Patents

Literature

2330 results about "Raised temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

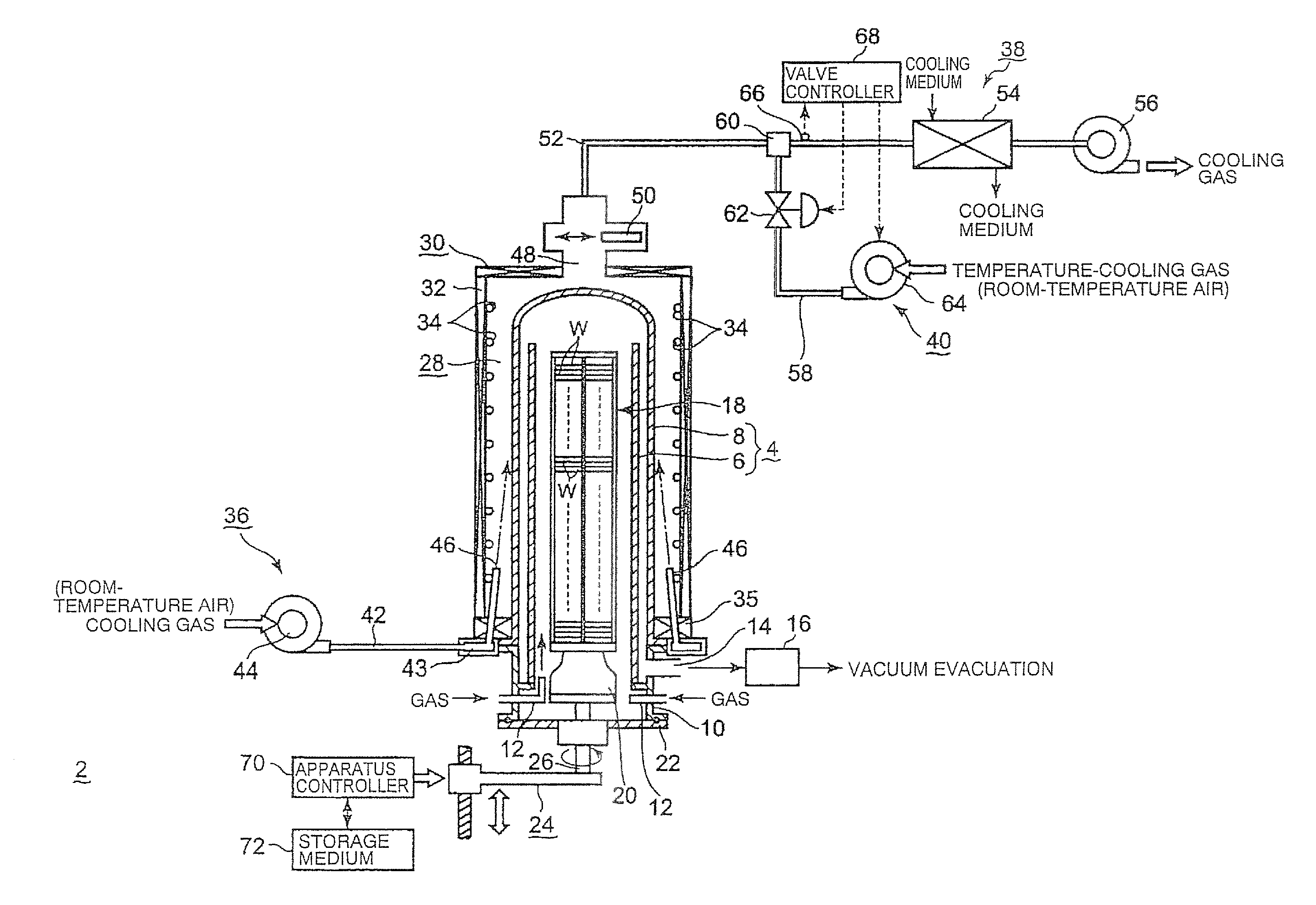

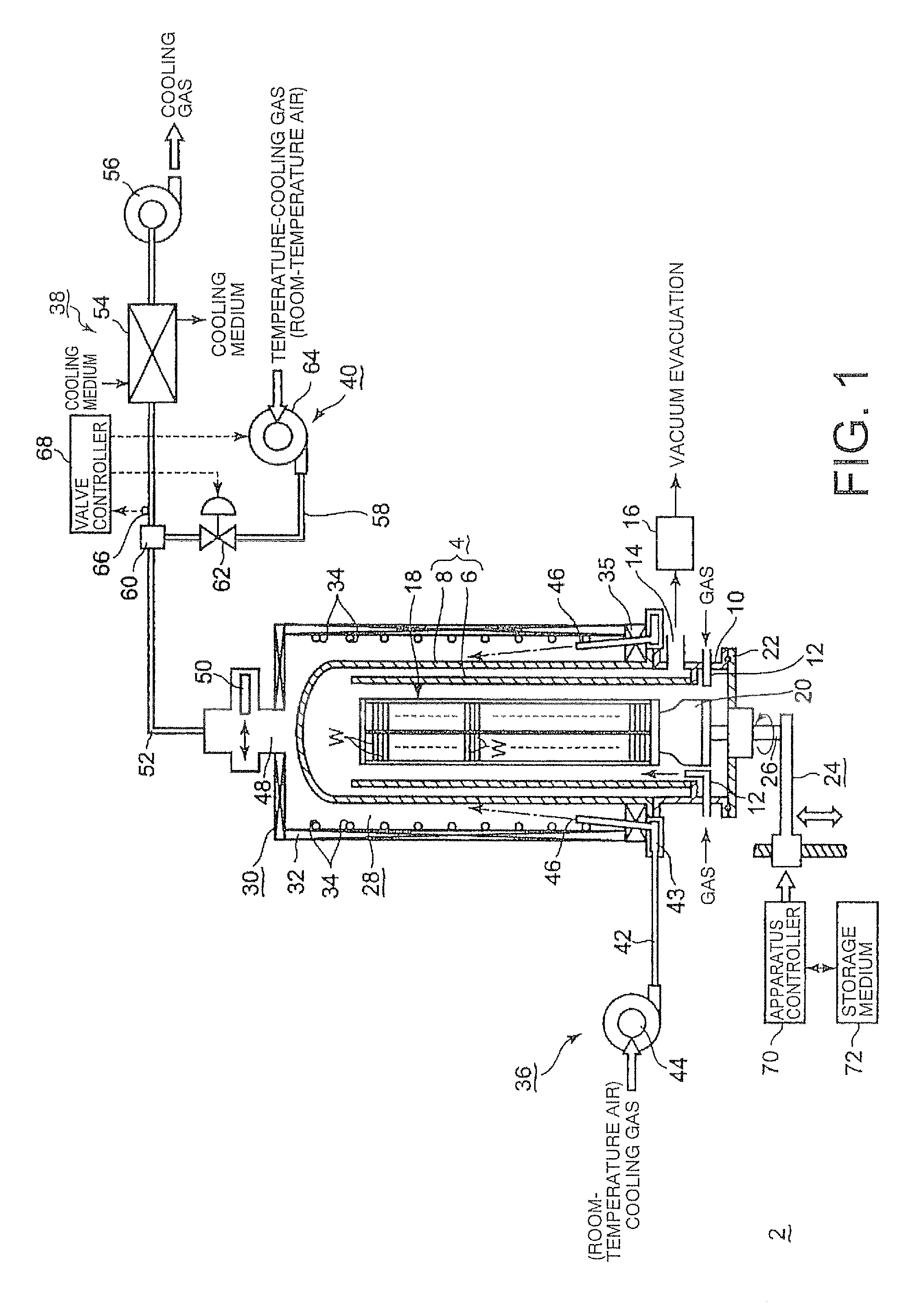

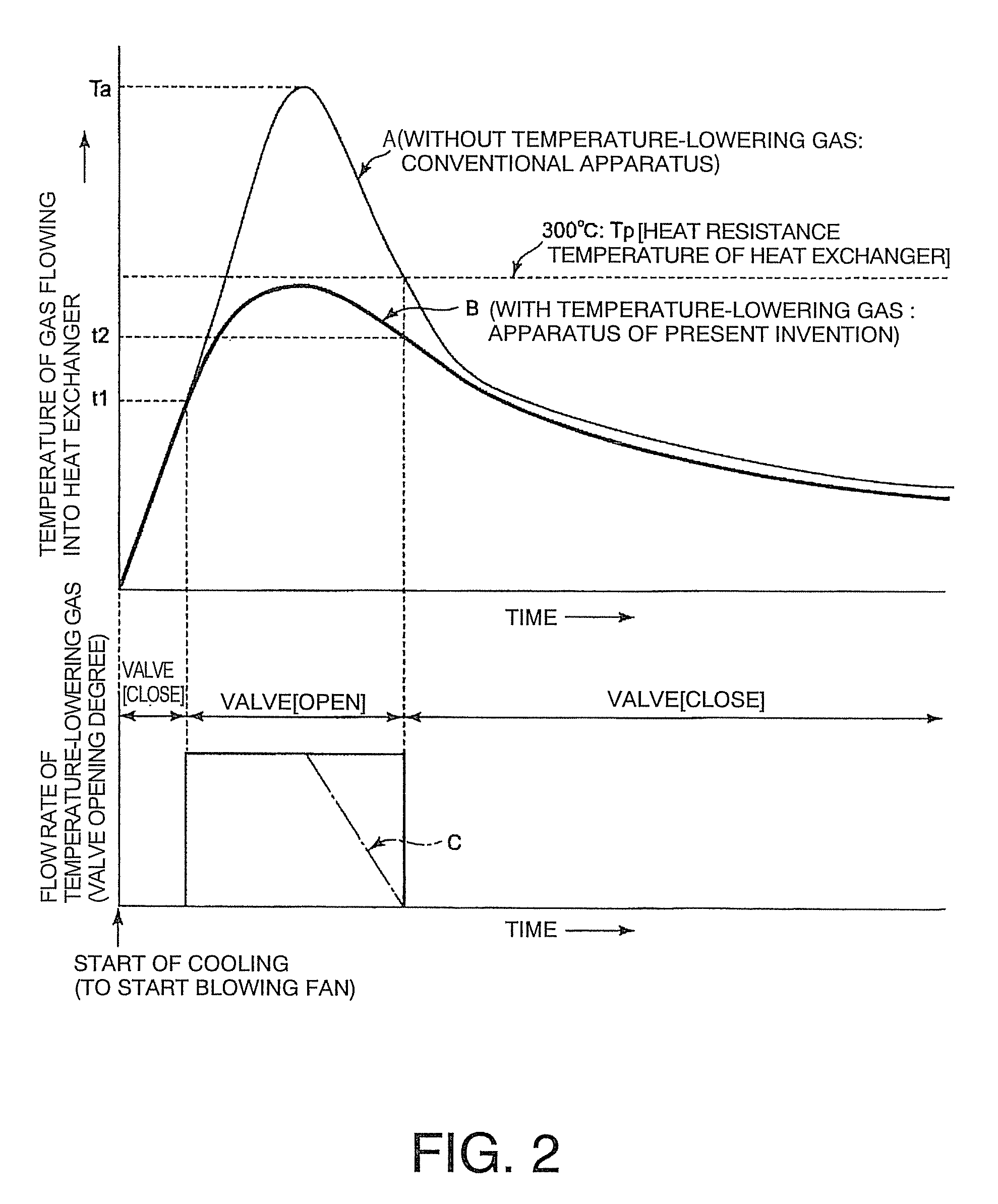

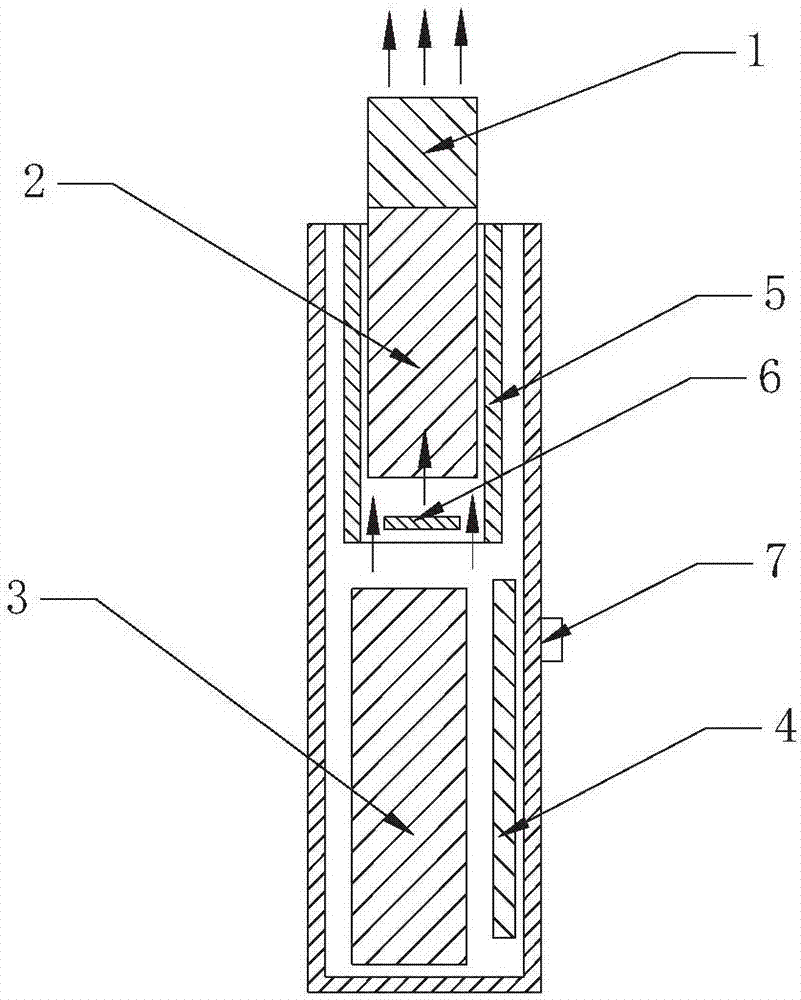

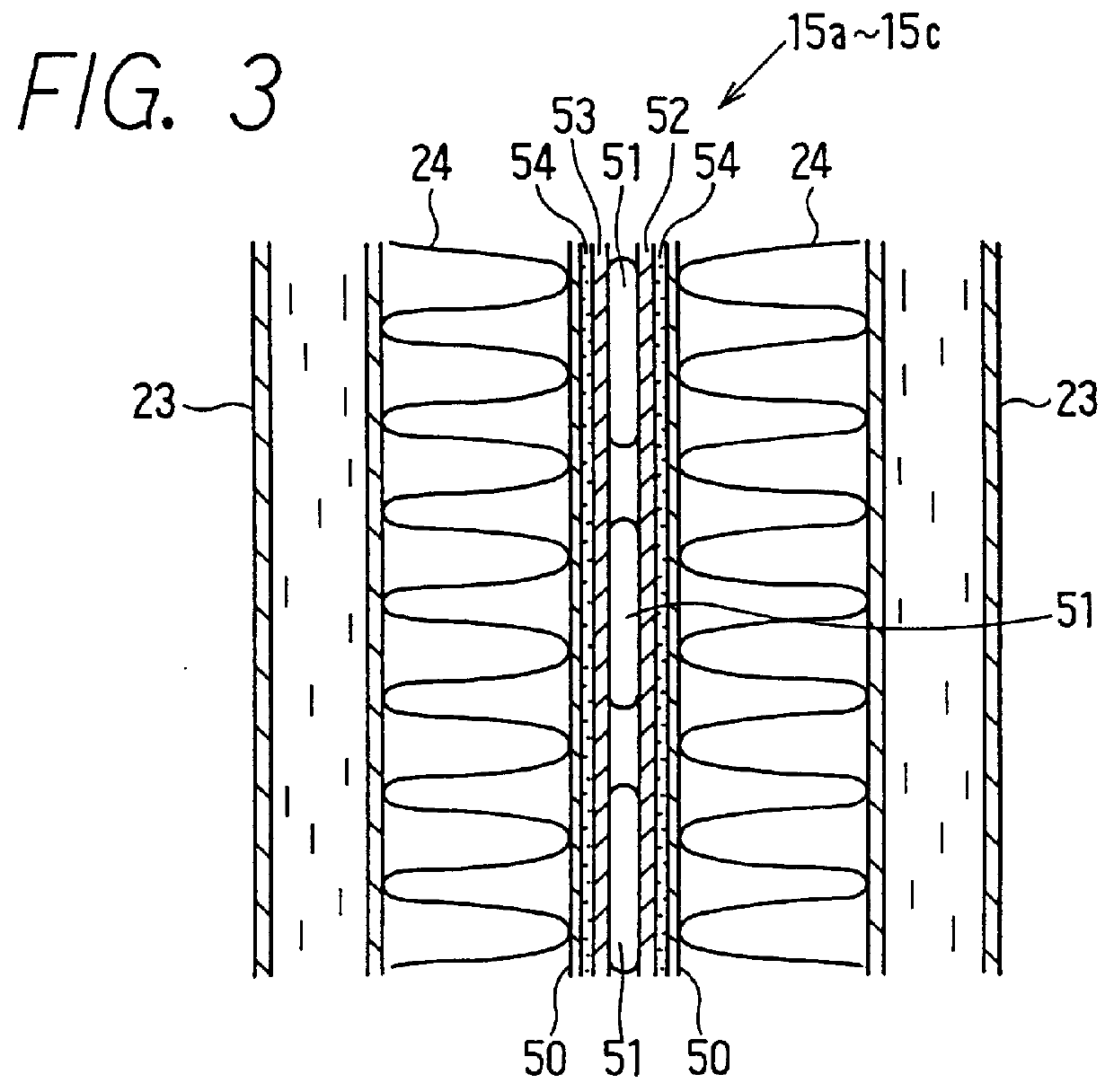

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

Subsurface heaters with low sulfidation rates

Owner:SHELL OIL CO

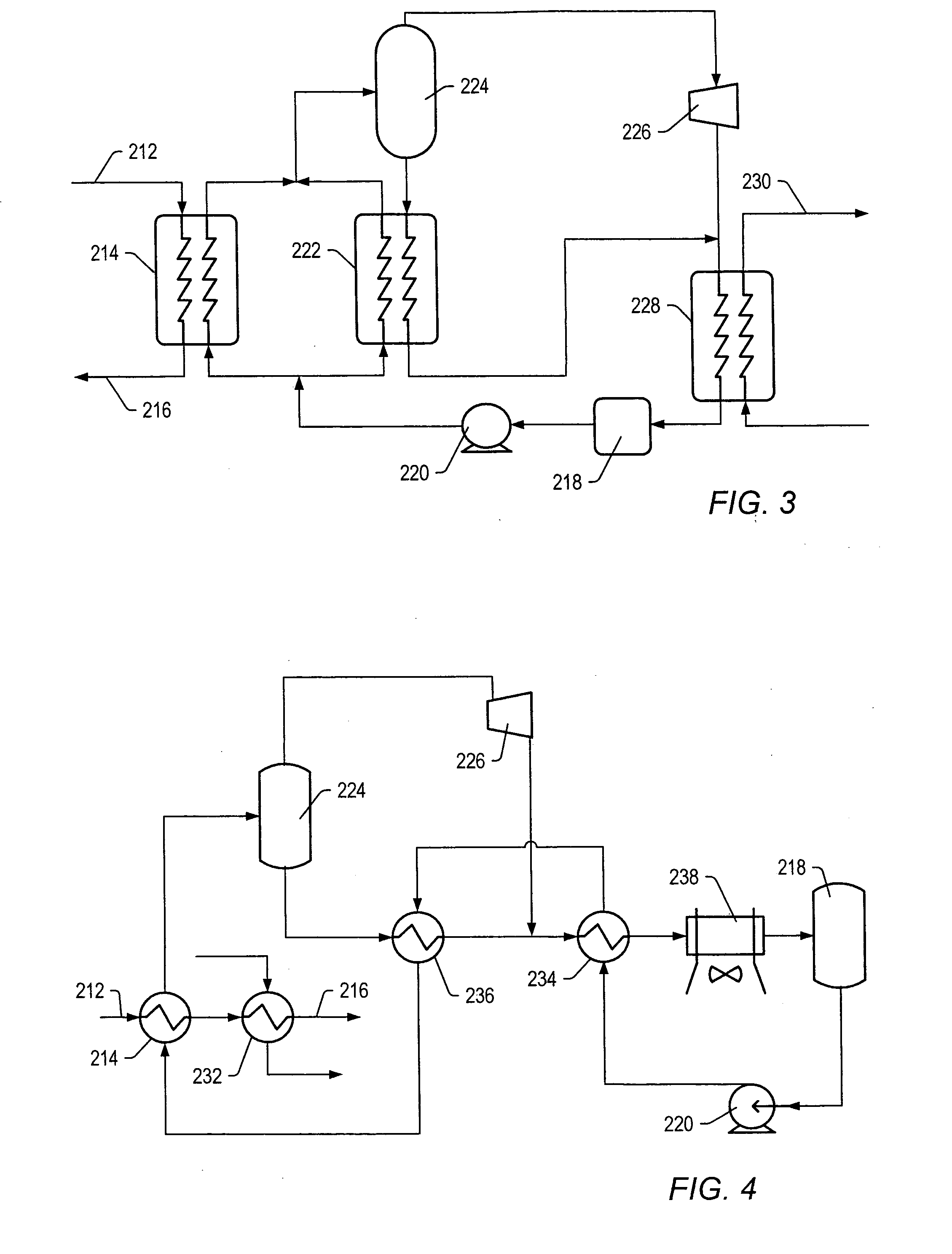

Non-linear fin heat sink

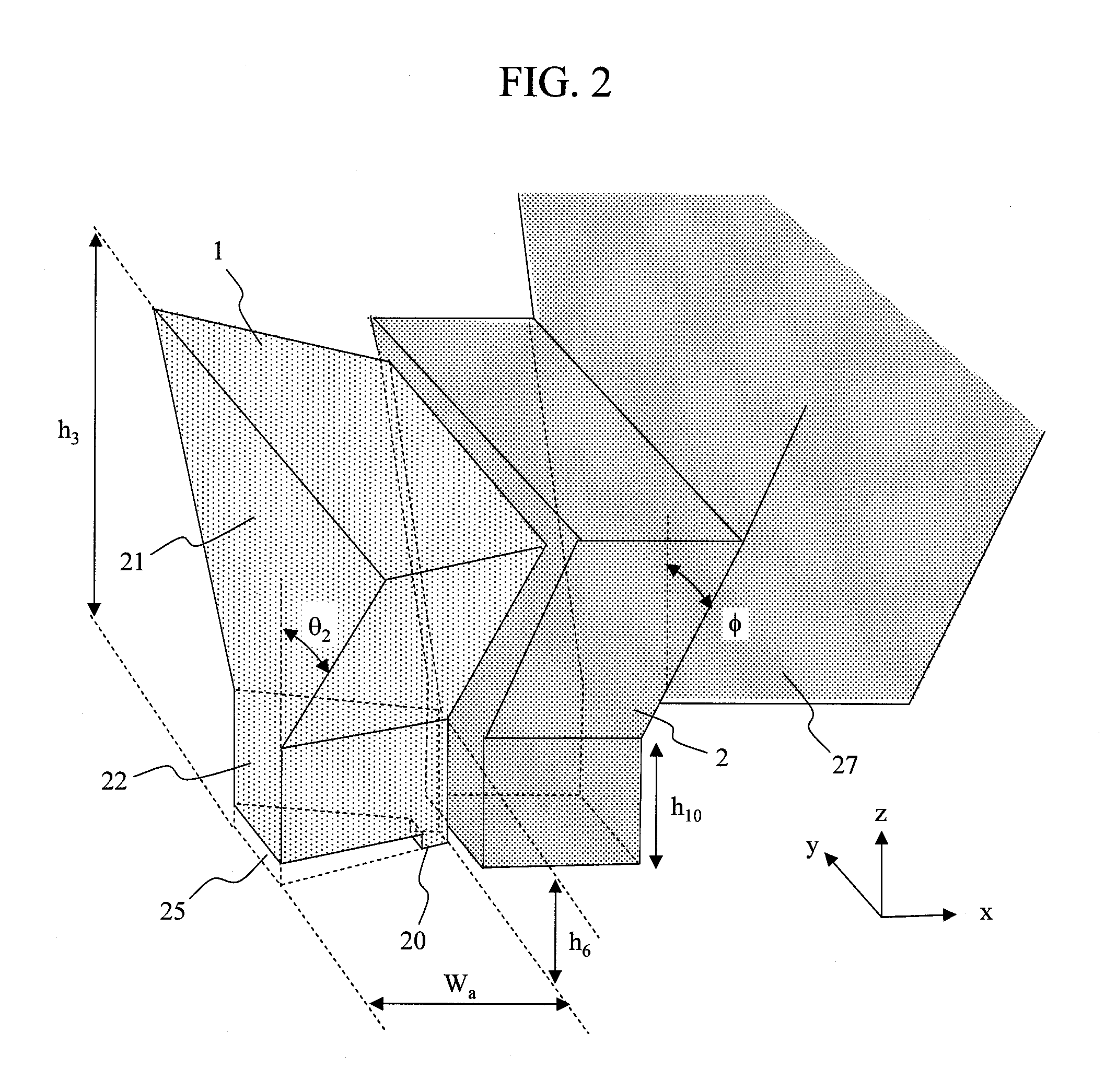

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

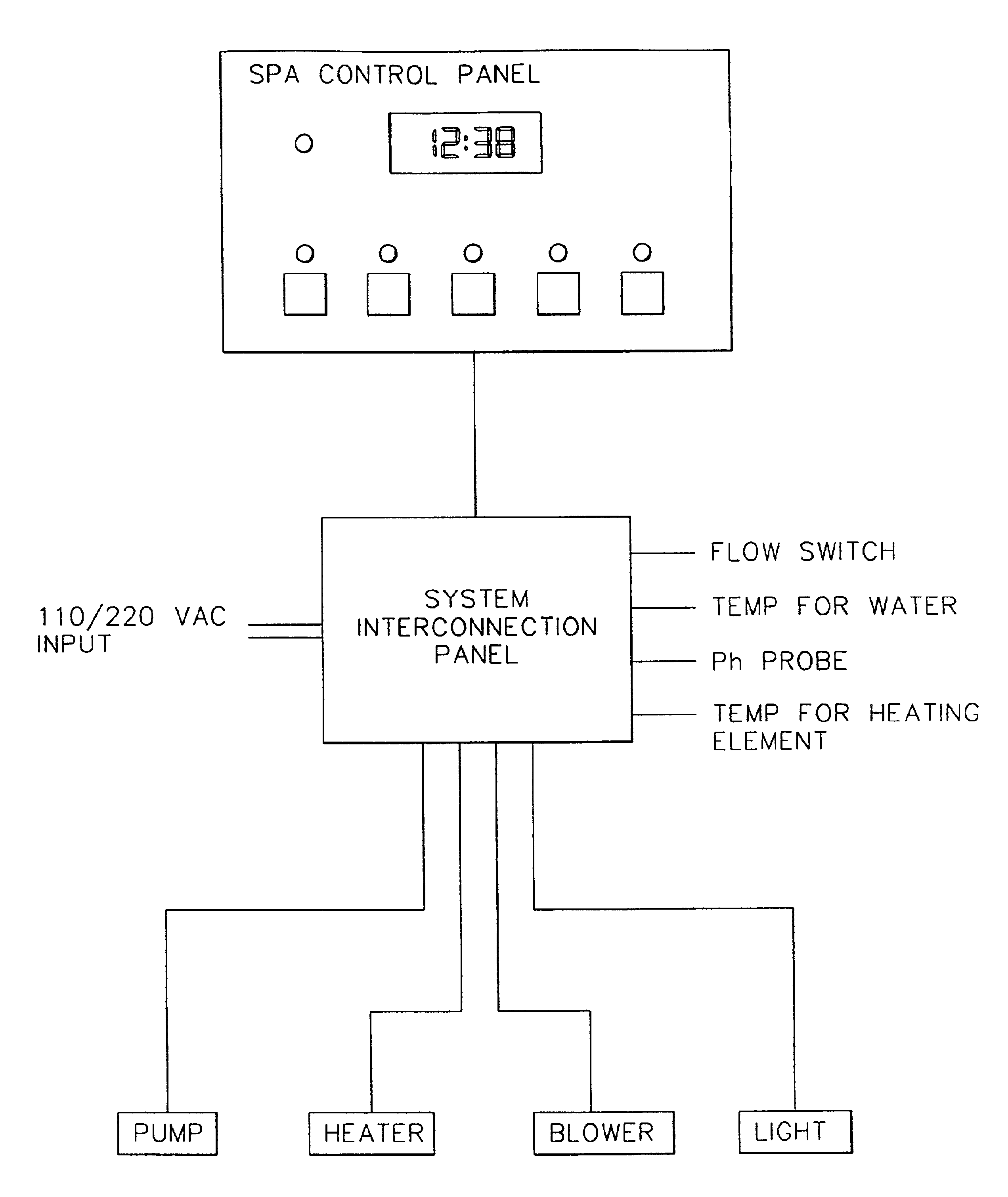

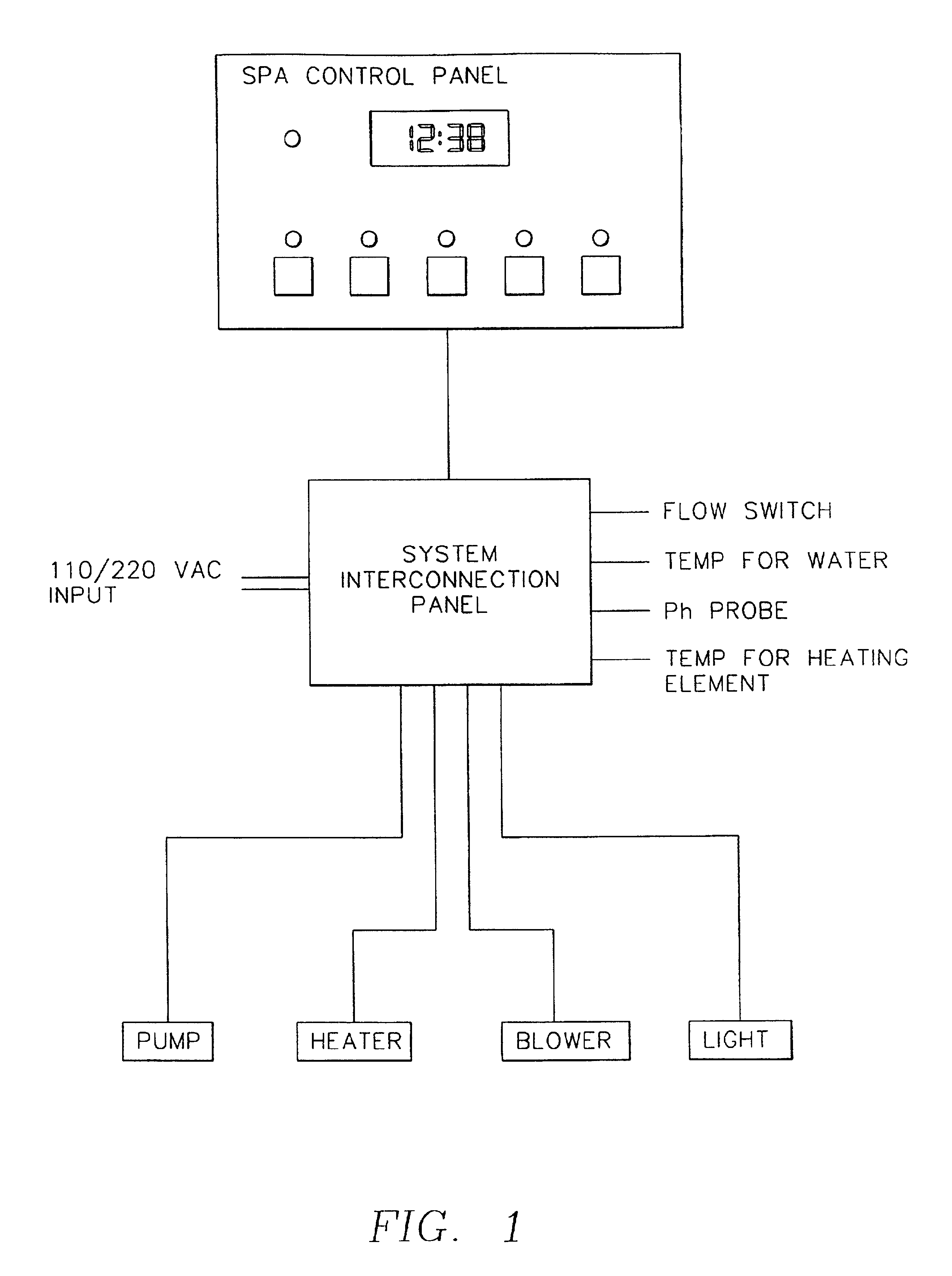

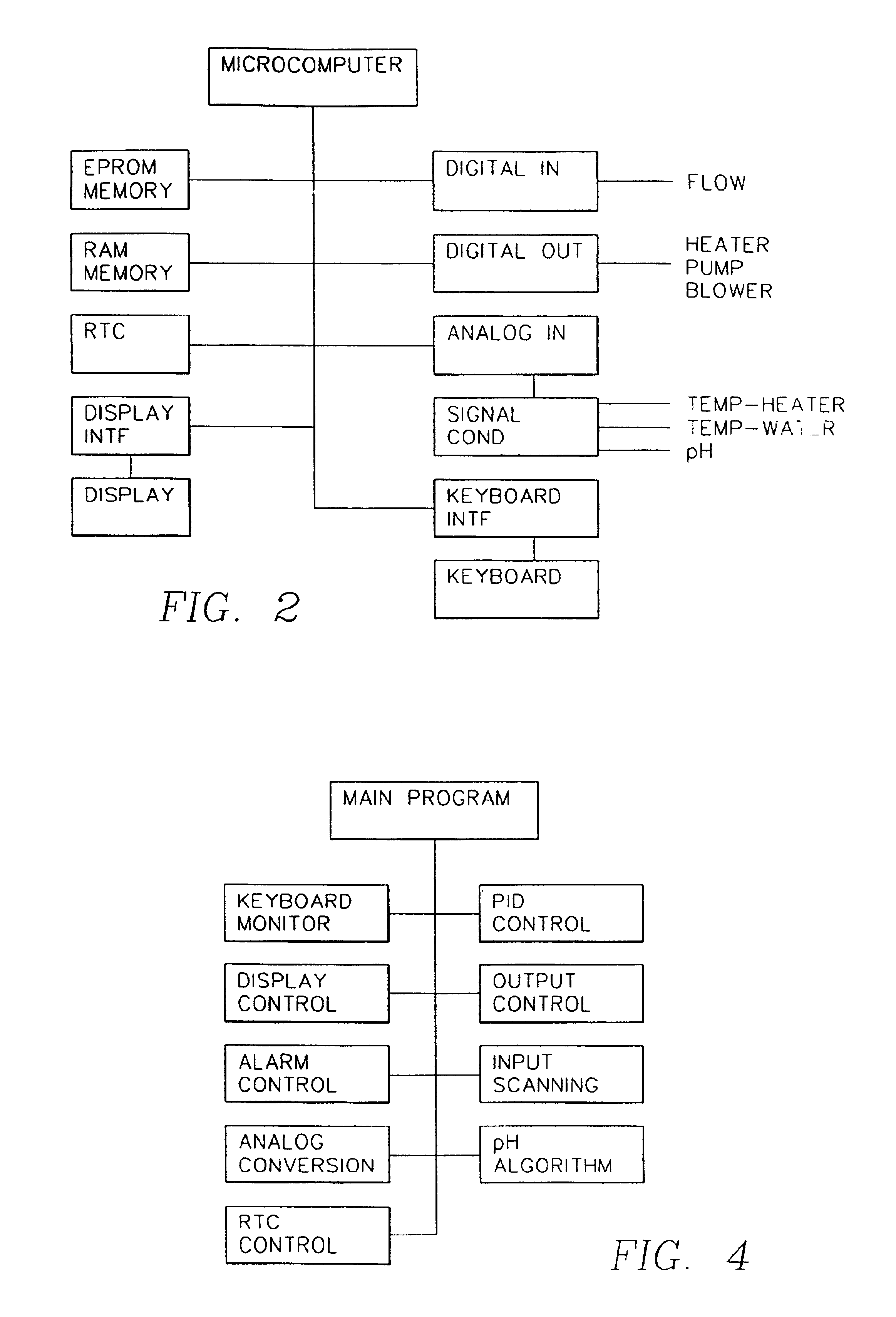

Spa control system

InactiveUS6976052B2Accurately and efficiently controls operationNot adversely affectedTemperatue controlWater/sewage treatmentControl systemWater flow

An improved spa control system is disclosed. The invention describes a spa control system which calculates the time required to heat the water in the spa system to a desired temperature. From that information, the heating rate of the spa system can be determined, and the heating element of the spa system can be activated at the proper time to raise the temperature of the water to a selected temperature by a desired time. The spa system also monitors information which might show errors in the operation of the spa system such as a blockage in the flow of water over the heating element in the spa system.

