Patents

Literature

469 results about "Pressure decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for control of fluid pressure

ActiveUS20070128046A1Gentler handlingEliminates and reduces disadvantageFluid parameterFlexible member pumpsPressure decreaseEngineering

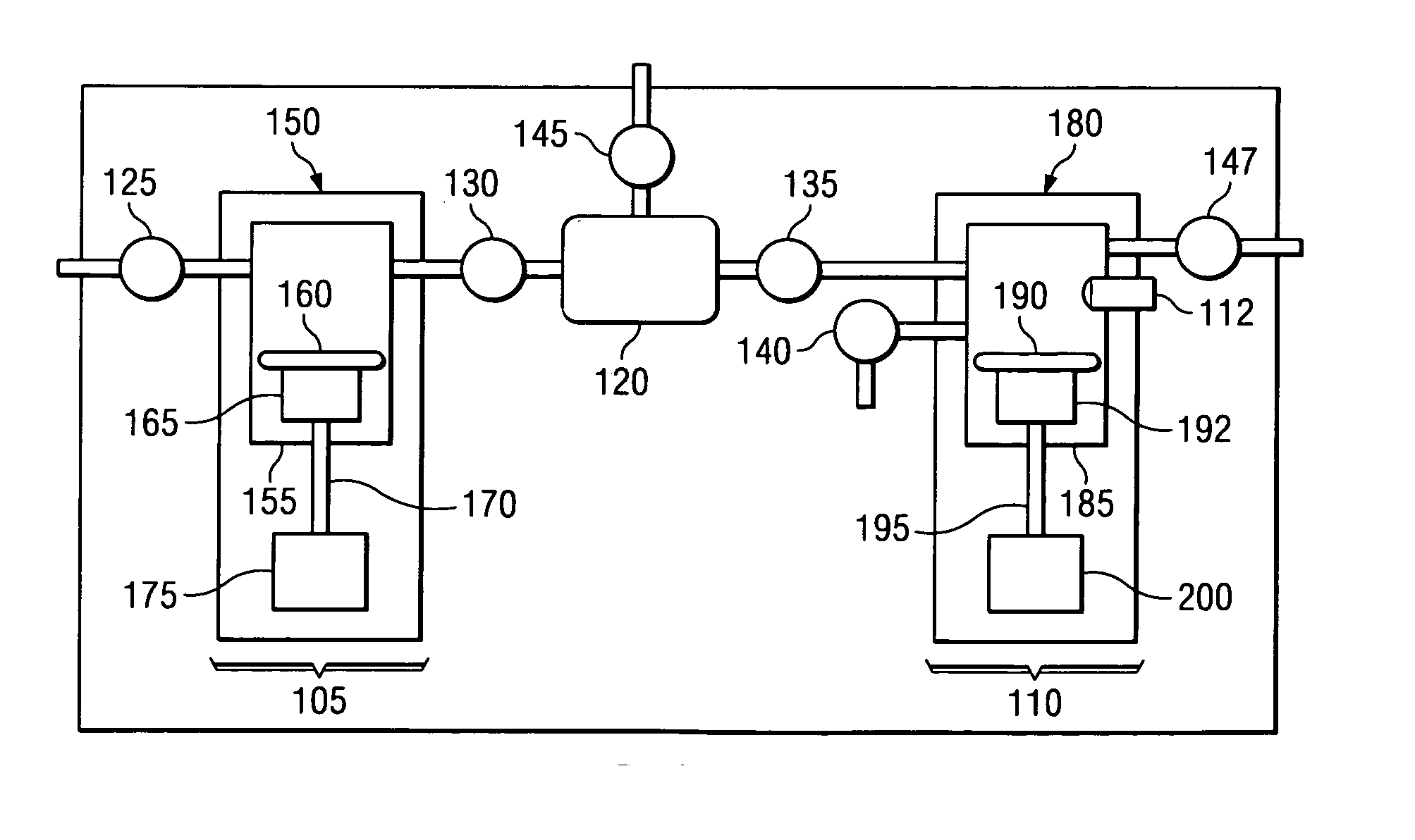

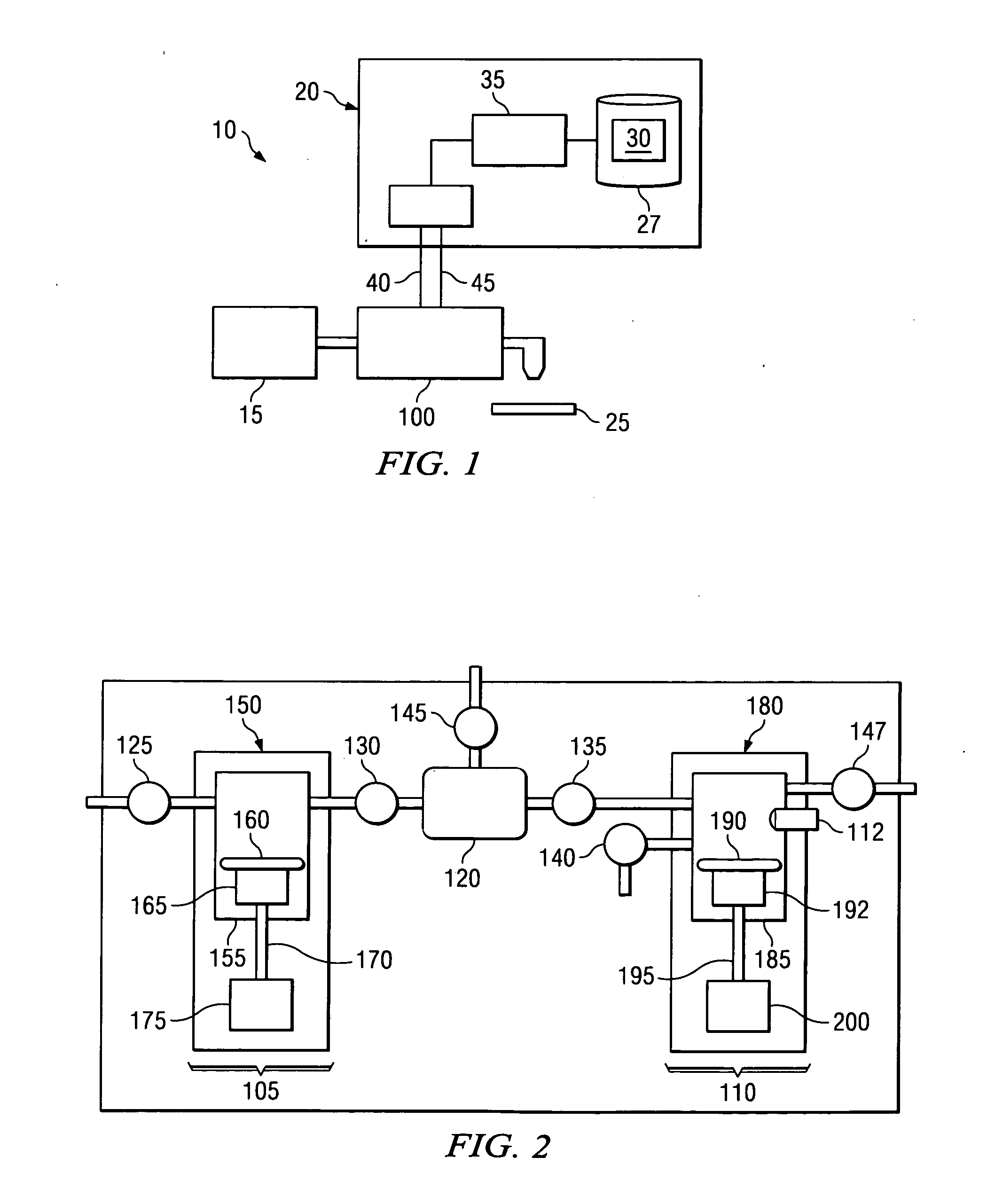

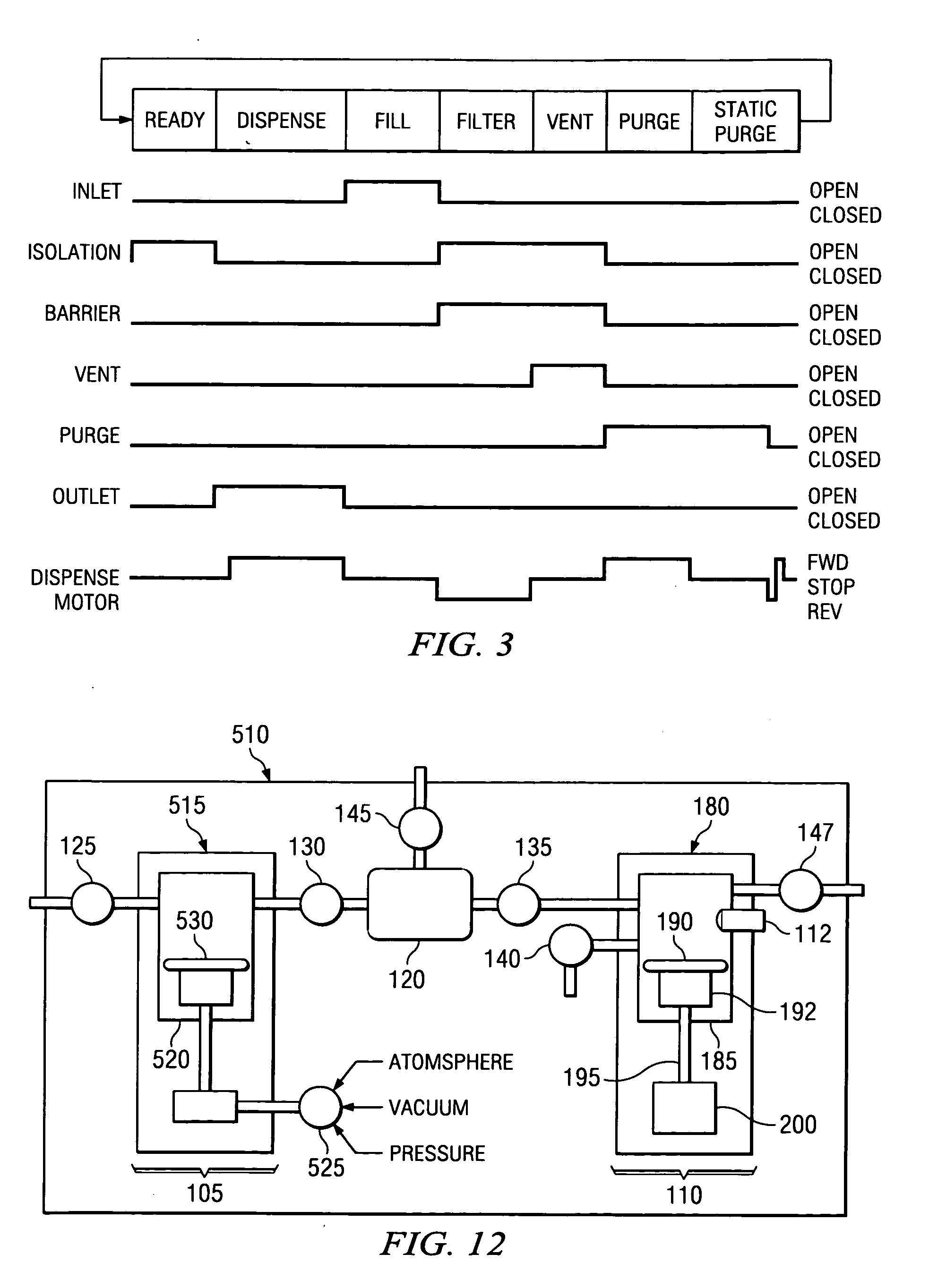

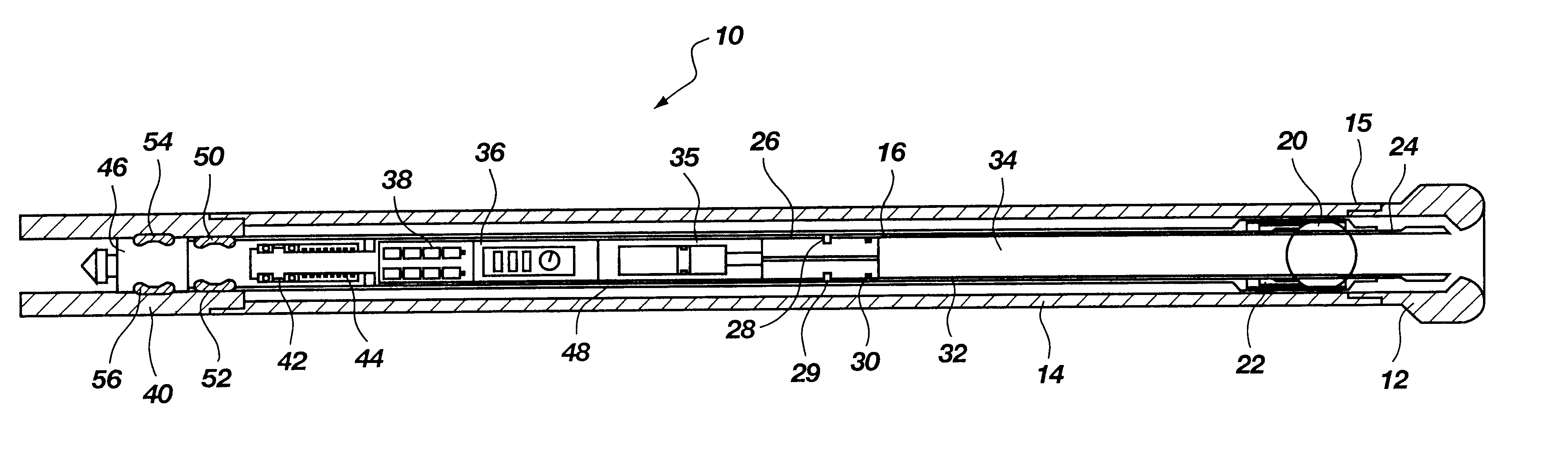

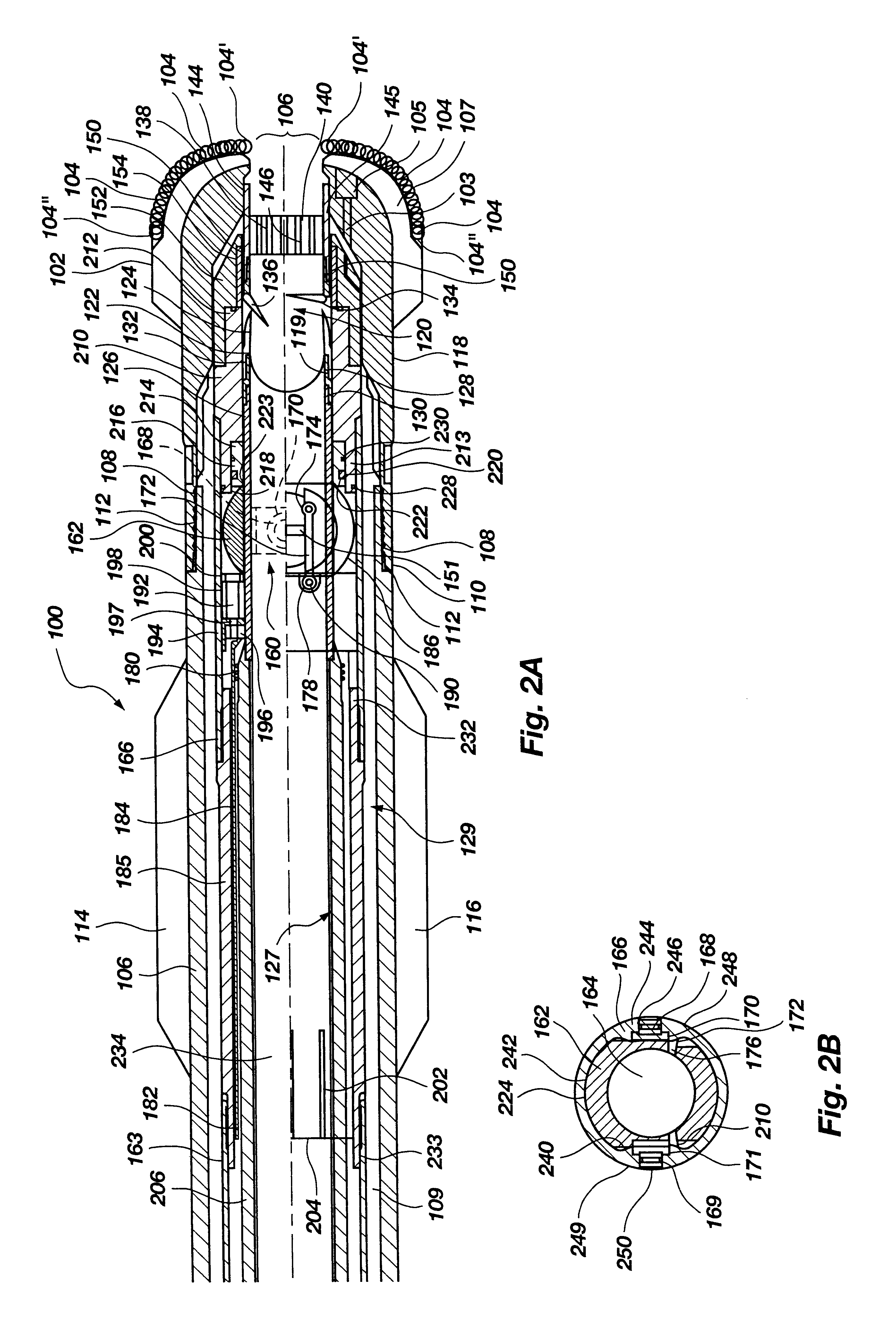

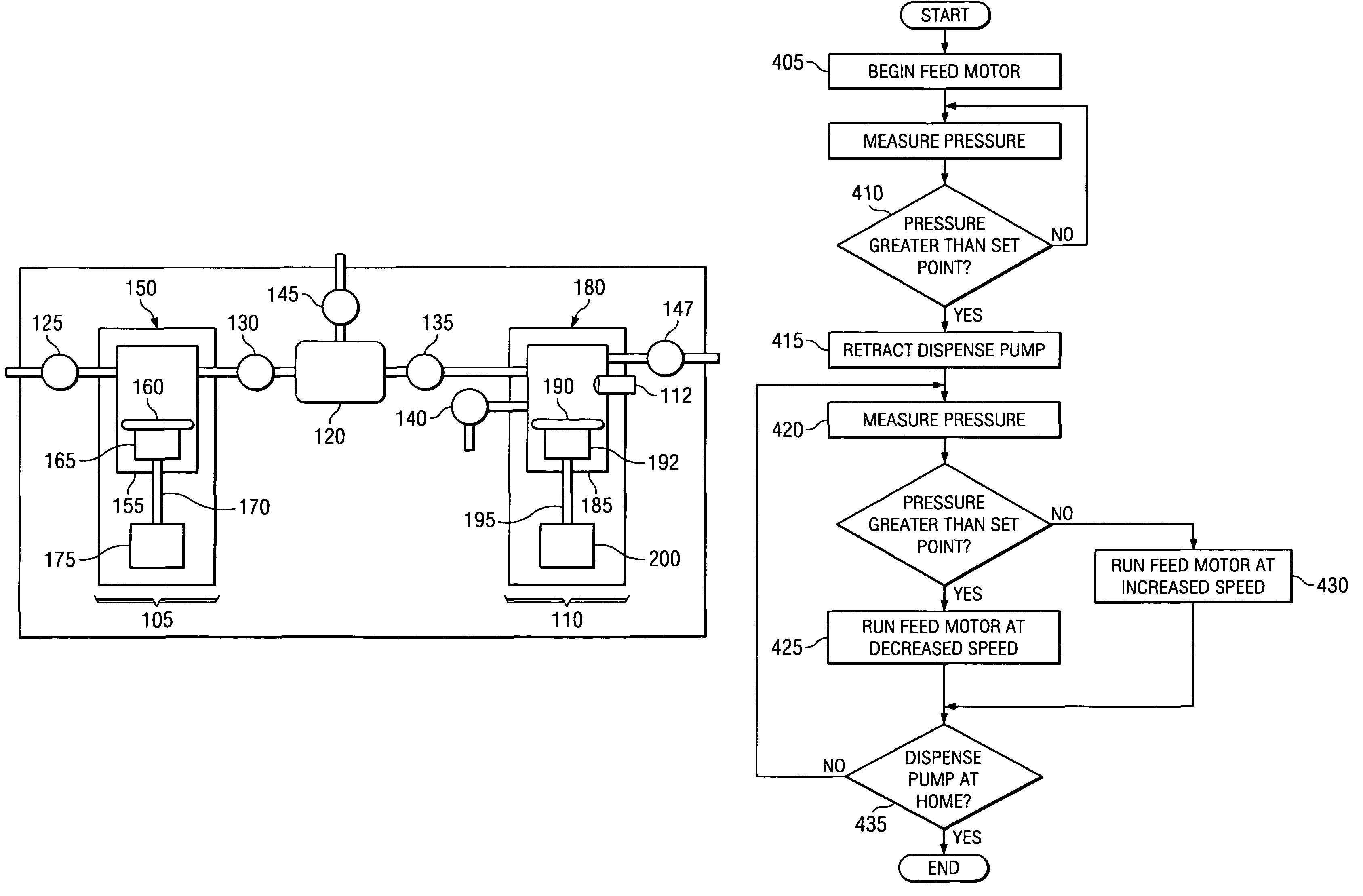

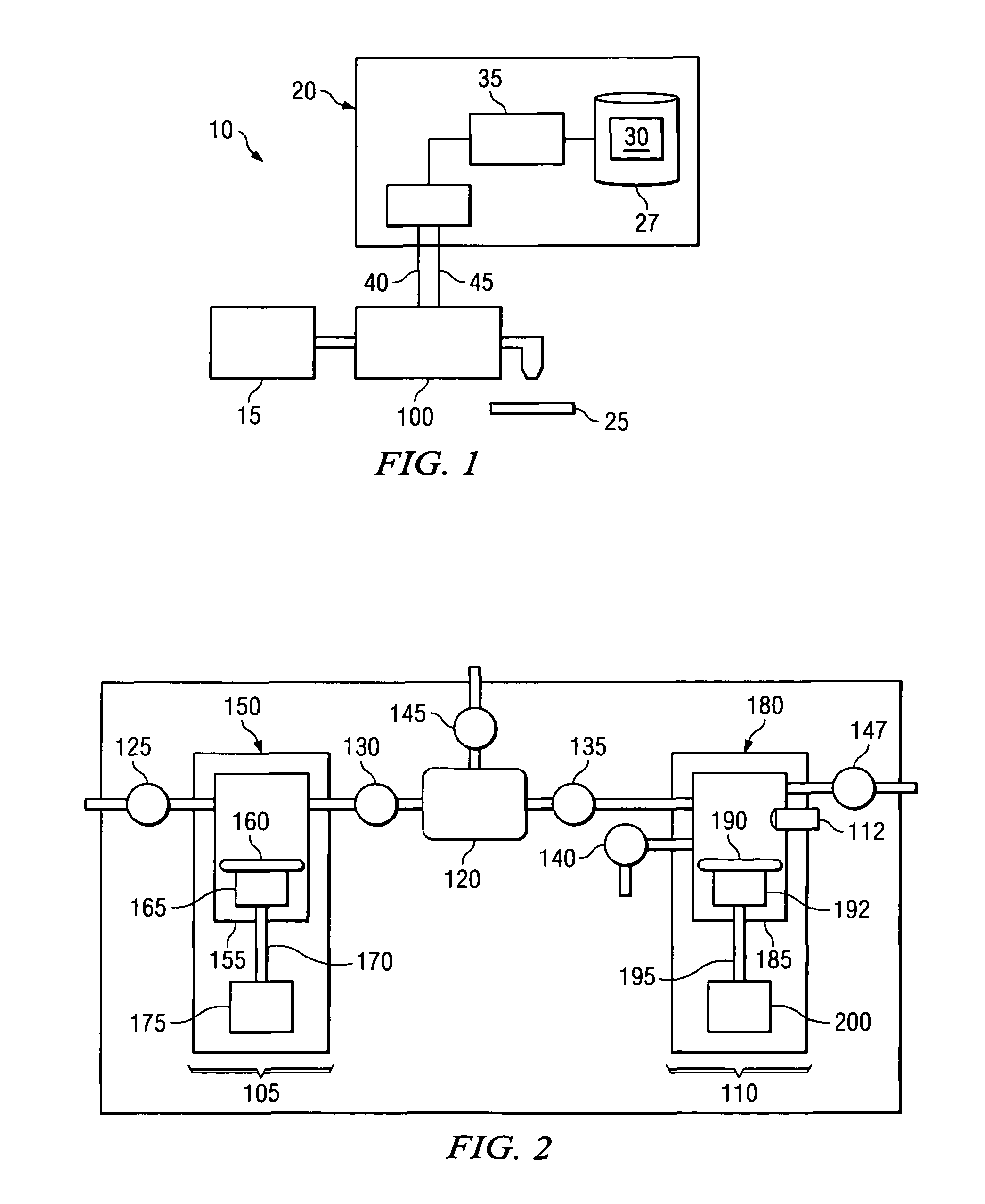

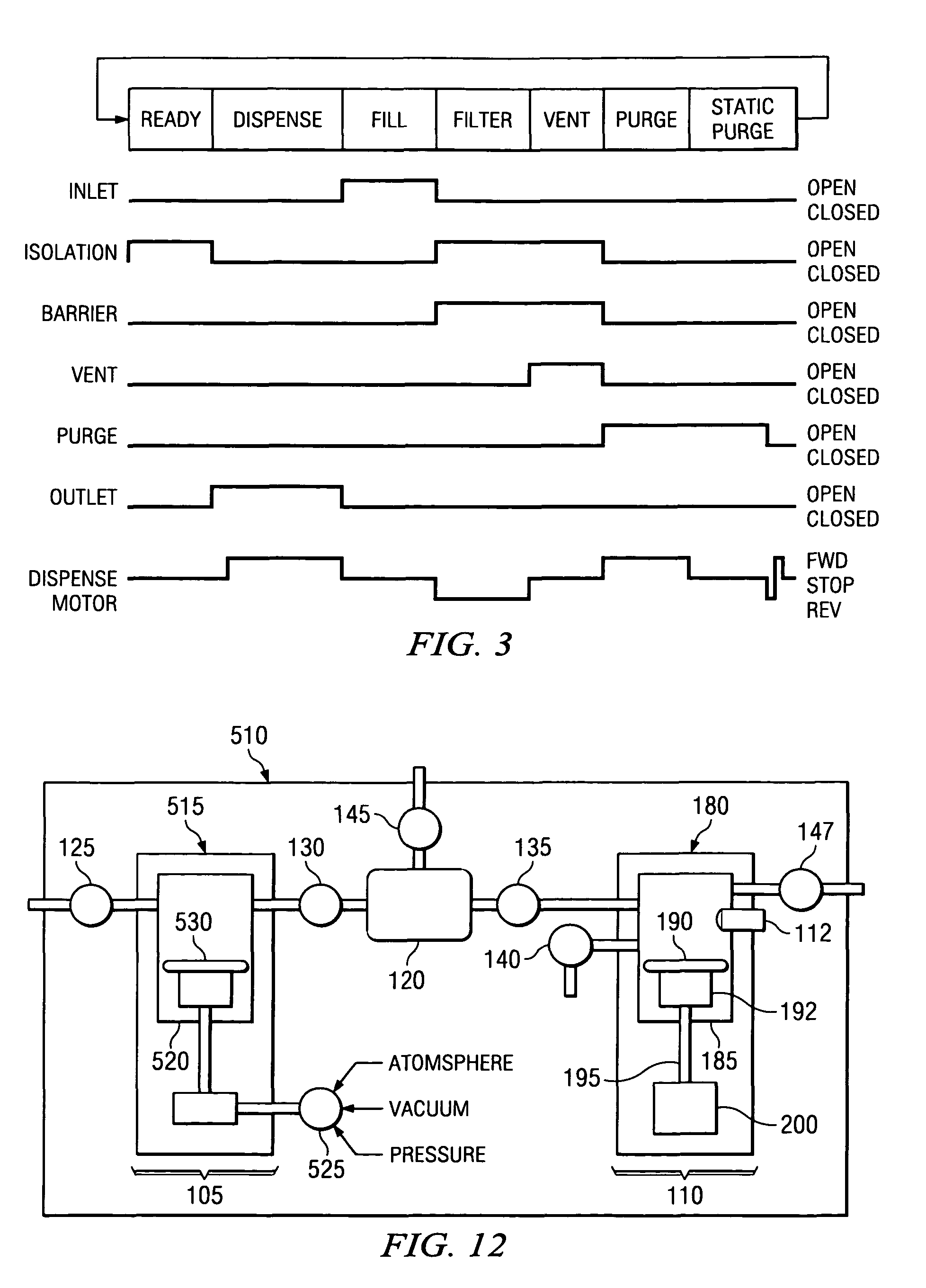

Embodiments of the present invention are related to a pumping system that accurately dispenses fluid using a multiple stage (“multi-stage”) pump. More particularly, embodiments of the present invention provide for control of a feed stage pump to regulate fluid pressure at a downstream dispense stage pump. According to one embodiment of the present invention, a pressure sensor at the dispense stage pump determines the pressure in a dispense chamber. When the pressure reaches a predefined threshold, the dispense stage pump can begin to increase the available volume of the dispense chamber, thereby causing the pressure in the dispense chamber to drop. As the pressure decreases / increases at the downstream pump, the pressure applied by the upstream pump can bed increased / decreased.

