Patents

Literature

53results about How to "Liquid evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

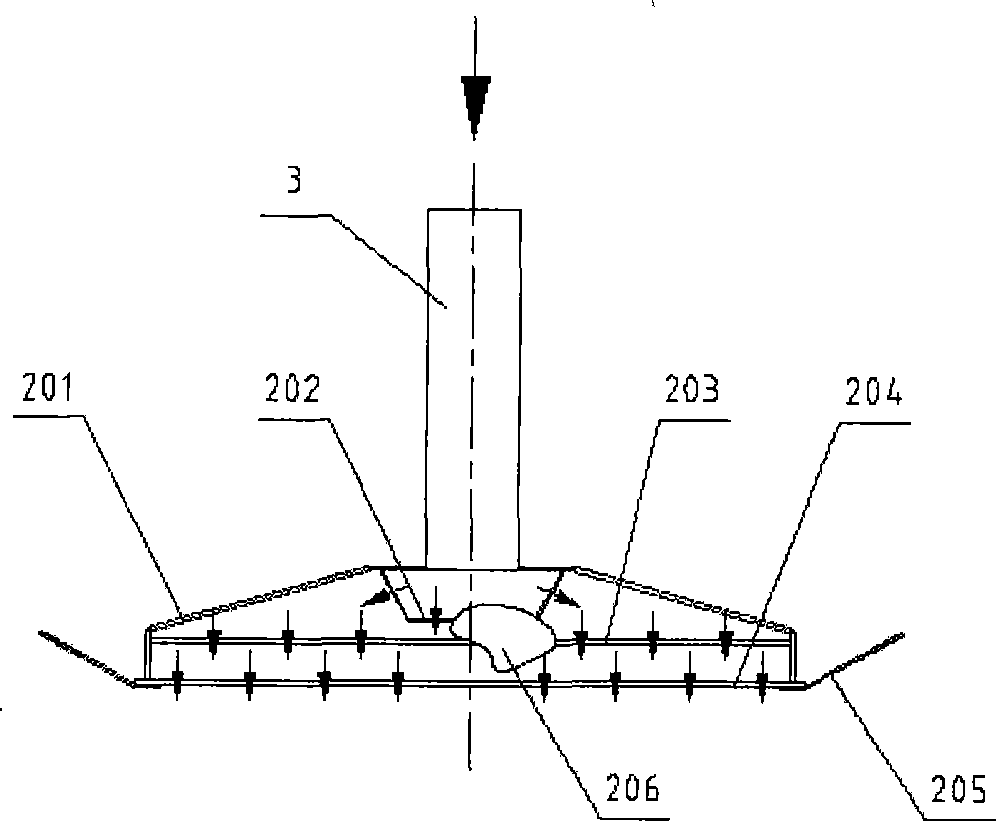

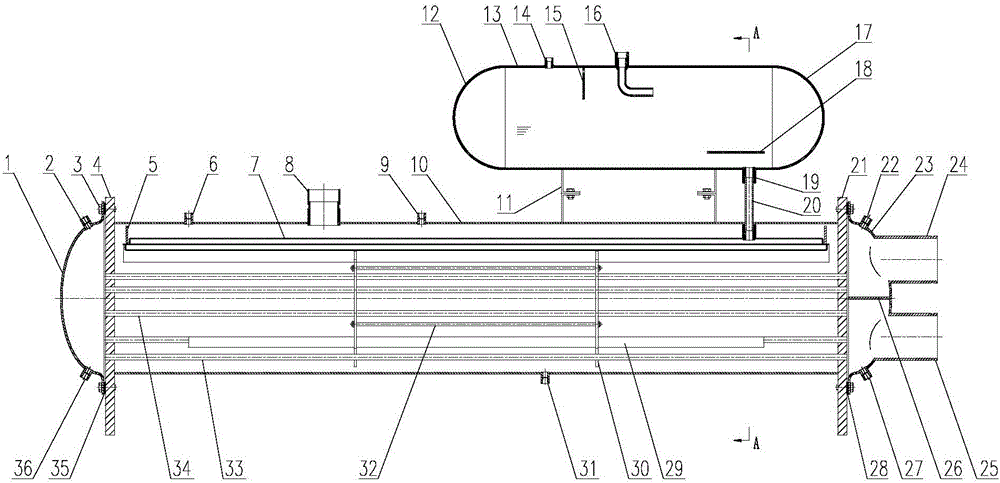

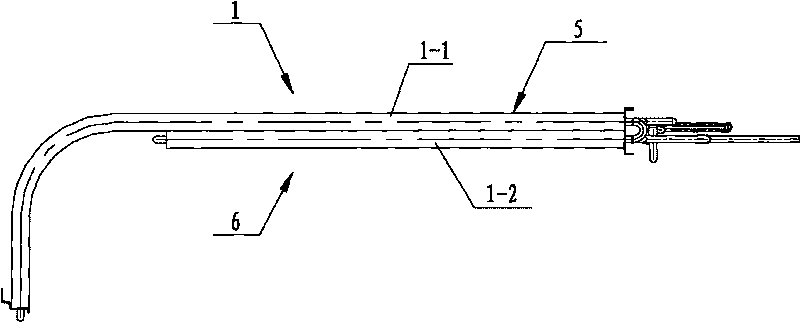

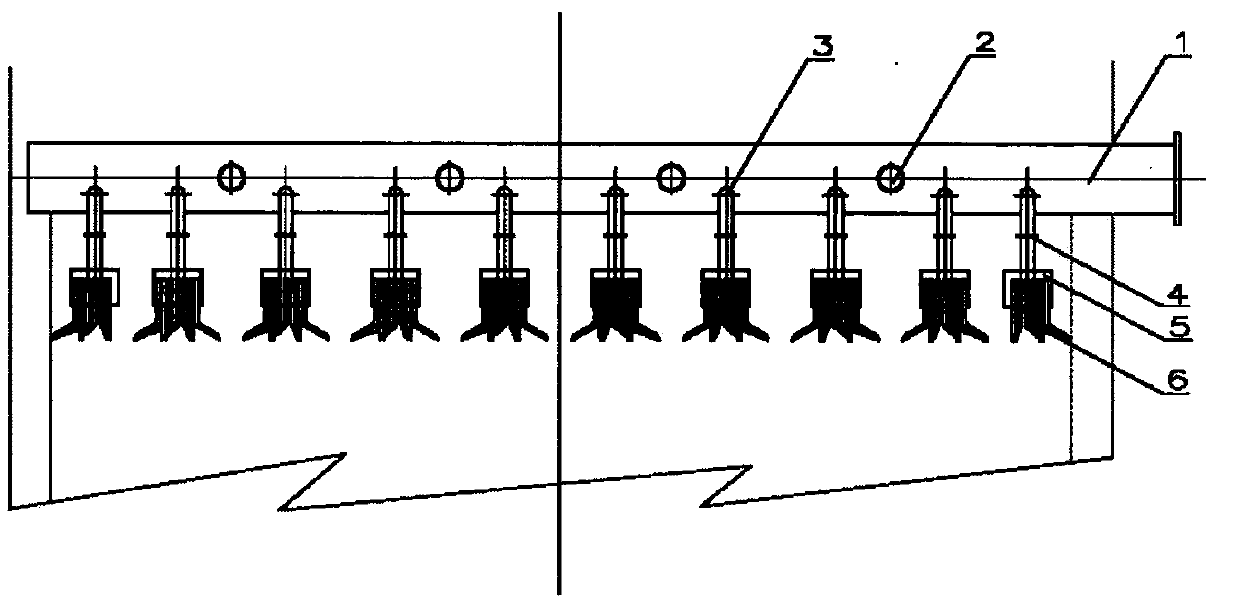

Trickle falling film type evaporator device and use method

ActiveCN101382359AReduce chargeLiquid evenlyEvaporators/condensersStationary conduit assembliesVena contracta diameterPressure decrease

The invention relates to a trickle downward film type evaporator device and a using method thereof; the downward film type evaporator of the prior art which is the two-phase refrigerant distributor technology has a five-layer orifice plate structure and a capillary structure, as the structure is more complicated and the processing and assembling difficulty is high, the uneven liquid distribution is easily caused, the heat transfer performance is decreased and the energy efficiency is lowered. The trickle downward film type evaporator device adopts the technical proposal of a multi-directional two-grade pressure decrease distribution device, a two-phase refrigerant distributor which consists of a trapezoidal shell body, a multi-directional flow distribution plate, a grade-one distribution orifice plate, a grade-two distribution orifice plate, a gas absorption distribution plate and an end seal plate is used for carrying out the multi-directional two-grade pressure decrease distribution, thereby leading a gas-liquid refrigerant to be evenly and effectively trickled at the outer surface of the pipe wall of an evaporation pipe bundle and further carry out the full heat exchange. The trickle downward film type evaporator device has the advantages that: the two-phase refrigerant distributor technology has simple structure, easy production, even liquid distribution of the gas-liquid refrigerant and improved heat transfer performance. Compared with the existing flooded evaporator, the energy is saved by 15-20 percent, and the filling amount of the refrigerant is reduced by 20-30 percent, thereby being economic and energy-saving.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

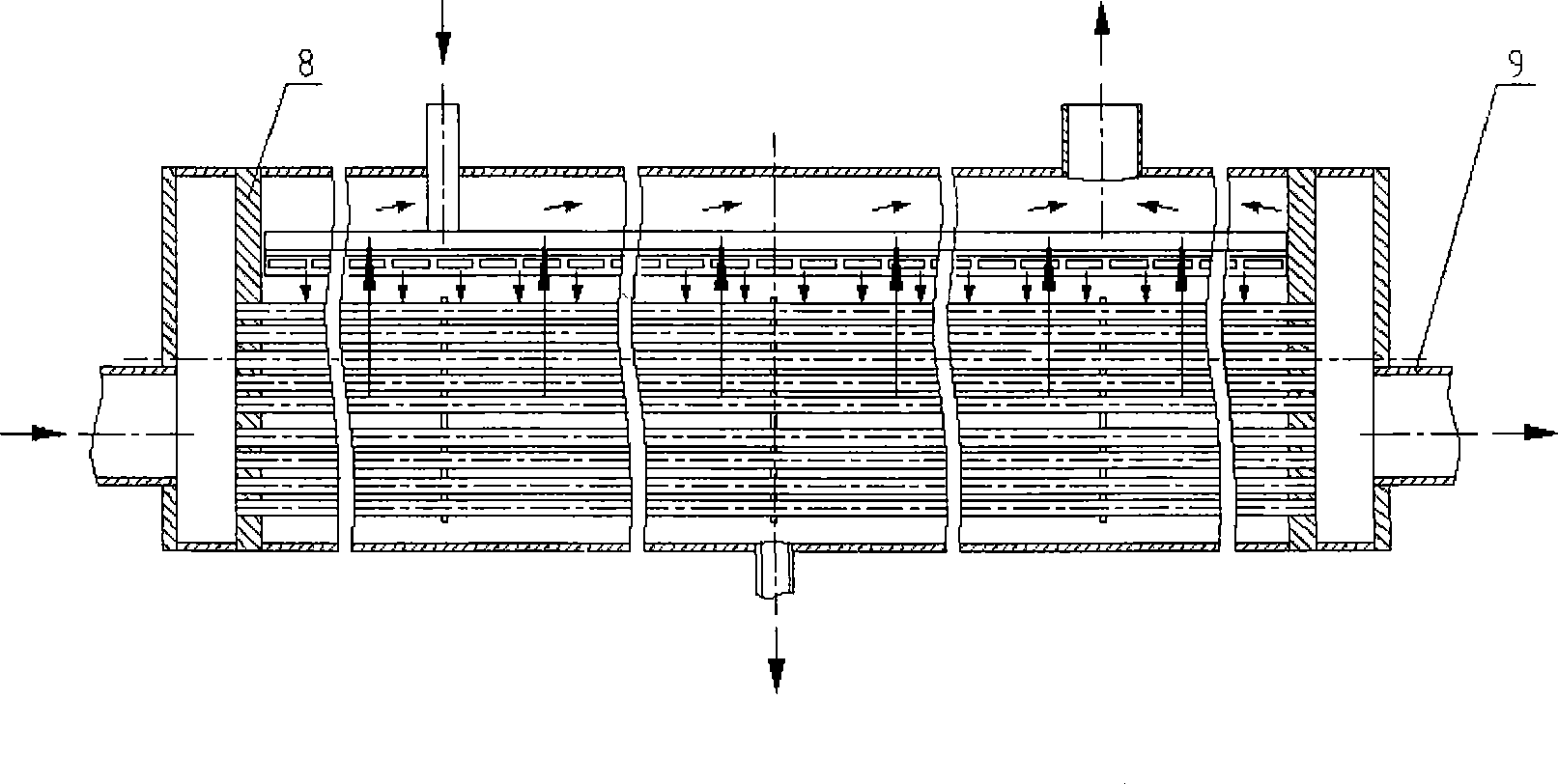

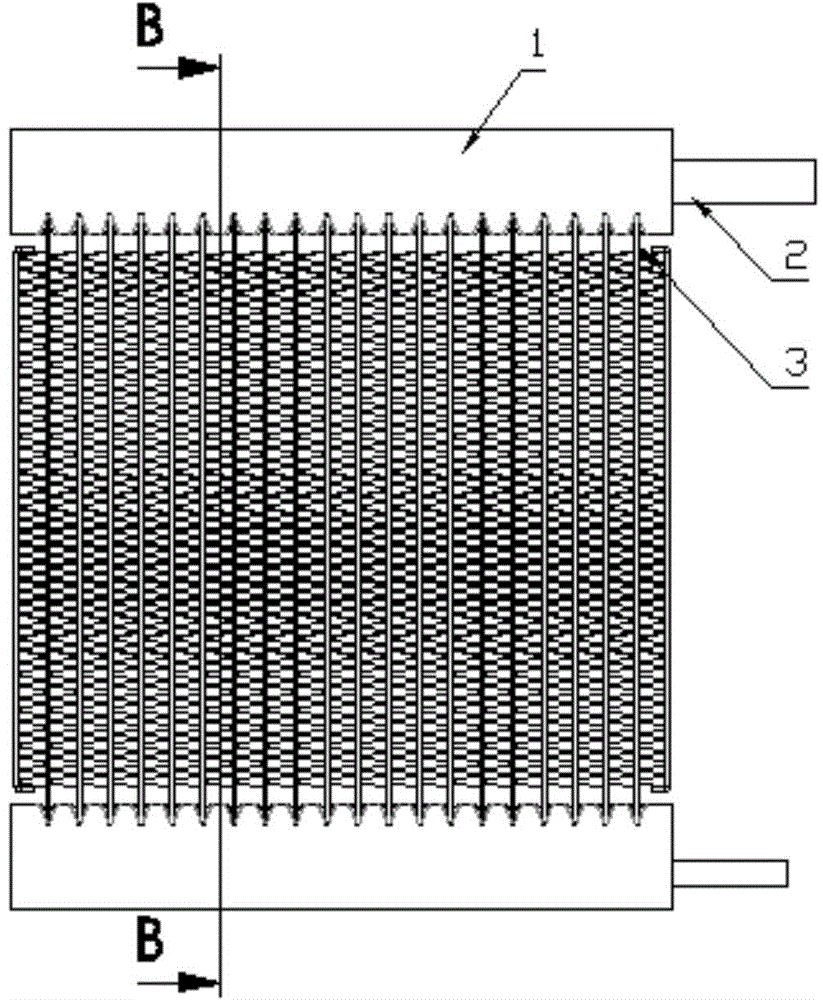

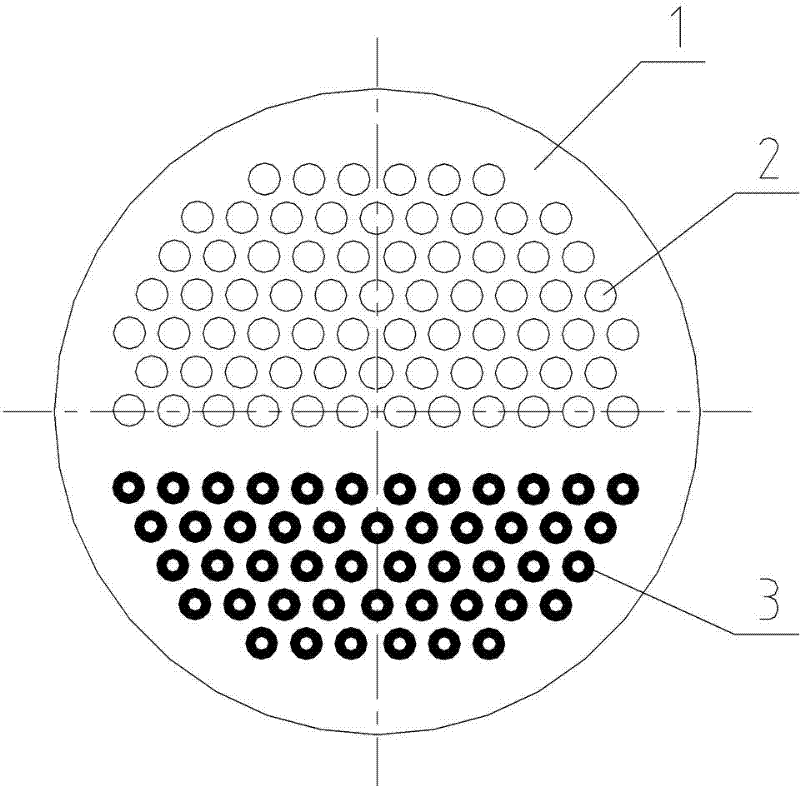

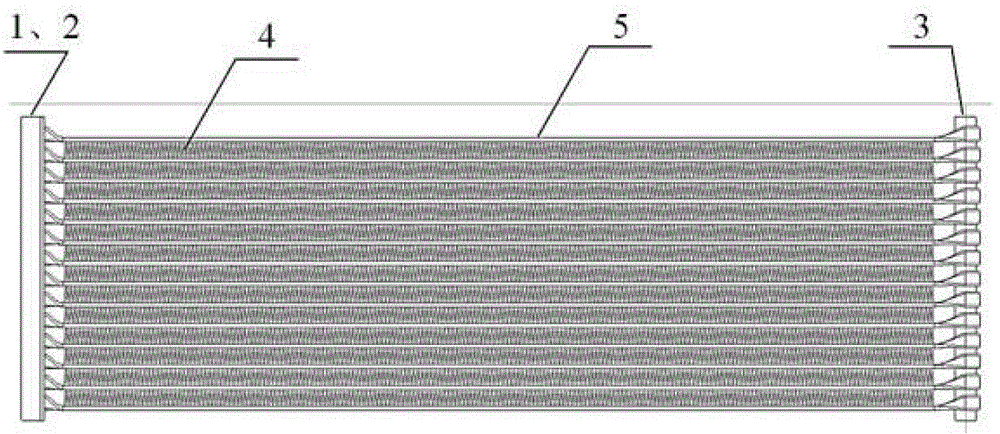

Shell and tube heat exchanger

InactiveCN102374799ALiquid evenlyEnhanced turbulence effectEvaporators/condensersHeat exchanger casingsShell and tube heat exchangerPlate heat exchanger

The invention discloses a shell and tube heat exchanger, which comprises an end plate, a channel and a core group, wherein the core group comprises a tube plate and a plurality of U-shaped internal-thread heat exchange tubes; the lower half part of the channel is provided with a liquid division plate; the liquid division plate, the channel and the end plate form a sealed space; the liquid division plate is provided with a plurality of liquid division tubes; and the first ends of the liquid division tubes and the U-shaped internal-thread heat exchange tubes are in tight coupling. In the shell and tube heat exchanger, the liquid division tubes and the liquid division plates are combined to evenly divide a refrigerating fluid, and the heat exchange area of each heat exchange tube is fully utilized. The spiral traverse baffle structure is used so as to increase the turbulence performance, a heat transfer coefficient is improved, and a heat exchange effect is greatly improved.

Owner:SHANGHAI HANYE REFRIGERATION MACHINERY +1

Spraying type evaporator

InactiveCN105135755ALiquid evenlyIncrease the heat exchange areaEvaporators/condensersPhysicsRefrigerant

The invention discloses a spraying type evaporator. The spraying type evaporator comprises a heat exchanger and a gas-liquid separator. The gas-liquid separator comprises a shell, a liquid inlet connection pipe extending into the shell, a gas return opening connection pipe extending into the shell, and a connector base which is arranged at the bottom of the shell and connected with a connection pipe. The inlet of the liquid inlet connection pipe is connected with a refrigerant outlet of a throttling mechanism of the previous stage. A partition plate is arranged between the liquid inlet connection pipe and the gas return opening connection pipe. The outlet of the liquid inlet connection pipe and the inlet of the gas return opening connection pipe are separated from each other through the partition plate. The gas-liquid separator is arranged, gas-liquid separation is conducted on throttled refrigerant, it is ensured that the refrigerant entering the heat exchanger is in a pure liquid state, liquid distribution of a liquid distributor can be more uniform, and therefore the heat exchange efficiency of the whole heat exchanger is improved, the heat conduction temperature difference is reduced, the energy efficiency ratio of running of a refrigerating unit is increased, and the aim of saving energy is achieved.

