Patents

Literature

1678results about How to "Conductive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

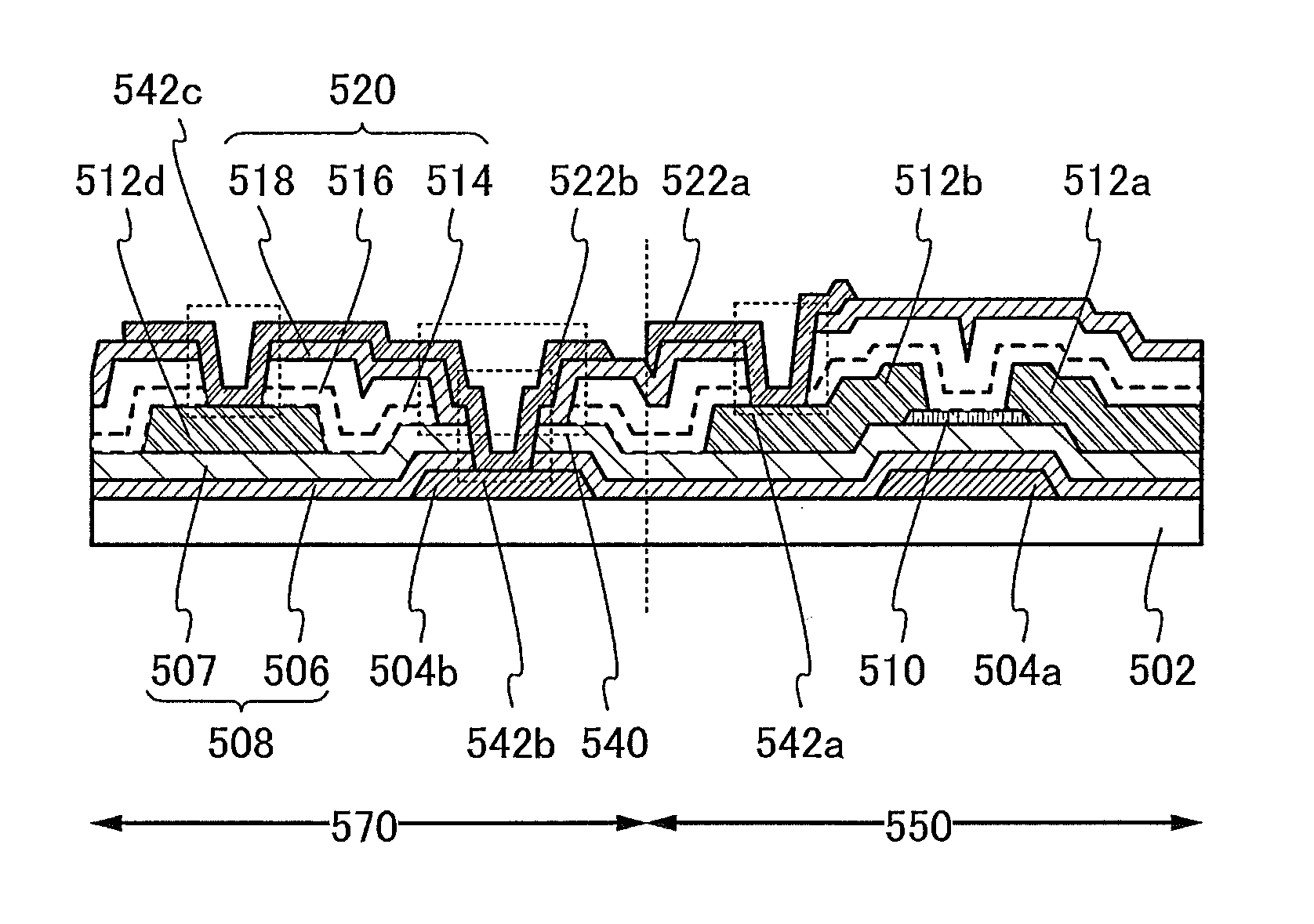

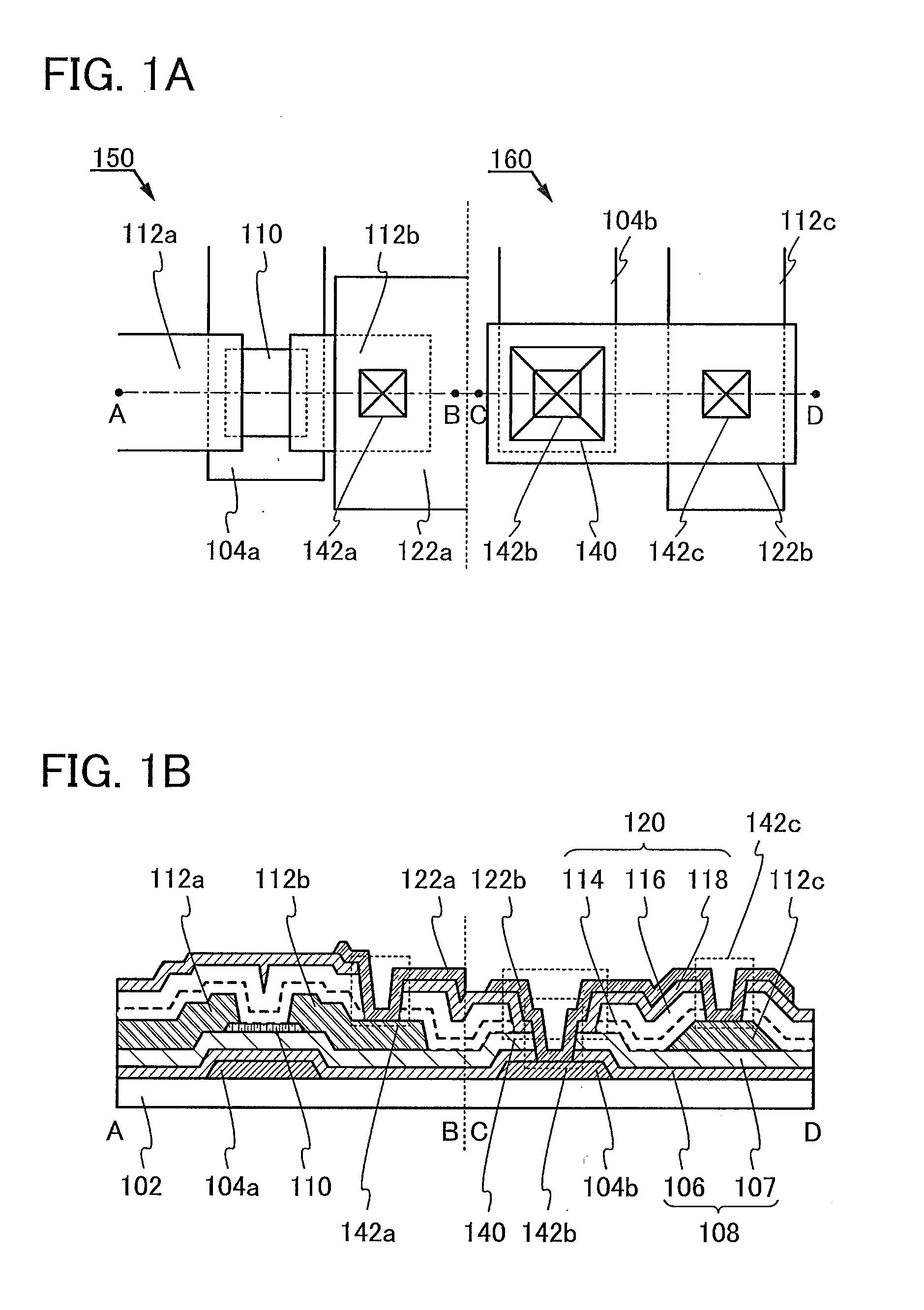

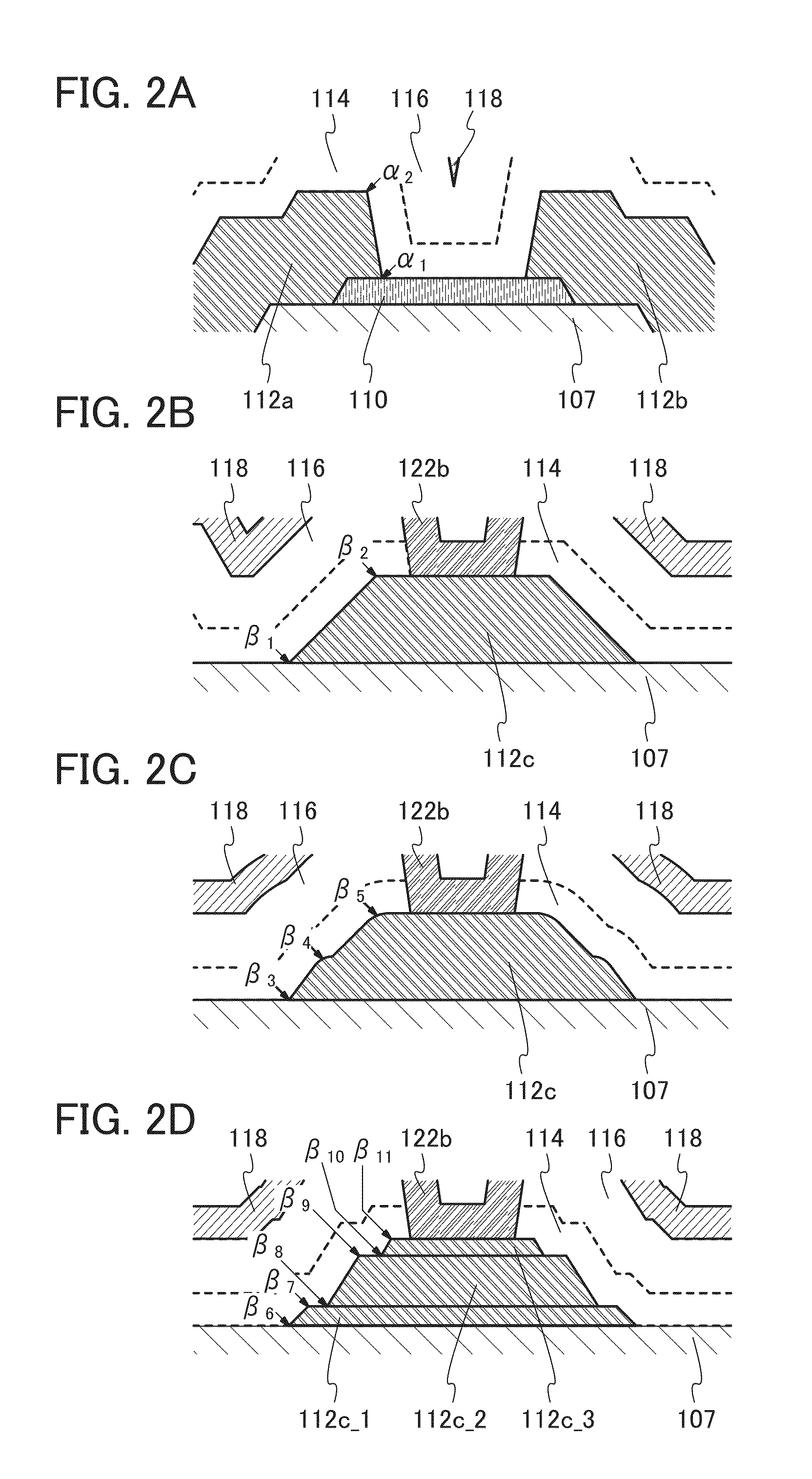

Semiconductor device and display device including the semiconductor device

ActiveUS20150014680A1Excellent electrical propertiesImprove featuresSolid-state devicesNon-linear opticsPower semiconductor deviceDisplay device

A semiconductor device including a transistor and a connection portion is provided. The transistor includes a gate electrode, a first insulating film over the gate electrode, an oxide semiconductor film over the first insulating film and at a position overlapping with the gate electrode, and source and drain electrodes electrically connected to the oxide semiconductor film; and the connection portion includes a first wiring on the same surface as a surface on which the gate electrode is formed, a second wiring on the same surface as a surface on which the source and drain electrodes are formed, and a third wiring connecting the first wiring and the second wiring. The distance between an upper end portion and a lower end portion of the second wiring is longer than the distance between an upper end portion and a lower end portion of each of the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

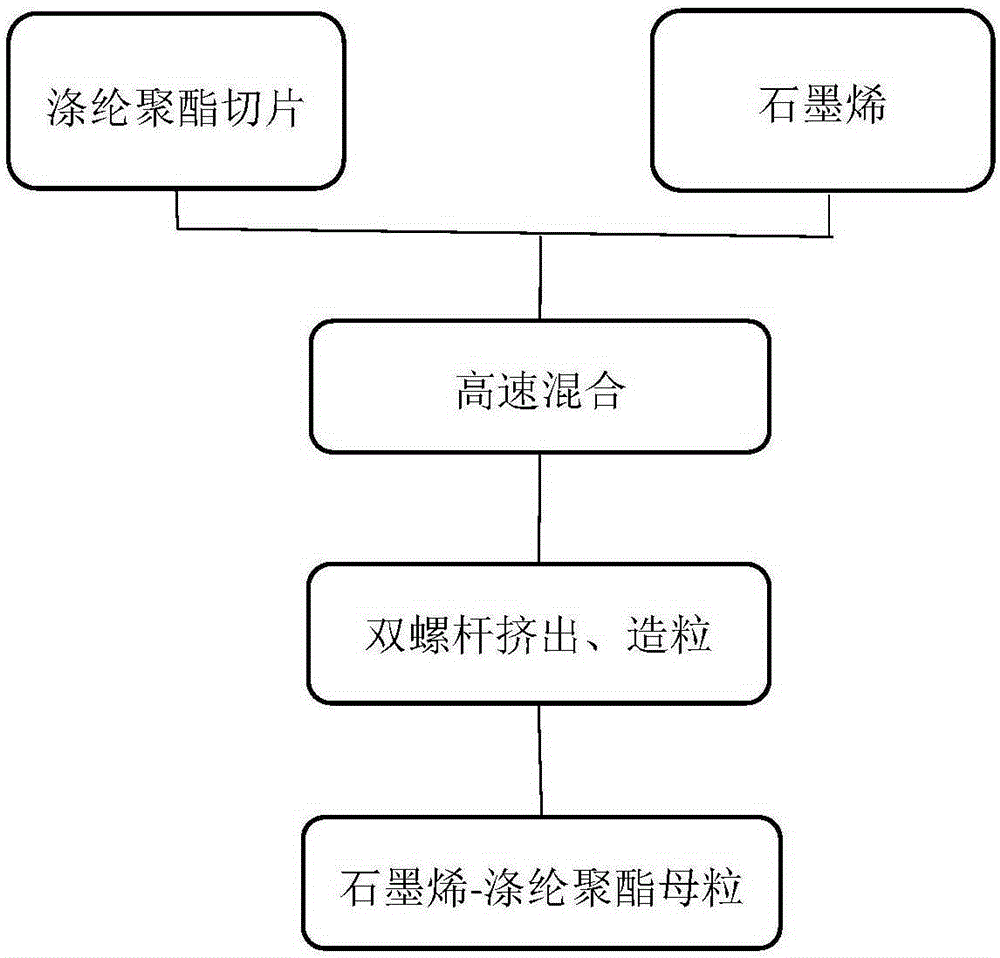

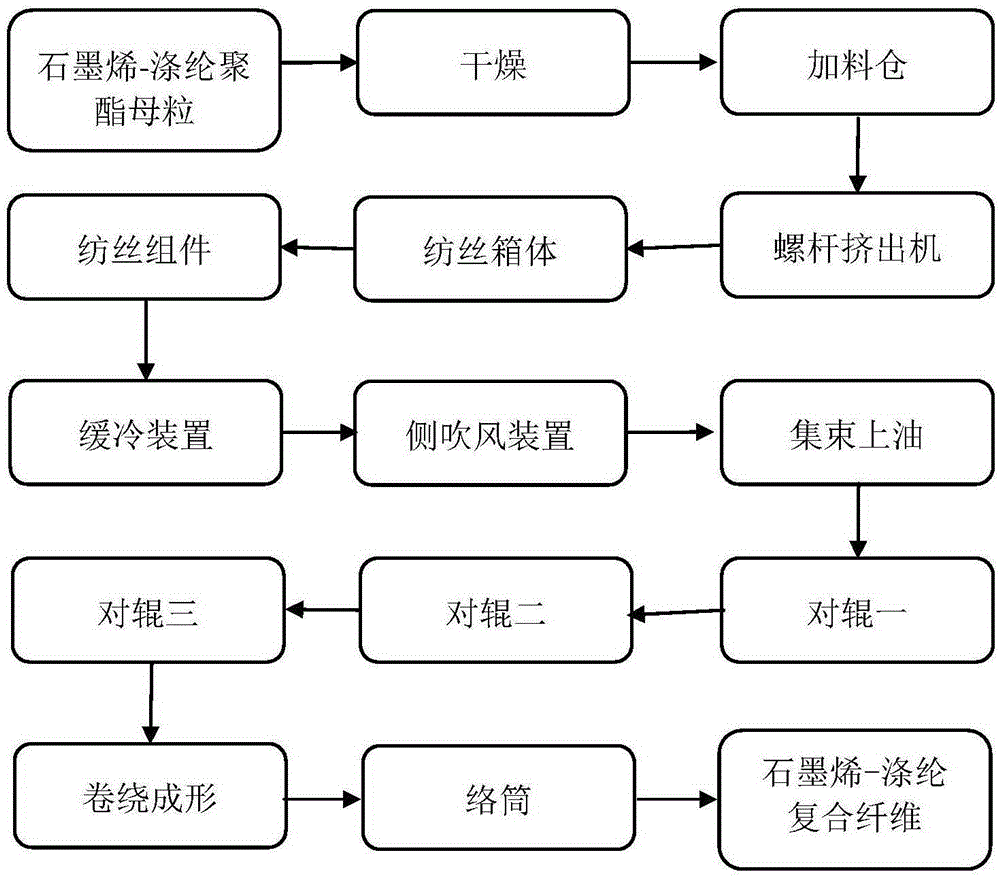

Preparation method of graphene-polyester nano-composite fiber

ActiveCN105200547AHigh breaking strengthEasy to prepareElectroconductive/antistatic filament manufactureFilament/thread formingNanometreSurface modification

The invention discloses a preparation method of graphene-polyester nano-composite fiber. The preparation method comprises the step of preparing graphene-terylene polyester composite master batch and the step of preparing the graphene-polyester nano-composite fiber from the composite master batch. Compared with other conventional methods, the preparation method has the advantages that the technology is extremely simple, the reinforcing material is excellent in performance and low in cost; besides, excellent mechanical property and functional characteristics of graphene self endow the nano-composite fiber with functionalities like high strength and antistatic property, surface-modified and modified graphene has good dispersity and perfect interfacial compatibility in terylene polyester polymer matrix, which enables graphene to be effectively and uniformly compounded with a terylene polyester chip base material.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

