Patents

Literature

342 results about "Machine maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machinery maintenance workers do basic maintenance and repairs on machines. They clean and lubricate machinery, perform basic diagnostic tests, check the performance of the machine, and test damaged machine parts to determine whether major repairs are necessary.

Dialysis machine with servicing indicator

A dialysis machine that monitors an elapsed time and a number of accumulated hours during a current servicing interval is disclosed. The machine executes a machine-servicing algorithm on at least the elapsed time and the accumulated operating hours to generate a projected servicing interval duration. A servicing event indicator displays servicing event schedule information based on the projected servicing interval duration. A transfusion pump, similarly equipped, is also provided.

Owner:B BRAUN MEDIZINTECH

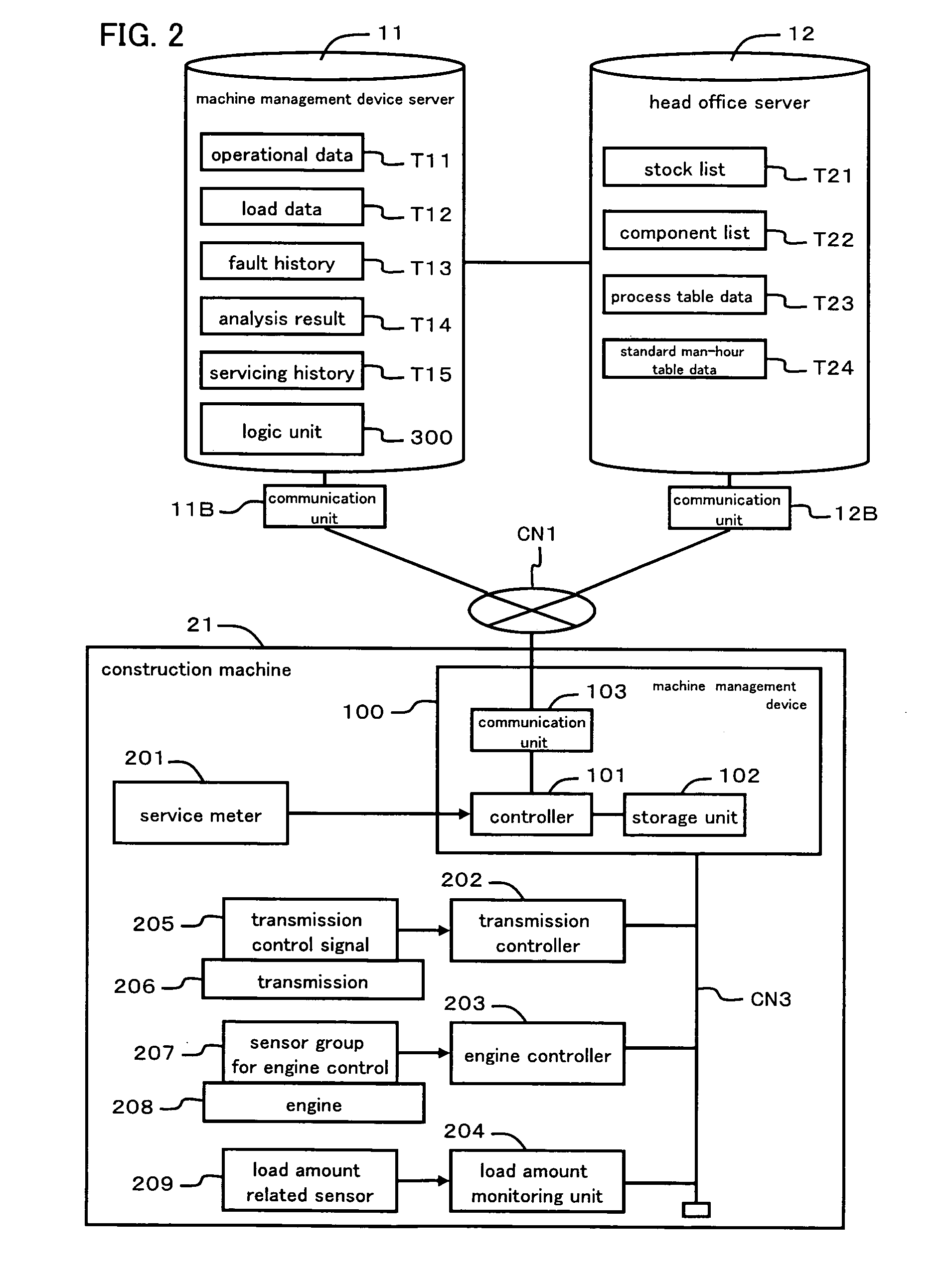

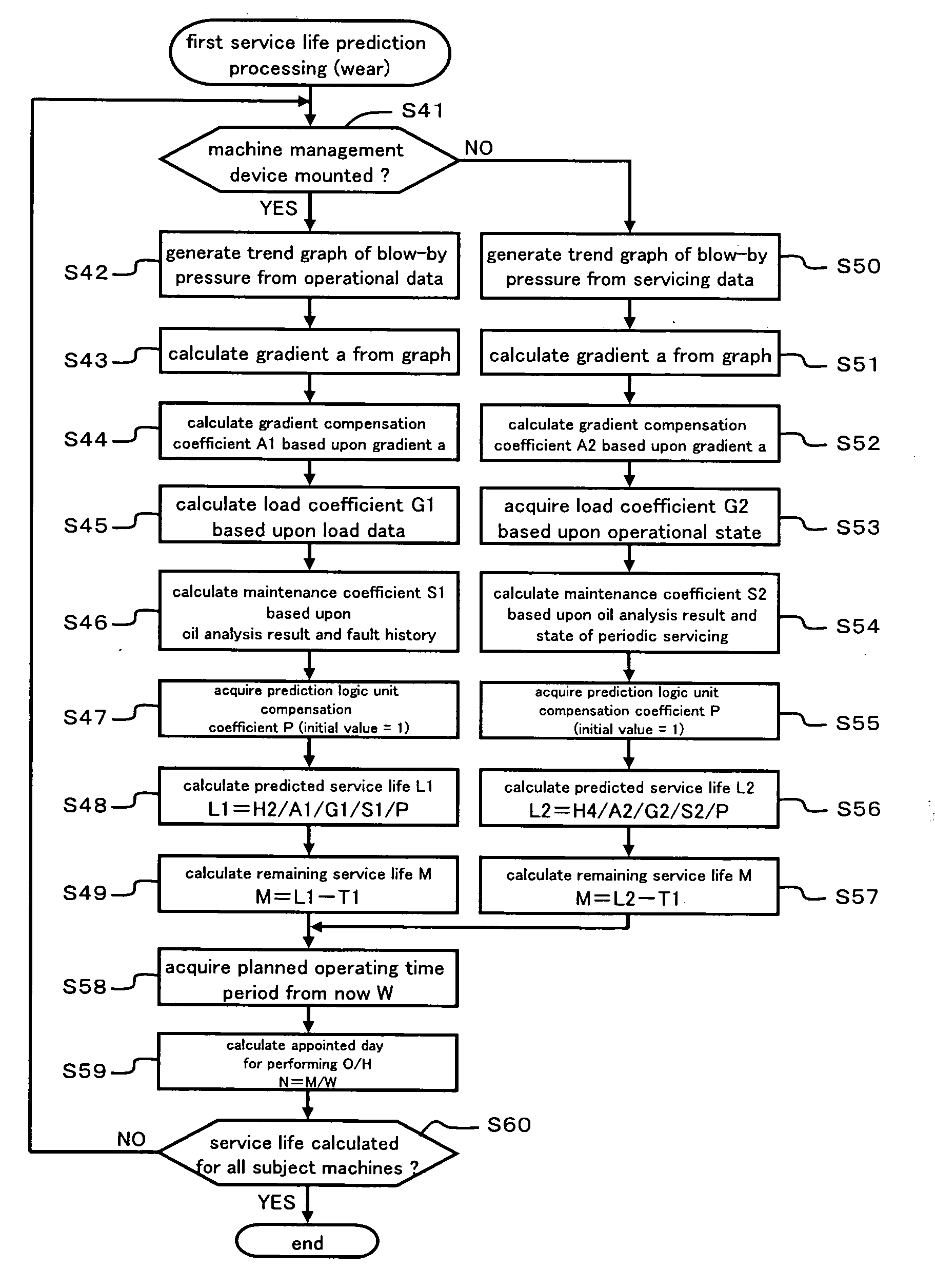

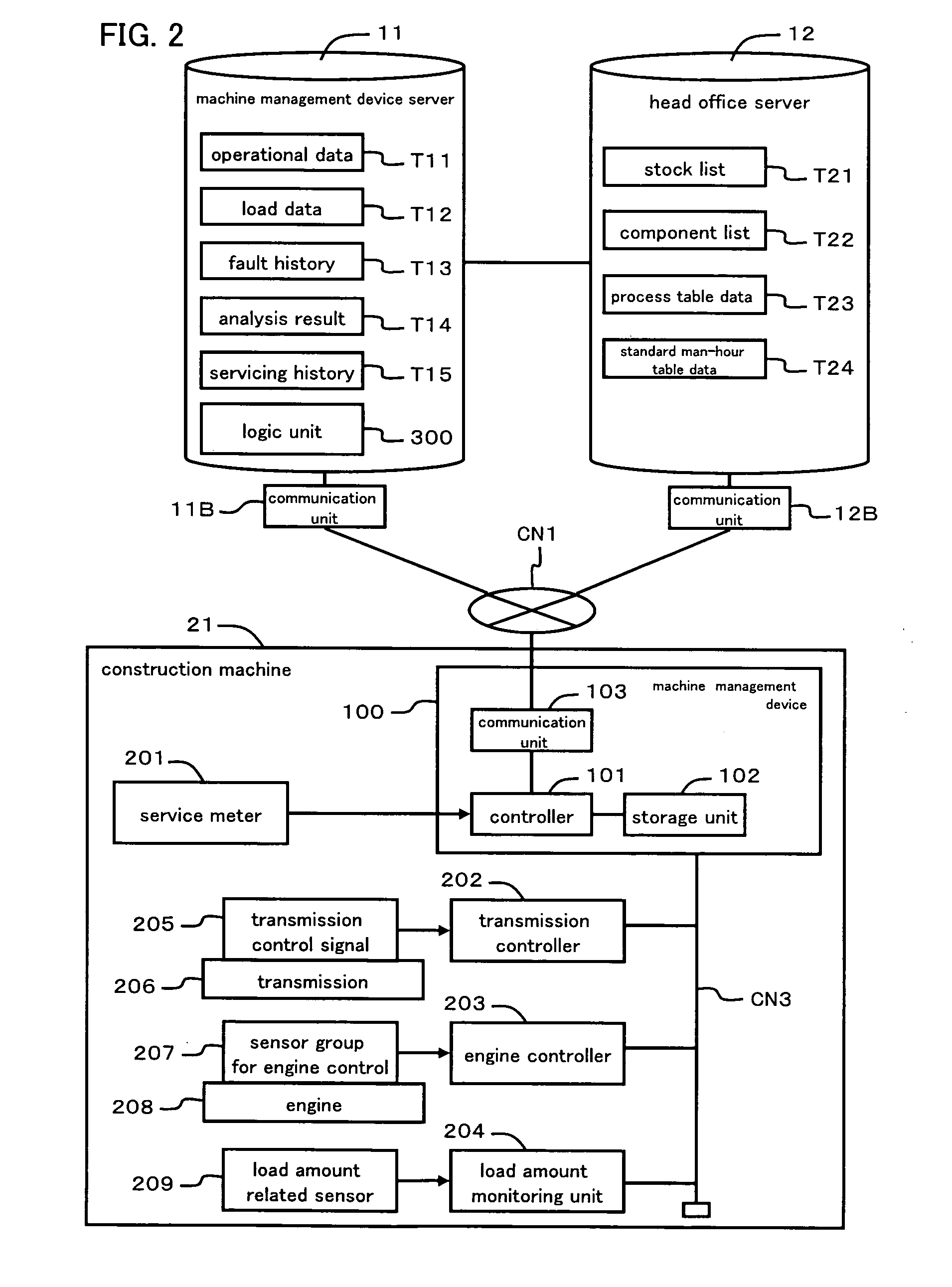

System for construction machine maintenance based on predicted service life

ActiveUS8533018B2Improve accuracyWorking capability of the maintenance workplace is exceededForecastingSoil-shifting machines/dredgersMachine maintenancePaper document

To predict the service life of a construction machine more accurately, and to make it possible to draw up an appropriate overhaul implementation plan at an early stage.A first service life prediction unit 311 predicts the service lives of main components such as an engine and the like, based upon their actual wear states. And a second service life prediction unit 312 predicts the service lives of the same components, based upon their cumulative load amounts. An order setting unit 320 selects the ones of these two predicted service lives which are the shorter, and sets a priority order for overhaul in order of shortness of predicted service life. An overhaul schedule table generation unit 330 creates a schedule table D1 based upon this priority order. The contents of this schedule table D1 are decided upon by a judgment unit 340, and, if necessary, are corrected by a correction unit 341. And a plan creation unit 350 creates an overhaul implementation plan document D2 and the like, based upon the corrected schedule table D1a. The result of the overhaul task and the present states of components are tested, and these test results are reflected by the service life prediction units 311 and 312.

Owner:KOMATSU LTD

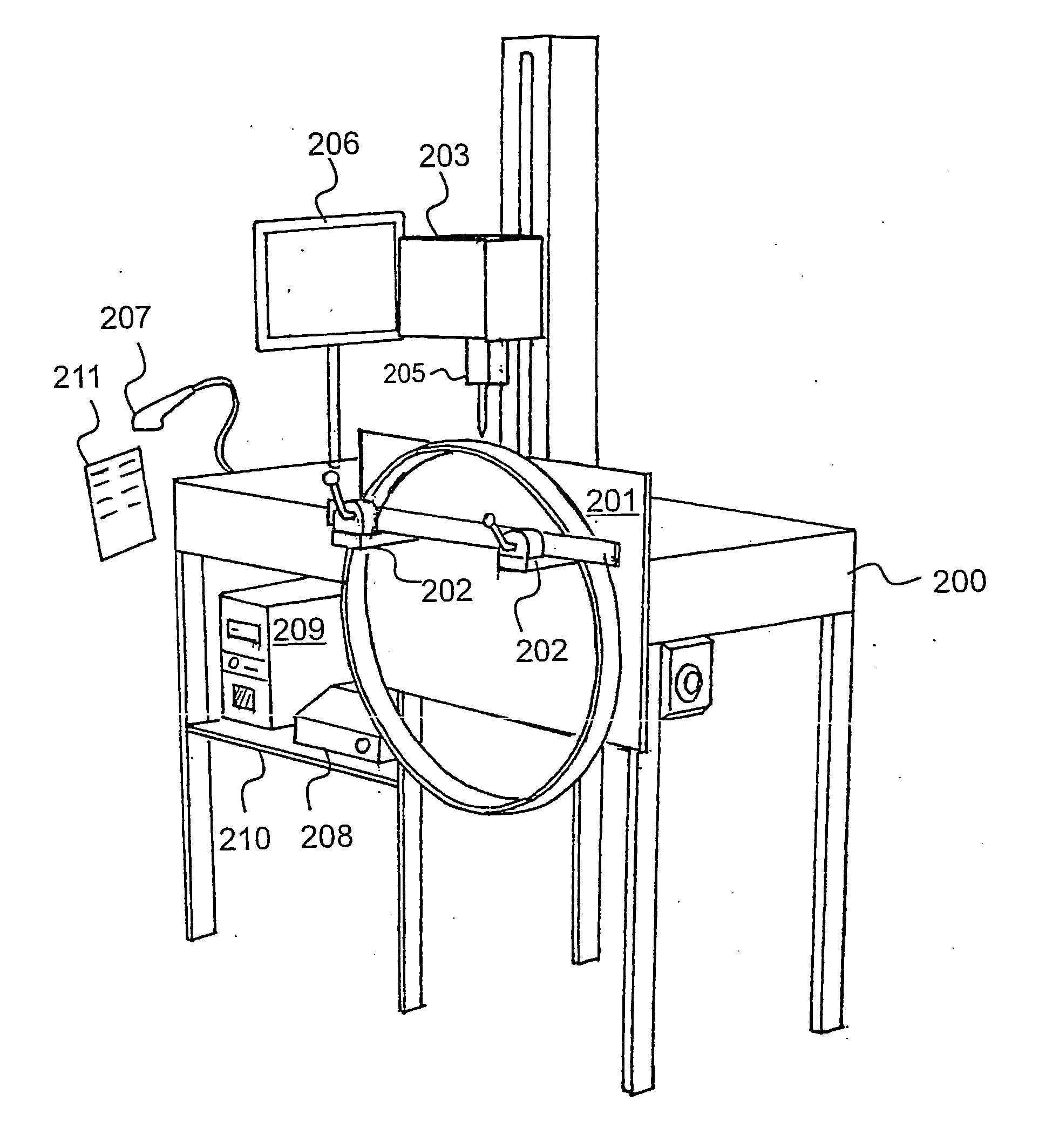

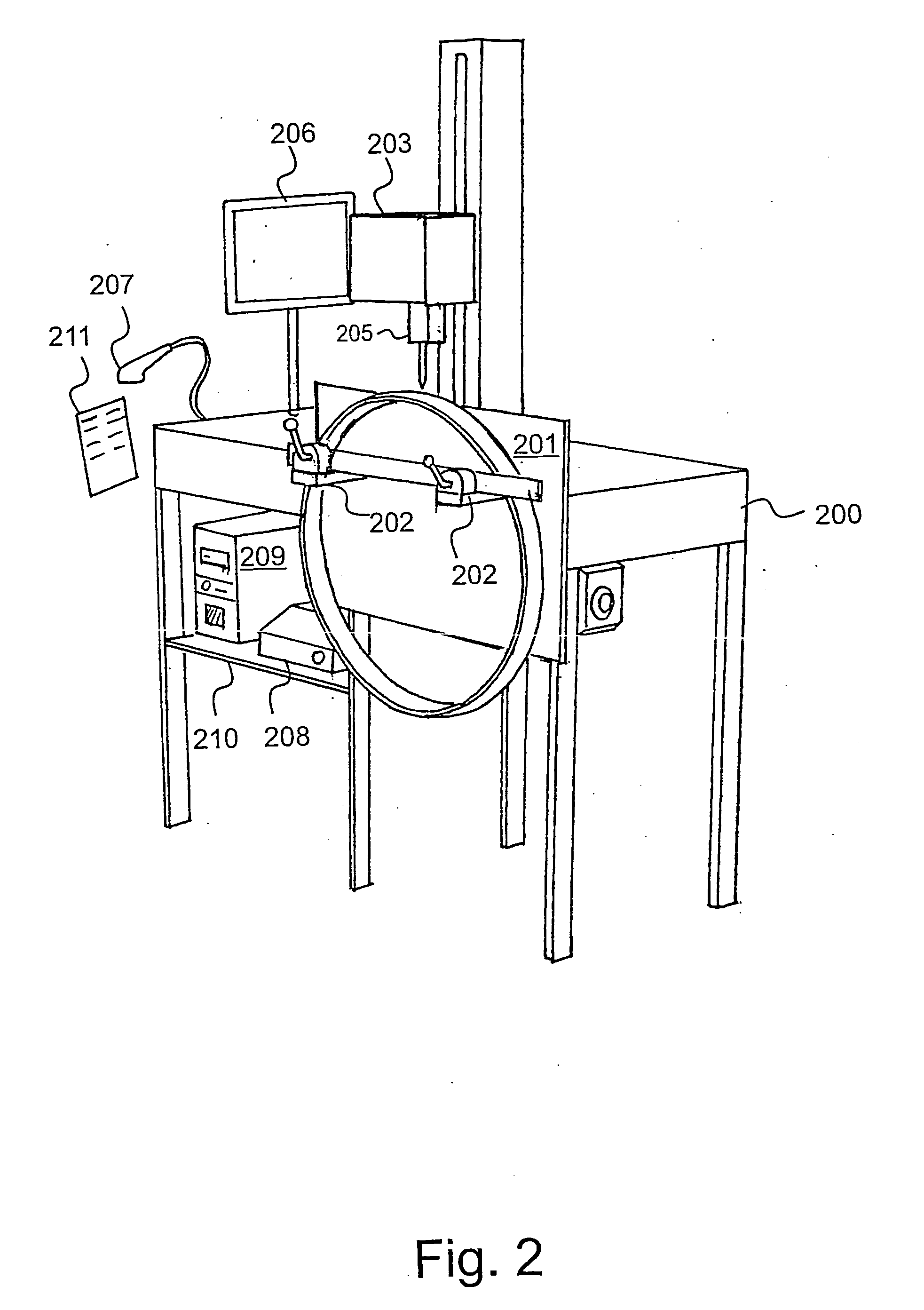

System for marking components and for verifying the applied marking

InactiveUS20050180804A1Sure easyMaterial analysis by optical meansTypewritersRating systemMachine maintenance

A system for applying a set of marks; and automatically verifying marks is disclosed, having user interface comprising a bar code scanner and a visual display. The system applies a mark to a component, and verifies the machine readability of the mark, without readjustment of marked component An operator is given a simplistic pass / fail indicator for verification. The system features a status monitoring facility whereby a maintenance status of the system is monitored by analysing an image of an applied mark. Automatic alert signals are generated and displayed on the user interface, when the system detects, from an analysis of an image of an applied mark, that machine maintenance is required. The system further features security systems which restrict access for configuration and set up of the system.

Owner:ANDREW NEIL +1

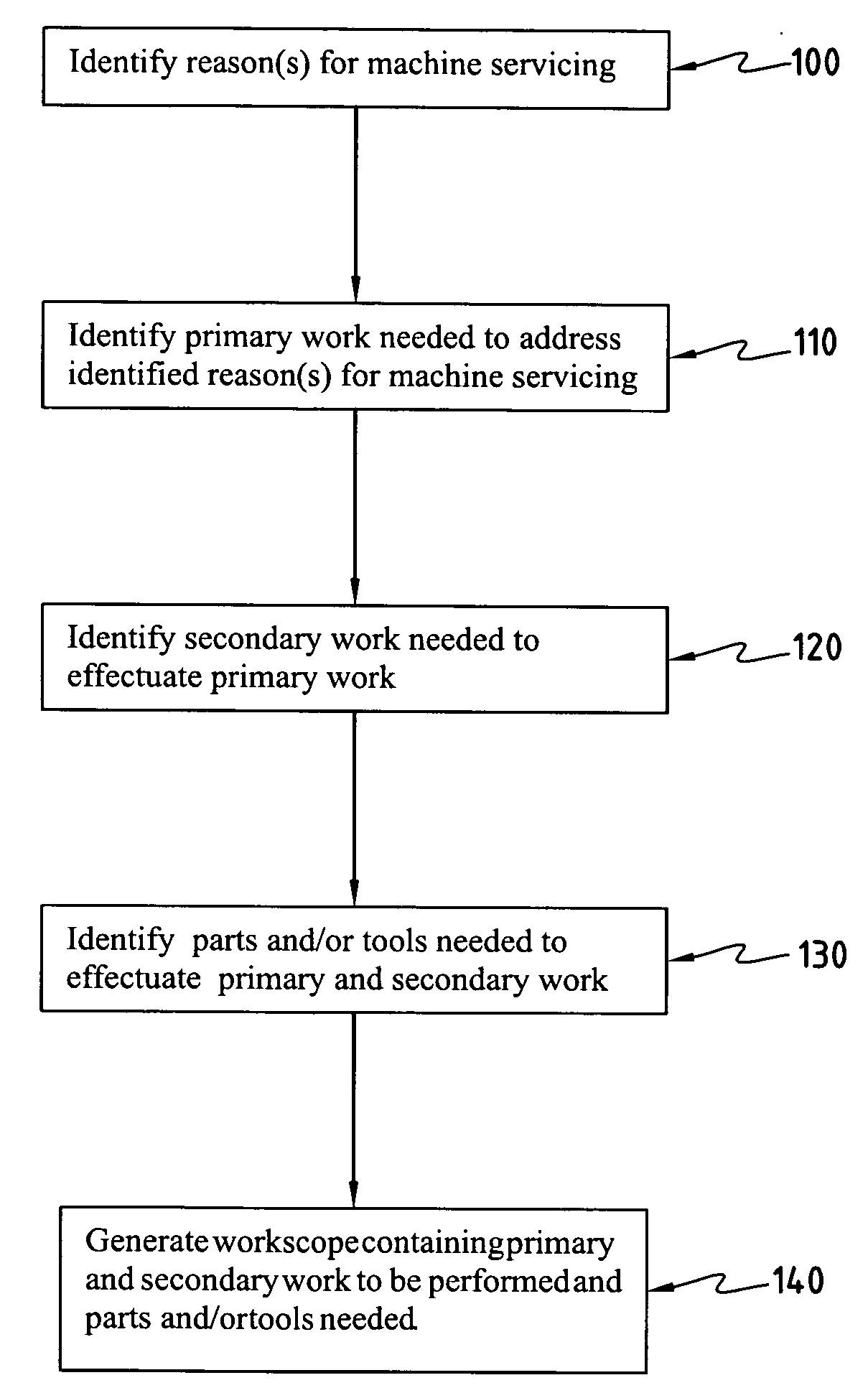

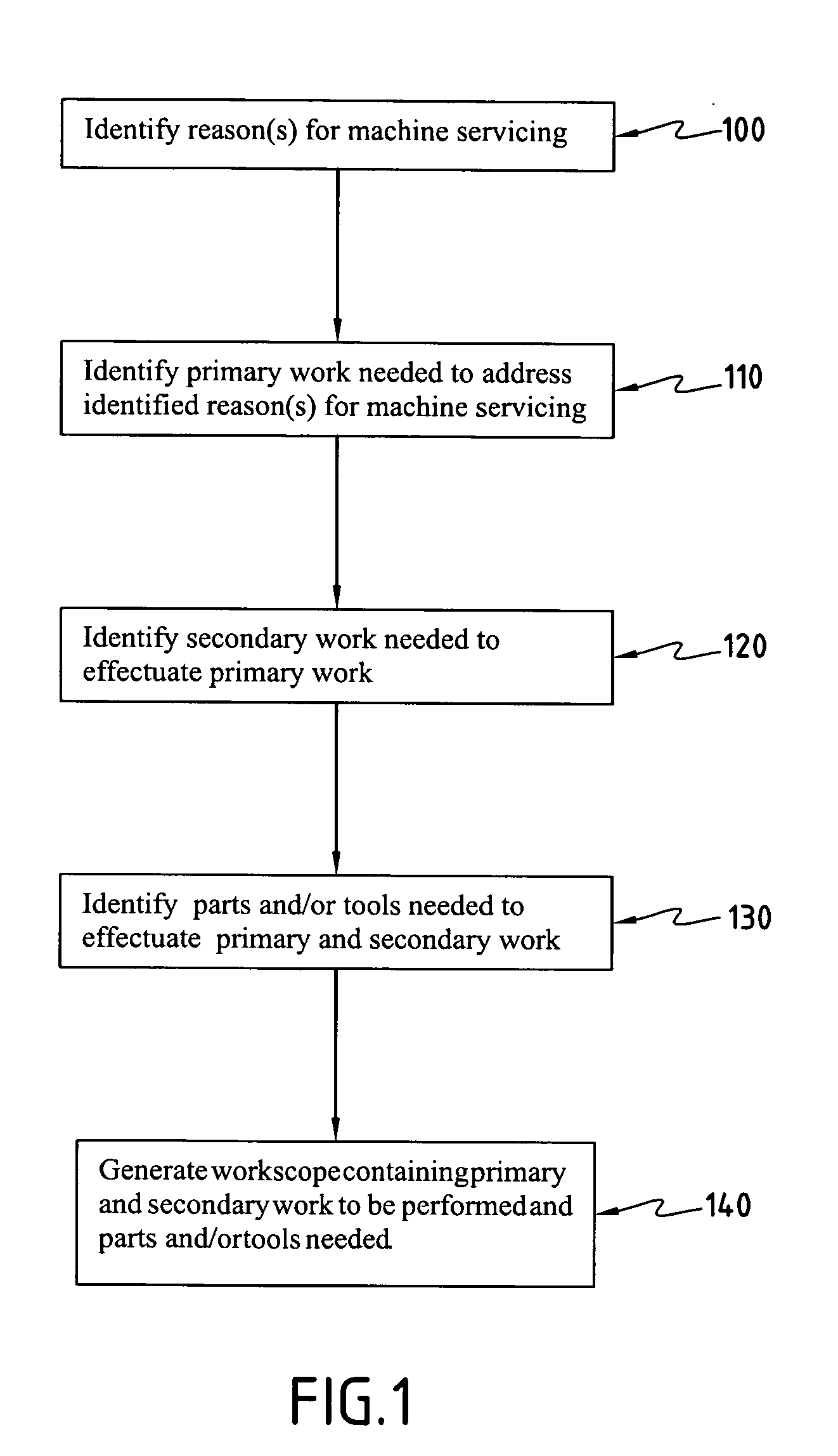

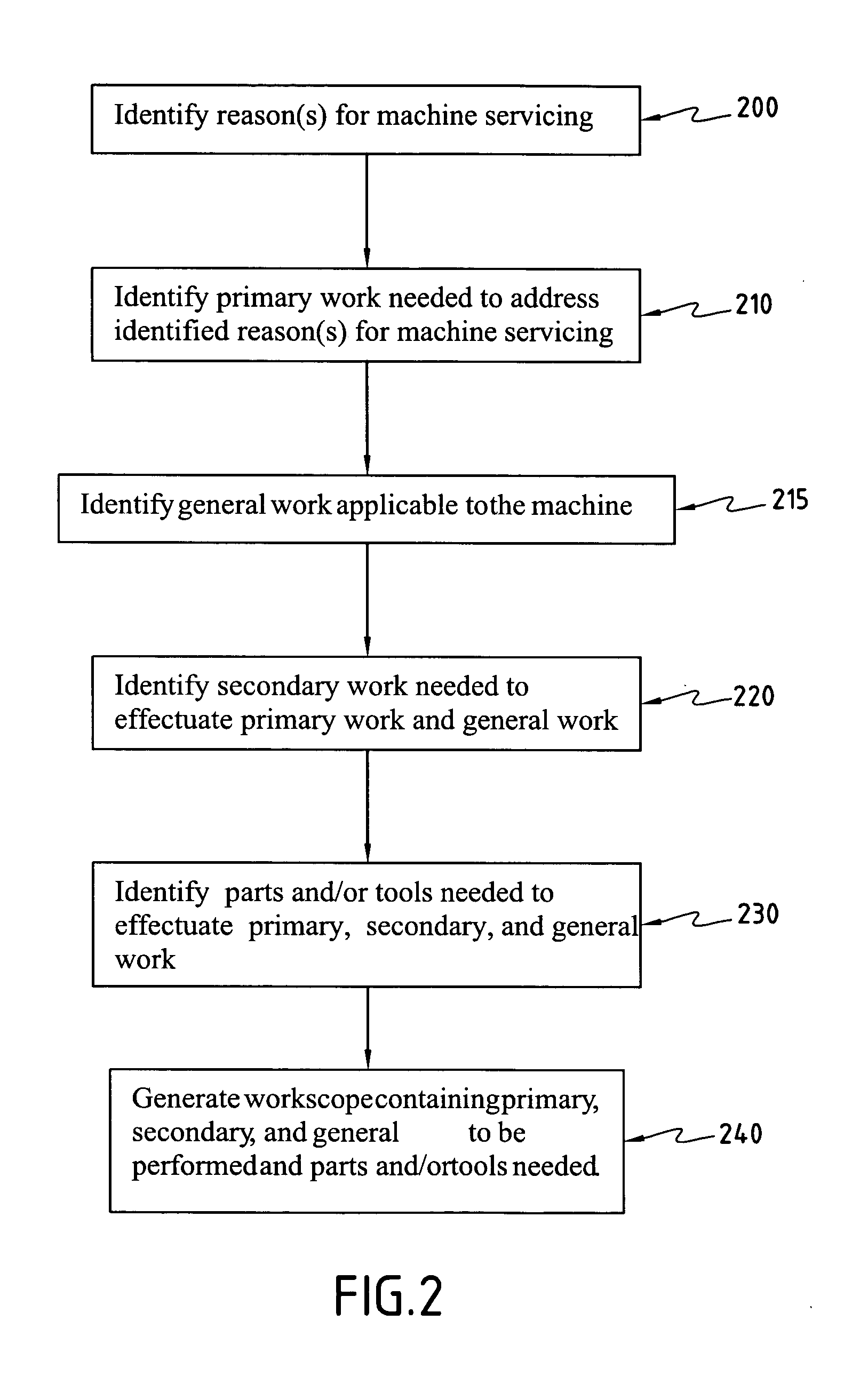

System and method for managing machine servicing including workscope generation

InactiveUS20060010152A1ResourcesSpecial data processing applicationsMachine maintenanceCost estimate

The present invention relates to management of machine servicing, particularly, but not only, aircraft engine servicing. When a machine is received in a service facility for one of a plurality of predefined reasons, repair and / or maintenance procedures known to correspond to that reason are identified and a workscope defining work to be performed is generated. It is desirable (but not required according to the present invention) to identify what parts and / or tools will be needed to carry out the repair and / or maintenance procedures. It is additionally desirable to permit the parts and / or tools to be ordered or otherwise requested in anticipation of carrying out the defined work. The workscope can be enhanced by taking into account work (required or not) that is customarily performed for a given client. A cost estimate corresponding to the workscope may also be generated, and may also be modified according to client-specific parameters such as the nature of the client's service contract

