Patents

Literature

290results about How to "Automate the packaging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

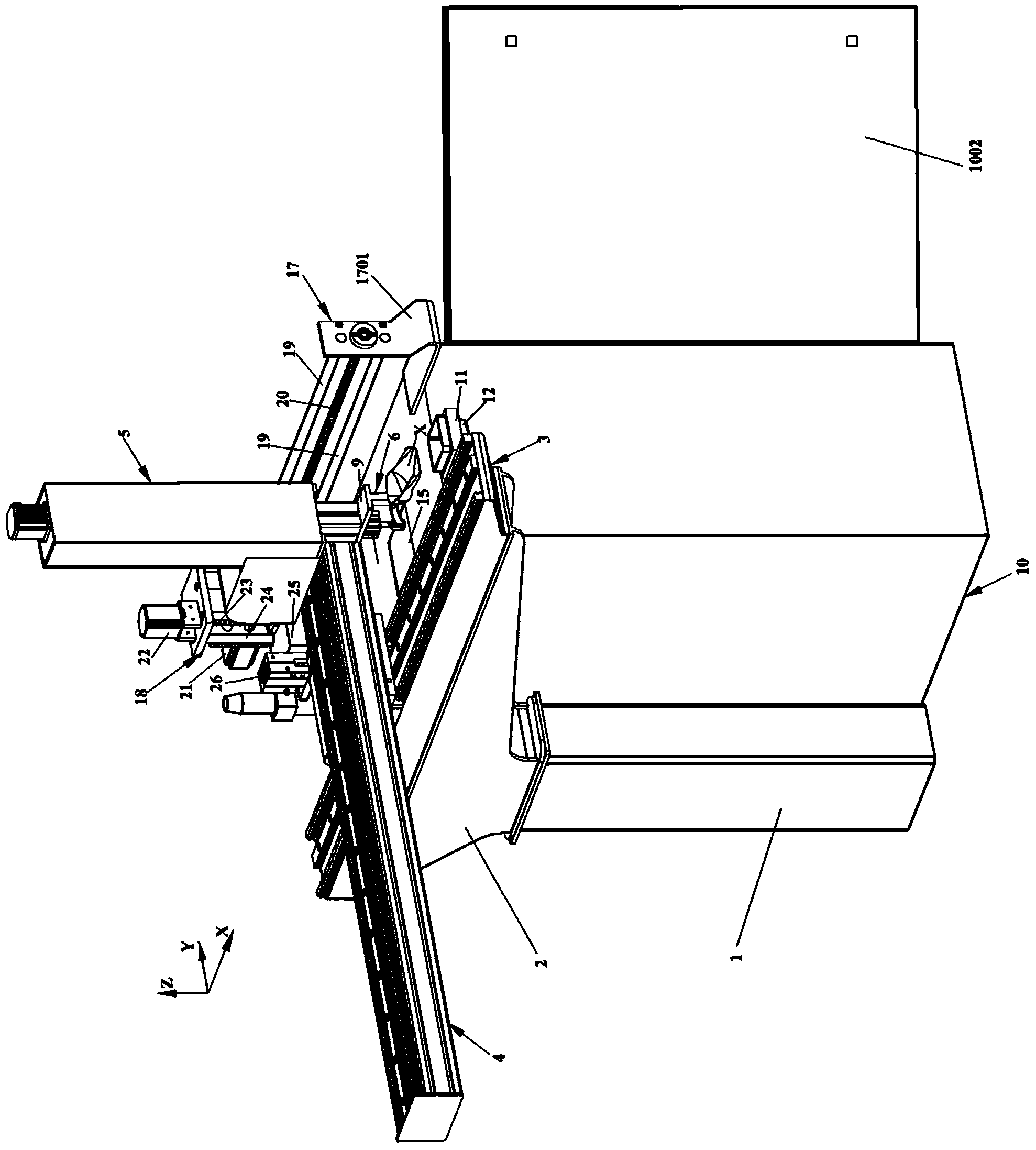

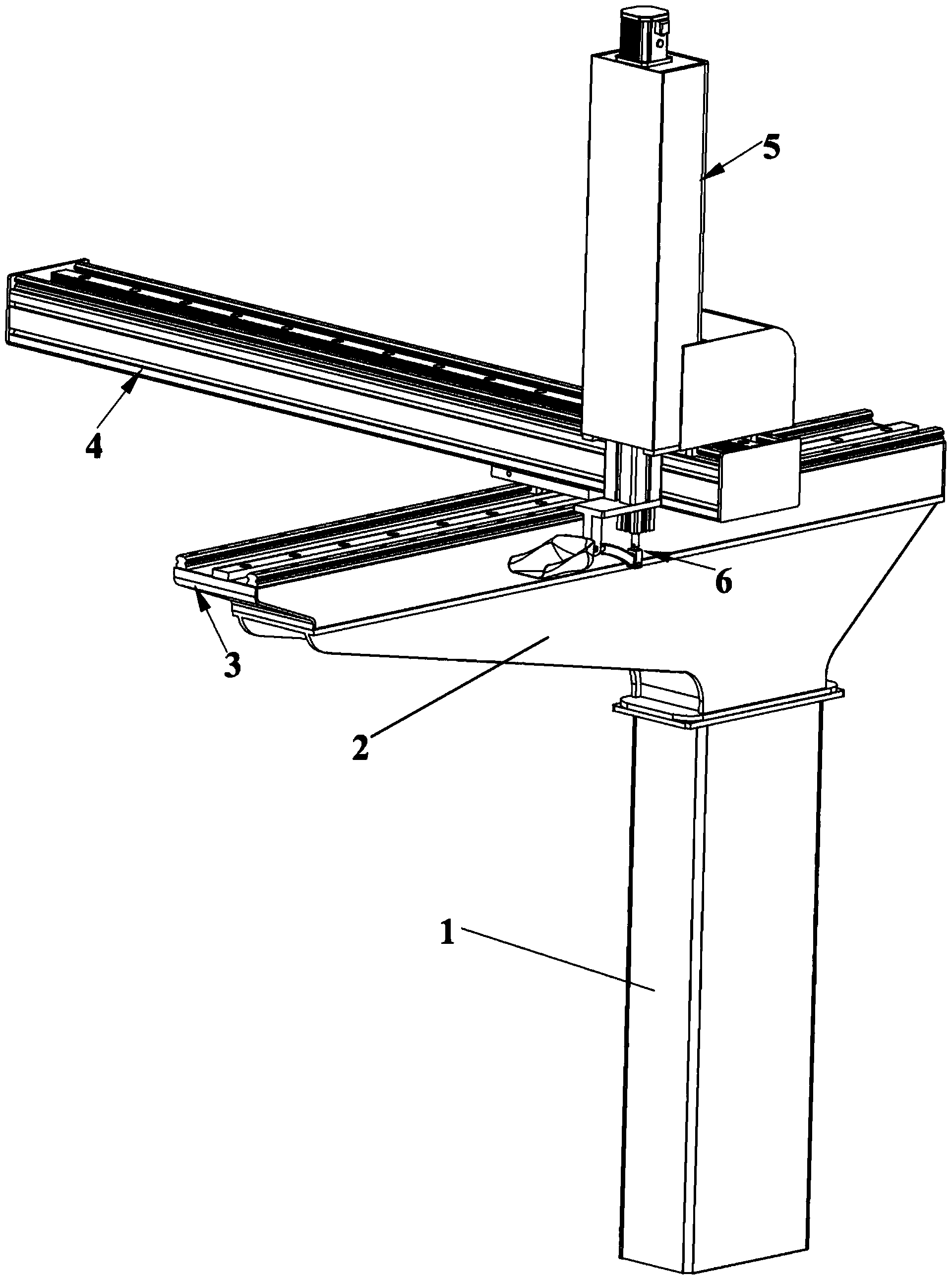

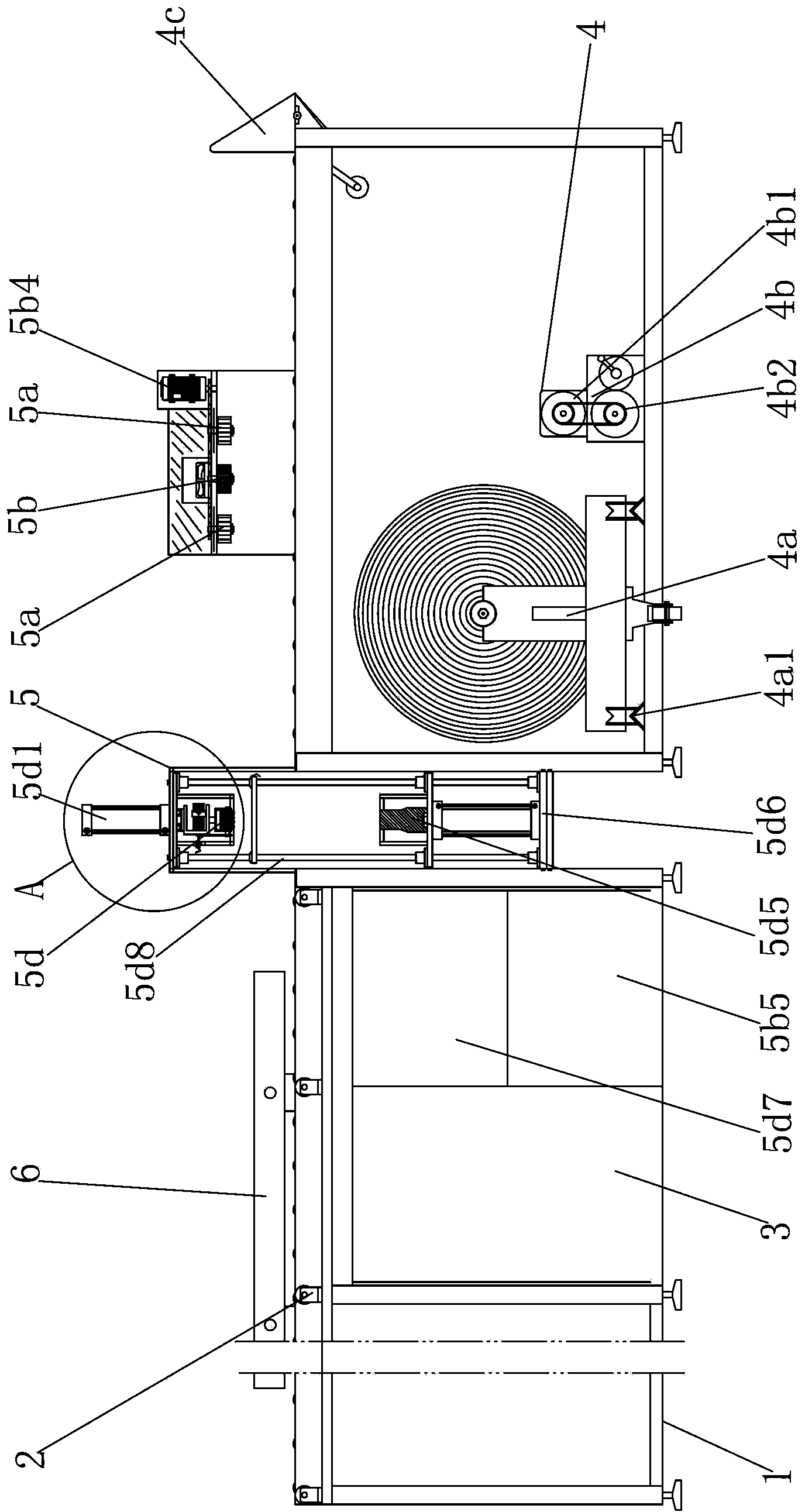

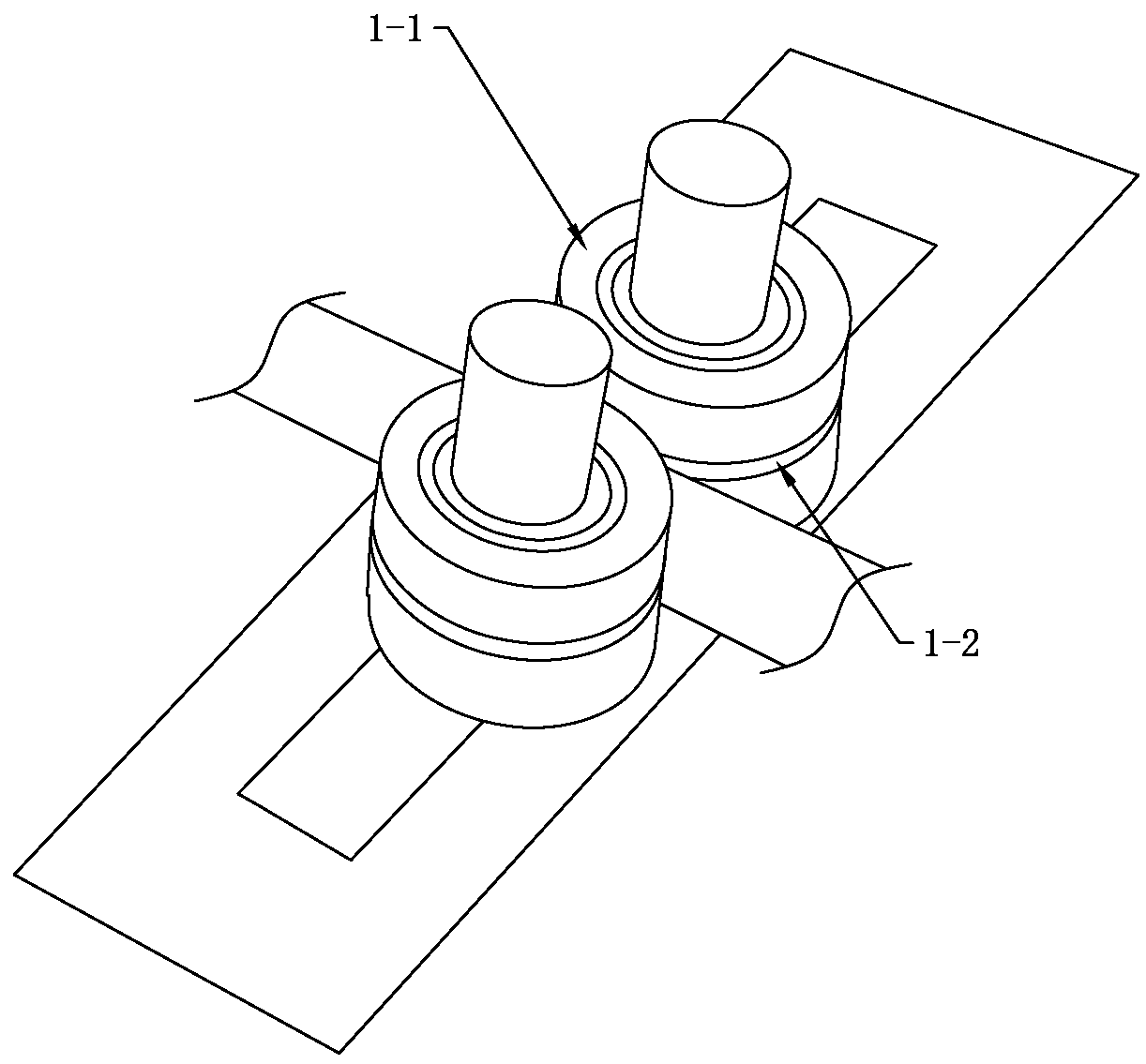

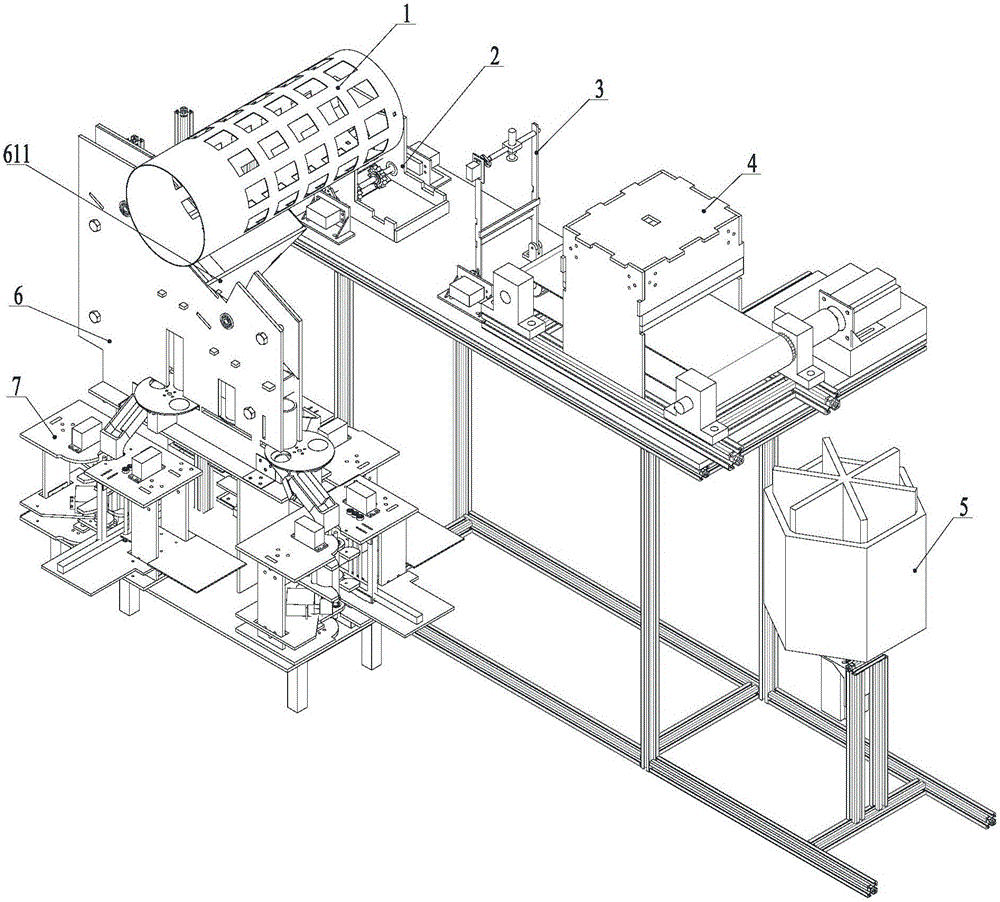

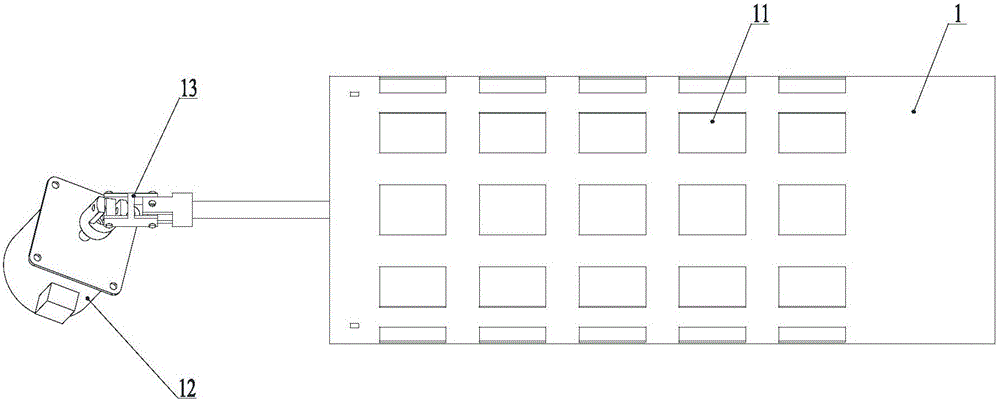

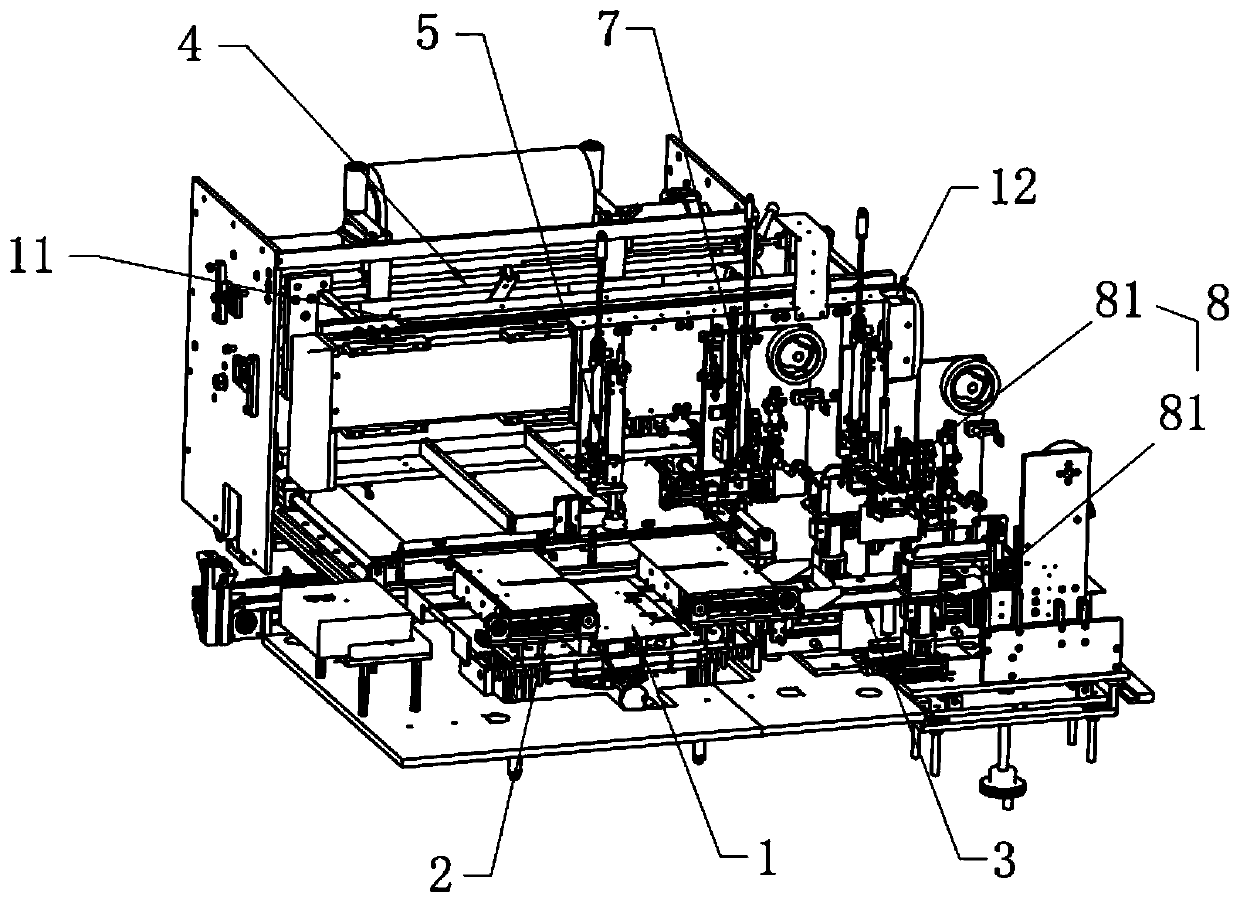

Sampling system

ActiveCN104101512AVersatileImplement automatic samplingWithdrawing sample devicesSolid materialThird partyEngineering

