Patents

Literature

180results about How to "Reduce pulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

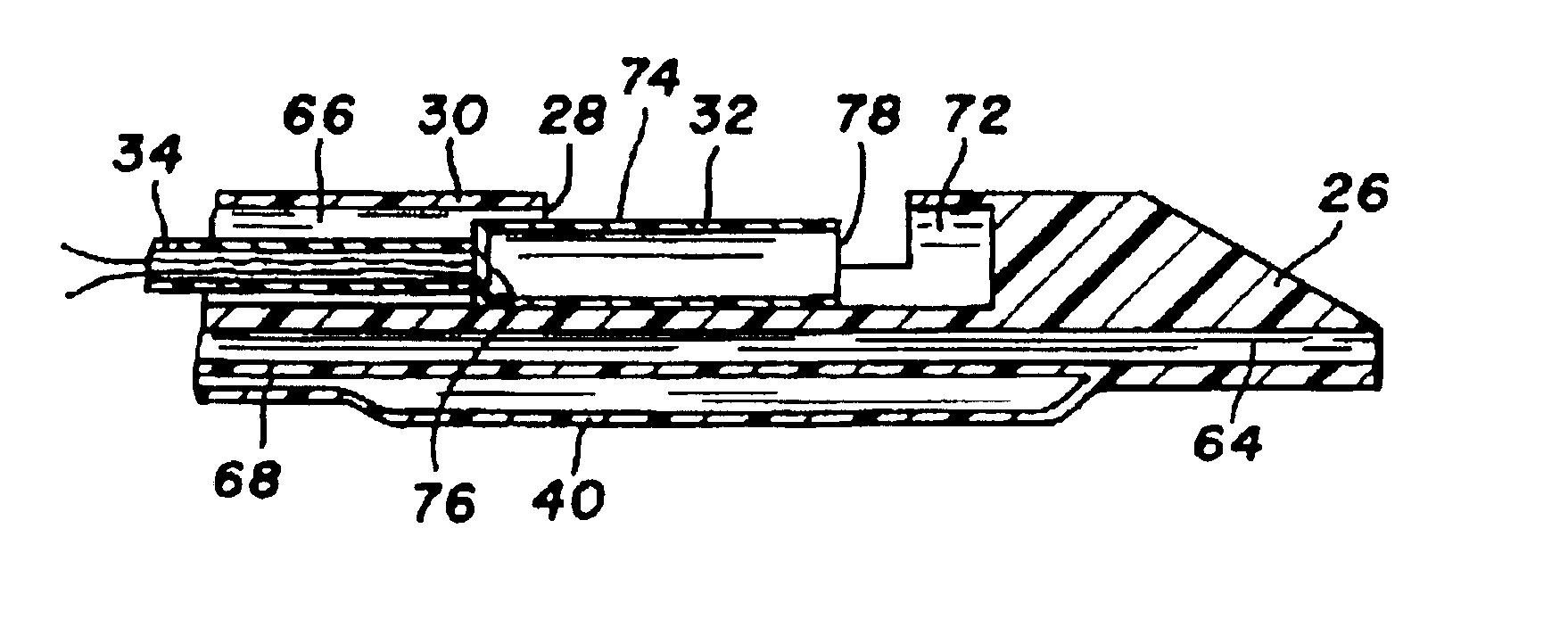

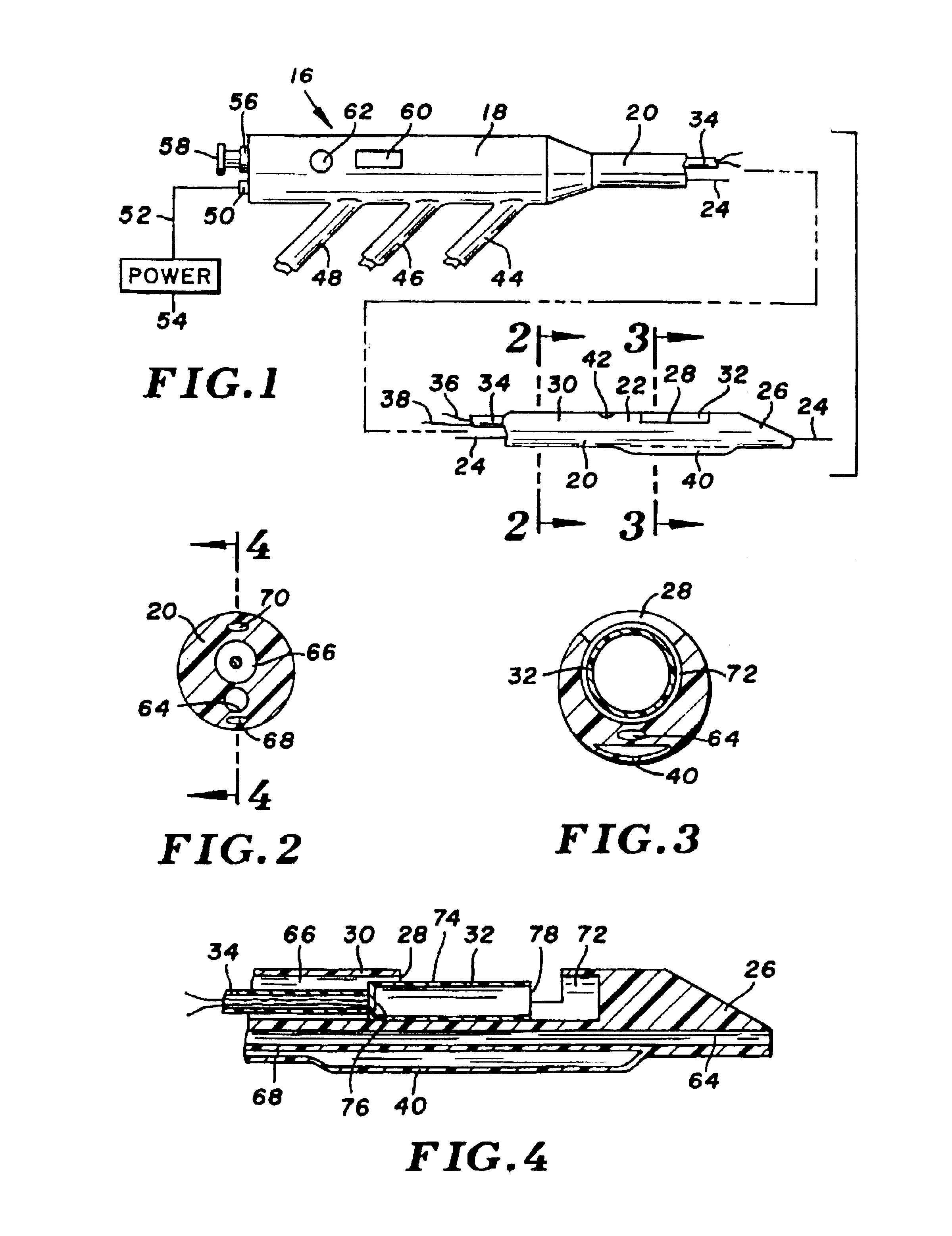

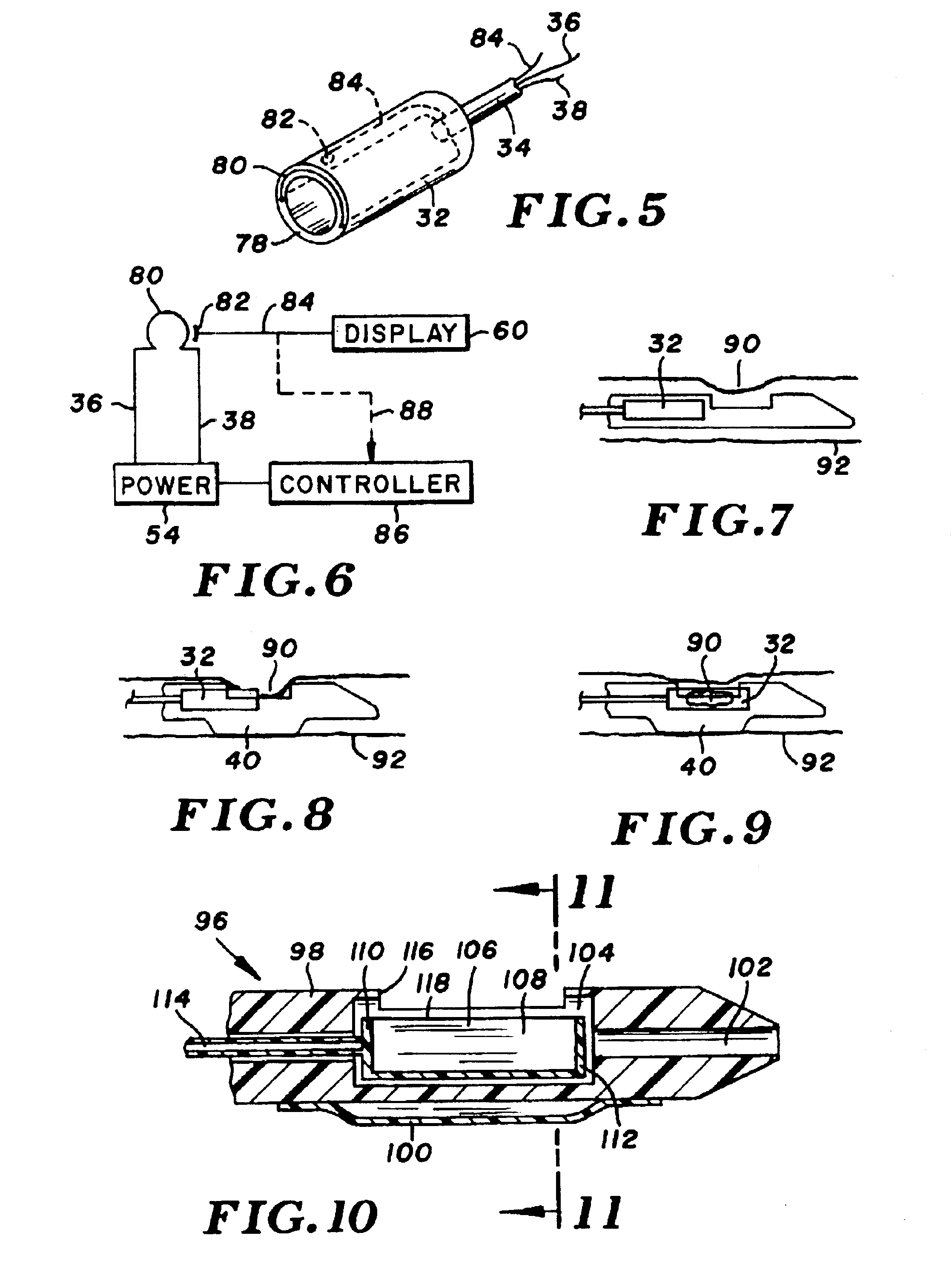

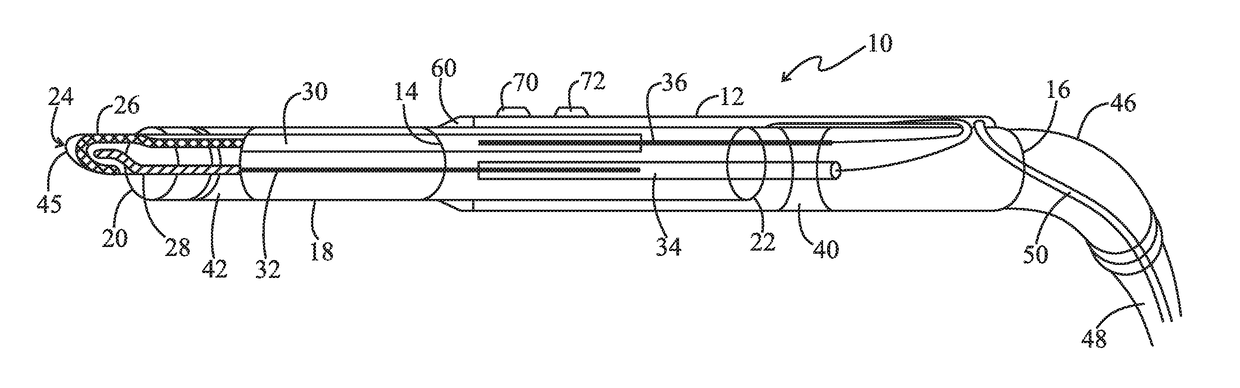

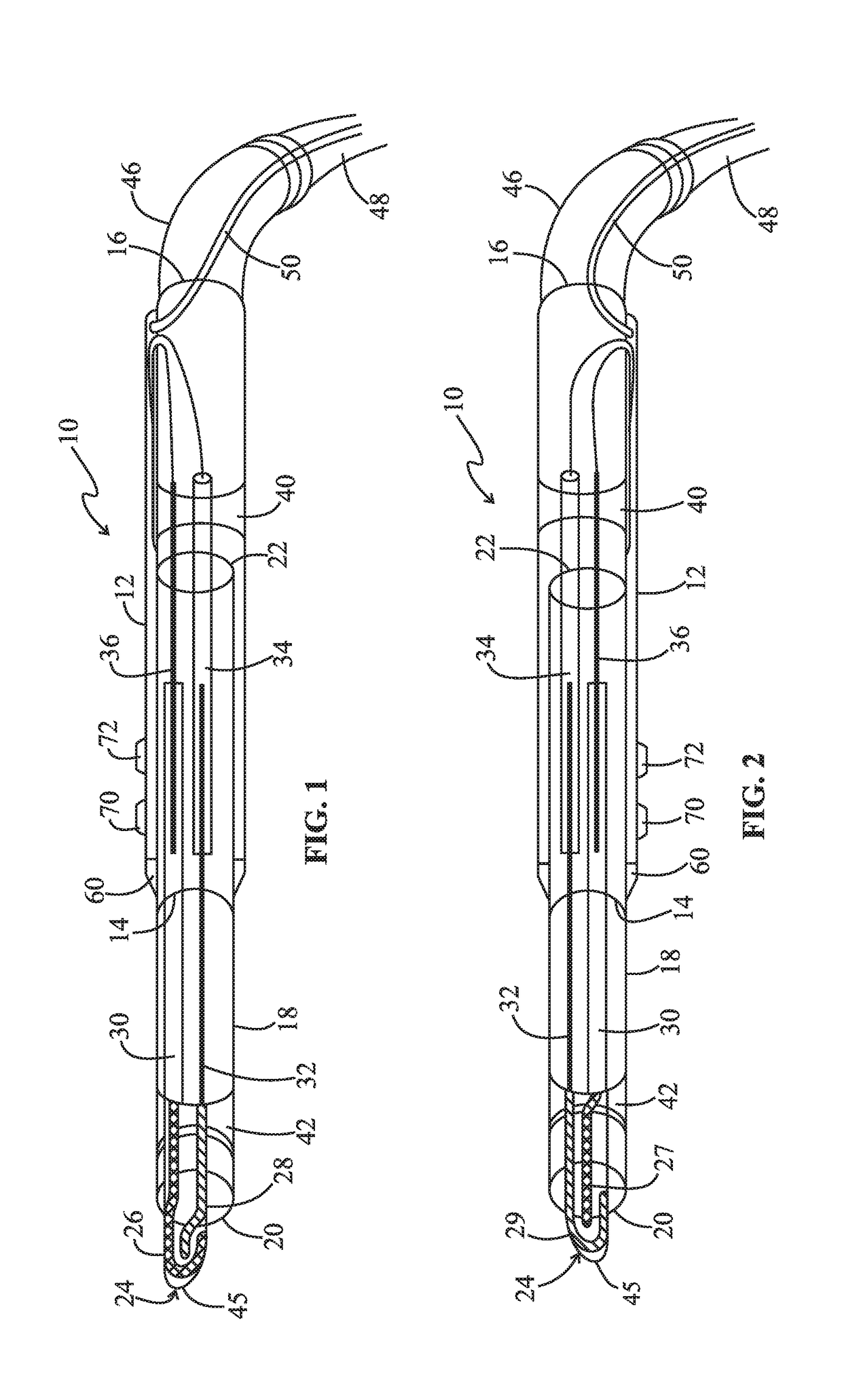

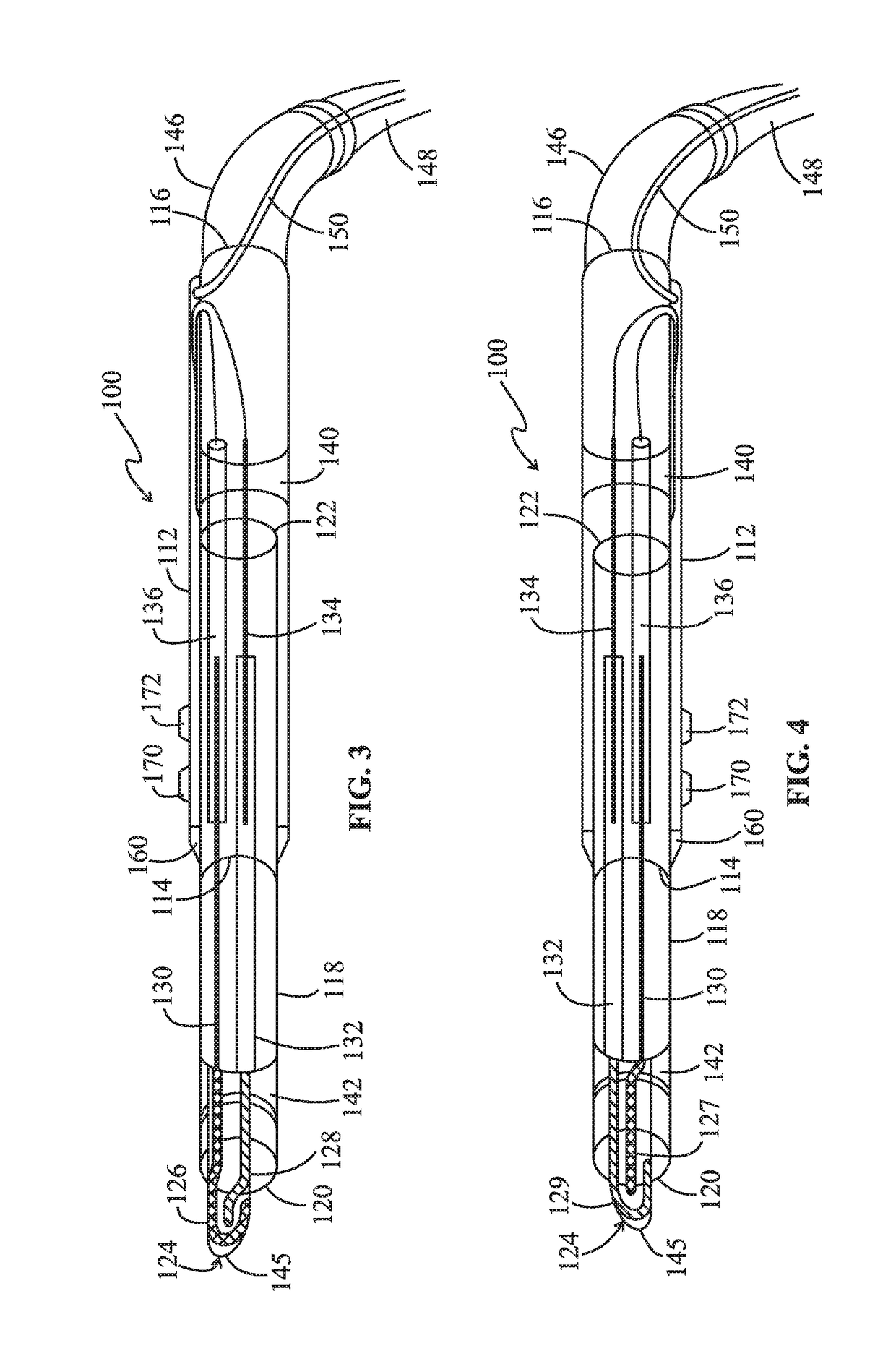

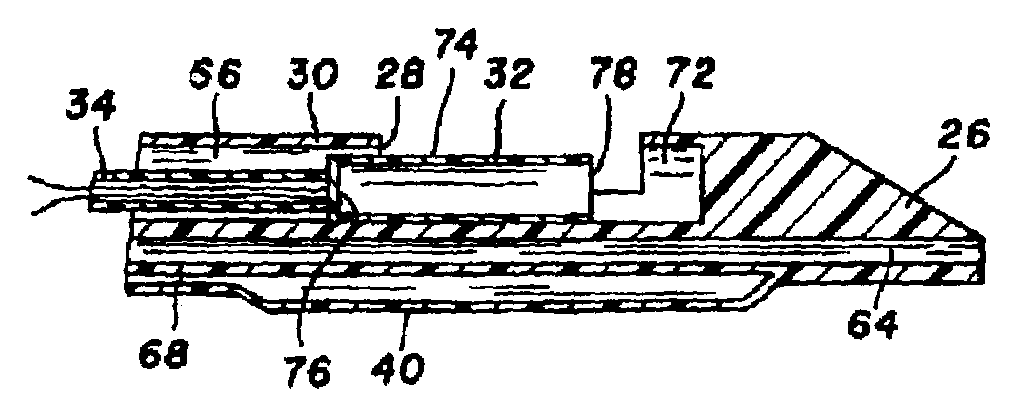

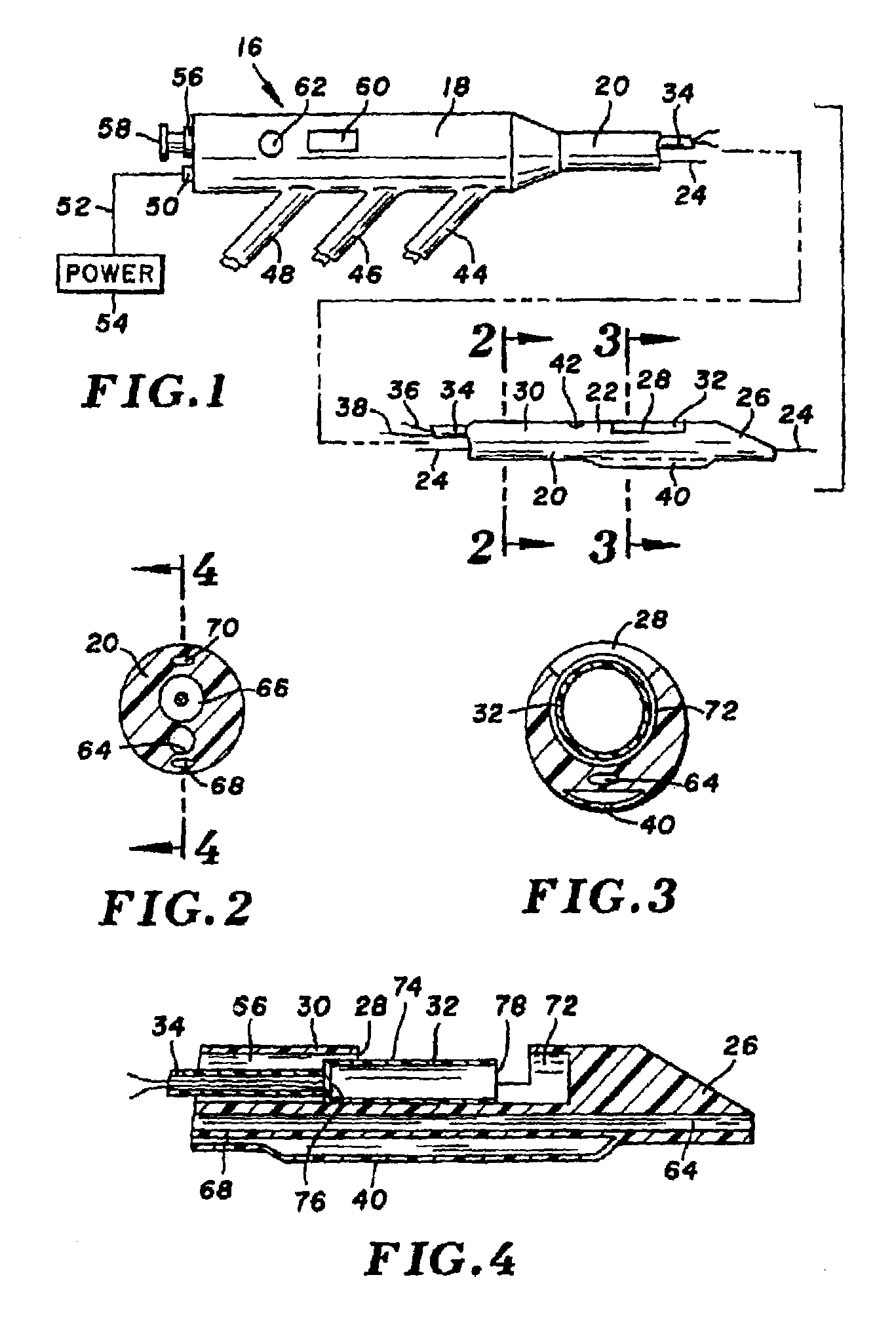

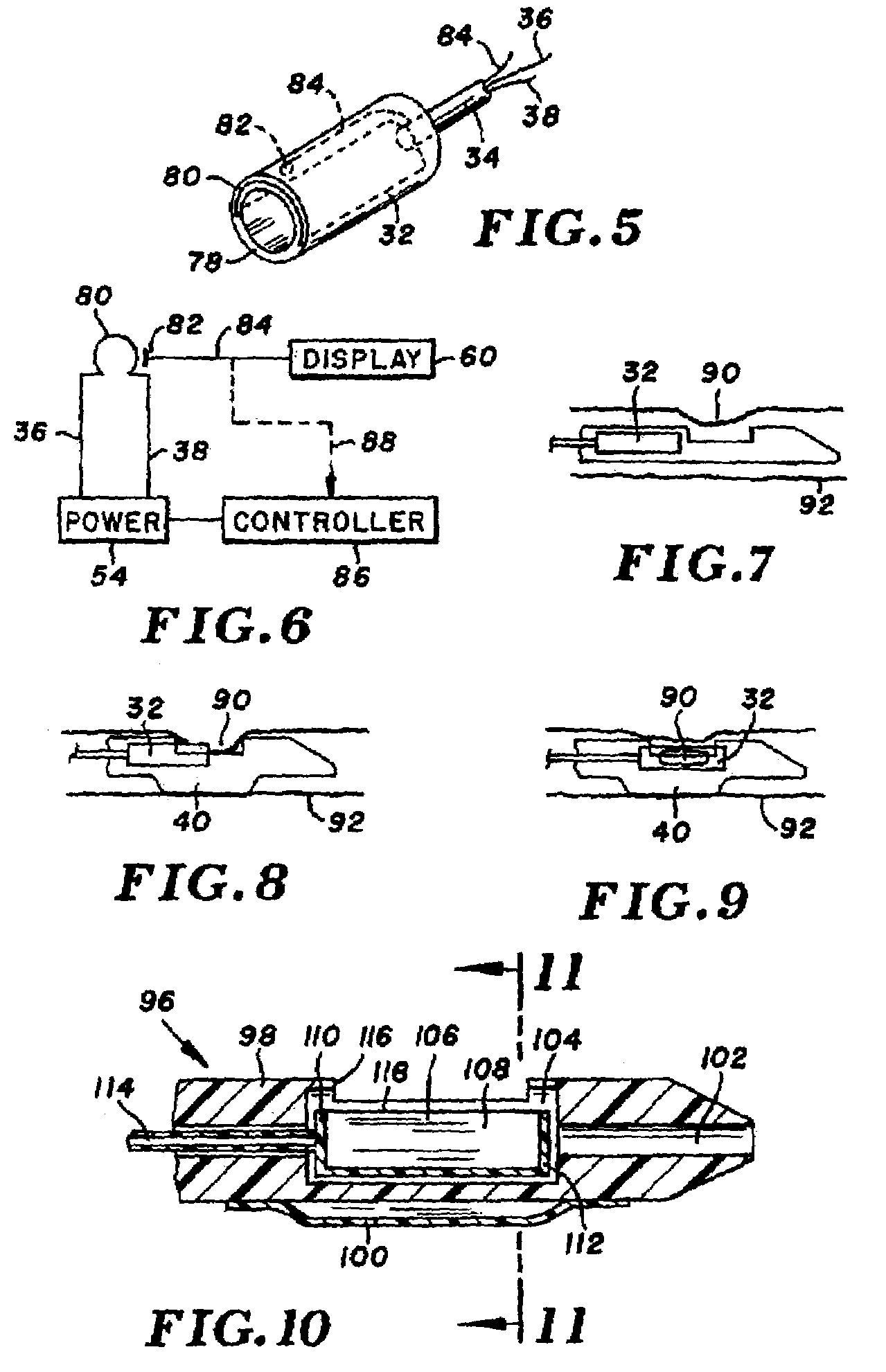

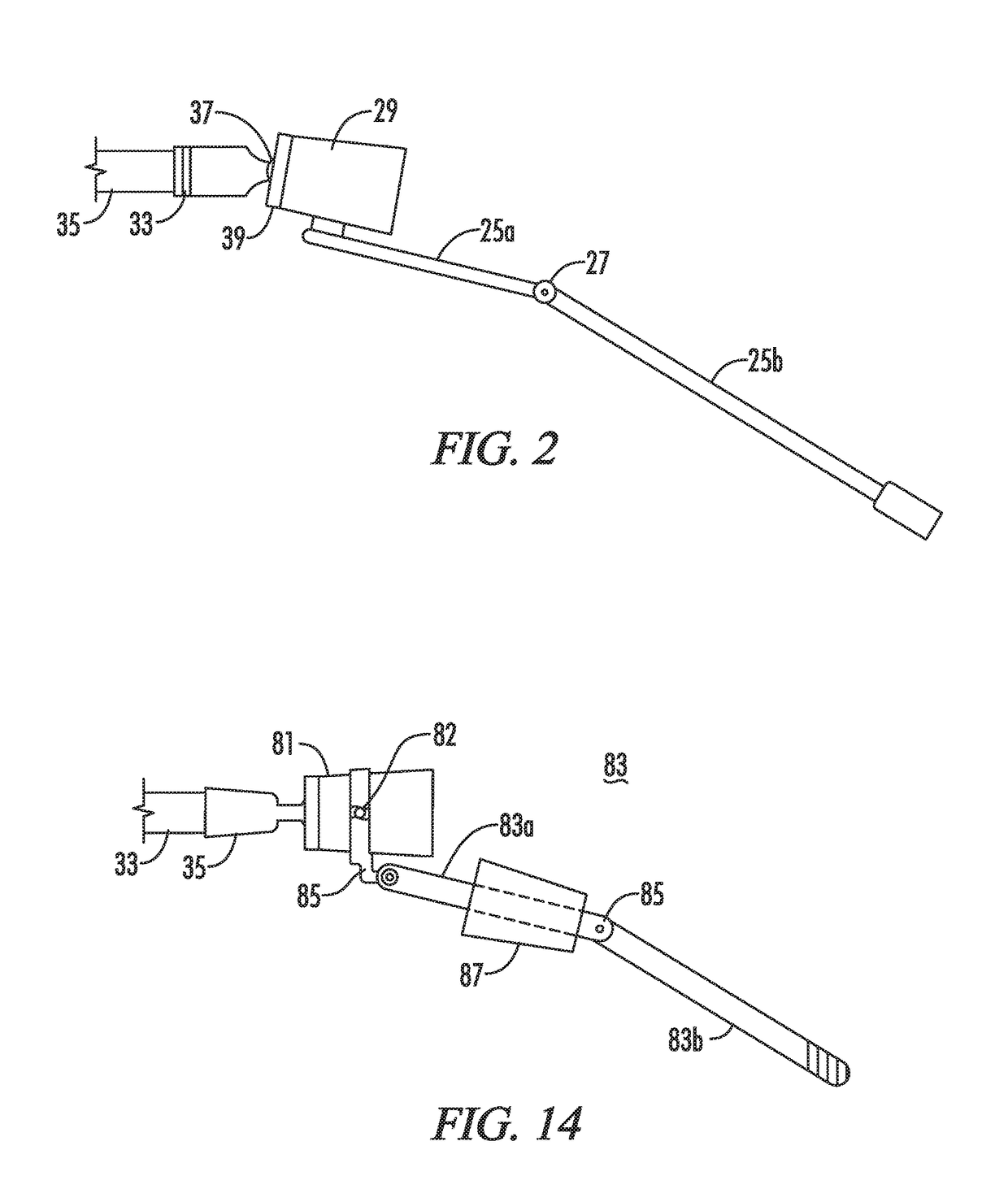

Tissue cutting catheter and RF cutting method

InactiveUS6872204B2Highly accurate and fine cutReduce pullingDiagnosticsCatheterElectrical resistance and conductanceTissue heating

A tissue cutting device includes a catheter with a window at its distal tip for admitting tissue into a catheter compartment. A cylindrical cartridge in the compartment has a cutting edge that supports an electrically conductive cutting element, e.g. a band or wire. The cutting element and adjacent tissue can be heated to a selected temperature by generating an electrical current through the cutting element. The catheter is maneuverable to position its distal end near the tissue to be cut. The catheter incorporates a dilatation balloon or other feature to urge the catheter against the tissue, so that at least part of the tissue may enter the compartment through the window. Then, the cartridge is manipulated from the catheter's proximal end to move the cutting edge across the window, cutting the tissue. According to alternative embodiments, the cartridge is either rotated or moved axially relative to the catheter and, in either event may be capable of closing the catheter window when the cut is complete. Further alternatives involve either placing an indifferent electrode on the patient and providing an RF signal via a single conductor to the cutting element for ohmic heating, or providing an RF (or a DC) current through the cutting element and two separate conductors for direct resistive heating of the cutting element.

