Patents

Literature

4269results about How to "Realize automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

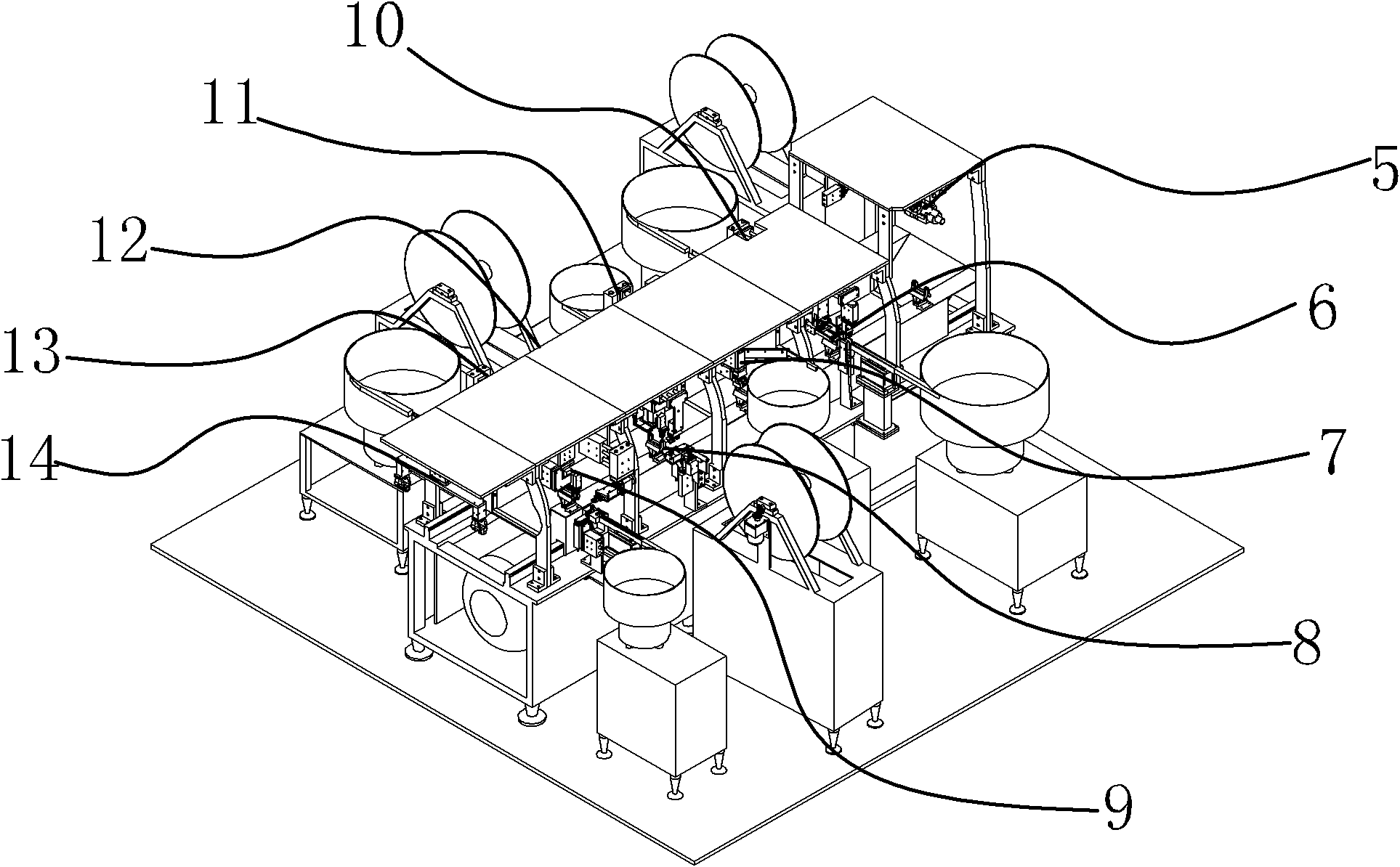

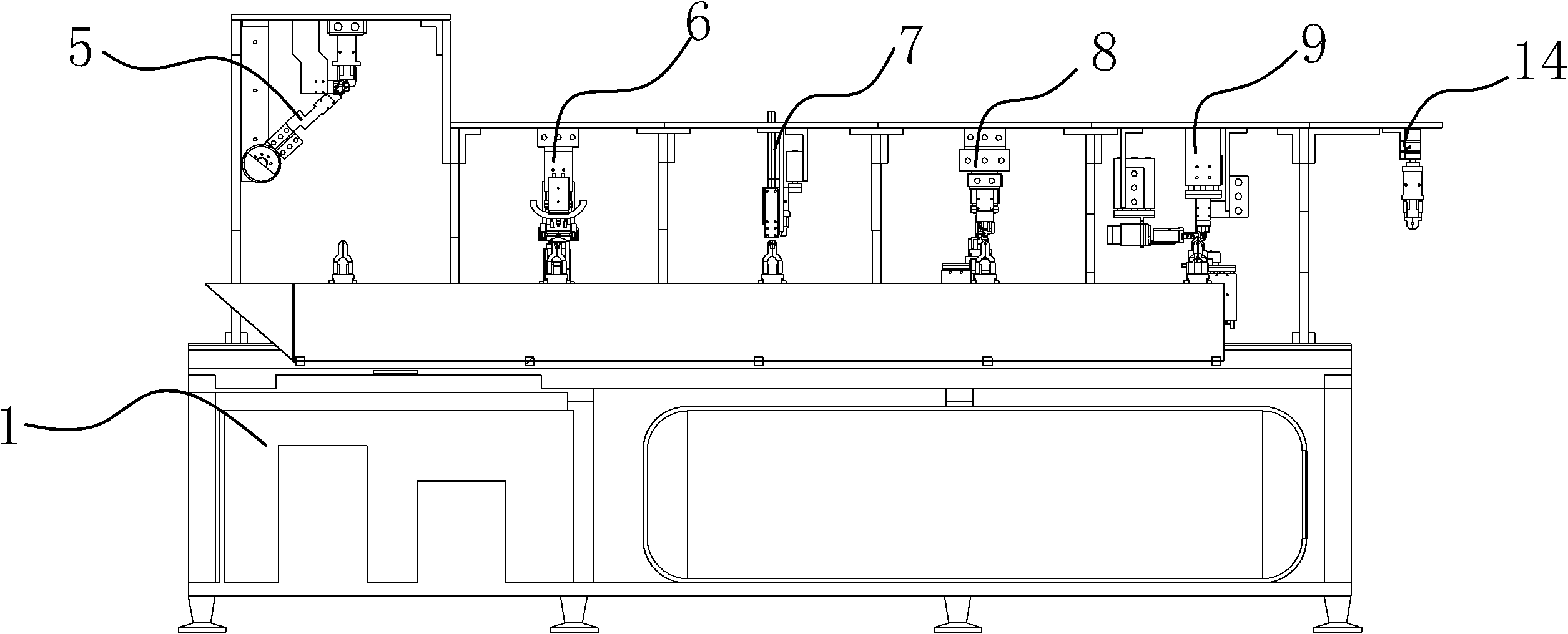

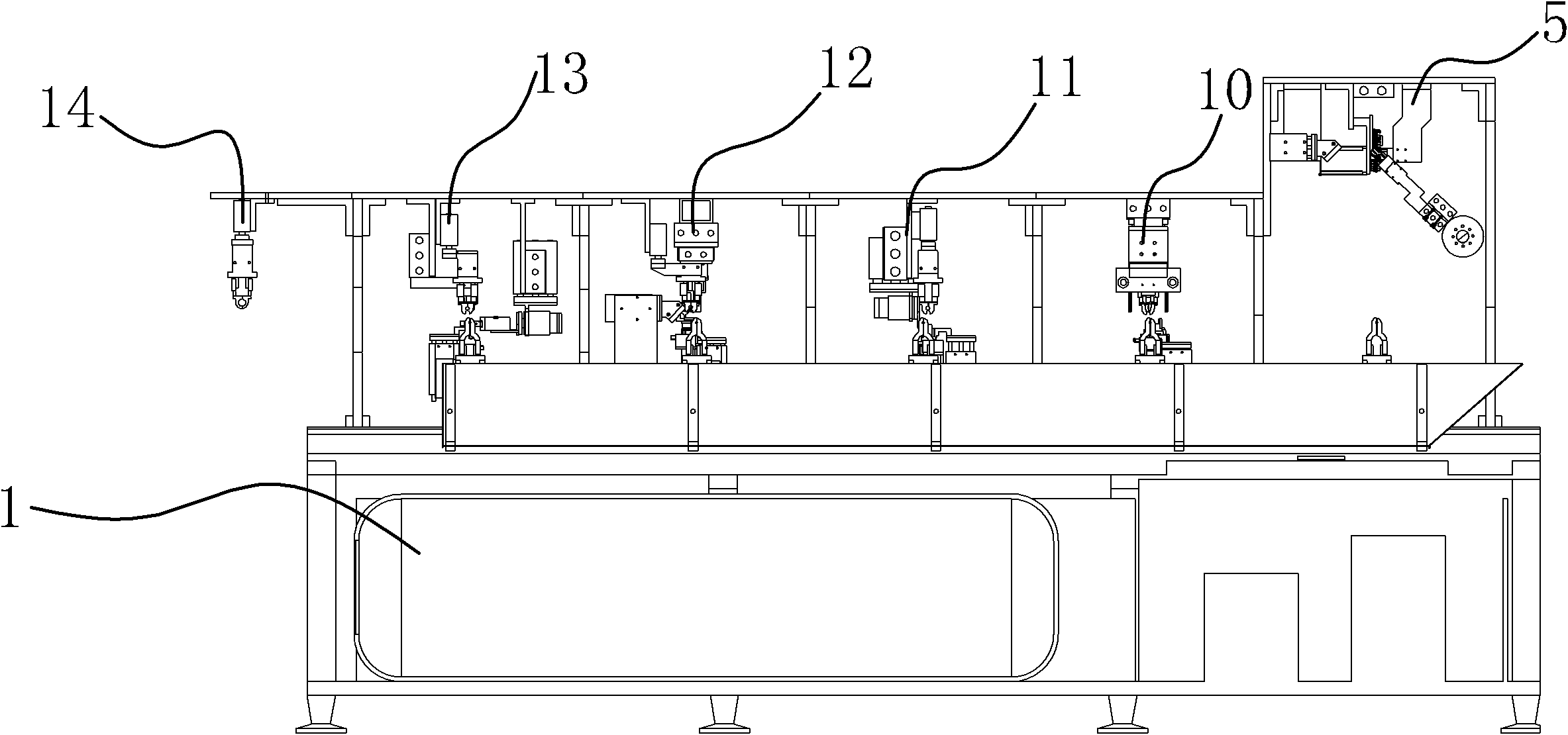

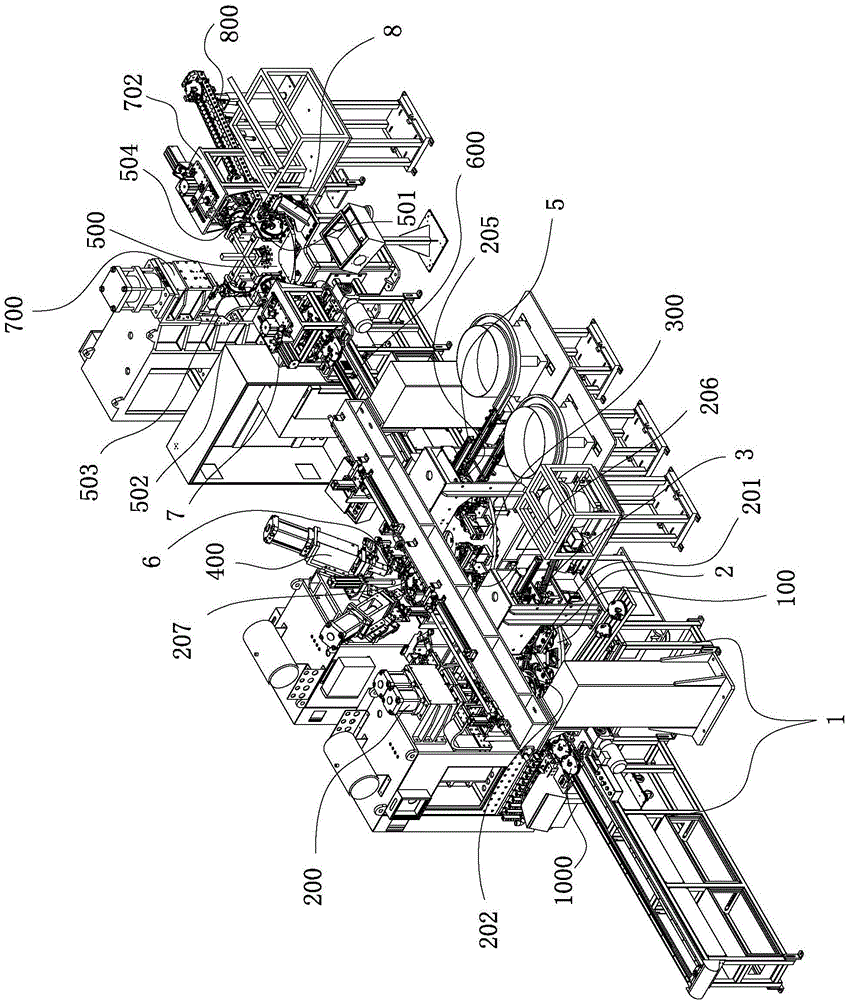

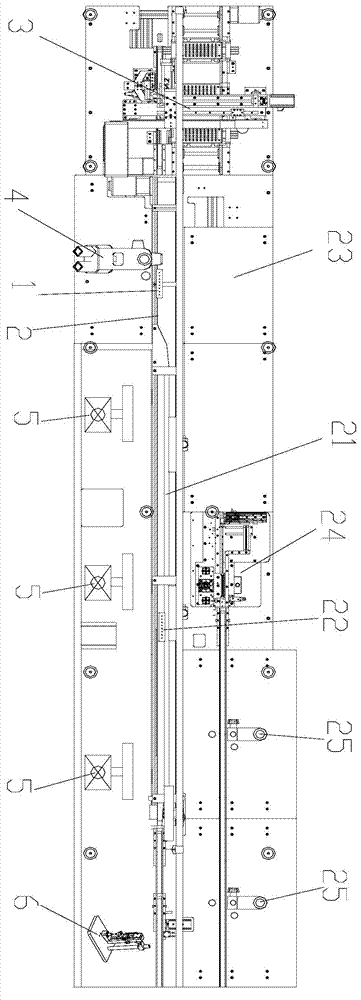

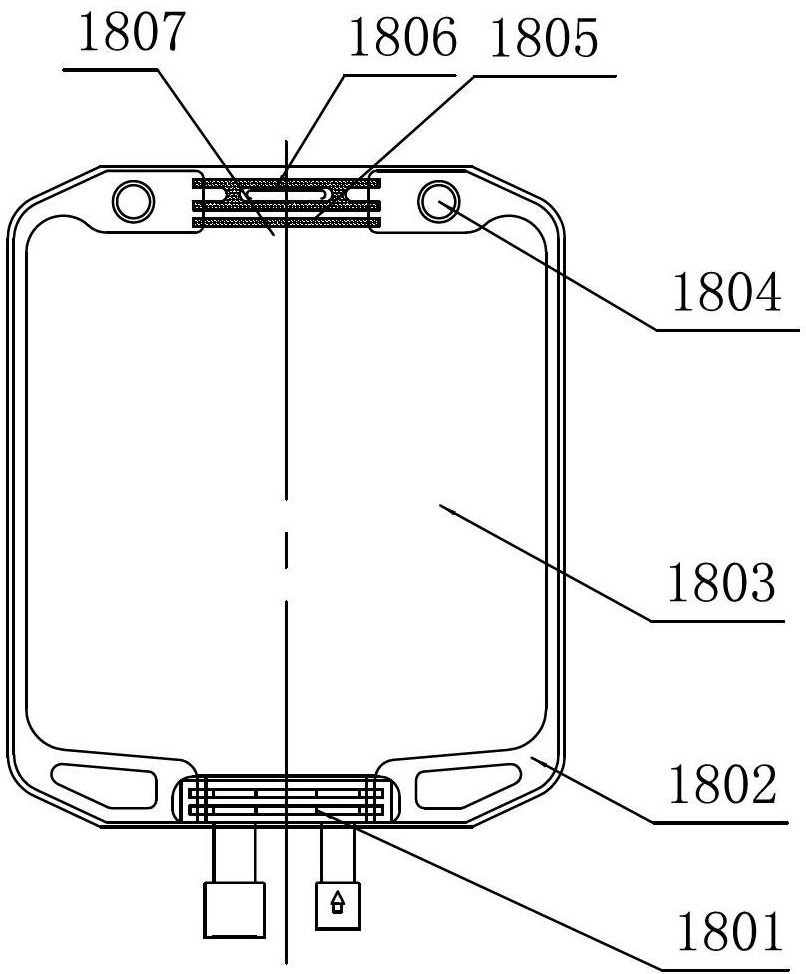

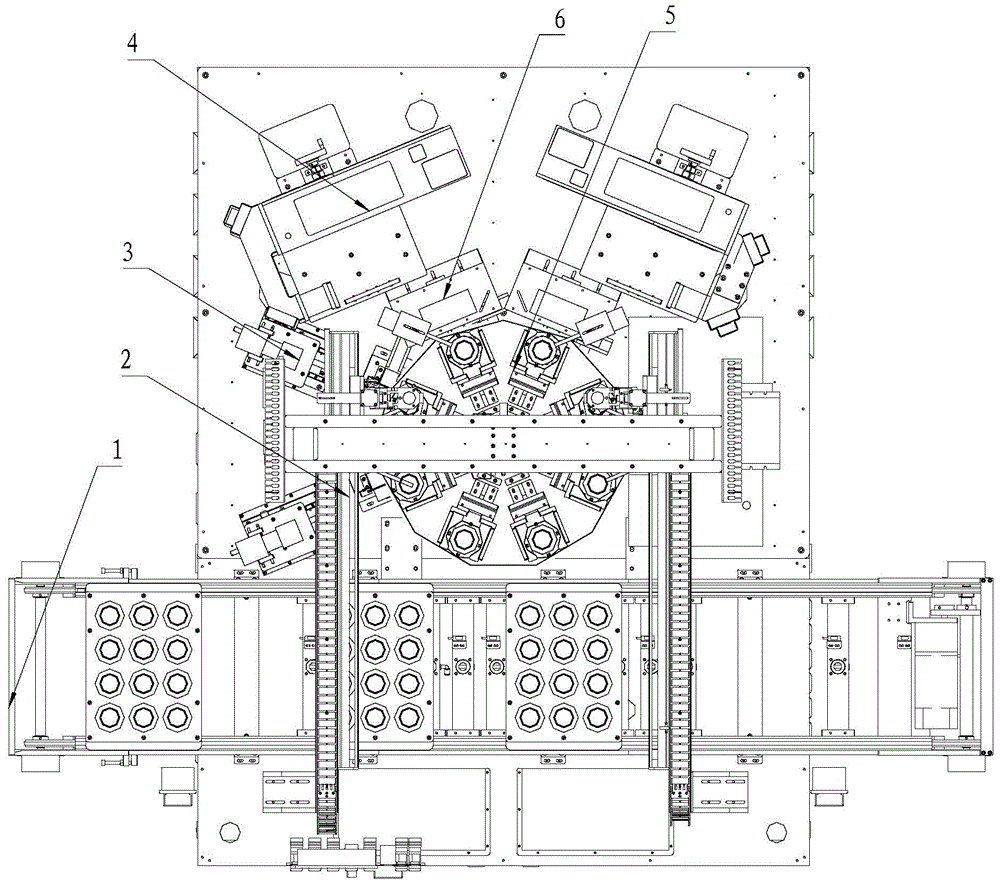

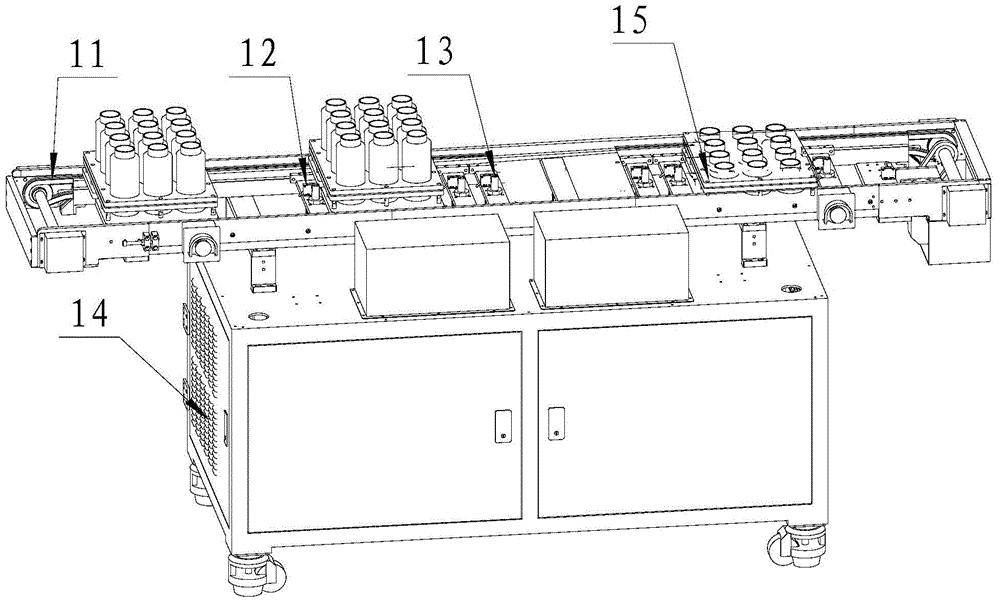

Automatic assembly machine for infusion apparatus

The invention provides an automatic assembly machine for an infusion apparatus, and belongs to the technical field of medicinal instruments. The automatic assembly machine solves the problem of low automation degree of the conventional infusion apparatus assembly machine. The automatic assembly machine for the infusion apparatus comprises a frame, wherein the frame is glidingly connected with a feeding sliding table; a feeding driving mechanism is arranged between the frame and the feeding sliding table; two sides of the feeding sliding table are fixedly provided with a plurality of pairs of clamping stations distributed opposite; the inlet end of the feeding sliding table is provided with an infusion long tube feeding device; one side of the feeding sliding table is sequentially providedwith a flow box assembly device, a switching wheel assembly device, an infusion short tube assembly device and a filter assembly device; the other side of the feeding sliding table is sequentially provided with a dropping bottle assembly device, a two-way tube assembly device, an infusion medium tube assembly device and a bottle inserting needle assembly device; and the outlet end of the feeding sliding table is also provided with an unloading device for taking the assembled infusion apparatus assembly out of the clamping station. The automatic assembly machine for the infusion apparatus has high positioning accuracy, accurate clamping position and high automation degree.