Owner:DYMAS FUNDING COMPANY +1

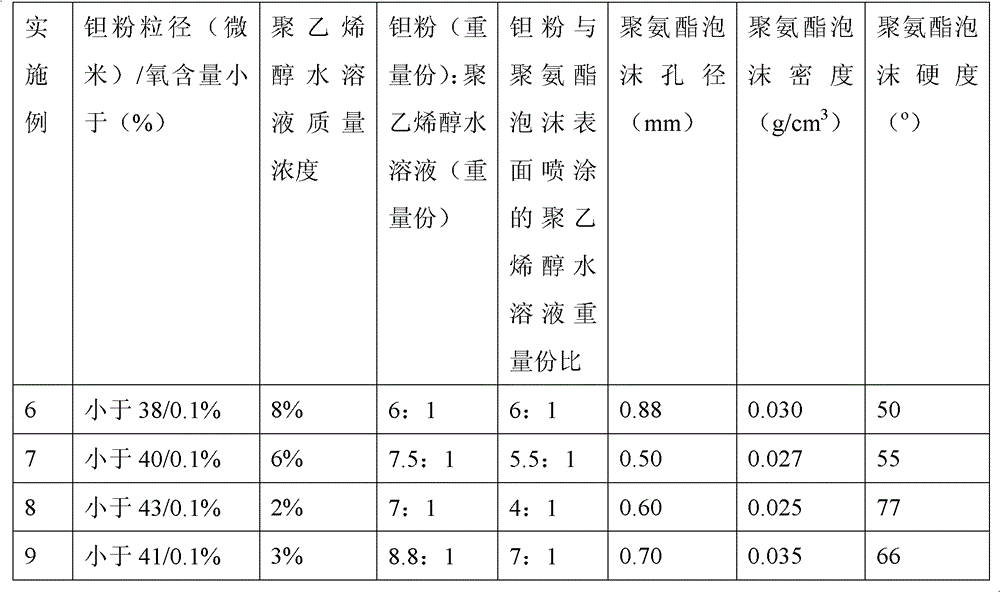

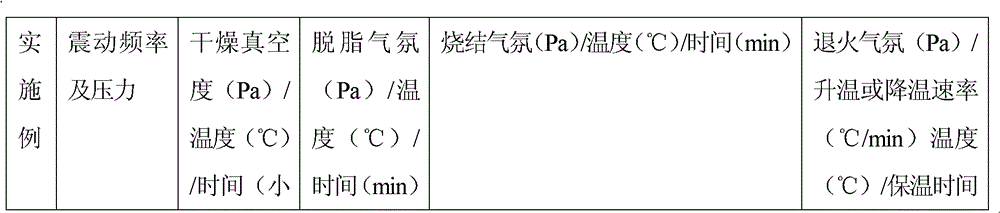

Method for preparing medical porous tantalum implant material

ActiveCN102796894AReduce contentImprove mechanical propertiesProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention discloses a method for preparing a medical porous tantalum material. The method comprises the following steps of: mixing a poly ethanol aqueous solution and tantalum powder to obtain slurry, wherein the mass concentration of the poly ethanol aqueous solution is 2 to 8 percent; injecting the slurry into an organic foam by vibrating and pressurizing, wherein the vibrating frequency is 20 to 80 times / min; drying; degreasing; sintering, namely raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3>Pa, preserving heat for 120 to 240 minutes, cooling to 200 to 300 DEG C along with a furnace, raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min again, preserving heat for 180 to 240 minutes, raising temperature to 2,000 to 2,200 DEG C at the speed of 5 to 10 DEG C / min, and preserving heat for 120 to 360 minutes; cooling; and performing thermal treatment, namely raising temperature to 800 to 900 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DGE C at the speed of 2 to 5 DGE C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with the furnace. The porous tantalum prepared by the method is very suitable to be used for the medical implant material for replacing bearing bone tissues, and biocompatibility and the mechanical property can be guaranteed simultaneously.

Owner:CHONGQING RUNZE PHARM CO LTD

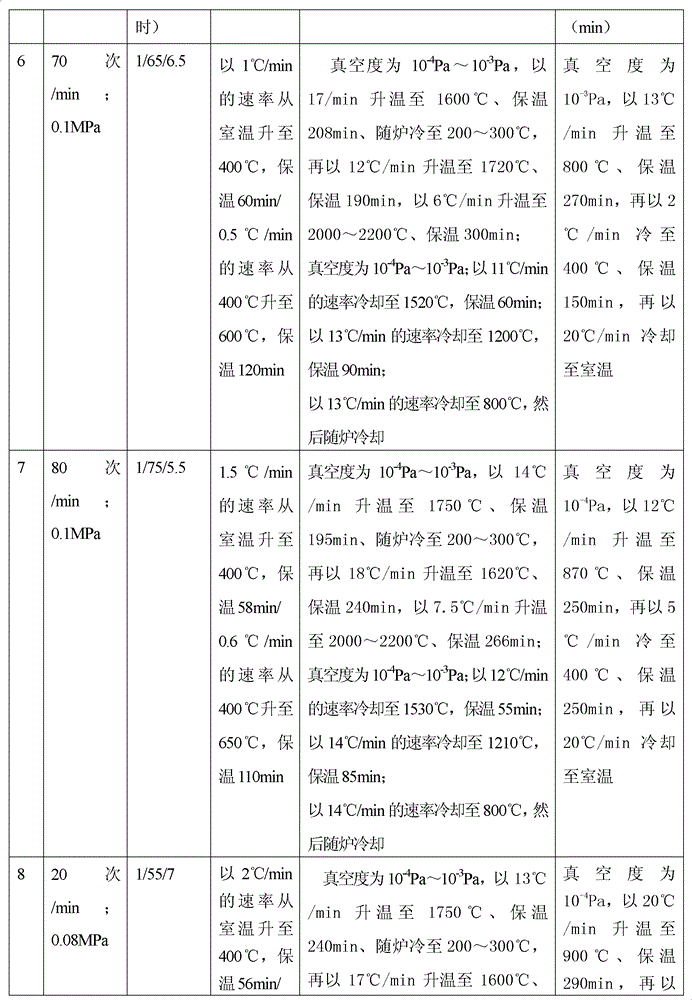

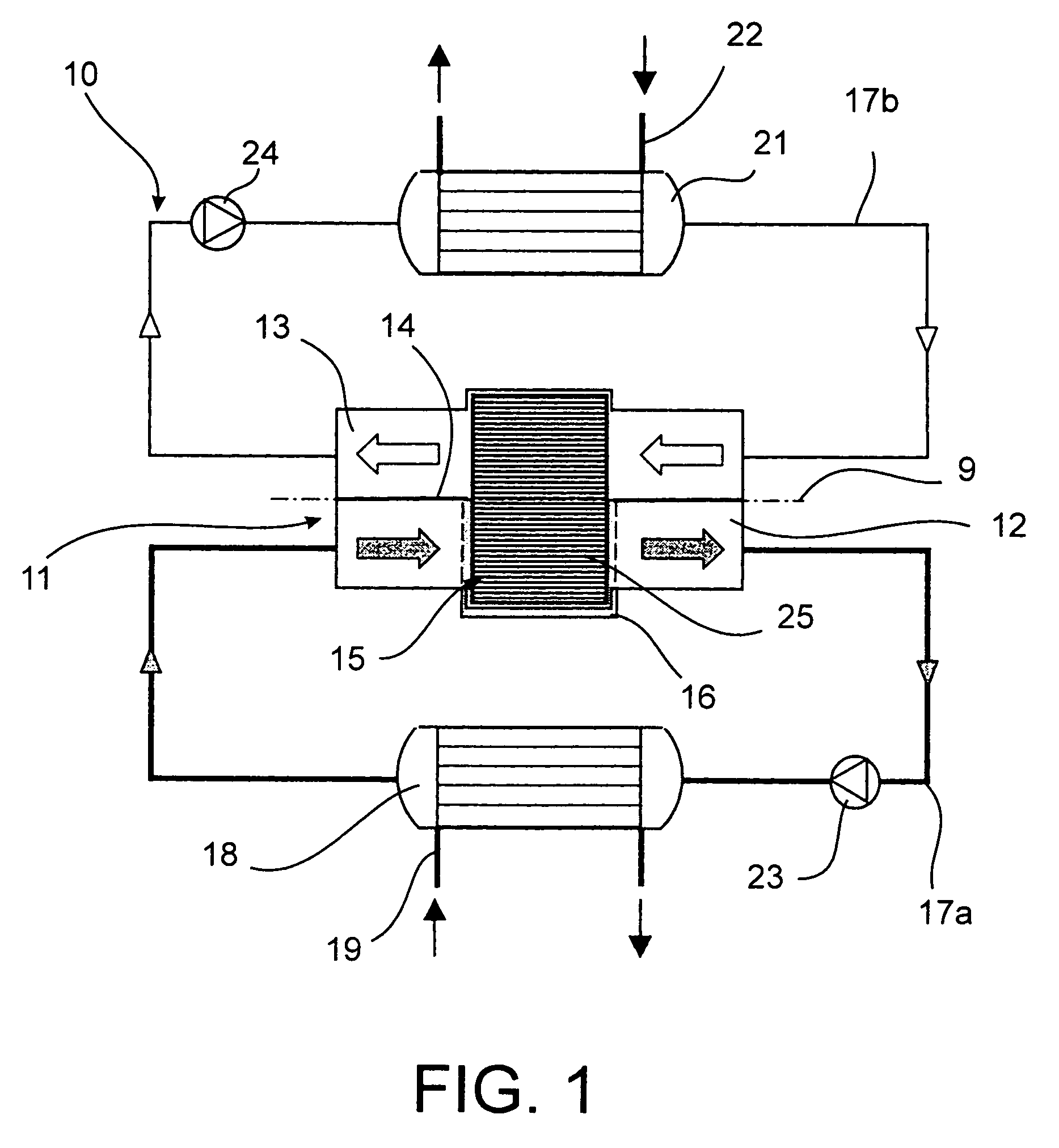

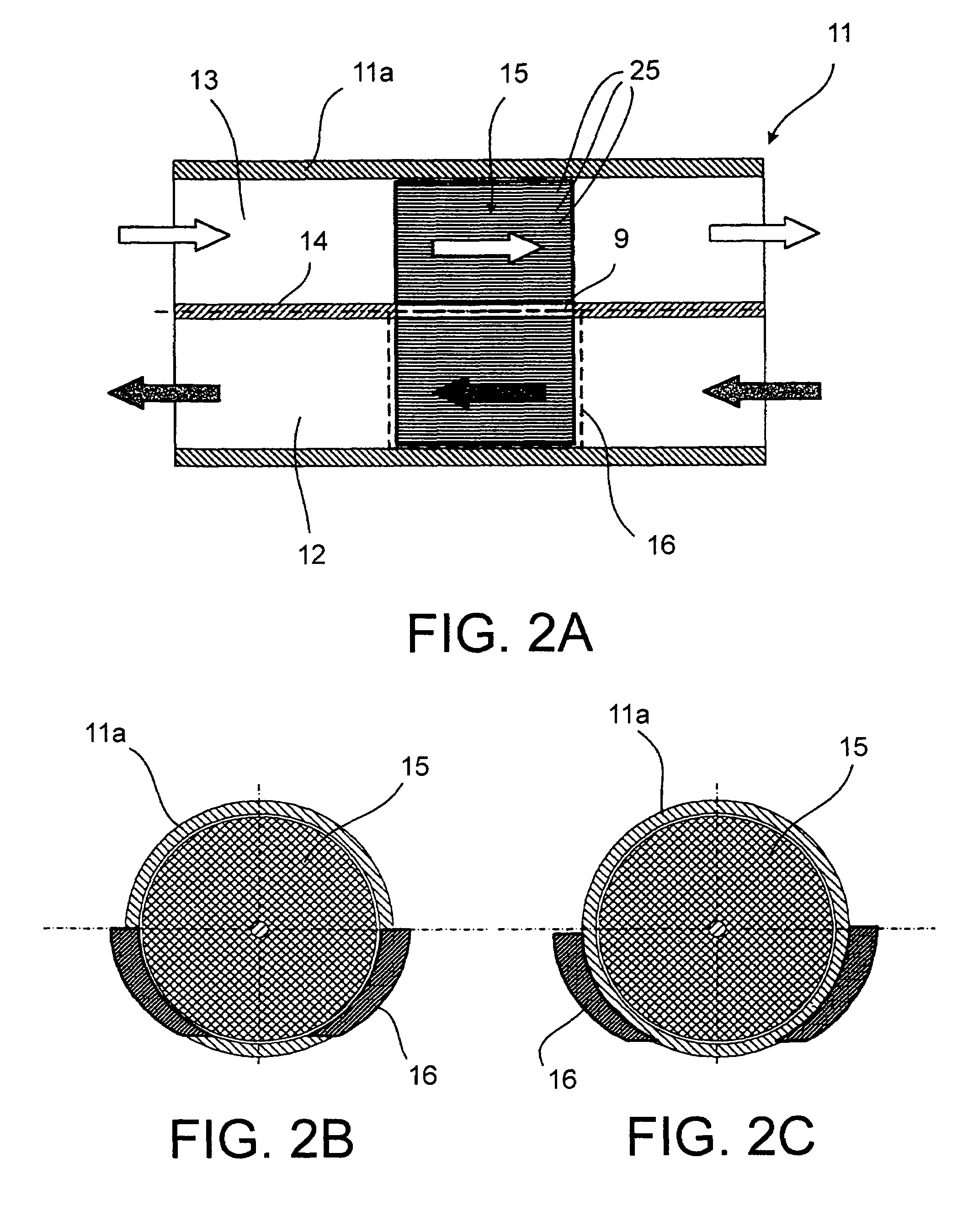

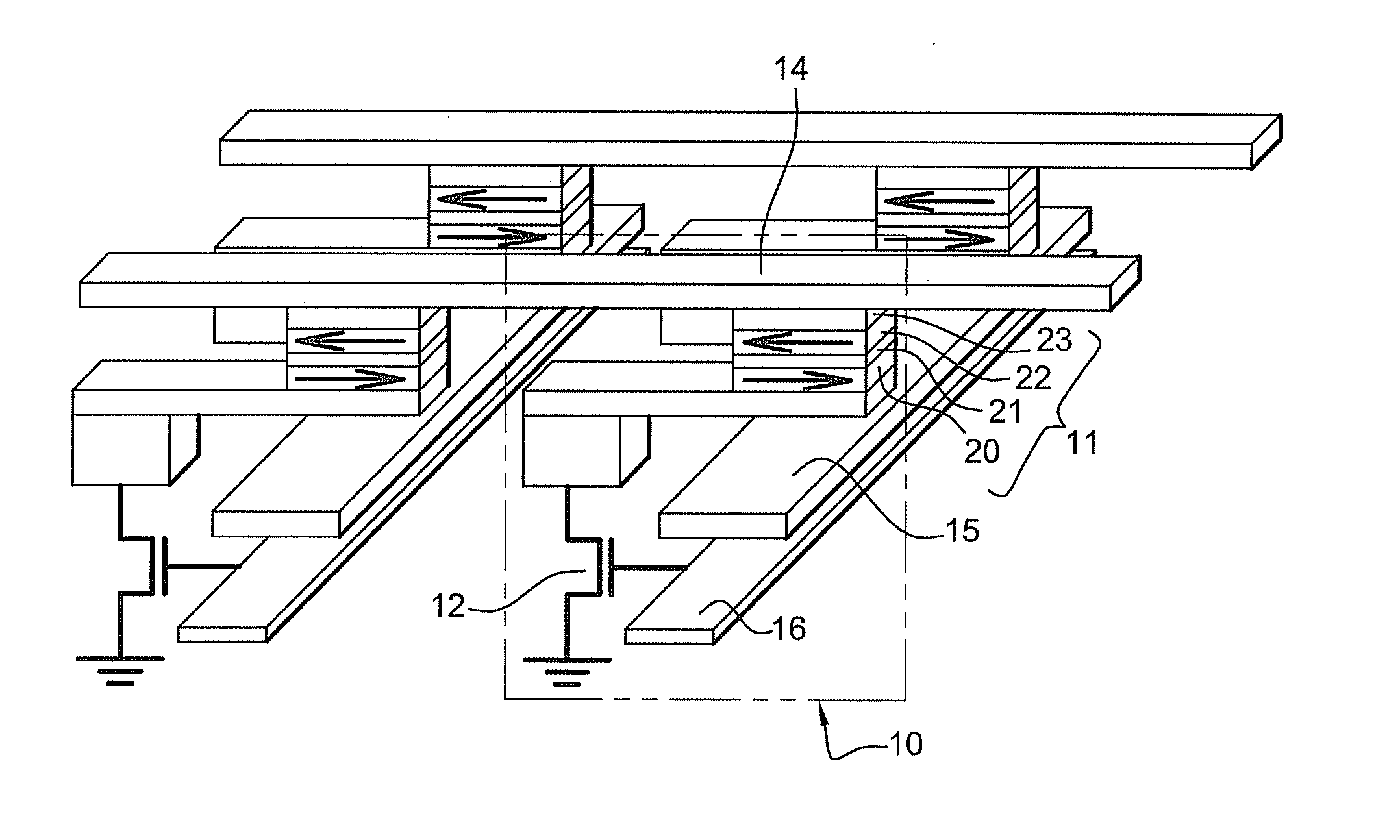

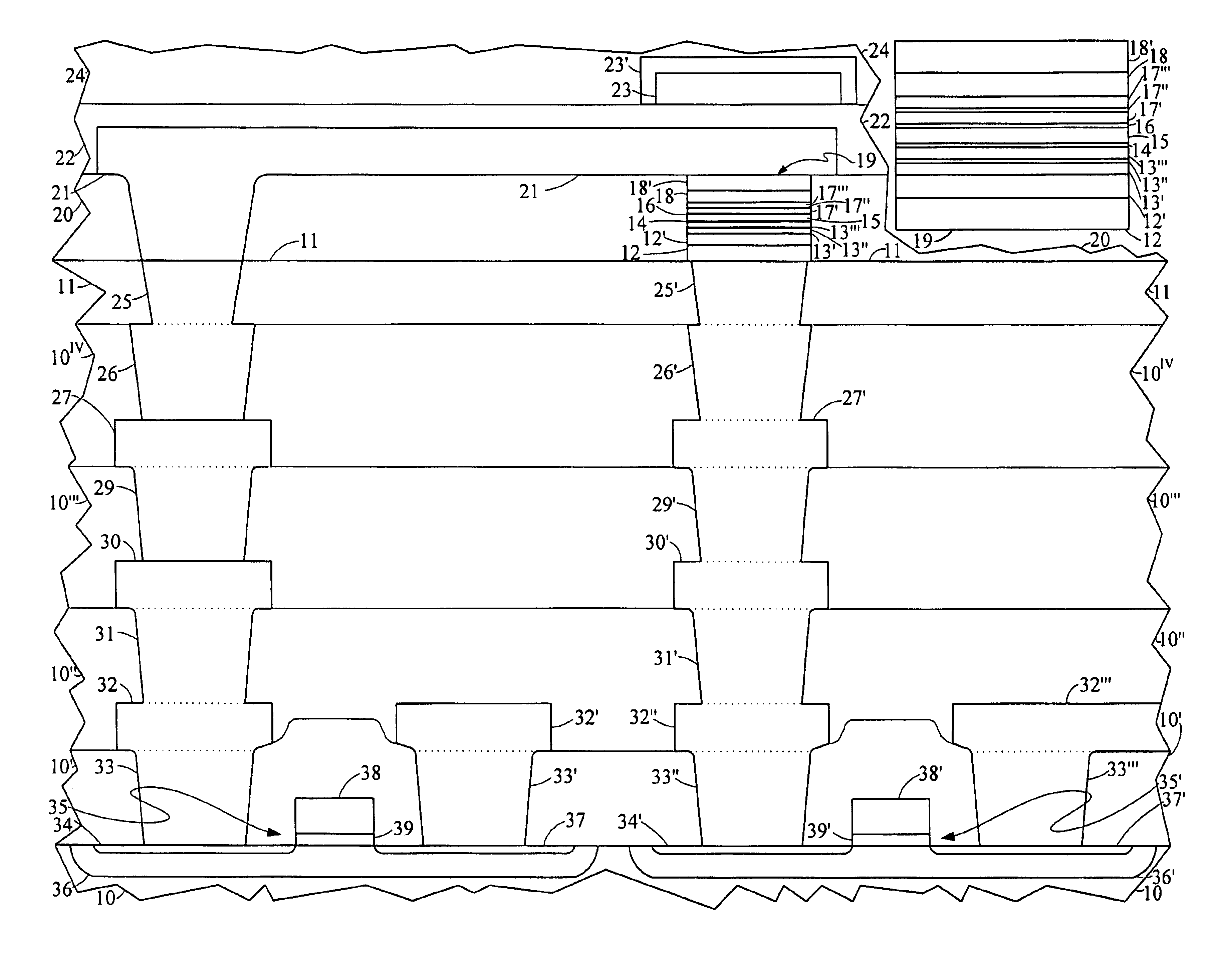

Method and device for continuous generation of cold and heat by means of the magneto-calorific effect

InactiveUS7481064B2Improve equipment efficiencyPrevent escapeEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringMagnetic field

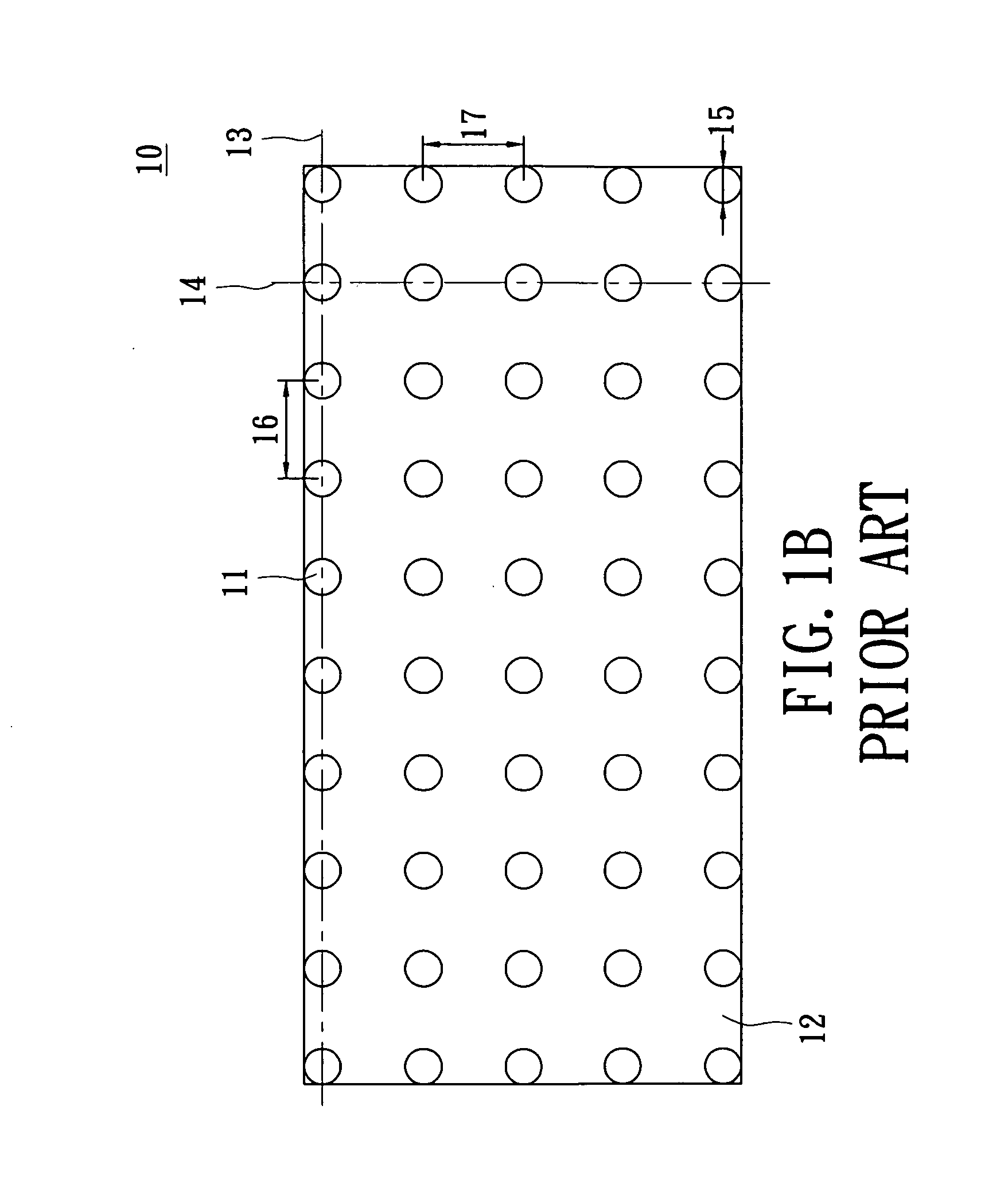

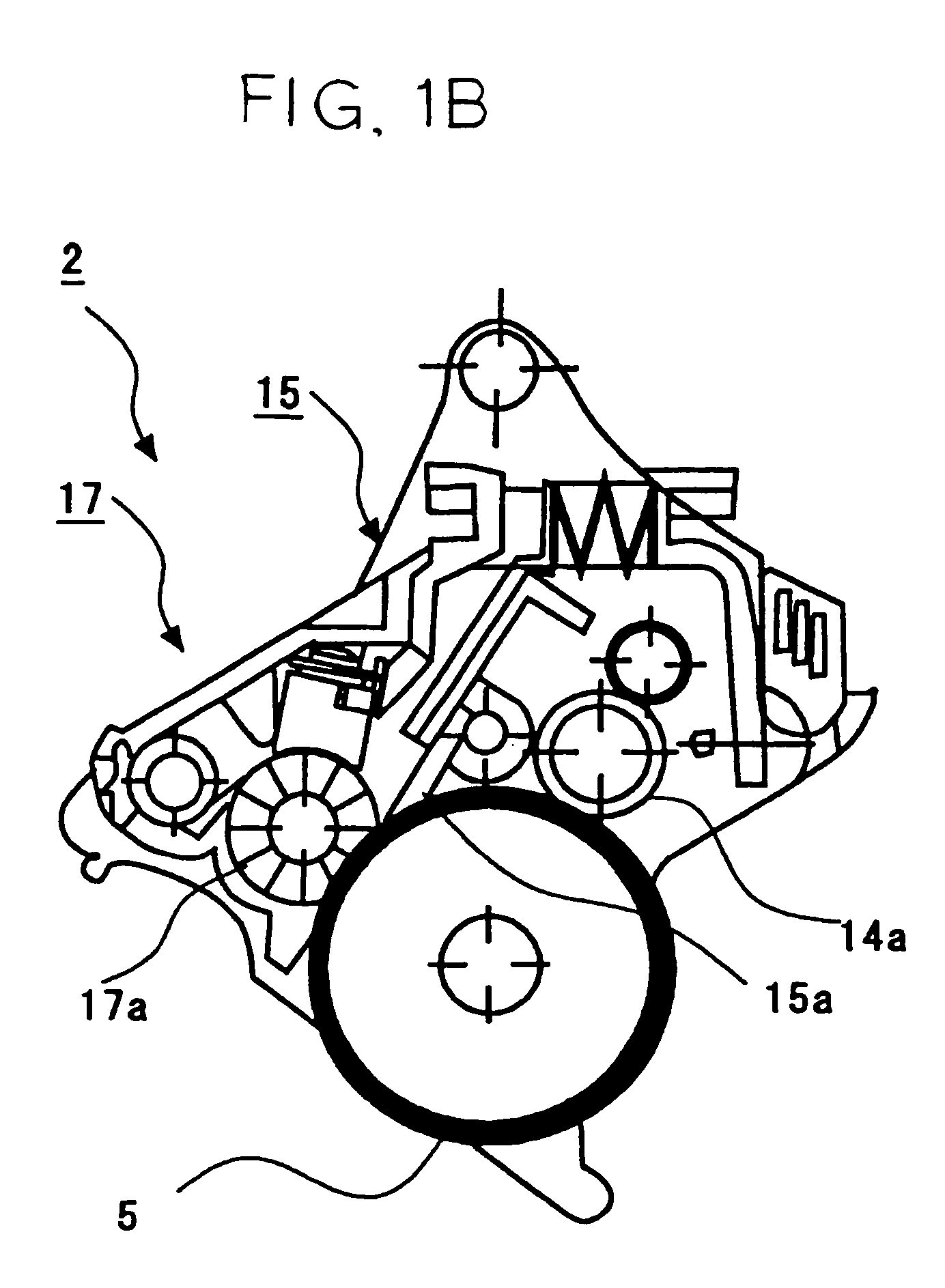

The device (10) for continuous generation of cold and heat by the magneto-calorific effect, comprises a chamber (11), divided into two adjacent compartments (12, 13), separated by a wall (14). The chamber (11) contains a rotating element (15) made from at least one magneto-calorific material, a first circuit (17a) with a first heat exchange fluid circulating therein and a second circuit (17b) with a second heat exchange fluid circulating therein. The chamber (11) is connected to magnetic device (16) for generating a magnetic field in the region of the compartment (12) in which the rotating element (15) is located. When the above is set in rotation the part thereof located in the first compartment (12) is magnetized upon undergoing an increase in temperature. On passing into the second compartment (13), the part is demagnetized upon undergoing a cooling. The heat and the cold thus generated are transmitted by the heat exchange fluids respectively to user circuits for heat (19) and cold (22) for recovery and use for ulterior purposes.

Owner:HAUTE ECOLE DINGIE & DE GESTION DU CANTON DE VAUD

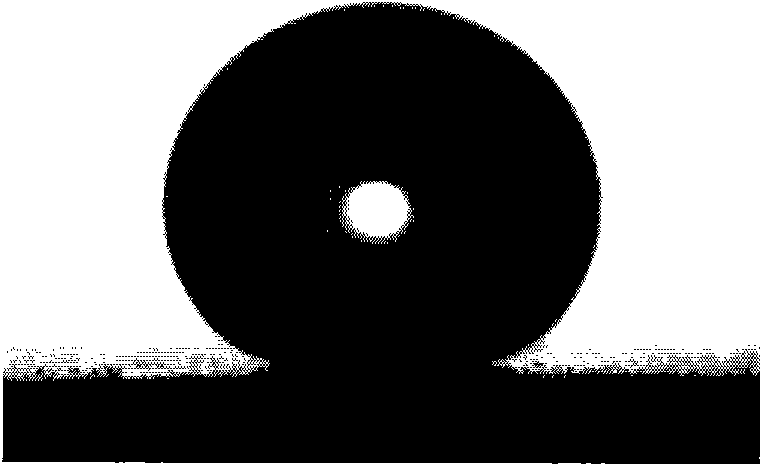

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

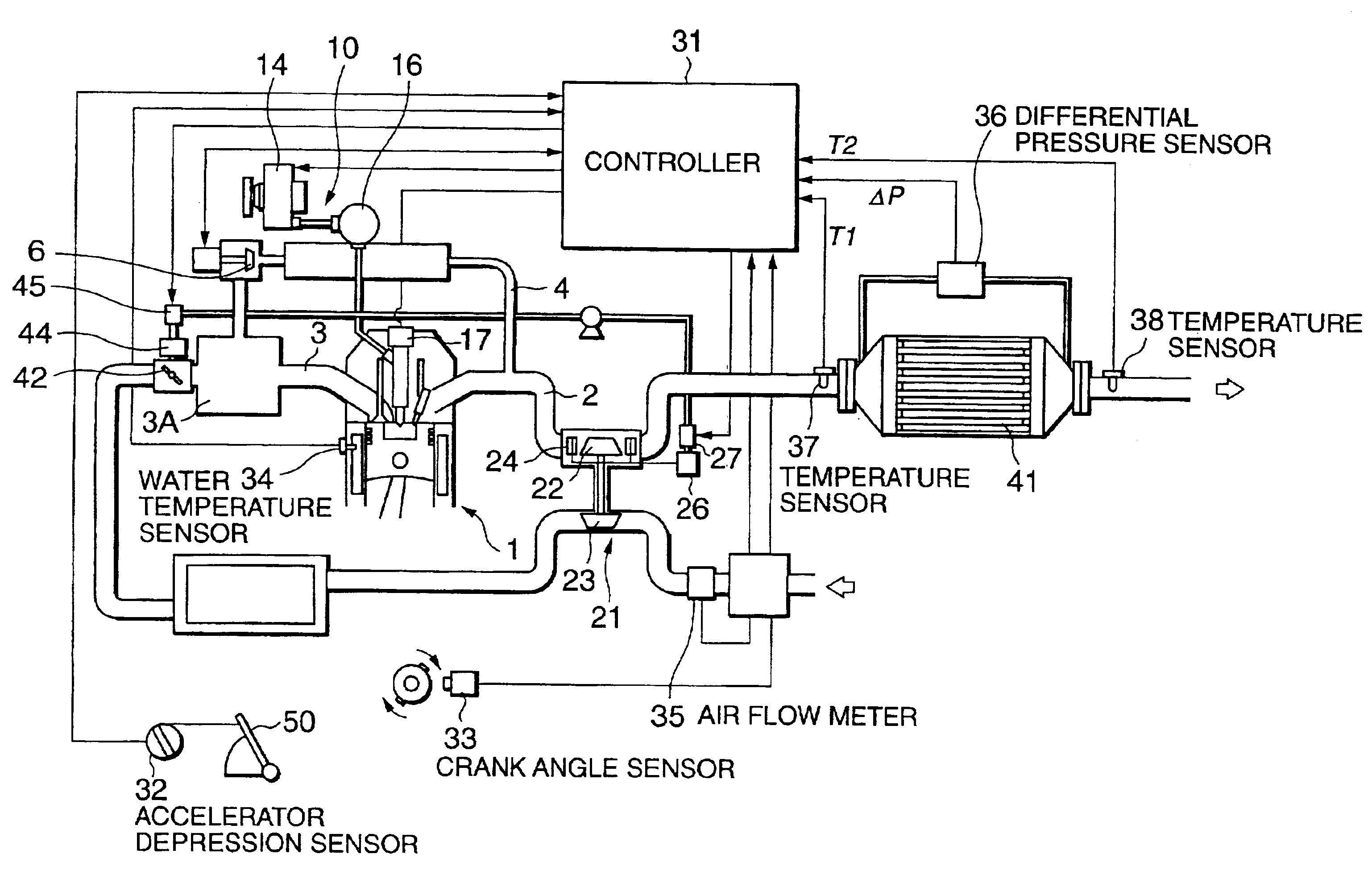

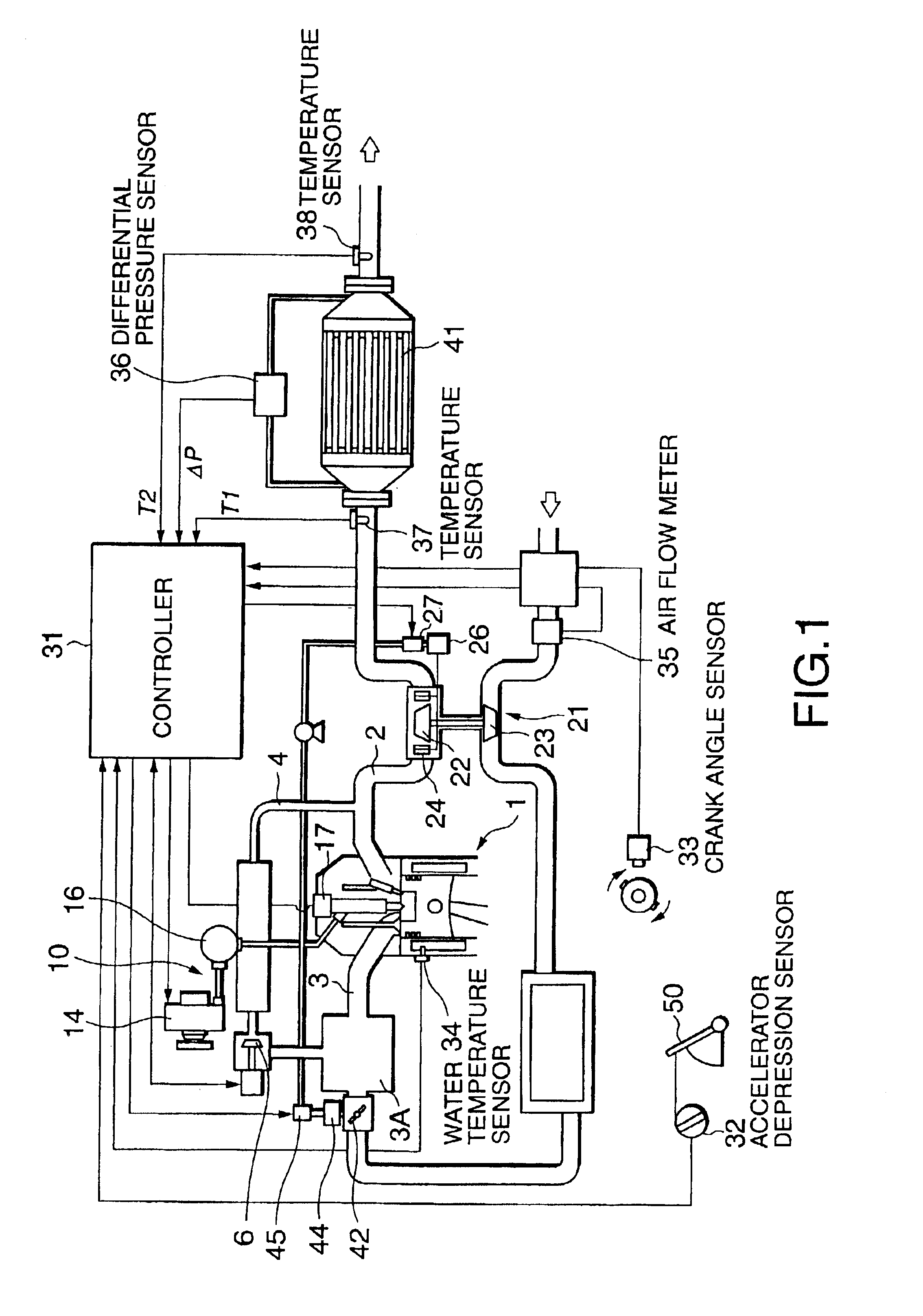

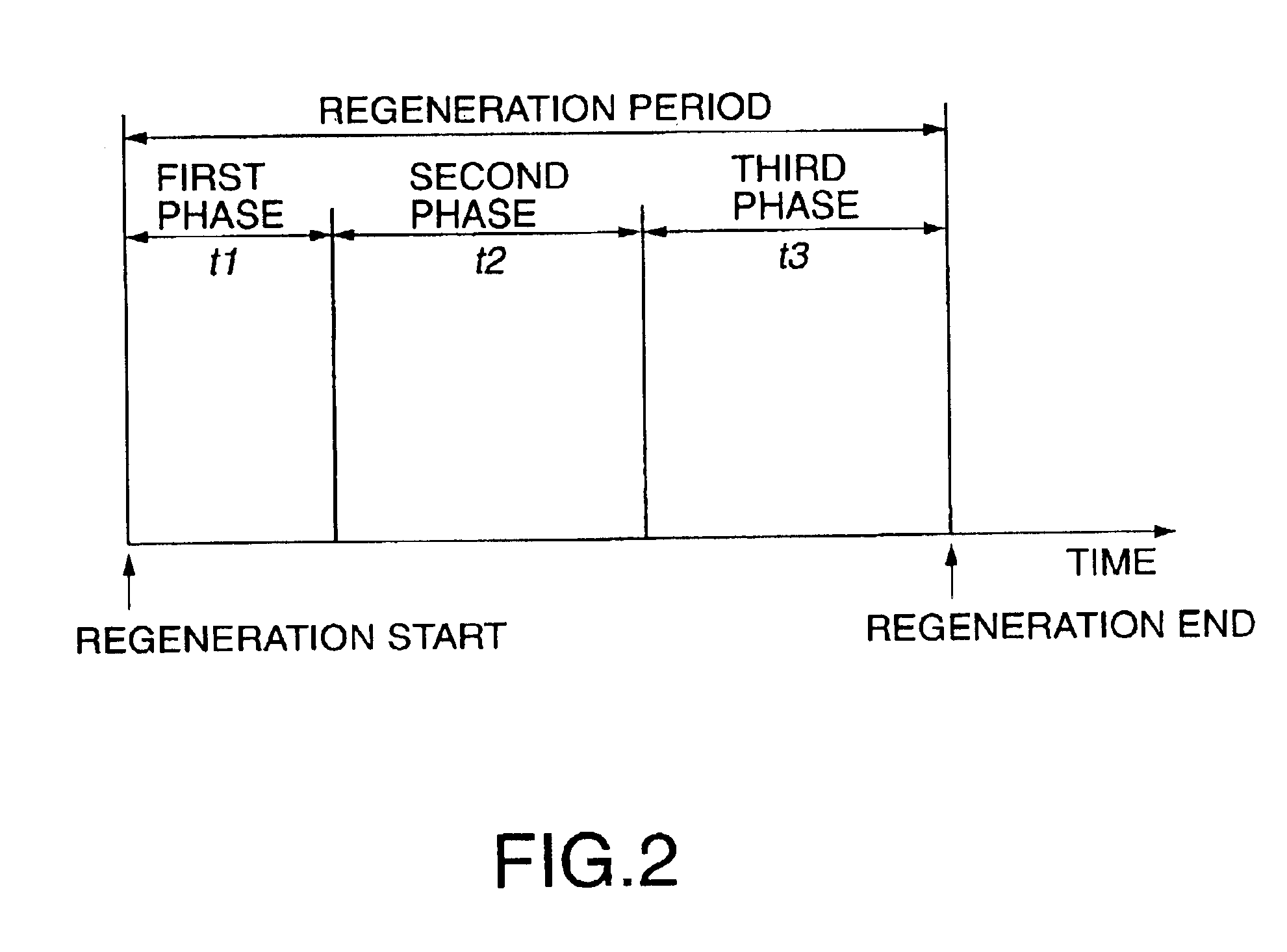

Regeneration of particulate filter

InactiveUS6851258B2Inhibit deteriorationShorten the overall cycleElectrical controlNon-fuel substance addition to fuelParticulatesCombustion

An exhaust passage (2) of a diesel engine (1) is provided with a filter (41) for trapping particulate matter. Regeneration of the filter (41) is divided into first to third phases. In the first phase the filter temperature is raised to the combustion temperature of the particulate matter in a short period of time through control of the exhaust gas temperature. In the second phase, the oxygen concentration of the exhaust gas is held at a predetermined low level while the filter temperature is maintained so as to prevent excessive combustion of particulate matter. In the third phase, wherein the amount of trapped particulate matter has been reduced, the oxygen concentration of the exhaust gas is held at a predetermined high level while the filter temperature is maintained so as to complete the combustion of the trapped particulate matter.