Owner:CARDIOVASCULAR TECH INC

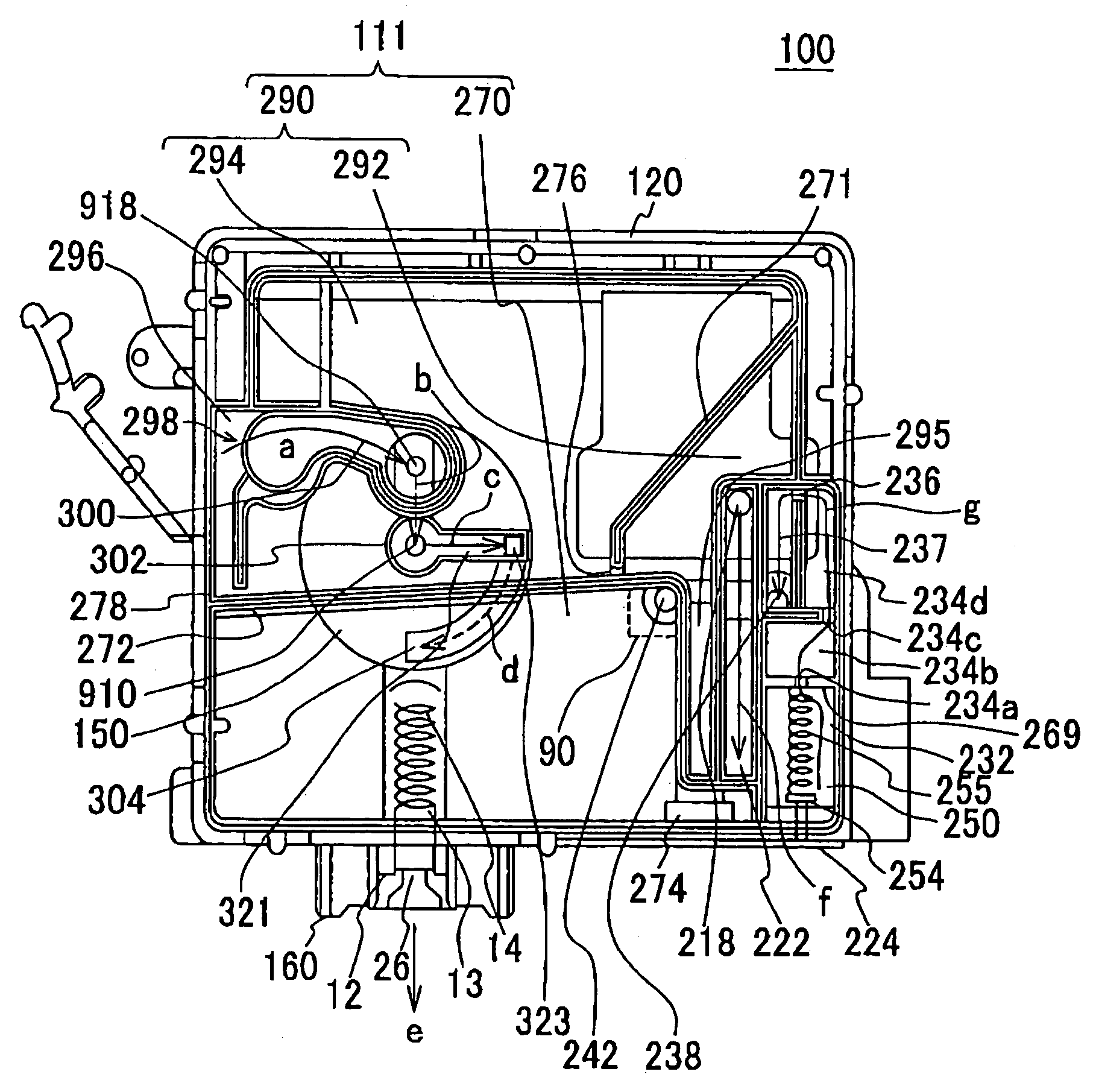

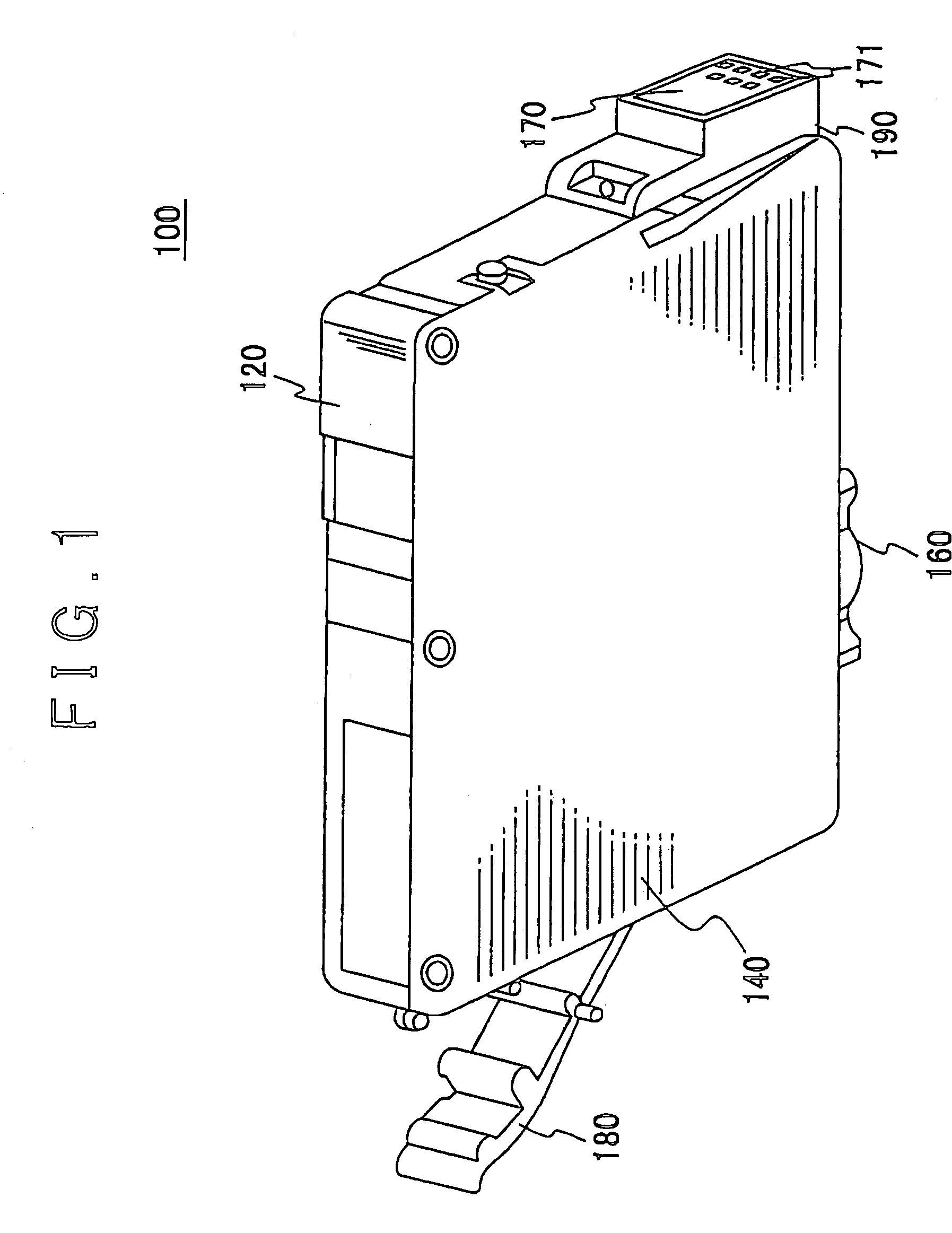

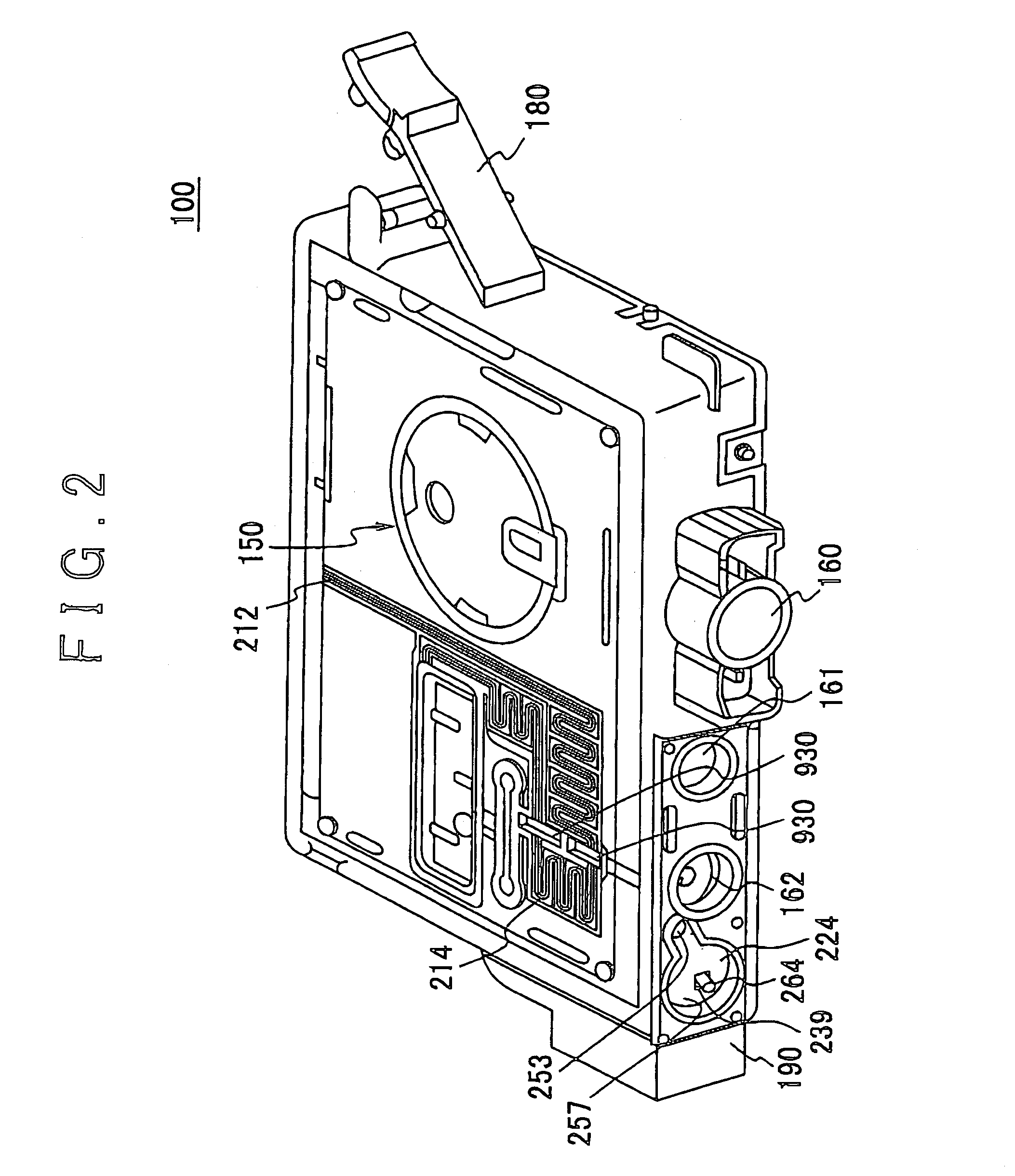

Liquid cartridge

A liquid cartridge is provided that supplies liquid to a liquid ejecting apparatus by being mounted in the liquid ejecting apparatus. The liquid cartridge includes a cartridge body having a side face in which an opening is formed; and a flexible film for forming an ink accommodating chamber that is a closed space for accommodating the liquid, with the cartridge body by covering the opening of the cartridge body. The flexible film is caused to deform toward the ink accommodating chamber by atmospheric pressure that acts on the flexible film when the liquid cartridge is got out from a vacuum bag in which the liquid cartridge is packaged, thereby increasing the pressure in the ink accommodating chamber.

Owner:SEIKO EPSON CORP

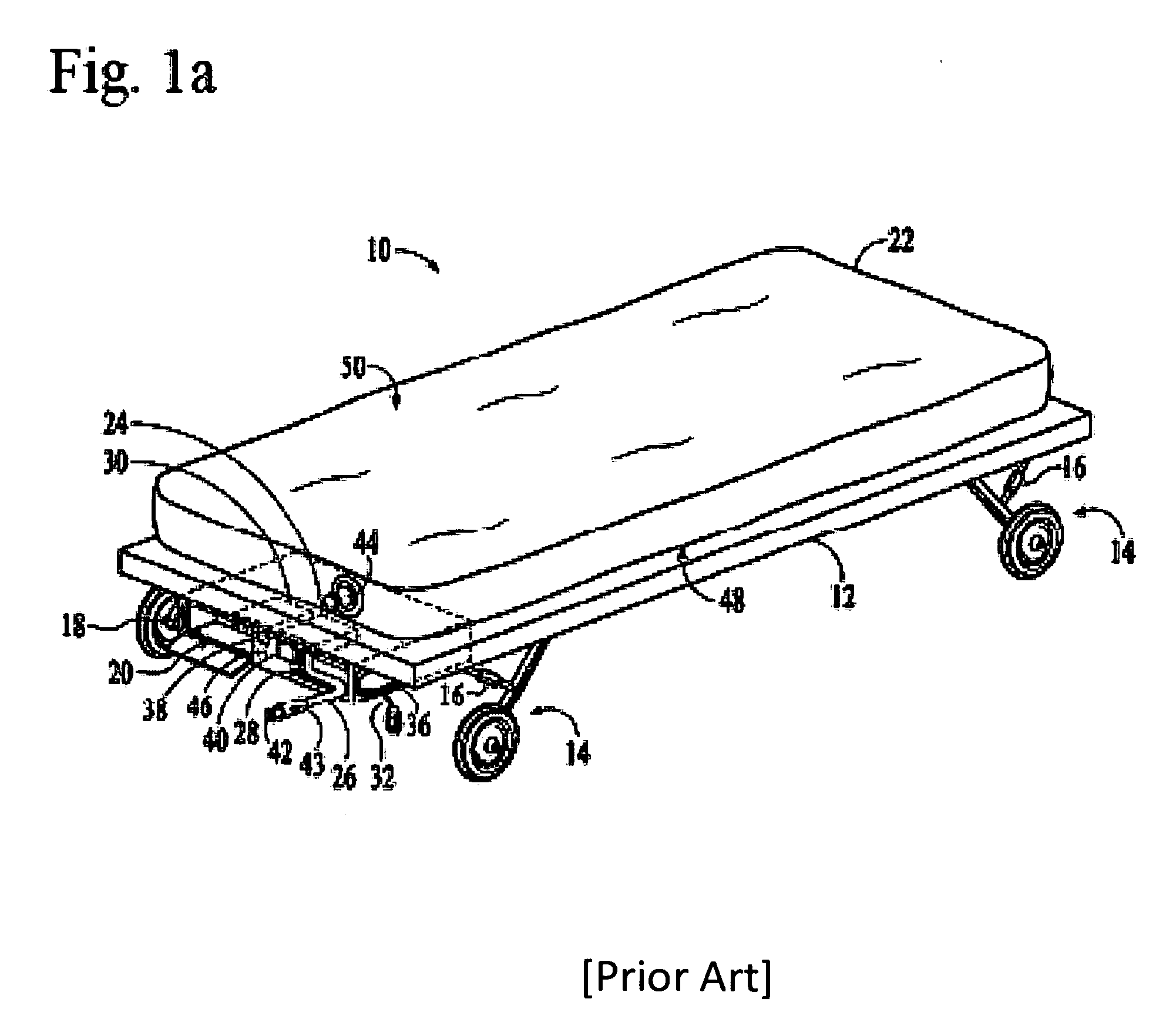

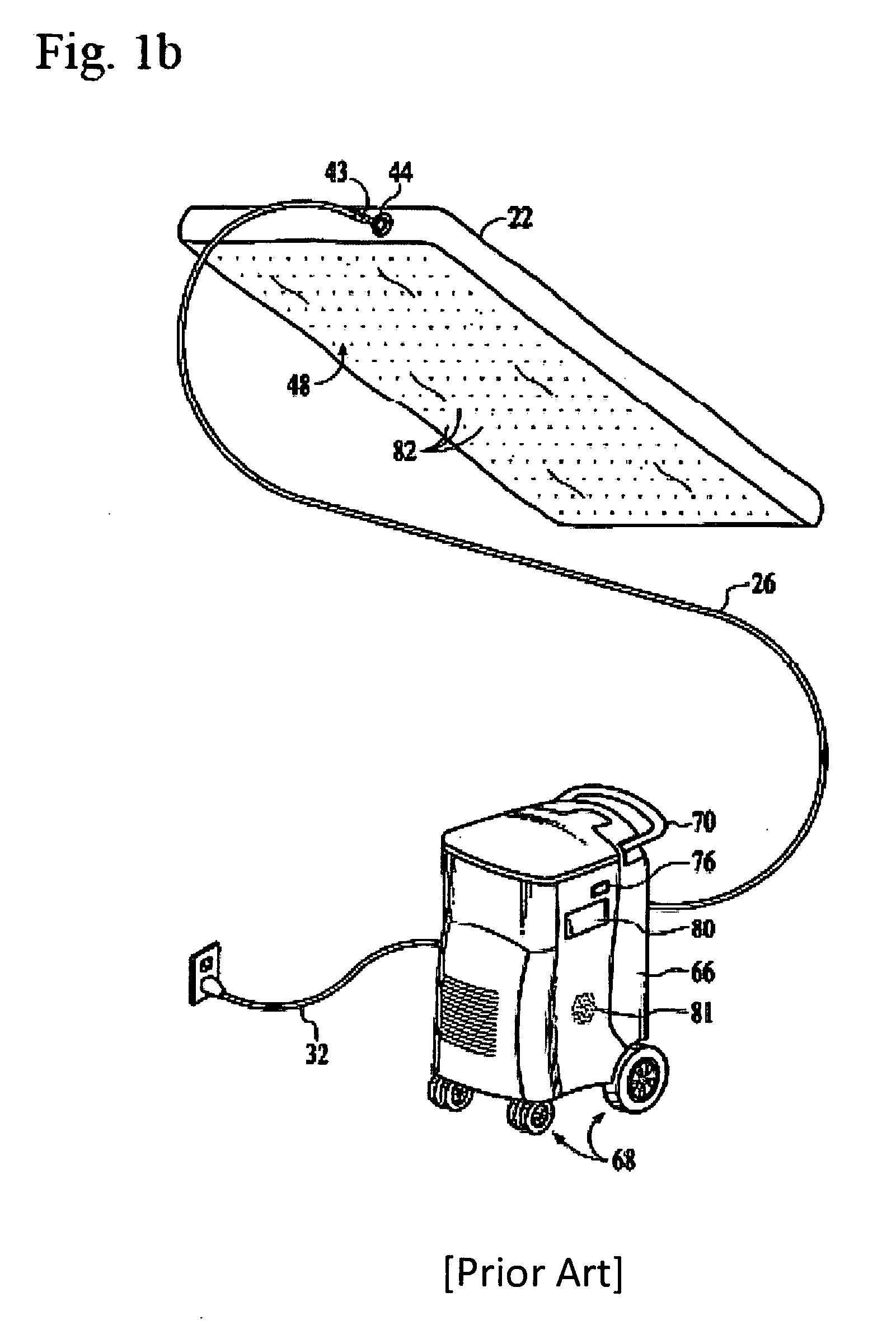

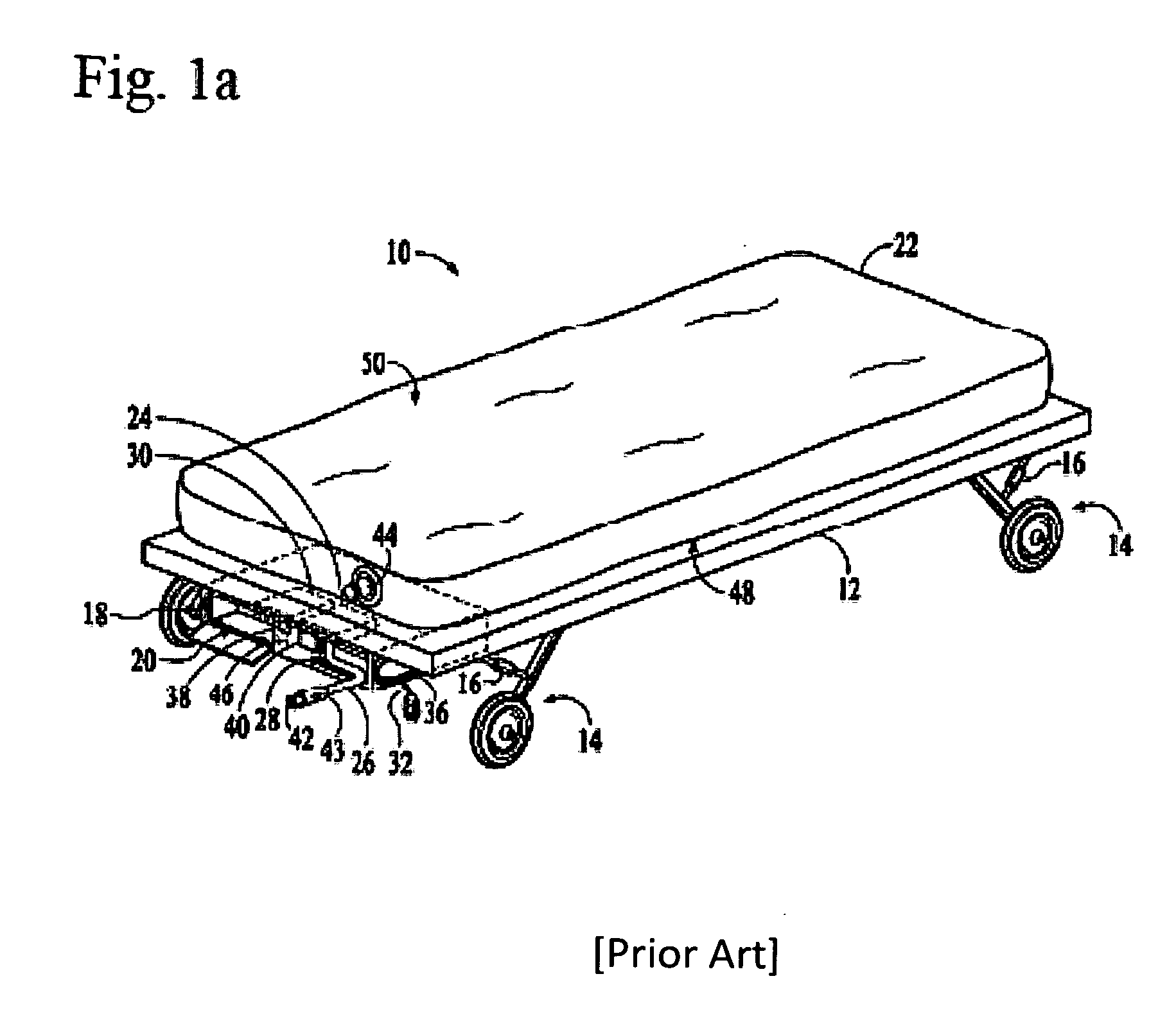

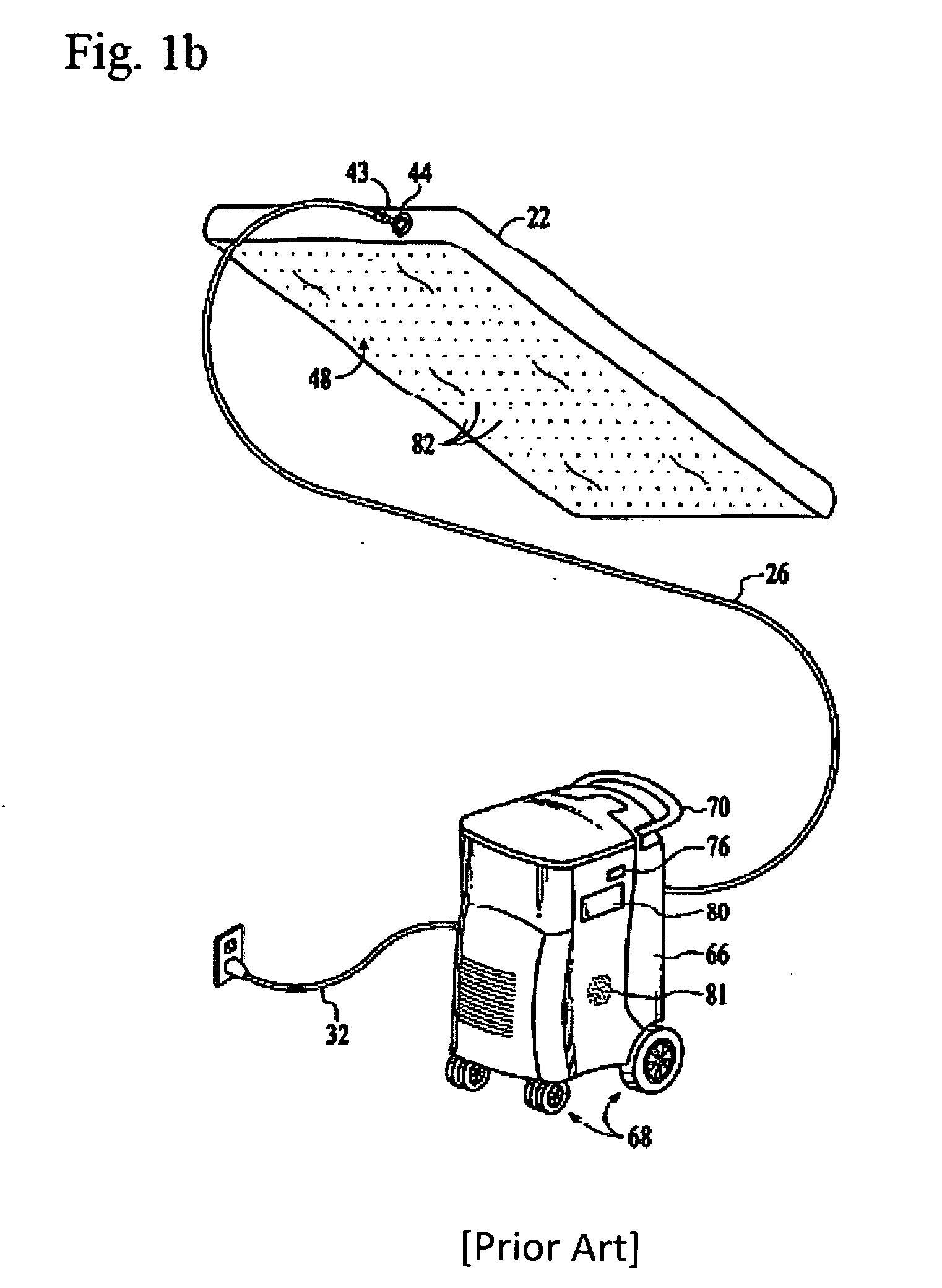

Patient lifter with intraoperative controlled temperature air delivery system

InactiveUS20120079656A1Increase air pressureWithout excessive forceStuffed mattressesDiagnosticsEngineeringPatient transfer

A combination patient-transfer and intraoperative heater has top and bottom chambers separated by a barrier. The patient rests on the top chamber, which has plural apertures for discharge of temperature-controlled heated or cooled air at regulated pressure. Heated or cooled air is delivered to the area surrounding the patient, maintaining body temperature during anesthesia. The bottom chamber has plural apertures. When air pressure is low or off, the bottom chamber is flat and un-inflated. When air pressure is increased, air enters the bottom chamber and the apertures emit air, creating an air cushion facilitating lateral movement of the lifter device. The device is light, flexible, easily stored, and preferably disposable, thereby reducing risk of infection and avoiding cleaning costs. The device performs two functions that now require separate devices and air blowers, it saves space and reduces both costs and complexity in the operating room.

Owner:LEWIS RANDALL J

Power cord spooling machine

InactiveCN1738109AReduce vibrationReduce jitterFlexible lead accommodationElectrical connectionEngineering

Disclosed a coiling machine for power cord comprises a coiling box, a coiling wheel inside the coiling box, limited rings on the two ends of coiling wheel, and crinkle spring inside the coiling axle sleeve to connect the coiling axle corn. The invention is characterized in that the protruded part of coiling axle sleeve is equipped a electric connecting component formed by a conducting outer layer, a insulated inner layer and a conducting axle corn; a coiling-proof wheel formed by stop arm and vertical binding post is arranged on the outside of limited ring, as a stop connecting component which can rotate to make a group of electrical contacts connect. The stop function which is synchronous to the electrical connection can reduce the tensity between plug and the power cord, to make the plug connect the adapter firmly; in addition, it coils without electric to improve the safety of household appliance which also can prevent the knotting inside the box.