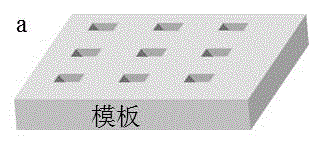

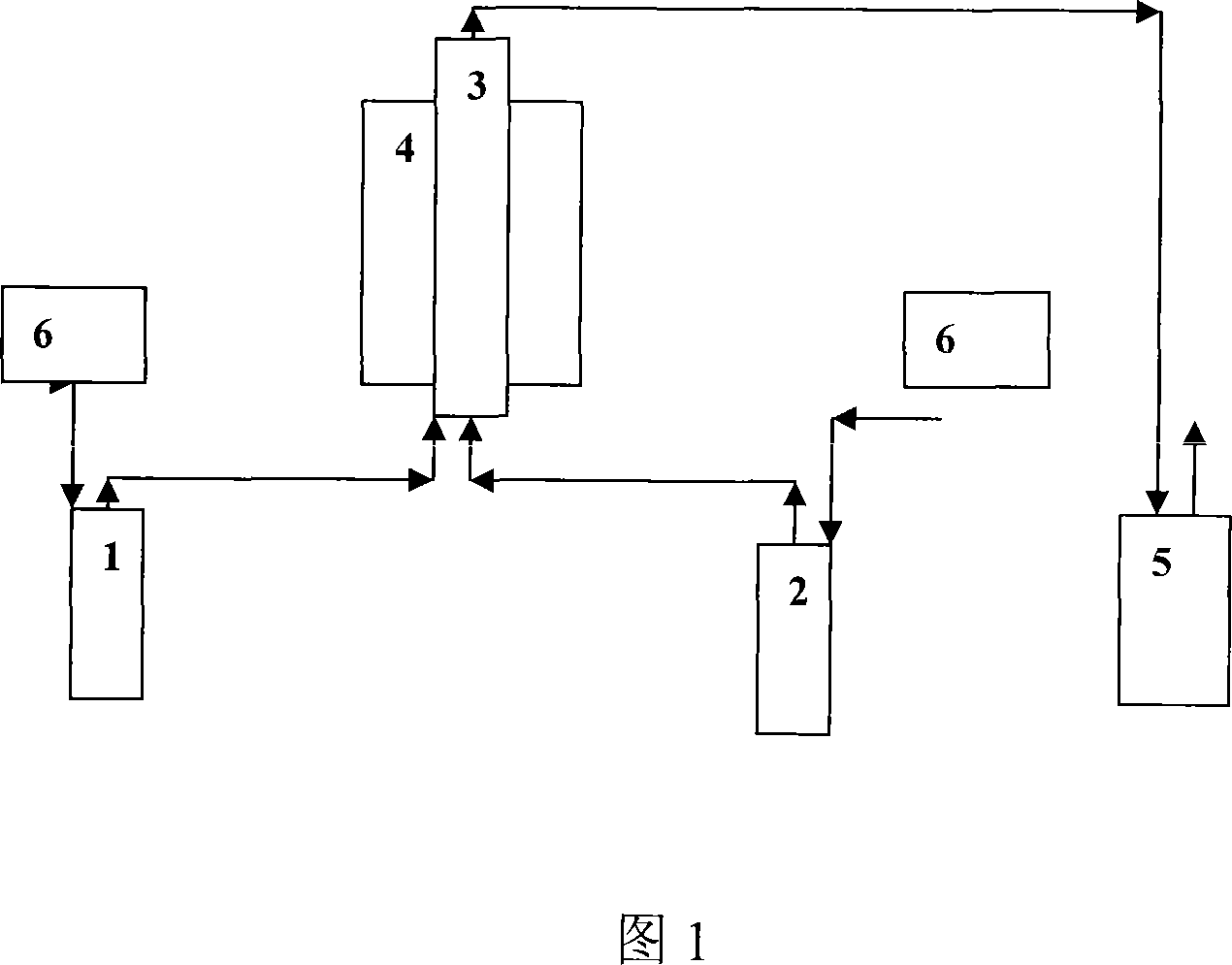

Nano generator and manufacturing method thereof

ActiveCN102646788AImprove efficiencyImprove stabilityPiezoelectric/electrostrictive device manufacture/assemblyNanotechnologyNanogeneratorPower flow

The invention provides a nano generator and a manufacturing method thereof. The nano generator comprises a base, a first electrode, a zinc oxide nano wire array, a macromolecule insulating layer and a second electrode, wherein the first electrode is arranged on the base; the zinc oxide nano wire array vertically grows on a first electrode layer; the macromolecule insulating layer is coated on a zinc oxide nano wire array layer; the zinc oxide nano wire array layer covers the zinc oxide nano wire array, and the second electrode is arranged on the macromolecule insulating layer; and the first electrode and the second electrode are used as a voltage output pole and a current output pole of the nano generator. The nano generator disclosed by the invention adopts a unique structure so that the electric performance output and the stability are effectively improved.

Owner:NAZHIYUAN TECH TANGSHAN LLC

Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

InactiveCN101165127AImprove dispersion uniformityNo subsidencePolyurea/polyurethane coatingsEmulsion paintsPolyesterCarbon nanotube

The present invention belongs to the field of chemical technology, and is especially one kind of conducting water soluble polyurethane paint containing carbon nanotube and its preparation process. The conducting paint is prepared through the first modifying carbon nanotube chemically for the surface to carry hydroxyl group, carboxyl group or amino group; the subsequent introducing to polyester polyol or isocyanate terminated polyurethane pre-polymer through chemical bonding and self-emulsifying to prepare water soluble polyurethane dispersoid containing carbon nanotube; and final adding deionized water and assistants through high speed stirring to obtain the conducting paint. The conducting paint can form coating with volume resistivity of 1x10<-5>-4x10<-4. ohm.cm, surface resistivity of 1x10<-1>-2x10<2> ohm, adhesion of 0 grade, shielding effectiveness of 70-85 dB, and long term stability, and has wide application.

Owner:SHANGHAI SAFEGREEN TECH

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

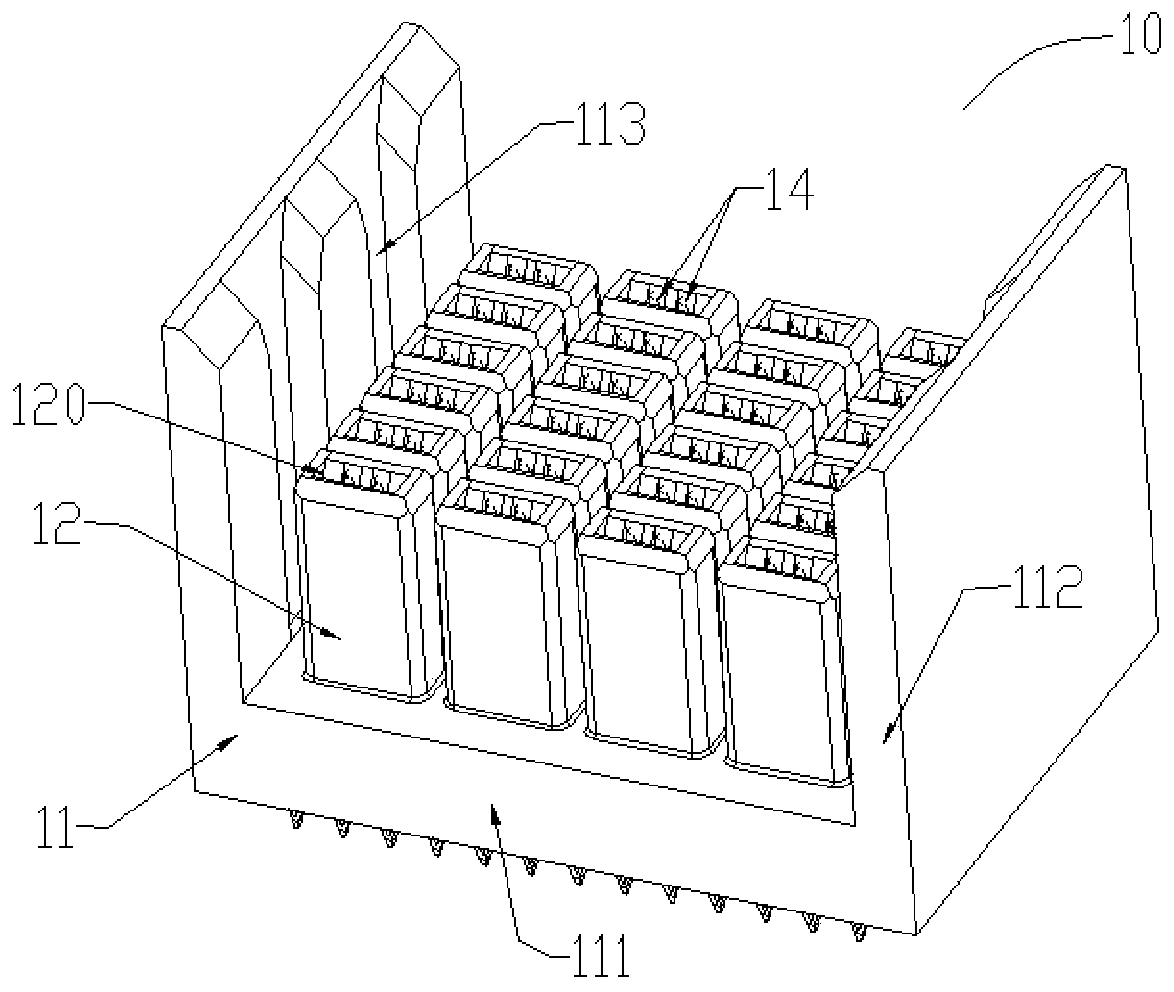

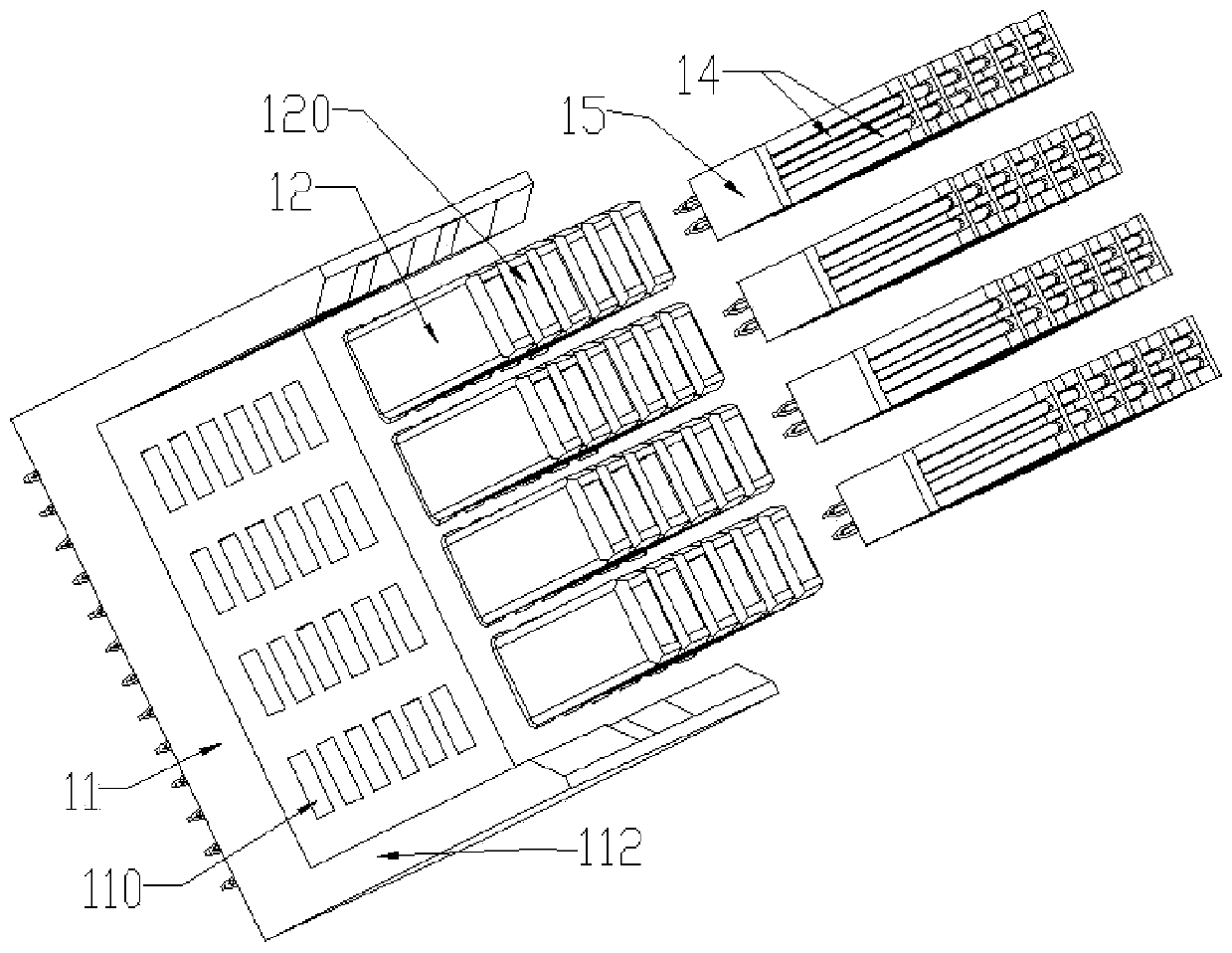

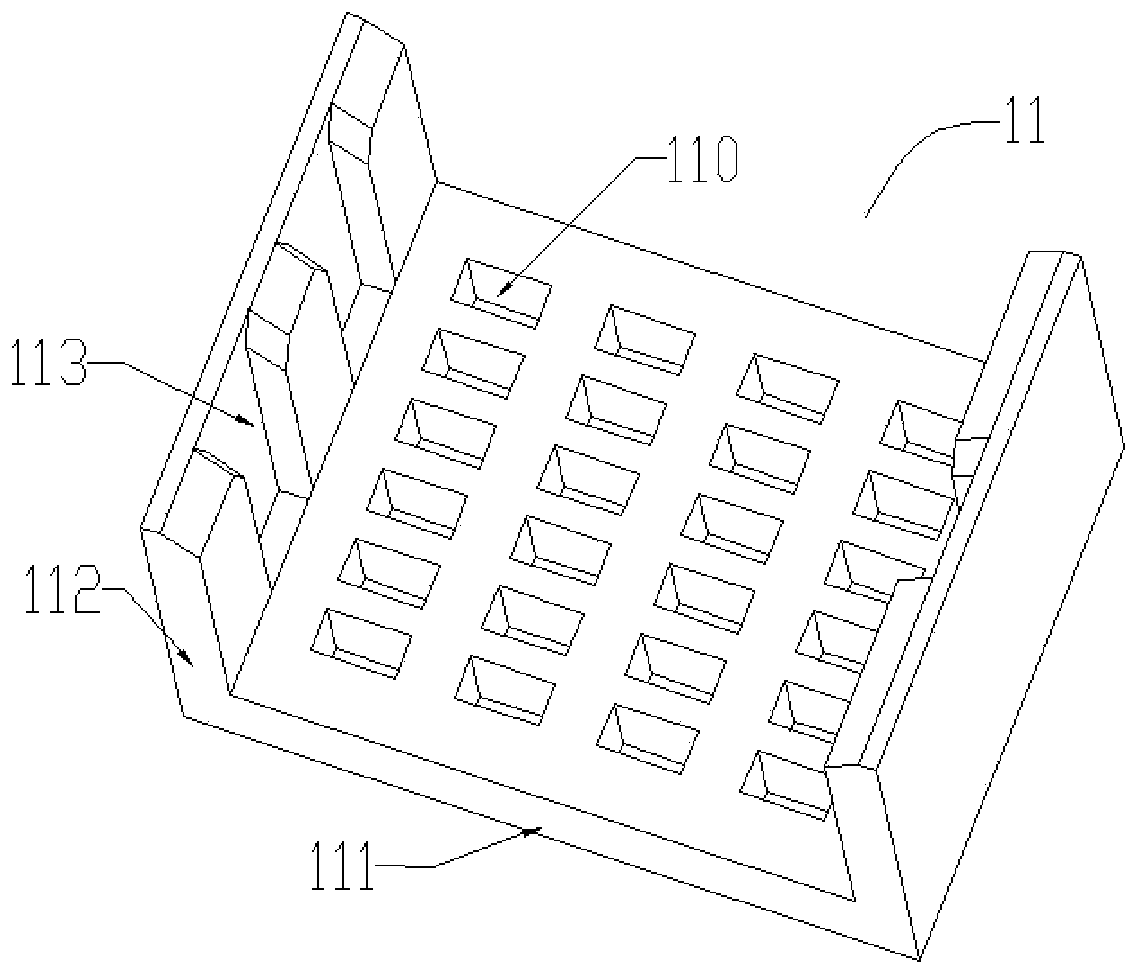

Male connector, female connector, connector assembly and communication equipment

ActiveCN110808499AEasy to processHigh mechanical strengthCoupling device detailsNetwork connectorsAnatomyElectrical connection

The present application provides a male connector, a female connector, a connector assembly and a communication equipment. The male connector comprises a male conductive base, wherein a plurality of first through holes are arranged on the male conductive base; a plurality of shielding sleeves which are fixed on the male conductive base and electrically connected with the male conductive base, theshielding sleeves have a sleeve structure, a front-back through shielding cavity is formed in the shielding sleeves, a plurality of the shielding sleeves are corresponding to a plurality of first through holes in a one-to-one way and the shielding cavity is communicated with the corresponding first through holes; and a plurality of male differential pairs, wherein a plurality of male differentialpairs are corresponding to a plurality of shielding sleeves in a one-to-one way, the male differential pairs are fixed in the shielding cavity by penetrating through the first through holes and the male differential pairs are electrically insulated from the male conductive base and the shielding sleeves. Compared with the connectors in the prior art, the connector has the advantages of convenientprocessing, high mechanical strength and good shielding effect.