Owner:NISSAN MOTOR CO LTD

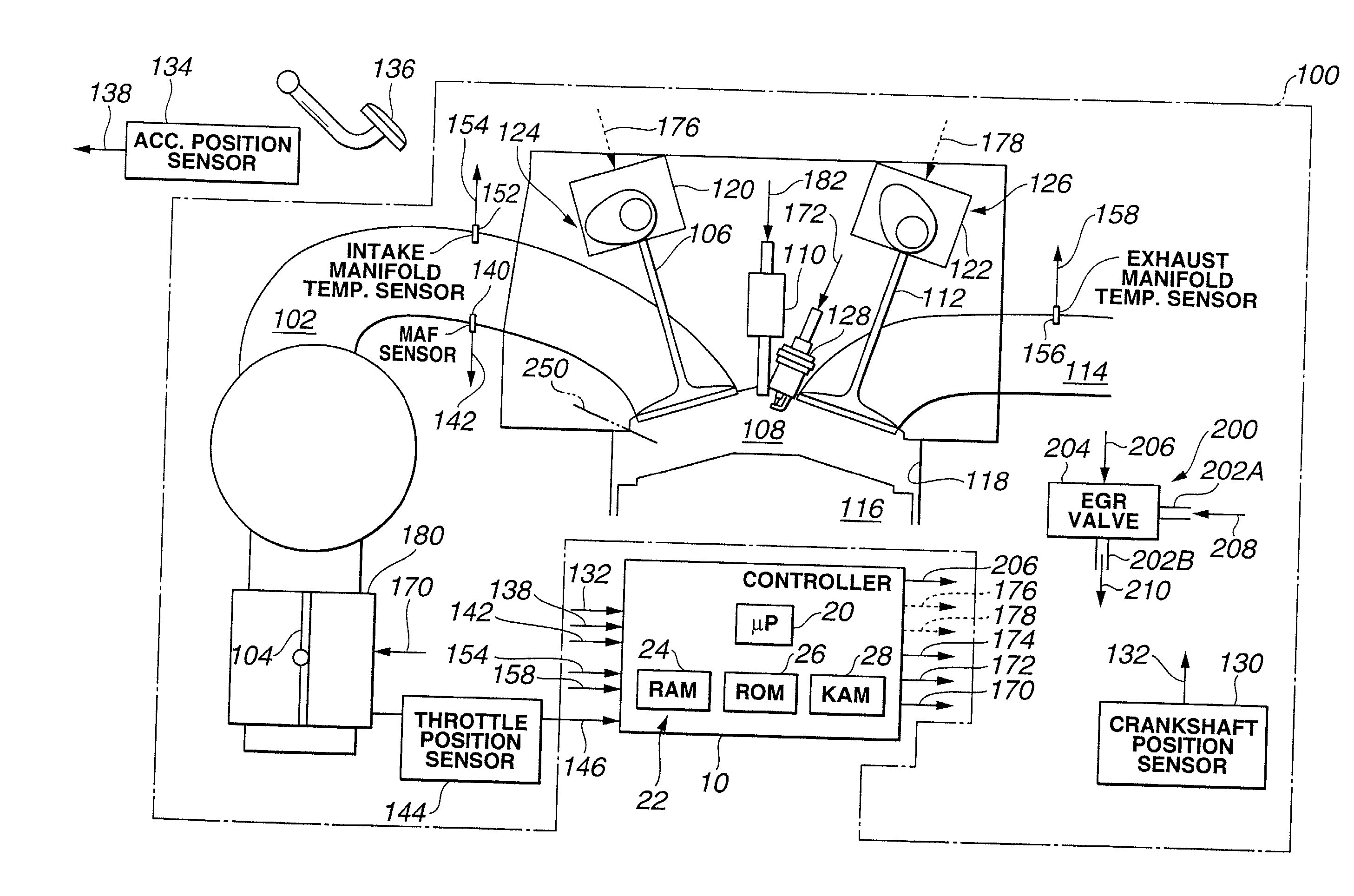

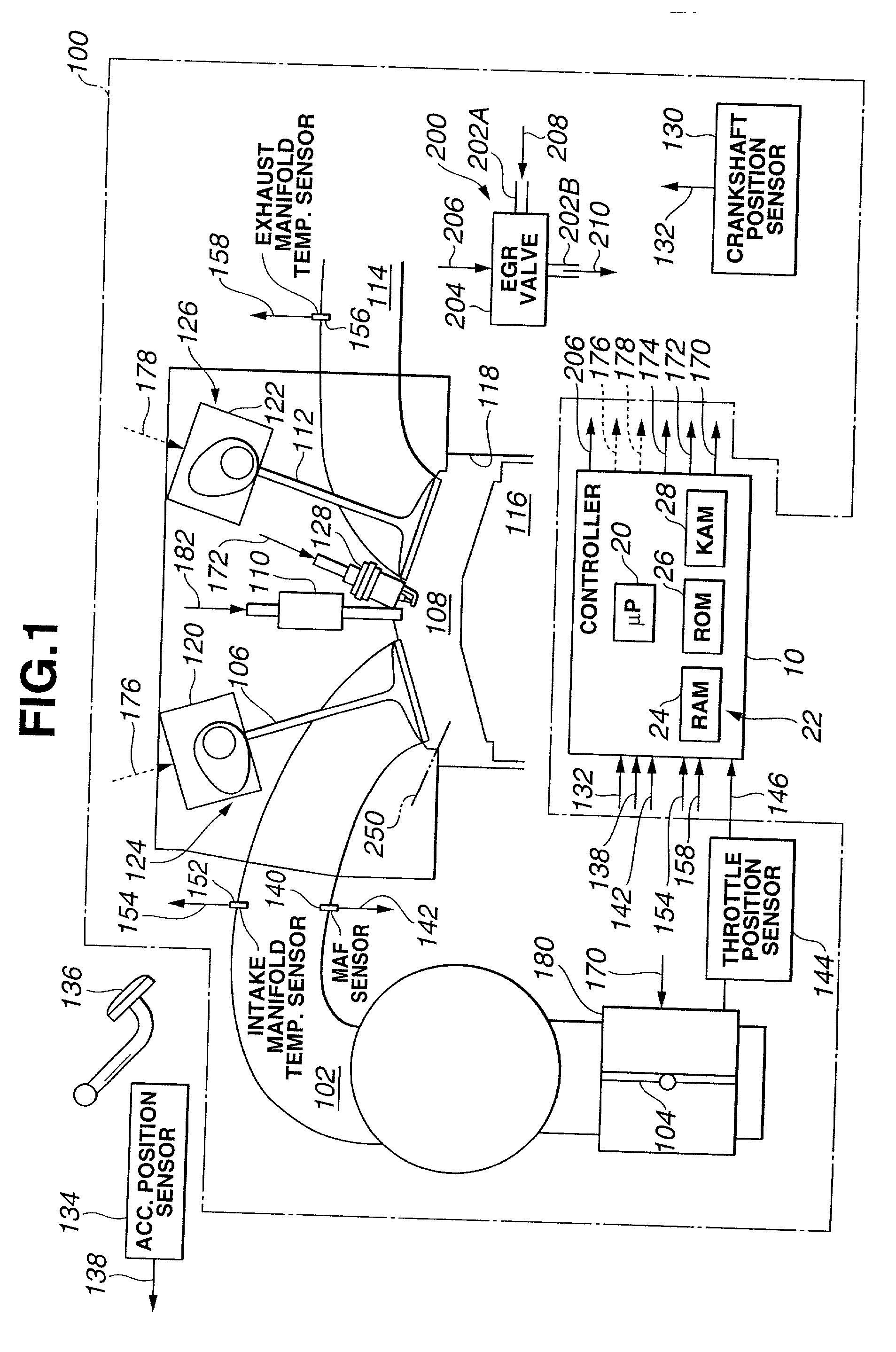

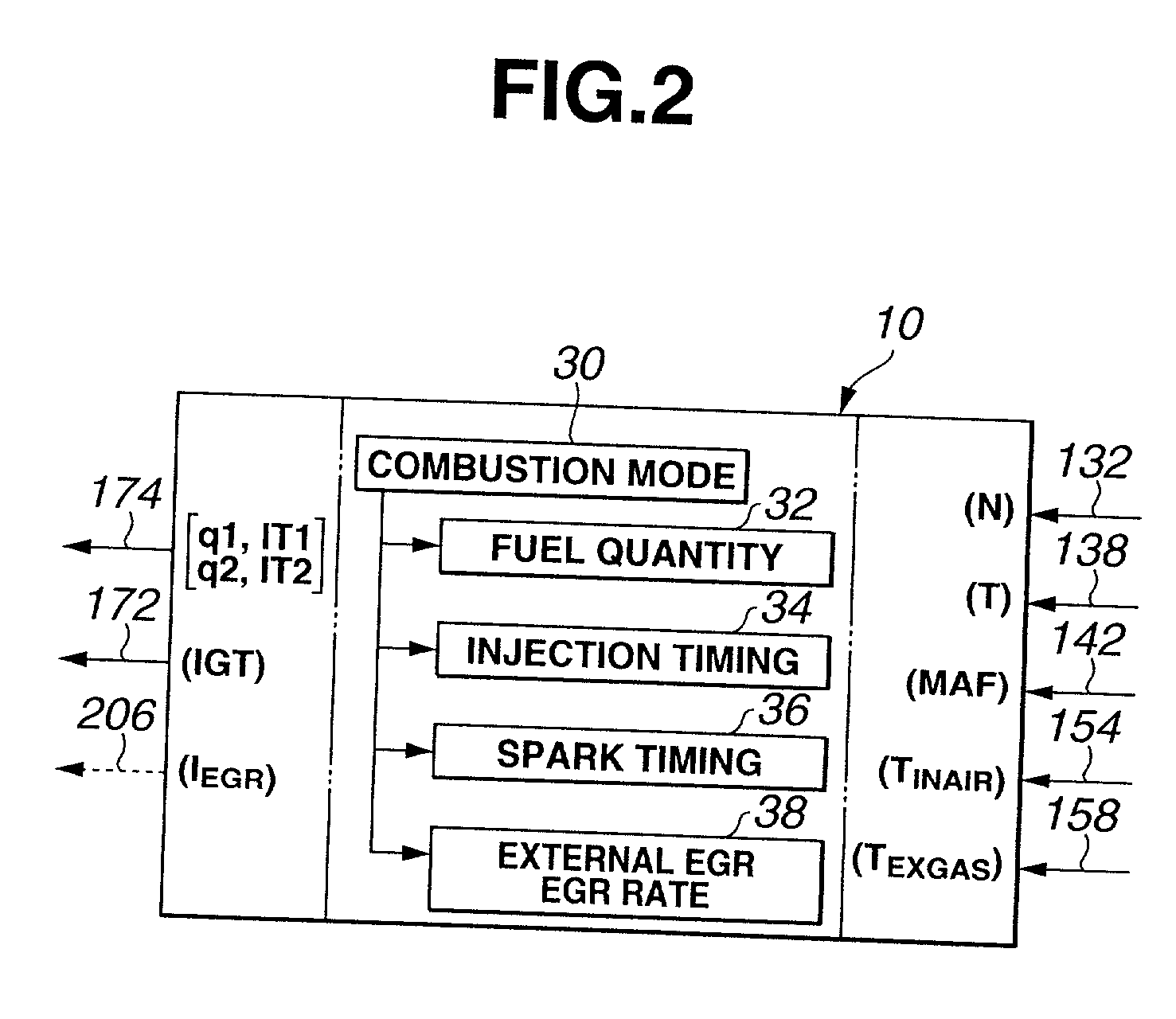

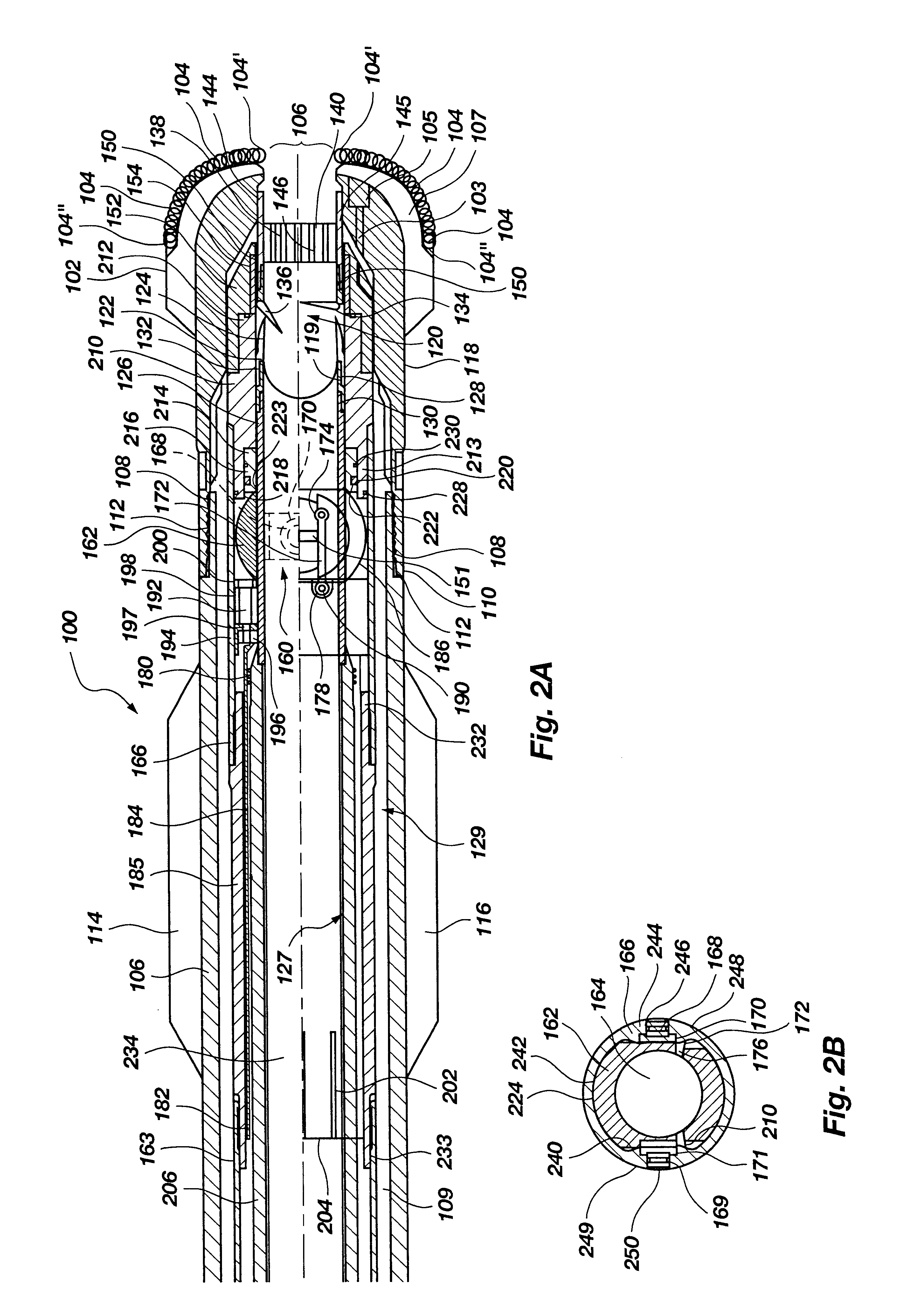

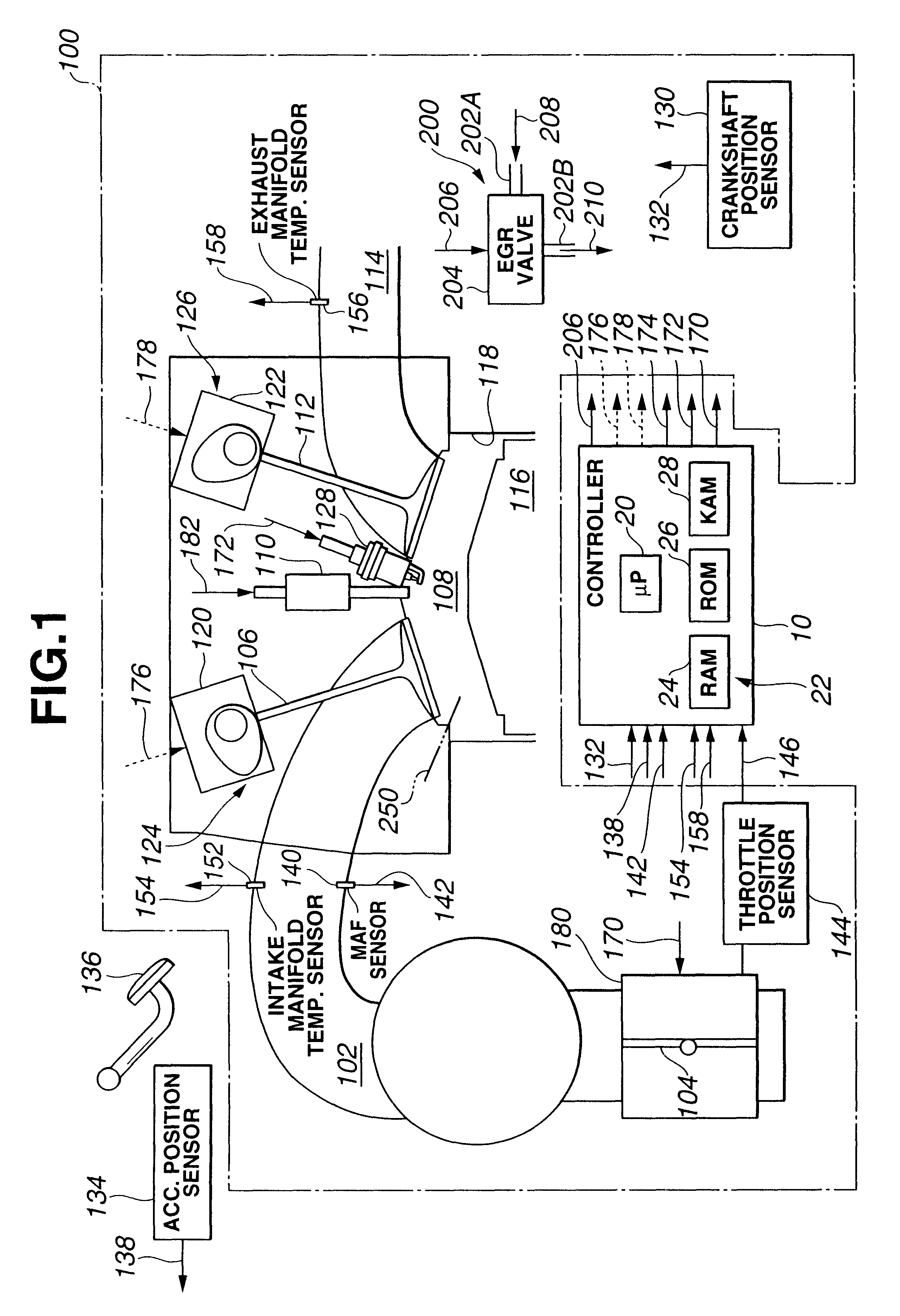

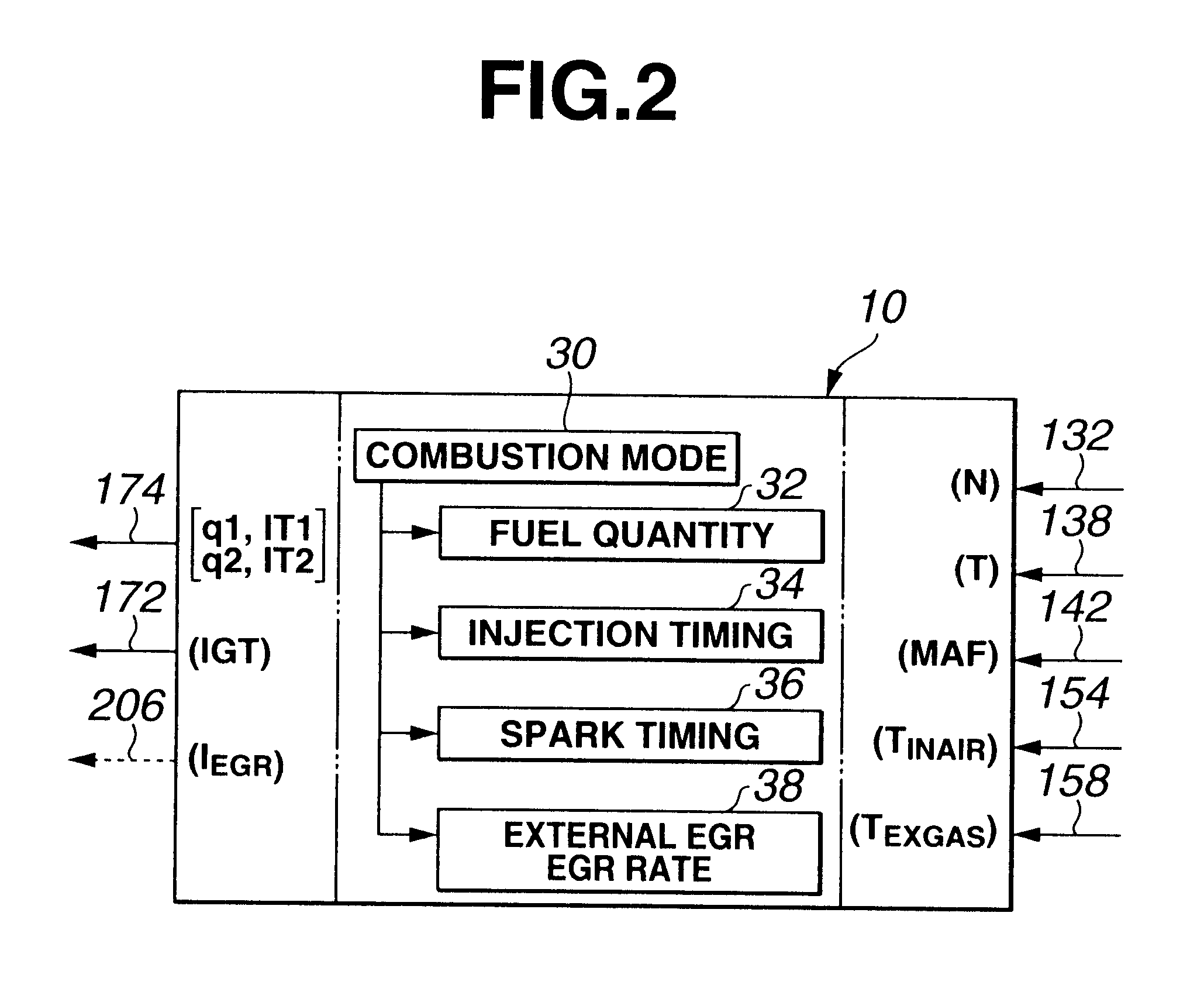

System and method for enhanced combustion control in an internal combustion engine

InactiveUS20020059914A1Electrical controlInternal combustion piston enginesExternal combustion engineStaged combustion

A system and method for enhanced combustion control in an internal combustion engine is disclosed. A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. An engine controller is programmed to perform control over initiation timing of the second stage combustion in response to at least one of the engine speed and load. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

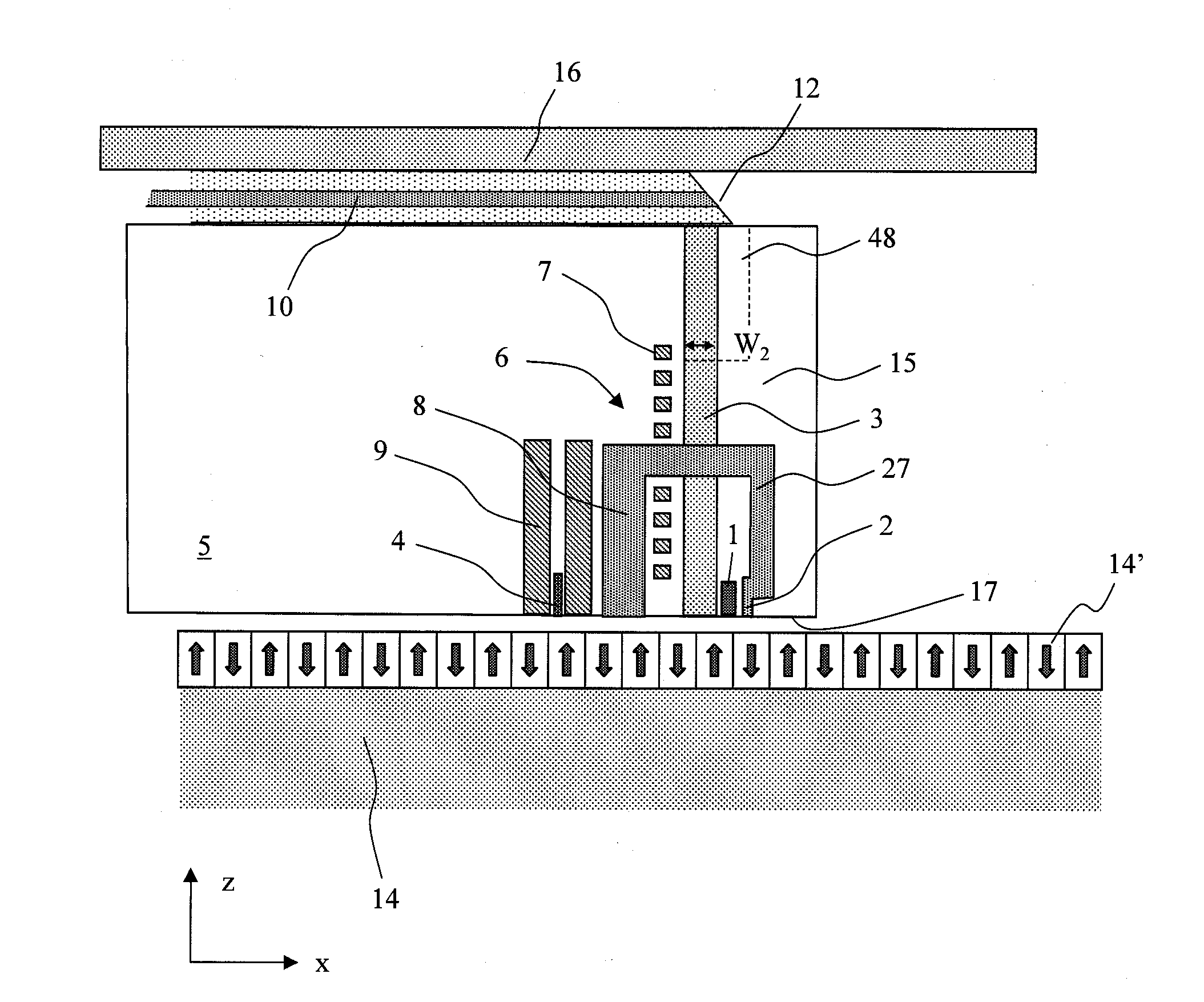

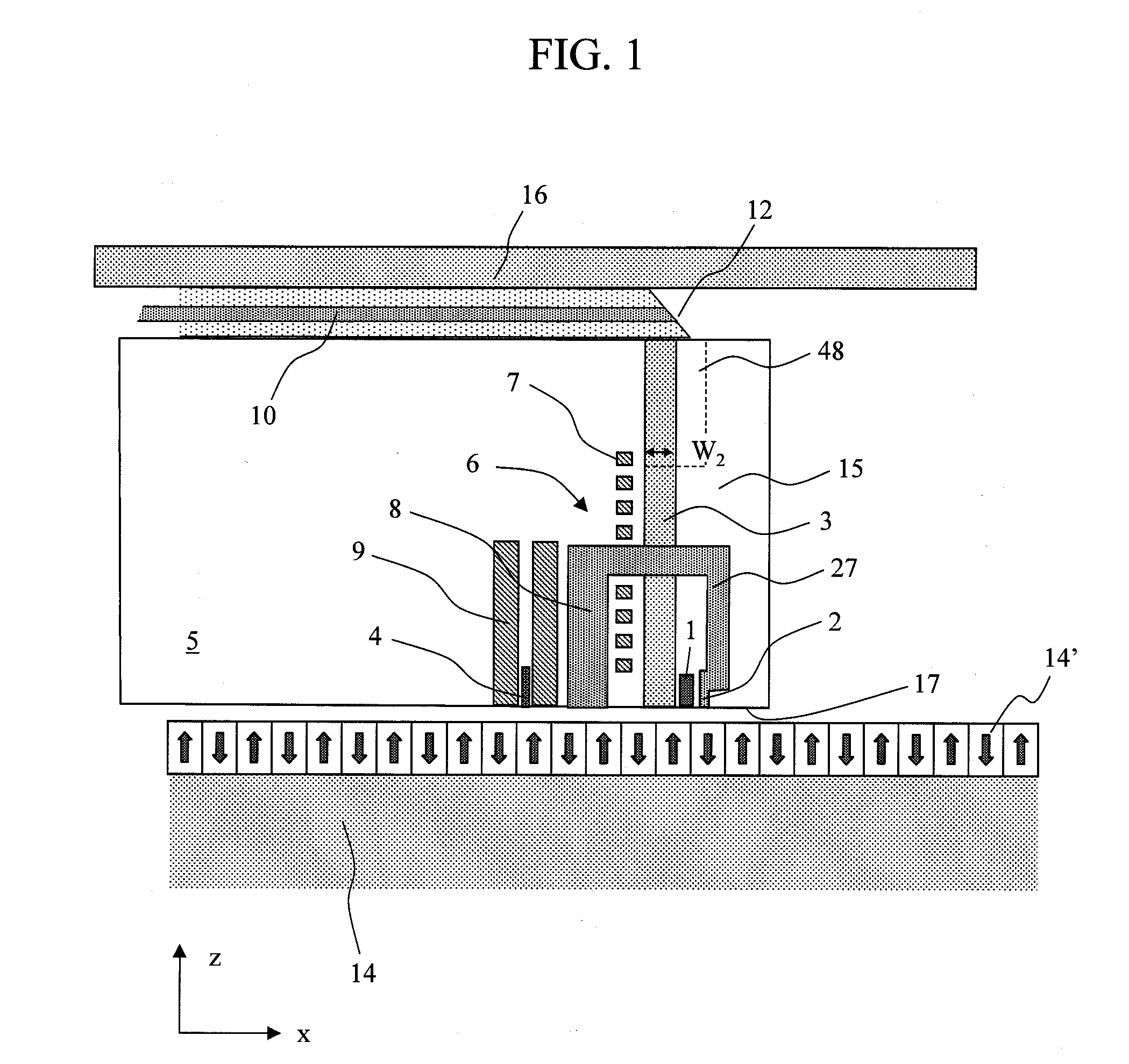

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

InactiveUS20110170381A1Improve performanceInhibit temperature riseCombination recordingRecord information storageHeat-assisted magnetic recordingSurface plasmon

An optical near-field generating efficiency of an optical near-field generating element is improved and a temperature rise of the element is suppressed. An optical near-field is generated using a conductive structure having a cross-sectional shape whose width in a direction perpendicular to a polarization direction of incident light transmitted through a waveguide gradually becomes shorter toward a vertex where an optical near-field is generated and having a shape whose width gradually, or in stages, becomes smaller in a traveling direction of the incident light toward the vertex where an optical near-field is generated. The waveguide is arranged beside the conductive structure and an optical near-field is generated via a surface plasmon generated on a lateral face of the conductive structure.