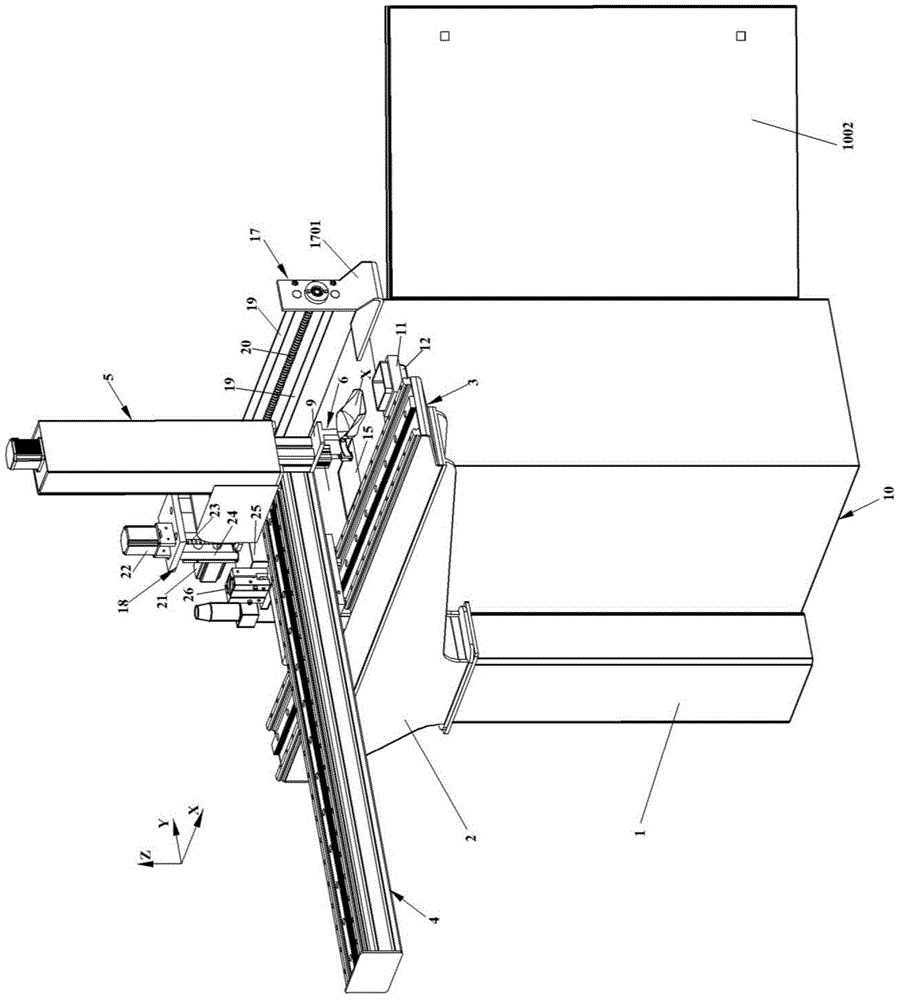

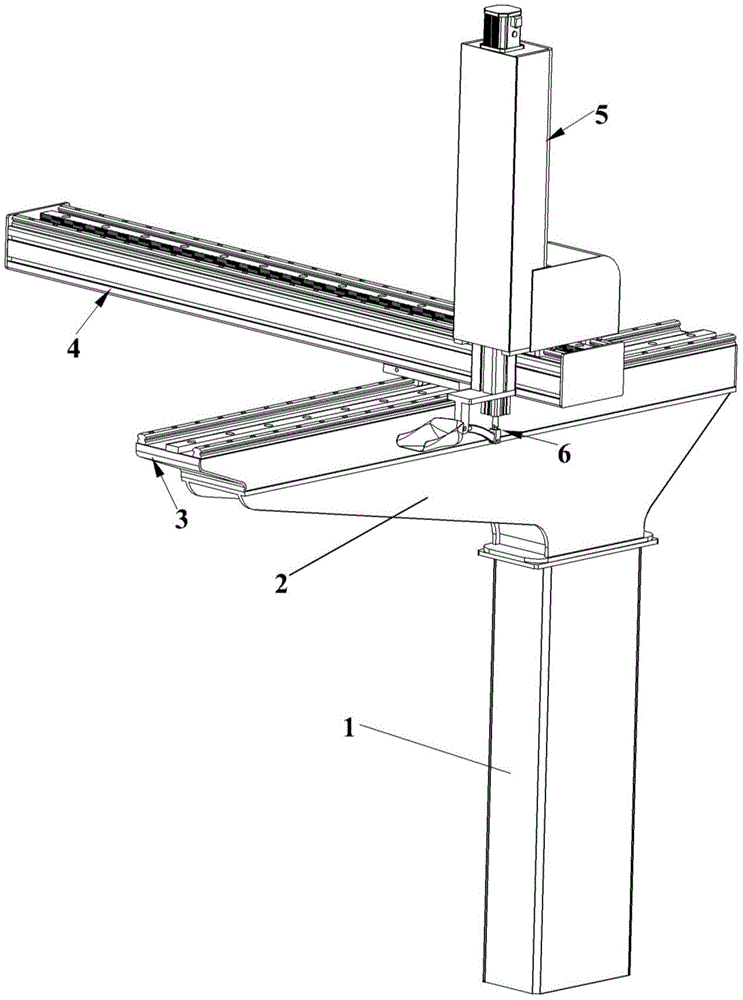

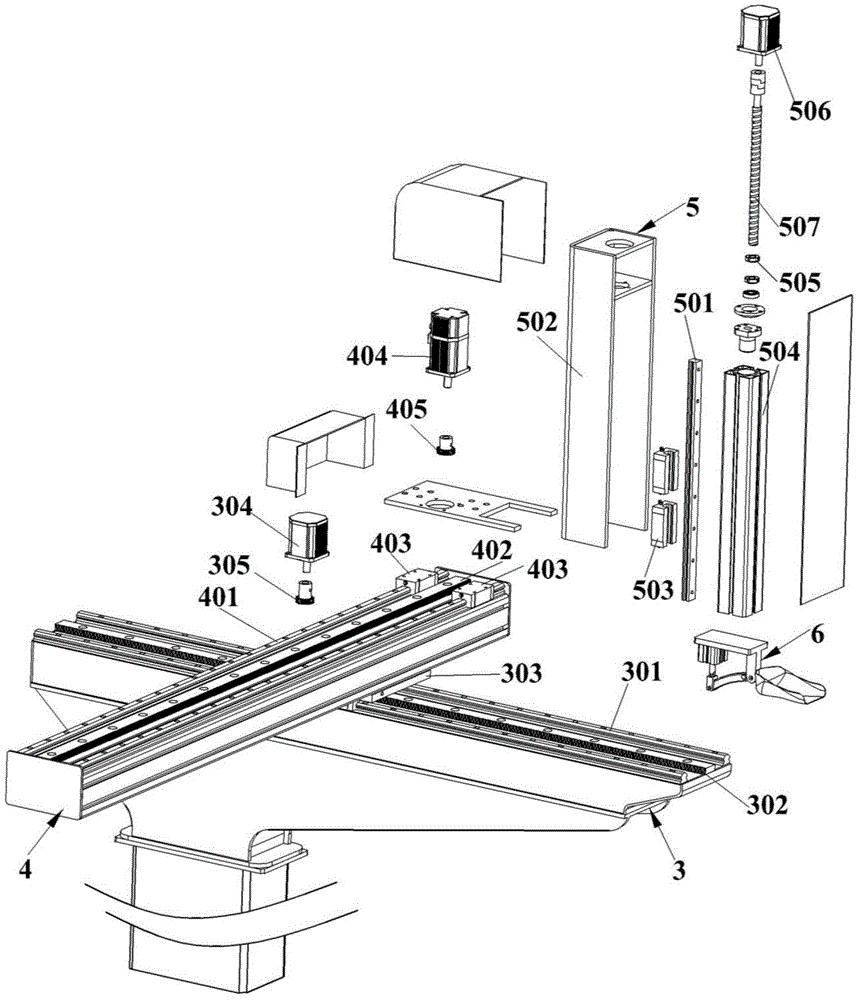

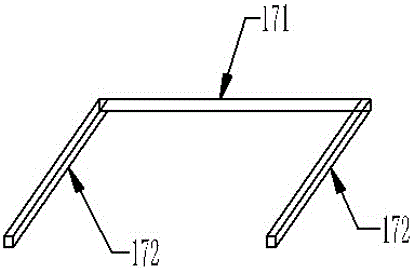

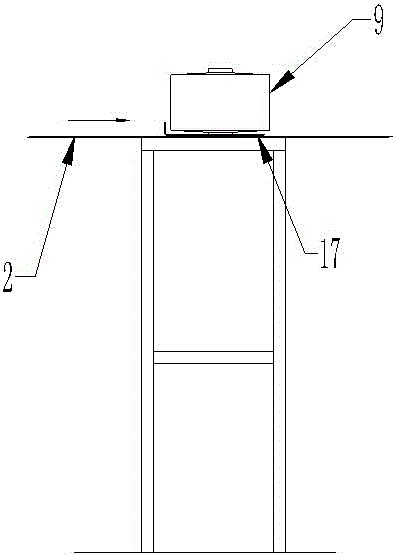

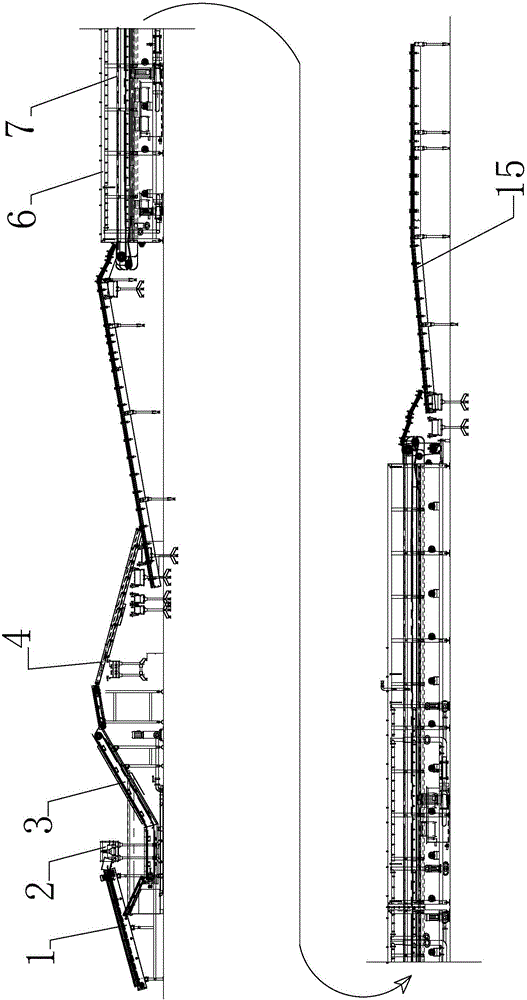

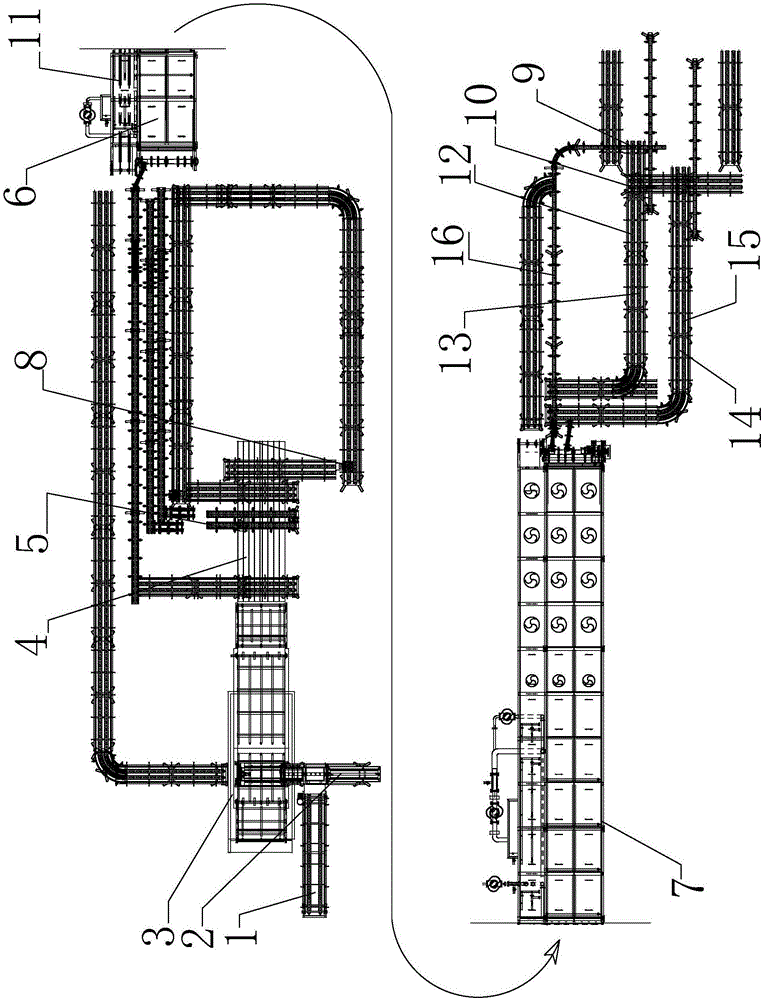

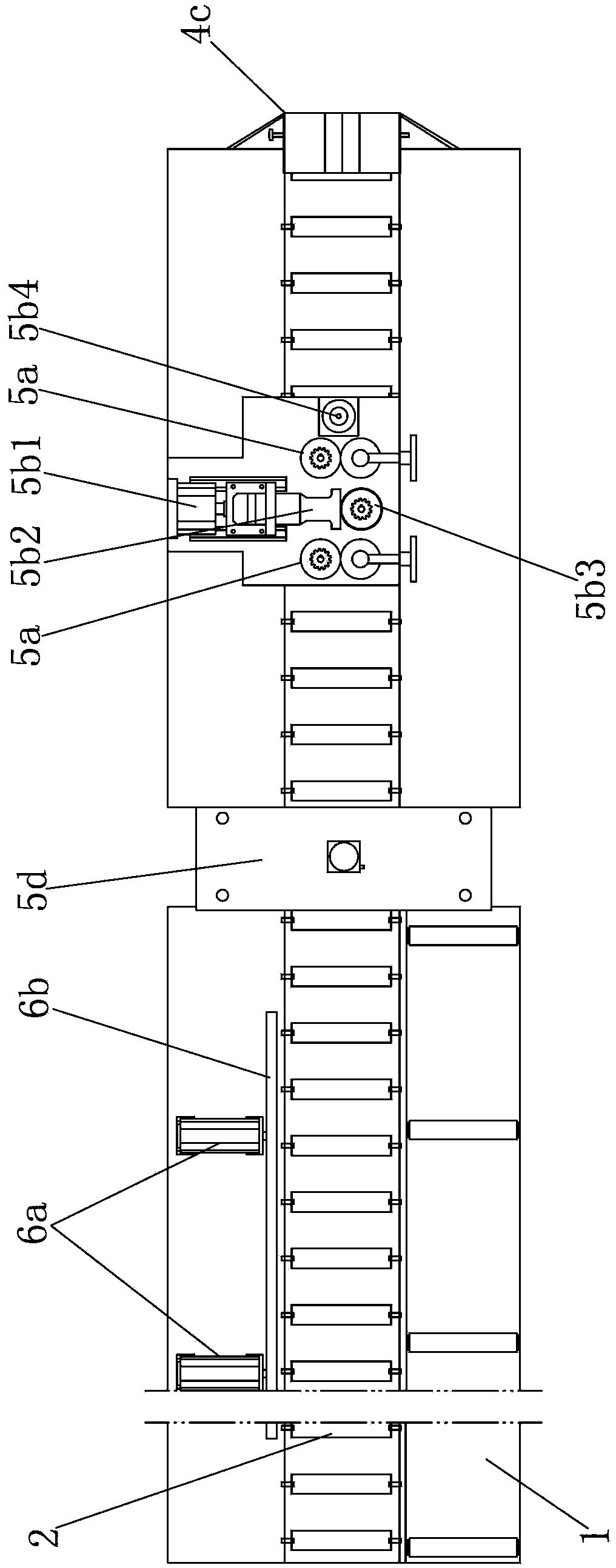

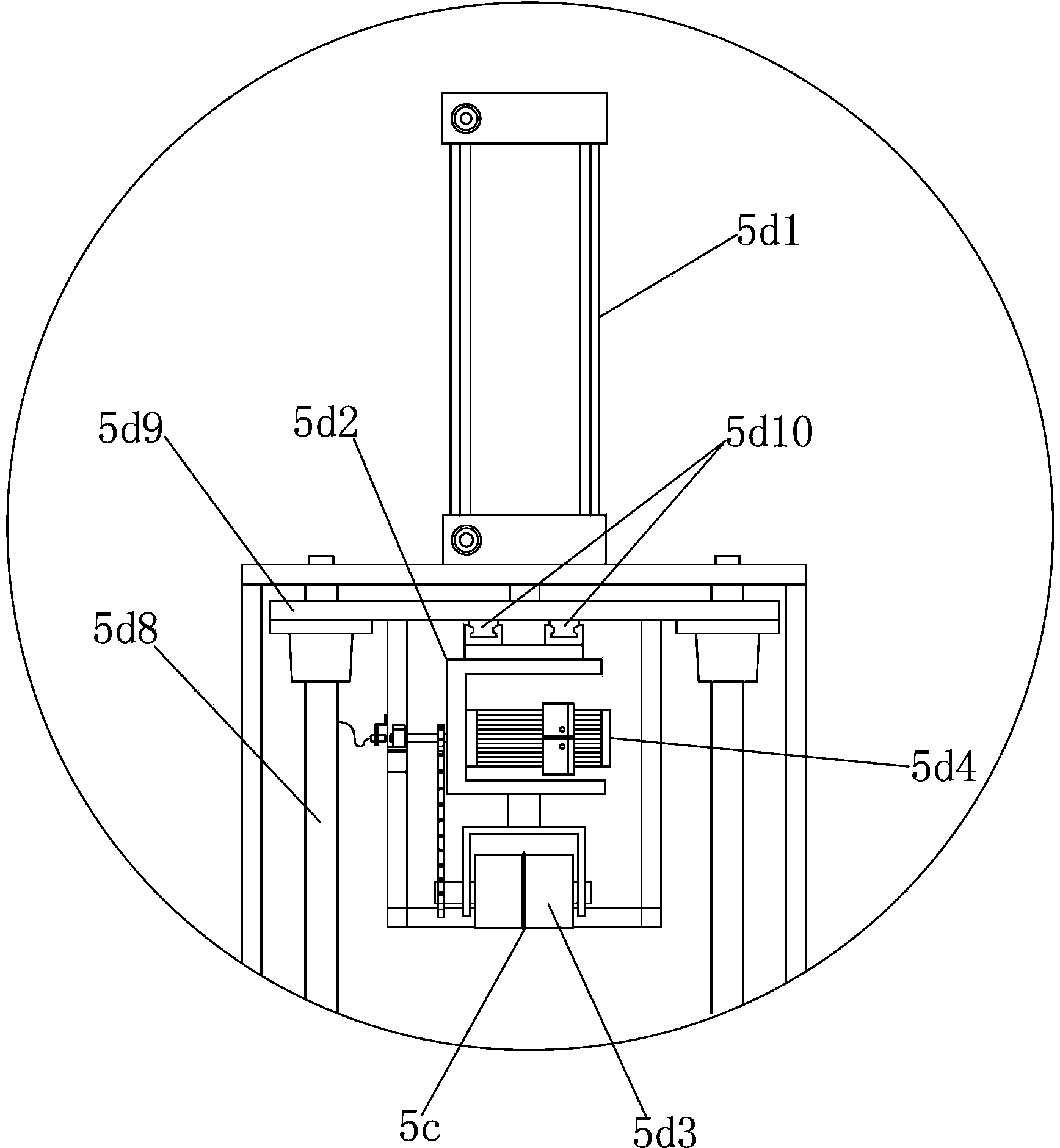

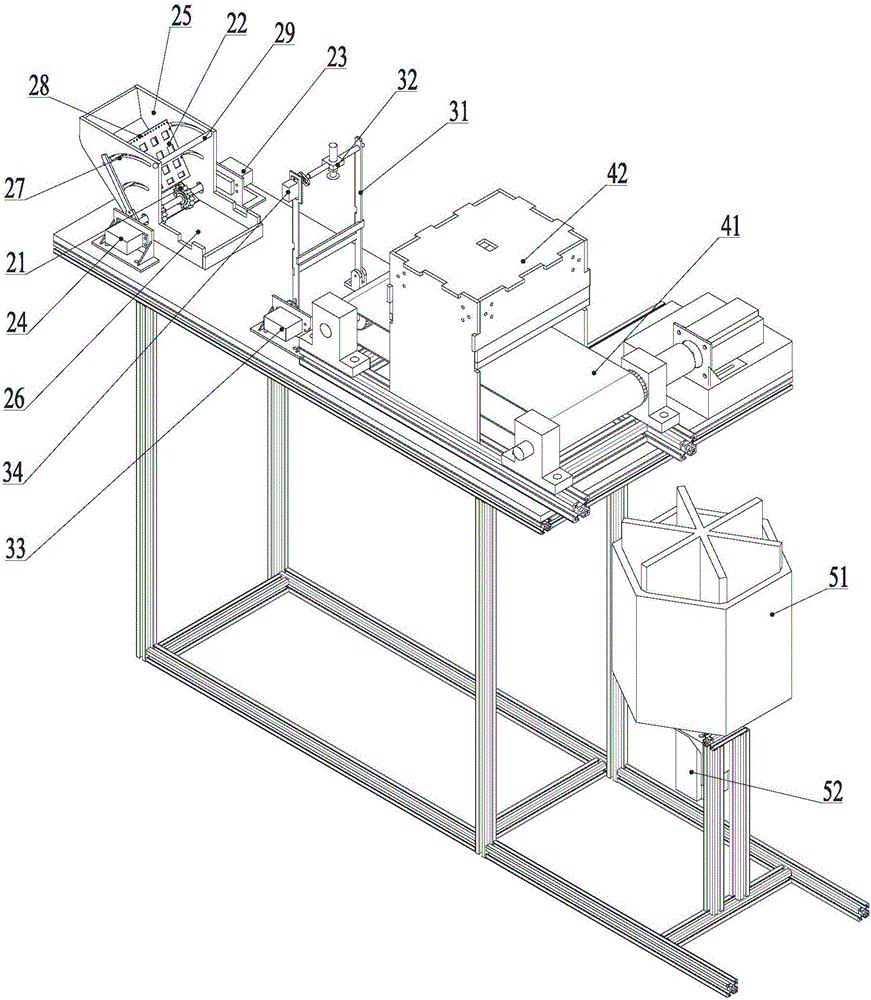

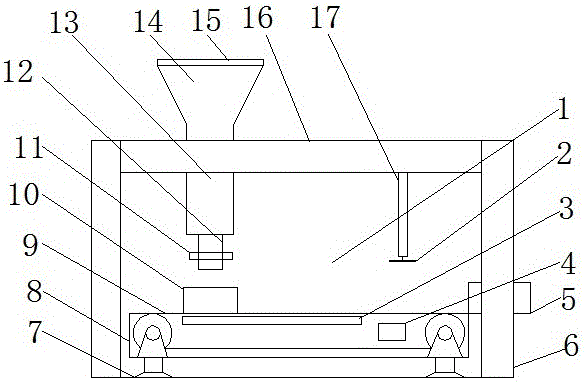

The invention discloses a sampling system. The sampling system comprises a sampling bracket and a sampling device, wherein the sampling device comprises a chassis, an X directional moving mechanism, a Y directional moving mechanism, a Z directional moving mechanism and a sampling mechanism; the chassis is positioned at the top end of the sampling bracket; the X directional moving mechanism is fixedly arranged on the top surface of the chassis; the Y directional moving mechanism is positioned on the X directional moving mechanism; the Z directional moving mechanism is positioned on the Y directional moving mechanism; the sampling mechanism is positioned on the Z directional moving mechanism; the X directional moving mechanism, the Y directional moving mechanism and the Z directional moving mechanism are adopted to control the sampling mechanism to move respectively to a storing device filled with particles; part of particles are acquired as samples by the sampling mechanism, and then the samples moves to a packing device for packing. The sampling system has the advantages that the sampling system is capable of adapting different production frequencies, realizes the purposes of automatic sampling and automatic packaging, can conduct the third-party encryption security on the samples, and can carry out remote operation monitoring.