Owner:HUAWEI MACHINERY

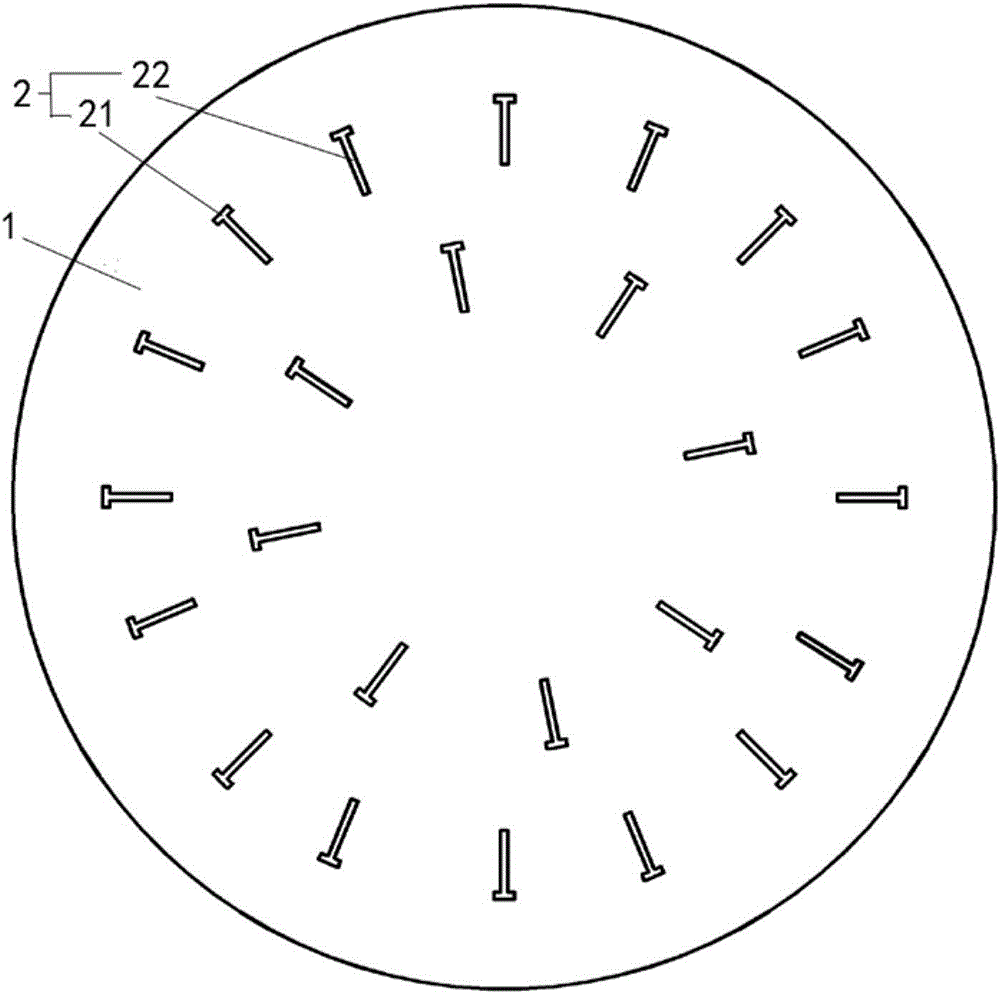

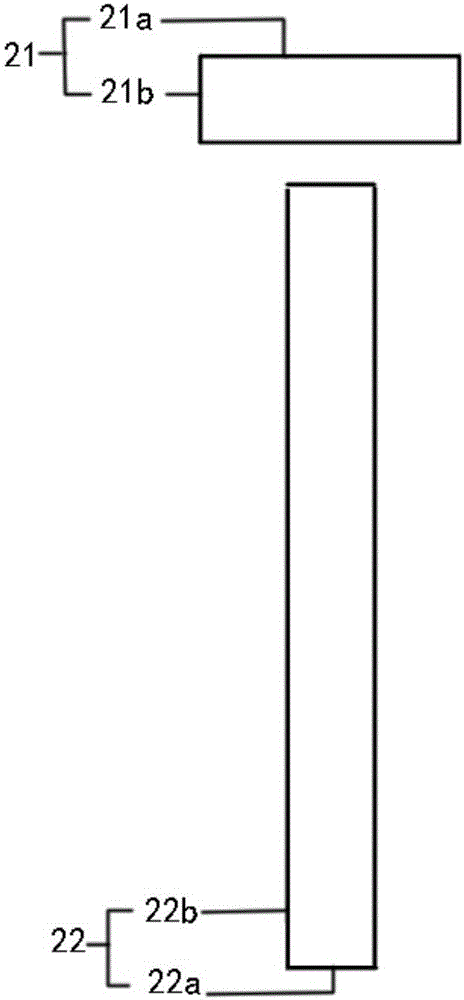

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

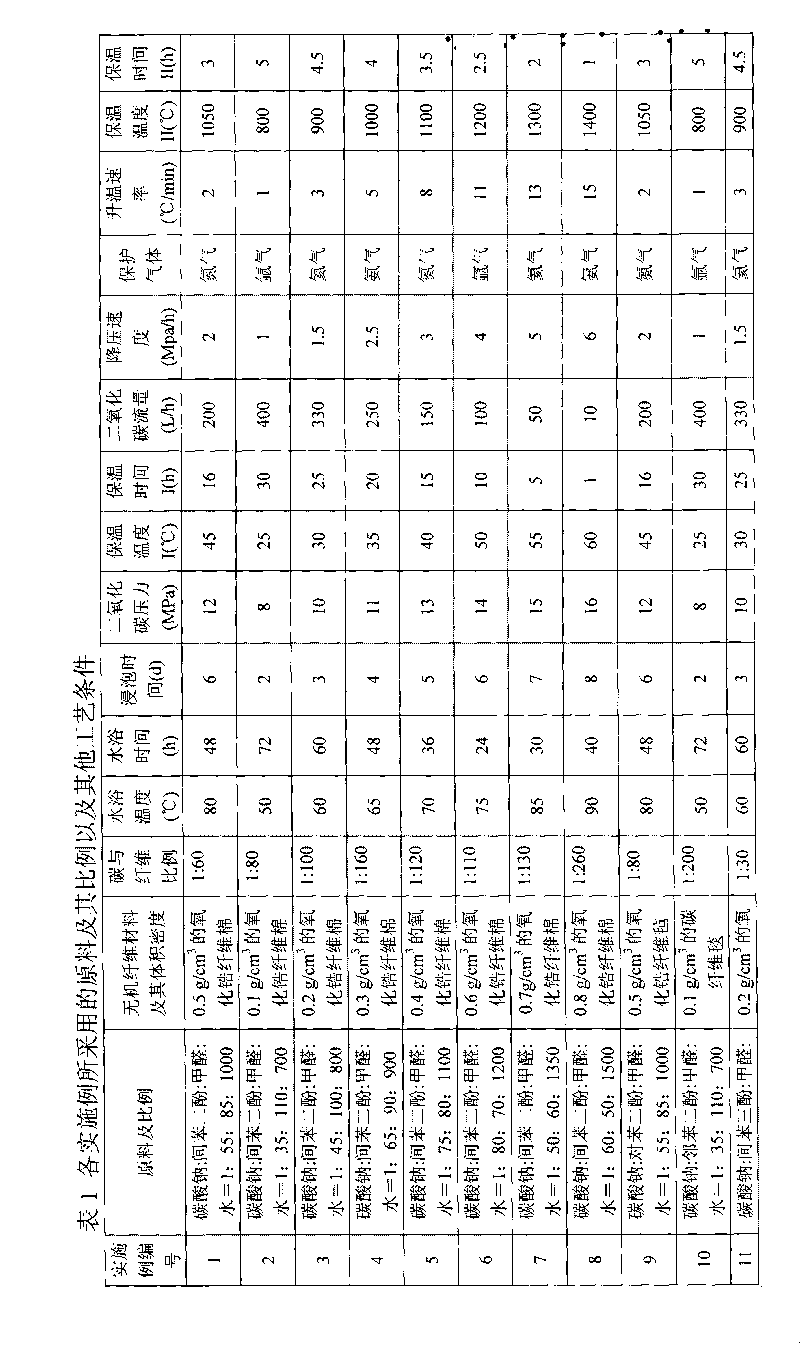

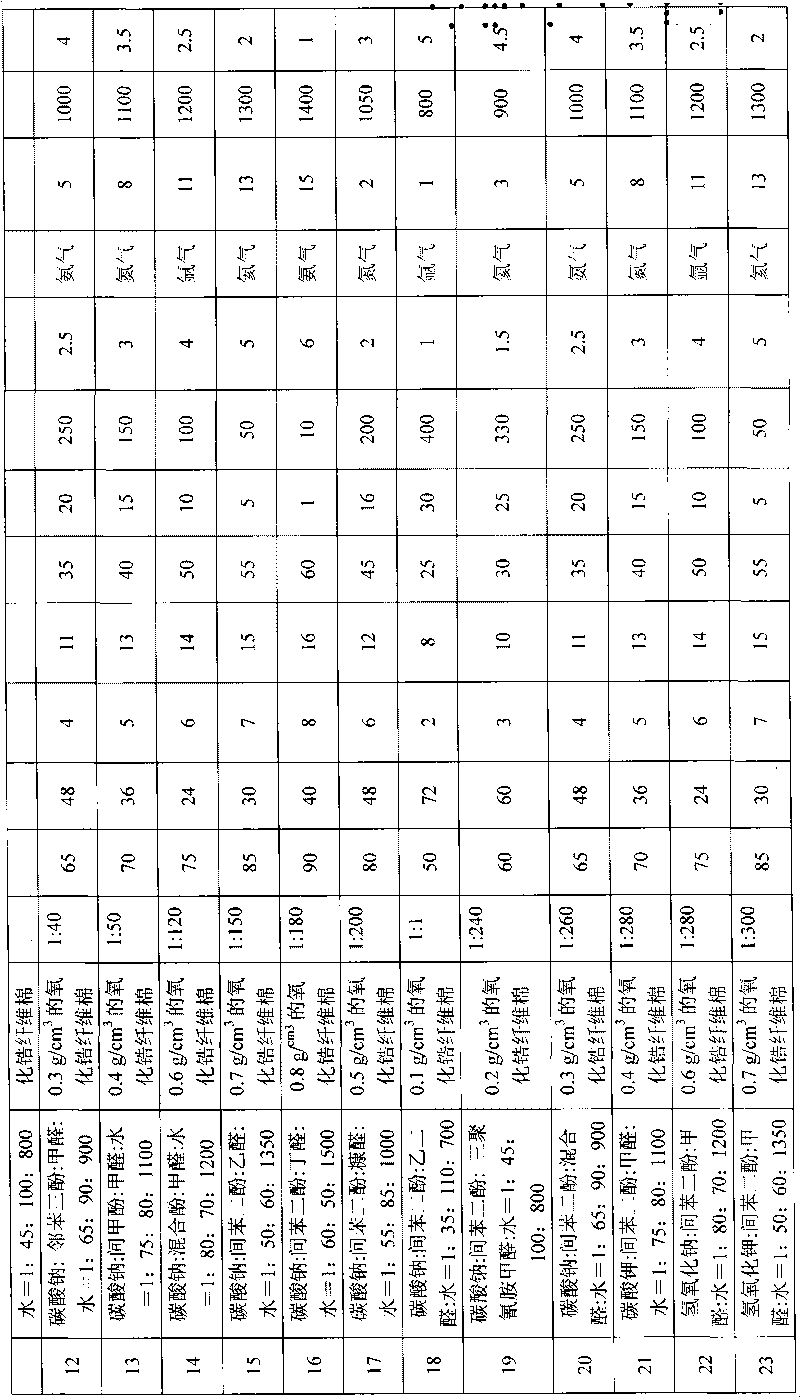

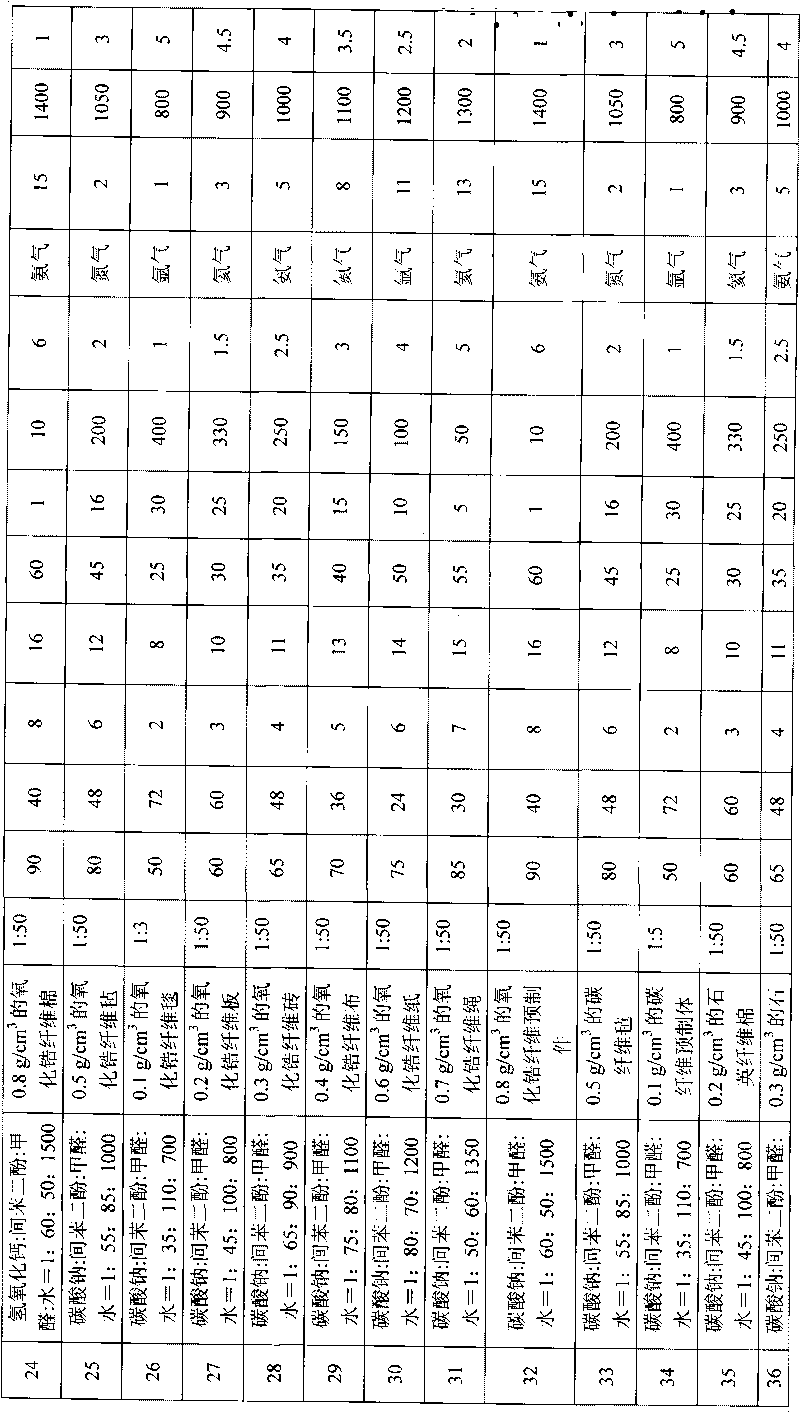

Fiber composite carbon aerogel material and preparation method thereof

The invention provides a fiber composite carbon aerogel material which comprises carbon aerogel and an inorganic fiber material, wherein the mass ratio of the carbon element to the inorganic fiber material in the carbon aerogel is 1:1-300. The invention also provides a method for preparing the fiber composite carbon aerogel material, which comprises the following steps: preparation of phenolic aldehyde solution, preparation of fiber composite phenolic aldehyde gel, aging of the fiber composite phenolic aldehyde gel, drying of supercritical fluid, reaction in an atmosphere cracking furnace, and the like. The fiber composite carbon aerogel material has the advantages of favorable moldability, good high temperature resistance, outstanding high-temperature heat-insulating property, low density and high compressive resistance; and the fiber composite carbon aerogel material can conduct electricity, be used as a catalyst carrier material, electrode material or high-temperature heat-insulating material, meet the special requirements for aviation, spaceflight, military affairs and other aspects, and be used in the civil field having high requirements for high-temperature heat-insulating property.

Owner:海鹰空天材料研究院(苏州)有限责任公司

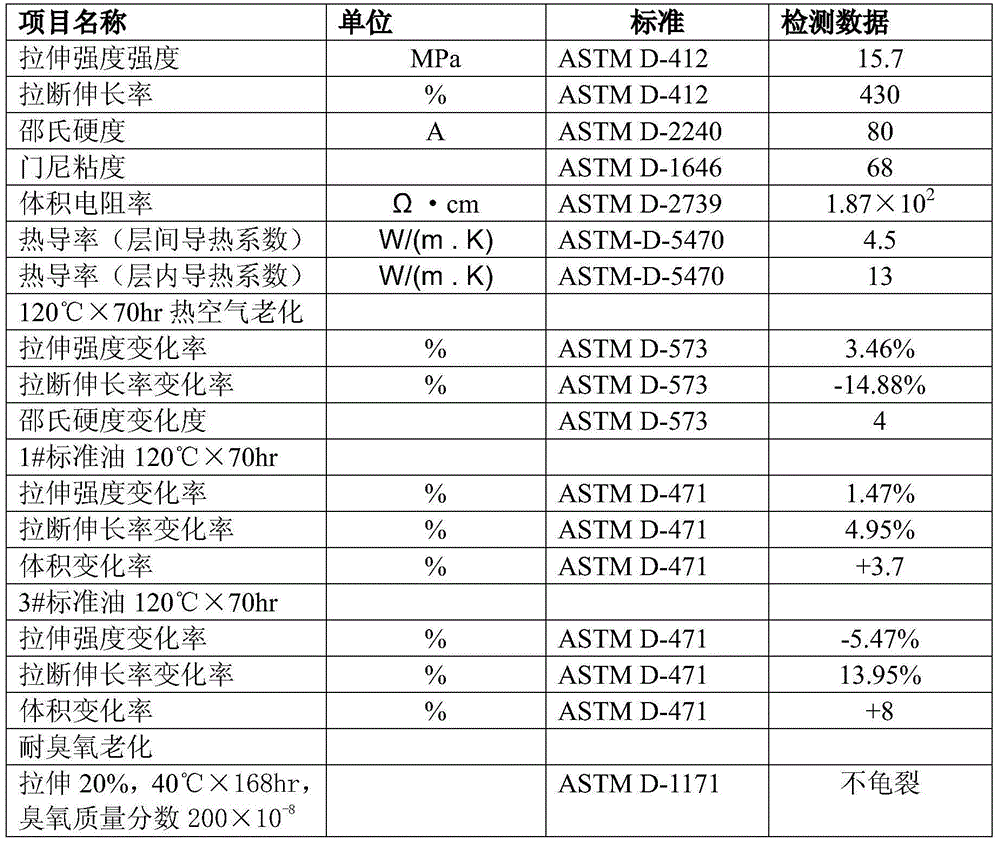

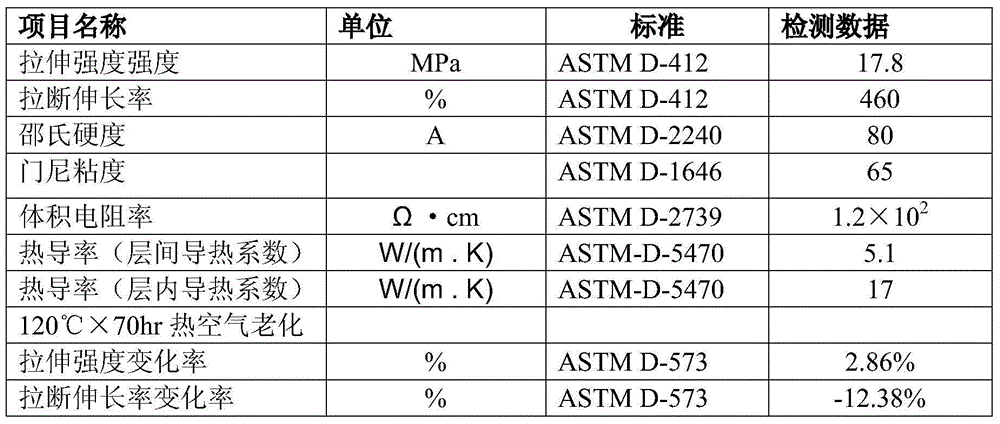

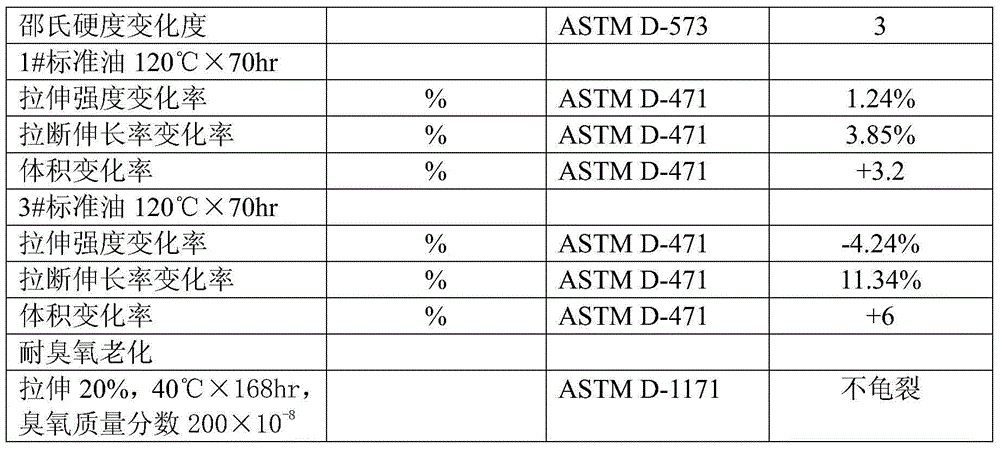

High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

ActiveCN104961983AExcellent electrical and thermal conductivityExcellent mechanical properties and oil resistancePetroleumConductive rubber

The invention relates to a high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material is prepared from following ingredients, by weight, 50 to 100 parts of an electroconductive thermal conductive rubber master batch, 40 to 60 parts of an auxiliary rubber material, 30 to 50 parts of a reinforced material, 30 to 50 parts of a flexibilizer, 30 to 50 parts of a filling material, 8 to 10 parts of a stabilizing agent, 10 to 15 parts of a tackifier, 3 to 5 parts of a vulcanizing agent, and 2 to 3 parts of a vulcanizing assistant agent. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent electrical conductivity and thermal conductivity; volume resistivity is as high as 102 omega.cm; heat conductivity coefficient is higher than 4W / (m.K); the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material can be applied to special fields such as petroleum, coal mine, and spaceflight; the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent mechanical properties, oil resistance, and air aging resistance, and can be used in oil medium or in outdoor environment.

