Mixing and filling bottle assembly

A bottle group and mixing technology, which is applied to containers with multiple items, containers, and sealing parts with auxiliary devices, etc., can solve the problems of inability to effectively increase production capacity, high mold production costs, and high finished product costs, and achieve mold production costs. Low cost, low finished product cost, low injection cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]Hereinafter, the preferred embodiment of the mixed filling bottle set of the present invention will be described in detail in conjunction with the accompanying drawings:

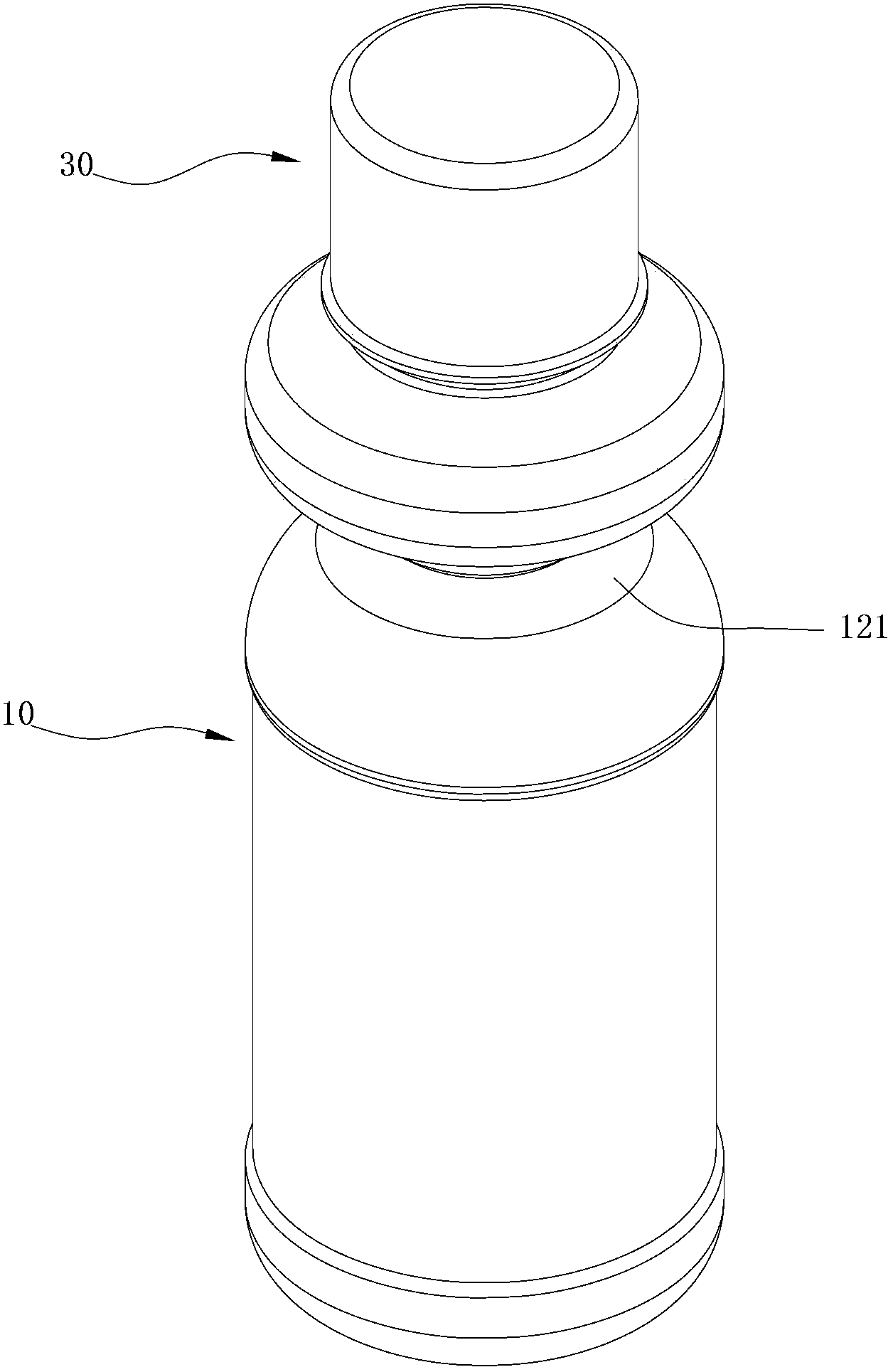

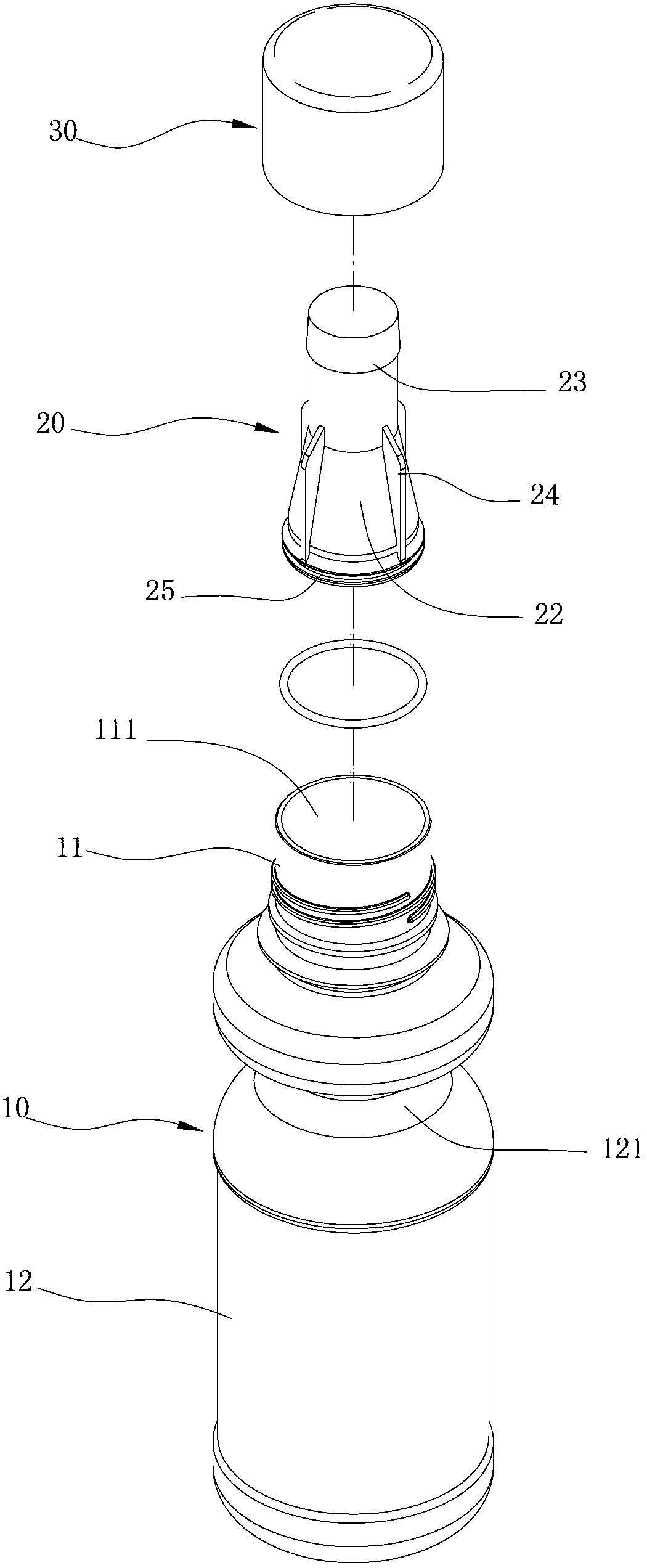

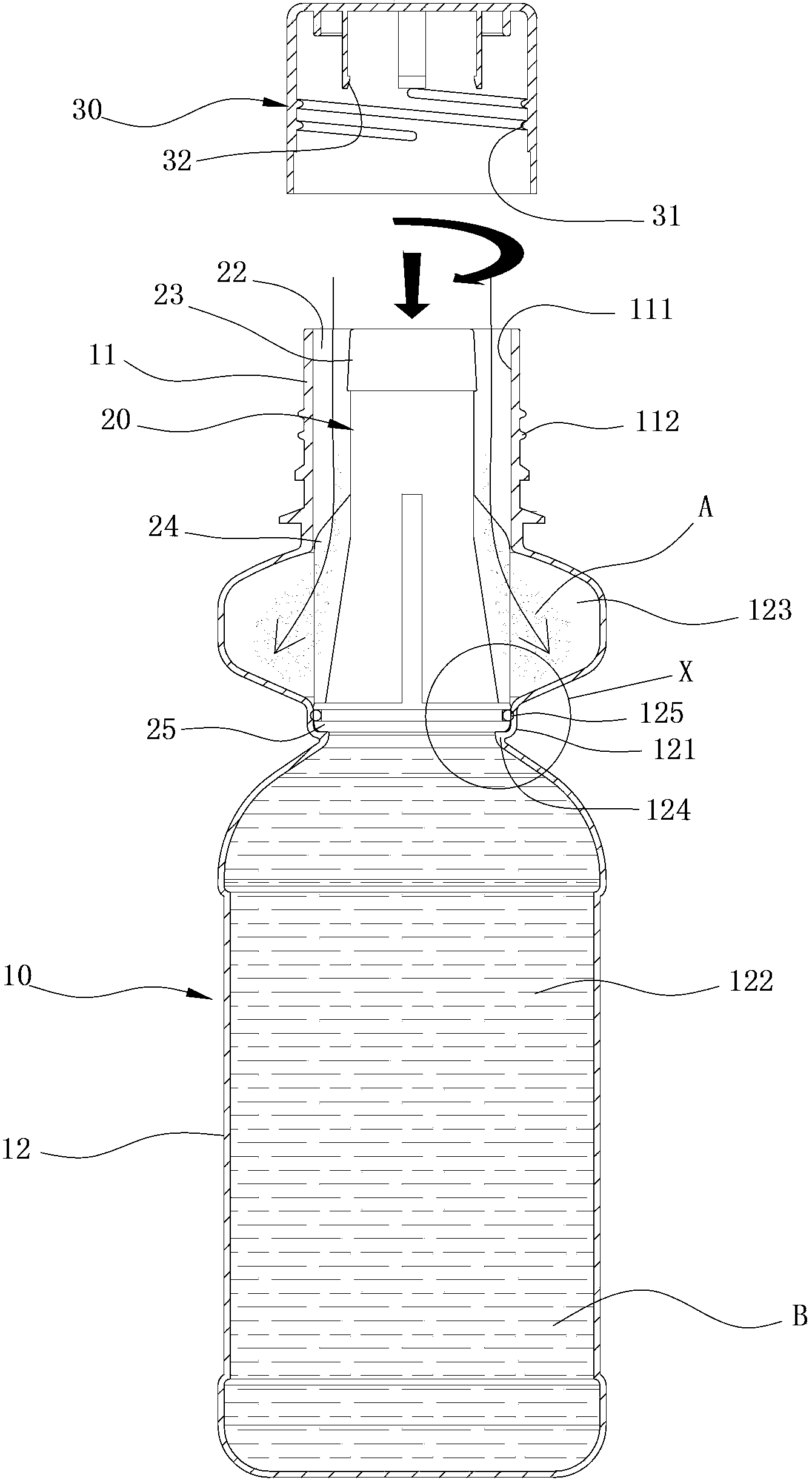

[0070] see figure 1 with figure 2 , the mixed filling bottle set of the present invention, comprising:

[0071] A bottle body 10 has a bottle mouth 11 and a bottle body 12. The bottle mouth 11 has an inner opening 111 and an outer peripheral edge 112 with screw teeth. The bottle body 12 is provided with a waist 121, so that the bottle body 12 The interior is divided into a lower space 122 and an upper space 123 , and the waist portion 121 is provided with a position-limiting lower part 124 and a water-stopping peripheral part 125 .

[0072] A spacer 20 is placed into the upper space 123 by the inner opening 111 of the bottle mouth 11 of the bottle body 10, and the outer channel 22 is connected to the upper space 123 by the bottle mouth 11 on the periphery of the spacer 20. The upper part of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com