Owner:庞一鸣

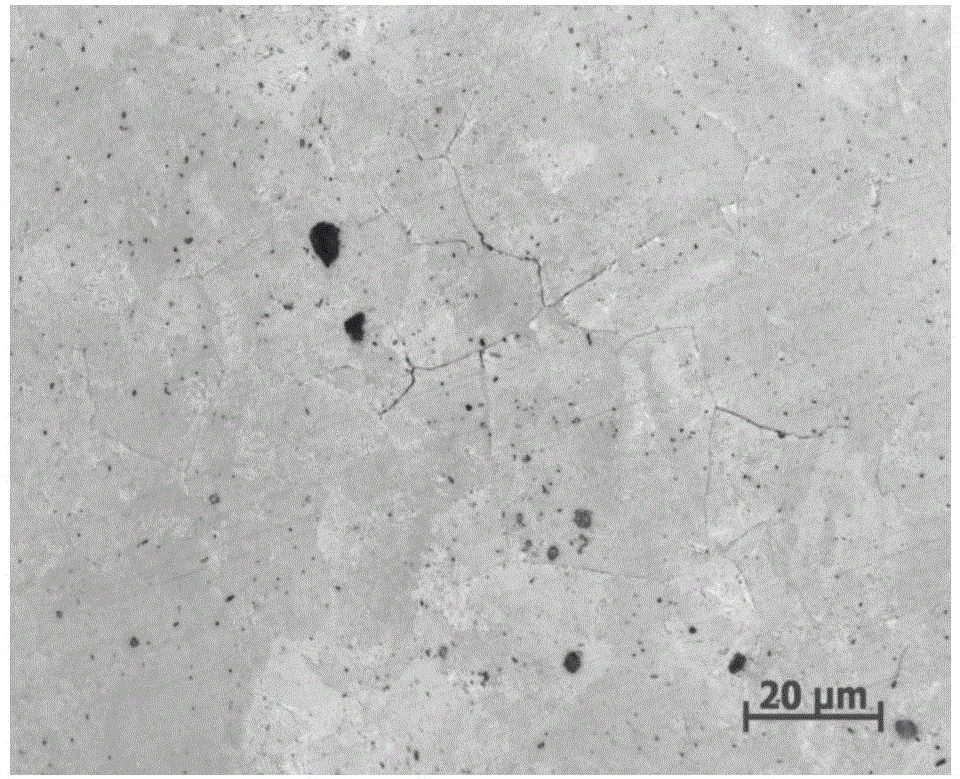

Control method for reducing network cementite of steel wire rod for cord thread

ActiveCN103817148AReduced network cementite structureLower pullMetal rolling arrangementsAir volumeProcess engineering

The invention discloses a control method for reducing network cementite of a steel wire rod for a cord thread and belongs to the technical field of steel rolling. The control method includes the steps of heating process control for a heating furnace in a steel wire rod factory, precision rolling and sizing milling control, water cooling control, thread discharging temperature control and air cooling line cooling process control. A precision rolling inlet temperature and a thread discharging temperature need to be specifically adjusted according to different seasons, namely controlling the precision rolling inlet temperature within 930-960DEG C, controlling a precision rolling outlet temperature to be not higher than 1060DEG C, controlling the thread discharging temperature within 860-900DEG C, adjusting openness of a Jialing device to 60%, starting the first 8 fans with 100% of fan delivery and 260KW in power, and controlling a roller way speed of an inlet section within 0.9-1.1m / s. When the controlled method is utilized for continuously casting the steel wire rod for the cord thread by short-process small square billets which are 140mm<2>-150mm<2>, the probability for happening of the network cementite at the center of the steel wire rod can be reduced by 10%-15%.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

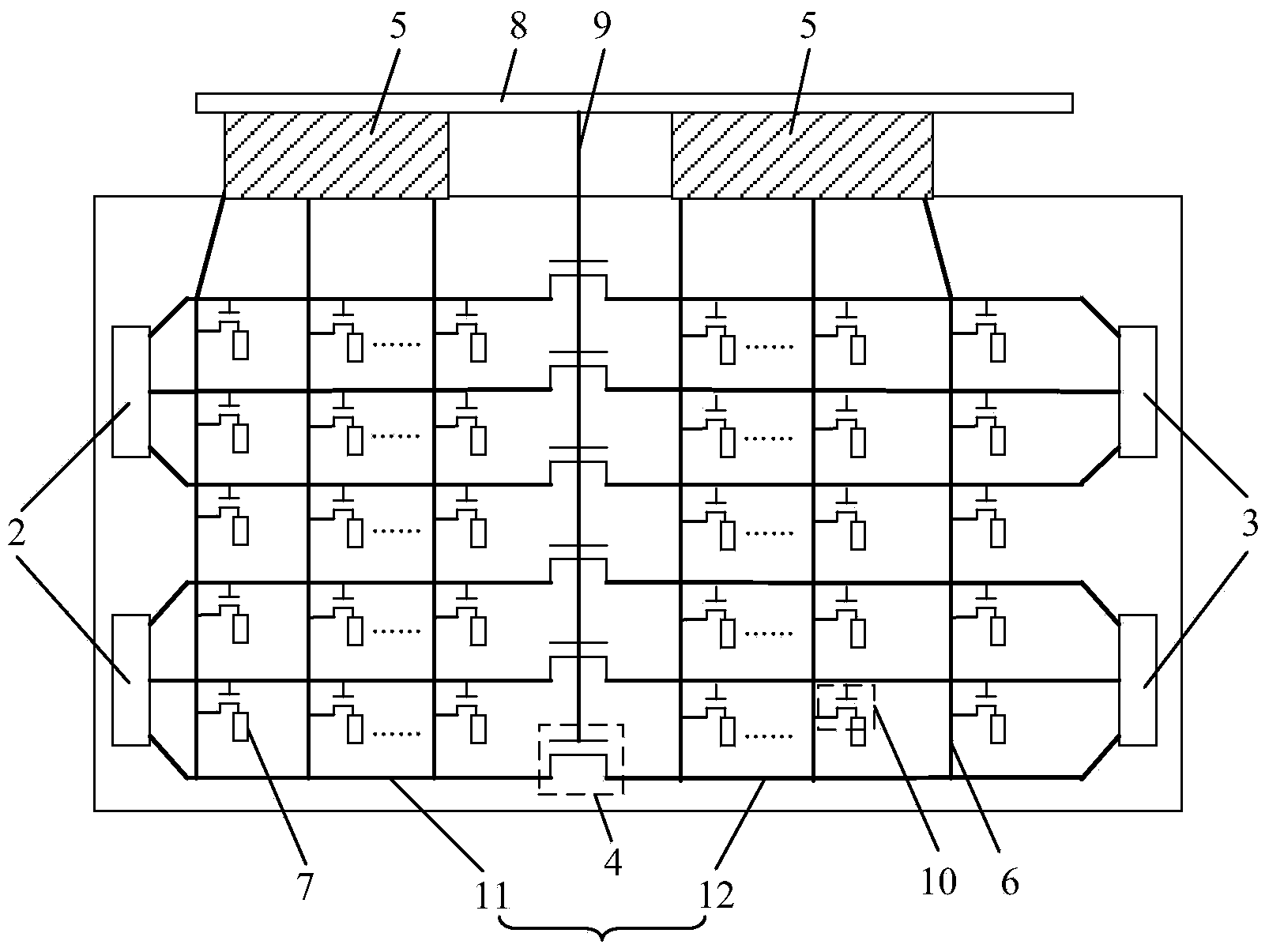

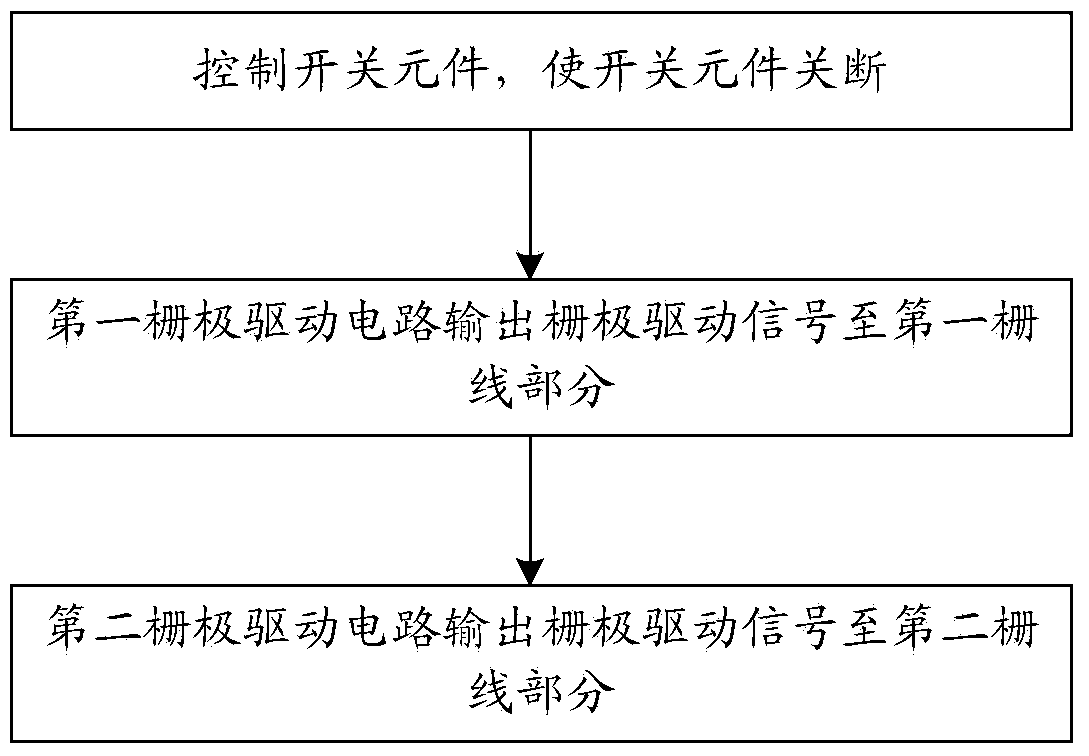

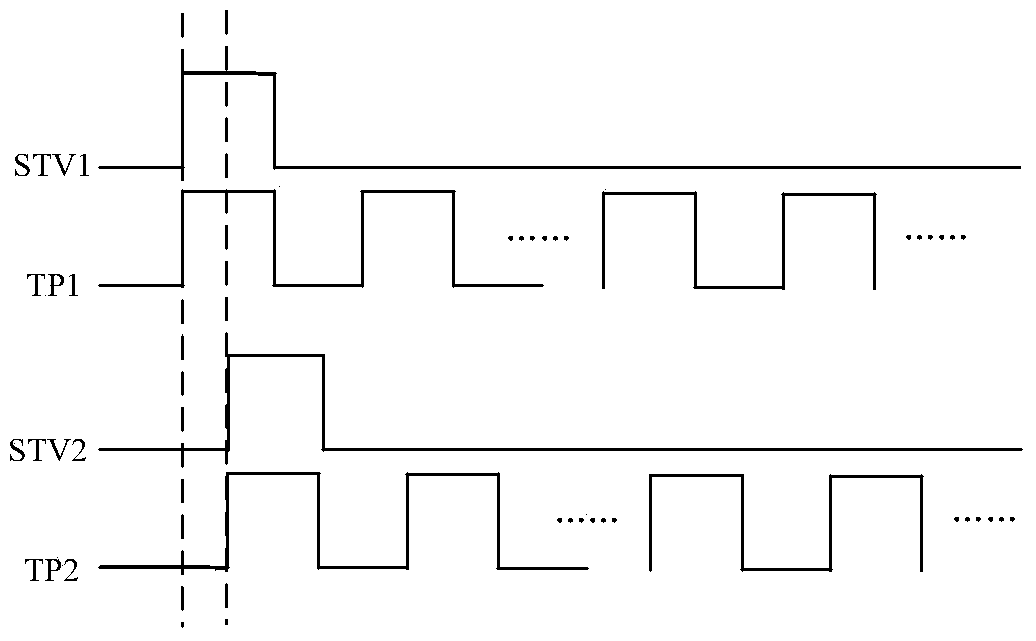

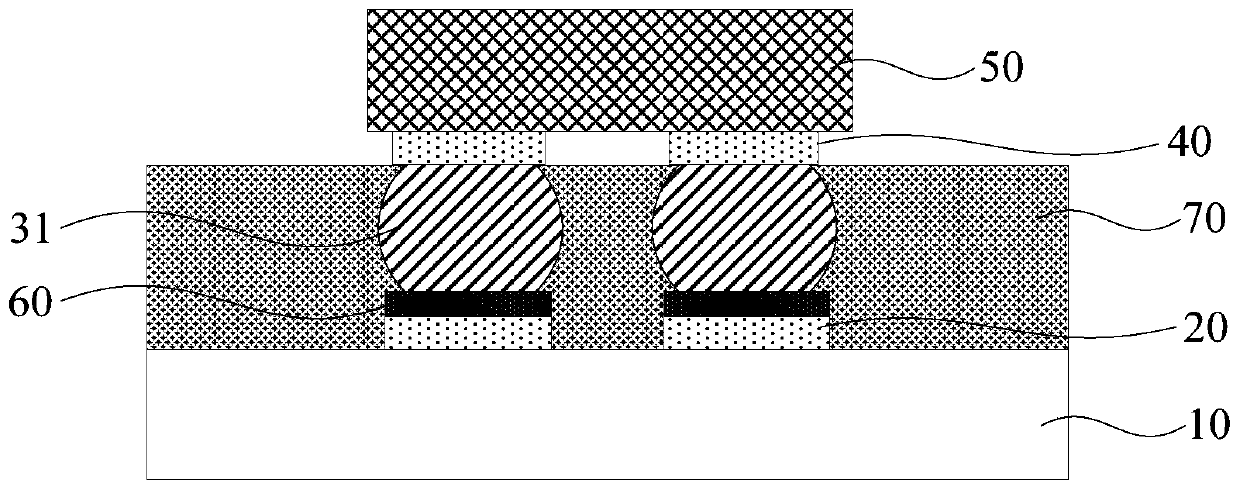

Array substrate, driving method thereof and display device

InactiveCN104318890AAvoid synchronous openingReduce pullingStatic indicating devicesSolid-state devicesDisplay deviceEngineering

The embodiment of the invention discloses an array substrate, a driving method of the array substrate and a display device, and relates to the technical field of display. Display thin film transistors controlled by a grid line can be prevented from being started on synchronously, and then pulling to a public electrode voltage is reduced. A plurality of grid lines are arranged on the array substrate. The two ends of each grid line are connected with a first grid drive circuit and a second grid drive circuit respectively, and each grid line is divided into a first grid line portion connected with the first grid drive circuit and a second grid line portion connected with the second grid drive circuit, wherein a switch element is arranged between the first grid line portion and the second grind line portion.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

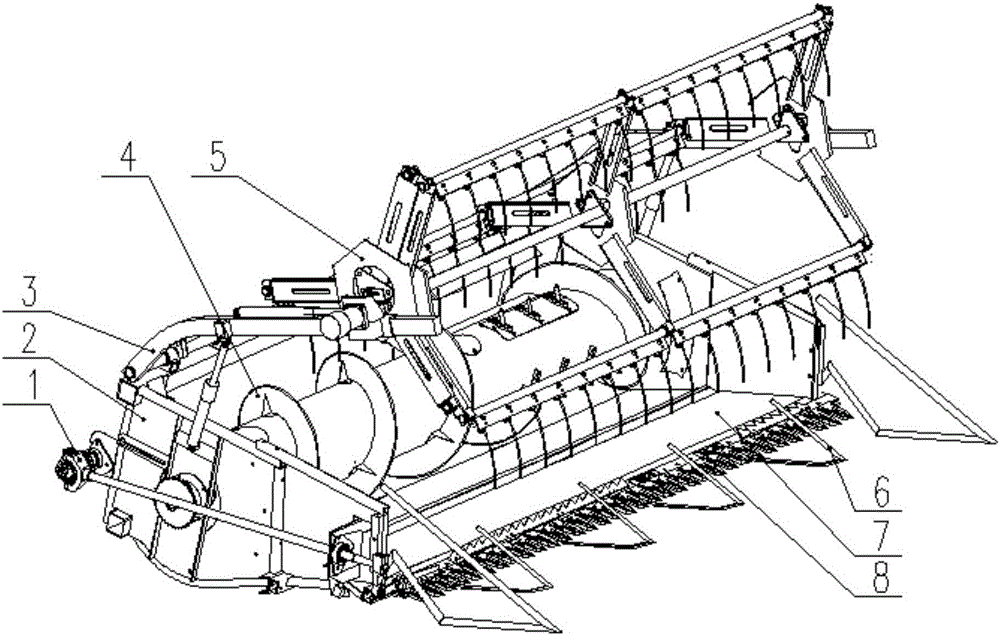

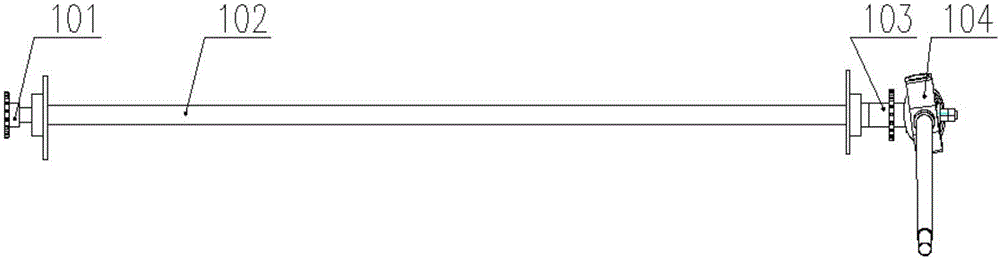

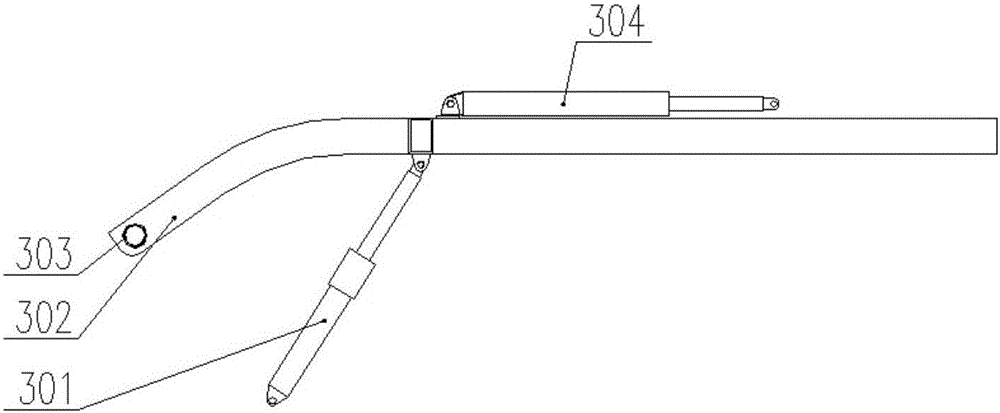

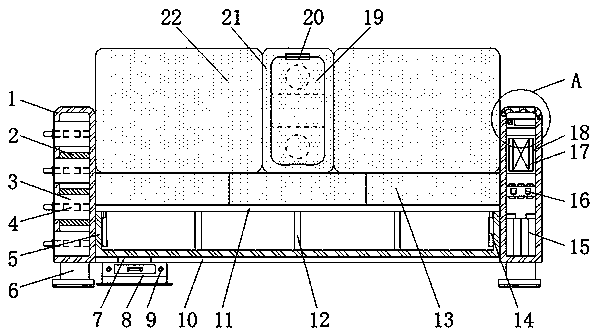

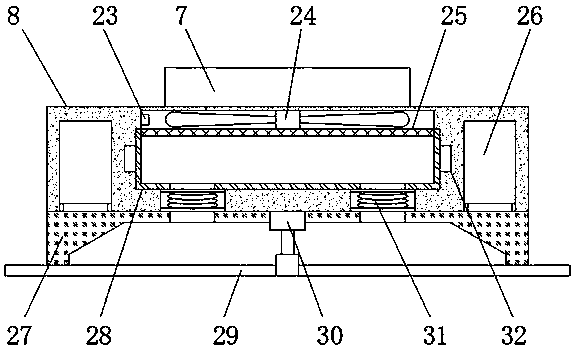

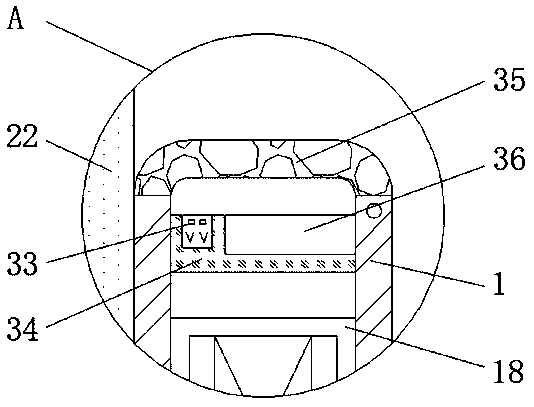

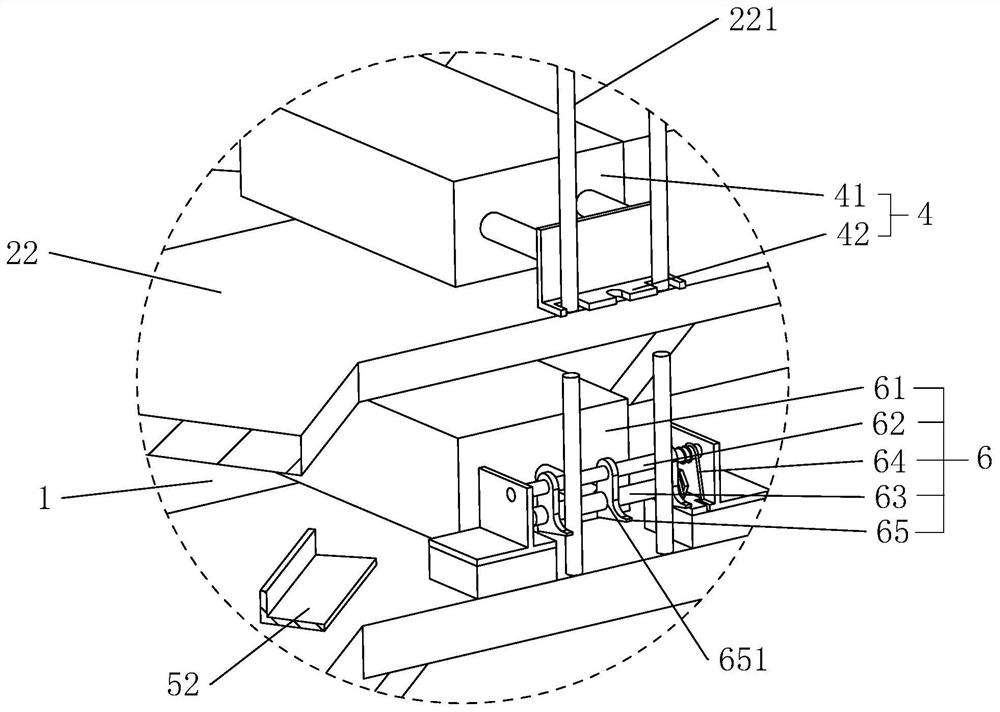

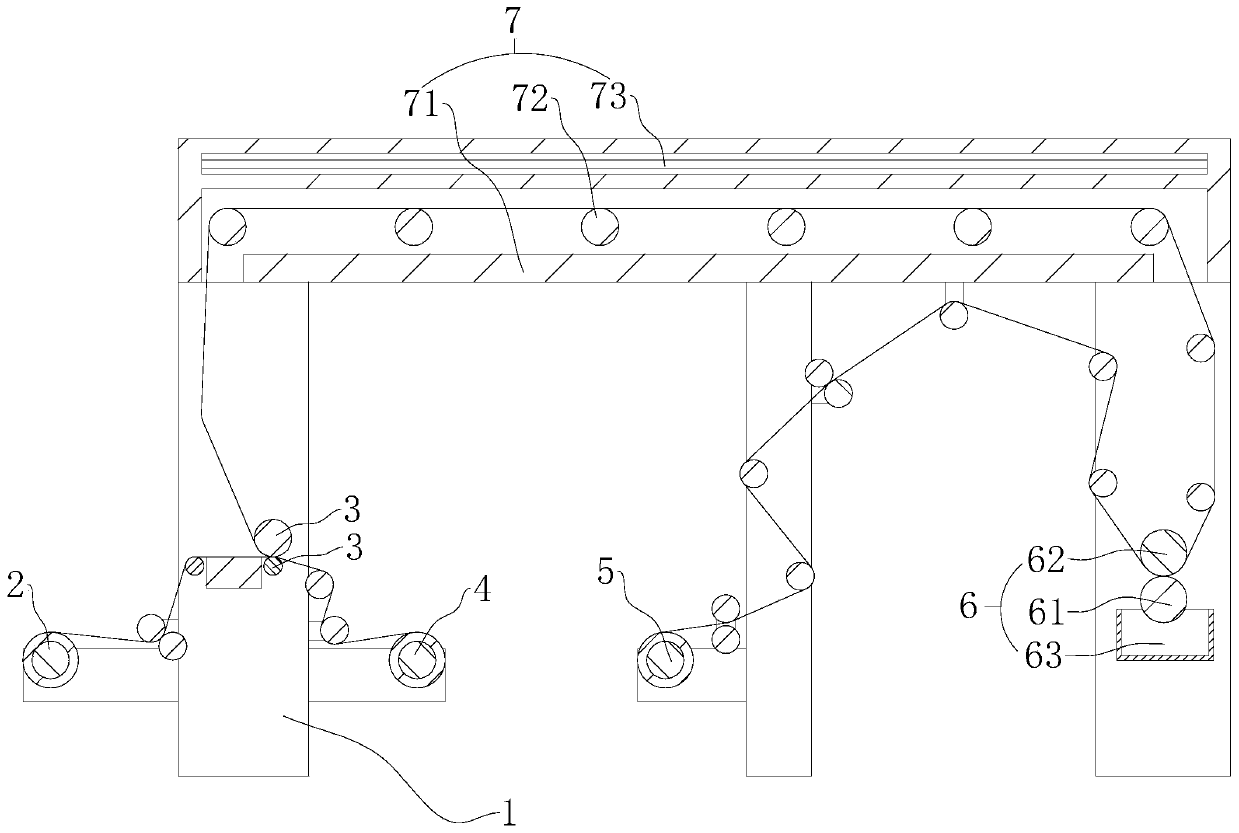

Combined harvester profiling cutting table capable of harvesting high stems and laid crops thereof

The invention discloses a combined harvester profiling cutting table capable of harvesting high stems and laid crops thereof. The combined harvester profiling cutting table comprises a cutting table frame, a cutting table forward stretching device, a feeding auger, a swinging ring mechanism, a horizontal cutter, a reel supporting arm, a triangular reel, a profiling grain lifting device and the like. The combined harvester profiling cutting table is mainly and structurally characterized in that the triangular reel is located above a horizontal cutter, the profiling grain lifting device is installed behind the horizontal cutter, and the front end of the profiling grain lifting device stretches out of the horizontal cutter. The harvesting requirement of high stems and laid crops thereof can be met, the novel profiling grain lifting device and the triangular reel are adopted, land profiling is achieved through the forward-stretching grain lifter, laid crops are supported, harvesting of the high stems and the laid crops thereof is achieved through the matching of the triangular reel and the horizontal cutter, and when the triangular reel dials in the high-stem crops, the grass winding phenomenon normally existing on a pentagonal reel can be effectively avoided.