Owner:南京冷德节能科技有限公司 +1

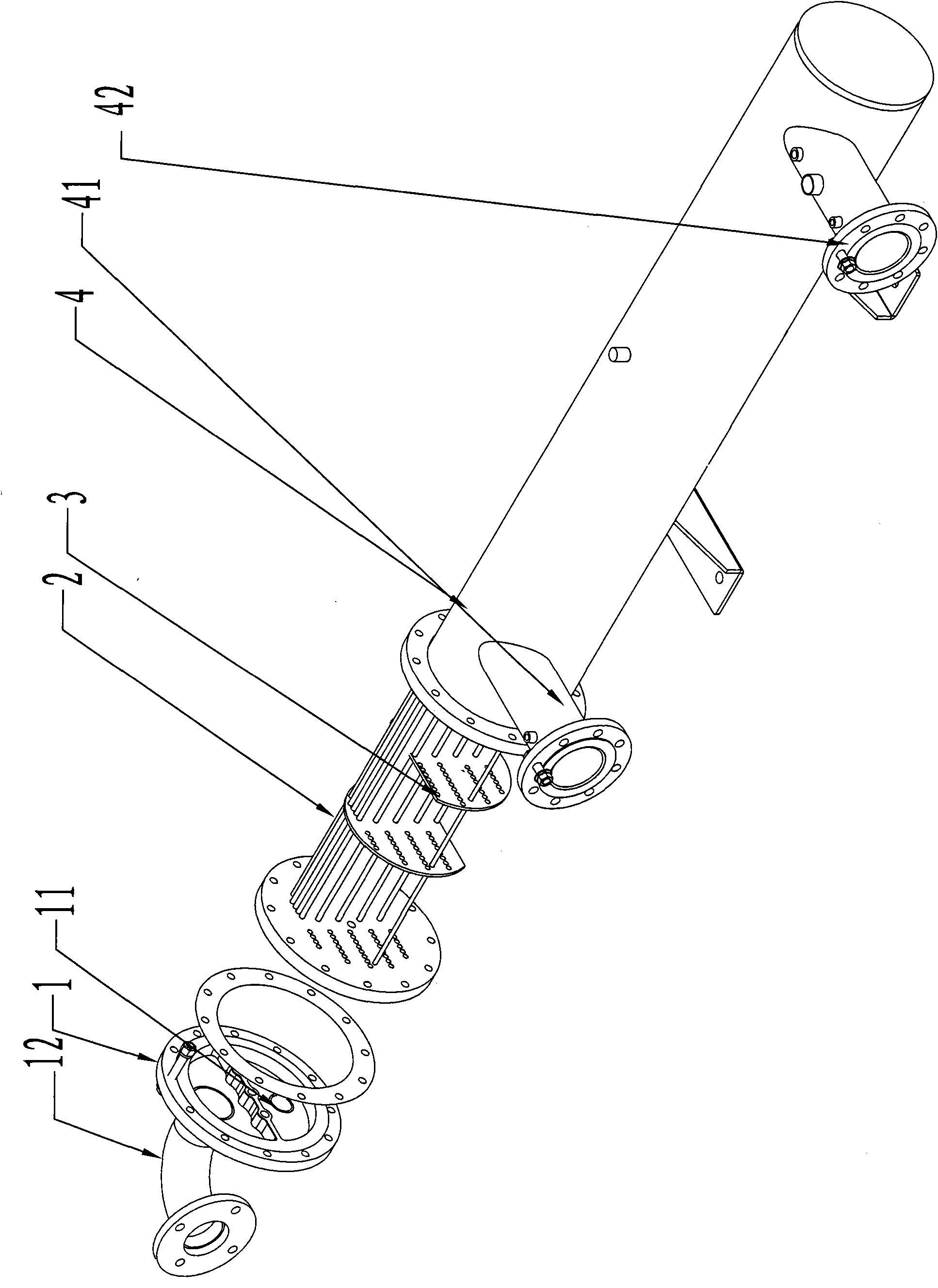

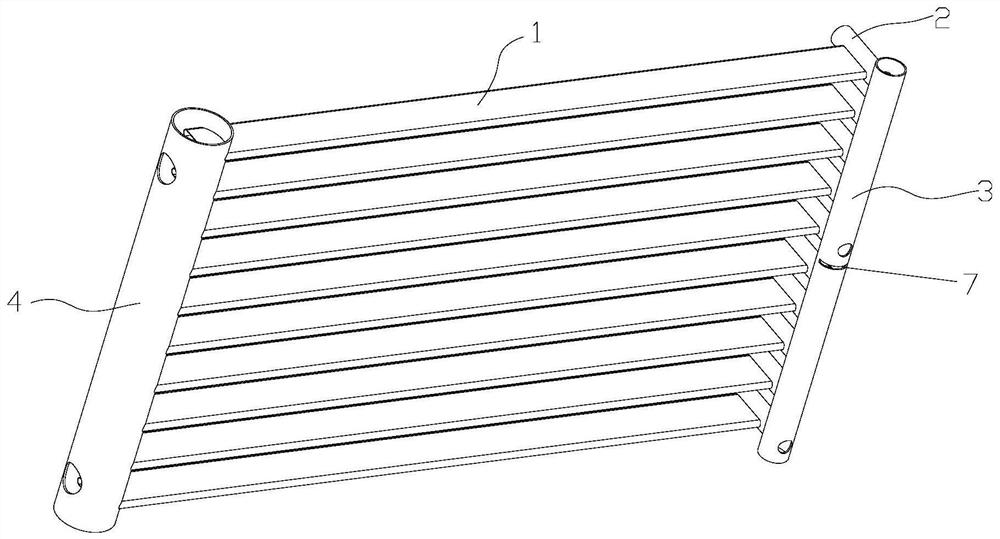

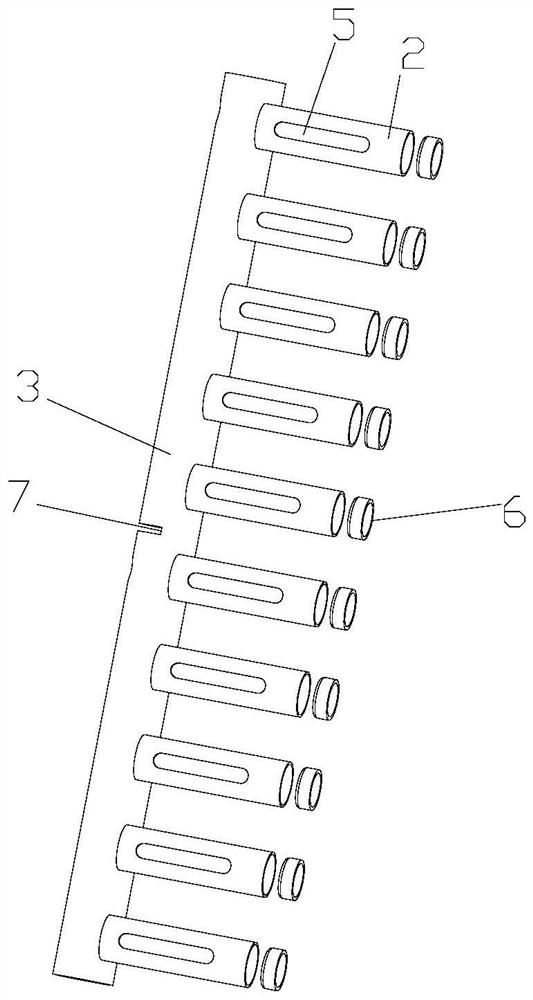

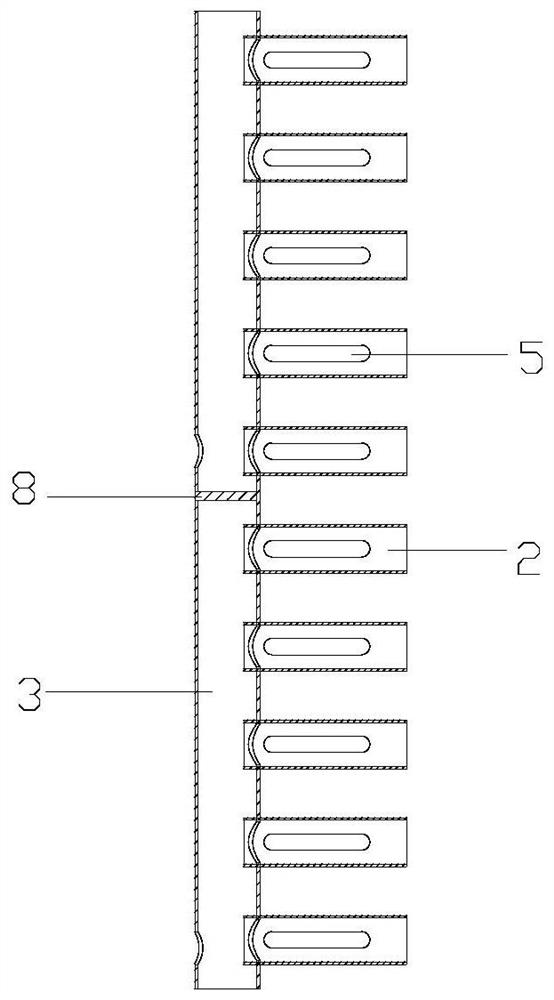

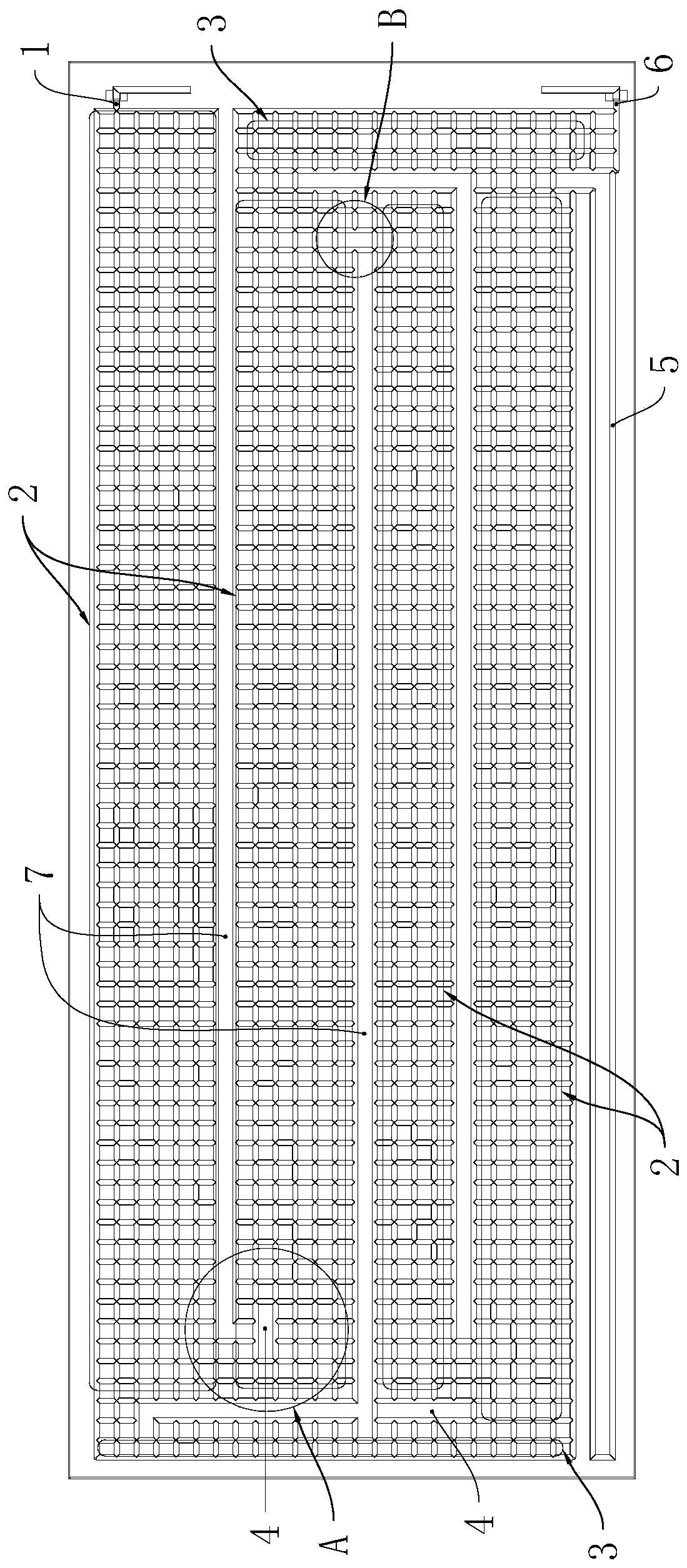

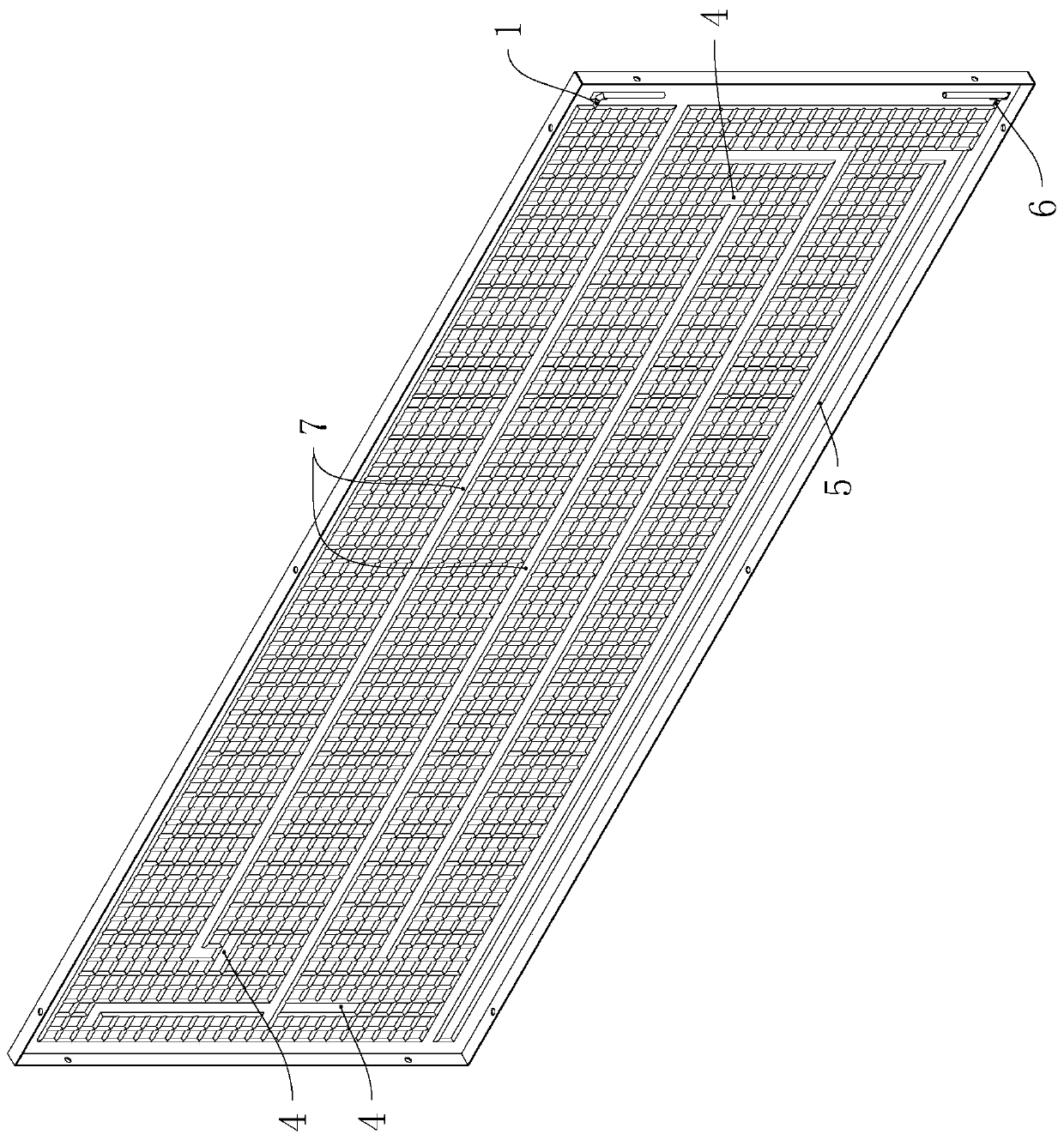

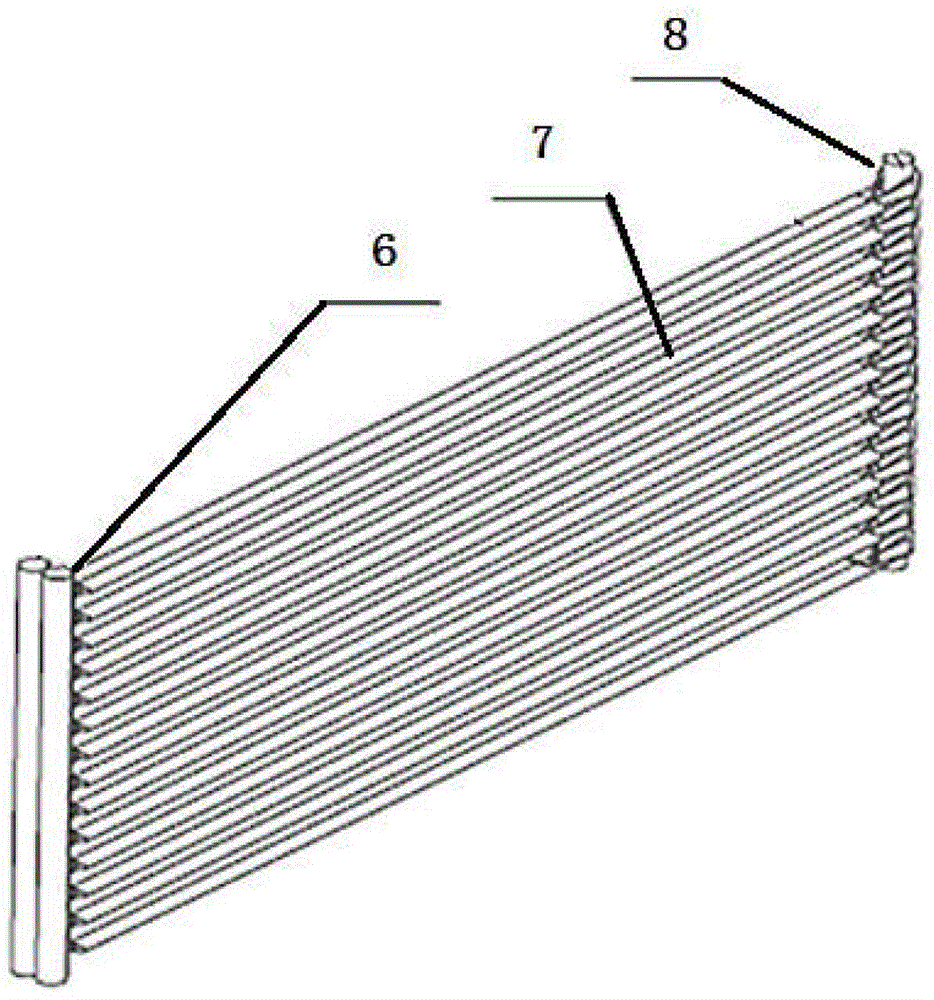

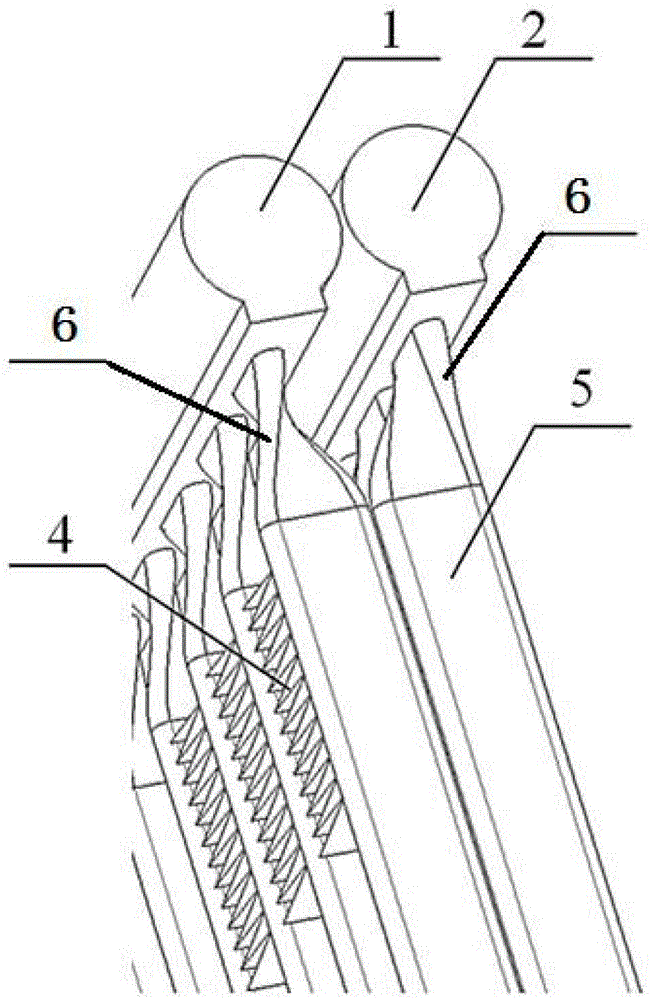

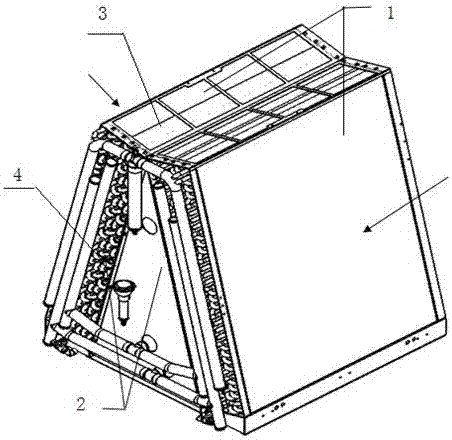

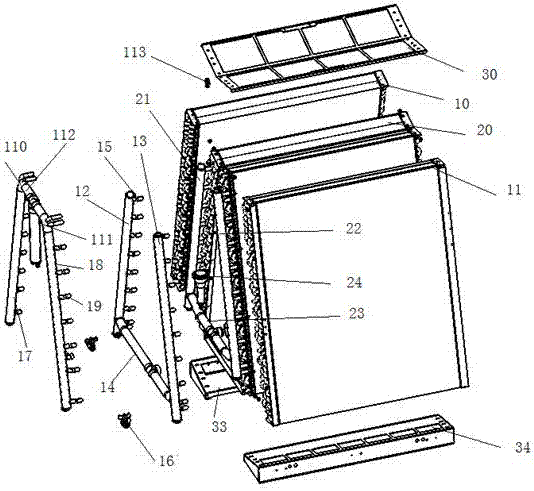

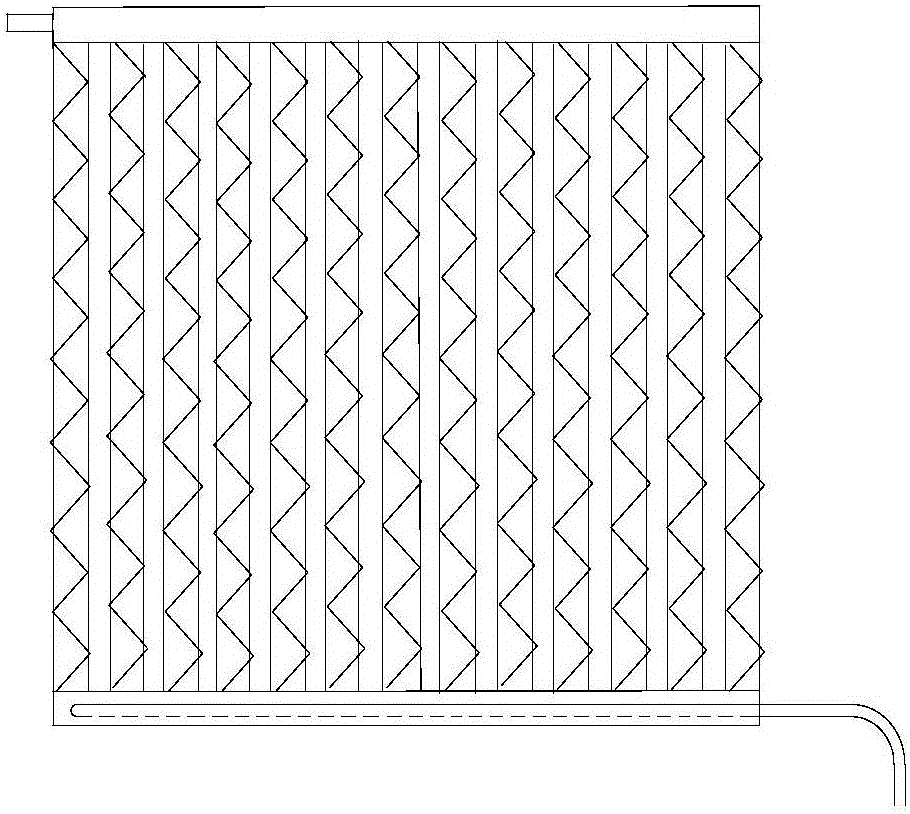

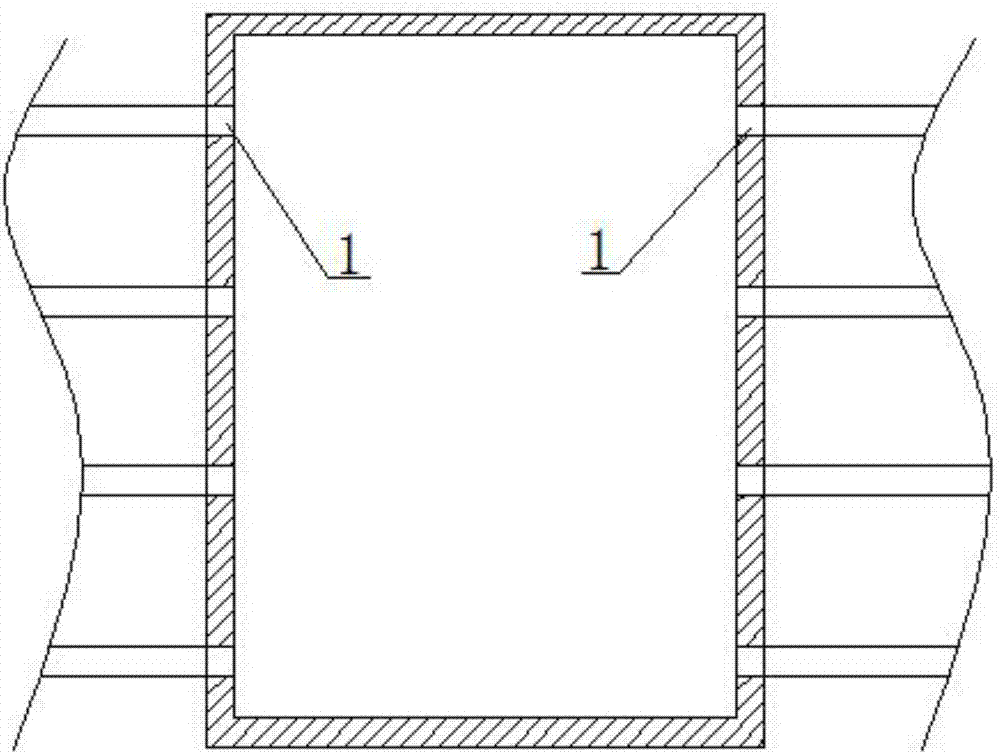

Micro-channel heat exchanger and mounting method

ActiveCN105485972AGuaranteed StrengthLiquid evenlyEvaporators/condensersHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a micro-channel heat exchanger and a mounting method. The micro-channel heat exchanger comprises collecting pipes and distributing pipes arranged in the collecting pipes, wherein the distributing pipes are provided with a plurality of distributing holes in the axial direction, and the end parts of flat pipes are inserted into the collecting pipes side by side; a plurality of baffles are integrally fixed on the distributing pipes in the axial direction, and the distributing pipes are movably inserted into the collecting pipes; sealing members for fixing the distributing pipes are also inserted into the collecting pipes, and the baffles, the sealing members and the inner walls of the collecting pipes are matched in the collecting pipes, so that a plurality of independent liquid distributing regions are formed. According to the mounting method disclosed by the invention, the baffles and the distributing pipes are integrally fixed, and then are movably inserted into the collecting pipes, so that the collecting pipes can keep integral structures, and defects caused by the condition that plate grooves are cut in a conventional structure are overcome; therefore, the intensity of the collecting pipes is guaranteed, and the leakage is avoided.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

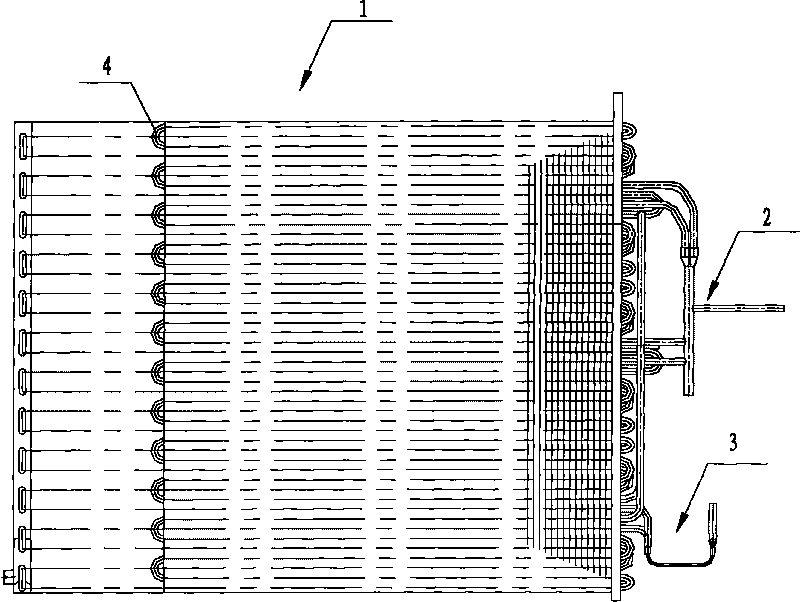

High-efficiency condenser and air conditioner with same

InactiveCN101738016ASimple processImprove heat transfer efficiencyEvaporators/condensersEngineeringRefrigerant

The invention provides a high-efficiency condenser and an air conditioner with the same. The high-efficiency condenser can solve the problem that a heat exchanger of the prior art cannot give full play to heat exchange capacity, and adopts the technical scheme that: the high-efficiency condenser comprises a front row condenser, a back row condenser, a U-shaped tube, a fin, an inlet tube stack, an intermediate liquid distributing tube stack and an outlet fluid diversion tube stack, wherein the front row condenser and the back row condenser are provided with a plurality of fluid diversion branches; the front row condenser has a long row; and the back row condenser has a short row. The high-efficiency condenser is characterized in that: the flow paths of the fluid diversion branches are set into a combination of inverted U shapes and regular U shapes. The high-efficiency condenser optimizes the flow path of the condenser, newly designs the inner row heat exchanger, the outer row heat exchanger, the inlet tube stack, the outlet tube stack and the intermediate liquid distributing tube, uniformly distributes refrigerants in each flow path of the heat exchanger, improves the overall heat exchange balance, improves the heat exchange efficiency of the condenser and reduces the manufacturing cost of the condenser.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