Owner:ENTEGRIS INC

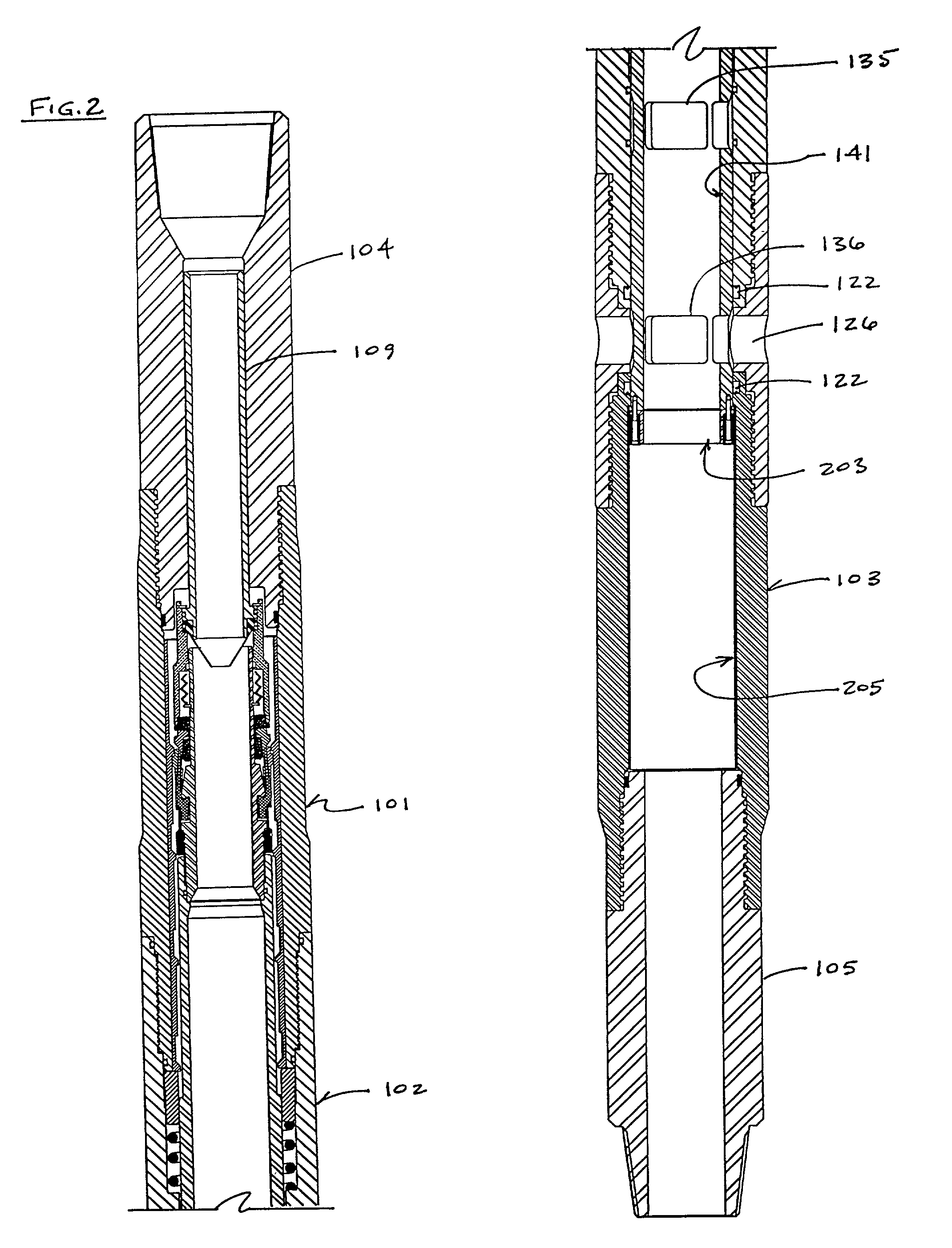

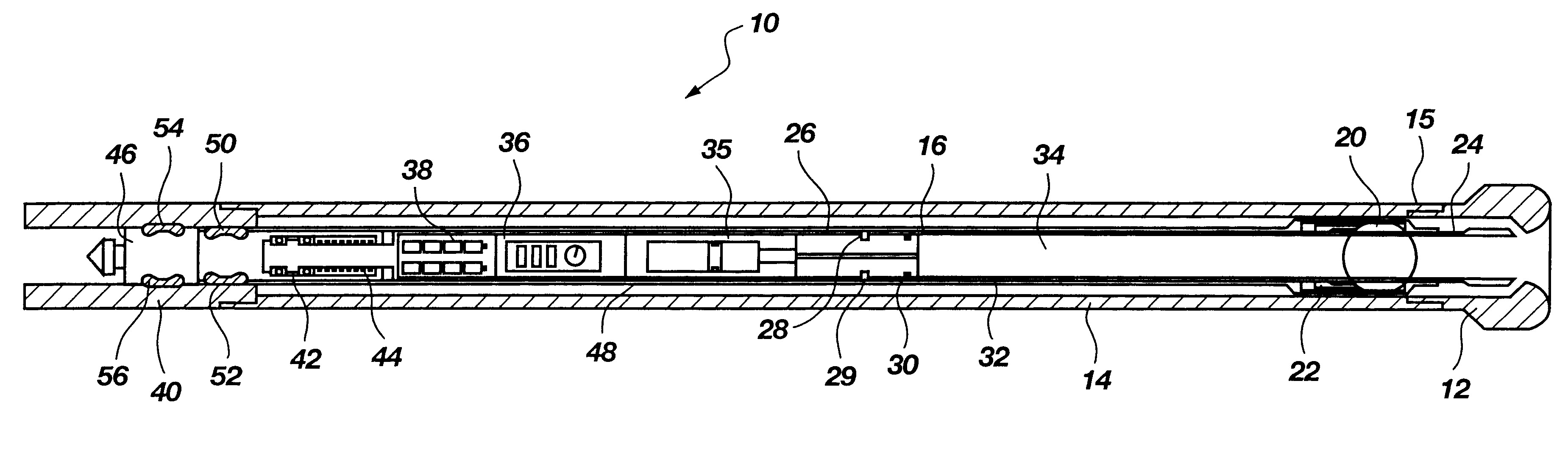

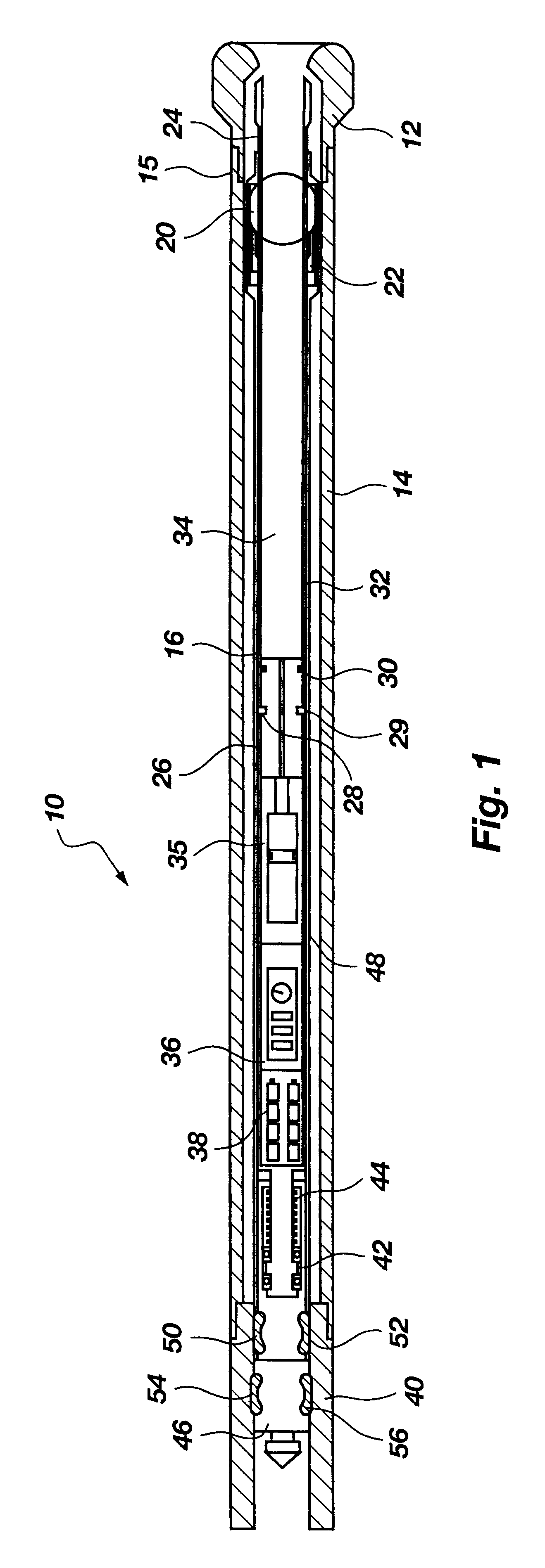

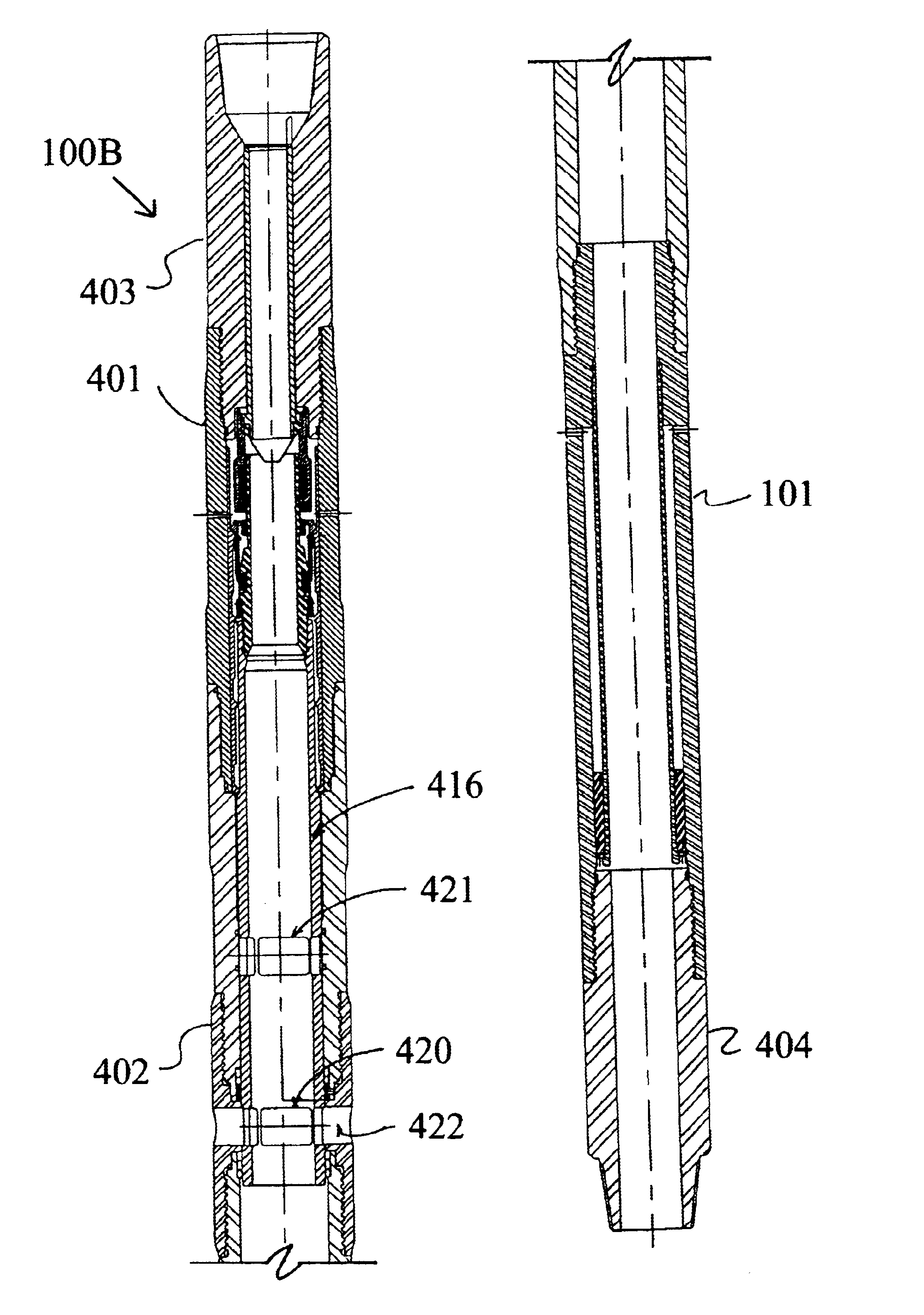

Apparatus for recovering core samples under pressure

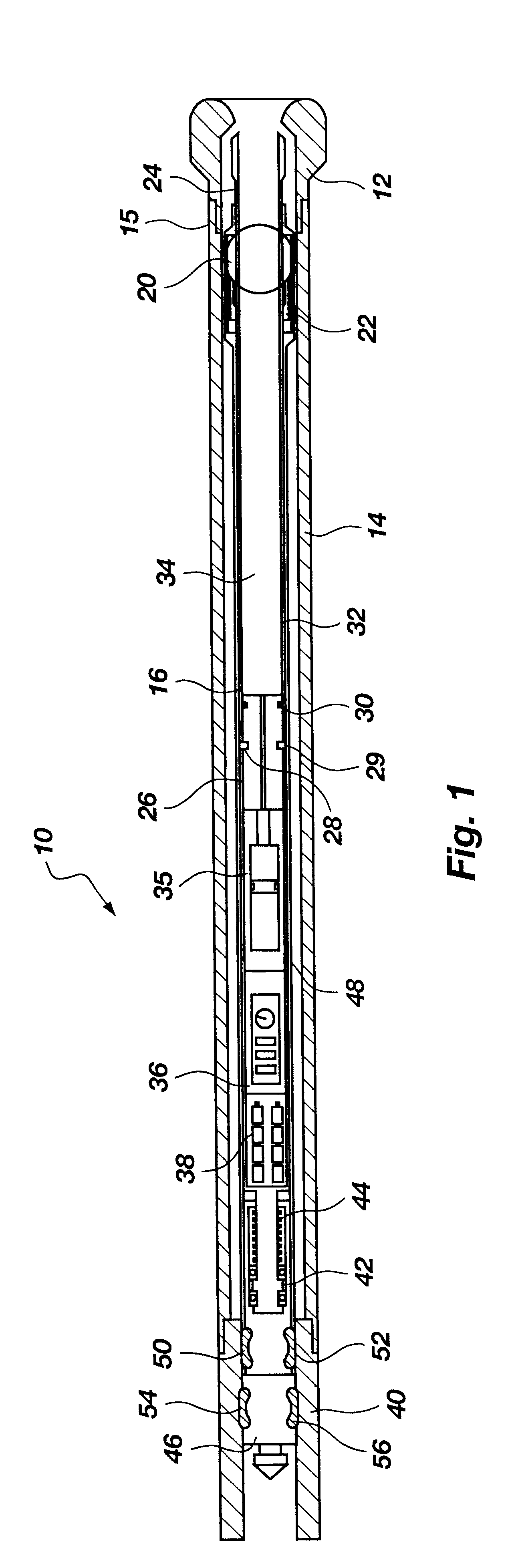

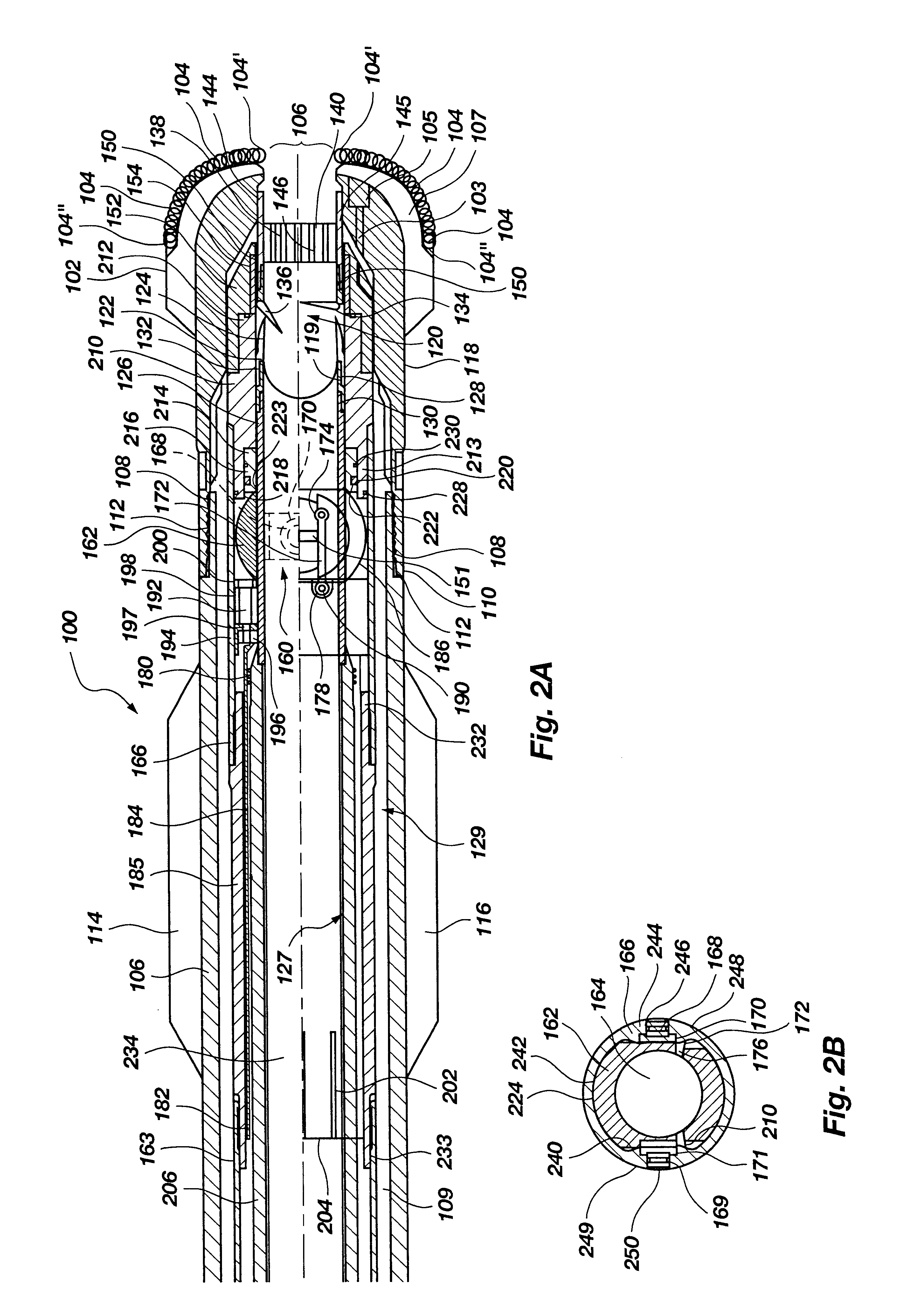

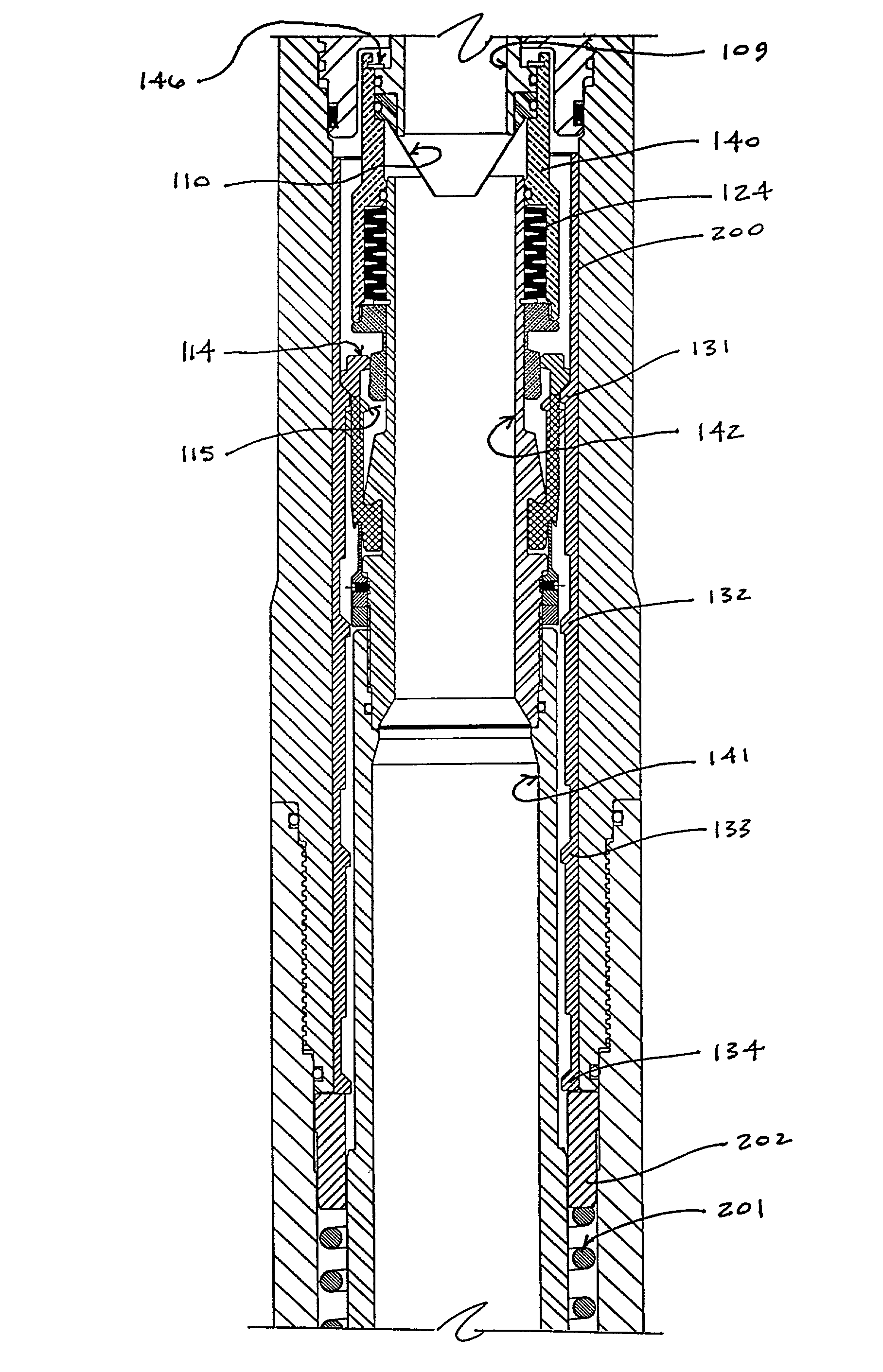

A pressure and temperature core sampler comprises a tool for recovering cores specifically enabling the evaluation of methane hydrate resources. Because methane hydrate tends to decompose under conditions of pressure decrease and / or temperature increase as the samples are retrieved to the surfaces a coring tool in accordance with the present invention provides a self-contained system for retrieving core samples at or near in situ pressure while cooling the core sample. The coring tool is preferably a wire line retrievable device that provides for nearly continuous coring during the drilling operation.

Owner:JAPAN OIL GAS & METALS NAT CORP

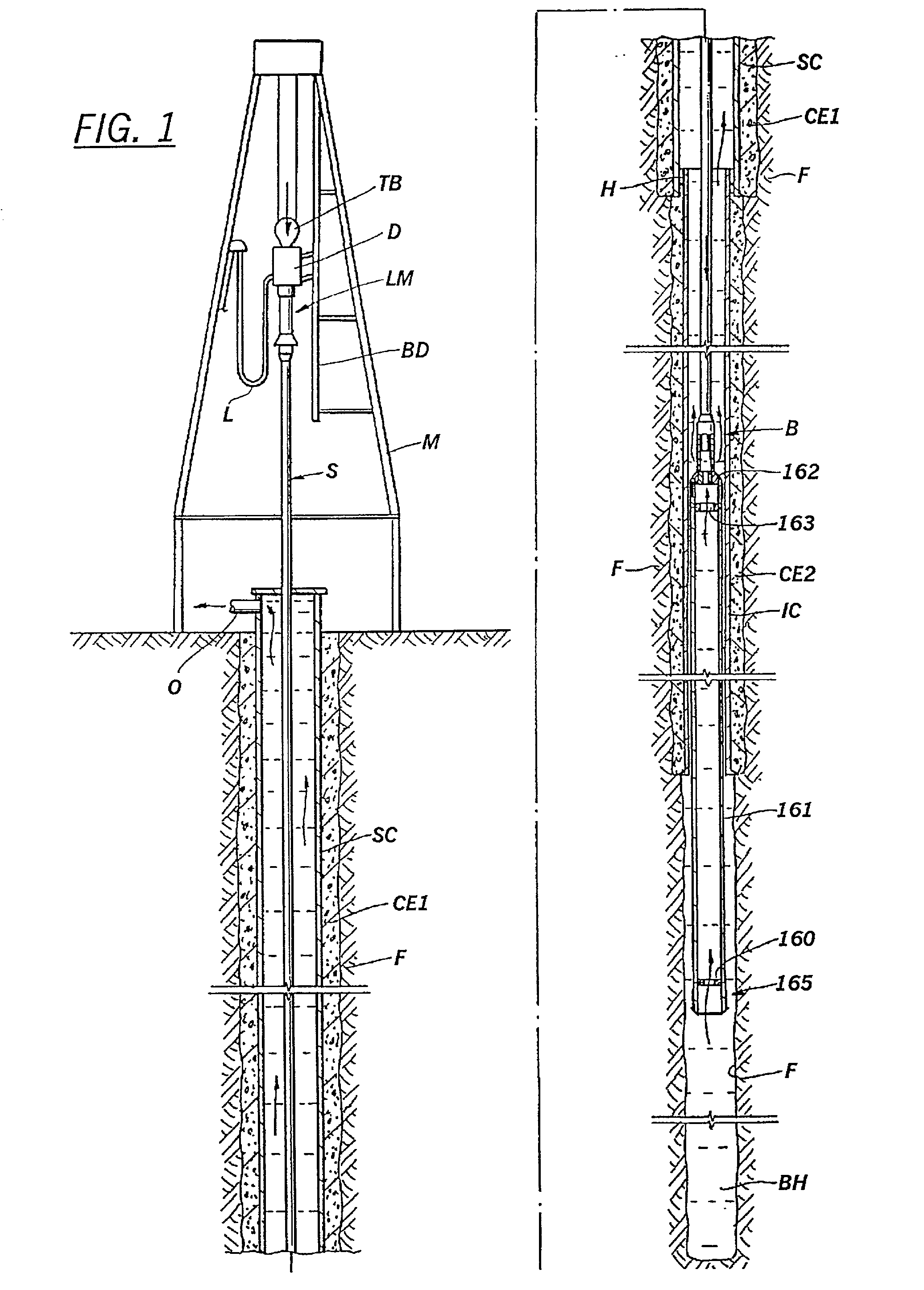

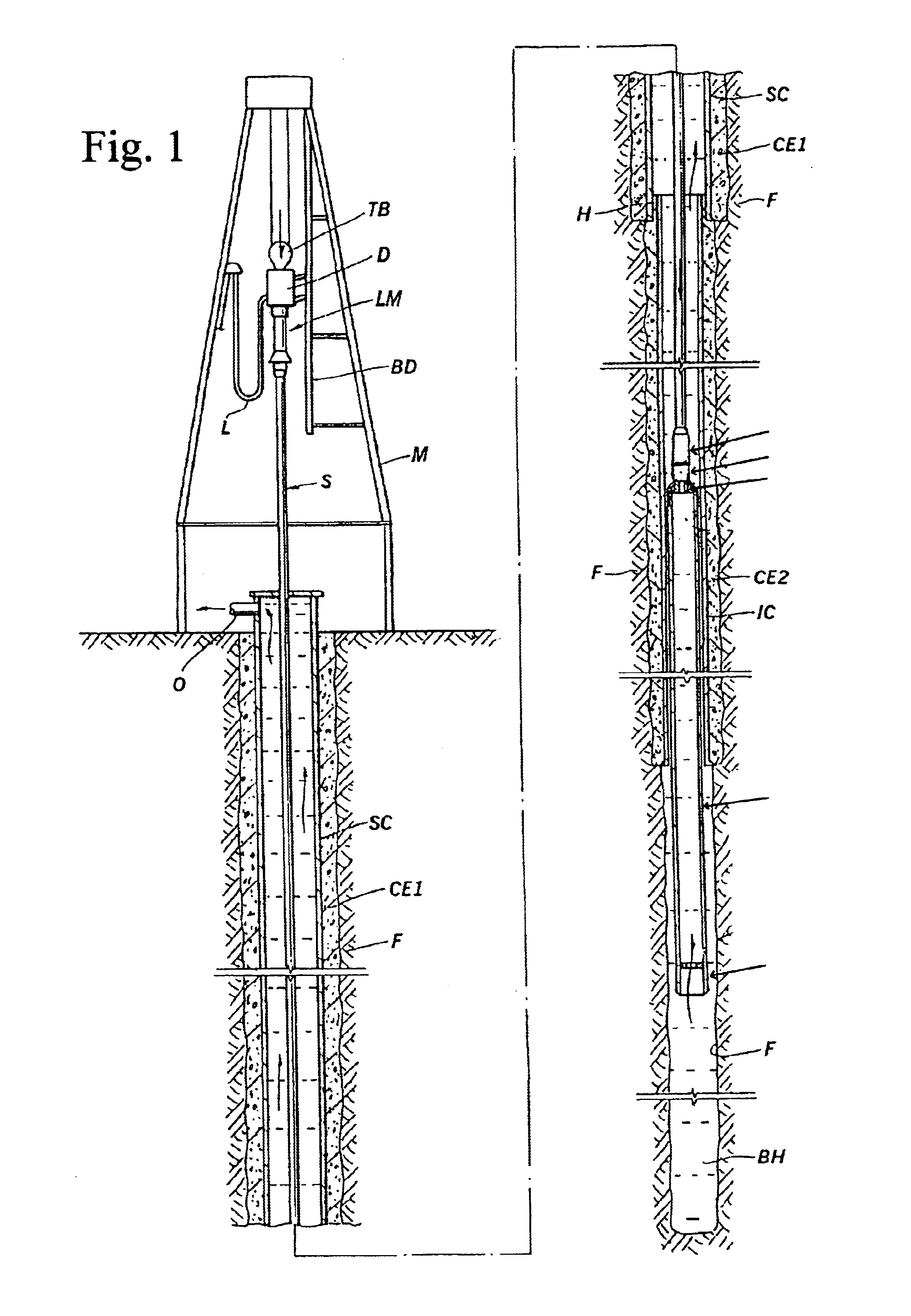

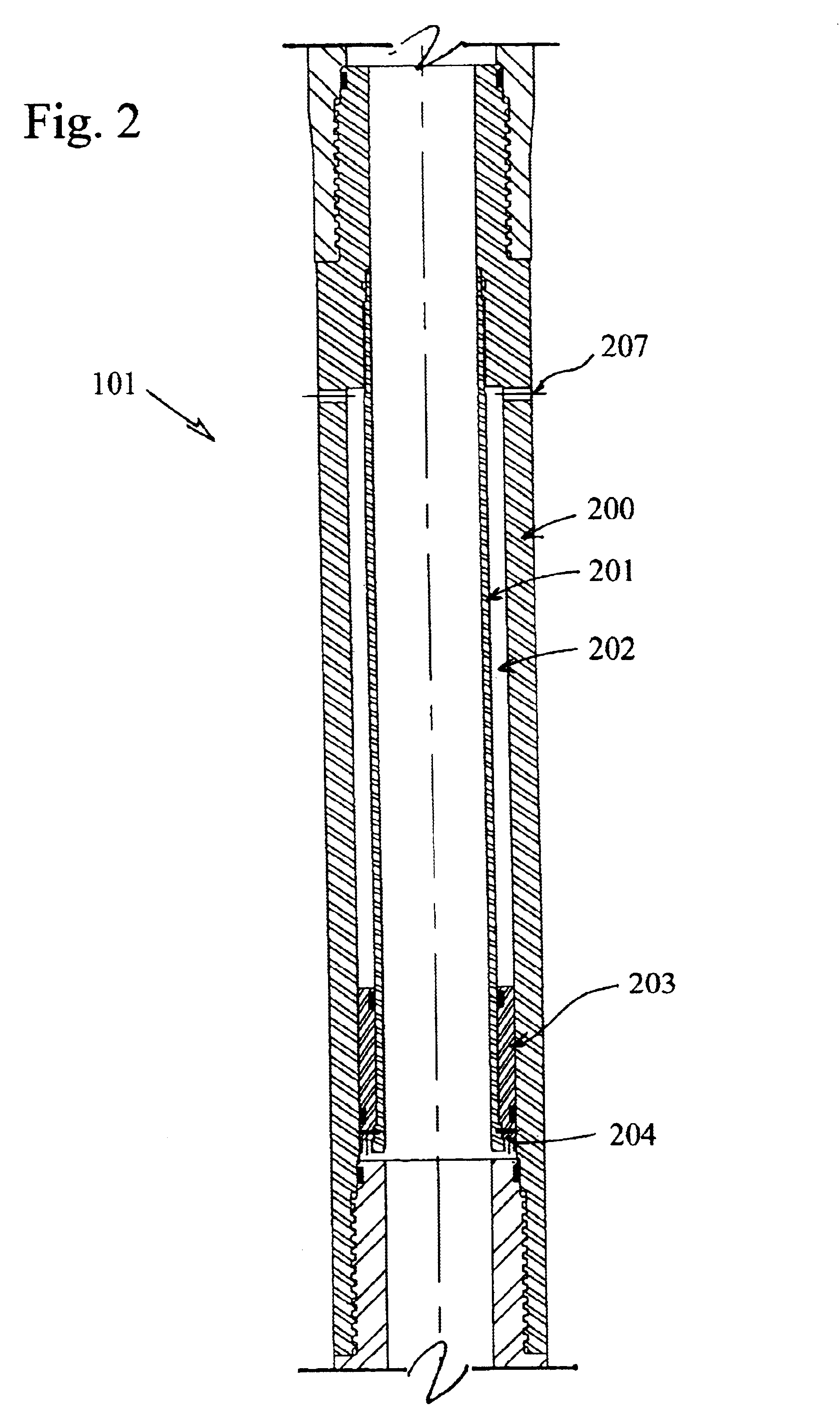

Downhole surge reduction method and apparatus

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a multifunction diverter tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a multi-function diverter tool includes a housing assembly with a set of flow holes formed therein and a sliding sleeve arranged within the housing assembly having two sets of flow ports formed therein at different axial locations along the sleeve. By aligning either set of flow ports of the sleeve with the flow holes of the housing, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes becomes blocked by the sleeve thus setting the tool in a "circulation" or "cementing" mode. This shifting or indexing is accomplished using an indexing mechanism. The multi-function diverter tool of the present invention can be shifted from a first "surge pressure reduction" mode to a "circulation mode," from the "circulation mode" to a second "surge pressure reduction" mode, and finally from the second "surge pressure reduction" mode to a "cementing" mode. The indexing mechanism of the present invention includes a return spring and brake system which provides the tool with more reliable shifting functionality.

Owner:ALLAMON INTEREST

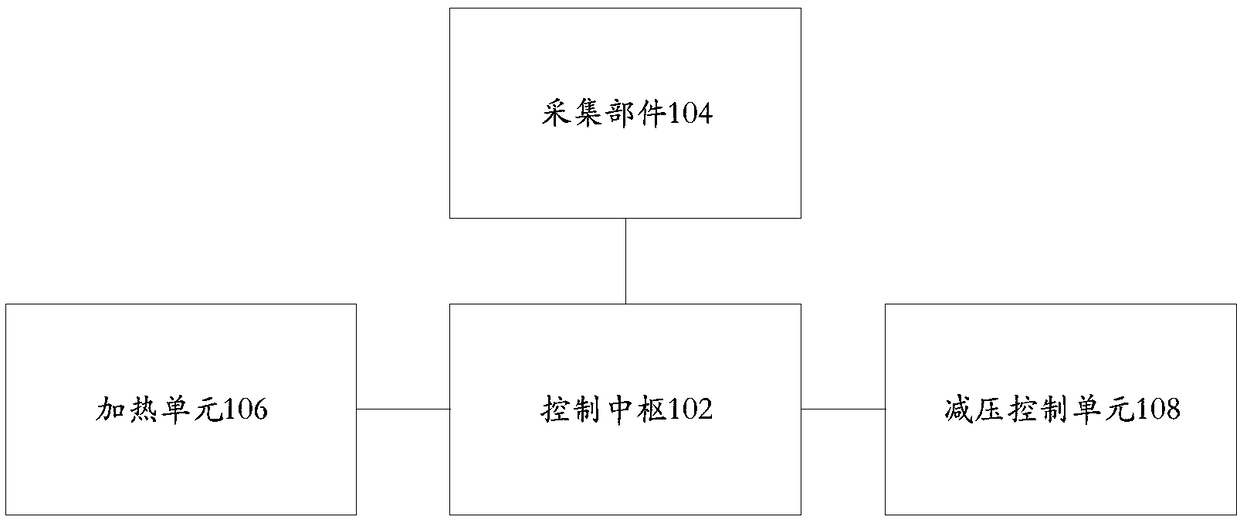

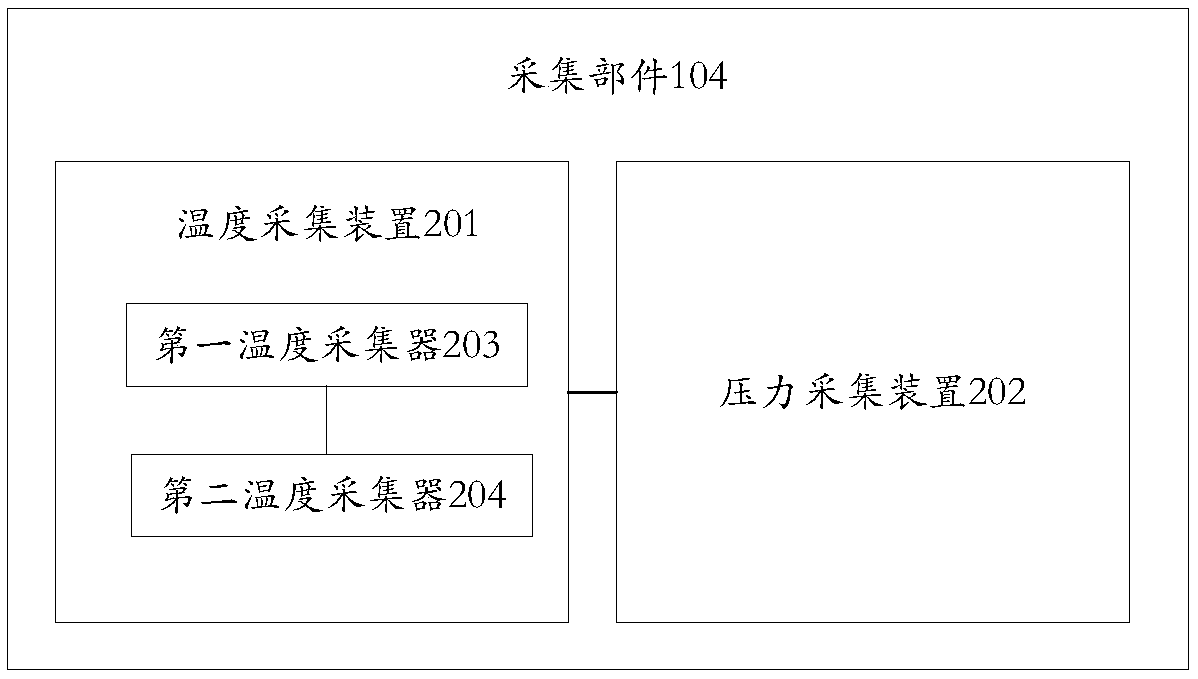

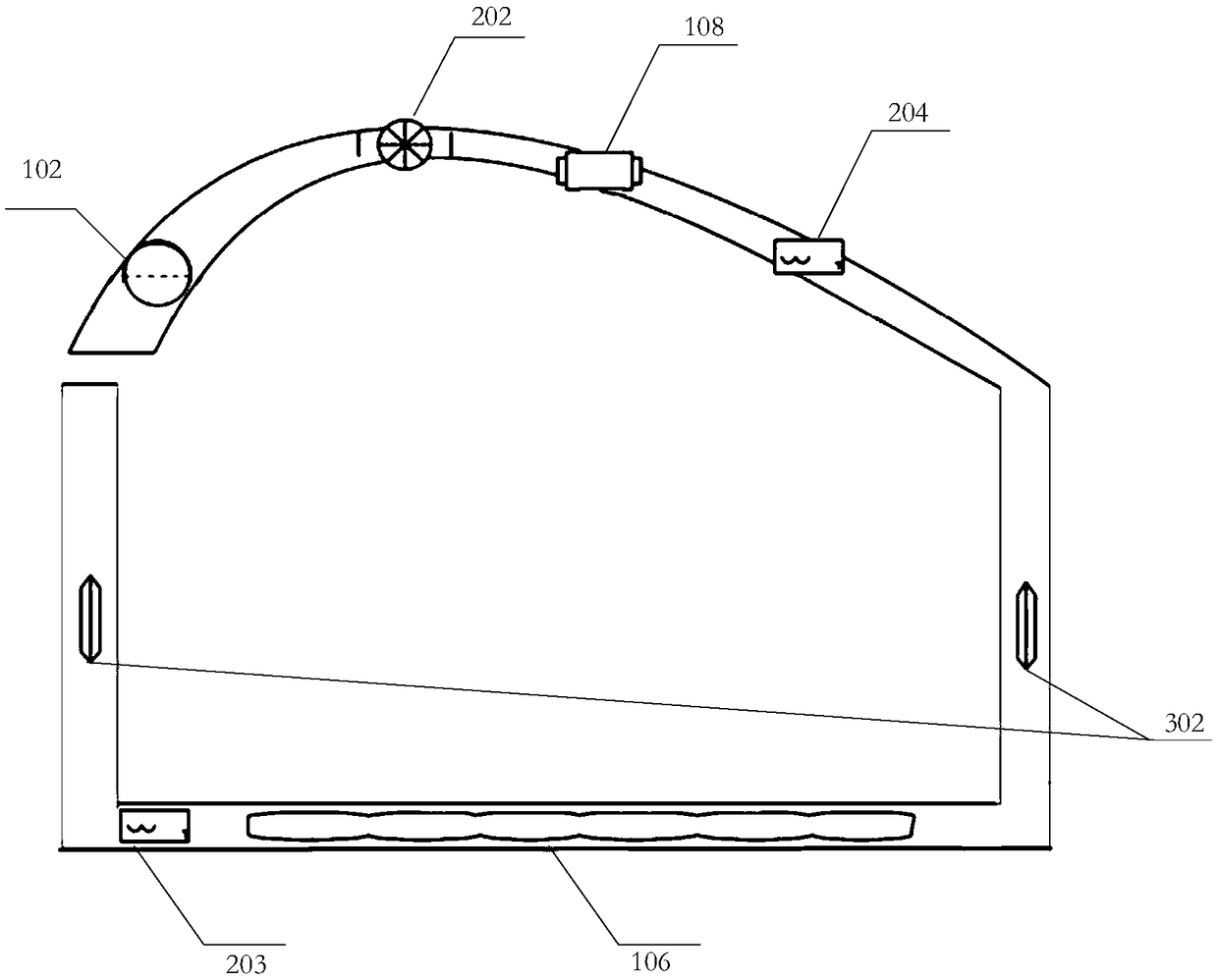

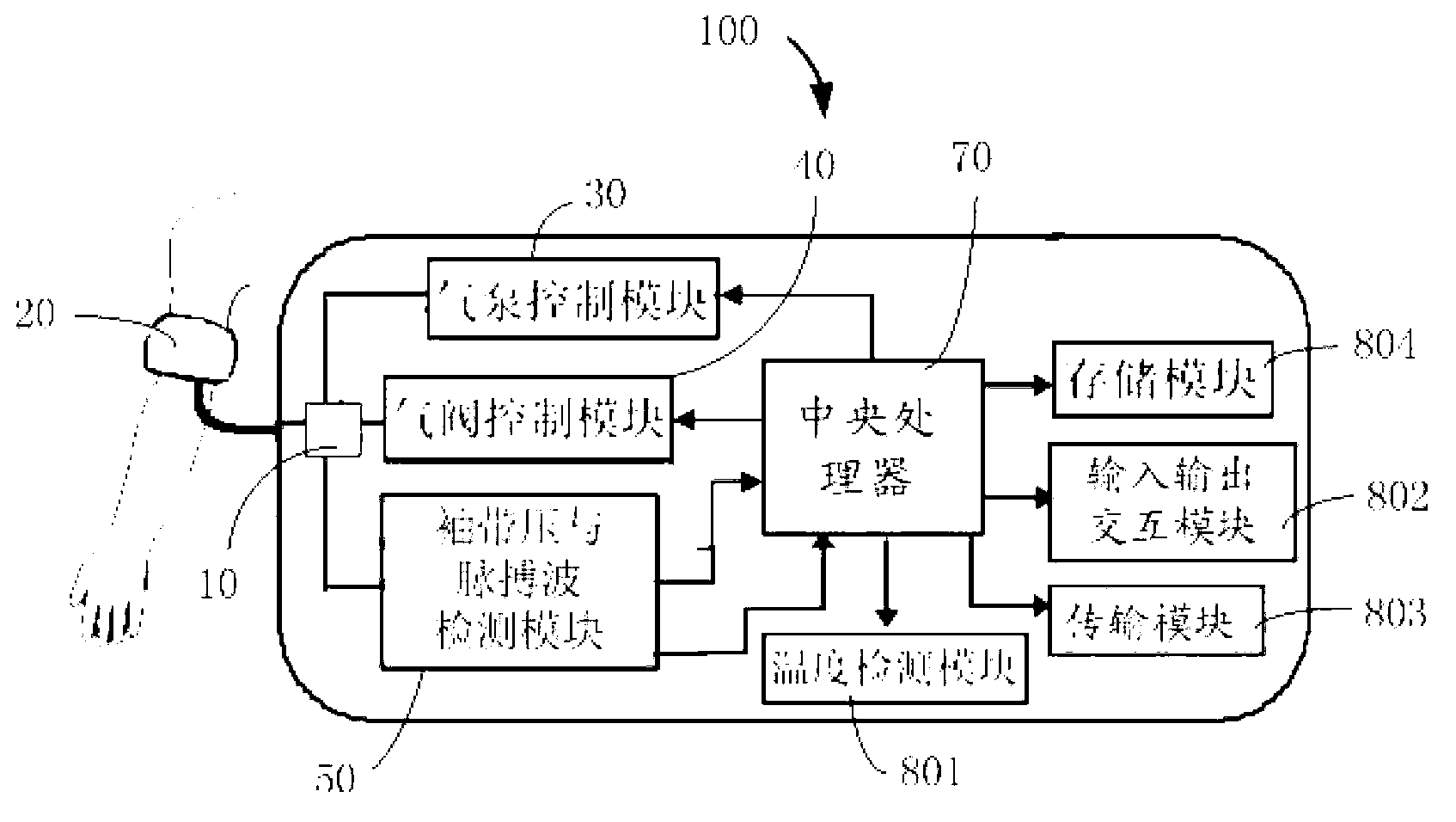

Intelligent pressure cooker and using method thereof

InactiveCN108937559ARealize control regulationMonitor pressure in real timePressure-cookersTime-controlled ignitorsInternal pressurePressure decrease

The invention provides an intelligent pressure cooker and a using method thereof, and relates to the technical field of electric appliances in life. When a main loop is connected, a heating unit heatsa pressure cooker cavity; during heating, a collecting component collects cooking parameters in the cavity in real time, and the cooking parameters are sent to a control center; the control center stores cooking modes of the intelligent pressure cooker in advance and cooking threshold values corresponding to the cooking modes, wherein the cooking modes comprise the constant-pressure control mode,the temperature-constant control mode and the normal mode; under different cooking modes, the control center controls a pressure decrease control unit or the heating unit according to the received cooking parameters, temperature-constant pressure-constant control adjustment is realized for the pressure cooker, pressure and temperature in a cooker body are monitored easily in real time in the process of cooking, it is avoided that a common pressure cooker is monotonous and random in working pressure and temperature, accordingly, food heating speed is increased, food heating quality is improved, and using experience of a user is improved.

