Autonomous working robot system

A robot system and technology for industrial robots, applied in the field of industrial robots, can solve problems such as difficult movement of large-sized workpieces, and achieve the effects of expanding intelligence and practicability, high operation accuracy, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

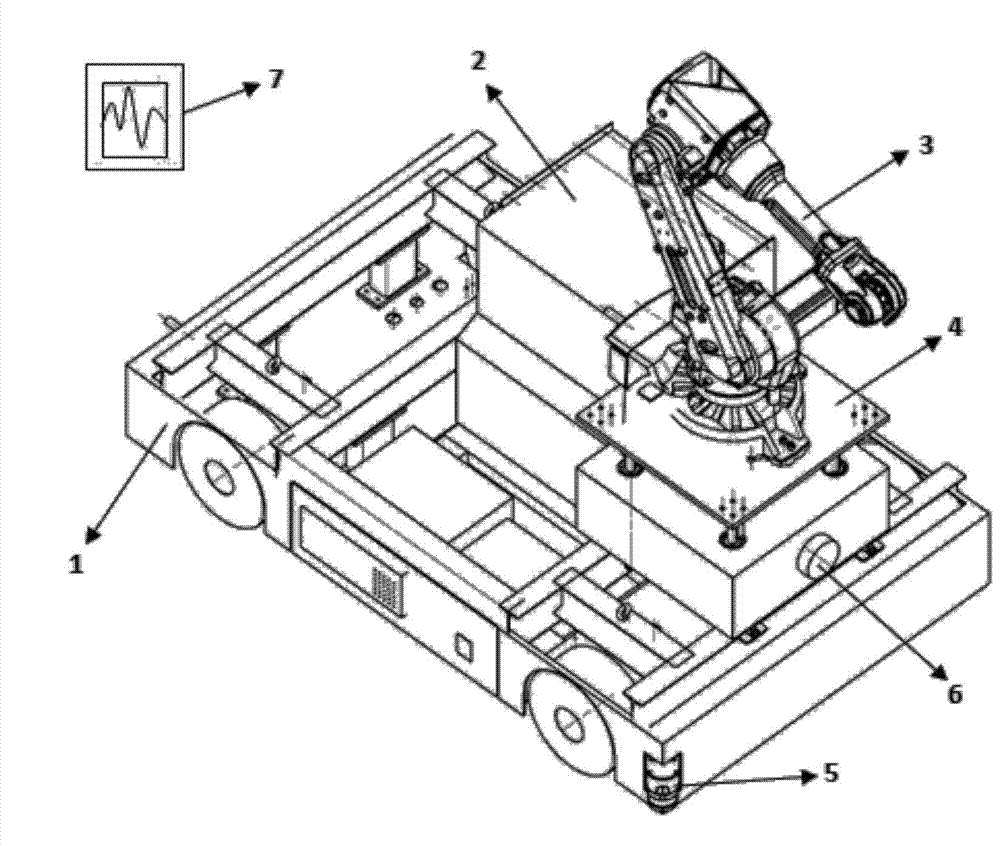

[0022] Embodiment one: see attached figure 1 shown. An autonomous working robot system includes a robot body and a remote control system 7 .

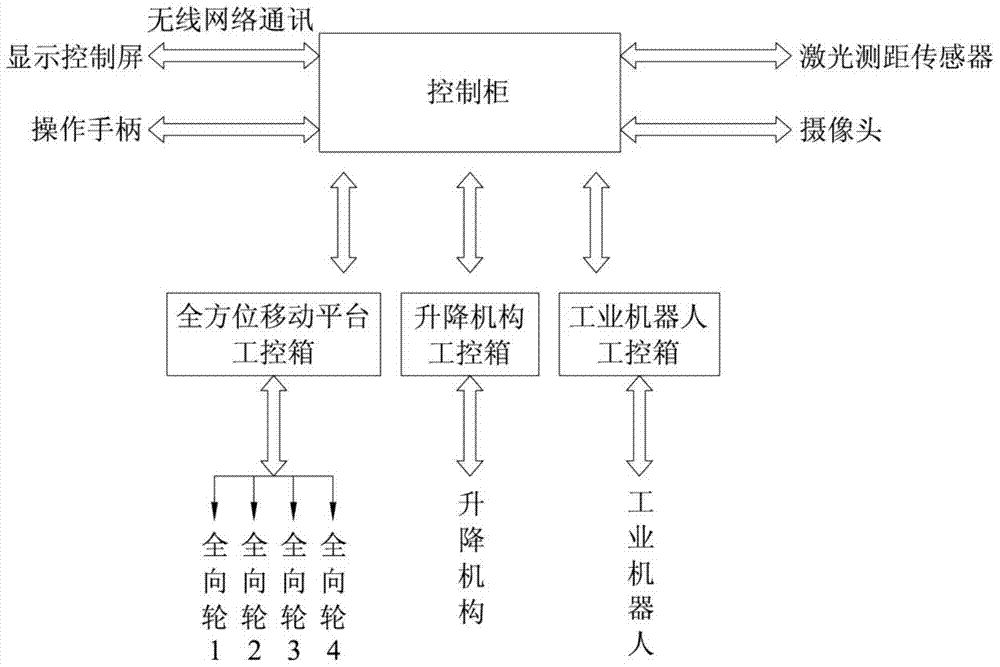

[0023] The robot body includes an omnidirectional mobile platform 1, a lifting mechanism 4, an industrial robot 3, a control cabinet 2 and a positioning recognition system. Among them, the omnidirectional mobile platform 1 can move arbitrarily in the horizontal plane, and it includes a platform body and several omnidirectional wheels installed on the bottom of the platform body, and the omnidirectional wheels can be ordinary omnidirectional wheels or Mecanum wheels, so that the omnidirectional The azimuth mobile platform 1 can realize movement with zero turning radius. In this embodiment, the platform body is roughly in the shape of a cuboid, and is provided with four omnidirectional wheels. The lifting mechanism 4 is fixedly installed on the platform body of the omnidirectional mobile platform 1 by several screws, which includes a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com