Patents

Literature

825results about How to "Insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

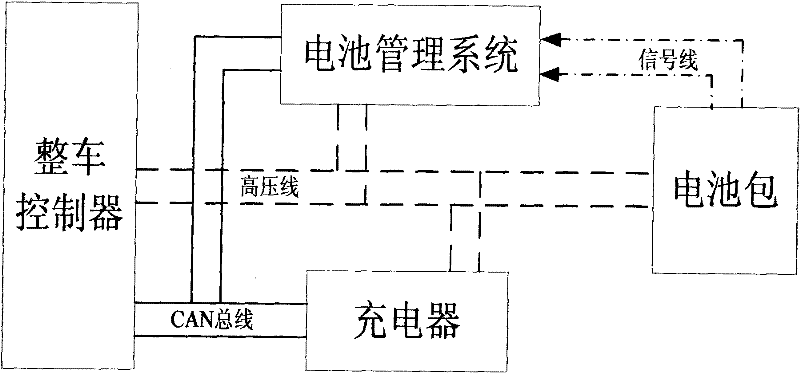

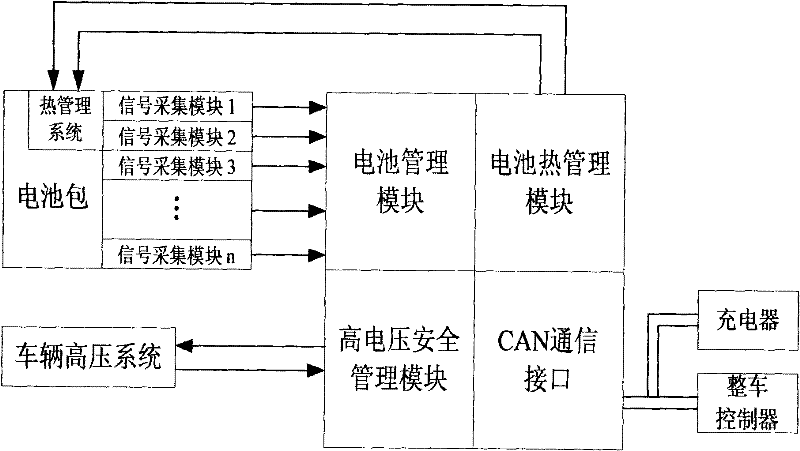

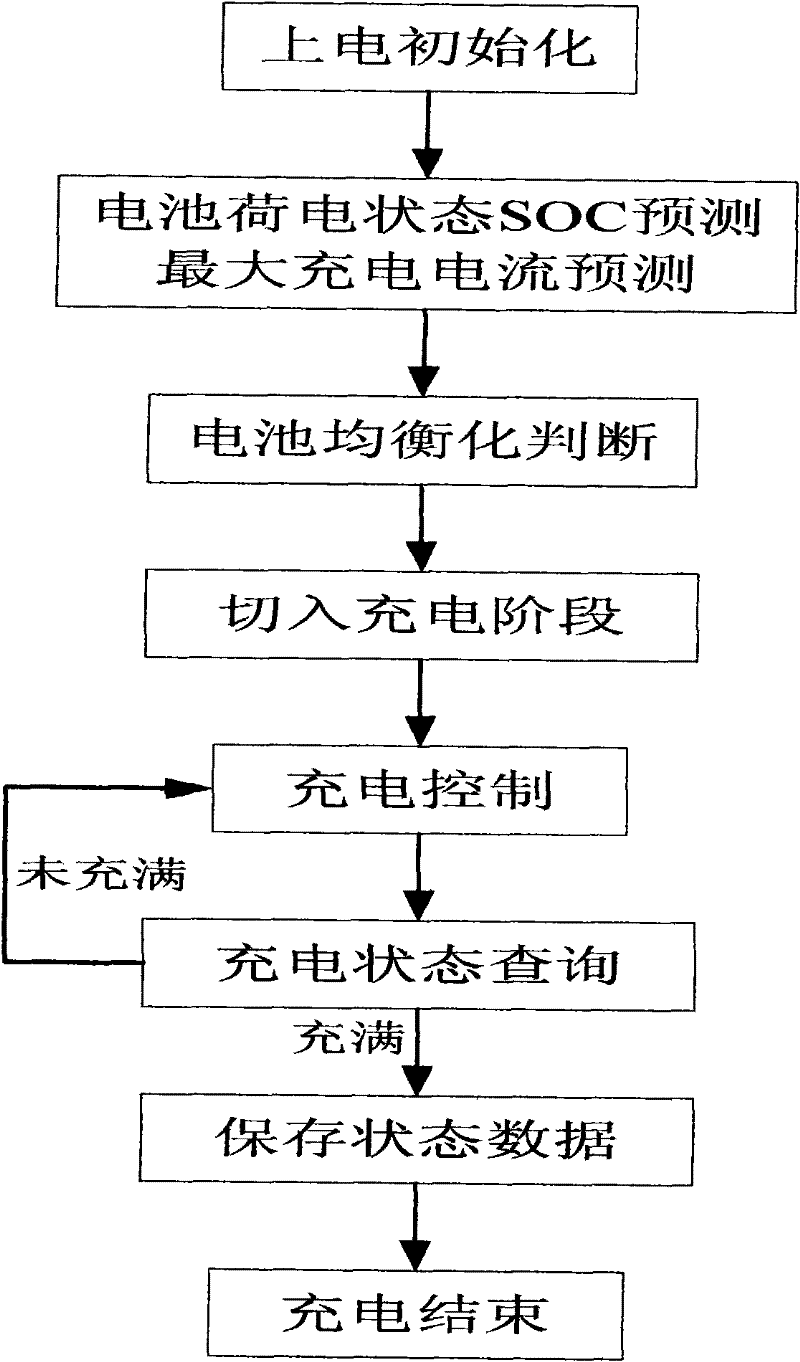

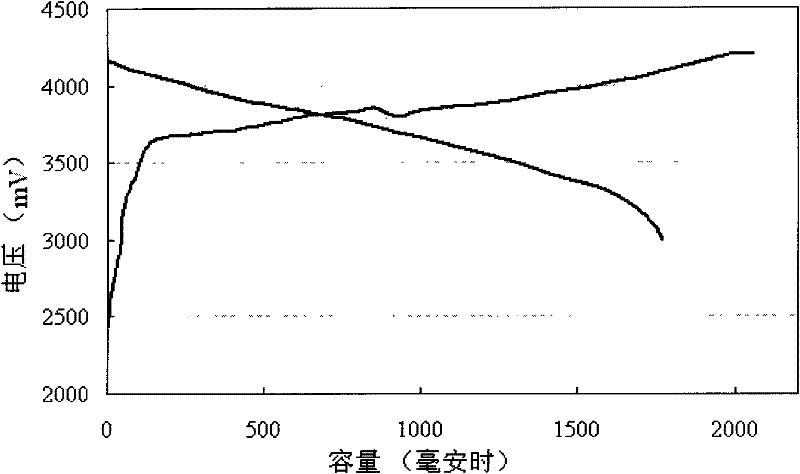

Vehicle-mounted lithium battery charging system

ActiveCN101752620AReduce harness lengthLow costBatteries circuit arrangementsSecondary cells charging/dischargingCommunication interfaceCharge current

The invention discloses a vehicle-mounted lithium battery charging system, which comprises a battery management system and a charger, wherein the battery management system comprises a battery management module, a battery thermal management module, a high-voltage safety management module and a CAN bus communication interface, and is used for monitoring and controlling the charging and discharging processes of each battery module in a battery pack; and the charger comprises a charging port, an auxiliary power port and a power output port, is used for monitoring and controlling the charging current and the charging voltage of the battery pack. Therefore, each battery module in the battery pack and a battery monomer are charged according to an ideal charging curve. The vehicle-mounted lithium battery charging system reduces the cost, realizes the balanced and safe charge of the battery pack, and can prolong the service life of the battery.

Owner:CHERY AUTOMOBILE CO LTD

Perovskite solar cell and manufacturing method of perovskite solar cell

ActiveCN104576930AInsulationImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilanesEvaporation

The invention discloses a perovskite solar cell. The perovskite solar cell is characterized by sequentially comprising a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and an evaporation silver electrode layer. Interface modification is carried out on the methylamine lead iodine polycrystalline film through long-chain alkyl silane coupling agents, and the number of carbon atoms of the long-chain alkyl silane coupling agents is larger than six and smaller than sixteen. The invention further discloses a manufacturing method of the perovskite solar cell. Compared with the prior art, the perovskite solar cell and the manufacturing method have the advantages that as interface modification is carried out through the long-chain alkyl silane coupling agents, the recombination of electrons in the cell can be suppressed, and the stability of the cell in the wet environment can be improved.

Owner:NINGBO UNIV

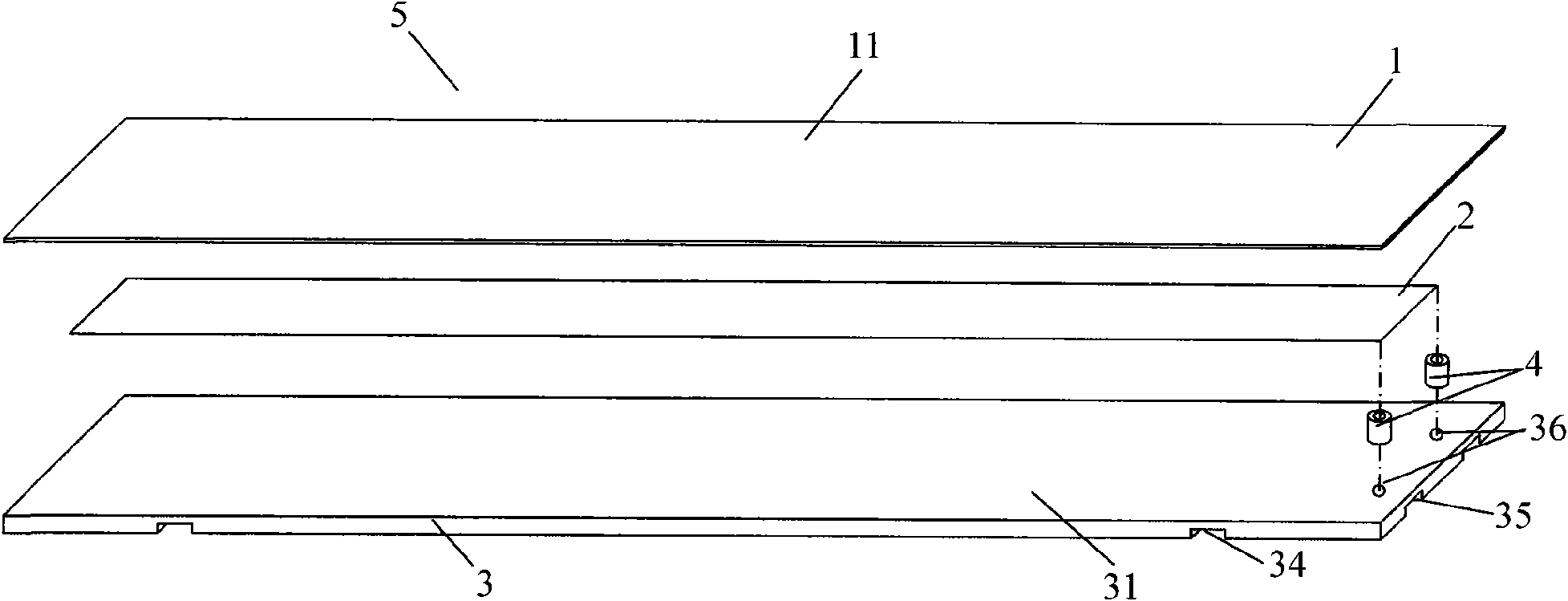

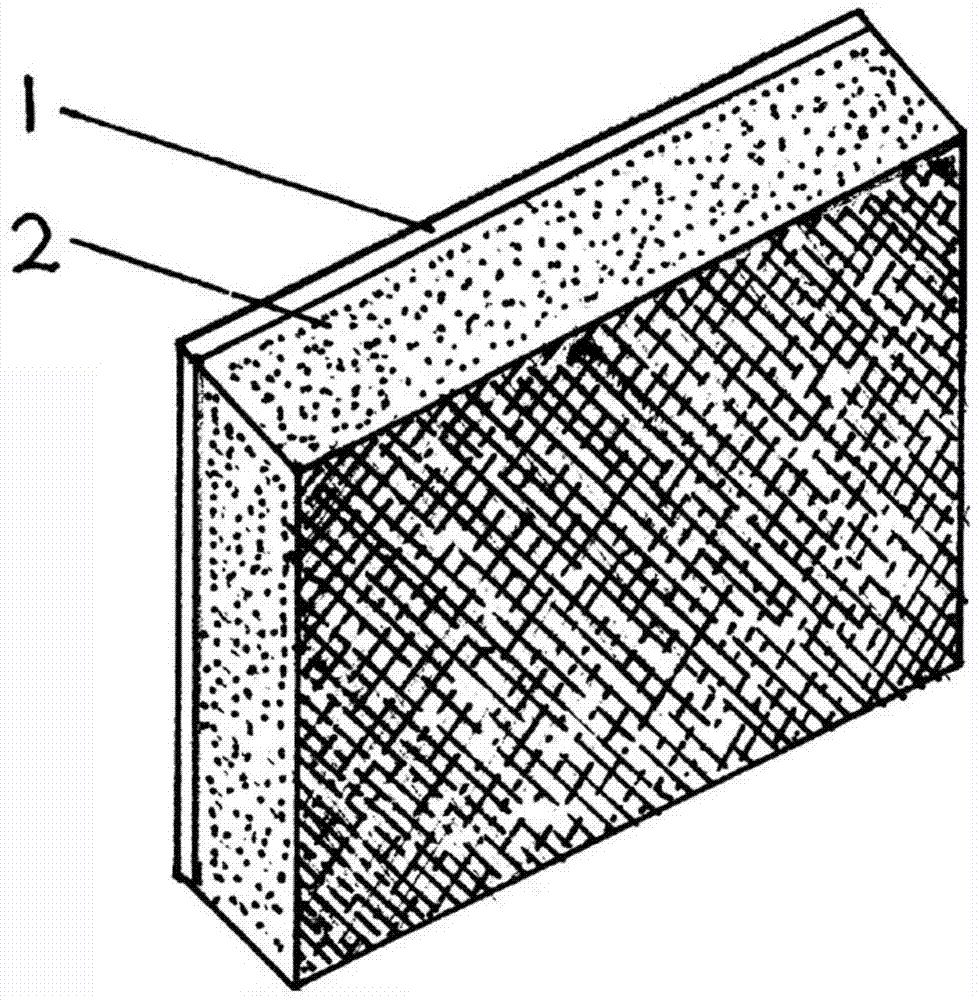

Far-infrared heat energy wood floor and manufacturing method and paving method thereof

InactiveCN101660803AIngenious designBreak through the natural functionLighting and heating apparatusElectric heating systemElectric heatingHardwood

The invention relates to a far-infrared heat energy wood floor, the carbon crystal electric heating material sheets of which are respectively pasted on the second surface of a surface board of the wood floor and the third surface of a base board of the wood floor. Preferably, the surface board of the wood floor is a hardwood board, the air-dry density of which is 0.5-0.7g / cm<3>, the thickness of which is 2-4mm and the moisture content of which is 6-8%; the thickness of each of the carbon crystal electric heating material sheets is 0.2-0.5mm; and the base board of the wood floor is a softwood board, the air-dry density of which is 0.3-0.6g / cm<3>, the thickness of which is 13-16mm and the moisture content of which is 6-8%. The far-infrared heat energy wood floor comprises an even number of layers of wood boards which are sequentially pasted, and the textures of the wood boards are crisscrossed; and air guiding grooves are arranged on the fourth surface of the base board of the wood floor. The invention also provides a manufacturing method and a paving method. The invention has the advantages of skillful design, safety, environment protection, energy saving and automatic adjustment oftemperature, breaks through the natural functions of the wood floor, organically combines a far-infrared heat energy heating element and the wood floor, has important breakthrough in the aspects of service life, energy saving, safety, environment protection, health, physical therapy and the like of the geothermal heating materials, and is a revolution in the international wood floor industry.

Owner:陆上驰 +1

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

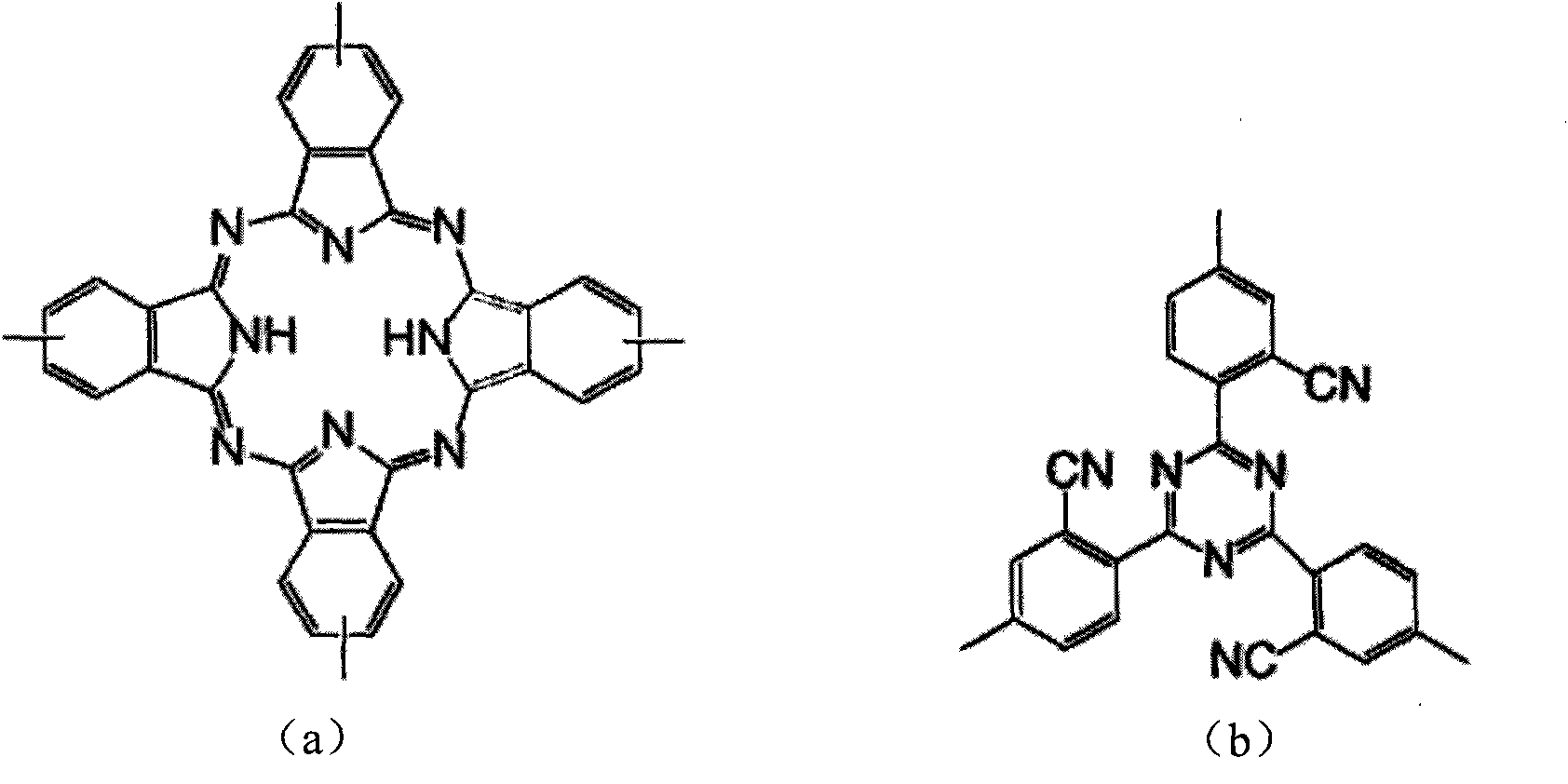

Nitrile resin monomer, nitrile resin polymer and preparation method of nitrile resin monomer and nitrile resin polymer

InactiveCN102976972ALow viscosityReduce liquidityCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceResin matrix

The invention discloses a nitrile resin monomer, a nitrile resin polymer and a preparation method of the nitrile resin monomer and the nitrile resin polymer, belonging to the technical field of organic polymer materials. The nitrile resin monomer is a tetraphthalonitrile resin monomer containing benzoxazine cycle, and the nitrile resin polymer is a product obtained by heating polymerization of the nitrile resin monomer. The nitrile resin monomer has a low viscosity, a good mobility and the processing performances of low-temperature curing and the like at a low temperature. The nitrile resin polymer has the good curing performances of self-flame resistance, adhesion, heat stability and the like. The resin monomer has the good processing performances of benzoxazine resins, and the resin polymer has the high-temperature resistance of nitrile resins, thus reducing the curing processing temperature and being capable of being used in a high-temperature temperature, namely, having the advantages of low temperature processing, medium temperature formation and high temperature use; and the resin monomer and the resin polymer can be used in the fields of coatings, adhesives, electronic packaging materials, aeronautics, astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, low in reaction temperature, energy-saving, and suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Cordierite honeycomb ceramic and preparation method thereof

The invention discloses cordierite honeycomb ceramic comprising 50-70 parts of cordierite, 30-40 parts of kaolin, 1.8-3.5 parts of clay, 10-16 parts of talc, 4-8 parts of magnesium carbonate, 1-3 parts of stearic acid, and 5-10 parts of deionized water. The cordierite honeycomb ceramic is prepared with a special raw material formula. The cost is low, and comprehensive performances are excellent. The ceramic has the performances such as heat resistance, wear resistance, corrosion resistance, and thermal insulation. The preparation process is simple, and is easy to realize.