Owner:青岛科凯达橡塑有限公司

Preparation method of flexible pressure sensor having high sensitivity

InactiveCN105136375AQuick response to external forceHas multiple functionsFluid pressure measurement using ohmic-resistance variationElastomerElectrical resistance and conductance

The invention discloses a preparation method of a flexible pressure sensor based on a carbon nanotube and a high-molecular polymer. According to the preparation method, the carbon nanotube is doped in a polymer substrate, thereby obtaining an elastomer material having electrical conductivity; and an electrode and a composite material are assembled, thereby building a flexible pressure sensor. After a circuit is accessed, the conductive elastomer converts self-deformation into a resistance change under the function of external force, and detection of pressure is realized through measurement of an electrical signal. A microcosmic structure of the surface of the elastomer material is modified, unique surface appearance enables the elastomer material to only present elastic behavior, but creepage does not occur, and a rapid response can be made to pressure applied by the outside world, thereby greatly improving sensitivity of the sensor.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

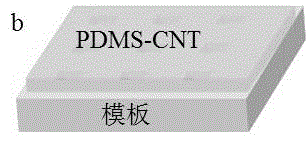

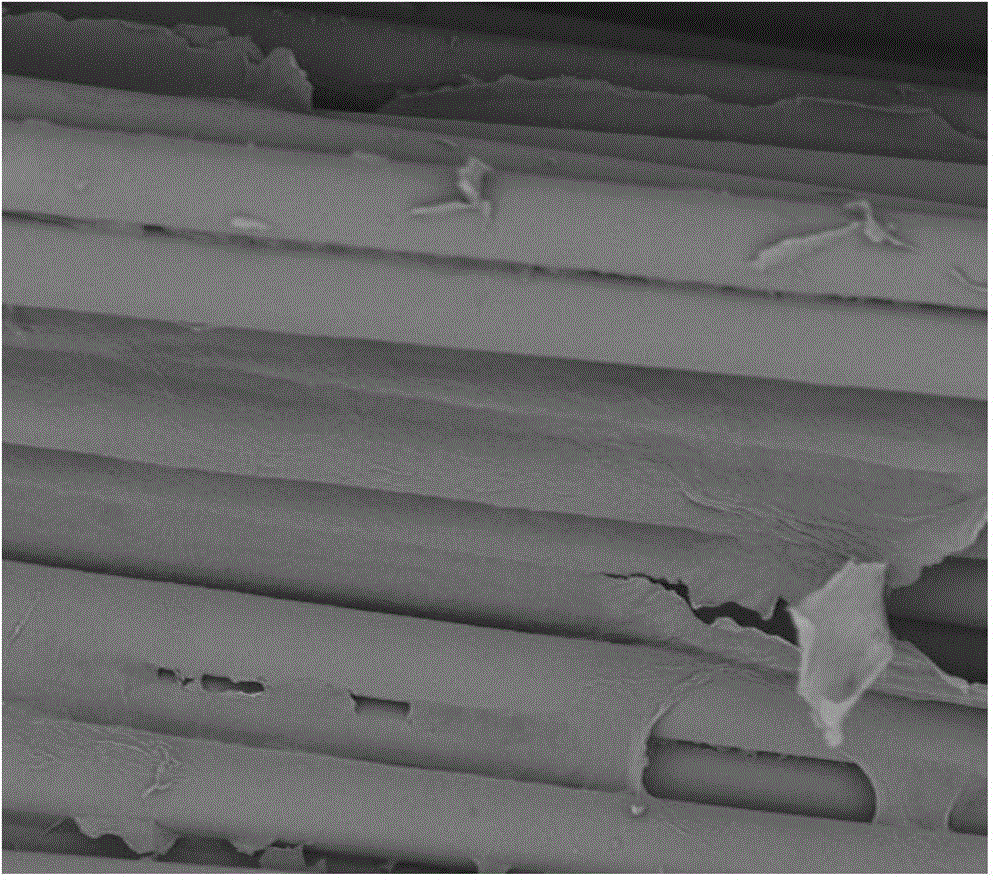

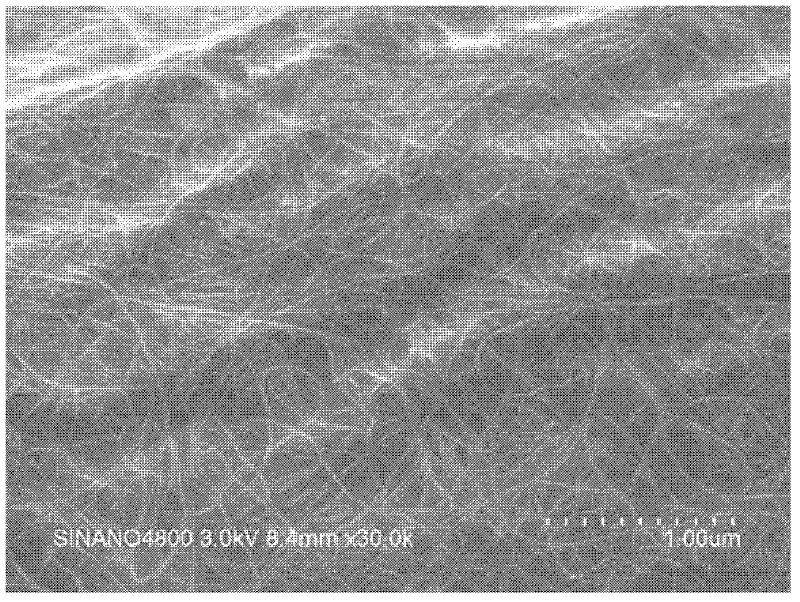

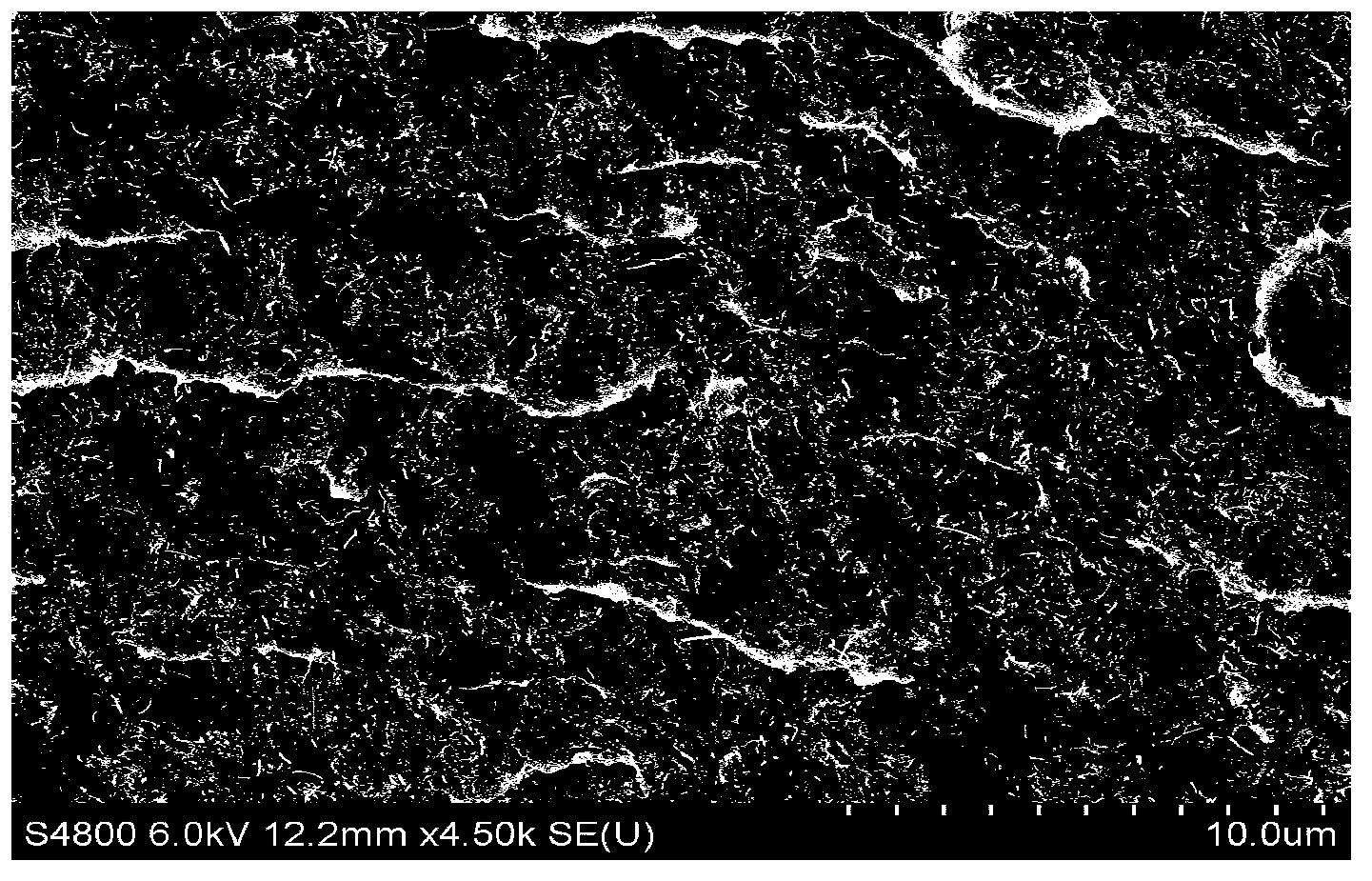

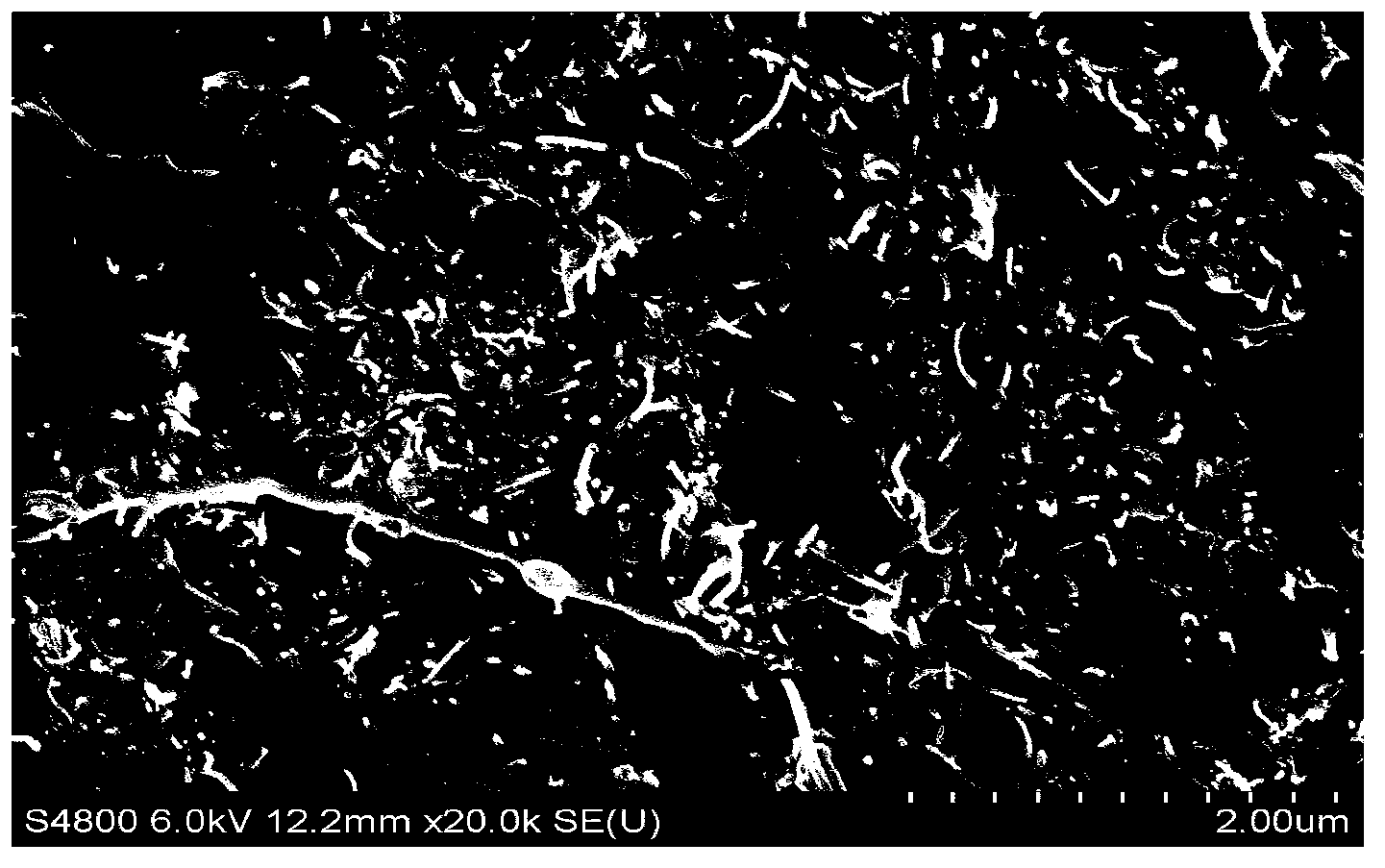

Preparation method of graphene-coated glass fiber composite material

The invention relates to a preparation method of a graphene-coated glass fiber composite material. The preparation method comprises the following steps of: (1) carrying out heat cleaning treatment on a glass fiber, then washing by respectively using acetone, hydrochloric acid and deionized water, and drying for later use; (2) carrying out dipping dip-coating treatment on the glass fiber in a bovine serum albumin solution to obtain a bovine serum albumin functionalized glass fiber; (3) carrying out dipping treatment on the bovine serum albumin functionalized glass fiber in a graphite oxide dispersion solution, and drying to obtain a graphite oxide-coated glass fiber; (4) reducing the obtained graphite oxide-coated glass fiber by adopting a reducing agent to obtain the graphene-coated glass fiber composite material. The preparation method disclosed by the invention is simple in process, easy to operate, and easy for realization of industrial production, and the prepared glass fiber composite material achieves the conductive grade; in addition, the prepared glass fiber composite material achieves the conductivity at 1-6 S / m, is greatly enhanced in conductivity compared with an electrical insulating glass fiber, and has great application in the fields of electromagnetic shielding and the like.

Owner:DONGHUA UNIV

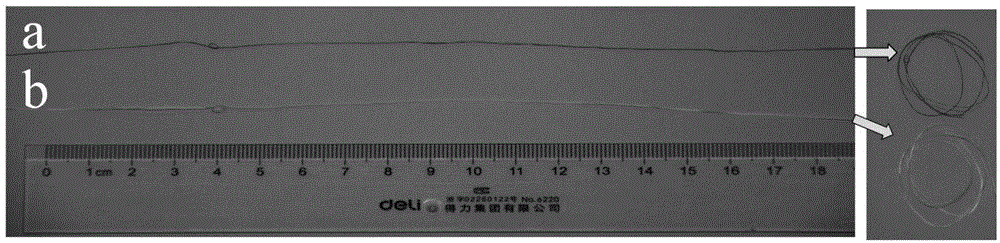

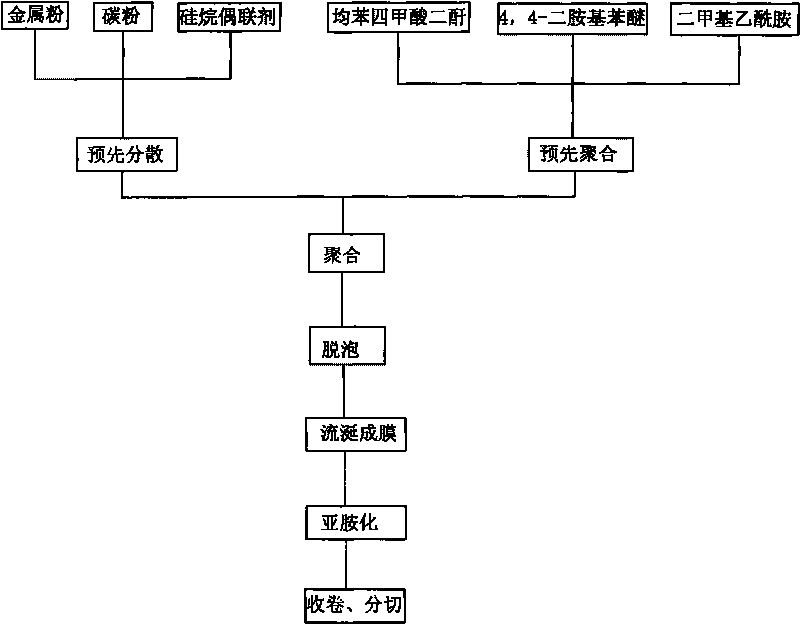

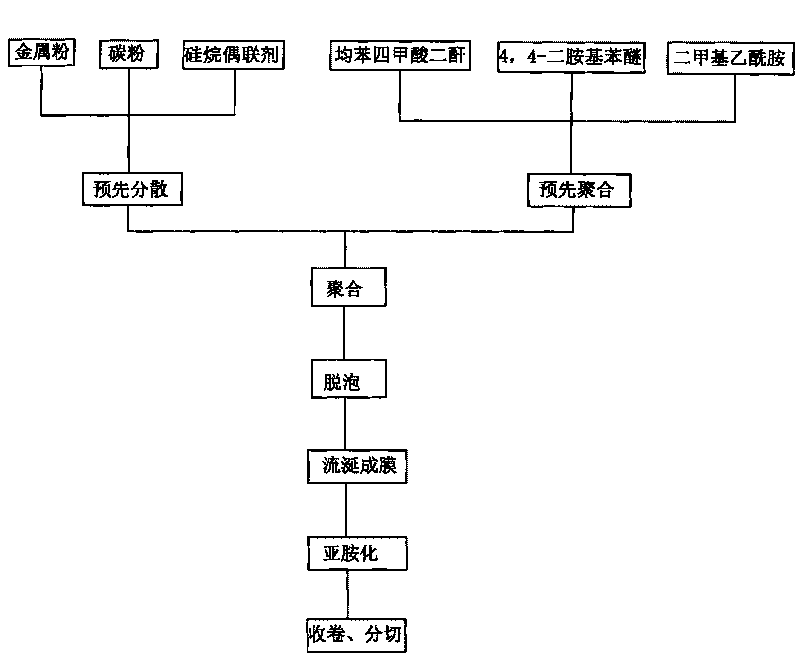

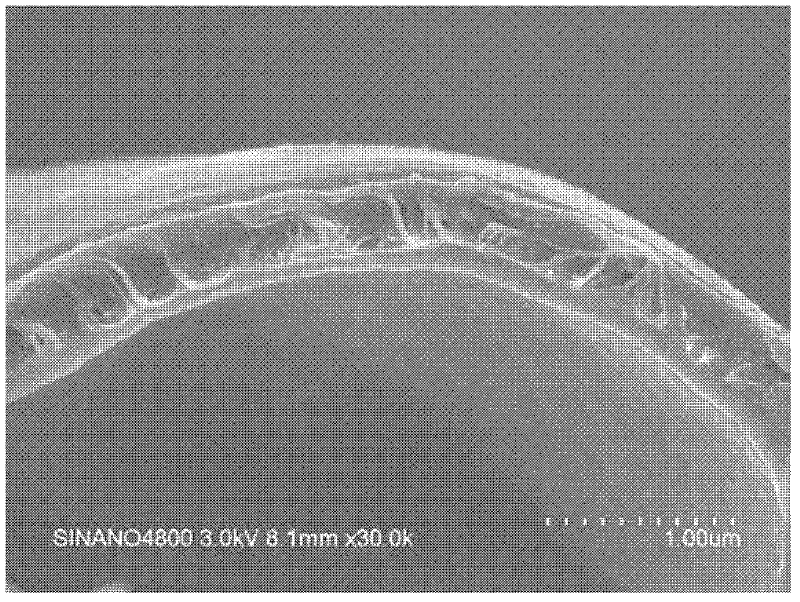

Preparation method of electric-conduction polyimide film

ActiveCN101698746AGood dispersionConductiveNon-conductive material with dispersed conductive materialOrganic solventPolyamic acid

The invention provides a preparation method of an electric-conduction polyimide film, comprising the following steps: step one: electric-conduction nano particles are placed in organic solvent for being dispersed in advance; step two: polyamic acid resin is polymerized in advance; step three: the electric-conduction nano particles and the polyamic acid resin are stirred in a reaction vessel for uniformly dispersing the electric-conduction nano particles in the resin and carrying out polymerization reaction; step four: the polyamic acid resin is pressed in a defoaming kettle to defoam the resin; step five: the polyamic acid resin is salivated into a polyamic acid film; step six: the polyamic acid film is placed in an imine furnace for carrying out imidization treatment; step seven: the film is flattened and coiled and then is cut. In the invention, the nano electric-conduction metal powder and carbon powder are uniformly dispersed in the polyamic acid resin, the film produced by the invention has high mechanical property and good electrical conductivity when being used as flexible electrical heating film material; in addition, the film has the remarkable advantages of rapid temperature rise and wide using temperature range.

