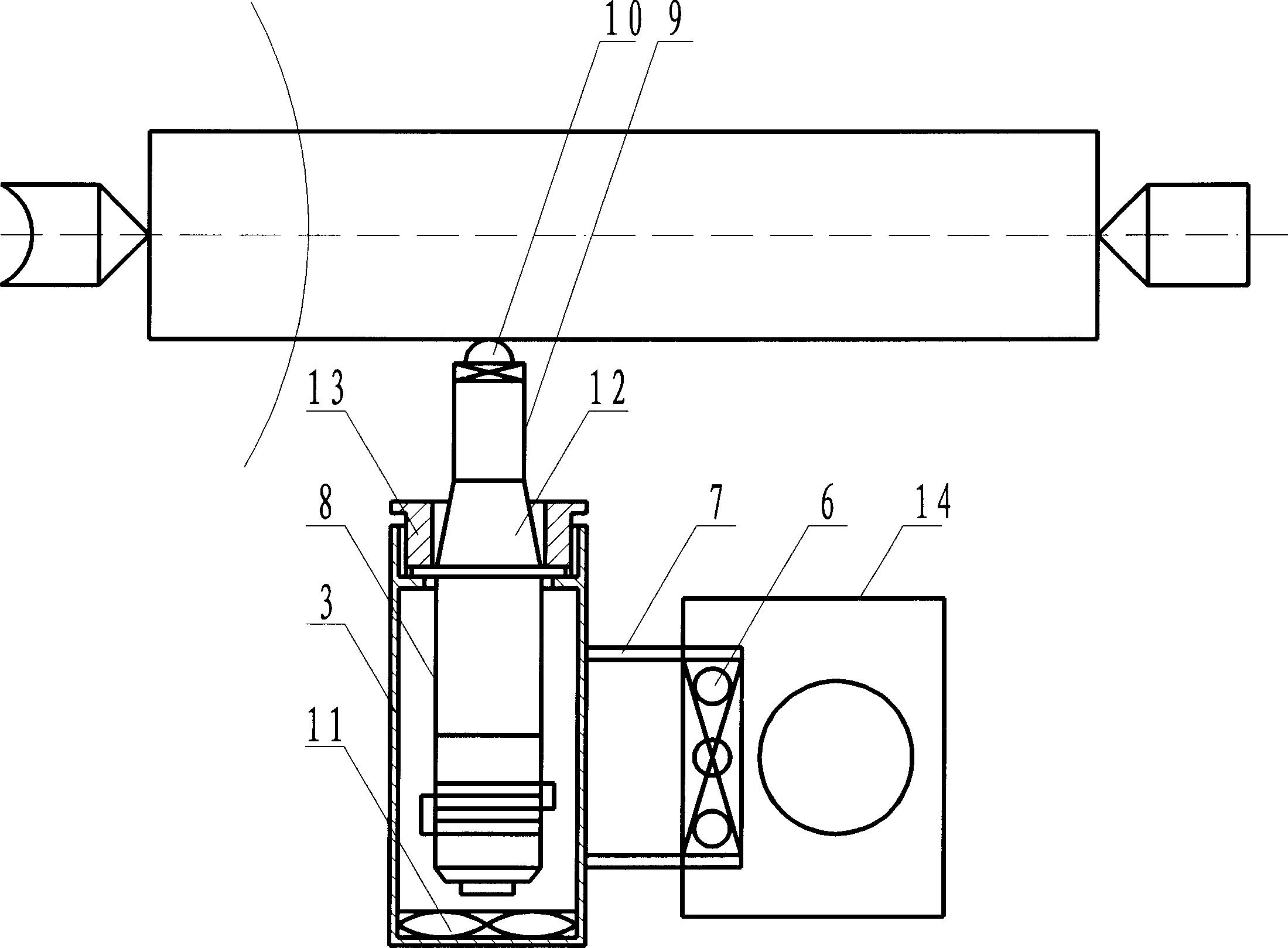

Ultrasonic metal surface processing device

ActiveCN1690231AIncrease productivityReduce investmentMechanical vibrations separationElectricityTransducer

The invention provides a ultrasonic working device for metallic surface, which comprises ultrasonic generator and ultrasonic working device linked together by cable conductor. The ultrasonic generator is existing device, and ultrasonic working device comprises shell which is equipped with spring connected to checkout gear for pressure one side and to briquette the other side besides with checkout gear for pressure and display for pressure, checkout gear for pressure, display for pressure, briquette, spring, piezoelectric ceramic transducer equipped in the shell and connected tight to one end of the half-wavelength complex varying amplitude pole by screw, half-wavelength complex varying amplitude pole whose outlet connected tight to tool caput by screw, tool caput and draught fan equipped on other end of the shell. Producing with the device for metallic surface can reduce the processing cost rapidly and effectively, simplify the productive technology, and advance the productive efficiency, as a result, it takes on a nice extendable and applicable value.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