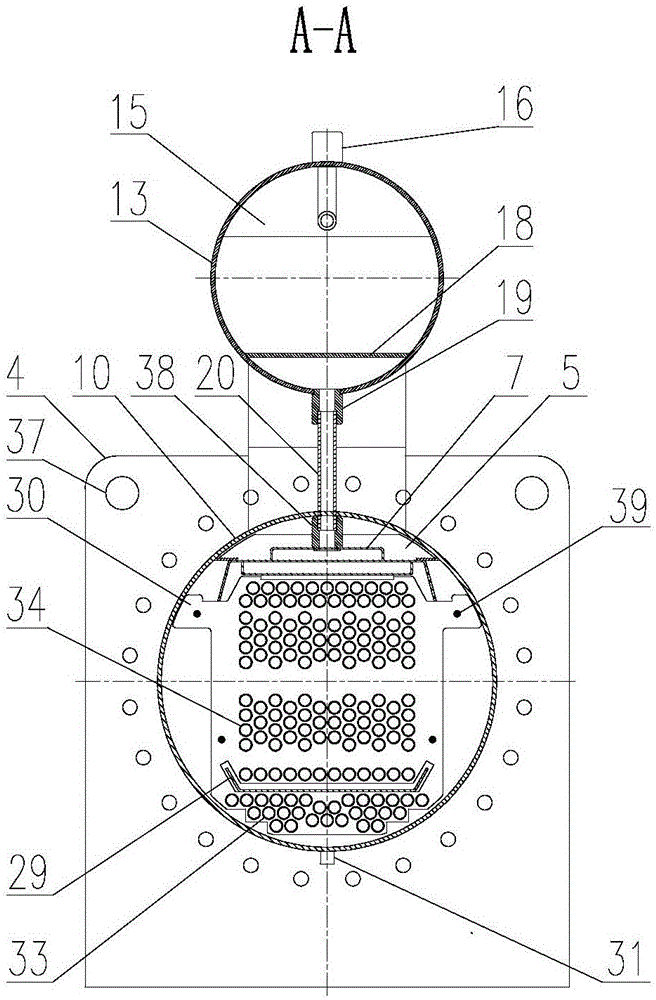

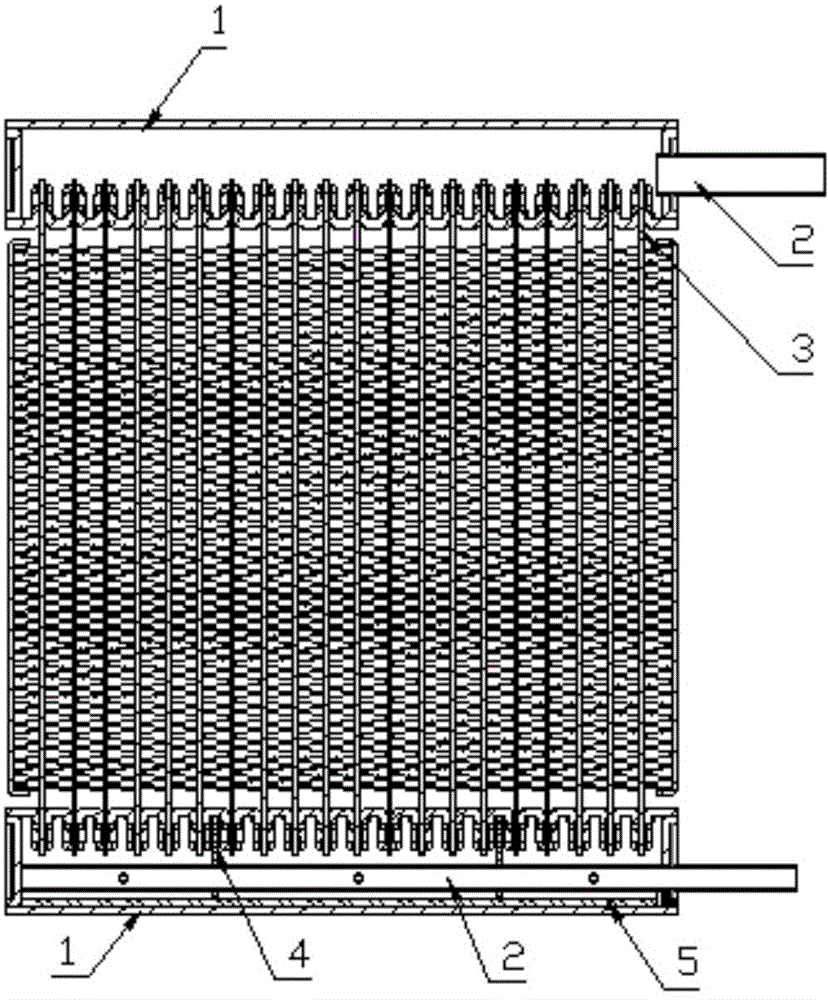

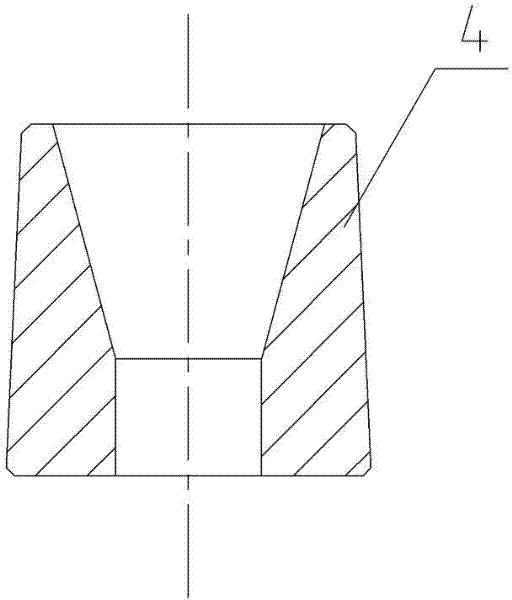

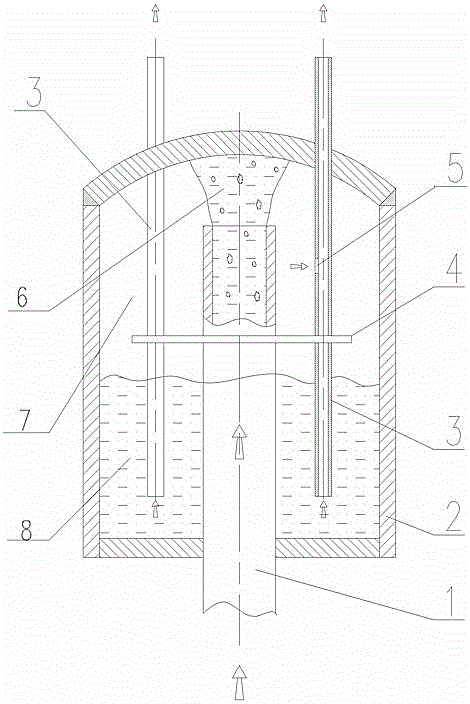

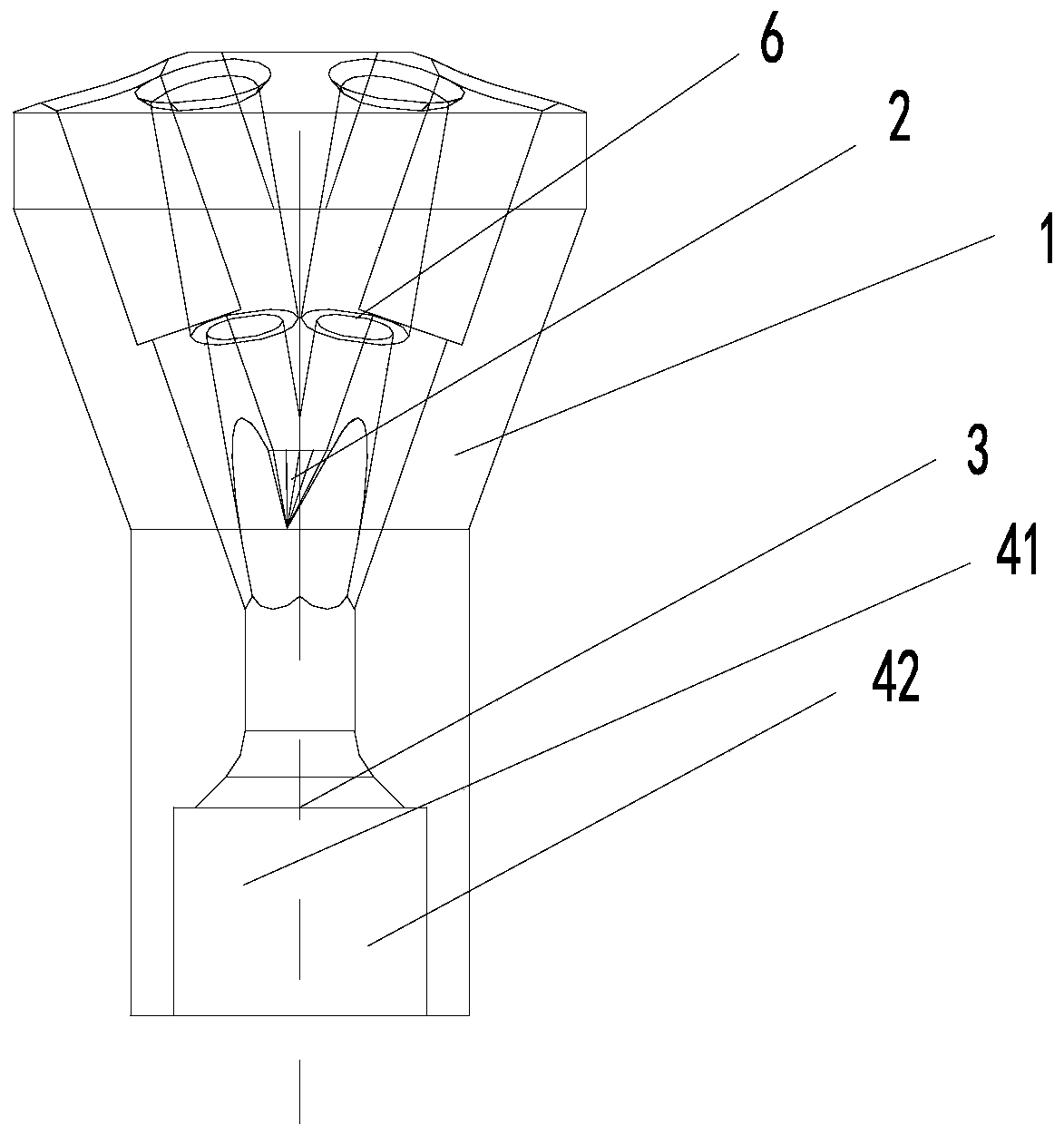

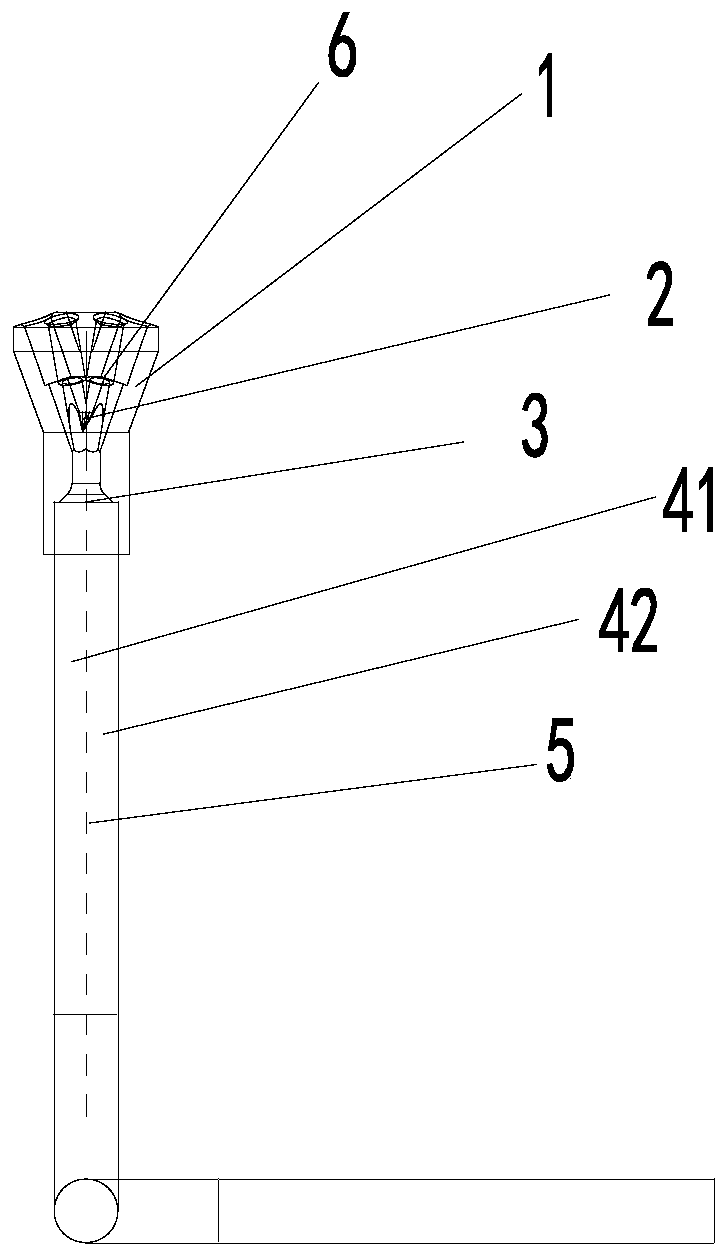

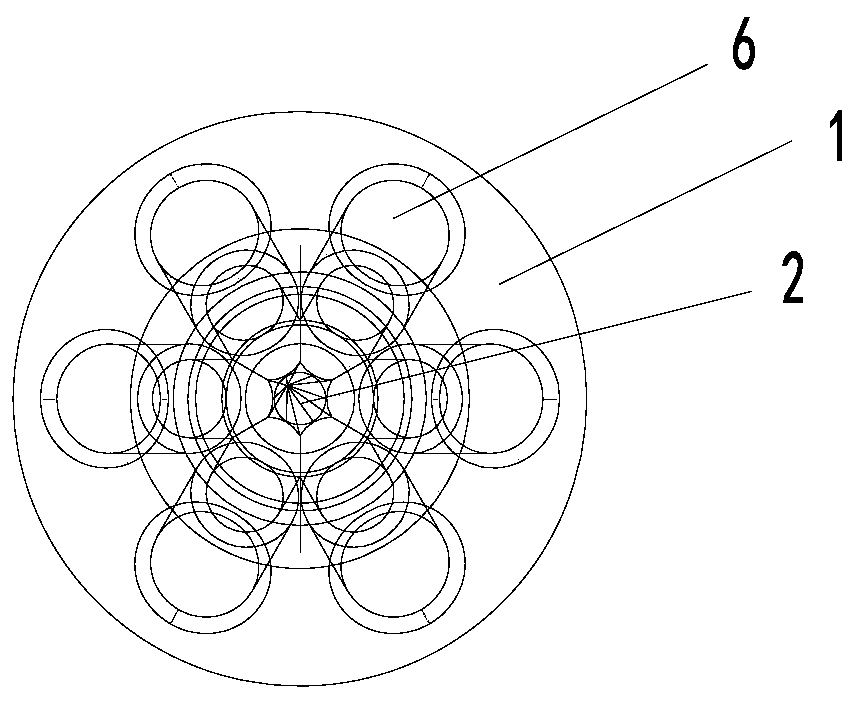

Device for uniformly distributing liquid by using dry evaporator and use method thereof

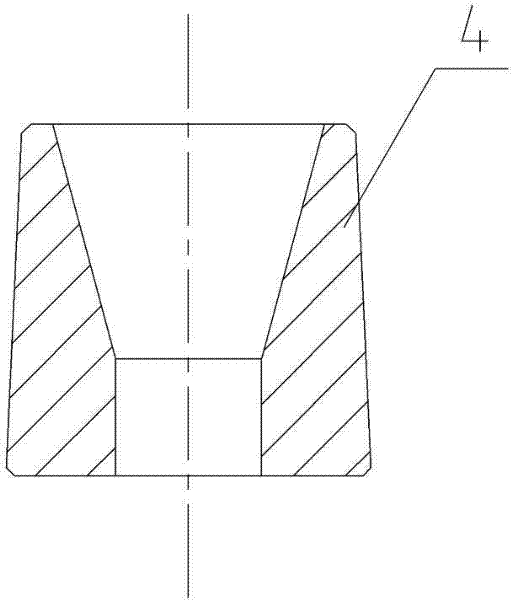

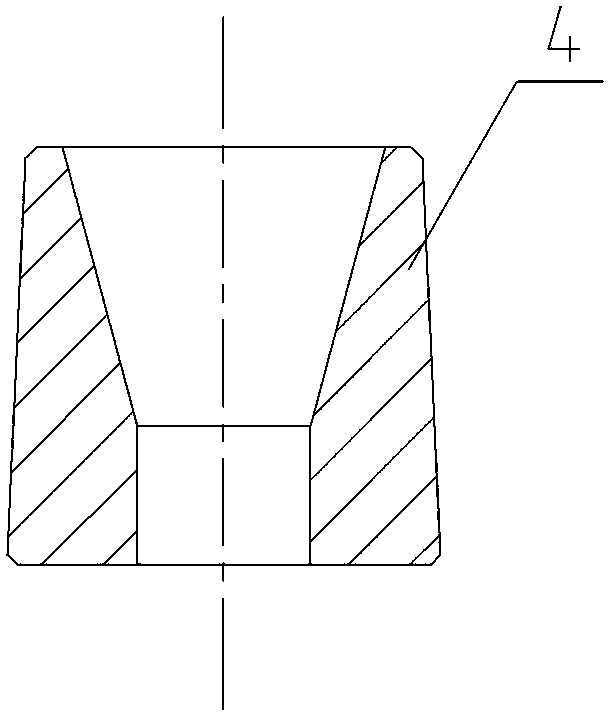

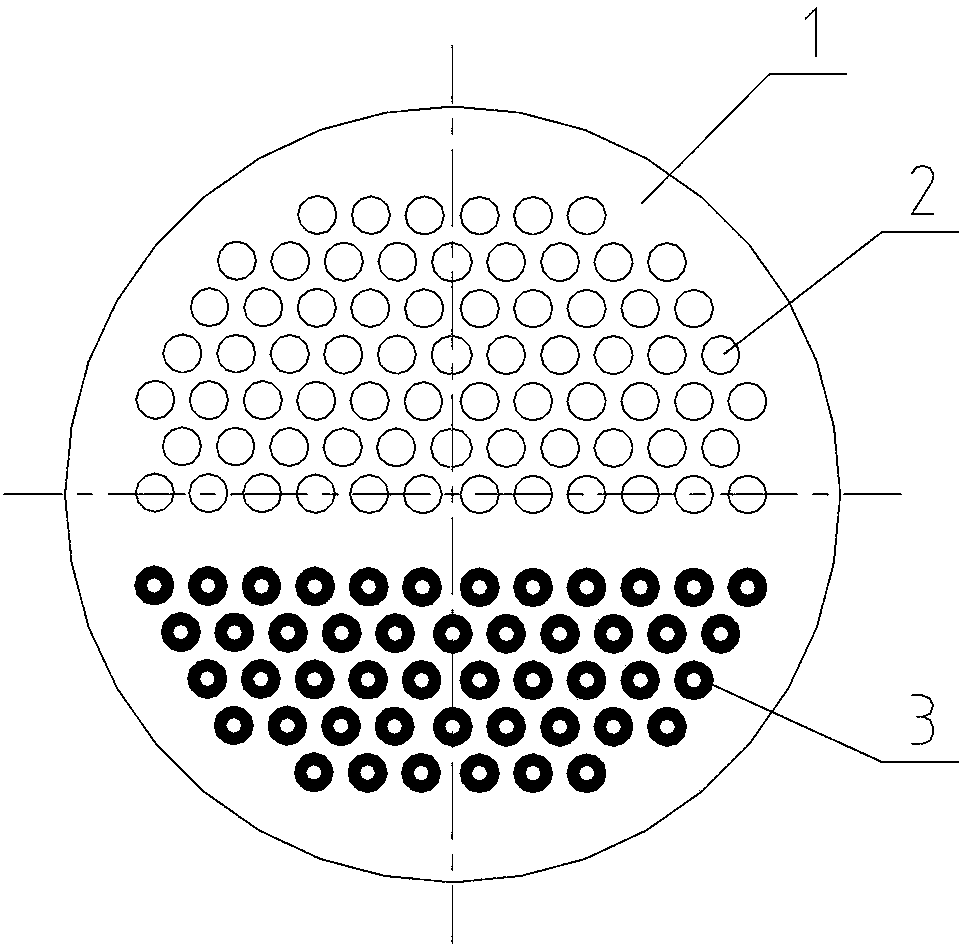

ActiveCN102494444ASpray evenlyLiquid evenlyEvaporators/condensersHeat exchanger casingsEngineeringDistributor

The invention relates to a device for uniformly distributing a liquid by using a dry evaporator and a use method thereof. The problems of complex structure, high sealing requirement and high processing difficulty exist in the conventional liquid distribution device. In a technical scheme of the invention, a gas-liquid refrigerant mixture is distributed more uniformly by using the uniform liquid distribution device in the dry evaporator. The device consists of a uniform liquid distributor, a correlated tube plate and a steam-generating bank. The device has the beneficial effects that: a conical cylindrical uniform liquid distributor is directly arranged in the tube orifice of the steam-generating bank, heat exchange is performed by fully utilizing all steam-generating banks, and energy efficiency is increased by 15-20 percent in comparison to the conventional liquid distribution device. The device is an energy-saving device which has a compact structure and low processing cost and is convenient to manufacture and install.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