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

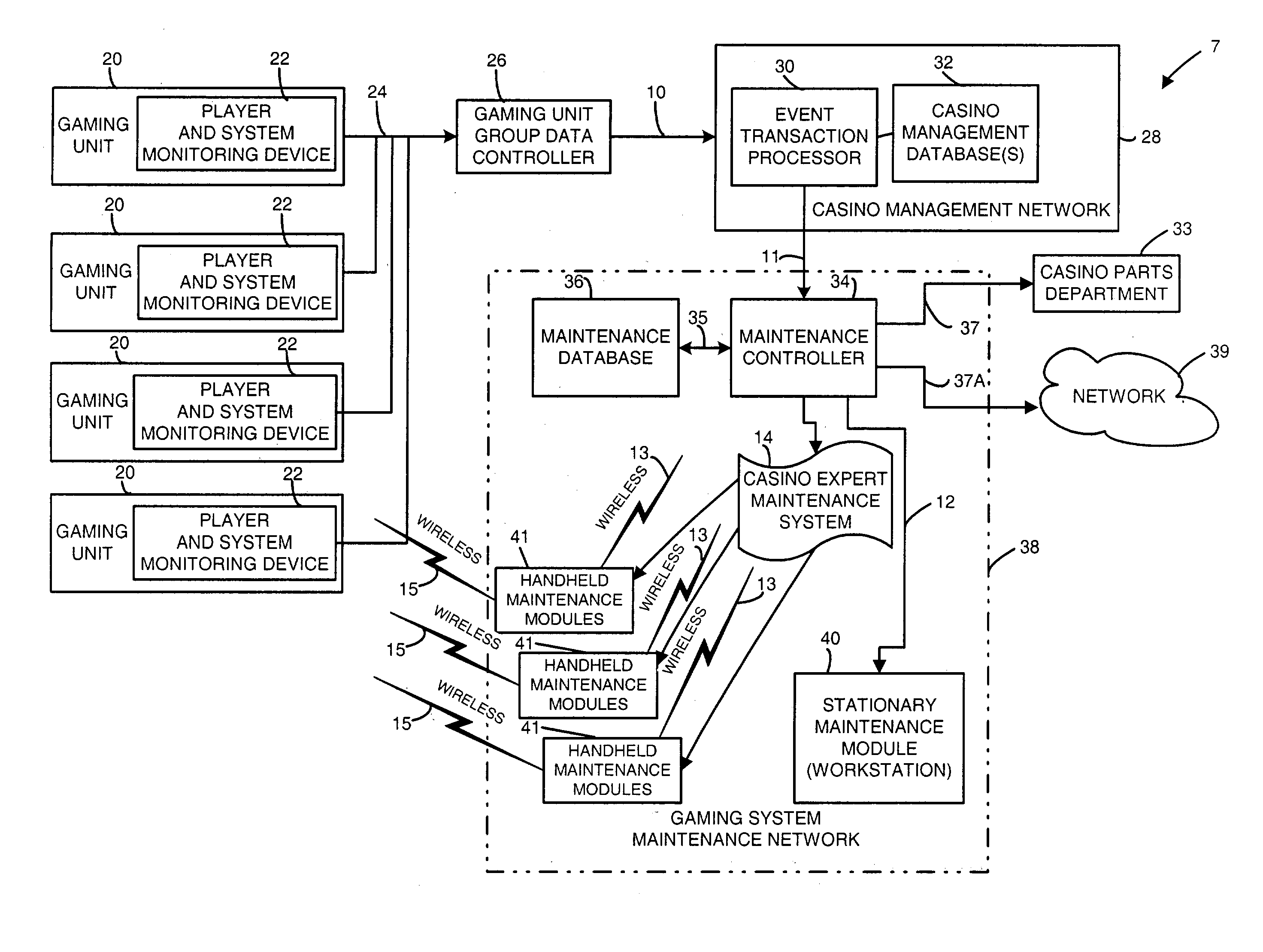

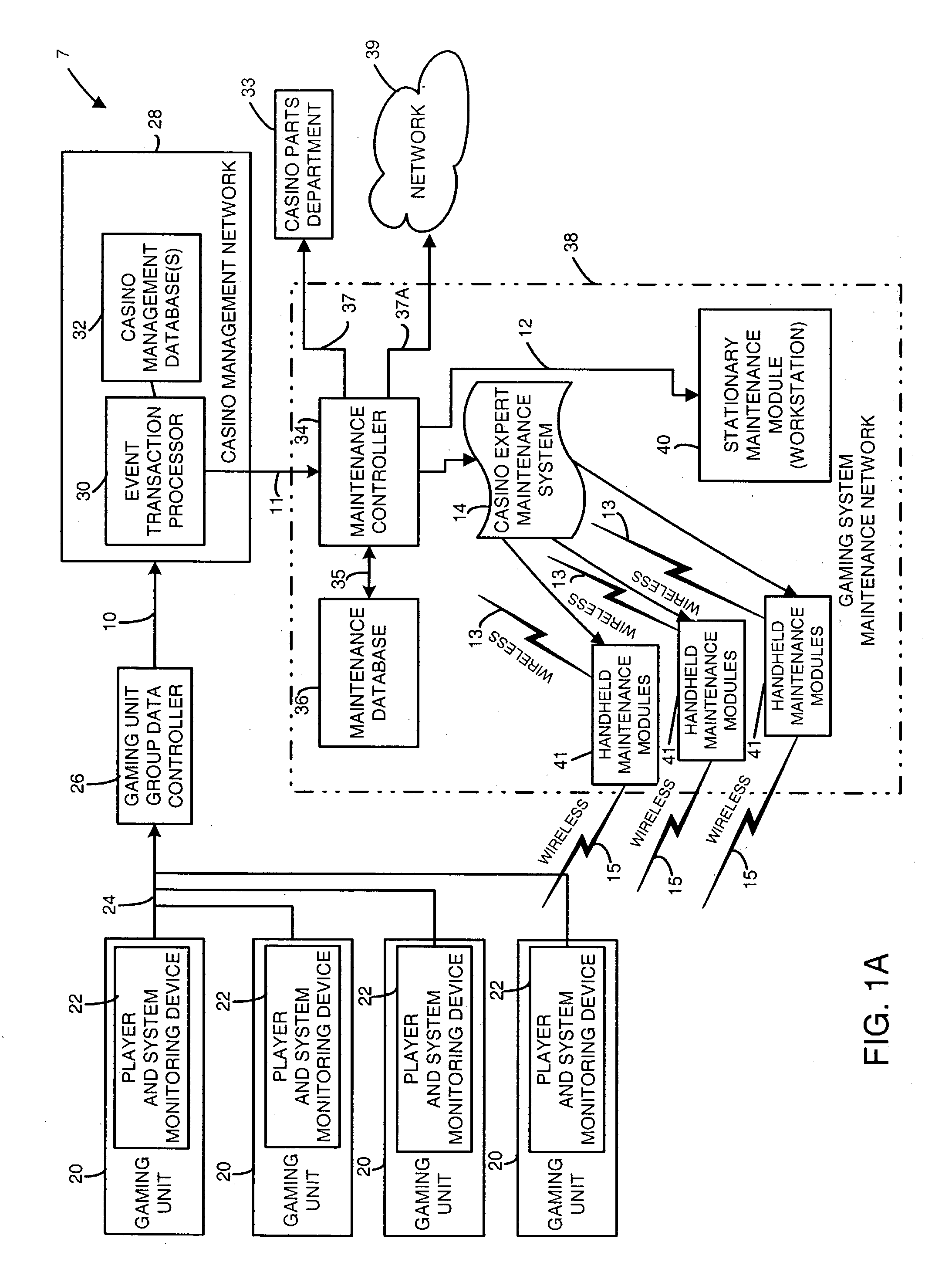

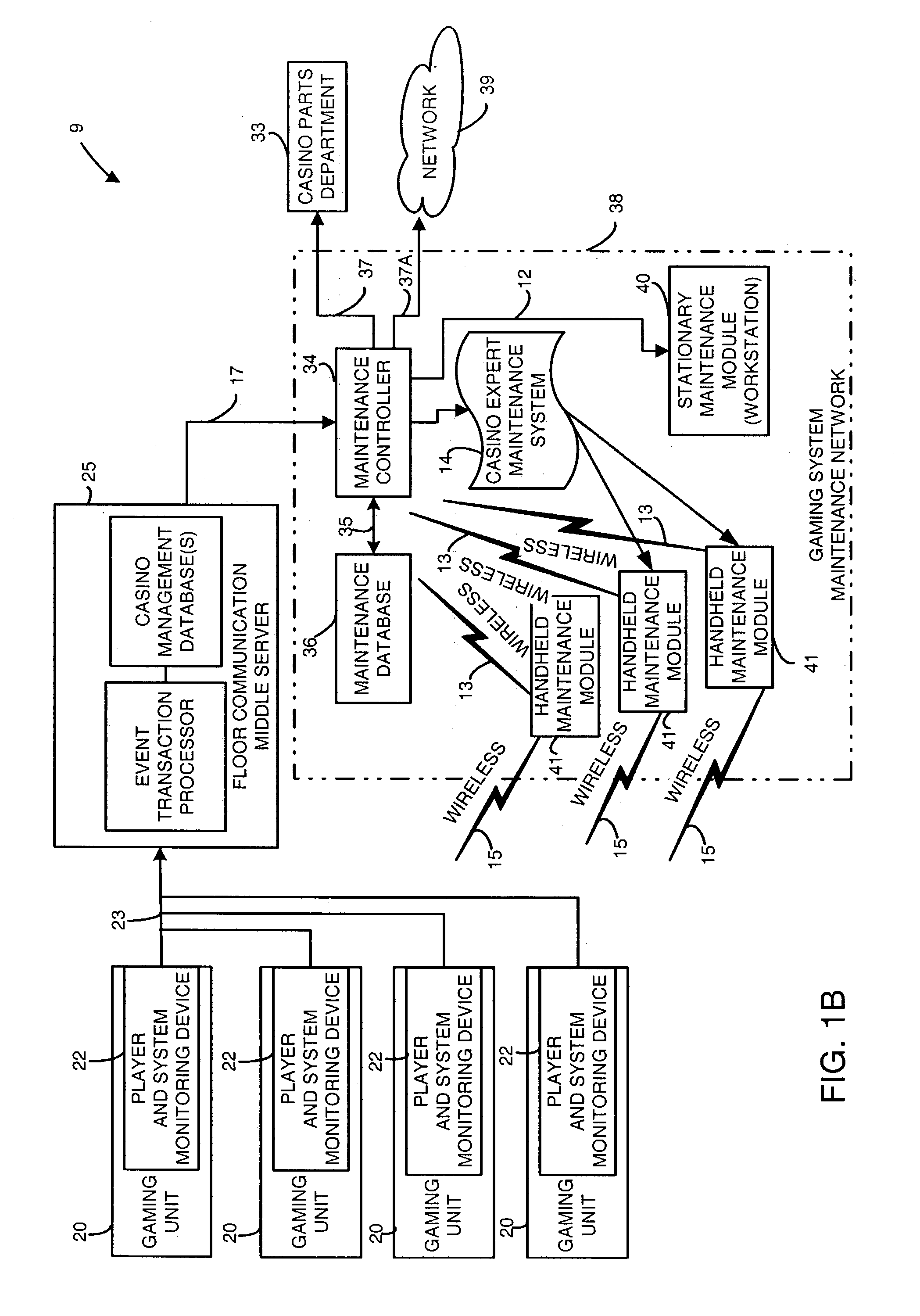

Gaming machine maintenance system and method

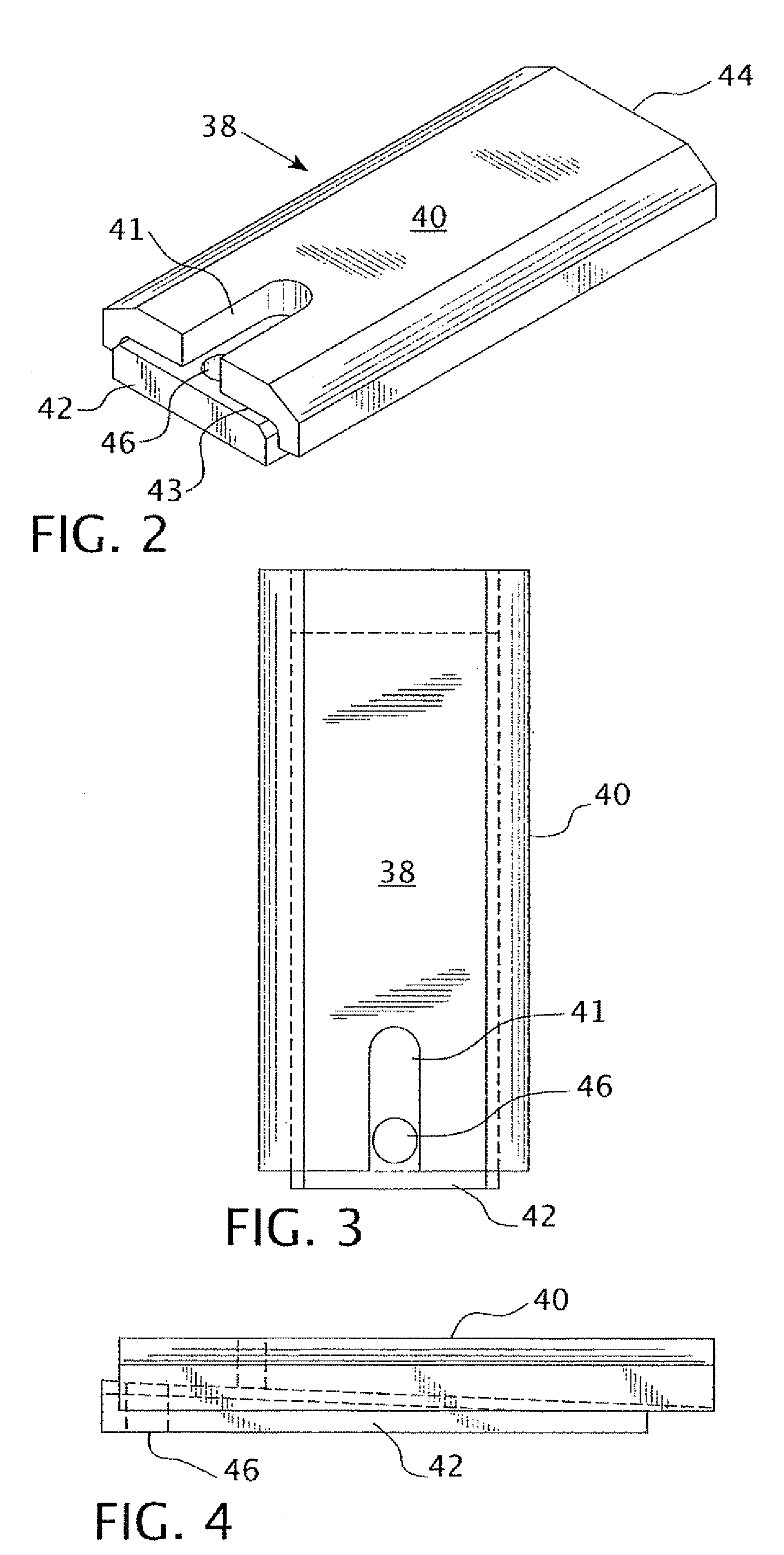

ActiveUS7201660B2Electric signal transmission systemsRadio/inductive link selection arrangementsWireless transceiverTransceiver

A handheld maintenance module may be provided with a display unit capable of generating video images, a wireless transceiver device capable of wireless dats transmission and reception and adapted to be wirelessly coupled to a maintenance controller, and a module controller coupled to the display unit and the wireless data transceiver device. the module controller may be programmed to allow a person to receive a gaming unit maintenance work order that represents a request for a repair of a gaming unit, to cause a video image representing the gaming unit maintenance work order to be displayed on the display unit, to cause a video image of one or more instructions to repair the gaming unit to be displayed, to allow the gaming unit maintenance work order to be closed upon completion of the repair of the gaming unit, and to forward repair data to the maintenance controller.

Owner:IGT

Working Machine Maintenance Work Management System

ActiveUS20090259507A1Improve accuracyWorking capability of the maintenance workplace is exceededForecastingSoil-shifting machines/dredgersMachine maintenanceOrder set

Owner:KOMATSU LTD

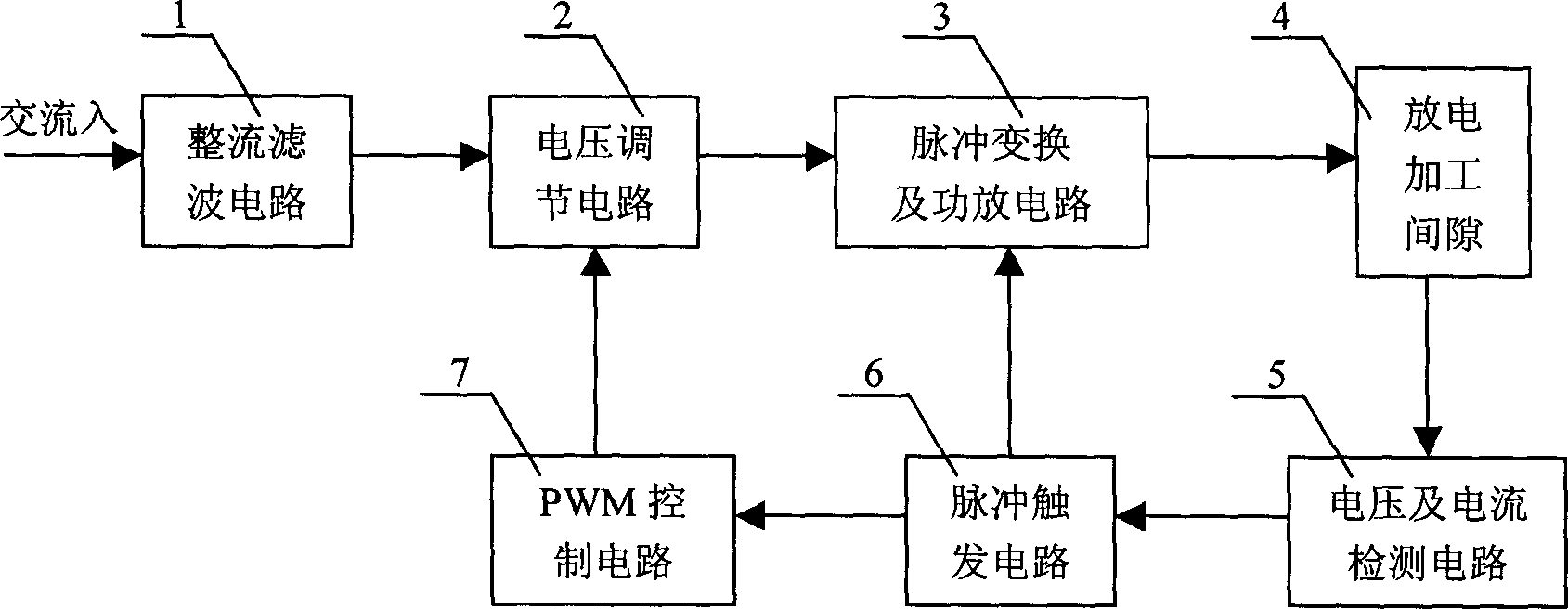

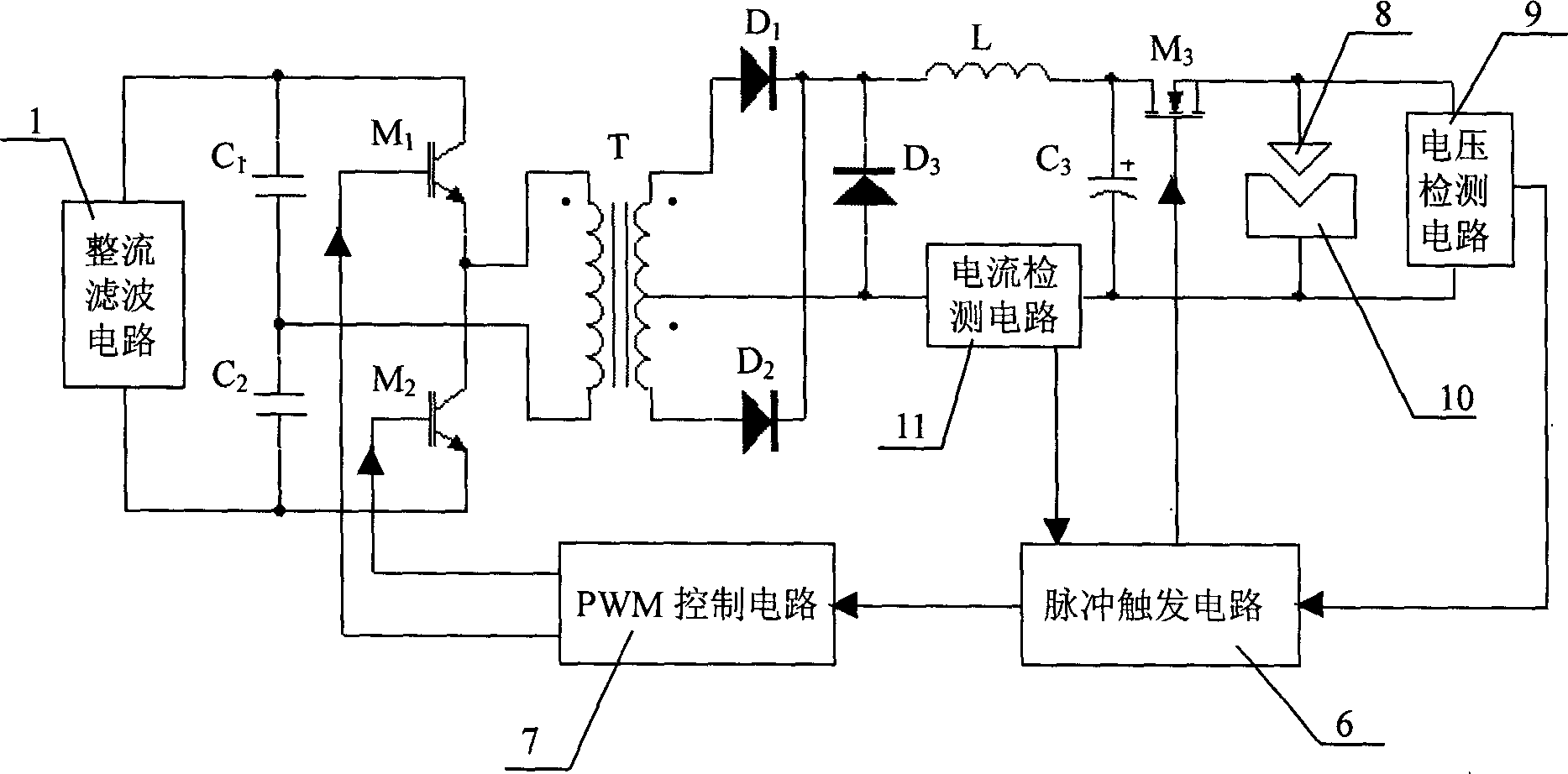

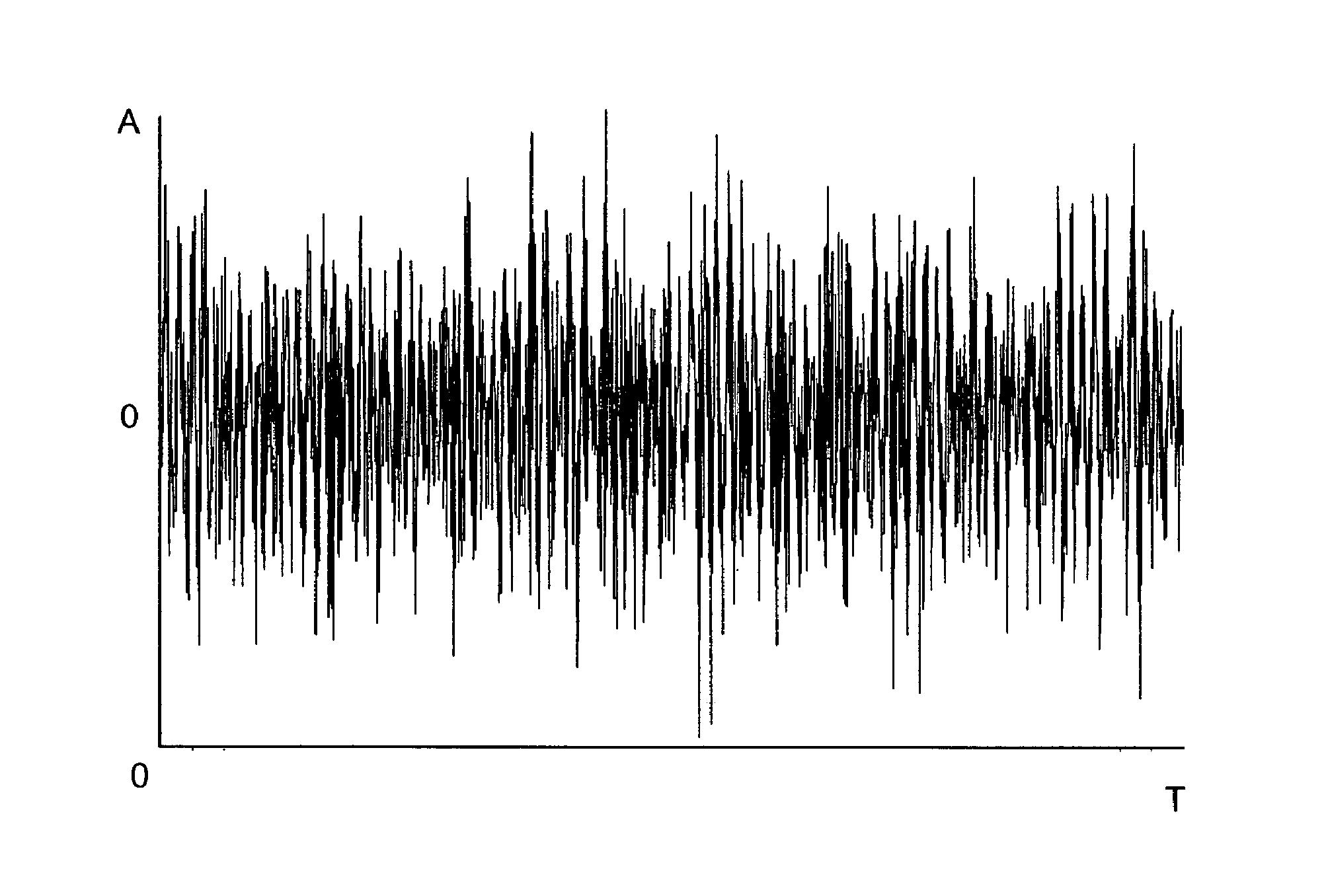

Voltage-regulating energy saving spark machining pulse power supply

ActiveCN1772425AIndependently adjustable pulse widthIndependently adjustable pulse intervalElectric circuitsMachine maintenanceEngineering

The present invention relates to machining technology, and is especially one voltage regulating energy saving spark machining pulse power supply. The pulse power supply includes rectification and filtering circuit, voltage regulating circuit, pulse converting and power amplifying circuit, voltage and current detecting circuit, pulse triggering circuit and PWM control circuit. The pulse power supply can provide no-load puncture voltage of about 100 V to the machining spark interval before puncture and machining maintenance voltage of about 25 V to the machining spark interval after puncture, and has the features of adaptive voltage regulation and equal current pulse width. The present invention can realize the independent regulation of pulse voltage, pulse width and pulse interval in wide ranges, and has no current limiting resistor with high power consumption and thus 2 times raised electric energy utilization rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

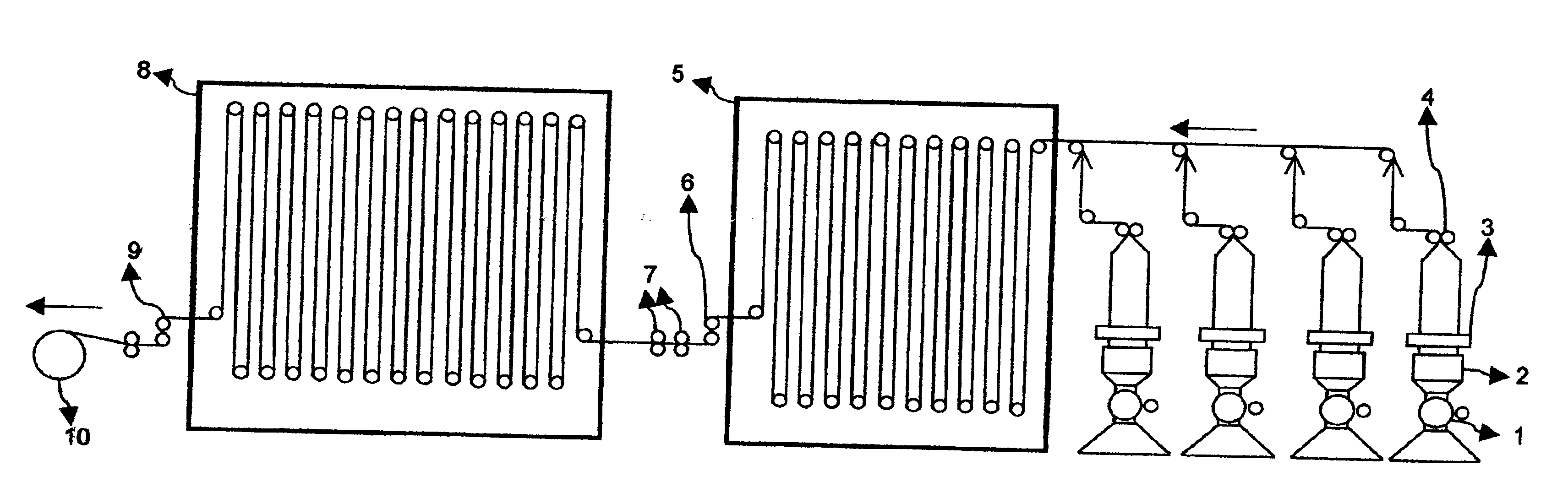

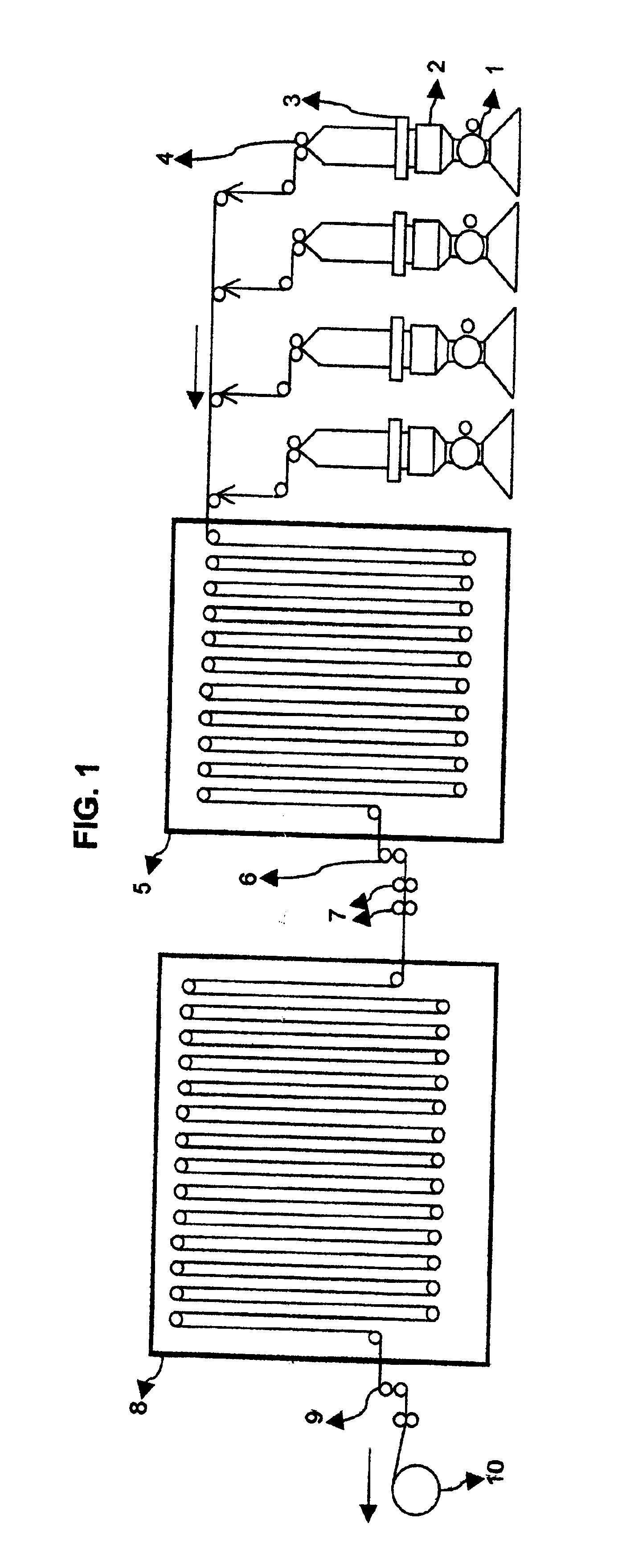

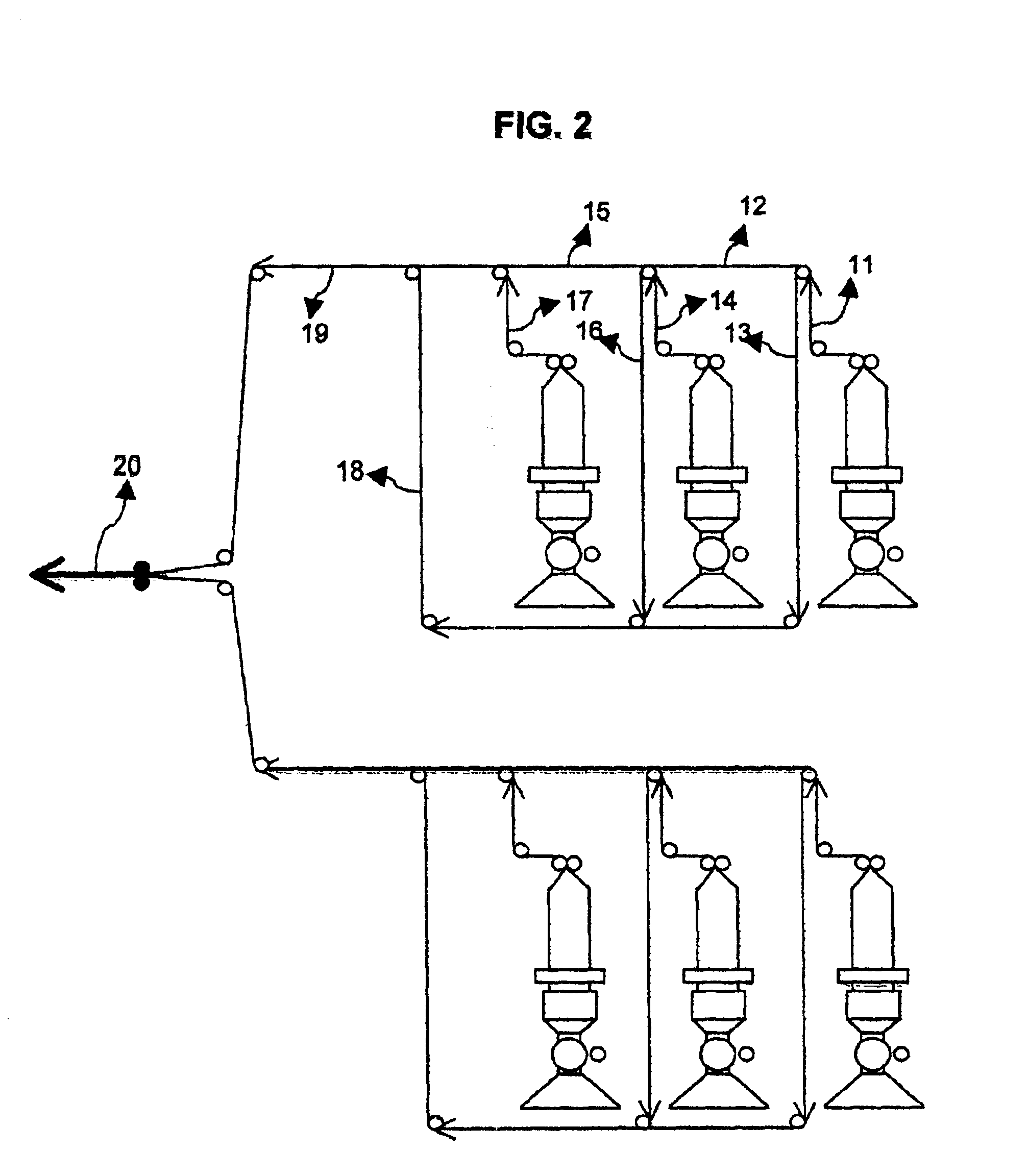

Continuous methods of making microporous battery separators

InactiveUS6878226B2Improve production yieldReduce operating costsLamination ancillary operationsSynthetic resin layered productsPolypropyleneMachine maintenance

A continuous method of making dry-stretch microporous membrane battery separators from polypropylene (PP) or polyethylene (PE) or both benefits to the manufacturers in the production efficiency. The precursor-film extrusion in this invention is accomplished by multiple small film-extrusion lines at a compatible line speed with the followed oven processes (annealing and stretching). The overall production process starts continuously from film extrusion to annealing and to stretching. The benefits of the inventive continuous process includes a higher product yield, more effective oven-time usage, no need to handle and manage the intermediate products, less need in labor and machine maintenance, and potentially more stable product quality.The dry-stretch membrane separators made with this inventive continuous method include (1) single-ply PP or PE separators having a thickness ranging from 0.2 mil to 2.0 mil; (2) PP / PE / PP trilayer microporous membrane separators having a thickness ranging from 0.6 mil to 4.0 mil. The PP / PE / PP trilayer can be accomplished in the early extrusion via either co-extrusion or extruding separately and then interposing PE layer between two PP layers, continuously, right before annealing / bonding and stretching process.