Owner:HANGZHOU ROKI TECH CO LTD

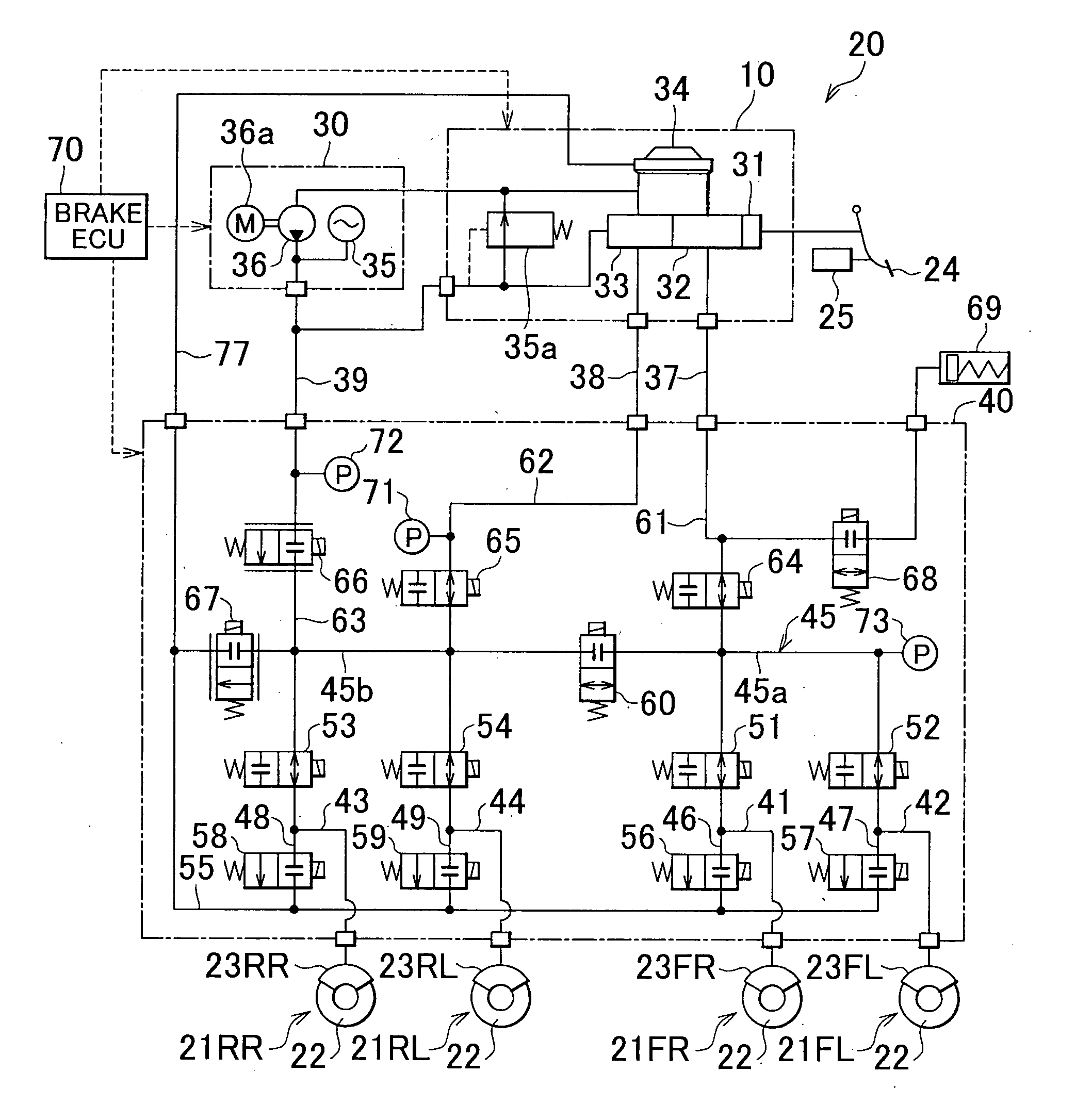

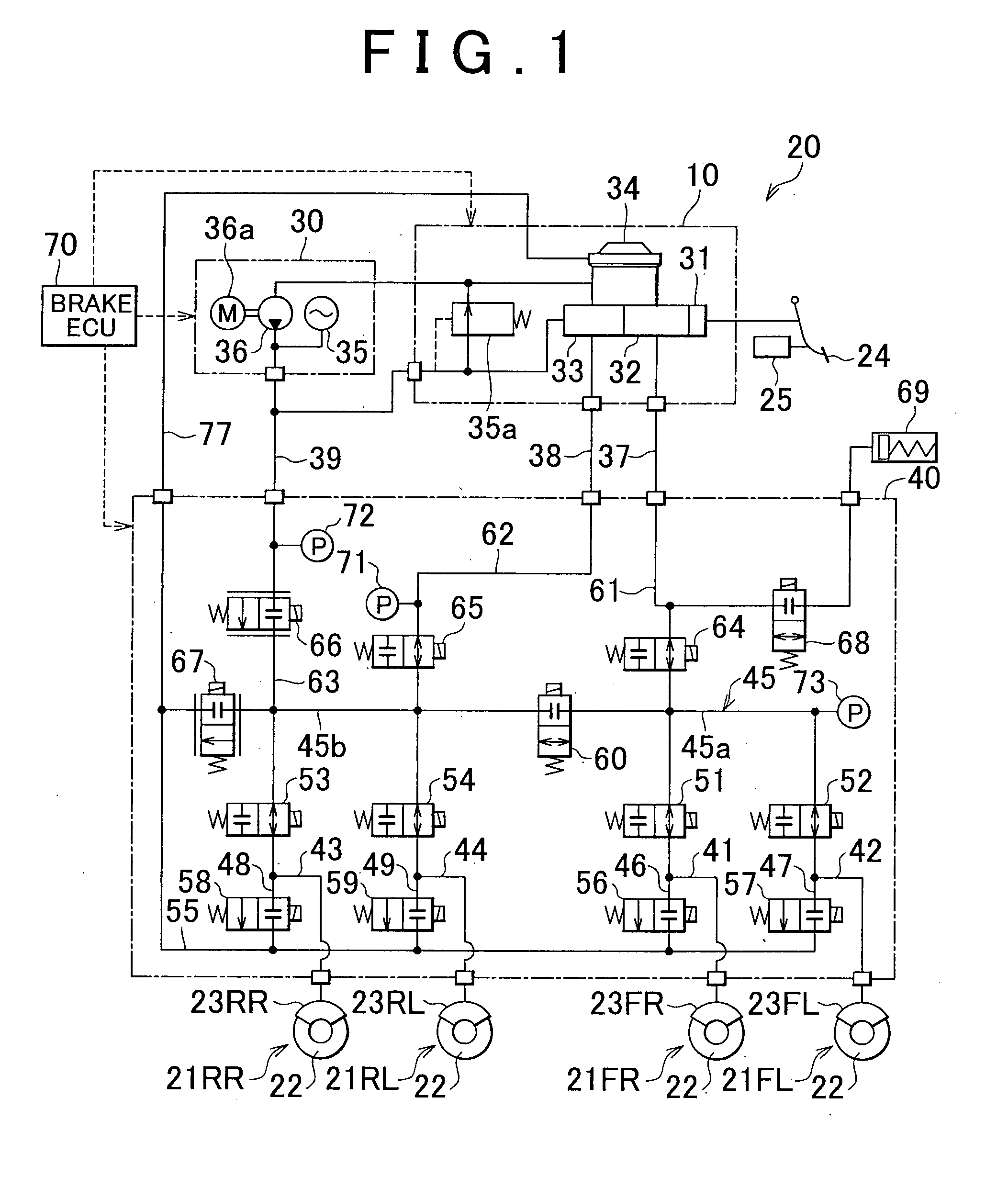

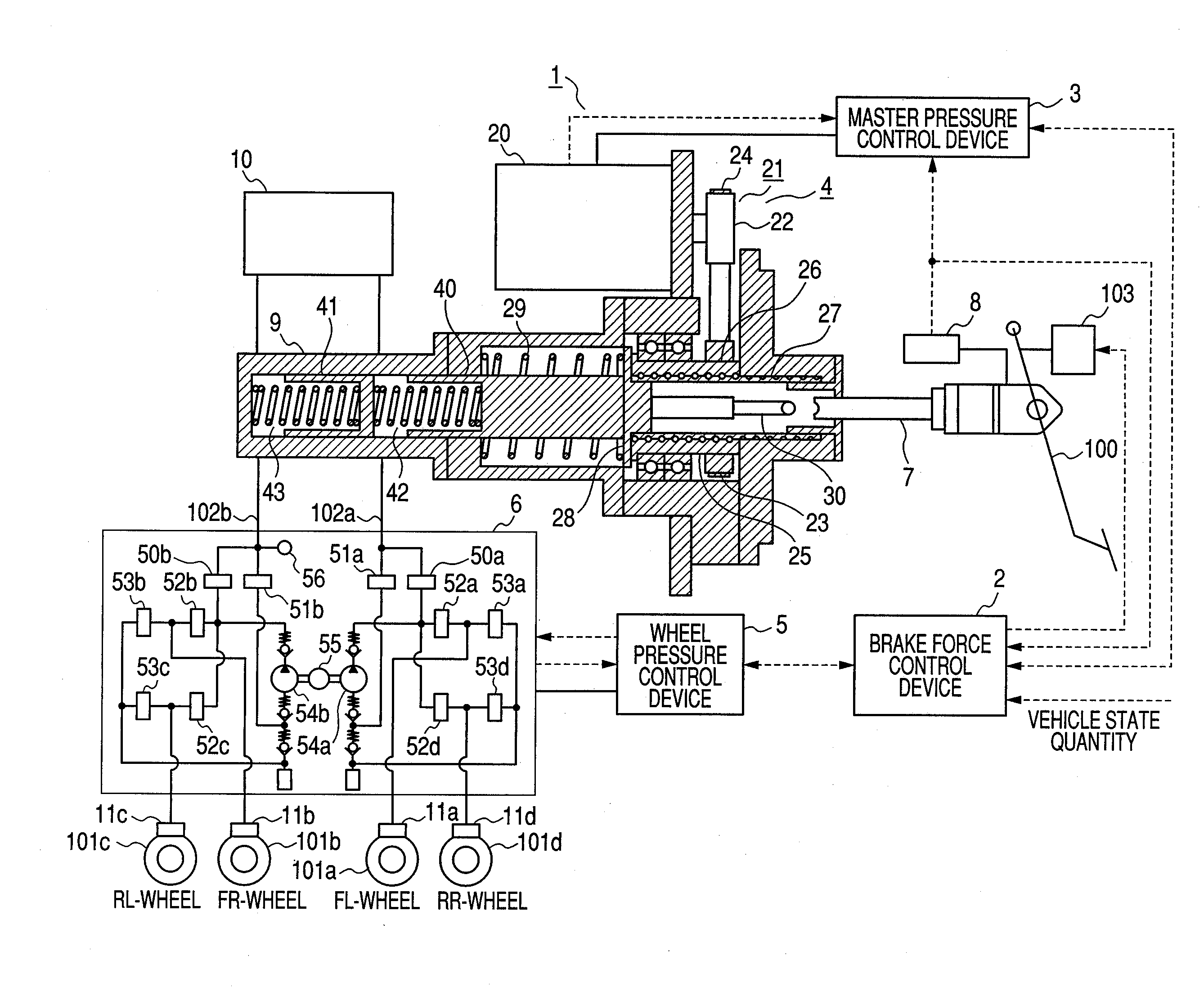

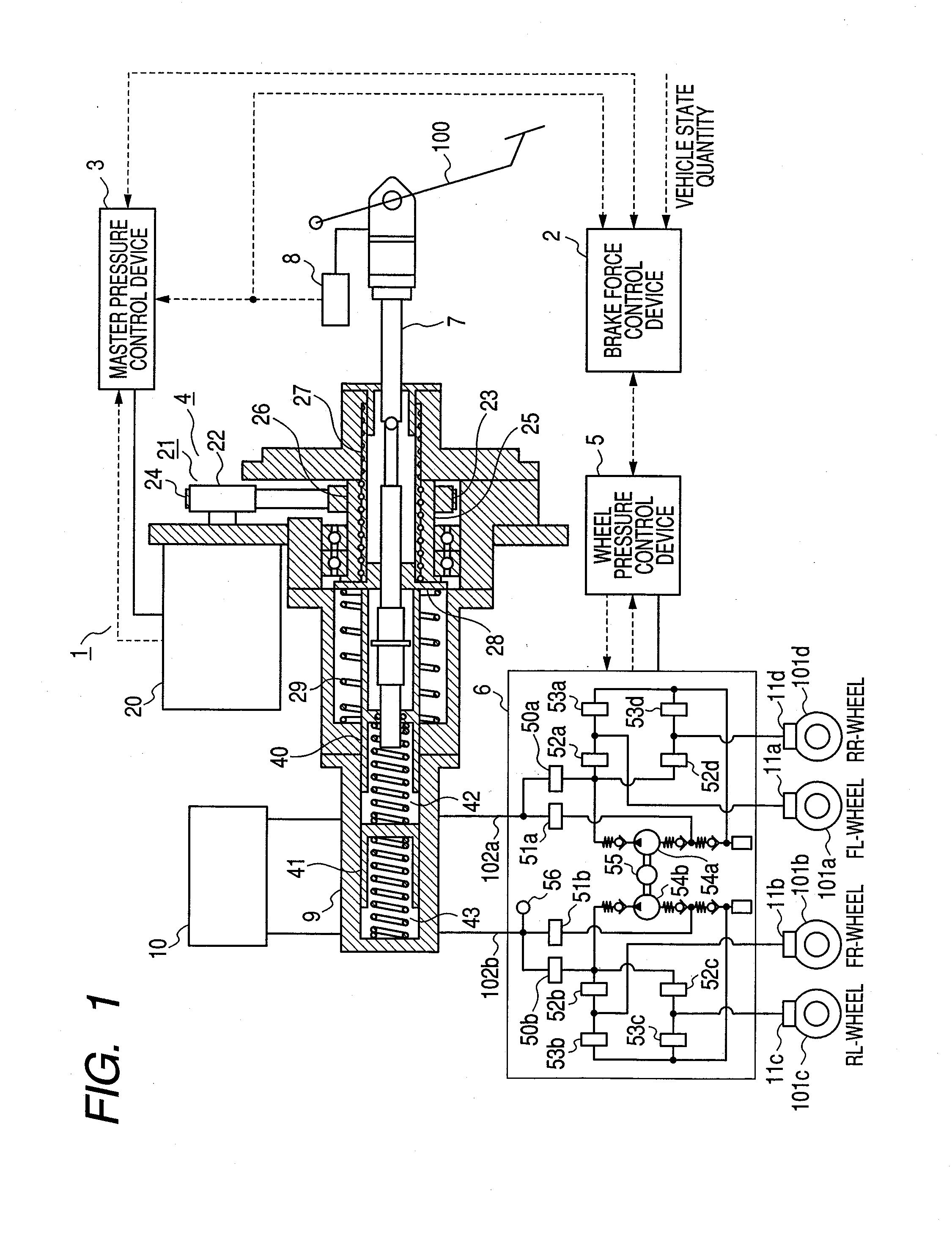

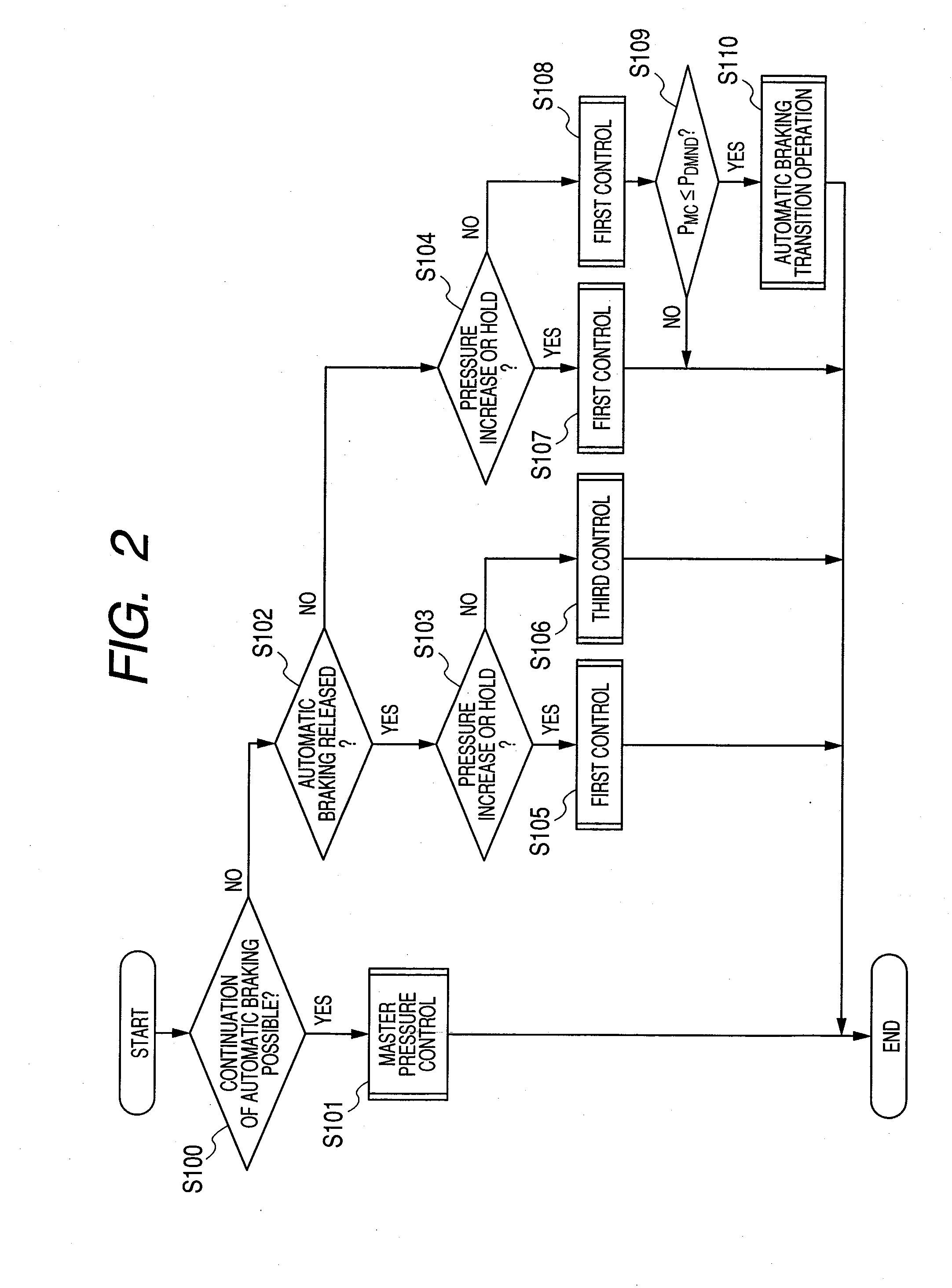

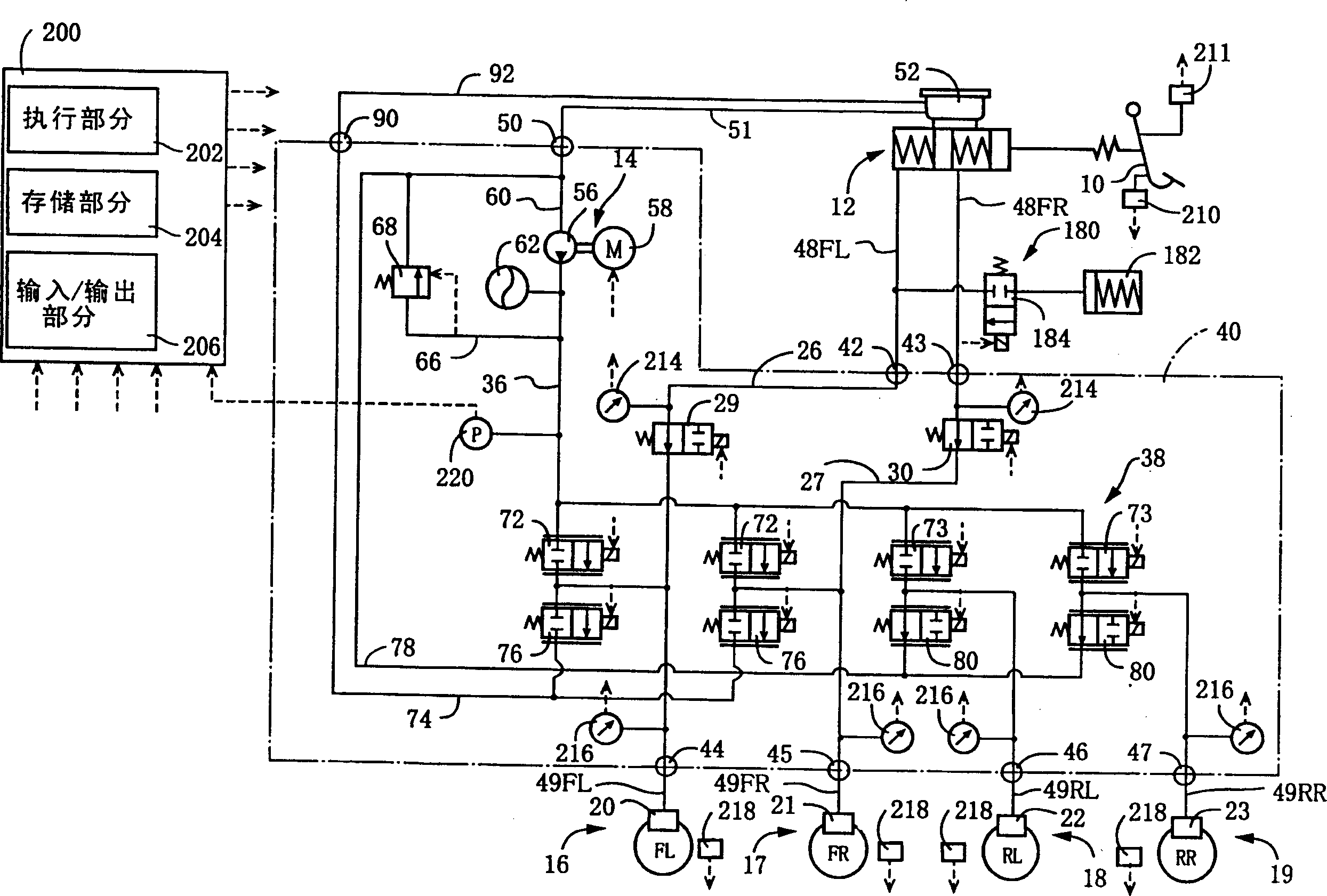

Brake control apparatus and control method for the brake control apparatus

ActiveUS20100211282A1Suppress occurrence of a malfunction in the pressure sensorAnalogue computers for trafficBraking action transmissionPressure decreaseHydraulic circuit

In a brake control apparatus that controls braking forces which are applied to wheels based on the pressure of the hydraulic fluid, when the pressure detected by a control pressure sensor (73) is equal to or higher than a predetermined value while a partition valve (60) is closed, a master cut valve (64) is closed to suppress an increase in the pressure in a first passage (45) in a first hydraulic circuit (37), to which the control pressure sensor (73) is connected. Alternatively, the control pressure sensor (73) is protected against overpressure by opening the outlet valve (56,57) or the pressure-decreasing valve (67).

Owner:TOYOTA JIDOSHA KK

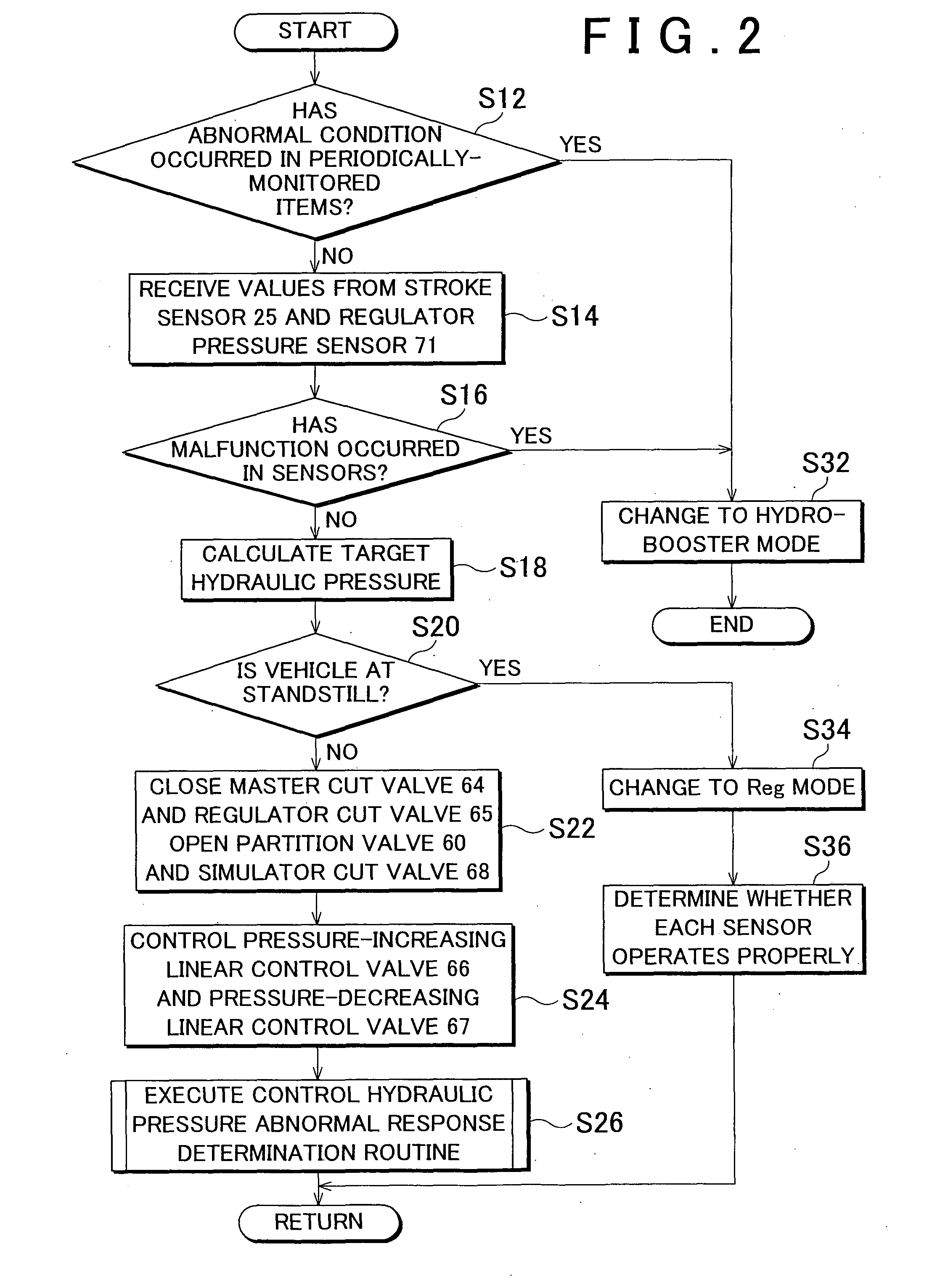

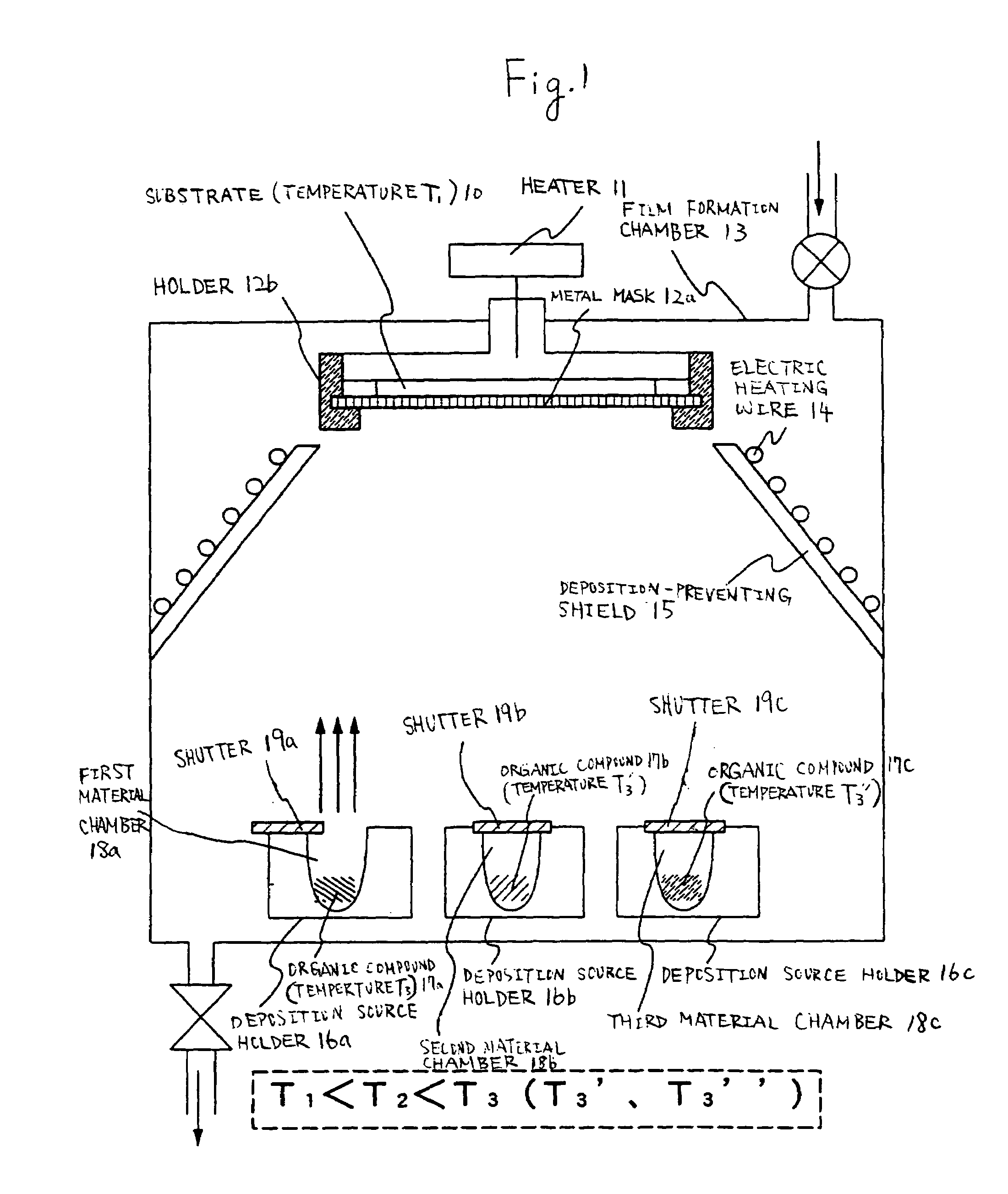

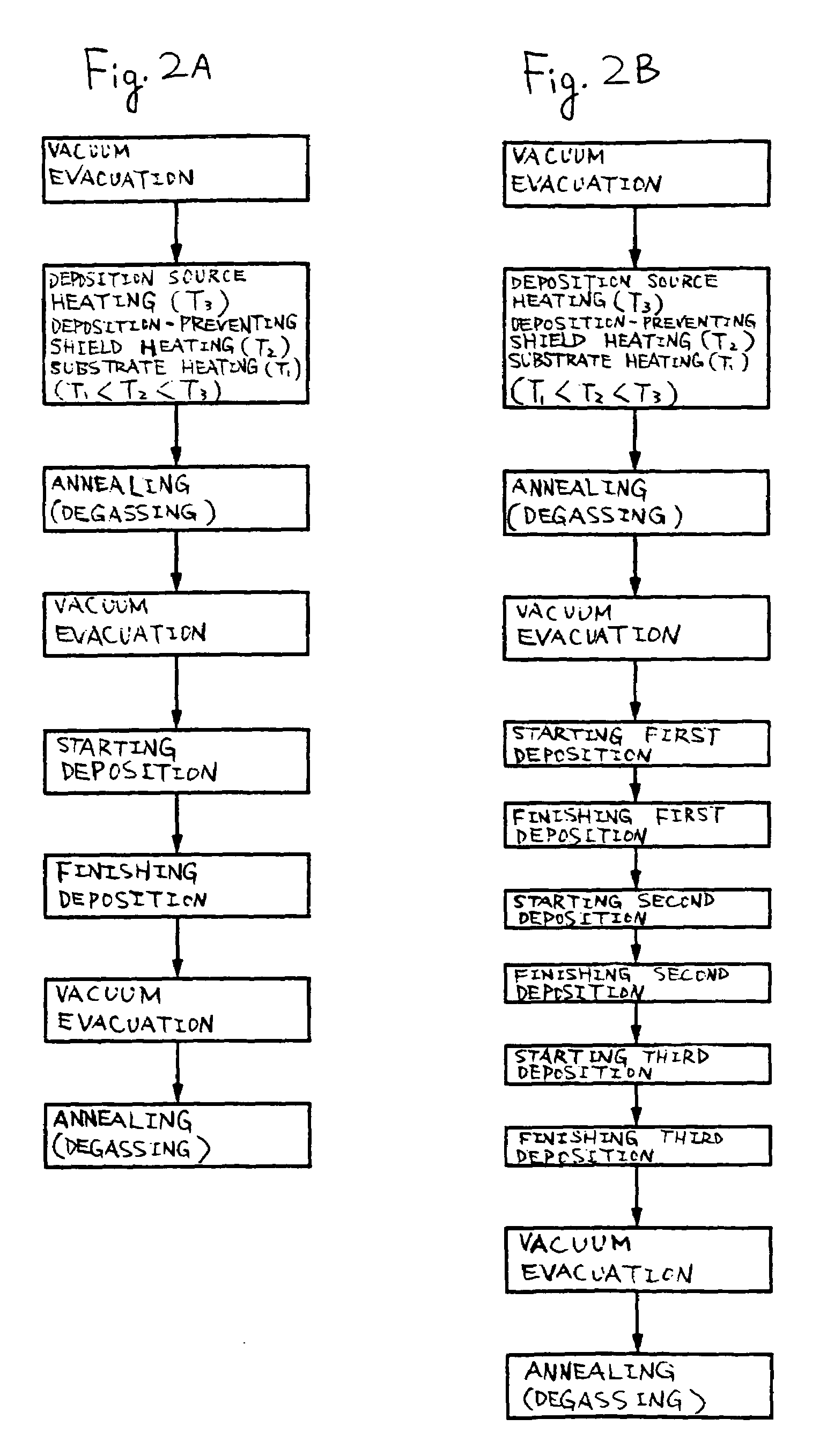

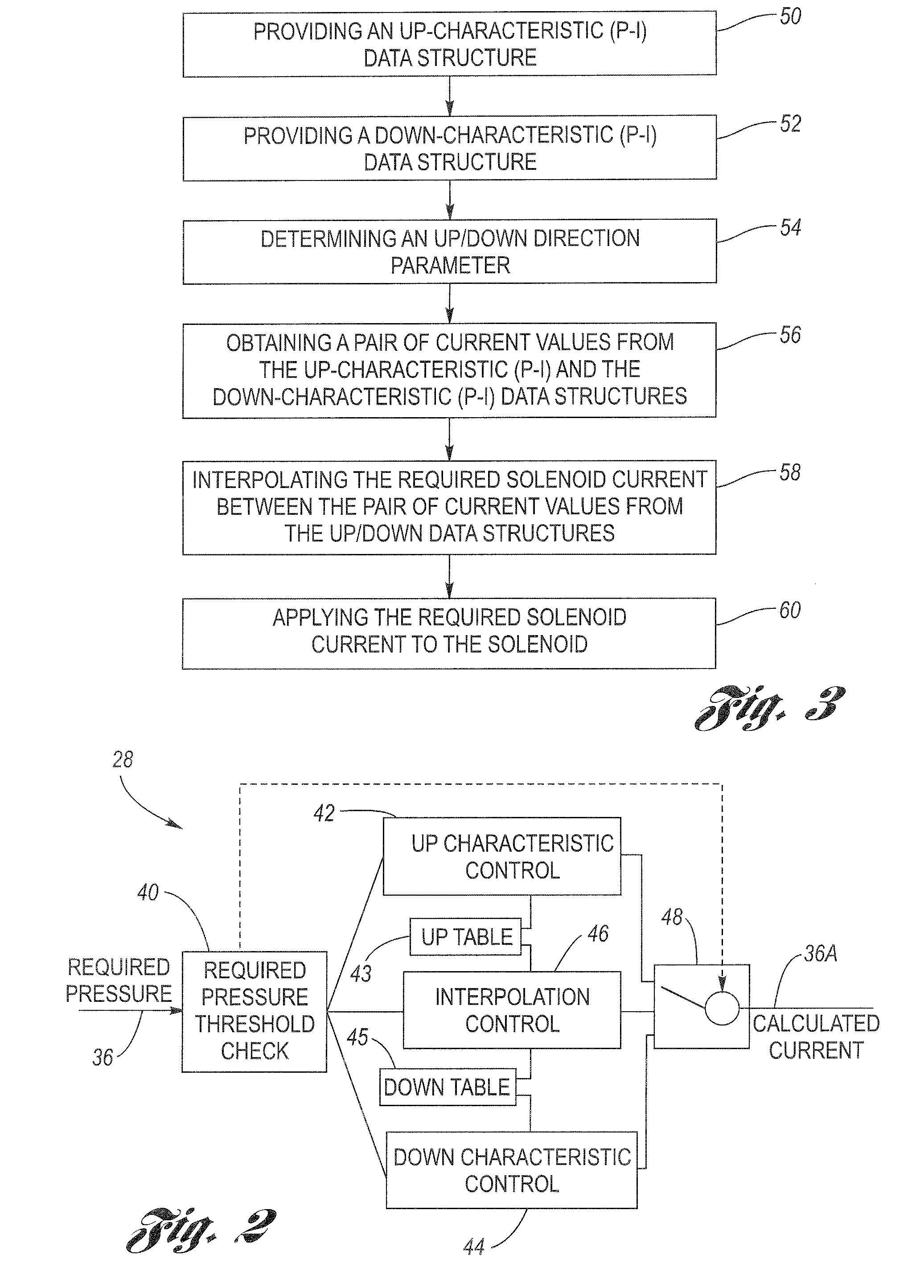

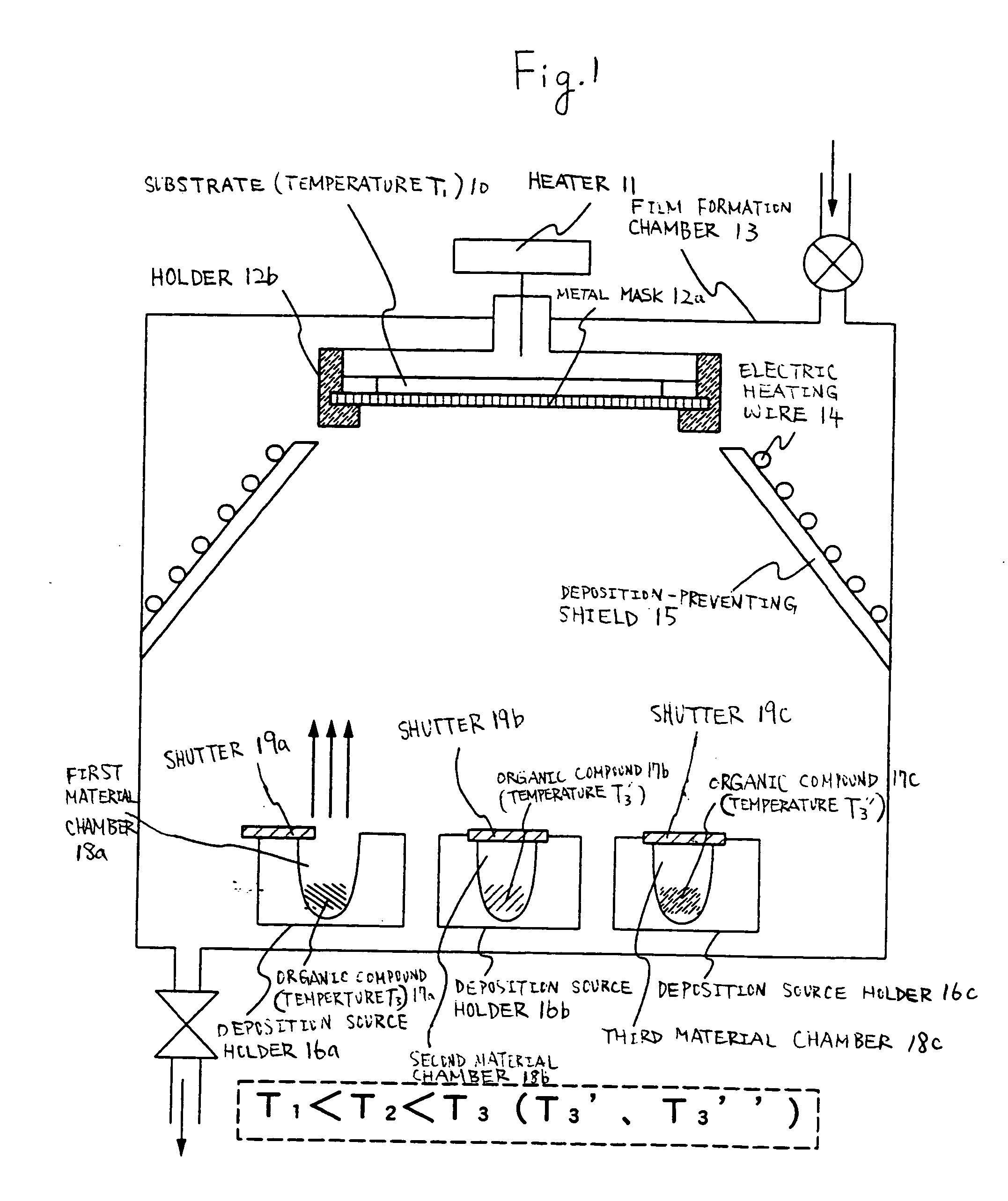

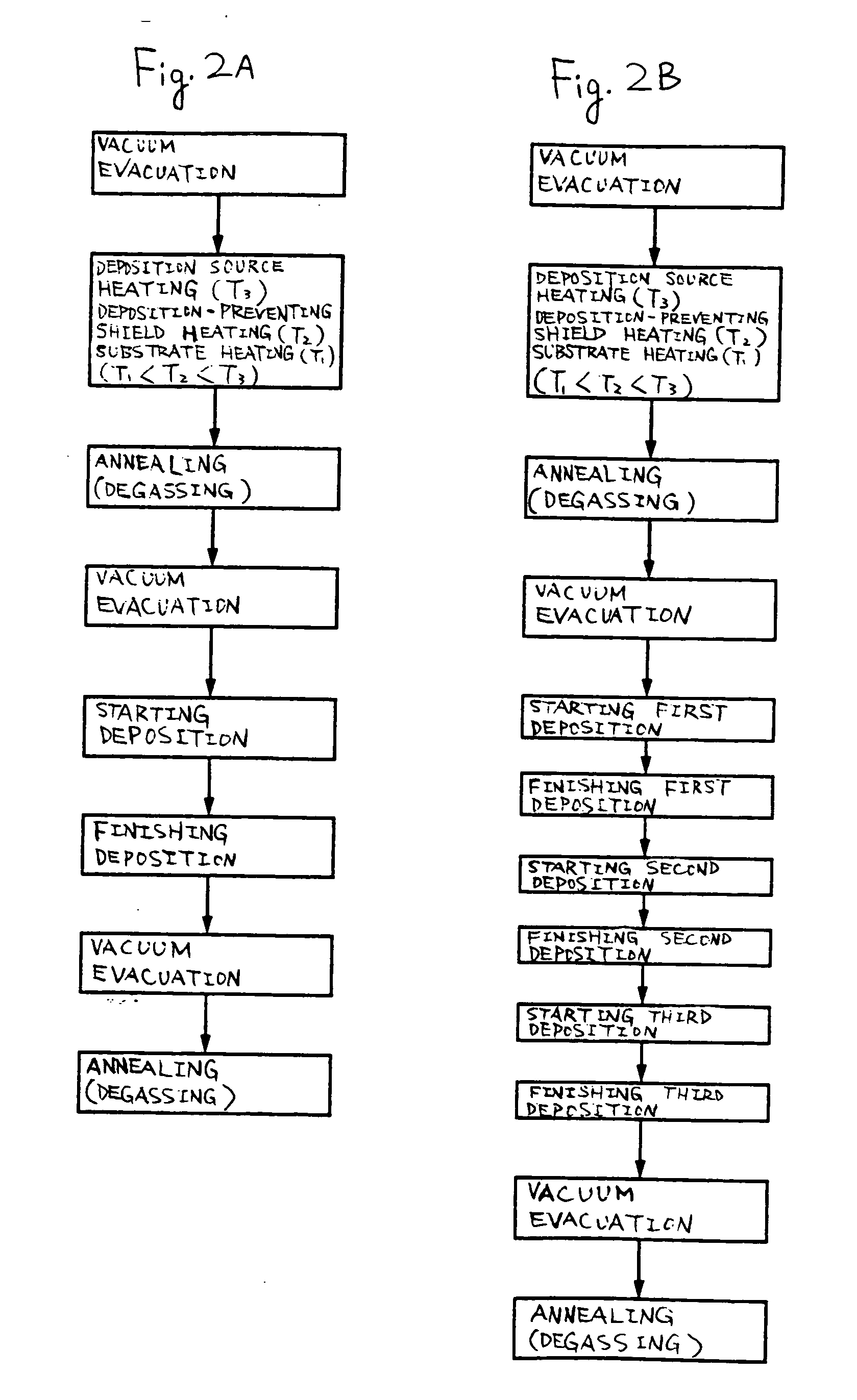

Film formation apparatus and film formation method and cleaning method

InactiveUS7316983B2Moderate energyReduce the driving voltageLiquid surface applicatorsVacuum evaporation coatingPressure decreaseHigh density

The purpose of the invention is to provide a film formation apparatus capable of forming an EL layer with a high purity and a high density, and a cleaning method. The invention is a formation of an EL layer with a high density by heating a substrate 10 by a heating means for heating a substrate, decreasing the pressure of a film formation chamber with a pressure decreasing means (a vacuum pump such as a turbo-molecular pump, a dry pump, or a cryopump) connected to the film formation chamber to 5×10−3 Torr (0.665 Pa) or lower, preferably 1×10−3 Torr (0.133 Pa) or lower, and carrying out film formation by depositing organic compound materials from deposition sources. In the film formation chamber, cleaning of deposition masks is carried out by plasma.