Owner:TAIZHOUSNG JIN AUTOMATION EQUIP MFG

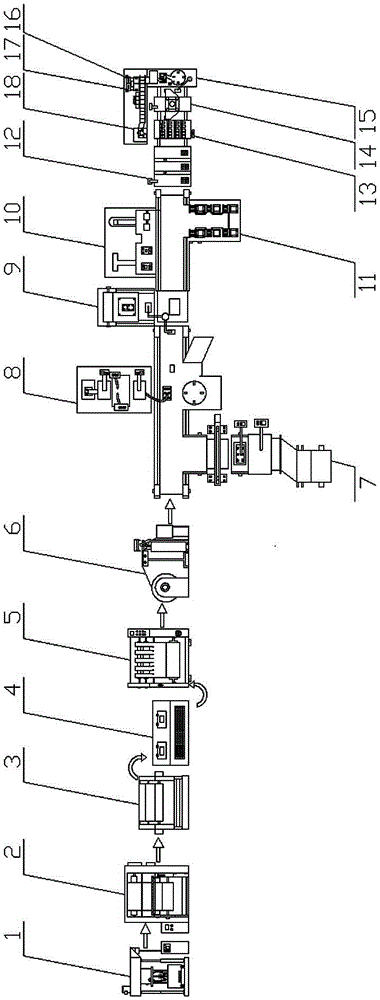

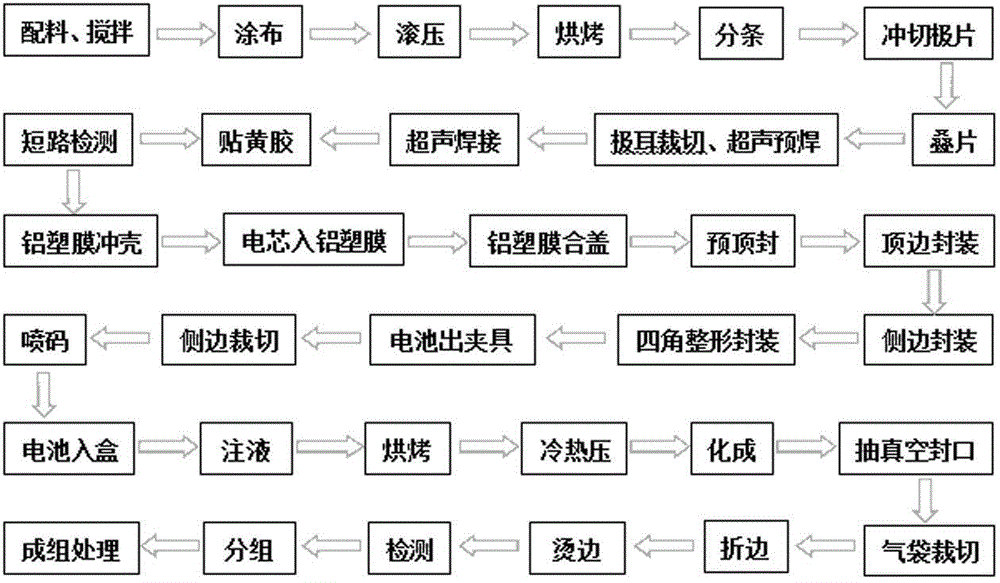

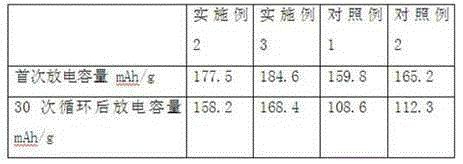

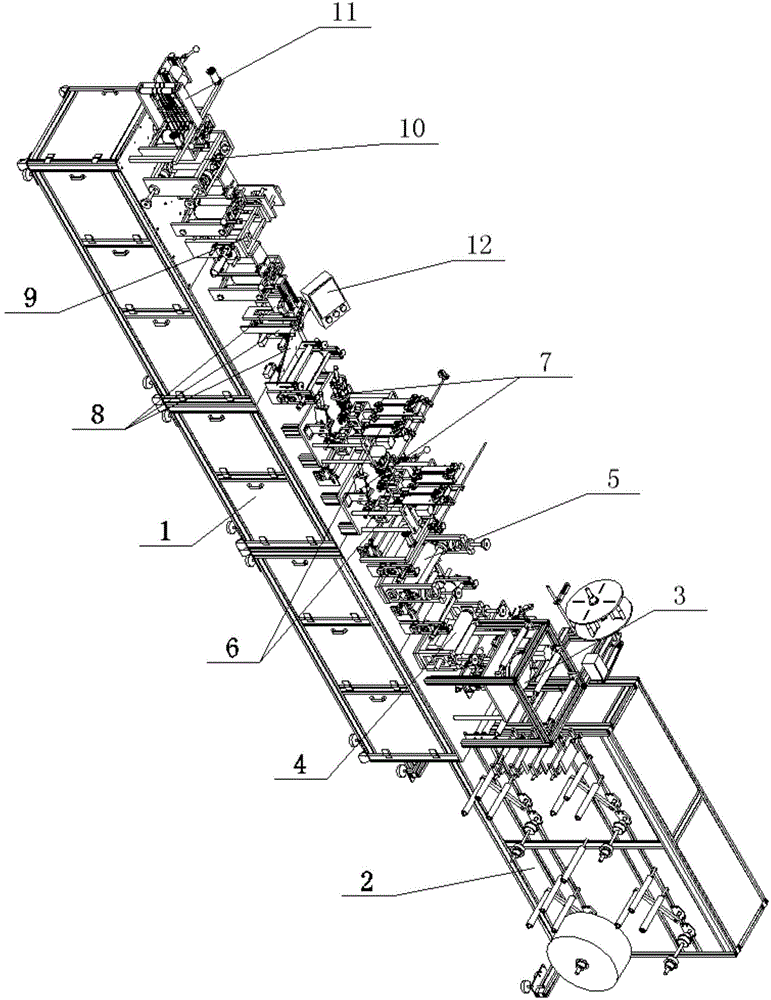

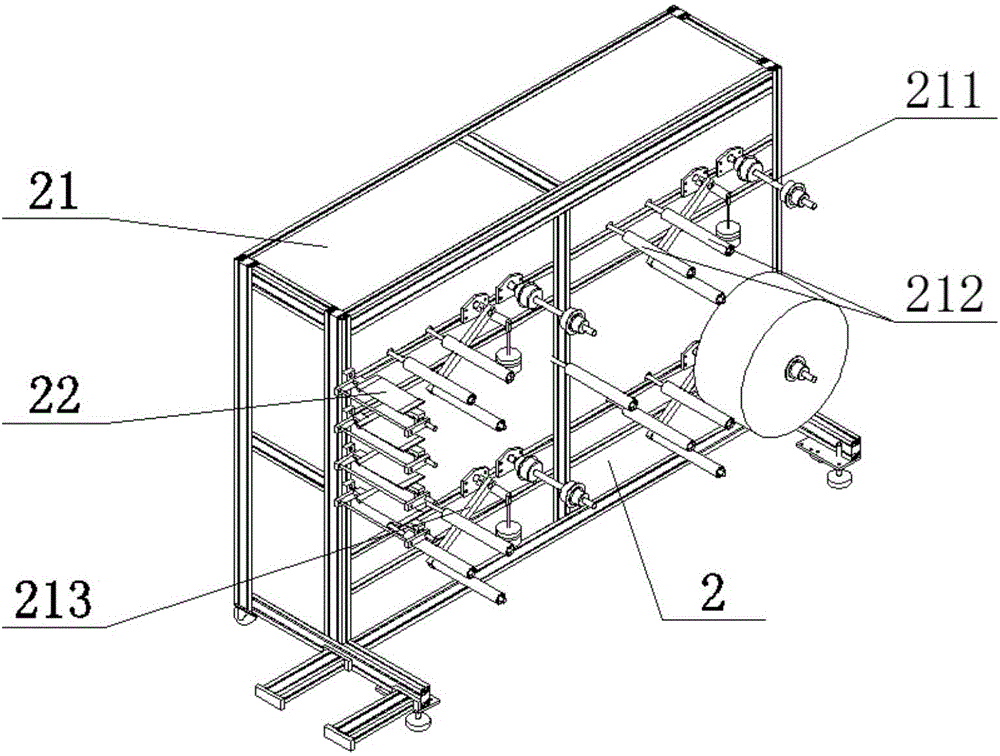

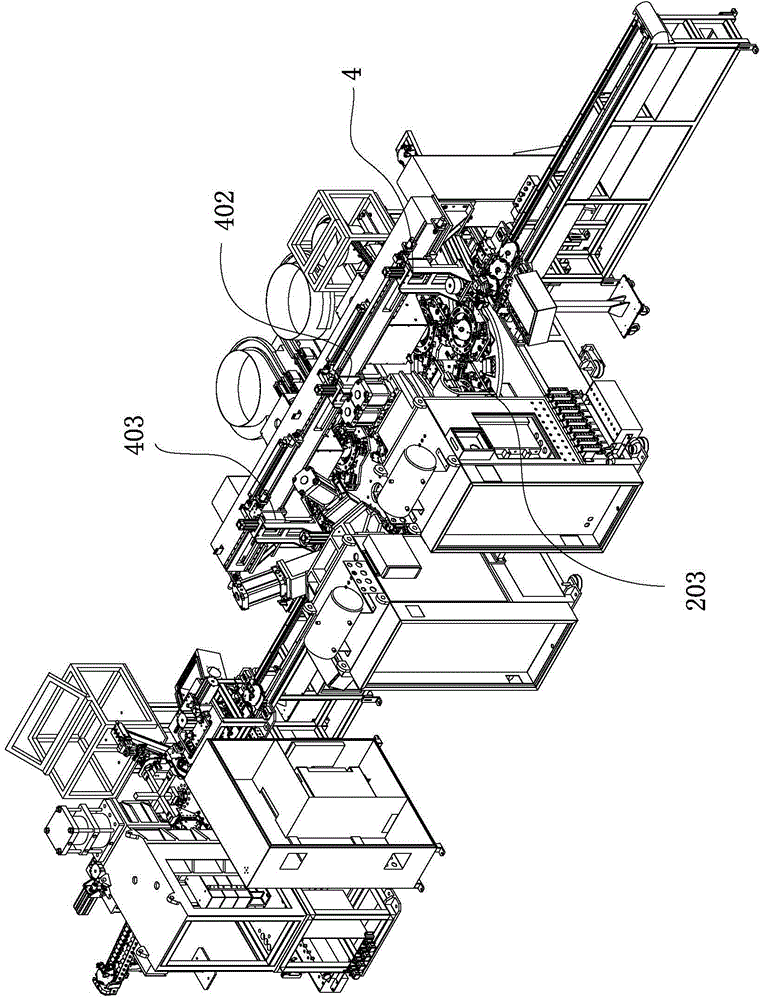

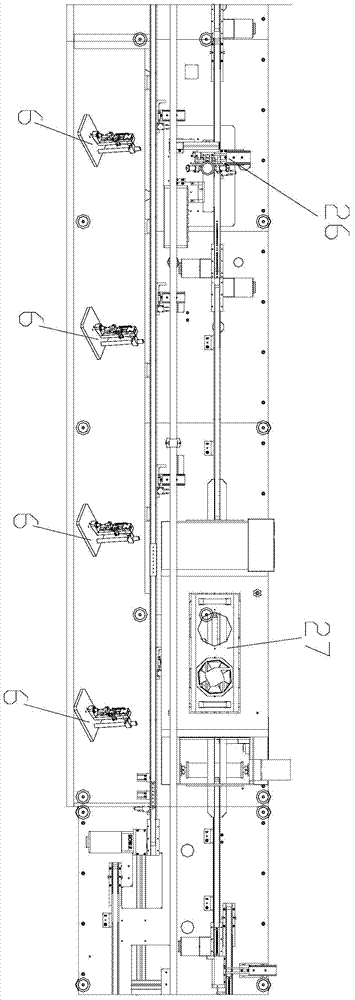

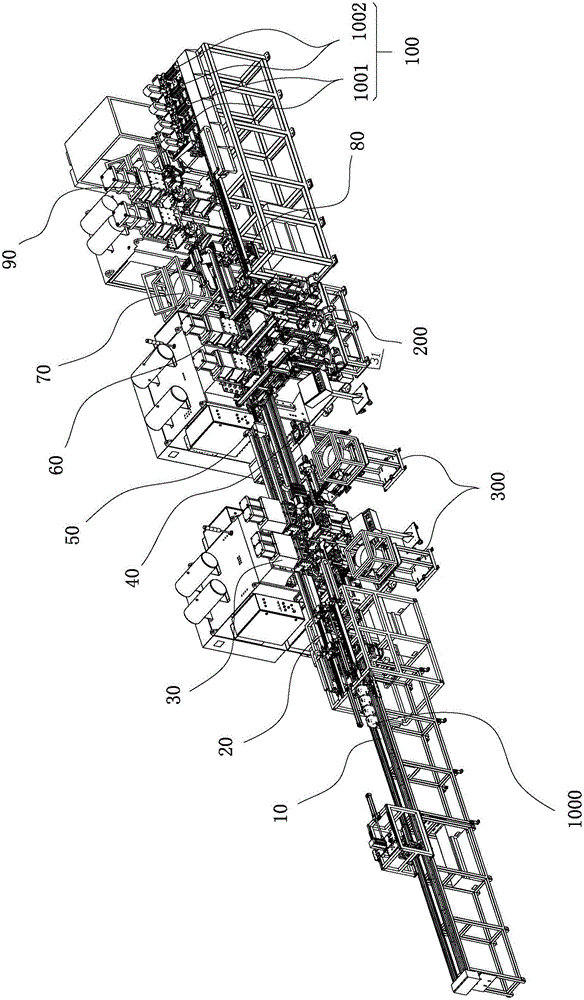

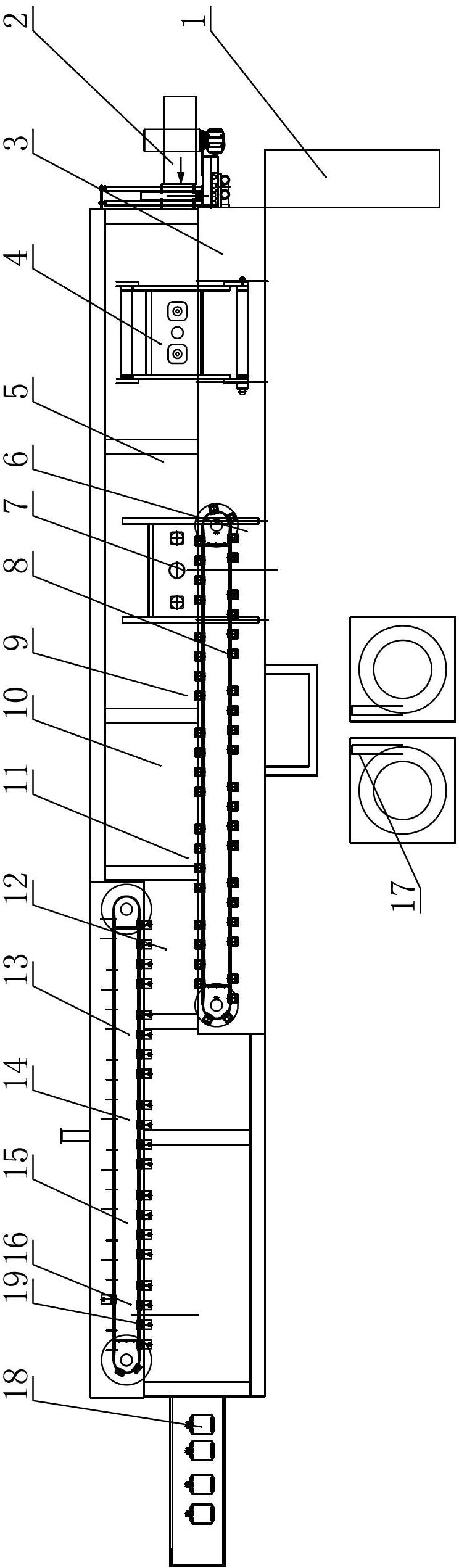

Power type lithium battery full-automatic production line and production technology thereof

ActiveCN105280957AStorableAchieve readFinal product manufactureElectrolyte accumulators manufactureProduction lineControl system

The invention relates to a power type lithium battery full-automatic production line and a production technology thereof. The power type lithium battery full-automatic production line mainly consists of a pole piece manufacturing unit, a battery assembling unit, a battery liquid injecting unit and a factory processing unit; each unit key equipment electrical control system is composed of a PLC, an industrial personal computer, a hydraulic and pneumatic component; the PLC controls each mechanism of the equipment to act in a coordinated manner; and the industrial personal computer collects data to realize the function that the data of the whole line can be stored, read and the like. The main effects lie in that mutual matching of production efficiency of each unit is realized through key debugging for production parameters, a conveyor is adopted in an intermediate link, and full automation of production process is finally realized; the production line is compatible with multi-standard battery production requirements, the production when the product is remodeled can be realized just by adjusting the equipment parameters and replacing partial work fixtures, and order form-based production requirement of the product is met; key equipment and technology on the line are independently researched and developed, the operation is reliable and stable, and the production line has higher cost performance.

Owner:东营黄蓝知识产权运营管理有限公司

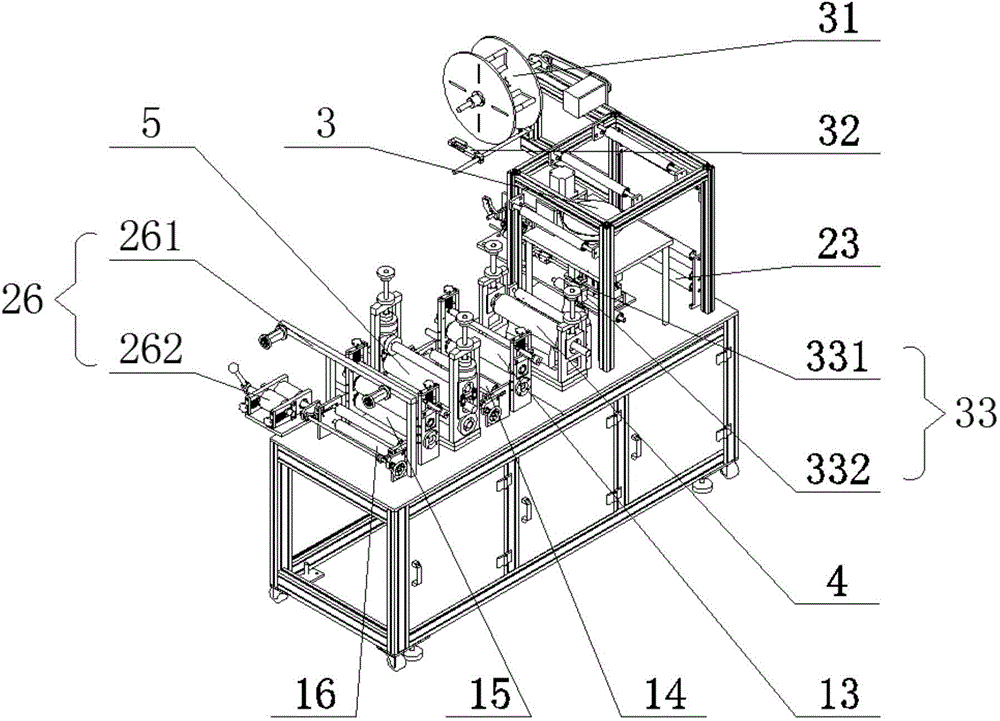

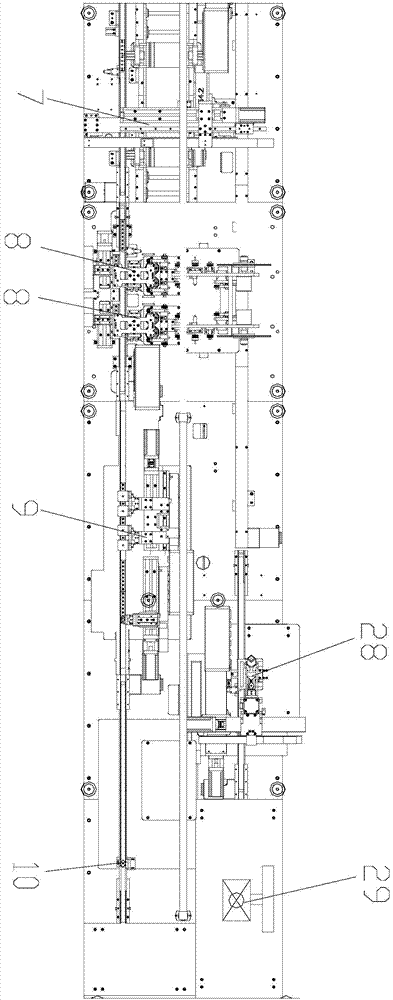

Full-automatic machine for producing foldable masks

ActiveCN104872866AImprove aestheticsRealize automated productionProtective garmentProduction lineRespirator

The invention relates to the technical field of mask machining equipment, in particular to a full-automatic machine for producing foldable masks. The full-automatic machine comprises a frame body. A mask body feeding device, a nose bridge part gripping and welding device, a roller welding device, a roller cutting device, an ear strap welding device, an ear strap cutting device, a folding device, a crease welding device, and a finished product cutting device, wherein the frame body is provided with a control device, and the control device is connected with the mask body feeding device, the nose bridge part gripping and welding device, the roller welding device, the roller cutting device, the ear strap welding device, the ear strap cutting device, the folding device, the crease welding device, and the finished product cutting device. Compared with the prior art, the full-automatic machine has the advantages that the full-automatic machine is a full-automatic production line for producing the foldable masks, batch production is achieved, manpower cost is saved, work efficiency is increased, and product quality is increased.

Owner:东莞快裕达自动化设备有限公司

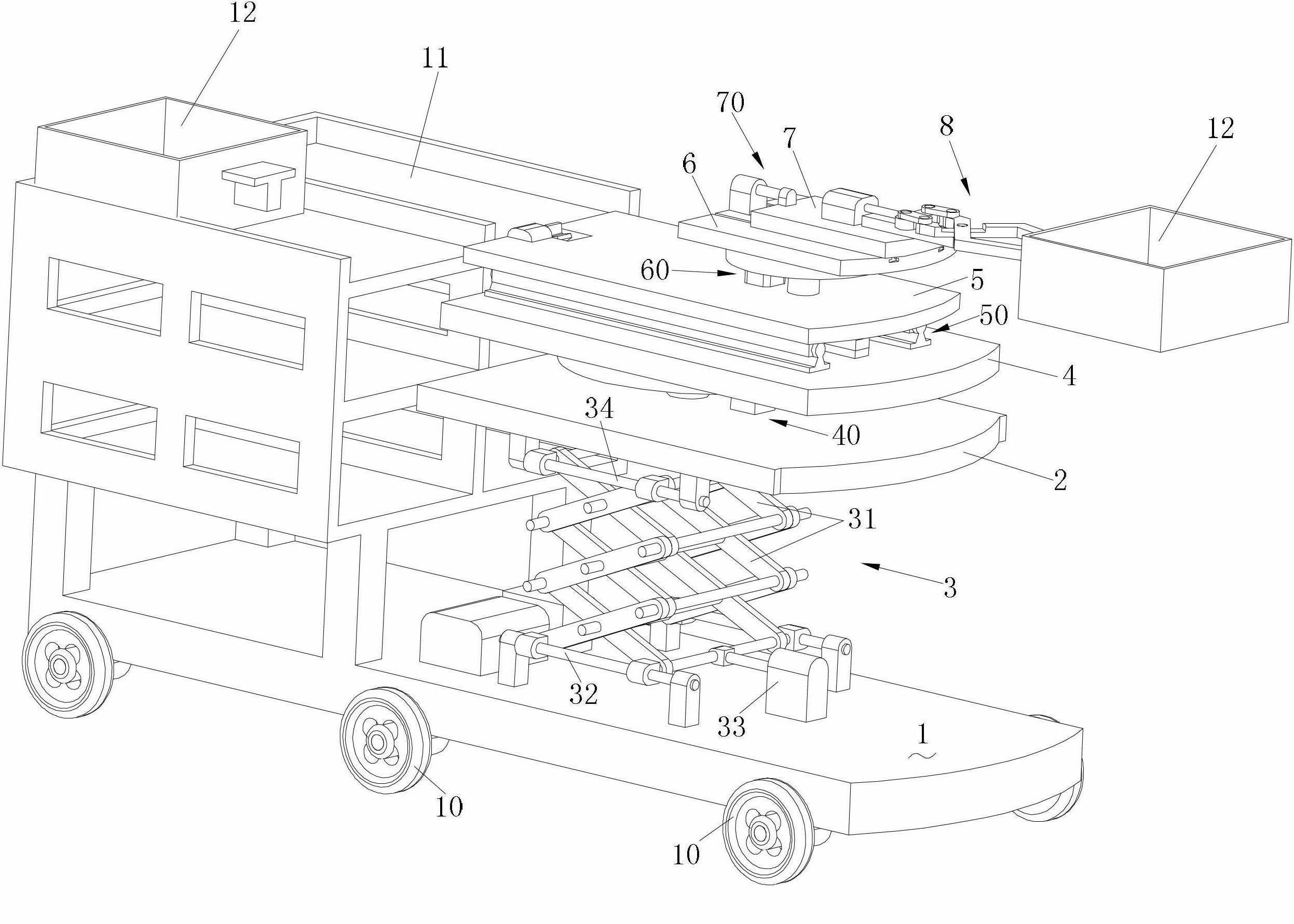

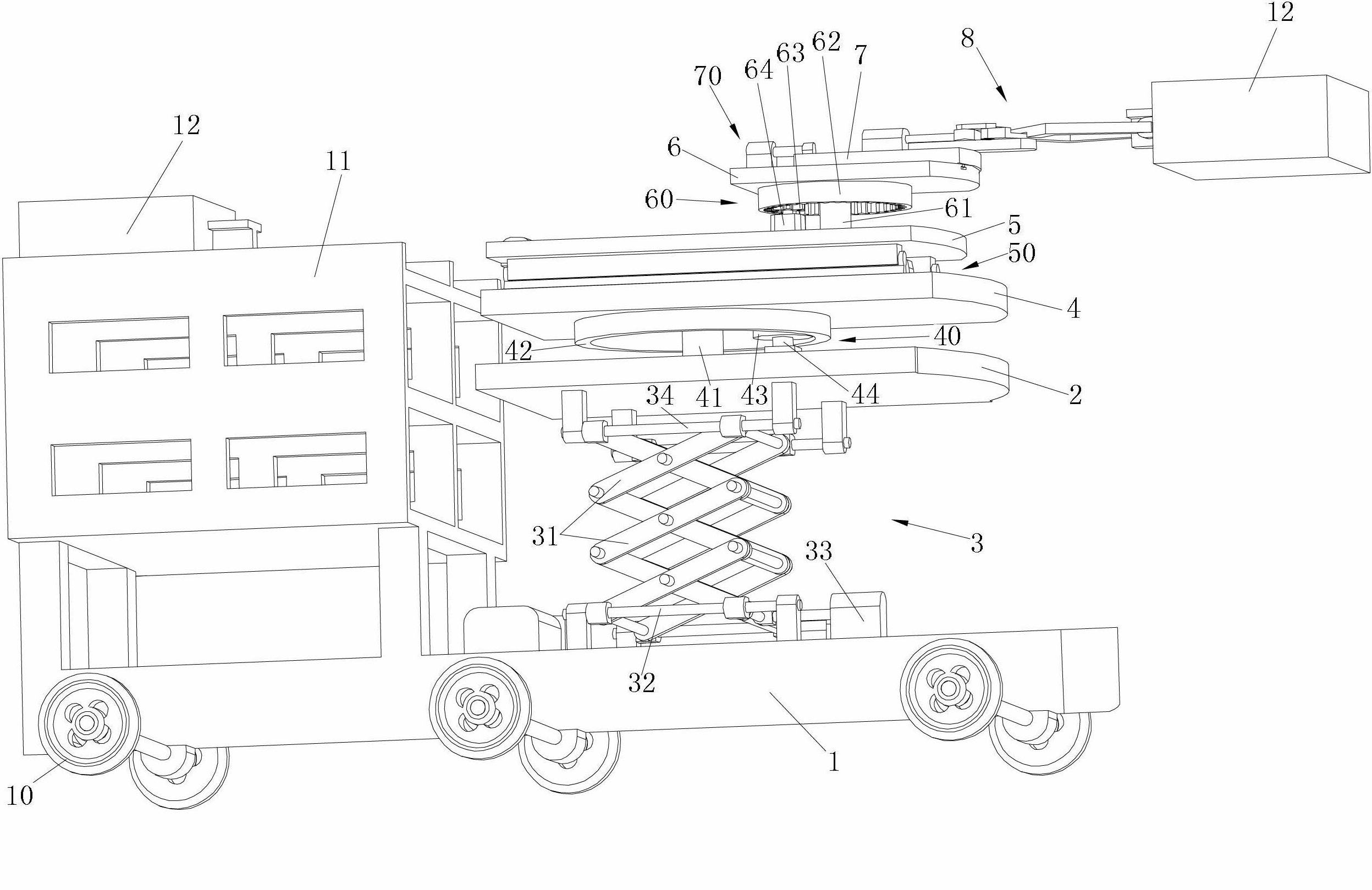

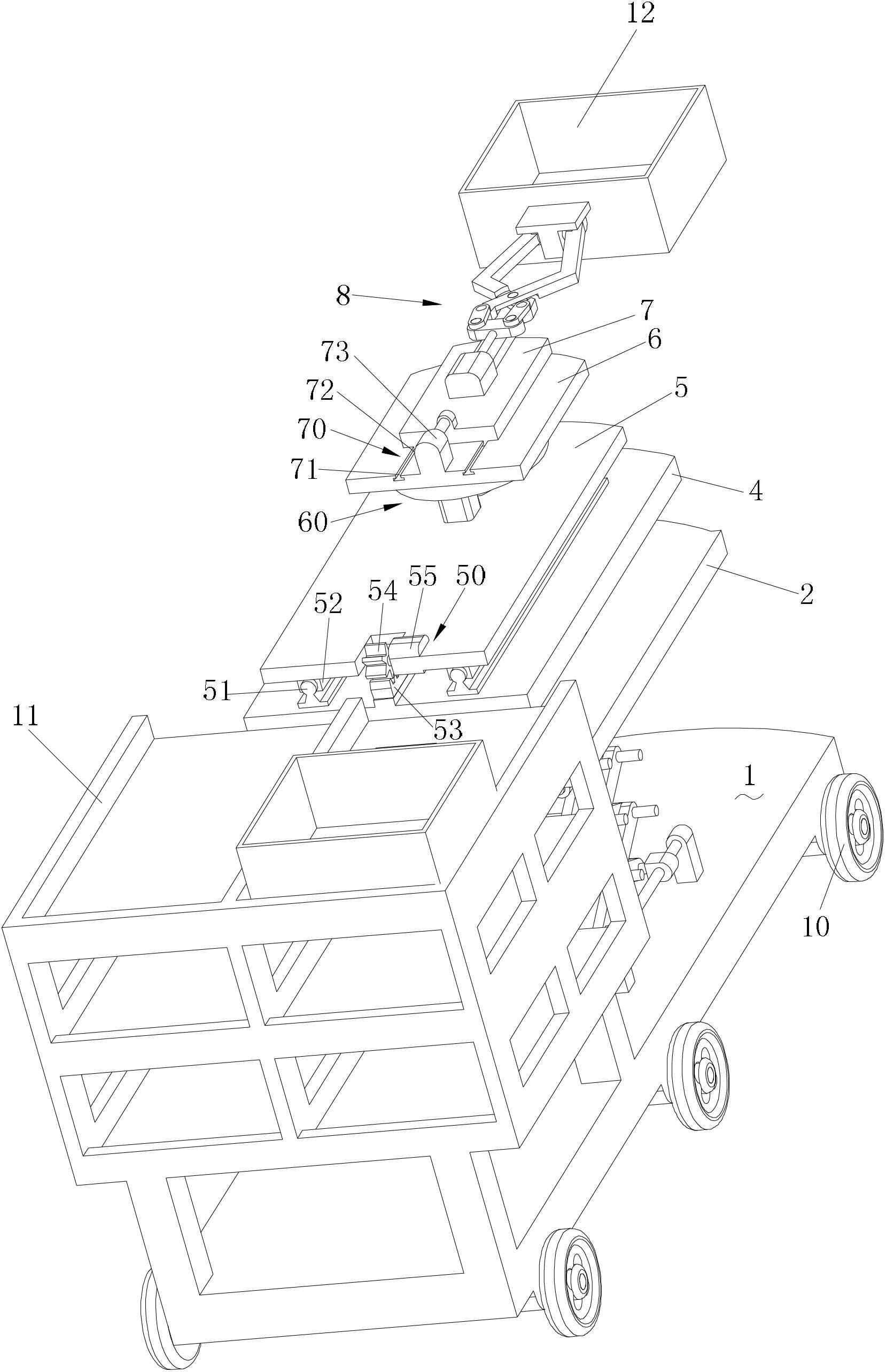

Rail type intelligent machine transporting truck

InactiveCN102658542AReduce physical laborIncrease the itineraryStorage devicesManipulatorVehicle frameTruck

The invention discloses a rail type intelligent machine transporting truck, comprising a frame, idler wheels located on the frame, a storage box located at the top of the frame, a supporting board, a lifting mechanism connected between the supporting board and the frame, a primary rotation board, a primary rotation mechanism connected between the primary rotation board and the supporting board, a primary translation board, a primary translation mechanism connected between the primary translation board and the primary rotation board, a secondary rotation board, a secondary rotation mechanism connected between the secondary rotation board and the primary translation board, a secondary translation board, a secondary translation mechanism connected between the secondary translation board and the secondary rotation board, and an executing mechanism connected on the secondary translation board, wherein a storage box is placed in the storage box. The rail type intelligent machine transporting truck provided by the invention replaces the conventional manual goods carrying manner, so that the human labor is reduced, and the production efficiency is improved. With the adoption of the two levels of rotation mechanisms and the two levels of translation mechanisms, the rail type intelligent machine transporting truck can expand the journey and increase the freedom degree. The rail type intelligent machine transporting truck can check more goods due to the vehicular storage box, so that the working efficiency is improved.