Owner:SUZHOU ZHONGHUI HONEYCOMB CERAMICS

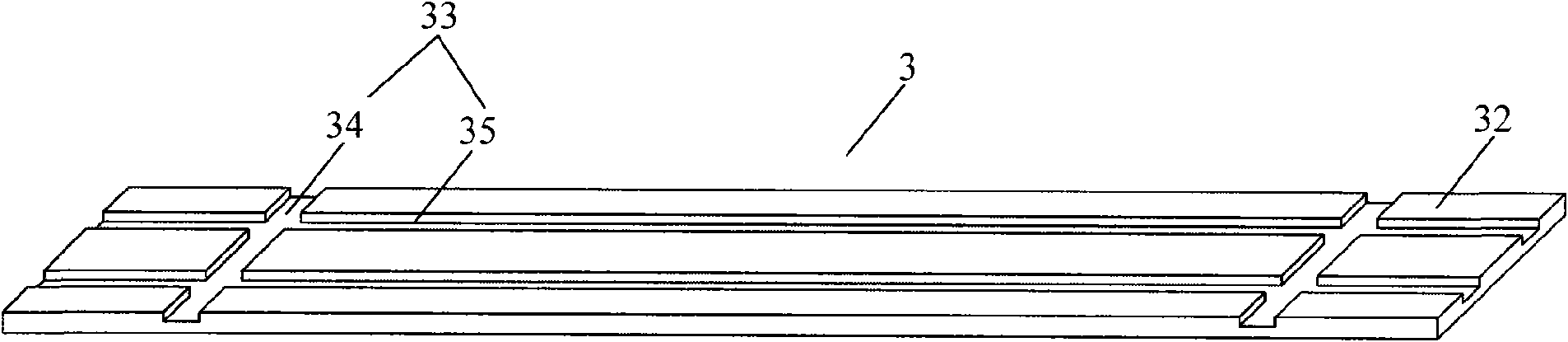

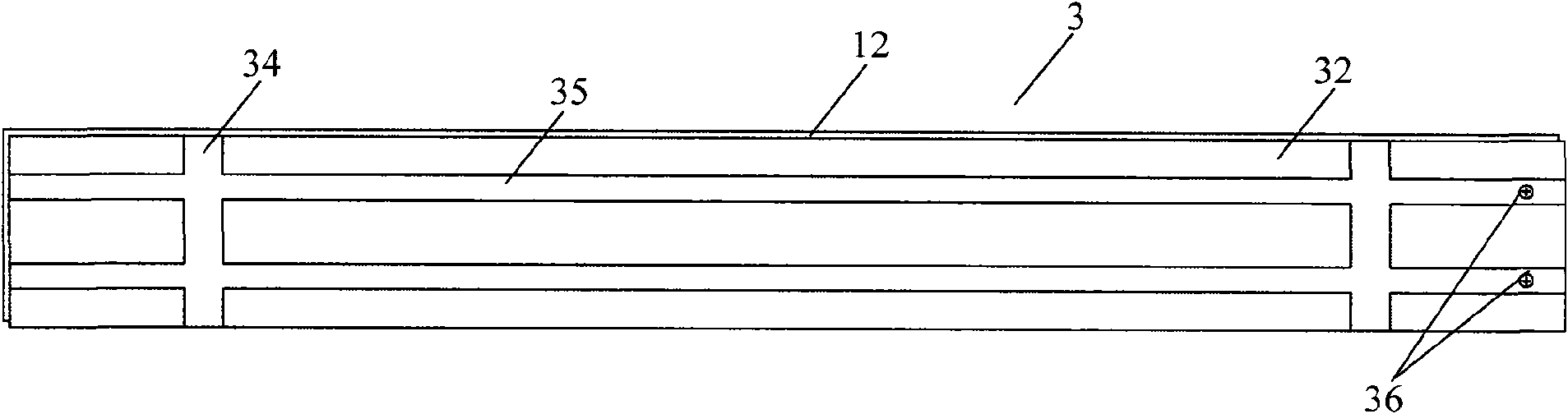

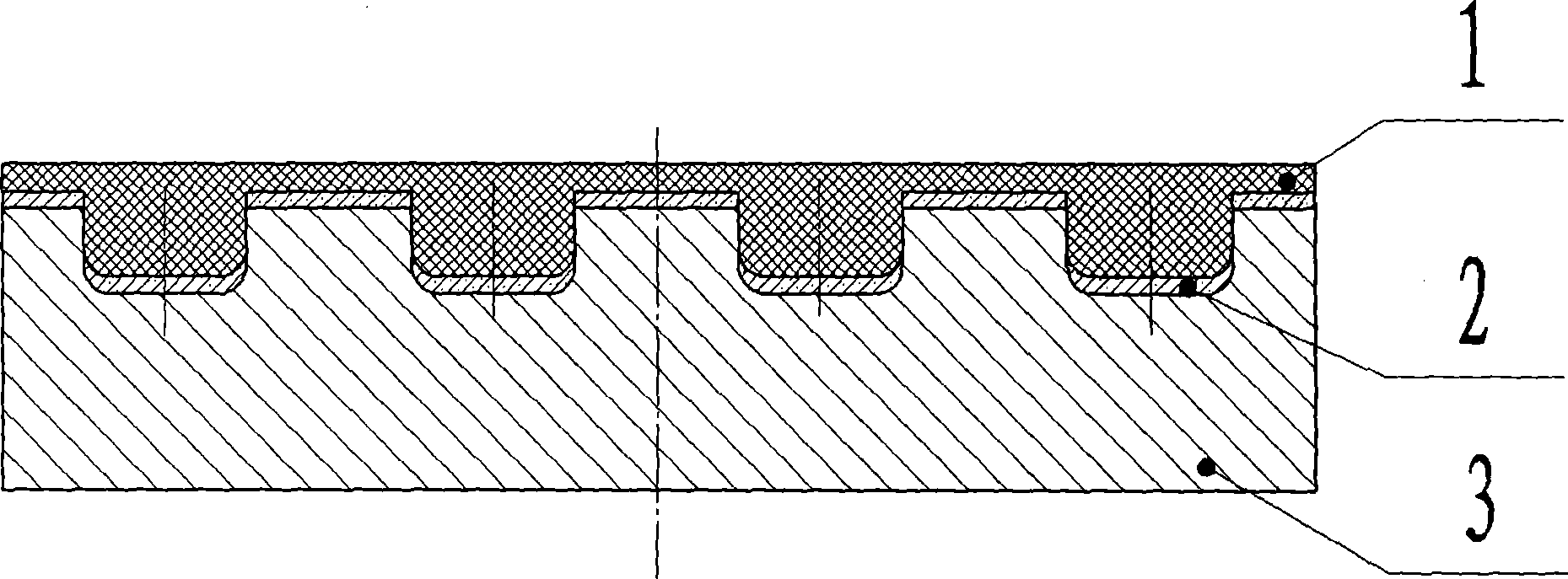

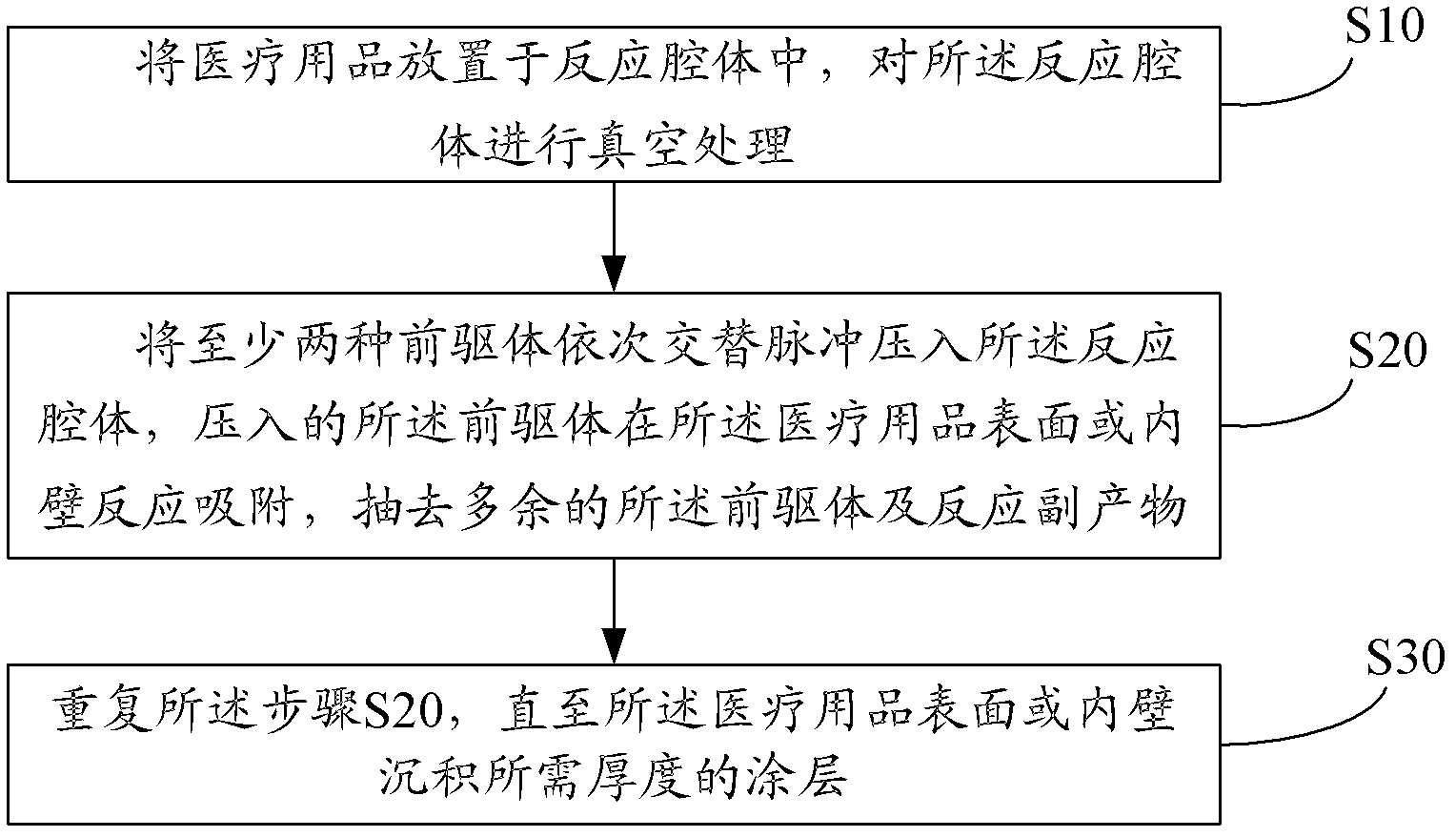

Preparation method for coatings of medical supplies and products thereof

InactiveCN103132045AUniform thicknessGood coating effectChemical vapor deposition coatingBiocompatibility TestingMedical treatment

The invention discloses a preparation method for coatings of medical supplies. The preparation method includes a first step of placing the medical supplies into a reaction cavity, and carrying out vacuum treatment on the reaction cavity, a second step of pressing at least two types of precursors into the reaction cavity in sequence in a pulse alternating mode, enabling the pressed precursors to carry out reaction and absorption on the surfaces or the inner walls of the medical supplies, sucking out the redundant precursors and reaction accessory substances, and a third step of repeating the second step until that coatings with needed thickness are deposited on the surfaces or the inner walls of the medical supplies. The invention further discloses the novel medical supplies manufactured through the preparation method. The preparation method can be used for preparing the coatings which are even in thickness, good in biocompatibility, antimicrobial, antiallergic, corrosion resisting, non-toxic, insulated or conductive, fully coated or partially coated, and smooth on the surfaces or the inner walls of any kinds of medical supplies.

Owner:英作纳米科技(北京)有限公司

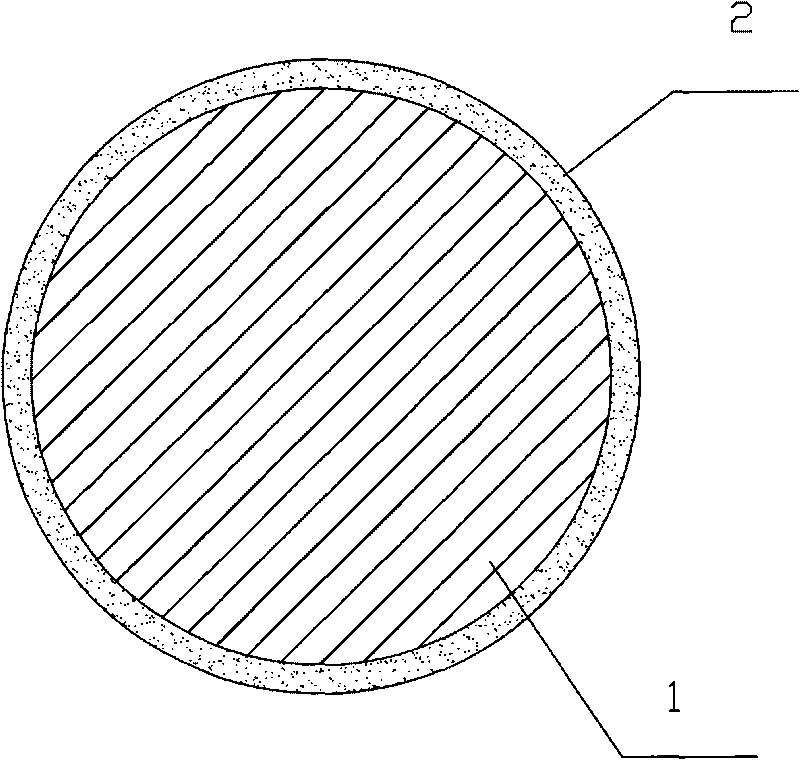

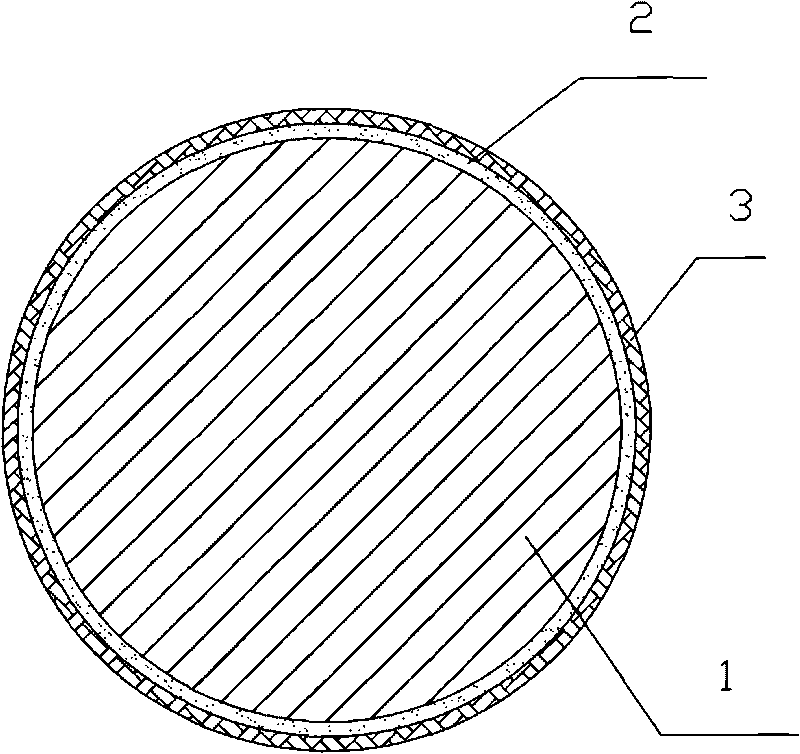

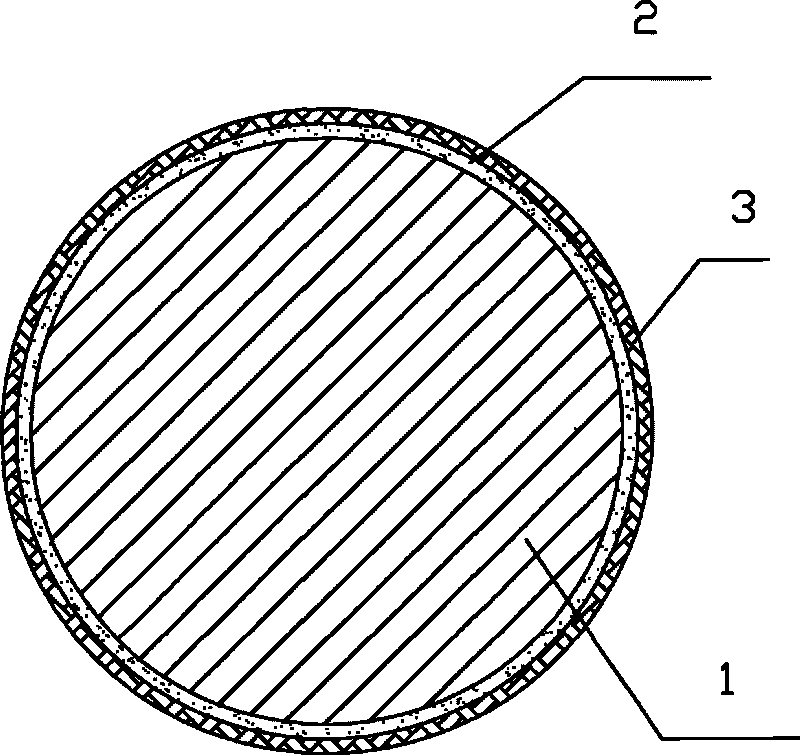

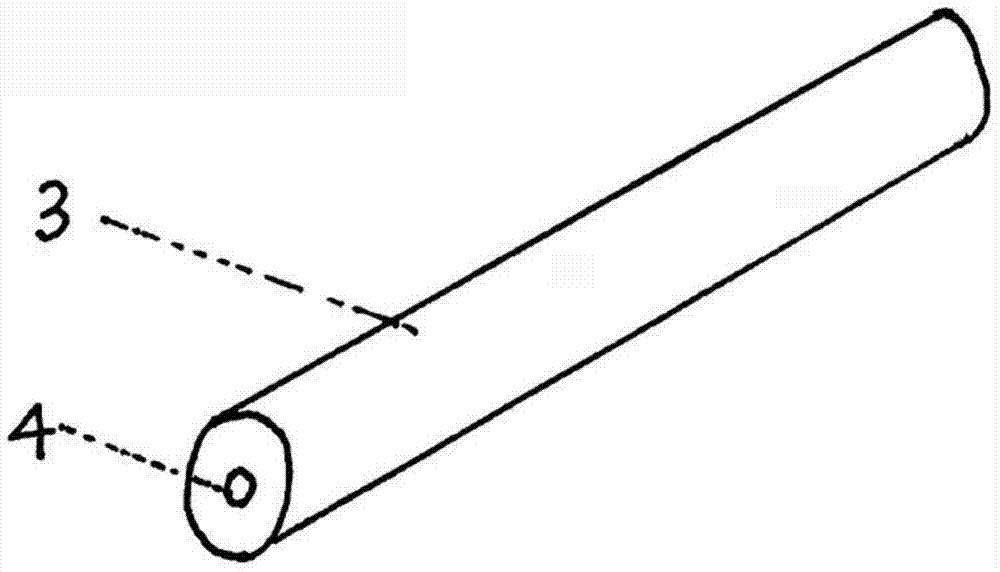

Copper wire with insulating layer and manufacture method thereof

InactiveCN101728011AHigh temperature resistanceInsulationInsulated cablesMetallic oxidesCopper wireTemperature resistance

The invention discloses a copper wire with an insulating layer and a manufacture method thereof. The copper wire comprises a copper core, a pure aluminum layer and an aluminum oxide layer, wherein the pure aluminum layer is compounded to the outer surface of the copper core through a metal composite technology, and the aluminum oxide layer which is prepared through hard anode oxidation treatment is arranged on the outer surface of the pure aluminum layer. In the method, the pure aluminum layer is compounded to the outer surface of the copper core through an extrusion-drawing method metal composite technology and is an auxiliary layer added in order to prepare the aluminum oxide layer, and the hard anode oxidation treatment is carried out on the outer surface of the pure aluminum layer so as to form the aluminum oxide layer. Because the copper wire manufactured by using the method is adopted, the aluminum oxide layer is arranged on the outer surface of the copper wire; the copper wire belongs to ceramic materials per se and has the advantages of high temperature resistance and insulation, therefore, when used at the temperature of below 400 DEG C, the copper wire can also keep favorable insulating performance, is safe to use and has the temperature exceeding a copper wire canned by conventional plastics by more than one time.

