Patents

Literature

6087 results about "Whiskers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whiskers or vibrissae (/vaɪˈbrɪsi/; singular: vibrissa; /vaɪˈbrɪsə/) are a type of mammalian hair that are typically characterised, anatomically, by their long length, large and well-innervated hair follicle, and by having an identifiable representation in the somatosensory cortex of the brain.

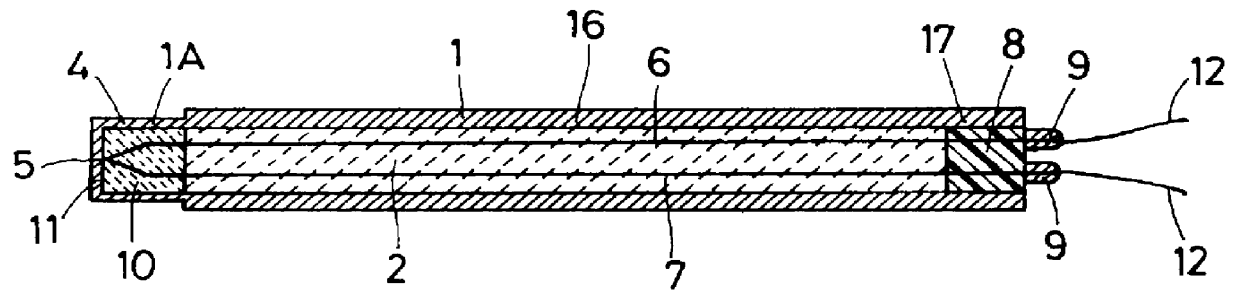

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

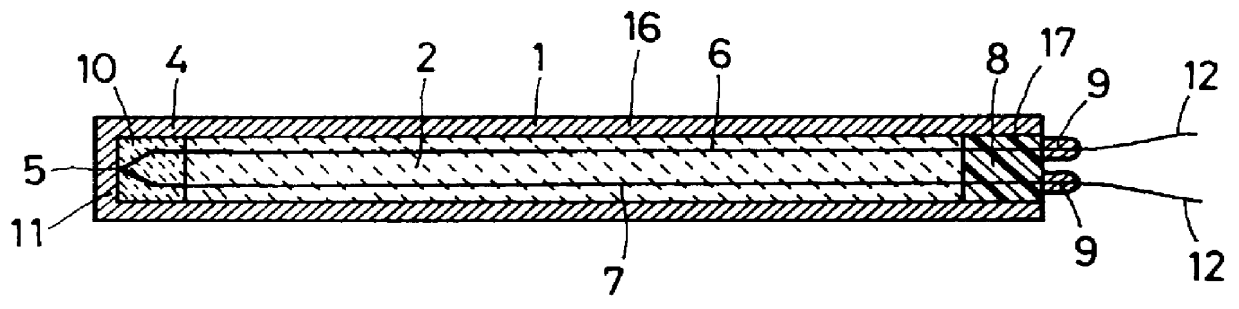

Nanostructures and methods for manufacturing the same

InactiveUS7335908B2Accurate weighingEnhances width controlPolycrystalline material growthIndividual molecule manipulationPhotonicsWhiskers

A resonant tunneling diode, and other one dimensional electronic, photonic structures, and electromechanical MEMS devices, are formed as a heterostructure in a nanowhisker by forming length segments of the whisker with different materials having different band gaps.

Owner:QUNANO

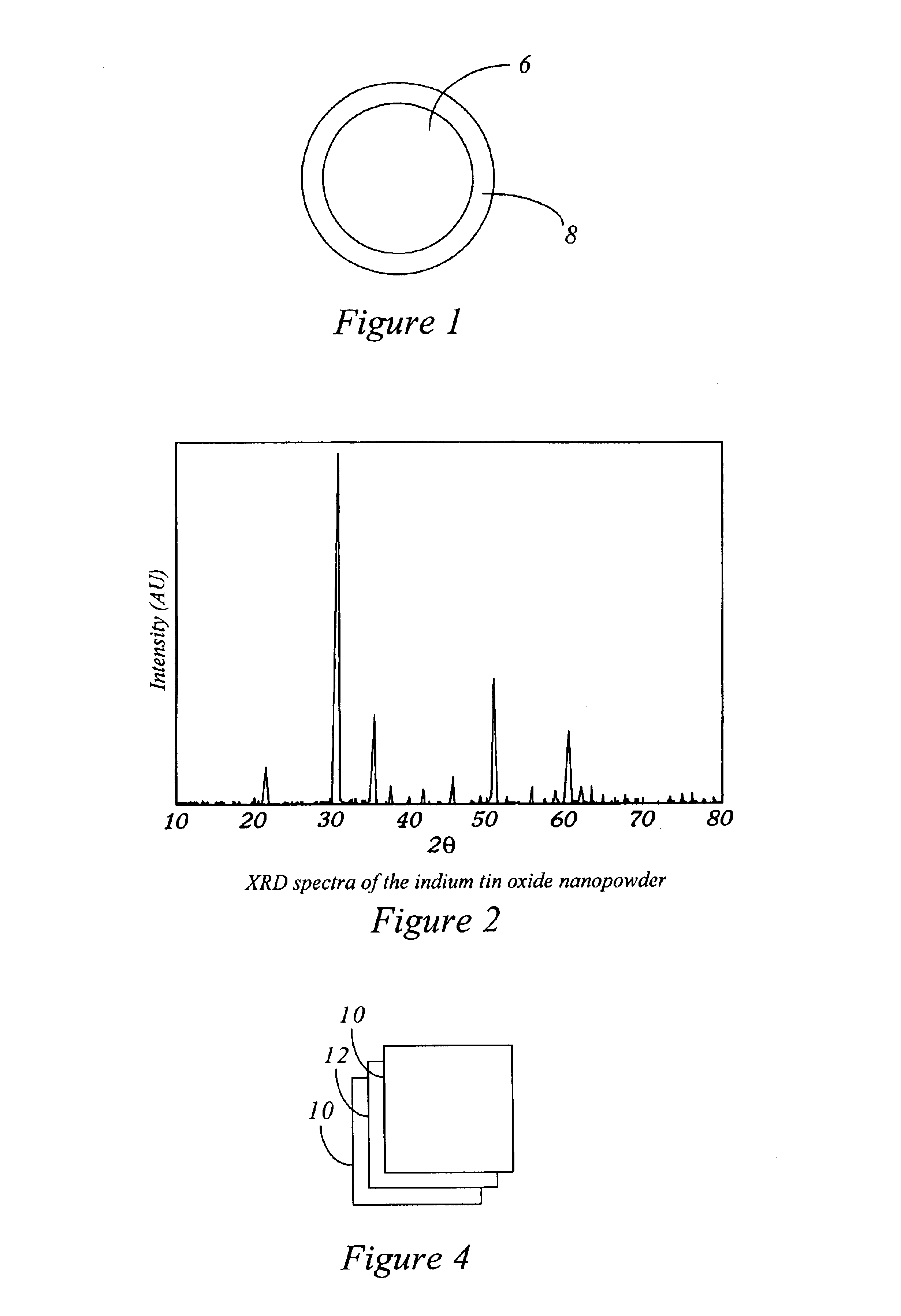

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

Lift-out probe having an extension tip, methods of making and using, and analytical instruments employing same

InactiveUS7009188B2Extended service lifeEfficient removalMaterial analysis using wave/particle radiationElectric discharge tubesIon beamConductive materials