Owner:HITACHI LTD

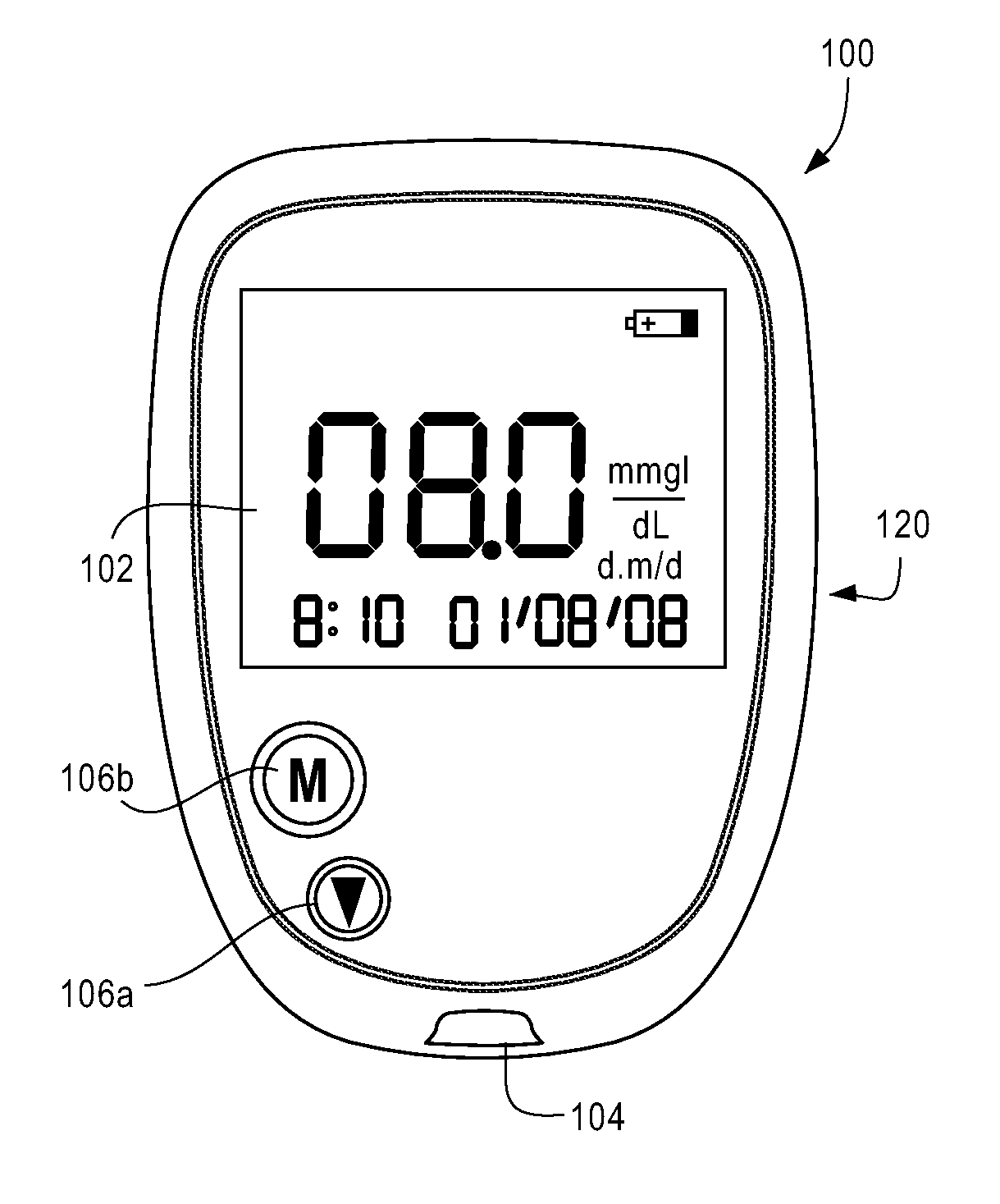

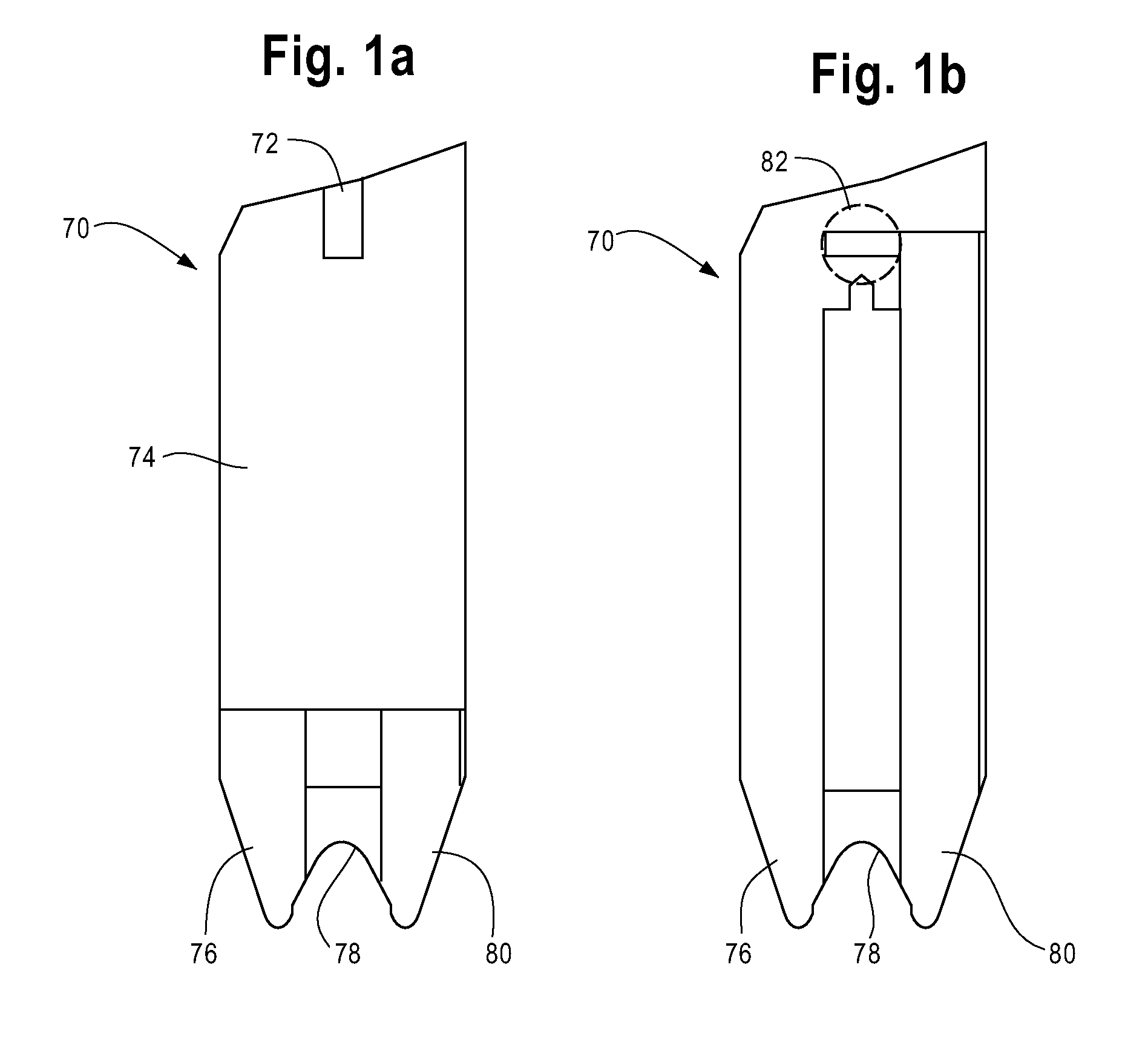

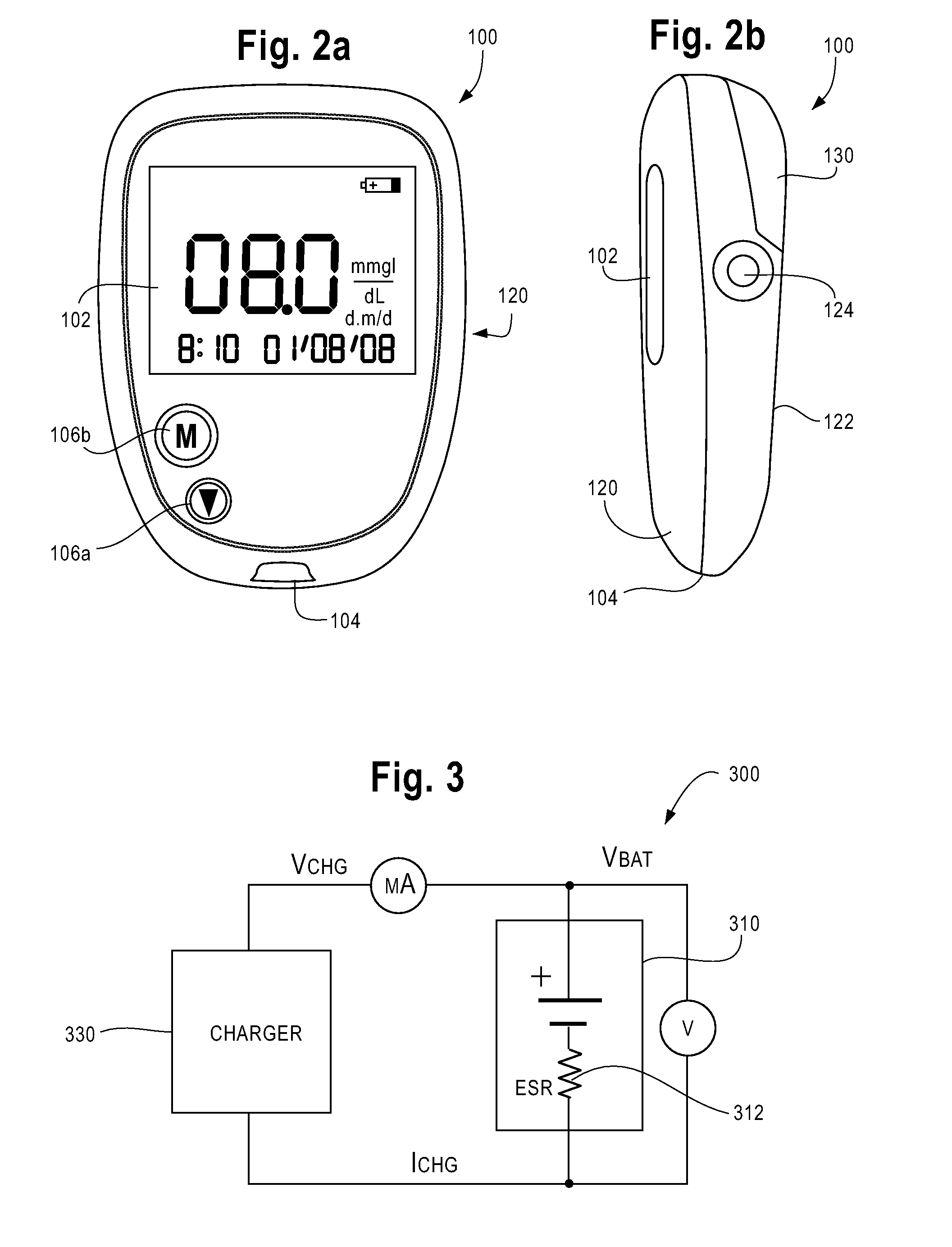

Rapid Charging And Power Management Of A Battery-Powered Fluid Analyte Meter

ActiveUS20090146826A1Rapid charge algorithmFast chargingElectrical testingSecondary cells charging/dischargingBattery state of chargeElectrical battery

A system and method is described for rapid charging and power management of a battery for a meter. A charger component is operably associated with the meter and is capable of executing a rapid charge algorithm for a rechargeable battery. The algorithm includes monitoring for a connection to an external power source and implementing a charging routine of a battery at a first charge rate and then at a second charge rate. The second charge rate is lower than the first charge rate. A temperature rise in the rechargeable battery due to the first charge rate has a negligible heat transfer effect on the fluid sample. The meter can also include a power switch for controlling current flow to a battery fuel gauge. The power switch is open when the meter enters into a sleep mode. The state of battery charge is determined after the meter exits the sleep mode.

Owner:ASCENSIA DIABETES CARE HLDG AG

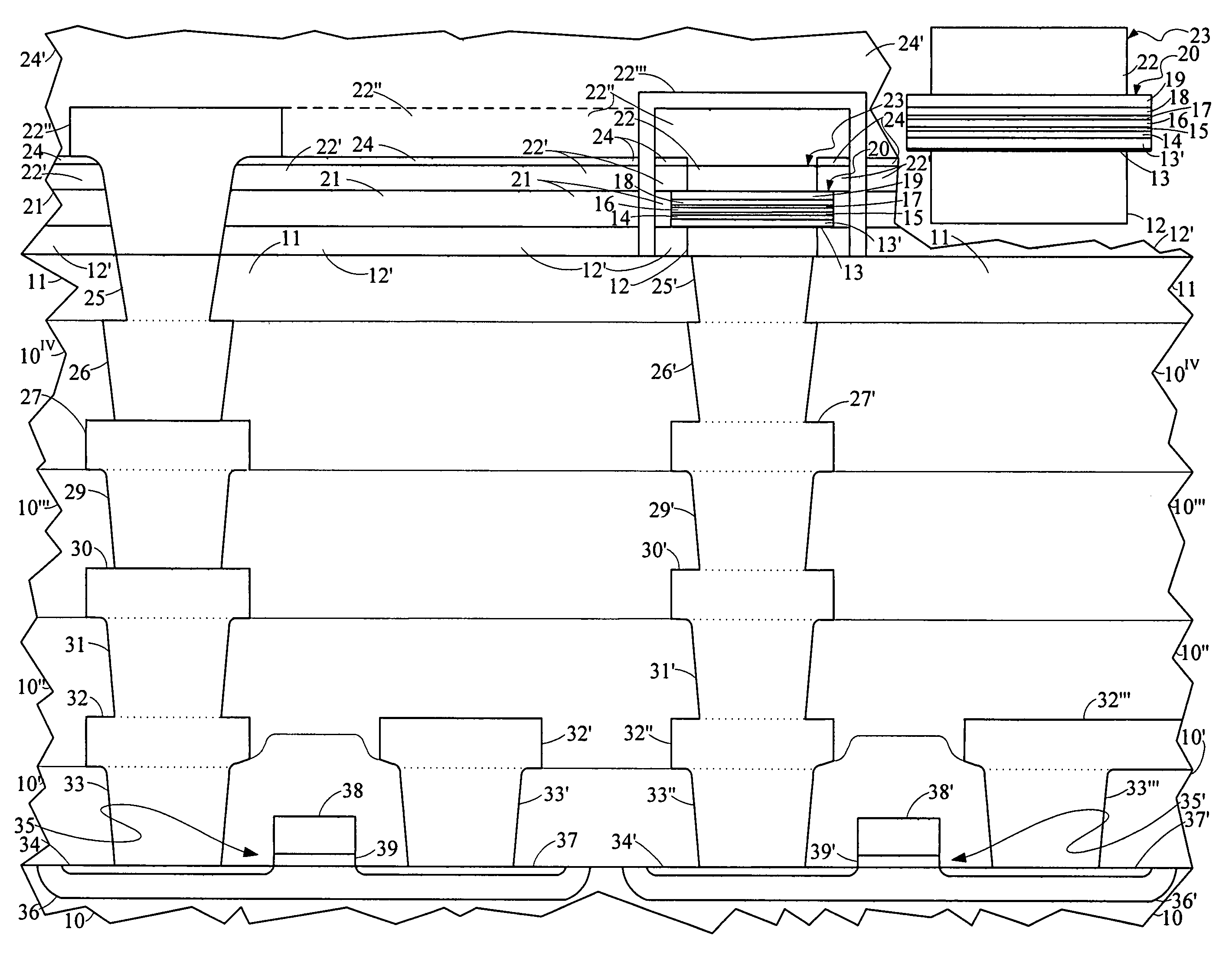

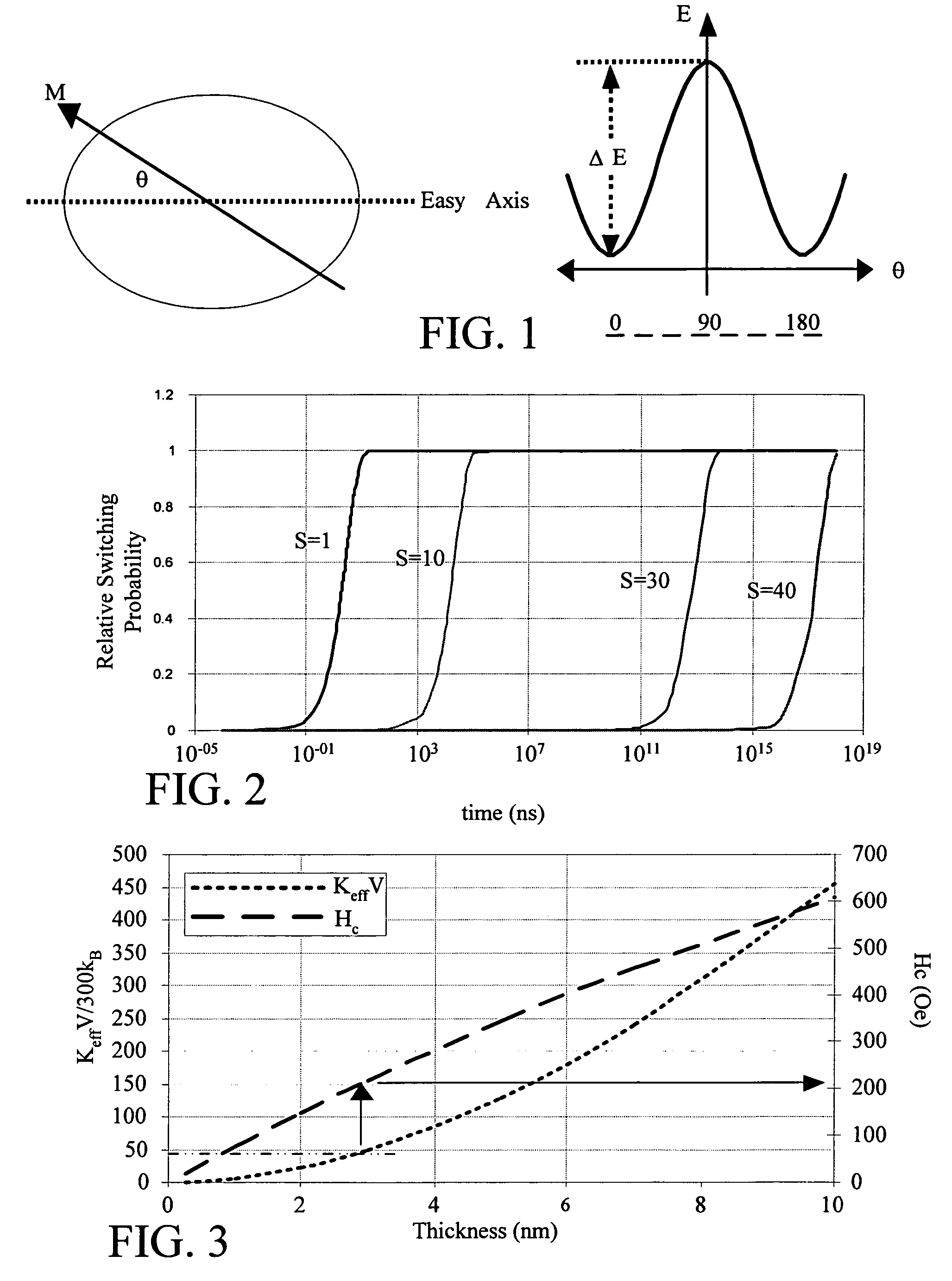

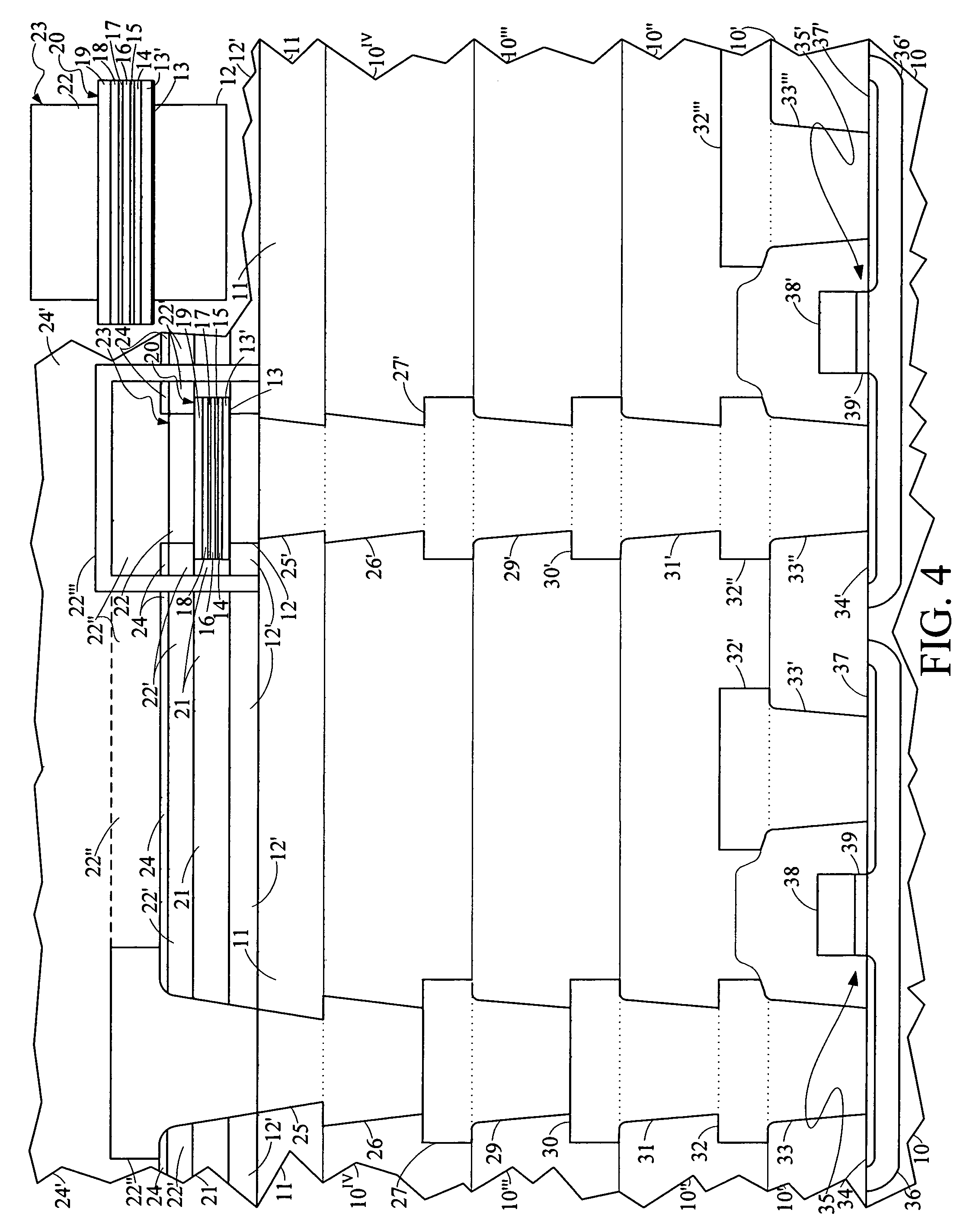

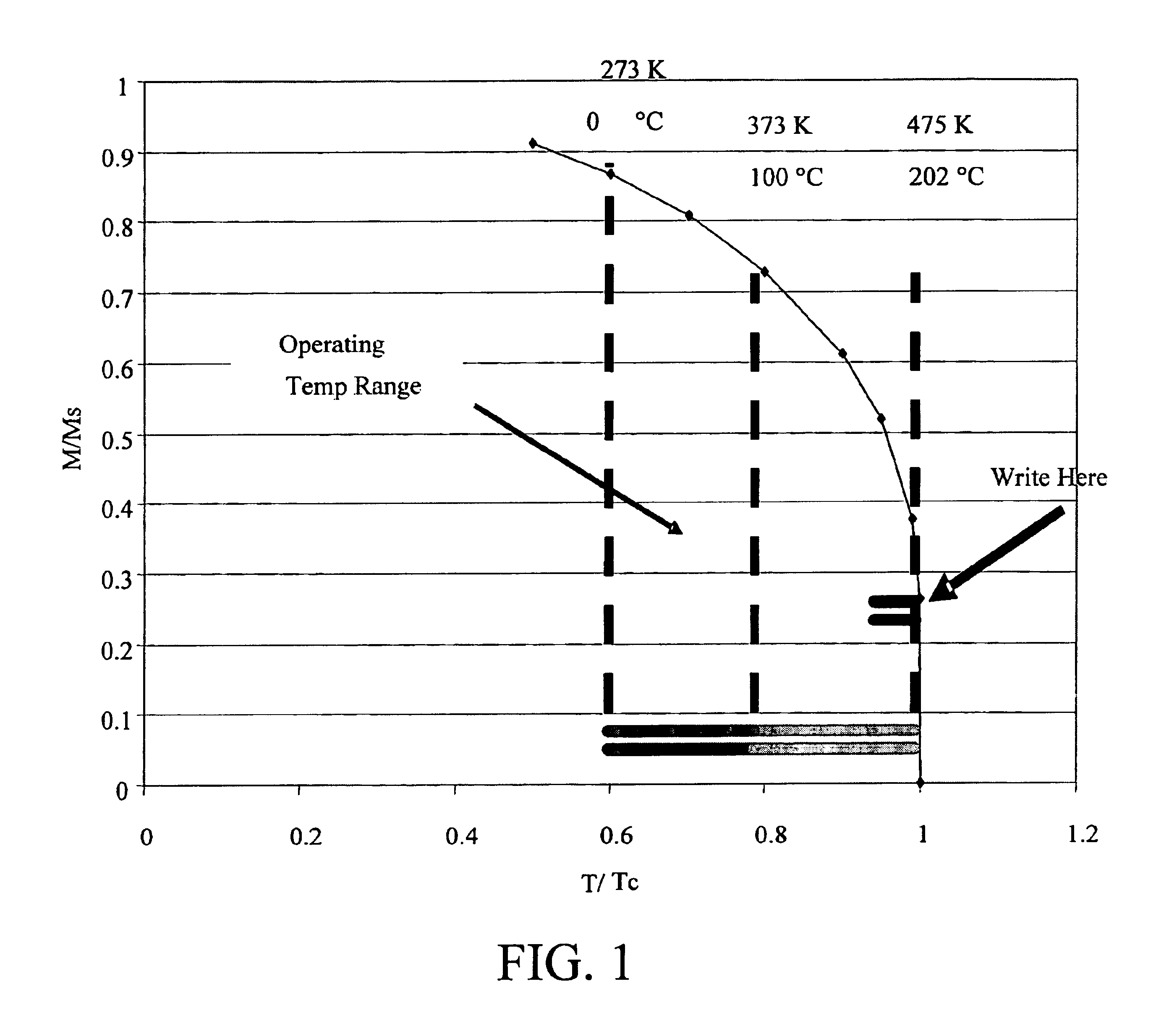

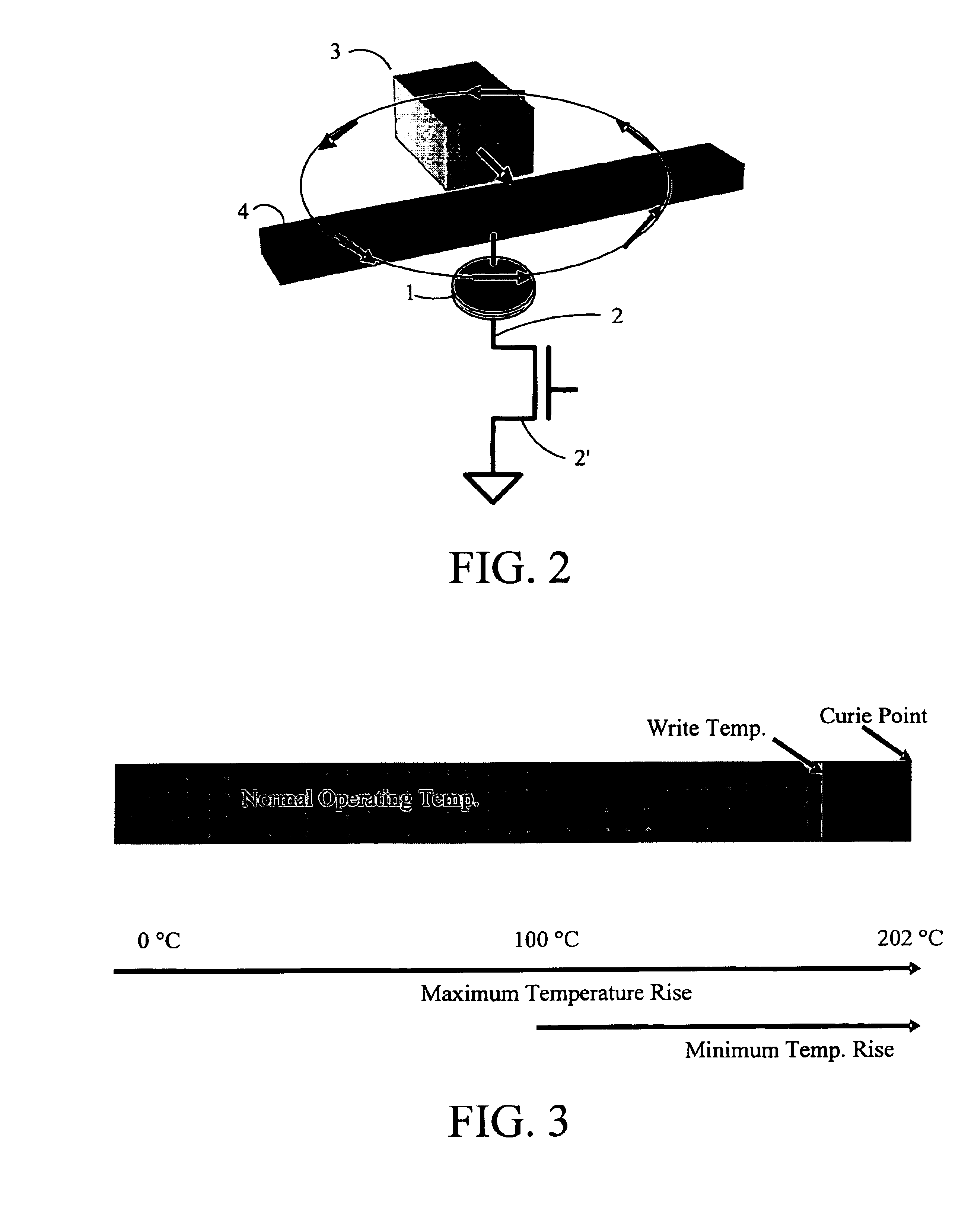

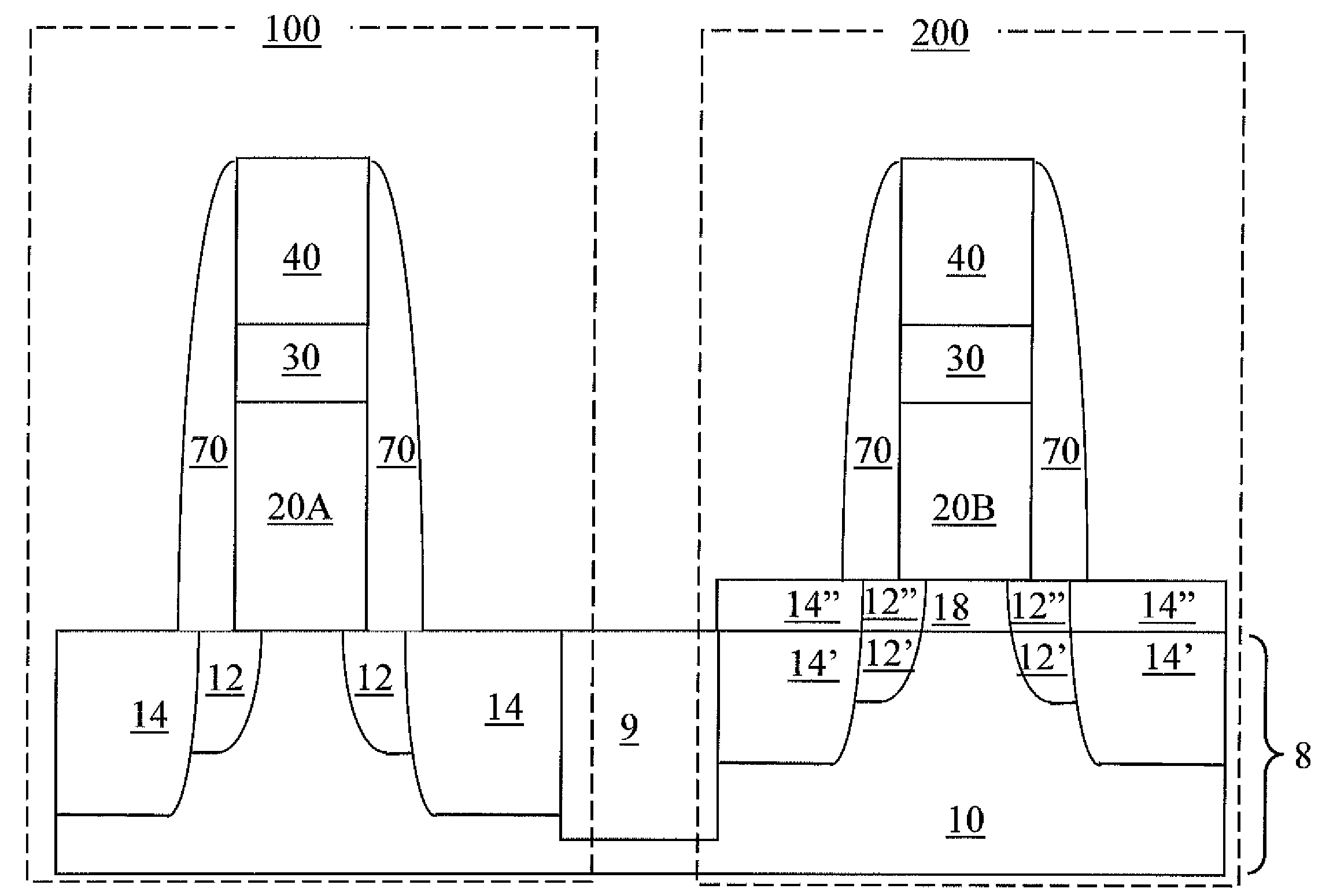

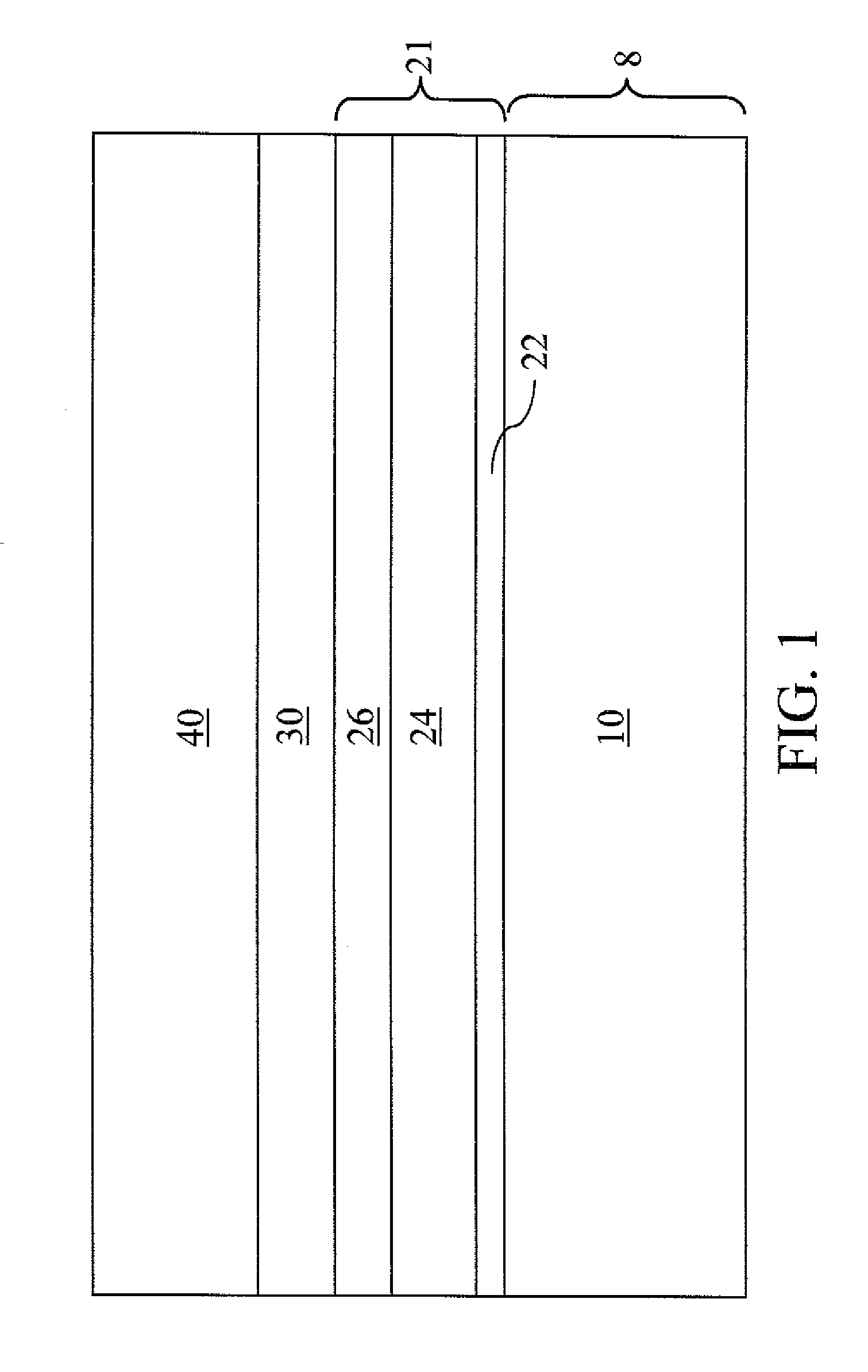

Thermomagnetically assisted spin-momentum-transfer switching memory

A ferromagnetic thin-film based digital memory having a substrate supporting bit structures that are electrically interconnected with information storage and retrieval circuitry and having first and second oppositely oriented relatively fixed magnetization layers and a ferromagnetic material film in which a characteristic magnetic property is substantially maintained below an associated critical temperature above which such magnetic property is not maintained. This ferromagnetic material film is separated from the first and second fixed magnetization films by corresponding layers of a nonmagnetic materials one being electrically insulative and that one remaining being electrically conductive. Each bit structure has an interconnection structure providing electrical contact thereto at a contact surface thereof substantially parallel to the intermediate layer positioned between the first contact surface and the substrate. A plurality of word line structures located across from a corresponding one of the bit structures on an opposite side. Electrical current selectively drawn through each of these bit structures and its interconnection structure can cause substantial heating of that bit structure to raise temperatures thereof while being above temperatures of at least an adjacent said bit structure because of sufficient thermal isolation.

