Waterborne electromagnetic shielding coating and preparation method thereof

An electromagnetic shielding paint, water-based technology, applied in the field of high-performance water-based electromagnetic shielding paint and its preparation, can solve the problems of poor wave absorption performance, narrow absorption frequency band of conductive fillers, and difficulty in meeting shielding requirements, and achieves obvious innovation and excellent performance. Shielding effectiveness, the effect of meeting the requirements of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

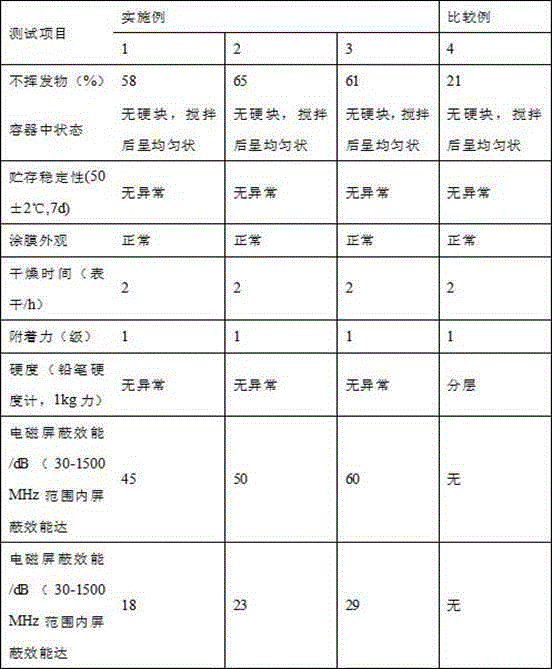

Examples

Embodiment 1

[0040] According to the ratio of parts by weight, put 10.0 parts of water into the dispersion kettle, and put in 0.1 parts of Dow Chemical BD-1090.1 parts, San Nopco Chemical SN-50400.4 parts, and San Nopco SN-DEFOAMER3280.1 at a speed of 500 rpm. 0.7 parts of propylene glycol, 0.5 parts of WACKER BS1680, evenly dispersed, slowly add 1.8 parts of Deqian RHEOLATE420, add 12.0 parts of graphene / nano-ferrite composite material, 4.0 parts of nano-silicon carbide, and 4.0 parts of nano-metal nickel powder , increase the rotation speed to 1000 rpm and disperse at high speed for 30 minutes until the fineness is less than 60um; then add 32.0 parts of Dow Chemical AC-261P in turn, and after dispersing for 5 minutes, add 1.3 parts of Eastman OE3000 and 0.2 parts of Dimei KSG1030 , 0.6 part of Dimei BDM paint film antifungal agent, 0.1 part of Ashland Chemical NLS2100, stir evenly to get the finished product.

Embodiment 2

[0042]According to the proportion by weight, put 18.0 parts of water into the dispersing kettle, and then put in 0.2 parts of Clariant LCN4070, 0.5 parts of Saint Nopco Chemical SN-50400, 90.2 parts of Blackburn CF1369, ethylene glycol at a speed of 900 rpm 1.0 parts, Dow Chemical AMP-950.3 parts, evenly dispersed, slowly add Deqian RHEOLATE4200.5 parts, add 0.133 parts of graphene / nano-ferrite composite material, 13.289 parts of zinc oxide whiskers, 13.289 parts of nano-silicon carbide, nano 13.289 parts of metal nickel powder, increase the rotation speed to 1000 rpm and disperse at high speed for 30 minutes until the fineness is less than 60um; then put in 25.0 parts of Yinyang resin YC-8360, and after dispersing for 3 minutes, put in 121.8 parts of Runtai Chemical C-121.8 parts and Dow Chemical LXE0. 4 parts, Sol ACTICIDEEPW 0.3 part, Dow Chemical RM-2020NPR 0.2 part, stir evenly to get the finished product.

Embodiment 3

[0044] According to the proportion by weight, put 60.0 parts of water into the dispersion kettle, and put in 50.3 parts of Deqian FX3650, 0.8 parts of San Nopco Chemical SN-50400.8 parts, 0.8 parts of Corning Foamstar2230.8 parts, 1.3 parts of propylene glycol, Sears Chemical Ammonia 0.2 parts, evenly dispersed, slowly add 2.0 parts of Dow Chemical TT-615, add 24.0 parts of graphene / nano-ferrite composite material, 12.0 parts of zinc oxide whiskers, 12.0 parts of nano-silicon carbide, nano-metal 12.0 parts of nickel powder, increase the speed to 1000 rpm and disperse at high speed for 30 minutes until the fineness is less than 60um; then add 40.0 parts of Shinko Chemical XG-2606, and after dispersing for 3 minutes, 0.8 parts of Eastman Texanol, 0.3 parts of Sol ActicdeRS, Sol EWPASTE 0.4 parts, San Nopco's SN-THICKENER 6120.3 parts, stir evenly to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com