Owner:SHANGHAI DIANJI UNIV

Production equipment of refrigeration compressor casing

ActiveCN104353943ARealize automated productionQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesRefrigeration compressorTechnical standard

The invention discloses production equipment of a refrigeration compressor casing. The production equipment comprises a false material recovery mechanism, a first calibration mechanism, a pin feeding device, a first material fetching device, a machine leg automatic feeding mechanism, a machine leg clamping device, a first casing fetching and placing mechanism, a glass terminal fetching mechanism, a first rotary table, a pin welding machine, a second rotary table, a machine leg welding machine, a third rotary table, a conveying belt, a glass terminal electric welding machine and a material conveying frame. The production equipment has the advantage that the false material recovery mechanism, the first calibration mechanism, the pin feeding device, the first material fetching device, the machine leg automatic feeding mechanism, the machine leg clamping device, the first casing fetching and placing mechanism, the glass terminal fetching mechanism, the first rotary table, the pin welding machine, the second rotary table, the machine leg welding machine and the conveying frame are welded into the automatic production equipment, so the uniformity of technical standards of one product in the production process is realized, the automation degree is high, the production efficiency is greatly improved, and the production cost is reduced.

Owner:东莞市鹏煜威科技有限公司

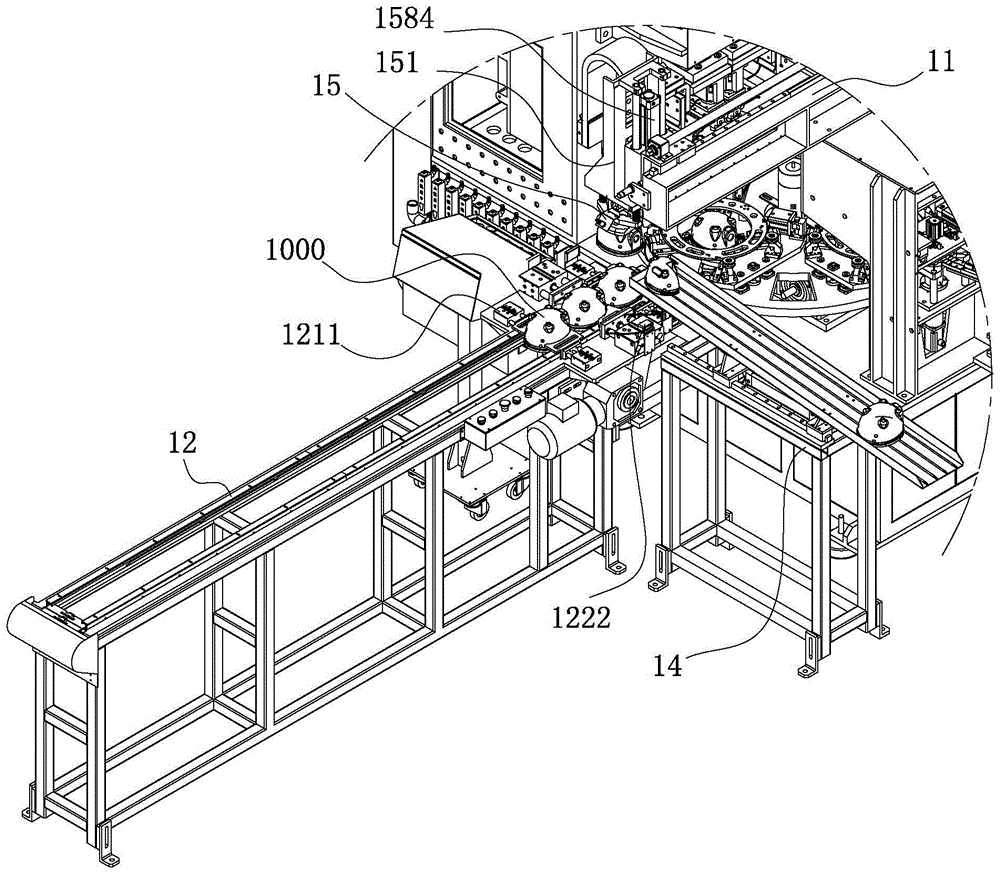

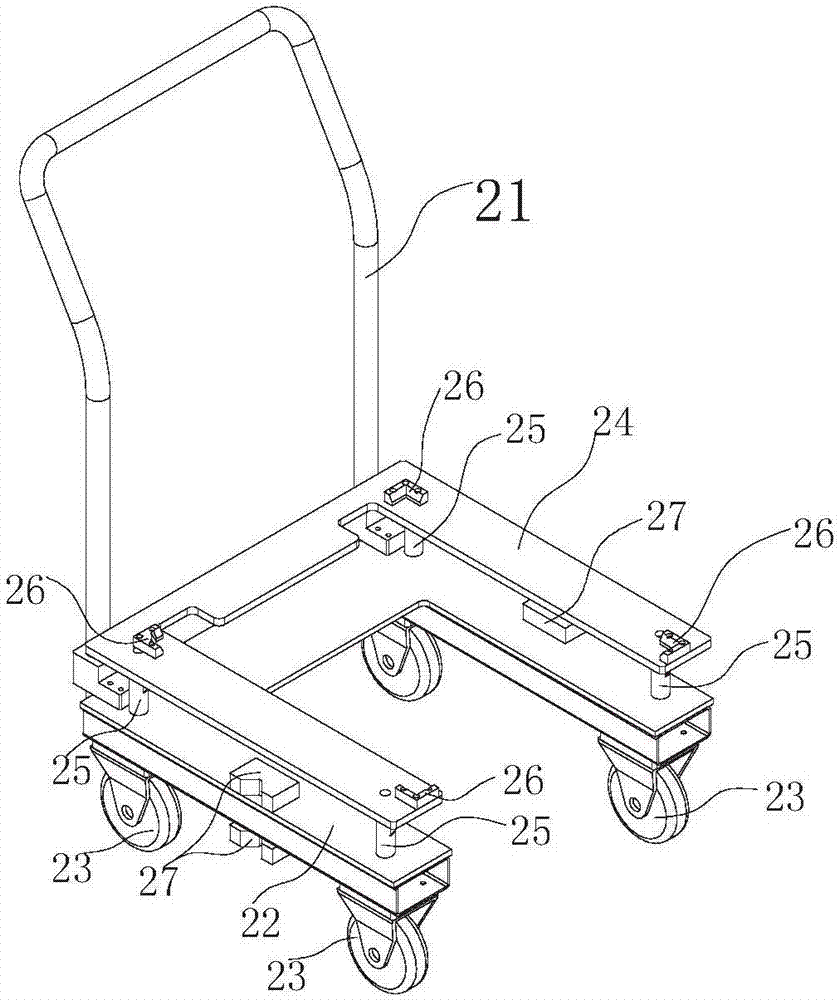

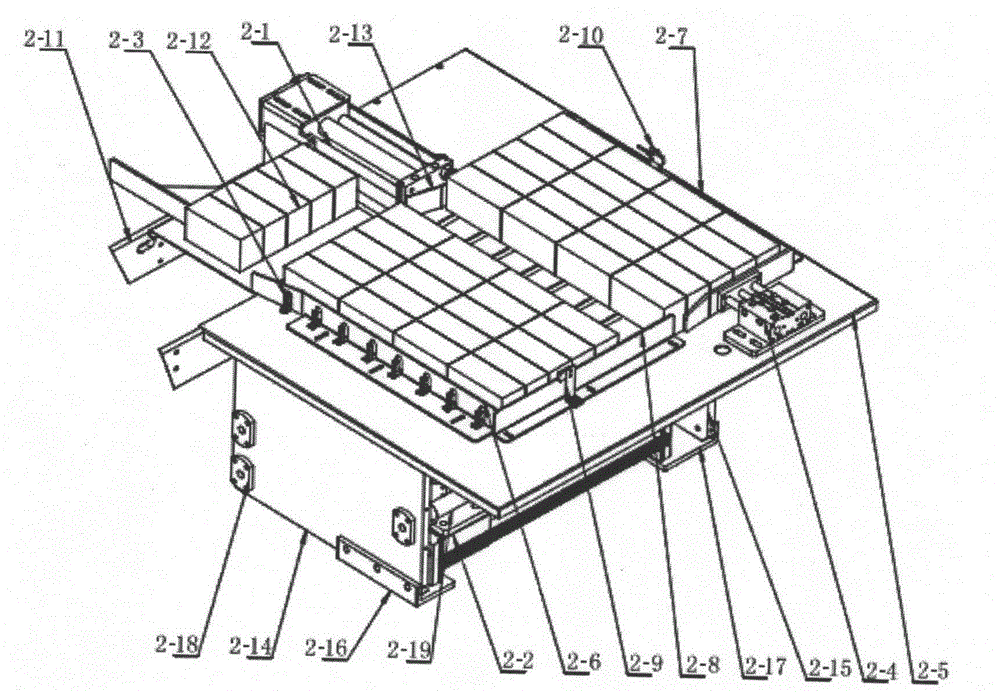

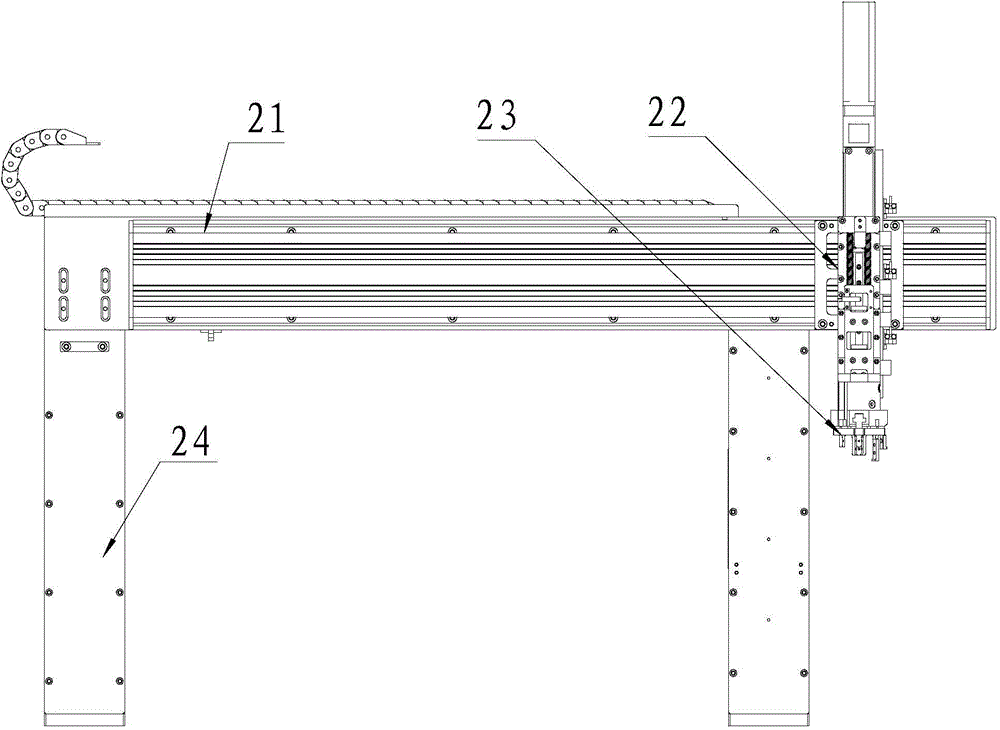

Fully-automatic tray loader for cylindrical lithium ion batteries

PendingCN107381082AImprove yield rateReduce manual handlingConveyorsIndividual articlesLithium electrodeStructural engineering

The invention provides a fully-automatic tray loader for cylindrical lithium ion batteries. The fully-automatic tray loader comprises a rack, a loading trolley, an empty tray lifting mechanism, an empty ray transfer mechanism, a tray positioning mechanism, a battery cell rotary-grabbing mechanism, a battery cell reshaping mechanism, an automatic grabbing and placing mechanism, a full-load tray transfer mechanism, a full-load tray lifting mechanism and an unloading trolley, wherein the empty tray transfer mechanism and the full-load tray transfer mechanism share a double-tray transverse moving part for transferring an empty battery cell tray at the lower end of the empty tray transfer mechanism to the tray positioning mechanism and transferring a battery cell tray which supports and is filled up with circular battery cells to the lower end of the full-load tray transfer mechanism. Through the mechanisms, the empty battery cell trays are transmitted to the tray positioning mechanism for being positioned, are automatically loaded with the reshaping battery cells, are automatically transmitted, superposed and stacked onto the unloading trolley, and are in fully-automatic butt joint with an automatic winding machine for manufacturing circular batteries or battery cells, so that multiple functions are integrated, manual tray loading is completely replaced, production efficiency is improved, and labor power is saved.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

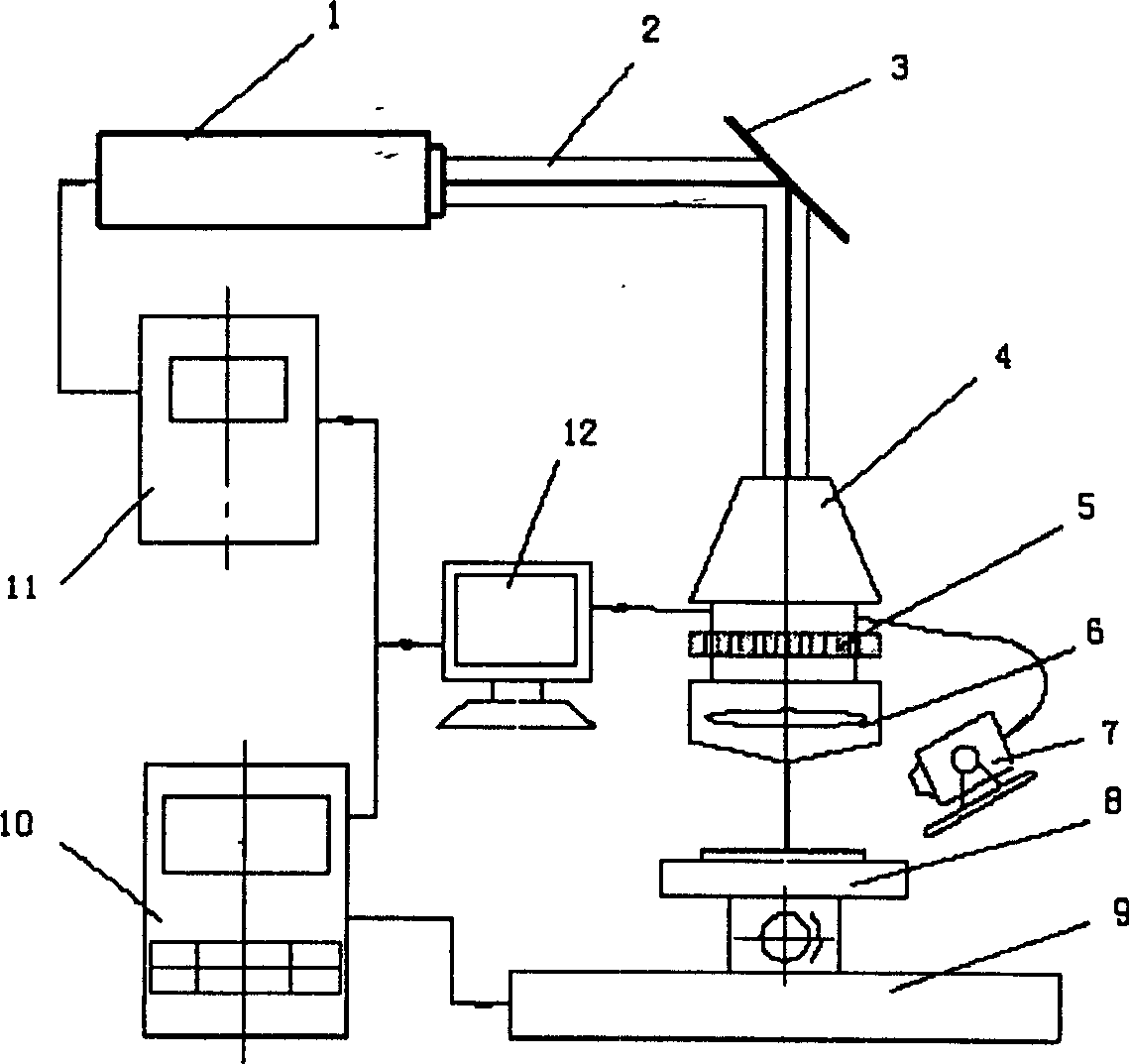

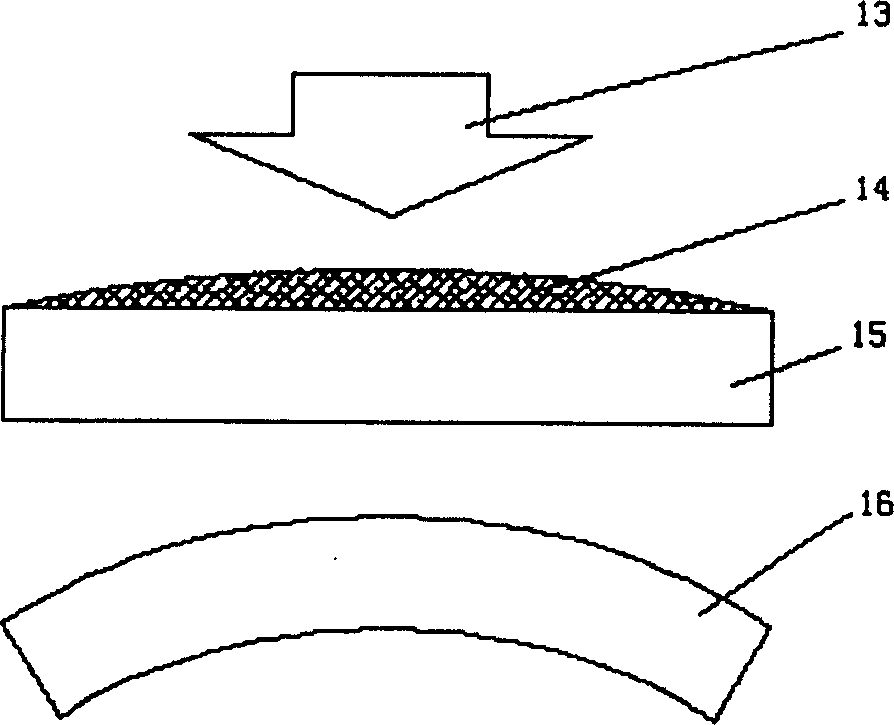

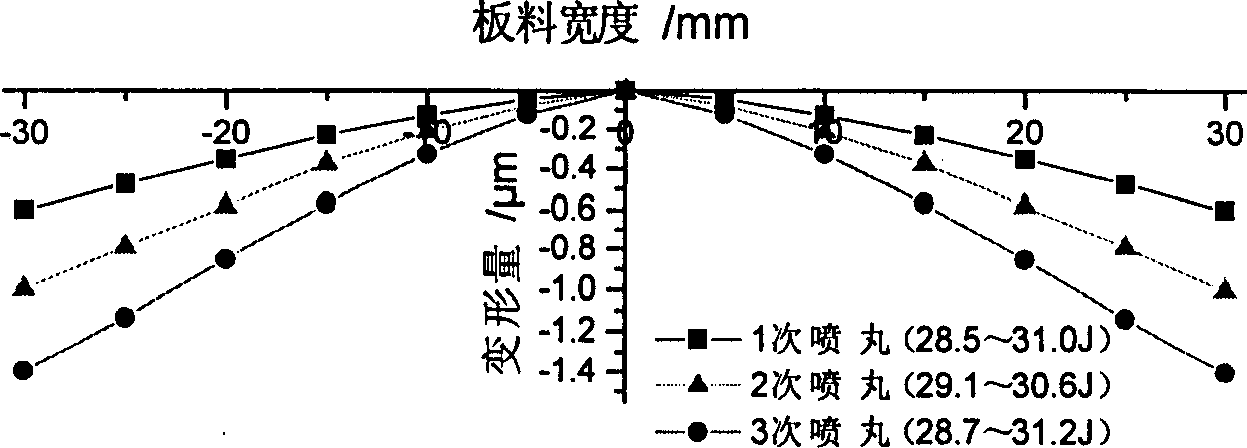

Method and equipment for forming plate of moderate thickness through laser shot blast

InactiveCN1695873AReduce surface roughness valueGood finishComputer controlNumerical controlShock waveEngineering

A laser blasting apparatus for shaping on the surface of medium-thick plate is composed of laser device, optical guide system, laser blasting head, fixture system for workpiece, and control system. Its shaping process includes computer simulation of the stress field distribution according to the curved surface shape to be processed, optimizing it to obtain the distribution of shock wave pressure and blasting tracing on the surface of plate, automatically choosing the parameters of laser pulse optical beam converte and optical mask, writing control program, generating strong short laser pulses, covering them to several pulse clusters, passing through optical mask, acting on energy converting body on the surface of workpiece to obtain shock waves, acting on the surface of workpiece for shaping.

Owner:JIANGSU UNIV

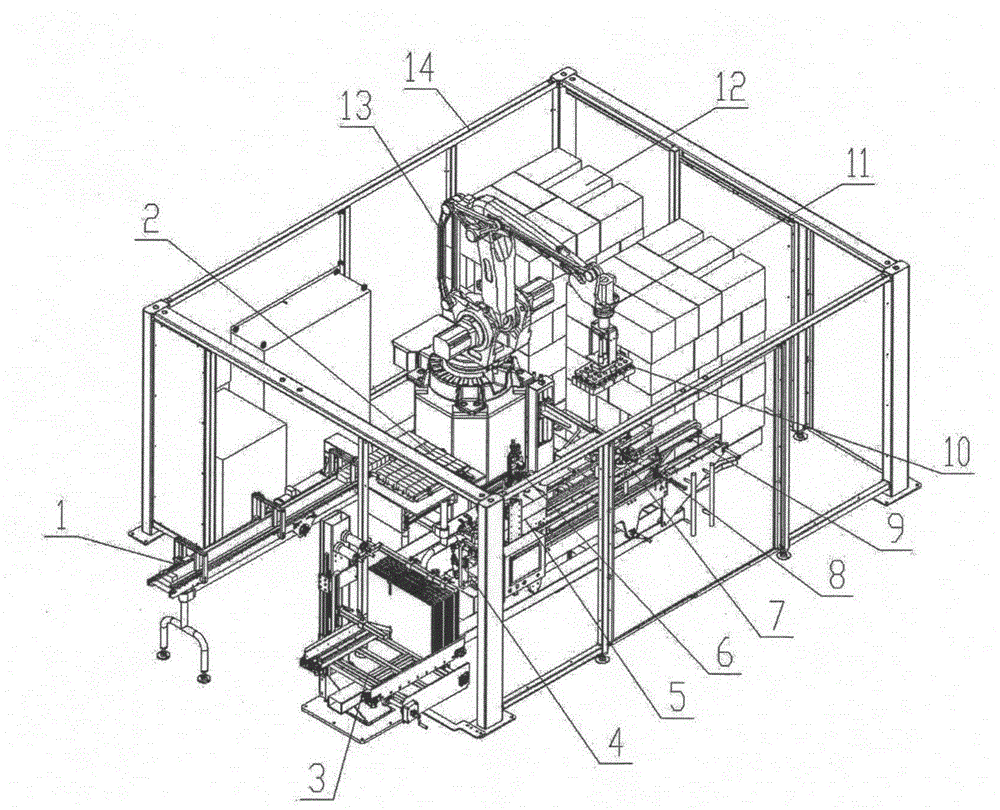

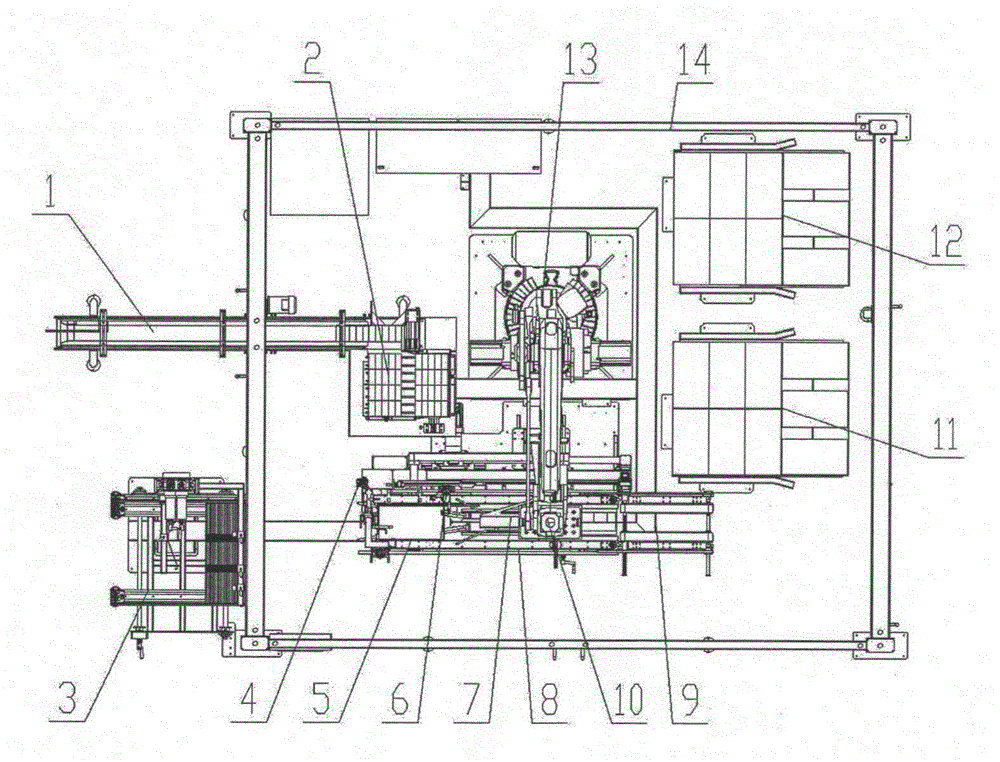

Carton filling and stacking all-in-one machine

ActiveCN104859894AReduce the difficulty of operationSmall footprintPackaging machinesCartonEngineering

The invention discloses a carton filling and stacking all-in-one machine. The carton filling and stacking all-in-one machine is characterized by comprising a carton conveying line and a storage device, wherein the head portion of the carton conveying line is connected with one side of a carton alignment device; the storage device is connected with one side of a carton filling station through an unpacking forming mechanism; the other side of the carton filling station is connected with one side of a carton strutting device; the other side of the carton alignment device is provided with a robot body; the robot body is provided with a carton filling and stacking grasp structure; a carton clamping and conveying device is arranged on the other side of the carton strutting device and connected with a carton sealing device; a carton labeling station is arranged on one side of the carton sealing device; a first tray and a second tray are arranged on one side of the carton labeling station. The functions of existing single machines are completely integrated on one machine, stations are linked tightly, the structure is compact, and operation is easy. The carton filling and stacking all-in-one machine is suitable for various specifications, stable in performance, high in efficiency and capable of greatly reducing labor cost.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Method for manufacturing soft magnet silicon-aluminium magnetic powder core

InactiveCN1622236ADoes not affect electromagnetic performanceReduce curing stressInorganic material magnetismInductances/transformers/magnets manufactureAl powderBreaking strength

The production process of soft magnetic Fe-Si-Al powder core includes the steps of compounding magnetic powder in different sizes, surface treatment, mixing magnetic powder, insulating agent, adhesive and demolding agent, molding, curing, magnetic heat treatment, soaking and surface coating. The present invention has the advantages of: breaking strength after curing in radial direction of 7-12 kg, less surface stripping, small demolding force, final breaking strength in radial direction of 17-24 kg, no influence of the insulating lacquer on electromagnetic performance and capability of realizing automatic production.