Owner:DALIAN MARITIME UNIVERSITY

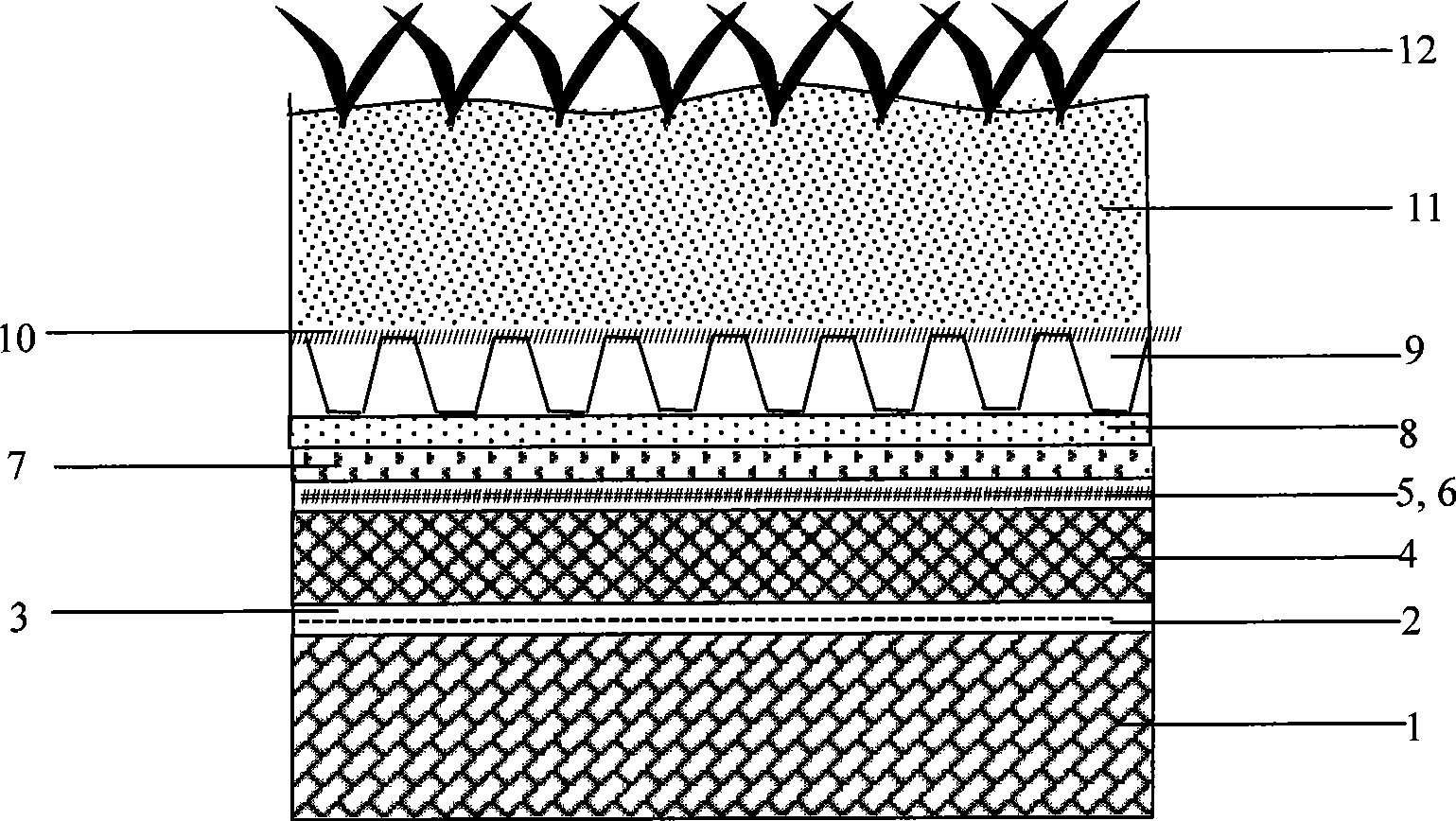

Roof green insulation system and method thereof

InactiveCN101545307ASelf-organizingAvoid crackingRoof improvementClimate change adaptationThermal insulationGreening

The invention relates to a roof green insulation system and a method thereof, which belong to the field of building roof green insulation. The green insulation system comprises a cement mortar screeding basal plane layer 2, an adhesive mortar layer 3, an insulation board layer 4, a finishing layer 5, a self-organizing waterproof sealant 6, a waterproof layer 7, a moisturizing blanket 8, a storage and drainage plate 9, a filter cloth 10, planting soil 11 and a green plant12 upwards from a building roof concrete roof 1 in sequence. The system is suitable for being arranged on a roof of a building or a top slab of a substructure, has the advantage of simple structure, has the functions of thermal insulation, water resistance and greening, effectively protects the building roof, not only can prolong the service life, but also can effectively solve the problem of roof leakage of the building.

Owner:上海英硕聚合材料股份有限公司

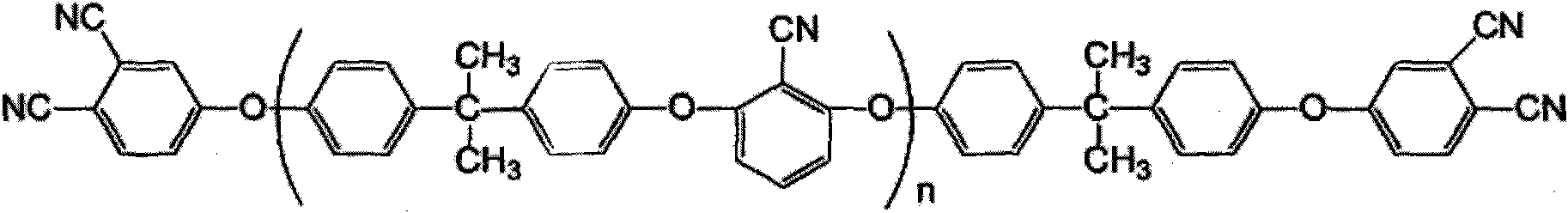

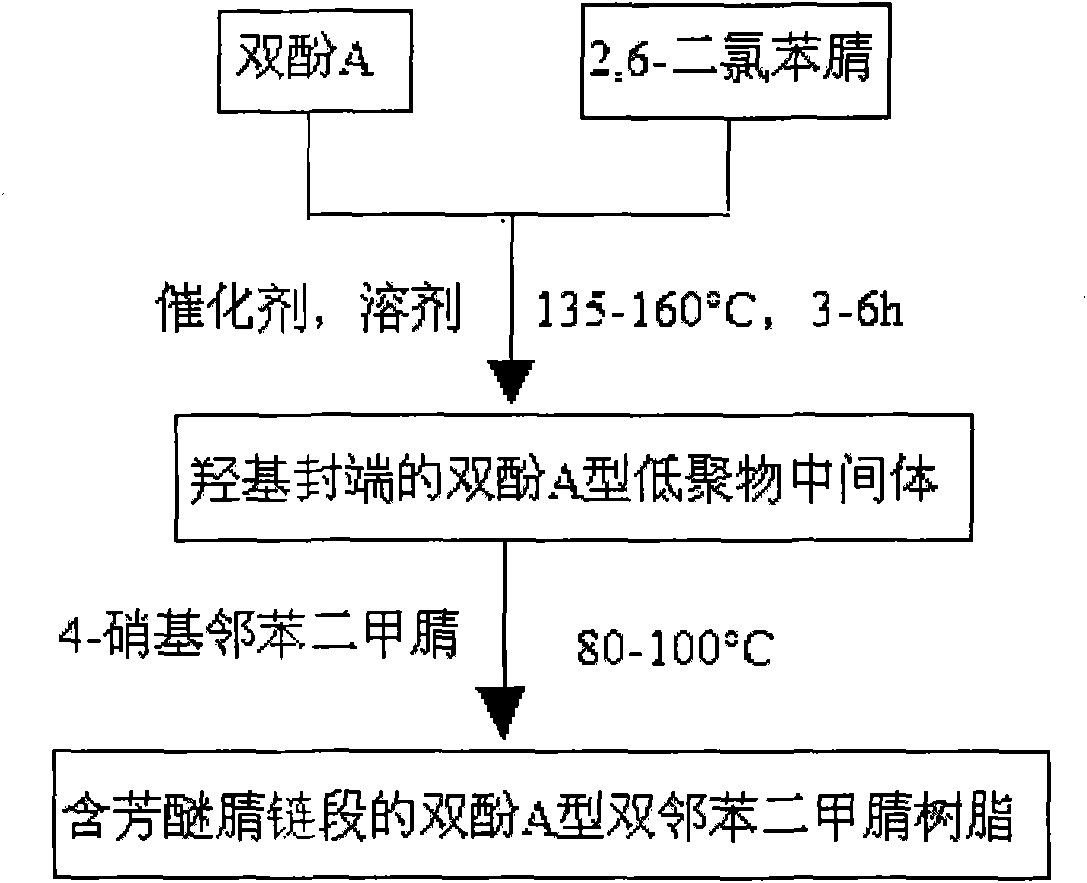

Bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, cured product and preparation method thereof

InactiveCN101914038ALow water absorptionImprove curing effectCarboxylic acid nitrile preparationOrganic compound preparationPhthalonitrileSolvent

The invention discloses a bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, a cured product and a preparation method thereof and belongs to the field of polymer materials. Raw materials of bisphenol A and 2,6-dichlorobenzonitrile are subjected to nucleophilic substitution reaction, anhydrous potassium carbonate and anhydrous sodium carbonate are used as a catalyst, a hydroxyl-terminated bisphenol A type oligomer intermediate is formed in mixed liquor of a strong polar solvent and toluene, and then hydroxyl groups are substituted by 4-nitrophthalonitrile, thus obtaining the resin. A cure-crosslinking agent, the mass of which is equal to 5 percent of the resin, is added into the resin, and then after pre-curing at 220-240DEG C and heat treatment at 375DEG C at least, the cured product of the resin can be obtained. The bis-phthalonitrile resin provided by the invention has different chain lengths and the aryl ether nitrile segments as well as a low melting point and wider curing process temperature, and the cured product is of a net structure which comprises a phthalocyanine ring and a triazine ring and has excellent heat stability. The manufacturing methods of the resin and the cured product are simple and controllable and are suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

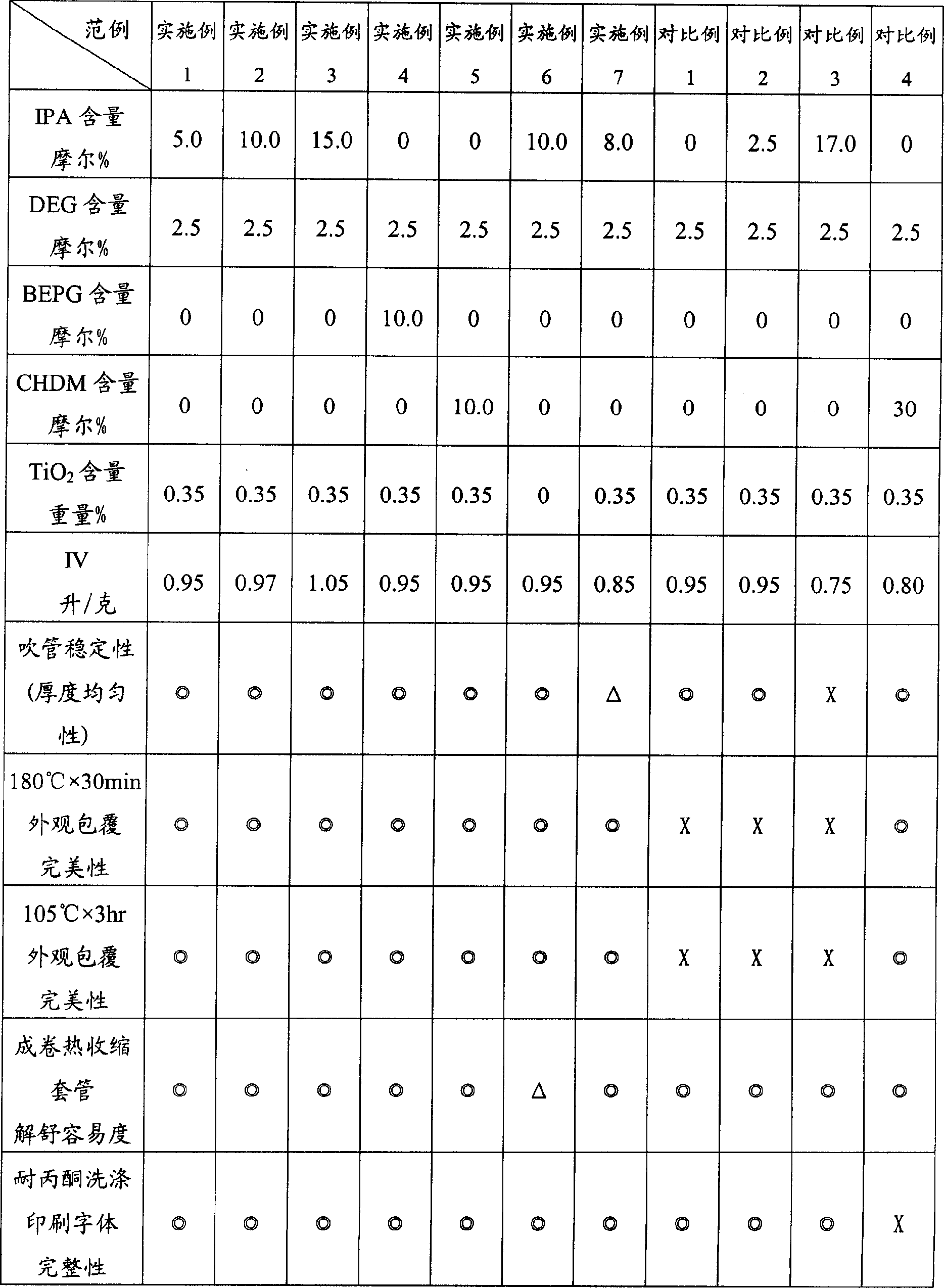

Copolymerized ester and method for making heat-shrinkable double-pipe using same

This invention refers to the thermoplastic copolyester, whose viscosity can be increased to between 0.85L / g and 1.05L / g after polymerization, and can be used in producing heat shrinking sleeve. The invention also refers to a way of making heat shrinking sleeve: the heat shrinking copolyester is changed into tubular shape after being melted and is made into copolyester heat shrinking sleeve after being huffed and stretched. And the lengthways shrinkage of the heat shrinking sleeve (MD) is no more than 15%, the transverse shrinkage (TD) is no less than 14%. This kind of heat shrinking sleeve can be used as the coats and insulating coats of all kind of conductors.

Owner:NANYA PLASTICS CORP

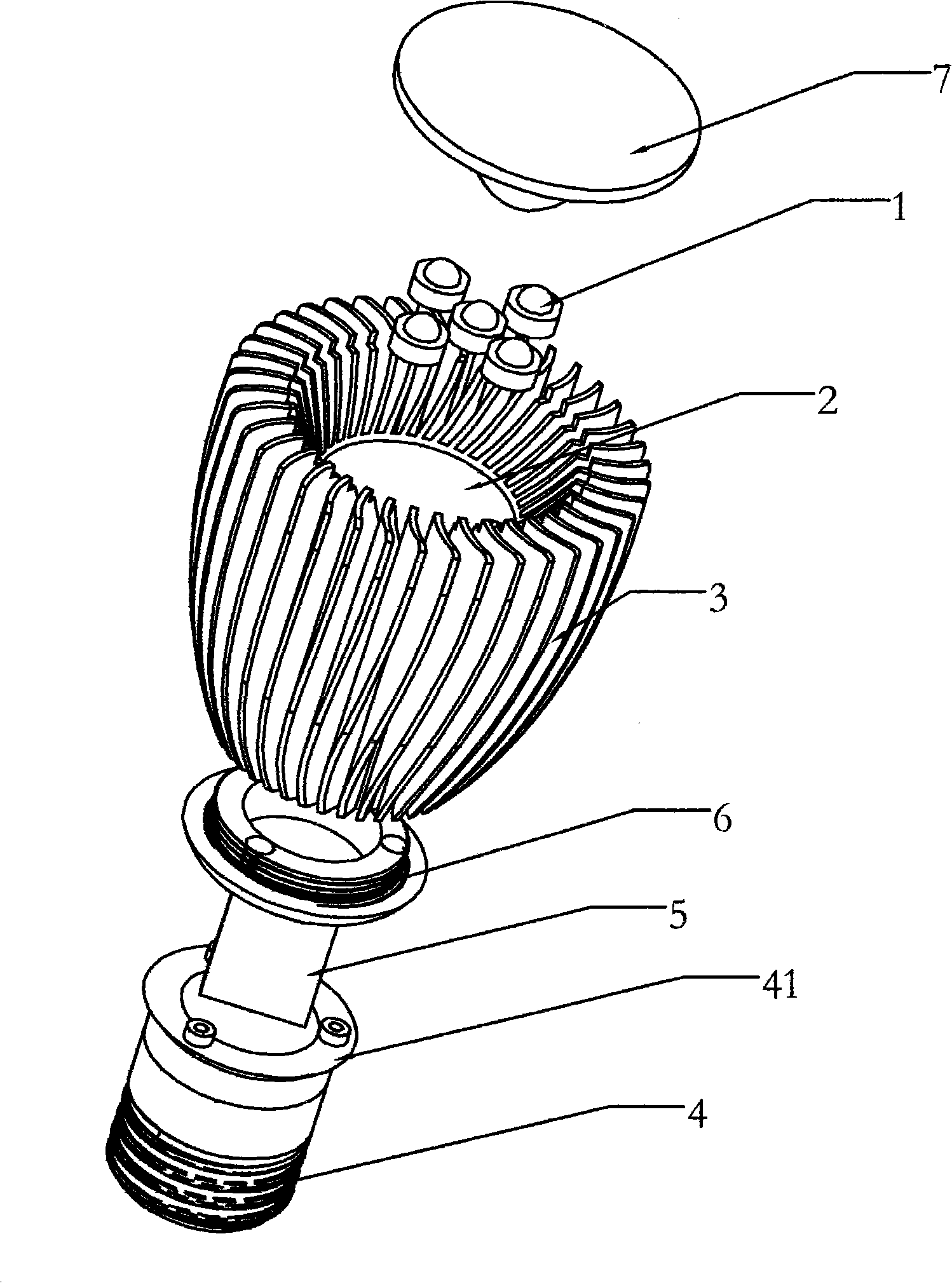

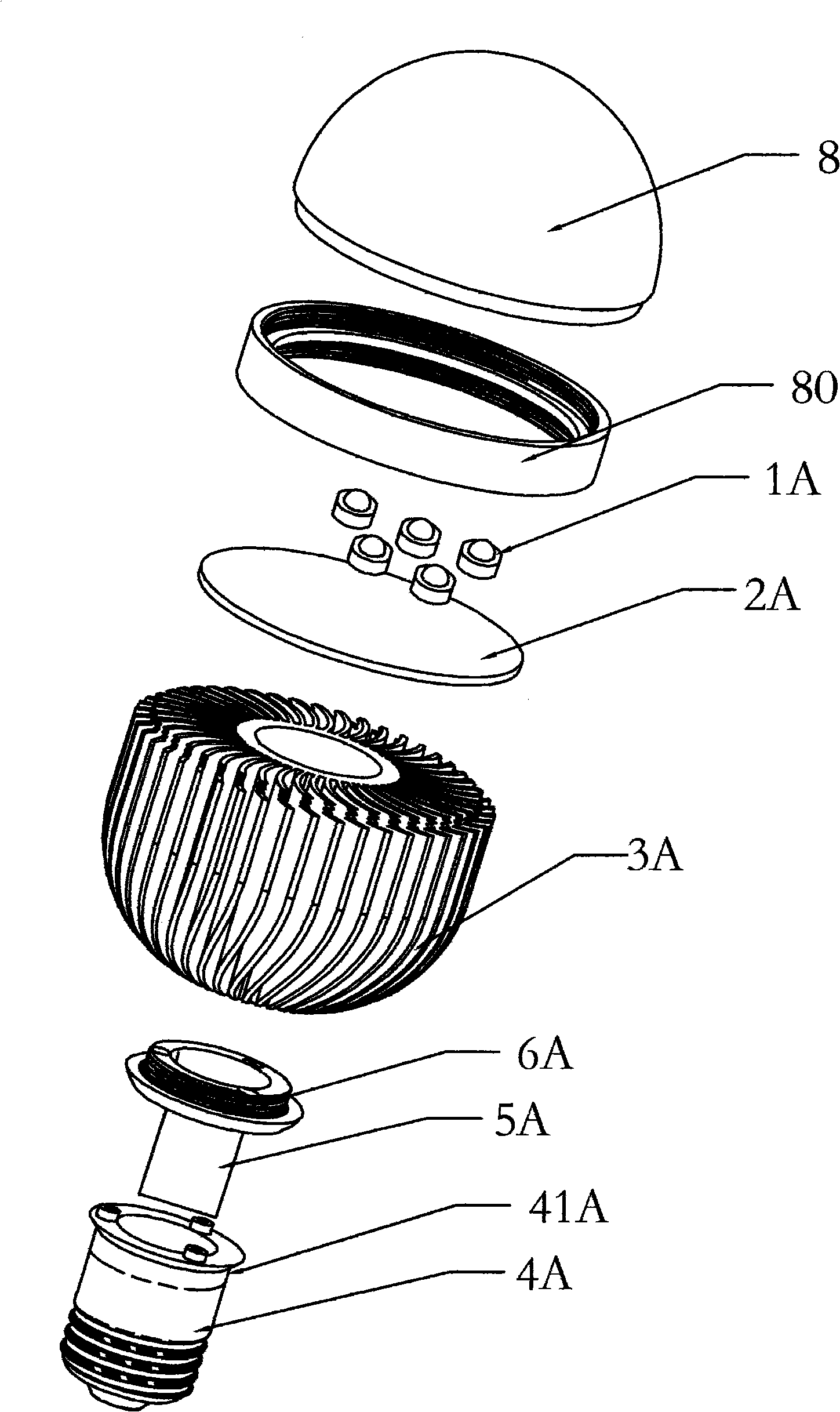

High-power LED lamp structure and manufacturing method thereof

InactiveCN101275735AAchieving anodizingExtend your lifePoint-like light sourceSemiconductor/solid-state device detailsInterference fitEngineering

The invention discloses a high power LED lamp structure, including a high power LED illuminator, an aluminum base circuit board used for fixing the high power LED illuminator and a metal lamp case connected with the aluminum base circuit board; the metal lamp case is a cylinder provided with a plurality of radiators at the cirumferential, wherein the aluminum base circuit board and the metal lamp case are connected tightly. The LED lamp uses the section steel shaped by the mould extruding and stretching as the materials to process, then the aluminum base circuit board is extruded into the central hole of the metal lamp case in the interference fit. The invention has the characteristic of simple structure, fast heat emission, low cost etc, which greatly increases the service life of the LED lamp, reduces the temperature round the LED illuminator. The invention is used for the daytoday illuminating with great extending and using value.