Owner:安徽省一一通信息科技有限公司

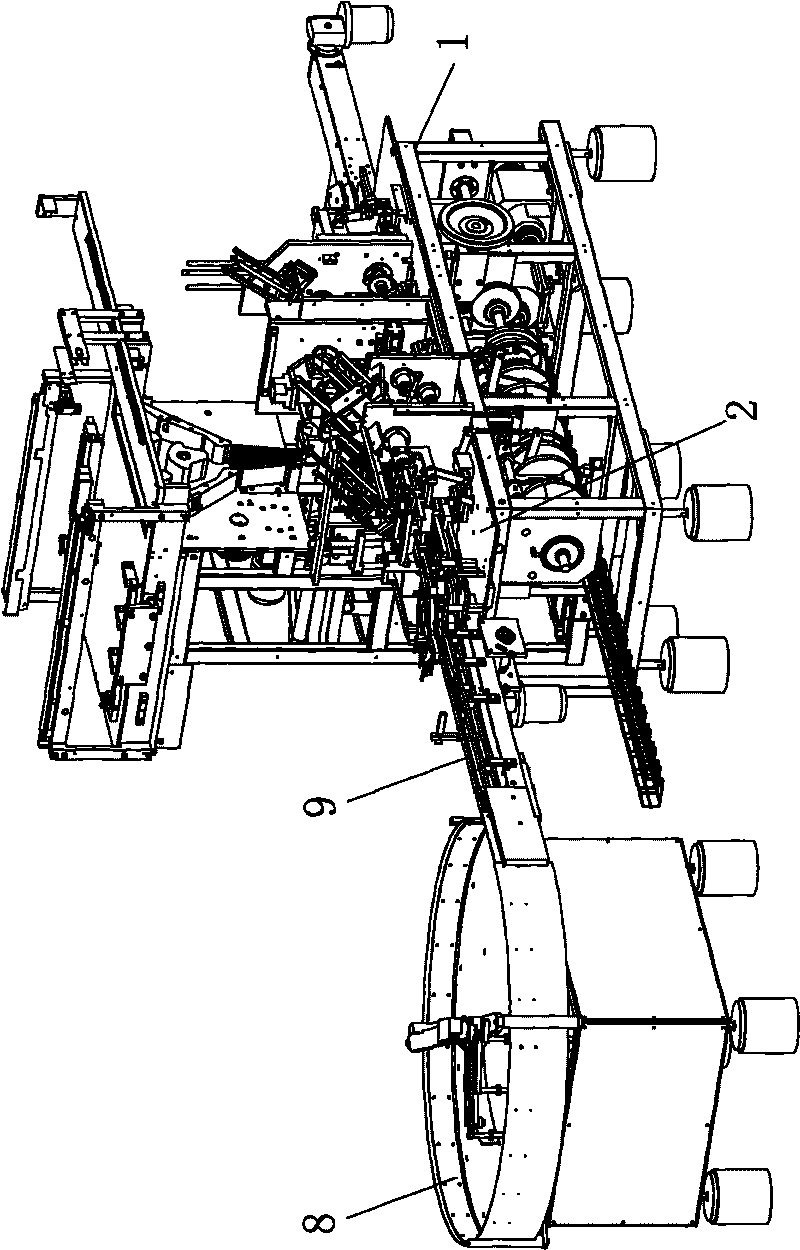

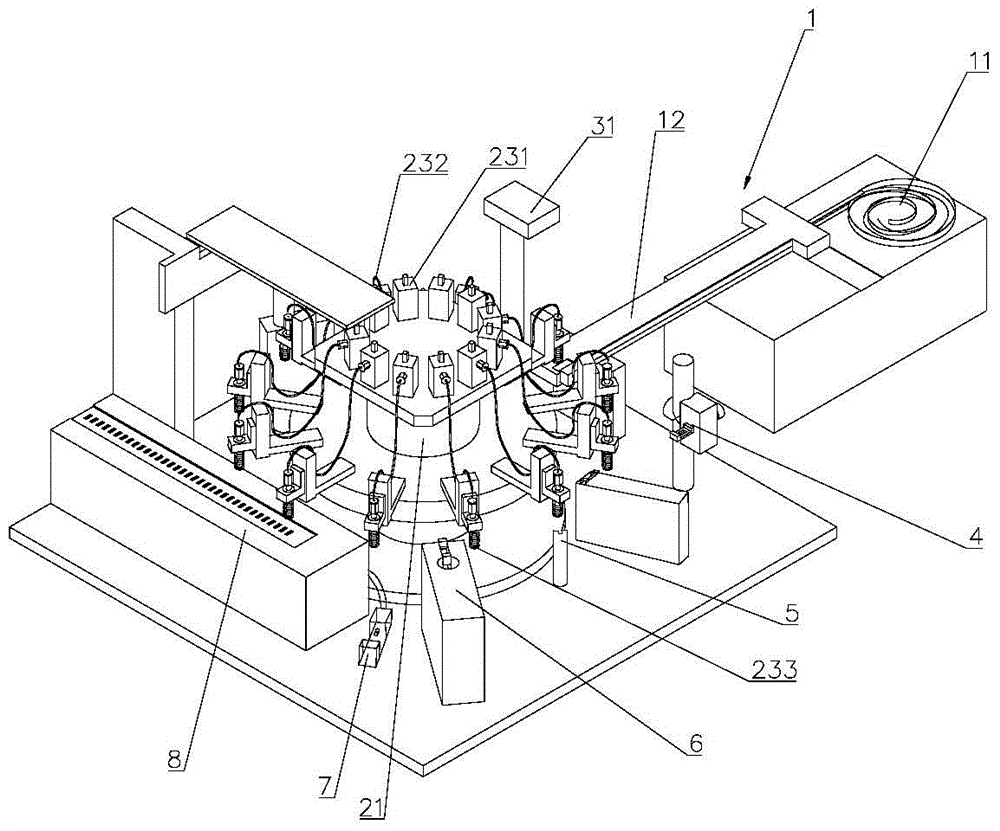

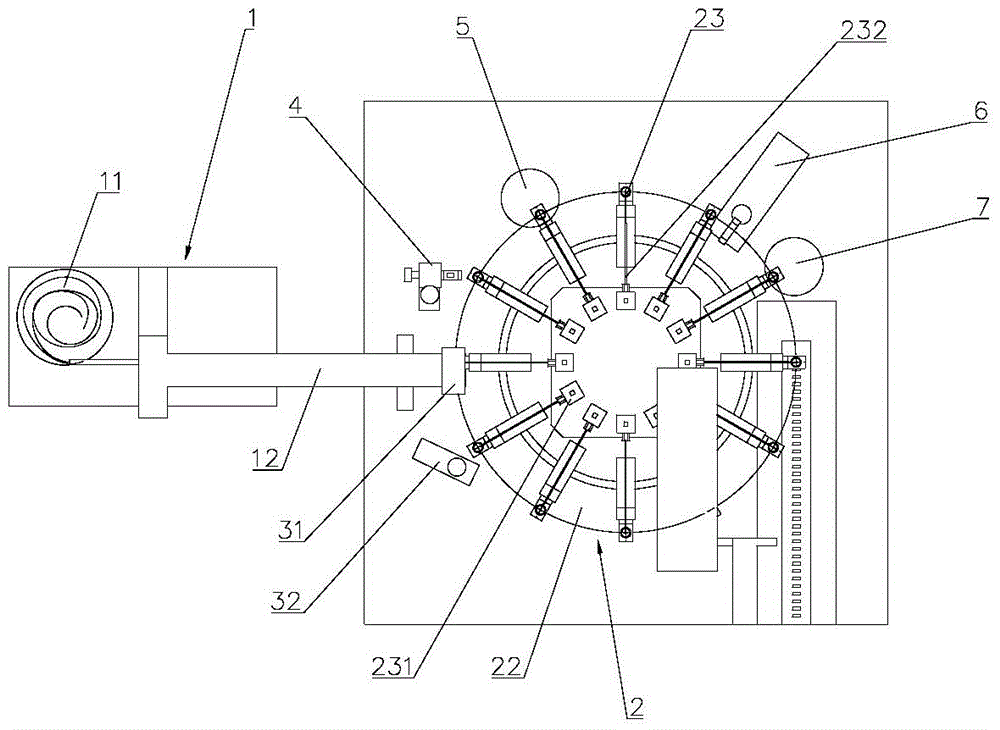

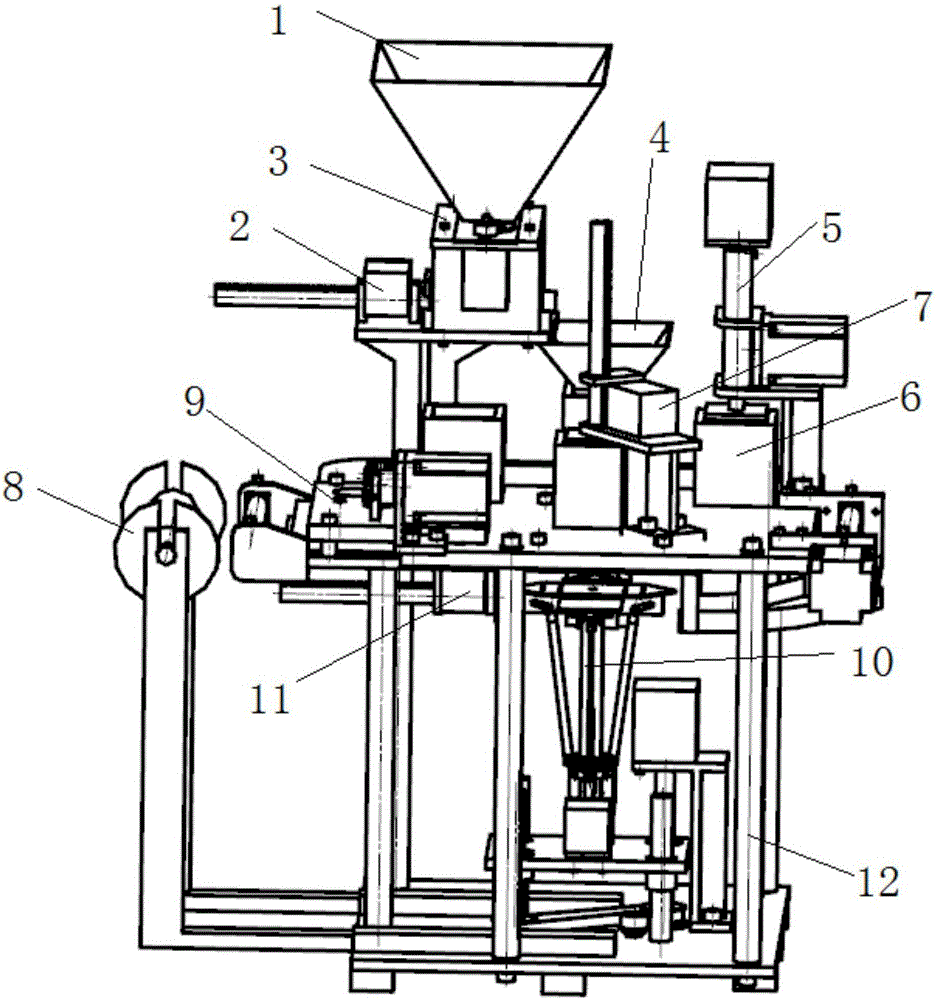

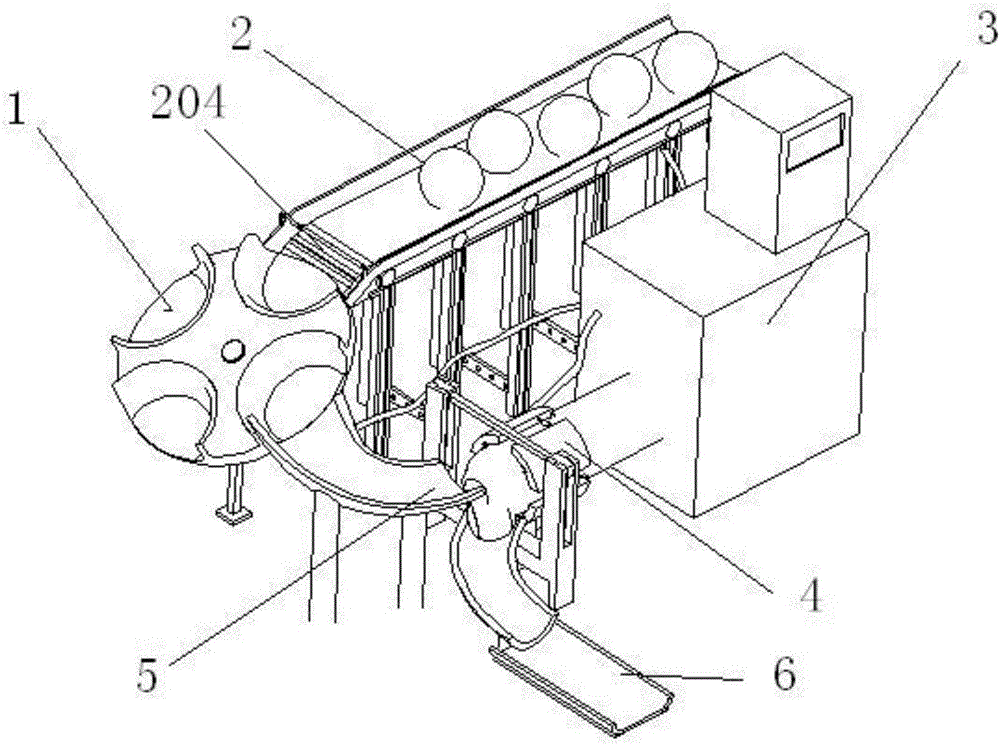

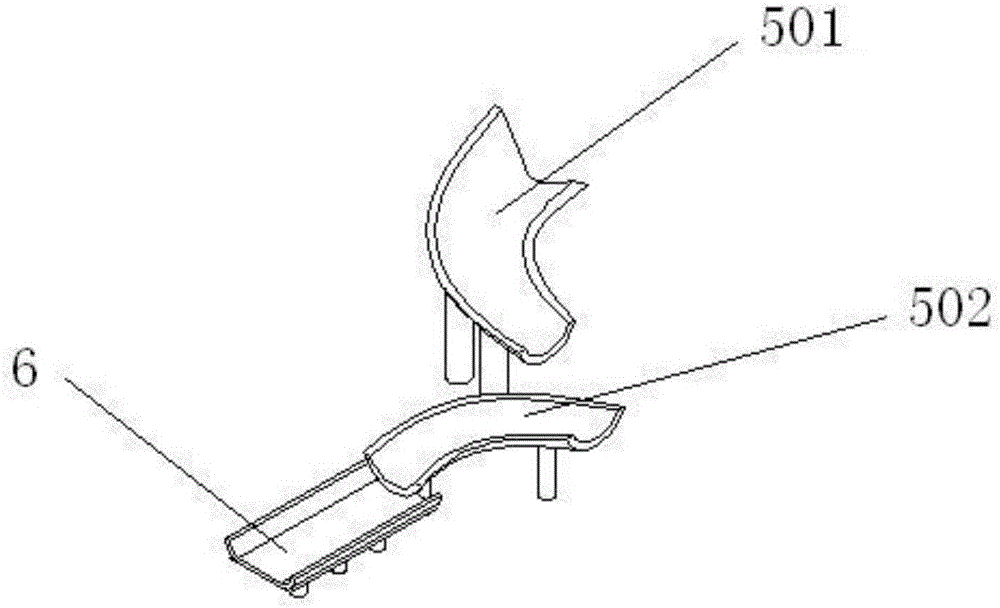

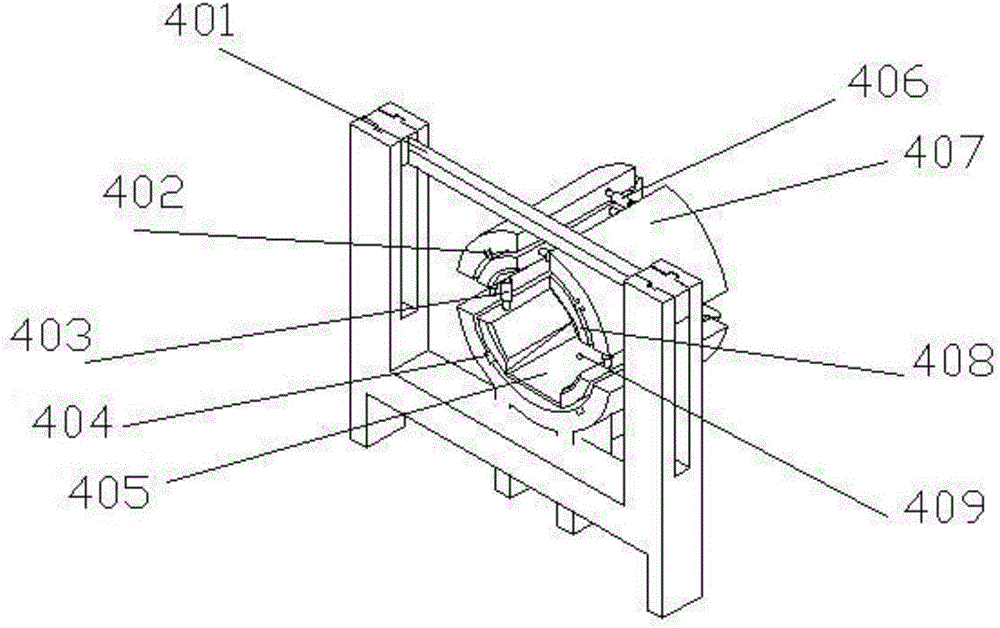

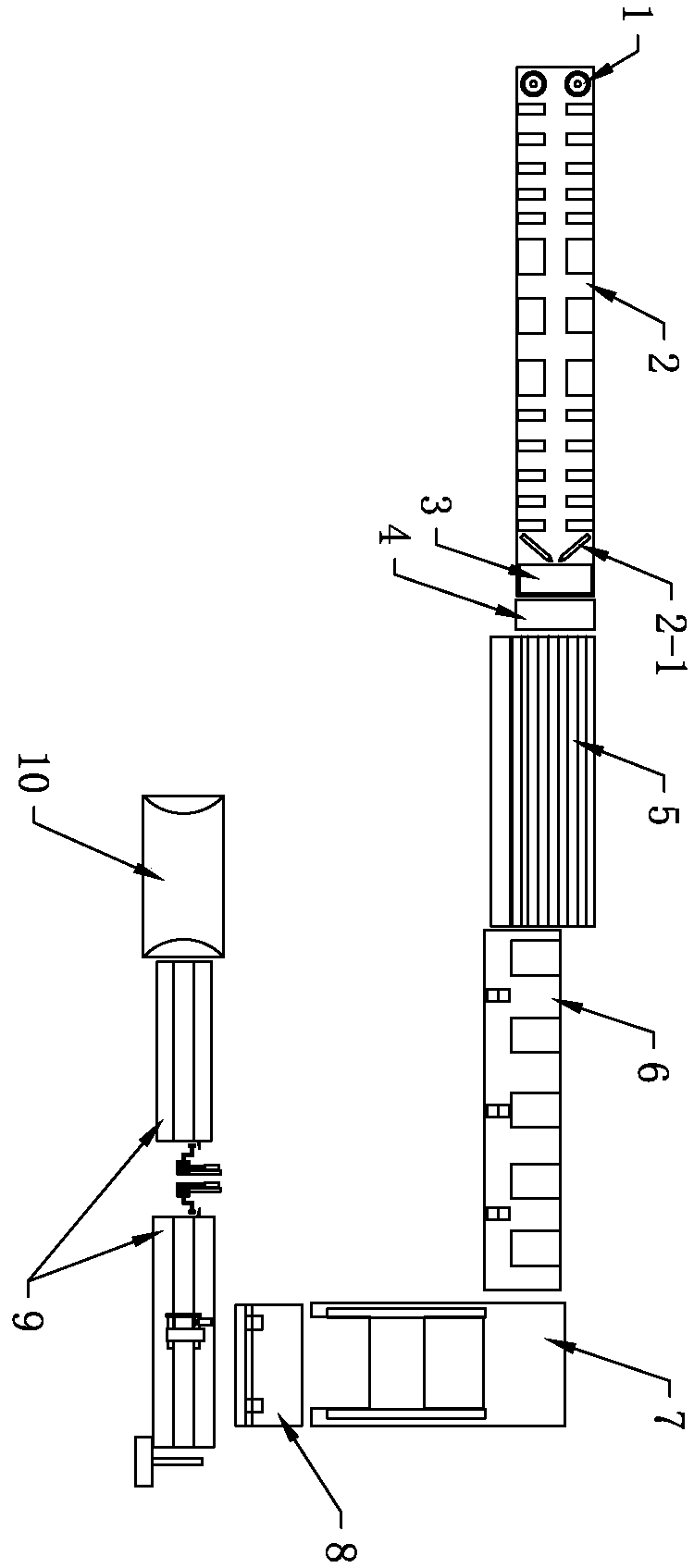

Spindle automatic package system and spindle separation counter weight method

ActiveCN105059615AAutomate the packaging processRealize automated productionPackaging automatic controlEngineeringAutomatic testing

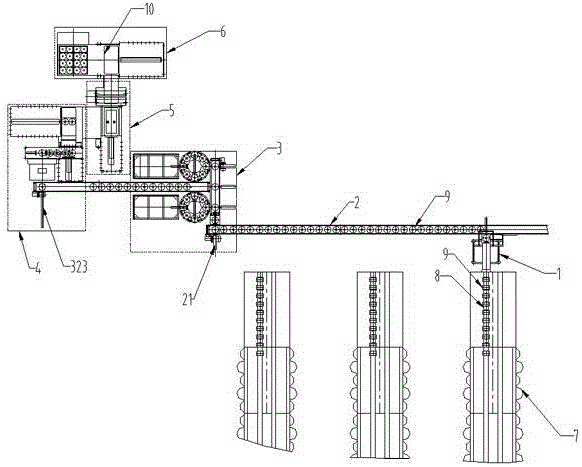

The invention discloses a spindle automatic package system comprising a doffing dolly, a spindle conveyer belt, a quota weight sorting mechanism, an automatic sleeving bagging mechanism, an automatic packing belt mechanism and an automatic bag loading mechanism; the doffing dolly is arranged between a spinning machine and the spindle conveyer belt; a discharge end of the spindle conveyer belt is provided with a charging cylinder. The spindle automatic package system is suitable for automatic weighing, counterweight, sleeving, bagging, packing belt, and bag loading steps of the spindle weaved and formed by the spinning machine like a ring spinning, an air spinning, an air-jet spinning, a vortex spinning, a siro spinning and a compact spinning; the method only needs to do artificial intervention in the automatic sleeving bagging mechanism so as to complete a spindle bag seal step, so full automation production of the spindle package can be basically realized, thus greatly reducing workshop labor number, and saving labor cost.

Owner:LUZHOU SHUIYUAN HYDRAULIC MACHINE +1

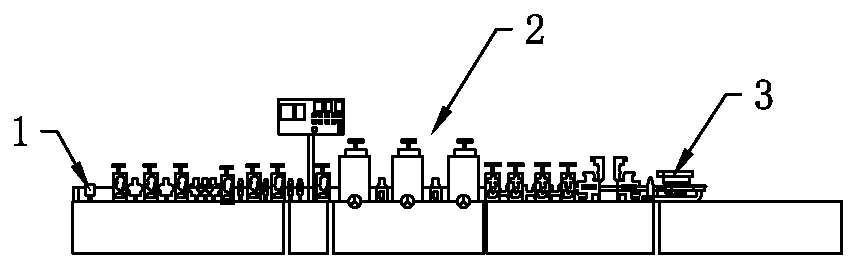

Tableware cleaning line

PendingCN106725183APrevent overturningAvoid wastingTableware washing/rinsing machine detailsCleaning equipmentSlagEngineering

The invention discloses a tableware cleaning line which comprises a top box elevator, an automatic turnover machine, a coarse washing machine, a box body conveyor, a tableware sorting device, tableware conveyor belts, a can turnover device, a cleaning tunnel, a packaging and conveying belt and a tableware assembly device, wherein the discharge end of the top box elevator is close to the feeding end of the automatic turnover machine; an inclined slag remover and a coarse washing machine elevator are arranged in a pond of the coarse washing machine separately; the discharge end of the coarse washing machine elevator is connected with the feeding end of an anti-patterning machine; the out-box end of the automatic turnover machine is provided with the box body conveyor which passes through a box body cleaning room of the cleaning tunnel; the discharge end of the anti-patterning machine is connected with the feeding end of the tableware sorting device; each tableware outlet of the tableware sorting device is correspondingly provided with one tableware conveyor belt separately; and spoons and chopsticks are directly conveyed through the tableware conveyor belts and enter the feeding end of a spoon and chopstick conveyor mesh belt. According to the tableware cleaning line, classifying and cleaning of the tableware are achieved, cleaning is more thorough, and the cleaning efficiency of a table set is greatly improved.

Owner:SHANDONG DINGTAISHENG FOOD IND EQUIP

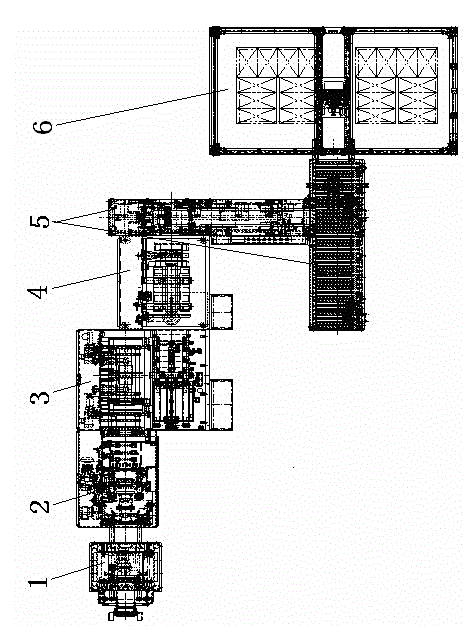

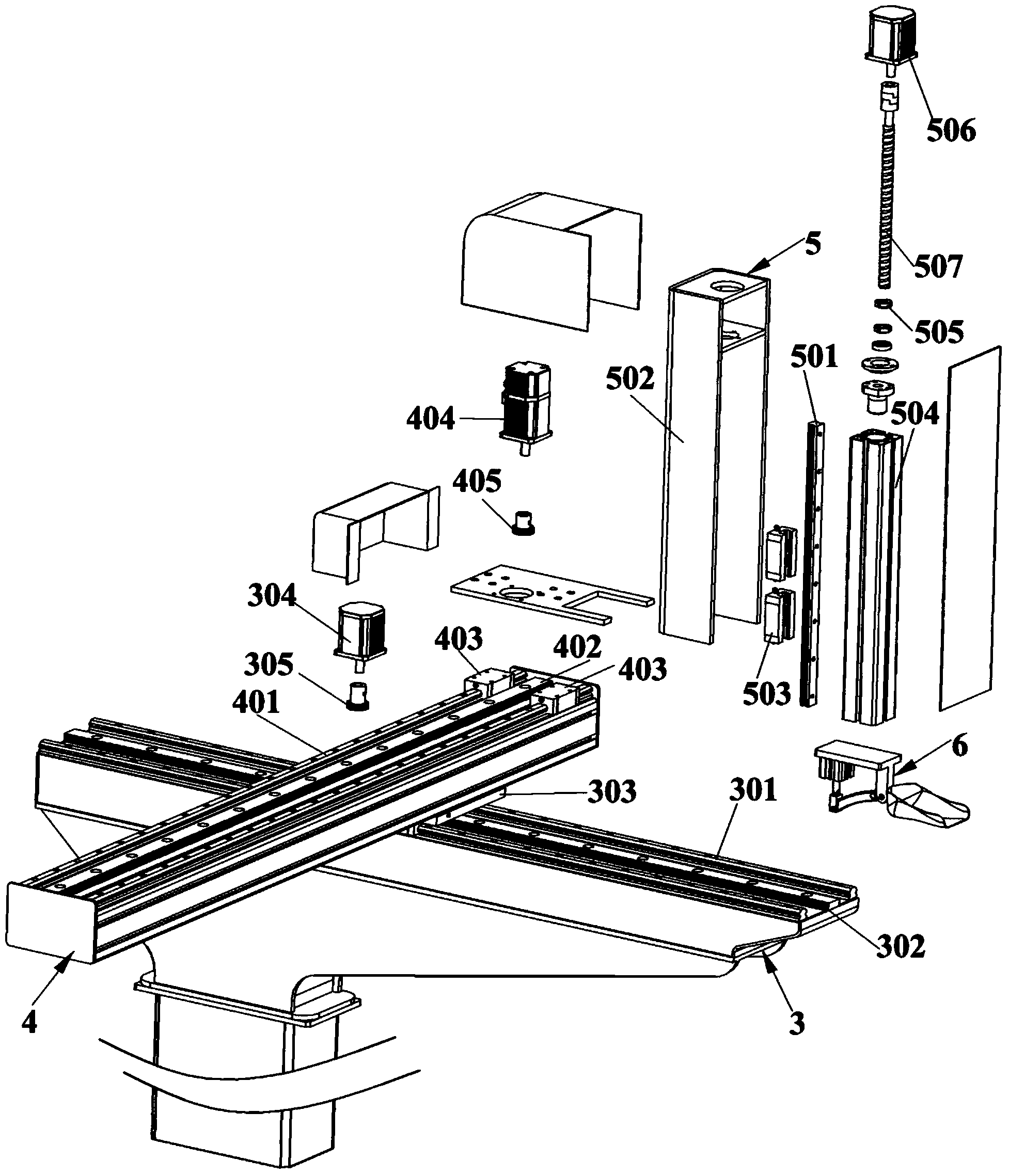

Automatic packaging unit

InactiveCN102717912AFull performanceAutomate the packaging processWrapping material feeding apparatusWrappingManufacturing lineStacker

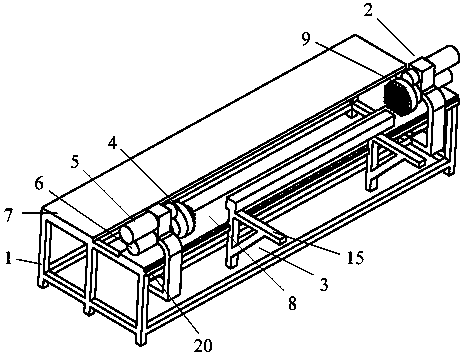

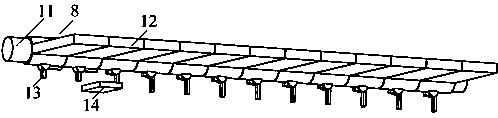

The invention provides an automatic packaging unit which comprises a feeding machine, an automatic buffer lifting machine, an automatic barrel packaging machine, an automatic film packaging machine, a boxing machine and a stacker crane that are sequentially connected with one another. When a production line has abnormal conditions, strip-shaped materials are continuously sent to the automatic buffer lifting machine through the feeding machine; on one hand, the strip-shaped materials are directly sent to the automatic barrel packaging machine in a subsequent procedure through the automatic buffer lifting machine, on the other hand, when the equipment in the subsequent procedure fails, the strip-shaped materials in the equipment in the former procedure are temporarily stored in a bin; when the equipment in the former procedure fails, the strip-shaped materials stored in the bin can be conveniently sent to the equipment in the subsequent procedure; and therefore, the whole production line and the whole process cannot stop due to local maintenance. The strip-shaped materials to be packaged are simultaneously sent to barrels to be packaged through the automatic barrel packaging machine while being automatically counted, and films wraps the barrels through the automatic film packaging machine, so that the strip-shaped materials are packaged with good quantity and quality, and the grade of the products is improved. The automatic packaging unit realizes autonomic packaging and counting of the strip-shaped materials, and is suitable for packaging any strip-shaped material.