Owner:王锋 +1

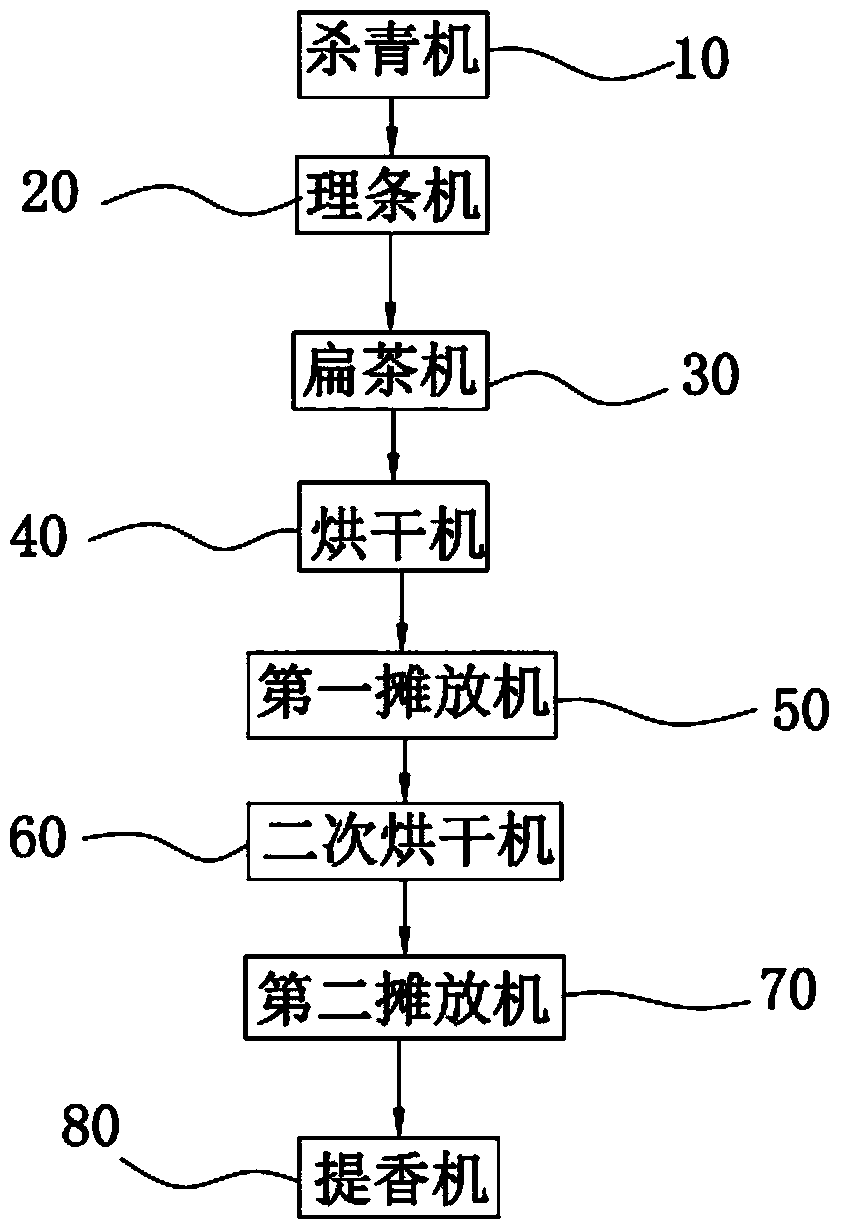

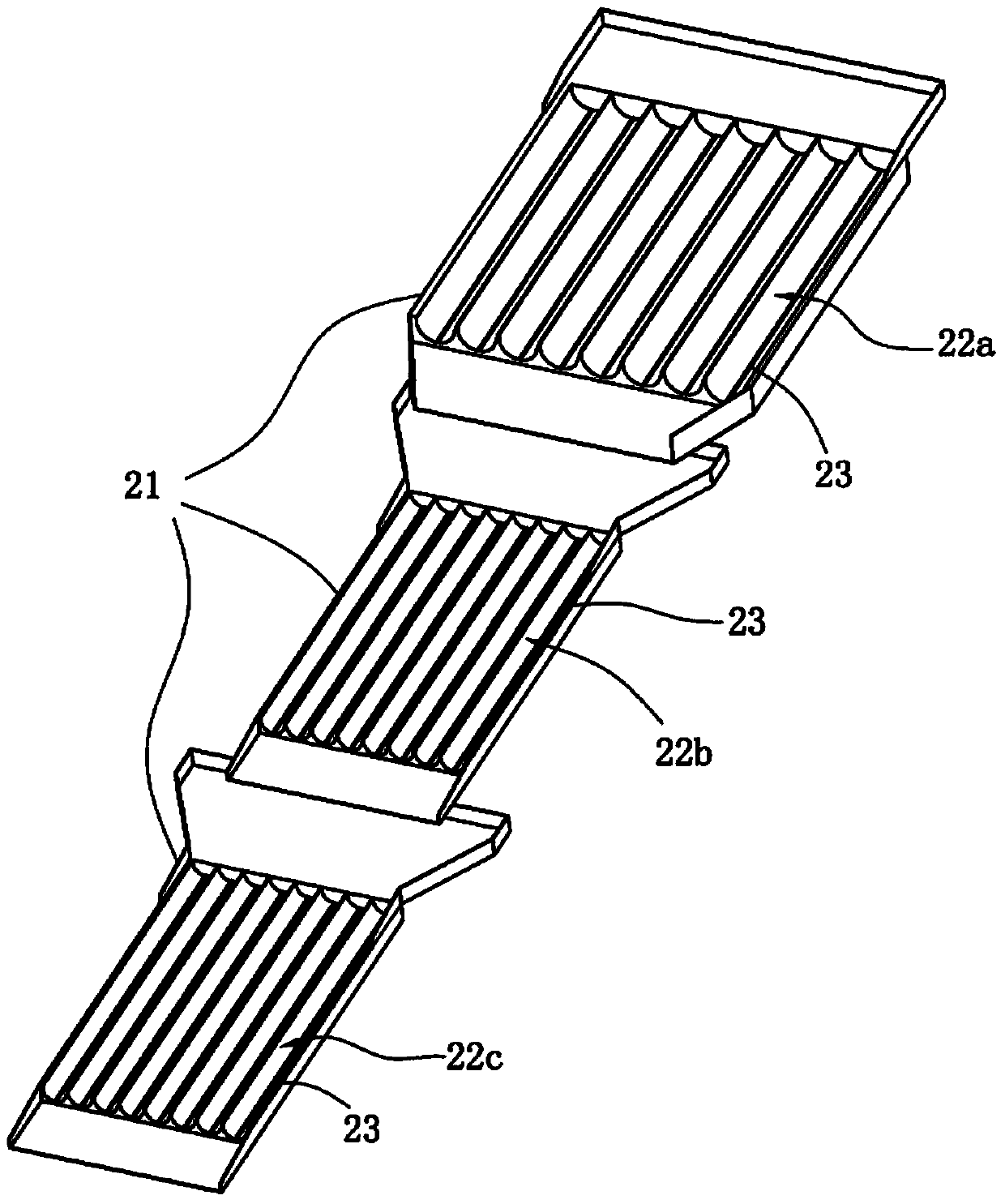

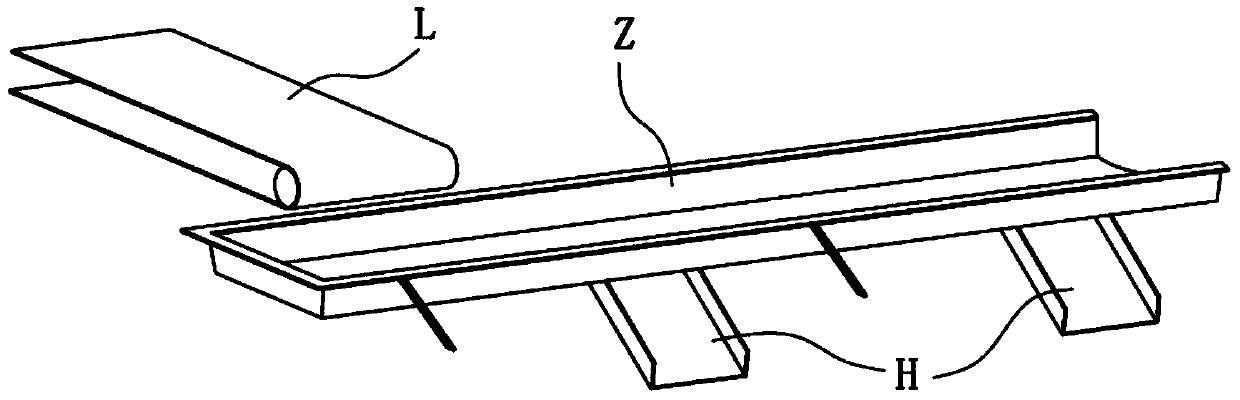

Automatic production line for Houdou Lanxiang

InactiveCN104255959ARealize automated productionIncrease productivityPre-extraction tea treatmentProduction lineEnzyme

The invention belongs to the tea production processing field, and specifically relates to an automatic production line for Houdou Lanxiang. The production line comprises an enzyme-deactivating machine, a tea-processing machine, a tea flattening machine, a drying machine, a first spreading machine, a secondary drying machine, a second spreading machine and a fragrance-enhancing machine which are connected in sequence through a conveying mechanism. The automatic production line integrates and improves a traditional tea-making technology, realizes full-automatic production of the tea, increases production efficiency of the tea and guarantees the quality of the tea simultaneously.

Owner:黄山市猴坑茶业有限公司

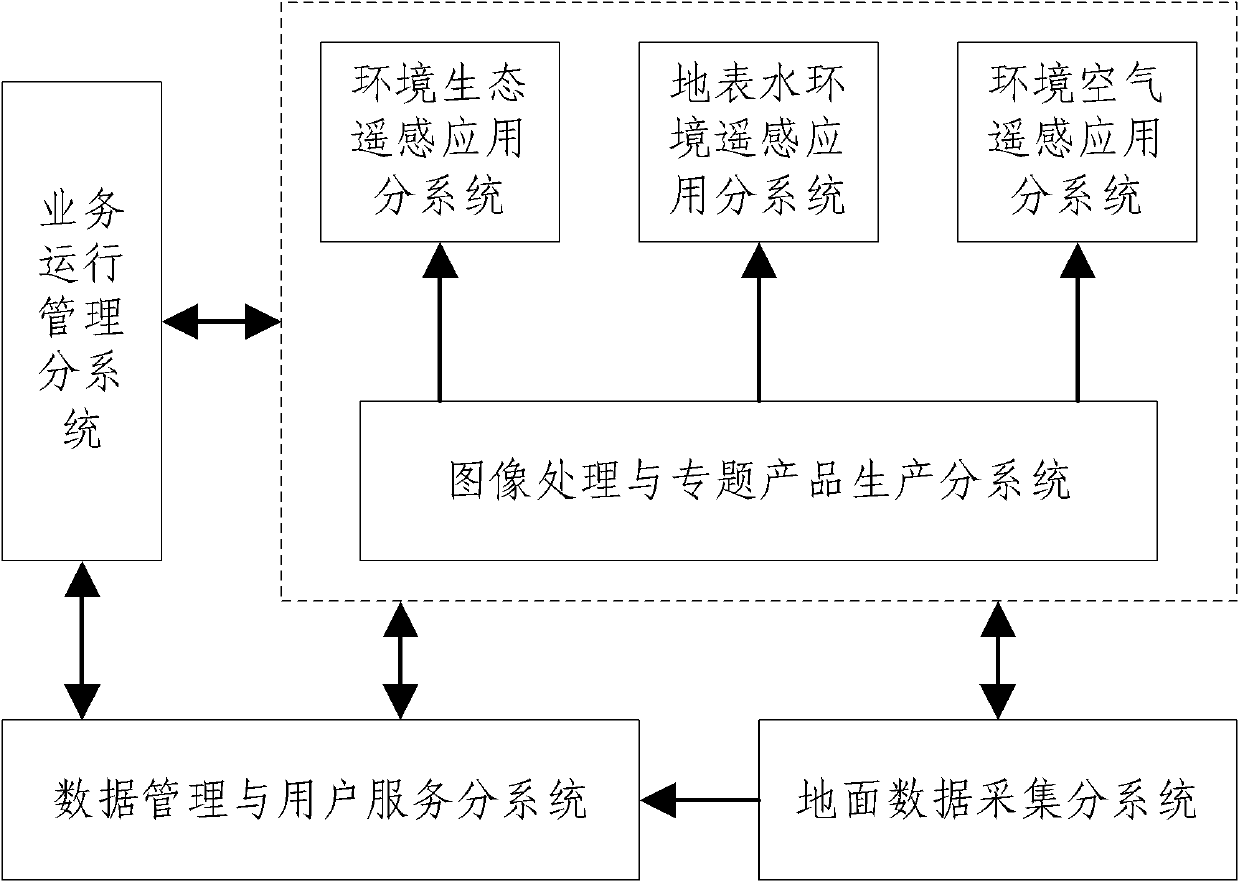

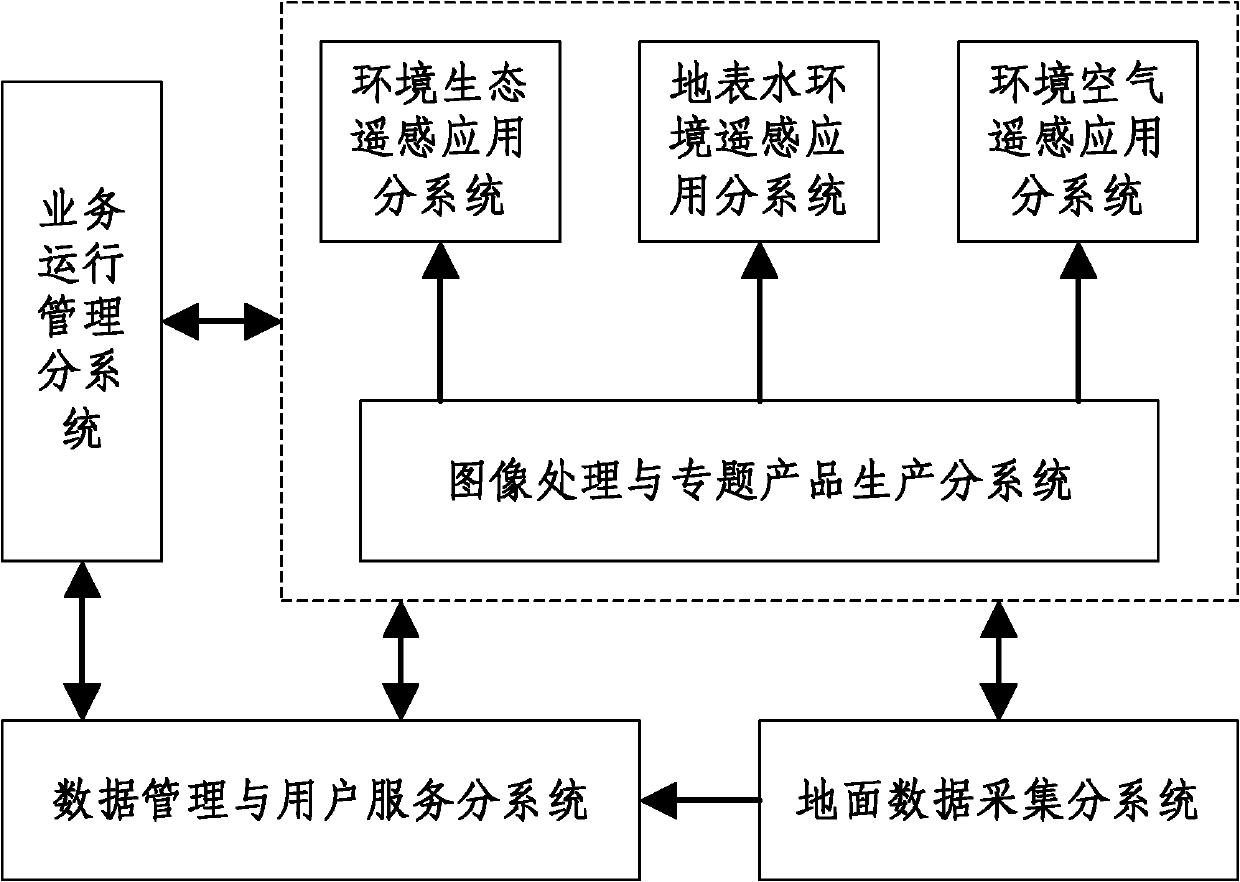

Environment remote sensing application system

InactiveCN102169557AImprove effective useRealize automated productionInstrumentsData acquisitionRemote sensing application

The invention discloses an environment remote sensing application system, which comprises a business operation and management subsystem, an image processing and special product production subsystem, a data management and subscriber service subsystem, an environment ecology remote sensing application subsystem, a surface water environment remote sensing application subsystem, an environment air remote sensing application subsystem, and a ground data acquisition subsystem. In the invention, environment spatial data resources for supporting environment satellite remote sensing monitoring businesses are built, and the automatic processing of environment satellite data and automatic production of special data products are realized, the operation of environment remote sensing monitoring and a task-driven business model integrating business requirement, task schedule formulation and task execution are achieved, and the processing and application capability of environment satellite data is formed, therefore, the problems of lag construction and poor operation capability of a satellite application system are solved, the effective utilization of a satellite is comprehensively promoted, and the operation of environment remote sensing monitoring businesses is supported.

Owner:王桥

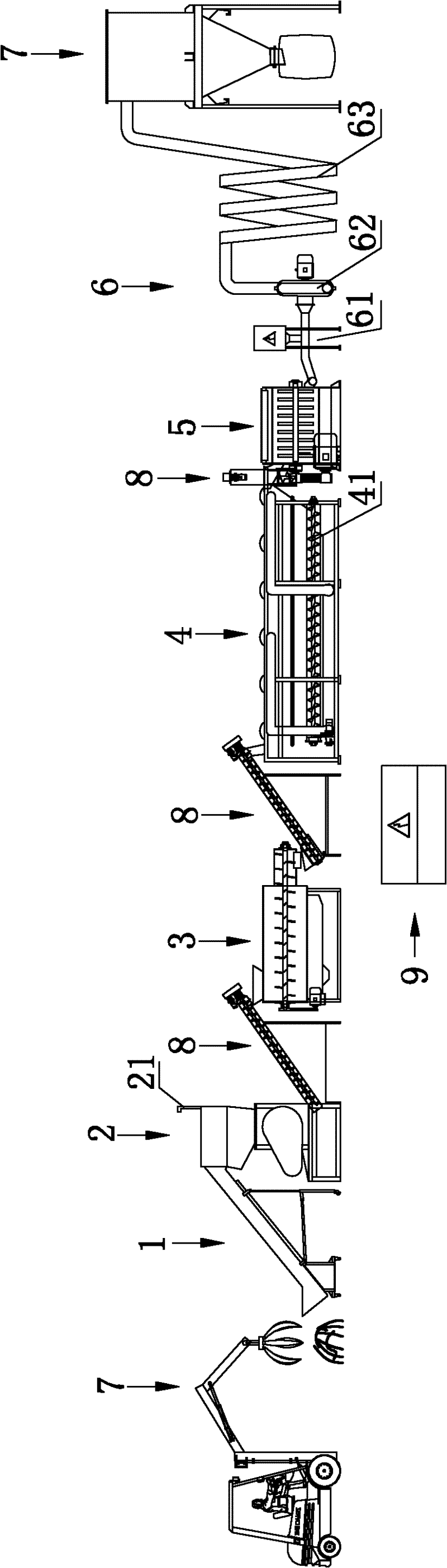

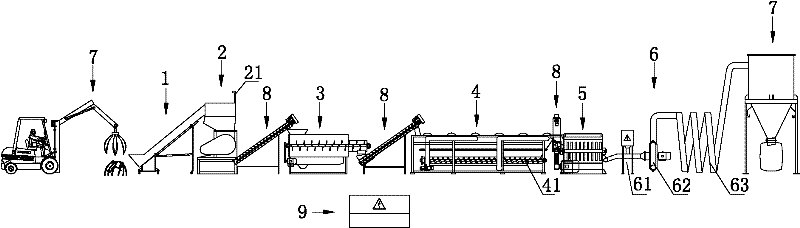

Film crushing washing line

ActiveCN102179883ARelieve pressureImprove efficiencyPlastic recyclingFlat articlesEngineeringWhirlwind

A film crushing washing line comprises, in a working procedure order, a conveyer belt, a crusher for crushing a film conveyed by the conveyer belt, a cleaning machine for cleaning the film and detaching the film from impurities on the film, a washing rinsing machine for thoroughly separating the film from the impurities on the film, a dewaterer for dewatering the cleaned film, a drying system forfurther drying the dewatered film, and a whirlwind storage hopper for bagging. The drying system comprises a heater, a drying pipe, and a blower disposed between the heater and the drying pipe for allowing the film to enter the pipe. With the invention, not only bad production environment for original manual washing is got rid of and human-oriented enterprise idea is embodied; but also productionautomation is realized with greatly improved yield and increased factory benefits; and the recovery and the utilization of waste and old films reduce the dependence on petroleum and the pressure to the environment.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

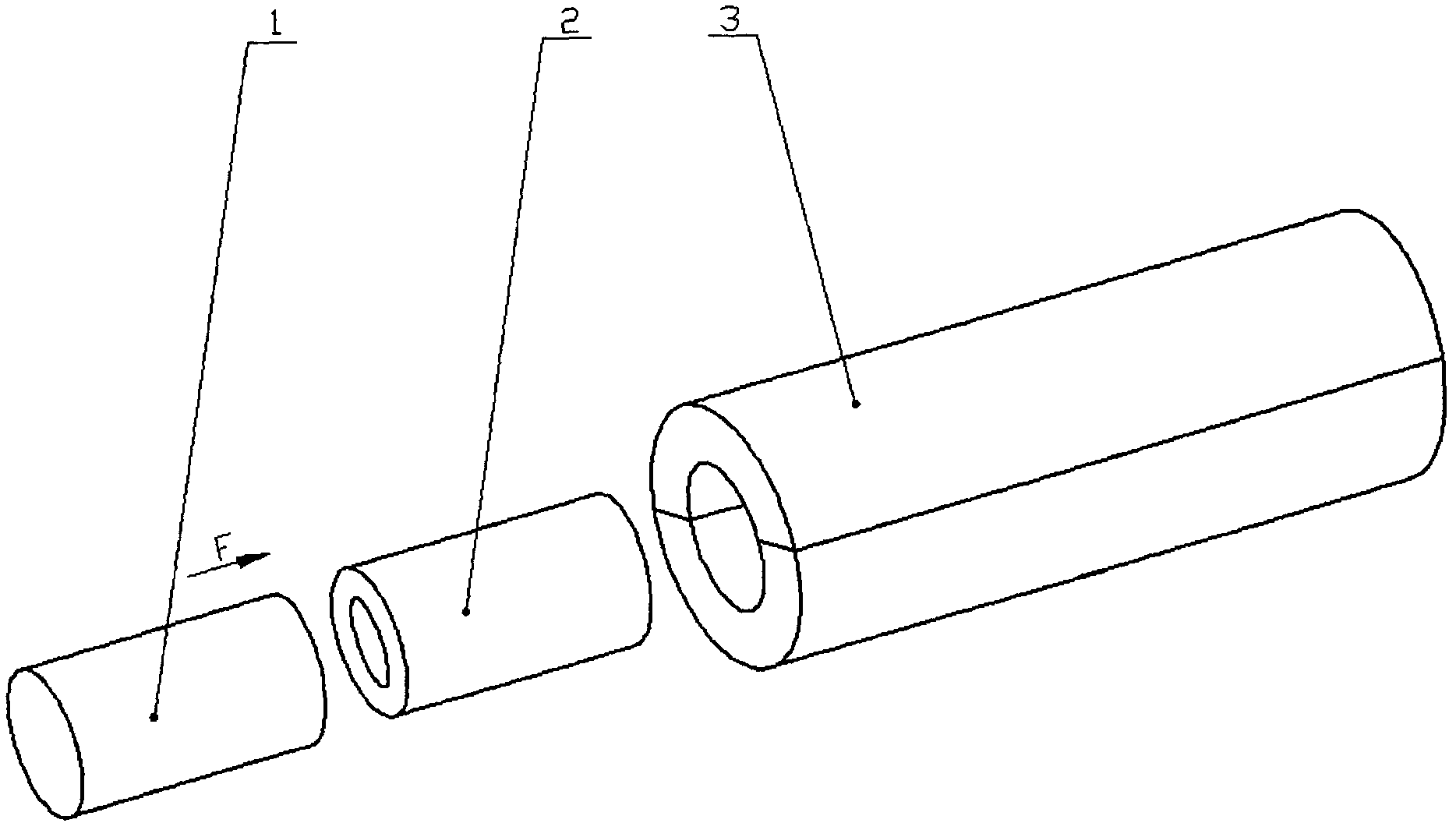

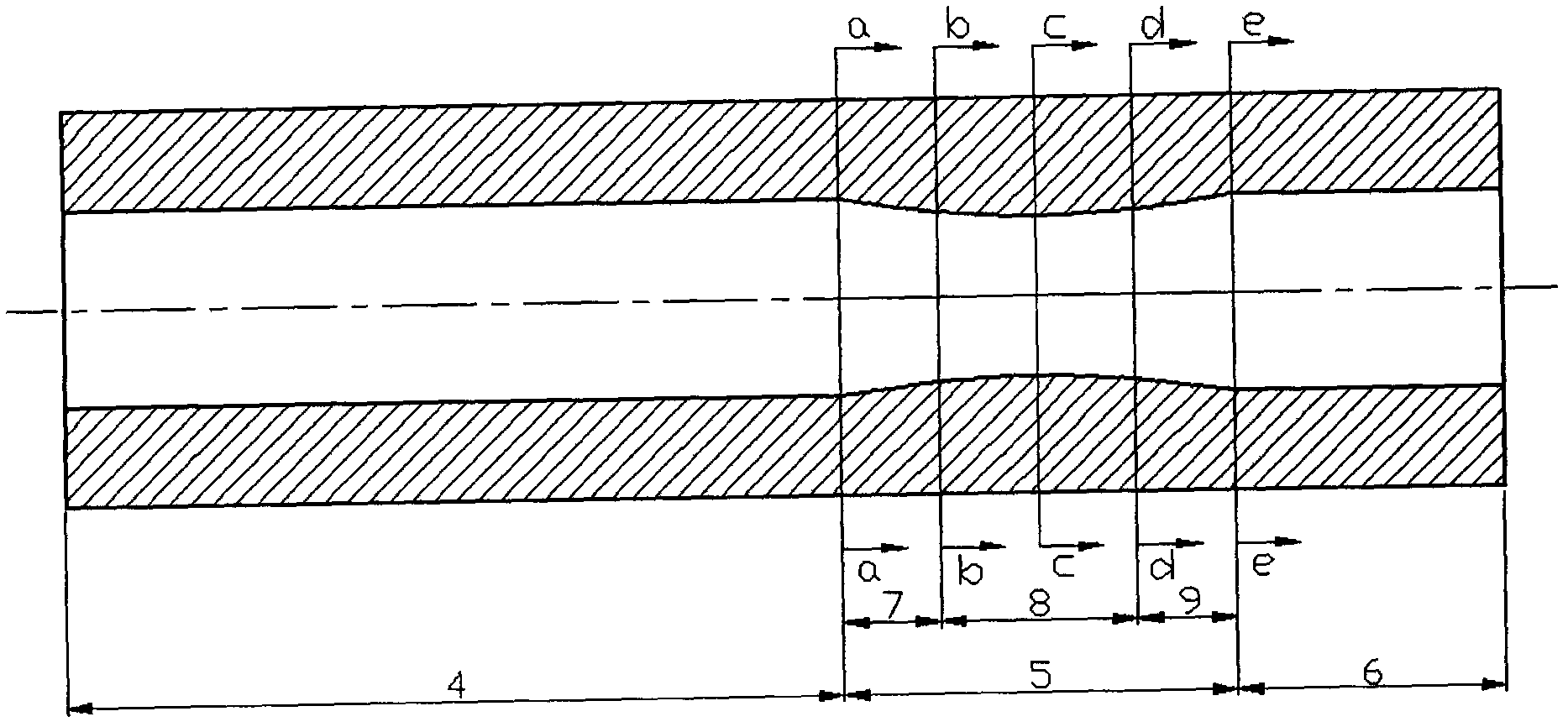

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

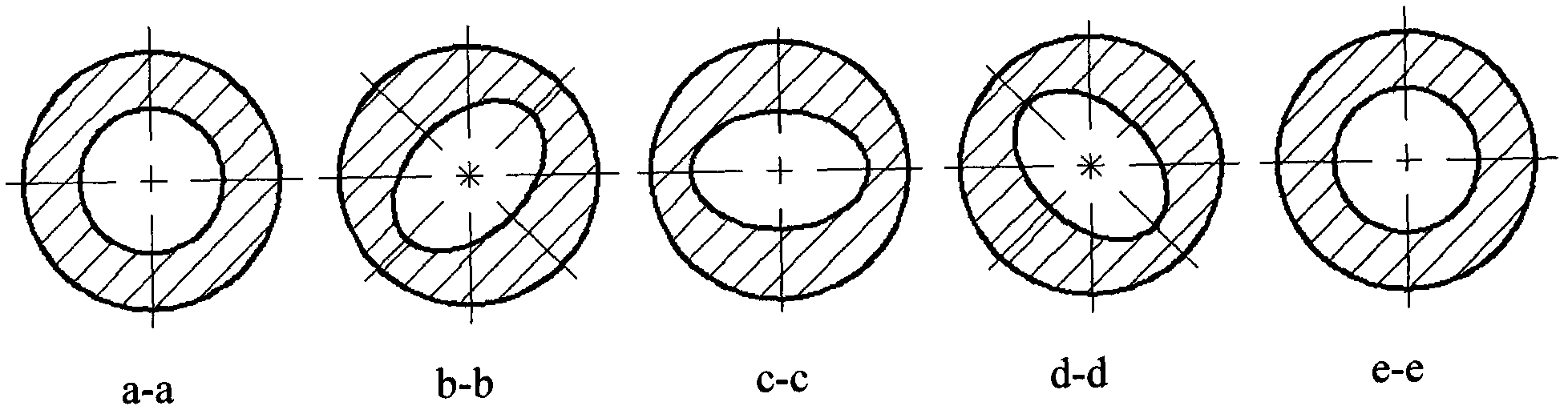

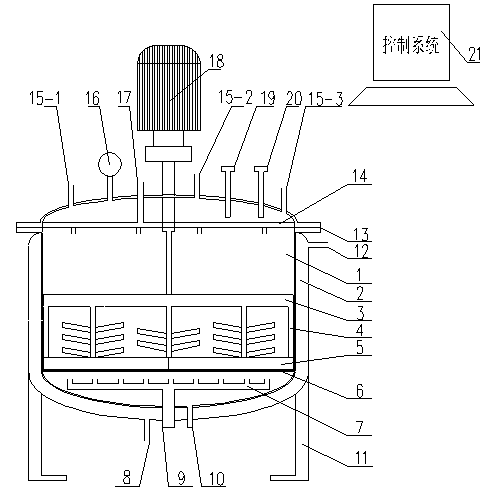

Solid state fermentation cylinder and solid state fermentation method

ActiveCN102839119AWell mixedAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationEngineering

The invention discloses a solid state fermentation cylinder and a solid state fermentation method. The solid state fermentation cylinder comprises a cylinder body and a jacket provided with an upper port and a lower port, the upper end of the cylinder body is an upper end cover, a mixing system capable of lifting is arranged on the upper end cover, and according to the mixing system, a mixing frame is driven by a driving system. The mixing frame is formed by a wall surface scraper plate, a bottom surface scraper plate and mixing blades, the wall surface scraper plate and the bottom surface scraper plate form a frame-shaped structure, and the mixing blades are fixedly connected in the frame-shaped structure. The solid state fermentation cylinder and the solid state fermentation method effectively resolve the problem of low fermentation performance caused by uneven thickness and uneven heating of a feed layer. According to the solid state fermentation cylinder and the solid state fermentation method, all the processes from feeding to discharging are concentrated in the solid state fermentation cylinder, the process of transportation of materials is simplified, and the mixing system and a cooling thermal-insulation system of equipment are strengthened. Automatic bulk production of solid state fermentation can be achieved, the pure culture in the solid state fermentation process is effectively guaranteed, quality and safety of products are improved, and homogeneity property in the same bulk is guaranteed.

