Patents

Literature

246 results about "Anhydrous Calcium Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium sulfate is a salt that occurs abundantly in the natural environment and also appears as a byproduct of some industrial processes. It is a compound of calcium, sulfur and oxygen, and in its purest form has the chemical formula CaSO4; this is known as anhydrous — water-free — calcium sulfate, or the mineral anhydrite.

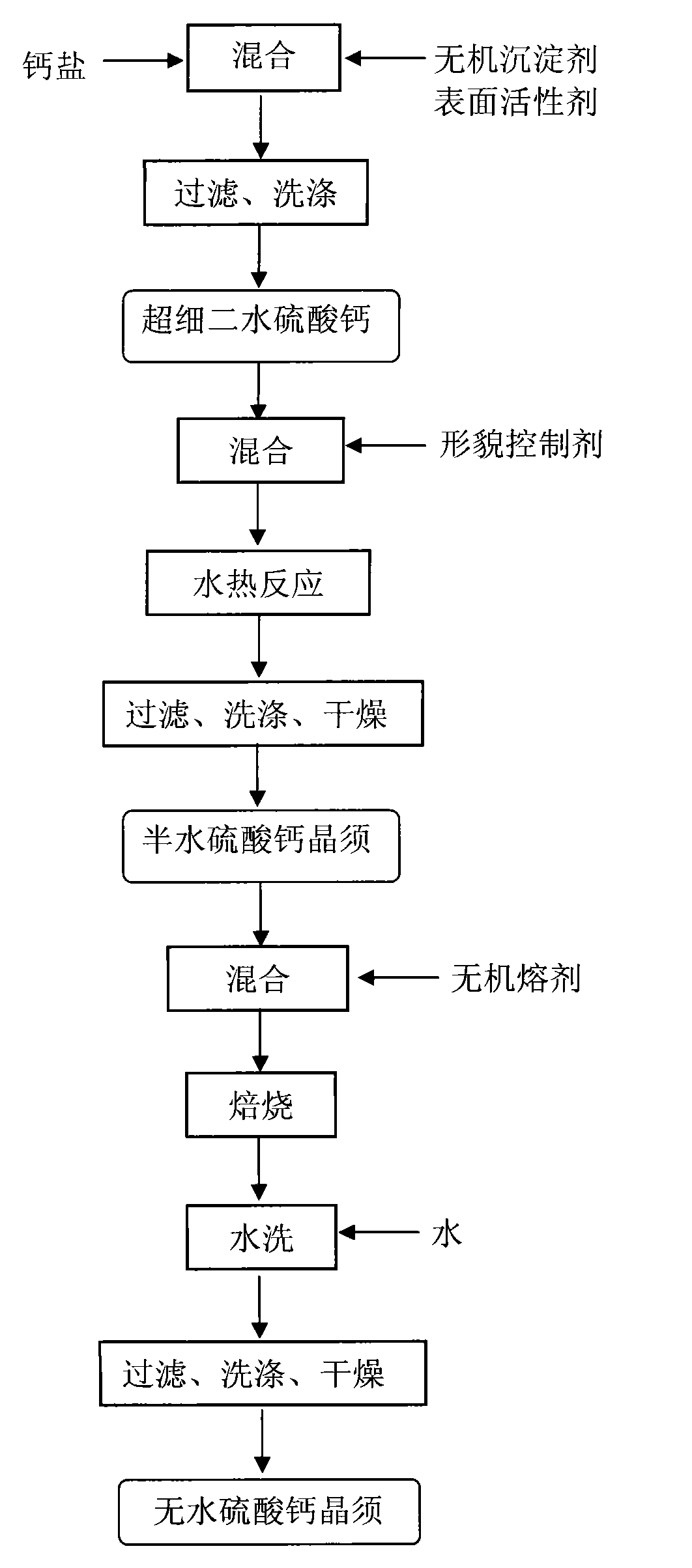

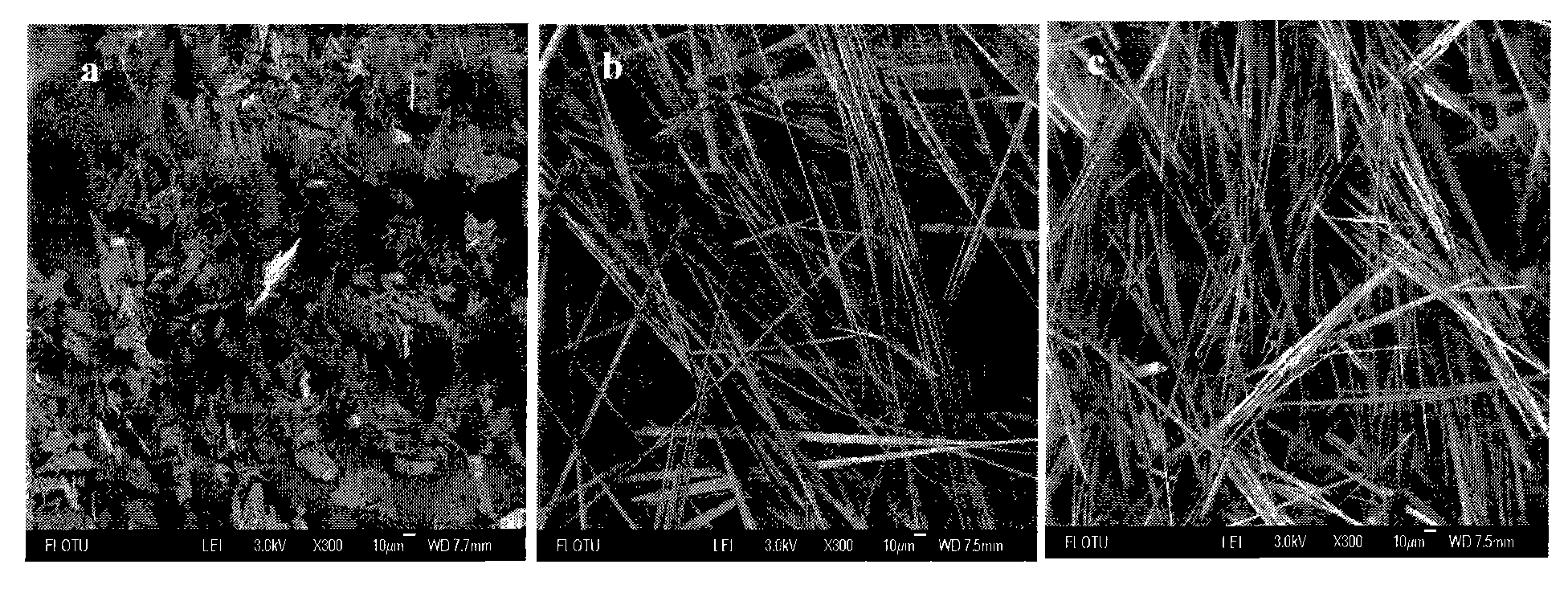

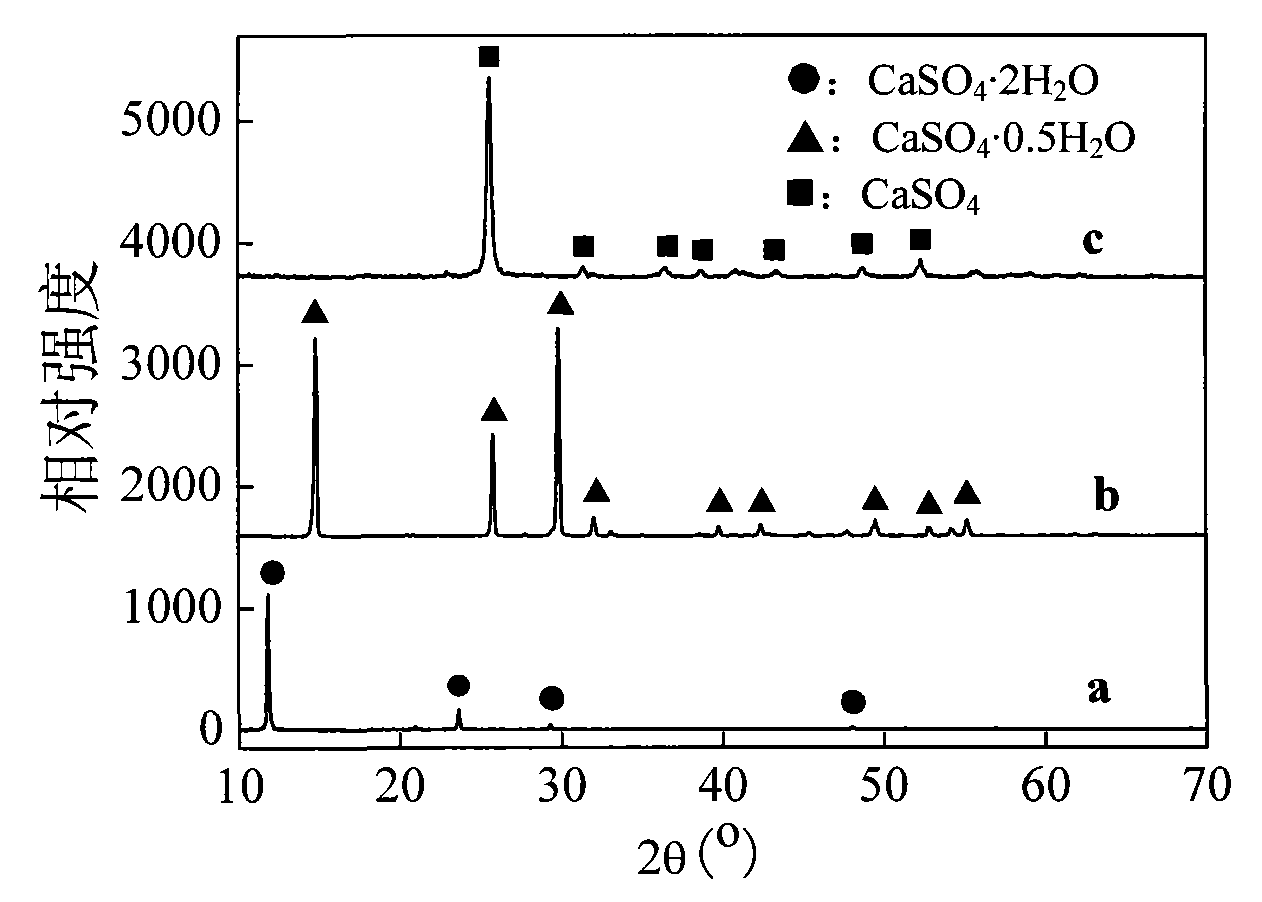

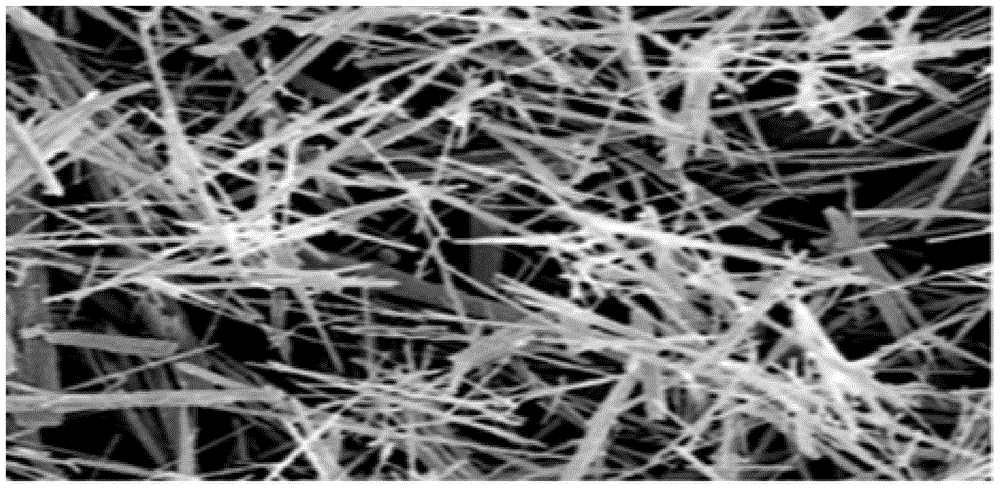

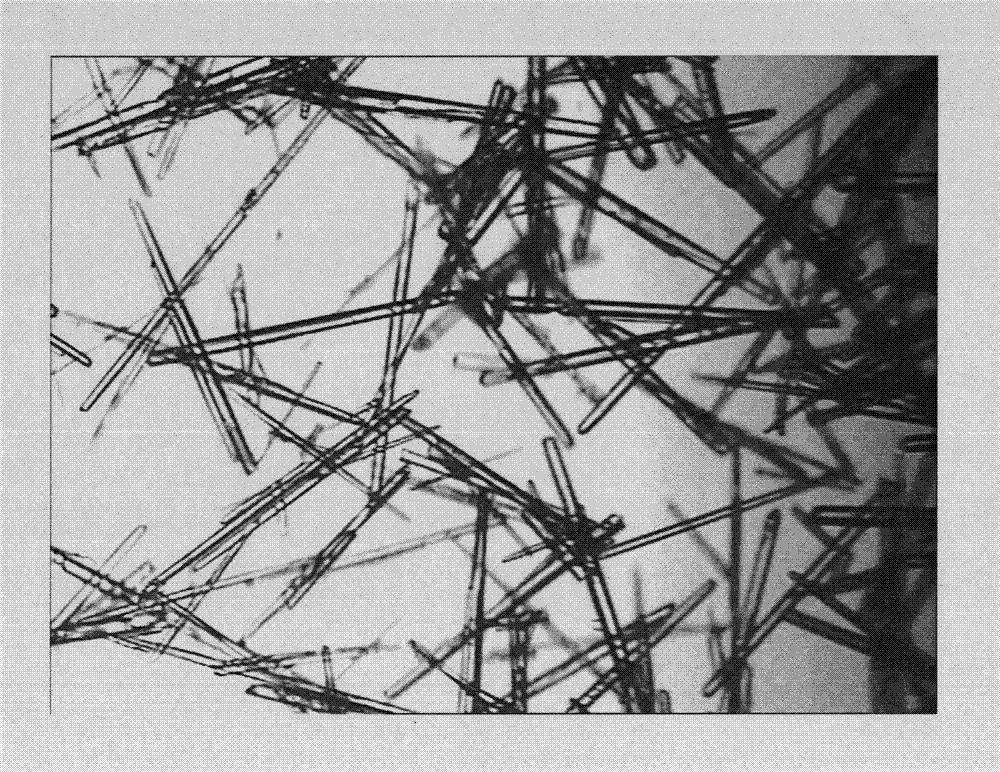

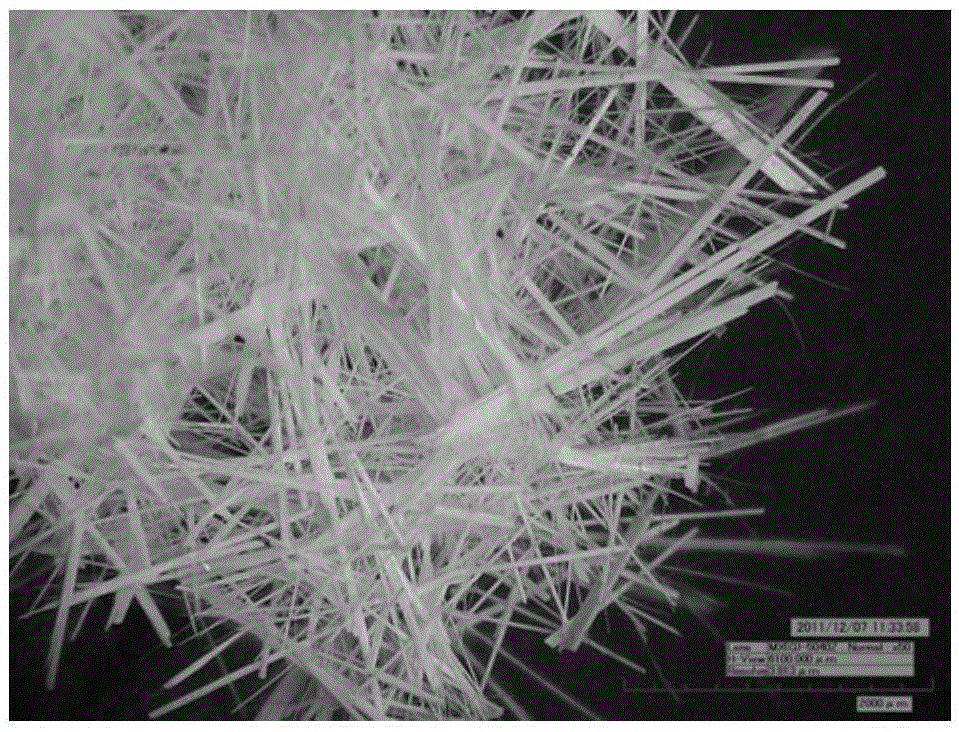

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

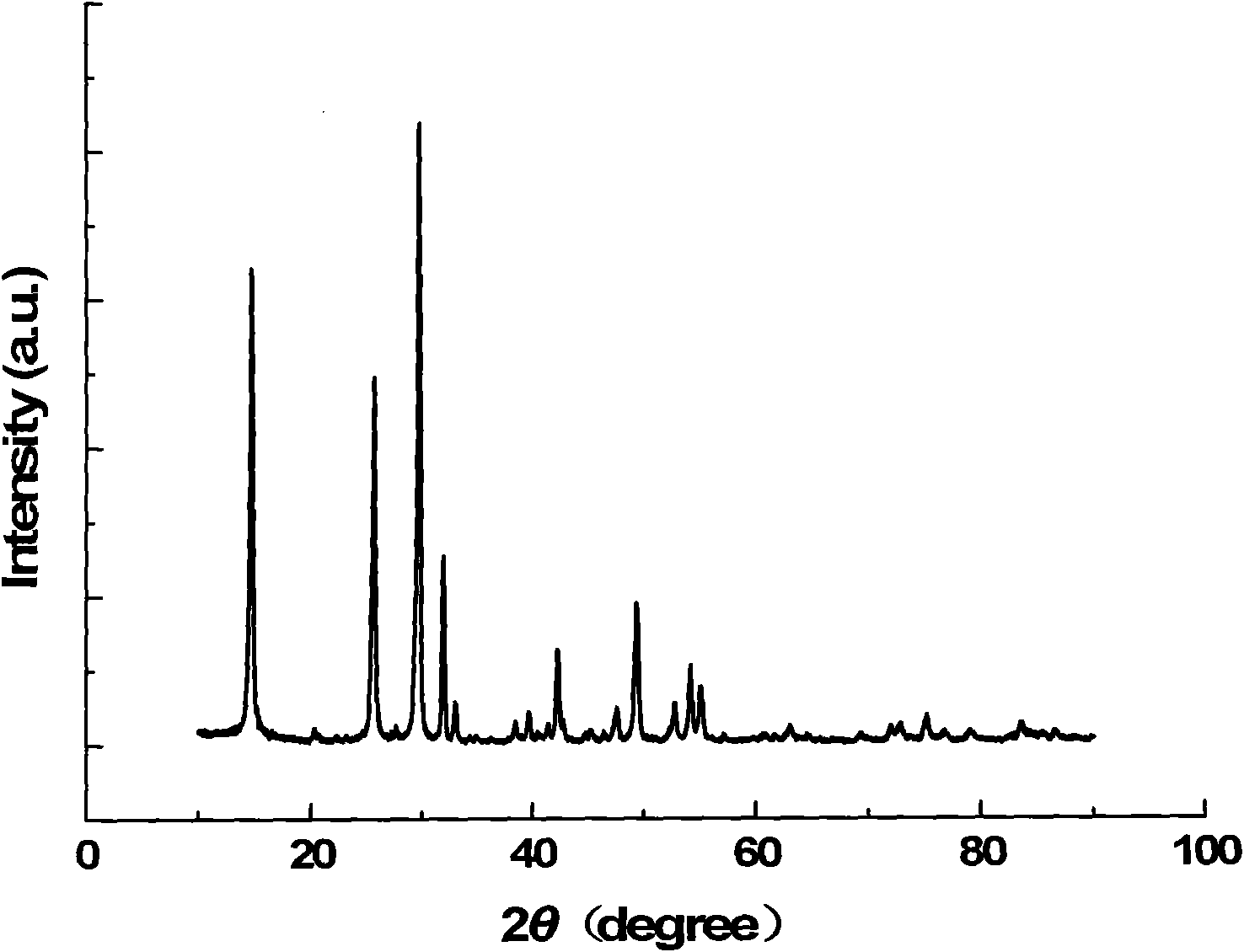

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

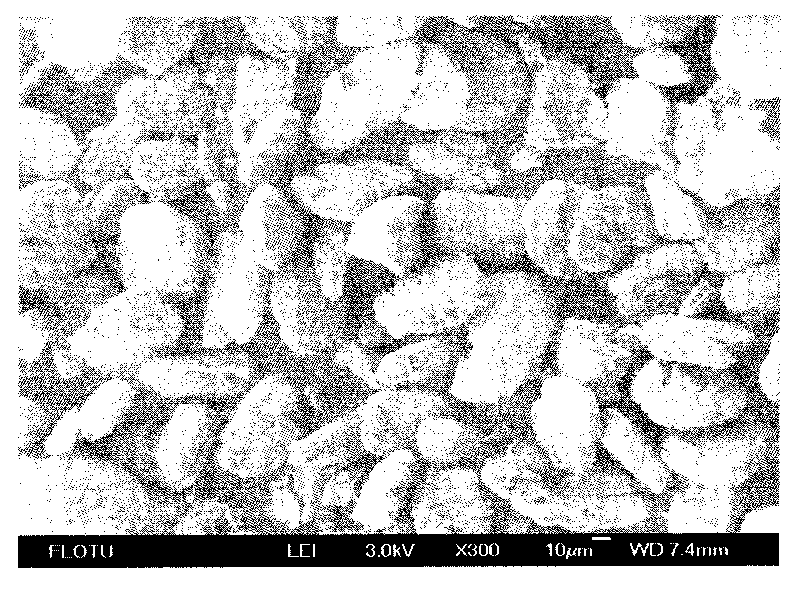

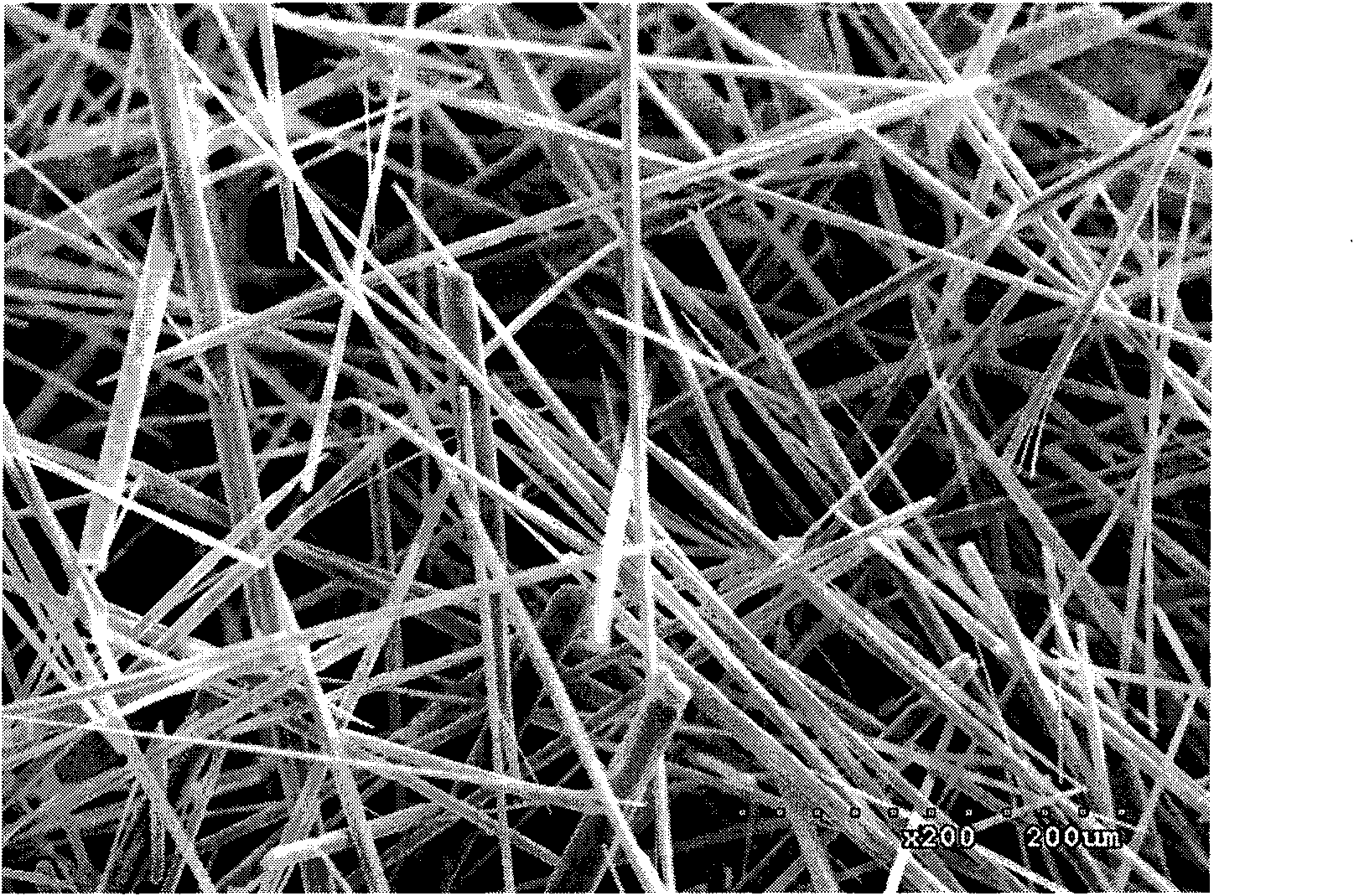

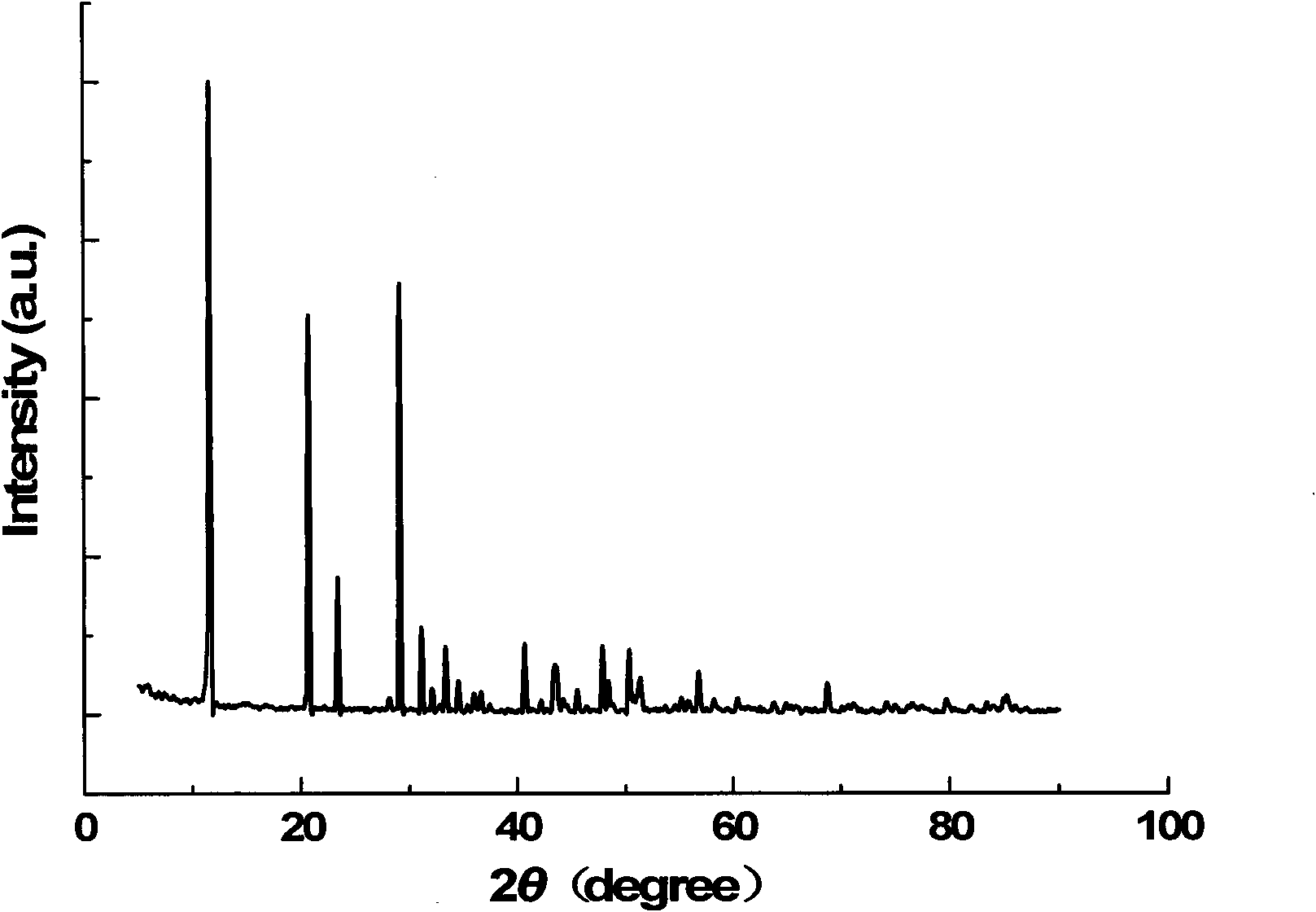

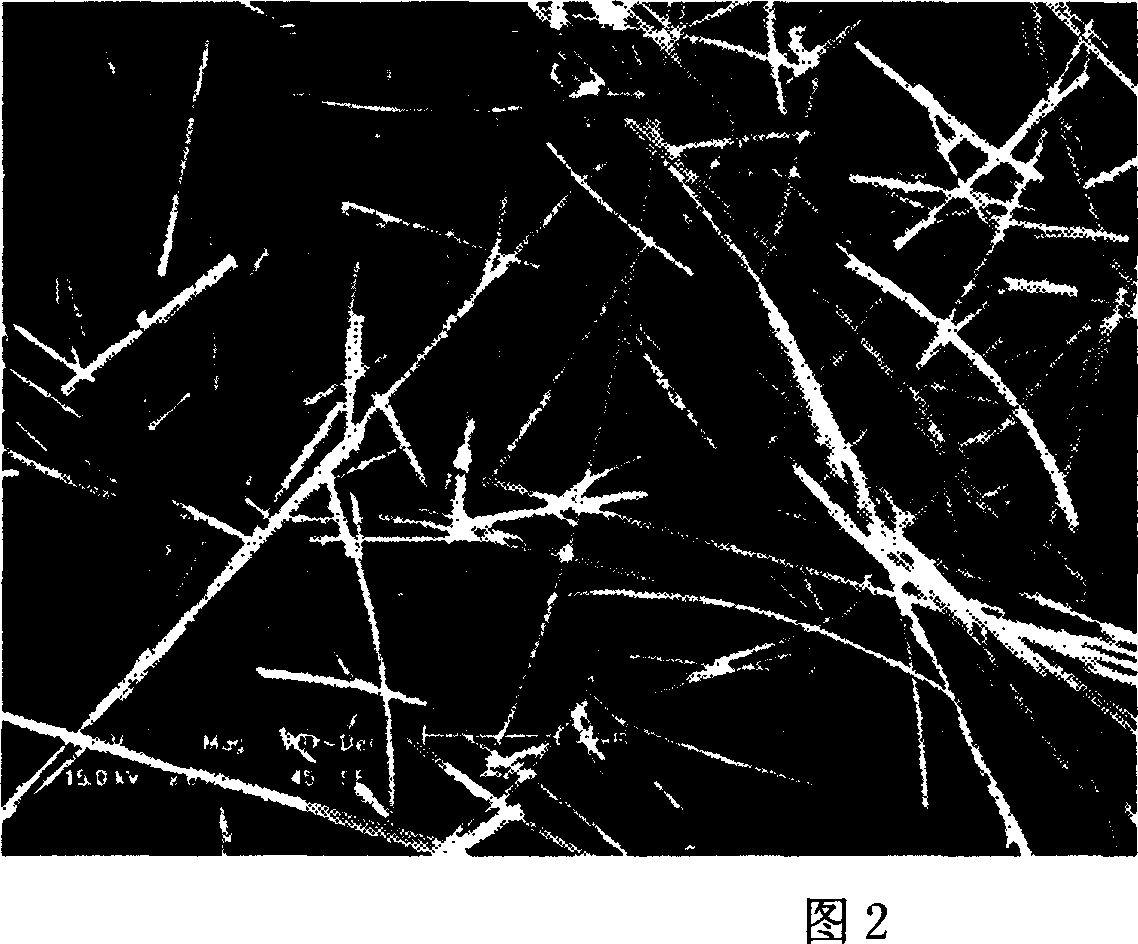

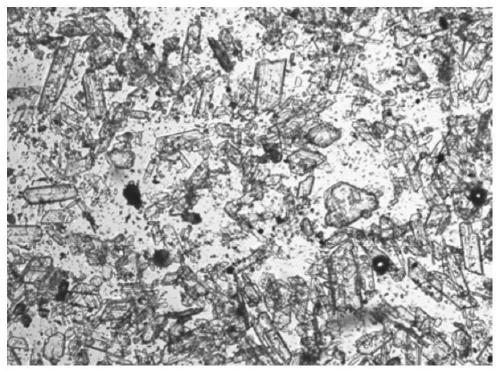

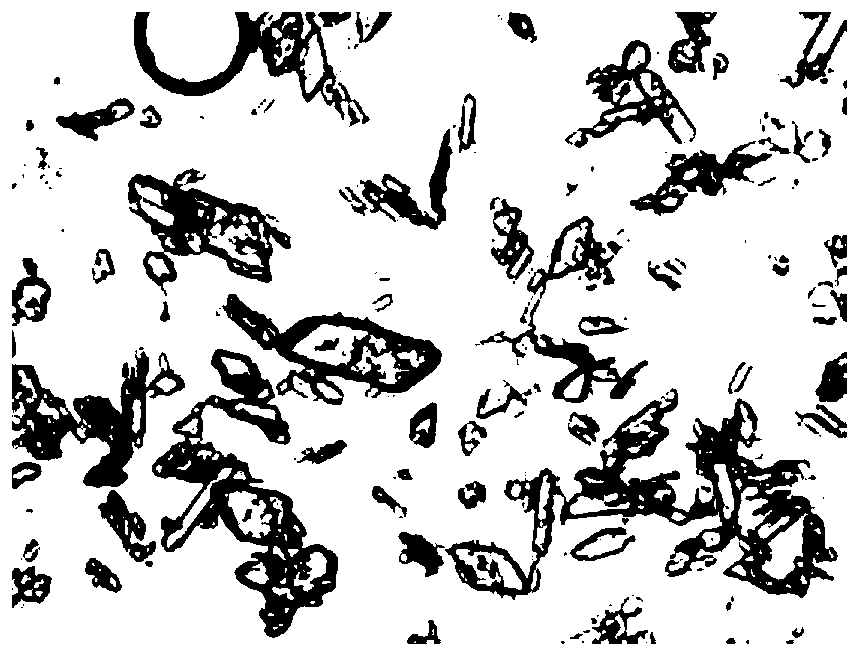

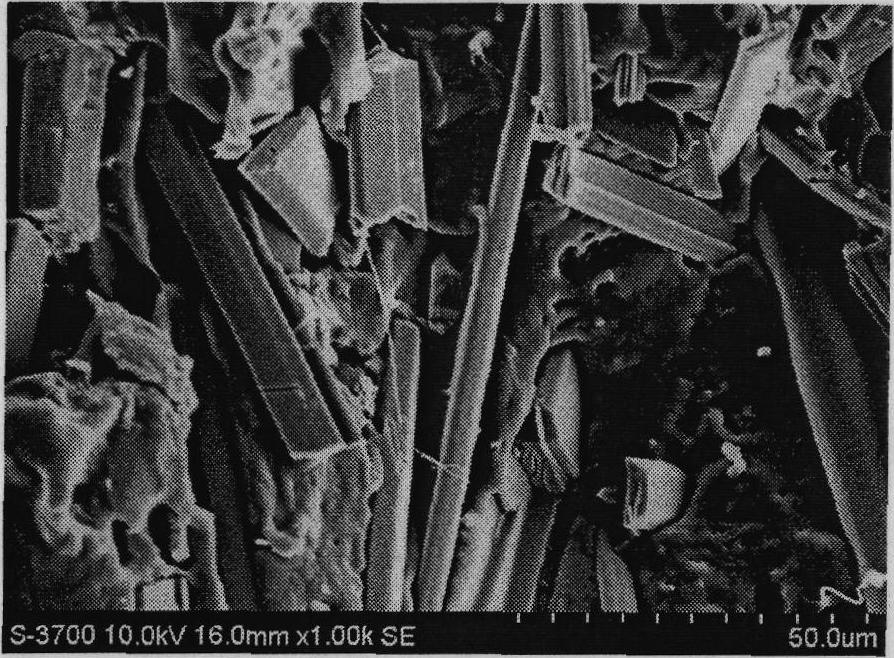

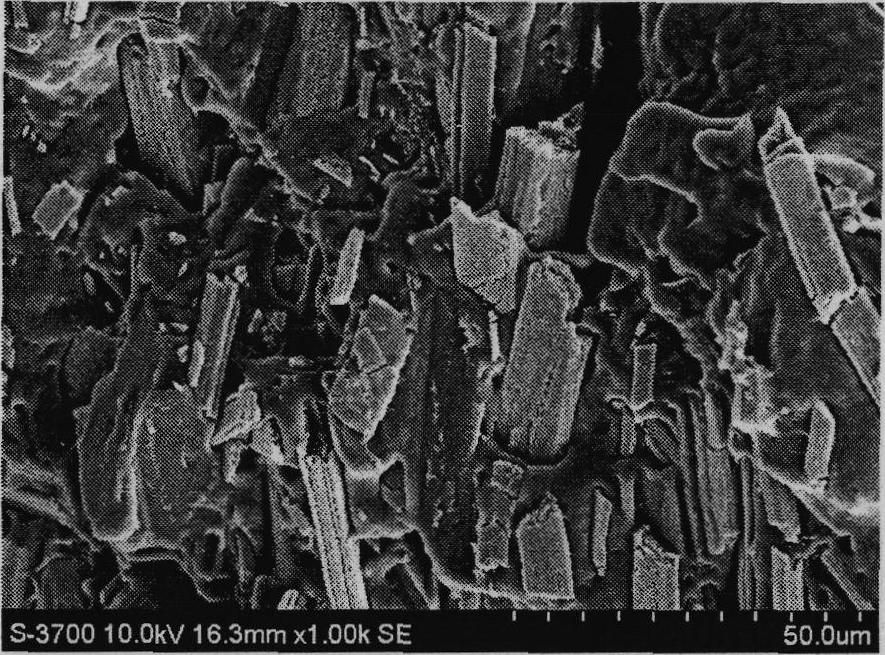

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

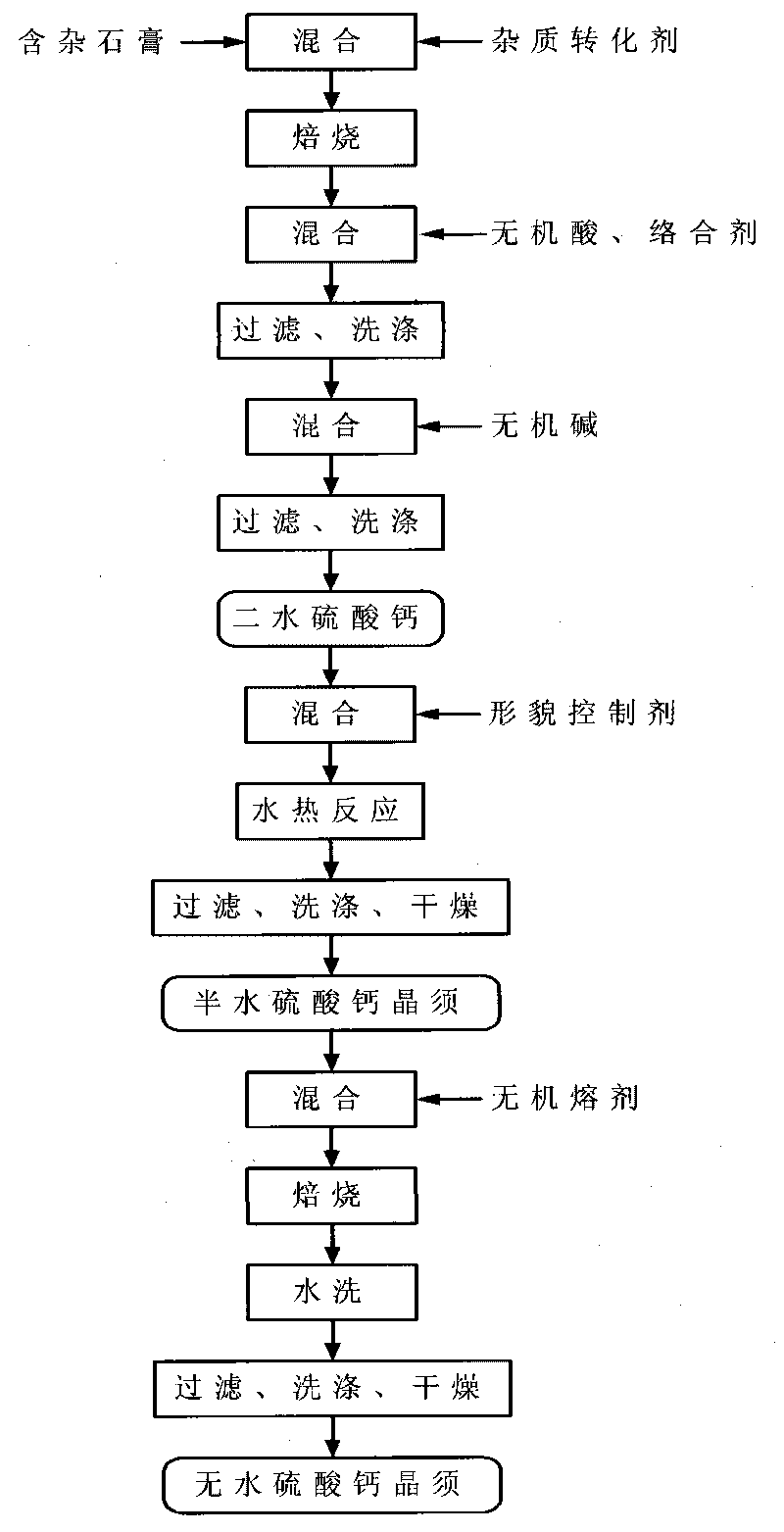

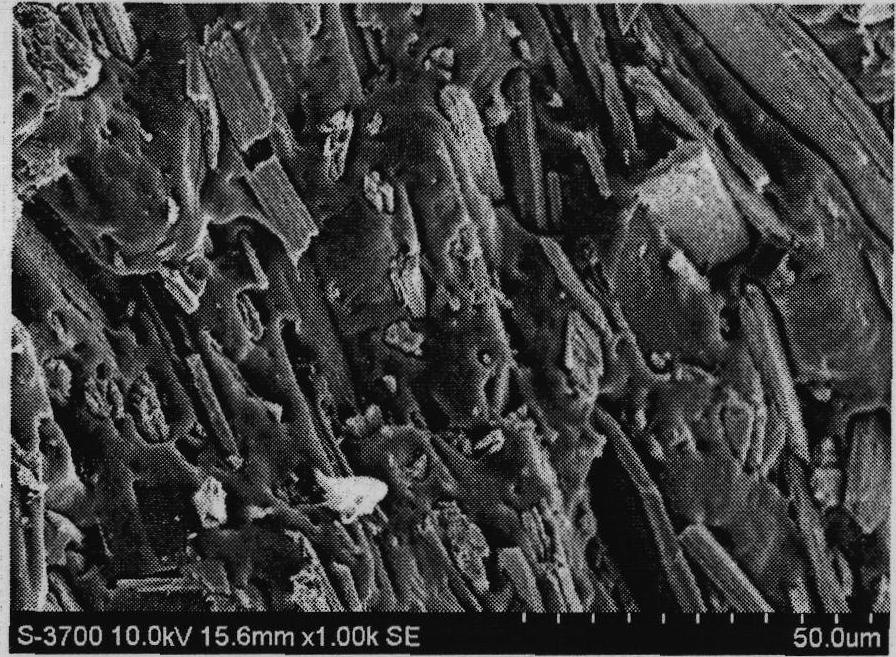

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403AHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

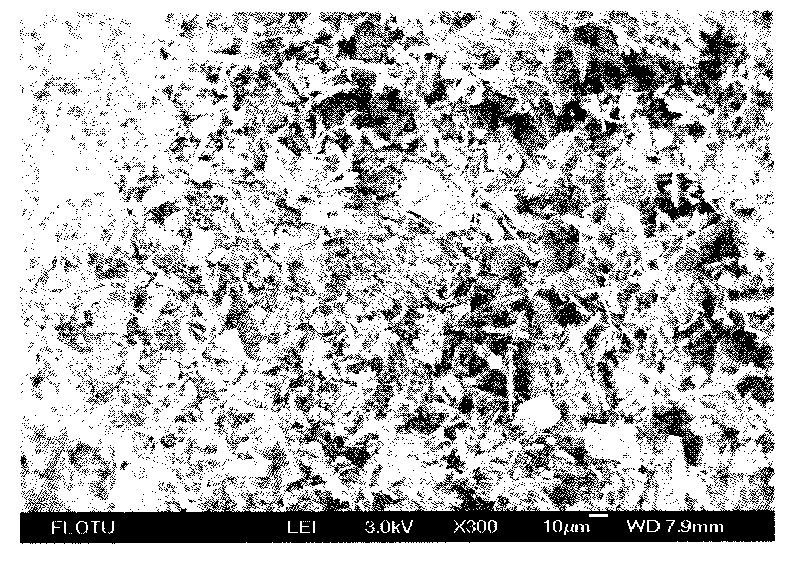

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

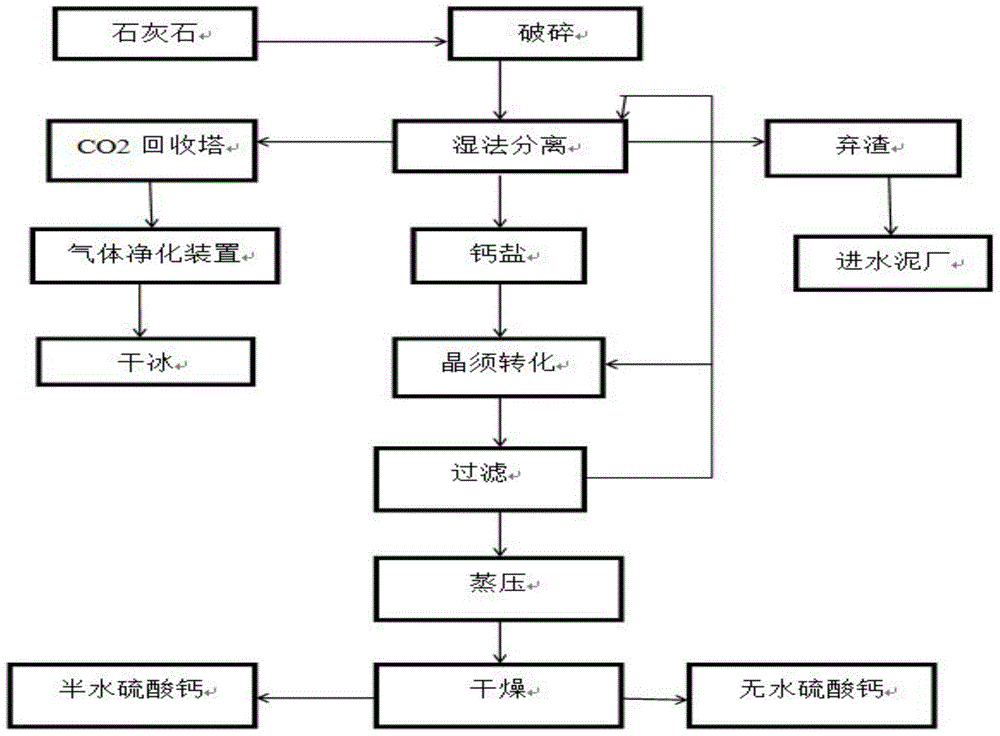

Method for preparing calcium sulfate crystal whisker in low cost

InactiveCN102965721AIncrease profitReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateHigh pressure