Owner:KUNMING DINGCHENG TECH

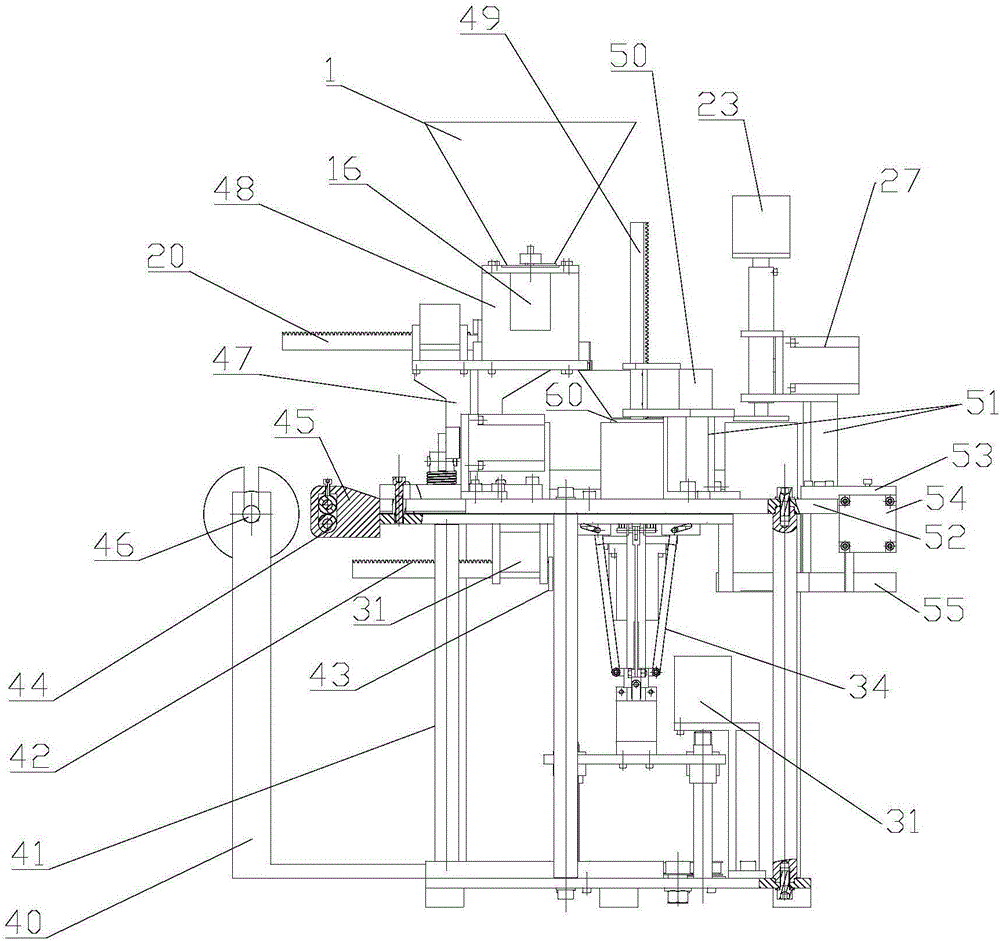

Fully-automatic packaging production line of beef tallow hot pot seasoning

ActiveCN101734382AAutomate the packaging processTake the time easilyPackaging automatic controlLiquid materialFully automaticBeef Tallow

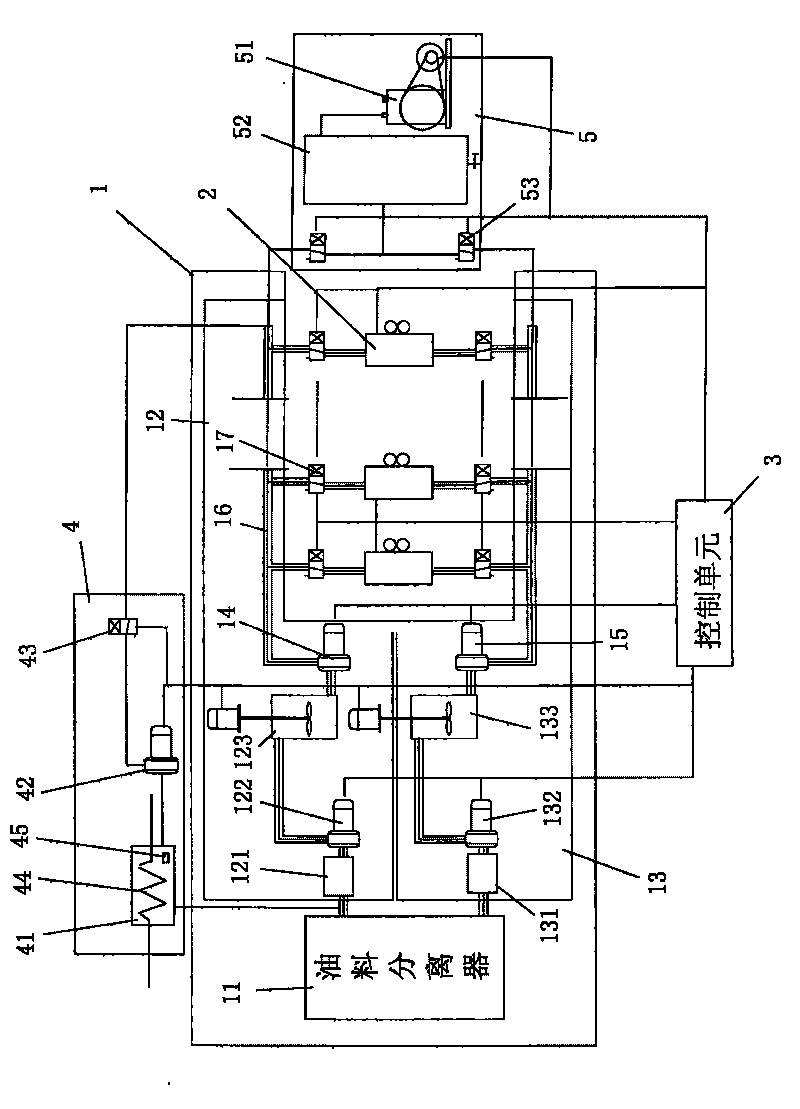

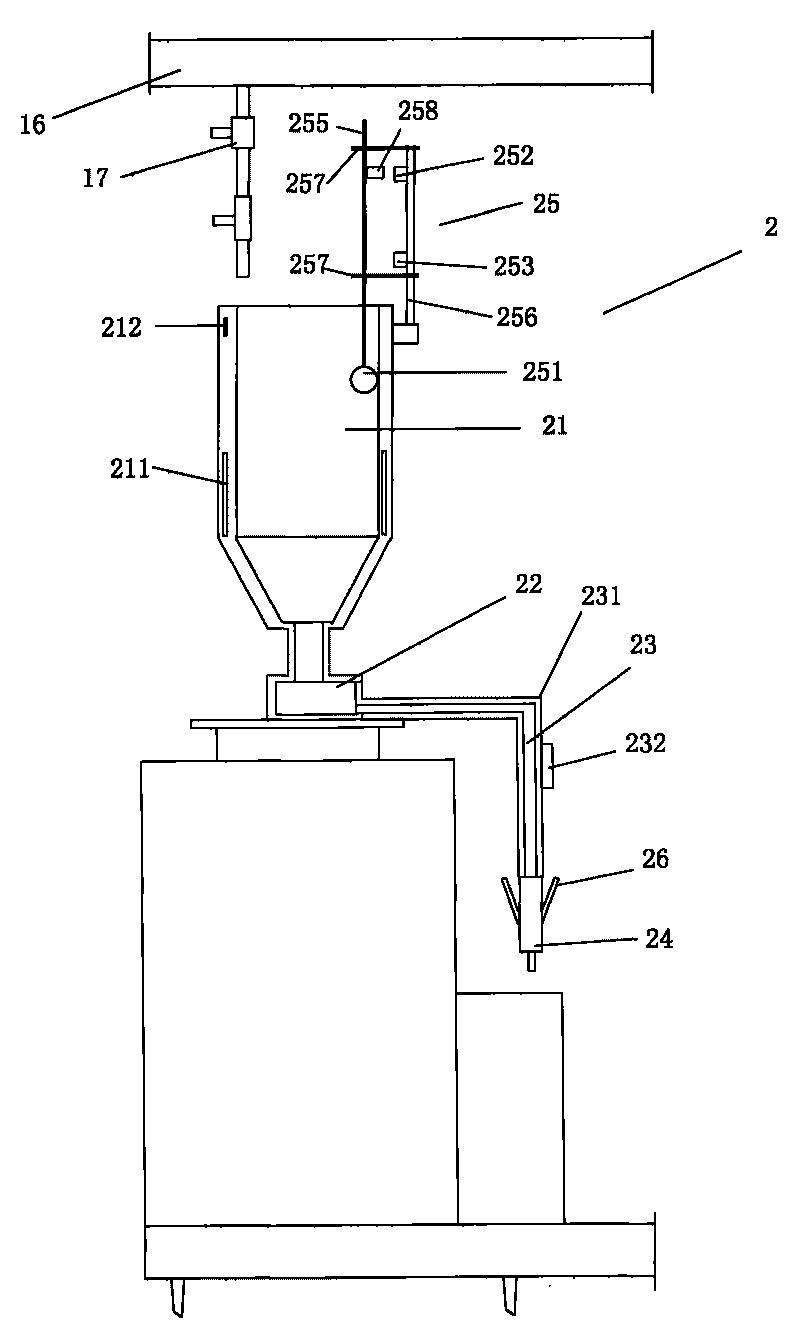

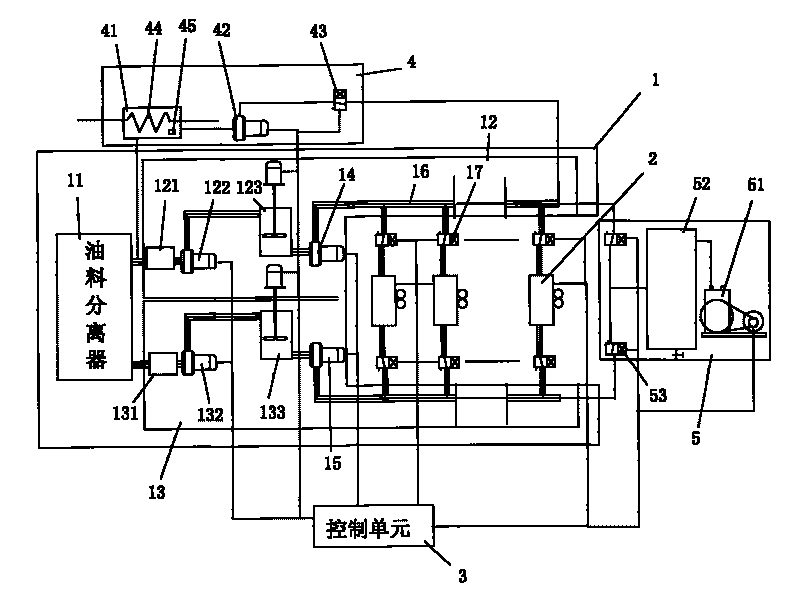

The invention relates to an automatic packaging production line, in particular to a fully-automatic packaging production line of a beef tallow hot pot seasoning. The production line comprises a feeding and conveying device, a packaging machine and a control unit, wherein the packaging machine is a horizontal type fully-automatic constant temperature packaging machine; the feeding and conveying device comprises a tallow separator, a material feeding device and a tallow feeding device connected with the tallow separator, a booster pump respectively connected with the material feeding device and the tallow feeding device and an insulating conveying pipe provided with an insulating interlayer; the insulating conveying pipe is connected with the packaging machine through an electromagnetic valve; a heating device is arranged and connected with the feeding and conveying device; and the control unit is electrically connected with the horizontal type fully-automatic constant temperature packaging machine, the feeding and conveying device and the heating device so as to control the feed, the temperature, the quantitative loading and the packaging of materials and the cleanness of production line equipment. The production line realizes the packaging automation of the beef tallow hot pot seasoning, improves the productivity and avoids pollutions to products by manual operations.

Owner:四川天味食品集团股份有限公司

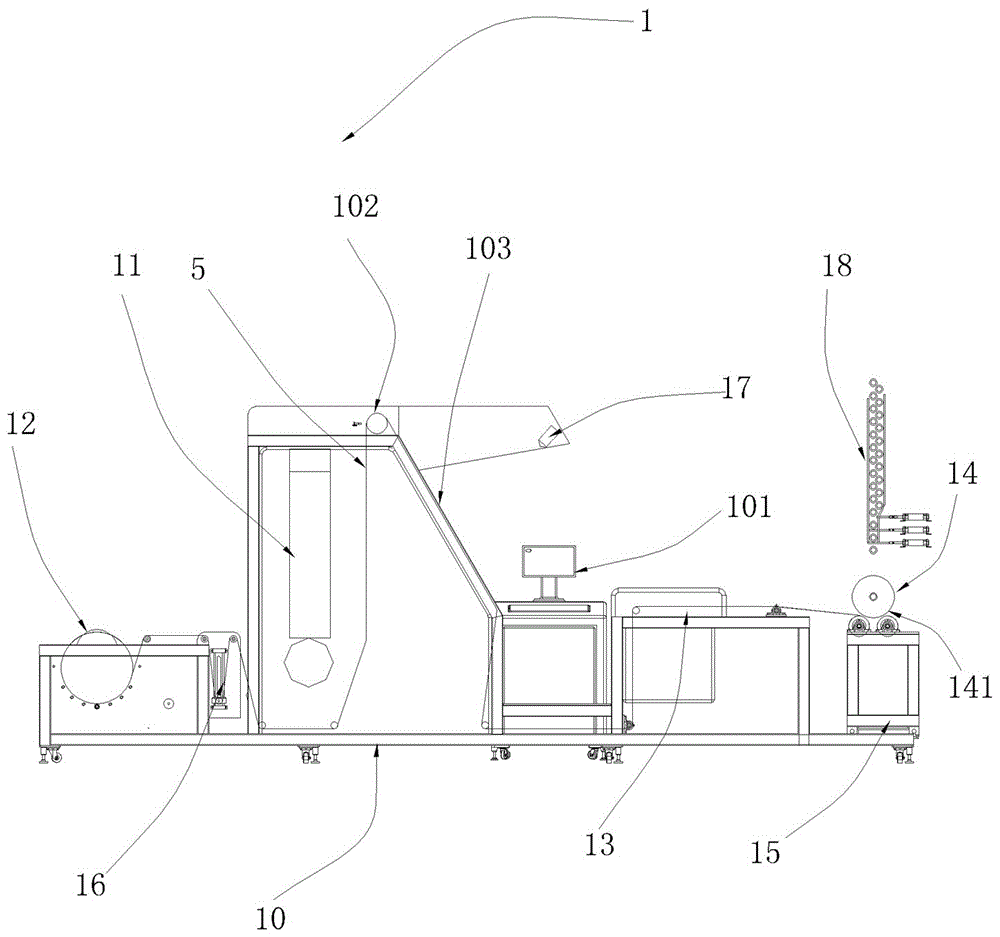

Intelligent cloth inspecting machine and cloth inspecting method thereof

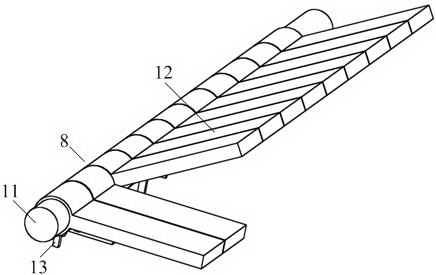

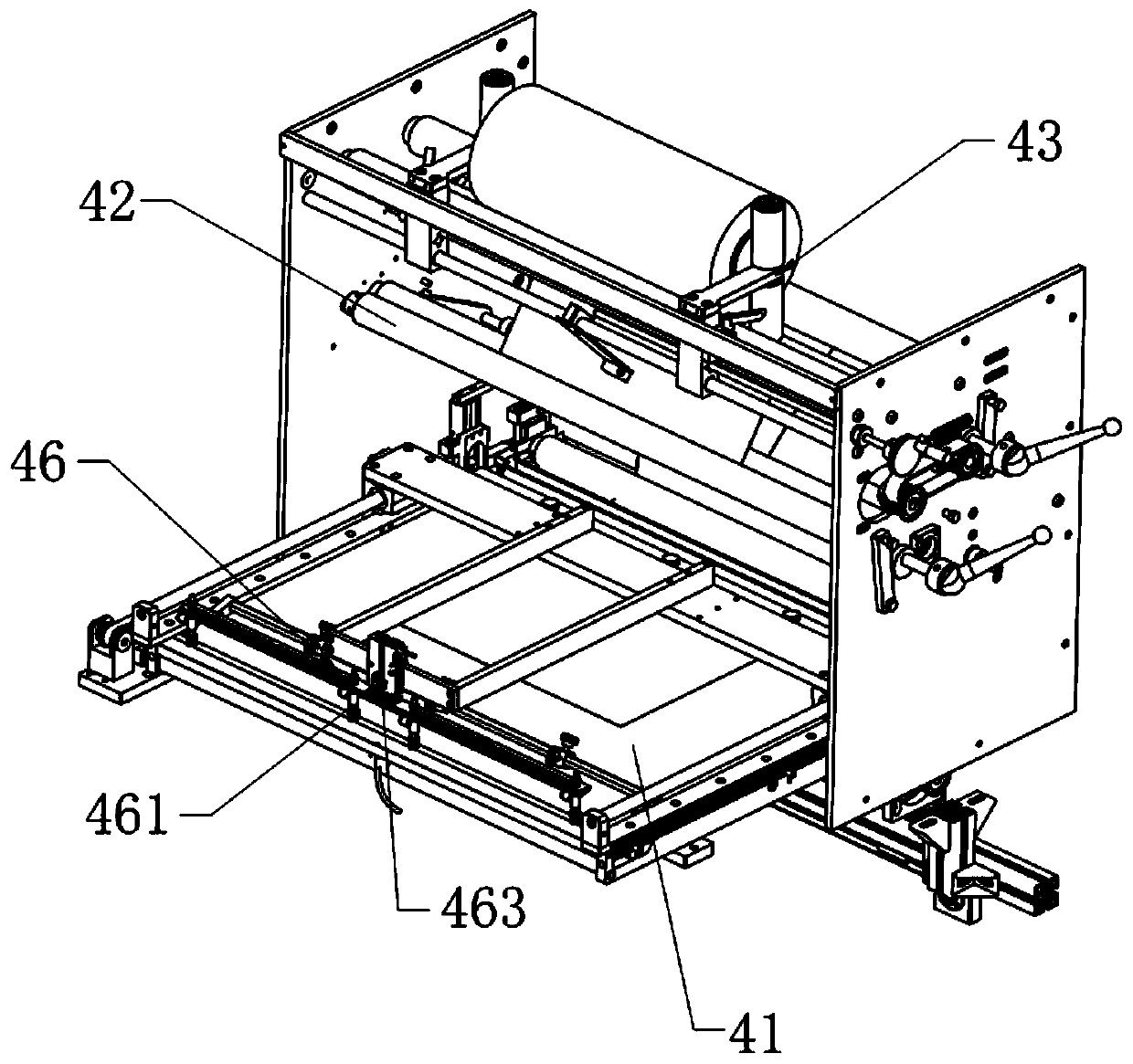

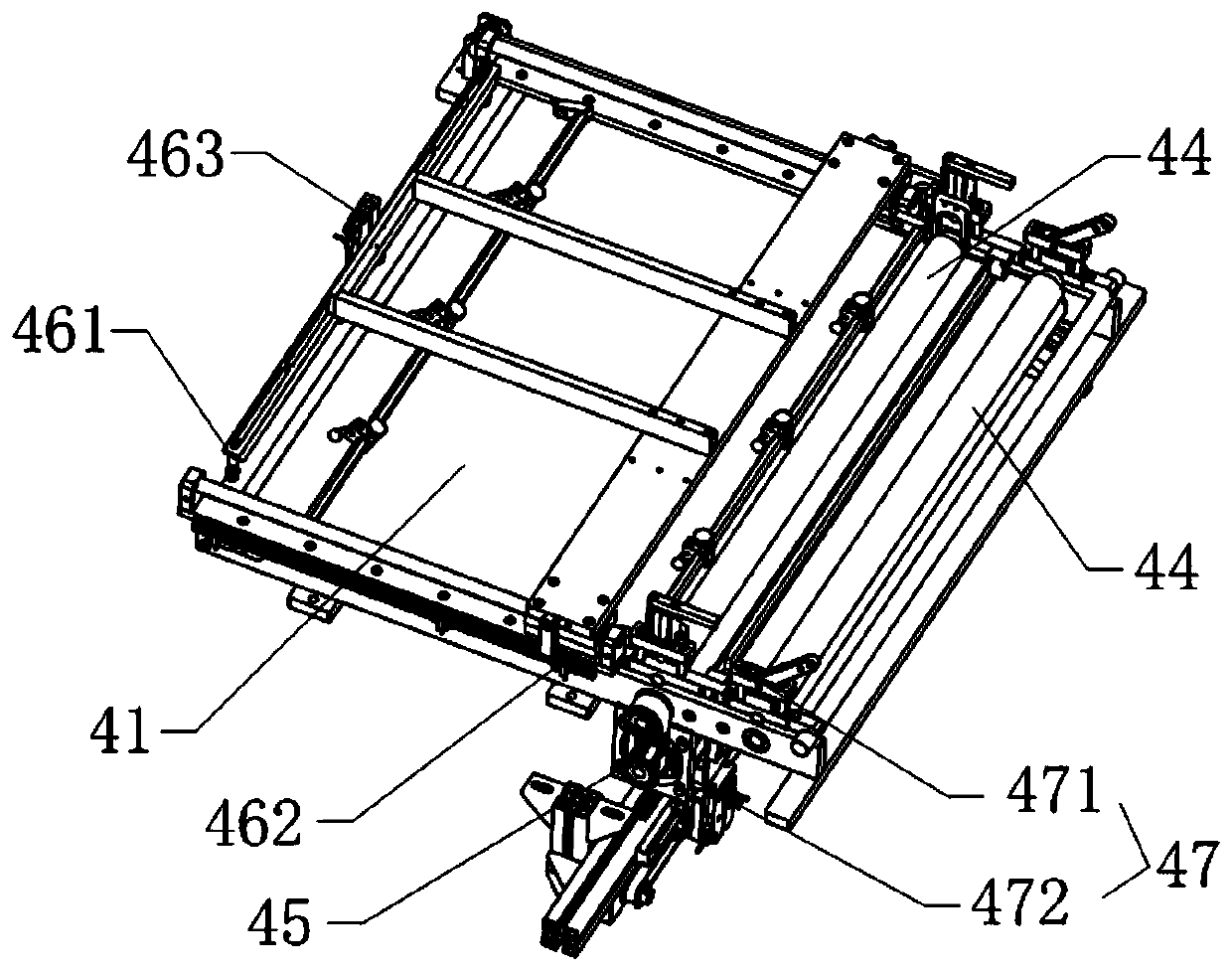

ActiveCN105699392AImprove detection efficiencyImprove efficiencyMaterial analysis by optical meansEngineeringMechanical engineering

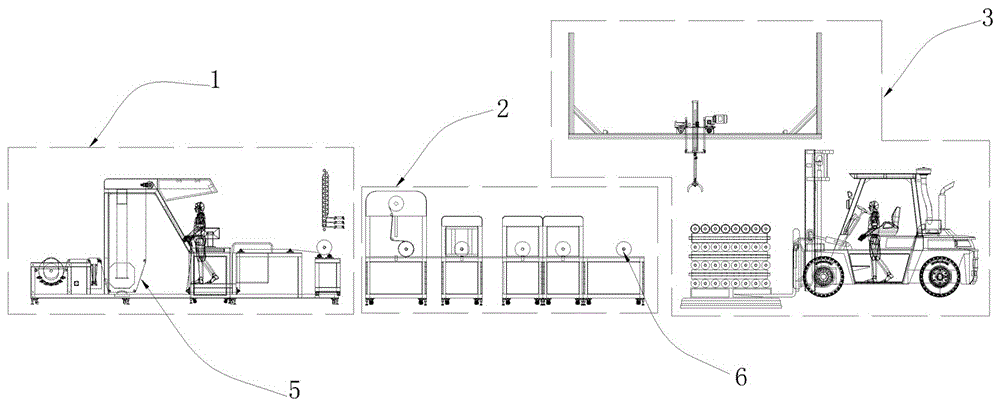

The invention discloses an intelligent cloth inspecting machine and a cloth inspecting method thereof.The intelligent cloth inspecting machine comprises a defect inspection device used for conducting defect inspection on cloth, a shrink-packaging device used for conducting hot shrinkage forming on cloth rolls which have been detected and formed, and a stacking and transporting device used for stacking and transporting the cloth rolls which have been subjected to hot shrinkage forming.The defect detection device, the shrink-packaging device and the stacking and transporting device are sequentially connected.By means of the intelligent cloth inspecting machine and the cloth inspecting method, automatic defect detection is achieved, the labor intensity is lowered, and the omission ratio and false inspection rate are decreased.The precision of cloth defect detection is improved.An automatic winding mechanism, an automatic edge cutting mechanism and the shrink-packaging device can be used in cooperation for winding the detected cloth, the cloth automatically enters the shrink-packaging device to be subjected to hot shrinkage forming after being wound, and therefore automatic cloth cutting, winding and automatic packaging are achieved when a roll of cloth is wound.

Owner:SHENZHEN MAIKESITAI CO LTD

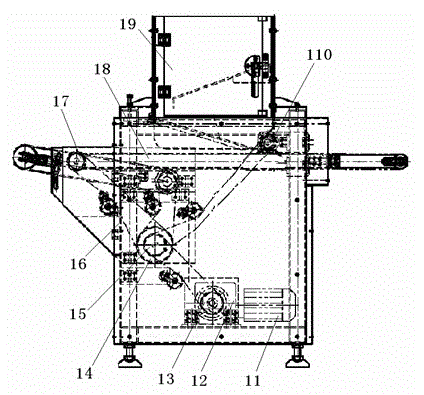

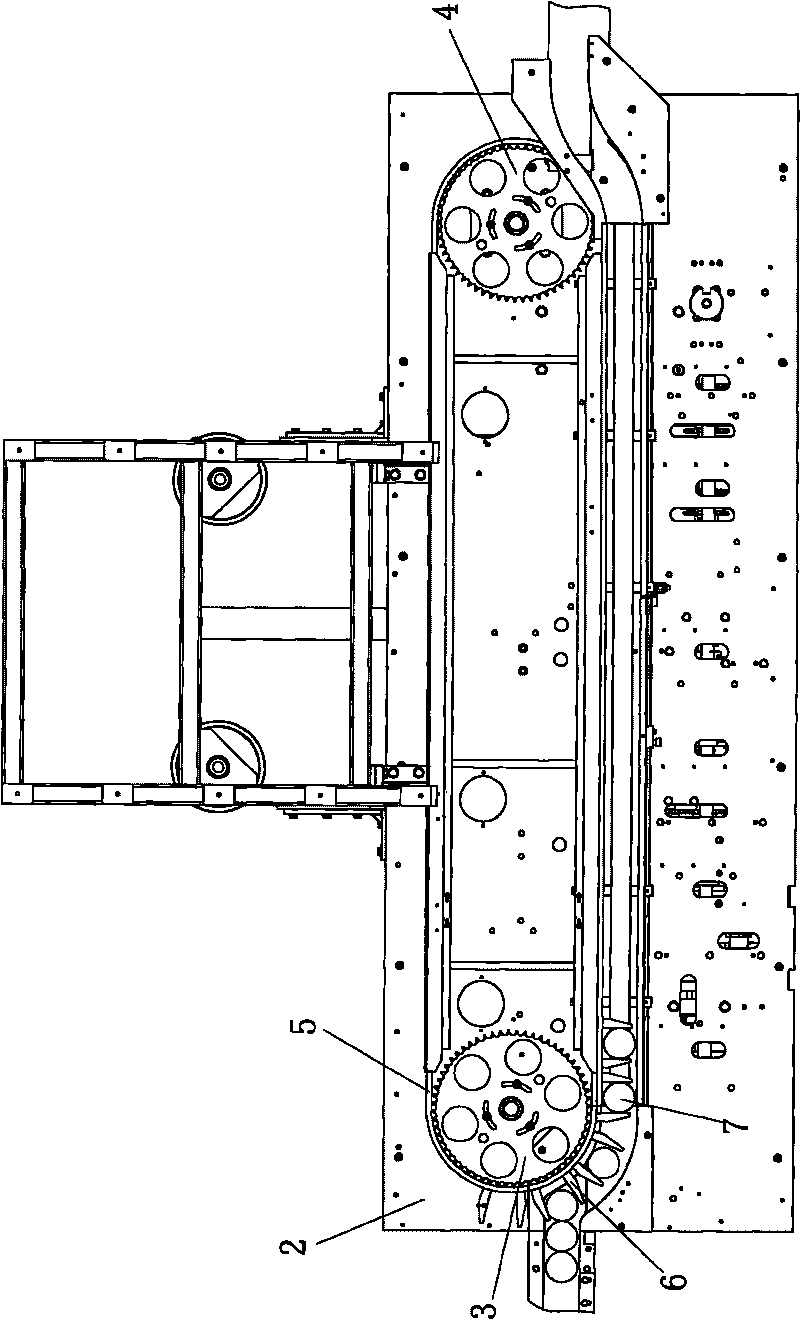

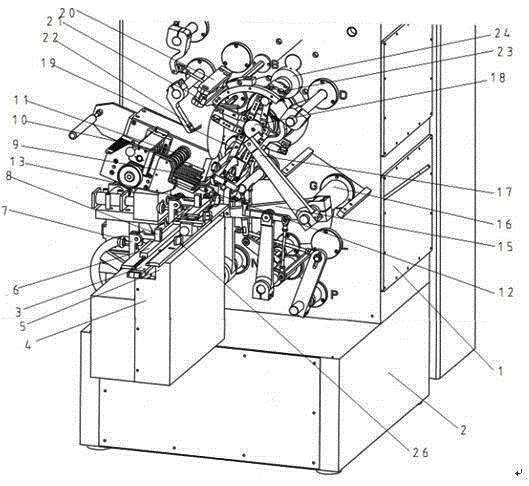

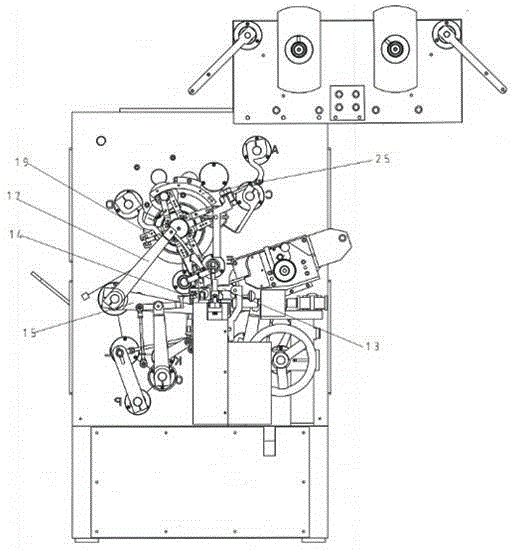

Tinned cigarette packing machine

ActiveCN101691142AAutomate the packaging processNot easy to polluteWrapping material feeding apparatusPackaging cigaretteDrive motorSprocket

The invention discloses a tinned cigarette packing machine comprising a rack which is provided with a working platform. The working platform is provided with a front driven sprocket and a rear driving sprocket, wherein the driving sprocket is connected with a stepping main driving mechanism which drives the rear driving sprocket to rotate; the front driven sprocket and the rear driving sprocket are respectively tensioned with a chain, the chain is provided with a can clamp, and the chain and the clamp form a conveying chain; a turntable is arranged in front of the working platform, the center of the turntable is provided with a turntable spindle which is connected with the output shaft used for rotating a driving motor; the turntable is provided with an outlet, the back of the outlet of the turntable is communicated with a conveying rail used for conveying the cigarette tin, and the rear end of the conveying rail is connected with the conveying chain; the upper part of the conveying chain sequentially comprises a lining paper supplying and canning station, a drawing paper supplying and canning station, a cigarette supplying and canning station, a bottom cover paper supplying and canning station and the bottom cover supplying and canning station from front to back in conveying direction. The invention realizes automatic packing of tinned cigarettes.

