Method of recovering and reproducing substrates and method of producing semiconductor wafers

a substrate and substrate technology, applied in semiconductor/solid-state device manufacturing, basic electric elements, electric apparatus, etc., can solve the problems of reduced production efficiency, nitride substrate, difficult to grow in liquid phase,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example

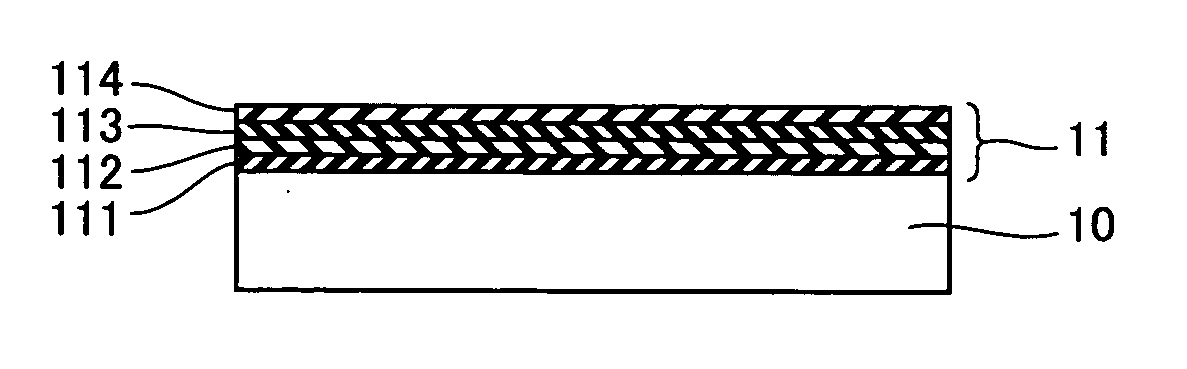

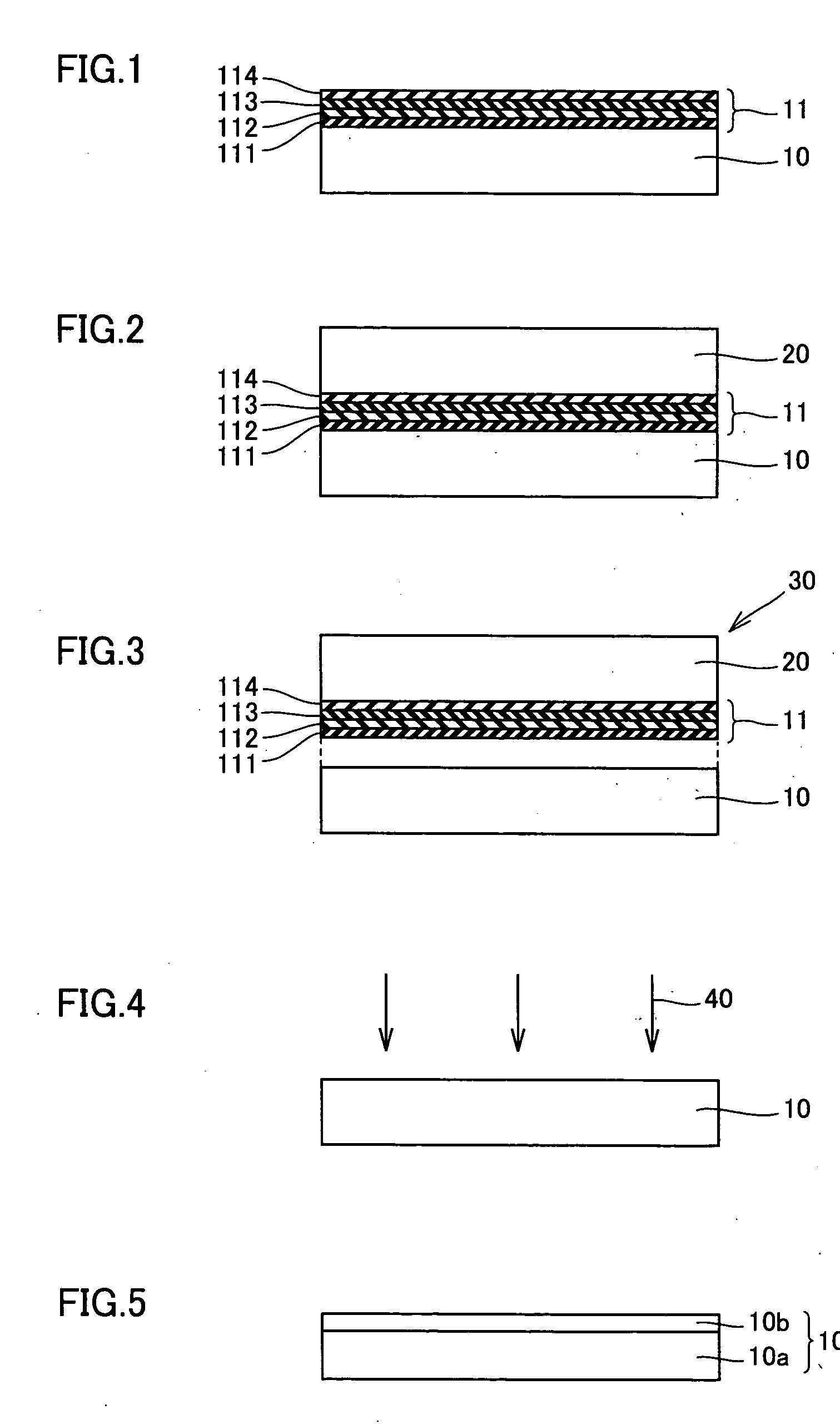

[0036] With reference to FIG. 1, the first substrate 10 implemented by a group III nitride, GaN substrate having a thickness of 1.5 mm is used and MOCVD is employed to deposit semiconductor layer 11 on the GaN substrate heated to 1000° C. Semiconductorlayer 11 is implemented by group III nitride semiconductor layer formed of a p-GaN layer 111 having a thickness of 150 nm, a p-Al0.2Ga0.8N layer 112 having a thickness of 60 nm, an In0.2Ga0.8N layer 113 having a thickness of 3 nm, and an n-GaN layer 114 having a thickness of 5000 nm deposited successively.

[0037] Then, with reference to FIG. 2, on the semiconductor layer 111 outermost, surface layer or n-GaN layer 114, Ag serving as a wax member is sputtered and thus deposited and then melted and the second substrate 20 implemented by a Si substrate having a thickness of 30 μm is stuck thereon. Then, with reference to FIG. 3, a wire saw is used to separate semiconductor layer 111 and the first substrate 10. More specifically, although ...

second example

[0039] Except that the first and second substrates are AlN and Cu substrates, respectively, the wax material is Ni, and the AlN substrate is homoepitaxially grown with AlN used as material, the first substrate has a semiconductor layer deposited thereon, the semiconductor layer has the second substrate stuck thereon, the semiconductor layer and the first substrate are separated, the first substrate separated is surface processed and then homoepitaxially grown, similarly as has been described in the first embodiment. The result is also shown in Table 1.

third embodiment

[0040] Except that the first and second substrates are InN and Cu—W substrates, respectively, the wax material is Ti, The semiconductor layer and the first substrate are separated with an inner, radial blade and the InN substrate is homoepitaxially grown with InN used as material, the first substrate has a semiconductor layer deposited thereon, the semiconductor layer has the second substrate stuck thereon, the semiconductor layer and the first substrate are separated, the first substrate separated is surface processed and then homoepitaxially grown, similarly as has been described in the first embodiment. The result is also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com