Owner:NINGBO JINSHAN NEW MATERIAL

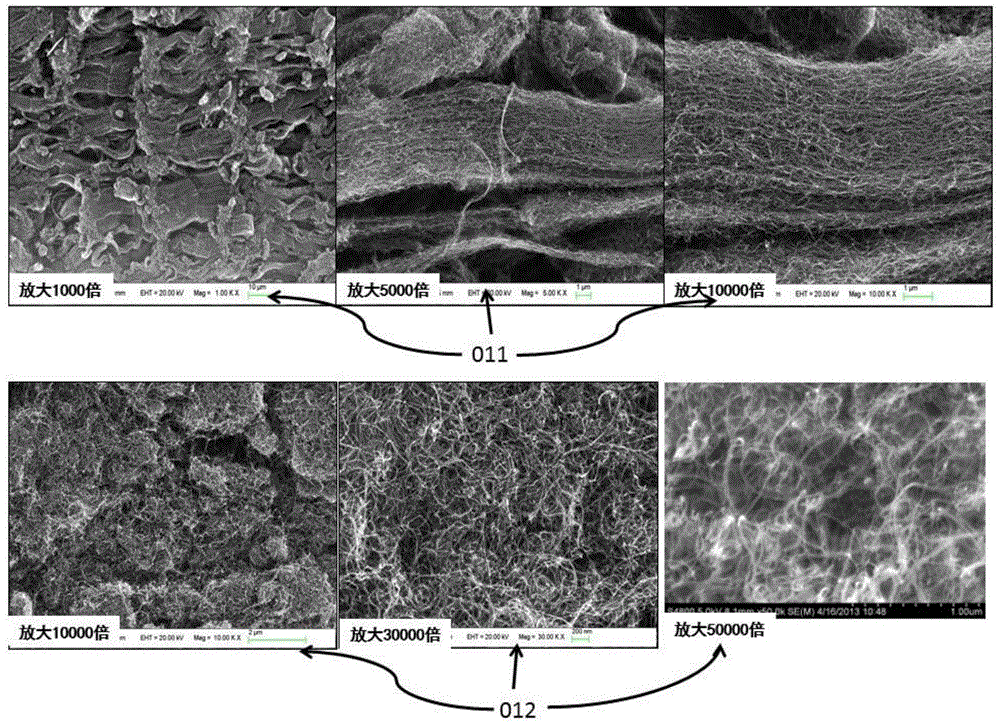

CNT (carbon nano tube)/macromolecule composite film and preparation method thereof

The invention discloses a preparation method of a CNT (carbon nano tube) / macromolecule composite film. The composite film comprises a framework network made of a CNT film and filled and coated with a macromolecular material; moreover, the composite film can be as thin as 100nm. The preparation method of the composite film comprises the following steps of: laying the CNT film on a solid substrate with a sacrificial layer on the surface; soaking the CNT film with a macromolecular solution; laying the solid substrate horizontally; removing the sacrificial layer after the macromolecular solution is solidified or dried; and separating the formed CNT (carbon nano tube) / macromolecule composite film from the solid substrate to finally obtain the target product. The composite film disclosed by the invention has the advantages of uniform shape, thickness controllable between 100nm and dozens of microns, good transmittance and high mechanical strength; moreover, the preparation method is simple, easy to operate and low is cost. The CNT / macromolecule composite film and the preparation method thereof have wide application prospect in the fields of electrostatic prevention, electromagnetic shielding, microwave absorbing, heat conduction and transfer and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

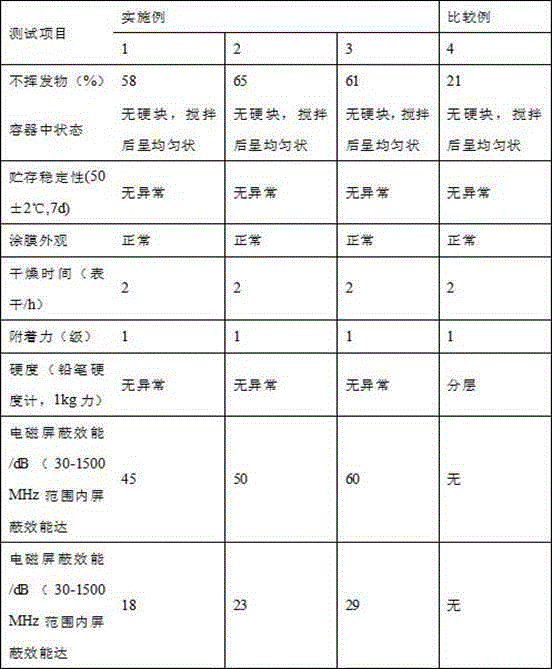

Waterborne electromagnetic shielding coating and preparation method thereof

InactiveCN105238179AConductiveImprove magnetic propertiesAntifouling/underwater paintsPaints with biocidesElectromagnetic shieldingImpedance matching

The invention relates to a preparation method of waterborne electromagnetic shielding coating. According to the formulation, the waterborne electromagnetic shielding coating is prepared from, by weight, 10.0-60.0 parts of water, 0.1-0.3 part of wetting agents, 0.4-0.8 part of dispersant, 0.1-0.3 part of defoamer, 0.7-1.3 parts of anti-freezing agents, 0.2-0.5 part of pH modifier, 20.0-60.0 parts of electromagnetic shielding additives, 0.5-2.0 parts of thickener, 25.0-40.0 parts of acrylic emulsion, 0.8-1.3 parts of coalescing agents, 0.2-0.4 part of preservative, 0.3-0.6 part of mould-proof anti-alga agents and 0.1-0.3 part of theological additives. The preparation method has the following advantages that the waterborne electromagnetic shielding coating prepared from graphene / nano ferrite, zinc oxide whiskers, nano silicon carbide, nanometal nickel powder and other materials has the advantages of being light, wide in frequency band, excellent in shielding performance, safe, environmentally friendly and the like, and the requirements of the electromagnetic shielding materials for impedance matching are met.

Owner:GUANGDONG SANVO CHEM IND TECH

Method of preparing titanium dioxide, stannum dioxide and doping composite fiber material thereof

InactiveCN101033082AGood lookingSimple structureNanostructure manufactureTitanium dioxideTin dioxideNitrogen gas

This invention relates to a method for preparing fiber TiO2, SnO2 and its doped compound material characterizing in utilizing a fiber material as a template, taking TBT, titanium tetrahalide, tin tetrachloride or a mixture as a precursor, which is carried by nitrogen or argon and enters into a reactor with a gas containing ammonia for chemical gaseous phase deposition, in which, the gas flow, deposition temperature and the sinter atmosphere and temperature are controlled, the inert gas is heated to get load-type fiber material to be sintered under the atmosphere of oxidation and reaction to remove the fiber template and form an oxide fiber material, and utilize the active carbon fiber template and ignition process to form porous fiber or tubular fiber material.