Owner:YU WEI CHING

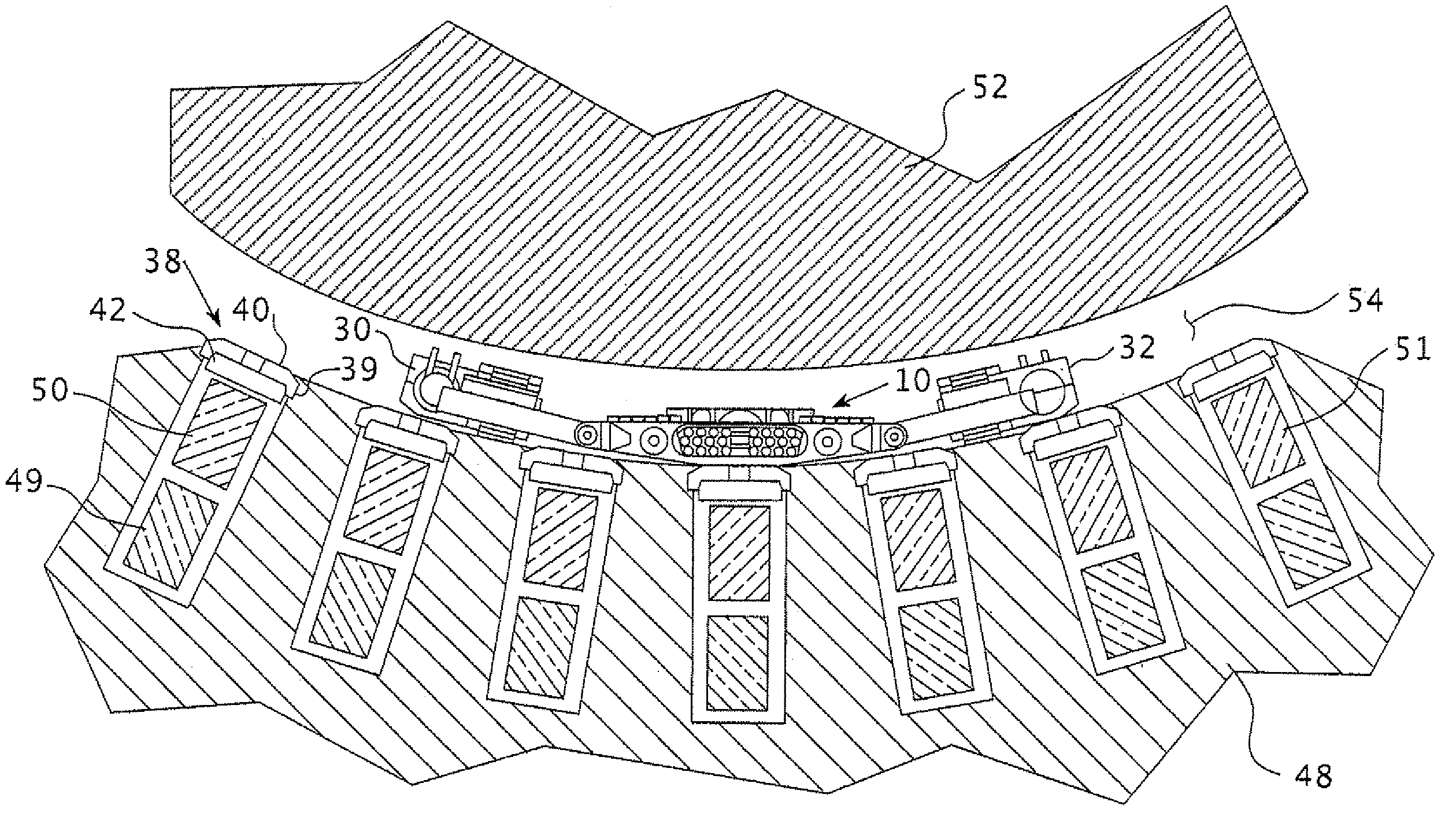

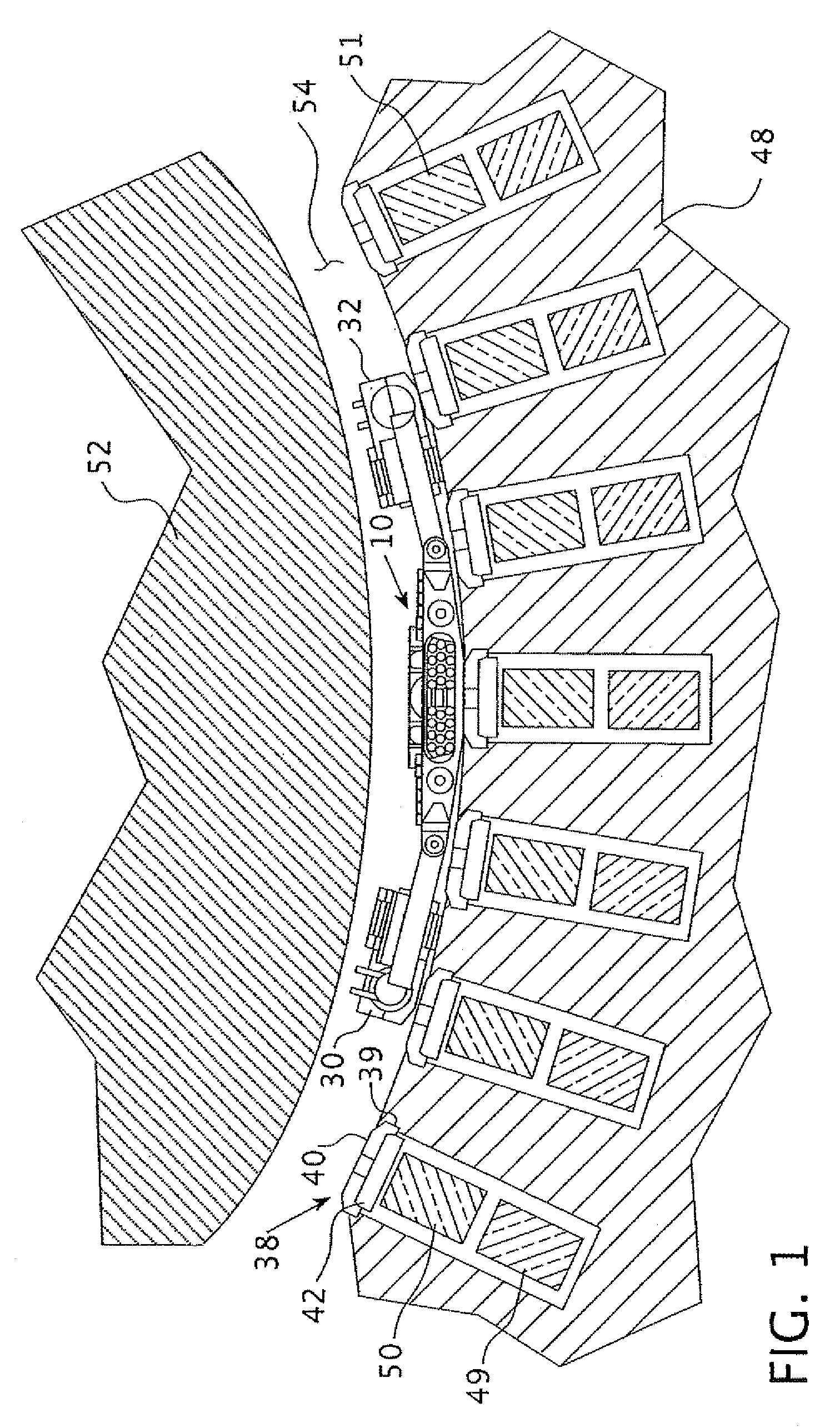

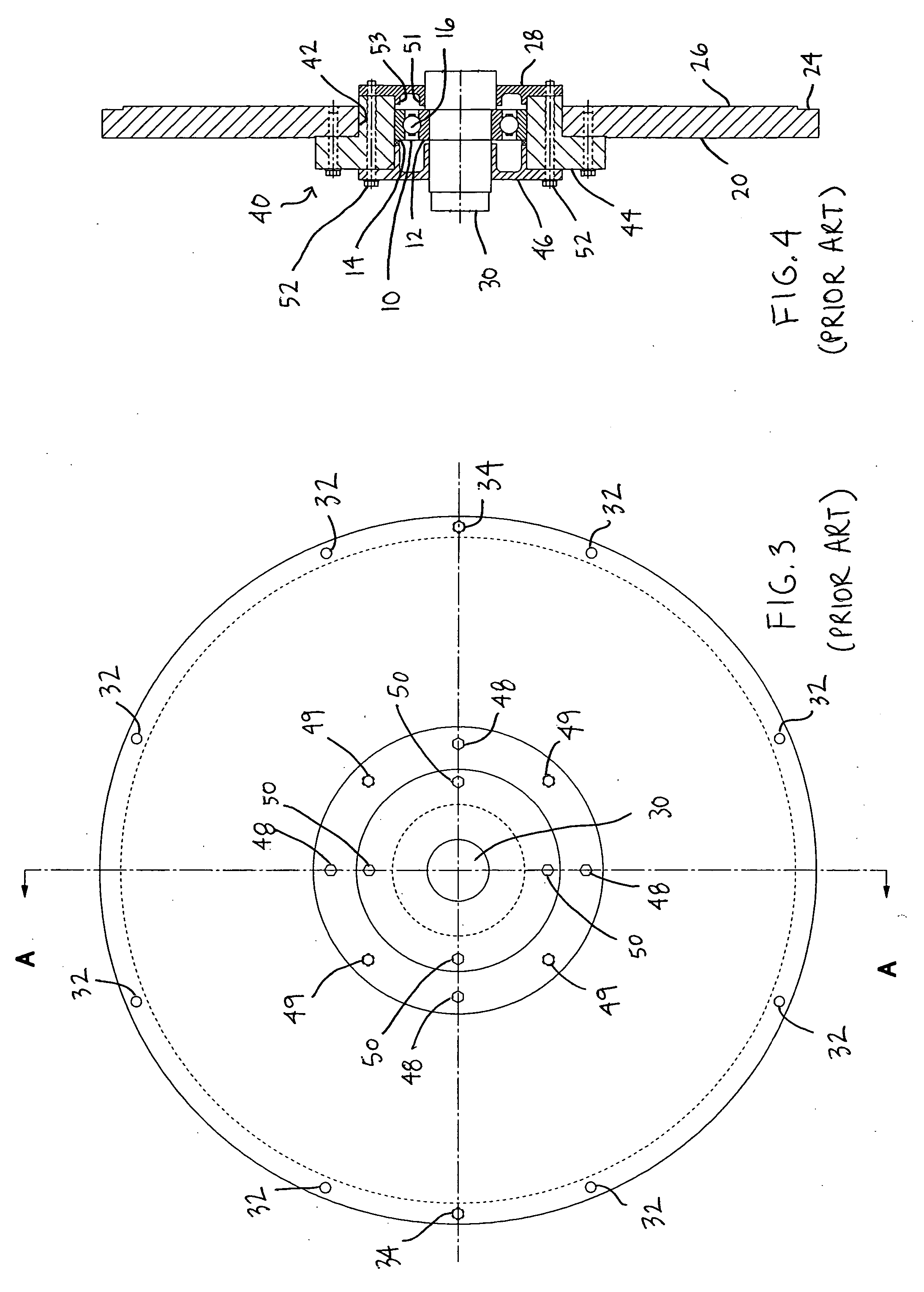

Automated remote carriage for tightening generator wedges

ActiveUS7866421B2Increase widthDigital data processing detailsColor television detailsRemote controlMachine maintenance

