Patents

Literature

123results about "Packaging biscuits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

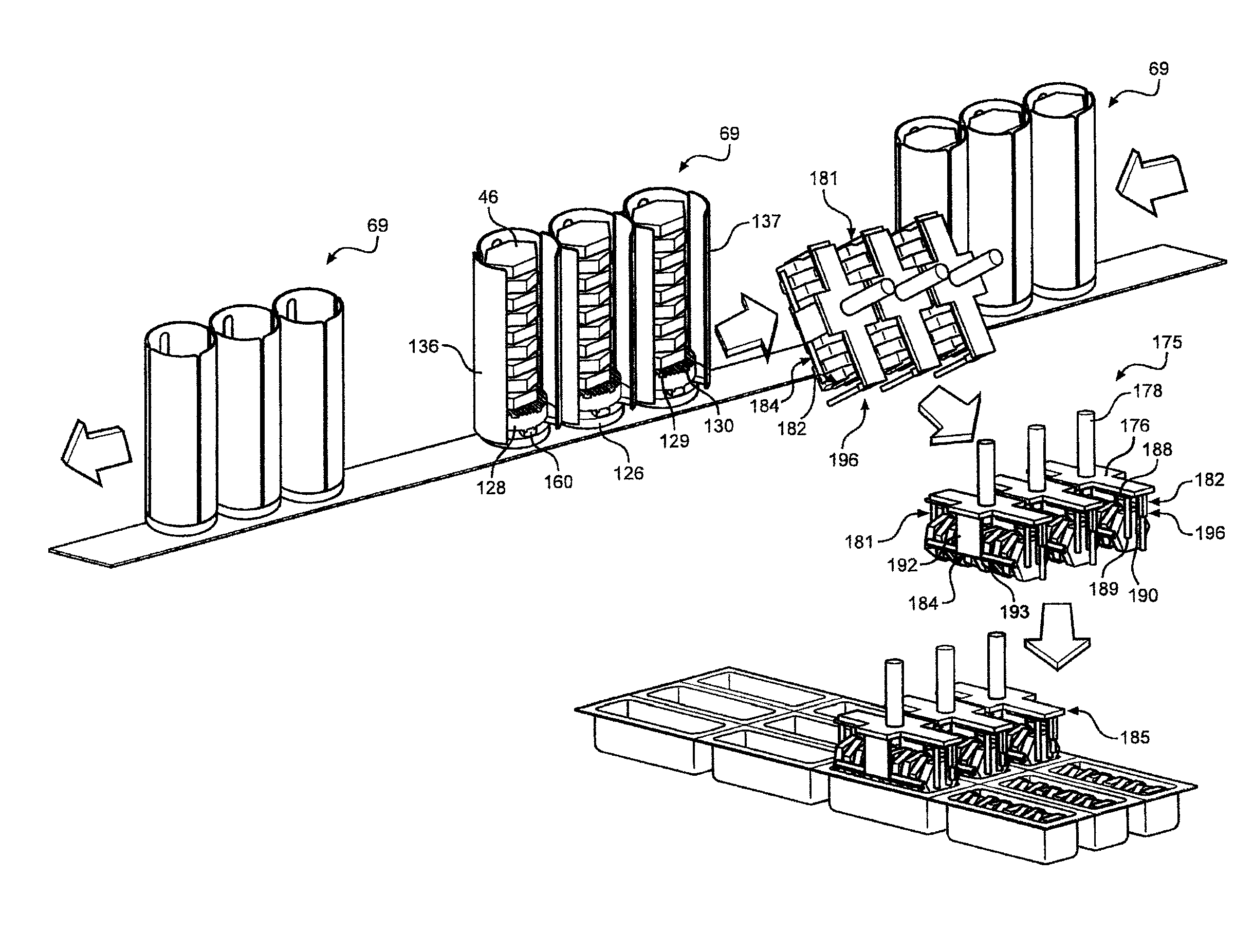

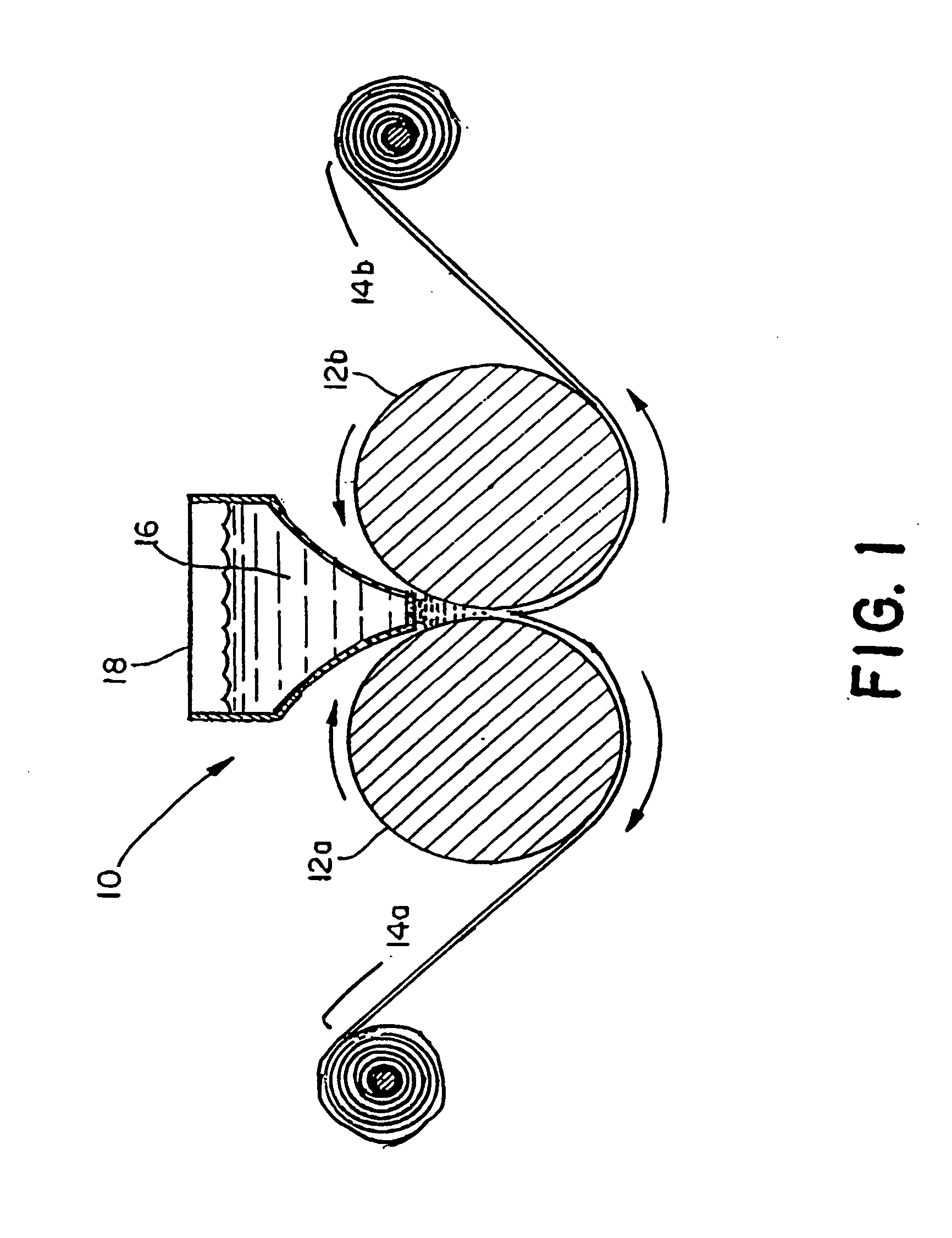

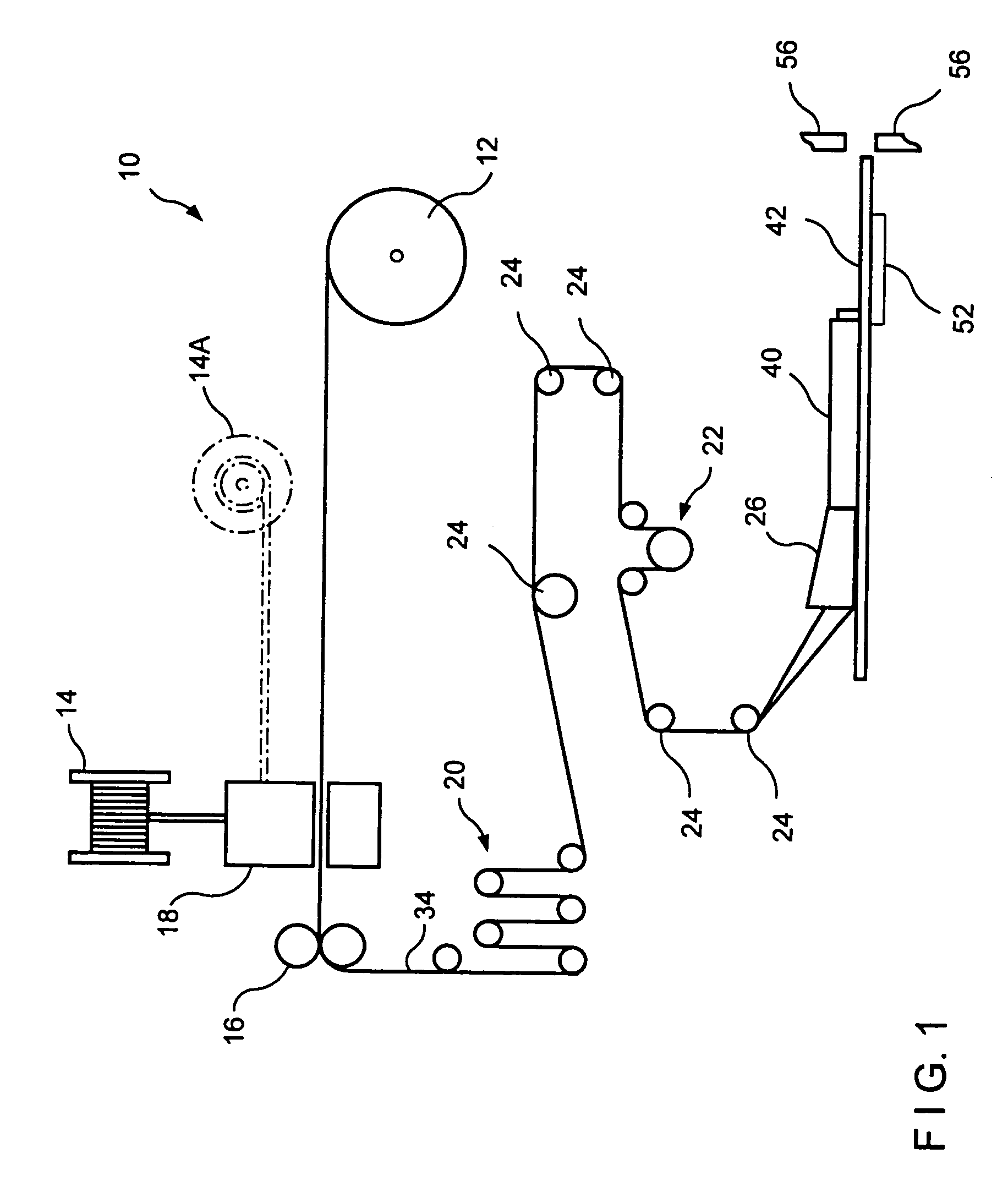

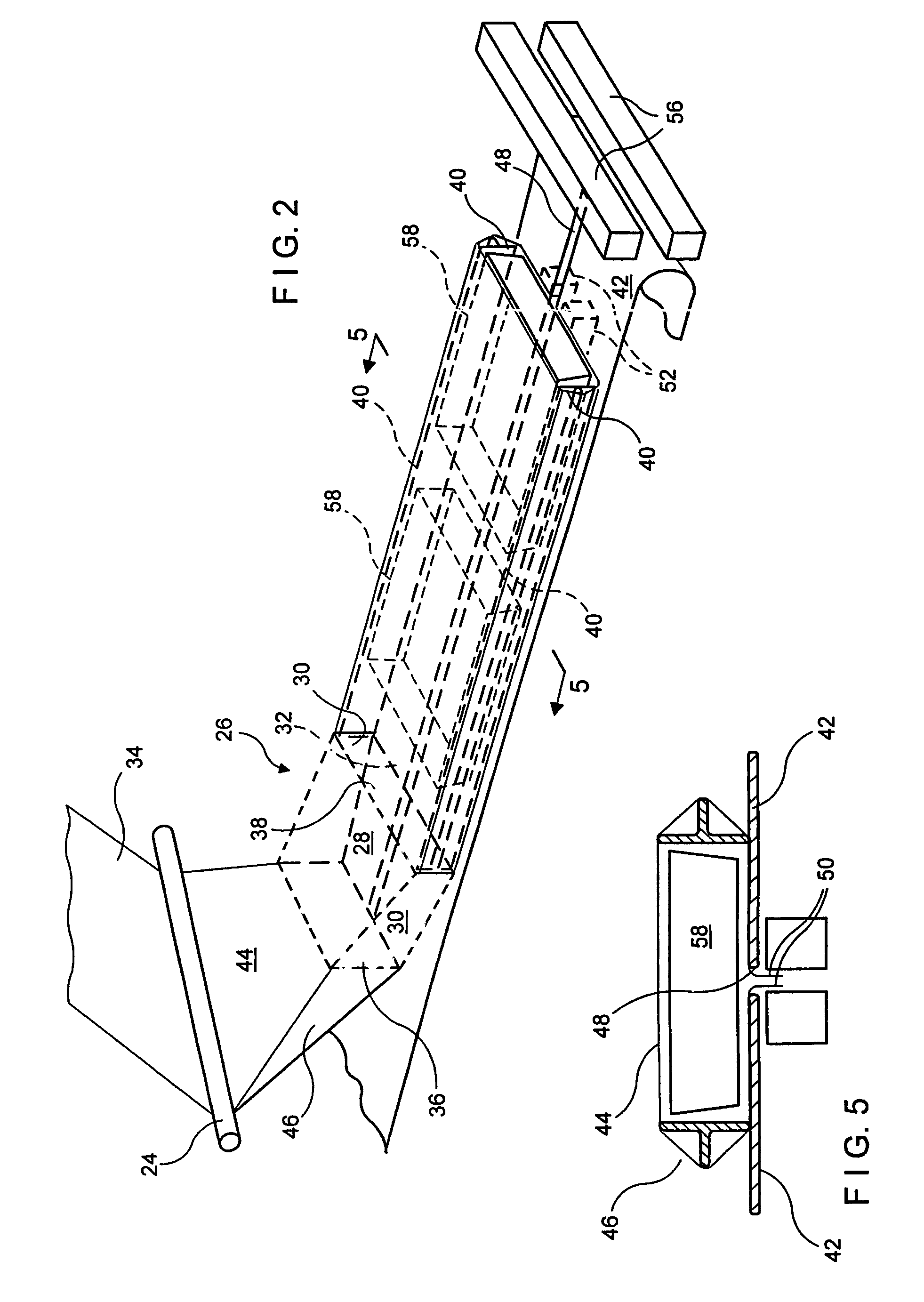

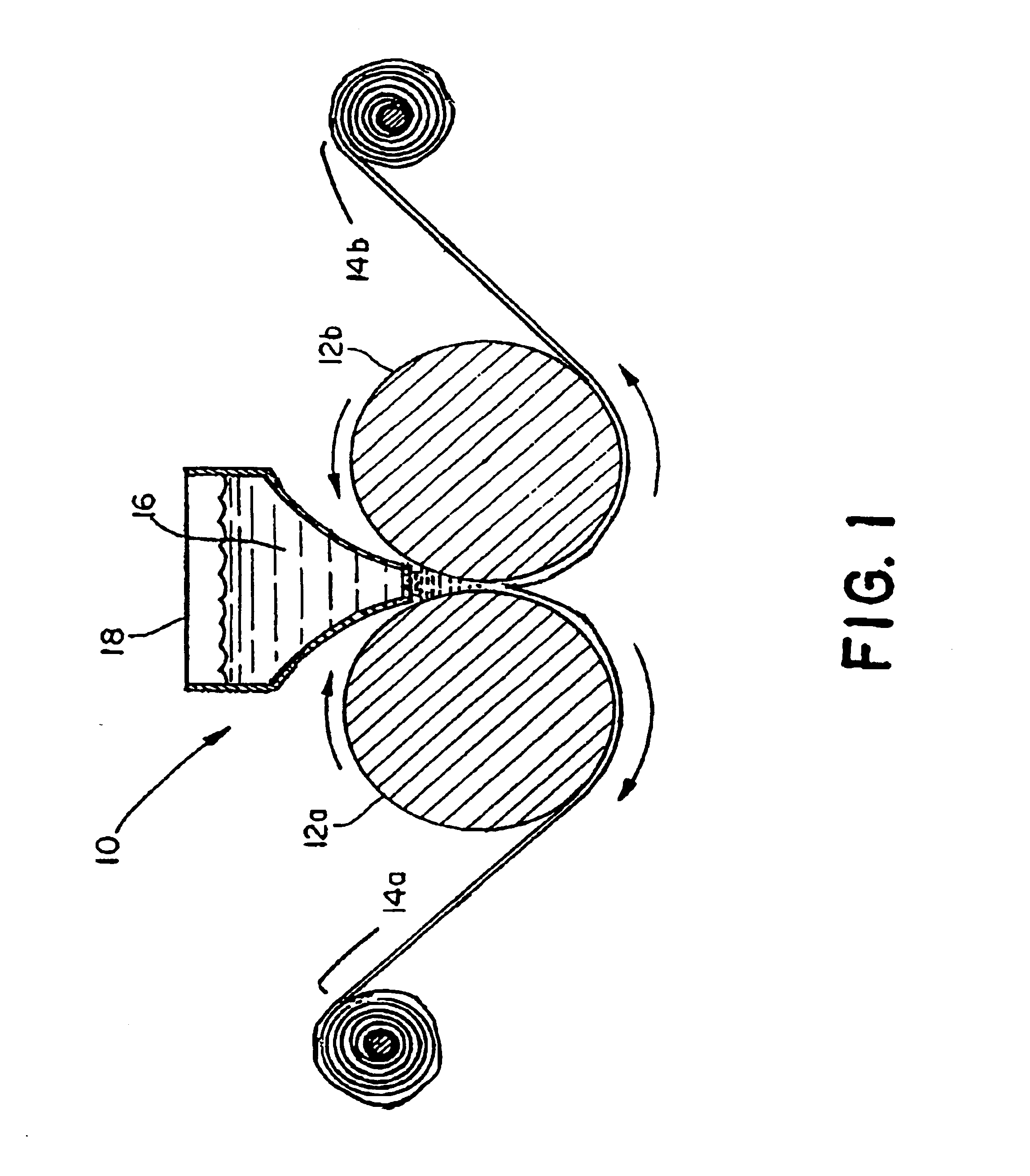

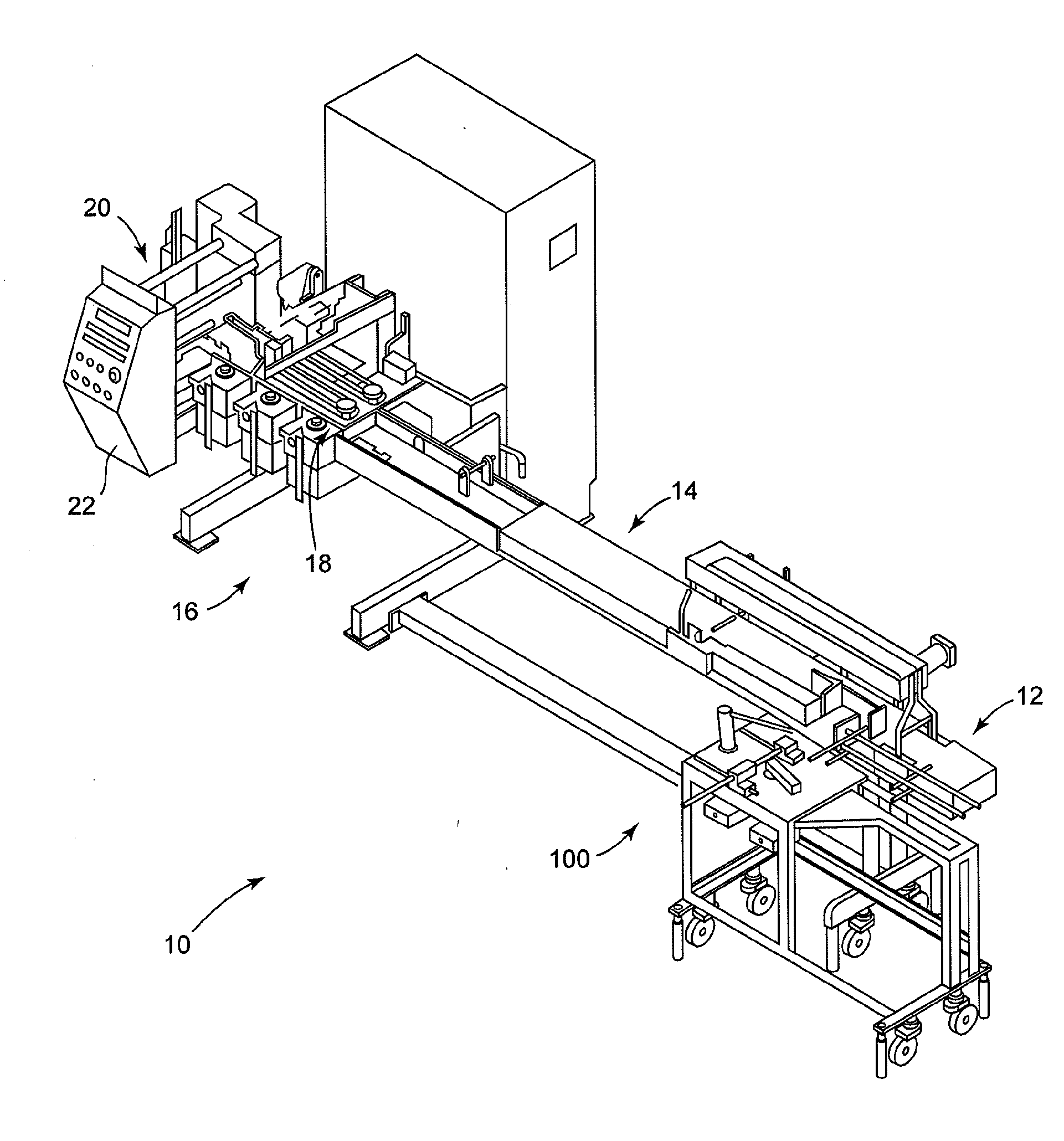

Food packaging with vertical to horizontal transfer loading

A method and system for packaging products provides for initially, vertically stacking a plurality of products during production in a transfer canister, simultaneously removing a stack of the products from the transfer canister, reorienting the stack and horizontally loading the stack into a final product package cavity. The invention has applicability to a wide range of products, particularly food products, such as refrigerated dough products. In one embodiment of the invention, the product package cavity is thermoformed as part as an overall horizontal form, fill and seal system.

