Preparation method of calcium sulfate whisker

A calcium sulfate whisker and calcium oxide technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve problems such as high temperature, pressure, and yield can not reach 100%, Achieve the effect of uniform length and diameter, good for environmental protection and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

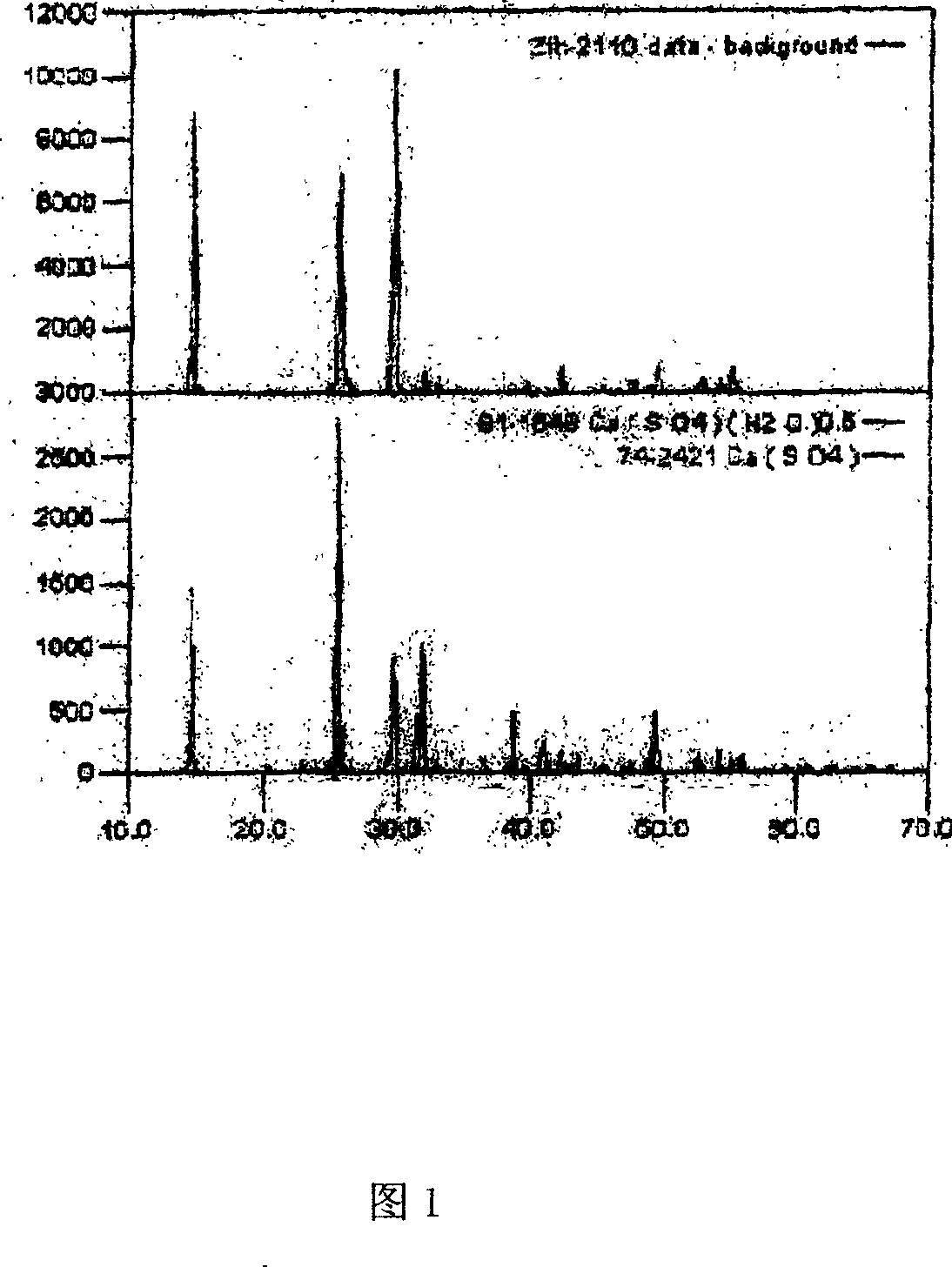

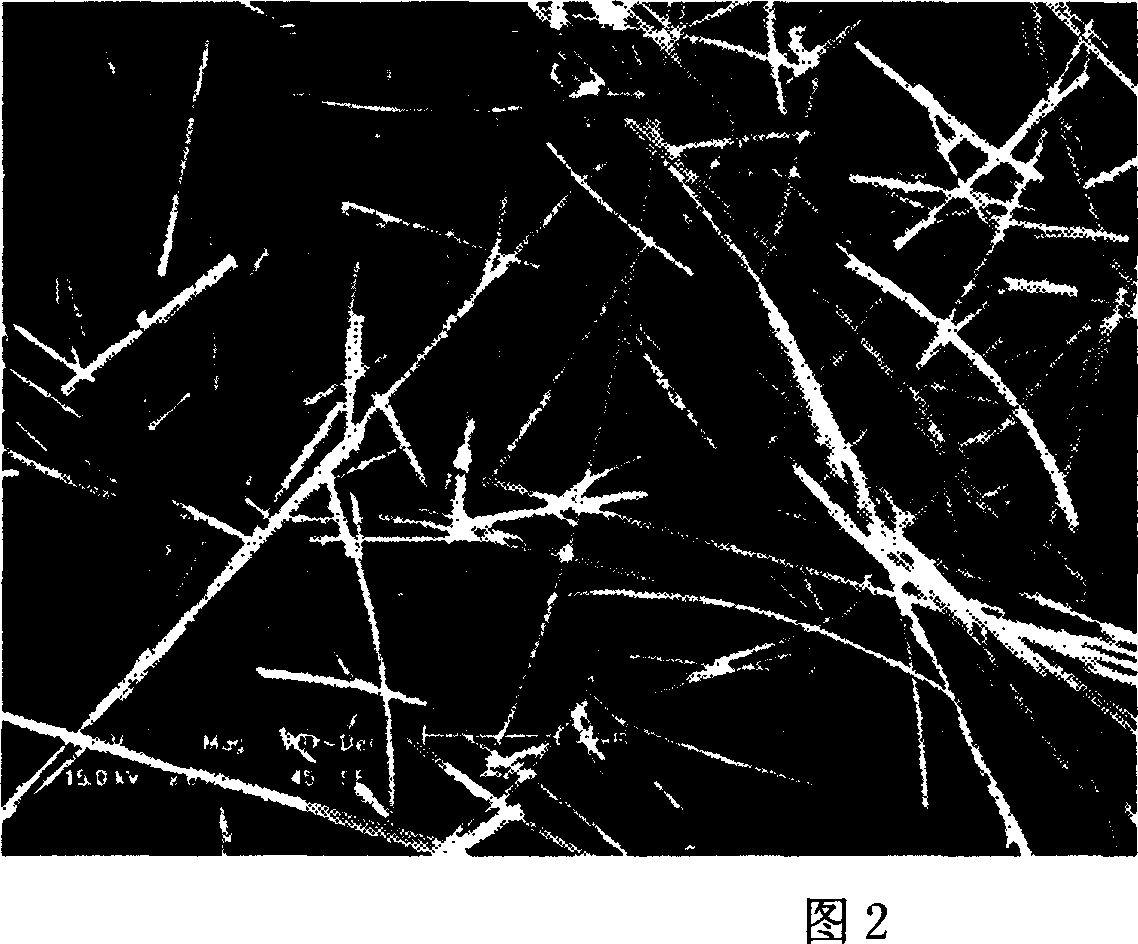

[0021] Weigh 100g of industrial grade CaO into the reactor, add 500ml of distilled water, pretreat in ultrasonic to make large particles fully pulverized, then add 500ml of distilled water, and digest at 40-60°C. To obtain the lime emulsion, raise the temperature to 80°C, add sulfuric acid solution equimolar to calcium oxide, add self-made crystallization directing agent in the reaction process, the addition amount is 1% of the theoretical product production amount, stir for 40min, make it fully react, The reaction solution was separated by suction filtration while hot as soon as possible, and the X-ray diffraction spectrum and the electron microscope figure of the obtained product are as shown in Figure 1 and Figure 2.

[0022] The obtained calcium sulfate whisker products need different surface modifications according to different application objects to make them blend well with other materials. Easy to play its performance.

Embodiment 2

[0024] Except that the reaction temperature is 40° C., and 2% of a self-made crystallization directing agent is added, the other conditions are the same as in Example 1.

Embodiment 3

[0026] Except that the reaction temperature is 60°C, and 3% crystallization directing agent is added, the other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com