The invention discloses a method for preparing calcium sulfate crystal whisker in low cost and relates to a method for preparing the calcium sulfate crystal whisker. The method comprises the following steps of: crushing raw materials consisting of ground limestone and anhydrite, treating the crushed ground limestone and anhydrite by a sulfuric acid solution, adding a crystal growth substance to prepare a mixture solution, preparing calcium sulfate hemihydrate crystal whisker with higher length-diameter ratio by a hydrothermal synthesis method at high temperature under high pressure, and carrying out filtering, washing and high-temperature crystal water removing steps on the calcium sulfate hemihydrate crystal whisker to obtain high-quality anhydrous calcium sulfate crystal whisker products. The calcium sulfate crystal whisker prepared by the method disclosed by the invention can be applied to high polymer material such as plastic and rubber to improve the performances of polymer materials by serving as a reinforcing material. The method disclosed by the invention has the advantages of low production cost, simple operation and high additional value of products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

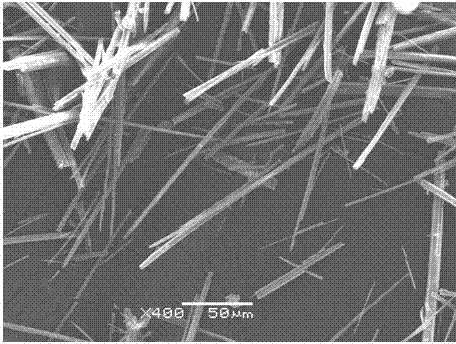

Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

InactiveCN102534773ASimple processThorough responsePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateCalcium EDTA

The invention discloses a preparation method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The method comprises the following steps that: firstly, limestone powder is added into stirred water to be prepared into calcium salt aqueous emulsion; then, sulfuric acid and crystal modifiers are sequentially added into the stirred water to be prepared into sulfuric acid water solution; next, the calcium salt aqueous emulsion containing 1 mol part of Ca<2+> is added into the sulfuric acid water solution containing 2 mol parts of SO4<2-> with the temperature reaching 100 to 110 DEG C, then, morphology control agents are added, the materials are subjected to