Owner:DALIAN UNIV OF TECH

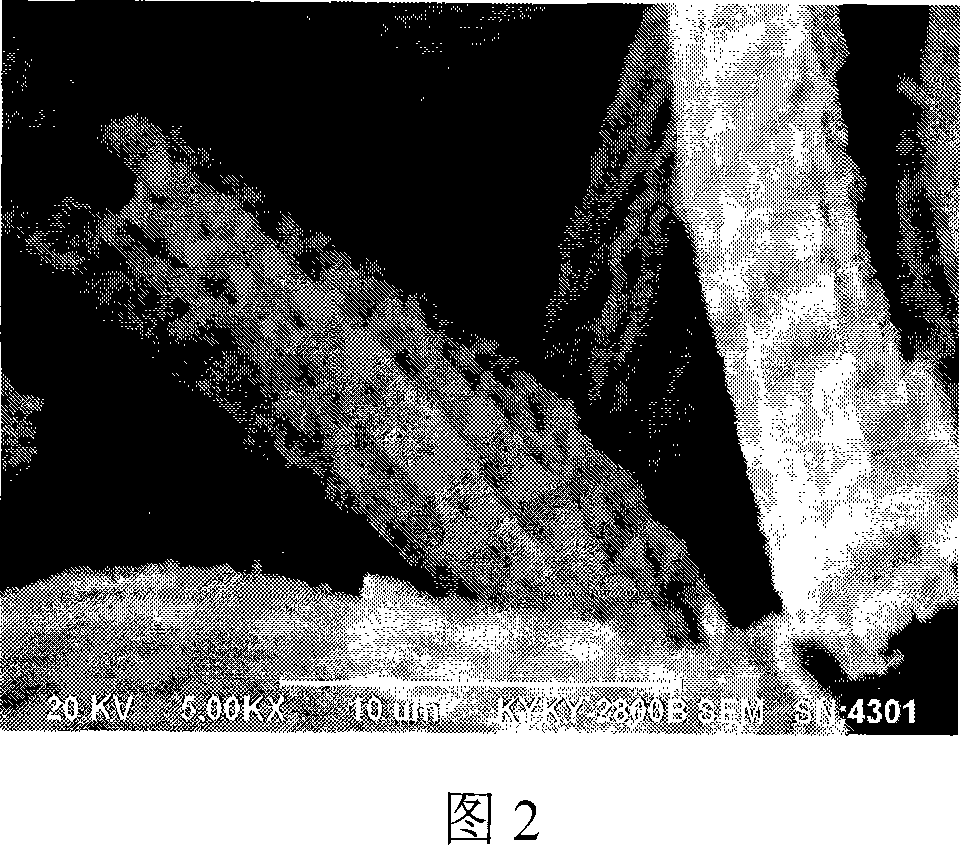

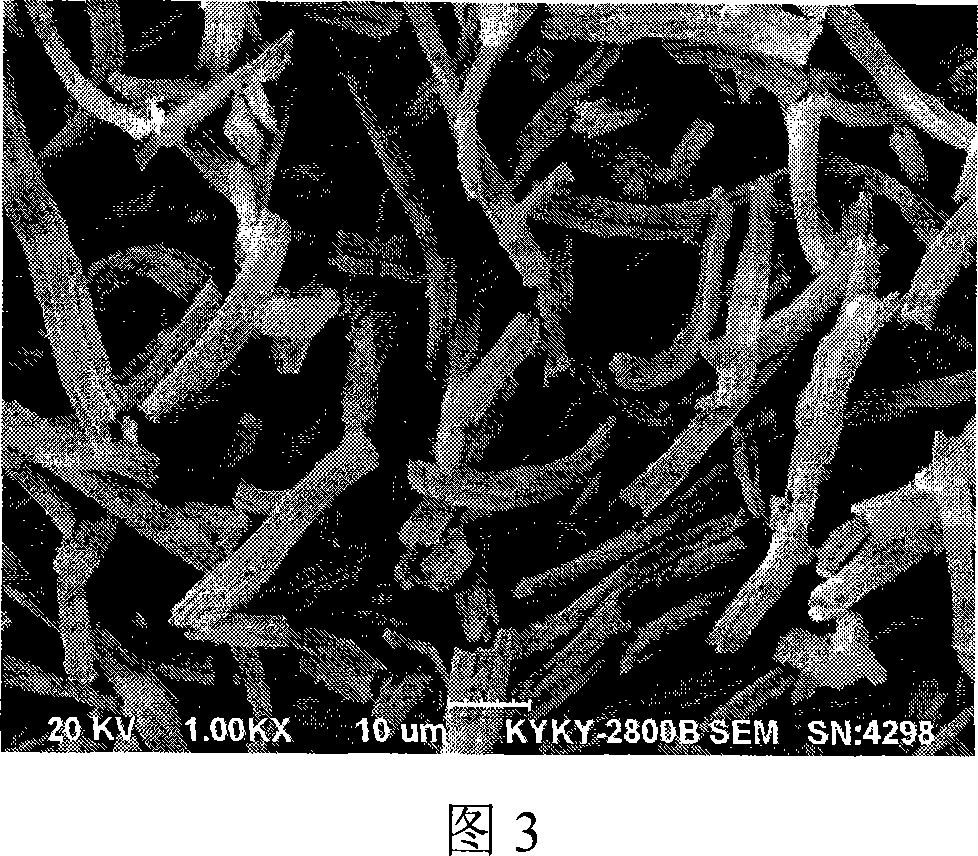

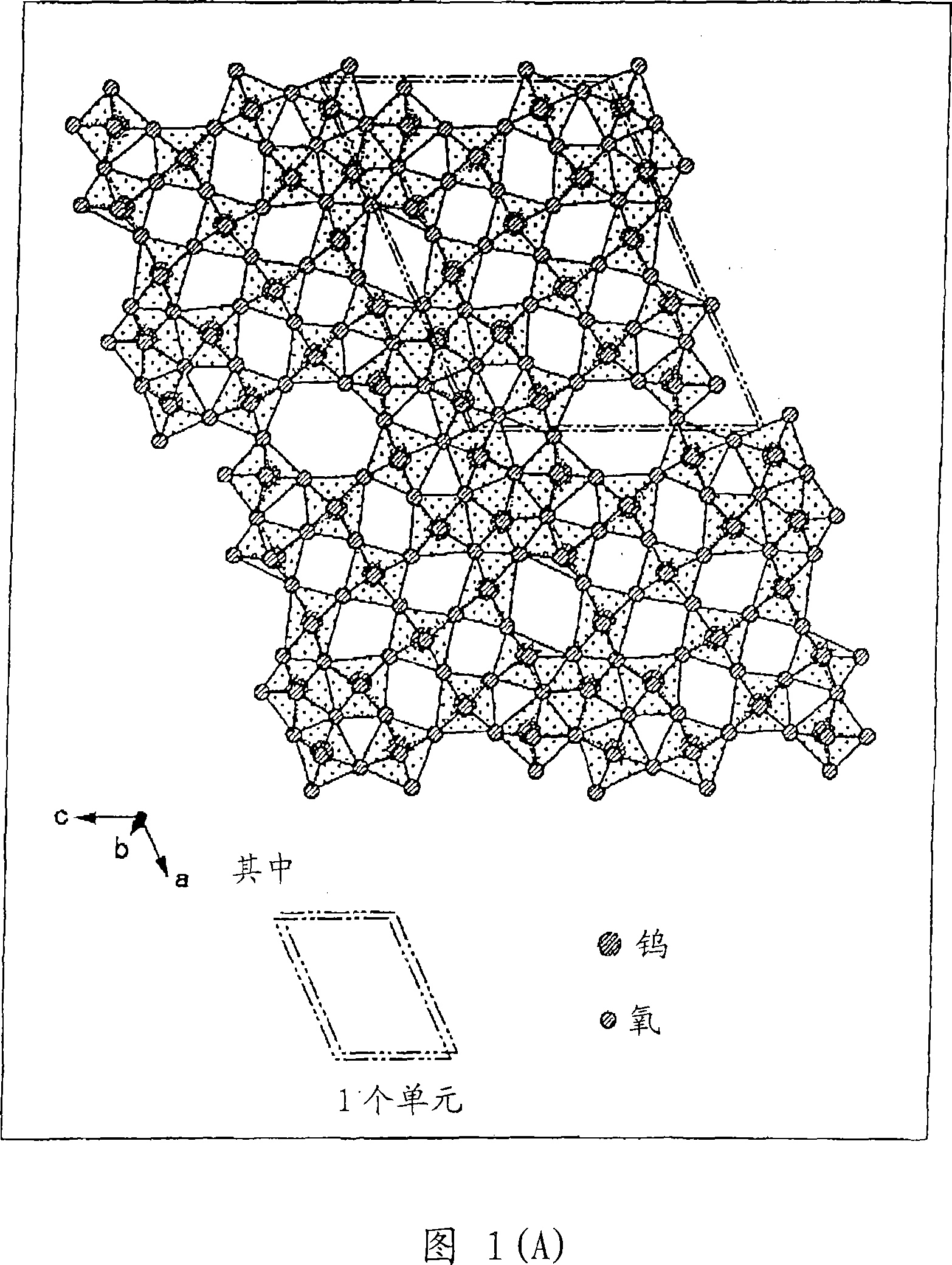

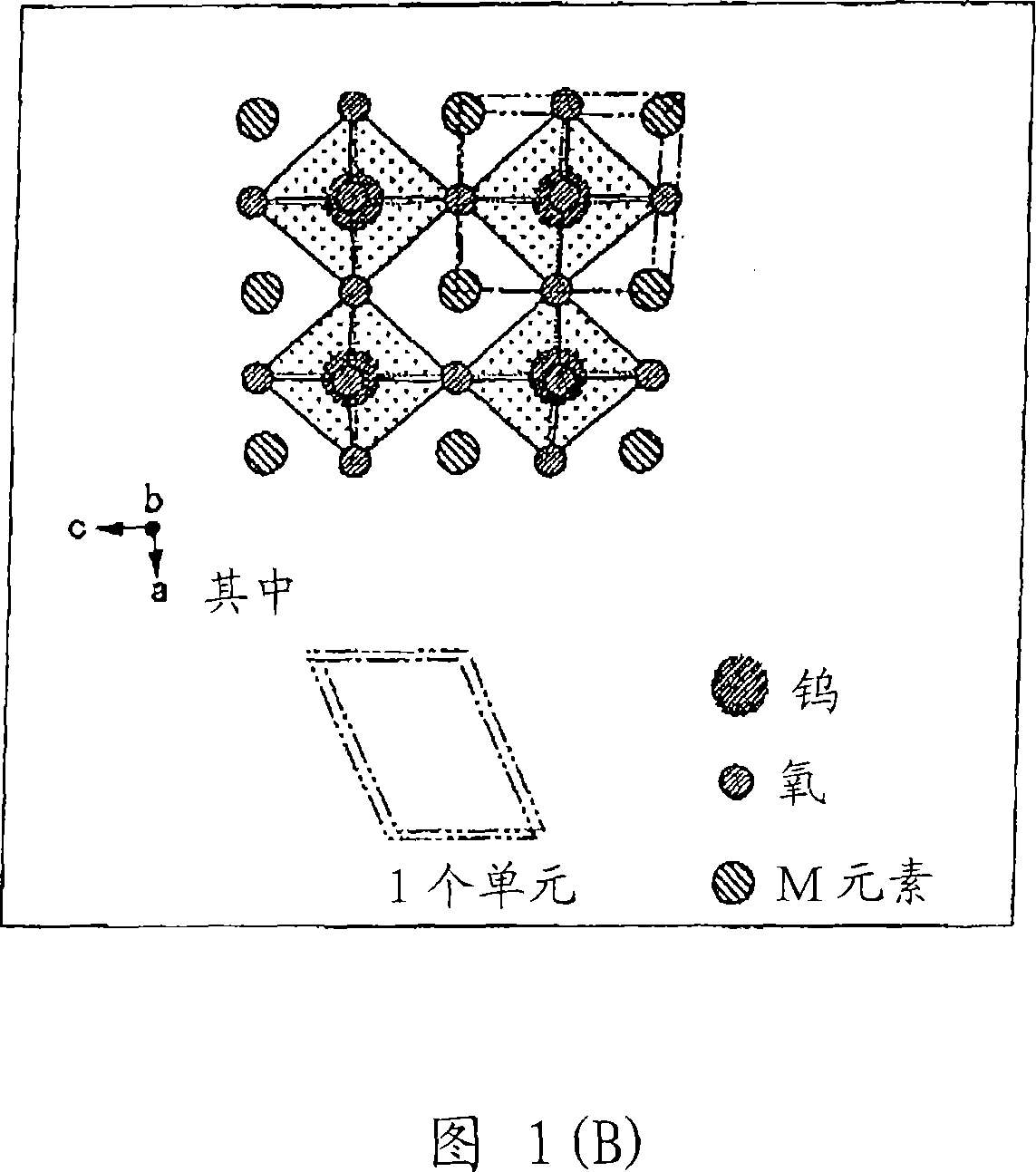

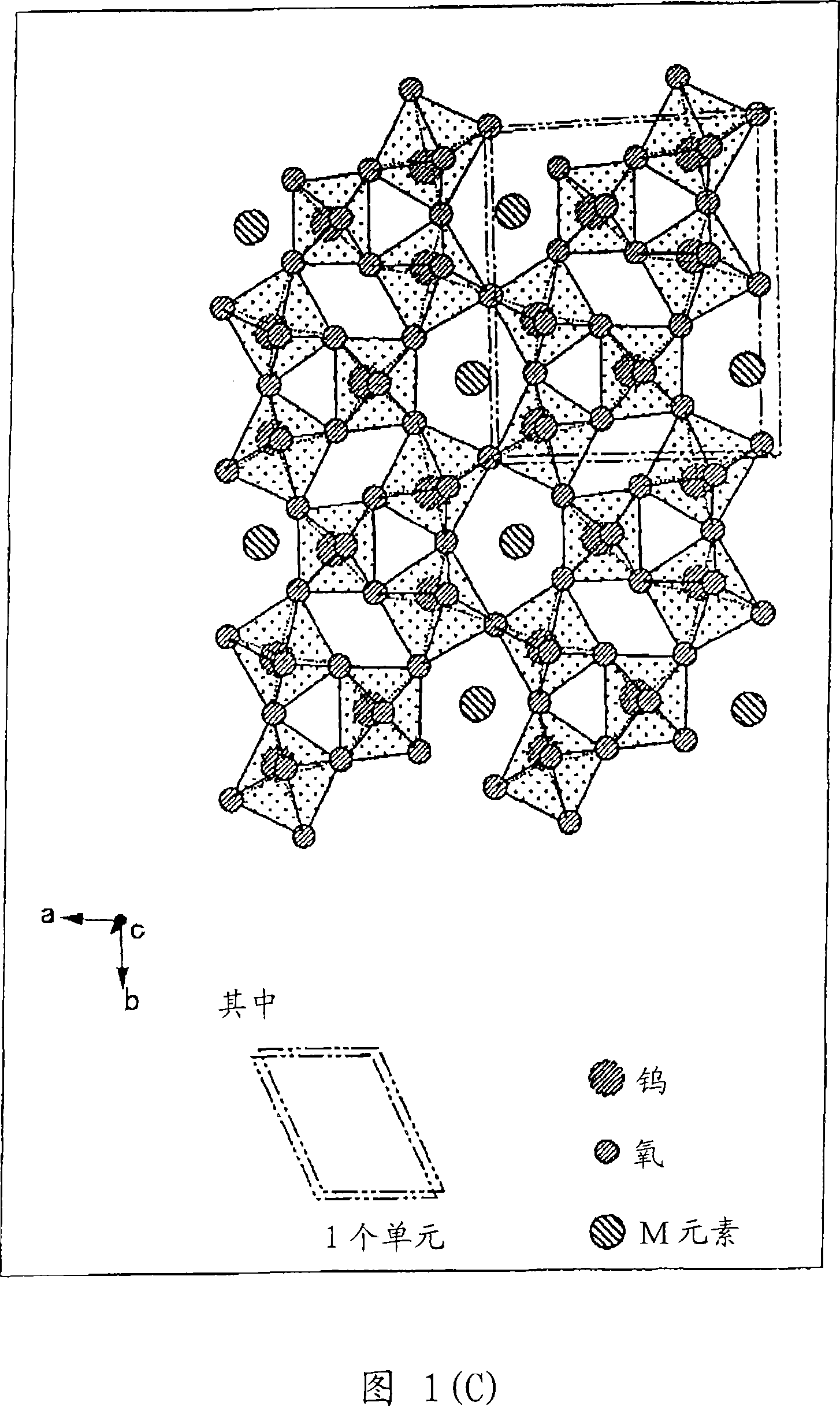

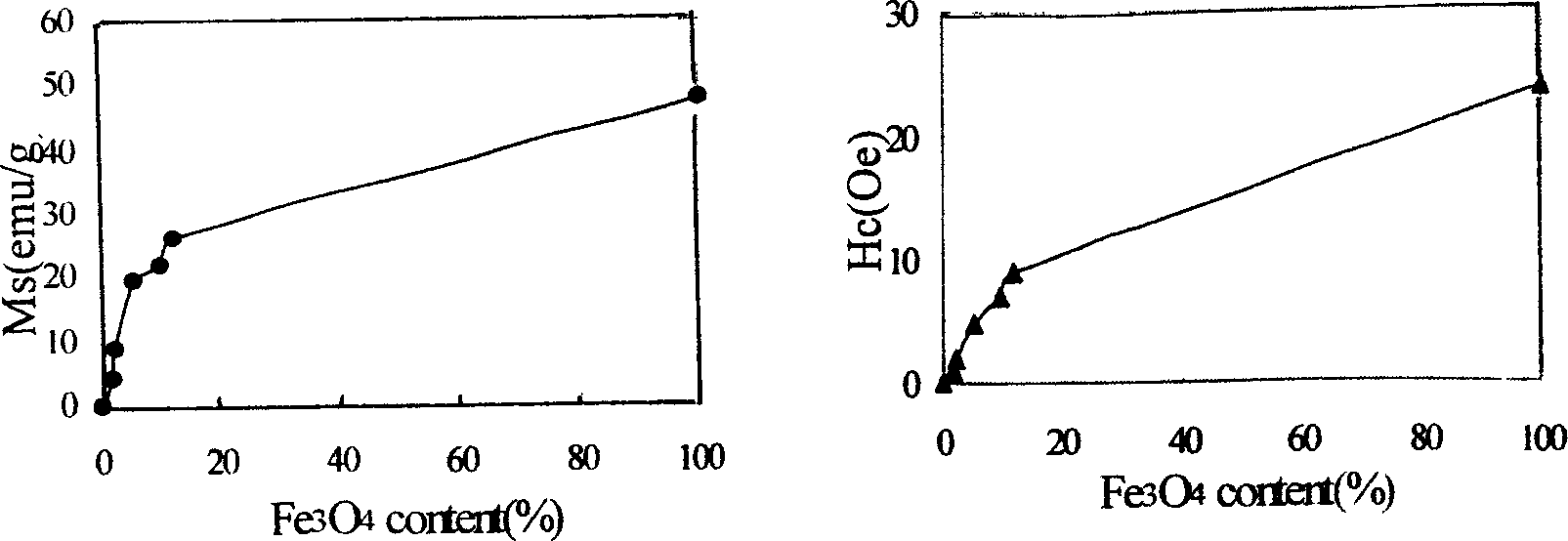

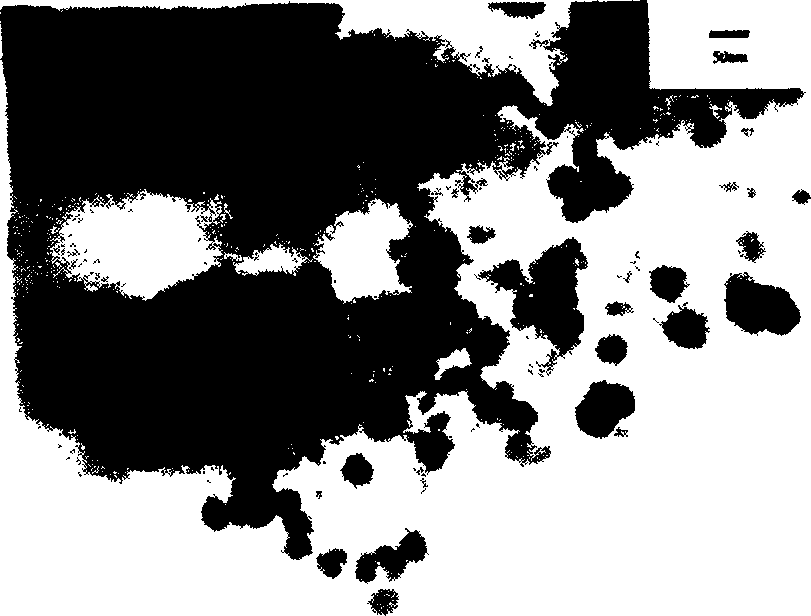

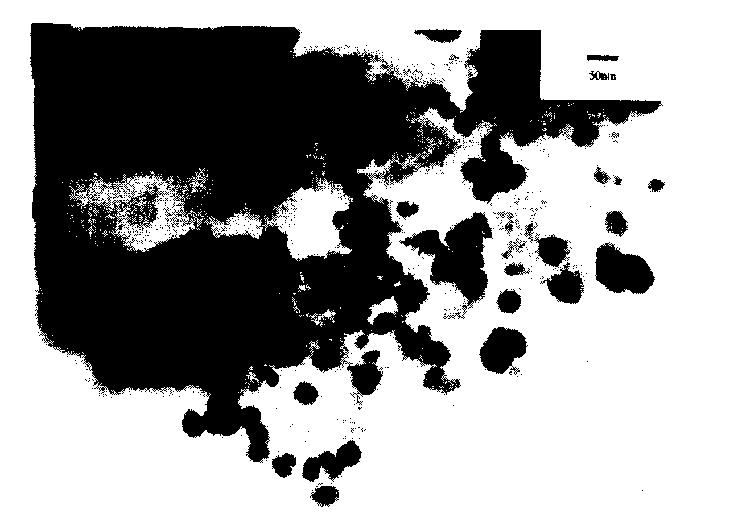

Conductive particle, visible light transmissive particle dispersed conductor, method for producing same, transparent conductive thin film, method for producing same, transparent conductive article usi

ActiveCN101023498AImprove permeabilityImprove conductivityConductive layers on insulating-supportsMolybdeum compoundsInfraredElectrical resistance and conductance

Disclosed is a visible light transmissive particle dispersed conductor using conductive particles containing a tungsten oxide or / and a composite tungsten oxide. Also disclosed are a visible light transmissive conductive article made of such a visible light transmissive particle dispersed conductor, conductive particles used for such a visible light transmissive particle dispersed conductor and visible light transmissive conductive article, and a method for producing such conductive particles. For providing a visible light transmissive particle dispersed conductor having excellent visible light transmittance and excellent conductivity at low cost, there are used conductive particles containing a tungsten oxide represented by the general formula: WyOz (wherein 2.2 = z / y = 2.999) or / and a composite tungsten oxide represented by the general formula: MxWyOx (wherein 0.001 <= x / y <= 1.1 and 2.2 <= z / y <= 3.0) and having a particle diameter of not less than 1 nm, visible light transmissivity, and a powder resistivity measured at a pressure of 9.8 MPa of not more than 1.0 O.cm.

Owner:SUMITOMO METAL MINING CO LTD

Conductive 3D (three-dimensional) printing plastic wire and production method thereof

The invention discloses a conductive 3D (three-dimensional) printing plastic wire and a production method thereof. The conductive 3D printing plastic wire comprises the following components in parts by mass: 100 parts of ABS (acrylonitrile butadiene styrene), 35 to 55 parts of nanometer conductive carbon black and 0.5 to 3 parts of titanate coupling agent. The 3D printing plastic wire is conductive; a small amount of conductive carbon black is added, so that the reduction extent of plasticity of the wire can be reduced as much as possible.

Owner:GUANGZHOU YOUSU PLASTIC TECH CO LTD

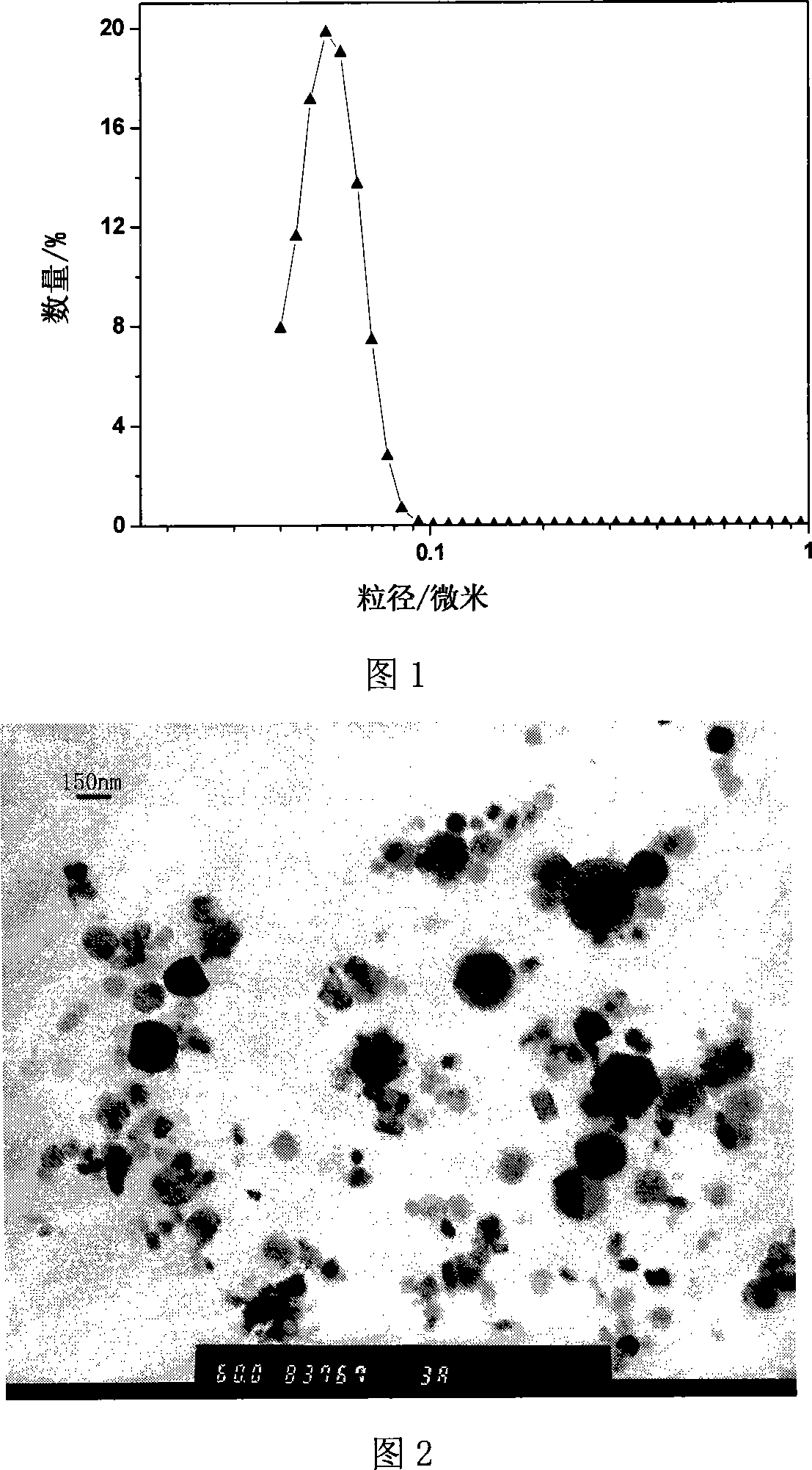

Nano high-molecular microsphere with conductivity and magnetism and its preparation method

The present invention discloses a nano high-molecular microsphere with electric conductivity and magnetism and its preparation method. It belongs to the field of functional material. The structure of microsphere is core-shell type, core is formed from magnetic matter and the shell layer is composed of any kind of polyaniline, cross-linked polyaniline, polypyrrole and polythiophene and copolymer of them and other monomer with reactive funcitonal group. Its preparation method includes the following steps: firstly, in the pressure of magnetic flow body and initiator making polymerization to obtain core-shell type magnetic high-molecular nano microsphere, then making adulteration reaction to make the above-mentioned microsphere have electric conductivity.

Owner:中国科学院成都有机化学研究所

Carbon nanotube-water-soluble polymer composite flexible electric-heating film as well as preparation method and use thereof

ActiveCN103173003ASimple manufacturing processReduce operating costsHeating element materialsLow voltageCarbon nanotube

The invention relates to a carbon nanotube-water-soluble polymer composite flexible electric-heating film and a preparation method thereof. The composite electric-heating film comprises a water-soluble polymer matrix and carbon nanotubes which are dispersed in the water-soluble polymer matrix. The carbon nanotubes are dispersed in the water-soluble polymer matrix to form a plurality of conductive networks. The composite electric-heating film has good flexibility, environment-friendliness and human affinity. The preparation method can be used for preparing the electric heating film with the carbon nanometer tube content between 0wt% and 95wt% (not including 0wt%), so that the heating power of the composite electric-heating film can be adjusted within a large range by adjusting the resistivity, and therefore, the composite electric-heating film can achieve a quick and stable heating-up effect when the voltage of a direct-current low-voltage power supply is generally lower than 24V and particularly lower than 12V; and moreover, the preparation method is simple in operation process, low in cost and suitable for large-scale industrial production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

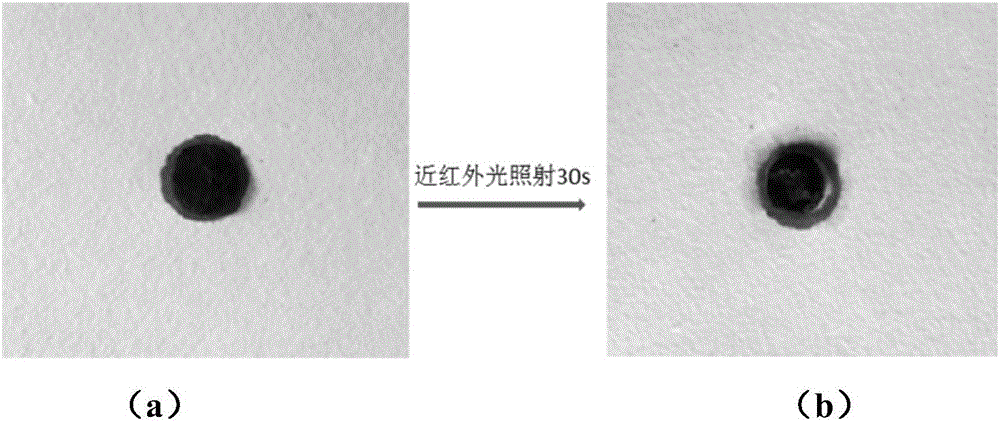

Preparation method of electrical stimulation-near infrared dual response high strength hydrogel

The invention discloses a preparation method of electrical stimulation-near infrared dual response high strength hydrogel. The preparation method comprises the following steps: with taking a thermosensitive polymer monomer as a main raw material, adding a natural polymer to prepare thermosensitive deformable hydrogel with a semi-interpenetrating network structure; and then sequentially adsorbing an oxidizing agent and a pyrrole monomer by utilizing the swelling effect of the hydrogel so that the pyrrole monomer sufficiently permeates into a hydrogel network and is oxidized into polypyrrole by the oxidizing agent. Due to the introduction of polypyrrole, the prepared hydrogel has conductivity and near-infrared responsibility. When the hydrogel is in an energized state or is irradiated by near infrared light, temperature of the hydrogel rises, and the thermosensitive polymer network in the hydrogel structure contracts, so that volume and shape change, and light-electricity dual stimulation response is realized; meanwhile, stimulation response behaviour of the hydrogel has good sensitivity. The prepared hydrogel also has good mechanical properties and biocompatibility and can be applied to multiple fields of drug controlled release systems, memory element switches and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method and application of polypyrrole/polyurethane sponge electric conduction composite

ActiveCN106188610AConductiveIncreased sensitivityForce measurement using piezo-resistive materialsPolymer sciencePolypyrrole

The invention discloses a preparation method and application of a polypyrrole / polyurethane sponge electric conduction composite, and belongs to the field of functional high molecular materials. The preparation method comprises the following steps of (1) preparing a surfactant aqueous solution: adding pyrrole monomers to the surfactant aqueous solution so as to obtain a mixed solution of the pyrrole monomers and the surfactant aqueous solution which are uniformly mixed; and soaking polyurethane sponge in the mixed solution so as to obtain a mixed solution of the polyurethane sponge and the pyrrole monomers, which are uniformly mixed; and (2) adding a neutral or acidulous water solution containing an oxidizer to the mixed solution of the polyurethane sponge and the pyrrole monomers, and performing washing and drying by air so as to prepare the polypyrrole / polyurethane sponge electric conduction composite. The polypyrrole / polyurethane sponge electric conduction composite prepared by the preparation method disclosed by the invention not only has certain electrical conductivity, but also the specific surface area of samples is enlarged, so that the contact sensibility of the sponge in a compression process is improved, and the polypyrrole / polyurethane sponge electric conduction composite can be used in the respects of flexible pressure sensors.