Owner:宁波升瀚烟草机械有限公司

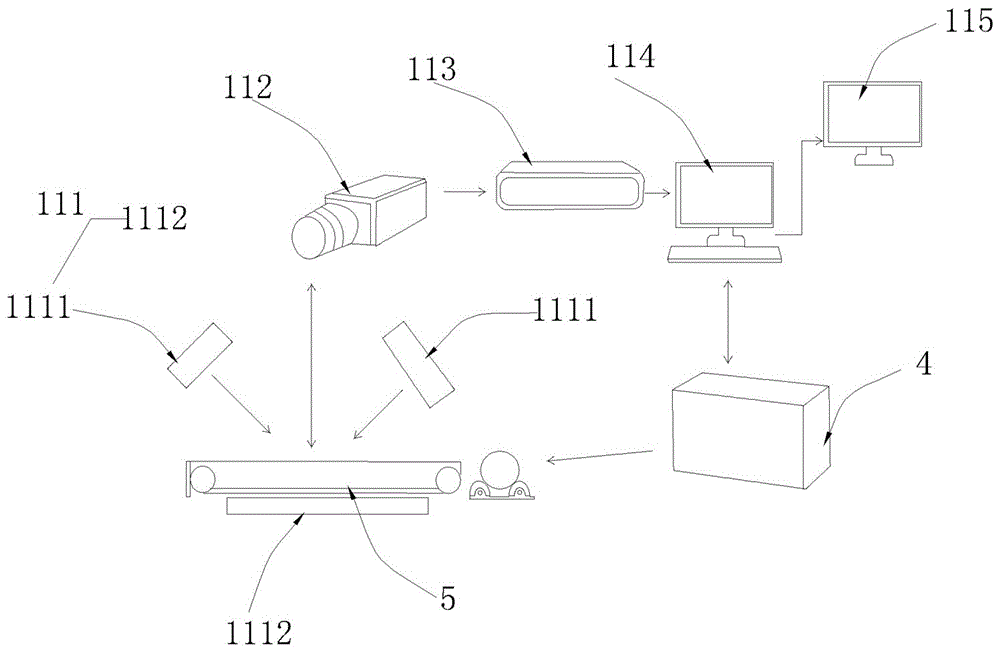

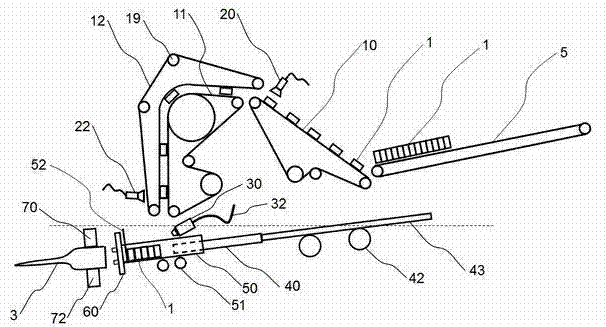

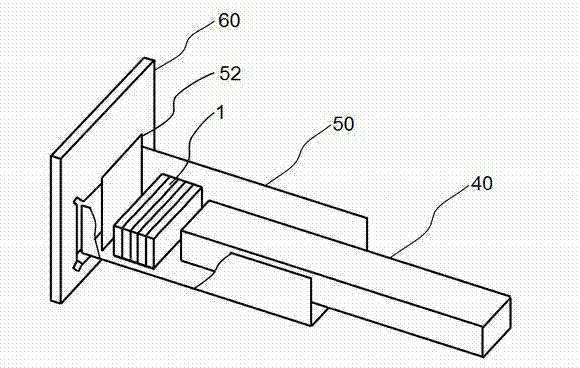

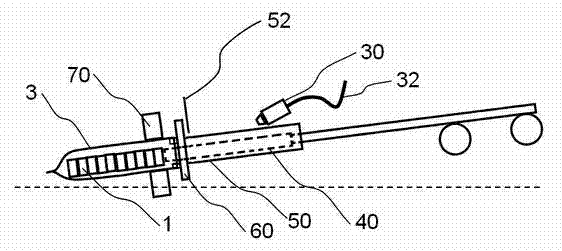

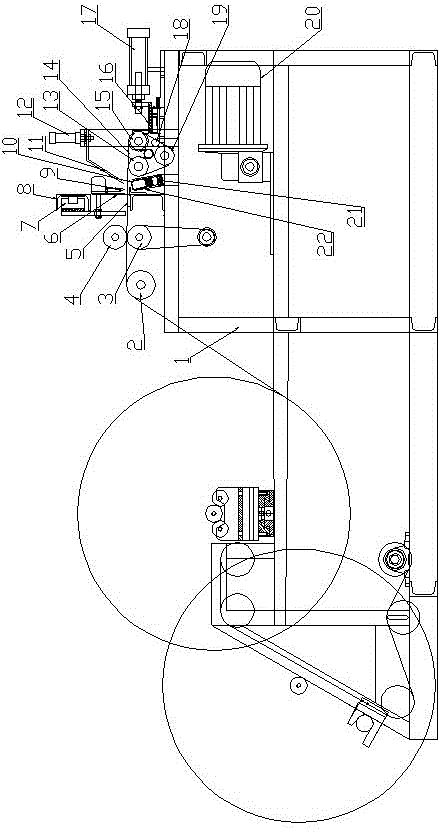

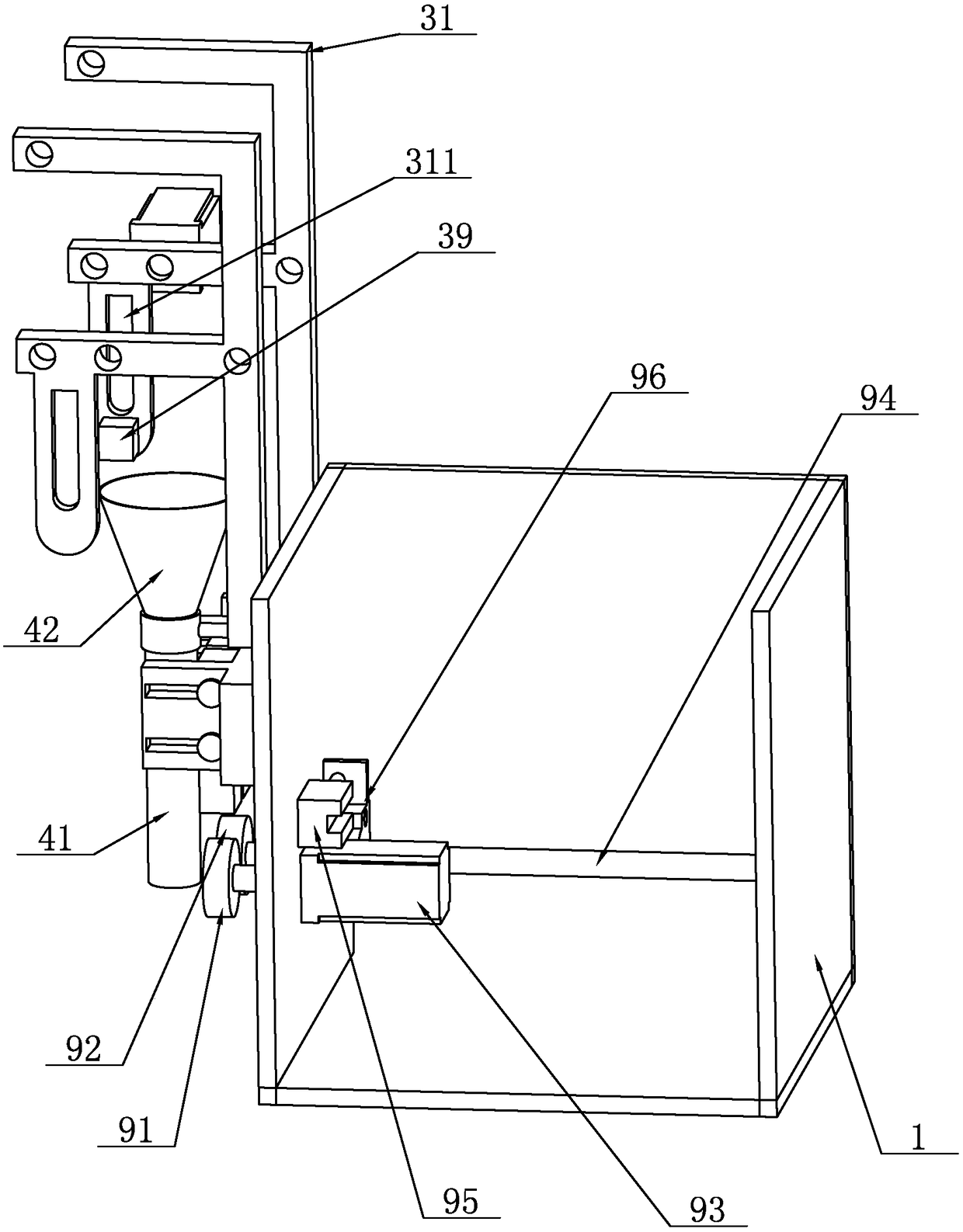

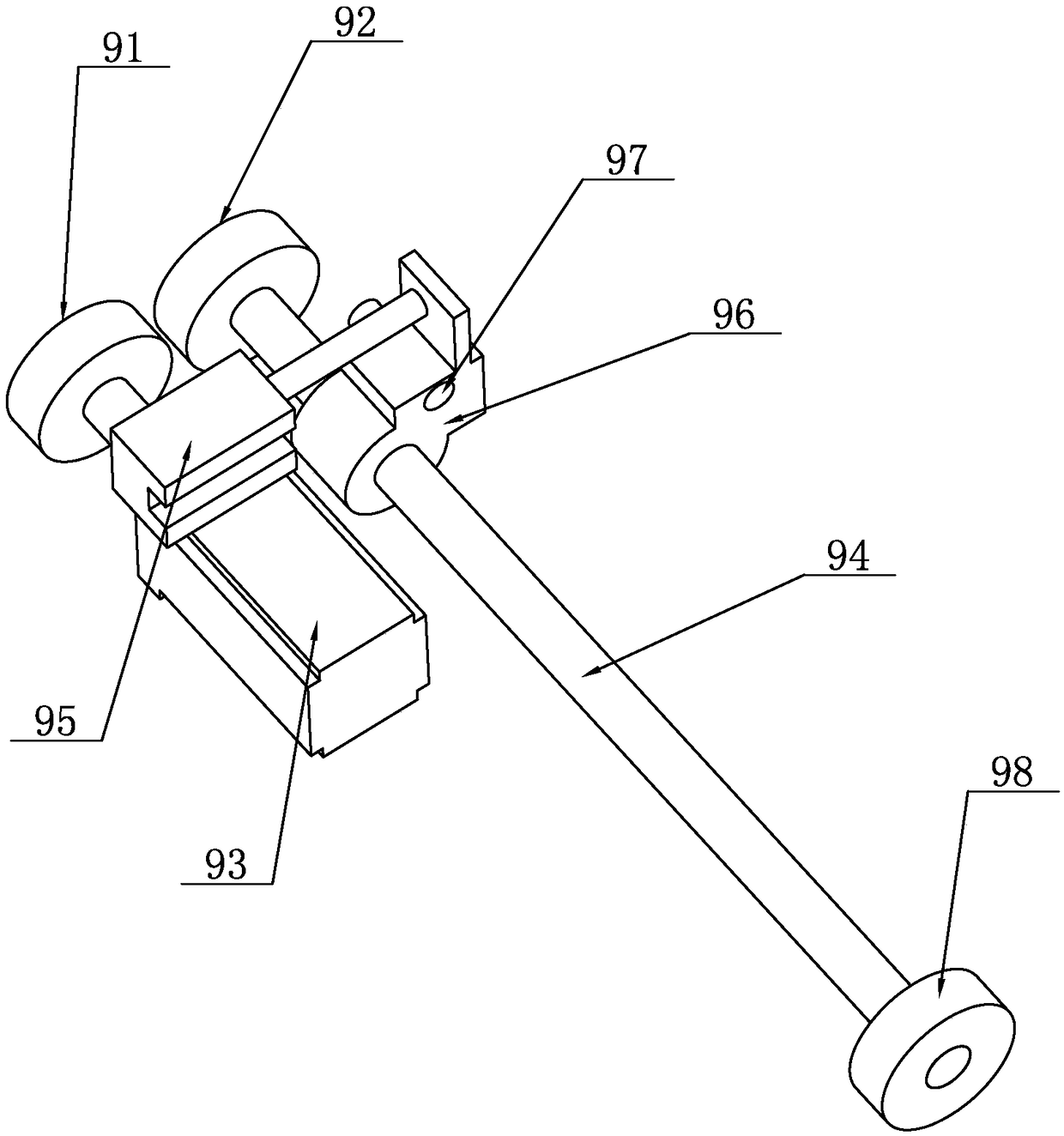

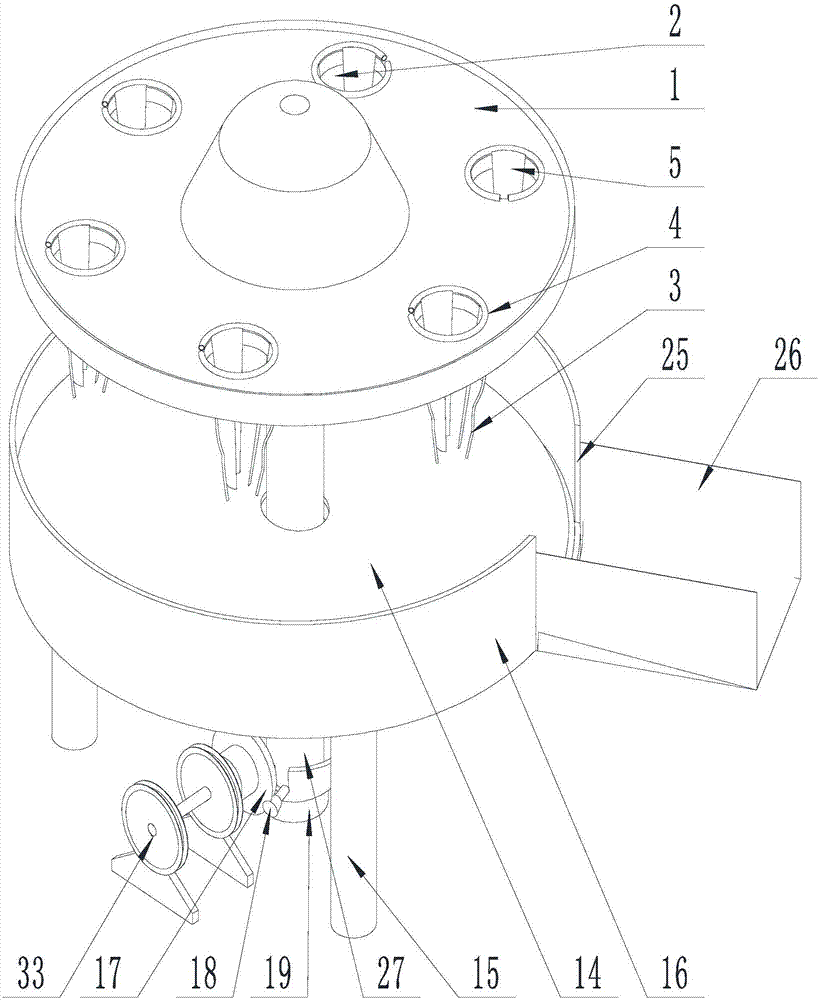

Sampling method of object sampling system

ActiveCN104165778AImplement automatic samplingAutomate the packaging processWithdrawing sample devicesParticulatesThird party

The invention discloses a sampling method of an object sampling system. The object sampling system comprises a sampling bracket and a sampling device. The sampling device contains a chassis, an X-direction mobile mechanism, a Y-direction mobile mechanism, a Z-direction mobile mechanism and a sampling mechanism. The chassis is positioned at the top of the sampling bracket. The X-direction mobile mechanism is fixedly arranged on the top surface of the chassis. The Y-direction mobile mechanism is positioned on the X-direction mobile mechanism. The Z-direction mobile mechanism is positioned on the Y-direction mobile mechanism. The sampling mechanism is positioned on the Z-direction mobile mechanism. The X-direction mobile mechanism, the Y-direction mobile mechanism and the Z-direction mobile mechanism respectively control motion of the sampling mechanism. Thus, the sampling mechanism moves onto a storage device filled with a particulate matter, and the sampling mechanism acquires a part of the particulate matter as a sample. Then, the sampling mechanism moves to a split charging device for split charging. The sampling method of the object sampling system can adapt to different production cycle time and can be adopted to achieve purposes of automatic sampling and automatic packaging. Third-party anti-counterfeiting encryption of a sample can be carried out, and remote operation and monitoring can be realized.

Owner:安徽省一一通信息科技有限公司

Crystal oscillator automatic packaging machine

ActiveCN104960710AAutomate the packaging processPackaging automatic controlShock-sensitive articlesElectrical and Electronics engineeringCrystal

The invention provides a crystal oscillator automatic packaging machine which can automatically sort crystal oscillators. The crystal oscillator automatic packaging machine comprises a feeding mechanism, a conveying mechanism, a detecting mechanism, a removing mechanism, a turnover mechanism, a position correcting mechanism, a counting mechanism, a packaging mechanism and a controller. The controller is electrically connected with the feeding mechanism, the conveying mechanism, the detecting mechanism, the removing mechanism, the turnover mechanism, the position correcting mechanism, the counting mechanism and the packaging mechanism, and a first inducting device, the feeding mechanism the removing mechanism, the turnover mechanism, the position correcting mechanism, the counting mechanism and the packaging mechanism are arranged around a rotating disc sequentially. The crystal oscillator automatic packaging machine has the beneficial effects that through cooperation of the feeding mechanism, the conveying mechanism, the detecting mechanism, the removing mechanism, the turnover mechanism, the position correcting mechanism, the counting mechanism, the packaging mechanism and the controller, crystal oscillators precisely enter the packaging mechanism in a side-up manner, and automatic packaging of the crystal oscillators is achieved.

Owner:MANICIPL YONTAKING ELECTRONICS QUARTZ

Hygienic product packaging machine

ActiveCN103693221AAutomate the packaging processExact numberPackaging automatic controlIndividual articlesBiomedical engineeringInjection device

The invention relates to a hygienic product packaging machine which comprises a sheet counting module, a sheet neatening module, a bag opening module, a push rod module, a sealing and cutting module and at least one gas injection device, wherein the sheet counting module comprises at least one first-stage sheet counting sub-module and at least one second-stage sheet counting sub-module; the gas injection device can unidirectionally inject gas to prevent a single sheet from falling off; the bag opening module comprises at least one opening sub-module; each opening sub-module comprises at least four guide vanes capable of moving towards the positions of four corners of a bag opening of a packaging bag; the guide vanes can open the bag opening towards the direction of four corners of the bag opening; the sheet neatening module comprises at least one sheet neatening groove; the sheet neatening groove is at an included angle of 10 to 80 degrees with the horizontal plane.

Owner:帝益喜(北京)科技有限公司

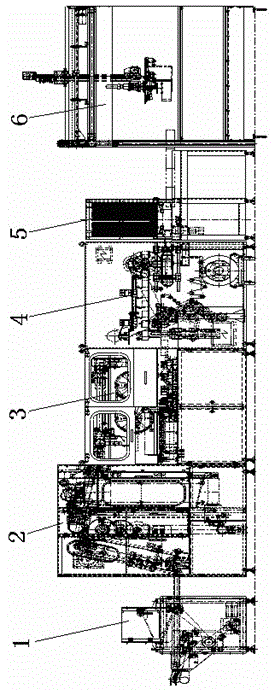

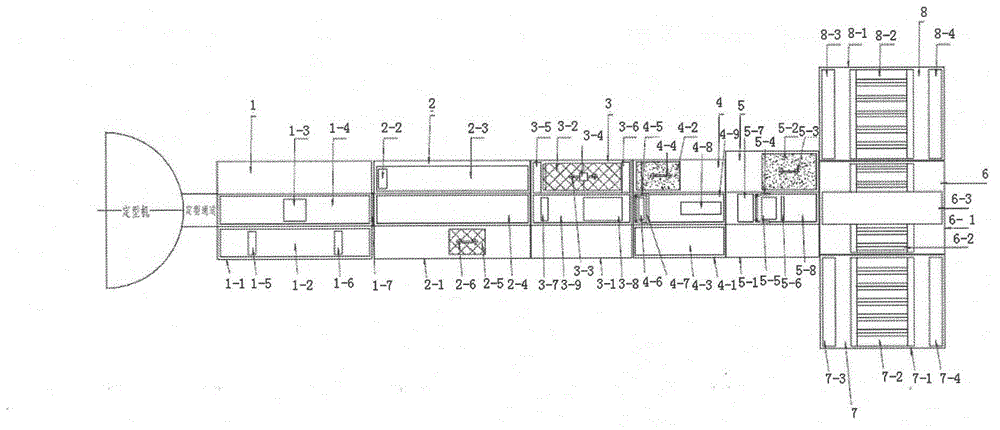

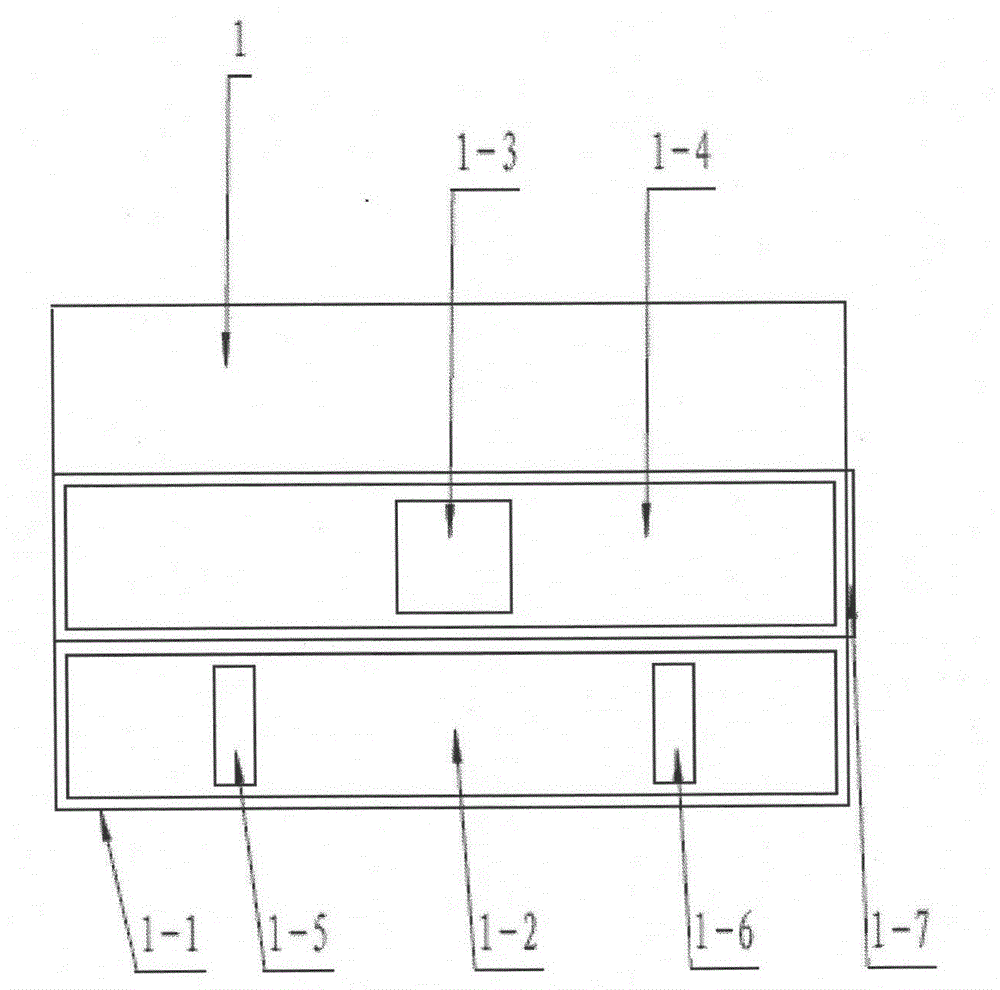

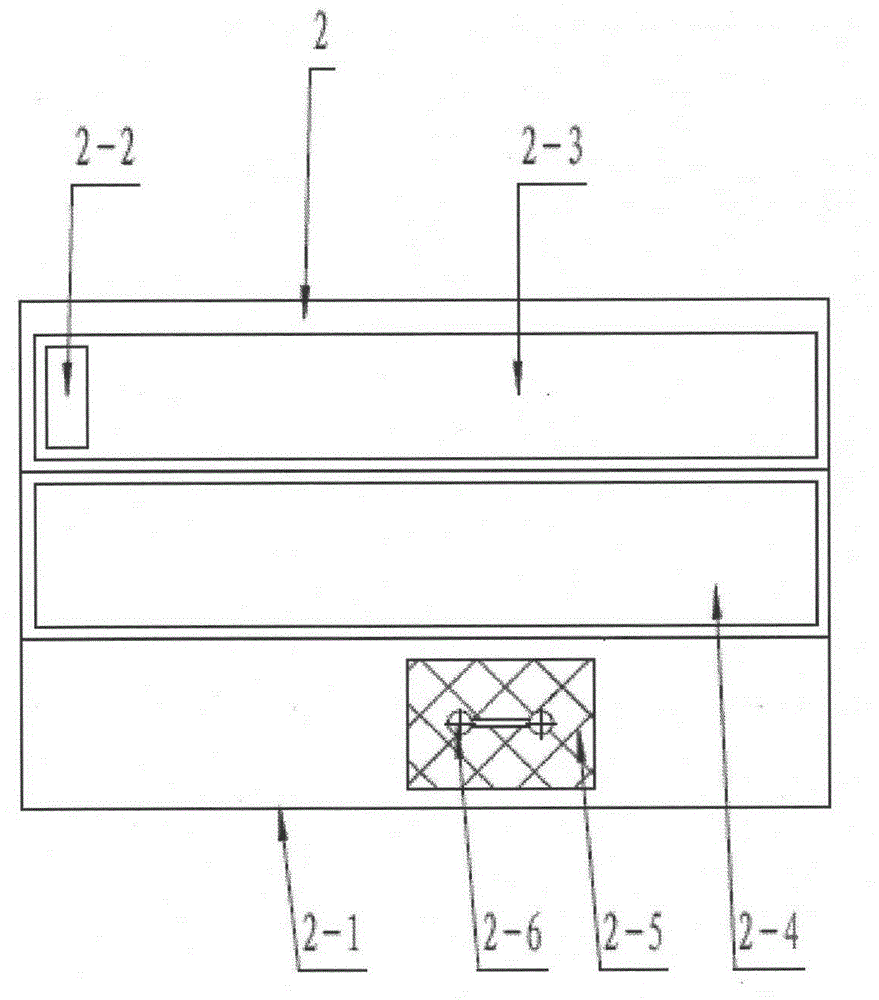

Modular panty-hose whole process automatic packing production line and working method thereof

ActiveCN103144793AAutomate the packaging processFlexible working stylePackaging automatic controlIndividual articlesProduction lineModularity

The invention provides a modular panty-hose whole process automatic packing production line. The production line comprises a detecting module, a folding module, an outer packing module, a bagging module, a baling module, a binning module, a boxing module and a box sealing module. The invention further provides a working method for the automatic packing production line. The automatic packing production line is characterized in that the automatic packing production line can run together with a forming machine in a matching way or run separately, and the method comprises eight working processes, such as detecting, folding, outer packing, bagging, baling, binning, boxing and box sealing. The advantages of the technical scheme of the invention are that whole process automatic packing of panty-hoses from forming to box sealing is realized, and the production line can run together with the forming machine in a matching way or run separately; eight components are fully-independent modules, so that convenience is brought to installation, debugging and transport; each module can work separately to complete respective functions; the same / similar mechanisms of each module are provided with the same / similar parts, and a large quantity of standard pieces and purchased parts are used, so that the research and development costs of the automatic packing production line are lowered, and the running reliability is improved.

