Angle in-place device of turnover mechanism

A flipping mechanism and angle technology, which is applied in the direction of flipping objects, transportation and packaging, pile separation, etc., can solve the problems of battery chips broken, easy to break, and low efficiency of production methods, and achieve the effect of reducing the probability of battery damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

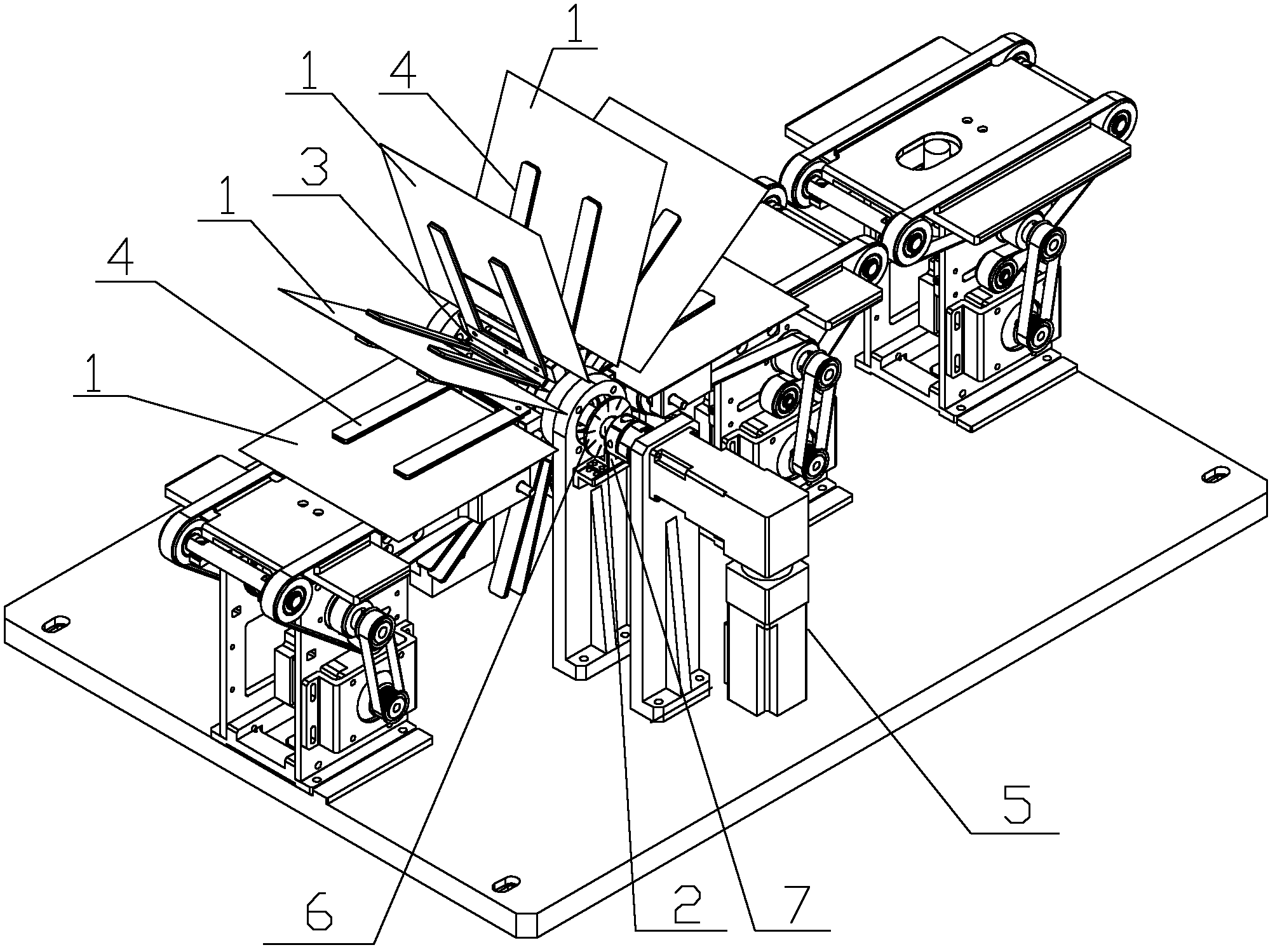

[0016] see figure 1 The angle in place device of an overturning mechanism is shown, wherein the overturning mechanism is used for overturning the solar battery sheet 1 during the transmission process. The overturning mechanism includes a rotating shaft 2, a turntable 3 arranged on the rotating shaft 2 and synchronously rotating with the rotating shaft 2, and the turntable The circumferential side of the turntable 3 is connected with multiple sets of turning pieces 4, and these sets of turning pieces are distributed on the circumferential side of the turntable 3 at intervals. Mechanism 5 adopts a motor here.

[0017] see figure 1 As shown, the angle setting device of the present invention includes a disc-shaped member 6 fixedly sleeved on the rotating shaft 3 and rotating synchronously with the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com