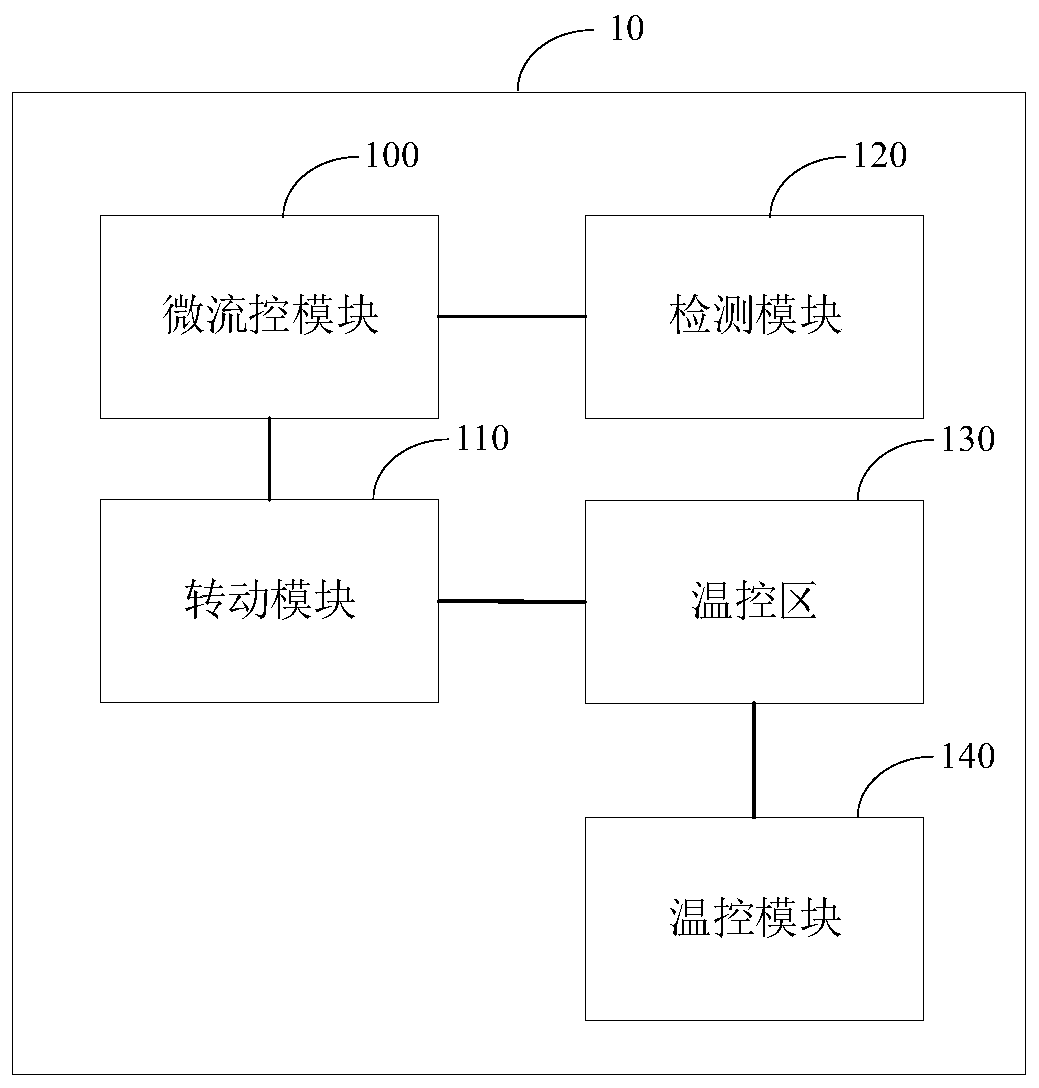

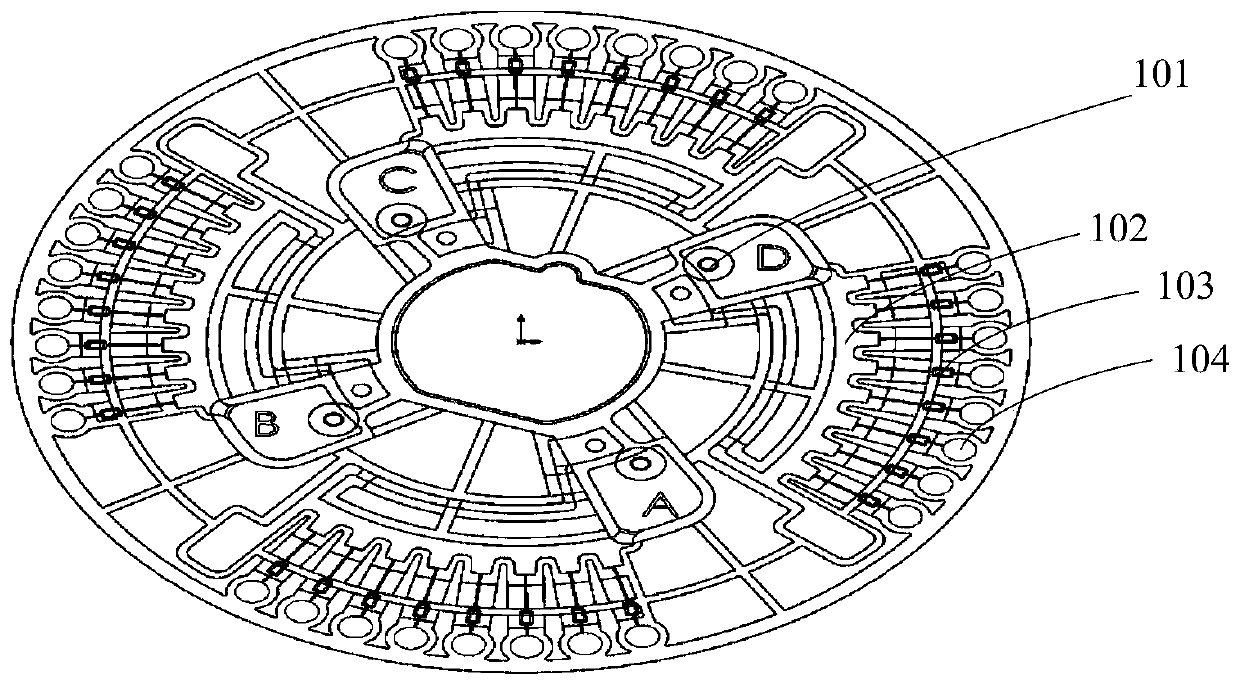

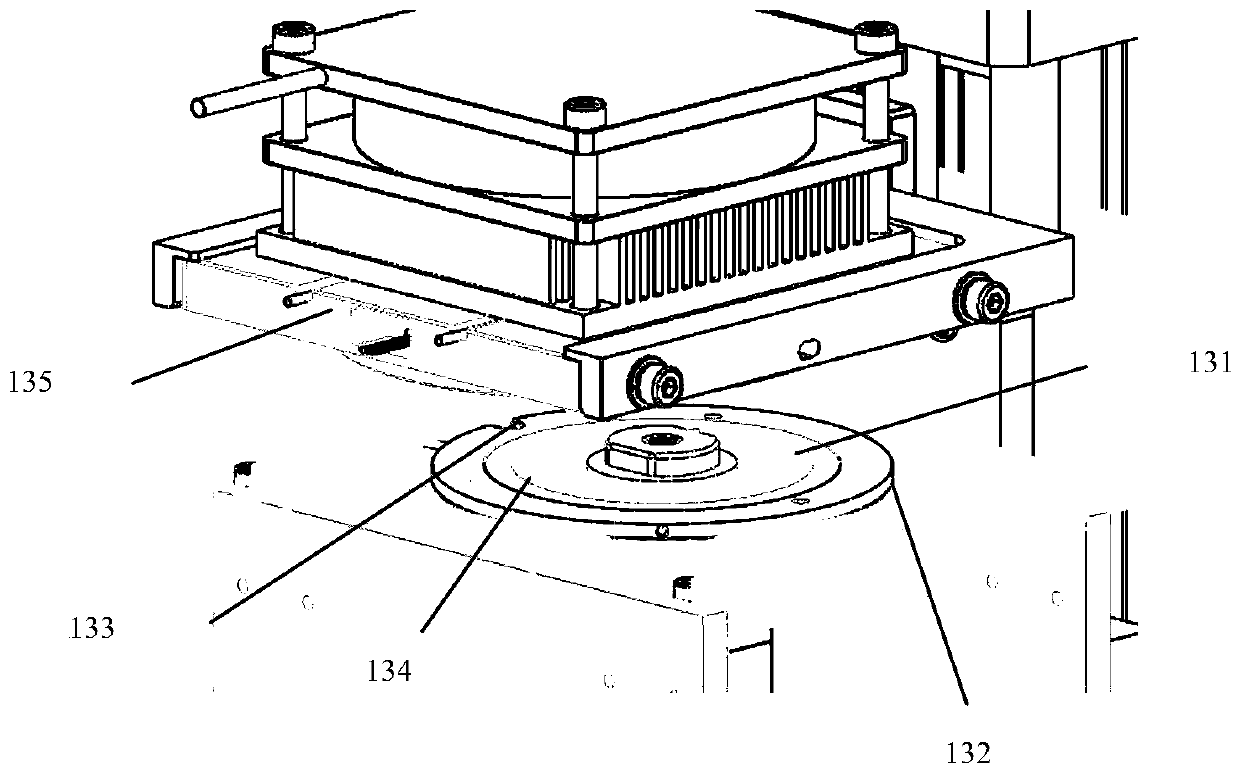

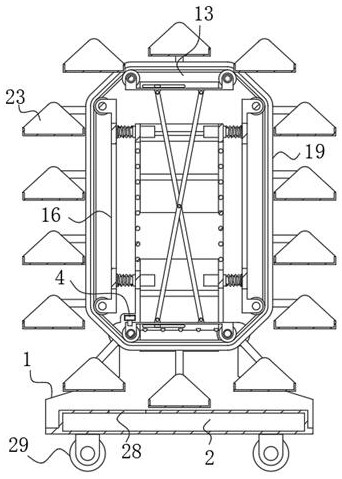

Nucleic acid detection device, method and system

PendingCN110791423AImprove accuracyStable detectionBioreactor/fermenter combinationsHeating or cooling apparatusTemperature controlNucleic acid detection

The invention relates to a nucleic acid detection device, method and system. The device comprises a microfluidics module, a temperature control area, a rotation module, a temperature control module and a detection module, wherein the microfluidics module comprises a microfluidic chip; the temperature control area is arranged below the microfluidic chip and comprises a first temperature area, a second temperature area, a thermal insulation area and detection holes; the rotation module is connected to the microfluidic chip; the temperature control module is connected to the temperature control area; and the detection module is used for detecting a fluorescence signal generated by samples in reaction holes through the detection holes, and a detection result is output. Through the cooperationof each module of the nucleic acid detection device, according to the nucleic acid detection device of the embodiment of the invention, nucleic acid purification and nucleic acid detection integrationcan be realized, operation flows are reduced, and therefore, working efficiency is improved.

Owner:SHANGHAI IGENETEC DIAGNOSTICS CO LTD +1

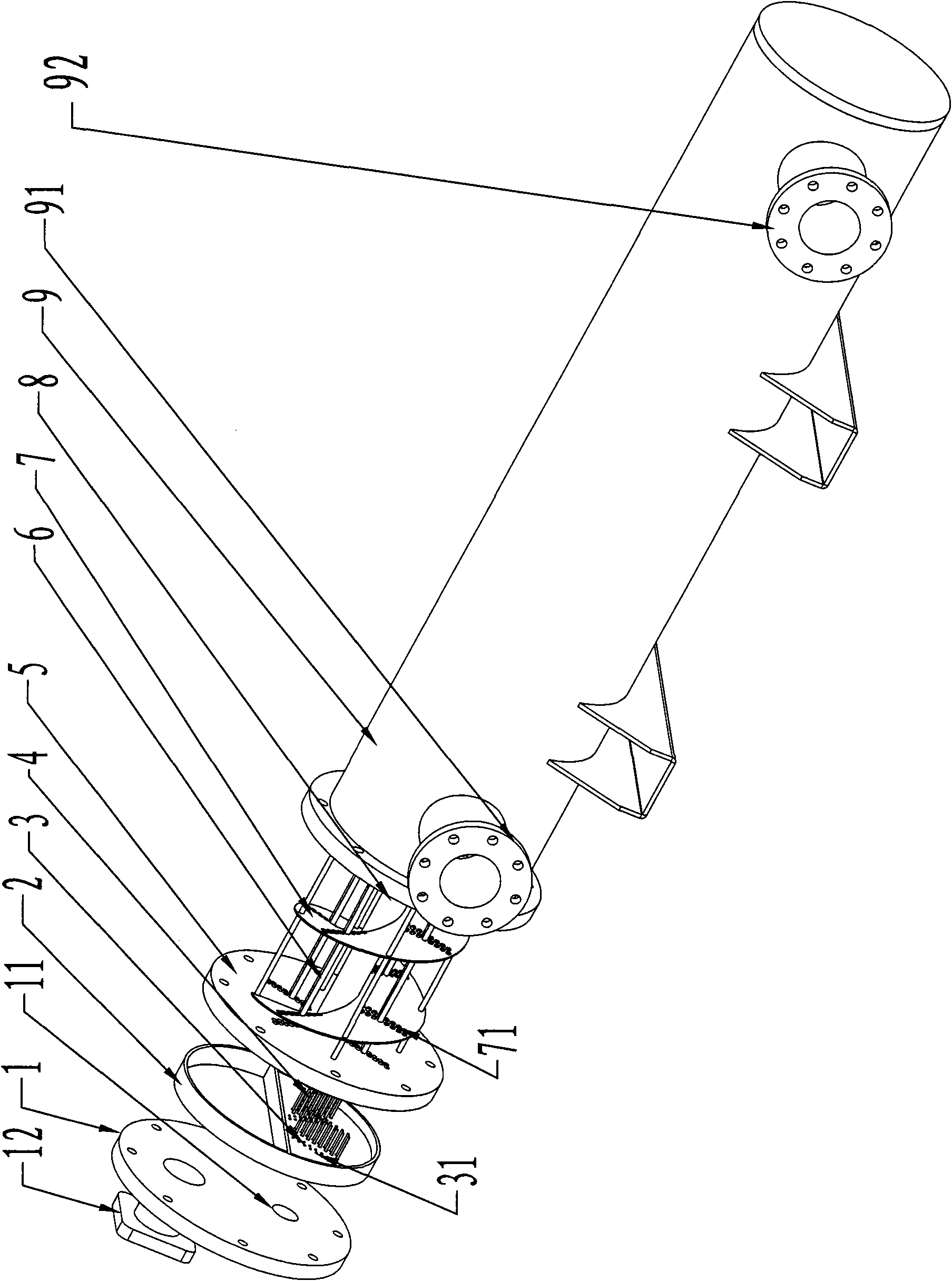

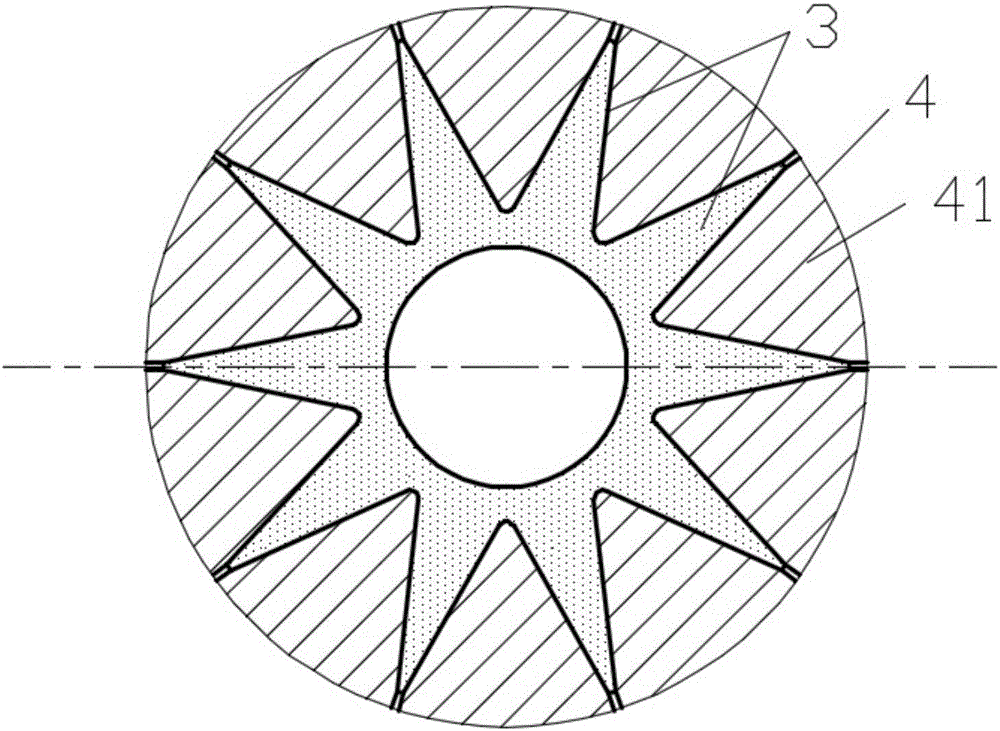

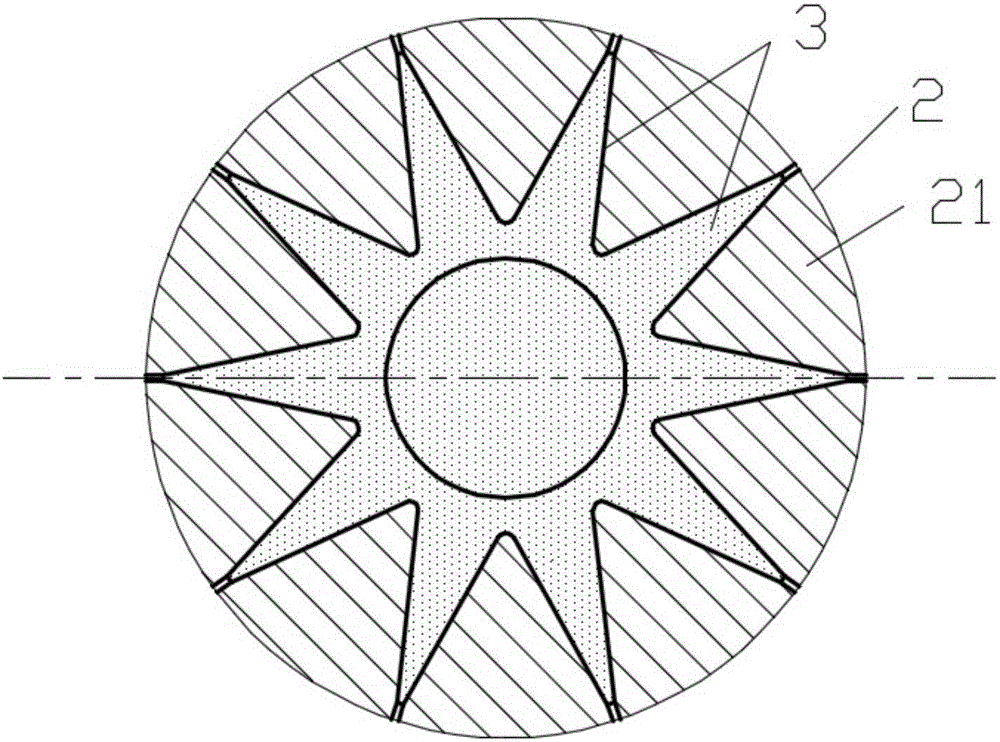

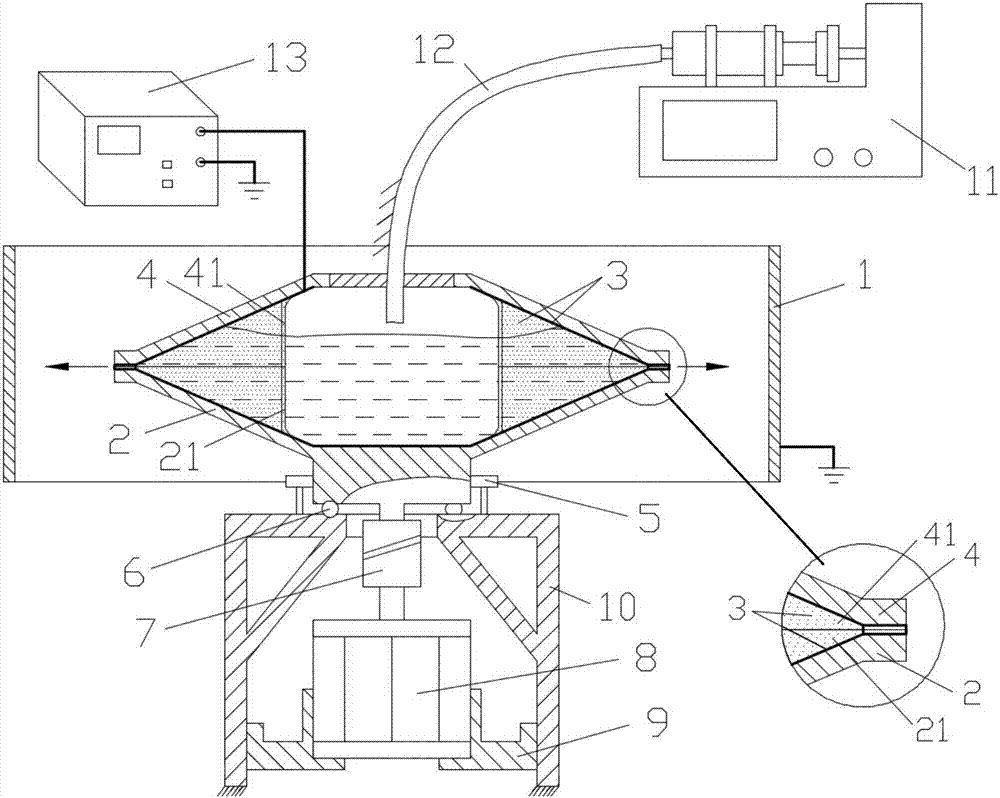

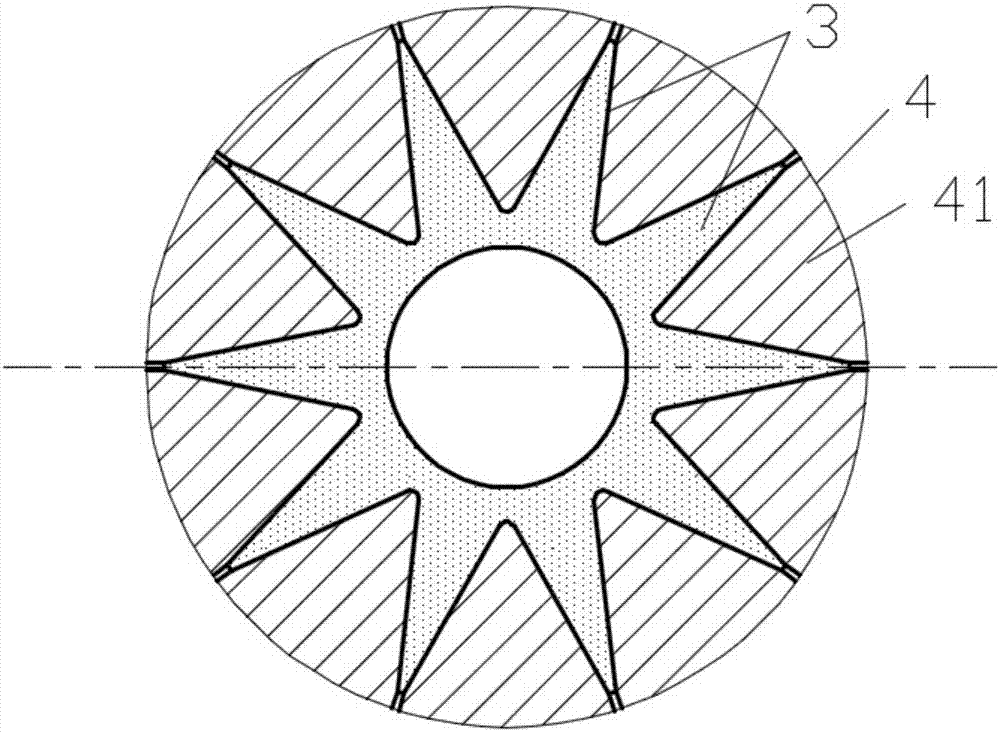

Turbo expander with uniform liquid distribution function and refrigeration system

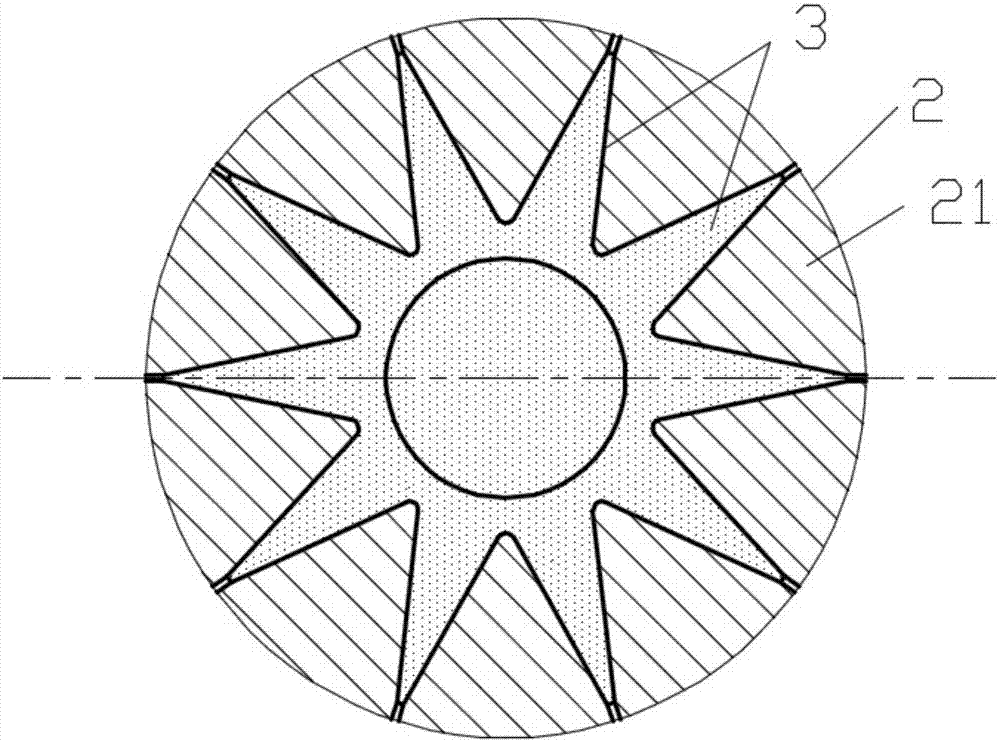

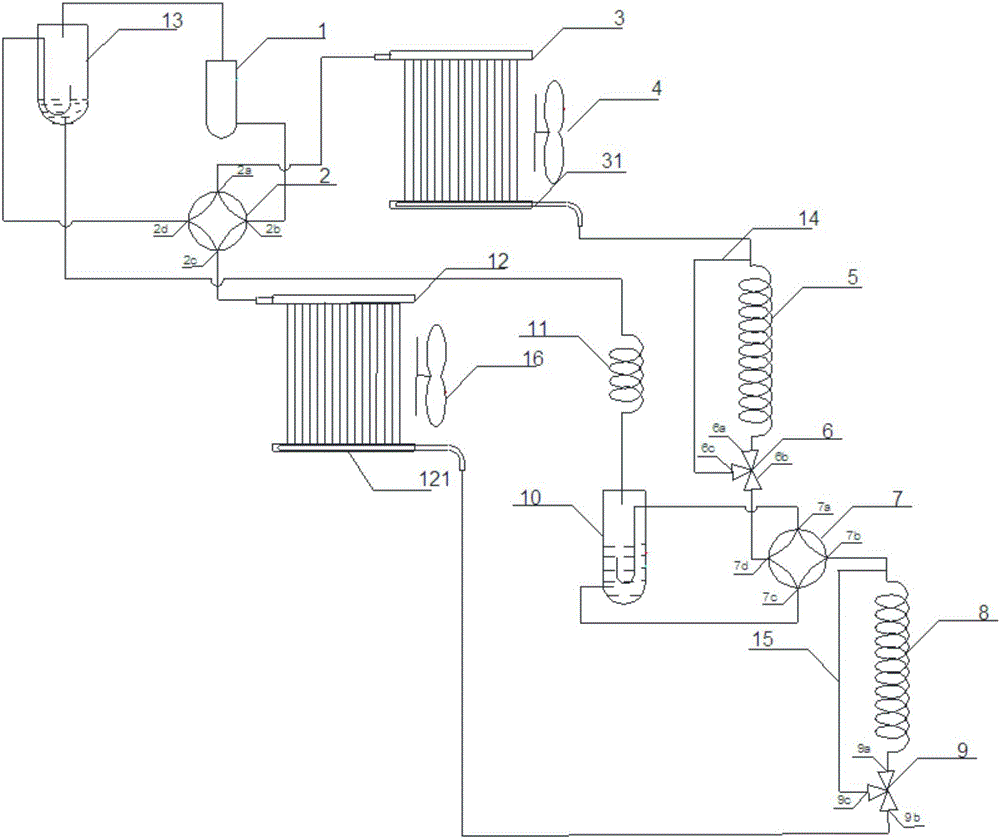

InactiveCN104534750AUniform supplyImprove heat transfer effectMechanical apparatusFluid circulation arrangementImpellerRotational axis

The invention discloses a turbo expander with a uniform liquid distribution function and a refrigeration system. By means of the turbo expander and the refrigeration system, uniform liquid supply is achieved for all flow paths of an evaporator, and the throttling loss in the refrigeration system can be recycled. A liquid supply cavity at the center and an annular distribution cavity in the circumference are formed in a distribution body of the expander. The annular distribution cavity is divided into a plurality of distribution chambers through partition plates. Each distribution chamber is communicated with a liquid distribution pipe. A high-pressure refrigerant liquid supply pipe communicated with the liquid supply cavity is arranged at the center of one end face of the distribution body. A penetrating rotating shaft is installed in the liquid supply cavity. The portion, located in the liquid supply cavity, of the rotating shaft is provided with a plurality of rotating impellers. An opening facing the liquid supply cavity is formed in the inner side of each distribution chamber. The lengths of the openings in the distribution chambers are equal. The high-pressure refrigerant liquid supply pipe, the rotating shaft, the rotating impellers, the liquid supply cavity and the annular distribution cavity are coaxial. By means of the expander, the heat exchange performance of the evaporator is improved, and the efficiency of the refrigeration system is improved.