Owner:WUHAN TEXTILE UNIV

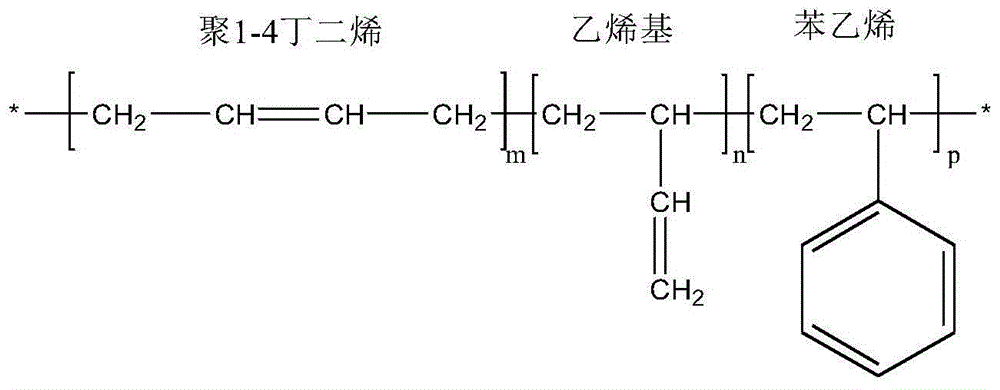

Low-hysteresis antistatic tread rubber material for fuel-efficient tires, and preparation method thereof

ActiveCN104130478AConductiveImprove reliabilitySpecial tyresRolling resistance optimizationRubber materialHysteresis

The invention relates to a low-hysteresis antistatic tread rubber composite material and a preparation method thereof. According to the rubber composite material, mixed rubber formed by solution polymerization of styrene-butadiene rubber and butadiene rubber is adopted as substrate rubber. Carbon nano-tube bundles, white carbon black, and carbon black enhancing filling materials are added. A silane coupling agent, an anti-aging agent, an accelerator, and a cross-linking agent are added. The mixing of the rubber composite material can be carried out with a multi-stage manner in an open mill or an internal mixer. The rubber composite material provided by the invention has low-dynamic-hysteresis and antistatic characteristics. Under a temperature of 60 DEG C and dynamic strain of 7%, dynamic loss factor tandelta is no higher than 0.14. According to GB / T1410-2006 determination, a volume resistivity is lower than 1*10<9>omega.cm. The mechanical strength and wear resistance of the material are better than or equivalent to those of a regular tire tread rubber material. When the rubber composite material provided by the invention is used for preparing a tire tread, tire rolling resistance can be reduced, and a problem of high white carbon black tire material static electricity accumulation can be solved.

Owner:BEIJING UNIV OF CHEM TECH

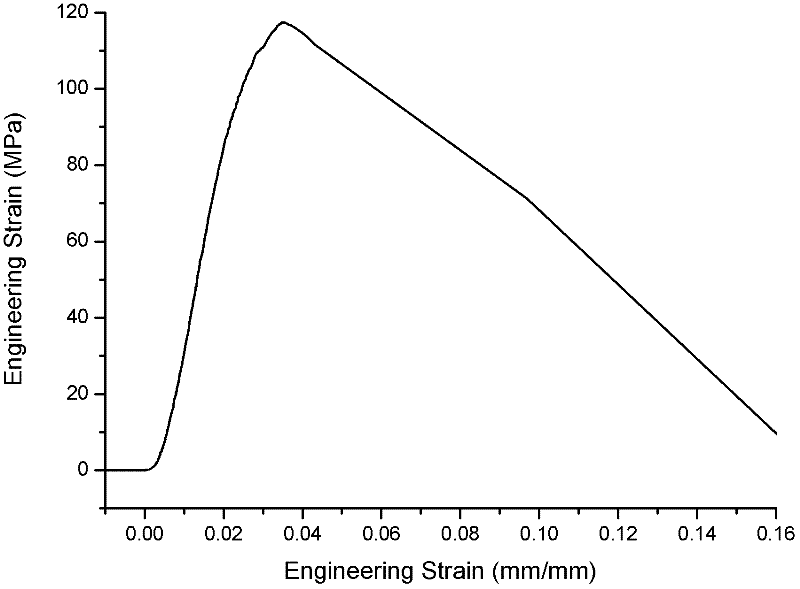

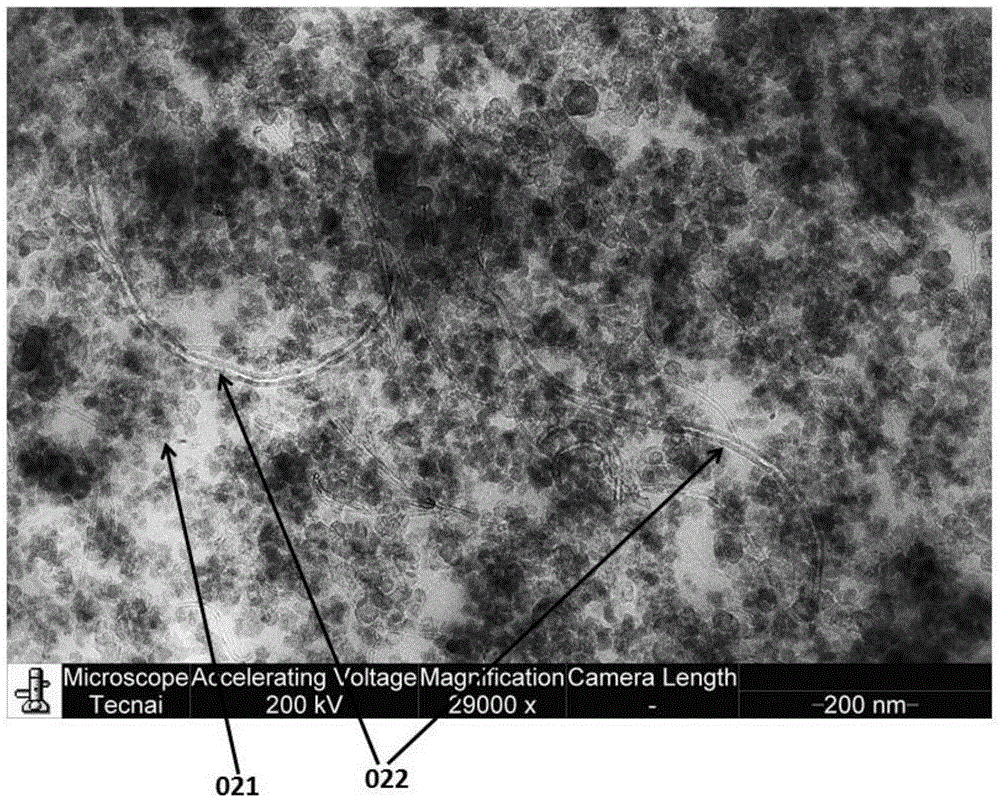

Carbon nanotube/polyurethane/polyacrylonitrile composite conductive fiber and preparation method thereof

InactiveCN103031617AConductiveHigh strengthElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentCarbon nanotubeMicrofiber

The invention discloses a carbon nanotube / polyurethane / polyacrylonitrile composite conductive fiber. The composite conductive fiber consists of 1 to 10 mass percent of carbon nanotube, 9 to 40 mass percent of polyurethane and 50 to 90 mass percent of polyacrylonitrile. The carbon nanotube / polyurethane / polyacrylonitrile composite conductive fiber is prepared by a wet spinning method and by modifying the polyacrylonitrile by using the carbon nanotube and polyurethane. Polyurethane is formed into microfiber in situ in the spinning process by a shape control method in the polymer mixture spinning process, and the carboxyl on the surface of the carbon nanotube which is acidized and polyurethane form a hydrogen bond, so the carbon nanotubes are selectively distributed in the in-situ microfiber. The carbon nanotube / polyurethane microfiber forms a continuous network chain-shaped microfiber conductive channel in the polyacrylonitrile substrate so as to obtain the composite conductive fiber.

Owner:ZHONGYUAN ENGINEERING COLLEGE

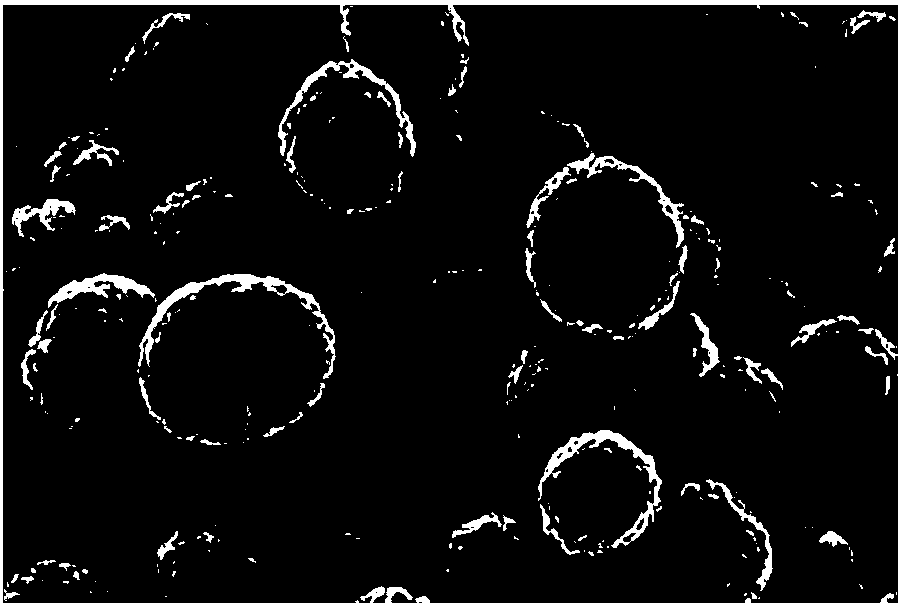

Composite cladded lithium ion cathode material, and preparation method thereof

InactiveCN108206276AFast transferImprove uniformity of charge distributionCell electrodesSecondary cellsSolventElectrically conductive

The invention discloses a composite cladded lithium ion cathode material, and a preparation method thereof. According to the composite cladded lithium ion cathode material, Li(NiCoMn)O2 and / or Li(NiCoAl)O2 is taken as a matrix; the surface of the matrix is cladded with an electrically conductive cladding layer; the electrically conductive cladding layer comprises a lithium fast ion conductor material, and optionally comprises an electronic conductor material. The preparation method comprises following steps: 1, the lithium fast ion conductor or raw materials of the lithium fast ion conductor are dispersed in a solvent, and optionally, an electronic conductor material or raw materials of the electronic conductor material are dispersed in the solvent so as to obtain an electrically conductive cladding layer solution; 2, a cathode material is dispersed in the electrically conductive cladding layer, and stirring is carried out so as to obtain a mixed solution; 3, the mixed solution is stirred, and is subjected to distillation with stirring so as to obtain a dried powder; and 4, the dried powder is subjected to annealing, smashing, and sieving successively so as to obtain the compositecladded lithium ion cathode material. The composite cladded lithium ion cathode material possesses following advantages: cracking is not easily caused, the electrical properties are excellent, the preparation method is simple, and is convenient for industrialized production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

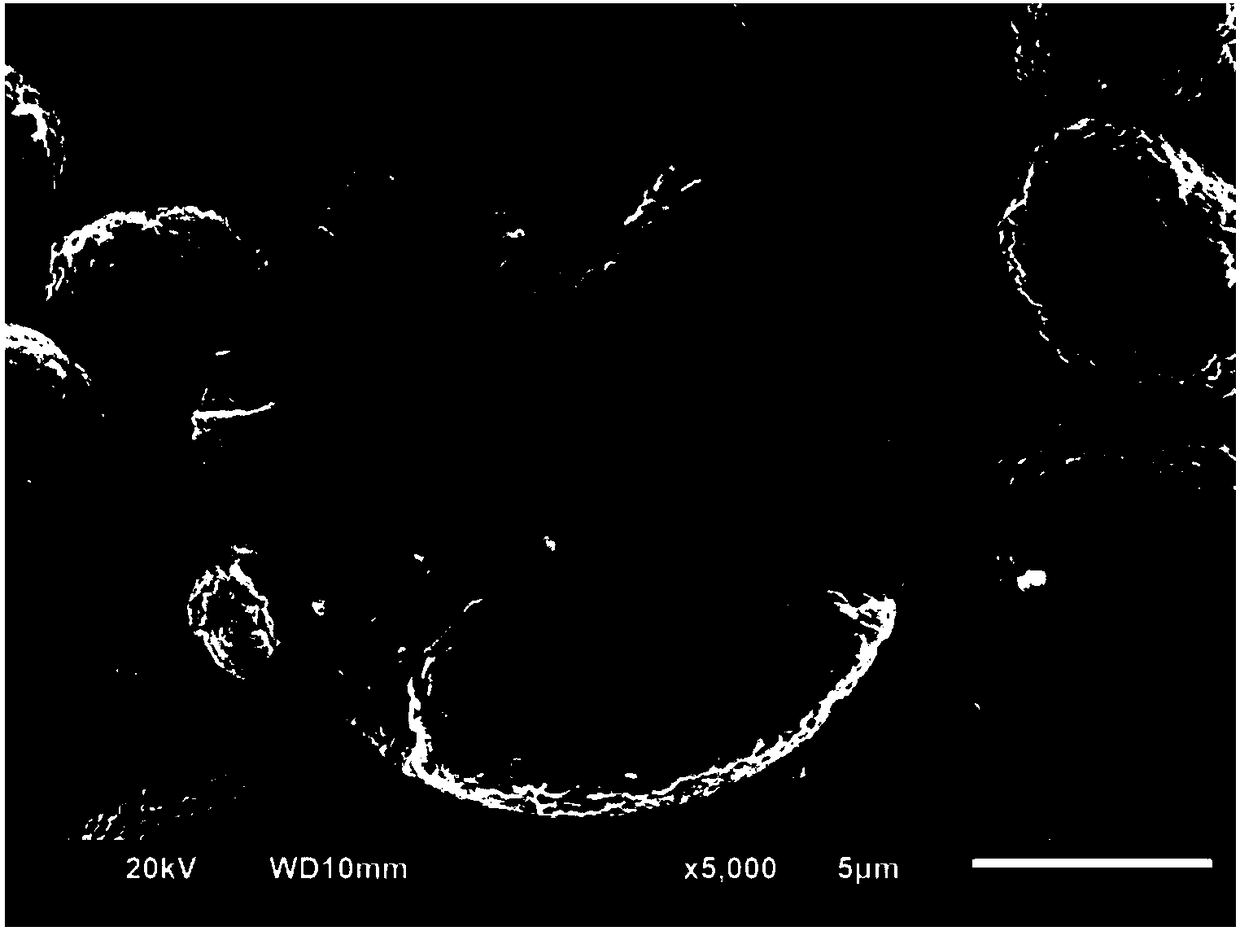

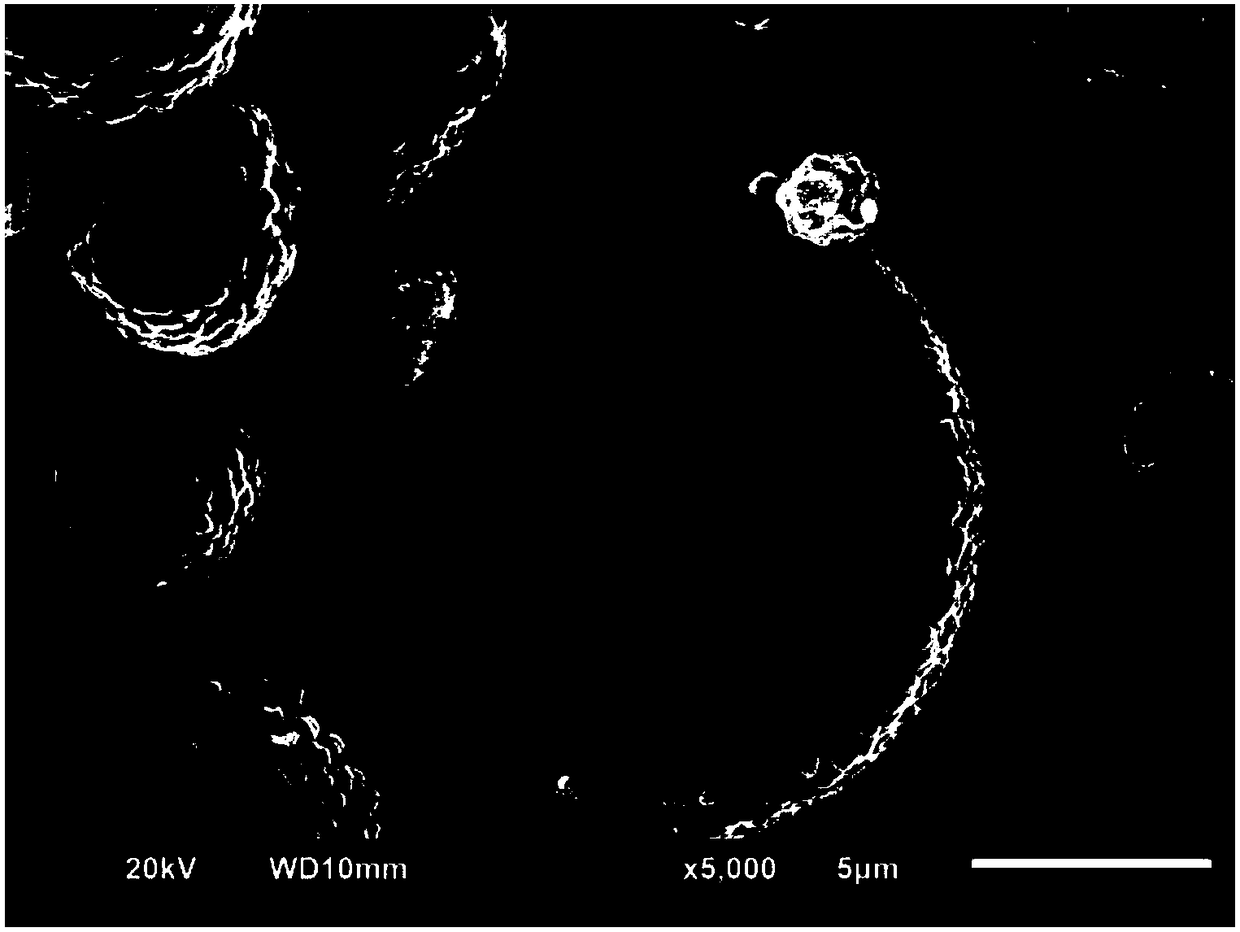

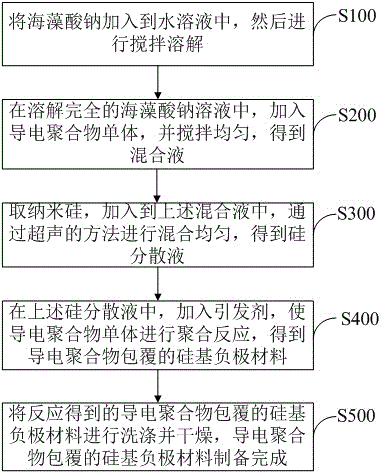

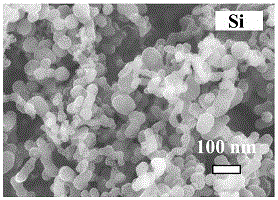

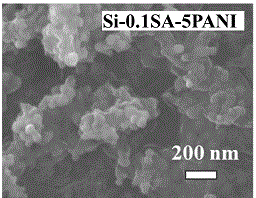

Conductive polymer-coated silicon-based negative electrode material and preparation method thereof

ActiveCN106229495AImprove electrochemical performanceAlleviate volume effectCell electrodesSecondary cellsConductive polymerUltrasound method

The invention discloses a conductive polymer-coated silicon-based negative electrode material and a preparation method thereof. The method comprises the following steps of adding sodium alginate to a water solution, and then stirring and dissolving the sodium alginate; adding a conductive polymer monomer to the completely dissolved sodium alginate solution and stirring evenly; adding taken nanometer silicon to a mixed solution and mixing evenly through an ultrasound method to obtain a silicon dispersion liquid; adding an initiator to the silicon dispersion liquid and carrying out polymerization reaction on the conductive polymer monomer to obtain the conductive polymer-coated silicon-based negative electrode material; and carrying out washing and drying and finishing preparation of a final product. A three-dimensional mesh structure is built by the conductive polymer, so that the conductive polymer-coated silicon-based negative electrode material has conductivity and also provides a certain accommodation space for volume expansion of the silicon; and the silicon is embedded into the mesh structure, so that the volume effect of the silicon is effectively relieved. Furthermore, the hydroxyl-containing sodium alginate is introduced, so that the structure stability of the overall silicon-based negative electrode material is strengthened.