Owner:SEMICON ENERGY LAB CO LTD

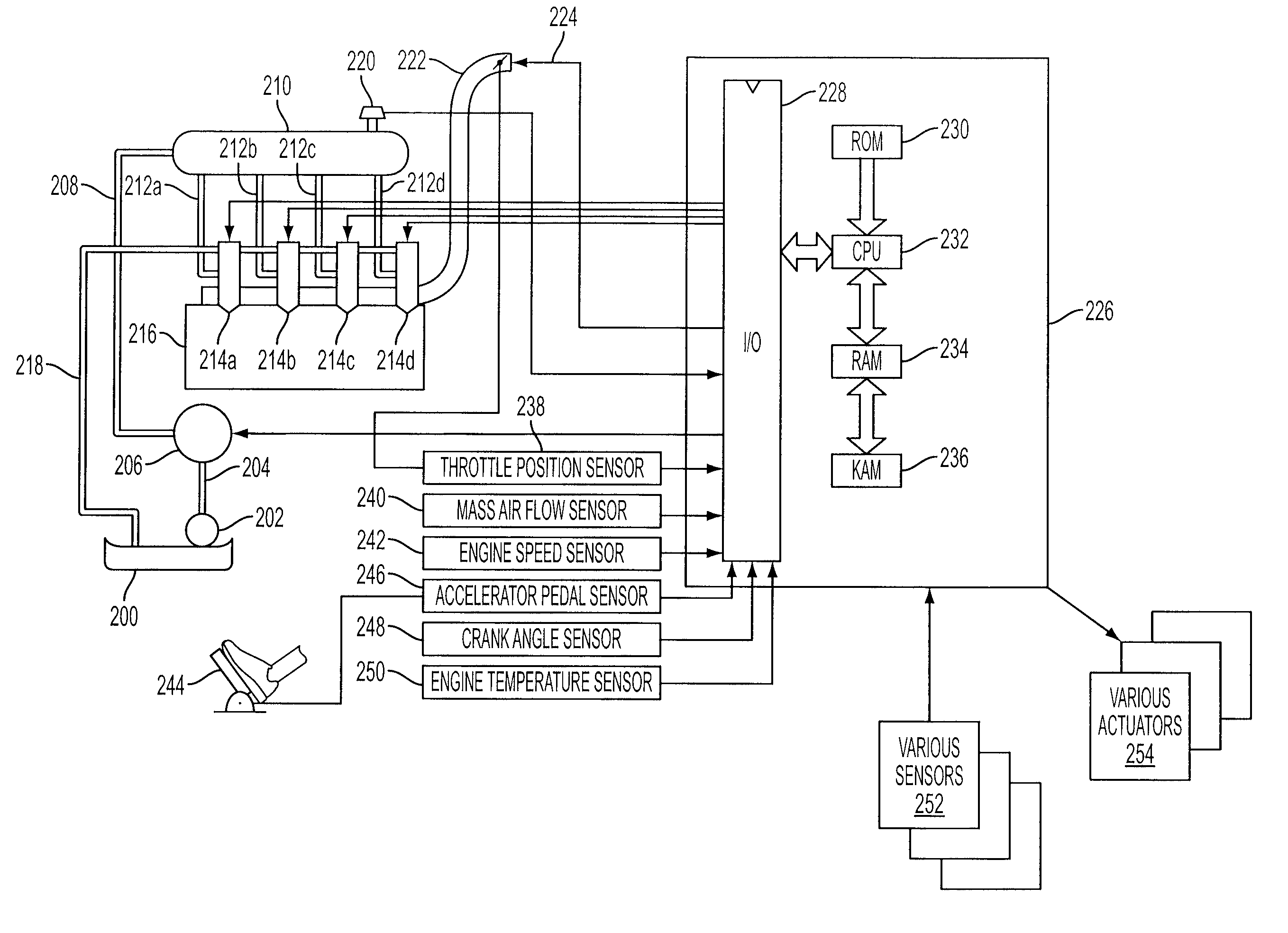

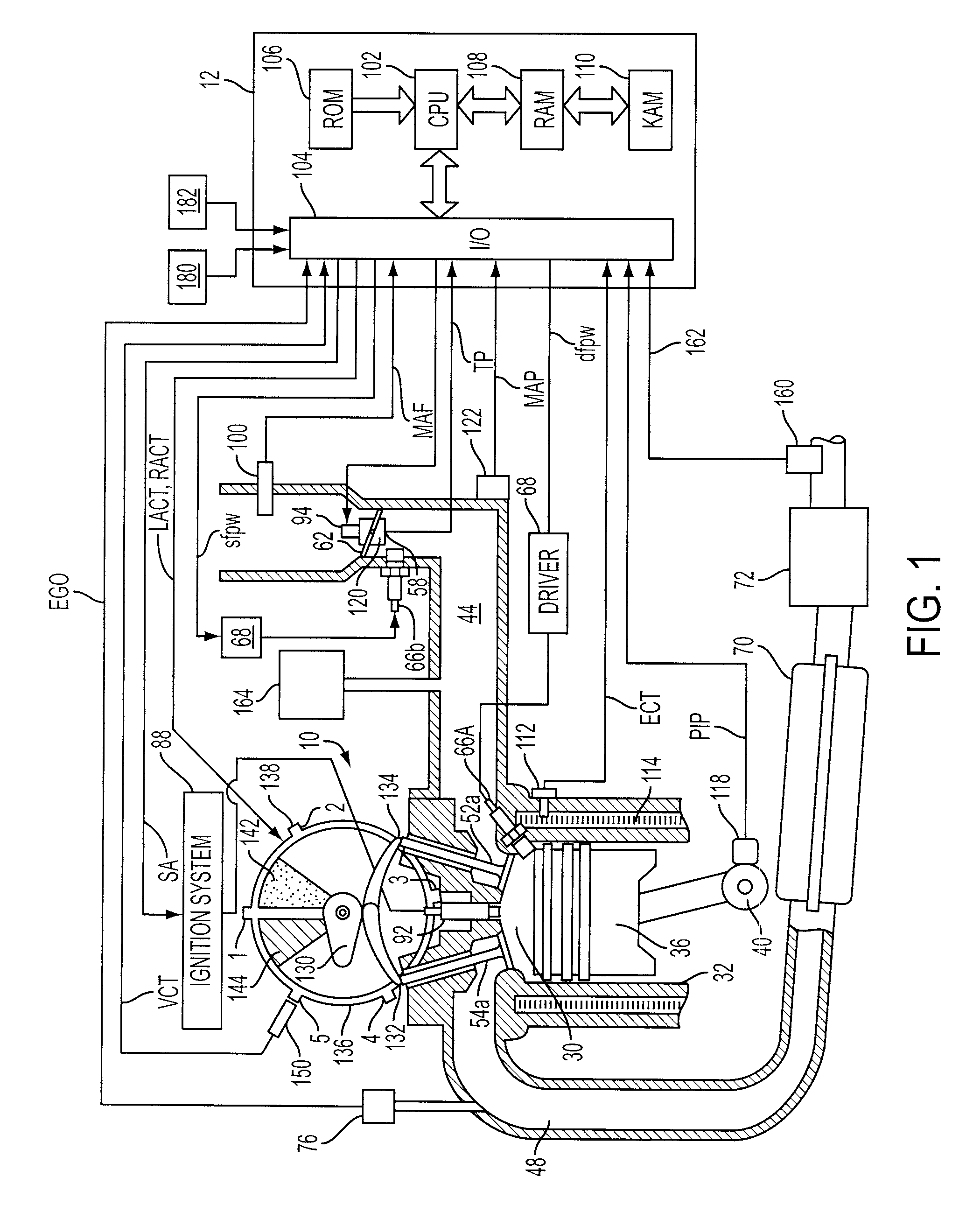

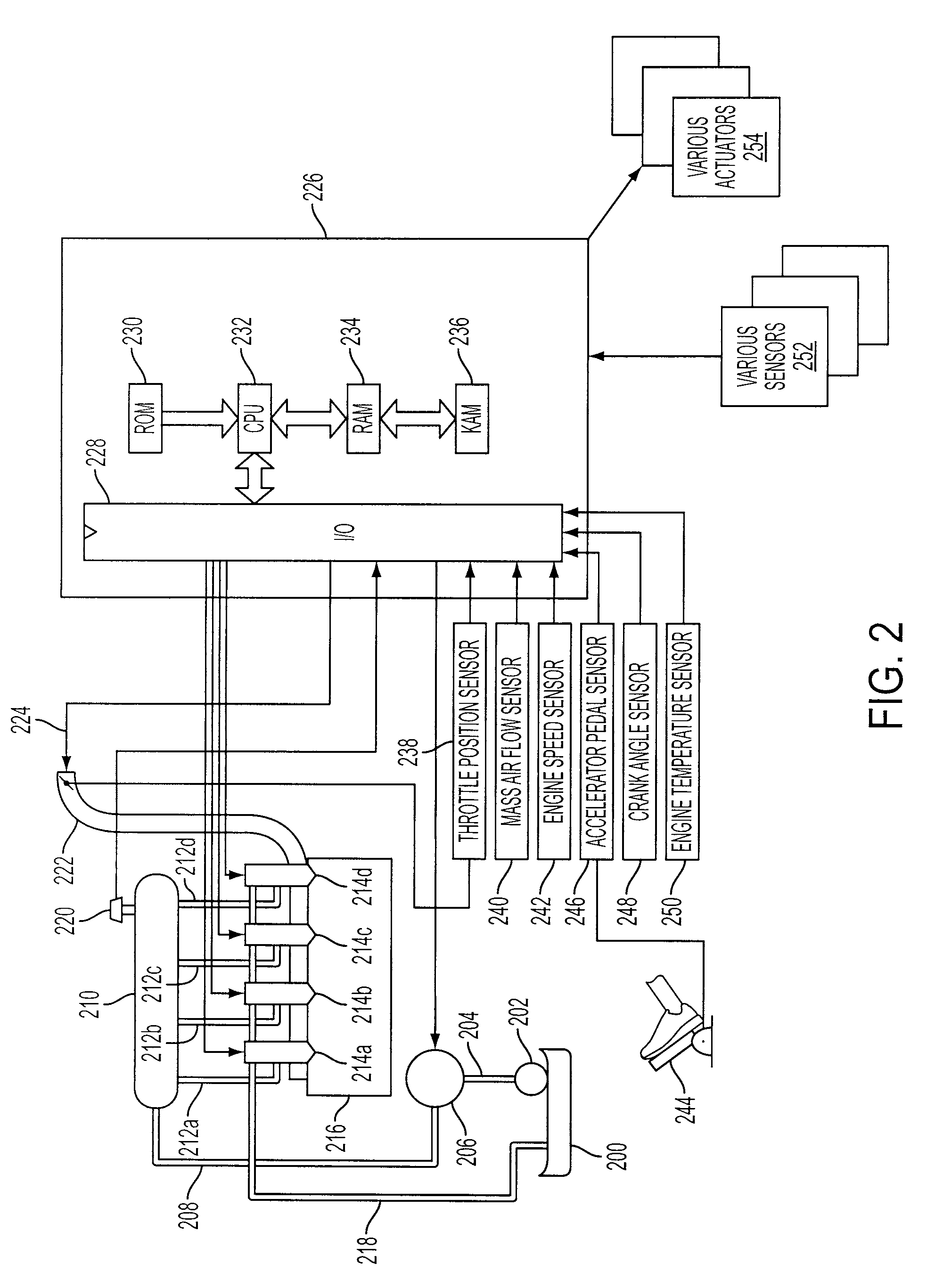

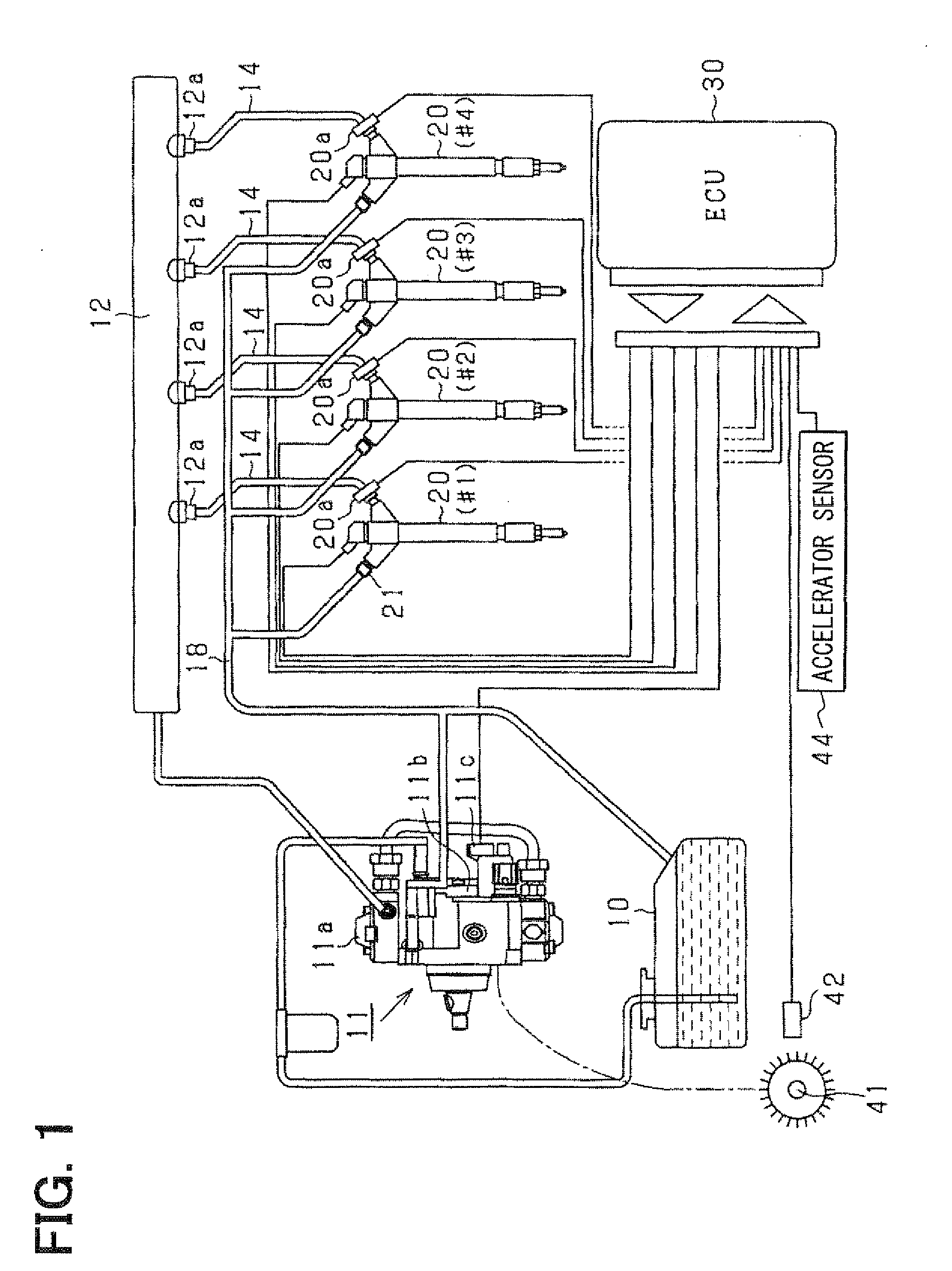

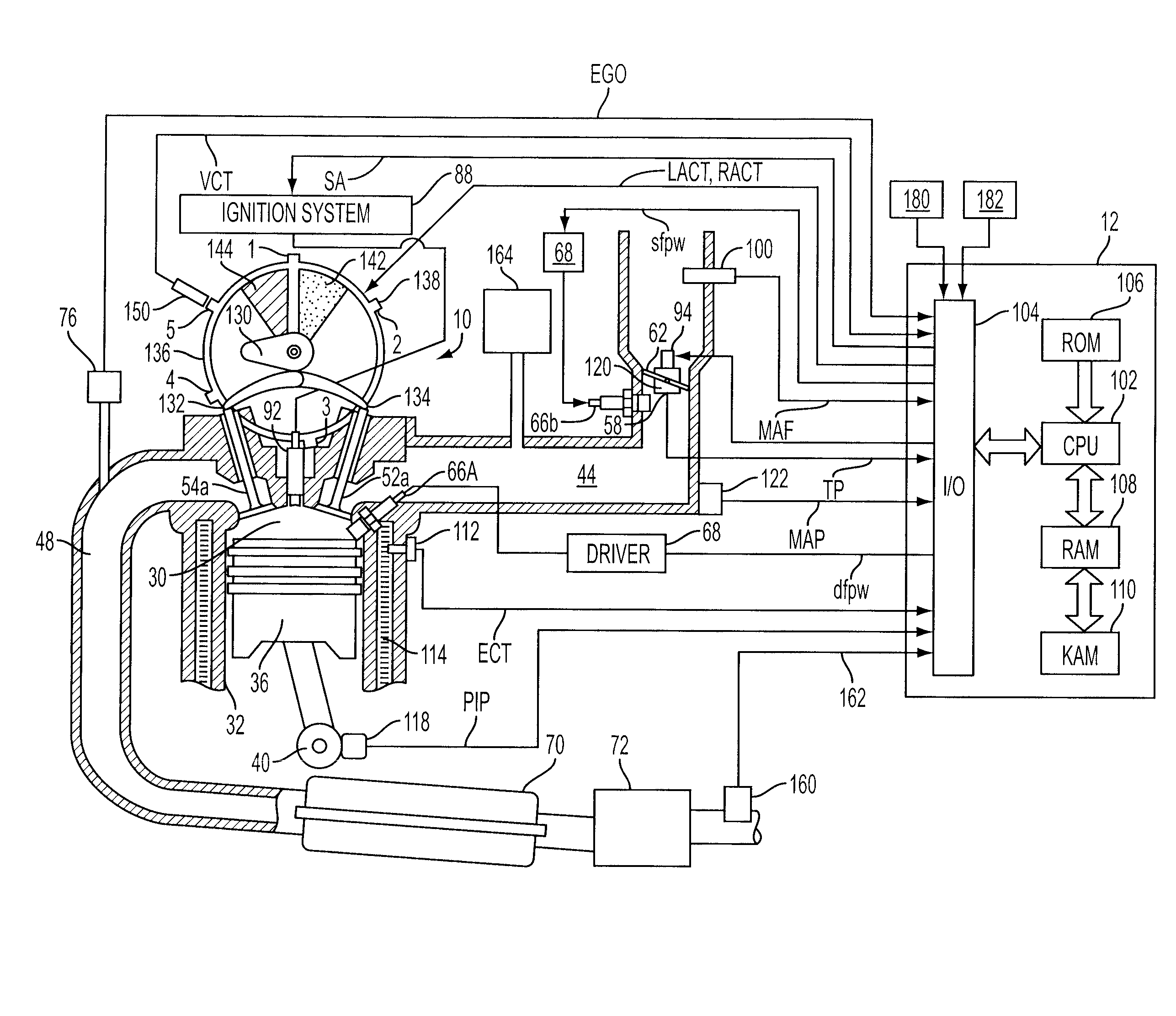

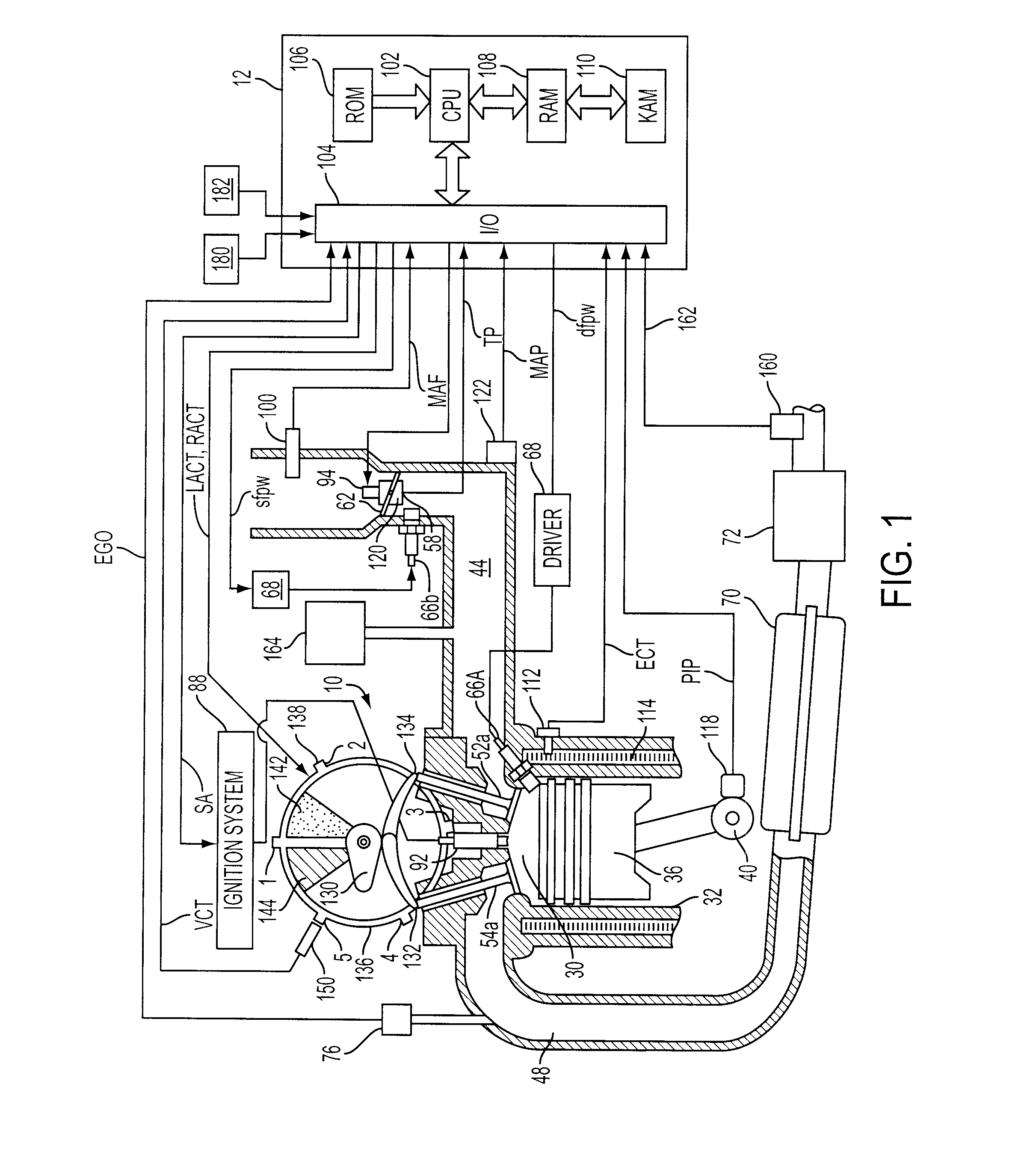

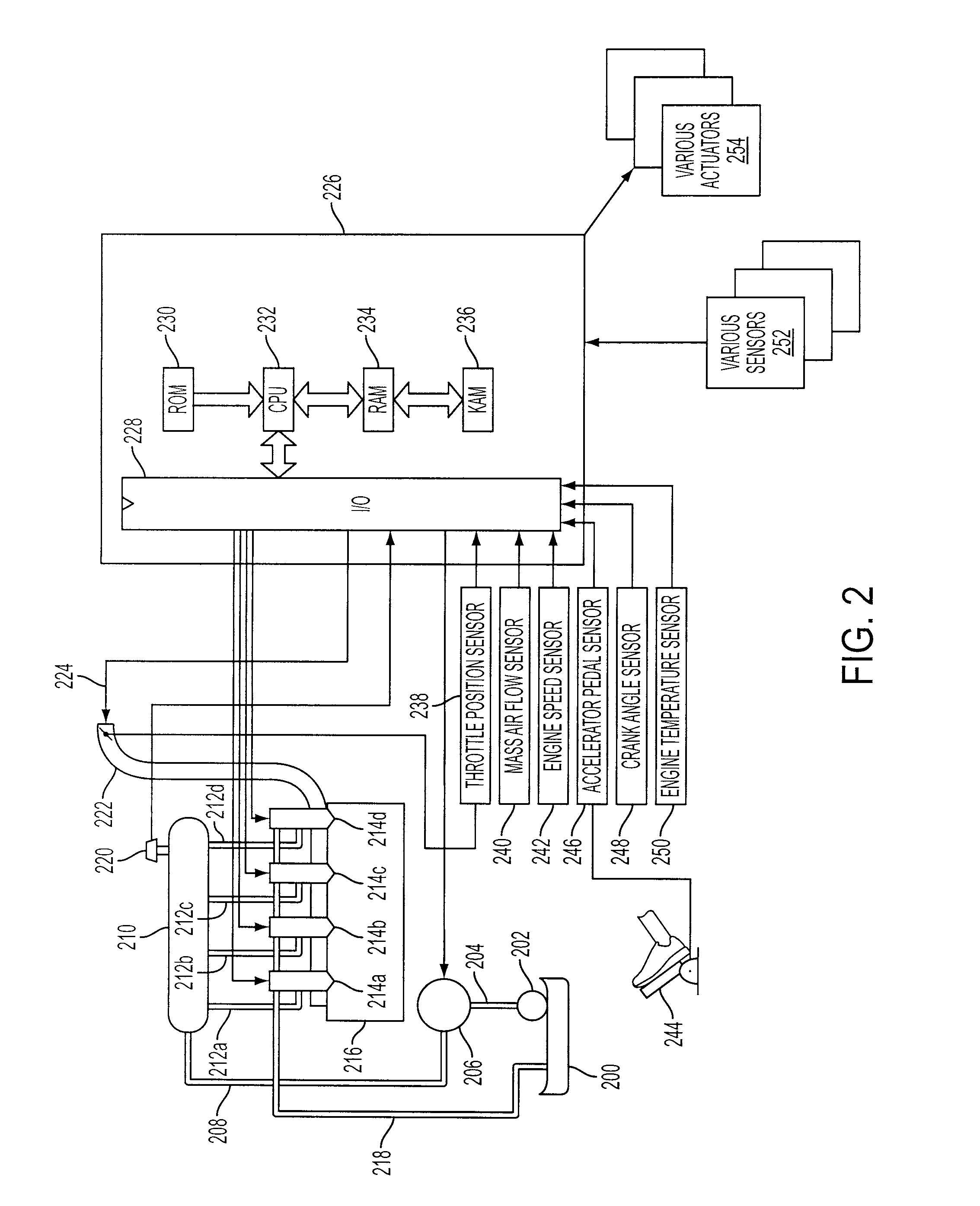

Method of detecting and compensating for injector variability with a direct injection system

ActiveUS7717088B2Improve pressure resistanceReduce temperature sensitivityElectrical controlInternal combustion piston enginesPressure decreaseEngineering

A method for controlling fuel injection of a direct injection fuel system, the fuel system having a fuel pump, the method comprising: variably operating the fuel pump to maintain a fuel pressure at a selected pressure, temporarily increasing pump operation to increase pressure sufficiently above said selected pressure and then reducing pump operation; during at least a fuel injection subsequent to the reduction in pump operation, correlating pressure decrease to injector operation, and adjusting fuel injection operation based on the correlation.

Owner:FORD GLOBAL TECH LLC

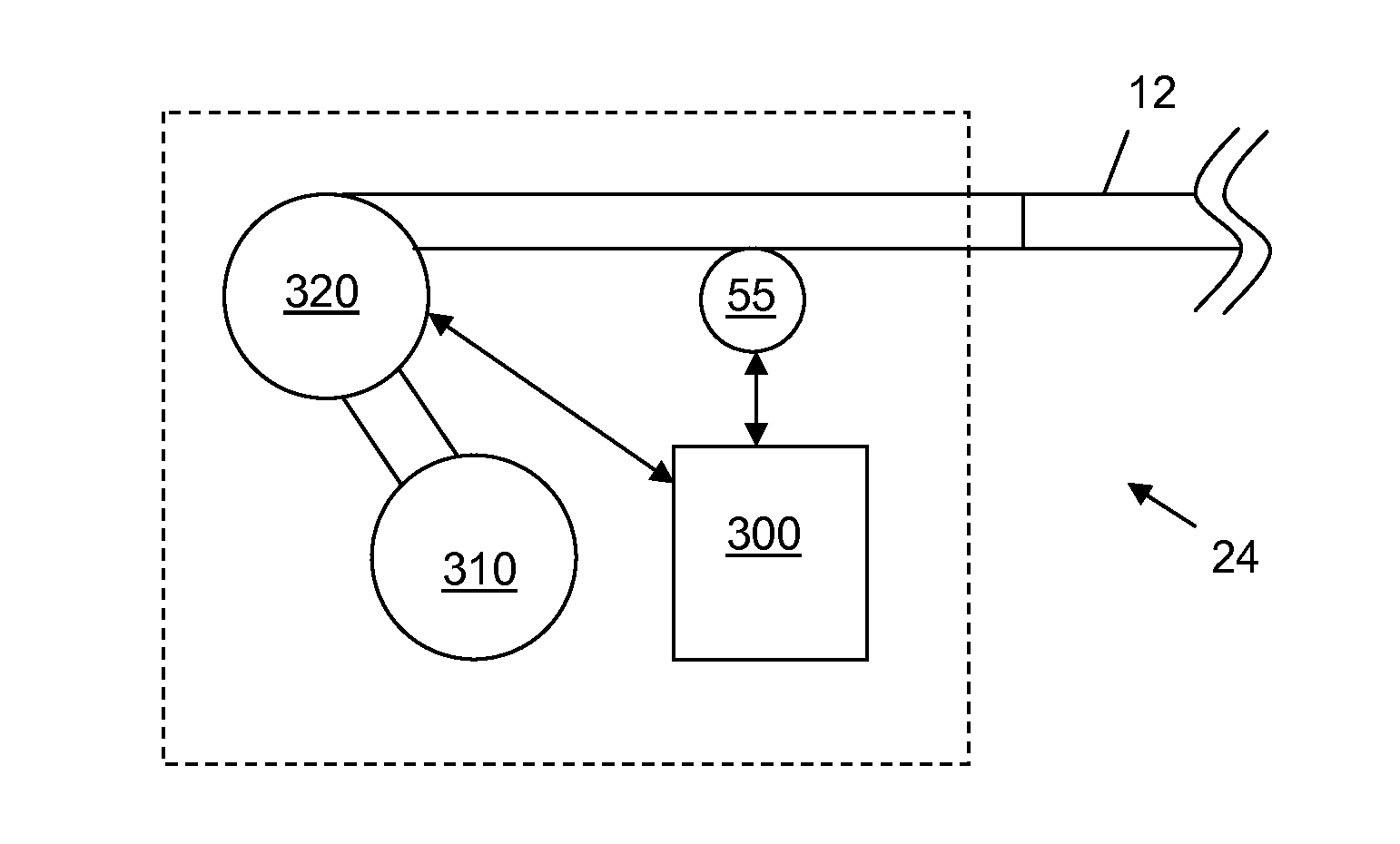

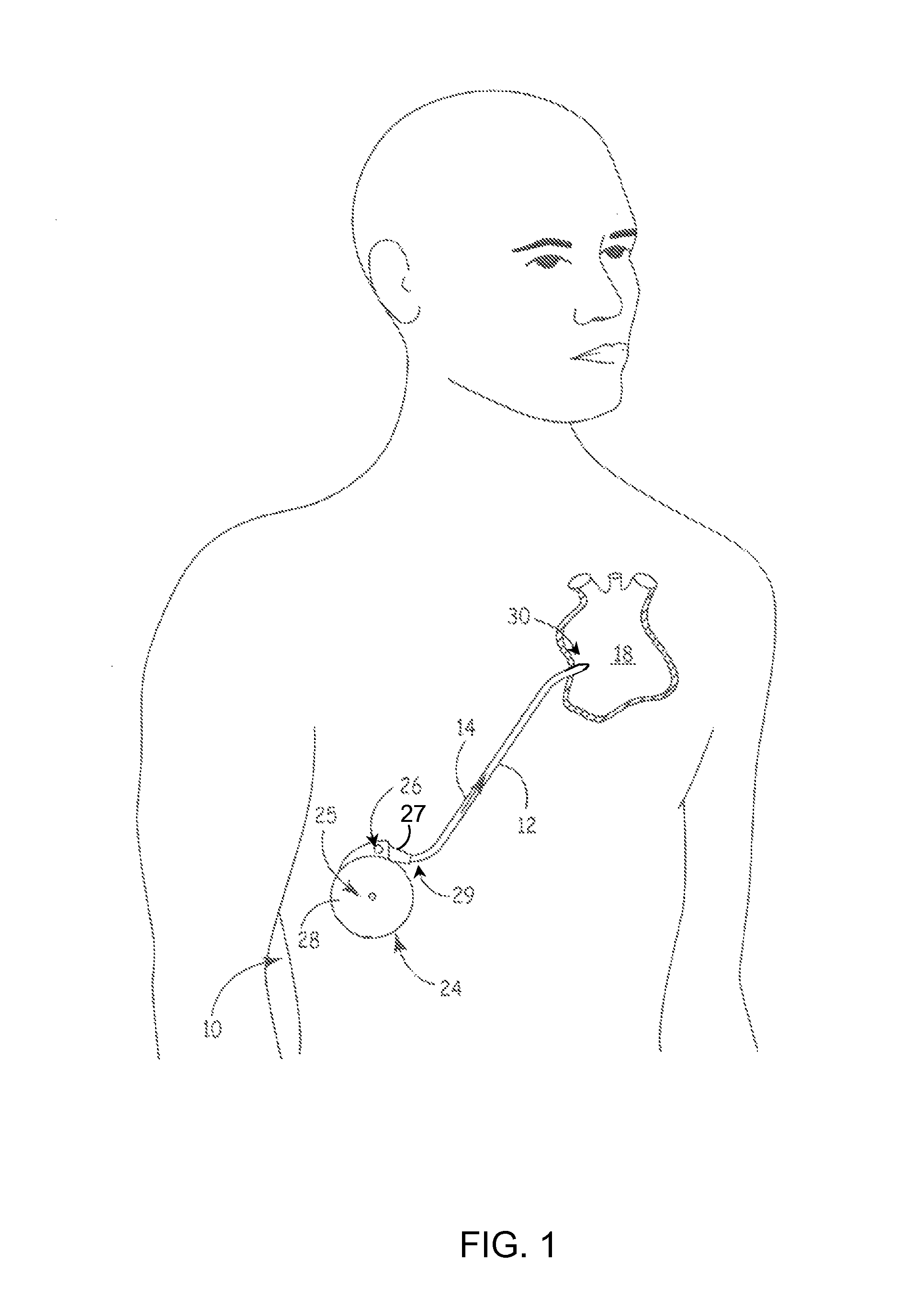

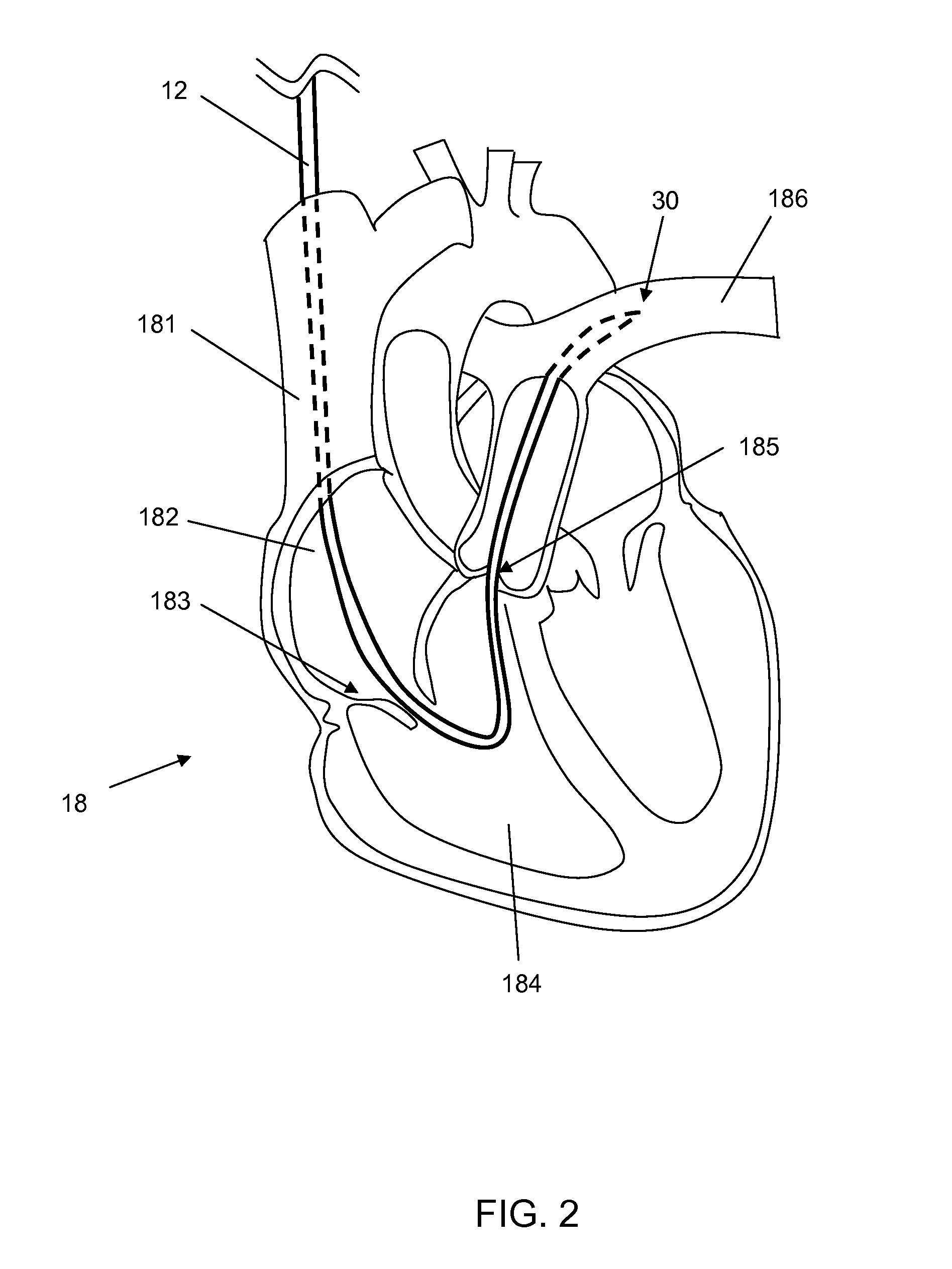

Pressure monitoring to control delivery of therapeutic agent

A method for adjusting delivery of a therapeutic fluid to a patient suffering from or at risk of pulmonary arterial hypertension includes introducing the therapeutic fluid to a patient via a catheter at a predetermined rate. The catheter is positioned to deliver the fluid to the right ventricle or the pulmonary artery. The catheter a one-way valve configured to allow the fluid to flow from the catheter to the target location. The method further includes monitoring pressure of the target location by monitoring internal catheter pressure, and adjusting the rate at which the therapeutic fluid is introduced to the catheter based on the monitored pressure. The rate at which the fluid is introduced to the catheter is increased if internal catheter pressure increases, and the rate at which the fluid is introduced to the catheter is decreased if the internal catheter pressure decreases.