Owner:JIANGSU UNIV

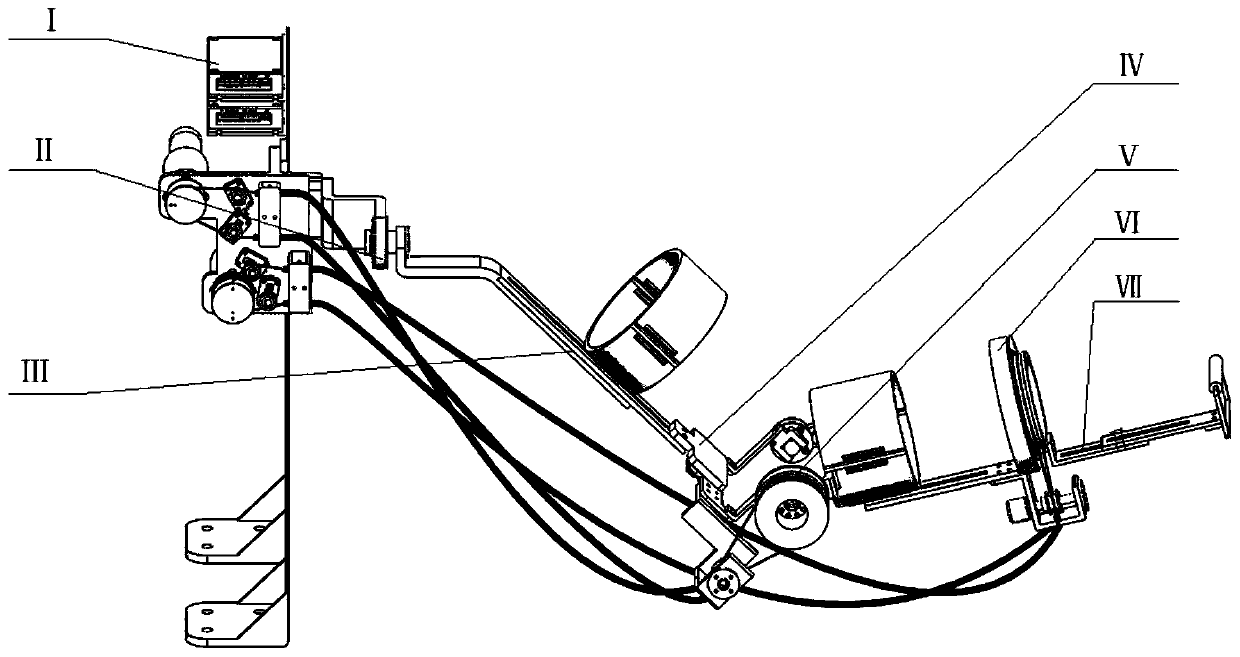

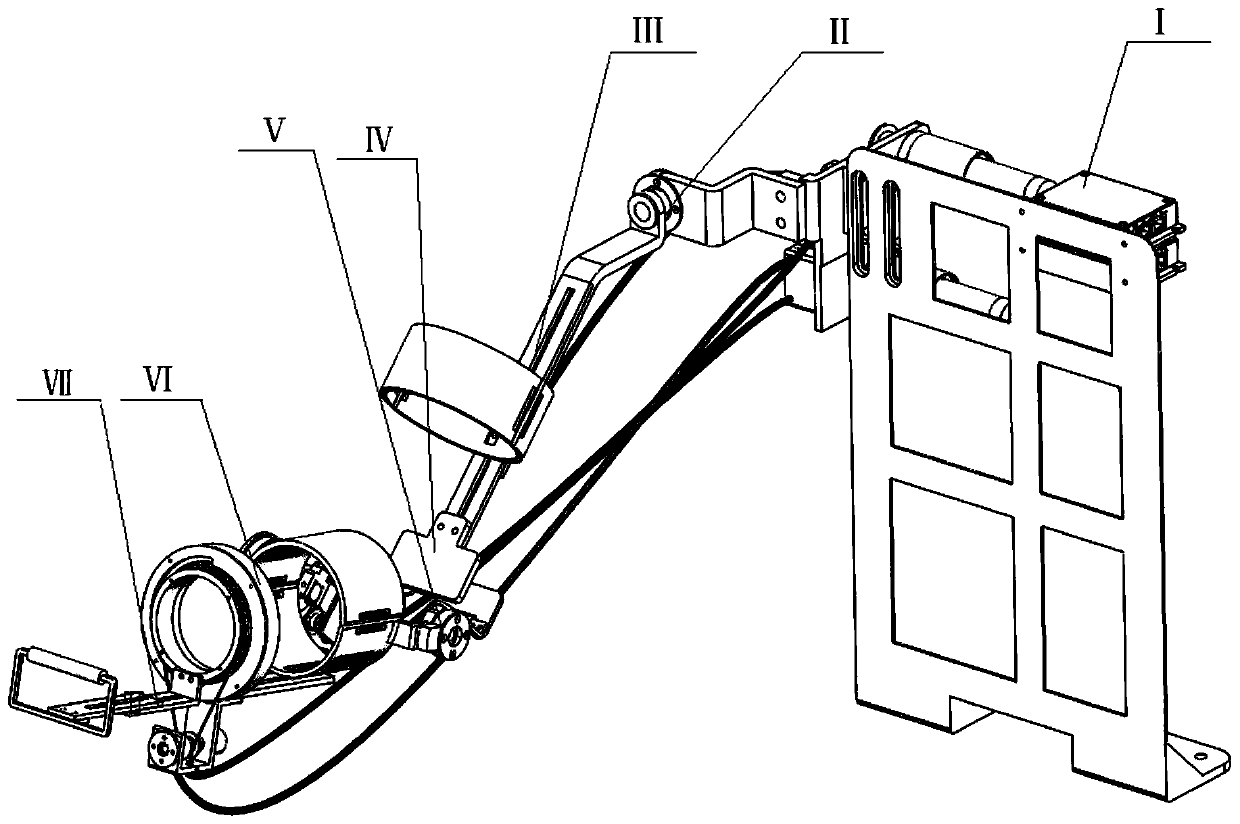

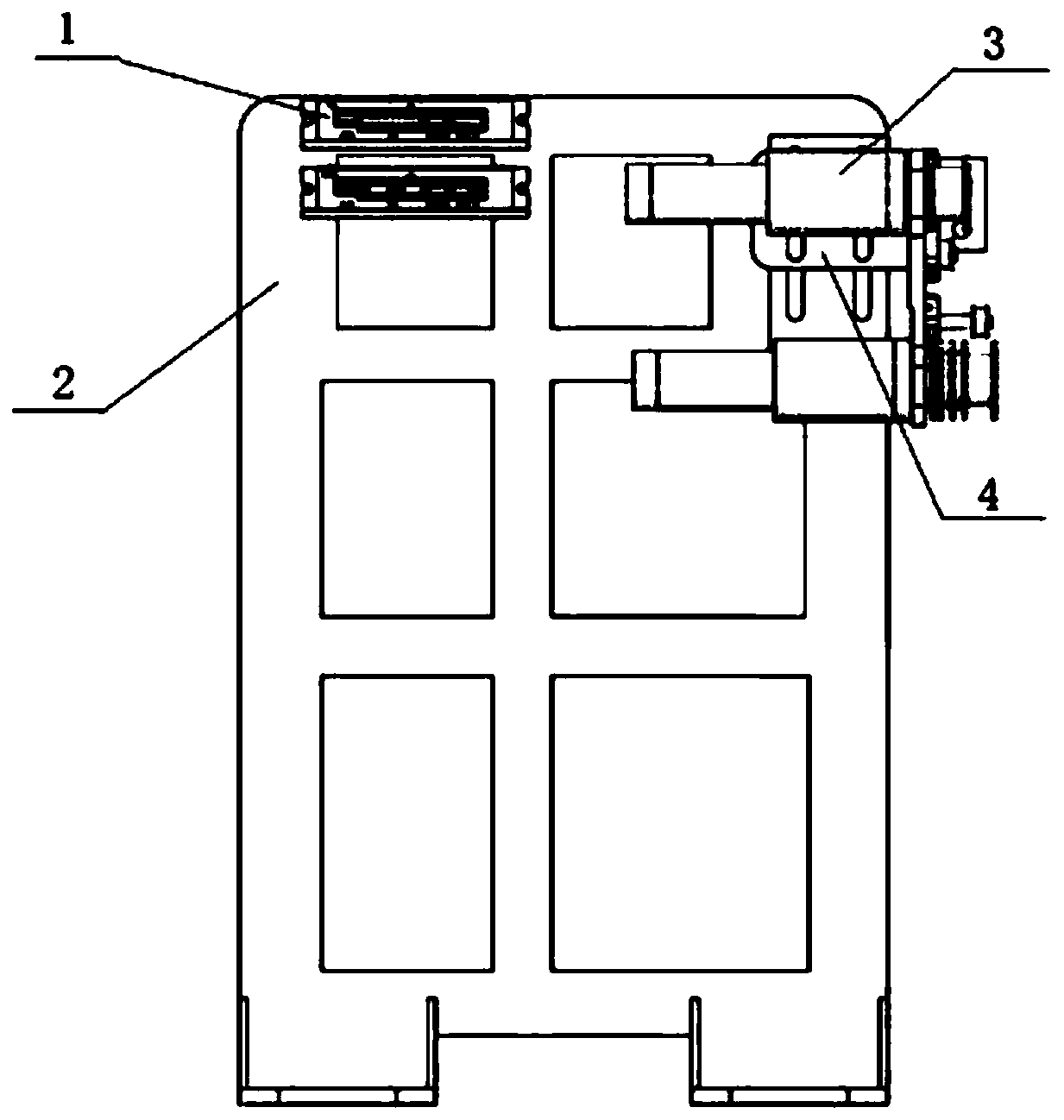

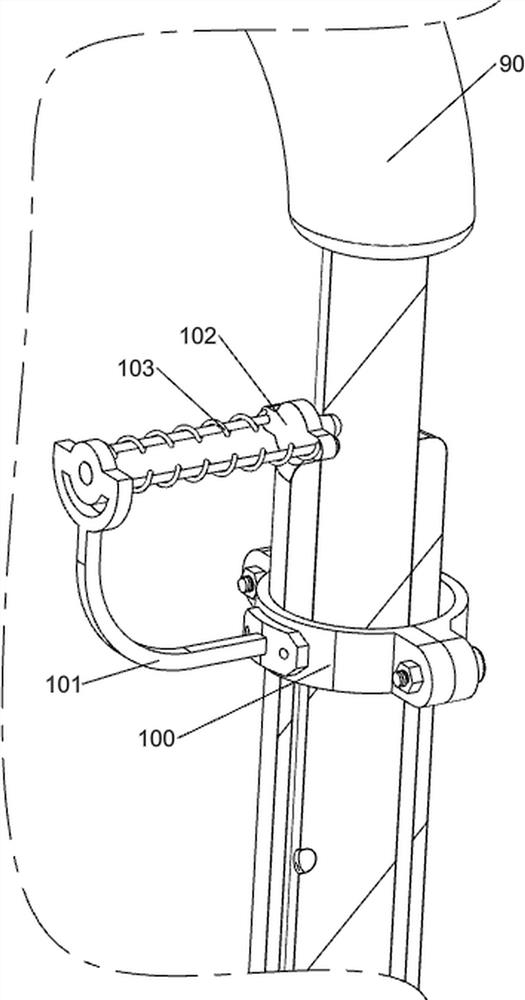

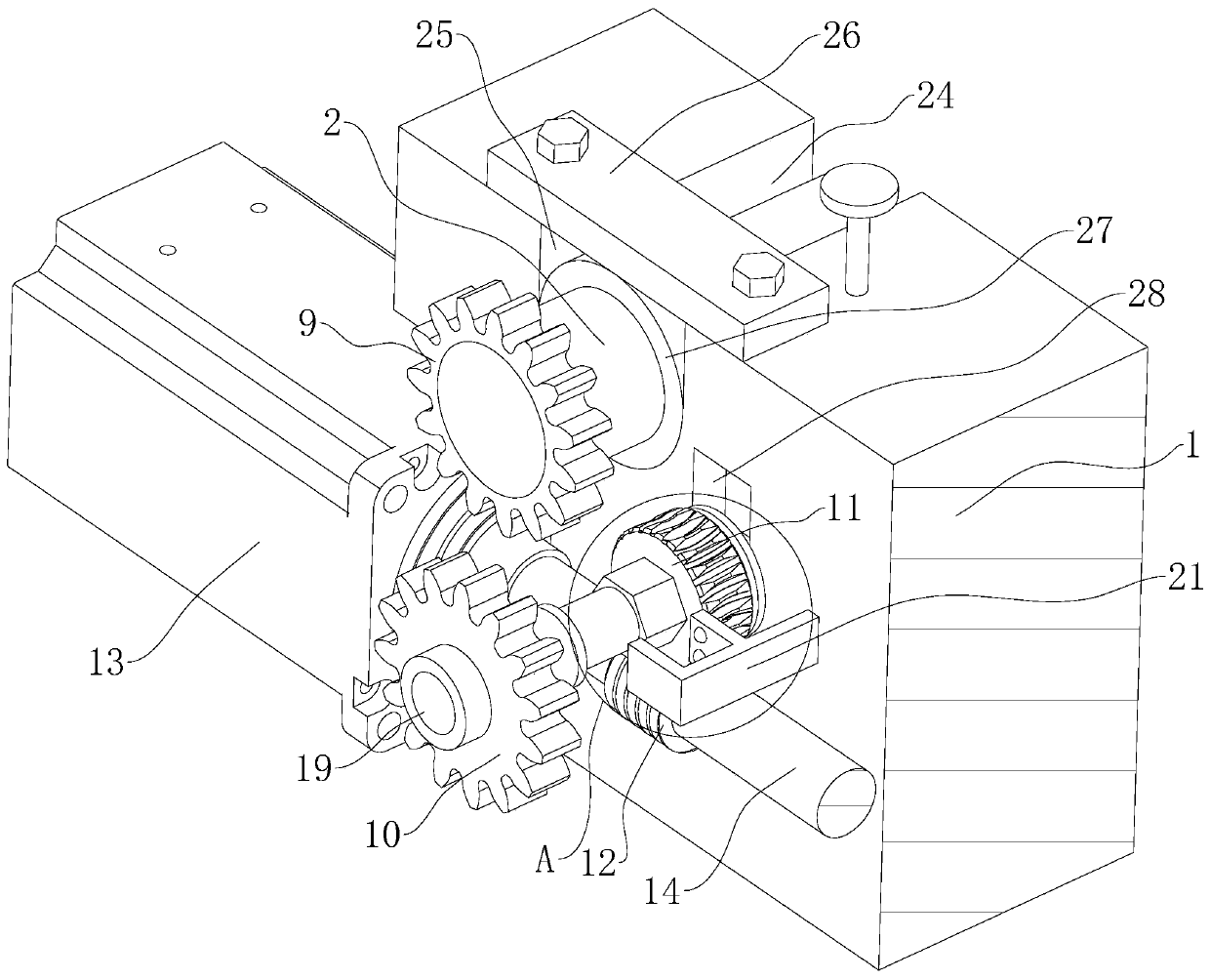

Flexible rope-driven elbow joint exoskeleton robot with compensation device

ActiveCN111184620AAutomatically compensates for pulling problems caused by offset misalignmentAutomatically compensates for pull issuesGymnastic exercisingChiropractic devicesExoskeleton robotBowden cable

The invention discloses a flexible rope-driven elbow joint exoskeleton robot with a compensation device. The invention relates to the exoskeleton robot and aims at solving the problems that existing auxiliary rehabilitation equipment is single in function and not suitable for rehabilitation training. The robot comprises a back plate, a driving device, a shoulder joint device, a big arm device witha length adjusting function, a dislocation compensation device, an elbow joint flexion and extension device, an elbow joint self-rotation device, a forearm device with a length adjusting function andtwo sets of Bowden cables. The driving device is mounted on one side surface of the back plate; the shoulder joint device is mounted on one side of the back plate; the shoulder joint device, the bigarm device with the length adjusting function, the dislocation compensation device, the elbow joint flexion and extension device, the elbow joint self-rotation device and the forearm device with the length adjusting function are connected in sequence; one ends of the two sets of Bowden cables are connected to the driving device; the other end of one set of the Bowden cables is connected to the elbow joint flexion and extension device; and the other end of the other set of the Bowden cables is connected to the elbow joint self-rotation device. The robot is used for the field of rehabilitation training.

Owner:HARBIN INST OF TECH

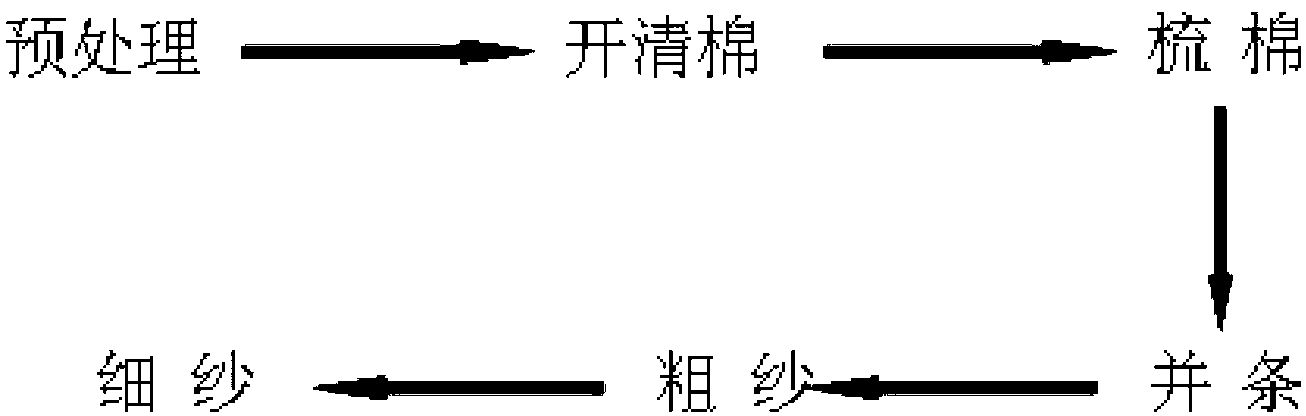

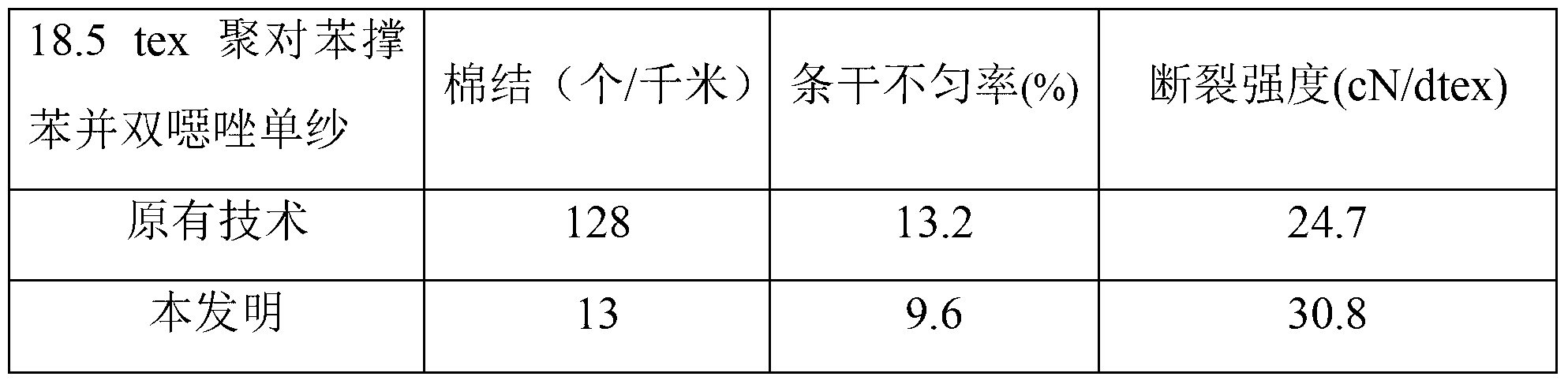

Method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres

The invention discloses a method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres. The method comprises the steps of pre-treatment, cotton opening and picking, cotton teasing, drawing, rough spinning and fine spinning. The method solves the difficult problem of spinning the poly-p-phenylenebenzobisthiazole fibres, and establishes a technical foundation of pure spinning of the PBO fibres, which is performed on cotton spinning equipment; yarns obtained via spinning have the advantages of glabrous surface, smoothness, less neps, uniform evenness and the like, can be widely applied to high-grade protective textiles and industrial textiles.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

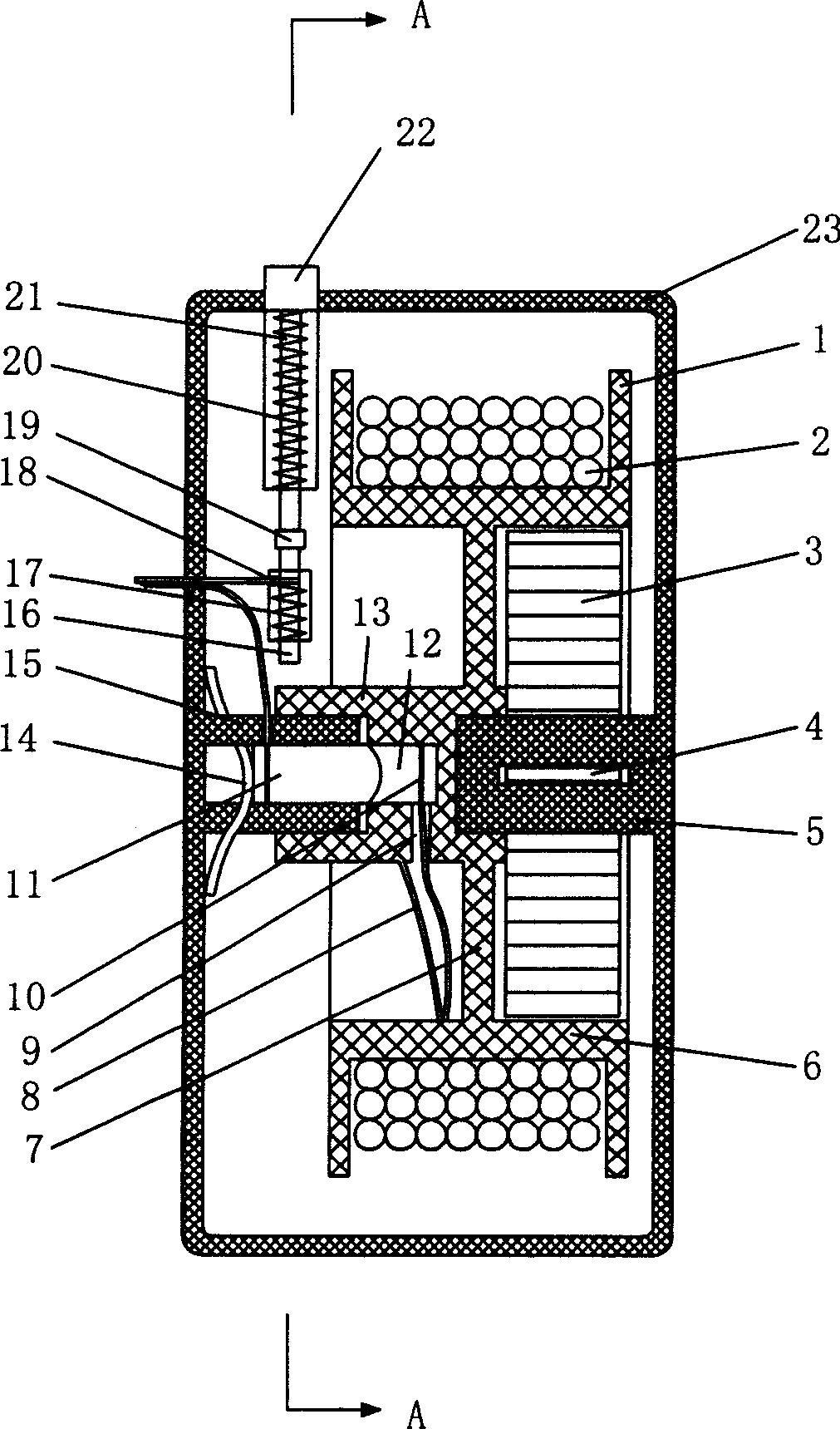

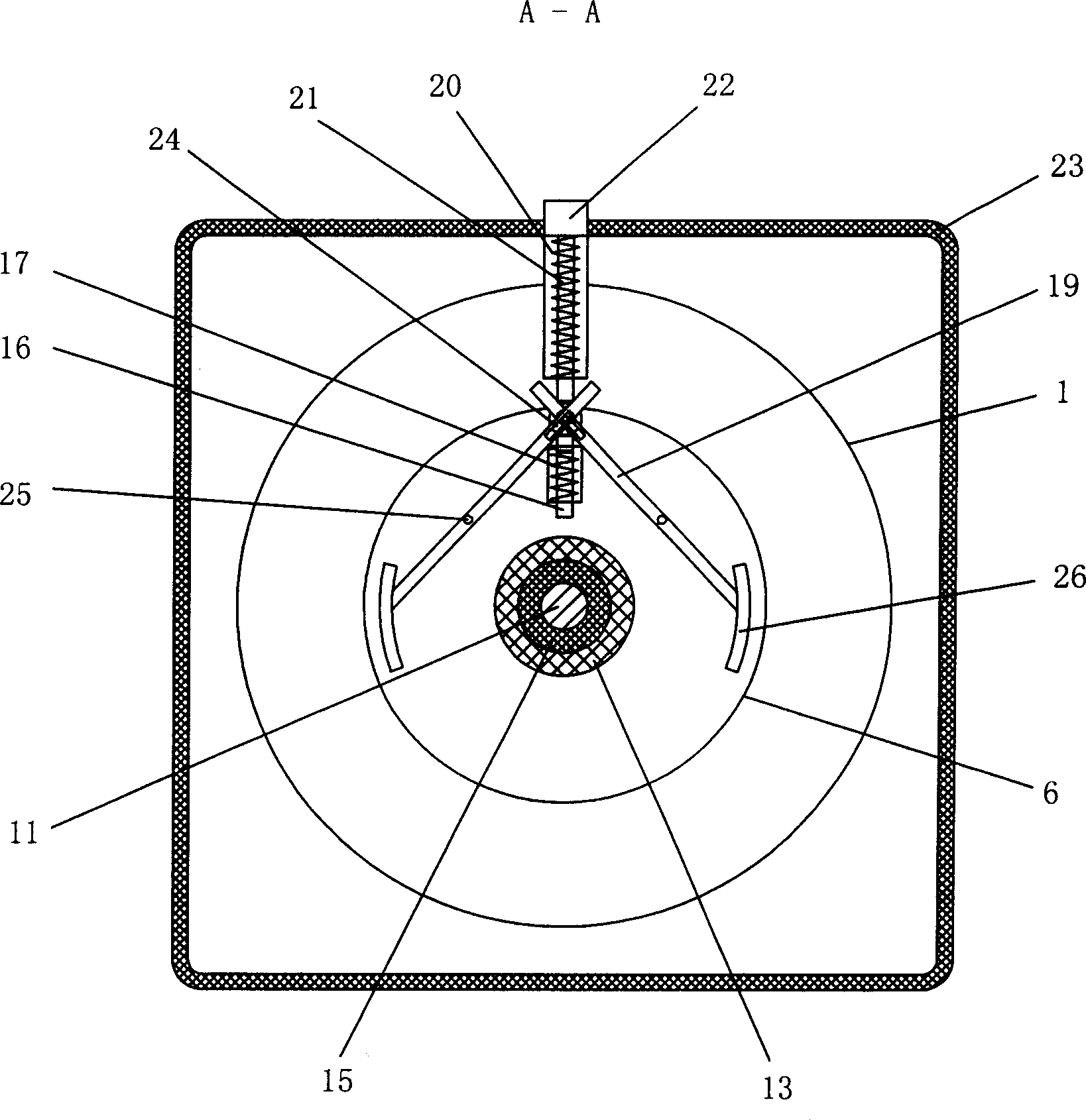

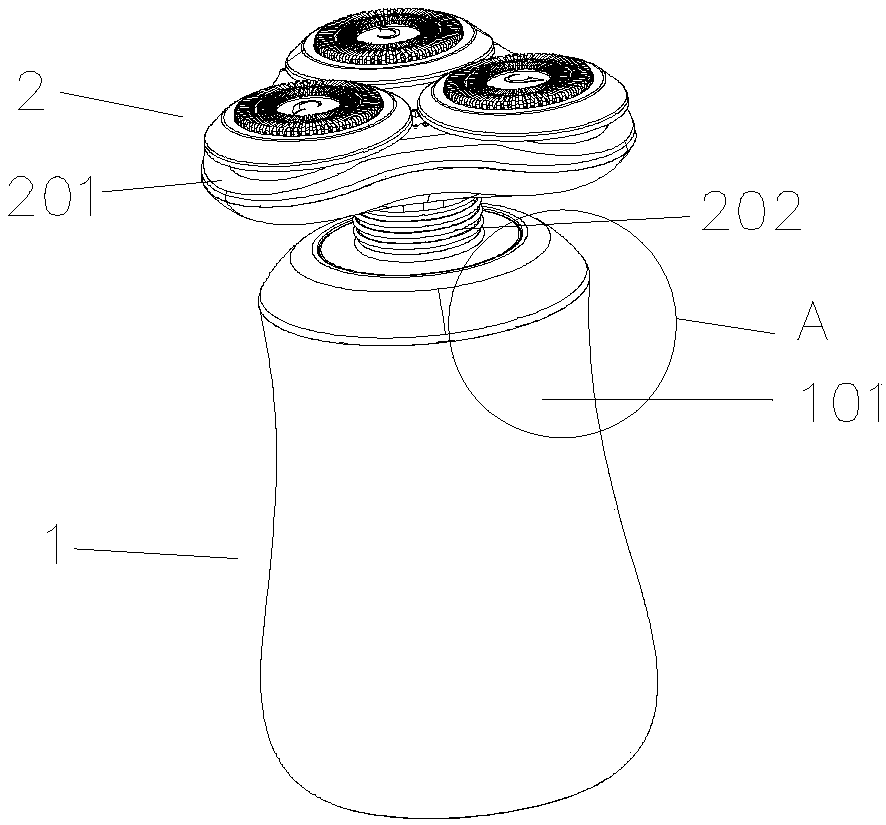

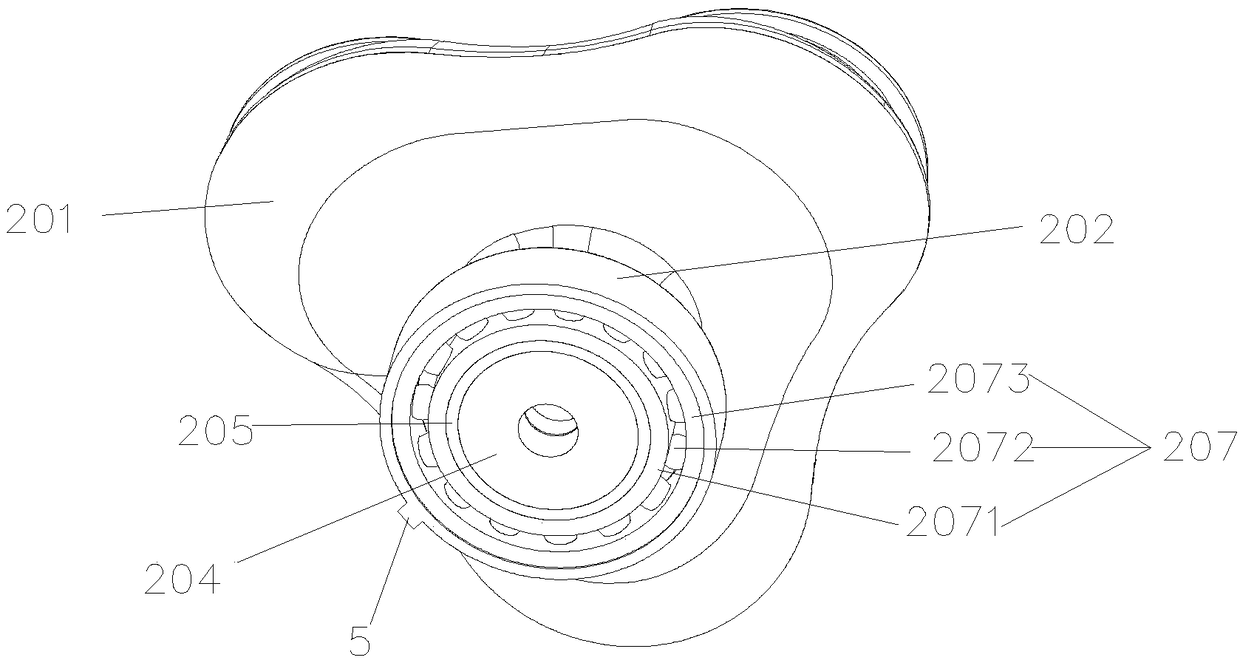

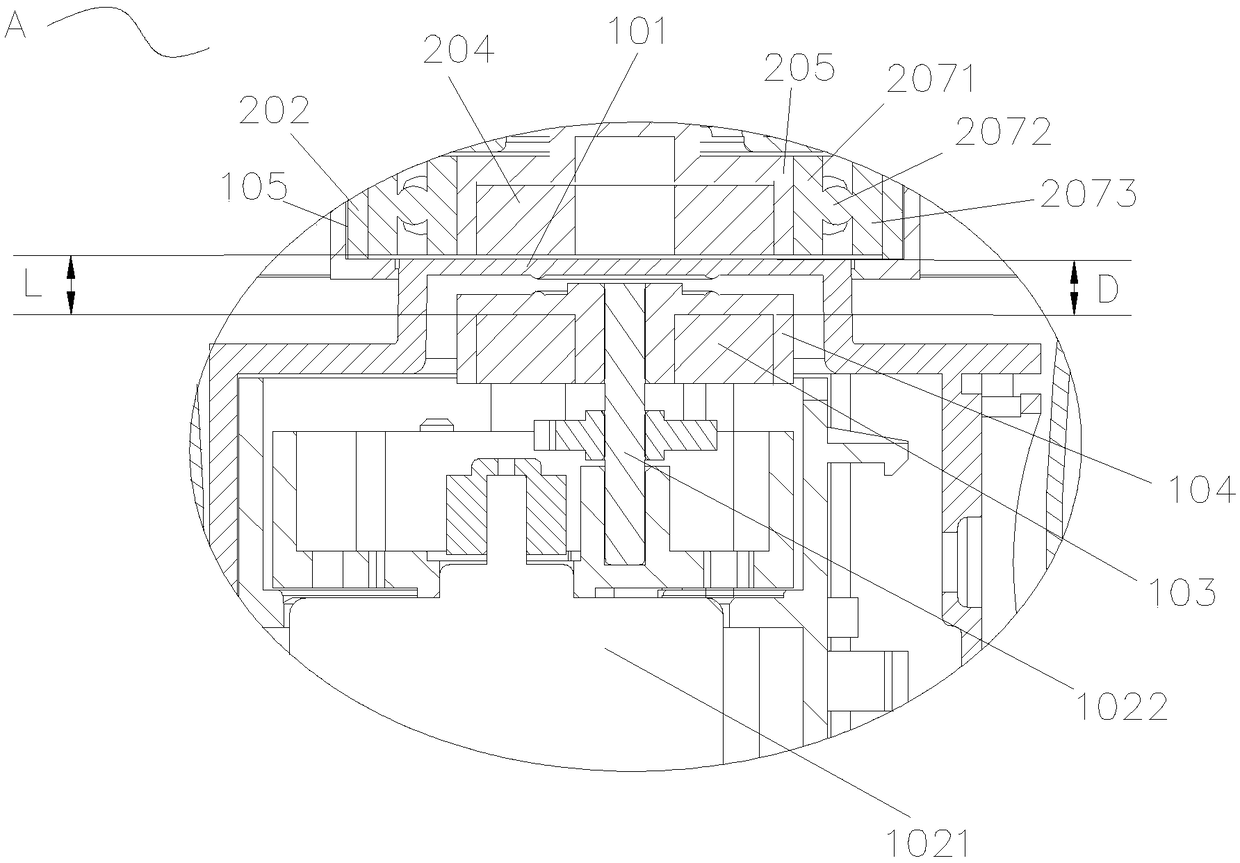

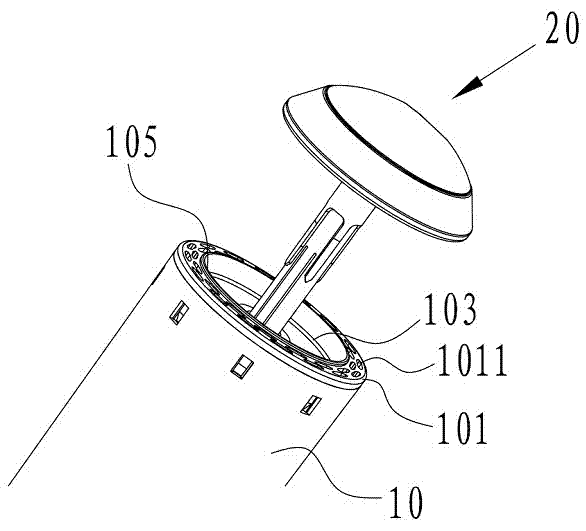

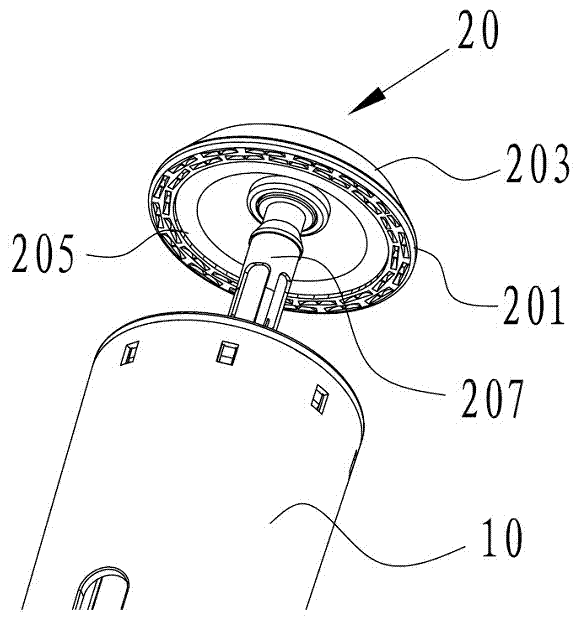

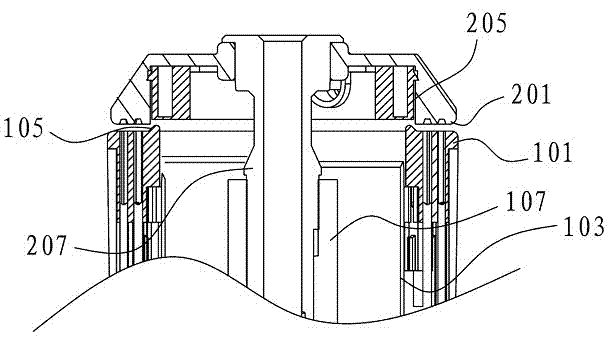

Magnet drive electric shaver

PendingCN108687804AReliable rotationReliable deliveryMetal working apparatusElectric machineMagnetization

The invention relates to the field of domestic appliance, in particular to a magnet drive electric shaver. The magnet drive electric shaver solves the problem of waterproof sealing difficulty and thetransmission structure without overload protection function in an electric shaver with a current transmission structure. The magnet drive electric shaver comprises a main body assembly and a cutter head assembly; the cutter head assembly is arranged on the main body assembly; the main body assembly comprises a main body and a driving unit arranged in the main body; the cutter head assembly comprises a movable cutter unit and a shell used for supporting the movable cutting tool unit; the driving unit comprises a motor, a driving magnetic body arranged in the main body and a driven magnetic bodyarranged in the shell; the driving magnetic body and the driven magnetic body are arranged to be multipole magnetization magnetic bodies; and the movable cutting tool unit is driven to rotate by themotor, the driving magnetic body and the driven magnetic body. Excellent waterproofing effect is achieved and overloading protection is achieved by magnet drive.

