Patents

Literature

2029results about How to "Reduce the chance of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

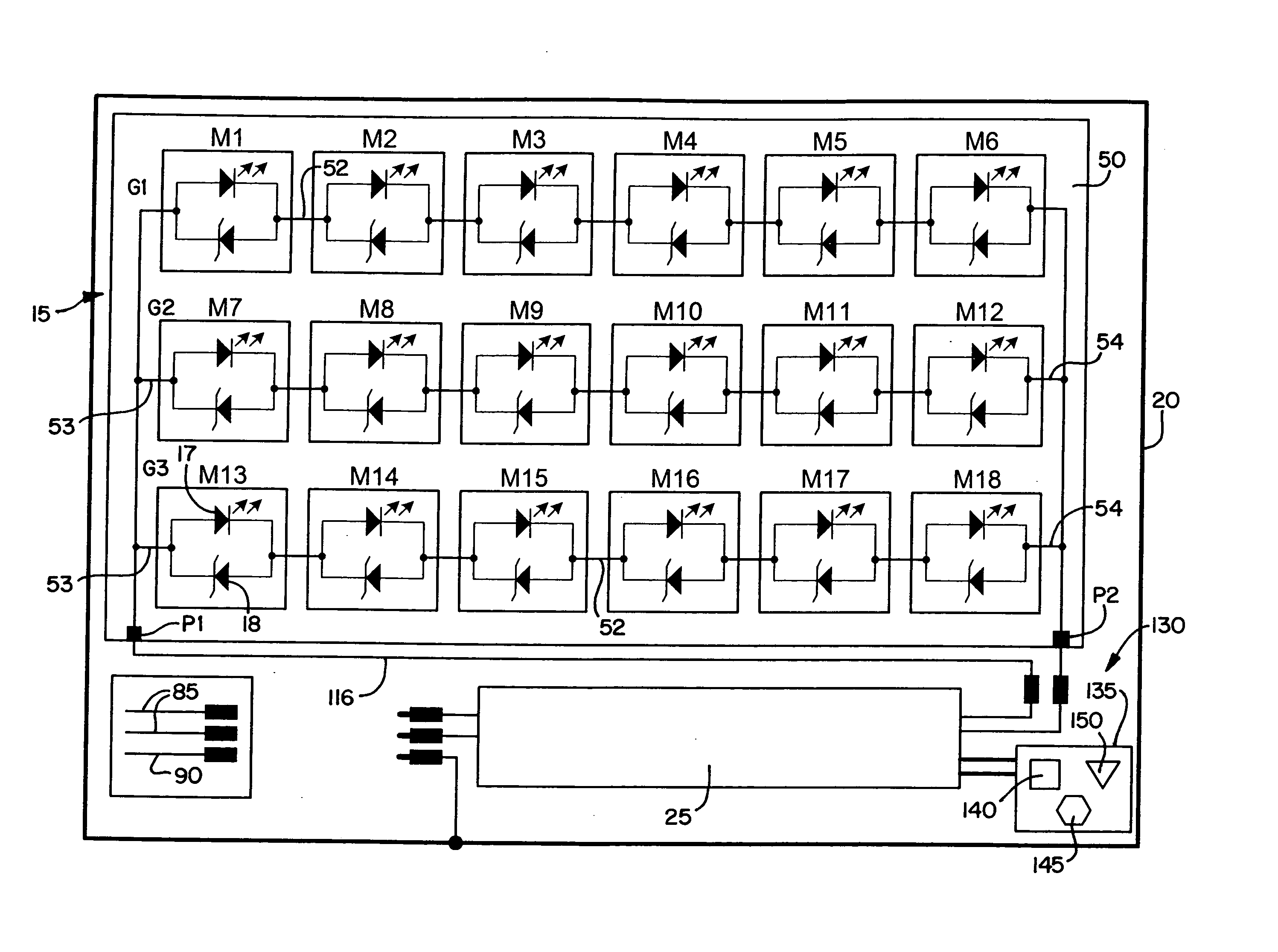

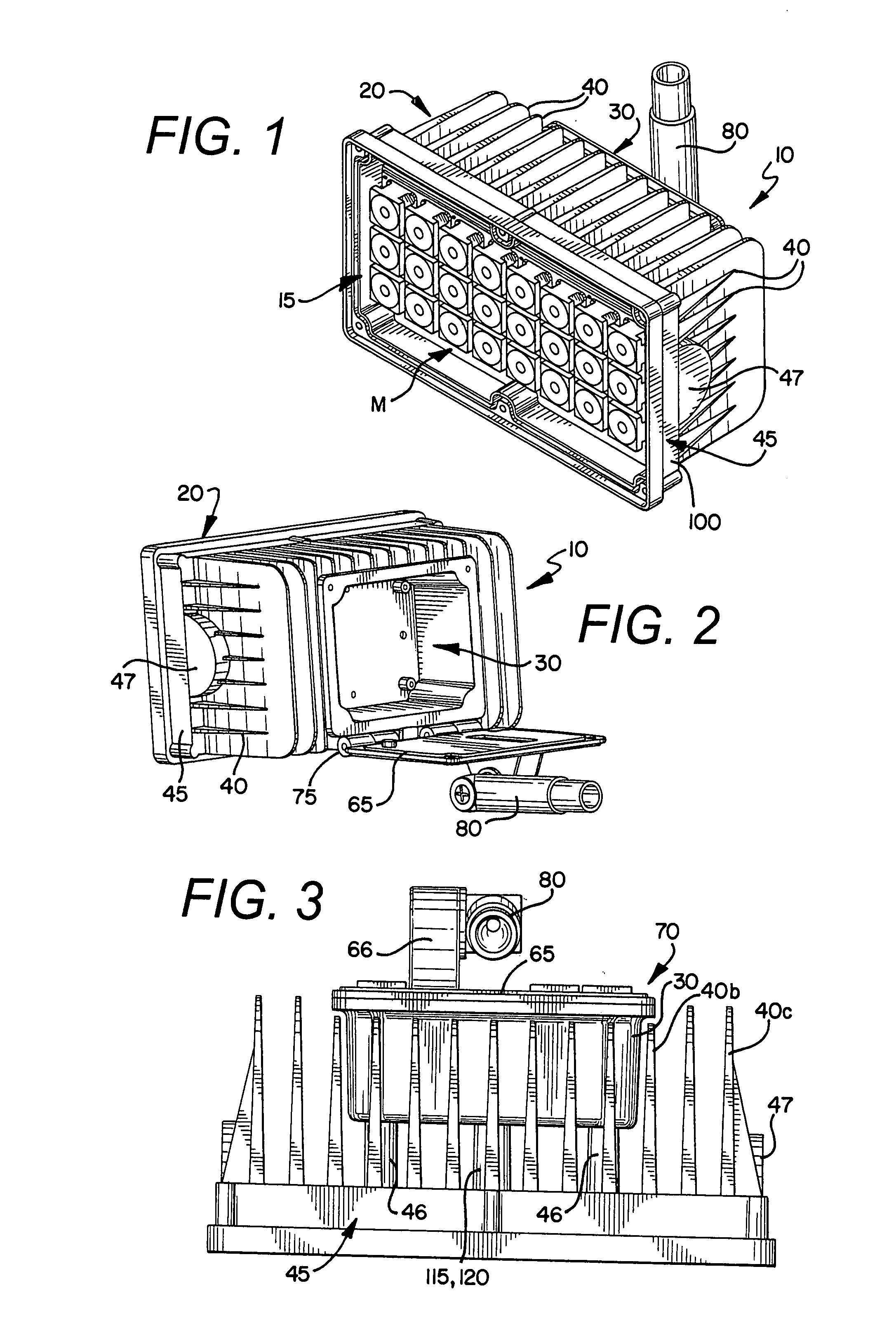

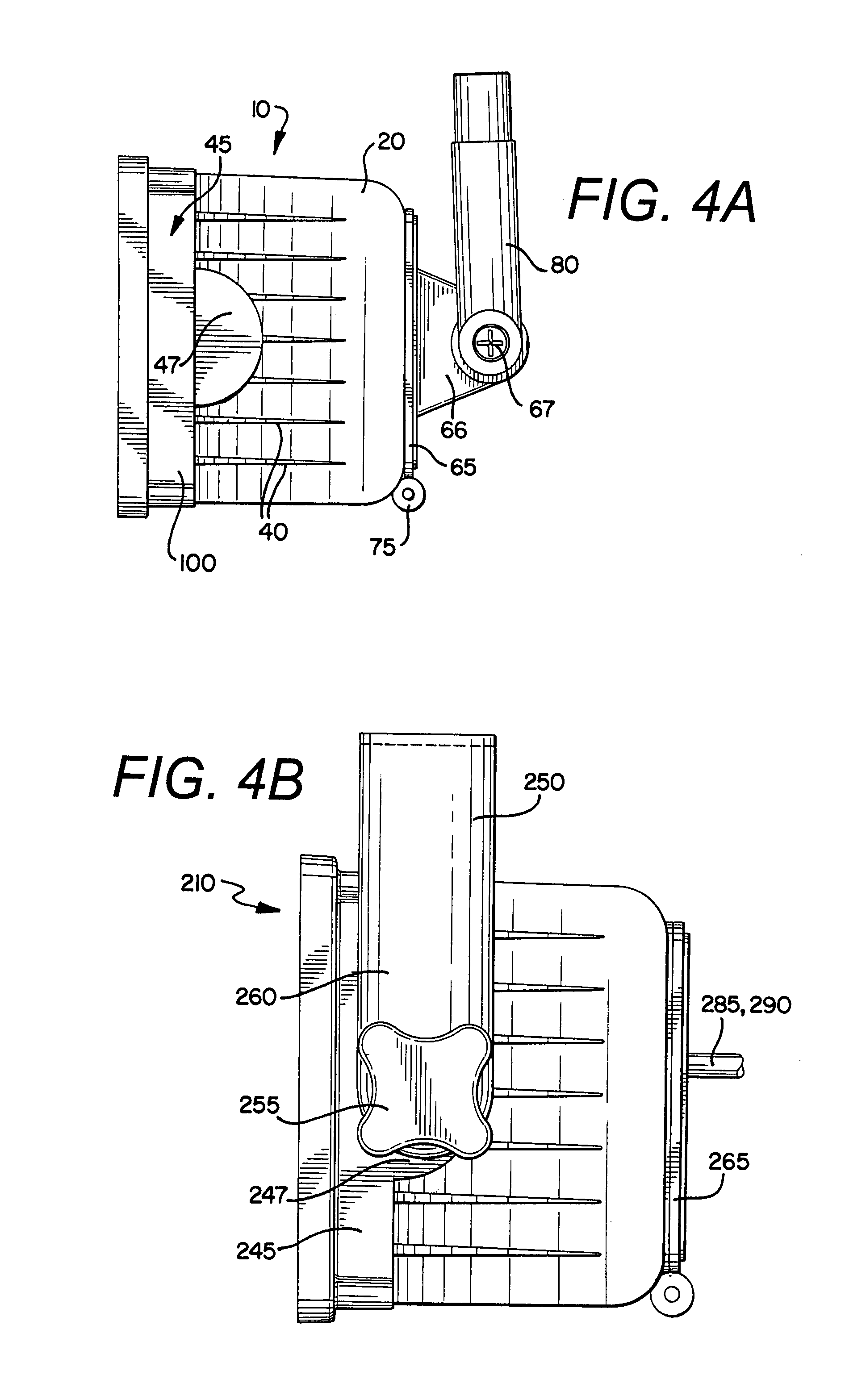

LED light fixture with internal power supply

ActiveUS20080310162A1High light outputEnergy efficientMechanical apparatusLighting support devicesHeat sinkZener diode

The invention provides a light fixture that includes a light engine, a rugged housing, and an internal power module that is thermally isolated. The light fixture includes several novel heat management features designed to thermally isolate the power supply in order to reduce the risk of failure and thereby increase the reliability of the light fixture. The light engine includes groups of light modules, each having a light emitting diode (LED) and a zener diode. The power module resides within a rear receptacle of the housing and includes a power supply, a box, and a cover that enclose the power supply. The housing also includes an arrangement of external fins that dissipate heat generated by the light engine. During operation, heat is generated by the light modules, namely the LEDs, and then is transferred along a flow path through a main body portion of the housing and the fins for dissipation to ambient without negatively impacting the power supply.

Owner:ELECTRALED

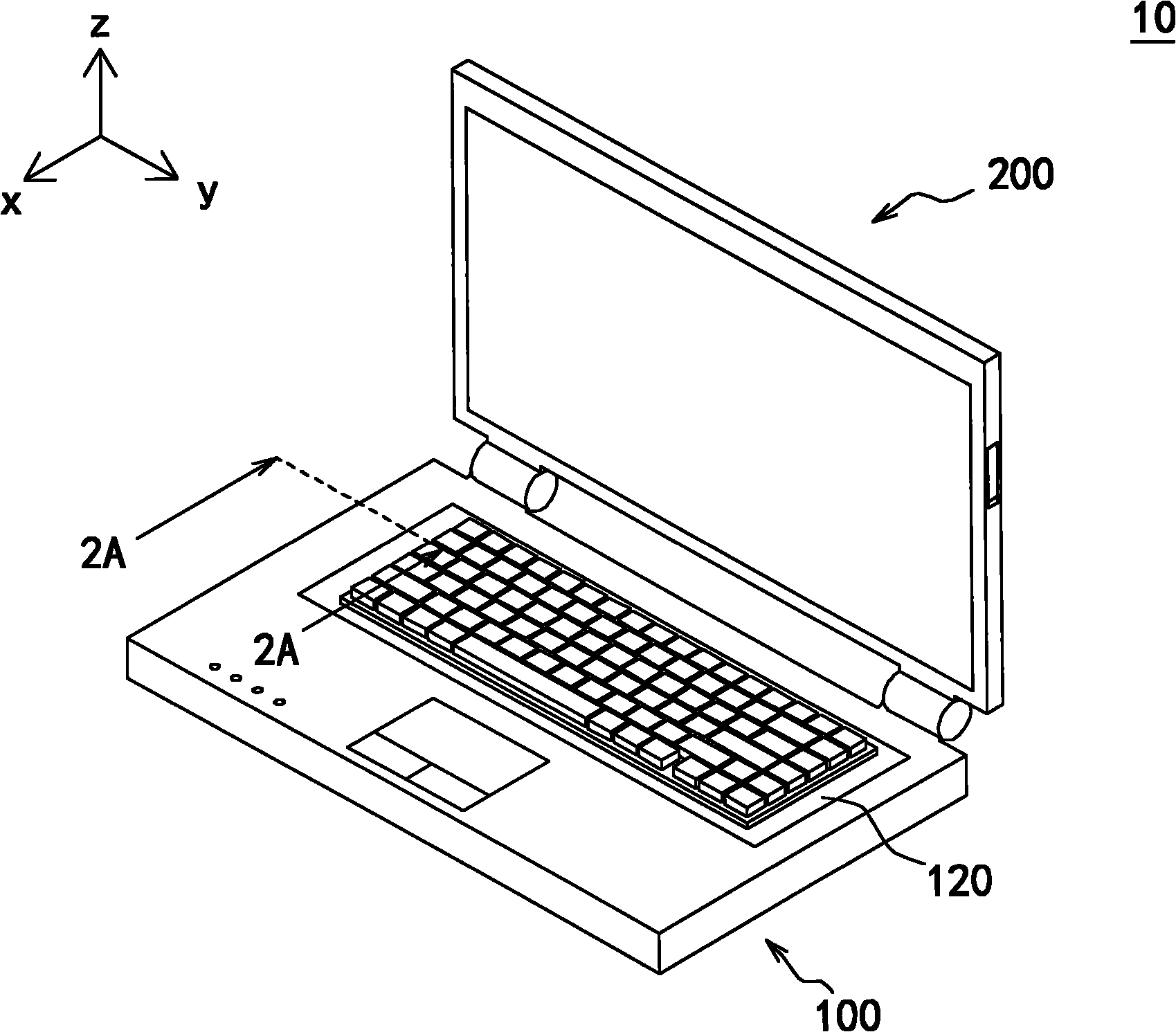

Protective film, and keyboard body and portable electronic device employing protective film

InactiveCN102375550AEasy to fixReduce the chance of damageInput/output for user-computer interactionFouling preventionTectorial membraneElectron