Owner:GENERAL MILLS INC

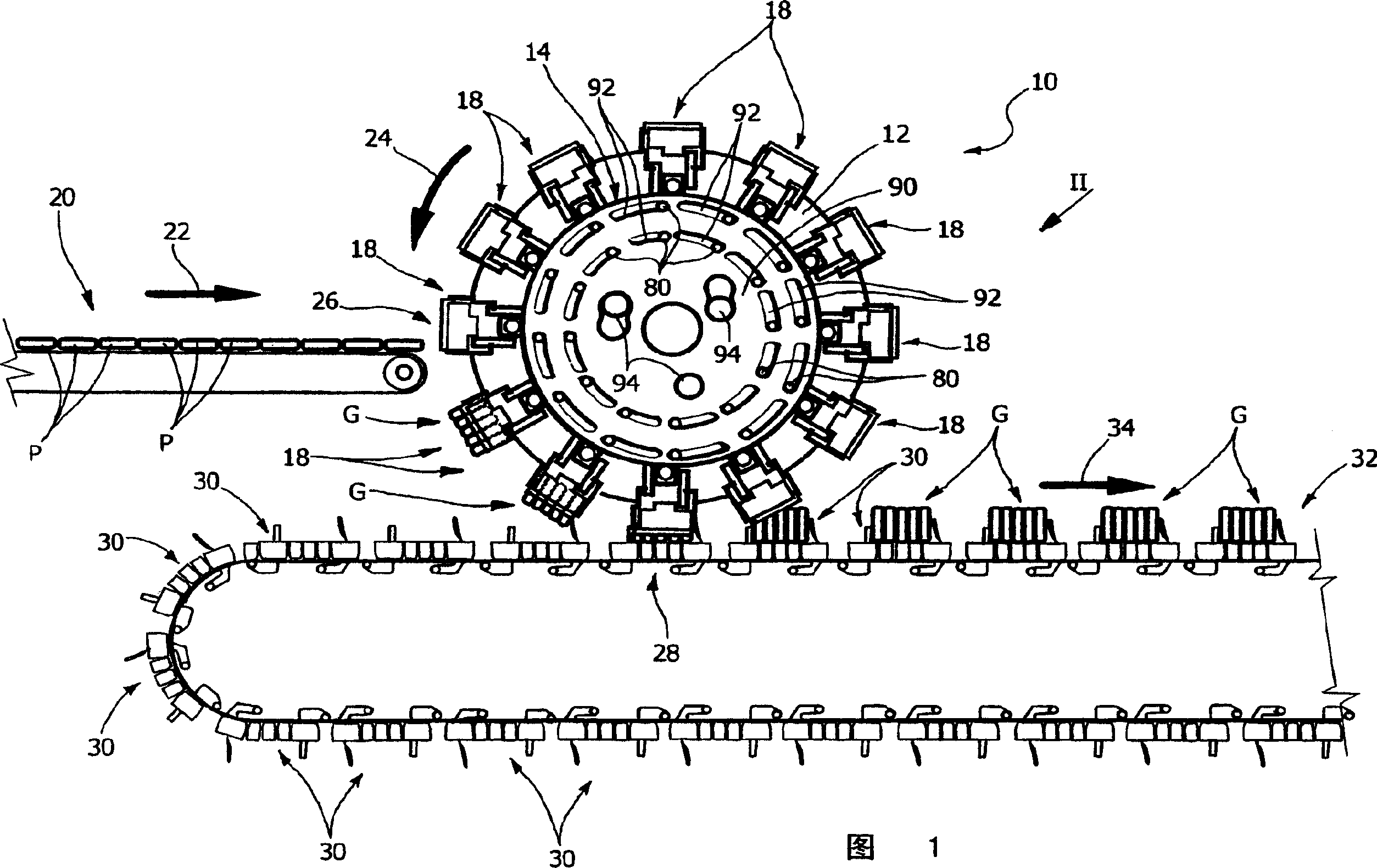

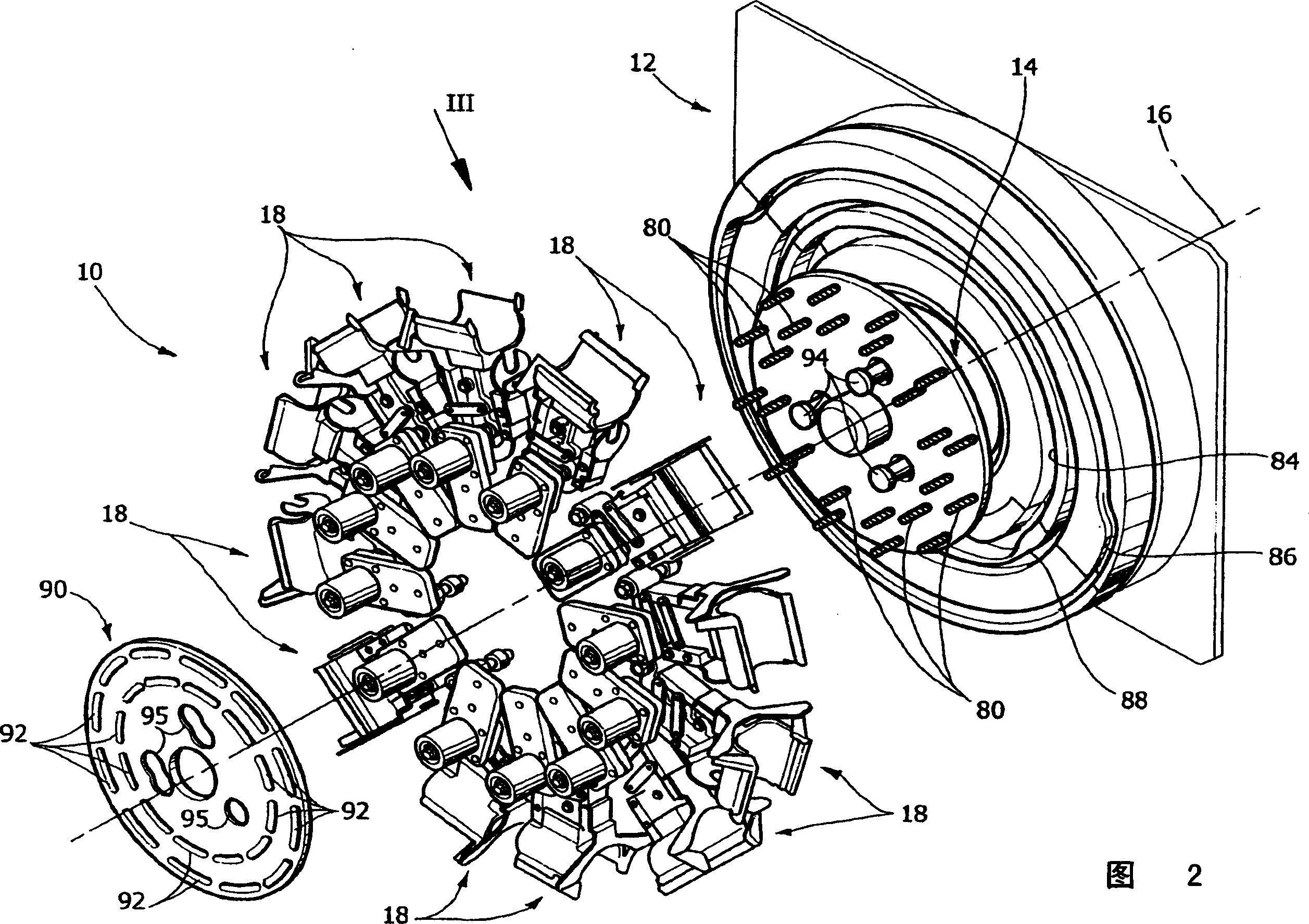

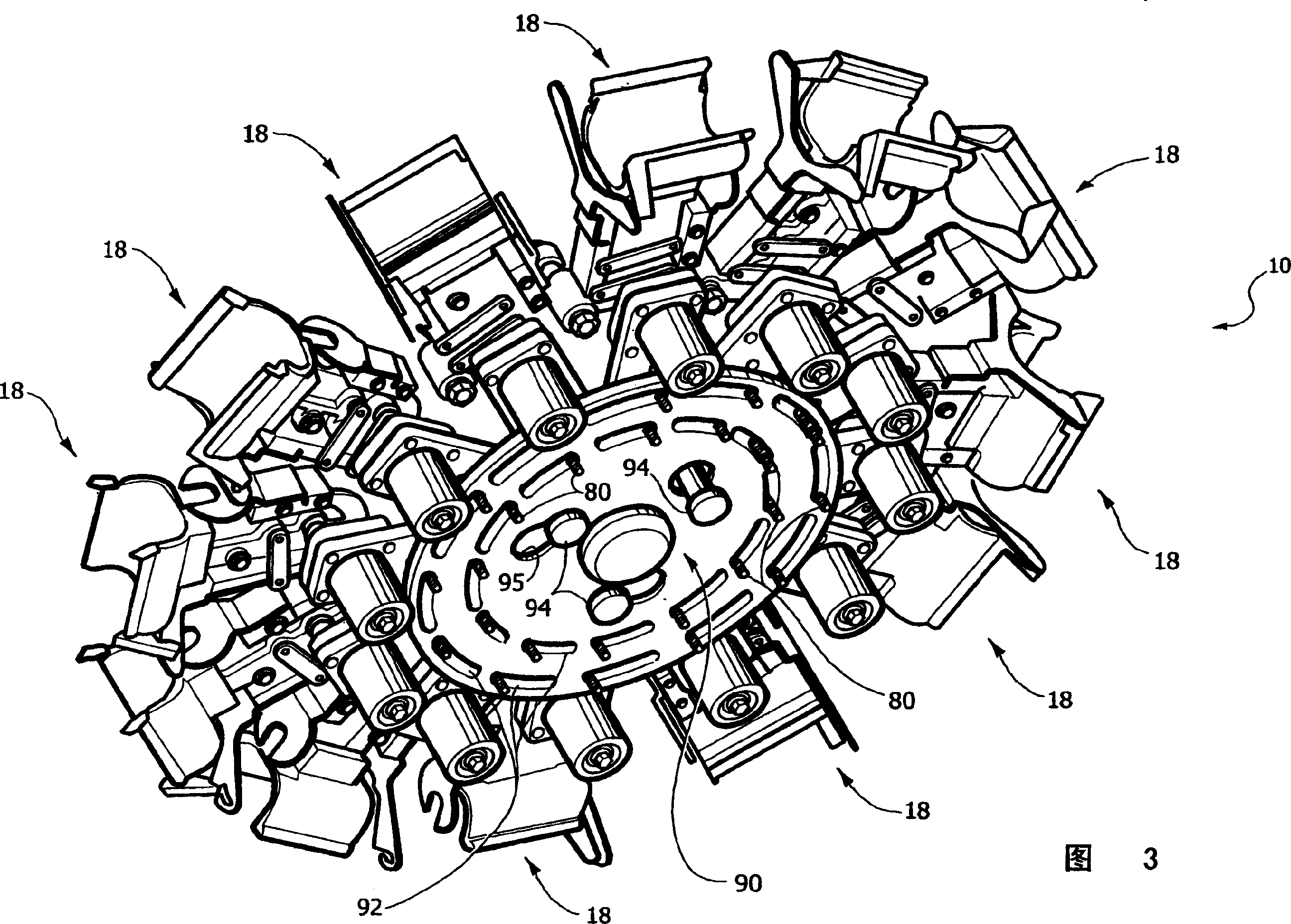

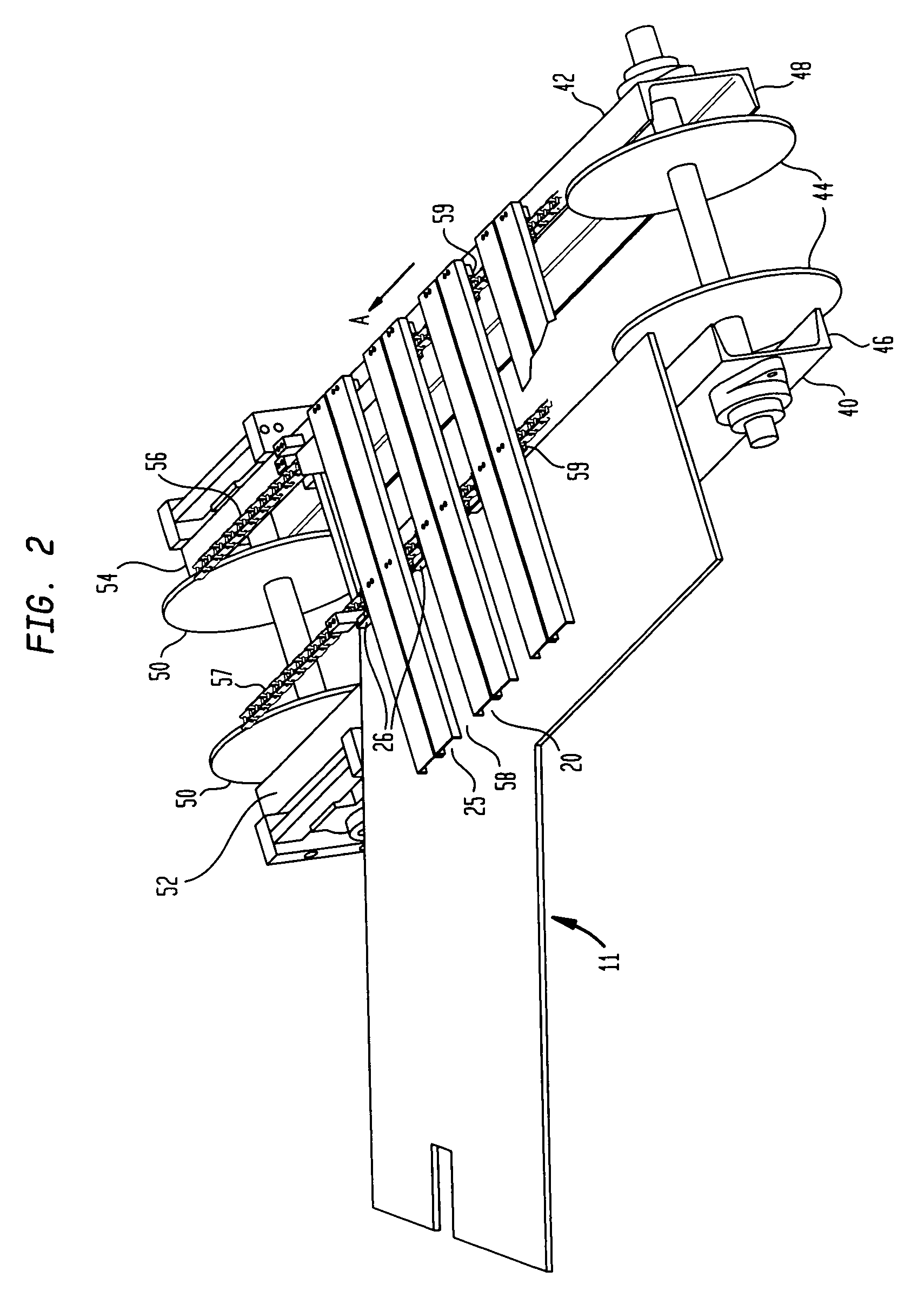

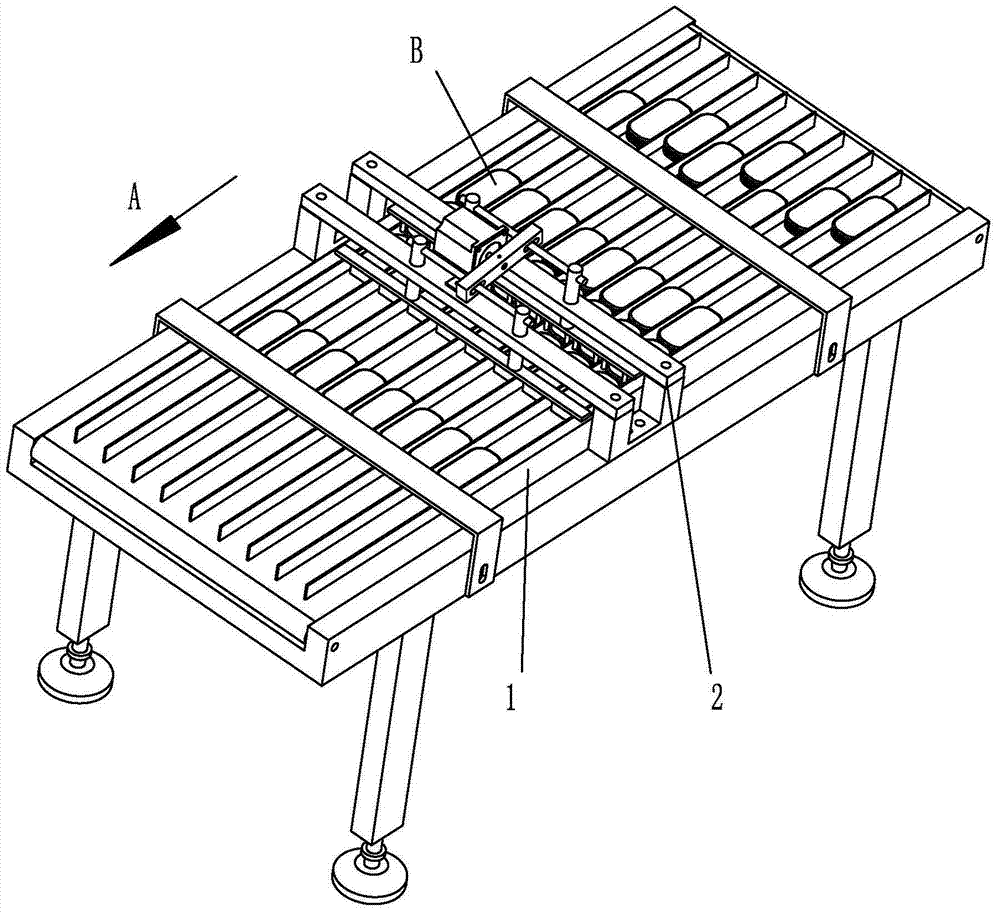

Device for forming groups of products, for instance for automatic packaging machinery

A device for forming product groups, which includes a stationary base structure (12); a bracket (14) movable relative to the base structure (12); and a plurality of components supported by the movable bracket (14). Clamping units (18) which are movable from a position (26) for receiving the product (P) to a position (26) for releasing the product group (G), and which are capable of receiving in this receiving position (26) advancement in a given direction (22) products (P) and form a product group (G) including a predetermined number of products (P). The clamping units (18) can be selectively disassembled and reassembled independently of each other relative to the movable bracket (14).

Owner:CAVANNA SPA PRATO SESIA

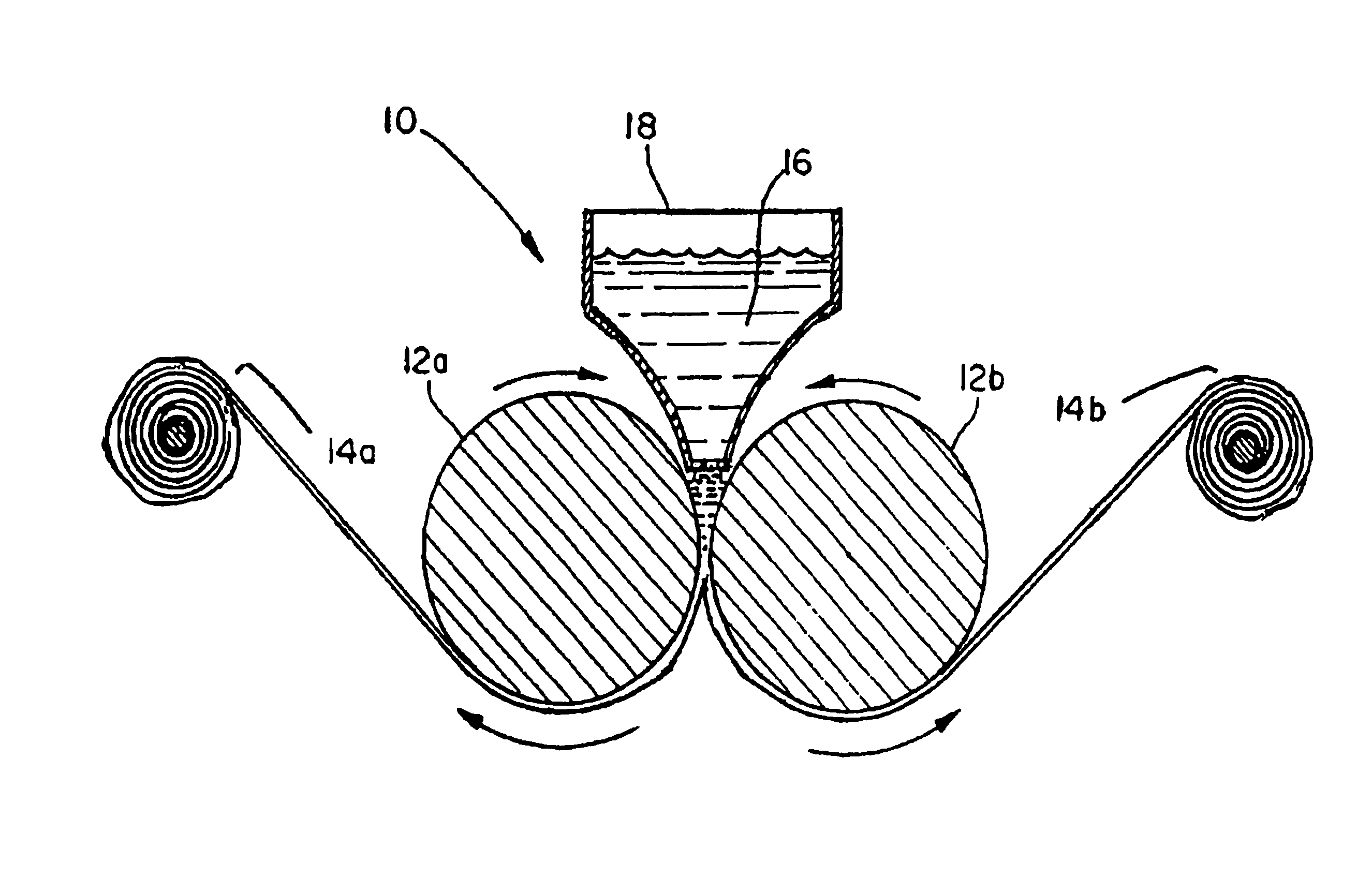

Method of producing edible cellulosic films

Disclosed is a process for continuous casting of edible cellulose-containing film sheets having unique physical characteristics. The cellulose film sheets have diverse applications in the processed food industry.

Owner:WEIBEL

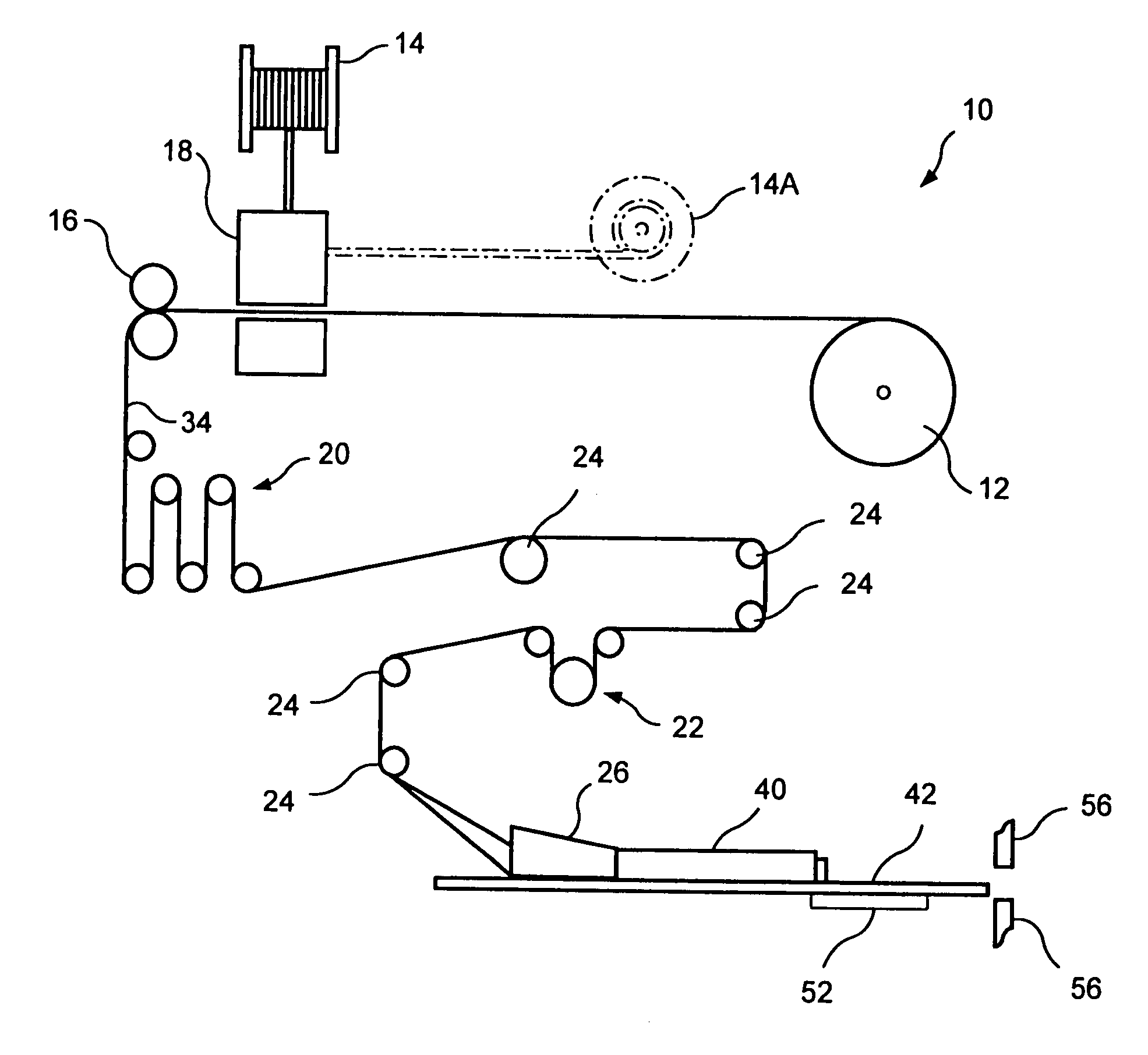

Horizontal form, fill and seal machine for loose fitting packages

A horizontal form, fill and seal machine has a hollow forming box into which a continuous film is longitudinally fed from a packaging film supply. The forming box has a top, sides and open inlet and outlet ends. A pair of guide bars extend from the outlet end of the forming box adjacent the forming box sides and extending away from the inlet end. The forming box transforms the flat packaging film into a film envelope that extends about the guide bars and has a product-receiving surface that rests on a conveyor between the guide bars. Sealing bars are provided to join the longitudinal edges of the packaging film together and to form seals across the envelope at package length intervals after each deposit of product onto the product-receiving surface. A zipper attaching mechanism applies zipper to the film upstream of the forming box.

Owner:ILLINOIS TOOL WORKS INC

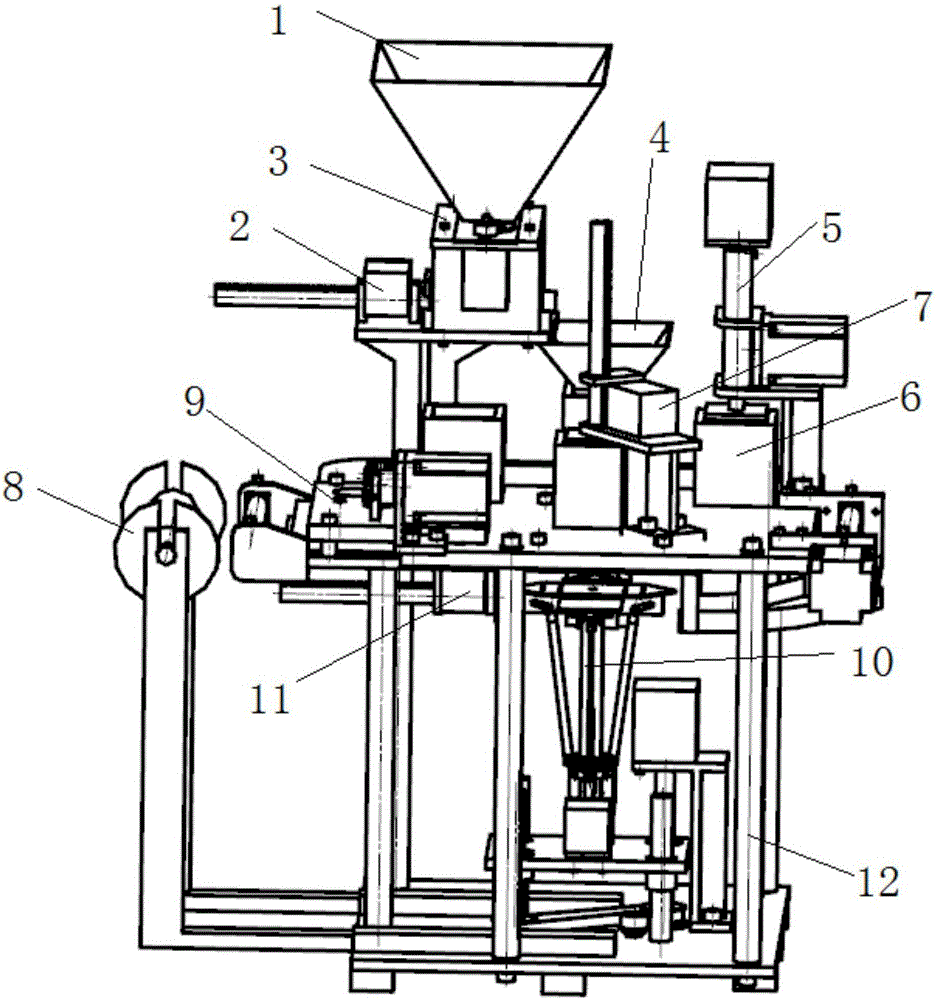

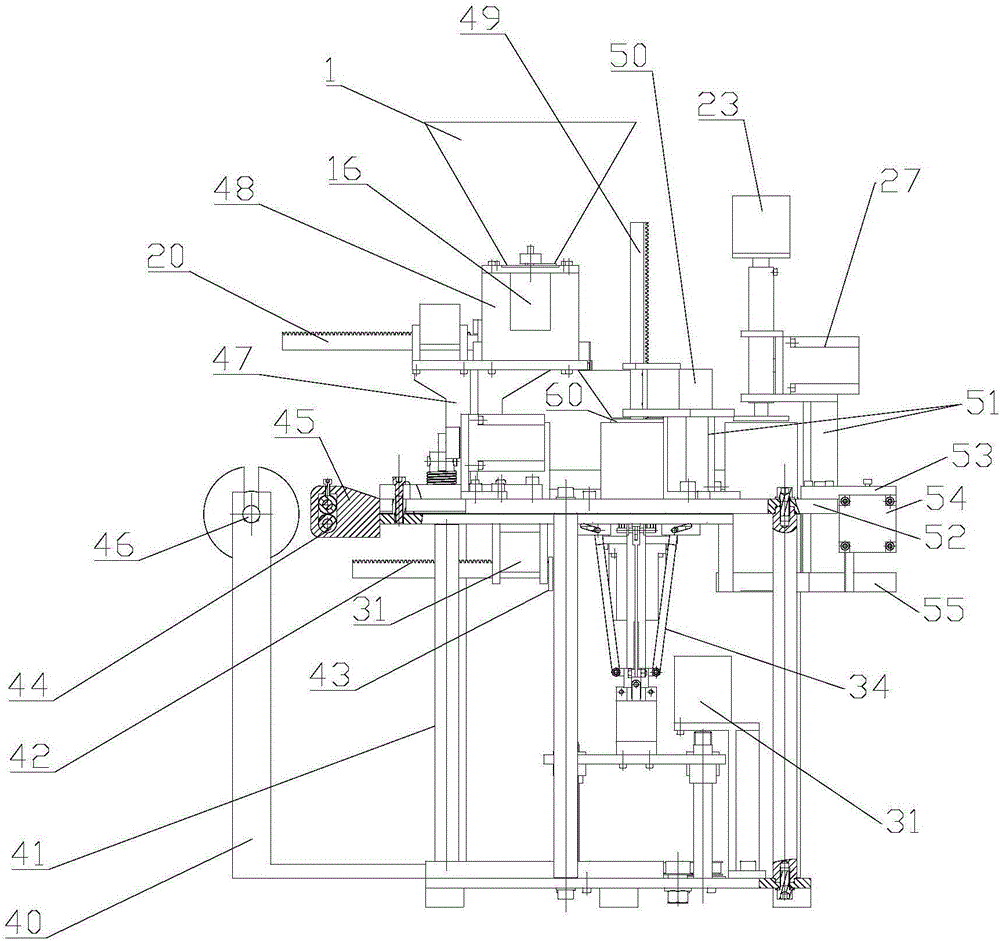

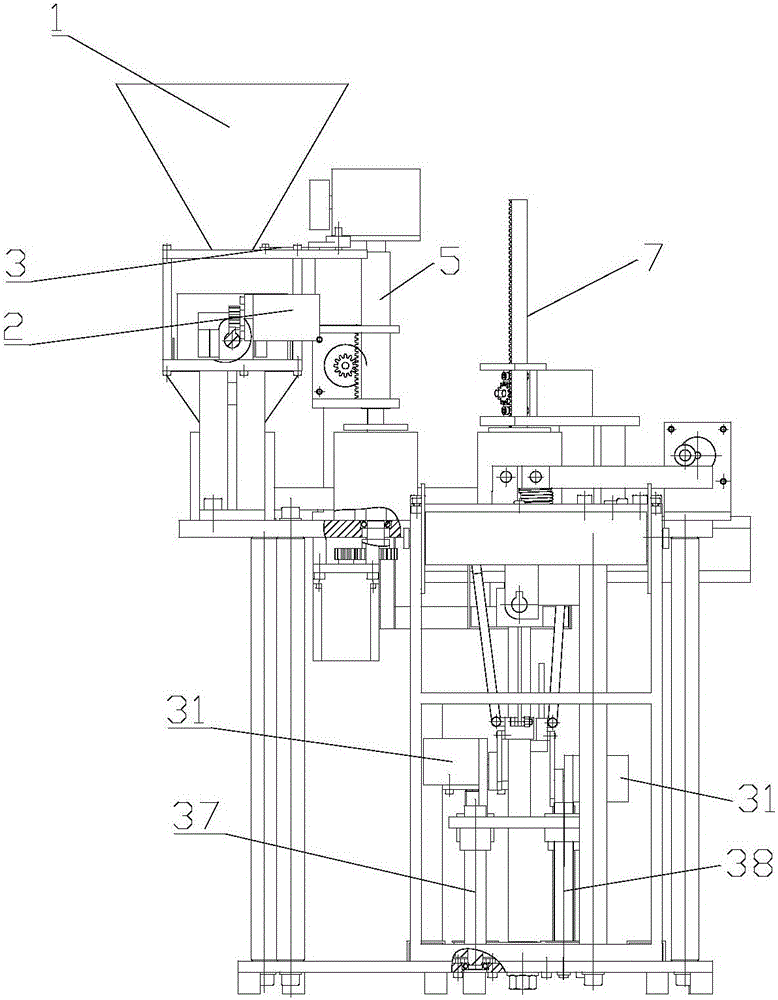

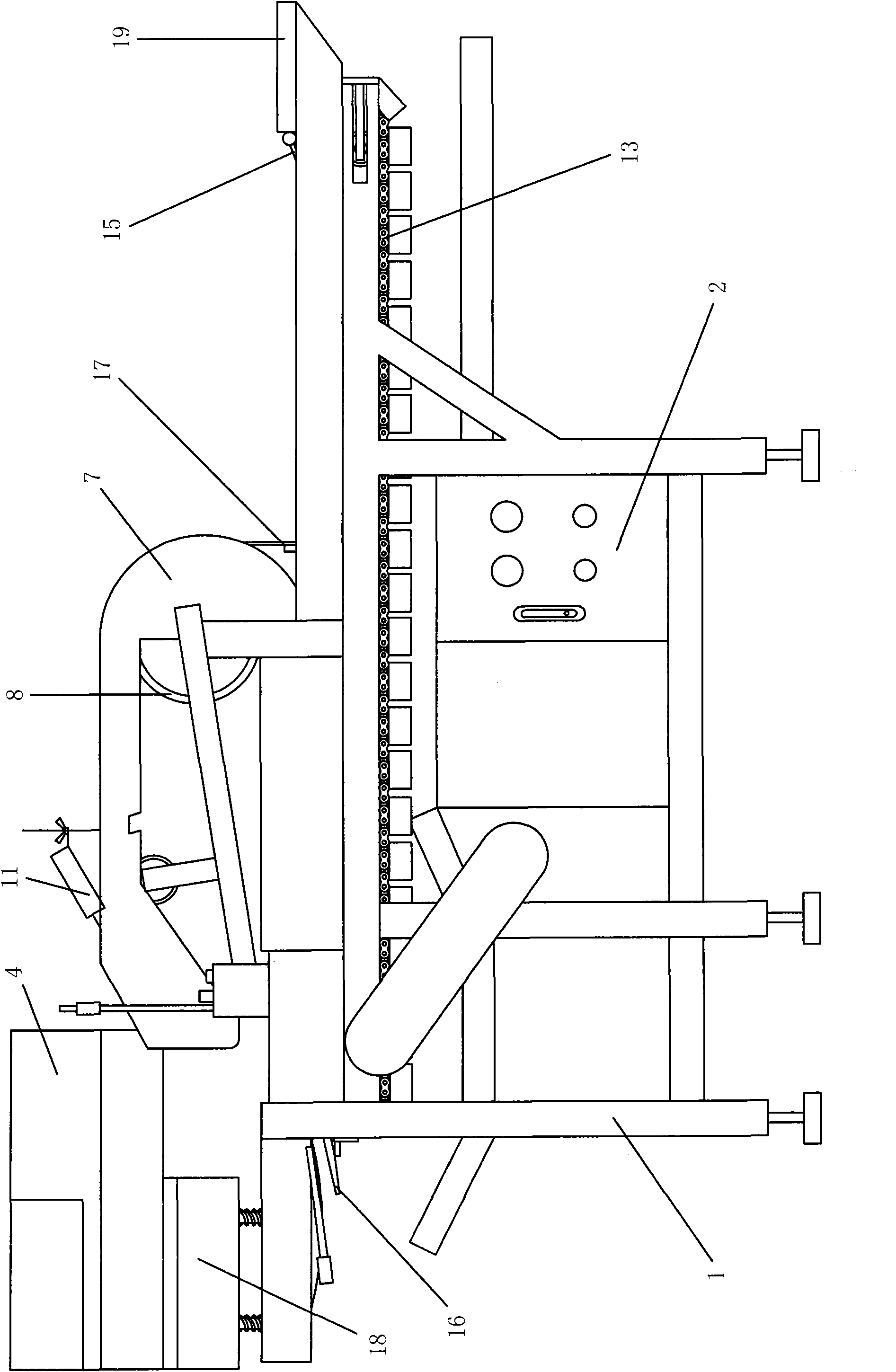

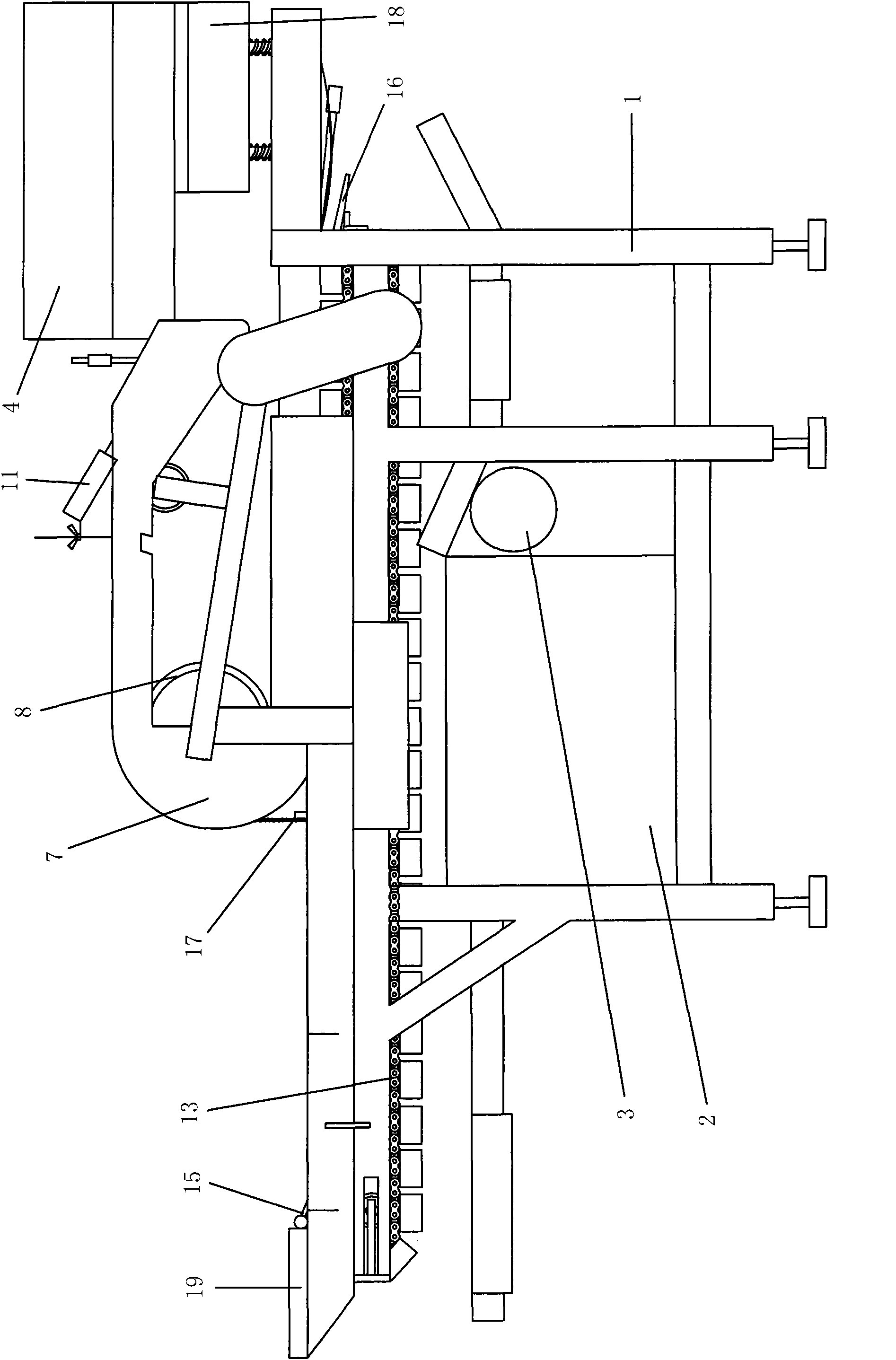

Automatic packing machine for tea cakes

ActiveCN105905340AThe manufacturing process is simple and easy to controlAutomate the packaging processPackaging automatic controlPackaging biscuitsReciprocating motionEngineering

The invention discloses an automatic packing machine for tea cakes. The automatic packing machine comprises model boxes; the model boxes are matched with an inverted hammer device, the inverted hammer device repeatedly beats tea leaves in the model boxes to manufacture the tea cakes, the tea cakes are pushed out of the model boxes to a packing mechanism by a pushing device after being manufactured, and the packing mechanism receives packing materials conveyed by a conveying device and conducts inclusion packing on the tea cakes. The packing mechanism can replace manual packing and can achieve six-face inclusion of the tea cakes in place in one time, and accordingly the novel combination mechanism is designed to replace manual inclusion action; and the mechanism is not only limited to tea cake packing but also can achieve six-face inclusion of all cubes with the suitable size, the problems that manual packing efficiency is low, and the packing specifications are unequal can be solved, and thus automatic packing of the tea cakes can be achieved.

