Patents

Literature

433results about How to "Improve working accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

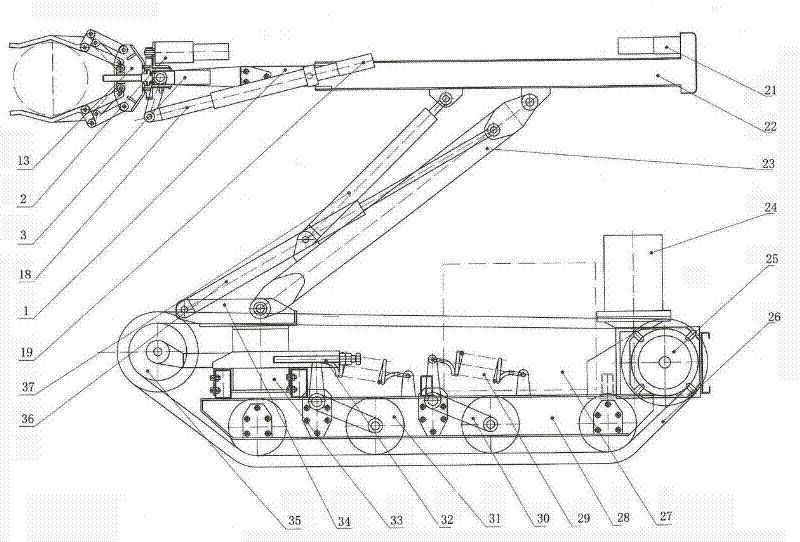

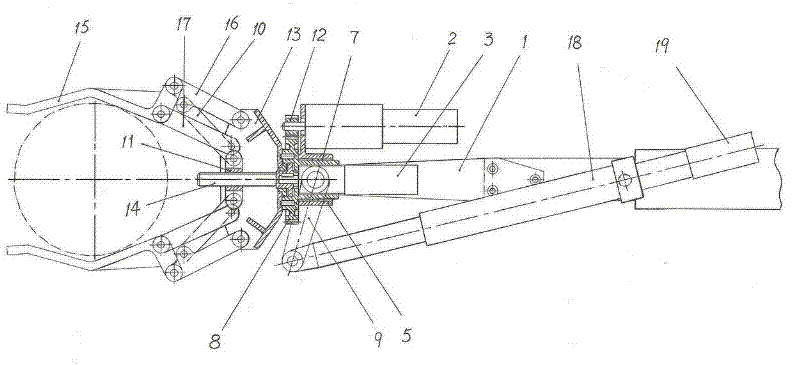

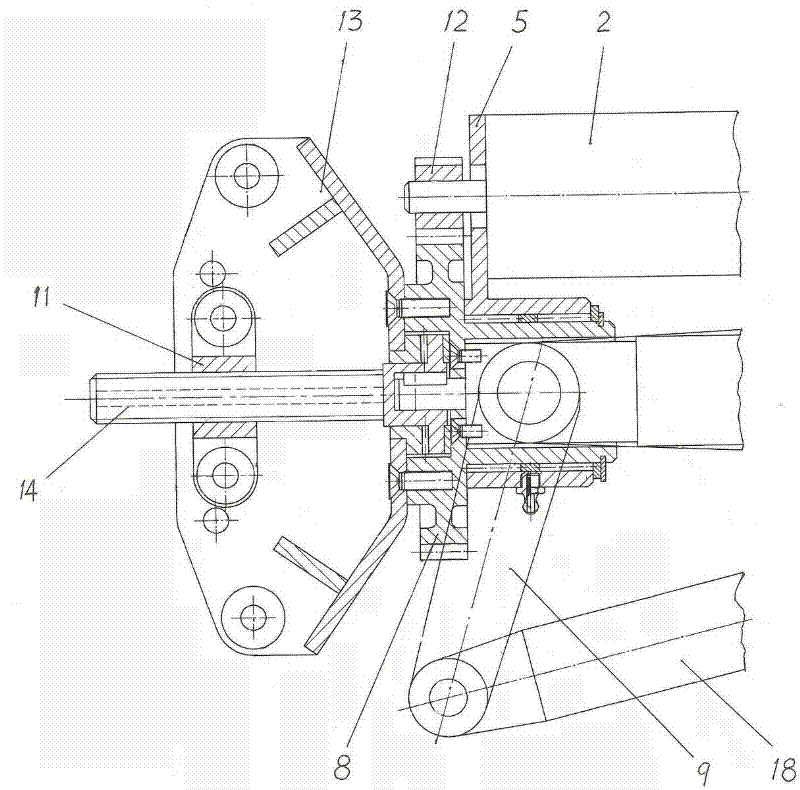

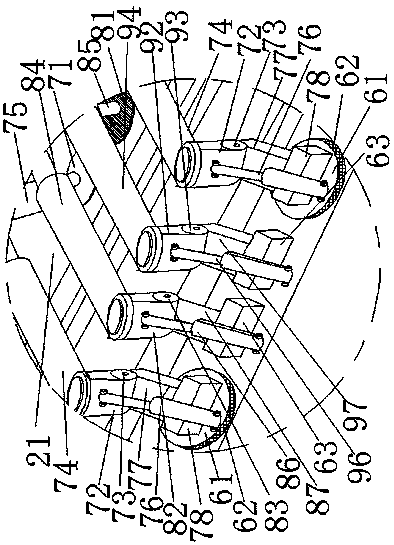

Robot for disposing dangerous goods and ammunition

InactiveCN102490171ASimple structureEasy maintenanceProgramme-controlled manipulatorGripping headsRemote controlEngineering

The invention relates to a robot for disposing dangerous goods and ammunition, which is structurally characterized in that a rotation platform and a crawler-type travelling mechanism are mounted on a frame, a mechanical arm is mounted on the rotation platform, a manipulator is connected to the front end of the mechanical arm, a rotation cylinder is mounted on the lower portion of the rotation platform, the mechanical arm comprises a large arm, a small arm, a telescopic arm, a large arm cylinder, a small arm cylinder and a telescopic control motor, and the manipulator comprises a wrist lifting mechanism, a wrist rotating mechanism and a pick-and-place mechanism. The robot is large in grabbing torque, high in precision, fine in stability, wide in operation range, convenient and flexible in control, convenient in operation, stable and reliable in running, high in cost performance and capable of disposing the dangerous goods, the ammunition and the like within a limited distance by means of remote control.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

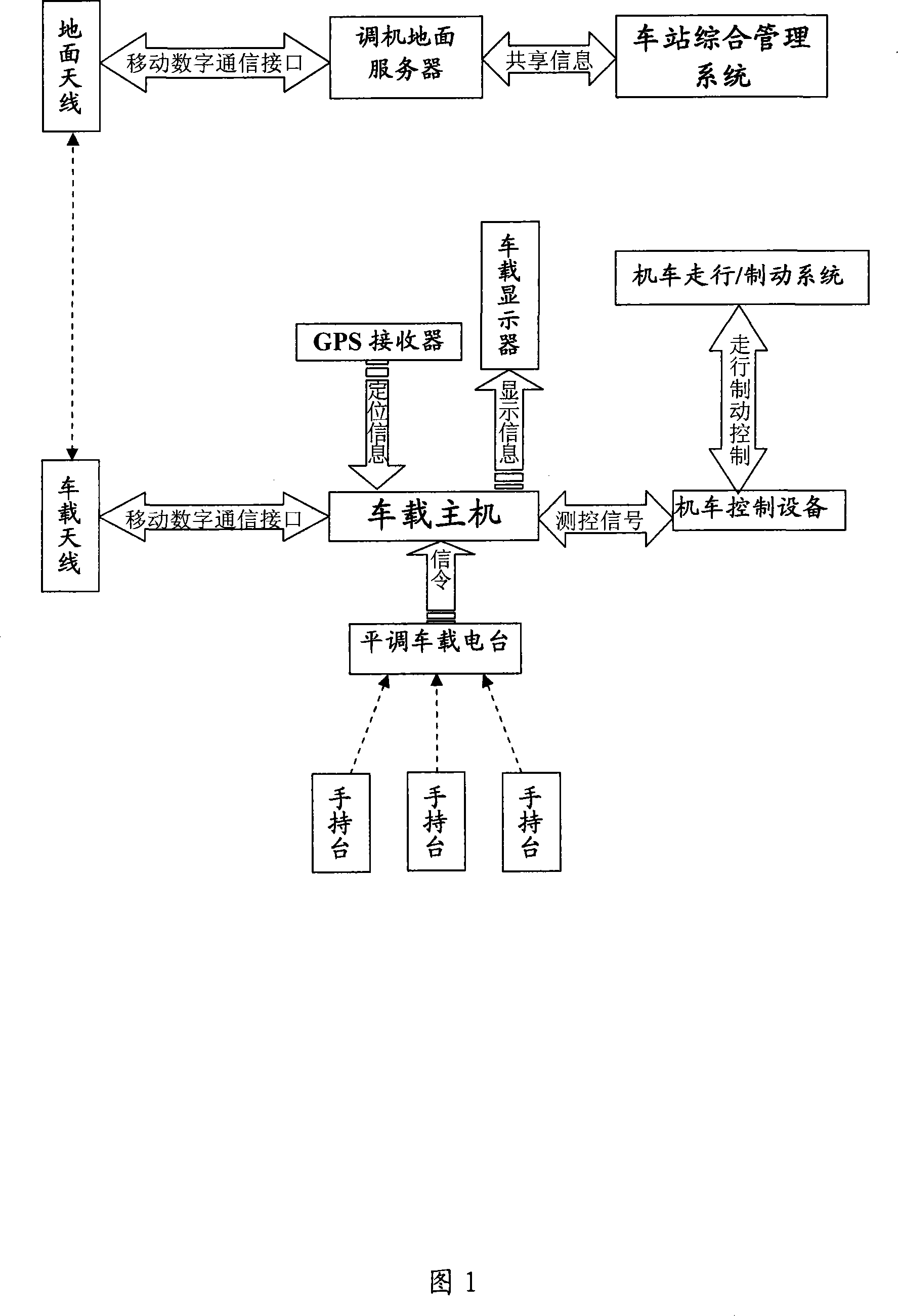

Station adjusting machine automatic drive system

ActiveCN101117128AReduce acknowledgment signal timeImprove shunting operation efficiencySignal boxes station blockingAutomatic controlProgram planning

The invention discloses a station locomotive regulating autopilot system which is relative to a station comprehensive integrated automatic system. Furthermore, as a component of the station comprehensive integrated automatic system, the station regulating autopilot system is used to enable the locomotive regulation to automatically control running of the locomotive according to a locomotive regulating and shunting operation plan, in coordination with ground shunting route automatic control and under the support of the comprehensive integrated automatic system. The invention works under the environment of the station comprehensive integrated automatic system and on the precondition of integrated management control, information sharing and exchange. The locomotive regulating autopilot system of the invention further develops functions based on a marshalling station locomotive regulating automatic system which is another patent of invention of the applicant.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

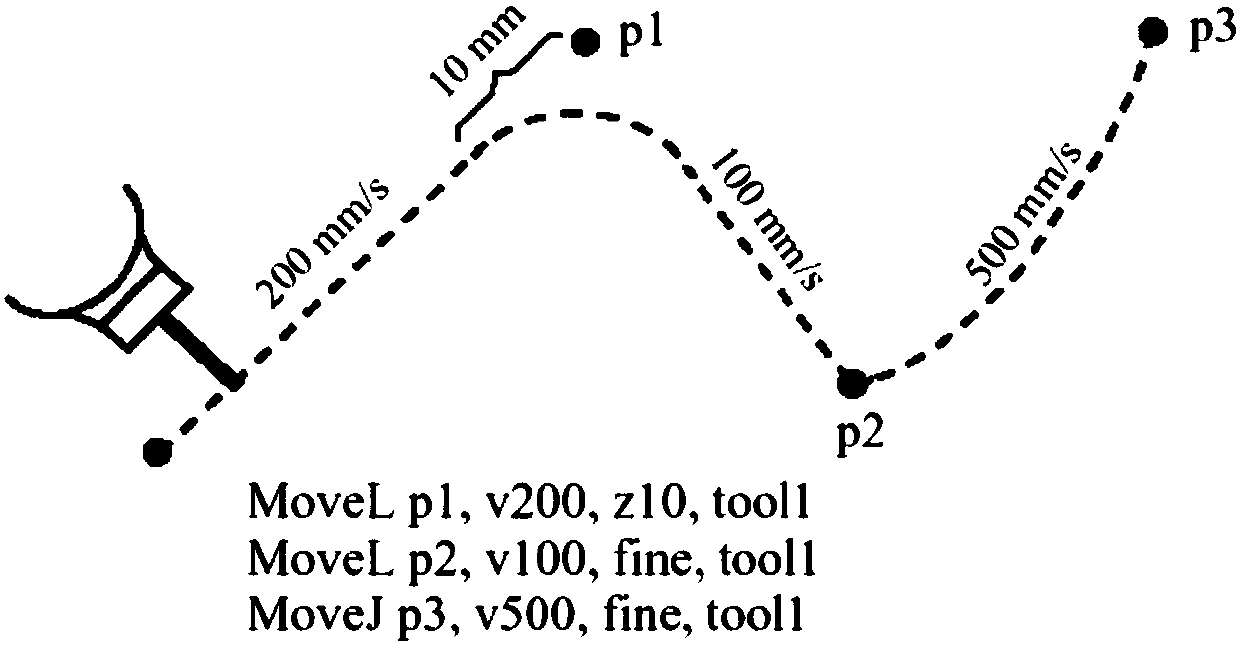

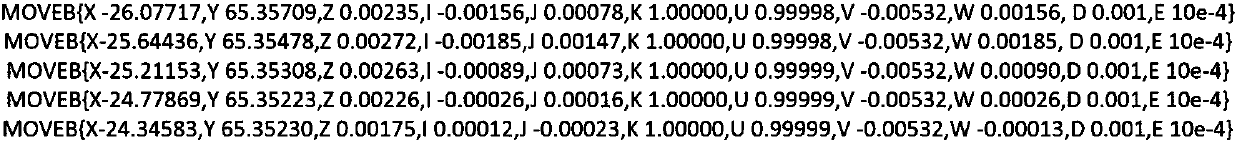

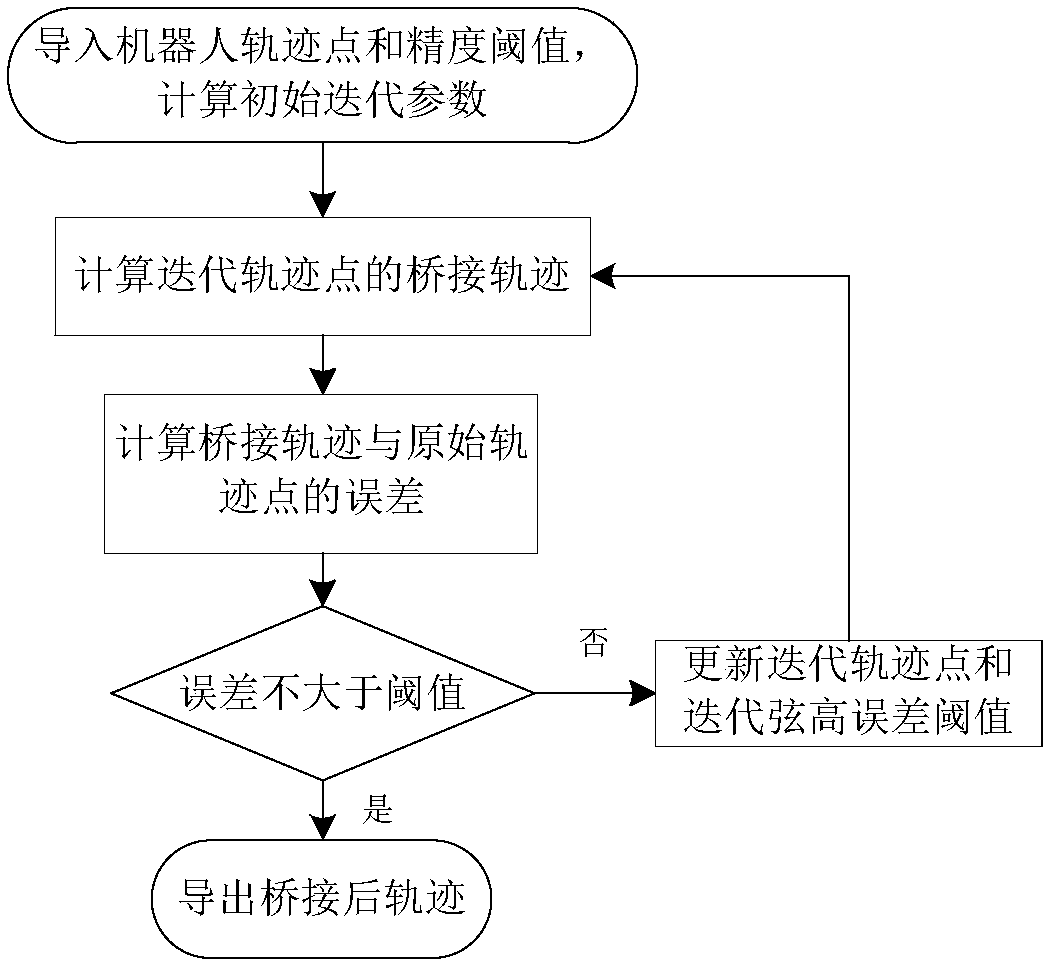

Error-controllable industrial robot fairing movement track generation method

ActiveCN106826829AImprove accuracyFulfil requirementsProgramme-controlled manipulatorComputer scienceRobot trajectory

The invention discloses an error-controllable industrial robot fairing movement track generation method which comprises the following steps: S1, generating an MOVEB movement instruction, describing an industrial robot movement track which comprises a track point and posture, a track point error threshold input by a user, and a chord height error threshold; S2, performing interpolation on a robot track point, namely performing interpolation on a high-order B sample curve into the track point according to the track point error and the chord height error threshold by using the high-order B sample interpolation algorithm, and respectively achieving G2 interpolation and G3 interpolation of the robot track point, so as to obtain an interpolation track which has high continuity and meets the track point error and chord height error requirements; S3, performing interpolation on the posture of the robot so as to obtain a robot posture curve with sectional G2 and continuous G3; S4, acquiring a movement track of the robot after interpolation according to the track point interpolation curve and the robot posture curve. By adopting the error-controllable industrial robot fairing movement track generation method, real-time continuous interpolation of the movement track can be achieved, calculation can be simple, efficient and precise, and vibration and abrasion of the robot can be reduced.

Owner:武汉瀚迈科技有限公司

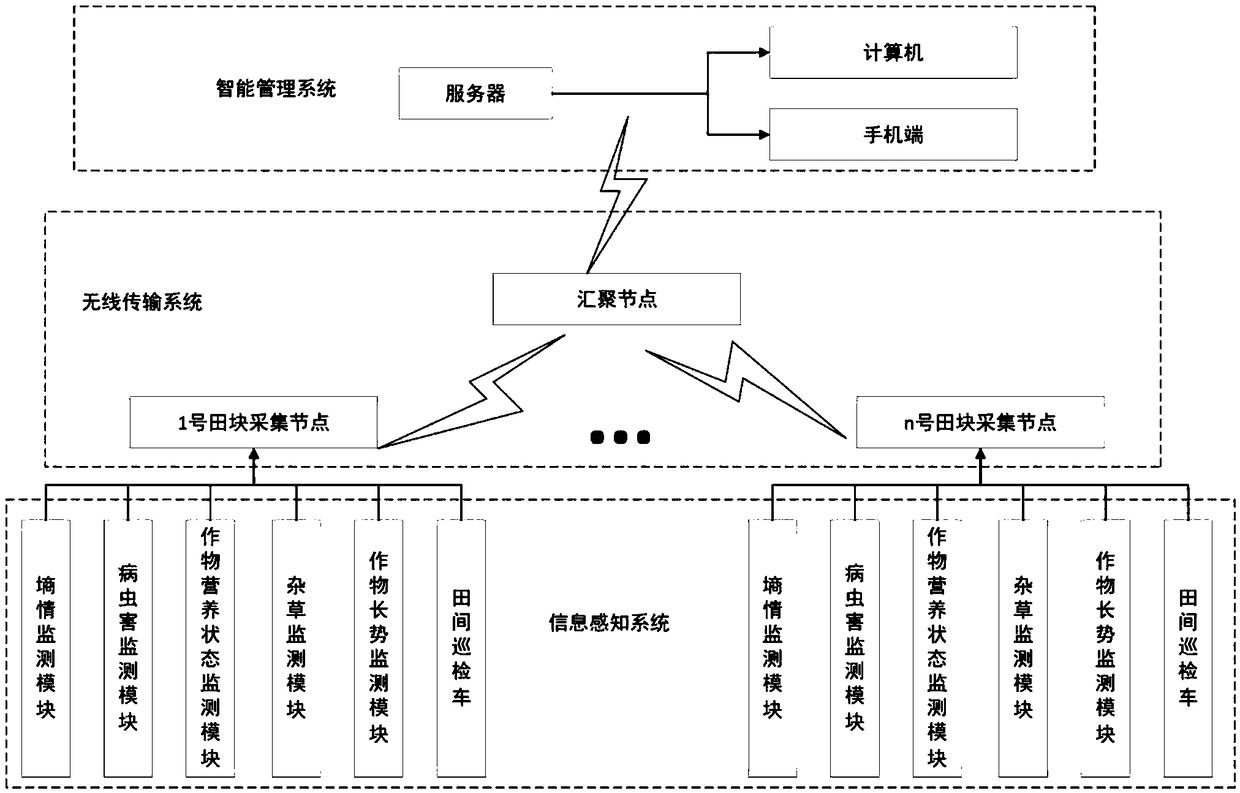

Crop growth information monitoring system and method based on internet of things

InactiveCN109470299ARealize monitoringRealize acquisitionMeasurement devicesDiseaseNutritional status

The invention discloses a crop growth information monitoring system and method based on internet of things. The system comprises an information perception system, a wireless transmission system and anintelligent management system, wherein the information perception system includes a soil moisture content monitoring module, a plant disease and insect pest monitoring module, a crop nutrition statemonitoring module, a weed monitoring module and a crop condition monitoring module. After crop planting, relevant information and threshold values of a crop growth environment are set through an intelligent management system interface, the soil moisture content, diseases and insect pests, nutritional status, weed growth and growth vigor information of growing crops are acquired through the perception system in real time and are sent to a server for data storage, analysis and display, if the information exceed threshold values, workers are remind of corresponding processing, plants are helped to accurately judge the crop growth conditions, real-time effective decision information is provided for accurate operation, the problem is solved that the crop growth conditions in planting field pieces need to be checked regularly in traditional planting process and accordingly the labor intensity is high, the labor cost is reduced, and the operating efficiency and accuracy are improved.

Owner:JIANGSU UNIV

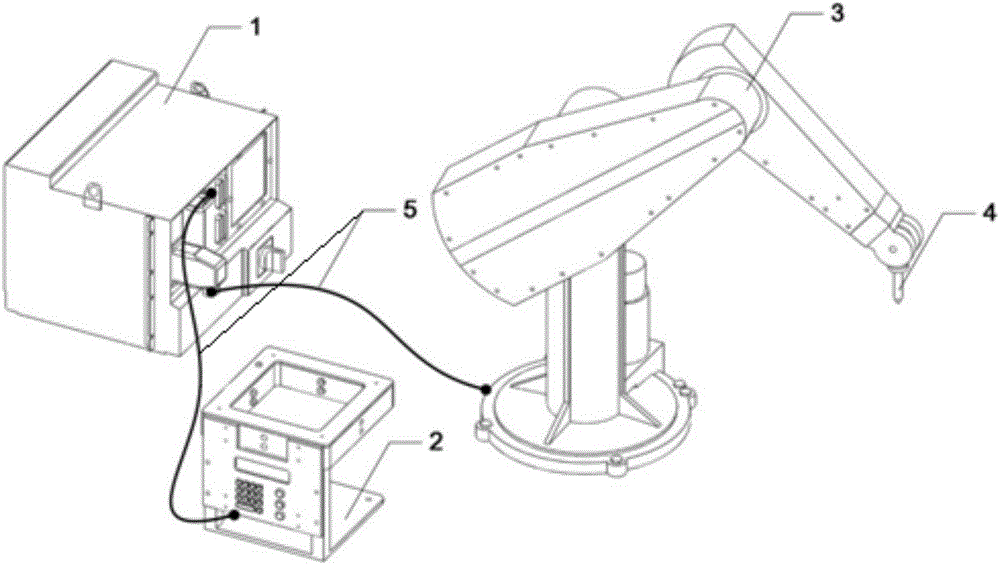

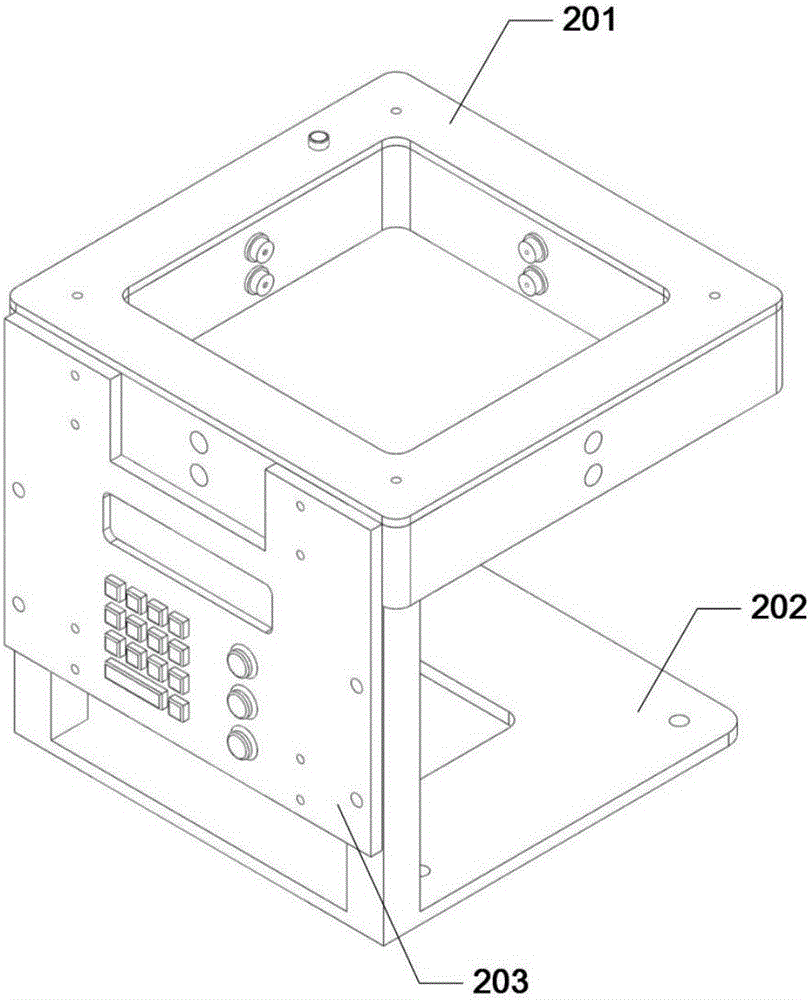

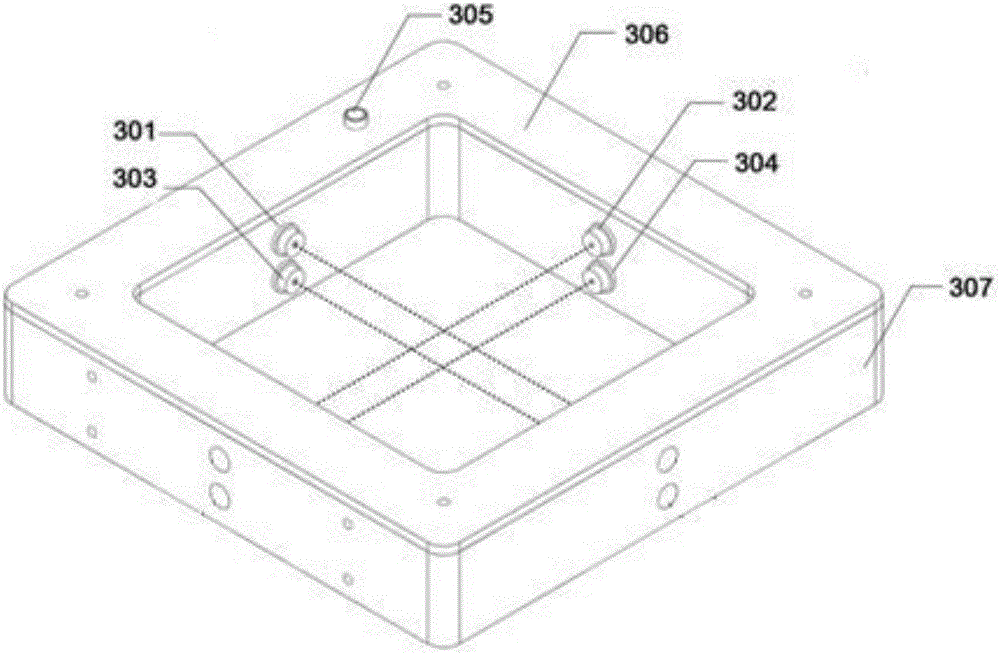

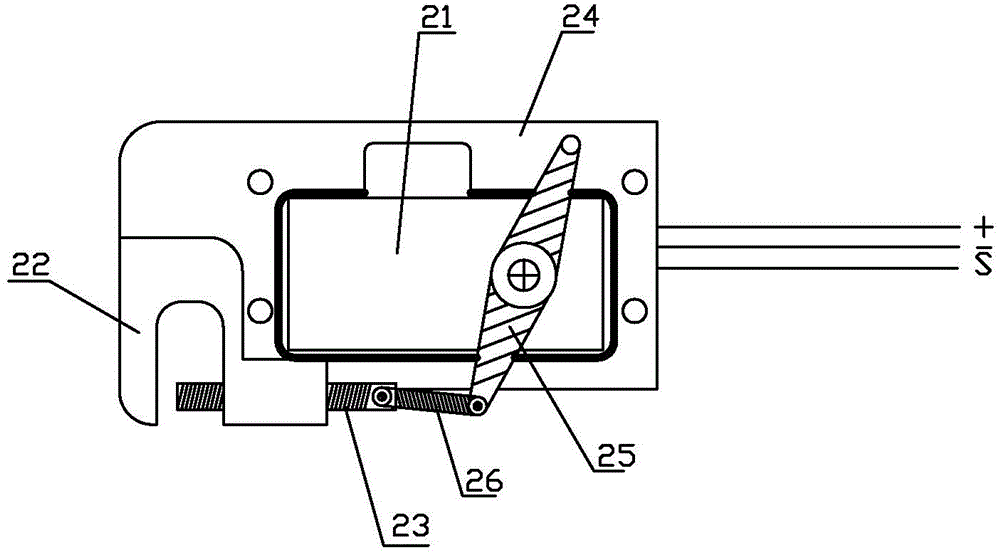

TCP online quick calibration method and device applied to industrial robot

ActiveCN105945948AImprove working accuracyReduce downtime for maintenanceProgramme controlProgramme-controlled manipulatorProduction lineComputer science