Owner:CHENGUANG BIOTECH GRP CO LTD

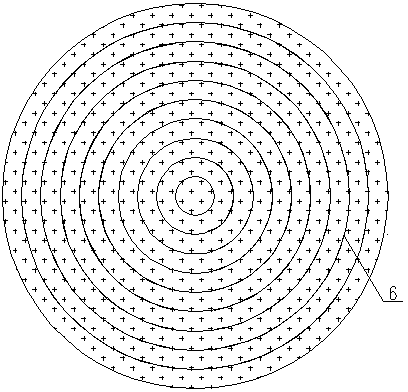

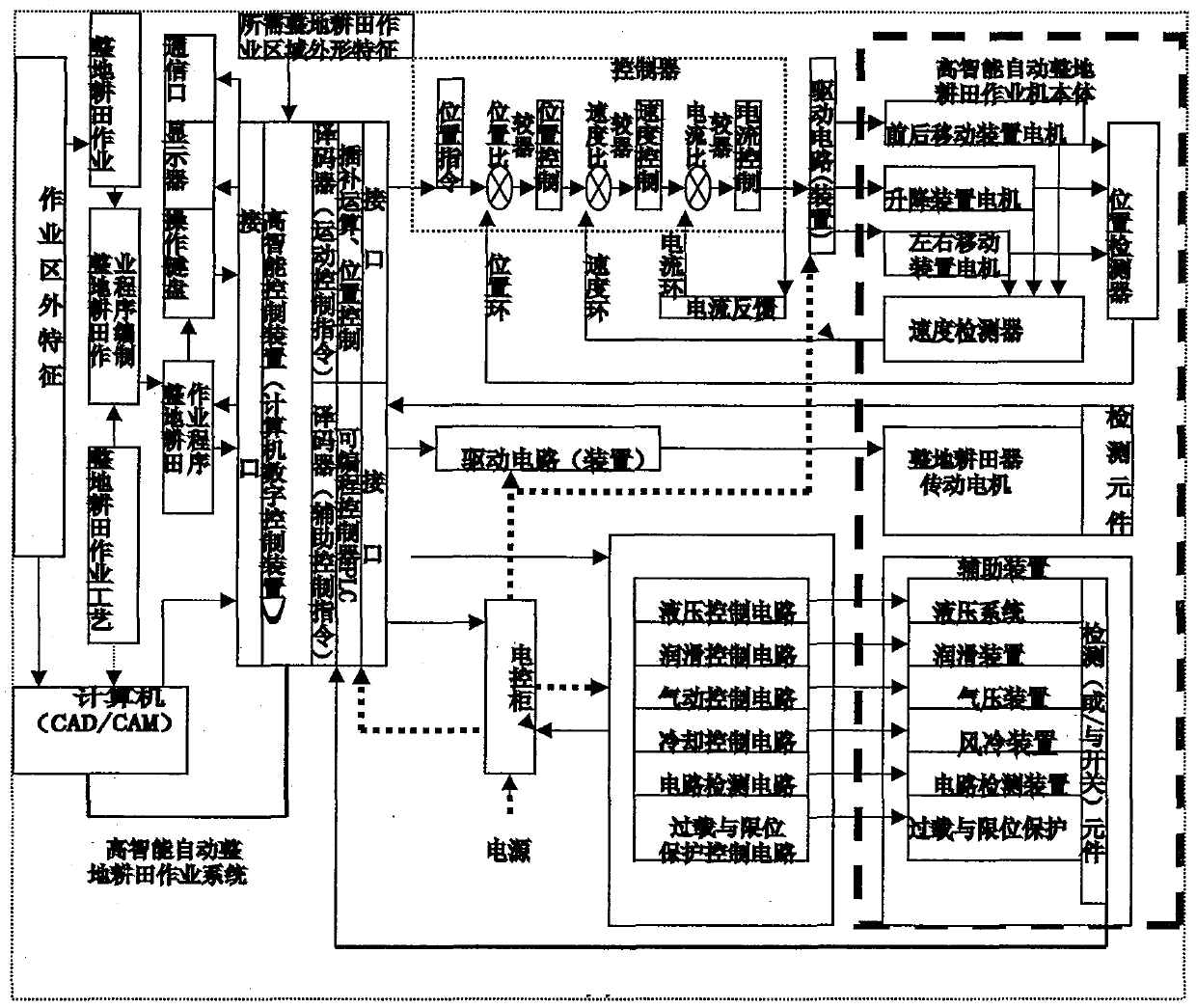

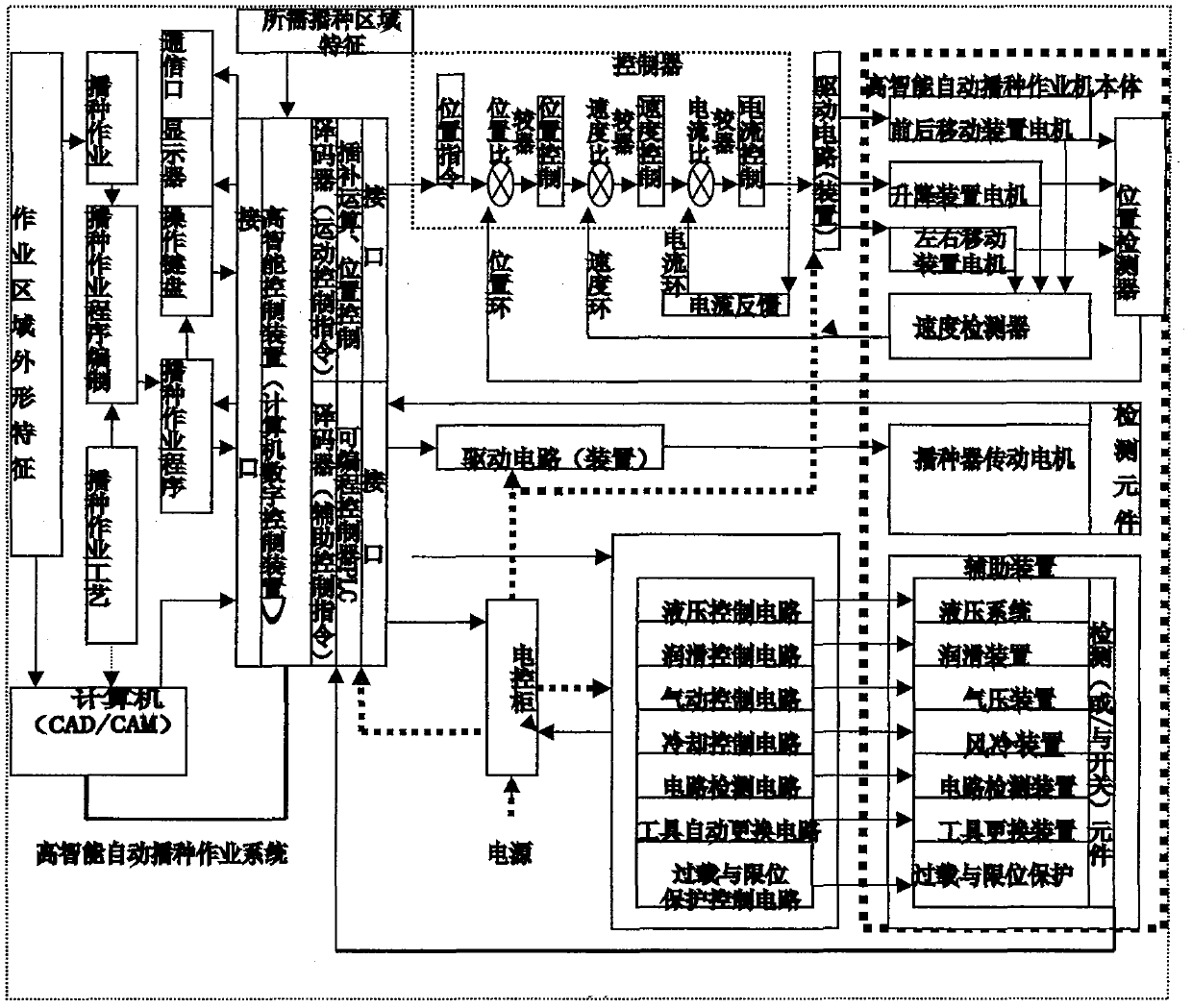

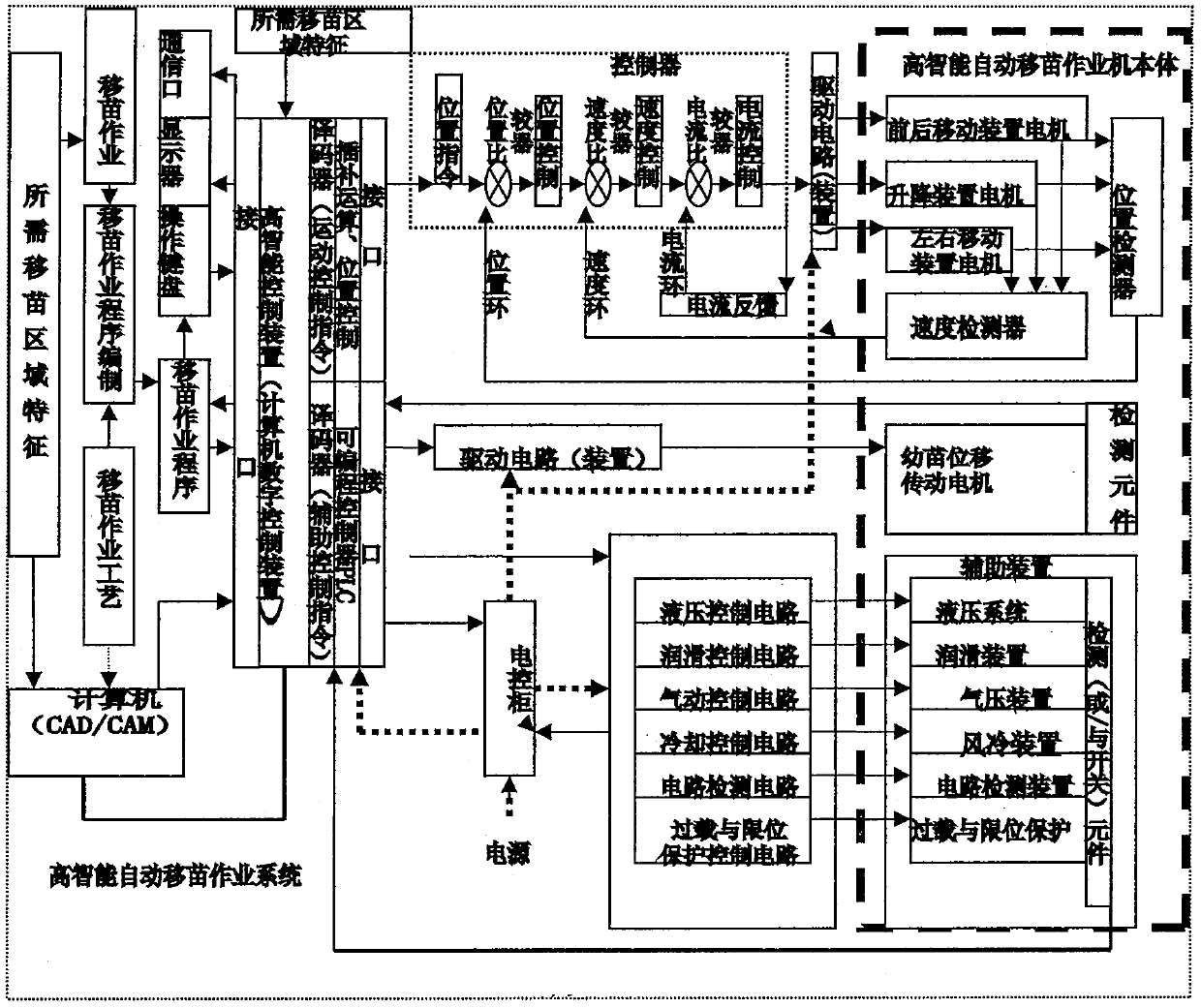

High-intelligence agricultural mechanical apparatus and system

InactiveCN108170104ARealize automated productionRealize zero emission at workAgricultural undercarriagesProgramme total factory controlElectric machineryAgricultural engineering

The invention belongs to the agricultural machinery field and relates to an agricultural mechanical apparatus and system. With the agricultural mechanical apparatus and system adopted, the problem that agricultural machinery cannot perform automatic operation can be solved. According to the agricultural mechanical apparatus and system, electric energy, motors and tracks are adopted to perform automatic operation; operation and work which are required by an operation area can be automatically and orderly completed according to the shape feature of the operation area or / and the crops of the operation area and an operation mode required by the operation area or / and the crops of the operation area; one such agricultural mechanical apparatus can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops; and one or more agricultural mechanical apparatuses can be driven and controlled to complete various operation of thefull-process management of plough, farming and harvest of the crops.

Owner:杨新高

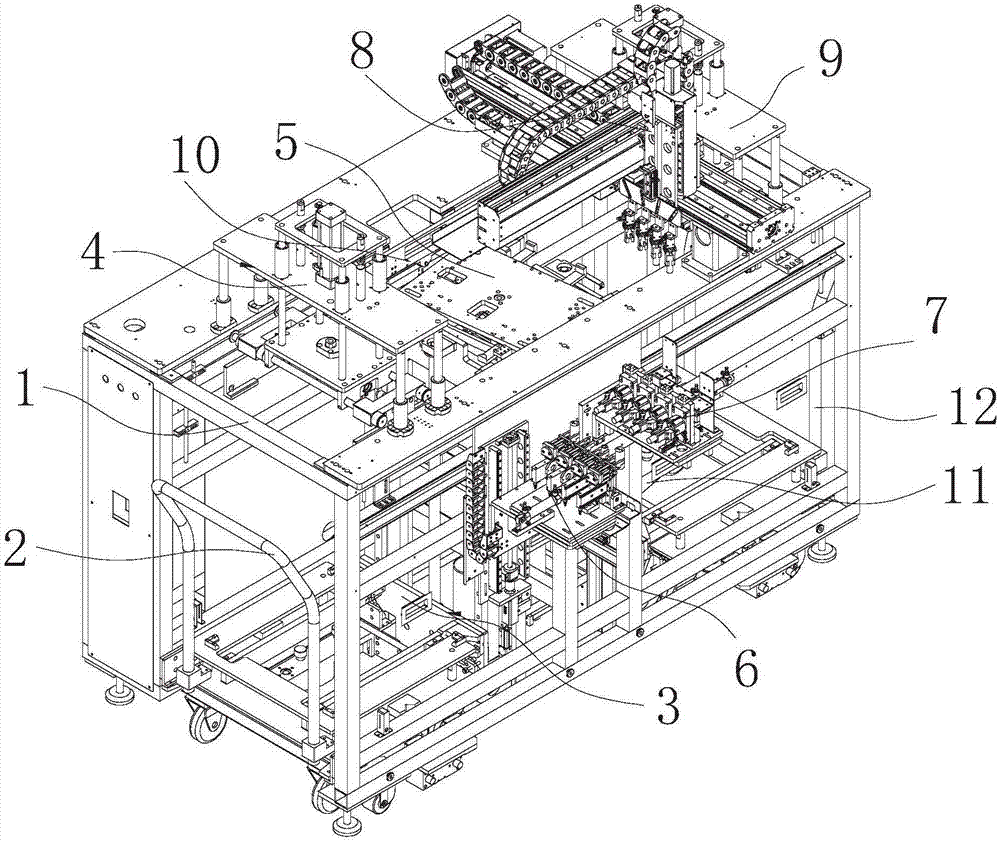

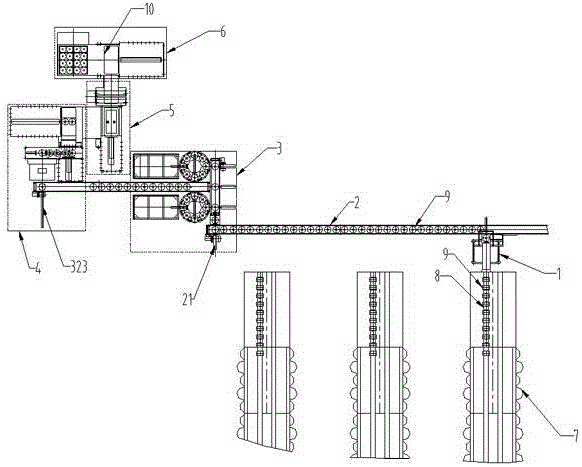

Mobile phone motor automatic assembly production line

ActiveCN103501085ARealize automatic assemblySave human effortManufacturing dynamo-electric machinesMobile phoneManufacturing line

The invention discloses a mobile phone motor automatic assembly production line which comprises a rotor assembly production line, an end cover assembly production line and a motor assembly production line which are arranged on one production line. The rotor assembly production line and the end cover assembly production line are arranged side by side; and the motor assembly production line is arranged at the tail ends of the rotor assembly production line and the end cover assembly production line. According to the mobile phone motor automatic assembly production line disclosed by the invention, the rotor assembly production line and the end cover assembly production line are arranged side by side, a stator housing assembly is combined at the position where assembly of a rotor assembly and an end cover assembly is completed, two production lines which are arranged side by side are converged into one motor assembly production line and all production processes are completed on the same production line, and thus, automatic assembly of the rotor assembly, the end cover assembly and a motor assembly can be implemented, labor can be saved, turnaround time is reduced and production efficiency is improved.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

Spindle automatic package system and spindle separation counter weight method

ActiveCN105059615AAutomate the packaging processRealize automated productionPackaging automatic controlEngineeringAutomatic testing

The invention discloses a spindle automatic package system comprising a doffing dolly, a spindle conveyer belt, a quota weight sorting mechanism, an automatic sleeving bagging mechanism, an automatic packing belt mechanism and an automatic bag loading mechanism; the doffing dolly is arranged between a spinning machine and the spindle conveyer belt; a discharge end of the spindle conveyer belt is provided with a charging cylinder. The spindle automatic package system is suitable for automatic weighing, counterweight, sleeving, bagging, packing belt, and bag loading steps of the spindle weaved and formed by the spinning machine like a ring spinning, an air spinning, an air-jet spinning, a vortex spinning, a siro spinning and a compact spinning; the method only needs to do artificial intervention in the automatic sleeving bagging mechanism so as to complete a spindle bag seal step, so full automation production of the spindle package can be basically realized, thus greatly reducing workshop labor number, and saving labor cost.

Owner:LUZHOU SHUIYUAN HYDRAULIC MACHINE +1

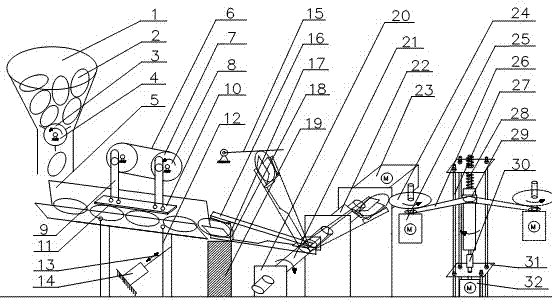

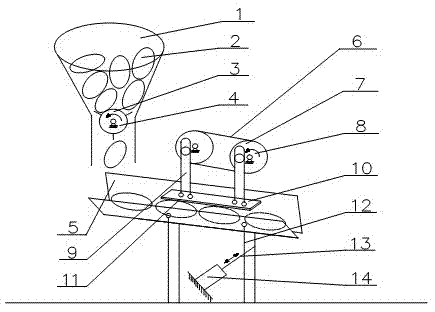

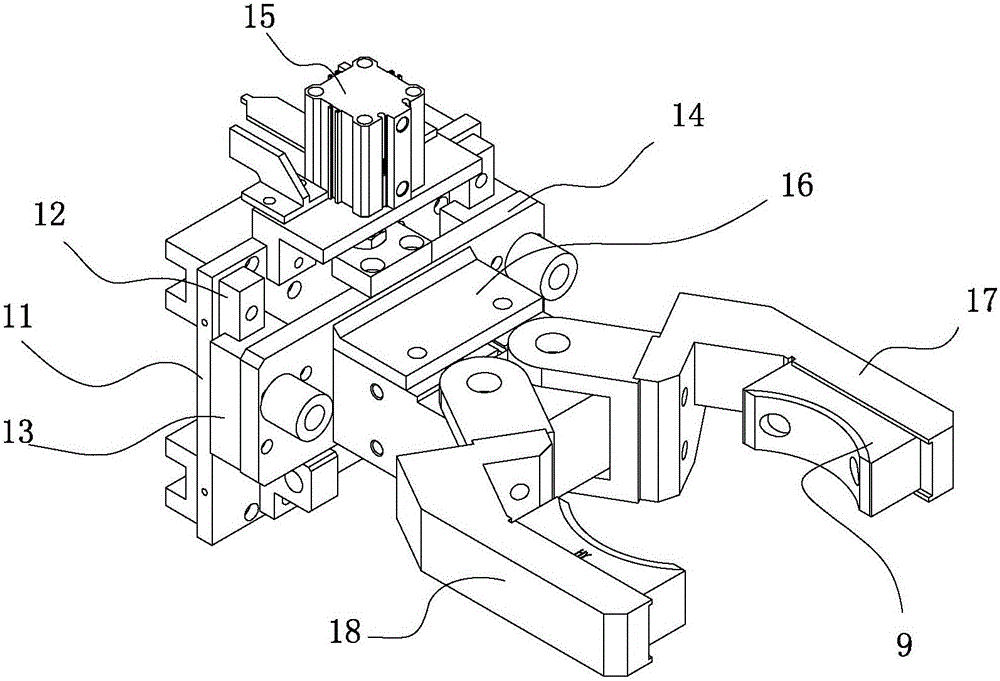

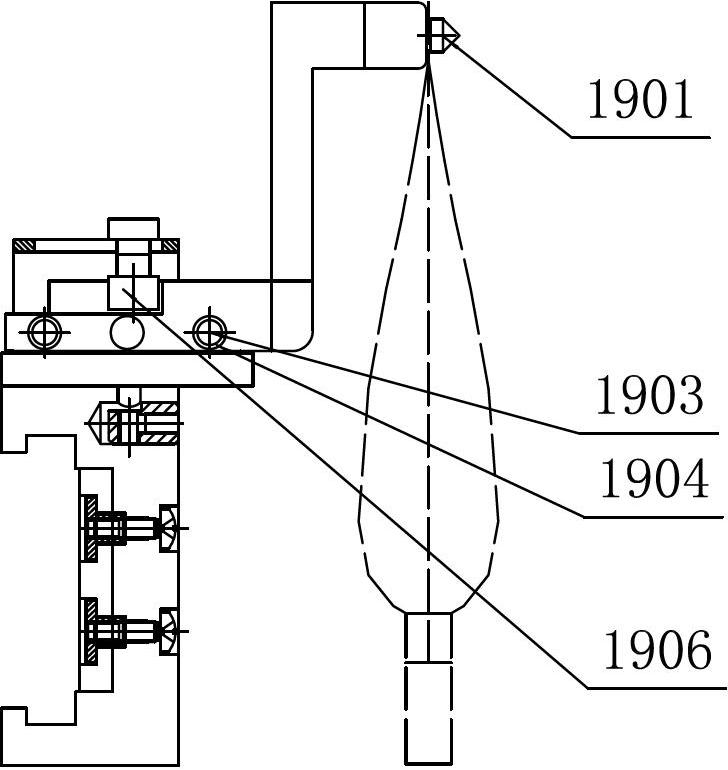

An automatic cocoon cutting and separating device

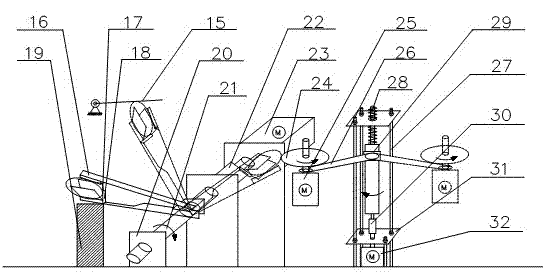

InactiveCN102285533AEasy to controlImprove the efficiency of cocoon cuttingMetal working apparatusConveyor partsEngineeringSpring steel

The invention discloses a silkworm cocoon automatic cutting and separating device. The device is characterized by comprising a silkworm cocoon automatic arranging and delivering device and a silkworm cocoon automatic cutting and separating device, wherein the silkworm cocoon automatic arranging and delivering device comprises a hopper (1) for placing silkworm cocoons; a cocoon stripping plate (4)which is driven by a first motor (3) is arranged at an entrance in the bottom of the hopper (1); a channel consisting of a clamping plate (5) is arranged at an exit in the bottom of the hopper (1); acocoon pressing plate (10) installed on the bottom part of a guide rail (9) is arranged above the channel; the guide rail (9) is connected to an eccentric wheel (8); the cocoon pressing plate (10) can horizontally and vertically move along the rotation of the eccentric wheel (8); and a spring steel sheet (13) is arranged on the bottom part of the channel and connected with the bottom part of the channel through an electromagnet (14). The device is compact in structure, small in size and organic combination of mechanical and electrical integration. By the device, full-automatic action such as automatic arrangement, automatic cutting and automatic separation of the silkworm cocoons is realized, the production efficiency is greatly improved, the cost is reduced, and the device is applicable for cutting and separating of mass silkworm cocoons. Moreover, due to the adoption of a mechanical structure, the device is easy to install and process and low in cost.