Owner:LONGYAN UNIV

Machine and method for grouping products in stacks having a pre-set length

A machine and a method for carrying out portioning of products in stacks having a pre-set length. One or more portioning stations are provided, in which there are present at least two elements for supporting the stack, the supporting elements being mobile in translation, parallel to the longitudinal axis of the stack, between an initial position of separation of the stack from the respective row and a final position distant from the initial position at a distance greater than or equal to the pre-set length of the stack.

Owner:PFM

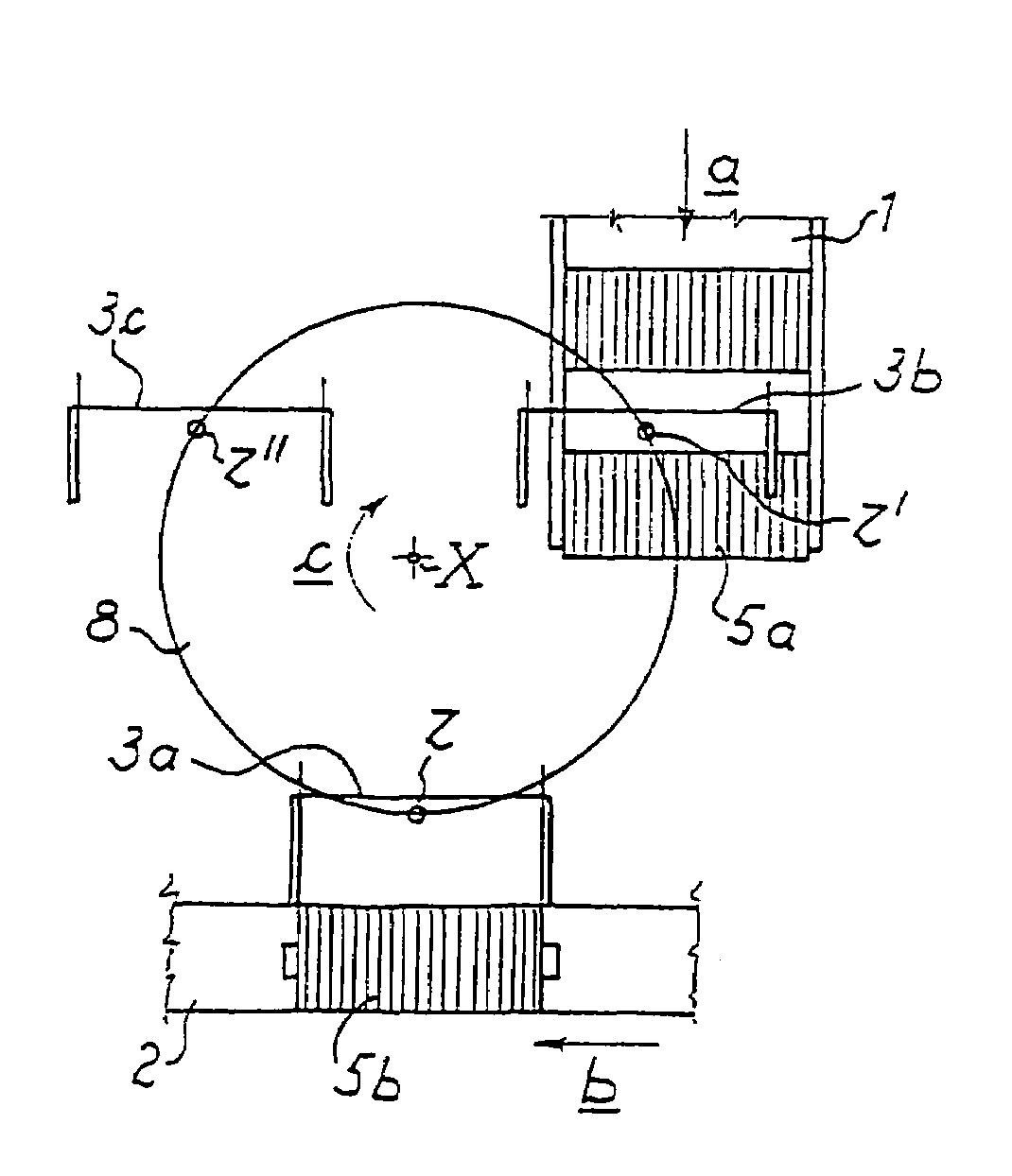

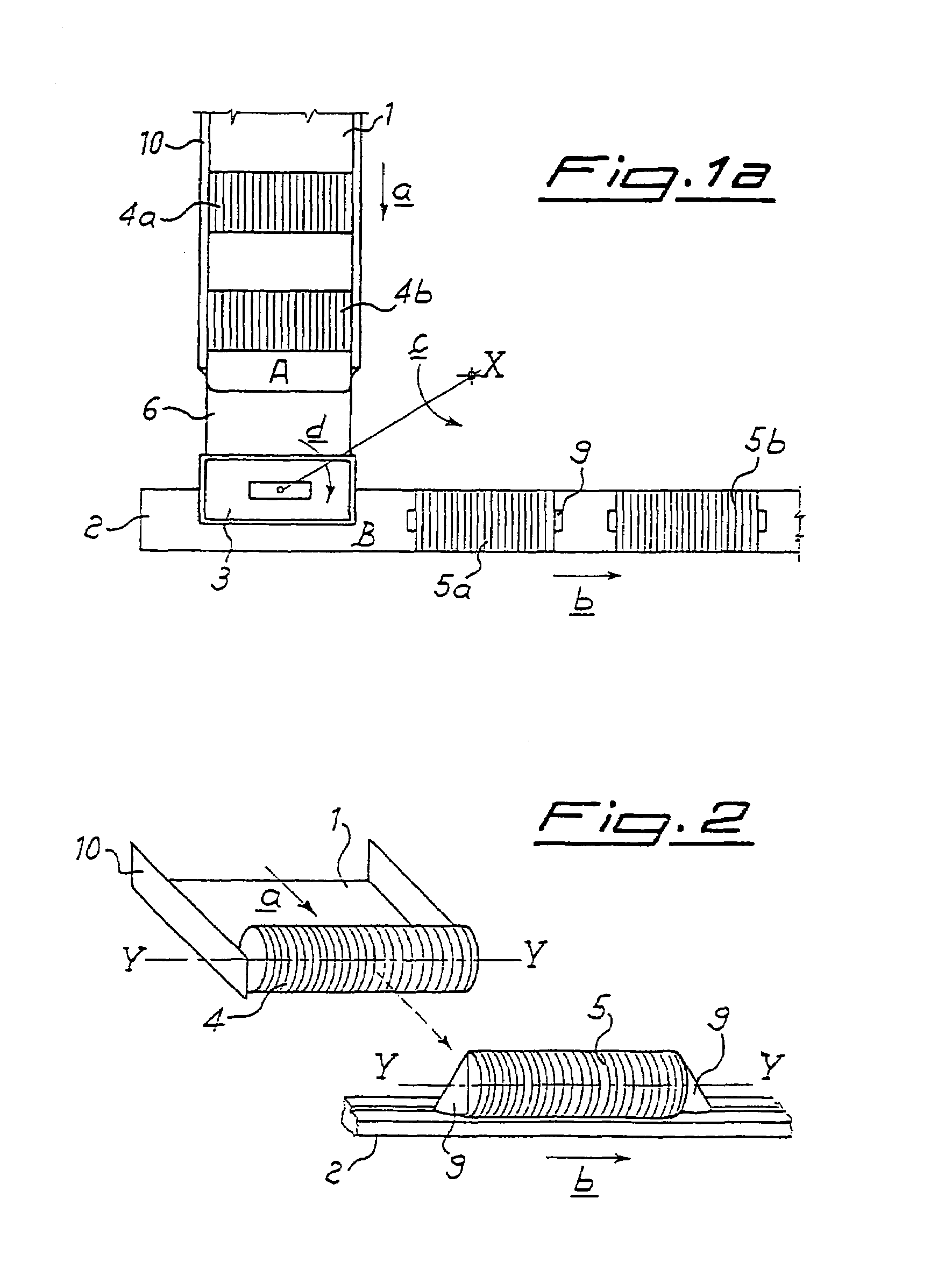

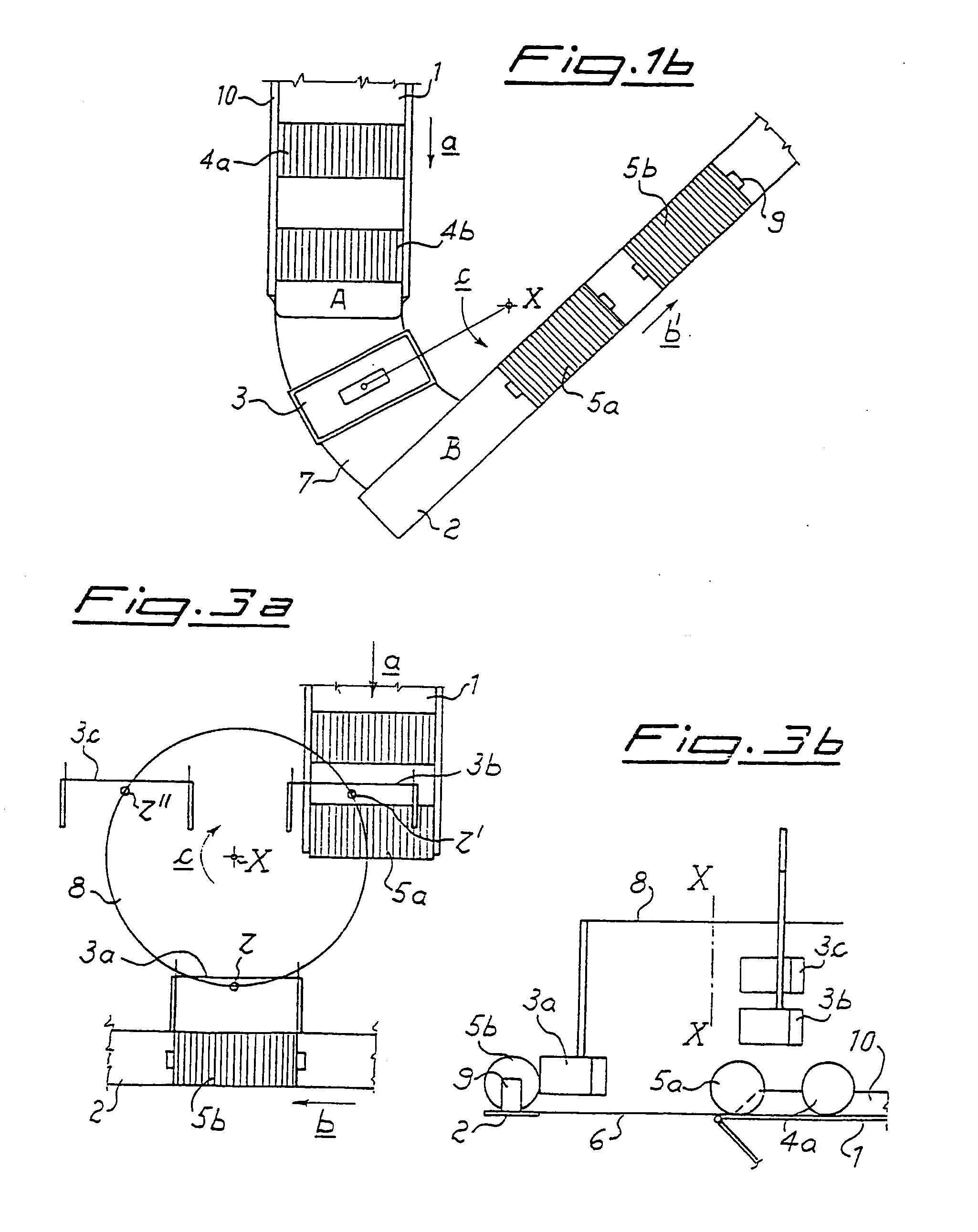

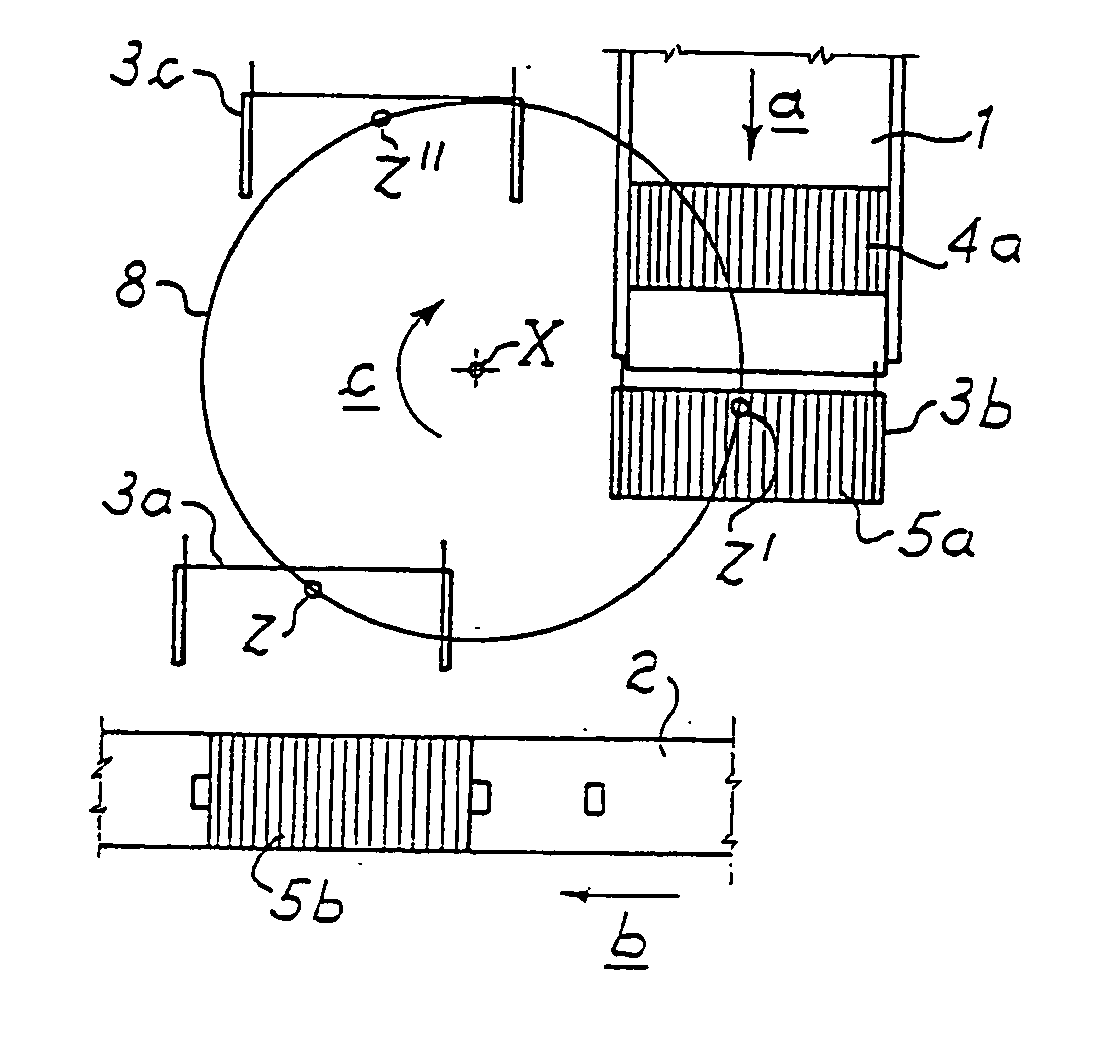

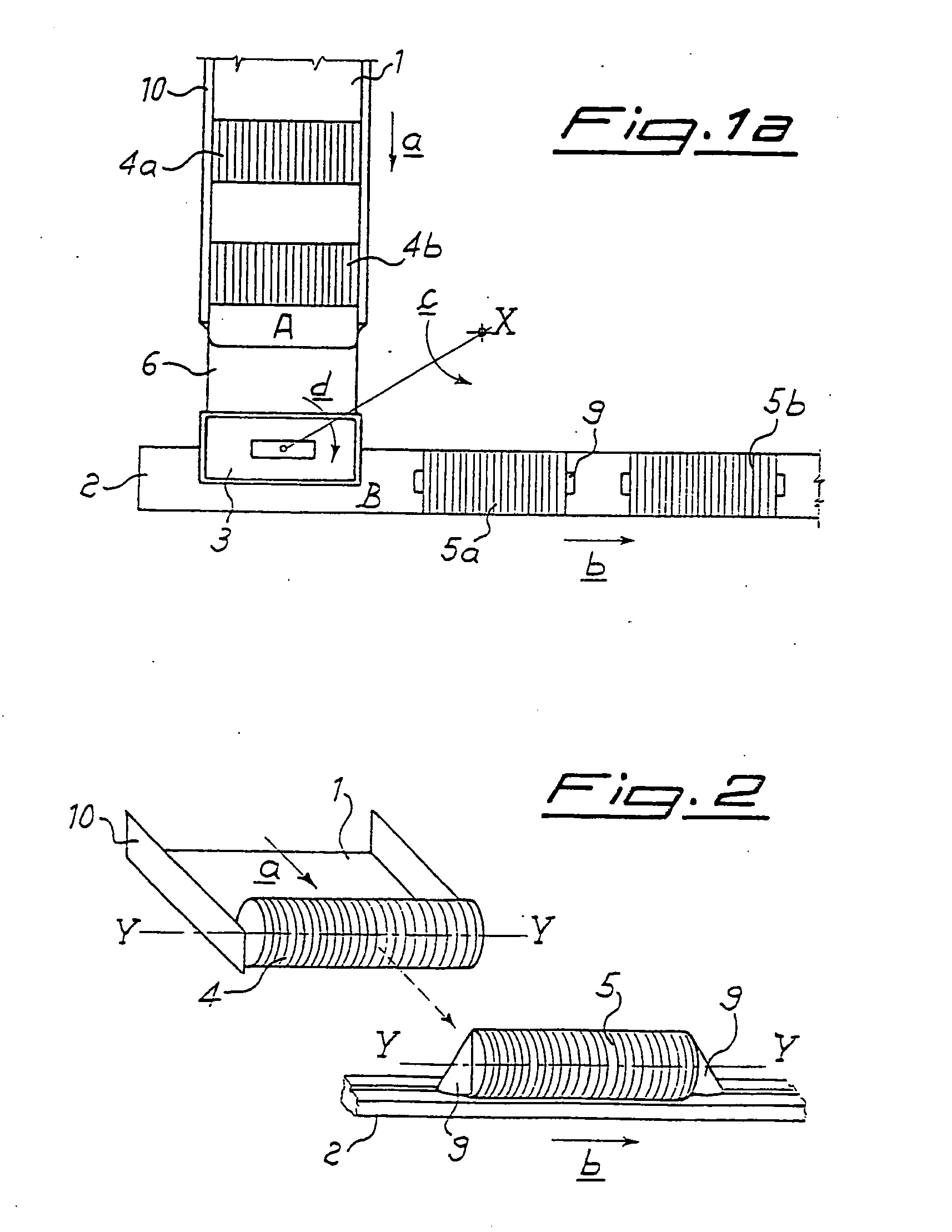

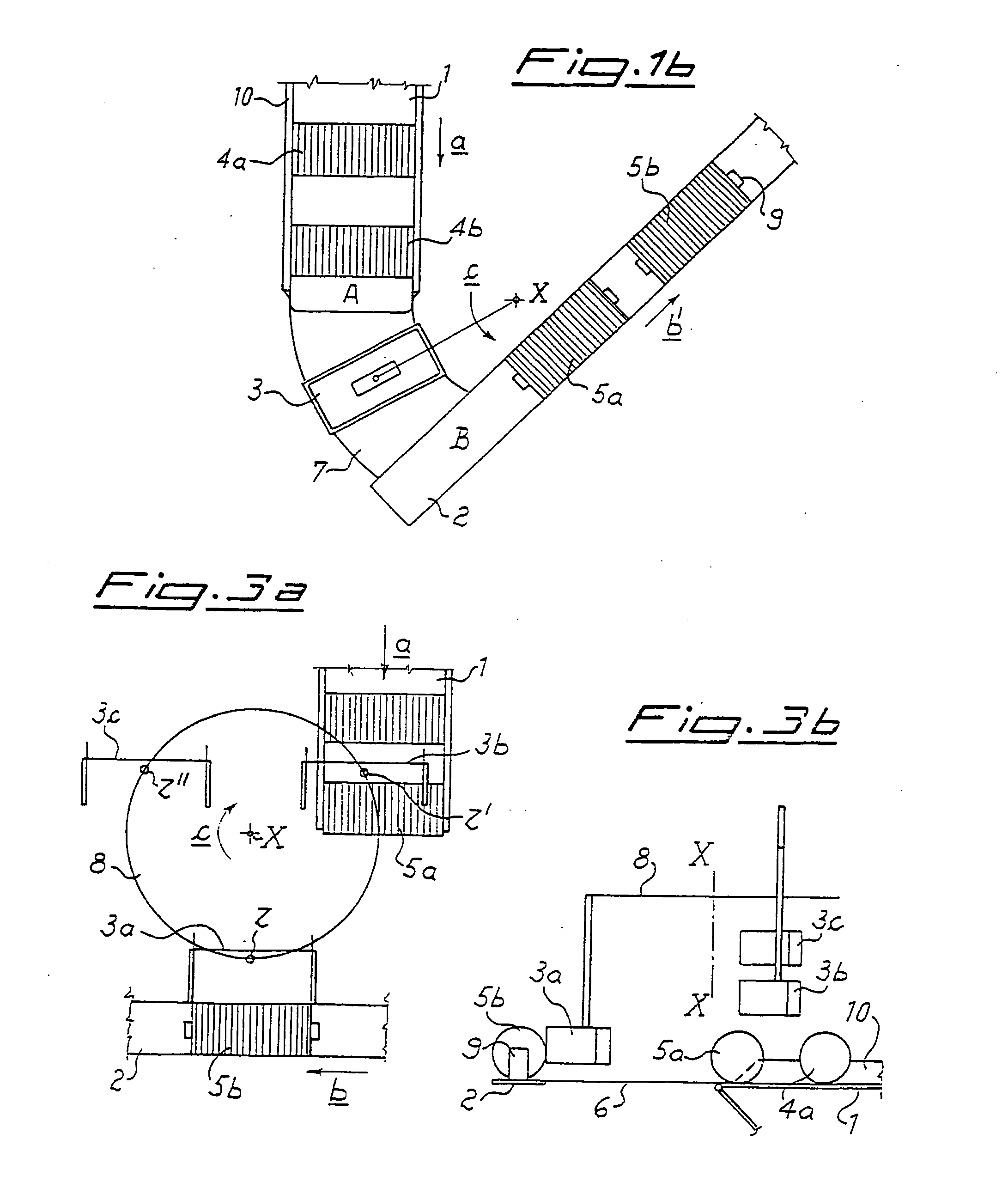

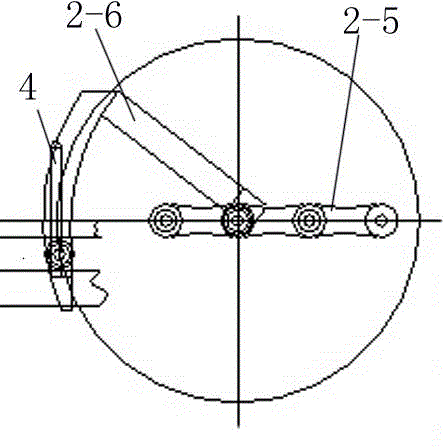

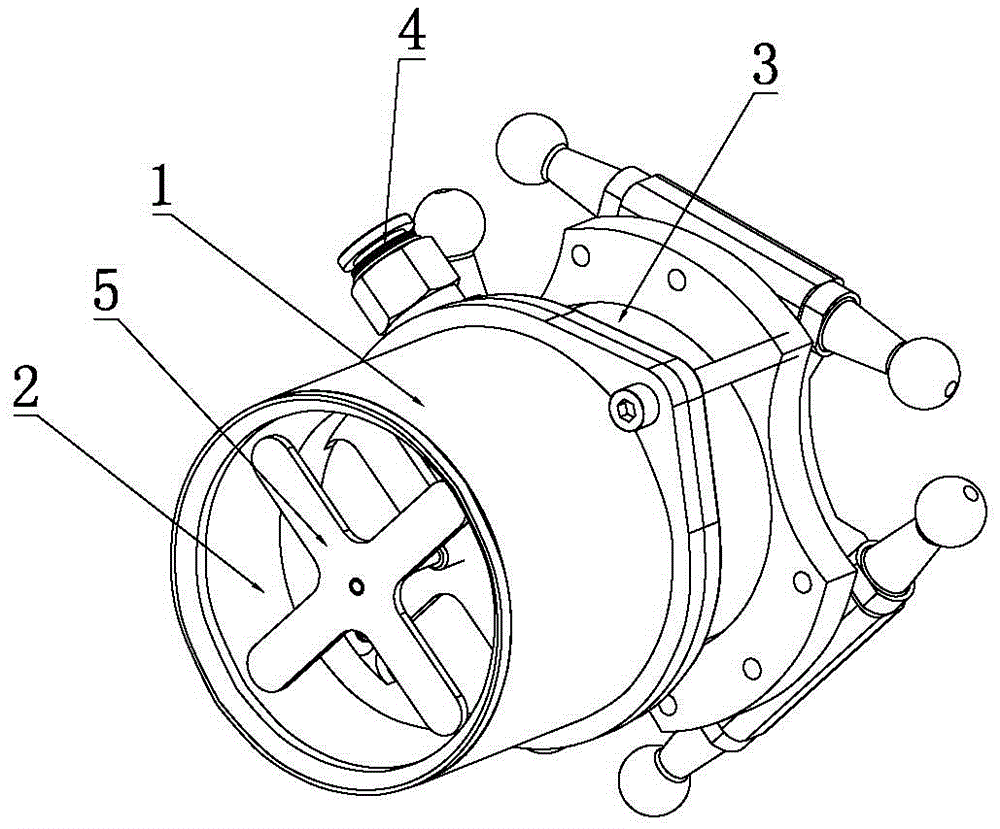

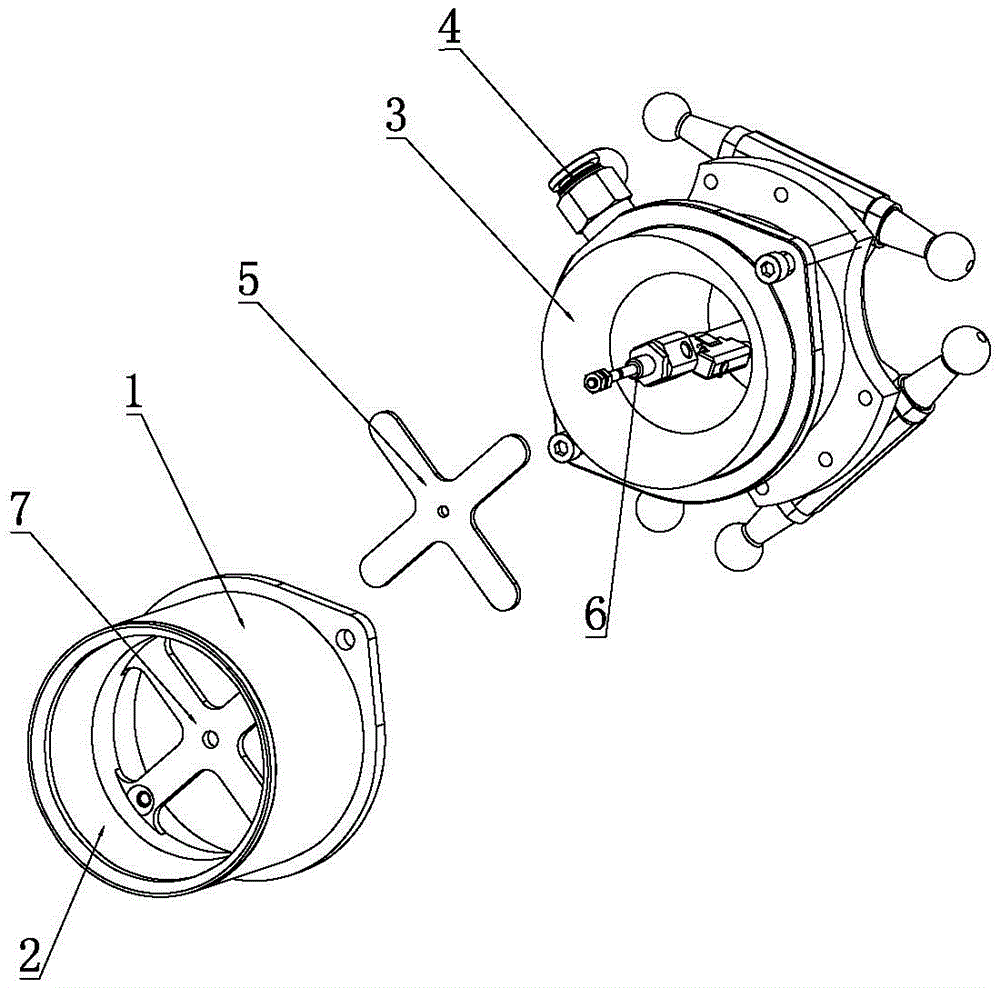

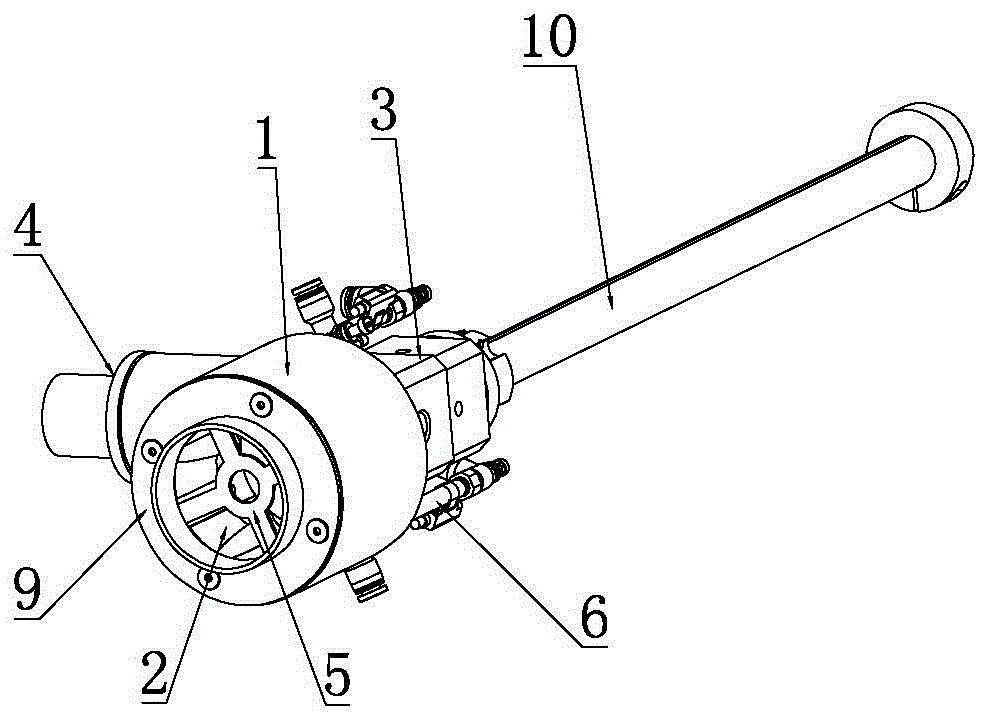

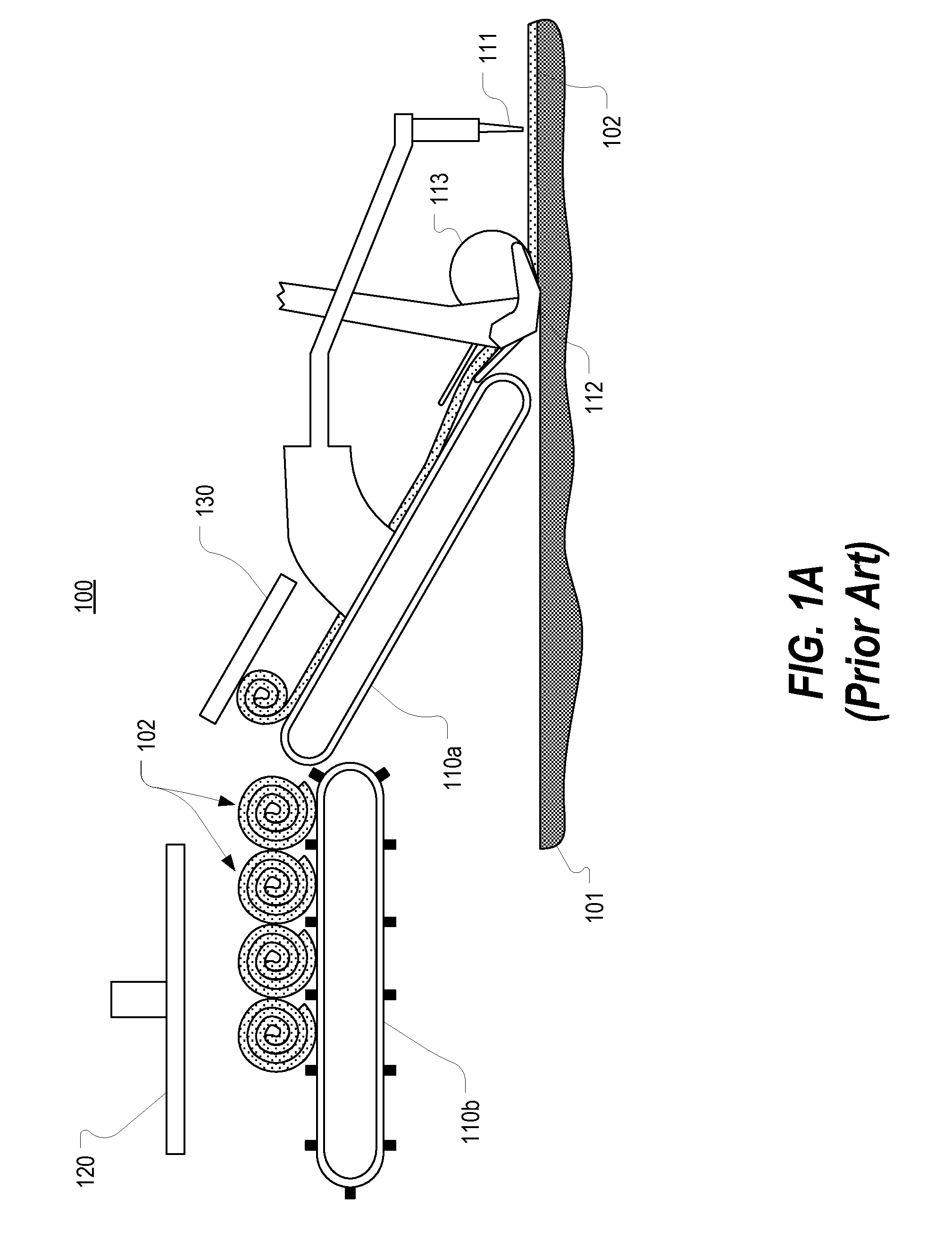

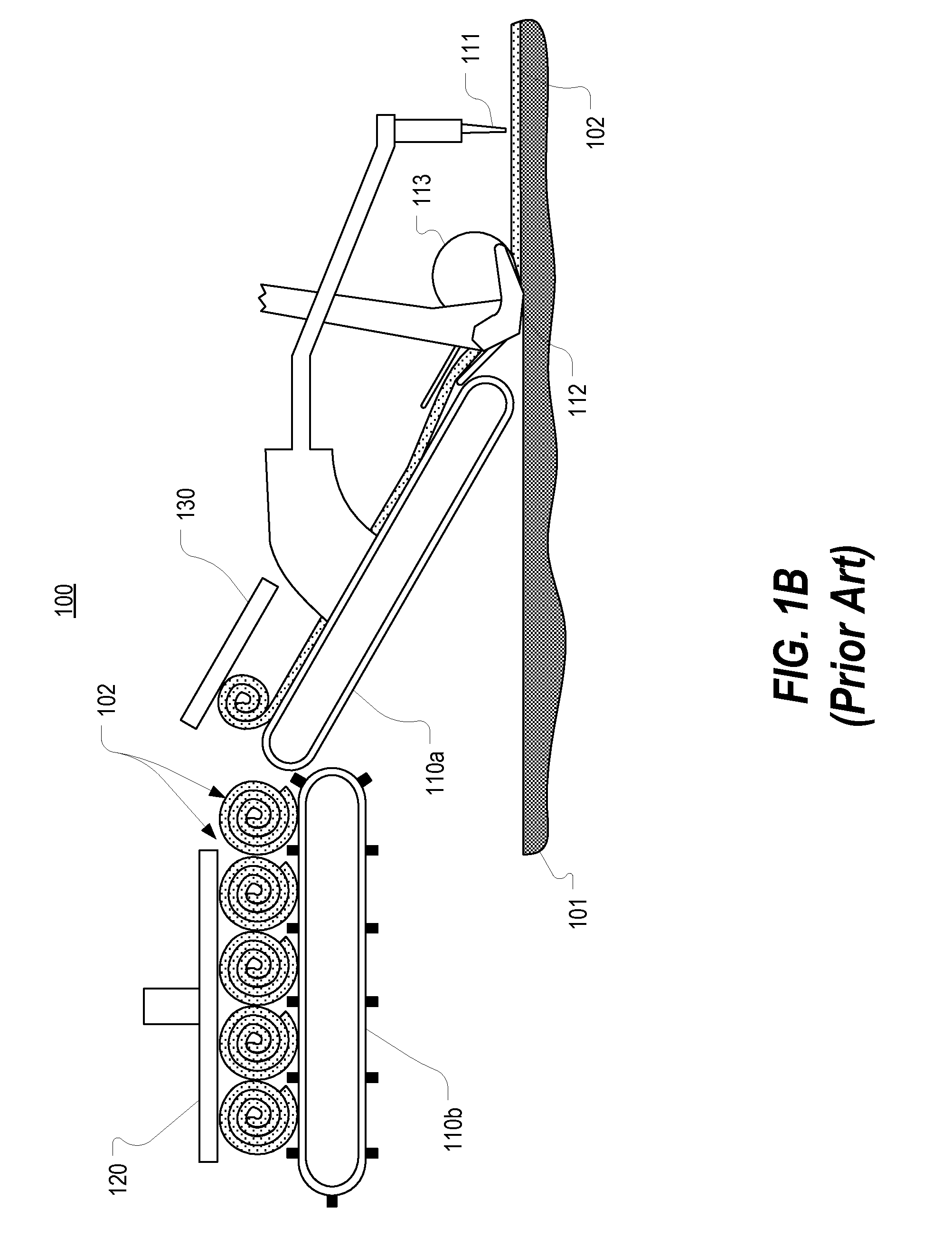

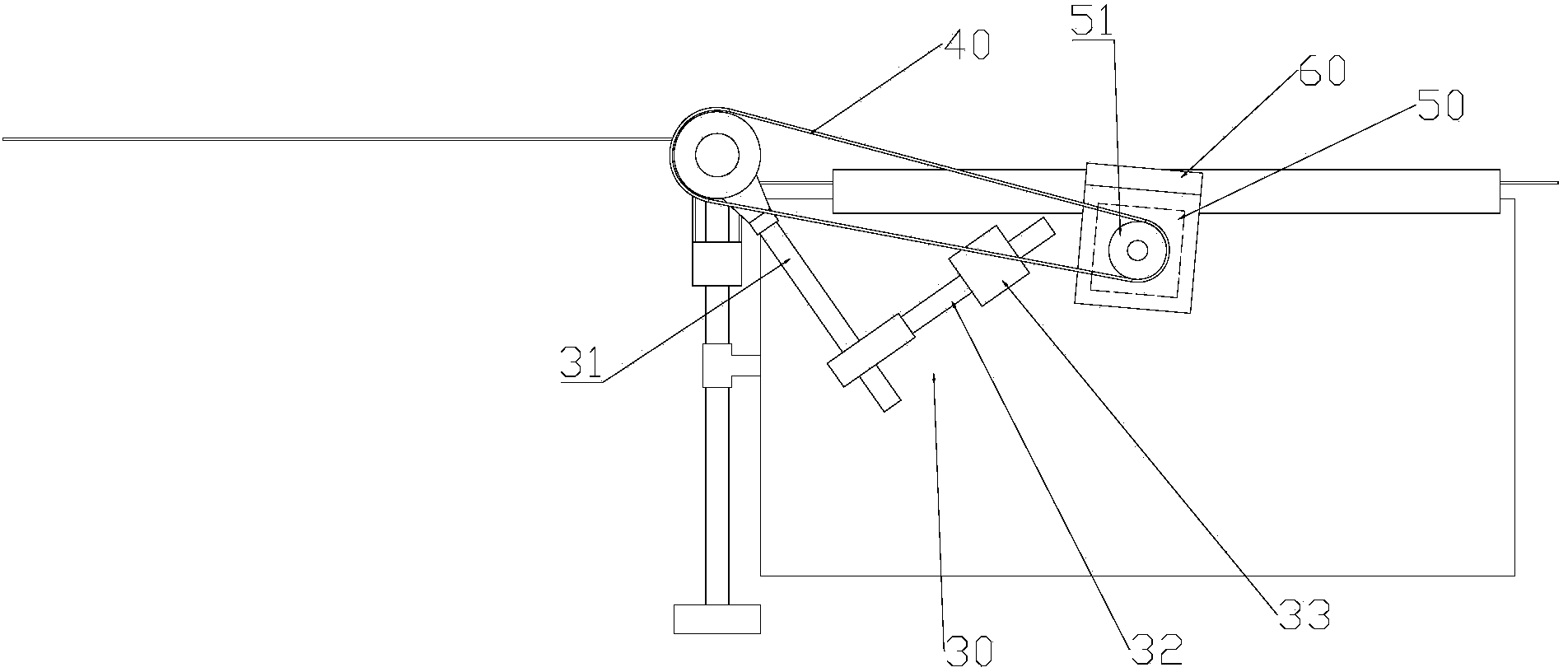

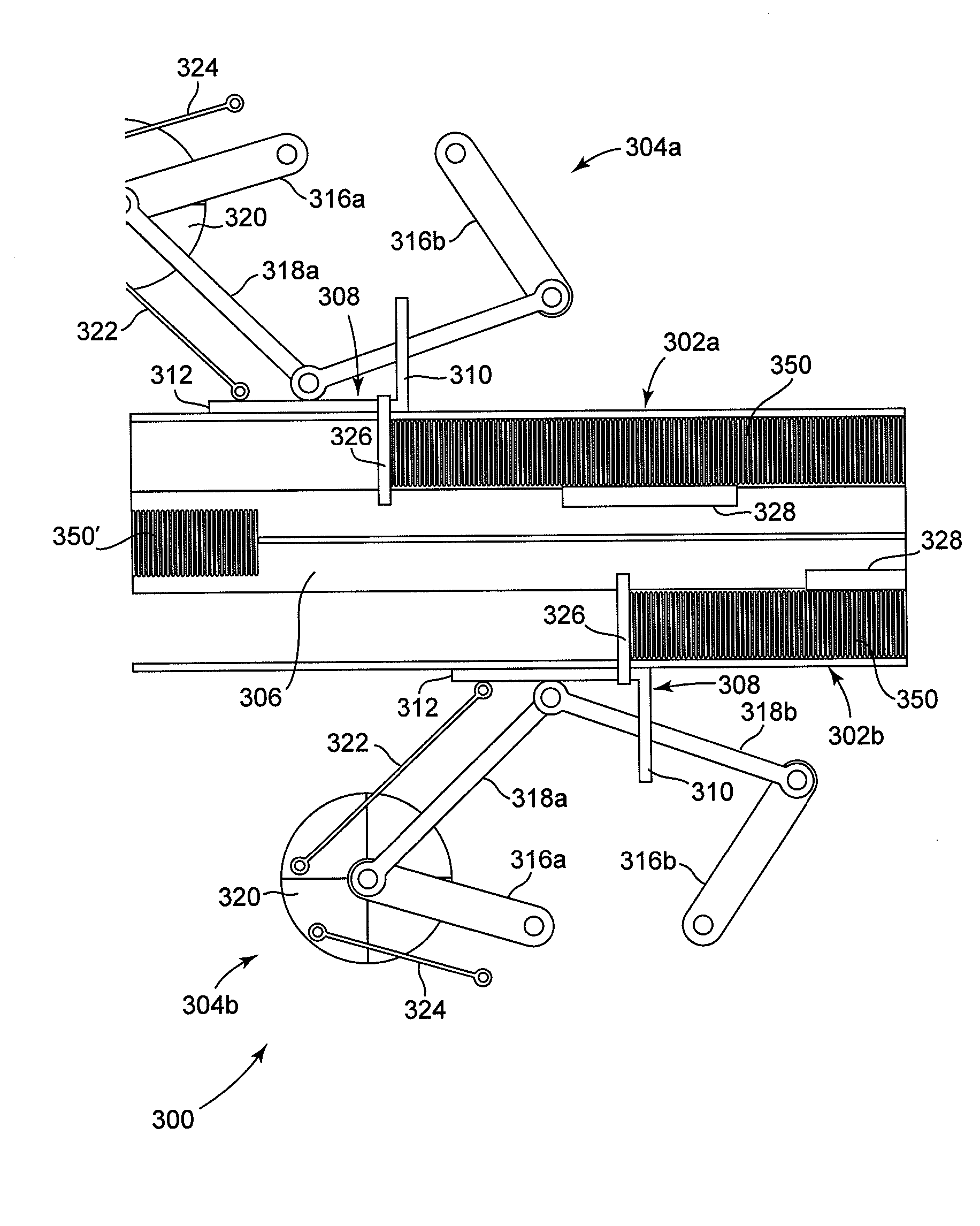

Transfer device for cylindrical stacks of products arranged on an edge

A transfer device for transferring stacks (4, 4a, 4b, 5, 5a, 5b), which have a cylindrical external shape, of products resting on one of their edges between a conveyor (1) set upstream for advance of the stacks (4, 4a, 4b, 5, 5a, 5b) in a direction (a) transverse to the generatrices of the aforesaid cylindrical shape, and a conveyor (2) set downstream for advance of the stacks In a direction parallel to said generatrices, or vice versa, the said transfer device being operatively set between said conveyor (1) set upstream and said conveyor (2) set downstream. The transfer device comprises at least one gripping assembly (3) for picking up and conveying a stack. Said gripping assembly (3) moreover turns, according to a motion of revolution. (C) about a first axis (X), between a position in which it engages a stack (4, 4a, 4b, 5, 5a, 5b), in a position (A) corresponding to an output end of the conveyor (1) set upstream, and a position (B) in which it releases the stack onto the conveyor (2) set downstream.

Owner:PFM

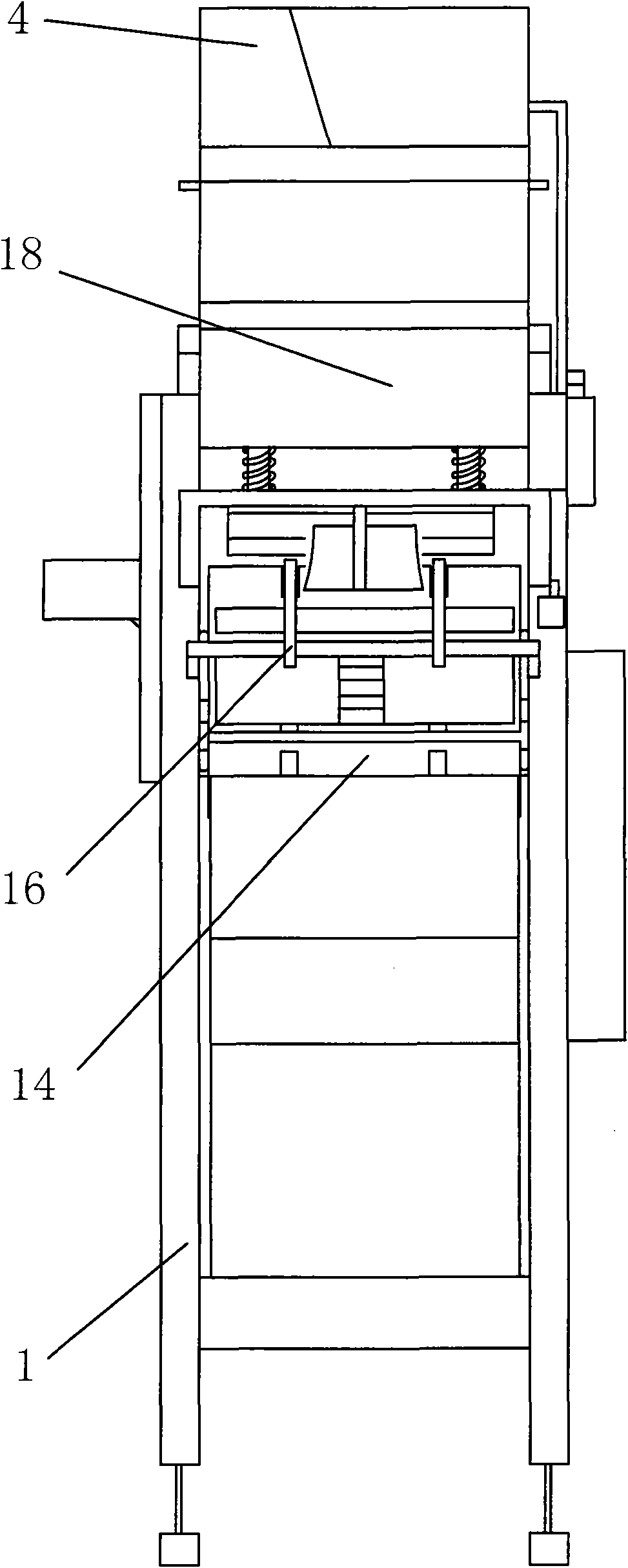

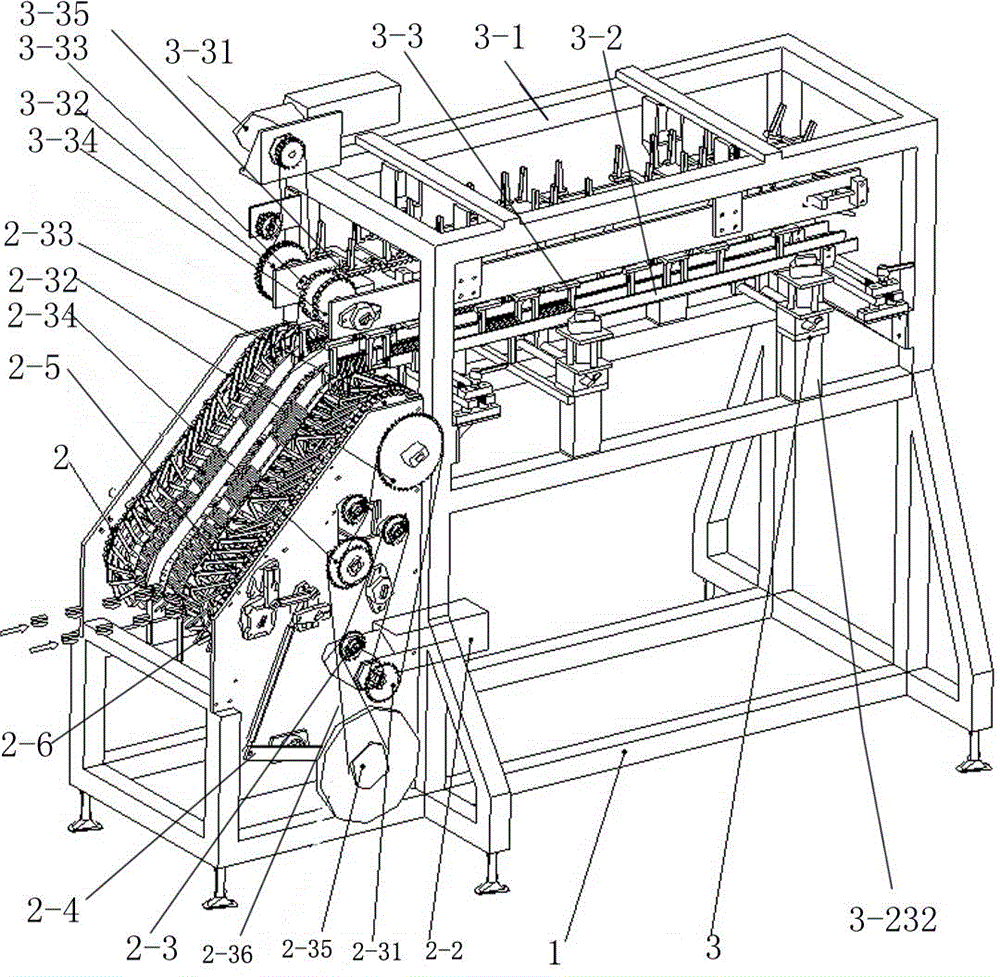

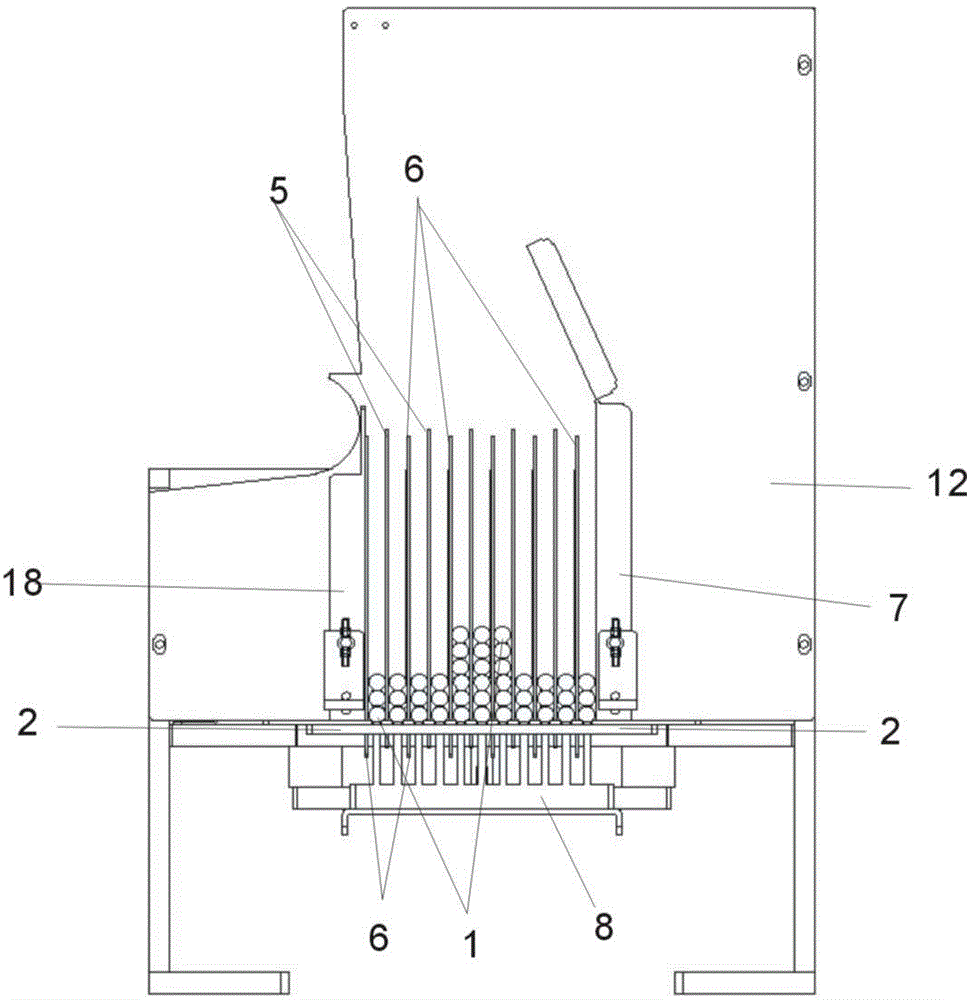

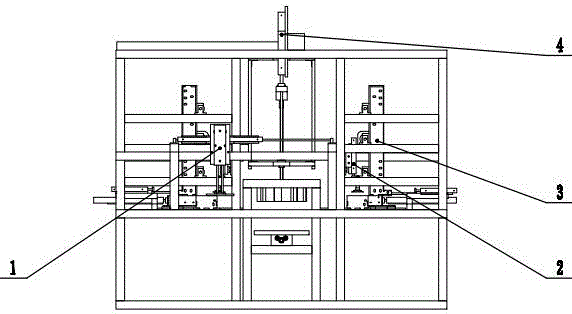

Quantitative racking machine of biscuit

InactiveCN102009756AReduce manufacturing costComply with the quantity requirement of subpackagePackaging biscuitsTransmitted powerEngineering