stirring and aging for 2 to 3.5 hours under the temperature condition being 110 to 120 DEG C, leaching and washing are carried out, and calcium sulfate hemihydrate crystal whisker wet products are obtained; the calcination drying finally is carried out under the temperature condition higher than 200 DEG C to obtain the anhydrous calcium sulfate crystal whiskers; and then, the surface modification treatment is carried out to finally obtain the high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The preparation method has the advantages that the product quality is high, the cost is low, the preparation process is short, the reaction condition is mild, and in addition, green and environmental-friendly effects can be realized.

Owner:四川万润非金属矿物材料有限公司

Method for preparing baking-free bricks from waste aluminum ash residues

The invention relates to a method for preparing baking-free bricks from waste aluminum ash residues. The method has the advantages that the production cost of the baking-free bricks is low, the energy consumption is low, the manufacturing time is short, and the environmental pollution caused by waste aluminum ash residues is reduced. In addition, the baking-free brick prepared by the method disclosed by the invention is high in compressive strength. The raw materials used in the method for preparing the baking-free bricks from the waste aluminum ash residues are waste aluminum ash residues, water-quenched slag, silica fume powder, anhydrous calcium sulfate, silicate cement, slaked lime, sodium chloride, sodium iodide, Al (13) polymer, triethanolamine and water. The method for preparing the baking-free bricks from waste aluminum ash residues comprises the following steps: (1) preparing crushed mixture; (2) preparing a waste aluminum ash residue raw material mixture; (3) preparing a baking-free brick mixture; (4) forming a baking-free brick; and (5) curing the baking-free brick.