Owner:INVENTEC CORP

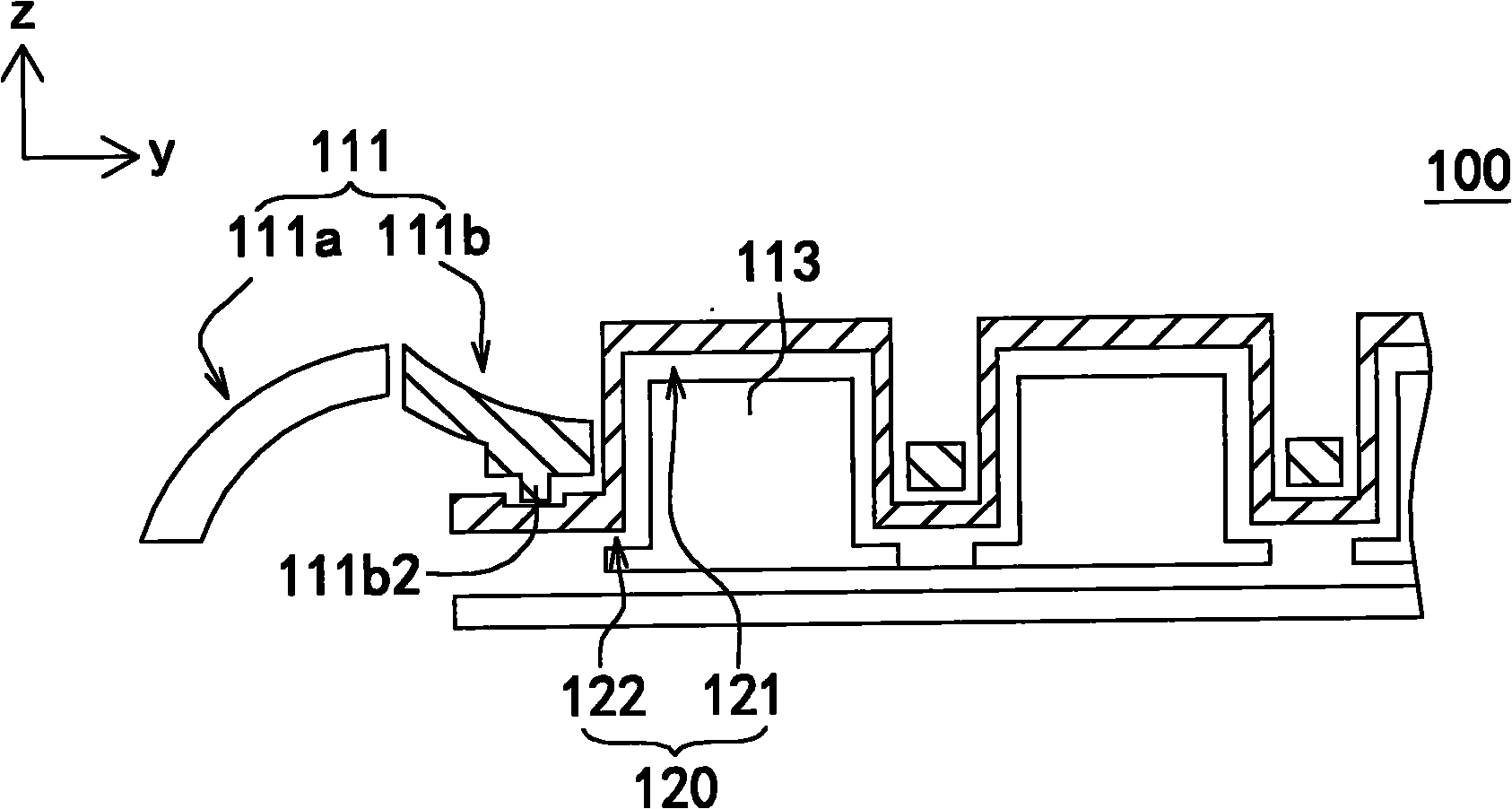

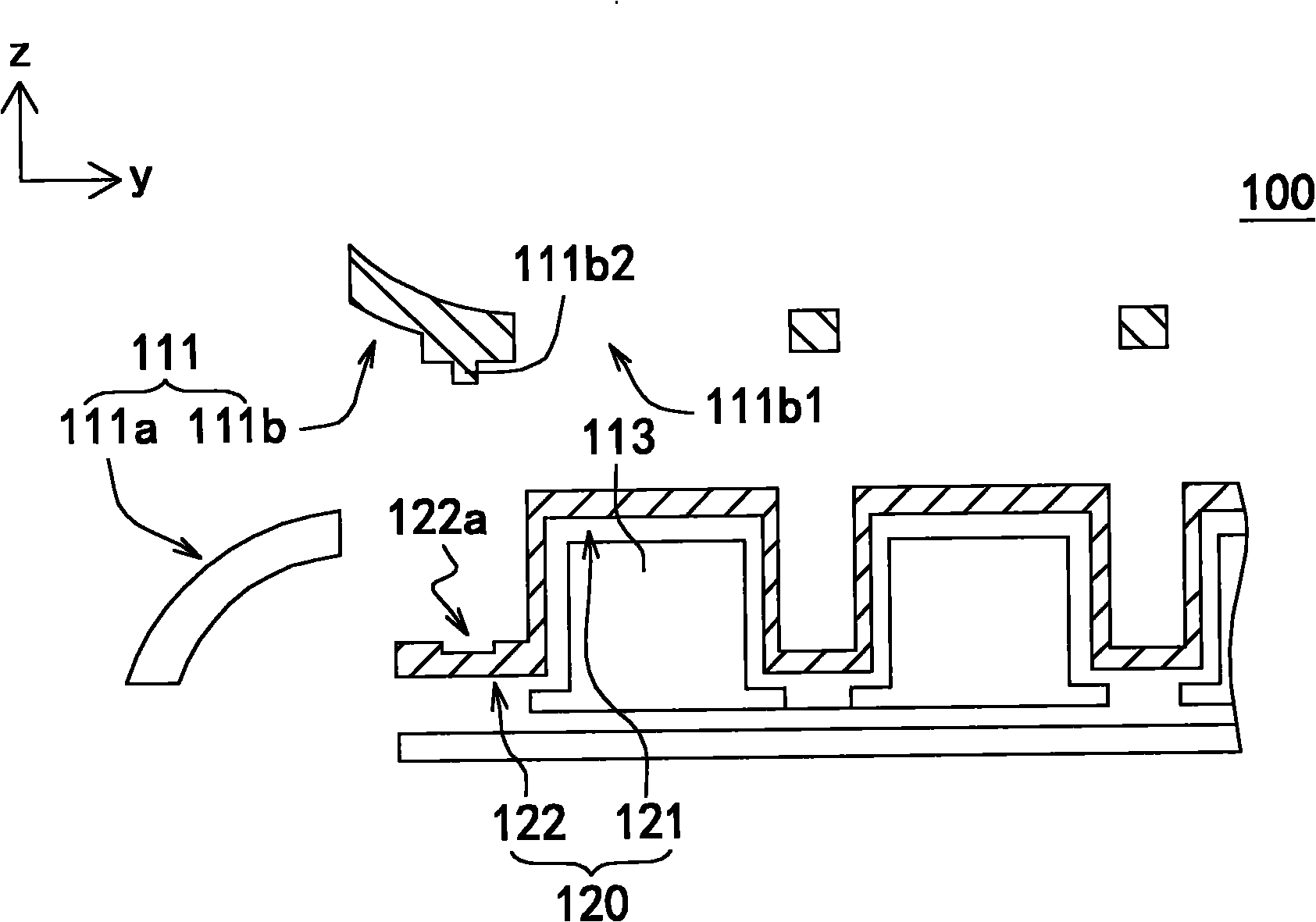

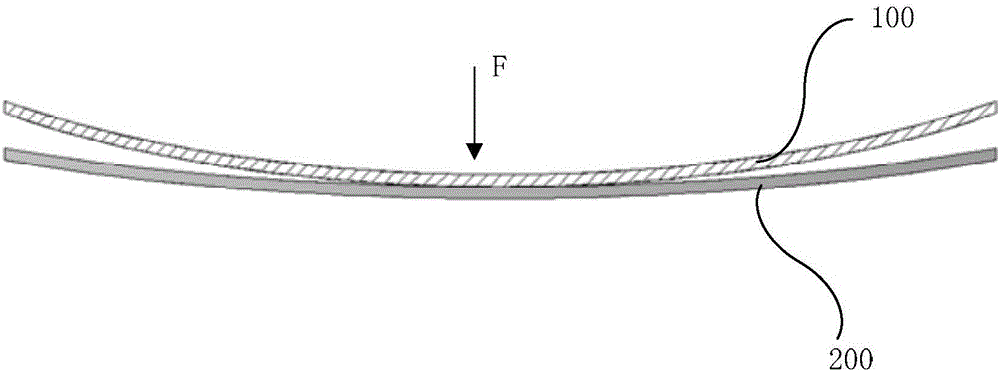

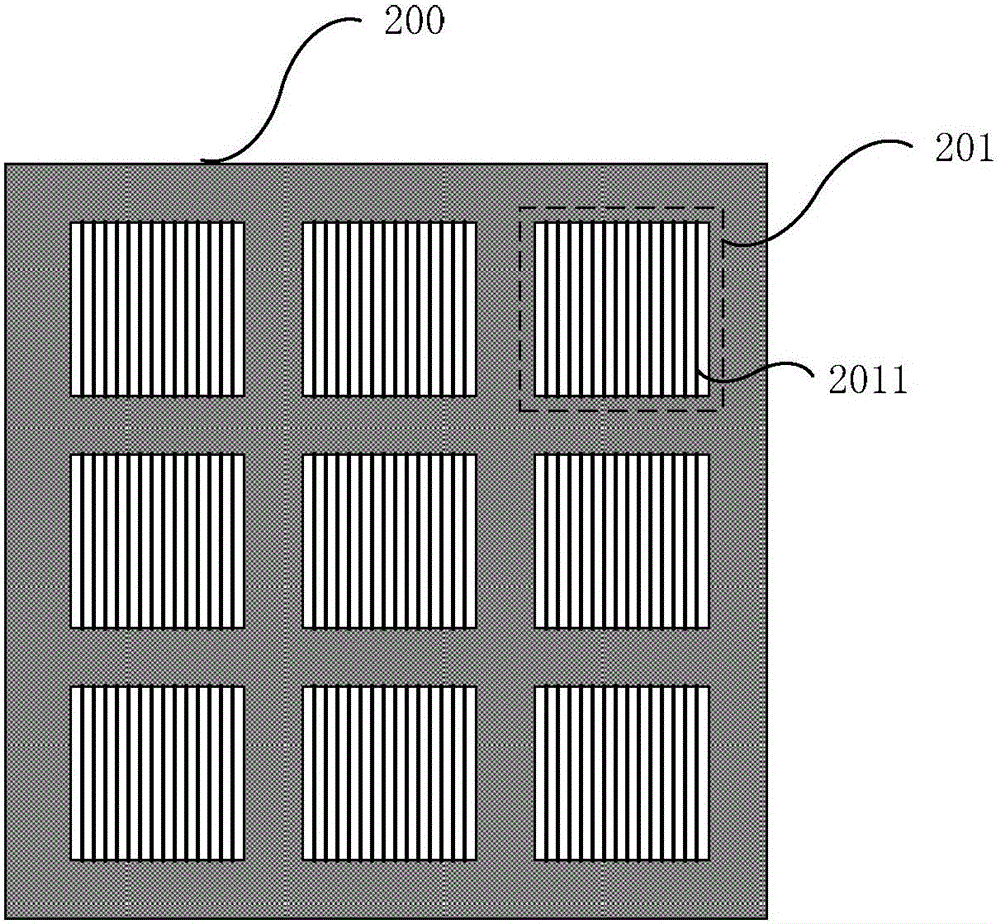

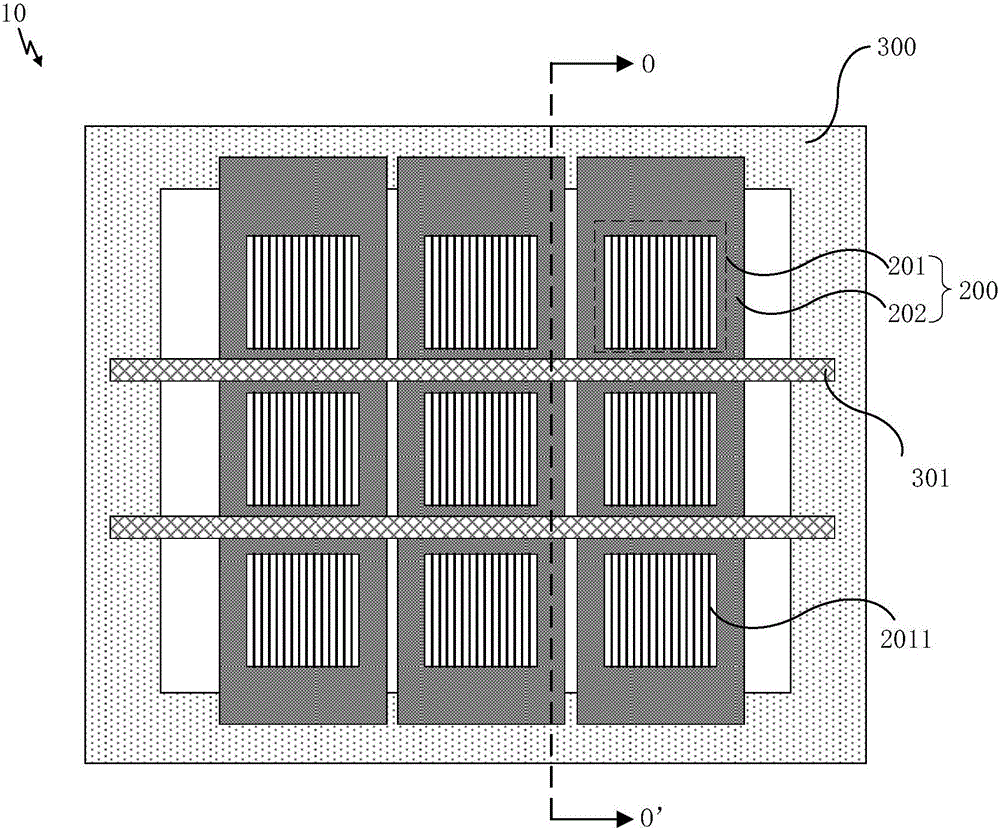

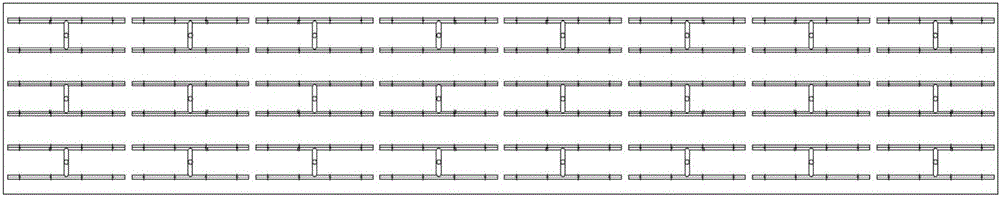

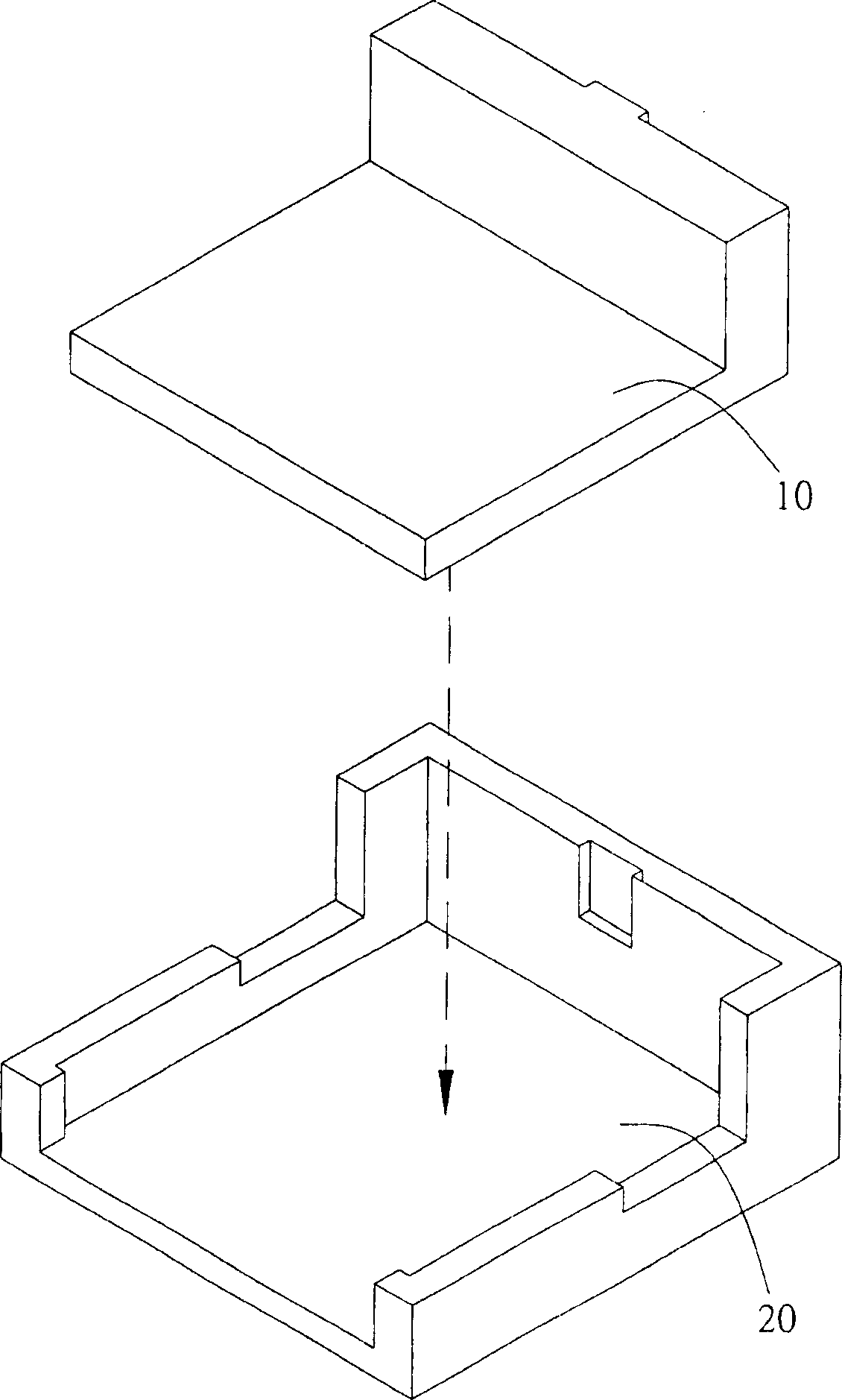

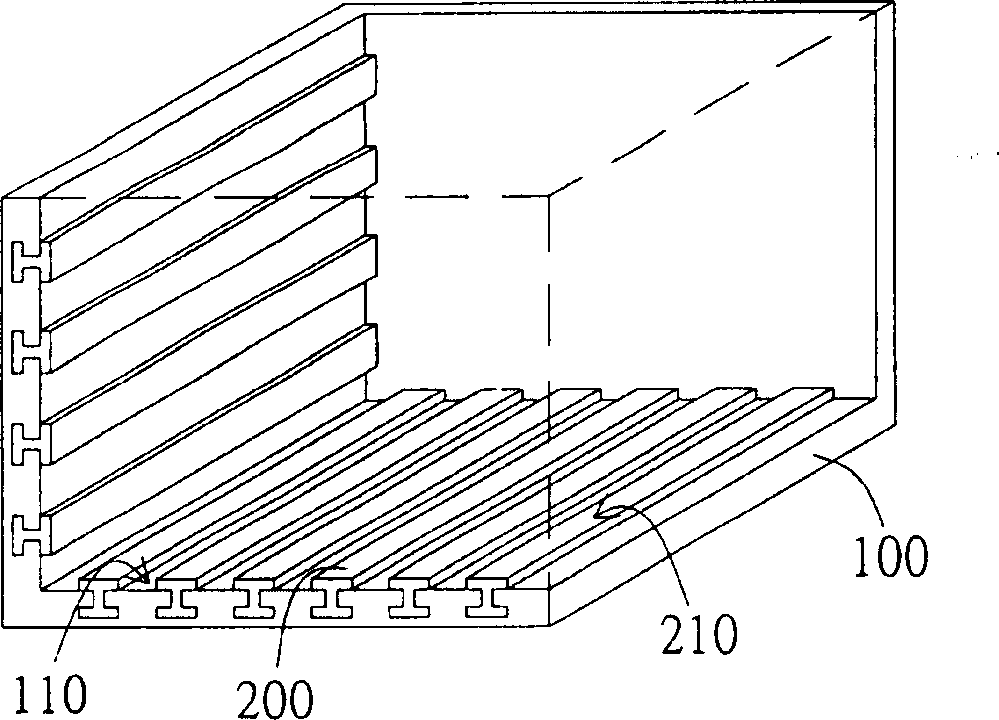

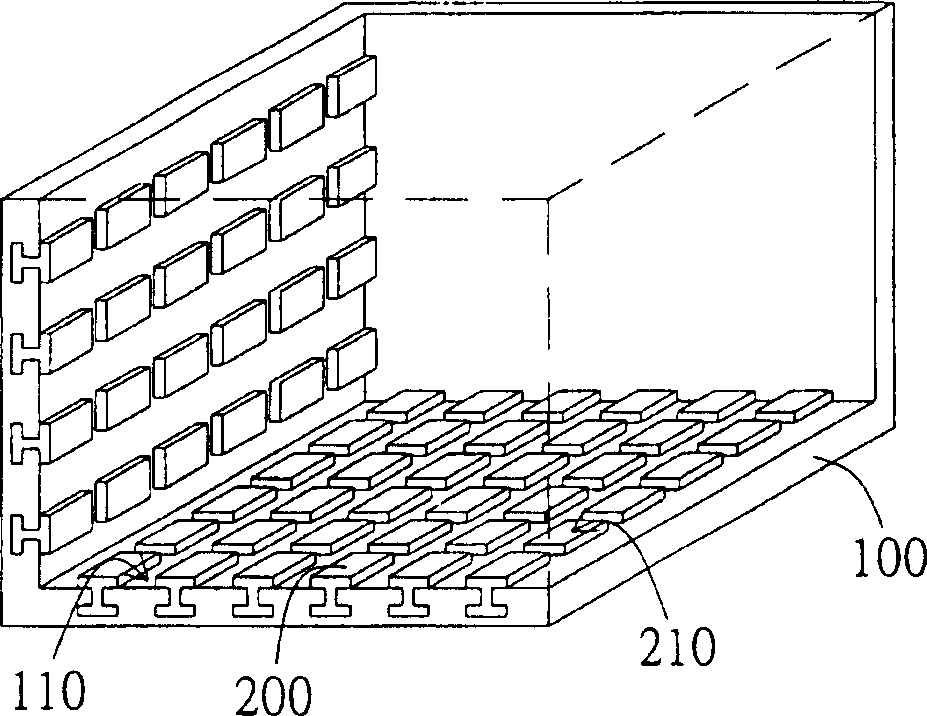

Mask plate assembly, installation method thereof and evaporation device

ActiveCN106086782AReduce saggingReduce extrusion pressureLiquid surface applicatorsVacuum evaporation coatingEvaporationEngineering

The embodiment of the invention provides a mask plate assembly, an installation method thereof and an evaporation device, and relates to the technical field of display. The offset of the mask plate when a mask plate is attached to a backboard can be reduced, and then the product yield is improved. The mask plate assembly comprises a supporting frame and the mask plate fixed to the supporting frame. The mask plate comprises an effective mask area and an ineffective mask area surrounding the effective mask area. The mask plate assembly further comprises a first supporting strip fixed to the supporting frame. The first supporting strip is arranged on the side, away from the supporting frame, of the mask plate, the projection of the first supporting strip in the plane where the supporting frame is located and the projection of the mask plate in the plane where the supporting frame is located have a first overlapped part, and the first overlapped part is located in the projection area of the ineffective mask area in the plane where the supporting frame is located.

Owner:BOE TECH GRP CO LTD +1

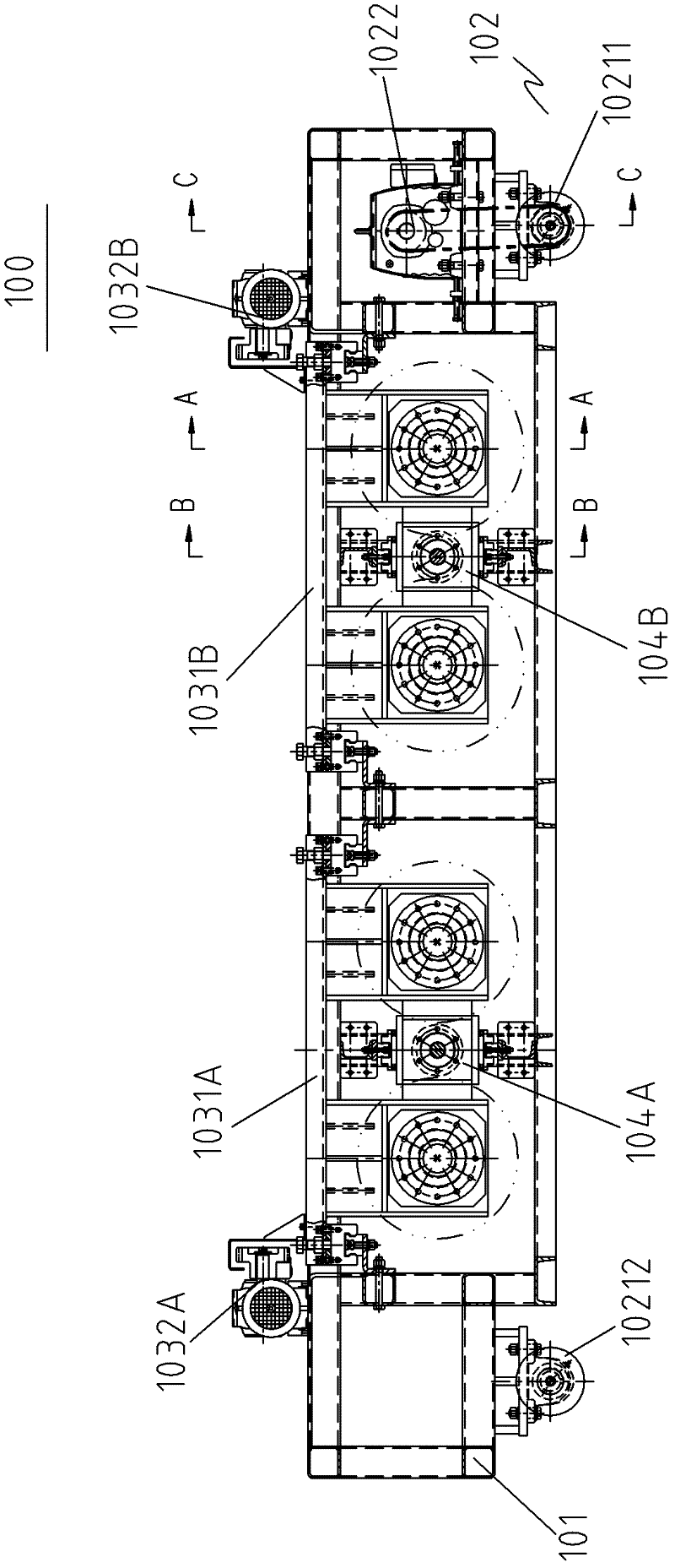

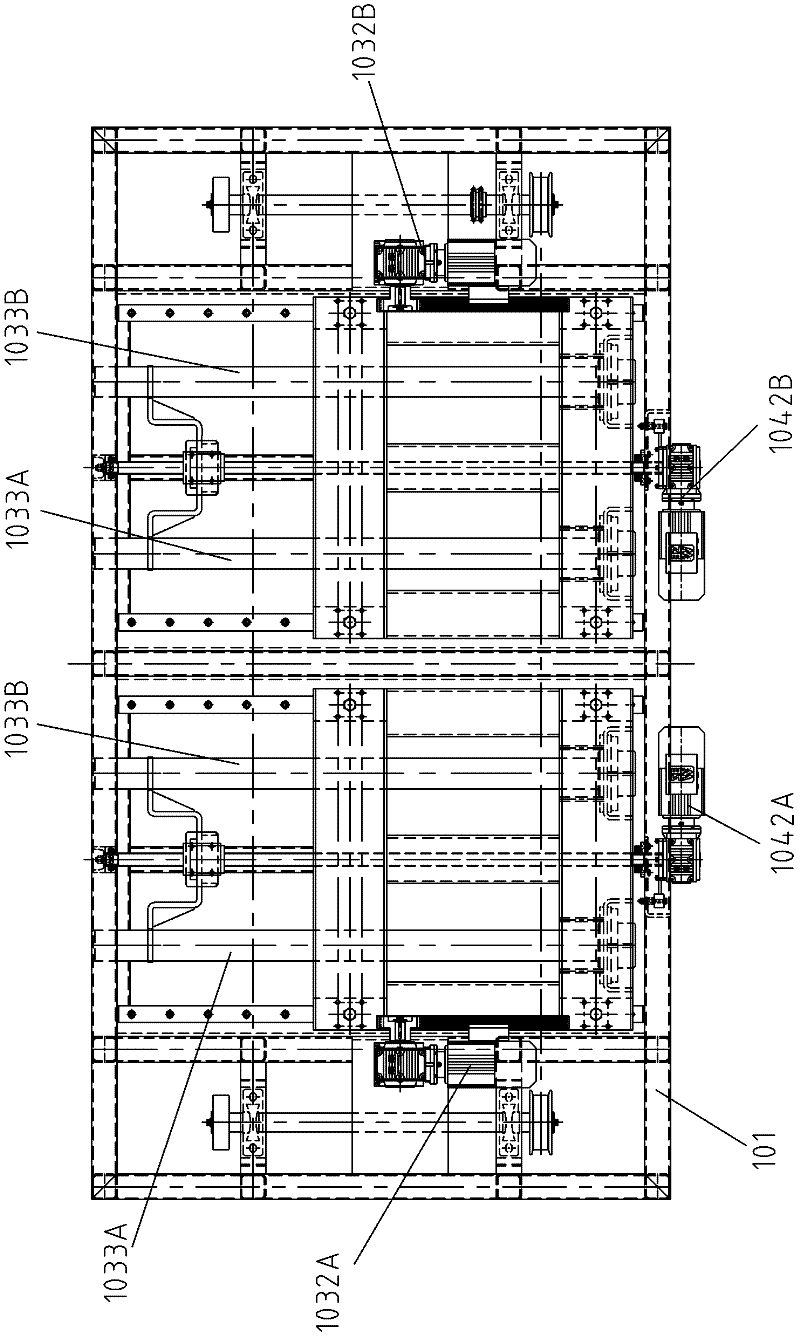

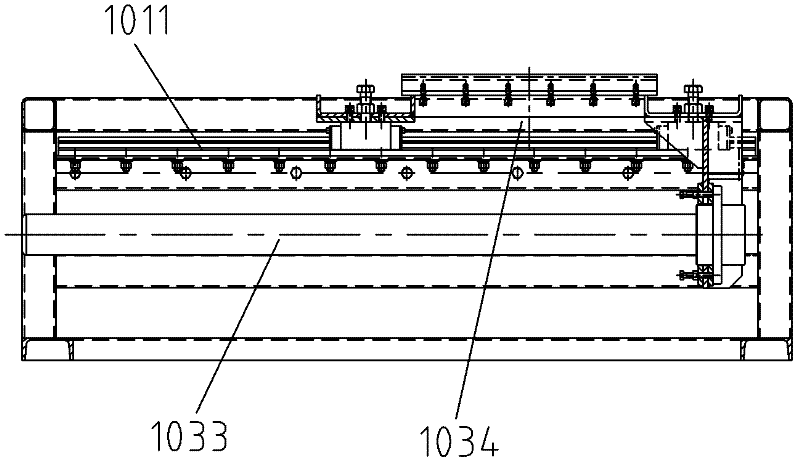

Spooling transport vehicle and automatic spindle conveying system and method

The invention discloses a spooling transport vehicle, an automatic spindle conveying system and an automatic spindle conveying method, belonging to the technical field of chemical fiber production. The automatic spindle conveying system is arranged between a winding machine and a special yarn vehicle, is used for taking down formed spindle from the winding machine and hanging the formed spindle on the special yarn vehicle, and comprises a temporary storage rotary table, a manipulator, the spooling transport vehicle and a control module, wherein the temporary storage rotary table is used for temporarily storing the formed spindle and corresponds to the manipulator, the manipulator is used for hanging the spindle stored on the temporary storage rotary table on the special yarn vehicle, the spooling transport vehicle runs between the winding machine and the temporary storage rotary table, and the control module is in communication connection with the temporary storage rotary table, the manipulator, the spooling transport vehicle and the winding machine respectively. With the arrangement of the spooling transport vehicle, a large amount of labor is replaced, the labor intensity of workers is greatly reduced, the management cost is reduced, and the probability of polluting and damaging the spindle is reduced.