Owner:张春涛

An alginate dressing for treating bedsore and a preparing method thereof

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

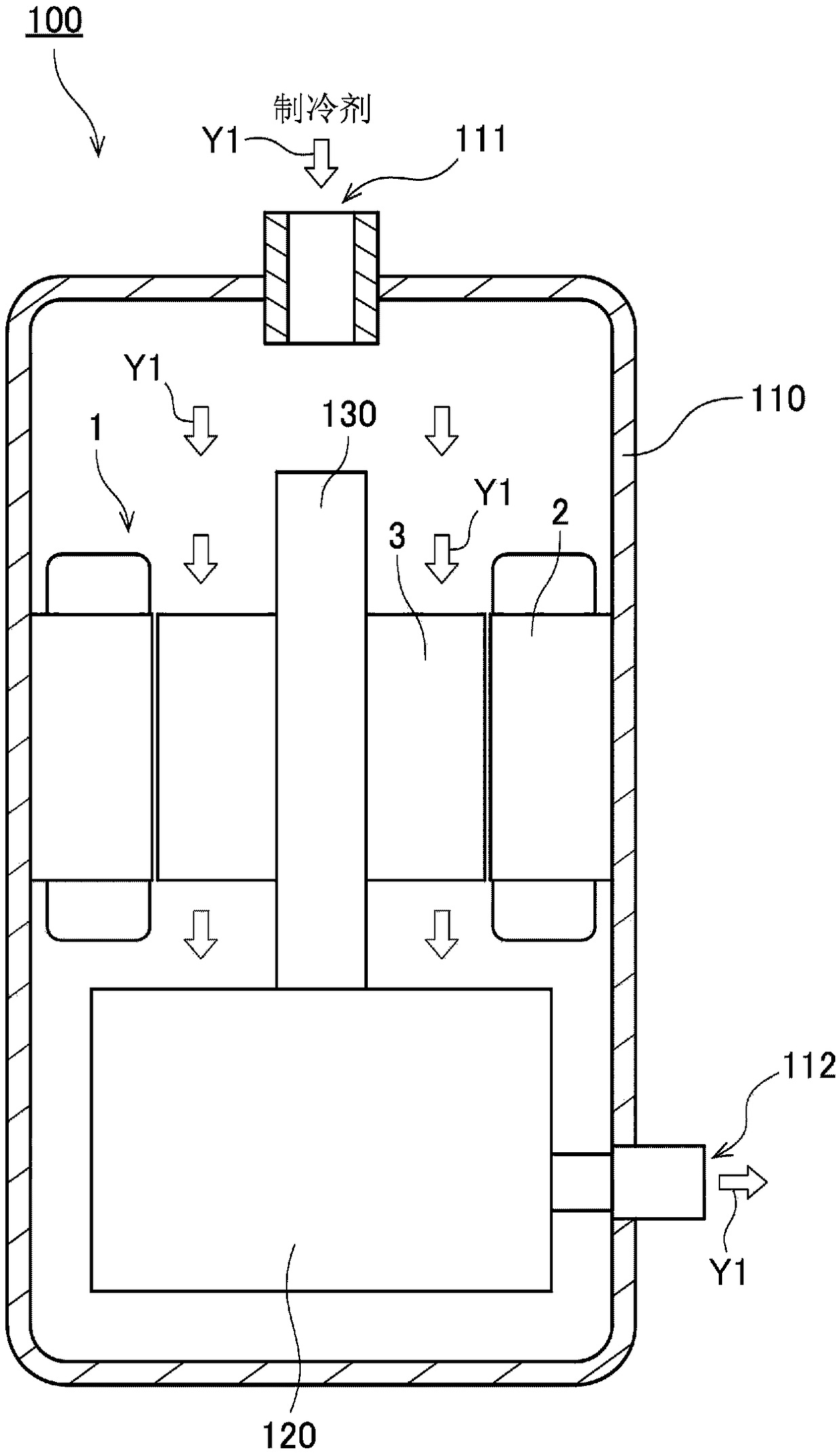

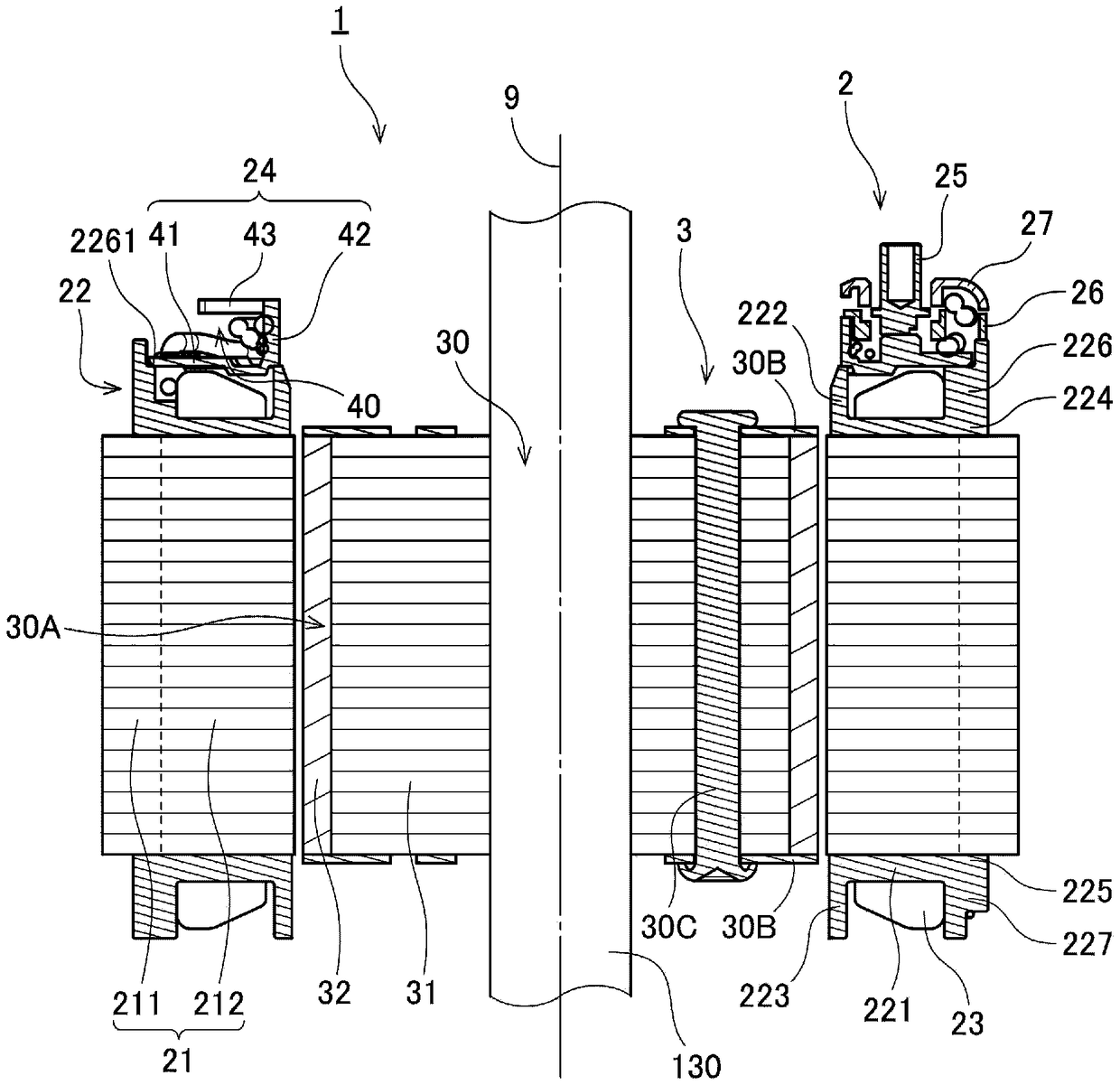

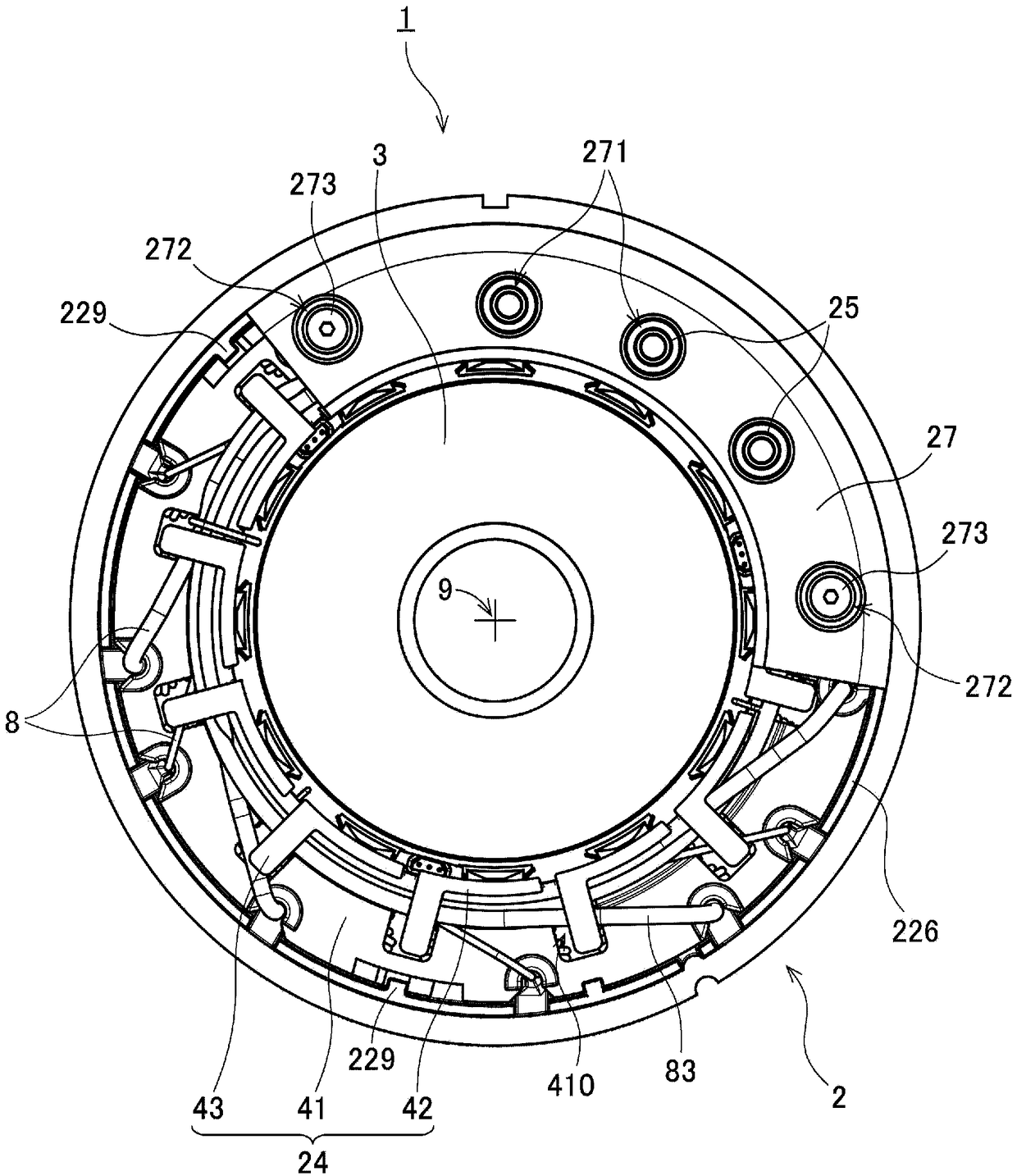

Stator, motor, and compressor

ActiveCN108702052ACompact configurationSimple configurationWindings insulation materialWindings insulation shape/form/constructionSingle leadMechanical engineering

This stator has a plurality of lead lines extending from coils toward the upper side and a guide member for supporting the lead lines on the upper side from the coils. The guide member is an insulatorand has a lower plate portion, an inner wall portion, and an upper plate portion, wherein said lower plate portion circularly extends around the central axis, said inner wall portion extends upward from the inner circumference portion of the lower plate portion, and said upper plate portion extends from the inner wall portion toward the radial direction outside. There is a single lead-line housing space on the upper side of the lower plate portion, the lower side of the upper plate portion, and the radial direction outside of the inner wall portion. In the lead-line housing space, the lead lines are disposed along the inner wall portion in a circumferential direction. This makes it possible to arrange the lead lines in a compact manner without requiring a bus bar while ensuring the insulation between the coils and the lead lines. This also satisfies both the size reduction of the stator and the insulation properties of the lead lines. Further, winding the lead lines on the inner wallportion enables the lead lines to be easily disposed between the lower plate portion and the upper plate portion.

Owner:NIDEC CORP

Inorganic flake water-based epoxy resin coating

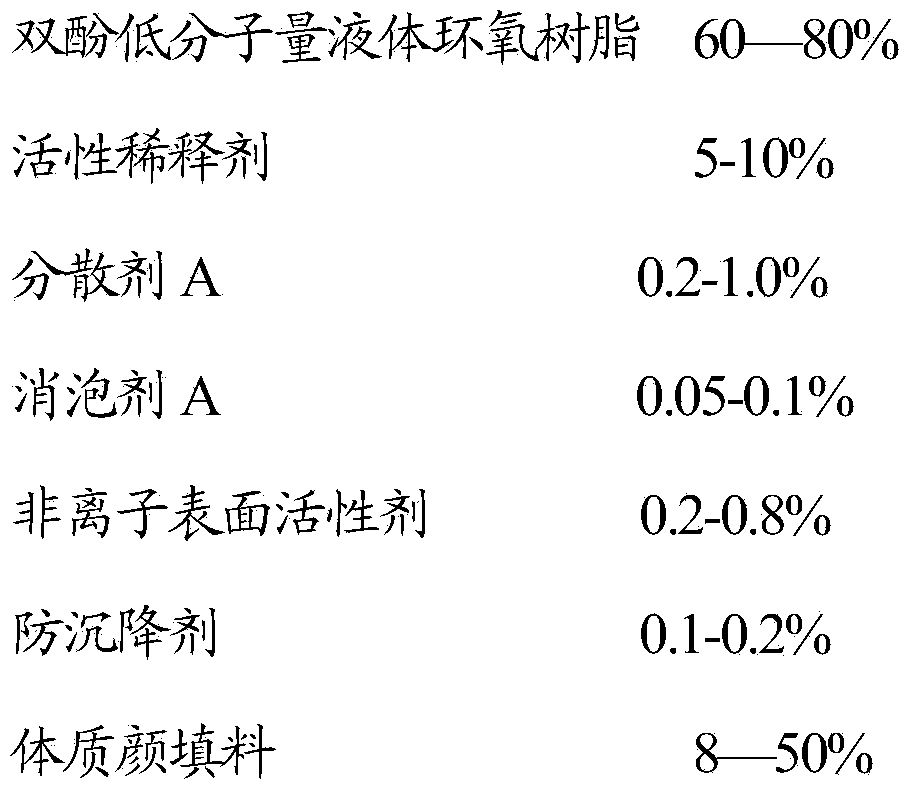

The invention discloses an inorganic flake water-based epoxy resin coating, which is composed of a component A and a component B, wherein the component A is an epoxy resin dispersion and comprises the following components by weight percent: 60-80% of bisphenol low-molecular-weight liquid epoxy resin, 5-10% of active thinner, 0.2-1.0% of dispersing agent A, 0.05-0.1% of deforming agent A, 0.2-0.8% of non-ionic surface active agent, 0.1-0.2% of anti-settling agent, 8-40% of physical filler, and 5-20% of inorganic flake material; and the component B is a hydrophilic water-based curing agent dispersion and comprises the following components by weight percent: 43-65% of modified water-based amine curing agent, 35-50% of water, 0.2-0.4% of dispersing agent B, 0.2-0.5% of deforming agent B, and 0.2-0.8% of flatting agent. The inorganic flake water-based epoxy resin coating disclosed by the invention has good water-resistance performance and is applied to buildings, therefore, the surface of a concrete or mortar substrate layer can be closed after being coated; various penetrated water vapour is thoroughly isolated; and surface decorative layers of building envelopes, such as coatings, wallpapers, wood floors and the like, are prevented from being affected with damp.

Owner:HAINAN SEQUOIA CREATION

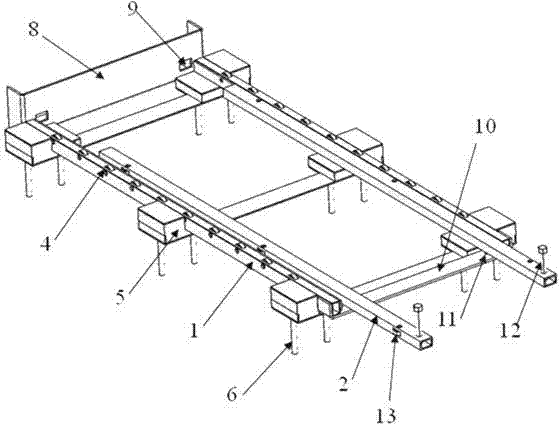

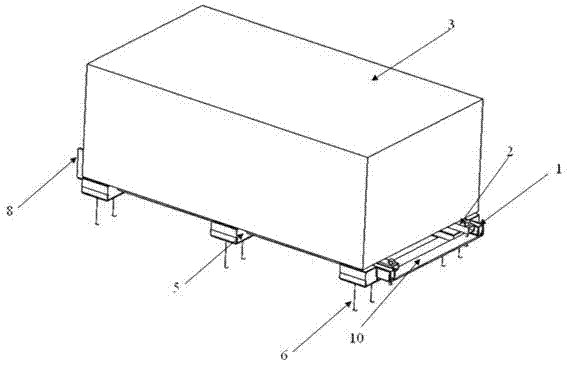

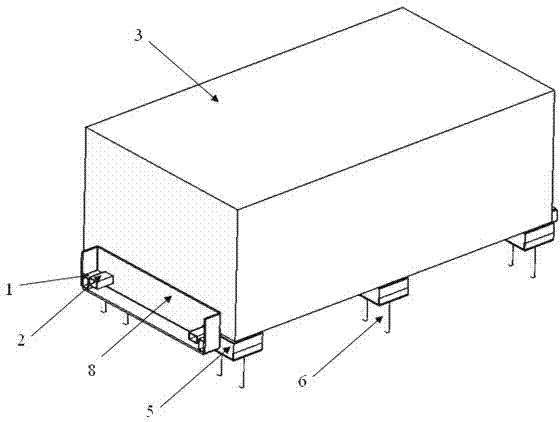

Battery box fixing device

InactiveCN102381173AIncrease available spaceMeet the versatilityElectric propulsion mountingCell component detailsElectrical and Electronics engineeringChassis