Owner:ZHEJIANG NORMAL UNIVERSITY

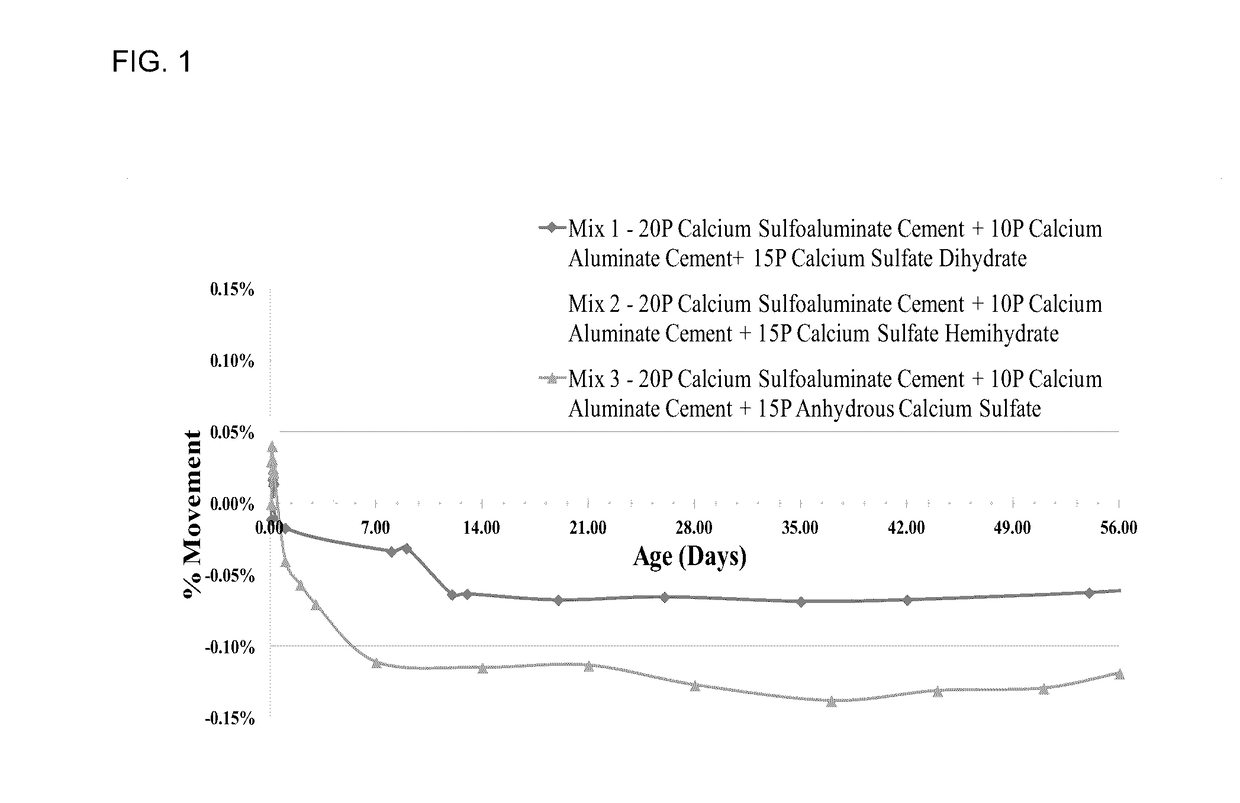

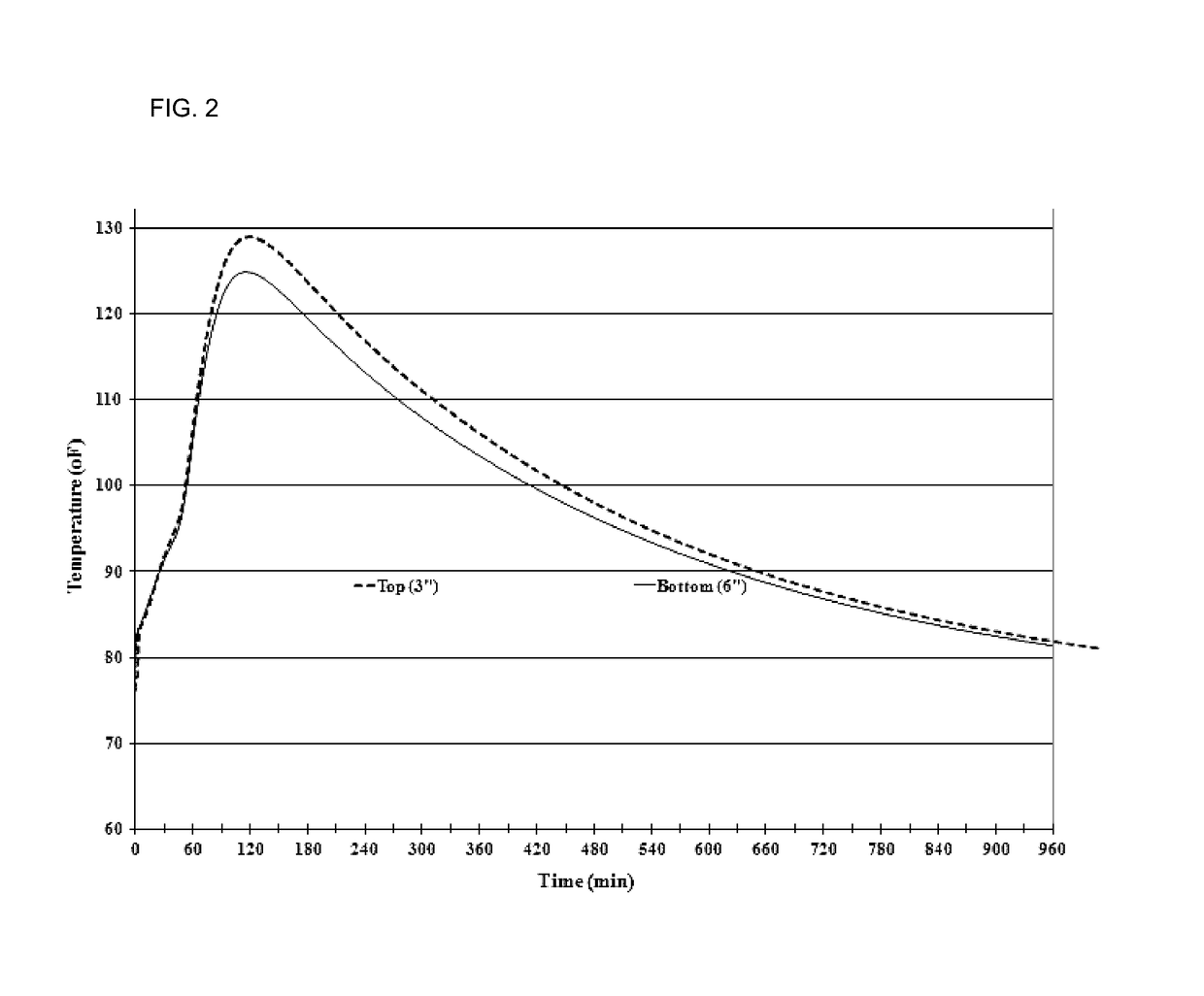

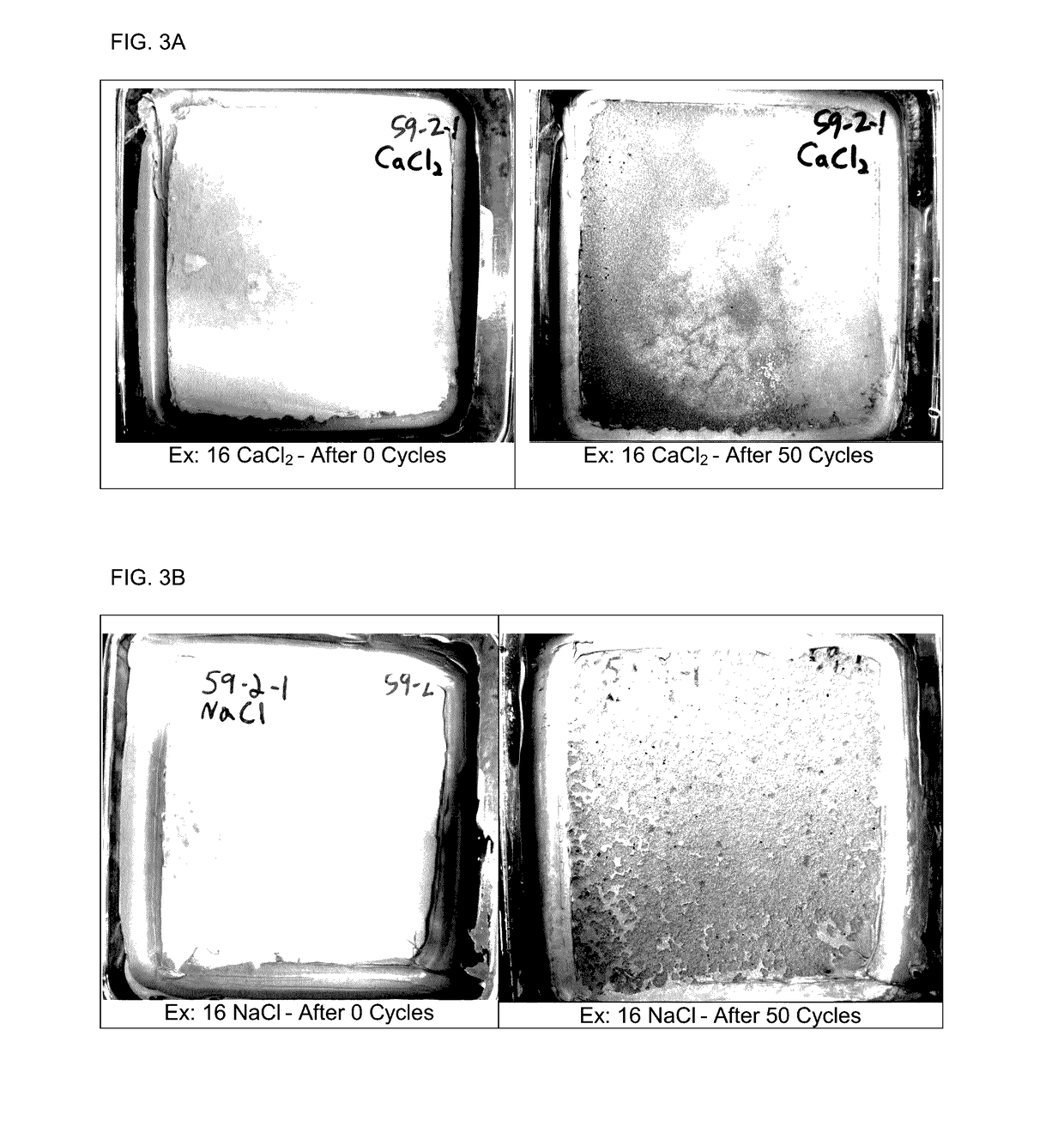

Freeze-thaw durable geopolymer compositions and methods for making same

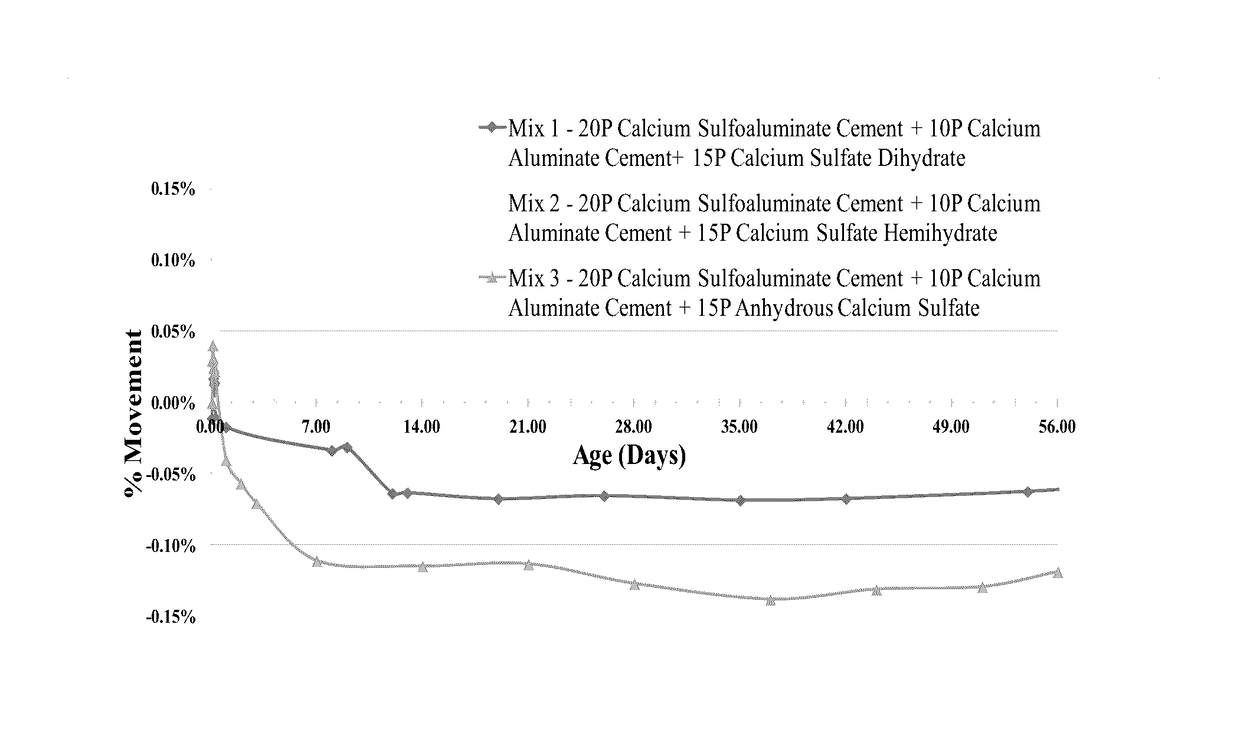

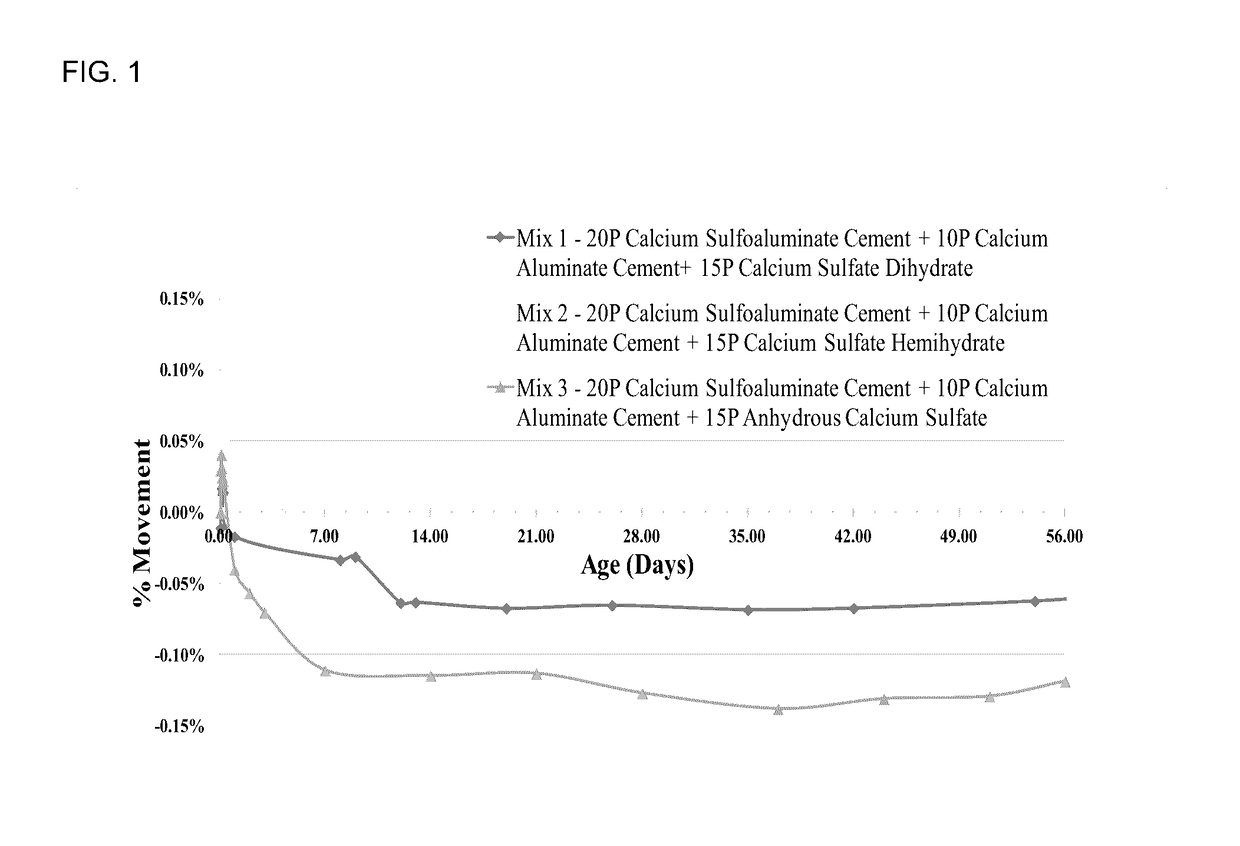

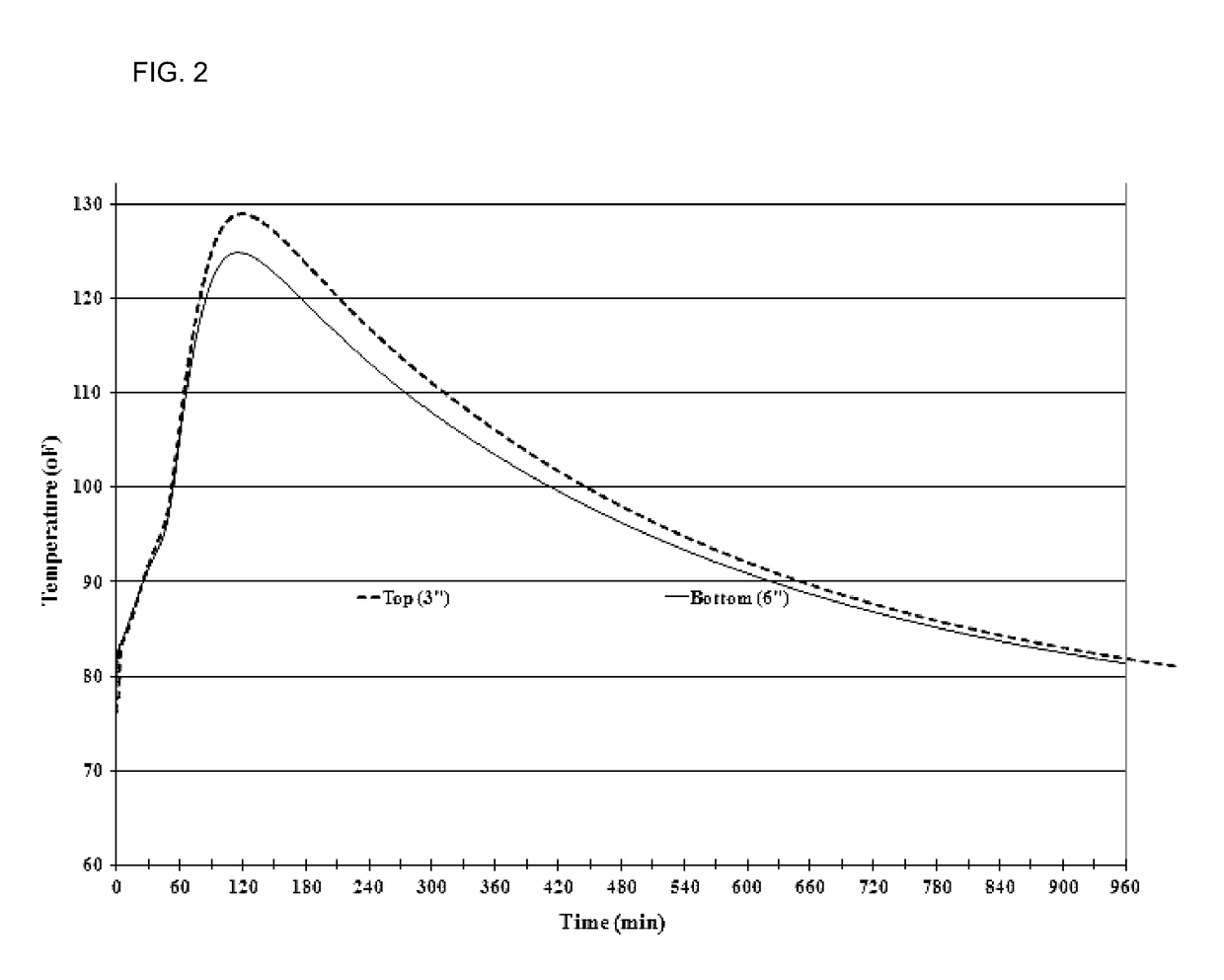

ActiveUS9624131B1Excellent freeze-thaw durability behaviorGood dimensional stabilityIn situ pavingsSolid waste managementFreeze thawingAnhydrous Calcium Sulfate

A freeze-thaw durable, dimensionally stable, geopolymer composition including: cementitious reactive powder including thermally activated aluminosilicate mineral, aluminate cement preferably selected from at least one of calcium sulfoaluminate cement and calcium aluminate cement, and calcium sulfate selected from at least one of calcium sulfate dihydrate, calcium sulfate hemihydrate, and anhydrous calcium sulfate; alkali metal chemical activator; and a freeze-thaw durability component selected from at least one of air-entraining agent, defoaming agent, and surface active organic polymer; wherein the composition has an air content of about 4% to 20% by volume, more preferably about 4% to 12% by volume, and most preferably about 4% to 8% by volume. The compositions are made from a slurry wherein the water / cementitious reactive powder weight ratio is 0.14 to 0.45:1, preferably 0.16 to 0.35:1, and more preferably 0.18 to 0.25:1. Methods for making the compositions are also disclosed.