The invention discloses a quantitative racking machine of biscuits, belonging to the machinery field of food racking. The existing biscuit racking operation is manually finished by workers. The quantitative racking machine comprises a rack, an electric control box, a motor, a power transmission mechanism, a feeding mechanism, a racking mechanism, a packaging mechanism and a safety security device, wherein the electric control box, the motor, the power transmission mechanism and the packaging mechanism are respectively installed on the rack; the racking mechanism installed on the rack is positioned on the upper part of the packaging mechanism and is matched with the packaging mechanism; the feeding mechanism installed on the rack is positioned at one end of the racking mechanism and is matched with the racking mechanism; the power transmission mechanism transmits power generated by the motor to the racking mechanism and the packaging mechanism; and the safety security device positioned at the other end of the racking mechanism is installed on the rack. The quantitative racking machine is used for quantitatively racking biscuits, the working efficiency for racking the biscuits can be greatly improved by the machine, and the number of biscuit racked in each machine is the same. The quantitative racking machine conforms to the food hygienic standard.

Owner:东莞市金富士食品有限公司

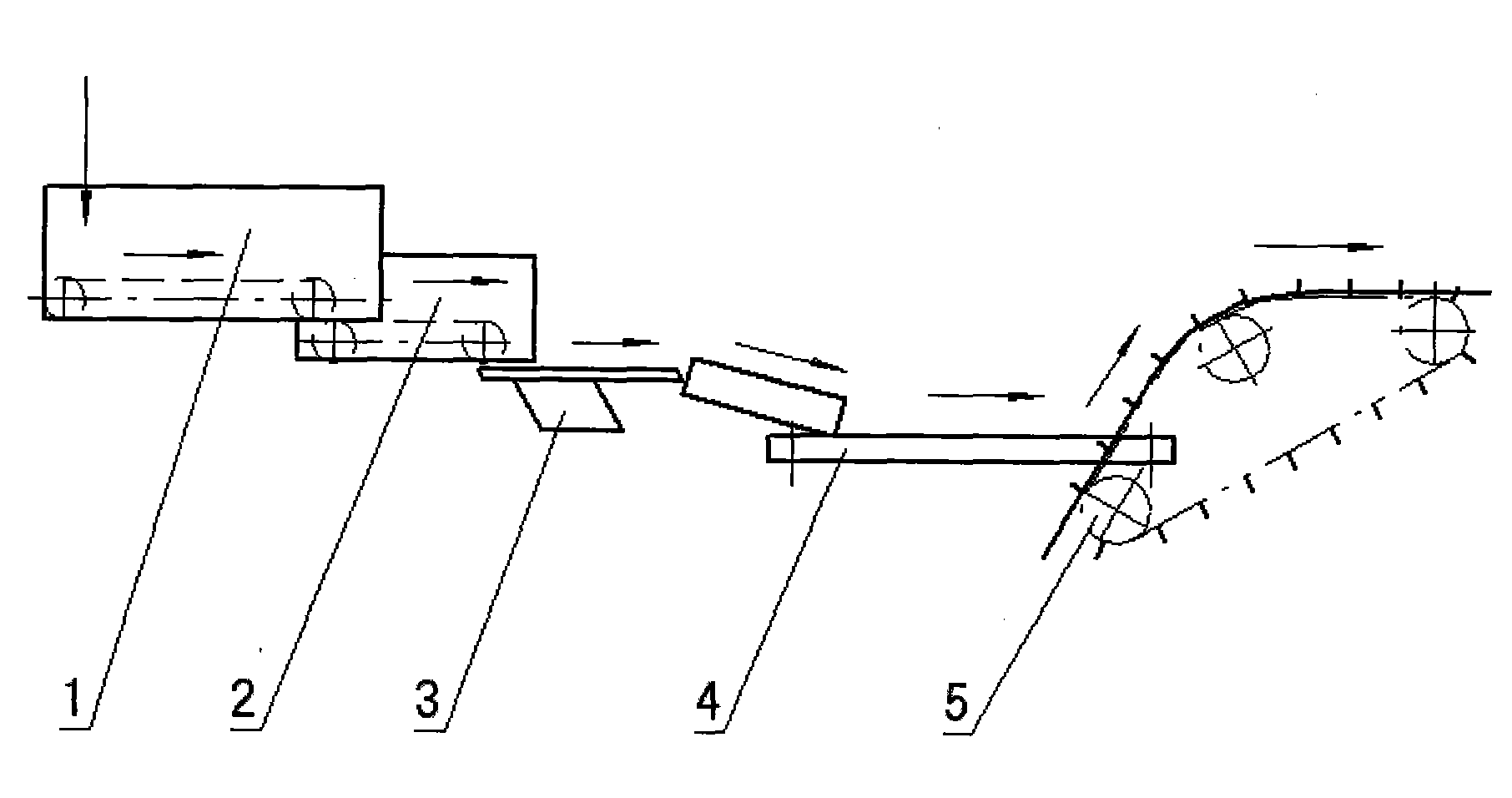

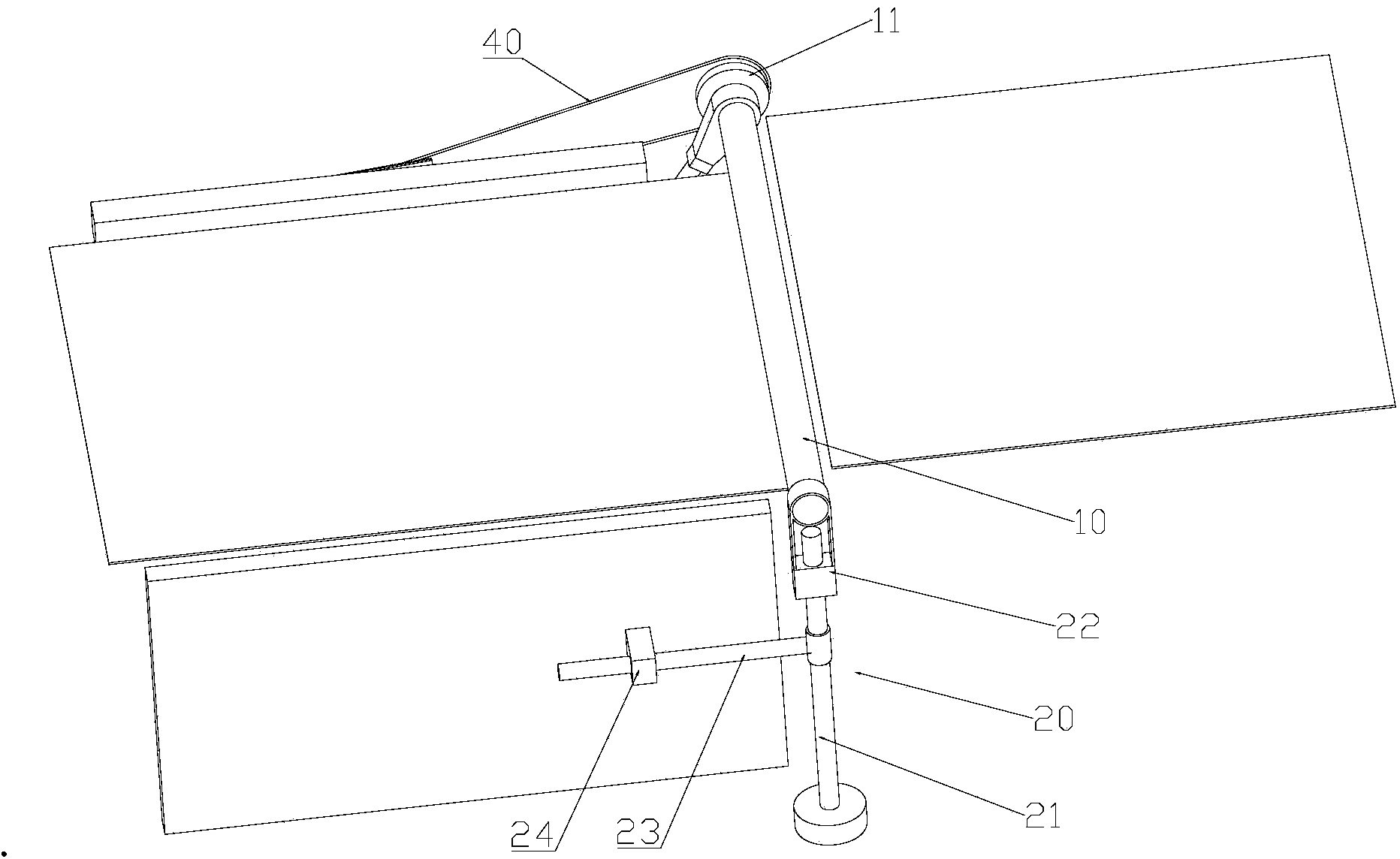

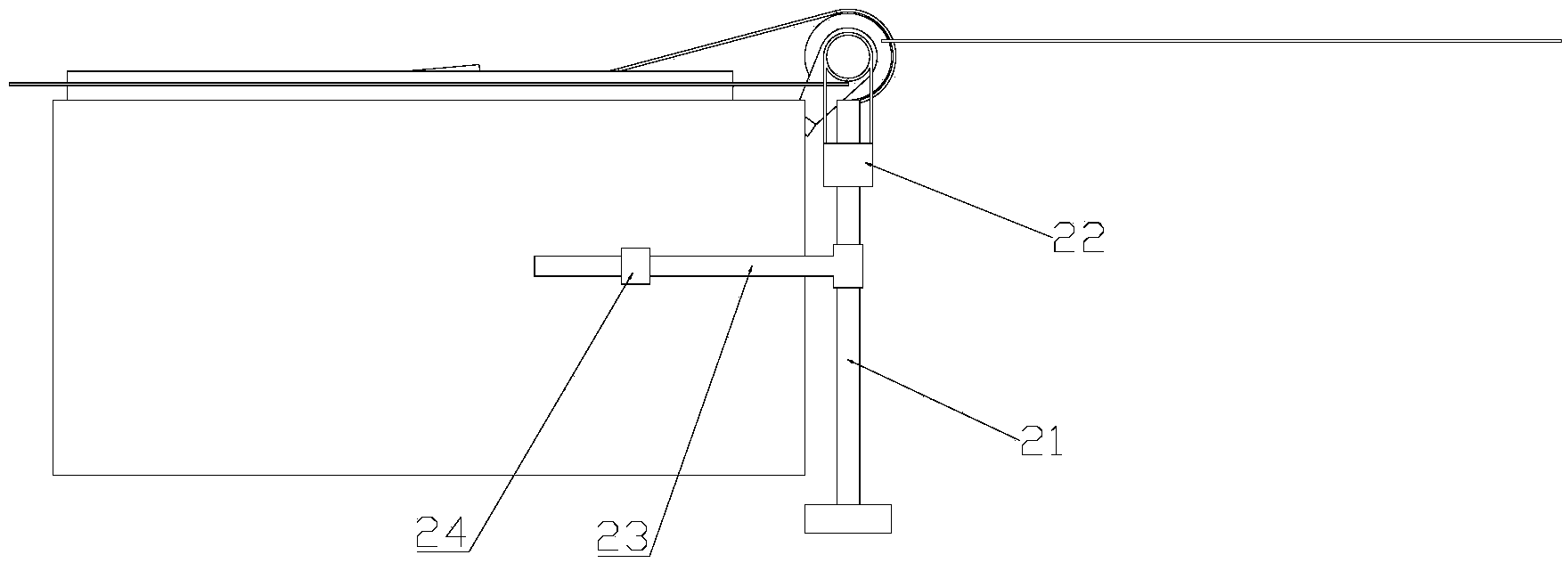

Transfer device for cylindrical stacks of products arranged on an edge

A transfer device for transferring stacks (4, 4a, 4b, 5, 5a, 5b), which have a cylindrical external shape, of products resting on one of their edges between a conveyor (1) set upstream for advance of the stacks (4, 4a, 4b, 5, 5a, 5b) in a direction (a) transverse to the generatrices of the aforesaid cylindrical shape, and a conveyor (2) set downstream for advance of the stacks In a direction parallel to said generatrices, or vice versa, the said transfer device being operatively set between said conveyor (1) set upstream and said conveyor (2) set downstream. The transfer device comprises at least one gripping assembly (3) for picking up and conveying a stack. Said gripping assembly (3) moreover turns, according to a motion of revolution. (C) about a first axis (X), between a position in which it engages a stack (4, 4a, 4b, 5, 5a, 5b), in a position (A) corresponding to an output end of the conveyor (1) set upstream, and a position (B) in which it releases the stack onto the conveyor (2) set downstream.