The invention discloses a TCP online quick calibration method and device applied to an industrial robot. The device comprises a control cabinet, a TCP calibration device, the industrial robot, a terminal tool and control buses; the control cabinet is separately connected with the TCP calibration device and the industrial robot through the control buses; the terminal tool is mounted on the industrial robot; the TCP calibration device includes a TCP detecting device, a calibration controller and a mounting base; the TCP detecting device is fixedly mounted on one side of the industrial robot through the mounting base; and a measuring plane is parallel to a XOY plane of an industrial robot base coordinate system. According to on-off signals of a correlation photoelectric sensor, the pose data of a flange is recorded, and the pose deviations of the terminal tool in X / Y axis and Z axis directions are calculated and compensated; and through multiple times of repeated operations, the TCP calibration errors are reduced, the operation precision of the industrial robot is effectively improved, the stop maintenance time of the industrial robot is reduced, and the automation degree of an industrial production line is improved.

Owner:南京速之海自动化设备有限公司

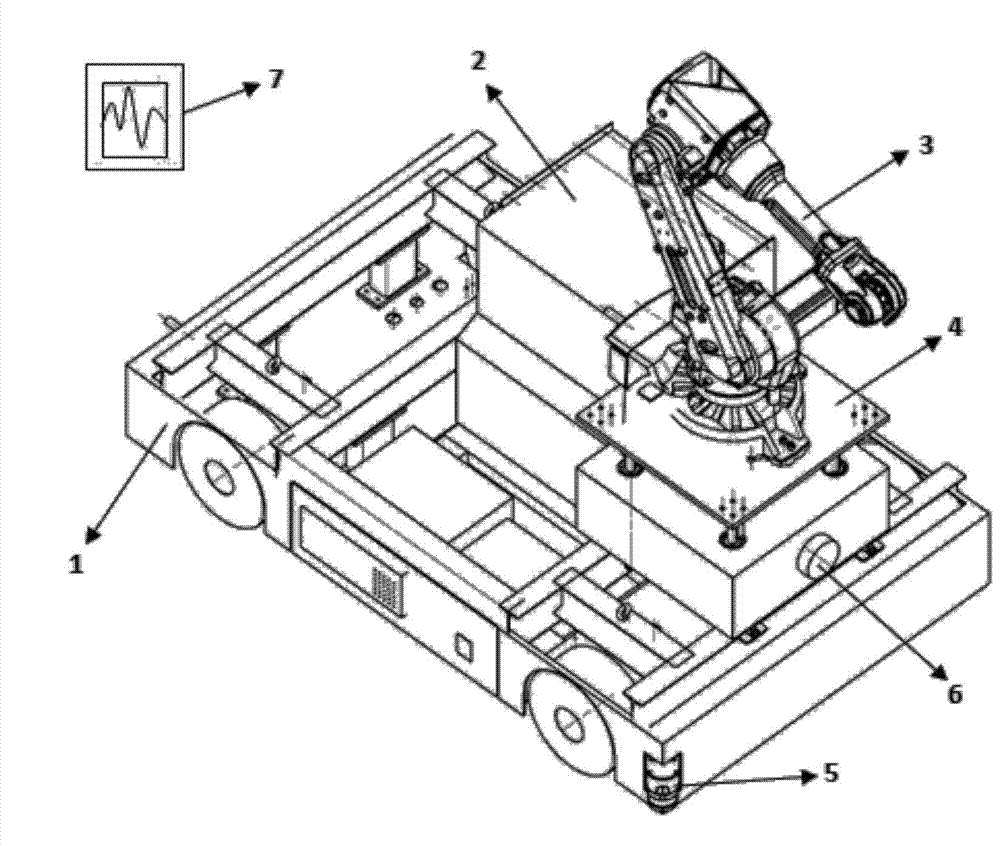

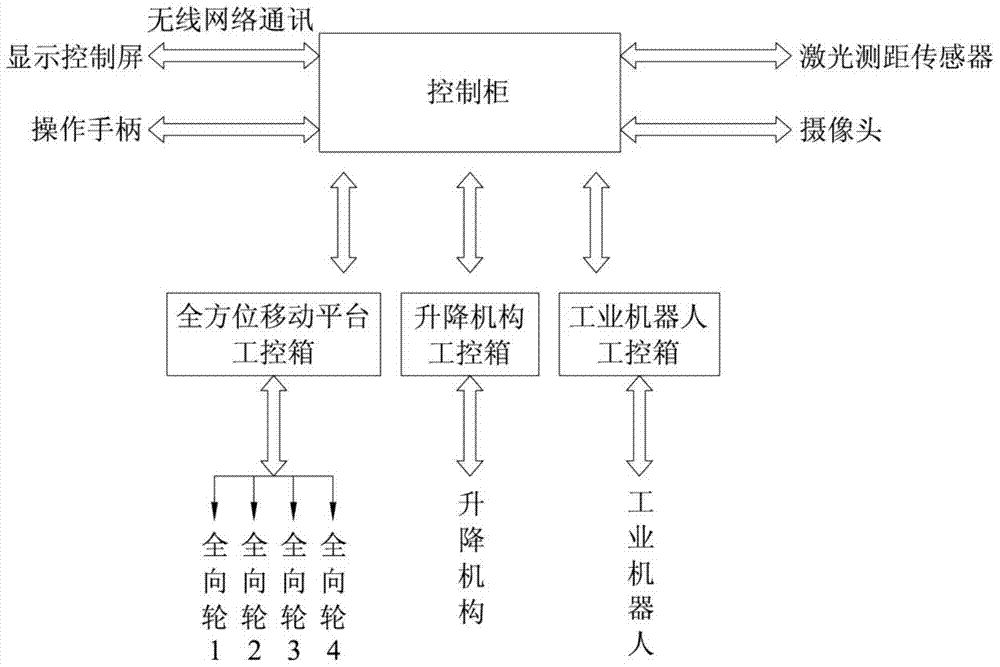

Autonomous working robot system

ActiveCN104723318ACompact structureImprove working accuracyManipulatorRobotic systemsAutomatic control

The invention relates to an autonomous working robot system. The autonomous working robot system comprises a robot body and a remote control system; the robot body comprises an all-directional moving platform cable of moving in the horizontal plane at will, a lifting mechanism installed on the all-directional moving platform and capable of lifting relative to the all-directional moving platform, an industrial robot installed on the lifting mechanism, a control cabinet and a positioning and recognizing system, wherein the control cabinet and the positioning and recognizing system are installed on the all-directional moving platform; the remote control system transmits automatic control signals to the control cabinet, the positioning and recognizing system feeds back positioning and recognizing signals to the control cabinet, and the control cabinet controls moving of the all-directional moving platform, lifting of the lifting mechanism and work of the industrial robot according to the automatic control signals and the positioning and recognizing signals. The autonomous working robot system can move in an all-directional mode, and is simple and compact in structure and high in operation accuracy, reliability and safety, and the intelligence and the practicability of the industrial robot are greatly improved.

Owner:SUZHOU IND ROBOT TECH

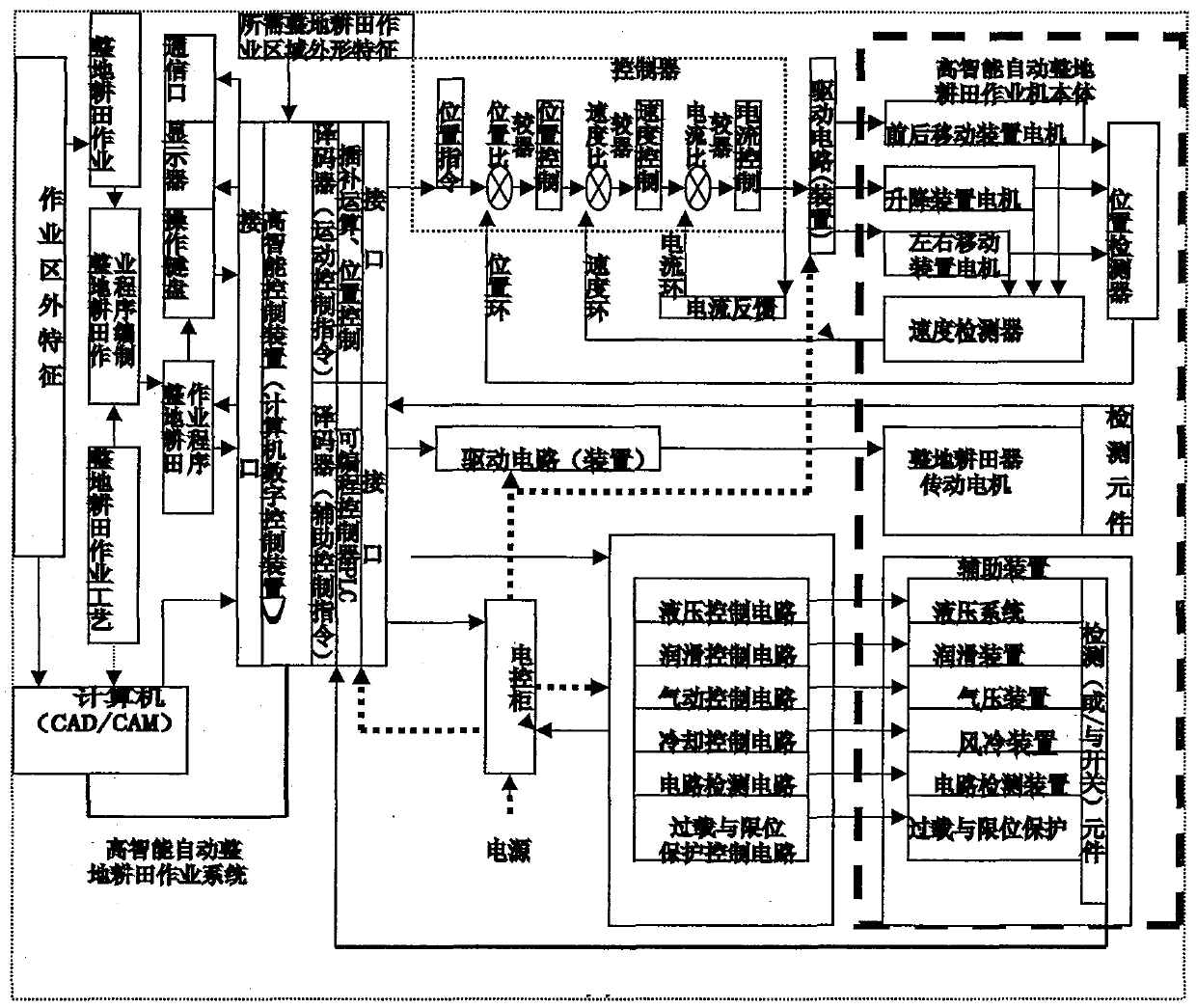

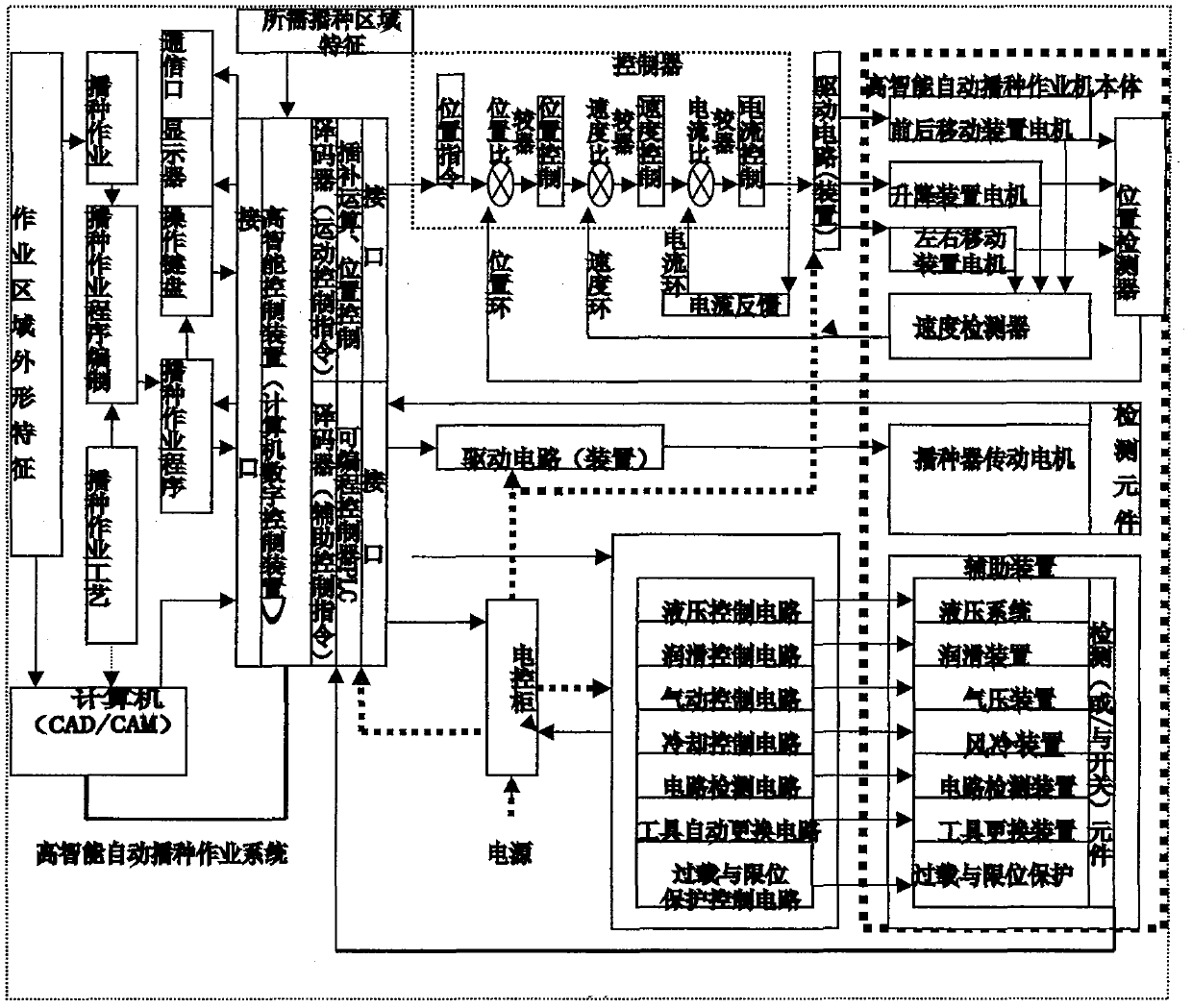

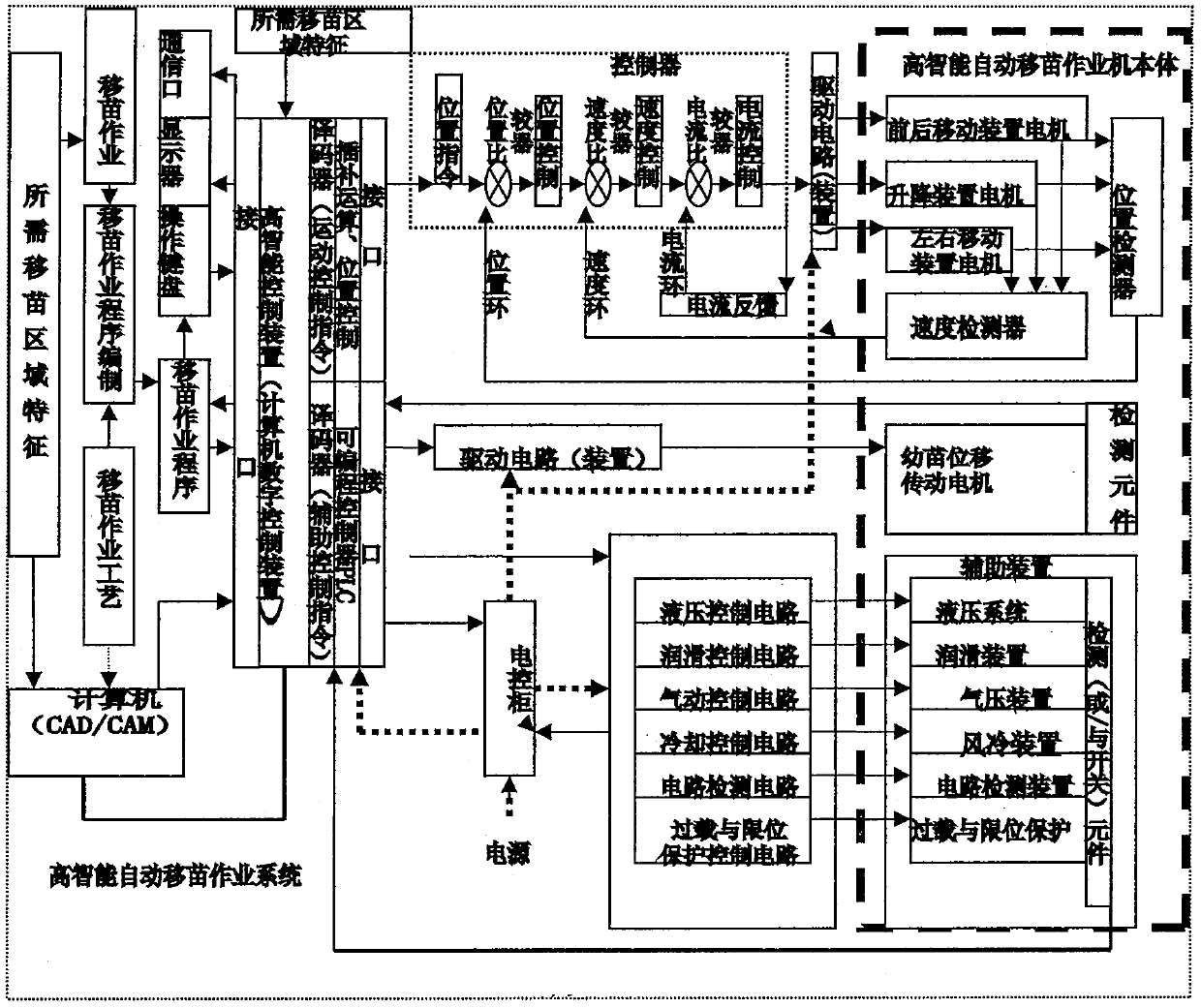

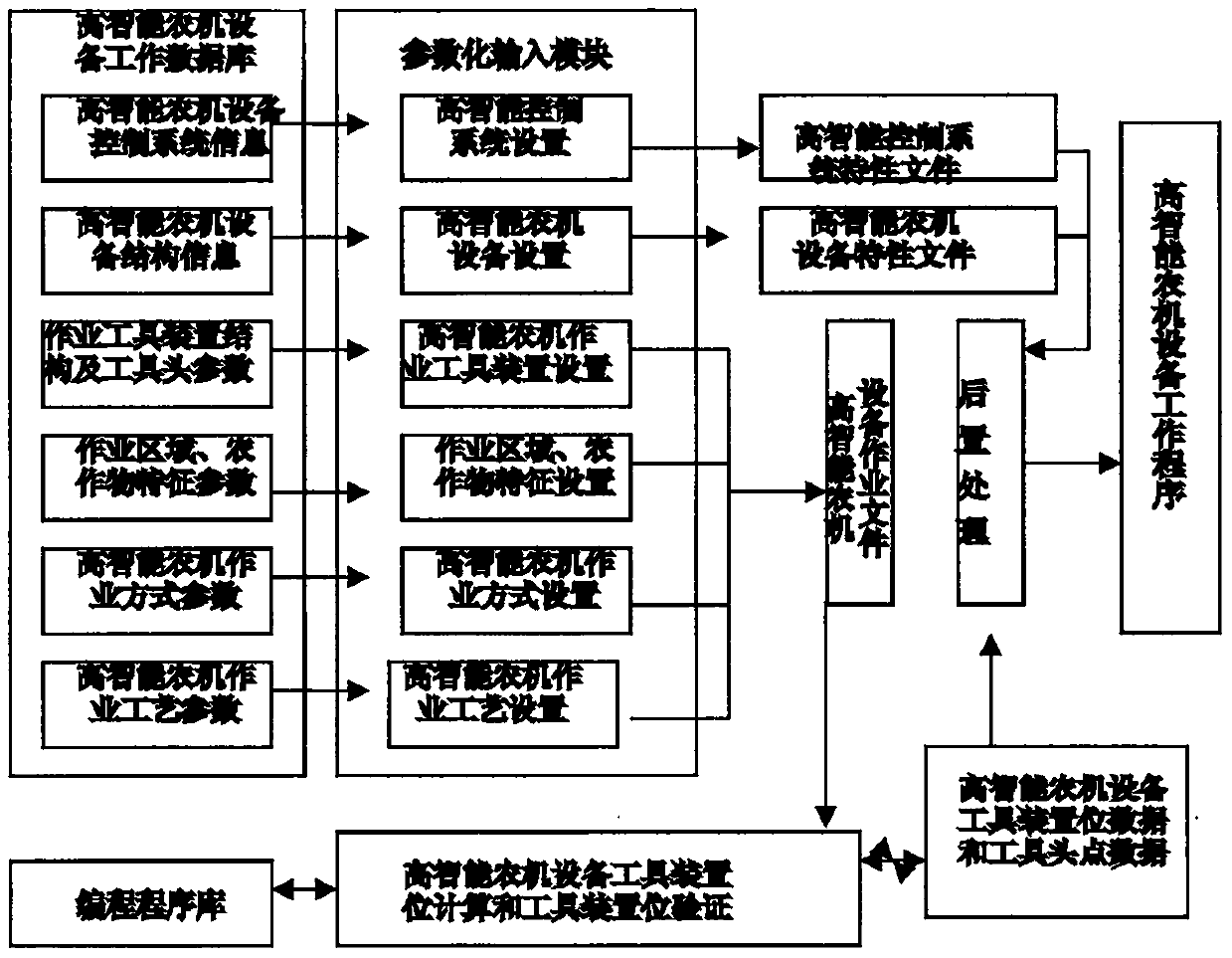

High-intelligence agricultural mechanical apparatus and system

InactiveCN108170104ARealize automated productionRealize zero emission at workAgricultural undercarriagesProgramme total factory controlElectric machineryAgricultural engineering

The invention belongs to the agricultural machinery field and relates to an agricultural mechanical apparatus and system. With the agricultural mechanical apparatus and system adopted, the problem that agricultural machinery cannot perform automatic operation can be solved. According to the agricultural mechanical apparatus and system, electric energy, motors and tracks are adopted to perform automatic operation; operation and work which are required by an operation area can be automatically and orderly completed according to the shape feature of the operation area or / and the crops of the operation area and an operation mode required by the operation area or / and the crops of the operation area; one such agricultural mechanical apparatus can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops; and one or more agricultural mechanical apparatuses can be driven and controlled to complete various operation of thefull-process management of plough, farming and harvest of the crops.