Owner:NVE CORP

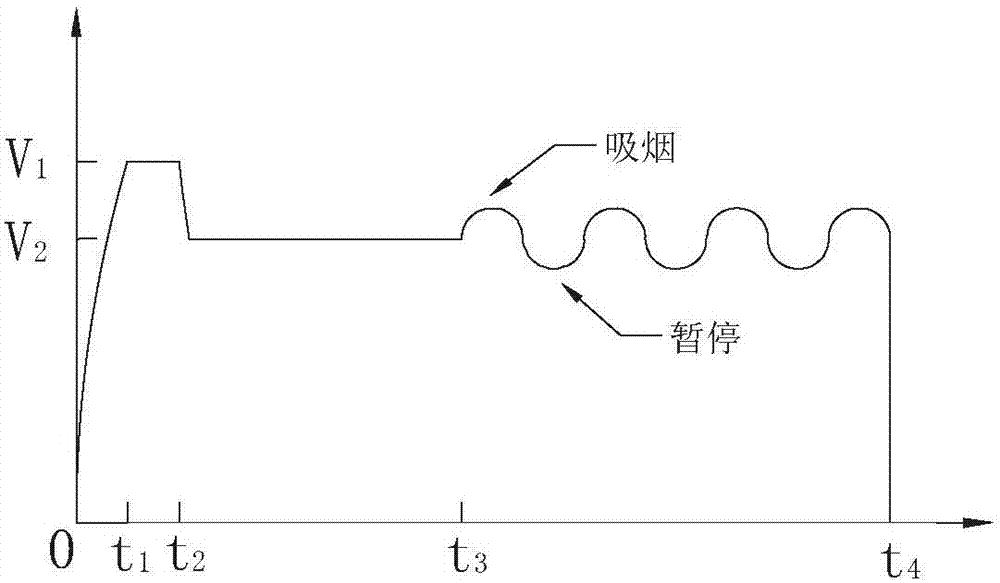

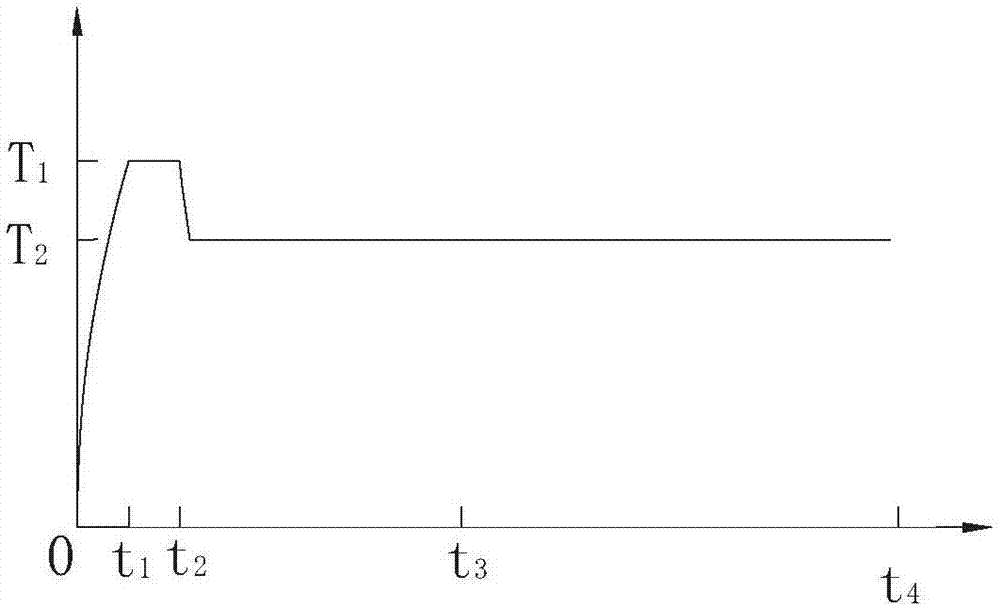

Heating method of electronic smoking set

The invention discloses a heating method of an electronic smoking set. The heating method comprises the following steps of a first heating device preheating stage before smoking, a second heating device preheating stage before smoking, a heat preservation stage during smoking, heat preservation stage pausing during smoking and smoking stage completion. The heating method has the advantages that the outer wall portion of a tobacco core and air flowing through the inside of the tobacco core are simultaneously preheated by adopting the method, a first heating device rapidly improves the temperature and exceeds normal heating temperature to make heat rapidly and evenly transferred to the inside of the tobacco core, the preheating time is short, and a user can be more quickly in a smoking state. During smoking, two heating devices can adjust voltage to keep constant temperature heating and ensure that sufficient smoke amount is produced in unit time, the user can smoothly smoke, the voltage can be also adjusted to keep constant temperature heating when smoking is paused, and the scorched flavor produced due to tobacco overburning in the tobacco core caused by temperature rise is avoided.

Owner:HUIZHOU HAPPY VAPING TECH LTD

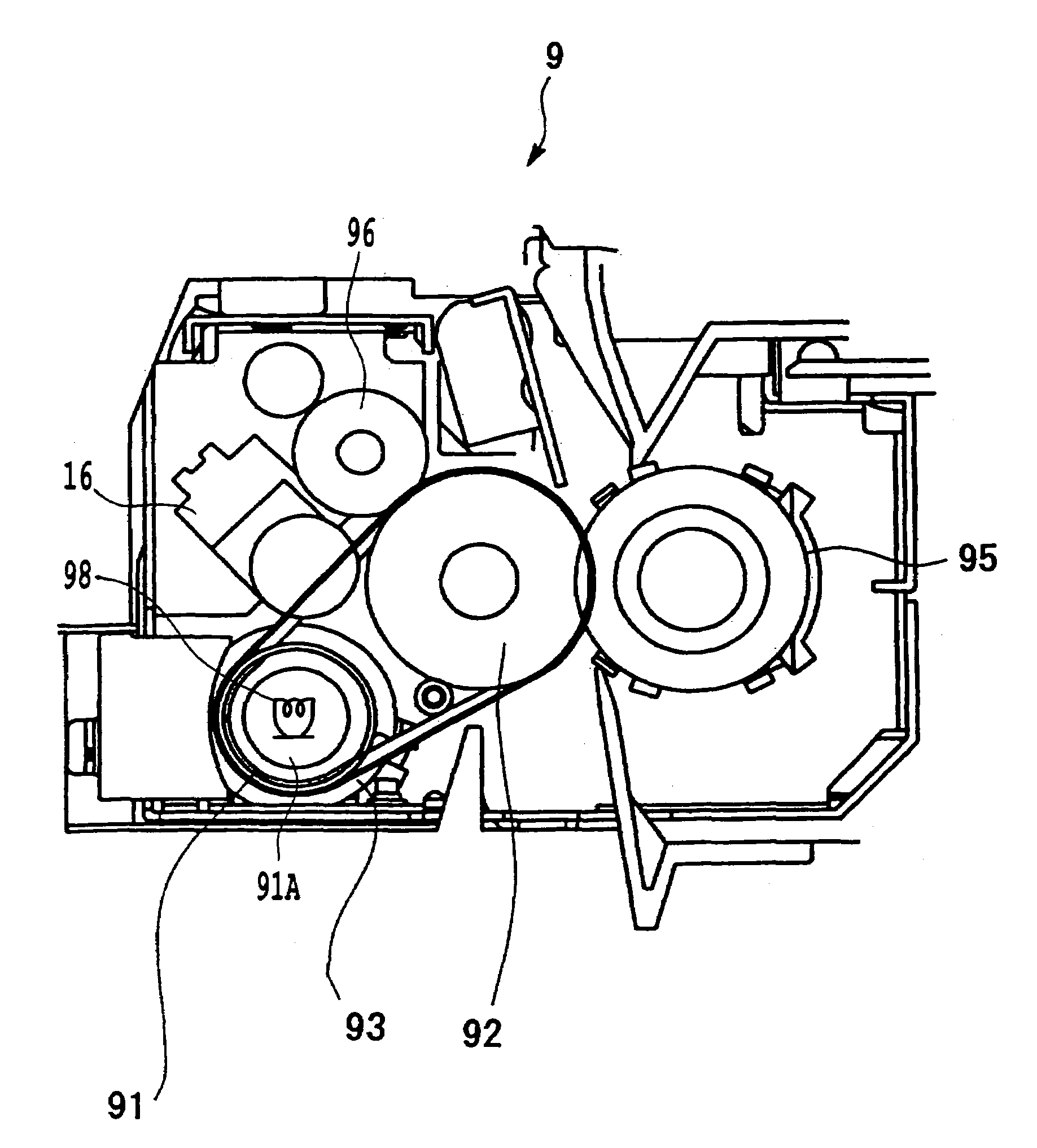

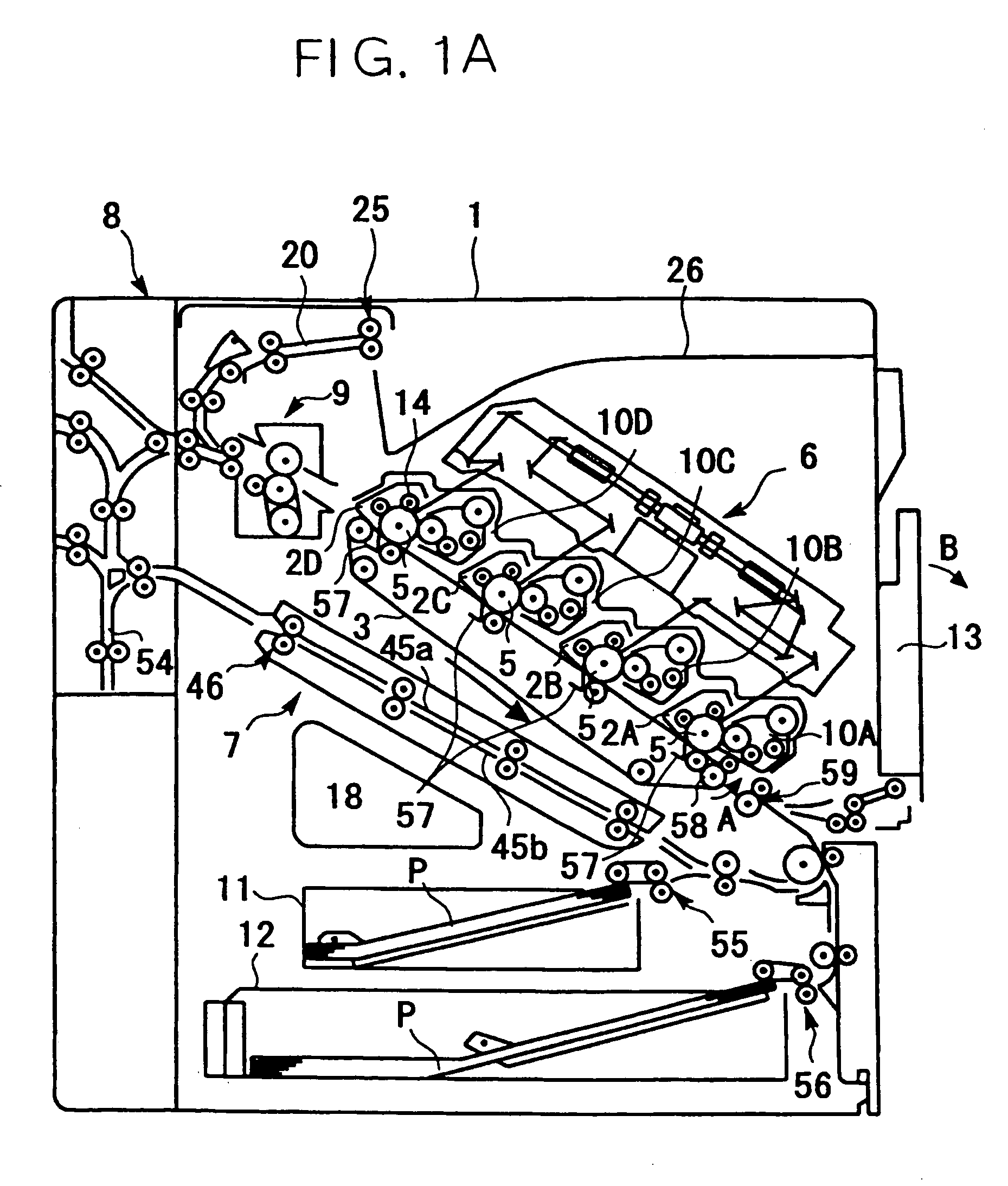

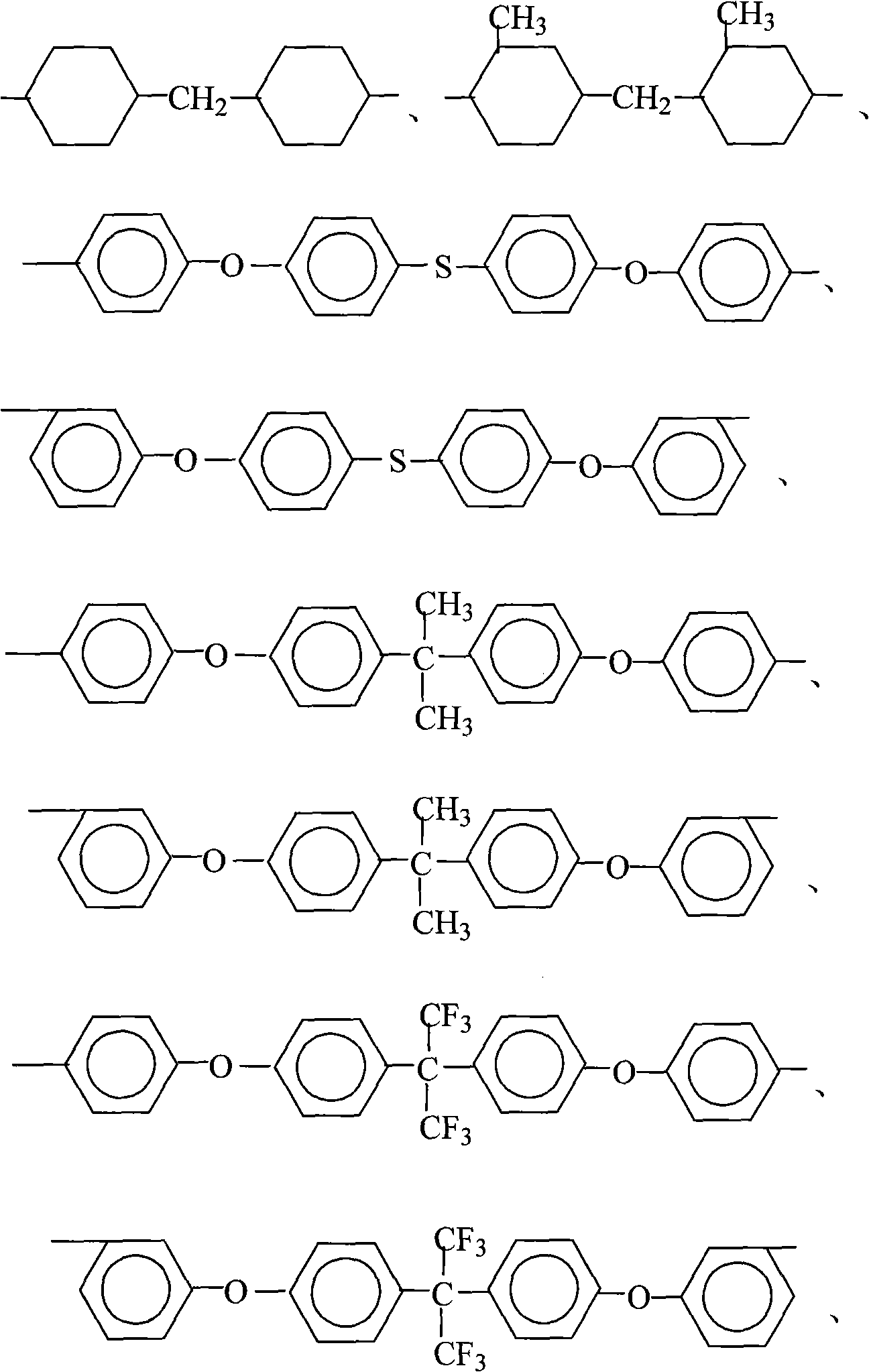

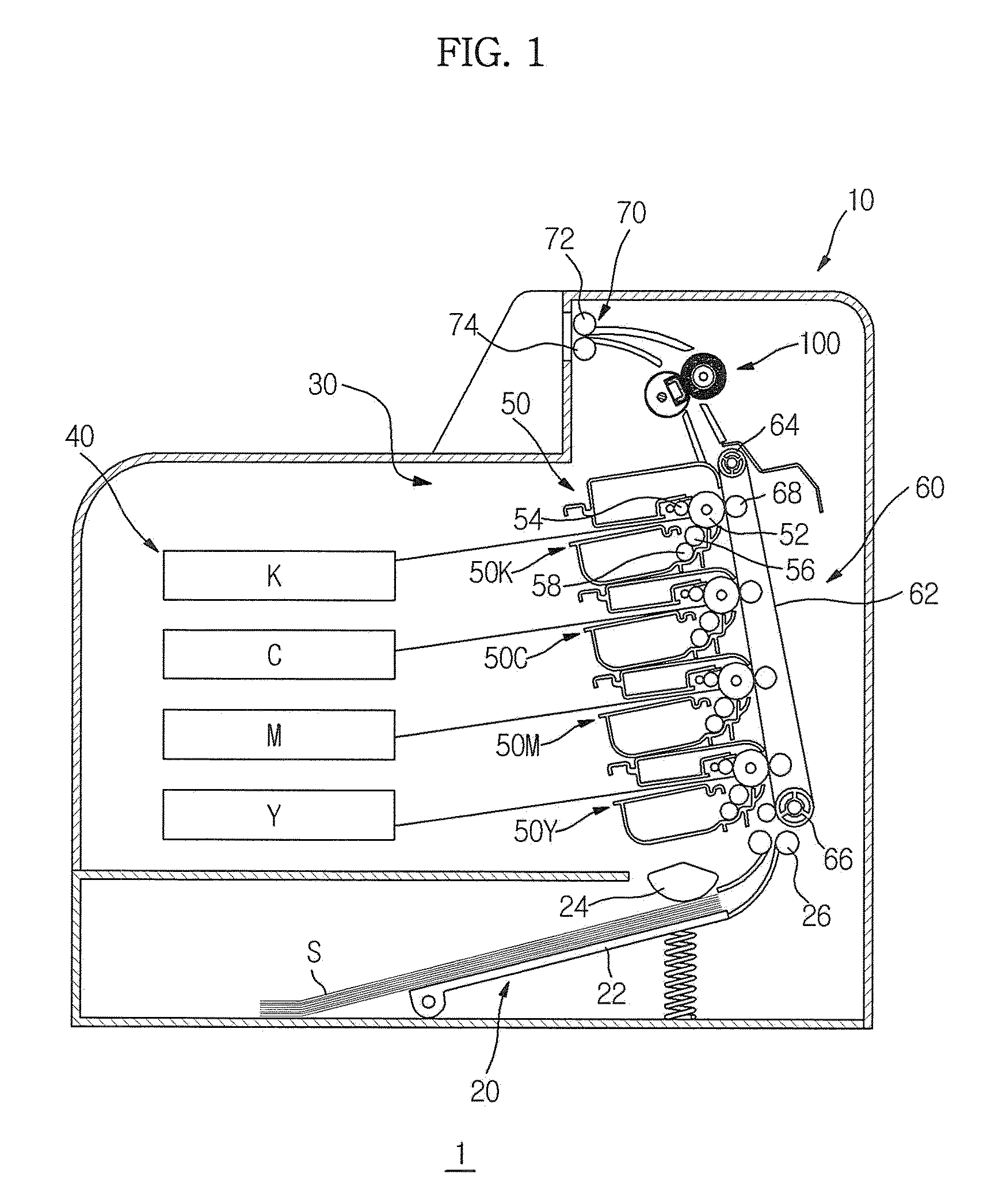

Fixing apparatus and image formation apparatus using same

InactiveUS7239838B2Shorten the timeDecrease riseElectrographic process apparatusDevelopersImage formationEngineering

It is an object of the present invention to provide a fixing apparatus with which the movement of heat to the fixing belt during warm-up is suppressed, and the time it takes for the heating roller temperature to rise can be shortened, by reducing the contact surface area between the fixing belt and the heating roller, and an image formation apparatus that makes use of this fixing apparatus, and a toner used therein. A separation member provided on the inside of the fixing belt forms a pair with a tension roller, and a switching device for switching the positions thereof switches the positions when a set temperature is detected by temperature sensing device installed on the heating roller, so that the contact surface area of the fixing belt on the heating roller is different during warm-up and during fixing.

Owner:RICOH KK

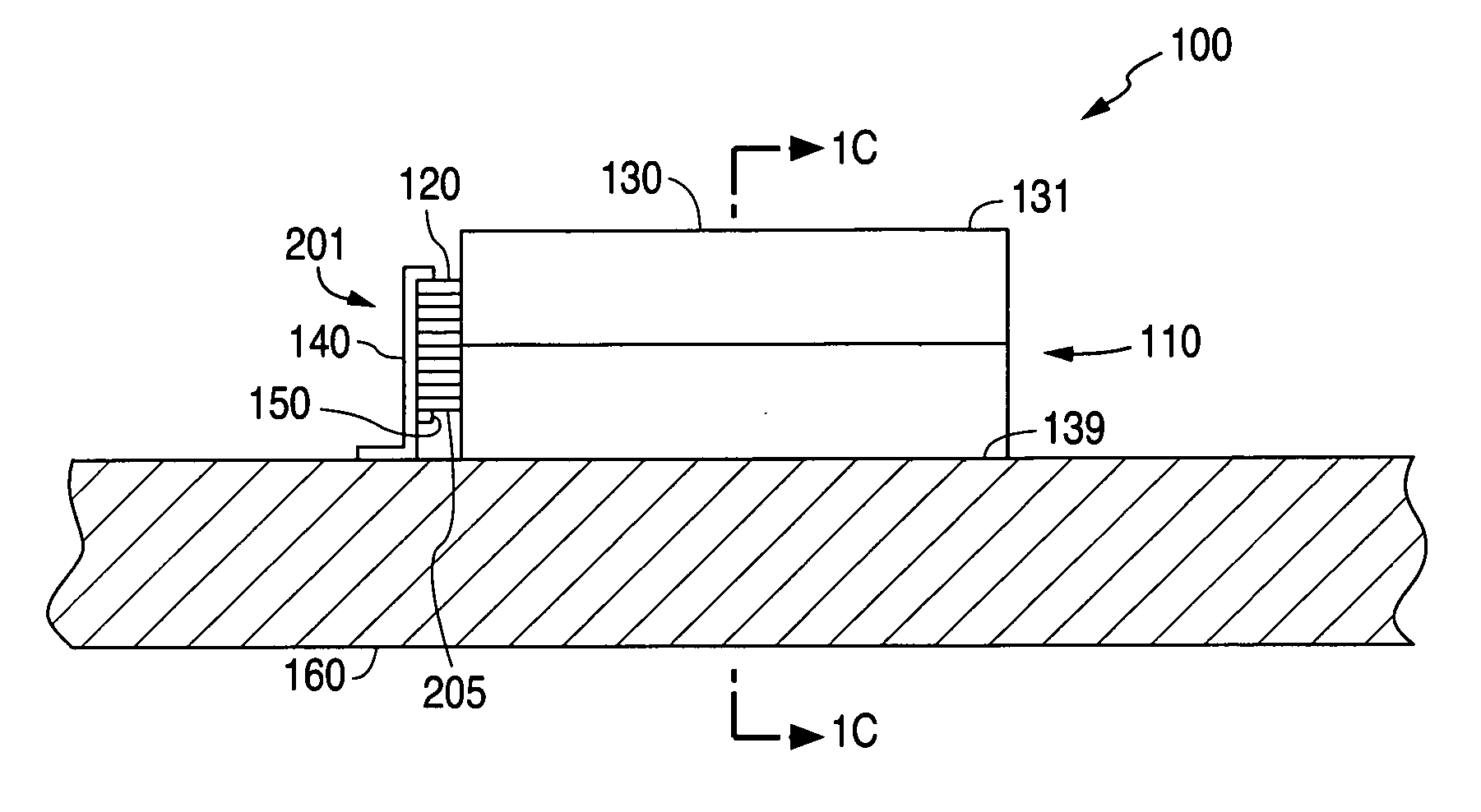

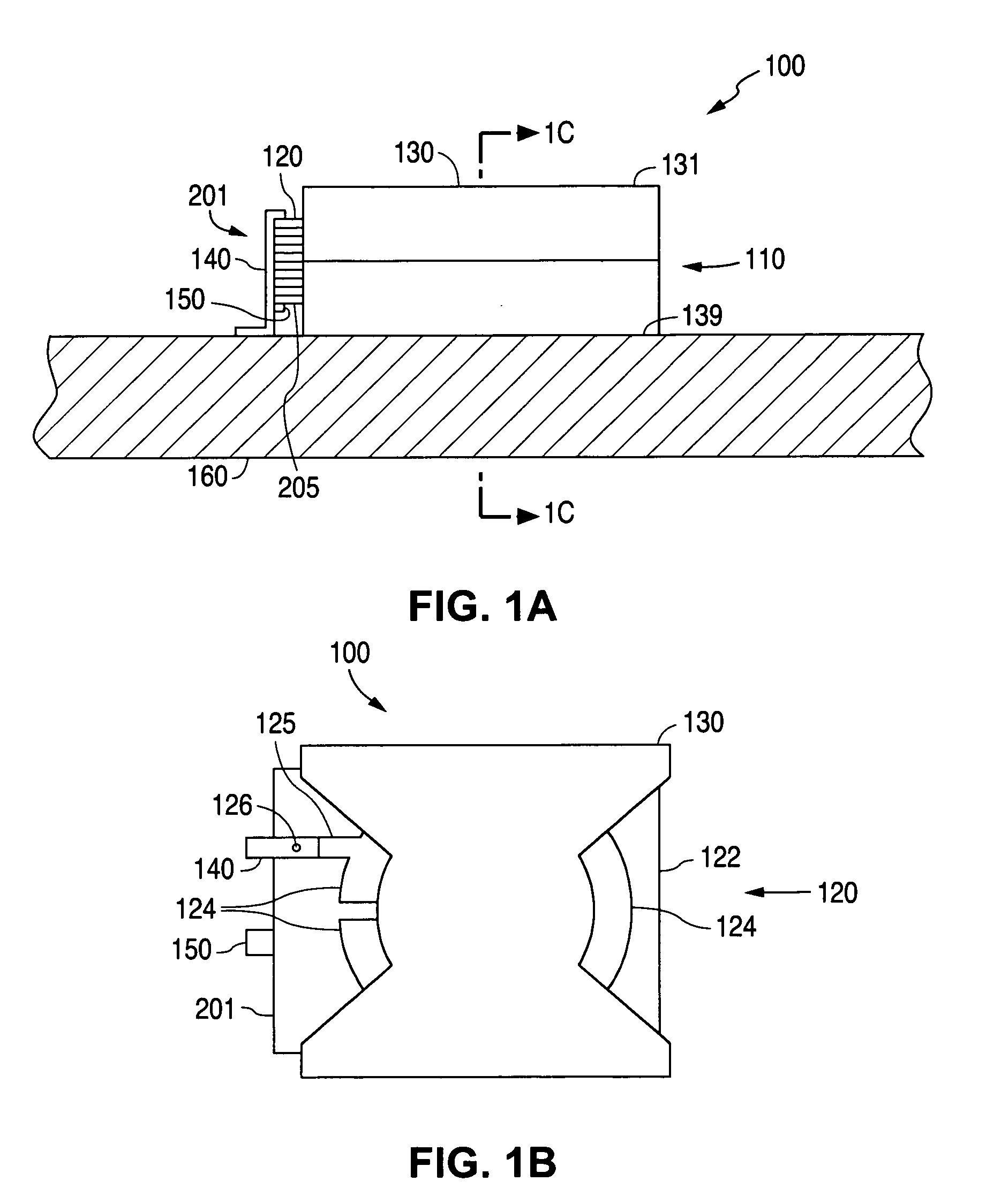

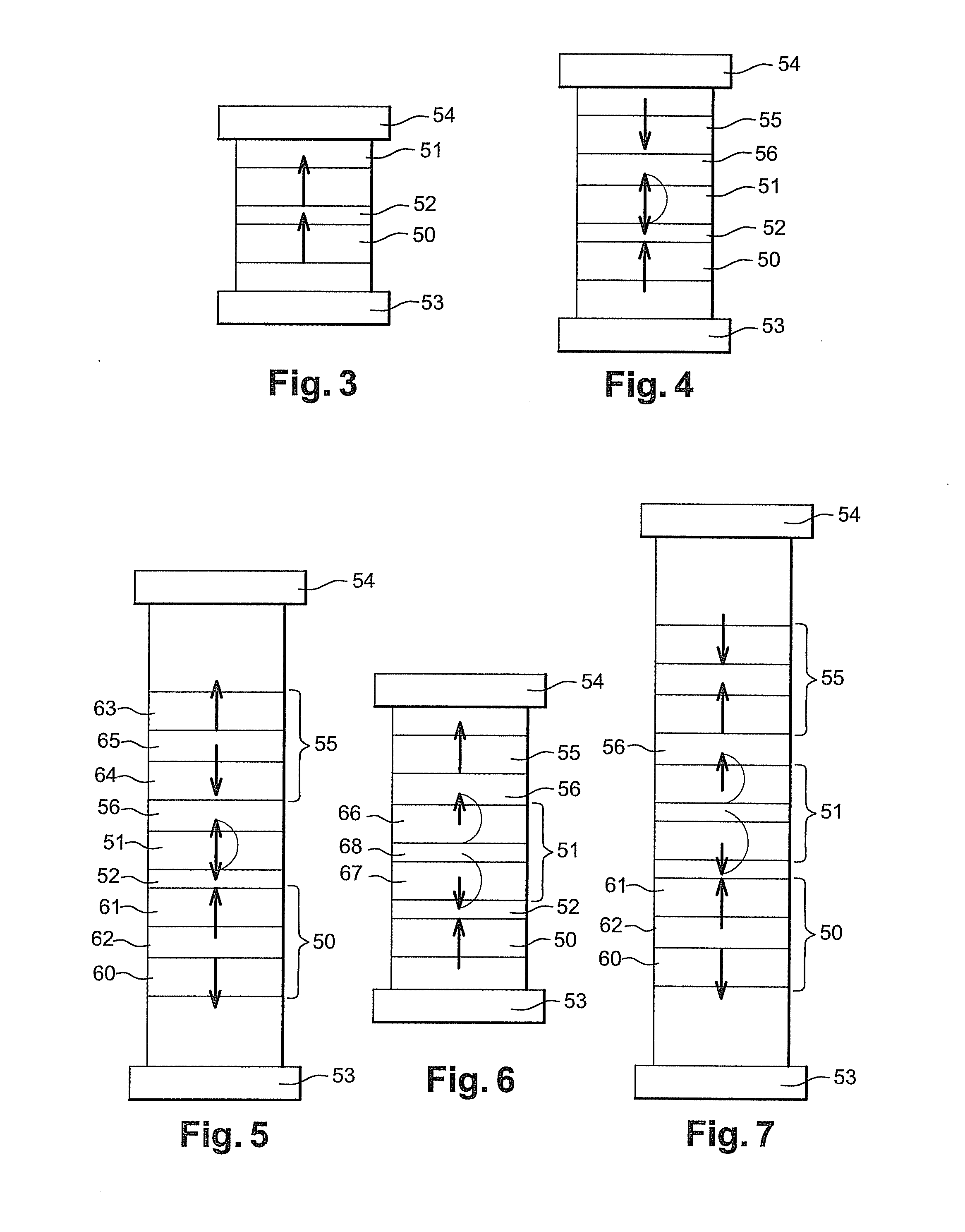

Multi-layer printed circuit board transformer winding

InactiveUS20050212640A1High currentImprove efficiencyTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsSurface mountingEngineering

The present invention provides a transformer formed from adjacent conducting layers of a multi-layer PCB and at least one additional conducting layer in contact with the PCB. The inventive transformer includes one or more winding turns of a first winding formed by connecting the multiple layers of the multi-layer PCB with conductive vias and one or more winding turns of a second winding formed by connecting one or more other layers of the multi-layer PCB. The additional conducting layer or layers is connected to respective selected one or more of said conducting layers of said PCB. In one embodiment, an additional conducting layer is soldered to a top conducting layer of the PCB, effectively increasing the cross-sectional area of the top winding layer. In another embodiment, an additional conducting layer is separated from a conducting PCB layer formed on the surface thereof by a layer of insulation, permitting the additional conducting layer to form a separate winding turn. The inventive transformer can be surface mounted to a PCB, and can be used in other electromagnetic devices. The windings thus constructed are capable of accepting larger currents with lower resulting temperature increases than windings formed only from PCBs, and are less expensive to manufacture than PCB-only windings.

Owner:ASTEC INT LTD

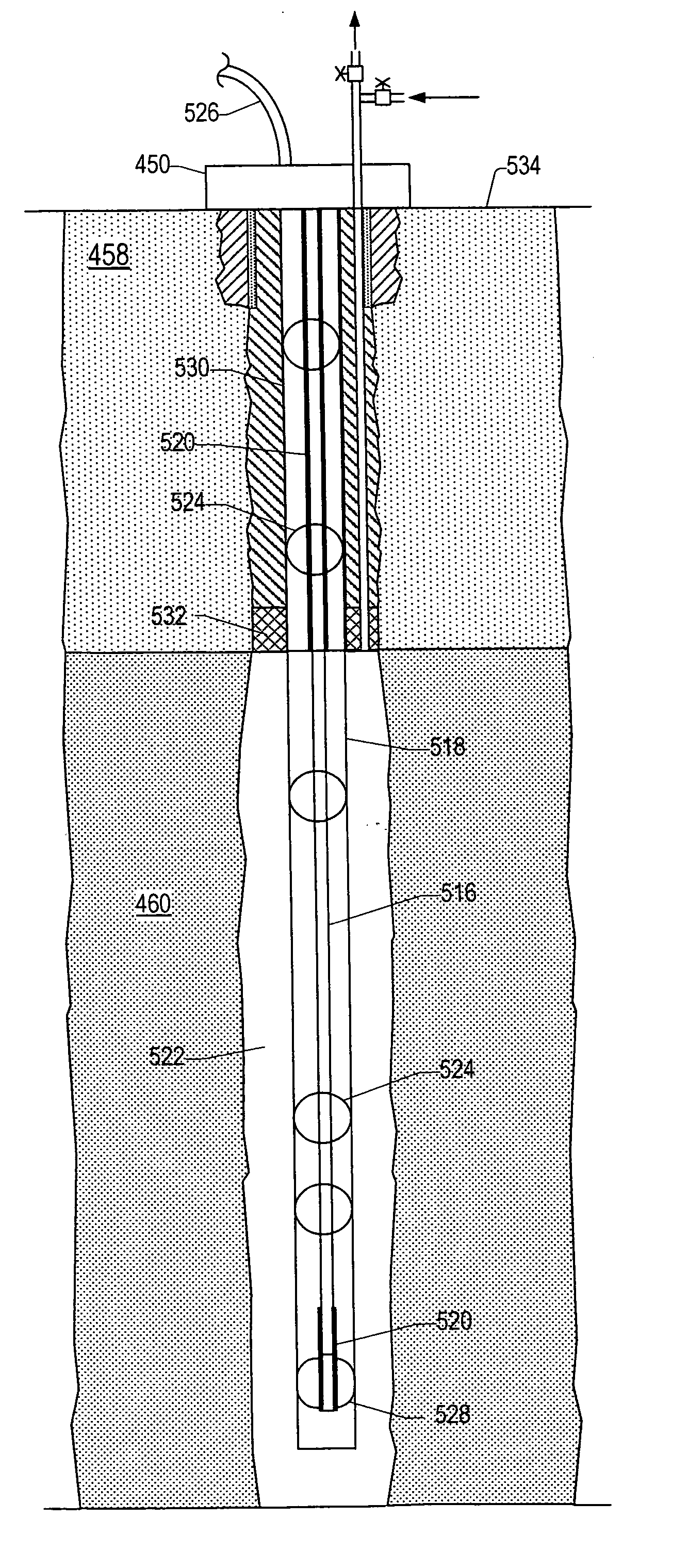

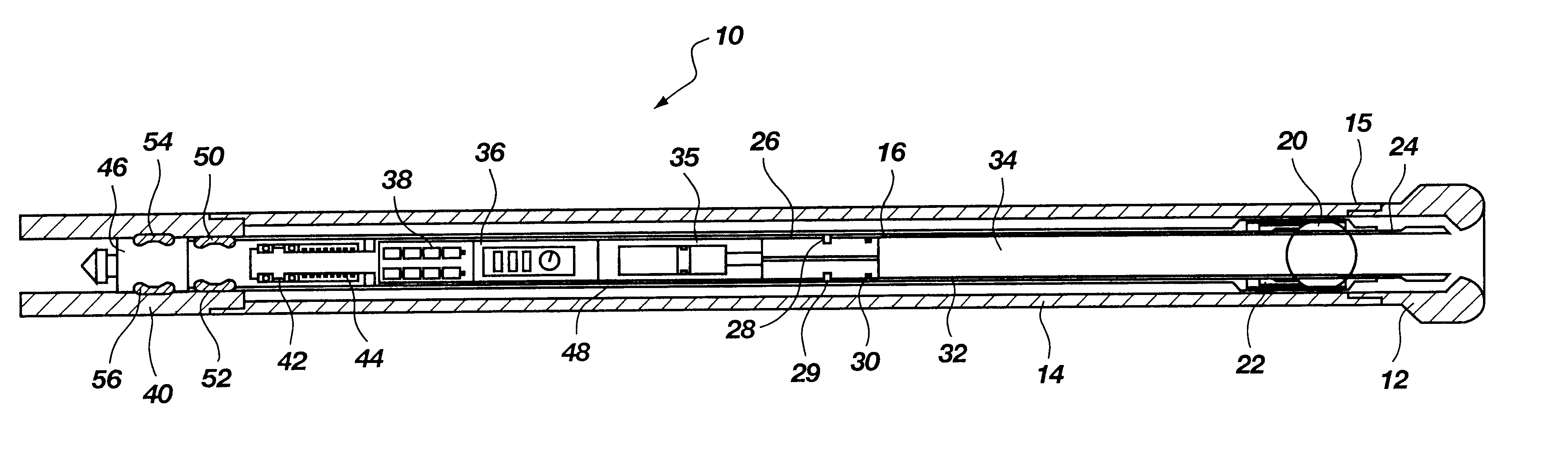

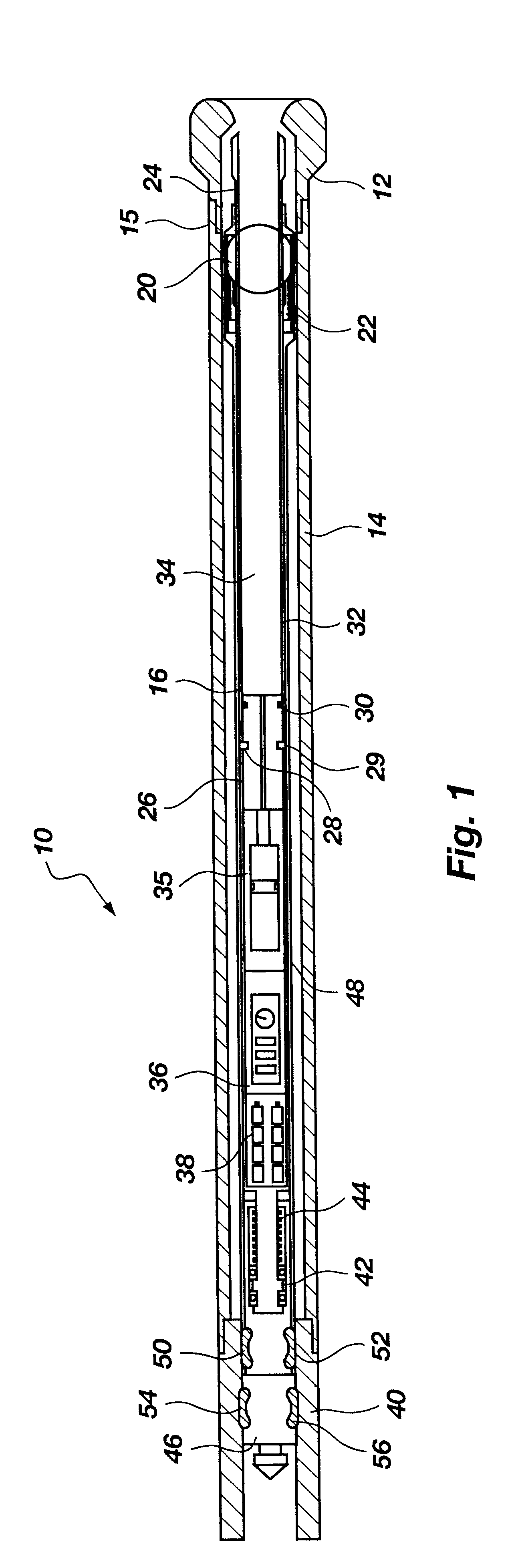

Apparatus for recovering core samples under pressure

A pressure and temperature core sampler comprises a tool for recovering cores specifically enabling the evaluation of methane hydrate resources. Because methane hydrate tends to decompose under conditions of pressure decrease and / or temperature increase as the samples are retrieved to the surfaces a coring tool in accordance with the present invention provides a self-contained system for retrieving core samples at or near in situ pressure while cooling the core sample. The coring tool is preferably a wire line retrievable device that provides for nearly continuous coring during the drilling operation.