Owner:MEDTRONIC INC

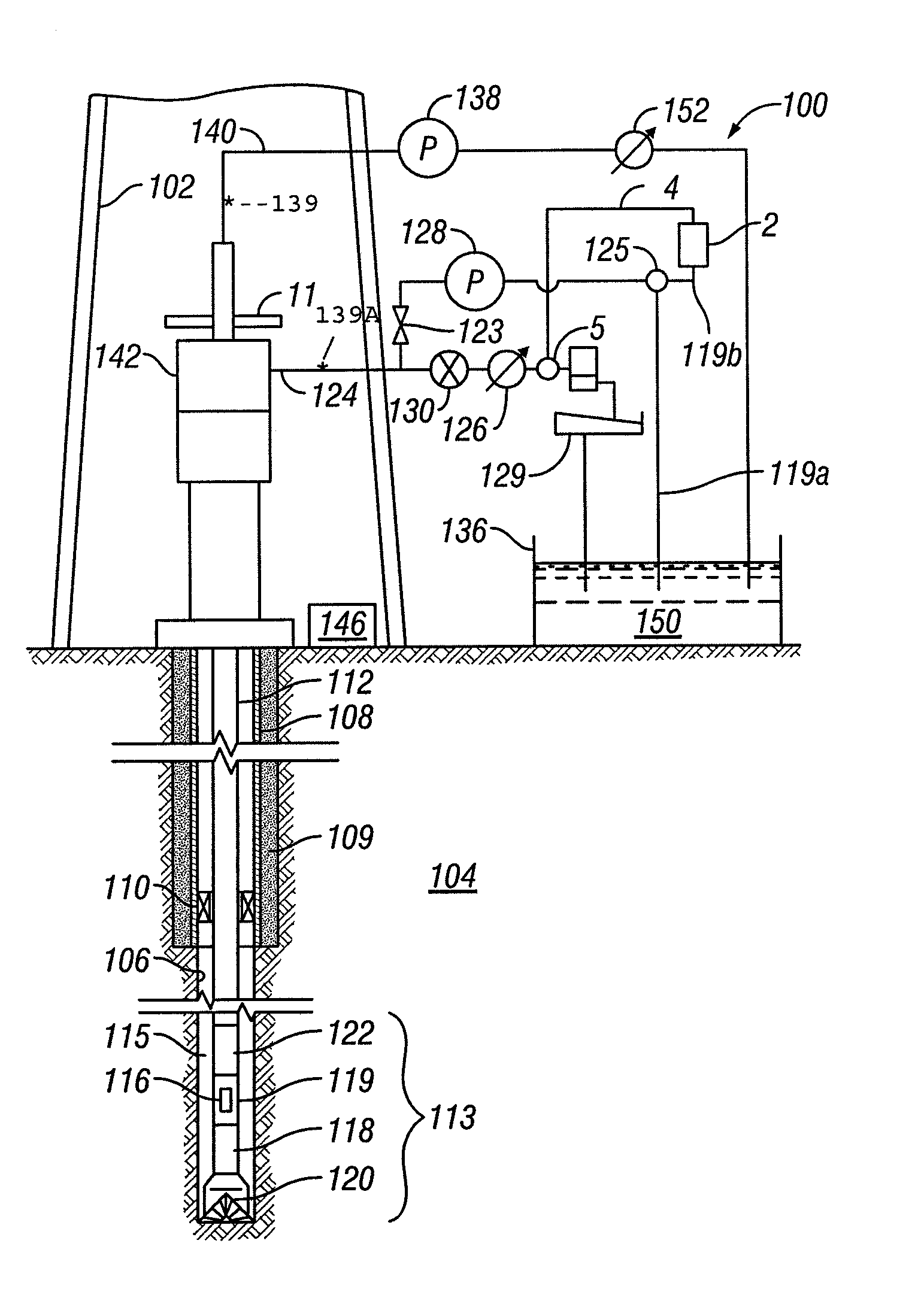

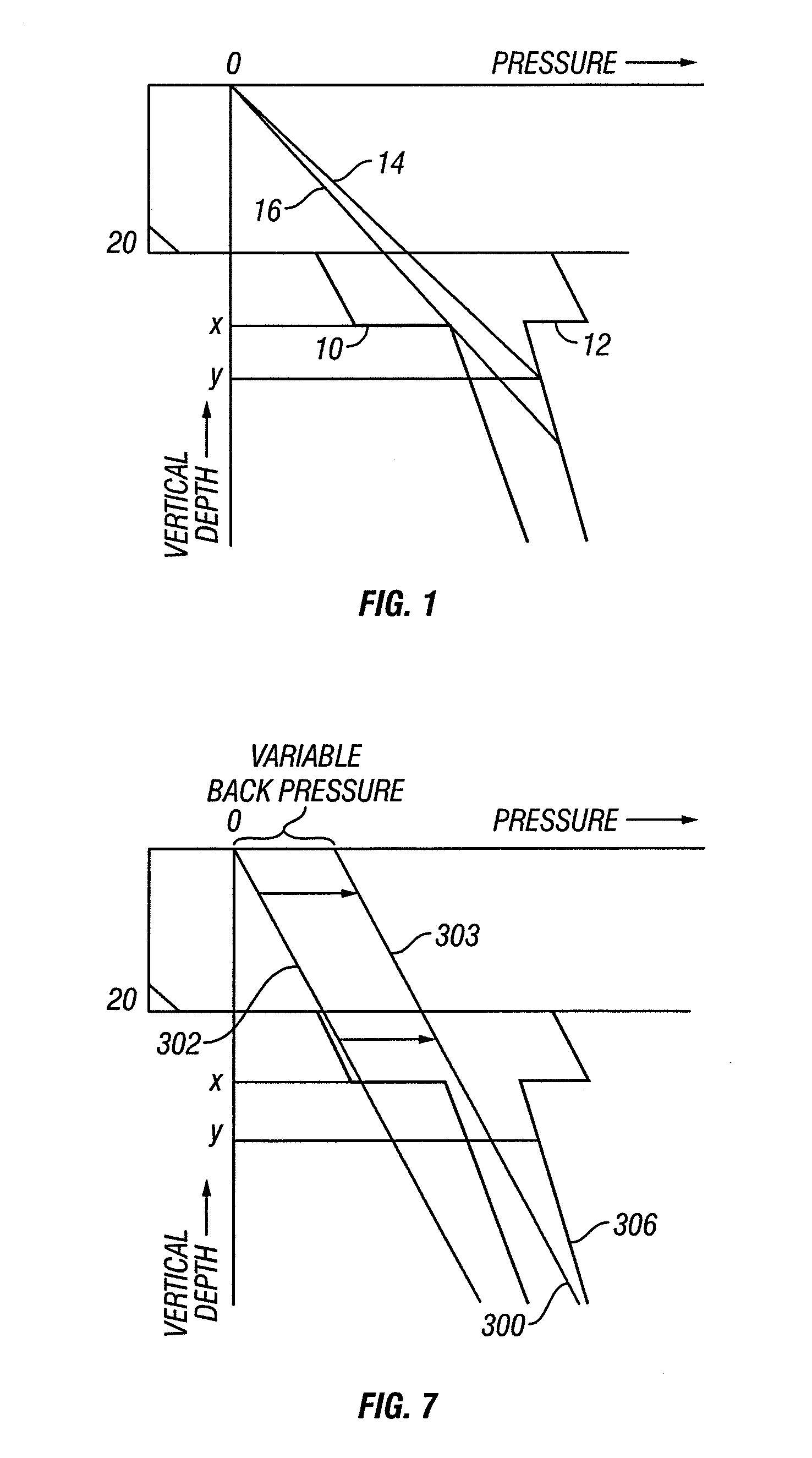

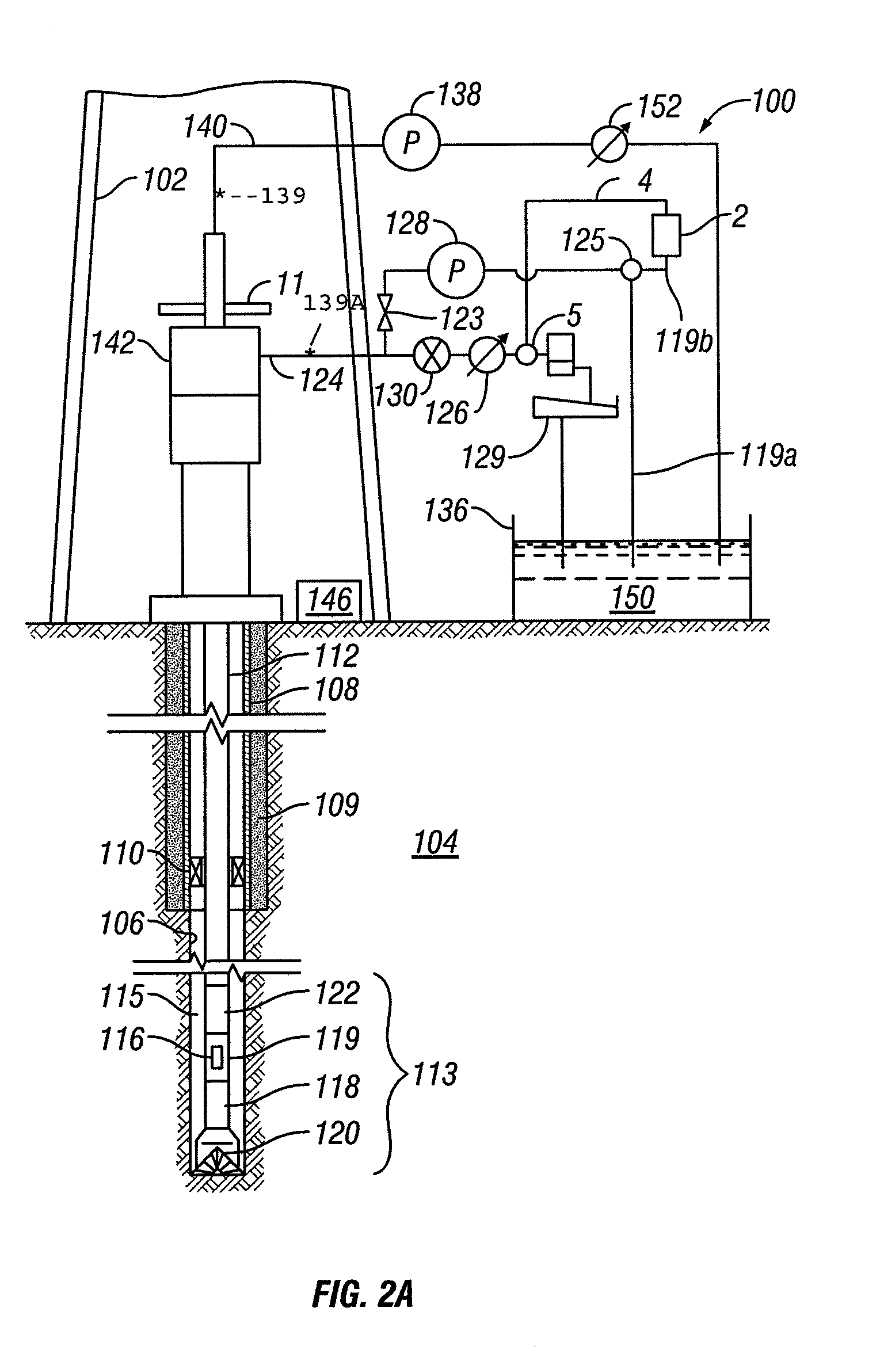

Method for determining fluid control events in a borehole using a dynamic annular pressure control system

A method for determining existence of a borehole fluid control event by controlling formation pressure during the drilling of a borehole includes selectively pumping a drilling fluid through a drill string extended into a borehole, out a drill bit at the bottom end of the drill string, and into an annular space between drill string and the borehole. The drilling fluid leaves the annular space proximate the surface. Existence of a well control event is determined when at least one of the following events occurs: the rate of the selective pumping remains substantially constant and the annular space pressure increases, and the rate of the selective pumping remains substantially constant and the annular space pressure decreases.

Owner:SMITH INT INC

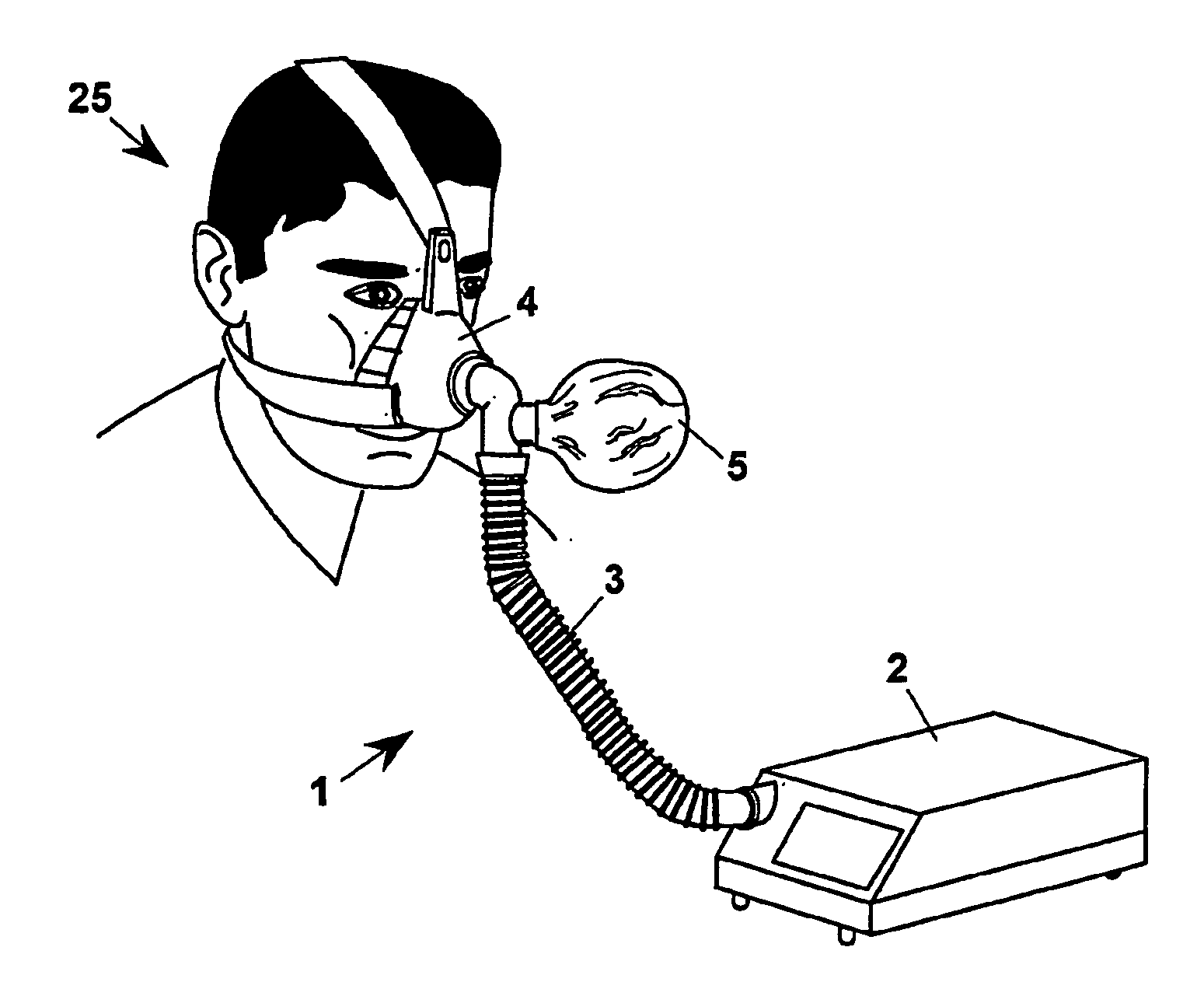

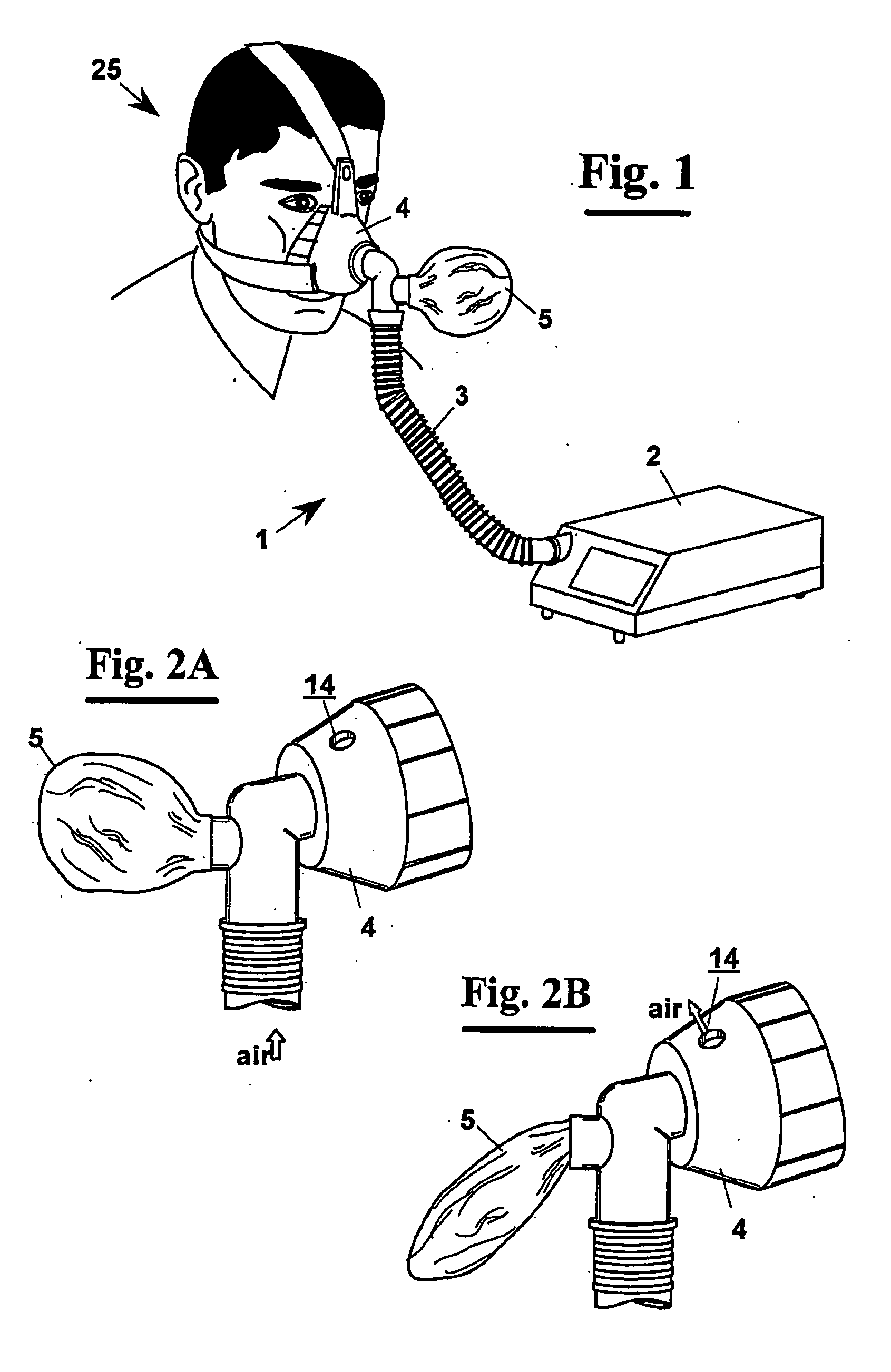

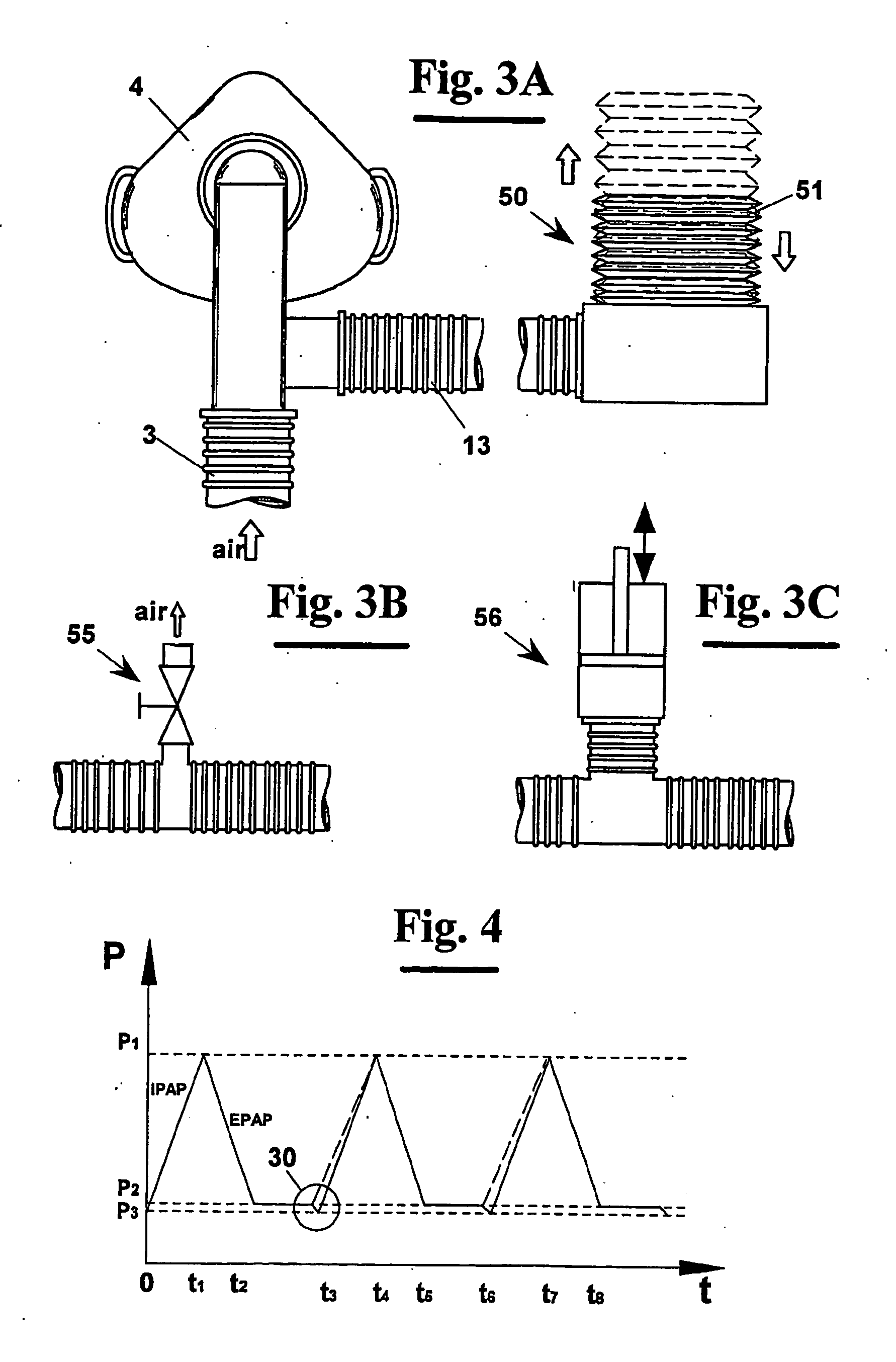

Apparatus for non-invasive mechanical ventilation

InactiveUS20060283451A1Facilitates gas exchangeShorten the construction periodOperating means/releasing devices for valvesRespiratory masksPressure decreaseEngineering

An apparatus (1) for non-invasive mechanical ventilation comprises a fan (2) of Bi-level type, or BiPAP, for generating an air flow according to a succession of inspiration steps, or IPAP, and exhalation steps, or EPAP. The flow is conveyed in the aerial ducts of a patient (25) by means of a flexible tube (3) connected to a nasal mask (4). A flexible air reservoir (5) is provided pneumatically connected to the duct (3) and the nasal mask (4) in order to subtract from the inspiration flow a certain air amount before that it reaches the patient (25) at the beginning of an IPAP step. During the exhalation EPAP step, since the air flow pressure decreases automatically, there is the emptying at least partial of the flexible air reservoir (5), whereas the air exhaled by the patient exits through an opening (14) made on the nasal mask (4). This way an air exchange occurs also in the most peripheral patient's aerial ducts and the amount of gaseous exchanges is increased, reducing at the same time the duration of the treatment.

Owner:AZIENDA OSPEDALIERA PISANA

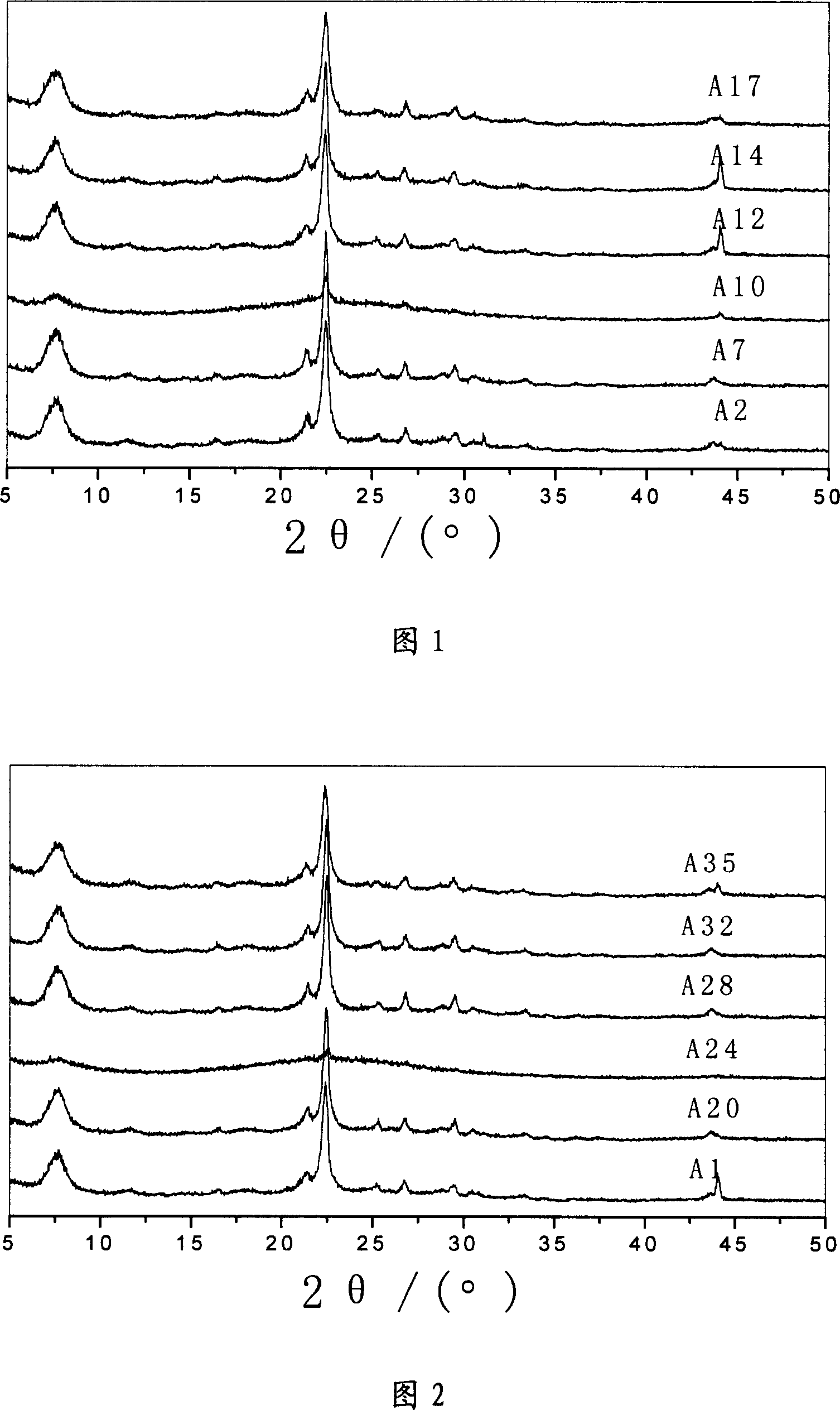

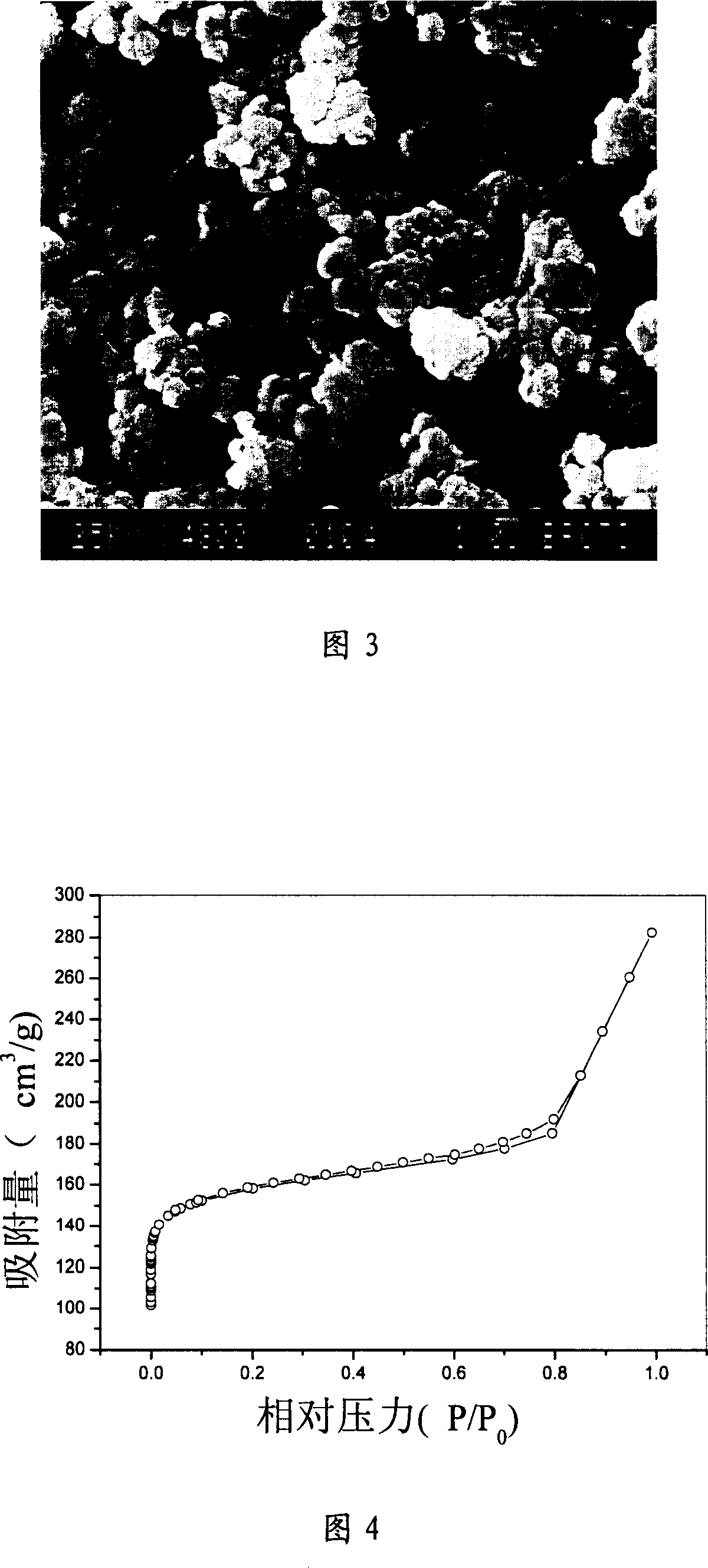

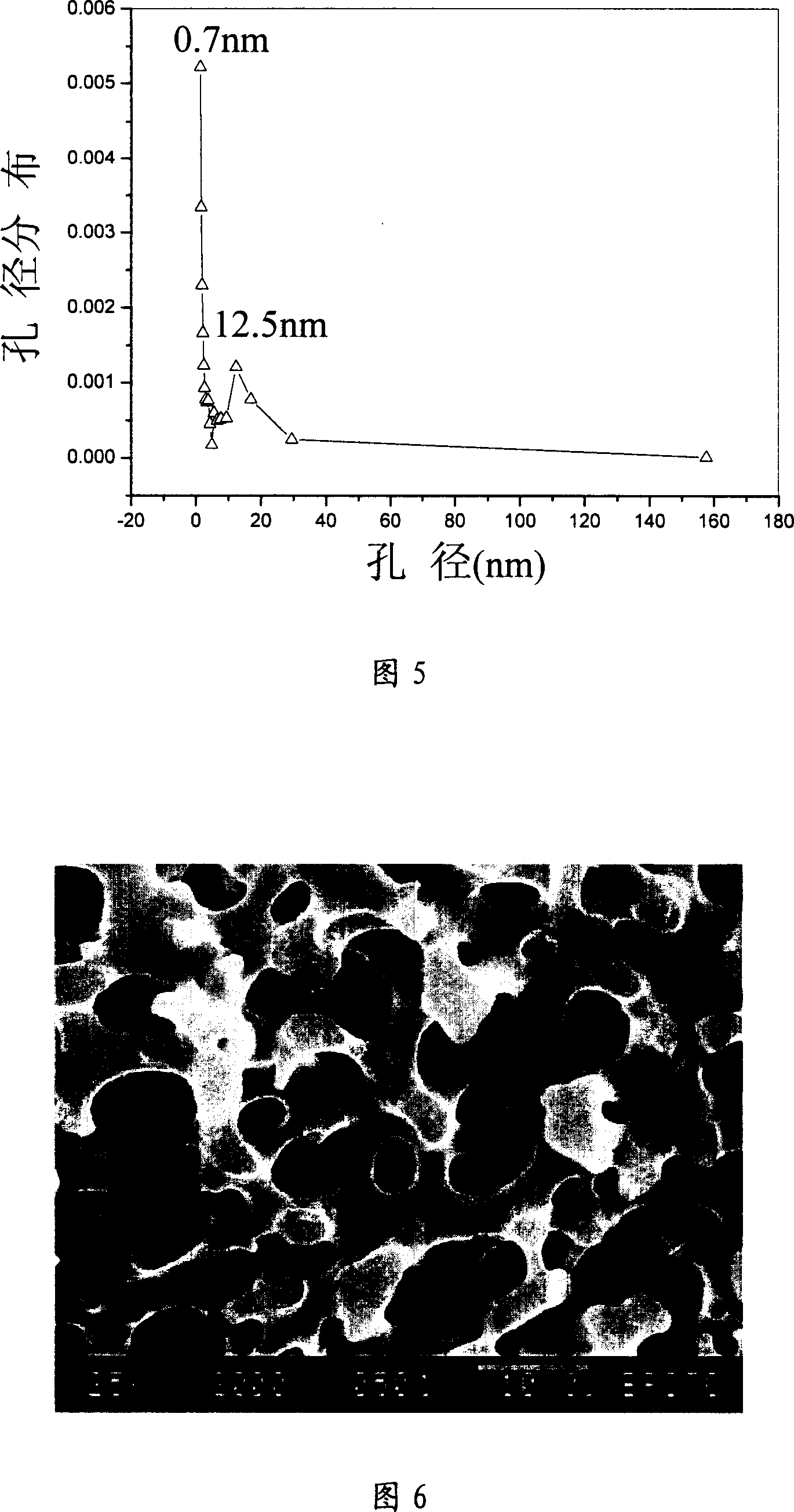

Method for preparing beta zeolite with multilevel pore canals

ActiveCN101003378AEasy to operateShorten the diffusion distanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesPressure decreaseMicrometer scale

This invention discloses a method for preparing multi-level porous beta-zeolite. The method comprises: soaking monolithic silica gel column in sucrose solution, drying, polymerizing, carbonizing to obtain C-Si composite, wetting the C-Si composite with a mixed solution of Al source, inorganic alkali, organic amine and water, crystallizing, and recovering the product. In this method, carbon material can effectively protect the porous structure of monolithic silica gel column from damage during crystallization process. The obtained beta-zeolite has multi-level pores, including micrometer-scale macropores, mesopores and micropores. The macropores can shorten the diffusion distances of reactive molecules, reduce the pressure decrease of the equipment, raise the unit processing capacity of the equipment, and make the adjustment and control of the product selectivity easier. The mesopores can provide large inner specific surface area, which is meaningful to the catalytic reaction of macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +2

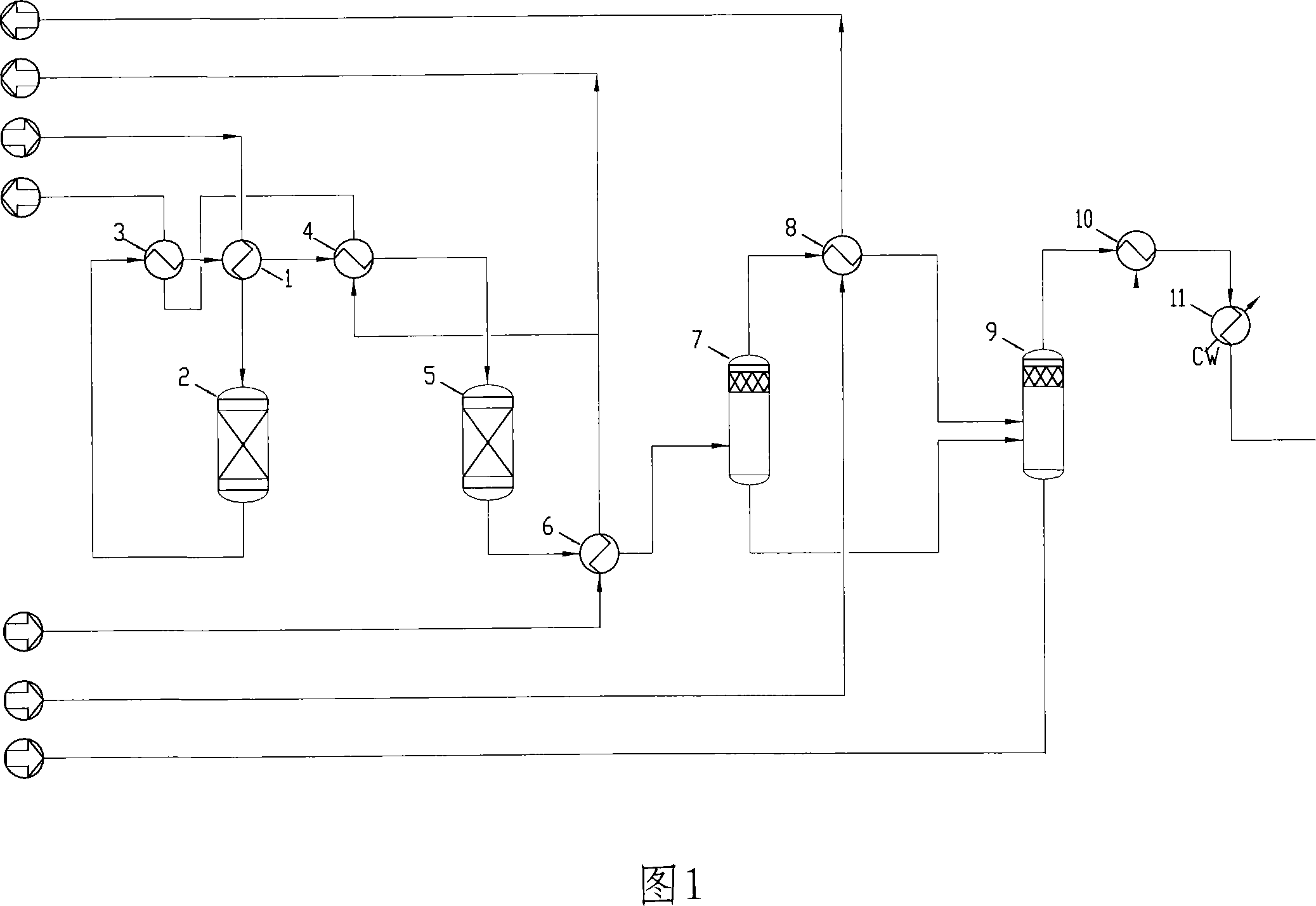

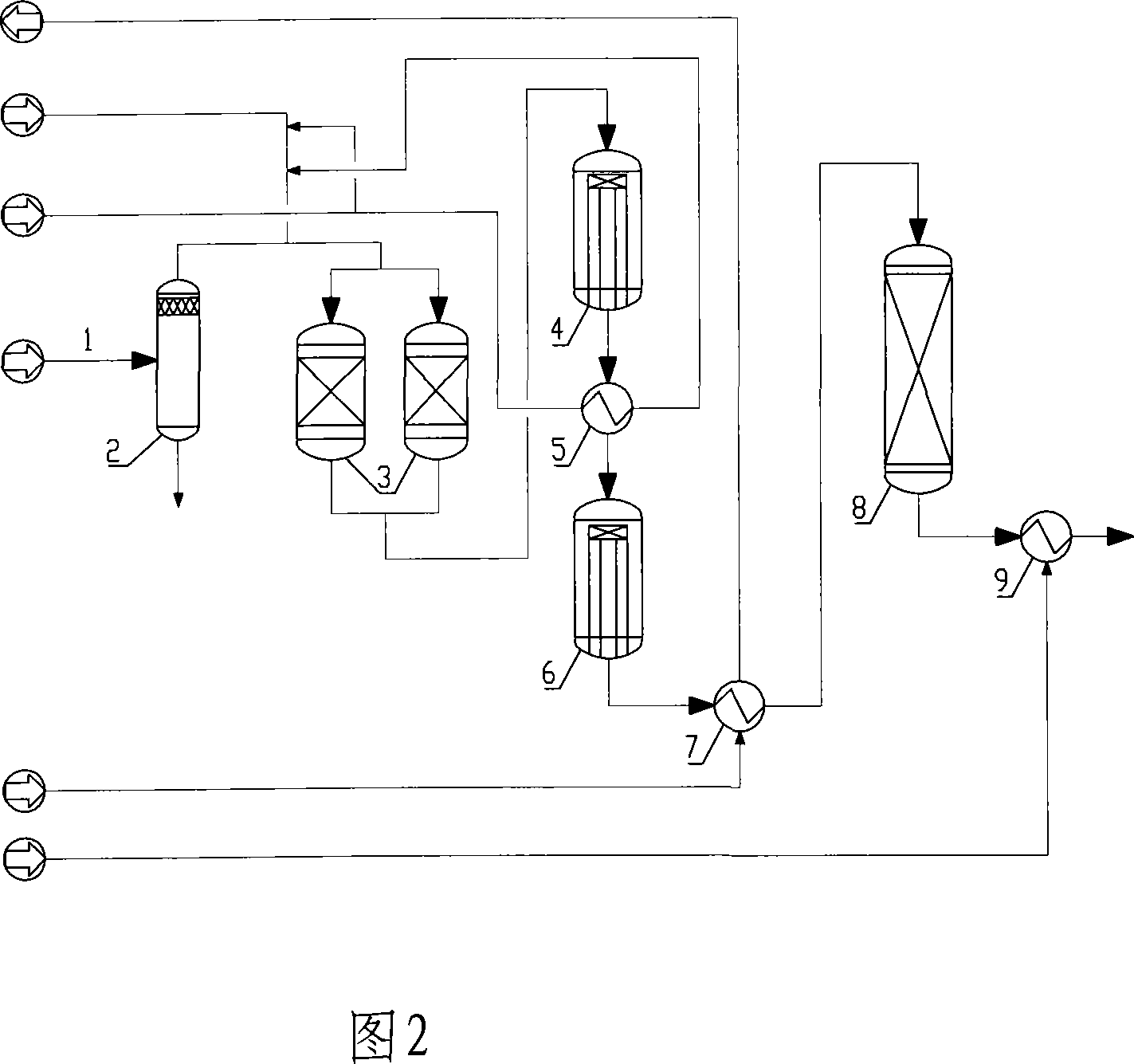

CO conversion technique matched to coal gasification

ActiveCN101050390AEasy to handleExtended service lifeCombustible gas catalytic treatmentEnergy inputPressure decreaseVapor–liquid separator

This invention discloses a process for converting CO in pulverized coal gasification. The process comprises: introducing crude synthesis gas from pulverized coal gasification into a gas-liquid separator, mixing the gas from separator top with outside middle-pressure overheated steam, middle-pressure steam and a small amount of condensate from steam stripping, introducing into a pre-conversion furnace, controlling the temperature increase, introducing the converted gas into 1# conversion furnace, performing in-depth CO conversion, introducing high-temperature shift gas into a middle-pressure waste boiler to generate4.0 MPa steam with the condensate produced in the process, introducing all middle-pressure steam into fresh converted gas for recycling, quenching with the condensate for humidification, converting in 2# conversion furnace, cooling he converted gas by a water preheater, introducing into 3# conversion furnace, recovering waste heat until the output gas is less than or equal to 40 deg.C, and introducing into the following procedures. The CO concentration is decreased from 60-65 mol. % to less than or equal to 0.4 mol. %. The pre-conversion furnace can prevent catalyst poisoning. The pressure decrease of the conversion system is reduced, thus can ensure the pressure at the inlet of the synthesis gas compressor.