Owner:杨新高

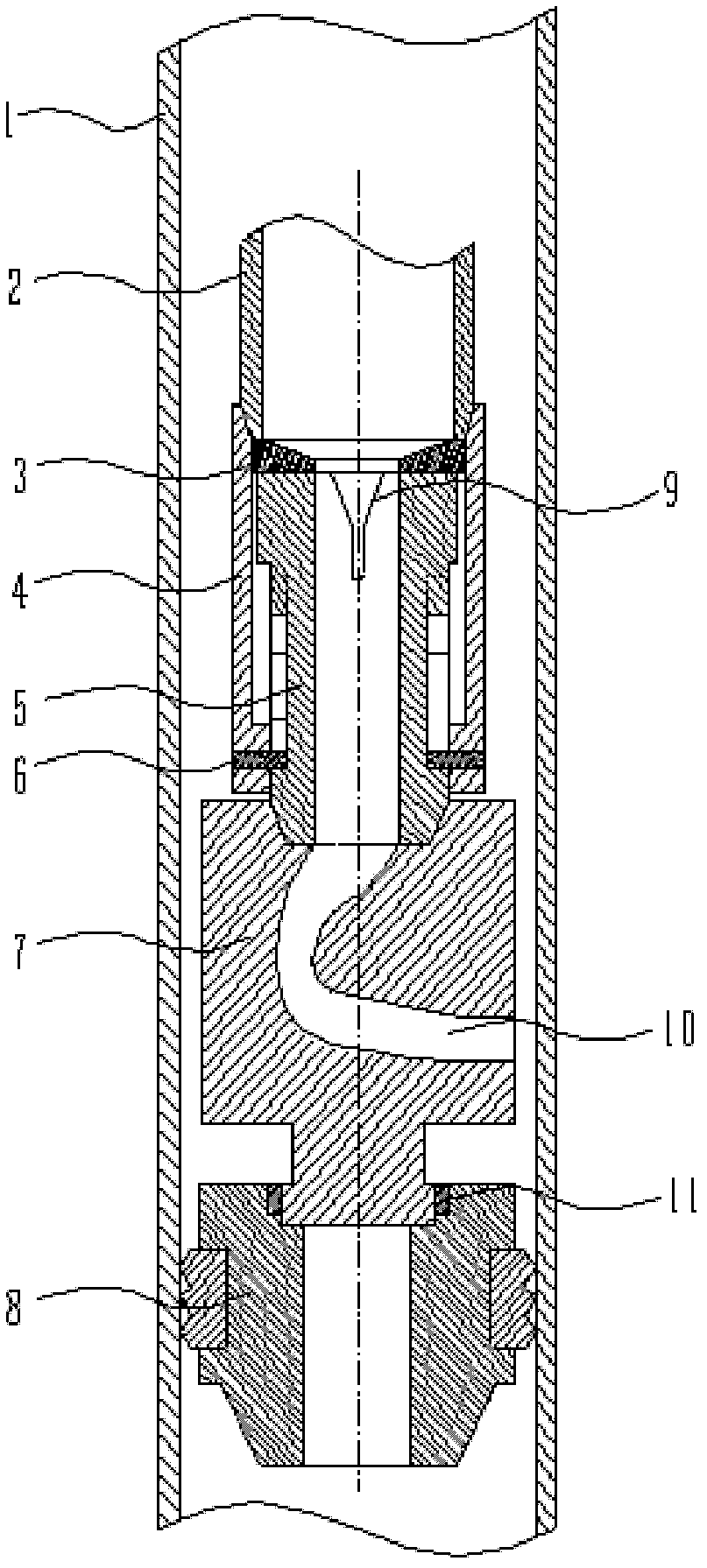

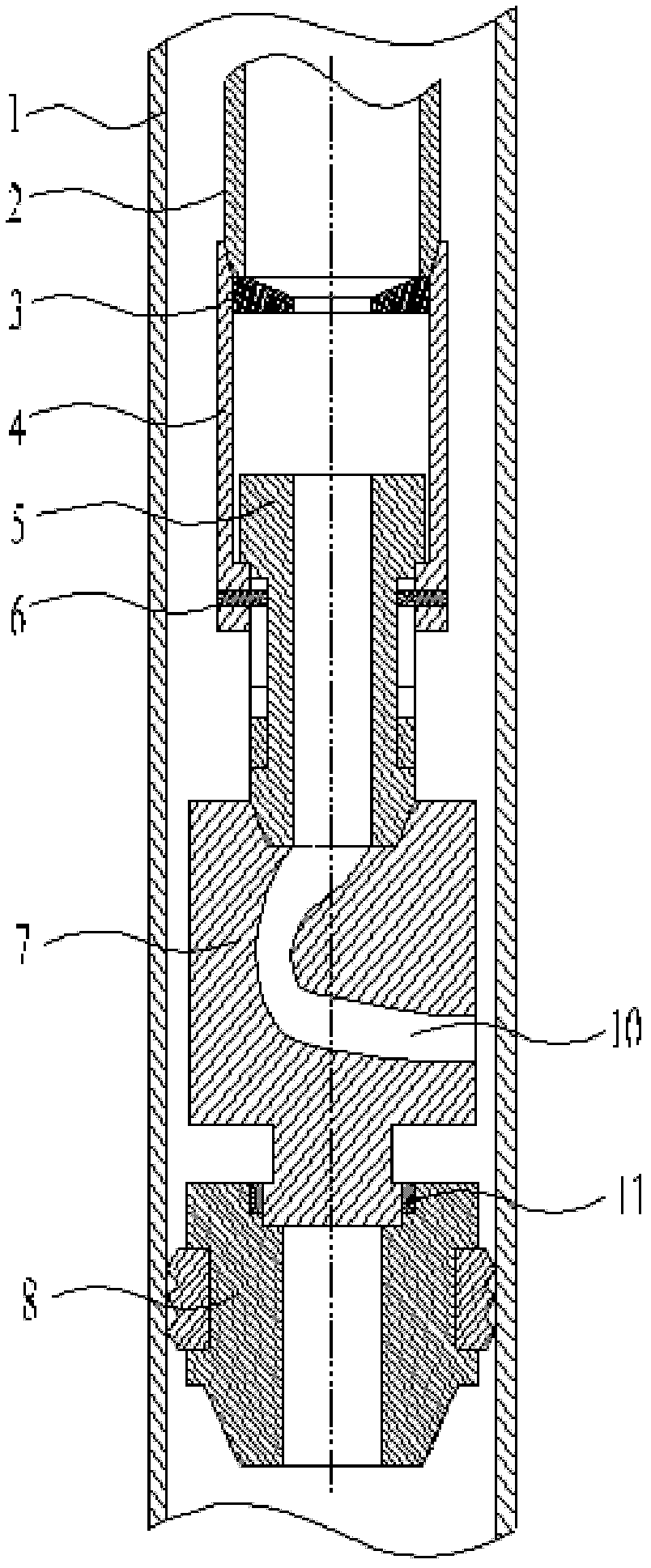

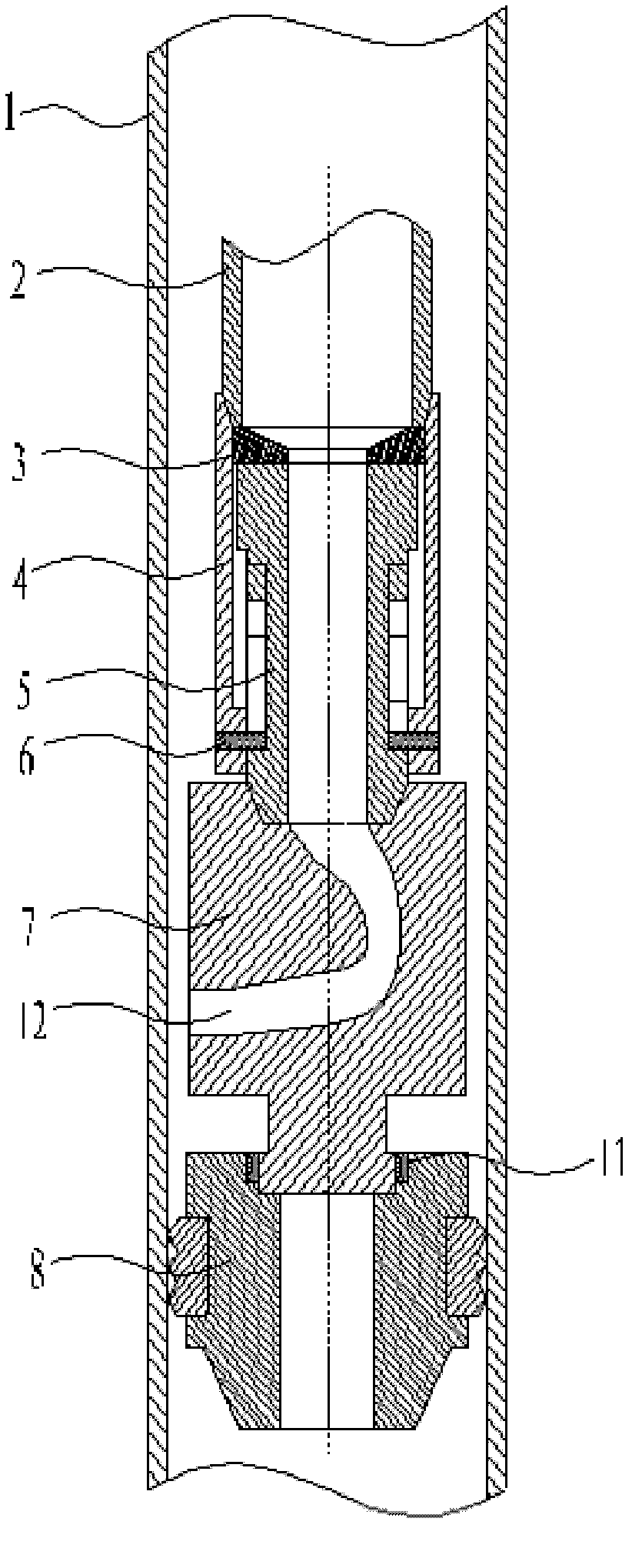

Radial horizontal well orienting device and method for operating same

InactiveCN103375140ASolve complex directional window opening problems in radial wellsSolve the problem of directional window openingDirectional drillingBorehole/well accessoriesPetroleum engineeringLateral thrust

The invention discloses a radial horizontal well orienting device and a method for operating the same. The radial horizontal well orienting device and the method are designed for achieving the purpose of arranging a plurality of casing windows on a string at one step. The radial horizontal well orienting device is characterized in that an oil string and a steering rod are connected with a steering barrel of the device, the steering rod is connected with a steering gear, and guide pins of the steering barrel are inserted into guide slide grooves of the steering rod; when the oil string is lifted upwardly and placed downwardly and the steering barrel is driven to move up and down, the guide pins generate lateral thrust in the guide slide grooves, and the steering gear is pushed to realize a steering effect. The radial horizontal well orienting device and the method have the advantages that the radial horizontal well orienting device and the method are mainly applied to radial horizontal well operation for drilling a plurality of wells on the same oil layer, the complicated oriented windows can be arranged on a radial well without cable or down-hole electric device descending, well descending, azimuth measuring and multi-azimuth radial horizontal well orienting can be completed at one step only by the aid of the simple mechanical device, positioning and orienting are accurate, an operation procedure is simple, the operation cost is low, and the operation efficiency and accuracy are high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