Owner:TIANJIN UNIV OF COMMERCE

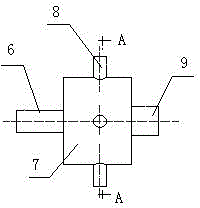

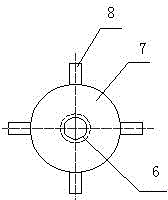

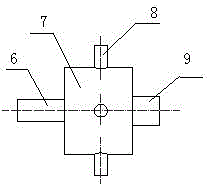

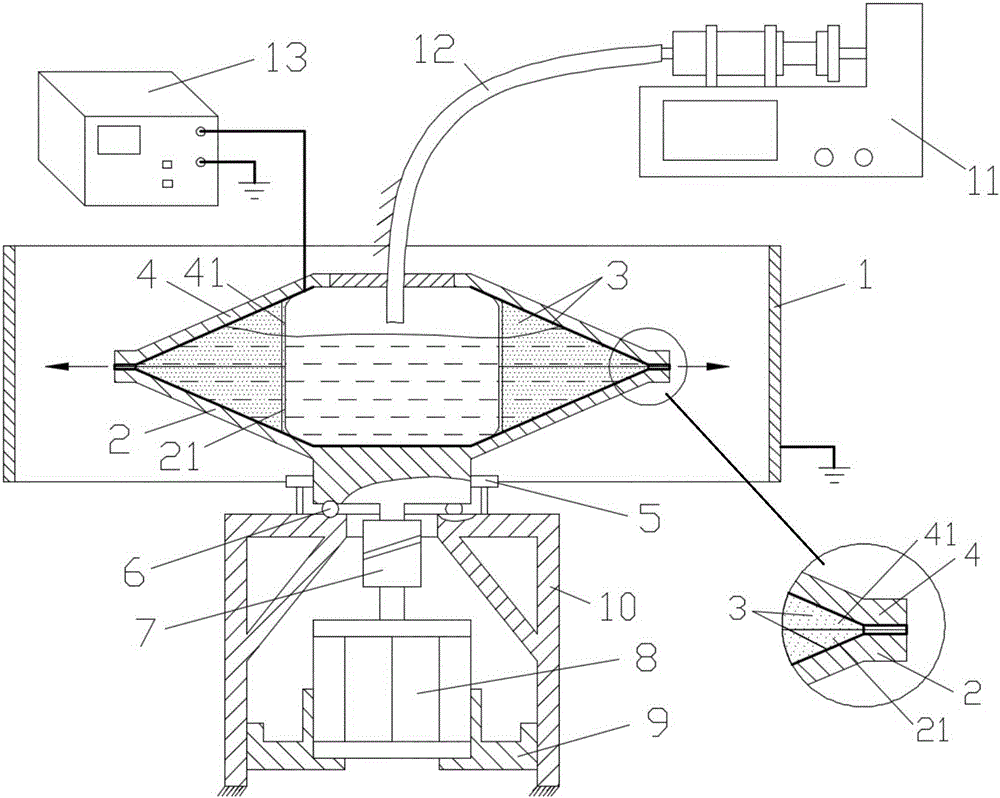

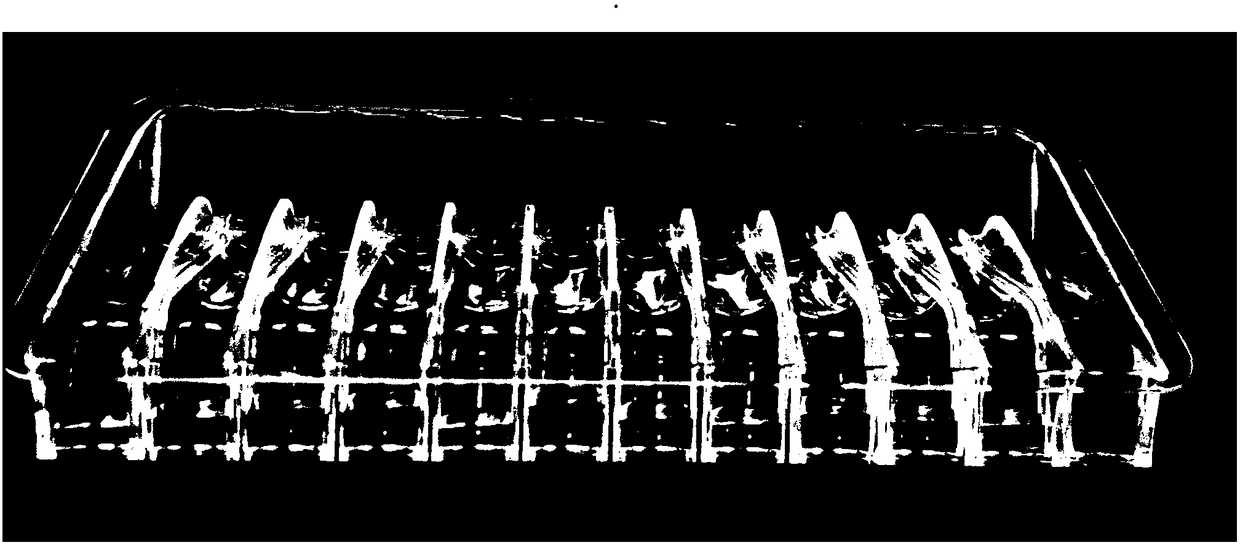

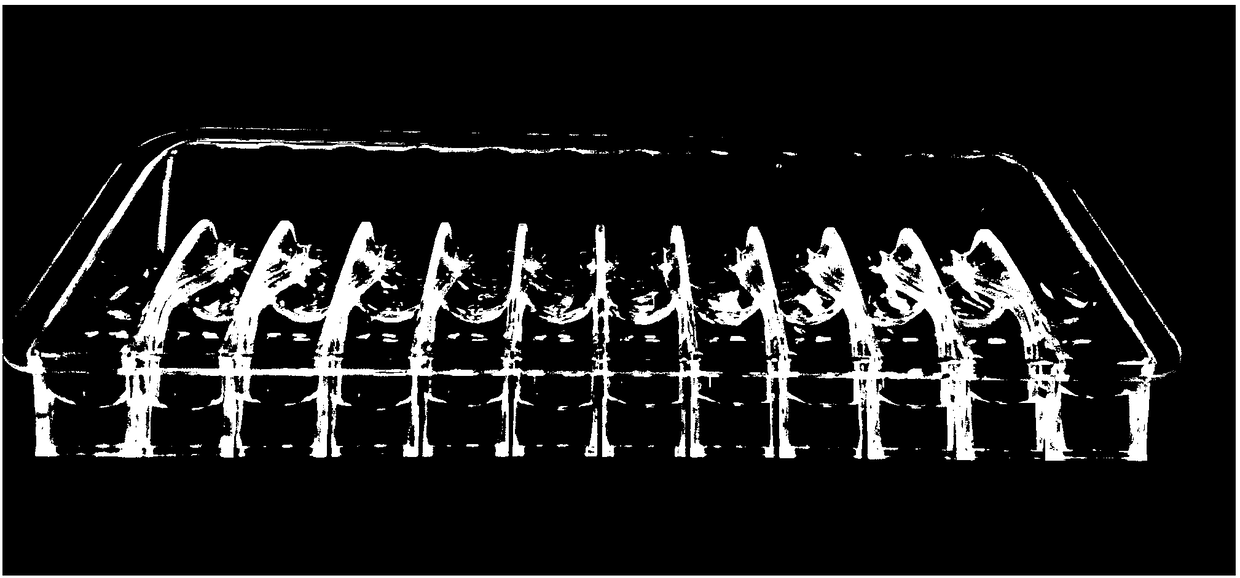

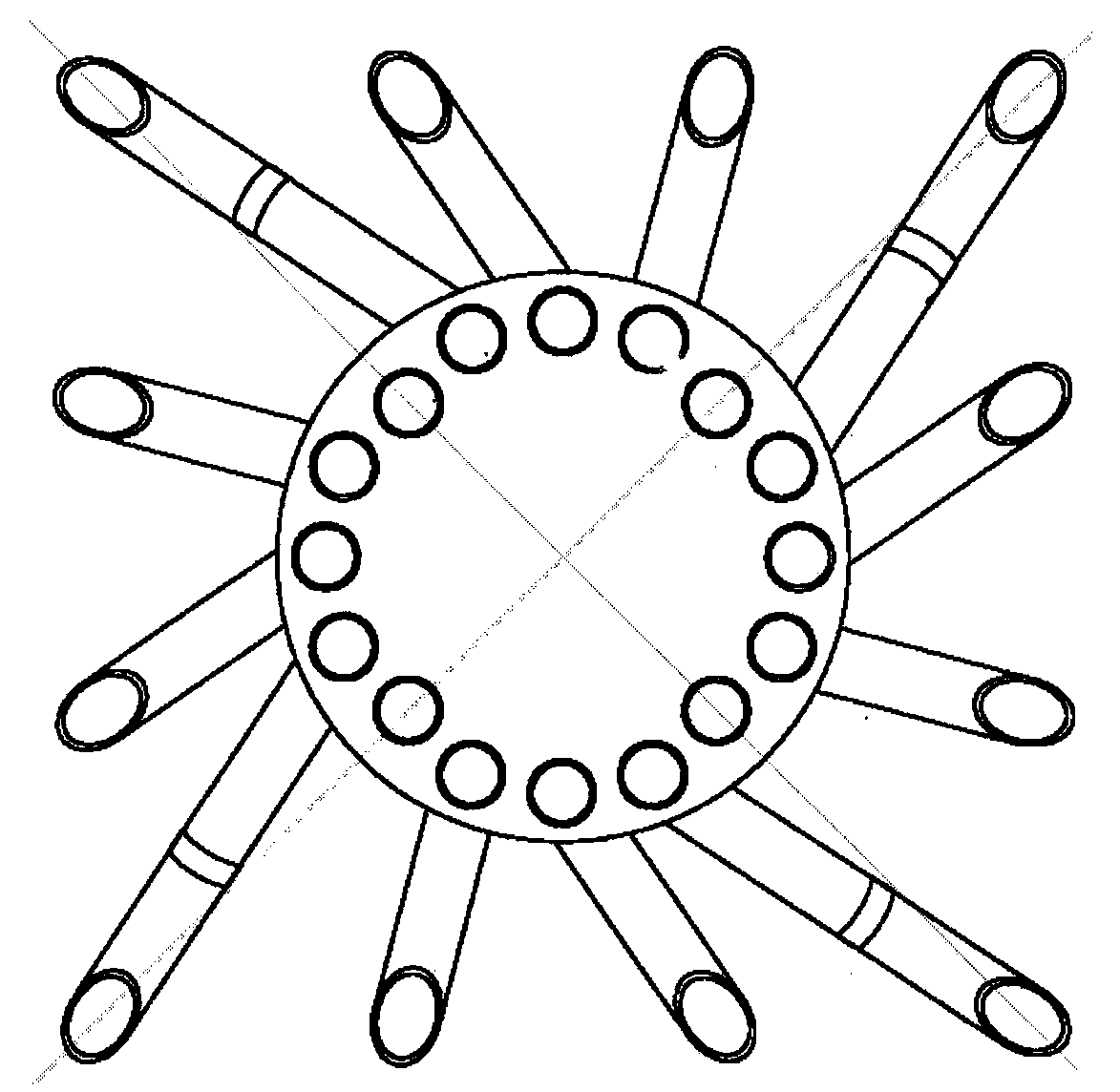

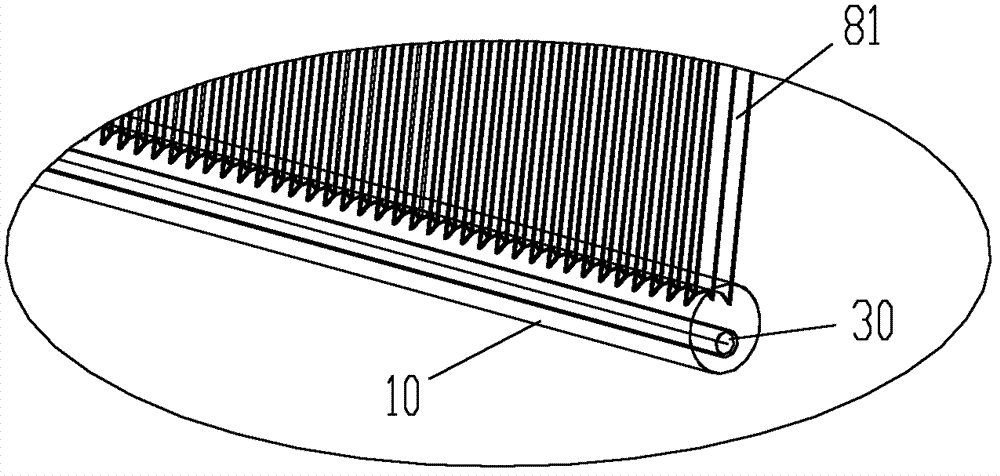

Rotary multi-jet batch spinning device

Provided is a rotary multi-jet batch spinning device, relating to a static spinning device.The rotary multi-jet batch spinning device is provided with a collection drum, a liquid separation table, metal thin films, a cap table, rollers, roll balls, a coupler, a server motor, a motor rack, a support, a liquid supply device, a guide pipe and a high voltage power supply. An upper-layer guide board array and a lower-layer guide board array are arranged on the cap table and the liquid separation table. The liquid separation table and the cap table form a spinning nozzle body. Edges of the liquid separation table and the cap table are provided with groove arrays. Each groove in each groove array is distributed between two guide boards in the upper-layer guide board array. Upper and lower grooves are connected to form a micropore structure. Insides of the liquid separation table and the cap table are sprayed with the metal thin films connected with the power source. The bottom of the liquid separation table and the top of the support are provided with annular tracks, between which the roll balls for supporting are arranged. The bottom of the liquid separation table is provided with the rollers. The shaft segment at the bottom of the liquid separation table is connected with the server motor through the coupler. The server motor is fixedly connected with the support. The collection drum is of a circular structure. The collection drum and a spinning nozzle are arranged coaxially and connected to the ground.

Owner:厦门定慧力教育科技有限公司

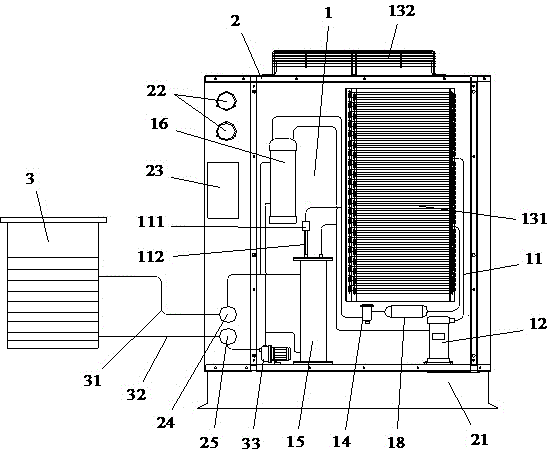

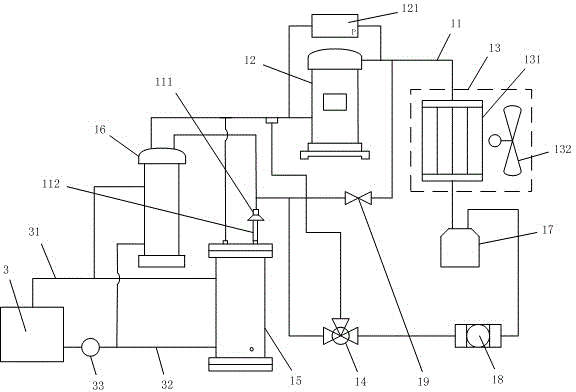

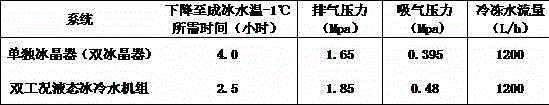

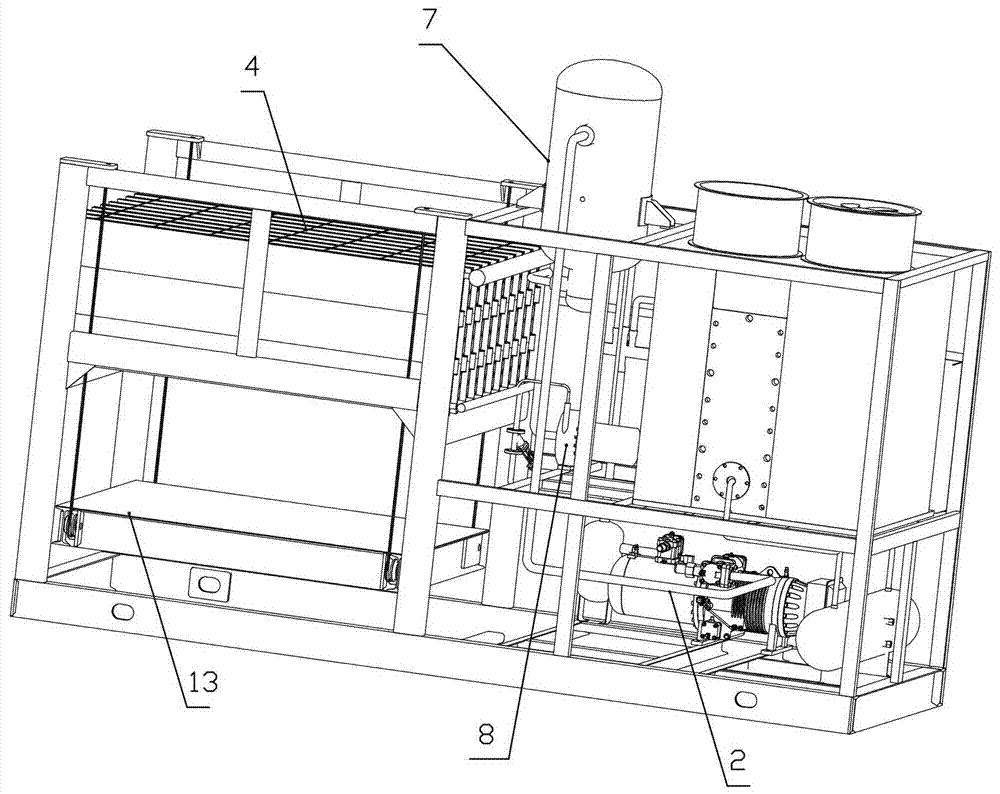

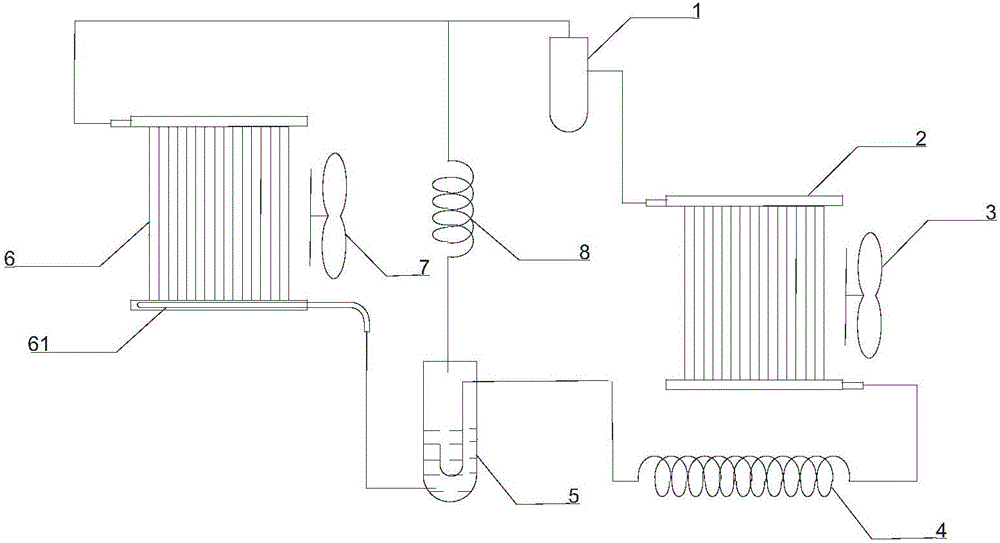

Double-working condition liquid cold water unit

ActiveCN104567061AEasy to controlCompact structureMechanical apparatusFood processingRefrigeration compressorIce water

The invention discloses a double-working condition liquid cold water unit which comprises a liquid ice making system arranged in a metal box body and an ice water storage box connected to the exterior of the metal box body. The double-working condition liquid cold water unit is characterized in that the liquid ice making system consists of a refrigeration compressor, an air-cooled condenser, a thermal expansion valve, an ice crystal device and a titanium pre-cooled heat exchanger which are sequentially connected by virtue of refrigerant pipes; the ice crystal device and the titanium pre-cooled heat exchanger are arranged in parallel; a distributor is arranged on a pipeline on which the refrigerant outlet of the thermal expansion valve is connected with the ice crystal device; and the distributor is connected with the ice crystal device by virtue of a capillary tube. The liquid ice making system is arranged in the metal box body, and the unit is compact in structure, small in occupied area and convenient to move; the ice crystal device and the titanium pre-cooled heat exchanger are arranged in parallel, so that the heat exchange efficiency is effectively improved, liquid ice is synchronously made, the ice output is rapid, and the energy consumption is reduced; and moreover, the thermal expansion valve and the distributor are utilized for throttling twice, so that liquid distribution is uniform, and the operating stability of the system is effectively improved.