Owner:RIAMB (BEIJING) TECH DEV CO LTD

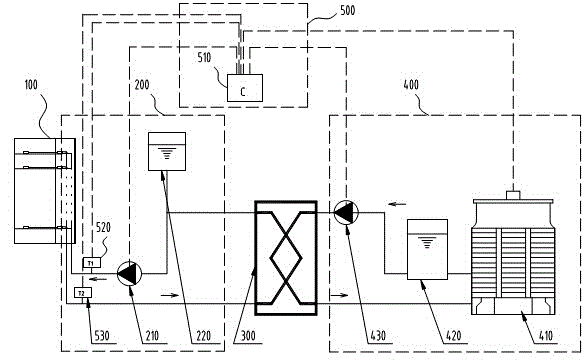

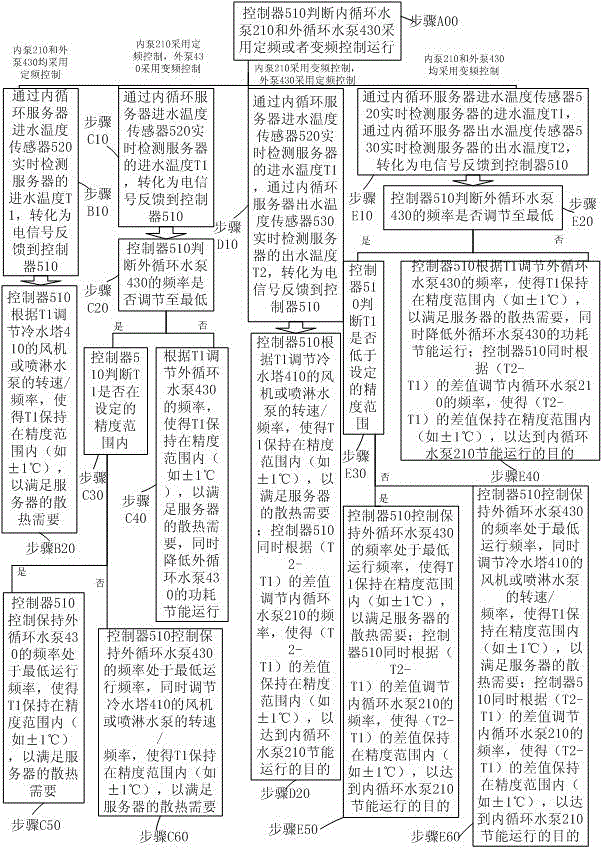

Secondary water-loop server cabinet cooling system

ActiveCN104320953AAvoid enteringReduce the chance of damageSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlCooling tower

Disclosed in the invention is a secondary water-loop server cabinet cooling system. Heat radiation is carried out by using a liquid conducting method. The cooling system comprises an internal circulating system, an external circulating system, and a control system. An internal circulating loop secondary refrigerant absorbs heat from a server core component by a server heat pipe assembly and then flows to an intermediate heat exchanger to carry out heat exchange with an external circulating flow for heat radiation; after the external circulating flow absorbs heat, the heat is dissipated to the external environment by a cooling tower, thereby realizing the natural heat radiation process. And precise temperature control and energy-saving running of the cooling system can be realized by the control system. According to the invention, no compressor refrigerating system is needed. Effective heat radiation of the server is realized by using a complete natural cooling way; and the energy saving effect is obvious. Meanwhile, a heat pipe indirect cooling scheme is used for the server chip and the water can not enter the inside of the server directly, so that compared with other direct liquid-cooled schemes, the provided scheme enables security of the server to be improved.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

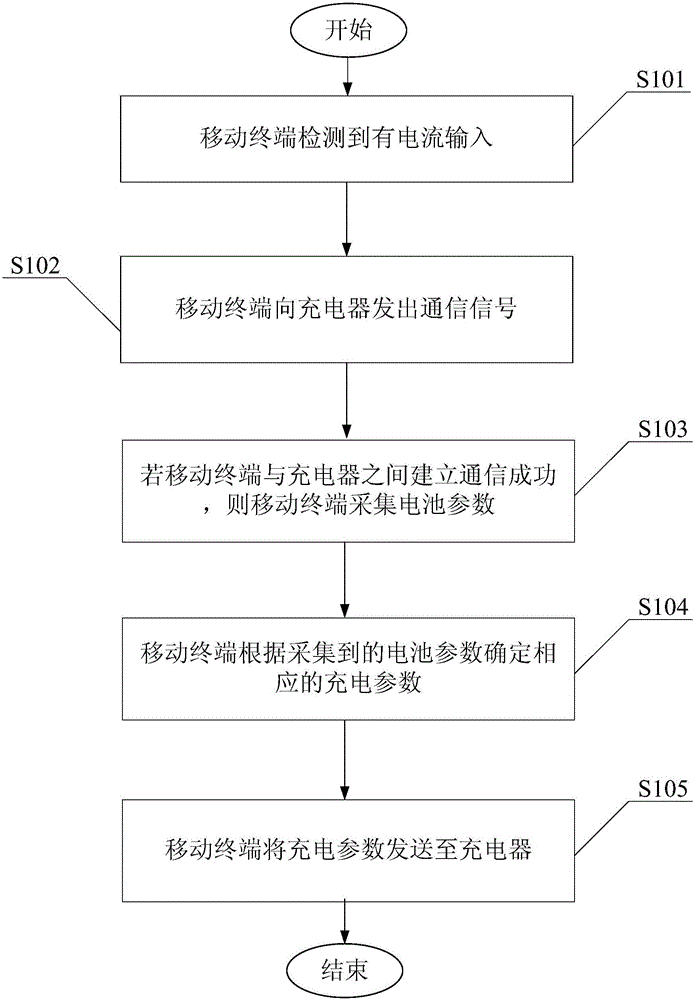

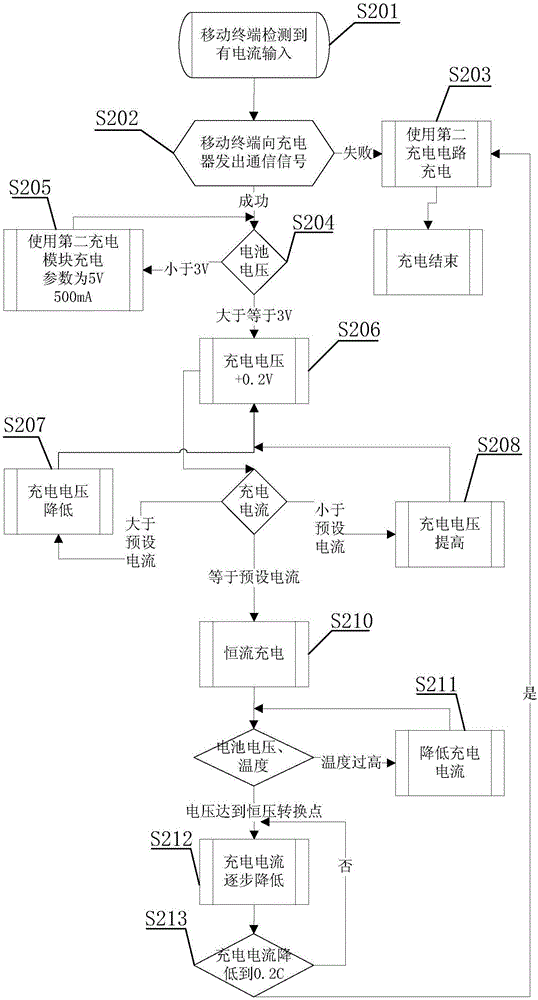

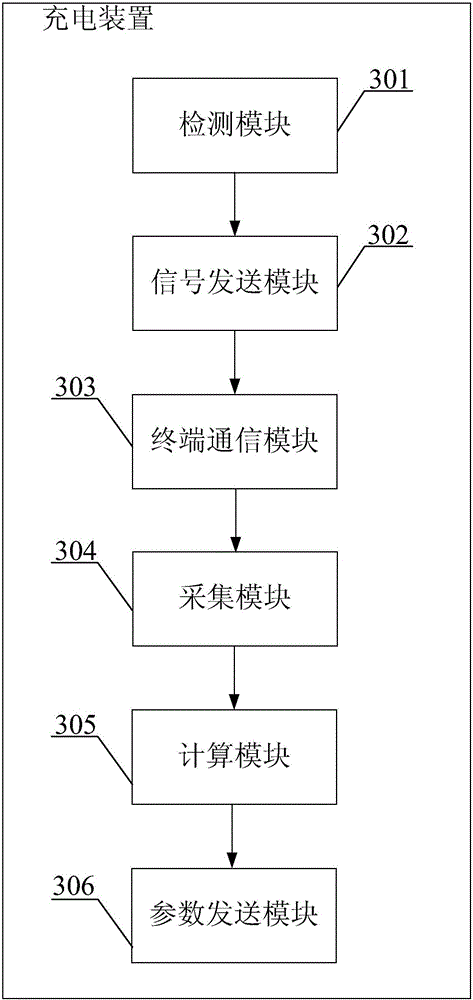

Charging method, charging device and charger

InactiveCN105720645AReduce feverImprove feverCircuit monitoring/indicationElectric powerPower flowElectrical battery

The invention discloses a charging method. The method comprises the following steps: detecting current input by a mobile terminal; sending out a communication signal to a charger by the mobile terminal; if communication established between the mobile terminal and the charger is successful, collecting battery parameters by the mobile terminal; determining corresponding charging parameters according to the collected battery parameters by the mobile terminal; and sending the charging parameters to the charger by the mobile terminal. The charger can charge a battery according to the charging parameters determined in the mobile terminal; when the temperature of the battery is relatively low and lower than a threshold value and the potential safety hazard is relatively low, quick charging can be carried out by using high voltage and high current, so that the charging efficiency is quickened; and when the temperature of the battery is relatively high or when the battery is ready to be full, charging can be carried out by using safer voltage and current, so that the heating of the battery is reduced, and the safety of the battery is improved. The invention also discloses a charging device and a charger.

Owner:ZHEJIANG TECHAIN ELECTRONICS TECH CO LTD

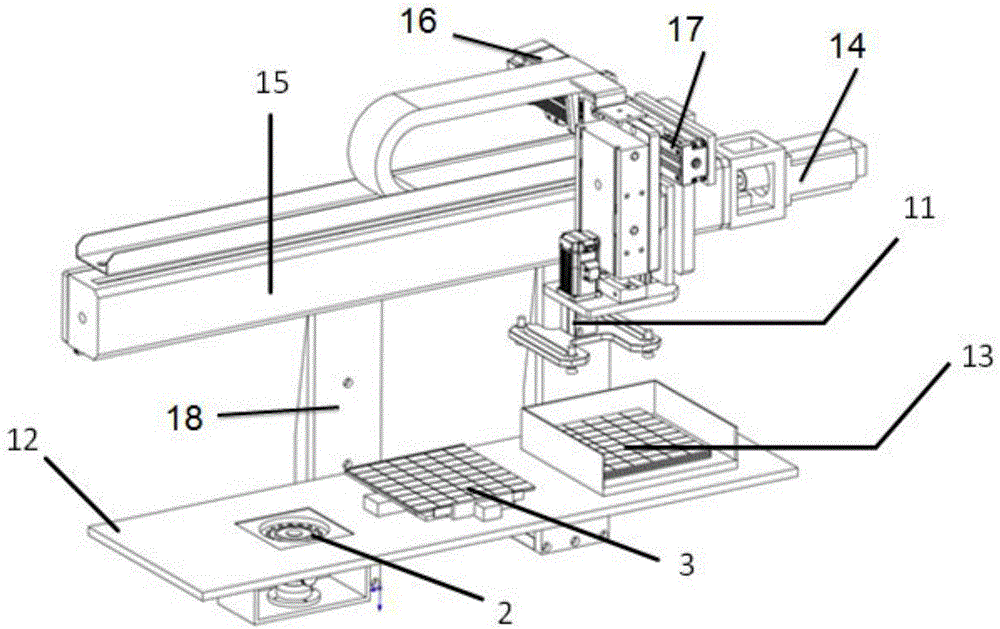

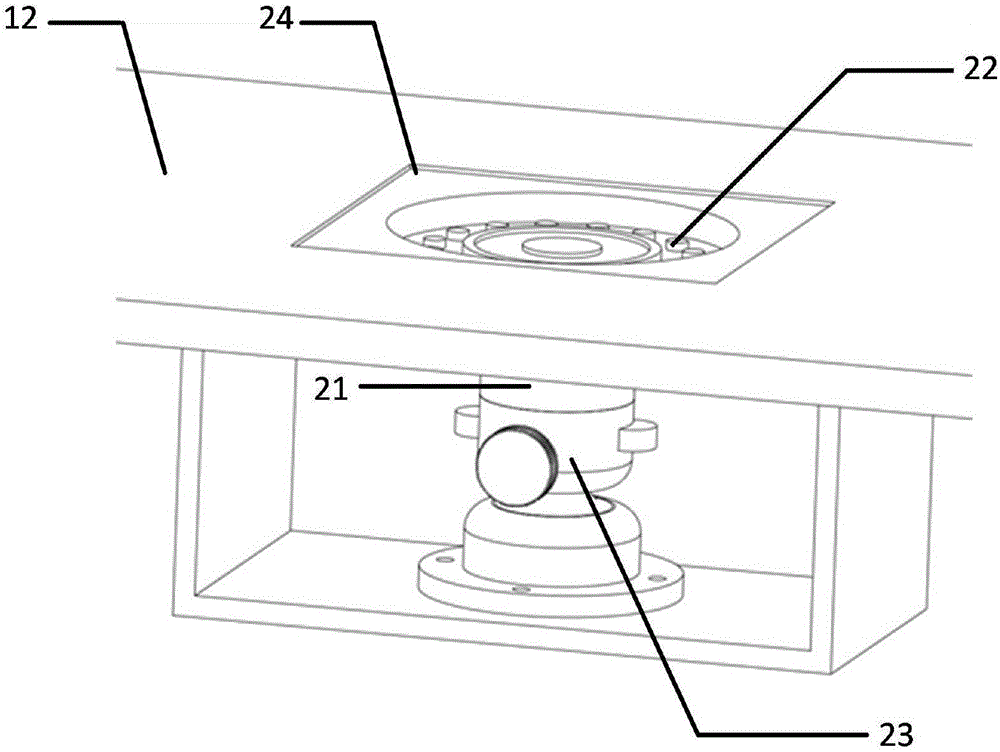

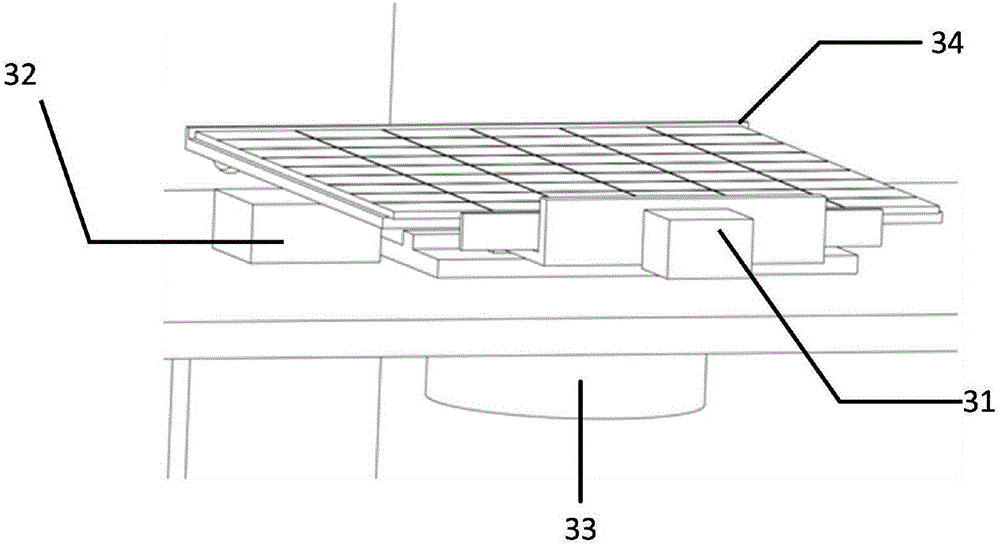

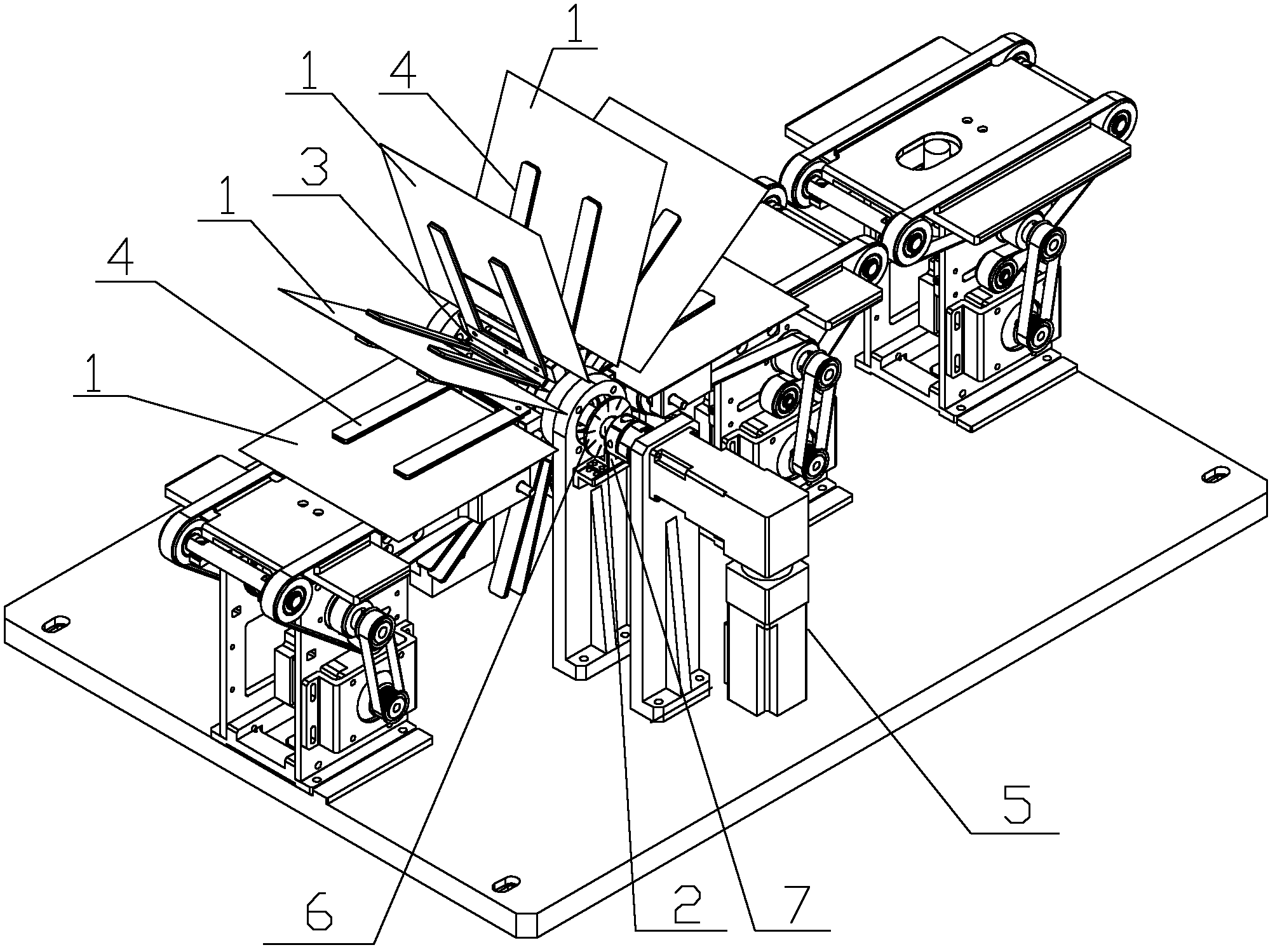

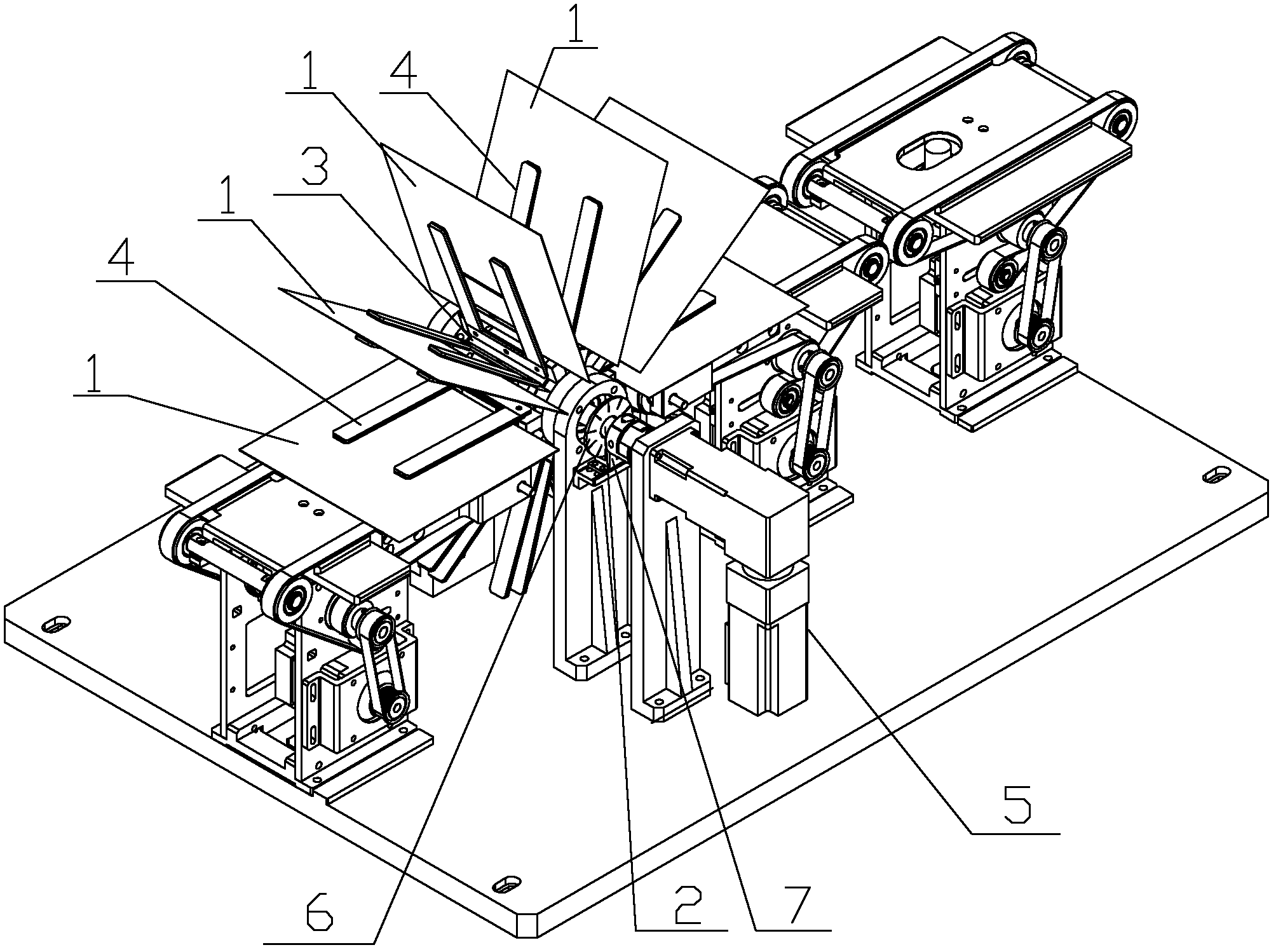

Equipment used for visual positioning and angle detection of solar cells before series welding

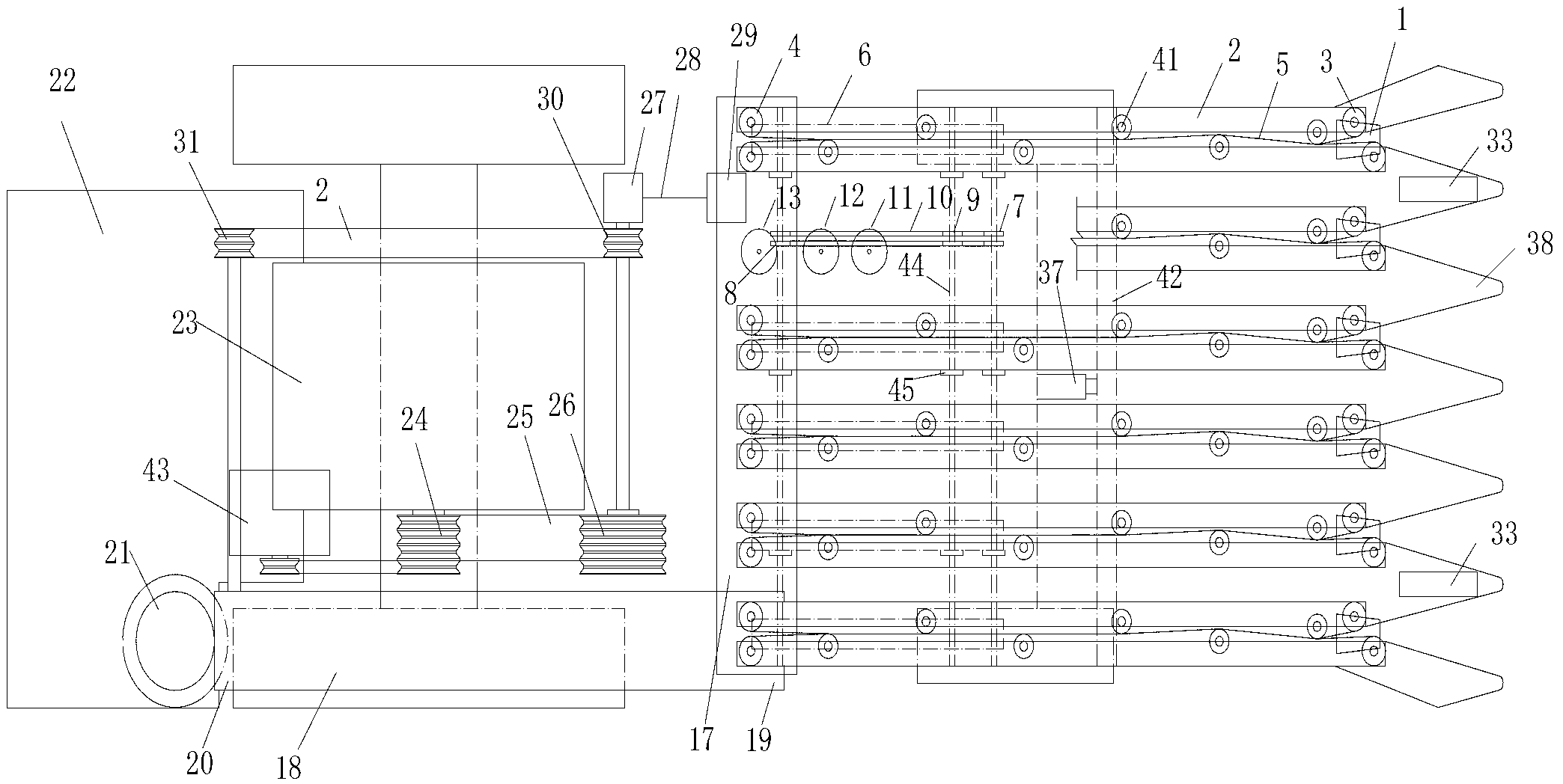

ActiveCN106272426AIncrease productivityIncrease production capacityProgramme-controlled manipulatorProduction lineEngineering

The invention provides equipment used for visual positioning and angle detection of solar cells before series welding. The equipment comprises a support rack, a Y-axis slide rail, an X-axis slide rail, a manipulator, a bracket bedplate, an imaging mechanism, a cell correction mechanism, and a feeding plate, wherein the Y-axis slide rail is fixed at the top end of the support rack; the X-axis slide rail is mounted on the Y-axis slide rail and can move along the Y-axis slide rail; the manipulator is mounted on the X-axis slide rail and can move along the X-axis slide rail; the bracket bedplate is mounted below the Y-axis slide rail; the imaging mechanism is mounted on the bracket bedplate; the cell correction mechanism is mounted at the right side of the imaging mechanism; and the feeding plate is mounted at the right side of the cell correction mechanism. According to the equipment, the position and angle correction of the solar cells can be realized automatically in a moving process, so that the production efficiency and the production line flexibility are improved. The invention further provides a method for used for visual positioning and angle detection of the solar cells before series welding. According to the method adopting visual correction, the correction process of solar cell workpieces can be performed fast and accurately, and the series welding efficiency and precision of the solar cells are improved.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