Owner:PFM

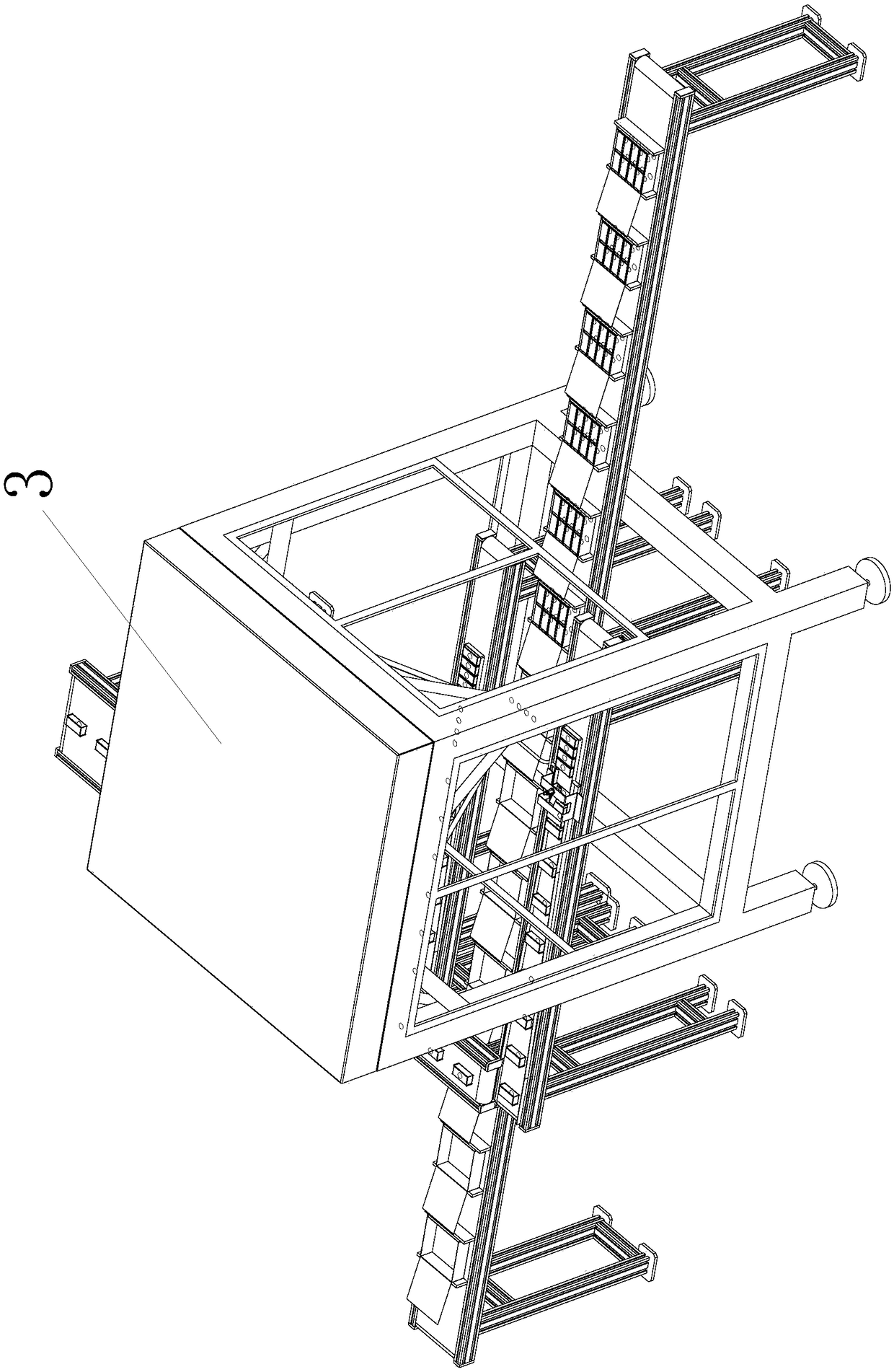

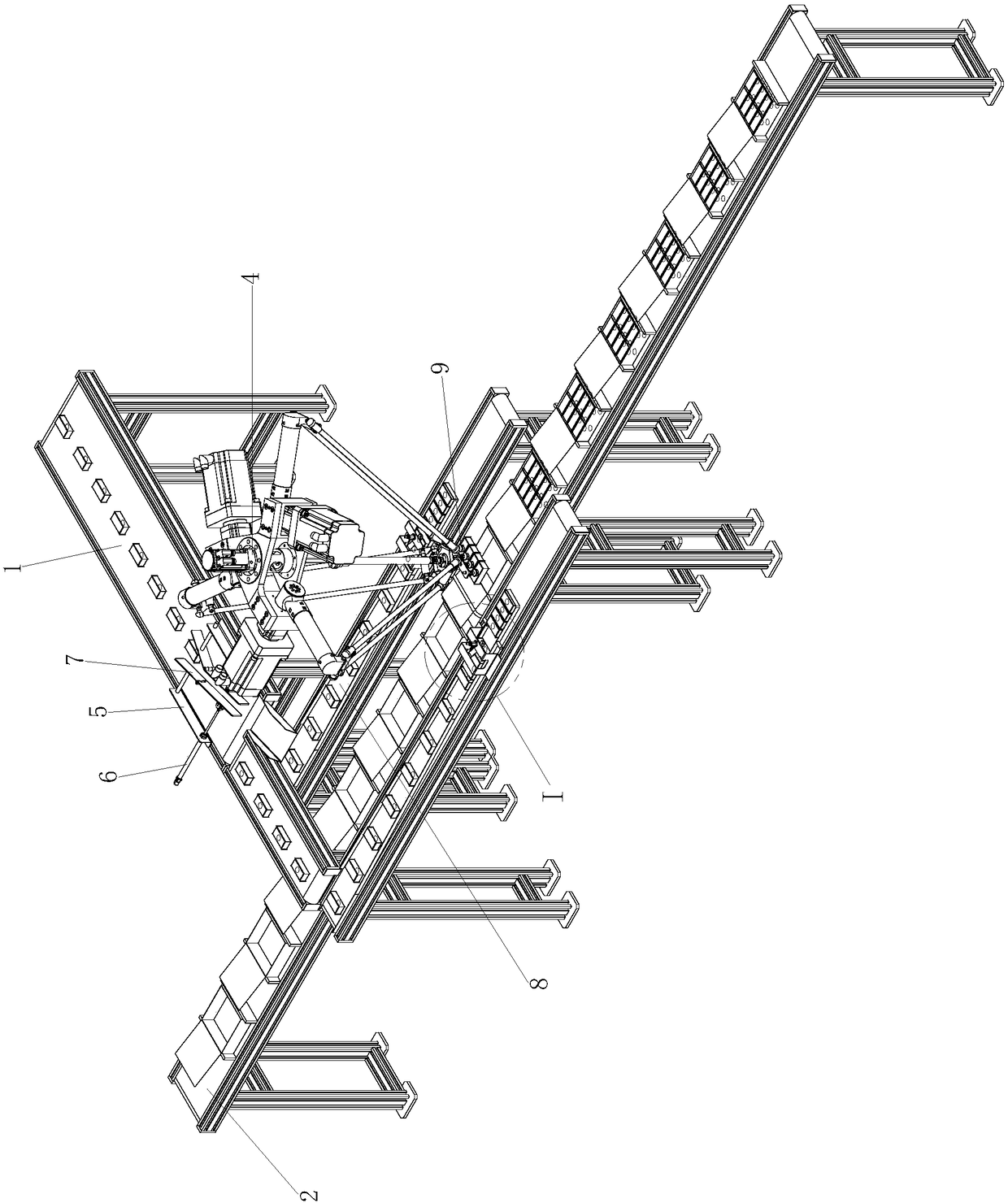

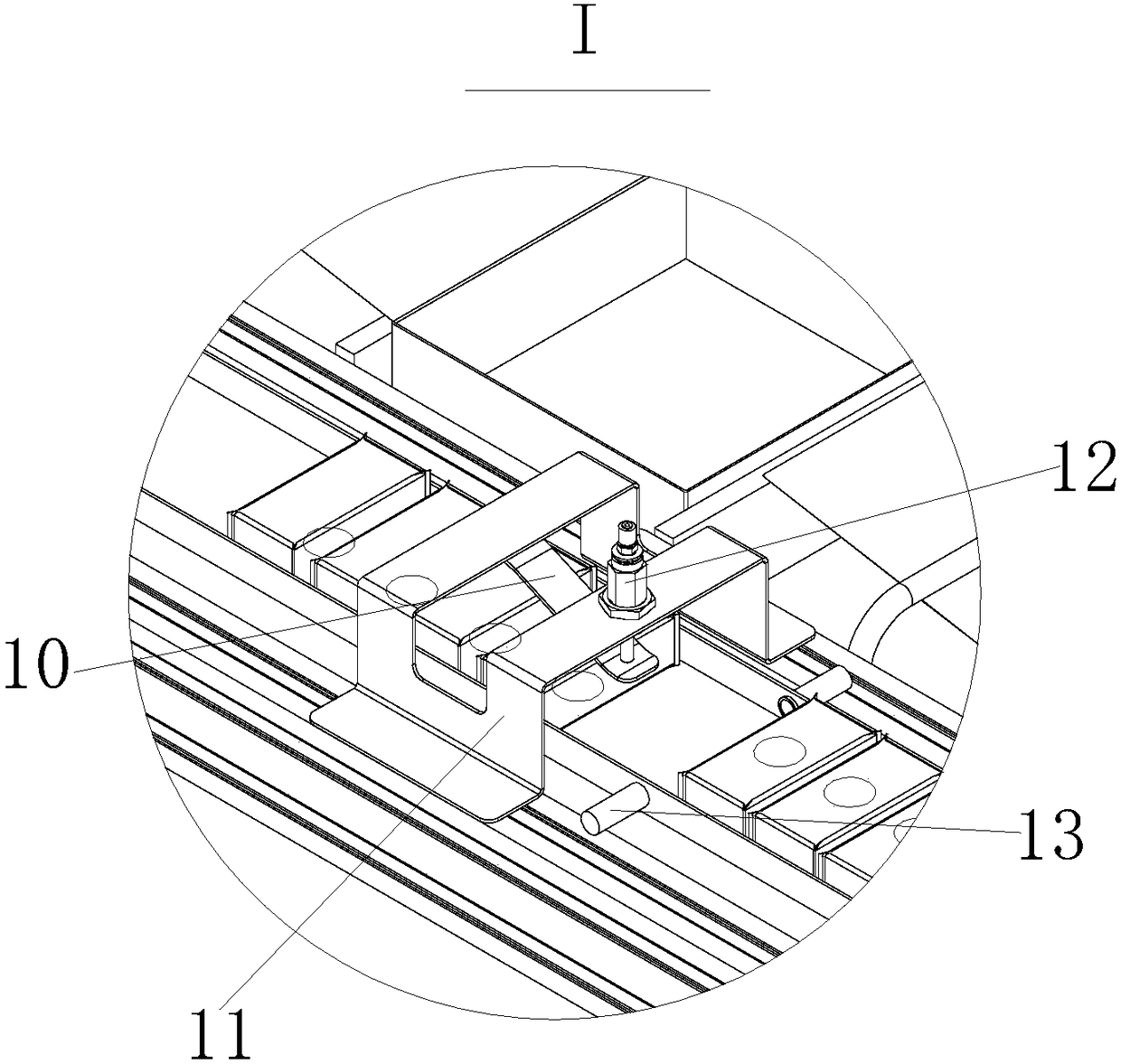

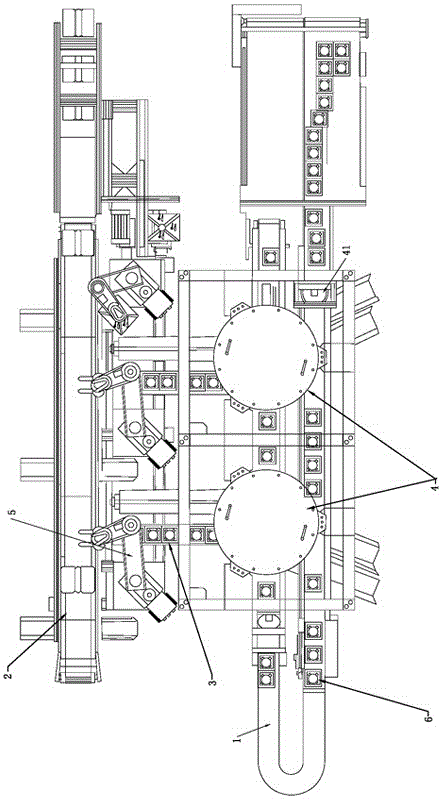

Biscuit boxing system and application method thereof

The invention relates to the field of biscuit boxing, in particular to a biscuit boxing system and an application method thereof. The biscuit boxing system comprises a first biscuit assembly line, a second biscuit assembly line coordinating with the first biscuit assembly line, a carton conveying line coordinating with the first biscuit assembly line and the second biscuit assembly line, a rack arranged on the carton conveying line and a parallel robot arranged on the rack. The first biscuit assembly is provided with a dividing device. The carton conveying line is provided with a limiting device. The first biscuit assembly line and the second biscuit assembly line are both provided with blocking devices. Each blocking device is provided with a sensor. The parallel robot is provided with asucking device. The application method of the biscuit boxing system comprises the first step of dividing, the second step of number limiting and the third step of sucking. A plate with a bending degree serves as a device for intercepting biscuits, and the situation that the plate damages the biscuits, and the appearances of the biscuits are damaged cannot occur; and the biscuits are divided so that a single line can be changed into two lines, the biscuit boxing speed is increased, and the biscuit boxing efficiency is improved.