Owner:SIEMENS ENERGY INC

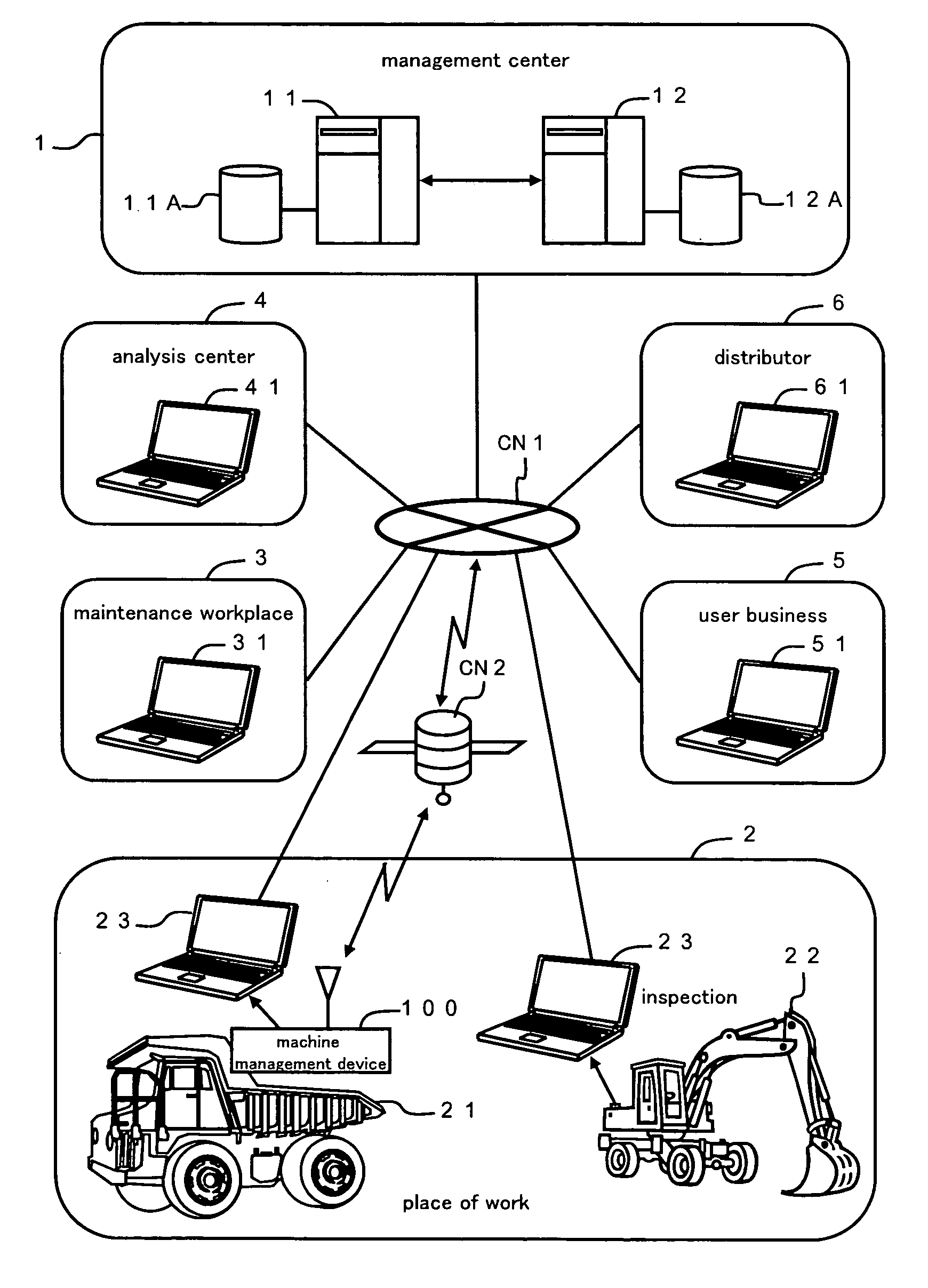

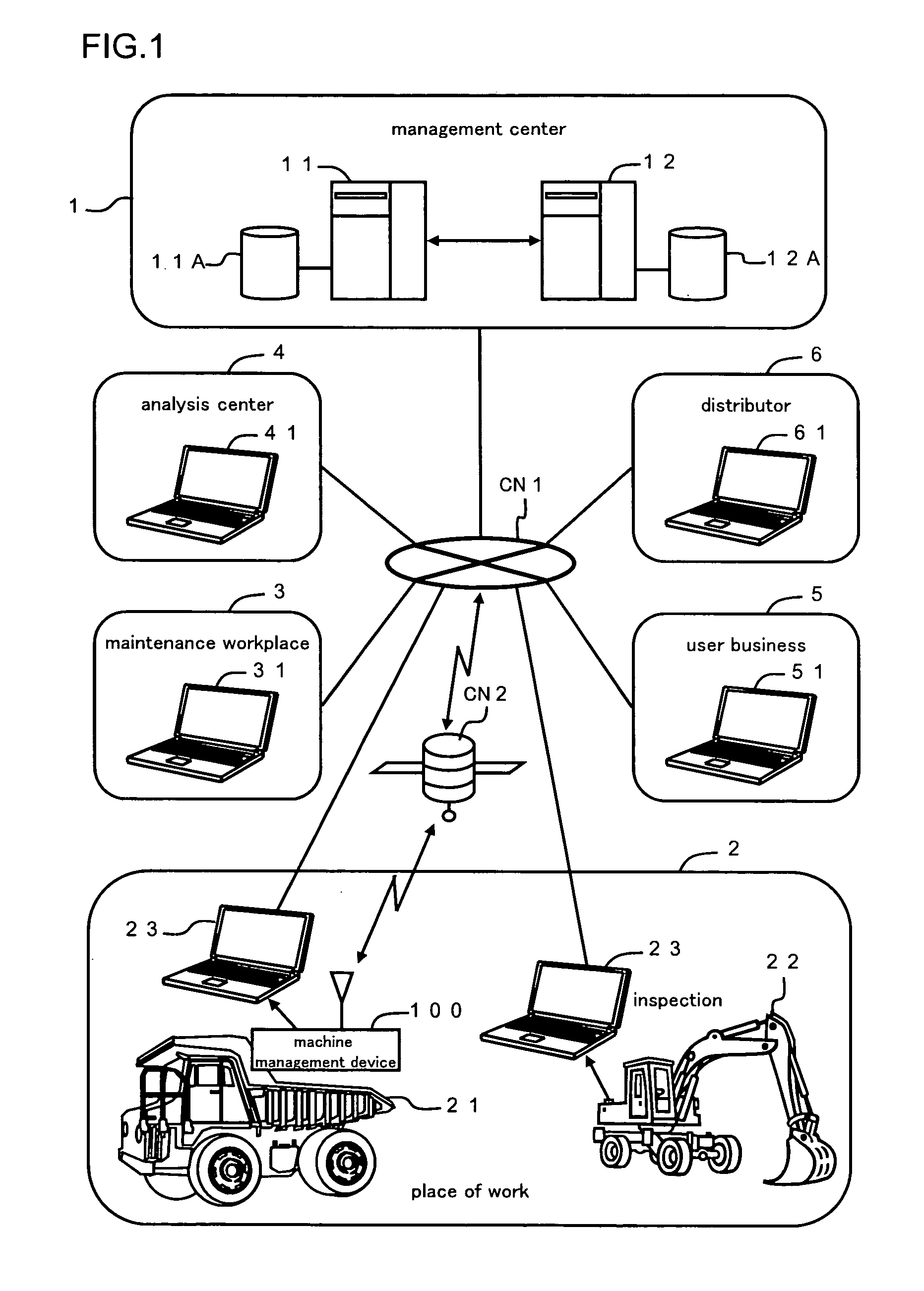

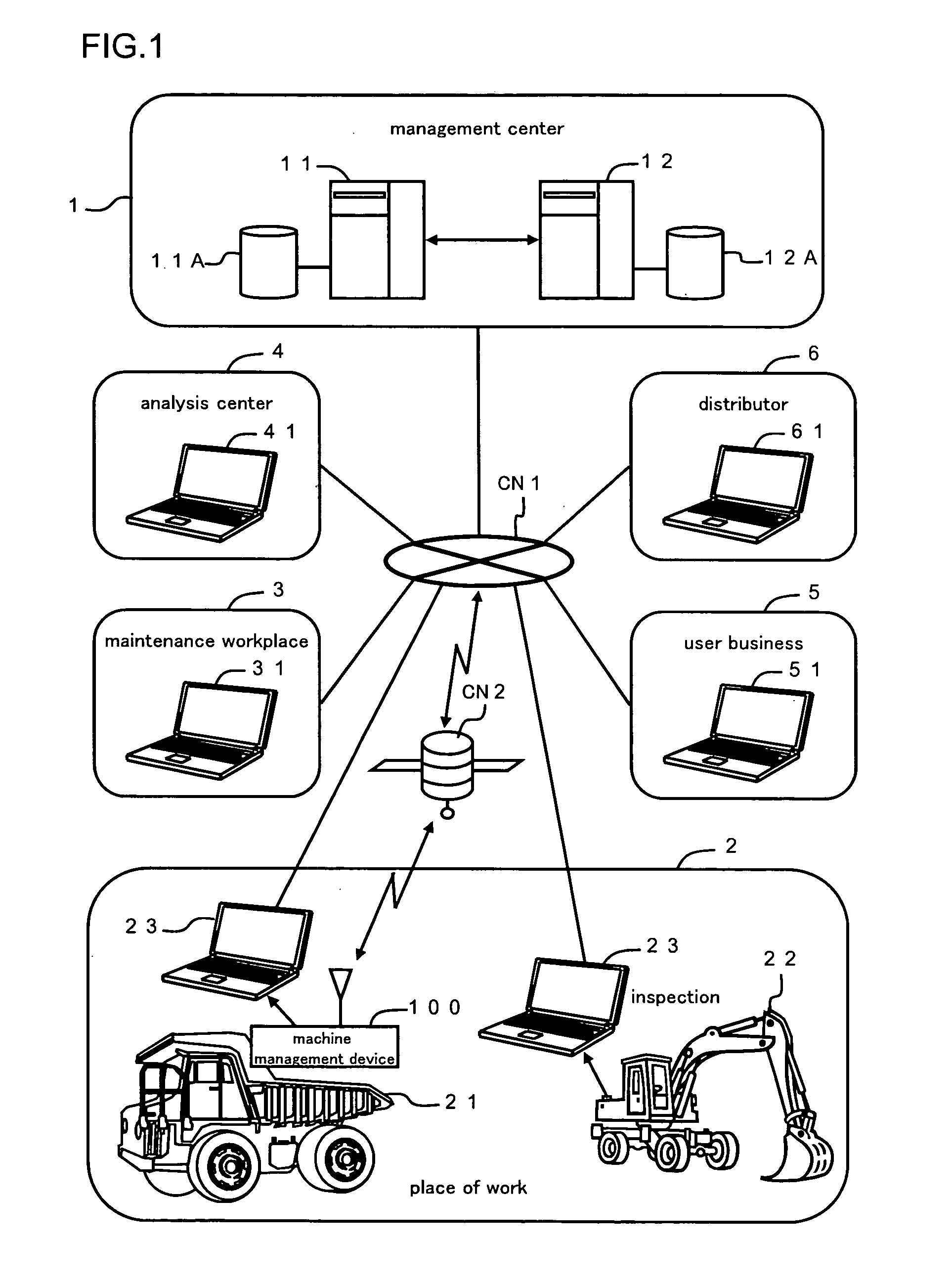

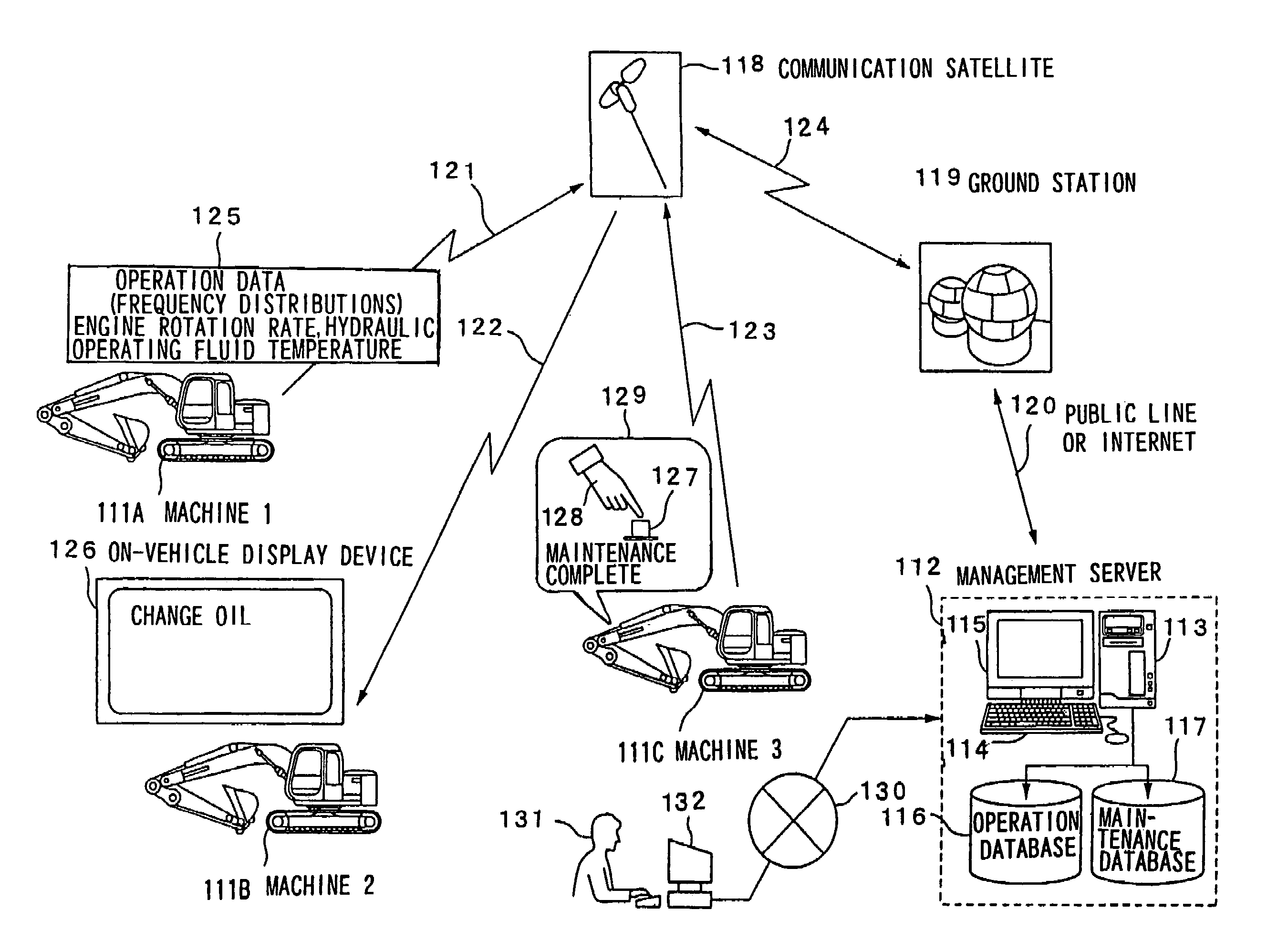

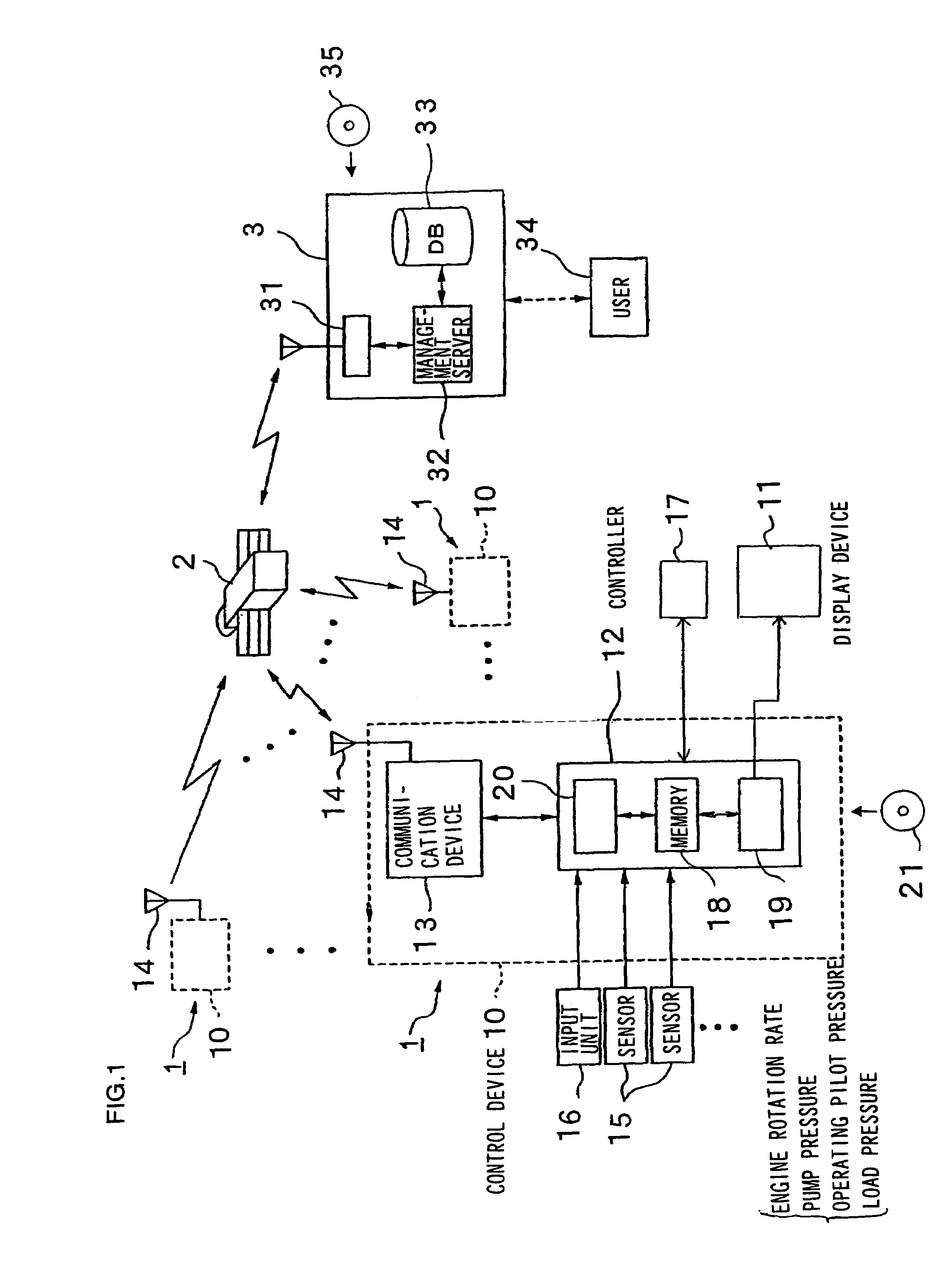

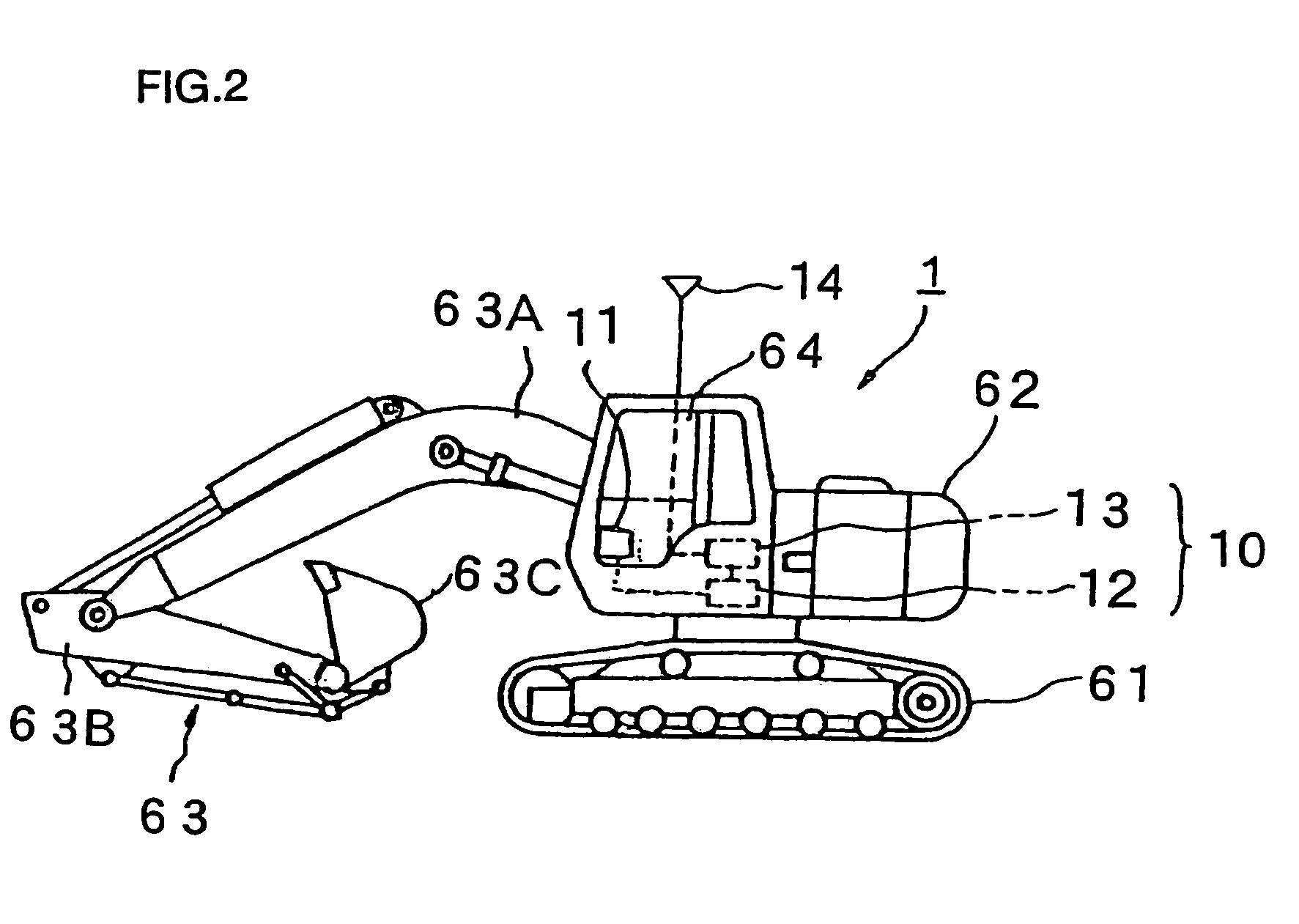

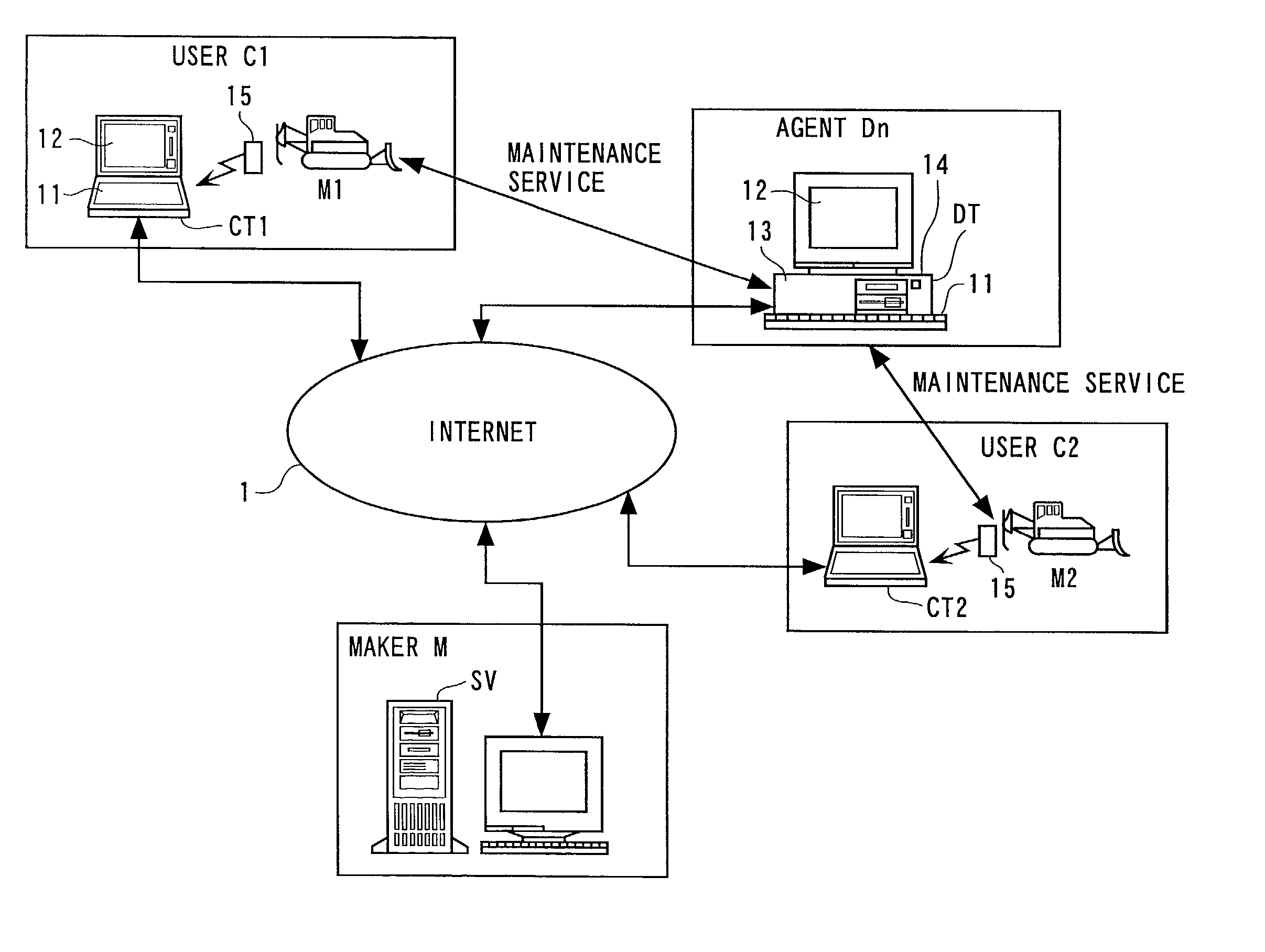

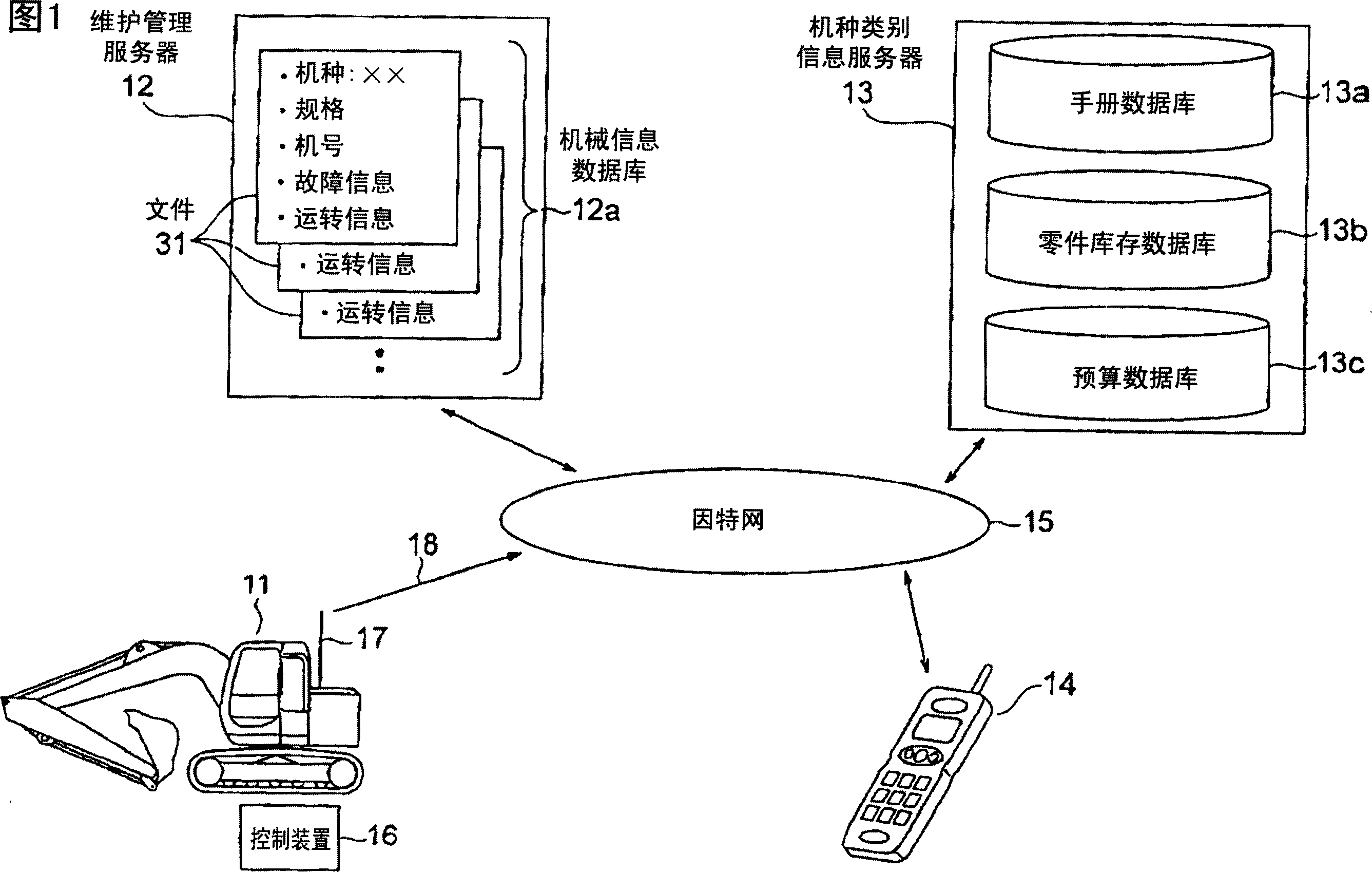

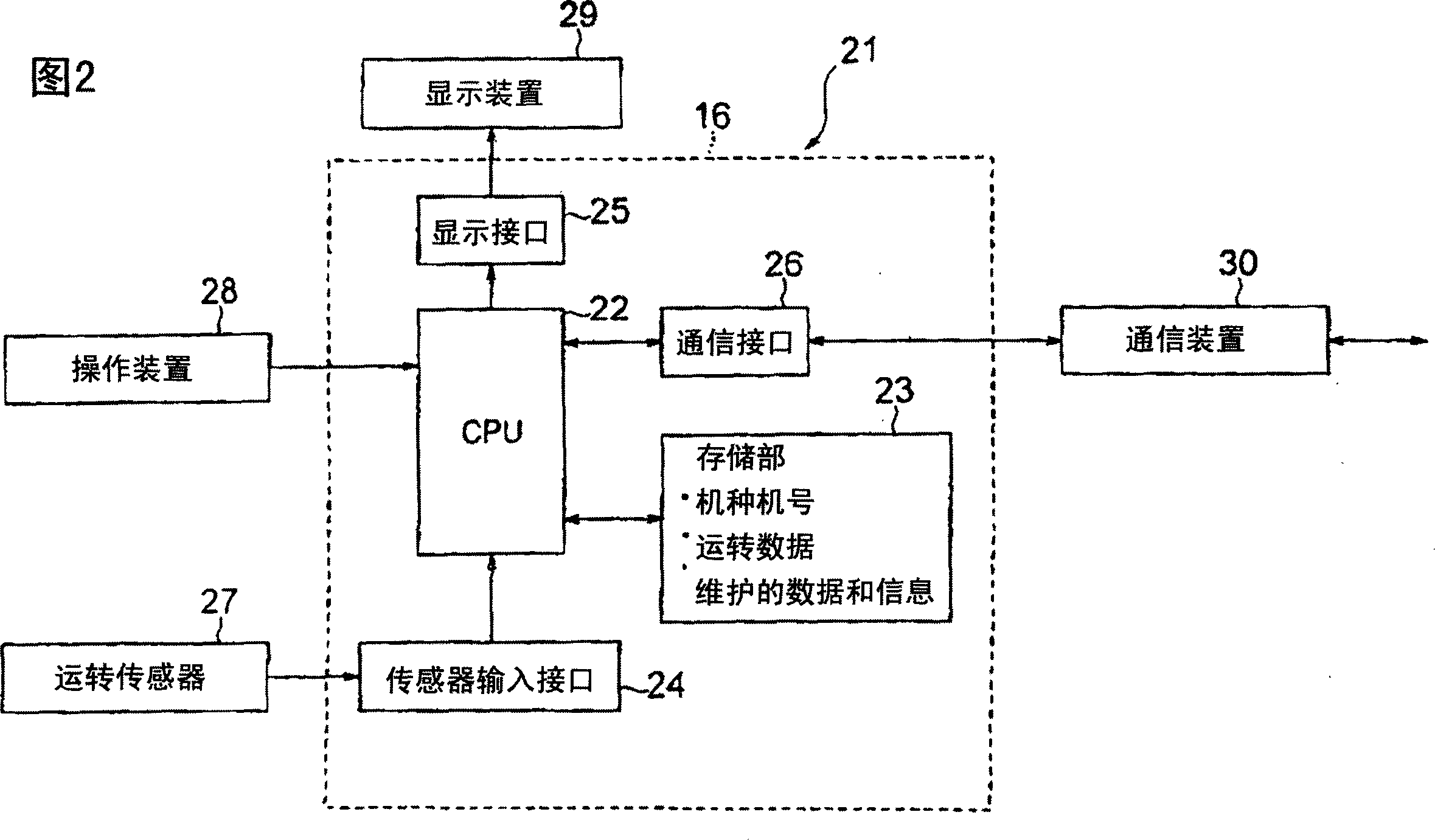

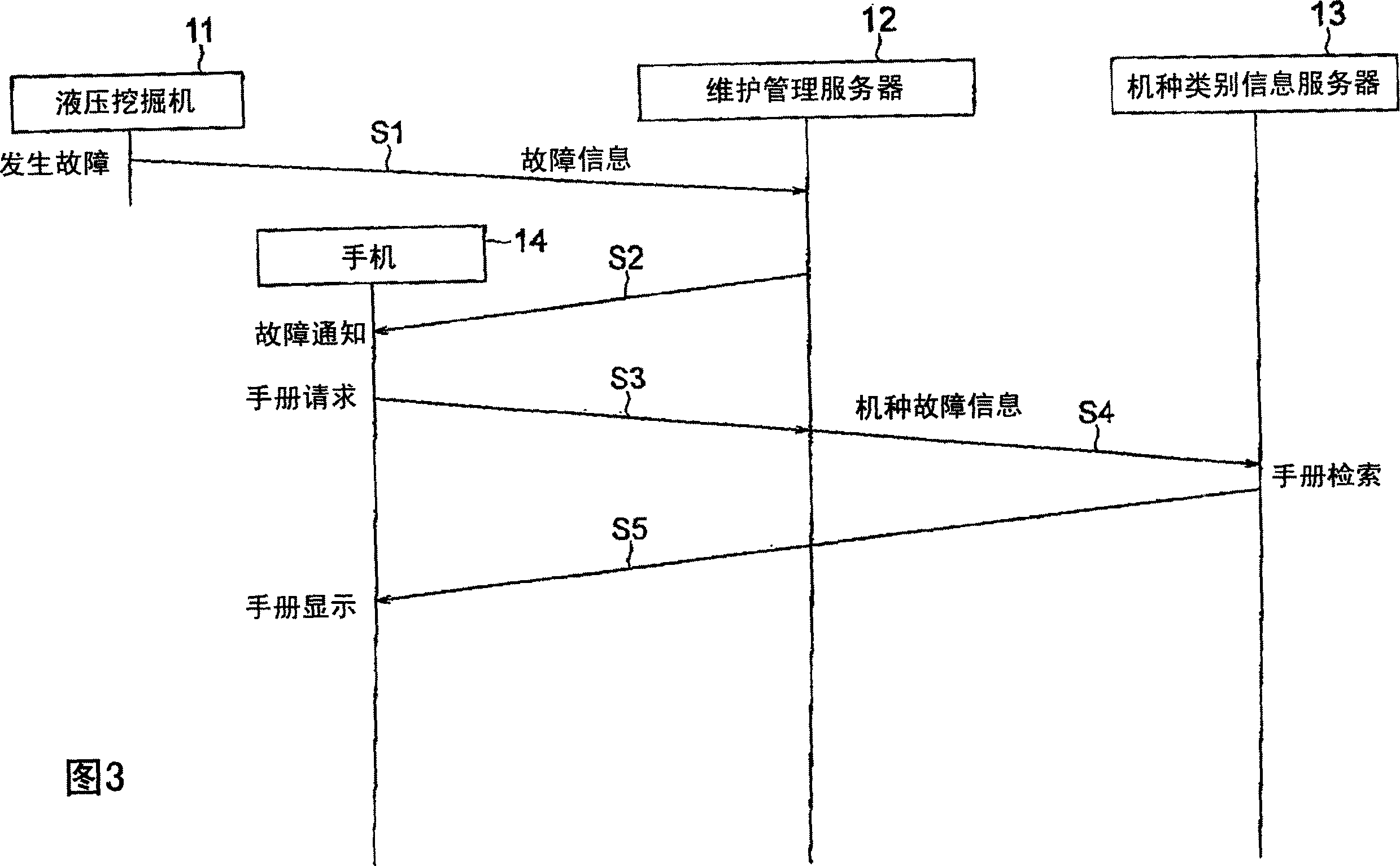

Working machine, failure diagnosis system for work machine and maintenance system for work machines

InactiveUS7222051B2Guaranteed to workAnalogue computers for vehiclesAnalogue computers for trafficMachine maintenanceDisplay device

A working machine maintenance system having a plurality of working machines. A center server is provided that manages maintenance on the plurality of working machines by engaging in data exchange through bidirectional communication with each of the plurality of working machines via a communication line. The working machines each include an operation data storage device, an operation device operated to enter a maintenance work completion, a data transmission device, a data reception device, and a display device at which the maintenance information is displayed. The center server includes a data reception device that receives the operation data, the maintenance work completion data, and the maintenance data that have been transmitted, an operation database in which the operation data are stored, a maintenance database, a calculation device that calculates maintenance timing. and a data transmission device that transmits data related to the maintenance information.

Owner:HITACHI CONSTRUCTION MACHINERY CO LTD

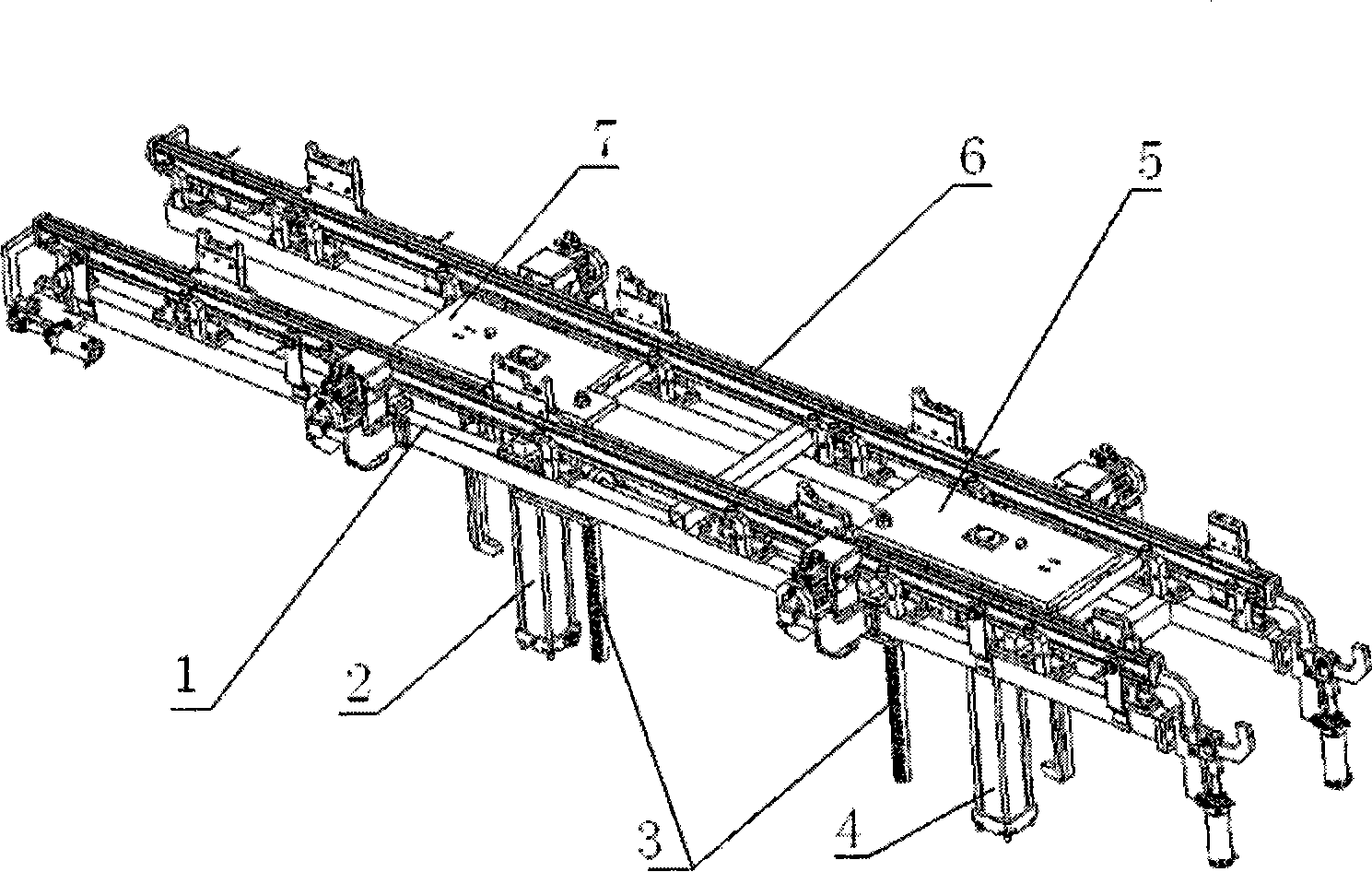

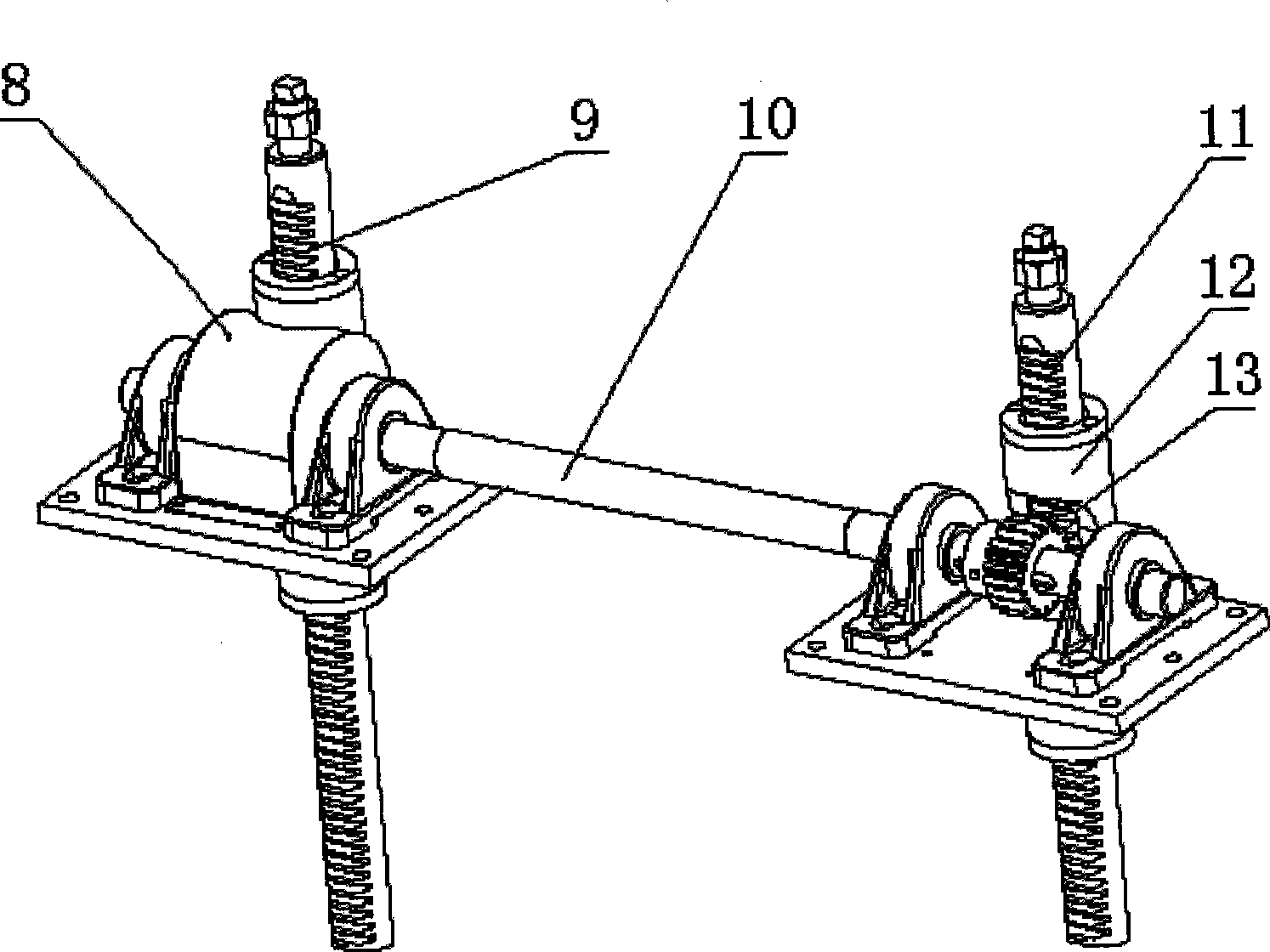

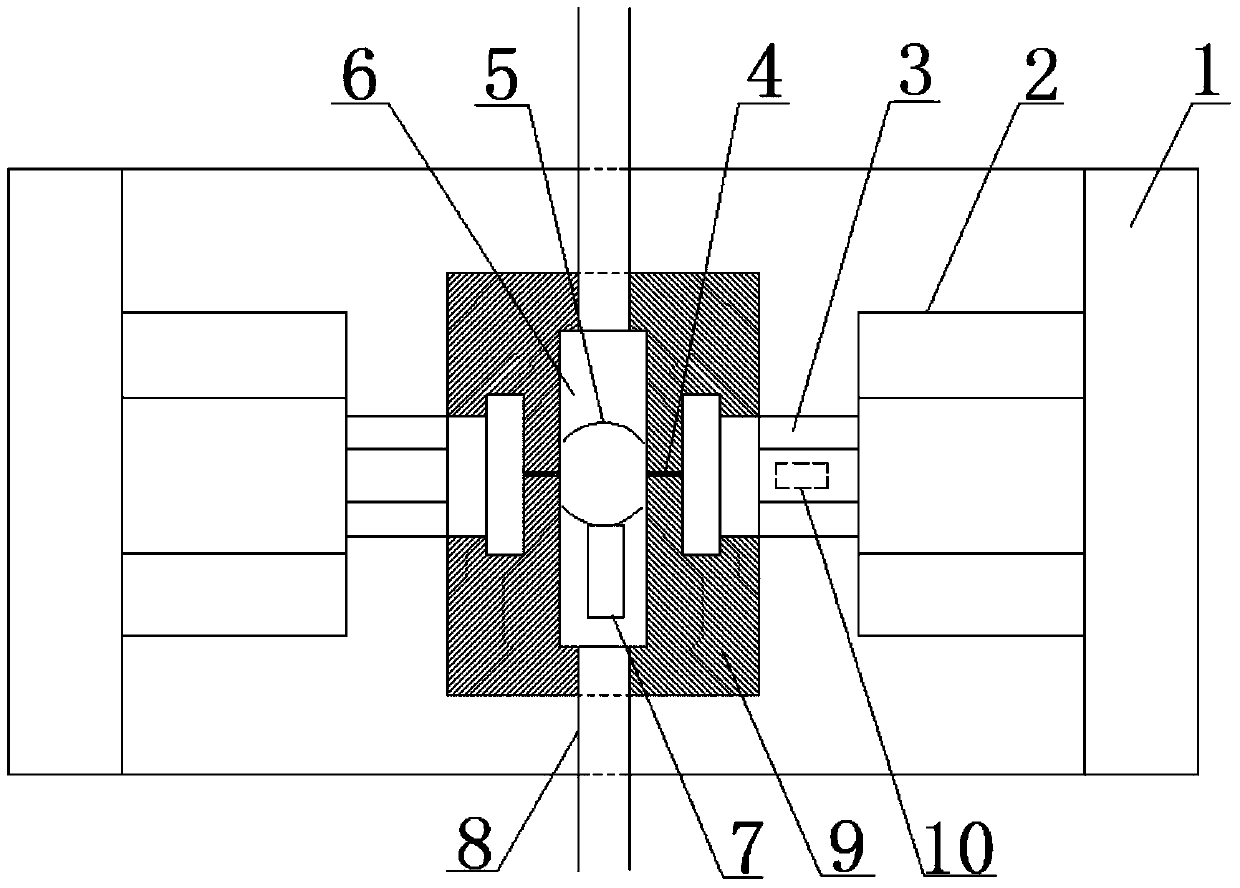

White car body assembly product line ski reciprocation conveying system branch station lifting mechanism

ActiveCN101428660AReduce kinetic energy lossPromote repairConveyor partsVehiclesProduction lineMachine maintenance

The invention discloses a substation lifting mechanism for a skid round trip conveying system on a sedan white body assembly production line. The invention has a plurality of substation lifting mechanisms with the same structure, and each substation lifting mechanism comprises an erect first steam cylinder (2) under a first mounting plate (7) within a skid (6), an erect second steam cylinder (4) under the second mounting plate (5) inside the skid (6) and a synchronizer (3) which keeps the lifting speed of the first steam cylinder (2) in accordance with that of the second steam cylinder (4). The substation lifting mechanism for the skid round trip conveying system on the sedan white body assembly production line adopts the structure which can reduces the kinetic energy consumption, is convenient to maintenance, and relieves the workload of machine maintenance.

Owner:ANHUI RUIXIANG IND

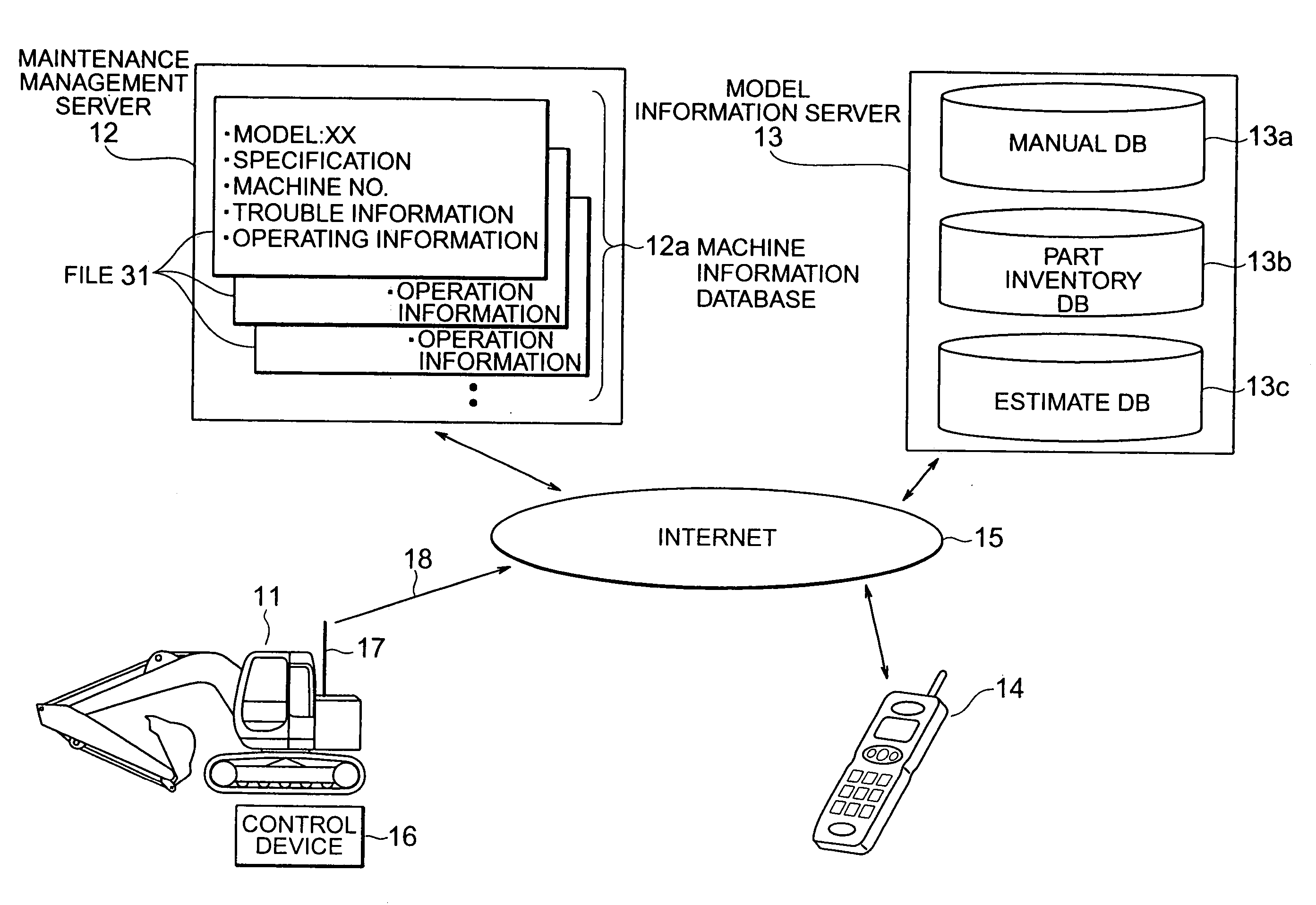

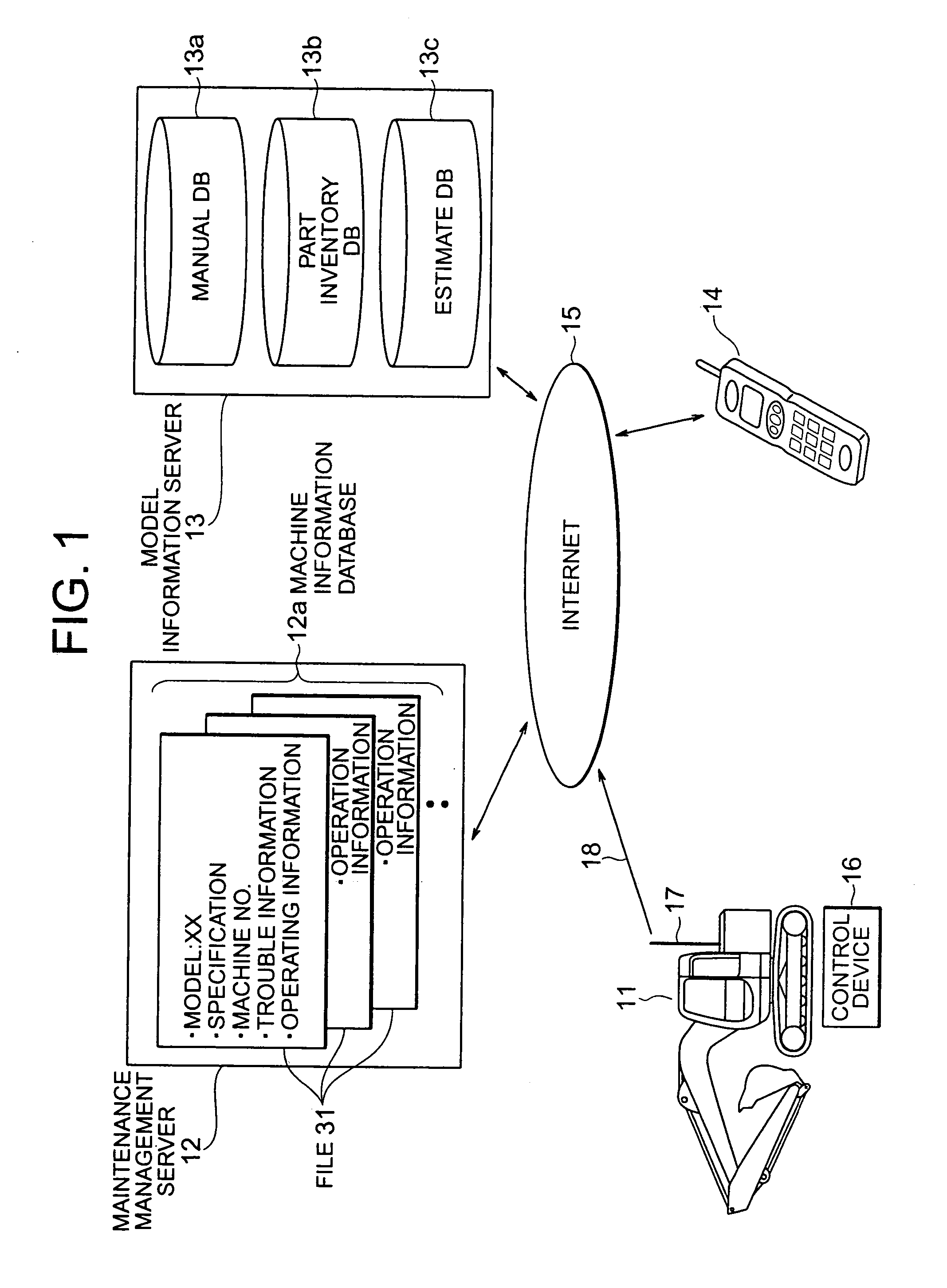

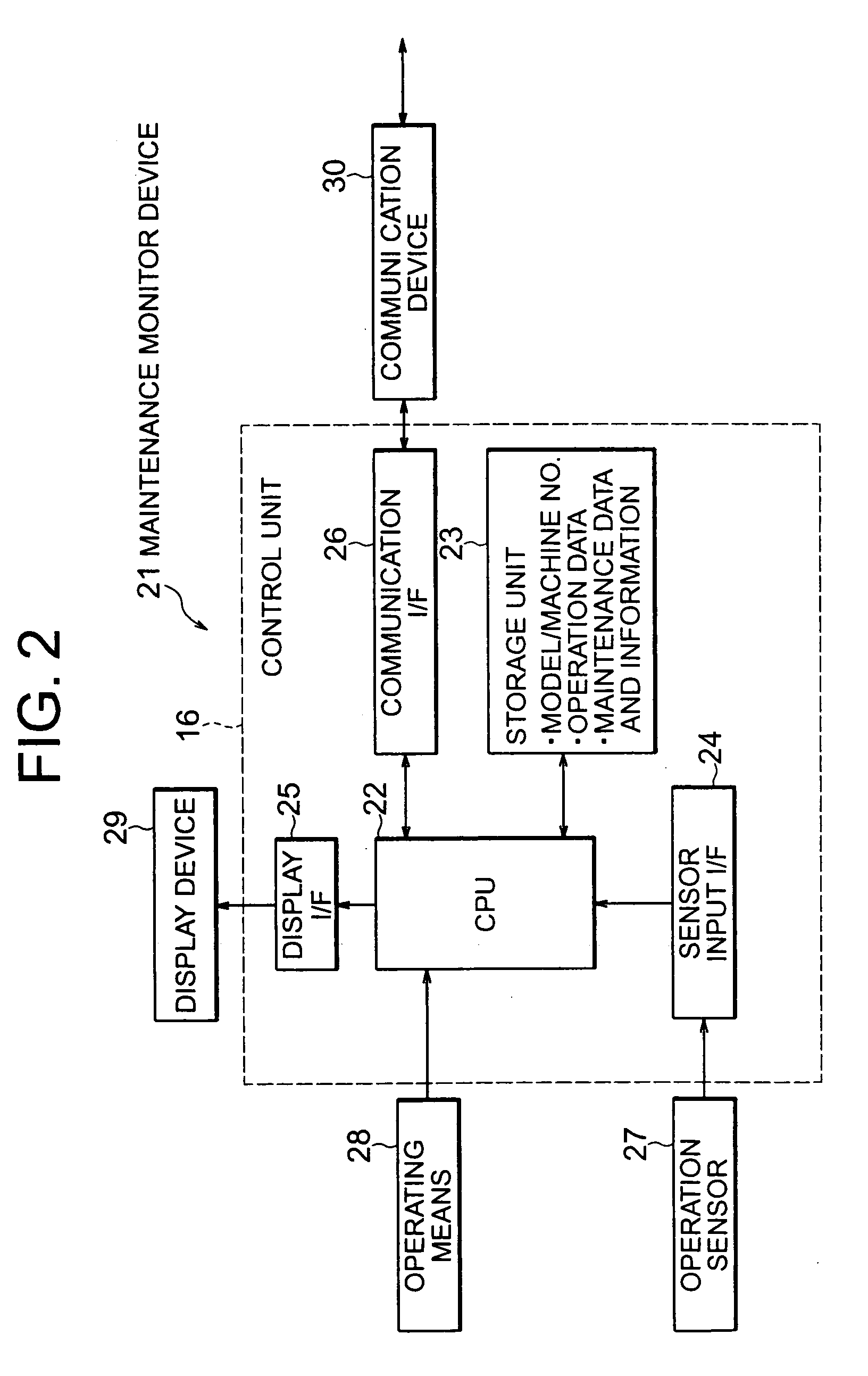

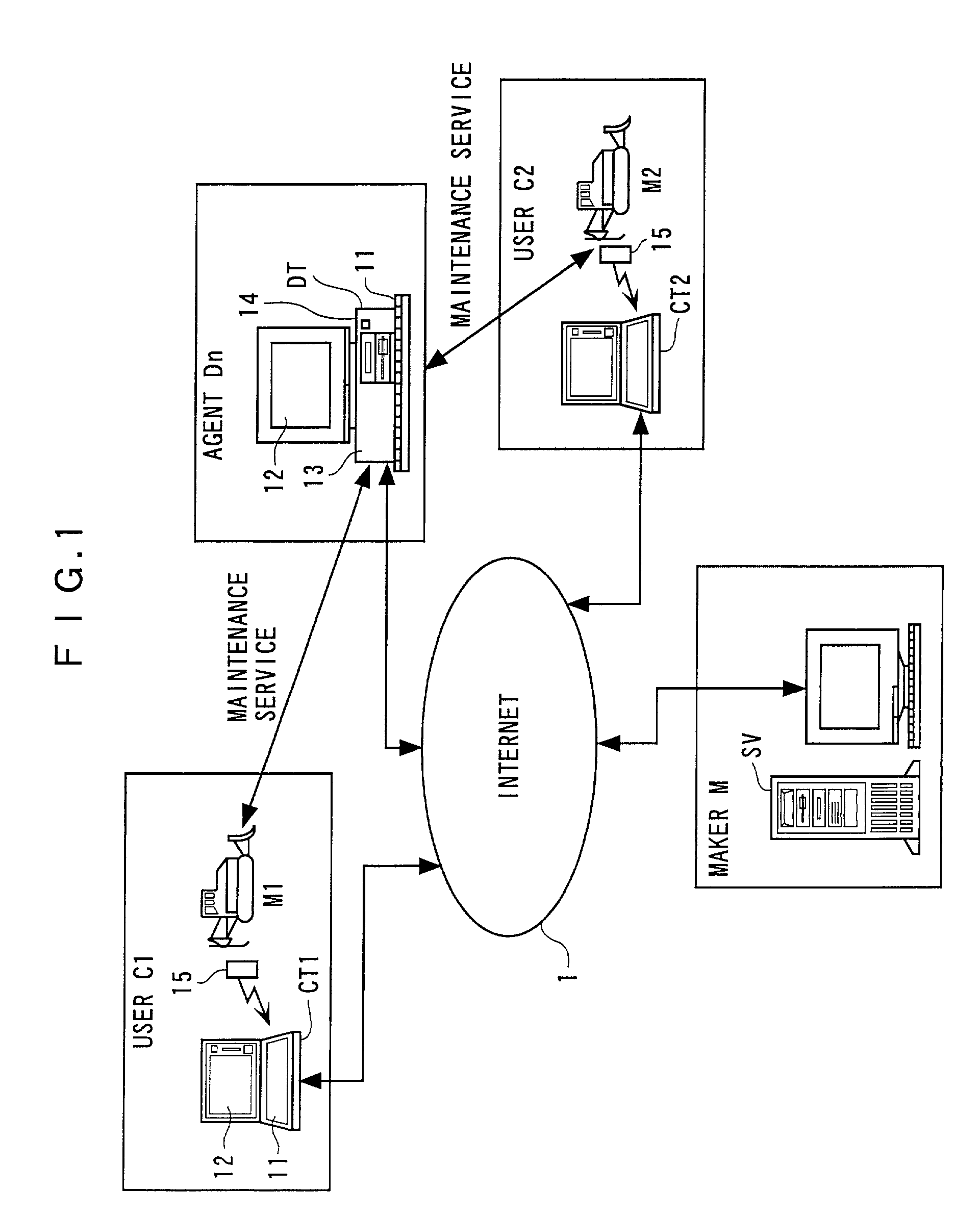

Work machine maintenance system

InactiveUS7287188B2Easy to determineEasy to processData processing applicationsError detection/correctionService personnelSystems management

A maintenance system of a hydraulic excavator (11) is provided with a maintenance monitoring device (21), a maintenance management server (12) for managing trouble information and operating information for each working machine, a model information server (13), and a service personnel mobile terminal (14) connected to one another through the Internet (15). When trouble occurs in the hydraulic excavator, the maintenance system (21) transmits trouble information to the maintenance management server (12), and the maintenance management server (12) transmits information on occurrence of trouble to the mobile terminal (14) and displays it on a display unit. This system manages the maintenance manuals and other data for each model in a model information database separate from the maintenance database and correlates the two databases based on the model data.