Owner:SINOPEC NINGBO ENG +1

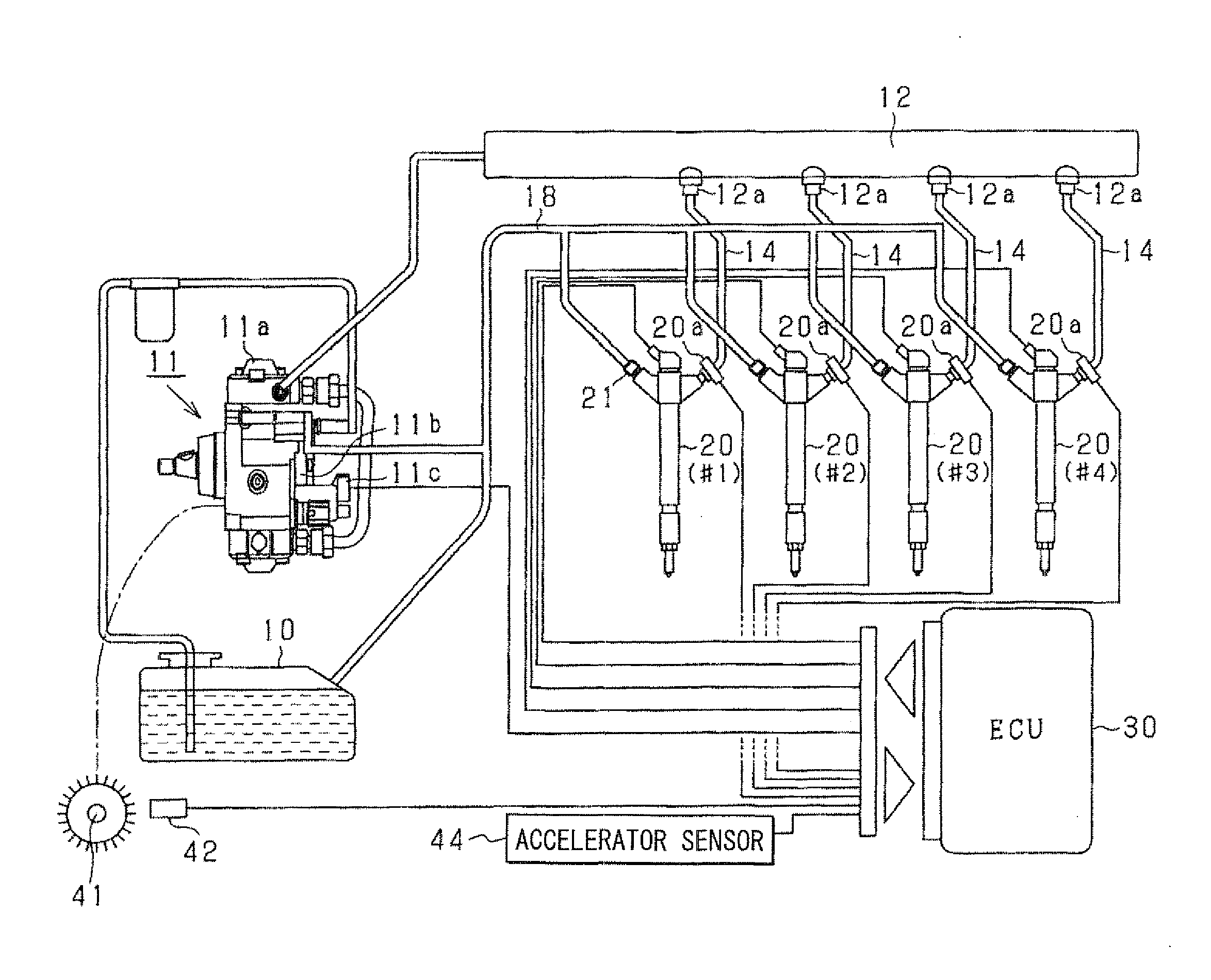

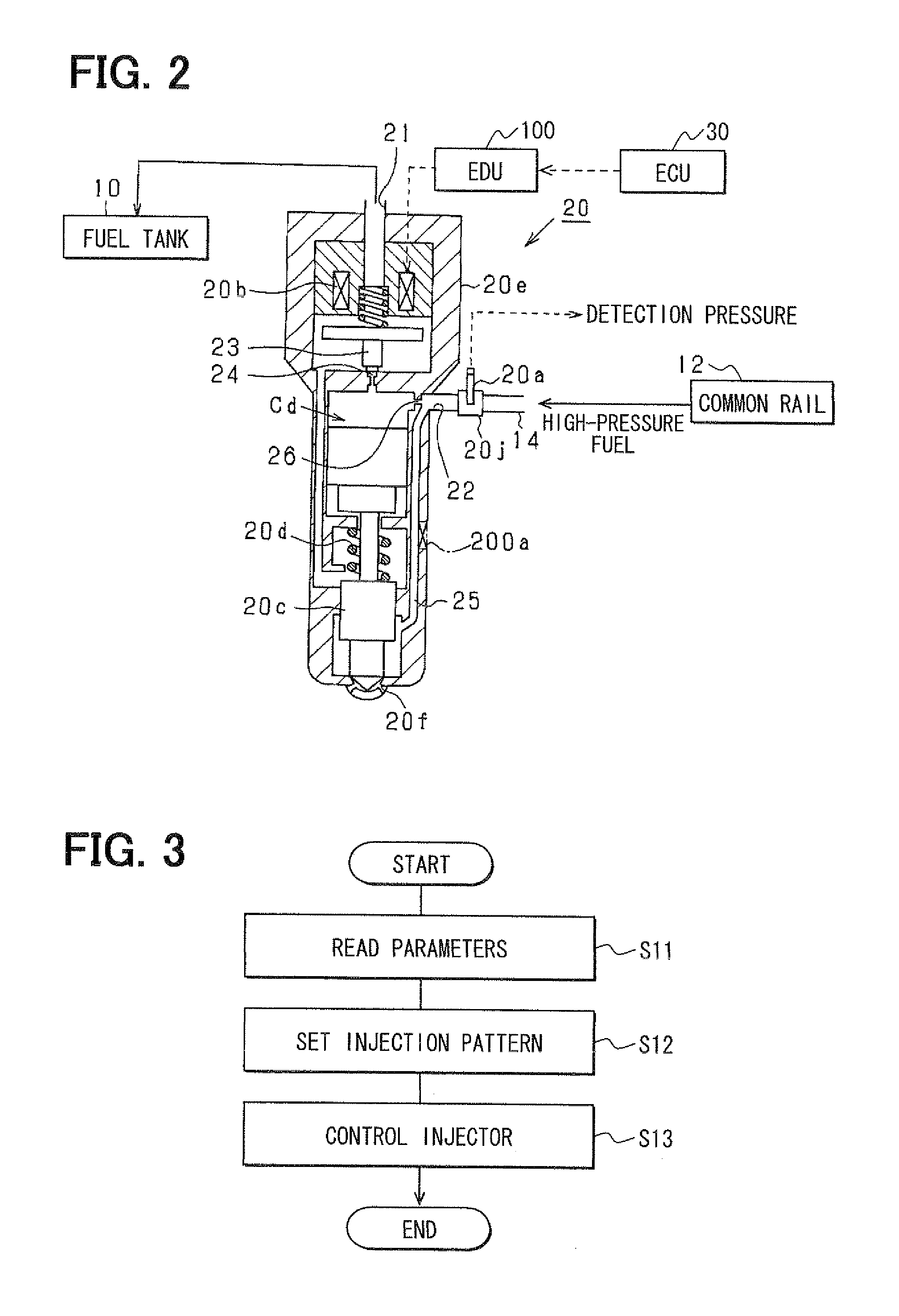

Fuel injection detecting device

ActiveUS20100250095A1Electrical controlDigital data processing detailsPressure decreaseFuel injection

A fuel injection detecting device computes a maximum-fuel-injection-rate-reach timing and a fuel-injection-rate-decrease-start timing based on a falling waveform of the fuel pressure and a rising waveform of the fuel pressure. The falling waveform represents the fuel pressure detected by a fuel sensor during a period in which the fuel pressure increases due to a fuel injection rate decrease. The rising waveform represents the fuel pressure detected by the fuel sensor during a period in which the fuel pressure decreases due to a fuel injection rate increase. The rising waveform and the falling waveform are respectively modeled by modeling function. In a case of small fuel injection quantity, an intersection timing at which lines expressed by the modeling functions intersect with each other is defined as the maximum-fuel-injection-rate-reach timing and the fuel-injection-rate-decrease-start timing.

Owner:DENSO CORP

Apparatus for recovering core samples under pressure

Owner:JAPAN OIL GAS & METALS NAT CORP

System and method for control of fluid pressure

ActiveUS7850431B2Eliminates and reduces disadvantageAvoid high pressureFluid parameterFlexible member pumpsPressure decreaseEngineering

Owner:ENTEGRIS INC

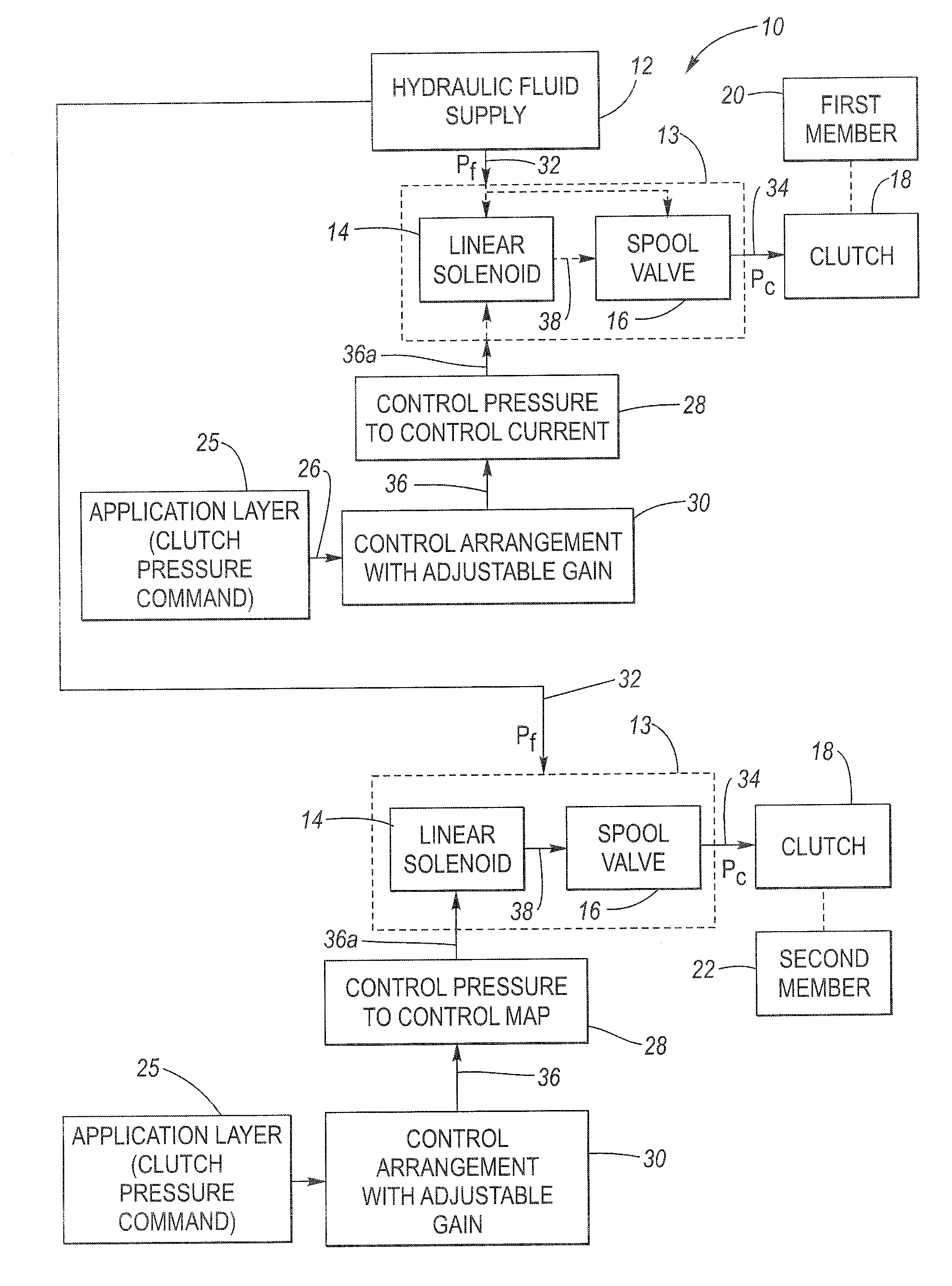

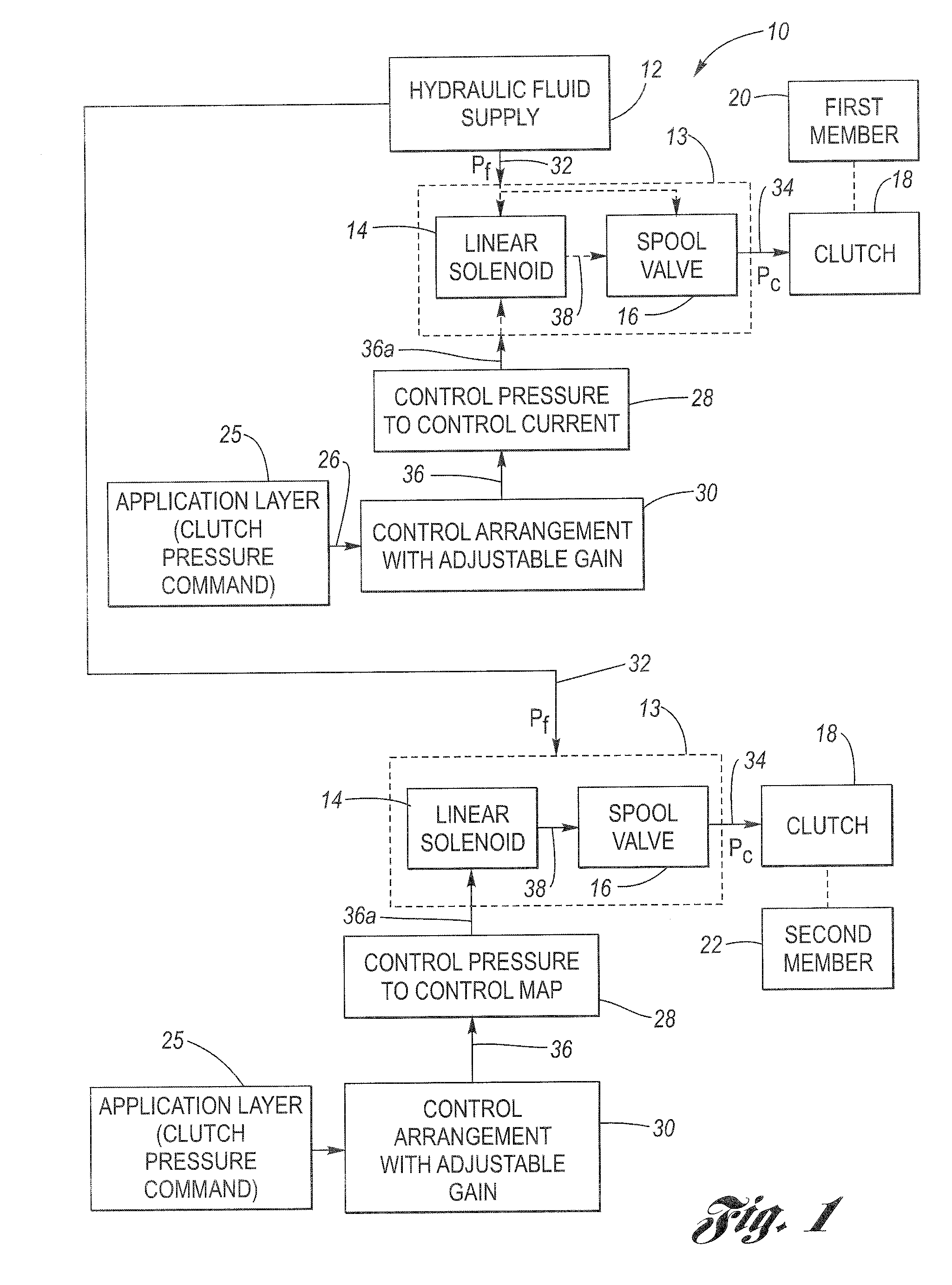

Method for determining solenoid control current using hysteresis interpolation for transmission clutch control

ActiveUS7373234B1Improve accuracyIncrease control pressureClutchesDigital data processing detailsHysteresisPressure decrease

A transmission control arrangement controls the generation of a required solenoid control current that is provided to an electro-hydraulic pressure control module to ultimately control clutch pressure. The module includes a linear solenoid, which has an up direction pressure-current (P-I) data table and a down direction pressure-current (P-I) data table associated therewith. For large pressure increase change requests the up P-I table is used. For large pressure decrease change requests the down P-I table is used. An interpolation process uses current values taken from both the up and down P-I data tables for pressure change requests that are neither large increases nor large decreases. The control arrangement also includes a variable gain feature that changes the gain in dependence on the gear state of the transmission.

Owner:DELPHI TECH IP LTD

Film formation apparatus and film formation method and cleaning method

InactiveUS20050106322A1Moderate energyReduce the driving voltageSolid-state devicesVacuum evaporation coatingPressure decreaseHigh density

The purpose of the invention is to provide a film formation apparatus capable of forming an EL layer with a high purity and a high density, and a cleaning method. The invention is a formation of an EL layer with a high density by heating a substrate 10 by a heating means for heating a substrate, decreasing the pressure of a film formation chamber with a pressure decreasing means (a vacuum pump such as a turbo-molecular pump, a dry pump, or a cryopump) connected to the film formation chamber to 5×10−3 Torr (0.665 Pa) or lower, preferably 1×10−3 Torr (0.133 Pa) or lower, and carrying out film formation by depositing organic compound materials from deposition sources. In the film formation chamber, cleaning of deposition masks is carried out by plasma.

Owner:SEMICON ENERGY LAB CO LTD

Hydraulic Braking Device

InactiveUS20090026835A1Easy to operateBraking action transmissionAutomatic initiationsPressure decreaseDriver/operator

The first control is to displace the primary piston by the amount obtained by multiplying the input rod displacement quantity by a proportional gain. The second control is to propel the primary piston by a prescribed offset thereby executing the first control. The third control is to displace the primary piston by the amount obtained by multiplying the input rod displacement quantity by a proportional gain specifically at a pressure decrease request. The brake force control device properly selects a control method from the first to third control methods to control the primary piston based on the automatic braking release conditions and a driver's brake request when a driver executes a brake operation during the automatic braking.

Owner:HITACHI LTD

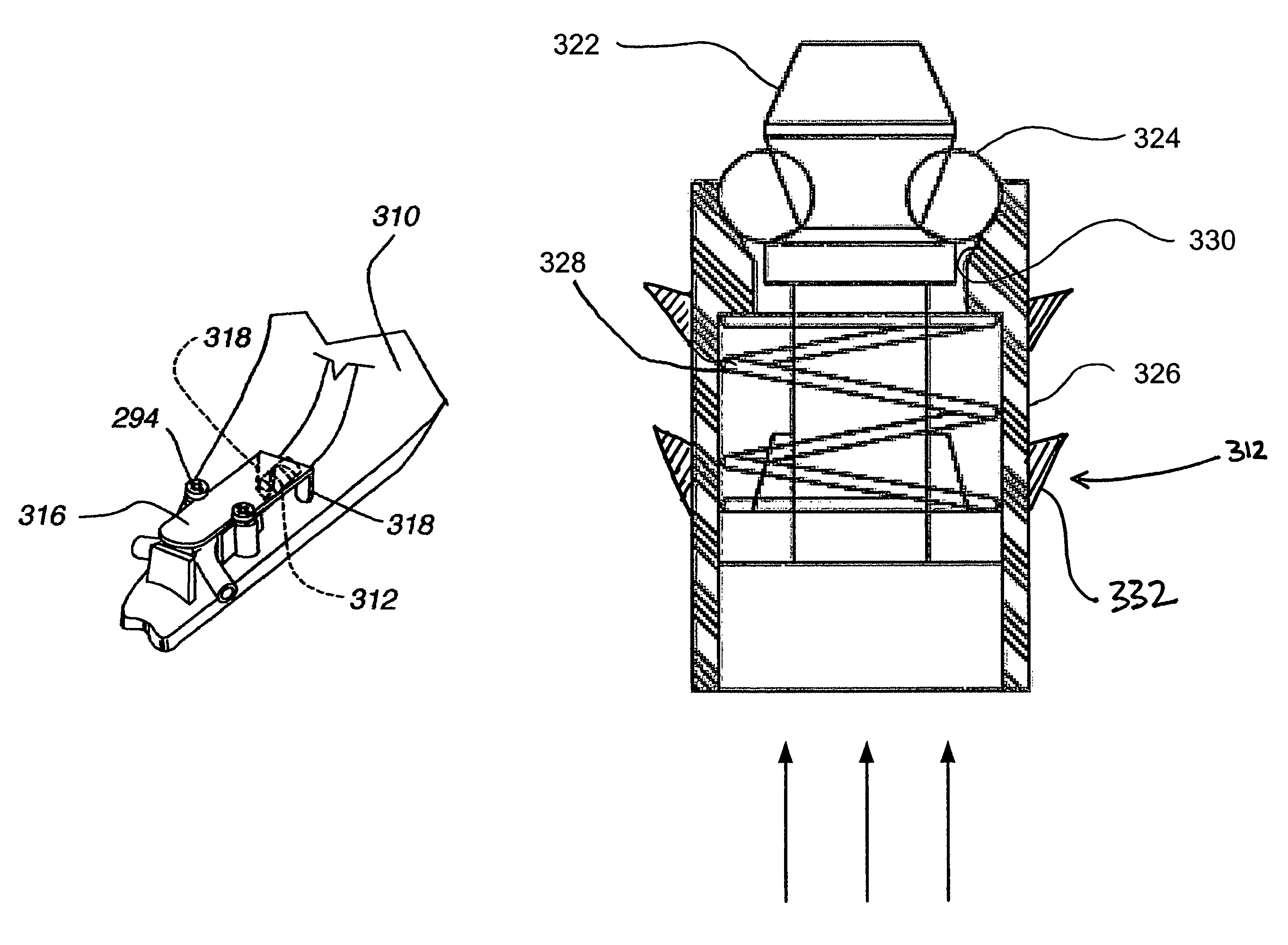

Surge pressure reduction apparatus with volume compensation sub and method for use

InactiveUS6695066B2Promote circulationEasy to operateFluid removalFlushingPressure reductionBiomedical engineering

A device for providing surge pressure reduction with volume compensation and methods of use are presented. Surge pressure reduction and volume compensation are accomplished by pressure-actuated release of the compensation device.

Owner:FRANKS INT +1

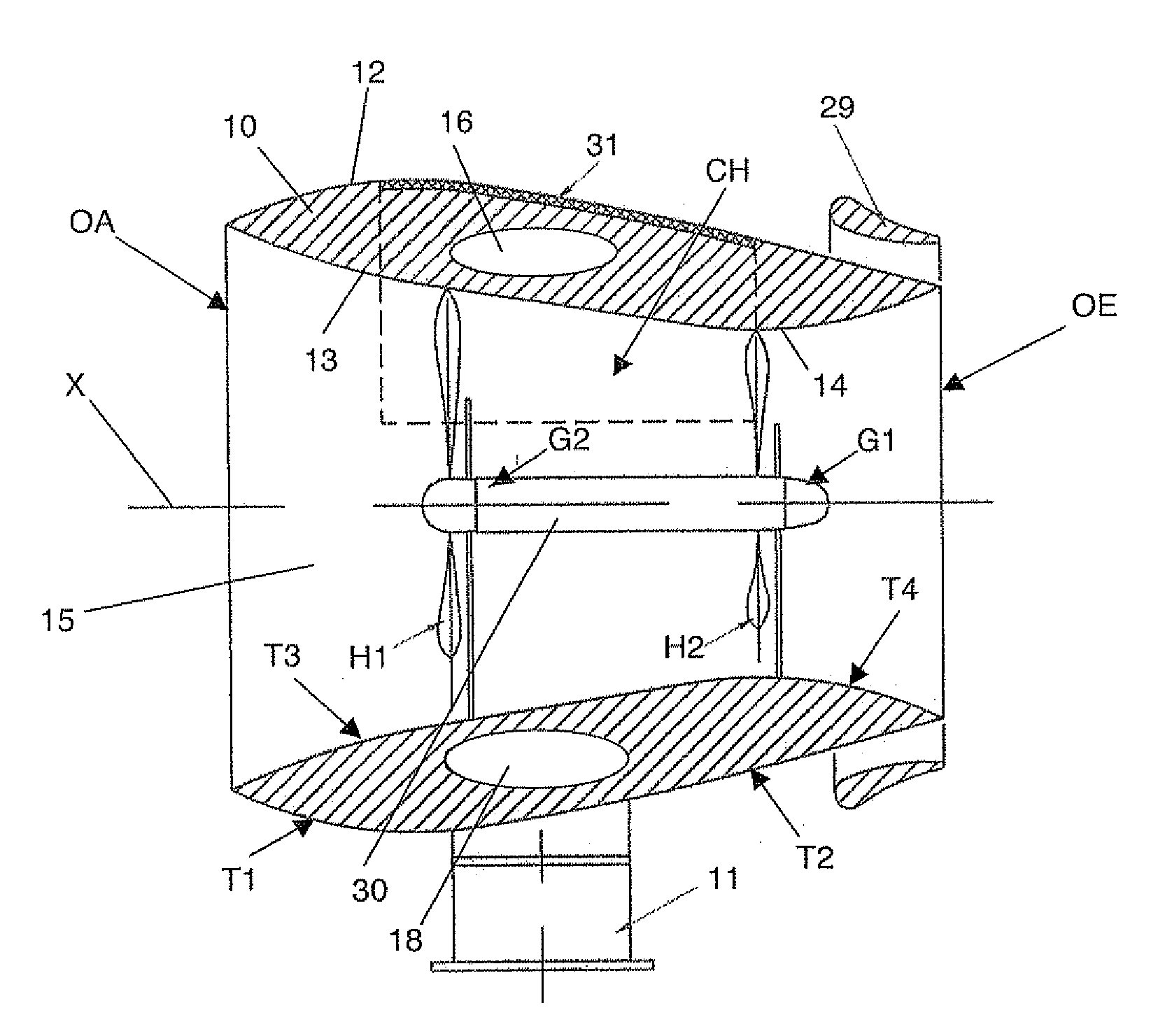

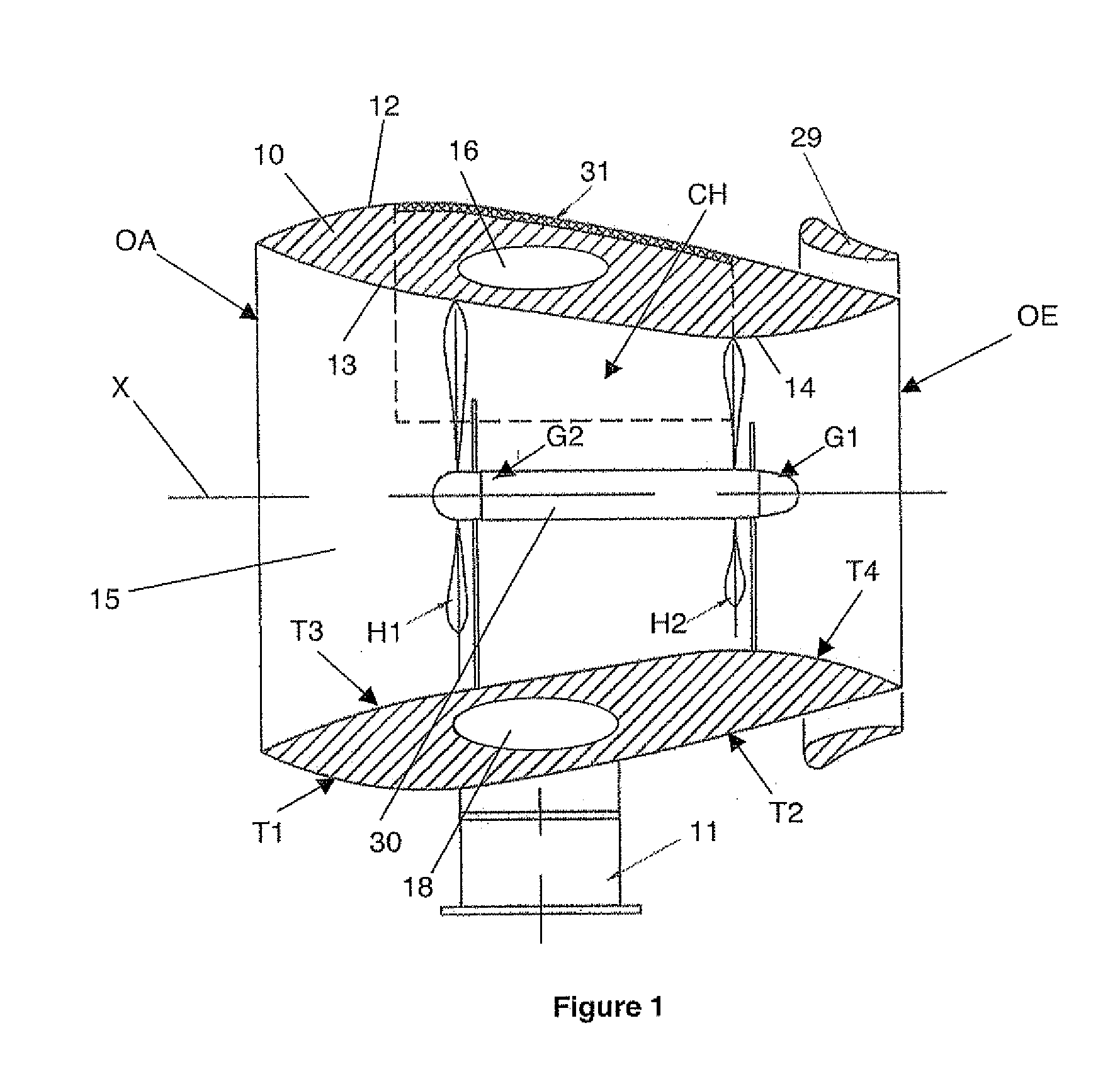

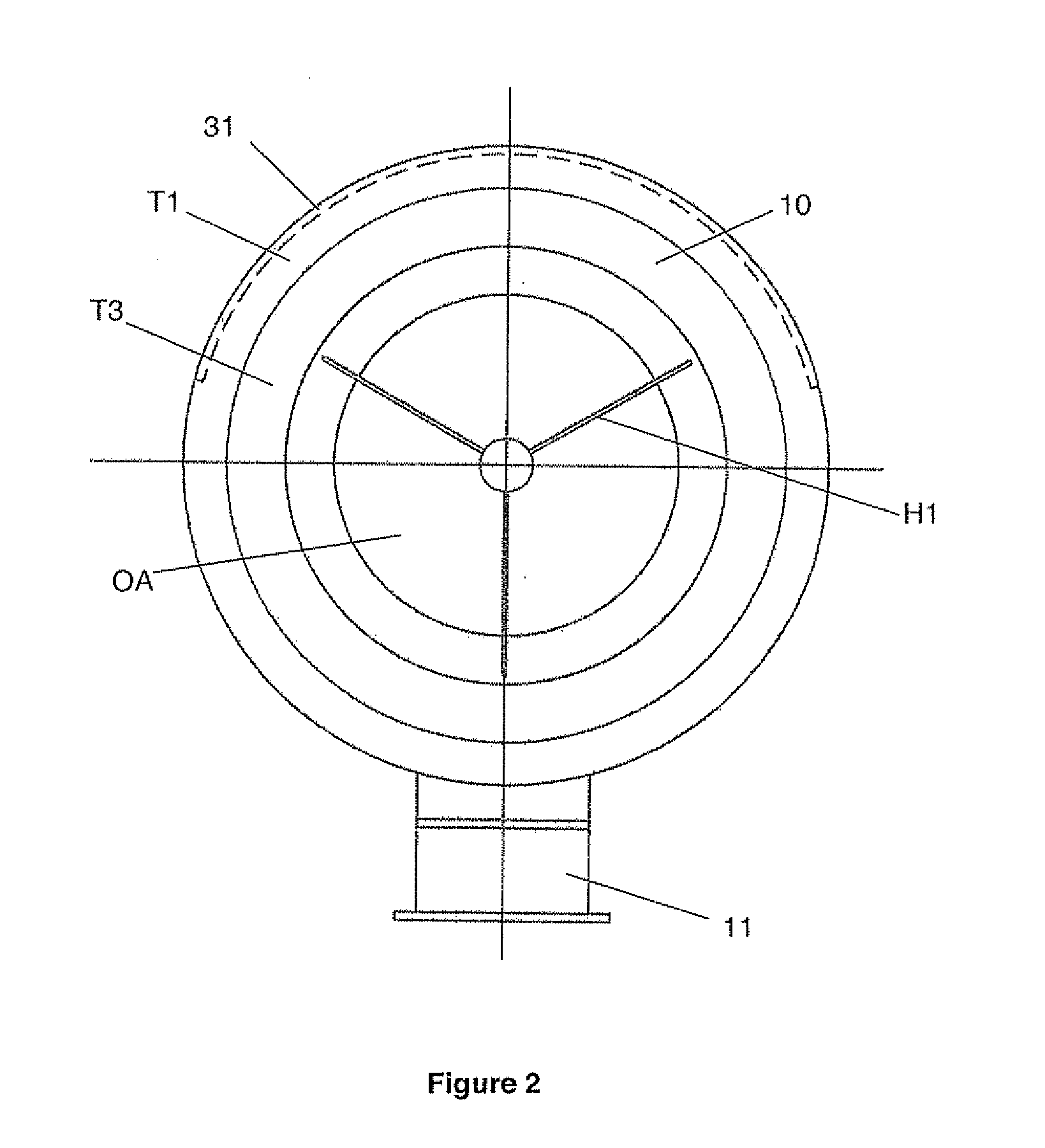

Wind turbine with two successive propellers

InactiveUS20100310361A1Improve efficiencySufficient pressurePropellersPump componentsPressure decreasePropeller

A wind turbine comprises a tubular casing having an inlet opening, an outlet opening, an outer surface generating a pressure decrease, an inner surface presenting a convergent section joined to the inlet opening, a divergent section joined to the outlet opening and to the convergent section by a throat, and a propeller mounted rotating with respect to the tubular casing in proximity to the throat. It is coupled to a first generating machine. It comprises another propeller mounted rotating with respect to the tubular casing, placed upstream from the first propeller in the convergent section.

Owner:ELENA ENERGIE

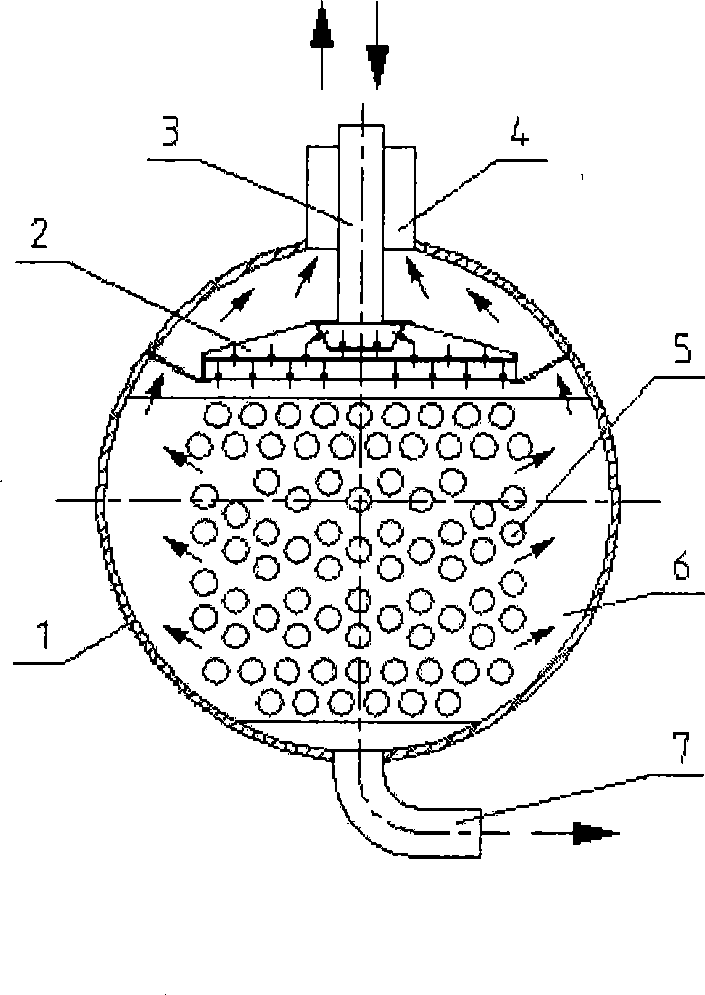

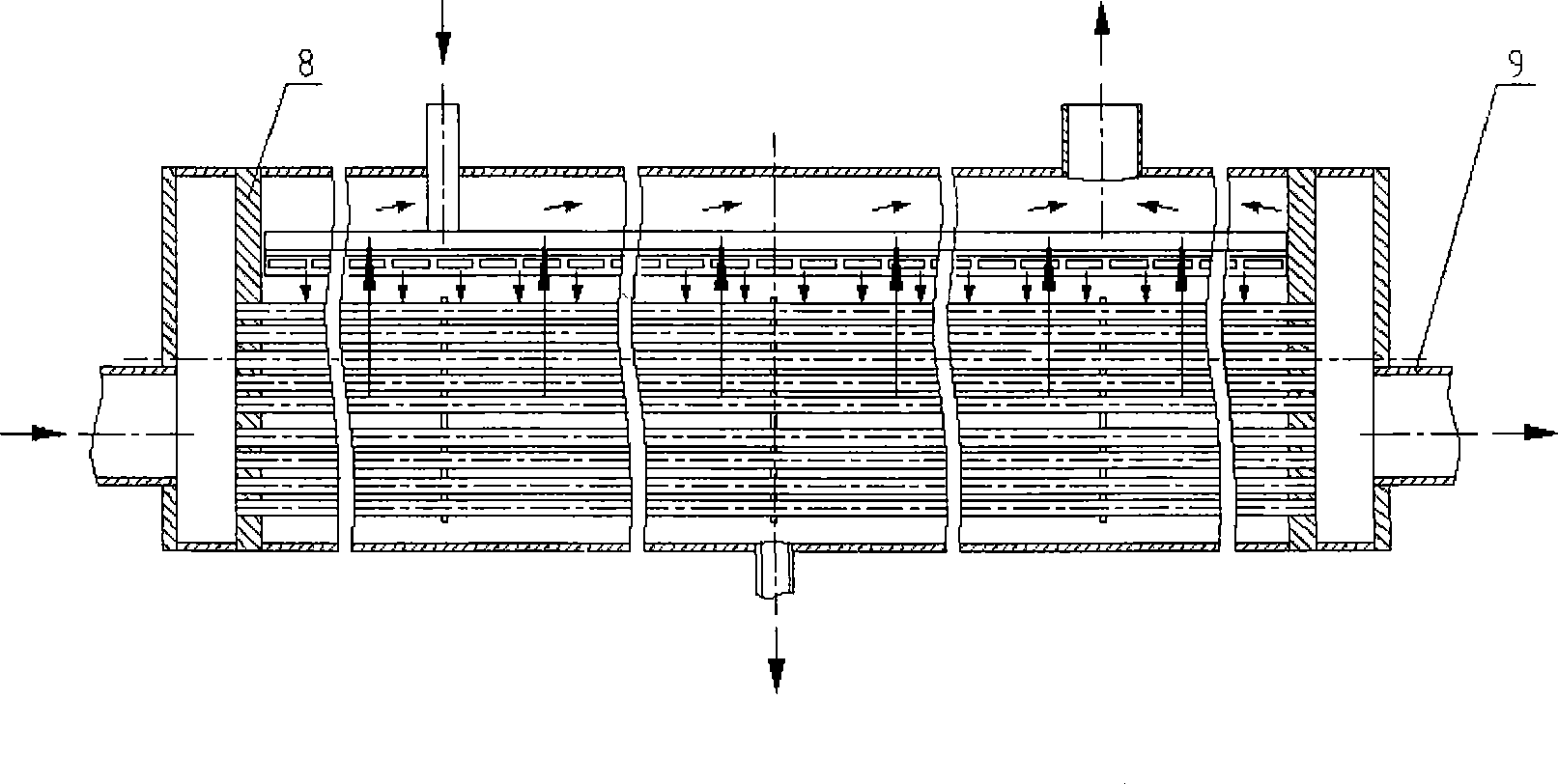

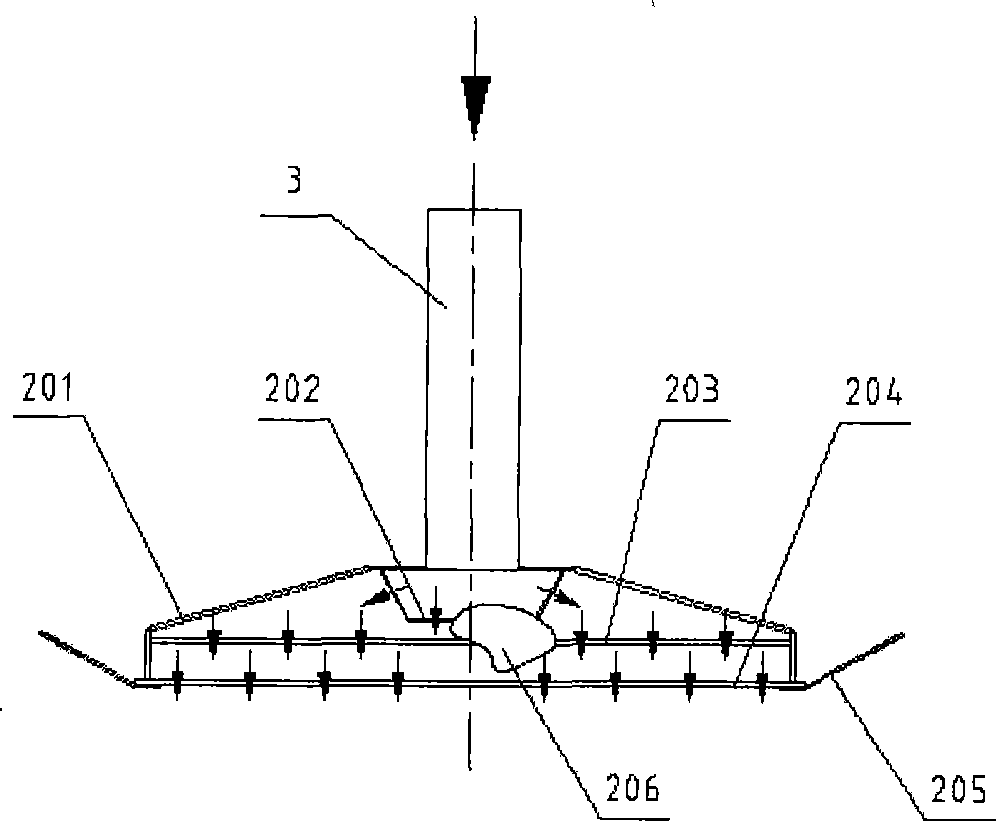

Trickle falling film type evaporator device and use method

ActiveCN101382359AReduce chargeLiquid evenlyEvaporators/condensersStationary conduit assembliesVena contracta diameterPressure decrease