Owner:MICRON TECH INC

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

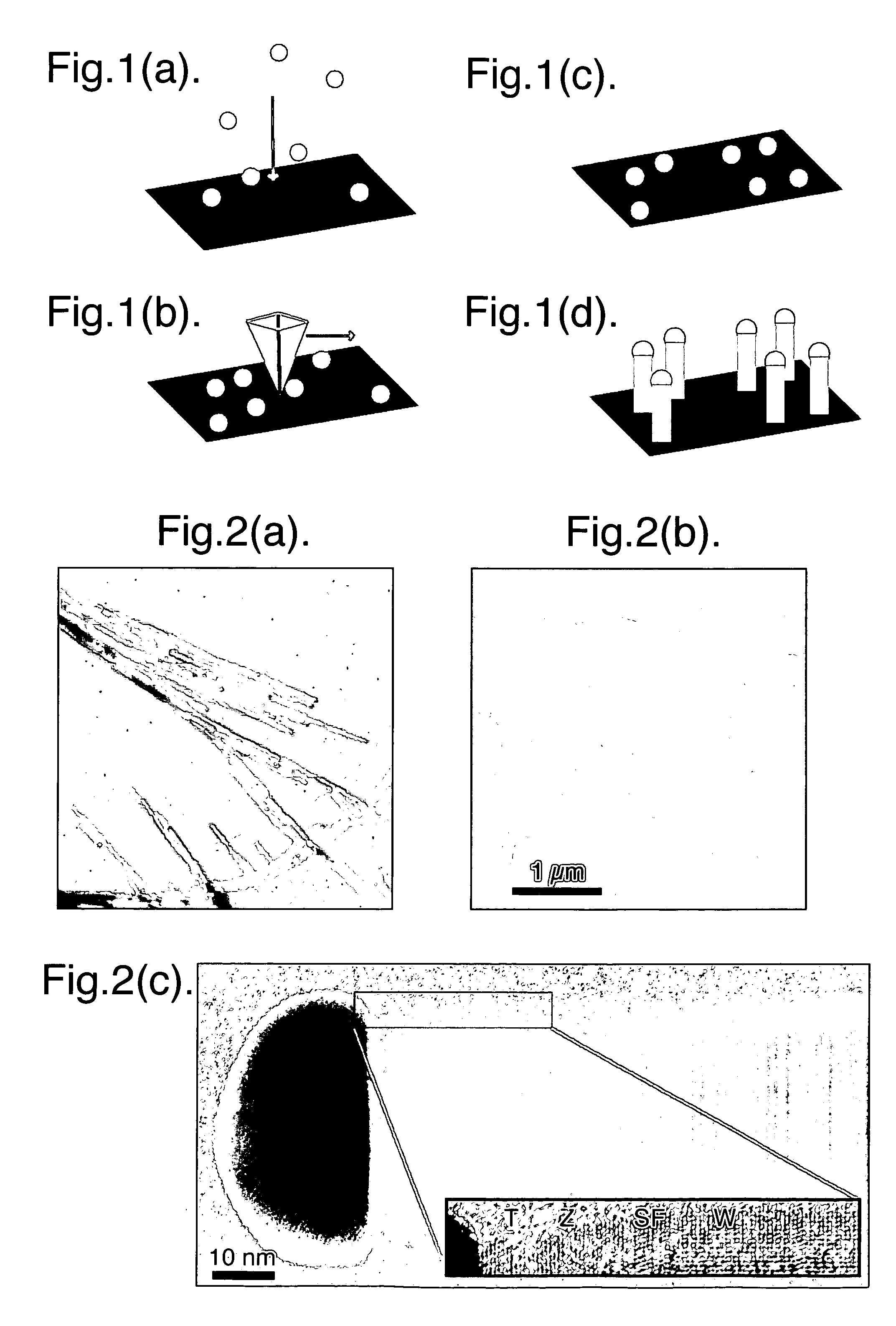

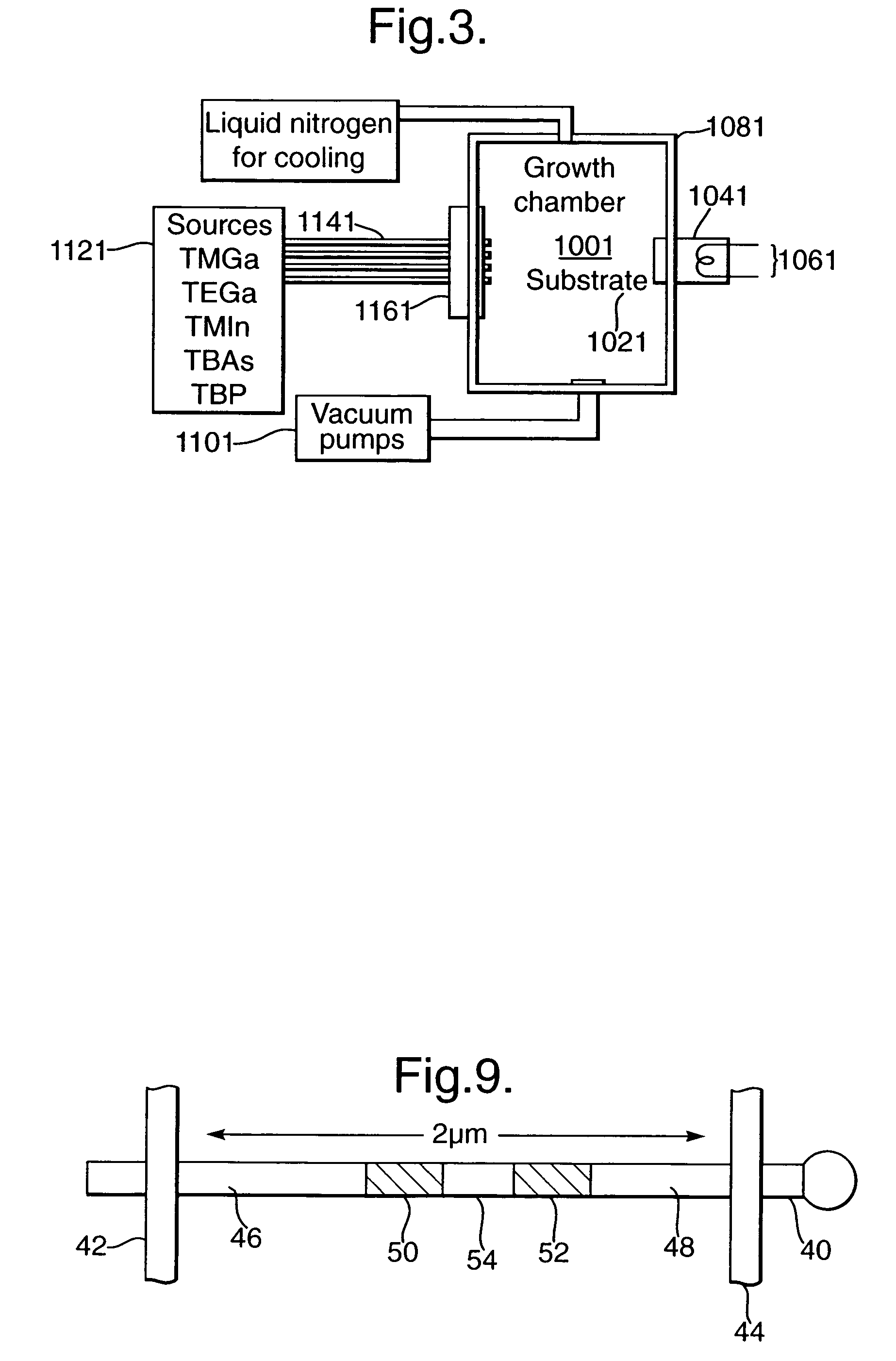

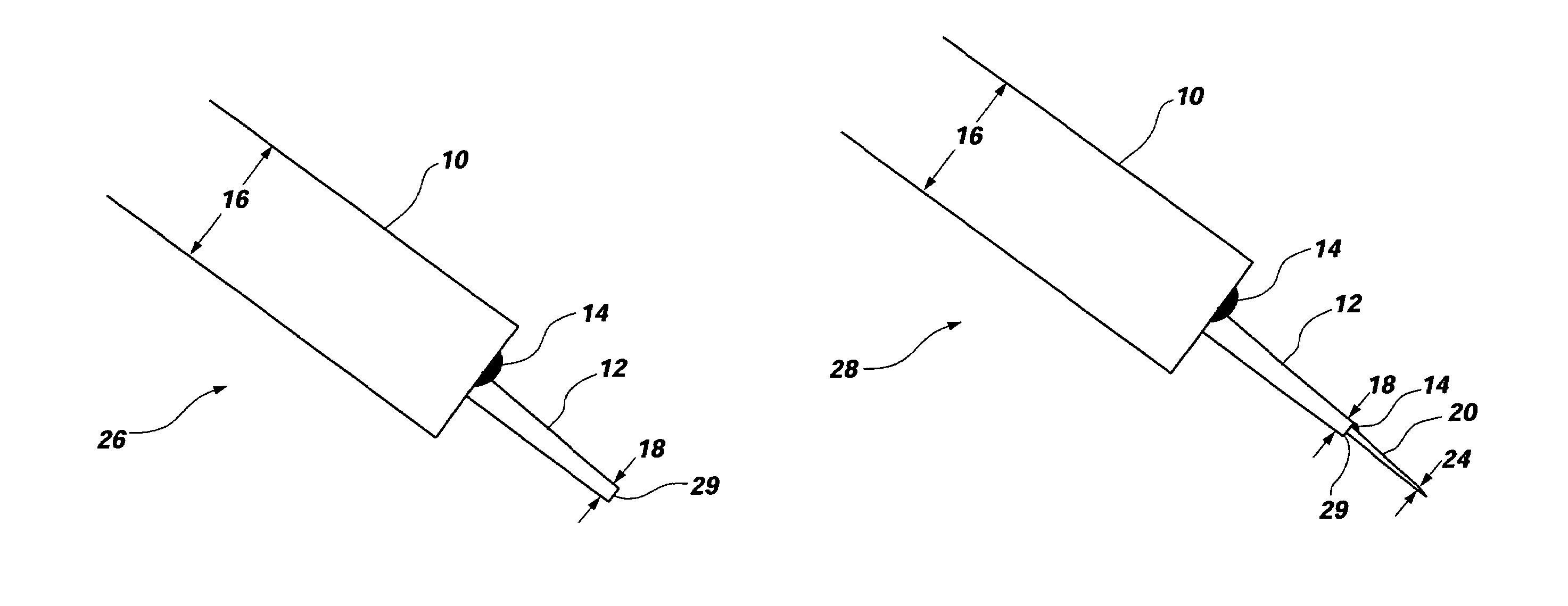

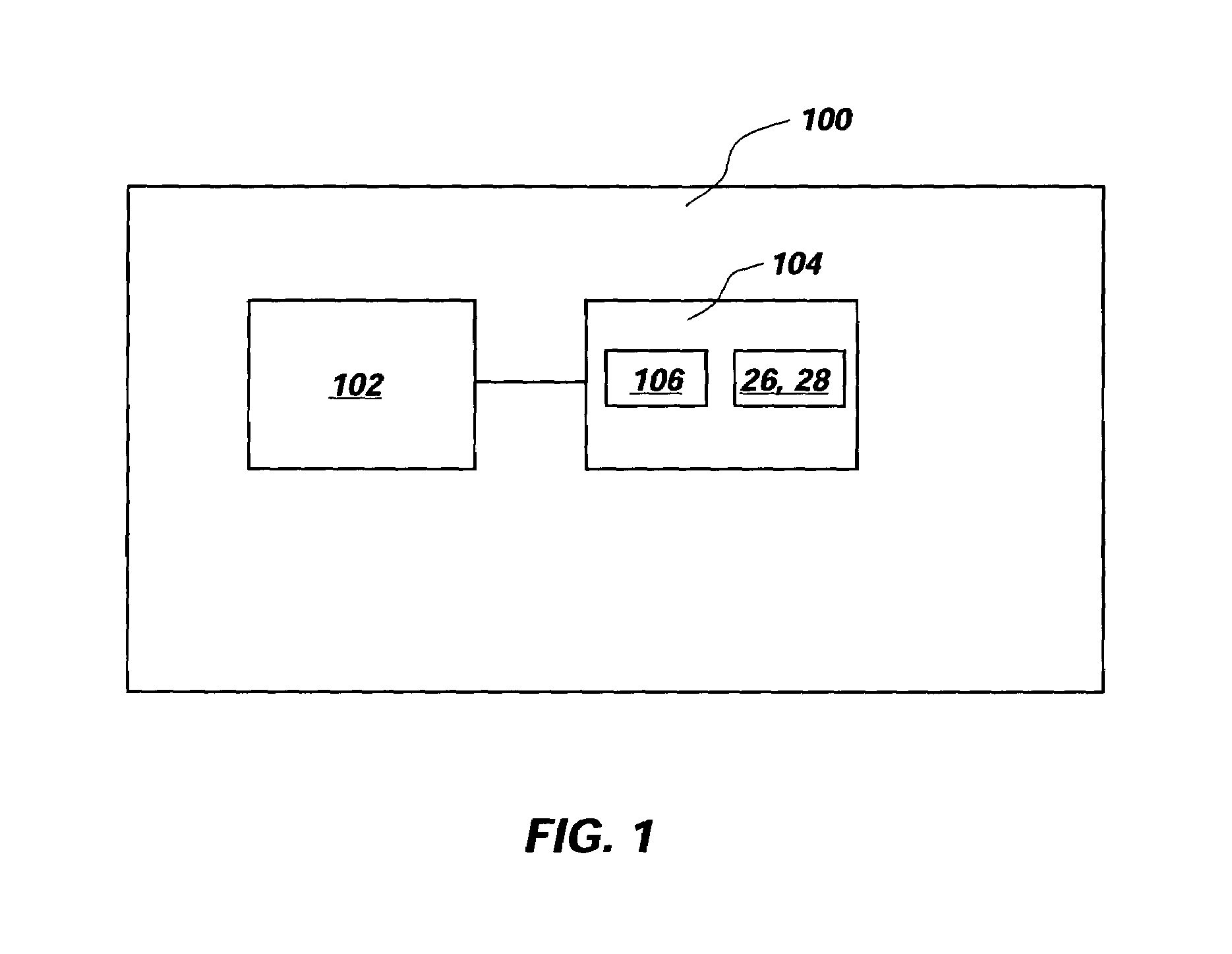

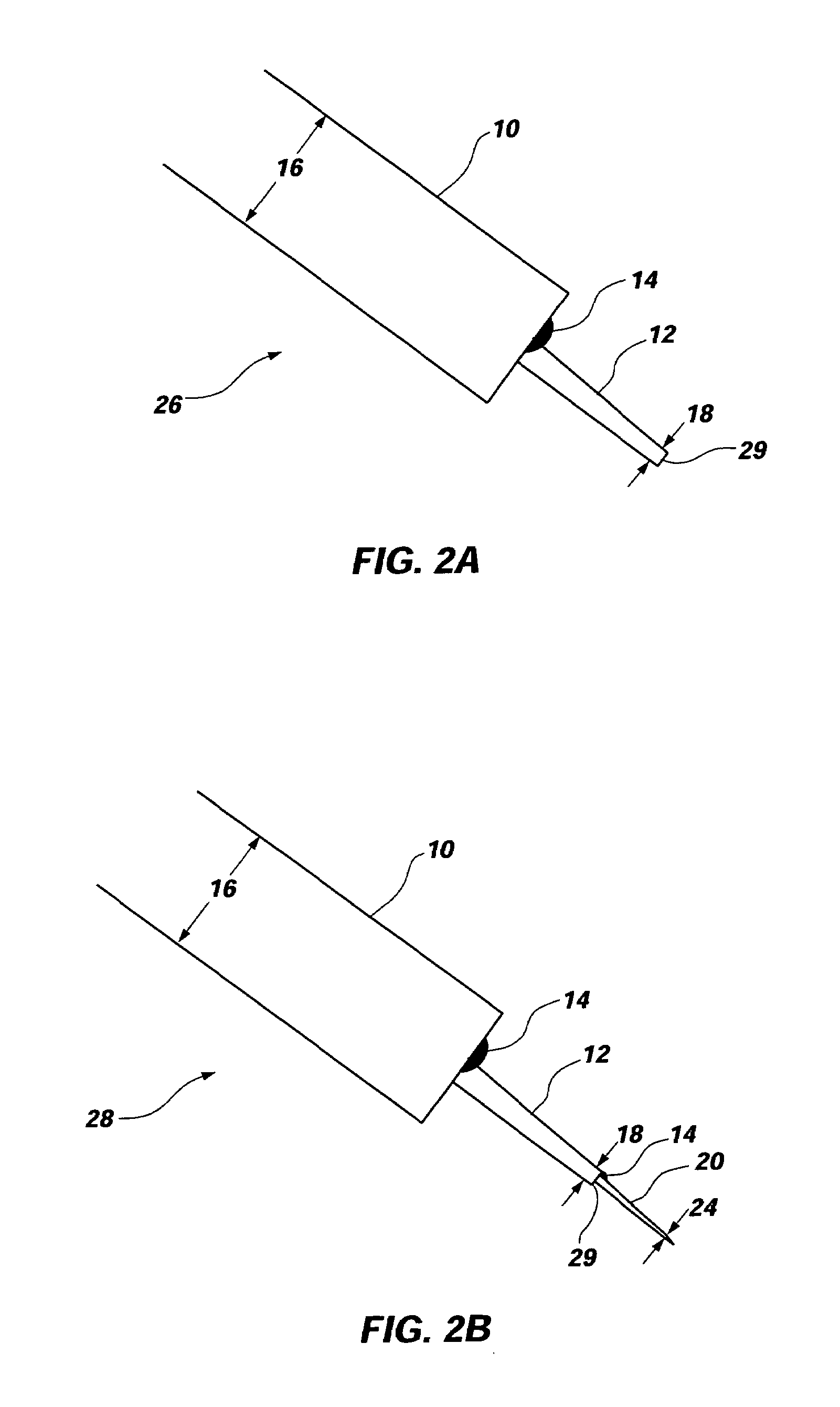

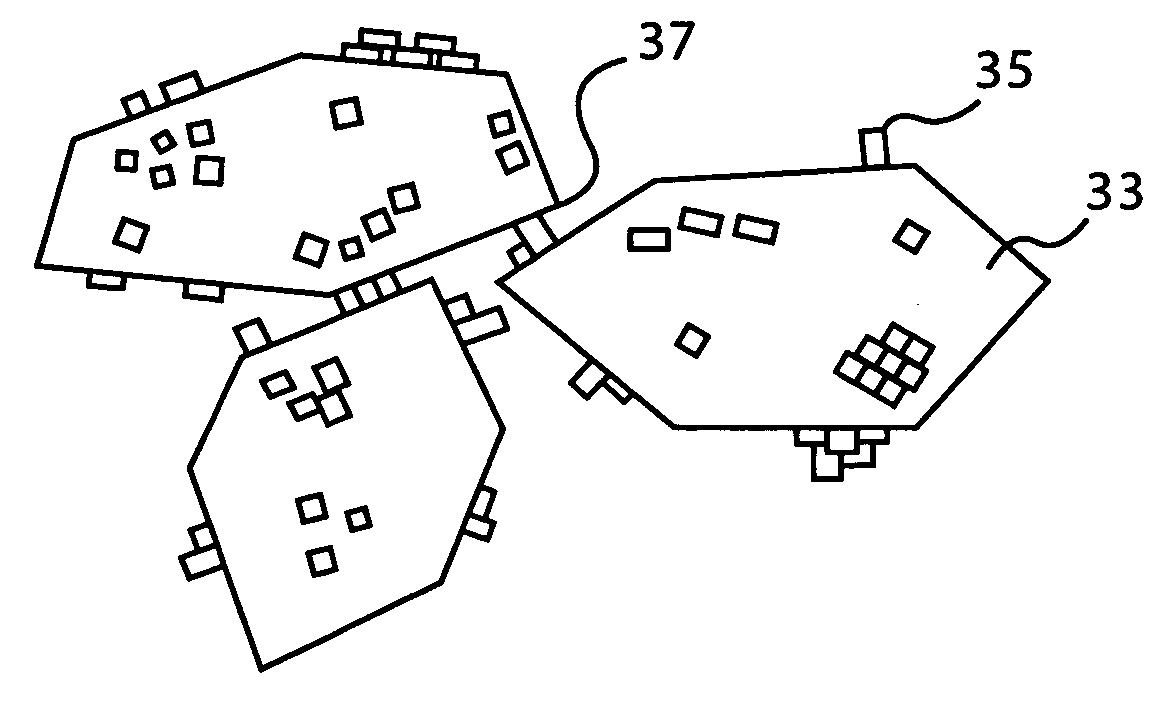

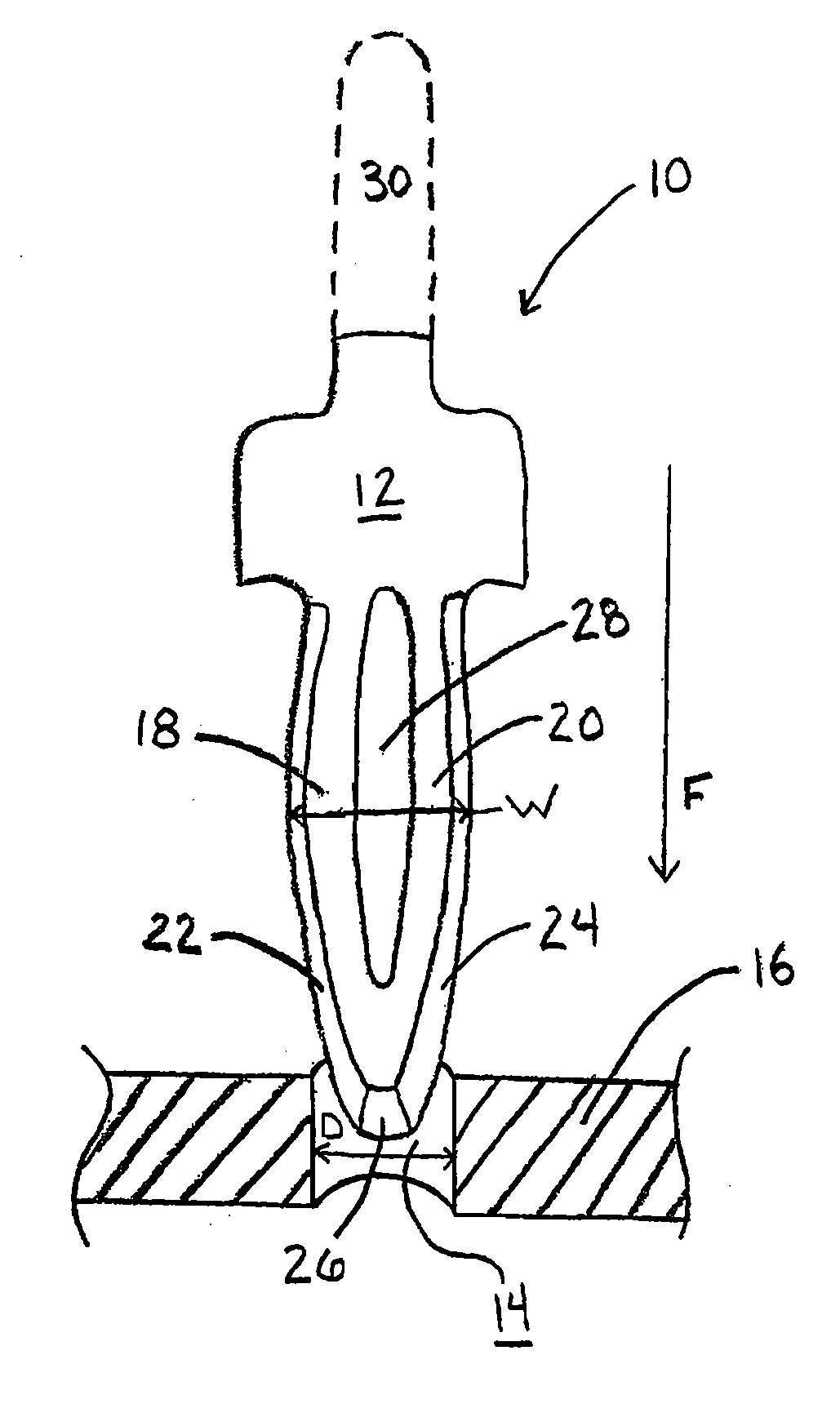

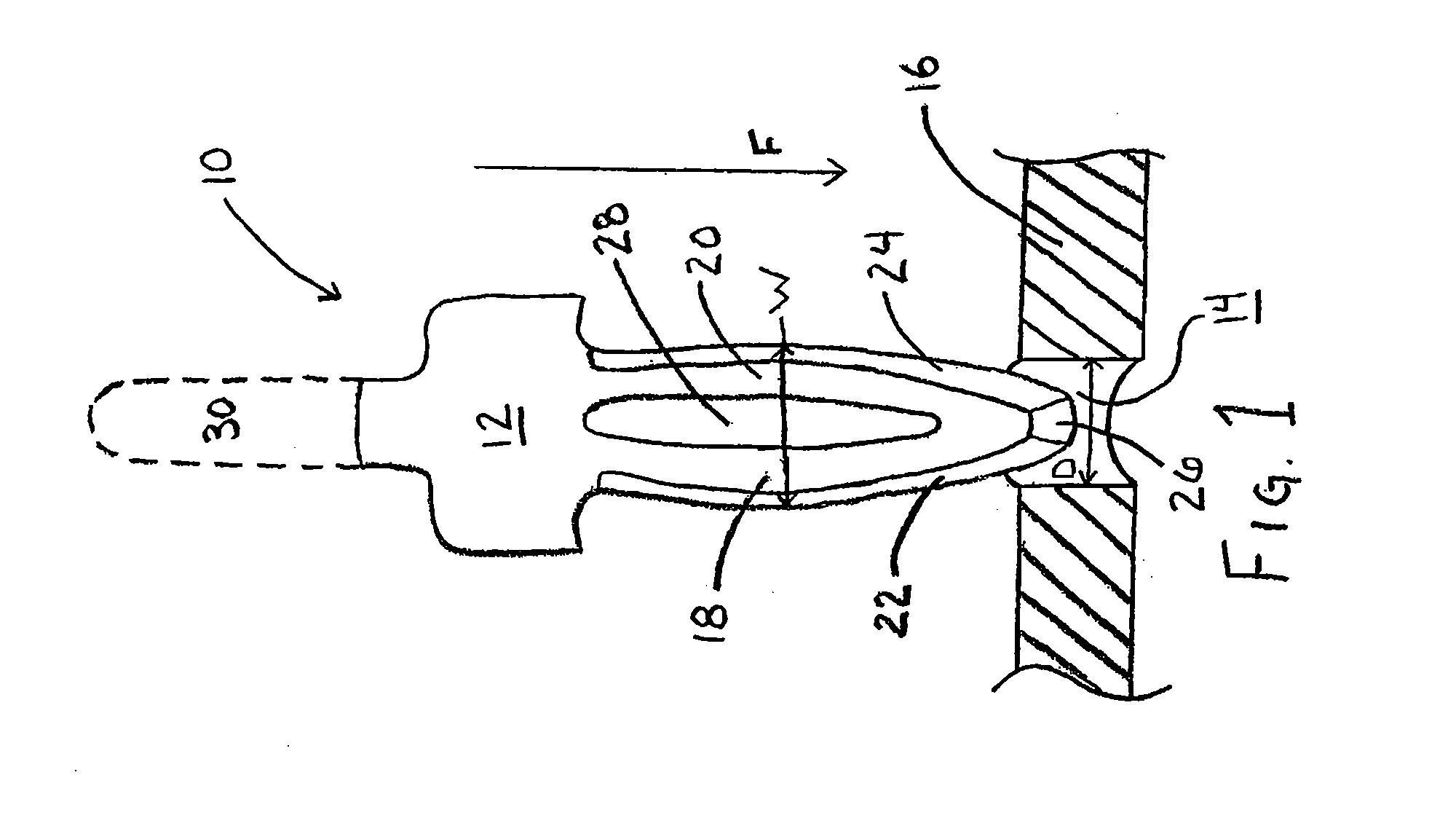

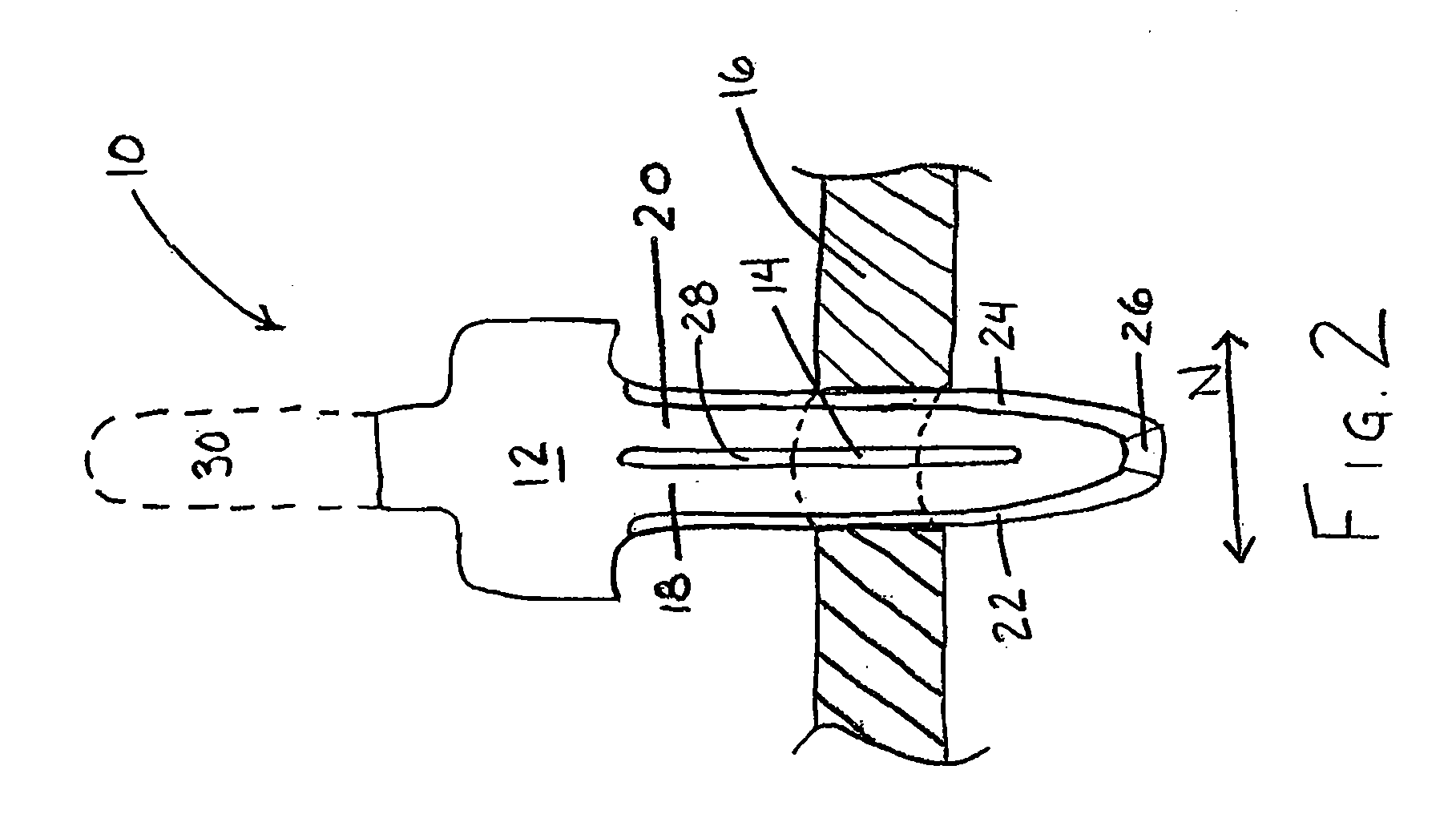

Probe structures incorporating nanowhiskers, production methods thereof and methods of forming nanowhiskers

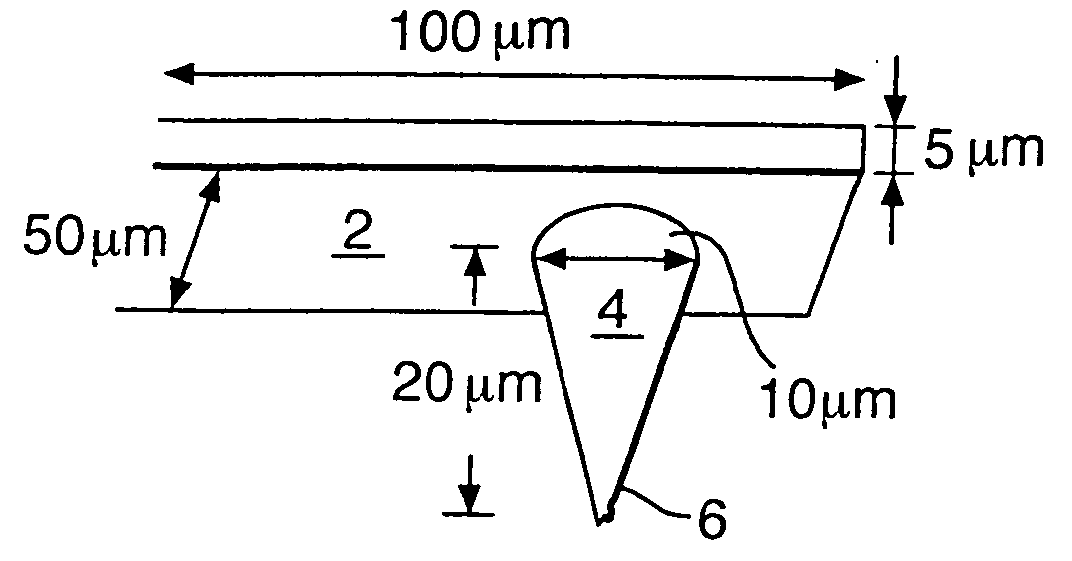

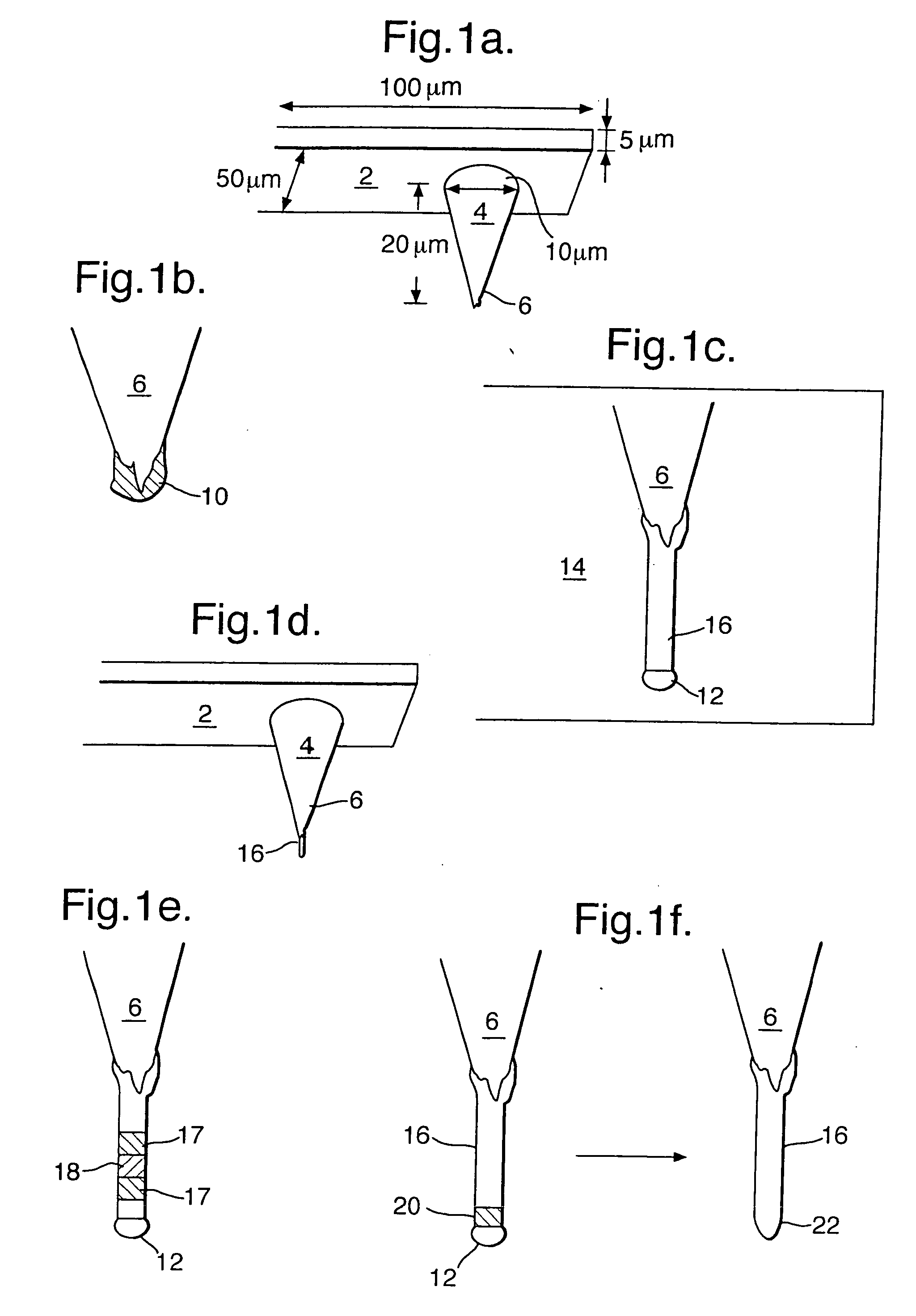

InactiveUS20050017171A1Small sizeReduce the overall diameterMaterial analysis using wave/particle radiationInorganic material artificial filamentsEtchingWhiskers

A probe structure for a scanning probe microscope comprises a nanowhisker (16,34) projecting from a free end of an upstanding tip member (4,26), and being formed integrally with the tip member. In another embodiment, a data storage medium comprises an array of nanowhiskers (54), each nanowhisker being formed from magnetic material, the diameter of the nanowhisker being such that a single ferromagnetic domain exists within the nanowhisker, preferably having a diameter not greater than about 25 nm and more preferably not greater than about 10 nm, and a read / write structure comprising the probe structure for injecting a stream of spin-polarised electrons into a selected nanowhisker of the array, either for sensing the direction of magnetisation in the nanowhisker, or for forcing the nanowhisker into a desired direction of magnetisation. When the probe nanowhisker is formed by a VLS process using a catalytic particle melt, the whisker may be formed with a sacrificial segment to allow for removal of the catalytic material by selective etching of the segment.

Owner:QUNANO

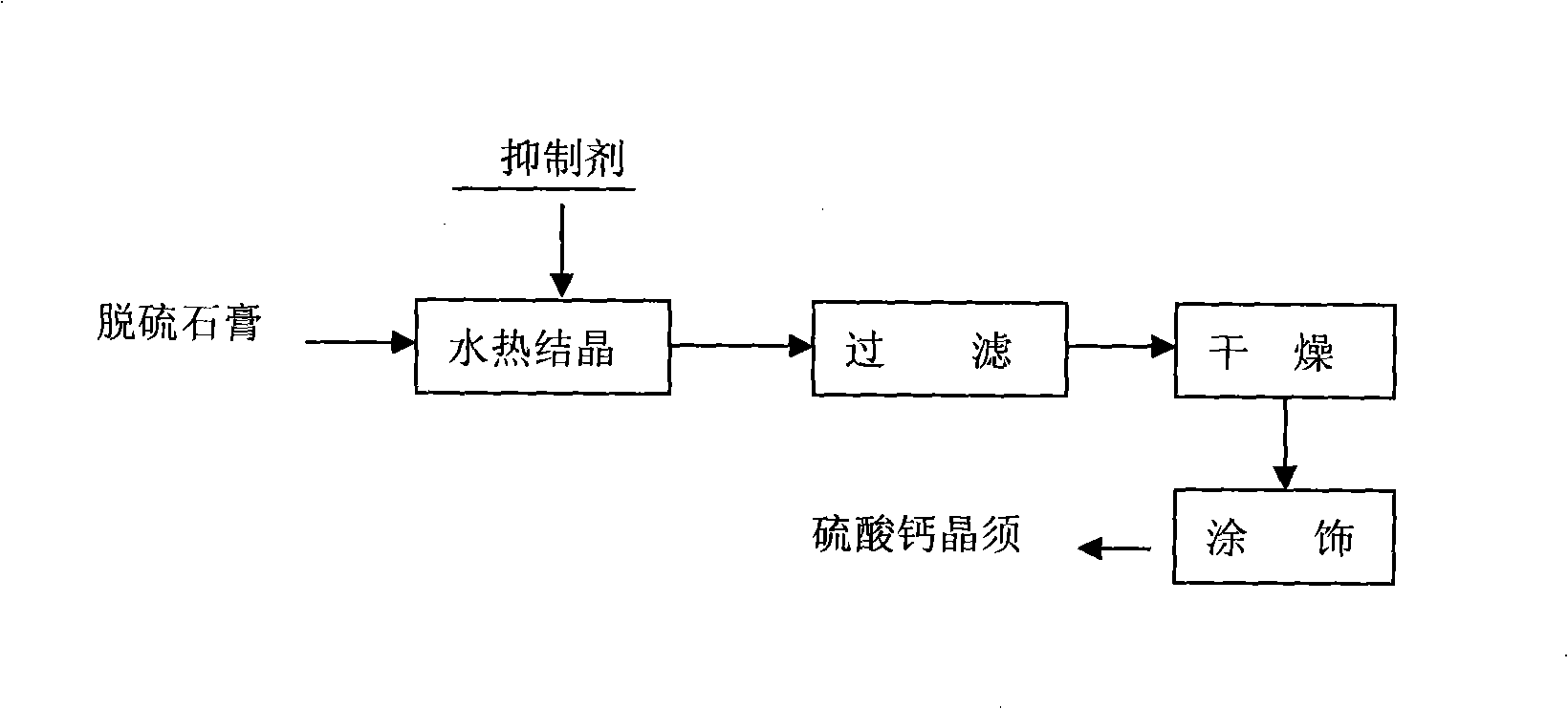

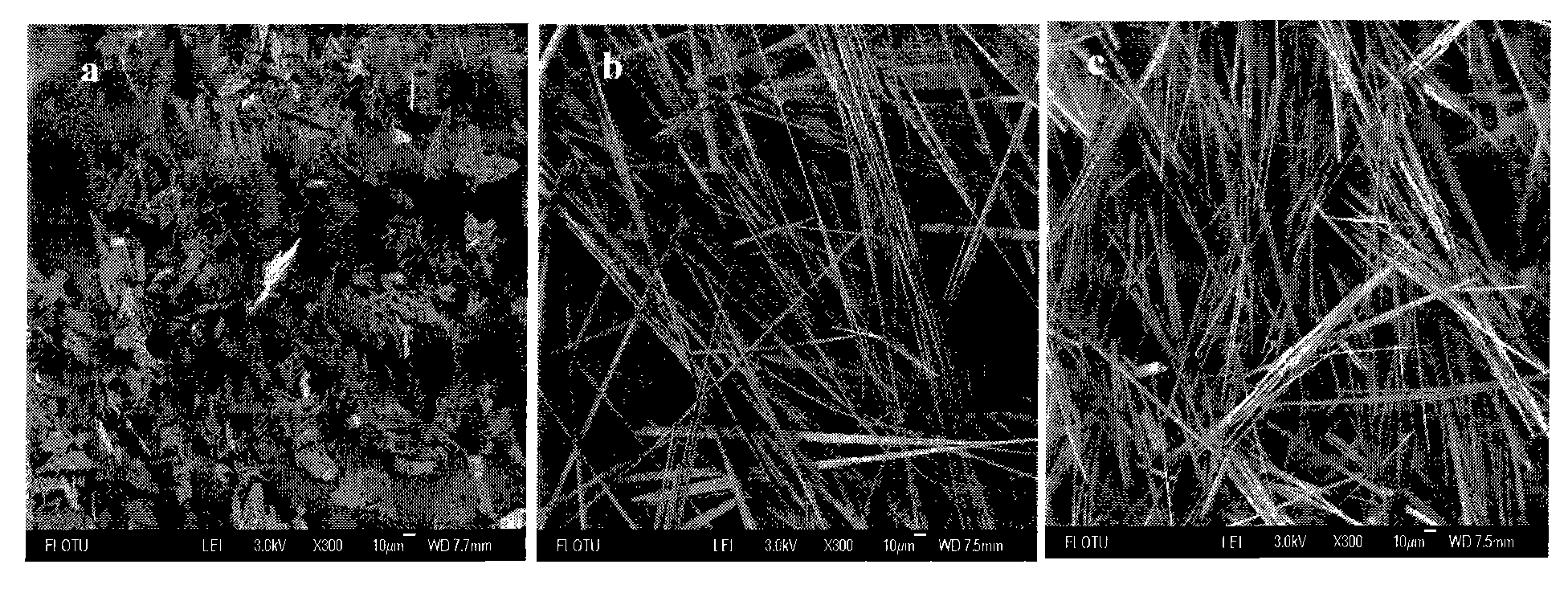

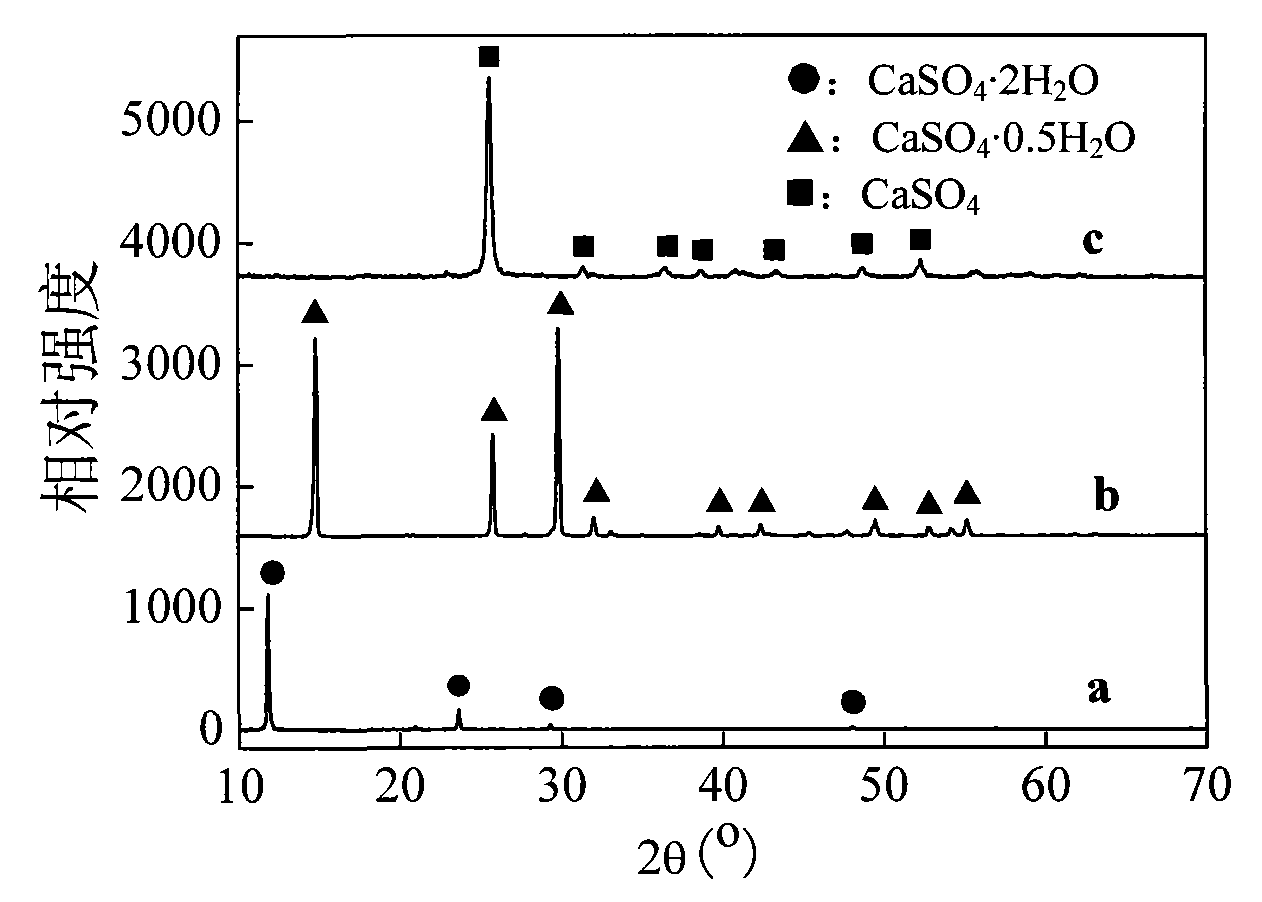

Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

InactiveCN101311337AReduce environmental problemsMitigation resourcesPolycrystalline material growthFrom normal temperature solutionsGlass fiberSulfate

The invention discloses a method for using flue gas desulfurization gypsum to prepare calcium sulfate whisker, comprising process steps of size mixing, high-temperature crystallization, drying and coating, etc. The method utilizes the flue gas desulfurization gypsum as the raw material, which has low production cost, short technological process and saves natural gypsum mine and effectively relieves the environmental pollution problem of the flue gas desulfurization gypsum. The product purity can be up to more than 98 percent, which can be used as filler with medium intensity or as friction material, building material or insulating material, and the like, instead of asbestos. The product can also partly replace organic macromolecular compounds such as glass fiber, resin, rubber and plastic, and the like, and has good describability.