Owner:NIHON KENKI CO LTD

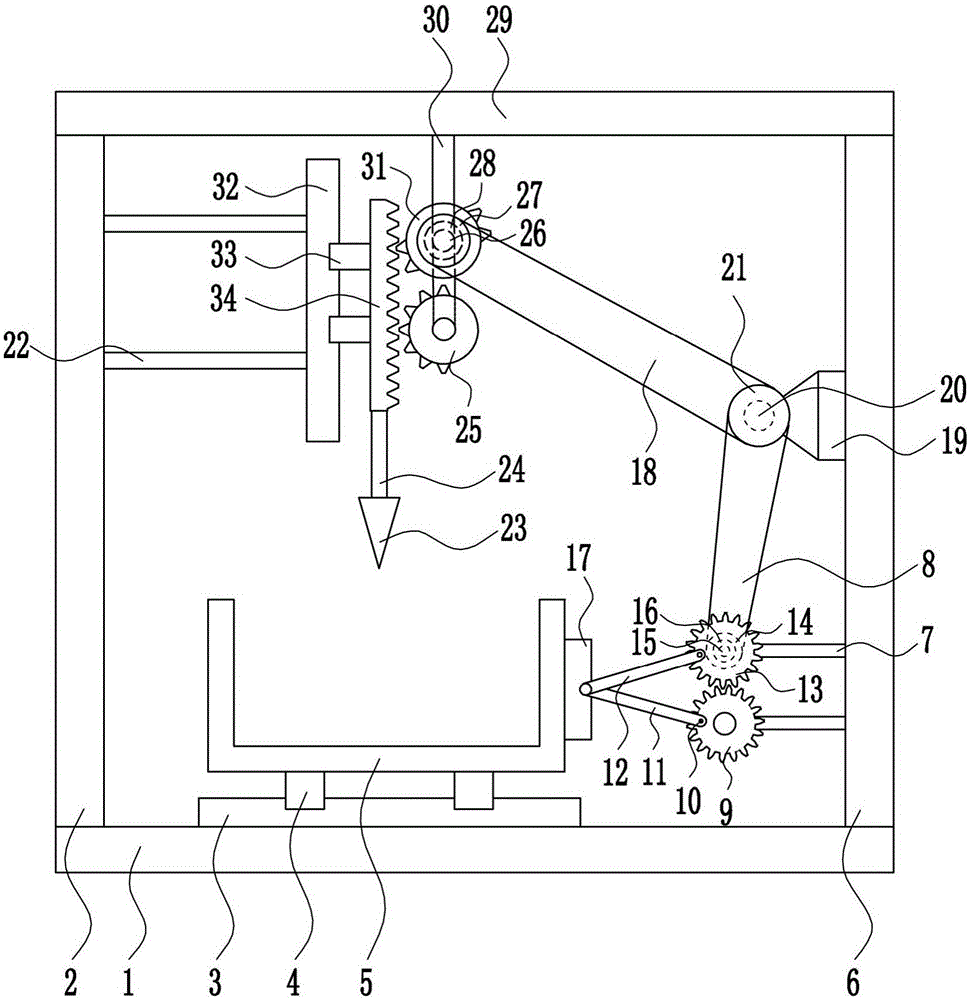

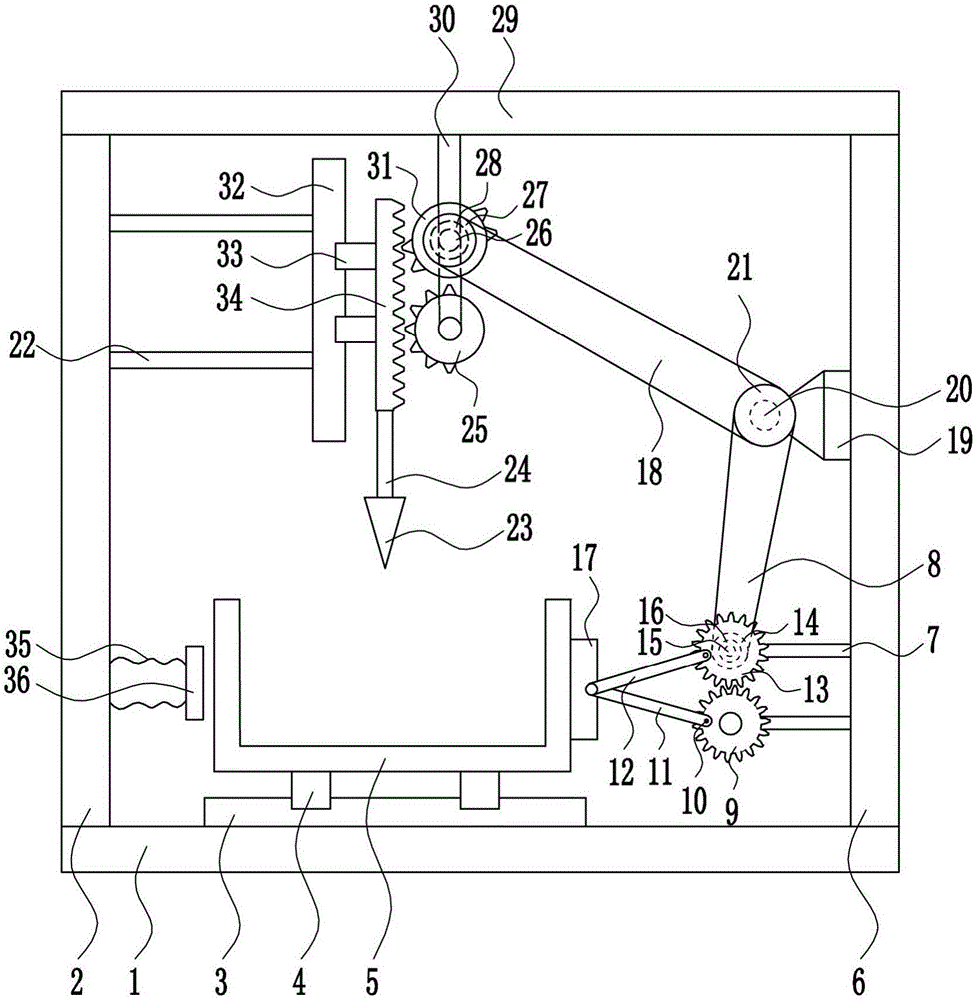

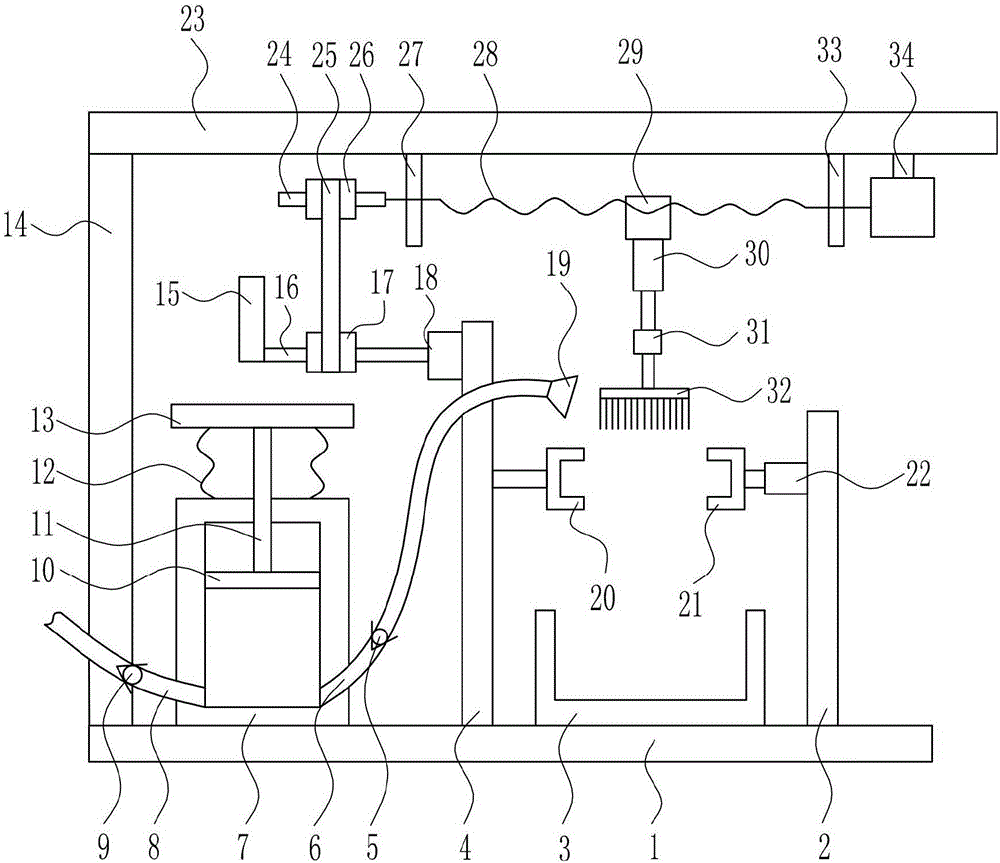

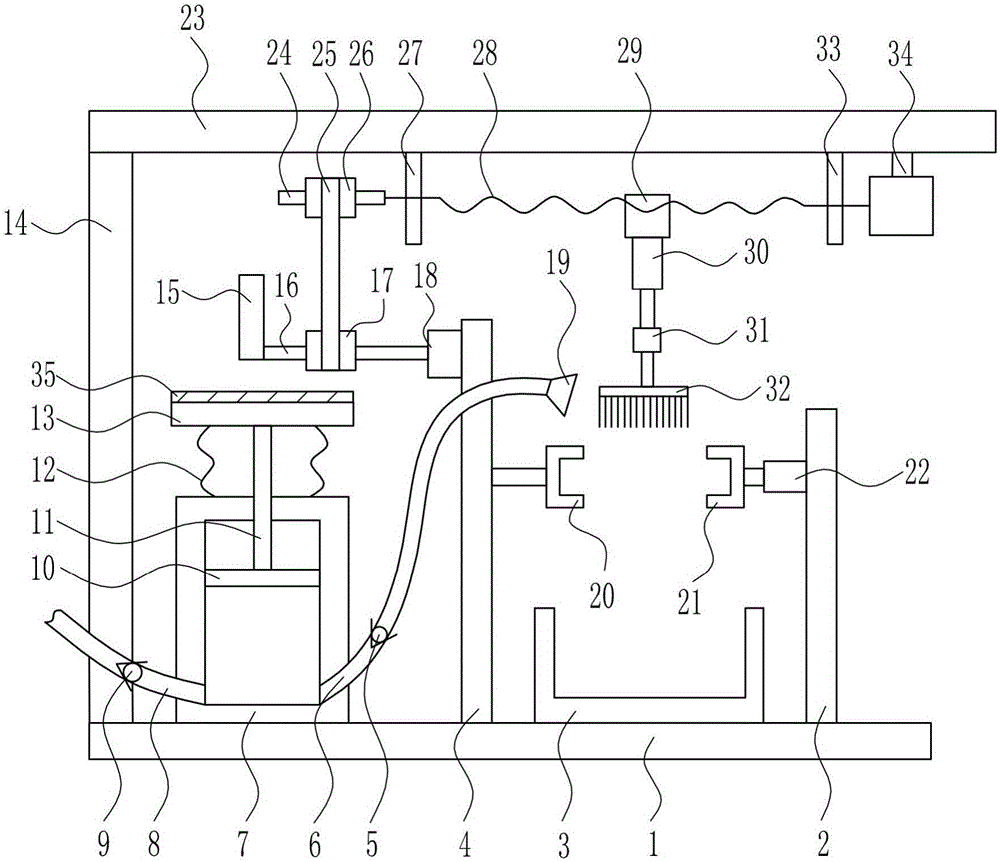

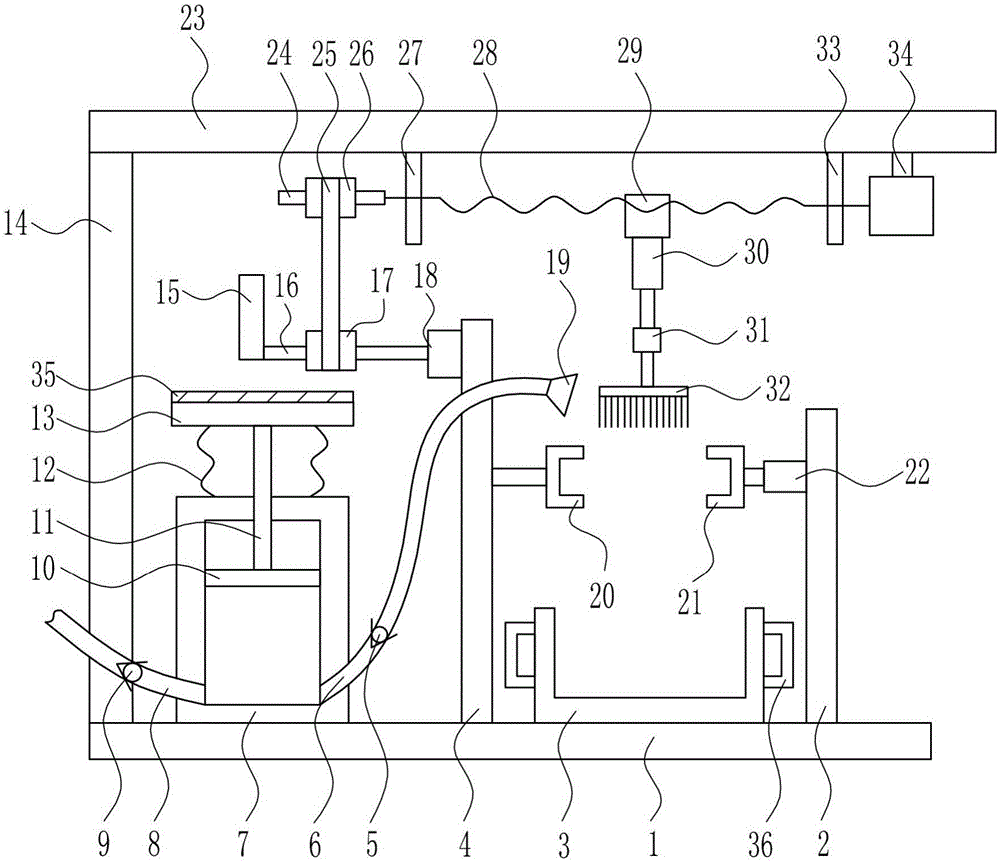

Pasture treatment equipment for animal husbandry breeding

The invention relates to pasture treatment equipment, in particular to pasture treatment equipment for animal husbandry breeding. The invention aims to solve the technical problem and provide the pasture treatment equipment for the animal husbandry breeding, having the advantages of high treatment efficiency, quick treatment speed and convenient operation. For solving the technical problem, the invention provides the pasture treatment equipment for the animal husbandry breeding; the pasture treatment equipment comprises a baseboard, a left stand, a first slide rail, a first slider, a treatment frame, a right stand, a fixing rod, a first flat belt, a first gear, a hinge part, a first connecting rod and the like; the left stand is welded at the left side of the top of the baseboard, two fixing stands are welded at the upper part of the right side of the left stand, and the right sides of the two fixing stands are connected with a second slide rail in a bolt connection manner. The pasture treatment equipment has the effects of high treatment efficiency, quick treatment speed and convenient operation, can be used to reduce machine maintenance time and save a great amount of manpower, and has a good treatment effect.

Owner:吴波

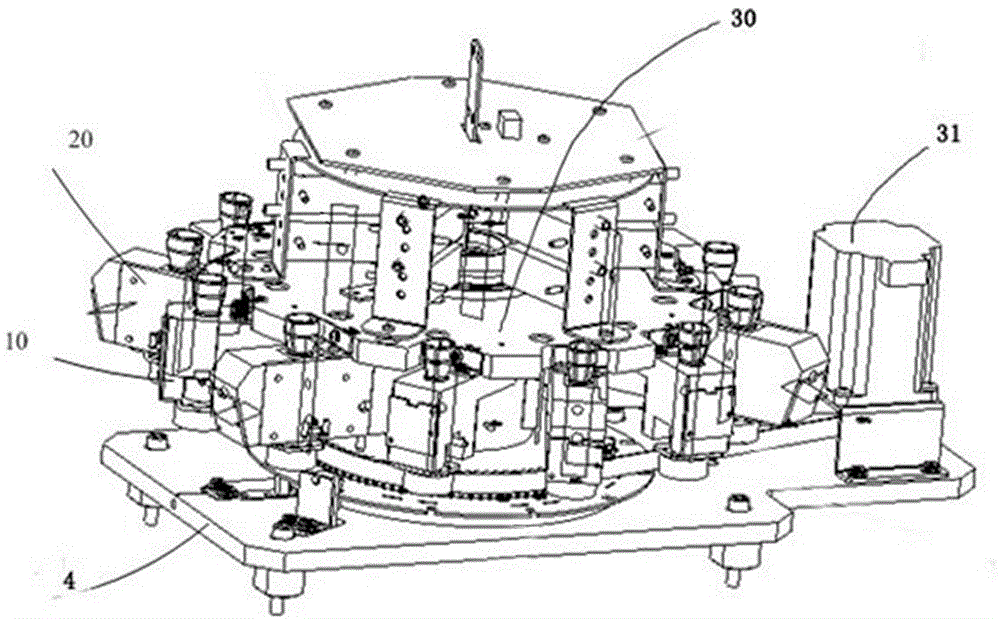

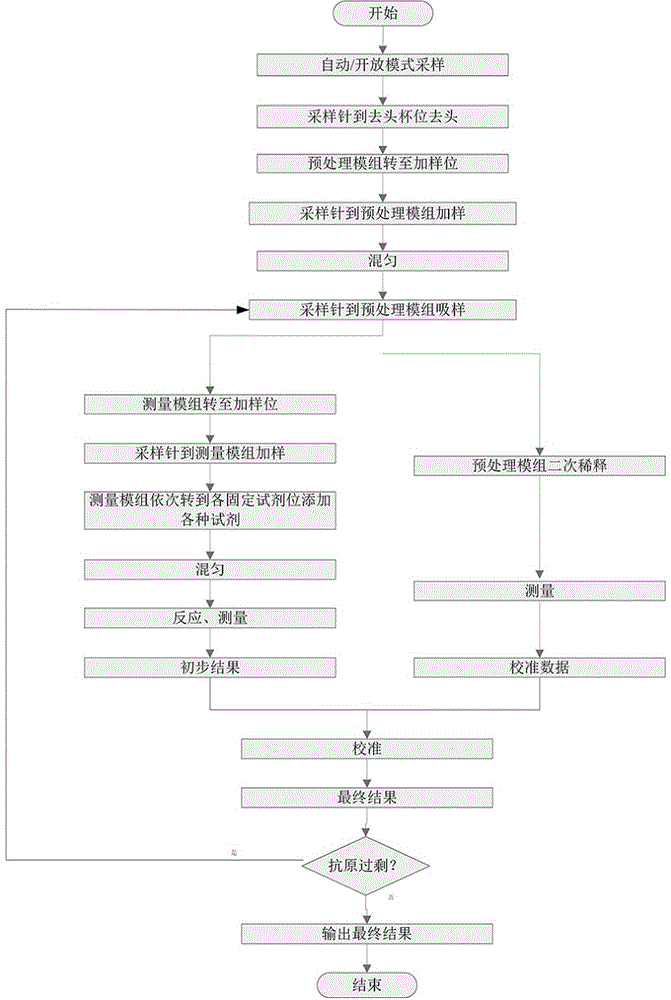

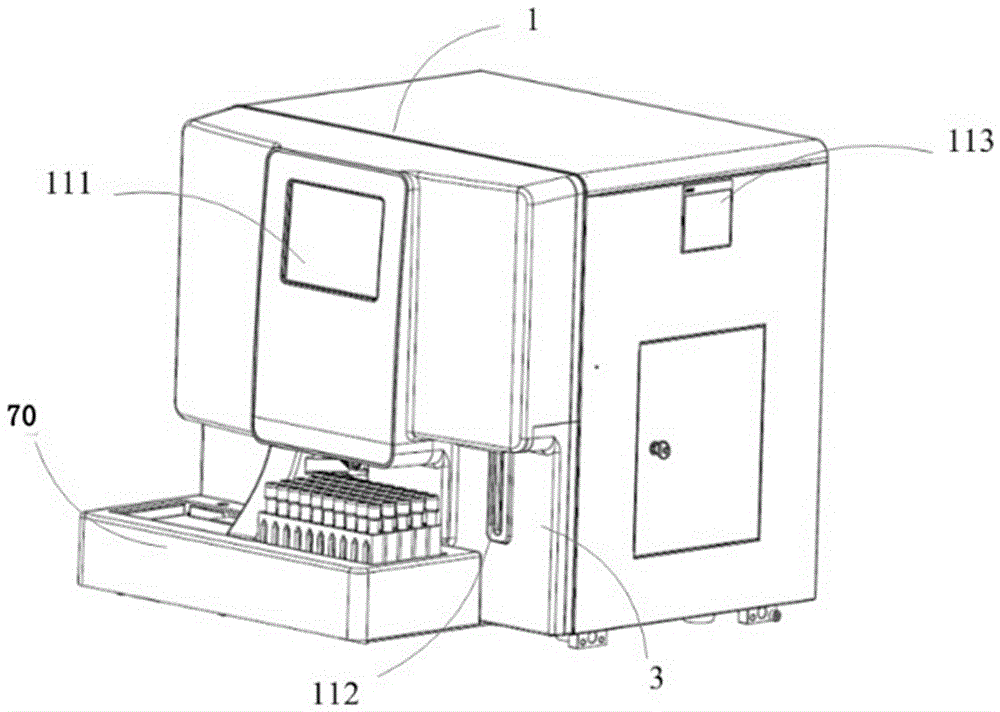

High-speed C reactive protein analyzer and analyzing method thereof

ActiveCN105628948AEasy maintenanceSolve the detection speed is slowMaterial analysisMotor driveAutosampler

The invention discloses a high-speed C reactive protein analyzer. The high-speed C reactive protein analyzer comprises a machine frame and a machine shell and is characterized in that a measuring rotating disk and a motor driving the measuring rotating disk are arranged at the bottom of the machine frame; a plurality of measuring units are arranged on the outer circle of the measuring rotating disk; each measuring unit comprises a preprocessing module and a measuring module; the portion, on the periphery of the measuring rotating disk, of the machine frame is provided with a reagent adding station, an automatic two-dimensional arm with a sampling needle and a manual two-dimensional arm; an automatic sample injector is arranged on the outer side of the automatic two-dimensional arm; a manual sample injector is arranged on the outer side of the manual two-dimensional arm; a control board card is arranged on the machine frame; a touch display screen and an output unit are arranged on the machine shell. The high-speed C reactive protein analyzer has the advantages that due to the automatic reagent adding structure of the independent measuring units, the automatic two-dimensional arm and the reagent adding station, a plurality of samples can be detected at high speed at the same time, and detection speed is greatly increased; an automatic sample injection mode and a manual sample injection mode can be freely switched; due to the structure of the independent measuring units, complete machine maintenance is facilitated.

Owner:SHENZHEN LIFOTRONIC TECH

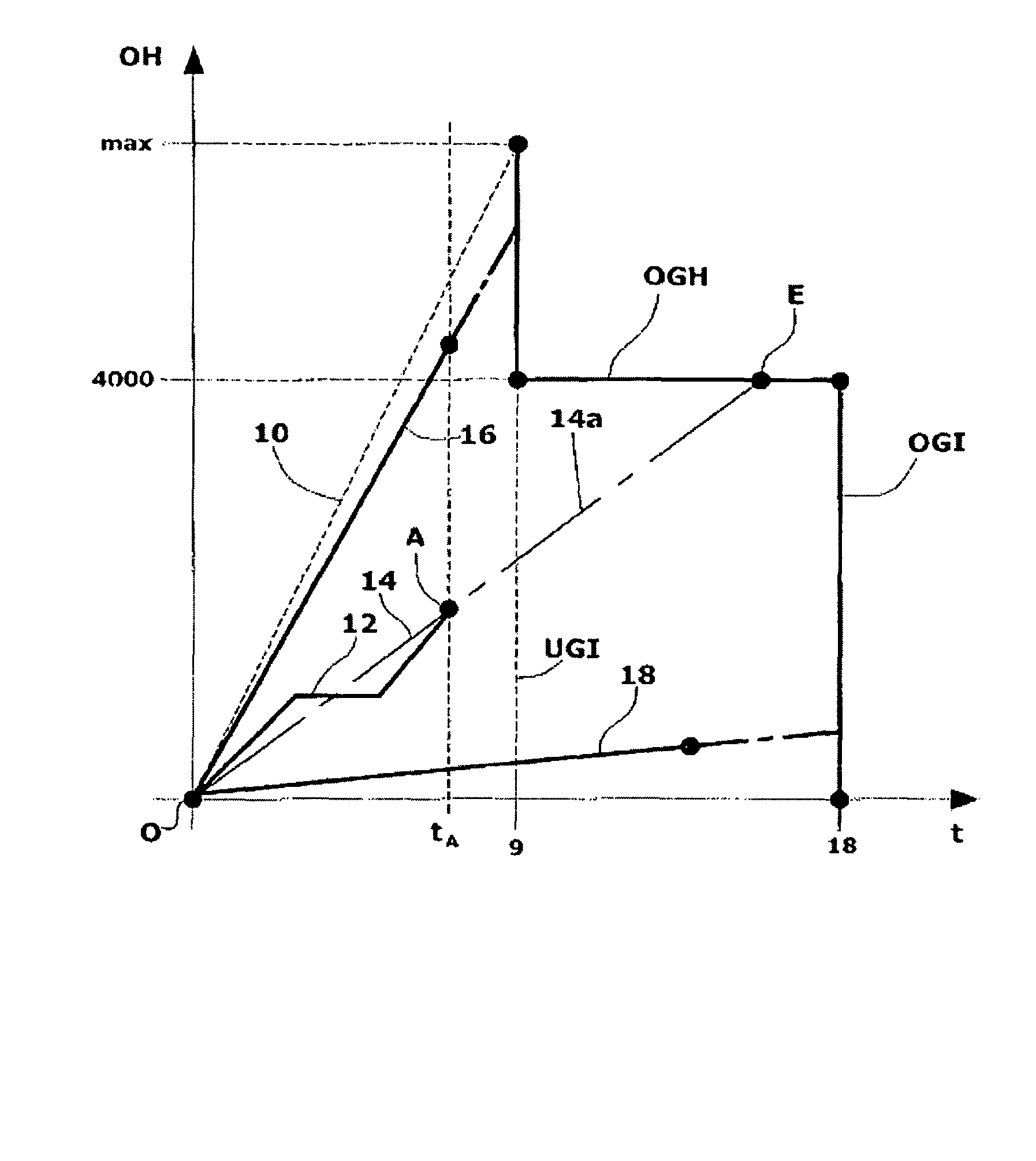

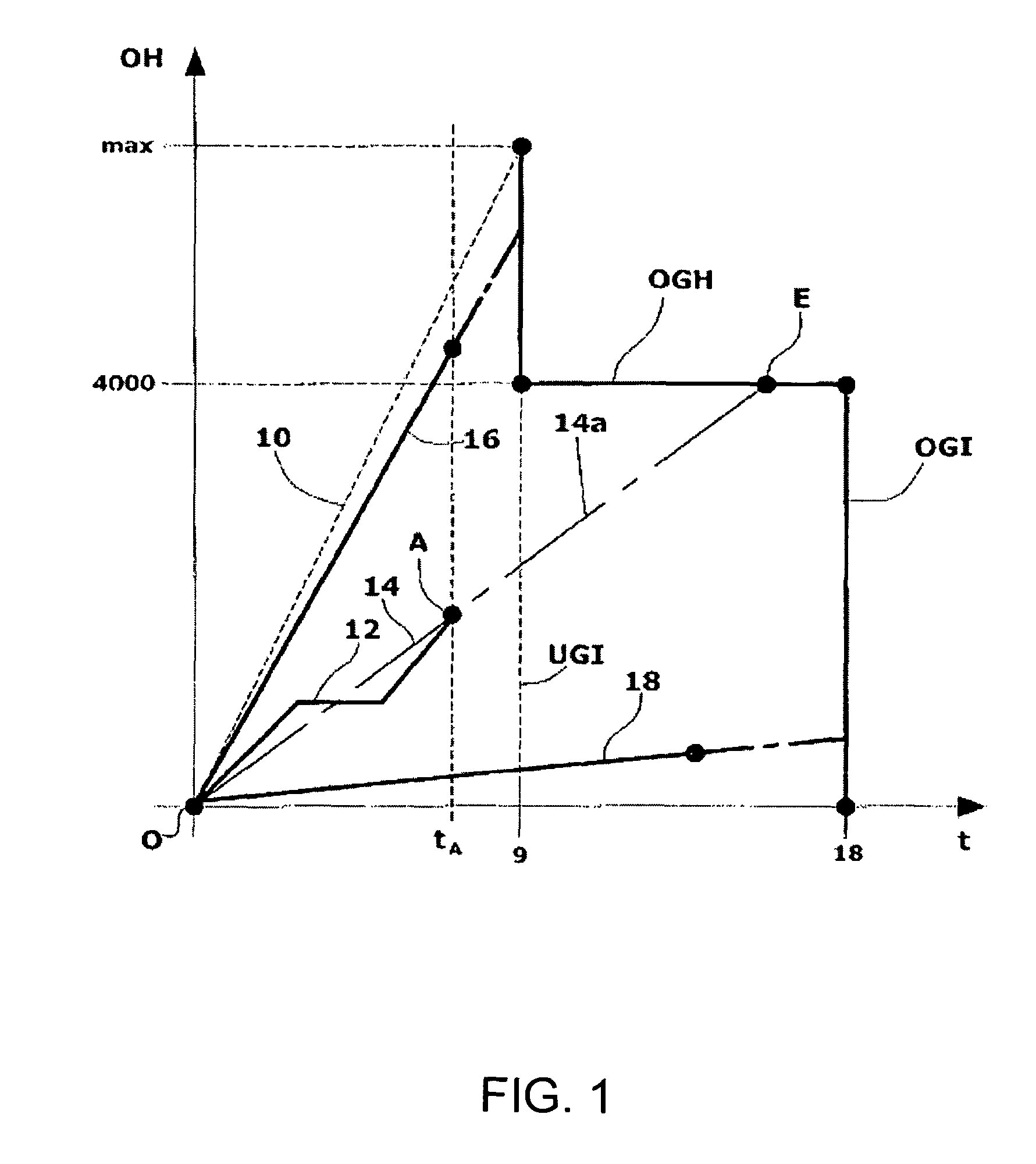

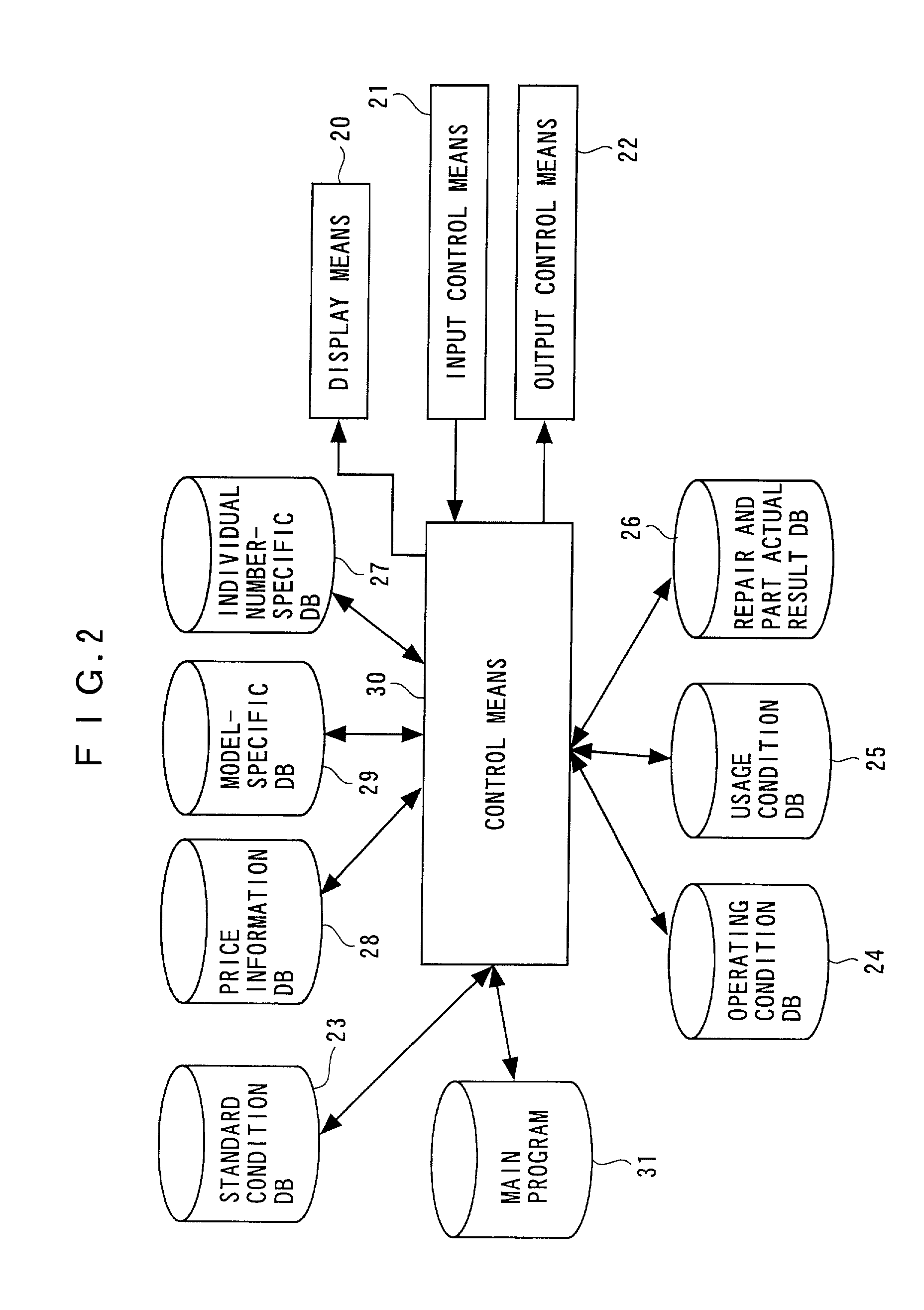

System, method, computer program, and recording medium for machine-management

InactiveUS20020046048A1Easy maintenanceEasy to manageSimulator controlElectric testing/monitoringTime limitMaintenance management

A management system of a machine equipped with a driving-power source reads out maintenance conditions from a storage means of maintenance management information when data and conditions, concerned about a maintenance management of a machine, the features of the machine, and so on, including the maintenance conditions, are inputted from the input means. Then, information about predicted maintenance management under a certain operation time of the machine is predicted with reference to the maintenance conditions. Subsequently, the information about the predicted maintenance management is represented on a display means. Furthermore, a maintenance predicted value is previously stored in a data base or the like with respect to the maintenance within an operation time under the contract or within a contract term for each of a plurality of contract ranks. A maintenance actual result value of the machine being entered is accumulatively stored. After a termination of the maintenance contract of the machine, the maintenance predicted value that corresponds to a model and a contract rank of the machine is read out, and simultaneously the maintenance actual result value of the machine is read out, followed by making a judgment whether the maintenance actual result value is larger or smaller than the maintenance contract predicted value.