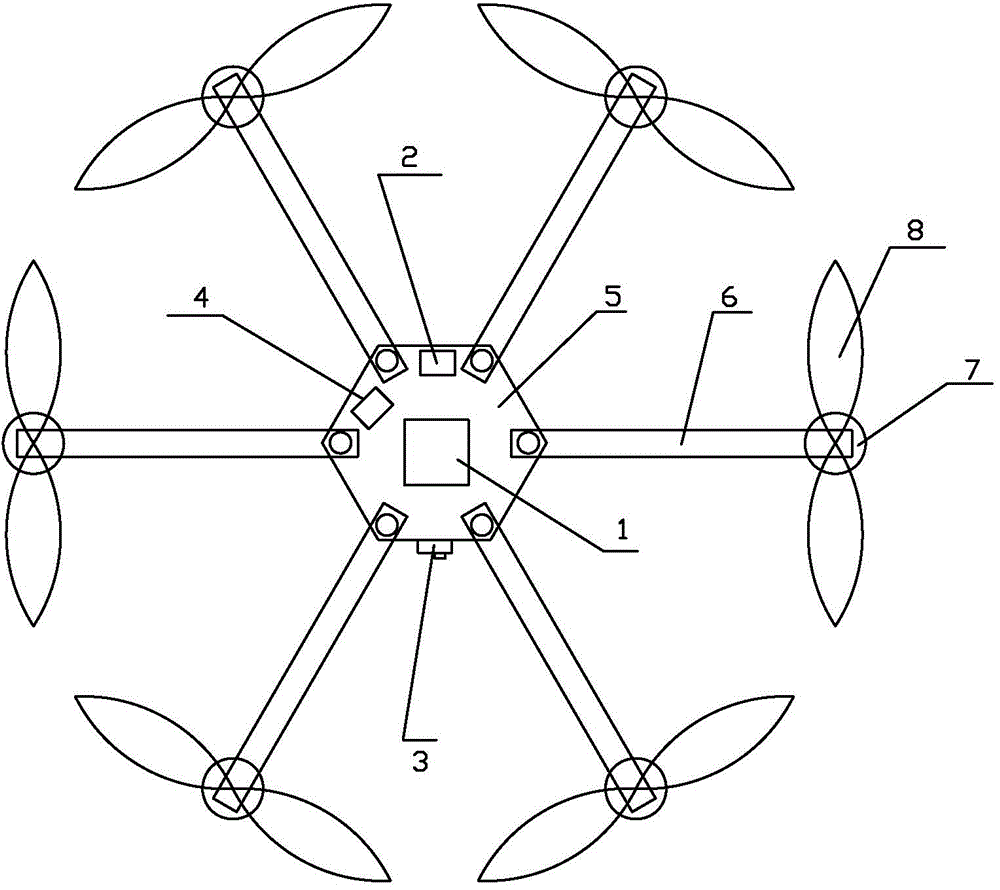

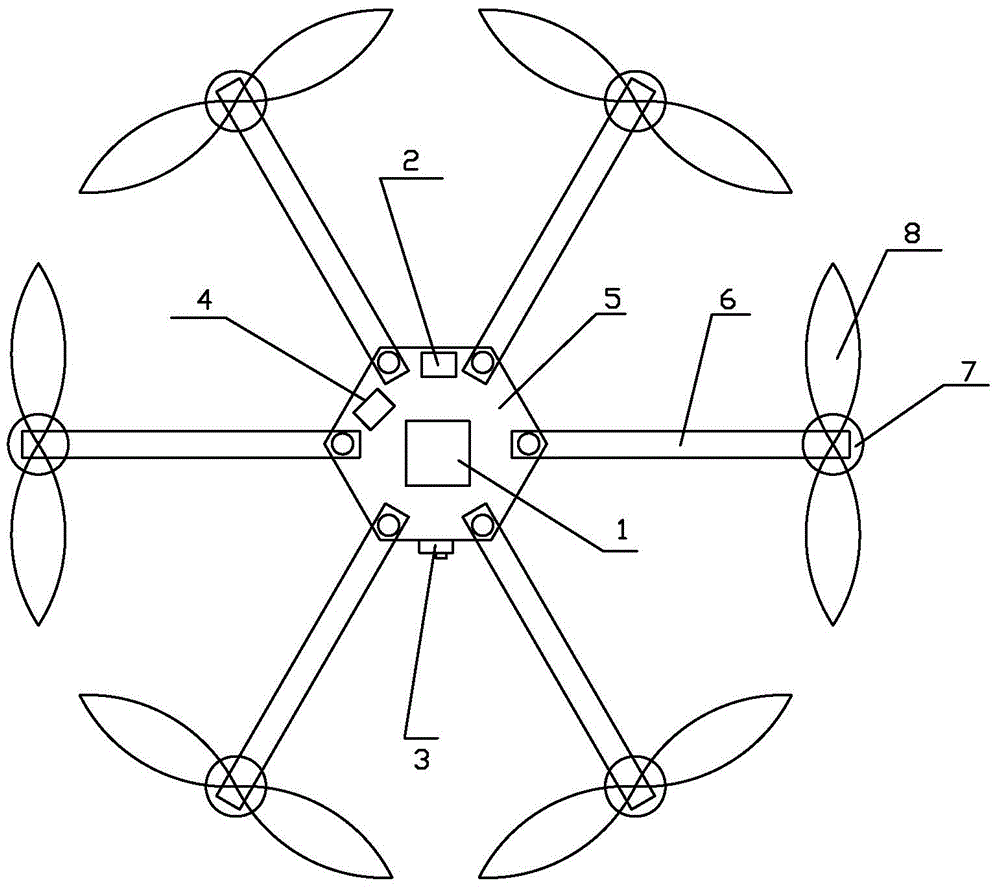

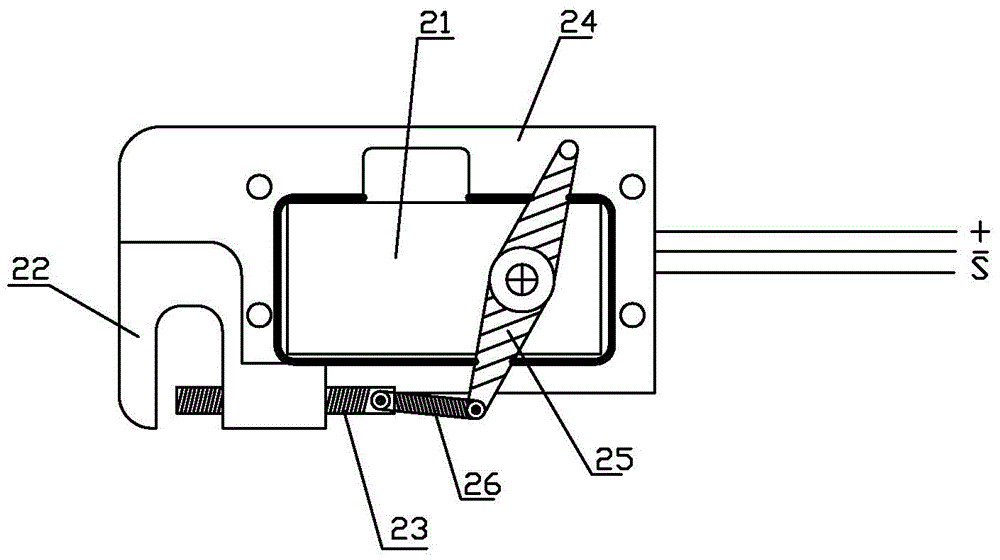

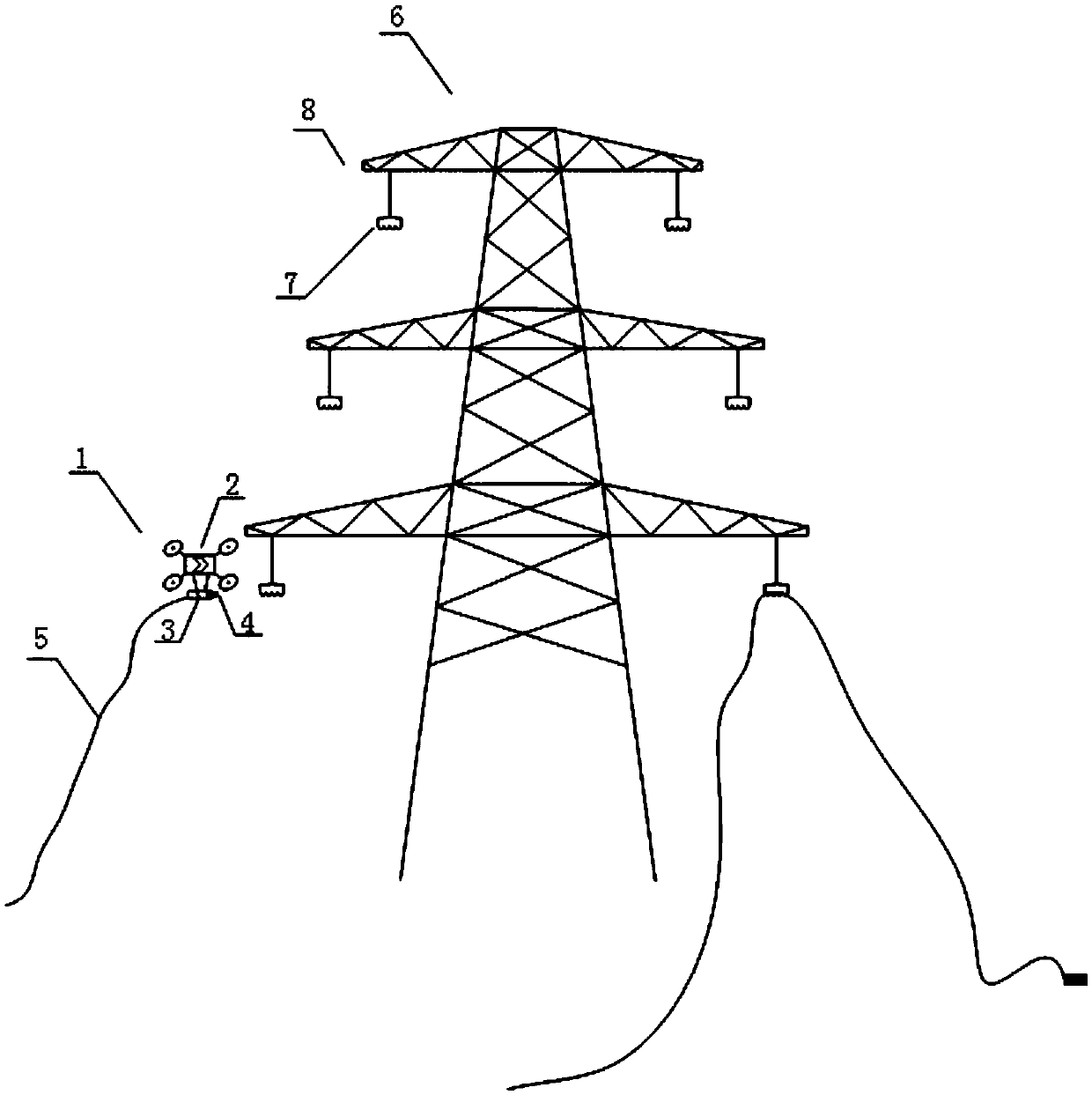

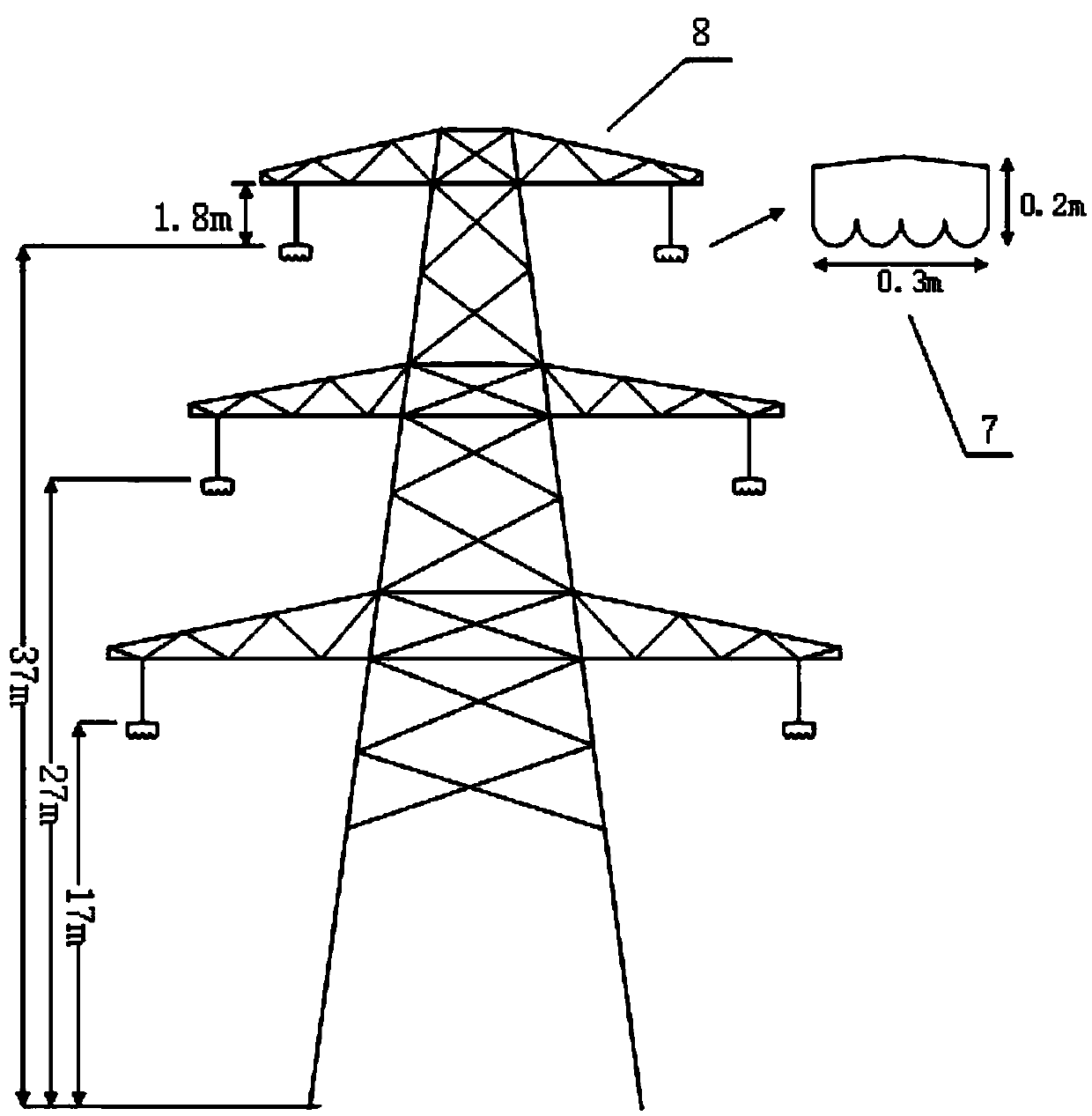

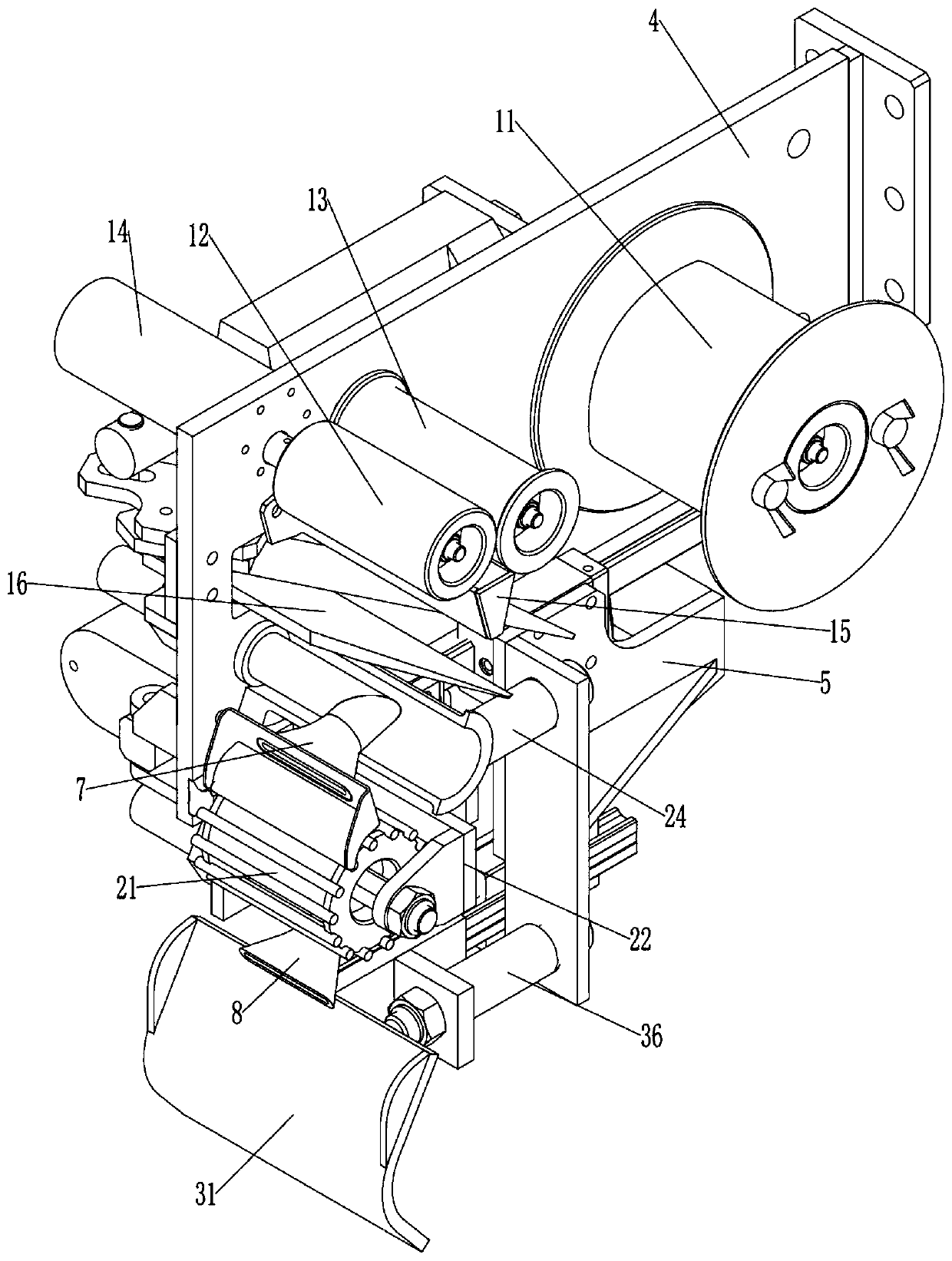

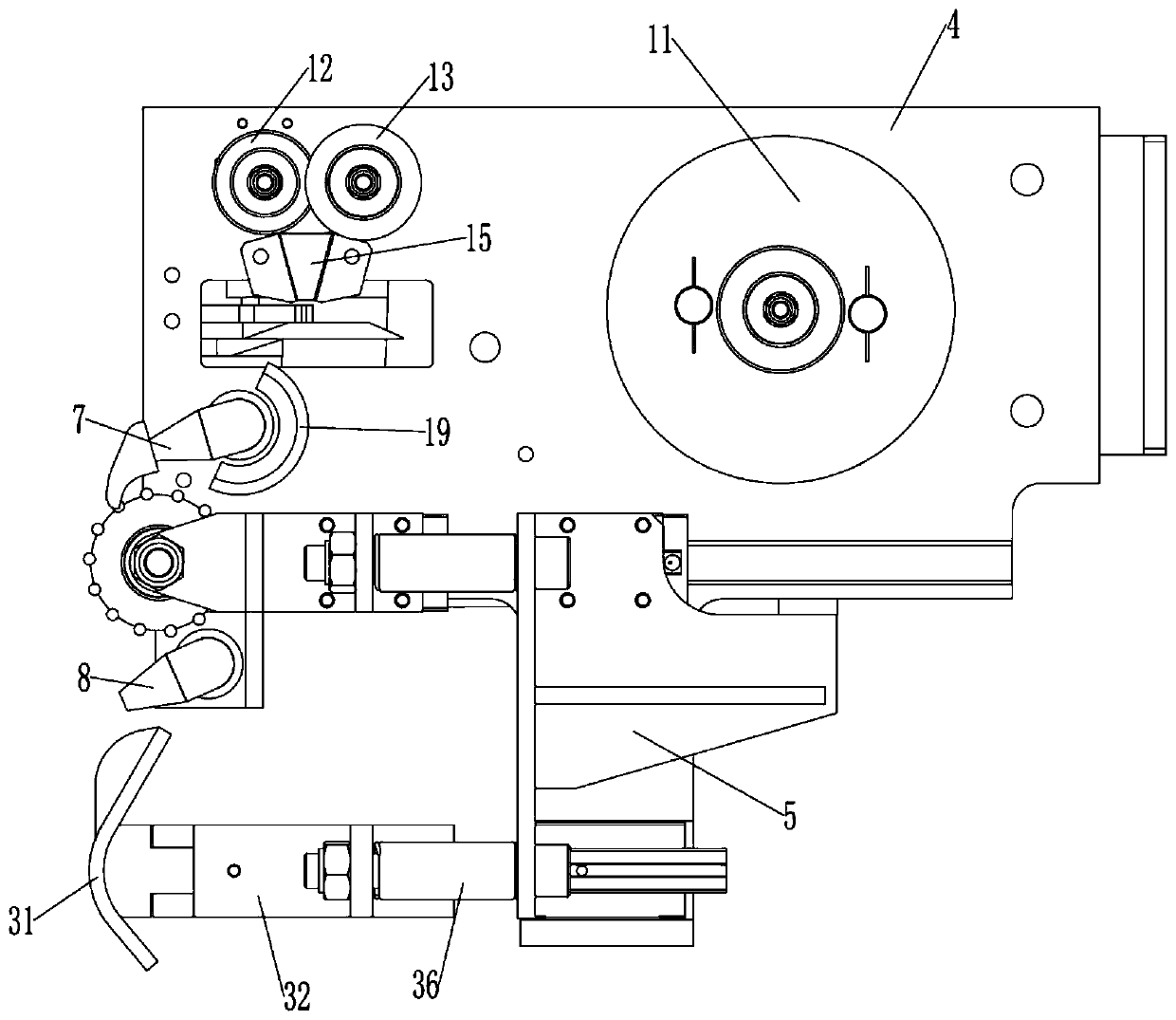

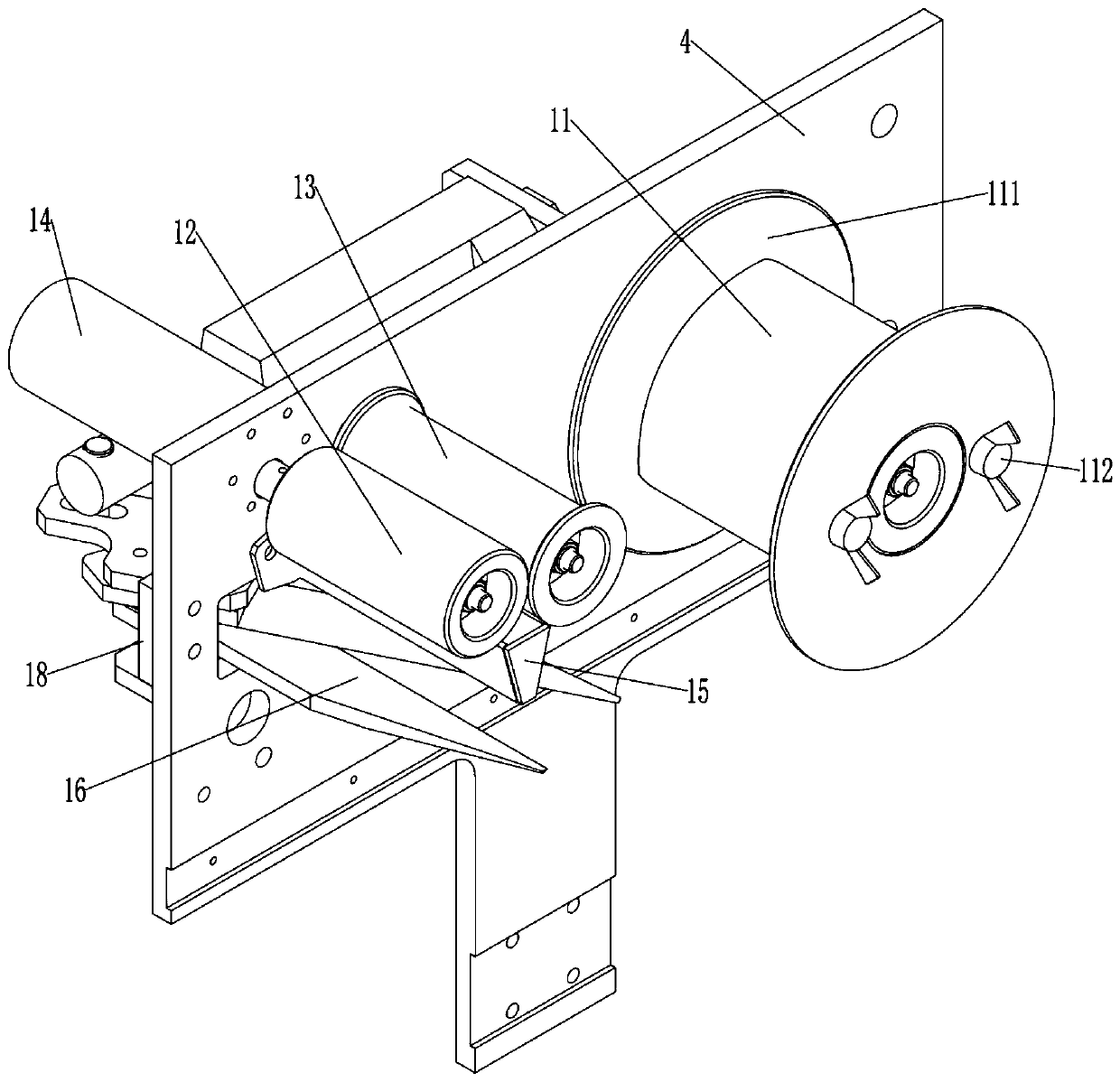

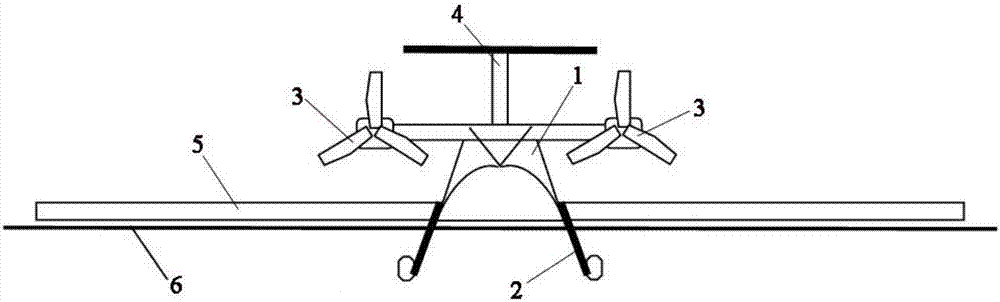

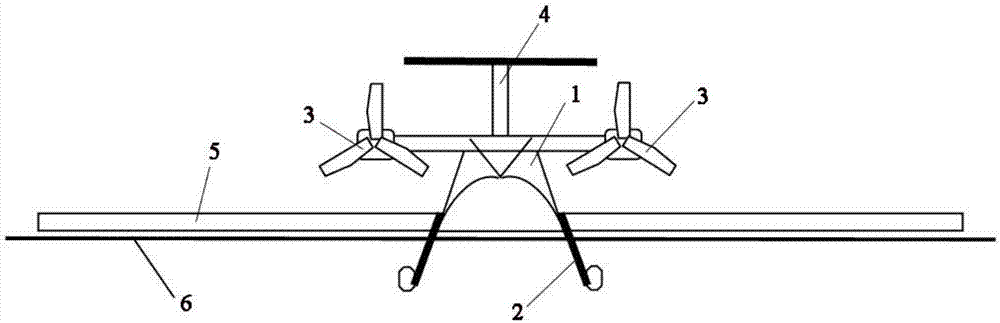

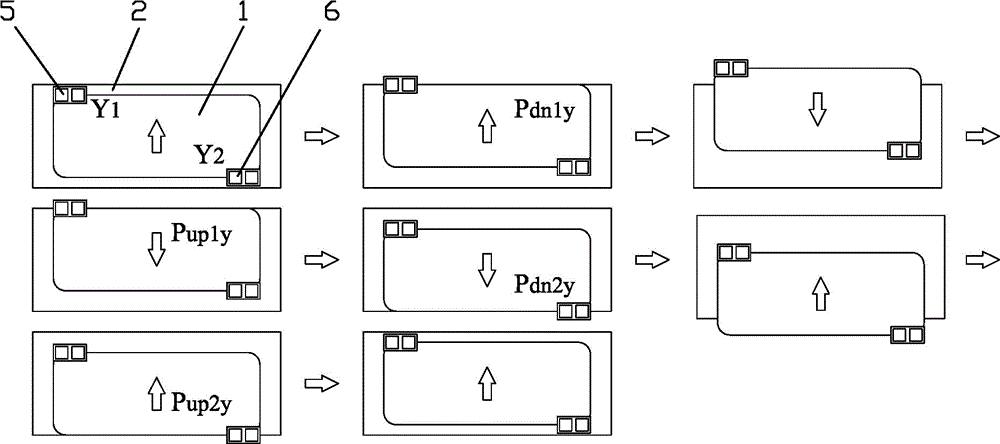

Pulling rope release system of small multi-shaft unmanned aerial vehicle

InactiveCN104485606AWon't breakHigh precisionClosed circuit television systemsApparatus for overhead lines/cablesControl systemLocking mechanism

The invention discloses a pulling rope release system of a small multi-shaft unmanned aerial vehicle, which comprises a multi-shaft unmanned aerial vehicle, a lead wire release device and a video monitor, wherein the multi-shaft unmanned aerial vehicle is equipped with a control system; the lead wire release device comprises a payoff rack wound with a pulling rope and a lead wire unhooking controller; the payoff rack is arranged on ground; the lead wire unhooking controller is mounted on the multi-shaft unmanned aerial vehicle and comprises a power mechanism and a locking mechanism; the power mechanism is connected with the control system of the multi-shaft unmanned aerial vehicle and with the locking mechanism to drive the locking mechanism to carry out locking or unlocking; one end of the pulling rope penetrates through the locking mechanism; the video monitor is mounted on the multi-shaft unmanned aerial vehicle and comprises an onboard camera and a real-time image transmission system; and the onboard camera and the real-time image transmission system are connected with the control system respectively. The system can carry out pay-off operation of the unmanned aerial vehicle in a high precision and controllability manner, so that the pay-off time is greatly saved, and a construction effect is significant.

Owner:STATE GRID CORP OF CHINA +3

Deep hole underwater installation and locating method of steel pipe column in weak watery stratum

ActiveCN101824919AReduce construction costsJob safetyArtificial islandsUnderwater structuresUnderwaterEarth surface

The invention discloses a deep hole underwater installation and locating method of a steel pipe column in a weak watery stratum, concretely comprising the following construction steps of firstly, pouring concrete with a design height in the steel pipe column, and installing and locating a screw jack at the bottom of the steel pipe column; secondly, measuring and paying off on the construction ground surface, and drilling by a drill; thirdly, installing a drilling pile reinforcement cage in a hole; fourthly, installing a location platform on the construction ground surface; fifthly, hoisting the steel pipe column and putting the steel pipe column in a drilling pile hole; sixthly, locating the top part of the steel pipe column by the ground surface location platform; seventhly, locating and measuring the verticality of the steel pipe column by a laser plummet; eighthly, locating the bottom of the steel pipe column by the screw jack; ninthly, pouring drilling pile concrete underwater to the design burying height of the steel pipe column; and tenthly, pouring steel pipe column internal concrete to the top of a steel tube after the drilling pile internal concrete achieves the design strength of 70 percent. The method has the advantages of simple operation, high construction efficiency, low construction cost, high and controllable installation accuracy and little safety risk.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

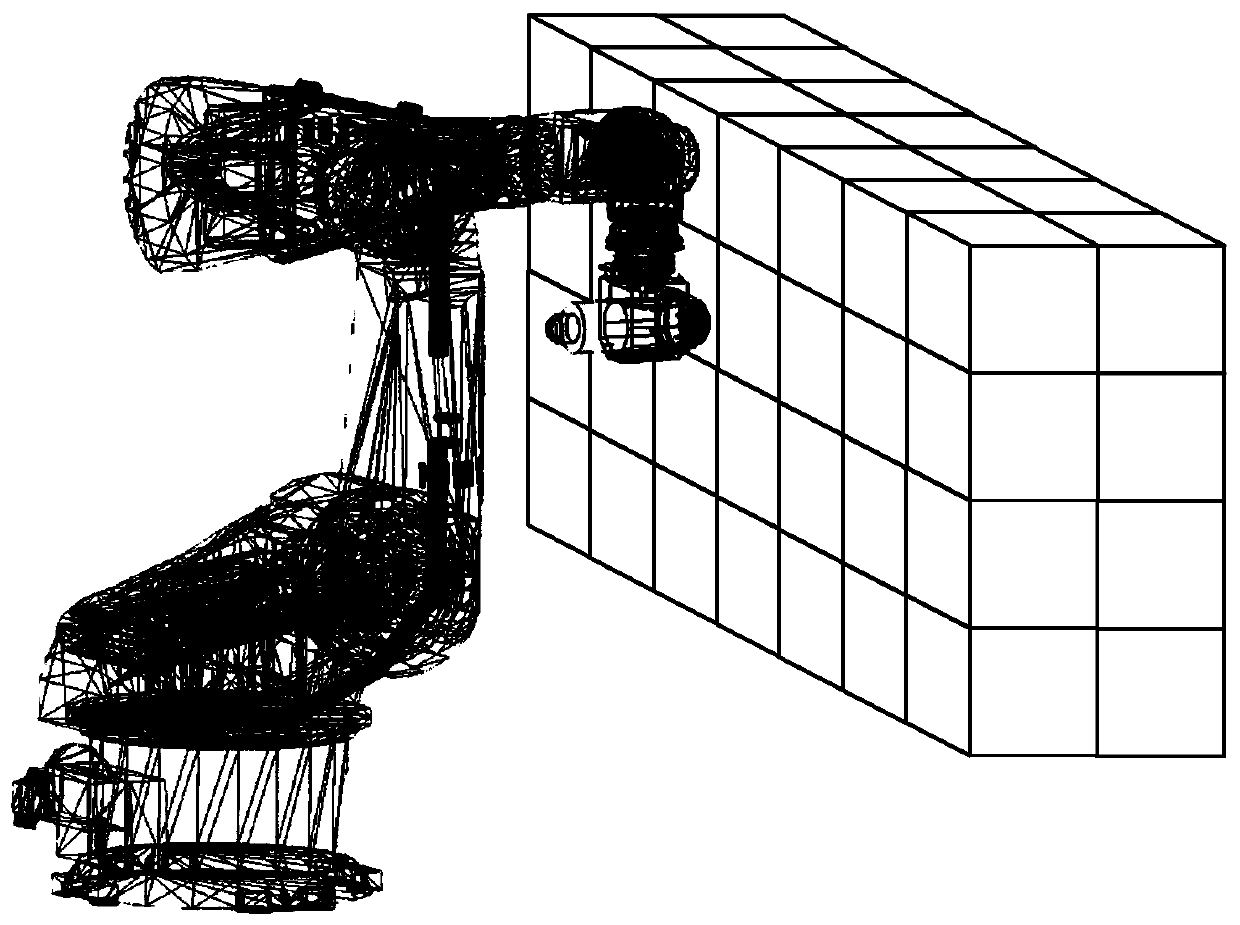

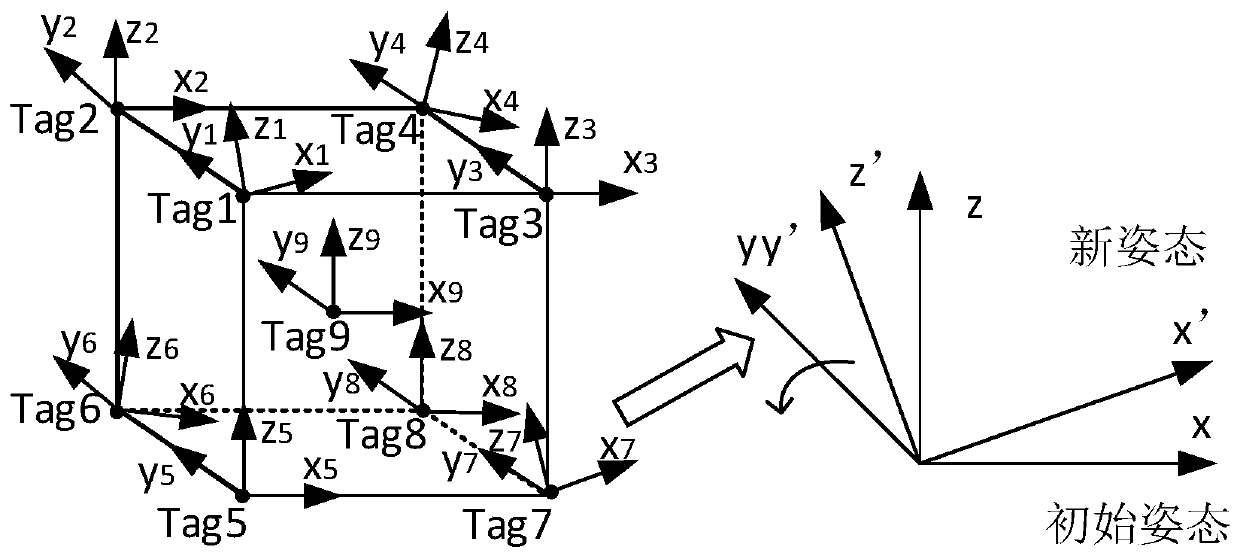

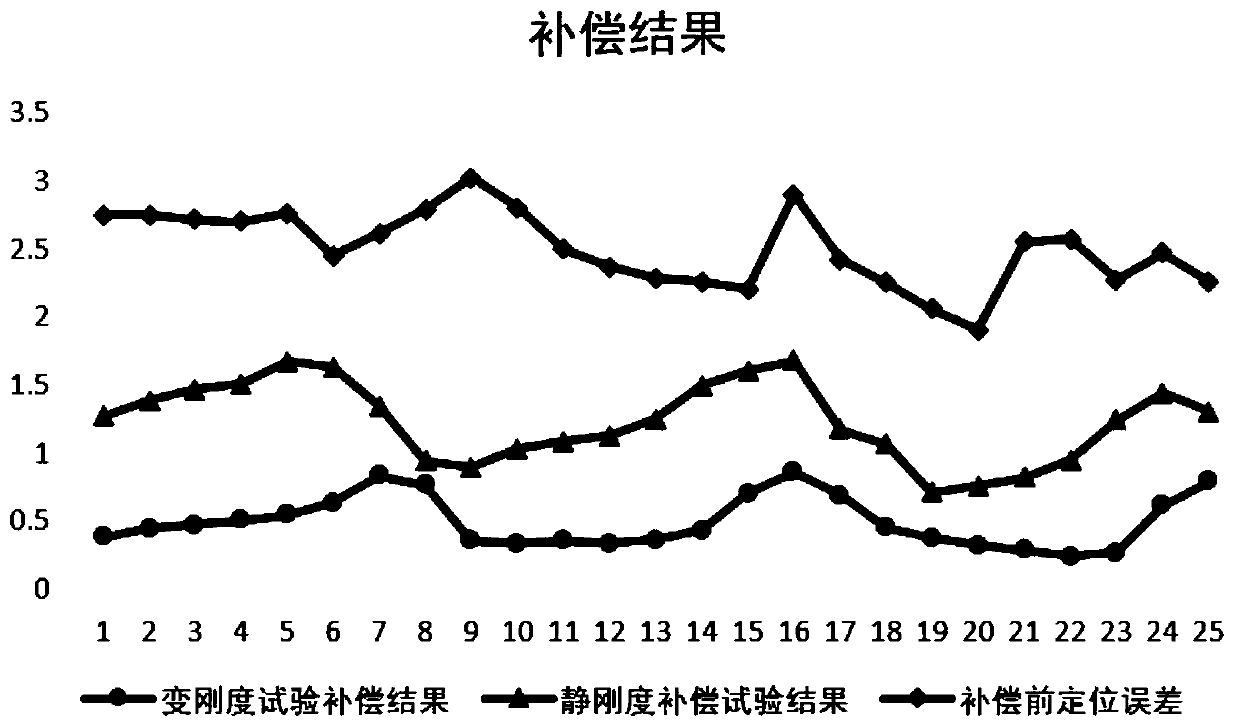

Industrial robot variable parameter stiffness identification and modeling method

ActiveCN110161850AGet to work quicklyReduce workloadProgramme controlProgramme-controlled manipulatorSimulationActuator

The invention discloses an industrial robot variable parameter stiffness identification and modeling method, which belongs to the technical field of industrial robot stiffness identification. In the method, the effective working space of the robot is divided to multiple cubic regions; in view of a working task for a certain processing region, through applying different loads to an end effector under multiple positions and multiple postures in the region, based on the relationship between a load and end deformation, the robot joint stiffness in the interval can be identified and acquired, and accurate stiffness control on the robot at different working intervals during the processing process is realized. The method can realize accurate evaluation on the stiffness performance of the robot during the working process, the end deformation during the loaded processing process is thus accurately predicted, the effects of improving the processing precision and the quality are further achieved,and the application requirements of the robot in the field of high precision machining such as milling and hole making can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

