Technology for internal surface small space protection in air flue of dry-type air-core reactor

A technology of air-core reactors and reactors, which is applied in the direction of surface coating liquid devices, electrical components, pretreatment surfaces, etc., can solve the short circuit between turns, accelerate the epoxy resin of the reactor, and the inner surface of the airway is not effectively Protection and other issues, to reduce the probability of reactor damage, prolong the service life, the effect of simple protection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

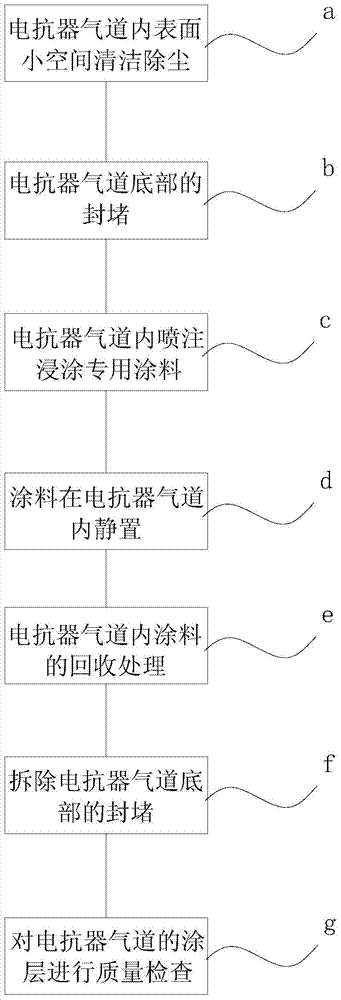

[0030] Such as figure 1 As shown, the protection process of a small space on the inner surface of a dry-type air-core reactor air duct of the present invention mainly includes the following steps:

[0031] The first step is to use a dust removal device to remove the dust in the small space on the inner surface of the reactor air duct; use an electric small brush or a rag to clean the small space on the inner surface of the reactor air duct, and then use a dust removal spray gun to blow off the dust to ensure that the inner surface of the air duct is clean .

[0032] The second step is to block the bottom of the reactor airway; use a rubber airbag that matches the specifications of the reactor airway to block, and the rubber airbag is equipped with a T-shaped copper iron pipe for support. First, place the rubber airbag Fill the bottom of the reactor airway, and then inflate the rubber airbag to a certain extent through the gas distributor to block the bottom of the reactor air...

Embodiment 2

[0039] In a protection process for the small space inside the air duct of a dry-type hollow reactor, the blocking device in the second step is made of fireproof mud or rubber, silicon rubber and other materials with a valve to recover the diversion pipe, and the bottom of the reactor air duct is equipped with The supporting plate, the supporting plate exerts force on the blocking device, and blocks the bottom of the reactor air passage; complete the removal of the blockage at the bottom of the reactor airway; or remove the construction operation that makes the reactor airway into a semi-enclosed container environment in other ways, and complete the removal of the bottom blockage of the reactor airway.

[0040] In this embodiment, other implementation steps are the same as those in Embodiment 1, and will not be described here one by one, and the invention objective of the present invention can also be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com