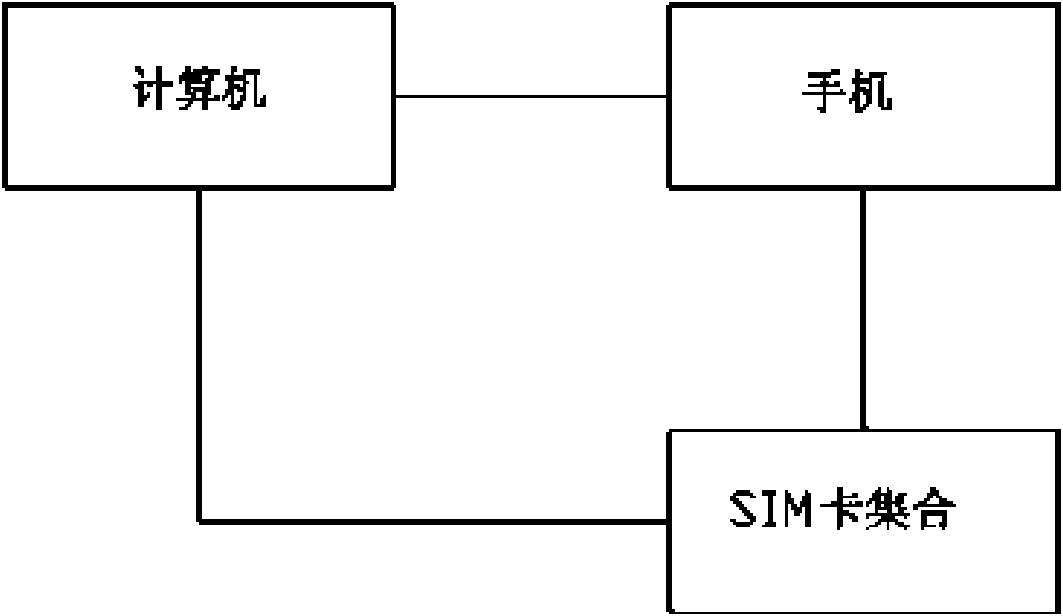

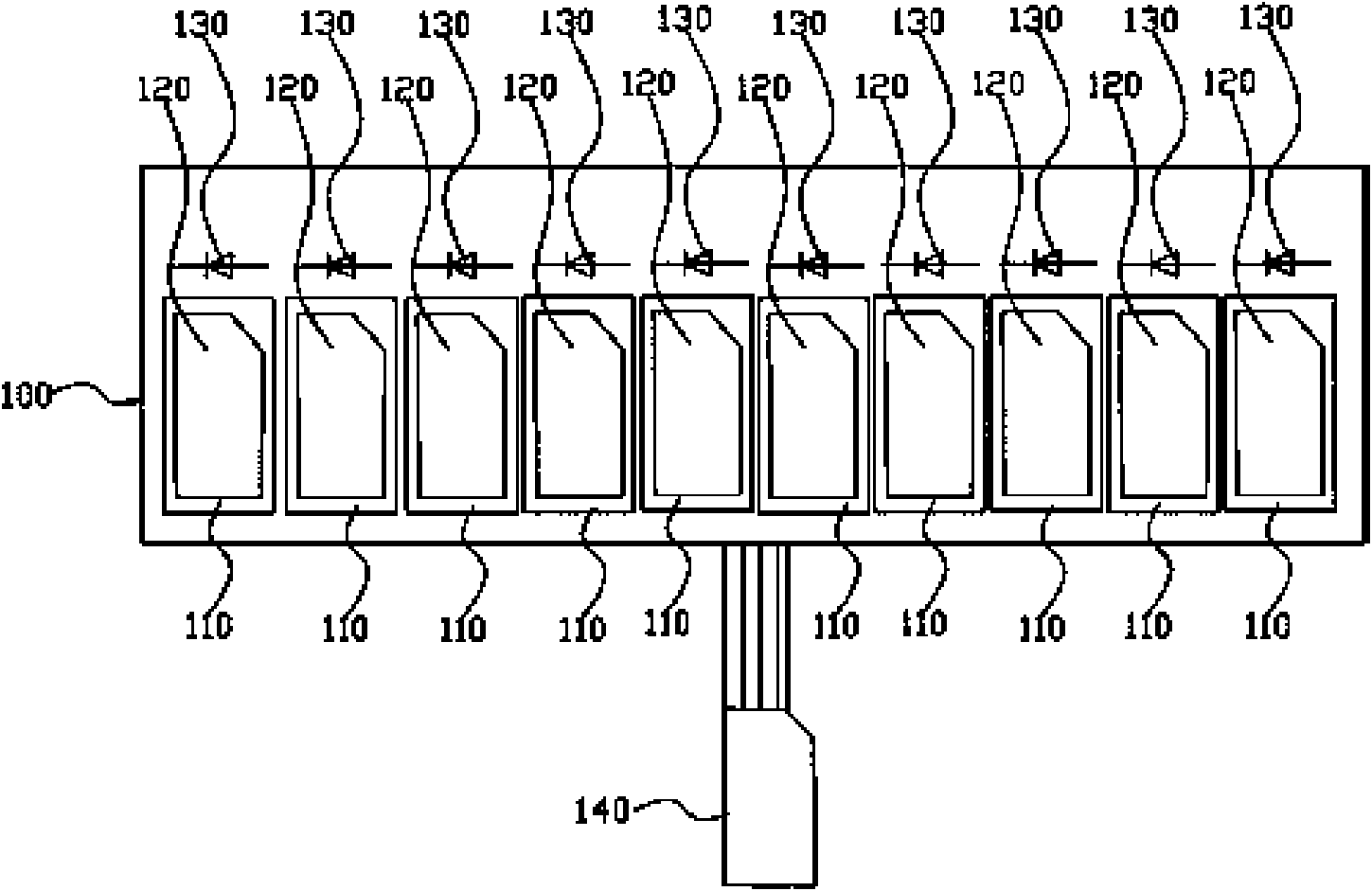

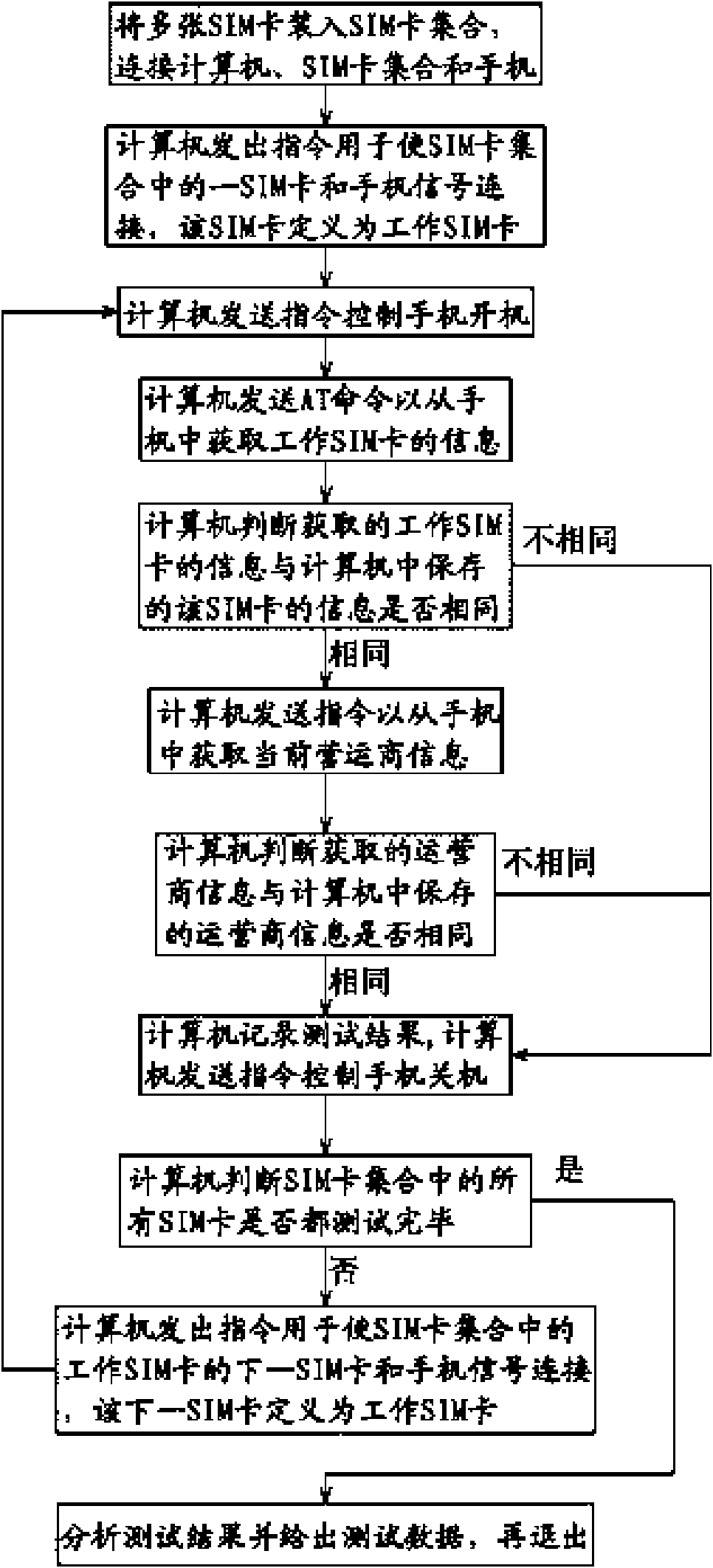

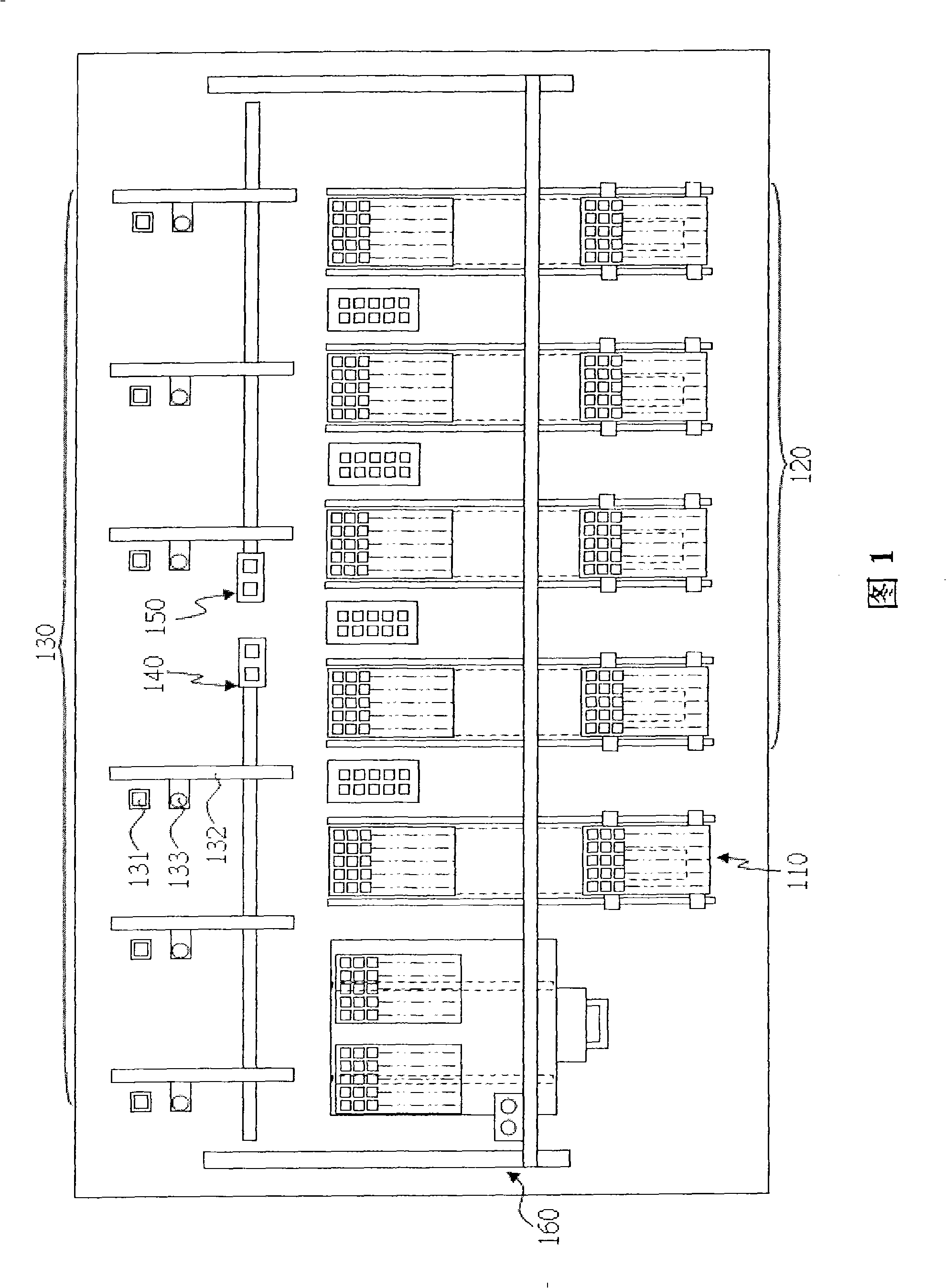

SIM card compatibility automated test method and device

InactiveCN101656974AAvoid frequent plugging and unpluggingReduce the chance of damageWireless communicationComputer hardwareAutomatic testing

The invention discloses an SIM card compatibility automated test method and an SIM card compatibility automated device. The SIM card compatibility automated test method comprises the following steps:step01: a computer, an SIM card set and a mobile phone are connected; step02: the computer sends out an instruction to connect one SIM card of a SIM card set and a mobile phone signal, wherein, the SIM card is defined as a working SIM card; step03: the computer sends out an instruction to test whether the working SIM card and the mobile phone are compactable or not; step04: the computer judges weather all SIM cards in the SIM card set finish the test or not; if all the SIM cards in the SIM card set finish the test, step 06 is executed, and otherwise, the step 05 is executed; step05, the computer sends out an instruction for connecting a next SIM card of the working SIM card in the SIM card set and the mobile phone signal, and the next SIM card is defined as a working SIM card, and then thestep 03 is executed; and step06: logout. The invention has the advantages that automated test can be realized.

Owner:XIAMEN STELCOM INFORMATION & TECH

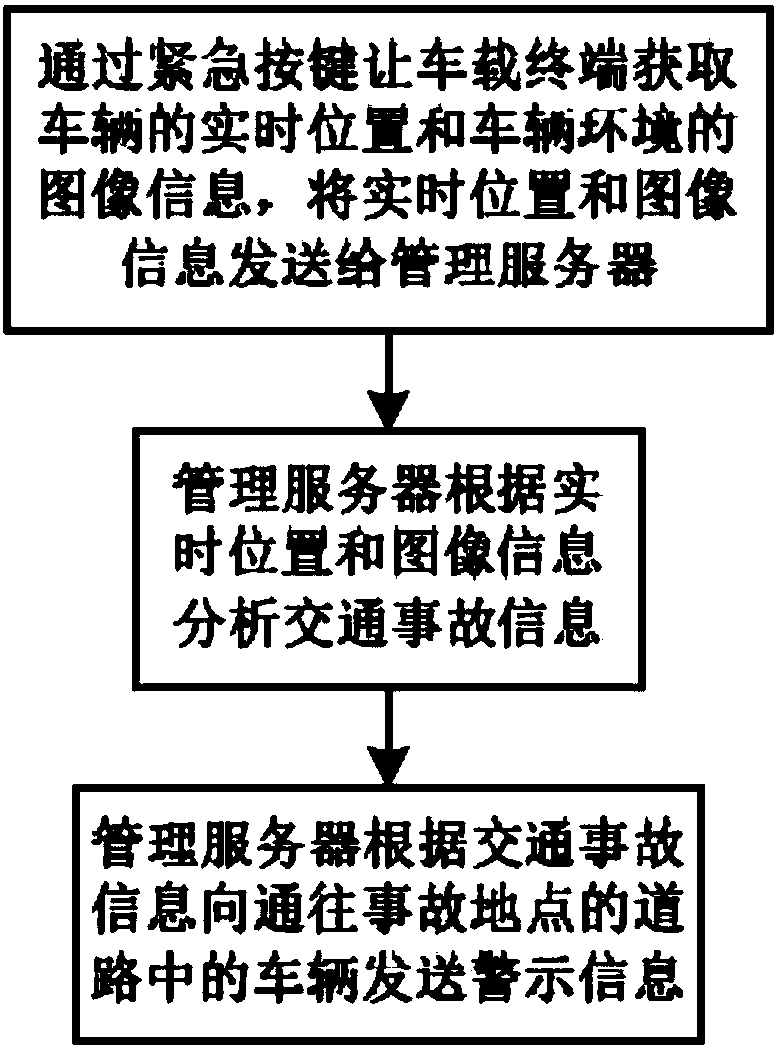

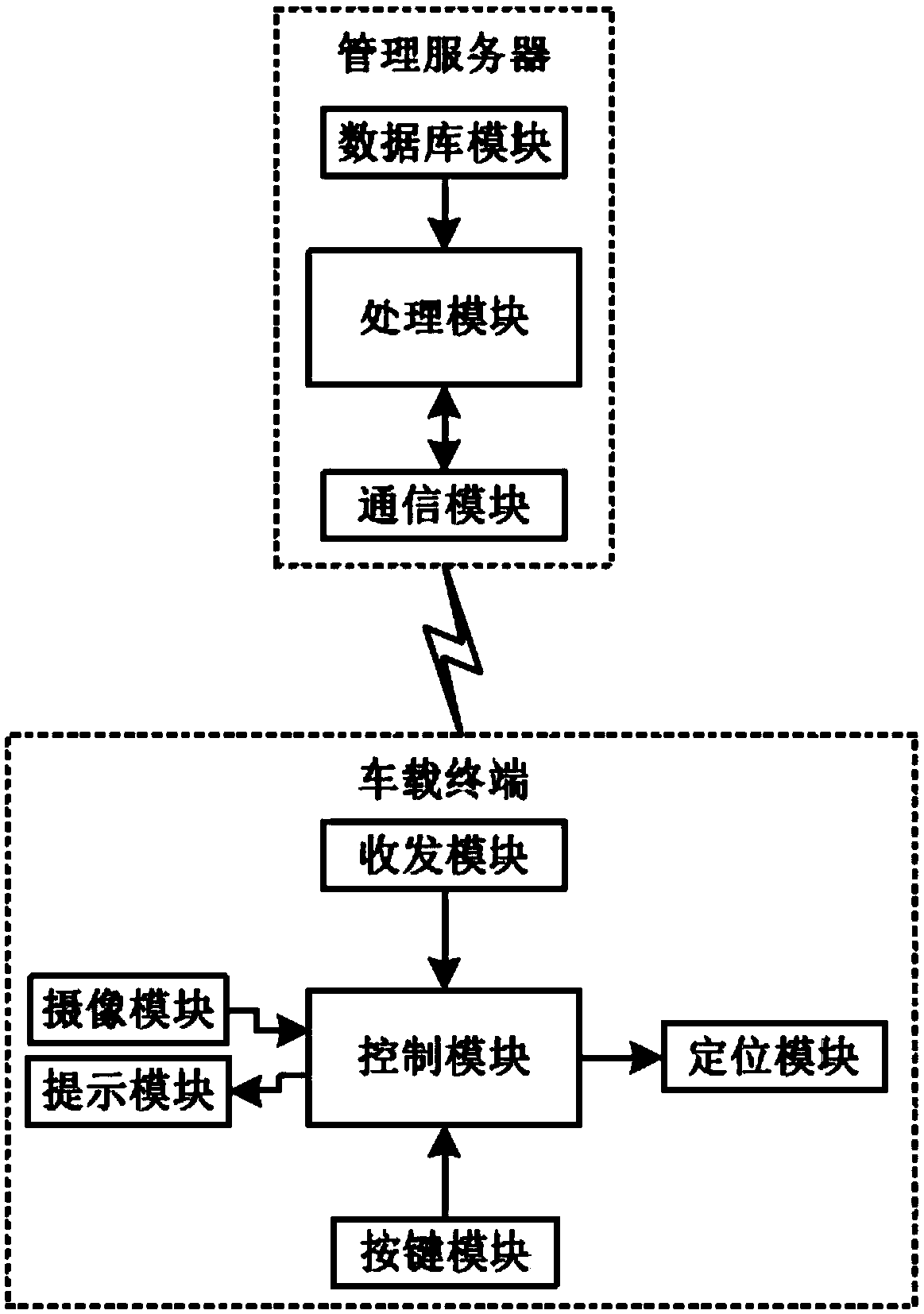

Vehicle accident management system and method

InactiveCN108154696AAvoid evacuationReduce the situation of being stuck on the road and unable to move forwardRoad vehicles traffic controlCharacter and pattern recognitionTraffic accidentCamera module

The invention relates to the field of intelligent transportation technology, and particularly relates to the vehicle accident management system and method. The method includes the following contents:when a traffic accident occurs in S1, the vehicle terminal acquires the real time position of the vehicle and the image information inside and outside the vehicle through the emergency button, and thereal time position and image are obtained to send to the management server. The S2 management server analyzes the traffic accident information according to the real time location and the image information.The S3 management server sends the warning information to the vehicle in the road leading to the accident site according to the traffic accident information.The system includes the vehicle mounted terminal and management that communicated with each other. The vehicle terminal includes a button module, a positioning module, a camera module, a control module and a prompt module, and managementserver includes a processing module and a database module. The device can obtain the image information of the accident scene through the emergency button, save the evidence of accident scene in time,and prompt the vehicle in the road to make the way, so that the rescue vehicle can reach the accident scene more smoothly and perform timely rescue.

Owner:重庆冀繁科技发展有限公司

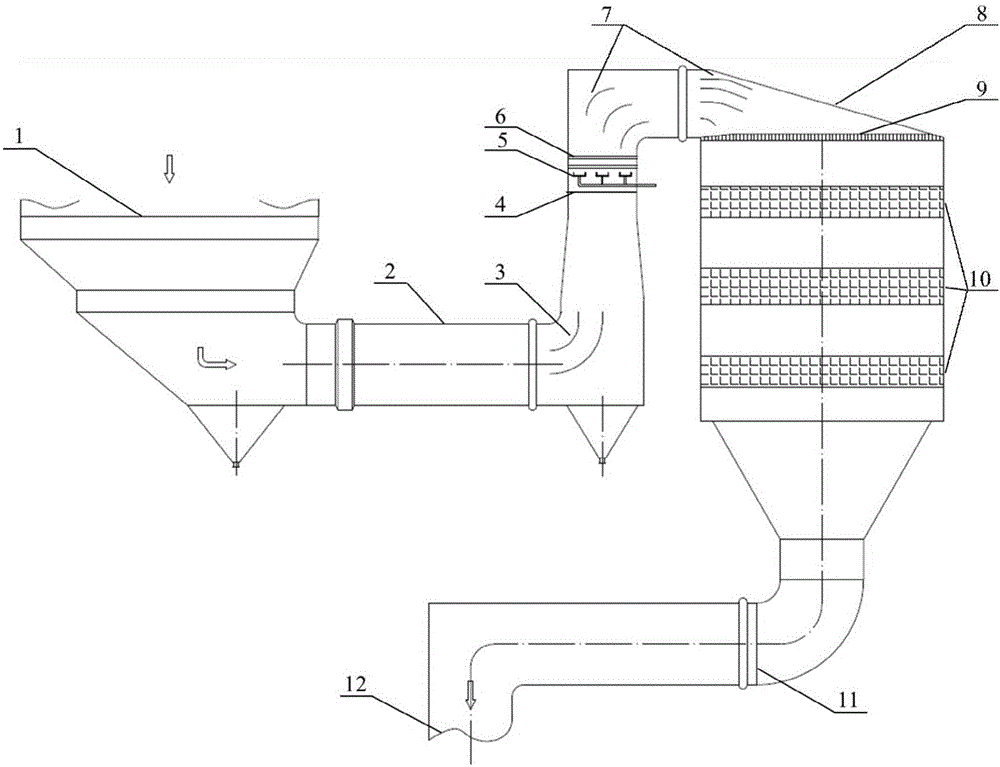

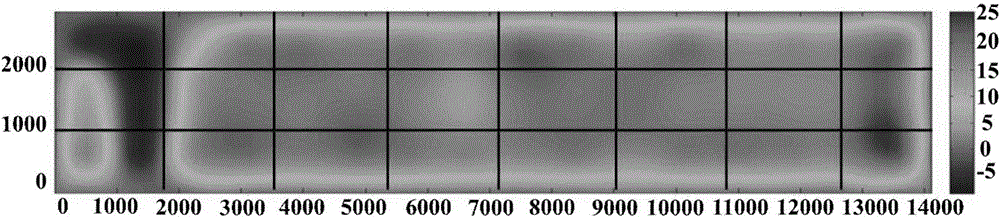

SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

InactiveCN105126616AMake targeted adjustmentsReduce escapeDispersed particle separationConstant loadFlue gas

The invention discloses an SCR denitration system ammonia spraying optimization method based on weight valve regulation and control. The method is divided into four steps: measurement of flue gas flow field characteristics, analysis of flue gas flow field regional flow characteristics, determination of ammonia spraying weight valves and pertinence adjustment of opening degrees of the ammonia spraying valves. The method comprises the particular steps: firstly, measuring the flue gas flow field characteristics of a flue transverse section in front of an ammonia spraying grille of an SCR denitration system under a condition of constant load; then combining with a distribution condition of spray nozzles of the ammonia spraying grille, and analyzing flue gas flow field regional flow continuous distribution characteristics matched with the ammonia spraying spay nozzle distribution; according to the flue gas flow field regional flow characteristics under various load conditions, obtaining the weights of the ammonia spraying valves; and finally, adjusting the opening degrees of all the valves according to the valve weight difference, simultaneously, with the help of a flue gas analyzer, measuring the NOx outlet concentration on an outlet section of the SCR denitration system, and timely feeding back the adjustment effect of the opening degrees of the ammonia spraying valves. The method can ensure good ammonia nitrogen mixing equivalent ratio, effectively improves the denitration efficiency, decreases the ammonia escape and reduces the ammonia amount.