Owner:HUANXING TECH HANGZHOU CO LTD

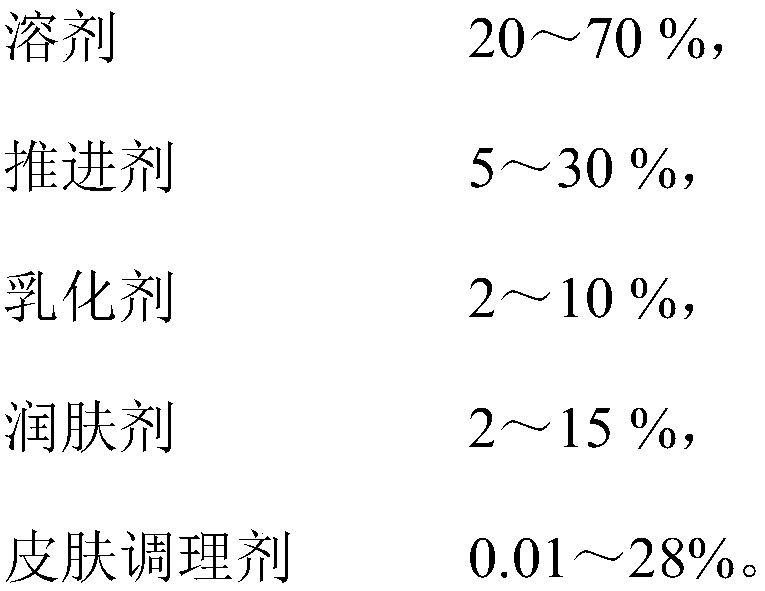

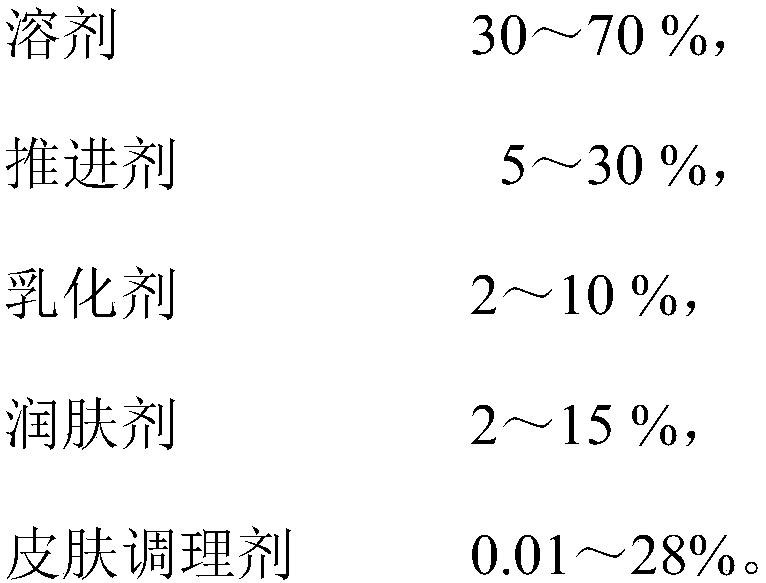

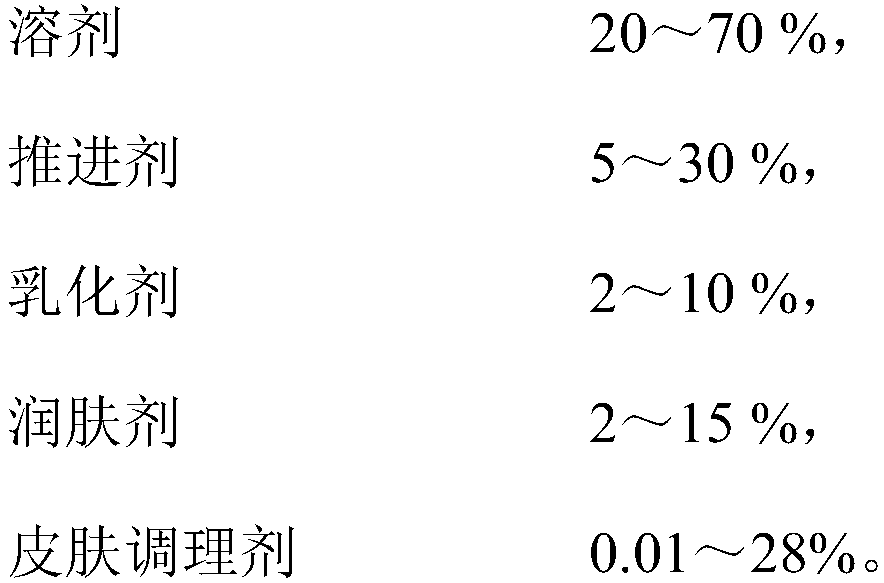

Mild makeup removing mousse and preparation method thereof

The invention discloses mild makeup removing mousse and a preparation method thereof. The mousse is prepared from the following components in percentage by weight: 30 to 70 percent of a solvent, 5 to30 percent of a propellant, 2 to 10 percent of an emulsifier, 2 to 15 percent of a skin moistening agent and 0.01 to 28 percent of a skin conditioning agent. The preparation method comprises the following steps: mixing the solvent with the emulsifier and part of the skin moistening agent and stirring until the materials are uniformly dispersed and dissolved; while stirring, adding the residual skin moistening agent and the skin conditioning agent; uniformly stirring until the materials are completely dispersed and dissolved to form material liquid; packaging the material liquid through an aerosol can and filling with the propellant; detecting that a product is qualified. According to the mild makeup removing mousse disclosed by the invention, a grease raw material is combined with aerosolpackaging and a unique emulsifying system; a material body is shown in a dense and elastic form; the mild makeup removing mousse has the advantages of no additives, easiness for washing and no residues; the dense makeup removing oil mousse can enter pores to dissolve makeup powder in the pores, so that a face is cleansed, and the makeup is more completely removed; the mild makeup removing mousse is convenient to use and easy to carry.

Owner:ZHONGSHAN TIANTU FINE CHEM CO LTD

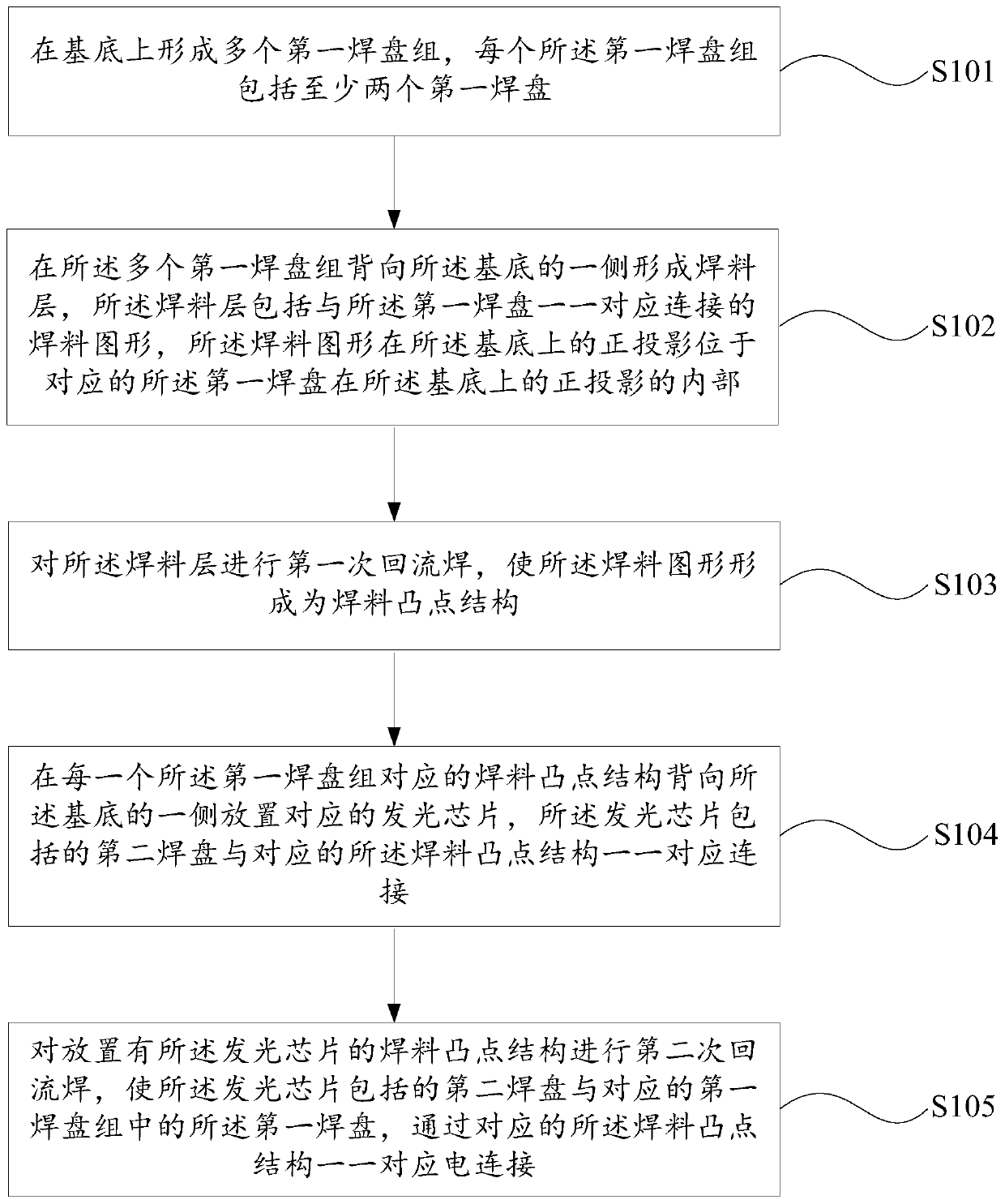

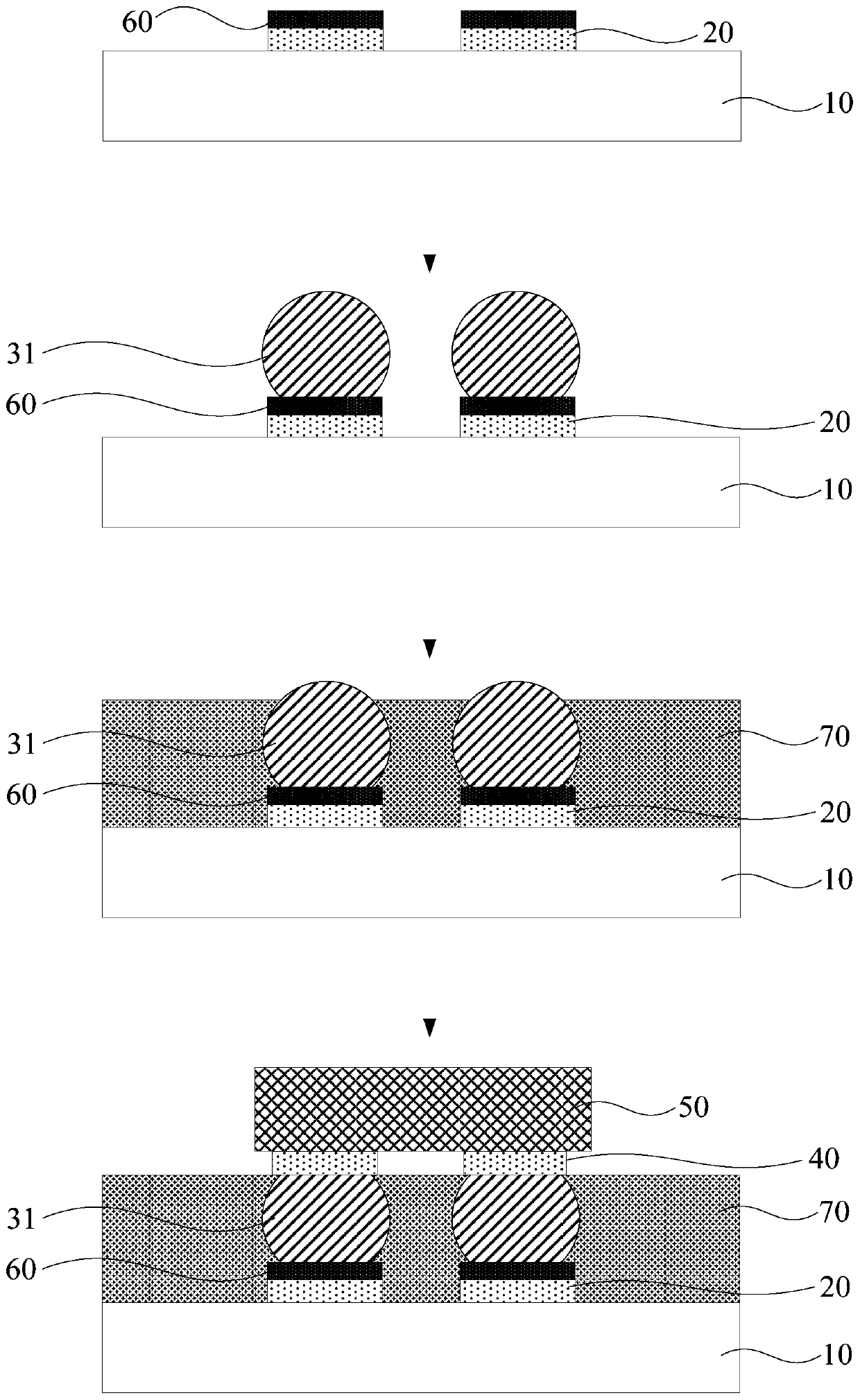

Backlight module, manufacturing method thereof and display device

ActiveCN111276471AReduce the ratio of tiltReduce chanceSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a backlight module, a manufacturing method thereof and a display device, relates to the technical field of display, and aims to solve the problem of uneven local or large-area light mixing of an existing backlight module. The manufacturing method of the backlight module comprises the following steps: forming a plurality of first bonding pad groups on a substrate, wherein each first bonding pad group comprises at least two first bonding pads; forming a solder layer, wherein the solder layer comprises solder patterns connected with the first bonding pads in a one-to-one correspondence manner; performing reflow soldering for the first time to enable the solder pattern to form a solder bump structure; placing a corresponding light-emitting chip on one side, back to the substrate, of the solder bump structure corresponding to each first bonding pad group, wherein second bonding pads included in the light-emitting chip are connected with the corresponding solder bump structures in a one-to-one correspondence manner; and performing reflow soldering for the second time, so that the second bonding pads included in the light-emitting chip are electrically connected with the corresponding first bonding pads in a one-to-one correspondence manner through the corresponding solder bump structures. The manufacturing method of the backlight module is used for manufacturing the backlight module.

Owner:BOE TECH GRP CO LTD +1

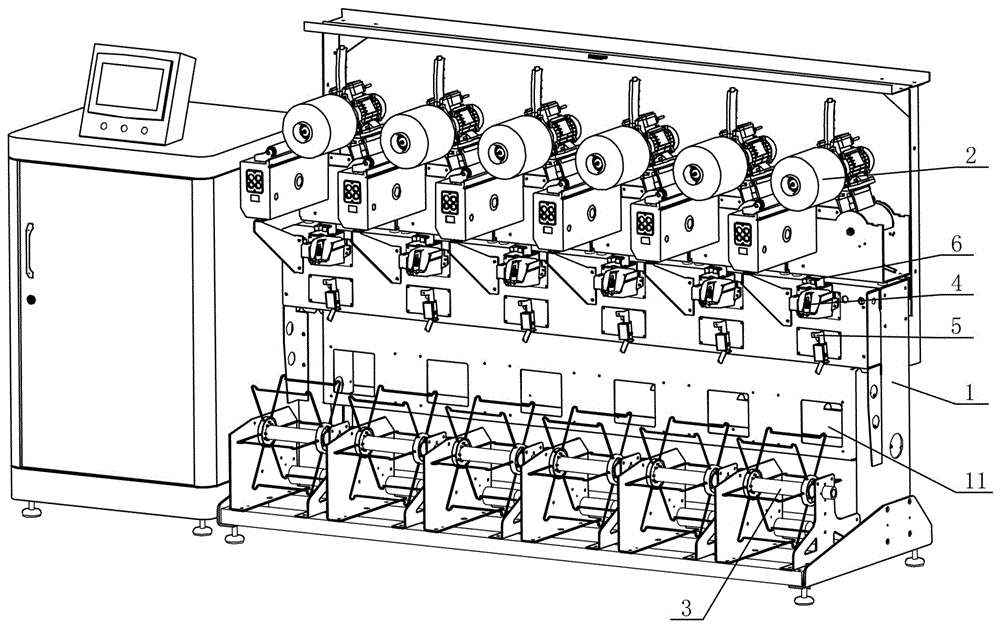

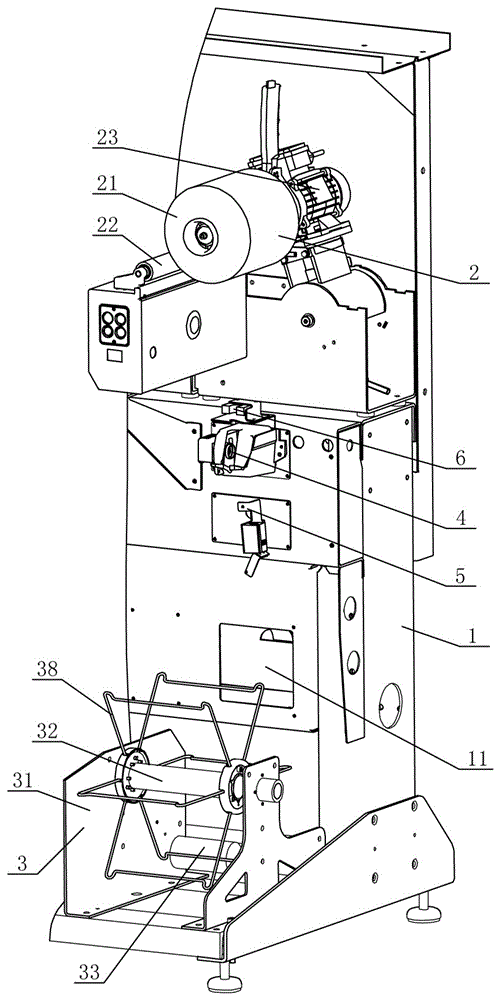

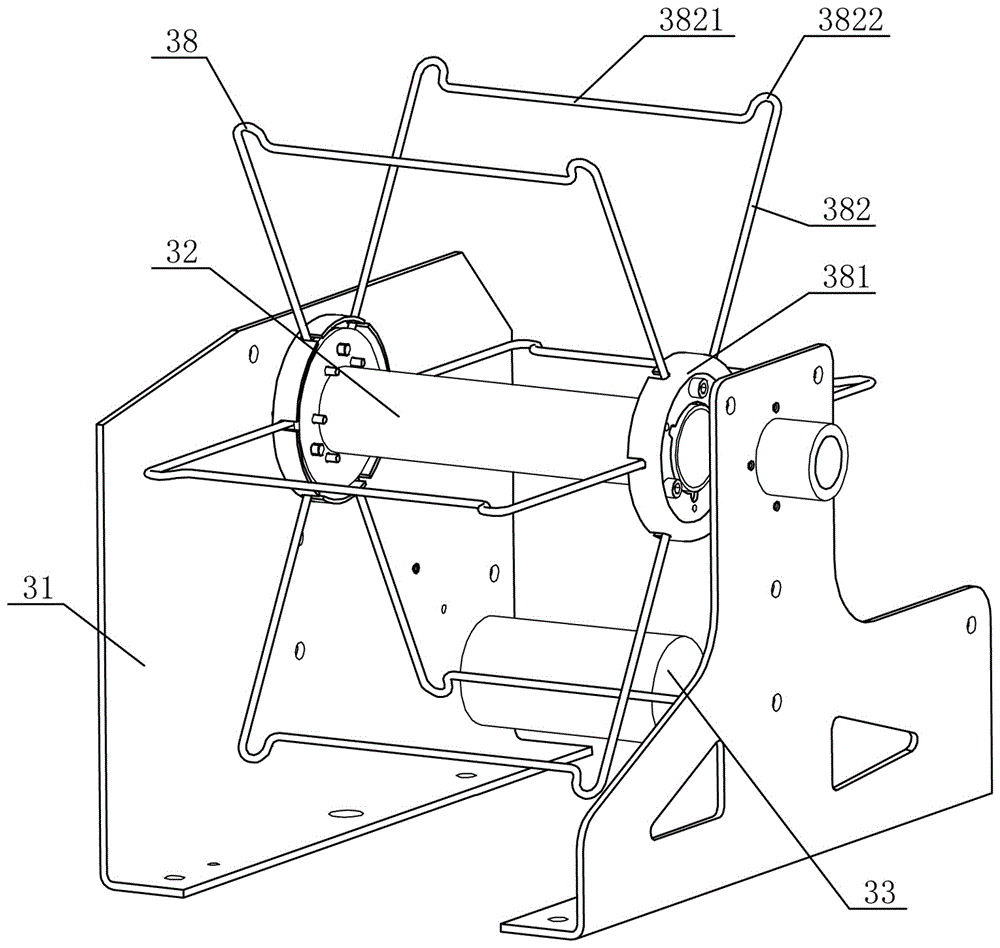

Winding machine

The invention discloses a winding machine. An unwinding motor of an active unwinding mechanism and a main winding motor of a main winding mechanism of the winding machine work simultaneously at the same speed. Yarn is unwound actively by hank holders or bobbin crades on a rotary shaft, and the yarn which is oiled and lubricated by an oiling device is wound by an active winding wheel. When the hank holders or the bobbin crades are driven by the rotary shaft to rotate, longitudinal wind is generated and blown into a hollowed-out opening, and thus, internal heat dissipation is conducted. According to the winding machine, the unwinding motor is additionally arranged to cooperate with the main winding motor of the winding machine so that the unwinding motor and the main winding motor can work together, the speeds of the two motors are kept identical, active unwinding in the positions of the hank holders or the bobbin crades and active winding in the position of a winding core are conducted simultaneously, pulling on the yarn is reduced, the quality of the yarn can be guaranteed, and the yarn is not prone to being damaged; and conveying is more stable, and shifting is not prone to occurring. Through the active unwinding mode, higher rotation speeds can be selected for both the unwinding motor and the winding motor, due to the fact that the resistance of the yarn is reduced, the yarn is prevented from being damaged, both unwinding and winding can be kept stable, the working efficiency of the winding machine is improved, and the product quality is improved.

Owner:XINCHANG WANSHIFA TEXTILE MACHINERY

Water collecting bottle

The invention relates to a water collecting bottle, which comprises a shell, two connecting pipes and a seal cover, wherein the shell defines a water storage space and is provided with a drain hole communicating the water storage space with the external; the two connecting pipes are respectively arranged on two opposite sides on the left and right of the shell and communicate the water storage space with the external; the two connecting pipes extend horizontally in the same direction; the gravity center of the shell and the two connecting pipes are substantially positioned at the same level position; and the seal cover is detachably arranged on the shell to seal the drain hole. Therefore, a gas pipe connected with the connecting pipes can be prevented from being pulled downwards due to the weight of the water collecting bottle so as to improve the use safety; and a user drains water collected in the shell conveniently.

Owner:GALEMED (XIAMEN) CO LTD

Circular tube type anastomat

The invention provides a circular tube type anastomat which comprises an anastomat body and an anvil component. A far-end of the amastomat body is provided with an annular nail bin and an annular cutter, and a plurality of nail placing holes are formed in the end face of the annular nail bin. The anvil component comprises an annular nail anvil which matches with the annular nail bin, an annular cutter anvil which matches with the annular cutter and a nail anvil shaft which can be movably connected with the anstomat body. The annular cutter anvil is arranged between the nail anvil shaft and the annular nail anvil. When the anastomat body and the anvil component are closed, the annular nail bin matches with the annular nail anvil and the annular cutter anvil to form at least two fixing spaces which are communicated and possess height difference. The circular tube type anastomat can fix cut coincided nails, is in favor of cutting nails, can regard structures which are adjacent to newly-molded coincided nails and structures which are adjacent to cut coincided nails as cushion isolation and reduces drawing of organizations on the nail anvil end face.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

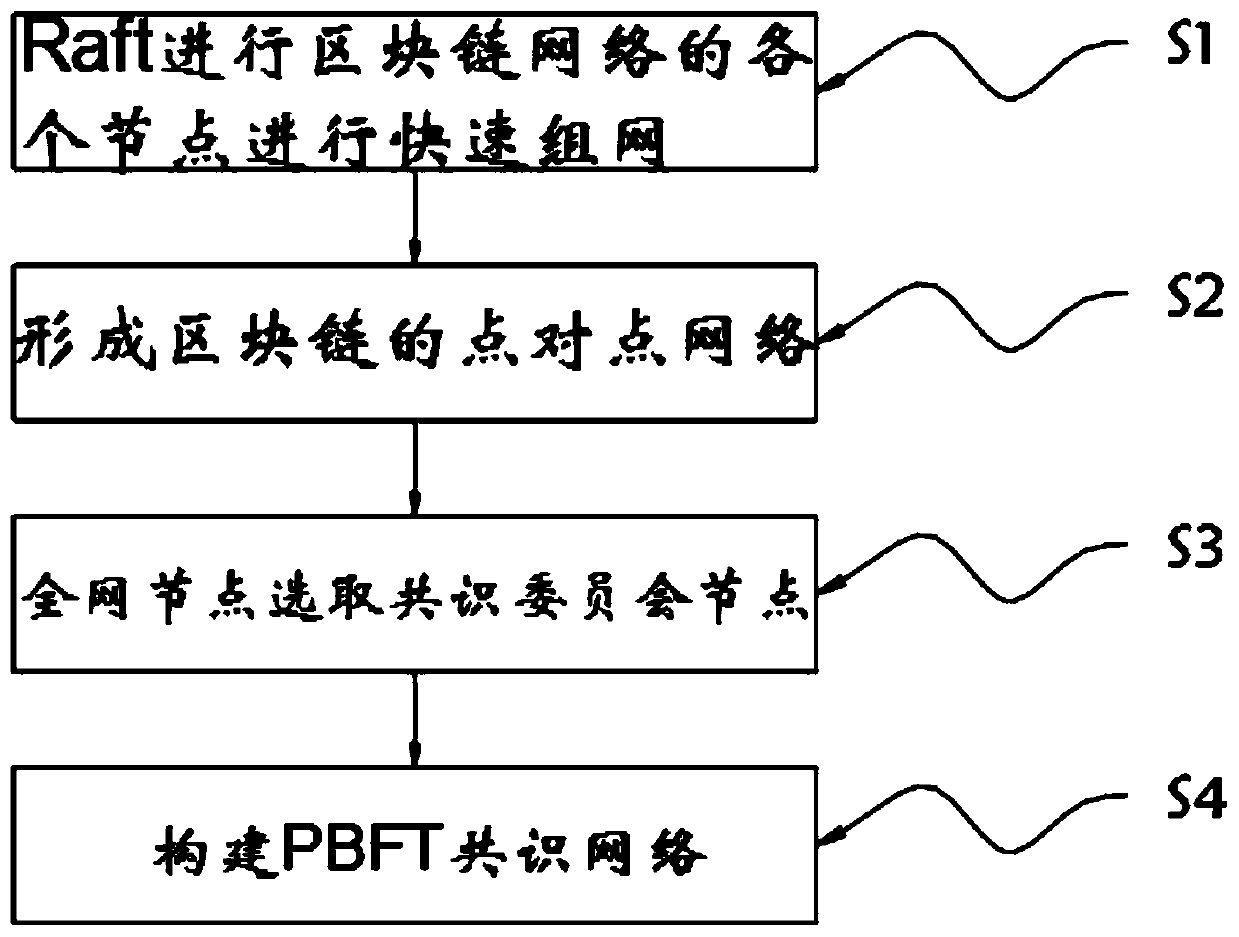

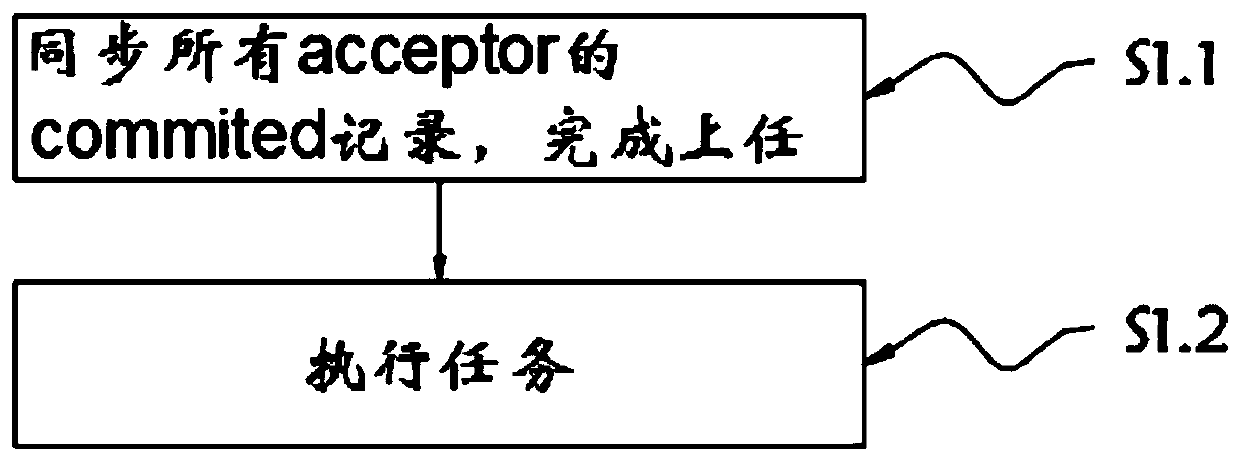

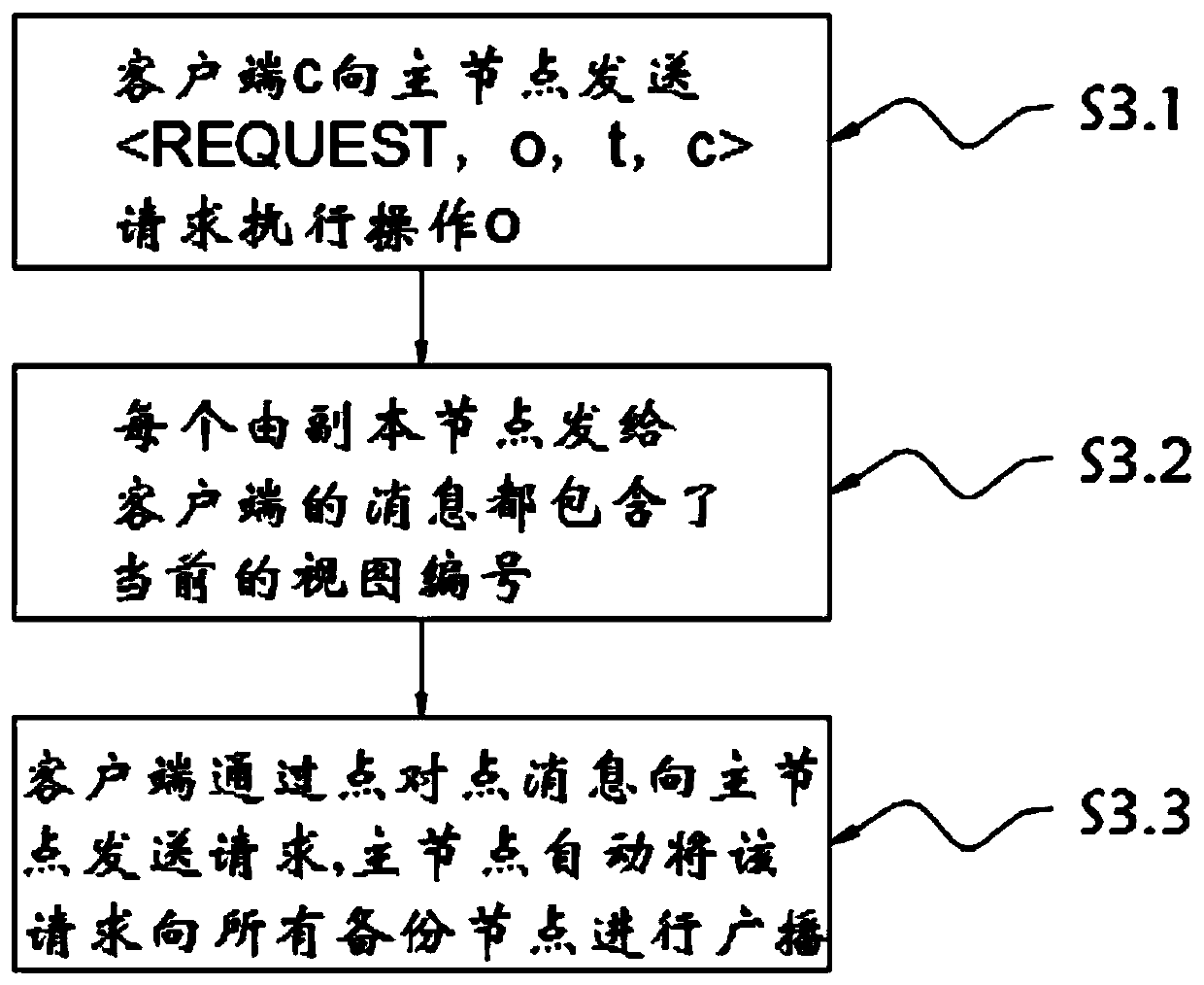

Hybrid consensus network algorithm and system of block chain Raft + PBFT

InactiveCN111464349AReduce pullingTake office quicklyData switching networksSecuring communicationPaxosStochastic algorithms

The invention relates to the technical field of block chains, in particular to a hybrid consensus network algorithm of block chain Raft + PBFT. The method comprises the following steps: selecting a host from paxos, synchronizing commid records of all acceptors, and completing the above steps; obtaining pass of the followers by commid, and completing a task; enabling a client c to send (REQUEST, o,t, c) a request to perform an operation o to the master node; wherein each message sent to the client by the replica node comprises a current view number; and enabling a main node to automatically broadcast the request to all backup nodes. Rapid networking is carried out on each node of a block chain network by adopting Raft to form a point-to-point network of a block chain, consensus committee nodes are selected from nodes of the whole network by adopting a random algorithm, a PBFT consensus network is constructed, relatively reliable consistency is ensured, and a consensus mechanism is formed.