Owner:NORTHEASTERN UNIV

Methods of forming semiconductor constructions and capacitors

InactiveUS20070048976A1Solid-state devicesSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideOxygen compound

The invention includes methods in which silicon is removed from titanium-containing container structures with an etching composition having a phosphorus-and-oxygen-containing compound therein. The etching composition can, for example, include one or both of ammonium hydroxide and tetra-methyl ammonium hydroxide. The invention also includes methods in which titanium-containing whiskers are removed from between titanium-containing capacitor electrodes. Such removal can be, for example, accomplished with an etch utilizing one or more of hydrofluoric acid, ammonium fluoride, nitric acid and hydrogen peroxide.

Owner:MICRON TECH INC

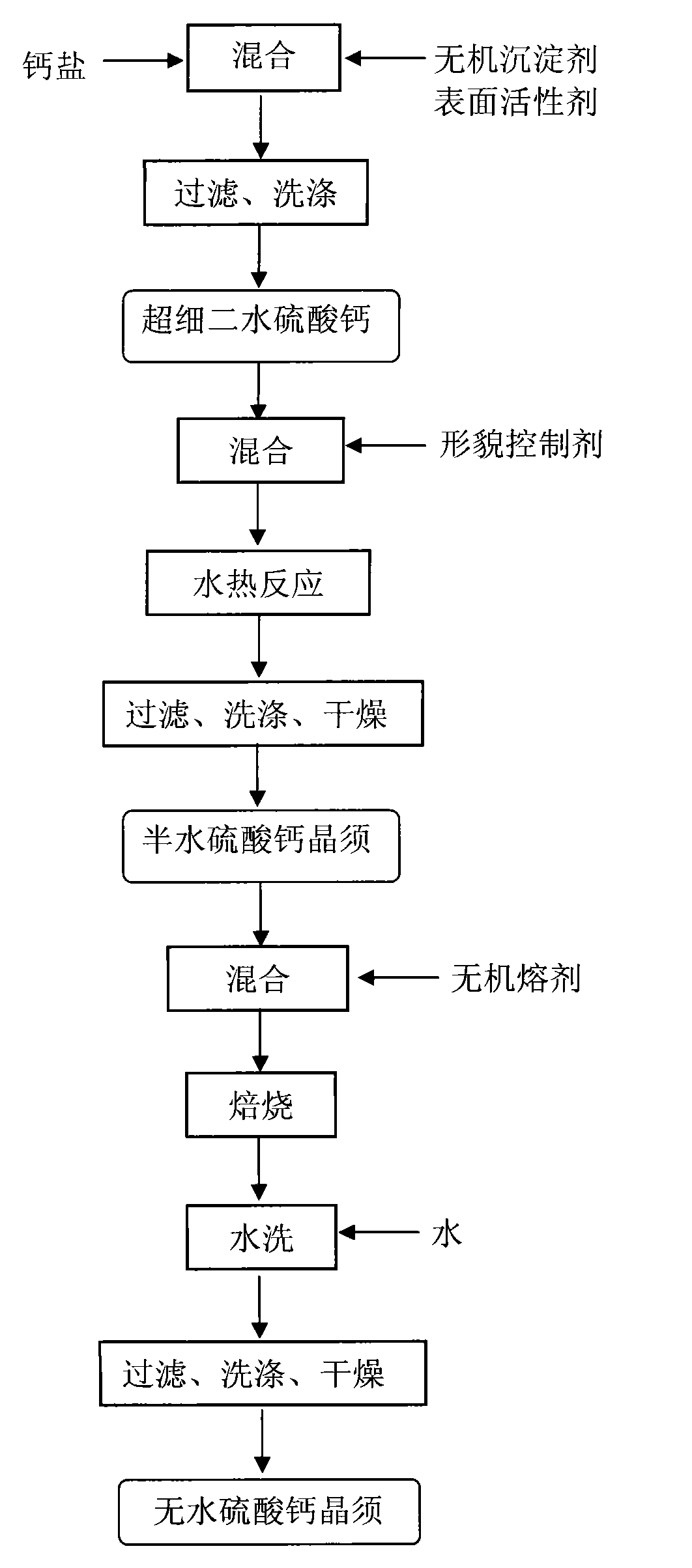

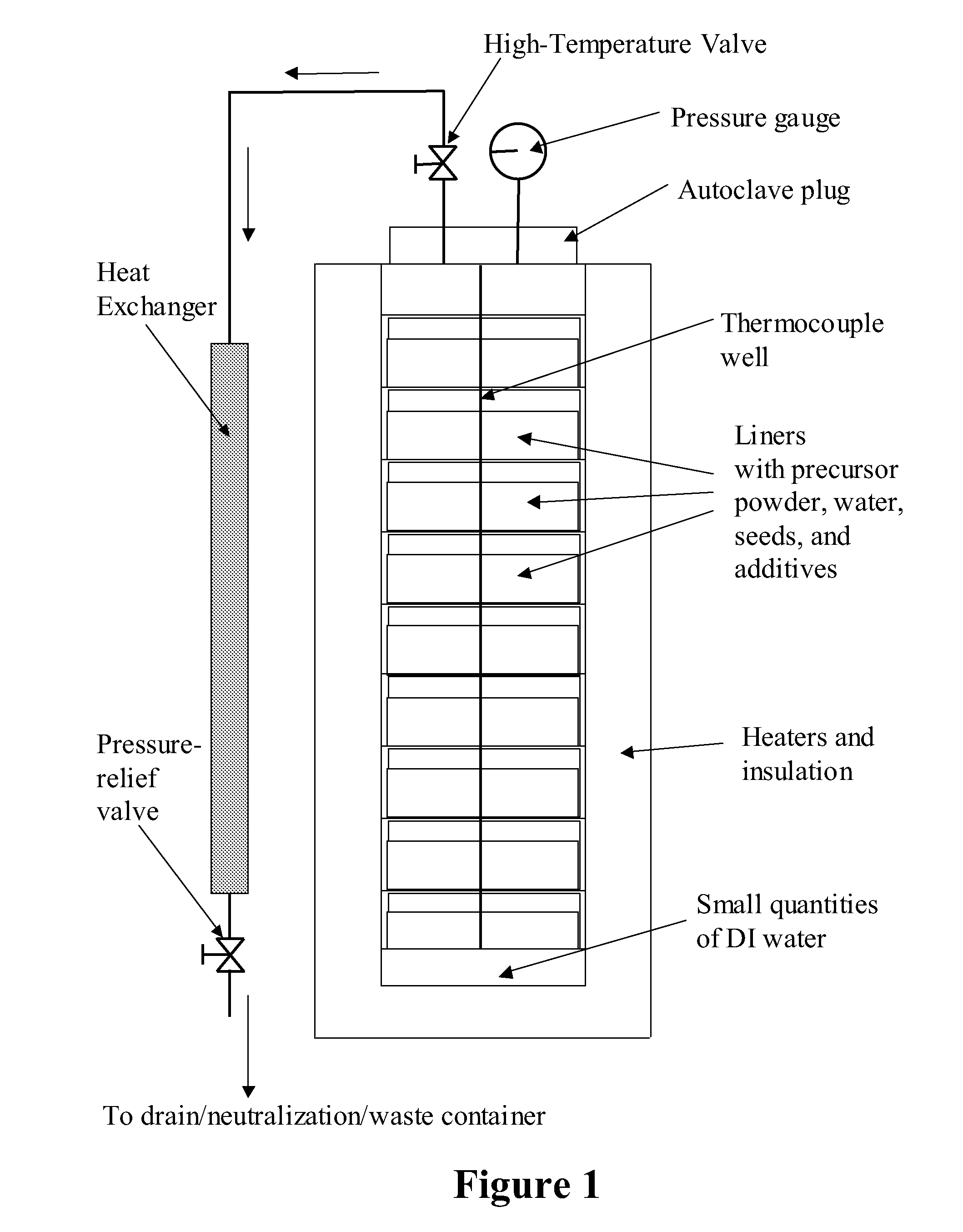

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

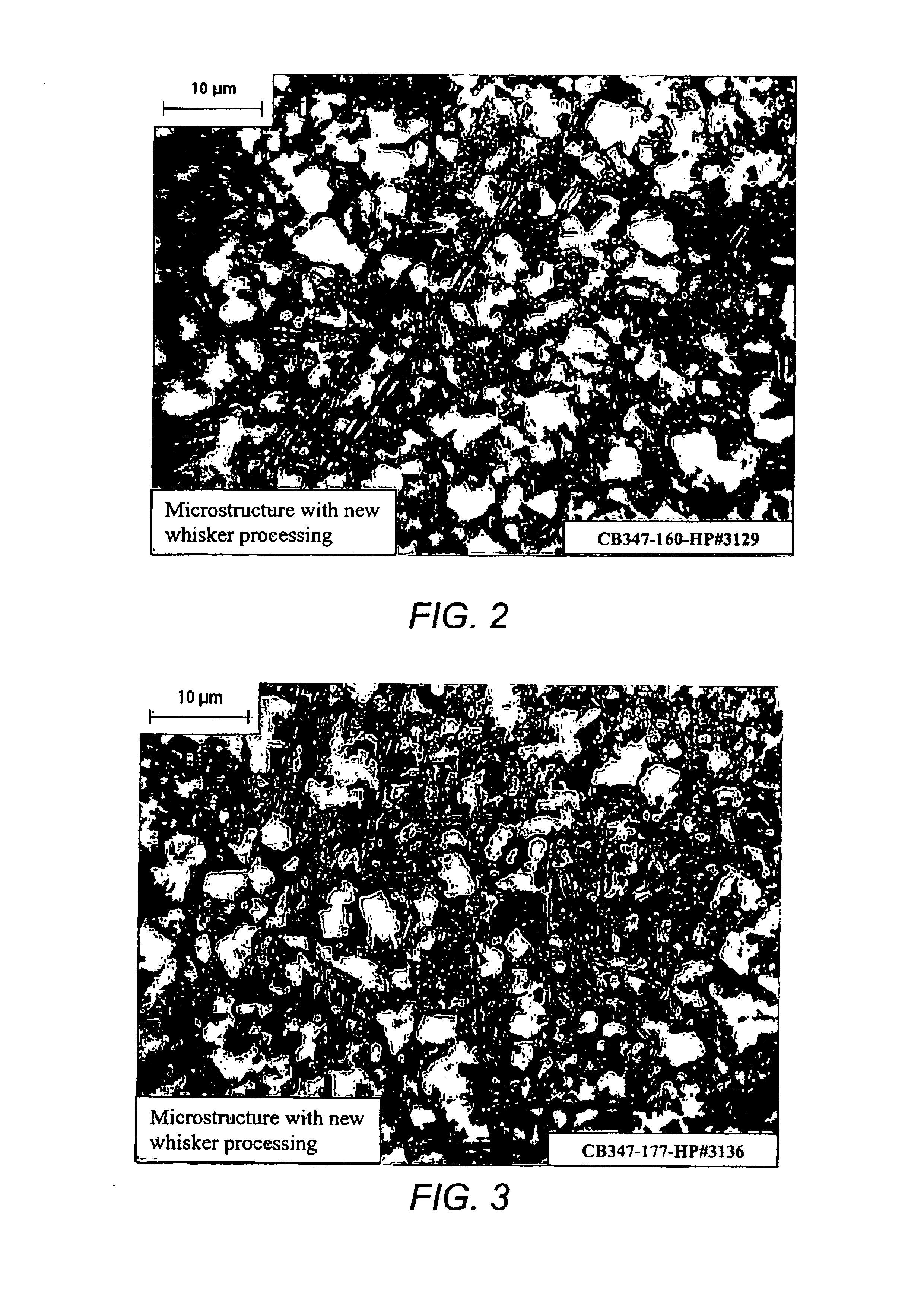

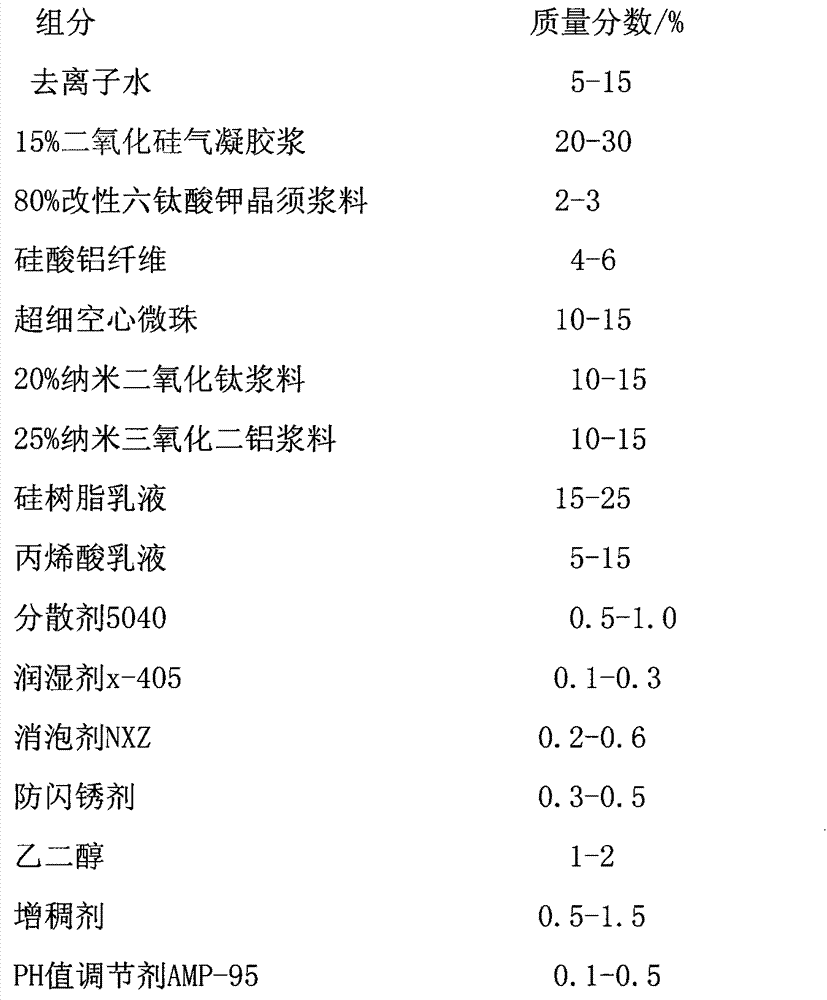

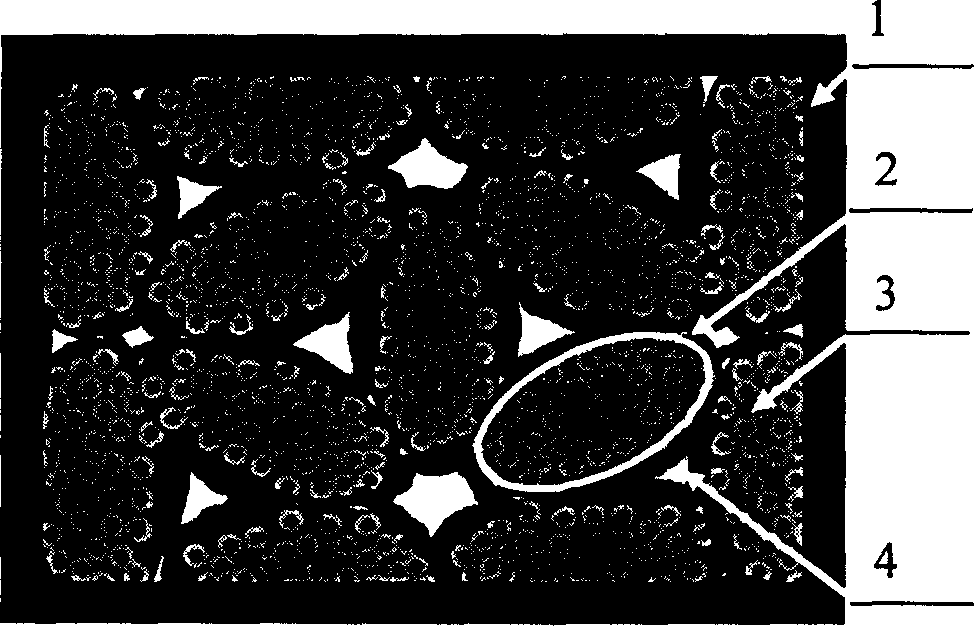

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

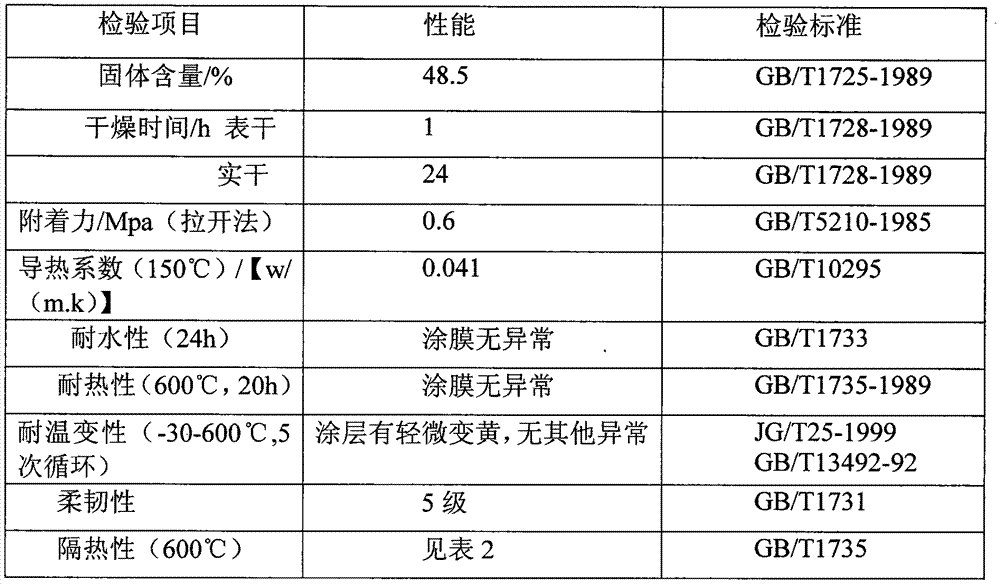