The invention relates to a trickle downward film type evaporator device and a using method thereof; the downward film type evaporator of the prior art which is the two-phase refrigerant distributor technology has a five-layer orifice plate structure and a capillary structure, as the structure is more complicated and the processing and assembling difficulty is high, the uneven liquid distribution is easily caused, the heat transfer performance is decreased and the energy efficiency is lowered. The trickle downward film type evaporator device adopts the technical proposal of a multi-directional two-grade pressure decrease distribution device, a two-phase refrigerant distributor which consists of a trapezoidal shell body, a multi-directional flow distribution plate, a grade-one distribution orifice plate, a grade-two distribution orifice plate, a gas absorption distribution plate and an end seal plate is used for carrying out the multi-directional two-grade pressure decrease distribution, thereby leading a gas-liquid refrigerant to be evenly and effectively trickled at the outer surface of the pipe wall of an evaporation pipe bundle and further carry out the full heat exchange. The trickle downward film type evaporator device has the advantages that: the two-phase refrigerant distributor technology has simple structure, easy production, even liquid distribution of the gas-liquid refrigerant and improved heat transfer performance. Compared with the existing flooded evaporator, the energy is saved by 15-20 percent, and the filling amount of the refrigerant is reduced by 20-30 percent, thereby being economic and energy-saving.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

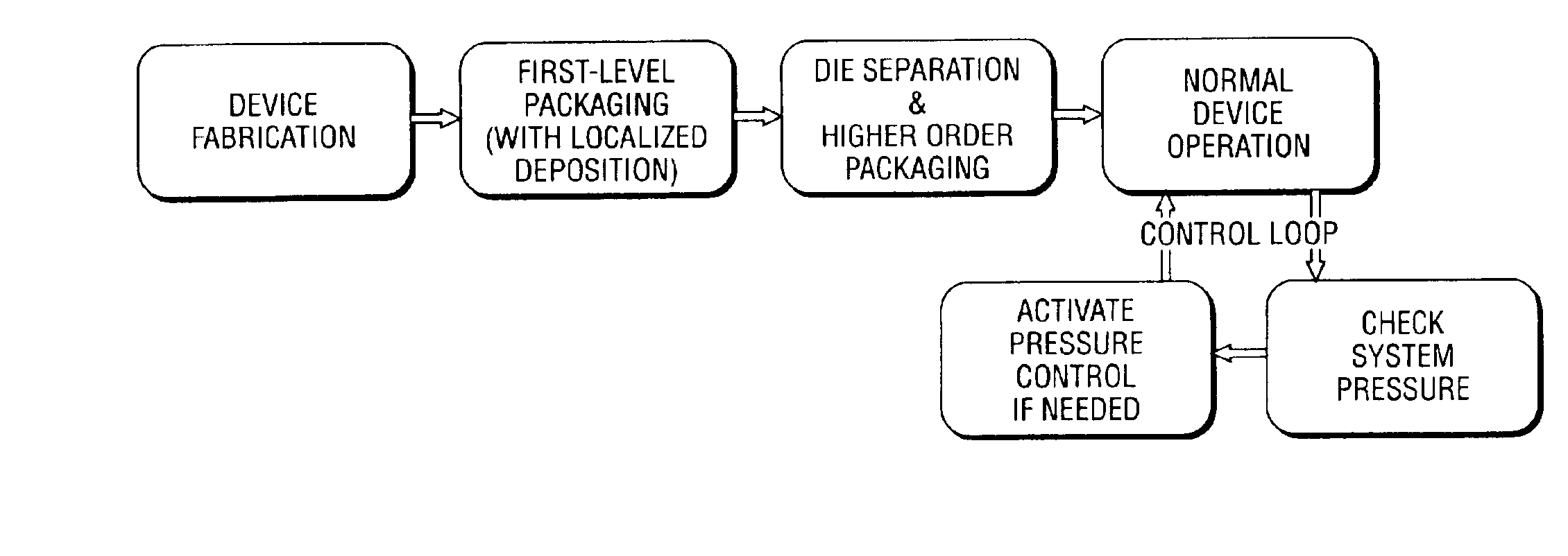

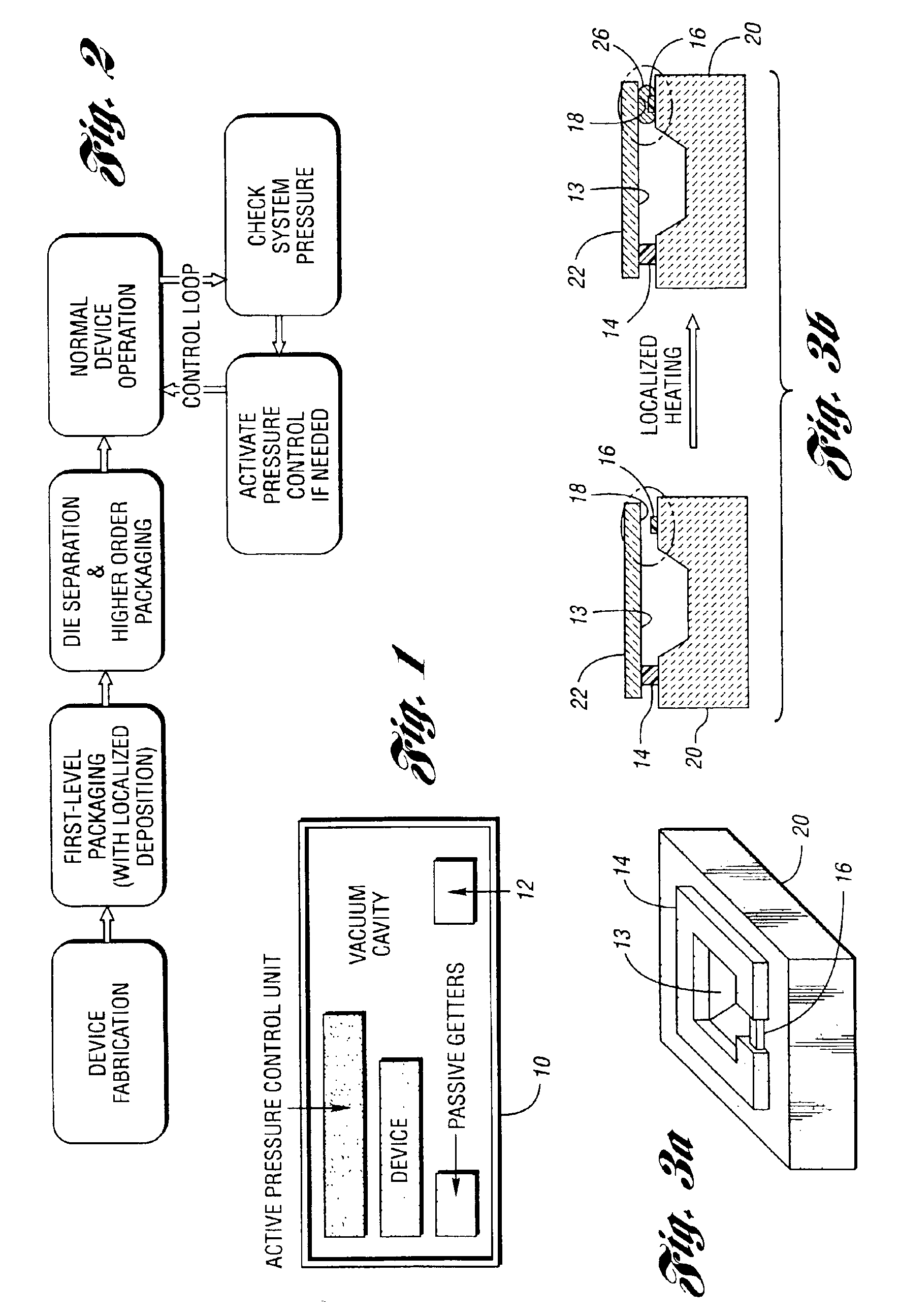

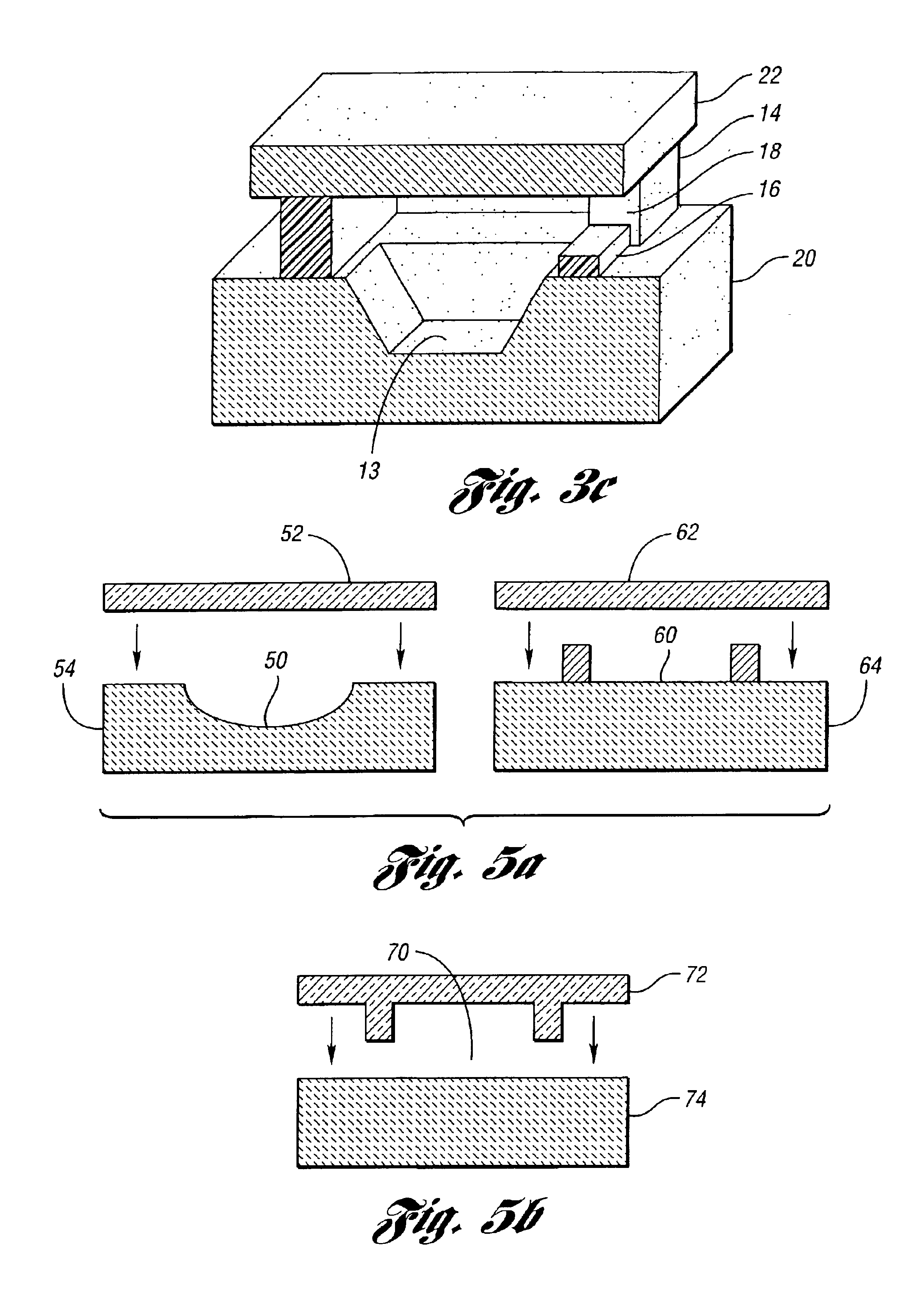

Method and system for locally sealing a vacuum microcavity, methods and systems for monitoring and controlling pressure and method and system for trimming resonant frequency of a microstructure therein

InactiveUS7004015B2Lower resonance frequencyQuality improvementSemiconductor/solid-state device testing/measurementDecorative surface effectsPressure decreaseEngineering

A method and system for locally sealing a vacuum microcavity, methods and systems for monitoring and controlling pressure in the microcavity and method and system for trimming resonant frequency of a microstructure in the microcavity are provided. The microcavity has an initial base pressure therein after the microcavity is locally sealed at an access passageway. The monitoring and control methods include measuring pressure in the microcavity and providing a signal when the pressure exceeds a maximum desired level. The control method also includes reducing the pressure in the microcavity to a pressure at or below the maximum desired level in response to the signal to compensate for vacuum degradation within the vacuum microcavity.

Owner:RGT UNIV OF MICHIGAN

Method of Detecting and Compensating for Injector Variability with a Direct Injection System

ActiveUS20080276906A1Reduce fuel rail temperature sensitivityImprove resultsElectrical controlInternal combustion piston enginesPressure decreaseEngineering

A method for controlling fuel injection of a direct injection fuel system, the fuel system having a fuel pump, the method comprising: variably operating the fuel pump to maintain a fuel pressure at a selected pressure, temporarily increasing pump operation to increase pressure sufficiently above said selected pressure and then reducing pump operation; during at least a fuel injection subsequent to the reduction in pump operation, correlating pressure decrease to injector operation, and adjusting fuel injection operation based on the correlation.

Owner:FORD GLOBAL TECH LLC

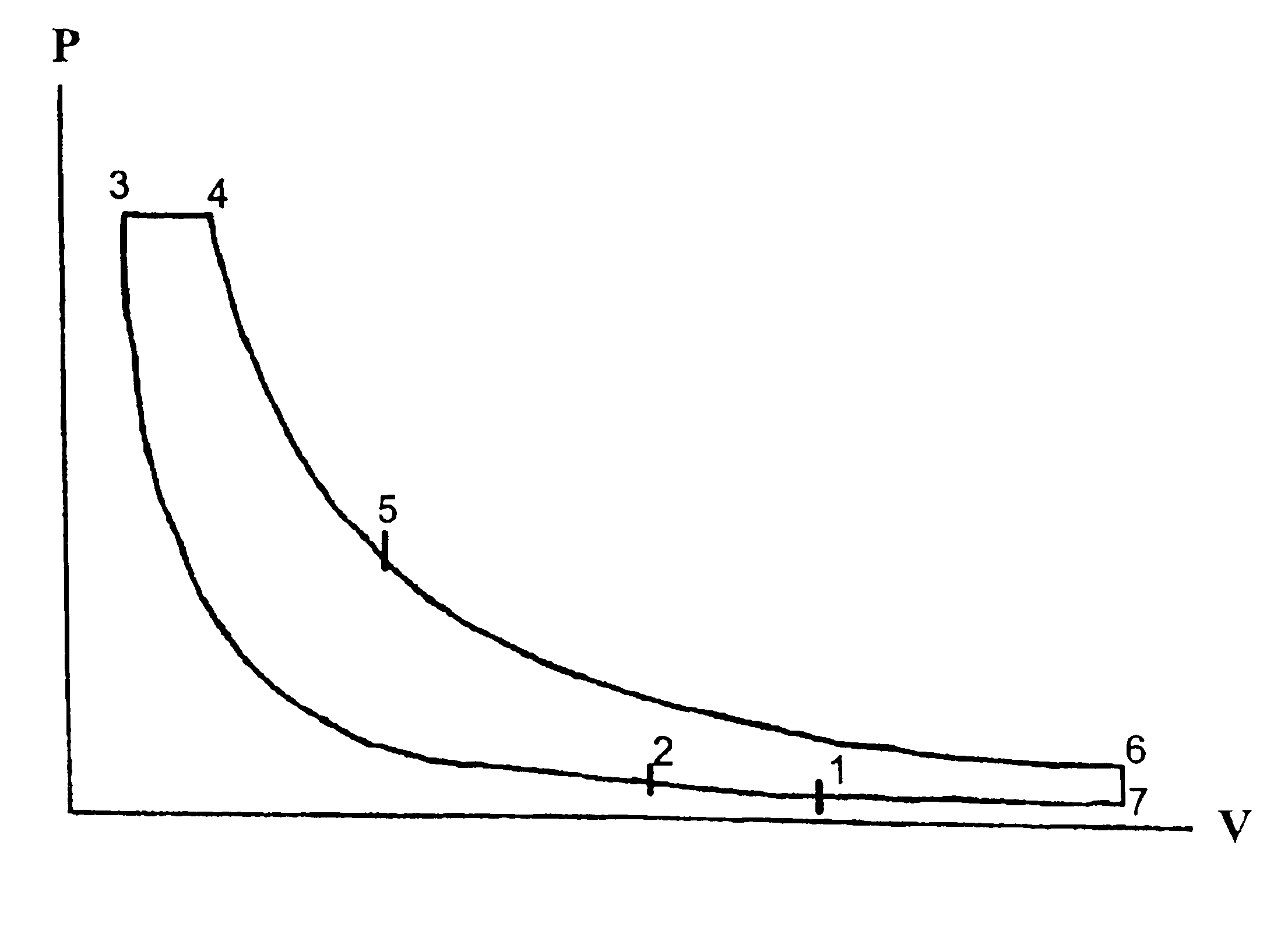

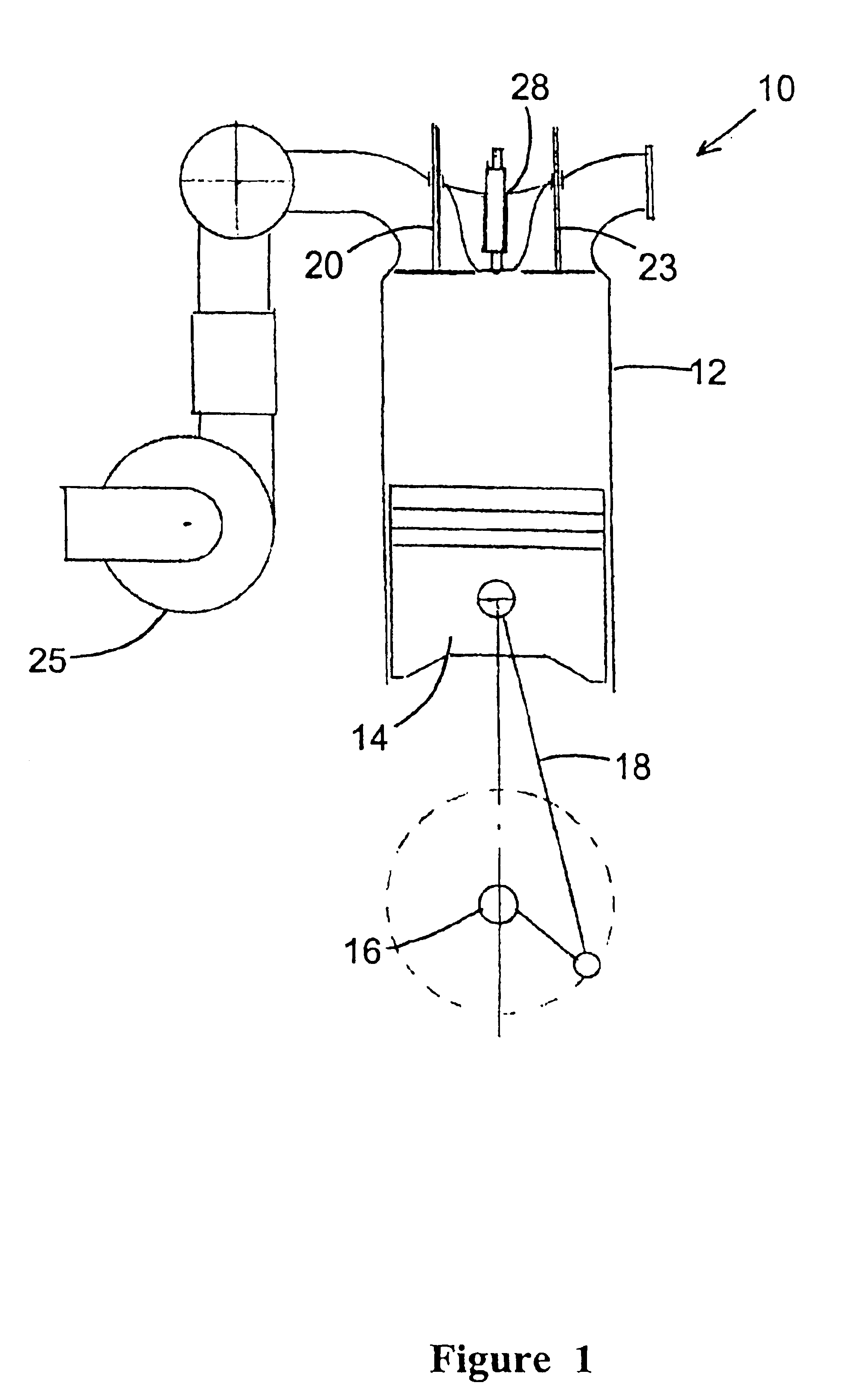

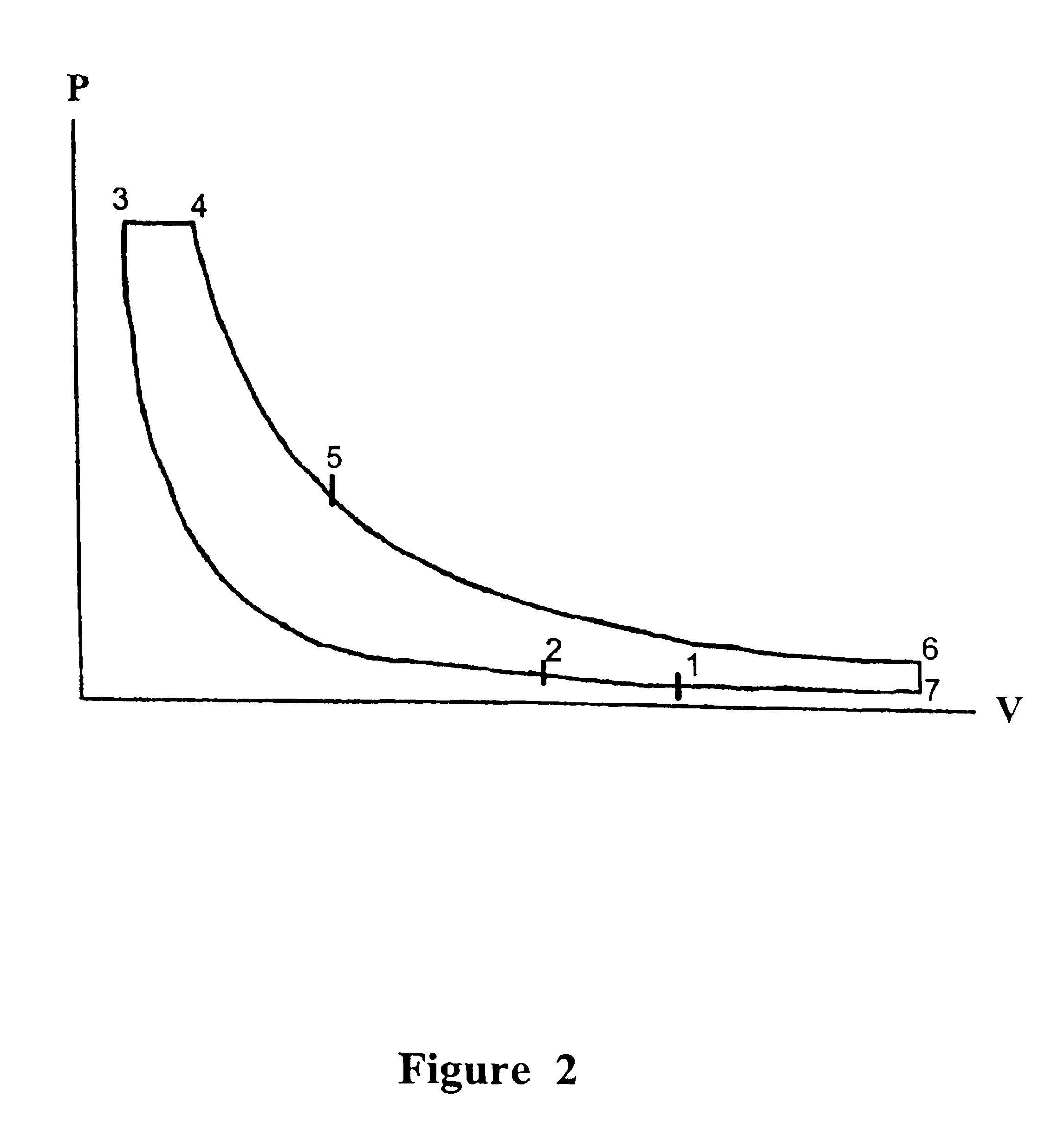

Over expanded limited-temperature cycle two-stroke engines

InactiveUS6848416B1Reduce NOx levelReducing post-combustion temperatureElectrical controlCombustion enginesPressure decreaseFour-stroke engine

A method for combusting fuel in an engine involving decreasing a first volume of gas to a second volume, in two stages, while increasing the pressure and temperature of that volume of gas (a compression process having a chosen compression ratio), then increasing the second volume to a third volume at constant pressure while adding heat until a predetermined temperature is obtained, increasing the third volume of gas to a fourth volume, in two stages while decreasing the pressure at the predetermined temperature (an expansion process having a chosen expansion ratio much greater than the compression ratio), decreasing the pressure to atmospheric pressure while removing heat under constant volume, and finally decreasing the volume of gas to the first volume while removing heat under constant pressure to complete an over expanded, limited-temperature cycle. Also disclosed is an engine employing said over expanded, limited-temperature cycle.

Owner:PIEN PAO C

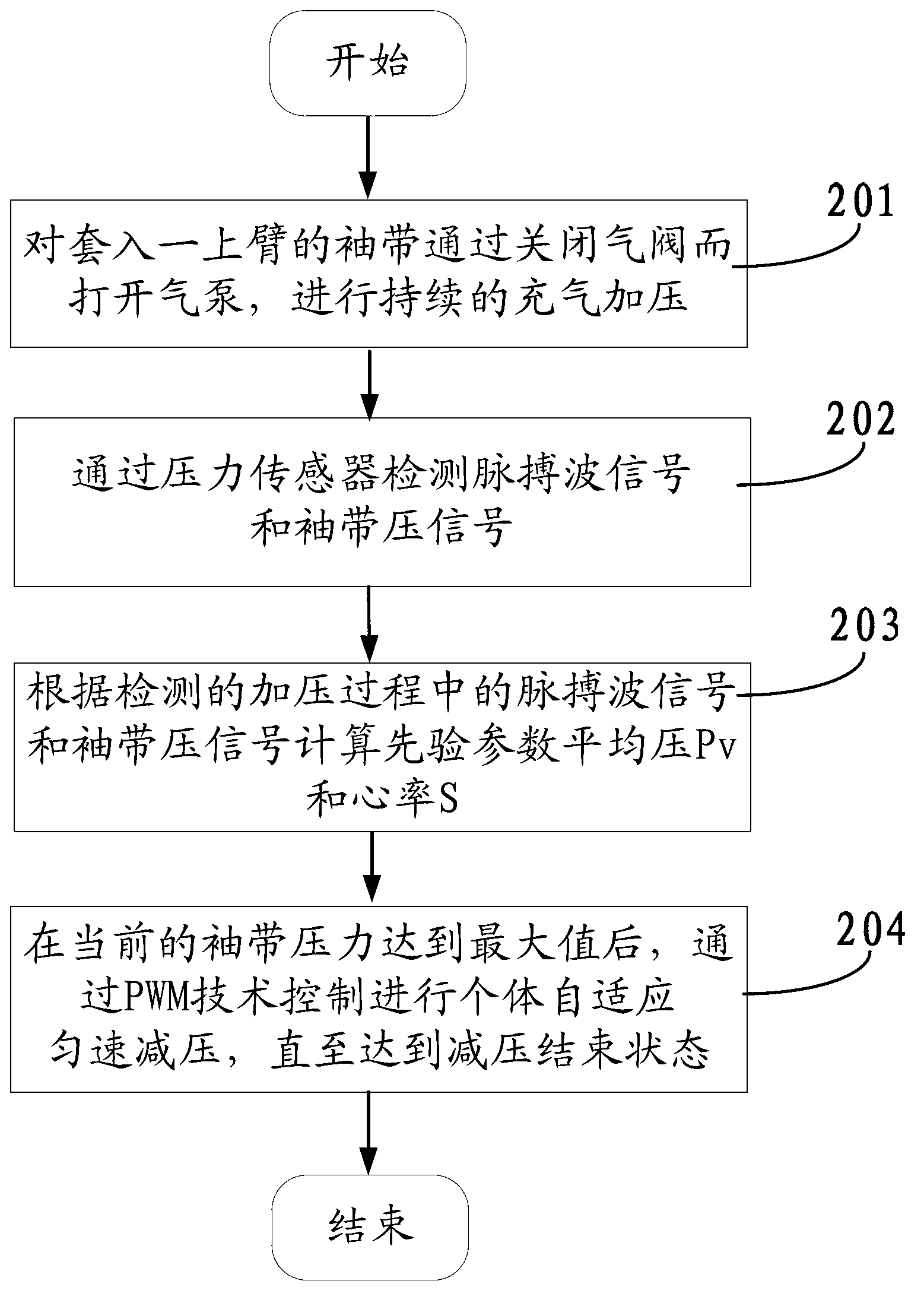

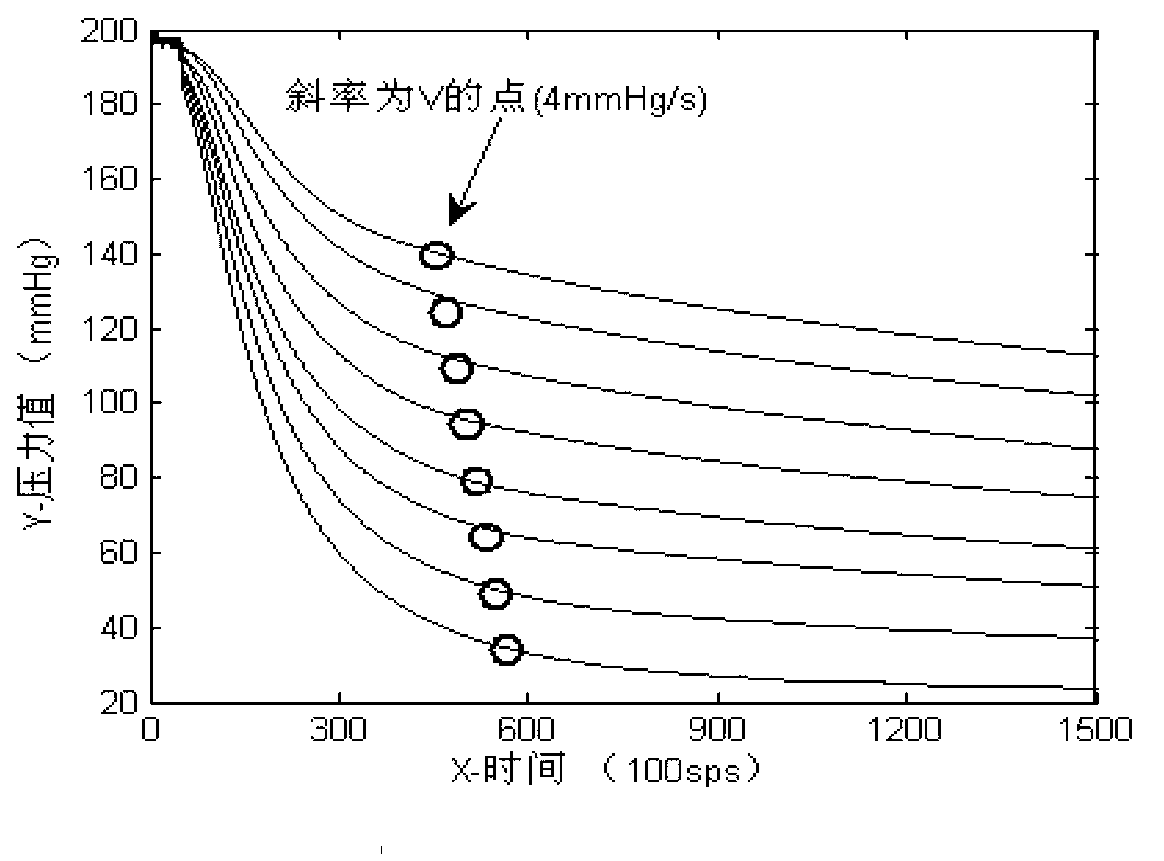

Individual adaptive pressure increasing and decreasing control method for electronic sphygmomanometer

The invention discloses an individual adaptive pressure increasing and decreasing control method for an electronic sphygmomanometer. The method includes: continuously inflating a cuff sleeved on an upper arm for pressure increasing; detecting pulse wave signals and cuff pressure signals; calculating mean pressure Pv and heart rate S according to the pulse wave signals during pressure increasing, calculating systolic pressure Ps according to the mean pressure Pv, and setting the maximum valve Pm of cuff pressure increasing; when the pressure of the cuff reaches the maximum value Pm, by a control air valve, performing individual adaptive constant-speed pressure decreasing until pressure decreasing is completed and the control air valve is completely opened to empty air. By the individual adaptive pressure increasing and decreasing control method for the electronic sphygmomanometer and the electronic sphygmomanometer, high-quality pulse wave signals with moderate pulse waves, reasonable amplitude and evident envelop features, a premise is provided for further identification and determining of blood pressure parameters, and comfortableness of a to-be-tested person is improved during the whole test. In addition, the method is high in individual adaptive measuring capability.