Owner:南京奥麦科仪器自动化有限公司

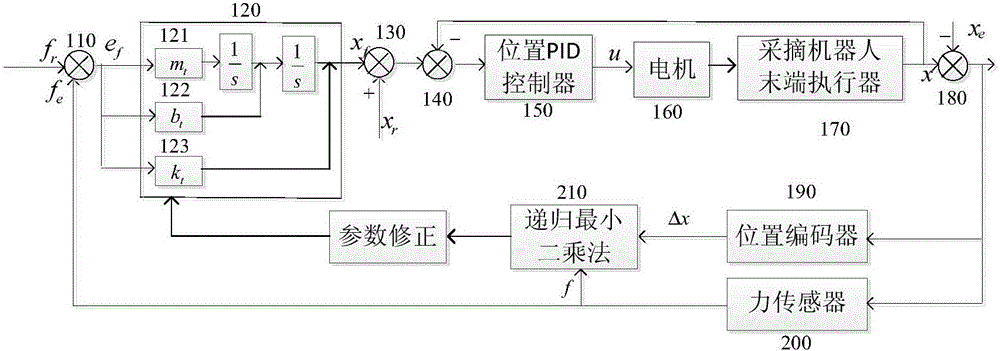

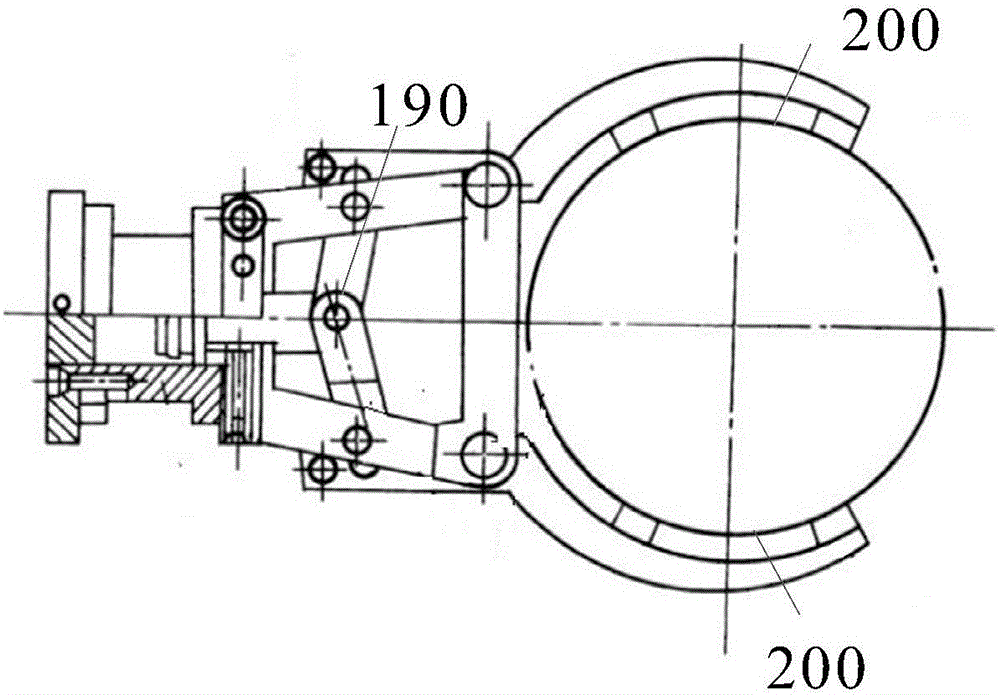

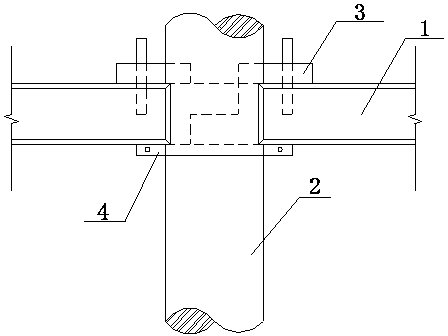

Grasping force active compliance control method of apple picking robot tail end actuator

InactiveCN106272428AAchieve dynamic balanceRealize active compliance controlProgramme-controlled manipulatorAnti jammingForgetting factor

The invention discloses a grasping force active compliance control method of an apple picking robot tail end actuator, and belongs to the technical field of picking robot control. The grasping force control method is characterized in that a force sensor and an encoder arranged on the apple picking robot tail end actuator obtain the position transformation quantity and the acting force on a grasping object through collection; the displacement and the force obtained through collection are used as the input of a recursive least squares method recognizer of a variable forgetting factor; the rigidity coefficient of an impedance controller is subjected to on-line identification; the rigidity parameters of the impedance controller for adapting to different environment requirements are automatically regulated in real time according to the output result of a second-order impedance controller. The control method has the advantages that the grasping damage rate of a picking robot to apples can be effectively reduced; in addition, the anti-jamming capability of the robot during field work is improved.

Owner:JIANGSU UNIV

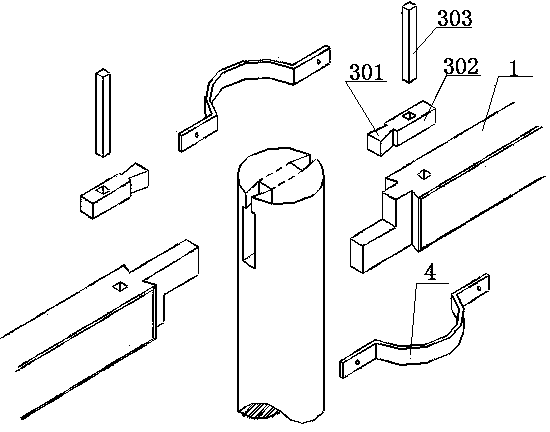

Steel-wood composited reinforcement device for ancient wood frames

InactiveCN103835525AImprove integrityImprove seismic performanceBuilding repairsMortise and tenonShock resistance

Disclosed is a steel-wood composited reinforcement device for ancient wood frames. The steel-wood composited reinforcement device needs not to be fixed with iron cramps or angle steel, horizontal displacement of mortises and tenons can be prevented through wood components, and bending resistance of beams and columns can be improved through steel fasteners. The steel-wood composited reinforcement devcie is high in flexibility, shock resistance and twisting resistance; with the reinforcement technology, maintenance and replacement can be achieved, and protection and renovation of the wood structure is benefited.

Owner:LUOYANG INST OF SCI & TECH

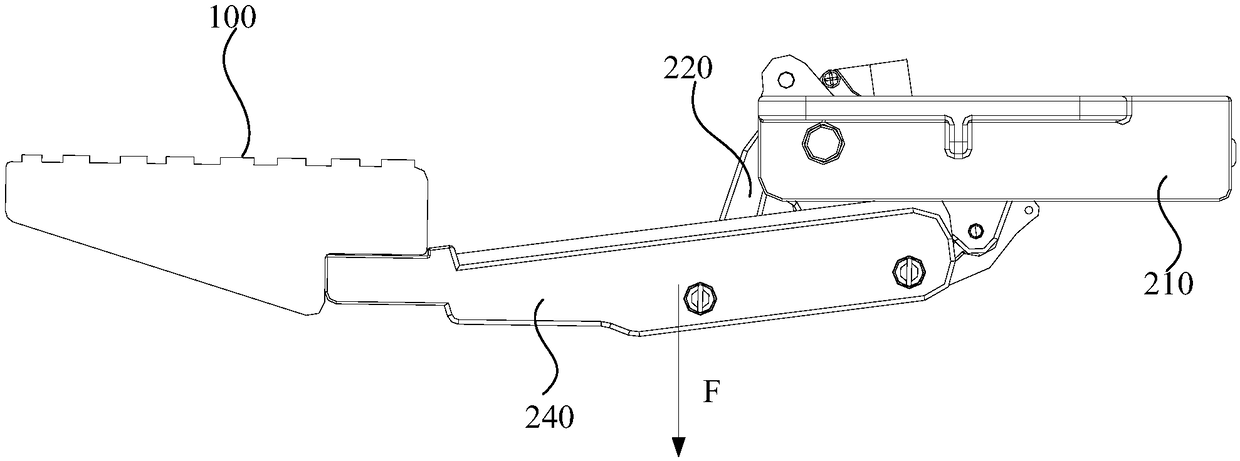

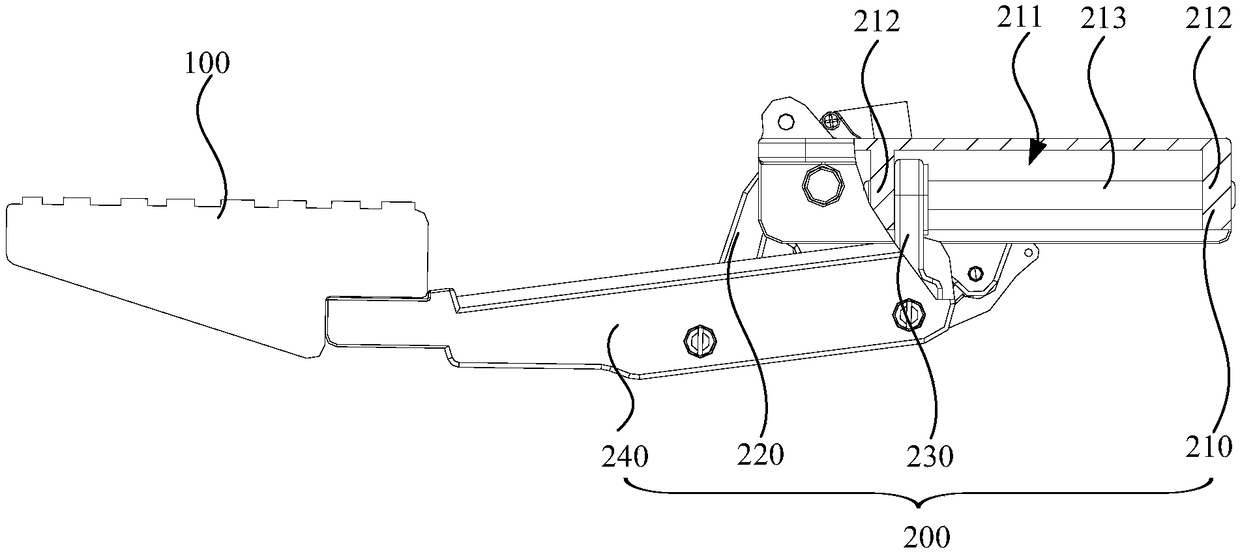

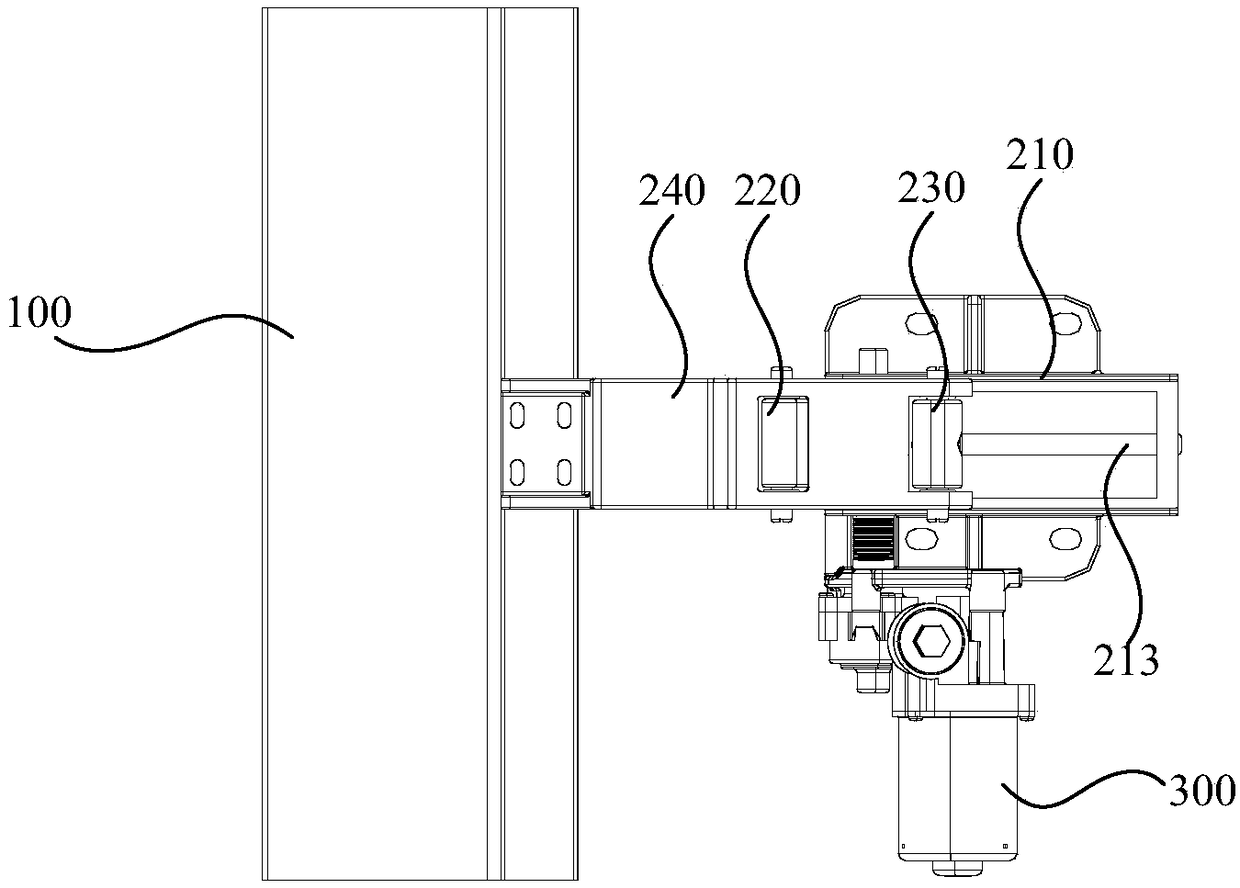

Vehicle step tread device

ActiveCN108791086AConstant output forceEasy to controlSteps arrangementElectric machineryDrive motor

The invention discloses a vehicle step tread device. The vehicle step tread device comprises a stepping plate, a telescopic mechanism and a driving motor. The telescopic mechanism comprises a fixed seat, a driving swing arm, a driven sliding arm and a connecting seat, one end of the driving swing arm is rotatably connected with the fixed seat, the other end of the driving swing arm is rotatably connected with the connecting seat. One end of the driven sliding arm is in sliding fit with the fixed seat, and the other end of the driven sliding arm is rotatably connected with the connecting seat.The driving swing arm and the driven slide arm are rotatably connected to different positions of the connecting seat, the stepping plate is fixed to the connecting seat, and a driving motor is used for driving the driving swing arm to rotate in a reciprocating mode. According to the vehicle step tread device, the stepping plate can automatically extend to assist the step tread and automatically retract to hide, meanwhile, the output force of the driving motor is relatively constant, the control process of the driving motor is simplified, the damage probability of the driving motor is reduced,and the service life of the driving motor is prolonged.

Owner:WINBO DONGJIAN AUTOMOTIVE TECHNOLOGY CO LTD

Angle in-place device of turnover mechanism

ActiveCN102616594AReduce the chance of cell damageReduce the chance of damageOverturning articlesPhysicsElectrical battery

The invention discloses an angle in-place device of a turnover mechanism. A disc-shaped piece capable of synchronously rotating along turnover sheets is arranged on a rotation shaft, grooves corresponding to the turnover sheets one by one and arranged along the circumferential direction at intervals are arranged on the disc-shaped piece, a sensor is adopted to detect rotation states of the grooves, after the front face of a battery sheet is completely printed, the battery sheet is transmitted to a group of turnover sheets from the turnover mechanism and turns over along rotation of the rotation shaft, the sensor detects the rotation states of the corresponding grooves, when the battery sheet rotates 180 degrees, and signals are sent to the controller which receives the signals and stops amotor to continuously rotate, so that the turnover battery sheet is transmitted from the other side of the turnover mechanism to conduct reverse side printing. Therefore, the battery sheet can accurately turn over 180 degrees along the turnover mechanism, and probability of damage of the battery sheet caused by rotation errors caused when the solar battery sheet is turned over by the turnover mechanism is reduced.

Owner:SUZHOU MAXWELL TECH CO LTD

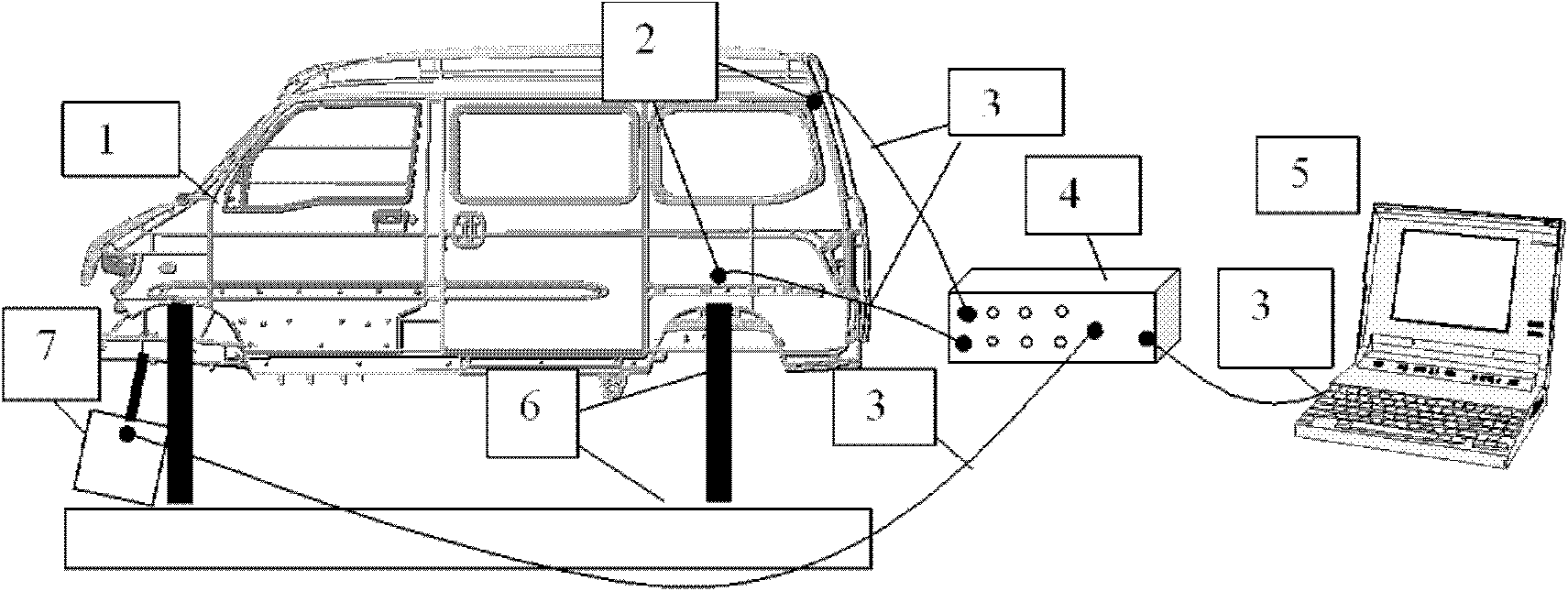

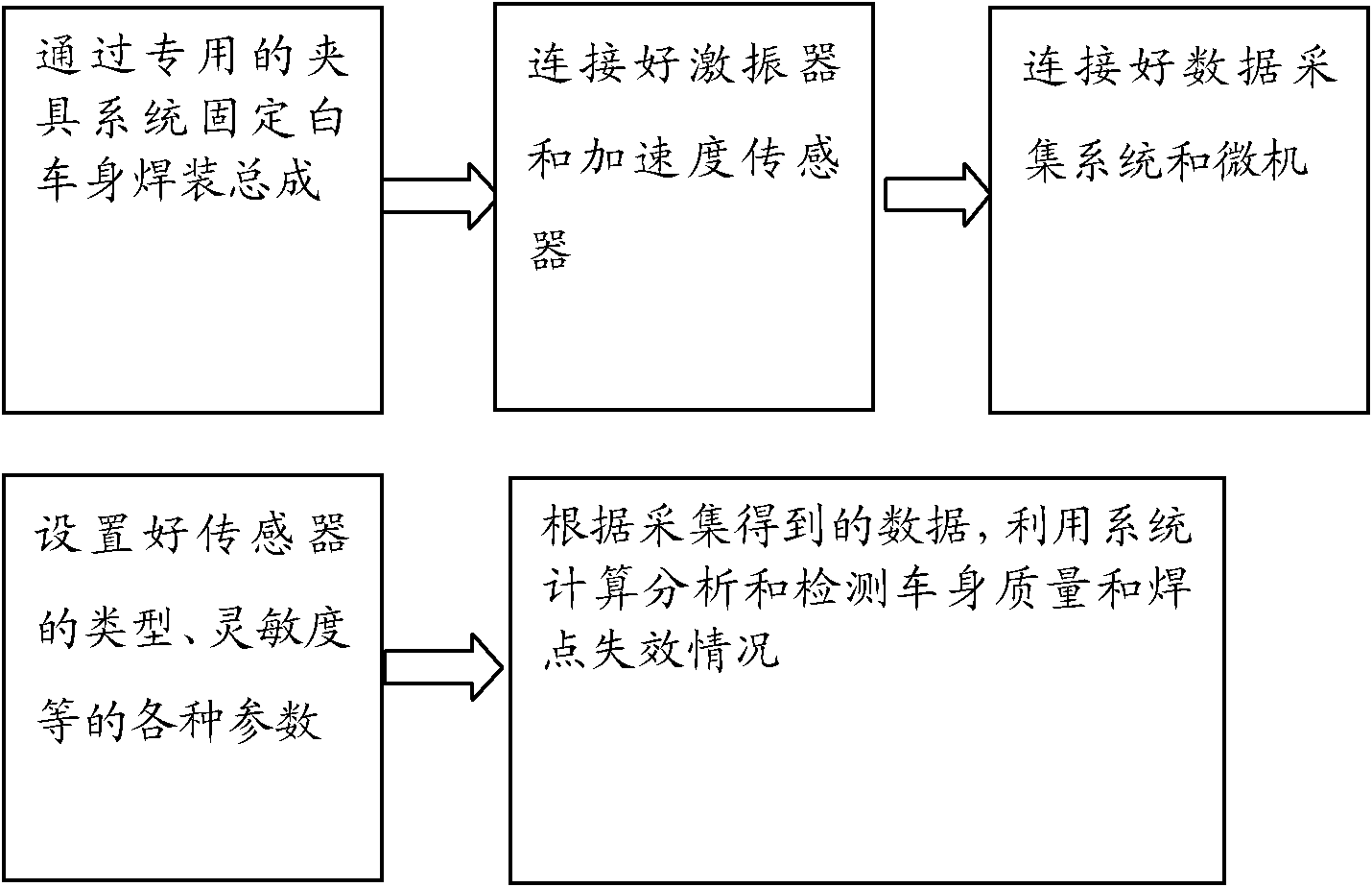

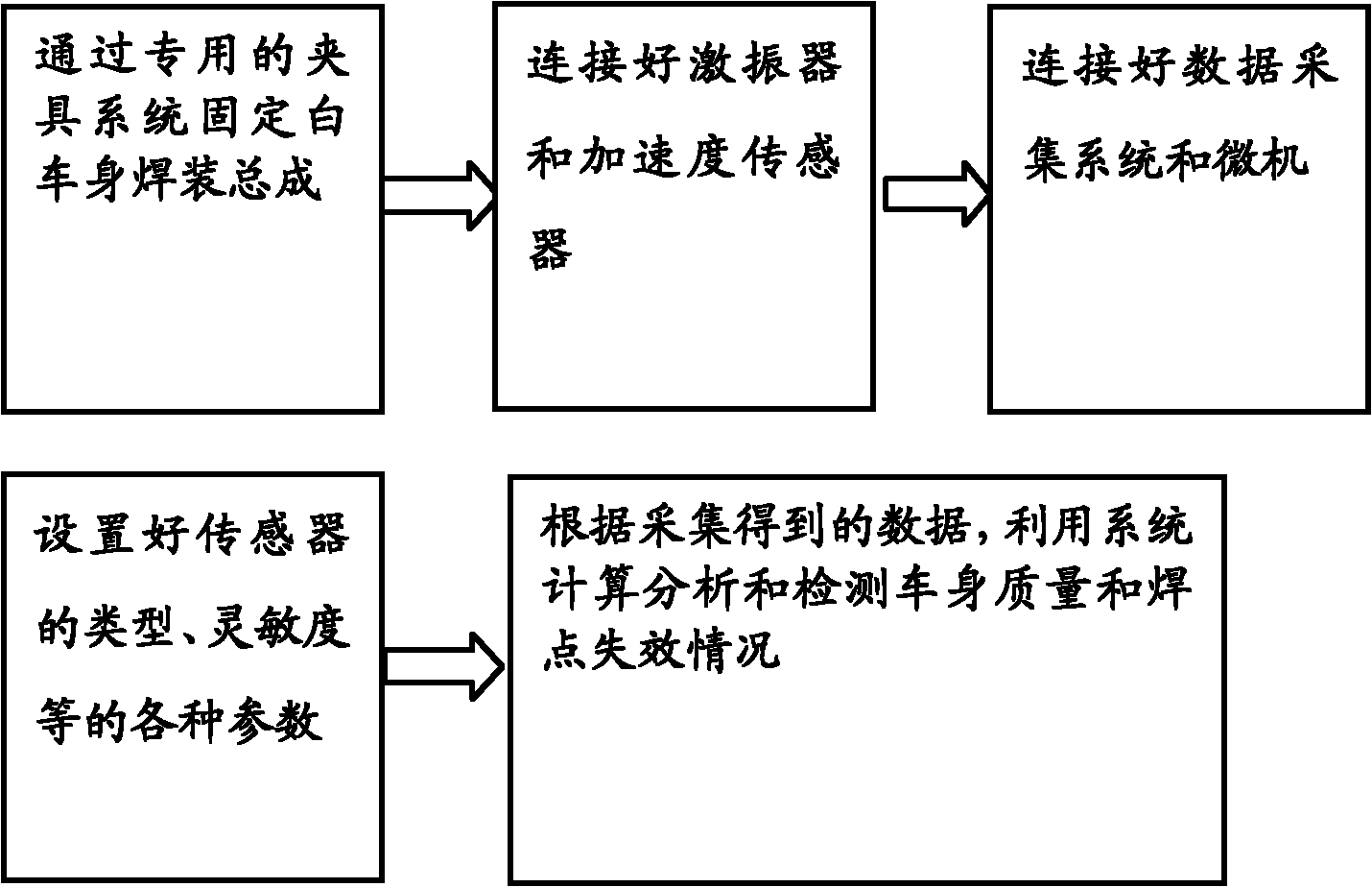

Detection equipment for welding spot failure of whole set of white vehicle body

ActiveCN102590340ASimple structureReduce the chance of damageAnalysing solids using sonic/ultrasonic/infrasonic wavesData acquisitionEngineering

The invention relates to detection equipment for welding spot failure of a whole set of white vehicle body. The detection equipment comprises a white vehicle body welding assembly, a vibration exciter and an acceleration sensor, wherein the white vehicle body welding assembly is fixedly arranged on a rack through a special clamp system; one side of the vibration exciter is connected with a data control and acquisition system; the other side of the vibration exciter is a free end for vibration excitation; the acceleration sensor is attached to a key part of the white vehicle body to be detected by using a magnet; the data control and acquisition system is connected with the acceleration sensor and is used for simply processing the acquired voltage signal and then transmitting data to a microcomputer; the data control and acquisition system and the microcomputer form a data detection and analysis system, i.e. an MIMO (Multiple Input Multiple Output) system; and the MIMO system integrates a signal acquisition system and can be used for modal analysis and damage identification of residual force vector as well as can be used for sampling, analyzing and processing the signal acquired in a current area to obtain an accurate detection result.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

Quantum dot sealing method, quantum dot compound particle and applications

ActiveCN105778887AReduce interactionReduce the likelihood of reunionsLuminescent compositionsNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a quantum dot sealing method, a quantum dot compound particle and applications. According to the method, quantum dots are made into quantum dot compound particles, then a blocking layer is arranged on the surface of each quantum dot compound particle so as to seal the quantum dots; after sealing, the interaction among quantum dots is reduced, thus the possibility of agglomeration is reduced; moreover, the air and water are obstructed; at the same time, the possibility that quantum dots are disturbed and destroyed by contacting the external environment, when the quantum dots are further dispersed into other materials or cured or during the device preparation process is reduced; the luminous efficiency of quantum dot is improved effectively, the service life of quantum dot is prolonged; and the provided quantum dot compound particle can be applied to optical devices such as light conversion material of liquid crystal display and has the advantages of high luminous efficiency of quantum dots and long service life.