Owner:ZHENGZHOU YUTONG BUS CO LTD

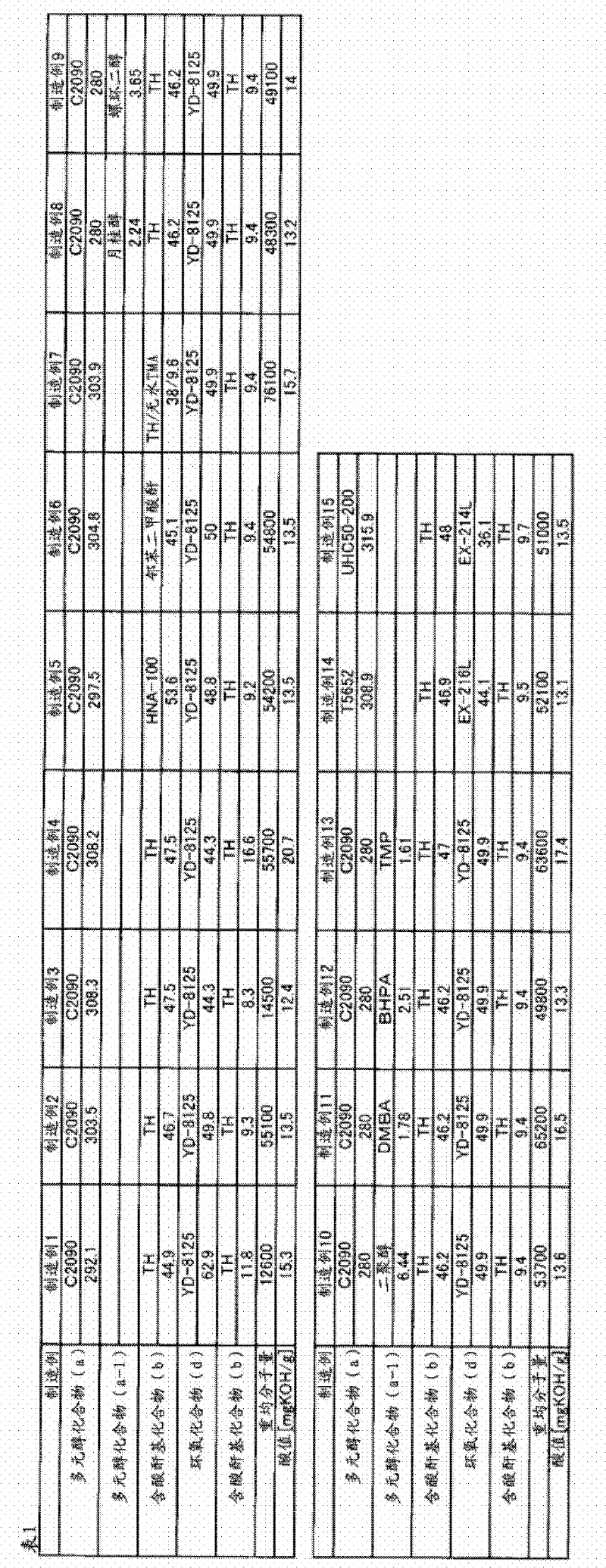

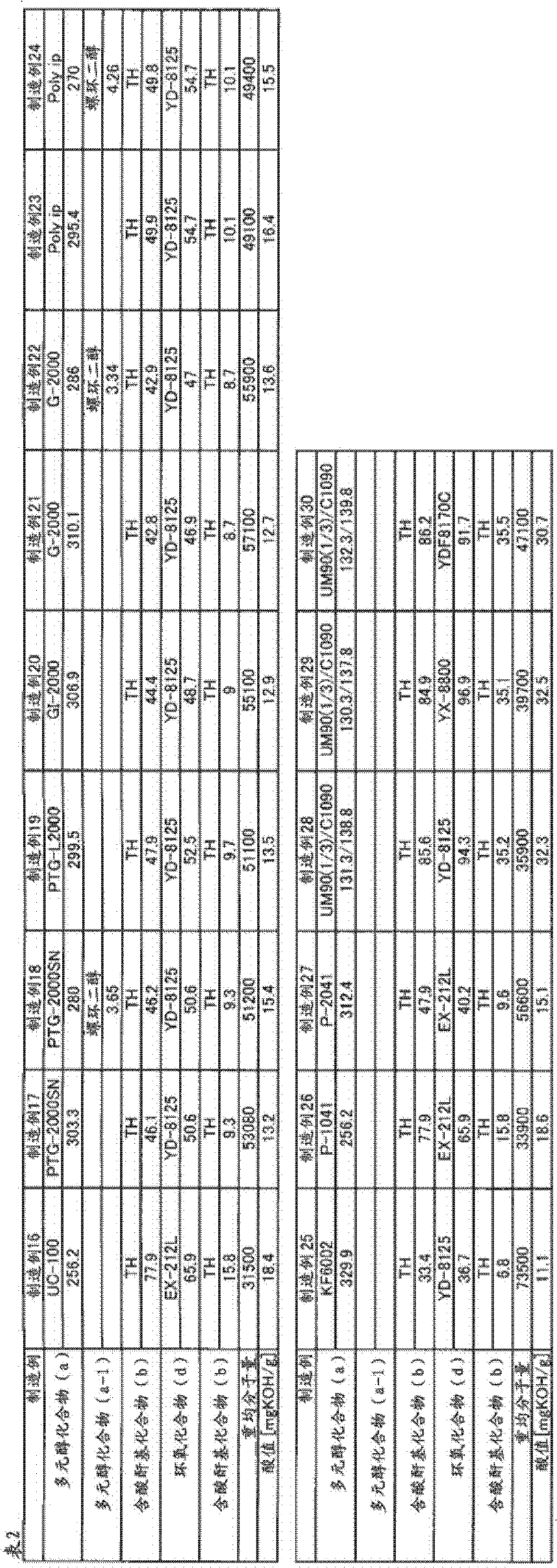

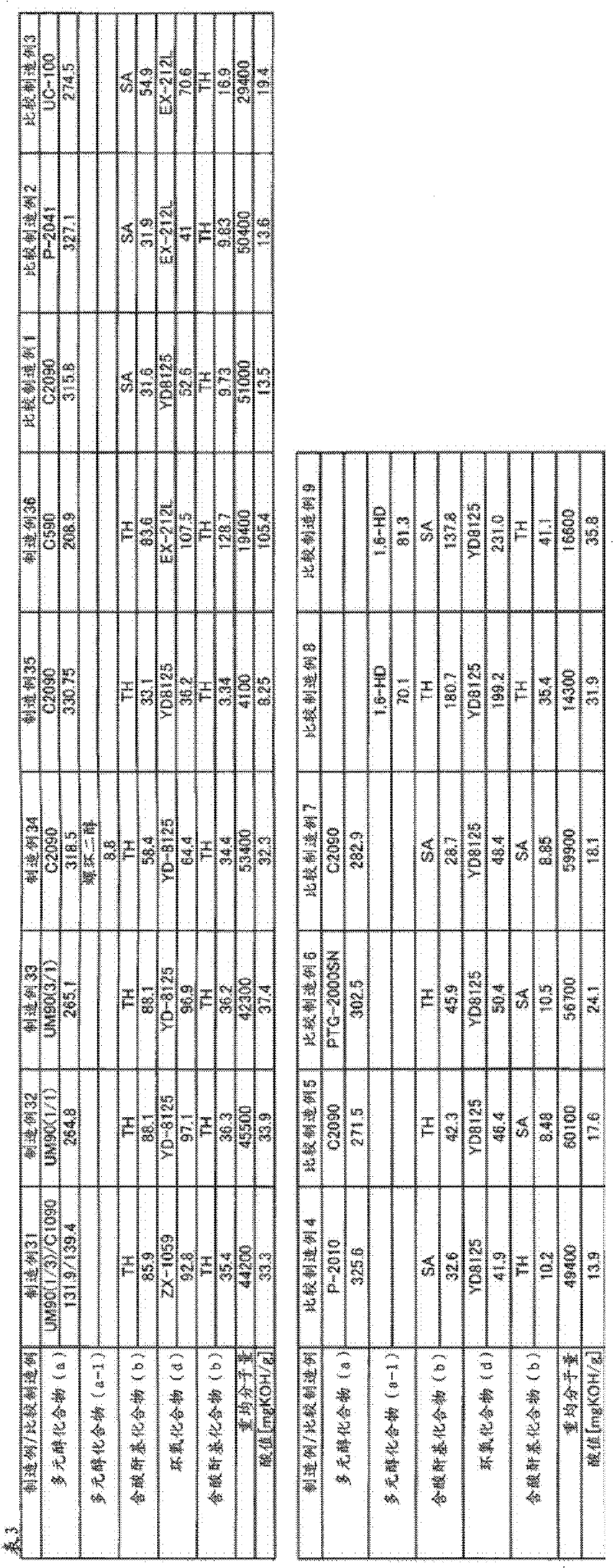

Thermosetting resin compound containing carboxyl modified polyurethane resin

ActiveCN102532483AGood adhesionTaking into account the flexibilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainEpoxide

Provided is a thermosetting resin compound containing carboxyl modified polyurethane resin, characterized by comprising the carboxyl modified polyurethane resin (A) which is at least one compound selected from a group consisting of an epoxy group contained compound, an isocyanate contained compound, and a closed isocyanate group contained compound, and a thermofixation assistant (C). The carboxyl modified polyurethane resin (A) is formed by making the polyatomic compound (a) and at least one anhydride group compound (b) selected from ring type multielement anhydride and aromatic aromatic anhydride produce reaction to generate carboxyl ester resin (c). Then the carboxyl ester resin (c) is made to react with an epoxy compound (d) in I molecules having at least two epoxy groups to produce side chain hydroxyl modified ester resion (e). Then the anhydride group compound (b) is made to react with the side chain hydroxyl modified ester resion (e) to generate the carboxyl modified polyurethane resin (A).

Owner:TOYO INK SC HOLD CO LTD +1

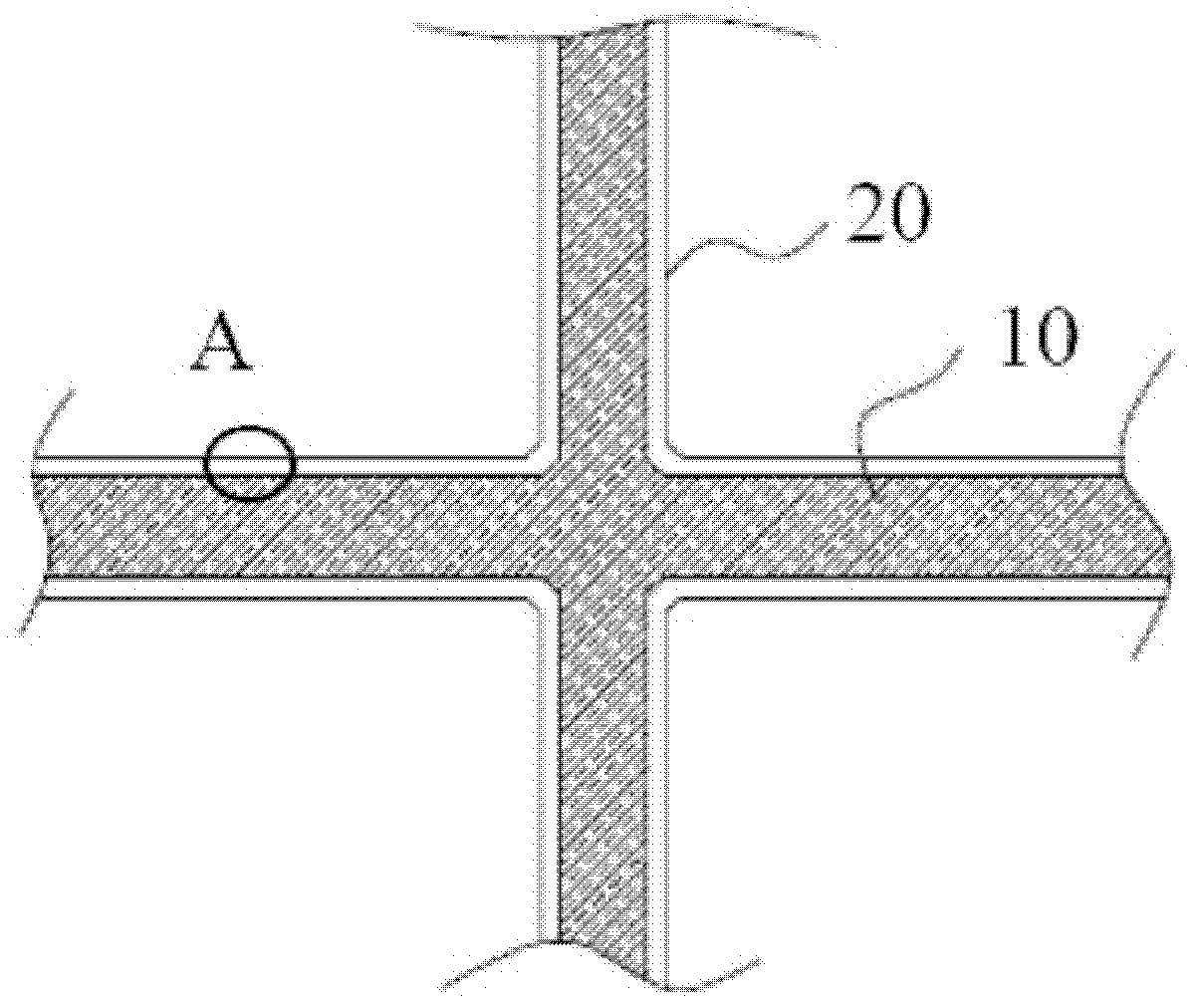

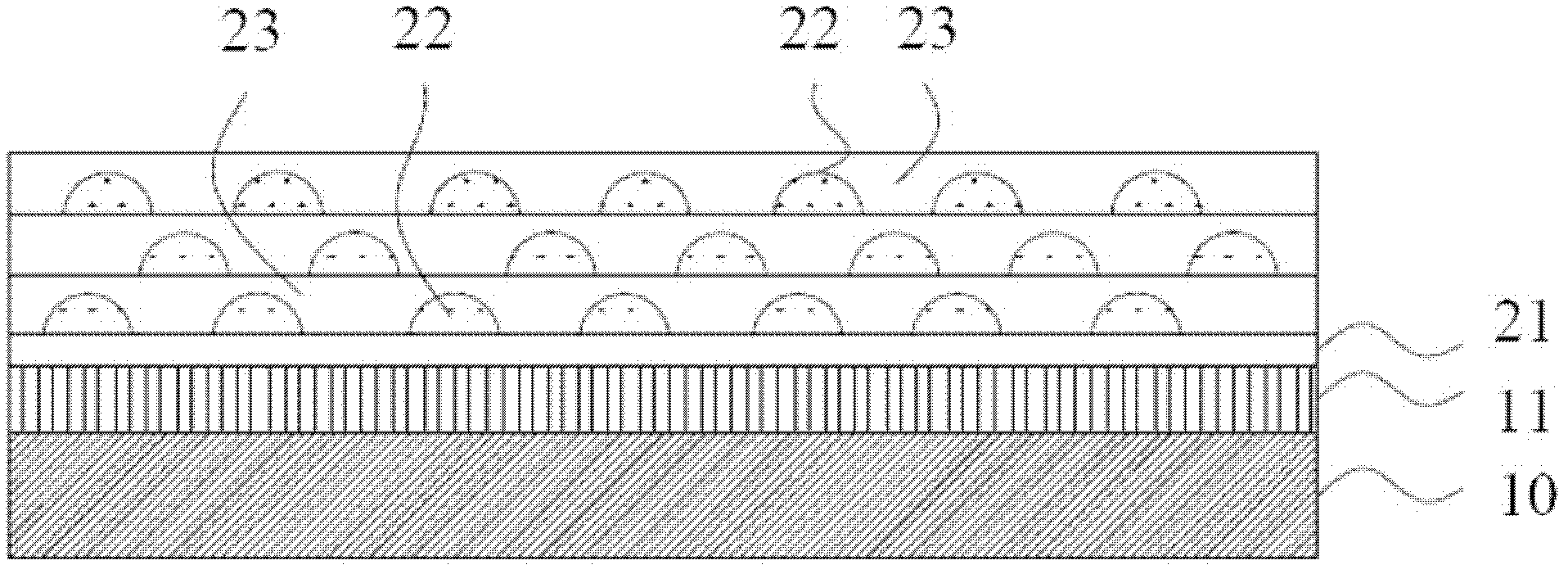

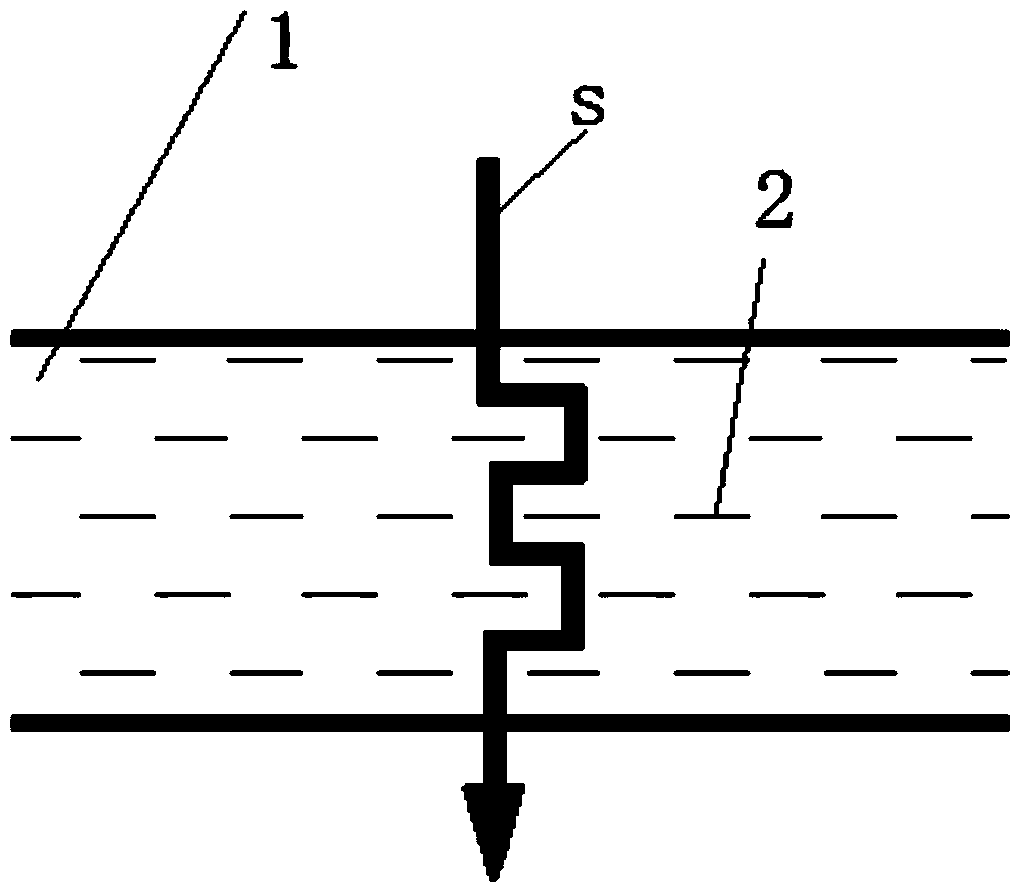

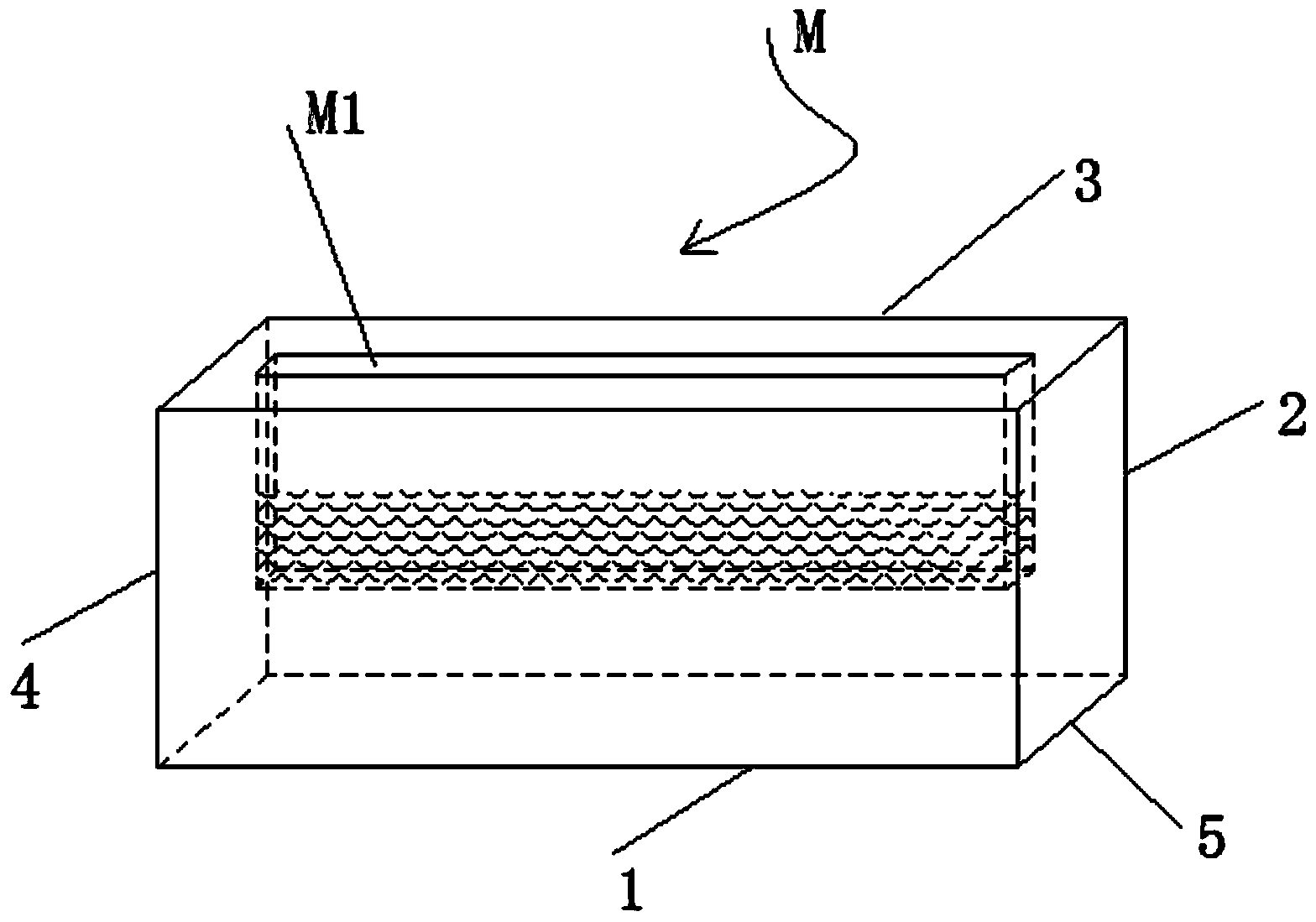

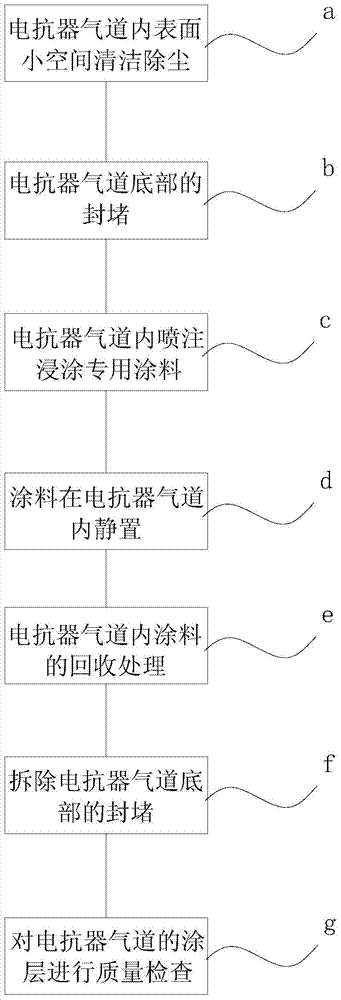

Technology for internal surface small space protection in air flue of dry-type air-core reactor