Owner:UNITED STATES GYPSUM CO

Preparation method of calcium sulfate whisker

InactiveCN1955345APurity is not strictly requiredEasy to handlePolycrystalline material growthCalcium/strontium/barium sulfatesFiberAnhydrous Calcium Sulfate

This invention relates to a preparation of crystal whisker of calcium sulfate, particularly relating a preparation that produces fibriform mon-crystal of half water or dried gypsum, its concrete steps as following: (1) Adopt hydrothermal synthesis etc technology to compose target agent of crystallizing; (2) Firstly calcium oxide that is technica grade is pretreated, added into reaction vessel to digest at 40-60DEG C, calcarea galacta is obtained; (3) The calcarea galacta that is obtained raises temperature to 40-110DEG C in reaction vessel, add equimolar solution of sulphuric acid, mix 30-60min,add targeting agent of crystallizing in reaction process. Make it react sufficiently, obtain products of required crystal whisker of calcium sulfate by filtering, cleaning, surface treatment and drying. Characteristic of this invention is: add targeting agent of crystallizing that is self produced, control different reactive temperature, obtain crystal whisker of calcium sulfate with different dolicho- diameter ratio, dolicho- diameter of this product is uniform, dolicho- diameter ratio is large, purity of raw material has no strict requirement.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for removing impurities and whitening phosphogypsum

PendingCN111302377AStrong source adaptabilityEasy to recycleCalcium/strontium/barium sulfatesAnhydrous Calcium SulfatePhysical chemistry

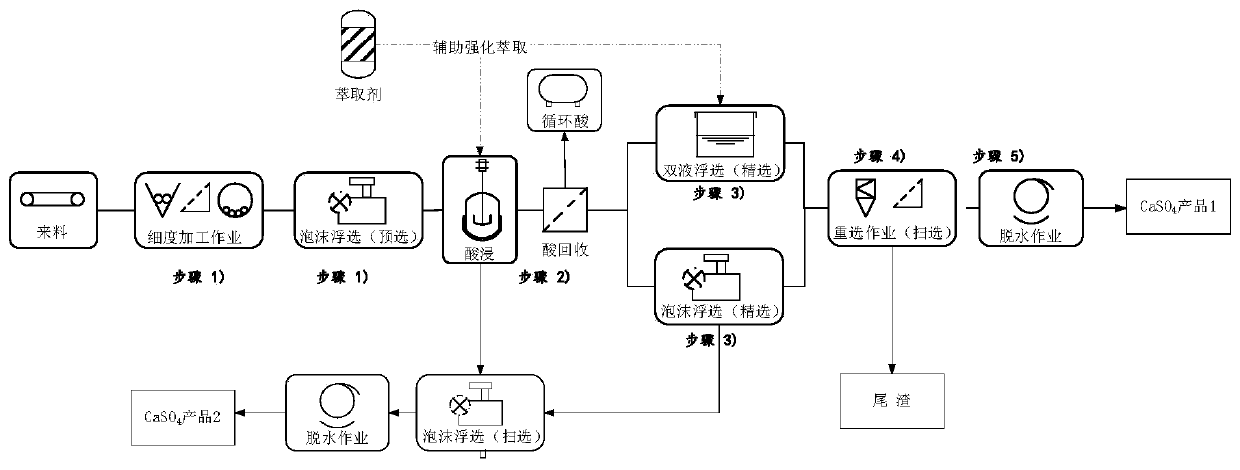

The invention discloses a method for removing impurities and whitening phosphogypsum. The method comprises the following steps: (1) carrying out fineness rough machining on a phosphogypsum raw material; (2) carrying out acid leaching on the phosphogypsum obtained in the step (1) by using sulfuric acid, performing heating and keeping the temperature constant to obtain a material; (3) adding a flotation agent into the material obtained in the step (2), and carrying out flotation concentration separation; (4) feeding the slurry subjected to flotation separation obtained in the step (3) into gravity separation operation for impurity removal to obtain concentrate; and (5) filtering the concentrate obtained in the step (4), washing a filter cake, and drying and crushing the filter cake to obtainthe finished product purified gypsum. According to the method, high-whiteness and high-purity anhydrous calcium sulfate is prepared from phosphogypsum by utilizing a flotation / extraction / gravity separation process in a weakly acidic environment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Metal peroxide-based oxygen slow release composite material and preparation thereof

InactiveCN101407358AImprove efficiencyExtend the life cycleWater/sewage treatment by substance additionAnhydrous Calcium SulfateReaction rate

The invention relates to the technical field of polluted groundwater bioremediation, in particular to a metal peroxide base oxygen slow-release composite material and a preparation method thereof. 40 percent to 60 percent of the metal peroxide, 20 percent to 50 percent of calcium phosphate cement, 1 percent to 3 percent of anhydrous calcium sulfate and 5 percent to 10 percent of clay are mixed evenly and added with water, then sent to a granulator for granulation; the obtained solid particles are soaked into the acrylic-itaconic acid copolymer liquid for 1 to 3 minutes and taken out, wherein,the mass ratio of the solid particles and the acrylic-itaconic acid copolymer liquid is 1:3-1:10, then drying and solidification are carried out at 18 to 25 DEG C, and then the metal peroxide base oxygen slow-release composite material is obtained. When in the polluted groundwater rehabilitation, the composite material can greatly slow the reaction rate of the metal peroxide and water, reduce unnecessary loss of the metal peroxide, and improve the service efficiency and period of the metal peroxide.

Owner:TIANJIN UNIV

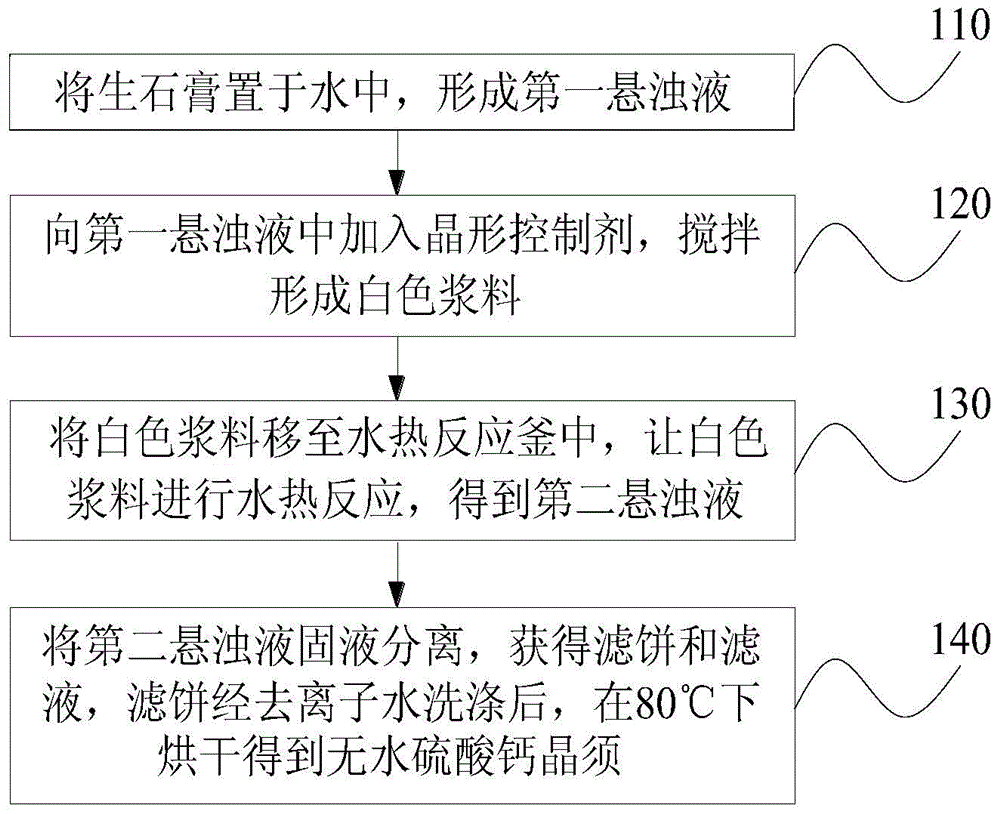

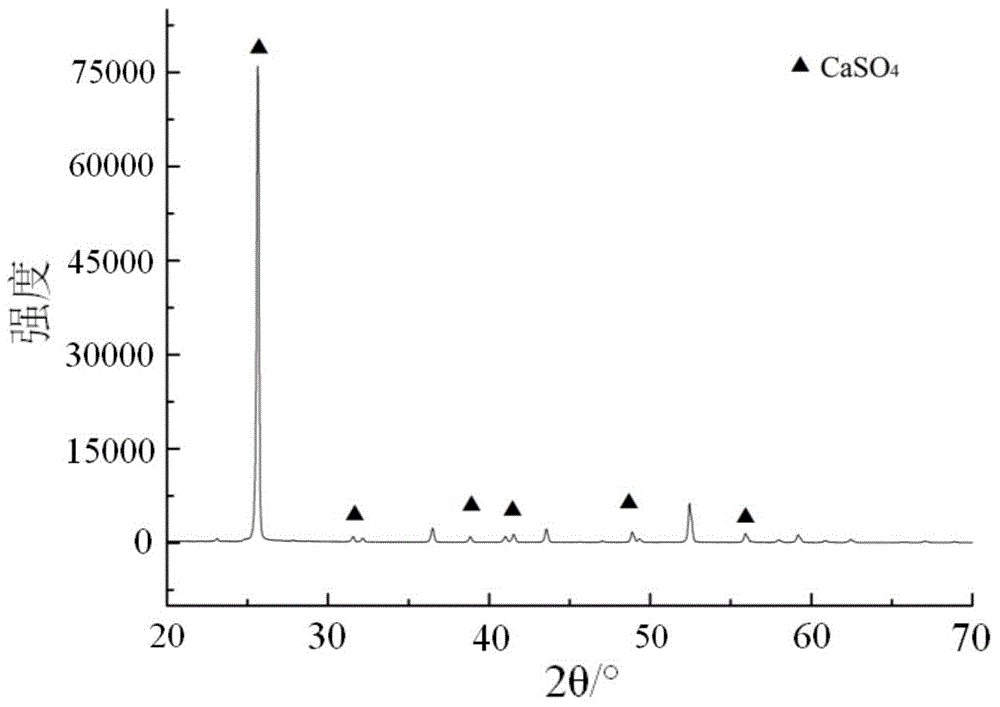

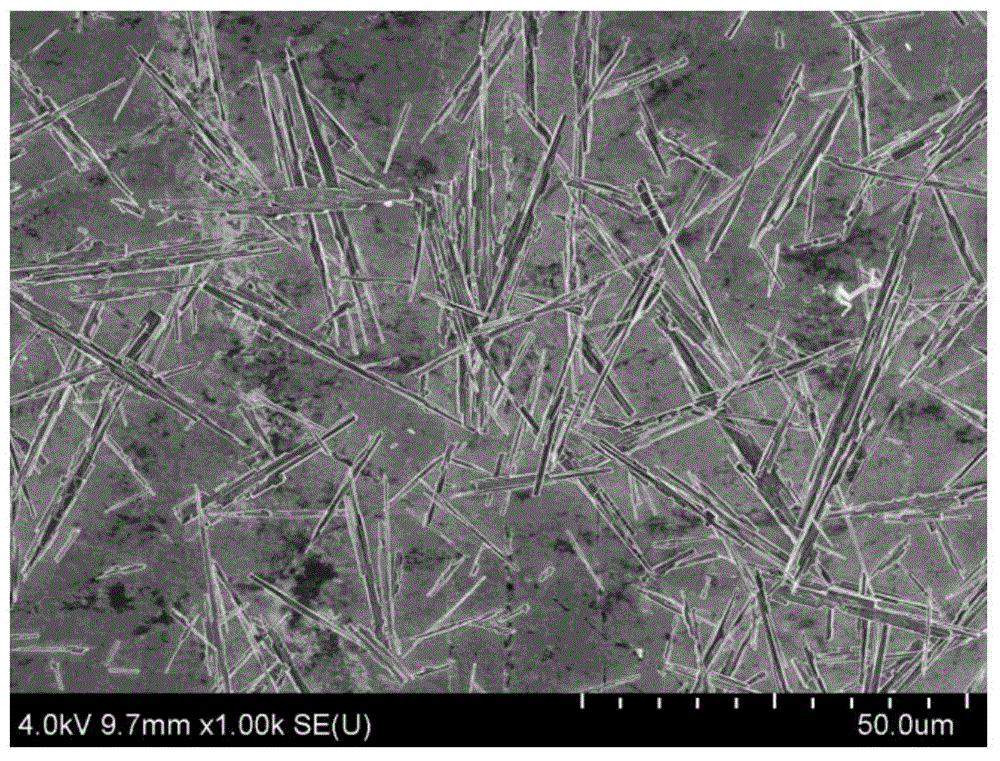

Preparation method of anhydrous calcium sulfate whisker

ActiveCN104911688AReduce manufacturing costSimple processPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateSlurry

The invention belongs to the technical field of whisker preparation and particularly relates to a method for preparing anhydrous calcium sulfate whisker by a one-step hydrothermal process. The method comprises the following steps: (A) putting gypsum in water to prepare a first suspension, stirring and adding a crystal form controller to form slurry, wherein the liquid-solid mass ratio of the water to gypsum is (5.5-30):1, and the molar ratio of the crystal form controller to gypsum is (0.7-5):1; (B) transferring the slurry into a hydrothermal reaction kettle, and stirring for a hydrothermal reaction for 2-10h to obtain a second suspension, wherein the set temperature of the hydrothermal reaction kettle is 170-220 DEG C; and (C) performing solid-liquid separation on the second suspension to obtain a filter cake and filtrate, washing the filter cake and drying to obtain the anhydrous calcium sulfate whisker. According to the preparation method, the anhydrous calcium sulfate whisker can be prepared by a one-step hydrothermal process, and the method is simple; and meanwhile, the problem of low purity and the use of a high-temperature sintering process are avoided, and the production cost is lowered.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Polycaprolactone/calcium sulfate composite material and preparation method thereof

The invention discloses a polycaprolactone / calcium sulfate composite material and a preparation method thereof, belonging to the field of macromolecule modification. The method comprises the following steps: utilizing biosurfactant to carry out surface modification on anhydrous calcium sulfate or calcium sulfate whiskers; and adopting a coprecipitation and mould pressing method to prepare anhydrous calcium sulfate or calcium sulfate whiskers reinforced polycaprolactone composite material. The composite material prepared by the method in the invention has the advantages of high mechanical strength and adjustable performance, thereby laying a foundation for the application thereof.

Owner:SOUTH CHINA UNIV OF TECH

Calcium sulfate-whisker compounded quartz stone board product and preparation method thereof

InactiveCN103408251AImprove performanceNo radioactive contaminationAnhydrous Calcium SulfateGlass particle

The invention discloses a calcium sulfate-whisker compounded quartz stone board product, which comprises the following materials in parts by weight: 58-75% of particle raw material, 10%-25% of quartz powder, 0.01%-10% of pigment, 0.1%-1% of silane coupling agent, 8%-12% of unsaturated polyester resin, 5%-10% of anhydrous calcium sulfate, and 0.8-2% of curing agent, wherein the particle raw material is one or two selected from quartz particles and glass particles. The product is an environment-friendly novel decoration material which has high property and no radioactive contamination, can be recycled, and has the characteristics of gay colors, high finish degree, uniform color, pressure-resistance and abrasion-resistance, good toughness, compact structure, low water absorption, corrosion-resistance, high strength, impact-resistance, innocuousness and zero radiation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

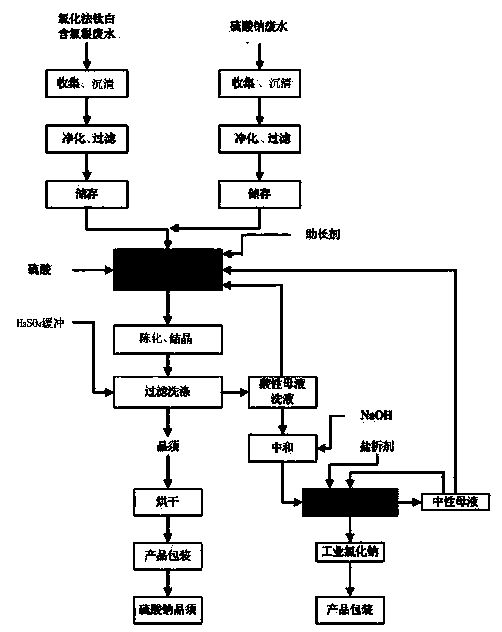

Process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production

ActiveCN103834989AImprove the level of cleaner productionSolve processing problemsPolycrystalline material growthFrom normal temperature solutionsFluidized bed dryingAnhydrous Calcium Sulfate

The invention relates to a process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production. The process comprises the following steps: respectively colleting, clarifying, purifying and filtering chloride-containing wastewater generated in chloride process titanium dioxide production and sodium sulfate-containing wastewater, mixing for reacting, stirring, heating and adding sulfuric acid to adjust the pH value; meanwhile, adding magnesium chloride as a growth substance; placing in a crystallization tank to age and crystallize to obtain calcium sulfate crystals; filtering, and adding H2SO4 to be buffered and heated to be boiled; thermally filtering and washing by deionized water at the same time to obtain calcium sulfate crystal whiskers; feeding to a fluidized bed dryer to be dried and hydrated, and packaging to obtain anhydrous calcium sulfate crystal whiskers. The process is simple and low in cost, and is suitable for industrialized production, so that wastewater is comprehensively utilized.

Owner:中信钛业股份有限公司

Gypsum base material system for 3-D spraying binding and preparing method therefor

The invention relates to a plaster base material system for 3D spray bonding fast forming technique, comprising composite base material and auxiliary bonder, where the composite base material is mixed uniformly of plaster powder, bonder, accelerator anhydrous calcium sulphate, dispersant, white carbon black, and intensifier; and the bonder is mixed of water base polyurethane glue, phenol resin, nonionic surface active agent, and alcohol cosolvent, dissolving in deionized water. And the composite base material and auxiliary bonder can completely meet use requirements.