Owner:KOMATSU LTD

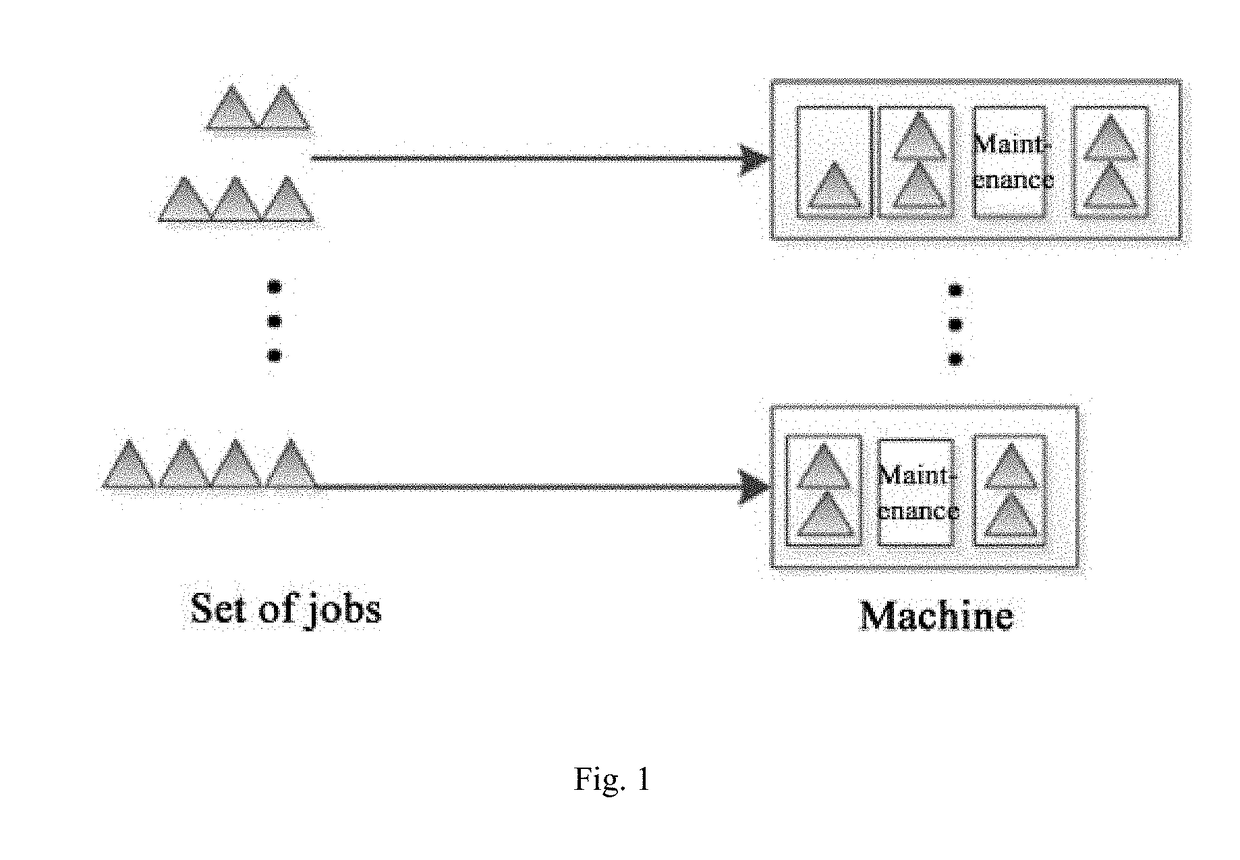

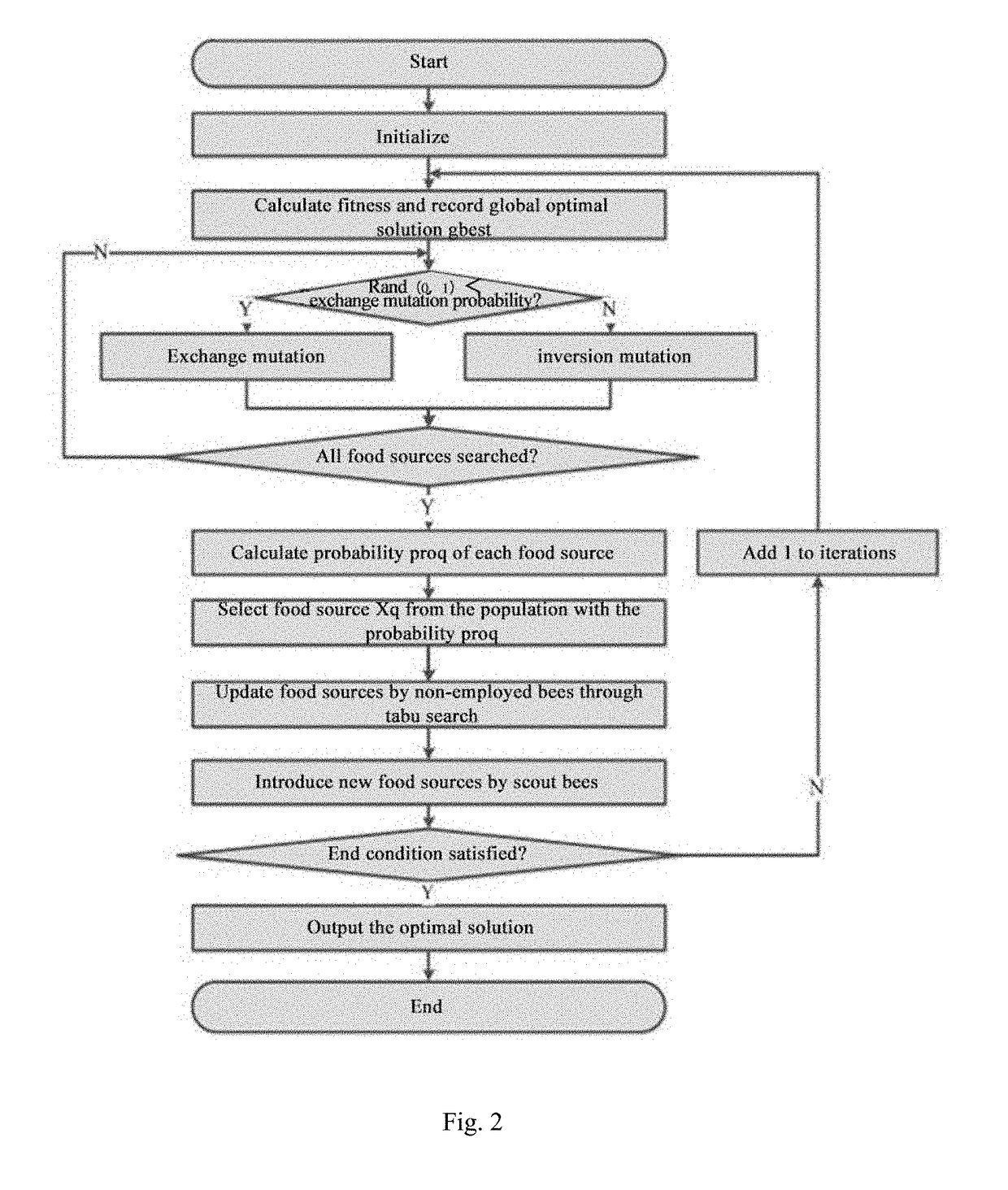

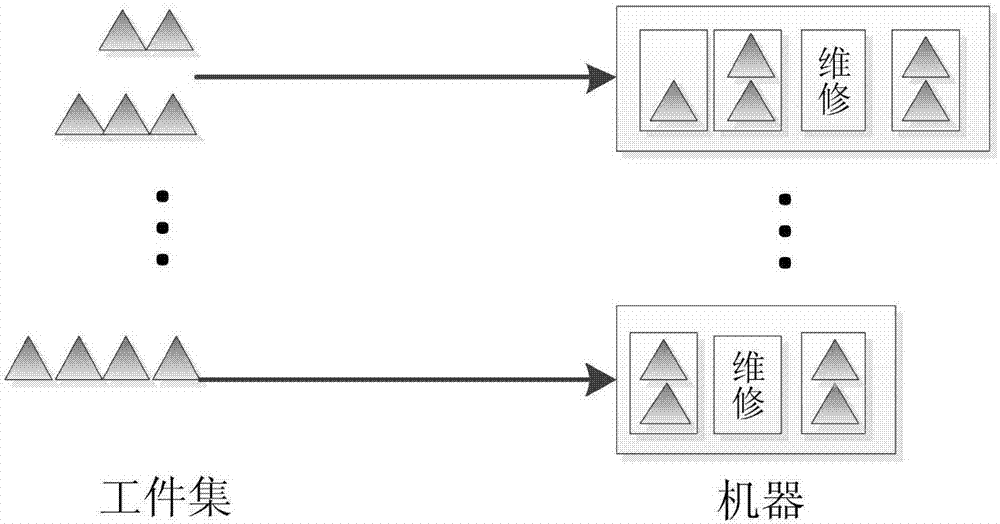

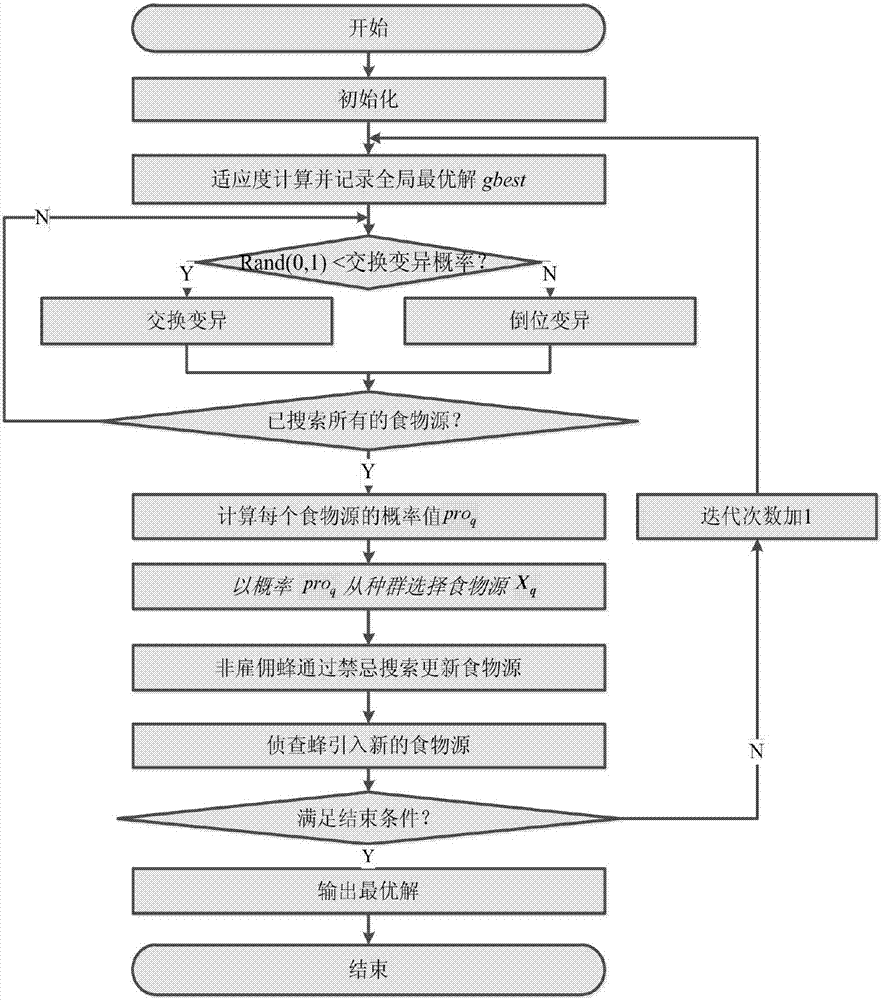

Production scheduling method and system based on improved artificial bee colony algorithm and storage medium

InactiveUS20190080270A1Reduce business operating costsIncreasing enterprise productivityResourcesProgramme total factory controlMachine maintenanceComputer science

The present invention disclose a parallel machine batch scheduling method and system based on an improved artificial bee colony algorithm in a deterioration situation. With this method, a near-optimal solution for the parallel machine batch scheduling problem with deteriorating jobs and maintenance consideration can be obtained. The model of the present invention is derived from an actual production process with considerations of machine maintenance and batching as well as additional processing and maintenance time for jobs and machines over time in actual production. According to the present invention, the settlement of this problem is conducive to providing reliable decision support for the production and maintenance of an enterprise in complex real production conditions, thus reducing enterprise operation costs, increasing enterprise productivity, and promoting building of a modern smart factory of the enterprise.

Owner:HEFEI UNIV OF TECH

Decontamination equipment for unmanned automobile parts

ActiveCN106583280AEasy maintenanceShorten maintenance timeCleaning using toolsCleaning using liquidsMachine maintenanceMarine engineering

The invention relates to decontamination equipment for automobile parts, in particular to decontamination equipment for unmanned automobile parts. The technical problem to be solved is to provide the decontamination equipment which is used for the unmanned automobile parts and is thorough in decontamination, high in decontamination speed and convenient to operate. In order to solve the technical problem, the decontamination equipment for the unmanned automobile parts is provided. The decontamination equipment for the unmanned automobile parts comprises a bottom plate, a first support, a waste water frame, a second support, a first one-way valve, a first water pipe, a cylinder body, a second water pipe, a second one-way valve, a piston, a connecting rod and the like. A left frame is welded to the leftmost side of the top of the bottom plate. The left side of the top of the bottom plate is connected with the cylinder body in a bolt connection manner. The second water pipe is connected to the lower portion of the left side of the cylinder body in a flange connection manner. By the adoption of the decontamination equipment for the unmanned automobile parts, the effects that decontamination is thorough, the decontamination speed is high, and operation is convenient are achieved, the machine maintenance time can be shortened, a great amount of manpower can be saved, and the decontamination effect is good.

Owner:NANJING HENGTIAN LINGRUI AUTOMOBILE CO LTD

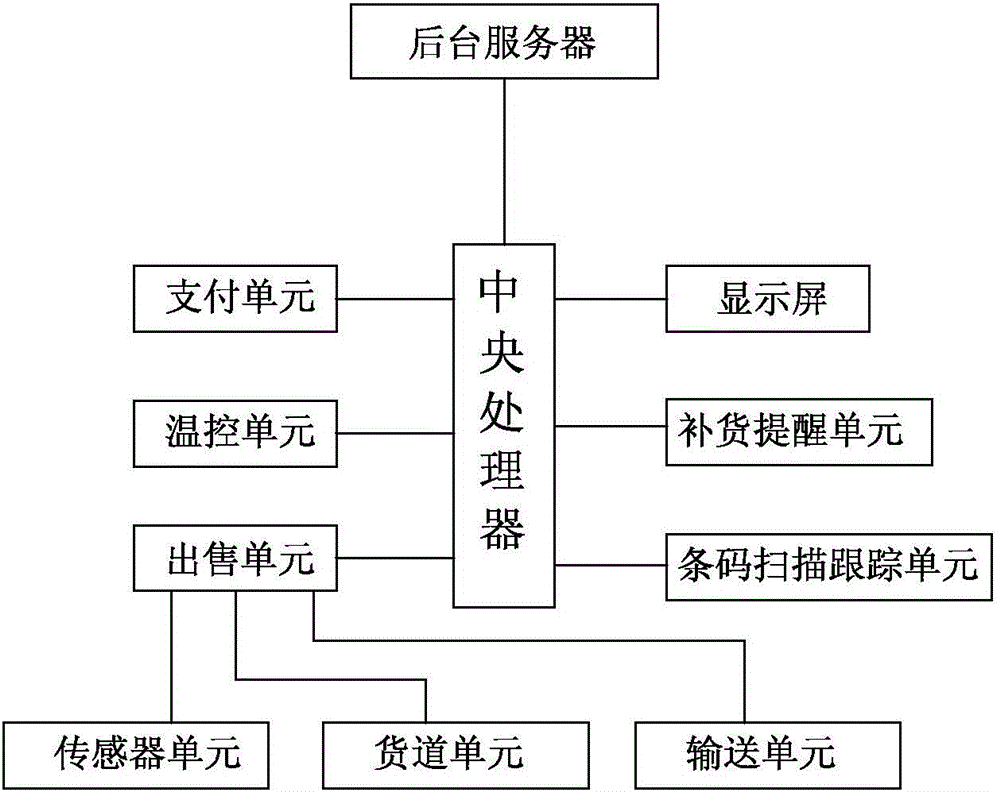

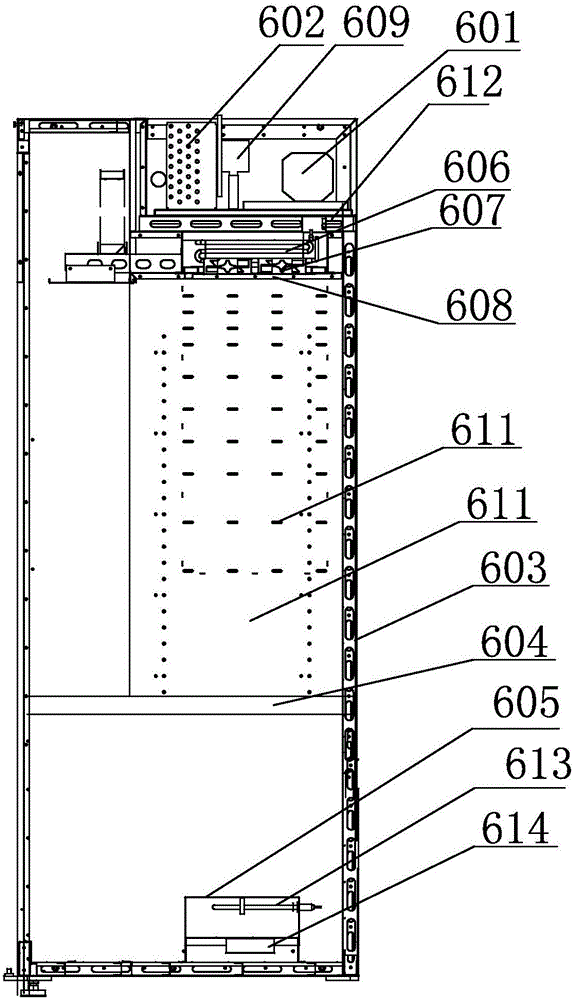

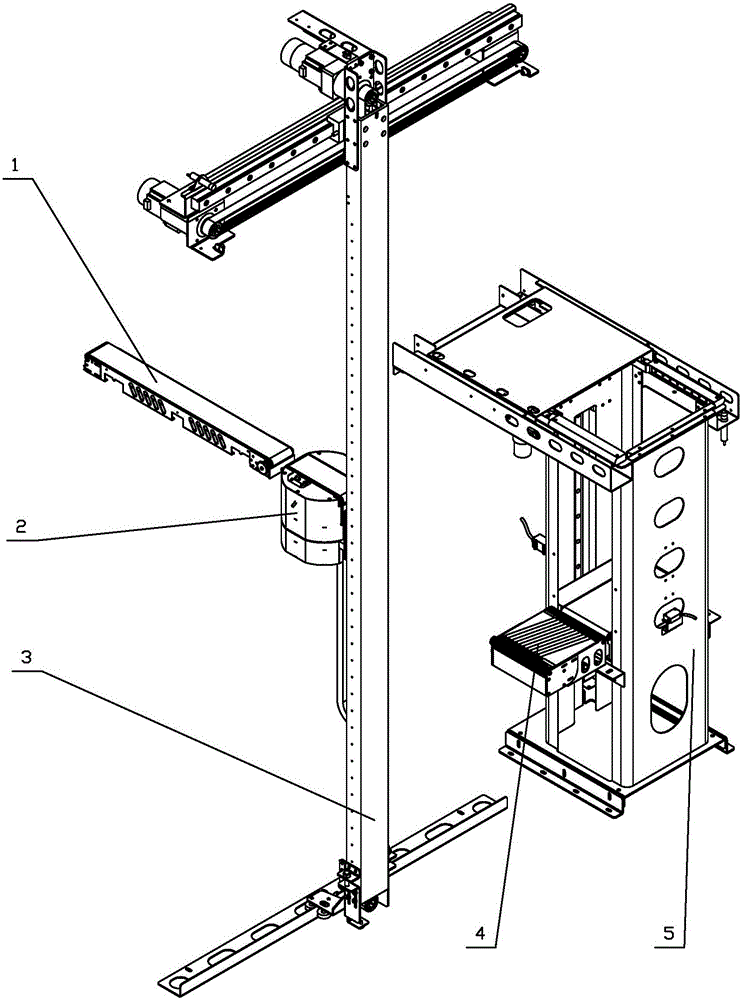

Electric control system for full-automatic self-service internet vending machines

ActiveCN106204920AReasonable designInnovative designCoin-freed apparatus detailsApparatus for dispensing discrete articlesMachine maintenanceThe Internet

The invention relates to an electric control system for full-automatic self-service internet vending machines. The electric control system for the full-automatic self-service internet vending machines comprises a background server system, wherein the background server system is in wireless or wired connection with a central processing unit for a plurality of vending machines, the central processing unit is connected with a vending unit, a payment unit, a temperature control unit, a display screen, a goods replenishment reminding unit and a bar code scanning and tracking unit; the vending unit comprises a sensor unit, a goods channel unit and a conveying unit. Therefore, the control mode is reasonable and novel in design, the oneness property of a conventional delivery mode is changed, various goods can be accurately vended, the temperature control unit for the vending machines is provided with a refrigerating system and a heating system, and goods can be stored in various environments; with the adoption of multiple payment modes, the human-machine exchange experience is good, the electric control system has functions of goods replenishment reminding and vending machine maintenance reminding, and goods replenishment and vending machine maintenance can be timely completed.

Owner:标致机床(天津)有限公司

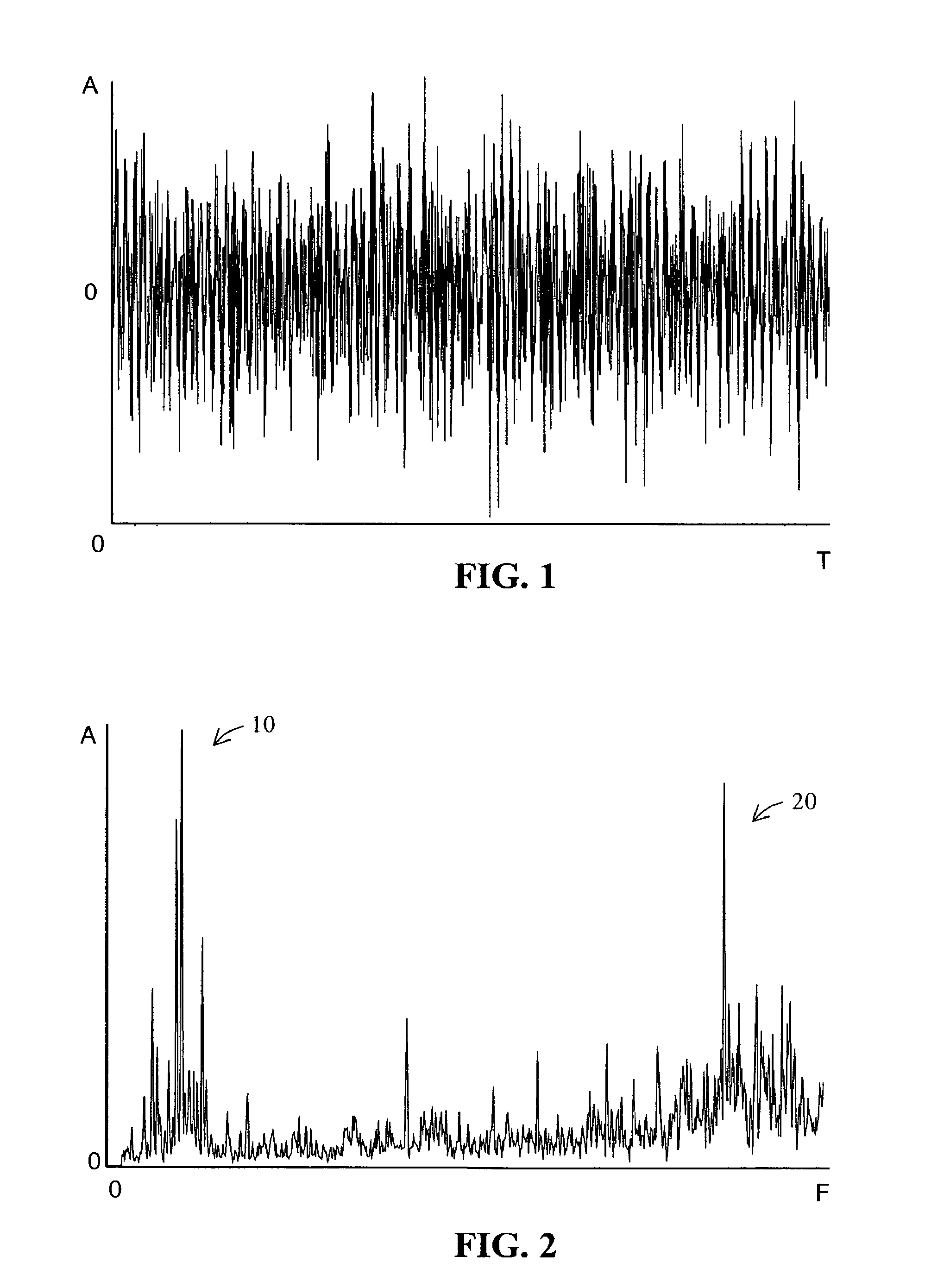

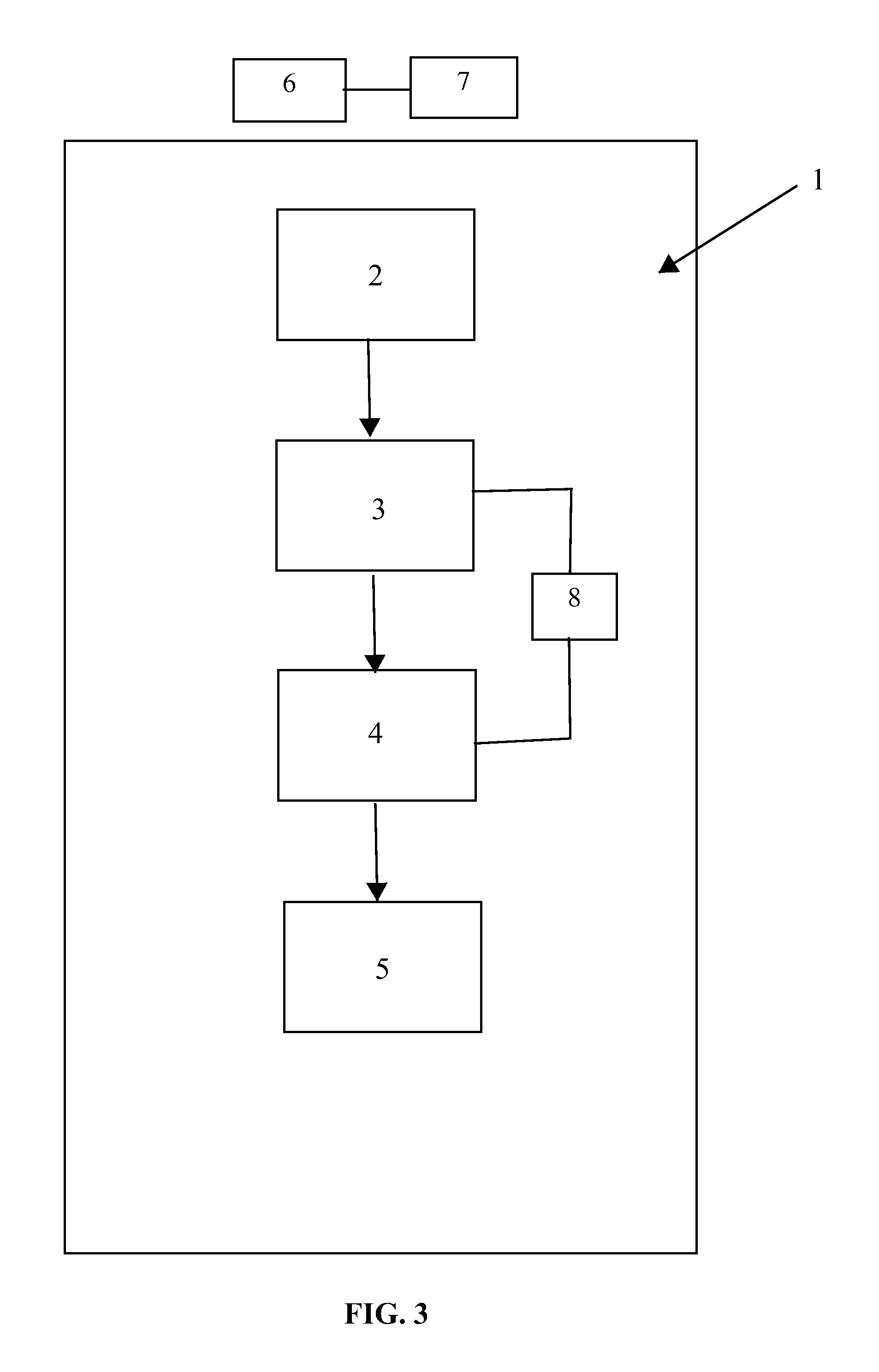

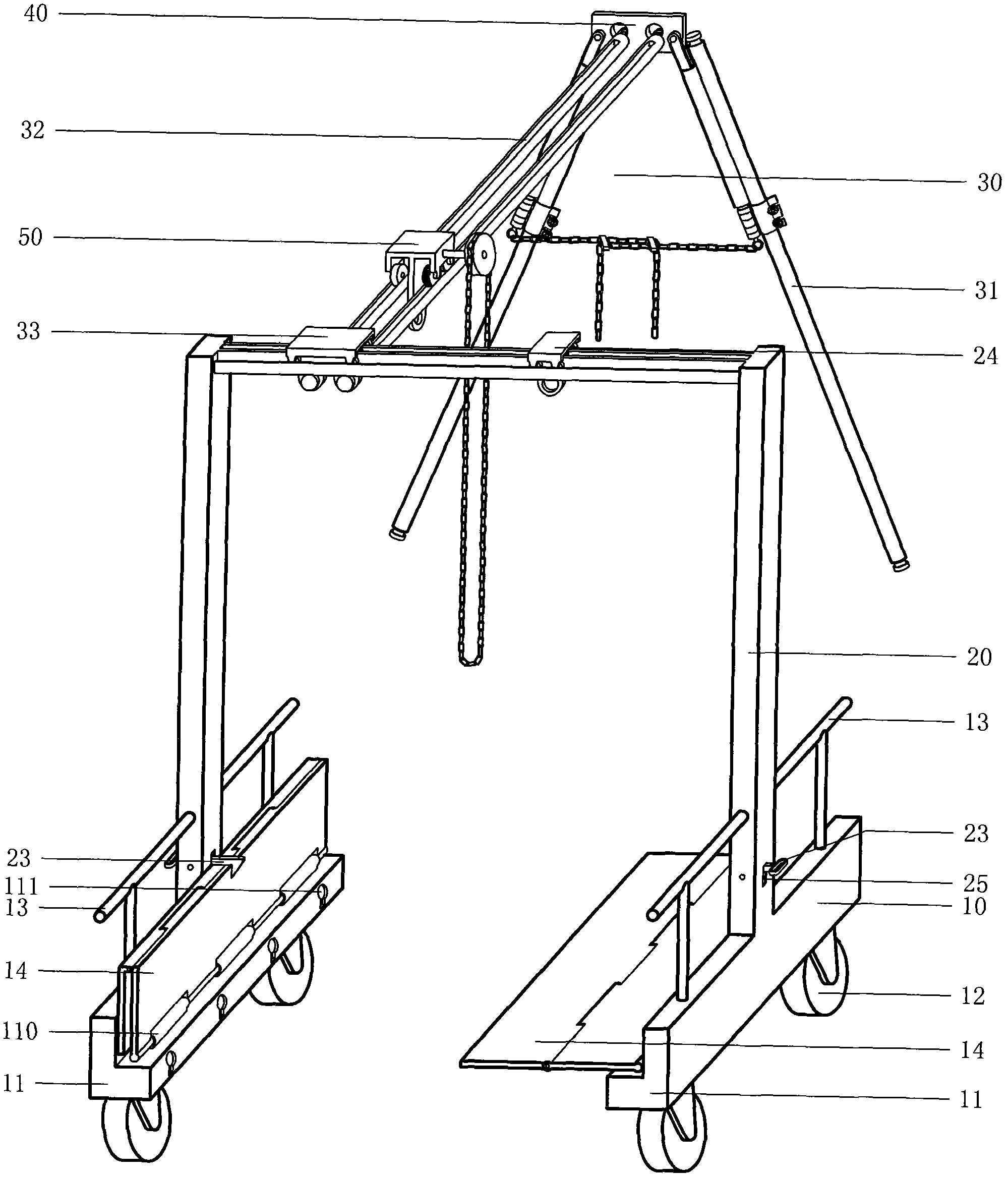

Systems and Methods for Dynamic Prognostication of Machine Conditions for Rotational Motive Equipment

InactiveUS20130173202A1Easy to predictImprove mean time between failuresVehicle testingProgramme controlMachine maintenanceDynamic prediction

Methods and systems for prognosticating high efficiency machine conditions, and testing thereof such as with machine condition assay agenda recommendations, sequenced machine condition assay schematic recommendations, a machine maintenance exigency prognosticator, or the like perhaps responsive to valued information indicia, extrinsic influential information, or the like.