ActiveCN103680908AImprove cleanlinessReduce the chance of damagePretreated surfacesInductances/transformers/magnets manufactureNuclear engineeringWater vapor

The invention provides a technology for internal surface small space protection in an air flue of a dry-type air-core reactor. According to the technology for internal surface small space protection in the air flue of the dry-type air-core reactor, the inner surface of the air flue of the dry-type air-core reactor is processed. The technology comprises the following steps that dust in small space of the inner surface of the air flue of the air-core reactor is removed through a dust collection device, the bottom of the cleaned air flue of the air-core reactor is plugged through a plugging device, and therefore the air flue of the air-core reactor becomes a semi-closed container; paint is injected into the air flue of the air-core reactor, the air flue of the air-core reactor in the step (b) is dipped and coated, standing of the paint in the air flue of the air-core reactor is conducted for a period, the plugging device at the bottom of the air flue of the air-core reactor is detached after the paint is recycled, and quality detection is conducted on the treated air flue of the air-core reactor. According to the air-core reactor protected through the technology, the probability that due to the fact that water vapor molecules permeate through the air-core reactor, short circuits among wire turns of the air-core reactor are caused and then the air-core reactor is damaged is greatly reduced, and the service life of the air-core reactor is prolonged.

Owner:GUANGDONG CROWNPOWER ELECTRIC POWER SCI & TECH DEV CO LTD +1

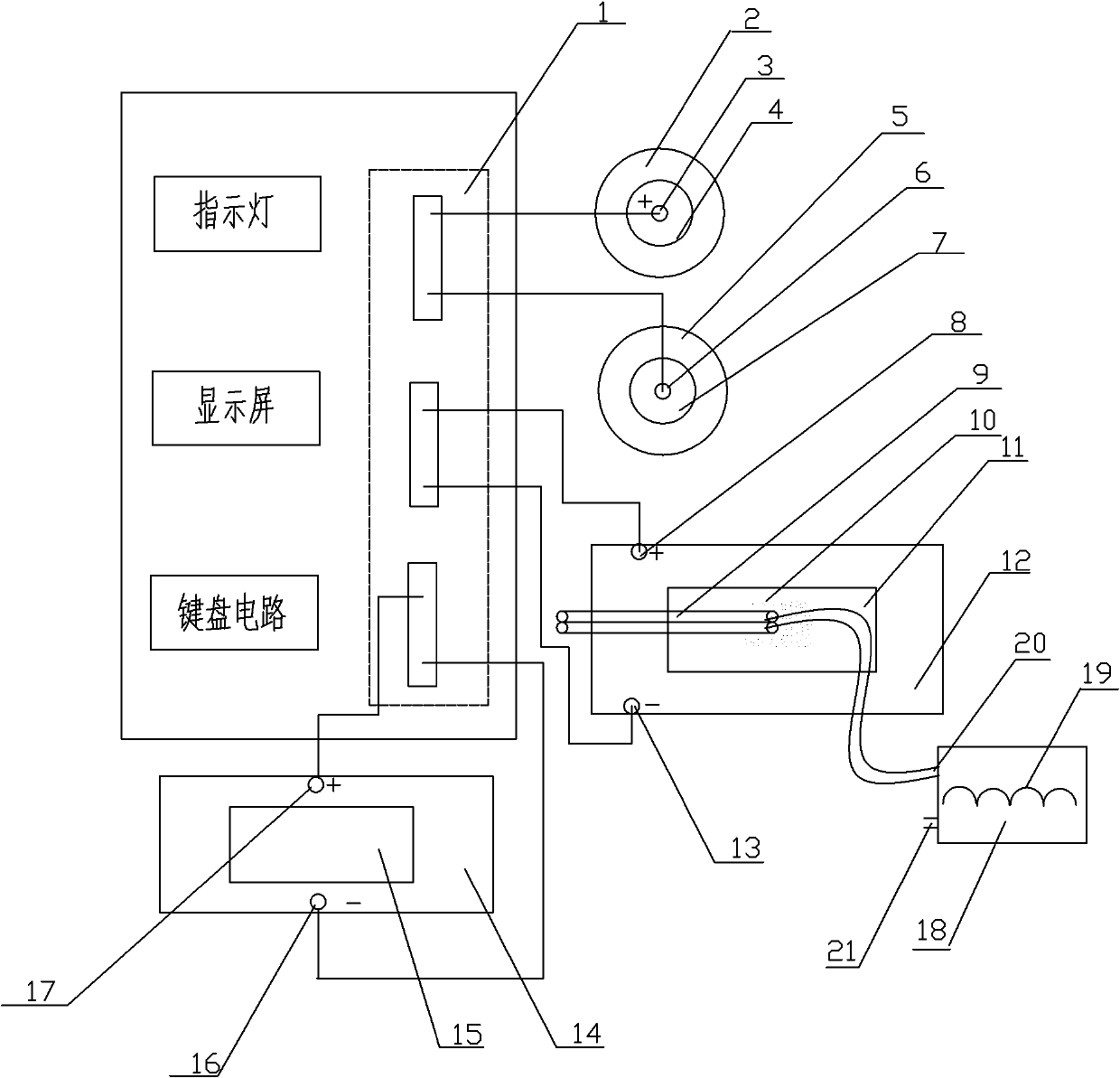

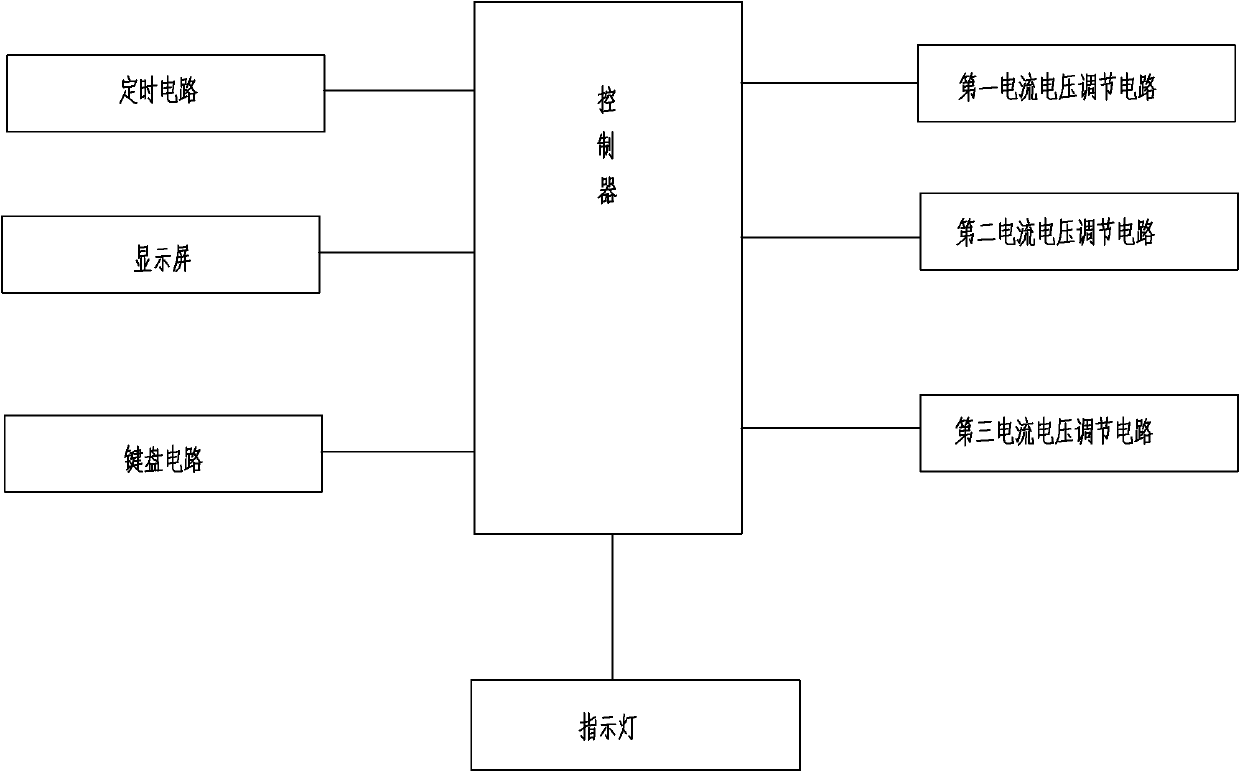

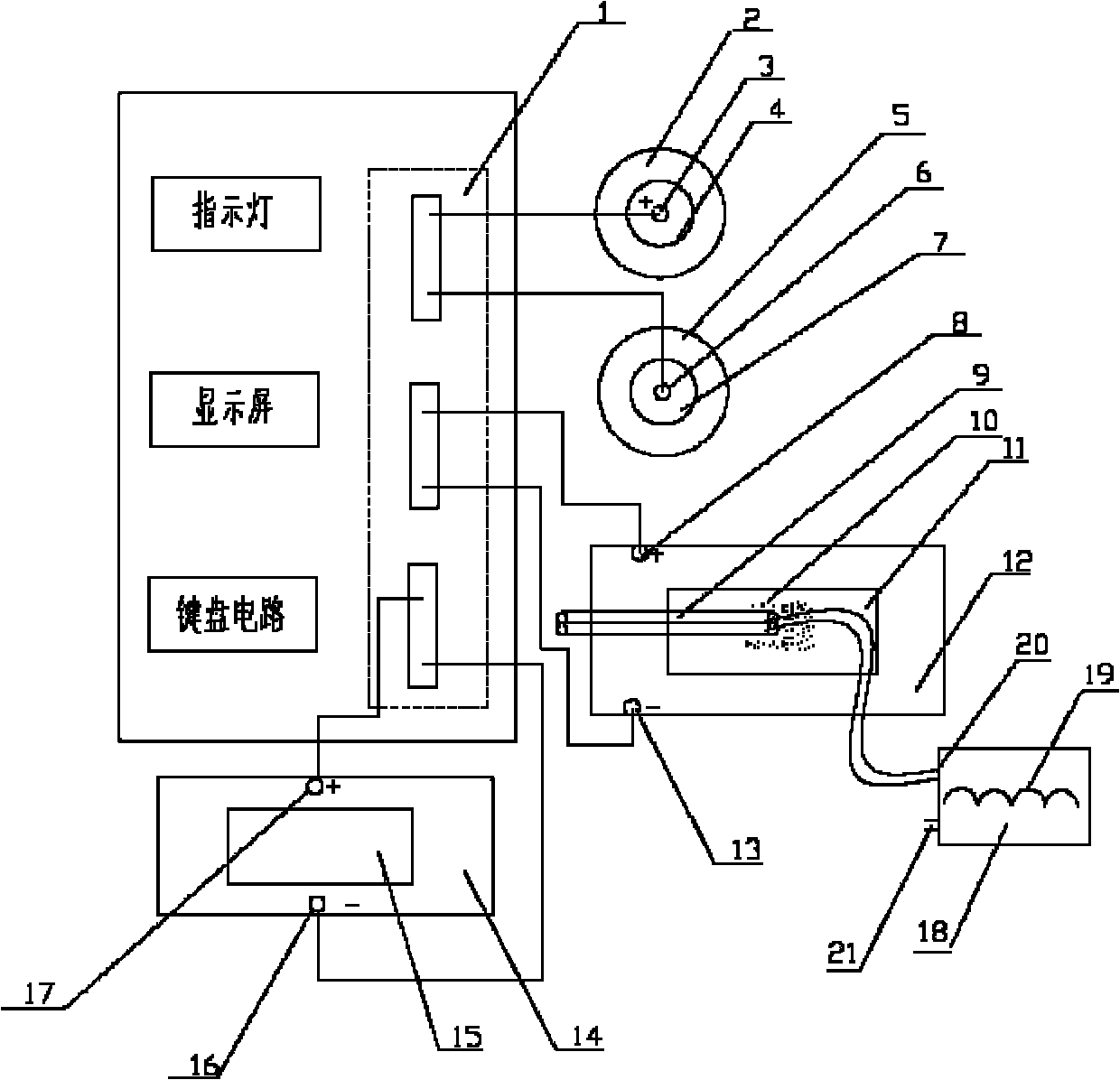

Wound pain quick recovery application instrument

ActiveCN101991484AGood paste performanceImprove conductivityElectrotherapyHydroxy compound active ingredientsMuscle nerveScar tissue

The invention discloses a wound pain quick recovery application instrument, which comprises a body, a controller, a keyboard circuit, an indicator light, a display screen, and three current and voltage regulating circuits, wherein the controller is respectively connected with the keyboard circuit, the display screen, the three current and voltage regulating circuits, a timing circuit and the indicator light; and the output ends of the three current and voltage regulating circuits are respectively connected with three groups of positive and negative electrodes which are respectively connected to three groups of application metal sheets. The wound pain quick recovery application instrument has a reasonable structure, is convenient to use, can form an electric field on the wound surface, accelerates the quick healing of the wound surface, reduces scar tissues, alleviates pain, prevents fat liquoring and postoperative pulmonary embolism, and accelerates the recovery of myoneural junctions.

Owner:龙丹

Semi-interpenetrating network structure double-component fire resistant paint

The invention discloses a bicomponent heat resistant coating with semi- IPN structure. It consists of component A and component B. The ingredients and weight percentage of Group A: solvent (ethanol, butanol, n-butyl acetate) 35-65, water 3-6, silicon mofetil 30-60. In the Group B, the ingredients and weight percentage: acrylic acid resin 15-35, heat resistant resin (silicone resin, silicone resin, ethyl cellulose) 10-28, the anti-sink help 5-12, aluminum 15-46, solvents (ethanol, butanol, n-butyl acetate ) 10-20. The ratio of Group A: Group B is equal to (1.8-2.5): (4.2-5.8). The paint through linking the inorganic and organic silicone materials has Si-O-Si inorganic structure, good heat resistance and durability, and Si-C bonds containing organic groups with the solubility and insulation. It has excellent heat resistance, water resistance and weatherability. Under high temperature thermal oxidation, the fracture of organic-based chain merely occurs, and the main chain of Si-O-Si bond is up to 350 deg.C until fracture, so it has a higher thermal stability.

Owner:CHONGQING SANXIA PAINTS CO LTD

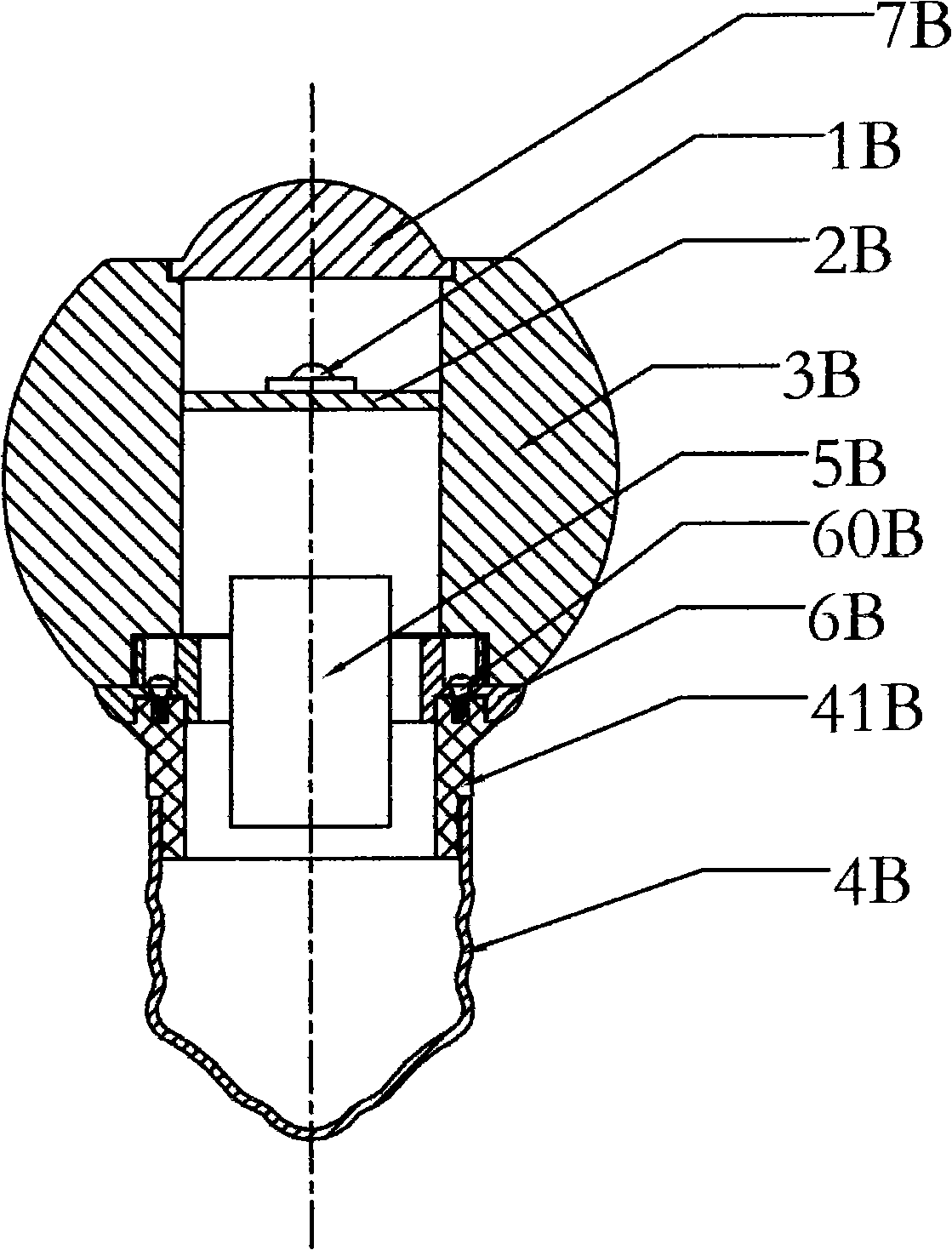

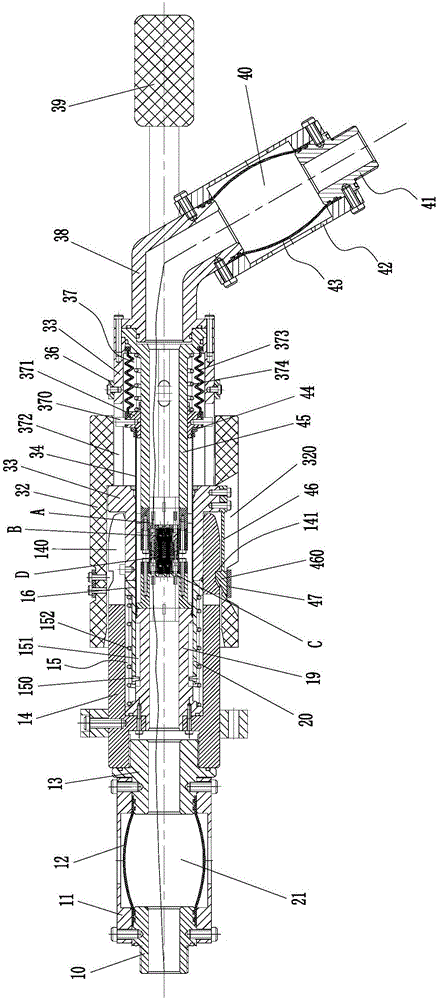

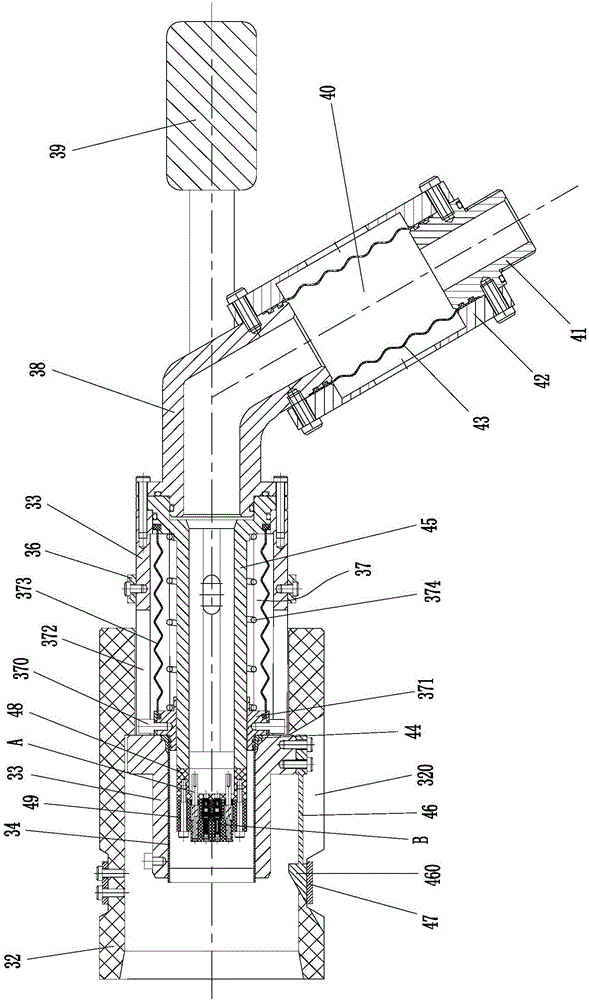

Photoelectric underwater plugging connector

ActiveCN106532374ARealize docking couplingImplementation of underwater plugging and unpluggingCouplings bases/casesTwo-part coupling devicesUnderwaterEngineering

The invention relates to a photoelectric underwater plugging connector. A plug is composed of an outer shell, a plug housing, a plug core, a first lip-shaped sealing element, an electrical contact pin A, a fiber plugging core B, a first adapter base and a first tail connecting element. A socket consists of a second tail connecting element, a second adapter base, a socket housing, a socket core, a socket sliding block, a second lip-shaped sealing element, an electrical contact pin C and a fiber plugging core D. When extending out of the inner cavity of the plug housing slightly, the left end of the first lip-shaped sealing element is closed and sealed; when retracting into the inner cavity of the plug housing, the left end of the first lip-shaped sealing element opens; when extending into the inner cavity of the socket sliding block, the right end of the second lip-shaped sealing element is closed and sealed; and when the socket sliding block separates from the right end of the second lip-shaped sealing element, the right end of the second lip-shaped sealing element opens and the outer shell and the socket housing are buckled and connected. Therefore, the operation is simple; underwater plugging is realized; the workload is reduced substantially; and underwater equipment can be repaired or replaced conveniently.