Owner:ZHONGBEI UNIV

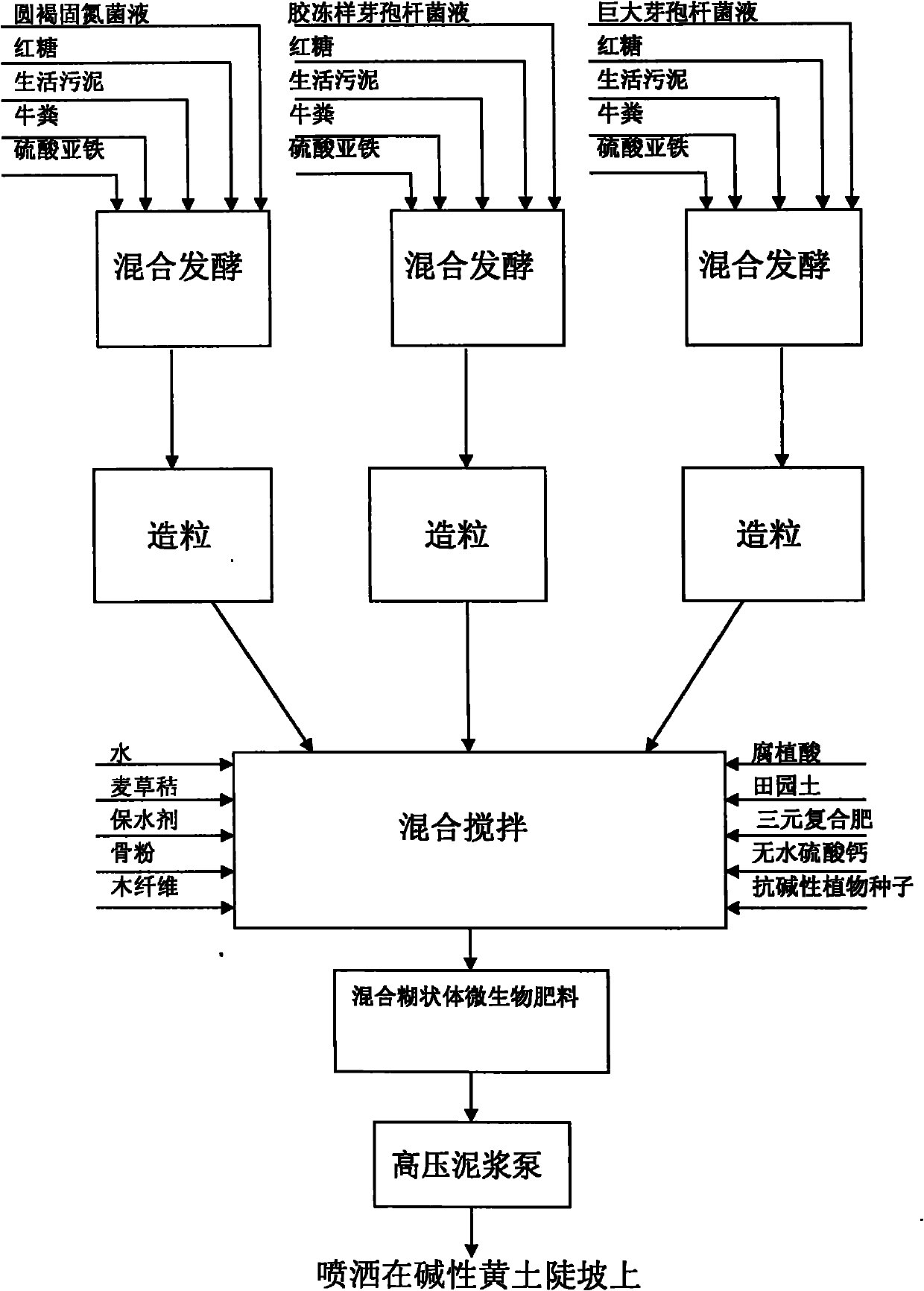

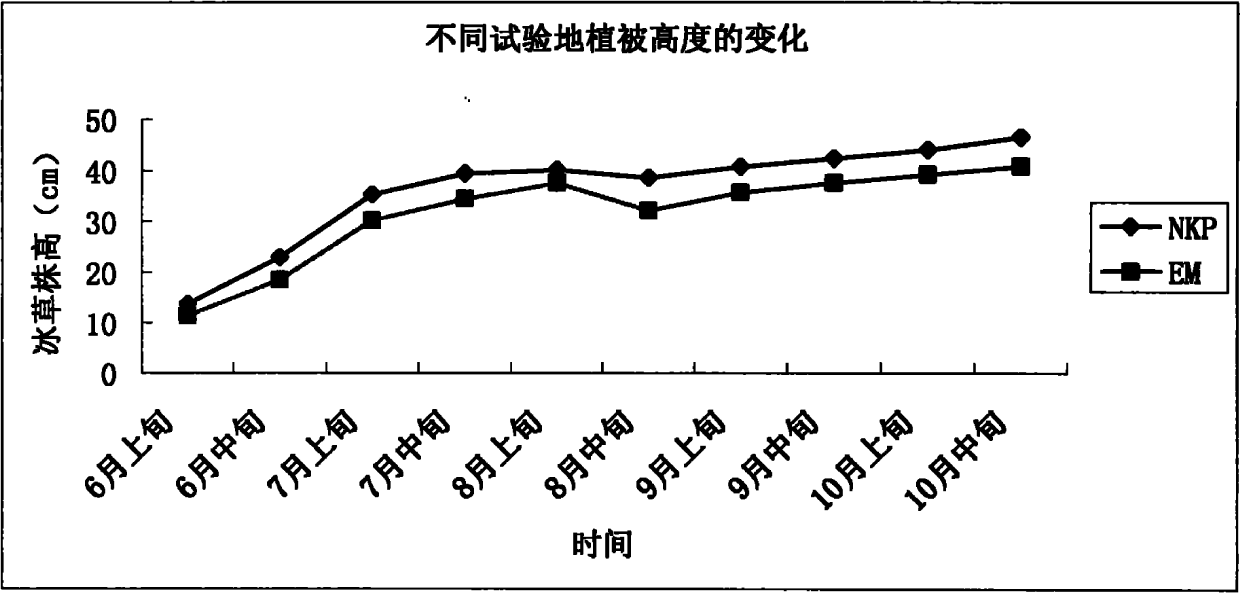

Pasty microbial fertilizer for planting plants on alkaline loess abrupt slope and use method thereof

InactiveCN102070364ALow costEasy constructionBio-organic fraction processingFertilising methodsAzotobacter chroococcumAnhydrous Calcium Sulfate

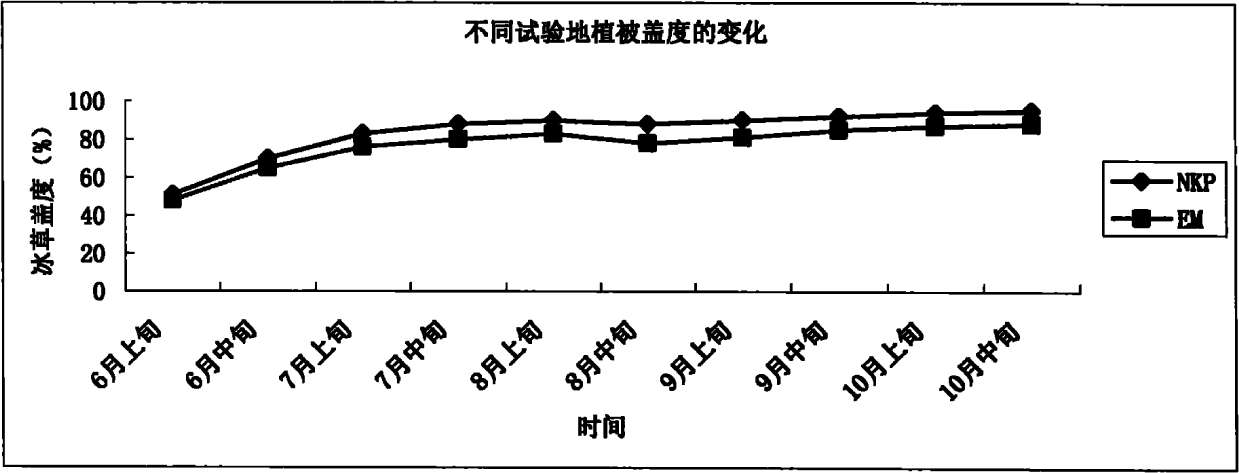

The invention relates to the field of protection of ecological environment and is suitable for an agricultural industry and a forestry industry. Plants are planted on an alkaline loess abrupt slope to afforest the alkaline loess abrupt slope. A pasty microbial fertilizer for planting plants on the alkaline loess abrupt slope is mainly characterized by comprising the following components in percentage by weight: 0.05-0.08 percent of Azotobacter chroococcum liquid, 0.03-0.05 percent of Bacillus mucilaginosus liquid, 0.02-0.04 percent of Bacillus megaterium, 0.01-0.03 percent of brown sugar, 10-20 percent of domestic sludge, 40-60 percent of water, 0.1-0.3 percent of ferrous sulphate, 3-8 percent of cow dropping, 5-10 percent of wheat straw, 0.01-0.8 percent of water-retaining agent, 1-3 percent of bone meal, 2-5 percent of wood fiber, 0.1-0.5 percent of humic acid, 15-25 percent of countryside soil, 0.01-0.05 percent of ternary compound fertilizer, 0.2-0.5 percent of anhydrous calcium sulfate and 0.002-0.006 percent of alkali resistant plant seed, wherein the Azotobacter chroococcum has the CGMCC (China General Microbiological Culture Collection) No. 3768; the Bacillus mucilaginosushas the CGMCC No. 3769; and the Bacillus megaterium has the CGMCC No. 3770.

Owner:兰州市南北两山环境绿化工程指挥部 +1

Powder for plugging air leaking crack

ActiveCN102352225AEasy to moveEffective blockingDrilling compositionAnhydrous Calcium SulfateSodium Bentonite

The invention discloses a powder for plugging an air leaking crack. The powder comprises, by mass, 20 to 25 parts of bentonite, 30 to 35 parts of talcum powder, 18 to 20 parts of a super absorbent resin, 12 to 15 parts of sodium alginate and 10 to 15 parts of anhydrous calcium sulfate, and all the above-mentioned components are directly mixed for utilization. The powder is especially applicable to plugging of air leaking cracks in underground coal mines caused by drilling in the process of gas extraction. According to the invention, under the action of positive pressure from a compressed air system and negative pressure from gas extraction, lubricity of talcum powder enables the powder to be transported to a deep crack; when transportation of the powder is stopped, bentonite and the superabsorbent resin absorb water and swell, sodium alginate powder becomes wet when meeting water, hydration of the sodium alginate powder enables the surface of the sodium alginate powder to have viscosity, the sodium alginate powder enables all the components of the powder to bond together to form aggregate and to adhere to crack walls, the powder continues to swell after anhydrous calcium sulfate absorbs water, and anhydrous calcium sulfate turns into hard gypsum at the same time, which enables the hardness of the powder aggregate to be increased and the powder aggregate to firmly plug the crack. All the materials used in the invention are common material on the market, which enables a low cost to be obtained.

Owner:周福宝

Method for preparing calcium sulfate whiskers

InactiveCN104947179ARich reservesWide variety of sourcesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateResource depletion

Owner:张灵芝

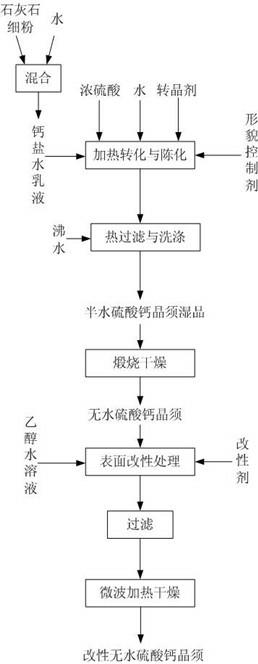

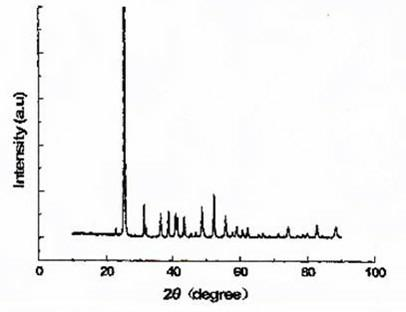

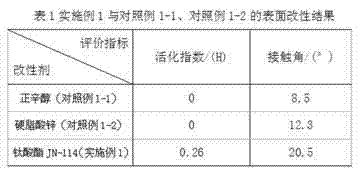

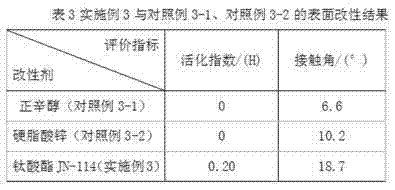

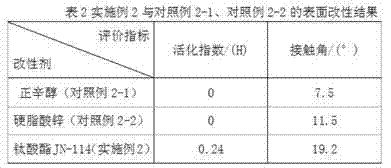

Modified anhydrous calcium sulfate and preparation method thereof

ActiveCN102212204AImprove surface activityImprove adhesionPigment treatment with non-polymer organic compoundsWater bathsAnhydrous Calcium Sulfate

The invention relates to a modified anhydrous calcium sulfate and a preparation method thereof. The modified anhydrous calcium sulfate is prepared from the following raw materials in parts by weight: 70-90 parts of calcium sulfate powder and 10-30 parts of coupling agent. The preparation method of the modified anhydrous calcium sulfate comprises the following steps: drying the calcium sulfate powder in a constant-temperature oven for 2-5 hours; preparing into a 40-60% calcium sulfate powder suspension, and heating in a water bath while stirring for 5-8 hours; dissolving the coupling agent in absolute ethanol, stirring at 30-45 DEG C for 5-7 hours, carrying out suction filtration 5 times, and collecting filtrate; then adding the coupling agent-ethanol solution to the calcium sulfate powdersuspension, stirring for 25-35 minutes, ultrasonically treating for 8-12 minutes, and then stirring for 25-35 minutes; and further carrying out suction filtration, collecting filter residues, washingwith absolute ethanol, carrying out suction filtration 5 times, and then drying to obtain the modified anhydrous calcium sulfate. The modified anhydrous calcium sulfate provided by the invention has high surface activity, and can be easily adhered to a polymer, and is particularly suitable for being used as a modifier or filler for a polymer material.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

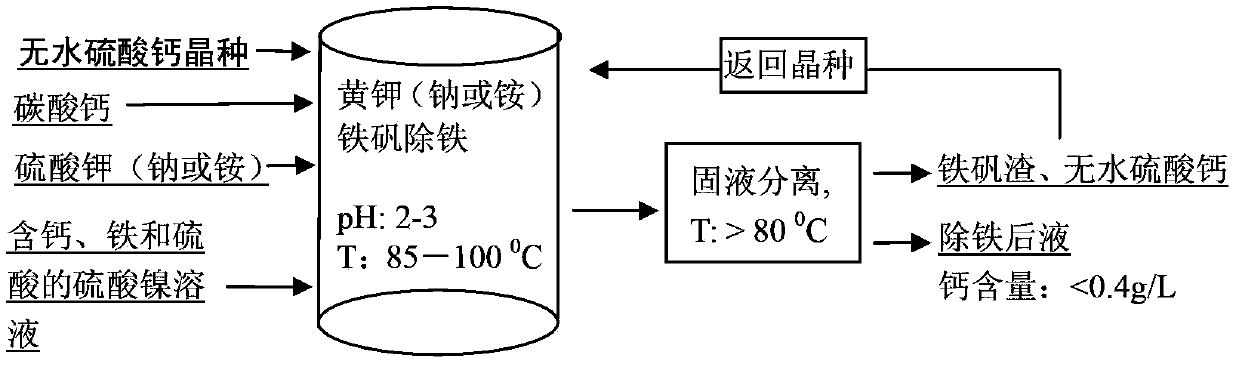

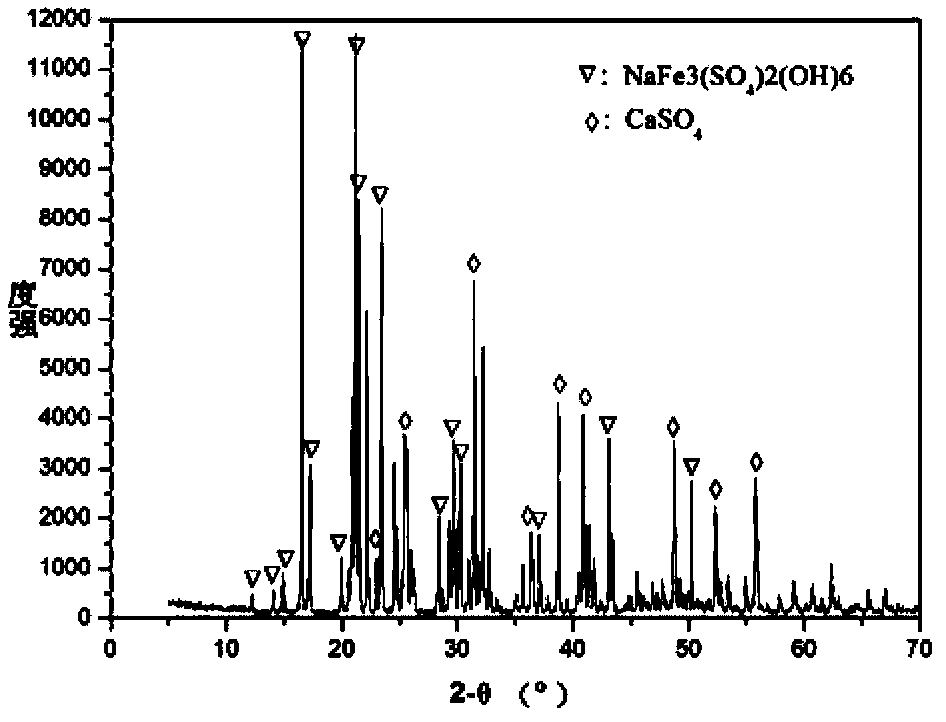

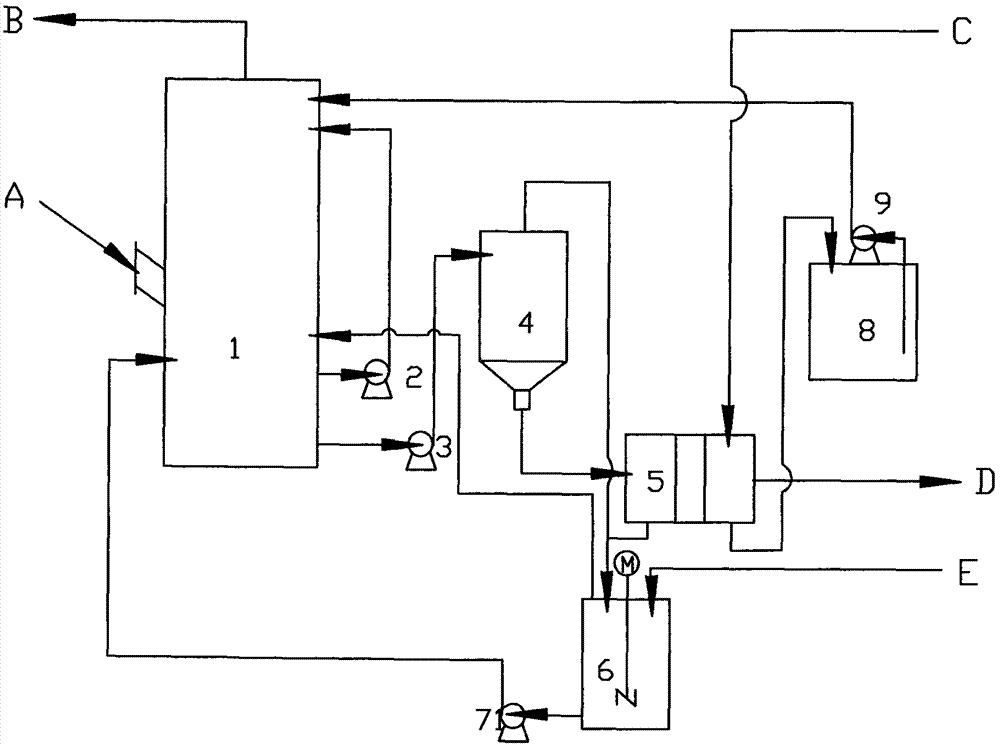

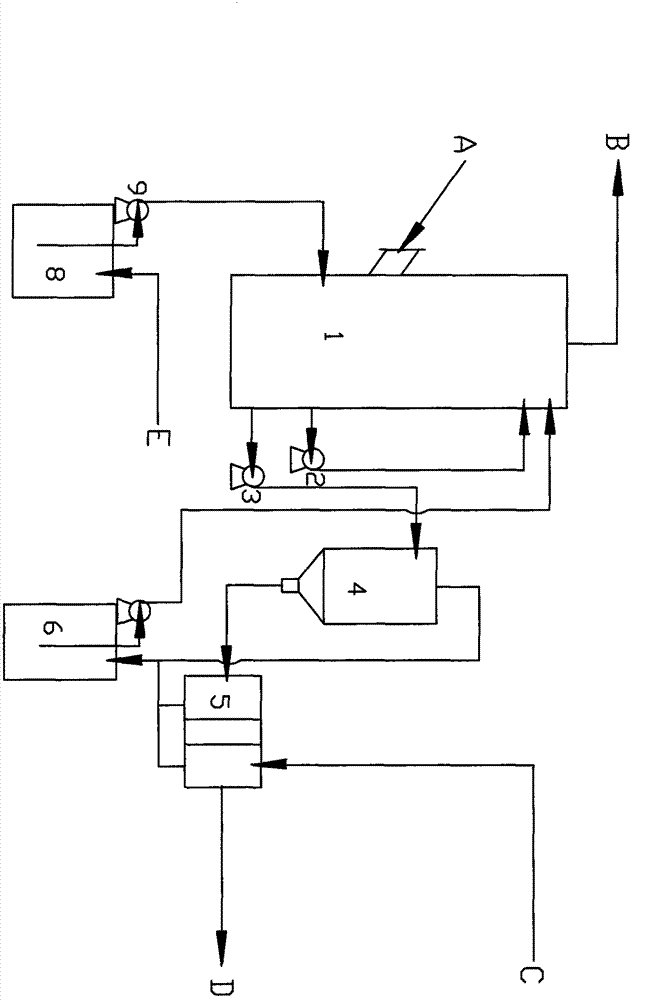

Method for calcium removal during iron precipitation of nickel sulfate solution containing iron and free sulfuric acid

InactiveCN103397185AEliminate hazardsReduce manufacturing costProcess efficiency improvementAnhydrous Calcium SulfateSulfate

Belonging to the technical field of wet metallurgy, the invention relates to a method for calcium removal during iron precipitation of a nickel sulfate solution containing iron and free sulfuric acid. The method includes: during removal of iron from the nickel sulfate solution containing iron and free sulfuric acid, taking calcium carbonate as a pH regulator of the solution, and simultaneously adding an anhydrous calcium sulfate seed crystal, inducing the calcium in the solution to crystallize and precipitate out, and at the end of reaction, conducting filtering immediately, thus obtaining an iron and calcium removed nickel-containing solution. The mass concentration of iron ions in the nickel sulfate solution containing iron and free sulfuric acid is not less than 1g / l, the mass concentration of nickel ions is greater than 10g / l, and the temperature is controlled at 85-100DEG C during calcium removal. The method provided in the invention has the characteristics of simple operation, short technological process, low cost, and good calcium removal effect, etc.