Owner:福建屹立智能化科技有限公司

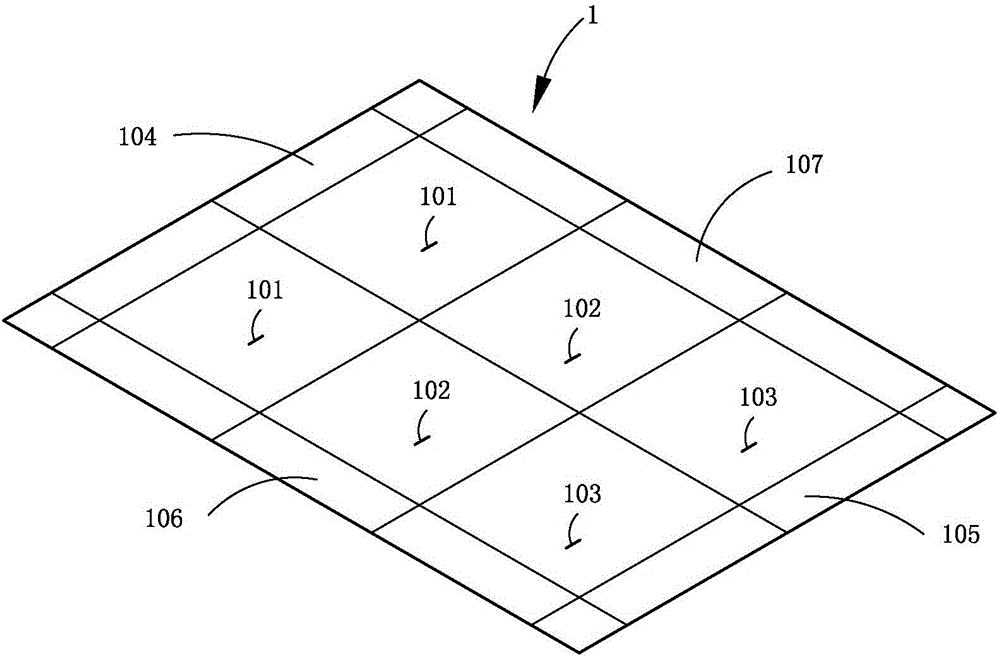

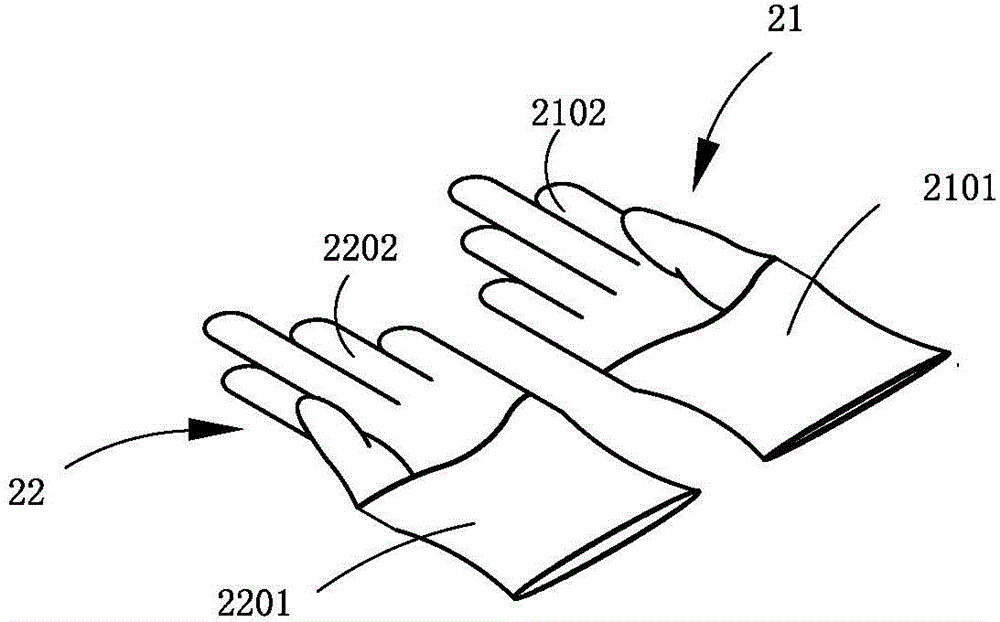

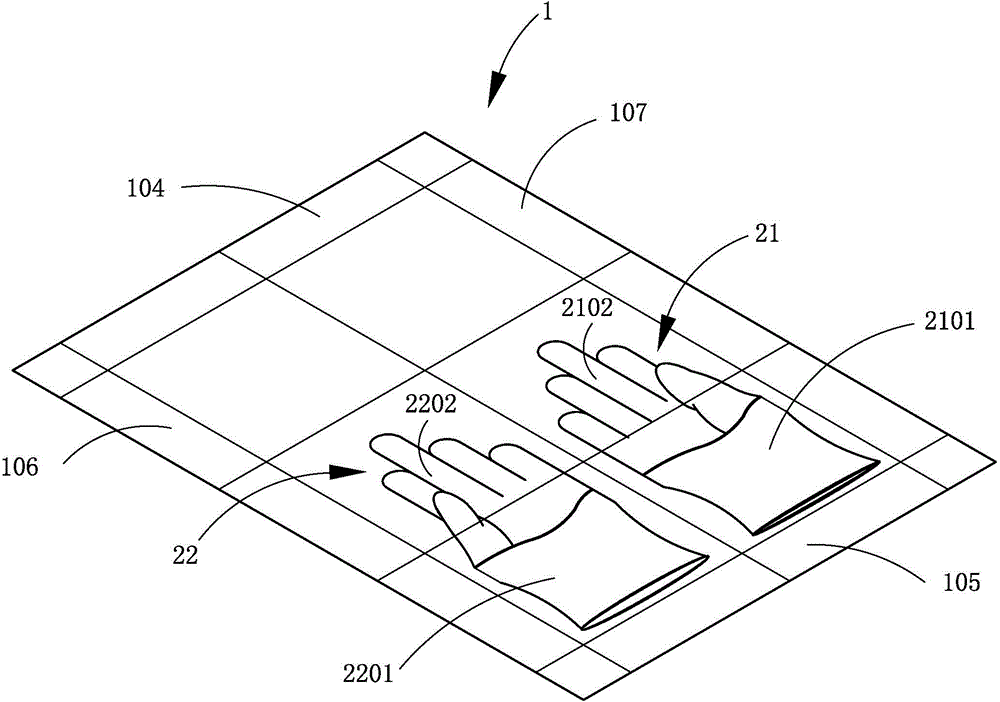

Inner packing method for medical sterile gloves

InactiveCN104528031ALittle risk of accidental contaminationReduce labor costsWrappingEngineeringAccidental pollution

The invention provides an inner packing method for medical sterile gloves, and specifically relates to a method for perform inner packing for the medical sterile gloves by folding and being wrapped with inner lining paper. The method comprises the steps of 1, positioning flanged gloves on one surface of the inner lining paper; 2, folding the inner lining paper along the finger tips of the flanged gloves to enable the folded inner lining paper to cover the finger roots of the flanged gloves, wherein the inner lining paper is folded along the fingertips of the flanged gloves, then covers the finger roots of the flanged gloves and forwards extends to form a first transverse folding edge; 3, folding the inner lining paper which covers the upper surfaces of the finger parts of the gloves in step 2, the inner lining paper padded on the lower surface of the finger parts of the gloves, and the finger parts of the gloves along the fingertips of the flanged gloves to cover the palm parts and wrist parts of the flanged gloves; 4, sealing the inner package into a sterilizing bag. The packing method is simple in packing structure, convenient to operate, automatic to pack, low in cost, and small in risk of accidental pollution.

Owner:陈仲璜 +2

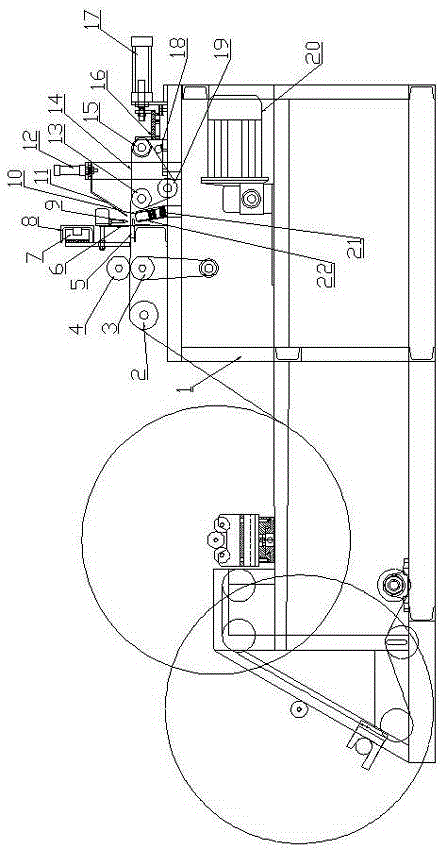

Bandage roller packing machine

ActiveCN104058120ASmooth paper cuttingImprove paper cutting efficiencyWrapping material feeding apparatusWrapper twisting/gatheringPaper cutPaper sheet

The invention relates to a bandage roller packing machine, which comprises a rack, wherein a packing paper conveying device for bandage rollers, a cut paper glue spraying device, a glue scraping device and a winding and sealing device are sequentially arranged on the rack. Upper and lower traction rollers are arranged to realize the automatic conveying of packing paper; a paper cutting base is arranged to bear the conveyed packing paper and ensure the smooth paper conveying; a bottom paper cutter and a lower paper cutter are arranged to improve paper cutting efficiency and paper cutting quality; a glue spraying nozzle is arranged to realize the automatic gluing; a glue scraper is arranged to avoid a poor sealing effect caused by excessive sprayed glue and improve sealing quality and sealing efficiency; a lifting cylinder is arranged so that the glue scraper can lift up and down, and the smooth conveying of the packing paper is unaffected after glue scraping; a lower supporting plate is arranged to ensure the smooth glue scraping and facilitate recycling of glue; an expansion winding belt is arranged to wind, pack and seal the bandage roller; an upper fixed roller, an upper movable roller and a lower roller are arranged, and are matched with a driving cylinder to be used, so that the expansion winding belt can smoothly pack the bandage roller to complete packing and sealing.

Owner:连云港市向阳机械有限公司

Automatic packing machine for tea cakes

ActiveCN105905340AThe manufacturing process is simple and easy to controlAutomate the packaging processPackaging automatic controlPackaging biscuitsReciprocating motionEngineering

The invention discloses an automatic packing machine for tea cakes. The automatic packing machine comprises model boxes; the model boxes are matched with an inverted hammer device, the inverted hammer device repeatedly beats tea leaves in the model boxes to manufacture the tea cakes, the tea cakes are pushed out of the model boxes to a packing mechanism by a pushing device after being manufactured, and the packing mechanism receives packing materials conveyed by a conveying device and conducts inclusion packing on the tea cakes. The packing mechanism can replace manual packing and can achieve six-face inclusion of the tea cakes in place in one time, and accordingly the novel combination mechanism is designed to replace manual inclusion action; and the mechanism is not only limited to tea cake packing but also can achieve six-face inclusion of all cubes with the suitable size, the problems that manual packing efficiency is low, and the packing specifications are unequal can be solved, and thus automatic packing of the tea cakes can be achieved.

Owner:LONGYAN UNIV

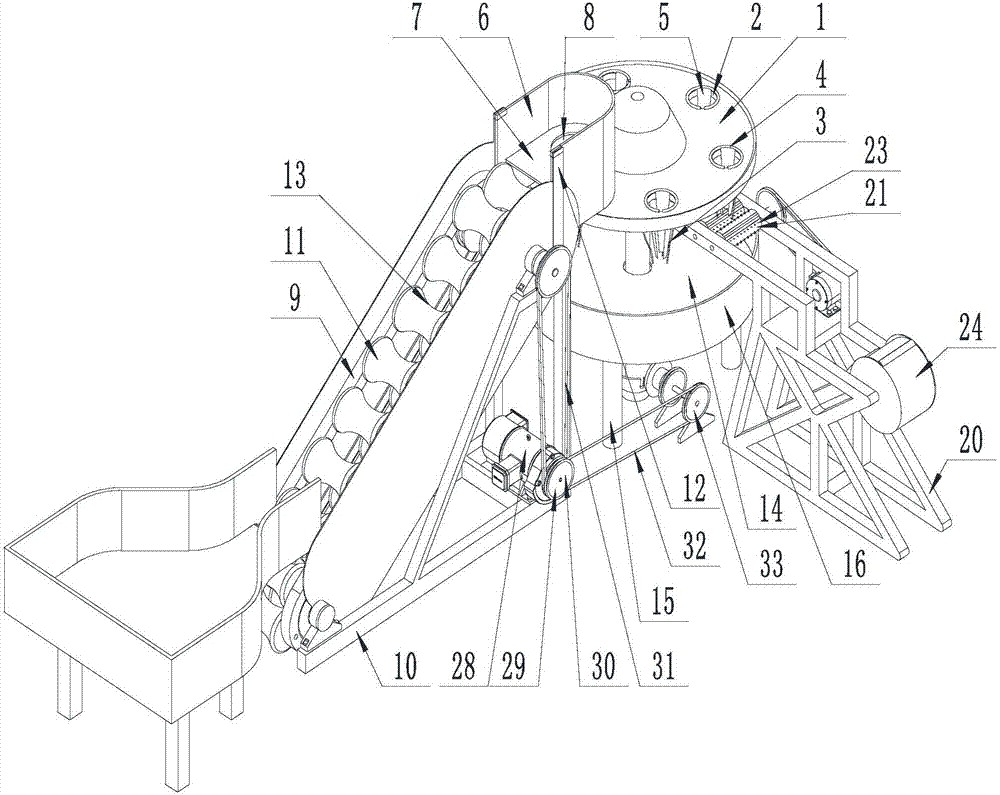

Fruit packing system and packing method

ActiveCN105730743AFree laborImprove efficiencyPackaging automatic controlPackaging fruits/vegetablesHorticulturePacking method

The invention relates to a fruit packing system. The fruit packing system comprises a fruit conveying device, a fruit separating device, a fruit reversing device and a fruit packing device; the fruit conveying device, the fruit separating device and the fruit packing device are connected with a control center; the fruit conveying device conveys fruits to the fruit separating device for separating; the separated fruits are conveyed to the fruit packing device for packing by a herringbone upper slide way of the fruit reversing device; and the packed fruits are conveyed to a fruit storage point by a herringbone lower slide way of the fruit reversing device. The invention further provides a fruit packing method. The fruit packing system is simple in structure, convenient for use and capable of packing the fruits, improves the fruit packing efficiency, and reduces the fruit packing cost. The packing method can improve the fruit packing efficiency and reduce the fruit packing cost.

Owner:绍兴市上虞区武汉理工大学高等研究院

Full-automatic packing machine for plastic pipes

ActiveCN103407601ARealize online automatic packagingAutomate the packaging processWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

The invention discloses a full-automatic packing machine for plastic pipes. The full-automatic packing machine for the plastic pipes comprises a machine frame, wherein a conveying mechanism, a PLC, a packing bag performing mechanism and a welding mechanism are arranged on the machine frame. The packing bag performing mechanism comprises a film winding supporting frame, an unwinding assembly and a bag maker, wherein the bag maker is installed at the front end of the machine frame, the film winding supporting frame is arranged at the bottom of the machine frame, and the unwinding assembly is arranged between the film winding supporting frame and the bag maker. The welding mechanism comprises a film belt traction assembly, a longitudinally-welding assembly and a transversely-welding assembly provided with a cutter, wherein the film belt traction assembly and the longitudinally-welding assembly are respectively installed at the front portion of the machine frame, and the transversely-welding assembly is located behind the longitudinally-welding assembly. The unwinding assembly, the film belt traction assembly, the longitudinally-welding assembly and the transversely-welding assembly are respectively connected with the PLC. As the packing bag performing mechanism is additionally installed on the machine frame, and packing bags are welded longitudinally and transversely and are cut in sequence through the welding mechanism, the pipes can be packed in an on-line and automatic mode. The full-automatic packing machine for the plastic pipes is simple in structure, convenient to operate, capable of lowering production cost and suitable for production of the pipes.

Owner:HUBEI KINGBULL PIPE IND

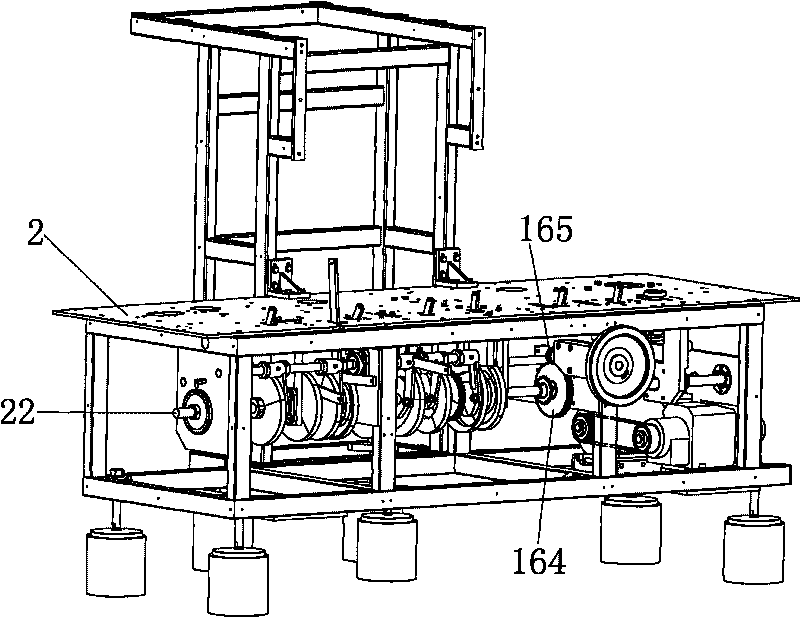

Automatic packing machine for all-model aluminium products

ActiveCN104044762AOvercome the overlay packaging challengeAutomate the packaging processWrapping material feeding apparatusWrapping with article rotationElectric machineEnergy conservation

The invention discloses an automatic packing machine for all-model aluminium products. The automatic packing machine comprises a rack, a packing mechanism arranged on the rack, and a feed mechanism and an adhesive tape pasting automatic paper changing mechanism which are used for transmitting an aluminium product to the packing mechanism, wherein the packing mechanism comprises universal catching plates symmetrically arranged at two ends of the rack, each universal catching plate fixes one end of the aluminium product, can rotate under the driving of a rotating motor, and can stretch and retract front and back under the driving of a pneumatic push rod, the rack is provided with a packing platform, and one side, corresponding to the universal catching plates, of the packing platform is provided with pressing parts capable of being upward turned. The aluminium product is fixed and rotated to be packed by the universal catching plates, and packing paper clings to the surface of the aluminium product with the matching of the pressing part, so the difficulty in covering type packing of aluminium products with different cross section sizes in the prior art is overcome, automatic linear packing of all-model aluminium products can be realized, the packing quality is greatly improved, the aluminium product packing efficiency is improved, energy conservation and environment protection are realized, and manpower is saved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

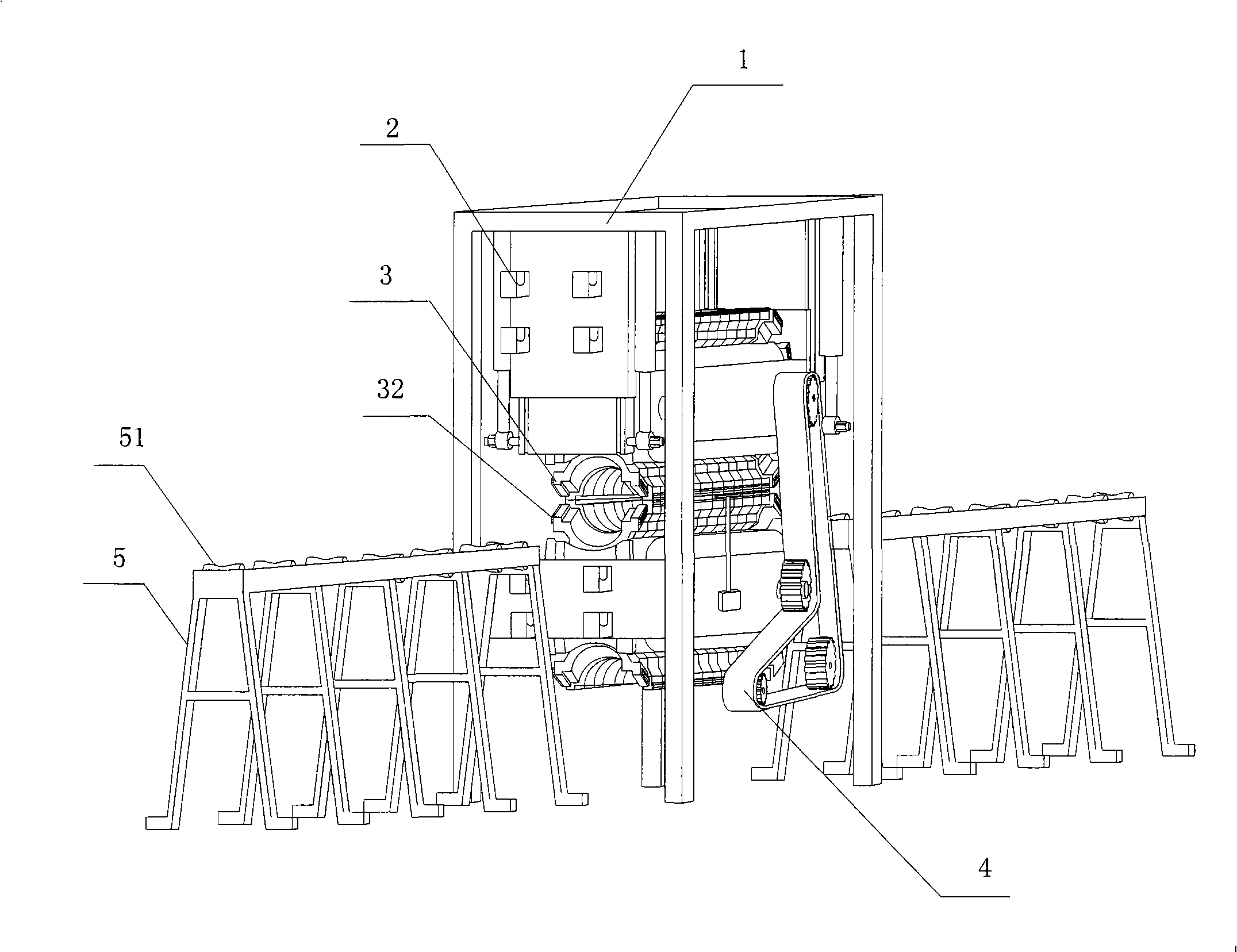

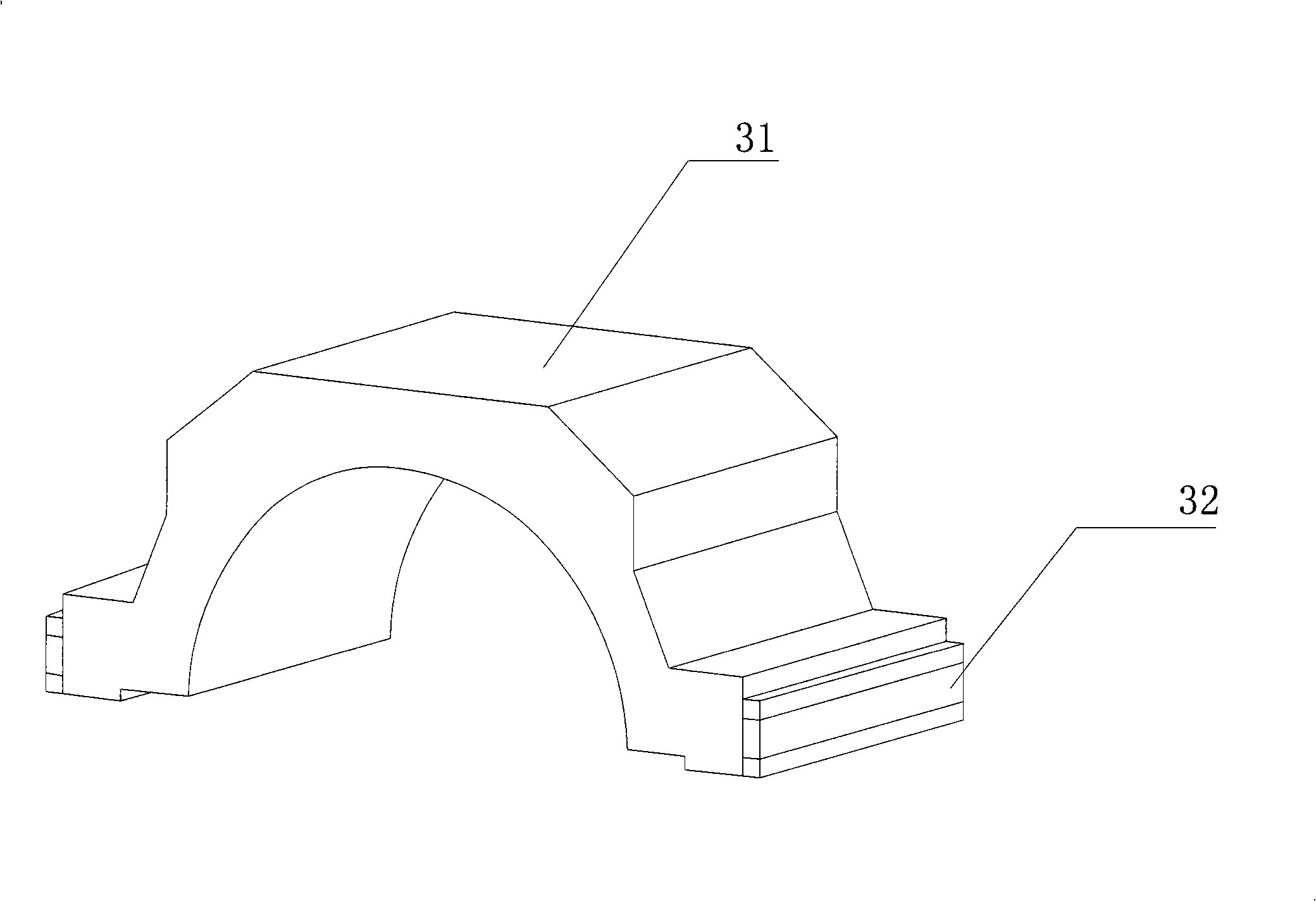

Pipe automatic packaging machine

InactiveCN101348173AAutomate the packaging processReduce labor intensityWrapper twisting/gatheringSuccessive articlesEngineeringUltimate tensile strength