Owner:惠州市采风科技有限公司

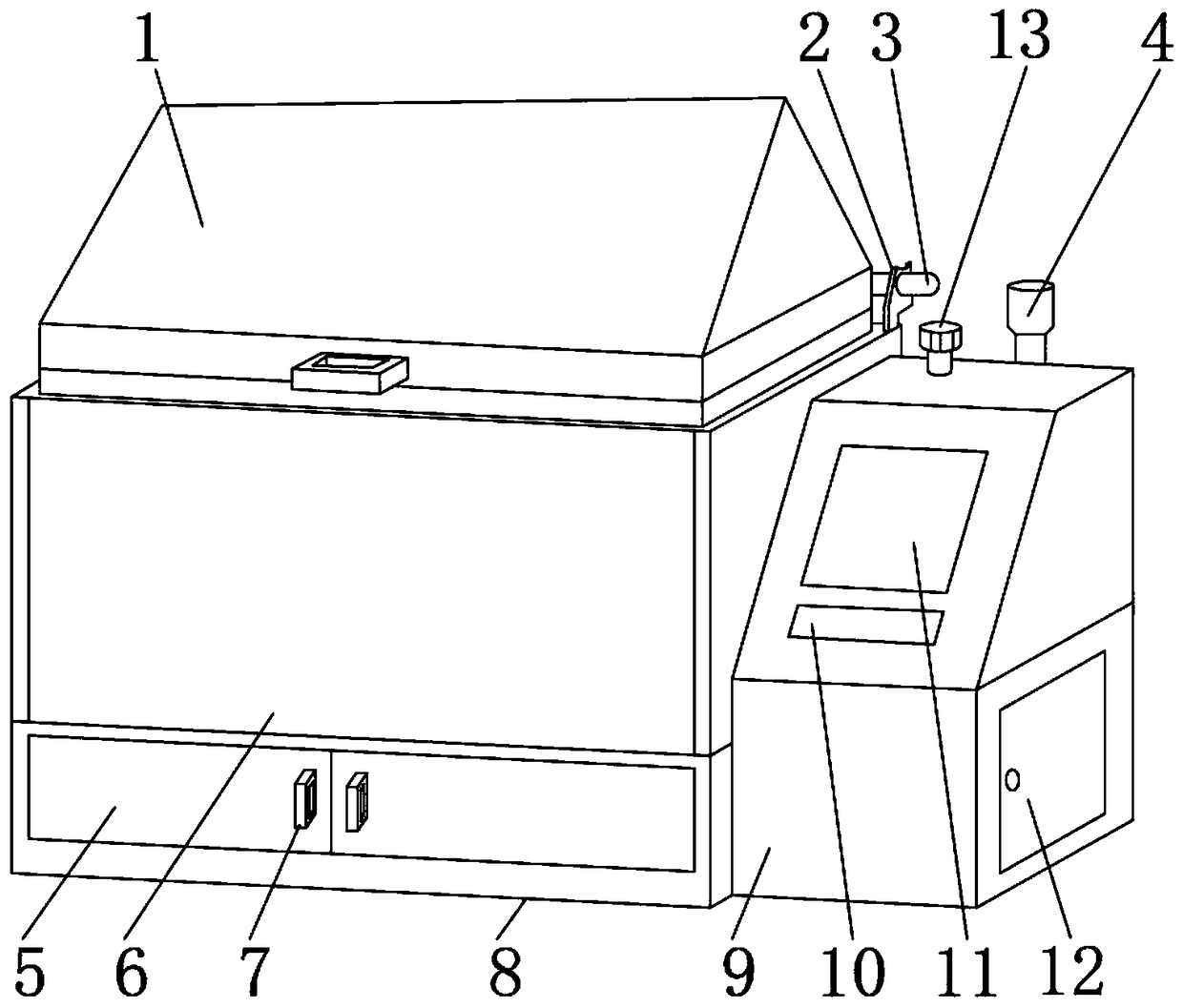

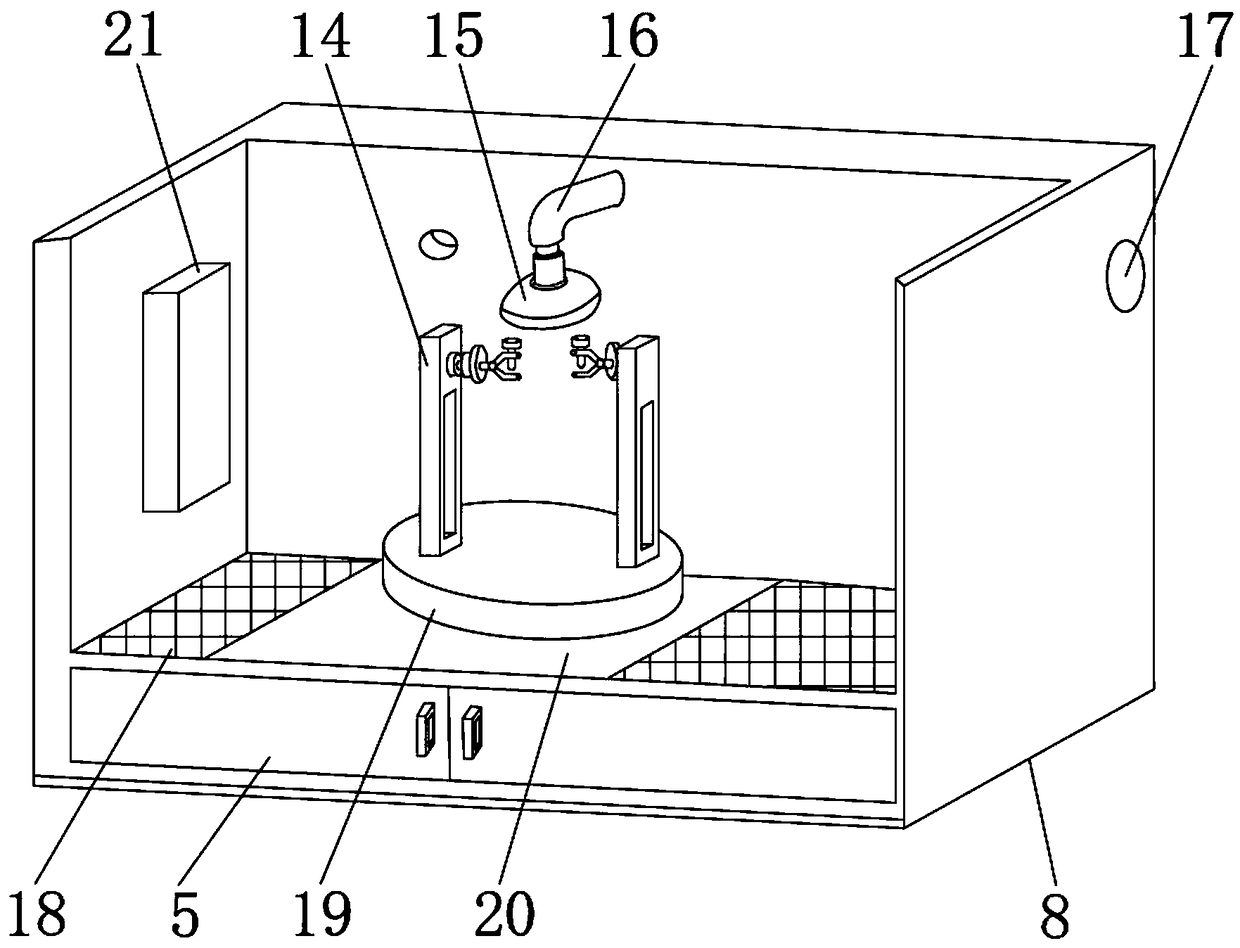

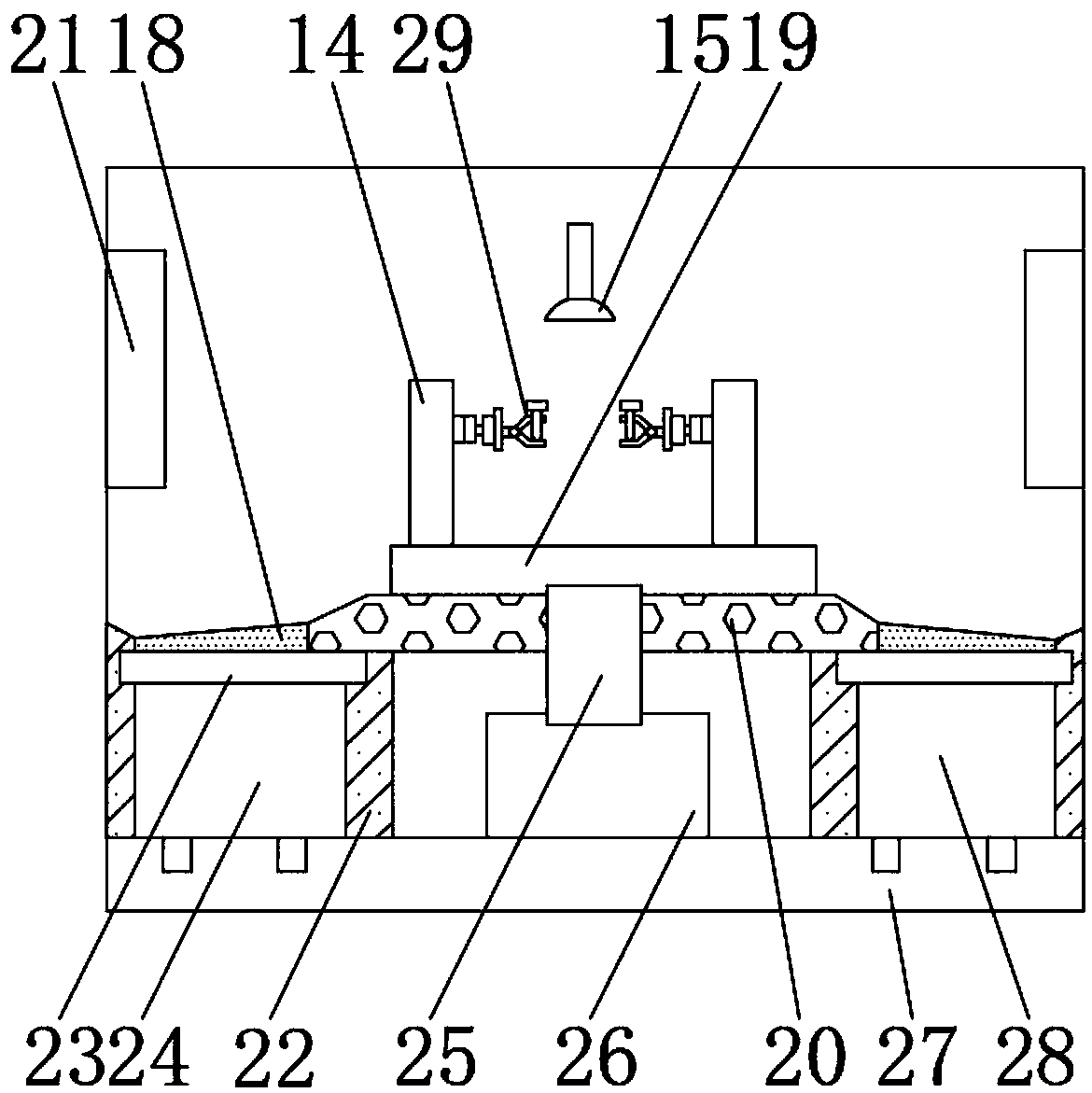

Automobile door hinge corrosion resistance detecting device

InactiveCN108918401AComprehensive detection effectEasy to fixWeather/light/corrosion resistanceTherapeutic effectEngineering

The invention discloses an automobile door hinge corrosion resistance detecting device comprising a main body casing and a control cabinet, wherein the outer surface of the upper end of the main bodycasing is movably provided with a visible box cover, a connecting shaft is fixedly connected to the outer surface of the rear end of the visible box cover, the outer surface of the connecting shaft iscovered with a fixed iron piece, and a test box is fixedly mounted on the outer surface of the lower end of the visible box cover. The automobile door hinge corrosion resistance detecting device hasa relatively-comprehensive detection effect, and can ensure that the outer surface of a hinge is evenly heated and receives a uniform liquid during detection, so that test results are more accurate, the automobile door hinge corrosion resistance detecting device has a better waste liquid treatment effect to ensure the inside of the automobile door hinge corrosion resistance detecting device may not be corroded by an acidic liquid, the automobile door hinge corrosion resistance detecting device can better carry out centralized treatment and movement of waste liquid, has a better fixing effect,can better fix the hinge, and can adjust the length of a clamp according to the size of the hinge. The scope of use of the device is enlarged.

Owner:安徽双红机械制造有限公司

Micro-channel machine room air conditioner provided with gas-liquid separation device arranged in front of evaporator and used for data center

InactiveCN106123414AGuaranteed heat exchange effectLiquid evenlyMechanical apparatusEvaporators/condensersData centerLiquid state

The invention discloses a micro-channel machine room air conditioner provided with a gas-liquid separation device arranged in front of an evaporator and used for a data center. The air conditioner comprises a compressor, a micro-channel condenser, a first capillary throttling device, a first gas-liquid separation device, the micro-channel evaporator (comprising a flute type distribution pipe), a second capillary throttling device and a second gas-liquid separation device, wherein one gas-liquid separation device is arranged in front of the micro-channel evaporator, so that a refrigerant in the micro-channel evaporator is in liquid state, uniform distribution by the aid of the micro-channel evaporator is facilitated, the refrigerating effect of the machine room air conditioner is guaranteed, and the heat exchange efficiency is improved.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD +1

Micro-channel heat exchanger and air conditioner

PendingCN112146467AImprove performanceMeet your connectivity needsEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

The invention provides a micro-channel heat exchanger and an air conditioner. The micro-channel heat exchanger comprises heat exchange flat pipes (1), adapters (2), a first collecting pipe (3) and a second collecting pipe (4), wherein the first collecting pipe (3) is arranged at the first ends of the heat exchange flat pipes (1), the second collecting pipe (4) is arranged at the second ends of theheat exchange flat pipes (1), and the adapters (2) extend in the width direction of the heat exchange flat pipes (1); the adapters (2) are arranged at the first ends of the heat exchange flat pipes (1), and the first ends of the heat exchange flat pipes (1) are connected to the first collecting pipe (3) through the adapters (2); and / or the adapters (2) are arranged at the second ends of the heatexchange flat pipes (1), and the second ends of the heat exchange flat pipes (1) are connected to the second collecting pipe (4) through the adapters (2). According to the micro-channel heat exchanger, refrigerant flow distribution can be more uniform, and the heat exchange efficiency of the heat exchanger is improved.

Owner:GREE ELECTRIC APPLIANCES INC

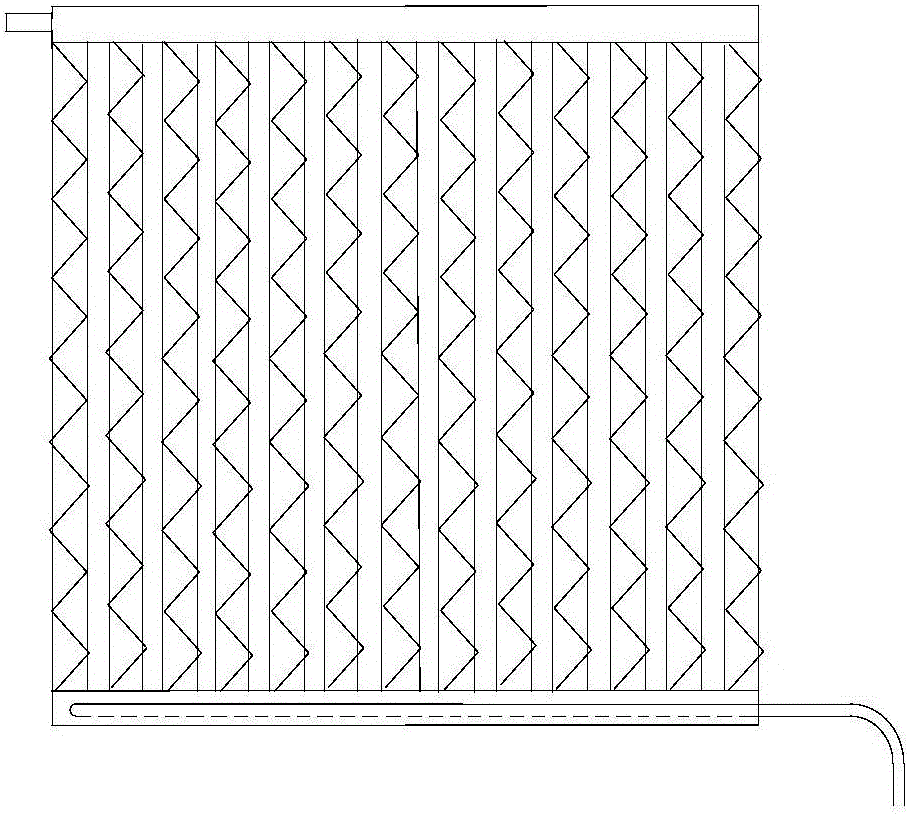

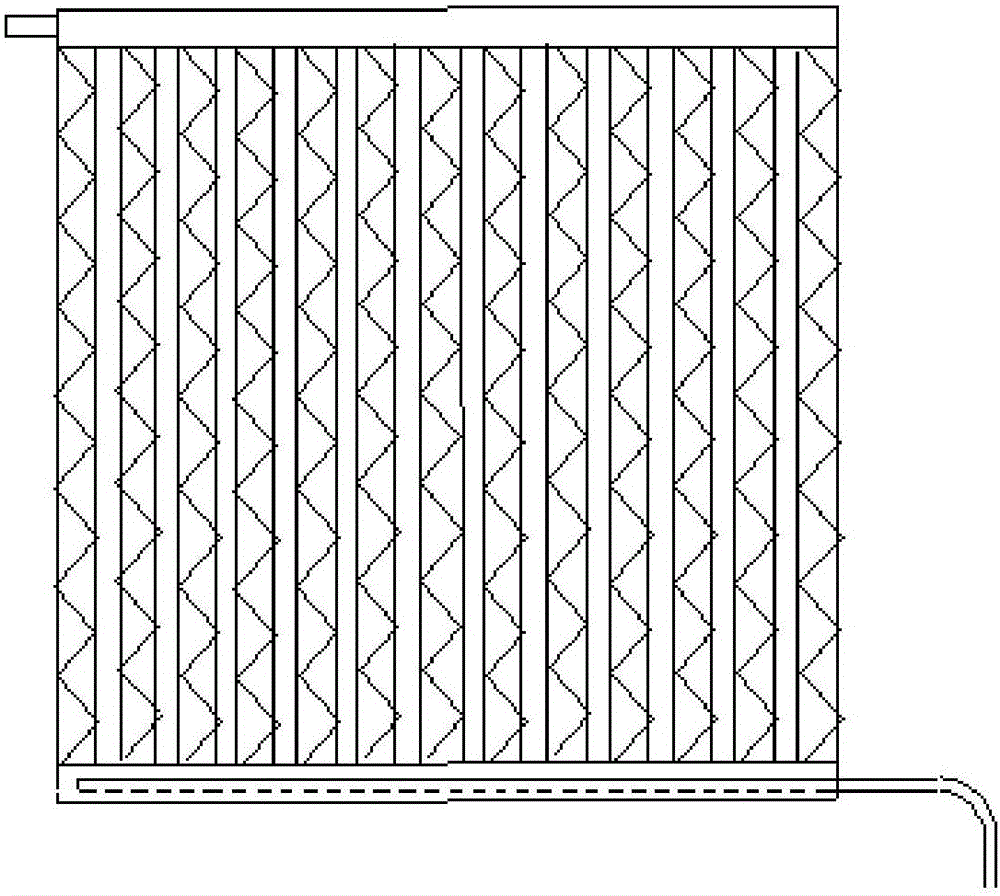

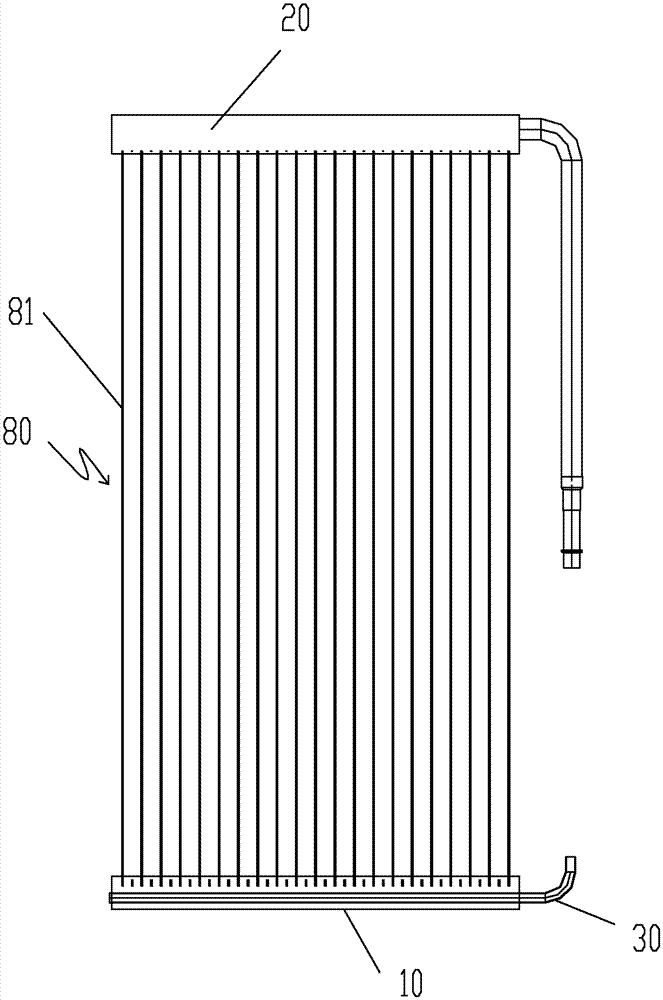

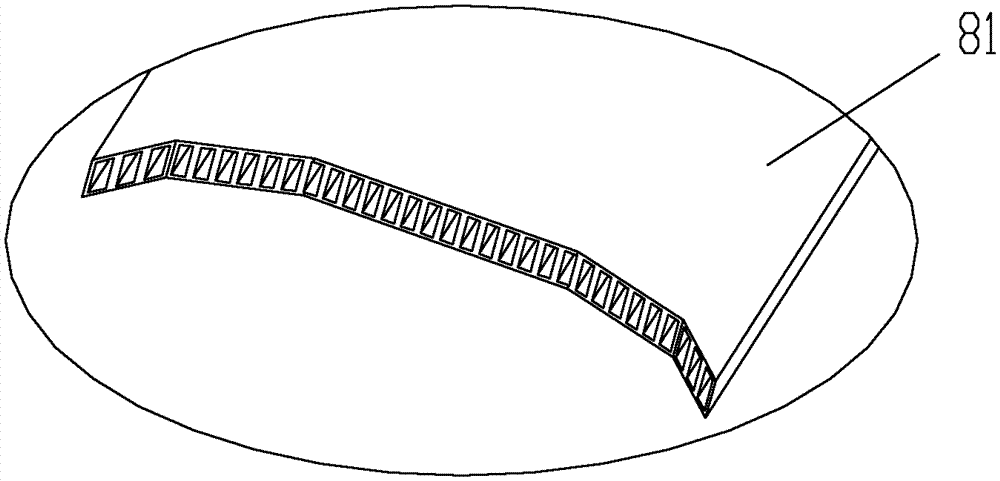

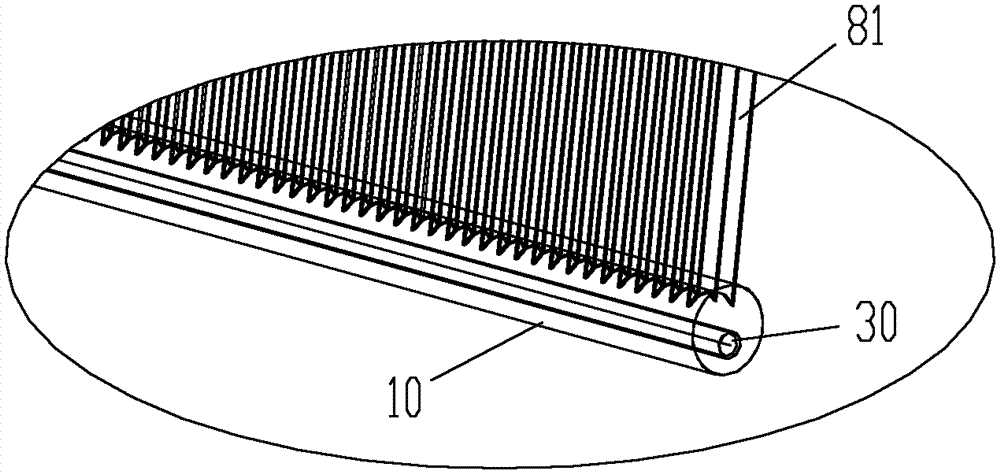

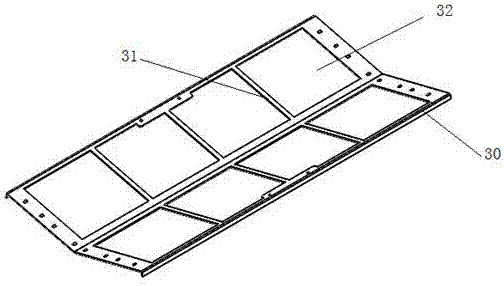

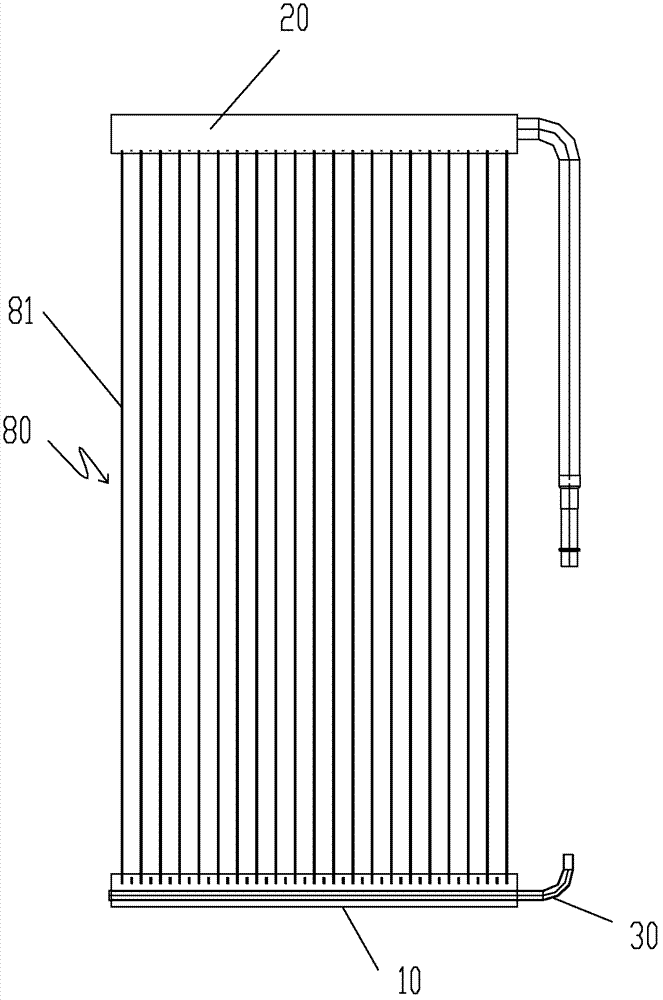

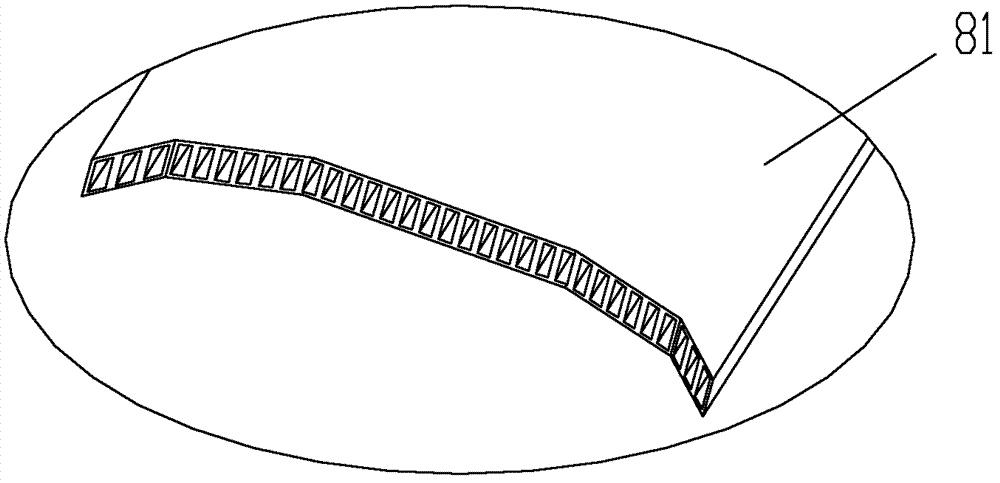

Heat collecting plate with high energy efficiency ratio and stable work

PendingCN111219891AFully absorbedReduce power consumptionSolar heating energySolar heat collectors with working fluidsThermodynamicsHigh energy

The invention relates to the field of solar panel manufacturing, and provides a heat collecting plate with high energy efficiency ratio and stable work. The heat collecting plate can be used for solving the problems that a working medium in an existing heat collecting plate is in a bottom-in and top-out working mode, the heat absorption is uneven, the energy efficiency ratio is low, and the oil return is unsmooth. The heat collecting plate with high energy efficiency ratio and stable work comprises a panel body, a working medium runner is arranged in the panel body, the panel body is further provided with a working medium inlet and a working medium outlet which are connected with the working medium runner, the working medium inlet is located in the top of the working medium runner, and theworking medium outlet is located in the bottom of the runner; and the heat absorption effect is balanced, the energy efficiency ratio is high, and oil return is smooth.

Owner:浙江柿子新能源科技有限公司

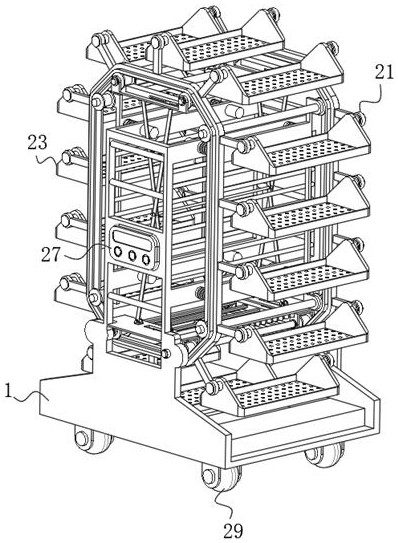

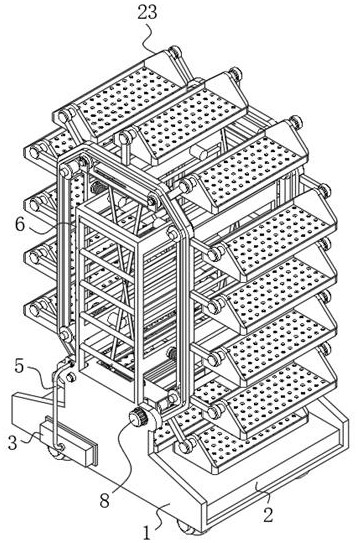

Adjustable seedling raising frame for agricultural planting

InactiveCN112586230AImprove convenienceImprove versatilityPressurised distribution of liquid fertiliserCultivating equipmentsElectric machineryAgricultural engineering

The invention discloses an adjustable seedling raising frame for agricultural planting, and belongs to the technical field of agricultural instruments. The adjustable seedling raising frame comprisesa supporting frame body; a liquid storage tank is fixedly connected to the top face of the supporting frame body, a water pump is fixedly installed on the surface of the supporting frame body, one endof a water inlet of the water pump fixedly communicates with the liquid storage tank, a liquid supplementing pipe is fixedly connected between the inner surfaces of the supporting frame body, one endof a water outlet of the water pump fixedly communicates with the liquid supplementing pipe through a liquid conveying pipe, and a connecting frame body is fixedly mounted on the top face of the supporting frame body; and a driving mechanism is fixedly installed between the inner surfaces of the supporting frame body, the surface of the connecting frame body is connected with the driving mechanism, the surface of the supporting frame body is fixedly connected with a transmission motor, and one end of an output shaft of the transmission motor is connected with the driving mechanism. Through the design of a driven pressure seat, an elastic piece, a bottom frame body and a movable frame body in the driving mechanism, a fixed specification type structure of a traditional seedling raising frame is changed into an adjustable specification type structure, and during use, the height and the width of the device can be changed according to an actual scene.

