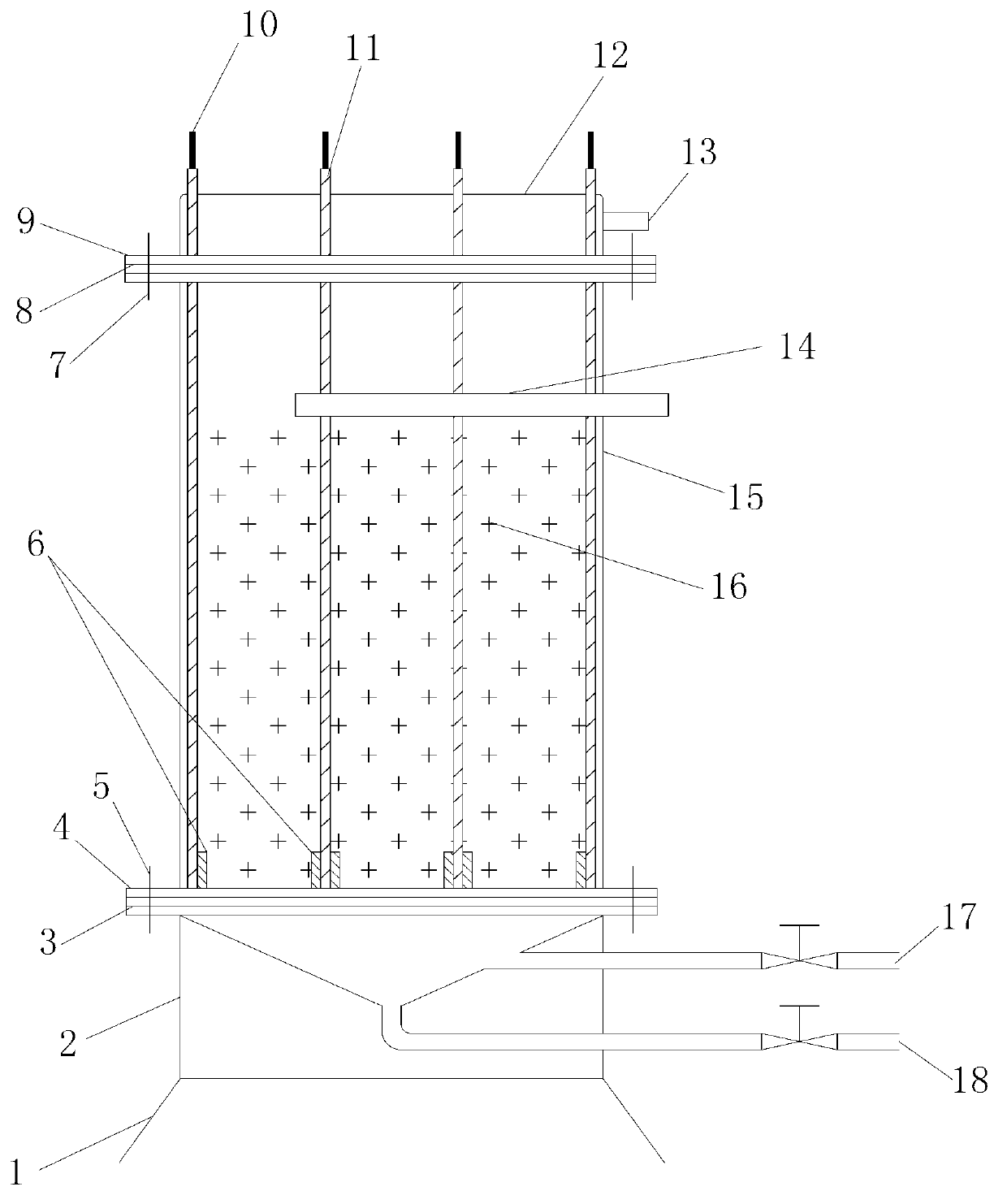

In-situ adsorption-microelectrolysis-catalytic oxidation sewage treatment equipment and method

A sewage treatment equipment and catalytic oxidation technology, which are applied in the fields of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of low space-time efficiency, slow reaction rate, low efficiency of pollutant degradation, etc. Achieve the effect of improving biodegradability and reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This technology is used for advanced treatment and reuse of sewage from petrochemical refineries. The cathode and anode of the equipment used are both graphite, the power supply is DC power supply, and activated carbon and loaded iron zeolite are used as mixed fillers. The ratio of mixed fillers is: activated carbon / loaded iron zeolite = 1 / 3, iron / zeolite = 1 / 200, The particle size is 10 mesh. The COD content of raw oil refinery sewage is below 100mg / L after conventional secondary biological treatment. The sewage after secondary biological treatment continuously enters the equipment for advanced treatment. The hydraulic retention time is 1 hour, and the COD content of the effluent is 20-30mg / L, which is lower than the primary reclaimed water quality standard of 40mg in the guidelines for the management of sewage reuse in oil refining and chemical enterprises. / L, power consumption is 0.6KWH / ton of water. The water can be reused as circulating water for hydration. ...

Embodiment 2

[0019] This technology is used for the advanced treatment of oilfield wastewater. The anode of the equipment used is graphite, the cathode is carbon steel, the power supply is DC power supply, and activated carbon and quartz sand are used as mixed fillers. The mixed filler ratio is: activated carbon / quartz sand = 1 / 2, and the particle size is 10-20 mesh. The original oily sewage is removed from the oil removal tank, and then pretreated by the sand filtration process, the oil content is below 100mg / L. The pretreated sewage continuously enters the equipment for advanced treatment. The hydraulic retention time is 1 hour, the oil content in the effluent is 2-3 mg / L, which is 5 mg / L lower than the oilfield reuse water standard, and the power consumption is 0.6KWH / ton of water. The water can be re-injected into the oil field after desalination.

Embodiment 3

[0021] This technology is used for the advanced treatment of domestic sewage. The cathode and anode of the equipment used are both graphite, the power supply is DC power supply, and activated carbon and sulfonated coal are used as mixed fillers. The ratio of mixed fillers is: activated carbon / sulfonated coal = 1 / 2, and the particle size is 10-16 mesh. The domestic sewage with a COD of 200-300mg / L can be reduced to about 100mg / L after sedimentation and biochemical treatment. The sewage after the secondary biological treatment continuously enters the equipment for advanced treatment, the hydraulic retention time is 1 hour, the COD of the effluent is less than 50mg / L, which meets the national urban sewage treatment plant reclaimed water reuse standard, and the power consumption is 0.5KWH / ton of water. This water can be reused as reclaimed water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com