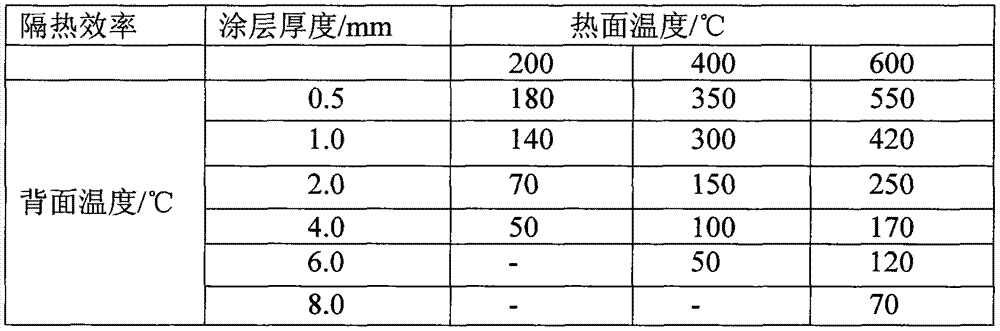

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

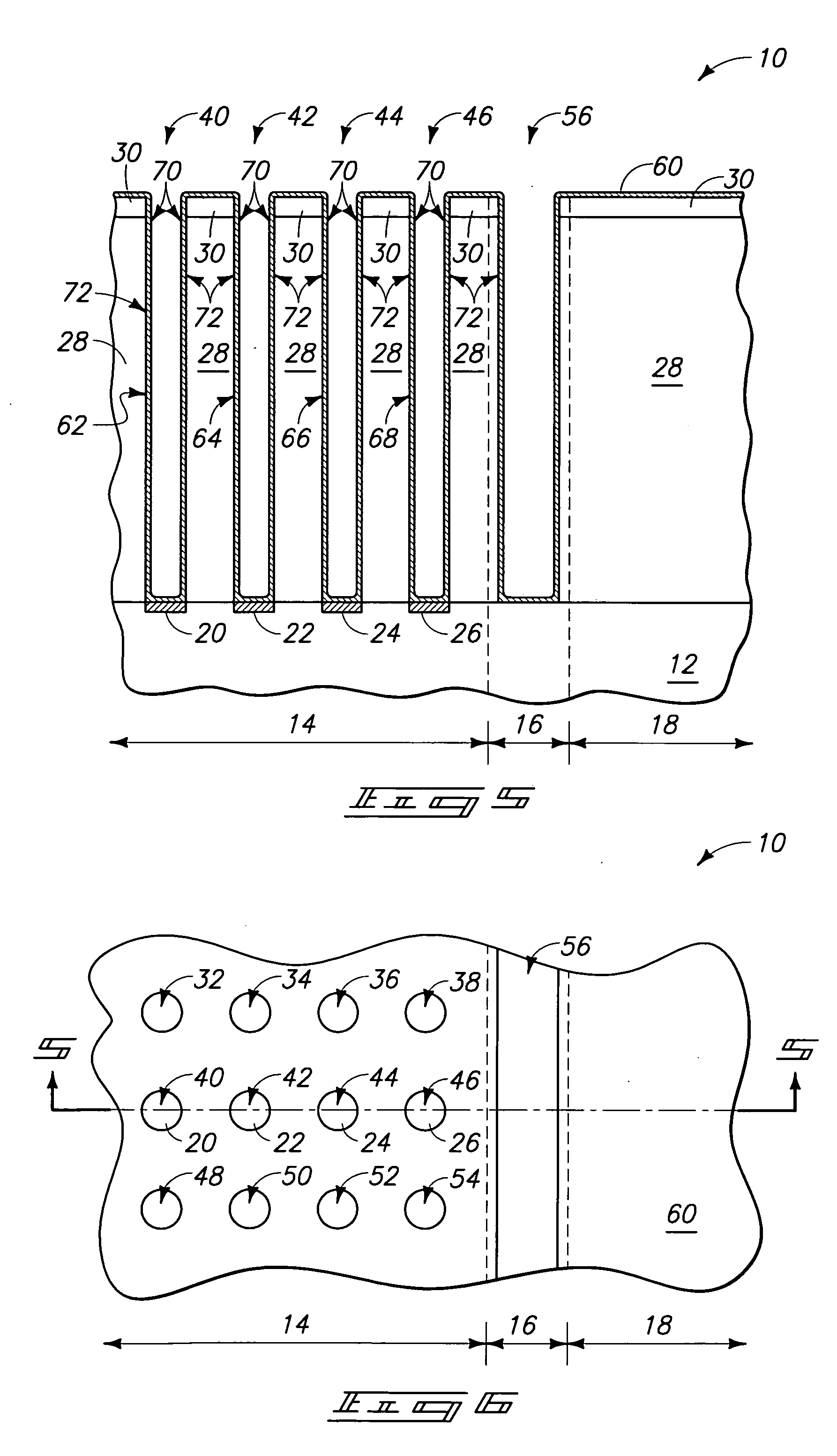

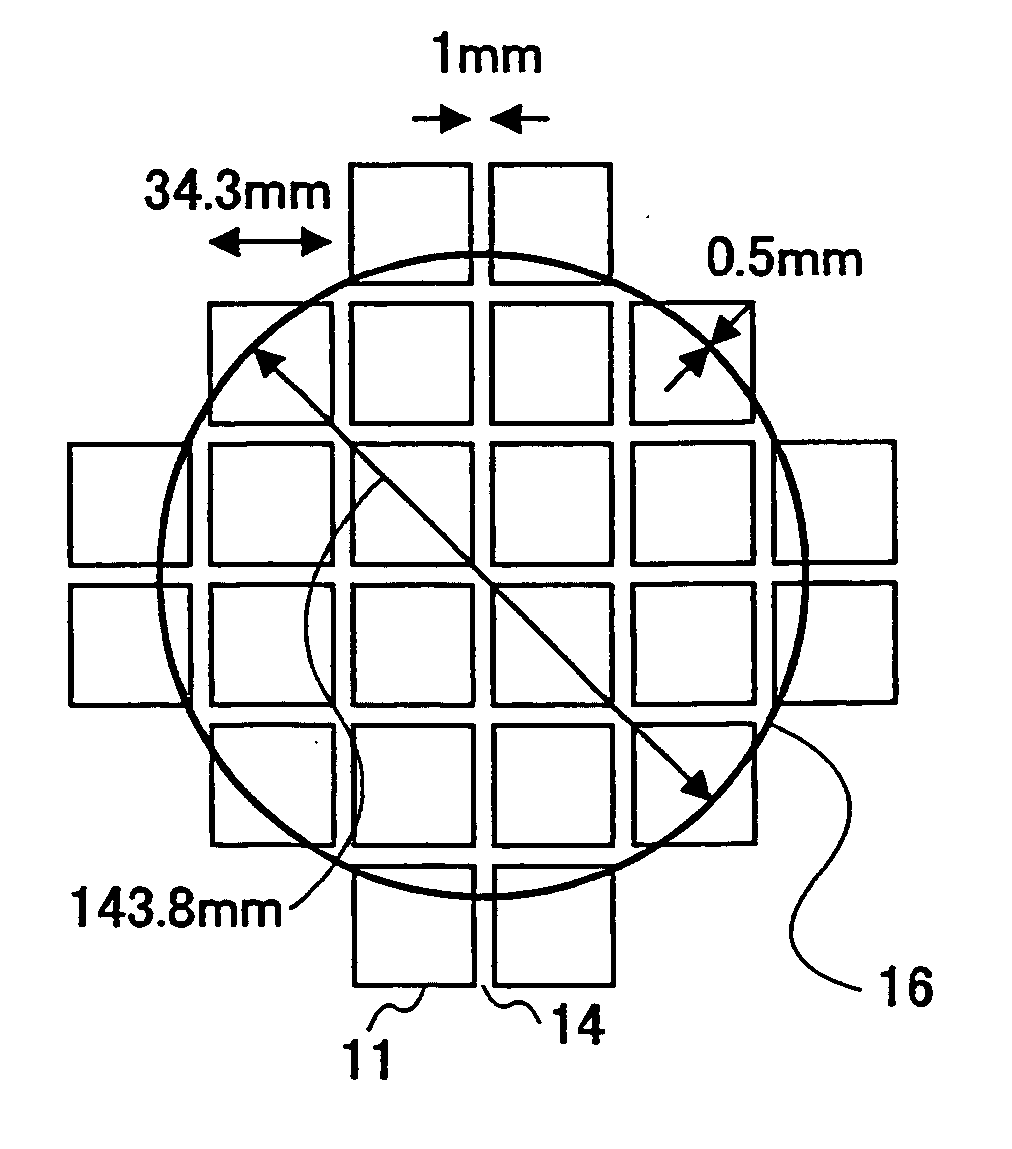

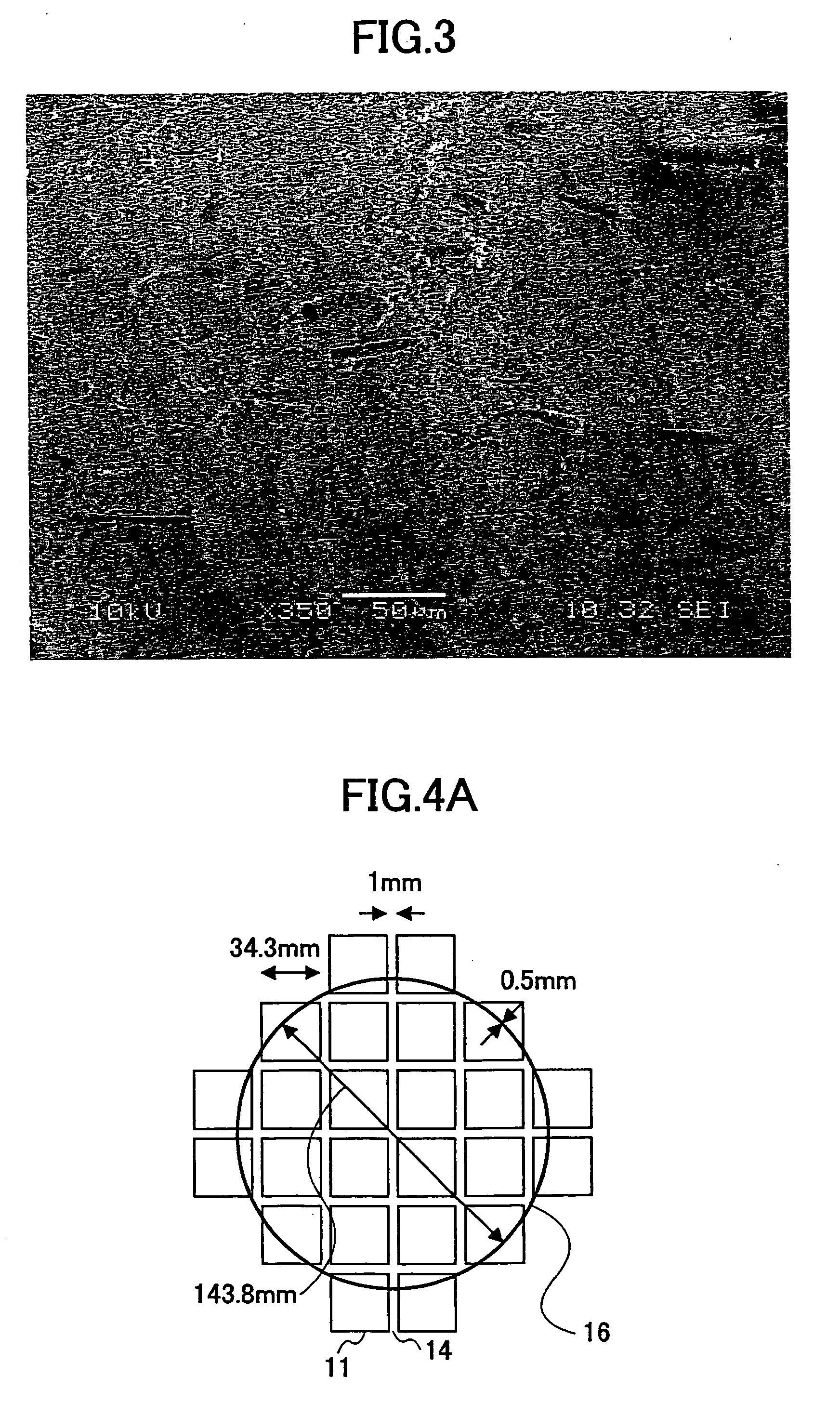

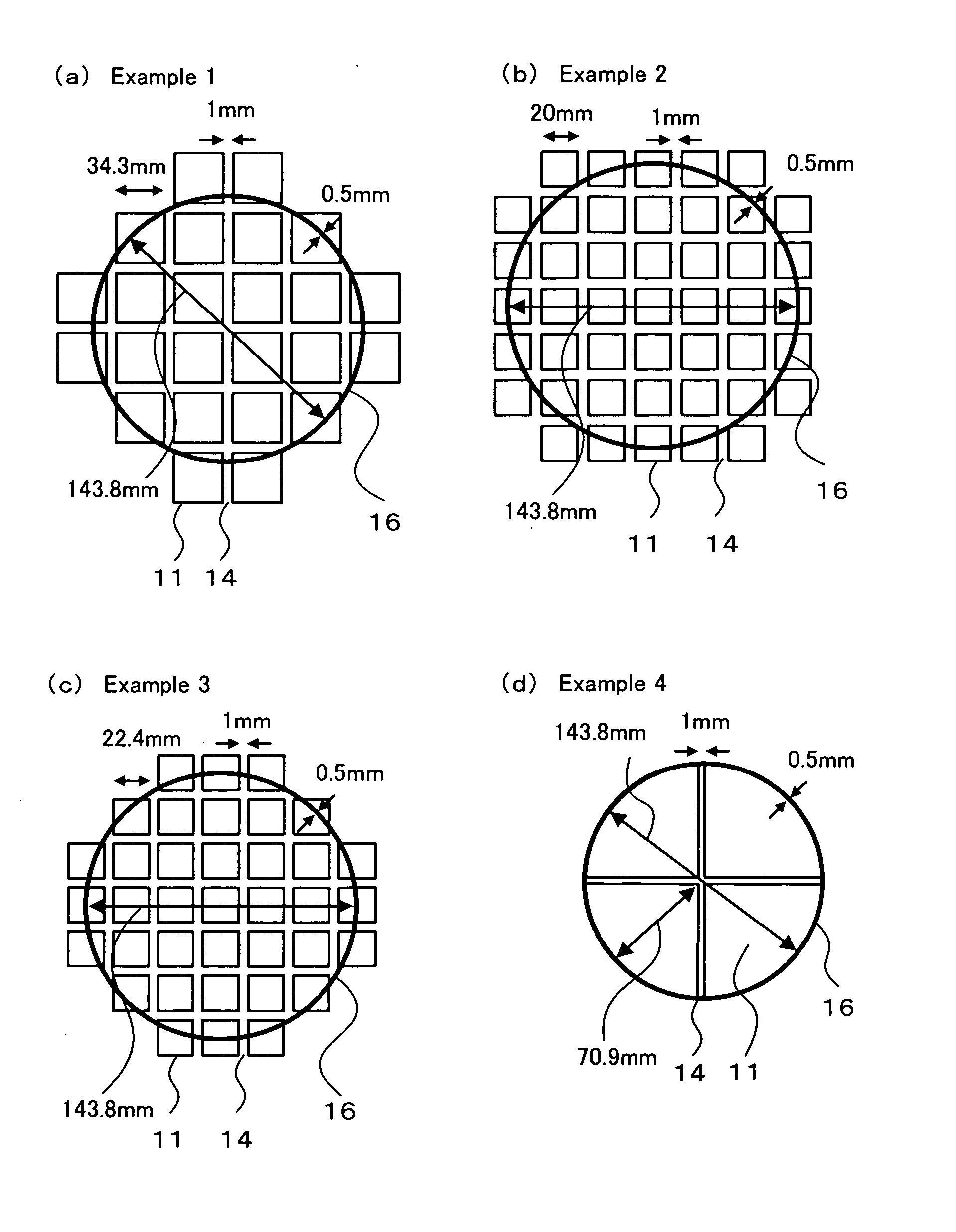

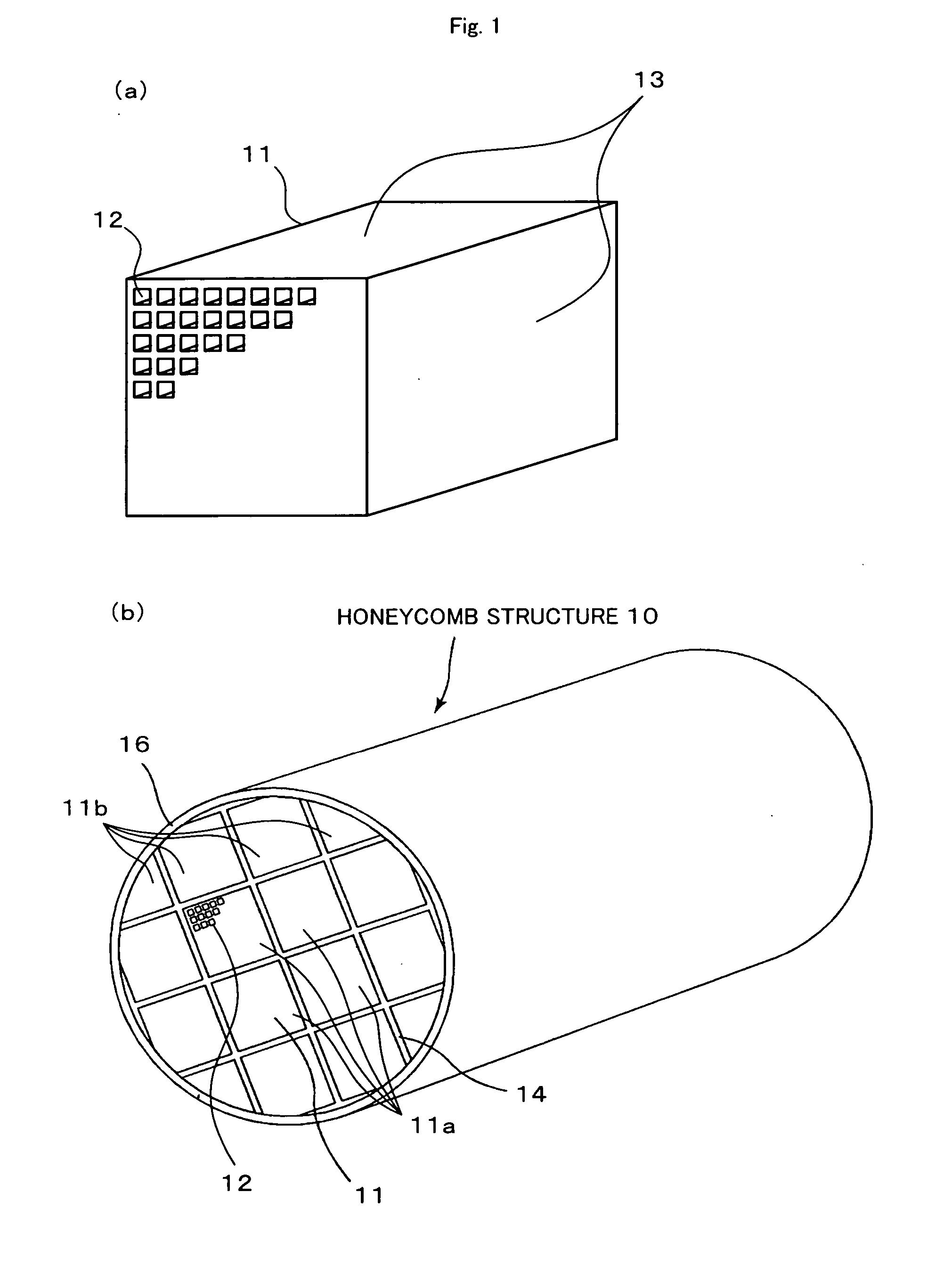

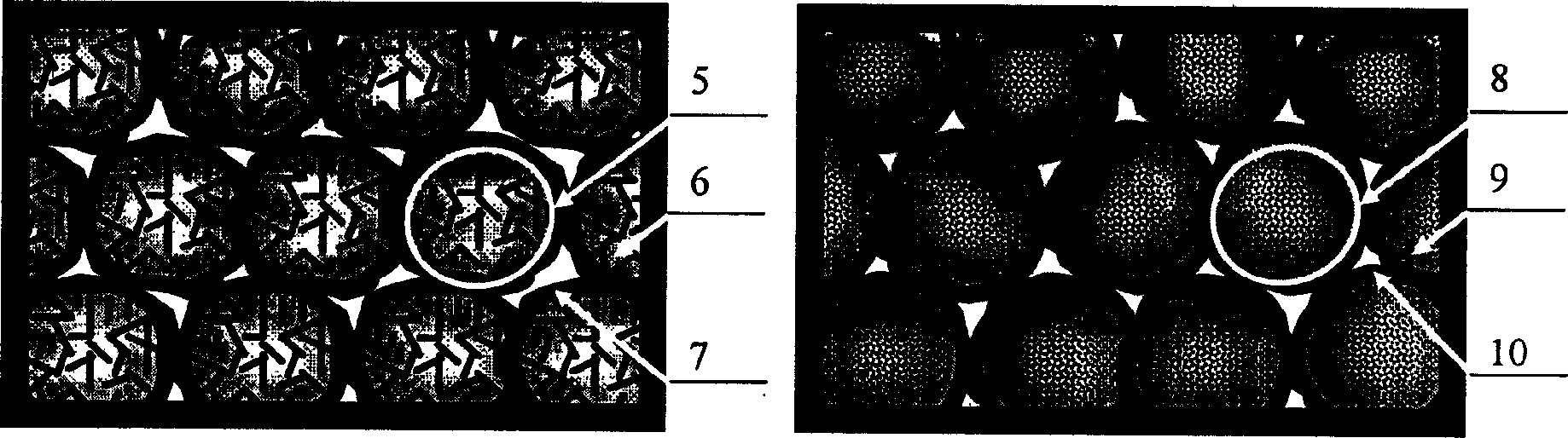

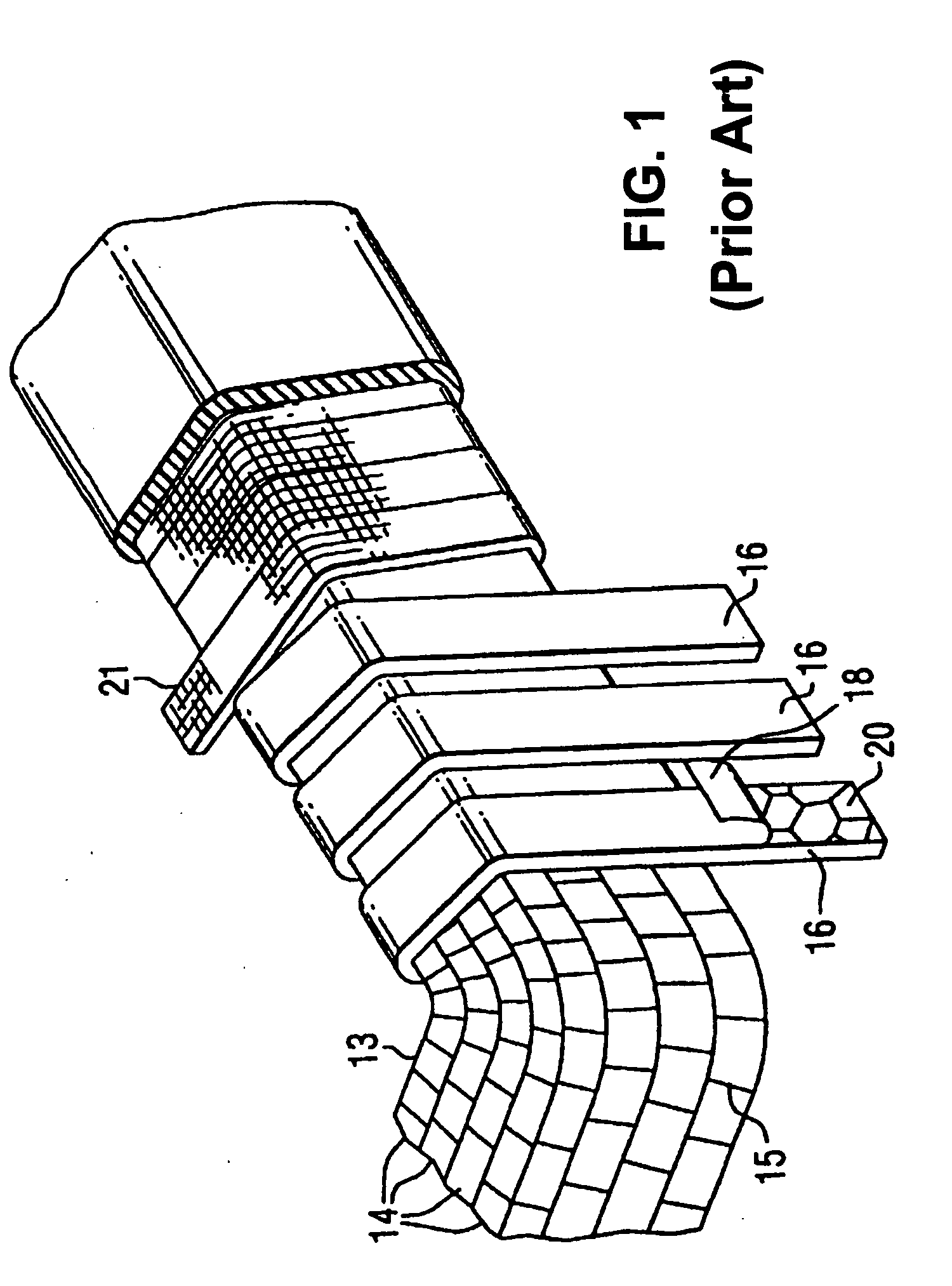

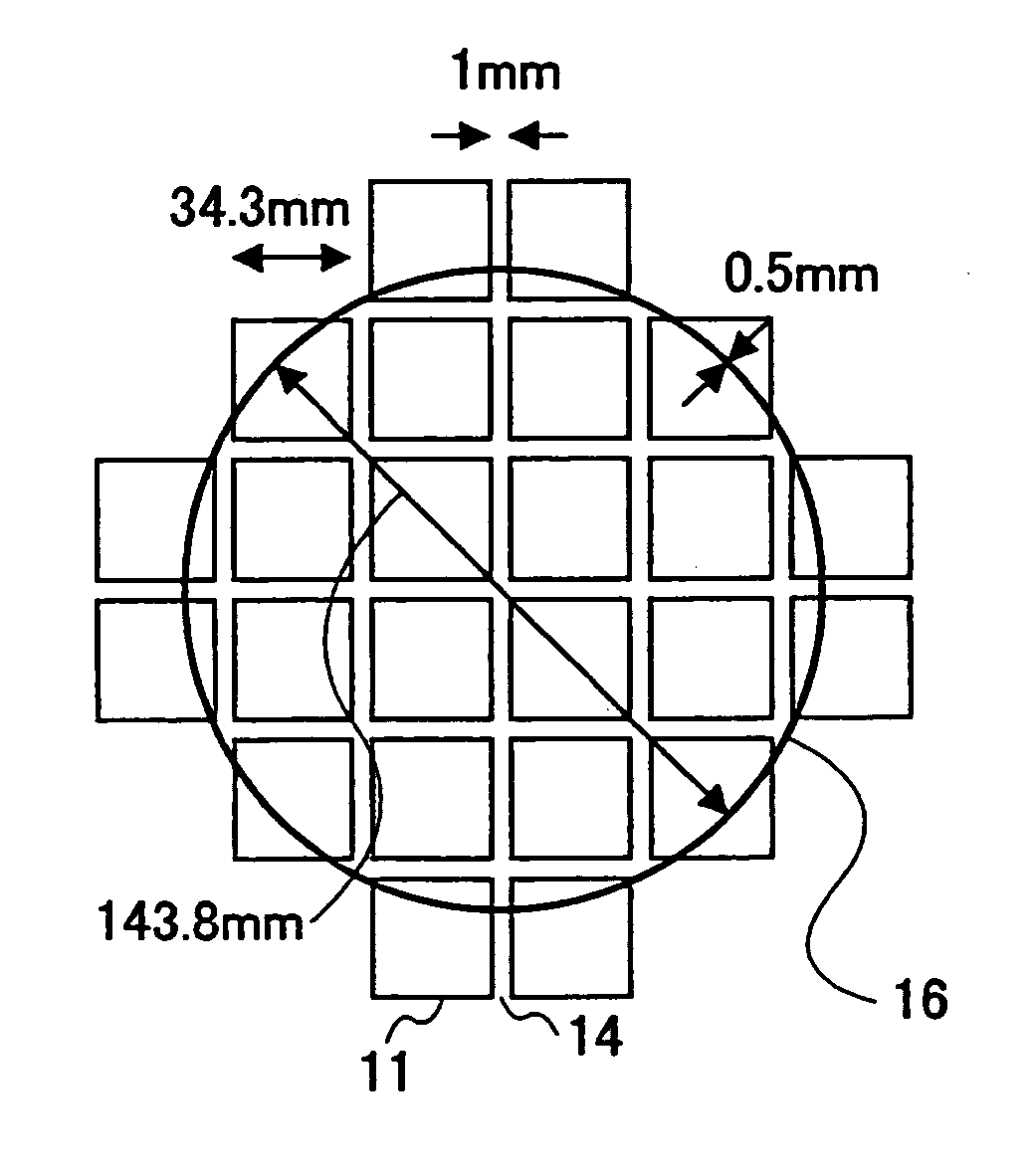

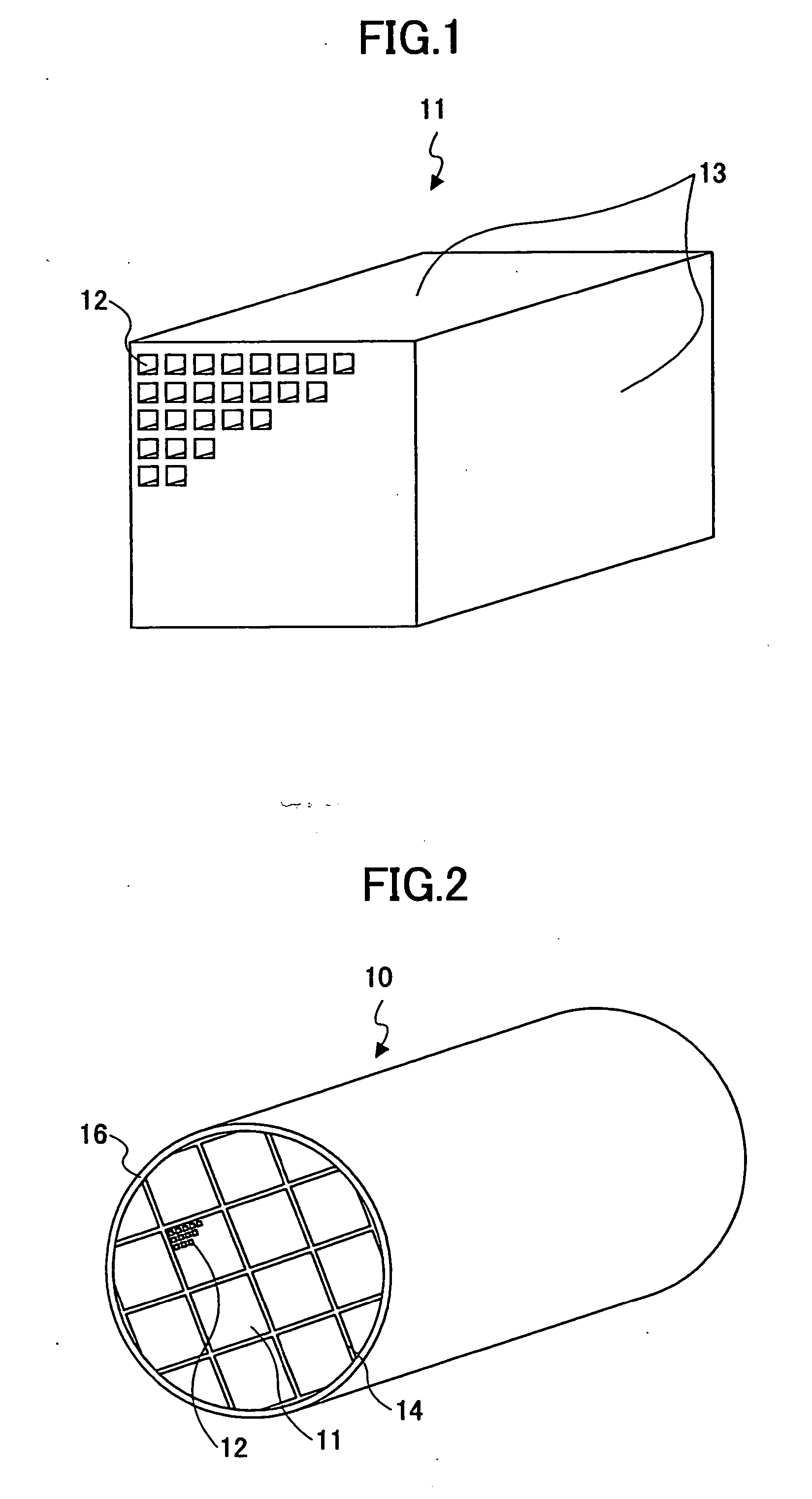

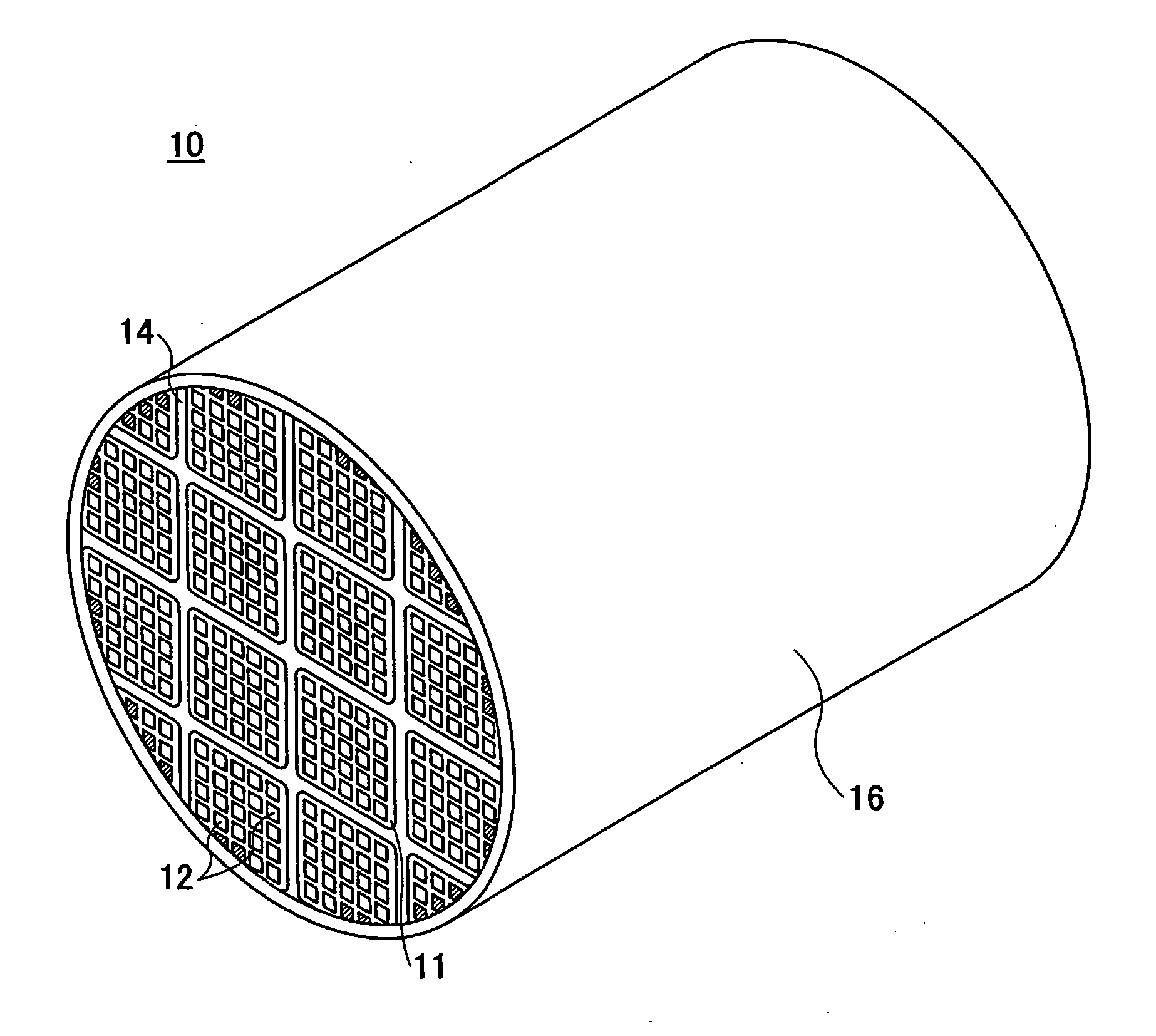

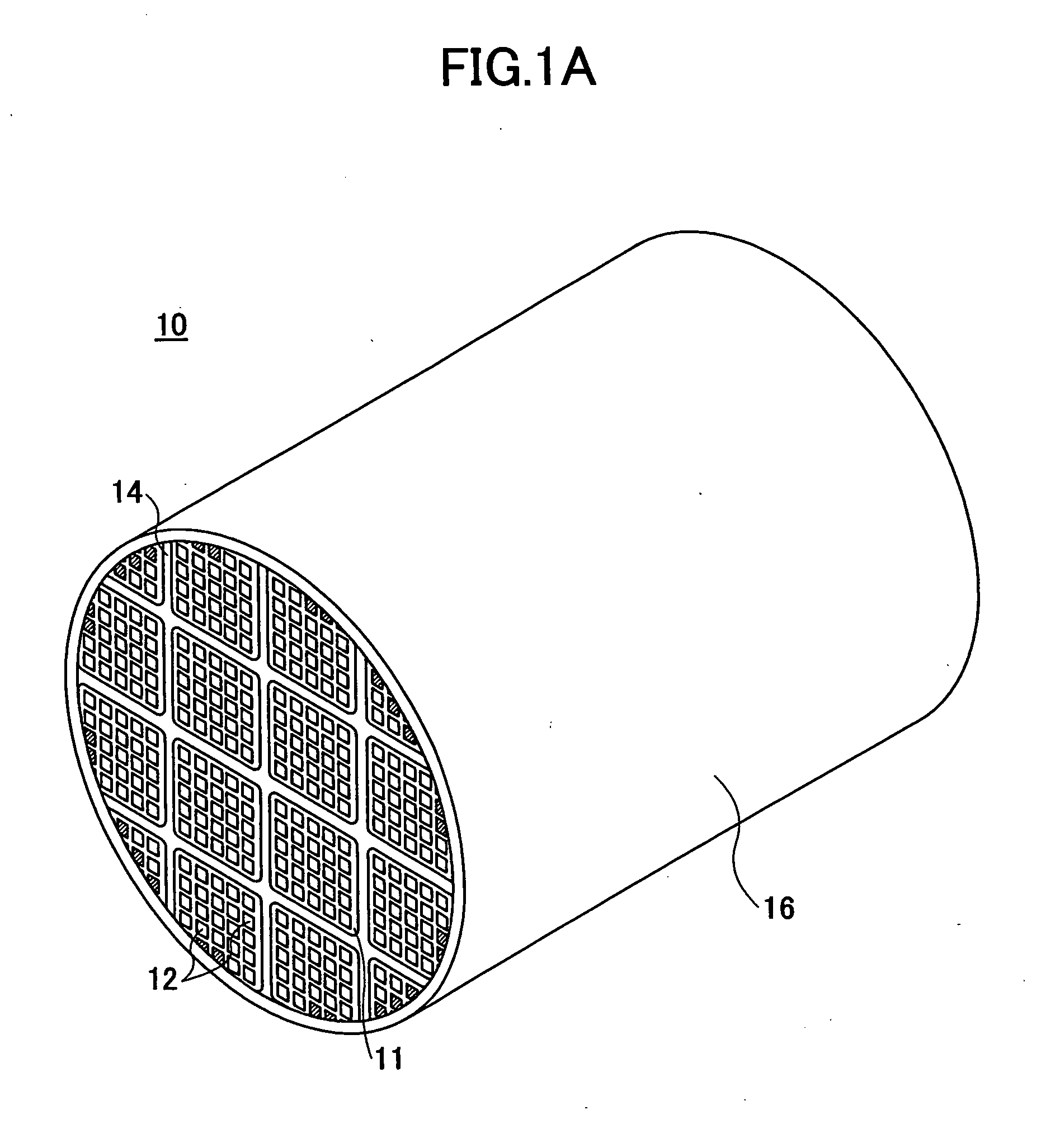

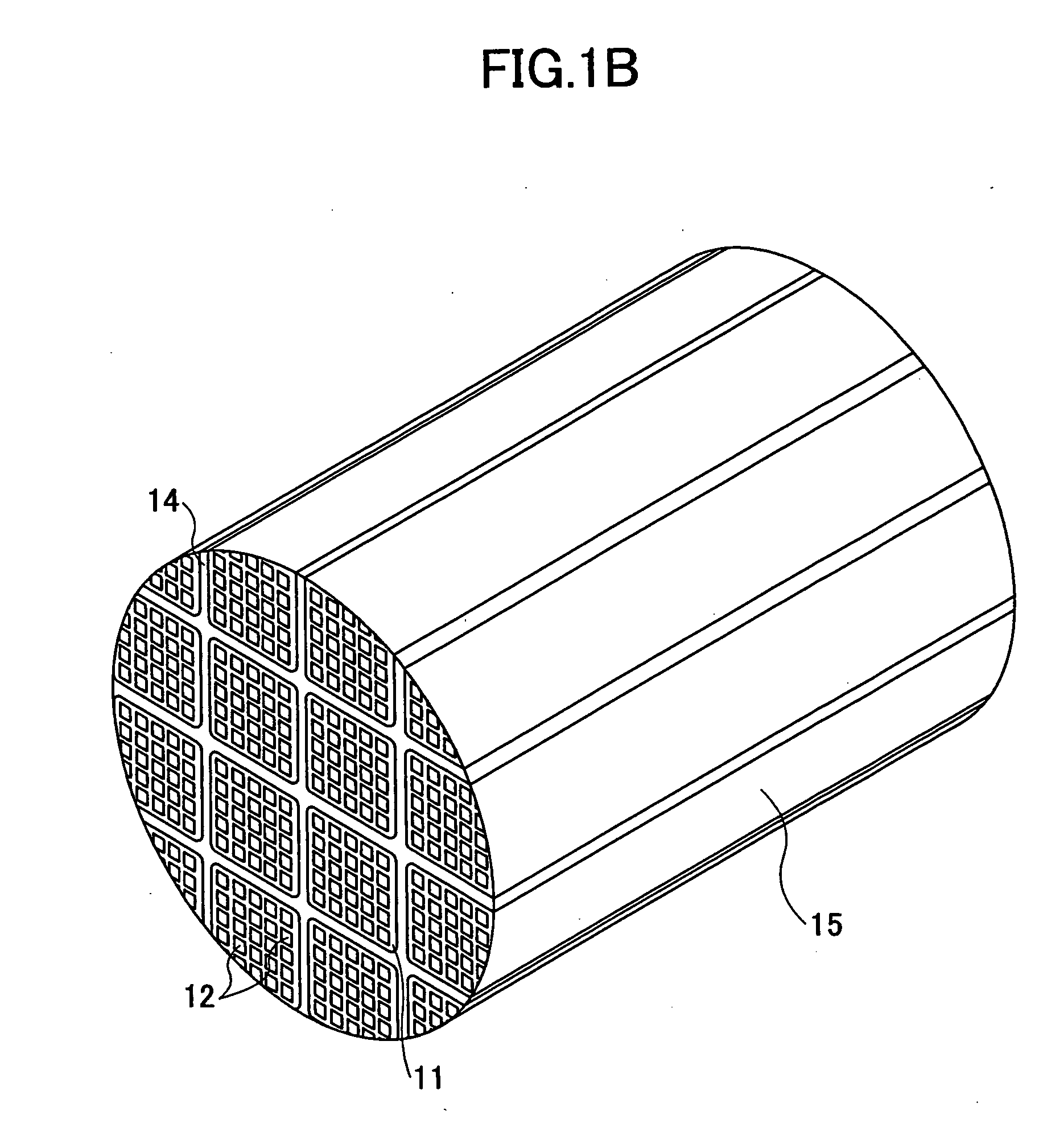

Honeycomb structure

InactiveUS20060292339A1Good dispersionIncrease resistanceLayered productsFiltration separationFiberSurface roughness

A honeycomb structure is disclosed that includes plural honeycomb units bonded together by using a sealing material layer, each of the honeycomb units including plural through-holes separated by plural partition walls and provided in parallel along a longitudinal direction of the honeycomb units, wherein a surface roughness Ra of an outer surface of the honeycomb structure is greater than or equal to about 1 μm and less than or equal to about 50 μm, each of the honeycomb units includes at least