Owner:楼小莲

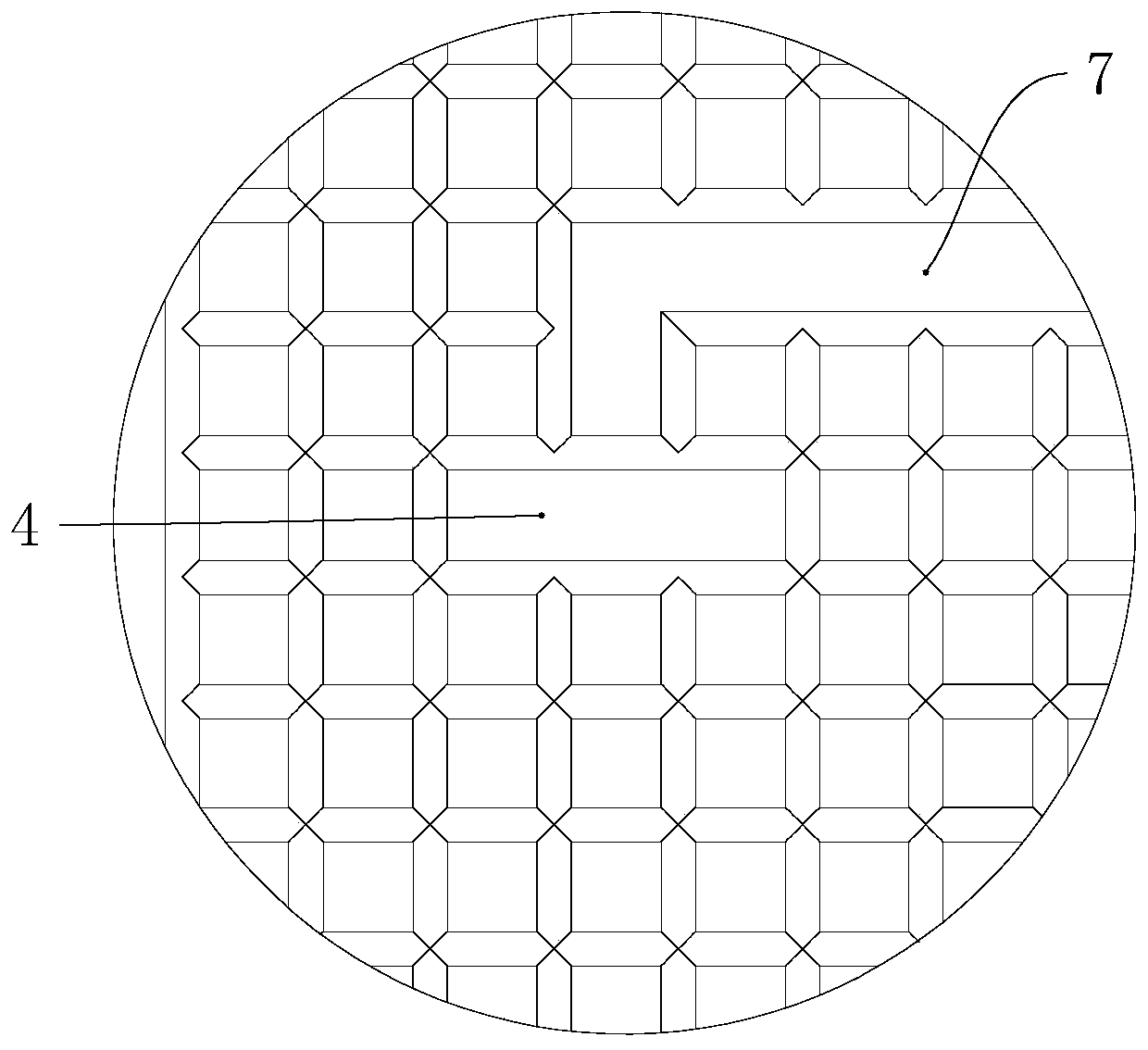

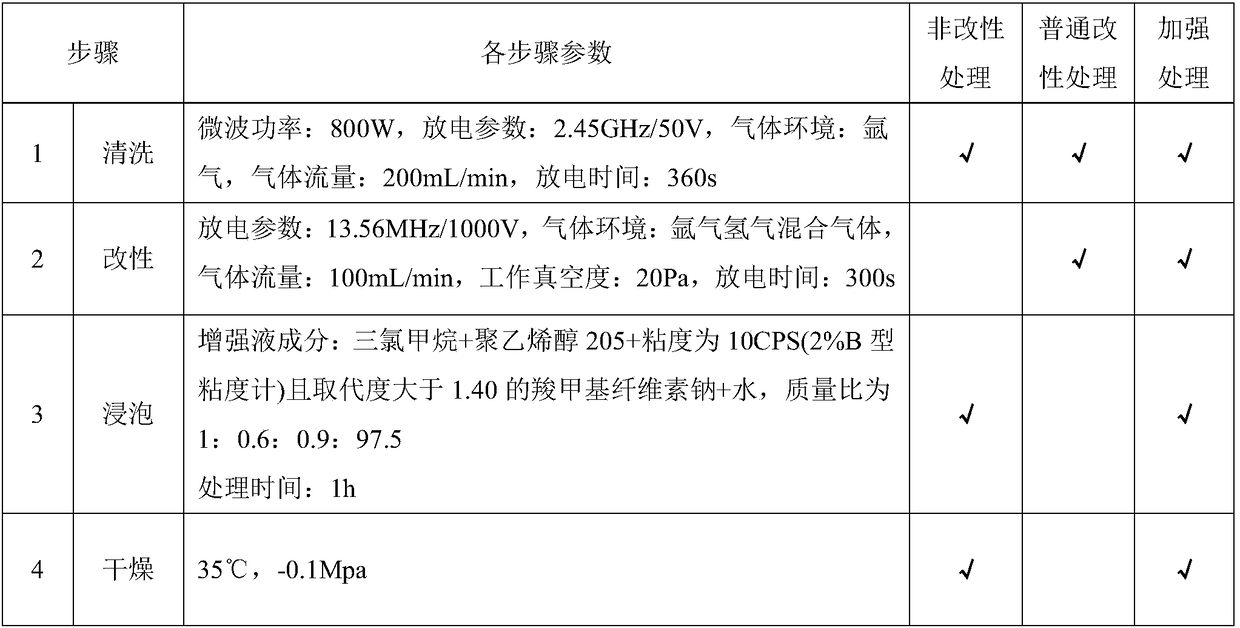

Method for realizing uniform liquid separation on hydrophobic polymer trace porous carrier

ActiveCN108341988AImprove hydrophilic performanceImprove hydrophilicityAnalysis by subjecting material to chemical reactionCoatingsSurface modificationRadio frequency plasma

The invention discloses a method for realizing uniform liquid separation on a hydrophobic polymer trace porous carrier. The hydrophilic modification method of the hydrophobic polymer trace porous carrier comprises the following steps: 1) cleaning a hydrophobic polymer trace porous carrier injection molded part; 2) placing the cleaned injection molded part into a generation cavity of a radio frequency plasma generator for surface modification treatment; 3) putting the surface-modified injection molded part into a hydrophilic modification enhancing liquid for soaking treatment; 4) taking out thesoaked injection molded part, draining off, and drying to obtain the hydrophilic trace porous carrier injection molded part. The obtained injection molded part has relatively high hydrophilicity, sothat the hydrophilic culture medium which is subpackaged or borne on the surface of the injection molded part can be rapidly and uniformly dispersed in each micro-hole under the small sub-packaging amount. A trace biochemical identification strip with the liquid separation function is treated by using the technology, after the trace biochemical identification strip is placed for 360 days, even liquid separation can still be carried out, and correct identification results can be guaranteed.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH +2

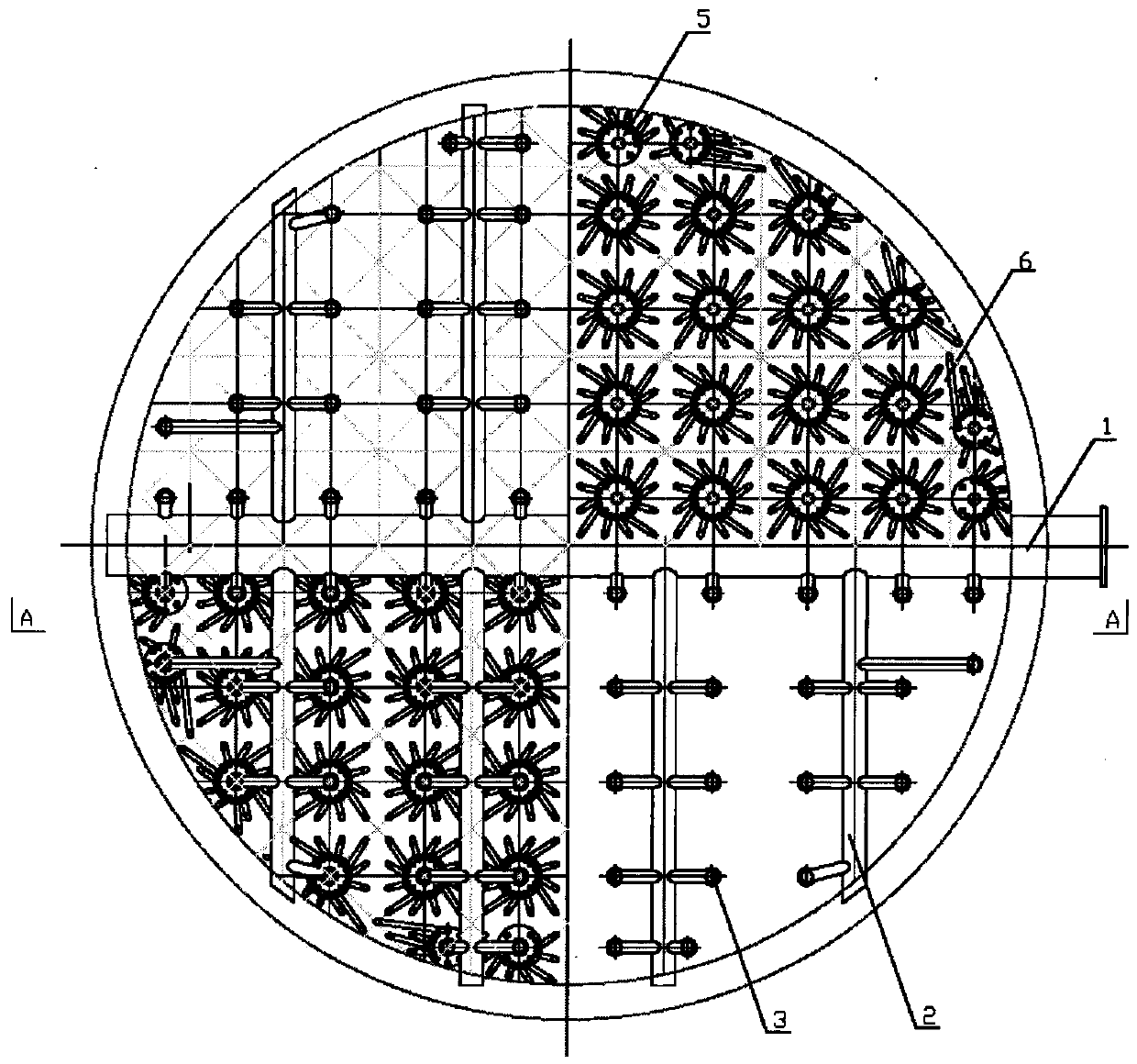

Multi-disc liquid distributor

ActiveCN104001463AMore liquid pointLiquid evenlyChemical/physical/physico-chemical processesEngineeringMechanical engineering

The invention discloses a multi-disc liquid distributor, which is used for distributing liquid in a packed tower. The multi-disc liquid distributor consists of a main liquid inlet pipe, liquid inlet branch pipes, liquid distribution pipes, flow limiting porous plates, liquid distribution discs and liquid falling pipes, wherein the liquid falling pipes are inserted into the liquid distribution discs; the liquid distribution discs are hung on the liquid distribution pipes; the flow limiting porous plates are arranged in the liquid distribution pipes; the liquid distribution pipes are connected with the main liquid inlet pipe or the liquid inlet branch pipes; the liquid inlet branch pipes are connected with the main liquid inlet pipe; each liquid distribution disc is of a circular structure with a bottom; nine to thirty eight liquid falling pipes are arranged in each liquid distribution disc and are arranged on one to four concentric circumferences; the number of the liquid distribution discs is determined by a tower diameter and liquid distribution point density; each liquid distribution disc corresponds to one liquid distribution pipe; the liquid radially flows to each liquid falling pipe after flowing out from the corresponding liquid distribution pipe; an overflow groove is formed in the side surface on the upper part of each liquid falling pipe; each liquid falling pipe penetrates out of the corresponding liquid distribution disc and extends to the respective liquid distribution point in packing. The multi-disc liquid distributor has the advantages of large number of liquid distribution points, uniform liquid distribution, light weight, convenience in installation and maintenance and the like.

Owner:丁华

Rotary multi-jet batch spinning device

Provided is a rotary multi-jet batch spinning device, relating to a static spinning device.The rotary multi-jet batch spinning device is provided with a collection drum, a liquid separation table, metal thin films, a cap table, rollers, roll balls, a coupler, a server motor, a motor rack, a support, a liquid supply device, a guide pipe and a high voltage power supply. An upper-layer guide board array and a lower-layer guide board array are arranged on the cap table and the liquid separation table. The liquid separation table and the cap table form a spinning nozzle body. Edges of the liquid separation table and the cap table are provided with groove arrays. Each groove in each groove array is distributed between two guide boards in the upper-layer guide board array. Upper and lower grooves are connected to form a micropore structure. Insides of the liquid separation table and the cap table are sprayed with the metal thin films connected with the power source. The bottom of the liquid separation table and the top of the support are provided with annular tracks, between which the roll balls for supporting are arranged. The bottom of the liquid separation table is provided with the rollers. The shaft segment at the bottom of the liquid separation table is connected with the server motor through the coupler. The server motor is fixedly connected with the support. The collection drum is of a circular structure. The collection drum and a spinning nozzle are arranged coaxially and connected to the ground.

Owner:厦门定慧力教育科技有限公司

Micro-channel heat pump loop provided with gas-liquid separation devices arranged in front of evaporators

ActiveCN106123387ALiquid evenlyReduce the liquid separation effectMechanical apparatusFluid circulation arrangementFour-way valveLiquid state

The invention discloses a micro-channel heat pump loop provided with gas-liquid separation devices arranged in front of evaporators. The loop comprises a compressor, a first four-way valve, a first micro-channel heat exchanger (comprising a flute type distribution pipe), a first capillary throttling device, a first by-pass pipe, a first three-way valve, a second four-way valve, a second capillary throttling device, a second by-pass pipe, a second three-way valve, a first gas-liquid separation device, a third capillary throttling device, a second micro-channel heat exchanger (comprising a flute type distribution pipe) and a second gas-liquid separation device, wherein one gas-liquid separation device is arranged in front of each micro-channel heat exchanger used as one micro-channel evaporator, so that a refrigerant entering the micro-channel evaporator is in liquid state, uniform distribution by the aid of the micro-channel evaporator is facilitated, the refrigerating effect of a refrigerating loop is guaranteed, and the heat exchange efficiency is improved.

Owner:浙江豪瓦特节能科技有限公司

Liquid separation device and air conditioner including the liquid separation device

ActiveCN103363733BLiquid evenlyImprove flow statusFluid circulation arrangementVapor–liquid separatorEngineering

The invention provides a liquid separating device and an air conditioner comprising the liquid separating device. The liquid separation device includes: a gas-liquid separator, which is provided with a first inlet, a first outlet, and a second outlet; a liquid introduction pipe, which communicates with the gas-liquid separator through the first outlet; and a connecting pipe, which is separated from the gas-liquid through the second outlet. The gas-liquid mixing chamber is provided with a third inlet, a second inlet and a third outlet, the third inlet is connected with the liquid introduction pipe, and the second inlet is connected with the connecting pipe; and the liquid distribution pipe is connected with the gas-liquid mixing chamber. The third exit connects. Applying the technical scheme of the present invention, by setting a gas-liquid mixing chamber between the liquid separation pipe and the gas-liquid separator, the gas-liquid two-phase refrigerant before entering the liquid separation pipe is uniformly mixed, the distribution of the refrigerant in the liquid separation pipe is improved, and the Dispensing tube dispenses liquid more evenly.

Owner:GREE ELECTRIC APPLIANCES INC

Microchannel Heat Exchanger Facilitating Reduced Refrigerant Charge

InactiveCN103245132BReduce allocationImprove heat transfer effectEvaporators/condensersEngineeringRefrigerant