Owner:JAPAN OIL GAS & METALS NAT CORP

System and method for enhanced combustion control in an internal combustion engine

InactiveUS6609493B2Electrical controlInternal combustion piston enginesExternal combustion engineEngineering

A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

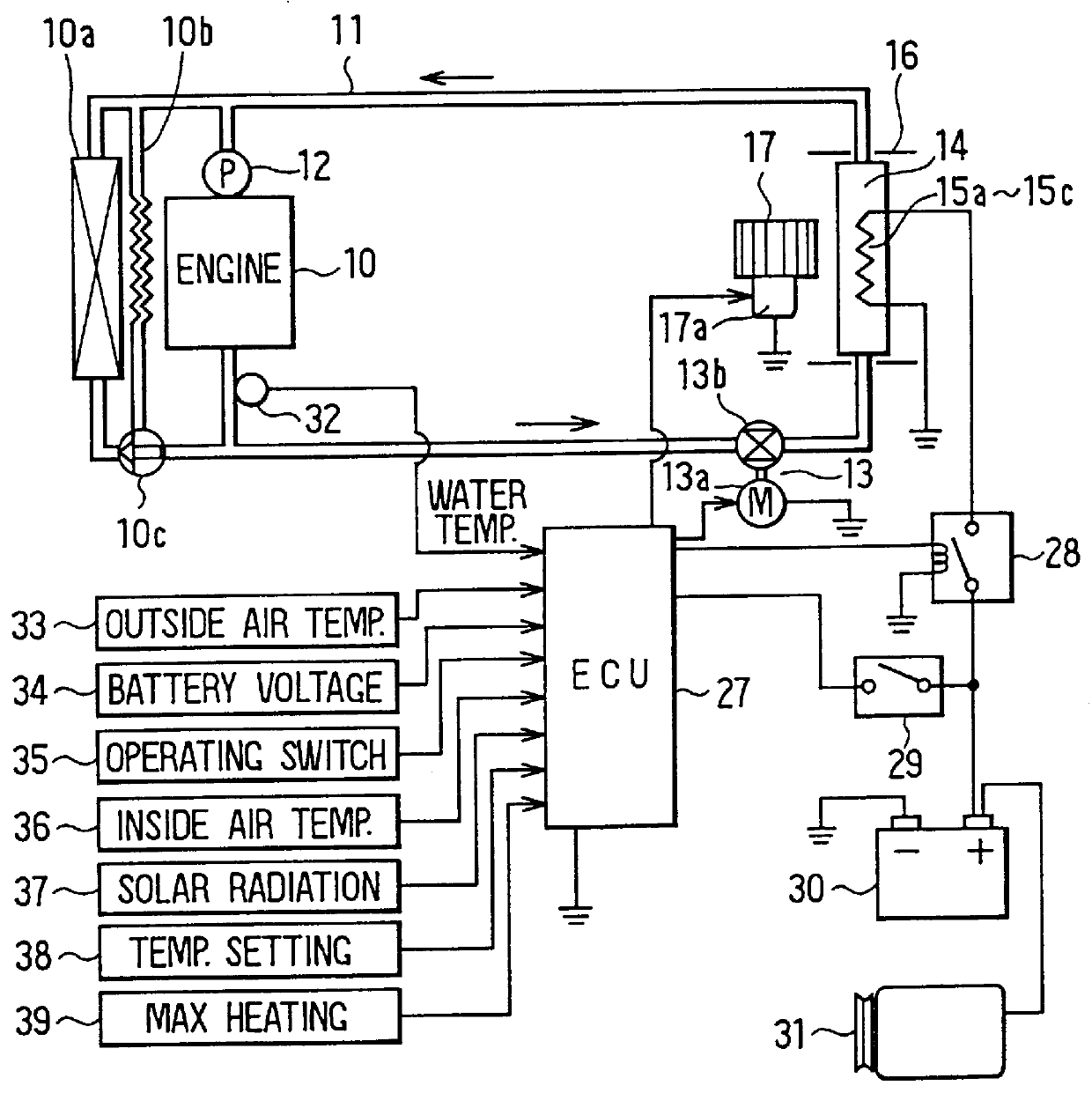

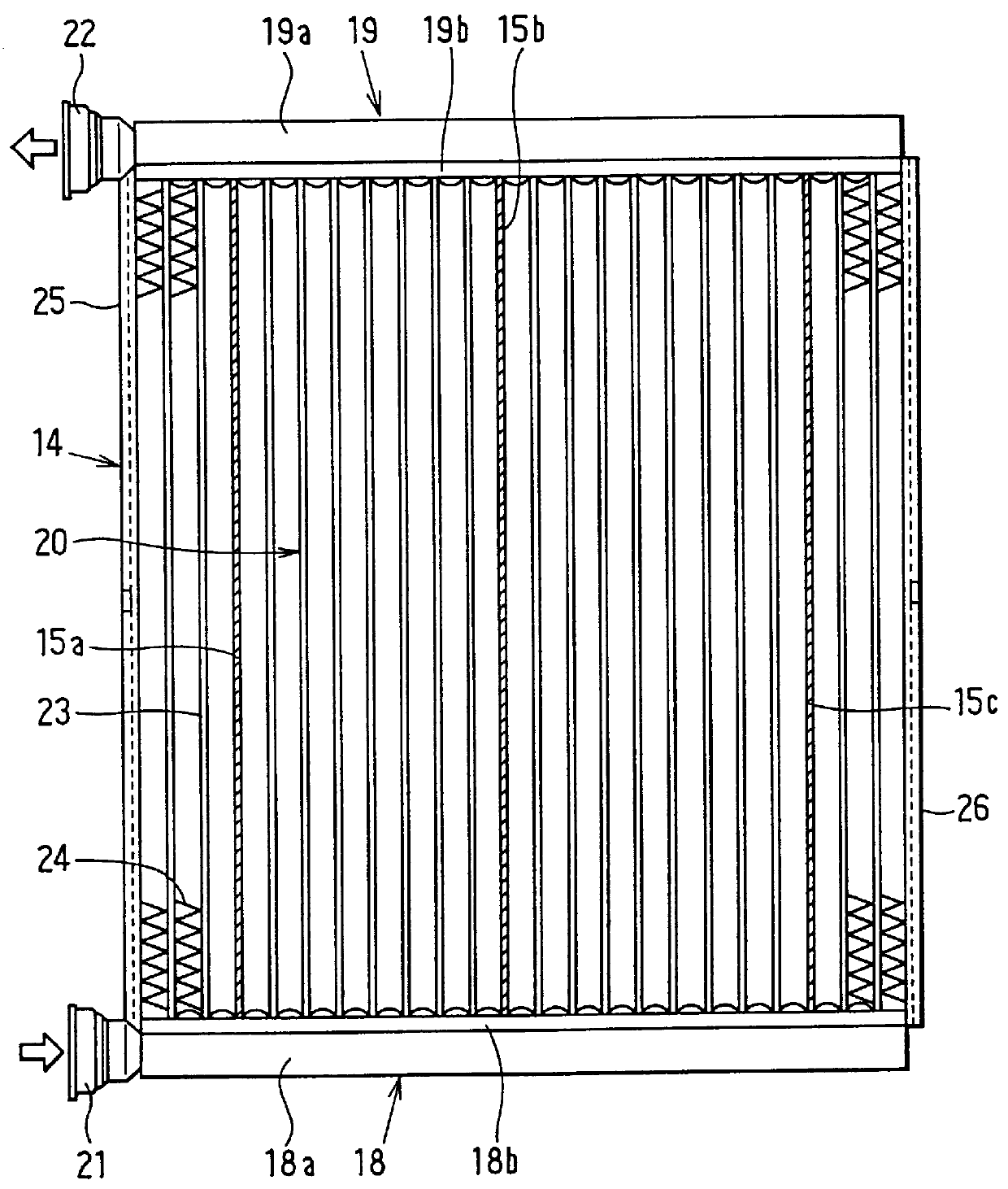

Vehicle air-conditioning system with heat exchanger having integrated electric heaters and temperature control system

A vehicle air-conditioning system includes electric heating devices to accelerate a rise in temperature of air for heating a passenger compartment by accelerating a rise in temperature of warm water used to heat the air and by directly heating the air. Electric heating devices are built into a heat exchanger for heating so that the devices can release heat into surrounding air through radiating fins. When the system is in a heating operation region and the temperature of warm water available to flow through the heat exchanger is below a set temperature T2, the electric heating devices are turned on. A blower for blowing heating air into a passenger compartment through the heat exchanger is stopped, and a warm water valve is opened to allow the warm water to flow through the heat exchanger, whereupon heat from the electric heating devices is released through the radiating fins into the warm water inside the heat exchanger. When the temperature of the warm water rises above the set temperature T2, the blower is started, and heat from the electric heating devices is released through the radiating fins into the air blown by the blower.

Owner:DENSO CORP

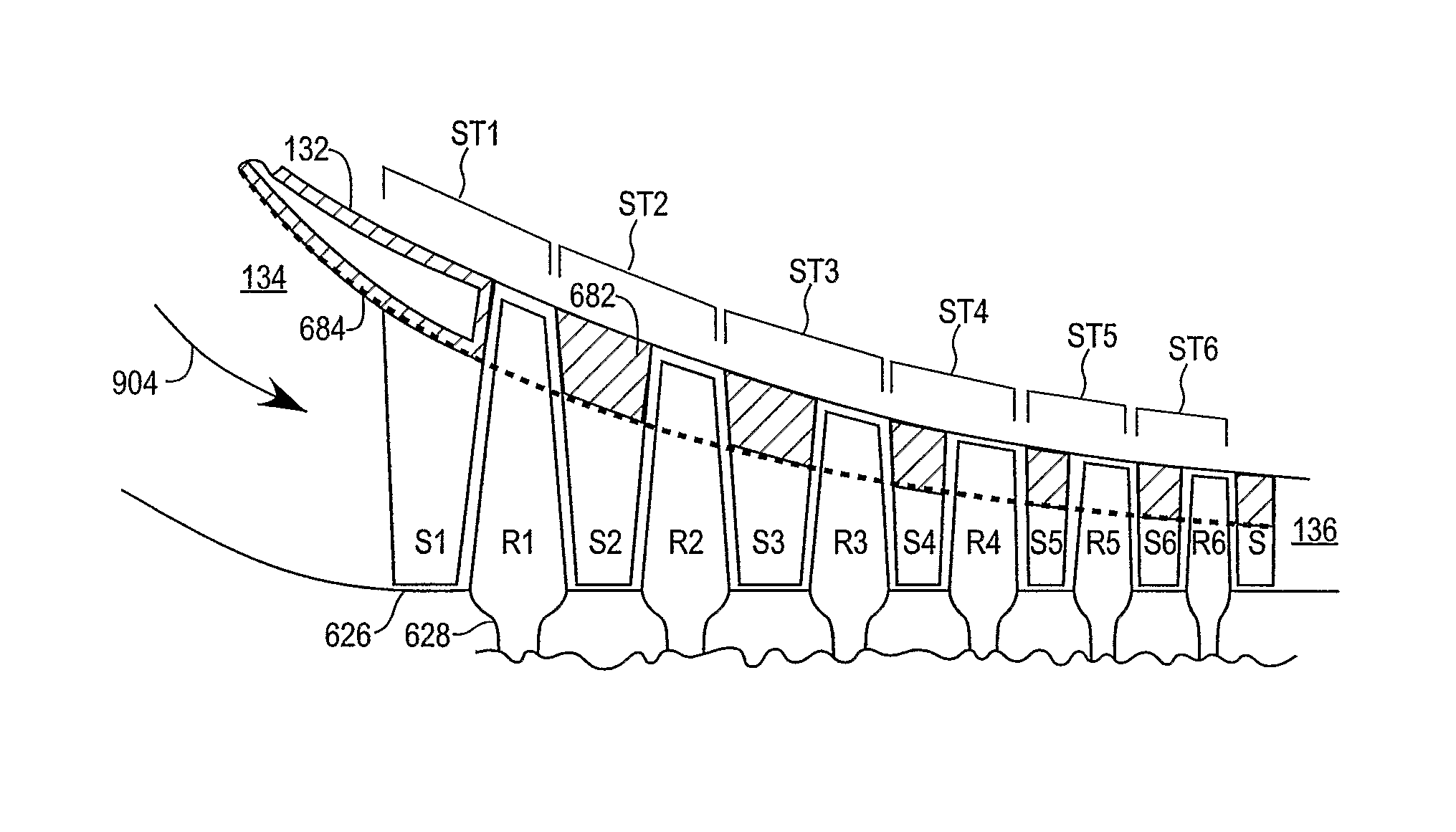

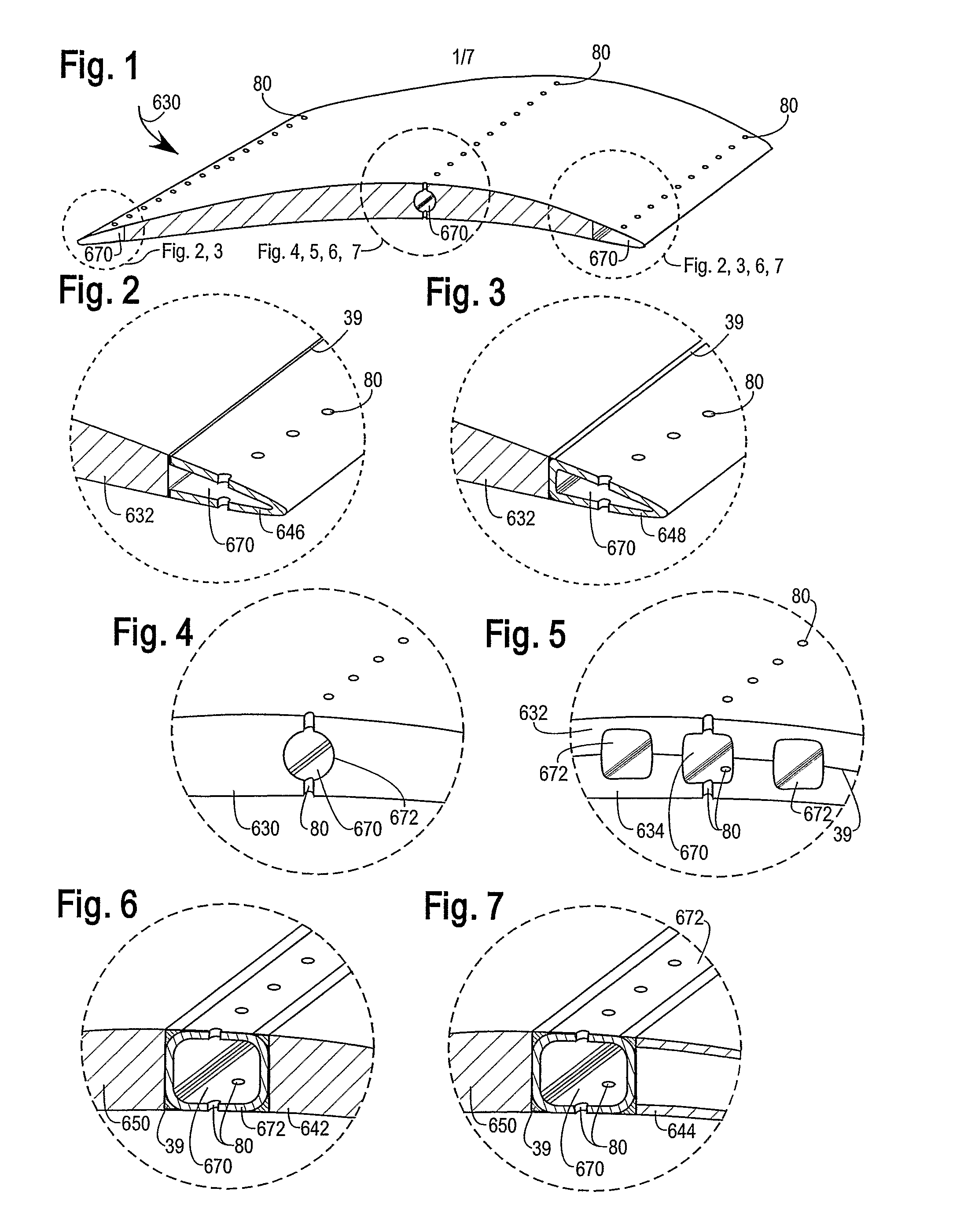

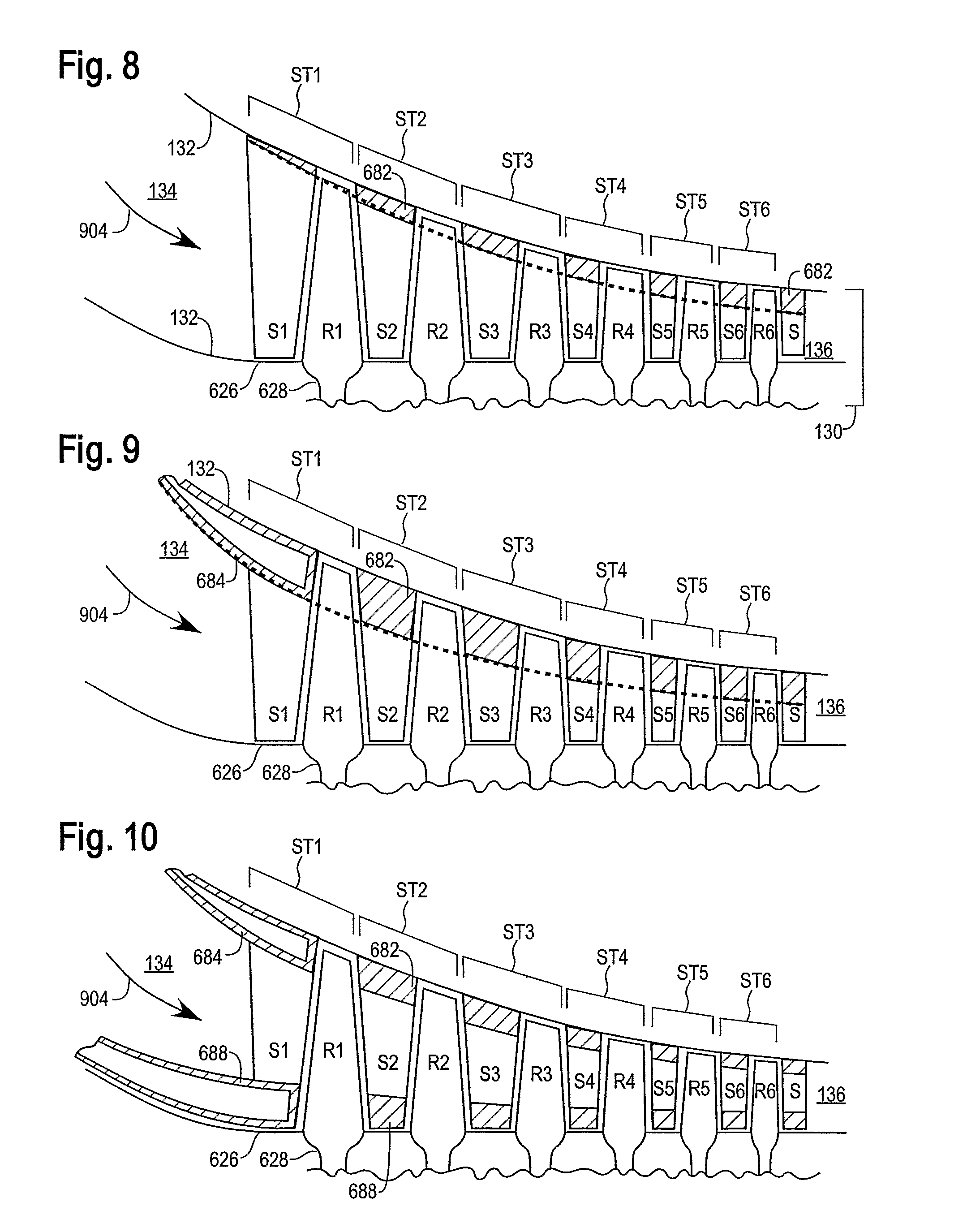

Wet compression apparatus and method

This wet compression invention with a vaporizable fluid mist demonstrates major performance improvements over the relevant art in achieving a high degree of saturation, providing sensible cooling, strongly reducing the temperature increase due to compression work, reducing excess diluent air flow for downstream combustion, reducing compression noise, and increasing the achievable compressor pressure ratio. These improvements are obtained by one or more of: high mist or overspray from a) progressive axial injection of vaporizable fluid along the streamwise compression flow path, and b) transverse vaporizable fluid delivery from stators, rotors, perforated tubes, and / or duct walls, matching the gaseous fluid flow distribution across the compressor stream; c) reducing the compressor cross-sectional flow area of downstream compressor stages relative to up-stream stages, and d) increasing the rate of downstream vaporizable fluid injection relative to the rate of upstream injection, as a function of each compressor stage pressure ratio.

Owner:VAST HLDG LLC

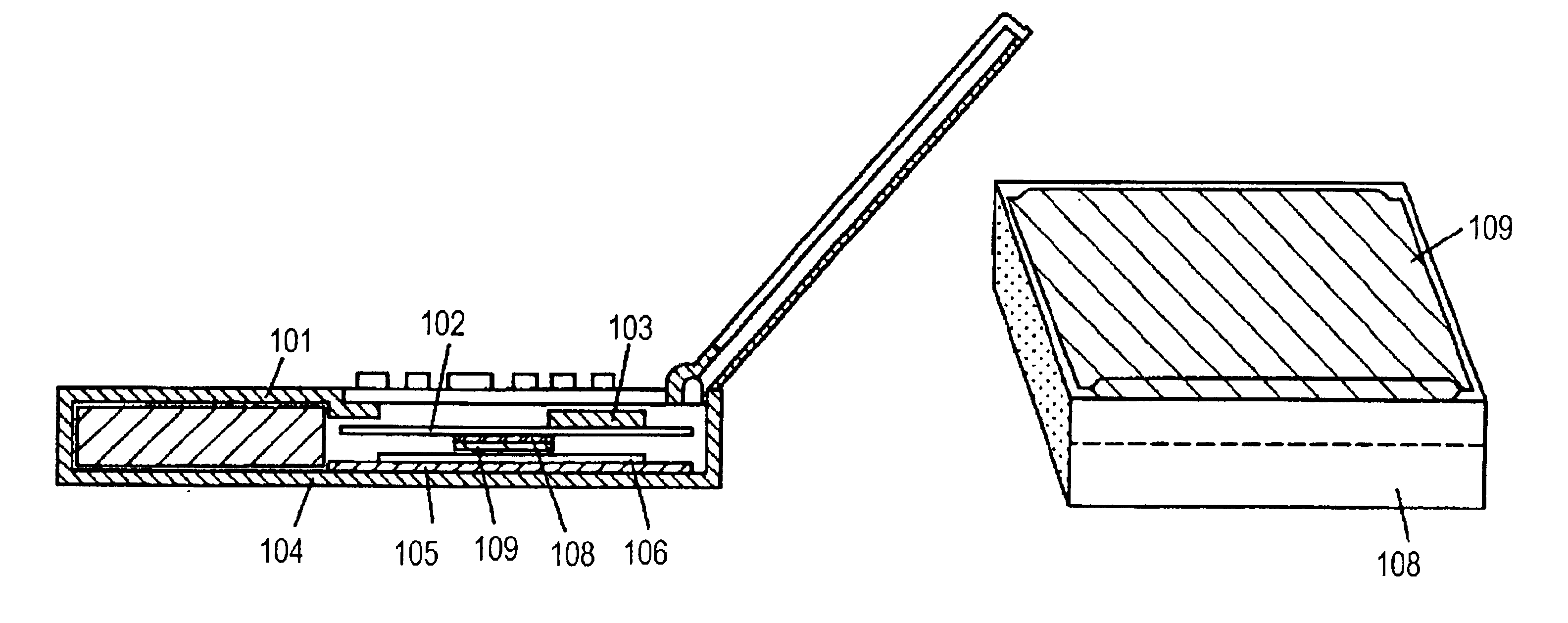

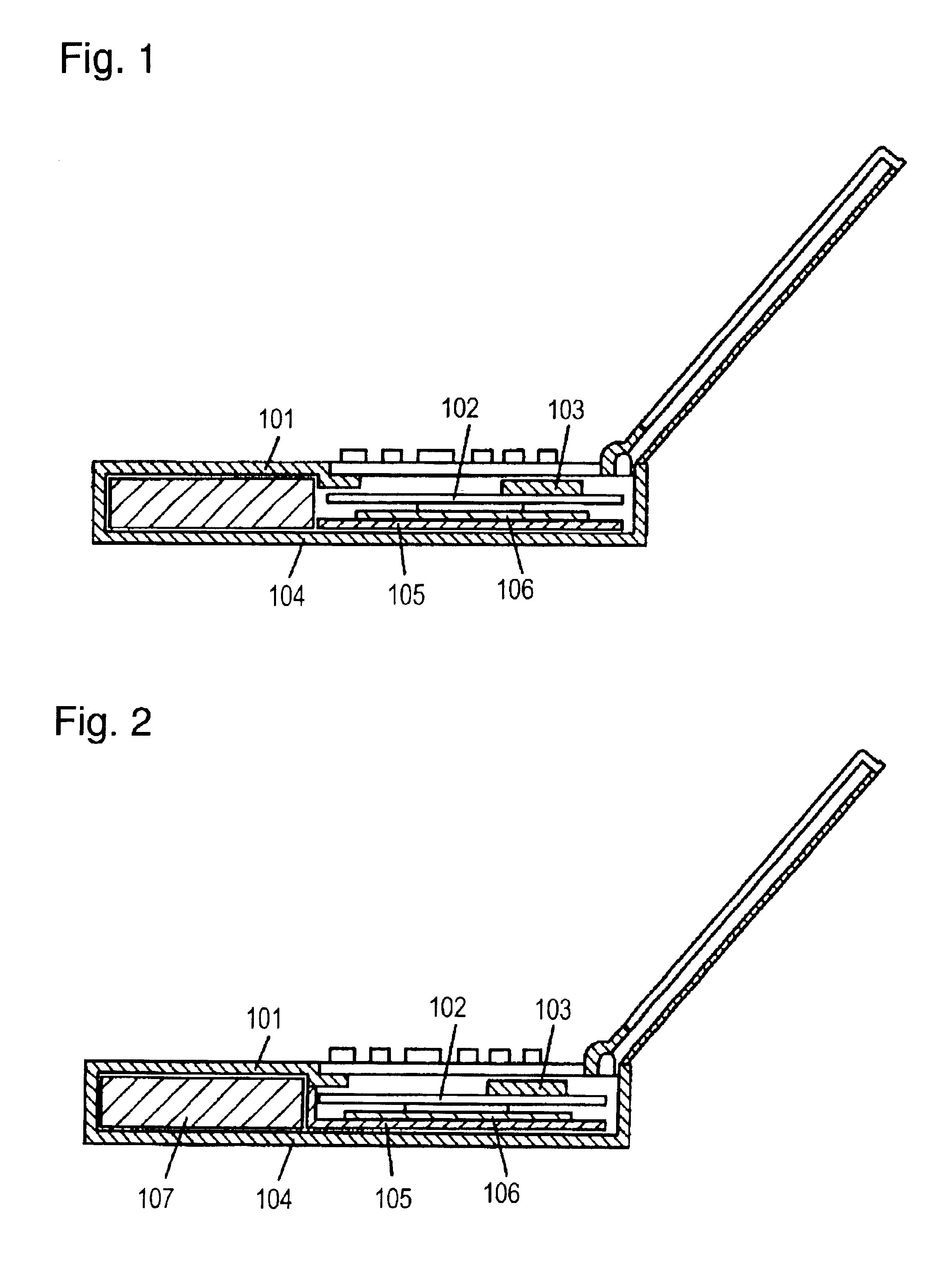

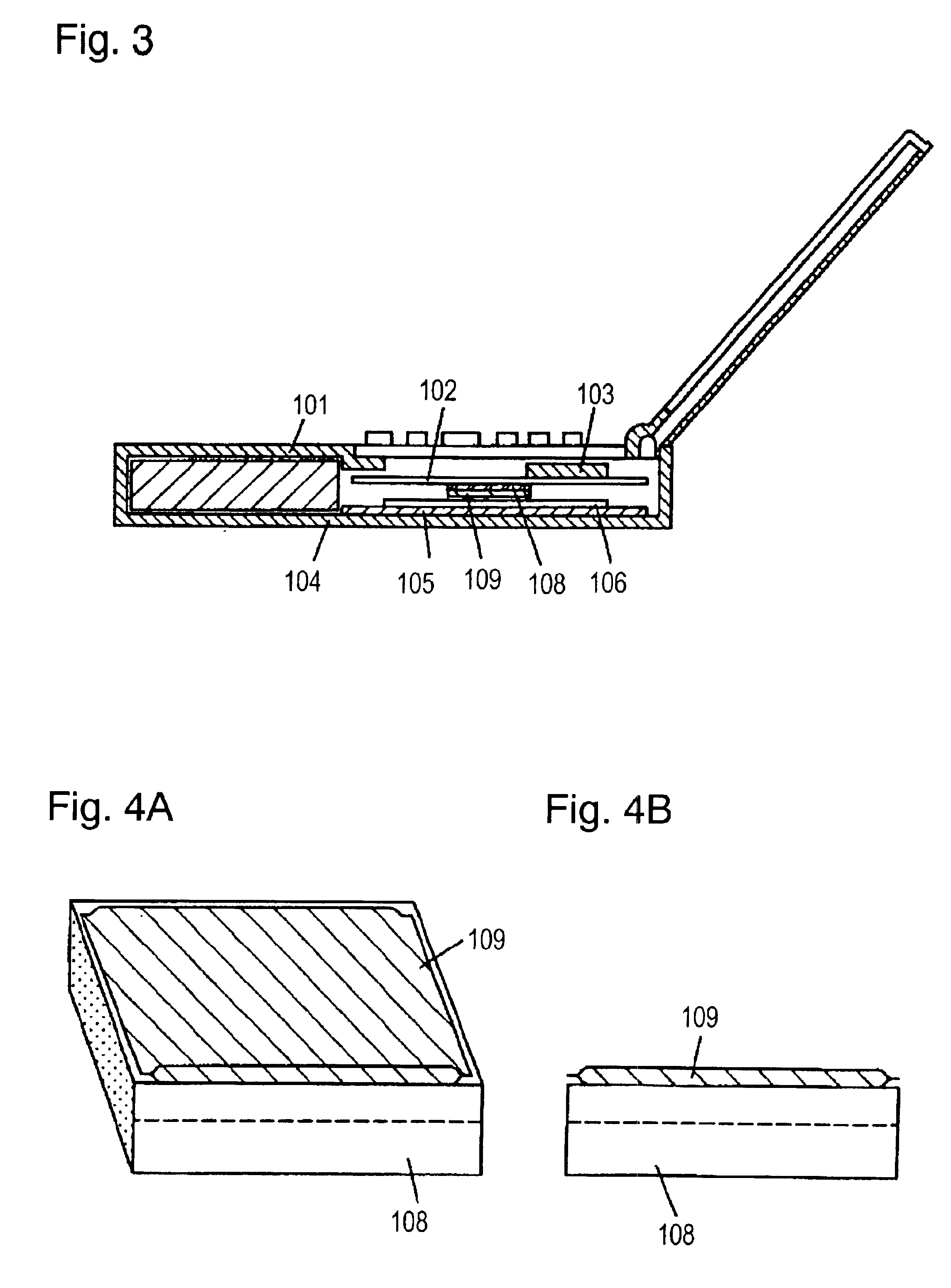

Portable information appliance

InactiveUS6859364B2Inhibit temperature riseNot to give uncomfortable feelingBiocideDomestic cooling apparatusFiberInformation device

A portable information device such as a notebook type computer is provided with a highly efficient thermal insulator capable of blocking transfer of heat between an internal heating component and a device enclosure, so as to reduce temperature rise on a surface of the device. The portable information device is also provided with a highly efficient thermal insulator to block transfer of heat between the heating component and an expansion unit mounting case, thereby reducing temperature rise and preventing malfunction of an external expansion unit. The information device includes the thermal insulator to separate between the internal heating component and the device enclosure, another thermal insulator to separate between the heating component and the expansion unit mounting case, and a heat sink. The thermal insulator is a vacuum thermal insulator including inorganic fiber as a core member.