Owner:邓亲恺 +1

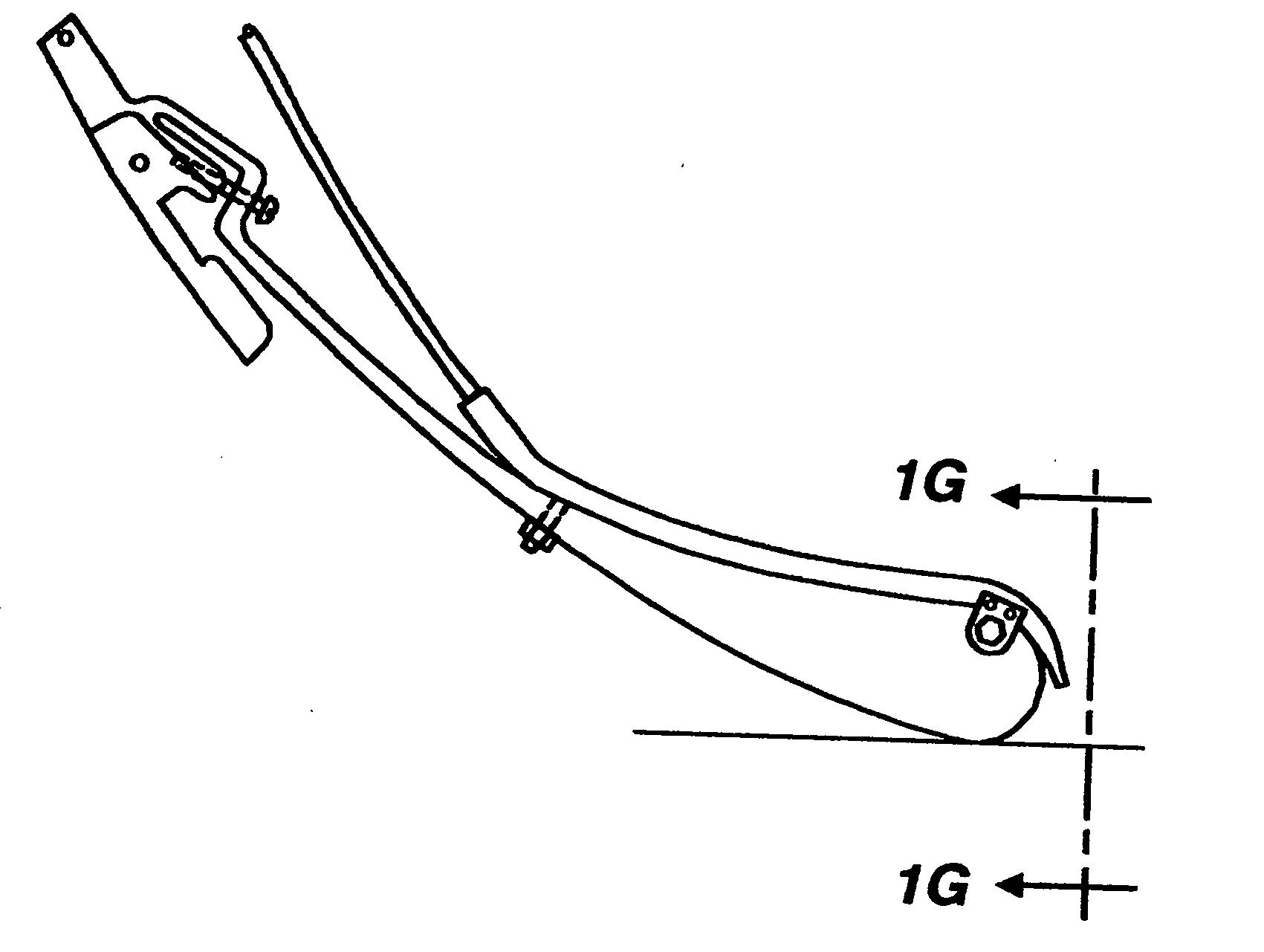

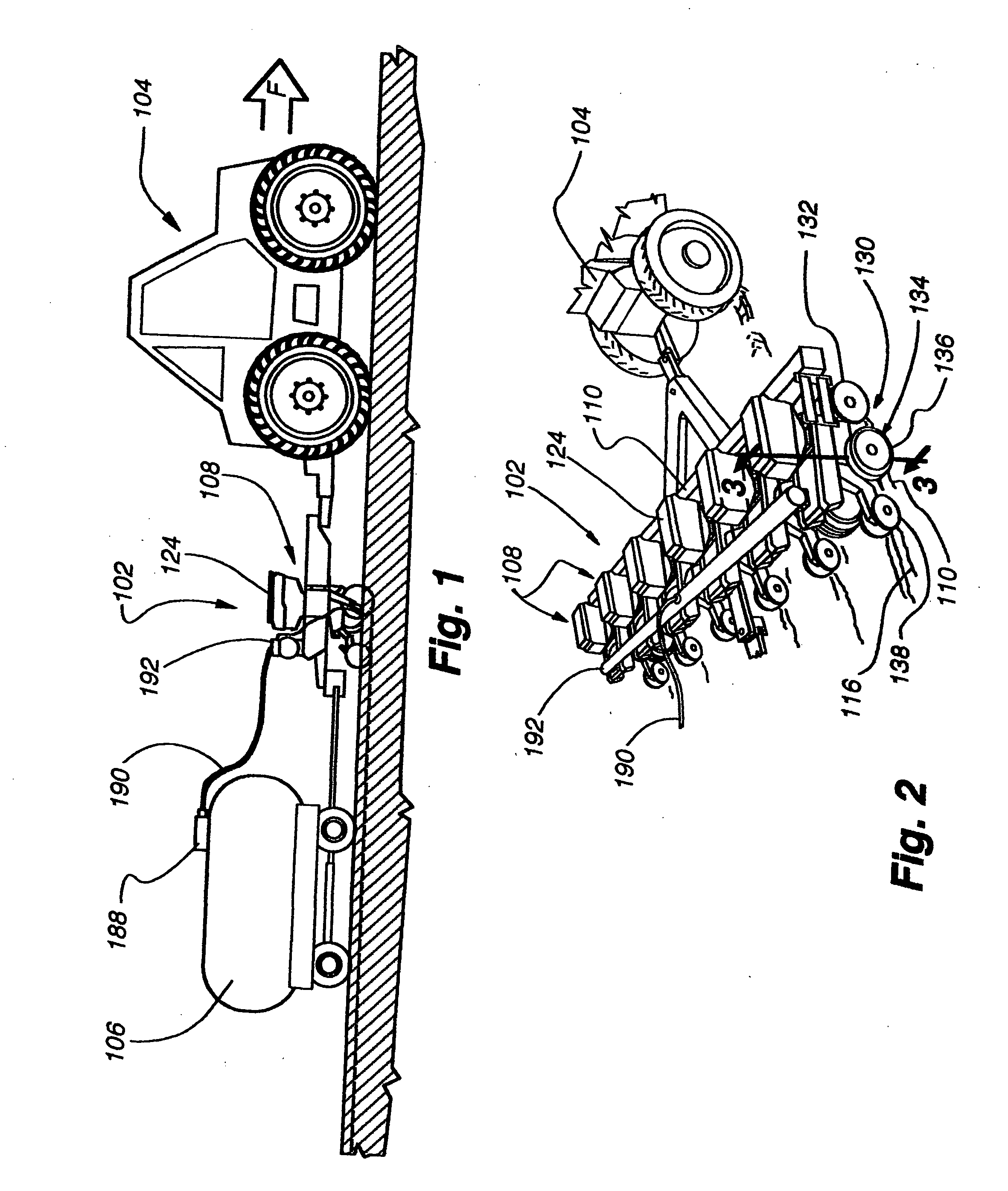

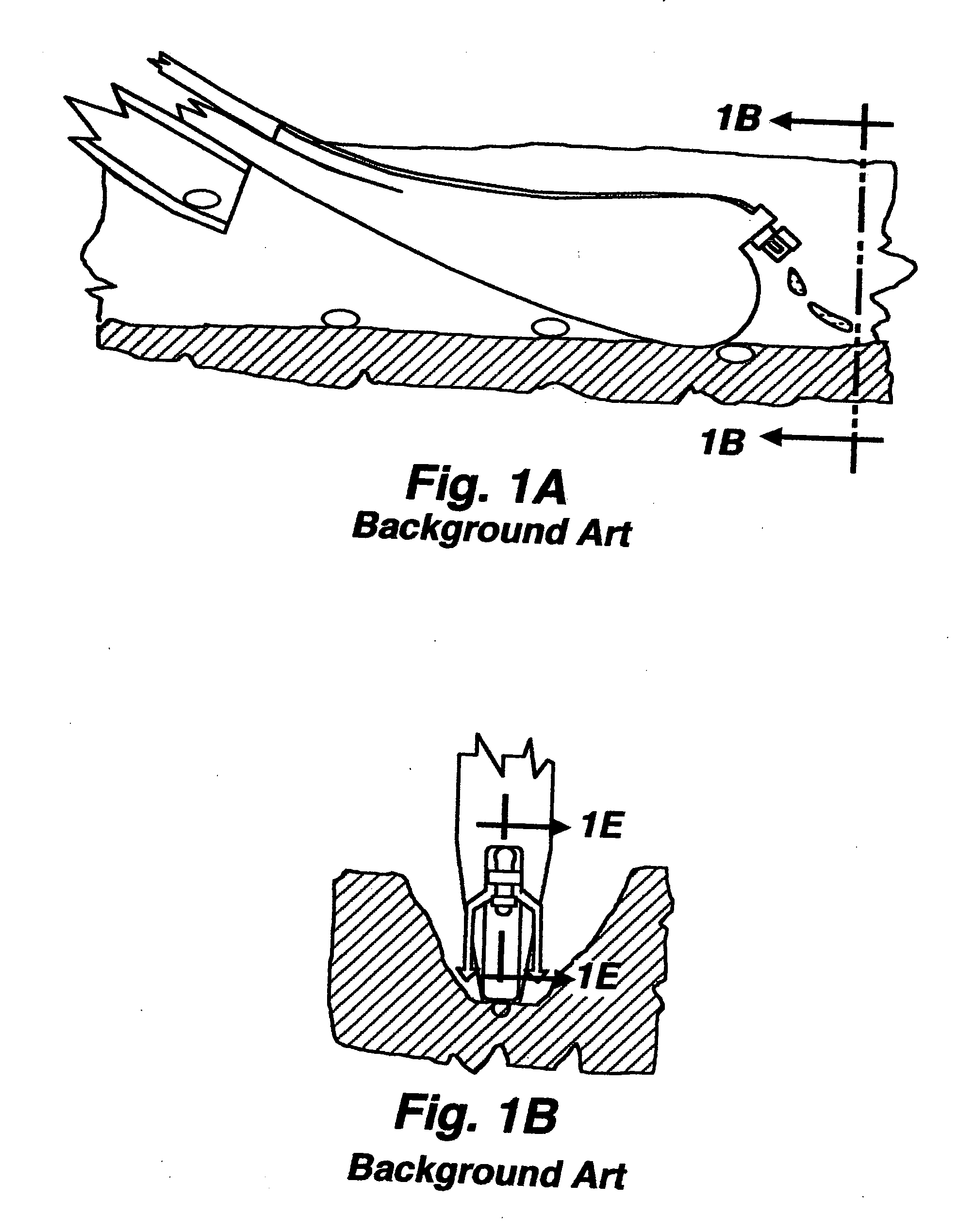

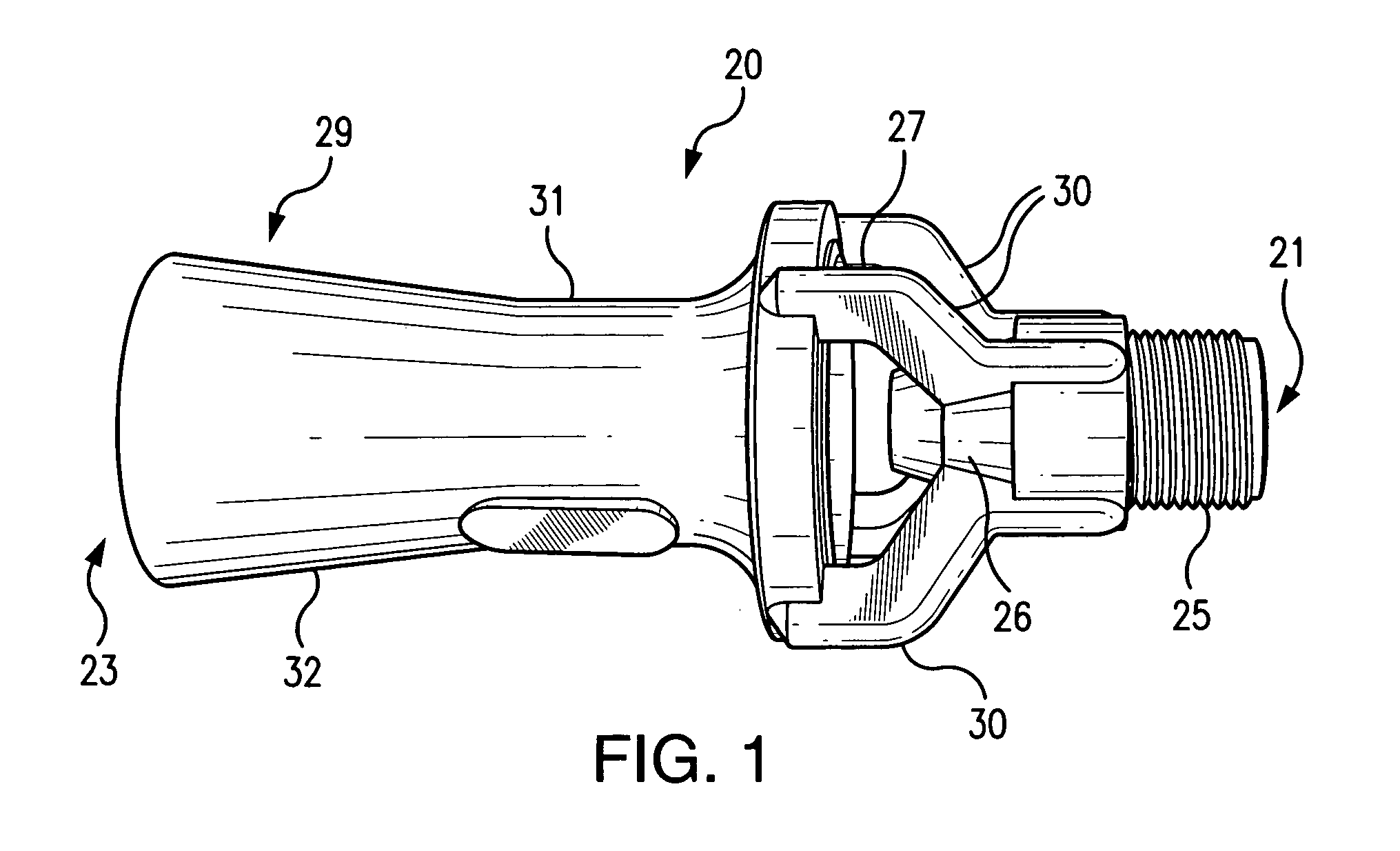

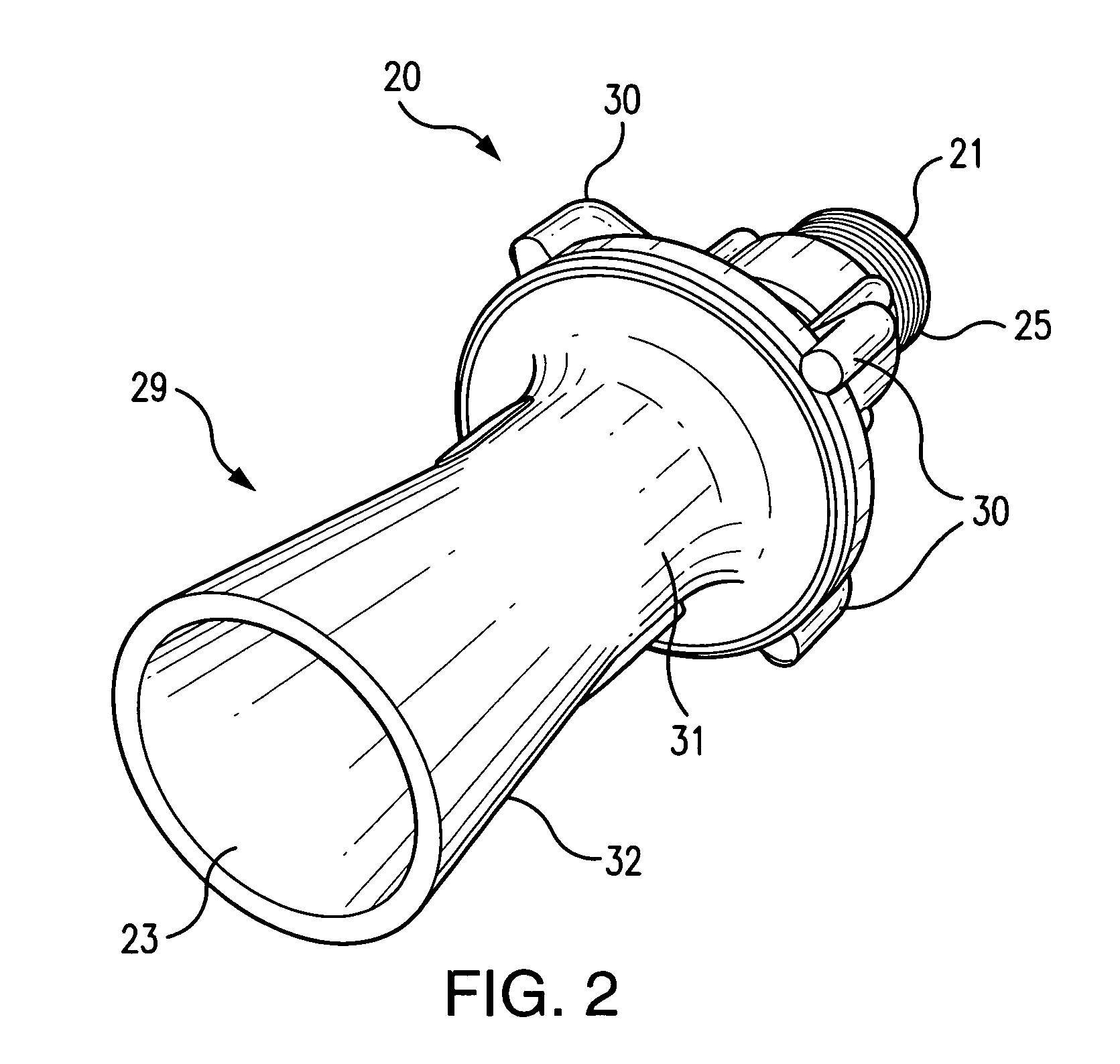

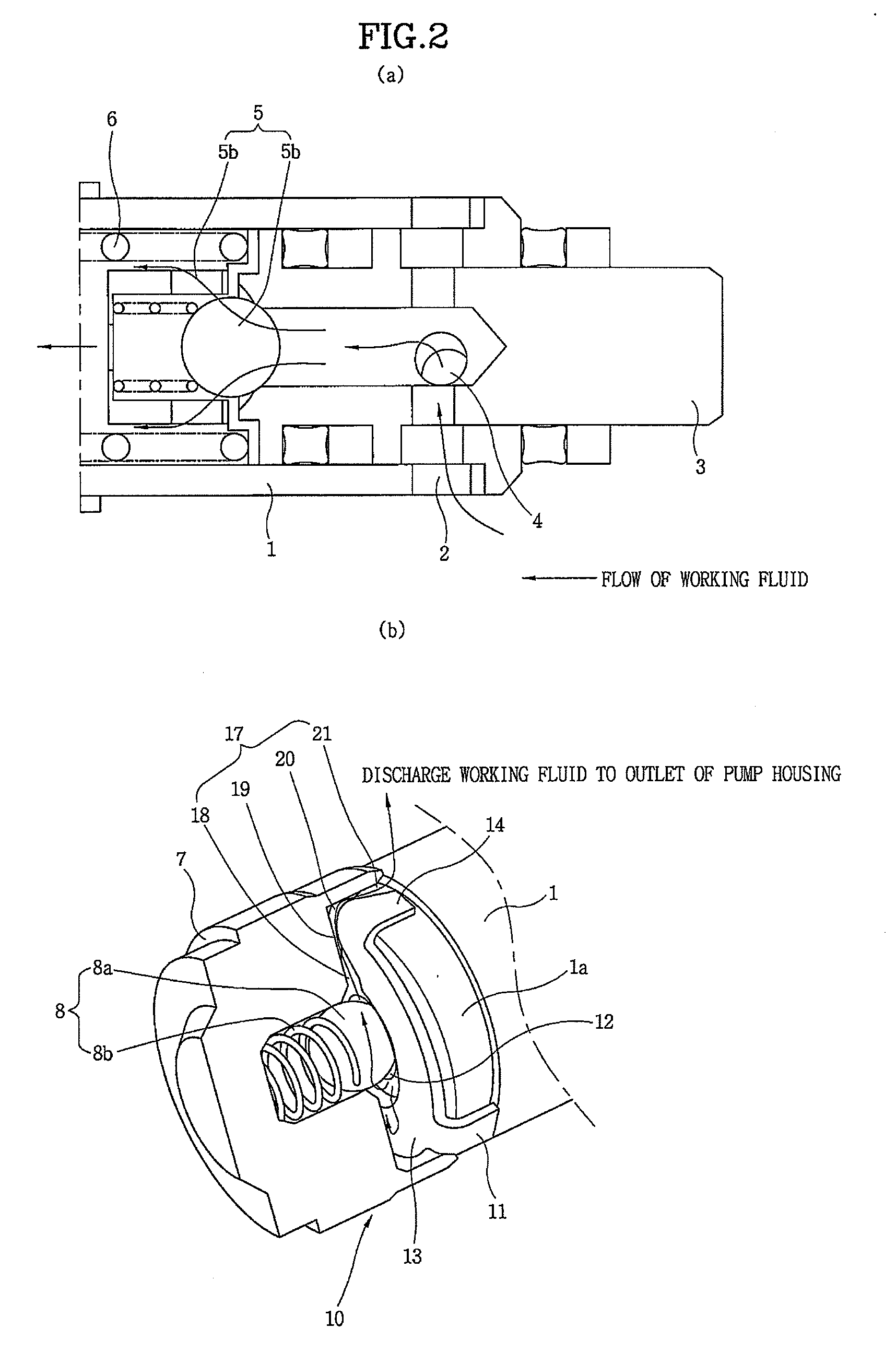

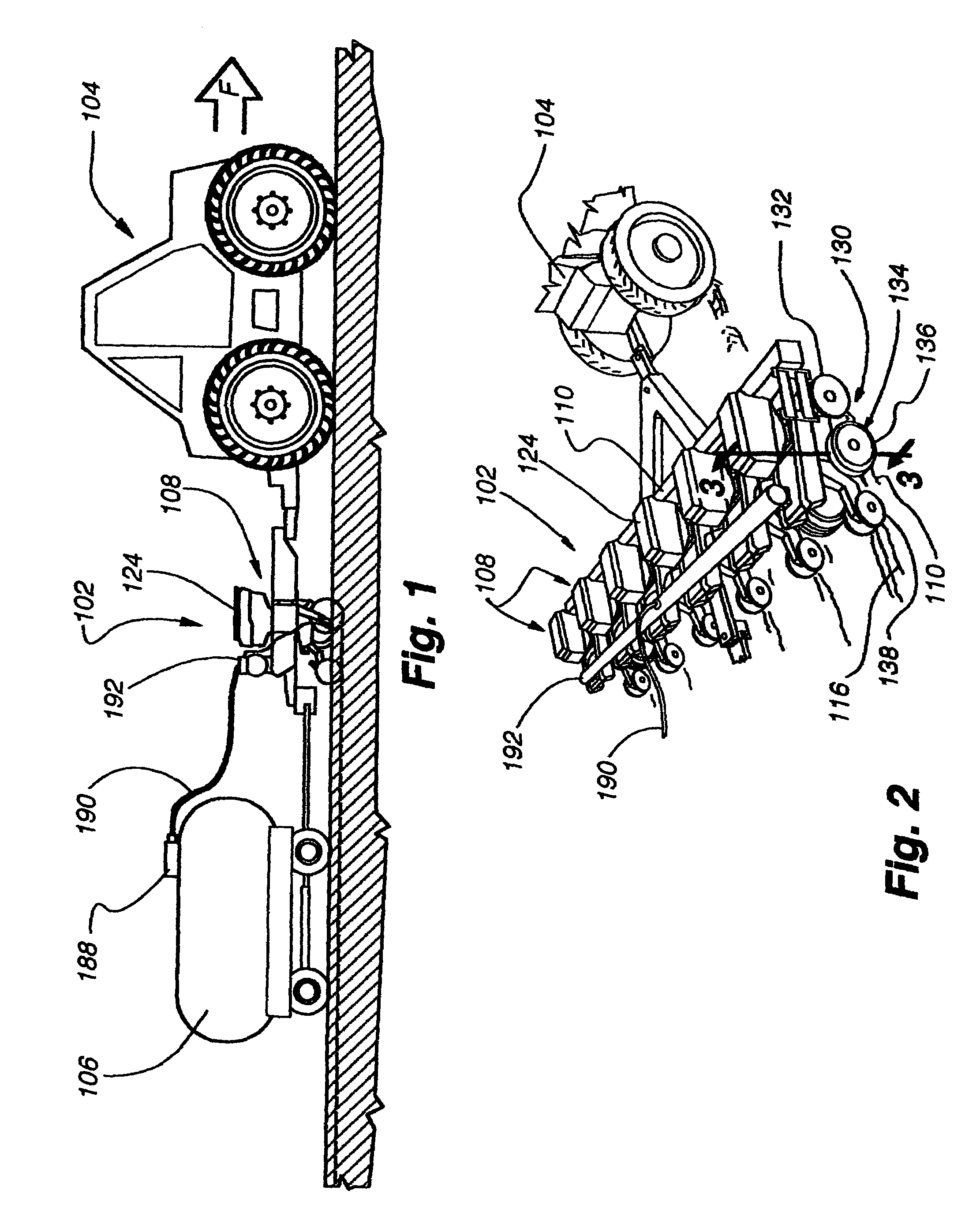

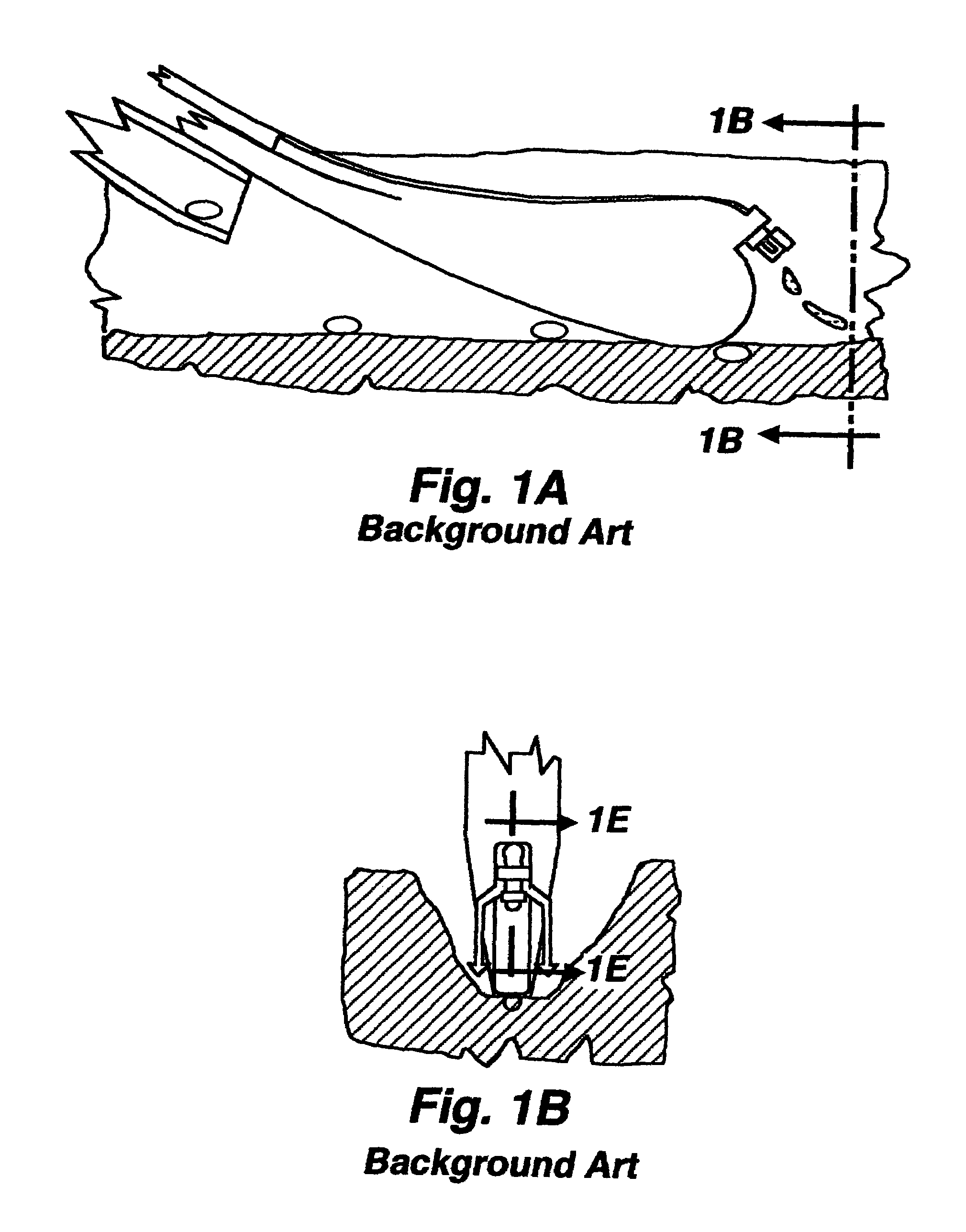

Liquid distribution apparatus employing a check valve for distributing liquid into a seed furrow

Aspects of the present invention involve an extension adapted to extend from a planter, such as the seed tube portion of the planter, into a seed furrow in order to engage seeds being deposited therein, where such engagement may involve deflecting the seeds toward the vertex region of the furrow and / or firming the seeds in the furrow. The extension includes or supports a fluid distribution arrangement such as a hose or the like, which may be separate or integral with the liquid supply hose of a planter. The fluid distribution arrangement is adapted to supply fluid, such as liquid fertilizer, insecticide, water, etc., to the furrow. A valve is provided in the fluid flow path in the region of the fluid distribution arrangement to control the distribution of fluid to the furrow. The valve may be a check valve that allows fluid flow therethrough when fluid pressure exceeds a value such that the valve opens, and prevents fluid flow when the pressure decreases below the valve activation pressure.

Owner:SCHAFFERT PAUL E

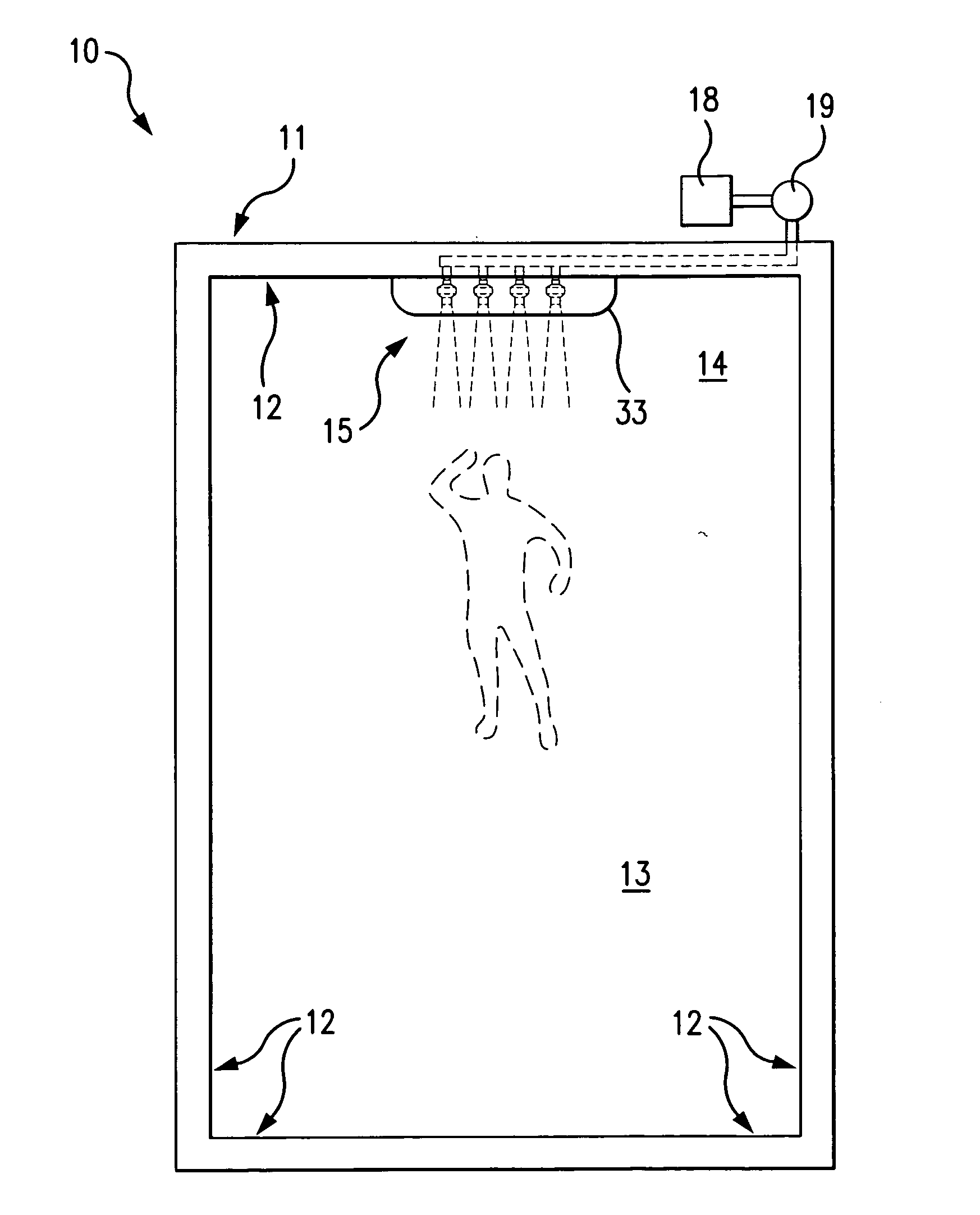

Swimming pool with eductor jets

InactiveUS20110004993A1Strenuous swimming workoutLow costJet pumpsMachines/enginesPressure decreaseWater flow

A swimming pool designed for stationary swimming uses Venturi-based eductor jets to generate a forceful water flow augmented by entrained pool water drawn from within the pool enclosure. The eductor jets use the kinetic energy of the inlet flow to entrain the low-pressure pool water, completely mix the two, and then discharge the mixture as an augmented outlet flow. The energy from the motive inlet flow is transferred to the entrained pool water via the Venturi effect. As the motive inlet water passes through a tapered nozzle in the eductor jet, kinetic energy increases and pressure decreases. This produces a Venturi effect which draws surrounding pool water into the Venturi orifice of the eductor jet. Consequently, the volume of the outlet flow from the eductor jets is 3 to 5 times the volume of the inlet flow. A larger and more powerful stream of water is thereby discharged into the pool enclosure and provides optimal resistance for in-place swimming in an energy-efficient manner.

Owner:GERMINARIO THOMAS J

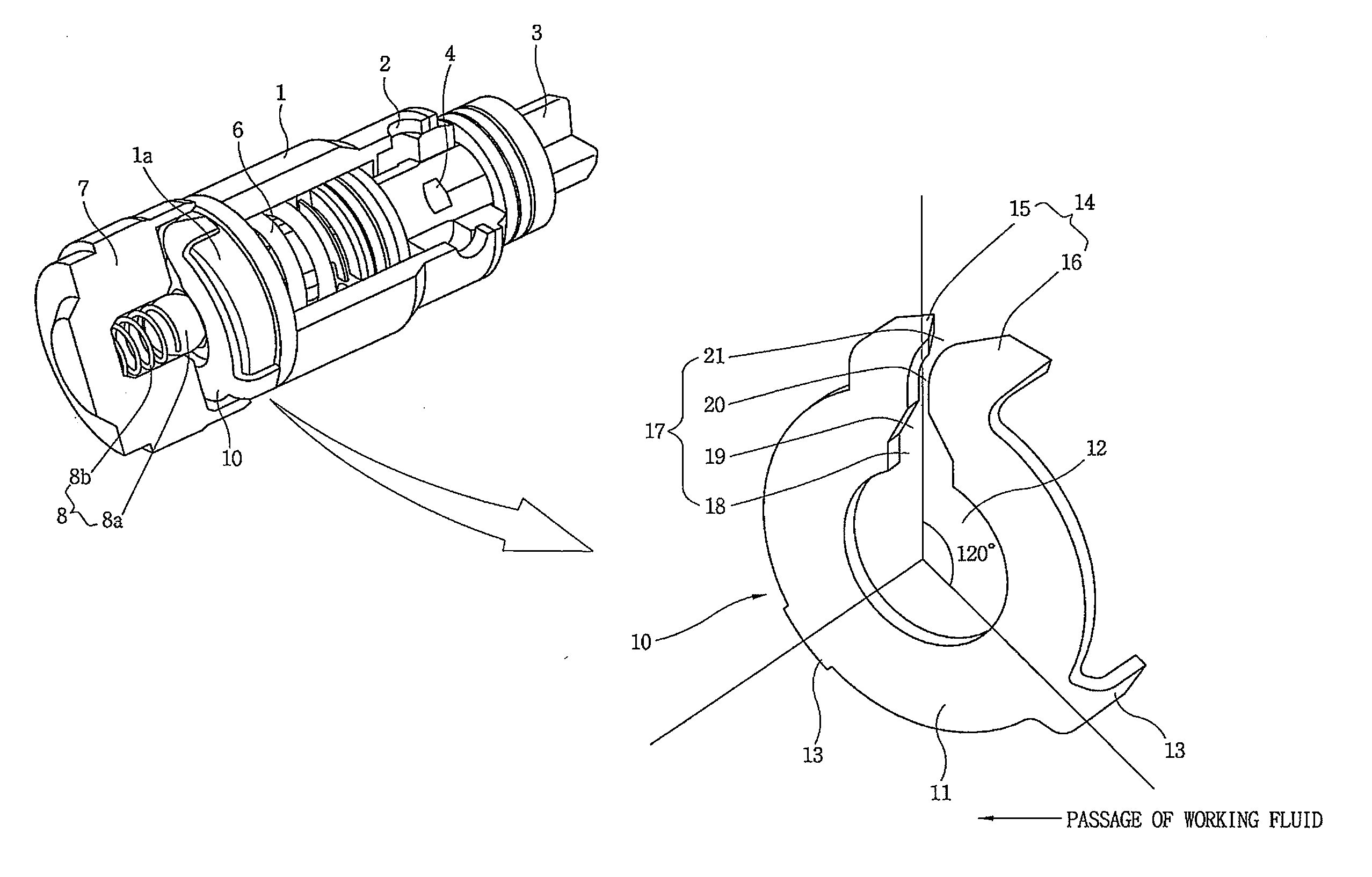

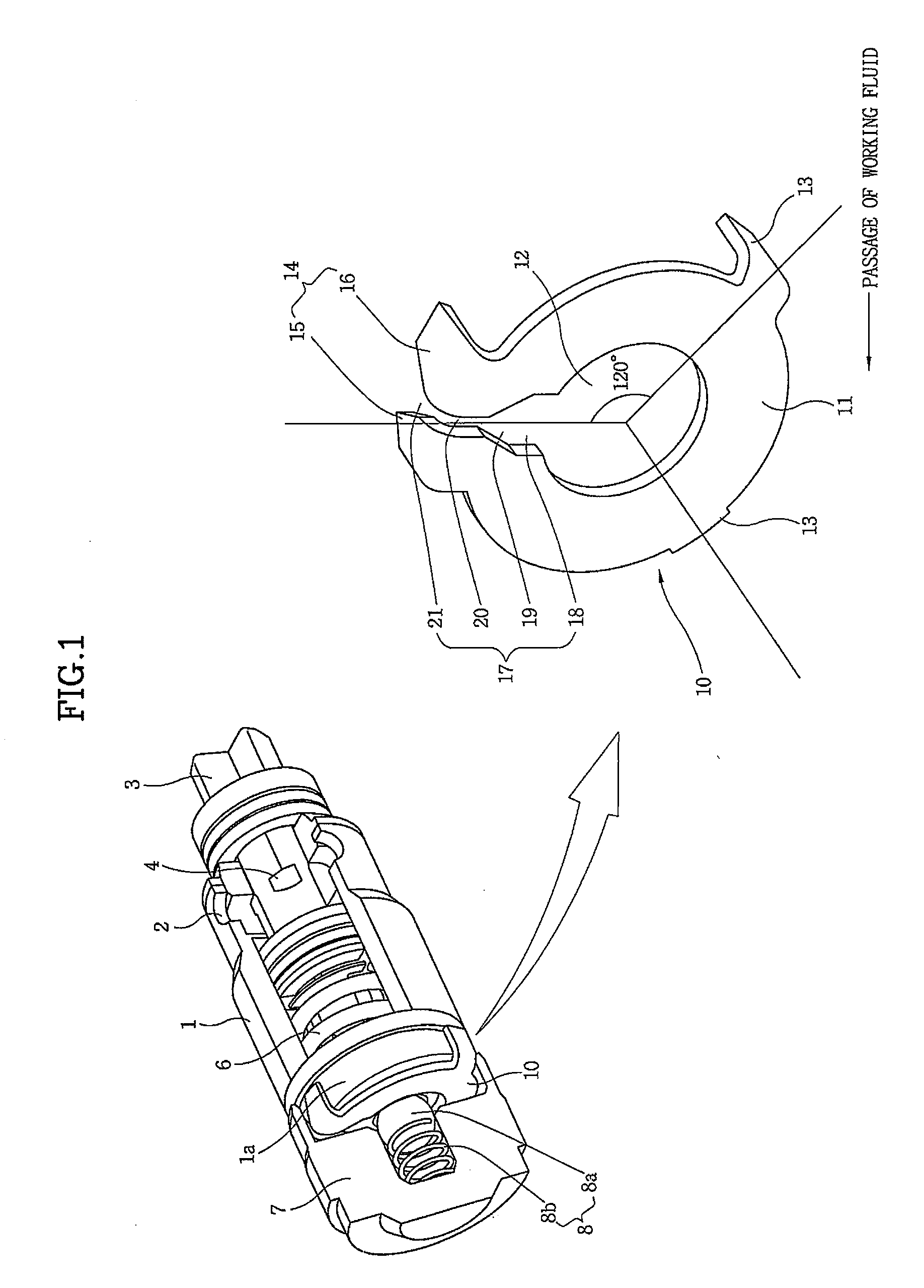

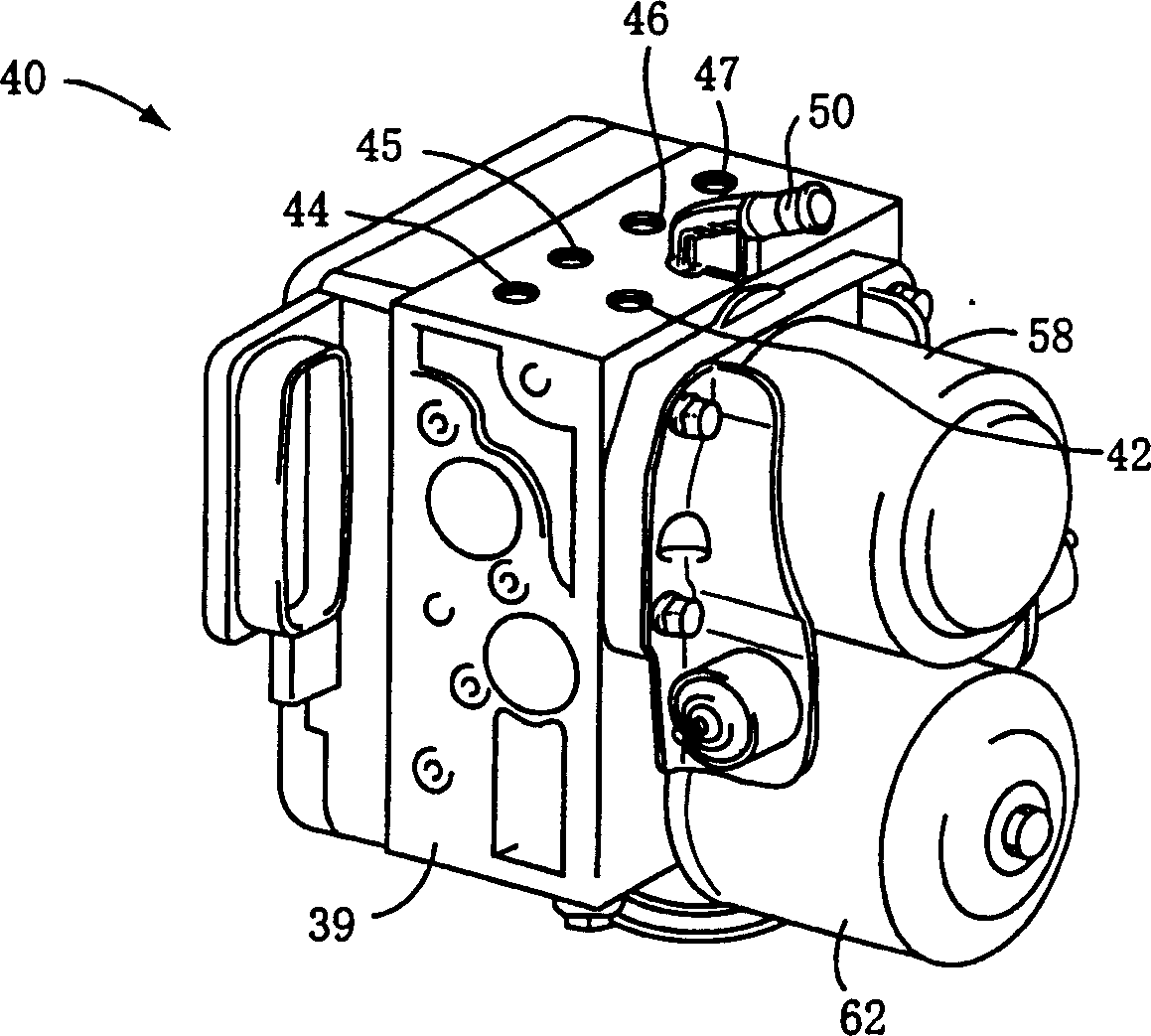

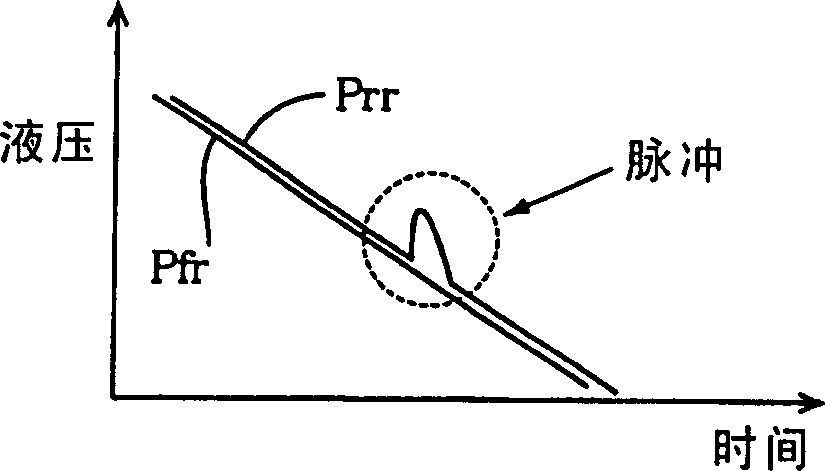

Pulsation pressure decreased type pump for vehicle slip control system

InactiveUS20080317618A1Overcomes drawbackReduce pressurePumpsPositive-displacement liquid enginesPressure decreaseWorking fluid

The present invention provides a pulsation pressure decreased type pump. When an oil pump that is driven by a motor during the operation of an electronically controlled brake system discharges a working fluid, the working fluid passes through an annular orifice provided at a position where the working fluid is discharged and is then discharged to an outlet of a pump housing through an outflow channel formed in the orifice so as to decrease a pulsating pressure using a piston reciprocated by a cam. Therefore, it is possible to decrease a pulsating pressure generated in the pump from 20 bar to 5 bar or less.

Owner:HYUNDAI MOBIS CO LTD

Liquid distribution apparatus employing a check valve for distributing liquid into a seed furrow

Aspects of the present invention involve an extension adapted to extend from a planter, such as the seed tube portion of the planter, into a seed furrow in order to engage seeds being deposited therein, where such engagement may involve deflecting the seeds toward the vertex region of the furrow and / or firming the seeds in the furrow. The extension includes or supports a fluid distribution arrangement such as a hose or the like, which may be separate or integral with the liquid supply hose of a planter. The fluid distribution arrangement is adapted to supply fluid, such as liquid fertilizer, insecticide, water, etc., to the furrow. A valve is provided in the fluid flow path in the region of the fluid distribution arrangement to control the distribution of fluid to the furrow. The valve may be a check valve that allows fluid flow therethrough when fluid pressure exceeds a value such that the valve opens, and prevents fluid flow when the pressure decreases below the valve activation pressure.

Owner:SCHAFFERT PAUL E

Electronically controlled hydraulic brake system

An electronically controlled hydraulic brake system comprising: a brake operating member; a reservoir containing a brake fluid; a front and a rear wheel cylinder; a front and a rear pressure-increase valve; a front and a rear pressure-decrease valve; a power-operated pressure source; a front and a pressure-decrease passage respectively connecting the front and rear pressure-decrease valves with the reservoir; an operating state detecting device detecting an operating state of the brake operating member, based on which the brake fluid is (i) supplied to the front and rear wheel cylinders from the power-operated pressure source by operation of the front and rear pressure-increase valves, so as to increase pressure in the front and rear wheel cylinders, and (ii) discharged from the front and rear wheel cylinders to the reservoir via the front and rear pressure-decrease passages, by operation of the front and rear pressure-decrease valves so as to decrease the pressure in the front and rear wheel cylinders; and pulse transmission restraining means restraining transmission of a pressure pulse from the brake fluid at a junction between the front and rear pressure-decrease passages to the brake fluid in the rear pressure-decrease passage.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com