Owner:CENT SOUTH UNIV +1

Preparation method of anhydrous calcium sulfate whisker

ActiveCN103757705APromote growthEasy to industrializePolycrystalline material growthFrom normal temperature solutionsProcess equipmentAnhydrous Calcium Sulfate

The invention provides a preparation method of anhydrous calcium sulfate whisker. The preparation method specifically comprises the following steps of by taking calcium carbonate or calcium hydroxide as a calcium source, sulfur dioxide as a sulfur source, and ammonium sulfate solution as a medium solution, adding the calcium source into the ammonium sulfate solution, introducing SO2 while agitating; reacting to obtain calcium sulfite whisker; and then filtering and drying with high temperature air to obtain the anhydrous calcium sulfate whisker. The preparation method has the advantages that the reaction condition is mild; the process equipment is simple; the equipment investment is low; the operation is high in flexibility; industrial production can be easily carried out; the whisker is high in length-diameter ratio and reaches 30 to 200 and high in quality; and the preparation method is applicable to independent production and also suitable for co-producing anhydrous calcium sulfate whisker in coal-fired flue gas desulphurization, as well as non-ferrous metal metallurgy, sulfuric acid production and other tail gas treatment.

Owner:淮南市明月环保科技有限责任公司

Surface modification method for calcium sulfate whiskers

InactiveCN105350084AReduce the burden onHigh hardnessPolycrystalline material growthAfter-treatment detailsAnhydrous Calcium SulfateWater processing

The invention discloses a surface modification method for calcium sulfate whiskers. The surface modification method comprises steps: anhydrous calcium sulfate whiskers are prepared; a surface modifier solution is prepared; the calcium sulfate whiskers are added slowly into the surface modifier solution with stirring, slow stirring is carried out, and a reaction is carried out; the modified anhydrous calcium sulfate whiskers are subjected to impurity removal processing. The method is simple, the steps are few, raw materials are saved, water processing burden is reduced, the anhydrous calcium sulfate whisker product has good performance, and tensile strength, the tear resistance, the folding strength and the pop strength are high. The solution synthesis method is employed, a calcium-containing industrial tail liquid is reacted with sulfuric acid, calcium sulfate whiskers are prepared, the cleaning utilization problem of calcium ions in the waste liquid is solved, which facilitates to achieve cyclic utilization of raw materials and resources are saved. The yield of the prepared calcium sulfate whiskers is high, the crystal form is structured and the length-to-diameter ratio is high.

Owner:SHANDONG UNIV OF SCI & TECH +1

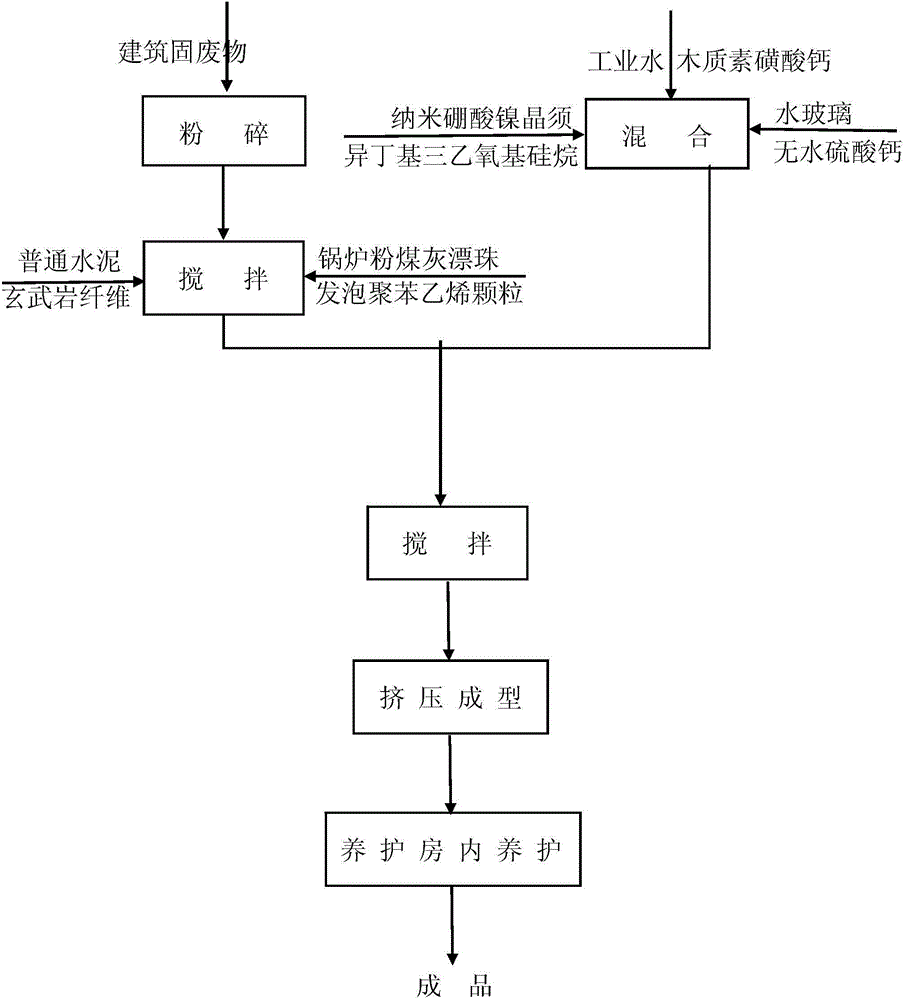

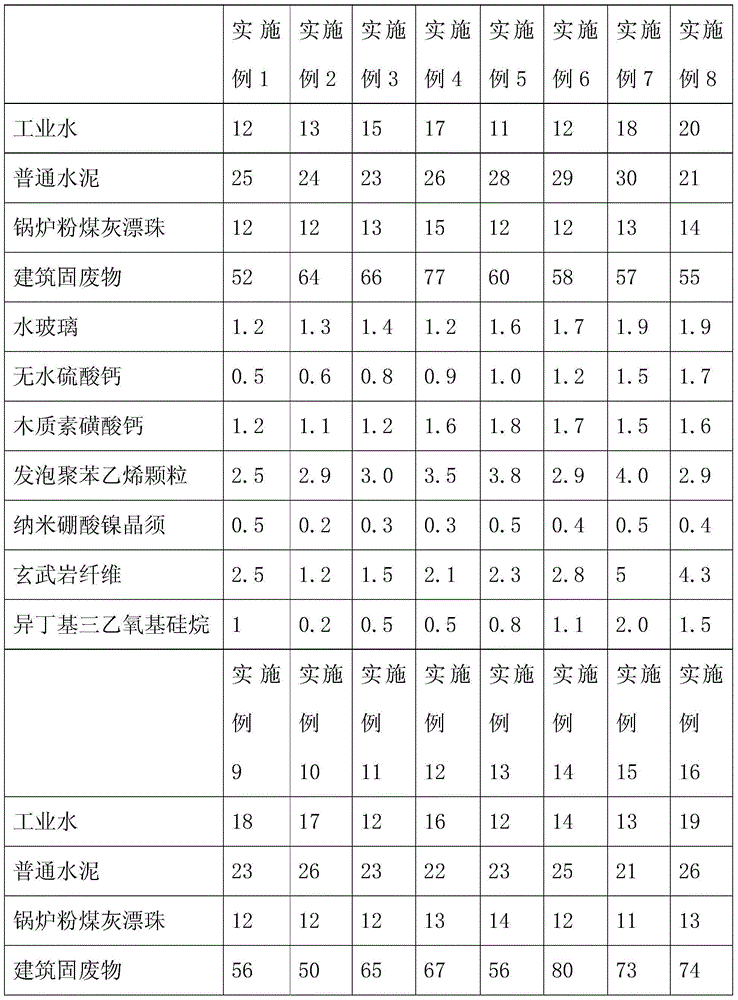

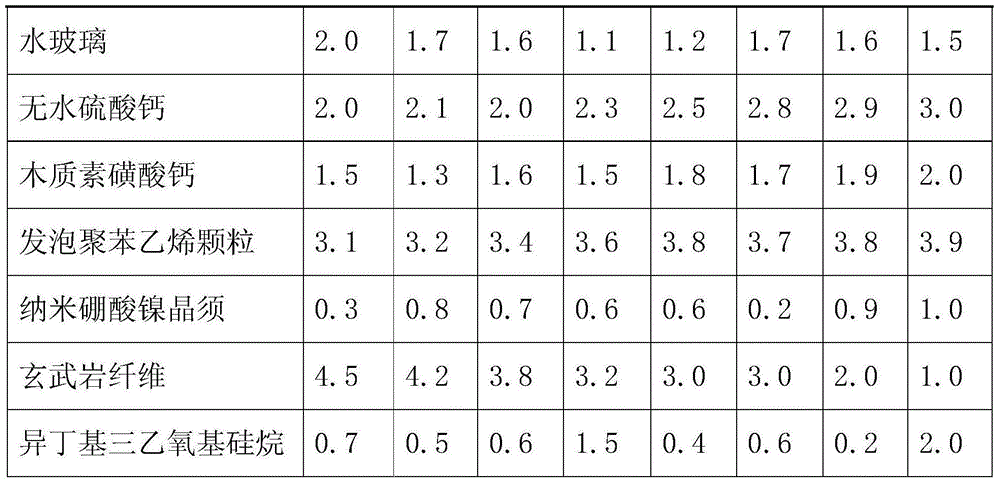

Energy-saving wall material produced by using construction solid wastes and producing method of wall material

InactiveCN104944862ASolve the pollution of the environmentPollution is notSolid waste managementEnvironmental resistanceAnhydrous Calcium Sulfate

The invention discloses an energy-saving wall material produced by using construction solid wastes and a producing method of the wall material, and belongs to the field of construction materials. The energy-saving wall material is produced by using the following raw materials in parts by weight: 50-80 parts of construction solid wastes, 12-20 parts of industrial water, 25-35 parts of portland cement, 0.1-1 part of nanometer nickel borate whiskers, 10-20 parts of boiler coal ash floating beads, 2-4 parts of expanded polystyrene particles, 1-5 parts of basalt fiber, 0.1-2 parts of sodium silicate, 0.2-3 parts of anhydrous calcium sulfate, 1-2 parts of calcium lignosulfonate and 0.1-2 parts of isobutyltriethoxysilane. According to the invention, the problem of construction waste pollution is solved, the wastes are reused, so that resources are saved; the finished product is light in weight, remarkable in heat preservation and good in anti-knock and anti-pressure properties, is a green construction material, and meets national energy conservation and emission reduction requirements; the process is simple, the construction is convenient, the energy consumption in the production process is low, and no pollution is caused to the environment, therefore, the energy-saving wall material and the producing method are energy-saving and environmental protection technologies.

Owner:GANSU YIHE NOVEL MATERIAL

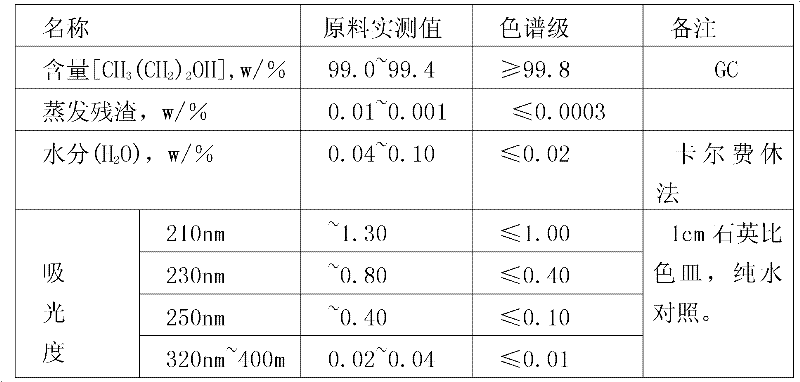

Method for purifying chromatographic grade organic solvent methyl tertiary butyl ether

InactiveCN102417441AHigh purityIncrease contentEther separation/purificationPurification methodsAnhydrous Calcium Sulfate

The invention relates to a method for purifying a chromatographic grade organic solvent methyl tertiary butyl ether. The method comprises the following steps of: allowing a raw material, namely methyl tertiary butyl ether to pass through alumina and silica gel so as to remove peroxide impurities, partially dehydrating, further dewatering by using a drying agent, namely anhydrous calcium sulfate, rectifying, filtering, and packaging to obtain a high-purity organic solvent methyl tertiary butyl ether product. In the method, the methyl tertiary butyl ether with the content of between 99.0 and 99.4 percent is taken as the raw material and the alumina and the silica gel are taken as adsorbents for adsorption separation so as to remove organic impurities such as peroxide, partial water and the like from the raw material, anhydrous calcium sulfate is used for further dewatering, and a methyl tertiary butyl ether product with the purity of more than 99.8 percent is obtained by the steps of adsorption, drying, rectification and purification; and various other chromatographic indexes all meet the requirements. The recovery rate is over 93 percent; and the yield approximately reaches over 93 percent.

Owner:天津市康科德科技有限公司

Color cement made from copper-smelting slag

InactiveCN101434460AColorful and brightUniform colorSolid waste managementAnhydrous Calcium SulfateSlag

Colored cement produced by copper-smelting slag is characterized by comprising portland cement clinker 525<#>, copper-smelting slag, lime, fly ash, plaster, composite excitant, paint and cement intensifier, wherein, the composite excitant consists of dead plaster and active aluminium silicon; cement intensifier consists of aluminium sulphate, silicon dioxide, alumina and common salt. The invention mixes a little amount of low-active copper-smelting slag in the cement composite material, and then adds additives such as the lime, the fly ash, the composite excitant, the cement intensifier and the like to excite the activity of the copper-smelting slag, thus preparing the bright, even and various colored cement which has the characteristics of saving energy, reducing discharge, having simple technique, reducing the cement cost, and the like.

Owner:苏艳杰

Preparation method of calcium sulfate whisker

ActiveCN104328480AReduce manufacturing costLow costPolycrystalline material growthFrom normal temperature solutionsFiberAnhydrous Calcium Sulfate

The invention relates to a preparation method of whisker, and particularly relates to a preparation method of calcium sulfate whisker. The preparation method of the calcium sulfate whisker comprises the following steps of (1) selecting a fiber gypsum raw material, carrying out primary crush on the fiber gypsum raw material to form fiber gypsum pieces with particle size of 5-15 cm; (2) immersing the fiber gypsum pieces in an immersion tank, wherein the immersion tank is filled with an immersion solution; (3) steam-curing the immersed fiber gypsum pieces in a steam-curing furnace, so that the fiber gypsum pieces become semi-hydrated gypsum; (4) carrying out primary crush on the semi-hydrated gypsum by using a roller machine so as to make the semi-hydrated gypsum present strip flocculent shapes, then grinding the strip flocculent shaped semi-hydrated gypsum by using a pulverizer to obtain fibrous gypsum; and (5) drying the fibrous gypsum through a drier, cooling and homogenizing to obtain an anhydrous calcium sulfate whisker product. The calcium sulfate whisker product produced by the preparation method has good quality stability, low cost and small influence on environment.