Owner:8TH RES INST OF CETC

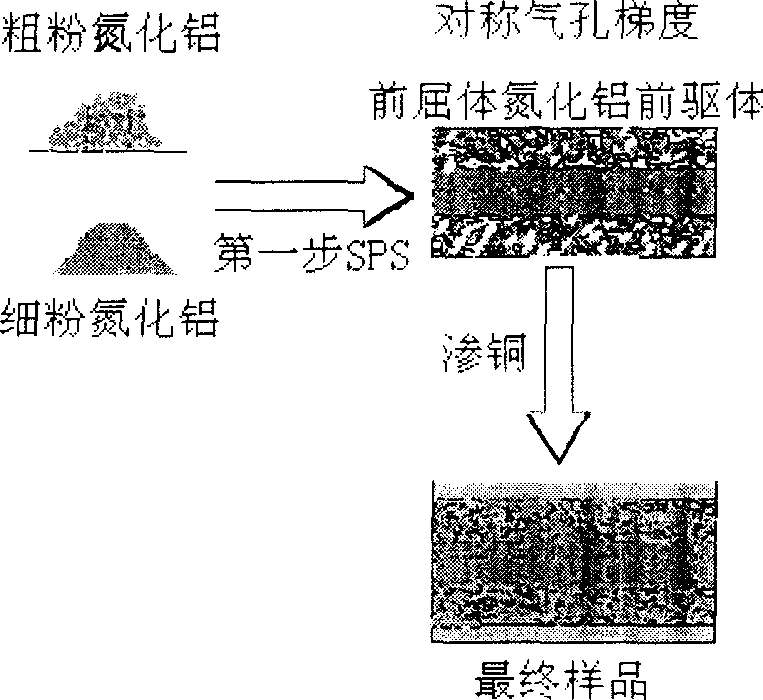

Method for preparing composite material in symmetrical gradient between metallic material and ceramic material

InactiveCN1916201AAchieve insulationImprove thermal conductivityConductive materialMetal layered productsCeramic compositeGradient material

This invention discloses a method for preparing symmetric gradient metal / ceramic composite. The method comprises: (1) sintering aluminum nitride ceramic at a low temperature by plasma-discharging sintering; (2) adding an appropriate amount of Cu powder into aluminum nitride coarse powder to improve its surface property; (3) preparing aluminum nitride symmetric porous gradient material, and infiltrating Cu into it at a low temperature. The method solves the problem of poor bonding between Cu and aluminum nitride ceramic, and can realize preparation of gradient composite with high temperature difference and poor compatibility. The composite has good insulation and thermal conductivity in the thickness direction and good planar electric conductivity, thus can be used as electric heater.

Owner:TSINGHUA UNIV

Polymer nanometer blocking agent for water-based drilling fluid and its preparation method

InactiveCN107915798ARealize bridging and blockingRealize compression deformation sealingDrilling compositionWater basedTemperature response

The invention discloses a polymer nanometer blocking agent for water-based drilling fluid and its preparation method, and belongs to the technical field of a drilling fluid function material. The polymer nanometer blocking agent for water-based drilling fluid is prepared from, by weight, 4-16 parts of emulgator, 2-14 parts of temperature sensitive monomer, 10-53 parts of hydrophilic monomer, 0.5-10 parts of hydrophobic monomer and 0.05-0.5 part of initiator. The polymer nanometer blocking agent is small in size, and can block micro and nano-sized holes of a shale well wall; through compressivedeformation property of the poymer, the compact blocking of the well wall hole can be realized; by means of the temperature response property of an intelligent polymer, the transformation from hydrophilia to hydrophobicity is realized in the well wall, and the zone closing to the well wall is transformed to be a hydrophobic environment, thus the diffusion and permeation of water in the water-based dirlling fluid towards the shale well wall is effectively stopped, thereby stabilizing the well wall and protecting reservoir, and providing an important technical guarantee for the development of the water-based drilling fluid system for shale development.

Owner:SOUTHWEST PETROLEUM UNIV

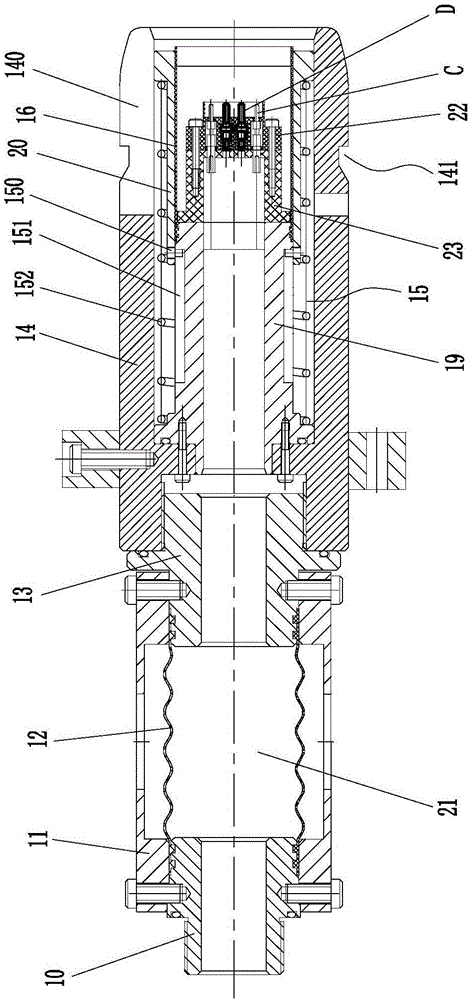

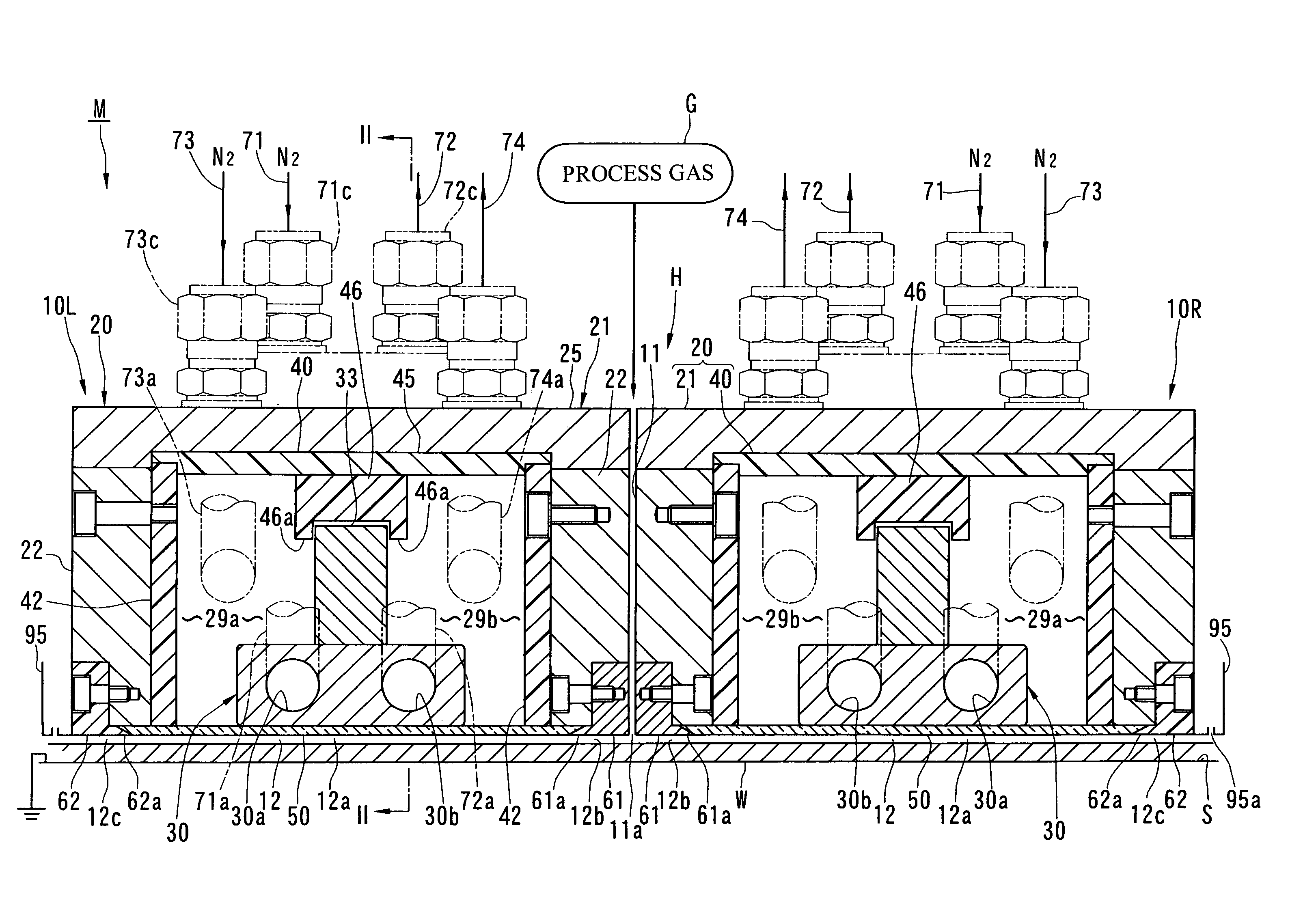

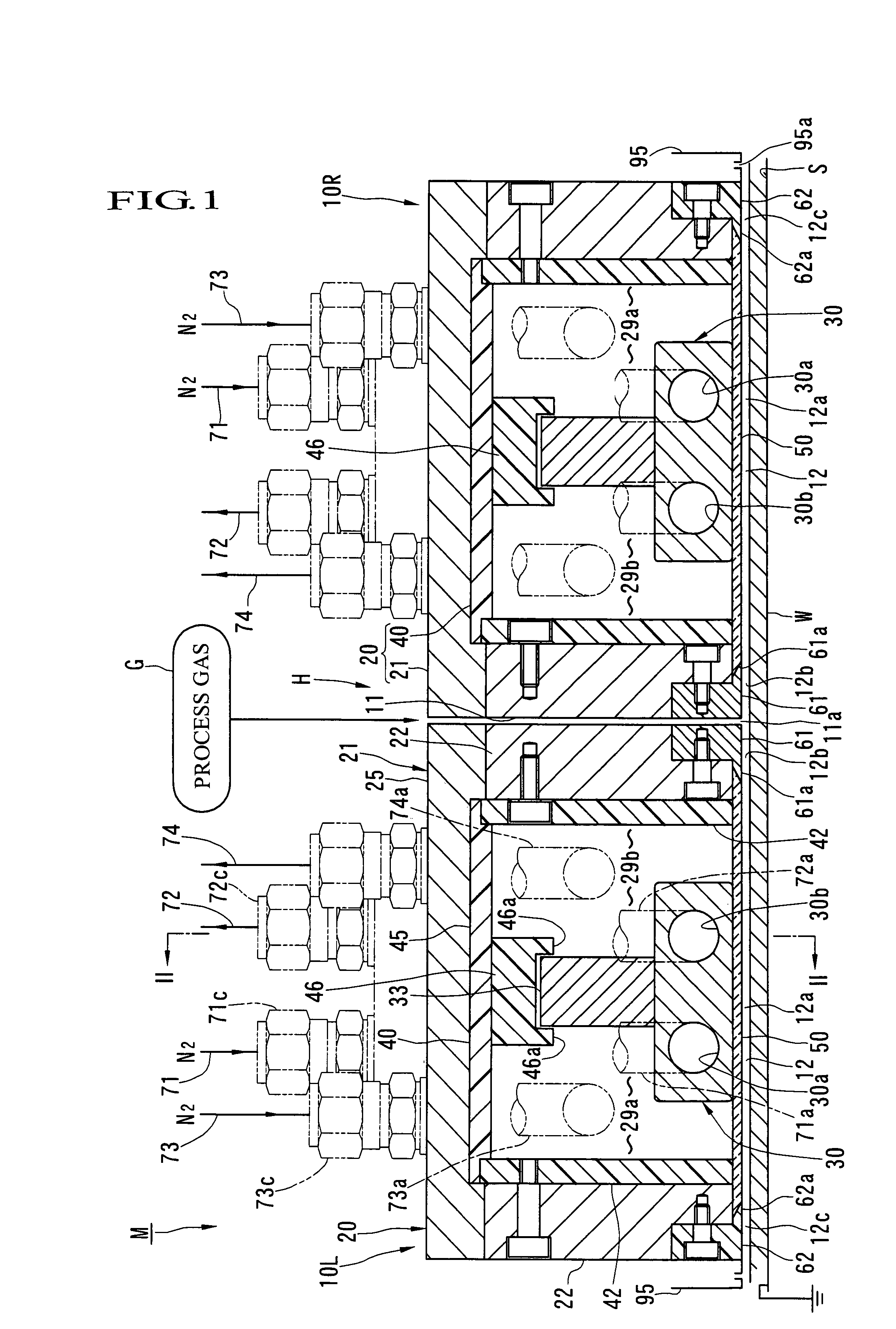

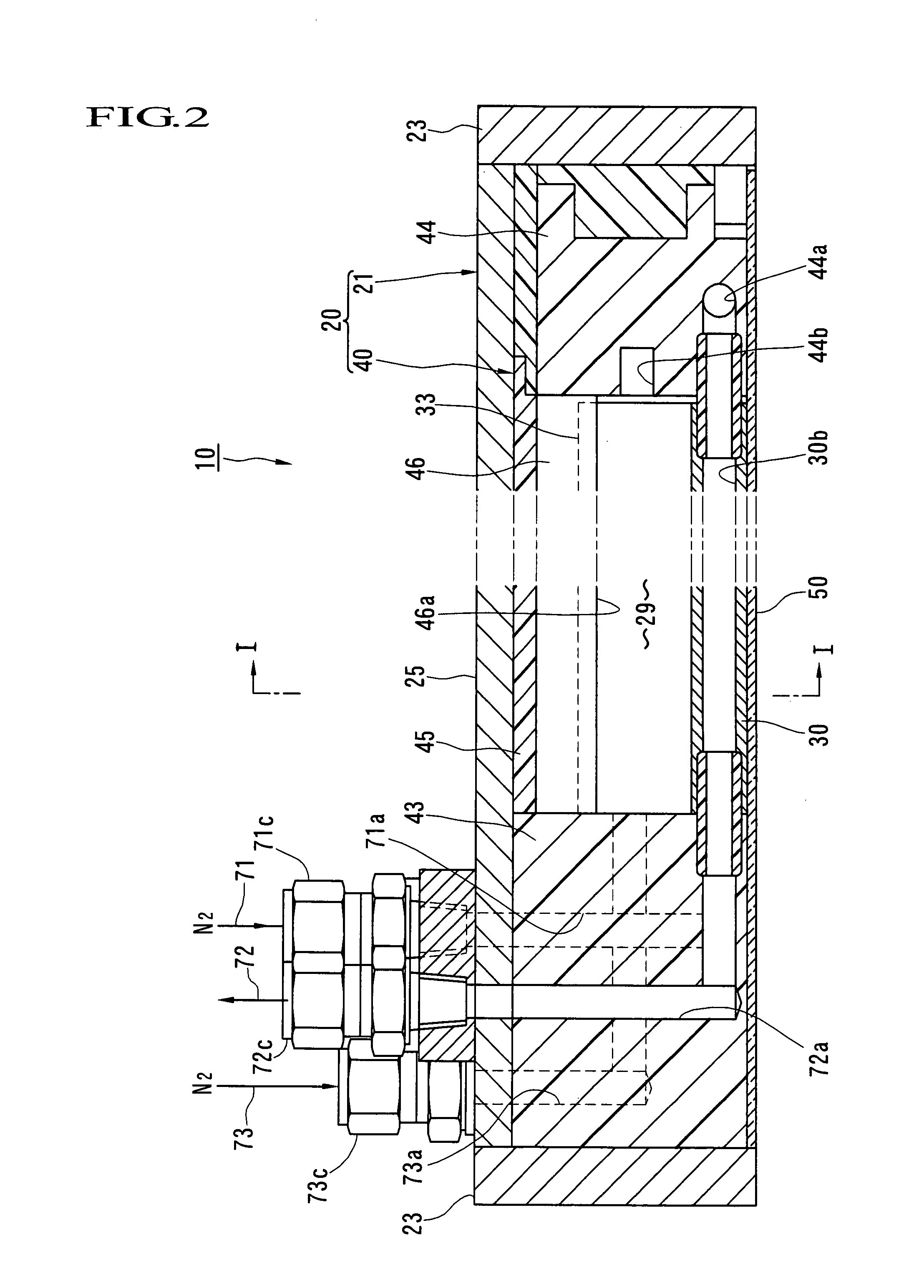

Plasma processing apparatus

InactiveUS7886688B2InsulationImprove insulation performanceElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringNitrogen gas

To provide a plasma processing apparatus capable of enhancing insulation between an electrode and a casing and adjusting the temperature of the electrode from outside.An electrode 30 is provided at its discharge space forming surface with a solid dielectric 50. The electrode 30 is received in a casing 20 such that the solid dielectric 50 on the discharge space forming surface is exposed. An in-casing space 29 between the casing 20 and the electrode 30 disposed in the casing 20 is filled with substantially pure nitrogen gas. This nitrogen gas pressure is more increased than the pressure in the discharge space. Preferably, nitrogen gas is allowed to flow.