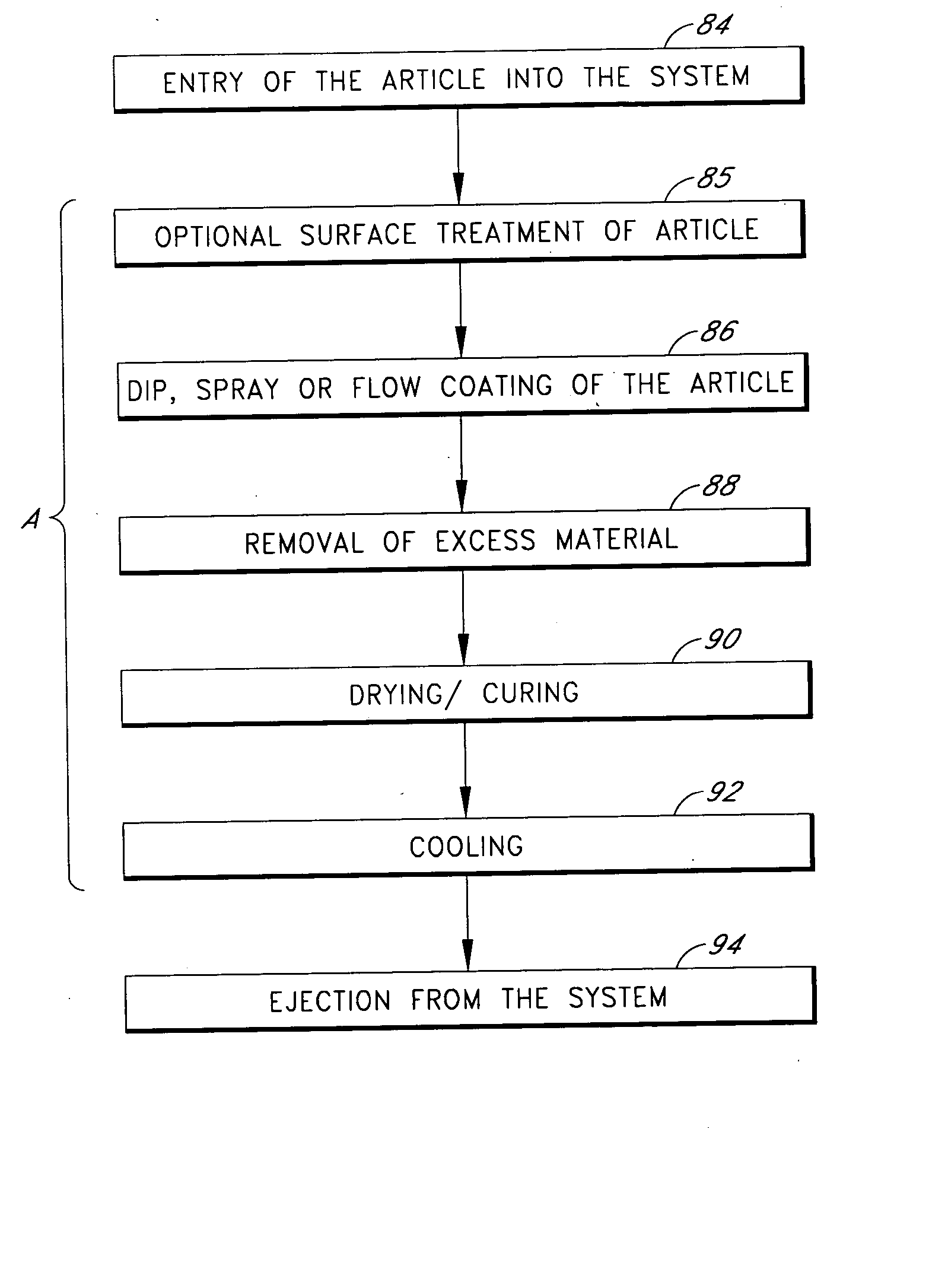

Methods of forming multilayer articles by surface treatment applications

InactiveUS20070087131A1Low water vapor transmission rateImprove adhesionPretreated surfacesCoatingsAir treatmentFlame treatment

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com