ceramic particles, and inorganic fibers and / or whisker, and an area of a cross section of one of the honeycomb units perpendicular to the longitudinal direction of the one of the honeycomb units is greater than or equal to about 5 cm2 and less than or equal to about 50 cm2.

Owner:IBIDEN CO LTD

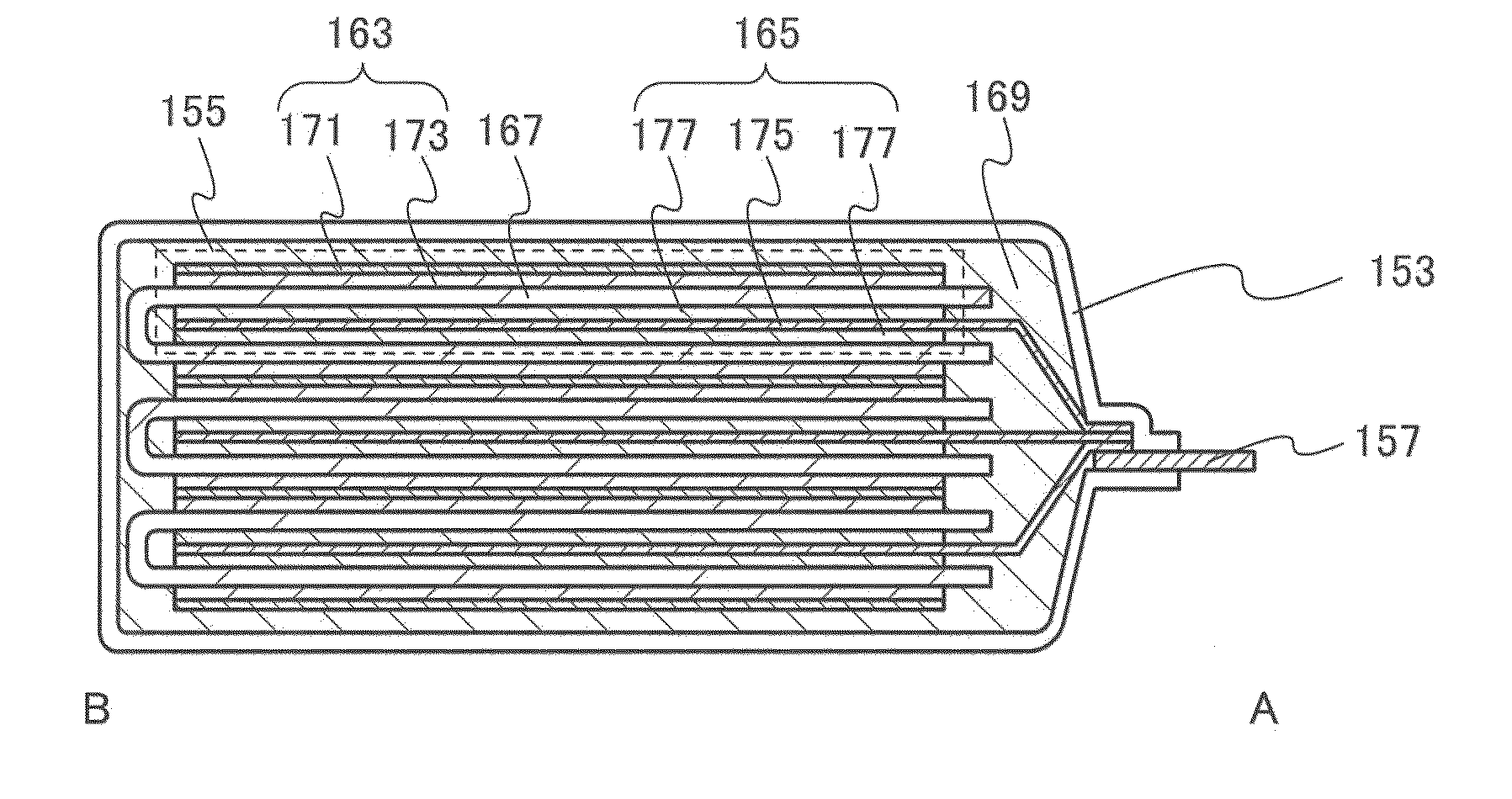

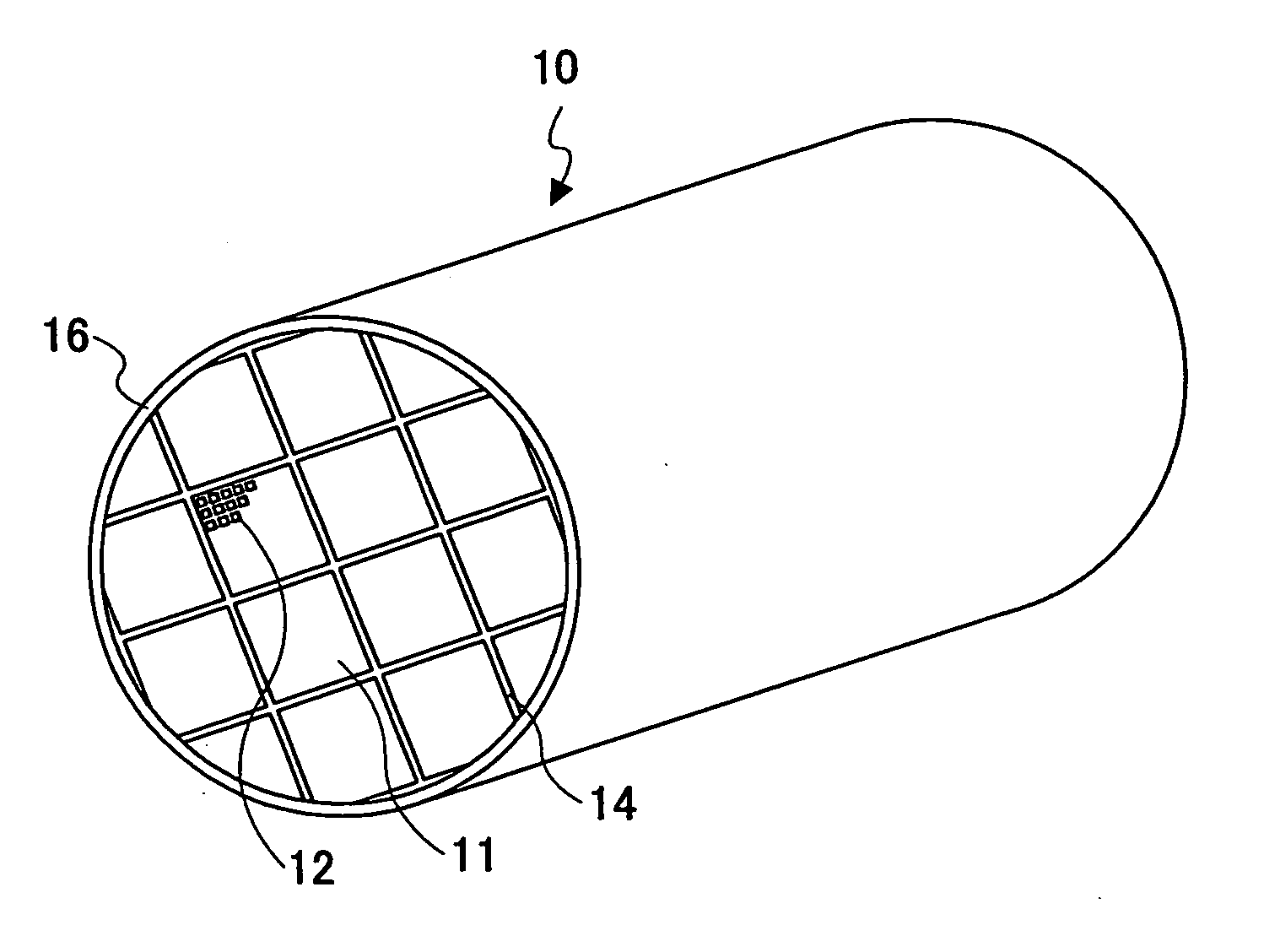

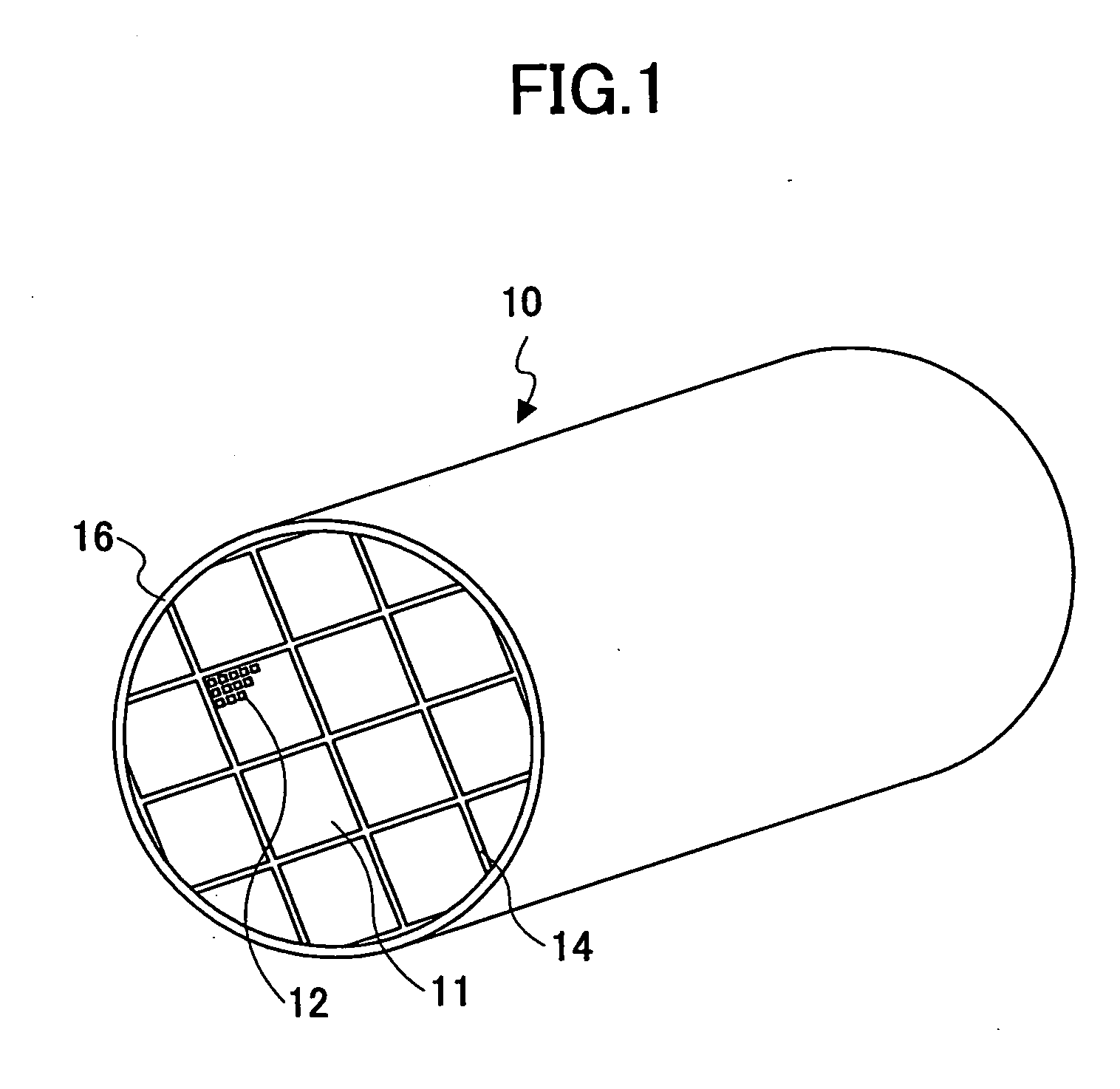

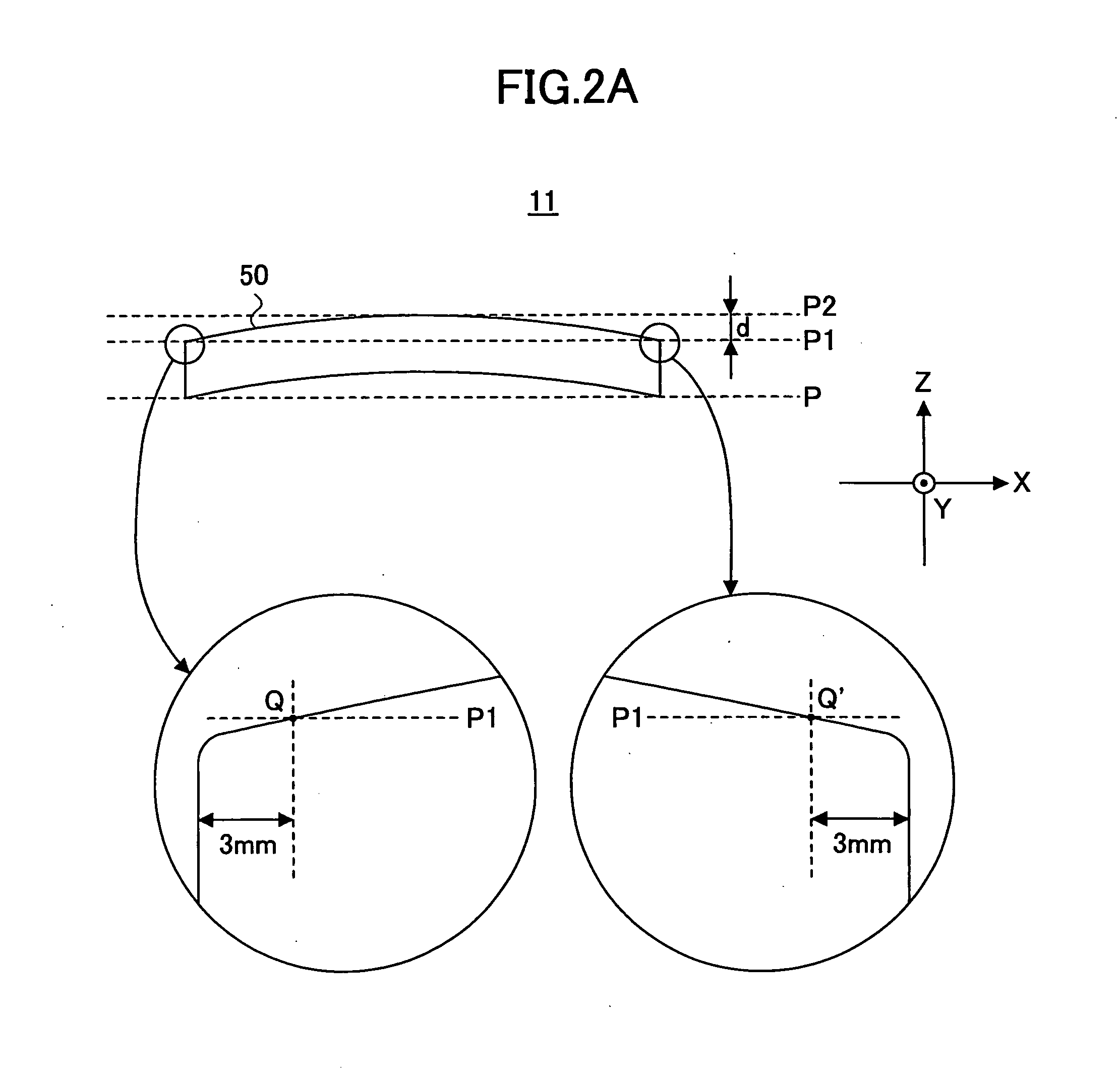

Honeycomb structure

InactiveUS20060292342A1Internal combustion piston enginesDispersed particle filtrationFiberInorganic particle

A honeycomb structure 10 includes: multiple honeycomb units 11 having multiple through holes 12; and a seal layer 14 that joins adjacent honeycomb units 11 with each other via respective closed outer faces 13 of the honeycomb units 11 that are different from respective honeycombed faces of the honeycomb units 11. The honeycomb unit 11 includes at least inorganic particles, inorganic fibers and / or whiskers. A cross section area of a honeycombed face of the honeycomb unit perpendicular to the through holes 12 is about 5 to about 50 cm2, and the surface roughness Rz of the outer face 13 is about 5 to about 50 μm.