Owner:JIANGXI FENGZHU NEW MATERIAL TECH

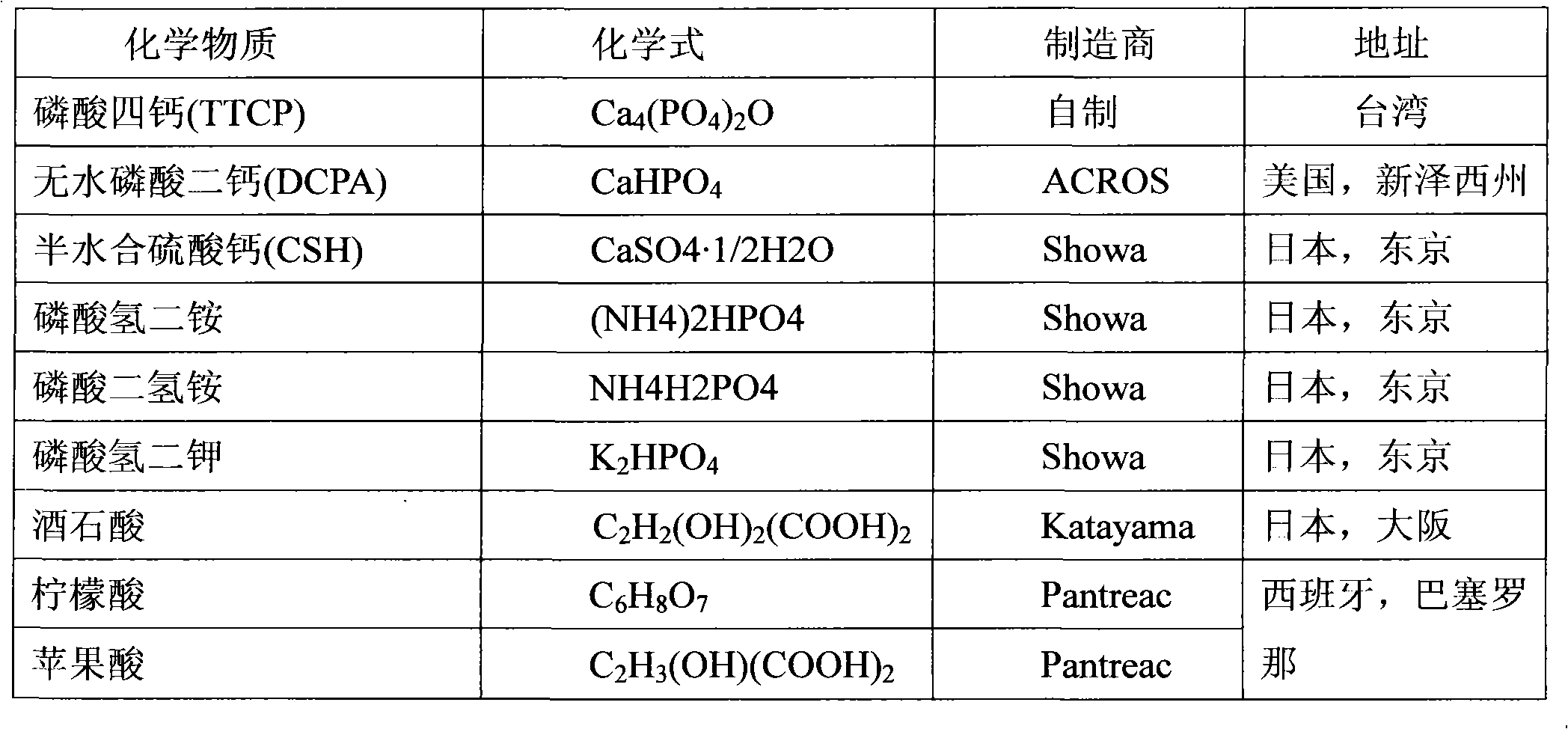

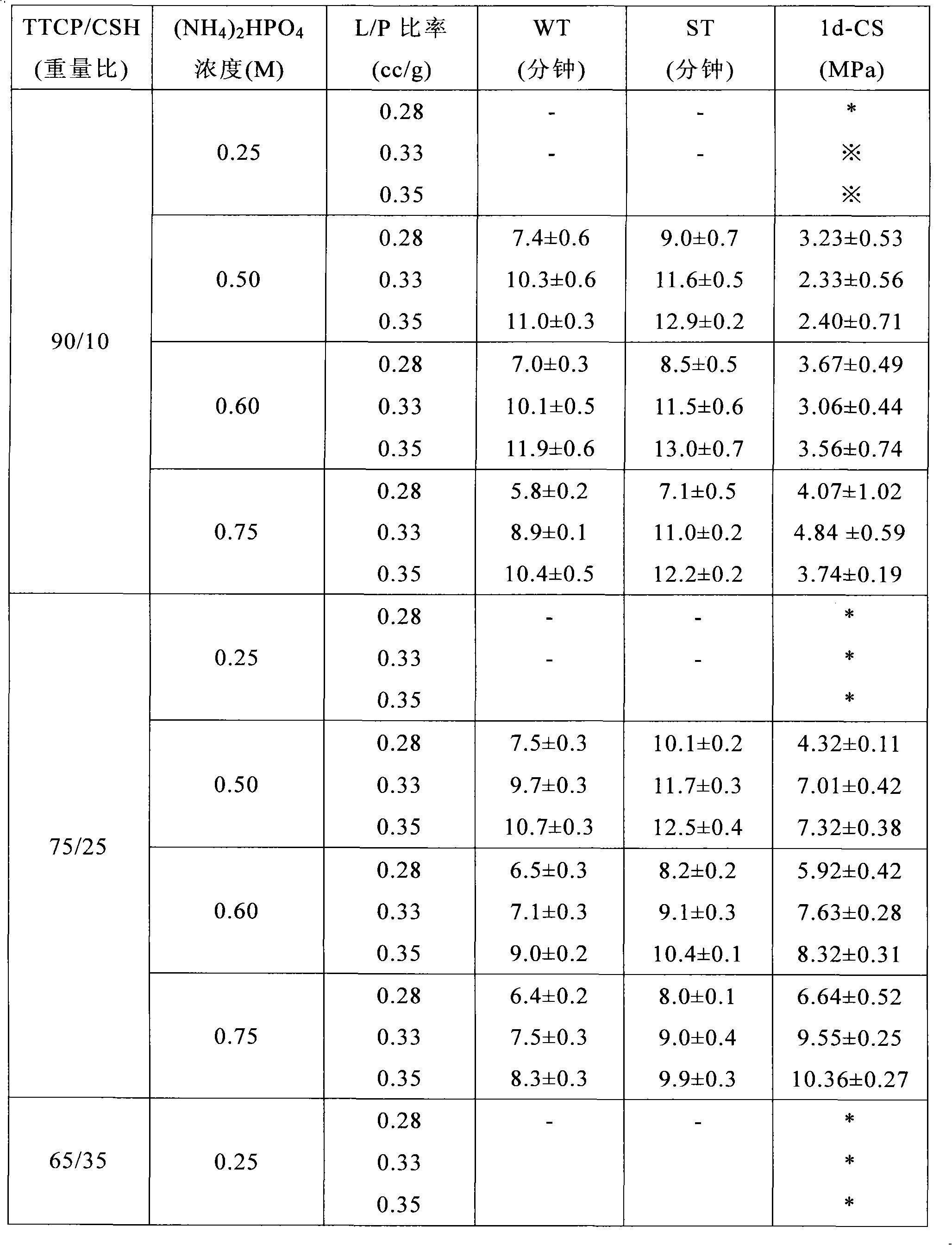

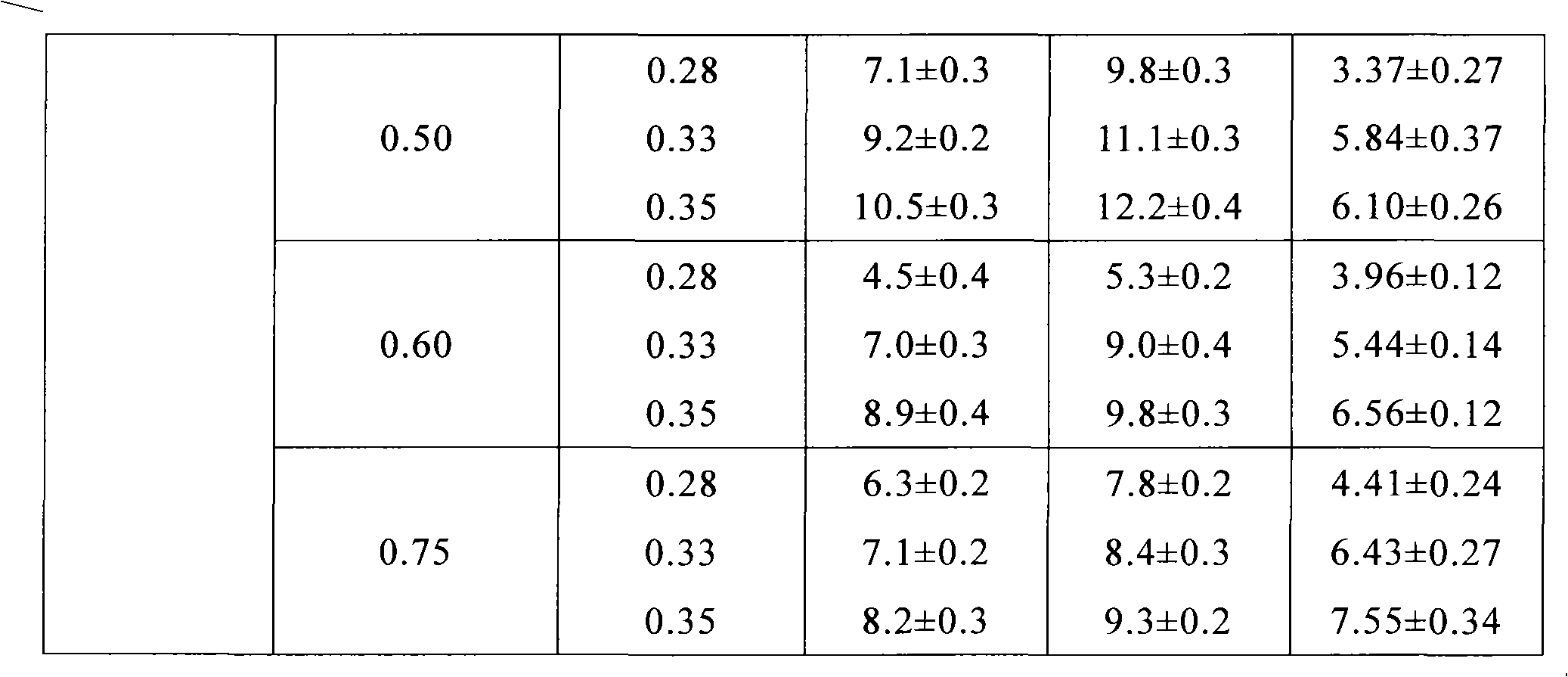

Bone cement formula and bioresorbable hardened bone cement composites prepared with the same

The present invention provides a bone cement formula having a powder component and a setting liquid component, wherein the powder component includes a calcium sulfate source and a calcium phosphate source with a weight ratio of the calcium sulfate source less than 65%, based on the total weight of the calcium sulfate source and the calcium phosphate source, and the setting liquid component comprises ammonium ion (NH4+) in a concentration of about 0.5 M to 4 M, wherein the calcium phosphate source includes tetracalcium phosphate (TTCP) and dicalcium phosphate in a molar ratio of TTCP to dicalcium phosphate of about 0.5 to about 2.5, and the calcium sulfate source is calcium sulfate hemihydrate (CSH), calcium sulfate dehydrate (CSD), or anhydrous calcium sulfate.

Owner:NAT CHENG KUNG UNIV

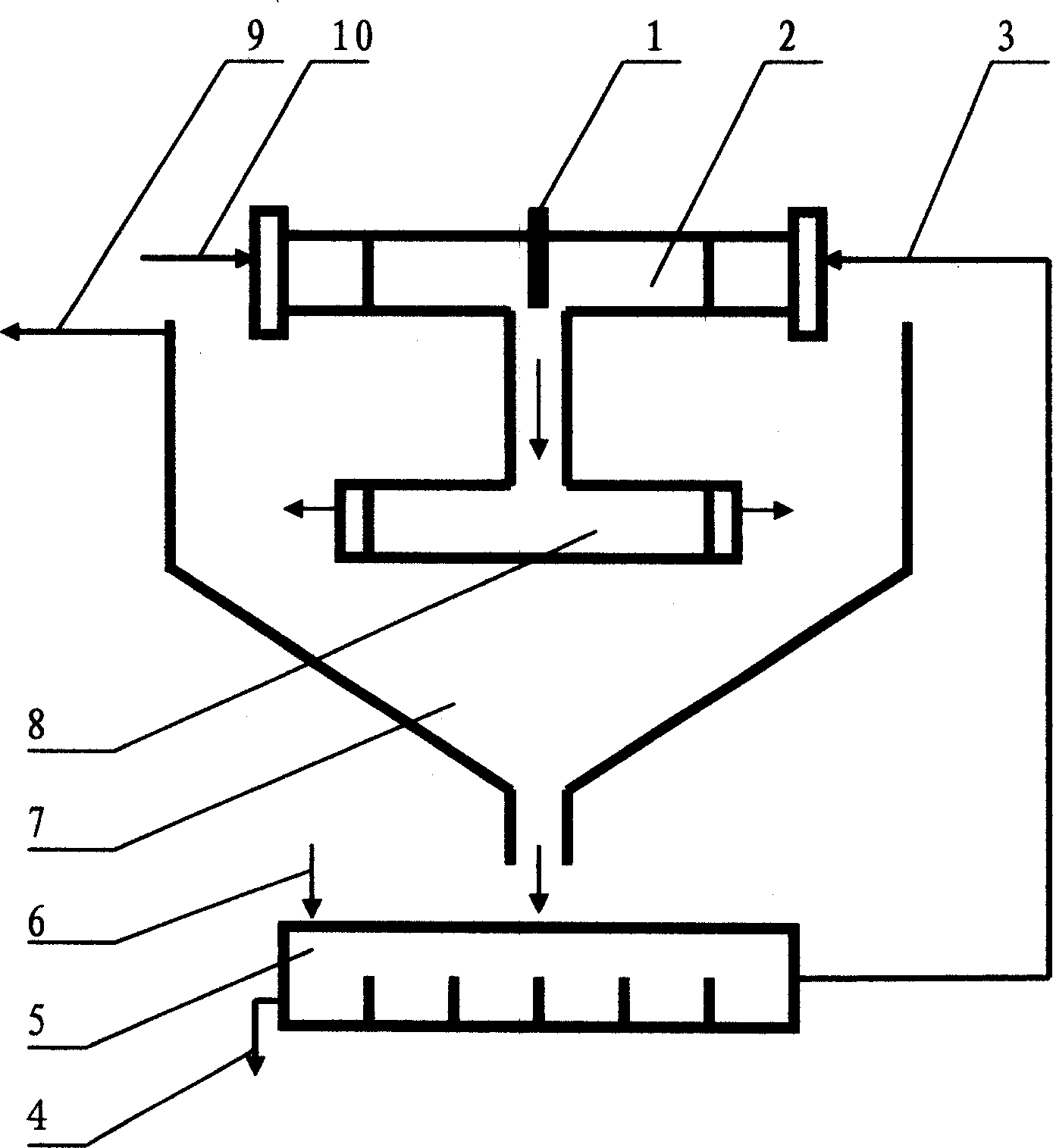

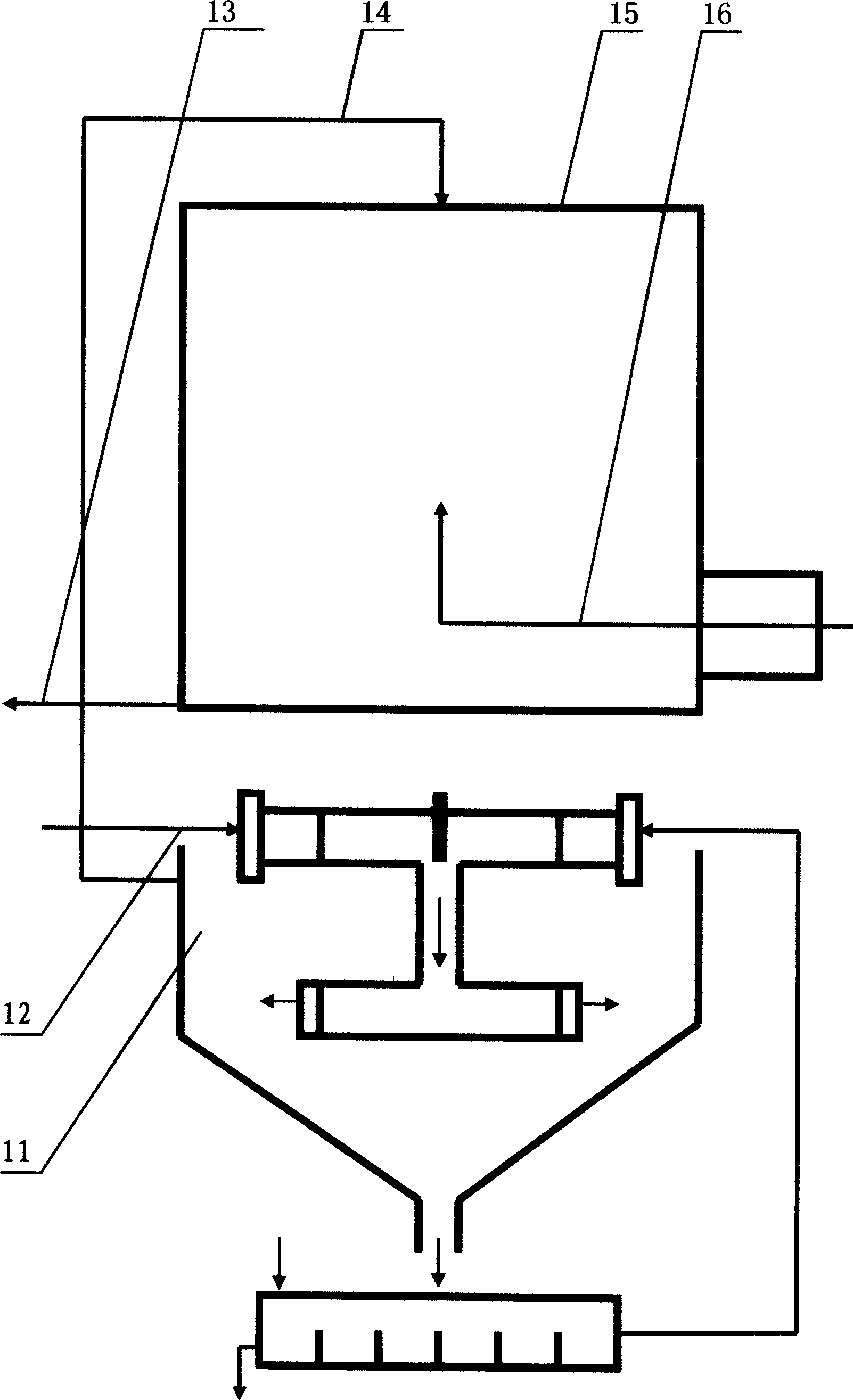

Method for removing calcium ion in zinc sulphate solution

InactiveCN1884092AIncrease the amount of crystallizationIncrease the rate of crystallizationZinc sulatesAnhydrous Calcium SulfateSulfate

The invention discloses a calcium ion removing method in the zinc sulfate solution, which is characterized by the following: adopting ultrasound to remove calcium in the zinc sulfate solution; accelerating calcium sulfate from ionic state to calcium; blending removed calcium liquid and inversed-solution with anhydrous calcium sulfate through crystal grower to accelerate growth of calcium sulfate crystal; adopting hydraulic stirrer to reinforce solid-liquid separation; utilizing dense groove structure within dense groove and ultrasonic calcium removing device as ultrasonic calcium groove. The ultrasonic calcium removing device contains ultrasonic crystallizing device, crystal grower, hydraulic stirrer and crystal geosynclinal.

Owner:XINGMIN TECH ZHUZHOU

Freeze-thaw durable geopolymer compositions and methods for making same

ActiveUS20170113969A1Excellent freeze-thaw durability behaviorGood dimensional stabilityIn situ pavingsSolid waste managementFreeze thawingAnhydrous Calcium Sulfate

Owner:UNITED STATES GYPSUM CO

Weather-proof PC-PPO (Poly Carbonate-Poly-p-Phenylene oxide) alloy plastic and preparation method thereof

InactiveCN103304975AGood mechanical propertiesImprove mechanical propertiesAnhydrous Calcium SulfatePolyvinyl alcohol

The invention aims to provide alloy plastic, and in particular relates to PC-PPO (Poly Carbonate-Poly-p-Phenylene oxide) alloy plastic, and belongs to the technical field of high molecular materials. The plastic comprises the following components in parts by weight: 100-140 parts of polycarbonate, 40-60 parts of polyphenyl ether, 5-15 parts of a methyl ester-butadiene-styrene copolymer, 5-10 parts of dibutyl phthalate, 10-14 parts of polyvinyl butyral, 3-5 parts of tertiary butyl phenol-formaldehyde resin, 2-4 parts of polydimethylsiloxane, 3-5 parts of polyvinyl ethyl ether, 5-20 parts of aluminum silicate fiber, 15-25 parts of epoxy resin, 5-10 parts of white carbon black, 1-6 parts of anhydrous calcium sulfate, 1-3 parts of nanoscale titanium dioxide, 4-8 parts of polystyrene granules, 6-12 parts of chitosan, 3-5 parts of an antioxygen, 4-12 parts of a coupler and 3-5 parts of an uvioresistant agent. The mechanical property of the plastic corroded by acids and alkalis is decreased to a small extent. After high temperature and high humidity destructive test, the plastic still has good mechanical property which is superior to that of a control sample.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com