Owner:SOUTHWEST UNIV

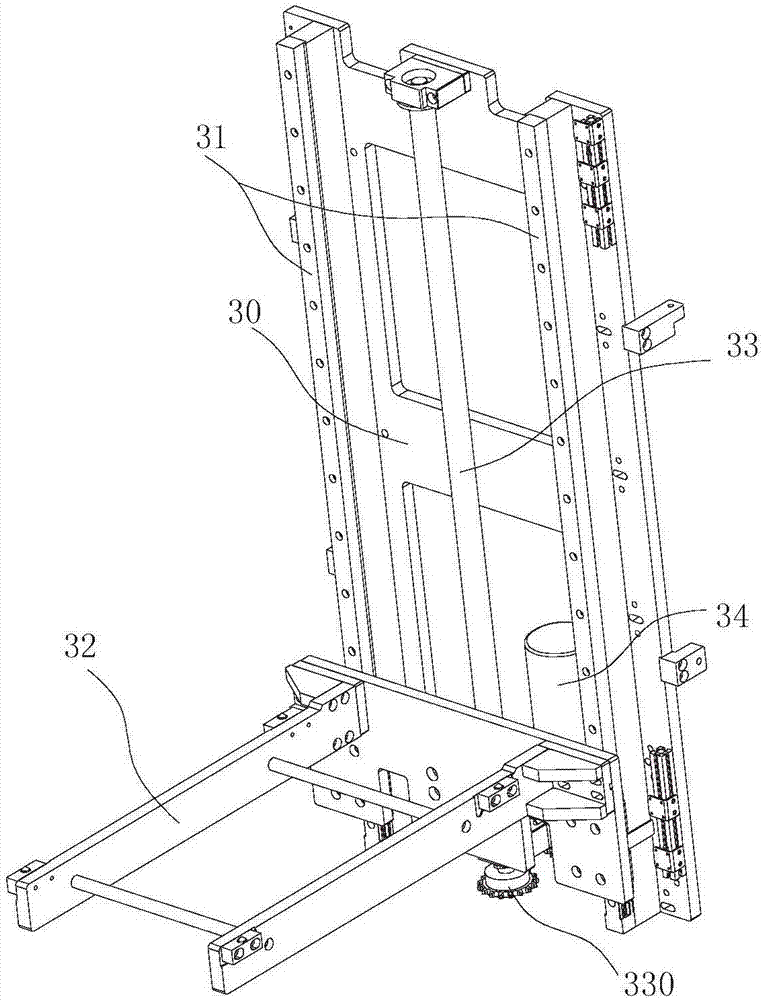

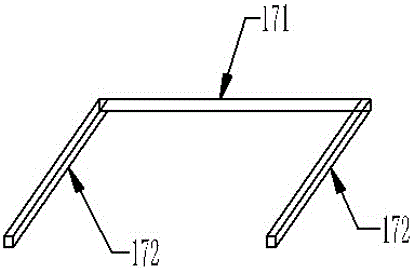

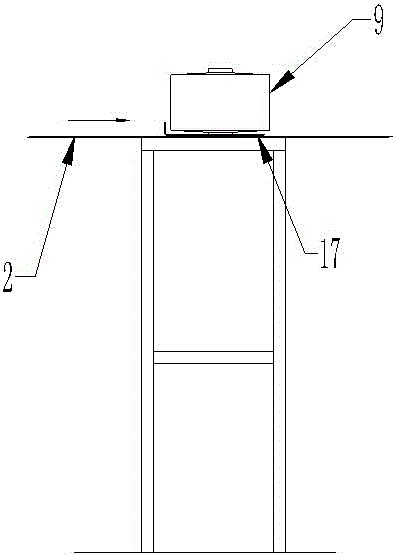

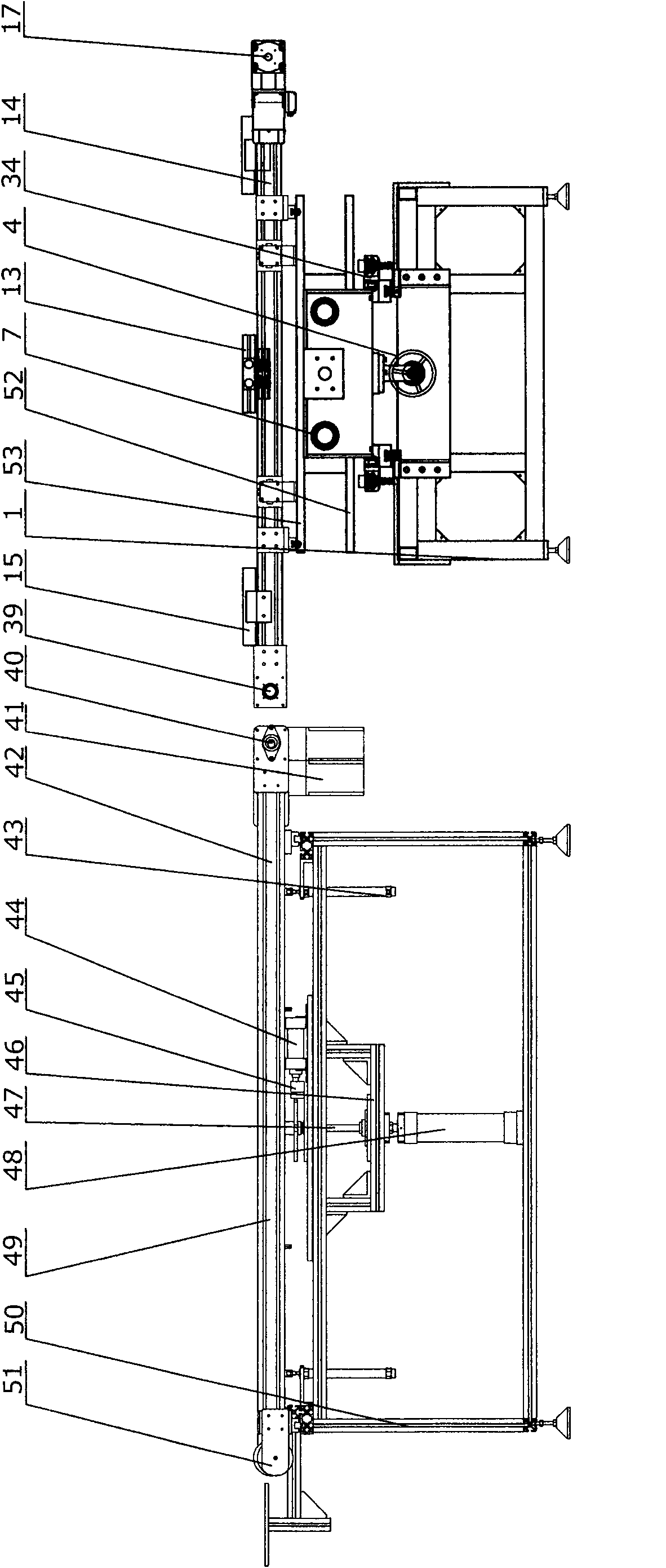

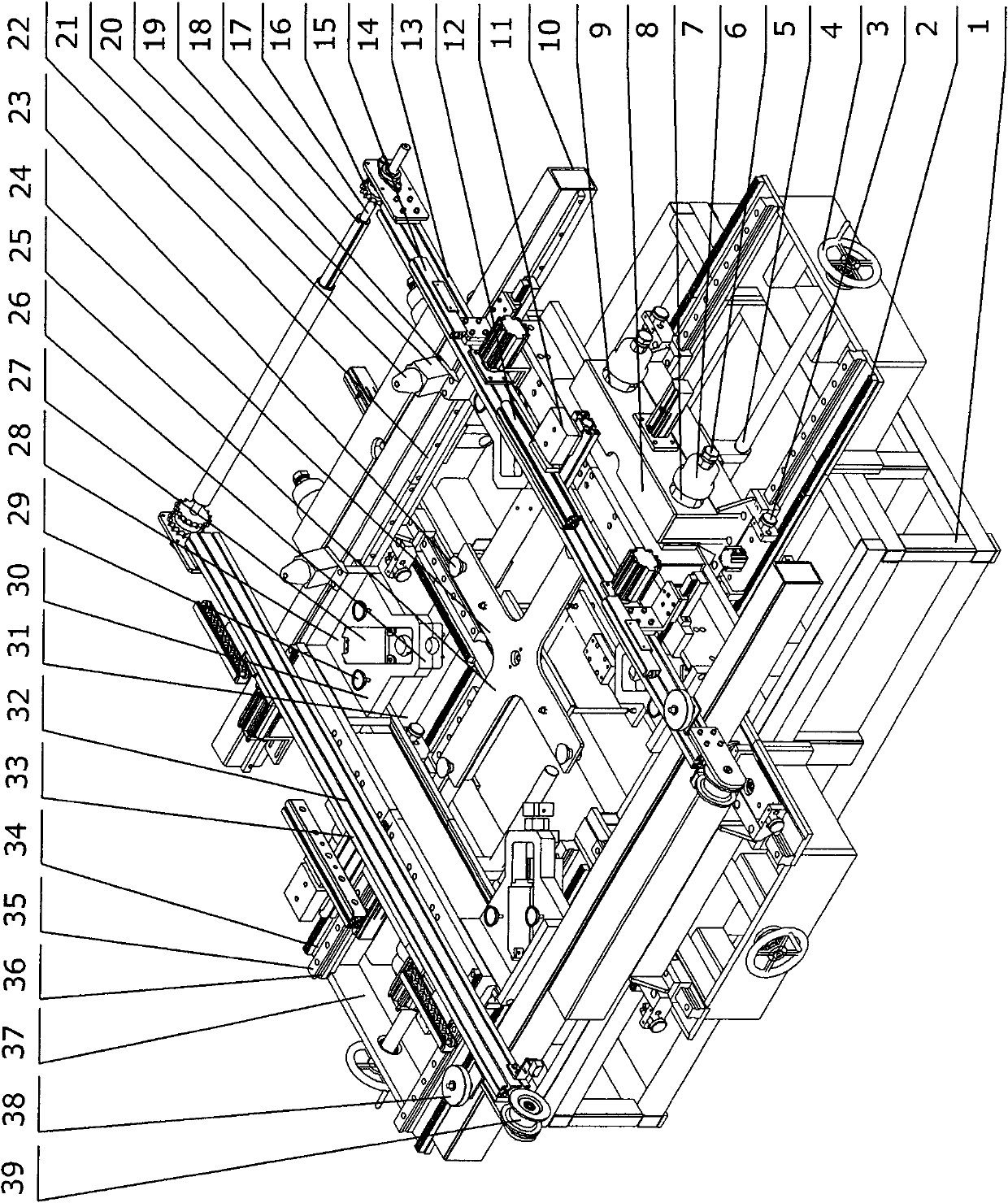

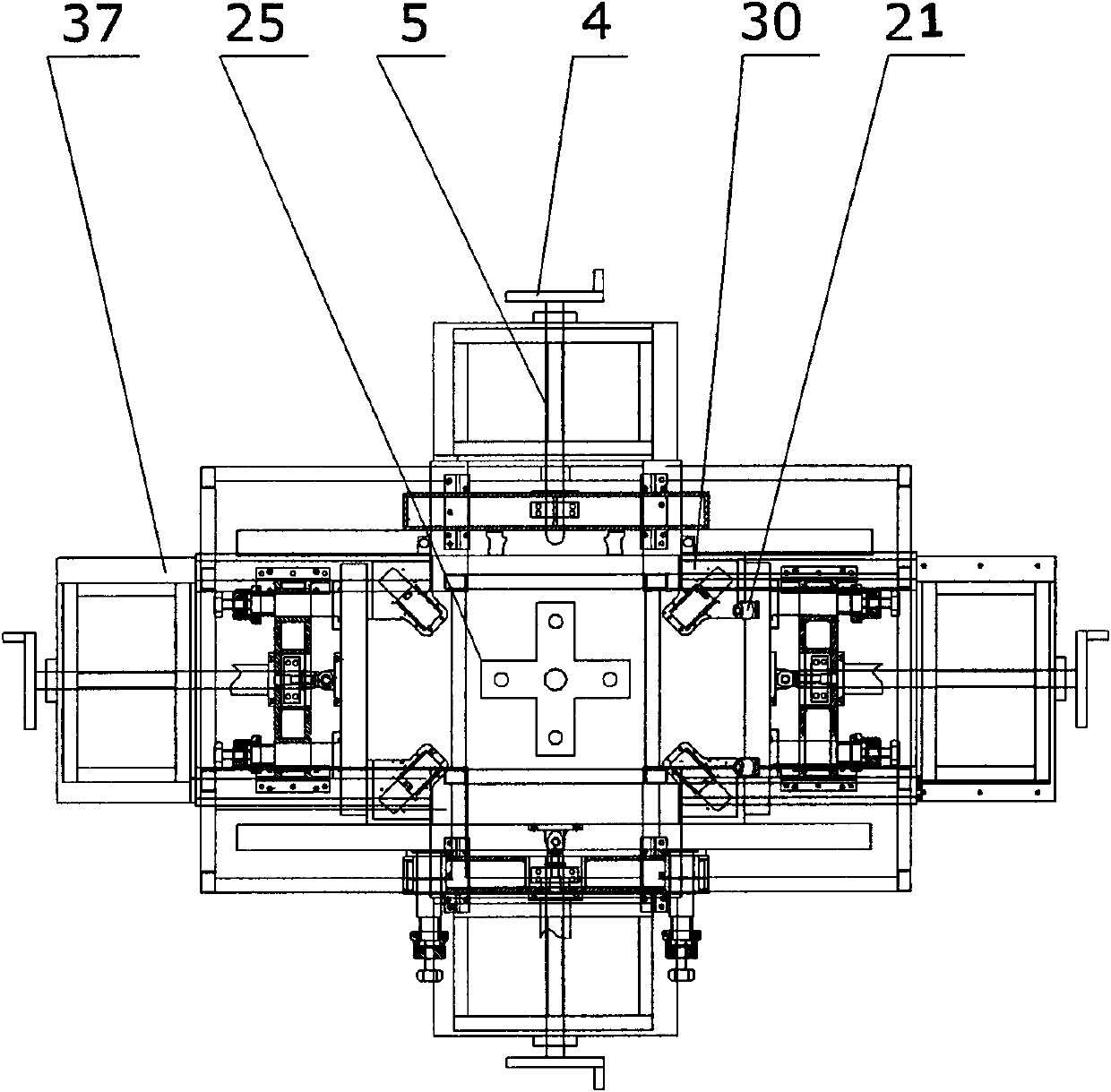

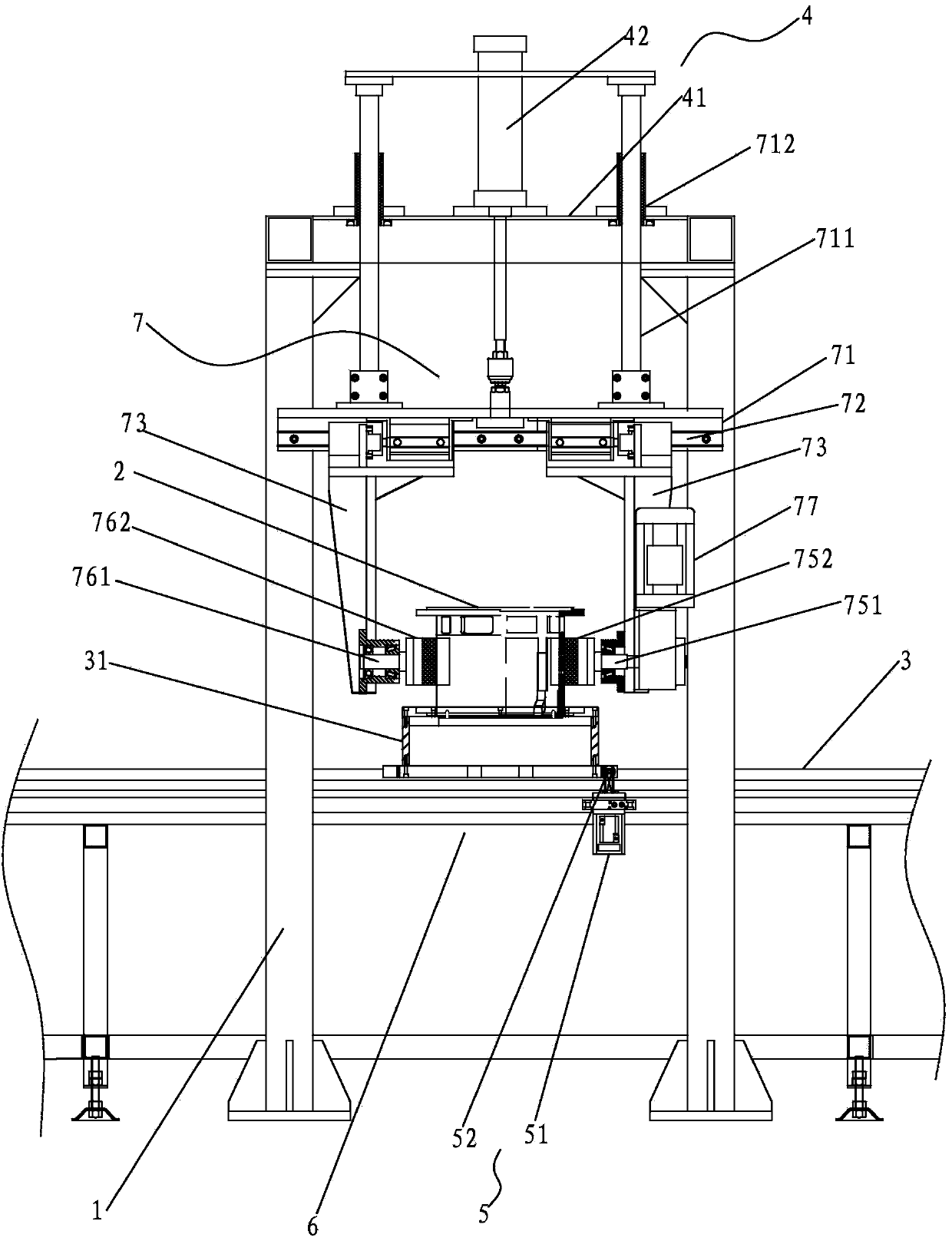

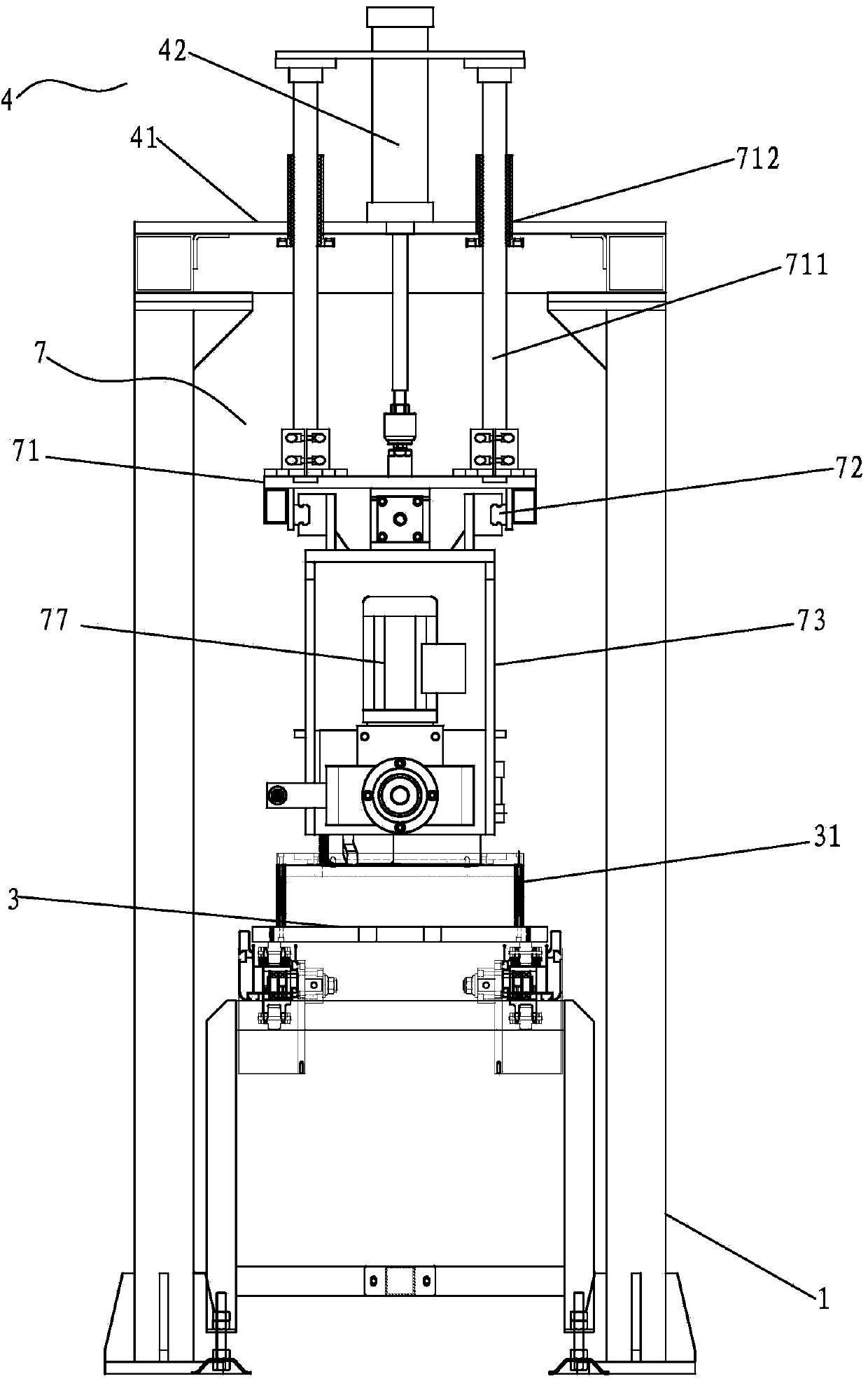

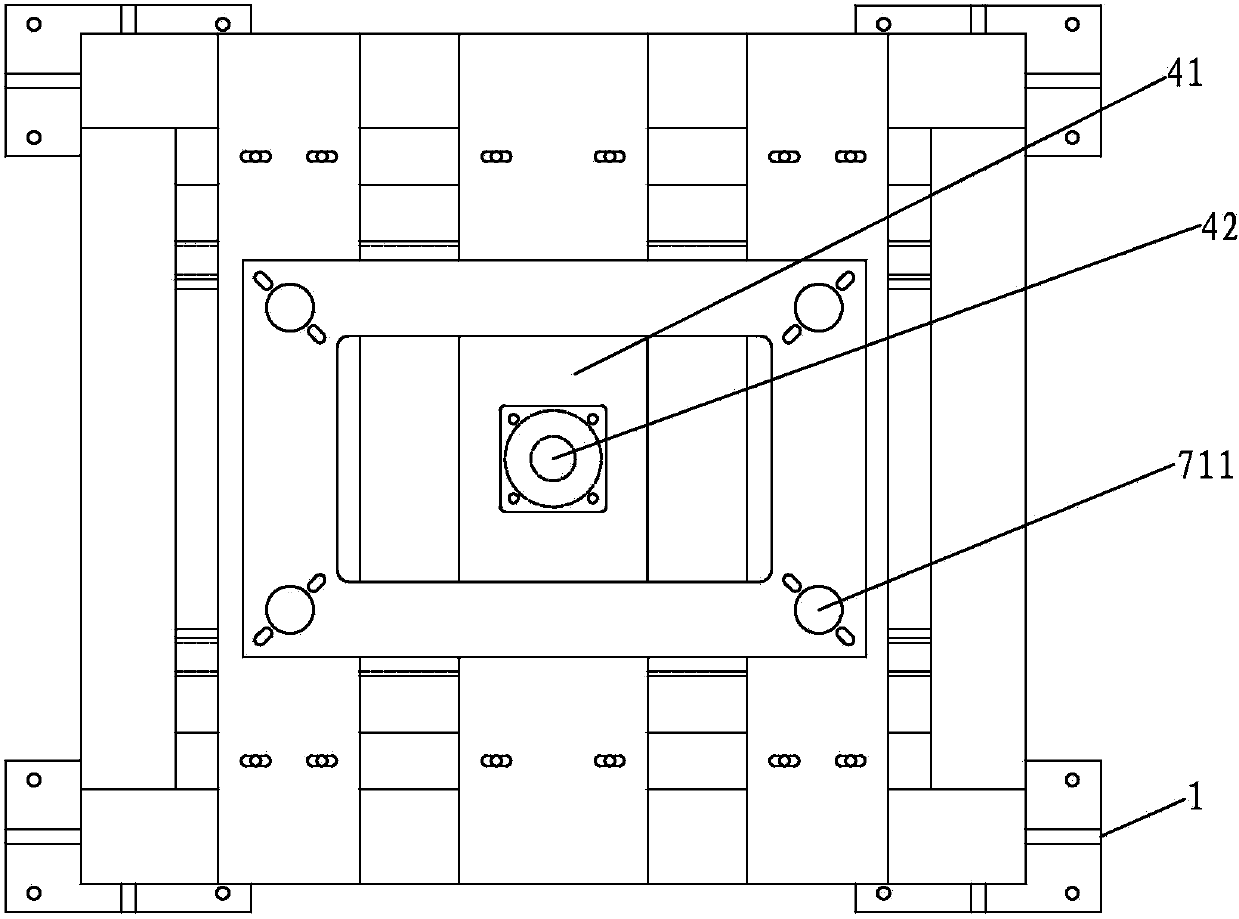

Solar cell assembly frame and angle assembling device and process thereof

InactiveCN102024868ARealize semi-automationNo need for manual handlingFinal product manufactureSemiconductor devicesDrive wheelEngineering

The invention discloses a solar cell assembly frame and angle assembling device and a process thereof, and relates to a solar cell assembly device. The invention provides the solar cell assembly frame and angle assembling device with good comprehensive use performance, scientific and reasonable structure, simple process and high automation degree. The device comprises a rack; the center of the rack is provided with a lifting mechanism; the sides of the lifting mechanism are provided with locking and adjusting mechanisms respectively, fixed on the rack and connected with movable supports; the movable supports are provided with frame assembling cross beams for connecting an upper guide plate and a lower guide plate respectively, the lower guide plate fixes an angle assembling bottom plate of an angle assembling cylinder and is connected with the frame assembling cross beam, and the angle assembling bottom plate fixed on the inner round angle of the rack is provided with an angle assembling mechanism; the upper guide plate of the frame assembling cross beam is provided with a transmission mechanism consisting of a motor, a telescopic pipe and a driving wheel set, and the two corresponding sides of the transmission mechanism are provided with positioning guardrails; and the transmission mechanism is connected with a frame closing mechanism.