Owner:IBIDEN CO LTD

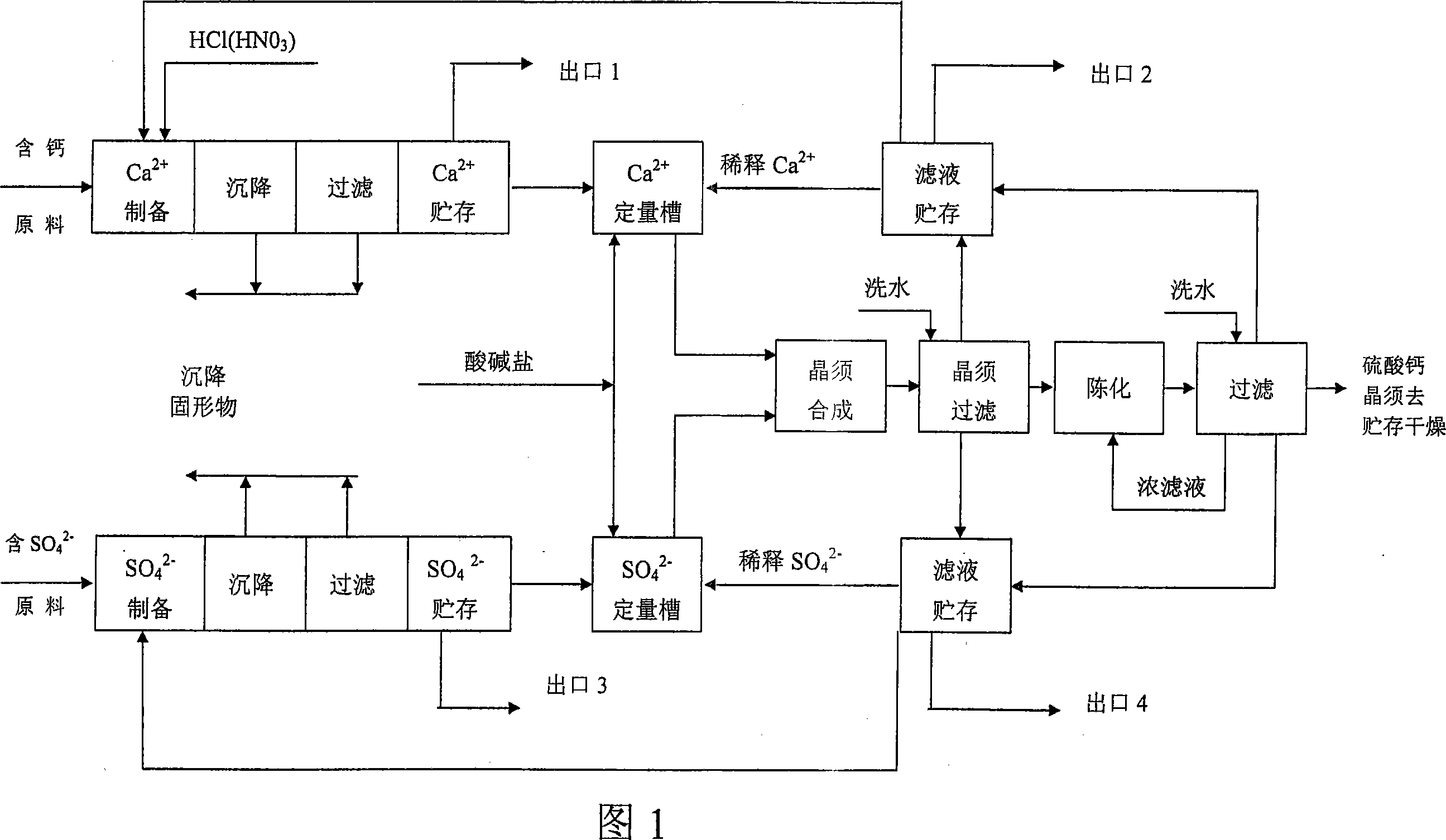

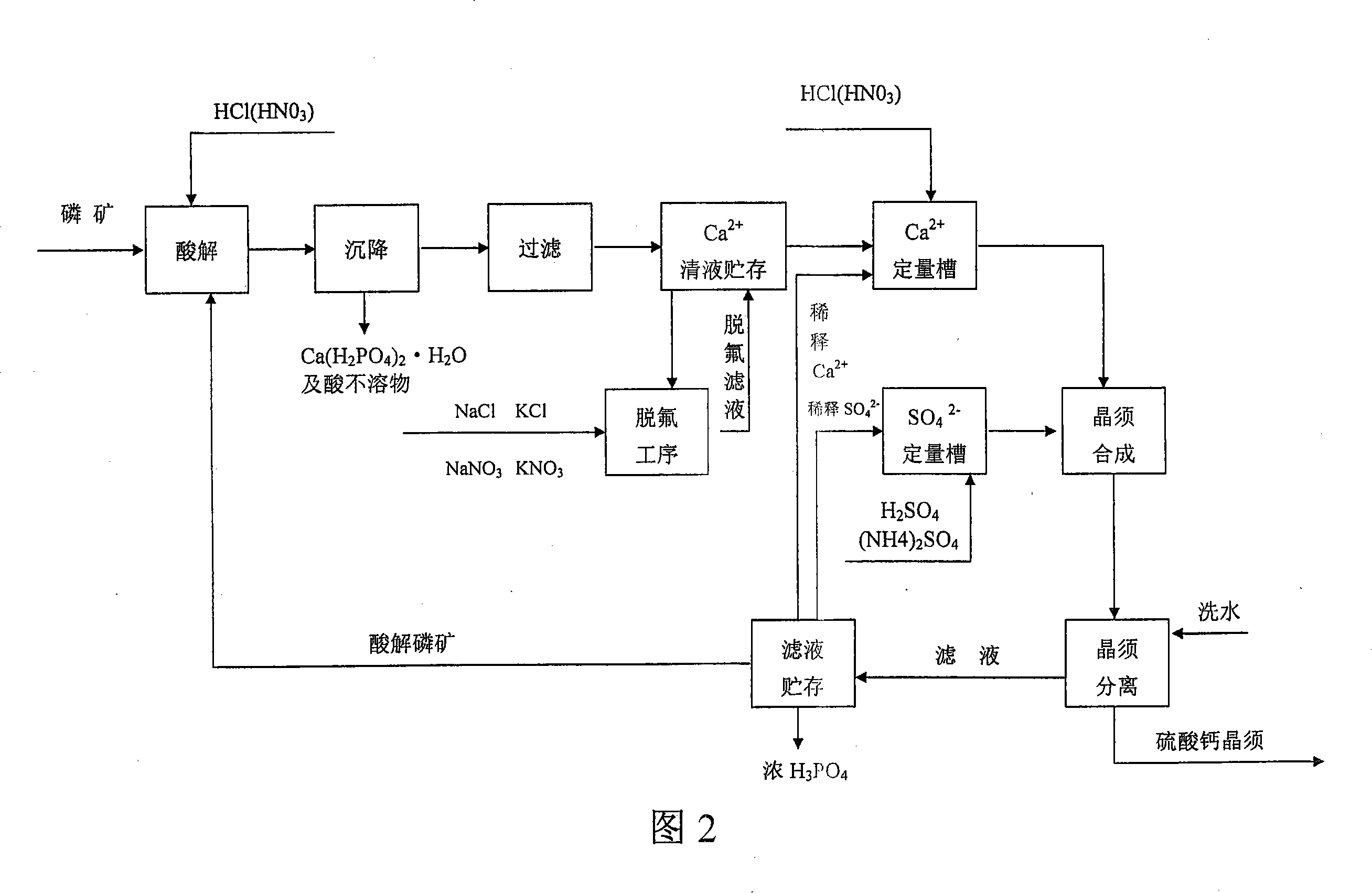

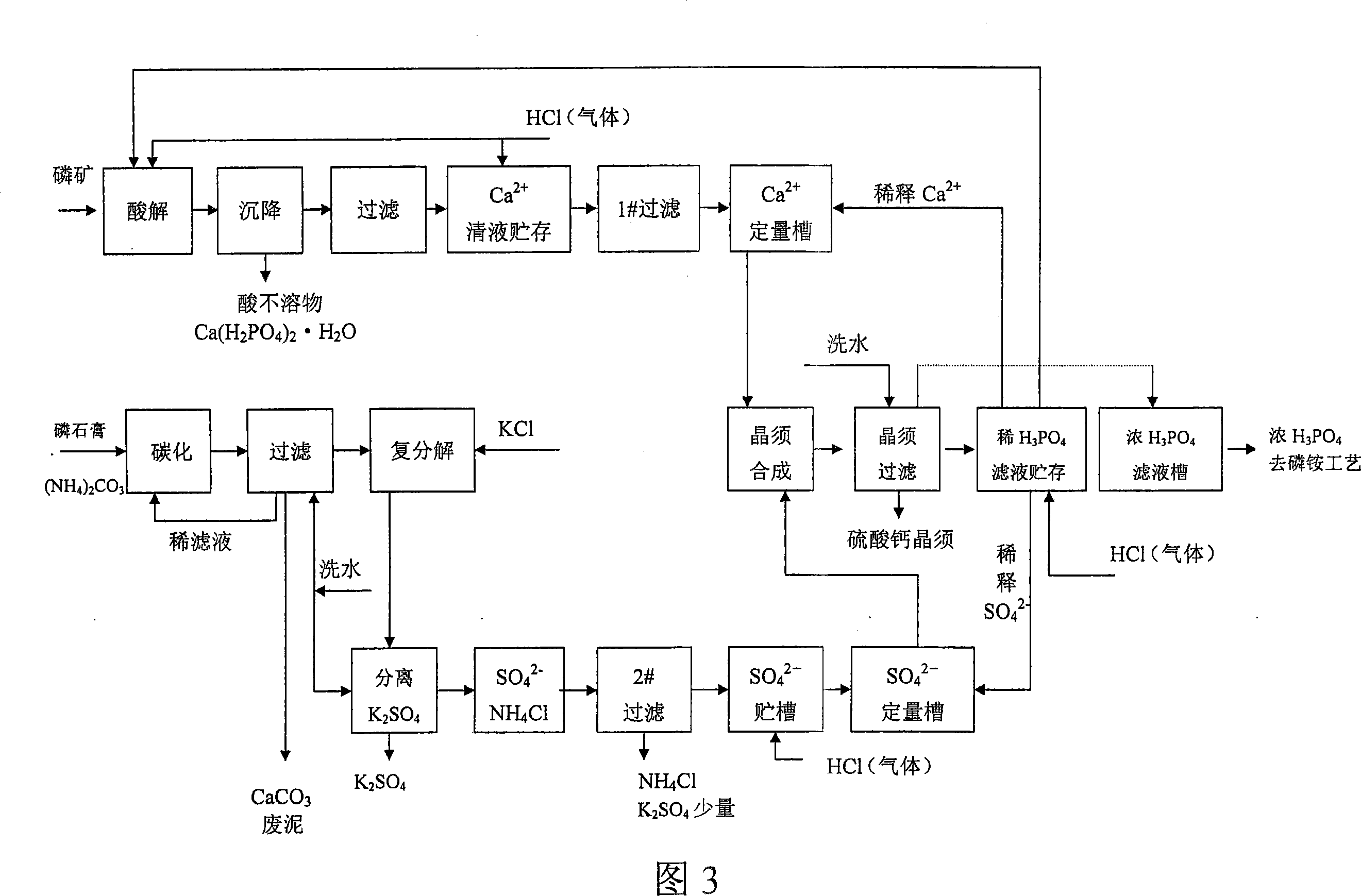

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

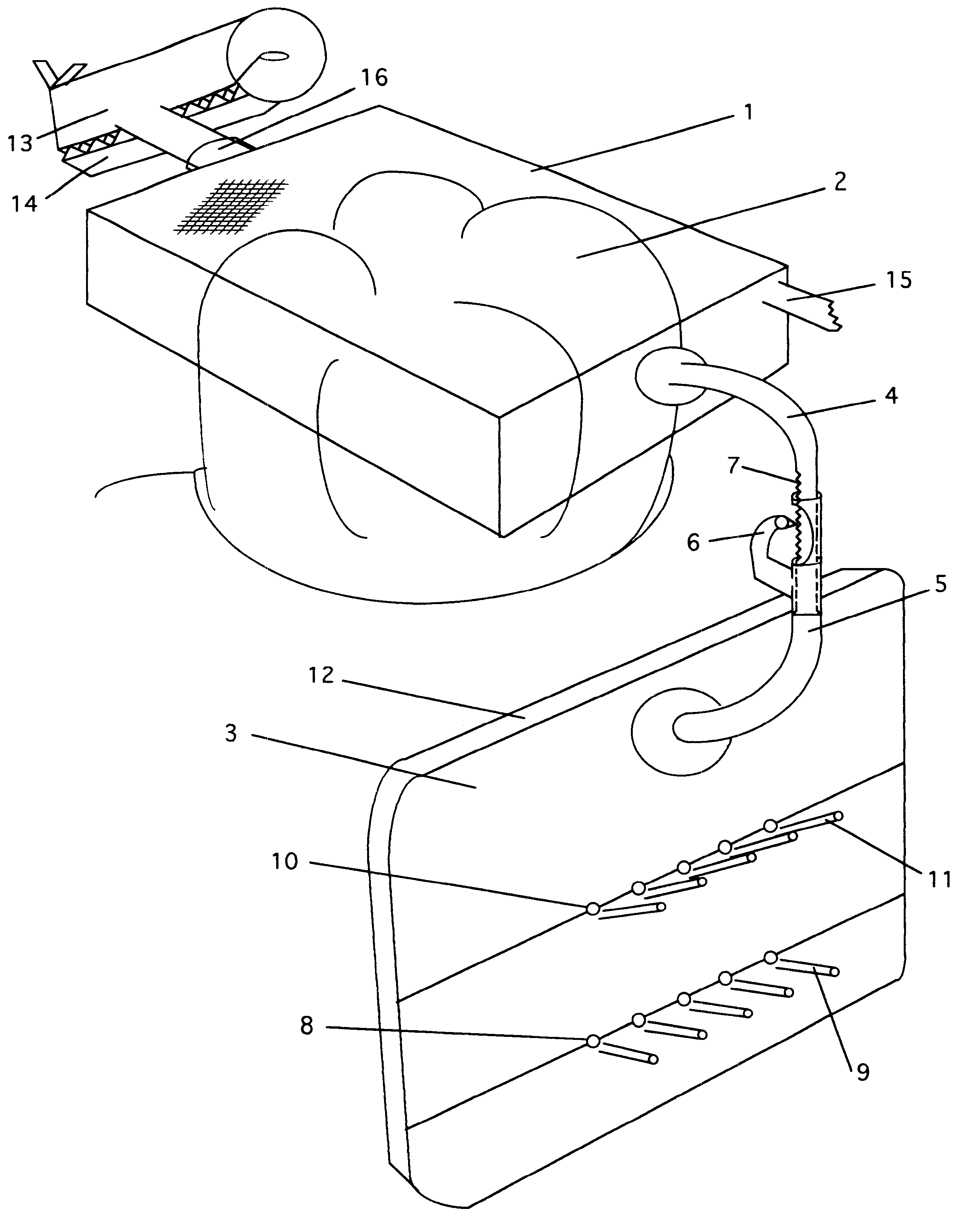

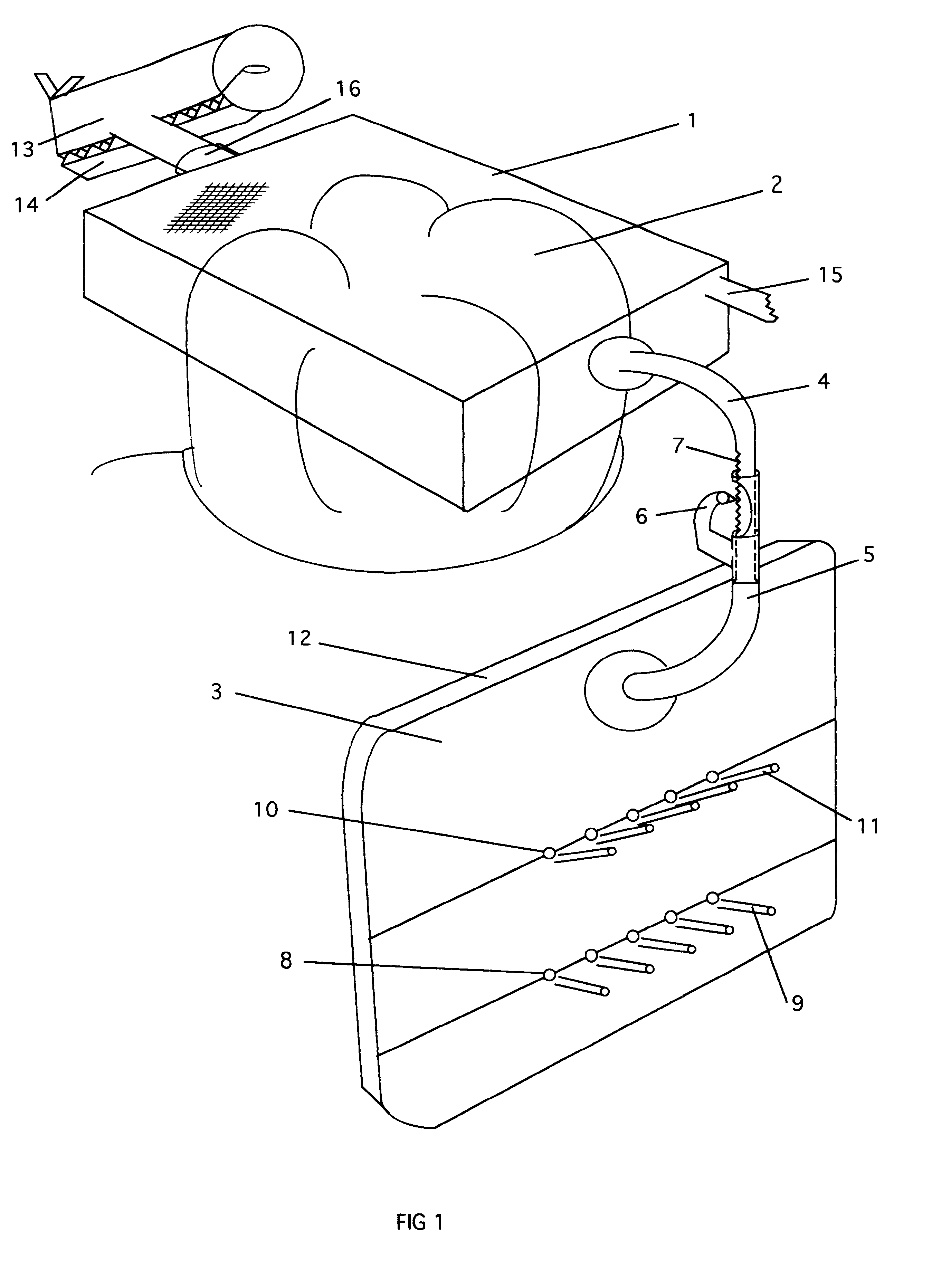

Dental cortical plate alignment platform

InactiveUS6592368B1Reduced risk of breakageReduce traumaImpression capsSurgical needlesOpaque markerCortical plate

This application relates to a dental apparatus for the initial and subsequent guidance of drills, hypodermic needles, or drug delivery devices into the cortical plate of human mandibular and maxillary bones. The invention comprises a thin platform with one or a plurality of angled or straight preformed perforations serving as entrance ports. Each port is optimally heralded by a radio-opaque marker to enable a view of the tooth root prior to drilling for a superior selection of a nerve deadening site and a whisker tubule visually displaying the drill's angle. The platform can be positioned on either the inner or outer side of the cortical plate, and is optimized for use with a dedicated indexing bite apparatus, a dedicated rubber dam style clamp, or by attachment to a RINN positioner or the like.

Owner:LVI GLOBAL

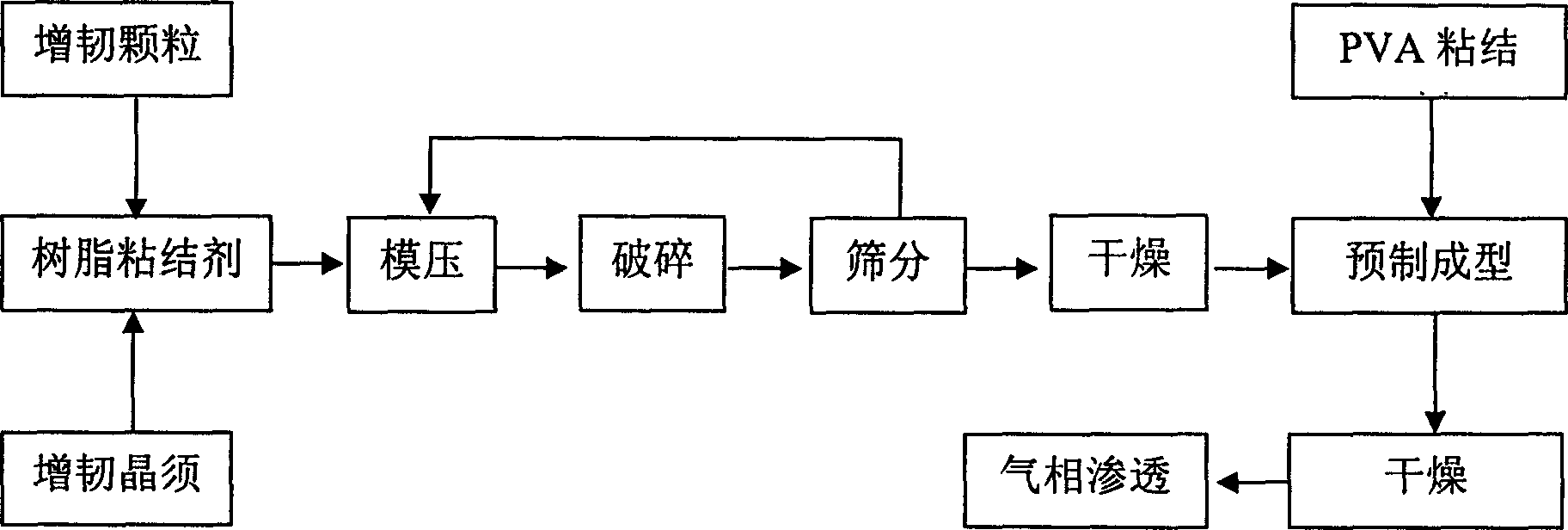

Preparation method of whisker and pacticle toughening ceramic base composite

A crystal whisker and particle toughened ceramic-based composition used to make large thin-wall member is prepared through granulating to prepare the coagulated substance of crystal whiskers and particles, preparing the prefabricated body of crystal whisker-particle reinforcing body, and depositing the ceramic base in said prefabricated body by chemical vapour osmosis process.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

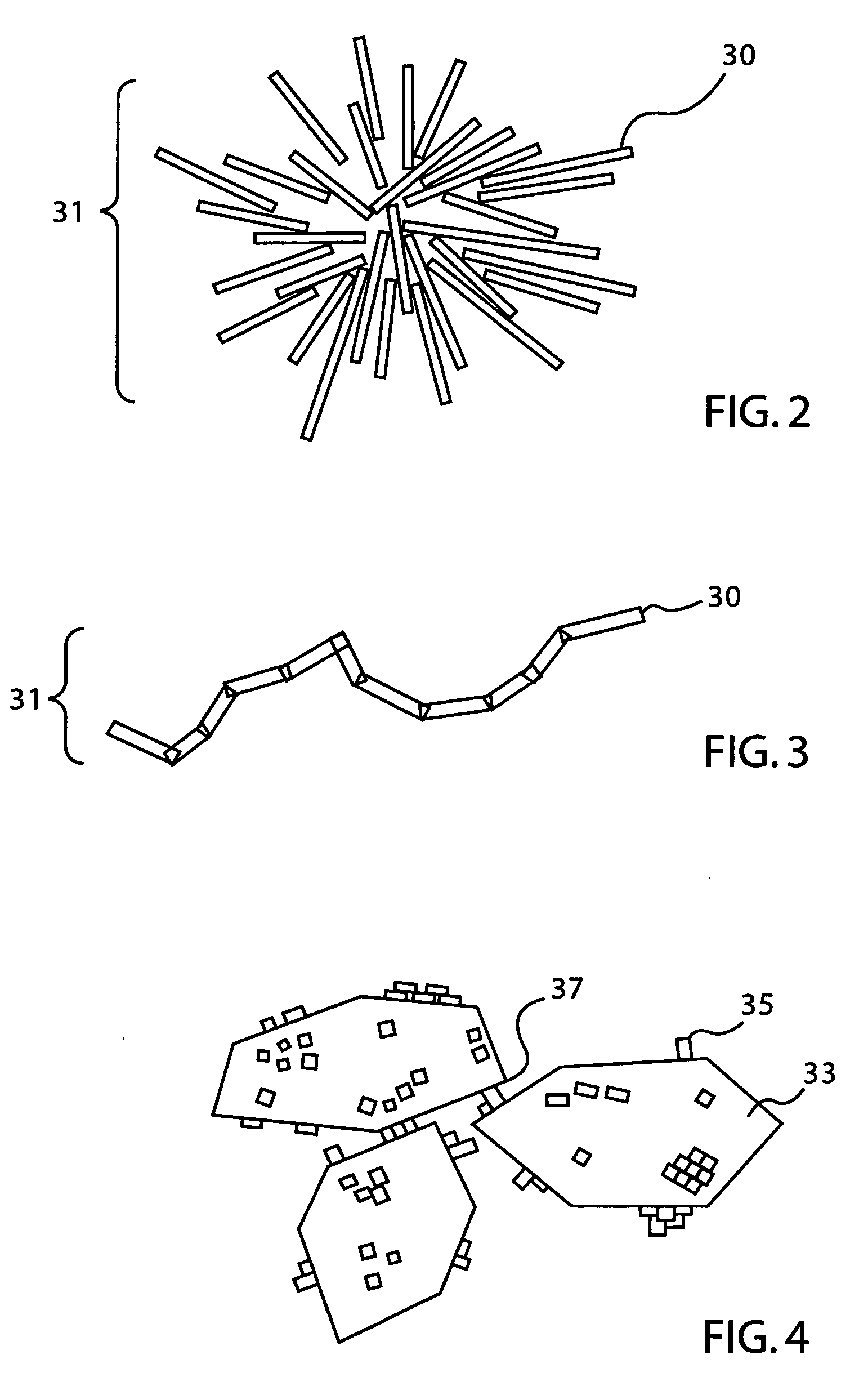

Morphological forms of fillers for electrical insulation

InactiveUS20070026221A1Easy to transportReduce distanceWindings insulation shape/form/constructionPrinted circuit aspectsElectricityResin matrix

A high thermal conductivity resin that has a host resin matrix, and a high thermal conductivity filler. The high thermal conductivity filler (30) forms a continuous organic-inorganic composite with the host resin matrix. The fillers are from 1-1000 nm in length, and have average aspect ratios of between 3-100. At least a portion of the high thermal conductivity fillers comprise morphologies (31) chosen from one or more of hexagonal, cubic, orthorhombic, rhombohedral, tetragonal, whiskers and tubes. In particular, some of the fillers will aggregate into secondary structures.