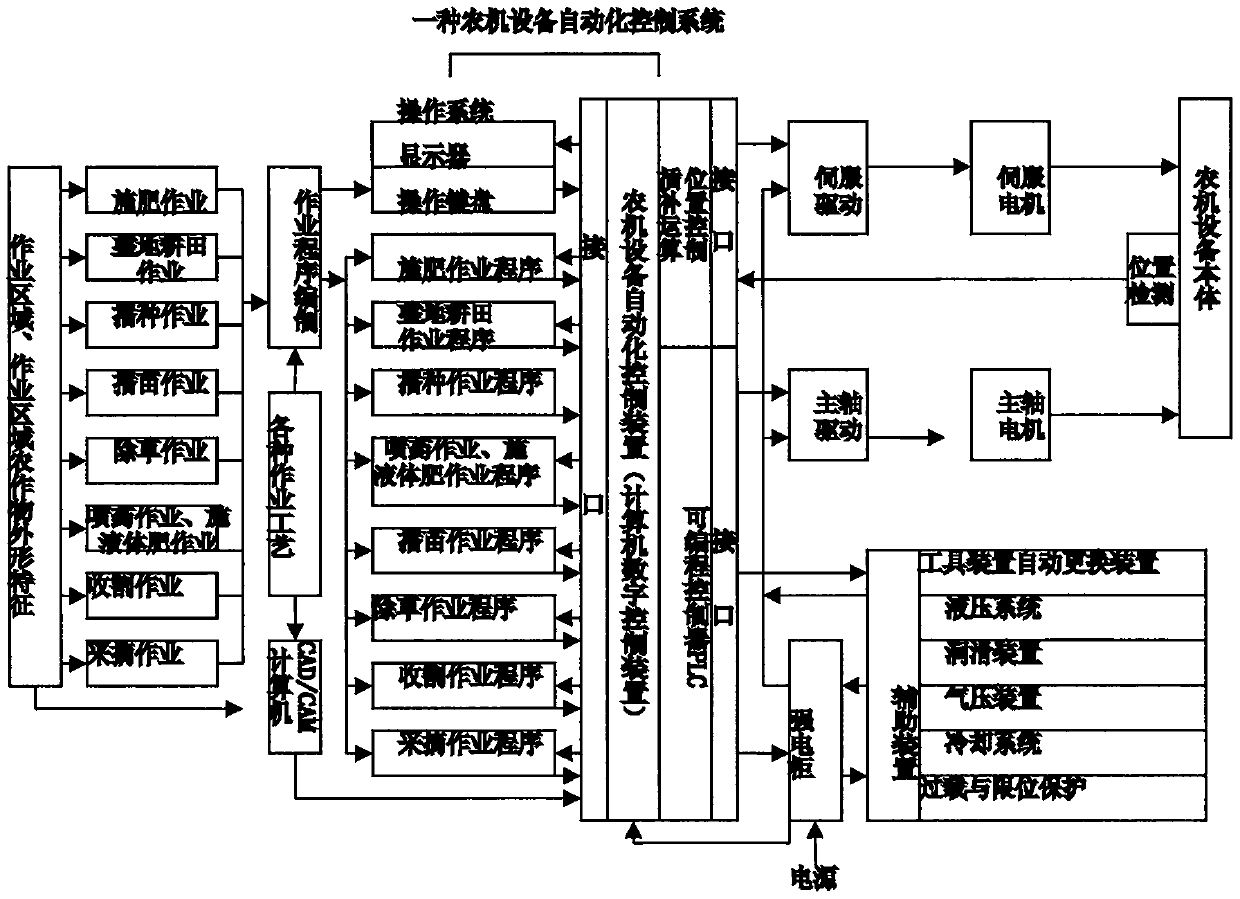

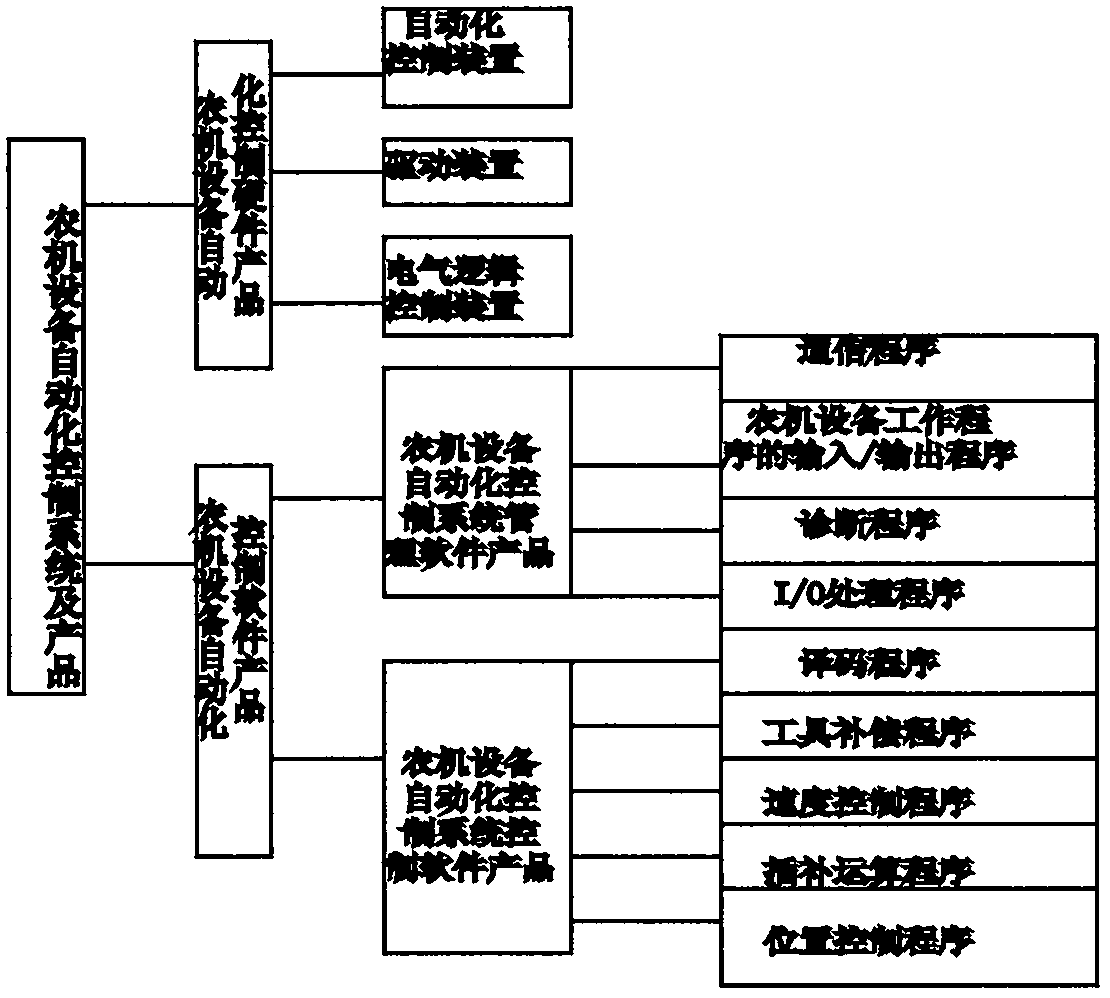

Automation control system and product for agricultural mechanical devices

InactiveCN108170084AFully automatedRealize zero emission at workSoftware maintainance/managementSoftware designControl systemAgricultural engineering

The invention relates to an automation control system and product for agricultural mechanical devices. With the automation control system and product for the agricultural mechanical devices adopted, aproblem that the agricultural mechanical devices cannot perform automated operation by using electric energy can be solved, and driving and control can be provided for the agricultural mechanical devices in using electric energy to carry out automated operation. According to the work of the automation control system and product for the agricultural mechanical devices of the provided by the invention, the agricultural mechanical devices are driven and controlled to automatically and orderly complete operation and work required by an operation area according to the shape feature of the operation area or / and the crops of the operation area; one agricultural mechanical device can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops; and one or more agricultural mechanical devices can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops.

Owner:杨新高

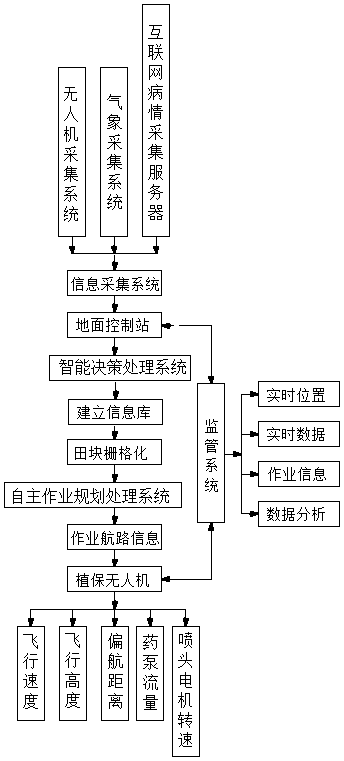

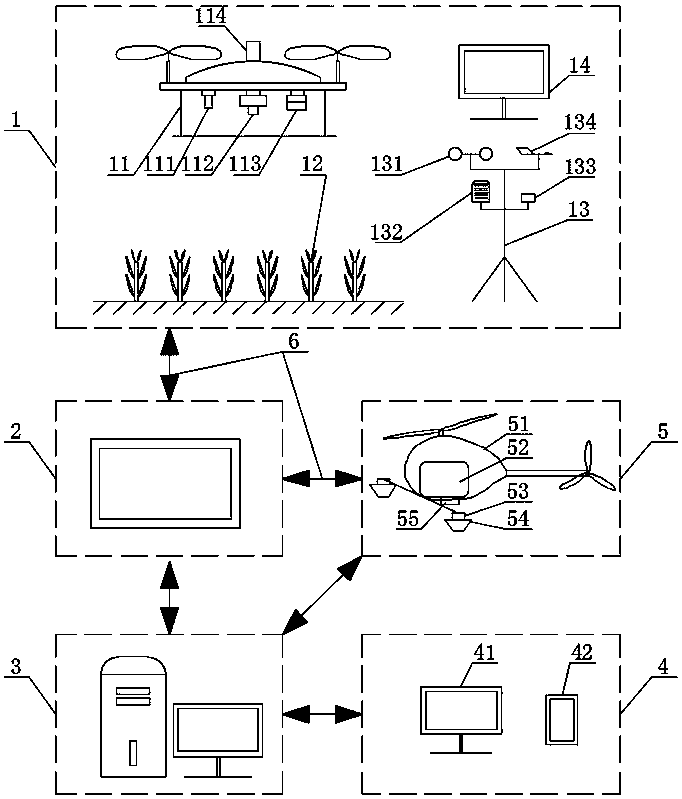

Multi-source information fusion and intelligent decision autonomous-flight plant protection unmanned aerial vehicle and control method thereof

PendingCN108594856AReduce in quantityReduce the difficulty of manipulationAircraft componentsMeasurement devicesDiseaseThe Internet

The invention discloses a multi-source information fusion and intelligent decision autonomous-flight plant protection unmanned aerial vehicle and a control method thereof. The multi-source informationfusion and intelligent decision autonomous-flight plant protection unmanned aerial vehicle comprises an information acquisition system, a surface control station and a plant protection unmanned aerial vehicle; the information acquisition system includes an unmanned aerial vehicle acquisition system, a weather acquisition system and an internet disease condition acquisition server; the unmanned aerial vehicle acquisition system includes a high-spectral camera, airborne radar, a CCD (charge coupled device) camera, and a GPS (global positioning system), a Beidou system and an acquisition unmanned aerial vehicle body; the weather acquisition system includes a wind speed sensor, a wind direction sensor and a weather acquisition controller; the plant protection unmanned aerial vehicle comprisesan unmanned aerial vehicle body, a pesticide application system and a navigation system; all the acquisition unmanned aerial vehicle body, the weather acquisition control unit, the internet disease condition acquisition server and the plant protection unmanned aerial vehicle body are in wireless communication connection with the surface control station. The problems are solved that, for instance,an existing plant protection unmanned aerial vehicle acquires little information, crop information, weather information and operation information are not fused, and intelligent precision automated pesticide application is difficult to implement.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

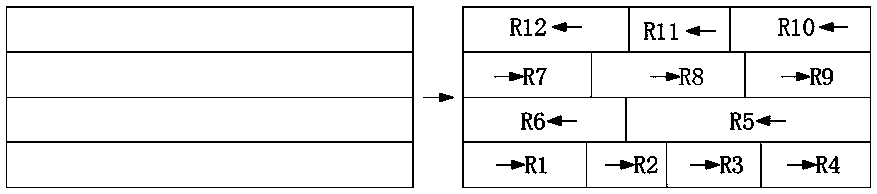

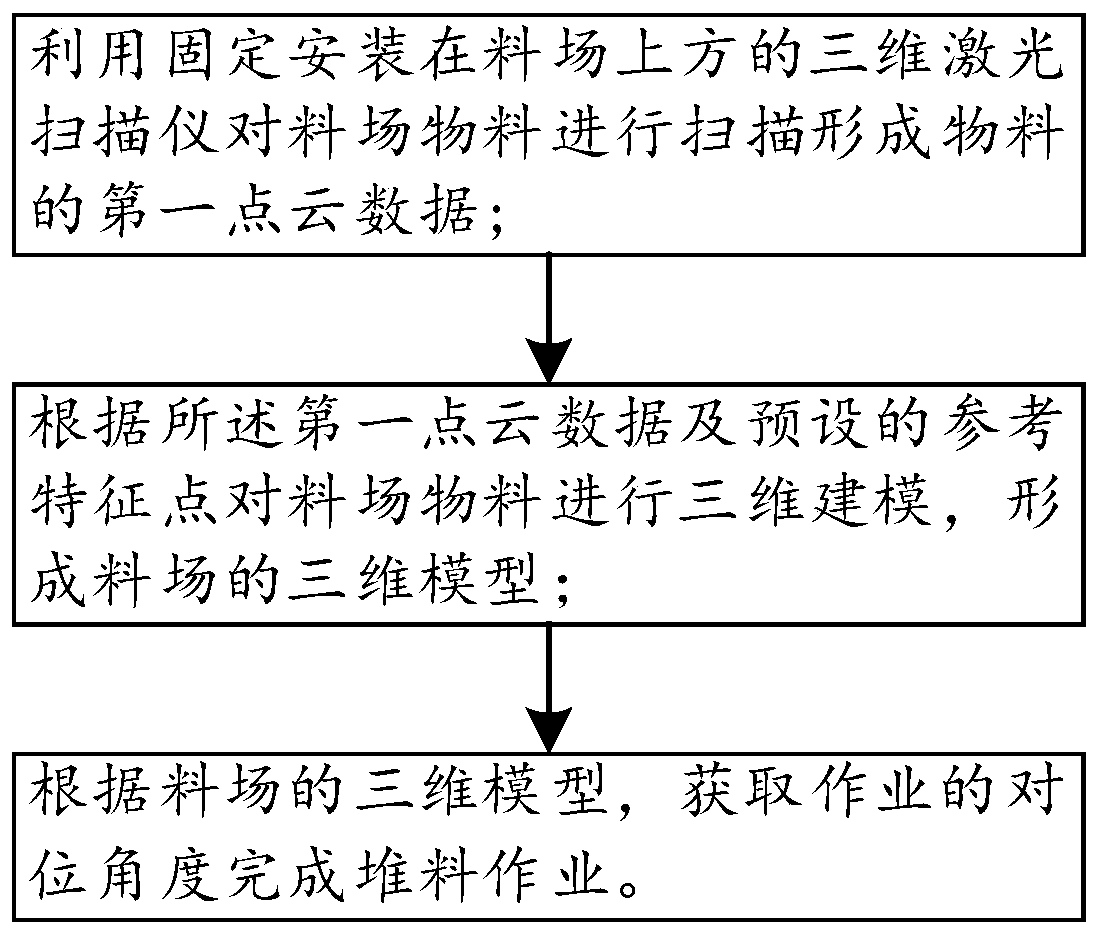

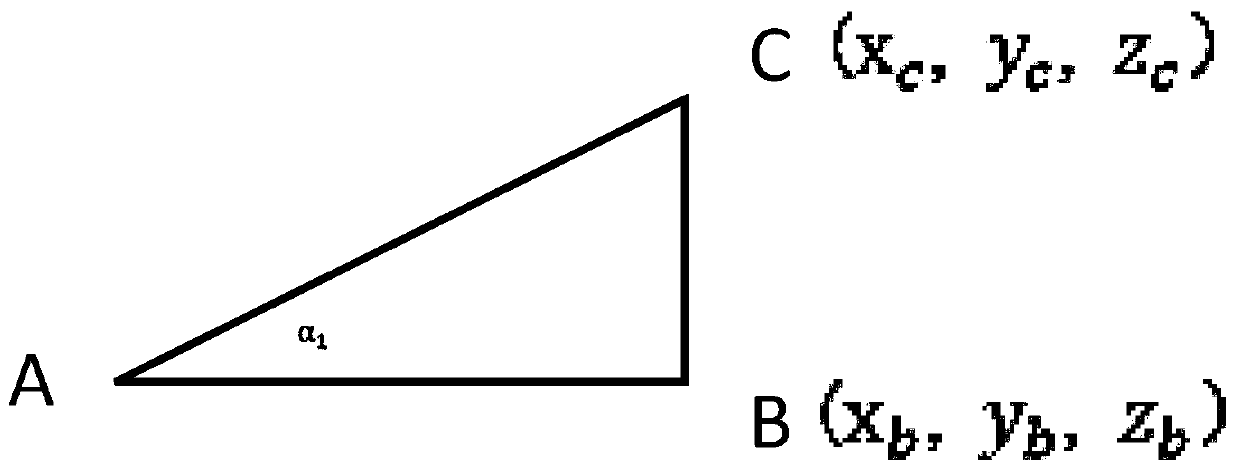

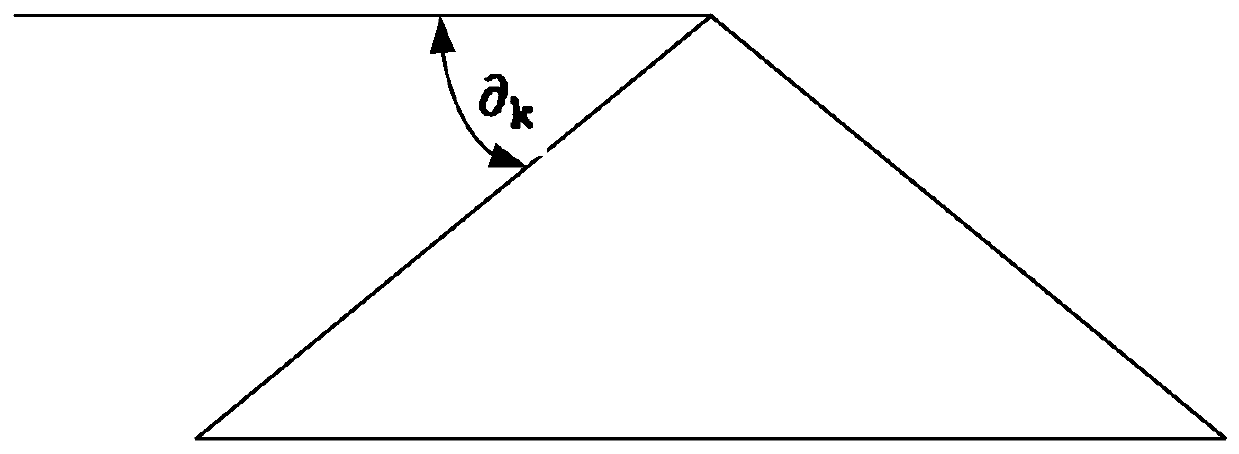

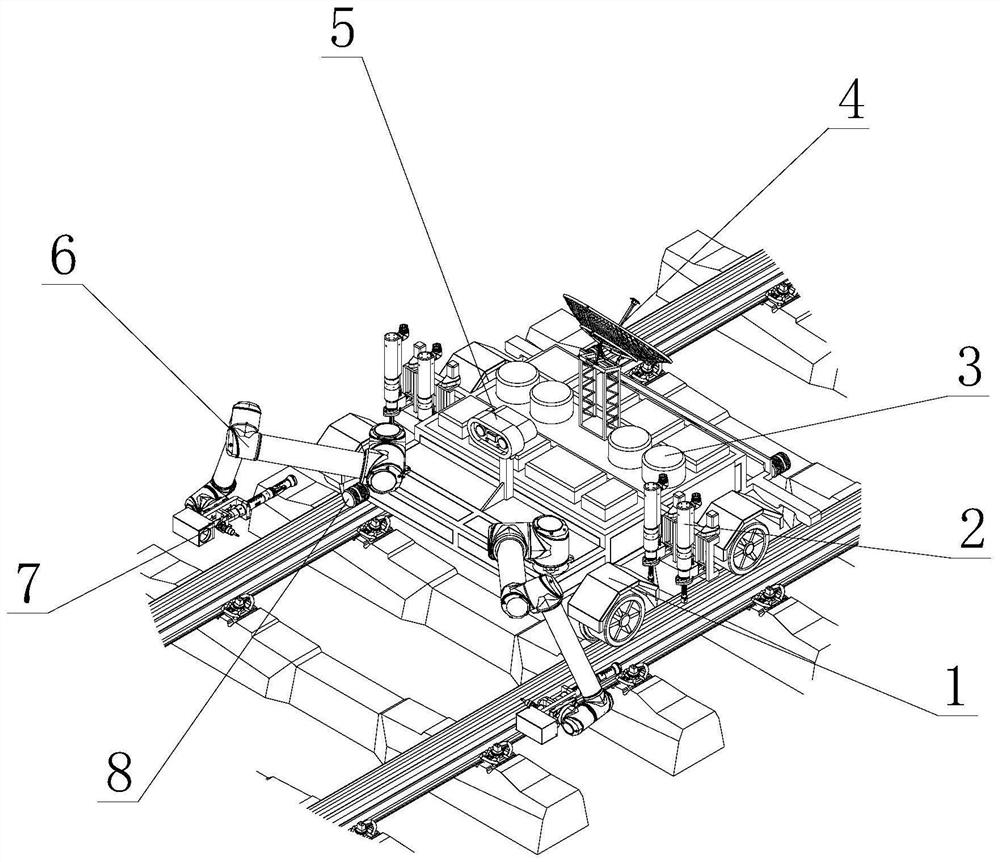

Automatic material stacking, material taking and material stacking and taking method and system for material yard

ActiveCN110194375AReduce empty runsRealize fully automatic operationUsing optical meansLoading/unloadingPoint cloudStack machine

The invention relates to an automatic material stacking and material taking method for a material yard. The method comprises the steps of scanning materials in the material yard by using a three-dimensional laser scanner fixedly installed above the material yard to form point cloud data of the materials, and carrying out three-dimensional modeling according to the point cloud data of the materialsand preset reference characteristic points and finishing material stacking and material taking operations, wherein forming of a three-dimensional model of the material yard comprises a cleaning step,a splicing step, a removing step, a filling step and a modeling step. The invention further discloses an automatic material stacking, material taking and material stacking and taking system. The three-dimensional laser scanner fixed above the material yard is used for scanning the point cloud data of the materials in the material yard, no material stacking and material taking machine participatesin the scanning process, the three-dimensional laser scanner can independently run in real time, working time is saved, and material stacking and material taking operations can be more accurately carried out by acquiring the alignment angle of a material stacking machine or acquiring a starting point and an ending point of a material taking machine.

Owner:BEIJING ZHONGSHENG BOFANG ENVIRONMENTAL PROTECTION ENG TECH

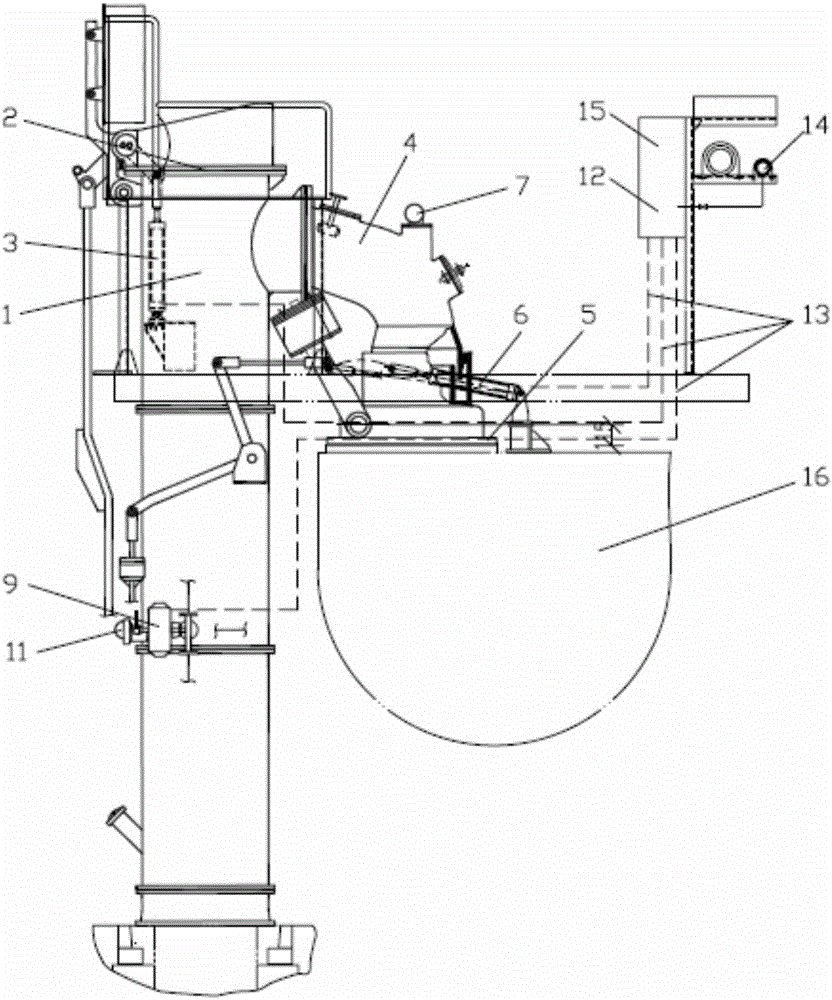

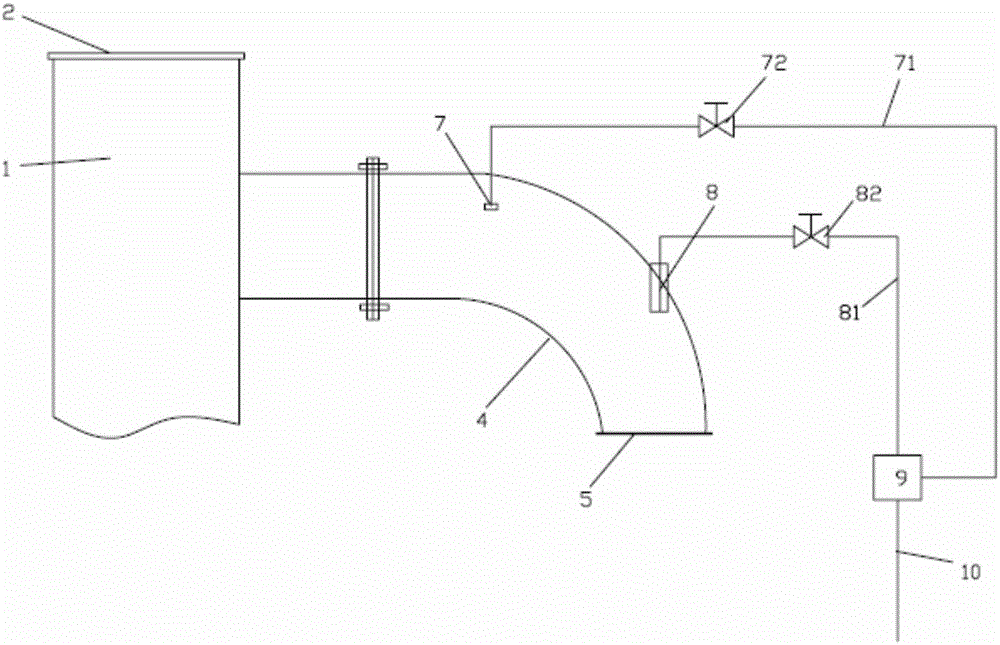

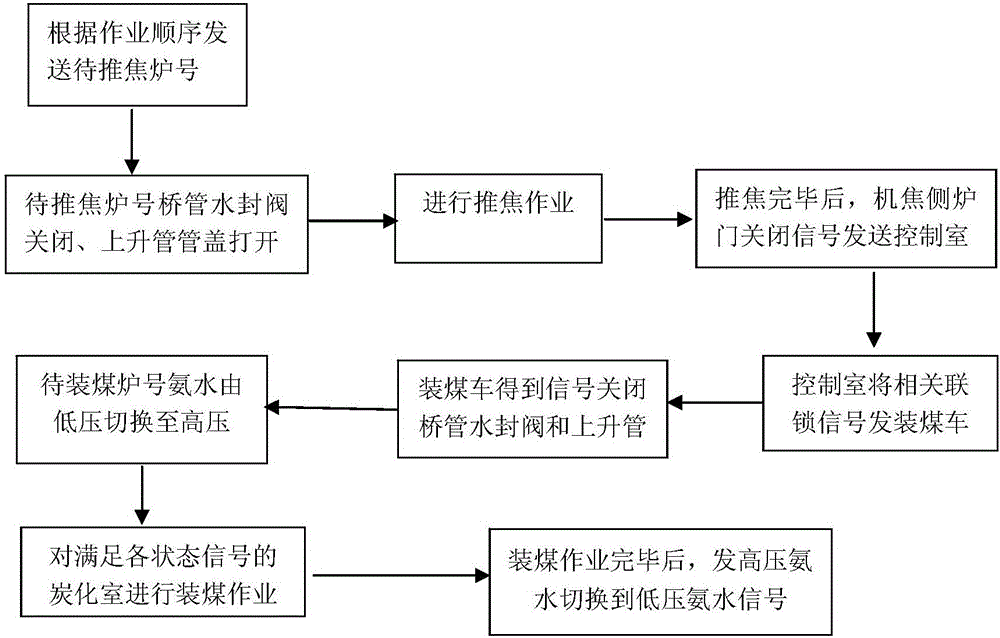

Control method and system for coke oven riser pipe

InactiveCN106753444ARealize safety interlockImprove working accuracyCoke oven safety devicesDistillation gas withdrawalTime deviationAutomatic control

The invention discloses a control method and system for a coke oven riser pipe. The system comprises the riser pipe, a bridge pipe, a low pressure ammonia water spray nozzle, a high pressure ammonia water spray nozzle, a corresponding low pressure ammonia water pipeline, a corresponding high pressure ammonia water pipeline and a programmable controller, wherein a pipe cover capable of being opened and closed and a pipe cover driving cylinder are arranged on the riser pipe; the bridge pipe is connected to an end opening in one side of the riser pipe; a water seal valve and a water seal valve driving cylinder are arranged at the lower end of the bridge pipe; the low pressure ammonia water spray nozzle is arranged at a position, which is close to a riser pipe joint, in the bridge pipe; the high pressure ammonia water spray nozzle is arranged at a position, which is located below the low pressure ammonia water spray nozzle, in the bridge pipe; the low pressure ammonia water pipeline and the high pressure ammonia water pipeline are respectively connected to two end openings of a three-way ball valve; the three-way ball valve is connected with a three-way ball valve driving cylinder or an electromagnetic driving valve; an electromagnetic switching valve or / and the electromagnetic driving valve is / are electrically connected with the controller, and is / are electrically connected with a coke oven control system. According to the control system disclosed by the invention, safe interlocking between all facilities of the riser pipe and work of a coal charging car of the coke oven and a coke pusher is realized; by automatic control and replacement of unmanned work for manual work, the cooperation order of workers and the time deviation of the manual work are eliminated, and the safety and environmental protection risk during work of the coke oven riser pipe is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