Owner:YINGKOU JINCHEN MACHINERY

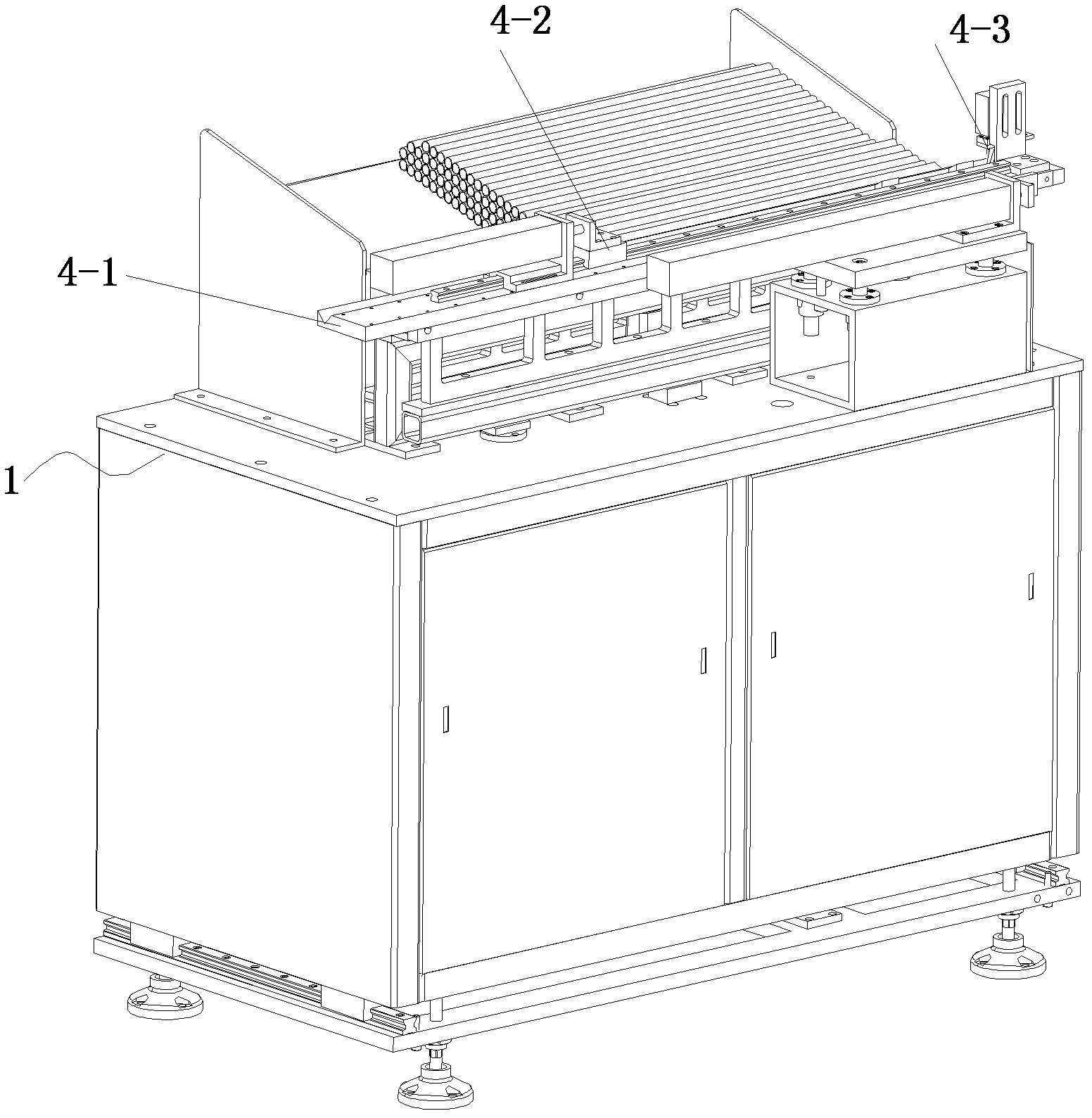

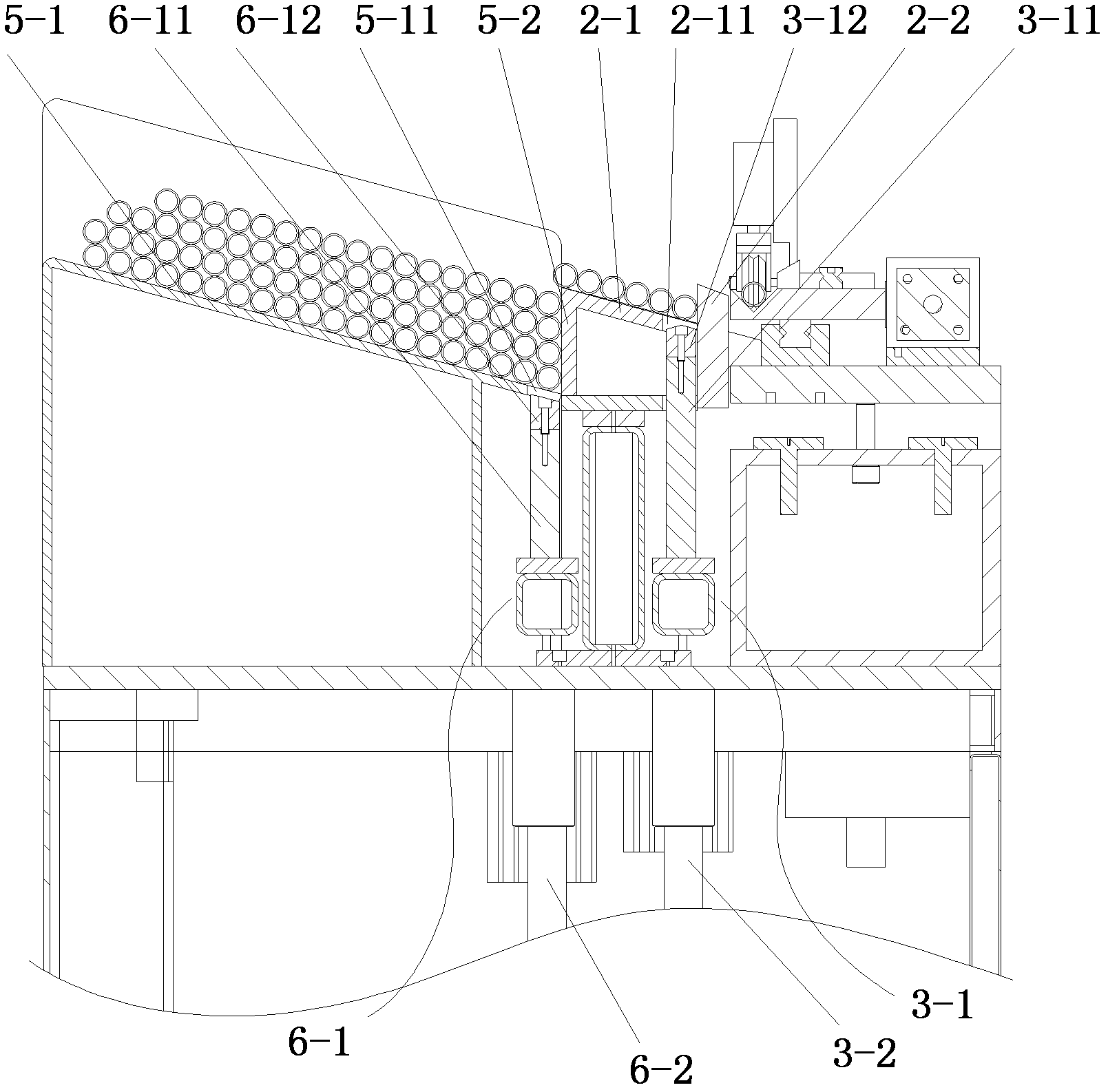

Automatic loading machine

ActiveCN102909283ARealize automated productionMetal-working feeding devicesPositioning devicesNumerical controlFixed length

The invention relates to an automatic loading machine which comprises a base, a copper pipe lining-up device, a copper pipe separation device and a feeding device. The copper pipe lining-up device is provided with a bottom plate of which the front part is inclined downward; a head baffle is arranged at the front end of the copper pipe lining-up device; a plurality of bottom plate openings are formed at the positions on the bottom plate, which are close to the head baffle; the copper pipe separation device comprises a material supporting ejector rod and a material supporting cylinder arranged on the base; the material supporting ejector rod is arranged on a push shaft of the material supporting cylinder; the material supporting ejector rod is provided with a plurality of ejector rods corresponding to the openings of the bottom plate; the upper end parts of the ejector rods are provided with material supporting modules; the material supporting ejector rod is pushed by the material supporting cylinder to ensure the ejector rods to pass through the openings of the bottom plate; the feeding device comprises a V-shaped groove; the lateral surface of the V-shaped groove is abutted on the head baffle; and one end of the V-shaped groove is provided with a push block pushed by a driving mechanism. The automatic loading machine has the advantage that a single copper pipe with a fixed length is fed into a chuck of a numerical control pipe bending machine, is automatically reset and is automatically taken out after being bent, so that the automation production of the numerical control pipe bending machine is implemented.

Owner:CHENZHOU ZHIZAO TECH CO LTD

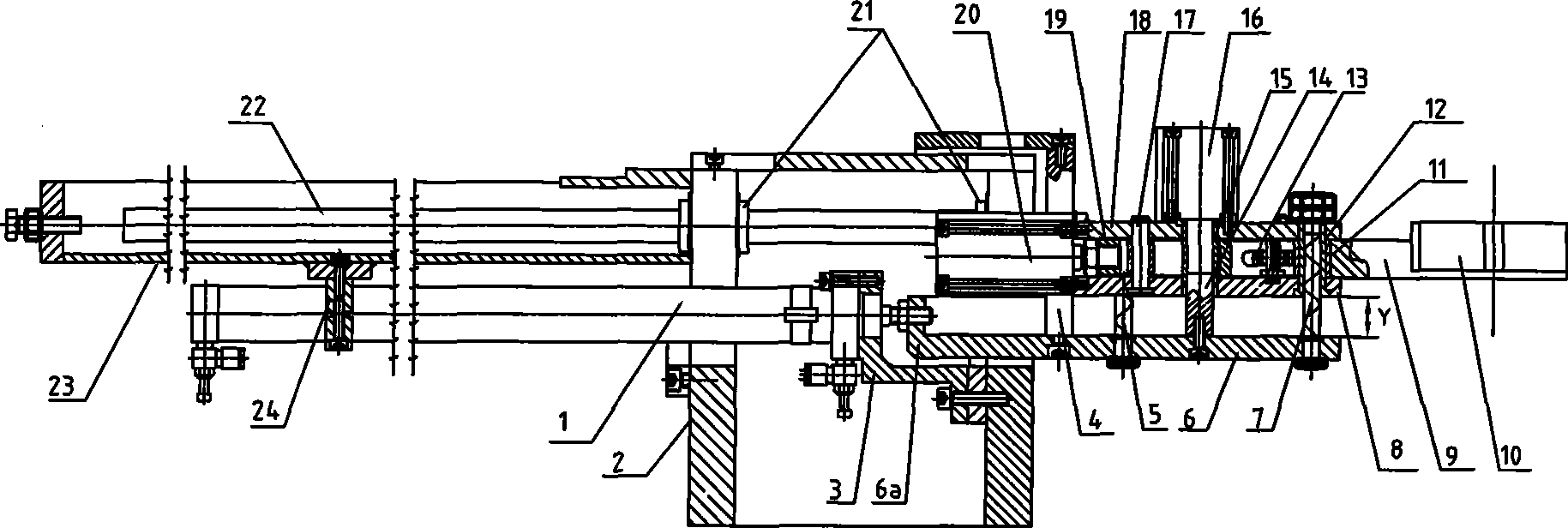

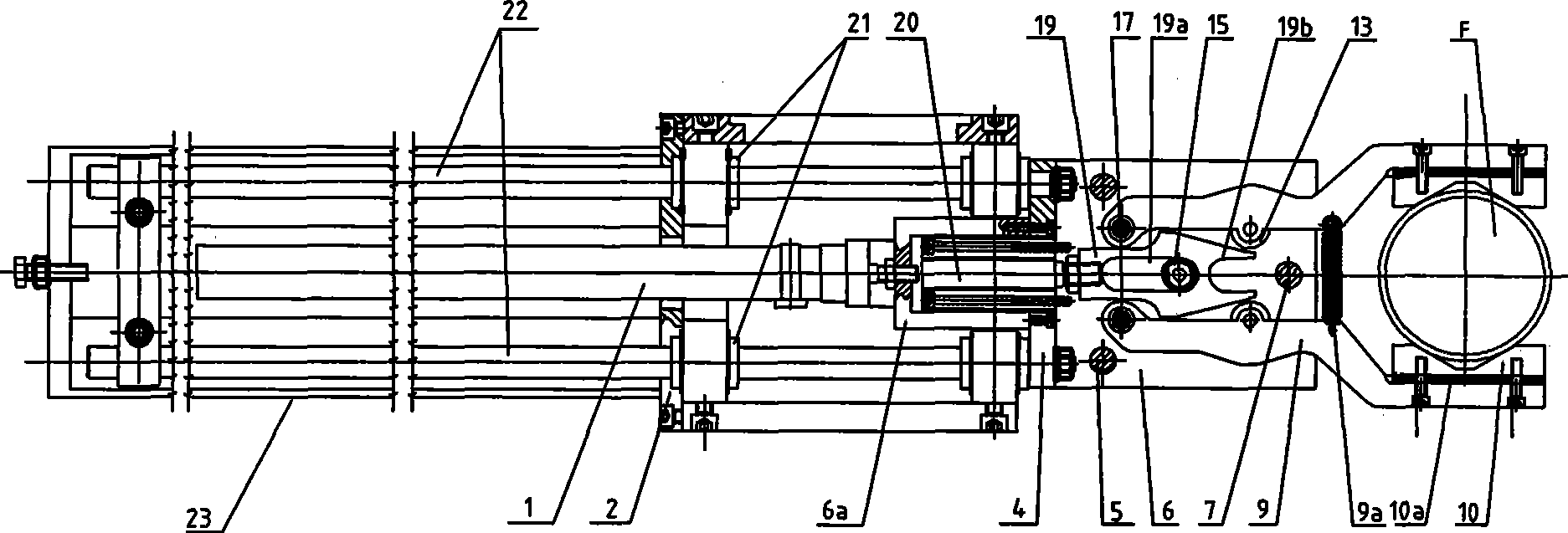

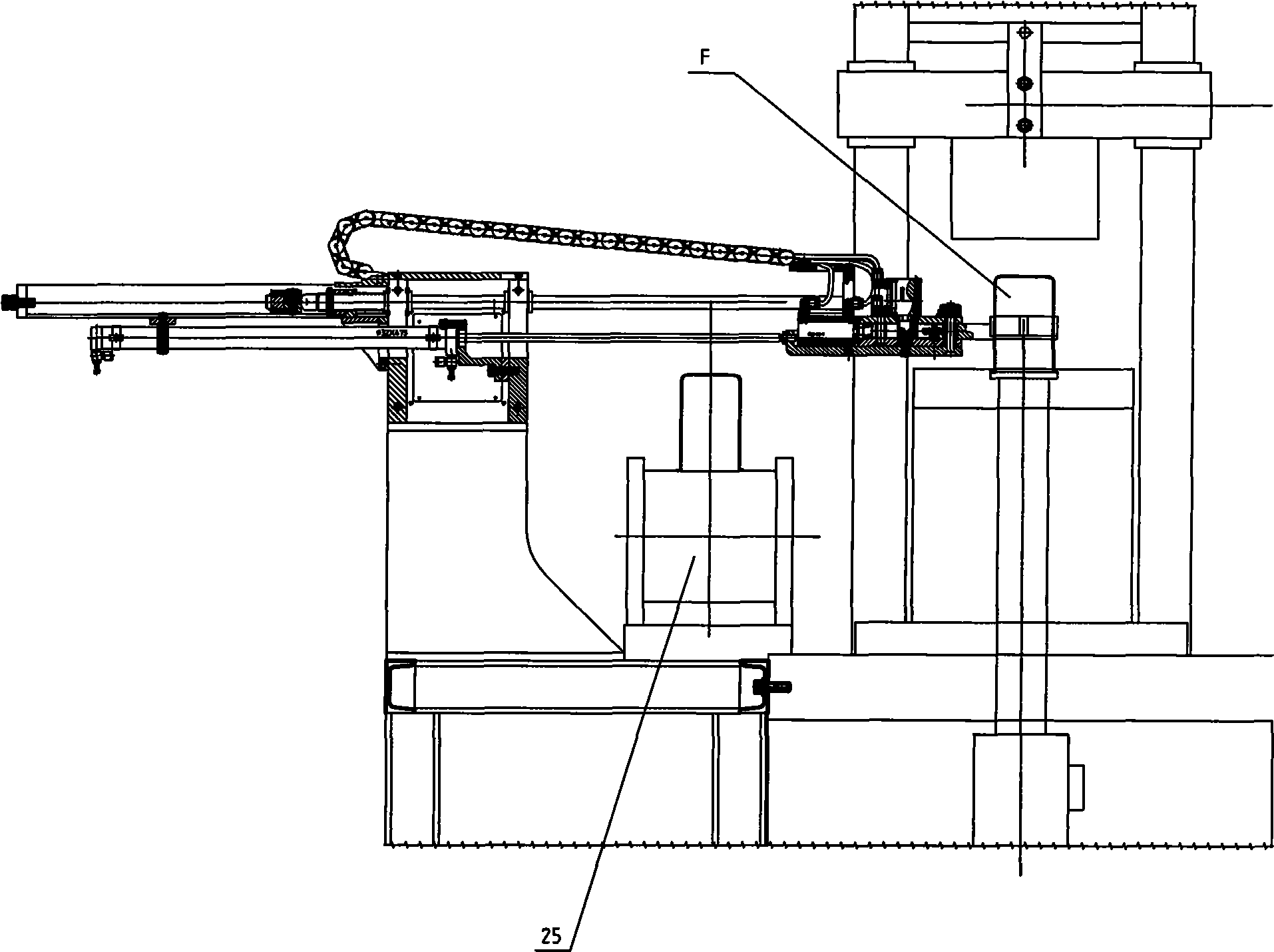

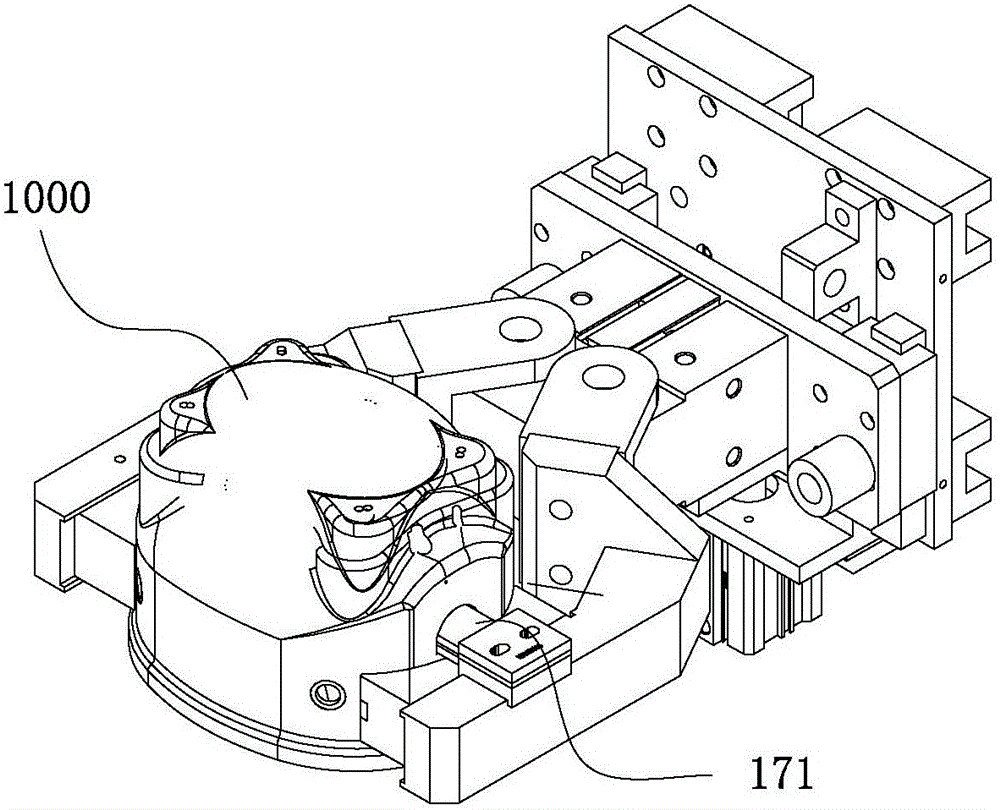

Automatic material-fetching machine for clarifier case formed by stretching

InactiveCN101497087ARealize automated productionIncrease productivityEngineeringMechanical engineering

The invention relates to an automatic stretching material taking machine for a filter shell, wherein a stander (2) is provide with a pair of guide rods (22) which are matched with a linear bearing (21); a piston rod of an arm cylinder (1) is connected with hand rest base plates (6a,6) which are connected with an upright plate (4); upper parts of the hand rest base plates are connected with the guide rods (22); the hand rest base plates are provided with a grabbing piece cylinder (20), a wedge block (19), a pair of clamping arms (9) and a tension spring (9a); and the inclined plane of the wedge block is matched with a bearing (13) of the clamping arms (9) to allow the clamping arms (9) and claws thereof to stretch and clamp. When a mechanical arm extends in place, the claws of the clamping arms stretch and clamp a workpiece F to lift the workpiece upward by 25mm, and retract the piston rod, and after the workpiece is in place, the claws stretch and put down the workpiece F. The automatic stretching material taking machine for the filter shell has the advantages of realizing automatic production of the filter shell, improving the production efficiency and preventing accidents at work.

Owner:BENGBU HAOYE FILTER

Shell welding production device

ActiveCN105057937ARealize automated productionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesTransfer mechanismWelding

The invention discloses a shell welding production device which comprises an automatic conveying device, a first transferring mechanism, a pin welding machine, a transferring and discharging mechanism, a second transferring mechanism, a machine leg welding machine, a third transferring mechanism, a correcting device, a terminal welding machine and a carrying mechanism. By means of the shell welding production device, pins, machine legs and terminals can be welded in a full-automatic mode, production efficiency is greatly improved, cost is reduced, automatic production is achieved, and safety and reliability are achieved.

Owner:SHENZHEN PREVAIL TECH

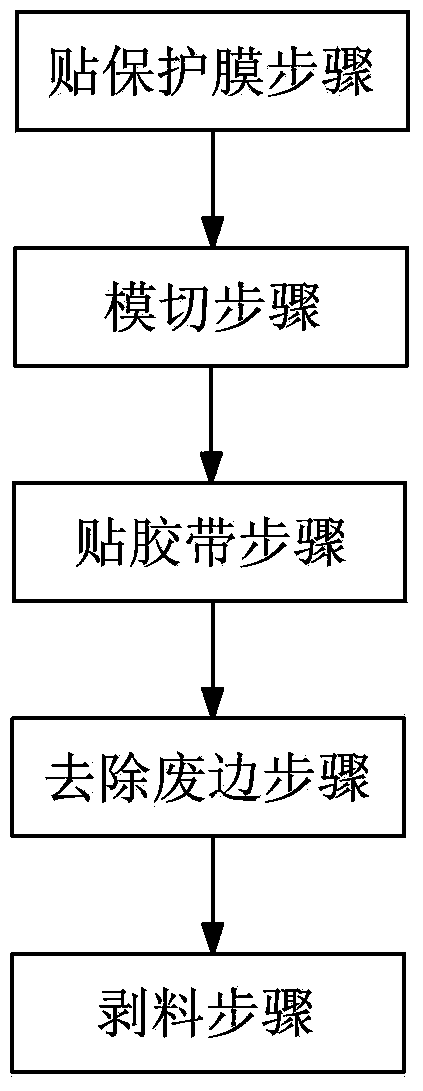

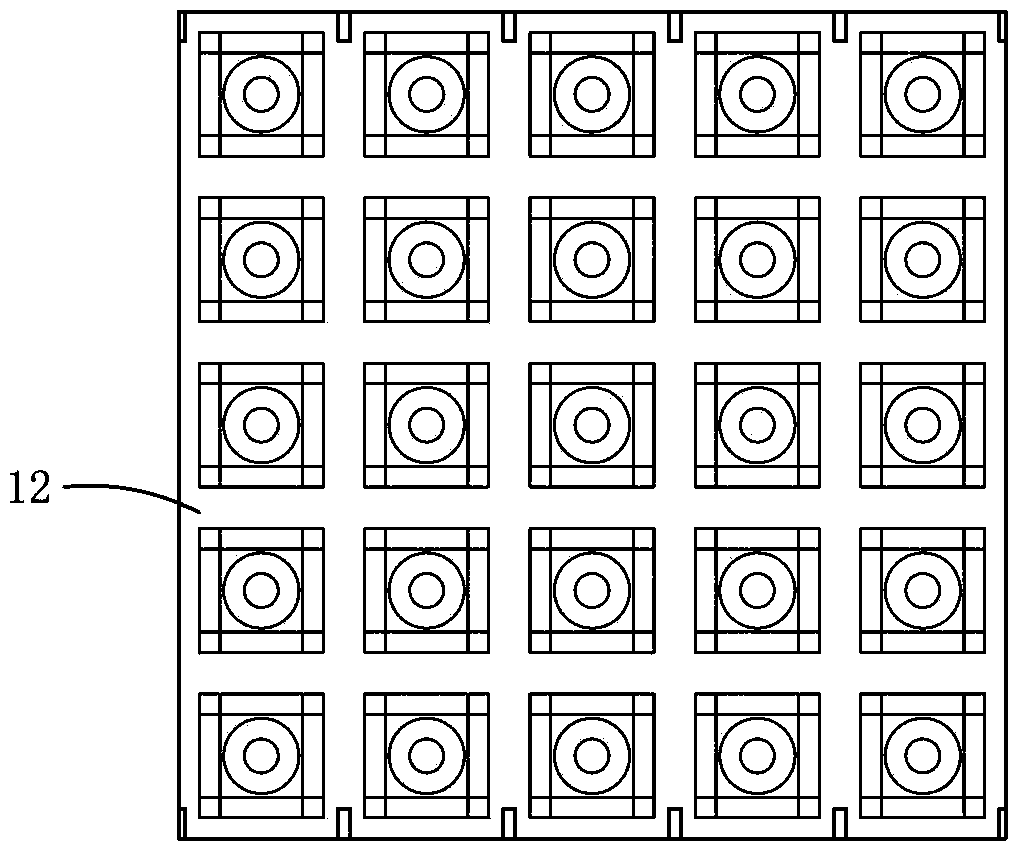

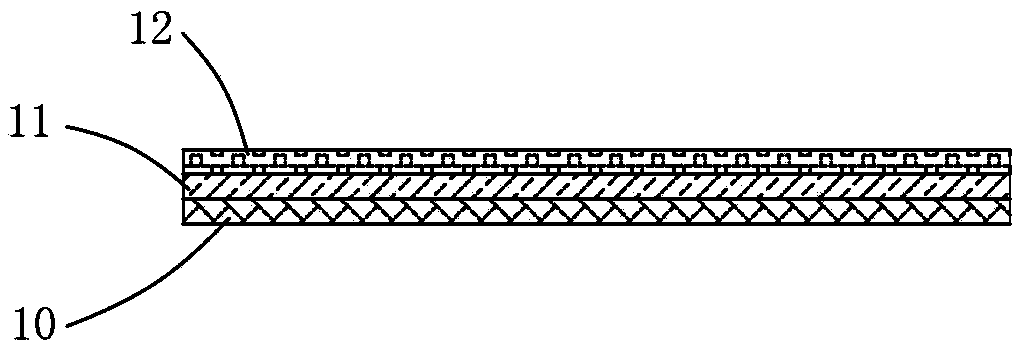

Method and system for removing slitter edges of sheet products by die cutting processing

ActiveCN103448087AEfficient removalHurt and achieveMetal working apparatusTectorial membraneAdhesion force

The invention relates to a method and a system for removing slitter edges of sheet products by die cutting processing. The method comprises the following steps of: a step of adhering a protection film, i.e. adhering the release paper side of a sheet raw material to the ribbon protective film of which the surface has viscosity; a step of carrying out die cutting, i.e. continuously feeding the sheet raw materials to which the protective films are adhered to a die cutting machine by a feeding machine and carrying out die cutting processing on the sheet raw materials by the die cutting machine to obtain primary semifinished products, wherein the die cutting depth needs to meet the requirement of just cutting to the surface of release paper, which faces one sides of sheets, without cutting the release paper; a step of adhering adhesive tapes, i.e. corresponding to the slitter edges, adhering the adhesive tapes to the positions on the surfaces of one sides of the primary semifinished products, which are opposite to the protective films; a step of removing the slitter edges, i.e. removing the adhesive tapes and simultaneously removing the slitter edges by utilizing the adhesion forces of the adhesive tapes on the slitter edges so as to obtain secondary semifinished products; and a step of stripping, i.e. stripping out the protective films on the secondary semifinished products to obtain finished products. According to the invention, the adhesion force of the adhesive tapes on the slitter edges is utilized to remove the slitter edges; the slitter edges can be rapidly and effectively removed; the finished products are not damaged; and automatic production can be implemented.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

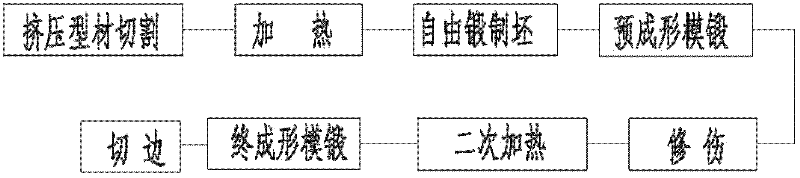

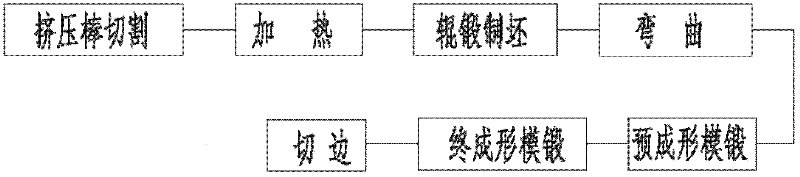

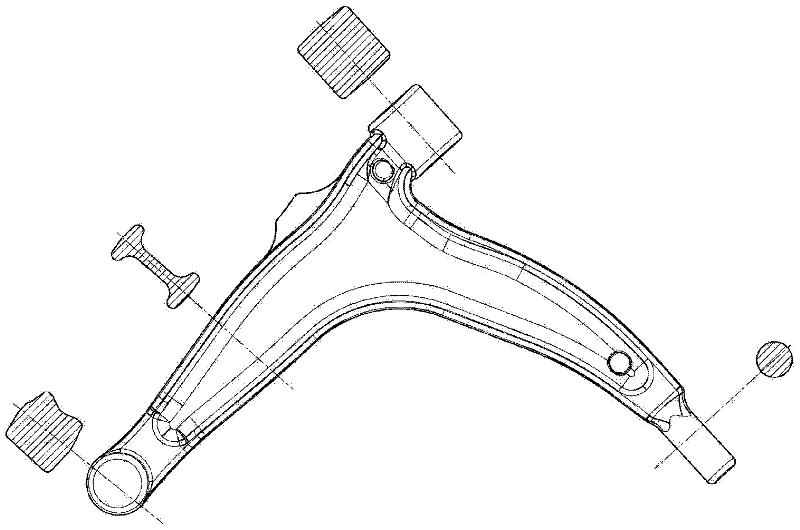

Manufacturing process for lambdoidal control arm

InactiveCN102500740AReduce preprocessing timeIncrease profitRailway componentsMetal-working apparatusProduction rateControl arm

The invention discloses a manufacturing process for a lambdoidal control arm. The manufacturing process comprises the following steps of: sawing an extruded bar; heating the extruded bar; rolling and forging the extruded bar to form a blank; bending to form the blank; preforming a forged die; finally forming the forged die; and trimming the forged die. In the manufacturing process, the extruded bar is taken as a raw material; the blank is heated to 440 DEG C-480 DEG C through electric induction; the blank is rolled and forged twice by a forging roll to realize volume distribution; the processes of bending to form the blank, preforming the forged die and finally forming the forged die are carried in sequence; and the trimming process is carried out in a thermal cutting manner. Compared with the prior art, a repairing process and a secondary heating process are reduced, the processing steps for the lambdoidal control arm are simplified, production cost for the product can be lowered, production rate can be increased, and product performances can be ensured.