Owner:WUHU IROBSYS ROBOT CO LTD

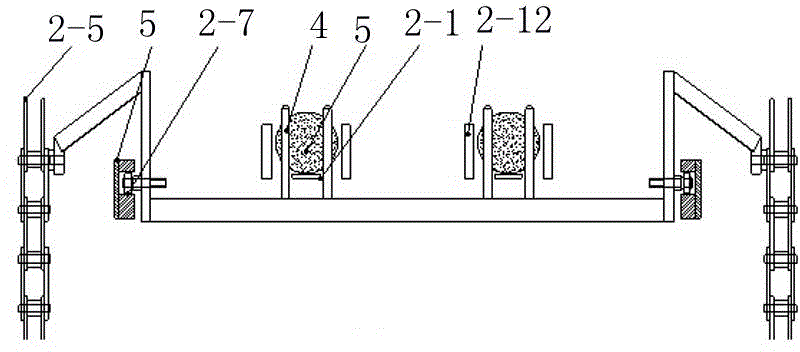

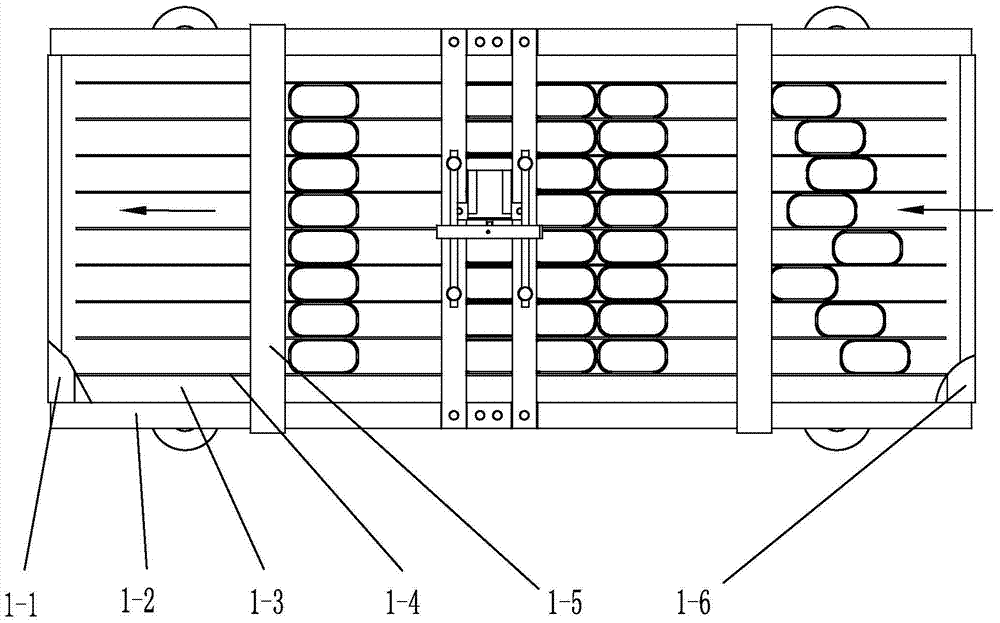

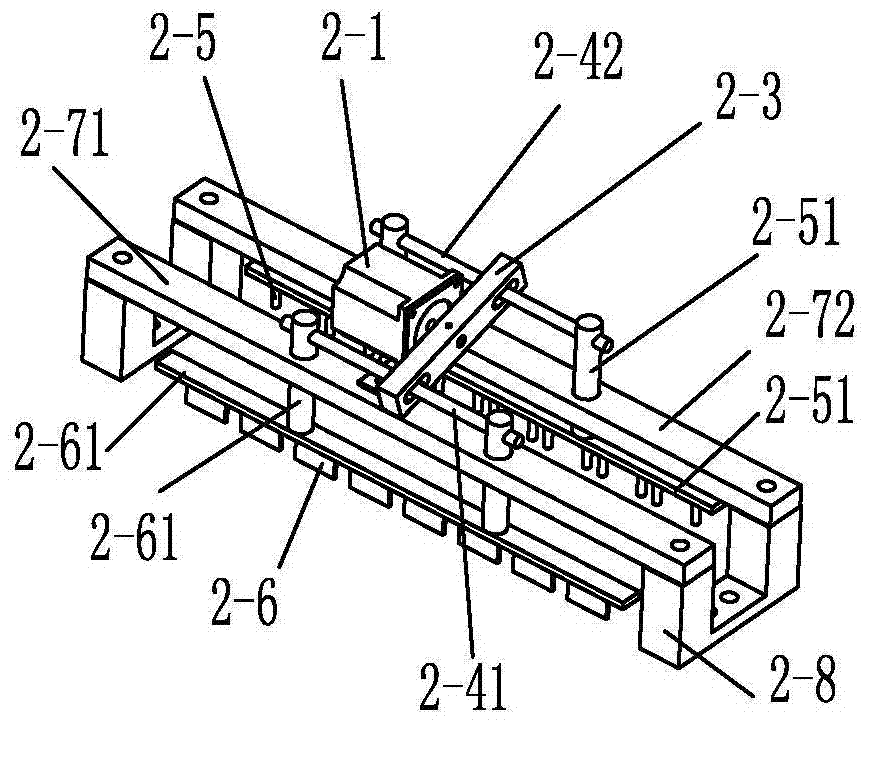

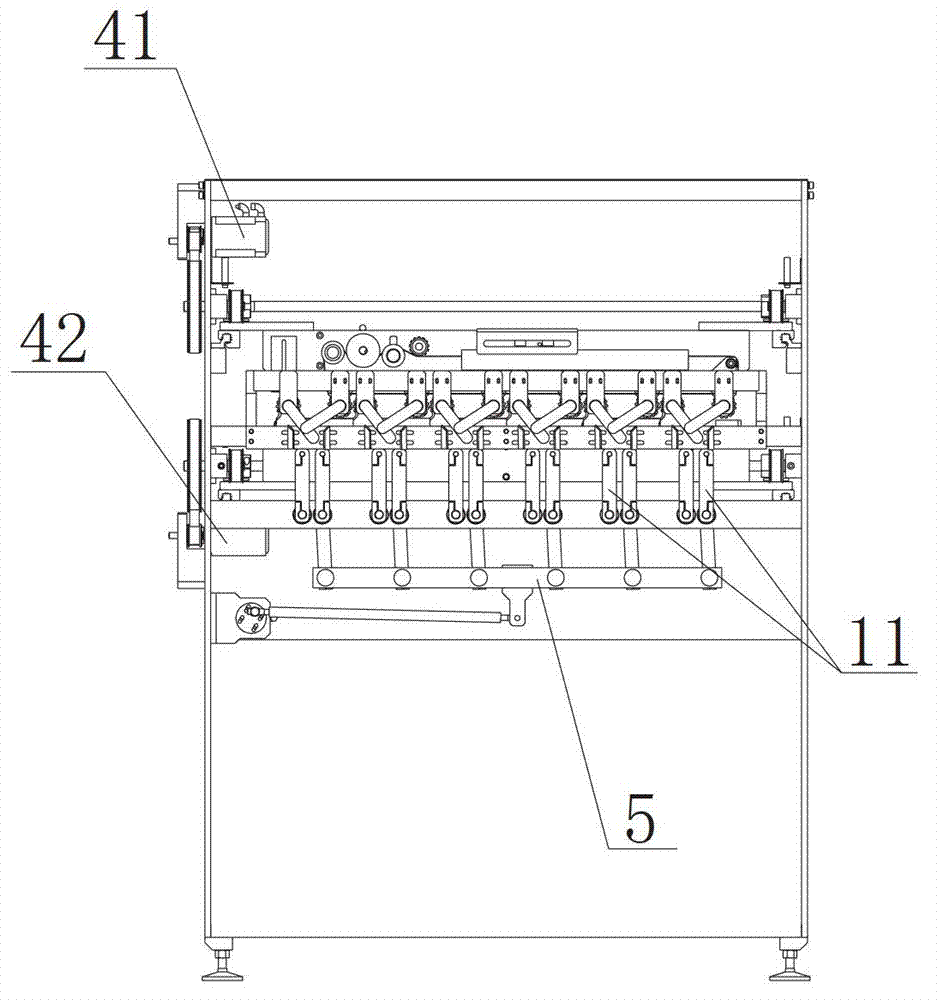

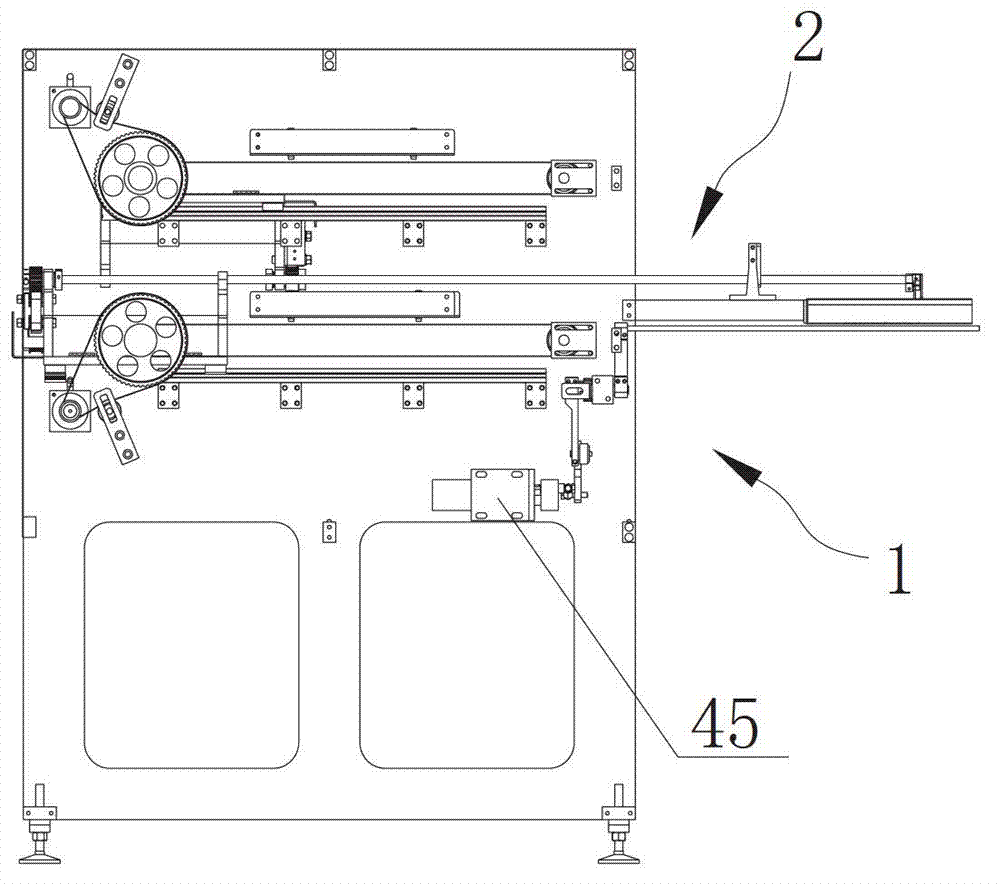

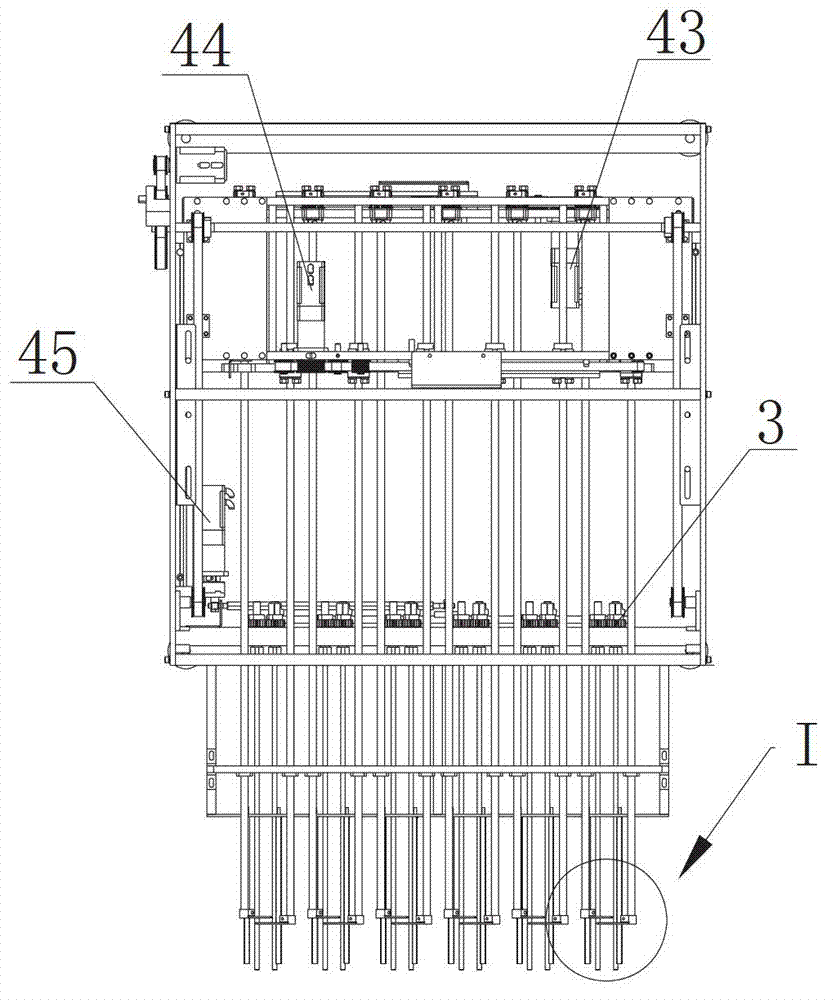

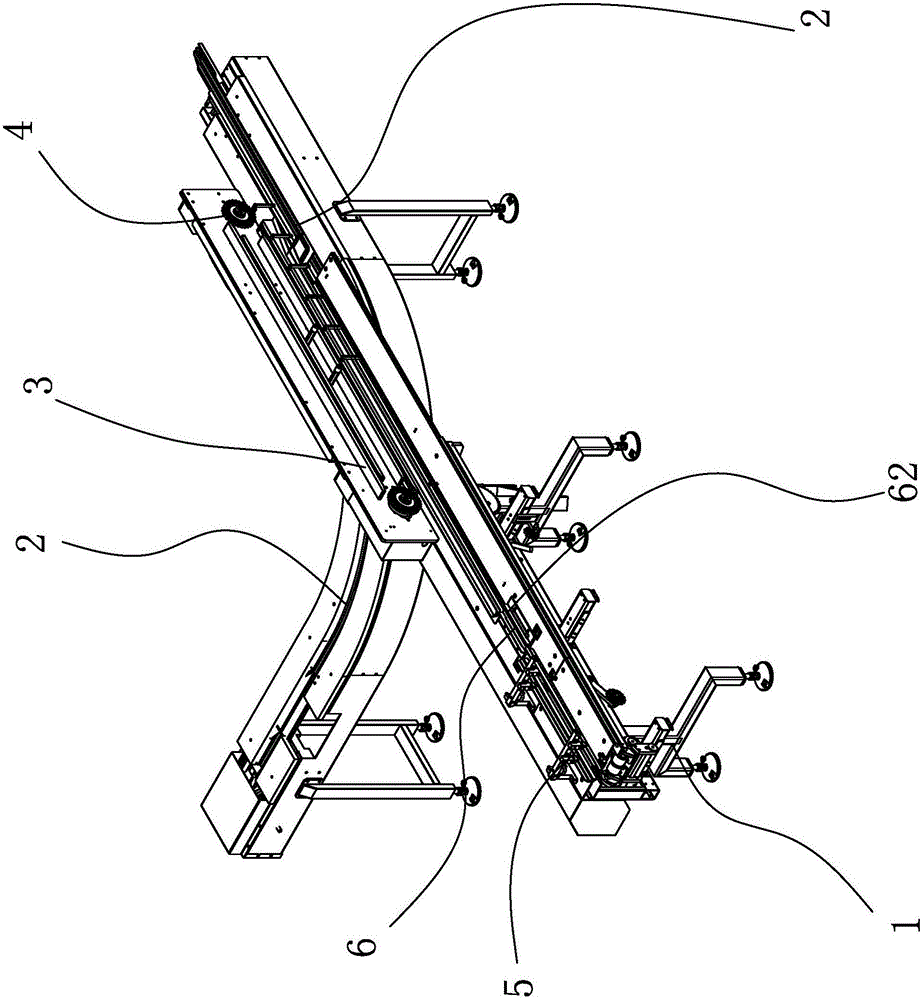

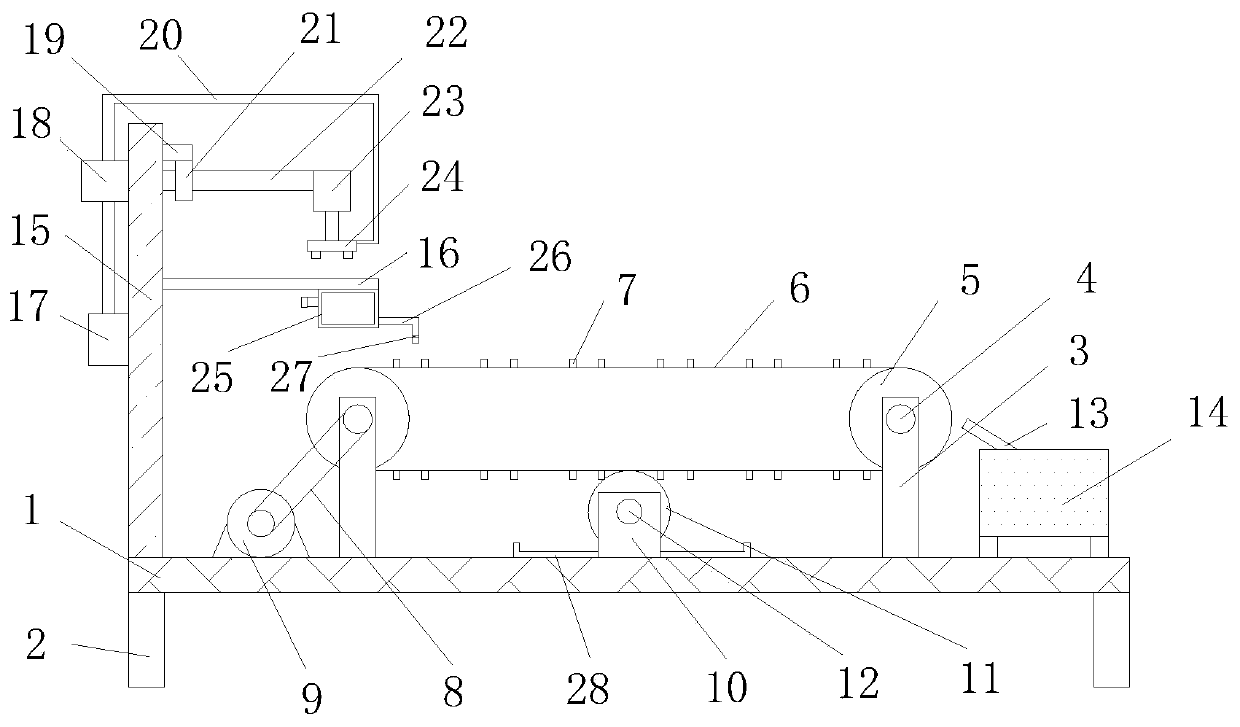

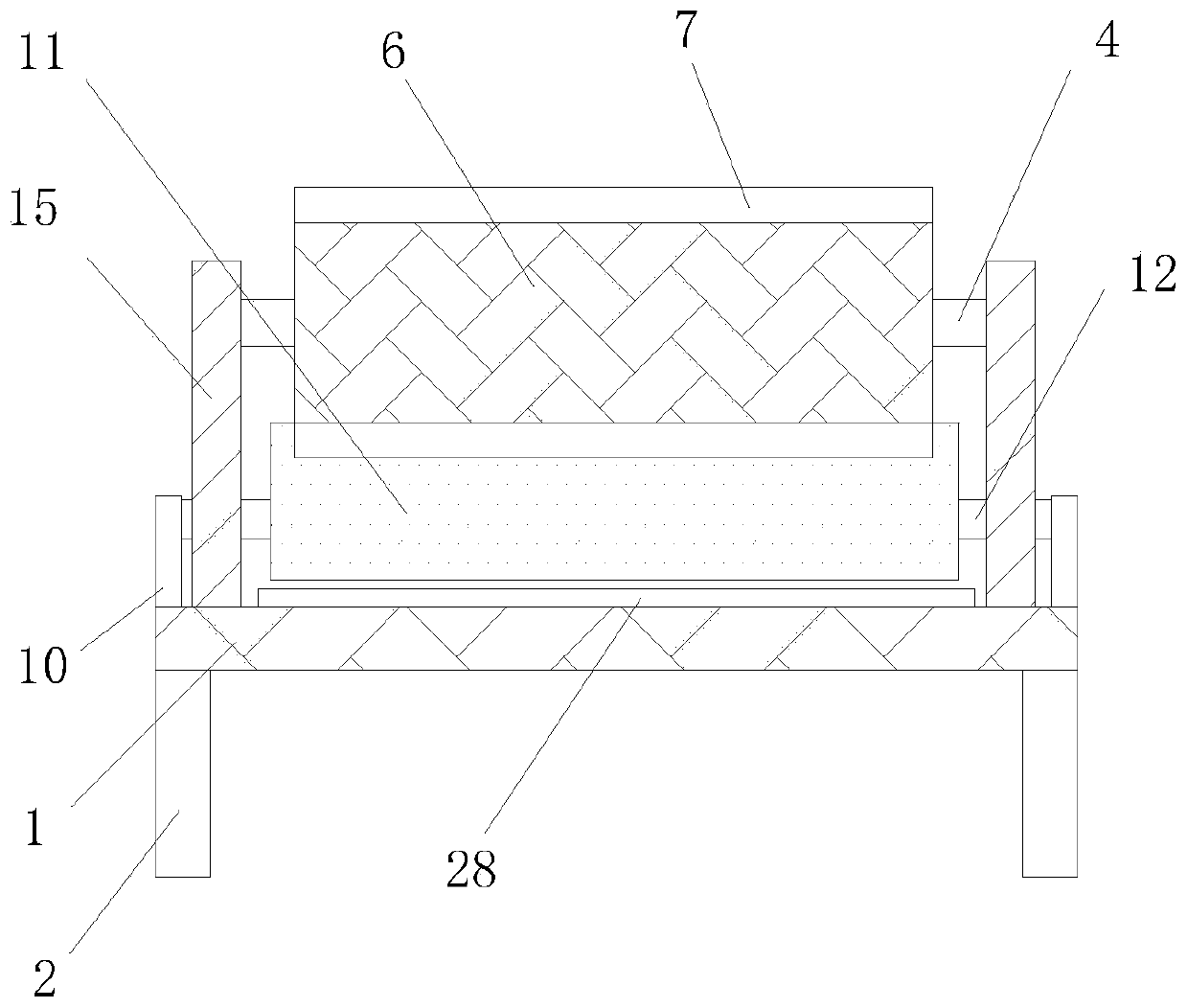

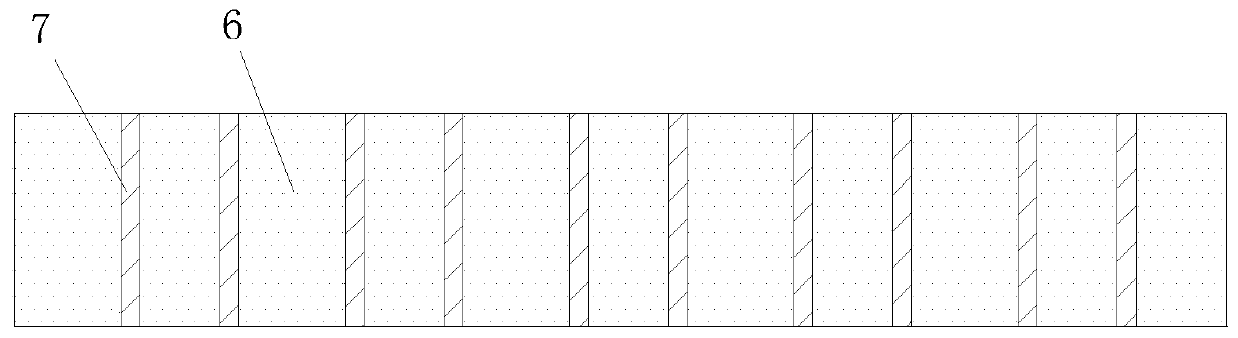

Pallet-free bar-forming conveying device for biscuits

InactiveCN104691812ARealize teaming and groupingSimple structurePackaging biscuitsCamHigh productivity

The invention discloses a pallet-free bar-forming conveying device for biscuits. The device is characterized by including a frame, as well as a biscuit sorting and grouping mechanism and a blanking and conveying mechanism which are sequentially arranged on the frame, wherein the biscuit sorting and grouping mechanism includes a biscuit support track, a motor, a transmission mechanism, a cam-linkage transmission mechanism, a left biscuit feeding chain, a right biscuit feeding chain, a shift fork, bearings, a first shift fork track, and a second shift fork track; the left biscuit feeding chain and the right biscuit feeding chain are respectively arranged on the two sides of the biscuit support track; the shift fork is mounted on the biscuit feeding chains; the bearings are arranged on the two arms of the shift fork; a third shift fork track is connected to the joint of the front ends of the first shift fork track and the second shift fork track, as well as the joint of the rear ends of the first shift fork track and the second shift fork track; a track connecting bridge, which swings in a rotatable manner, is arranged between the third shift fork track and the joint of the front ends of the first shift fork track and the second shift fork track; the blanking and conveying mechanism includes a support, a first moving support track, a second moving support track, a driving device and a biscuit pushing mechanism; the first moving support track and the second moving support track are arranged on the support side by side; the driving device is used for driving the first moving support track and the second moving support track in a connected manner; the biscuit pushing mechanism is arranged outside the first moving support track and the second moving support track. The device provided by the invention has the advantages of automatic biscuit grouping, high stability and smoothness in operation, as well as high productivity.

Owner:FOSHAN CITY SHUNDE DISTRICT RISHENG MECHANICAL EQUIP CO LTD

Method of producing edible cellulosic films

Disclosed is a process for continuous casting of edible cellulose-containing film sheets having unique physical characteristics. The cellulose film sheets have diverse applications in the processed food industry.

Owner:WEIBEL

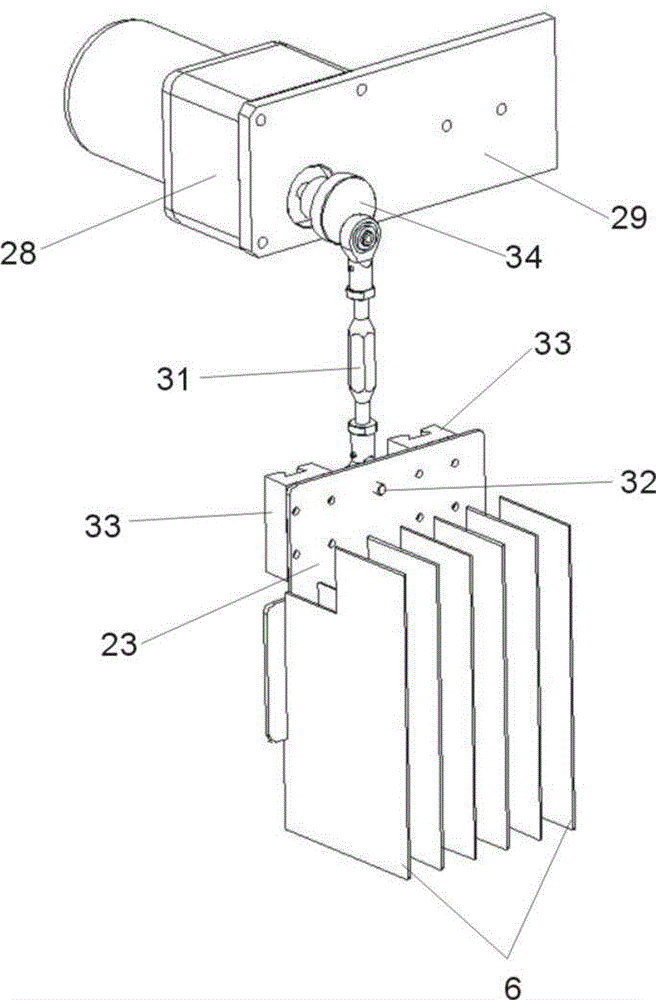

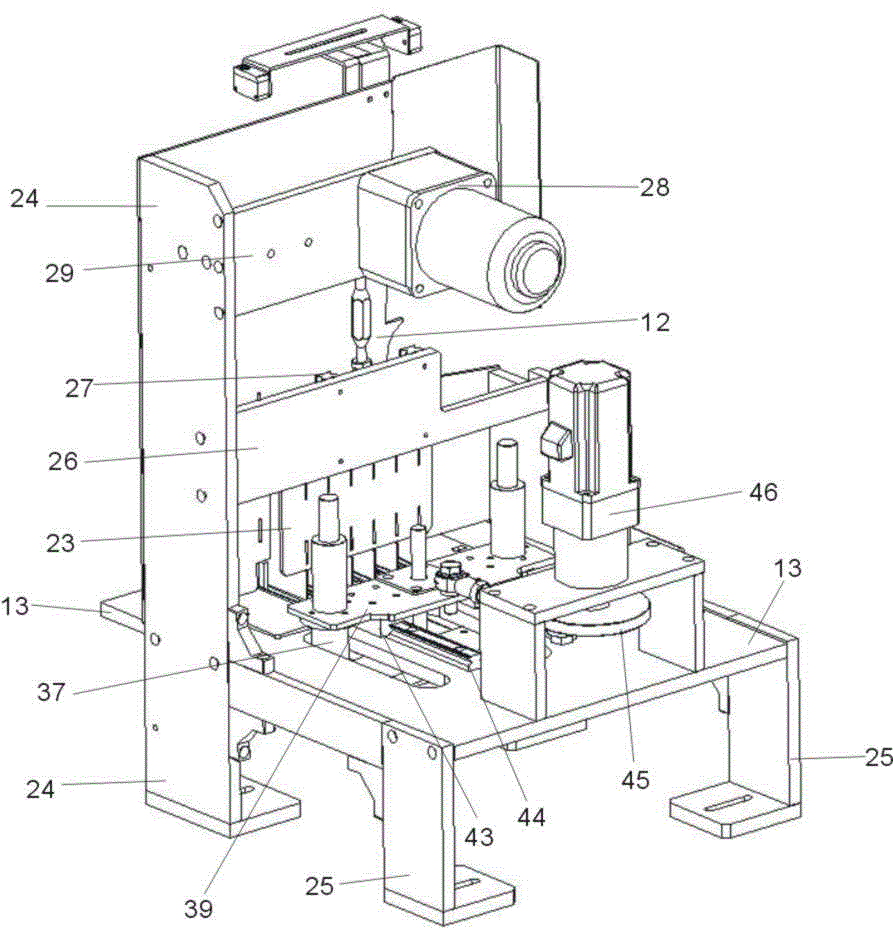

Settling machine for multiple bar-shaped materials

ActiveCN105984603AReasonable structureFully automatedPackaging biscuitsProduction rateVertical vibration

A settling machine for multiple bar-shaped materials comprises a settling bin which comprises a settling bin bottom plate, a settling bin front baffle, a settling bin rear baffle, a settling bin left baffle, a settling bin right baffle, settling bin fixed separating plates, settling bin vibrating plates, a vibration transmission plate and a settling bin push handle. The settling bin bottom plate is provided with supporting strips, and the supporting strips and the settling bin bottom plate are provided with slotted holes. The settling bin rear baffle is provided with grooves and concave openings. The settling bin push handle comprises a push palm and pushing plates. The settling bin fixed separating plates are mounted on the settling bin rear baffle, and the settling bin vibrating plates are mounted on the vibration transmission plate. The settling bin rear baffle is arranged on the supporting strips, and the settling bin fixed separating plates are arranged in the corresponding slotted holes. After the vibration transmission plate is arranged on the settling bin rear baffle, the settling bin vibrating plates penetrate through the grooves of the settling bin rear baffle to be arranged in the corresponding slotted holes for vertical vibration so as to achieve settling. The settling bin front baffle is mounted on the settling bin left baffle and the settling bin right baffle, and the bar-shaped materials can pass through the settling bin front baffle. The push palm is arranged under the settling bin bottom plate, the pushing plates are arranged between the corresponding supporting strips, and the pushing plates push the materials front and back through the concave openings of the settling bin rear baffle. The settling machine is mainly applied to stack the bar-shaped materials one by one and layer by layer for settling, such as bar-shaped biscuits, automation of a production line is achieved by connecting production and packaging, and the productivity is greatly increased.

Owner:佛山市永创智能设备有限公司

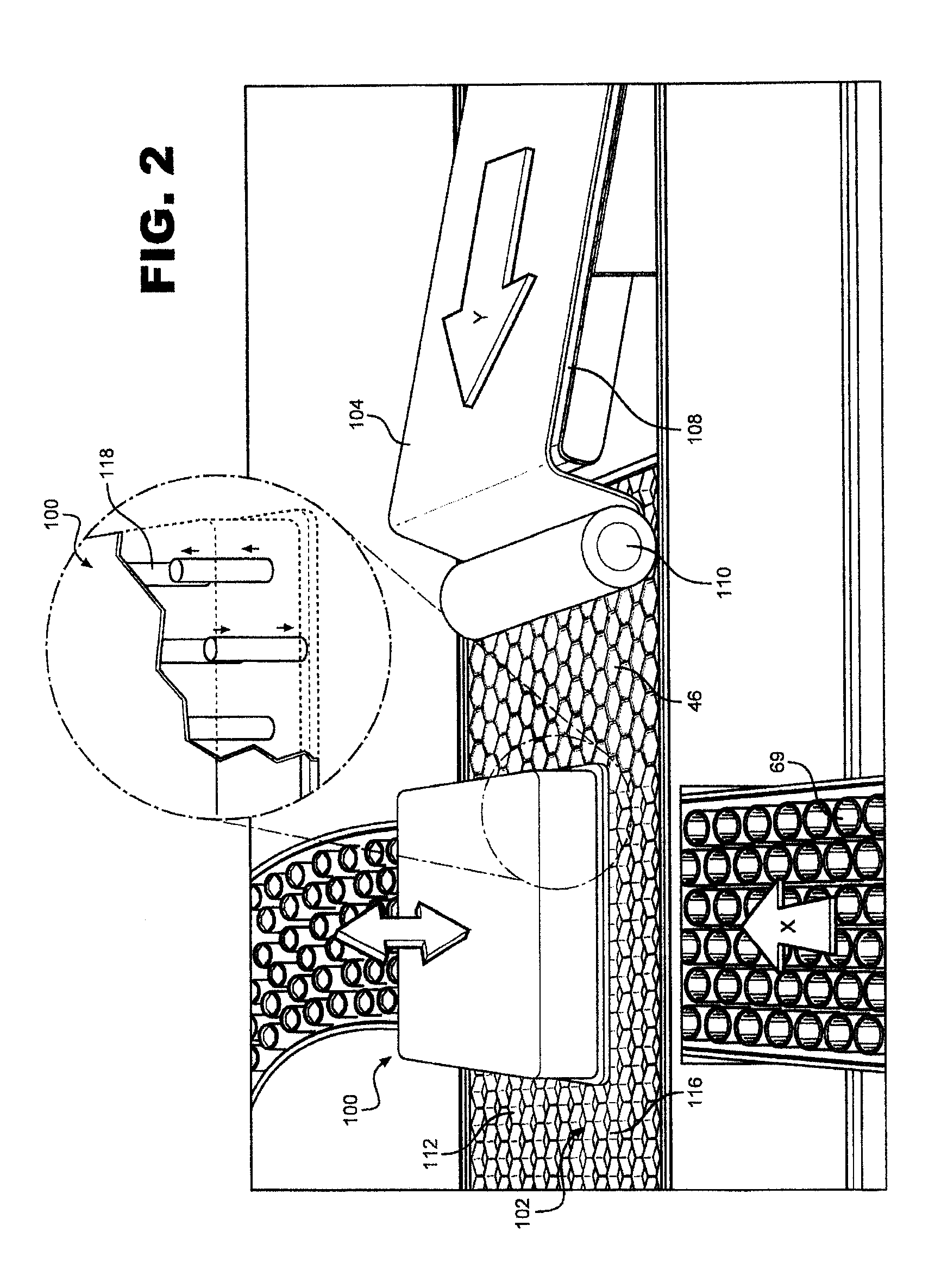

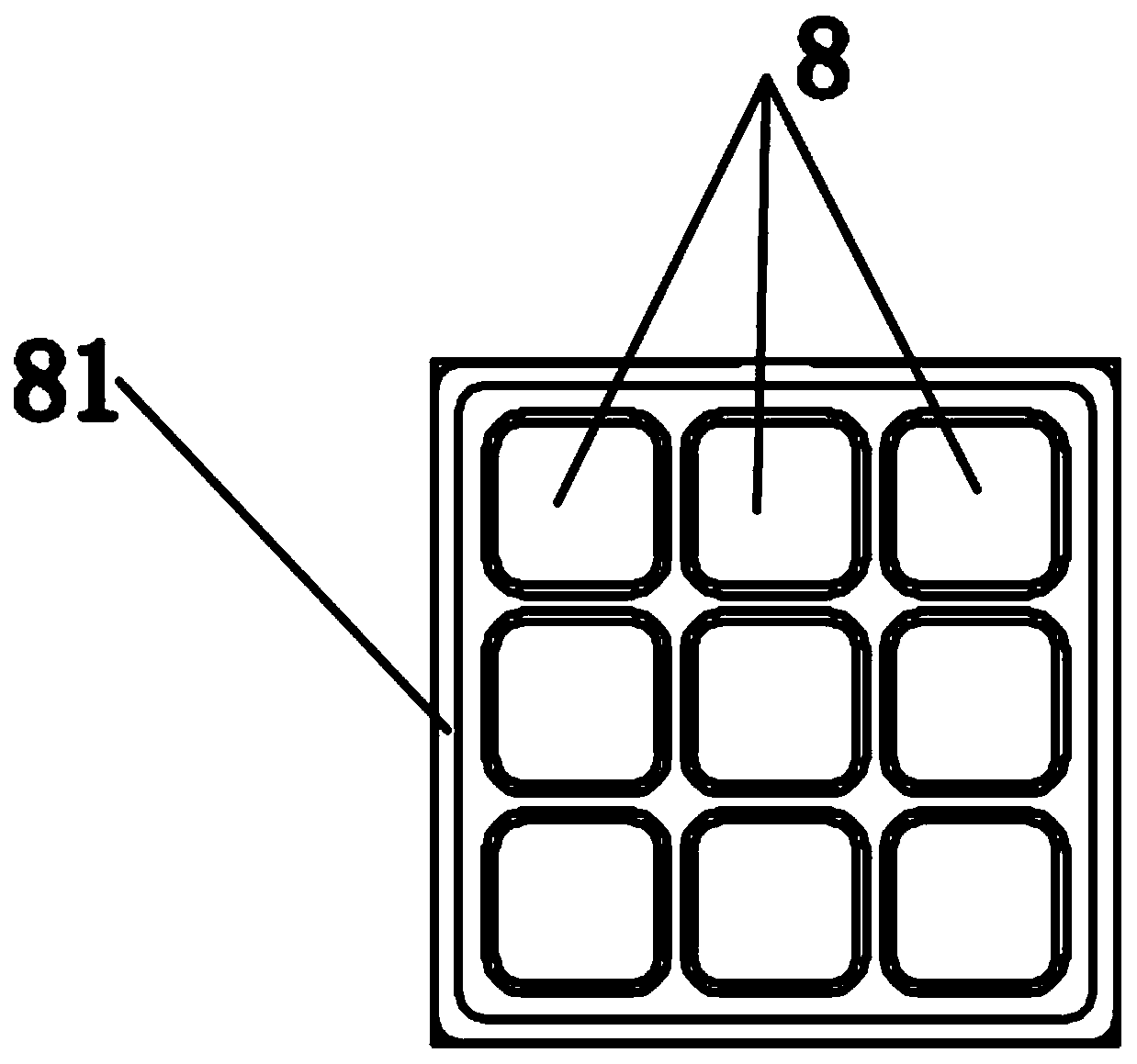

Method and device for filling a multi-row packaging tray with fragmented products

ActiveCN103118946AHigh encapsulation speedIncrease productivityPackaging automatic controlSolid materialEngineeringSingle row

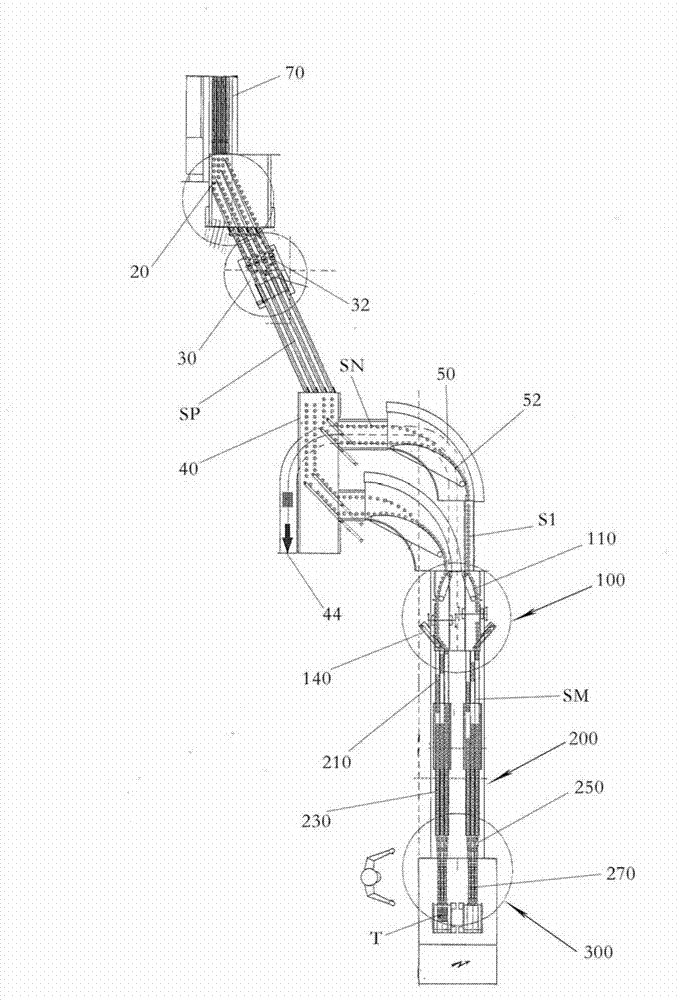

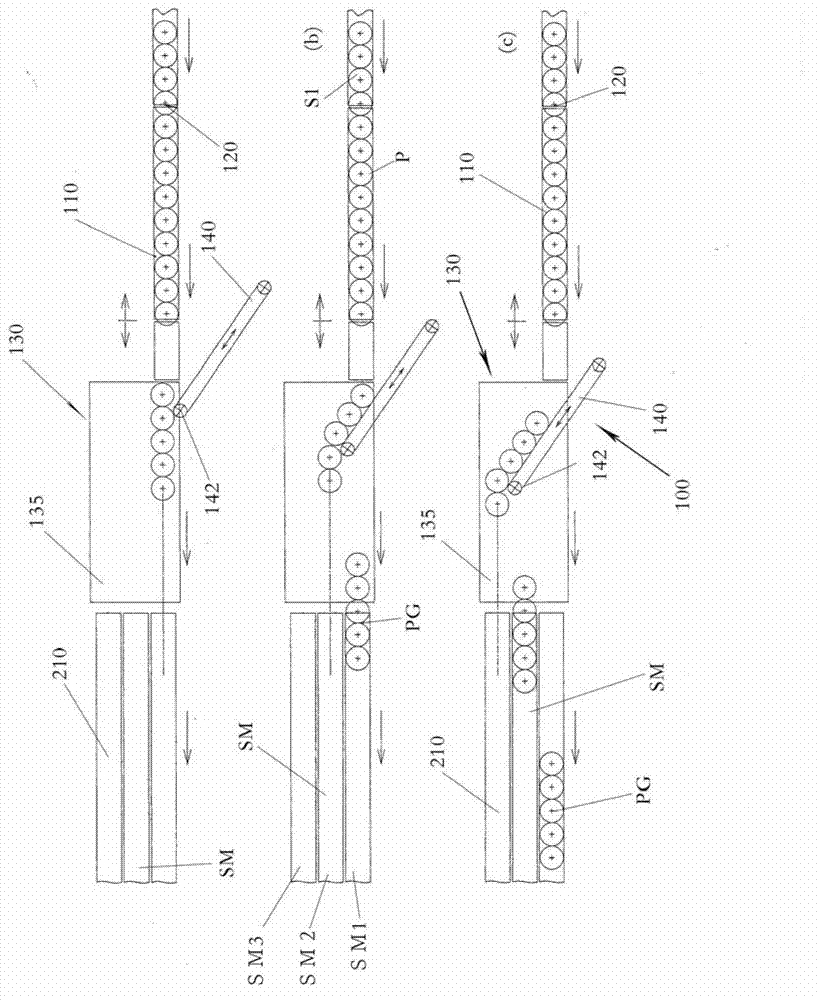

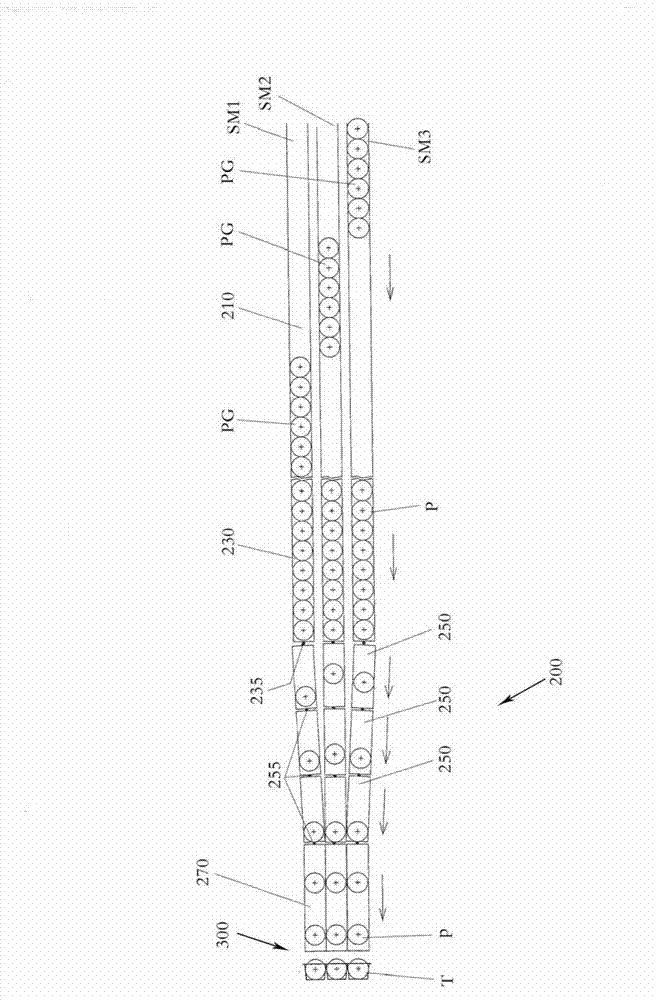

The invention relates to a tray loading packaging machine that carries out a method for filling a multi-row packaging tray (Tray T) with fragmented products (P) at a high performance level, having the following steps: dividing (100) a single-row flow (S1) of fragmented products (P) into a plurality of tracks (SM; SM1, SM2, SM3) disposed substantially parallel to each other for further transporting the products (P); synchronizing (200) the individual flows of the products (P) on the plurality of tracks (SM; SM1, SM2, SM3) to each other so that a product (P) can be transferred from each track (SM1, SM2, SM3) substantially simultaneously as a product (P) from each of the other tracks (SM1, SM2, SM3); and transferring the products (P) to the packaging tray (T), wherein a product is transferred from each track (SM1, SM2, SM3) to a row of the packaging tray (T).

Owner:LOESCH VERPACKUNGSTECHNIK GMBH CO KG

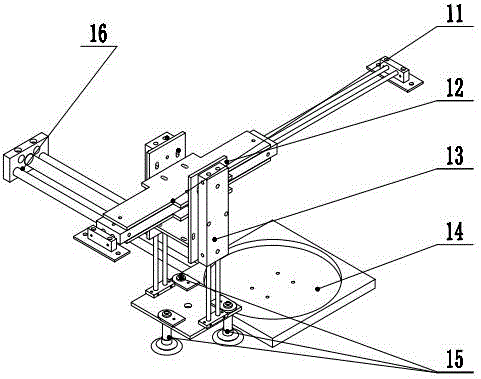

Sliced food sucking device

The invention discloses a sliced food sucking device and relates to the technical field of food packaging equipment. The sliced food sucking device structurally comprises a sucking head with a containing cavity. Due to the fact that a sliding buffer part is arranged in the containing cavity, the buffer part gets close to a sucking port of the sucking head before food is sucked, in this way, the first slice of food can be tightly attached to the buffer part by moving a quite small distance when food is sucked, side turning of the first slice of food can be prevented, smooth sucking of follow-up food is ensured, collision between the first slice of food and the buffer part is reduced, and then the food breakage probability is reduced. Meanwhile, due to the fact that the buffer part is moved towards the bottom of the containing cavity by the distance of the thickness of at least one slice of food every time the sucking head sucks one slice of food, side turning of follow-up sucked food can be prevented, collision between food can be reduced, and the food breakage probability is further reduced. In the discharge process, the buffer part pushes all food in the sucking head together, and rapid and smooth discharge is achieved.