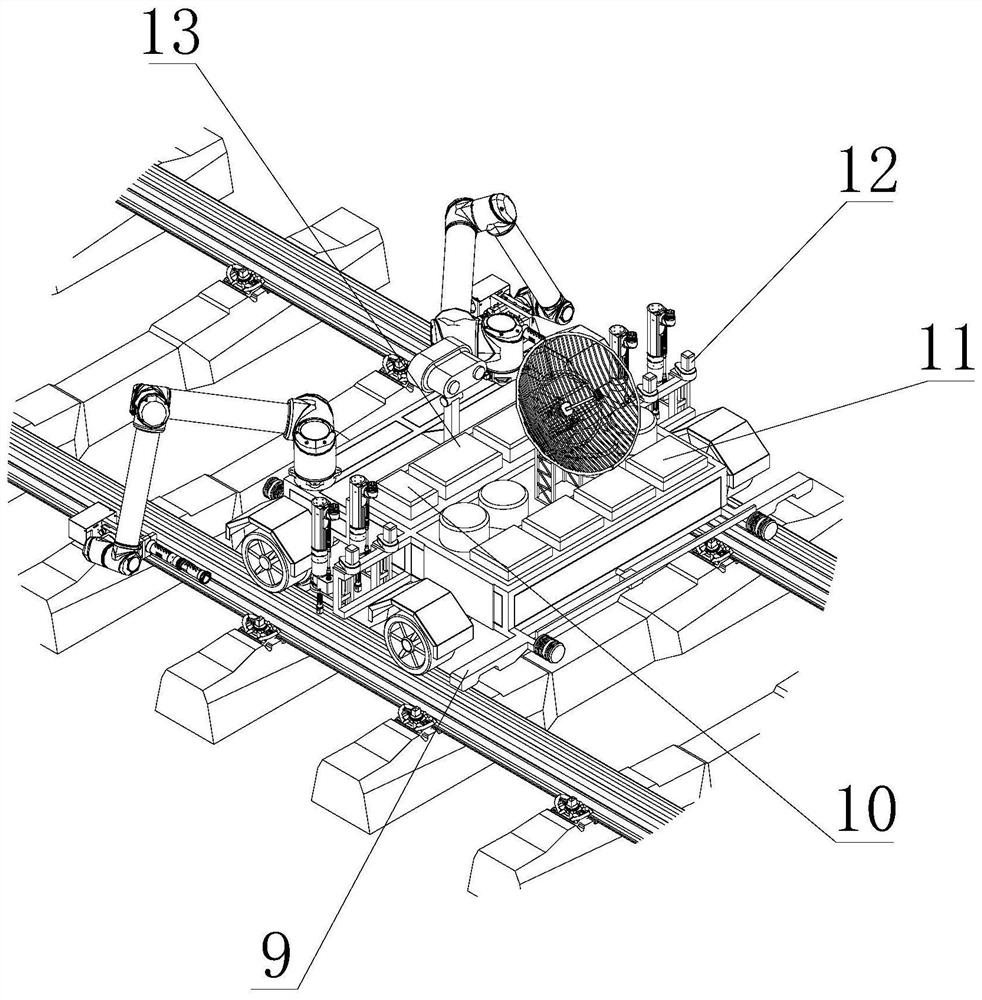

Automatic tightening system and method for rail fastener robot

ActiveCN112025281ARealize automated detectionImprove work efficiencyMetal working apparatusMachineServo

The invention belongs to the technical field of rail maintenance, and particularly discloses an automatic tightening system and method for a rail fastener robot. The system comprises a rail car, a rail car positioning module, a fastener and rail detection module, a servo electric tightening machine module, an elbow tightening robot module, a communication module, a workstation module and a management server module, the rail car positioning module is used for positioning position information of the rail car, the fastener and rail detection module is used for detecting crack damage of a steel rail to be detected and locking torque of a rail fastener bolt, the workstation module is used for judging the rail fastener bolt to be tightened according to position information of the rail car and the locking torque value of the rail fastener bolt and calculating the position information of the rail fastener bolt to be tightened and controlling a corresponding tightening machine to tighten or replace the rail fastener bolt to be tightened according to the direction of the rail fastener bolt. According to the system, automatic detection of rail flaw detection, rail fastener state and bolt locking torque is realized, and the working efficiency and the operation precision are high.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

Construction method for small multi-shaft unmanned aerial vehicle to unwind and release haulage cable

InactiveCN104536459AWon't breakHigh precisionPosition/course control in three dimensionsEngineeringGround station

The invention discloses a construction method for a small multi-shaft unmanned aerial vehicle to unwind and release a haulage cable. The construction method for the small multi-shaft unmanned aerial vehicle to unwind and release the haulage cable comprises the steps that a construction site is selected and a cable releasing frame wound with the haulage cable is arranged on the construction site; a cable unhooking controller is installed on the multi-shaft unmanned aerial vehicle and comprises a power mechanism and a lock catch mechanism, the lock catch mechanism is locked, and a weight is tied to the haulage cable after one end of the haulage cable penetrates through the lock catch mechanism; the multi-shaft unmanned aerial vehicle takes off and is suspended when reaching a first appointed pole tower, and a constructor on the tower rapidly grasps the carried haulage cable and enables the haulage cable to pass across a pulley on the tower; the multi-shaft unmanned aerial vehicle continues to fly to a next pole tower and the process that the cable is grasped and passes through pulleys is repeated; when the multi-shaft unmanned aerial vehicle reaches the last target pole tower, a worker on a ground station gives an instruction to the multi-shaft unmanned aerial vehicle, the lock catch mechanism is unlocked, one end of the haulage cable falls along with the weight, a worker on the last pole tower rapidly grasps the haulage cable, enables the haulage cable to pass across the pulleys, and firmly ties the haulage cable to the last pole tower or carries out subsequent cable erection operations.