Owner:SIEMENS ENERGY INC

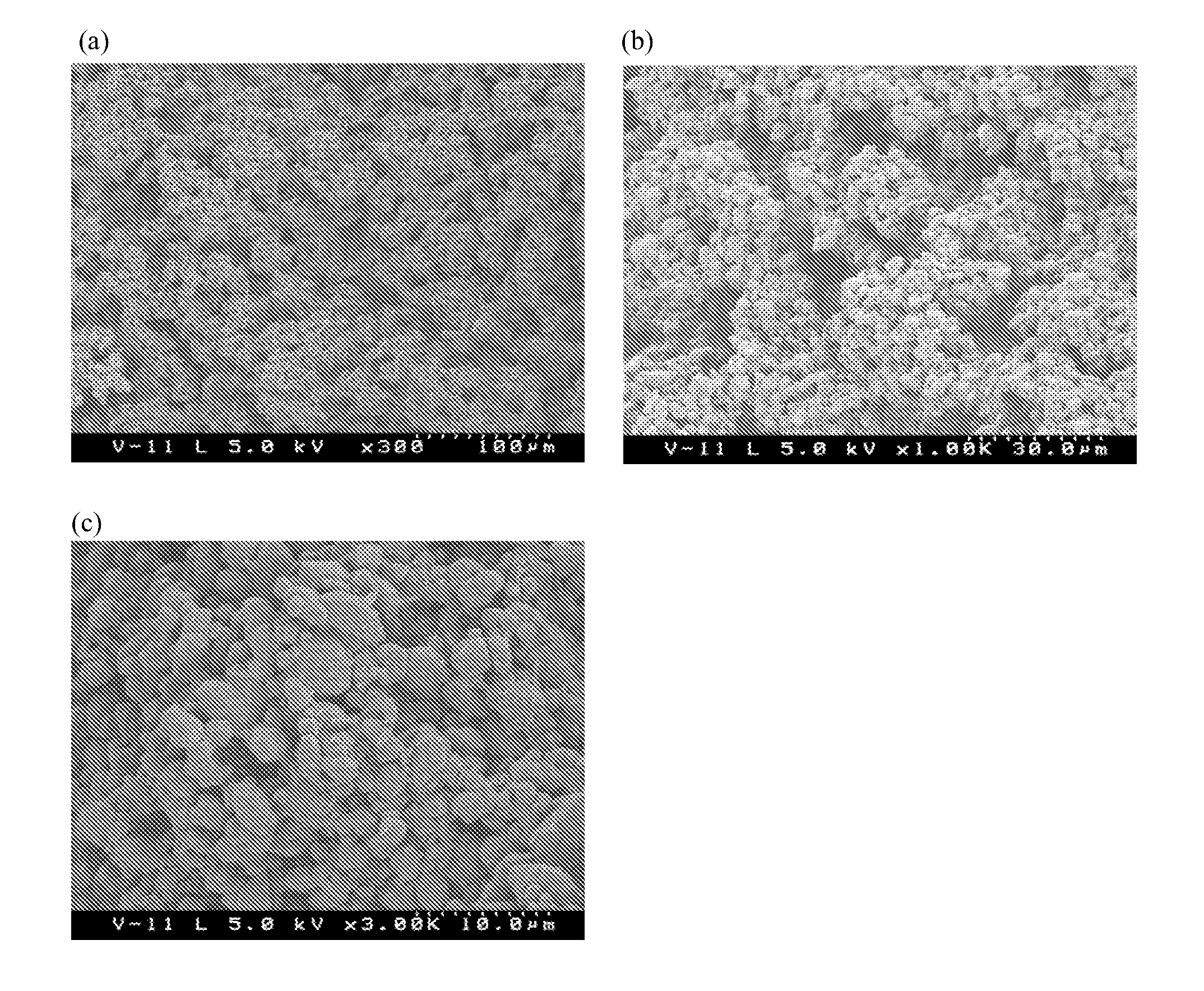

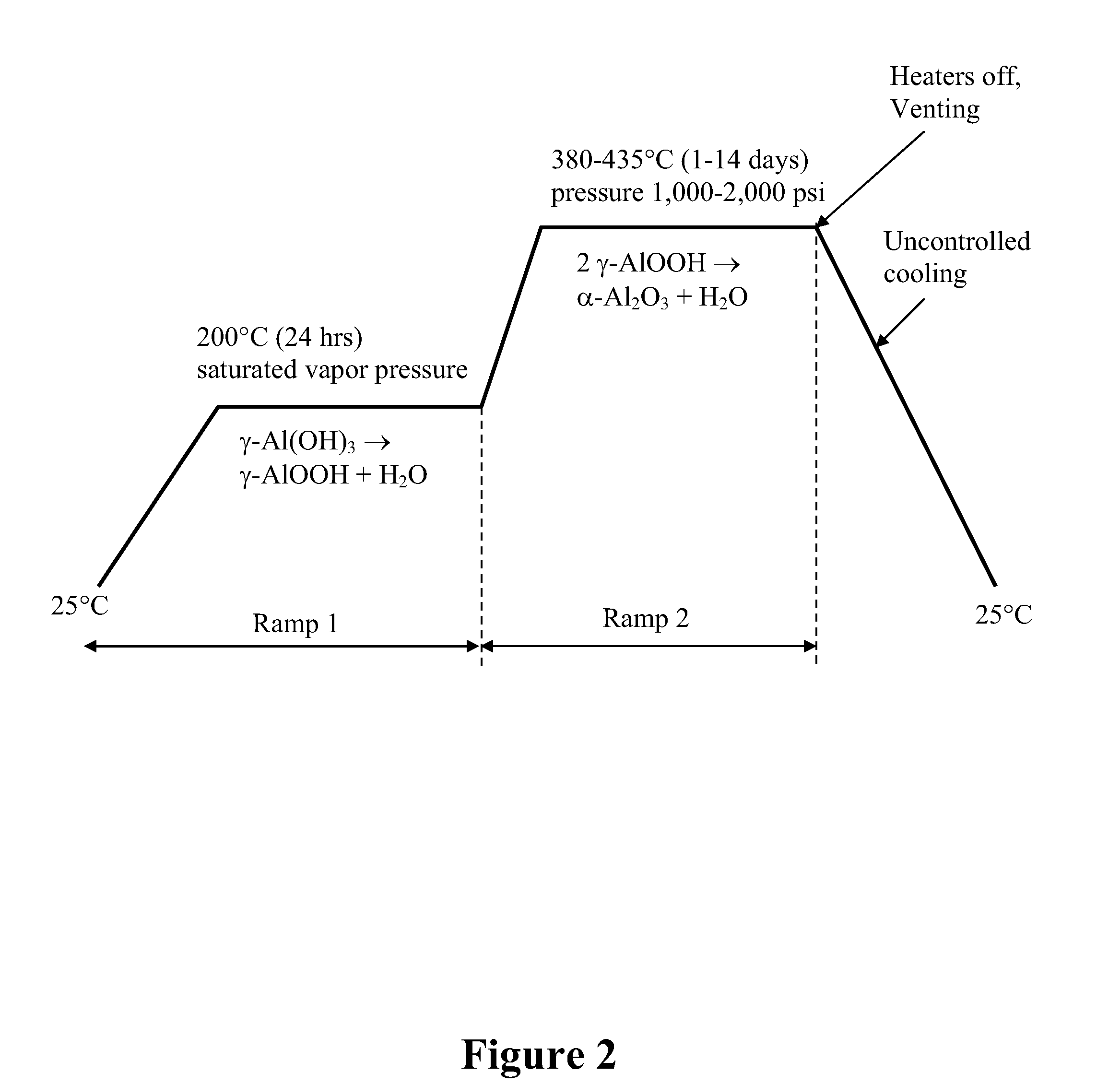

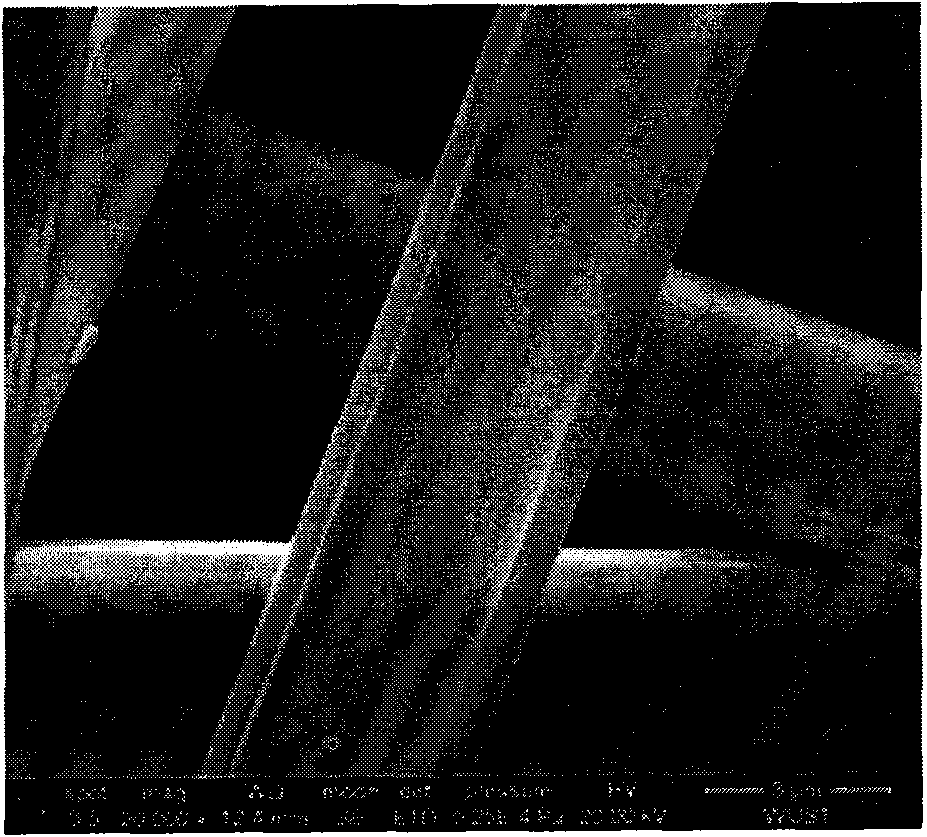

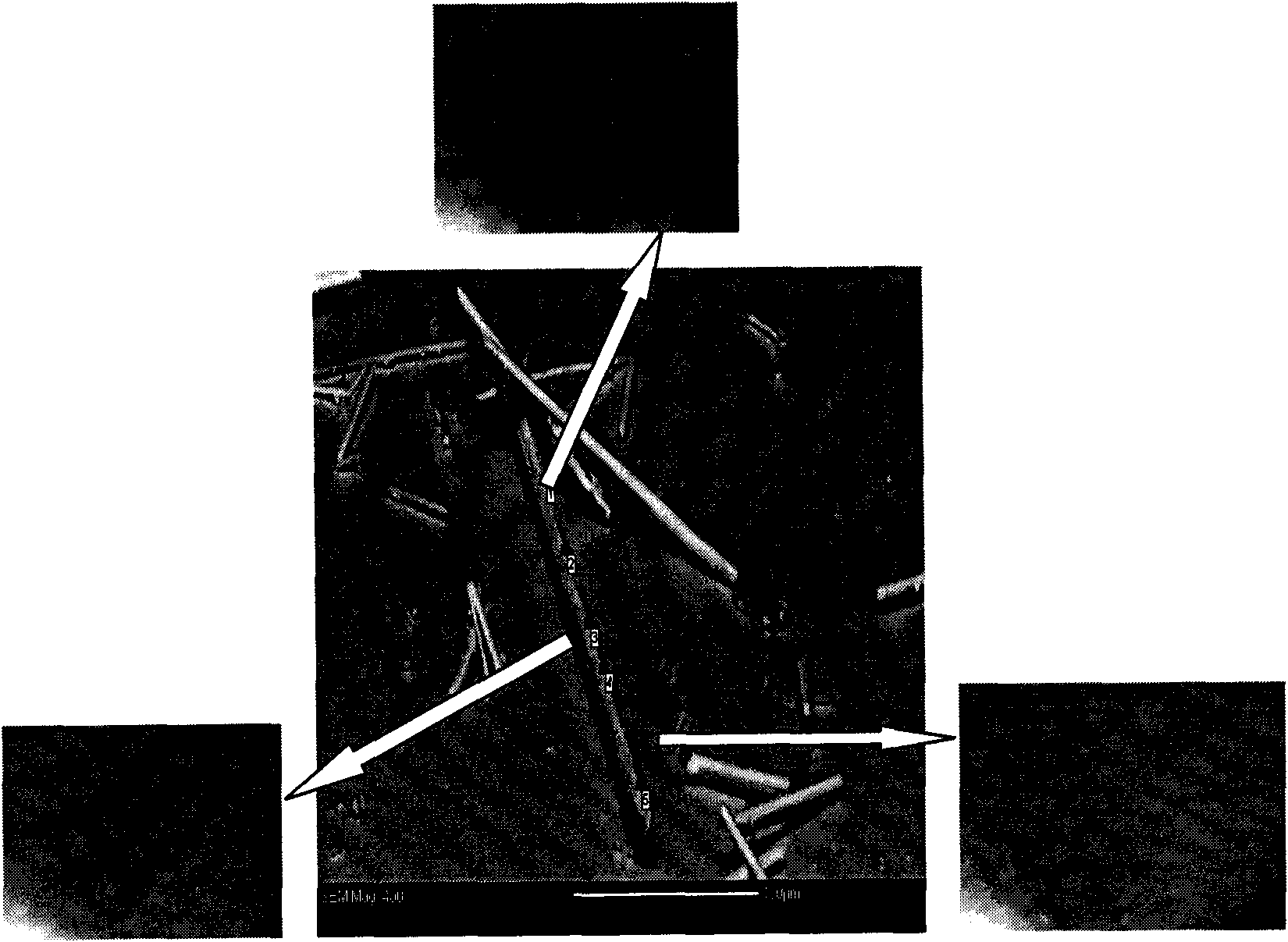

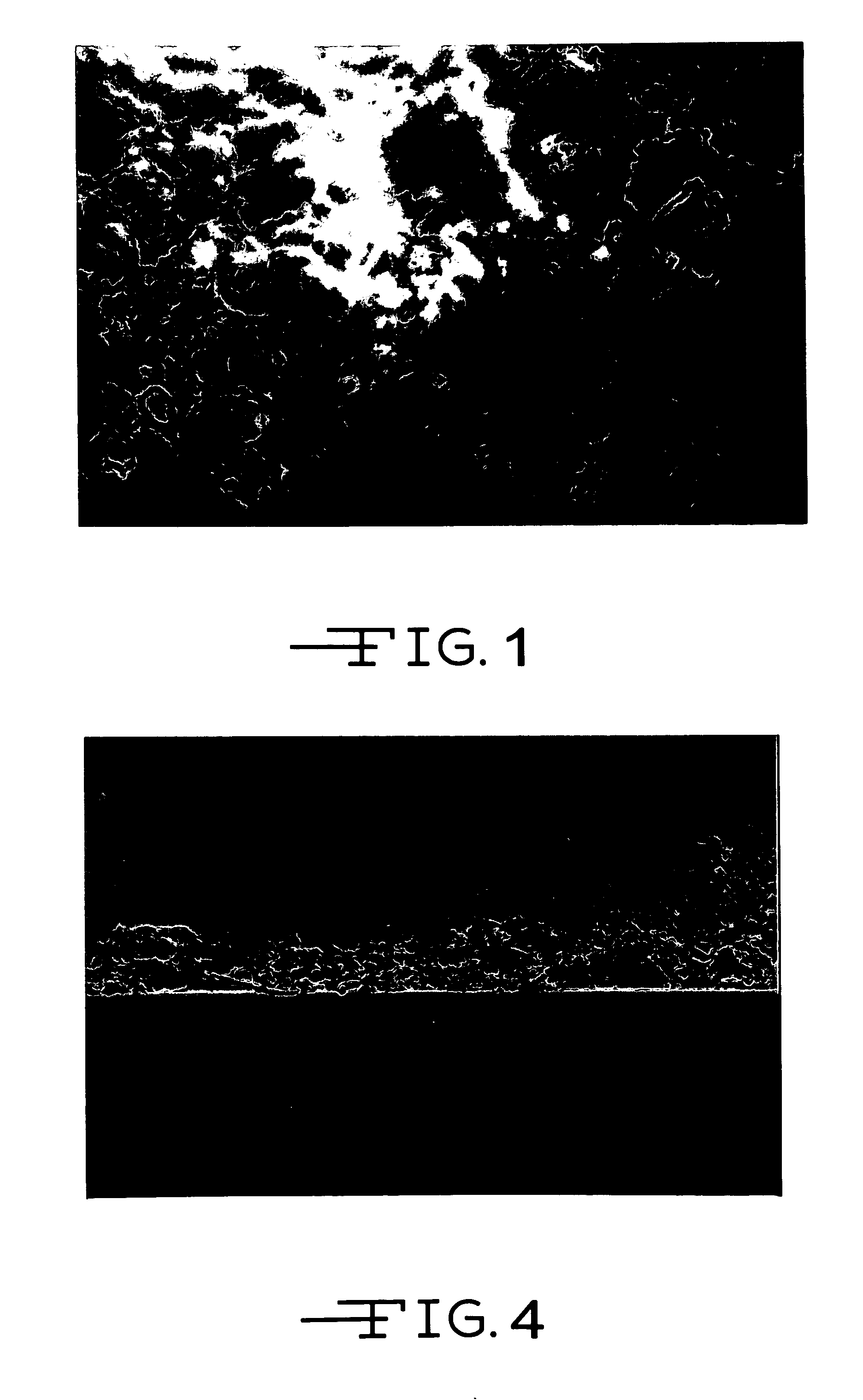

Alpha alumina (corundum) whiskers and fibrous-porous ceramics and method of preparing thereof

InactiveUS20120189833A1High mechanical strengthHigh porosityAluminium oxide/hydroxide preparationAluminium hydroxide preparationWhiskersPorous ceramics

Materials and associated processes for making the materials. For example the material may include alpha alumina crystalline whiskers. The process may include conducting the process as hydrothermal, and producing the whiskers to have a length to diameter aspect ratio of at least two.

Owner:SAWYER TECHN MATERIALS

CaSO* crystal whisker with desulfurized gypsum as raw material and preparing method

InactiveCN101550602AReduce pollutionShort processPolycrystalline material growthFrom solid stateWhiskersCalcium sulphate crystals

The present invention relates to a CaSO4 crystal whisker with desulfurized gypsum as raw material and a preparing method. A technical scheme includes: mixing desulfurized gypsum, water and habit modifier fully for forming suspension; wherein, mass concentration of desulfurized gypsum is 1-8%, mass concentration of habit modifier is 5-20%; or stirring the above suspension 1-3 hours under conditions of normal pressure, 100-128 deg c and 120-210 r / min stirring speed, adding calcium sulphate crystal whisker by weight of 0.5-1% as inoculating crystal, reacting 1-3 hours, adding modifying agent, or stirring the above suspension 3-8 hours, adding the modifying agent directly; or stirring the above suspension 3-8 hours, and adding the modifying agent directly, the amount of the modifying agent is 0.4-1% of the suspension weight, stirring 0.5-1 hours; then pump filtering, washing and three-section drying for obtaining three various type calcium sulphate crystal whisker. The method uses a normal pressure salt solution crystallization method for preparing CaSO4 crystal whisker which has short process flow, geniality condition and low cost, and is an efficient purpose for realizing resource utilizing.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of high-temperature-resistant aerogel and aerogel-type porous ceramics

PendingCN107098352AImprove high temperature resistanceAvoiding Densification ProblemsSilicaZirconium compoundsThermal insulationWhiskers

The invention discloses a preparation method of high-temperature-resistant aerogel. The method comprises: adding high-temperature-resistant powder or crystal whiskers to sol, performing in-situ compounding of sol and high-temperature-resistant powder or crystal whiskers, and performing aging, modification and drying to obtain high-temperature-resistant aerogel. The invention further discloses a preparation method of aerogel-type porous ceramics. Porous ceramics having an aerogel hole structure kept is obtained by sintering the high-temperature-resistant aerogel. The prepared high-temperature-resistant aerogel and aerogel-type porous ceramics can resist high temperature of 1000-1800 DEC C or more, keep the nanometer hole structure from collapse, have high porosity and strength and have hole diameters which can be adjusted from micropores to large holes. The aerogel and aerogel-type porous ceramics can be used as a super thermal insulation material and can be widely applied to fields of purification separation, adsorption, chemical industrial catalytic carriers, sound absorption and damping, sensing elements and electrochemistry. The method is simple and easy to carry out and suitable for massive production, and allows high temperature resistance of aerogel to be improved and application fields of aerogel to be broadened.

Owner:浙江圣润纳米科技有限公司

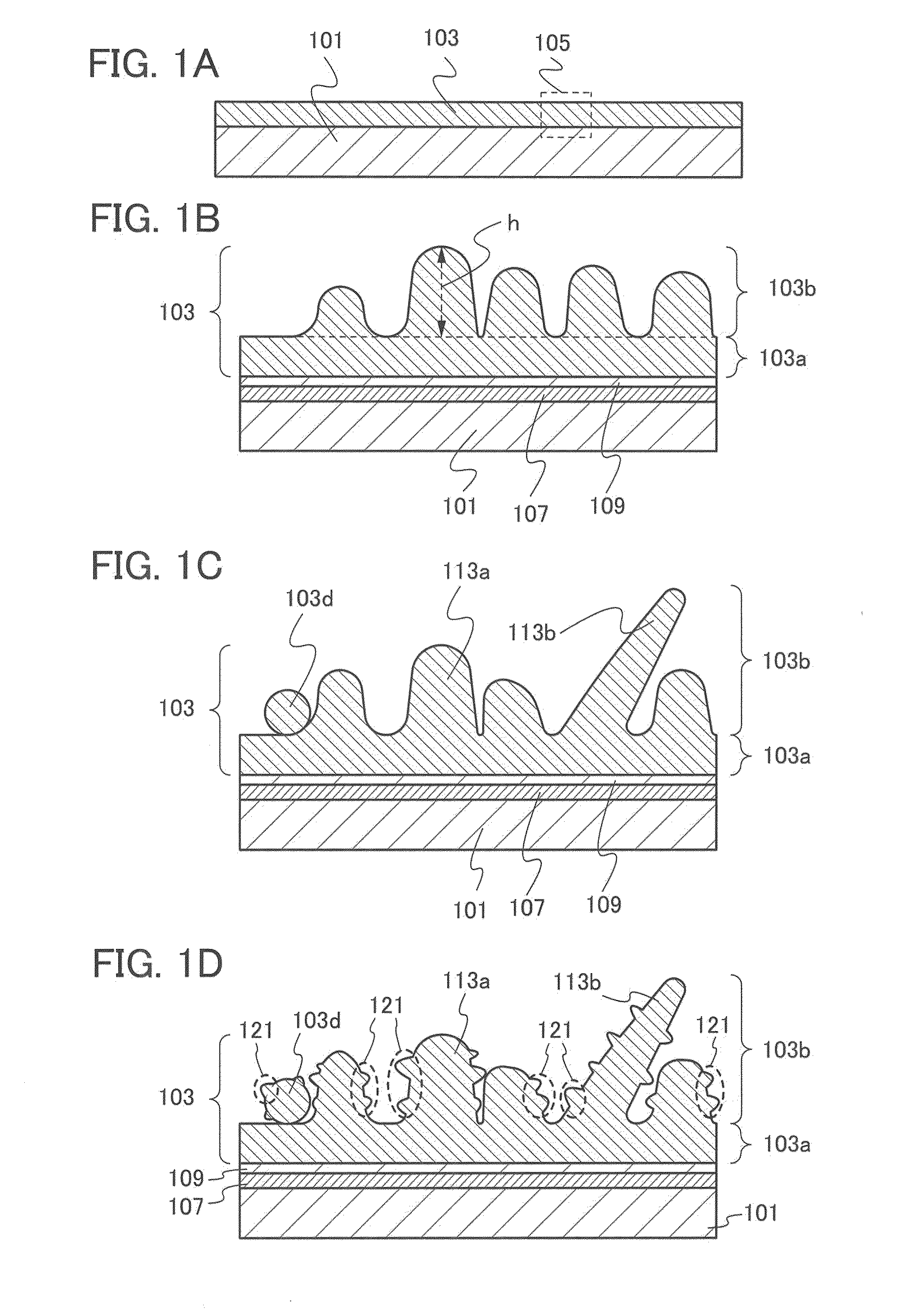

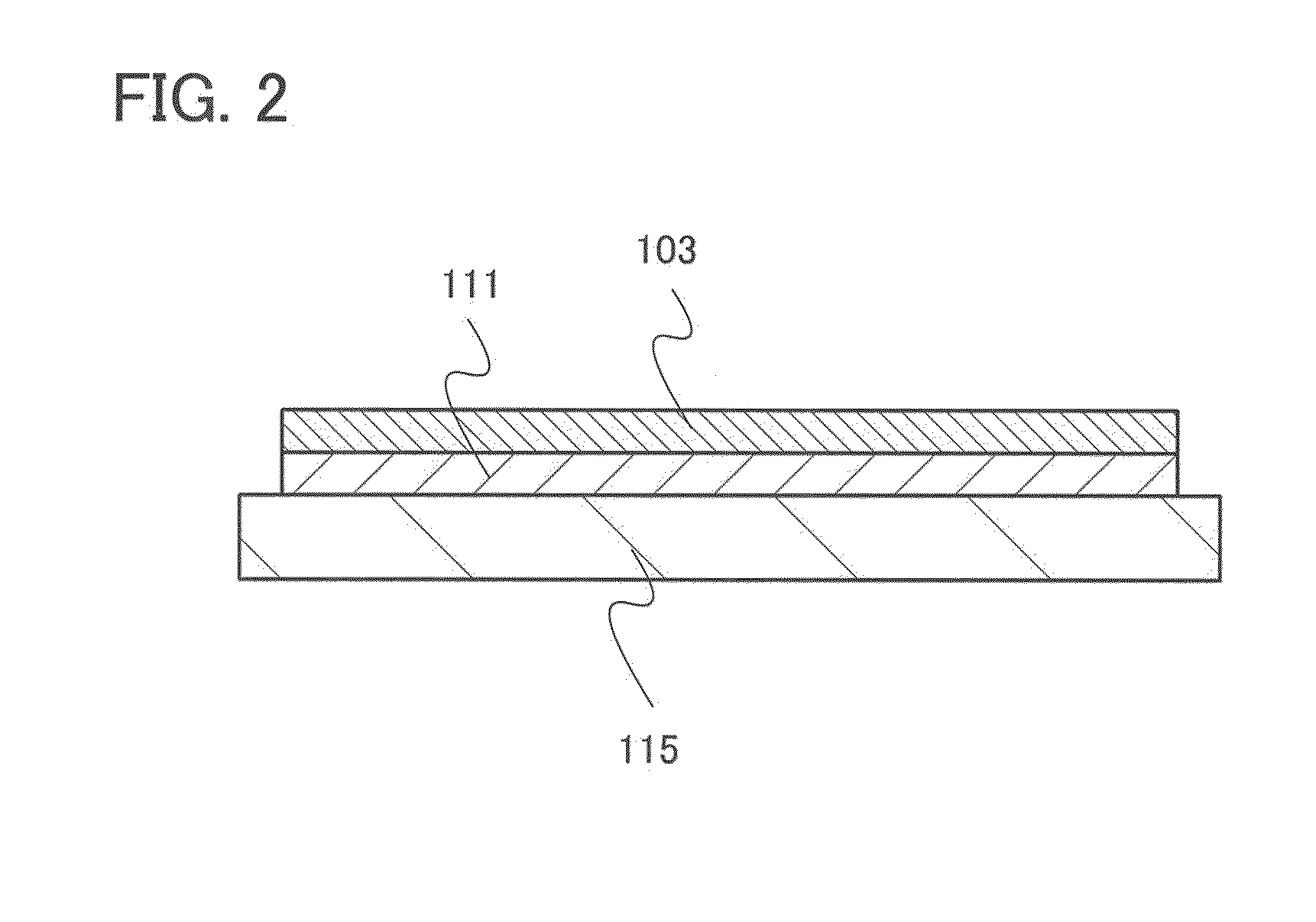

Power storage device and method for manufacturing the same

ActiveUS20110266654A1Improving interface characteristicResistanceFuel and secondary cellsFinal product manufactureEngineeringWhiskers

Provided is a method for manufacturing a power storage device in which a crystalline silicon layer including a whisker-like crystalline silicon region is formed as an active material layer over a current collector by a low-pressure CVD method in which heating is performed using a deposition gas containing silicon. The power storage device includes the current collector, a mixed layer formed over the current collector, and the crystalline silicon layer functioning as the active material layer formed over the mixed layer. The crystalline silicon layer includes a crystalline silicon region and a whisker-like crystalline silicon region including a plurality of protrusions which project over the crystalline silicon region. With the protrusions, the surface area of the crystalline silicon layer functioning as the active material layer can be increased.