Owner:NANJING ZHONGCHENG BLOCK CHAIN RES INST CO LTD

Household sofa making dust at bottom convenient to clear

Owner:HAINING SHUYOU FURNITURE CO LTD

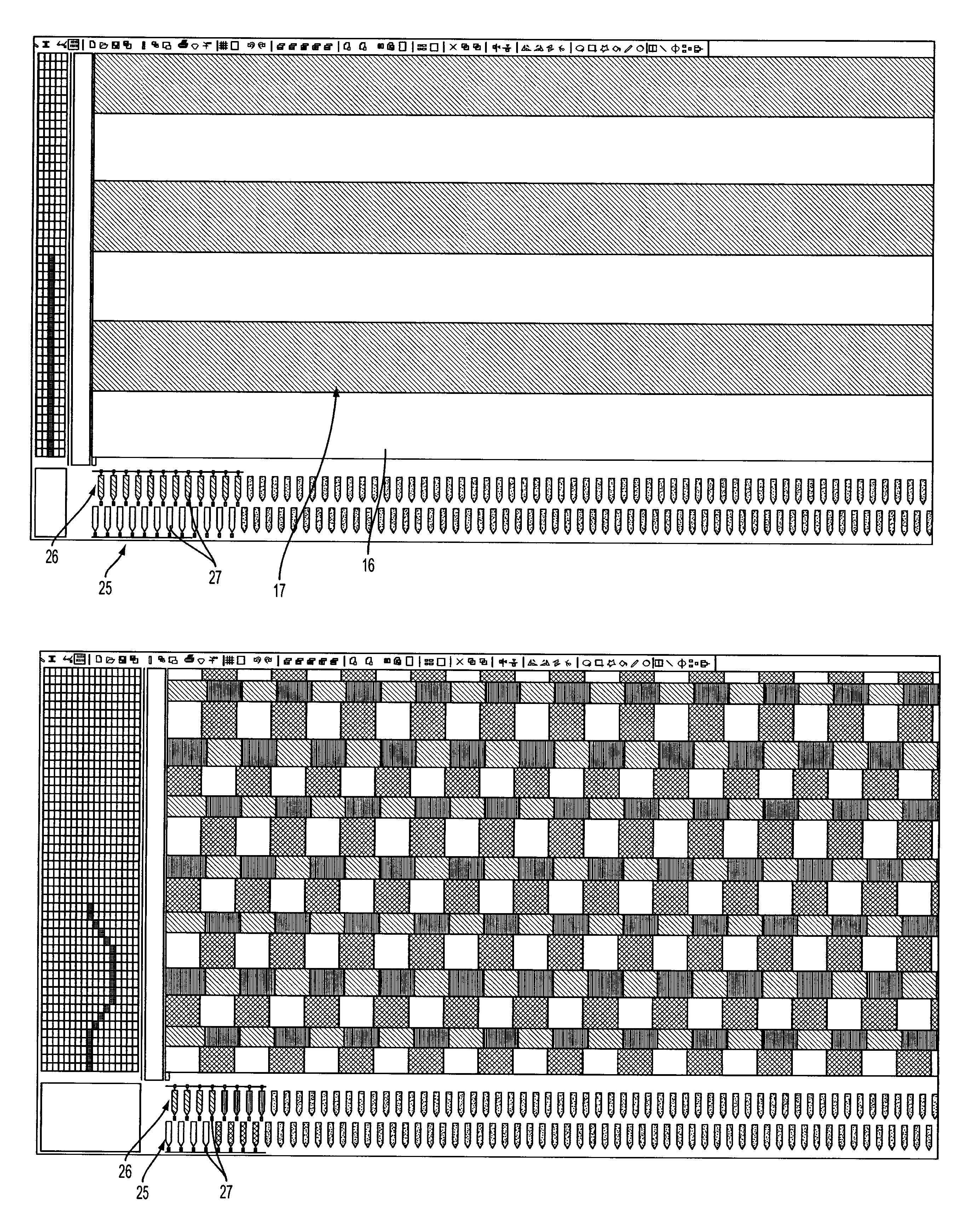

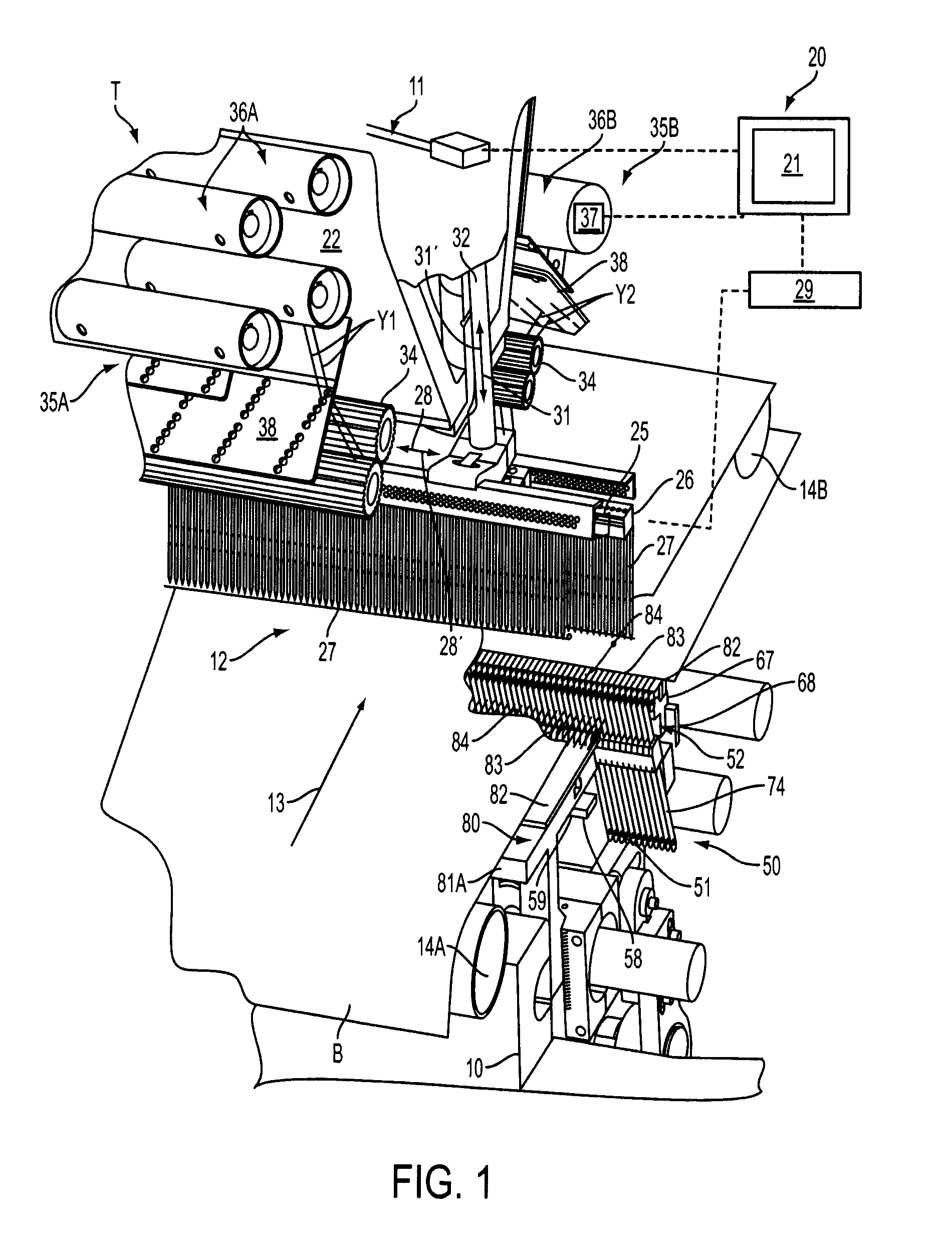

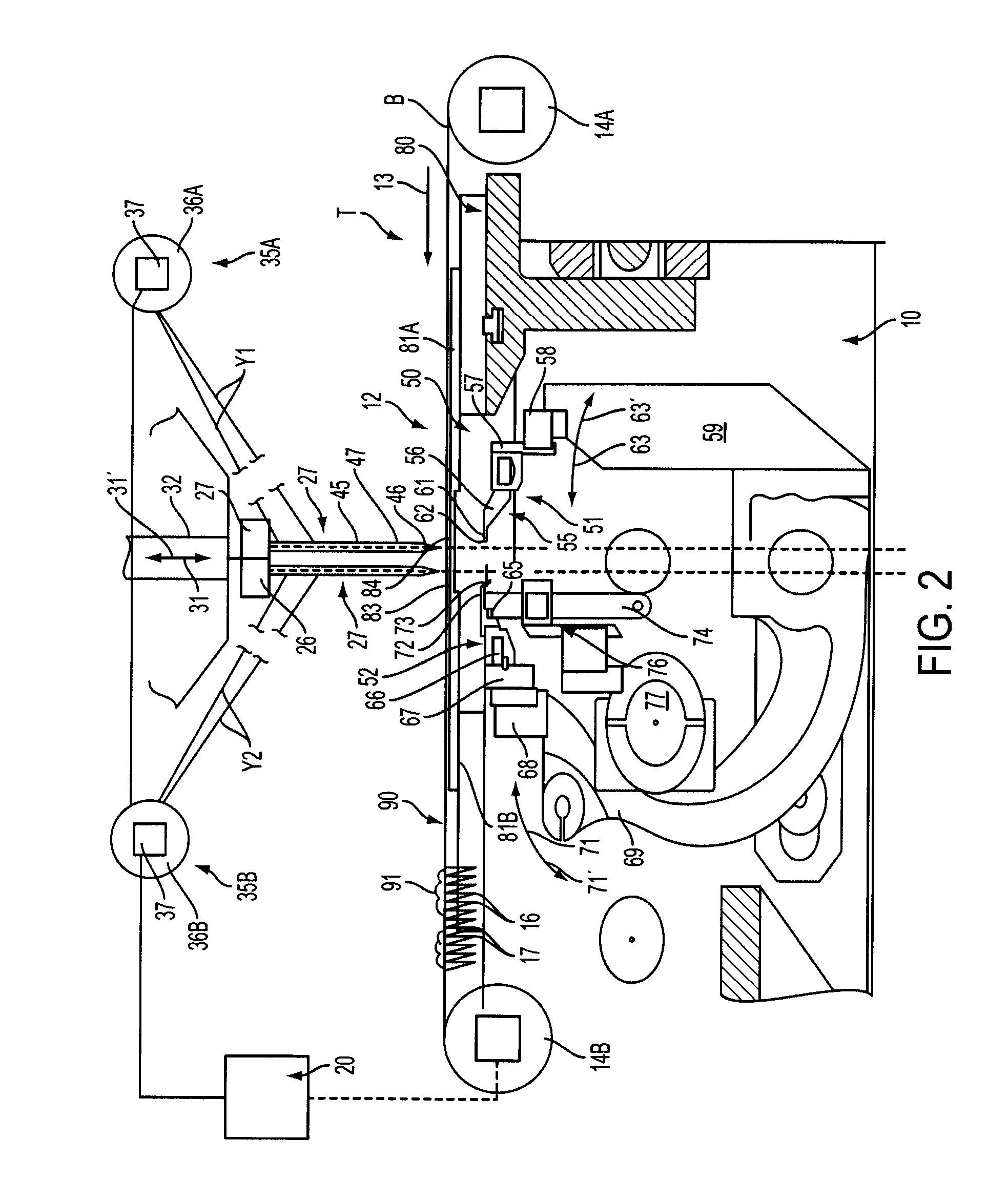

System and method for formation of woven style tufted cut/loop fabrics

ActiveUS20150159323A1Improve precisionImprove clarityTufting apparatusLayered productsYarnEngineering

A system and method for forming patterned tufted fabrics such as carpets, including the formation of patterns having cut pile and loop pile tufts therein. The system includes a pair of needle bars each carrying a series of needles to which a plurality of yarns are fed. Cut pile hooks are arranged along a cut pile side of a tufting zone, in a position to engage the needles of one of the needle bars, while loop pile loopers are arranged along the opposite loop pile side of the tufting zone, in a position to engage the needles of the other one of the needle bars. A backing material is fed through the tufting zone, and as loop pile tufts of yarns are formed in the backing material, the needles mounted along a needle bar extending along the cut pile side of the tufting zone can be shifted to an off-gauge position, with the yarn feed to these needles further being controlled, to substantially prevent engagement and pick-up of the yarns carried by such needles by the cut pile hooks.

Owner:CARD MONROE

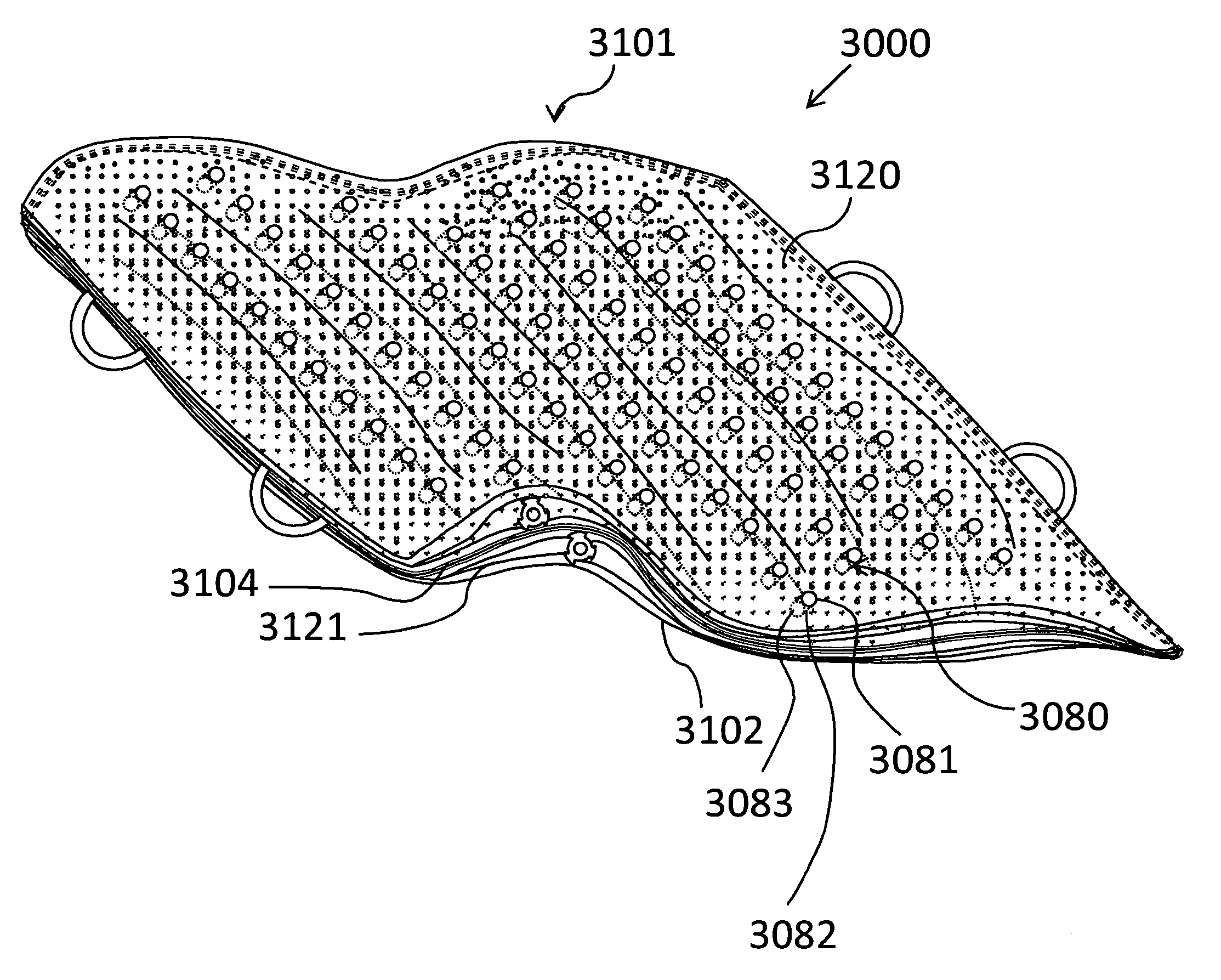

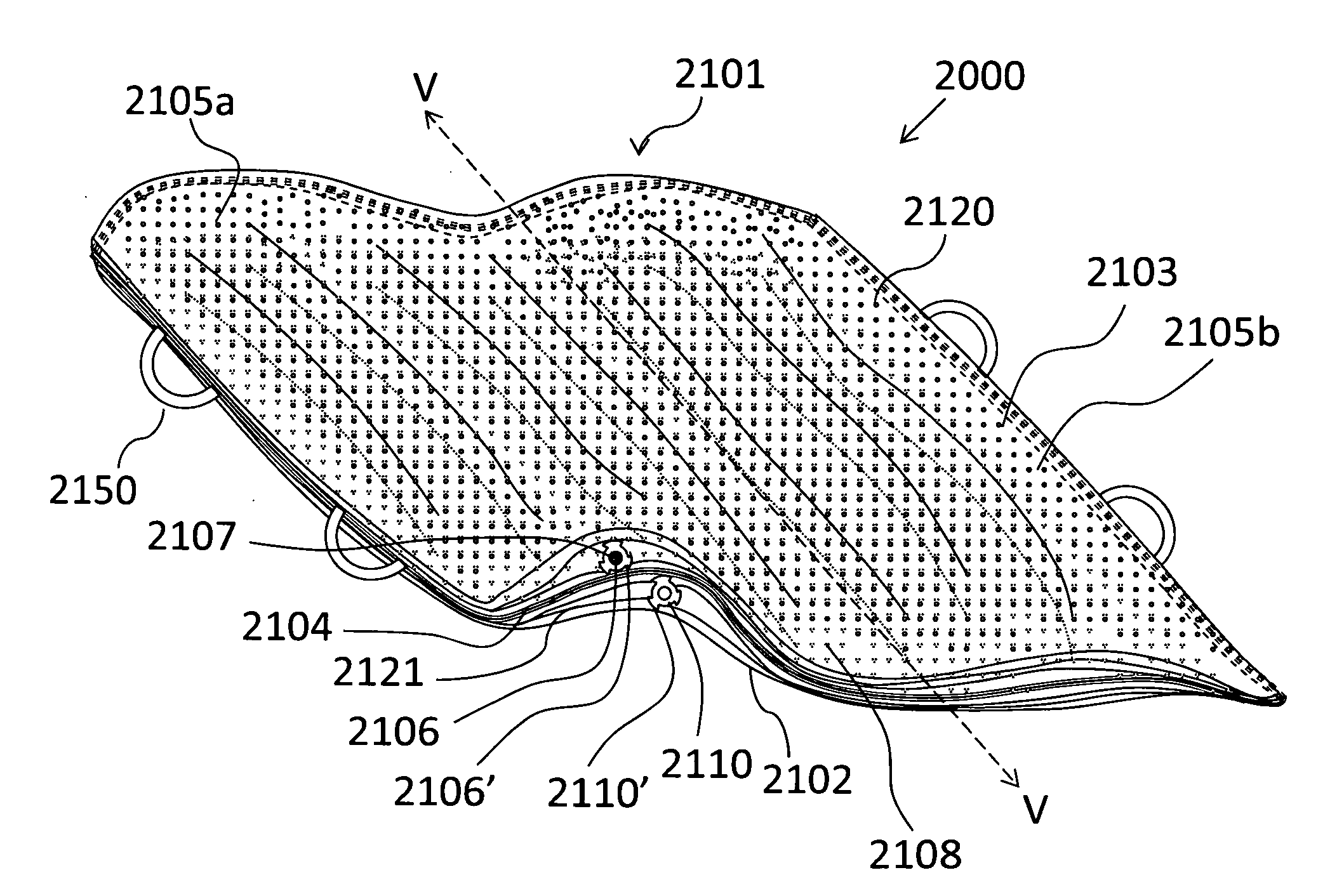

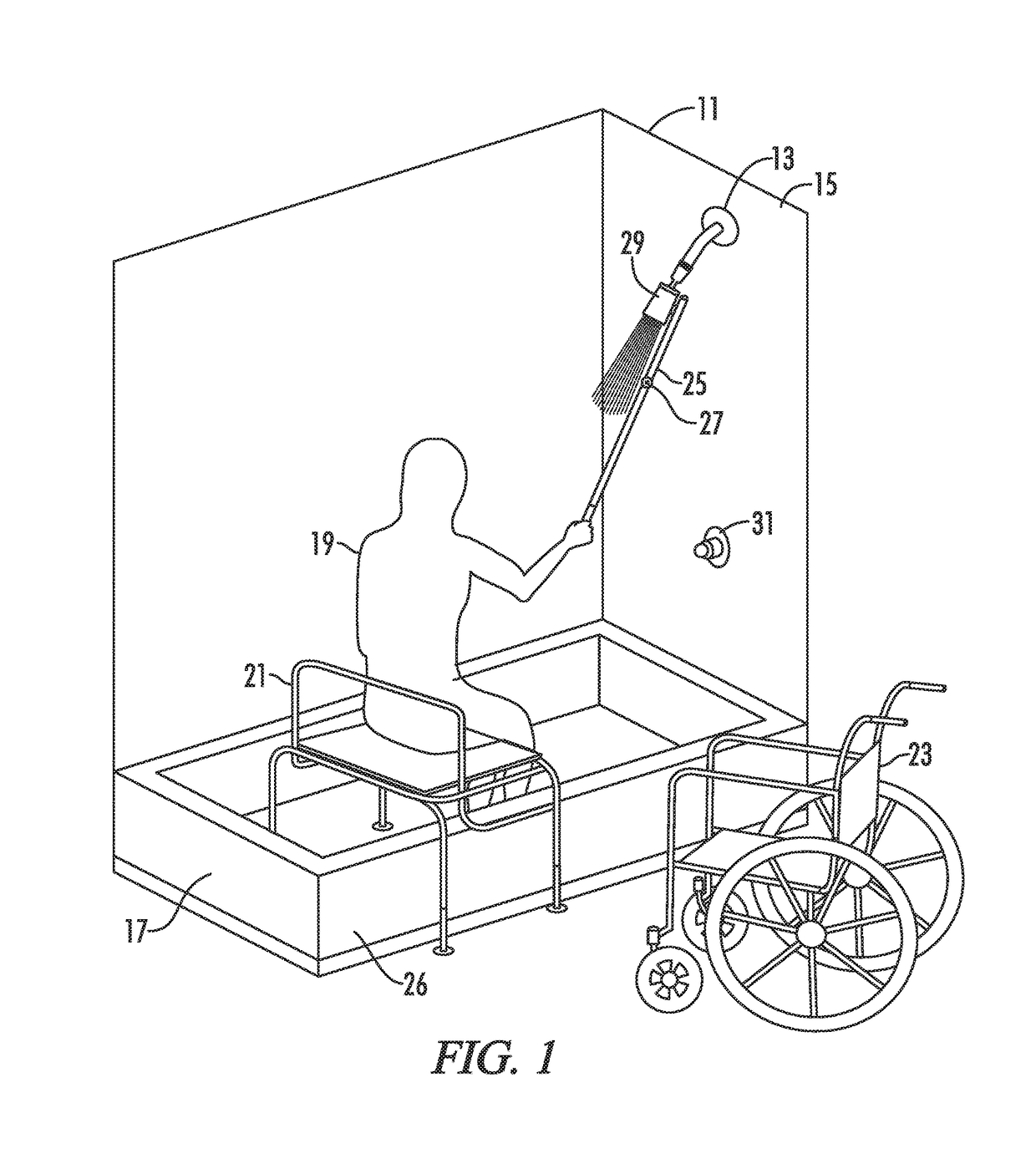

Patient lifter with intraoperative controlled temperautre air delivery system

ActiveUS20150231009A1Increase the sectionAvoid painNursing bedsTherapeutic coolingTemperature controlEngineering

A combination patient-transfer and intraoperative heater device has a top and bottom chamber separated by a barrier. The patient rests on the top chamber, which has a plurality of apertures for discharge of temperature-controlled filtered heated or cooled air at a regulated pressure for patient comfort and mitigation of infection. Heated or cooled filtered air is delivered to the area surrounding the patient, maintaining body temperature during anaesthesia. The bottom chamber has a plurality of apertures. When air pressure is low or off, the bottom chamber is flat and un-inflated. When air pressure is increased, air enters the bottom chamber and the apertures emit air, creating an air cushion facilitating lateral movement of the lifter device. The device performs two functions that now require separate devices and air blowers, it saves space and reduces both costs and complexity in the operating room while mitigating risk of infection.