Owner:STATE GRID CORP OF CHINA +3

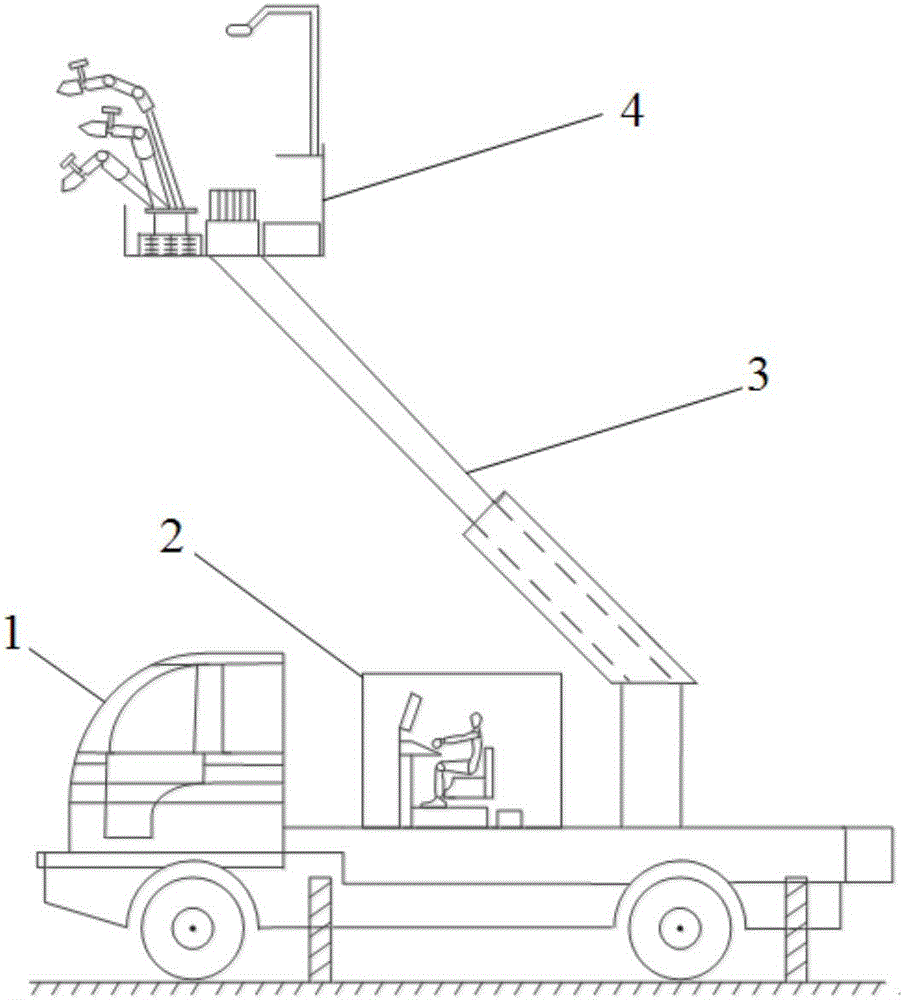

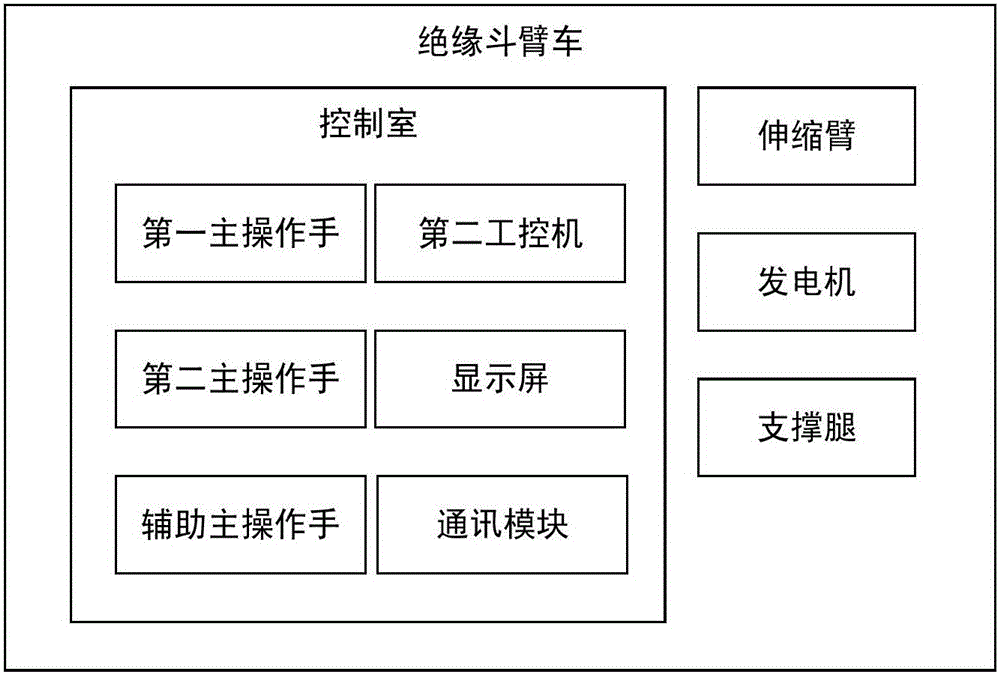

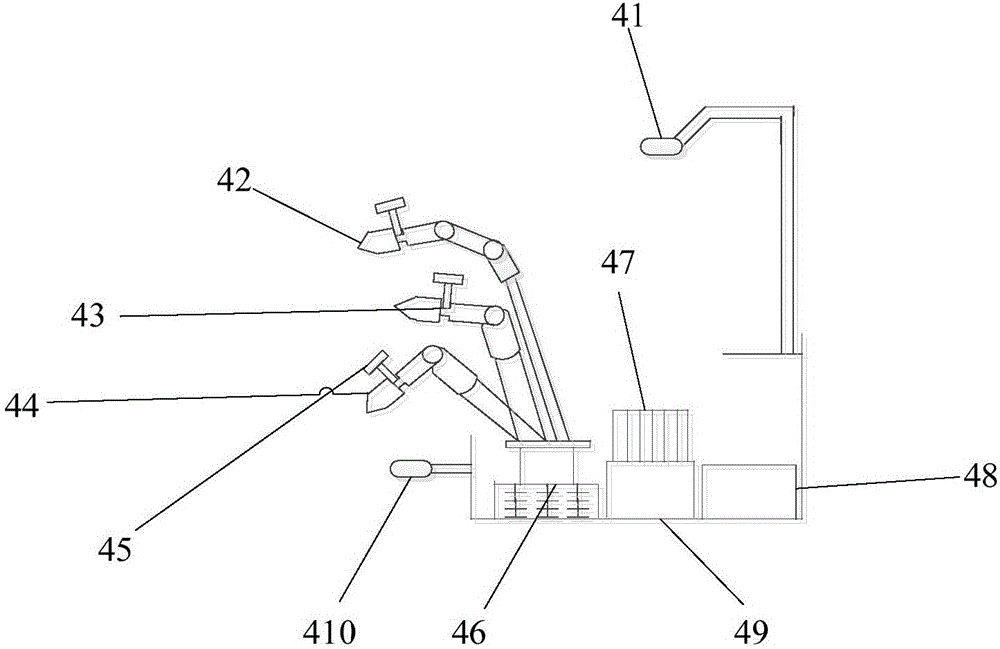

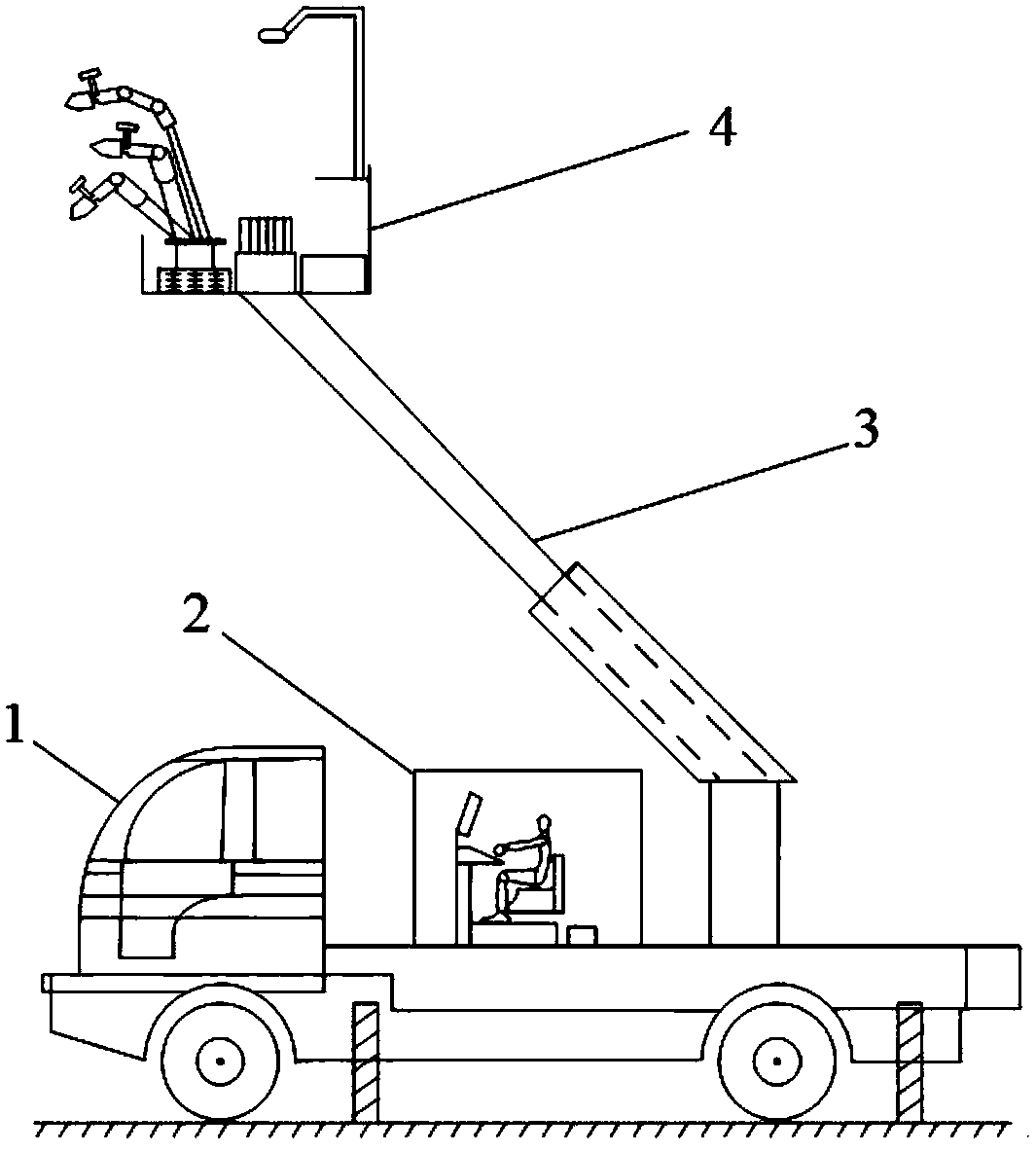

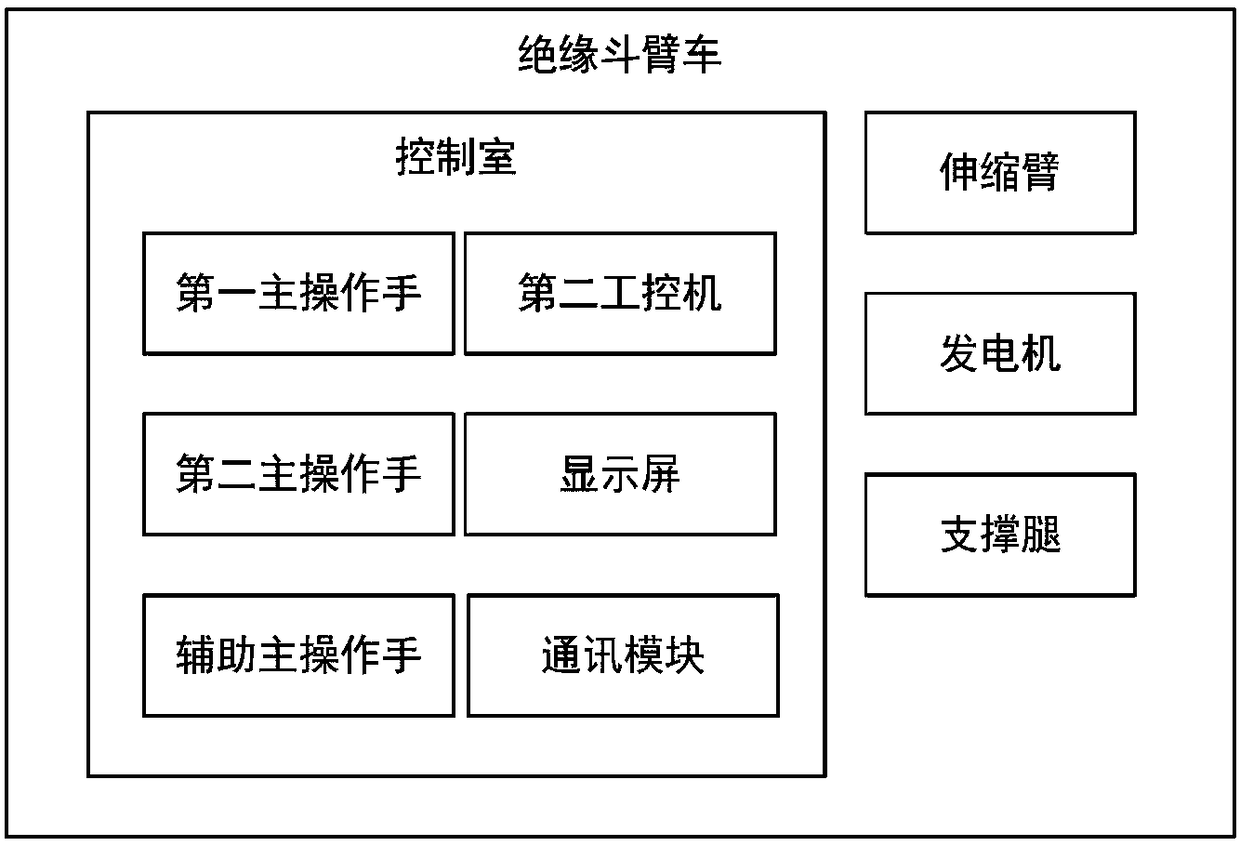

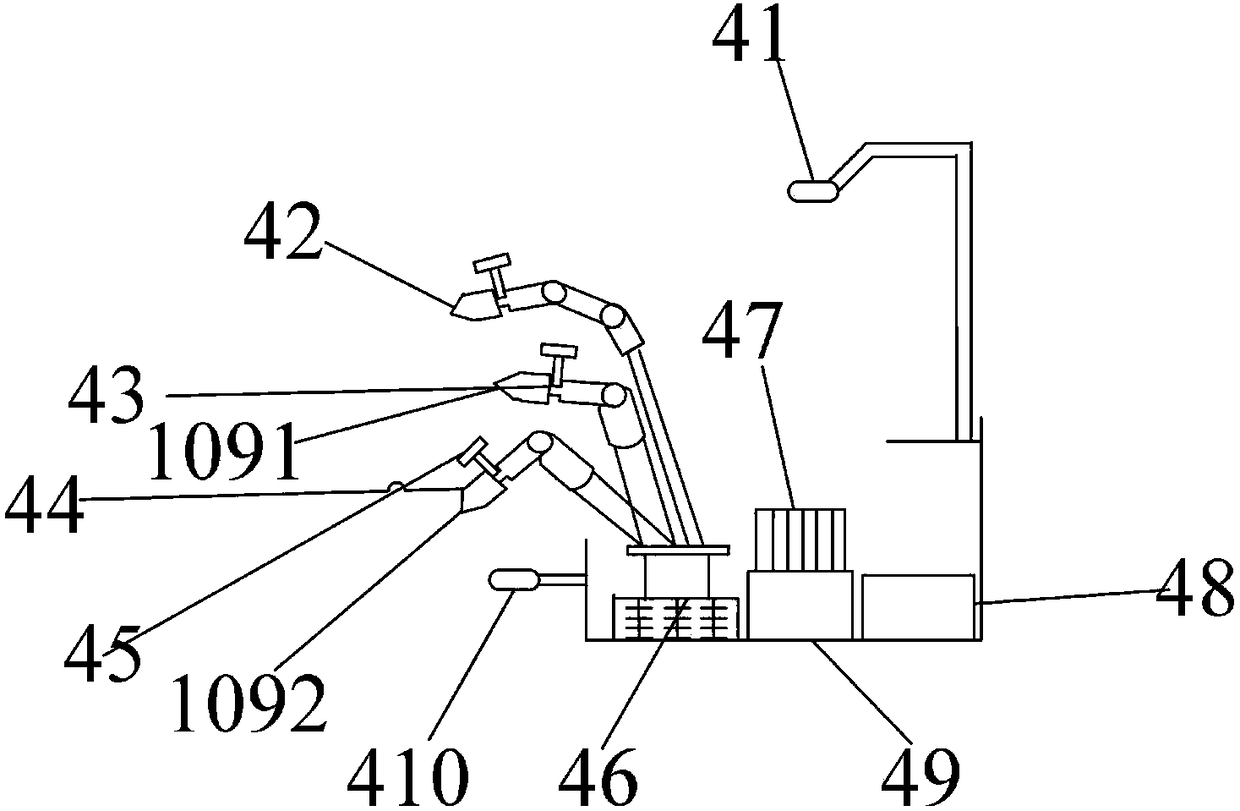

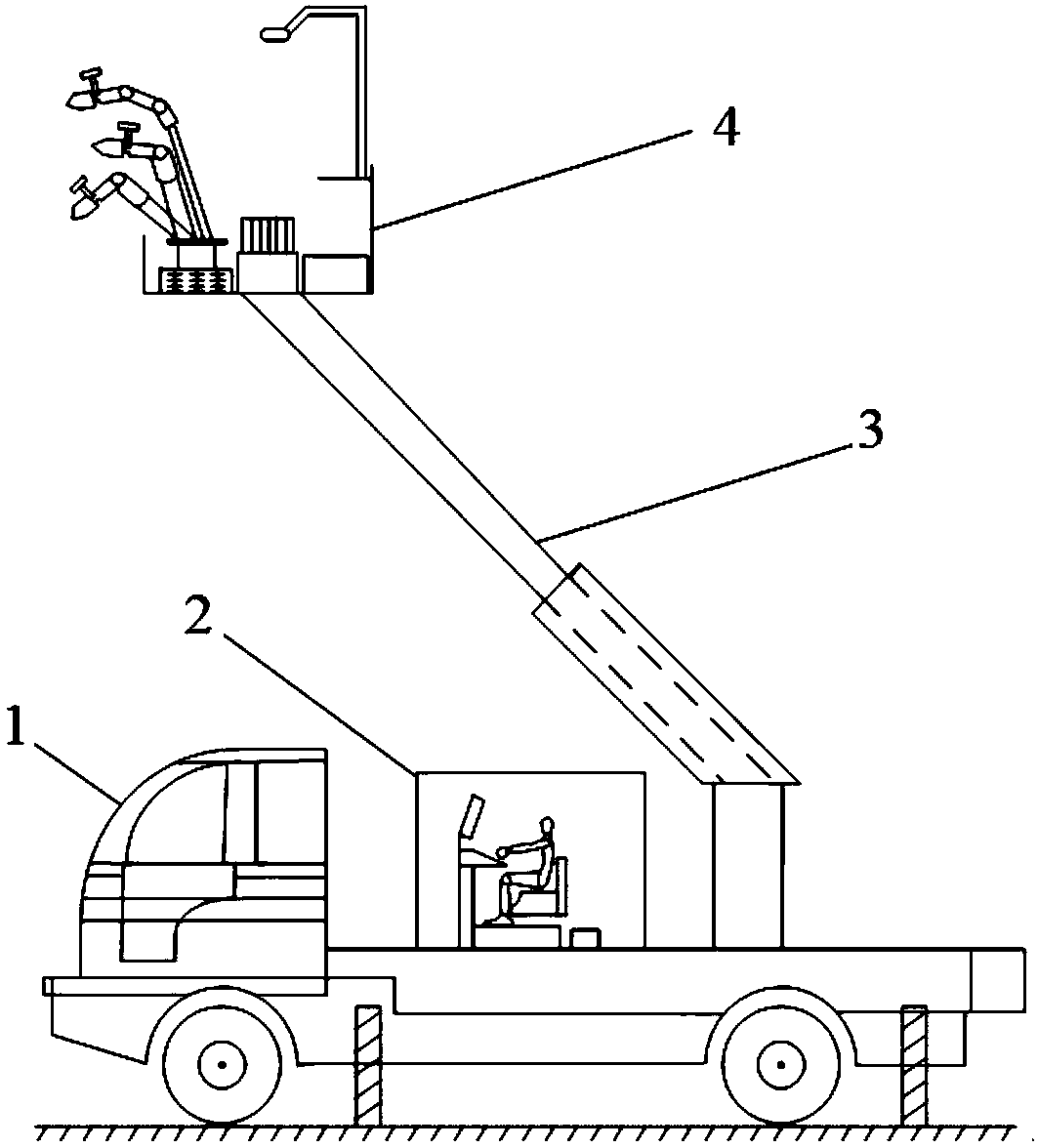

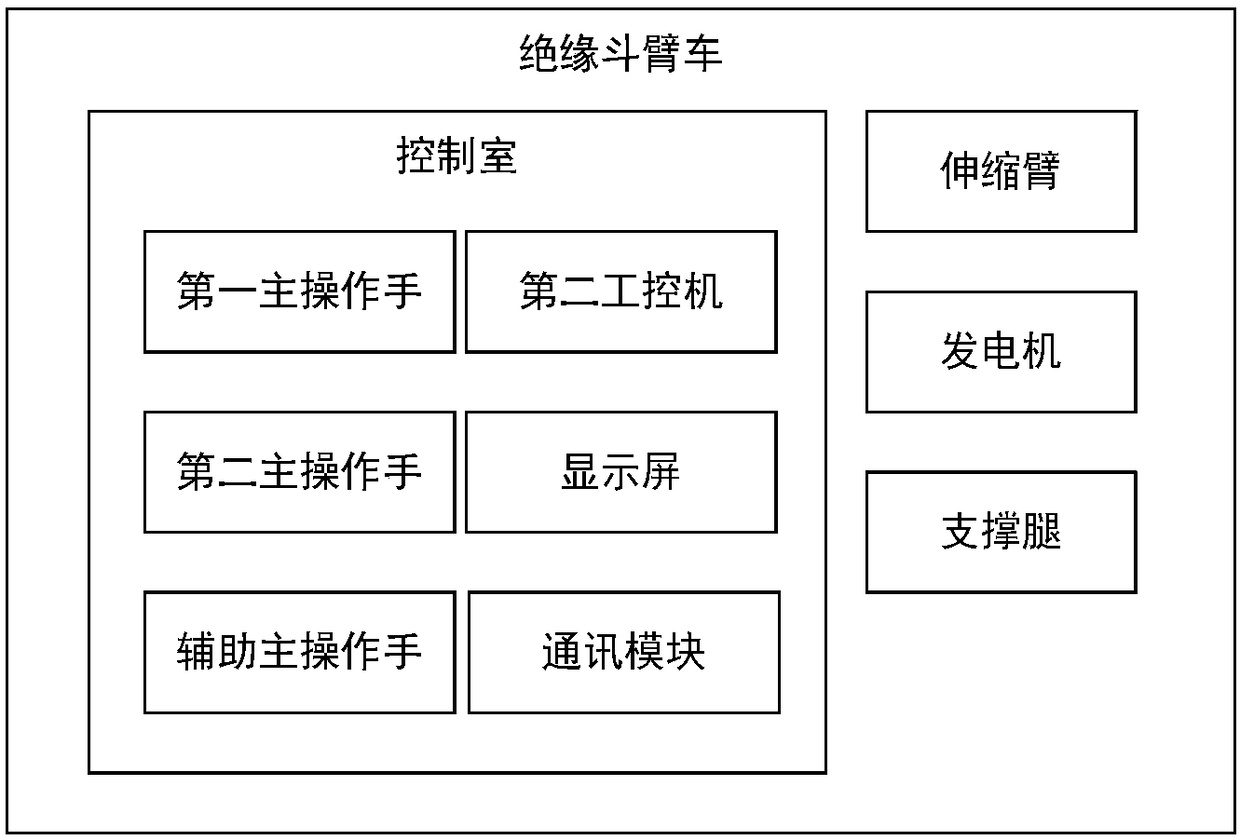

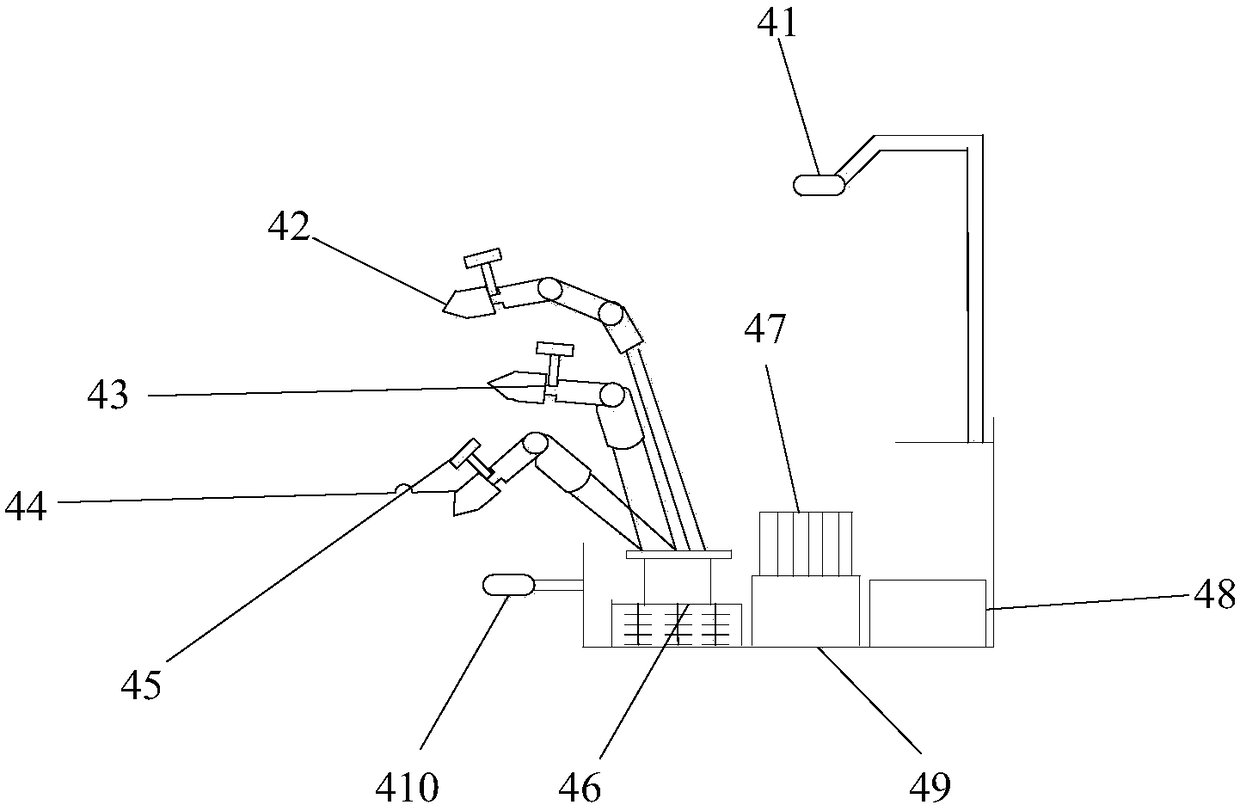

Hot-line working robot

InactiveCN106737547AGuaranteed isolationAccurate judgmentProgramme-controlled manipulatorGripping headsControl systemData acquisition

The invention provides a hot-line working robot. The hot-line working robot comprises an insulating bucket-boom vehicle, a robot platform carried on the insulating bucket-boom vehicle, a mechanical arm installed on the robot platform, a data acquisition system and a data processing and control system. The data acquisition system comprises a camera arranged on the robot platform and used for acquiring operation scene images of the mechanical arm and sending the scene images to the data processing and control system. The data processing and control system generates a 3D virtual operating scene or plans a space path of the mechanical arm according to the operation scene images. The hot-line working robot can complete hot-line working through remote operation, can also complete hot-line working by itself and can accurately and efficiently complete hot-line working while safety improvement.

Owner:NANJING UNIV OF SCI & TECH

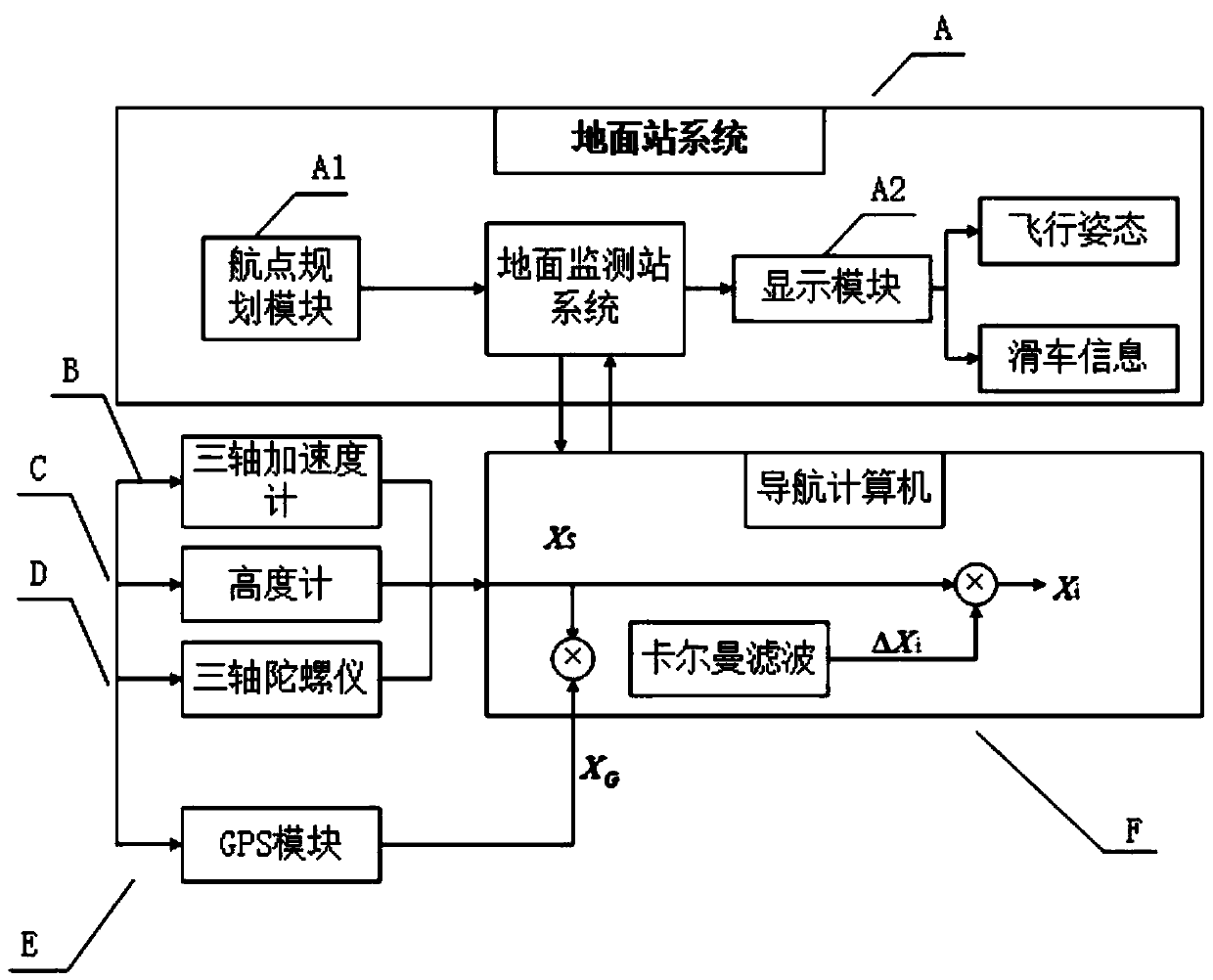

Unmanned aerial vehicle power wiring system based on combined navigation and computer vision

ActiveCN109683629AImprove working accuracyHigh positioning accuracyNavigational calculation instrumentsNavigation by speed/acceleration measurementsEngineeringLearning methods

The invention discloses an unmanned aerial vehicle power wiring system based on combined navigation and computer vision, which is characterized in that GPS satellite positioning is combined with priorinertial navigation positioning to update the pose state and adjust the position and the pose so as to achieve the optimal wiring pose; an unmanned aerial vehicle ground monitoring station system adopts a particle swarm optimization algorithm, can provide a one-key addressing function for a user, and achieves automatic flight path planning of the unmanned aerial vehicle; then according to a binocular vision positioning principle, a binocular camera acquisition module extracts the pulley position and the pulley threading hole information by using a neural network depth learning method, sends the pulley position information to an unmanned aerial vehicle controller, and automatically adjusts the pose of the unmanned aerial vehicle, the unmanned aerial vehicle system is navigated to an area which is 0.5m away from the trolley; and the information of the pulley threading hole is transmitted to an aiming device, and the aiming device ejects a guide wire counterweight block into the pulley hole according to the position analysis and dynamic analysis of the relative position of each pulley trained in advance, so as to complete the unfolding of the guide wire.

Owner:YANSHAN UNIV +1

Building construction equipment

ActiveCN110219444AScratch GuaranteeGuarantee the construction qualityBuilding constructionsSlurryStorage material

The invention relates to the technical field of building construction and discloses building construction equipment. The building construction equipment includes a feeding device, a material pressingdevice and a slurry scraping device; the feeding device includes an installation mechanism and a conveying mechanism, the installation mechanism is configured as the a storage material belt, and the conveying mechanism is configured as a material conveying belt; the material pressing device includes a material pressing wheel and a material pressing installation frame, the material pressing wheel is rotatably arranged on the material pressing installation frame, and the material pressing wheel is configured to press material belts to bottom slurry; and the slurry scraping device includes a slurry scraping plate and a scraping plate installation frame, the slurry scraping plate is hinged to the scraping plate installation frame, the slurry scraping plate can swing relative to the scraping plate installation frame to make the slurry scraping plate fit a wall face to strike the slurry. The feeding device can store and send the material belts to the material pressing wheel, the material pressing wheel can hang the material belts on the wall face, the slurry scraping plate can swing relative to the scraping plate installation frame to strike the slurry on the wall face, manual bottom slurry wiping, net hanging, and face slurry wiping are not needed in mechanical operation, operation accuracy is improved, construction efficiency is high, and the labor cost is lowered.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

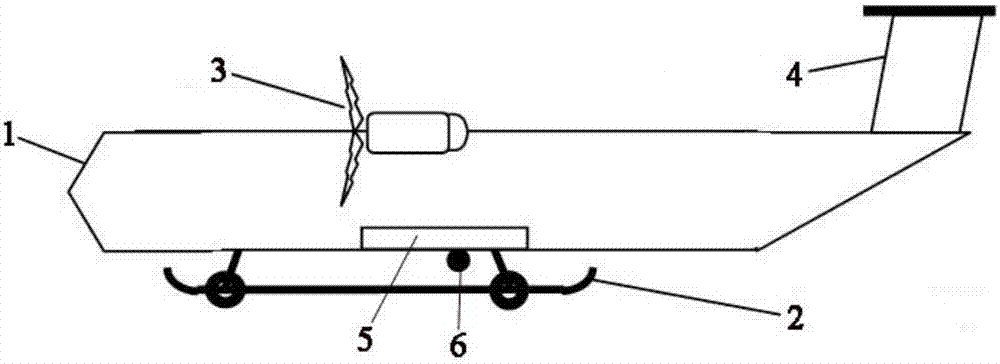

Low-altitude flight operation unmanned aerial vehicle and control system and application thereof

PendingCN107539453ALow costNo risk to life safetyConvertible alighting gearWingsAviationControl system

The invention discloses a low-altitude flight operation unmanned aerial vehicle and a control system and application thereof. Buffer mechanisms of a main undercarriage supporting column and a front undercarriage supporting column are designed and mounted on a force bearing structure on the outer side of a fuselage (1), the lower ends of the main undercarriage supporting column and the front undercarriage supporting column are connected into a slide-type undercarriage (2) structure, and the gliding ratio is increased through the high lift-drag ratio aerodynamic force design. A low-altitude crash prevention technology, a low-altitude link communication technology and an unmanned aerial vehicle system technology are integrated, the pneumatic and dynamic overall layout design of the fixed wingunmanned aerial vehicle suitable for low-altitude operation is adopted, and the new-layout unmanned aerial vehicle is suitable for low-altitude operation such as agricultural aviation plant protection and safety flight.

Owner:陶文英

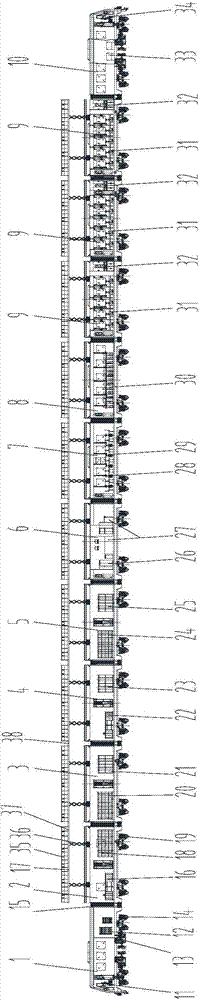

Electrified railway contact network overhaul train

ActiveCN103879418AImprove working environmentImprove working accuracyCarriagesContact networkMulti machine

The invention provides an electrified railway contact network overhaul train. The electrified railway contact network overhaul train is composed of a first tractor, a plurality of work vehicles and a second tractor. The work vehicles are arranged between the first tractor and the second tractor, the first tractor, the work vehicles and the second tractor are all connected through folding wind shields, the tops of the work vehicles are respectively provided with a lifting work platform, and the lifting work platforms are communicated with one another after being lifted. The electrified railway contact network overhaul train is provided with the communicated work platforms, construction work can be performed on a contact network with the line range of 160 m at the same time, the functions of erecting lines of the contact network, maintenance, repair, high-altitude work and the like are integrated, multi-machine multi-work type cooperative work is achieved, a large amount of skylight time is saved, the electrified railway contact network overhaul train has the highest self running speed of 120 km / h and has the functions of transportation and storage of construction materials, machine maintenance and transportation and storage of tools and safety spares, and thus the construction site can have the workshop operation functions, the operating environment of workers is improved, and the operating precision is improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

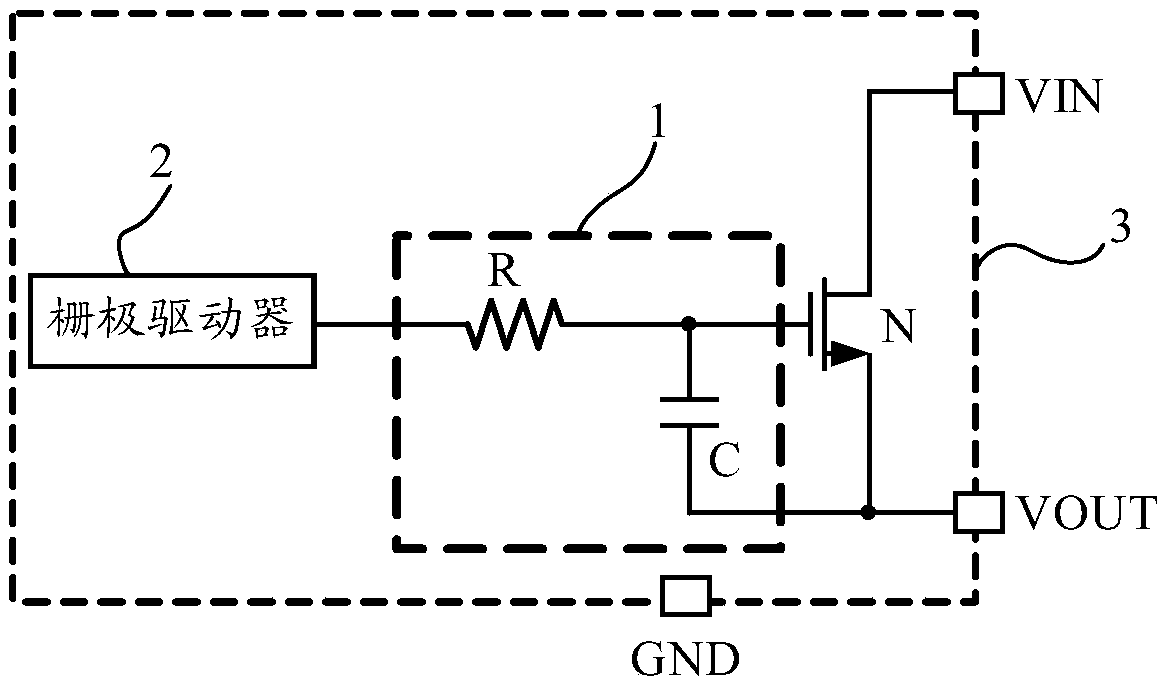

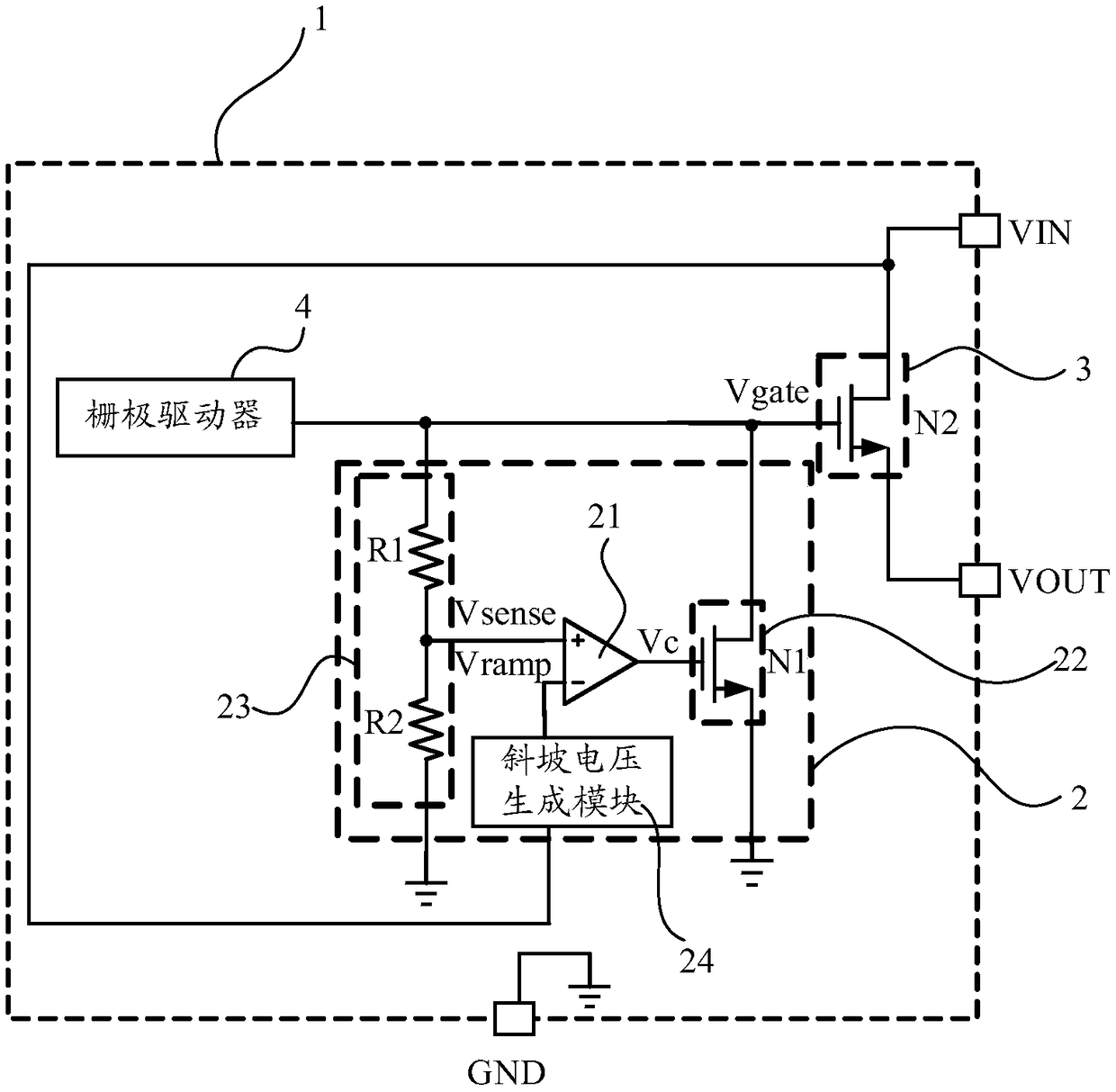

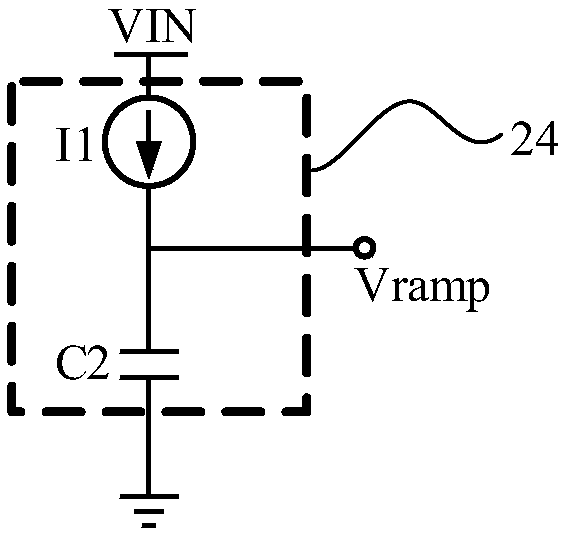

A soft start controller of a load switching device and a load switching device

The invention relates to a soft start controller of a load switching device and a load switching device, The soft start controller comprises: an error amplifier, receiving a ramp voltage at a first input of the error amplifier, receiving an associated voltage at a second input terminal of the error amplifier, outputting a control signal at an output terminal of the error amplifier, the associatedvoltage varying with a change of a driving voltage, the voltage value of the ramp voltage gradually increasing with time, and transmitting the driving voltage to a control terminal of the load switch;a pull-down module is connected with the control terminal of the load switch at the input end of the pull-down module, the output end of the pull-down module is grounded, and the pull-down module isadapted to determine whether to discharge power to the control terminal of the load switch according to the control signal. The technical proposal of the invention can effectively save the area of theswitching load device and optimize the circuit cost.

Owner:SOUTHCHIP SEMICON TECH SHANGHAI CO LTD

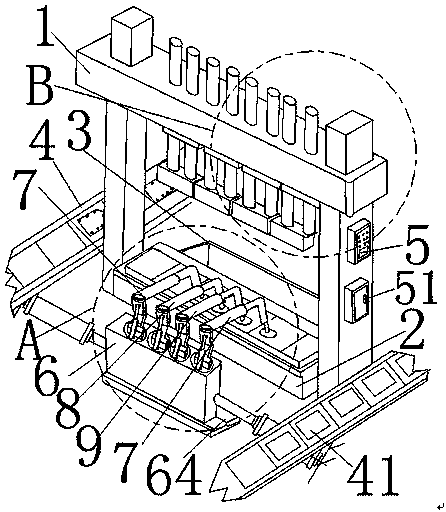

Supporting and connecting lead lapping method of live working robot based on force feedback master-slave control

InactiveCN108582031AEasy to operateFlexible operationProgramme-controlled manipulatorGripping headsControl systemVelocity vector

The invention provides a supporting and connecting lead lapping method of a live working robot based on force feedback master-slave control. A mechanical arm, a master manipulator and an industrial personnel computer form a force feedback master-slave control system, wherein the industrial personnel computer calculates torque data of joints of the master manipulator according to stress data at thetail end of the mechanical arm to control the joints of the master manipulate to output torque through a control interface of the master manipulator, so that the master manipulator feeds the force back, and an operator confirms the force of the mechanical arm according to the feedback stress of the master manipulator; the operator changes the posture of the tail end of the master manipulator, theindustrial personnel computer calculates a expected number of a velocity vector at the tail end of the mechanical arm according to the angle data of the rotary joints of the master manipulator; through the control interface of the mechanical arm, the mechanical arm is controlled to move according to the expected number to change the force of the mechanical arm. According to the method provided bythe invention, the operating sense of immediacy is improved, and whether operations are in position precisely or not can be precisely judged.