Owner:QKM TECH (DONG GUAN) CO LTD

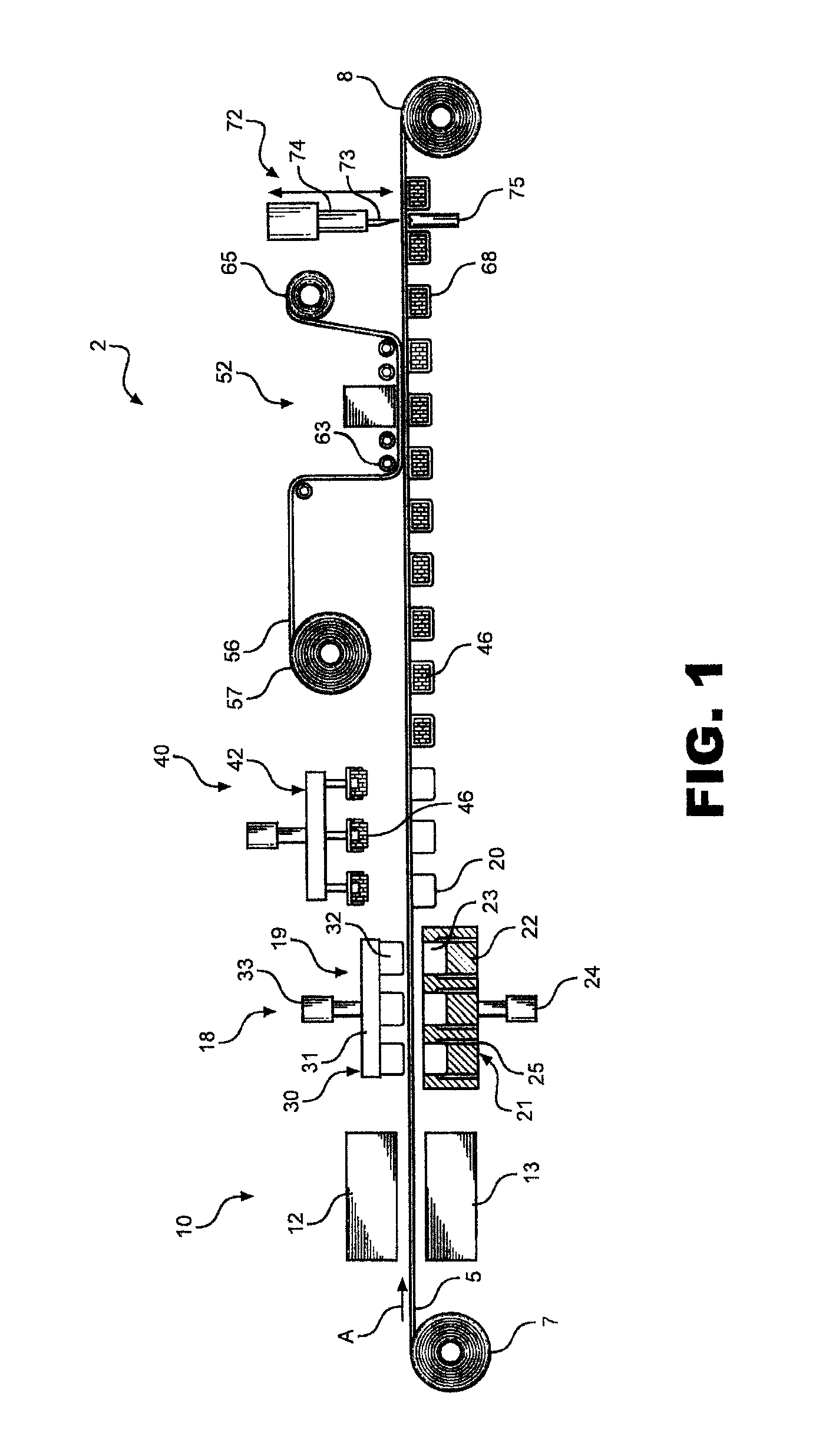

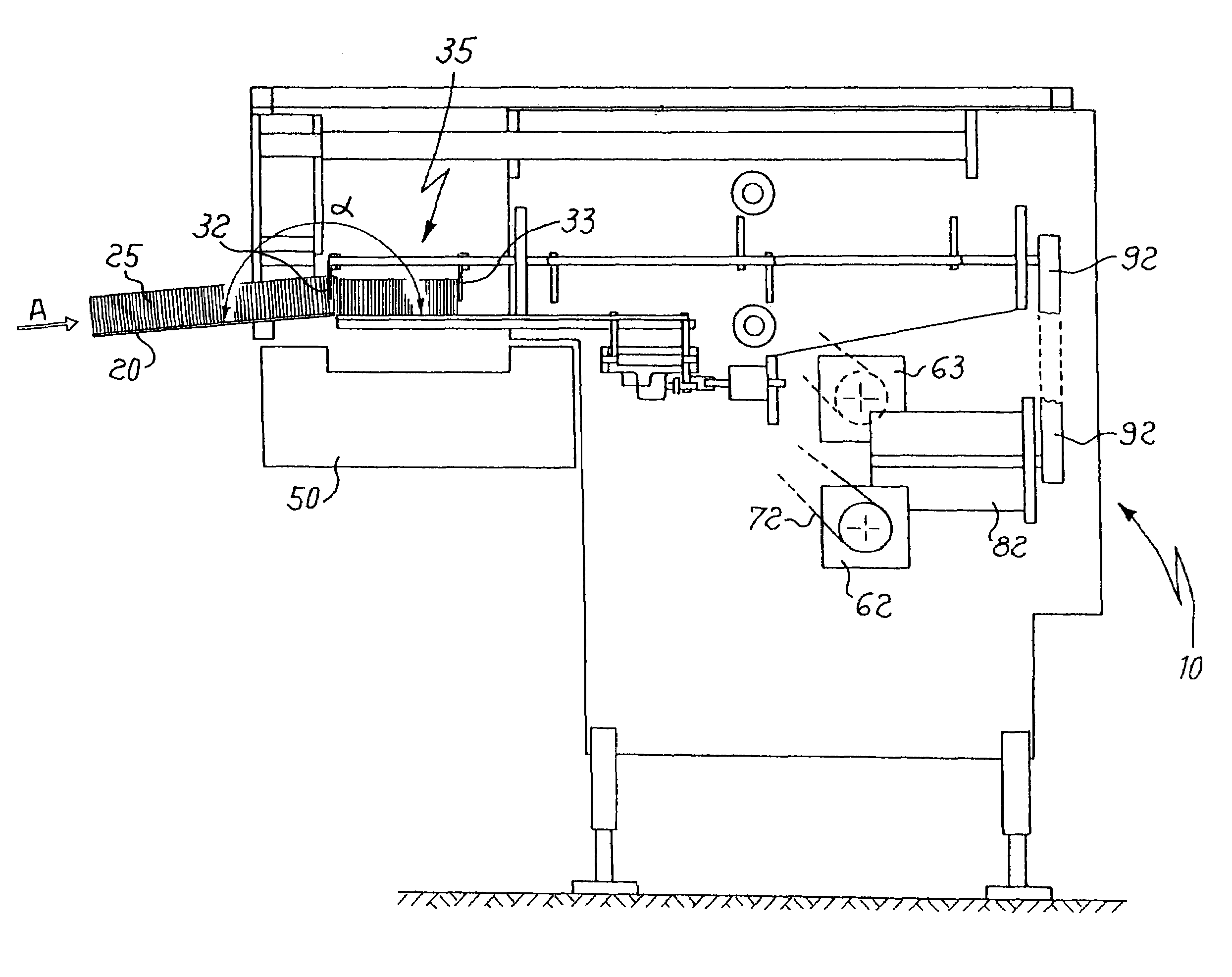

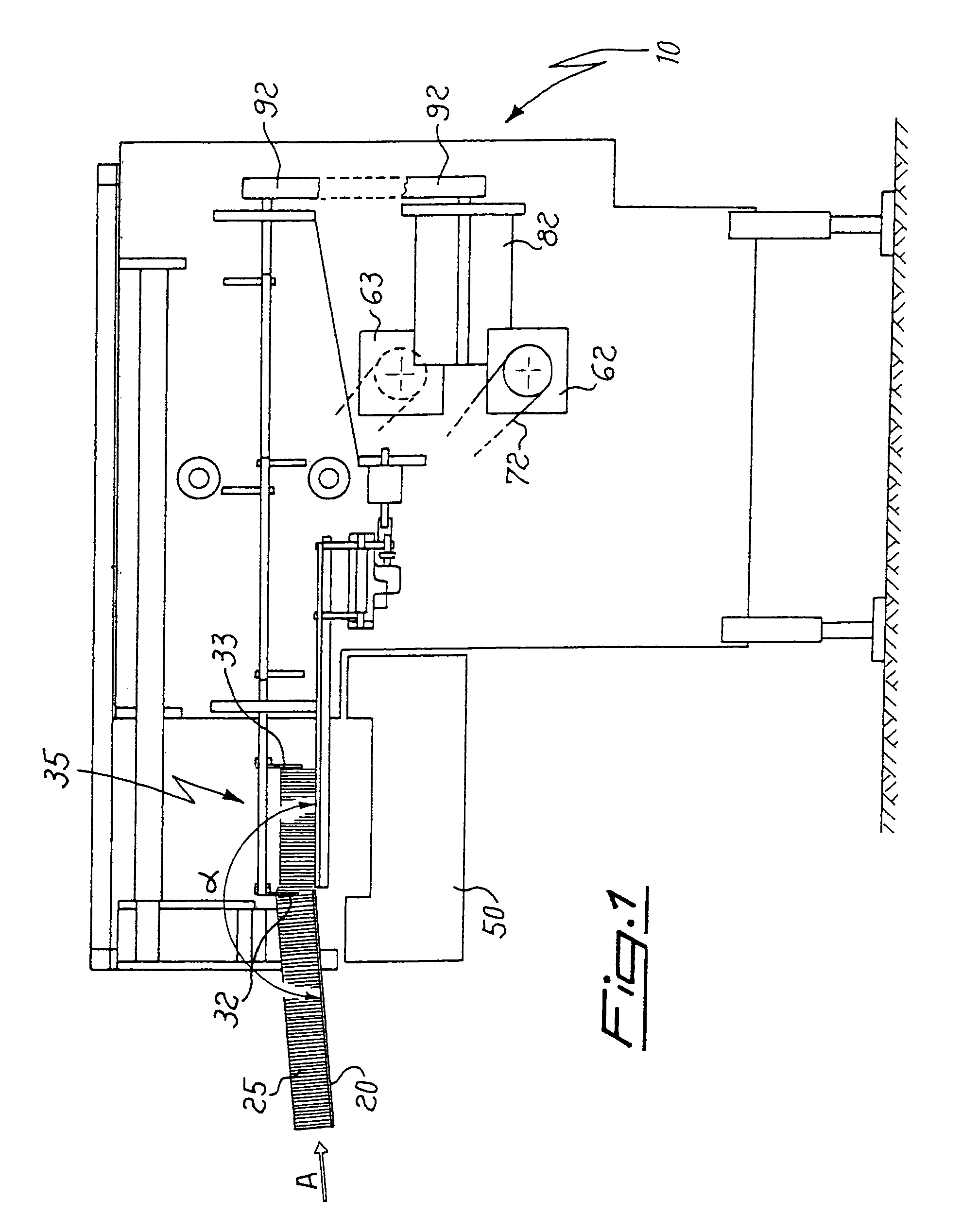

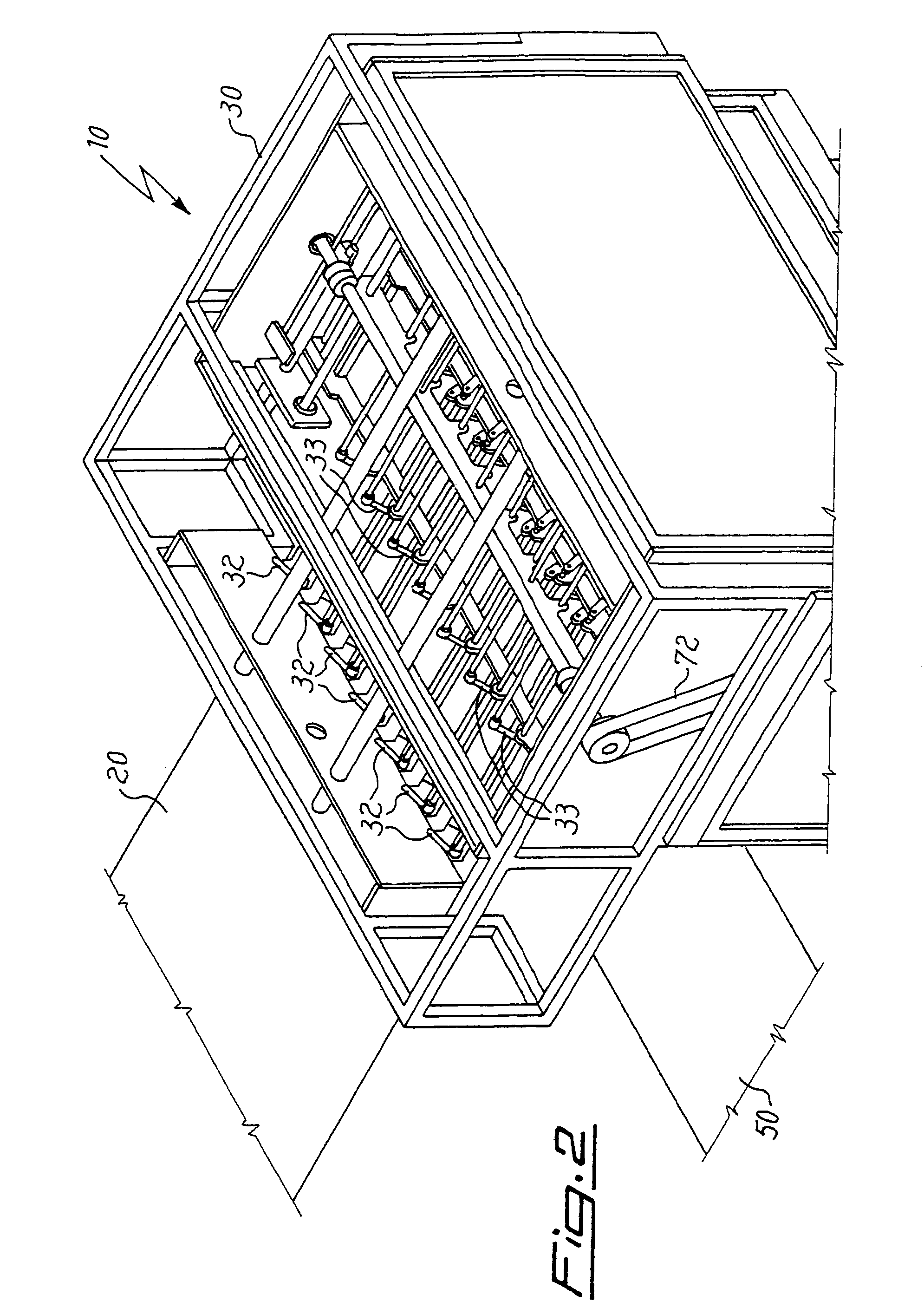

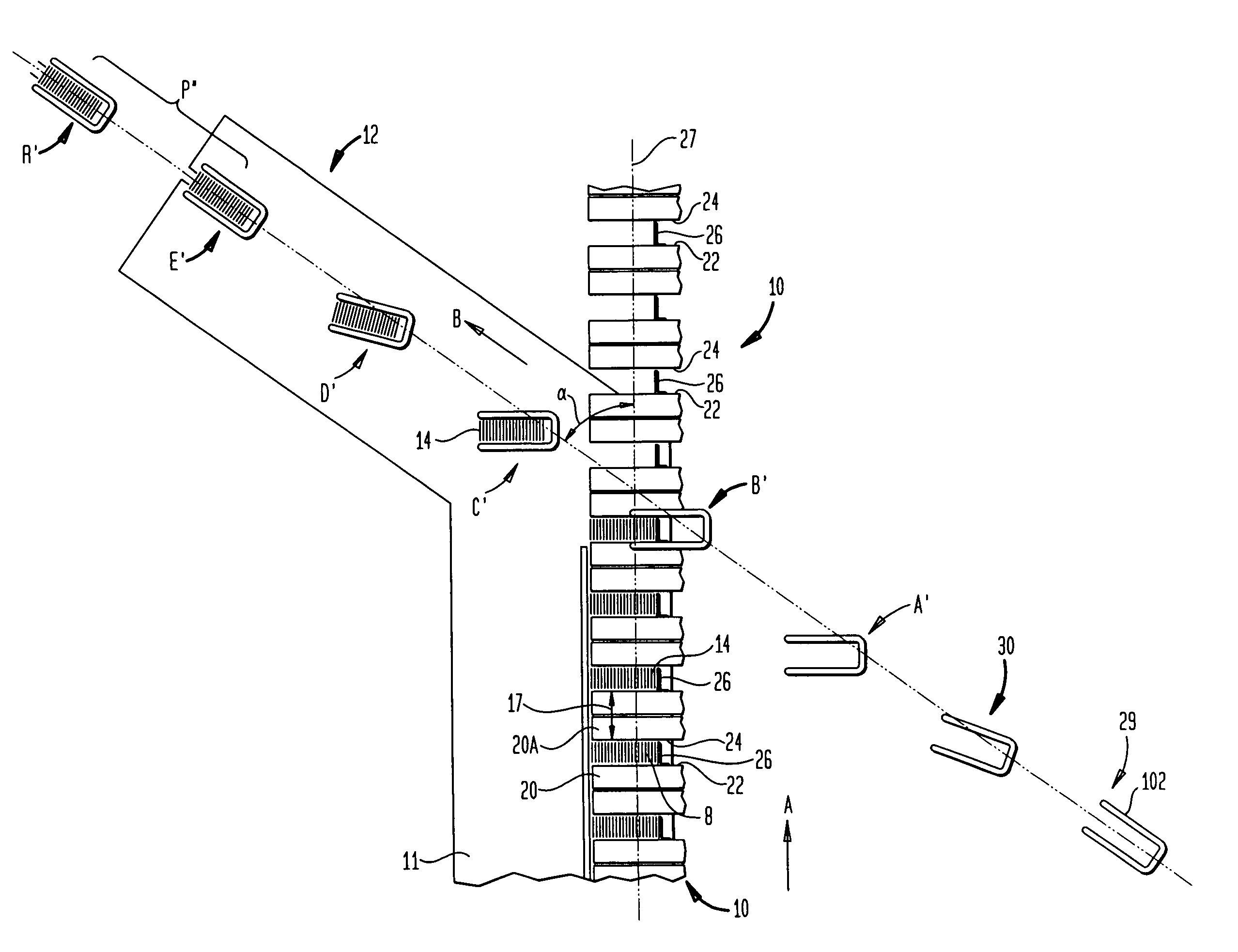

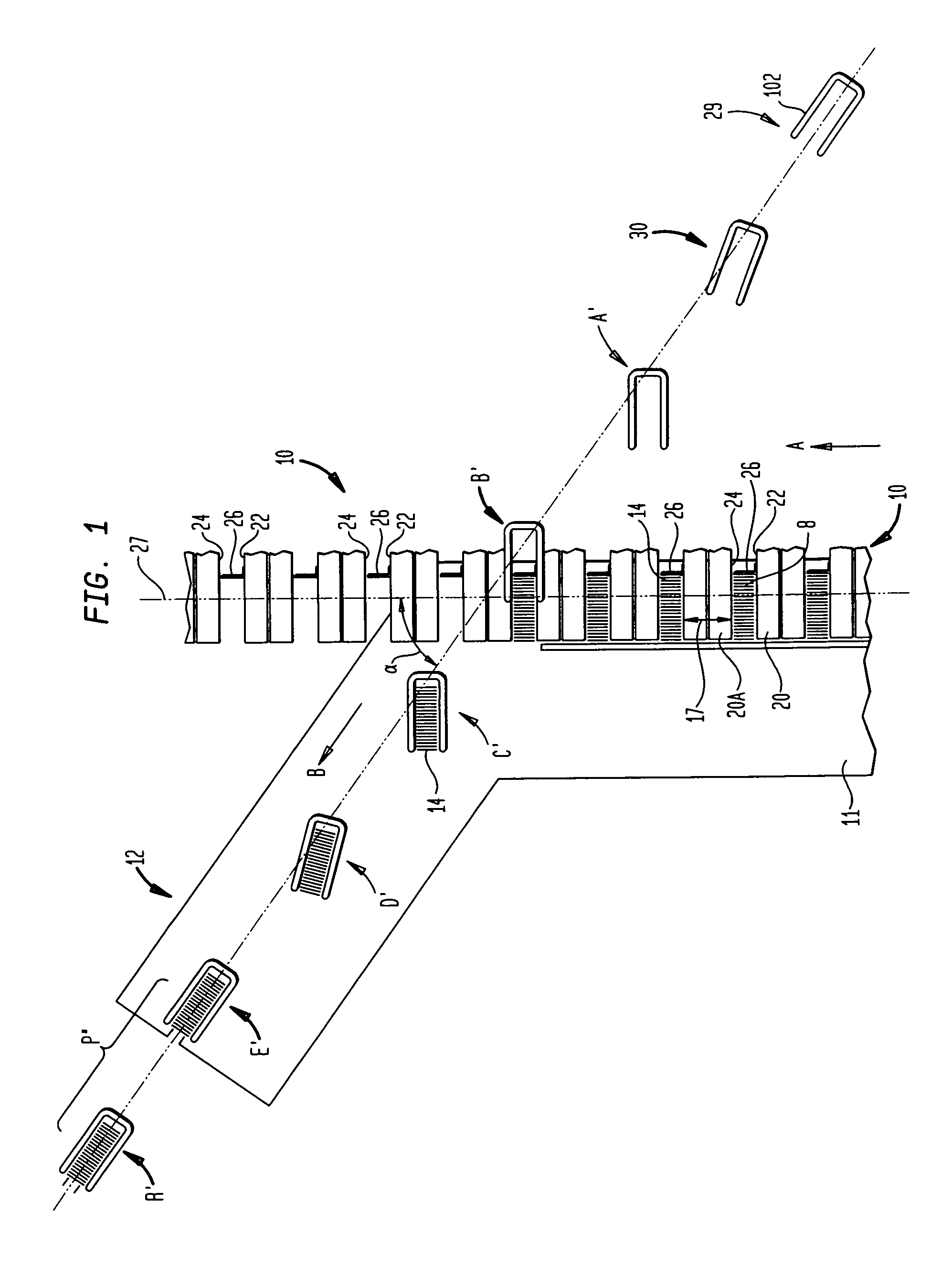

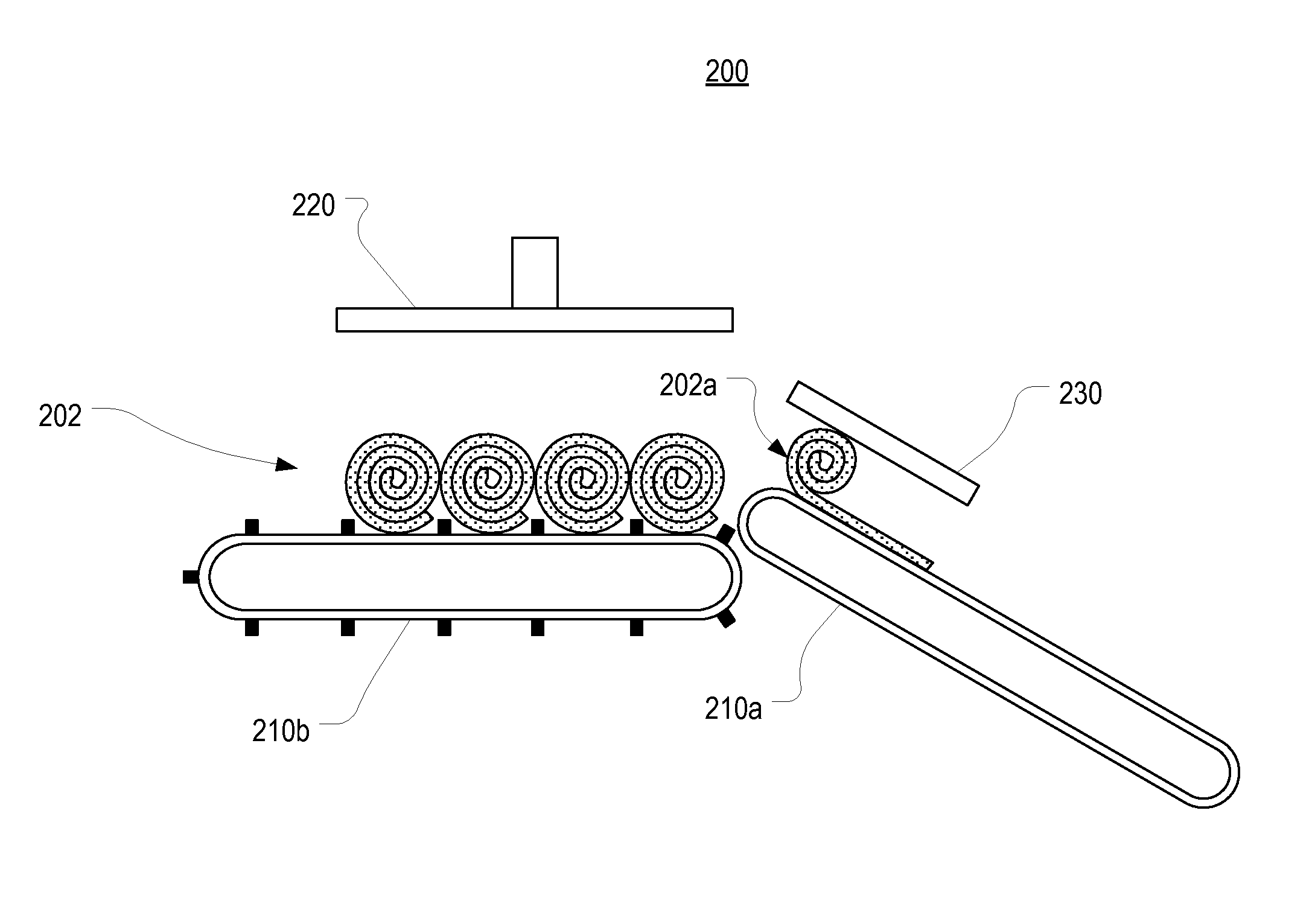

Continuous motion product transfer system with conveyors

InactiveUS7377375B2Increase speedRestrain the slug of a particular productConveyor partsMechanical conveyorsTransfer systemEngineering

A product transfer system preferably includes a first conveyor for conveying a series of product in a first direction. This system also includes a cross conveyor vertically spaced from the first conveyor and oriented in a second direction angled at an angle α with respect to the first direction. A plurality of rotatable transporters are mounted on the cross conveyor for transferring the product from the first conveyor to the cross conveyor. The transporters are initially oriented perpendicular to the first direction before receiving the products and are rotatable to the second direction after receiving the products.

Owner:CARDINAL MACHINE CORP USA

Finishing machine of forked cakes

The invention relates to a finishing machine of forked cakes, which belongs to finishing mechanical equipment for wheaten leisure food forked cakes before packing. The finishing machine of forked cakes comprises a collecting bin, a crumb removing device, a vibrating feeding device, a finishing and sorting device and a lifting device which are sequentially installed and connected by a fastening piece into a whole machine, wherein the lower bottom surface of the collecting bin is provided with a belt conveyor; the crumb removing device is arranged at the lower part of the discharge opening of the collecting bin, and the lower bottom surface of the crumb removing device is provided with a crumb removing belt conveyor; the vibrating feeding device is arranged at the discharge opening of the crumb removing device; the finishing and sorting device is arranged at the discharge opening of the vibrating feeding device and comprises a chute and a cake-hanging belt conveyor; and the lifting device is arranged behind the cake-hanging belt conveyor of the finishing and sorting device and comprises a bent plate worktable and a conveying chain. The finishing machine for forked cakes can automatically separate and remove crumbs mixed in the forked cake products, continuously finish and sort the forked cakes having complex shapes and quickly send the forked cakes to the packing process one by one.

Owner:东台市食品机械厂有限公司

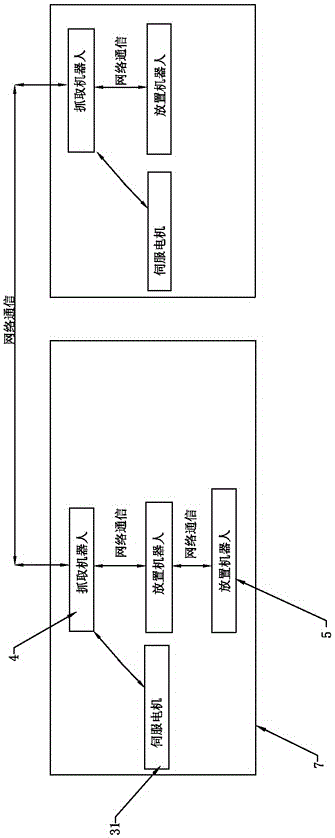

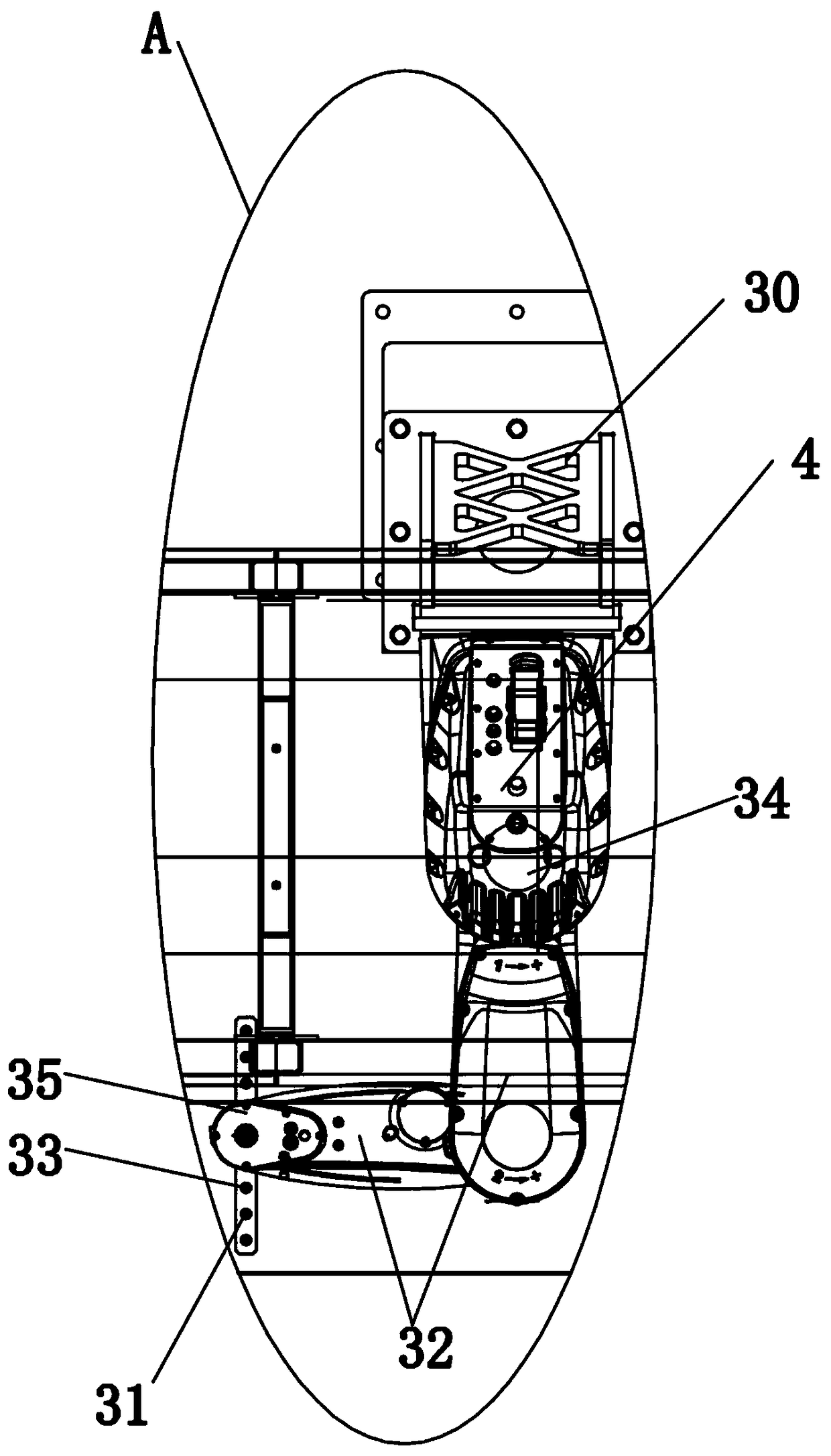

Automatic boxing system adopting robot

ActiveCN106240931AImprove efficiencyImprove stabilityPackaging automatic controlPackaging biscuitsSystem stabilityEngineering

The invention relates to the technical field of automatic robots, in particular to an automatic boxing system adopting a robot. A master robot and a slave robot are matched with each other; one of the master robot and the slave robot grabs a to-be-boxed product from a first transmission device, and puts the to-be-boxed product on a caching device, and the other one moves the to-be-boxed product to an accommodating box on a second transport unit from the caching device, and therefore, a coordination problem between two conveyor belts does not need to be taken into consideration, and efficiency can be greatly improved; moreover, master robots of adjacent working groups carry out information interaction, so that an upper computer which is intensively controlled and managed is not needed, and the problem that failure is caused by single upper computer operation and too heavy communication load is avoided; and an operation process and a communication process are distributed more reasonably, so that system stability is higher.