The invention provides an automatic packaging machine for a tubular product, which comprises a stander (1), wherein, a material placing frame (2) for placing package material and a welding mould (3) are arranged inside the stander (1); the welding mould (3) consists of an upper part and a lower part which are symmetric and are in abutting joint; abutting surfaces of the upper part and the lower part are respectively provided with a heating weld bar (32); after the abutting joint of the welding mould (3), the whole section is in a round shape or an elliptic shape matched with the section shape of the tubular product. The automatic packaging machine for the tubular product not only has the advantages of simple structure, convenient operation and high reliability, but also can relate to the automation of production and package of a water supply tubular product and a water drainage tubular product, improves work efficiency of production, reduces labor intensity of package work, and reduces the manufacturing cost simultaneously.

Owner:GUANGDONG LIANSU TECH INDAL

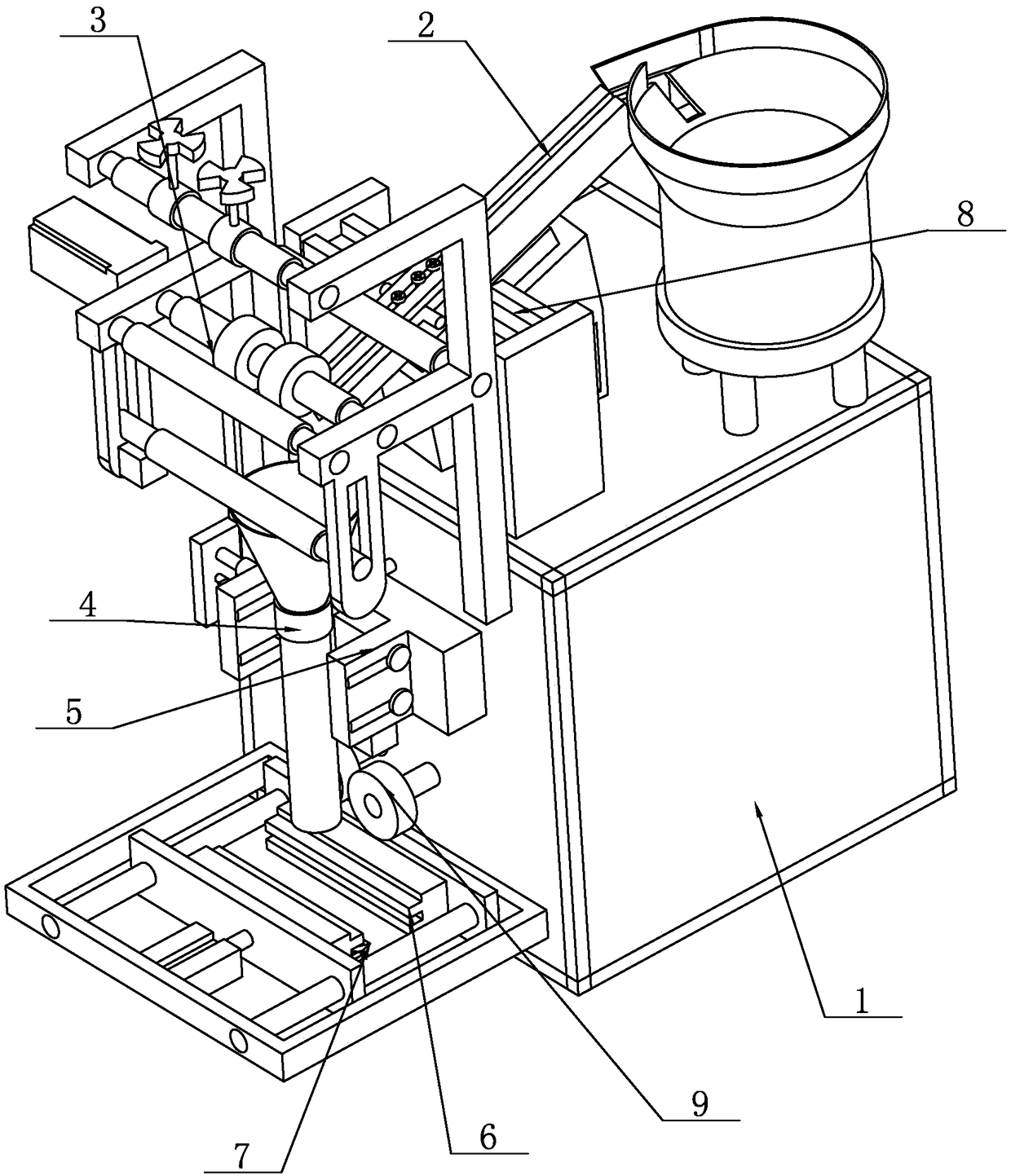

Intelligent packaging machine and control method thereof

PendingCN109051072AAutomate the packaging processImprove processing efficiencyWrapping material feeding apparatusWrapper twisting/gatheringEngineeringPackaging machine

The invention relates to the technical field of packaging, in particular to an intelligent packaging machine and a control method thereof. The intelligent packaging machine comprises a machine frame,a screw feeding mechanism, a thin film feeding and conveying mechanism, a thin film bag forming mechanism, a longitudinal heat sealing mechanism, a transverse heat sealing mechanism, a cutter mechanism and a controller are arranged on the machine frame, wherein the thin film bag forming mechanism comprises a bag forming device capable of curling a thin film into a cylindrical shape, the bag forming device is installed on the machine frame, a hopper is arranged above the bag forming device, the screw feeding mechanism comprises a conveying rail used for conveying materials, a discharging port of the conveying rail extends to the position of the hopper, a metering control assembly capable of controlling the quantitative output of the materials is arranged on the conveying rail, the longitudinal heat sealing mechanism is arranged on one side, close to the machine frame, of the bag forming device, the transverse heat sealing mechanism is arranged below the bag forming device, and a pressing wheel assembly for driving the thin film subjected to longitudinal heat sealing to be conveyed is arranged between the longitudinal heat sealing mechanism and the transverse heat sealing mechanism.By the adoption of the above scheme, automatic packaging of screws can be realized, and the processing efficiency is high.

Owner:温州市森曼智能包装设备有限公司

Automatic producing and packaging unit for stainless steel pipes

PendingCN109176041AImprove work efficiencyIncrease contactOther manufacturing equipments/toolsSteel tubeCivil engineering

The invention relates to an automatic producing and packaging unit for stainless steel pipes. The automatic producing and packaging unit for the stainless steel pipes sequentially comprises a pipe maker, a pipe cutter, a polisher and a steel pipe packager, wherein the pipe maker, the pipe cutter, the polisher and the steel pipe packager are controlled through a central controller, and a sheet lateral edge grinding device is installed on the feeding side of the pipe maker. Compared with the prior art, the automatic producing and packaging unit for the stainless steel pipes is reasonable in structural design, high in welding quality, good in polishing effect and high in operation efficiency.

Owner:广东昌华海利科技有限公司

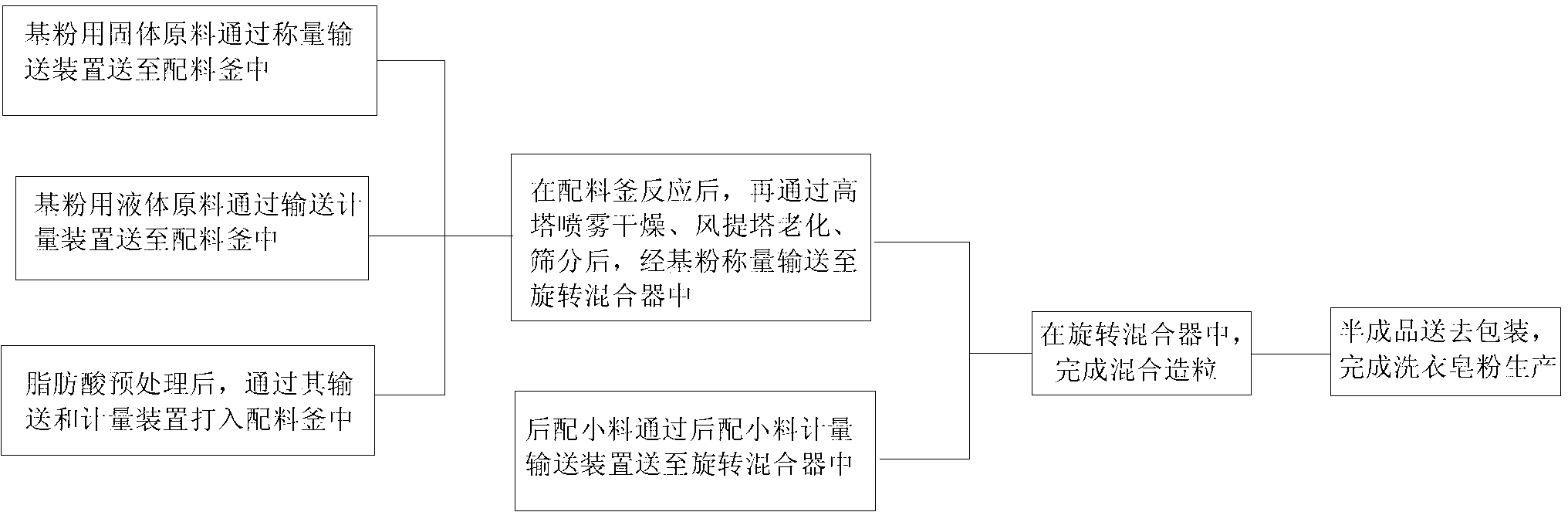

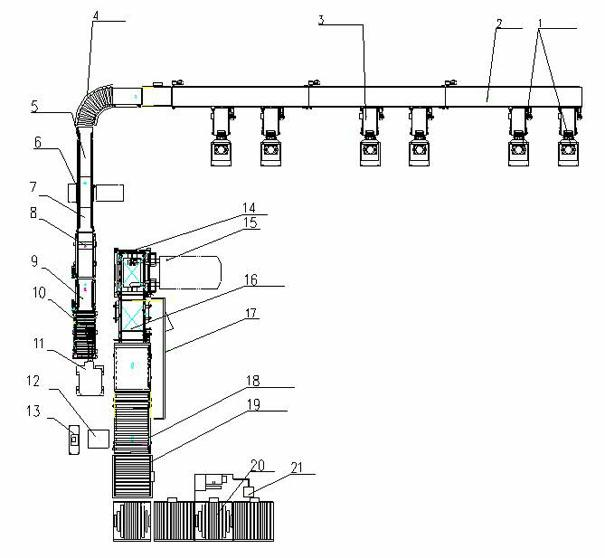

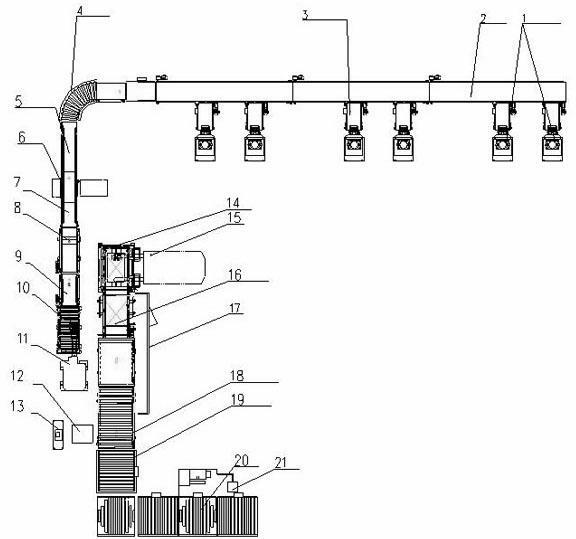

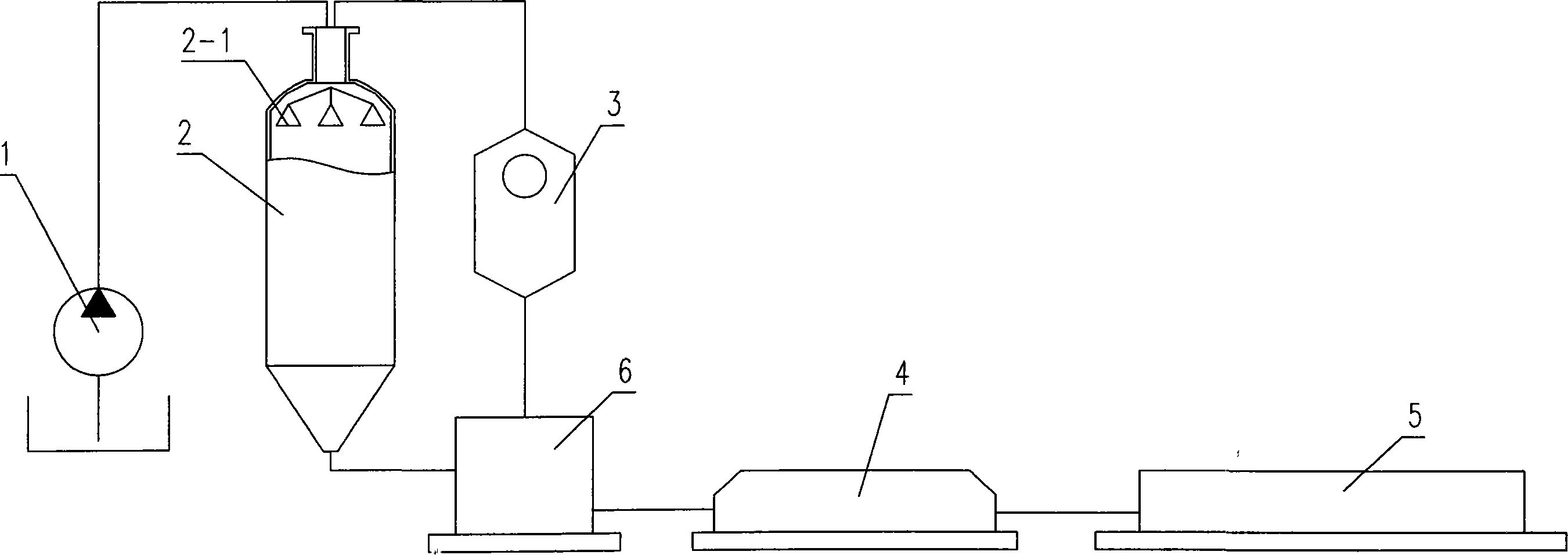

Laundry soap powder slurry, preparation method thereof and industrial production technology of laundry soap powder

ActiveCN103074182AUniform dispersion and adhesion stateLow viscositySurface-active non-soap compounds and soap mixture detergentsDetergent powders/flakes/sheetsWork in processLaundry

The invention discloses laundry soap powder slurry, a preparation method thereof and an industrial production technology of laundry soap powder. The industrial production technology mainly comprises the steps of: 1) directly adopting fatty acid and liquid alkali to conduct neutralization reaction in a batching kettle of a front preparation system to participate in slurry preparation, 2) allowing the slurry after technical optimization treatment to be capable of smoothly entering a high-tower powder spraying system through a high pressure pump to produce base powder, and 3) adding the base powder and other post preparation raw materials, continuously and evenly mixing with a screw mixer, preparing a semifinished product of the laundry soap powder, conveying to a powder bin with a conveyor belt, and packaging into a finish product. According to the technology, high-tower powder spraying equipment is adopted for production, and no other additional special device is added. Compared with the laundry soap powder produced by the original technology (adding powdered to granular sodium aliphatate during post preparation), the produced laundry soap powder has the characteristics of uniform dispersion and adhesion of sodium aliphatate, short product solution time, low agglomeration resistance and good liquidity, and automatic packaging and continuous mass production of the soap powder can be realized.

Owner:GUANGZHOU LIBY

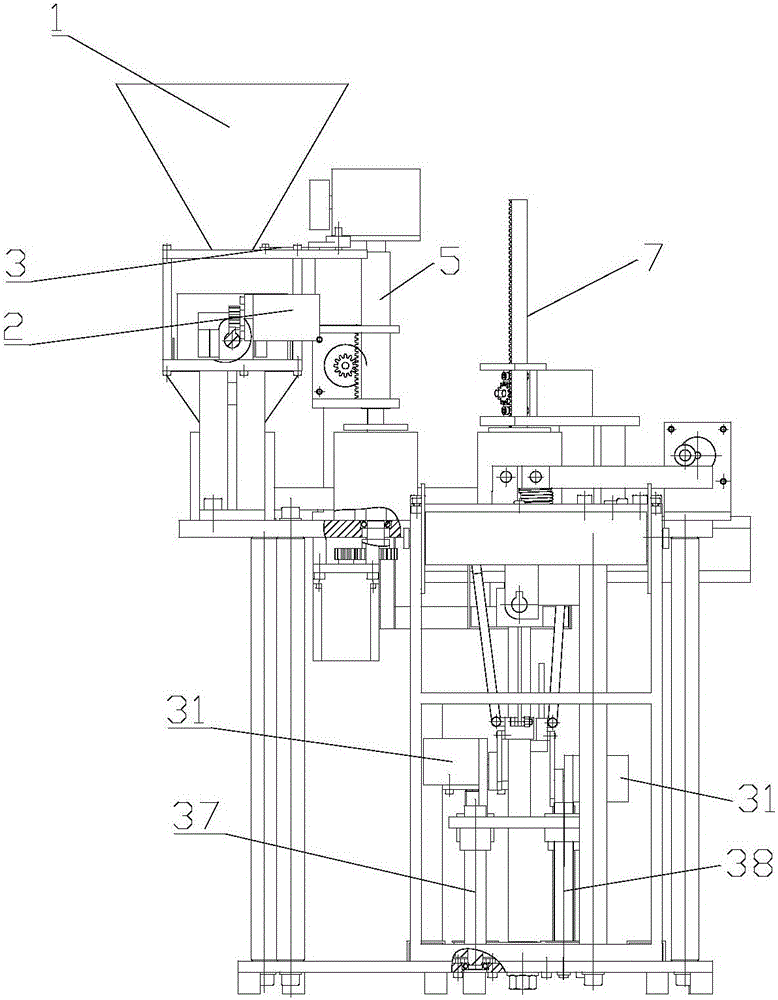

Titanium dioxide automatic packaging process and dedicated system thereof

InactiveCN102092576AIncrease the level of automationReduce labor loadSolid materialMechanical conveyorsProcess engineeringIndustrial engineering

The invention discloses a titanium dioxide automatic packaging process. The process comprises the following steps: loading a bag; measuring and packaging; unloading the bag; re-inspecting the bag weight; shaping; spraying codes on the bag; stacking; rechecking the tonnage; winding; and spraying the tonnage, wherein the steps are divided into two conveying chains from the stacking step. The titanium dioxide automatic packaging process overcomes various defects in titanium dioxide material automatic packaging, realizes automatic packaging on the titanium dioxide, and has an excellent using effect, so the automatic level of finished product package is greatly improved, the labor load of staff is reduced, the yield is improved, and the titanium dioxide automatic packaging process creates a precedent of finished product automatic packaging in the same industry in China.

Owner:JINAN YUXING CHEM

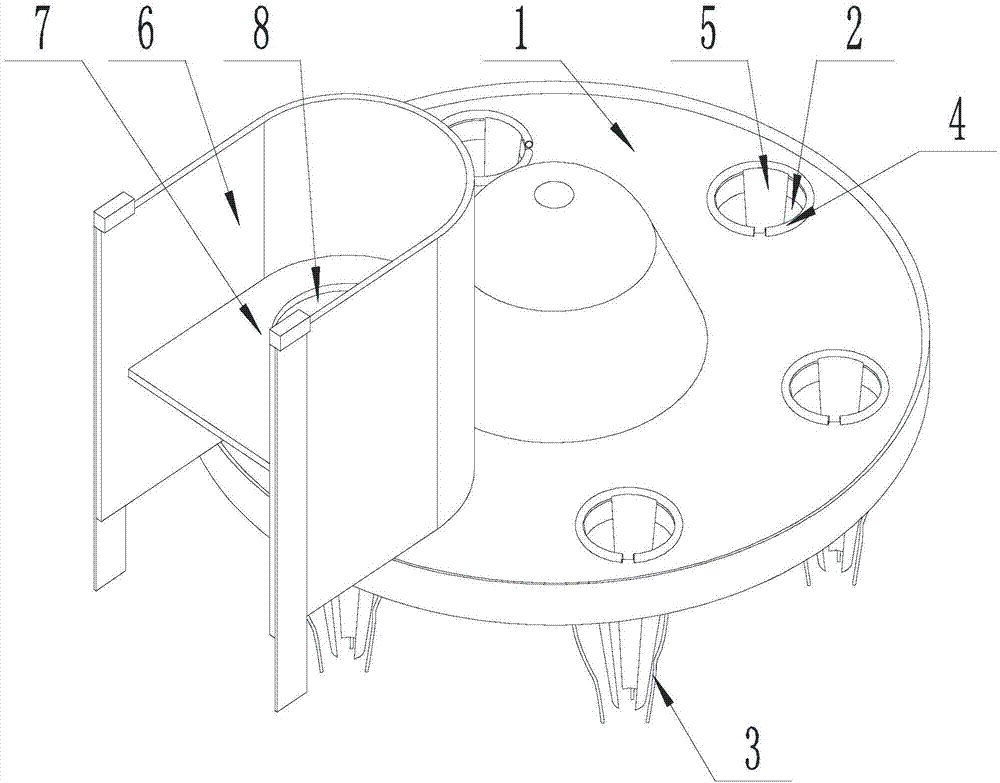

Hemispherical candy packaging system

ActiveCN105270663AAutomate the packaging processReduce manual labor intensityConveyor wrappingEngineeringPackaging machine

The invention relates to a hemispherical candy packaging system which comprises a packaging machine base, a conveying mechanism, a candy paper conveying mechanism, a candy conveying mechanism, a rotating mechanism, an overturning mechanism, a candy twisting mechanism and a candy blocking mechanism. The conveying mechanism is located at the feed inlet end of the packaging machine base; the candy paper conveying mechanism is installed on the side, close to the candy conveying mechanism, of the packaging machine base; the candy conveying mechanism is arranged on the side, close to the conveying mechanism, of the packaging machine base and located on a discharge opening of the conveying mechanism; the rotating mechanism is installed on the side, close to the candy conveying mechanism, of the packaging machine base and located above the candy conveying mechanism; the overturning mechanism is installed on the side, close to the candy conveying mechanism, of the packaging machine base and located above the left portion of the rotating mechanism; the candy twisting mechanism is installed on the side, close to the candy conveying mechanism, of the packaging machine base and located above the rotating mechanism; the candy blocking mechanism is installed on the side, close to the candy conveying mechanism, of the packaging machine base and located on the outer side of the rotating mechanism. The hemispherical candy packaging system has the advantage that hemispherical candies can be automatically packaged by means of the packaging system,

Owner:NANTONG WEALTH MASCH TECH CO LTD

Intelligent coin sorting device

InactiveCN106097562ARealize automatic sortingReduce labor costsCoin/currency accepting devicesPulp and paper industryPaper sheet

The invention relates to an intelligent coin sorting device which comprises the components of a mixed coin separating mechanism, a paper money sorting mechanism, a coin sorting mechanism and a coin packaging mechanism. The mixed coin separating mechanism comprises a screening roller and a roller driving assembly. The mixed coins are dumped from the top opening of the screening roller. The roller driving assembly drives the screening roller to rotate. The coins fall through screening holes. The paper money slides out through the bottom opening of the screening roller. The paper money sorting mechanism comprises a paper twisting trough assembly, a single-paper-piece conveying assembly, an image identification assembly and a paper money classifying and collecting assembly. The paper twisting trough assembly performs twisting on a single piece of paper money. The single-paper-piece conveying assembly conveys the single piece of paper money to the inlet of the image identification assembly. After the image identification assembly identifies the type of the paper money through image acquisition, the paper money is classified and put into the paper money classifying and collecting assembly. Compared with the prior art, the intelligent coin sorting device realizes automatic coil sorting and furthermore has advantages of saving labor cost, improving sorting efficiency and sorting precision, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