Owner:NANJING UNIV OF SCI & TECH

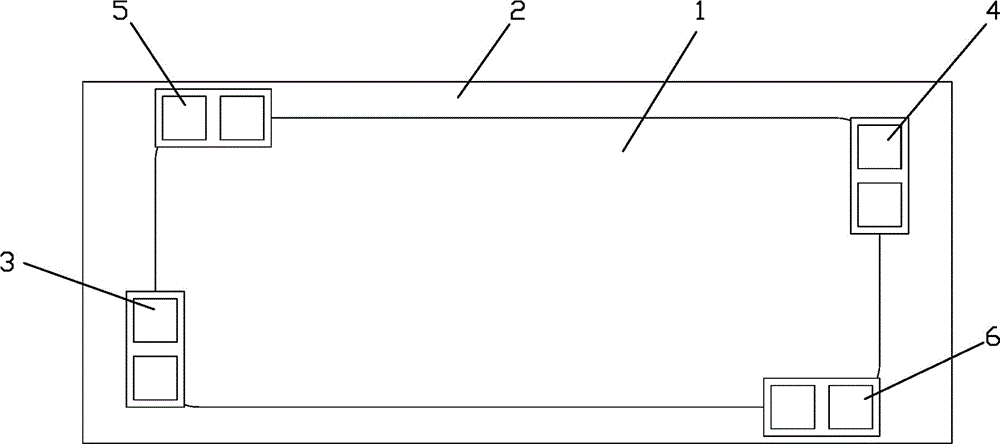

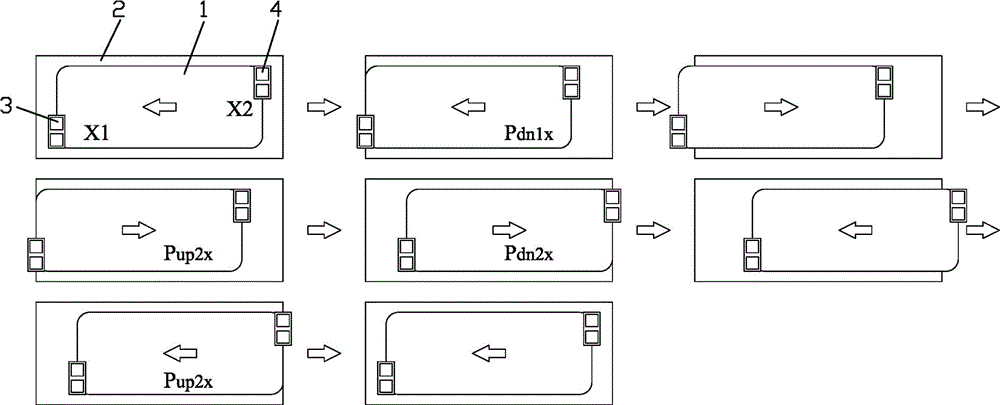

Material edge detecting method of tooling

ActiveCN103600353ASpeed up pickupImprove reliabilityUsing optical meansManipulatorReciprocating motionEngineering

Provided is a material edge detecting method of a tooling. A group of edge measurement sensors for detecting the edge position of a material is respectively arranged in the X-direction and the Y-direction of the tooling and includes two sensors installed at the diagonal line position of the tooling. The edge measurement sensors are photoelectric sensors, and the measurement directions and the transmitting-receiving directions of the edge measurement sensors are perpendicular to the measured edge. A robot carries the tooling to sequentially perform reciprocating motion in the X-direction and the Y-direction of the material for at least one time so as to obtain the material edge position, and a reciprocating stroke is + / -50mm-+ / -100mm. The lower portion of the connecting position of the tooling and a robot flange is provided with two calibration sensors for calibrating the positions of the two groups of edge measurement sensors of the tooling. The sensors for detecting the material position is installed on the tooling and used for detecting and confirming the position of the material so as to improve the accuracy of carrying and stacking operation of the robot.

Owner:BAOSHAN IRON & STEEL CO LTD +1

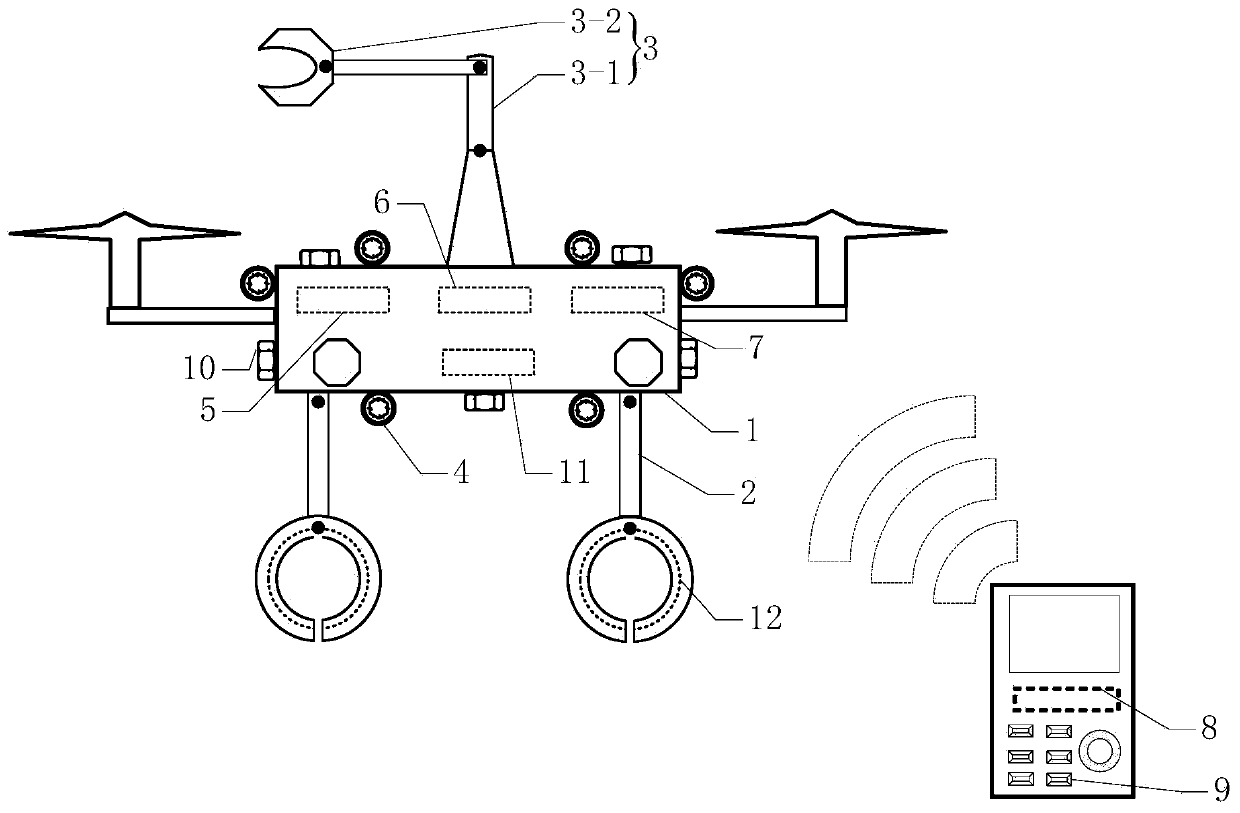

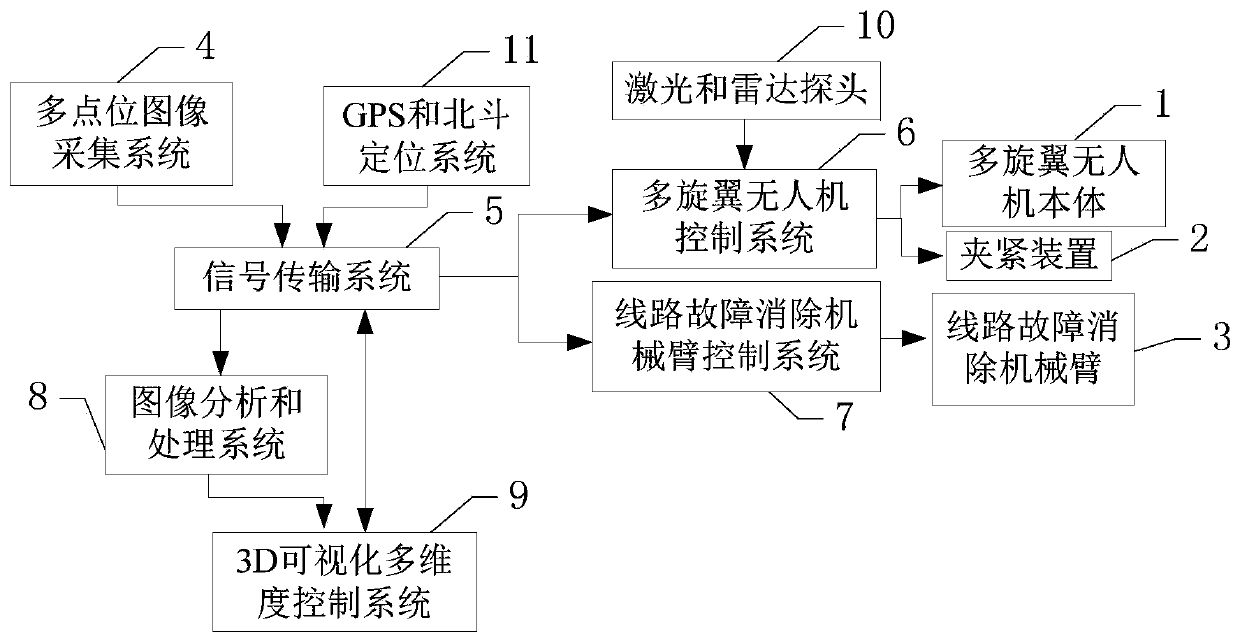

Power line fault overhaul unmanned aerial vehicle with live-working function

InactiveCN109941436AAchieve relative stillnessEliminate operational controlsProgramme-controlled manipulatorElectric signal transmission systemsRobotic armControl signal

The invention relates to a power line fault overhaul unmanned aerial vehicle with a live-working function, relates to the field of electric power overhaul, and aims to solve the problems that an existing unmanned aerial vehicle only can make a simple inspection tour, a power fault cannot be eliminated under complicated conditions, the existing unmanned aerial vehicle only can transmit a plane picture to a ground operator, and a complicated power fault is difficult to precisely diagnose. A multi-point image collecting system is used for collecting image information around the unmanned aerial vehicle; an image analyzing and processing system is used for analyzing and integrating the received image information into 3D images; a 3D visual multi-dimension control system is used for receiving the 3D images, and further used for sending a mechanical arm control signal and an unmanned aerial vehicle control signal to a signal transmission system so as to control a multi-rotor unmanned aerial vehicle body, a clamping device and a line trouble elimination mechanical arm. The live-working power line trouble shooting unmanned aerial vehicle is suitable for overhauling a power line.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD ELECTRIC POWER RES INST +1

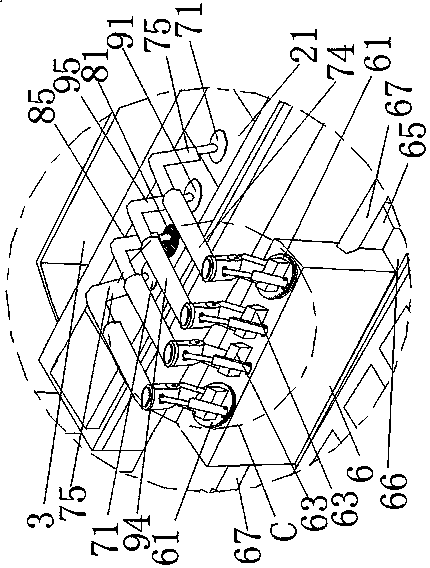

Live working robot mechanical-arm collaboration force feedback master-slave control method and system

InactiveCN108284425AImprove convenienceHigh precisionProgramme-controlled manipulatorControl systemPersonal computer

The invention relates to a live working robot mechanical-arm collaboration force feedback master-slave control method and system. The live working robot mechanical-arm collaboration force feedback master-slave control system comprises manipulators, mechanical arms and industrial personal computers, wherein six-degree-of-freedom force / torque sensors are mounted at the tail ends of the mechanical arms; during the main manipulator force feedback control, the industrial personal computers calculates the torque data of all joints of main manipulators according to tail-end stress data of the mechanical arms, and controls all the joints of the main manipulators to output torque through control ports of the main manipulators; and six-degree-of-freedom force / torque data serve as scalars of the tail-end stress data of the mechanical arms and comprise two parts; parts of the tail-end stress data come from stress data generated during the contact between the mechanical arms and an environment as well as are collected by the six-degree-of-freedom force / torque sensors mounted at the tail ends of the mechanical arms; and the other parts of the tail-end stress data come from stress data generatedduring the mutual collisions among the mechanical arms. By adoption of the live working robot mechanical-arm collaboration force feedback master-slave control method and system provided by the invention, the live working can be accurately, efficiently and safely completed.

Owner:NANJING UNIV OF SCI & TECH

Multi-station continuous stamping production line for automobile parts and stamping process thereof

ActiveCN109647974AReduce labor costsIncrease production capacityMetal-working feeding devicesMetal working apparatusProduction linePunching

The invention discloses a multi-station continuous stamping production line for automobile parts and a stamping process thereof. The multi-station continuous stamping production line comprises a stamping working system, a grabbing assembly, a debris containing assembly, a conveying assembly and a control system, wherein the stamping working system comprises a machine frame and a stamping working platform, and a plurality of stamping tools which are adapted to different punching procedures are transversely arranged on the stamping working platform; the grabbing assembly comprises a mechanical arm mounting base which is arranged on the front side or the rear side of the punching working platform and can transversely move, two mechanical grabbing arms, a plurality of longitudinal cleaning mechanical arms and a longitudinal grabbing mechanical arm are arranged on the mechanical arm mounting base; and the conveying assembly comprises a to-be-stamped automobile iron plate conveying belt anda stamped automobile part conveying belt which are longitudinally arranged on the left side and the right side of the grabbing assembly. According to the multi-station continuous stamping production line for automobile parts and the stamping process thereof, the multi-station automobile part punching machining is realized through multi-mechanism coordination operation, the automation degree is higher, the working efficiency and the operation accuracy are further improved, and the labor cost of enterprises can be greatly saved.

Owner:山东时风(集团)有限责任公司

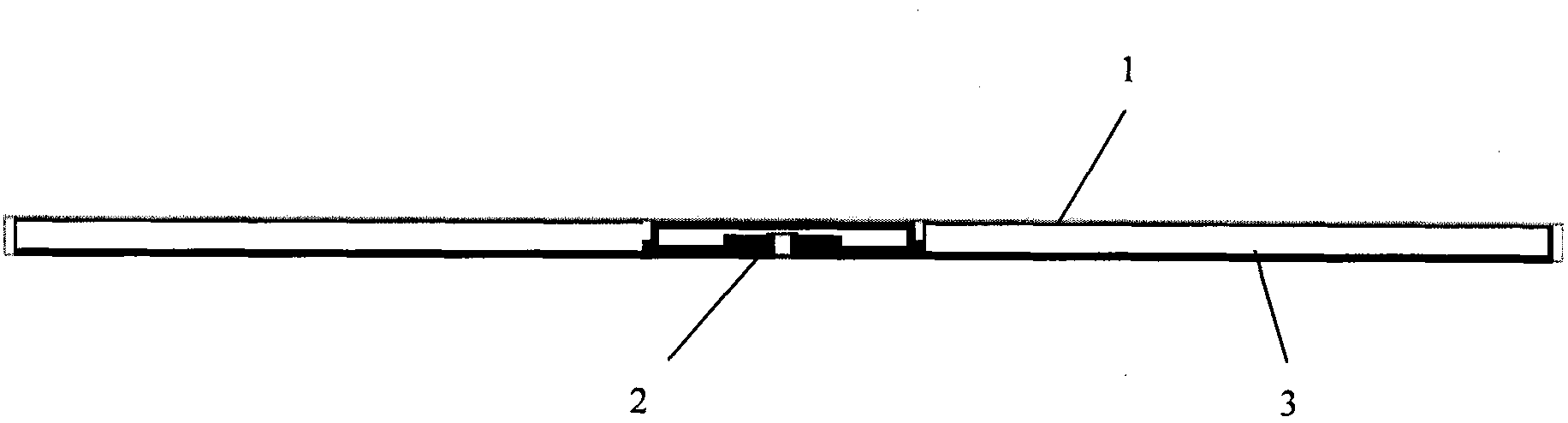

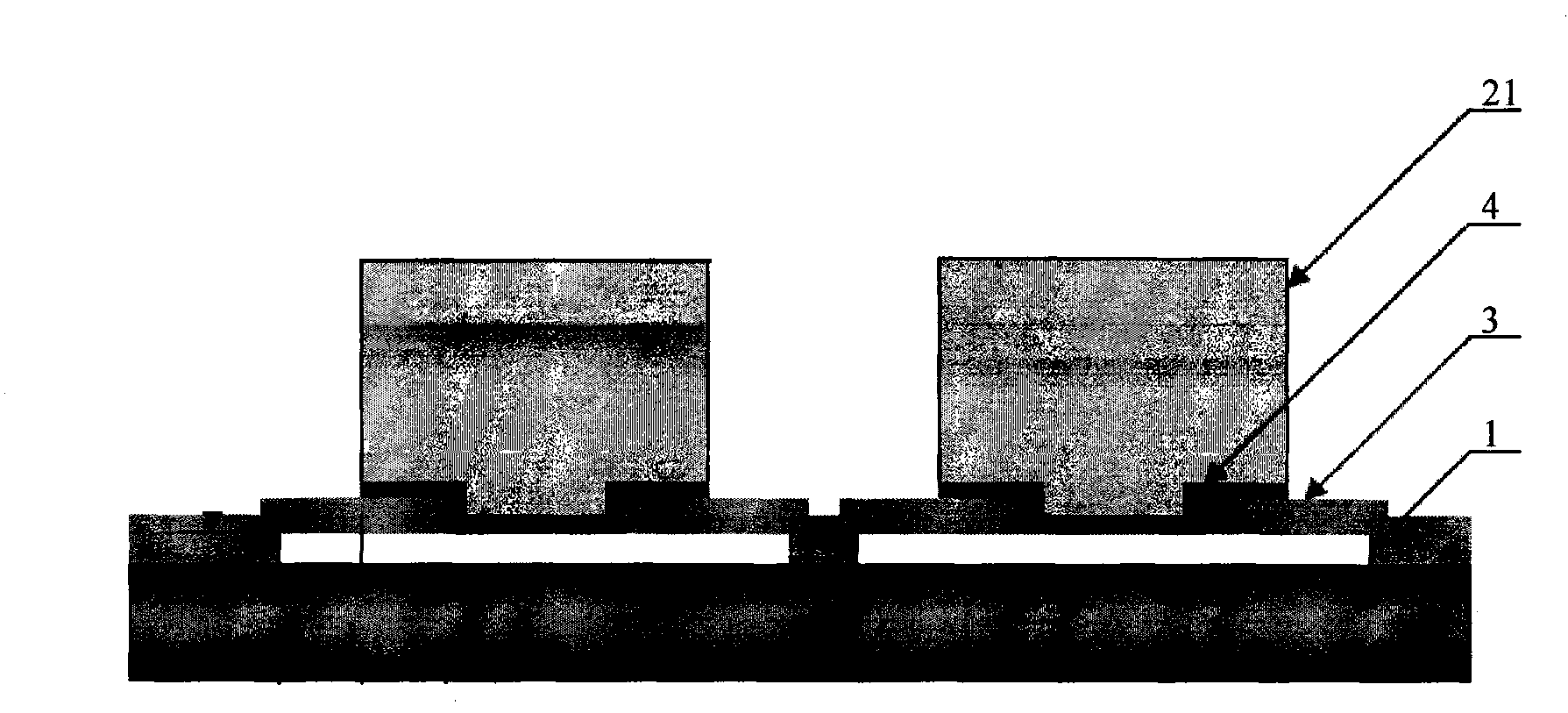

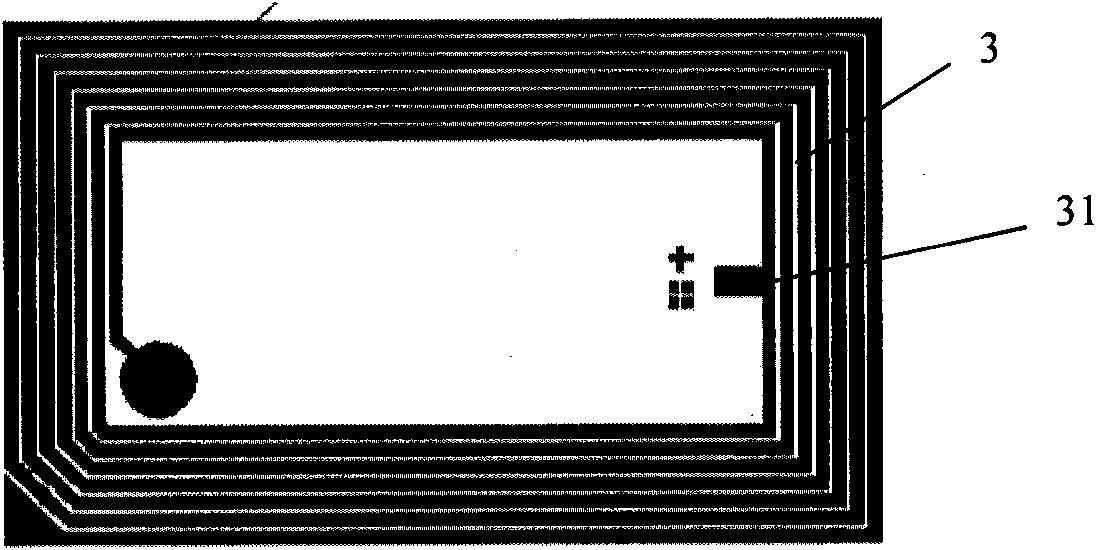

Printed circuit board with radio frequency identification and production method thereof

InactiveCN102014573AReduce labor costsImprove accuracyAntenna supports/mountingsPrinted electric component incorporationAdhesiveEngineering

The invention discloses a printed circuit board with a radio frequency identification, comprising a printed circuit board, a radio frequency identification chip, a radio frequency identification antenna and conductive adhesive, wherein the radio frequency identification chip is arranged on the printed circuit board; the radio frequency identification antenna is printed on the printed circuit board; an antenna pin is arranged at one side of the radio frequency identification antenna; and the pin antenna is closely connected with a connecting port of the radio frequency identification chip by the conductive adhesive. The production method comprises the following steps of: firstly, printing the radio frequency identification antenna on the printed circuit board; secondly, coating an insulating layer at the part of the radio frequency identification antenna, which corresponds to a jumper wire; thirdly, printing the jumper wire and respectively connecting two ends of the jumper wire with the head and the tail of the radio frequency identification antenna; fourthly, coating the conductive adhesive on the antenna pin by adhesive dispensing equipment; fifthly, turning over the radio frequency identification chip to be connected with the antenna pin; sixthly, hot pressing the conductive adhesive and curing the conductive adhesive; and seventhly, testing the qualified rate. By using the invention, the labor cost can be saved, the work accuracy can be improved, the quality of products can be ensured, the processing can be accelerated and the logistics dynamic can be effectively tracked.

Owner:上海中京电子标签集成技术有限公司 +5

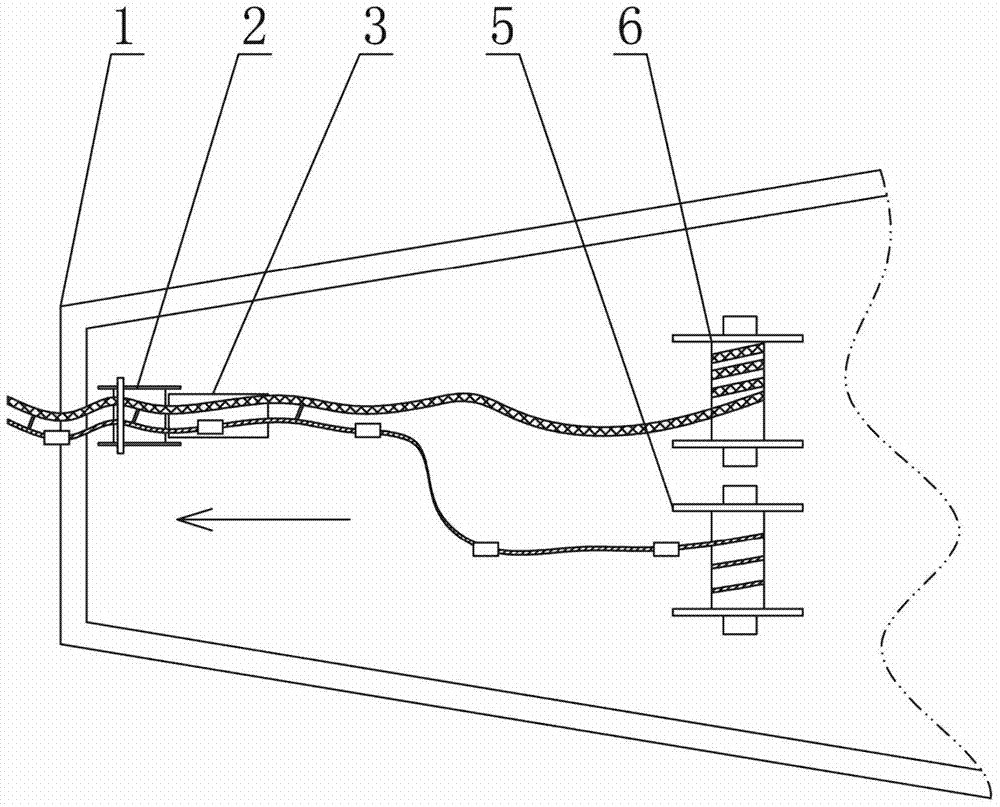

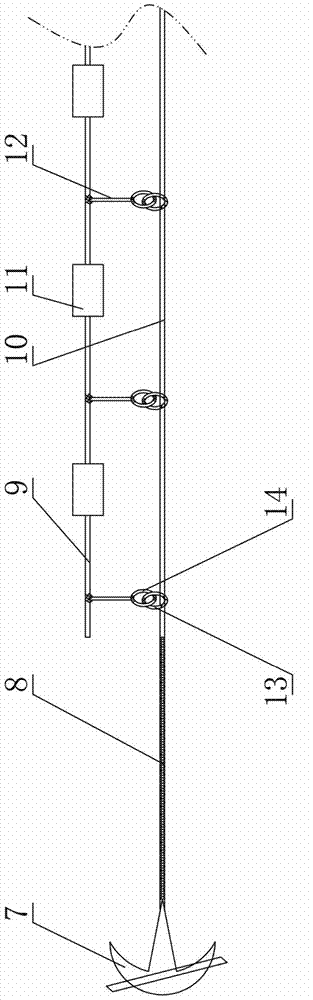

Cable laying precision control method and device

ActiveCN104269782AAchieve precision controlAchieve orientationApparatus for laying cablesMooring systemStern

The invention discloses a cable laying precision control method and device. The method includes the steps that a, when the stern is located over the target coordinate points, at the sea bottom, of a positioning anchor, a gravity anchor connected to the front end of a traction rope inside a positioning rope is thrown into the sea bottom, wherein the length of the traction rope is determined according to the suspension length, in the sea water, of a submarine cable with wave detectors. The device comprises a mooring rope system and a winch system, wherein the winch system is used for throwing the mooring system into the sea together. The cable laying precision control method and device can be applied to the technical field of submarine cable seismic exploration operation, by the utilization of the cable laying precision control method and device, the defects in the prior art can be effectively overcome, influences of multi-lamination currents, undercurrents, ocean currents and irregular currents inside a deep ocean region can be effectively avoided, and the technical effect of precision control over deep ocean operation is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com