Sliced food sucking device

A suction device and food technology, applied in the direction of packaging food, packaging biscuits, etc., can solve the problems of food rollover, food damage, and weak adsorption force, and achieve the effect of reducing the probability of food damage, reducing collisions, and reducing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

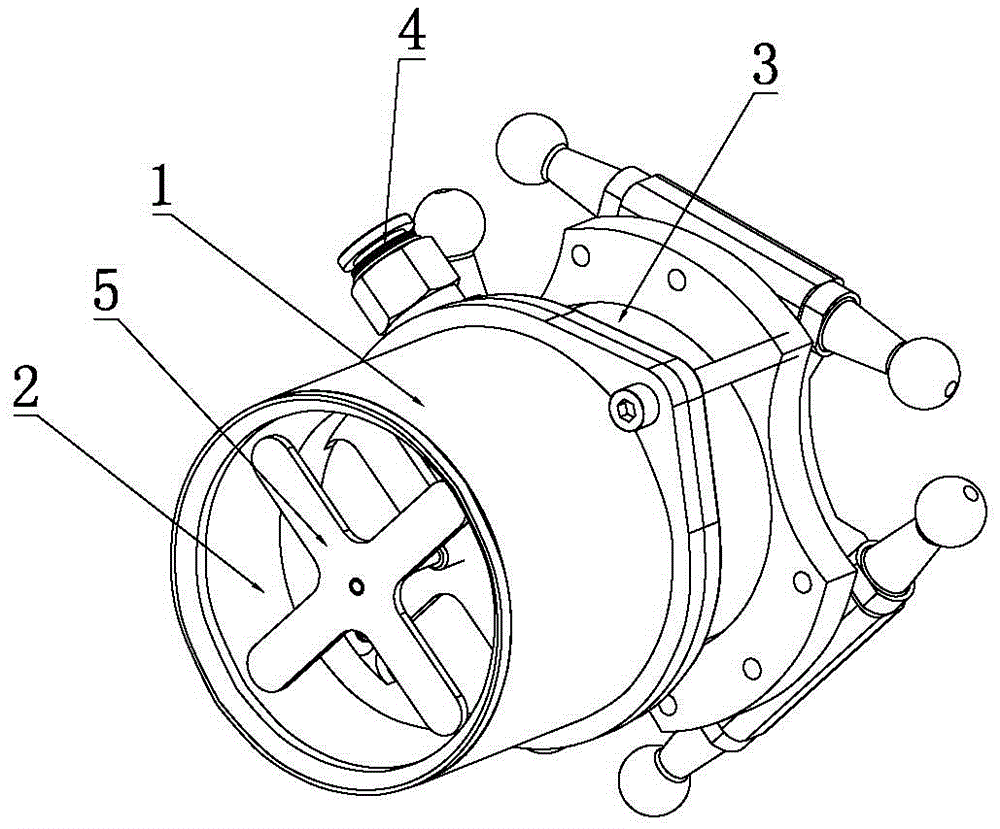

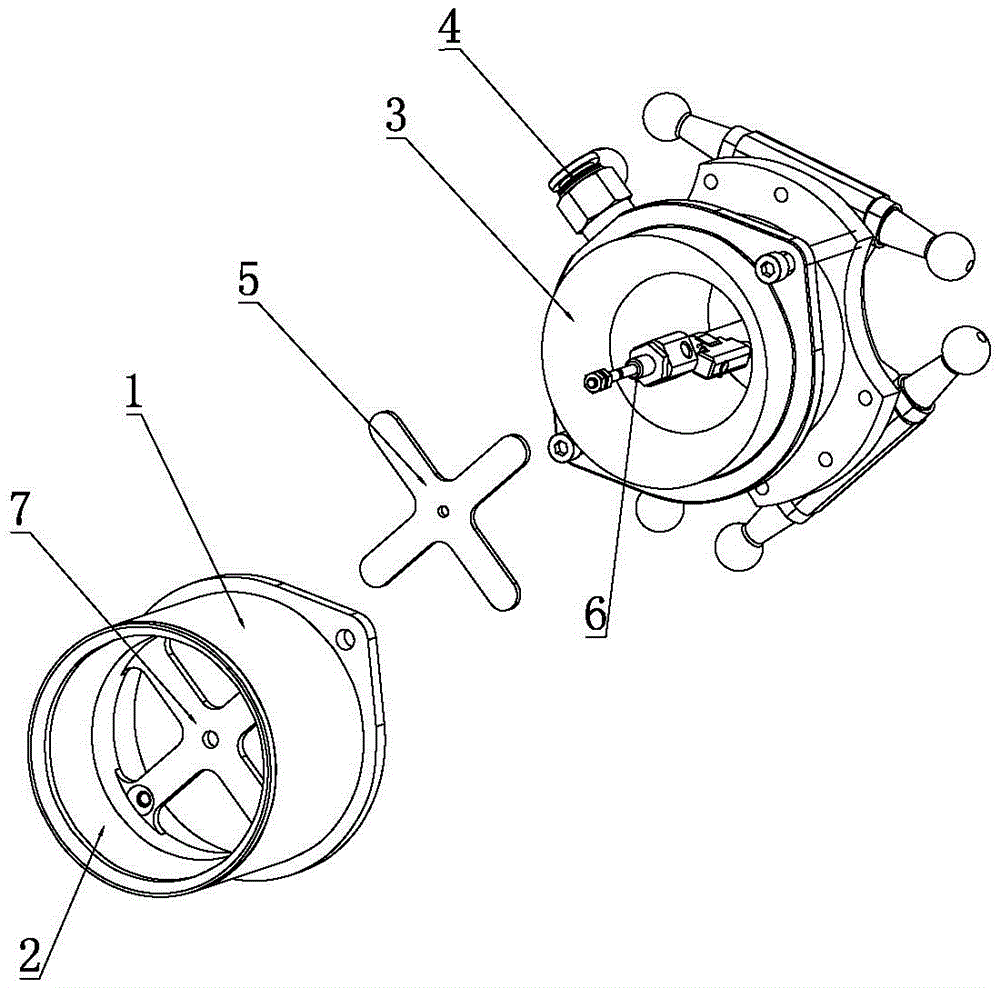

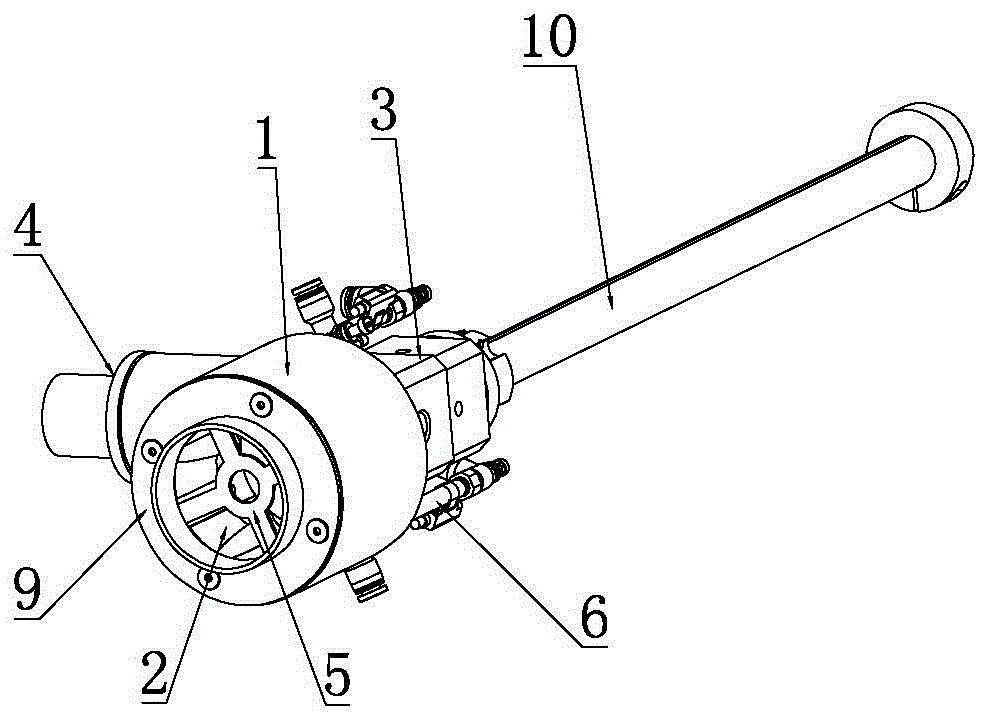

[0037] One of the specific implementations of a sheet-shaped food suction device of the present invention, such as figure 1 with 2 As shown, its structure includes a suction head 1 and a negative pressure device. The interior of the suction head 1 is a housing chamber 2. The negative pressure device can generate negative pressure in the housing chamber 2, thereby generating suction, so that the suction port of the suction head 1 is aligned with the The food on the production line can be sucked into the holding chamber 2. Corresponding to the suction port of the suction head 1 is the air outlet port, the air outlet port of the suction head 1 is fixed on the hollow base 3, the base 3 is also connected to the suction pipe 4, the negative pressure device passes through the suction pipe 4, the base in turn 3 Evacuate the air in the chamber 2.

[0038] In this embodiment, the negative pressure device can be a vacuum machine or an air amplifier. The vacuum machine can draw the gas ...

Embodiment 2

[0048] The second embodiment of a sheet-shaped food suction device of the present invention is as follows: image 3 with 4 As shown, the main technical features of this embodiment are the same as those of Embodiment 1, and the difference is that: the inner wall of the suction head 1 is provided with a concave chute 8, and the four ends of the cross-shaped buffer member 5 are respectively located at four In the chute 8, the chute 8 can effectively prevent the buffer member 5 from shaking.

[0049] In this embodiment, two pneumatic cylinders are used to drive the movement of the buffer member 5, the driving rods 6 of the two pneumatic cylinders are respectively fixed on the two ends of the buffer member 5, and the driving rods 6 of the two pneumatic cylinders are connected to the buffer member 5. The central axis of the center axis is arranged symmetrically, so that the force on the buffer member 5 can be uniformed, so that its movement is stable. In addition, in order to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com