Owner:TCL CORPORATION

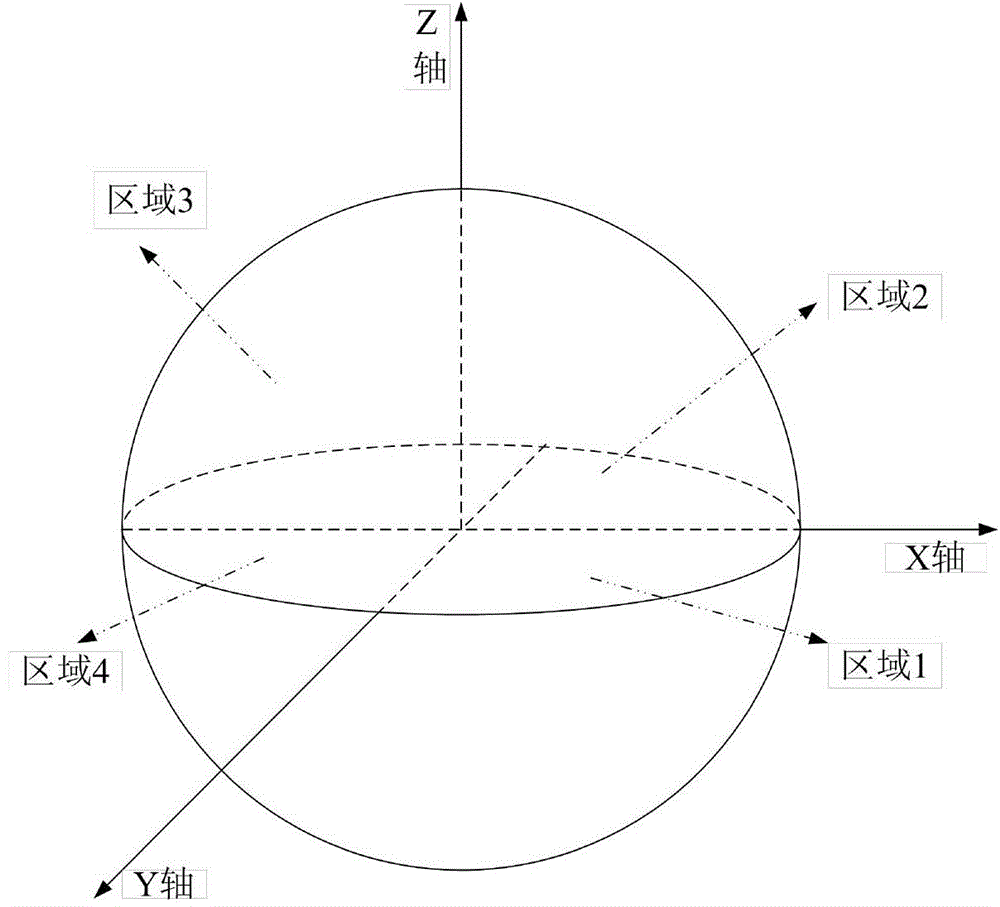

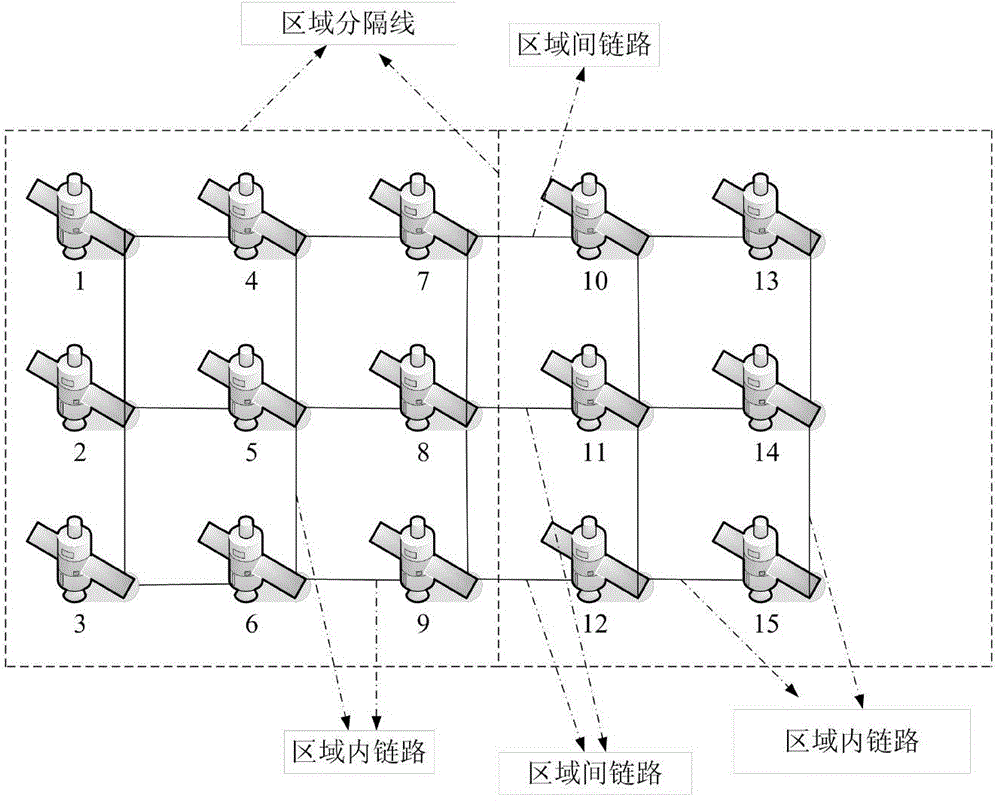

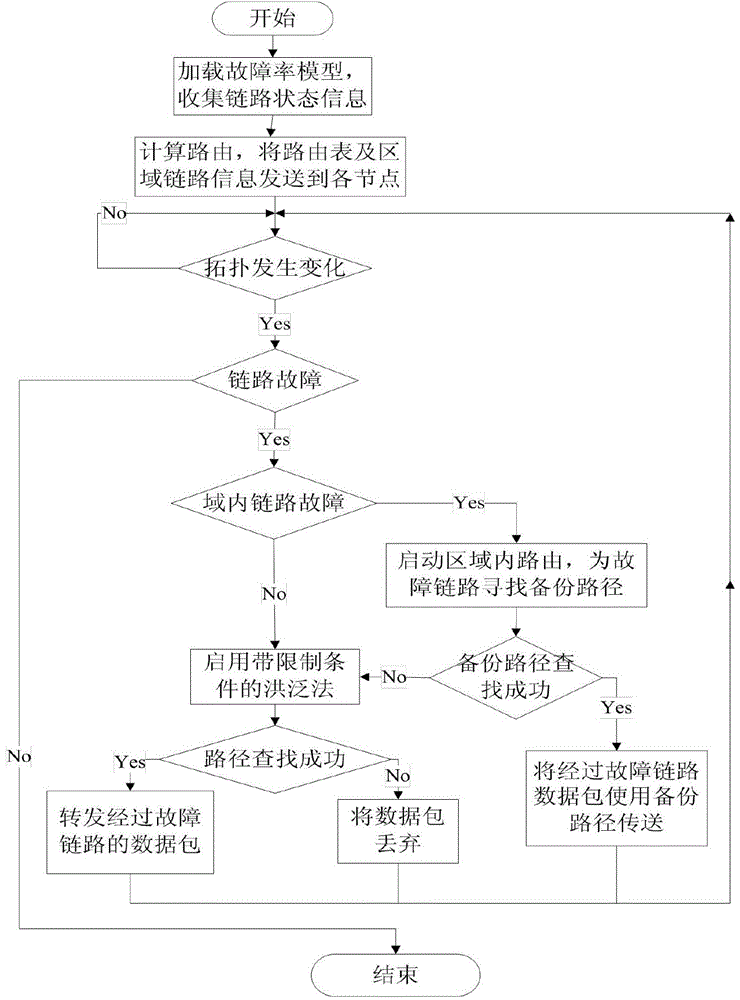

Satellite network inter-satellite link failure recovery method based on regional division

ActiveCN103986512AAvoid troubleSolve the real problemRadio transmissionRelay systems monitoringRecovery methodTime delays

Provided is a satellite network inter-satellite link failure recovery method based on regional division. Firstly, the link failure probability is added to a path cost formula to avoid links high in fault rate, and failures cannot happen to paths selected by services as far as possible; then a satellite network is divided into eight different regions, the topology of the satellite network is monitored, when a link failure occurs in the satellite network, rerouting is carried out in the regions of a small range, proper alternative paths are found for the fault links, and all the services passing through the failure links can be forwarded by the alternative paths; when no proper alternative paths exist in the regions, flooding information is sent by adopting a flooding method with limiting conditions, and proper forwarding paths are found for the services. The services in the satellite network avoid the failure links as far as possible, the alternative paths can be searched for fast after the link failure occurs, time delay needed by link failure recovery is shortened, resource waste is reduced, and therefore the communication efficiency of the satellite network is greatly improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

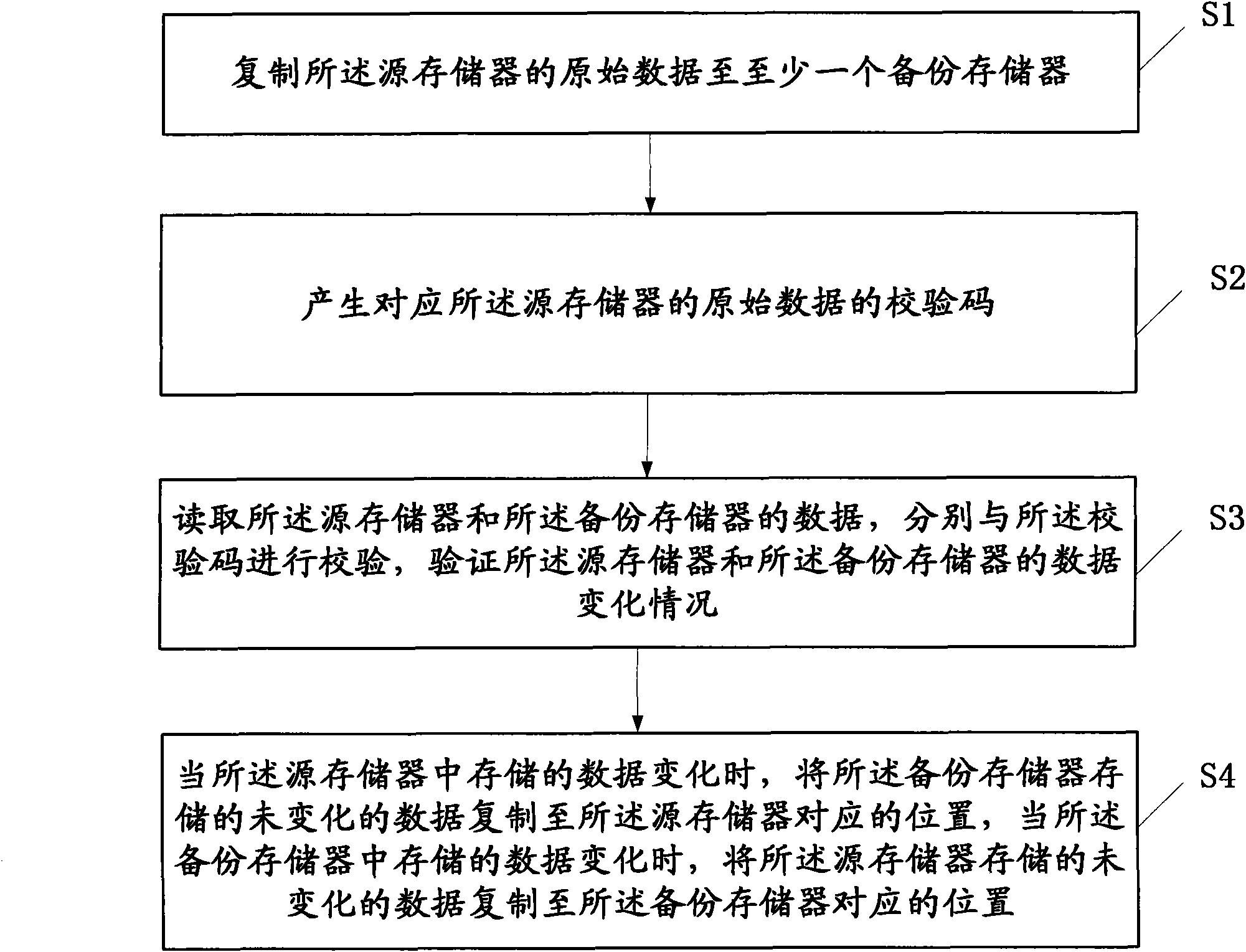

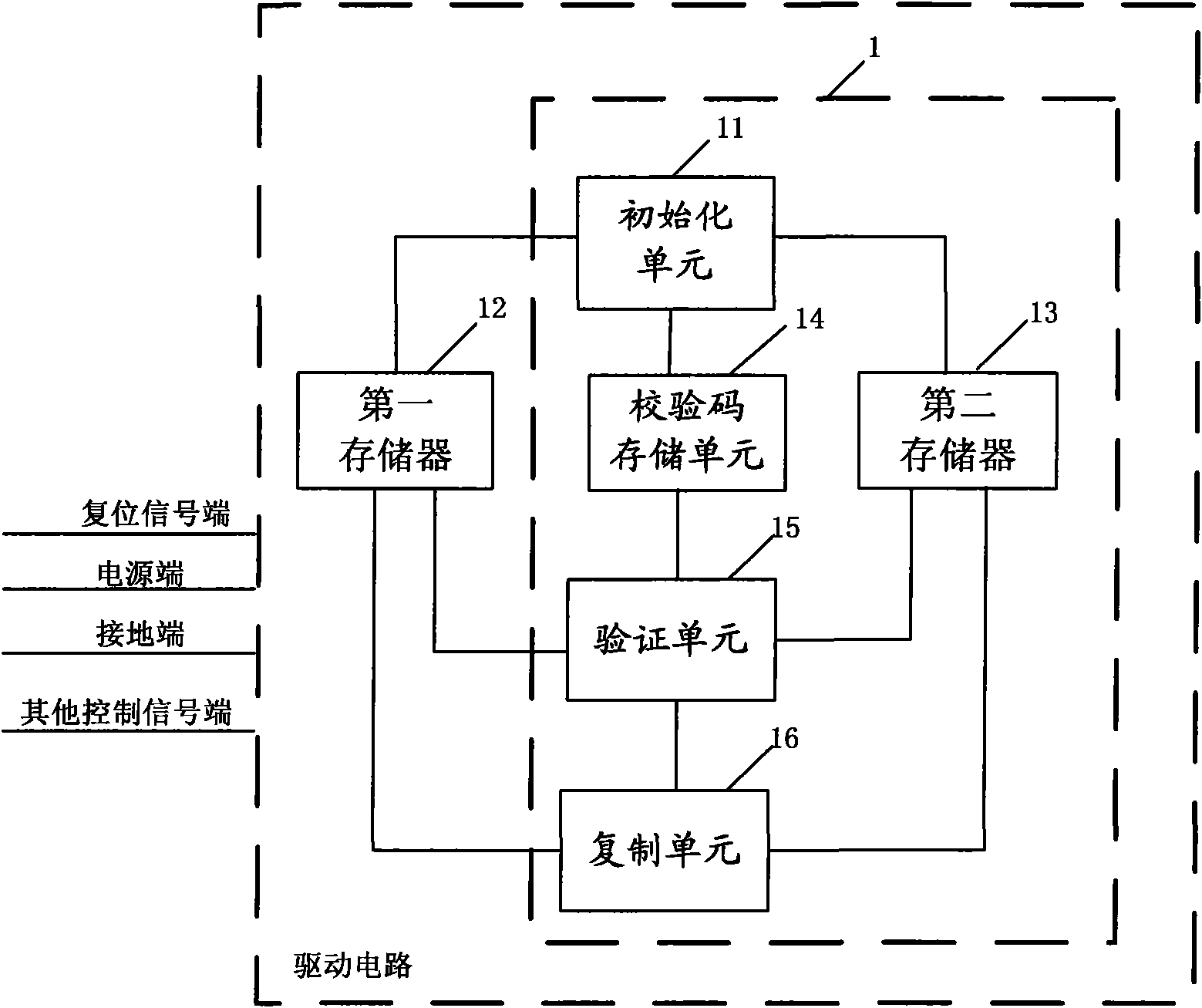

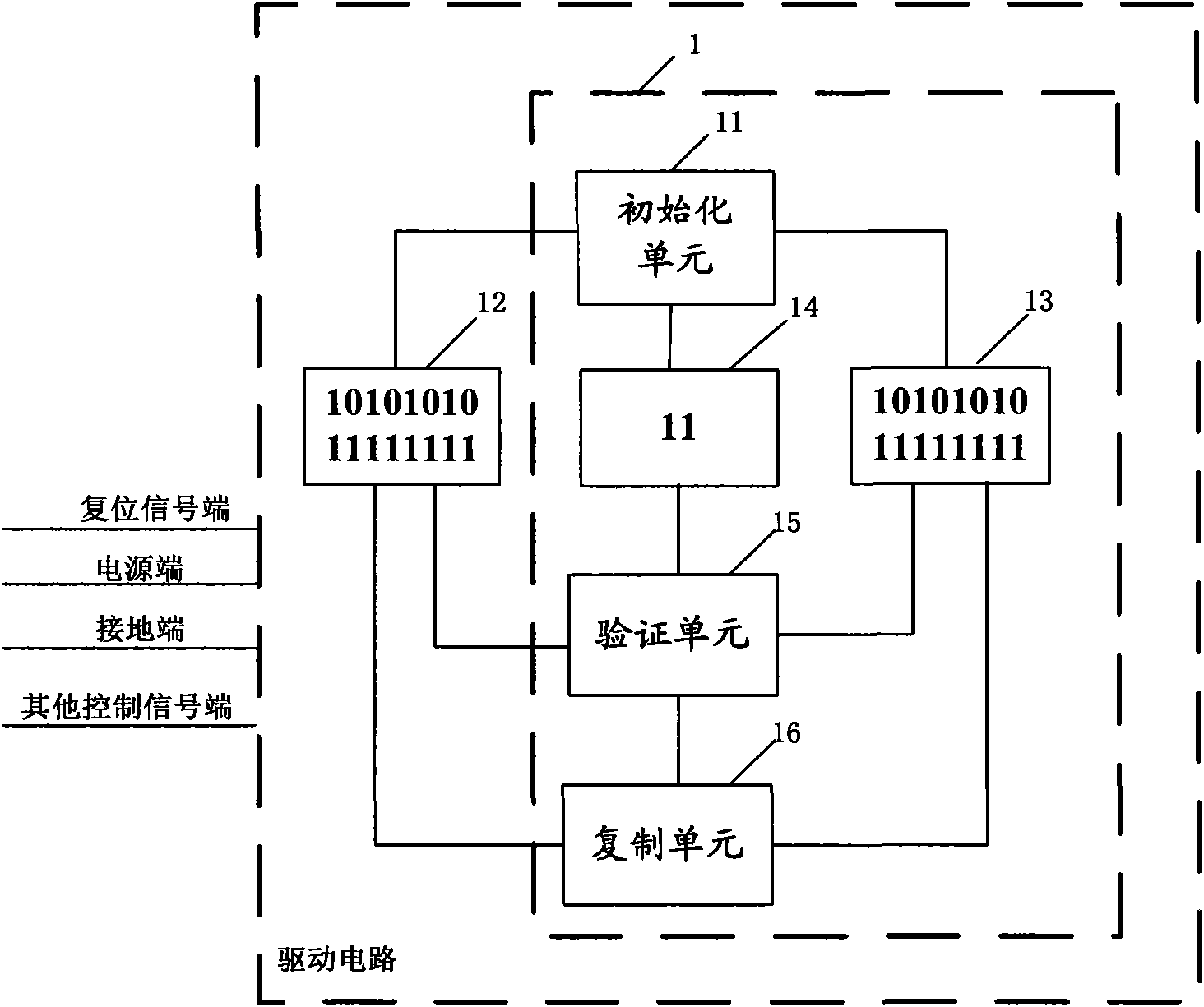

Method and device for maintaining data of drive circuit

ActiveCN102103834AAchieve data recoverySimplify the verification processCathode-ray tube indicatorsElectrostatic dischargeOperating system

The invention provides a method and device for maintaining data of a drive circuit. The drive circuit comprises a source memory for storing original data. The method comprises the following steps: duplicating the original data in the source memory to at least one backup memory; generating check codes corresponding to the original data in the source memory; periodically reading the data in the source memory and the data the backup memories and checking the data respectively with the check codes to verify whether the data in the source memory and the data in the backup memories change; and whenthe data stored in the source memory changes, duplicating the unchanged data stored in the backup memories to the corresponding positions of the source memory, and when the data stored in the backup memories change, duplicating the unchanged data stored in the source memory to the corresponding positions of the backup memories. According to the technical scheme adopted by the invention, the problem that destroying of the information in the memories caused by ESD (electrostatic discharge) leads to failure of the circuit to work normally can be effectively solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

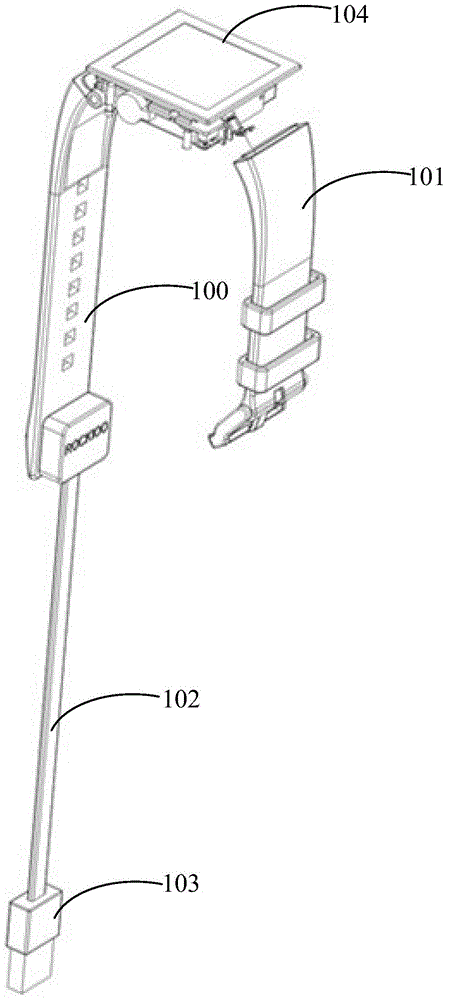

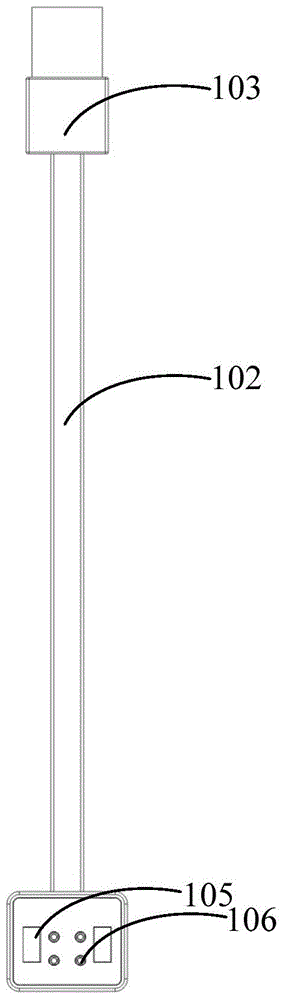

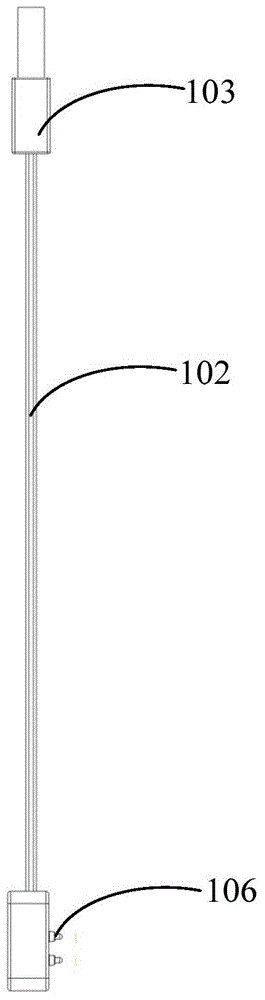

Watchband and transmission device applied to smart watch

InactiveCN104665130AEnsure convenience and reliabilityImprove waterproof performanceEngagement/disengagement of coupling partsIncorrect coupling preventionData transmissionPrinted circuit board

The embodiment of the invention provides a watchband and a transmission device applied to a smart watch. The problems that a smart watch watchband capable of conveniently and reliably performing data transmission is absent in the prior art and the actual requirements cannot be met are effectively solved. The watchband in the embodiment of the invention comprises a flexible printed circuit board inlaid in the watchband, and a 4pin interface arranged at the tail end of the watchband, wherein the 4pin interface is connected with the flexible printed circuit board. The watchband is simple in structure, ingenious in design, convenient to implement and easy to popularize and use, and the convenience and reliability of the watchband during use are obviously improved.

Owner:HANGZHOU LIANLUO INTERACTIVE INFORMATION TECH CO LTD

Supercritical CO2 variable-temperature variable-pressure extraction method of lucid ganoderma spore oil

The invention relates to a supercritical CO2 variable-temperature variable-pressure extraction method of lucid ganoderma spore oil. The method comprises the steps that: 1, lucid ganoderma spores are subjected to wall breaking, such that lucid ganoderma spore powder is obtained; 2, the wall-broken lucid ganoderma spore powder is prepared into particles with a dry-pressing method, such that particles with a size of 20-60 meshes are obtained; 3, the spore powder particles are placed into a supercritical CO2 extraction kettle with a three-stage separation structure; an ethanol water solution with a mass percentage of 20-95% is adopted as carrying agent, wherein 20-300ml of the 20-95% ethanol water solution is placed with each kilogram of material in the extraction kettle; and supercritical extraction is carried out, wherein an extraction pressure is 20-50MPa. The extraction process is a multi-stage extraction process, wherein extraction is carried out for 1-4h under a temperature of 30-40 DEG C, and extraction is carried out for 1-4h under a temperature of 40-60 DEG C. With the method, various effective components in lucid ganoderma spores can be more effectively extracted, such that the possibility for the lucid ganoderma spore active components to be broken is effectively reduced. The quality of the extraction product is improved, and the requirement of people is satisfied.