Owner:AB SKF

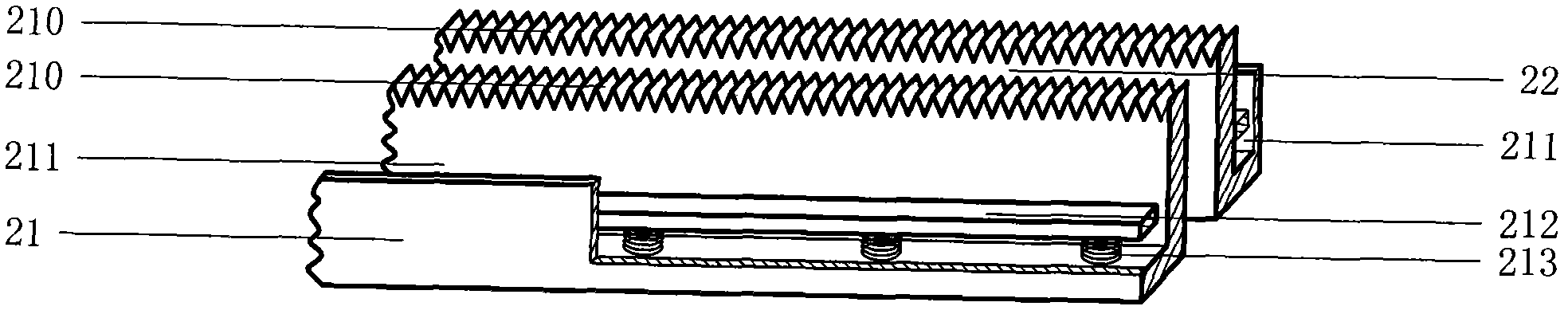

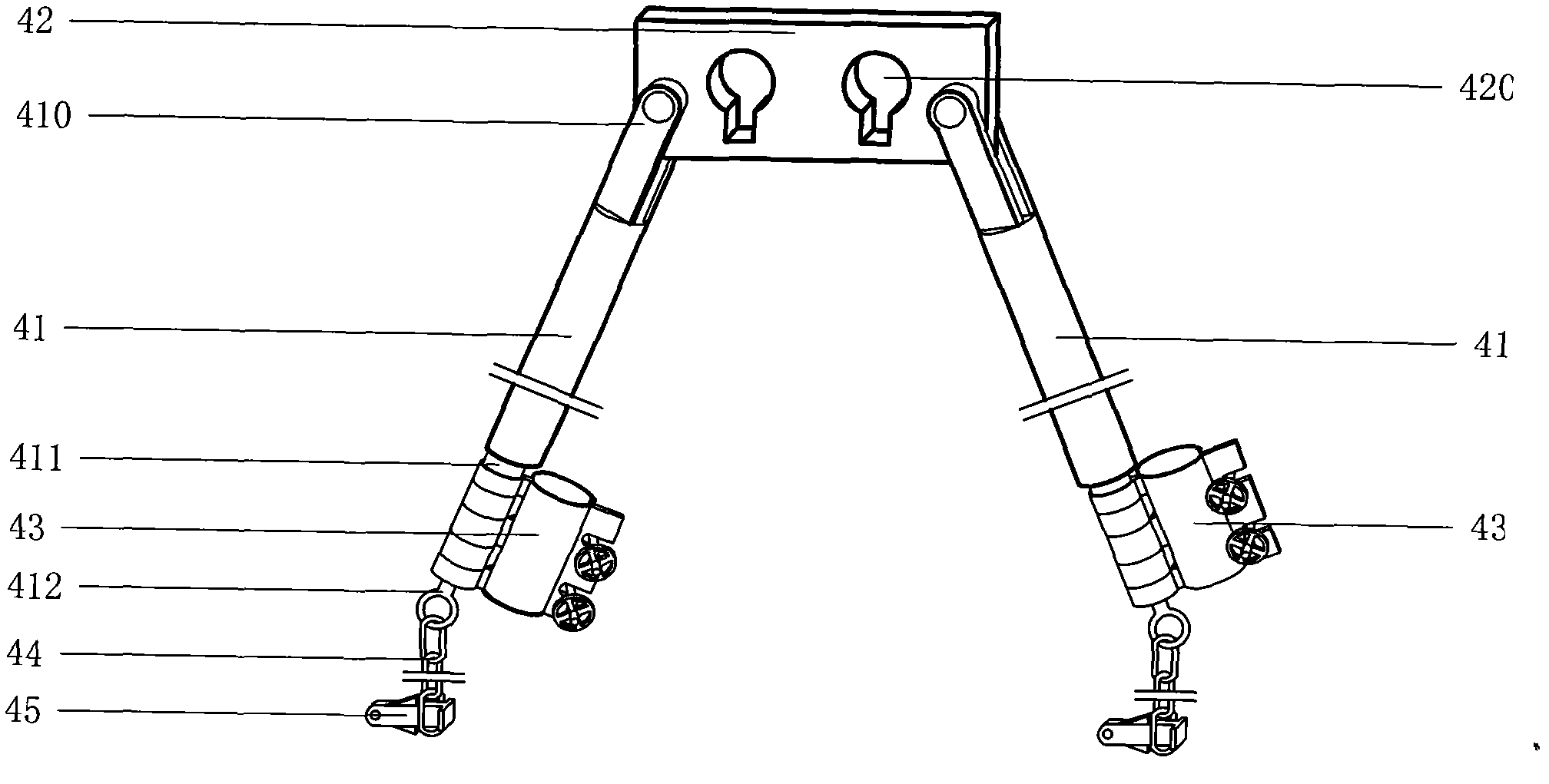

Combined type movable hanger

InactiveCN102659029AImprove work efficiencyIncrease job securityLoad-engaging girdersBase supporting structuresVehicle frameMachine maintenance

The invention provides a combined type movable hanger. The combined type movable hanger comprises a movable vehicle frame, a door type hanger and a fork type combination frame, and is characterized in that the movable vehicle frame comprises an angle form vehicle beam, carrying rollers, a push-pull handle and a carrying car plate, the door type hanger is installed on the movable vehicle frame, a top beam of the door type hanger comprises a groove type hanging beam and a rail hanger slideway, the fork type combination frame, the movable vehicle frame and the door type hanger are combined into a manual control carrier or a hoisting hanger, and the fork type combination frame comprises a comprehensive base frame, a fork frame vertical rod, a fork frame cross rod, a cross rod rail hanger and a chain driving rail hanger. According to the embodiment provided by the invention, an overhaul worker can conveniently and reasonably set a hoisting and hanging point at a production spot, without damaging a floor and affecting safety production of the whole device; moreover, equipment, hoisting tools and assembling / disassembling tools can be carried to the production spot or a machine maintenance plant together without needing other carriers; and therefore the combined type movable hanger has the advantages of reasonable structure and convenience for assembly, working efficiency of the overhaul worker can be effectively increased, and overhaul safety of the overhaul worker can be effectively improved.

Owner:QUZHOU YIKEDA ENERGY SAVING TECH

Work machine maintenance system

InactiveCN1552008AEasy and quick calculationData processing applicationsElectric testing/monitoringService personnelMachine maintenance

This maintenance system is comprised of a hydraulic excavator (11) provided with a maintenance monitoring device (21), a maintenance management server (12) for managing trouble information and operating information for each working machine, a model information server (13), and a service personnel mobile terminal (14). The maintenance monitor device, the maintenance management server, the model information server, and the mobile terminal are connected through the Internet (15). When trouble occurs in the hydraulic excavator, the maintenance system (21) transmits trouble information to the maintenance management server (12), and the maintenance management server (12) transmits information on occurrence of trouble to the mobile terminal (14) and displays it on a display unit. This system manages the maintenance manuals and other data for each model in a model information database separate from the maintenance database and correlates the two databases based on the model data. This enables centralization of the maintenance work, reduces the work time for maintenance and repair, and raises the maintenance efficiency.

Owner:NIHON KENKI CO LTD

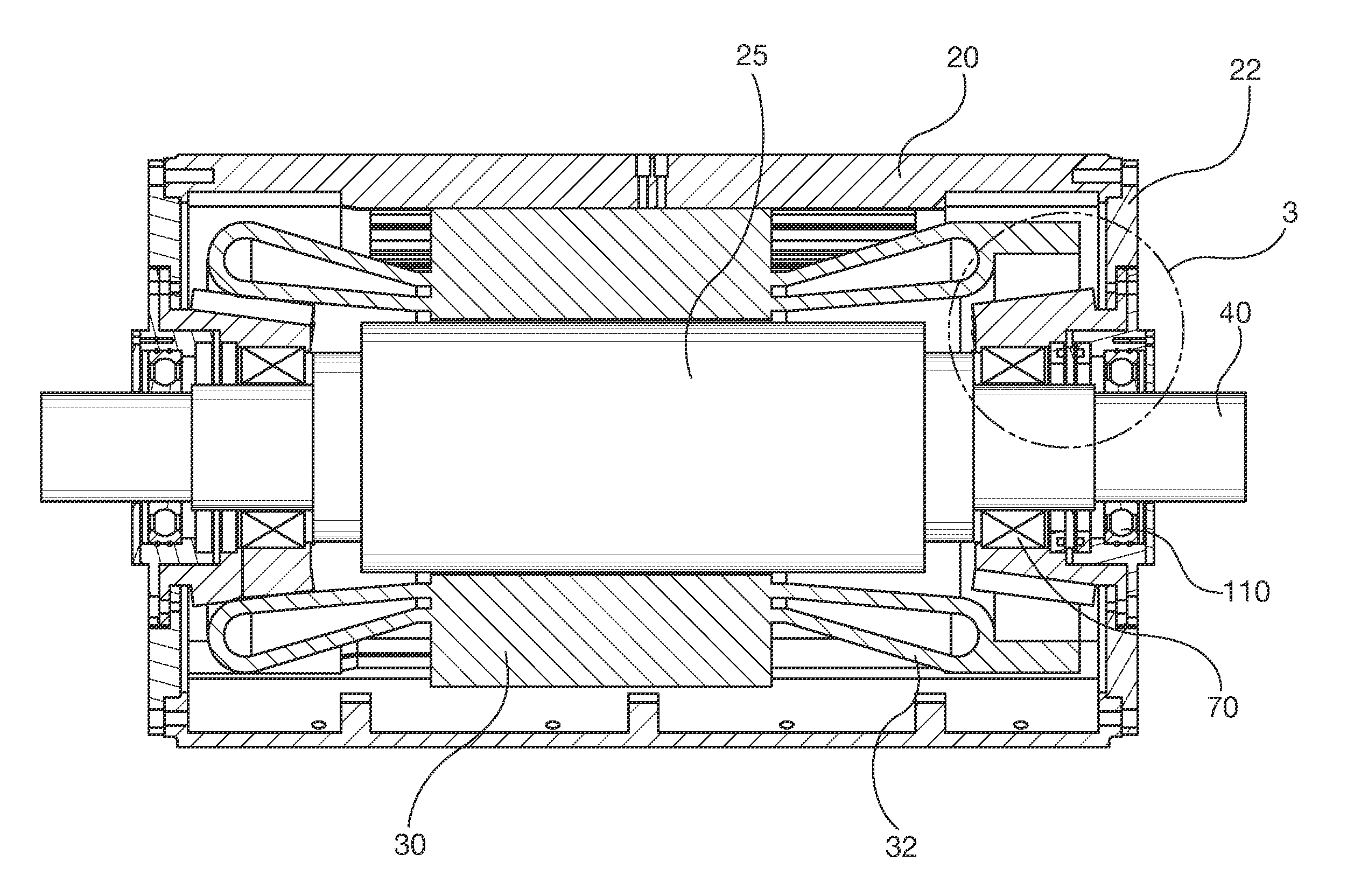

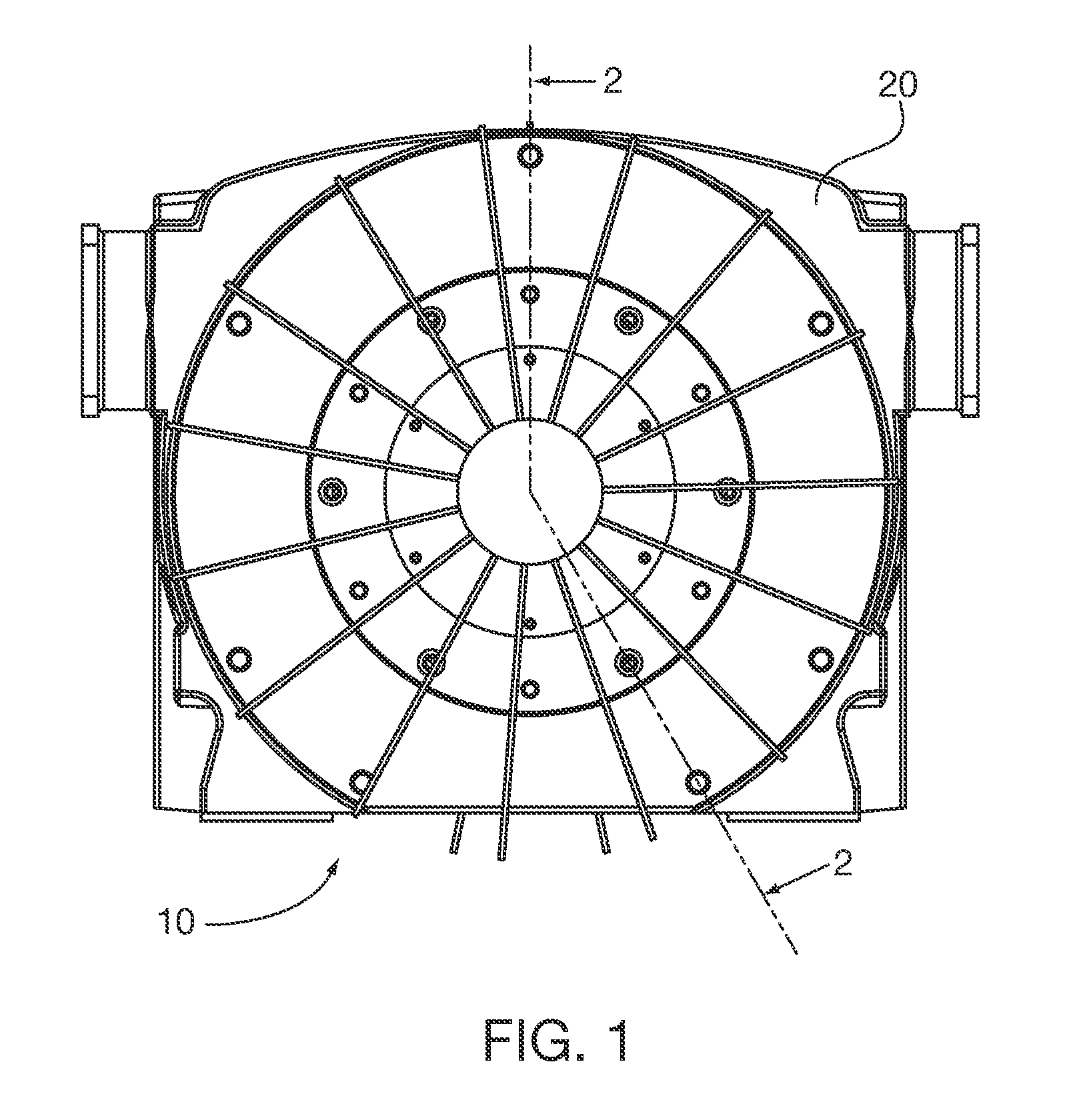

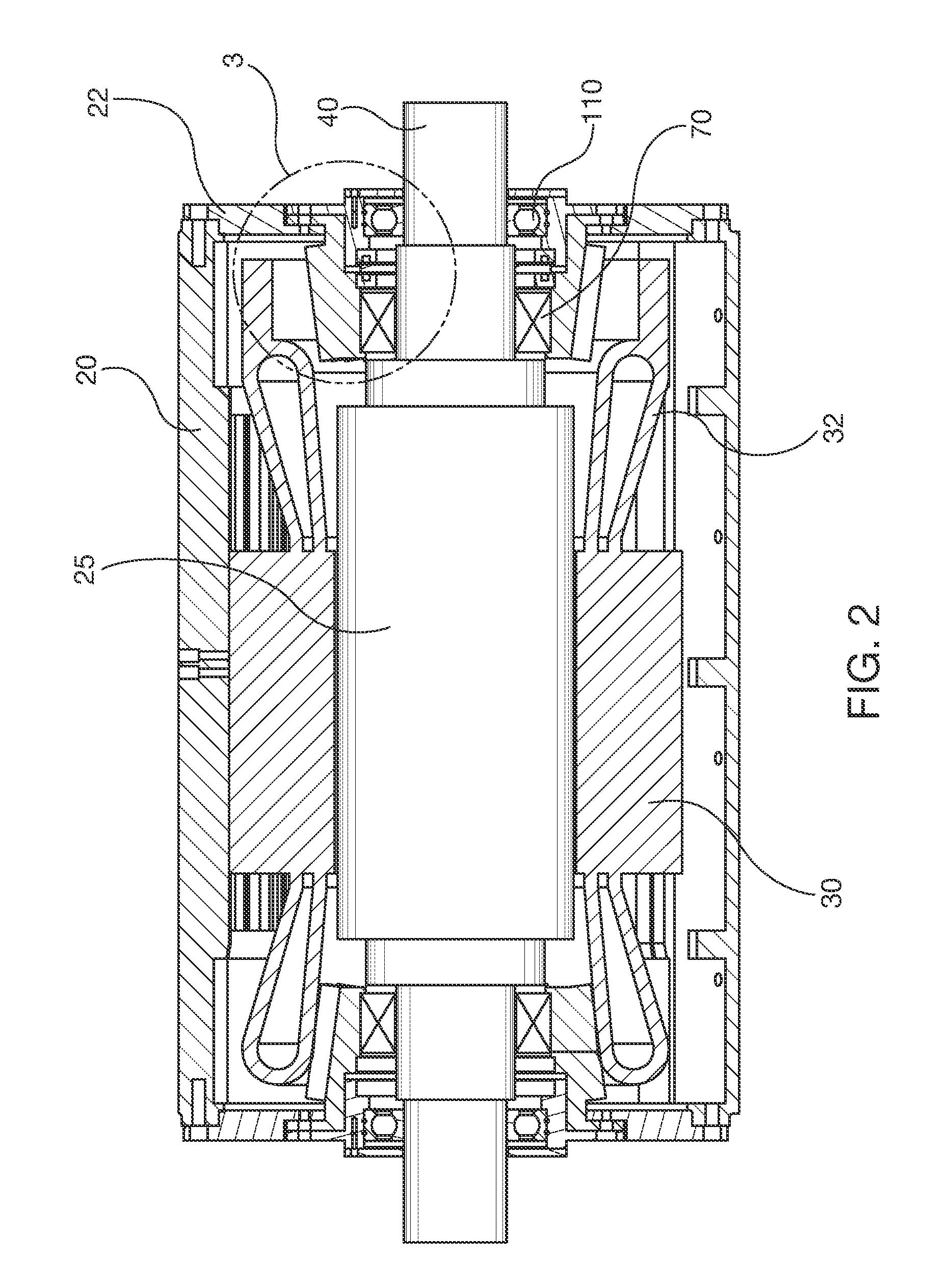

Induction machine bearing system

ActiveUS20110285233A1Reduces impact shockEasy maintenanceShaftsMagnetic bearingsMagnetic bearingMachine maintenance

A bearing assembly for an induction machine, such as an alternating current motor, includes a magnetic bearing for supporting a rotating shaft. An auxiliary bearing, also supporting the shaft in the event of magnetic bearing failure, is aligned with the motor end shield and frame so that shaft loads supported thereby are transferred to the frame in a manner that reduces likelihood of magnetic bearing contact with the shaft or its deformation. The bearing assembly may incorporate shock absorbing and vibration damping / isolation elements, such as o-rings, between the auxiliary bearing and its support structure interface to the frame. The auxiliary bearing may be incorporated in a removable cartridge for ease of machine maintenance. The bearing assembly may include heat dissipating fins.

Owner:SIEMENS IND INC

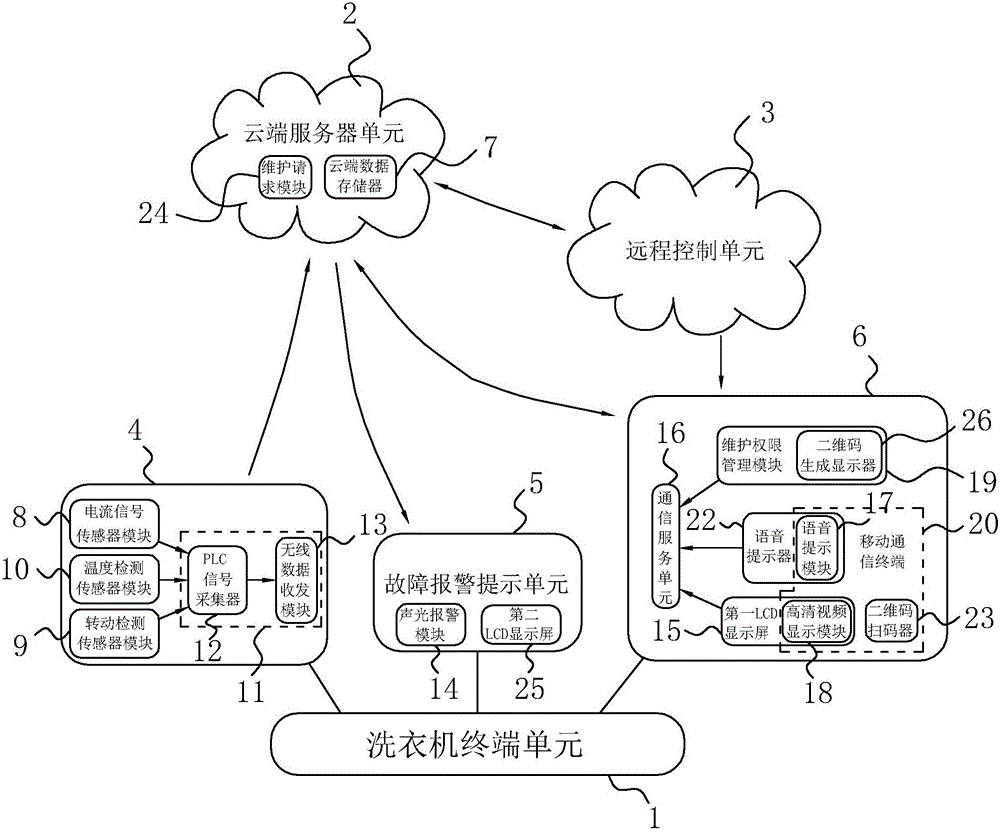

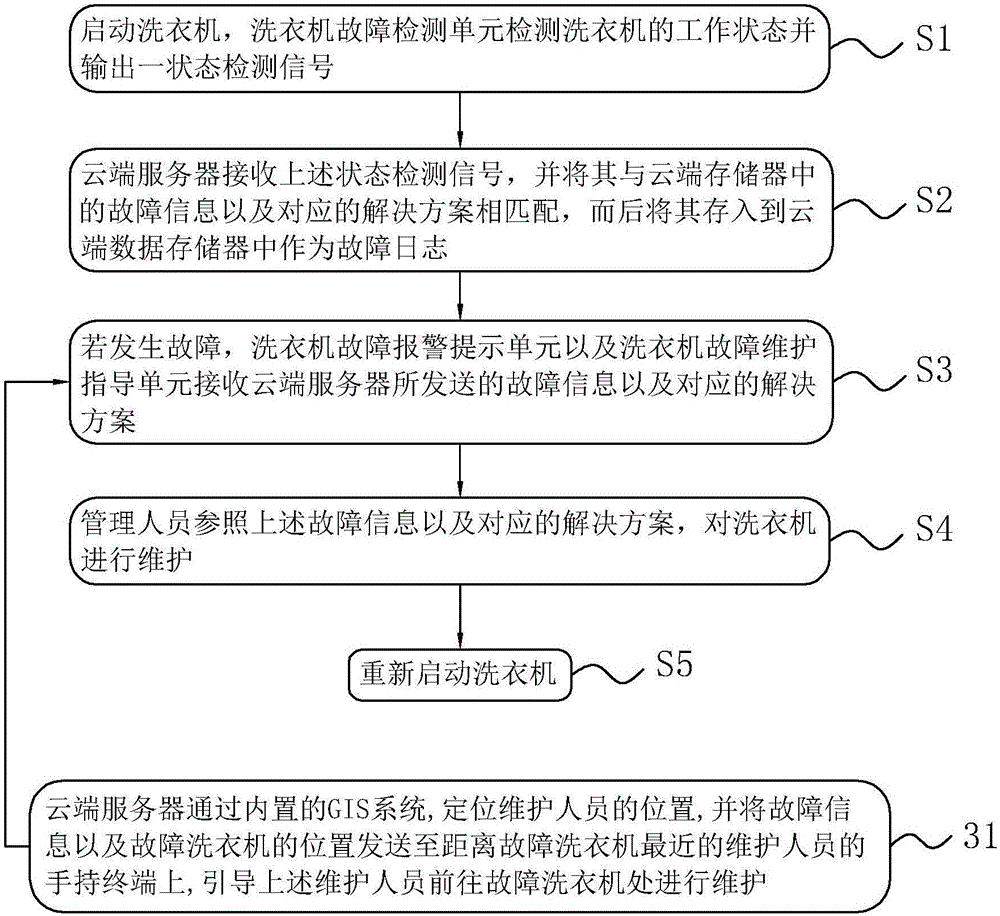

Commercial washing machine maintenance and management system

InactiveCN105780381AReduce fault detection timeReduce waiting timeControl devices for washing apparatusTextiles and paperRemote controlMachine maintenance

The invention discloses a commercial washing machine maintenance and management system, which comprises a washing machine terminal unit, a cloud server unit, a remote control unit, a washing machine fault detection unit, a washing machine fault alarm prompt unit, a washing machine fault maintenance guide unit and a cloud data memory, wherein the washing machine fault detection unit is used for detecting whether each function module normally works or not; the washing machine fault alarm prompt unit is used for emitting alarm information; the washing machine fault maintenance guide unit is used for receiving, displaying and guiding workers to maintain the washing machine; the cloud data memory is used for storing each piece of fault information and solution information of the washing machine; the cloud data memory emits fault information and the solution information corresponding to the fault information; the washing machine fault alarm prompt unit receives and displays the fault information; the washing machine fault maintenance guide unit receives and displays the solution information. According to the commercial washing machine maintenance and management system, the maintenance management of the washing machine is convenient, quick and intelligentized so as to be favorable for the management and the development of the commercial washing machine.

Owner:HANGZHOU HUIREN TECH CO LTD

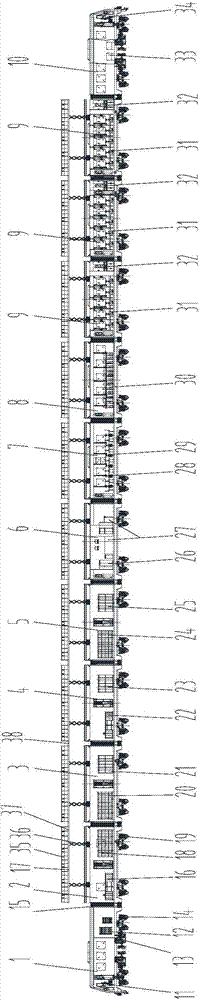

Electrified railway contact network overhaul train

ActiveCN103879418AImprove working environmentImprove working accuracyCarriagesContact networkMulti machine

The invention provides an electrified railway contact network overhaul train. The electrified railway contact network overhaul train is composed of a first tractor, a plurality of work vehicles and a second tractor. The work vehicles are arranged between the first tractor and the second tractor, the first tractor, the work vehicles and the second tractor are all connected through folding wind shields, the tops of the work vehicles are respectively provided with a lifting work platform, and the lifting work platforms are communicated with one another after being lifted. The electrified railway contact network overhaul train is provided with the communicated work platforms, construction work can be performed on a contact network with the line range of 160 m at the same time, the functions of erecting lines of the contact network, maintenance, repair, high-altitude work and the like are integrated, multi-machine multi-work type cooperative work is achieved, a large amount of skylight time is saved, the electrified railway contact network overhaul train has the highest self running speed of 120 km / h and has the functions of transportation and storage of construction materials, machine maintenance and transportation and storage of tools and safety spares, and thus the construction site can have the workshop operation functions, the operating environment of workers is improved, and the operating precision is improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

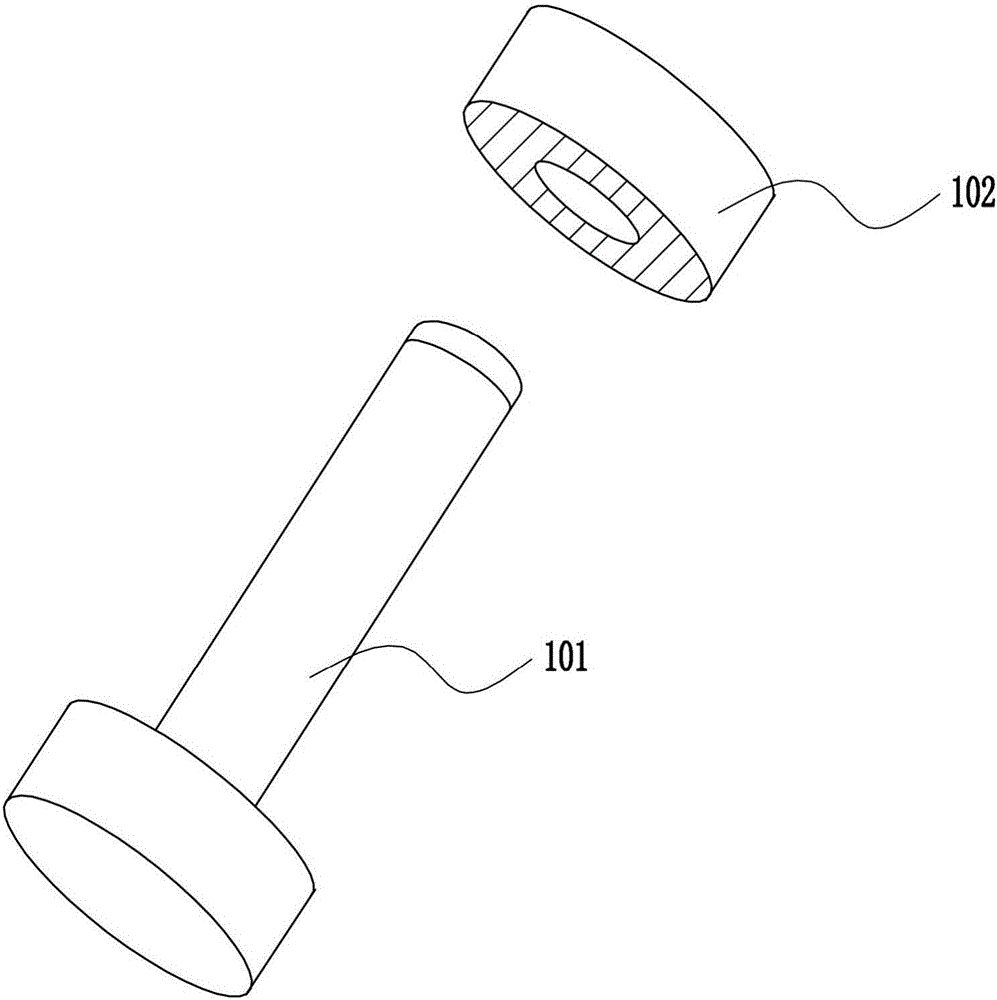

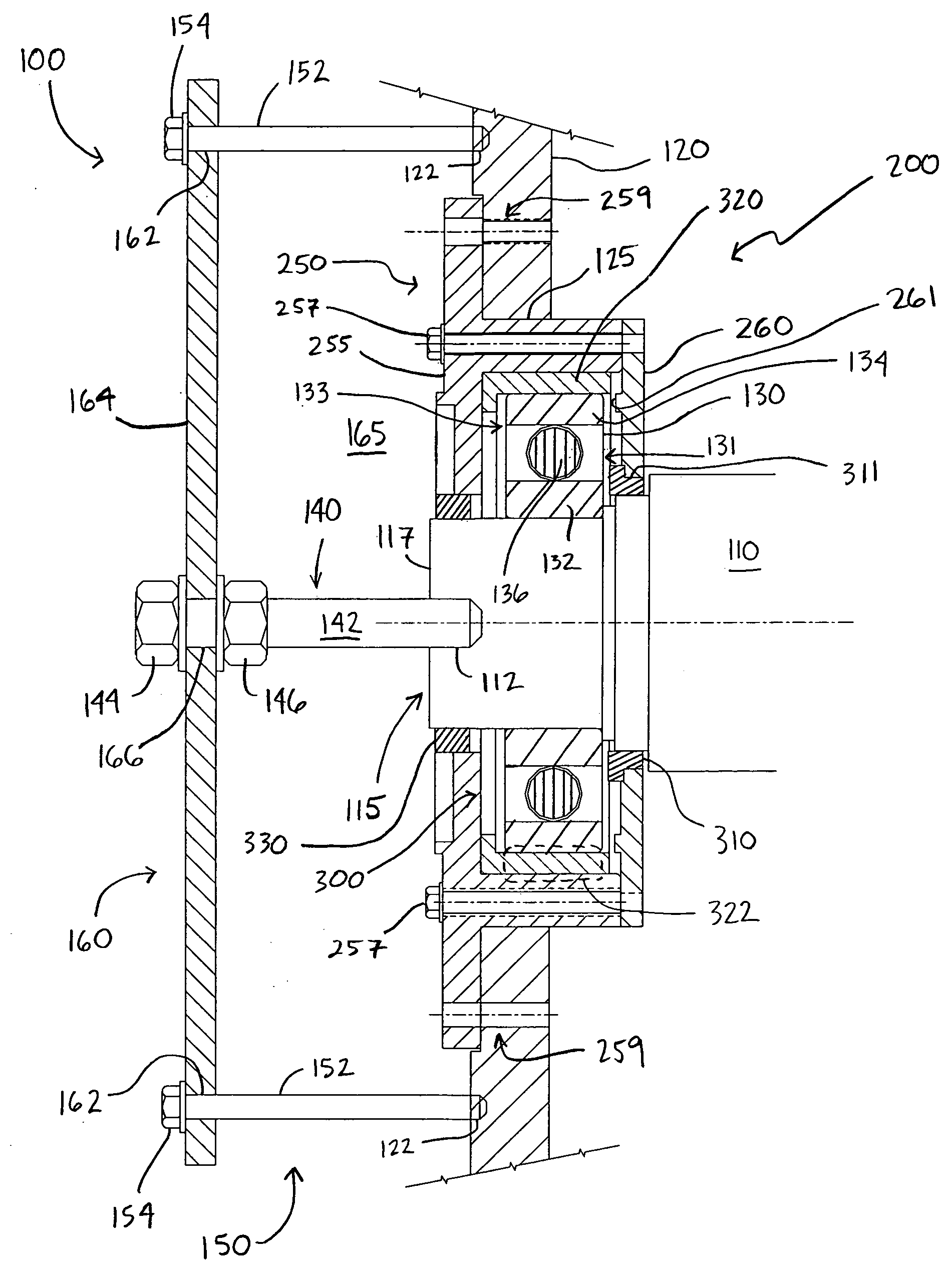

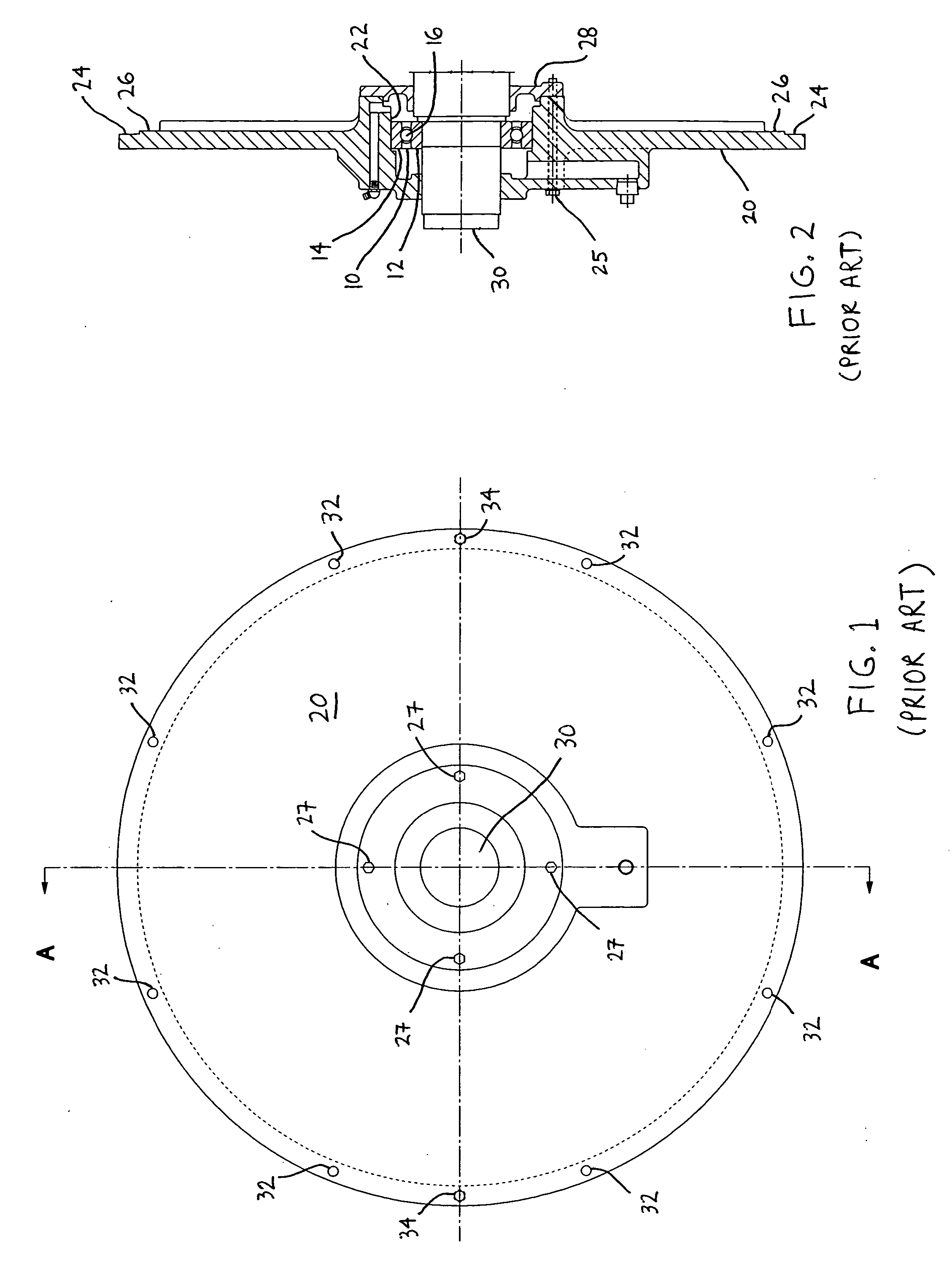

Load distribution devices and insulated bearing assemblies

InactiveUS20050246897A1Problem be addressShaftsStatic/dynamic balance measurementSynchronous motorRolling-element bearing

Load-balancing and bearing removal devices useful in removing bearings, such as rolling element bearings, for rotating machine maintenance and replacement. Insulation assemblies useful with bearing assemblies that fit in openings in bearing brackets of rotating machines, such as large synchronous motors or generators.