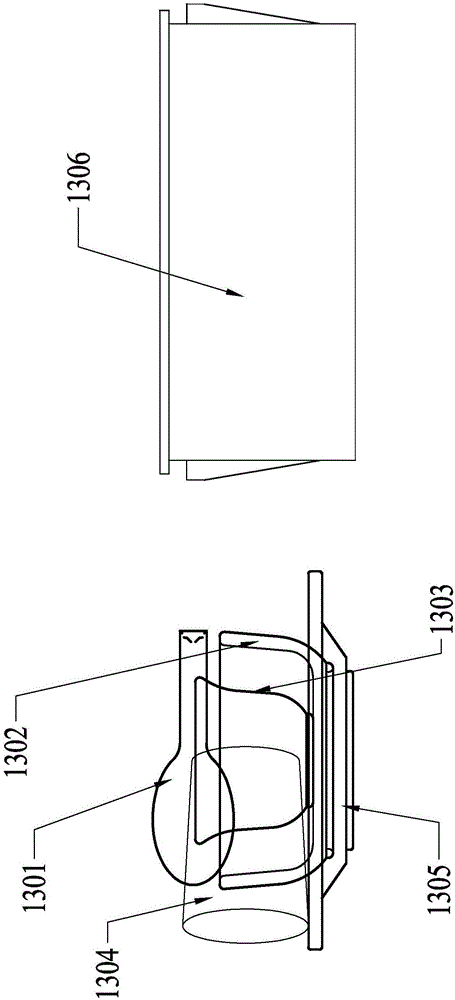

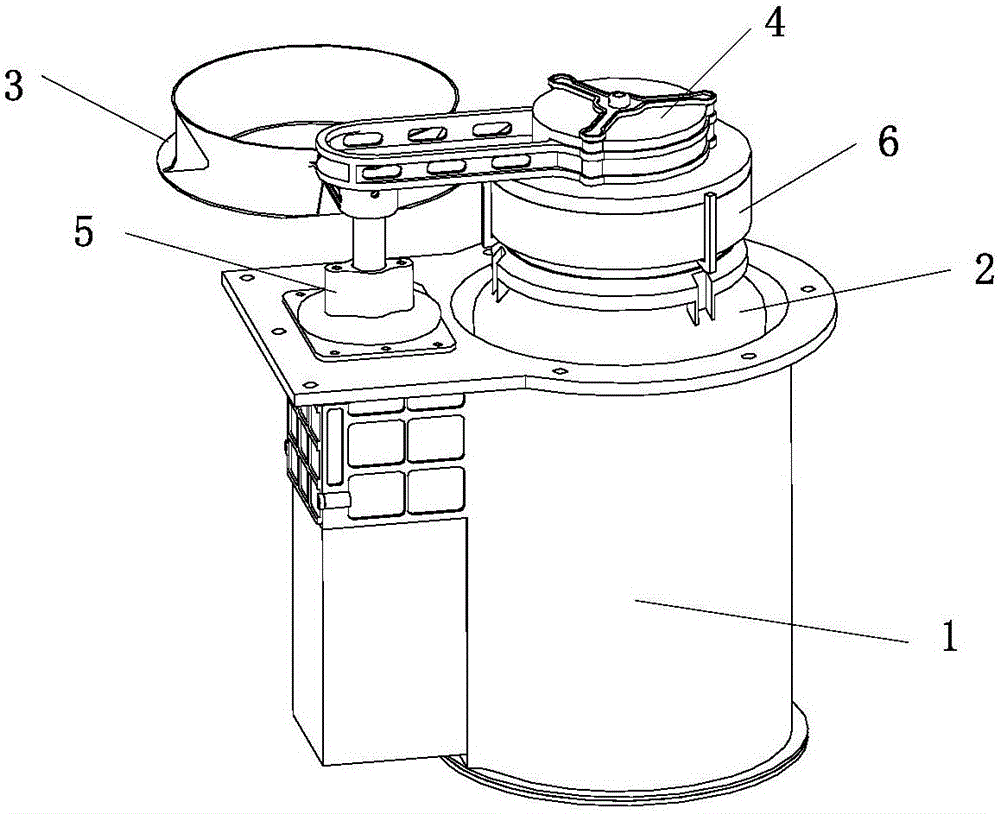

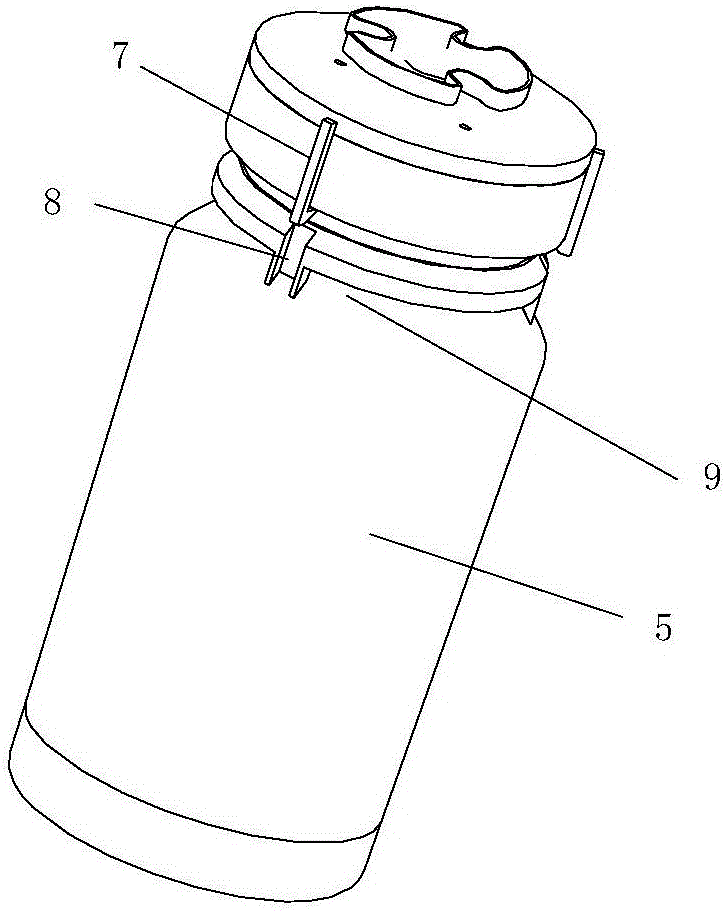

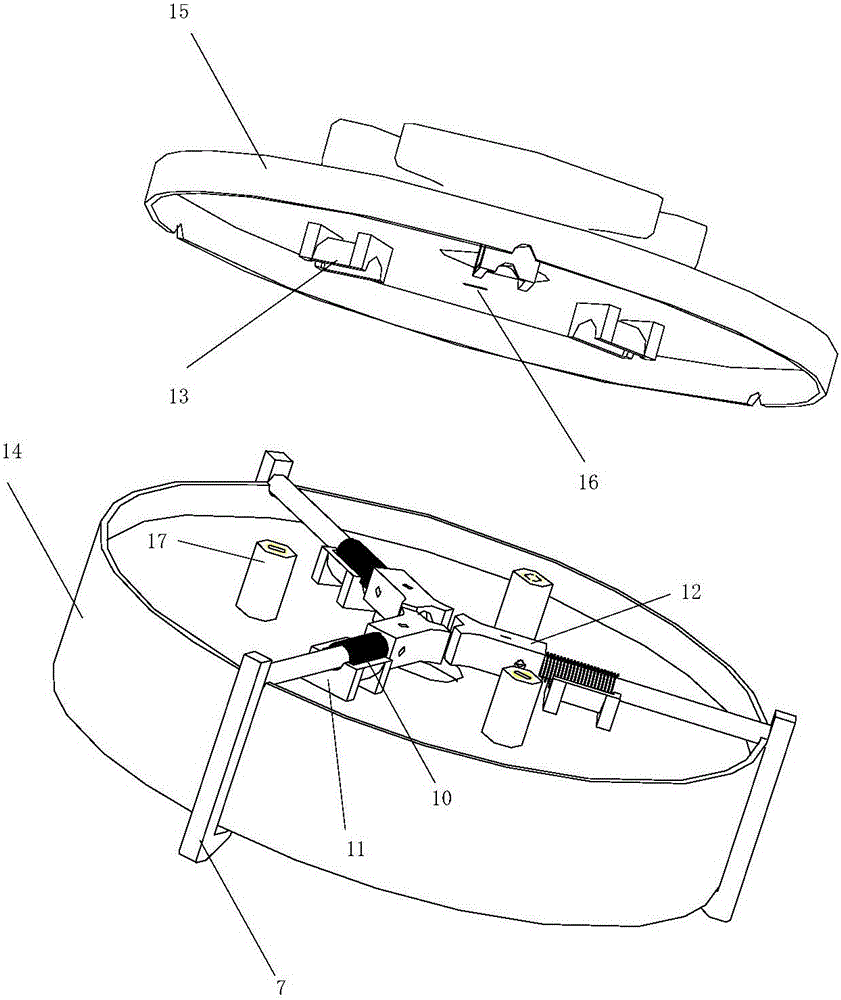

Primary packaging device for lunar surface sampling

ActiveCN106198094AEasy to pour and stake outRealize automatic openingWithdrawing sample devicesDrive shaftEngineering

The invention discloses a primary packaging device for extraterrestrial star surface sampling. The device comprises a main body, a sample container, a sample discharge tunnel, a container cap packaging assembly, a driving mechanism and a container cap. The main body comprises two fixing spaces respectively fixing the sample container and the driving mechanism. The driving mechanism is provided with a driving shaft for outputting driving power. The driving shaft realizes linear elevating motion and circumferential motion. The sample discharge tunnel is a flat bottom tunnel and the flat bottom tunnel is connected to the driving shaft through a tunnel support. The container cap packaging assembly is connected to the driving shaft through a casing support. The container cap is connected to the container cap packaging assembly through a spring spacing mechanism. When the driving shaft moves upward or downward, the driving shaft drives the container cap packaging assembly to move upward or downward so that the container cap is driven to move upward or downward. When the driving shaft moves circumferentially, the driving shaft drives the container cap packaging assembly to move circumferentially so that the container cap packaging assembly is separated from the container cap.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Fruit packaging system for improving packaging efficiency

ActiveCN107416255AImprove packaging efficiencyReduce labor intensityPackaging fruits/vegetablesElastic plasticManufacturing engineering

The invention discloses a fruit packaging system for improving the packaging efficiency. The fruit packaging system comprises a conveying device, wherein a foam screen sleeving mechanism is arranged on the discharge end of the conveying device, the sleeving mechanism comprises a rotary table and an intermittent driving mechanism which are connected in sequence, and the rotary table is driven to rotate around the axis of the rotary table by the intermittent driving mechanism; a plurality of fruit receiving holes are formed along the axis of the rotary table in a centrosymmetric mode, a plurality of support rods are respectively arranged on one end, which is close to the ground, of each fruit receiving hole, the distance between the support rods on each fruit receiving hole and the axis of the corresponding fruit receiving hole is gradually reduced as far away from the fruit receiving hole, and the support rods can adopt steel wires or elastic plastic rods. Compared with a manual packaging foam screen, the fruit packaging system has the advantages that the packaging efficiency is improved, and the labor intensity of workers is reduced; compared with an existing large packaging machine, the fruit packaging system has the advantages of small size and low production cost and maintenance cost and is suitable for packaging foam screens on fruits by fruiterer, and automatic packaging of the foam screens on apples can be realized.

Owner:重庆硕睿云科技有限公司

Automatic paper wrapping machine for article

PendingCN110294158AAutomate the packaging processIncrease productivityWrappingWrapper twisting/gatheringPulp and paper industryTransfer mechanism

The invention relates to the technical field of automatic equipment, in particular to an automatic paper wrapping machine for an article. The automatic paper wrapping machine comprises a paper wrapping workbench, a first side edge paper wrapping mechanism arranged on the paper wrapping workbench, a second side edge paper wrapping mechanism arranged on one side of the first side edge paper wrappingmechanism, a packaging paper feeding mechanism, an article picking mechanism, a first adhesive tape laminating mechanism, a second adhesive tape laminating mechanism and an article transferring mechanism, wherein the first side edge paper wrapping mechanism is used for turning packaging paper on the bottom surface of the article and attaching the packaging paper to the two opposite side surfacesof the article and the upper surface of the article, and the second side edge paper wrapping mechanism is used for laminating the other two side surfaces of the article output by the first side edge paper wrapping mechanism. According to the automatic paper wrapping machine, automatic packaging of the article is achieved, the structure is simple and compact, the automation degree is high, and operation is stable and reliable, so that the production efficiency of whole article packaging is improved, the labor cost is reduced, and the production quality is improved.

Owner:东莞市贞观盛智控科技有限公司

Traditional Chinese medicinal material packaging machine

InactiveCN105905327AReduce exposureReduce the growth of bacteriaSolid materialMedicinal herbsEngineering

The invention discloses a traditional Chinese medicinal material packaging machine. The traditional Chinese medicinal material packaging machine comprises a machine body. Supporting feet are arranged at the bottom of the machine body. A base is arranged on the tops of the supporting feet. A control panel is arranged on the outer side of the base. A conveying belt is arranged inside the base. A weight sensor is arranged in the conveying belt. An output channel is arranged on the right side of the conveying belt. A packaging box is arranged on the left side of the top of the base. The top of the machine body is connected with a transverse rod through supporting columns. A medicine feeding hopper is arranged on the top of the transverse rod. The bottom of the medicine feeding hopper is connected with a metering cylinder. A medicine outlet pipe is arranged at the bottom of the metering cylinder. An electromagnetic valve is arranged on the outer side of the medicine outlet pipe. The right side of the bottom of the transverse rod is connected with a telescopic rod. A sealing plate is arranged at the bottom of the telescopic rod. According to the traditional Chinese medicinal material packaging machine, the packaging time of medicinal materials is shortened, the medical efficiency is improved, the treatment of patients is not delayed under the situation that many patients see a doctor, and the illness state of the patients can be recovered as fast as possible.

Owner:WUXI KING MO MACHINERY

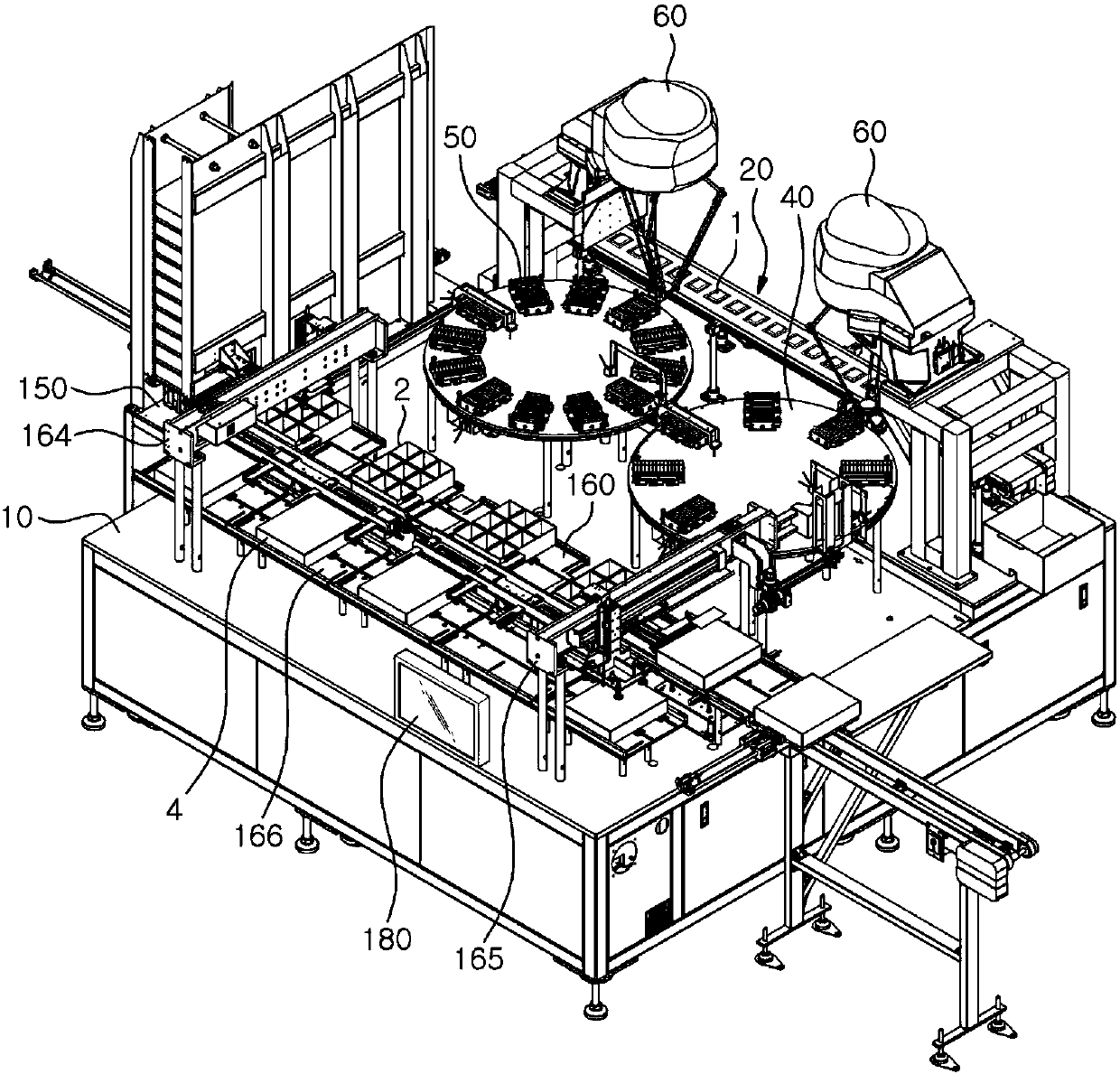

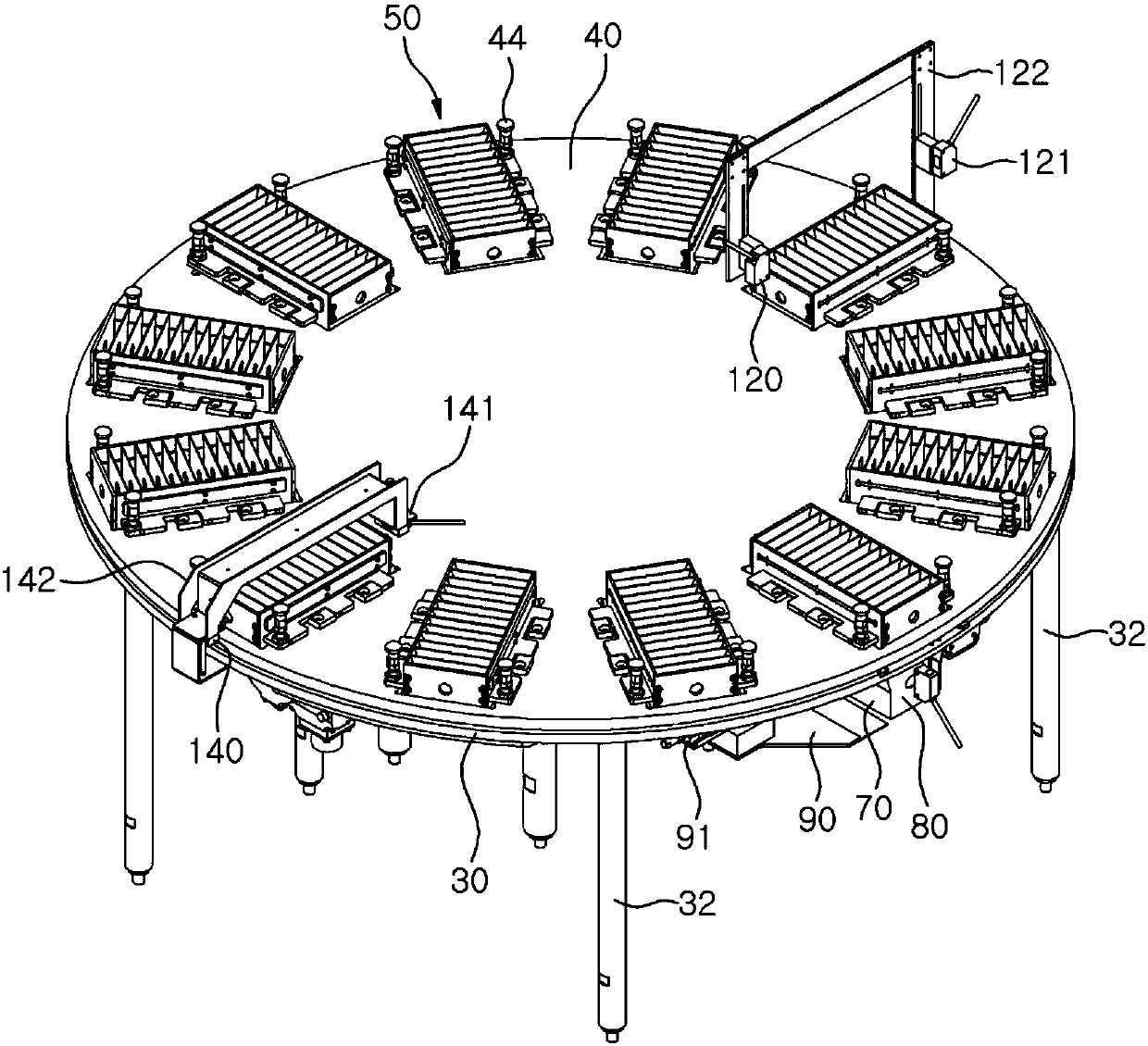

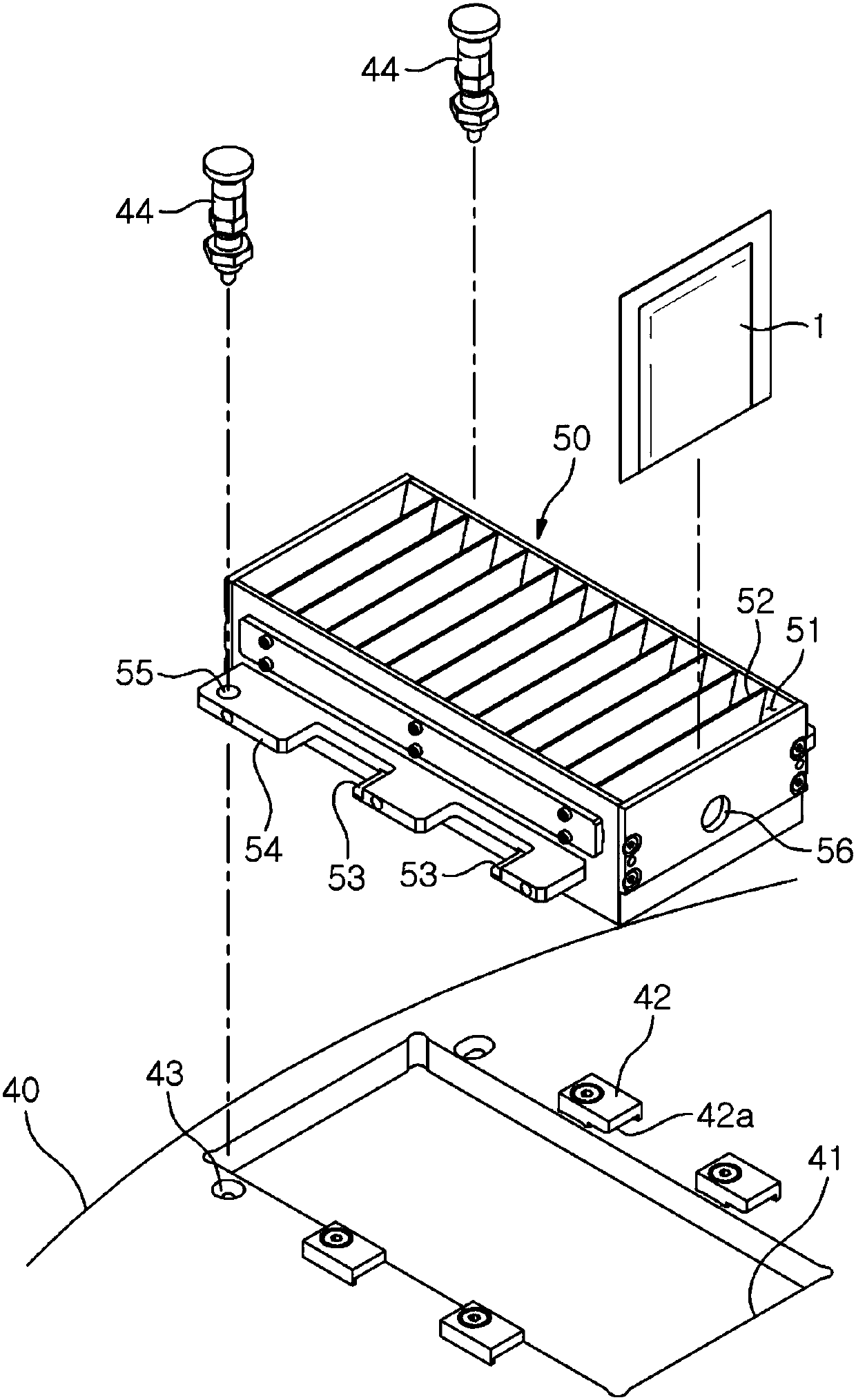

Auto packing machine of a pouch

InactiveCN107651240AEasy to operateReduce labor costsWrapper twisting/gatheringPackaging automatic controlPackaging machine

The present invention relates to an automatic pouch packaging machine comprising: a transfer conveyor to transfer a pouch forward; a turntable placed on a side of the transfer conveyor having a plurality of opening parts which extends in radial directions, formed on a plane with gaps therebetween in a circumferential direction; a plurality of slot magazines fixated to an upper surface of the turntable having a plurality of vertically penetrating slots arranged horizontally thereon, wherein the plurality of slots communicate with the respective opening parts of the turntable; a pick-up means placed on a side of the transfer conveyor, picking up the transferred pouch to insert the same into each of the slots of the slot magazines; an opening and closing plate to open and close the opening pats of the turntable, and dropping the pouch received in the slots of the slot magazines by opening the opening parts; a receiving guider arranged on a lower side of the turntable, guiding the pouch falling from the slot magazines to be inserted into each receiving groove of a box; a box supply means to supply a box to the lower side of an exit of the receiving guider; and a controller to control the operation of the turntable, the pick-up means, the opening and closing plate, and the box supply means.

Owner:YUHANNCI CO LTD +1

Producing method of novel soybean milk powder and manufacturing line

InactiveCN101032264AImprove instant solubilityImprove liquidityMilk preparationOther dairy technologyManufacturing lineFluidized bed

The present invention discloses one kind of bean milk powder and its production process and production line, and belongs to the field of instant solidified beverage technology. The instant bean milk powder is produced with semi-finished solid material, and through spraying with spray gum, returning fine powder, pelletizing in a fluidized bed, cooling and other steps. It has excellent solubility and good flowability, and may be dissolved in cold and hot water fast. The technology of the present invention may be used in the production of bean powder, bean milk powder, milk powder, peanut powder, etc.

Owner:VV FOOD & BEVERAGE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com