Owner:PANASONIC CORP

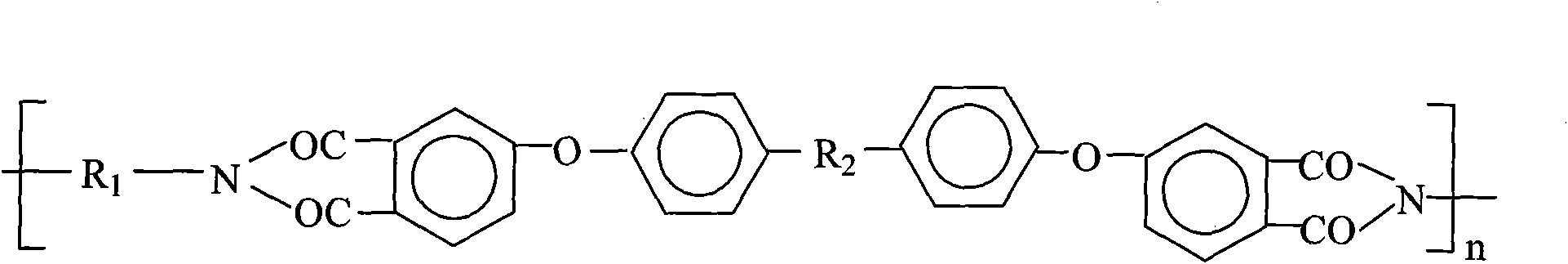

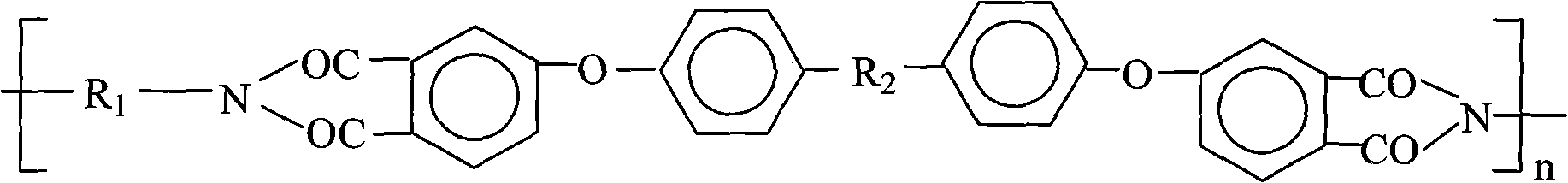

Polyimide film with high visible light permeability and preparation thereof

The invention related to a polyimide film with high visible light permeability, molecular structure formula of which is: (shown in figure). Preparation comprises steps of: dissolving primary diamine in a strongly polarnon-proton solvent, cooling the same by cold water to 5 DEG. C to 10 DEG. C, adding aromatic dianhydride, mixing, reacting 4h to 10h at 5 DEG. C to 10 DEG. C, acquiring homogeneous, transparent, sticky polyamic acid resin solution; wherein mol number of aromatic dianhydride is equal to that of primary diamine; adjusting viscosity of polyamic acid resin solution by N,N-dimethyl acetamide, forming film in a casting machine, heating to raise temperature, processing dehydration heat imidization, cooling, deciduating to acquire homogeneous and transparent polyimide thin film. The preparation method has mild reaction condition, sample to operate, low in cost and environmental friendly; mechanical property and thermal stability of the polyimide thin film are excellent with high visible light permeability reaching 94% and film thickness 50 micrometers.

Owner:DONGHUA UNIV +1

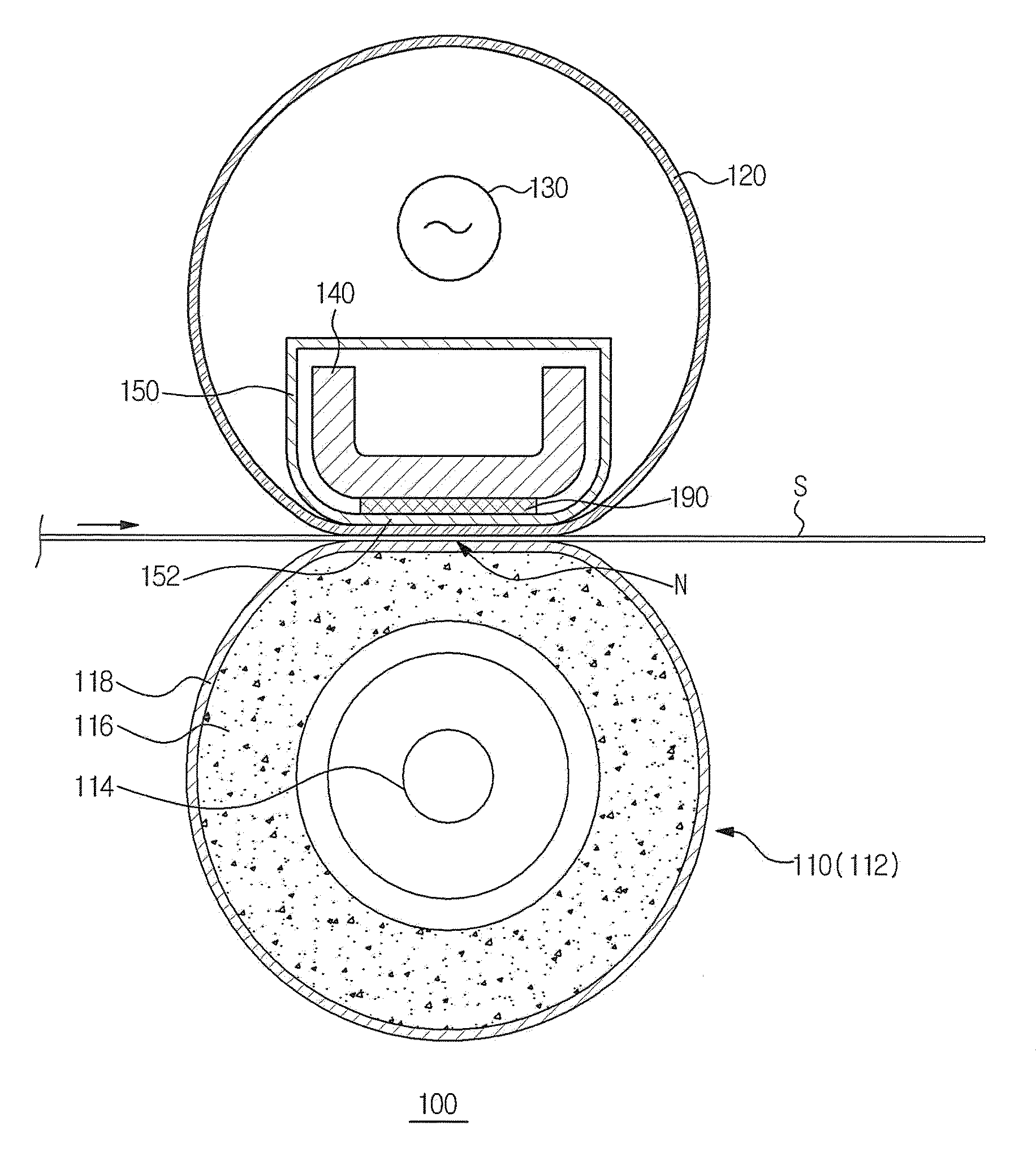

Fusing device and image forming apparatus having the same

Disclosed are a fusing device with improved temperature increase and fusing performance characteristics and an image forming apparatus having the same. The fusing device can include a heater to generate heat, a fusing belt arranged around the heater, a rotating member, a press member and a heat shield unit. The rotating member may be configured to come into contact with an outer periphery of the fusing belt. The press member may be configured to be press a portion of the fusing belt toward the rotating member to define a fusing nip between the fusing belt and the rotating member. The heat shield unit configured to surround the press member to reduce the amount of heat delivered to the press member.

Owner:HEWLETT PACKARD DEV CO LP

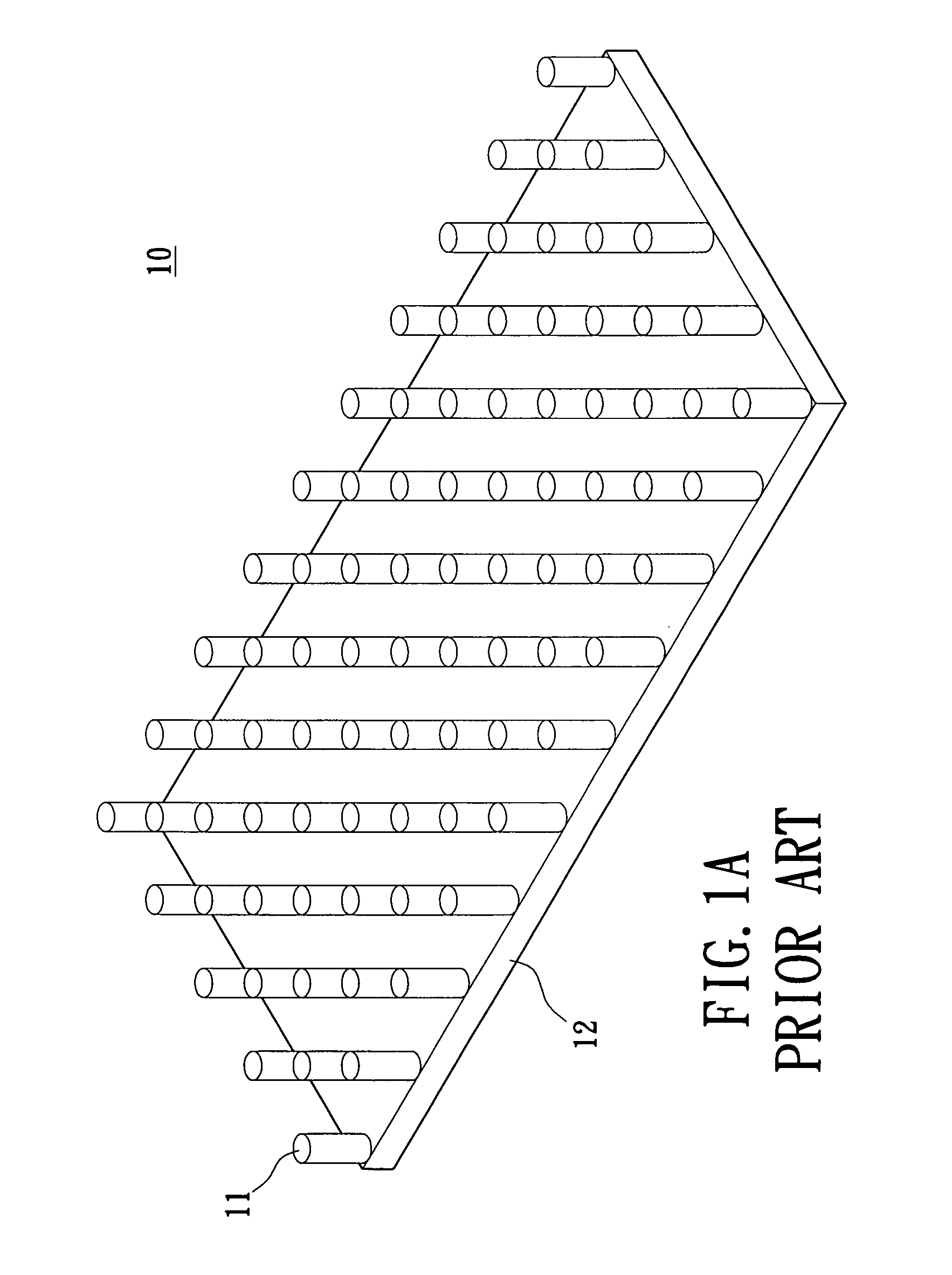

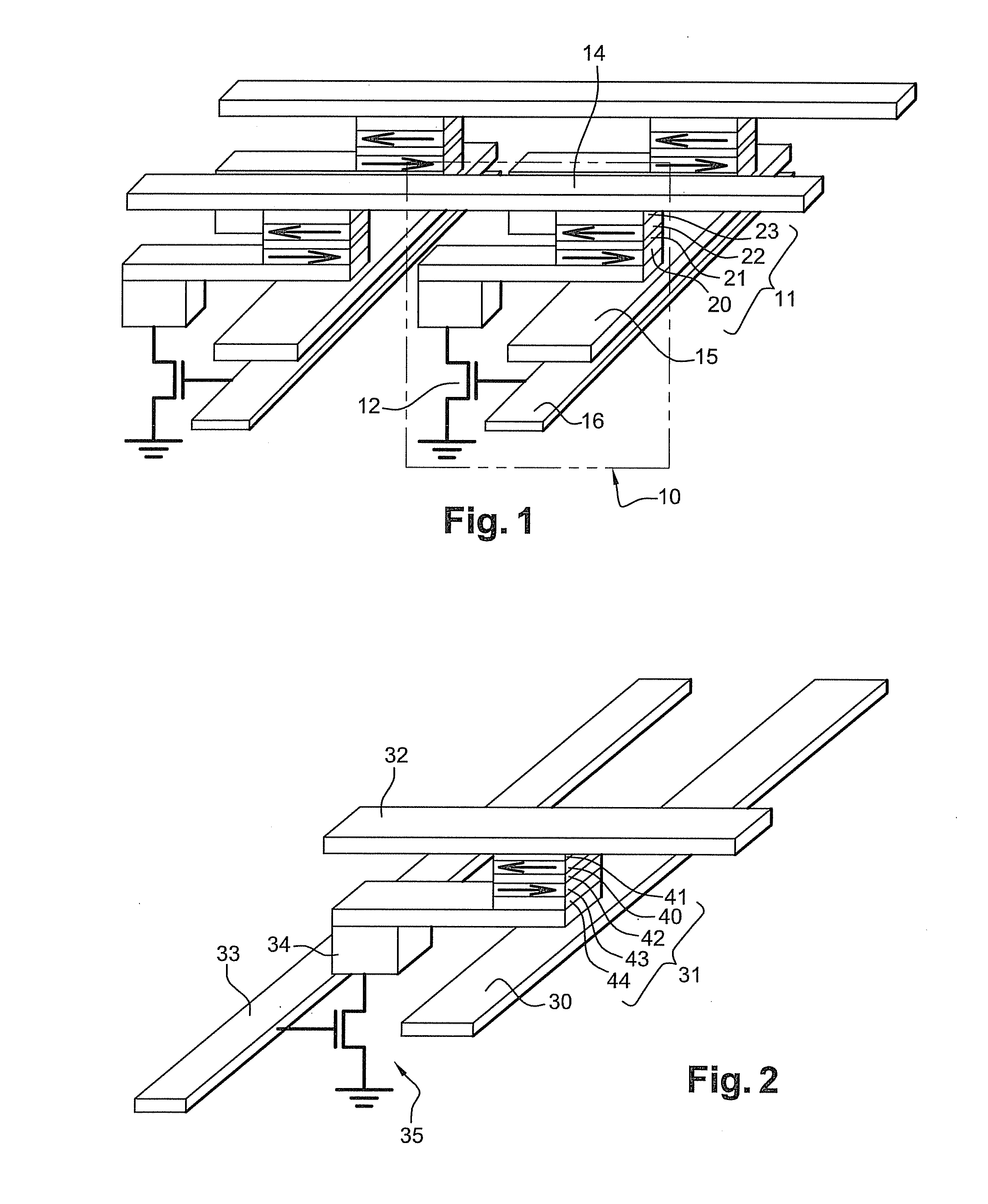

Heat assisted magnetic write element

ActiveUS20110044099A1Maximizing the magnetic torqueHigh torqueNanomagnetismMagnetic-field-controlled resistorsStable stateSpin transfer

This magnetic element for writing by magnetic field or heat assisted spin transfer comprises a stack consisting of:a free magnetic layer, also called storage layer or switchable magnetization layer (51), of which the magnetization direction is switchable between two nonwrite stable states, both directed out-of-plane and substantially perpendicular to the plane of said layer, and of which the magnetization is spontaneously reoriented from substantially perpendicular to the plane to substantially in the plane under the effect of the rise in temperature during the writing;at least one reference magnetic layer (50, 55), called pinned layer, of which the magnetization is oriented substantially perpendicular to the plane of said layer;a nonmagnetic spacer (52) inserted between the two layers;means for making an electric current flow perpendicular to the plane of said layers.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

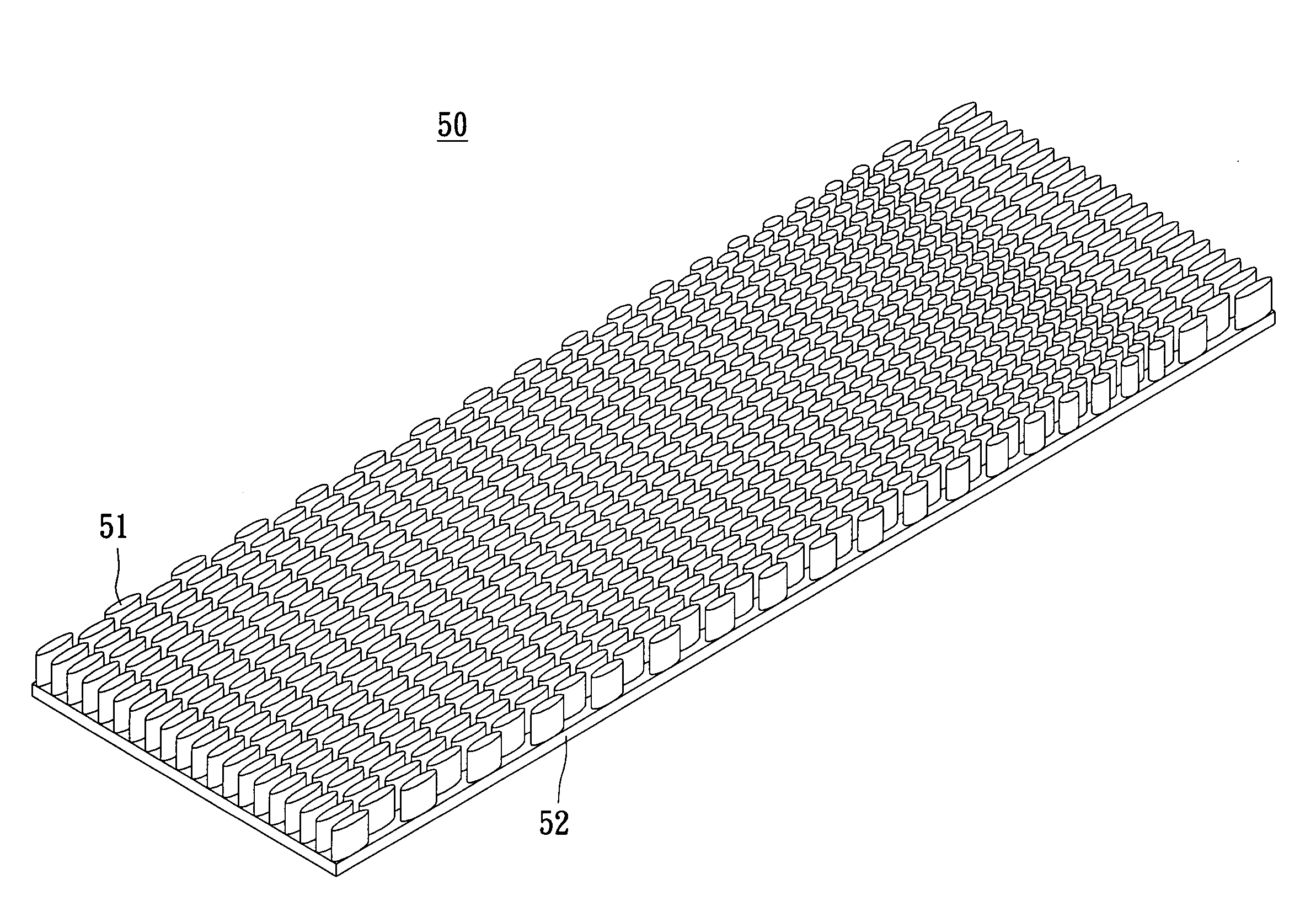

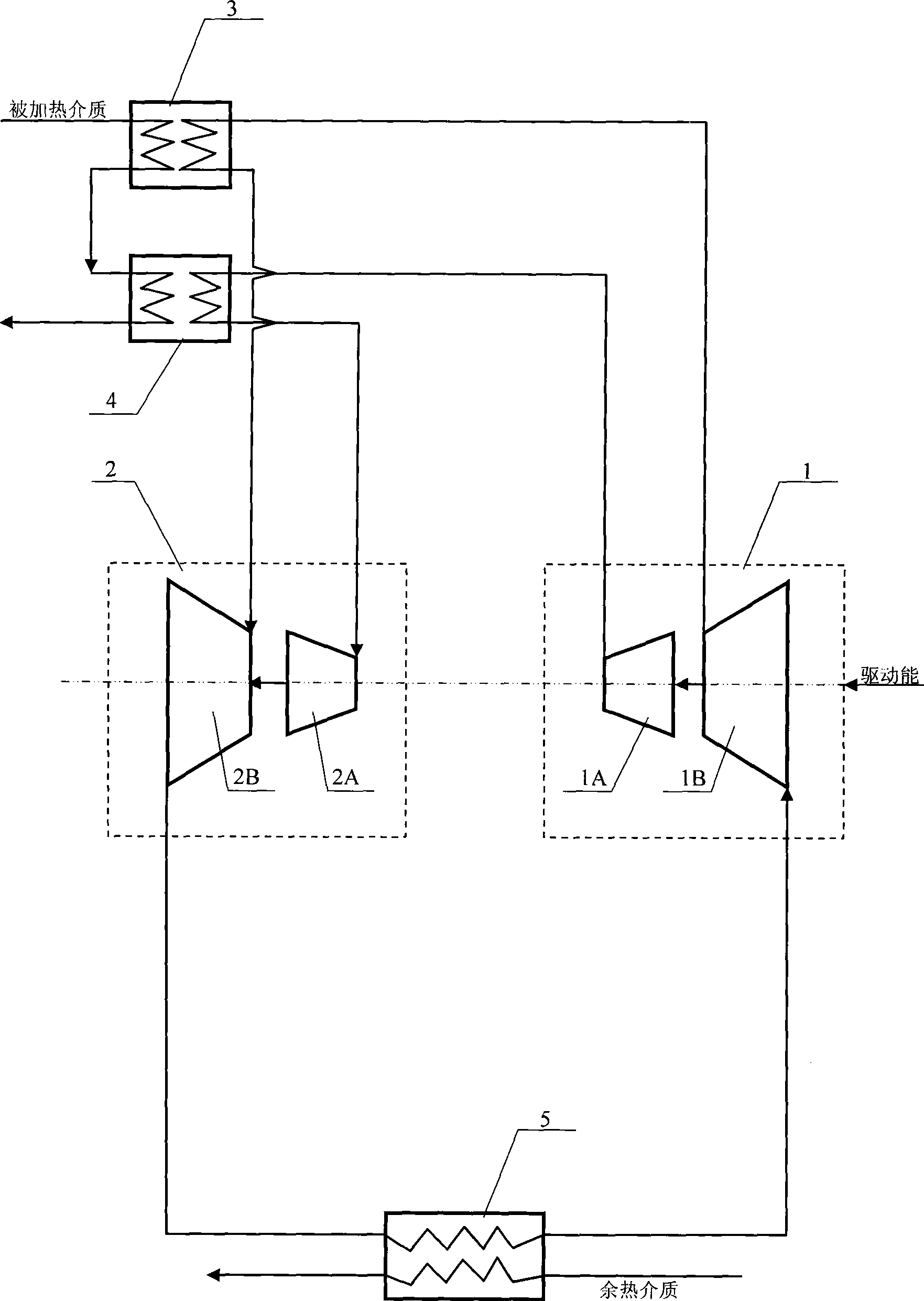

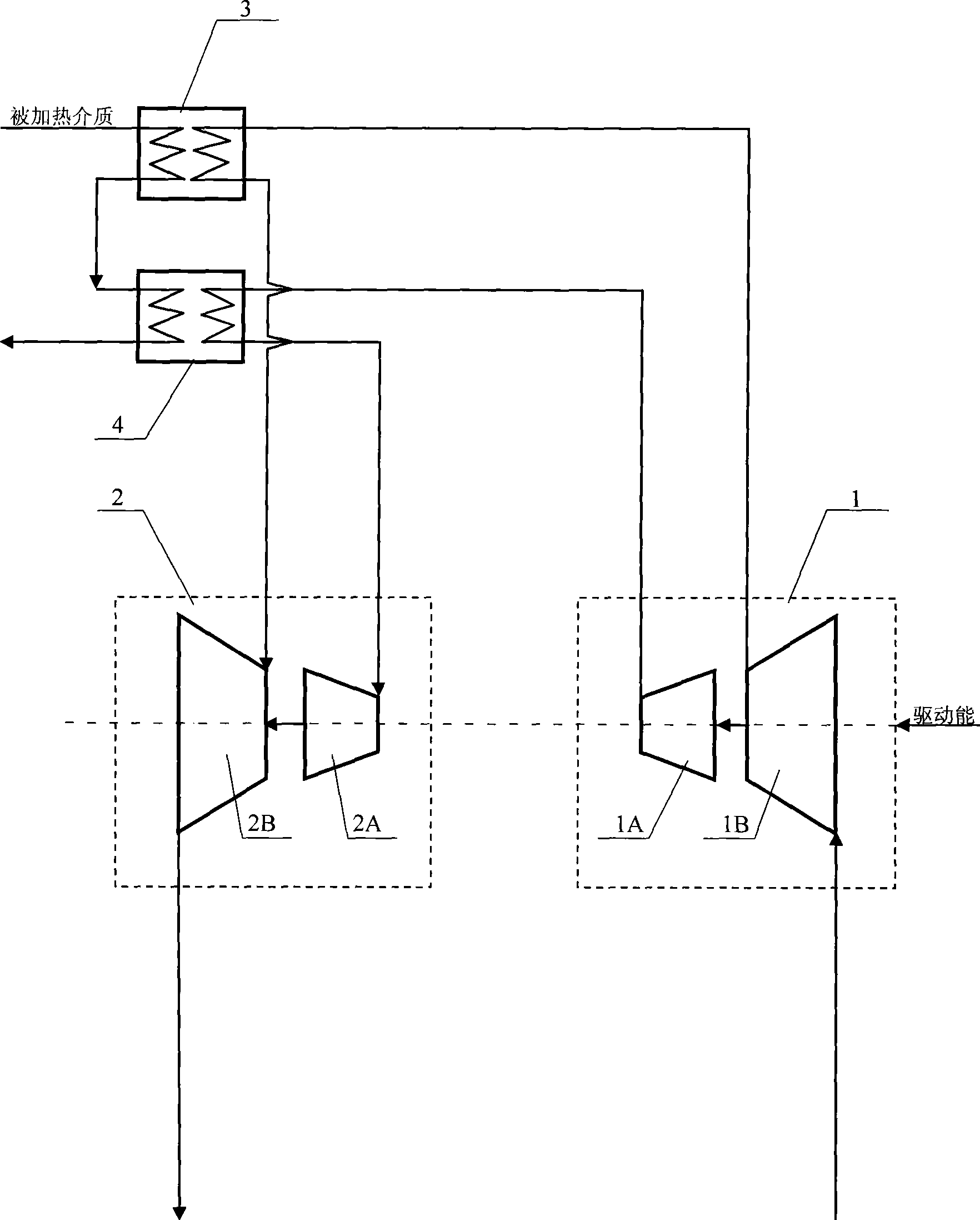

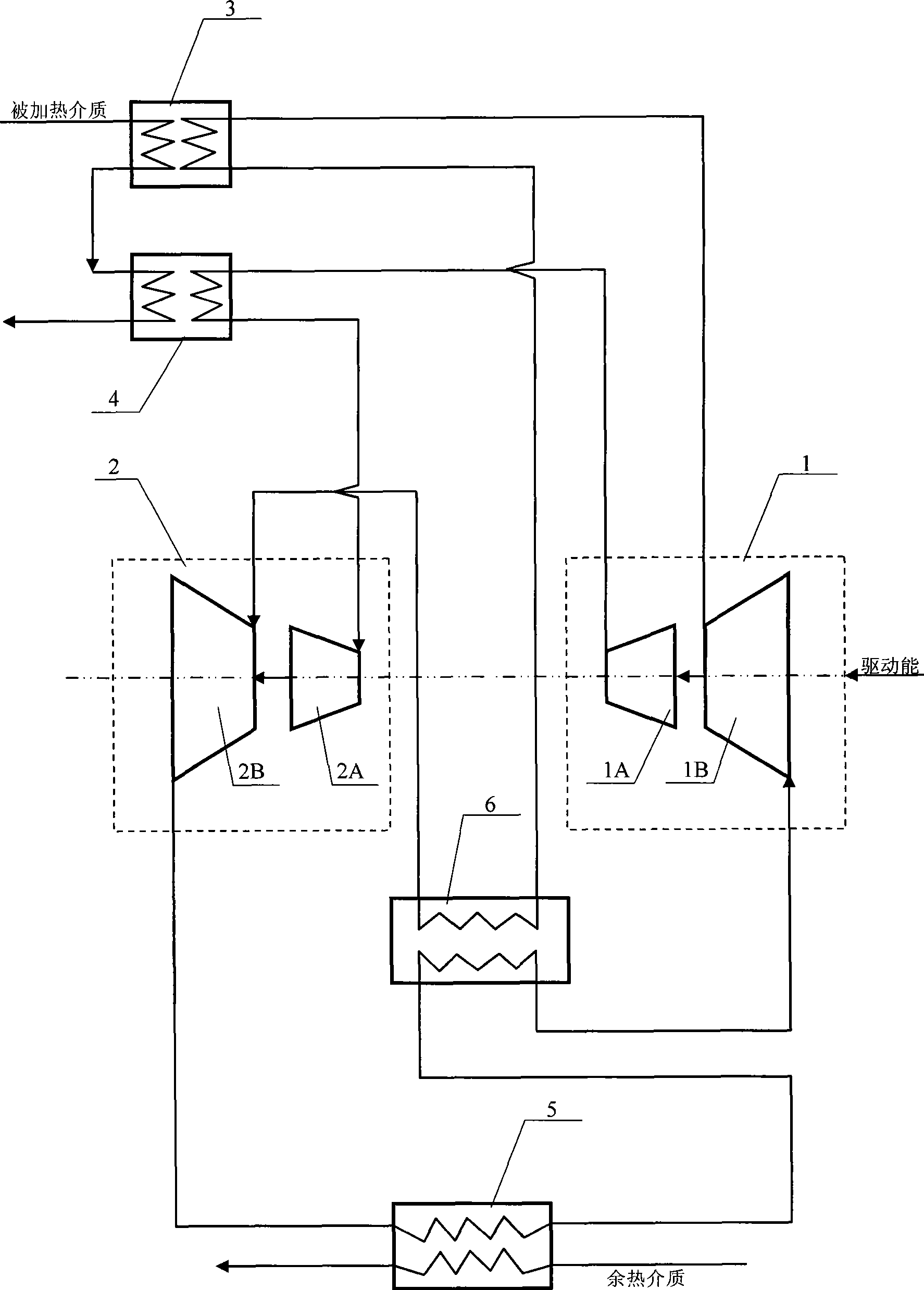

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

Thermally operated switch control memory cell

Owner:NVE CORP

Scalable high-k dielectric gate stack

InactiveUS20090108294A1Inhibited DiffusionAmenable to scalingTransistorSemiconductor/solid-state device manufacturingDielectricGate dielectric

A stack comprising a dielectric interface layer, a high-k gate dielectric layer, a group IIA / IIIB element layer is formed in that order on a semiconductor substrate. A metal aluminum nitride layer and, optionally, a semiconductor layer are formed on the stack. The stack is annealed at a raised temperature, e.g., at about 1,000° C. so that the materials in the stack are mixed to form a mixed high-k gate dielectric layer. The mixed high-k gate dielectric layer is doped with a group IIA / IIIB element and aluminum, and has a lower effective oxide thickness (EOT) than a conventional gate stack containing no aluminum. The inventive mixed high-k gate dielectric layer is amenable to EOT scaling due to the absence of a dielectric interface layer, which is caused by scavenging, i.e. consumption of any dielectric interface layer, by the IIA / IIB elements and aluminum.

Owner:SONY CORP +2

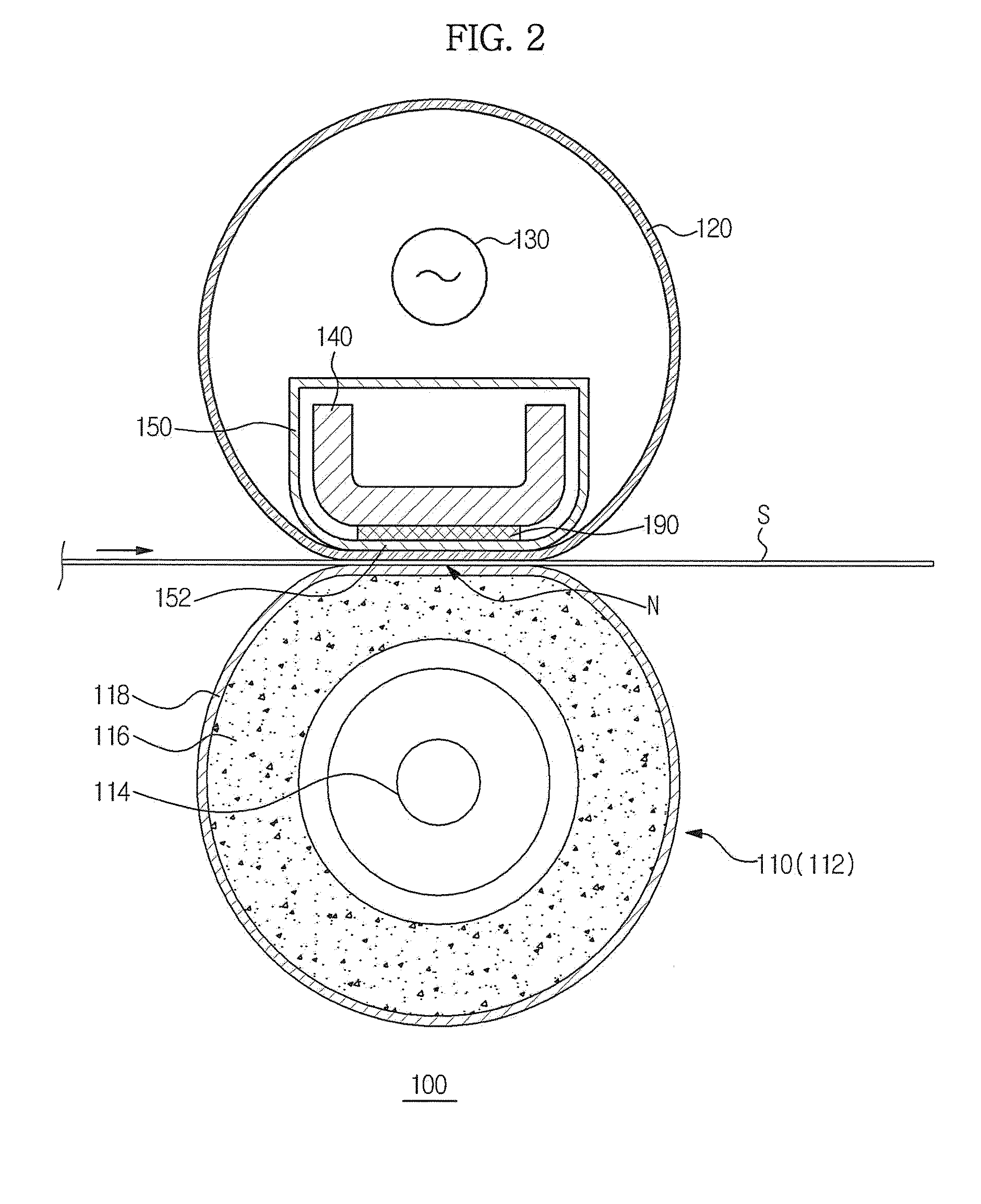

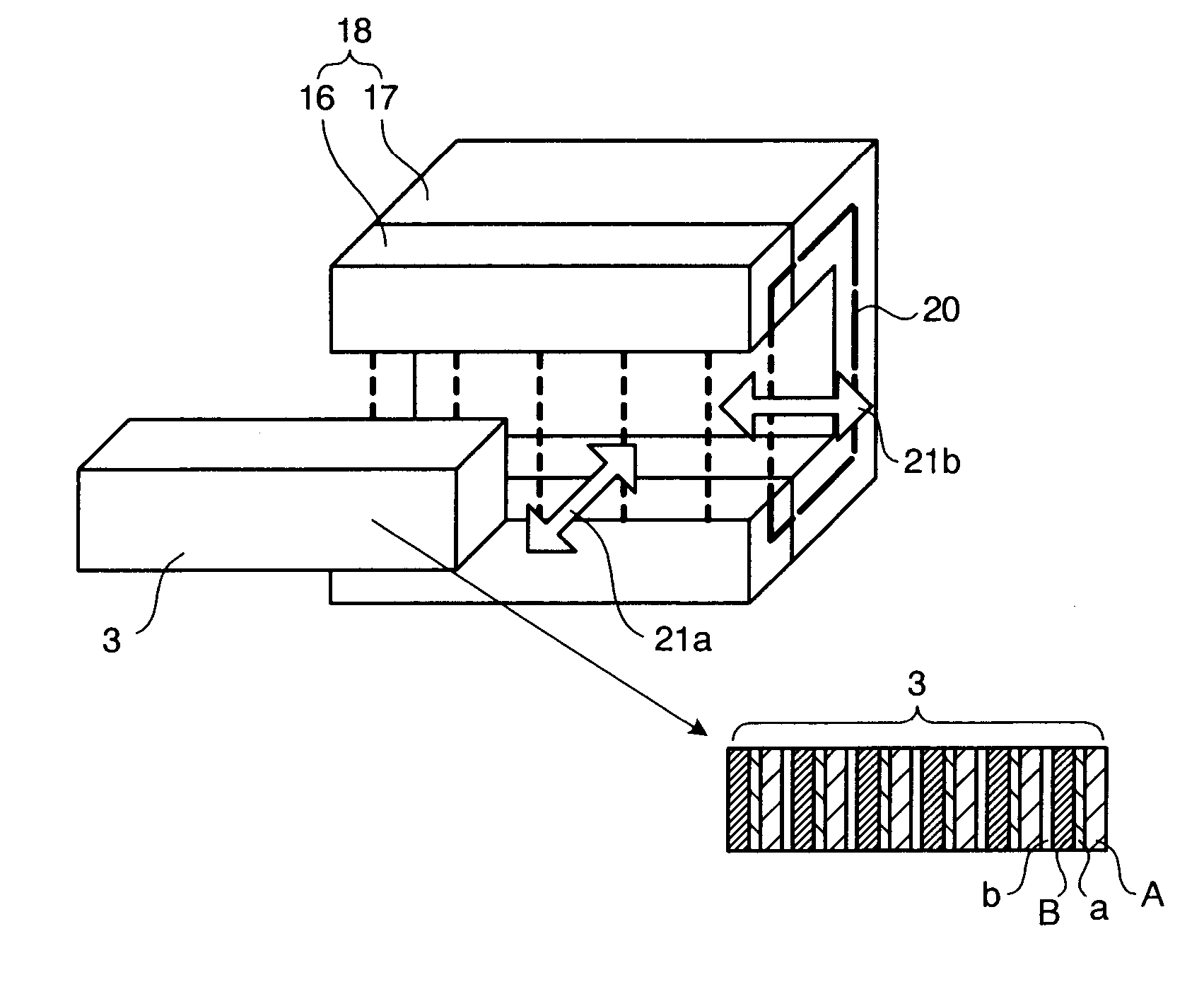

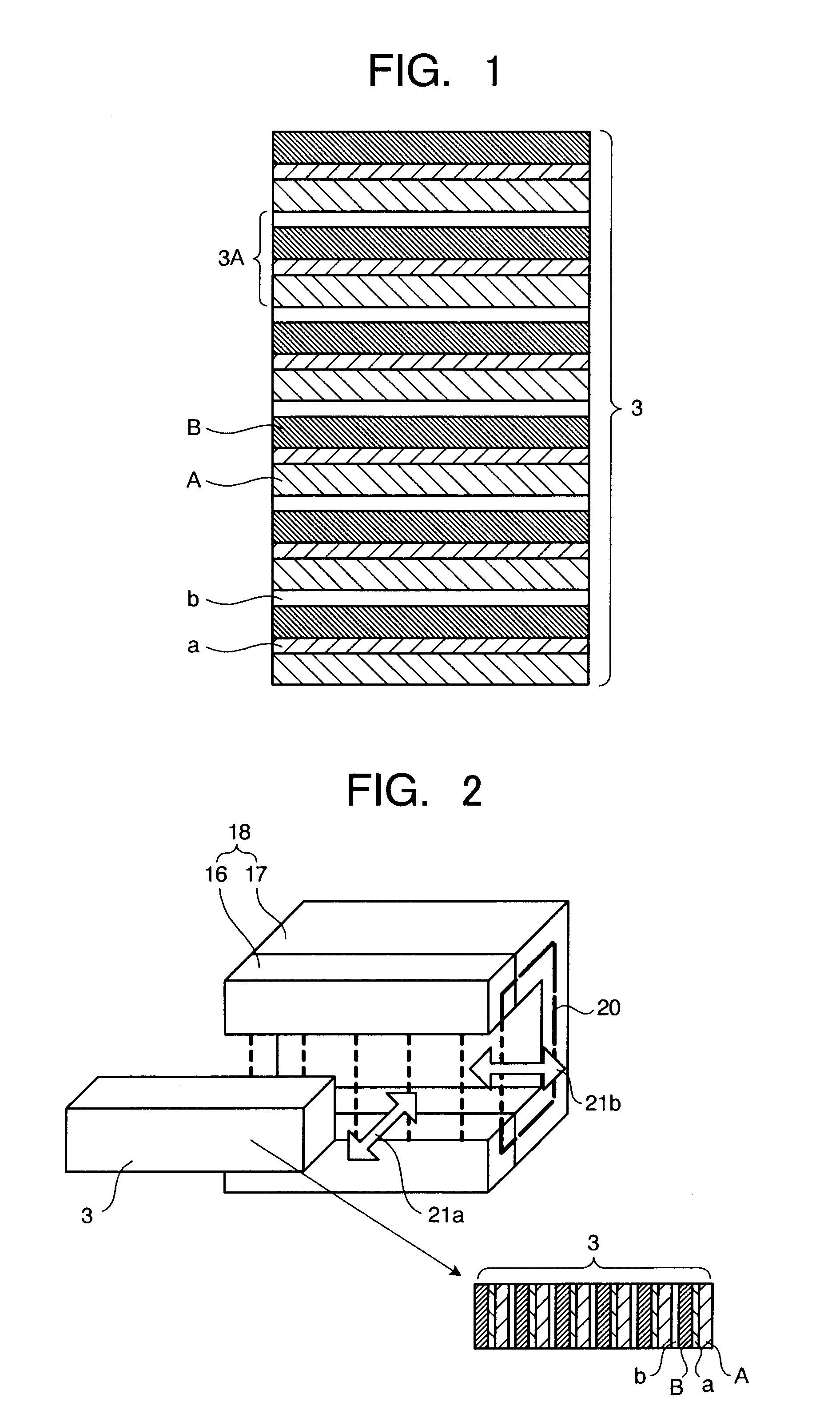

Magnetic refrigerating device and magnetic refrigerating method

ActiveUS20080078184A1Easy to optimizeReduce energy loadEnergy efficient heating/coolingPermanent magnetsConductive materialsMagneto