Owner:SHENZHEN UNIV

Electric catalyst with conducing high polymer modification one-dimensional nano carbon as carrier and producing process

InactiveCN1674330AReduce bond strengthSolve the weak combinationCatalyst carriersCell electrodesElectricityPolymer science

An electro - catalyst uses one - dimensional nanocarbon modified by conduction high polymer in large Pi bond structure as carrier. Its preparing process includes preparing one - dimensional nanocarbon modified by conduction high polymer first and then loading Pt or Pt alloy on its surface. The average particle diameter of electro - catalyst is less than or equal to 5 nm and power density of single cell prepared by electro - catalyst is 0.40 - 0.47 W / cm2 under test condition as H2 / Air and Pt loading capacity in 0.20mg / sq cm and 600 mA / sq.cm.

Owner:WUHAN UNIV OF TECH

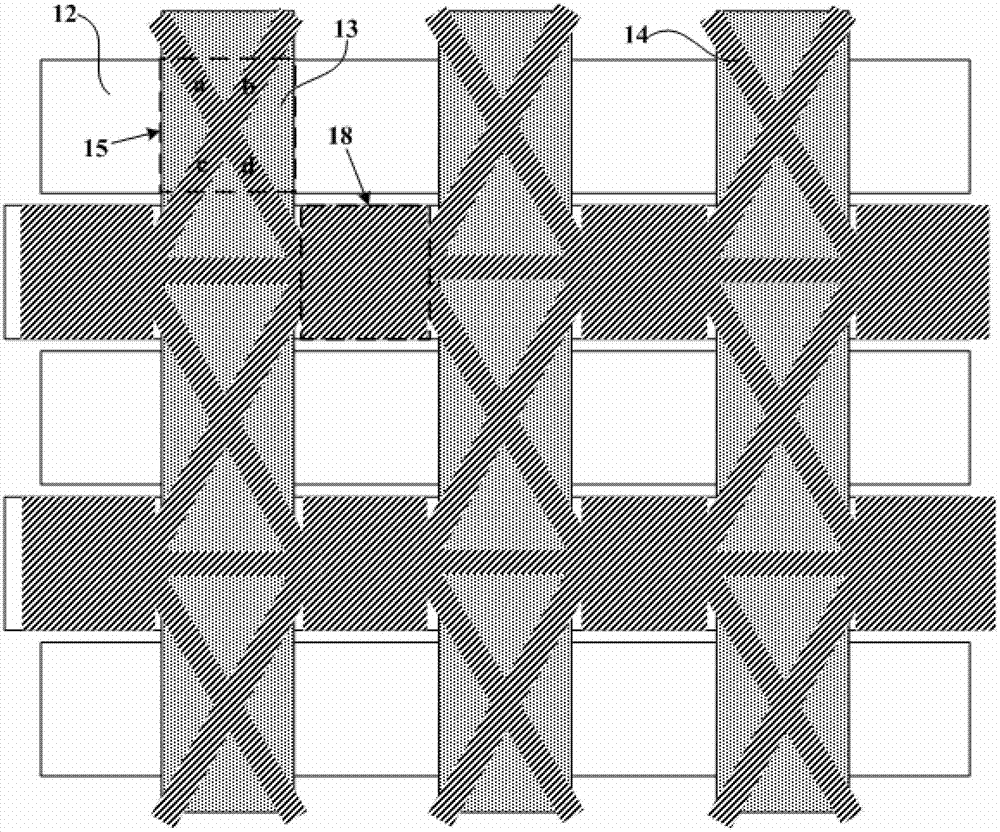

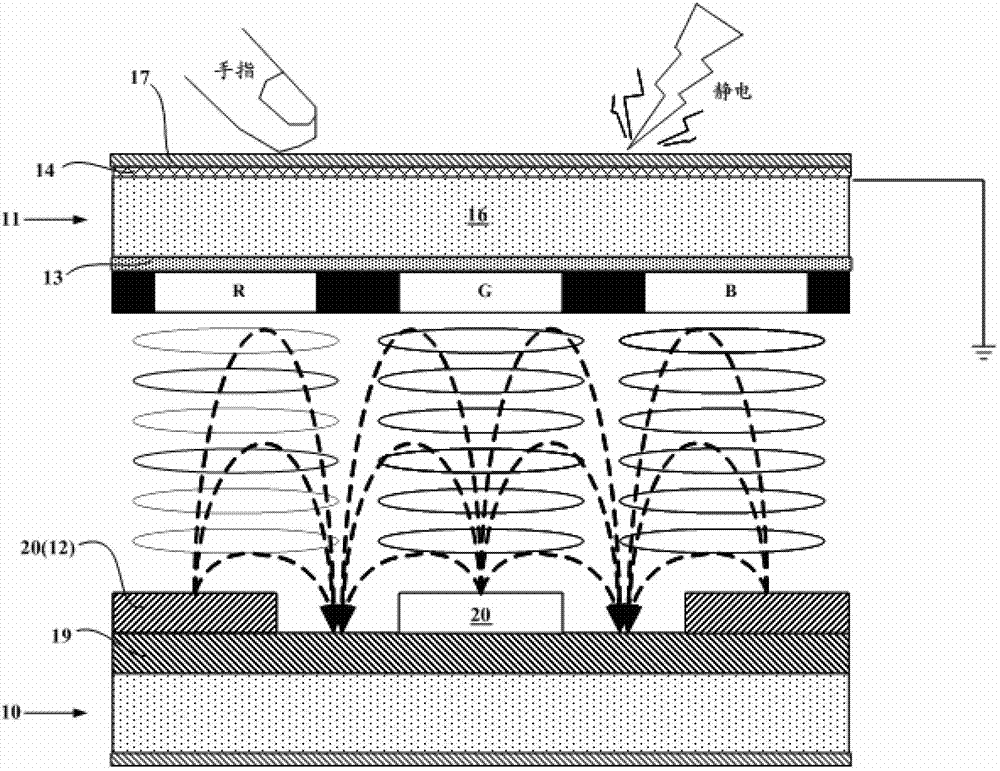

Touch display screen and touch display device

ActiveCN102955303AAvoid electrostatic damageImprove the display effectNon-linear opticsInput/output processes for data processingCapacitanceInductance

The invention discloses a touch display screen and a touch display device. The touch display screen comprises an array substrate, a color film substrate, a group of first electrode lines, a group of second electrode lines and transparent conductive shielding layers, wherein the array substrate and the color film substrate are symmetrically arranged; the group of first electrode lines is arranged on the array substrate or the color film substrate; the group of second electrode lines is arranged on the array substrate or the color film substrate and is in intersection arrangement with the group of first electrode lines; and the transparent conductive shielding layers are arranged on the color film substrate and are positioned on the group of first electrode lines and the group of second electrode lines, and one parts of the transparent conductive shielding layer corresponding to the first electrode lines and the second electrode lines are provided with hollow structures. Mutual inductance signals between the first electrode lines and the second electrode lines can pass through gaps of the hollow structure, and thus the implementation of the touch functional is ensured; and in addition, the transparent conductive shielding layers per se have conductivity, when a display screen is touched by external static electricity, electrostatic charges can be quickly led out and connected with the ground by the transparent conductive shielding layers, the electrostatic damage to the display screen due to the electrostatic charges can be prevented, and the display effect is further increased.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

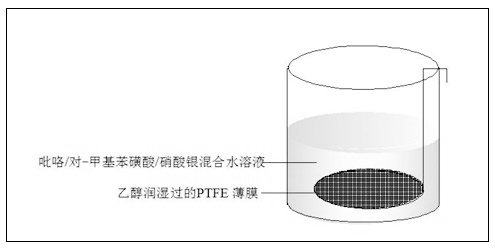

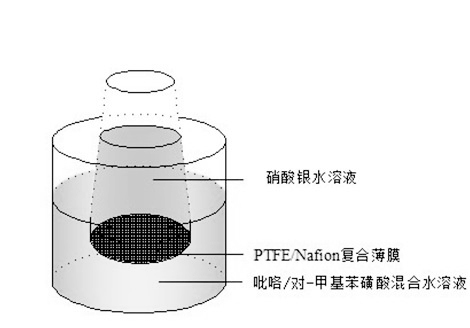

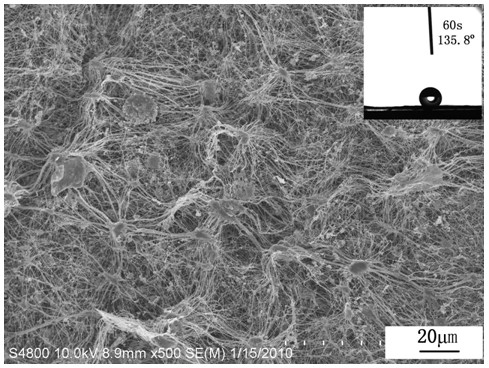

Conductive and antibacterial polytetrafluoroethylene composite thin film and manufacturing method thereof

InactiveCN102127243AEasy to prepareLow costSemi-permeable membranesDispersed particle filtrationOrganic acidPolytetrafluoroethylene

The invention discloses a conductive and antibacterial polytetrafluoroethylene composite thin film, which is a polytetrafluoroethylene / conductive polymer / silver composite film prepared by using polytetrafluoroethylene thin film as a substrate, wetting the substrate with a wetting agent, using solution containing silver ions as oxidizer and an inorganic or organic acid as a doping agent and performing chemical polymerization of a conductive polymer monomer on the surface of the substrate. Besides filtering dust in air, the polytetrafluoroethylene / conductive polymer / silver composite film also has conductive and antibacterial functions; meanwhile, the conductivity of the composite thin film can reach over 2*10<-4>S / cm, the static electricity in the filtering process can be eliminated, and the stripping of dust and the long-term effective, continuous and stable operation of the filtering process can be realized more easily. The composite filtering film can be used in fields of air purification, air-solid separation and the like. The invention also discloses the manufacturing method of the conductive and antibacterial polytetrafluoroethylene composite thin film.

Owner:NANJING UNIV

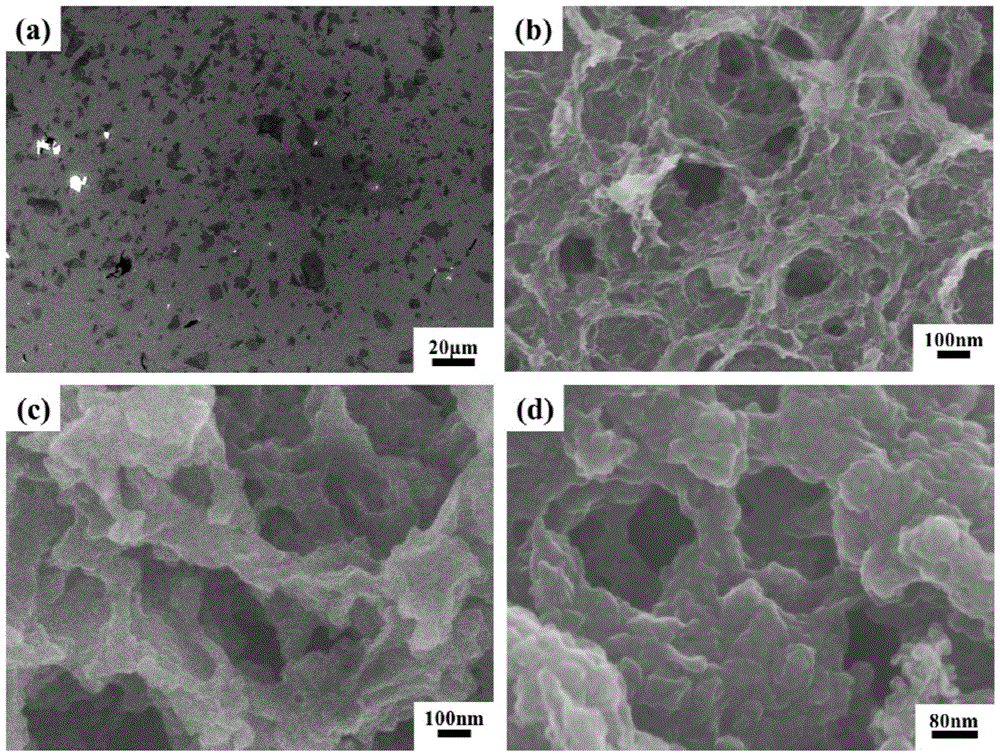

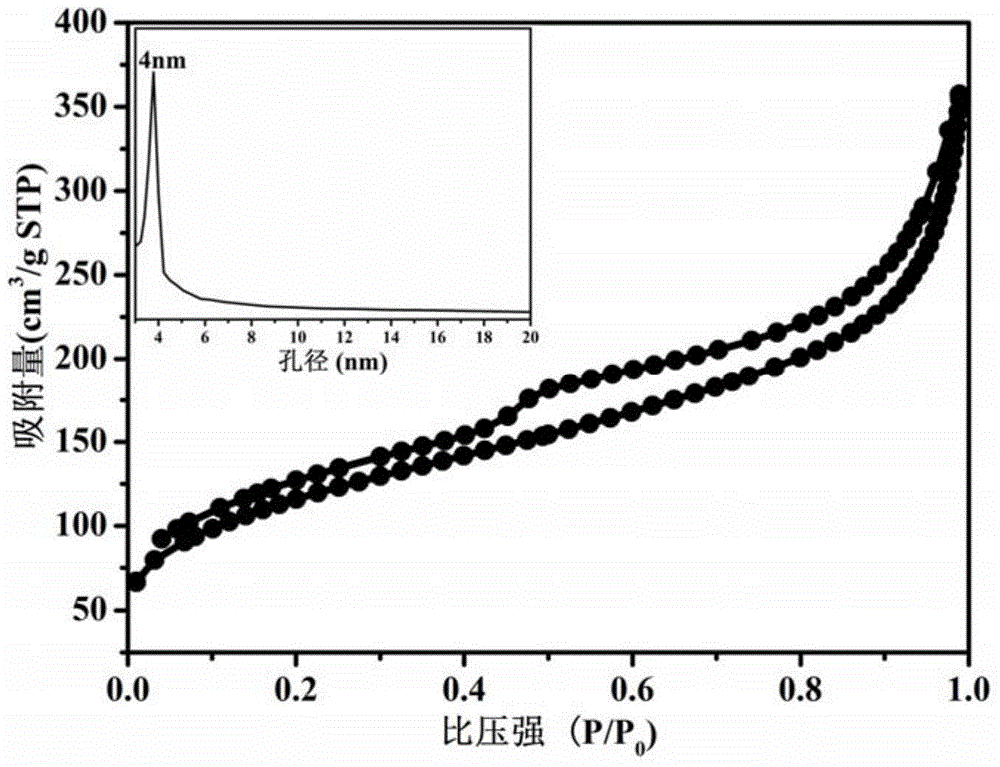

Flexible three-dimensional nano bioelectrode and preparation method thereof

The invention provides a flexible three-dimensional nano bio electrode and a preparation method thereof. The bioelectrode includes a flexible electrode substrate material, a carrier material adhered to the surface of the substrate material and enzyme supported on the carrier material. The carrier material is compounded by graphene with three-dimensional macroporous structure and mesoporous carbon bonded on the graphene surface; the mesoporous carbon is distributed in the surface of tunnel structure of the graphene; and the enzyme is glucose oxidase. The bioelectrode provided by the invention has the following advantages: the carrier with conductivity is beneficial to the transfer of electrons generated by catalysis of glucose oxidase to the electrode through the carrier material; the carrier material with larger specific surface area is conducive to the increase of immobilization amount of glucose oxidase on the carrier material in unit volume; and the carrier material with three-dimensional pore structure is conducive to the spread of solution, and can ensure that all the glucose oxidase in the carrier material conducts catalytic reaction. The invention can greatly promote the development of flexible green electronic products and implantable medical devices.

Owner:WUHAN UNIV OF TECH

Preparation method of high-diffusivity water-absorbent resin

The invention discloses a preparation method of a high-diffusivity water-absorbent resin. The preparation method comprises the following steps: adding acrylic acid, a 50% sodium hydroxide solution, a compound cross-linker, sodium bicarbonate, ethanol, silicon dioxide and deionized water to a reactor, mixing evenly, and then introducing nitrogen for 20 min to remove oxygen; next, adding an initiator at a temperature within the range of 5-10 DEG C to initiate a polymerization reaction, terminating the reaction when the temperature stops rising, and preserving heat for 2 hours at a temperature above 80 DEG C, thereby obtaining polymeric colloid; pelleting the colloid to obtain resin particles and drying at 180 DEG C until the moisture content is lower than 3%; and finally, evenly spraying a surface treating fluid to the particles for surface treatment, and preserving heat at 180 DEG C for 40 minutes, thereby obtaining the product. According to the preparation method of the high-diffusivity water-absorbent resin, the resin particles are of a loose porous structure, numerous pore passages are formed inside the resin particles and the contact area is greatly increased, and therefore, the high-diffusivity water-absorbent resin has an instantaneous absorption effect; and the pore passages are in contact and connected in series with each other, and due to the capillary action, moisture can be transferred among the particles smoothly.

Owner:诺宸股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com