Owner:SEKISUI CHEM CO LTD

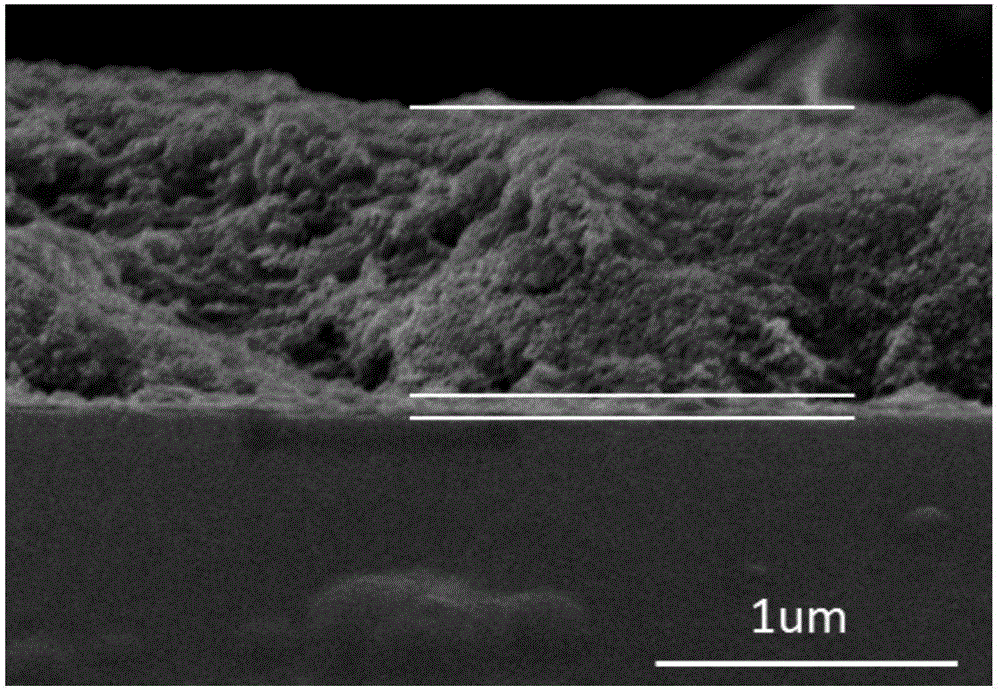

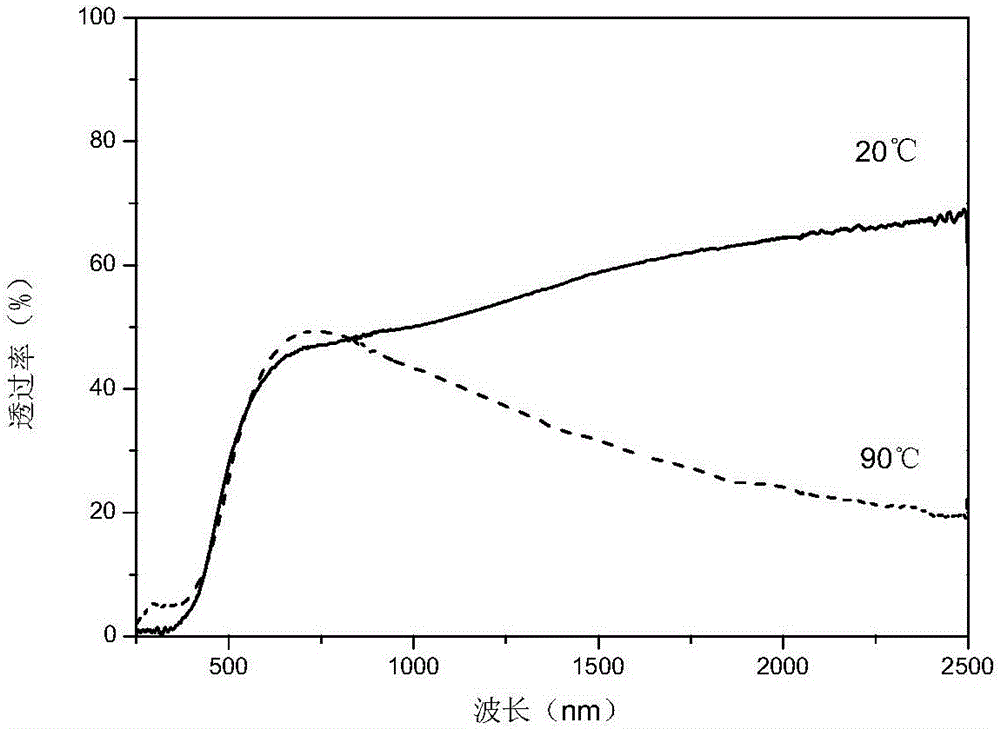

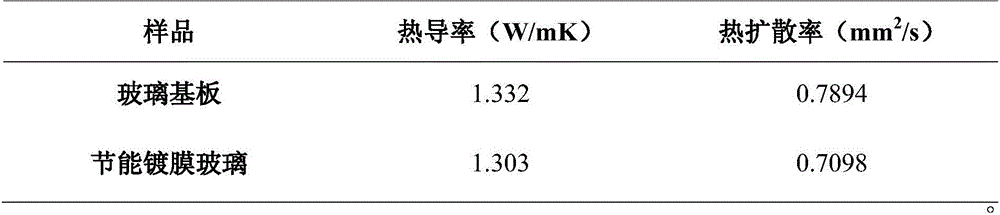

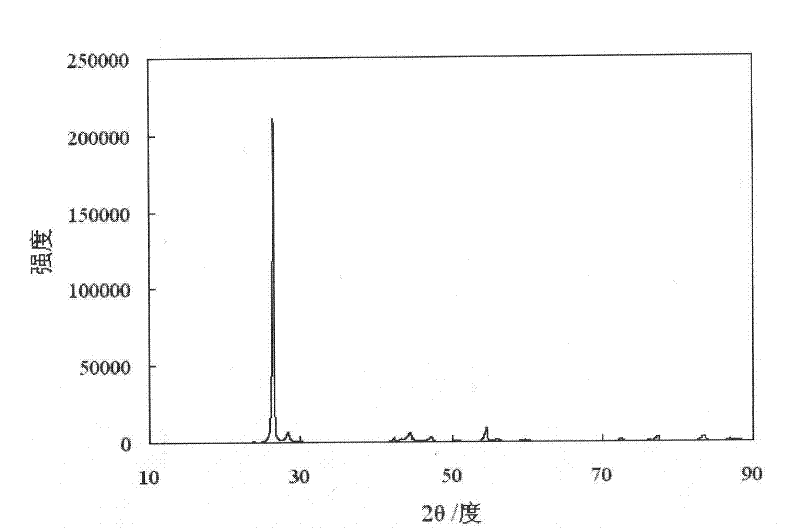

Energy-saving coated glass and preparation method thereof

The invention discloses energy-saving coated glass. Glass is used as a base plate, a vanadium dioxide thermochromic layer and a silicon dioxide aerogel layer sequentially deposit on the glass. Different heat propagation modes of heat conduction and radiant heat blocking are integrated, and the energy-saving coated glass has heat -insulating and thermochromic functions. Oxidization of the vanadium dioxide layer is retarded by introducing the silicon dioxide aerogel layer, and meanwhile a permeability improvement effect can be played. The invention further discloses a preparation method of the energy-saving coated glass. Firstly, the glass base plate is subjected to hydrophilic treatment; the surface of the glass base plate subjected to hydrophilic treatment is coated with a vanadium dioxide precursor layer by adopting a sol-gel method; the surface of the vanadium dioxide precursor layer is coated with a silicon dioxide aerogel precursor layer by adopting a sol-gel method; finally, the energy-saving coated glass is obtained through heat treatment, the heat treatment temperature is 550-580 DEG C, and the time is 1-10 hours.

Owner:ZHEJIANG UNIV

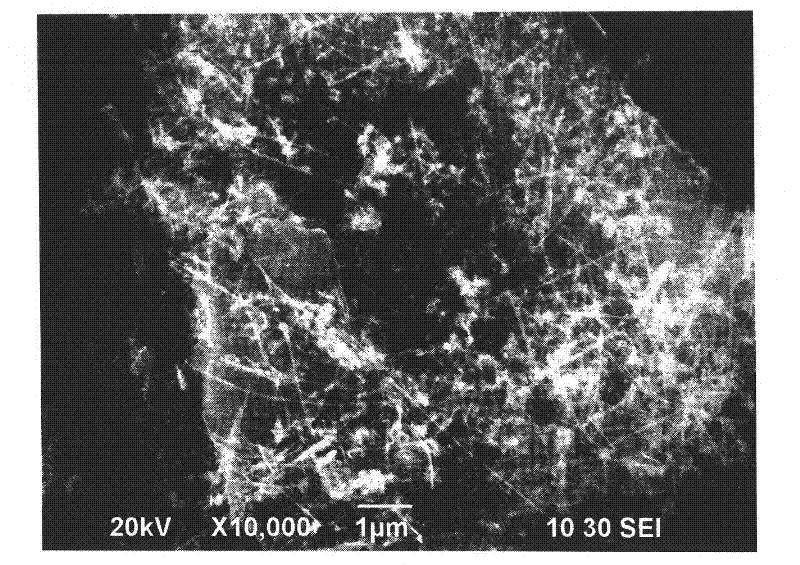

Lithium ion battery and negative electrode active material thereof

InactiveCN102332569ASi content controllableStable structureCell electrodesSecondary cellsCarbon layerNano silicon

The invention which belongs to the technical field of lithium ion batteries especially relates to a lithium ion battery and a negative electrode active material thereof. The negative electrode active material comprises graphite, silicon nanometer wires growing on graphite, and an amorphous carbon layer coated on the silicon nanometer wires. The lithium ion battery prepared with the negative electrode active material has the characteristics of high first efficiency, high capacity, low expansion, excellent cycle performance and the like. The invention also provides the lithium ion battery with the negative electrode active material.

Owner:DONGGUAN AMPEREX TECH +2

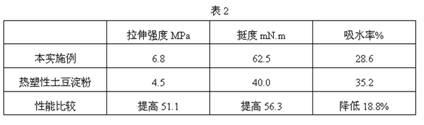

Plant fiber enhanced starch composite packaging material and preparation method thereof

The invention discloses a plant fiber enhanced starch composite packaging material and a preparation method thereof. The plant fiber enhanced starch composite packaging material is prepared by the steps of mixing 40 to 60 weight parts of cation modified potato starch, 10 to 20 weight parts of straw fiber, 5 to 10 weight parts of polyvinyl alcohol, 5 to 10 weight parts of inorganic filler, 5 to 10 weight parts of cross-linking agent, and 5 to 10 weight parts of plasticizer, and melting, mixing and extruding by using a double-screw extruder. Compared with the conventional thermoplastic potato starch composite packaging material, the plant fiber enhanced starch composite packaging material has the advantages that: the tensile strength is improved by 40 to 60 percent, the deflection is improved by 40 to 60 percent, and the water absorption rate is reduced by 15 to 30 percent.

Owner:广东普科特粉末涂料有限公司

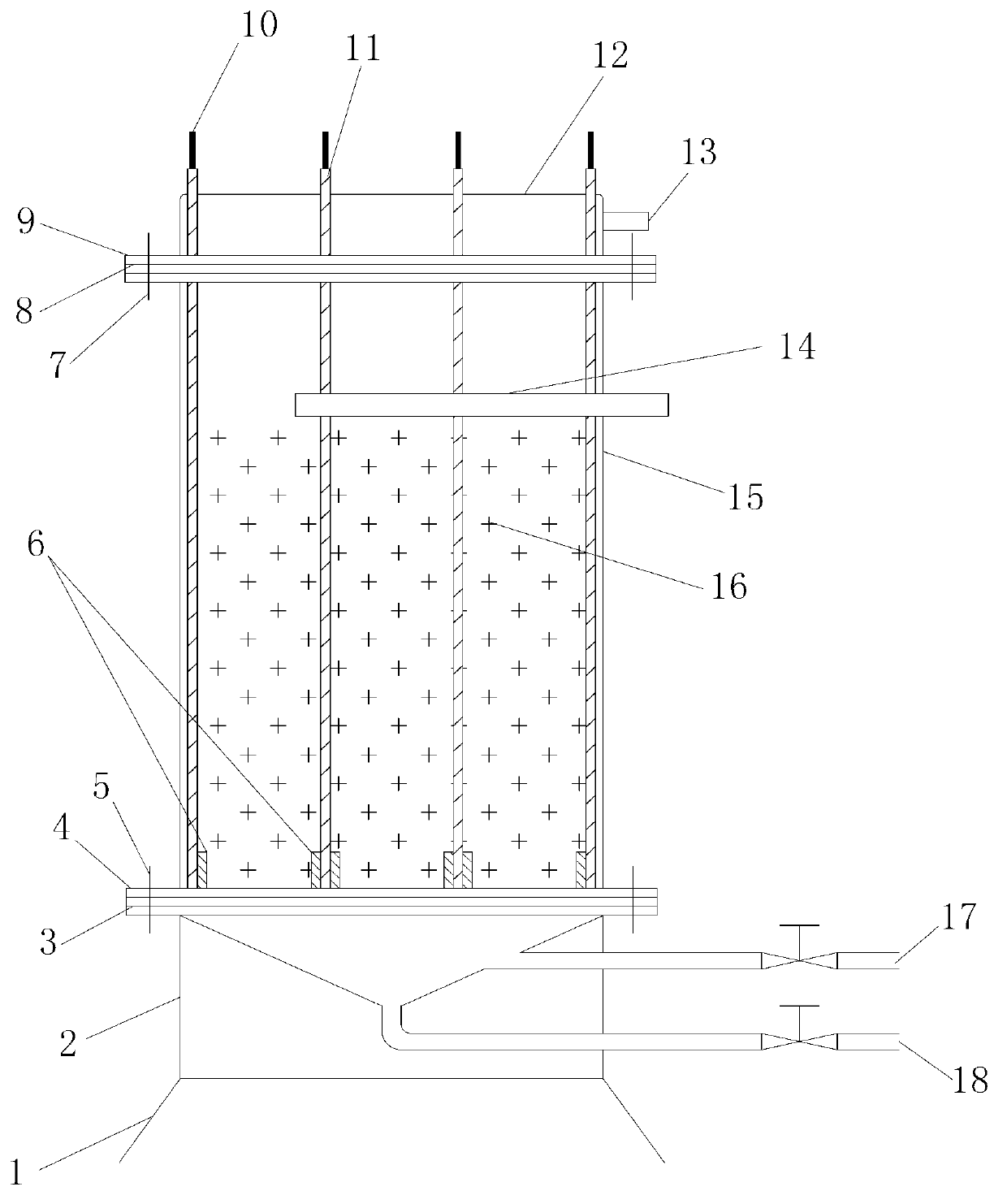

In-situ adsorption-microelectrolysis-catalytic oxidation sewage treatment equipment and method

InactiveCN102826632AConductiveInsulationWater/sewage treatment by sorptionWater/sewage treatment by oxidationElectrolysisSorbent

The invention discloses in-situ adsorption-microelectrolysis-catalytic oxidation sewage treatment equipment and method, belonging to the technical field of sewage treatment in environment engineering. The in-situ adsorption-microelectrolysis-catalytic oxidation sewage treatment equipment is characterized in that adsorption equipment, electrolysis equipment and catalytic oxidation equipment are integrated so as to gather enable pollutants to be gathered from a low-concentration water phase onto an adsorbent; by using the favorable electric conductivity, the adsorbent is used as a complexly polarized three-dimensional electrode to form countless micro electrolytic baths, so that the organic pollutants are electrolyzed while organic matters are adsorbed, and adsorption active sites are continuously regenerated; and by utilizing an electric insulation material, the three-dimensional electrode is complexly polarized and has a high-class oxidation catalyst function at the same time, so that a gas oxidant dissolved in water and an oxidant generated by side reaction of the electrode form a high-class oxidant to efficiently remove the organic pollutants. According to the equipment and the method, the problems of slow reaction speed, low space-time efficiency, low current efficiency and low pollutant degradation efficiency in the conventional electrolytic reactors are solved, and an excellent market prospect is provided.

Owner:DALIAN UNIV OF TECH

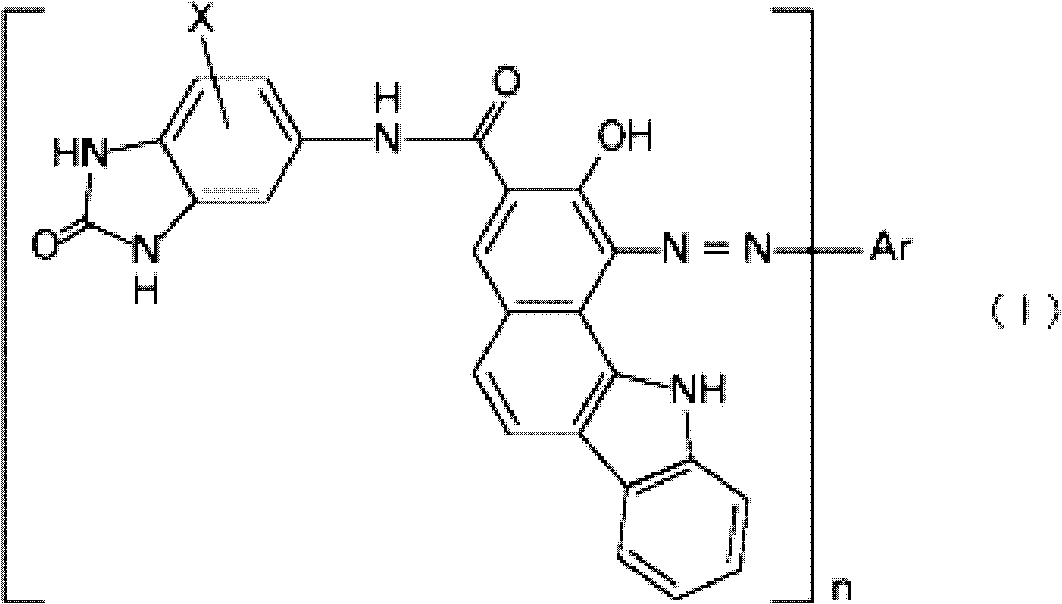

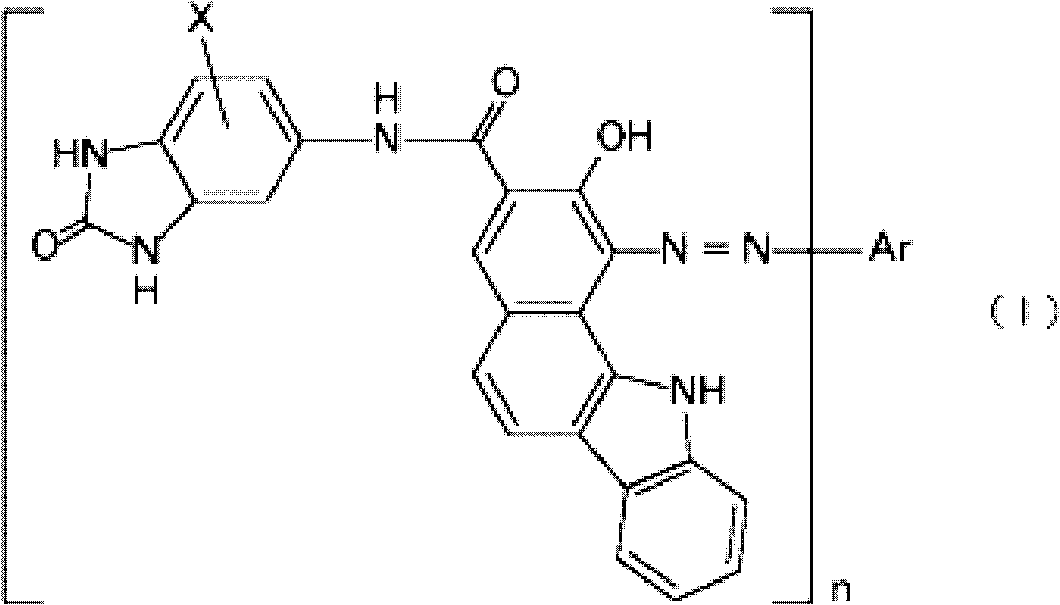

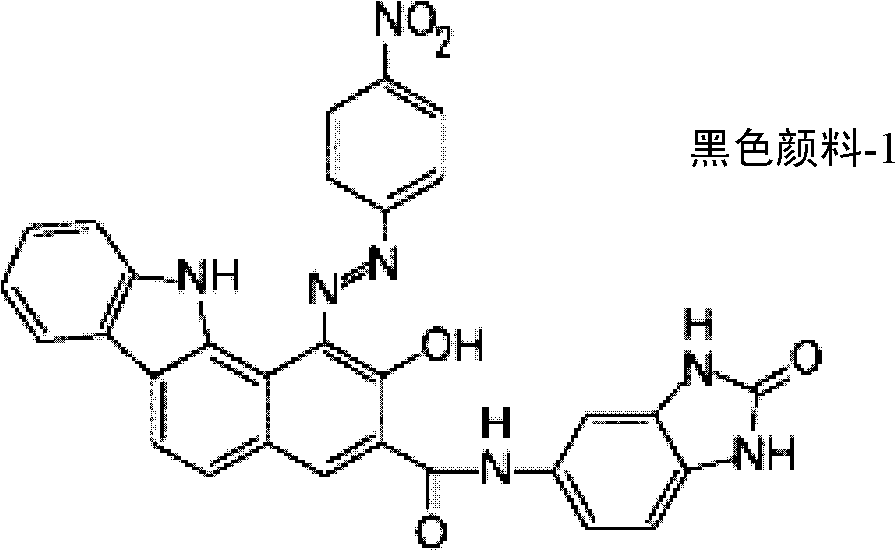

Azo pigments, coloring compositions, coloring method and colored articles

Dark-color azo pigments characterized by being represented by general formula (I). The azo pigments have properties of reflecting or transmitting infrared rays or solar heat rays as optical characteristics and exhibit excellent fastness, particularly excellent heat resistance, as pigment characteristics.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com