Owner:QKM TECH (DONG GUAN) CO LTD

Sod harvester stacking head that is movable with a stacking conveyor

Owner:FIREFLY AUTOMATIX

Linkage biscuit aligning device

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Novel automatic biscuit arrangement device

Owner:ANHUI YOUYUAN FOOD

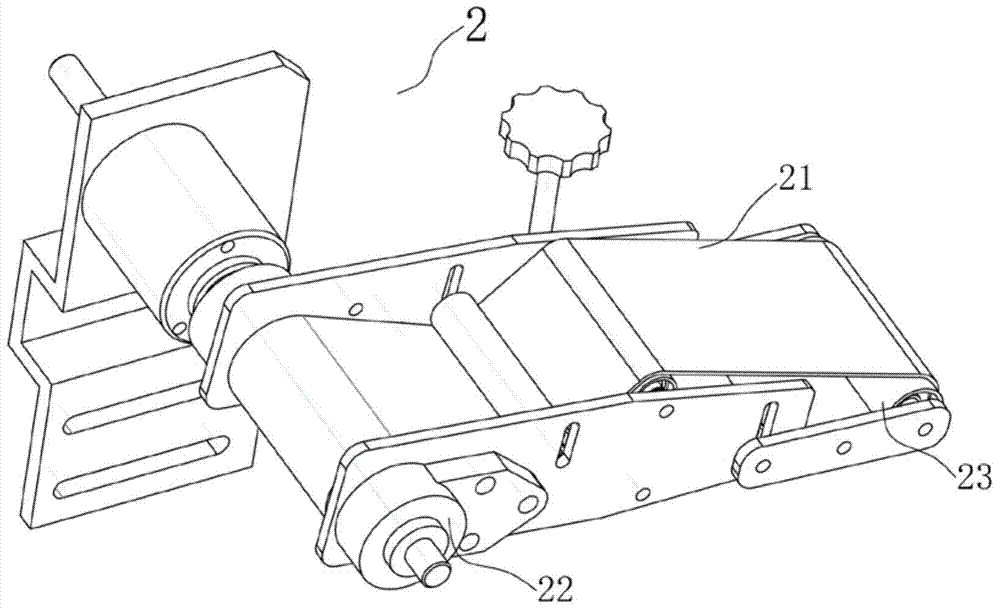

Automatic feed device for biscuit assembly packaging

ActiveCN102963555AImprove efficiencyAvoid human contactPackaging biscuitsManufacturing lineFixed length

The invention provides an automatic feed device for biscuit assembly packaging, which solves the problem in the prior art that the efficiency of the biscuit packaging is low. The automatic feed device for the biscuit assembly packaging comprises a support platform, a limiting fixed-length mechanism and a power mechanism, wherein the support platform is arranged below the tail end of a biscuit production line and above the initiating end of a conveying line of a packaging machine, and can allow produced biscuits to fall on the conveying line of the packaging machine automatically; the limiting fixed-length mechanism is arranged above the support platform and used for limiting the biscuits on the support platform; and the power mechanism is used for controlling the support platform and driving the limiting fixed-length mechanism. The device replaces manual feeding in the biscuit packaging process, can reduce the labor cost, improves the safety of food, and is very good in practicability.

Owner:青岛松本包装机械有限公司

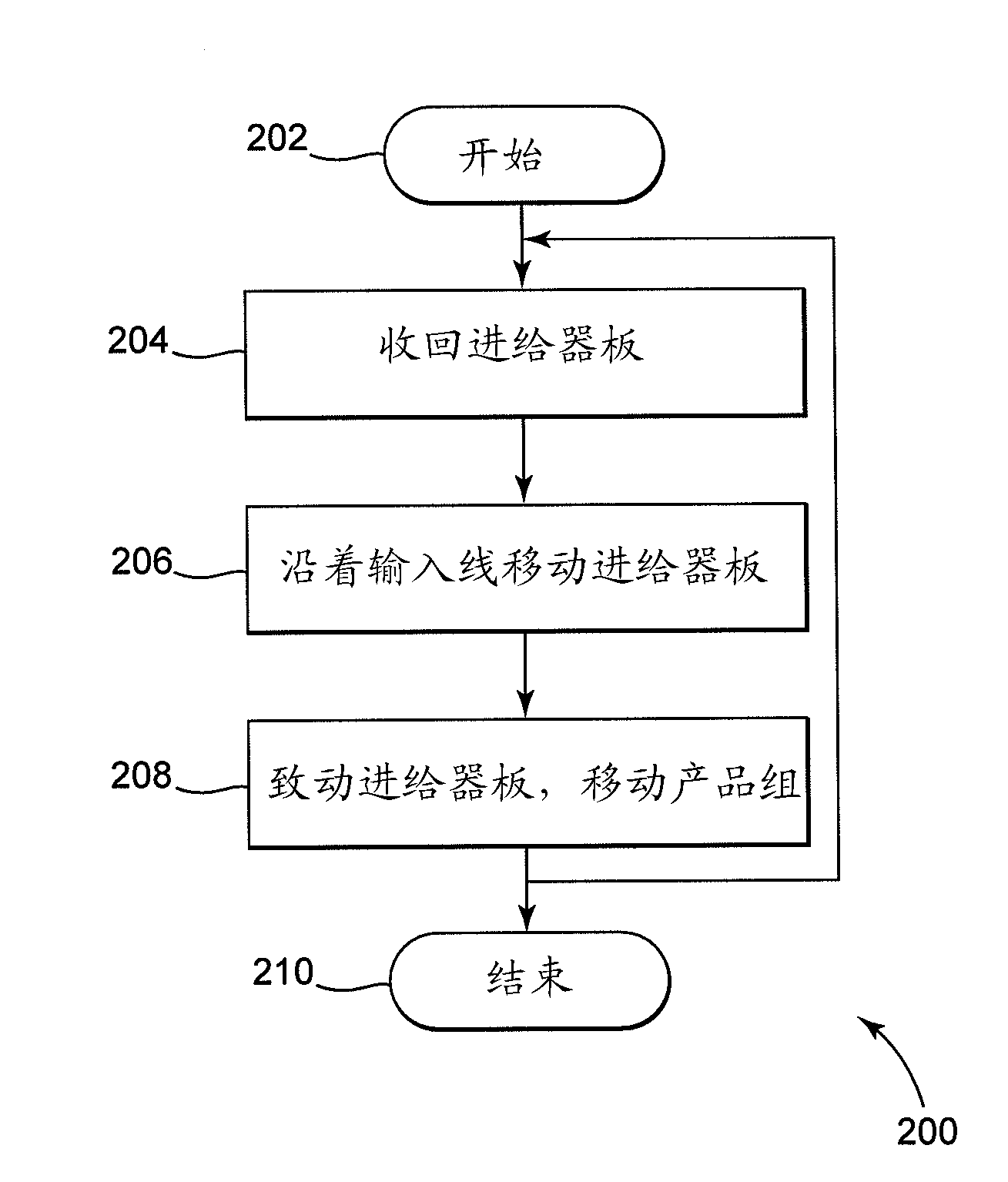

Continuous motion inline feeder

Owner:博世包装技术公司 +1

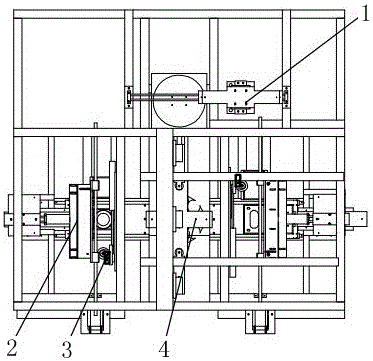

Multi-piece laminated food packaging and supporting machine

The invention discloses a multi-piece laminated food packaging and supporting machine which comprises a machine frame, conveying belts, a plurality of food channels and a pushing device, wherein the conveying belts and the food channels are installed on the machine frame. Each food channel comprises a horizontal moving section and a falling section. The multiple food channels are all installed above the conveying belts. The food channels become longer gradually from bottom to top. The falling sections of the food channels are located on different vertical planes. According to the multi-piece laminated food packaging and supporting machine, conveying before packaging and supporting is conducted through the arrangement of the food channels, and then food is packaged and supported one by one through a natural fall; and due to the fact that the conveying speed of the food is synchronous with the conveying speed of food brackets, the food can fall into the food brackets accurately during falling. By the adoption of the packaging and supporting mechanism, accurate packaging and supporting of the multi-piece laminated food can be achieved.

Owner:FOSHAN RUIPUHUA PACKING MACHINERY CO LTD

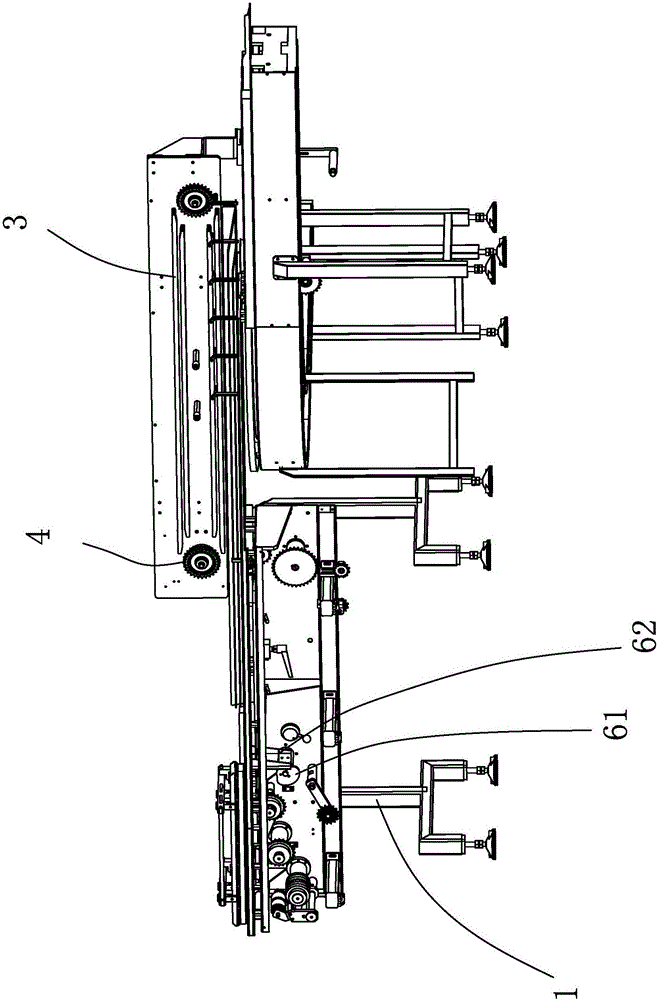

Packaging machine without tray

InactiveCN104290952AIncrease the upper and lower limitAvoid spreadingWrapper twisting/gatheringPackaging biscuitsFeed driveEngineering

The invention discloses a packaging machine without a tray. The packaging machine without the tray is characterized in that the machine comprises a feeding drive mechanism, a material pressing mechanism, a middle sealing packaging mechanism and an end sealing mechanism; a drive chain of the feeding drive mechanism is provided with at least two locating blocks in a spaced mode so that materials can be limited front and back; the material pressing mechanism is arranged on the upper portion of the drive chain so that the material can be limited up and down; the middle sealing packaging mechanism is arranged on the tail portion of the drive chain, the middle sealing packaging mechanism wraps packaging films on the outer portions of the materials, and the packaging films are sealed at the bottoms of the materials; the end sealing mechanism is arranged on the tail portion of the middle sealing packaging mechanism, a limiting drive chain of the end sealing mechanism is provided with at least two limiting rods in a spaced mode, the materials are embedded between the two limiting rods and move forwards along with the limiting rods, the packaging films between two materials are cut off through a cutter, and an end sealing device is used for sealing the packaging films at the two ends of each material. According to the packaging machine without the tray, a system standard foodstuff packaging machine is improved, and thus single-piece and multi-piece biscuit packaging with the tray and multi-piece biscuit packaging without the tray can be achieved at the same time.

Owner:YUYAO QINGDA MACHINERY

Filling and packing integrated machine for biscuits

ActiveCN109733699ARealize the degree of automationRealize automatic deliveryCleaningBaked articles handlingSolenoid valveEngineering

The invention belongs to the technical field of packing machines, and specifically relates to a filling and packing integrated machine for biscuits. The machine comprises a base, supporting legs, a supporting column, a rotating shaft, a roller, a conveyor belt, a clamping block, a belt, a motor, a fixing plate, a roller brush, a rotating rod, a feeding plate, a biscuit packing machine, a supporting plate, a storing plate, an air pump, a linear motor, a fixing block, an air pipe, a guide ring, an output rod, an electric pushing rod, a pneumatic claw, a storing barrel, a discharging pipe, a solenoid valve and a receiving plate. According to the machine, the biscuits are automatically filled, and meanwhile, the filled biscuits are automatically conveyed, so that the biscuit filling efficiencyis improved; and moreover, the filled biscuits are conveniently automatically conveyed into the biscuit packing machine, and thus the workload of a user is decreased, and the convenience of use is ensured; a cleaning mechanism is arranged and is used for cleaning impurities on the surface of the conveyor belt after conveying; and meanwhile, the cleaned impurities are discharged into the receivingplate, so that the workload of a cleaning worker is extremely reduced.

Owner:临沂文衡信息技术有限公司

Pneumatic DIY cookie packaging machine

ActiveCN105836184AImprove feeding efficiencyClosely connectedPackaging biscuitsPulp and paper industryPaper cup

The invention discloses a pneumatic DIY cookie packaging machine. The pneumatic DIY cookie packaging machine comprises a rack, a release paper feeding mechanism, a paper cup separation mechanism, a cookie feeding mechanism and a cookie boxing mechanism. The cookie boxing mechanism is arranged in the middle of the rack. The release paper feeding mechanism is located above the cookie boxing mechanism. The paper cup separation mechanism is located on one side of the cookie feeding mechanism. Release paper is put into packaging boxes of the cookie boxing mechanism through the release paper feeding mechanism. The cookie feeding mechanism puts cookies into paper cups of the paper cup separation mechanism. The paper cups with the cookies are conveyed and put into paper cup fixing bowels in the cookie boxing mechanism. The paper cups with the cookies are put into the packaging boxes through a cookie press-blocking air cylinder of the cookie boxing mechanism by means of a die, and packaging of the cookies is completed. By the adoption of the DIY cookie packaging machine, full-automatic packaging is achieved, the labor cost is lowered, the packaging accuracy is improved quickly, and the pneumatic DIY cookie packaging machine is suitable for Taobao merchants who need to package the cookies.

Owner:ZHEJIANG UNIV OF TECH

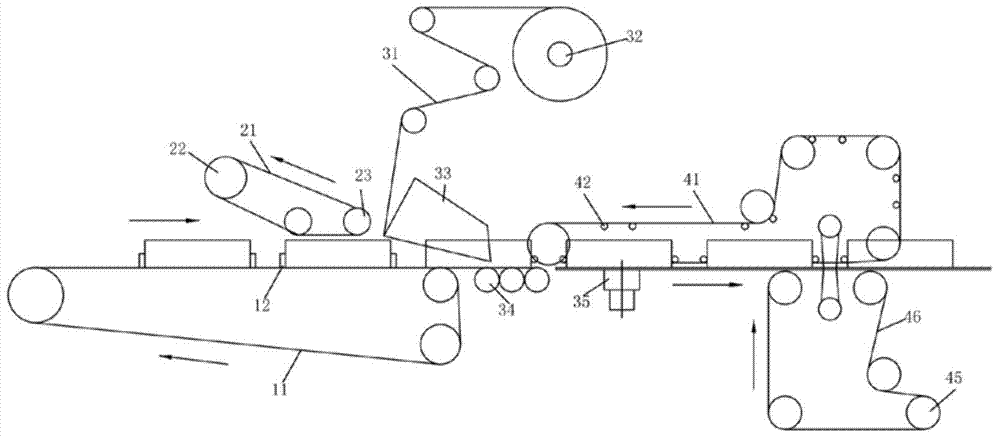

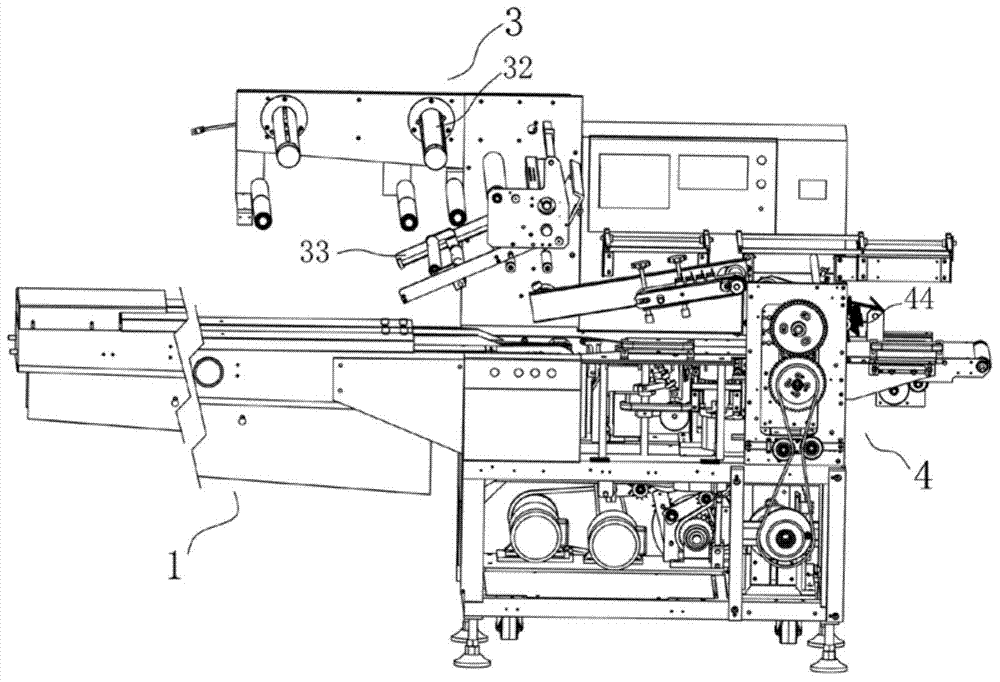

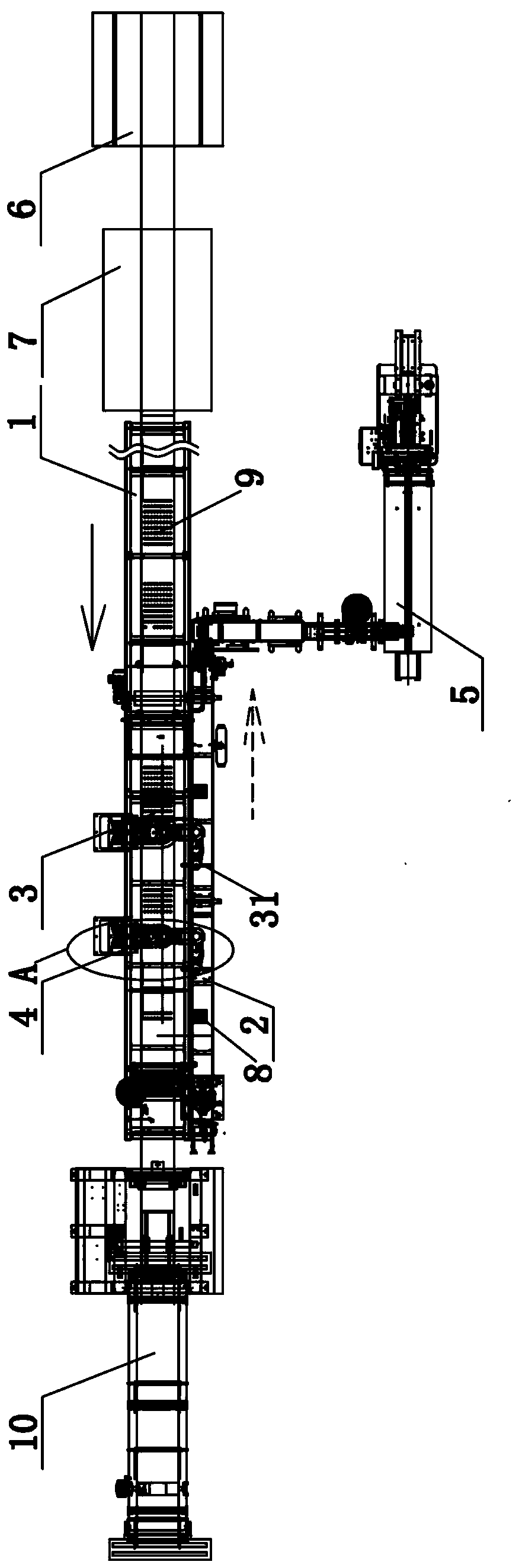

Cookie automatic settling and packaging system

InactiveCN106167110AOrganize effectivelyDoes not affect packagingPackaging biscuitsEngineeringMechanical engineering

The invention discloses a cookie automatic settling and packaging system which comprises a rack, a vertical settling mechanism is arranged on the rack, the system further comprises a belt conveying mechanism, a vibration conveying mechanism and a packaging mechanism, the front end of the belt conveying mechanism is connected with the vertical settling mechanism, the rear end of the belt conveying mechanism is connected with the front end of the vibration conveying mechanism, and the tail end of the vibration conveying mechanism is connected with the packaging mechanism; the vibration conveying mechanism comprises a conveying channel, and a plurality of sieve holes are formed in the surface of the conveying channel; a stacking mechanism is arranged between the conveying channel and the packaging mechanism. According to the cookie automatic settling and packaging system, belt conveying and vibration conveying are combined, food is effectively settled, the food broken in the production process can fall in the vibration conveying process, subsequent packaging is not affected, and the whole packaging process is efficient and stable.

Owner:FOSHAN RUIPUHUA PACKING MACHINERY CO LTD

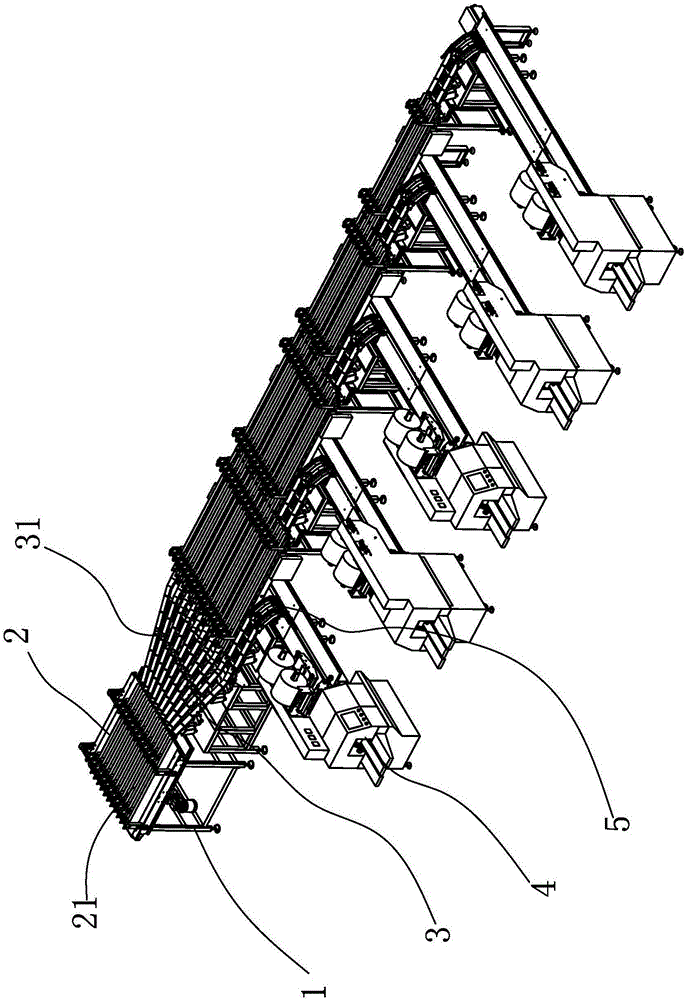

Loading production line for boxed letter biscuits and boxing method for letter biscuits

InactiveCN108891652AIncrease productivityHigh degree of production automationPackaging automatic controlPackaging biscuitsProduction lineVision sensor

The invention relates to a loading production line for boxed letter biscuits and a boxing method for the letter biscuits. In the patent of the loading production line, a vision sensor and a grabbing robot are matched to grab 27 letter biscuits on a biscuit conveying line, the vision sensor accurately recognizes the letter biscuits on the biscuit conveying line, meanwhile obtains ID information andposition information of the letter biscuits, and sends the information to the grabbing robot, the grabbing robot grabs the letter biscuits and places the biscuits into biscuit empty positions of onesupporting box until the biscuit empty positions in the supporting box are filled with the 27 letter biscuits, and then the supporting box is sent away. With the loading production line, distributing,sorting, loading and other operation for the 27 letter biscuits are completed, accordingly, the production efficiency of the biscuit production line is improved, the automation degree of the biscuitproduction line is increased, the amount of labor used is decreased, and meanwhile it is guaranteed that each supporting box which is conveyed out is filled with 27 letter biscuits.

Owner:江门新乐贝食品有限公司

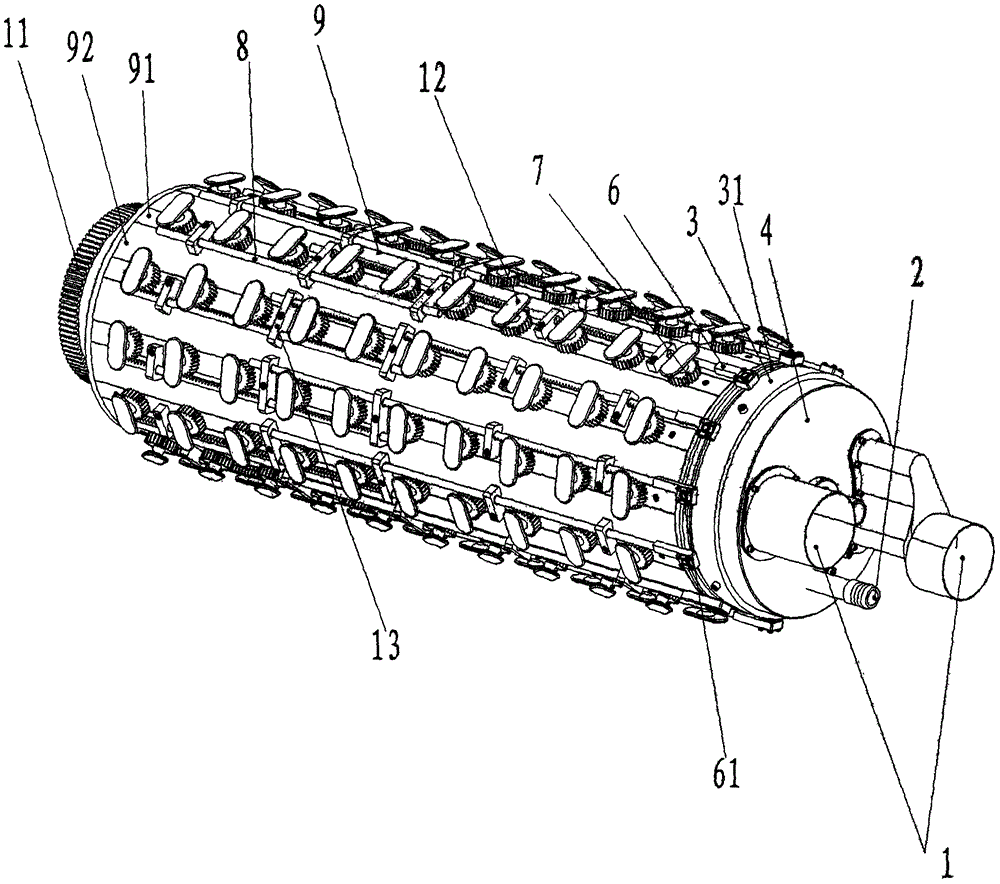

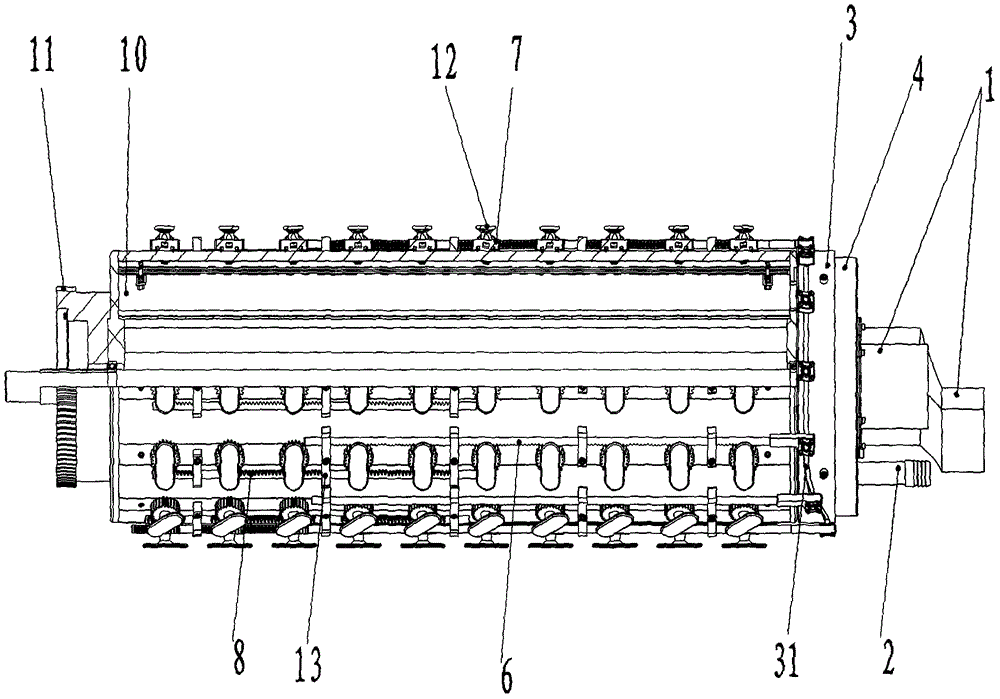

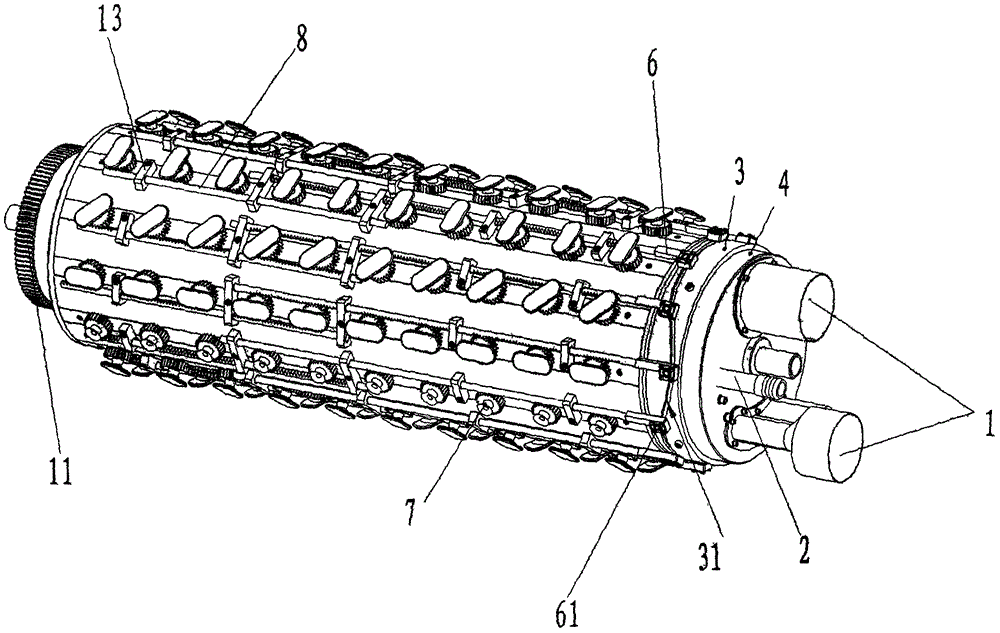

Suction roller device for baked food

ActiveCN106081217ASmall footprintIncrease productivityPackaging biscuitsAutomatic controlMotor drive

The invention discloses a suction roller device for baked food. The suction roller device for the baked food comprises cylinder cams, driven pieces, sucker gears, racks, air distribution blocks, a sealing end cover, a roller and a large gear set; 12 sub-air-cavities are arranged in the roller; a servo motor drives the large gear set which drives a suction roller body to rotate; according to the driven pieces, under the intervention effect of curved grooves of the cylinder cams, suckers on the sub-air-cavities can make sucker rotating bodies automatically rotate by 90 degrees before cake placement according to the cake placement design requirement matched with a packaging machine in advance; under the intervention of the air distribution blocks, the sub-air-cavities in movement perform automatic switching between negative pressure, positive pressure and zero pressure according to the design requirement of preset cake suction and placement position points; and when the suction roller rotates to the lowest end position point, namely the cake placement position, the sub-air-cavities communicate with air blowing holes of the air distribution blocks, the negative pressure is converted into the positive pressure, baked products are blown down to a packaging and conveying line, and the baked products enter the packaging machine. The suction roller device for the baked food is high in automatic control degree, small in occupied area and capable of obviously improving the production efficiency and saving labor and cost.

Owner:ZHEJIANG RIBON INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com