Owner:SEMICON ENERGY LAB CO LTD

High thermal conducting composite material and preparation method thereof

InactiveCN101775213AImprove thermal conductivityEasy to processHeat-exchange elementsGlass fiberMixed materials

This invention relates to a high thermal conducting composite material for injecting or extrusion molding, which is prepared from the following components in parts by weight: 100 parts of plastic substrate, 30 to 100 parts of thermal conducting filler with a diameter between 50 to 300 microns, 0 to 50 parts of thermal conducting filler with a small diameter between 1 to 10 microns, 10 to 50 parts of fiberglass or silicon whisker, 0 to 5 parts of coupling agent and 0 to 8 parts of additive. The preparation of the high thermal conducting composite material comprises the following steps: adding the coupling agent to the thermal conducting filler with a small diameter and the thermal conducting filler with a big diameter respectively to do surface treatment for later use; putting the plastic substrate material, the processed thermal conducting filler with a big diameter and other additives to a super mixer to mix for 1 to 5 minutes; adding the processed thermal conducting filler with a small diameter into the super mixer to mix for 2 to 3 minutes; putting the mixed material into a feeding bucket of a twin screw extruder; adding the fiberglass into a glass fiber orifice; and pelleting after melting and extruding. The composite material prepared by the invention has good thermal conducting property and processing property.

Owner:黄晓峰

Nanotube coatings for implantable electrodes

ActiveUS7162308B2Reduce polarizationIncrease surface areaSpinal electrodesMaterial nanotechnologyImplantable ElectrodesBoron nitride

Coatings for implantable electrodes consisting of single- or multi-walled nanotubes, nanotube ropes, carbon whiskers, and a combination of these are described. The nanotubes can be carbon or other conductive nanotube-forming materials such as a carbon-doped boron nitride. The nanotube coatings are grown “in situ” on a catalytic substrate surface from thermal decomposition, or they are bonded to the substrate using a metal or conductive metal oxide thin film binder deposited by means of a metal compound precursor in liquid form. In the latter case, the precursor / nanotube coating is then converted to a pure metal or conductive metal oxide, resulting in the desired surface coating with imbedded nanotubes.

Owner:WILSON GREATBATCH LTD

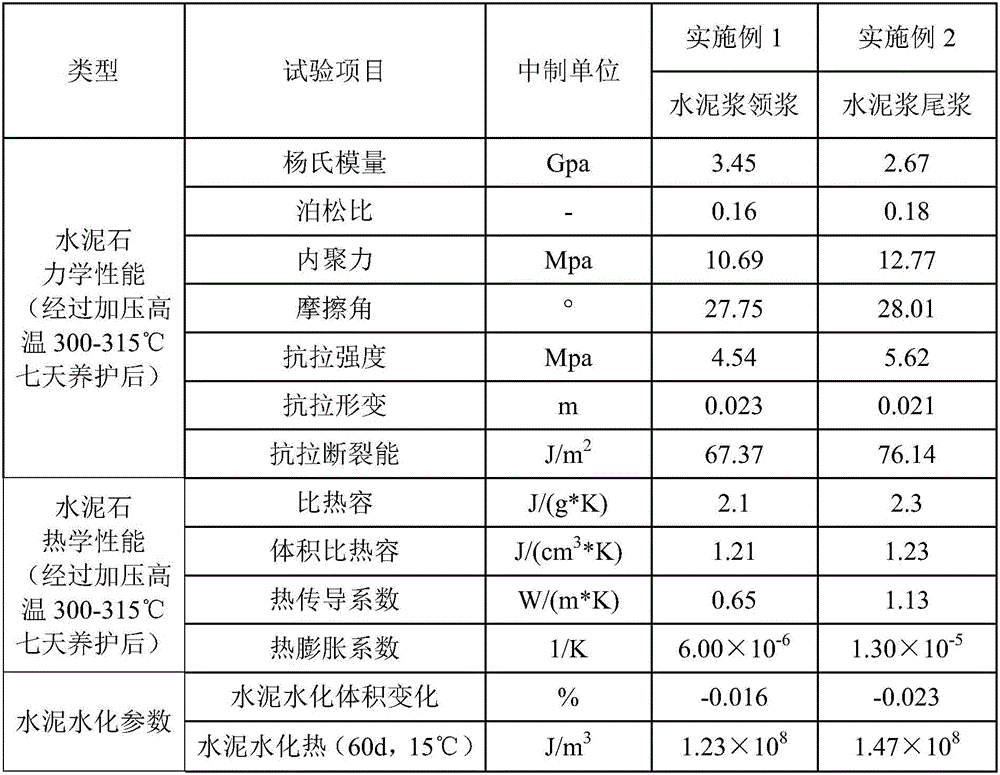

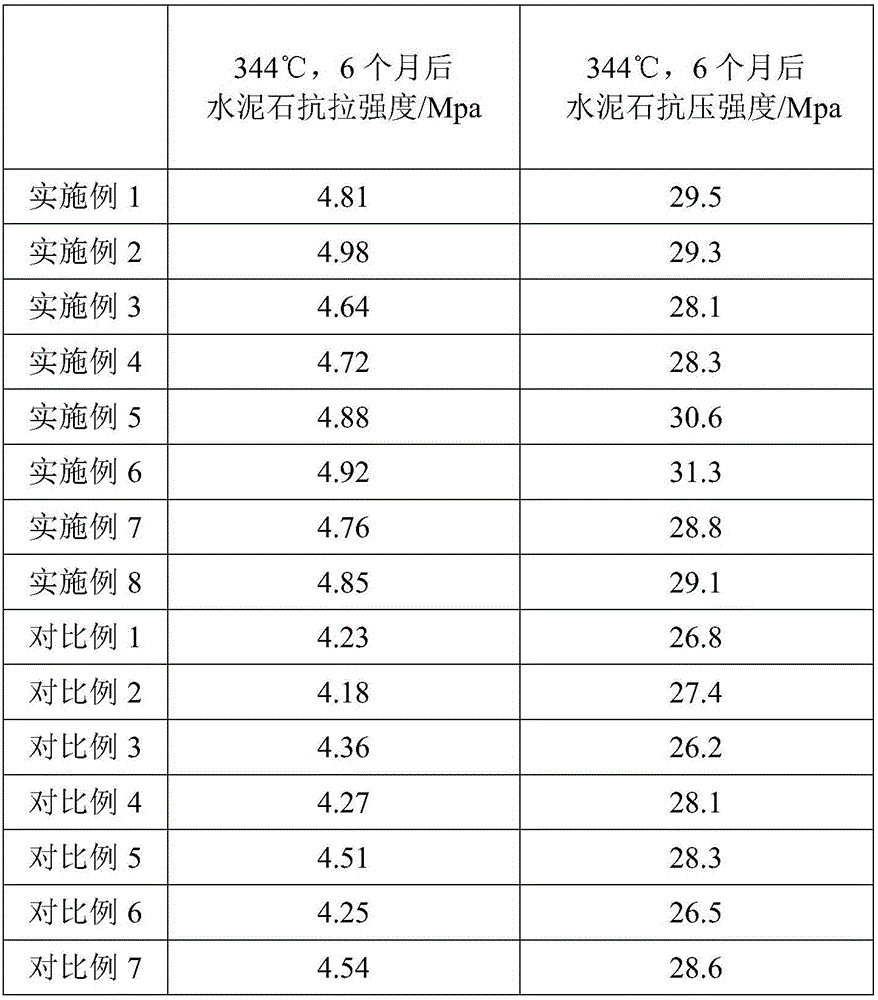

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

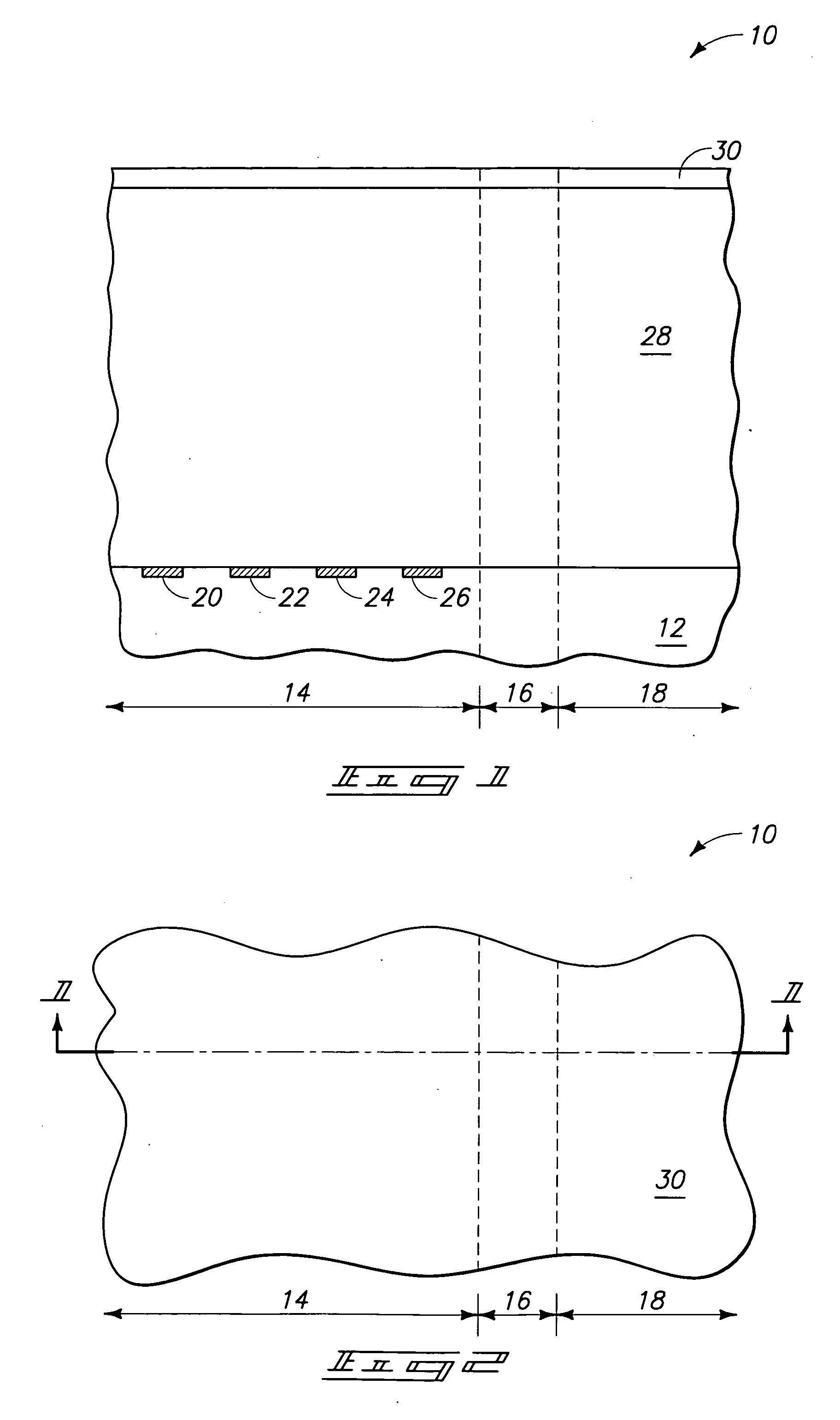

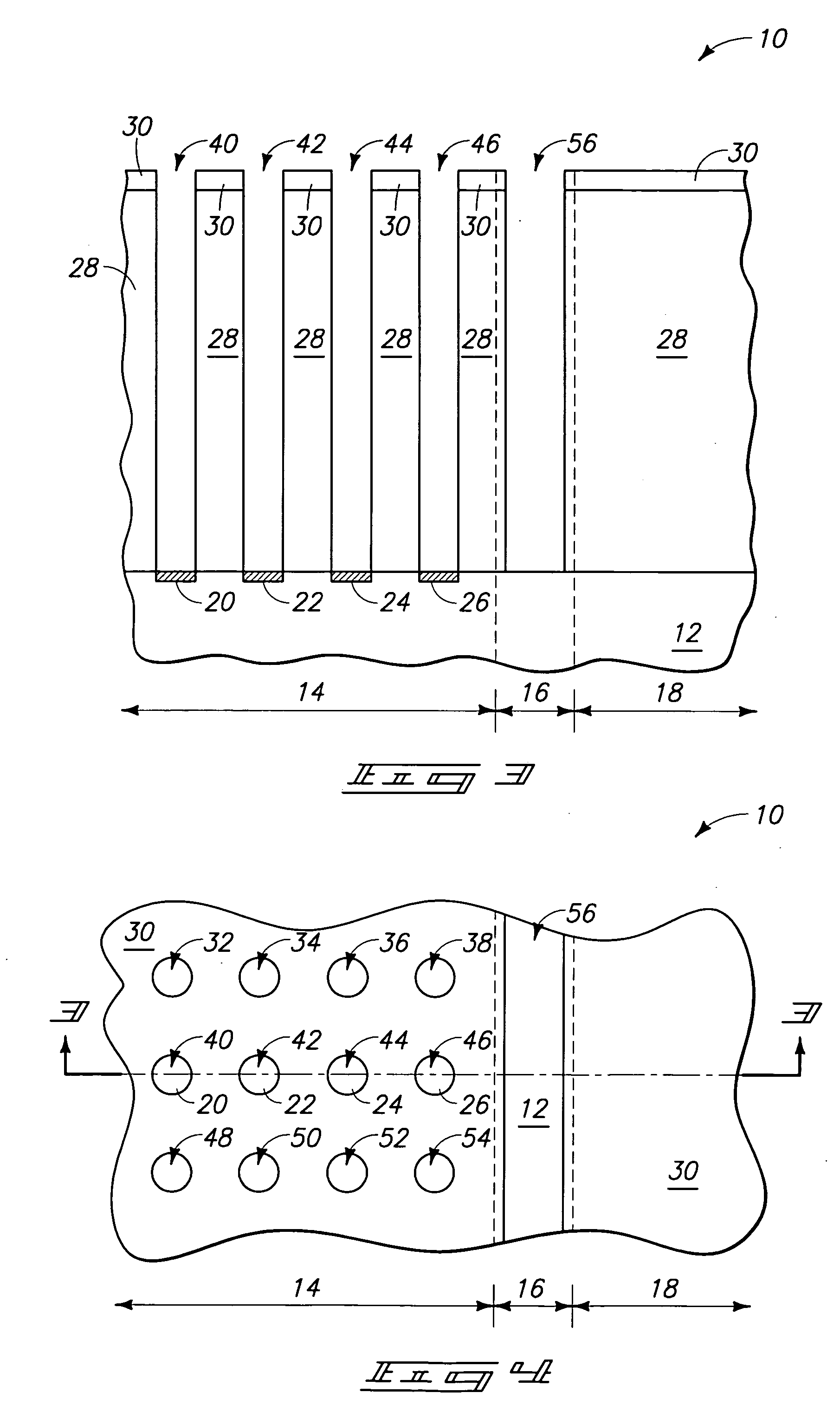

Honeycomb structure

InactiveUS20060292337A1Good dispersionIncrease resistanceDispersed particle filtrationLayered productsFiberWhiskers

A honeycomb structure is disclosed that includes plural honeycomb units bonded together by using a sealing material layer, each of the honeycomb units including plural through-holes separated by plural partition walls and provided in parallel along a longitudinal direction of the honeycomb units, wherein each of the honeycomb units includes at least ceramic particles, and inorganic fibers and / or whisker, an area of a cross section of one of the honeycomb units perpendicular to the longitudinal direction of the one of the honeycomb units is greater than or equal to about 5 cm2 and less than or equal to about 50 cm2, and a circularity of the cross section of the honeycomb structure perpendicular to the longitudinal direction of the honeycomb structure is greater than or equal to about 1.0 mm and less than or equal to about 2.5 mm.

Owner:IBIDEN CO LTD

Wood plastic composite composition, wood plastic composite and preparation method thereof

ActiveCN101747639AImprove mechanical propertiesImprove toughnessGlass fiberMagnesium Sulfate whiskers

The invention discloses a wood plastic composite composition, wood plastic composite and a preparation method thereof. The wood plastic composite composition comprises wood powder, resin, compatilizer, reinforcing agent and coupling agent, wherein the compatilizer is the copolymer of rubber and maleic anhydride, and the reinforcing agent is basic magneislum crystal whisker and / or glass fiber. Theinvention also discloses a wood plastic composite and a preparation method thereof, comprising the following steps: extruding the wood plastic composite composition to obtain an extruding product, and shaping the extruding product to obtain the wood plastic composite. The wood plastic composite disclosed by the invention has high mechanical property and favourable toughness.

Owner:BYD CO LTD

Honeycomb structure

A honeycomb structure having multiple honeycomb units united through a seal material layer, wherein each honeycomb unit has multiple through holes arranged side by side in a longitudinal direction and separated from each other by the wall surfaces of the through holes, is disclosed. The honeycomb units include at least: ceramic particles; and at least one of inorganic fibers and whiskers. At least one of the honeycomb units has a cross section perpendicular to a longitudinal direction thereof, the cross section having an area greater than or equal to about 5 cm2 and less than or equal to about 50 cm2. Each corner of each honeycomb unit has a shape of one of a substantially rounded surface and a substantially chamfered surface.

Owner:IBIDEN CO LTD

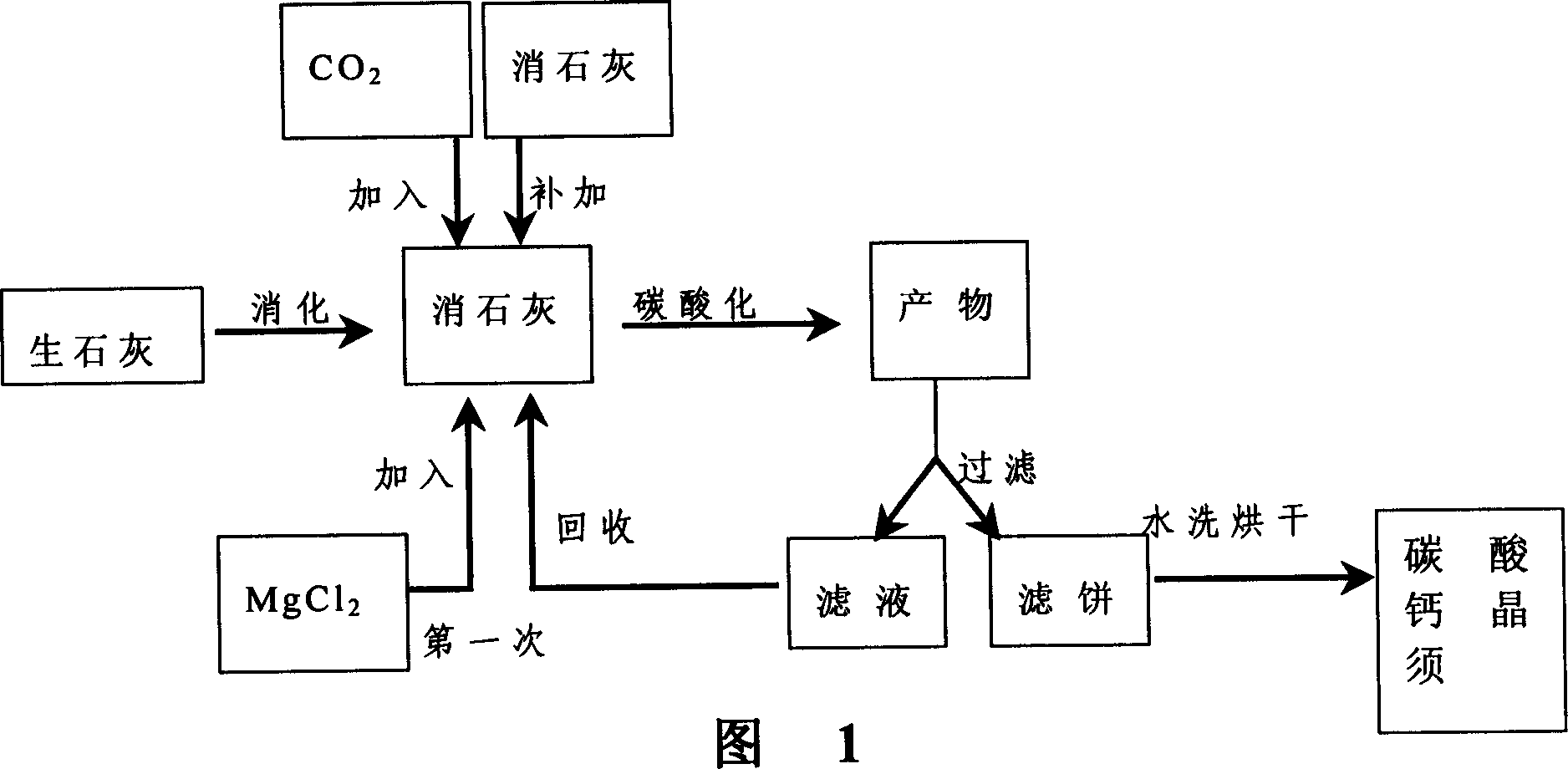

Method for preparing aragonite type calcium carbonate whisker

InactiveCN1641077AReduce manufacturing costReduce qualityCalcium/strontium/barium carbonatesPolycrystalline material growthMagnesium saltDiameter ratio

The present invention relates to the preparation process of high purity aragonite type calcium carbonate whisker. The present invention prepares aragonite type calcium carbonate whisker with lime or slaked lime as main material and magnesium salt as crystal salt controlling agent and through a CO2 carbonating process. The process features the repeated use of the magnesium salt solution and the homogeneous replenishment of lime slurry during carbonating reaction. The process has low production cost, less environmental pollution and high calcium carbonate whisker yield, and the prepared calcium carbonate whisker has high purity and high length / diameter ratio. The process is suitable for industrial production of calcium carbonate whisker.

Owner:NAT UNIV OF DEFENSE TECH

Press fit (compliant) terminal and other connectors with tin-silver compound

InactiveUS20090239398A1Increased riskInhibition formationLine/current collector detailsCoupling contact membersCompound aWhiskers

A tin-silver press-fit interconnect which includes a press-fit terminal having a coating or finish of a tin-silver compound for use with a terminal receiving device. The tin-silver compound serves to prevent the formation of tin whiskers which appear most frequently in pure tin coated electrical components under mechanical stress and which make the electronic device susceptible to short circuits. The tin-silver compound may include between 85 and 99.5% weight of tin and between 0.5 and 15% weight of silver and is applied at a thickness range between 0.4 and 5 microns using a technique such as electroplating, hot dip or immersion.

Owner:INTERPLEX IND

Honeycomb structure

InactiveUS20060292334A1Good dispersionHigh strengthPhysical/chemical process catalystsDispersed particle filtrationFiberWhiskers

A honeycomb structure having multiple honeycomb units united through a seal material layer, wherein each honeycomb unit has multiple through holes arranged side by side in a longitudinal direction and separated from each other by the wall surfaces of the through holes, is disclosed. The honeycomb units include at least: ceramic particles; and at least one of inorganic fibers and whiskers. At least one of the honeycomb units has a cross section perpendicular to a longitudinal direction thereof, the cross section having an area greater than or equal to about 5 cm2 and less than or equal to about 50 cm2. The flatness of the exterior wall of each of the honeycomb units is about 0.1 mm to about 1.5 mm.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com