Owner:TECO WESTINGHOUSE MOTOR

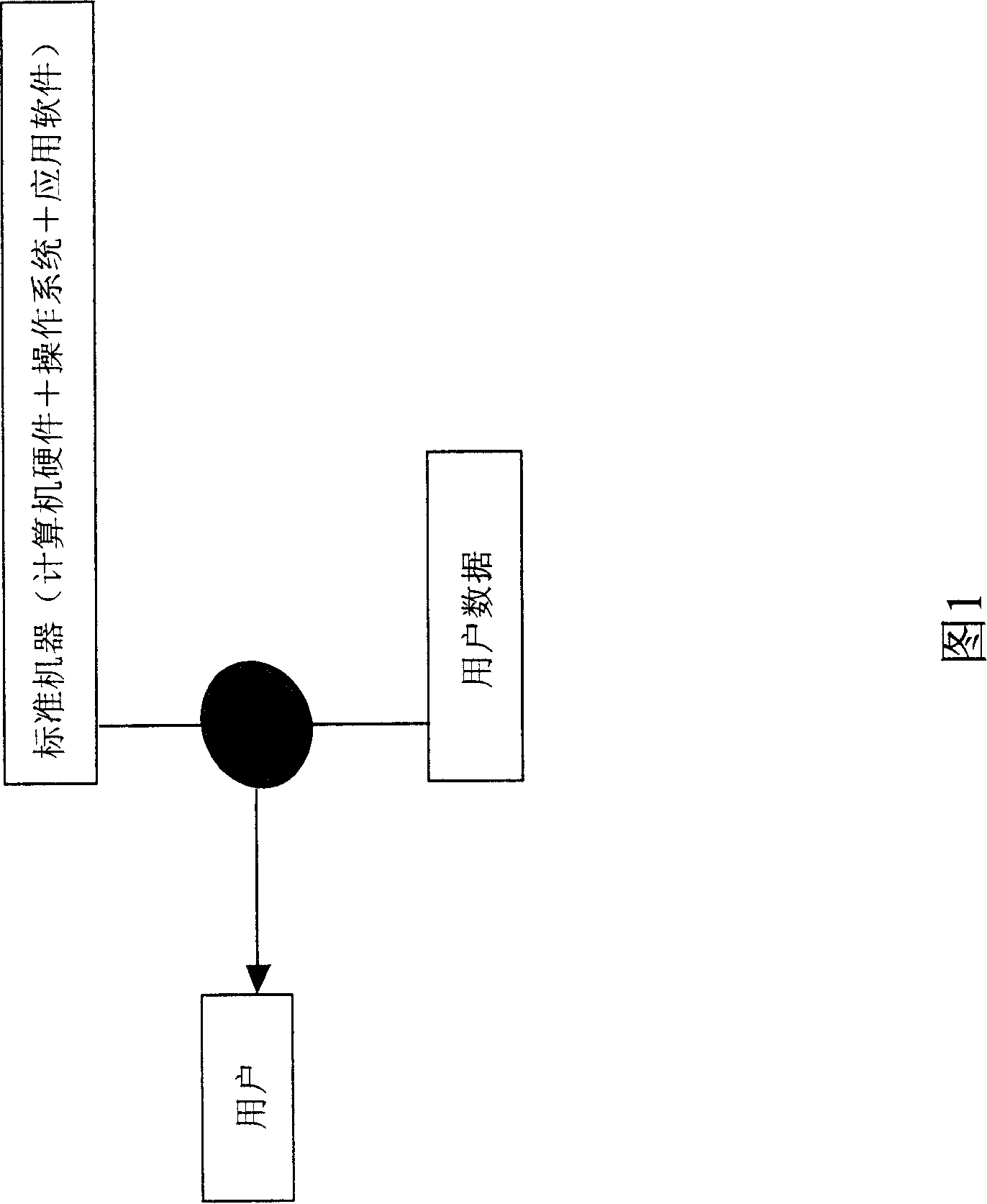

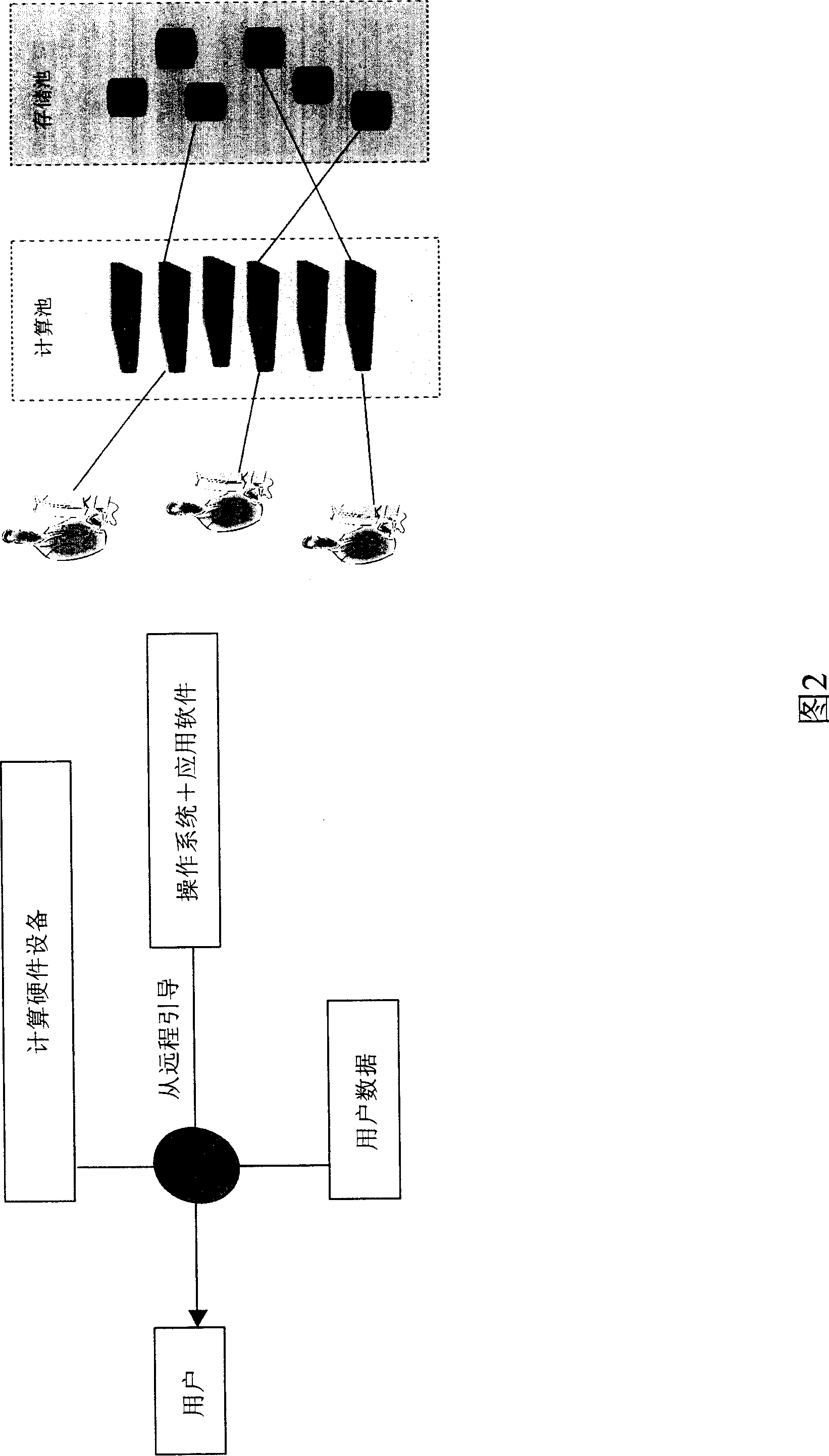

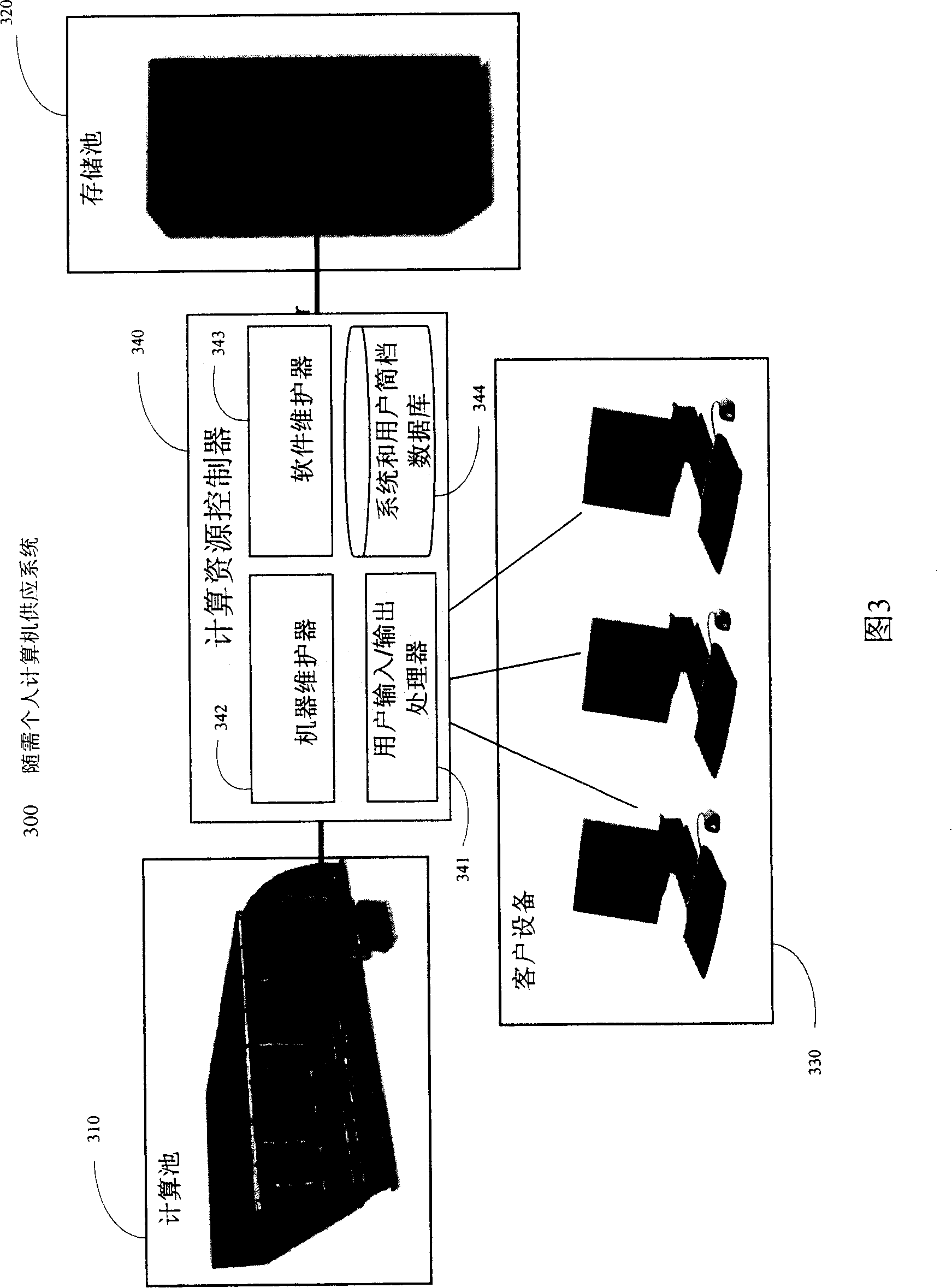

Personal computer supply system on demand and method

InactiveCN101169725AAvoid interactionAvoid interferenceMultiprogramming arrangementsProgram loading/initiatingMachine maintenanceUser input

The invention discloses a controller for personal computer supply on demand. The controller comprises a machine maintenance device for allocating a computation hardware equipment capable of meeting user's needs from a computation pool including a plurality of remote-boot computer hardware equipments according to user's needs to the hardware equipments; a software maintenance device for preparing software environment applied to the user in a memory pool according to user's needs to software environment, wherein, the machine maintenance device is also used for setting the boot address of the allocated computation hardware equipment as the prepared software environment, and booting the computation hardware equipment with the software environment; and a user input / output processor for switching the input / output of the booted computation hardware equipment to a customer equipment, so as to form a personal computer of the user. The computation hardware equipment is preferably a blade PC. The invention also discloses a system for personal computer supply on demand comprising the controller, and a corresponding method thereof.

Owner:IBM CORP

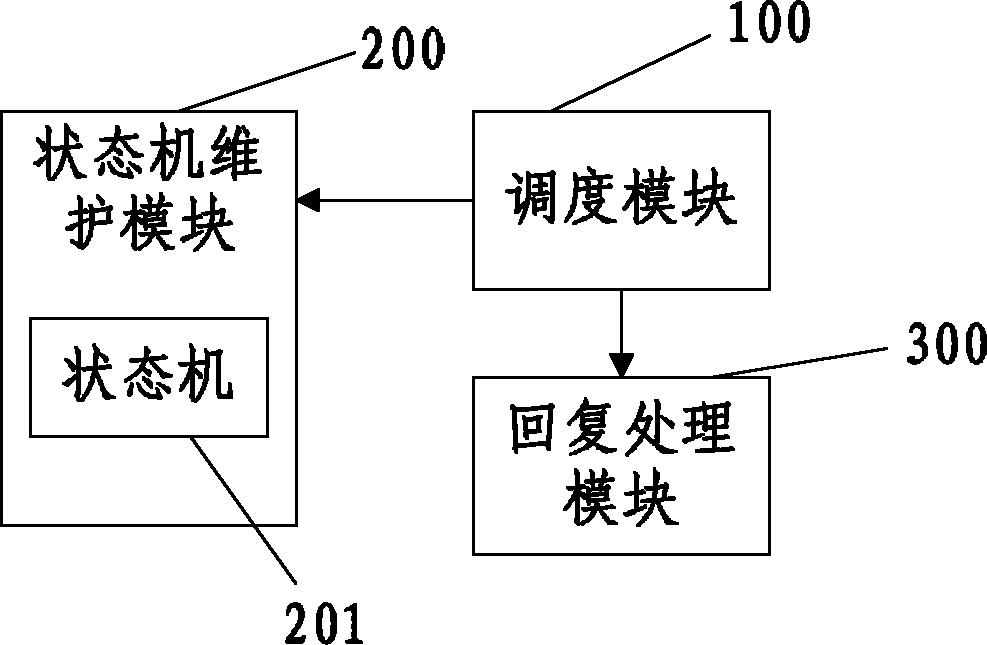

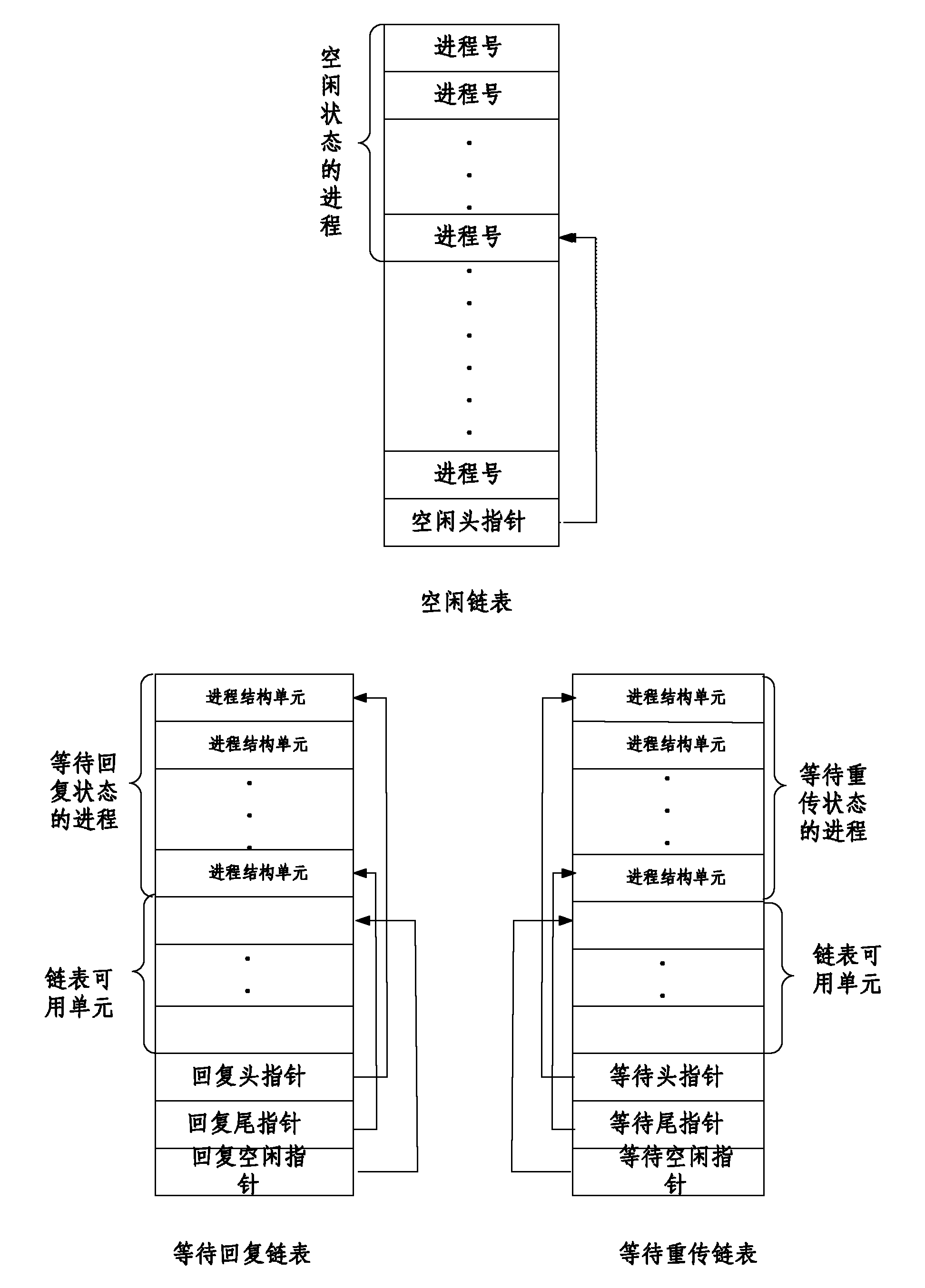

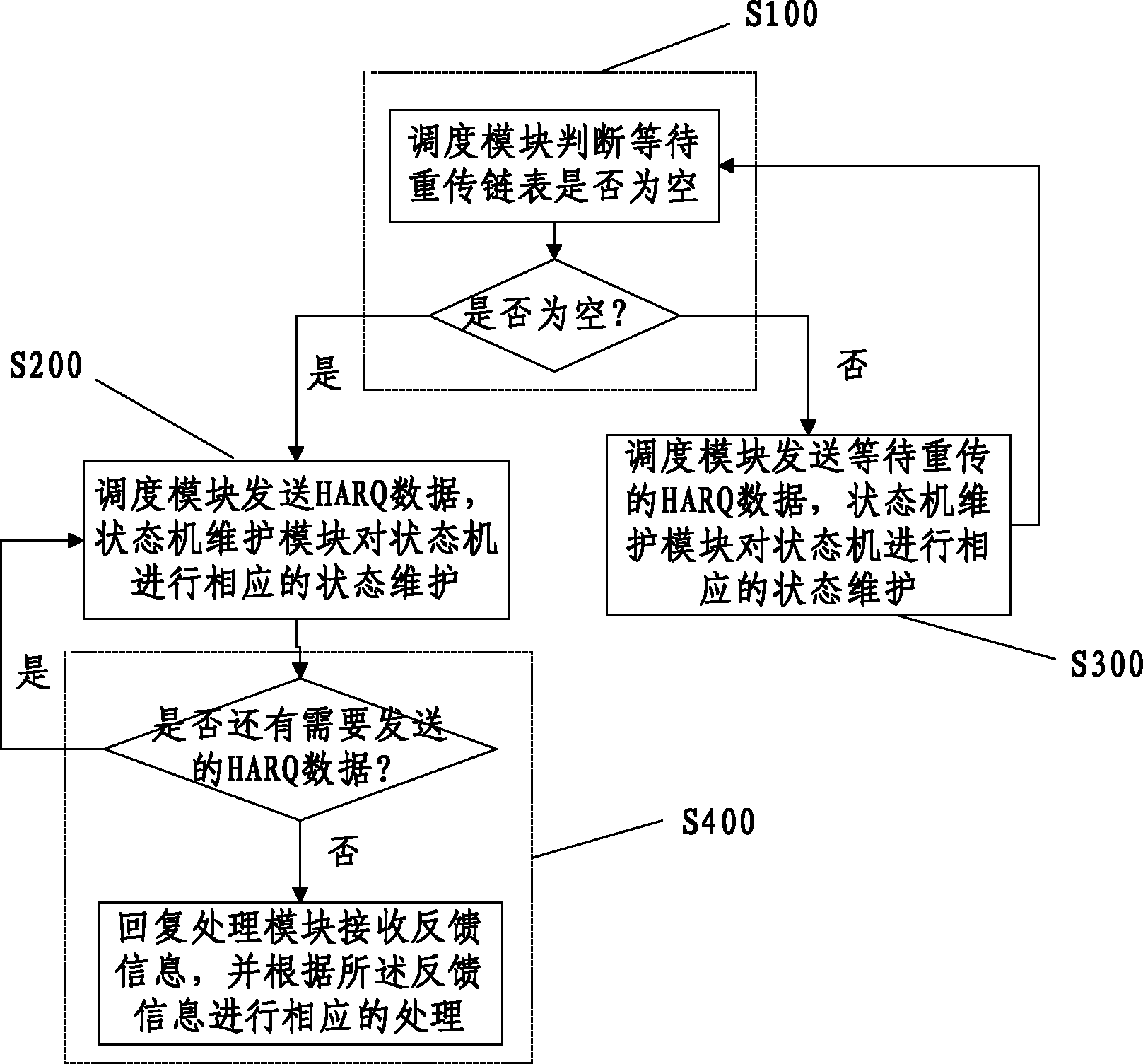

System and method for realizing downlink HARQ (hybrid automatic repeat request)

ActiveCN102148676AGuaranteed reliabilityGuaranteed timelinessError prevention/detection by using return channelWireless communicationTD-SCDMAMachine maintenance

The invention discloses a system and method for realizing downlink HARQ (hybrid automatic repeat request), relating to the technical field of TD-LTE (TD-SCDMA long term evolution). The system comprises a dispatching module, a state machine maintenance module and a reply handling module, wherein the state machine maintenance module is used for maintaining a state machine, the state machine is usedfor storing an HARQ process and a structural unit of the HARQ process; the dispatching module is used for making a decision according to information stored by the state machine, dispatching other modules of the system to realize according functions and selecting the HARQ process to send the HARQ data; and the reply handling module is used for handling according to feedback information of the sentHARQ data. By adopting the system and method for realizing the downlink HARQ disclosed by the invention, a state linked list in the state machine is stored with different states of the HARQ process, and the reliability and timeliness of downlink HARQ data transmission in a TD-LTE system can be effectively guaranteed.

Owner:BEIJING STARPOINT TECH COMPANY

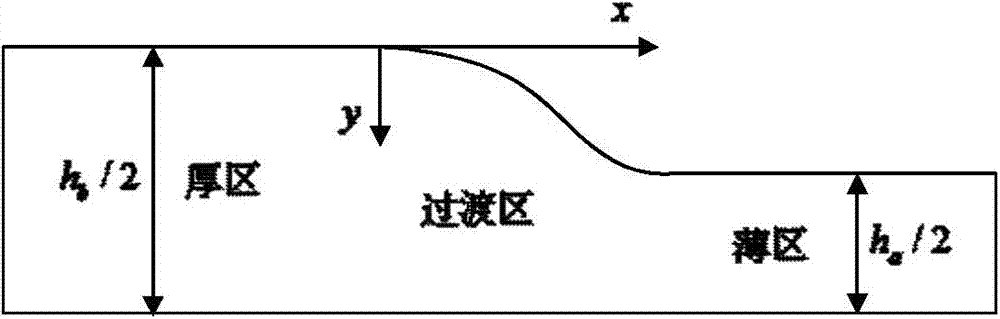

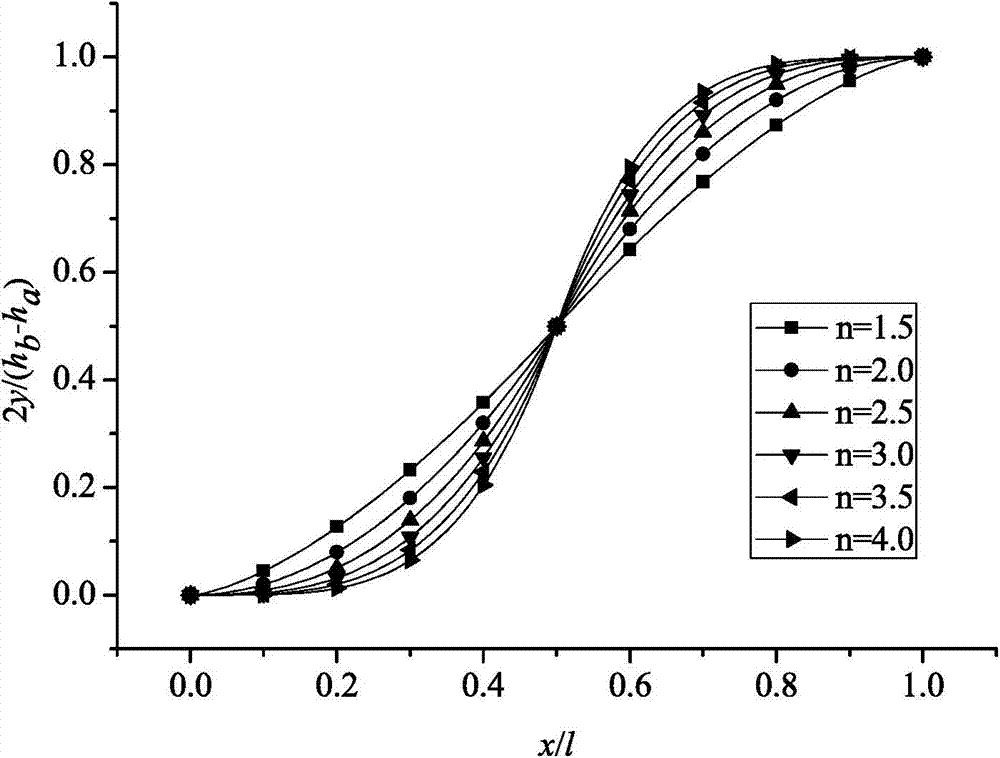

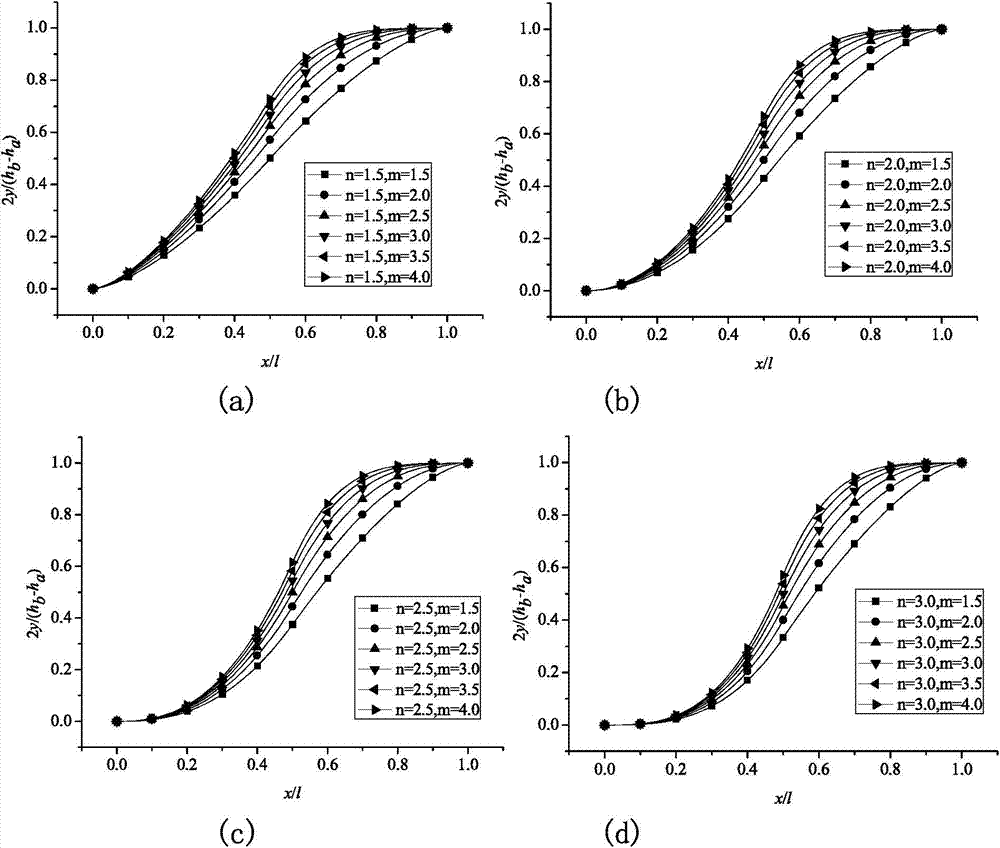

Curve transition method of variable thickness strip transition area

ActiveCN103926834AMeet the continuitySatisfies smoothnessAdaptive controlVariable thicknessMachine maintenance

The invention discloses a curve transition method of a variable thickness strip transition area, and relates to a variable thickness strip rolling technology. According to the method, the curve transition of the transition area is conducted through a double power function curve with the same front half power exponent and the rear half power exponent and a double power function curve with different front half power exponent and the rear half power exponent. The curve of the transition area has the advantages of being continuous and smooth, adjustable in shape, and capable of eliminating rolling force mutation in transition area rolling and reducing the maximum rolling force. The curve transition method of the variable thickness strip transition area is significant for rolling production of the variable thickness strip and rolling machine maintenance.

Owner:QINHUANGDAO CHANLINE PHOTOVOLTAIC ELECTRONICS

Drilling machine

InactiveCN103551622AImprove efficiencyAccurateDrilling/boring measurement devicesDirt cleaningPressure transmissionMachine maintenance

The invention relates to a drilling machine, which comprises a fixed substrate, power plants, a workpiece fixing device, drill pipes, drills, a far infrared inductor and a dust collection device, wherein the power plants are fixedly arranged on a bracket; the drills are connected with the power plants via the drill pipes; the power plants, the drill pipes and the drills form two drilling machine devices; the two drilling machine devices are respectively arranged on the left end and the right end of the workpiece fixing device; the workpiece fixing device comprises an air pressure transmission device, a clamping device and a sliding block, wherein the sliding block can slide on a guide rail; the air pressure transmission device is fixedly arranged on the sliding block; the guide rail is a circular ring shaped sealing guide rail and is positioned below the sliding block and above the dust collection device. The drilling machine disclosed by the invention has the efficiencies of high production efficiency, high workpiece drilling accuracy, easiness in drilling machine maintenance and the like, and workpieces can be subjected to batch drilling.

Owner:GUILIN FUGANG NEW MATERIAL

Production scheduling method and system based on improved artificial bee colony algorithm

ActiveCN107450498AReduce operating costsIncrease productivityProgramme total factory controlMachine maintenanceComputer science

The invention relates to a production scheduling method and system based on an improved artificial bee colony algorithm. The embodiment of the invention discloses a parallel machine batch scheduling method and system based on an improved artificial bee colony algorithm in a deterioration situation. The method can consider the problem of batch scheduling of parallel machines for maintenance in a deterioration workpiece situation and obtain a quasi-optimal solution, a model in the method is derived from an actual production process, and considers a machine maintenance and grouping machining mode in actual production and extra processing and maintenance processing time of workpieces and a machine that occurs with time, the method solves the problem, thereby facilitating providing of a reliable decision support for enterprise production and maintenance in complicated realistic production environment, reducing enterprise operation cost, improving enterprise production efficiency, and promoting building of a modernized intelligent factory of an enterprise.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com