Owner:SHANGHAI JIAOTONG UNIV

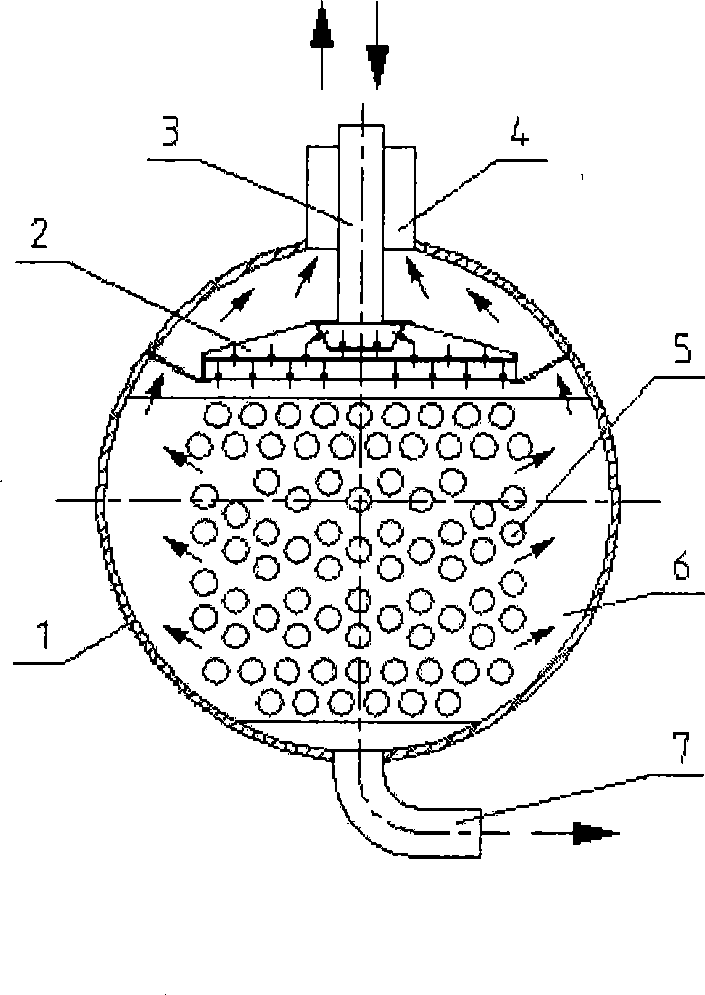

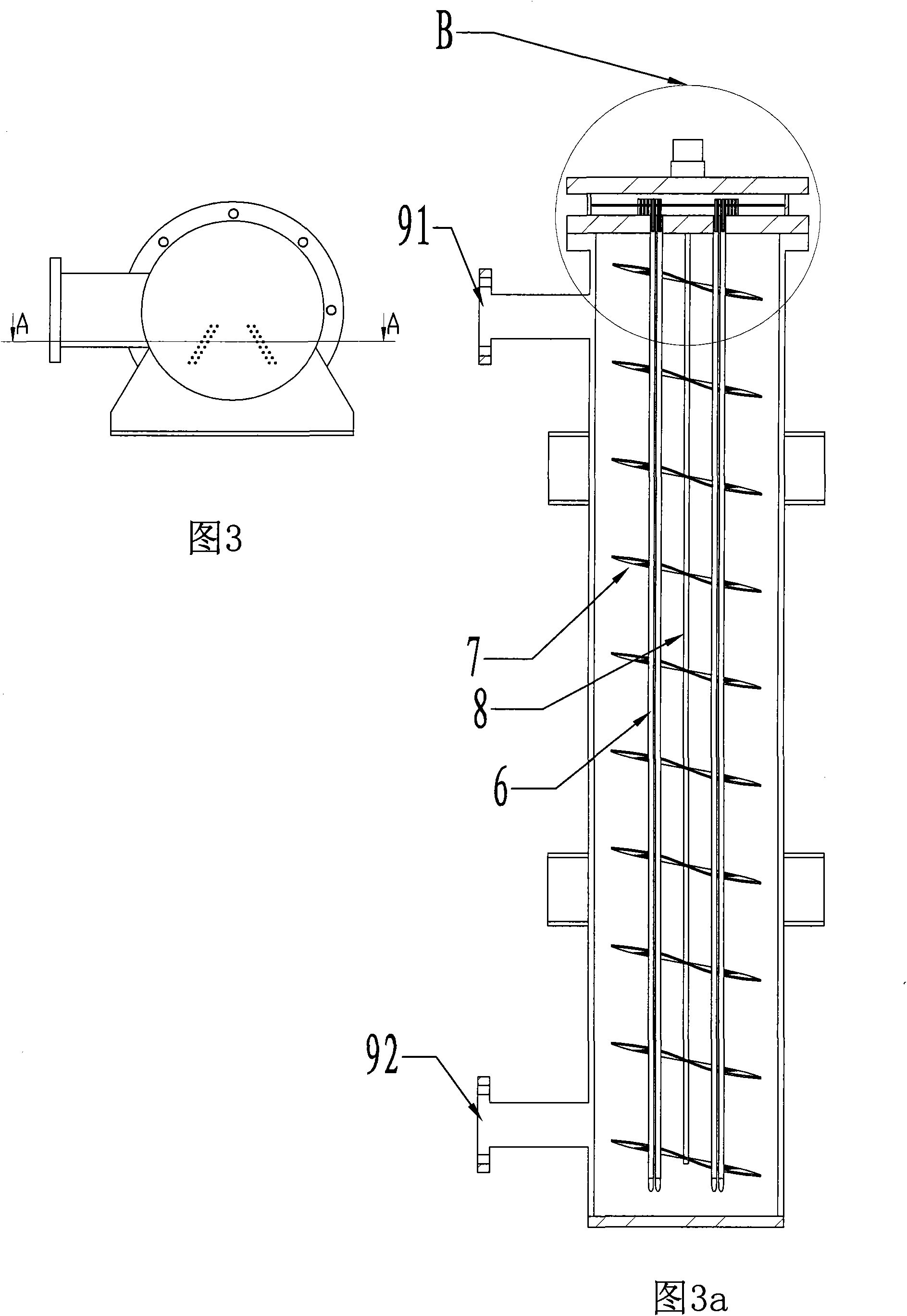

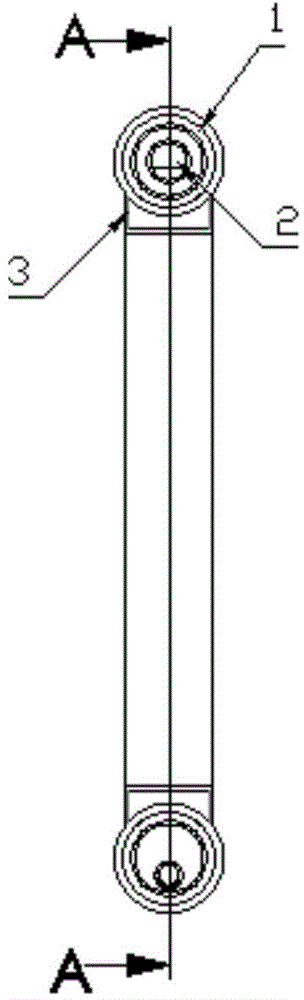

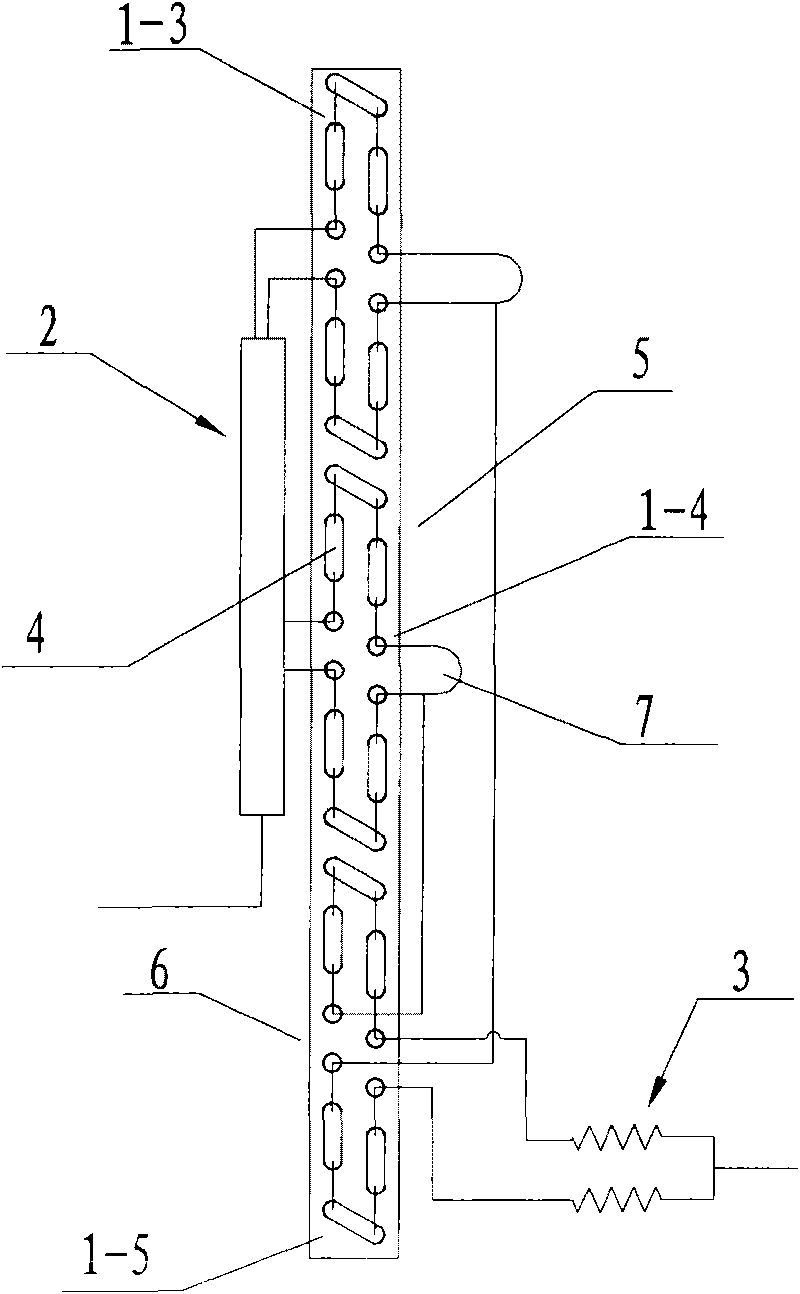

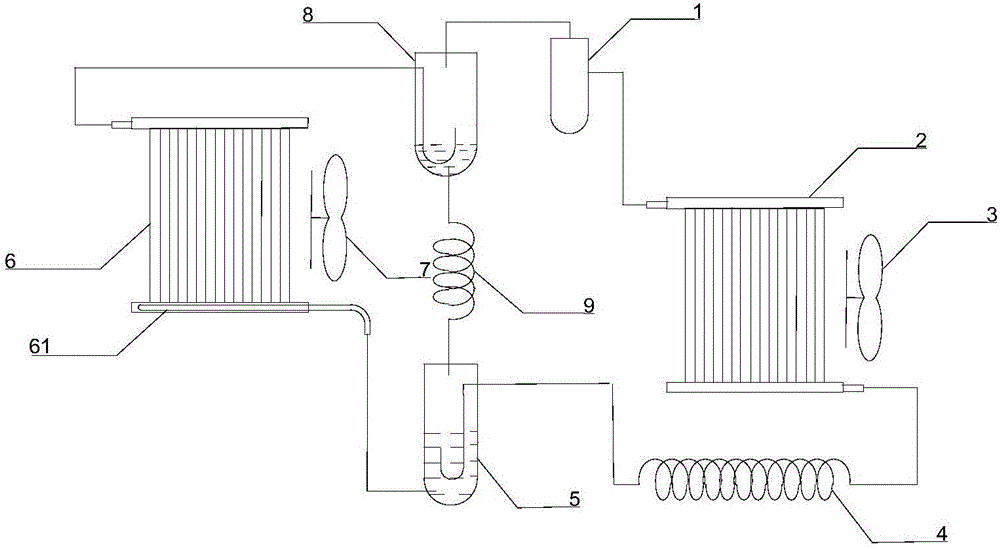

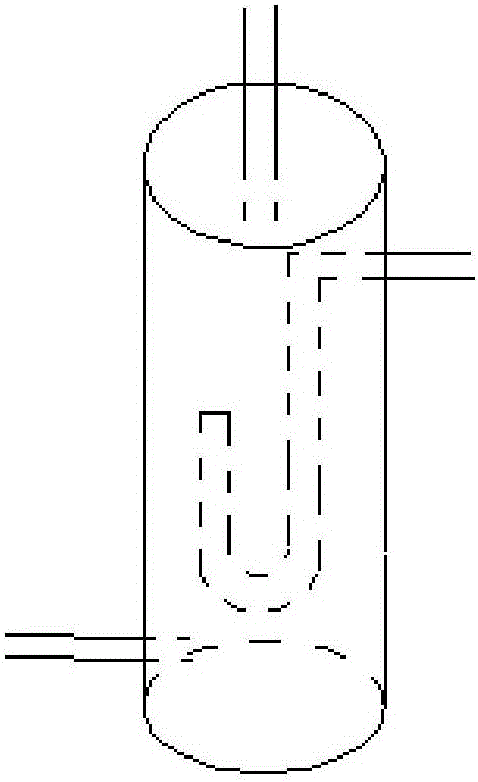

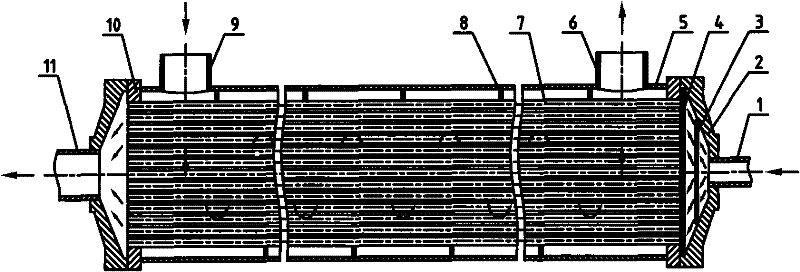

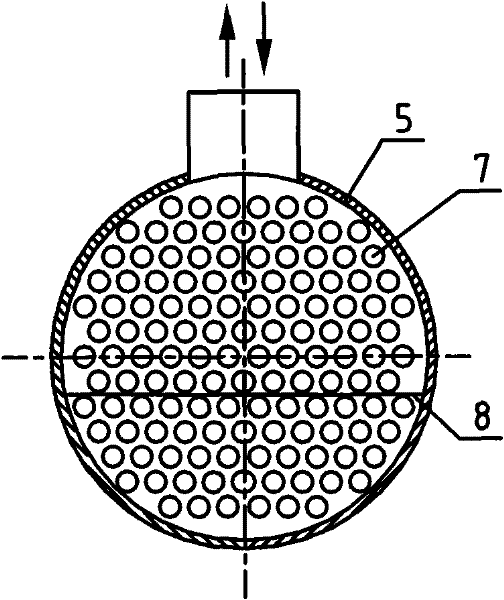

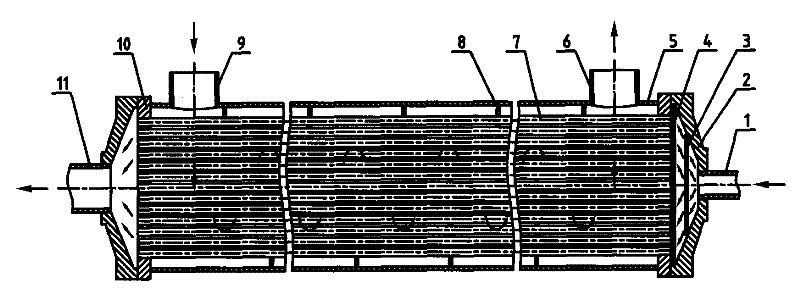

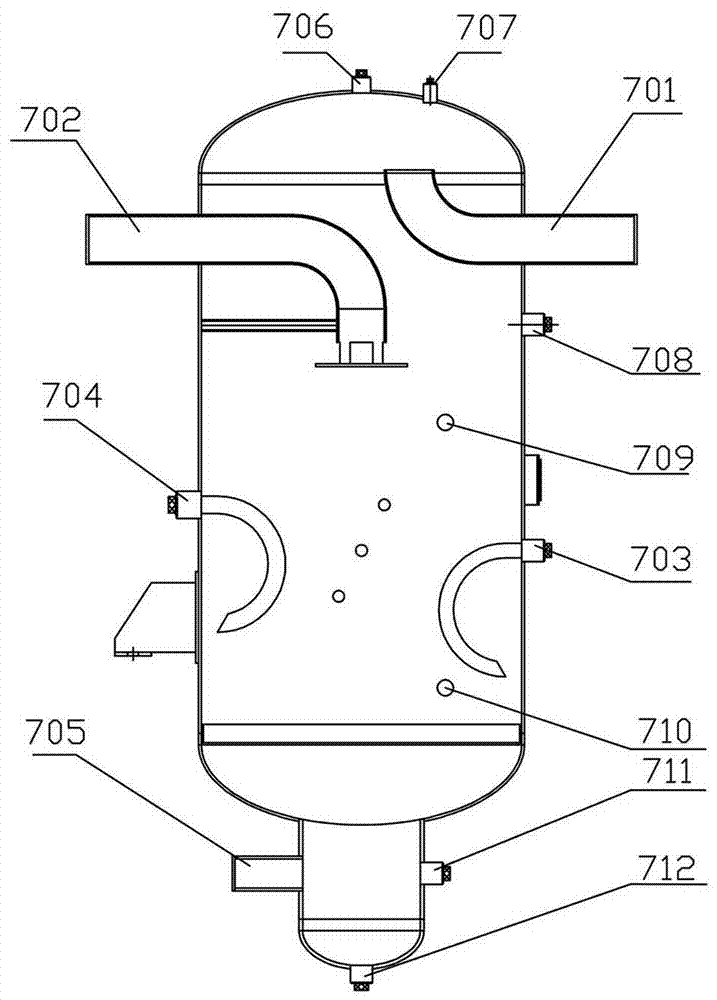

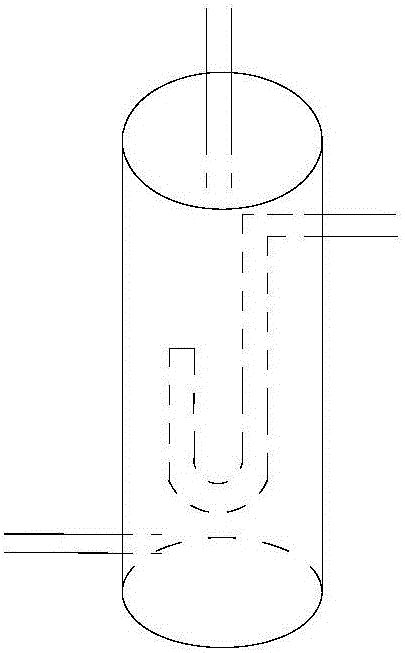

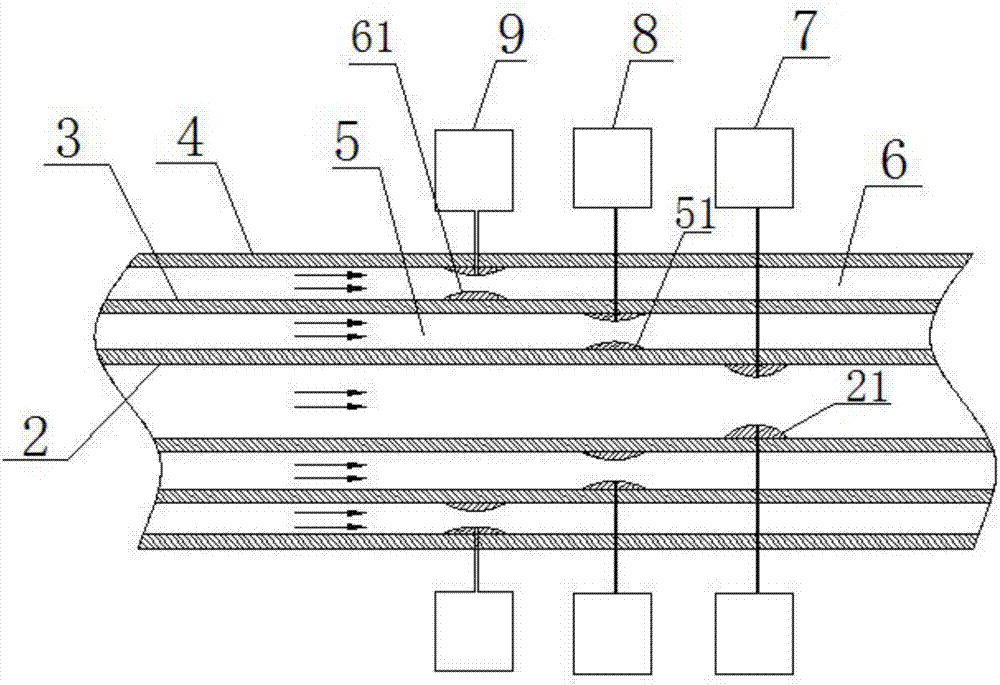

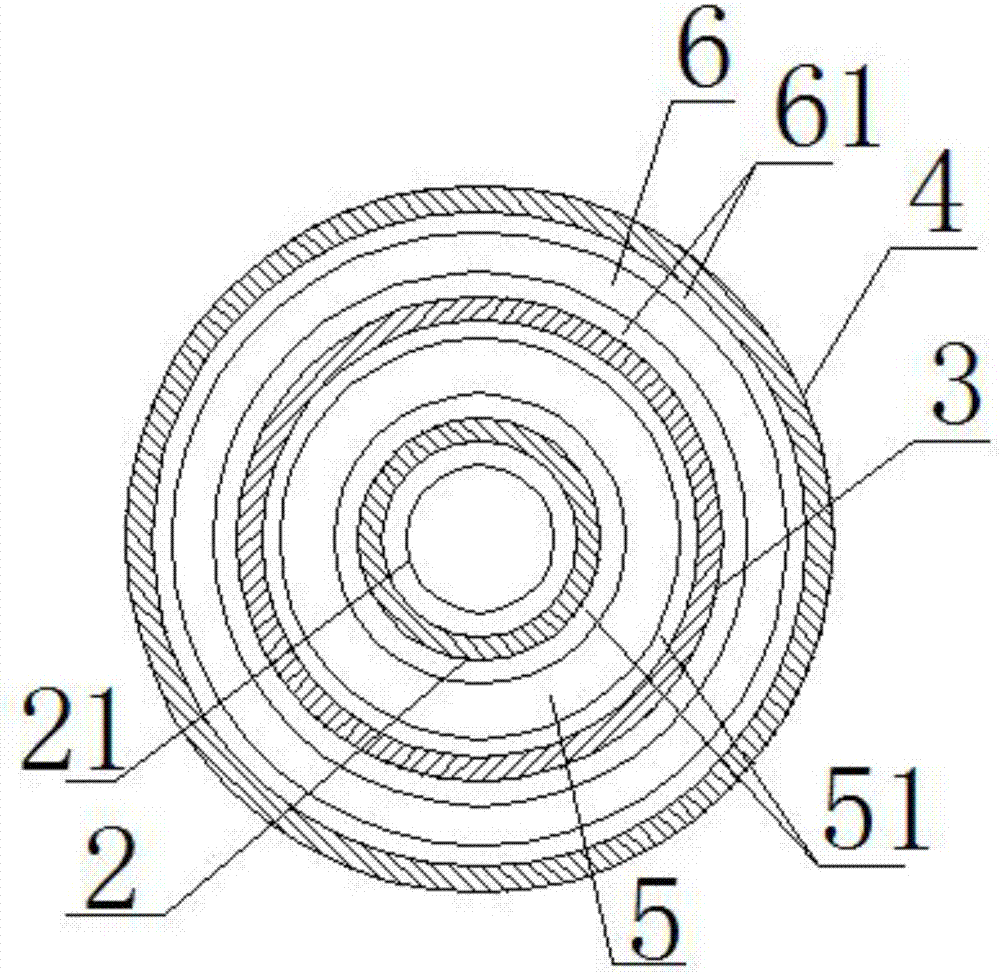

Pure reverse flow dry evaporator device and use method thereof

ActiveCN101738013BImprove energy efficiencyImprove heat transfer performanceEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

The invention relates to a pure reverse flow dry evaporator device and a use method thereof. The ordinary dry evaporator channel box generally used at present adopts multiple paths and has declined heat transfer performance caused by incomplete gasification. In the technical scheme, gas-liquid refrigerant mixture is divided more evenly by a distributing pore plate in the channel box. The pure reverse flow dry evaporator device consists of a liquid feeding pipe, a channel box, a first-level distributing pore plate, a second-level distributing pore plate, a cylinder, a refrigerating medium outlet, an evaporating pipe bundle, a baffle plate, a refrigerating medium inlet, a pipe plate and an exit pipe. The invention has the advantages that the distributing pore plate and the baffle plate device are used for realizing single-flow pure reverse flow heat exchange, thereby ensuring compact structure, convenient production and low processing cost; the gas-liquid refrigerant mixture is divided more evenly, improves the energy efficiency and heat transfer performance by 15-20 percent than the ordinary dry evaporator and reduces the pressure by 10 percent.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

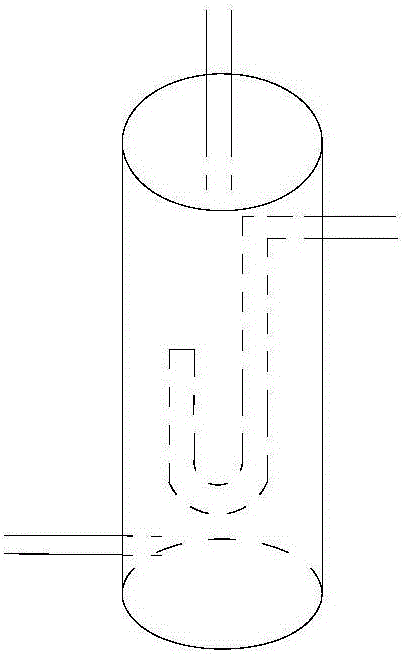

Vapor-liquid separation type liquid separator

The invention provides a vapor-liquid separation type liquid separator which comprises a liquid bag. The end of a liquid inflow header pipe extends to the upper portion of an inner cavity of the liquid bag. A fixing porous board is arranged in the inner cavity of the liquid bag and fixedly connected to the liquid inflow header pipe. Multiple liquid outflow branch pipes are inserted in holes of the fixing porous board. Each liquid outflow branch pipe is fixedly connected with the fixing porous board. One end of each liquid outflow branch pipe is located at the lower portion of the inner cavity of the liquid bag. The other end of each liquid outflow branch pipe is located on the outer side of the liquid bag. The portion, located at the upper portion of the inner cavity of the liquid bag, on each liquid outflow branch pipe is provided with a vent hole. By the adoption of the liquid separator, liquid is separated evenly, the problem that liquid of two-phase flow is not evenly separated through a traditional liquid separator is solved, the problem that the pressure losses of the traditional liquid separator are large is solved as well, and the liquid separator is particularly suitable for even liquid separation of the vapor-liquid two-phase flow. By the adoption of the vapor-liquid separation type liquid separator, the heat exchange efficiency of an air cooler can be improved through even liquid separation, and the energy consumption of a whole refrigeration system is reduced through reduction of pressure drop losses.

Owner:DALIAN REFRIGERATOR

Integrated type double cold source recombination heat exchange coil

PendingCN107131683AReduce the PUE valueGuaranteed uptimeEvaporators/condensersEngineeringRefrigerant

The invention discloses an integrated type double cold source recombination heat exchange coil. The integrated type double cold source recombination heat exchange coil pipe comprises a freeze water heat exchange coil, a refrigerating fluid heat exchange coil and connecting pieces. The freeze water heat exchange coil comprises a left core body, a right core body, a freeze water inlet collecting pipe and a freeze water outlet collecting pipe; the refrigerating fluid heat exchange coil comprises an inverted-V-shaped core body, the left core body is located on the left side of the inverted-V-shaped core body, the right core body is located on the right side of the inverted-V-shaped core body, and the left core body, the inverted-V-shaped core body and the right core body are connected into a whole through the connecting pieces. According to the integrated type double cold source recombination heat exchange coil, freeze water can be used for refrigerating, and refrigerating fluid can further be used for evaporative refrigerating. When a central air-conditioning is started, the freeze water of the central air-conditioning is used to conduct refrigerating, and after the central air-conditioning is shut down, the refrigerating fluid is used to conduct evaporative refrigerating, not only is the energy consumption reduced, but also the fact that machine room equipment can be refrigerated for 24 hours in 365 days is ensured. The design of the integrated type recombination heat exchange coil further reduces the size of the double cold source air-conditioning, and the construction of the machine room is better facilitated.

Owner:YIMIKANG TECH GRP CO LTD

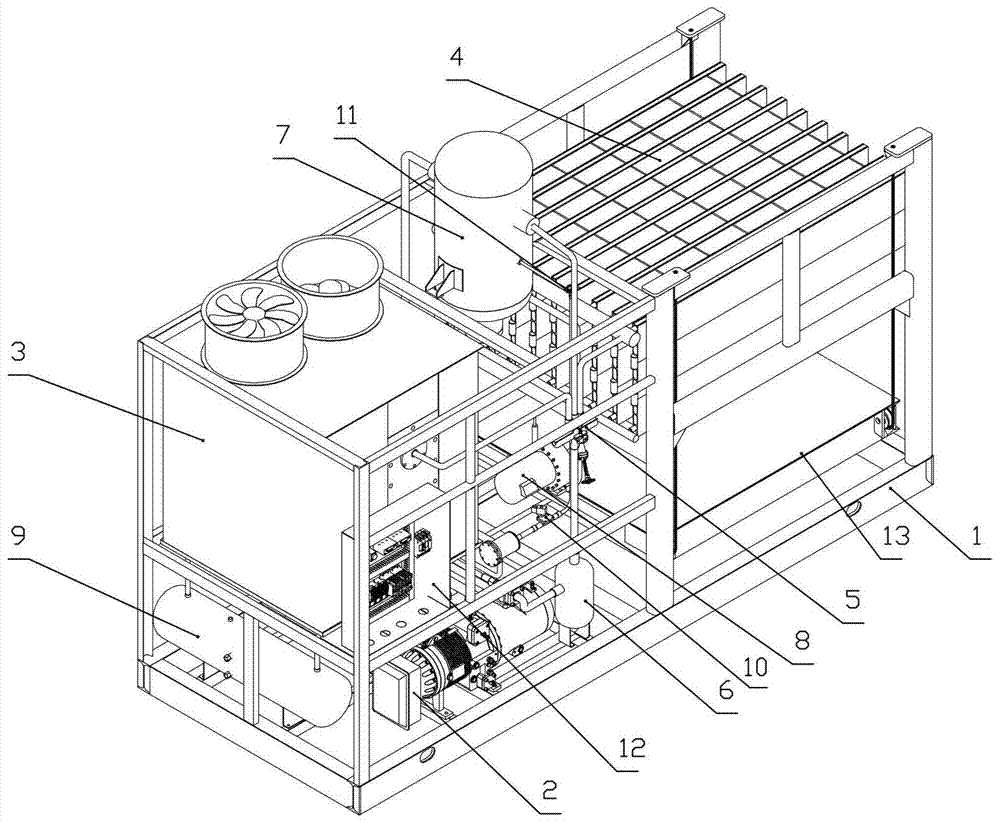

Novel energy-saving mobile ice producer

InactiveCN107339839AOvercoming immobilityEasy to useLighting and heating apparatusIce productionRefrigeration compressorFour-way valve

The invention relates to a novel energy-saving mobile ice producer. The novel energy-saving mobile ice producer comprises a frame, a refrigeration compressor, a condenser, a direct cooling ice mold, a four-way valve, an oil separator, a circulating barrel, a fluorine pump, a liquid storage barrel, an electromagnetic valve, a throttling valve, a control box and a lifting table; the direct cooling ice mold comprises an evaporator; a high-pressure end of the refrigeration compressor is connected with the oil separator through a pipe; four ports of the four-way valve are respectively connected with the oil separator, the condenser, the circulating barrel and the evaporator through pipes; the condenser is connected with the liquid storage barrel, the electromagnetic valve, the throttling valve and the circulating barrel in sequence through pipes; the circulating barrel is connected with the fluorine pump and the evaporator in sequence through pipes; and the circulating barrel is directly connected to a low-pressure end of the refrigeration compressor through a pipe. The novel energy-saving mobile ice producer adopts the fluorine pump to supply liquid, accelerates the flowing speed of the refrigerant on the side of the evaporator, is uniform in liquid separation, improves the heat transfer effect of the evaporator, is high in efficiency and energy conservation, and guarantees the ice production quality.

Owner:冰欧冷链科技芜湖有限公司

Liquid distribution mechanism with uniform liquid distribution function, installation method thereof and air conditioning system

ActiveCN110296555AOvercome the problem of large difference in drynessLiquid evenlyMechanical apparatusFluid circulation arrangementEngineeringLiquid phase

The invention provides a liquid distribution mechanism with a uniform liquid distribution function, an installation method thereof and an air conditioning system. The liquid distribution mechanism comprises a cylindrical body and a flow distribution pointed cone, wherein a liquid distribution cavity is formed in the cylindrical body, the flow distribution pointed cone is arranged in the liquid distribution cavity, and atop point of the flow distribution pointed cone is spaced from an axis of the cylindrical body. According to the liquid distribution mechanism with the uniform liquid distribution function, the installation method thereof and the air conditioning system provided by the invention, the distance between the top point of the flow distribution pointed cone and the axis of the cylindrical body is set, so that the top point of the flow distribution pointed cone points to a liquid phase concentration part, liquid phase refrigerant can uniformly enter a flow distribution hole under the flow guidance of the top point and a liquid distribution level, the problem that the refrigerant dryness in the flow distribution hole differs greatly due to uneven liquid distribution in theprior art is solved, and the purpose of uniform liquid distribution is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Microchannel refrigerating circuit

InactiveCN106152581ALiquid evenlyReduce the liquid separation effectMechanical apparatusCompression machines with non-reversible cycleLiquid stateEngineering

The invention discloses a microchannel refrigerating circuit. The circuit comprises a compressor, a microchannel condenser, a first capillary throttling device, a gas-liquid separation device, a microchannel evaporator (comprising a flute type liquid distribution pipe) and a second capillary throttling device, wherein one gas-liquid separation device is arranged in front of the microchannel evaporator, so that a refrigerant entering the microchannel evaporator is ensured to be in a liquid state, uniform liquid distribution of the microchannel evaporator is facilitated, the refrigerating effect of the refrigerating circuit is guaranteed, and the heat exchange efficiency is improved.

Owner:NANJING NORMAL UNIVERSITY

Liquid separation device and air conditioner comprising liquid separation device

ActiveCN103363733ALiquid evenlyImprove flow statusFluid circulation arrangementVapor–liquid separatorEngineering

The invention provides a liquid separation device and an air conditioner comprising the liquid separation device. The liquid separation device comprises a gas-liquid separator, a liquid guide tube, a connecting tube, a gas-liquid mixing chamber, and a liquid separation tube, wherein the gas-liquid separator is provided with a first inlet, a first outlet and a second outlet; the liquid guide tube is communicated with the gas-liquid separator by the first outlet; the connecting tube is communicated with the gas-liquid separator by the second outlet; the gas-liquid mixing chamber is provided with a third inlet, a second inlet and a third outlet; the third inlet is communicated with the liquid guide tube; the second inlet is communicated with the connecting tube; and the liquid separation tube is communicated with the third outlet of the gas-liquid mixing chamber. With the adoption of the technical scheme, the gas-liquid mixing chamber is arranged between the liquid separation tube and the gas-liquid separator, so that gas and liquid phase refrigerants before entering the liquid separation tube can be uniformly mixed, distribution of the refrigerants in the liquid separation tube is improved, and liquid separation of the liquid separation tube can be more uniform.

Owner:GREE ELECTRIC APPLIANCES INC

Production process of fresh-keeping preserved bayberries

The invention relates to a production process of fresh-keeping preserved bayberries and belongs to the field of processing of fruit type non-staple food. The production process of the fresh-keeping preserved bayberries, provided by the invention, has the benefits that the damage to fresh bayberries in the processing process is reduced, the immersion rate and the immersion speed of sugar and seasonings are improved, the consumption of the sugar and the seasonings are reduced, and the distribution and the blending of the sugar and the seasonings in the bayberries can be more uniform; the shape of the bayberries and the mouth feeling and the nutritional ingredient of the fresh bayberries can also be effectively kept; the bonding among all the preserved bayberries can also be prevented, so that the palatability of the preserved bayberries is improved.

Owner:福州高科新技术开发有限公司

Device for uniformly distributing liquid by using dry evaporator and use method thereof

ActiveCN102494444BSpray evenlyLiquid evenlyEvaporators/condensersHeat exchanger casingsEngineeringProcess engineering

The invention relates to a device for uniformly distributing a liquid by using a dry evaporator and a use method thereof. The problems of complex structure, high sealing requirement and high processing difficulty exist in the conventional liquid distribution device. In a technical scheme of the invention, a gas-liquid refrigerant mixture is distributed more uniformly by using the uniform liquid distribution device in the dry evaporator. The device consists of a uniform liquid distributor, a correlated tube plate and a steam-generating bank. The device has the beneficial effects that: a conical cylindrical uniform liquid distributor is directly arranged in the tube orifice of the steam-generating bank, heat exchange is performed by fully utilizing all steam-generating banks, and energy efficiency is increased by 15-20 percent in comparison to the conventional liquid distribution device. The device is an energy-saving device which has a compact structure and low processing cost and is convenient to manufacture and install.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com