Owner:浙江龙泉佳宝生物科技有限公司

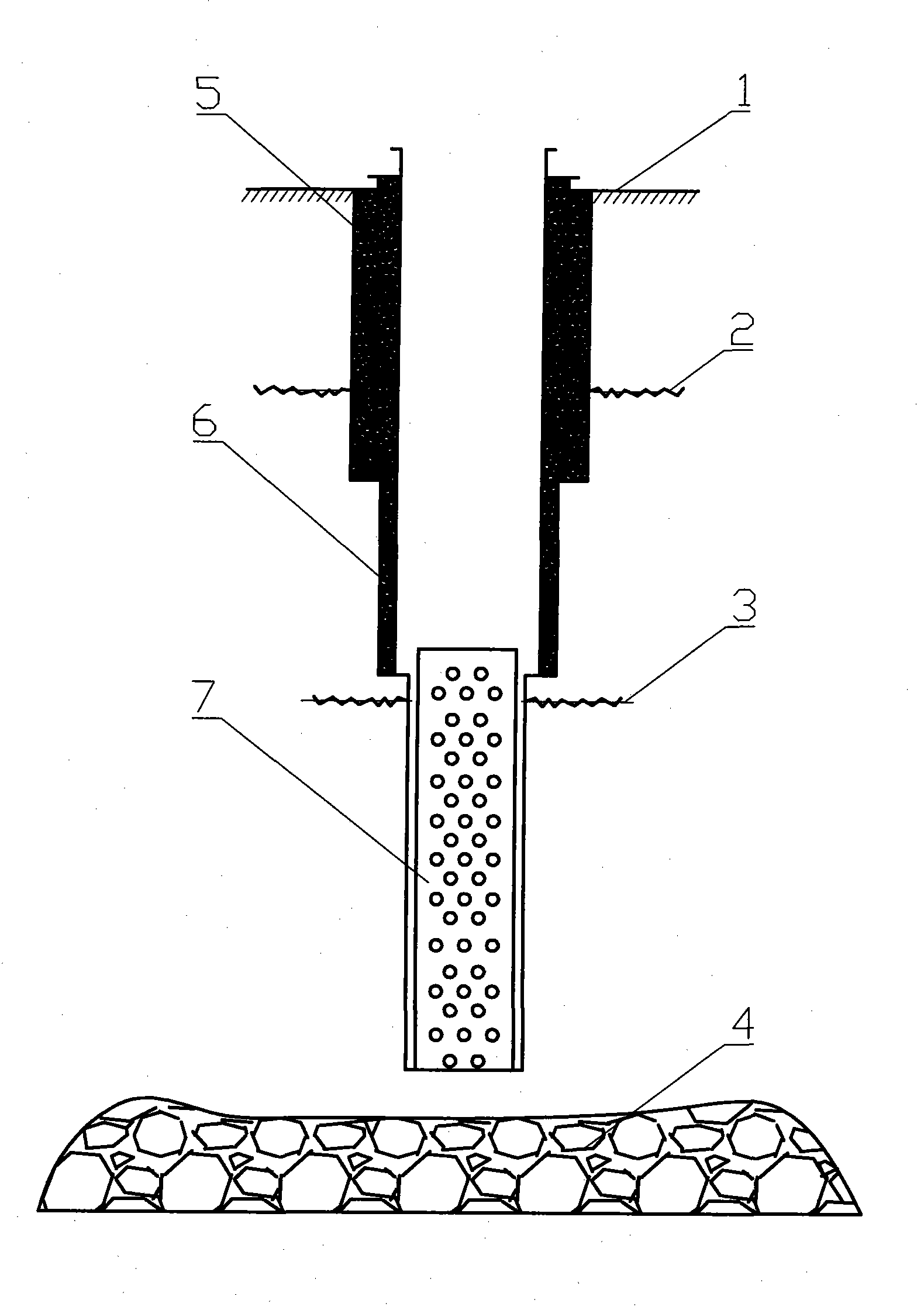

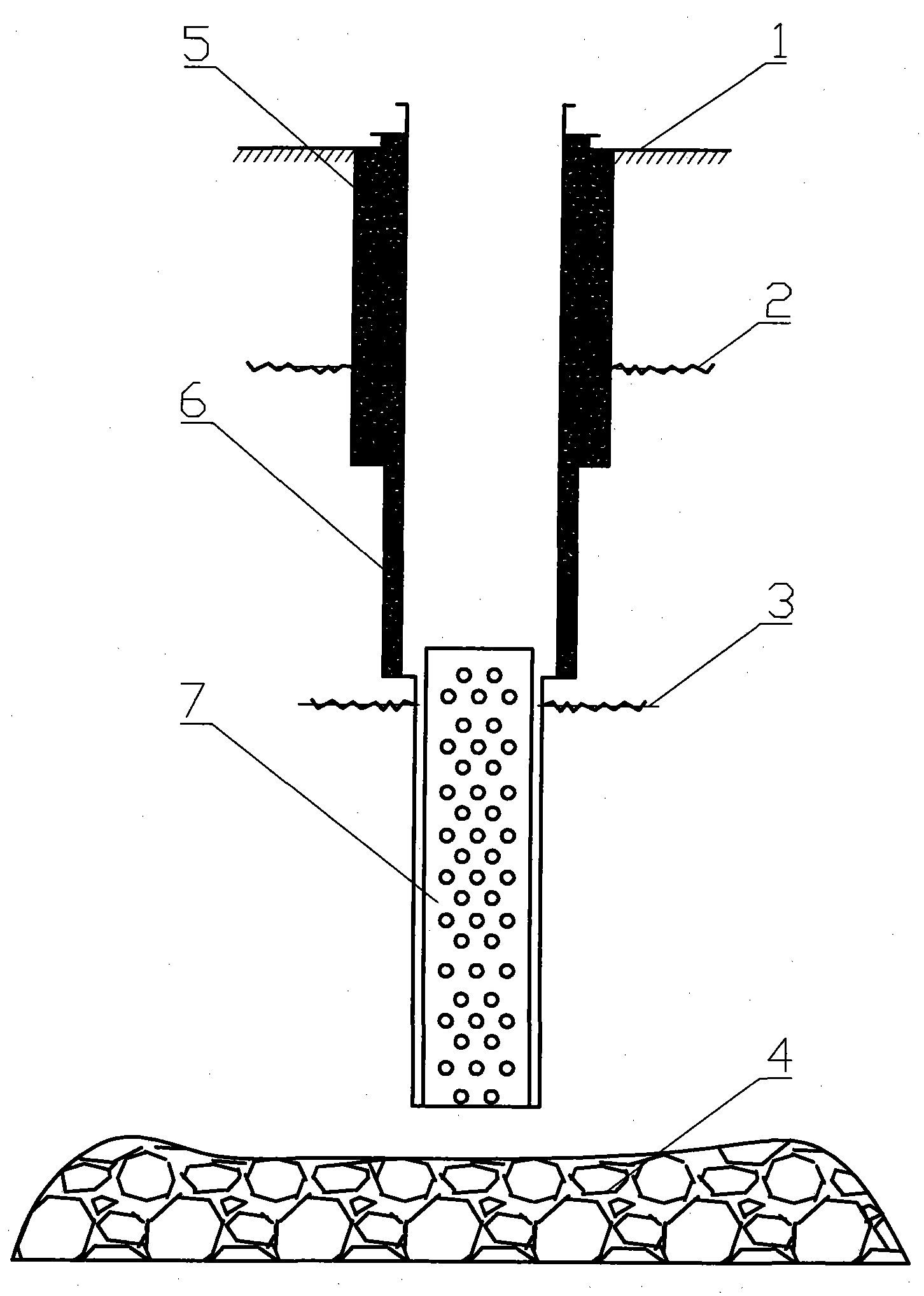

Method for extracting coal bed gas in stable mining region by ground well drilling

ActiveCN101915072AReduce the chance of damageIncrease profitFluid removalSealing/packingWell drillingWell cementing

The invention discloses a method for extracting coal bed gas in a stable mining region by ground well drilling, comprising the following steps of: hole distribution, well drilling, well cementation and well completion, wherein the hole distribution step can effectively reduce the destroy rate of a drilling well and improve the utilization rate of the drilling well by adopting a reasonable distribution principle so as to achieve the optimal extraction effect by using the least number of drilling wells; and simultaneously, the well drilling step adopts a third-opening well drilling way and selects reasonable well parameters, and two well completion processes of uncased hole well completion or liner tube well completion are adopted so that the well drilling structure and the construction process are reasonable, the extraction efficiency is also effectively improved, the possibility of destroying the drilling wells is reduced, and the well drilling accidents are reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

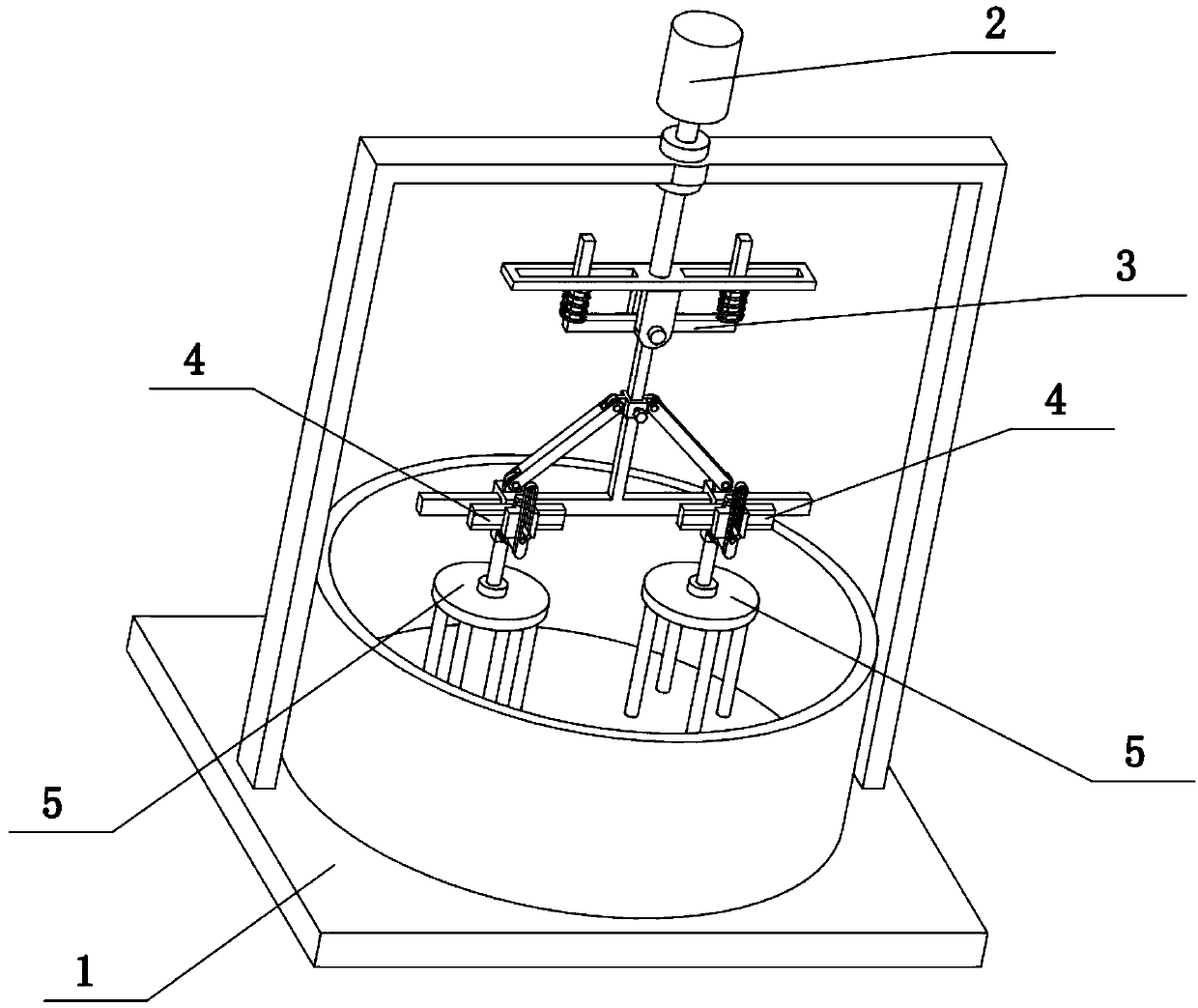

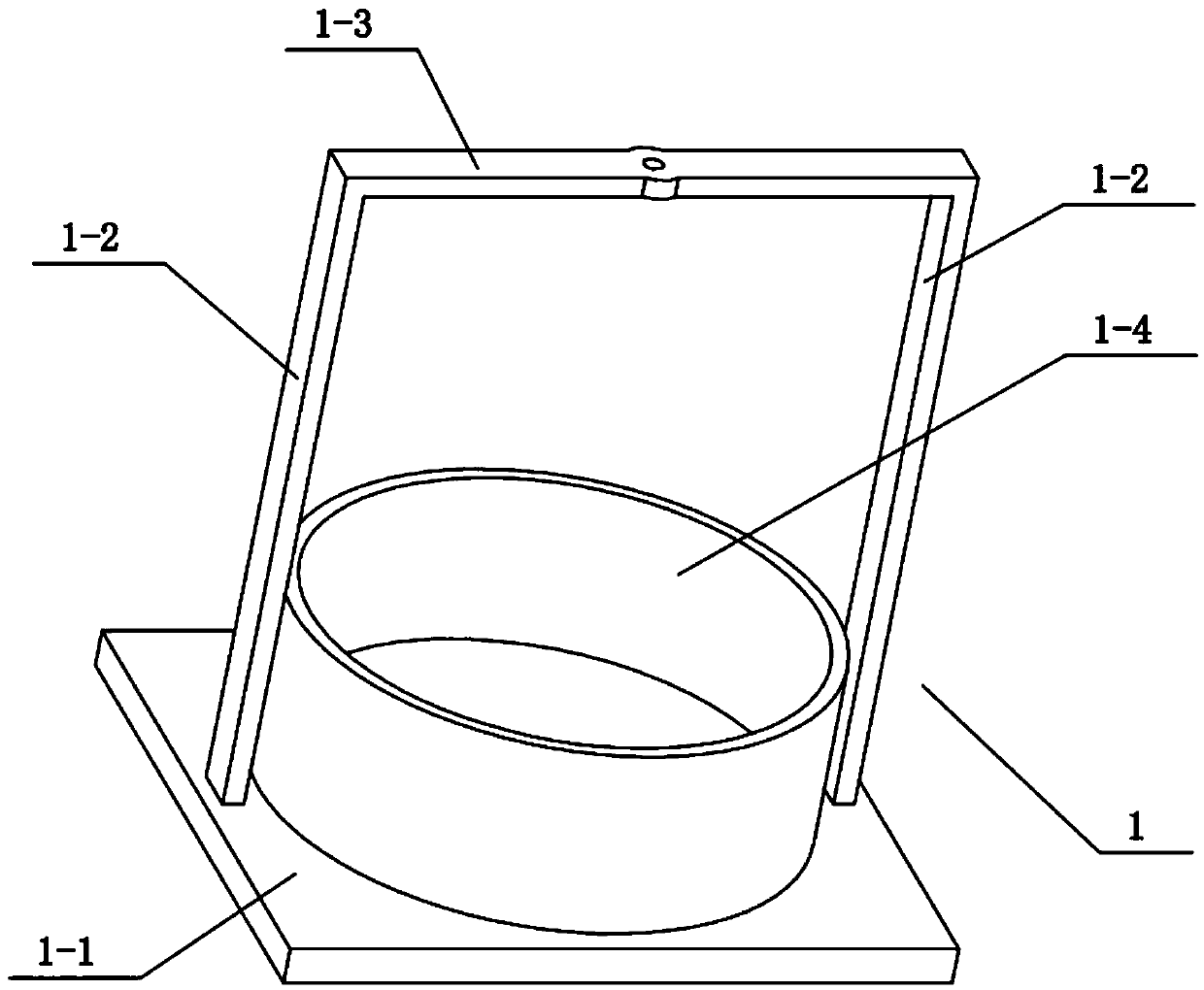

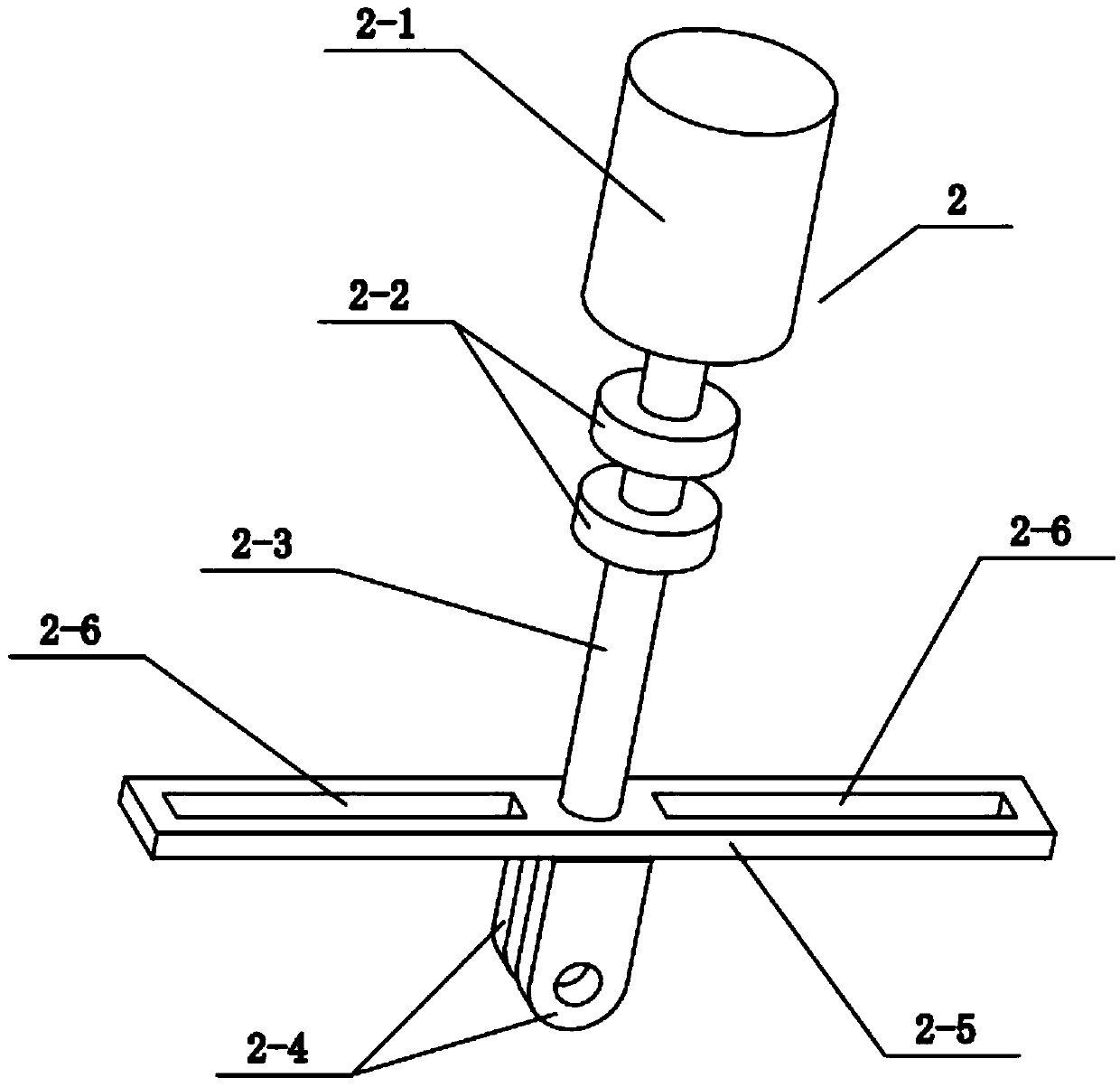

Glue production and processing system

ActiveCN109621786AReduce the chance of damageAvoid damageShaking/oscillating/vibrating mixersRotary stirring mixersPulp and paper industryMachining system

The invention relates to the field of glue production, in particular to a glue production and processing system. The glue production and processing system comprises a main frame body, a driving mechanism, a swing frame, sliding sleeve assemblies and stirring assemblies. The glue production and processing system has the advantages that the swing frame can swing laterally, and the swing frame can besubjected to the action of a compression spring when swinging laterally so that the swing frame can be restored to the original position; when high-viscosity glue is stirred, the swing frame can swing elastically to reduce the probability of the damage of the stirring assemblies; the positions of the two stirring assemblies both can be adjusted according to needs. The driving mechanism is rotationally connected to the upper end of the main frame body, the upper end of the swing frame is hinged to the lower end of the driving mechanism, the two sliding sleeve assemblies are arranged on the left and right, the two sliding sleeve assemblies are slidably connected to the left end and right end of the swing frame respectively, the two stirring assemblies are arranged on the left and right, andthe two stirring assemblies are arranged at the lower ends of the two sliding sleeve assemblies respectively.

Owner:NINGBO PASCO UNITED IND

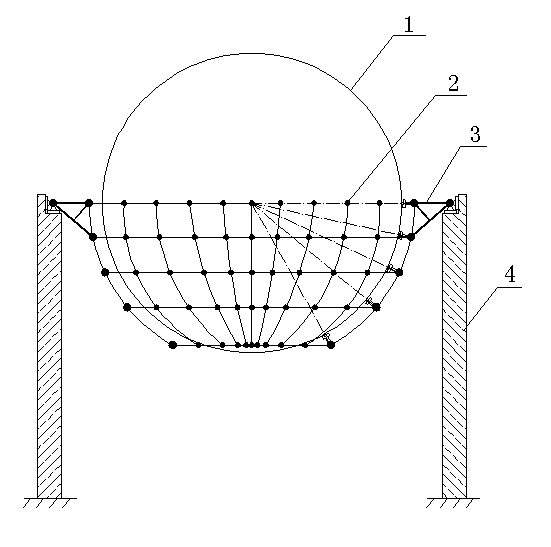

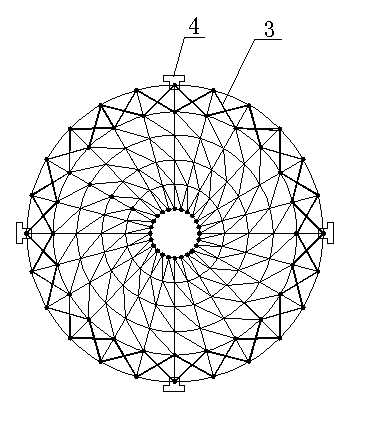

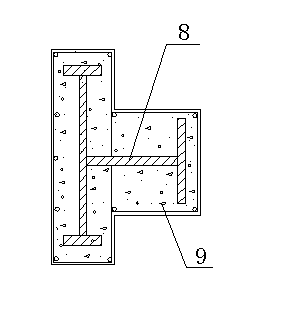

Reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving

InactiveCN103306531AGood energy dissipation and shock absorptionGood wind resistanceBulk storage containerShock proofingRebarReinforced concrete

The invention relates to a reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving. The system comprises combined spherical tanks, reticulated shell-annular truss frame-irregular-shaped combination column combined supports, a rubber ball-damper shock-absorbing energy consumption device, wherein annular truss frames are encircled outside the reticulated shells, and are connected with the irregularly-shaped combination columns; the combined spherical tanks are arranged on the reticulated shell-annular truss frame-irregularly-shaped combination column combined supports; the rubber ball-damper shock-absorbing energy consumption device is arranged between the reticulated shell pitch points and the combined spherical tanks; the rubber ball- damper shock-absorbing energy consumption device is composed of dampers and rubber balls; the rubber balls are arranged at one ends of the dampers; concave slide tracks are arranged on the outer walls of the combined spherical tanks; the rubber balls are positioned in the concave slide tracks; the other ends of the dampers are fixed with the pitch points of the reticulated shells; the irregularly-shaped combination columns are composed of solid-web section steel and reinforced concrete; the solid-web section steel is placed in the reinforced concrete; an L-shaped support seat is arranged at the top ends of the combination columns. The system can move slightly in any direction under the strong shock or the strong wind, and has excellent energy consumption shock-absorbing performance and wing resistance.

Owner:NORTHEAST GASOLINEEUM UNIV

Active component extraction method of plant polyphenol kind substance

ActiveCN1824084AAvoid oxidation reactionsHigh activityMagnoliophyta medical ingredientsPlant ingredientsMicrowaveActive component

A process for extracting the active polyphenol substances from the natural plants includes such steps as washing, drying, pulverizing, loading it along with the deoxidizing purified water in an extractor, heating at 50-90 deg.C under the protection of inertial gas while stirring for 30-60 min in order to extract the active components or ultrasonic or microwave extracting for 10-40 min 1-5 times, collecting liquid extract, filtering, cooling concentrating and drying.