Owner:芜湖禾田汽车工业有限公司

Full-automatic bag making and filling and sealing machine of bag tail filling non-PVC membrane transfusion soft bag

ActiveCN102642630ARealize automated productionSimple working principleWrapper twisting/gatheringLiquid materialFailure ratePolyvinyl chloride

The invention relates to a full-automatic bag making and filling and sealing machine of a bag tail filling non-PVC (polyvinyl chloride) membrane transfusion soft bag, which belongs to the technical field of pharmacy packing machine. The full-automatic bag making and filling and sealing machine comprises a machine body which consists of a frame component (3), wherein a distribution box (1) is arranged at one side of the machine body, and a bag making machine and a filling and sealing machine are arranged on the upper part of the machine body. The machine is characterized in that a bag body transfer mechanism (12) is arranged between the bag making machine and the filling and sealing machine, a connector supply mechanism (17) and a preheating mechanism (6) are arranged at one side of the bag making machine, the bag making machine is provided with a made bag annular conveying component (8), the made bag annular conveying component is provided with a connector fixture, the filling and sealing machine is provided with an annular conveying belt, and the annular conveying belt is provided with a bag fixture (19). According to the invention, full-automatic production of the tail filling non-PVC membrane transfusion soft bag is realized through improving the bag, the working principle is simple, the structure is reliable, the operation is stable, the failure rate is low, the occupied space is small, and according to the characteristics of the soft bag, the production cost can be obviously reduced. The action of the machine is fast, and the production efficiency is high.

Owner:SHINVA MEDICAL INSTR CO LTD

Device for automatically reversing generator shell

ActiveCN103434828ARealize automated productionReduce labor costsConveyor partsMechanical engineering

The invention discloses a device for automatically reversing a generator shell. A clamping reversing mechanism which is used for clamping and reversing the generator shell and can move up and down relative to a machine frame is arranged on the machine frame, a reversing working position and a location mechanism are arranged on a conveying track, the location mechanism controls the generator shell to be stopped at the reversing working position, the clamping reversing mechanism is located above the reversing working position, the clamping reversing mechanism is driven and controlled by a driving mechanism to go up or go down, the clamping reversing mechanism firstly clamps and holds the generator shell to go up to the predetermined height to perform 180-degree reversing, and then the clamping reversing mechanism goes down to enable the generator shell to be placed on a tool jig of the reversing working position. By means of the device, the automatic production is achieved, the labor cost is reduced, and the production efficiency is improved.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

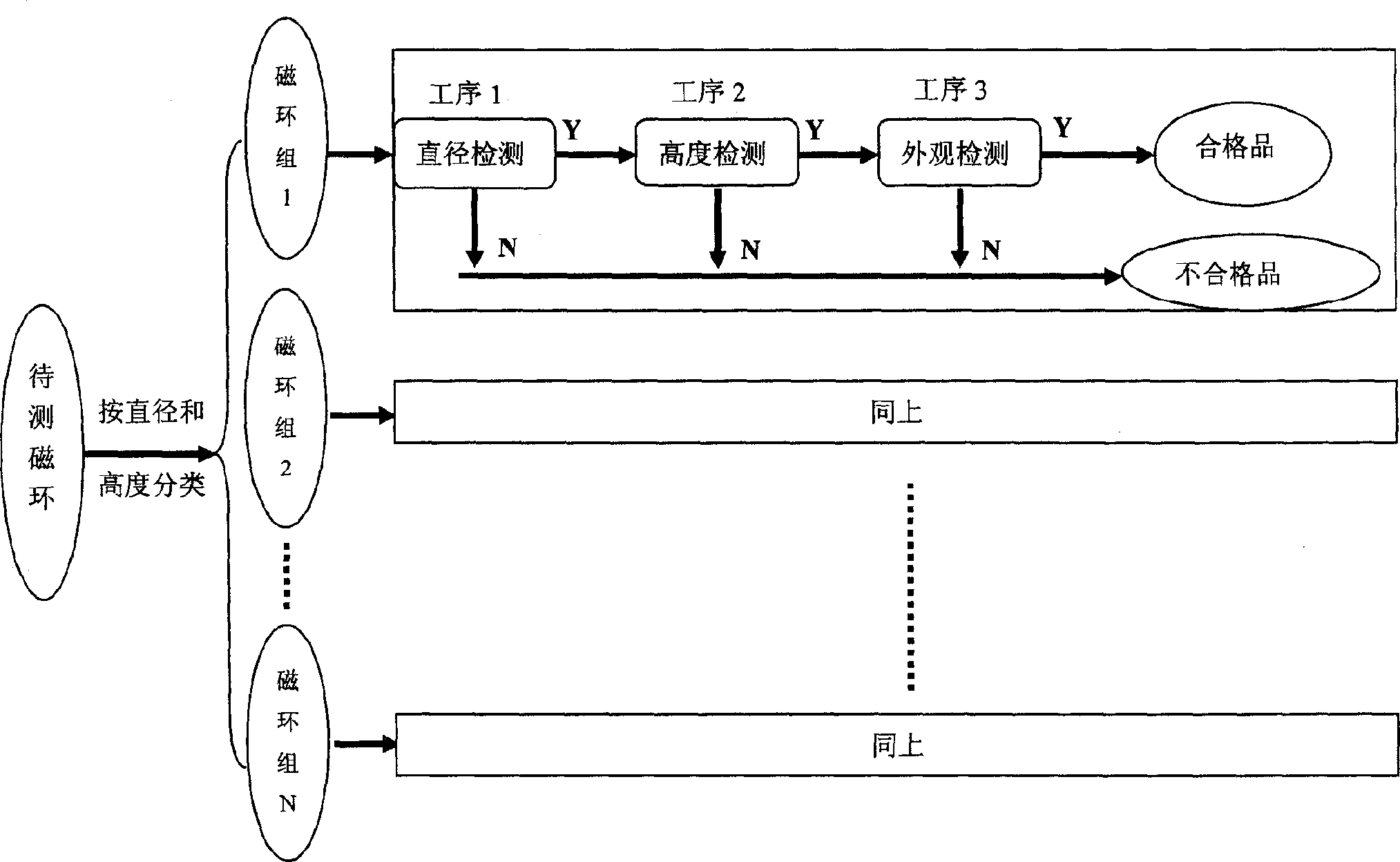

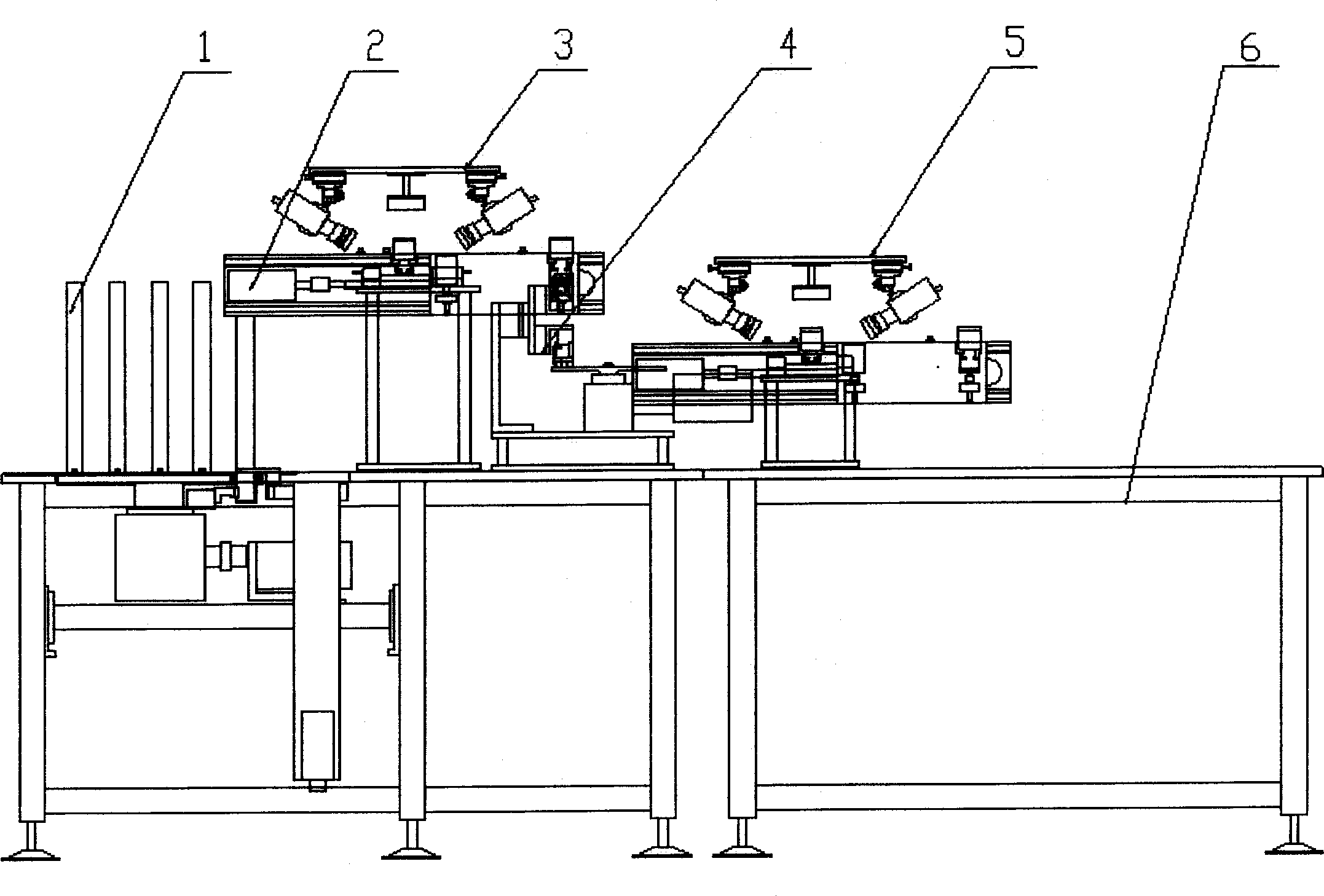

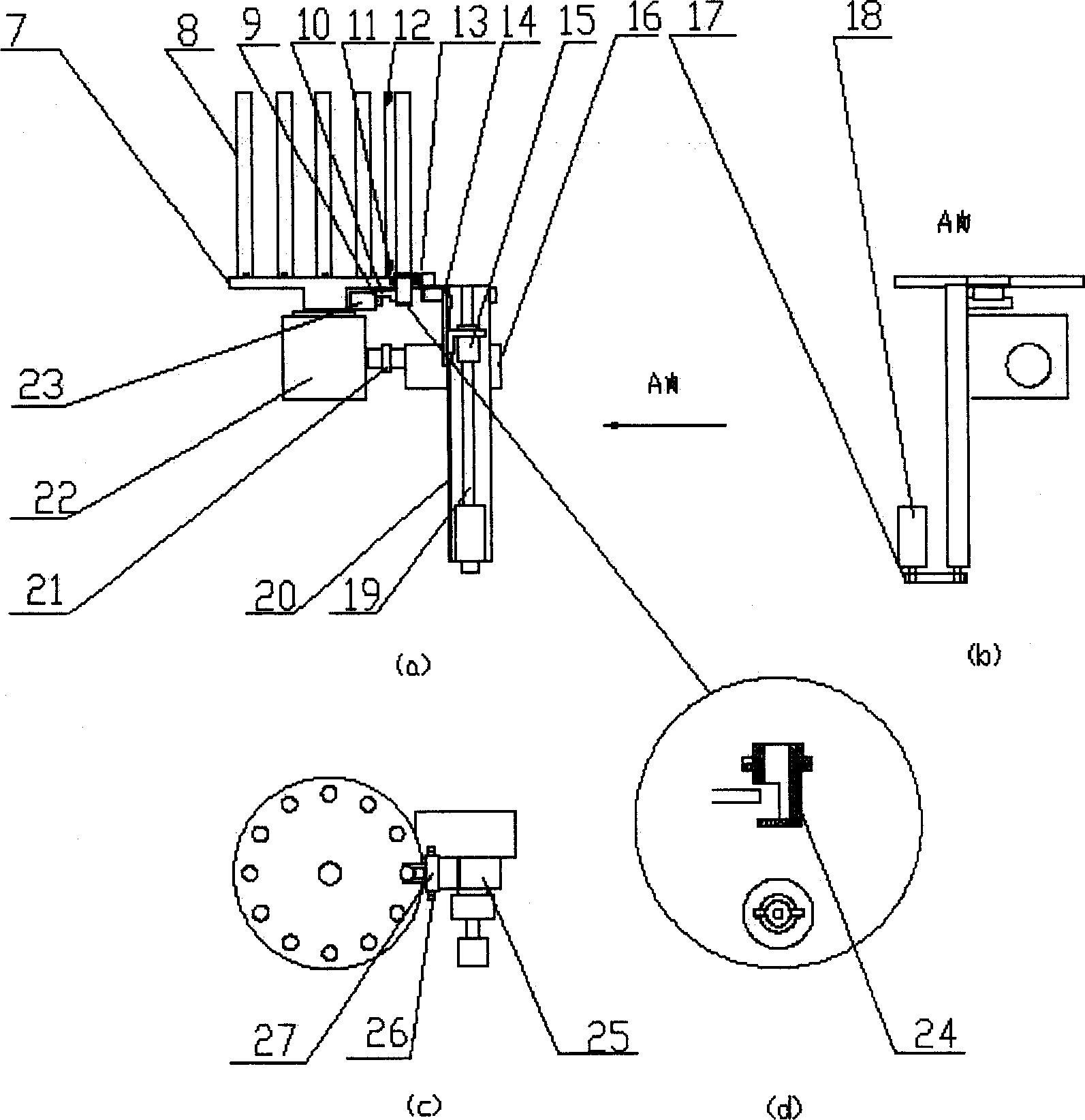

Automatic detection device for magnetic loop image

InactiveCN1865948ARealize fully automatic detectionRealize automated productionInvestigating moving sheetsOptically investigating flaws/contaminationImage detectionManipulator

The related natural detection device for magnet ring image comprises: a frame with an auto feeding pan for magnet ring on front and a first dual-head mobile manipulator on back; arranging a first image detection platform on the manipulator and a second manipulator as well as a ring turning device on back side of the platform; using the first manipulator and platform to detect diameter and top surface, and the second device to detect target thickness and bottom surface. This invention reduces time and cost.

Owner:SHANGHAI UNIV

Ganoderma lucidum mycelia powder production process

InactiveCN102835254ARealize automated productionHigh in polysaccharidesHorticulturePlant ingredientsHypsizygusHypha

The invention provides a ganoderma lucidum mycelia powder production process which comprises the following steps of: (1) making grain culture mediums; (2) preparing liquid strains; (3) inoculating the grain culture mediums; (4) sending bottles with inoculated strains into a mycelia growth room; (5) sending the bottles into a bottle digging workshop after the bottles of culture mediums are full of mycelia and digging the mycelia out of the bottles; (7) drying the mycelia in a hot air dryer; (7) grinding the dried corn mycelia, wheat mycelia and soybean mycelia into coarse powder in a proportion of 58-62%: 34-36%: 4-6%; (8) placing the ground coarse powder into a mixing agitator, adding water to agitate evenly and puffing after the water content is up to 10%, wherein the puffing temperature is controlled within 109-111 DEG C; and (9) sending the puffed granular mycelia into an ultra-micro grinder to grind into 150-mesh powder, and packing to obtain finished products. The ganoderma lucidum mycelia powder produced by the method is good in taste and easy to digest and has the advantages of adjusting the immunity and improving the anti-hypoxia capability of organisms.

Owner:YANTAI LONGYU GANODERMA LUCIDUM BIOLOGICAL DEV

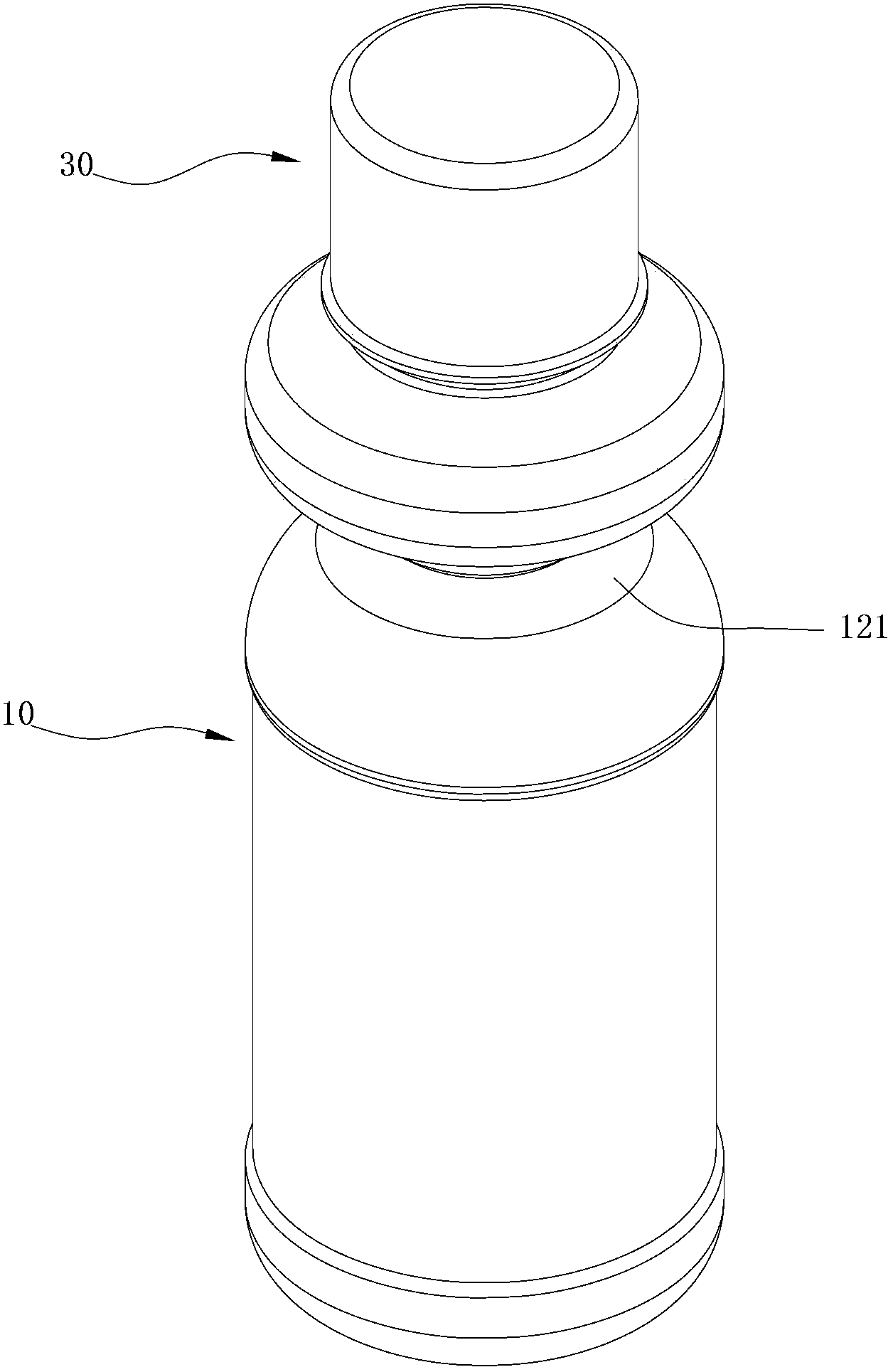

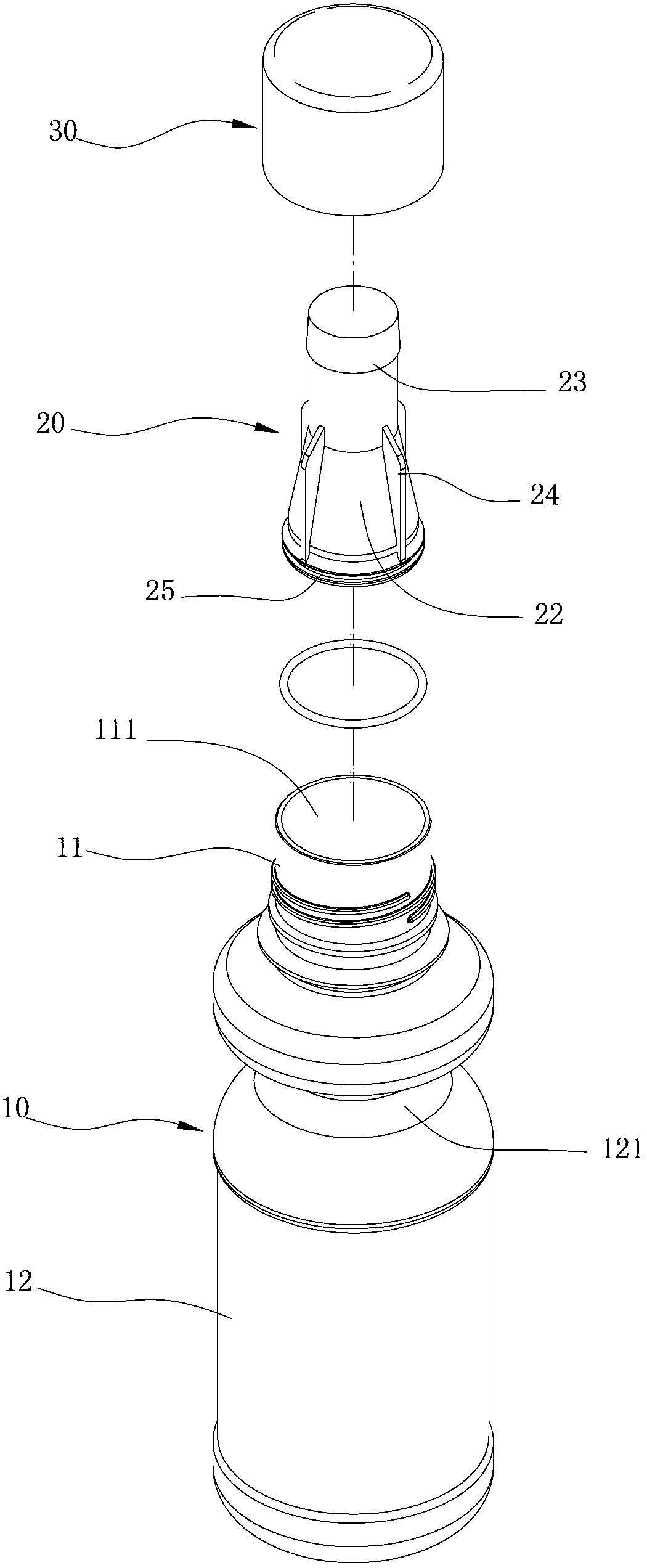

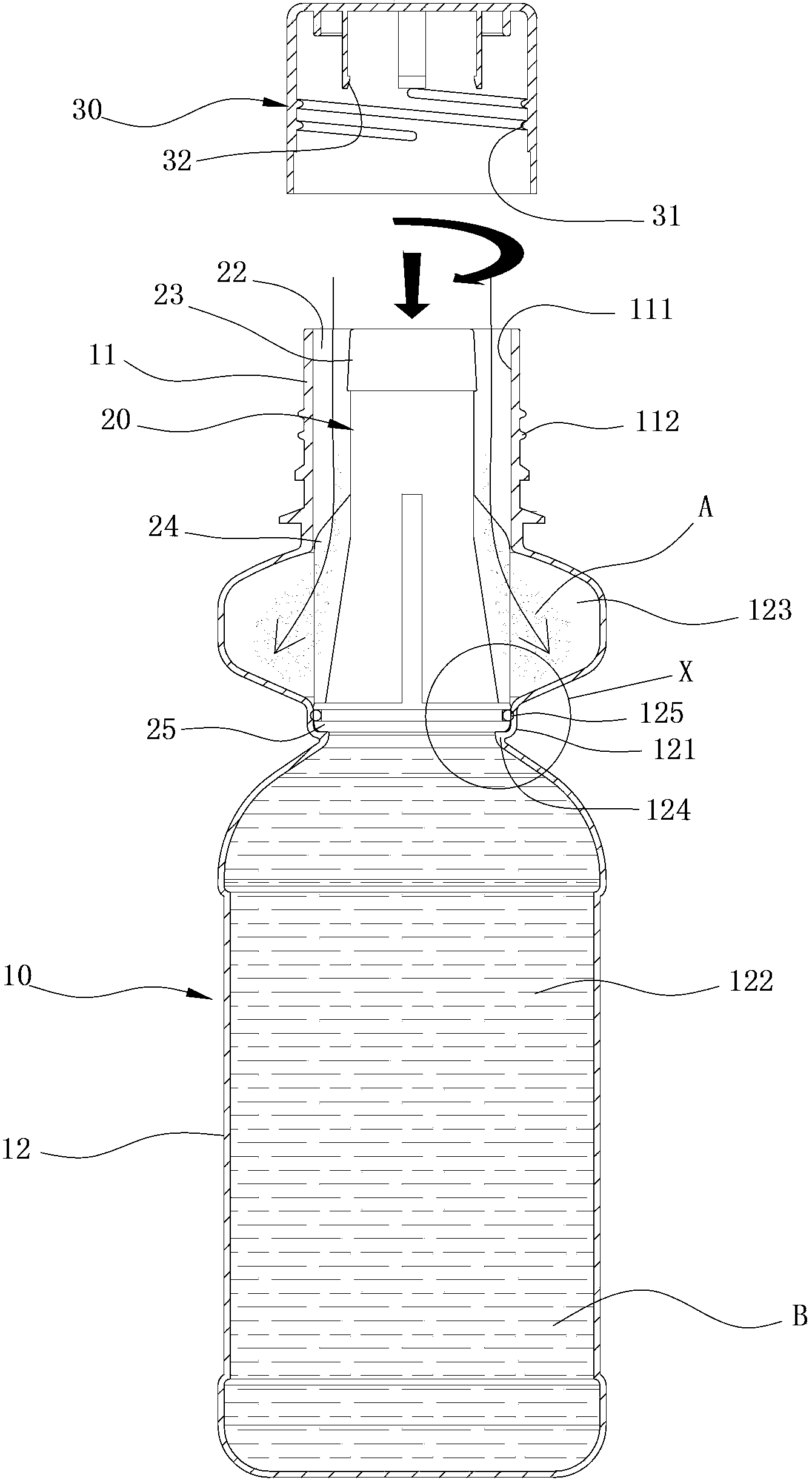

Mixing and filling bottle assembly

InactiveCN103538798AReduce manufacturing costLow injection costClosure with auxillary devicesContainers with multiple articlesEngineeringBottle cap

The invention discloses a mixing and filling bottle assembly. The mixing and filling bottle assembly comprises a bottle body, an isolation sleeve and a bottle cover. A waist binding part is arranged on the bottle body to divide the bottle body into a lower space and an upper space, and a lower abutting part and a matched periphery abutting part are arranged in the waist binding part. The isolation sleeve is arranged on the upper space of the bottle body and provided with an outer channel connected to the upper space, and a sealing part is arranged at the lower end of the isolation sleeve, abuts against the lower abutting part and the periphery abutting part, and abuts against the lower space and the upper space to achieve leakage stopping and isolation. The bottle cover is arranged on the outer periphery of the bottle body in a locked mode, and the inner end portion of the bottle cover is combined with the isolation sleeve. The mixing and filling bottle assembly has the advantages of achieving full-automatic production, being small in component number, exquisite and simple in structure, low in mold manufacturing cost, ejection cost and finished product cost, easy to assemble and the like.

Owner:杨芳林

Device and method for using laser technology to mark feeding bottle

The invention relates to the laser processing technology field and discloses a device and a method for using the laser technology to mark the feeding bottle. The device for using the laser technology to mark the feeding bottle comprises an automatic material feeding mechanism, a material receiving-taking mechanism, a laser marking mechanism and a rotary disc mechanism; the automatic material feeding mechanism is provided with a product to be processed and the product to be processed is delivered to a material taking-receiving position of the material taking-receiving mechanism, and the automatic material feeding mechanism is also used for delivering processed products; the taking-receiving material mechanism takes product to be processed and puts the product to be processed on the rotary disc mechanism; the processed product on the rotary disc mechanism is taken away and is put back on the automatic material feeding mechanism; the rotary disc mechanism clamps the product to be processed and drives the product to be processed to rotate to a position corresponding to the position of a laser marking mechanism; and the laser marking mechanism performs laser marking on the product to be processed. The device and method can perform laser calibration on the glass bottle, the structure is simple, the function is reliable and easy to implement, and the automation is realized.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com