A magnetic refrigerating device includes: a magnetic refrigerating unit including a magnetic material “A” exhibiting a magneto-caloric effect that the temperature of the material “A” is increased by the application of a magnetic field and the temperature of the material “A” is decreased by the removal of a magnetic field, a magnetic material “B” exhibiting a magneto-caloric effect that the temperature of the material “B” is decreased by the application of a magnetic field and the temperature of the material “B” is increased by the removal of a magnetic field, a heat conductive material “a” exhibiting higher heat conductivity under the application of a magnetic field and lower heat conductivity under the removal of a magnetic field, and a heat conductive material “b” exhibiting lower heat conductivity under the application of a magnetic field and higher heat conductivity under the removal of a magnetic field, wherein the magnetic refrigerating unit is configured so as to include at least one layered structure denoted by “AaBb” or “AbBa”; and a magnetic field-applying means to apply a magnetic field to the magnetic refrigerating unit.

Owner:KK TOSHIBA

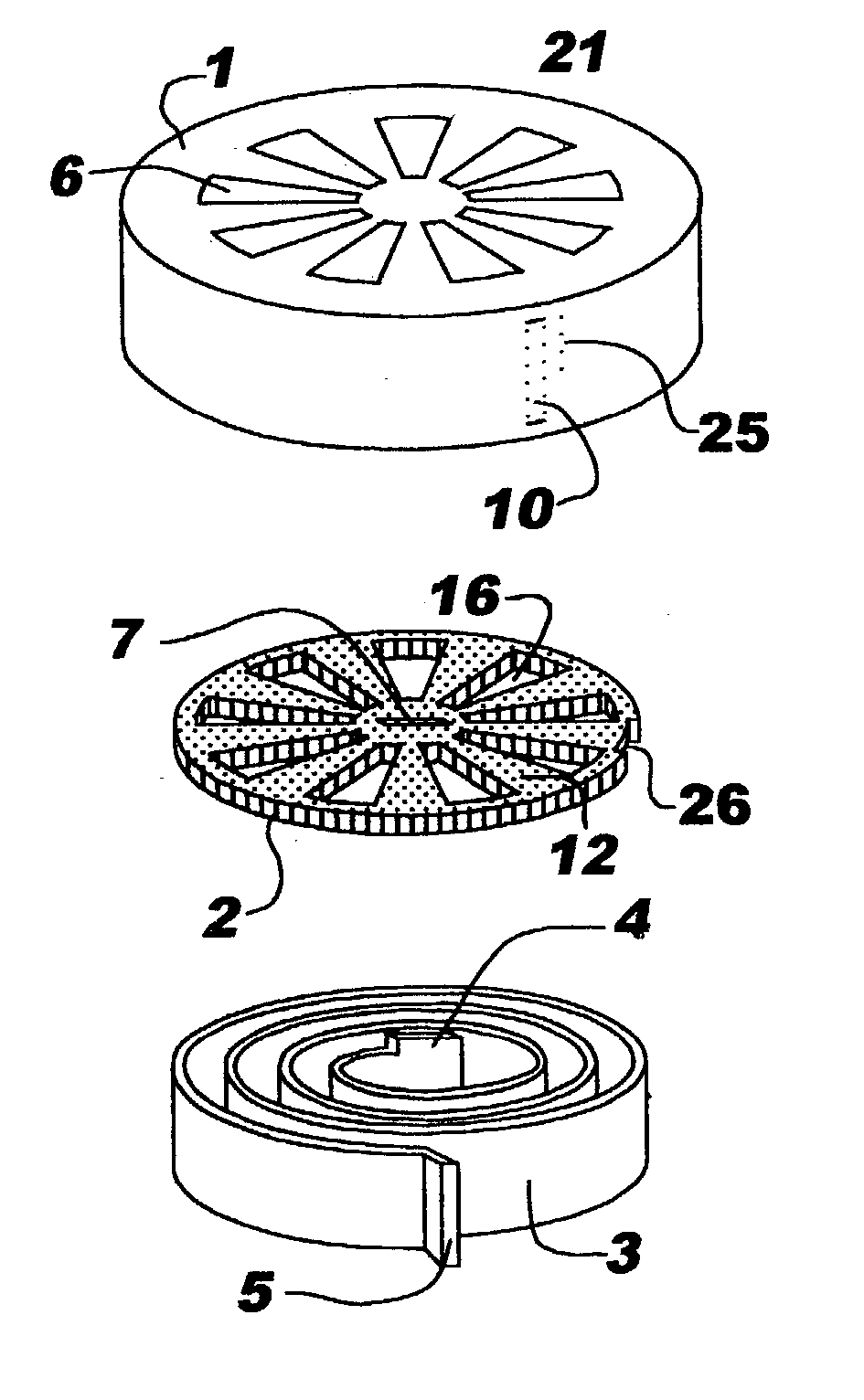

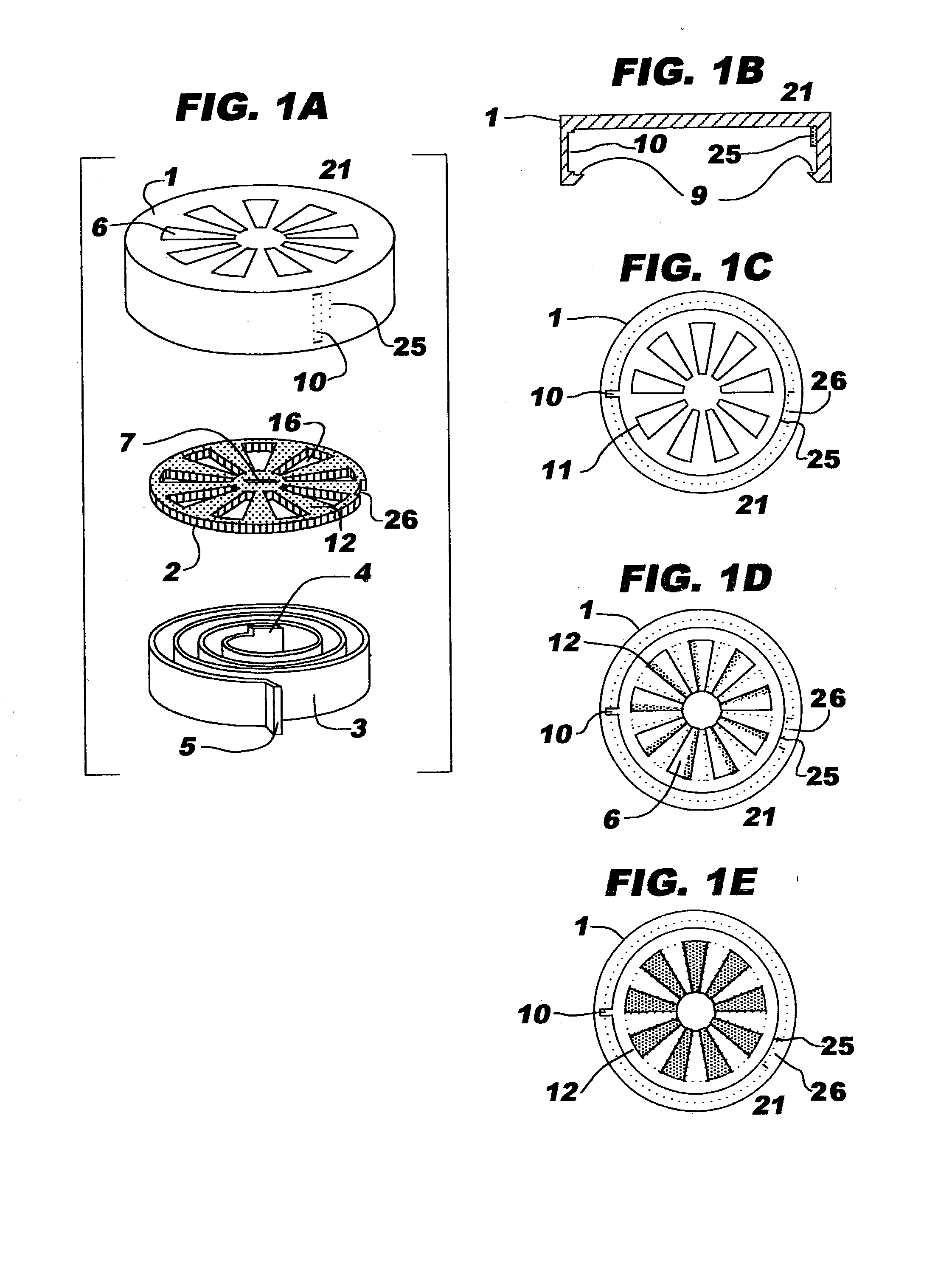

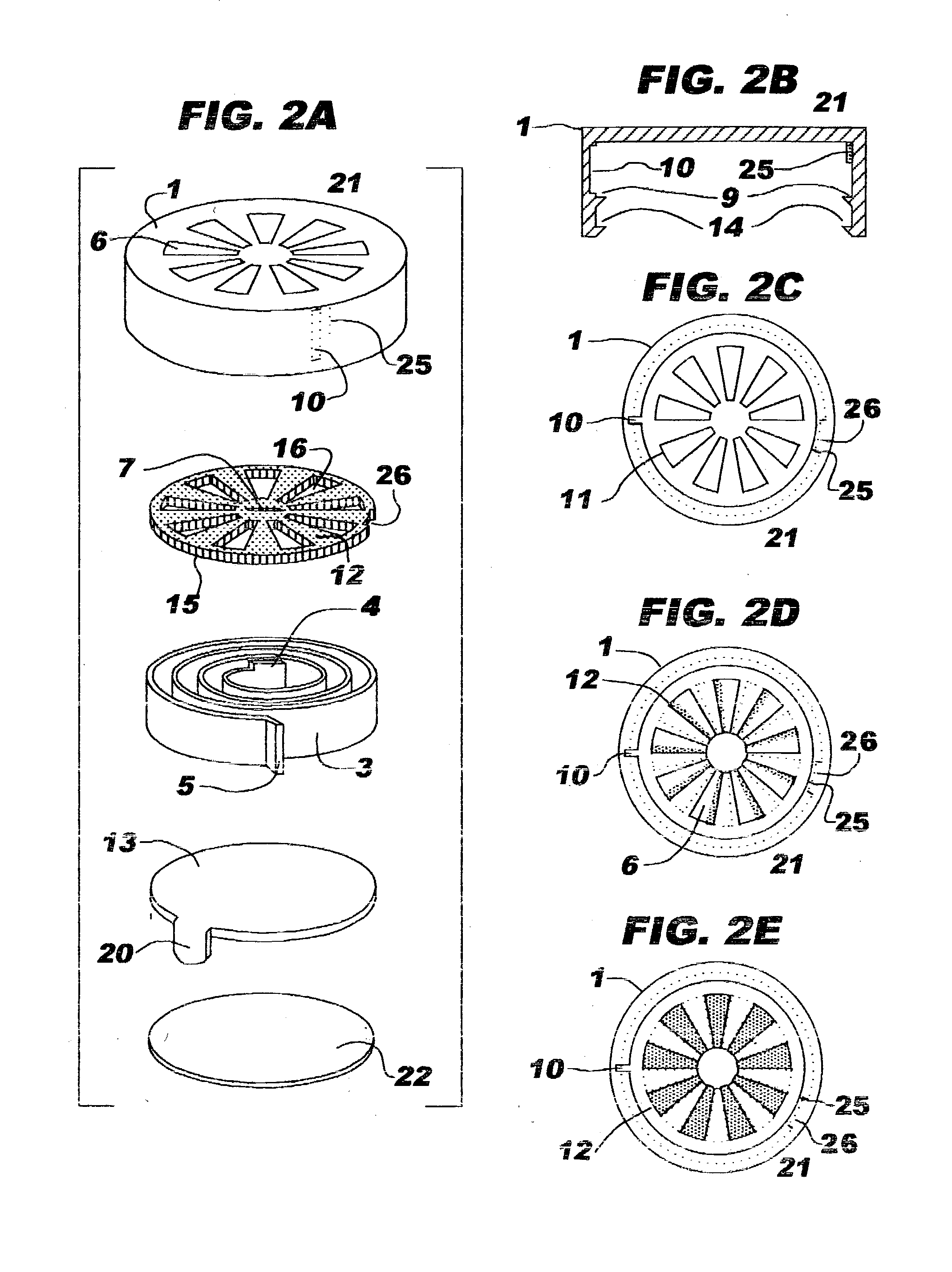

Automatically controlling the interaction of a medium with an external environment

InactiveUS20040003724A1Constant effectiveness of the medium in the external environmentTableware washing/rinsing machine detailsLighting and heating apparatusAutomatic controlEngineering

A device is presented which automatically controls the interaction of a medium with an external environment, the temperature of which varies or remains constant. In addition to the medium, the device includes a mechanism for providing constant effectiveness of the medium in the external environment, and an automatic drive mechanism which drives the mechanism for providing constant effectiveness of the medium in the external environment. Advantageously, the device includes a receptacle for the medium, and the receptacle includes a housing incorporating the mechanism for providing constant effectiveness of the medium in the external environment, which is beneficially a movable vent or an expandable vent. The automatic drive mechanism is advantageously a temperature-responsive member or a temperature-responsive fluid movement device. The temperature-responsive member, which manifests variations in the surface area thereof as the temperature thereof is raised, is beneficially one of the following: a linear spring, a spiral metallic spring, a multi-metallic spring, a polymeric spring, or a pop spring. A preferred embodiment of the device includes at least one static vent positioned within the housing in alignment with at least one movable vent positioned therein, and the at least one movable vent is driven by the automatic drive mechanism to move in relation to the at least one static vent, thereby providing constant effectiveness of the medium in the external environment by affording varying exposure thereof as the temperature of the external environment varies.

Owner:ELLIS EARLE R

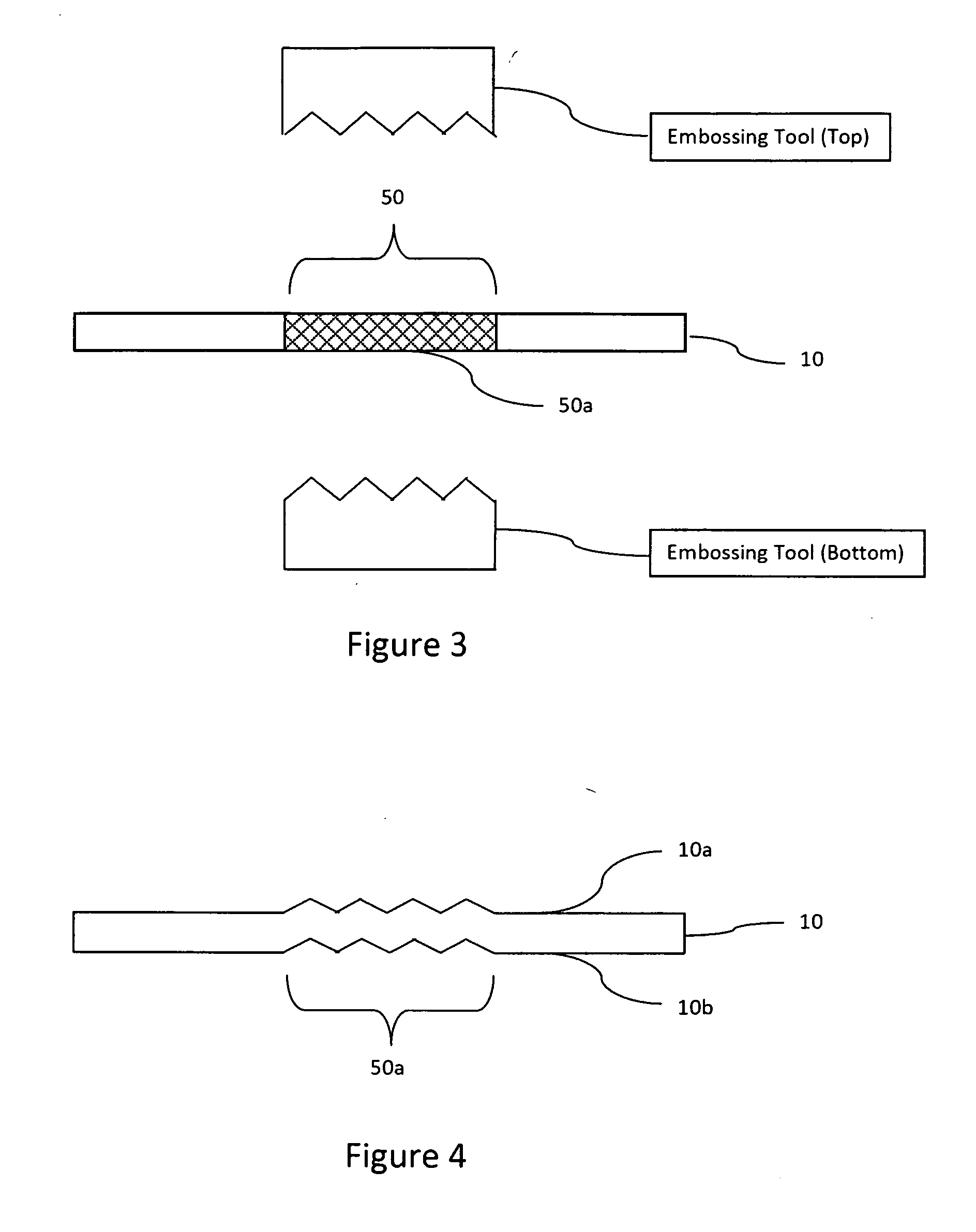

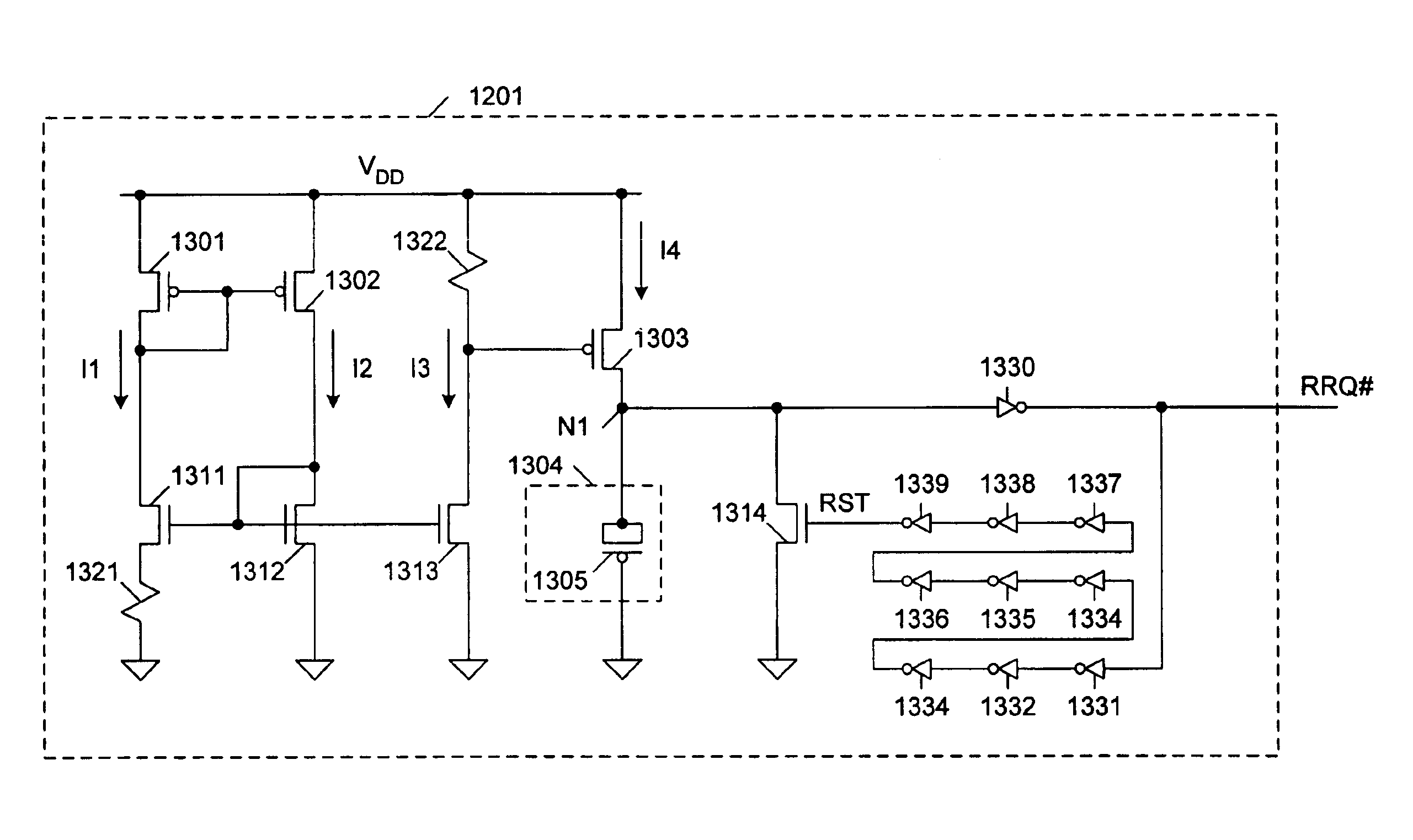

Metal card

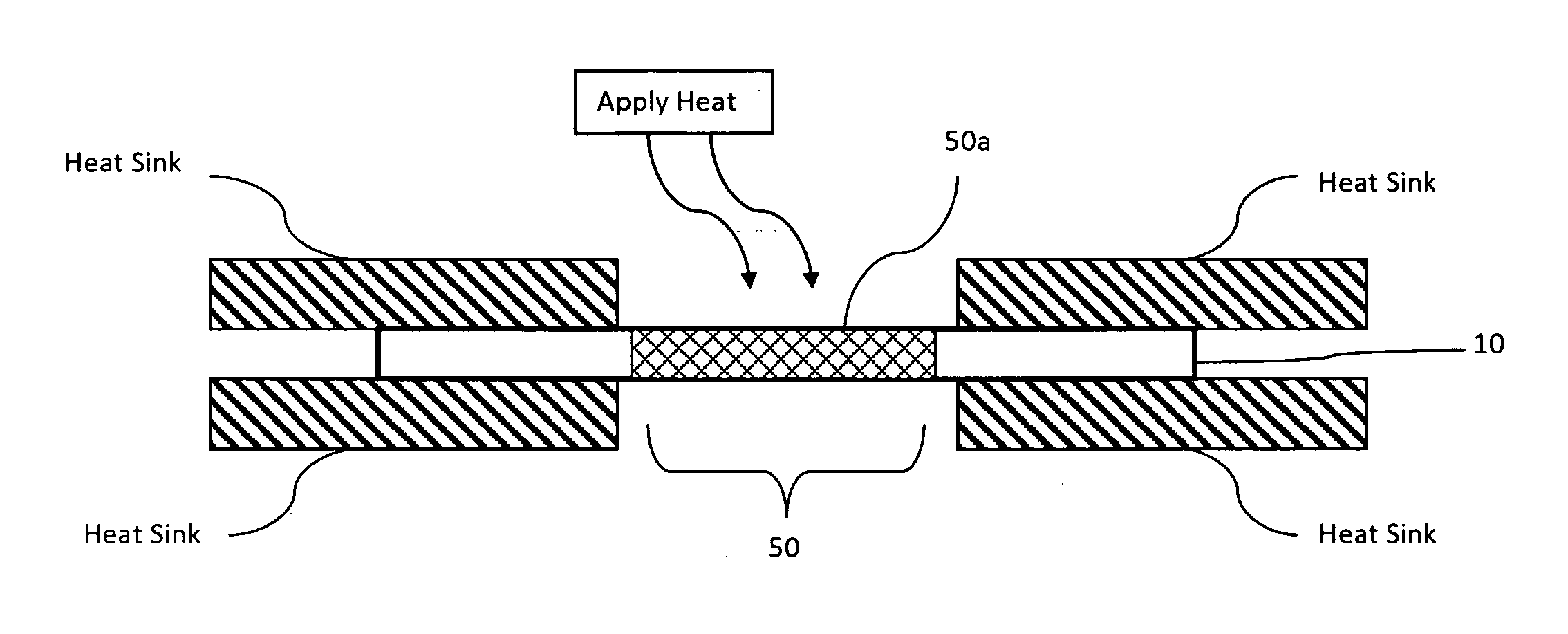

ActiveUS20110189620A1Easy embossingSimple equipmentOther heat production devicesCharge manipulationMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

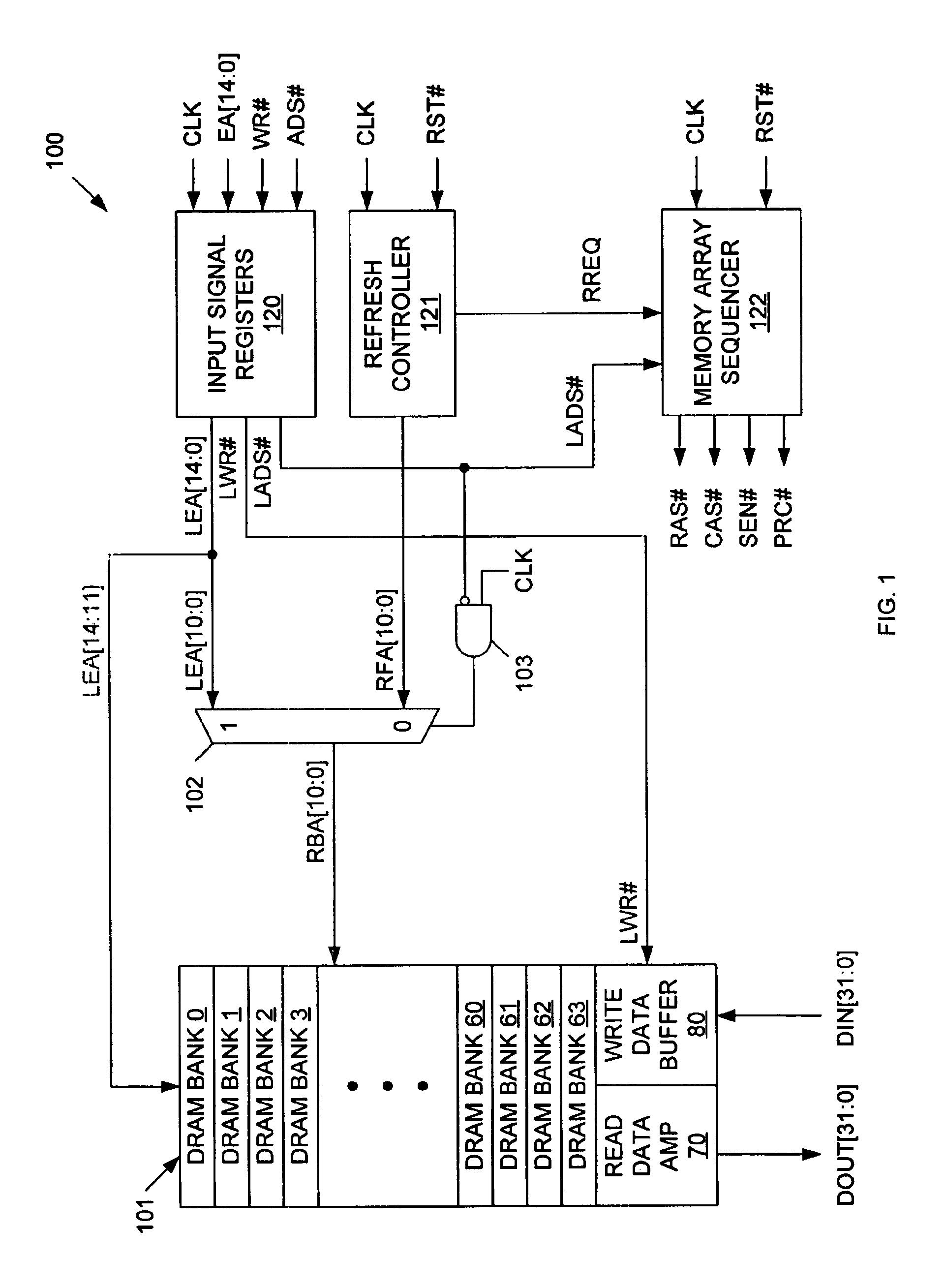

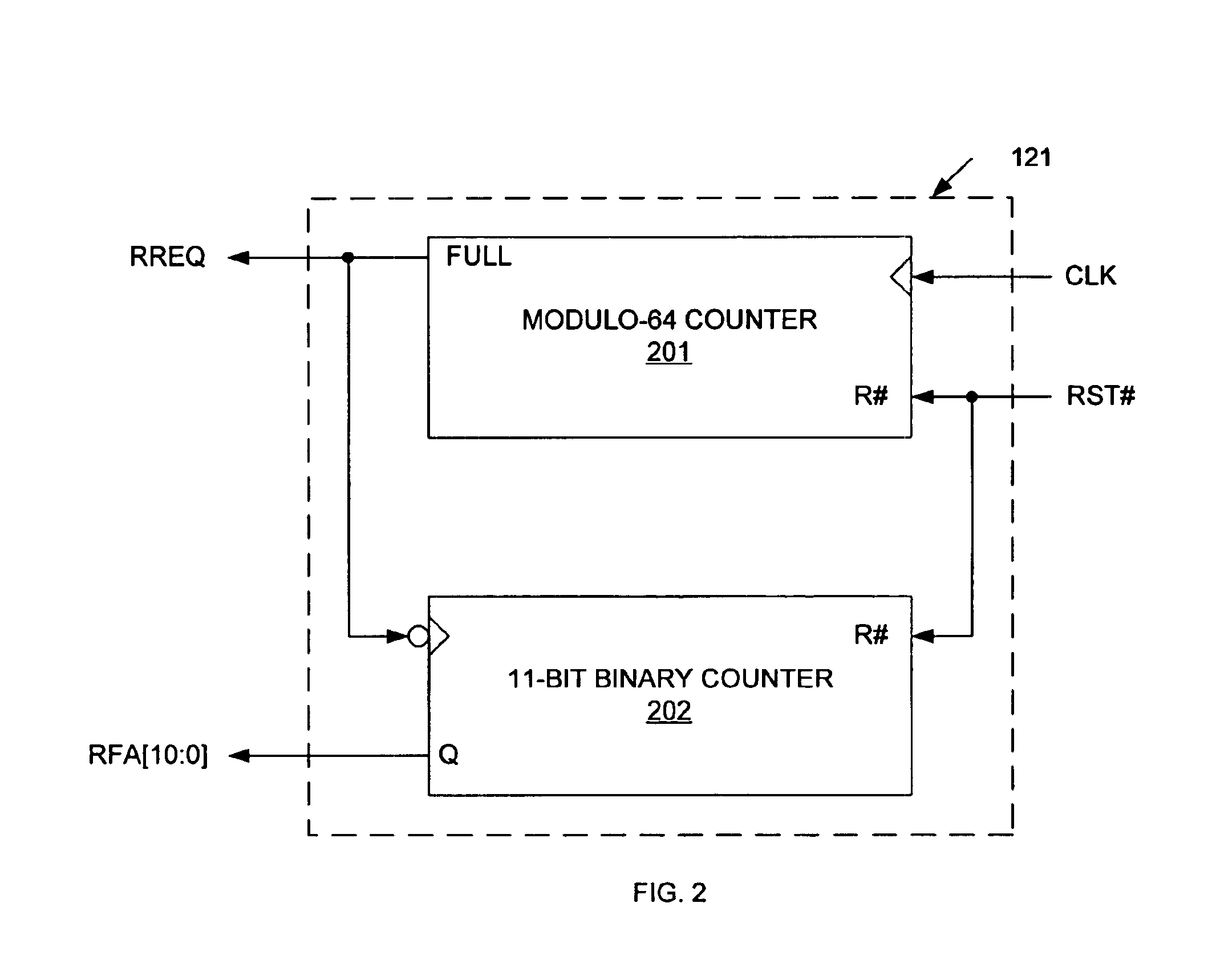

Method and apparatus for temperature adaptive refresh in 1T-SRAM compatible memory using the subthreshold characteristics of MOSFET transistors

A memory system is provided that includes an array of memory cells that require periodic refresh, and a temperature-adaptive refresh controller. Data retention time of the memory cells decreases exponentially as temperature increases. The temperature-adaptive refresh controller selects the refresh period of the memory cells in response to the subthreshold current of a reference transistor. The subthreshold current of the reference transistor increases exponentially as temperature increases As a result, the refresh period is empirically tied to the data retention time. Consequently, the power required for refresh operations decreases as temperature decreases. Power is therefore conserved in applications that operate predominantly at room temperature.

Owner:INVENSAS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com