Owner:谢君

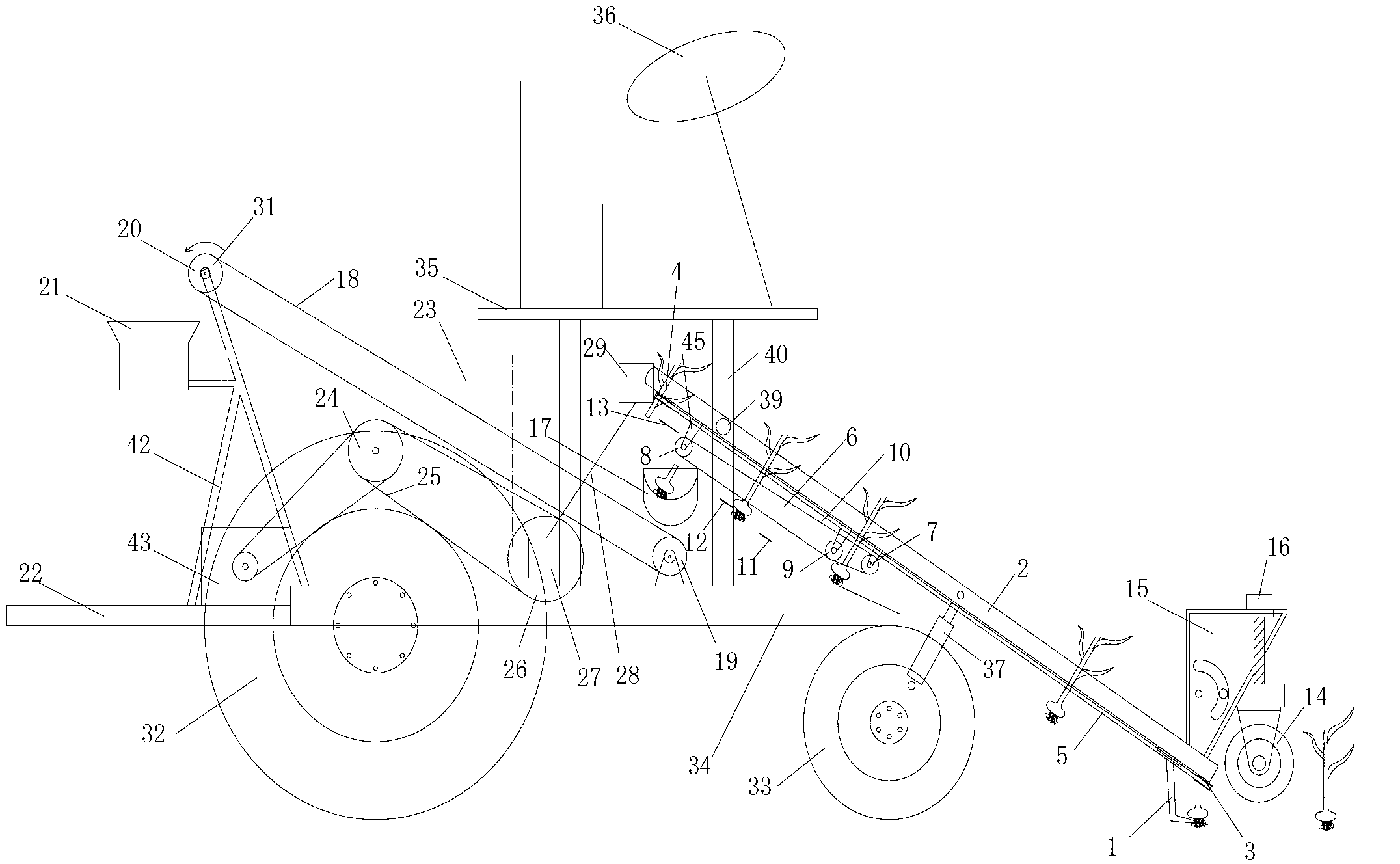

Multifunctional garlic combined harvester

ActiveCN102835214AReduce the chance of damageHigh degree of automationDiggersDrive wheelSteering wheel

The invention discloses a multifunctional garlic combined harvester which comprises a walking operation system, a power and transmission system and a framework main beam, wherein the walking operation system and the power and transmission system are respectively connected with the framework main beam; a bionic shoveling system, a cutting system and a garlic loading and transporting system are arranged on the framework main beam; the power and transmission system comprises an engine, a clutch wheel, a steering wheel, a loading and transporting driving wheel, a loading and transporting driven wheel, a power generator and a gearbox; a driving wheel on an output shaft of the engine is connected with the clutch wheel through a main V-belt; the clutch wheel is connected with the steering wheel; the steering wheel is connected with the gearbox through a transmission shaft; the gearbox is connected with the bionic shoveling system; the clutch wheel is connected with the loading and transporting driving wheel; the loading and transporting driving wheel is connected with the loading and transporting driven wheel; the clutch wheel is connected with a driving rear wheel of the walking operation system; and the power generator is connected with the output shaft of the engine. According to the multifunctional garlic combine harvester, a plurality of processes such as shoveling, hair cutting, garlic bulb shearing, loading and transporting can be completed at one time, so that the garlic digging efficiency and effect are improved, the labor intensity of farmers is reduced and the production efficiency is improved.

Owner:李为特

Stirring machine

ActiveCN104437166AReduce power consumptionReduce the chance of damageRotary stirring mixersEngineeringPower consumption

The invention discloses a stirring machine. The stirring machine comprises a base plate, a power mechanism, a rotating shaft, a suspension device and a stirring blade, wherein the power mechanism is fixed on the base plate, the rotating shaft is connected with the power mechanism and is driven to rotate by the power mechanism, the suspension device is fixed on the base plate and is used for supporting the rotating shaft for rotating, and the stirring blade is fixed on the rotating shaft. Due to the above mode, the power consumption of the power mechanism can be reduced, the damage probability of the power mechanism can be reduced and the cost can be saved.

Owner:GOLD EAST PAPER JIANGSU

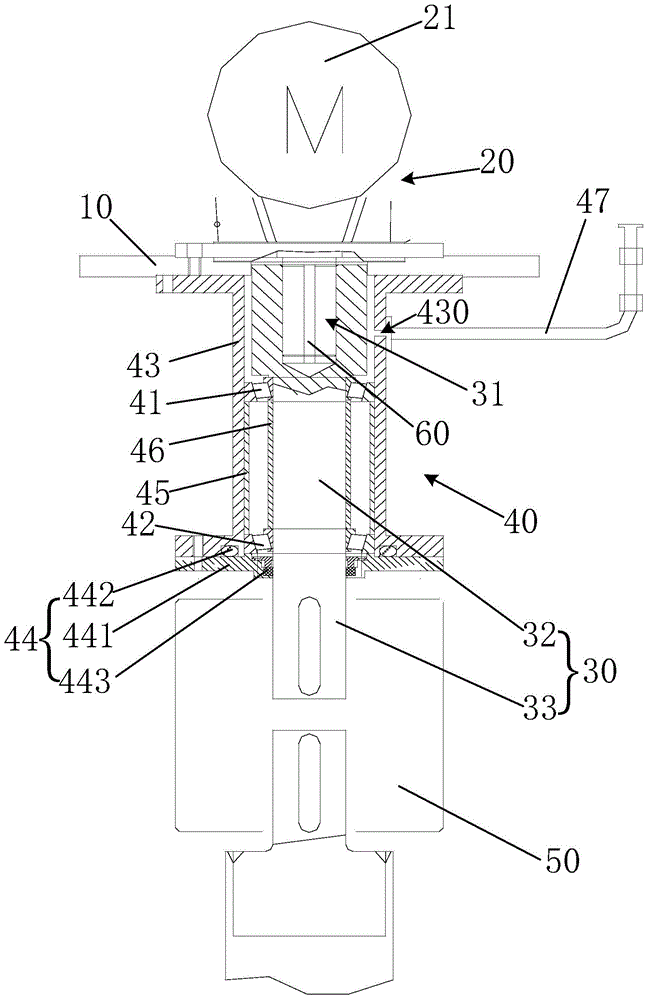

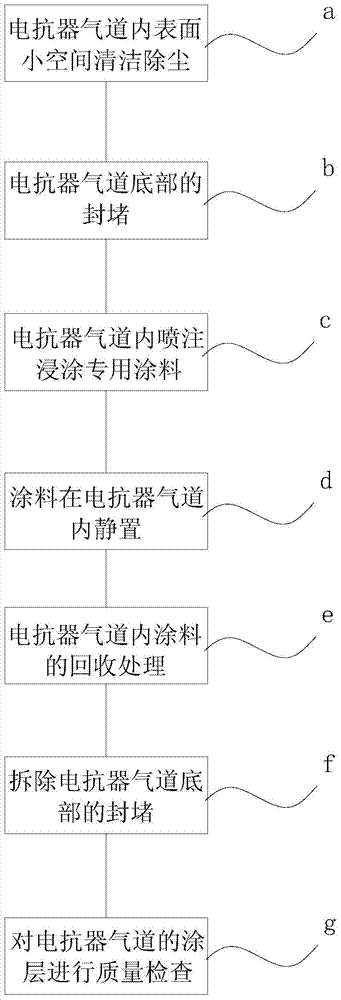

Technology for internal surface small space protection in air flue of dry-type air-core reactor

ActiveCN103680908AImprove cleanlinessReduce the chance of damagePretreated surfacesInductances/transformers/magnets manufactureNuclear engineeringWater vapor

The invention provides a technology for internal surface small space protection in an air flue of a dry-type air-core reactor. According to the technology for internal surface small space protection in the air flue of the dry-type air-core reactor, the inner surface of the air flue of the dry-type air-core reactor is processed. The technology comprises the following steps that dust in small space of the inner surface of the air flue of the air-core reactor is removed through a dust collection device, the bottom of the cleaned air flue of the air-core reactor is plugged through a plugging device, and therefore the air flue of the air-core reactor becomes a semi-closed container; paint is injected into the air flue of the air-core reactor, the air flue of the air-core reactor in the step (b) is dipped and coated, standing of the paint in the air flue of the air-core reactor is conducted for a period, the plugging device at the bottom of the air flue of the air-core reactor is detached after the paint is recycled, and quality detection is conducted on the treated air flue of the air-core reactor. According to the air-core reactor protected through the technology, the probability that due to the fact that water vapor molecules permeate through the air-core reactor, short circuits among wire turns of the air-core reactor are caused and then the air-core reactor is damaged is greatly reduced, and the service life of the air-core reactor is prolonged.

Owner:GUANGDONG CROWNPOWER ELECTRIC POWER SCI & TECH DEV CO LTD +1

Package design

ActiveCN1807198AImprove protectionReduce the chance of damageContainers to prevent mechanical damageDamagable goods packagingDamping factorPackage design

The invention discloses the package structure, comprising the first cushion material and the second cushion material. The first cushion material possesses the first contact surface, and the second cushion material possesses the second contact surface. The first contact surface and the second contact surface are used to contact articles. The first contact surface is exposed out of the second contact surface, and the second contact surface is projected out of the first contact surface. The first cushion material possesses the first elasticity coefficient and the first damper coefficient. The second cushion material possesses the second elasticity coefficient and the second damper coefficient. The first elasticity coefficient is the same with second elasticity coefficient, and the damper coefficient is different from the second damper coefficient.

Owner:AU OPTRONICS CORP

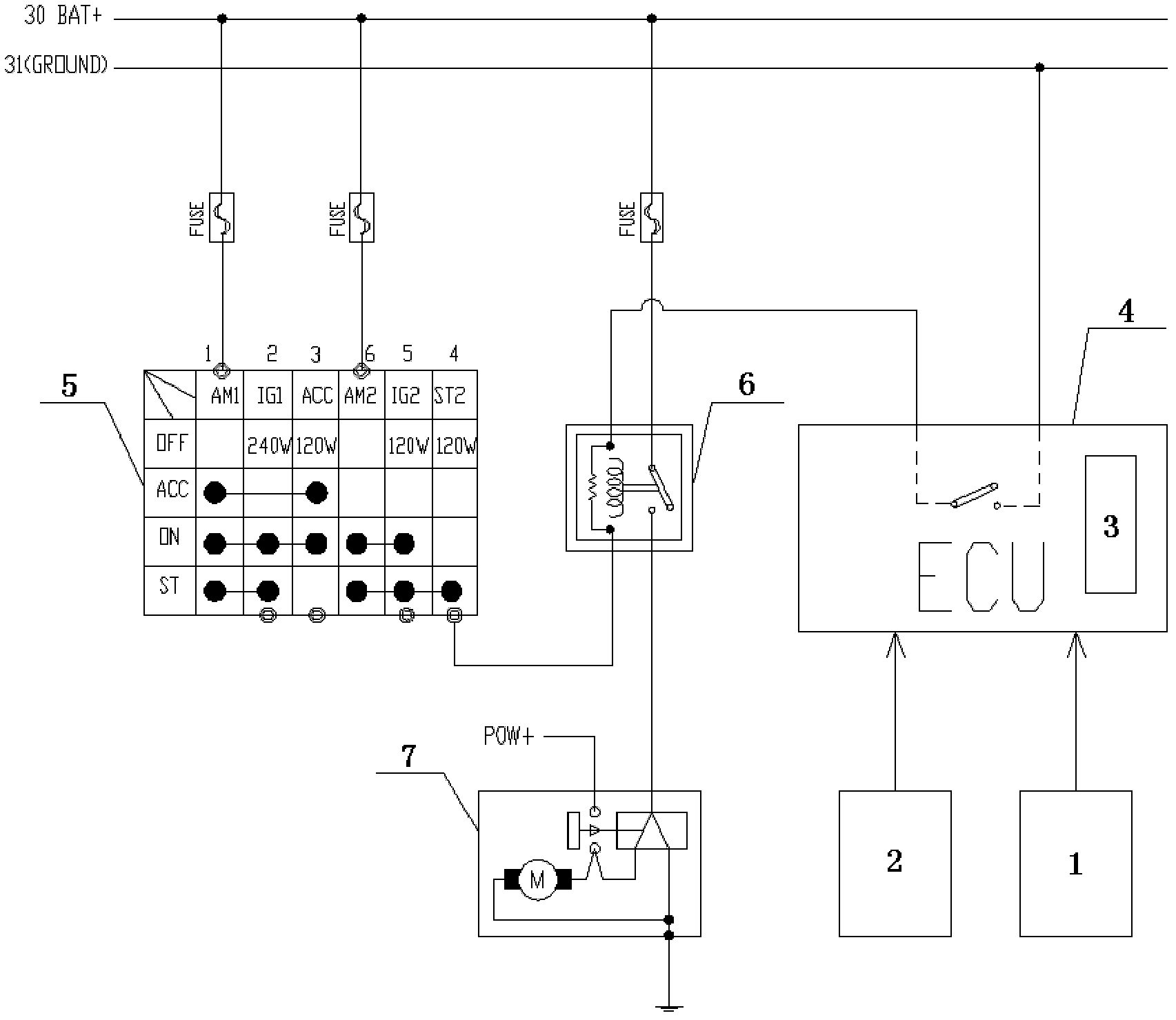

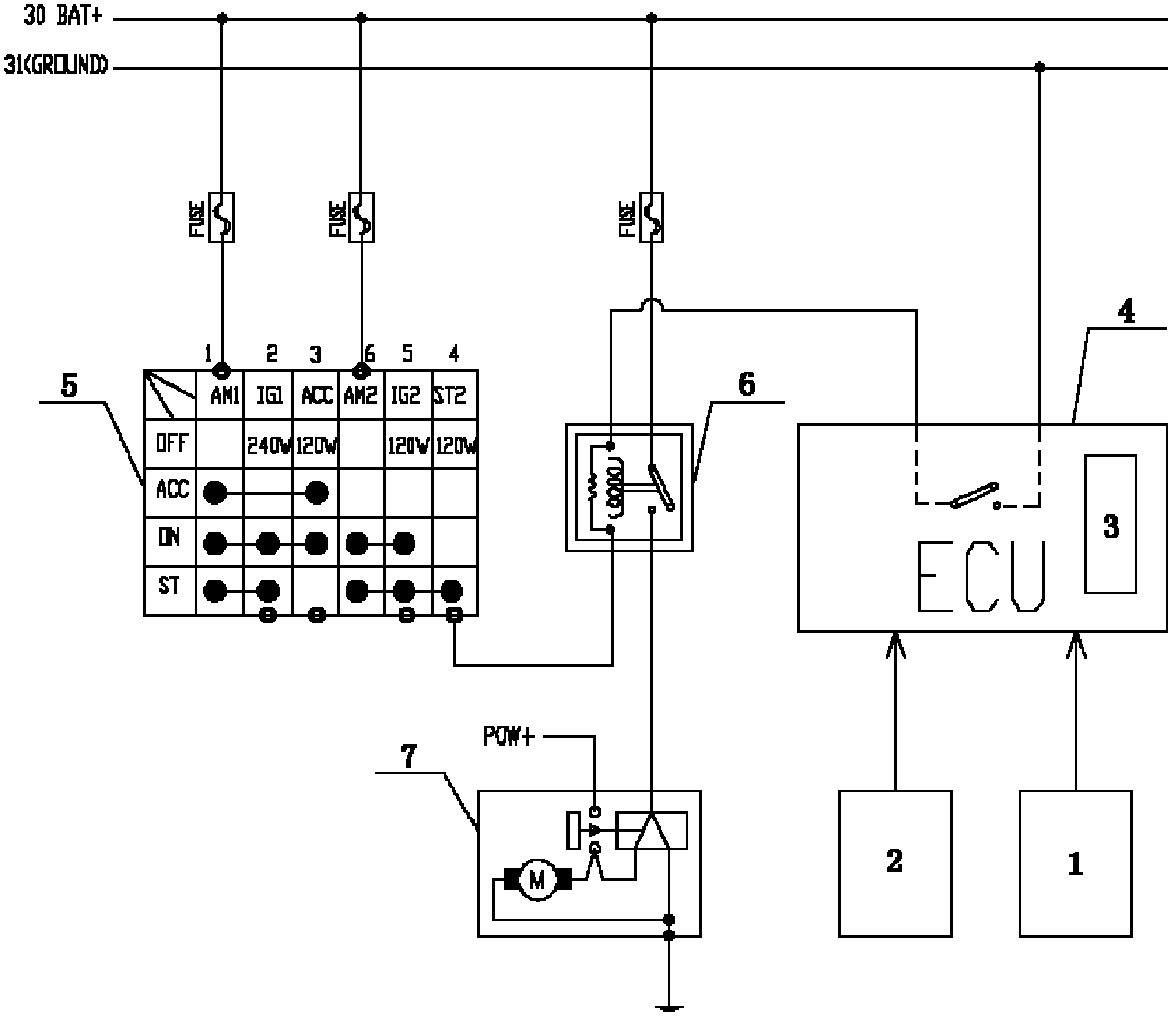

Protective control system and method of vehicle starting engine

ActiveCN102425522AReduce the chance of damageExtend working lifeElectric motor startersMachines/enginesControl systemComputer module

The invention discloses a protective control system and method of a vehicle starting engine. The system is provided with a rotating speed sensor for monitoring the rotating speed of a starter; a monitored rotating speed signal is transmitted to an engine control module; an ignition switch and a starter control module are connected in series to a coil end loop of a starting relay; the engine control module is used for controlling the switch-on / off of the coil end loop of the starting relay according to the rotating speed of the engine; and a normally-open contact at the control end of the starting relay accesses a relay loop of the starter, and is used for controlling the switch-on / off of the relay loop. Due to the adoption of the system and the method, the technical blank of starter protection is filled up; and moreover, a circuit has a simple structure and is easy to realize and popularize, the entire vehicle performance is enhanced, the damage rate of the starter is lowered, the working service life of the starter is prolonged, and the maintenance cost on a vehicle is lowered for a user.

Owner:CHERY AUTOMOBILE CO LTD

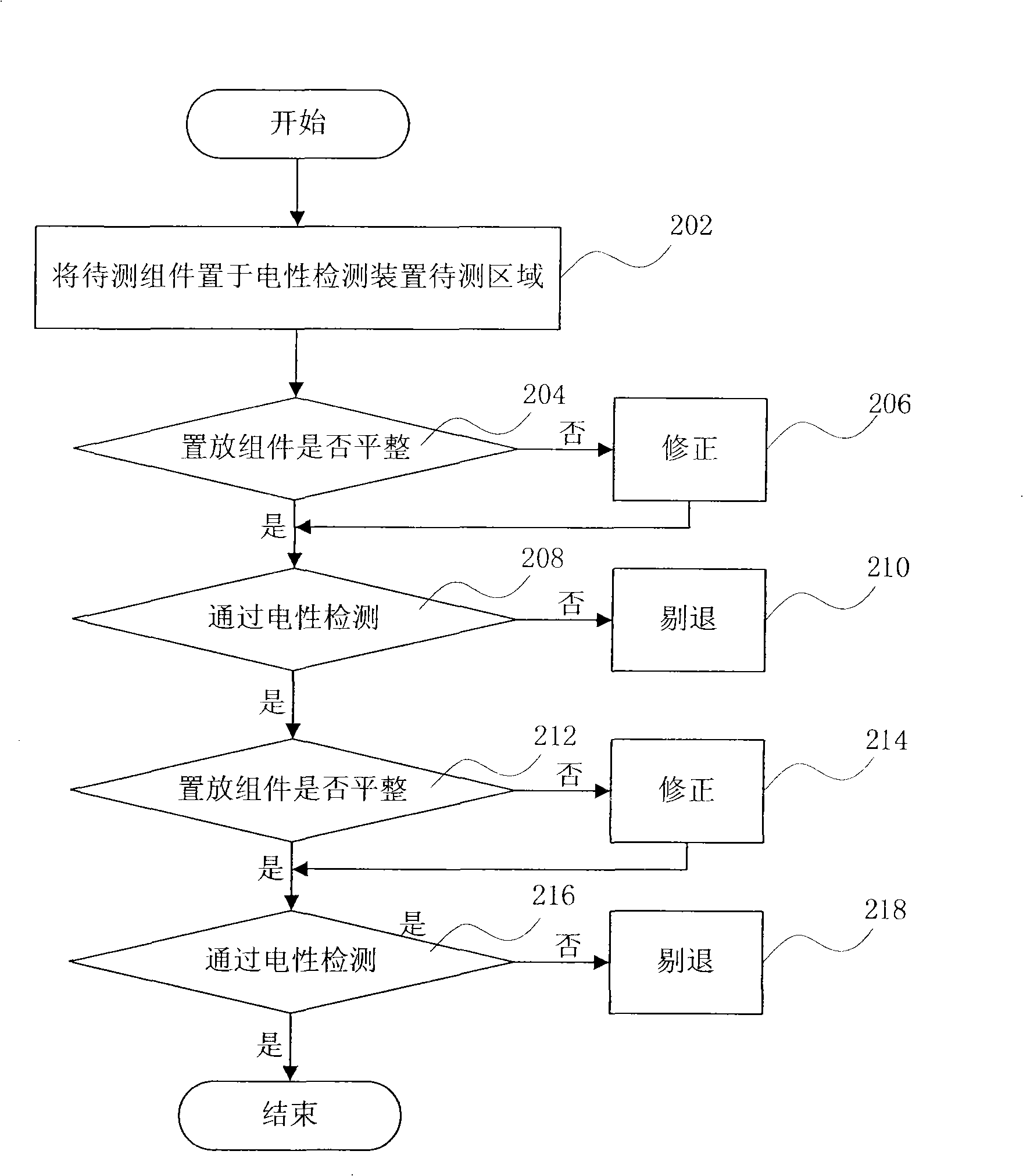

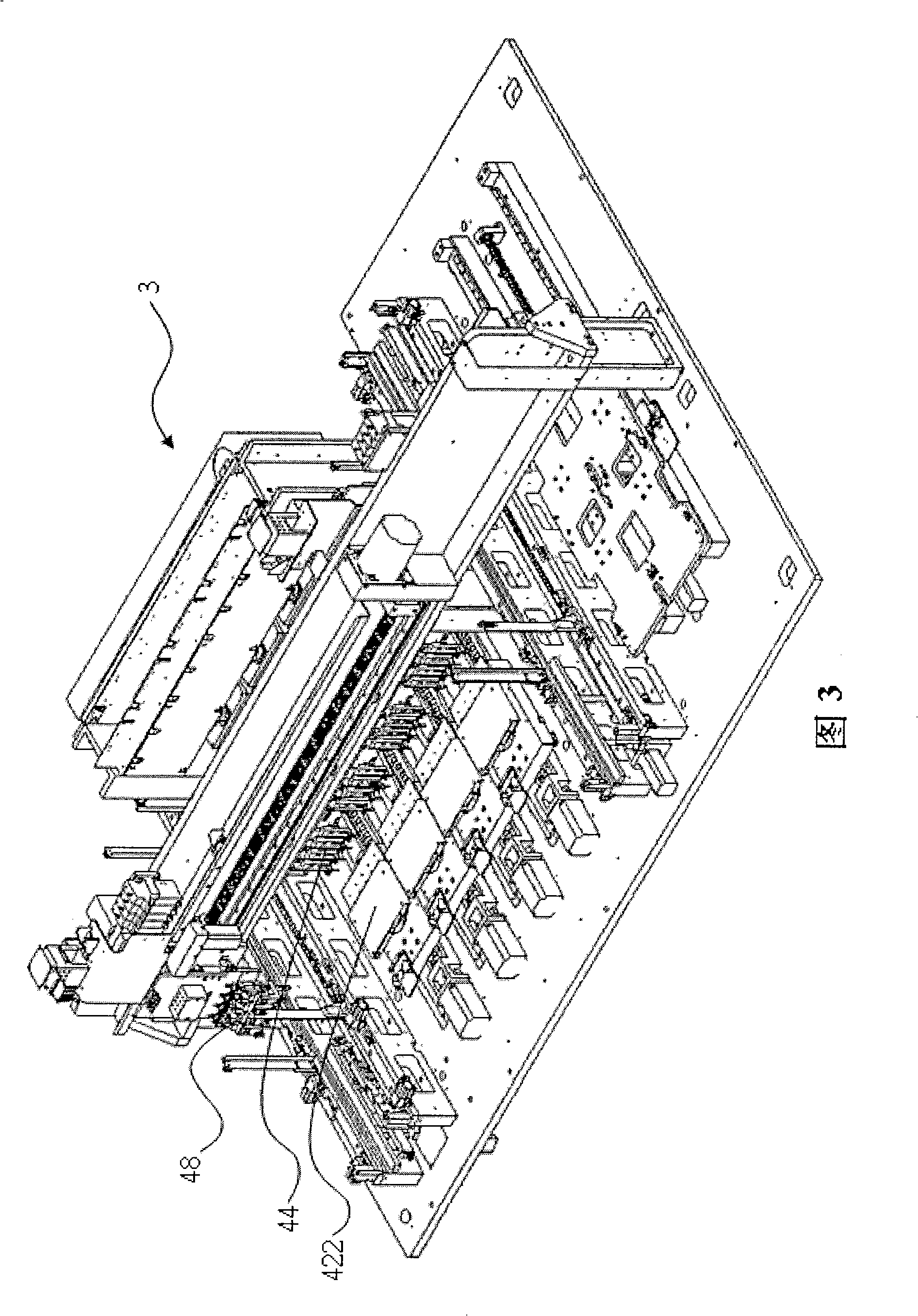

Semiconductor component test station with detachable electric property detecting system

InactiveCN101315405AGreat operating flexibilityFully functionalElectrical measurement instrument detailsIndividual semiconductor device testingElectricityElectric properties

The invention relates to a semiconductor component testing machine with a separable electrical detection system. After the semiconductor component to be tested is viewed for correct arrangement, the semiconductor component to be tested is moved to the position to be tested, and electrically connected to the electrical detection system for performing electrical detection through the switching of a connector, thereby carrying out a continuous detection procedure for efficiency detection by switching at the original testing position. The testing procedures are consecutive, the time of absorbing and moving the component to be tested is reduced, the damage probability of the component to be tested is reduced, and the detection efficiency and the proper handling rate of the tested component are improved. Two systems can be separated according to the requirement, and the efficiency detection procedure of the semiconductor component to be tested is respectively performed, thereby avoiding the pointless increase of the machine cost and improving the use elasticity.

Owner:CHROMA ATE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com