Owner:PGL 2020 SLAT

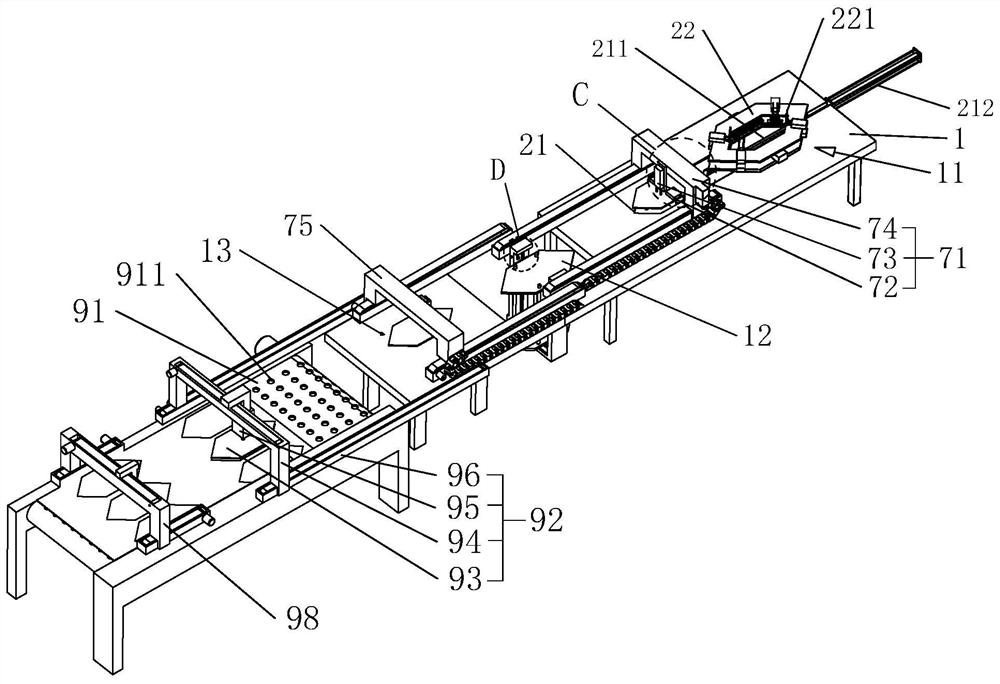

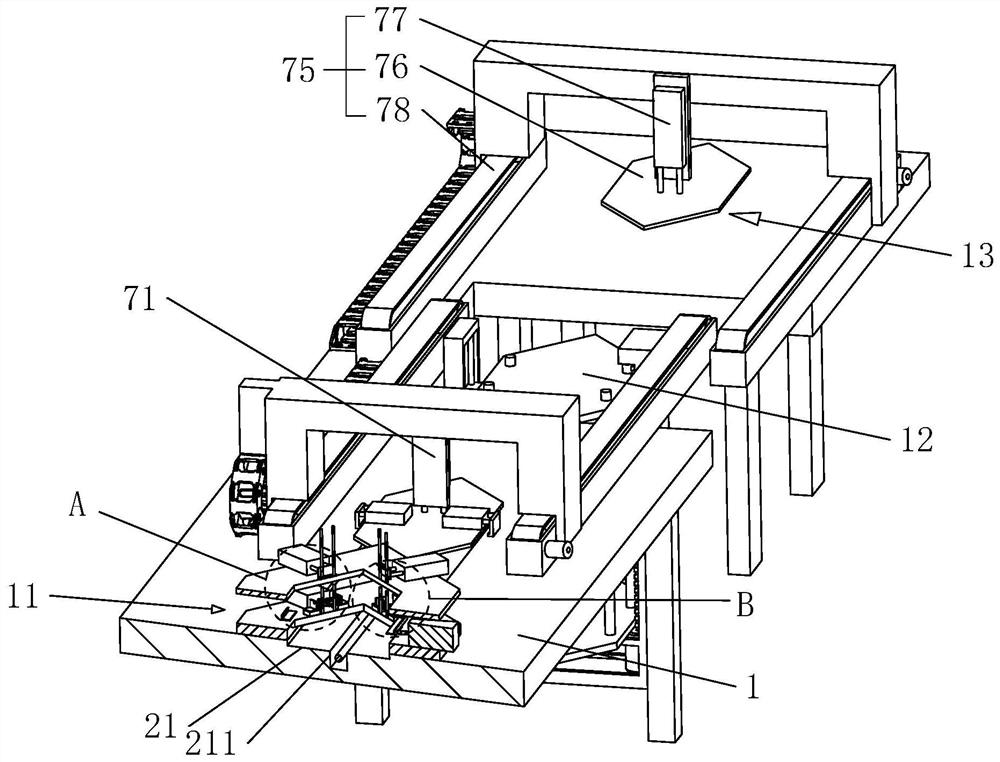

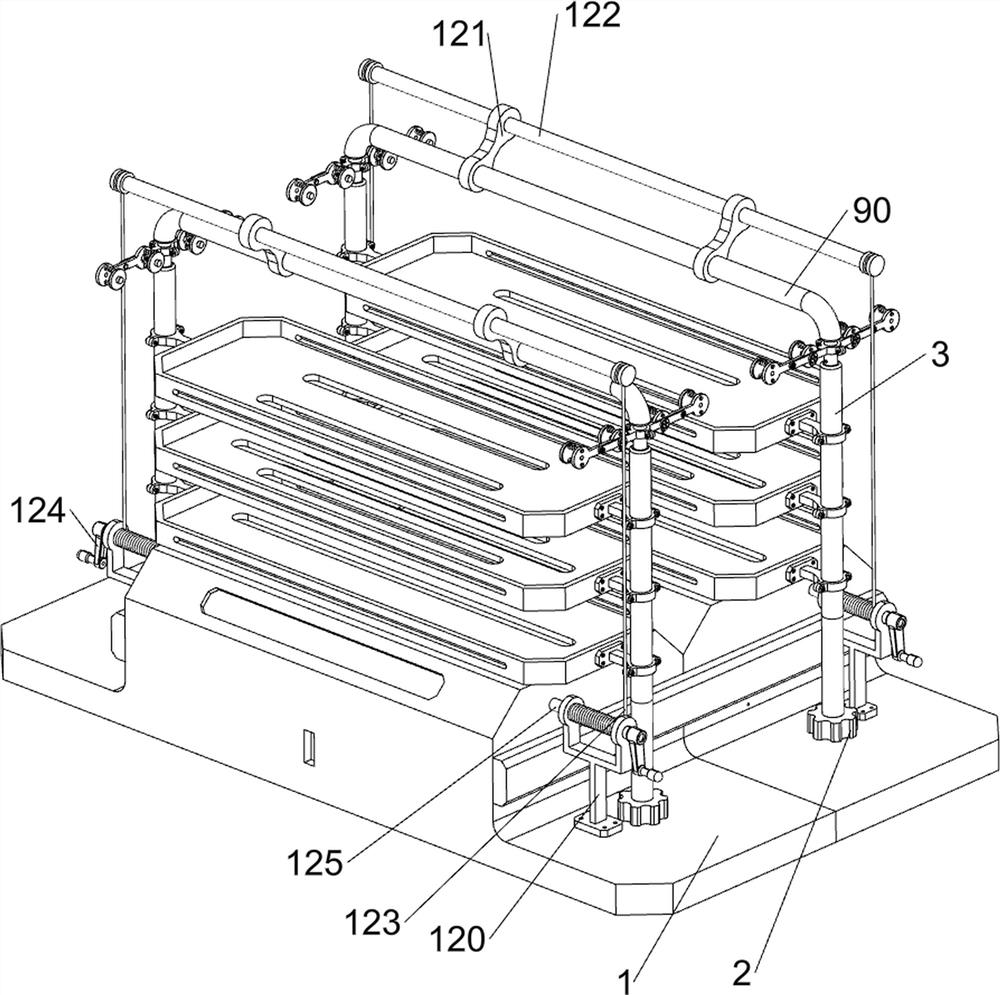

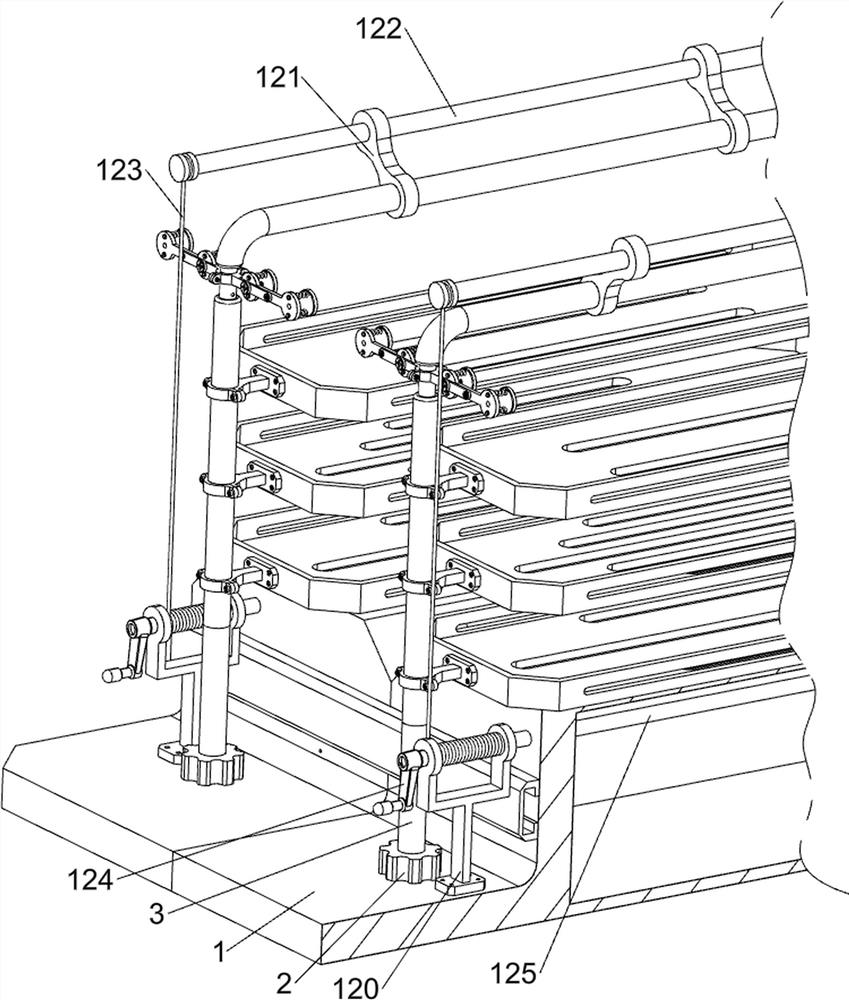

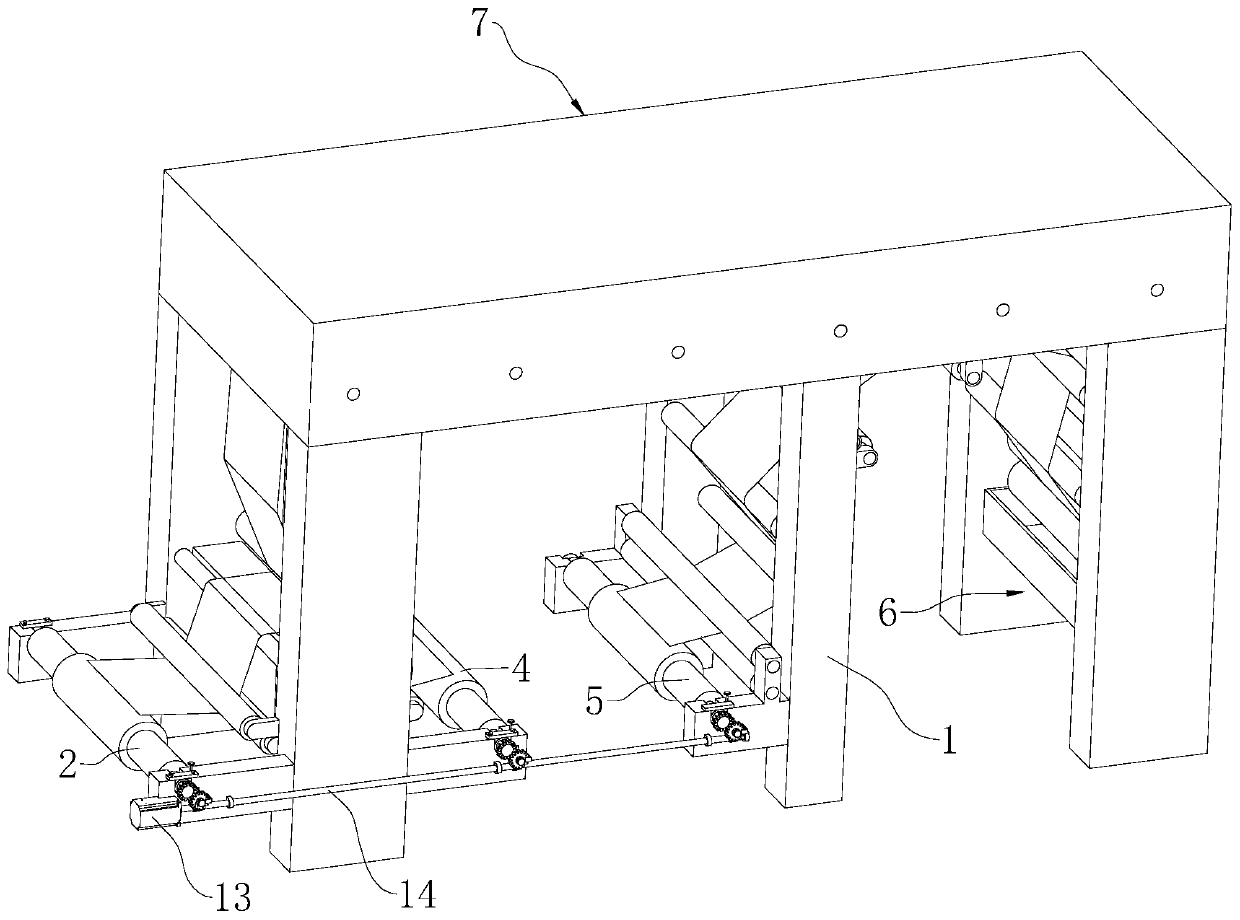

Automatic production line of total heat exchange core, and cutting and conveying structure thereof

ActiveCN112248109AProcess stabilityHigh degree of automationMetal working apparatusProduction lineEngineering

The invention relates to a cutting and conveying structure of an automatic production line of a total heat exchange core. The cutting and conveying structure comprises a rack, a conveyor belt used forplacing and conveying a diaphragm to be cut, a cutting mechanism arranged on the rack and used for cutting the diaphragm, and a conveying mechanism used for taking out the cut diaphragm; the conveying mechanism comprises a conveying sucker, a first driving part for driving the conveying sucker to move in the width direction of the rack, a second driving part for driving the conveying sucker to move up and down, and a third driving part for driving the conveying sucker to move in the length direction of the rack, and an auxiliary lifting mechanism is arranged on the rack, and comprises a jet head; air holes are formed in the surface of the conveyor belt, and the jet head is arranged on the rack, and located below the diaphragm; and the jet head is connected with an air source, and used forblowing air to the bottom surface of the diaphragm. The cutting and conveying structure has the effects of assisting the conveying sucker in sucking the cut diaphragm, and reducing the probability ofpulling the whole diaphragm during diaphragm sucking.

Owner:绍兴百立杰环保科技有限公司

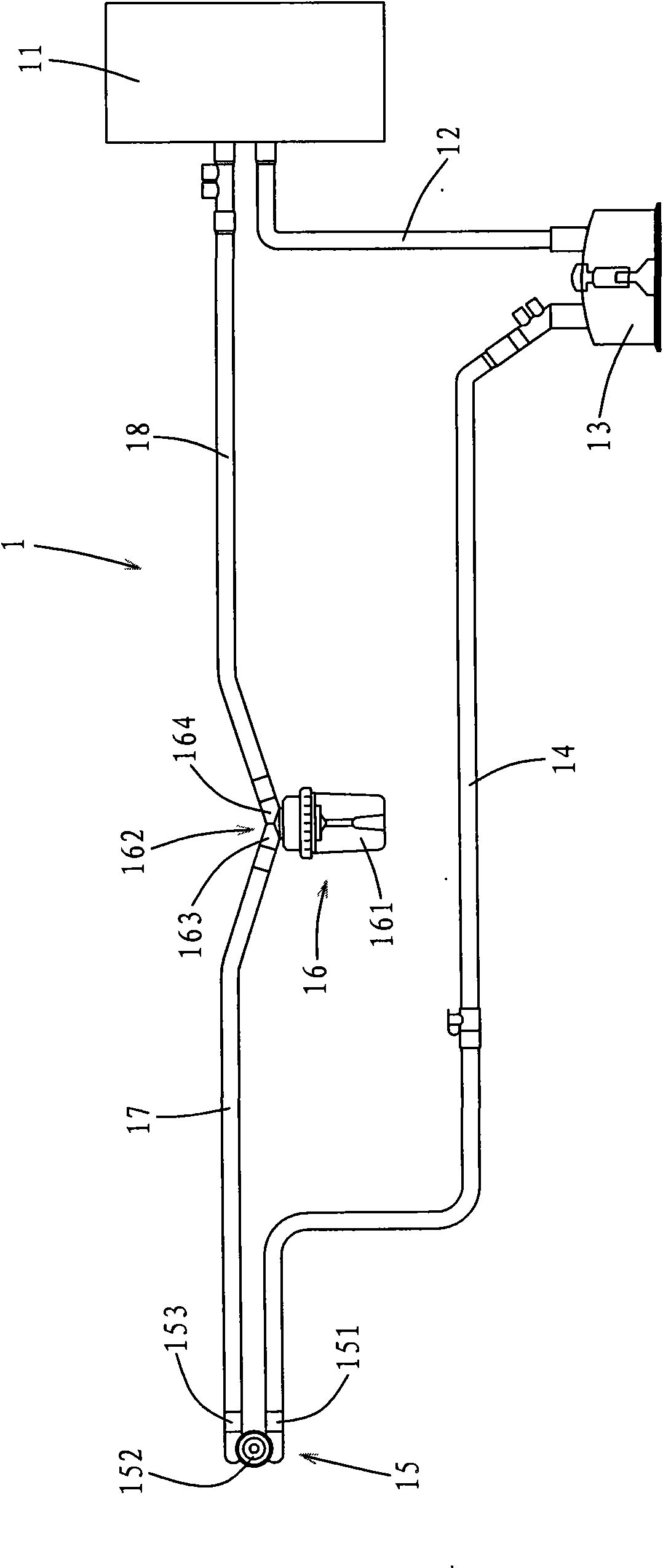

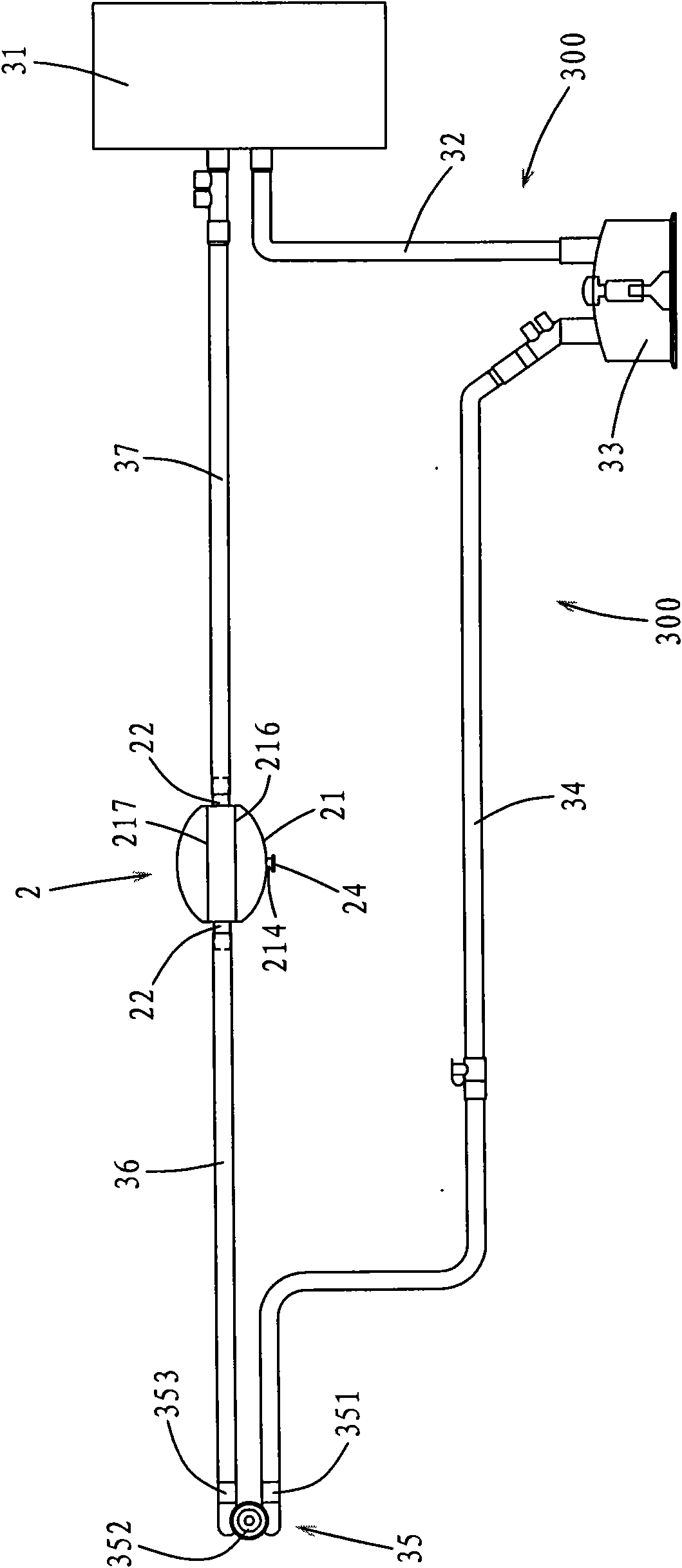

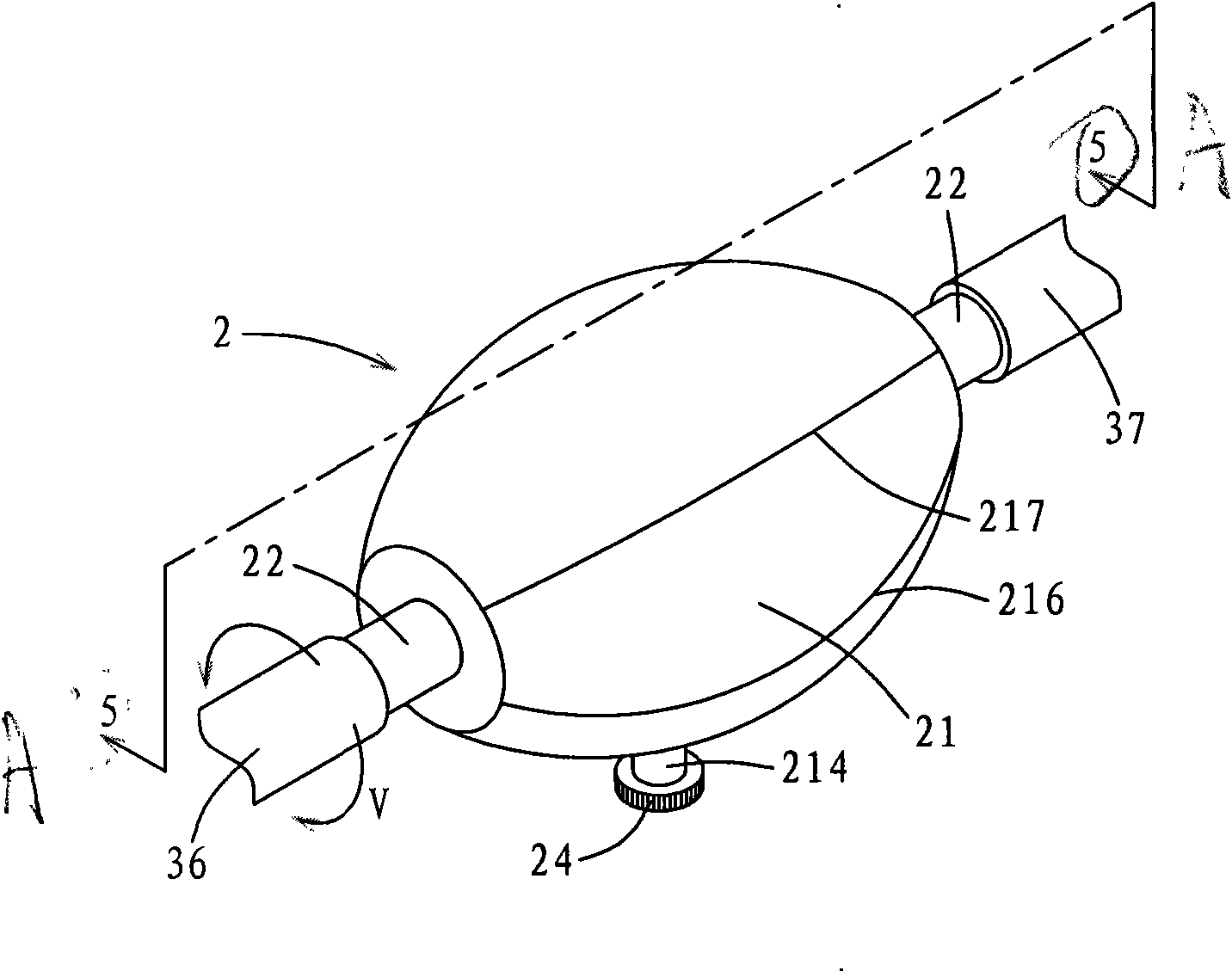

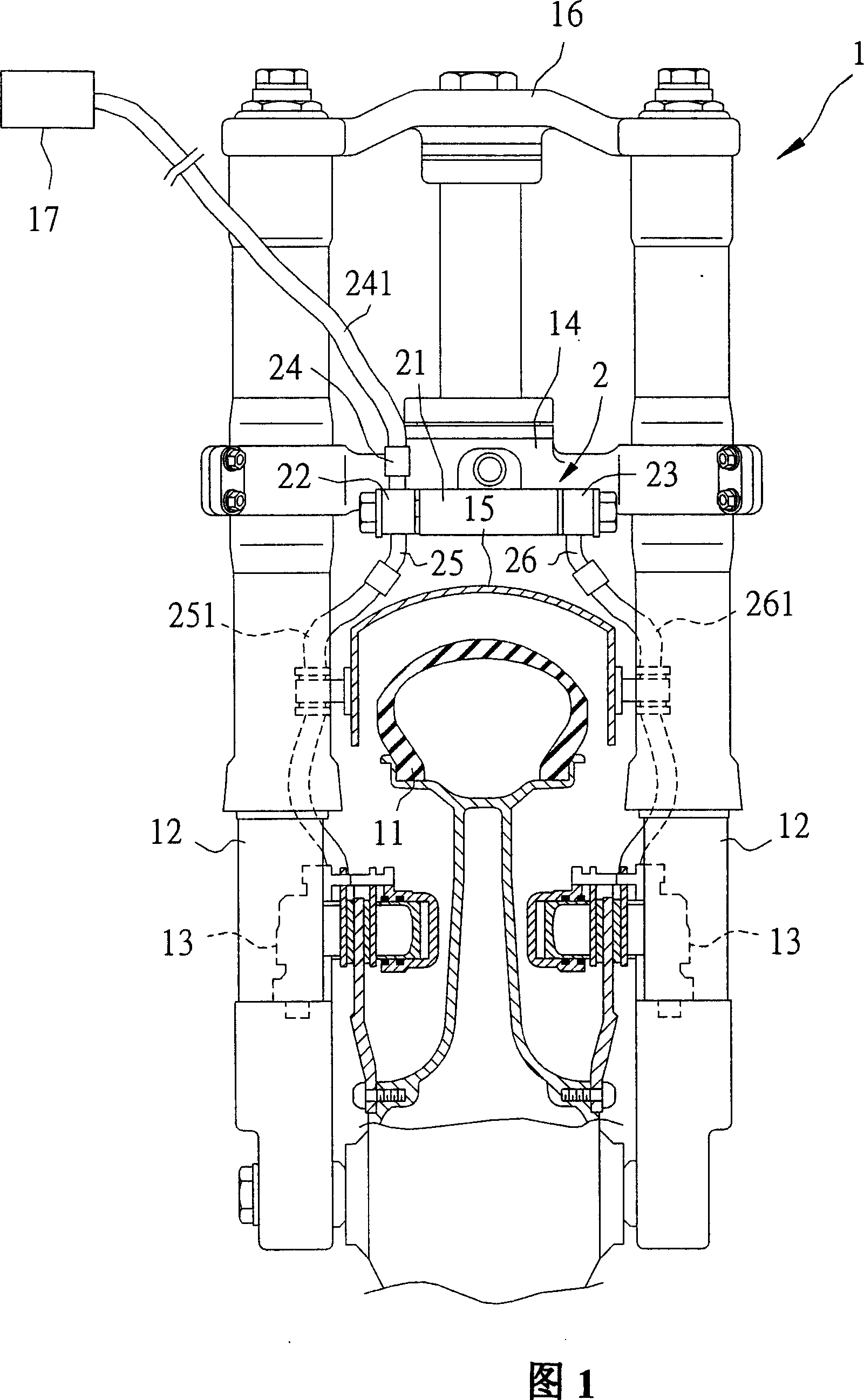

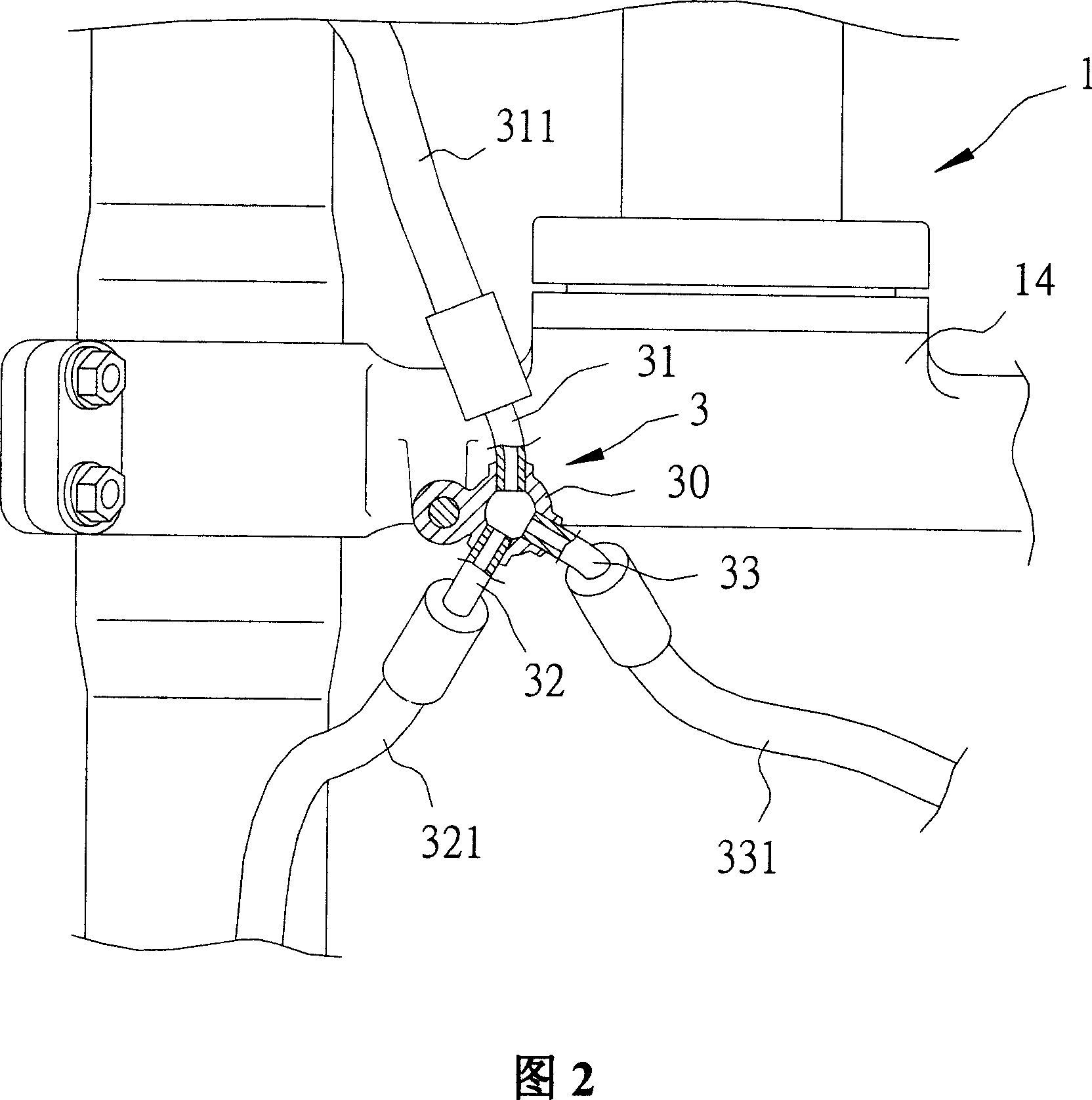

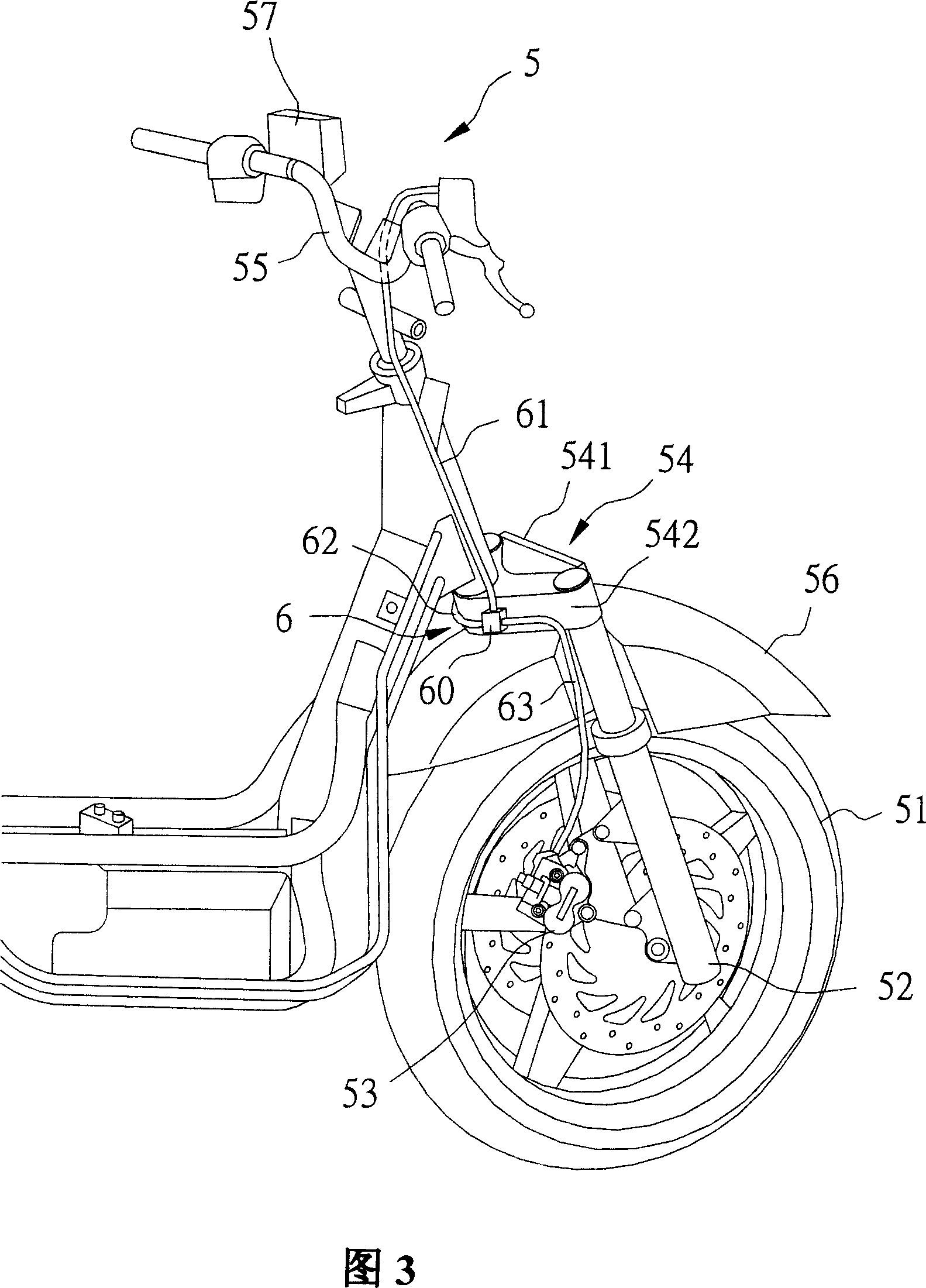

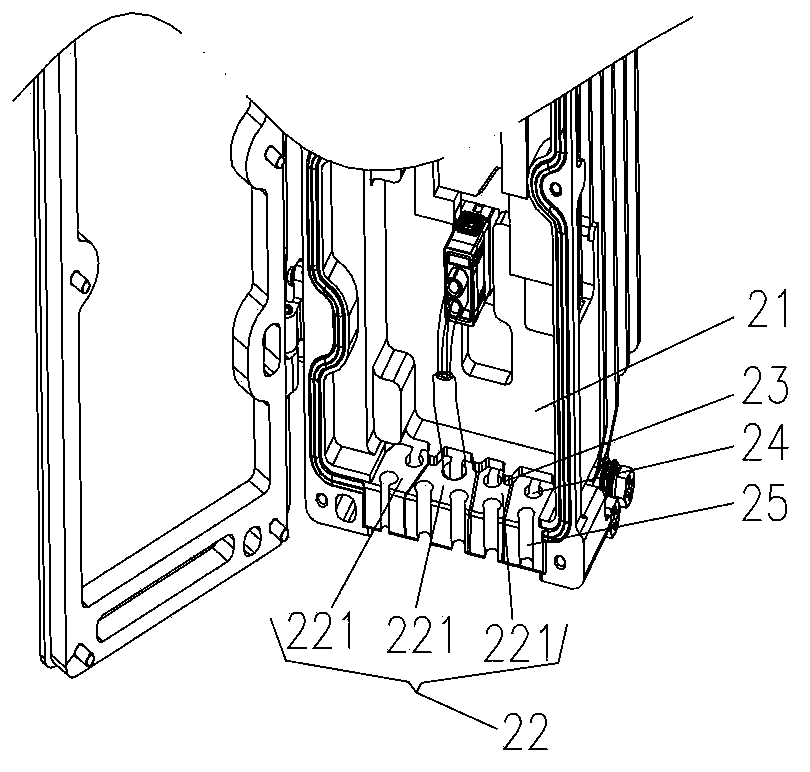

Motorcycle brake oil pipe device

InactiveCN1935589AAvoid damageLow costCycle brakesElectric/fluid circuitDisc brakePetroleum engineering

The invention is a motorcycle brake oil pipe device, equipped on a front wheel steering device of a motorcycle to transmit oil, and comprising a three-way piece, a first oil pipe, a second oil pipe and a third oil pipe, where the first oil pipe is connected with the three-way piece and a handle steering piece, the second and third oil pipes connect the three- way piece with two disc brake units arranged on a front wheel, respectively, and it is important that the three-way piece is configured in the back of a triangular platform. Thus, when turning to the left or right, it can effectively reduce length change caused by turning, so as to reduce the dragging and squeezing to the first oil pile and reduce the damage; besides, it can make the second and third oil pipes relatively not limited in configurations and thus save the costs.

Owner:KYMCO

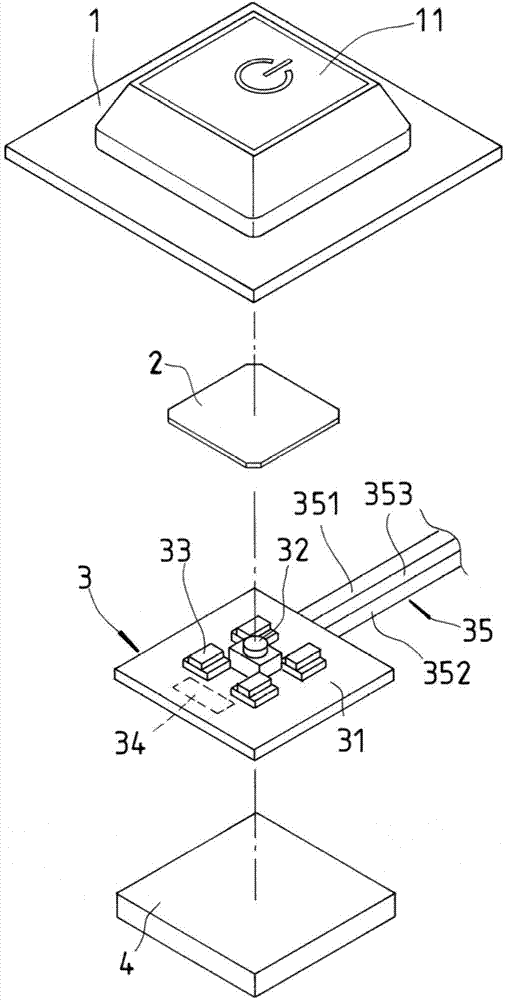

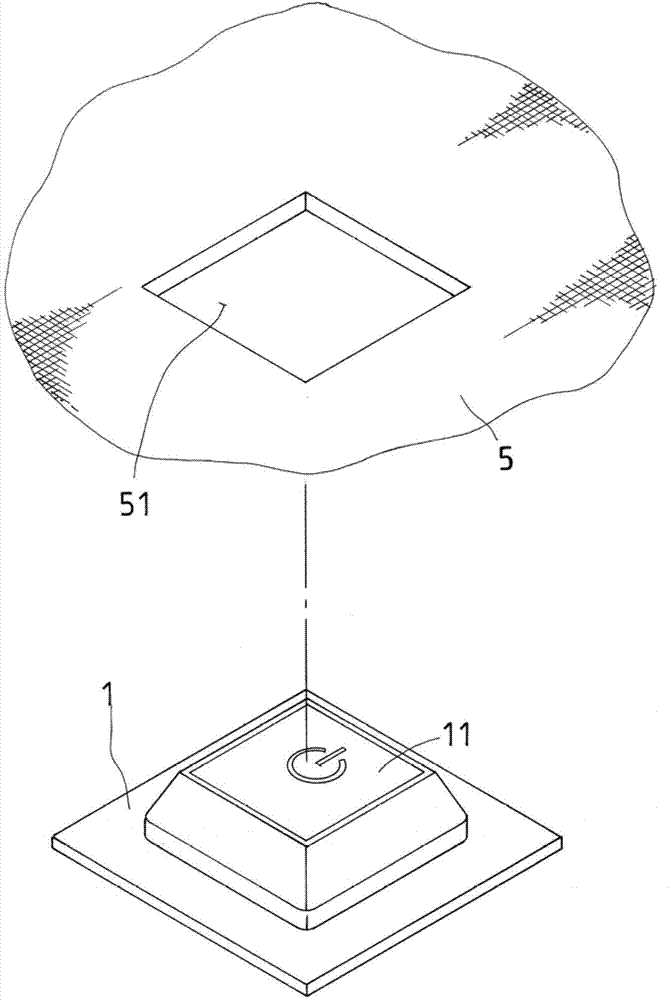

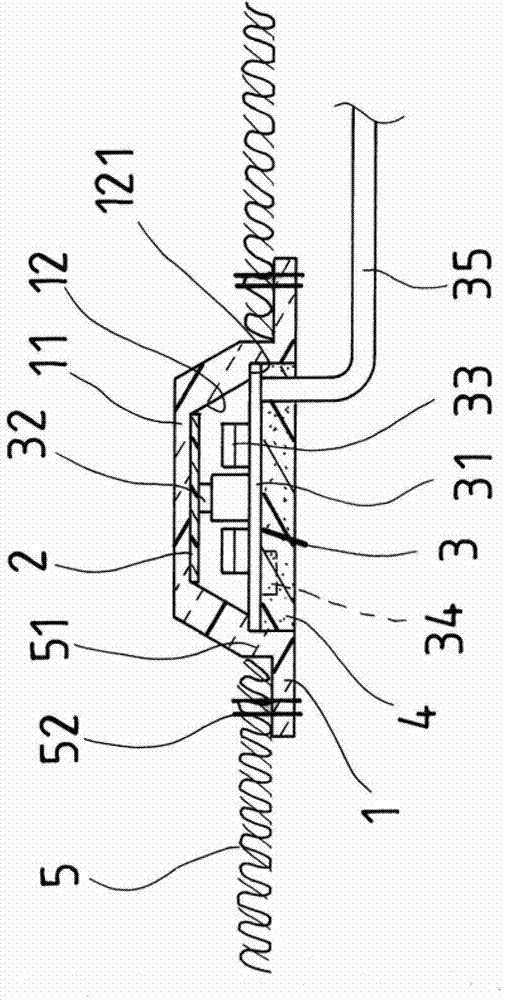

Temperature control key stitched in clothes

InactiveCN103584380AEasy to fixReduce pullingElectric switchesProtective garmentEngineeringTemperature control

The invention relates to a temperature control key stitched in clothes. The temperature control key comprises a key body, a control unit, and a fixed piece. A pressing portion arranged at the center of an upper surface in a protruding manner is arranged in through holes of the clothes, a concave holding groove portion is formed at the back of the pressing portion, and the key body is connected with the clothes in a stitching manner along the periphery of the pressing portion. The control unit is held on a holding groove portion of the key body. The fixed piece is arranged at the back of the key body, the control unit is fixed in the holding groove portion of the key body, and a conductor wire of the control unit extends out of the fixed piece and is hidden in the clothes. By the aid of the temperature control key stitched in the clothes, overall beauty of the clothes can be improved, the temperature control key and the conductor wire can be prevented from falling out of the clothes and further causing friction, pressing or pulling with outside objects, and accordingly quick damages of the temperature control key and the conductor wire are avoided.

Owner:陈建州

Ultrapolar telescopic electrosurgery pencil

ActiveUS20180014875A1Precise cuttingEffectively and efficiently accessingSurgical instruments for heatingSurgical instruments for aspiration of substancesSurgical operationElectrosurgery

An ultrapolar telescopic electrosurgery pencil / handpiece with or without smoke evacuation that is capable of cutting with a sharp non-conductive cutting end of an electrosurgery blade and cutting and coagulating with activation of active and return contacts both contained on each side of the electrosurgery blade.

Owner:IC MEDICAL

Knitted textile storage rack for textile sales

InactiveCN114343396AEasy to useNot easy to moveShow shelvesFeetMechanical engineeringIndustrial engineering

The invention relates to a storage rack, in particular to a knitwear and textile storage rack for textile sales. According to the knitwear and textile storage rack for textile sales, the storage rack can be moved, and use is more convenient. A knitwear and textile storage rack for textile sales comprises two supporting frames which are in contact with each other; the fixing blocks are arranged on the left sides and the right sides of the tops of the two supporting frames; the supporting rods are arranged at the tops of the four fixing blocks; and three first fixing rings are uniformly arranged at the upper parts of the four supporting rods at intervals. People push the supporting frame to move on the ground through the universal wheels, so that the storage rack is moved to the position where the storage rack needs to be used, people press the brake valve and control the universal wheels to move, the universal wheels stop rotating, and therefore the storage rack can be moved, and use is more convenient.

Owner:深圳市雅奥家纺有限公司

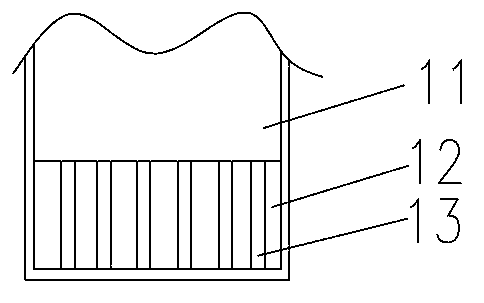

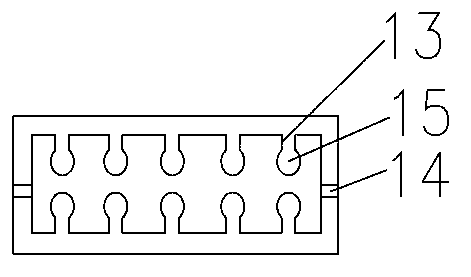

BBU wire distribution cavity

ActiveCN104143797AReduce pullingReduce the chance of damageElectrical apparatusFibre mechanical structuresEngineering

The invention discloses a BBU wire distribution cavity and relates to the technical field of mobile communications. The BBU wire distribution cavity solves the problem that when a damaged cable is maintained or replaced, other cables not needing to be maintained or replaced are prone to being pulled and damaged in the process of drawing the damaged cable out of a through hole. The BBU wire distribution cavity comprises a cavity body and a waterproof cable module, a cable interface and a fixing unit are arranged in the cavity body, the fixing unit is used for fixing the waterproof cable module, the waterproof cable protective module is provided with through holes for cables, each through hole is provided with a notch in the cable routing direction, the notches penetrate through the waterproof cable module, and the width of each notch is smaller than the diameter of the cable penetrating through the corresponding through hole, so that the cables are pressed into the through holes through the notches. The BBU wire distribution cavity is applicable to BBU equipment.

Owner:LINYI YIQUN PACKAGING PROD CO LTD

Tissue heating device and RF heating method with tissue attachment feature

InactiveUS7172590B1Highly accurate and fine cutReduce pullingCatheterSurgical instruments for heatingElectrical resistance and conductanceElectrical conductor

A tissue cutting device includes a catheter with a window at its distal tip for admitting tissue into a catheter compartment. A cylindrical cartridge in the compartment has a cutting edge that supports an electrically conductive cutting element, e.g. a band or wire. The cutting element and adjacent tissue can be heated to a selected temperature by generating an electrical current through the cutting element. The catheter is maneuverable to position its distal end near the tissue to be cut. The catheter incorporates a dilatation balloon or other feature to urge the catheter against the tissue, so that at least part of the tissue may enter the compartment through the window. Then, the cartridge is manipulated from the catheter's proximal end to move the cutting edge across the window, cutting the tissue. According to alternative embodiments, the cartridge is either rotated or moved axially relative to the catheter and, in either event may be capable of closing the catheter window when the cut is complete. Further alternatives involve either placing an indifferent electrode on the patient and providing an RF signal via a single conductor to the cutting element for ohmic heating, or providing an RF (or a DC) current through the cutting element and two separate conductors for direct resistive heating of the cutting element.

Owner:CARDIOVASCULAR TECH INC

Laminating machine

ActiveCN110466237AReduce pullingQuality improvementLamination ancillary operationsLaminationDrive shaftGear wheel

The invention relates to a laminating machine. The laminating machine comprises a frame, and further comprises a first unwinding roller, a laminating roller, a winding-up roller, a second unwinding roller and a gluing device sequentially arranged along the length direction of the frame, and a drying device arranged above the frame, wherein the first unwinding roller, the laminating roller, the winding-up roller and the second unwinding roller are arranged in parallel and are rotatably connected with the frame separately; both the first unwinding roller and the second unwinding roller are arranged to rotate along a direction opposite to the rotation direction of the winding-up roller; the same sides of the first unwinding roller, the winding-up roller and the second unwinding roller are coaxially and fixedly provided with gears I respectively, and the frame is correspondingly provided with gears II engaged with the gears I; the frame is also provided with a motor; the output shaft of the motor is coaxially fixed with a driving shaft which is arranged perpendicular to the first unwinding roller; the driving shaft is provided with three sets of gear transmission members that are in transmission connection with the gears II respectively; and the frame is further provided with a driving member used for removing linkage between the gear transmission members and the gears II. The laminating machine of the invention can ensure synchronous unwinding and winding-up of cloth and improve the quality of cloth lamination.

Owner:杭州宏达装饰布织造有限公司

Shower control

An economical shower conversion arrangement for enabling physically challenged persons to shower while seated without assistance embodying a showerhead mount including a pivotable control arm or handle connected to the showerhead assembly which arm is securable in multiple use positions so as to be easily reached and operated by a person seated in a shower chair to adjust the direction of water flow from the showerhead by application of a manual force upon the arm, which arm may be pivoted into a non-use position that does not obstruct use of the shower by non-disabled or standing persons, and including an adjustable balance support to aid in controlling the handle assembly while reducing the amount of stress on the pipe connections and fittings.

Owner:SHOEMAKER DAVID P

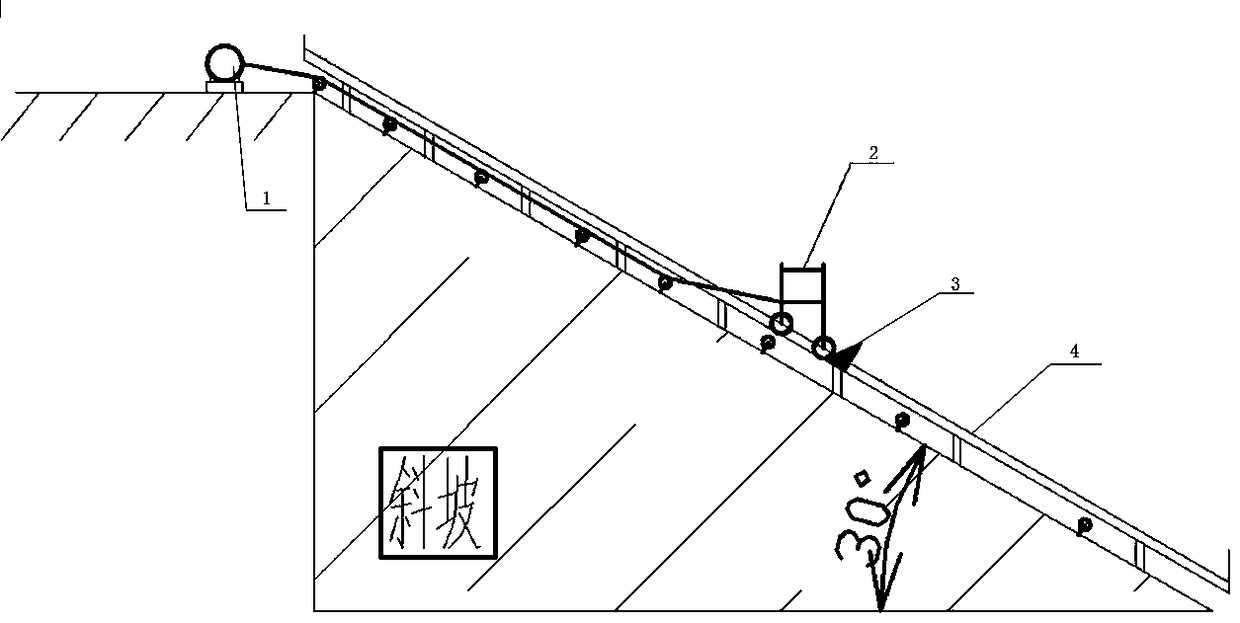

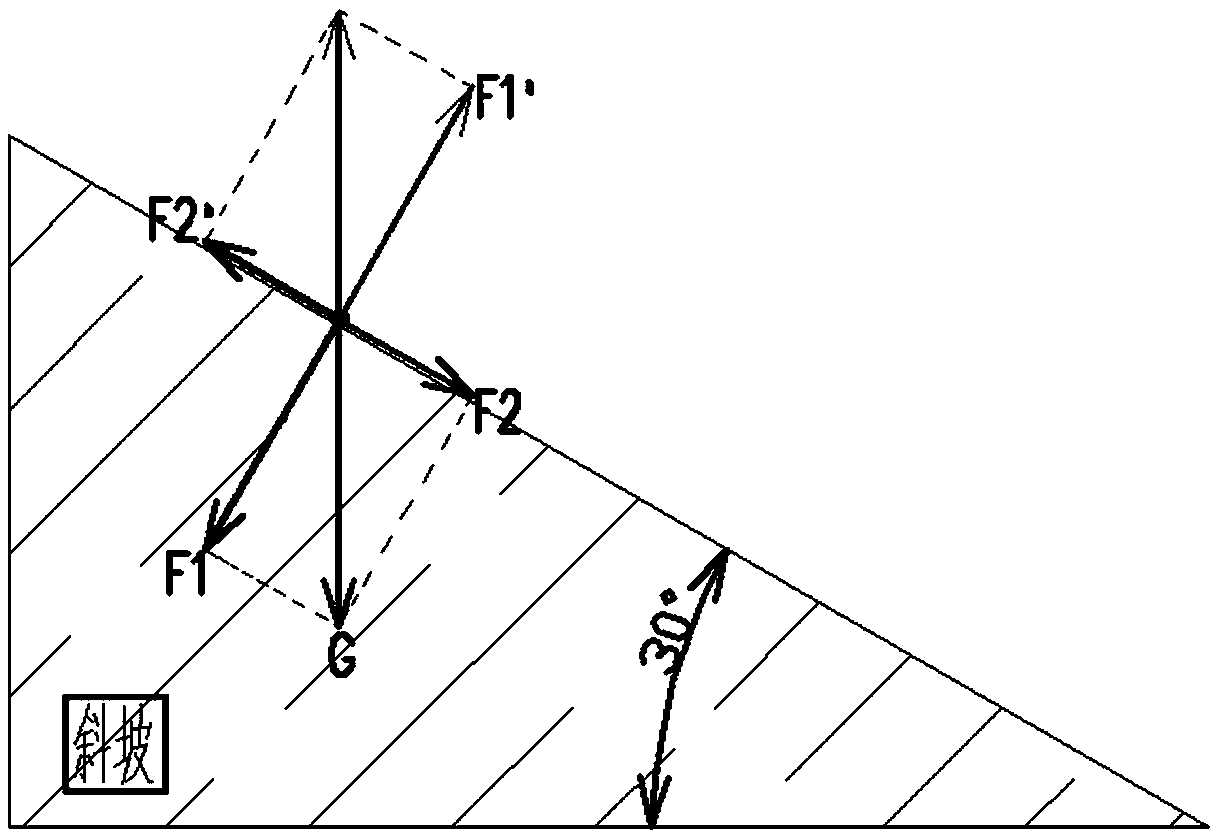

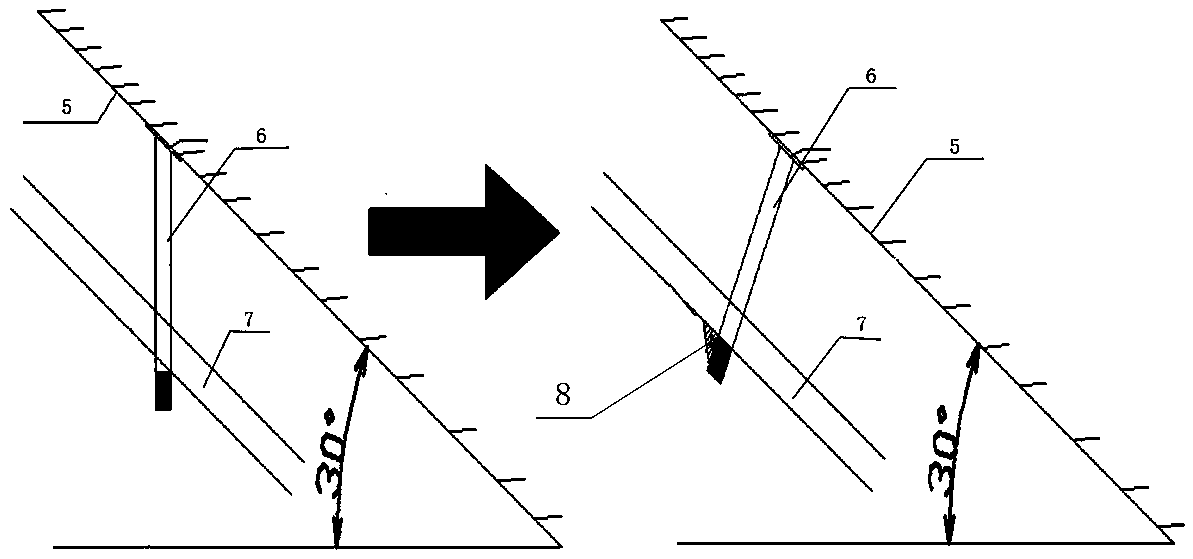

Mechanical and electrical installation construction method for entrance and exit of long heavy grade of subway

ActiveCN108899807AImprove transportation efficiencyEnsure safetyApparatus for laying cablesTransit systemBlock and tackle

The invention relates to a subway construction process, in particular to a mechanical and electrical installation construction method for the entrance and the exit of a long heavy grade of a subway. The construction method adopts a train guide rail operation principle, a simple guide rail, a power system, a brake system and transportation equipment are arranged to construct a long heavy grade guide rail material and equipment transportation system, and the problem of low material transportation efficiency is solved. A triangle stability principle is applied, a measurement of preventing forwardslippage and overturn is taken on the basis of the characteristic of the long heavy grade, an operation platform is erected in a staged and graded manner, and the safety of operators is ensured. A BIM technology is adopted as a guide in the construction process, the bracket direction is changed, the quantity of inclined fixed brackets is increased, a traditional bracket is improved, the practicality and the operability are improved, and the stability of an electromechanical system is enhanced. A large-section cable transportation system is self-made by combining a pulley block with a windlass, and the pull-up problem of a large-section cable is solved; and bunched rigid cables are arranged one by one by a self-made F-type wrench, so that the problem of jumbled arrangement of the bunched rigid cables is solved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

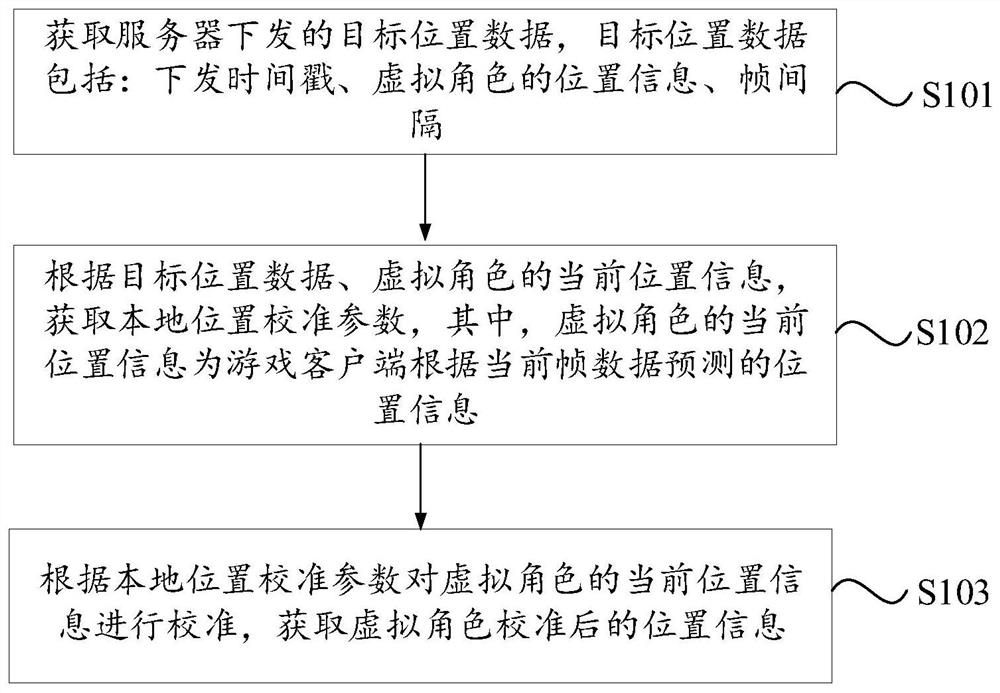

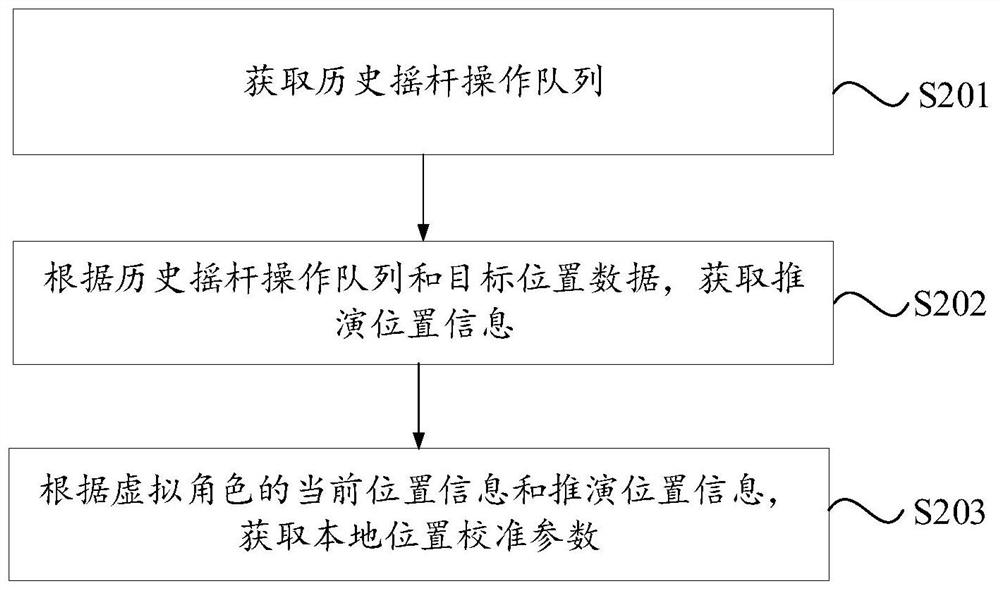

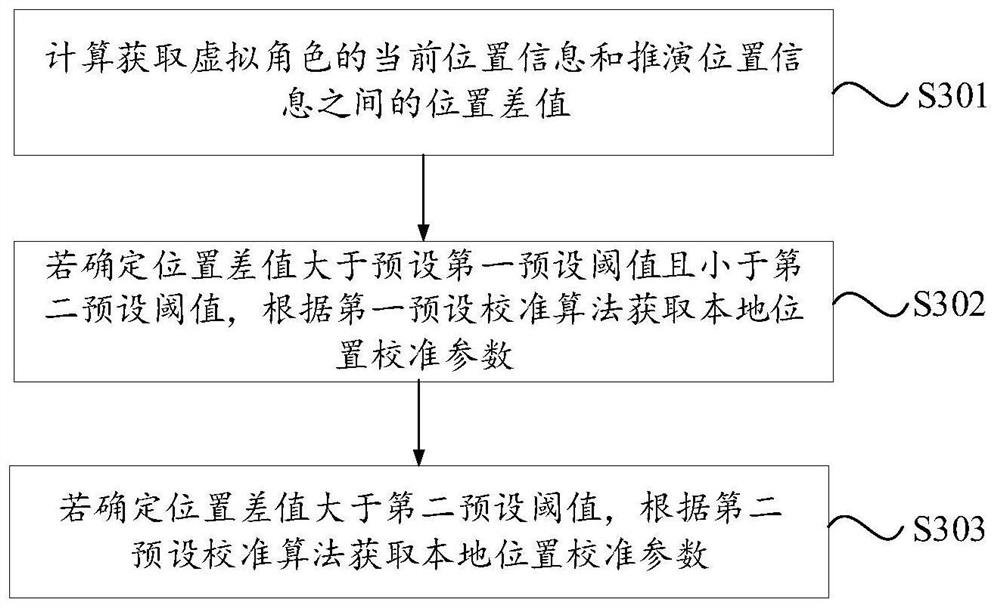

Action synchronization method and device in game, electronic equipment and storage medium

The invention provides an action synchronization method and device in a game, electronic equipment and a storage medium, and relates to the technical field of games. The method can be applied to a game client, and comprises the steps: acquiring target position data issued by a server; obtaining a local position calibration parameter according to the target position data and the current position information of the virtual character, the current position information of the virtual character being position information predicted by a game client according to current frame data; and calibrating thecurrent position information of the virtual character according to the local position calibration parameter, and obtaining the calibrated position information of the virtual character. By applying the method provided by the embodiment of the invention, the calibration can be performed based on the current position information of the virtual character predicted by the game client, so that smooth rollback can be realized. Therefore, when the position of the virtual character in the game client is updated and expressed, the pulling feeling caused by synchronization can be reduced in the expression process, and the player experience is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com